Patents

Literature

337 results about "Stress variation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1.8 Variation of Stress Within a Body. As pointed out in Section 1.5, the components of stress generally vary from point to point in a stressed body. These variations are governed by the conditions of equilibrium of statics.

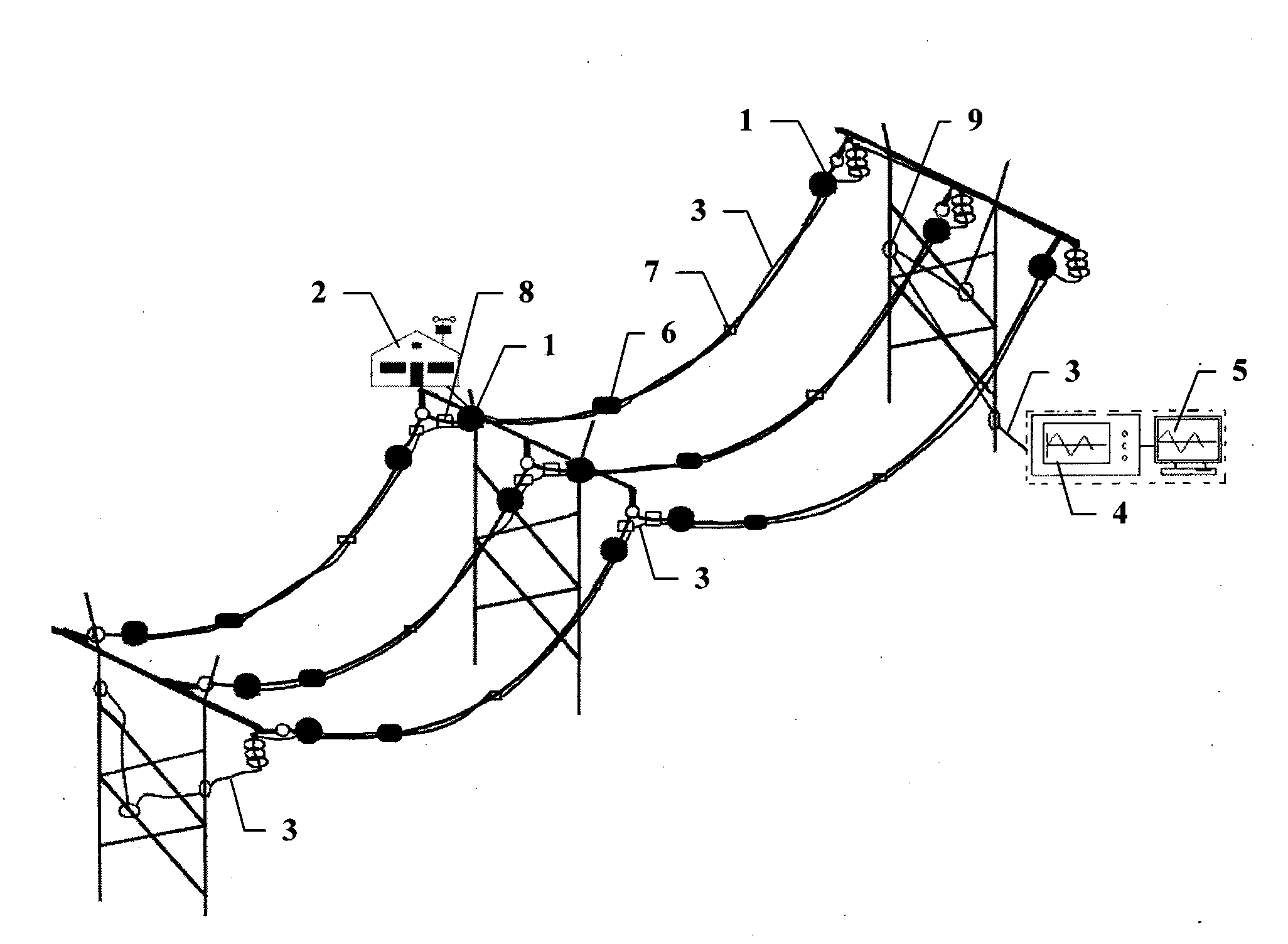

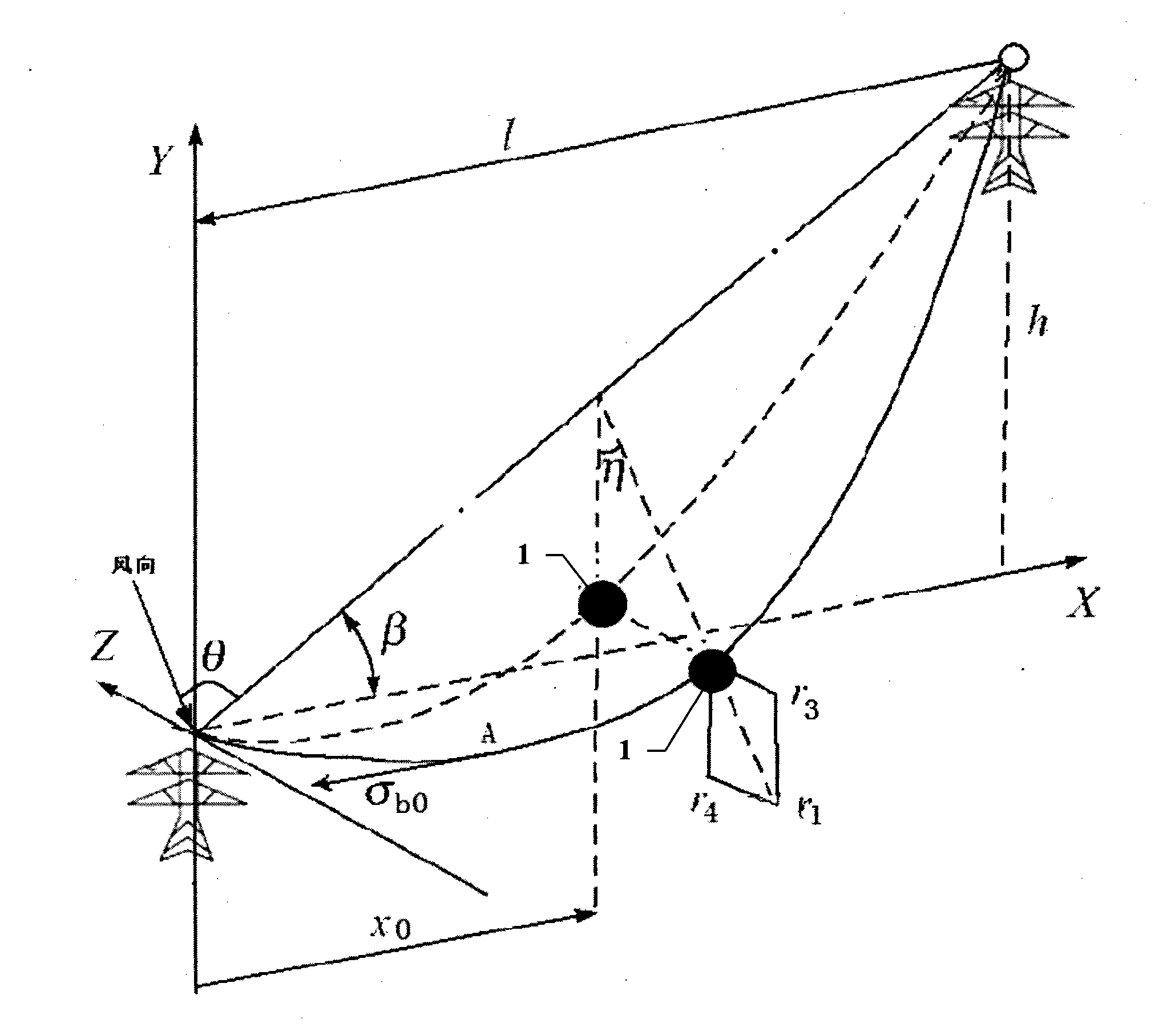

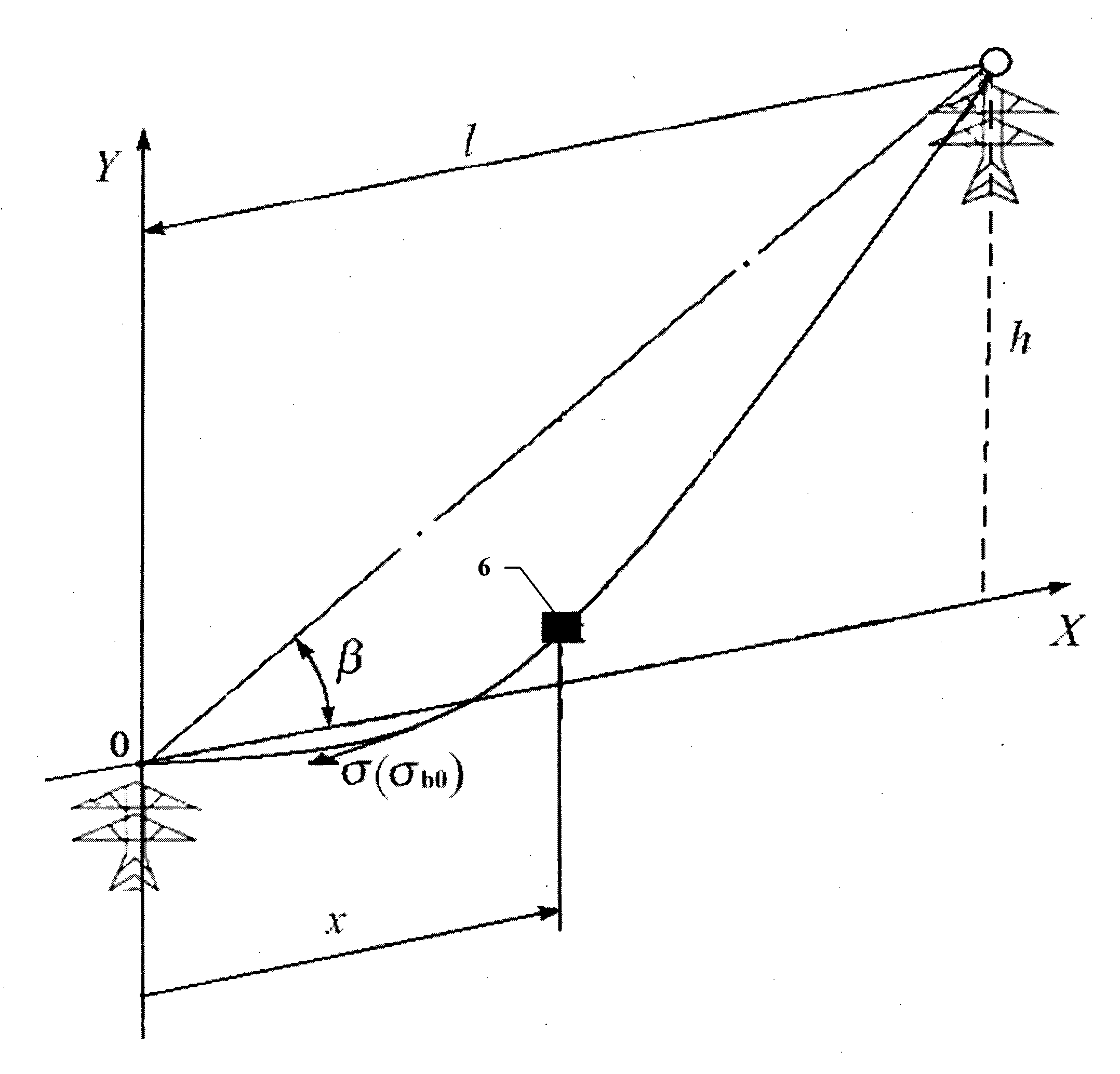

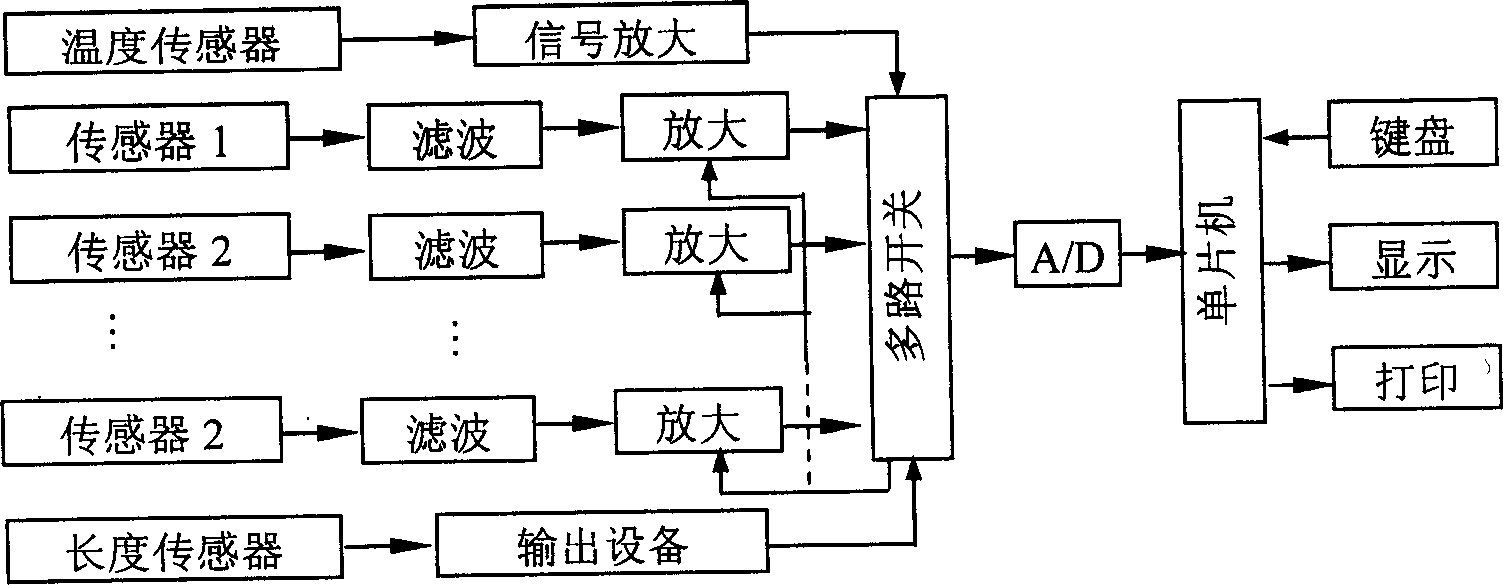

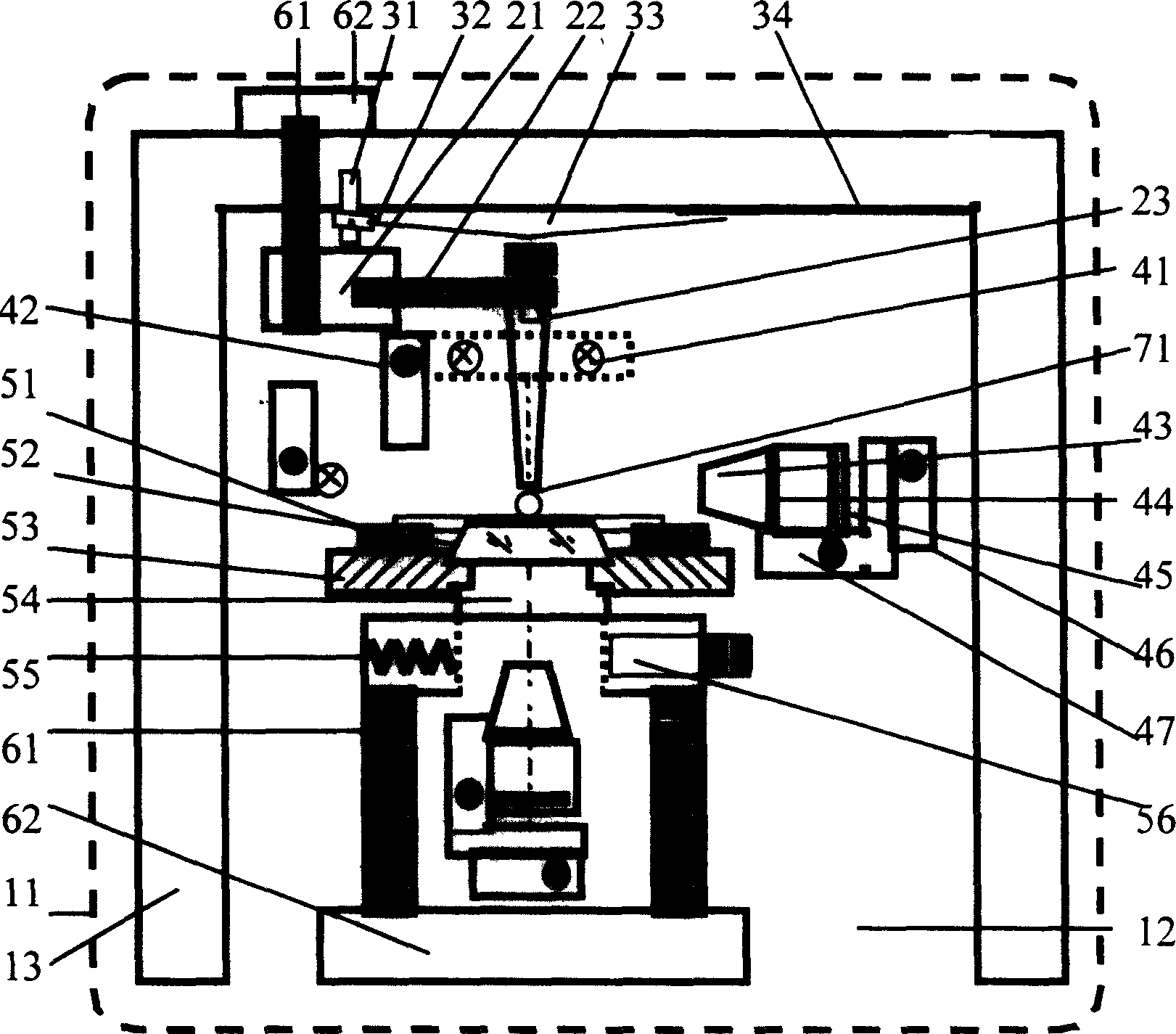

Device for monitoring state of power transmission line tower-line system

InactiveCN102042885AWide operating temperature rangeLong measuring distanceForce measurement by measuring optical property variationIndication of weather conditions using multiple variablesVibration amplitudeDistributed structure

The invention discloses a device for monitoring the state of a power transmission line tower-line system, which fully utilizes the advantages of corrosion resistance, wide operation temperature range, anti-electromagnetic interference, passivity, long measuring distance, reliable operation and long service life and the like of optical fiber sensors to configure the optical fiber sensors on a transmission conductor and a tower in a quasi-distributed structure for detecting the temperature, the strain and the acceleration of the transmission conductor and the multipoint stress variation on the tower which are transmitted to an optical modulator demodulator for demodulating and are sent to a computer analyzing and processing system for calculating to obtain the icing quality, the waving amplitude, the breeze vibration amplitude and frequency and the sag of the transmission conductor, and the inclination angle of the tower, thus realizing the simultaneous monitoring on the icing, the waving, the breeze vibration and the sag of the transmission conductor, and the inclination angle state of the tower, and being capable of finishing long-time reliable operation under the on-site severe environment conditions.

Owner:SICHUAN HUIYUAN OPTICAL COMM CO LTD

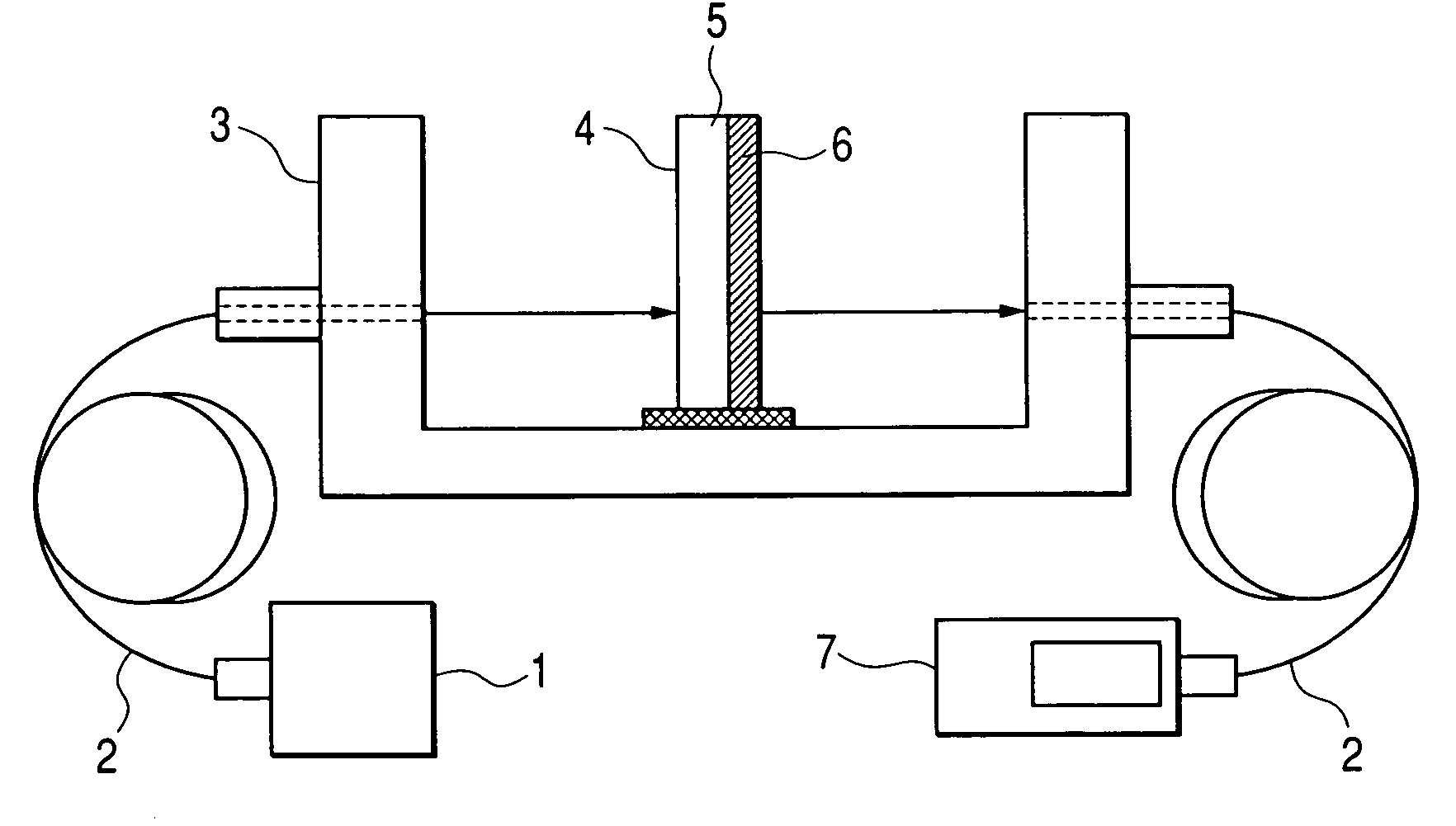

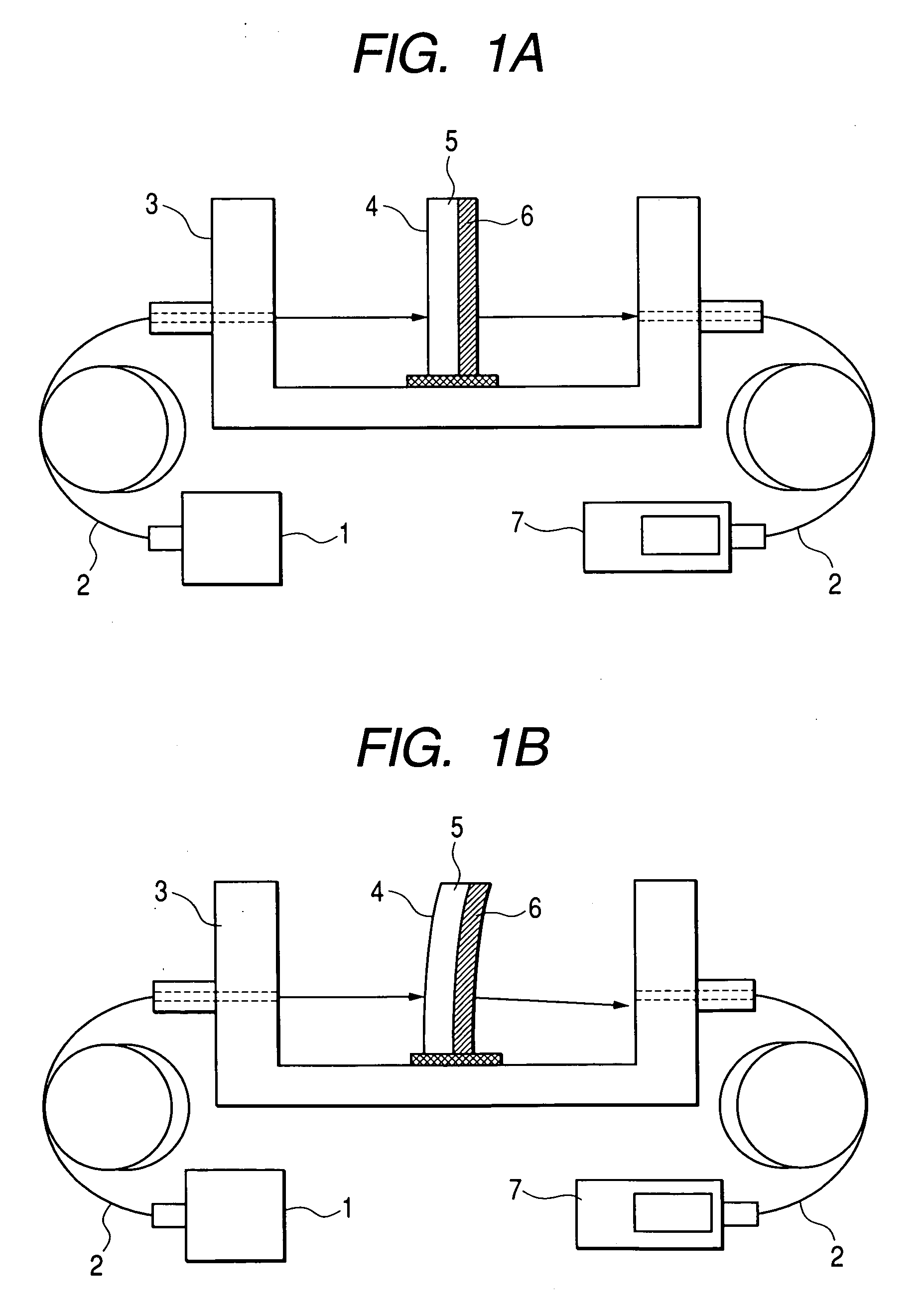

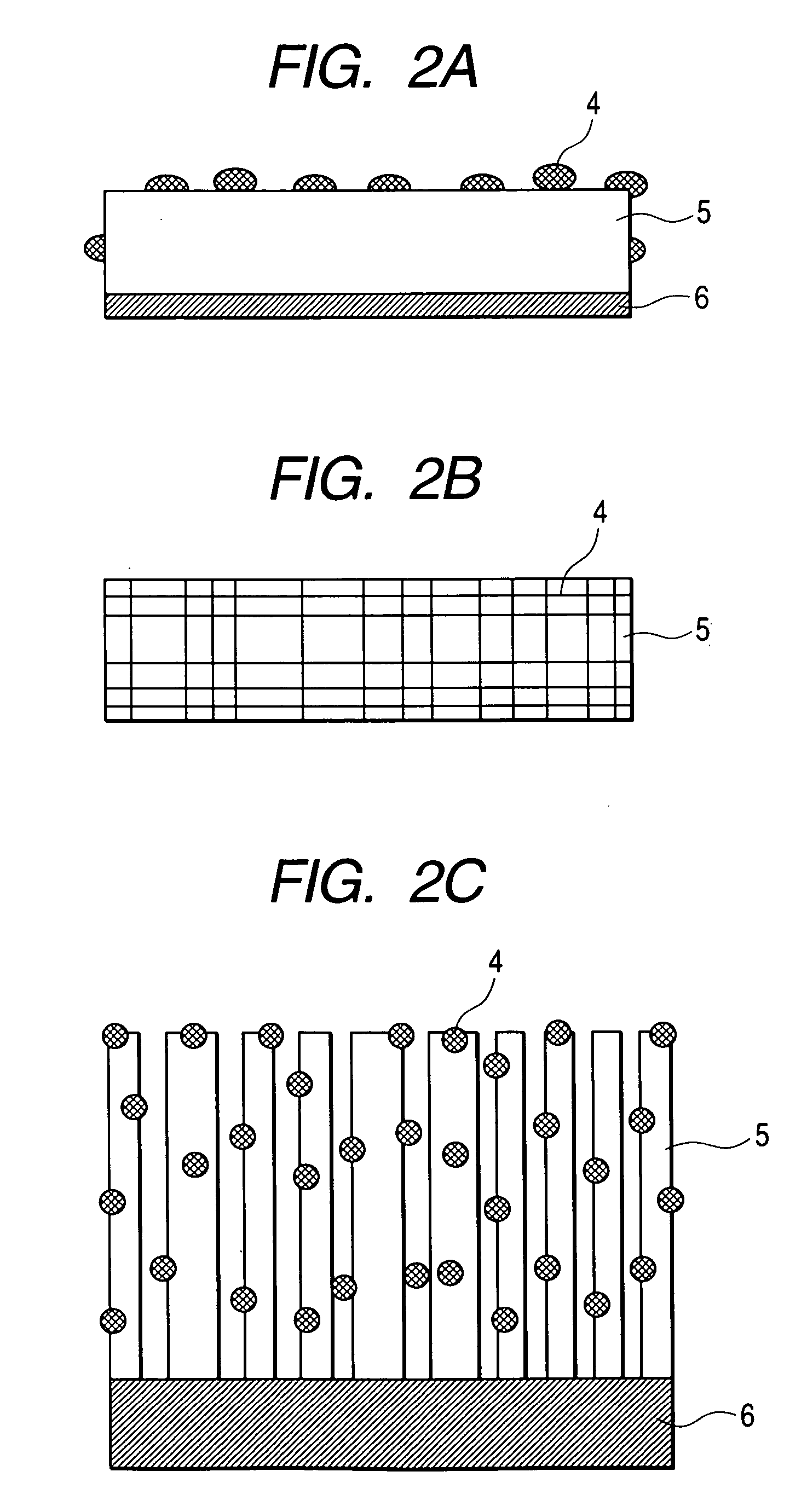

Gas detecting method and gas sensors

InactiveUS20050186117A1Easy to detectImprove gas selectivityWeather/light/corrosion resistanceMaterial analysis by observing effect on chemical indicatorCapacitanceCoupling loss

A gas detection method capable of solving the problem with respect to the operation at normal temperature that was impossible so far in the existent catalyst type sensor and detection with high sensitivity that was impossible by the light absorption type sensor. A multi-layered film formed of a first layer adsorbing a specified gas and a second layer having less adsorption are utilized as a detection film, and the detection film is disposed in the direction perpendicular to the optical channel and optically detects the change of stress caused in the detection film by gas adsorption as coupling loss. Alternatively, the stress generated in the detection film caused by gas adsorption is electrically detected by a piezoelectric element or capacitance element.

Owner:HITACHI CABLE

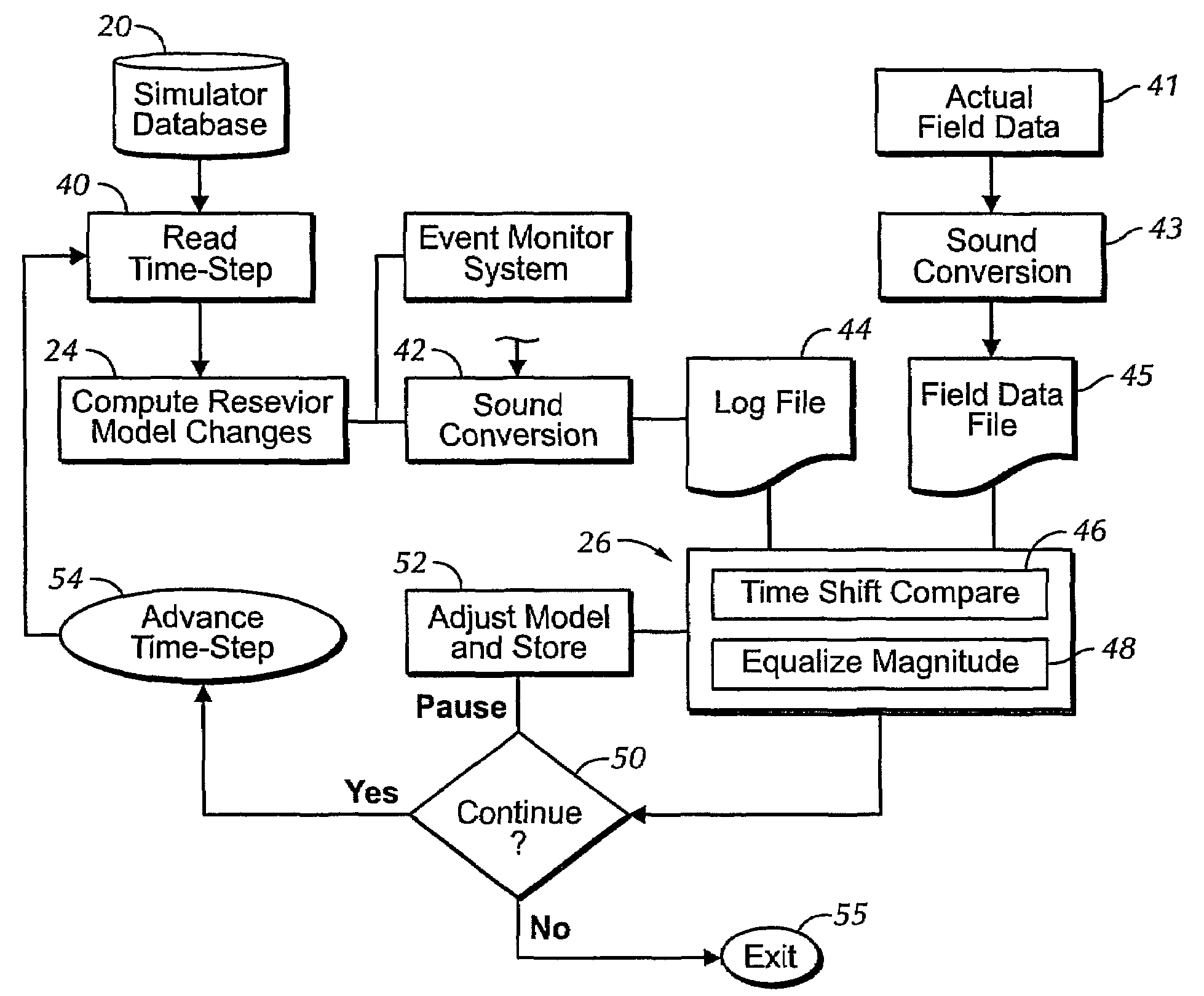

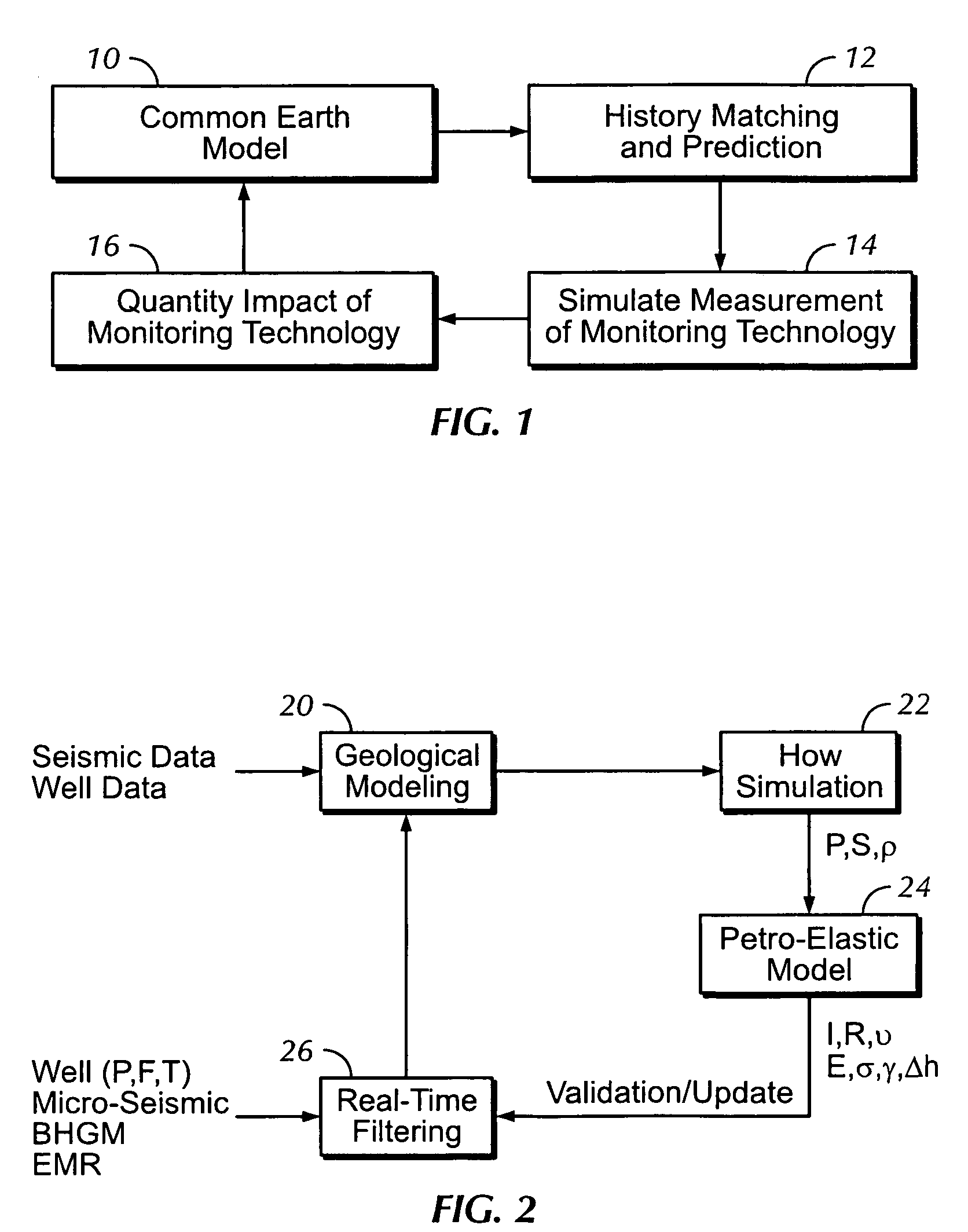

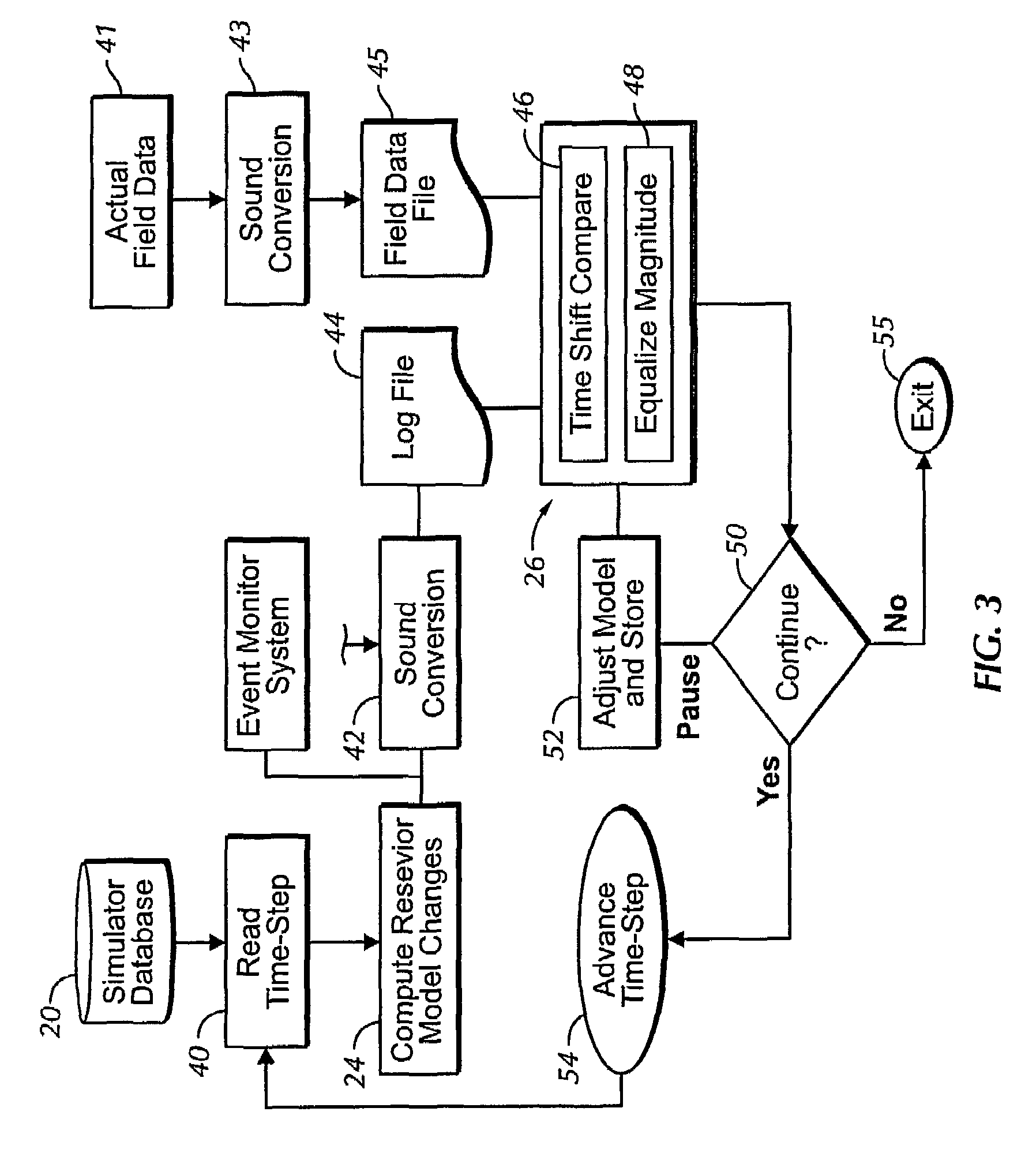

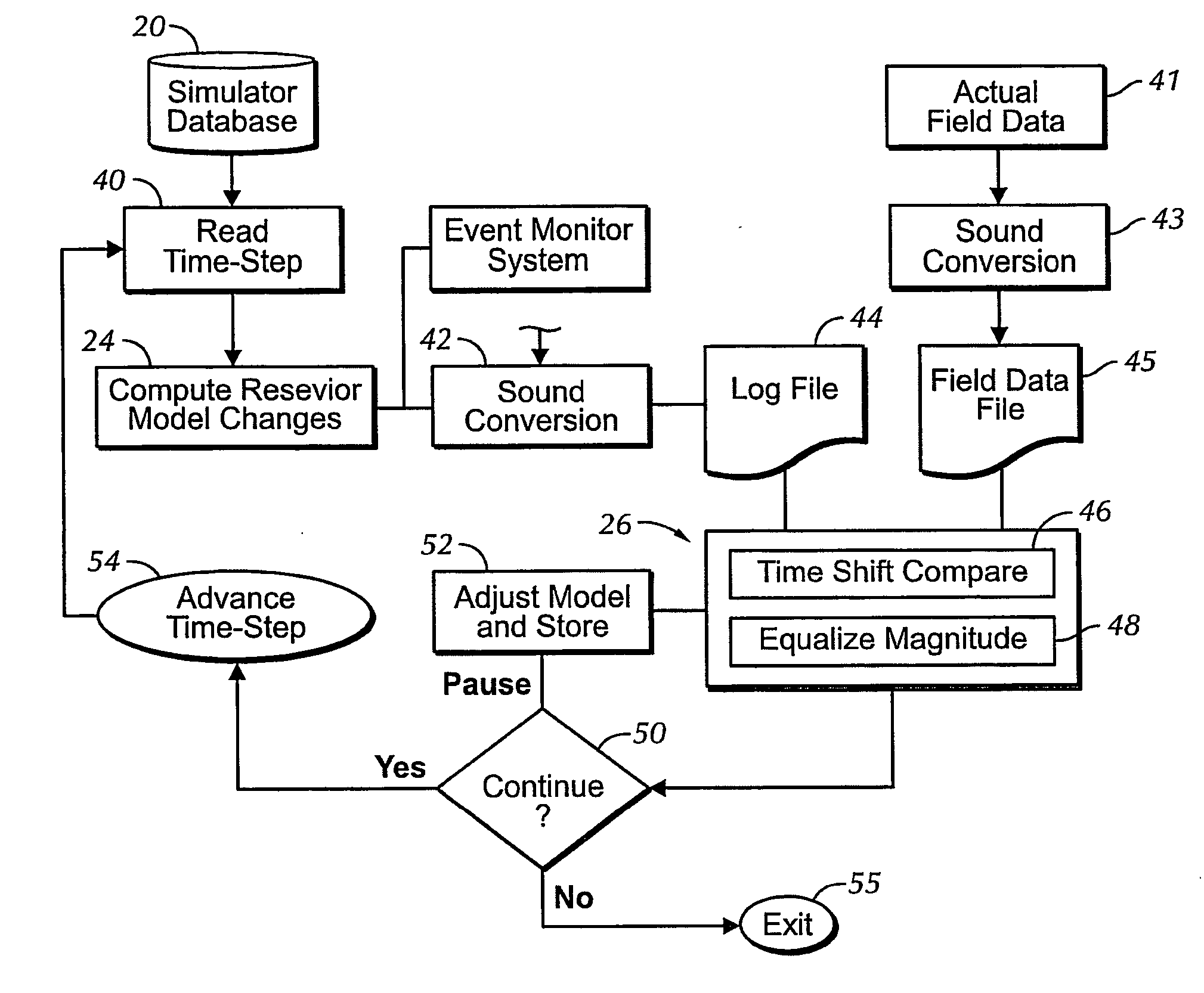

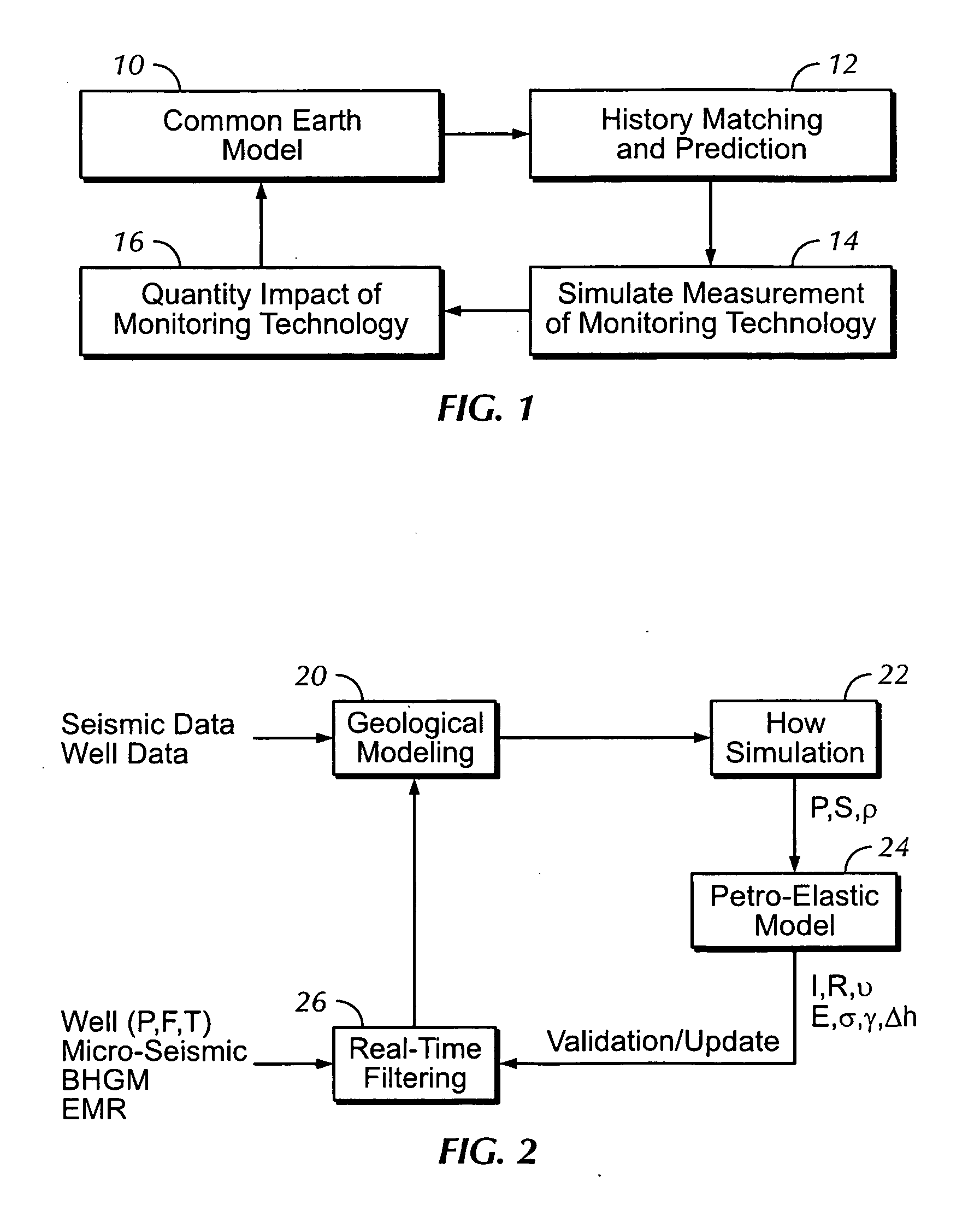

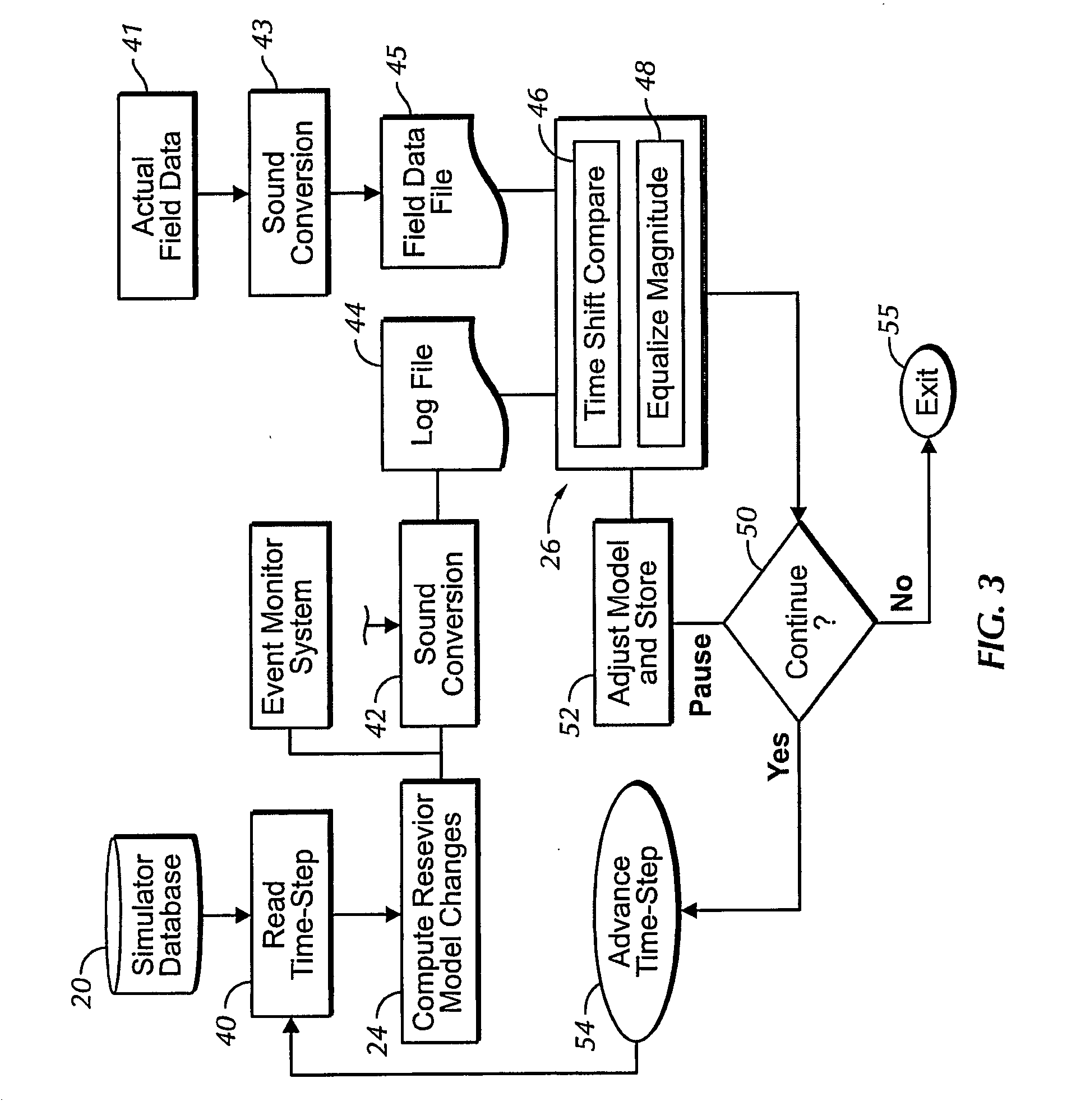

Sound enabling computerized system for real time reservoir model calibration using field surveillance data

ActiveUS7620534B2Digital data processing detailsVolume/mass flow measurementHydrocotyle bowlesioidesComputerized system

A computer-based system generates digital and audio responses to changes in fluid and rock properties of a producing hydrocarbon reservoir for surveillance analysis. The system calibrates observed changes against directly-measured field data in order to optimize the reservoir model. The changes may include, for example, stress changes in rock, impedance changes in rock, and fluid density changes.

Owner:ARAMCO SAUDI

Sound enabling computerized system for real time reservoir model calibration using field surveillance data

ActiveUS20070255500A1Digital data processing detailsVolume/mass flow measurementReliable computingComputerized system

A computer-based system generates digital and audio responses to changes in fluid and rock properties of a producing hydrocarbon reservoir for surveillance analysis. The system calibrates observed changes against directly-measured field data in order to optimize the reservoir model. The changes may include, for example, stress changes in rock, impedance changes in rock, and fluid density changes.

Owner:ARAMCO SAUDI

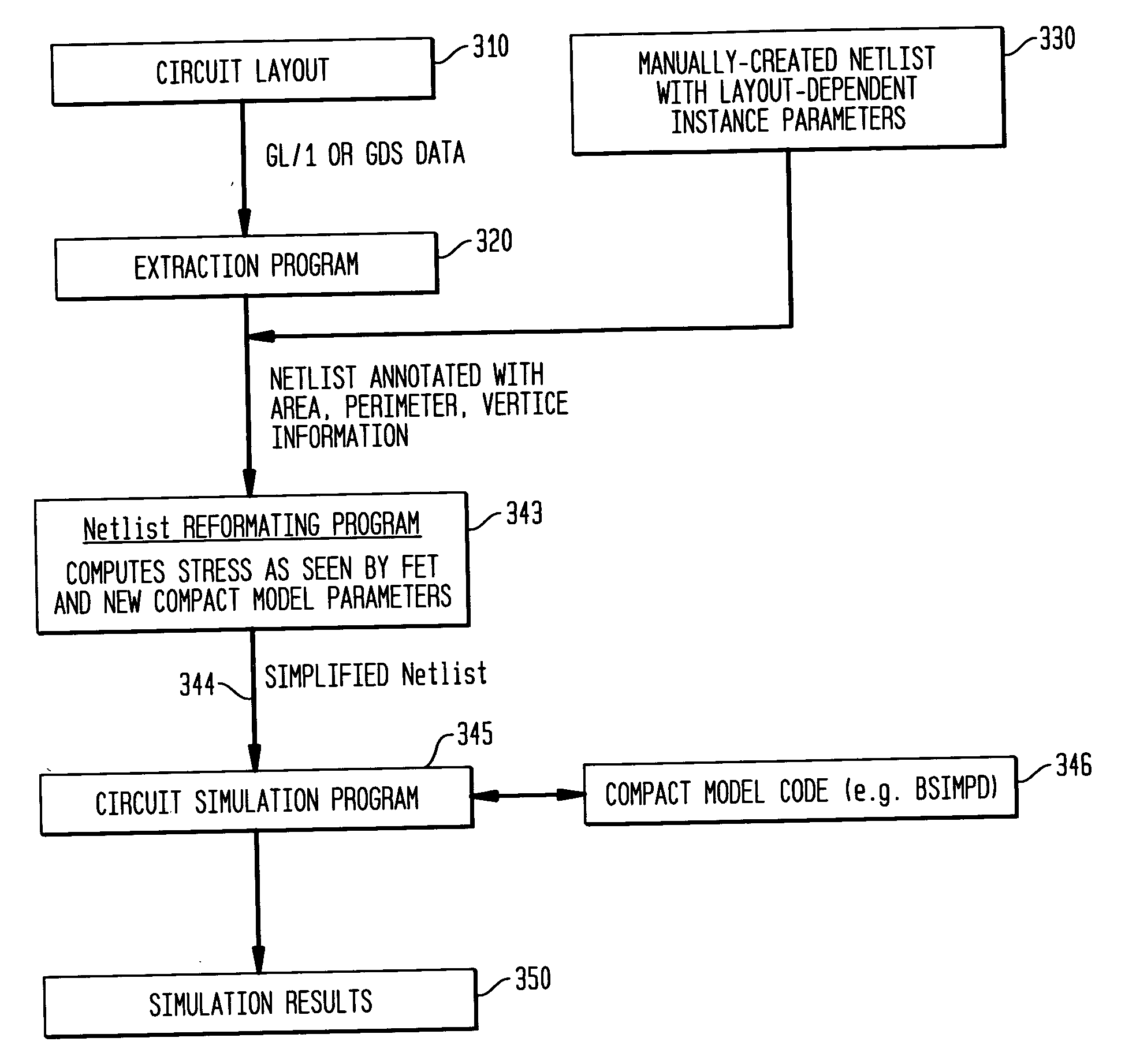

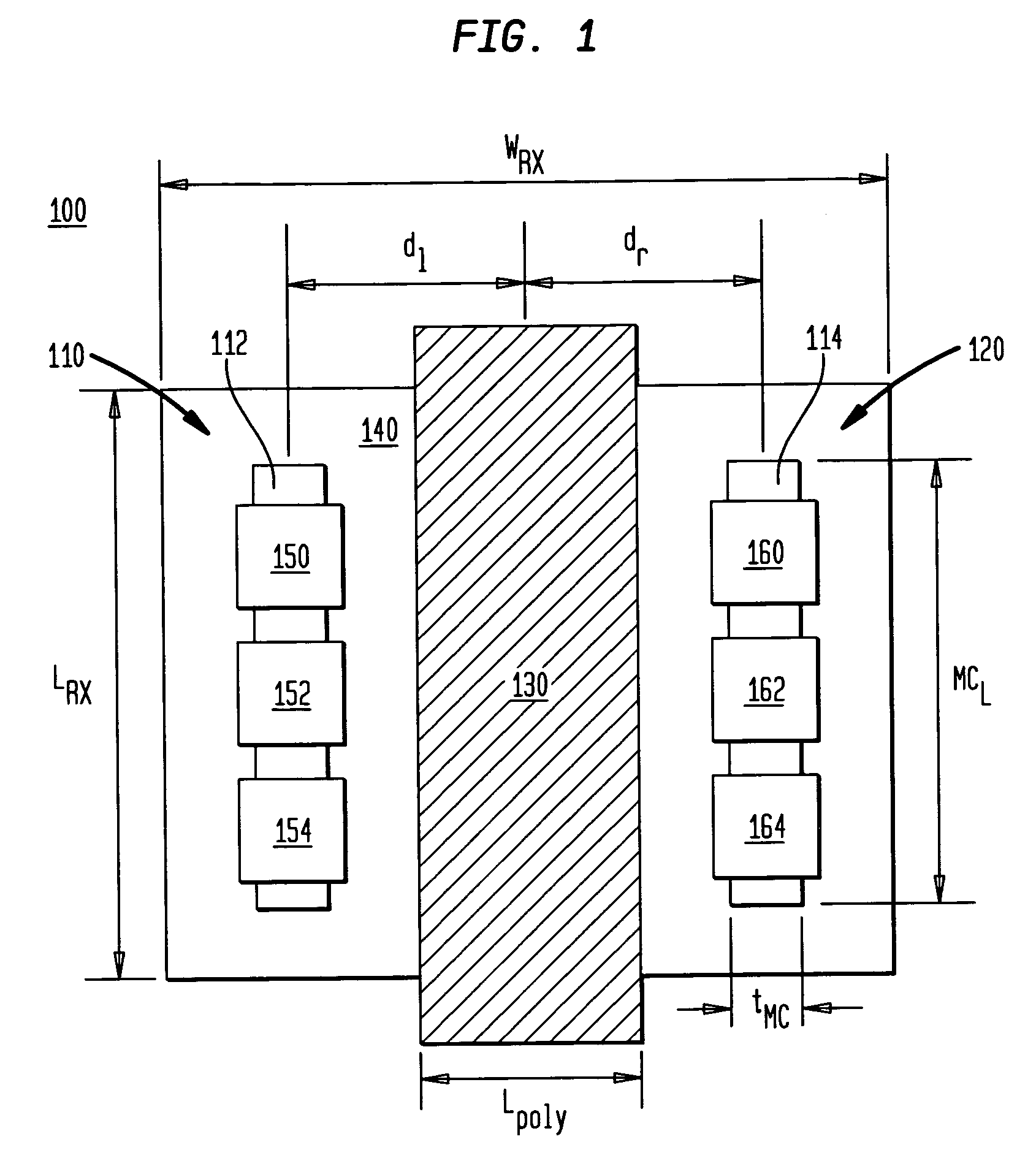

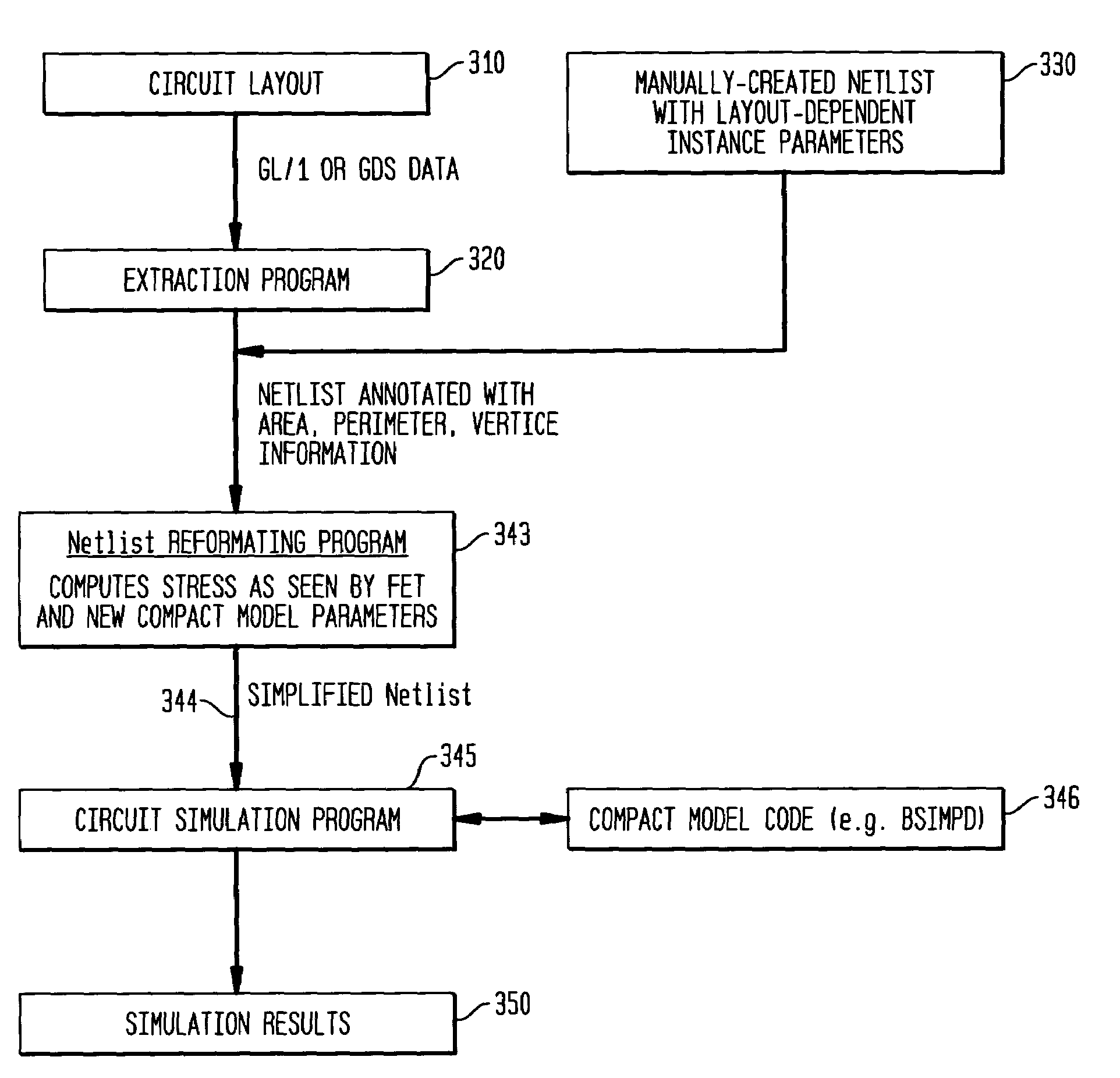

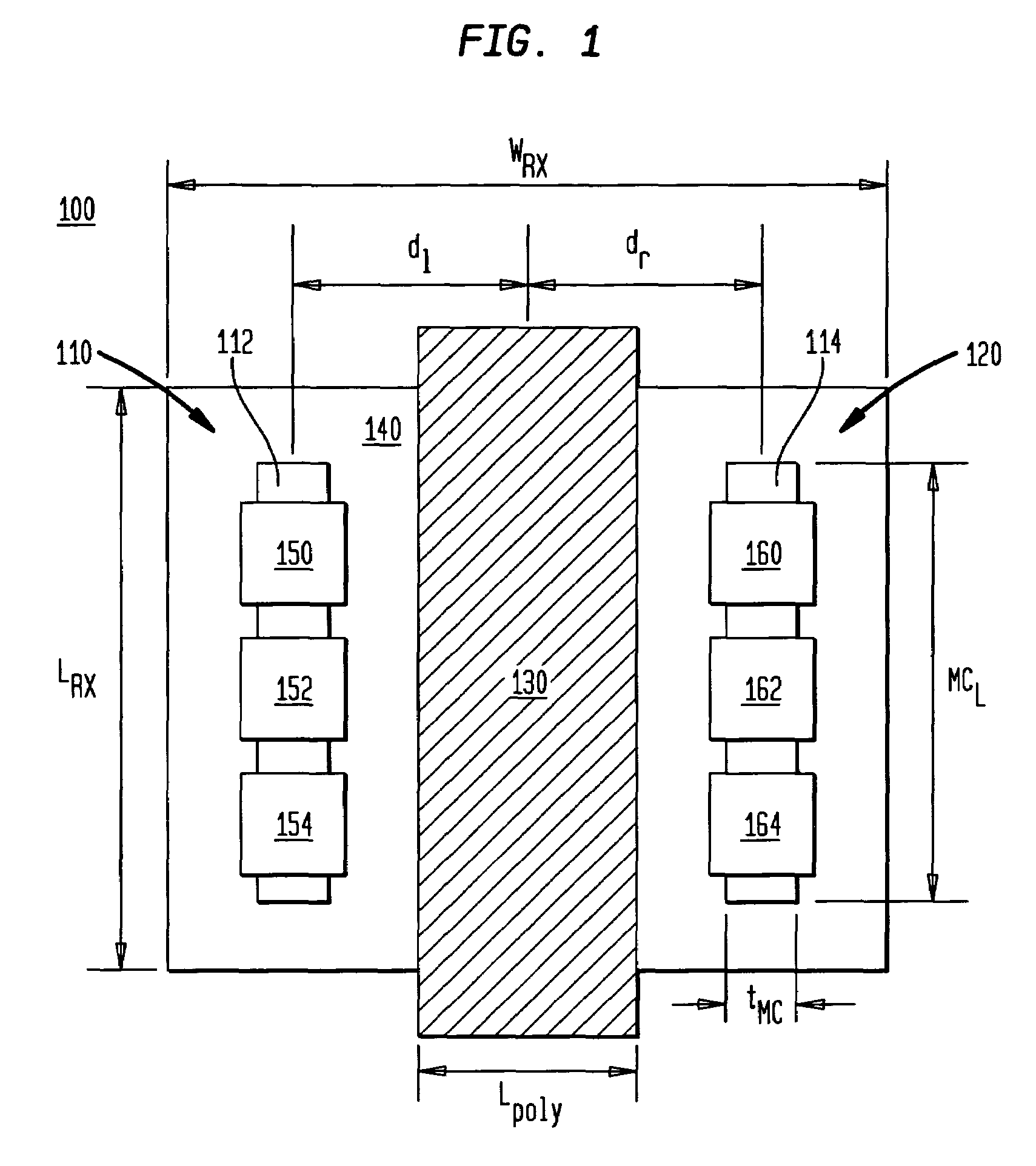

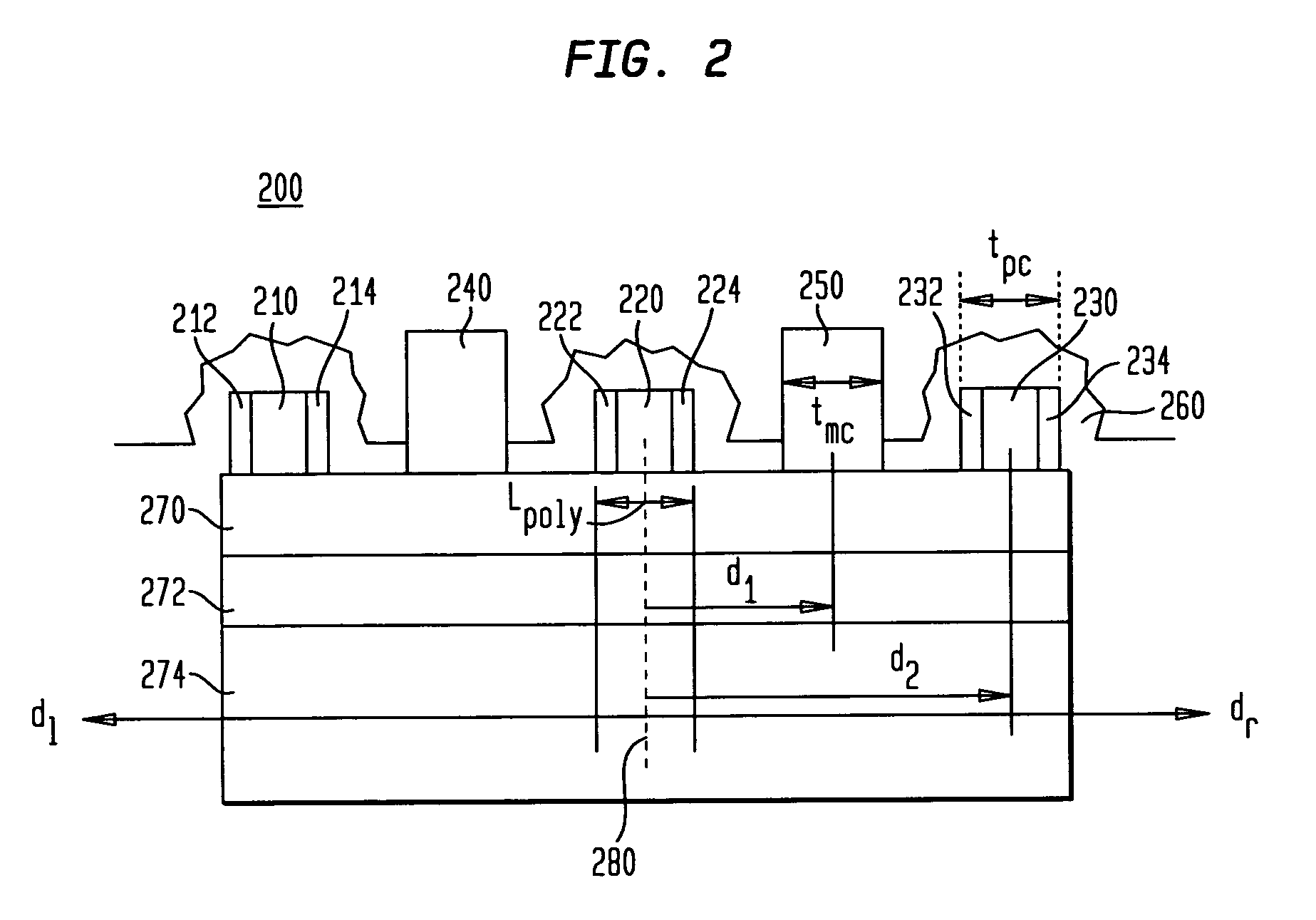

Methodology for layout-based modulation and optimization of nitride liner stress effect in compact models

ActiveUS20070028195A1CAD circuit designSoftware simulation/interpretation/emulationDevice materialModel system

System and method for compact model algorithms to accurately account for effects of layout-induced changes in nitride liner stress in semiconductor devices. The layout-sensitive compact model algorithms account for the impact of large layout variation on circuits by implementing algorithms for obtaining the correct stress response approximations and layout extraction algorithms for obtaining the correct geometric parameters that drive the stress response. In particular, these algorithms include specific information from search “buckets” that are directionally-oriented and include directionally-specific distance measurements for analyzing in detail the specific shape neighborhood of the semiconductor device. The algorithms are additionally adapted to enable the modeling and stress impact determination of a device having single stress liner film and dual-stress liners (two different liner films that abut at an interface).

Owner:GLOBALFOUNDRIES US INC

Methodology for layout-based modulation and optimization of nitride liner stress effect in compact models

ActiveUS7337420B2CAD circuit designSoftware simulation/interpretation/emulationModel systemStress variation

System and method for compact model algorithms to accurately account for effects of layout-induced changes in nitride liner stress in semiconductor devices. The layout-sensitive compact model algorithms account for the impact of large layout variation on circuits by implementing algorithms for obtaining the correct stress response approximations and layout extraction algorithms for obtaining the correct geometric parameters that drive the stress response. In particular, these algorithms include specific information from search “buckets” that are directionally-oriented and include directionally-specific distance measurements for analyzing in detail the specific shape neighborhood of the semiconductor device. The algorithms are additionally adapted to enable the modeling and stress impact determination of a device having single stress liner film and dual-stress liners (two different liner films that abut at an interface).

Owner:GLOBALFOUNDRIES U S INC

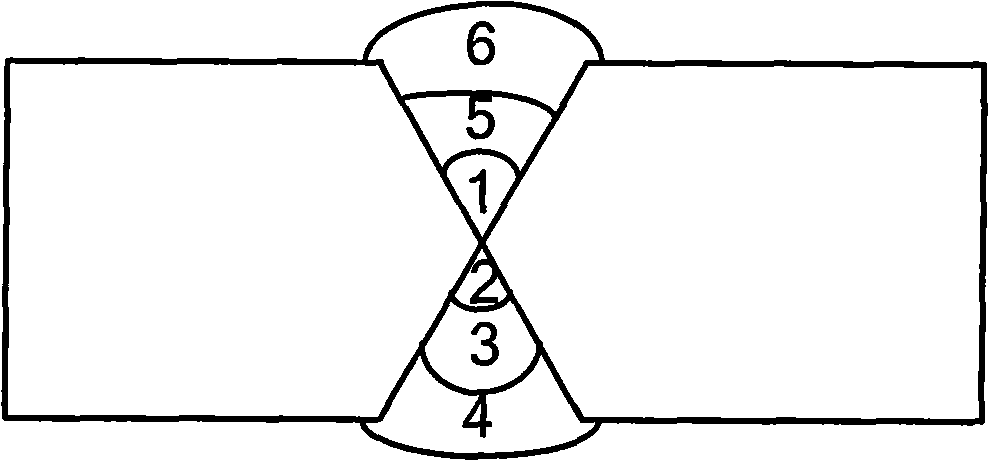

Method for measuring welding residual stress

InactiveCN101539506AReduce additional stressIntegrity guaranteedUsing mechanical meansMaterial analysisThick plateWelding residual stress

The invention relates to a method for measuring welding residual stress-a partial layer-by-layer blind hole removing method for measuring the residual stress on the basis of a blind hole method, which proposes to measure the residual stress in a component by using the partial layer-by-layer blind hole removing method. After materials of certain depth on both the front side and the opposite side of a component to be measured are partially removed, the blind hole method is used for measuring the residual stress. The method is a semi-destructive residual stress measuring method, can be used for carrying out multi-point measurement and measuring the residual stress in the component with severe stress change and has convenient operation and high measuring efficiency. Proved by a thick plate carbon steel welding residual stress measuring test, the method has more accurate measuring results.

Owner:XI AN JIAOTONG UNIV

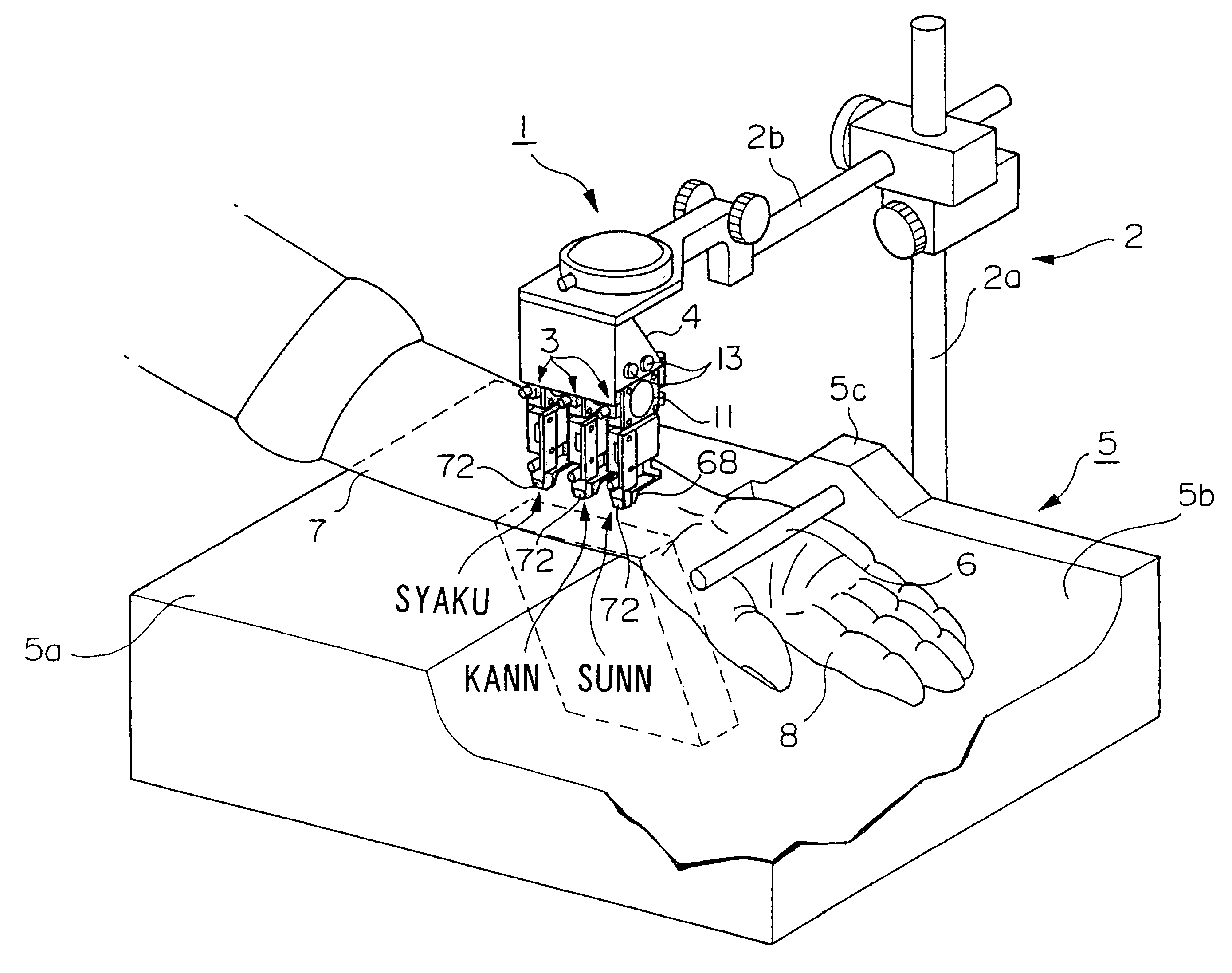

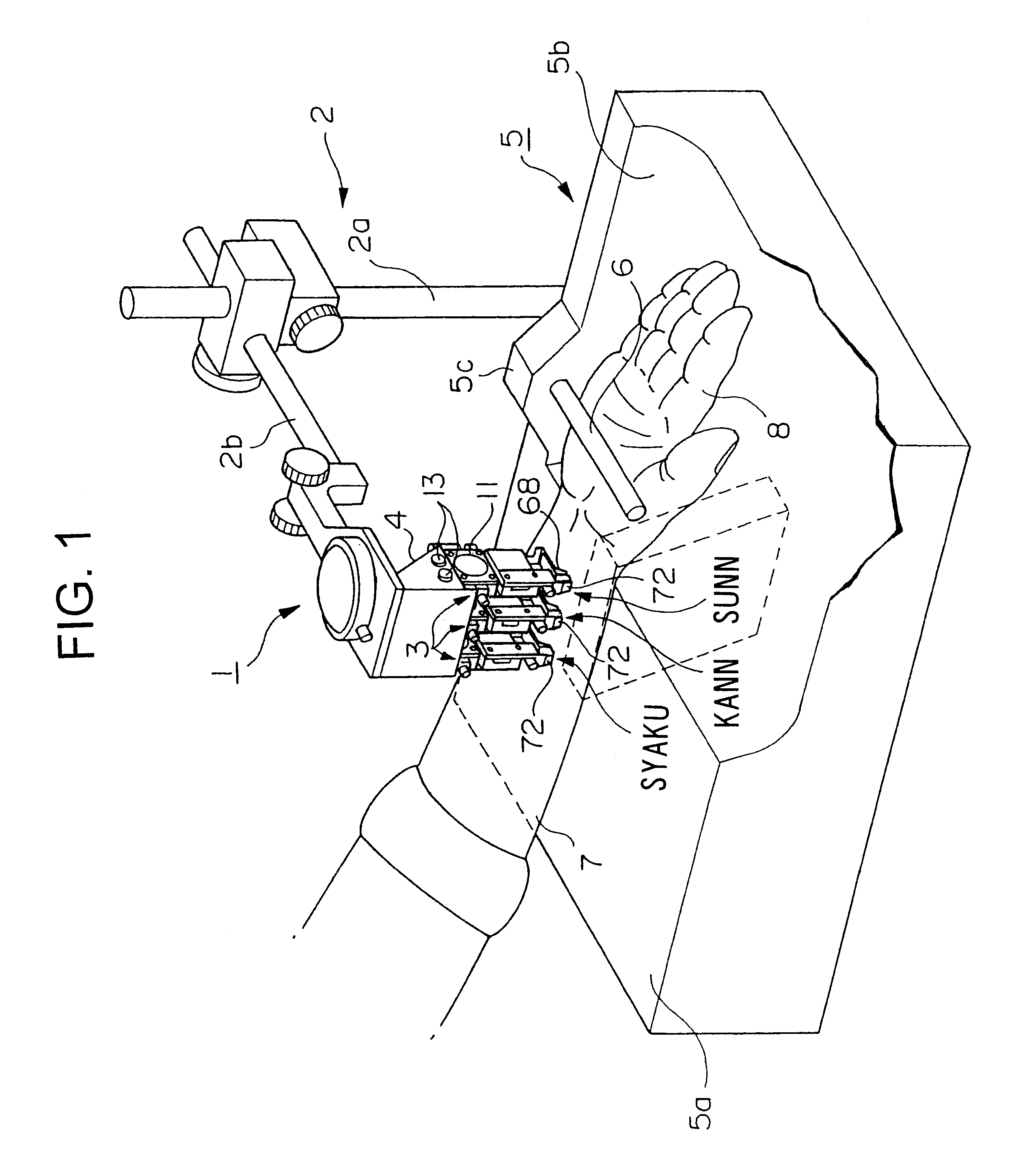

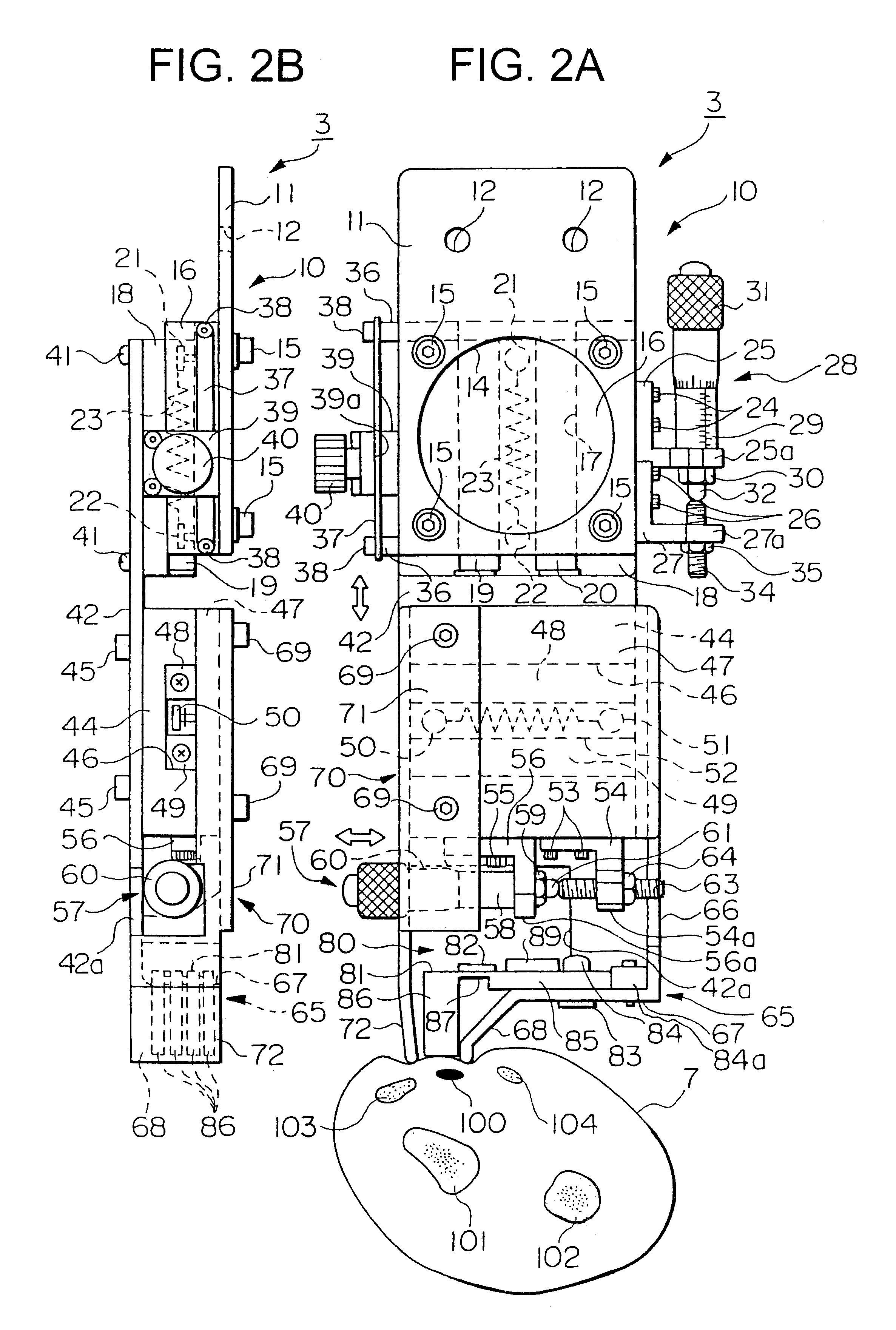

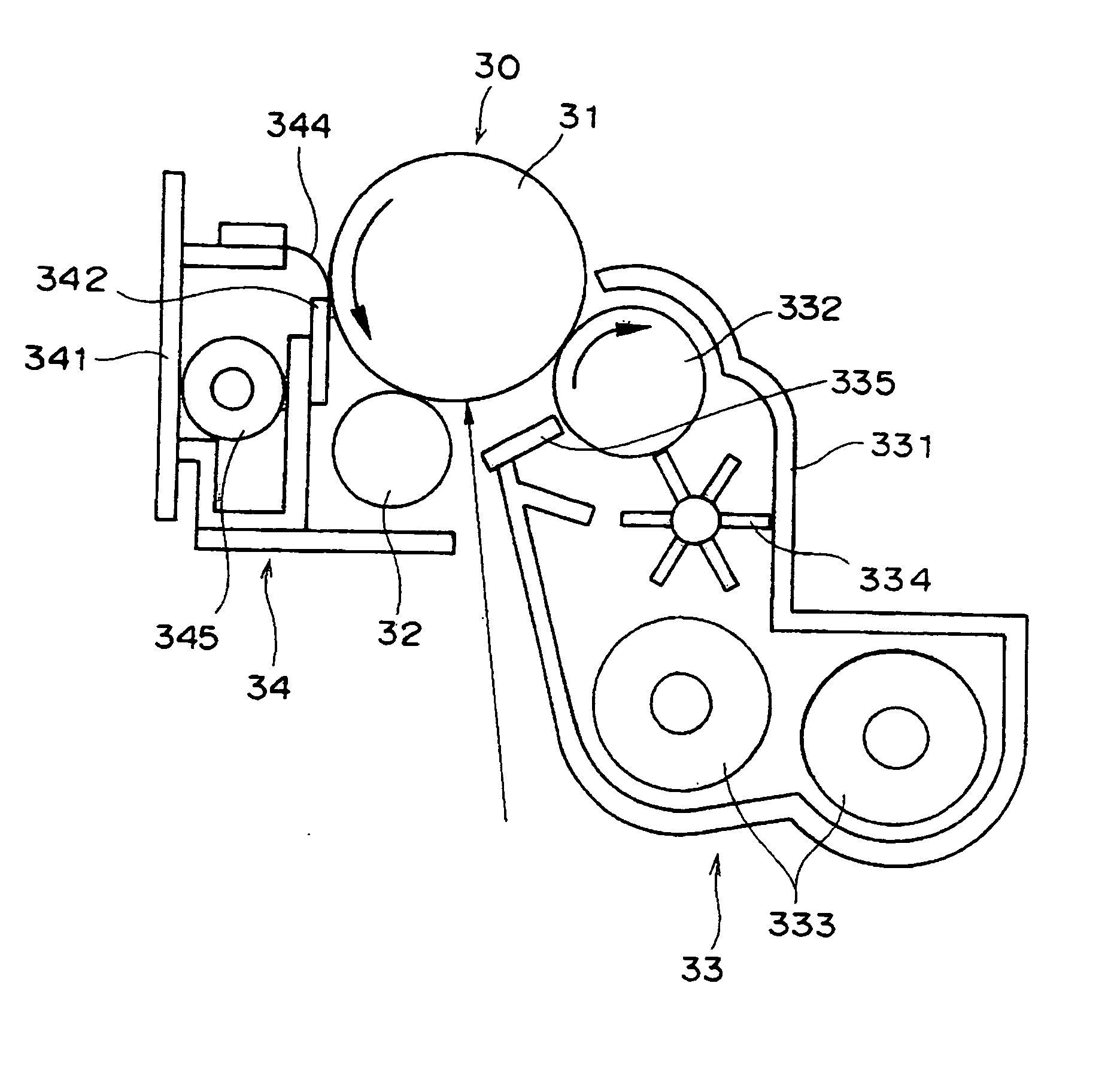

Blood pulse measuring device, pulsation measuring device, and pressure measuring device

A pulse wave measuring device is provided with a plurality of pulse wave measuring units. Each pulse wave measuring unit has a supporting member to which a beam of a pressure measuring device is attached. Contact portions at the distal end of the beam is in contact with the patient's arm, so that piezoelectric elements mounted on the beam measures the stress variation according to pulsation of the patient's radial artery. The supporting member has two pressing legs between which the contact portions of the beam are situated. The distal ends of the pressing legs are also pressed against the patient's arm. The pressing legs are harder than the radial artery. The interval between the pressing legs can be altered by handling a micrometer head. The contact portions are situated back from the distal ends of the pressing legs.

Owner:SEIKO EPSON CORP

Method for testing electrochemical corrosion of welded pipe seam in high-stress state and sample of welded pipe seam

InactiveCN101608995ACorrosion Resistance EvaluationFix damageWeather/light/corrosion resistanceMaterial electrochemical variablesSalt bridgeAuxiliary electrode

The invention relates to a method for testing electrochemical corrosion of a welded pipe seam in a high-stress state, which utilizes an electronic universal testing machine, an electrolytic cell component comprising a working electrode, an auxiliary electrode, a reference electrode, a salt bridge and the like, and an electrochemical workstation. Under a load stress of between 0 and 800 MPa, the stress change caused by stress relaxation is corrected regularly by a constant potential method or a constant current method to test the circumferential tensile stress of the welded pipe seam and the circumferential tensile stress of the working electrode. A tensile sample is wide and thick at both ends and narrow and thin in the middle part and is provided with connection holes at both ends. A groove corrosion depth d1 and an average corrosion depth d2 of the working electrode are tested under different loads, so a groove corrosion susceptibility coefficient alpha, alpha=d1 / d2, of the working electrode in practical application can be obtained. The method has no stress relaxation, and the stress is convenient to regulate during test; the sample is free from generating plastic deformation or detachment under the load of high stress, and can be used for corrosion test under the condition of high stress; and the electrochemical workstation can be made full use for testing.

Owner:BAOSHAN IRON & STEEL CO LTD

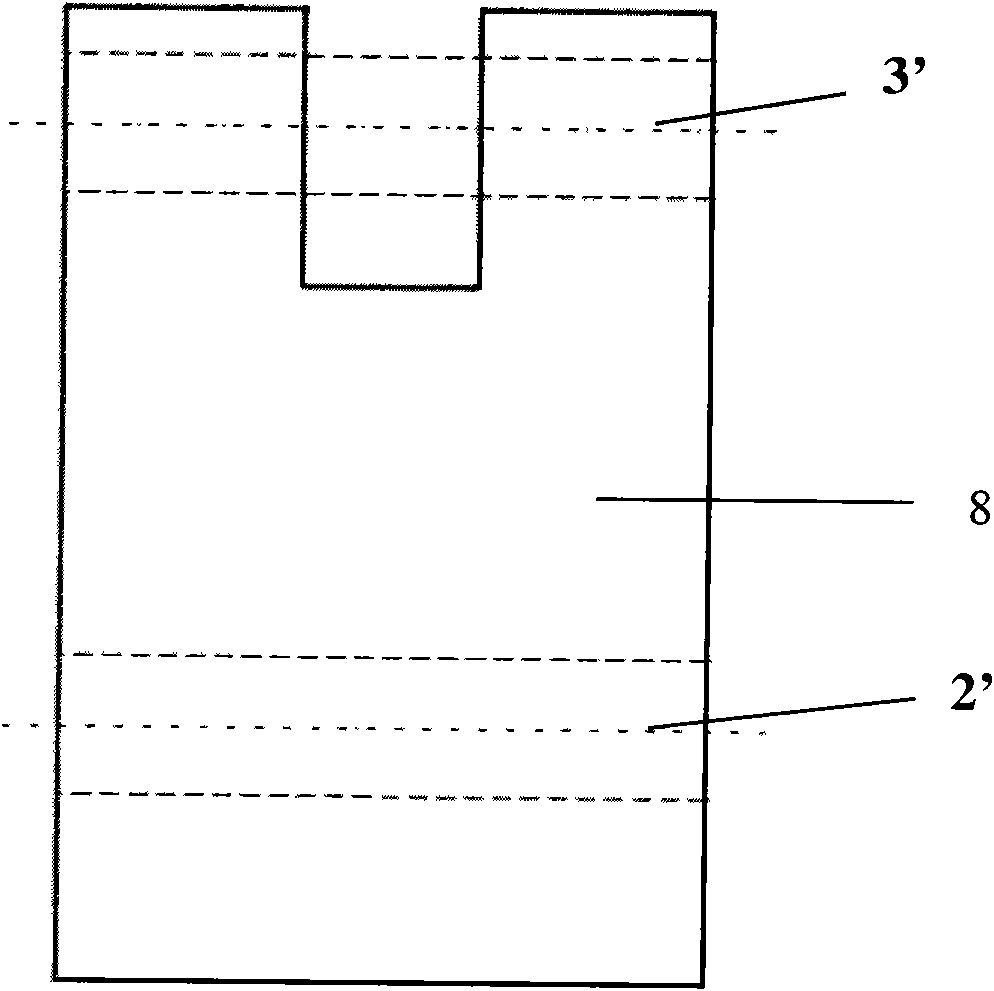

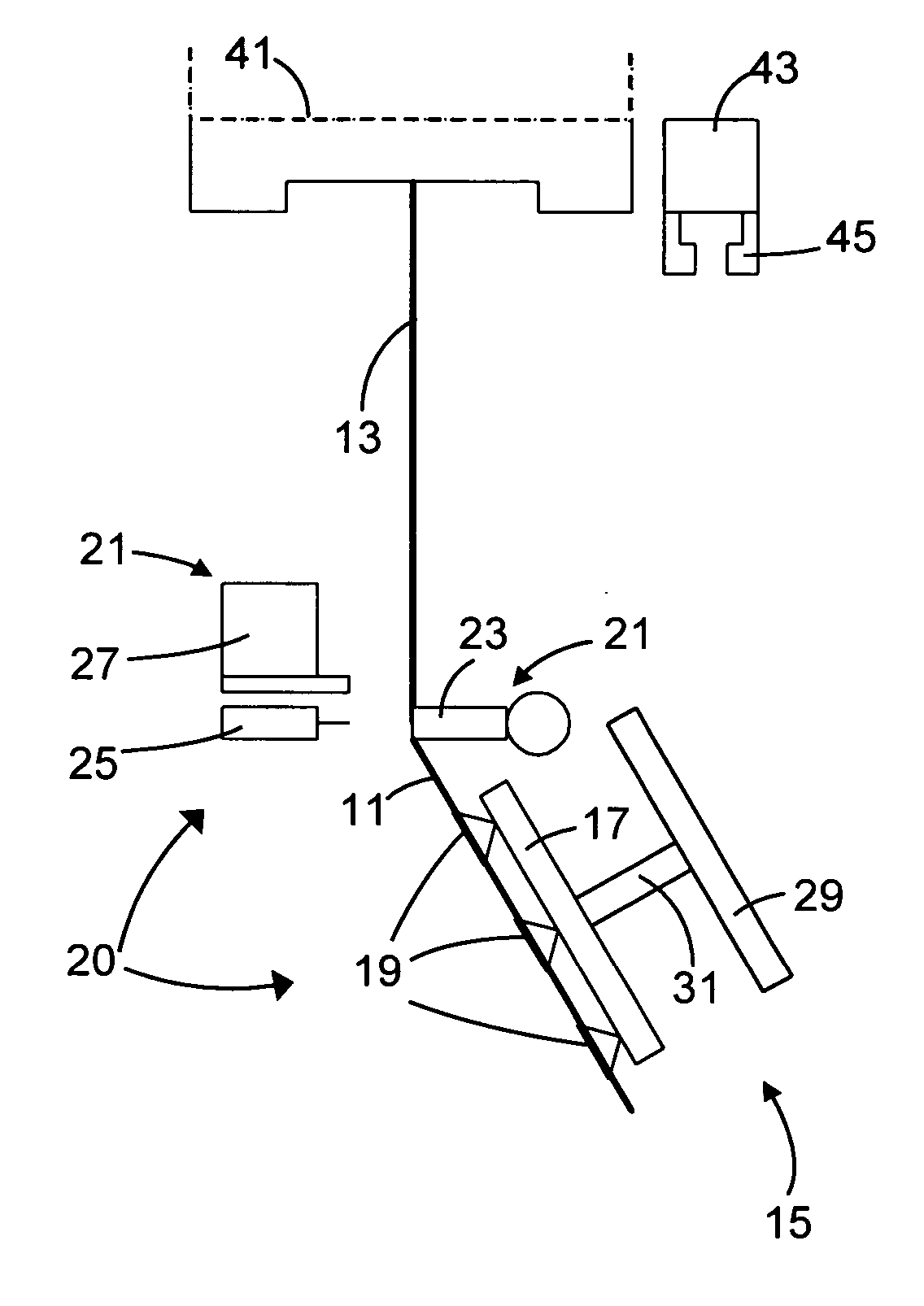

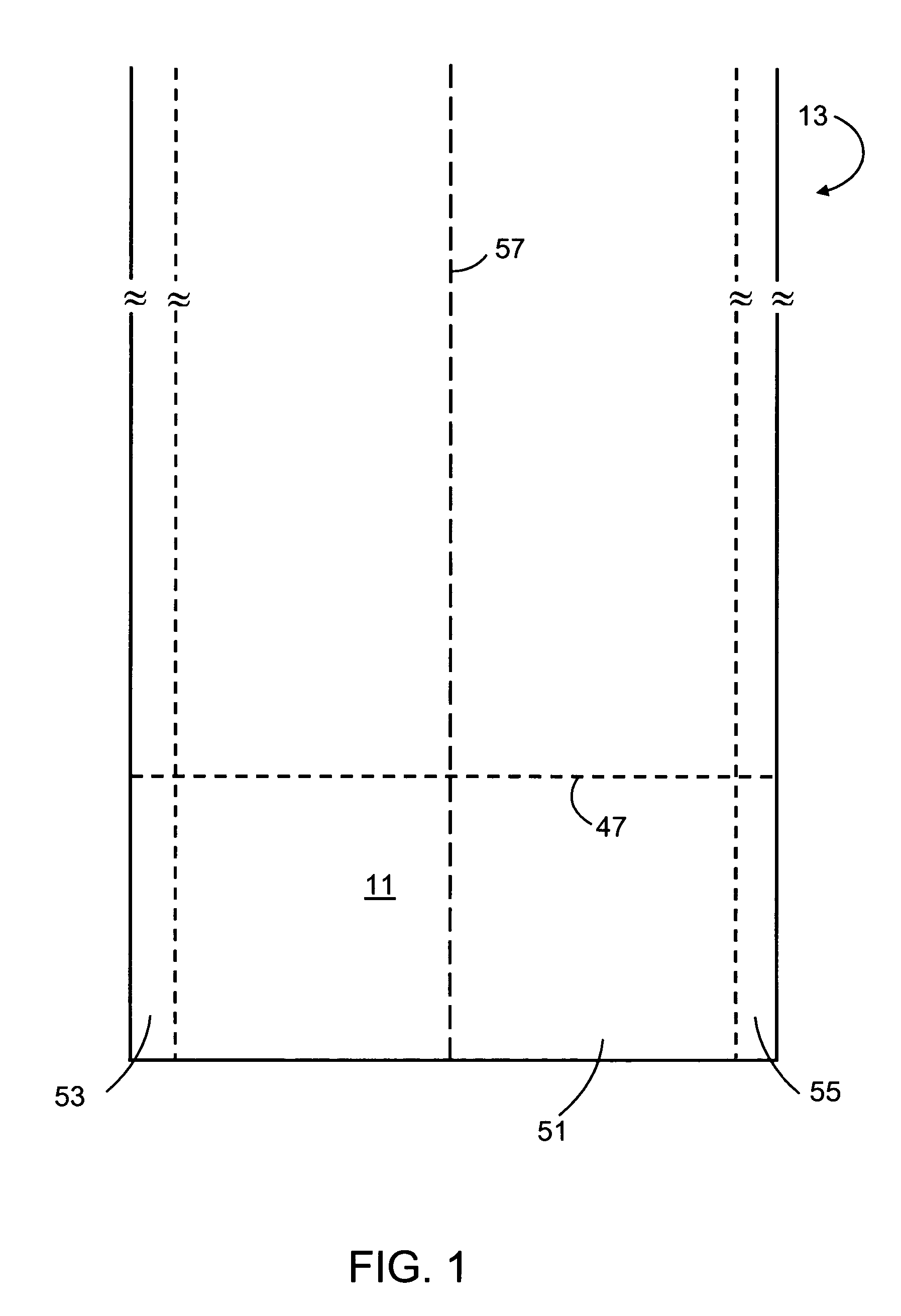

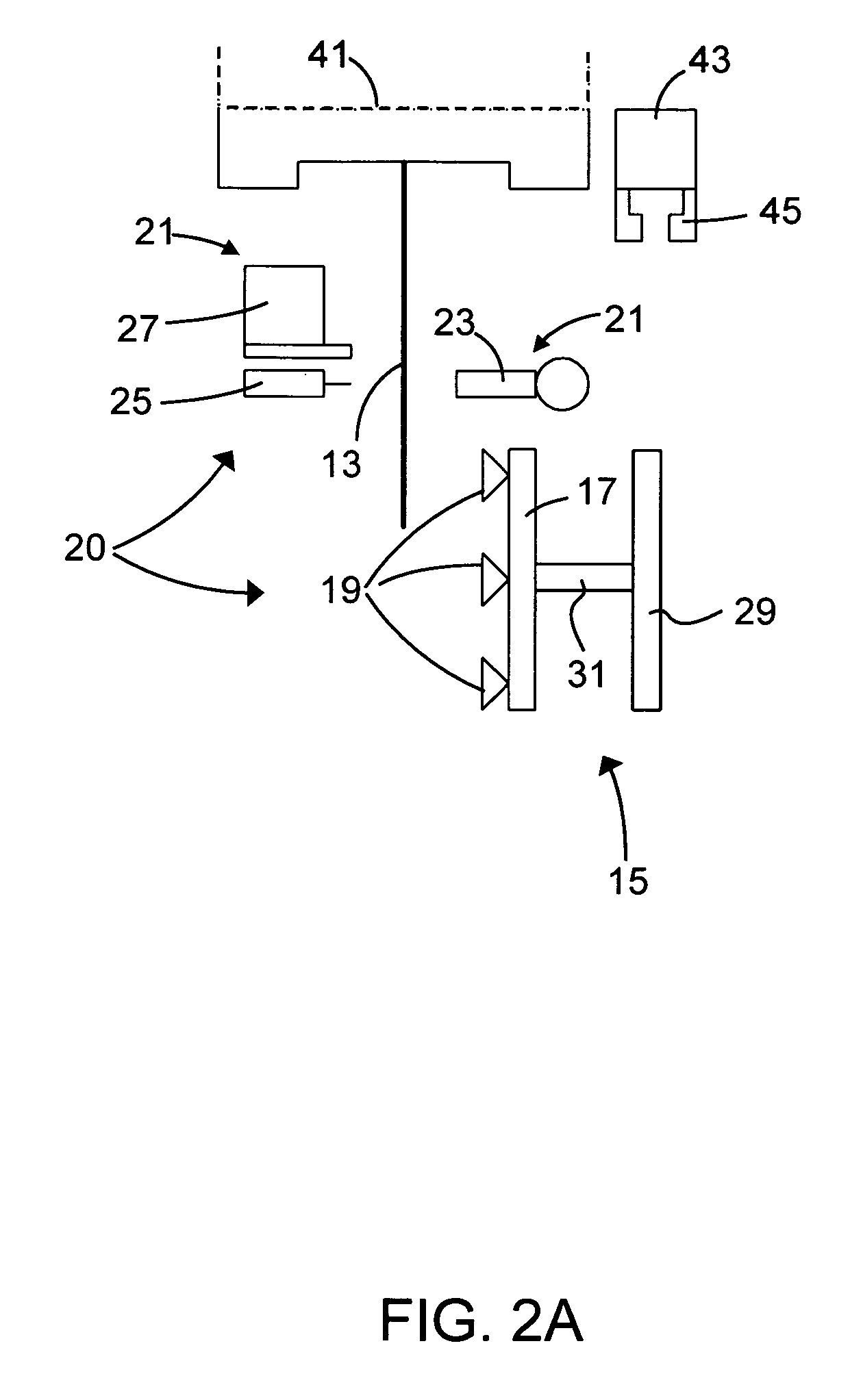

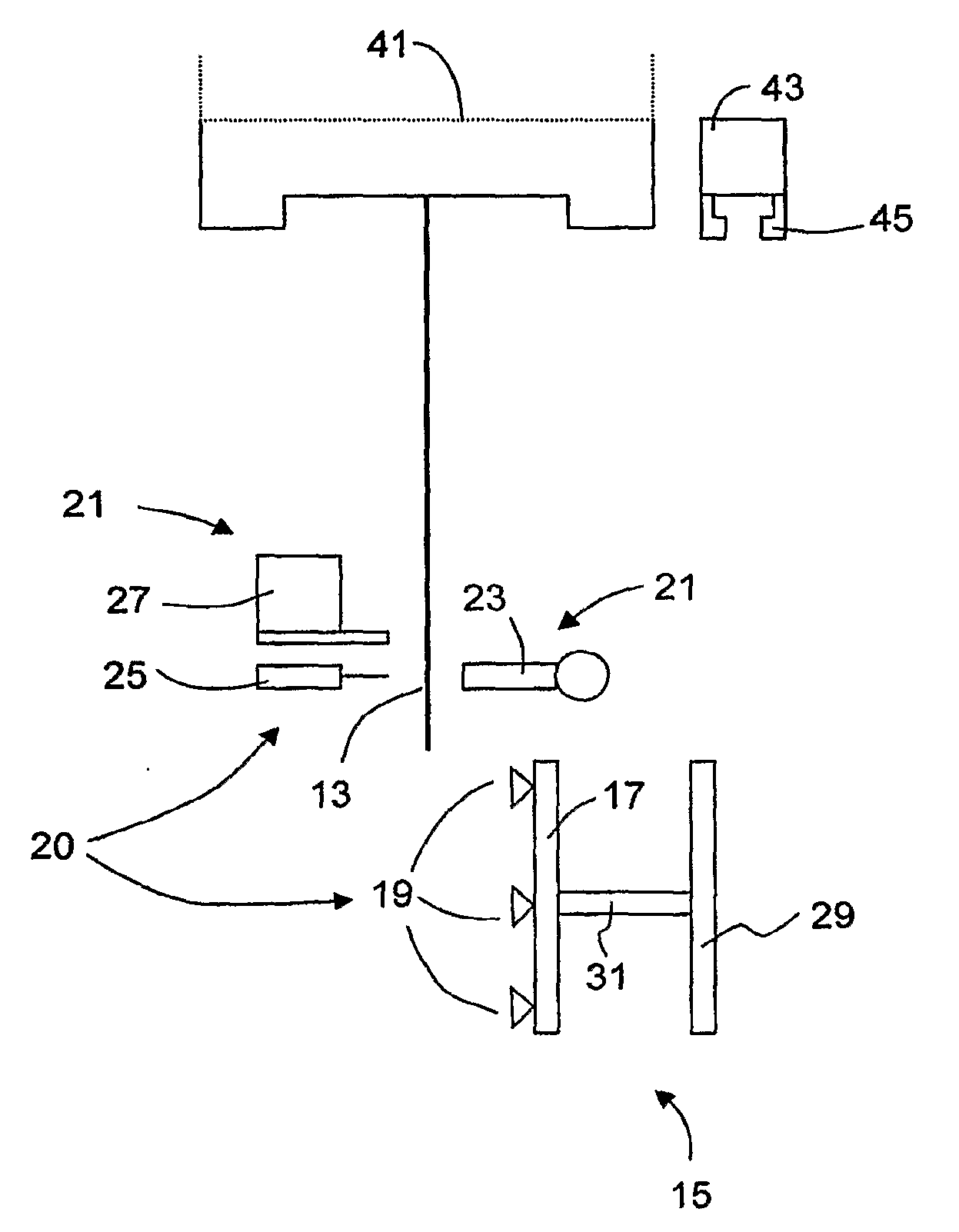

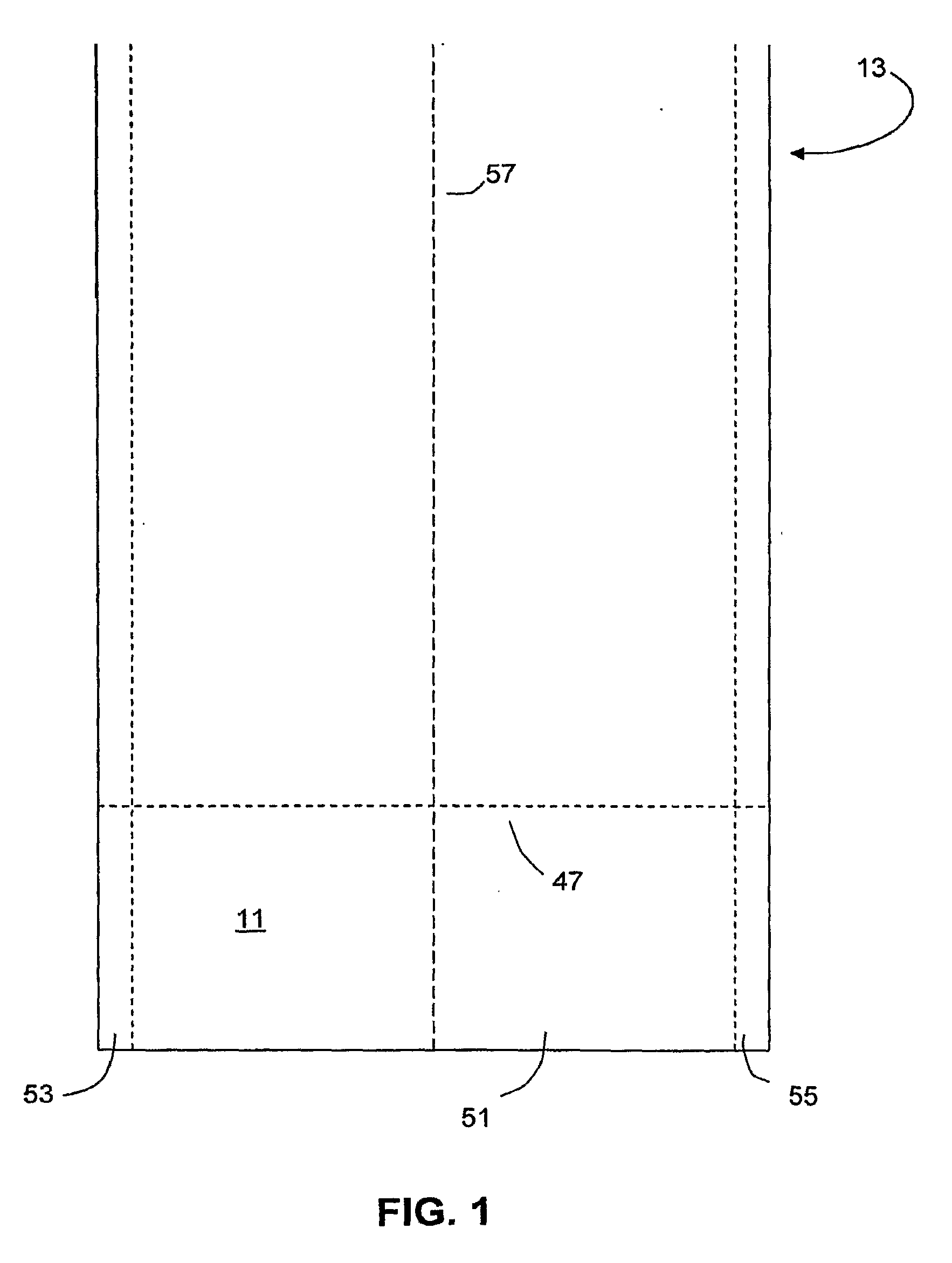

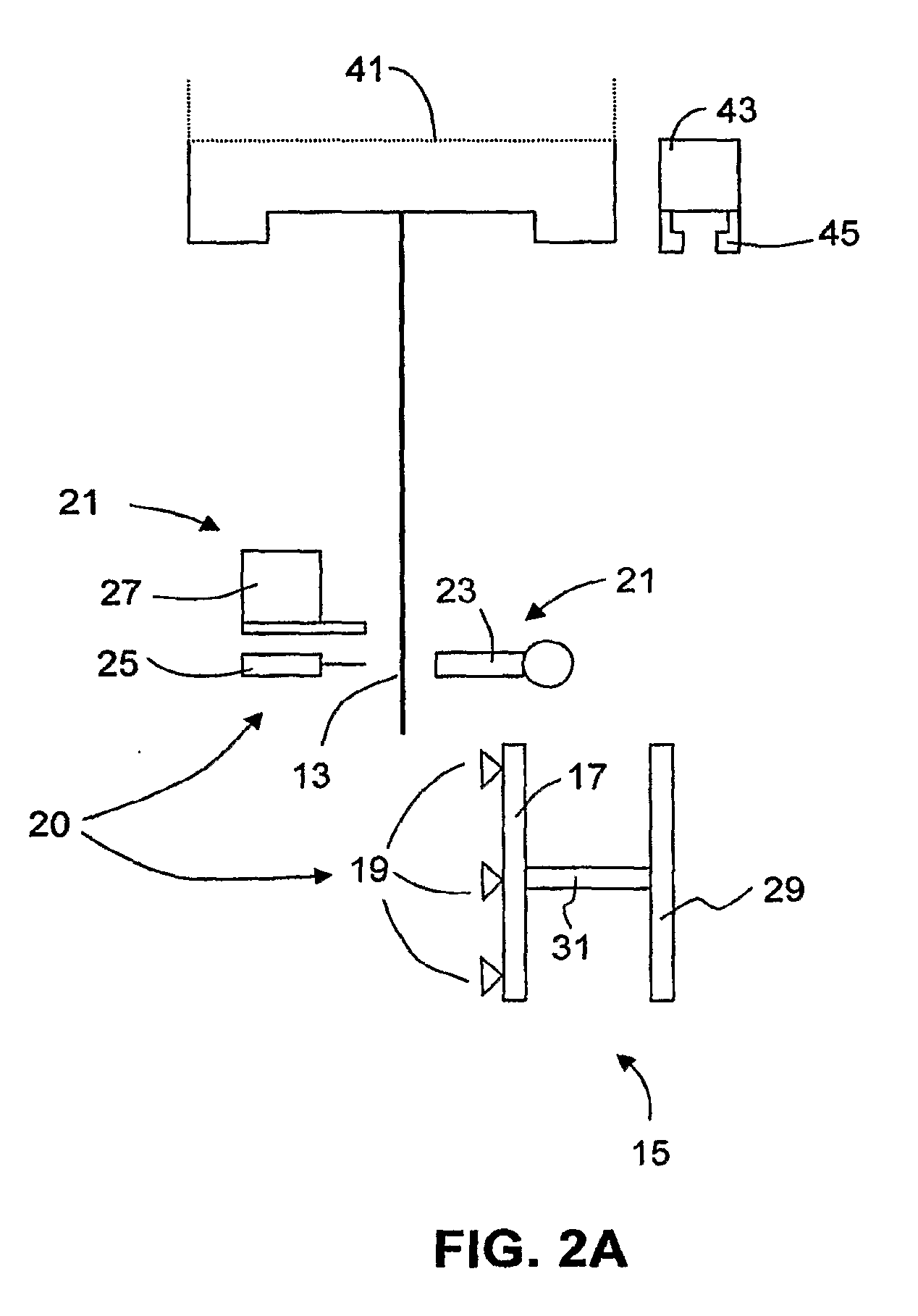

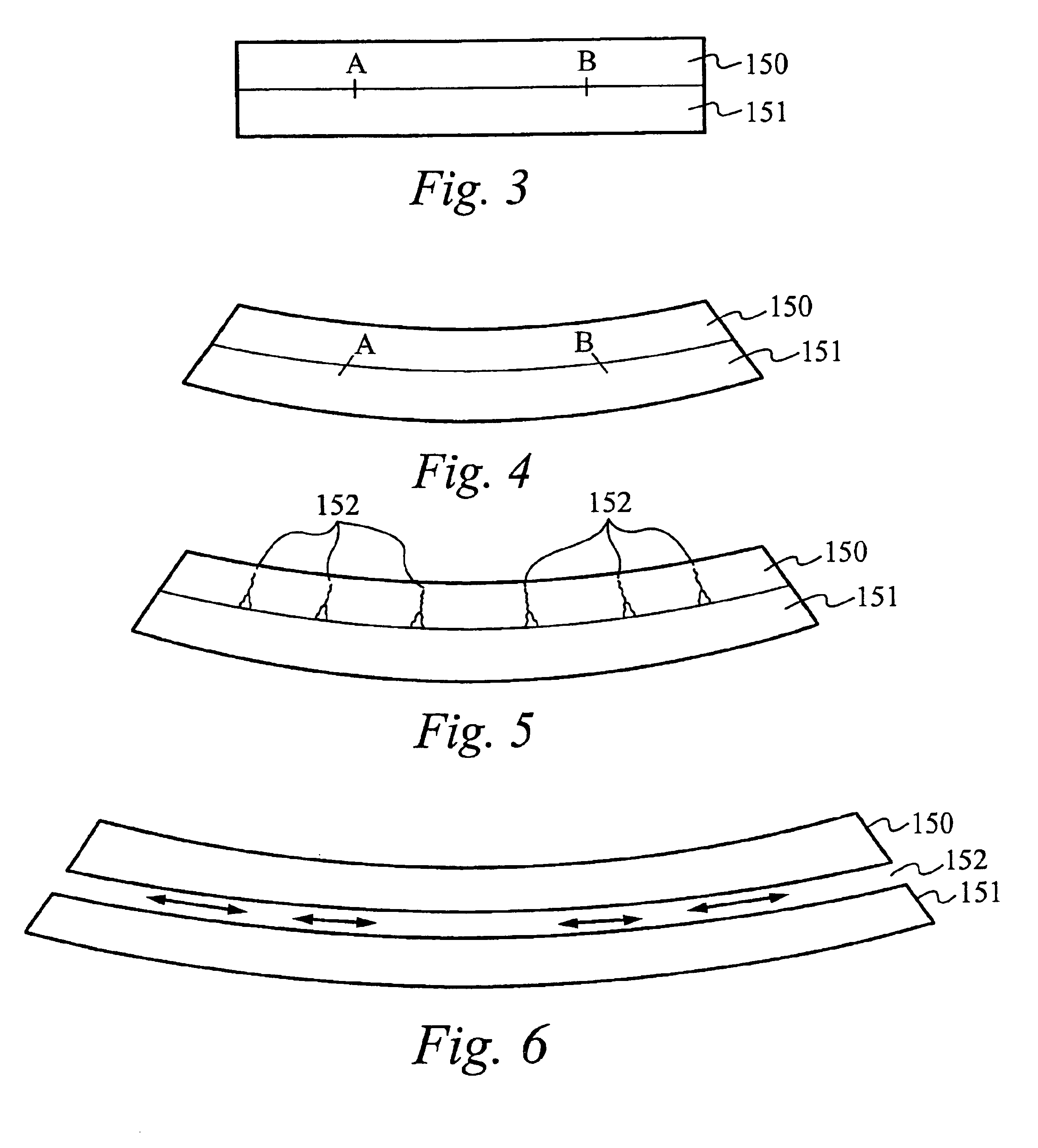

Methods and apparatus for reducing stress variations in glass sheets produced from a glass ribbon

InactiveUS20070095108A1Reduce exerciseStress variationRotary drum furnacesGlass transportation apparatusStress levelStress variation

Apparatus and methods are provided for reducing the variability of stress levels in glass sheets (11) cut from a moving glass ribbon (13). The reductions in variability are achieved by constraining the edge regions (53,55) of the ribbon (13) from movement in a horizontal plane at at least one location below the location where a separating assembly (20) forms a separation line (47) in the ribbon (13). Sets of vertically arranged wheels (35) which engage the edge regions (53,55) of the ribbon (13) can be used to provide the horizontal constraint without compromising the central, quality area (51) of the glass ribbon (13).

Owner:CORNING INC

Methods And Apparatus For Reducing Stress Variations in Glass Sheets Produced From a Glass Ribbon.

ActiveUS20100043495A1Reduce exerciseStress variationConveyorsGlass drawing apparatusStress levelStress variation

In a vertical glass drawing process, an edge guiding assembly (33) located between a glass forming apparatus (41) and a glass sheet separating apparatus (20) reduces horizontal motion of the glass ribbon (13) from which the glass sheets (11) are removed and results in the reduction of the difference in stress levels between the top and bottom edges of a glass sheet (11) made by the process. The edge guiding assembly also provides a reduction of the variation of stress levels between successive sheets of glass made by the vertical drawing process.

Owner:CORNING INC

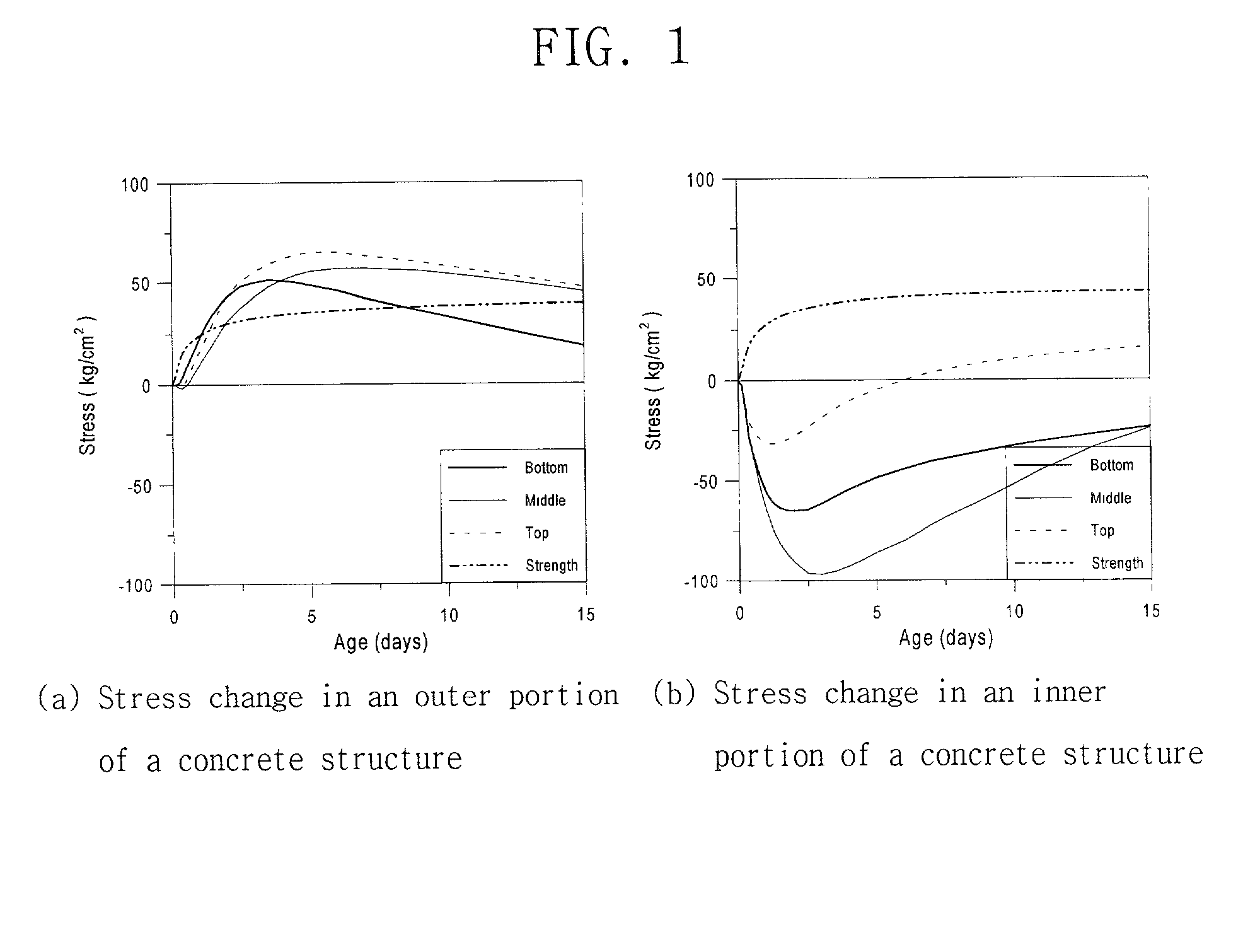

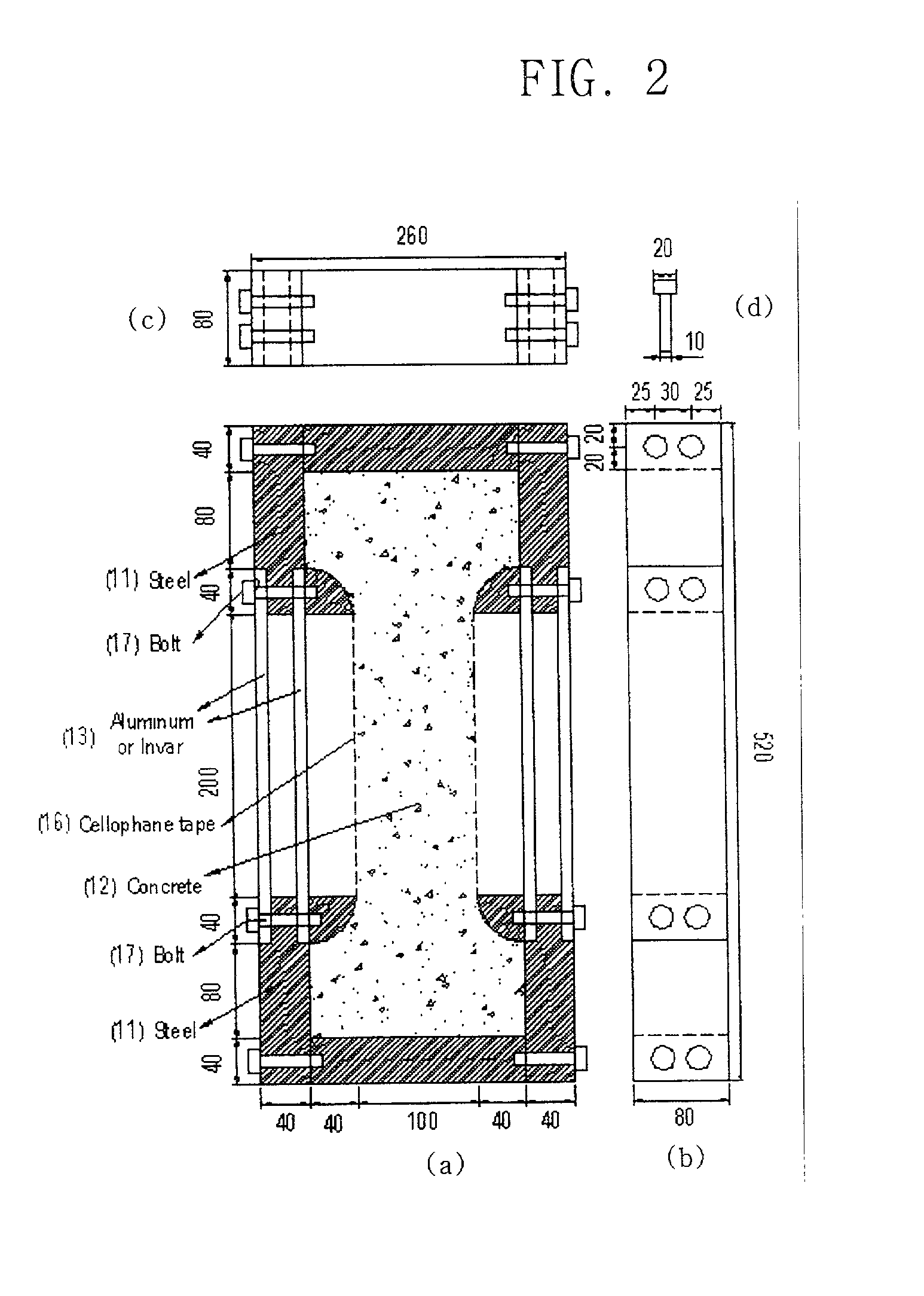

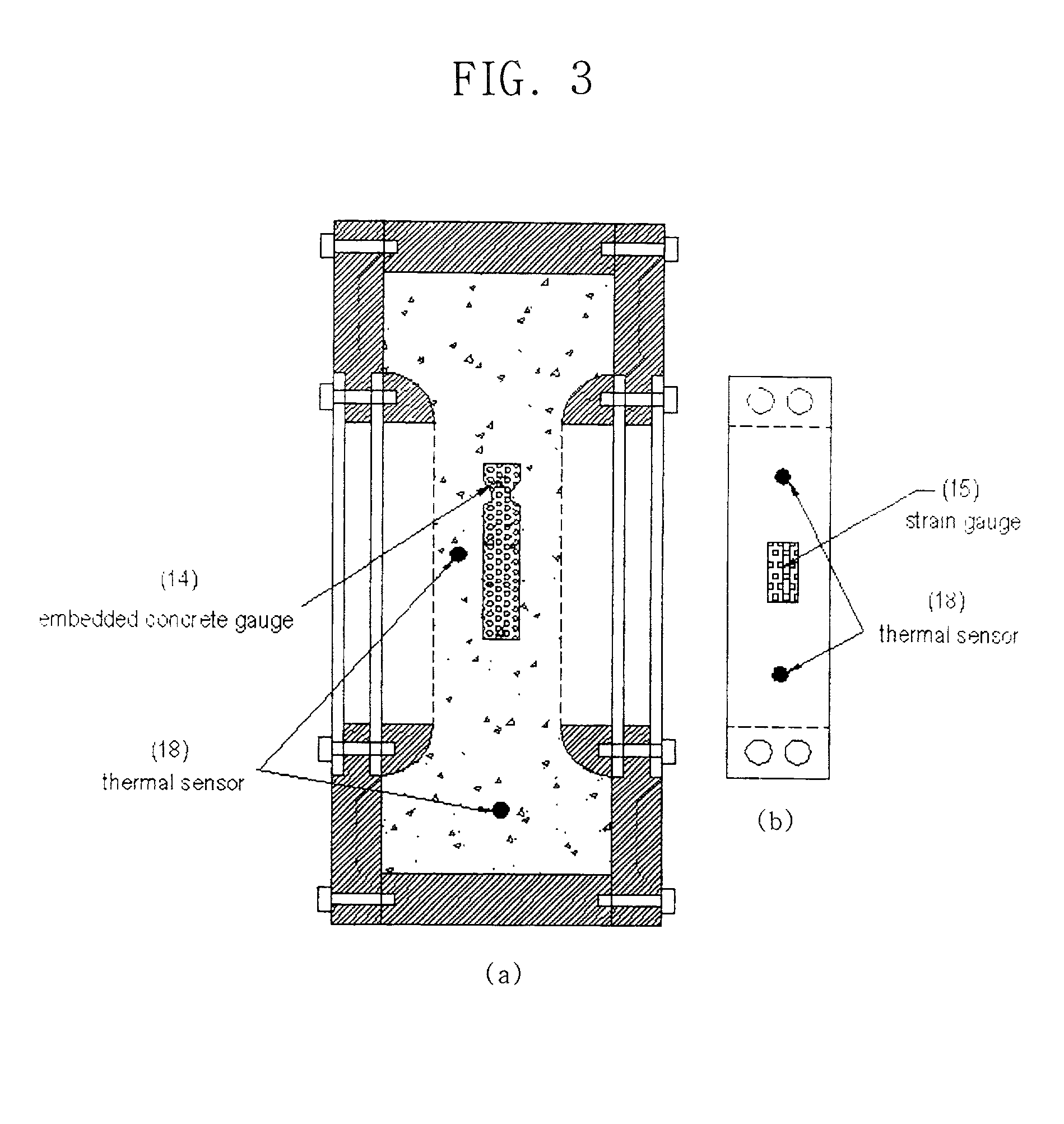

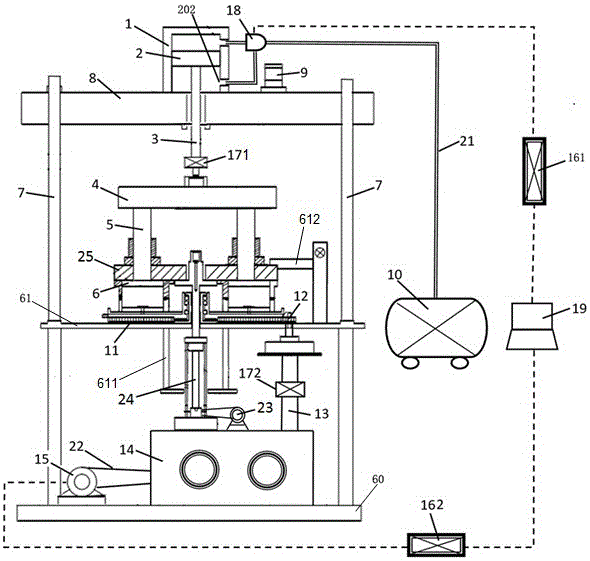

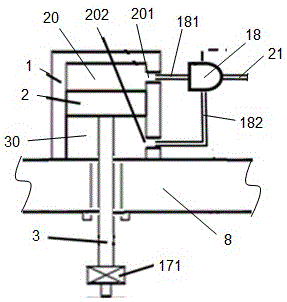

Apparatus for and method of measuring thermal stress of concrete structure

InactiveUS20010049968A1Material thermal coefficient of expansionForce measurementStress variationThermal expansion

Disclosed are a testing apparatus for and a method of measuring thermal stresses of concrete structures. Overcoming the limitations that conventional analytical access techniques have, the apparatus opens a new way to conveniently measure the thermal stress attributable to the heat of hydration generated in concrete structures indoors. Using a material different in coefficient of thermal expansion from concrete, the apparatus can directly measure the change in thermal stress of the concrete which is subjected to internal and / or external confinement. By using various materials, the thermal stress which varies depending on the confinement extent can be inferred. Additionally, an accurate prediction of the thermal stresses generated actually in concrete can be obtained, reflecting unclear physical properties of early-age concrete.

Owner:KOREA ADVANCED INST OF SCI & TECH

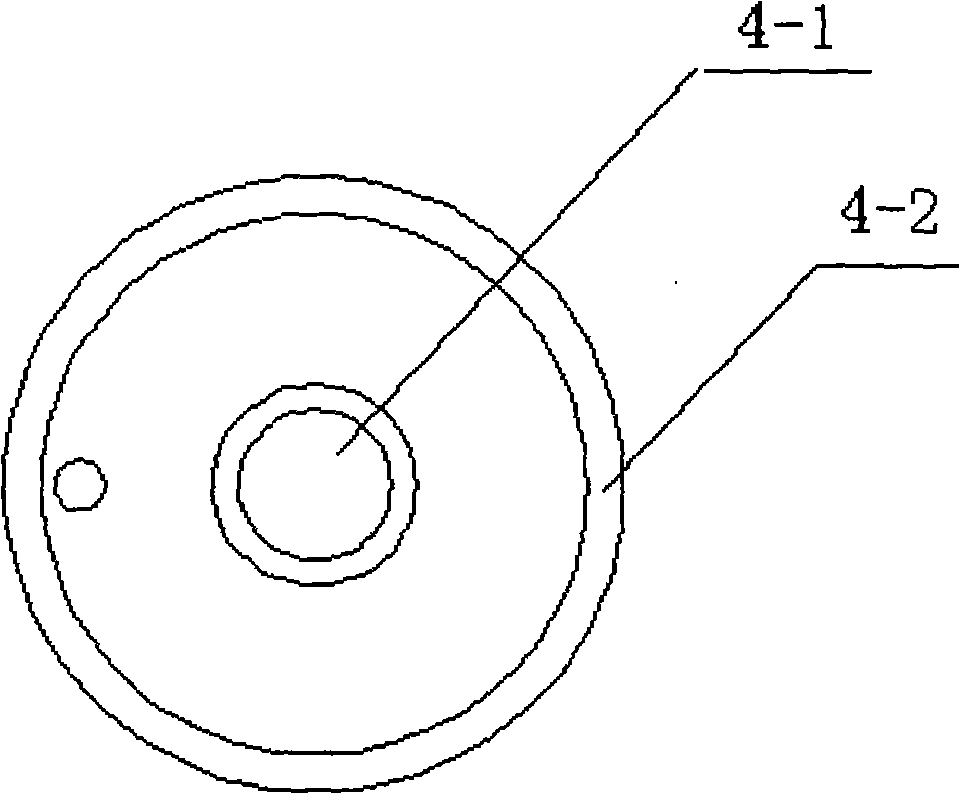

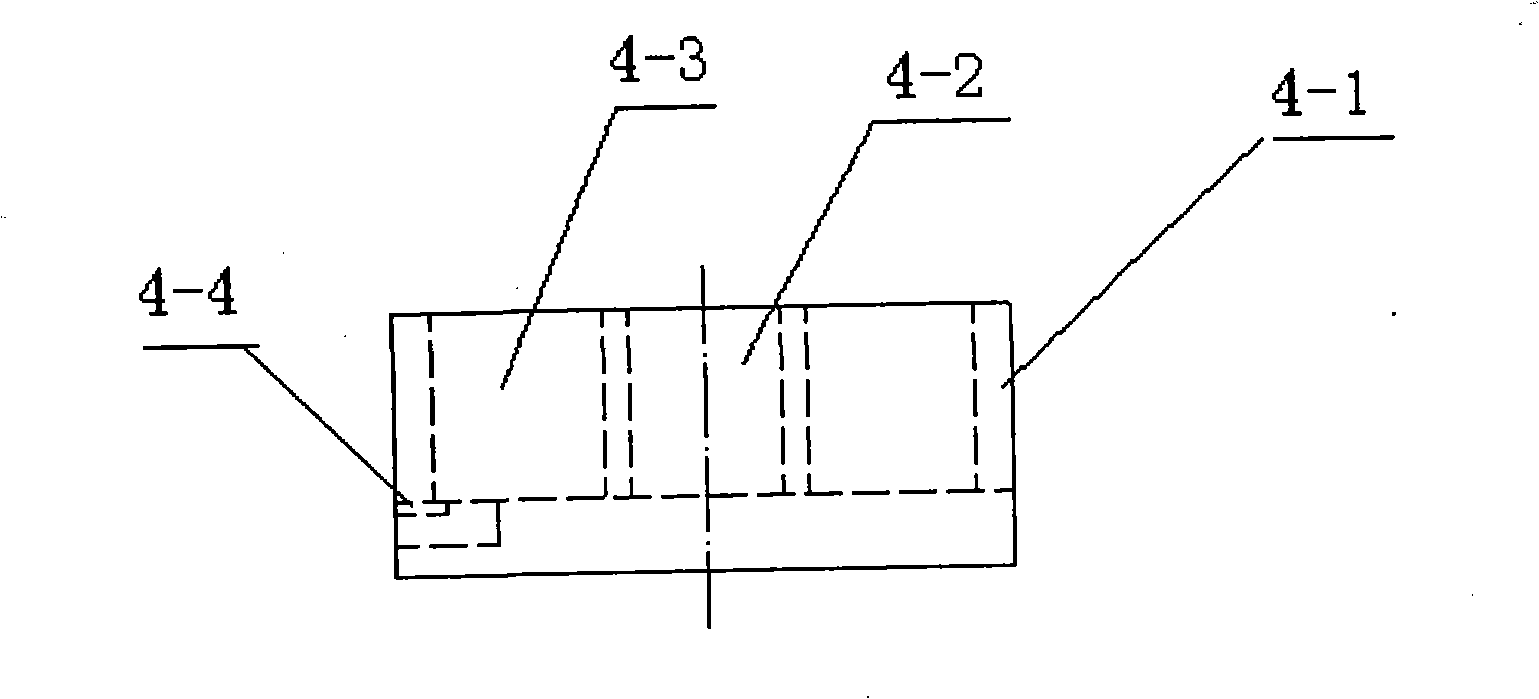

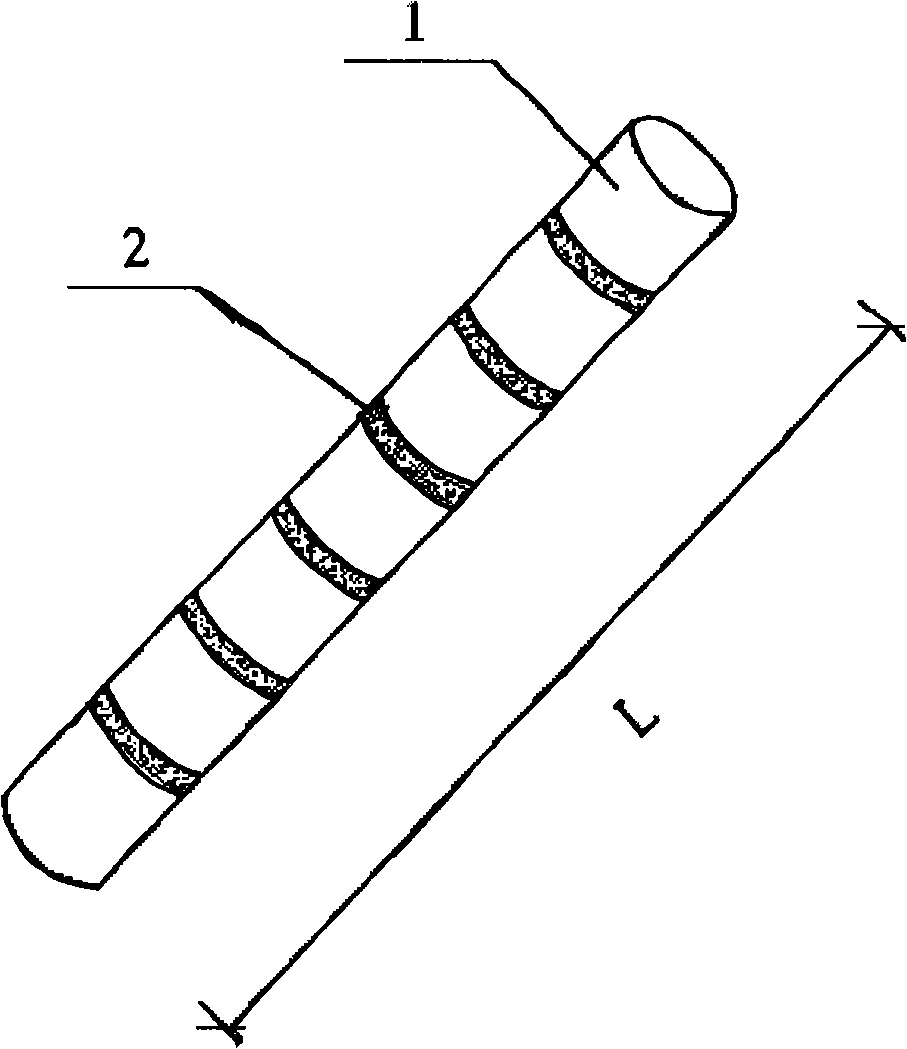

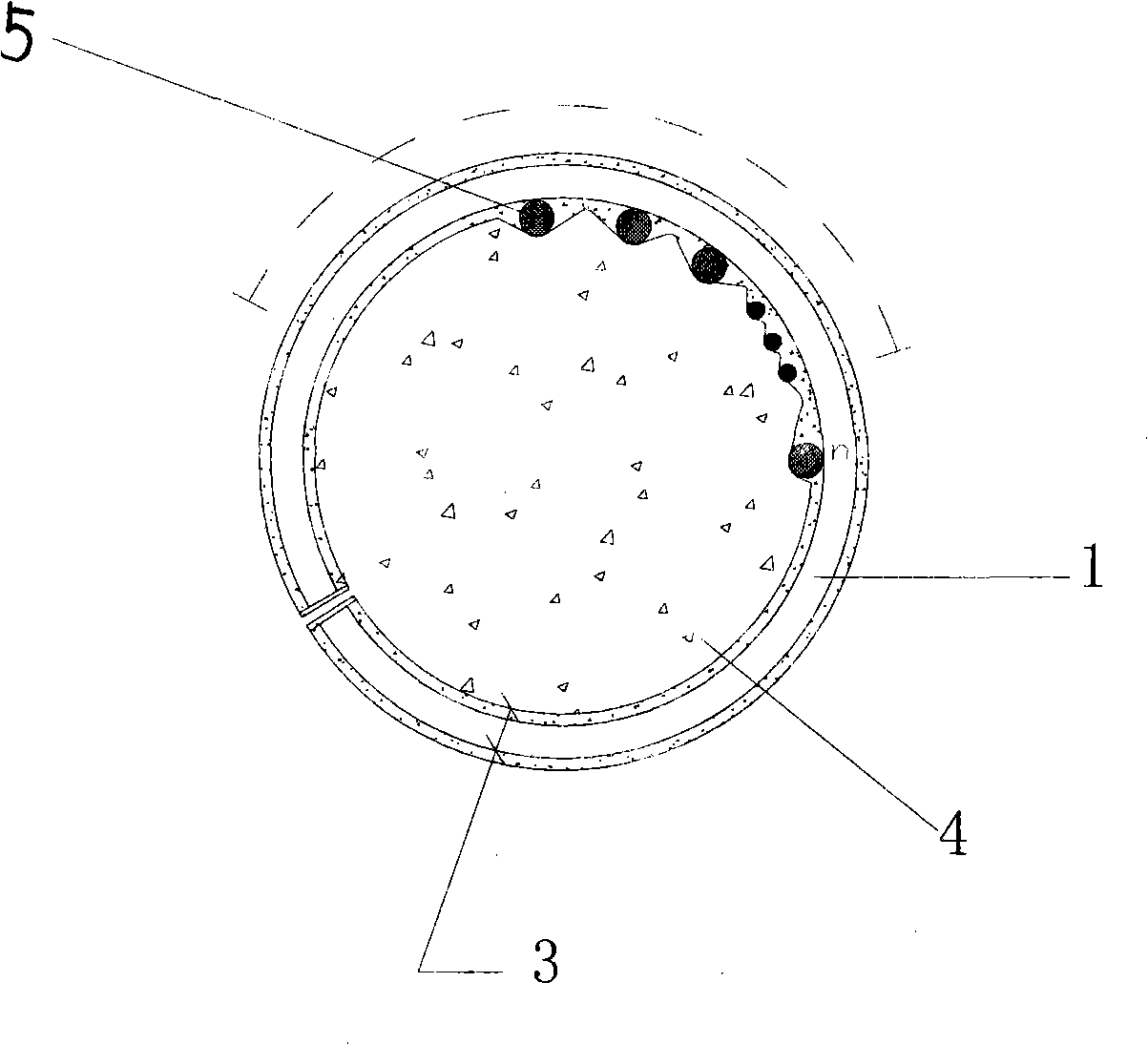

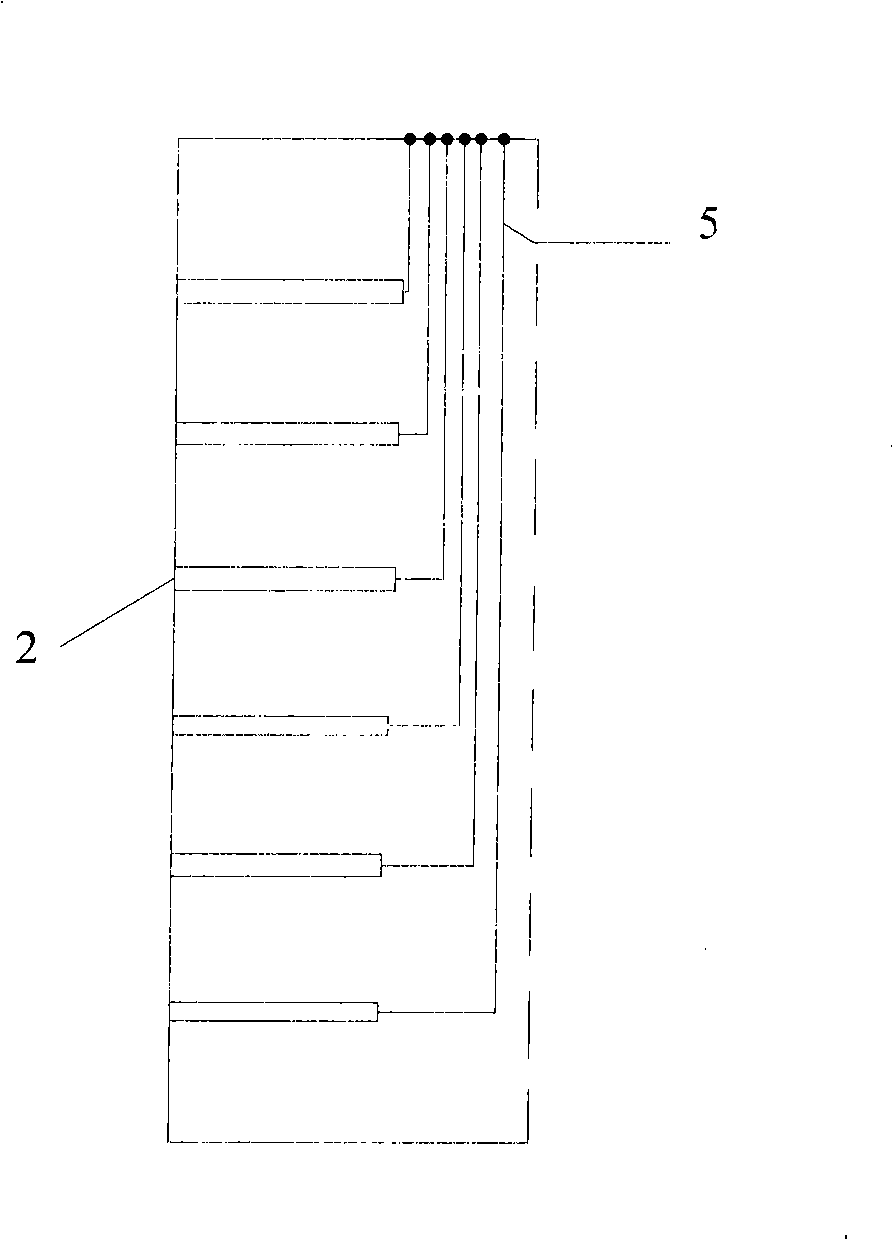

Grating anchor rod force-measuring device and method for monitoring anchor rod stress variation

InactiveCN101358886ASmall sizeReduce weightForce measurement by measuring optical property variationFiberGrating

The invention discloses an optical fiber raster anchor rod dynamometry device and an application method thereof, wherein, a manometer is connected with an oil pipe; a horizontal pipe is connected with a hydraulic cylinder; an anchor rod is inserted in the inner hole of the hydraulic cylinder; an vertical pipe is connected with an optical fiber raster sensor; the inside of the shell of the optical fiber raster sensor is connected with a cladding and a fiber core which is connected with a raster; the two ends of the fiber core are connected with an optical fiber raster sensing network analyzer and a computer. In the dynamometry device and the application method, an optical fiber raster demodulator detects the variation of the wavelength and converts the variation of the wavelength into an electrical signal; the optical fiber raster sensing network analyzer calculates the stress and strain of a point to be tested and a distribution state in the whole point to be tested; an optical fiber raster wavelength demodulation analyzing soft reads a testing data; a unitary linear regression model is established for getting the stress and strain value of the point to be tested under the action of external force, the invention has a simple structure, low cost and good anti-interference performance. Multi-parameter sensing measurement has a measurement with high precision and stable performance, which can be largely applied to the field of mine, tunnel or side slope, etc., and the signal can be transmitted far.

Owner:XIAN UNIV OF SCI & TECH

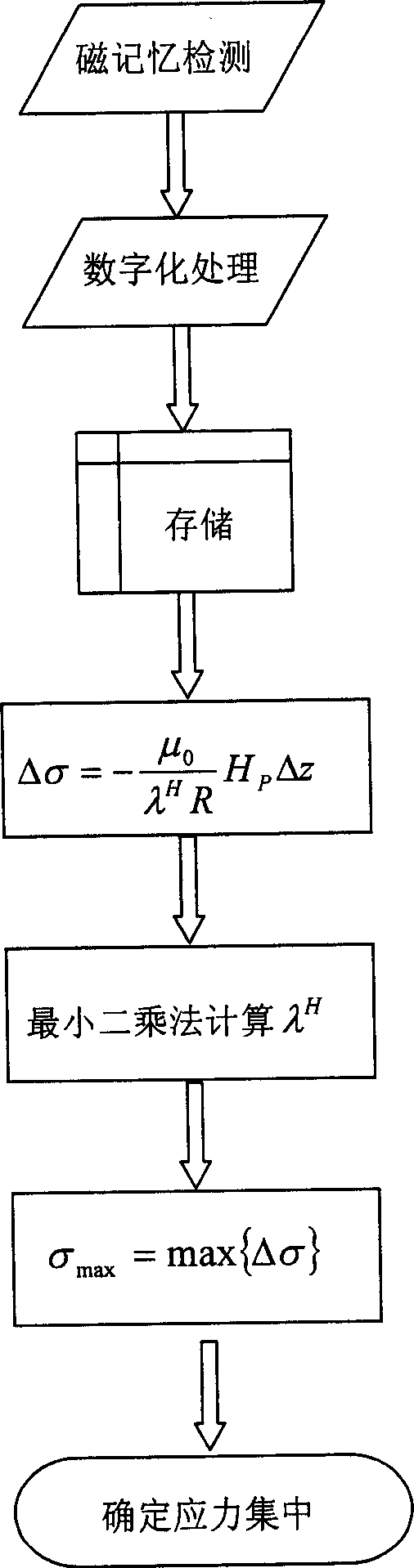

Method of determining pipeline welding crack stress concentration using metal magnetic memory detection technology

InactiveCN1793894AImplement security assessmentSpecial data processing applicationsWelding apparatusStress concentrationMagnetic memory

A method of using metal magnetic memory detection technique to confirm welding crack stress concentration of piping includes digitalizing magnetic memory signal obtained by metal magnetic memory detector and storing digital file in computer, confirming relation of pipe wall internal stress to self leakage magnetic field reacted by metal magnetic memory signal according to magnetic field Gauss theorem, defining maximum value of stress variation on welding crack pointed end as measuration of stress concentration degree on welding crack pointed end.

Owner:TIANJIN UNIV

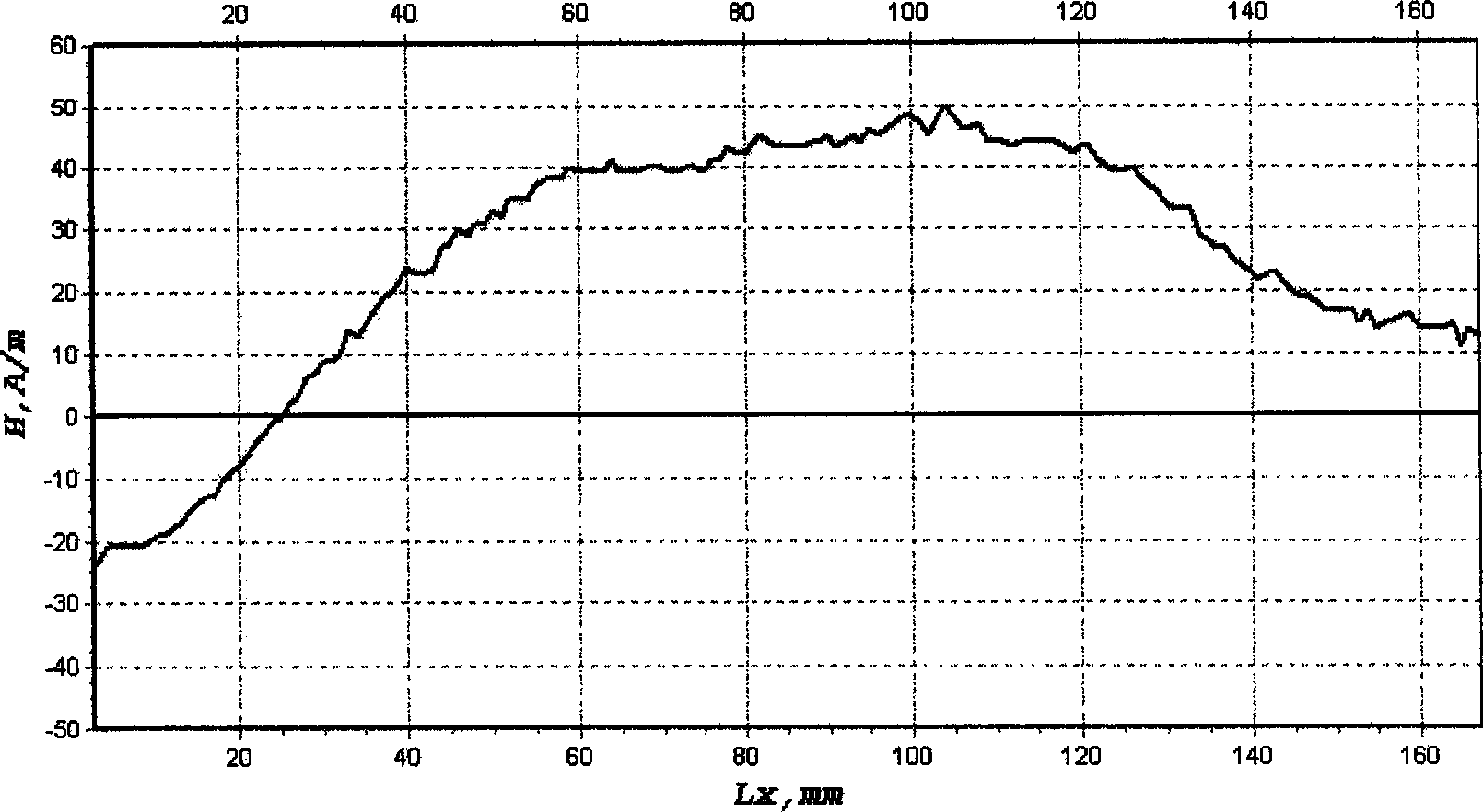

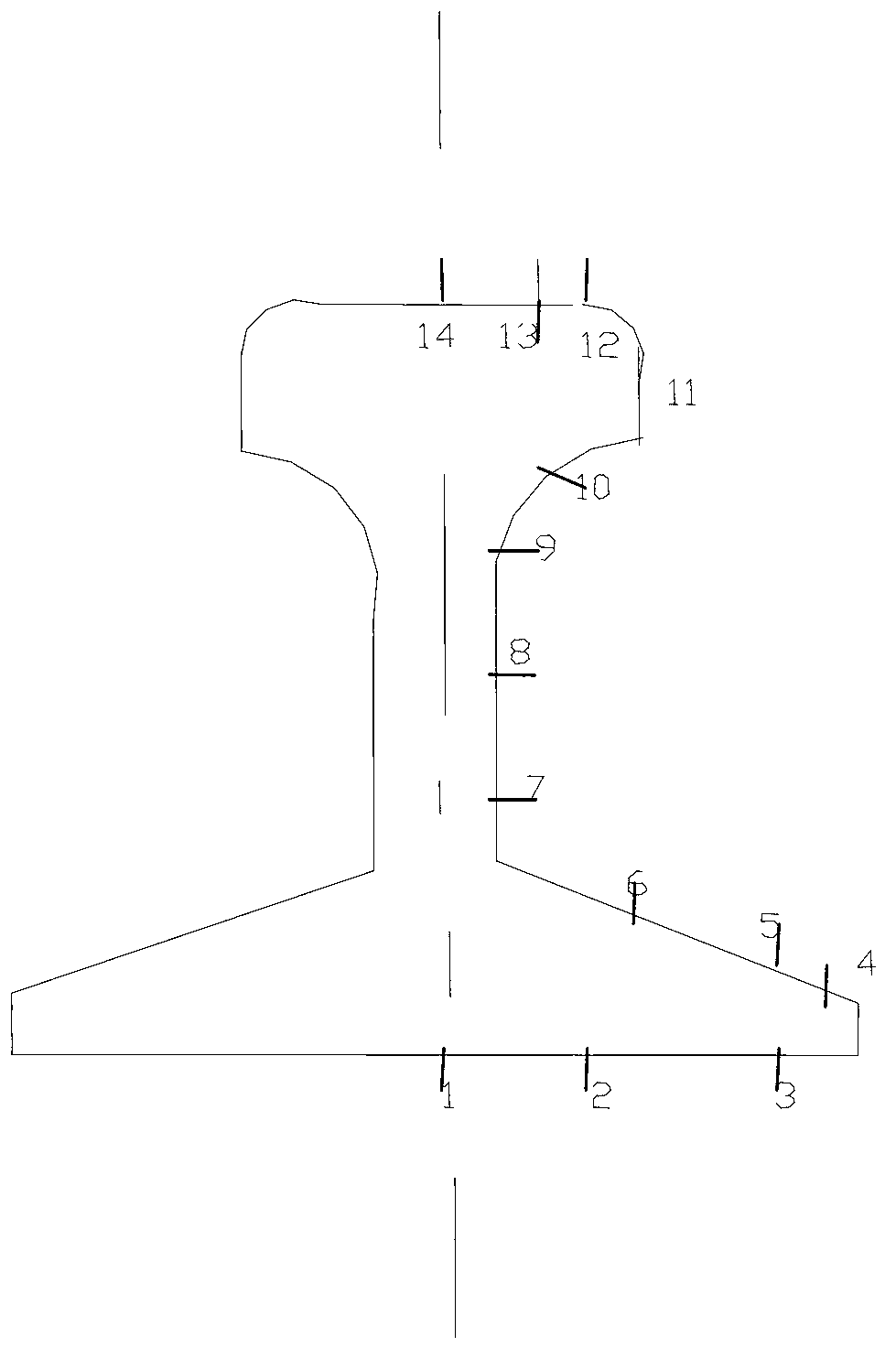

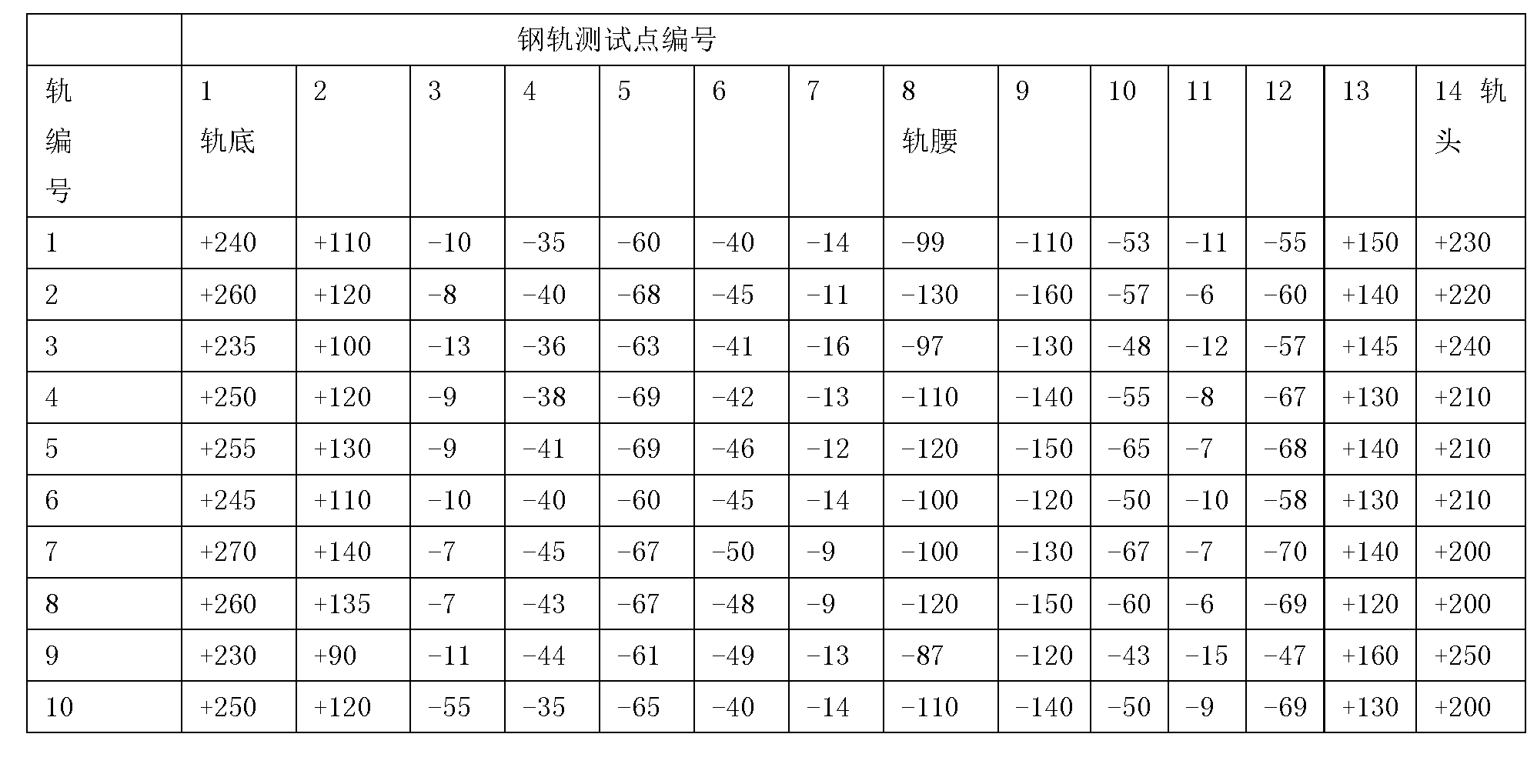

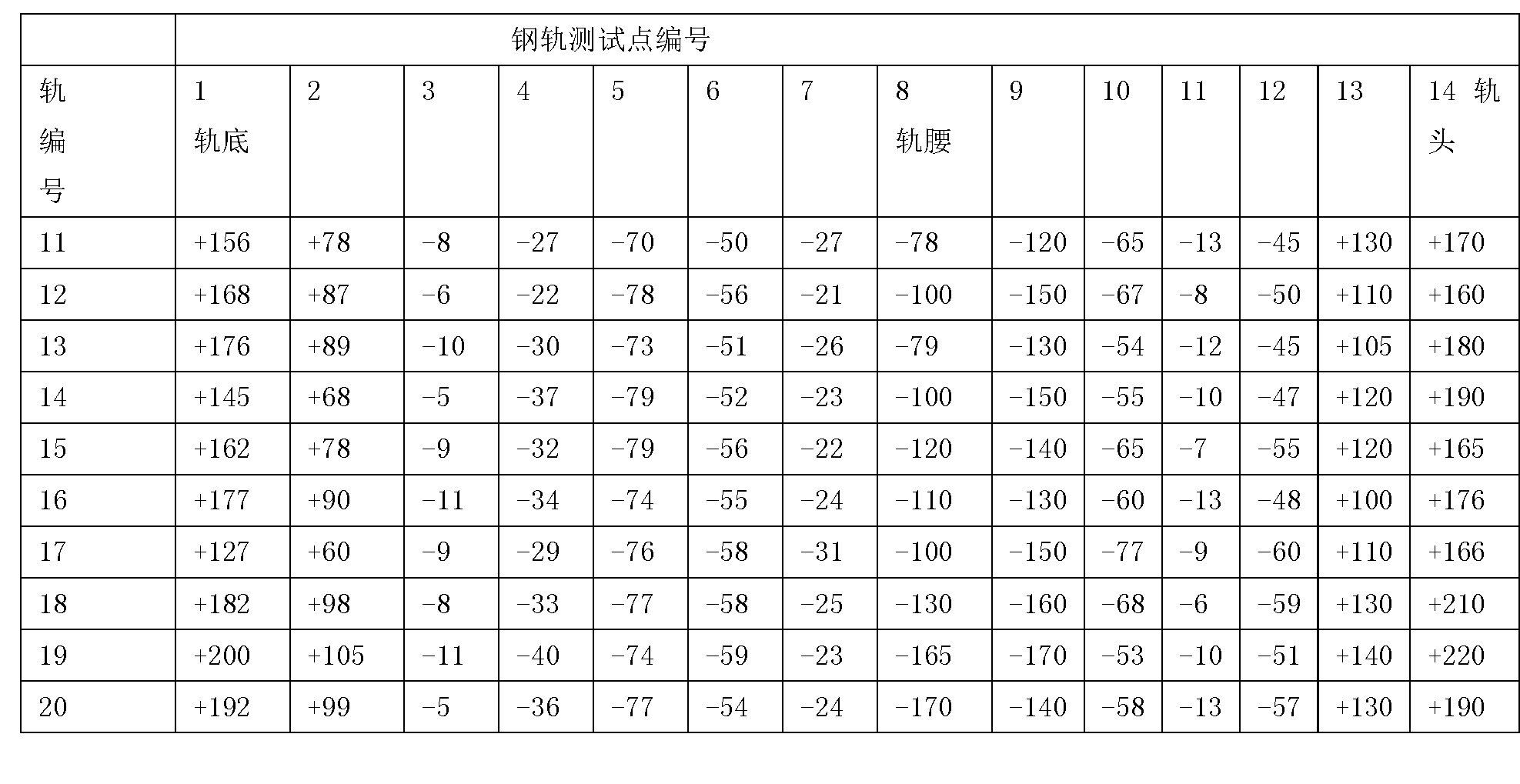

Method for testing residual stress of steel rail

The invention relates to a method for testing residual stress of a steel rail. The method is characterized by comprising the following steps of using a steel rail with the length of 1m, taking one point (namely a center position) 500mm away from the end of the steel rail, drawing a line which is arranged at the point in the circumferential direction vertical to the axis of the steel rail, sequentially and alternatively taking 14 points from the center point of the rail bottom to the center of the rail head in the linear direction, attaching each point with a strain sheet, measuring the initial value of the residual stress of each point by a static stress-strain gage, using the line drawn on the steel rail as a center line, cutting steel rail into 20mm thin sheets at each 10mm part of the two ends of the center line in the direction vertical to the axis of the steel rail, and then measuring the final value of the residual stress of each point by the static stress-strain gage. The method has the advantages that by adopting the multi-point testing, the stress distribution conditions of the rail bottom, the rail waist, the rail head and other parts are acknowledged, the stress change of each point is analyzed, then the pressing amount of a rolling machine is corrected, and the distribution of the residual stress is adjusted, so the steel rail is qualified.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

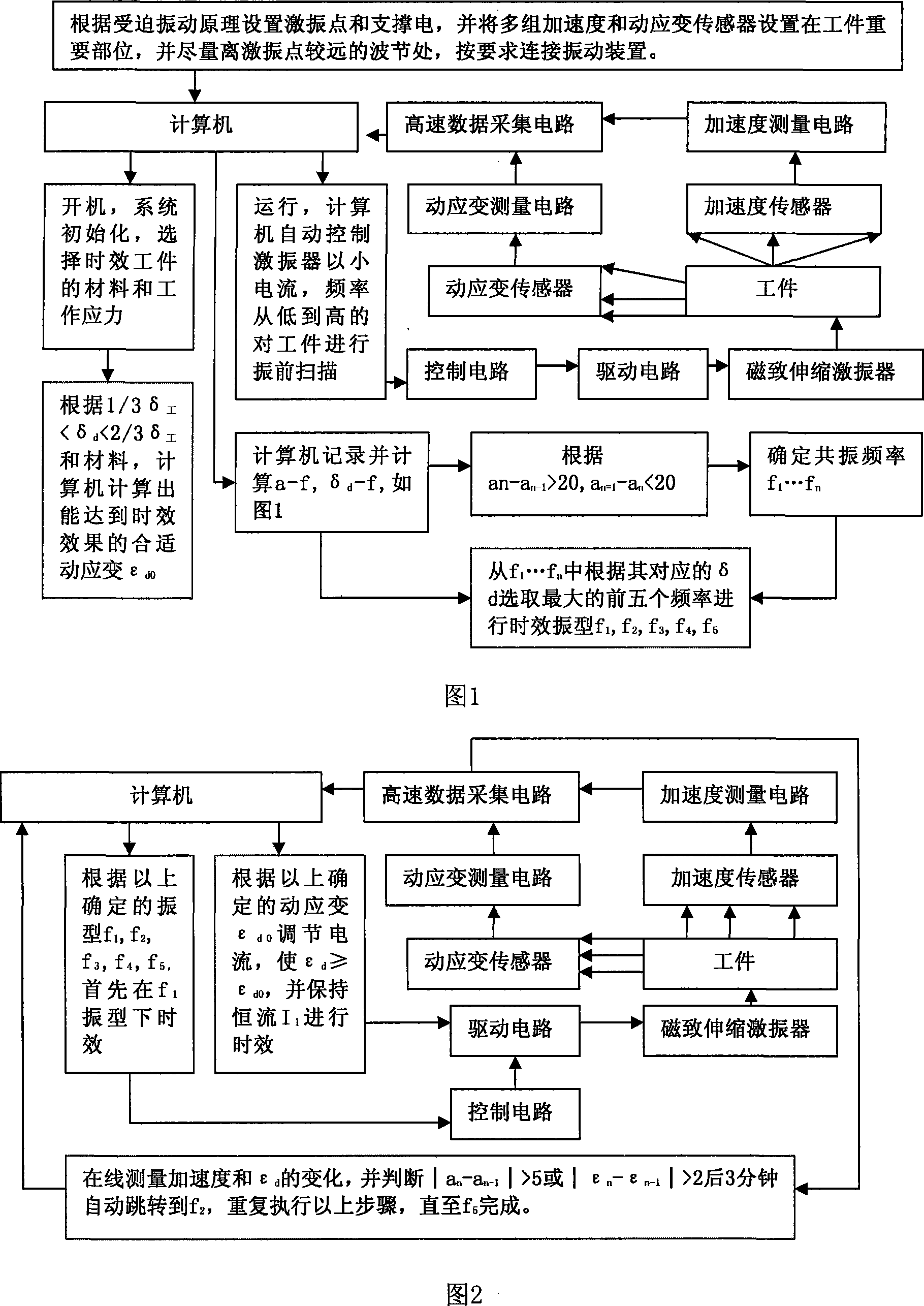

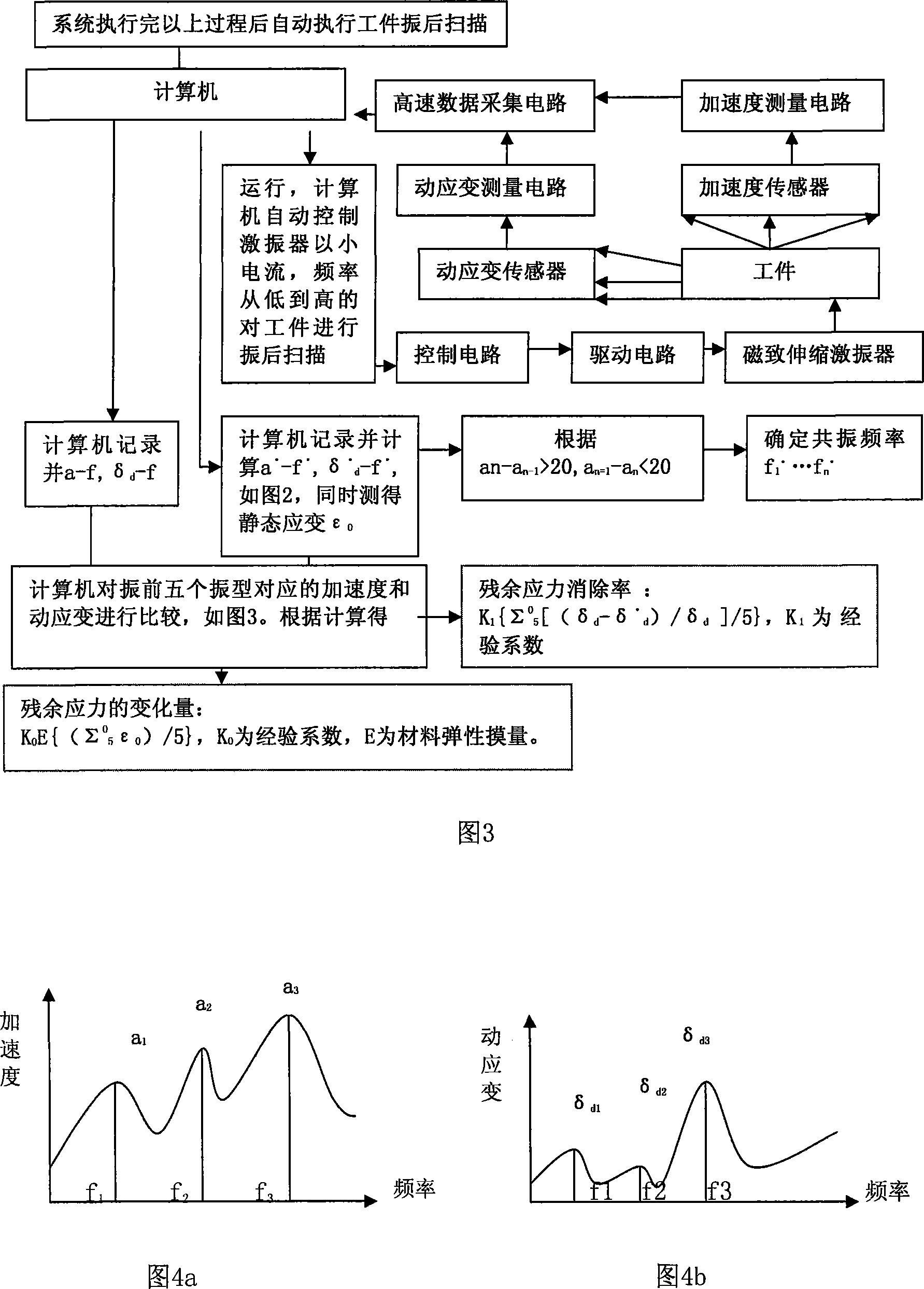

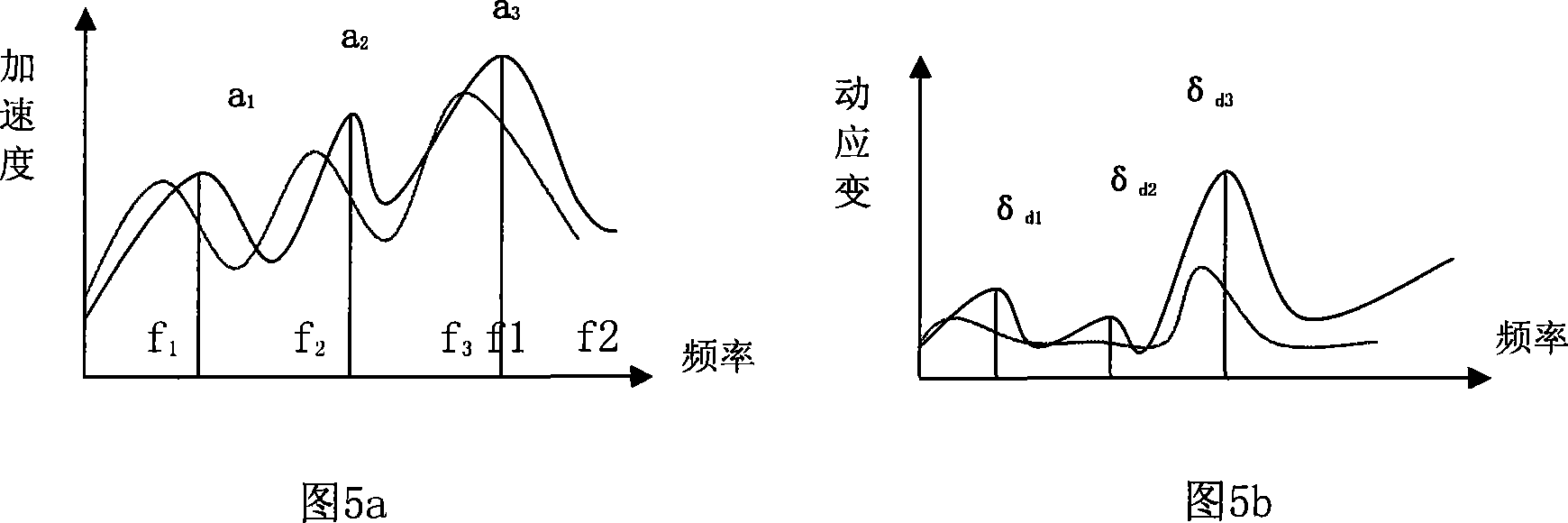

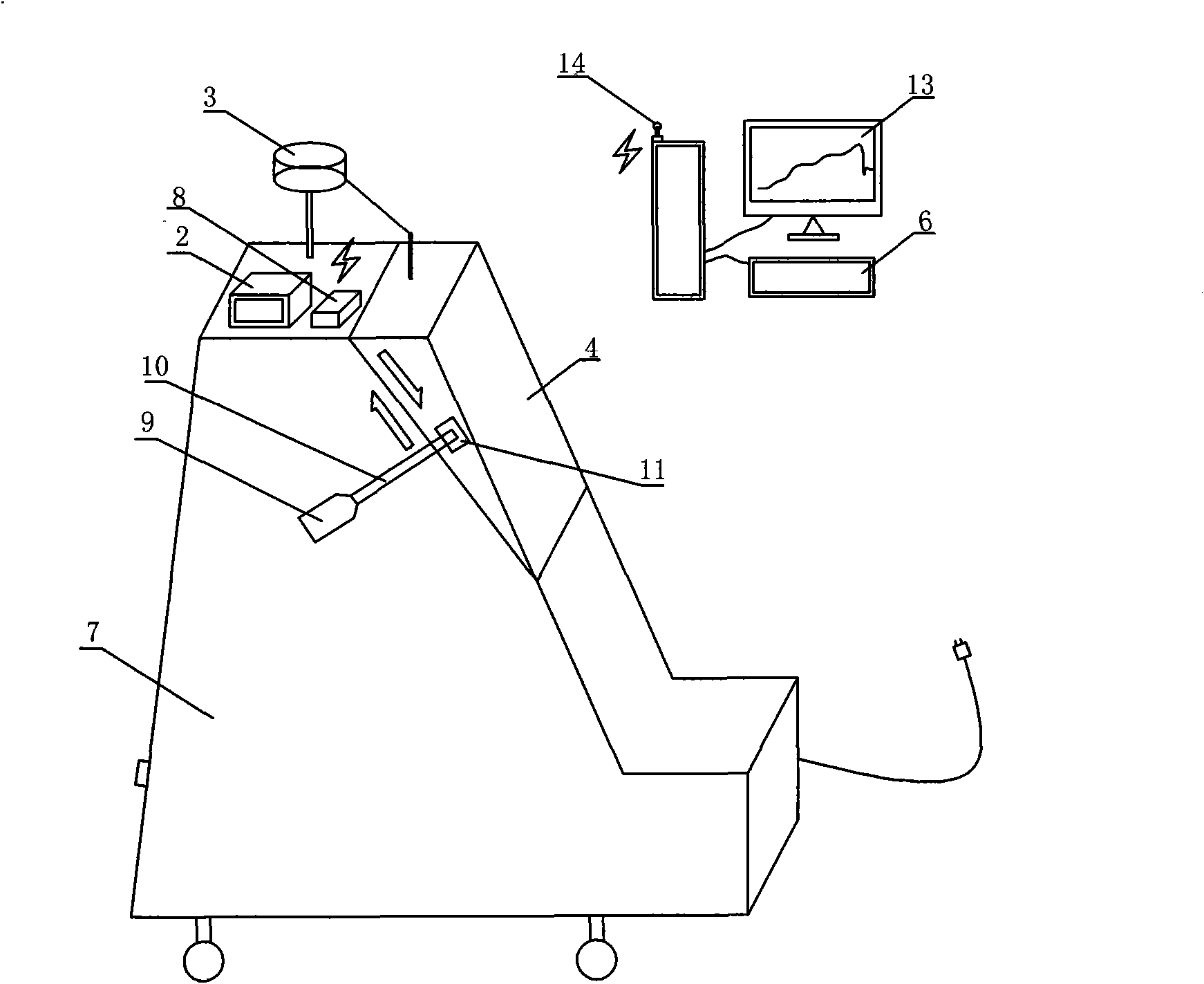

Novel vibration aging method

InactiveCN101225466ASolve the problem that manual adjustment affects real-time performanceMeet the requirements of dynamic stressMechanical vibrations separationAge methodStress variation

The invention discloses a vibration aging method, comprising a computer, a magnetostrictive vibration exciter, an acceleration sensor and a dynamic strain sensor. The vibration aging method is characterized in that the vibration exciter loads on the workpiece and exerts a cyclist exciting force, two sensors are respectively positioned on the easily cracking and deforming area of the workpiece, the sensors are analyzed and different frequency, the corresponding relationship between the dynamic strains and sorting are done by the computer, selecting the frequencies corresponding to the first biggest dynamic strains as the typical vibration, adjusting the working current and time of the vibration exciter, making the vibration exciter to vibrate at the above frequency till the aging is finished. The vibration aging method has the advantages of using the magnetostrictive vibration exciter as a vibration source, regulating the exciting force by the computer, timely responding the vibration variation to meet the dynamic stress, controlling the vibration source to vibrate at the resonation frequency by the computer, timely tuning the output current of the vibration exciter, analyzing and judging the vibration mode and the vibration time of the vibration aging, lively measuring the dynamic stress variation, and outputting the correct remaining stress variation as the prove for the experiment.

Owner:郝俊山

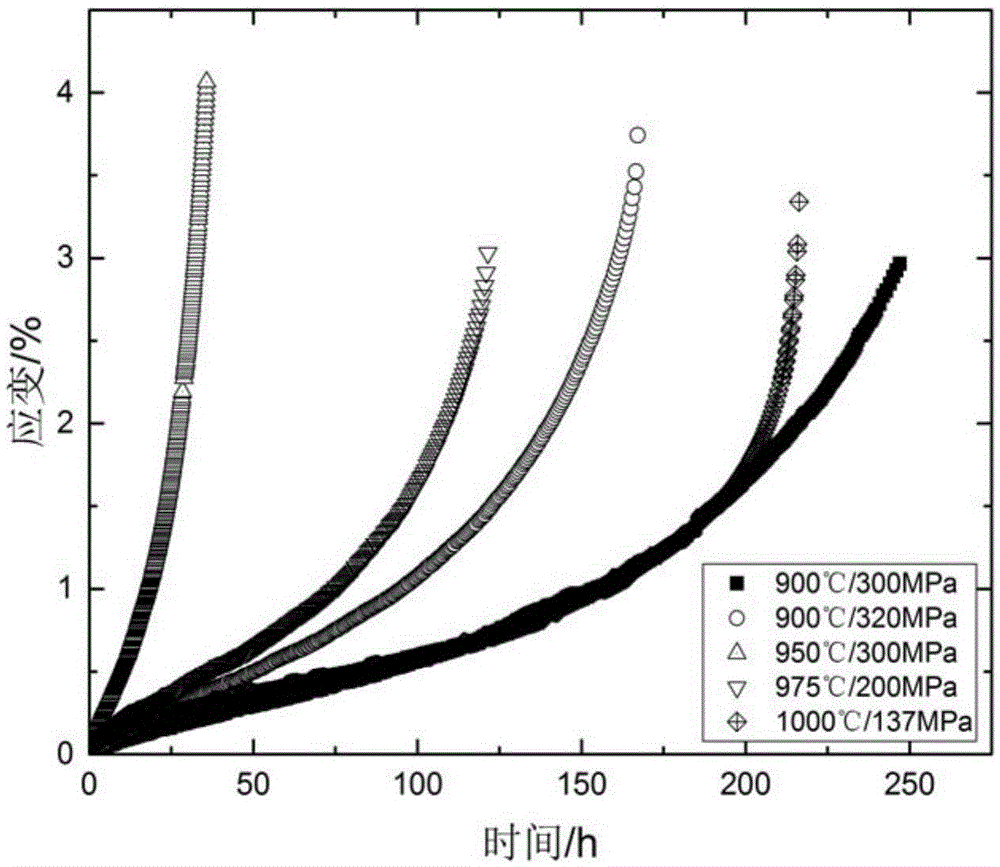

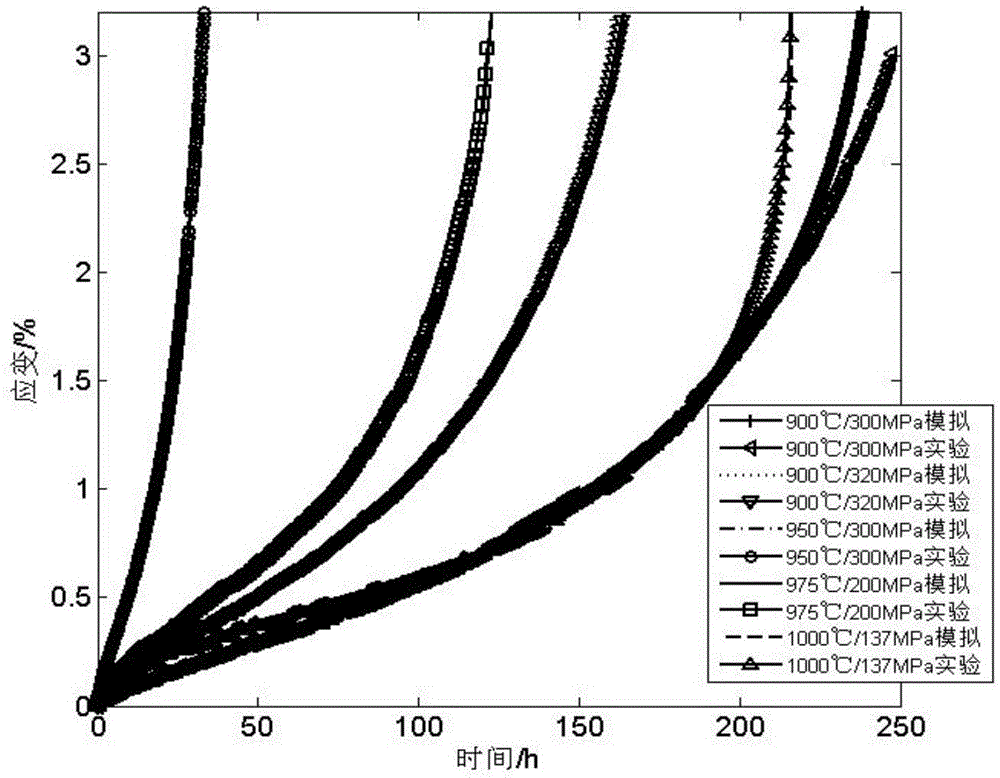

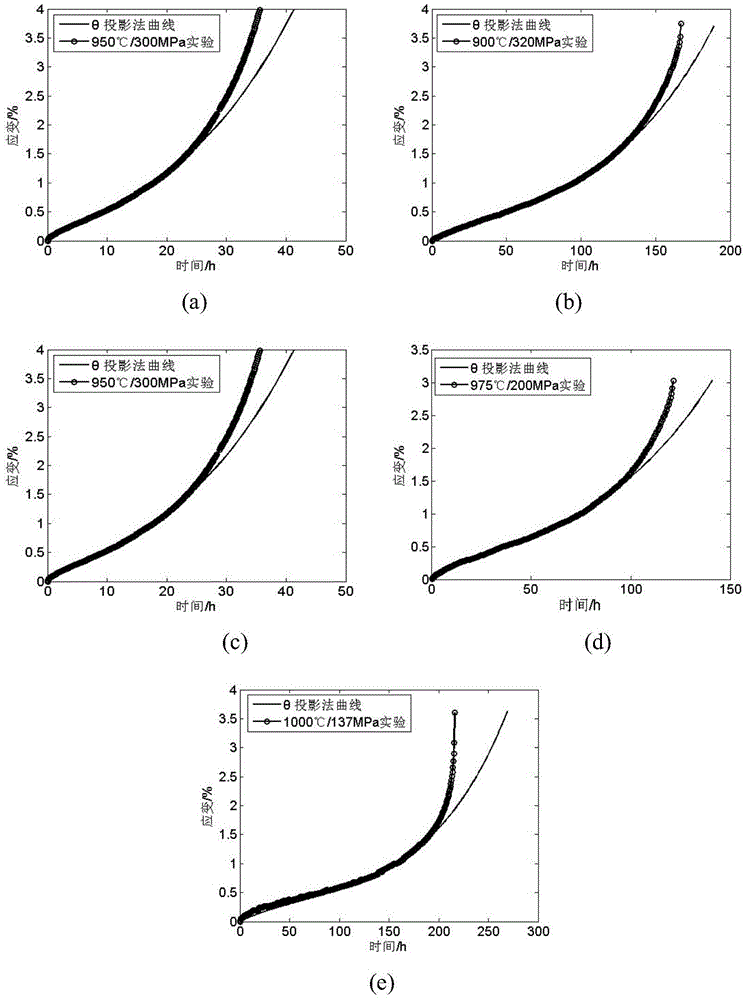

Method for forecasting high-temperature-alloy creep life

ActiveCN105628511AImprove forecast accuracyEstimated time of serviceMaterial strength using tensile/compressive forcesCreep strainPredictive methods

The invention provides a method for forecasting the high-temperature-alloy creep life. The method includes the steps that on the basis of the theta projection method, the factor that changes of true stress are caused by changes of the material shape in the creep process is introduced, the correction theta projection method is obtained, and the concrete form is epsilon= theta1*(1-exp(theta2*(1+theta5*epsilon)*t))+theta3*(exp(theta4*(1+theta5*epsilon)*t)-1). The method can be used for forecasting a creep curve at the whole homogeneous deformation stage through initial data from the first stage to the third stage of the creep curve, and the obtaining time of creep data can be shortened. Meanwhile, the method can be used for forecasting creep curves under other creep conditions, and the forecasting process comprises forecasting of the creep rupture time under the some creep condition and the creep interruption time corresponding to some creep strain. The method is simple, reliable and suitable for different-type high temperature alloy and engineering application, and has broad prospects in the aspect of high-temperature-alloy creep life management.

Owner:UNIV OF SCI & TECH BEIJING

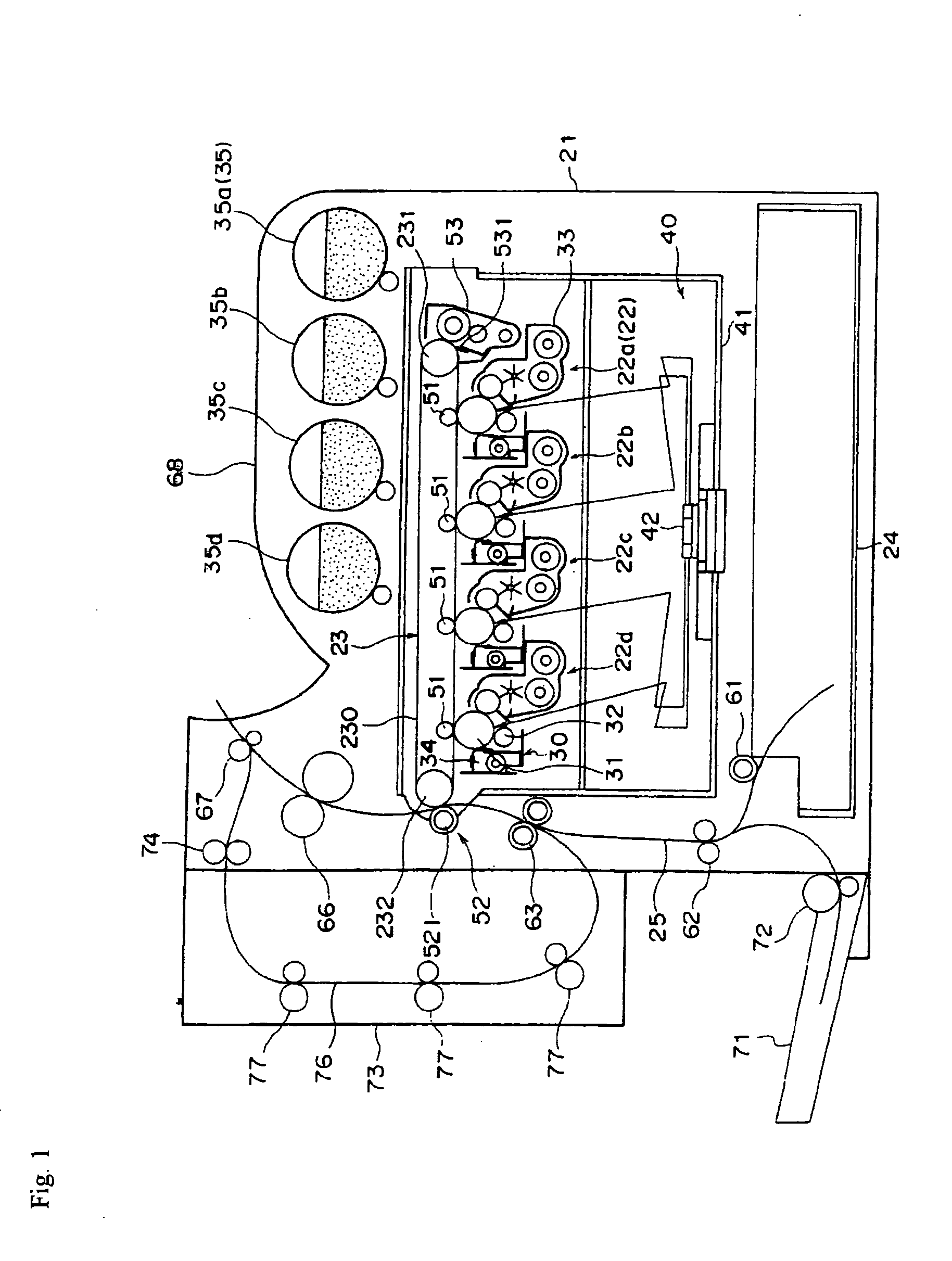

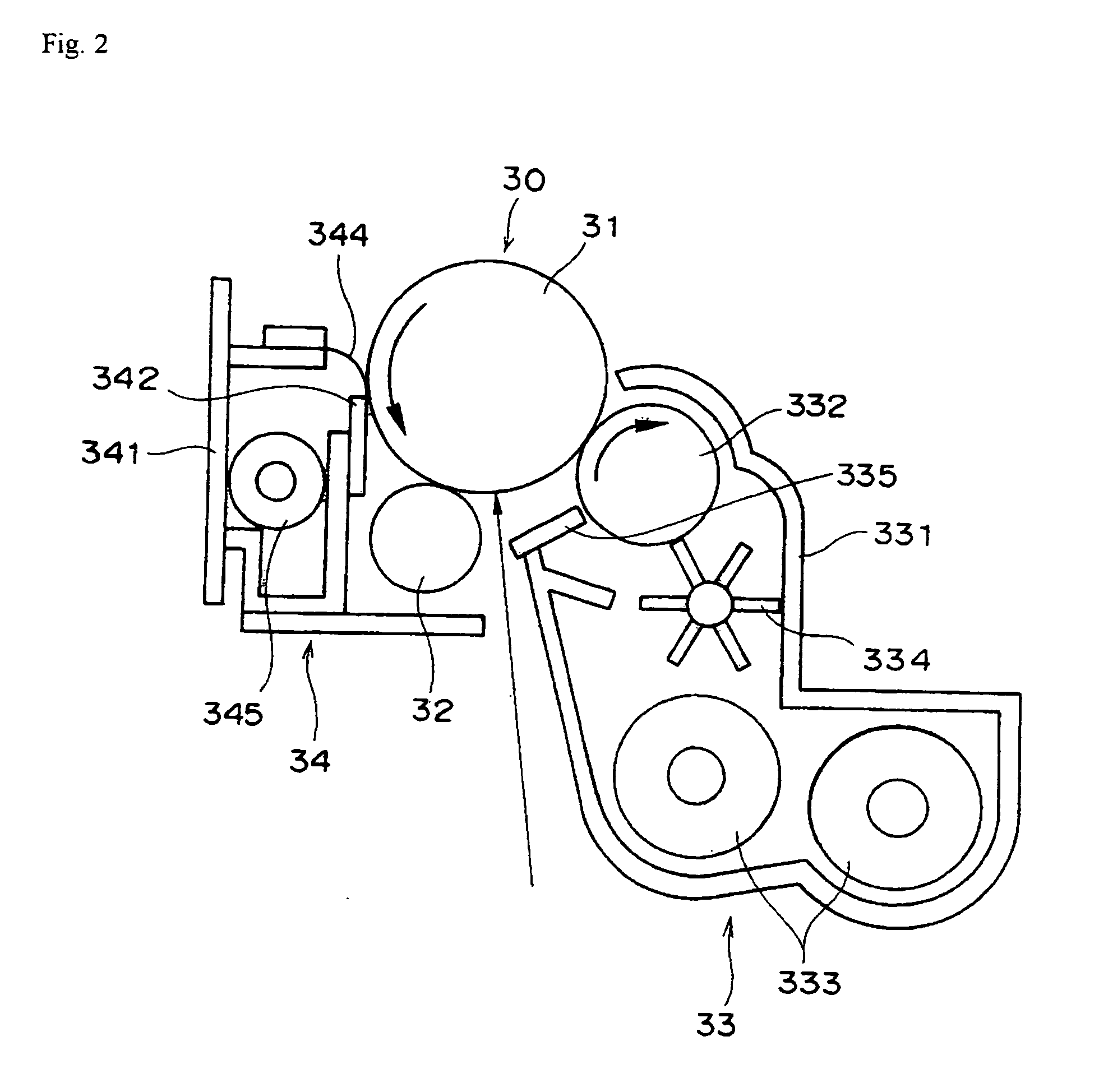

Image forming method and image forming apparatus

InactiveUS20070201917A1Electrographic process apparatusElectrographic processes using charge patternSurface layerStress–strain curve

An image forming method in which an image carrier that has a surface layer containing a resin having a crosslinking structure is used; a material of a portion of the cleaning blade which portion contacts the surface of the image carrier satisfies 3.92≦M≦29.42, 0≦α≦0.294, and S≦250; an absolute value of difference in circumferential velocity between the image carrier and the intermediate transfer member is larger than zero; a polishing agent is present at a contact portion between the image carrier and the intermediate transfer member; M represents 100% modulus; a represents a ratio of a change in stress (Δ stress) to a change in a strain amount (Δ strain amount) from 100% strain to 200% strain in a stress-strain curve; and S represents a breaking elongation measured according to JIS K6251 using a dumbbell type #3 test piece.

Owner:FUJIFILM BUSINESS INNOVATION CORP

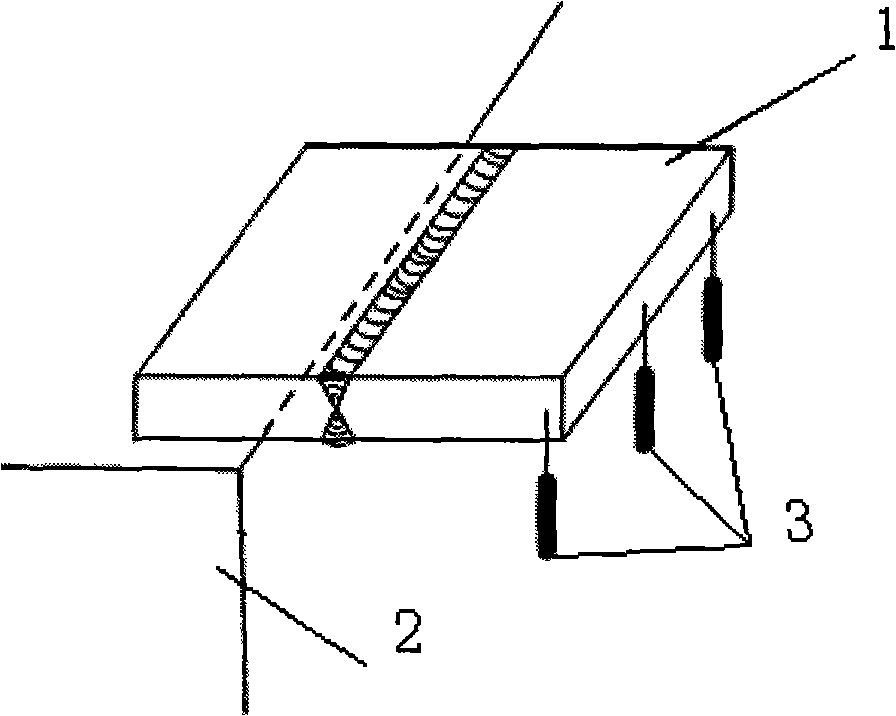

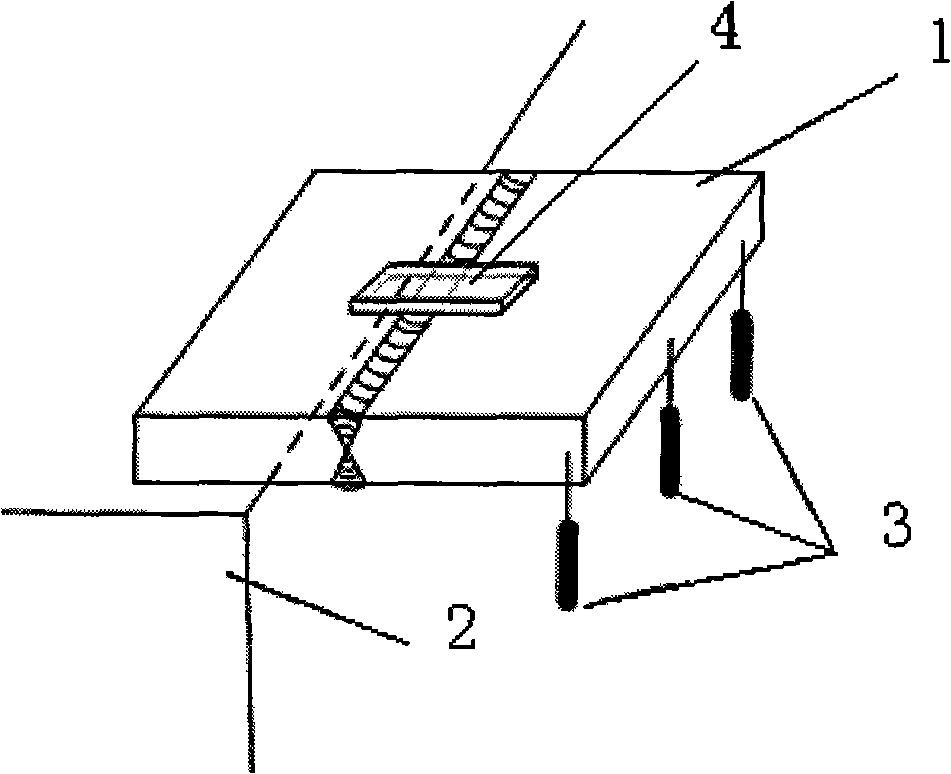

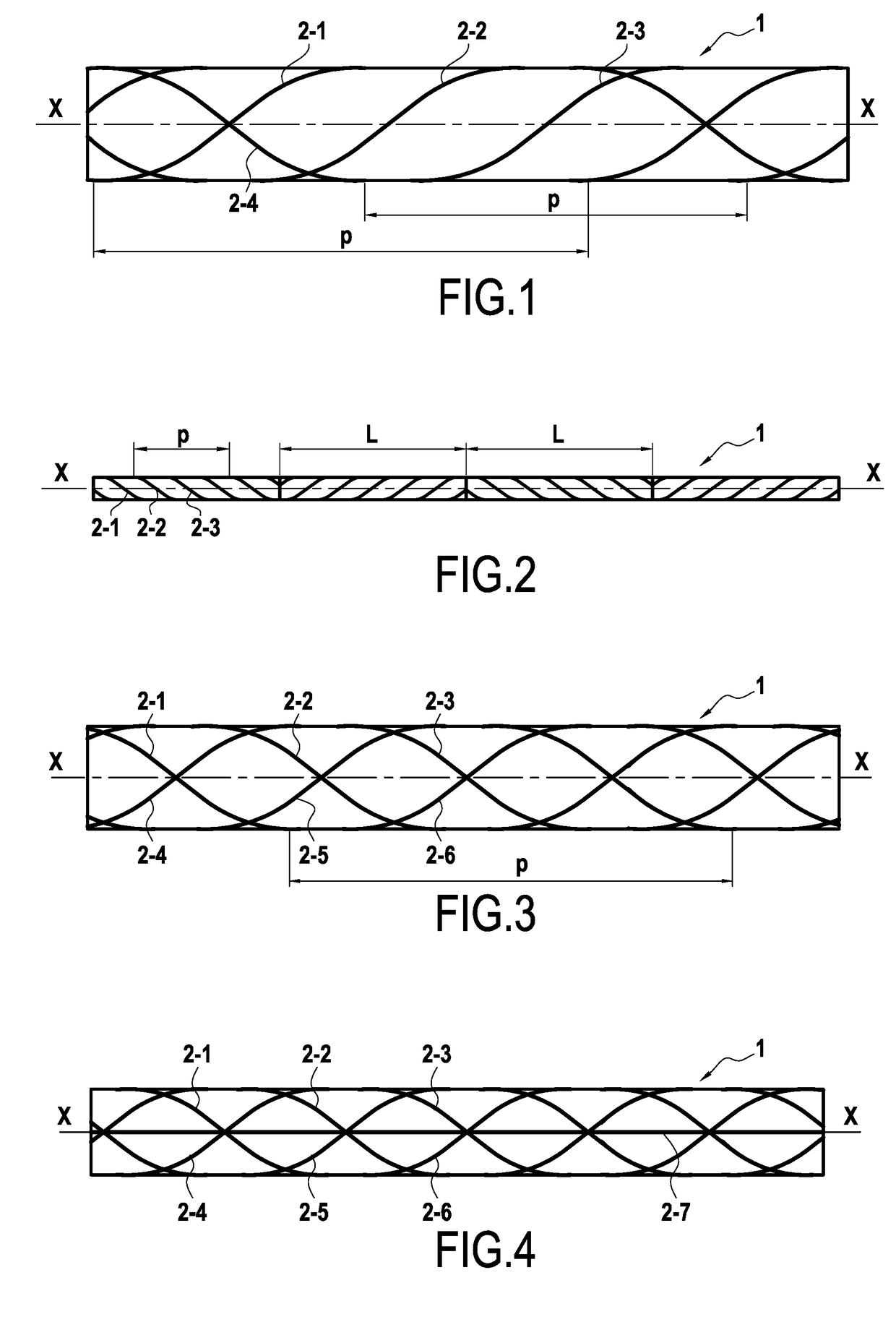

Method Of Determining Stress Variations Over Time In An Undersea Pipe For Transporting Fluids

ActiveUS20190064030A1Improve accuracyPerformed more accurately and moreForce measurementThermometers using physical/chemical changesOcean bottomTemporal change

A method of determining stress variations over time in an undersea pipe for transporting fluids, the method comprising: installing along the entire length of the pipe (1) at least one distributed optical fiber sensor (2-1 to 2-4) using Rayleigh backscattering, the sensor being dedicated to measuring at least one degree of freedom of movement variation over time in the pipe at each cross section of the pipe; continuously measuring movement variation of the optical fiber sensor over time; and determining stress variations over time at each point in the pipe by time integration of the measured movement variation of the optical fiber sensor.

Owner:SAIPEM SA

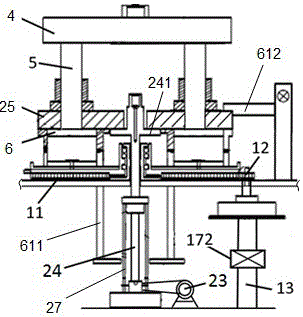

Annular shearing experiment equipment and testing method

InactiveCN105699189AGood for studying the influence of strength parametersGood for research impactMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesVertical vibrationPore water pressure

The invention provides an annular shearing experiment equipment and a testing method, the annular shearing experiment equipment includes a support seat, a shear box assembly located on the support seat, and a load applied to soil samples in the shear box assembly The loading device, the loading device includes a vertical vibration loading device and a horizontal shear vibration loading device, and the annular shear experimental equipment further includes a load control device for controlling the loading of the vertical vibration loading device and / or the horizontal shear vibration loading device. device. The vertical vibration loading device and / or the horizontal shear vibration loading device can apply vibration loads of different frequencies and amplitudes, which is beneficial to study the influence of dynamic loads on soil strength parameters, more conducive to simulating the actual stress situation, and conducive to revealing The stress changes, pore water pressure changes, local soil damage and liquefaction phenomena occurred during the shear test of the soil under the action of vibration loads, and then reveal the occurrence and movement mechanism of geological disasters such as landslides from the mechanical properties.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

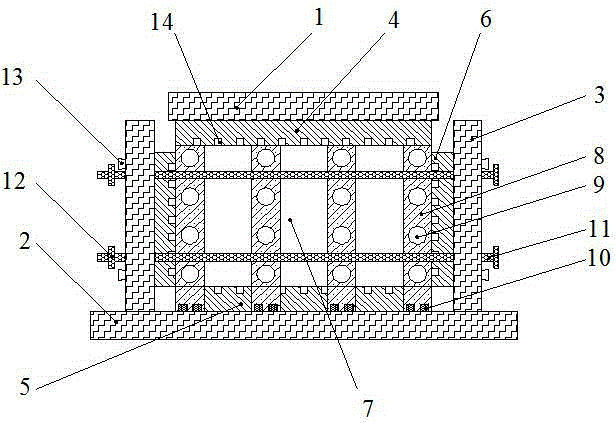

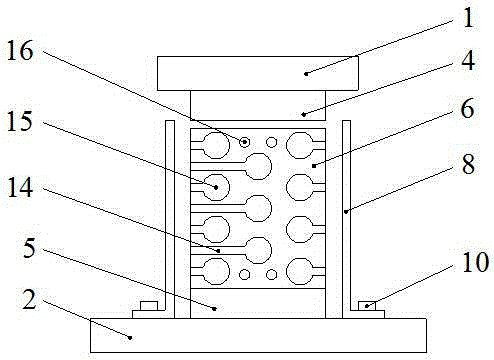

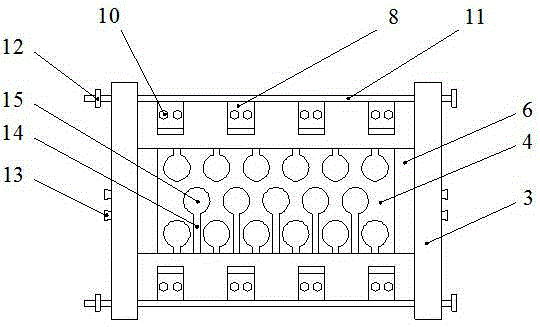

Long-term bearing test monitoring device for large-size cuboid coal and rock sample

ActiveCN105277441AThe test effect is goodSimple structureForce measurementMaterial strength using tensile/compressive forcesEngineeringStress variation

The invention discloses a long-term bearing test monitoring device for a large-size cuboid coal and rock sample, and relates to the technical field of rock mechanics tests. The long-term bearing test monitoring device comprises an upper pressing plate, a bottom plate, a lateral confinement restraining plate, an upper stress sensor locating plate, a bottom stress sensor locating plate, a lateral stress sensor locating plate and a displacement sensor locating plate. A space which is formed by the upper pressing plate, the bottom plate and the lateral confinement restraining plate and is approximately in a hexahedron shape is designed for monitoring the coal and rock sample to be tested. Stress sensors are arranged on the inner side face of the upper pressing plate, the inner side face of the bottom plate and the inner side face of the lateral confinement restraining plate respectively, displacement sensors are symmetrically arranged on the front side face and the rear side face of the whole device, the stress changes of different points of all non-free faces of the large-size cuboid coal and rock sample and the transverse deformation condition of different points of all free faces under long-term bearing are accurately tested, and then the mechanics characteristics and failure mode of the large-size cuboid coal and rock sample in the long-term bearing process are analyzed. High practicality is achieved.

Owner:SHANDONG UNIV OF SCI & TECH

Drilling hole stress sensor and drilling hole stress monitoring method thereof

The invention discloses a borehole stress sensor. The sensor comprises a metal tube with a longitudinal opening, a strain gauge, a waterproof pressed film, a concrete core and a signal transmission line. The metal tube with the opening which integrates the strain gauge, the signal transmission line and the waterproof pressed film is used for drilling and filling the core with concrete in site application; and the borehole stress sensor is completely manufactured and laid synchronously. The invention also discloses a borehole stress monitoring method based on the sensor. The method has the beneficial technical effects of being capable of effectively testing a stress change process of rock media at different depths in a borehole by the borehole stress sensor, effectively defining a 3D area with unsafe and less-safe rock body on a slope by joint application of a plurality of borehole stress sensors, disclosing a planar distribution range and a depth expansion range of the area, and providing an important scientific basis for subsequent project treatment and safety monitoring.

Owner:陈洪凯 +1

Landslide advancing sliding force physical simulation experimental method and device therefor

ActiveCN101609158AThe magnitude of the stress value is intuitiveReduce sizeForce measurementSeismologyInformation processingExperimental methods

The invention discloses a landslide advancing sliding force physical simulation experimental method and a device therefor. A stress sensor is utilized to detect the inner stress change of a sliding body on an inclined plane of a sliding bed model, and the curve of the relationship between the magnitudes of the sliding force applied on the sliding body before sliding, in sliding and after sliding and the time can be determined by combining the data of displacement of the sliding body detected by a displacement sensor, so that the value of the curve and the inner stress can be displayed; when in subsection alarm, the detection and the display of the advancing sliding data of the sliding body can be completed, so that the advanced and real-time pre-warning and warning of landslide geological disaster can be really realized. The whole device is reasonable in design and convenient for use, and completely imitates the whole process of landslide for simulate monitoring and information processing; the drawn monitoring curve is authentic, vivid and reliable; an electronic display device can visually and conveniently display the value of the stress, so that the change characteristics of the sliding force in the whole process of landslide can be fully reflected, and the simulation is accurate and vivid.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

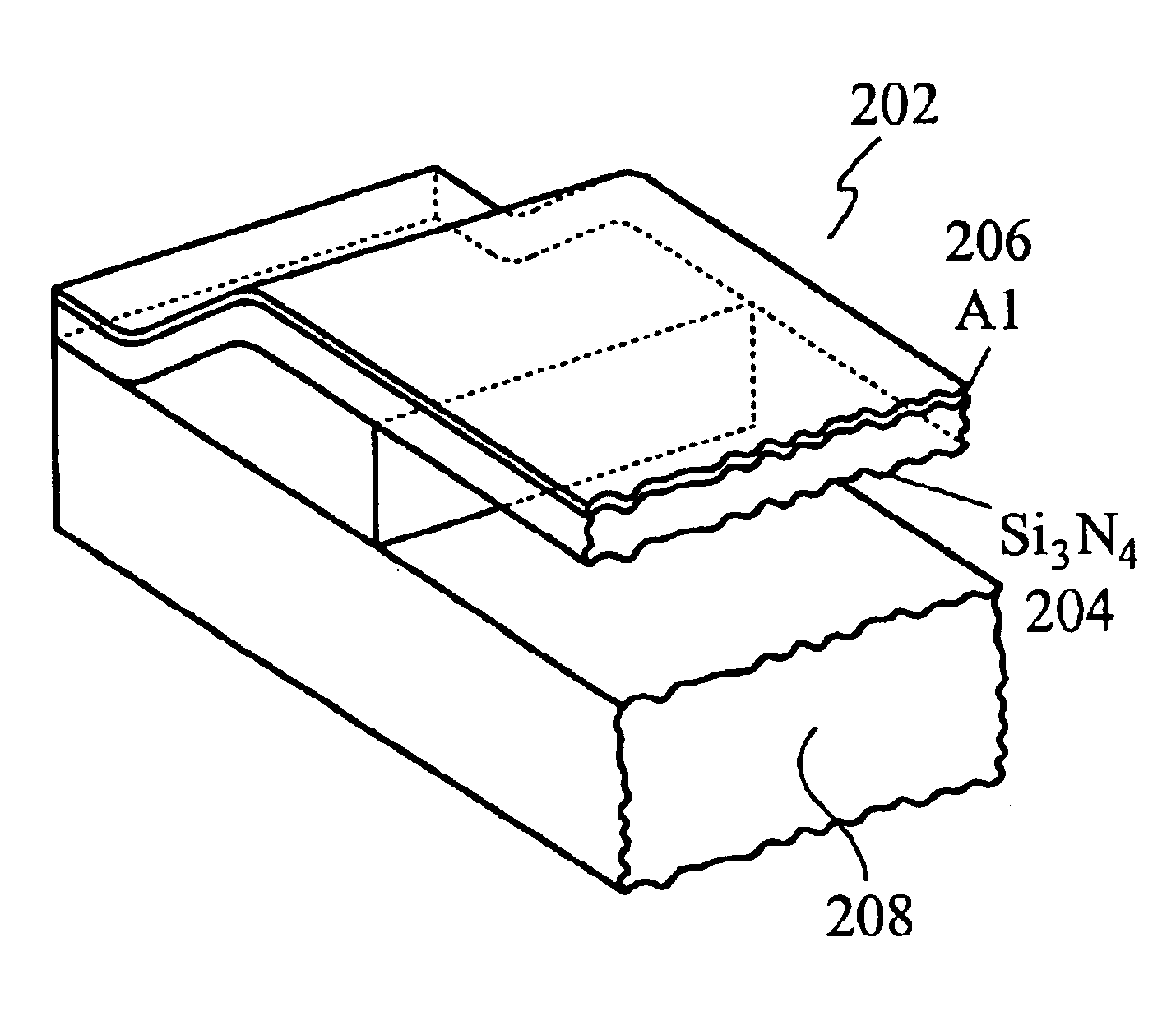

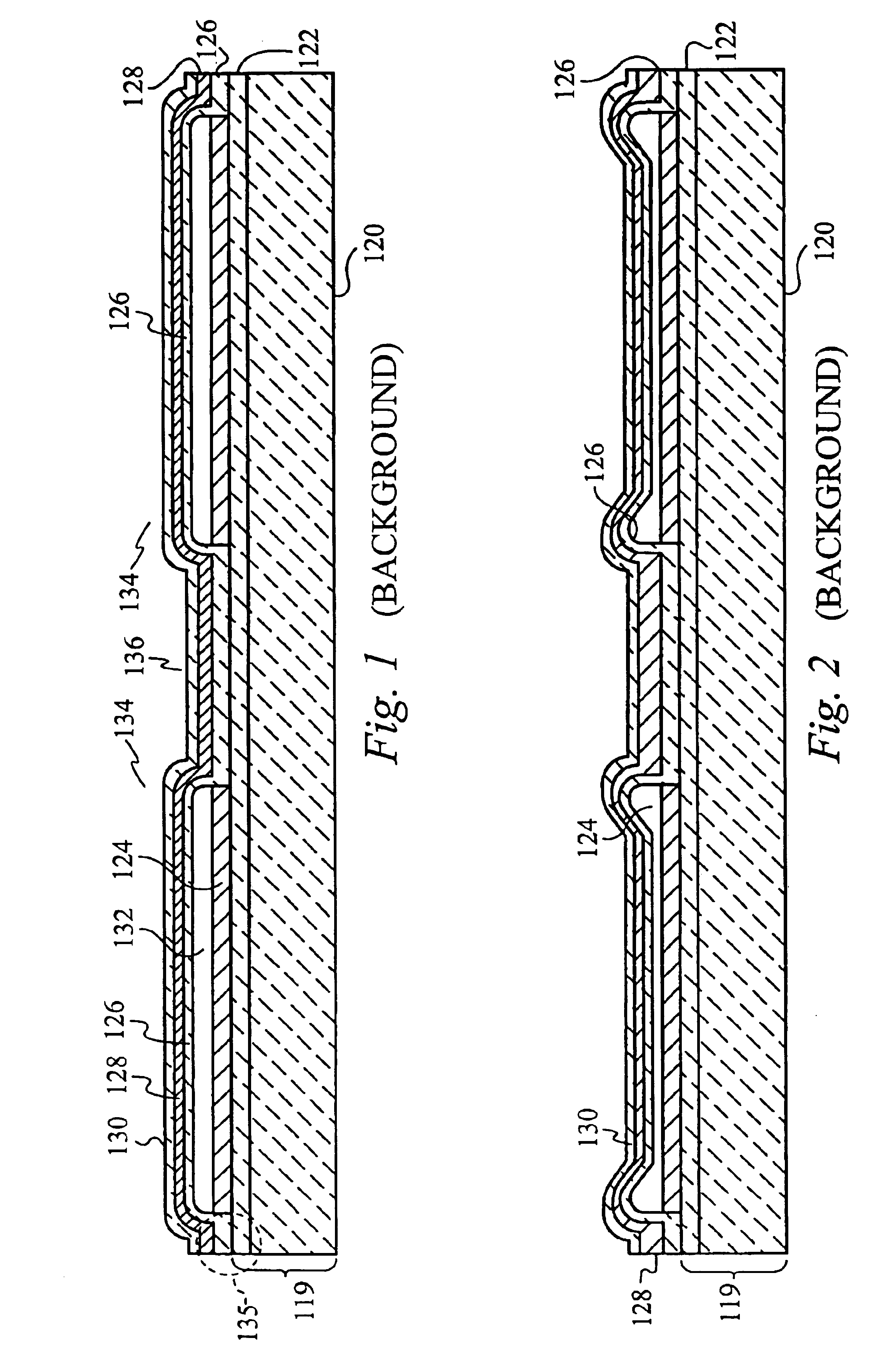

Method and apparatus for leveling thermal stress variations in multi-layer MEMS devices

InactiveUS6922272B1Reduce variationProcess stabilityDecorative surface effectsSemiconductor/solid-state device detailsThermal coefficientStress variation

A MEMS device such as a grating light valve™ light modulator is athermalized such that the force required to deflect the movable portion of the MEMS device remains constant over a range of temperatures. In MEMS embodiments directed to a grating light valve™ light modulator, a ribbon is suspended over a substrate, and the ribbon tension is kept constant over a temperature range by adjusting the aggregate thermal coefficient of expansion of the ribbon to match the aggregate thermal coefficient of expansion of the substrate. Various opposition materials have an opposite thermal coefficient of expansion as the aluminum layer of a grating light valve™ light modulator ribbon, using the thermal coefficient of expansion of the substrate as a zero coefficient reference. The adjustment of the thermal coefficient of expansion of the ribbon can be performed variously by thickening existing layers of opposition material or adding additional layers of new opposition material to the ribbon, or reducing the aluminum in aluminum layer. The aluminum layer may be reduced variously by reducing the thickness of the aluminum layer, or reducing the surface area that the aluminum covers, or reducing both the surface area and the thickness. Embodiments may combine the reduction of aluminum with the use of opposition materials.

Owner:SILICON LIGHT MACHINES CORP

Measuringm ethod and device for fiber material transverse compression property

InactiveCN1587965ASolving precise measurementsAccurate Lateral Compression MeasurementOptical rangefindersPhotogrammetry/videogrammetryFiberObservational error

The invention relates to lateral compression performance measuring method and device of fibrous material, comprising the parts of fiber lateral cimpression element using pressure head on cantilever beam to lateral compress filament and overlapping fiber sample in multiangular tray, fiber deformation observing parts using two objectives with different direction finish stereo-observation and measurement to compressed fiber, compressive stress measuring elements with deflection correction to put in real time change of stress of pressure head in computer and the deflection correction is to correct vertical compressed displacement by small deflection deflection of cantilever beam when laser reflects measuring compression. By using multiple measurement of stress and conformational change and compact and novel design, lateral compression shape measurement is fast, accurate, overall, its measurement error has decreased greatly and the method is suitable for various kinds of fibrous material.

Owner:DONGHUA UNIV

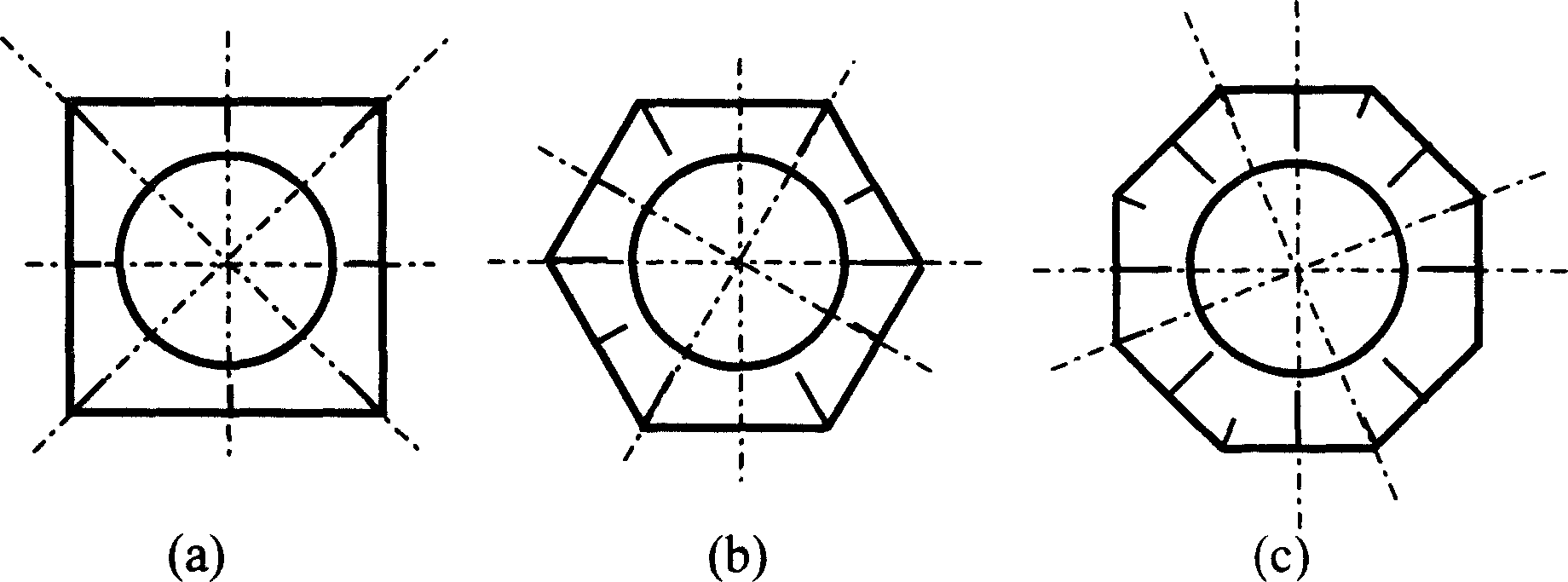

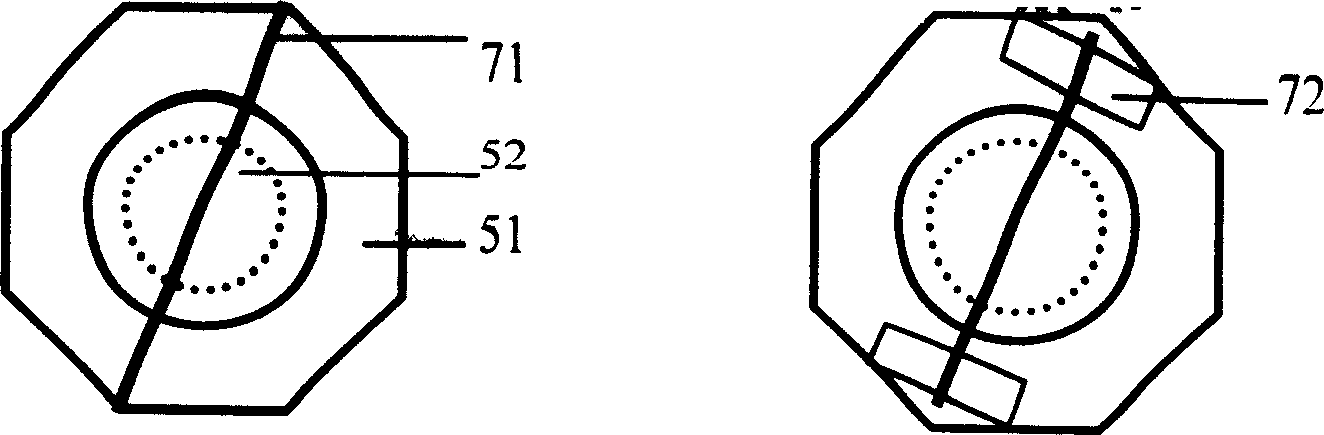

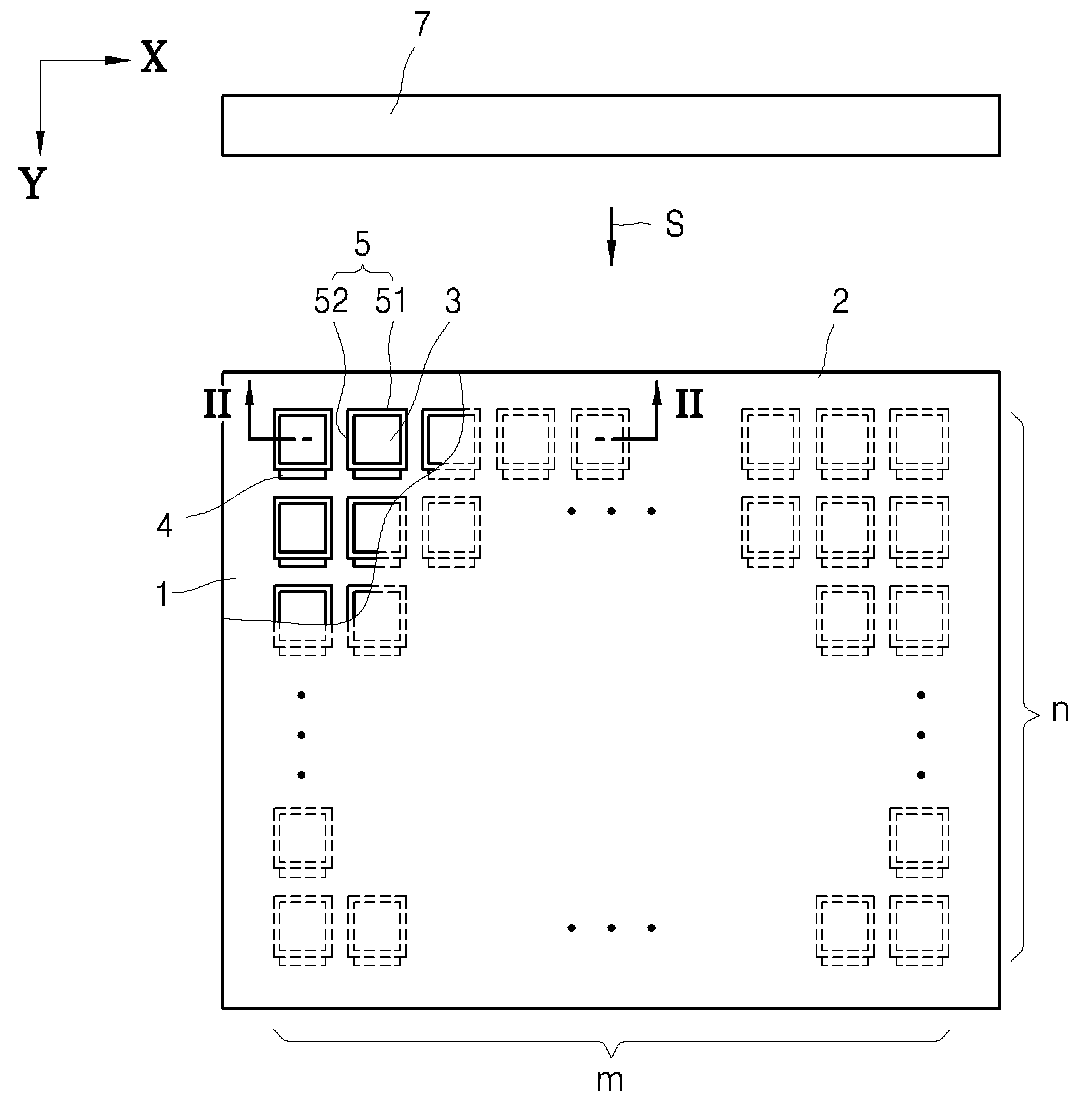

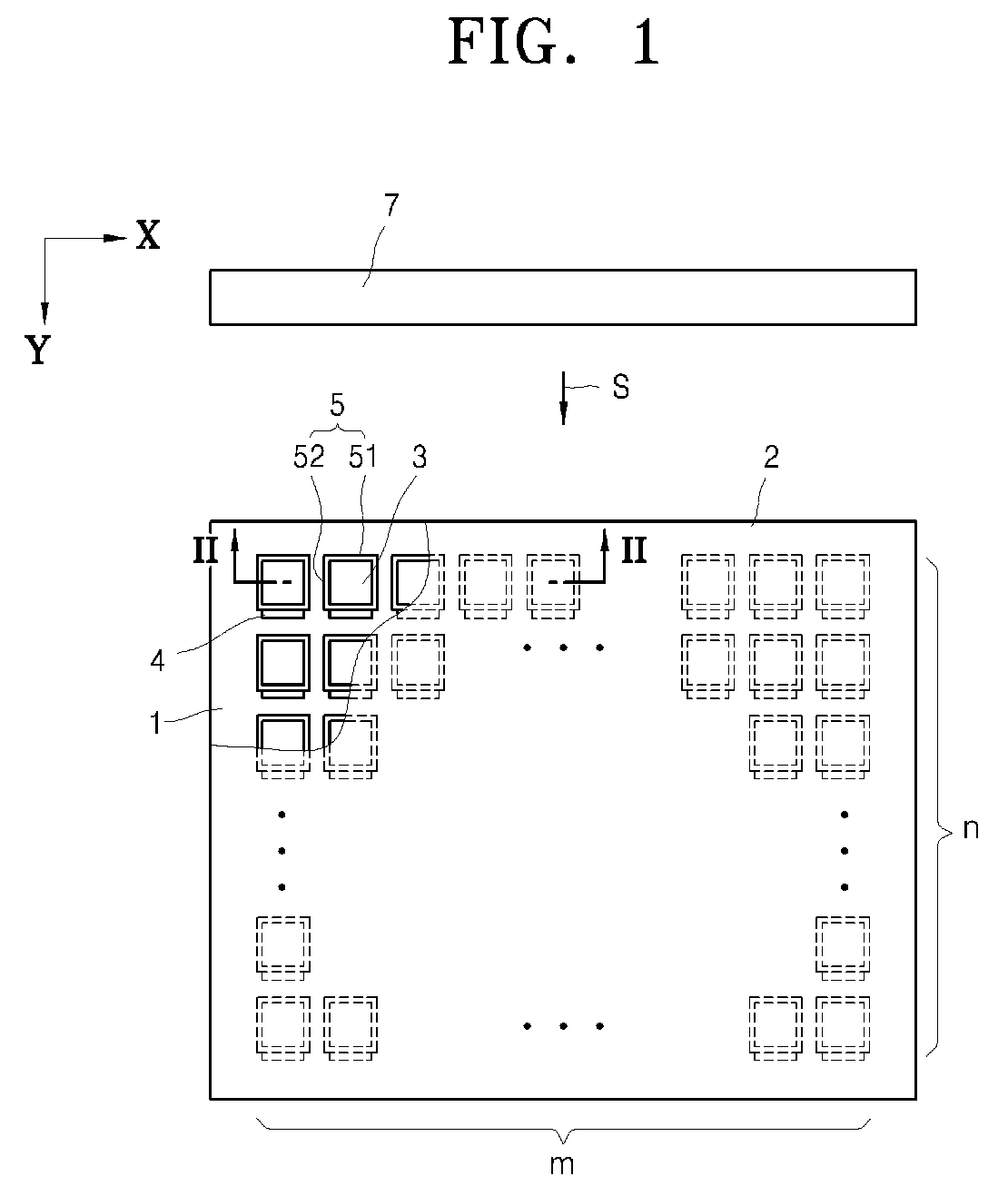

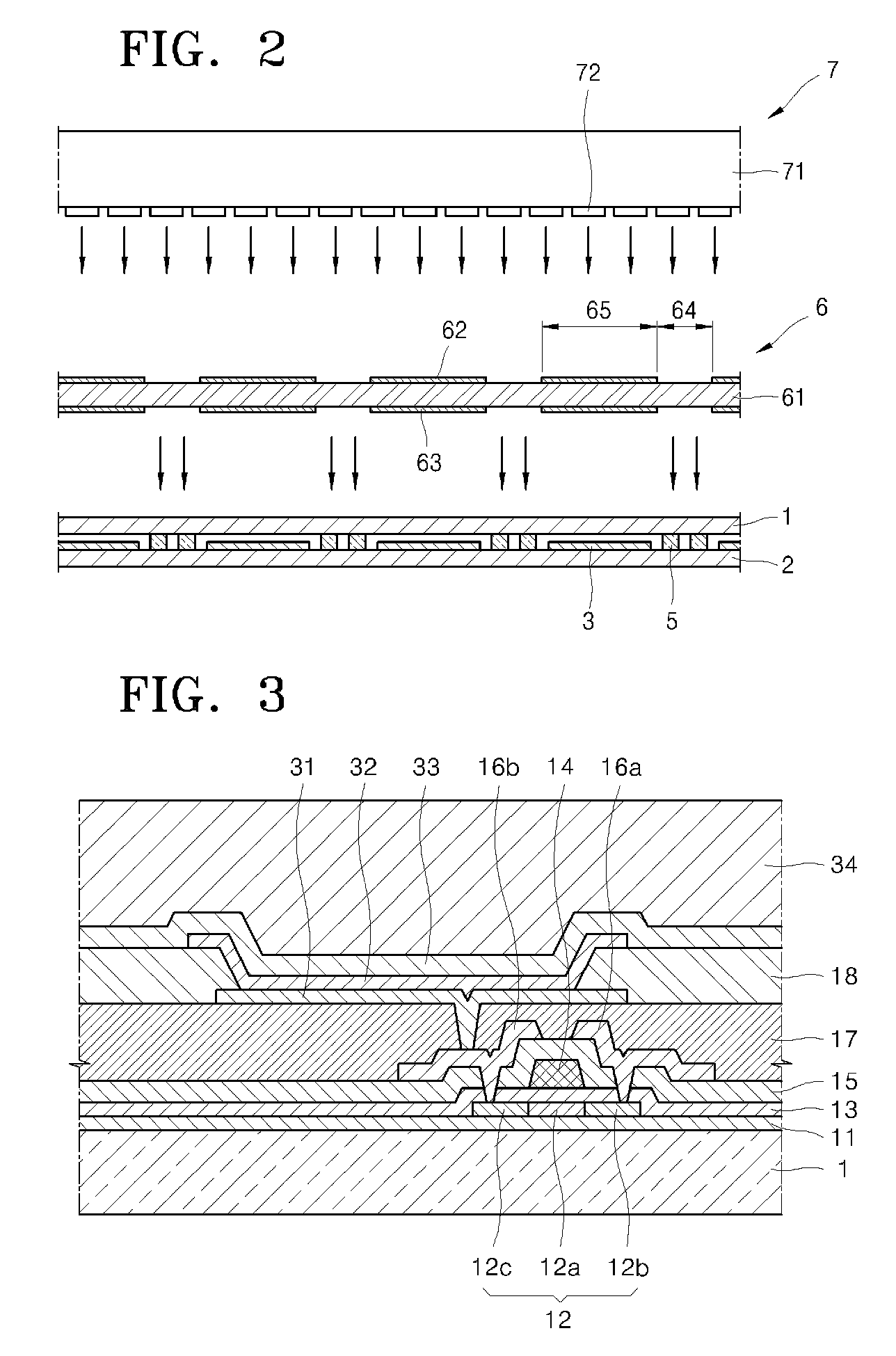

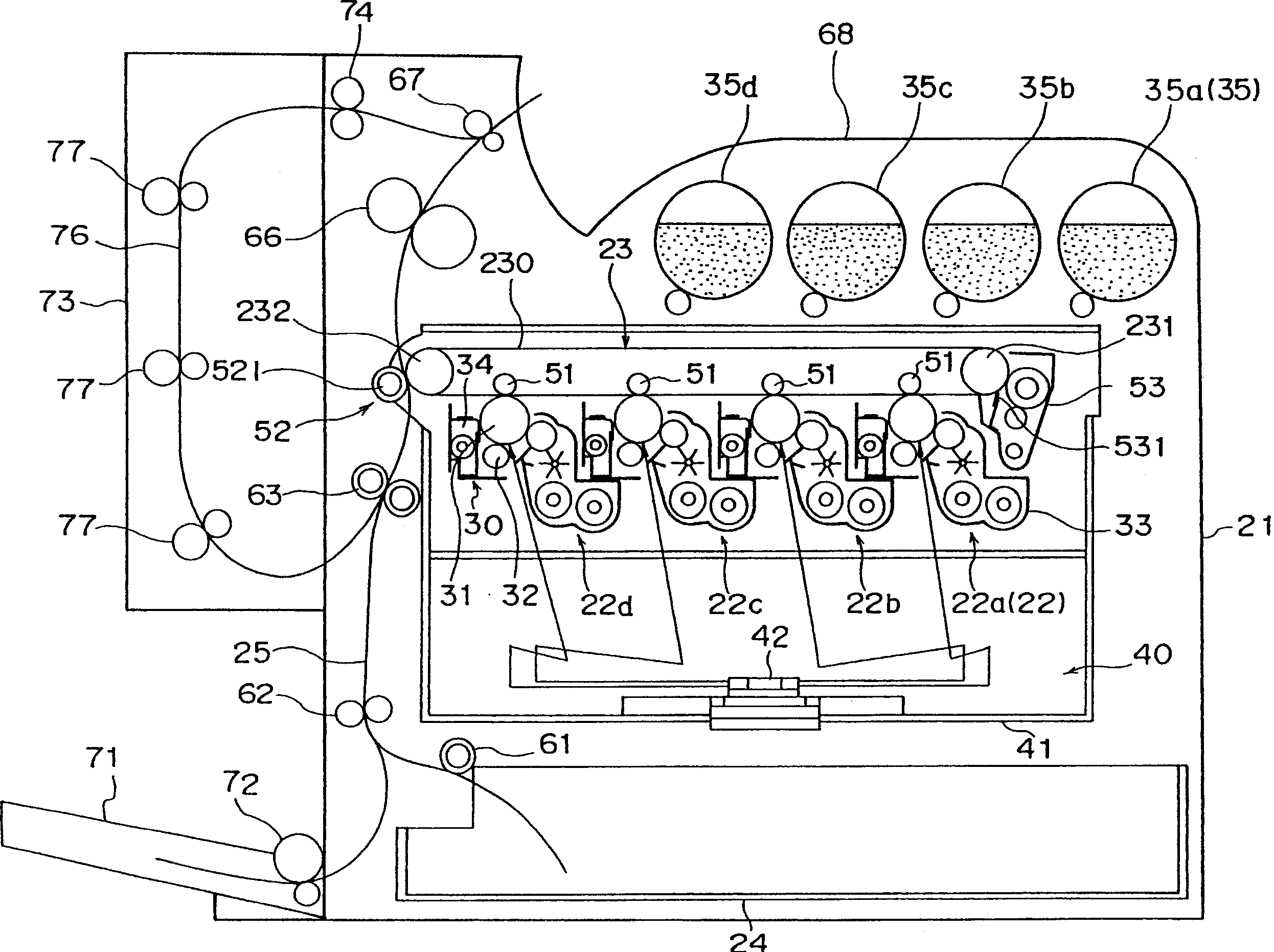

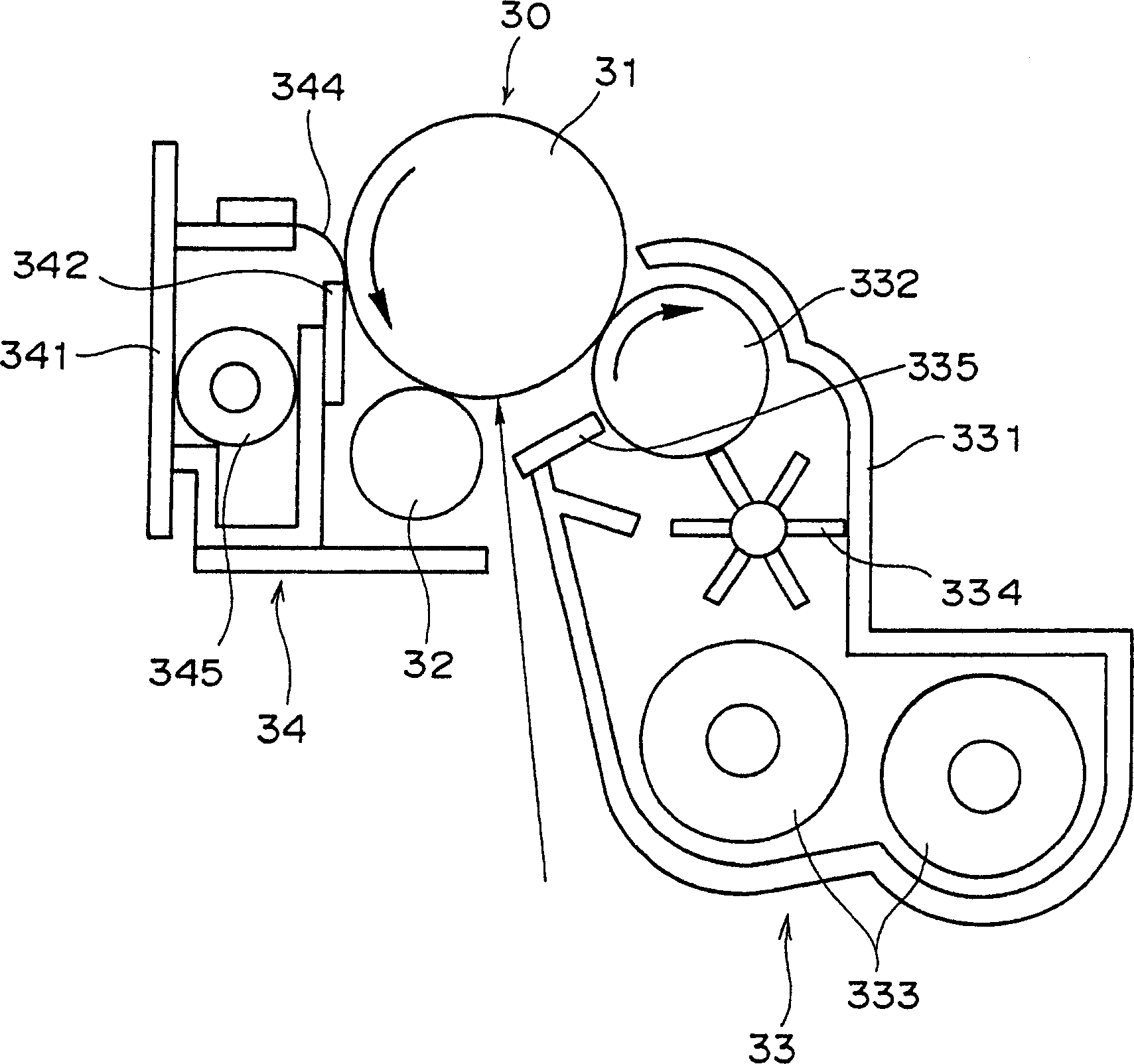

Method of manufacturing flat panel display device

To minimize stress variations applied to mother glasses when a glass sealing material is melted via a laser to combine the mother glasses, a method of manufacturing a flat panel display device includes providing a plurality of emission units between a first substrate and a second substrate, wherein the first substrates faces the second substrate and each emission unit forms a unit display device; providing a plurality of walls between the first substrate and the second substrate, wherein each wall respectively surrounds one of the emission units; irradiating a laser beam onto the walls, wherein the laser beam is simultaneously irradiated to wall portions aligned in a row in a first direction; scanning the laser beam in a second direction, wherein the second direction is different from the first direction to irradiate other wall portions of the plurality of walls; and cutting the first and second substrates to obtain individual display devices.

Owner:SAMSUNG DISPLAY CO LTD

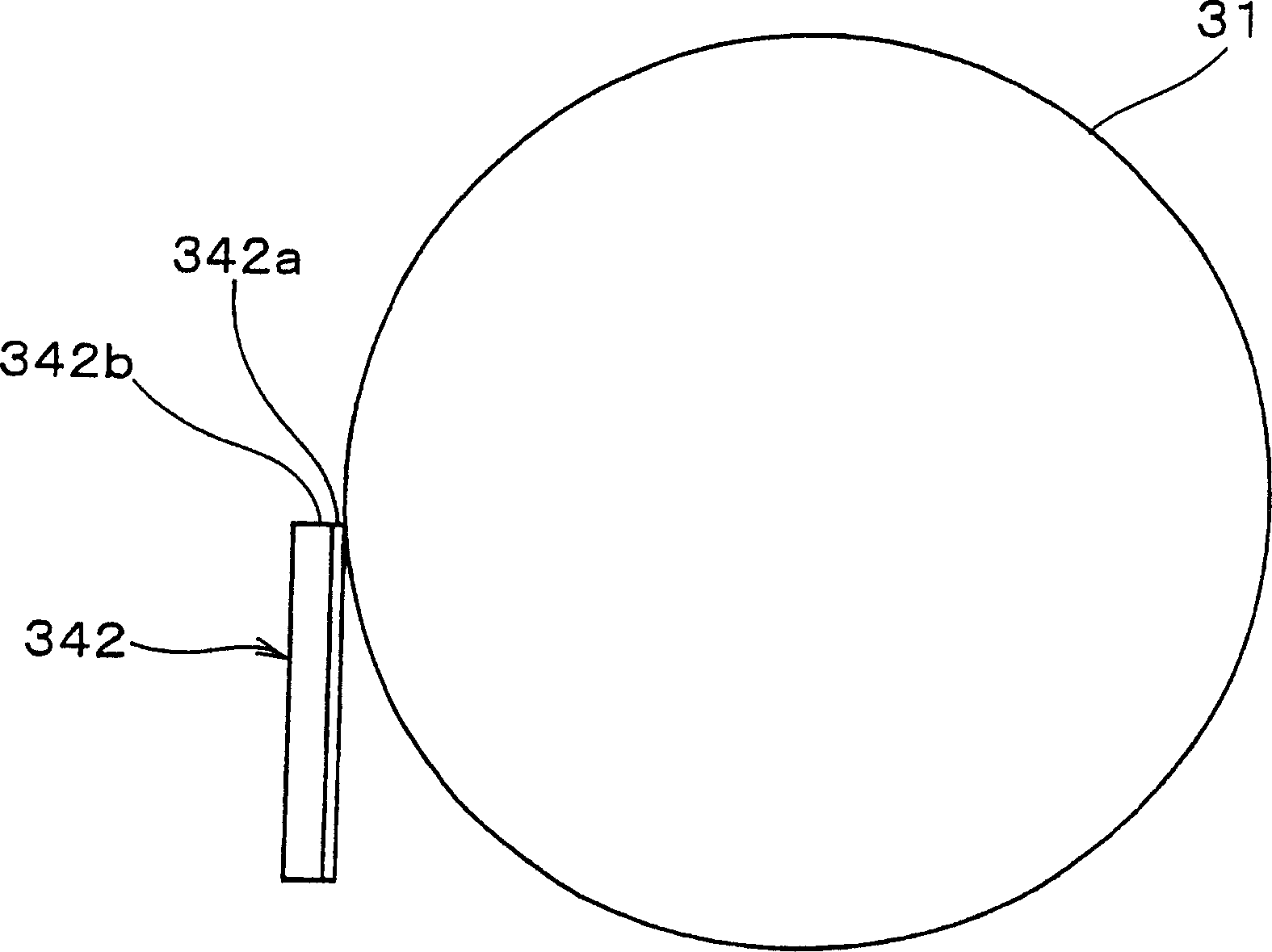

Cleaning blade, and cleaning apparatus, process cartridge, and image forming apparatus using the same

The invention provides a cleaning blade, which realizes cleanness by contacting the surface of parts needing cleanness with the blade, and it is characterized in that the material of contact site of said cleaning blade and said parts surface satisfies at least the following inequality (1)-(3): inequality (1)3.92<=M<=29.4. 2;inequality 0<=alpha<=0.294; inequality (3)S>=250, ( in the inequality (1)-(3), M represents 100% modulus (MPa); alpha represents the ratio of stress variation (delta stress) to strain variation (delta strain) [delta stress / delta strain= (the stress under 200% degree of strain - the stress under 100% degree of strain) / (200-100) ] (MPa / %)in the rang of 100%-200% strain degree and in stress-strain curve; furthermore, S represents elongation at break (%)determined with JIS,K6251(using dumbbell-type the third test piece). The invention also provides a cleaning arrangement containing a cleaning blade, a processing box and an image-forming device.

Owner:FUJIFILM BUSINESS INNOVATION CORP

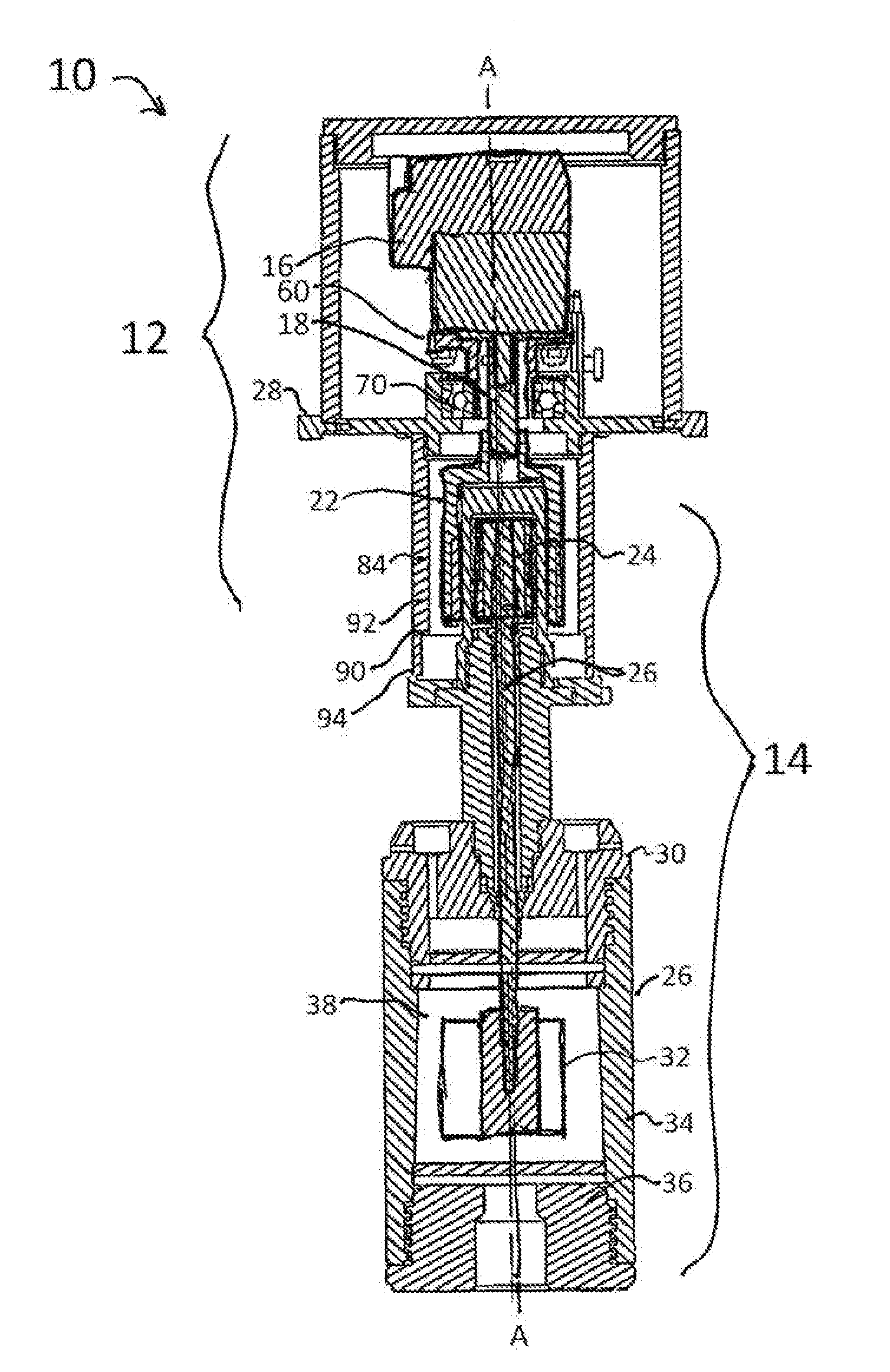

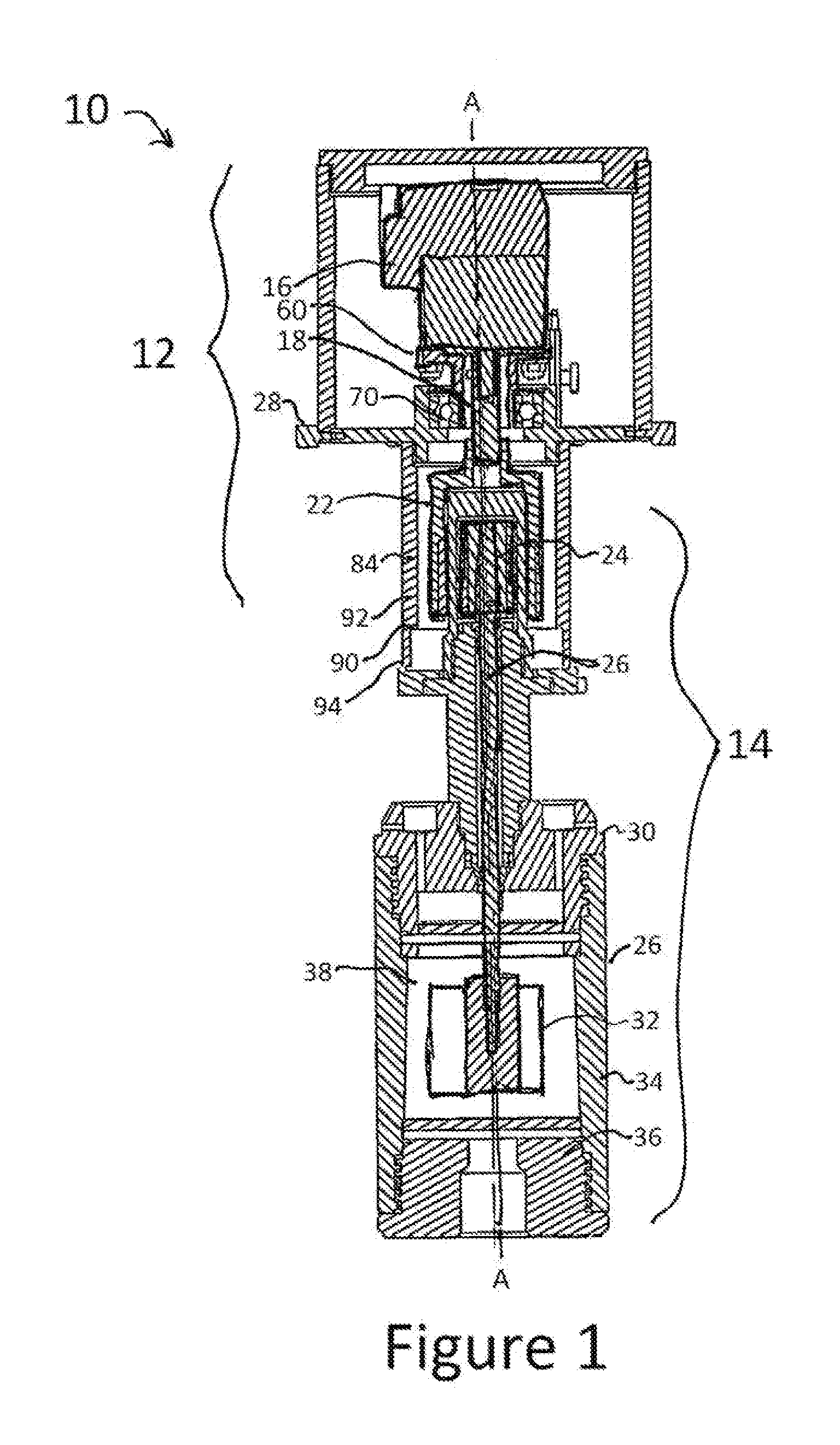

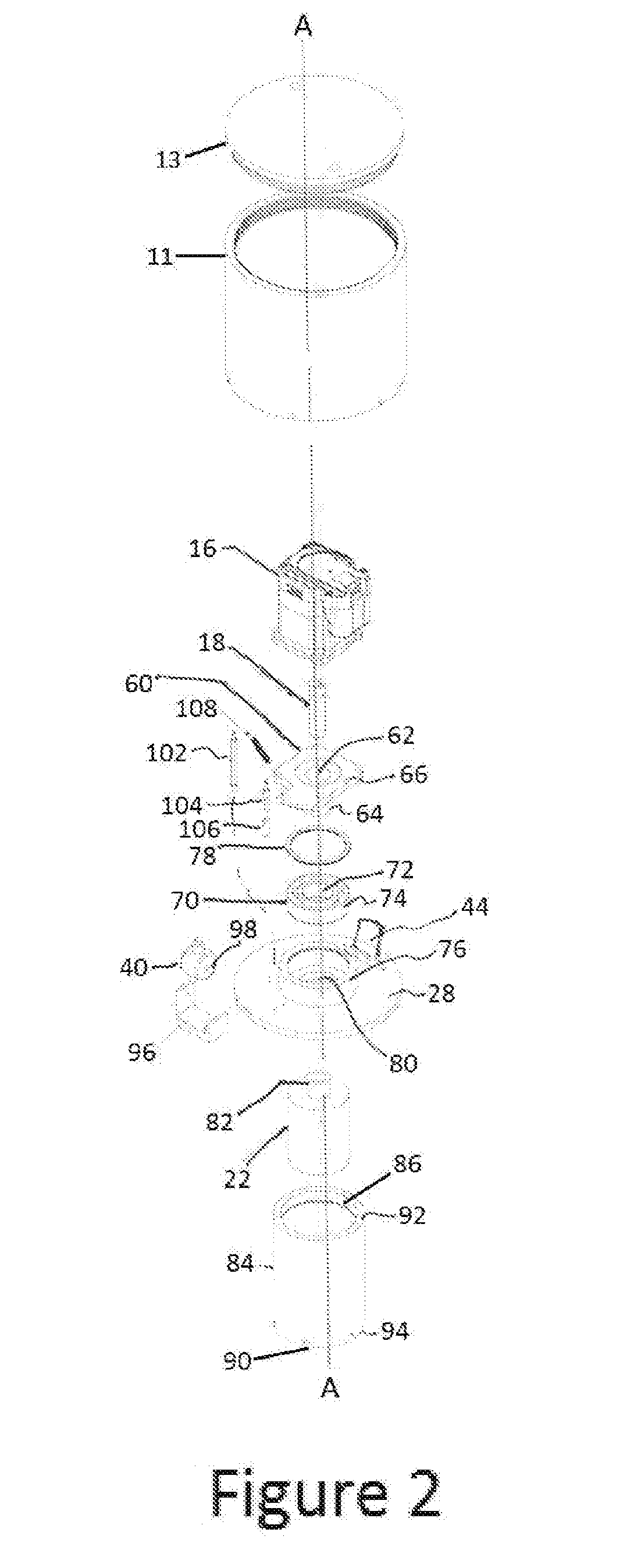

Static Gel Strength Measurement Apparatus and Method

ActiveUS20150198512A1Accurate measurementLow viscosityFlow propertiesMaterial strength using steady shearing forcesMeasurement deviceDrive motor

A fluid properties measurement apparatus for use with a conventional high temperature high pressure test cell includes a load cell assembly and a drive motor that drives a rotating shaft magnetically connected to a vane assembly having multiple vane elements, wherein the motor rotates in response to reactive forces of a fluid sample and the load cell assembly measures reactive forces of the sample. In one embodiment, a stepper motor allows for precise shaft rotation.A method of measuring fluid properties includes frequent measurements throughout a complete rotation cycle of a vane assembly within a test cell. A system interference profile is generated which identifies stress variations resulting from various system components throughout the cycle. Measurements of a sample's fluid properties are likewise performed to obtain a profile. Comparison of the sample profile with the interference profile provides fluid properties measurement independent of stress variations resulting from various system components.

Owner:OFI TESTING EQUIP

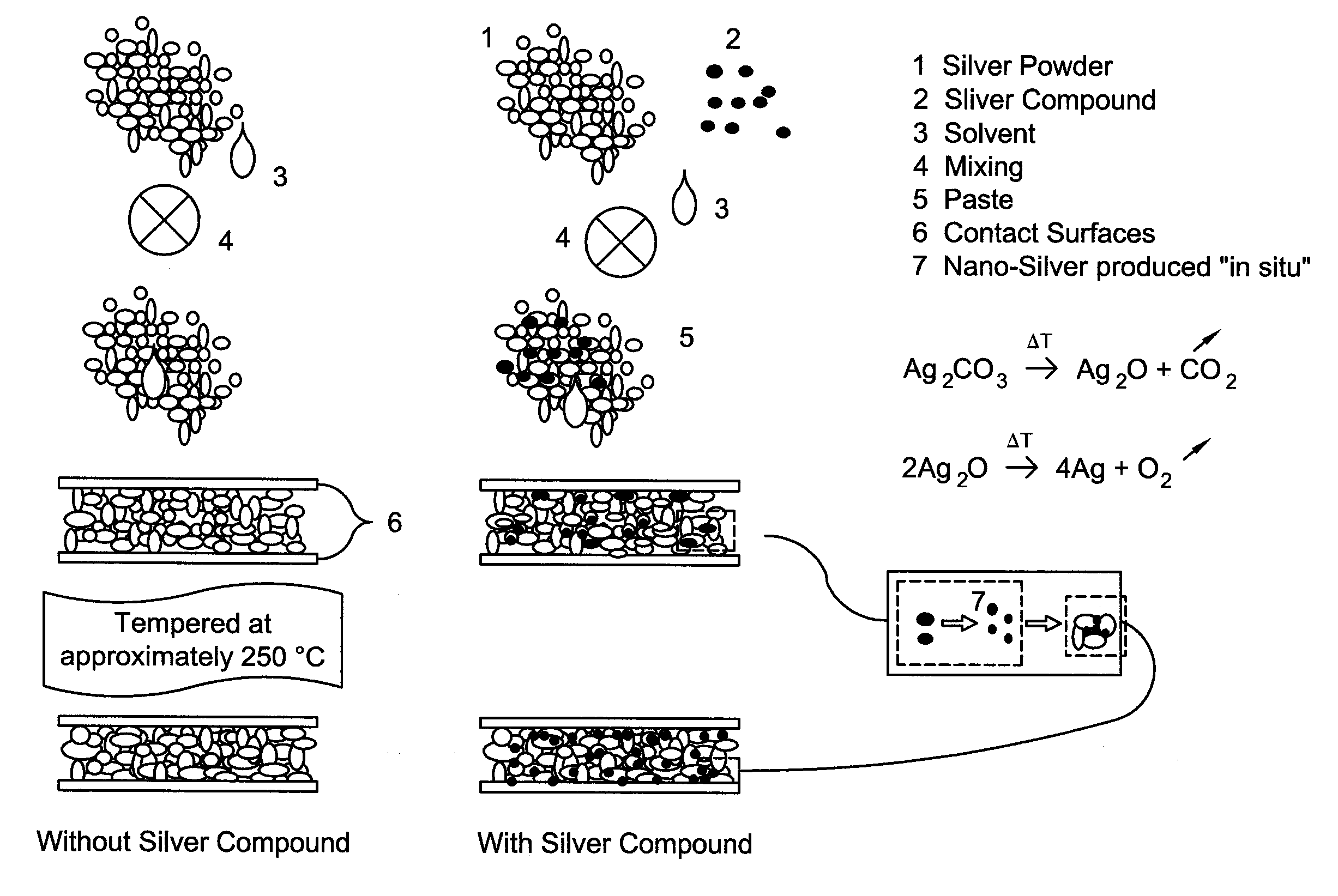

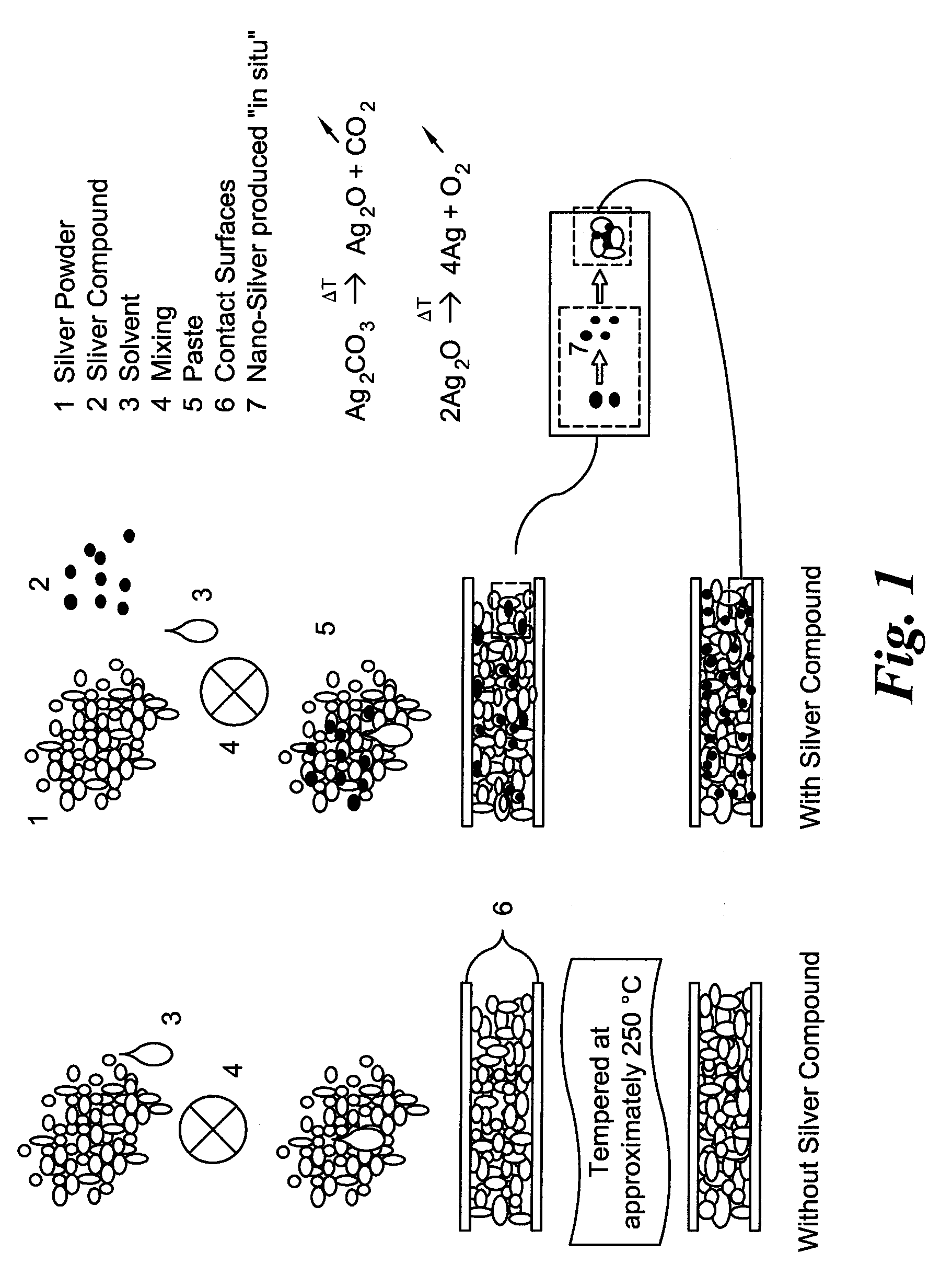

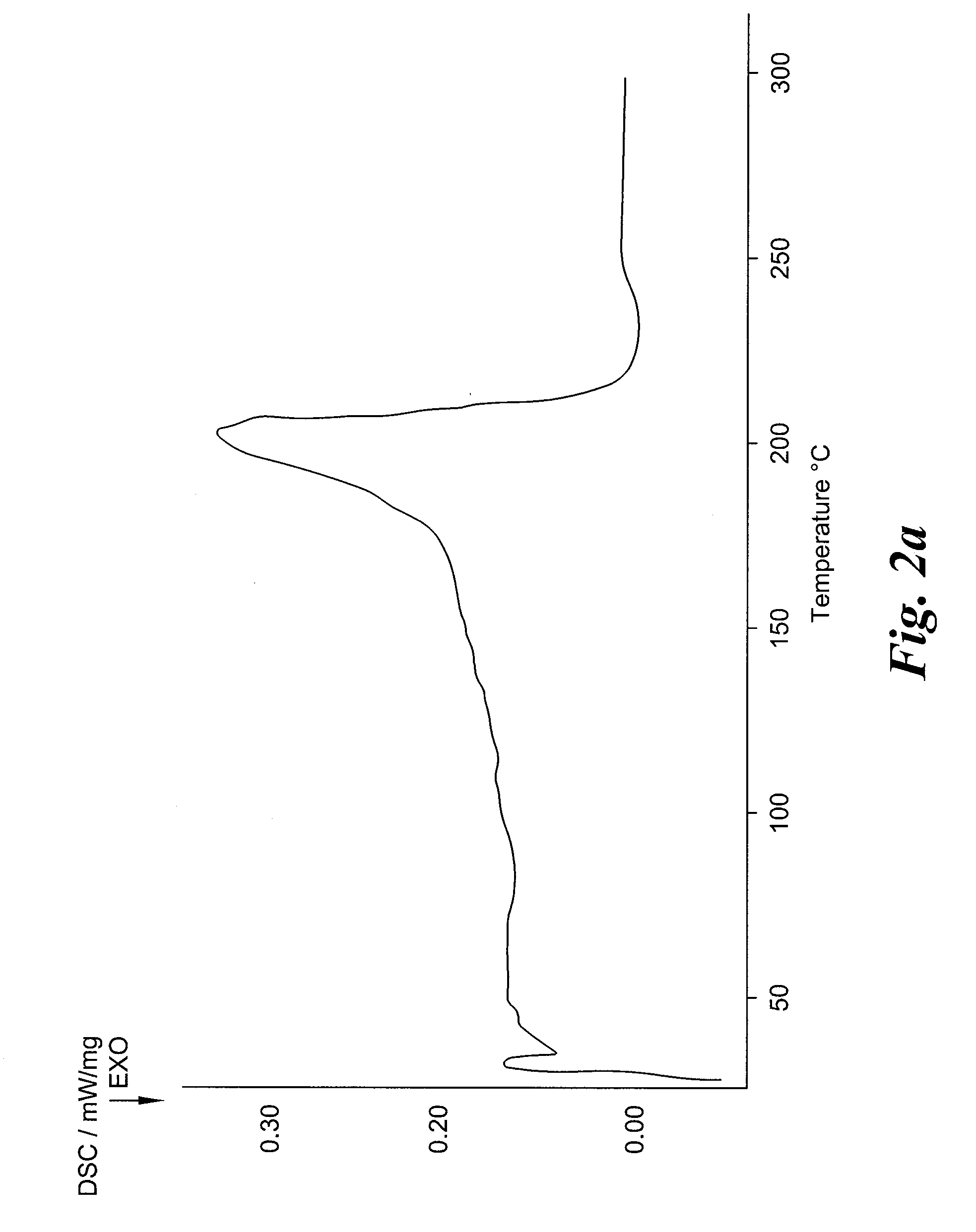

Controlling the porosity of metal pastes for pressure free, low temperature sintering process

InactiveUS20100051319A1Improve compactnessSpeed up the processLine/current collector detailsNon-insulated conductorsPorosityBoiling point

Metal pastes and methods make it possible to produce extremely compact layers between contact surfaces of structural components, which layers are sufficiently elastic to permanently withstand mechanical and thermal stress variations. This is achieved by the porosity of a corresponding contact area being controlled. For this purpose, a metal paste is provided which contains 70-90% by weight of a metal powder, 1-20% by weight of an endothermically decomposable metal compound and 5-20% by weight of a solvent having a boiling point or range above 220° C., the metal paste being compactable exothermically to form a metal contact.

Owner:HERAEUS MATERIALS TECHNOLOGY GMBH & CO KG

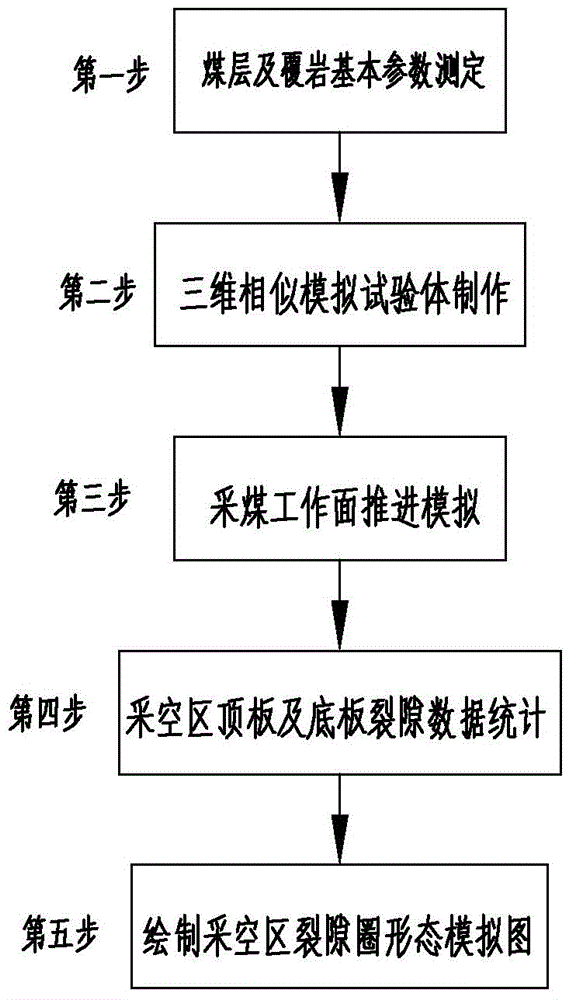

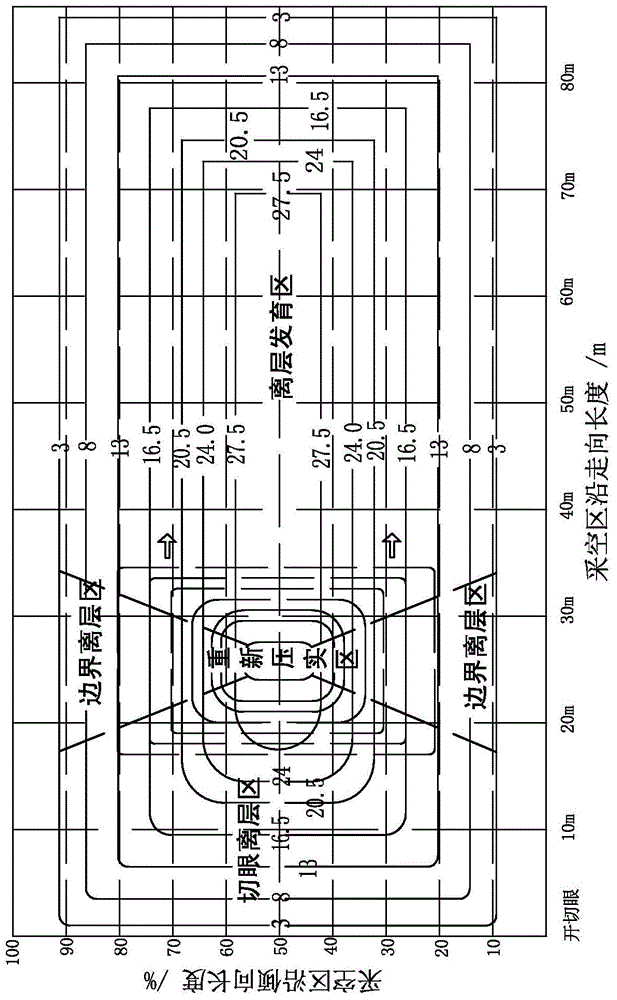

Three-dimensional simulating method for goaf fracture ring morphology

InactiveCN105223337ARealize simulationReal simulation mining processEarth material testingStress variationStress sensor

The invention discloses a three-dimensional simulating method for goaf fracture ring morphology. The method comprises the steps that according to the space similarity ratio between a coal seam and overlaying rock and time similarity ratio of coal seam working face propelling, a three-dimensional similar simulation test body is manufactured; according to the site mining working face ground stress situation and the mining sequence, the dynamic process of coal mine working face propelling under the three-dimensional stress condition is simulated; an embedded stress sensor is utilized for monitoring stress changes of a top plate and a bottom plate of a goaf in the mining working face propelling process, and a dynamic resistance strain gauge is utilized for recording data; after mining working face propelling simulation is finished, a tracer agent labeling method is used for carrying out drilling to pry and observe the goaf fracture morphology of the simulation test body, the top plate and the bottom plate of the goaf are separated layer by layer and section by section, and statistics is carried out on fracture data of all layers and all sections; according to the statistical fracture data, three-dimensional software is utilized for drawing a goaf fracture ring morphology simulation image. The method has the advantages that a three-dimensional mode is adopted for simulating the goaf fracture development morphology, and therefore the position of extraction holes can be determined conveniently and accurately.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com