Patents

Literature

1270 results about "Hexahedron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

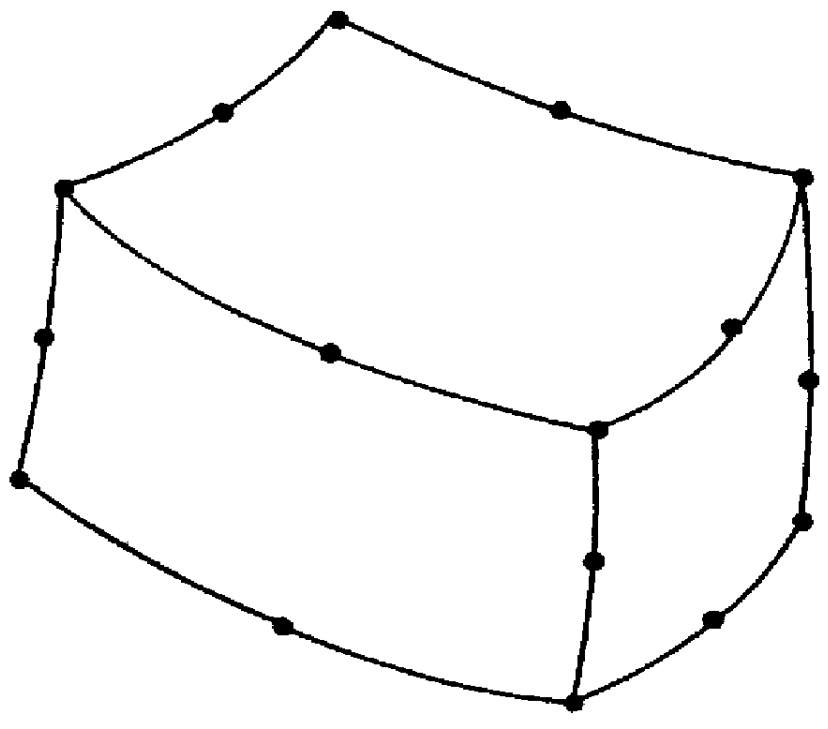

A hexahedron (plural: hexahedra) is any polyhedron with six faces. A cube, for example, is a regular hexahedron with all its faces square, and three squares around each vertex.

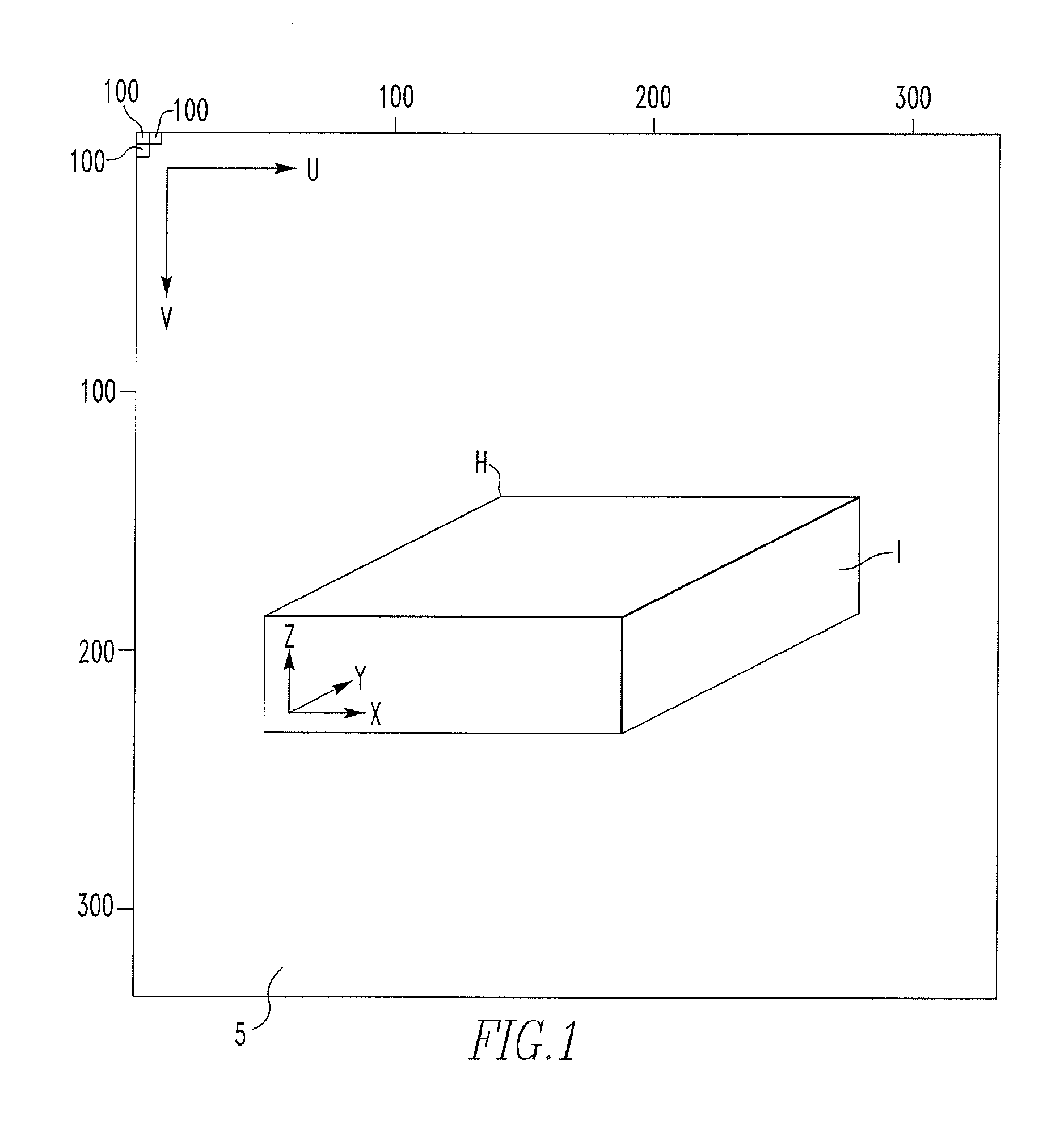

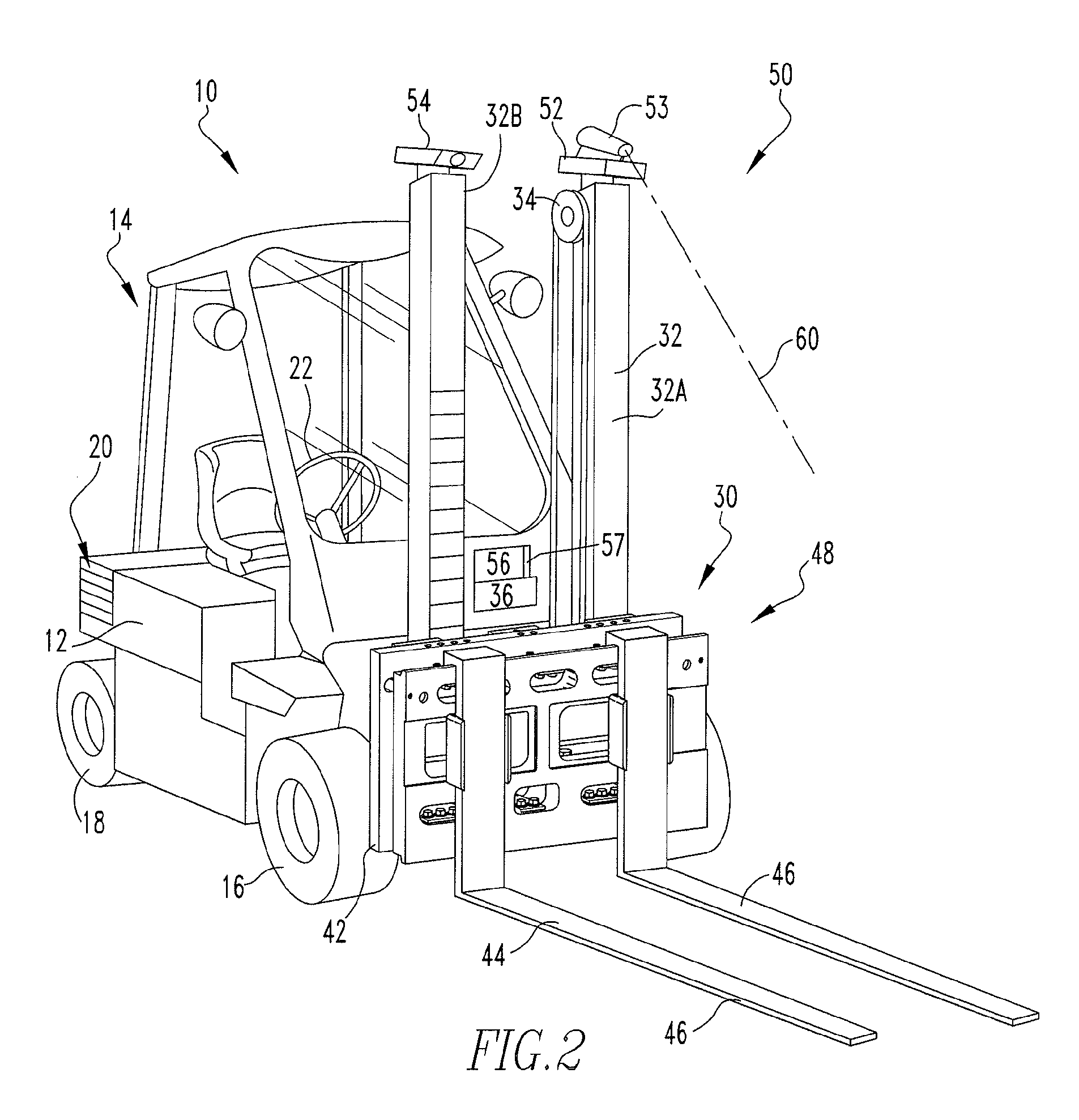

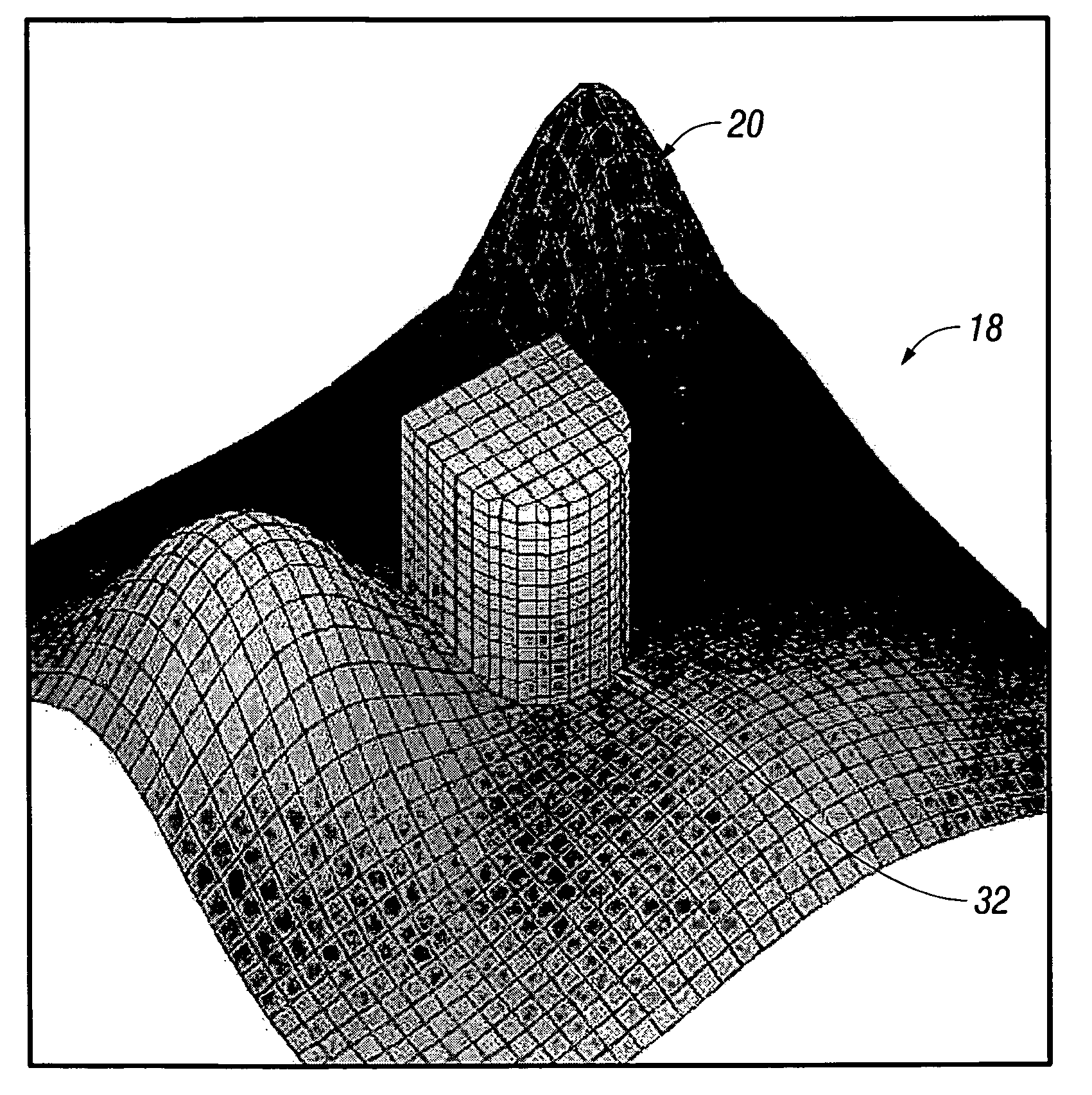

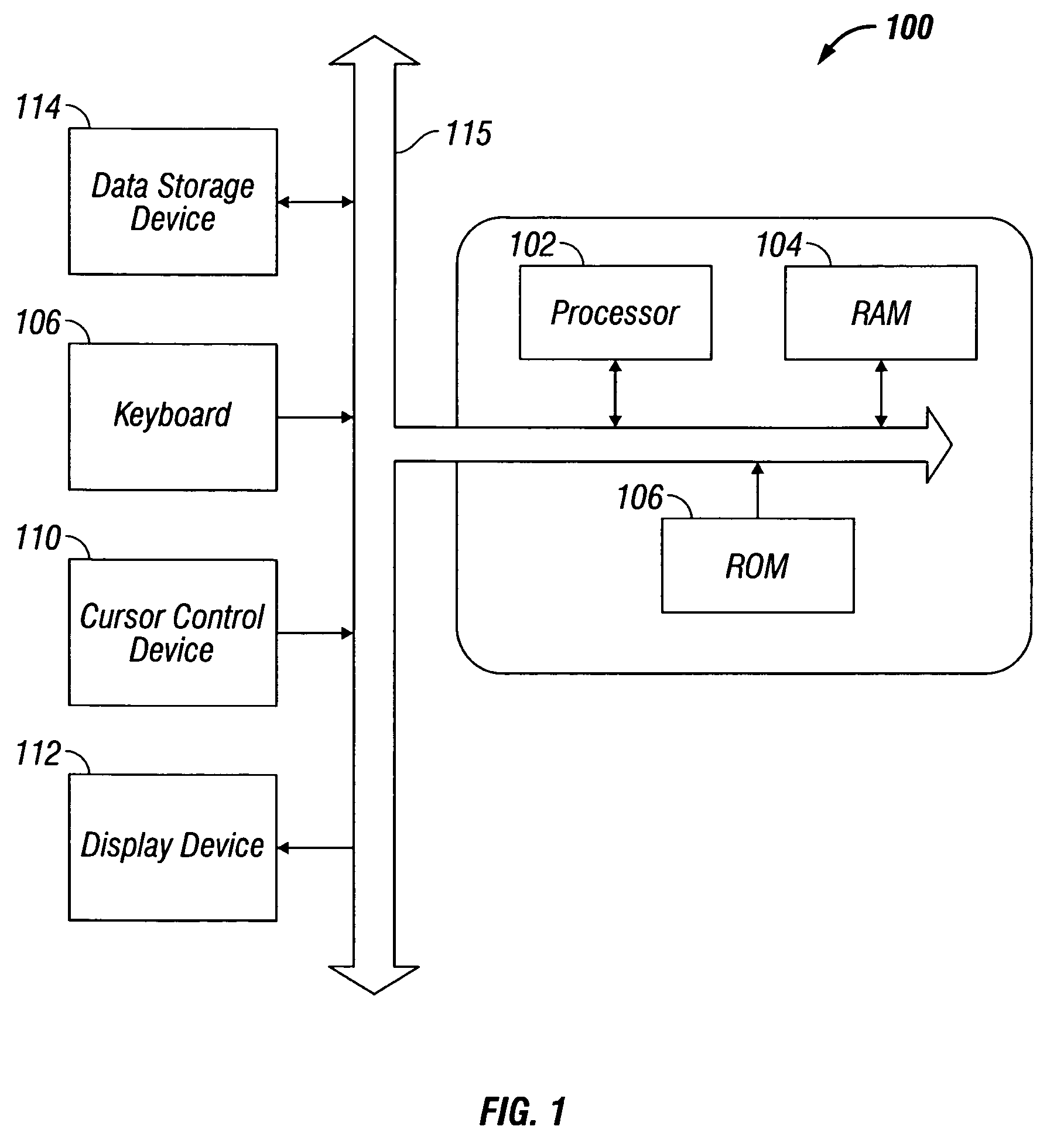

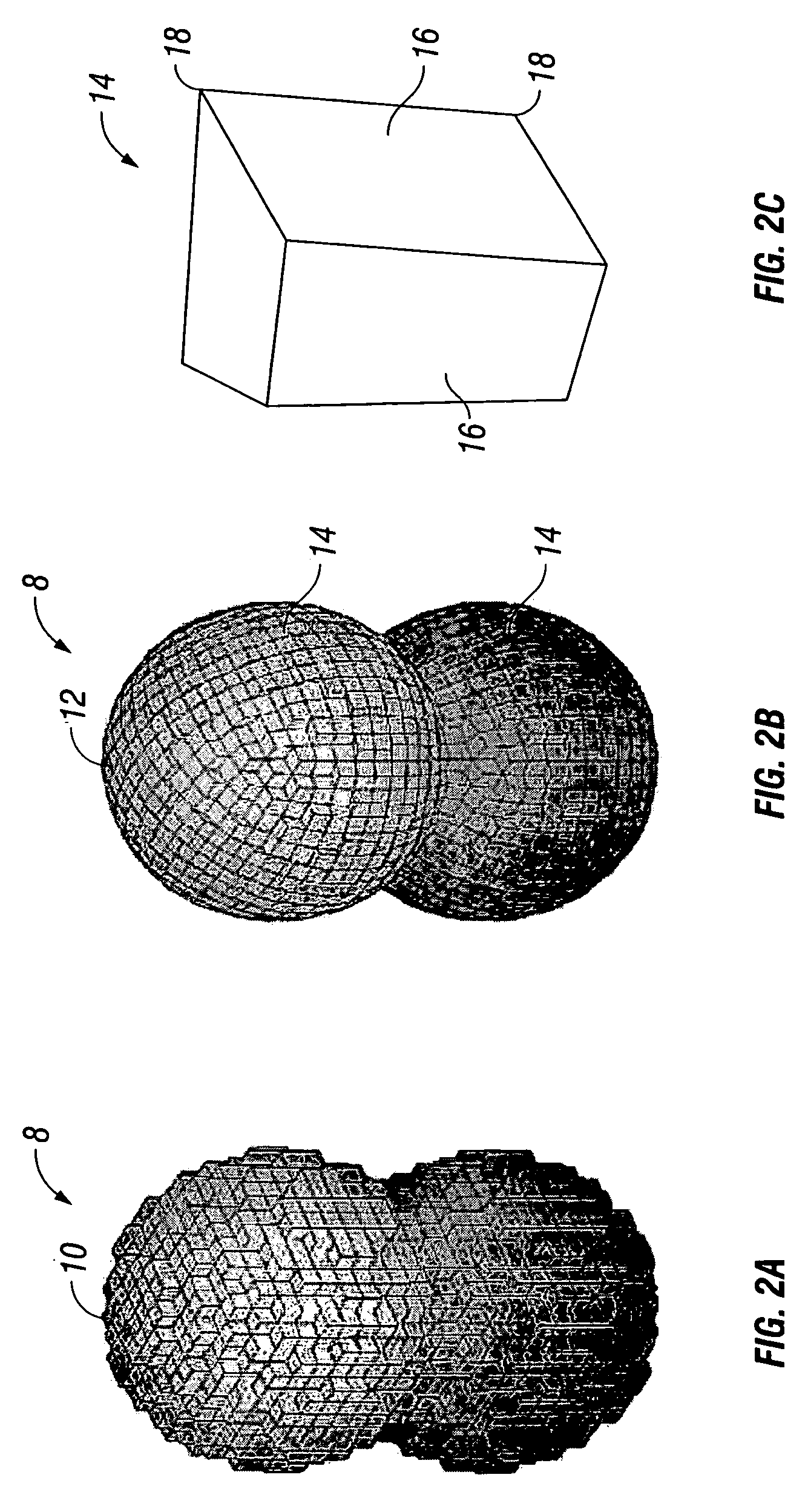

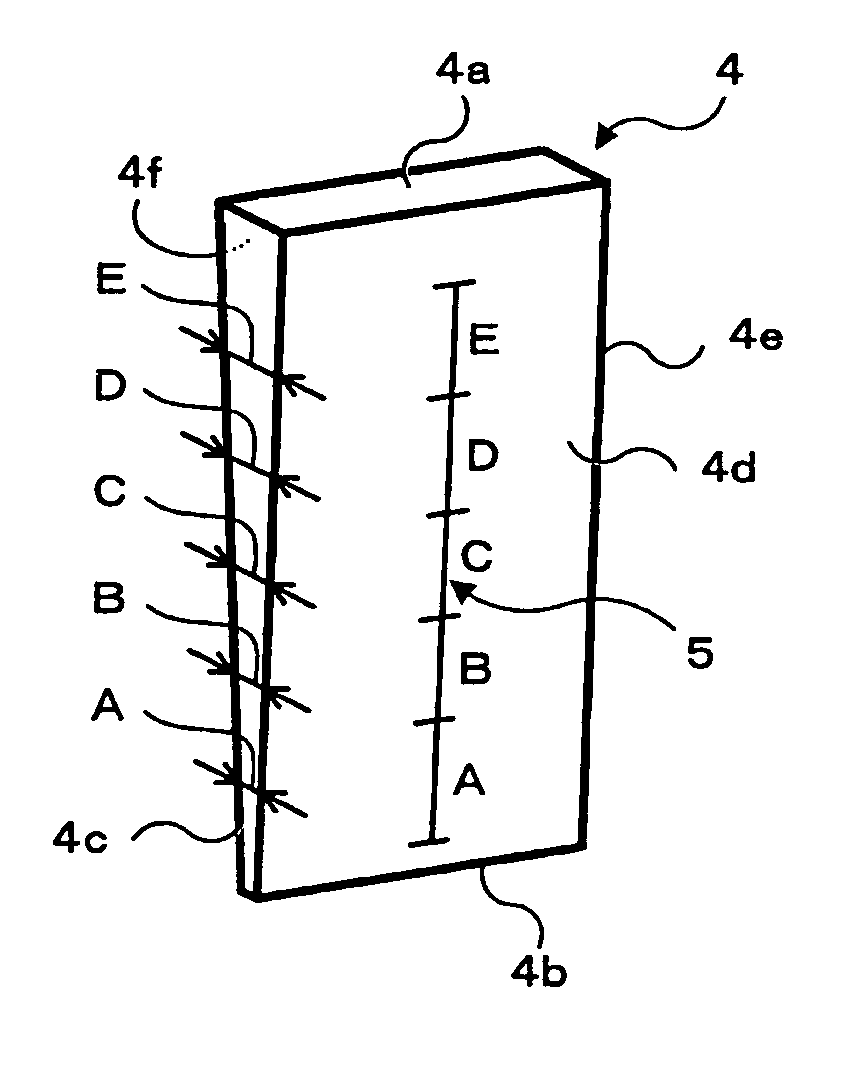

Dimensional Detection System and Associated Method

InactiveUS20110286007A1Clear visionSafety devices for lifting equipmentsCharacter and pattern recognitionData setLight beam

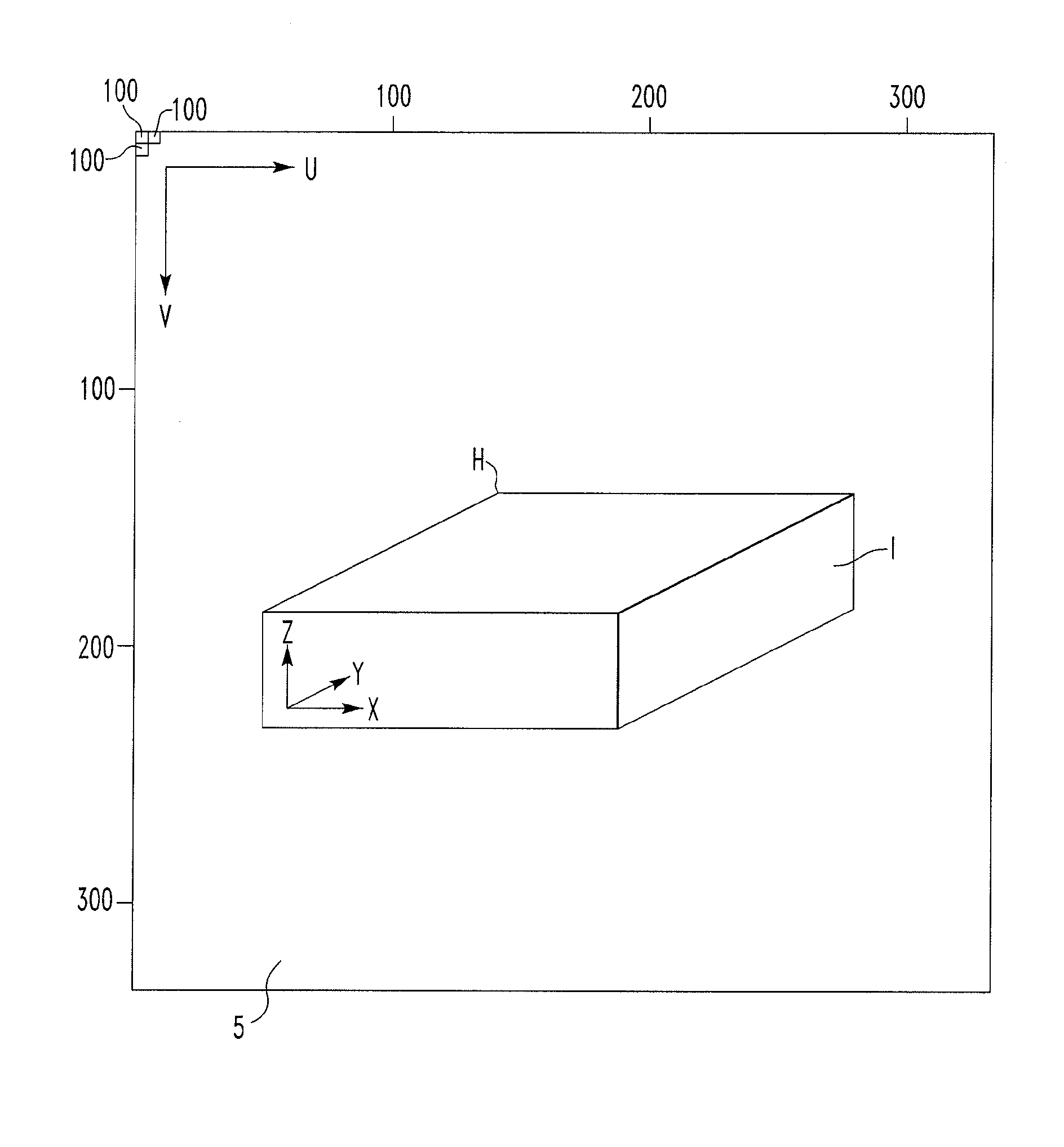

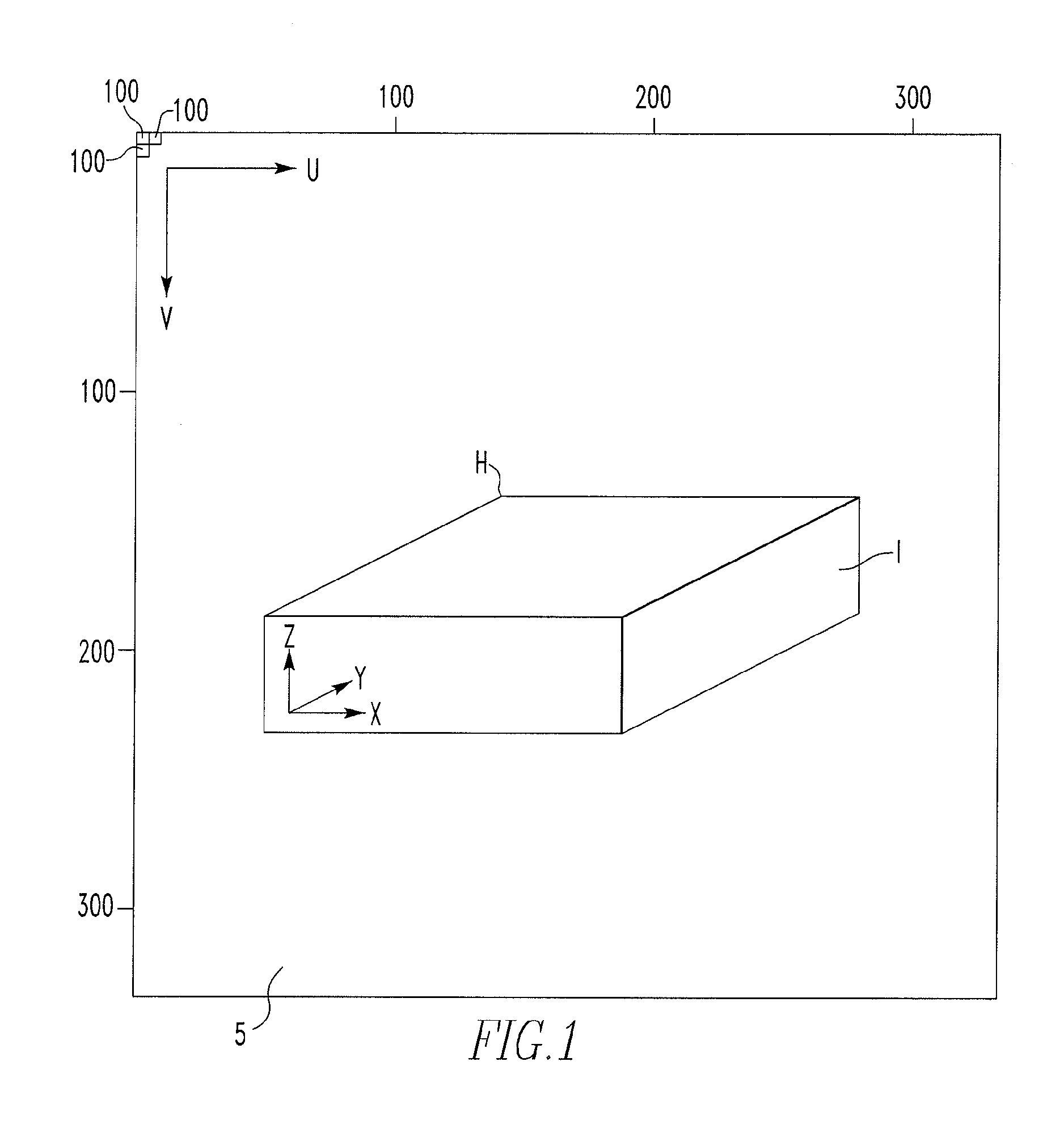

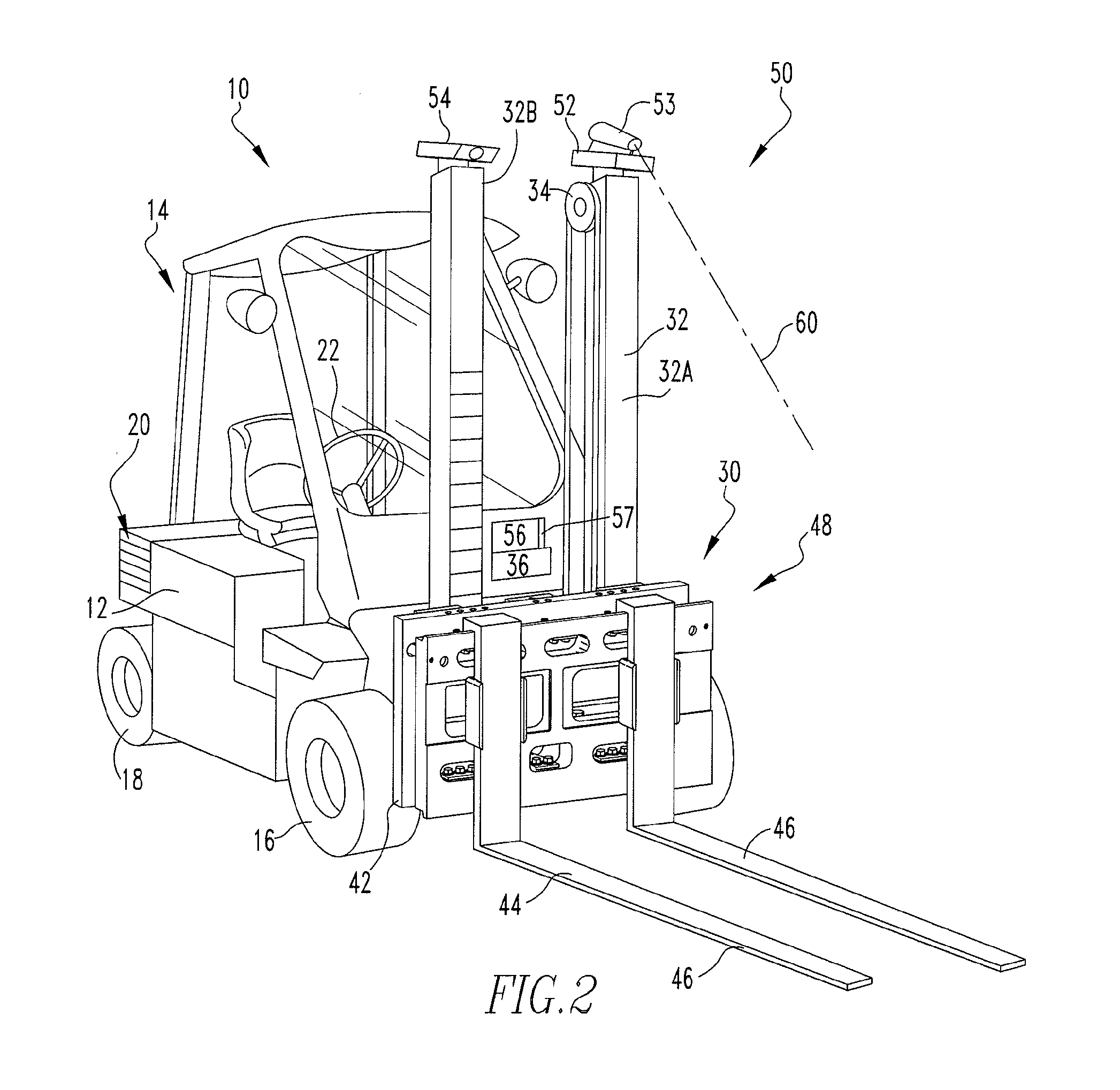

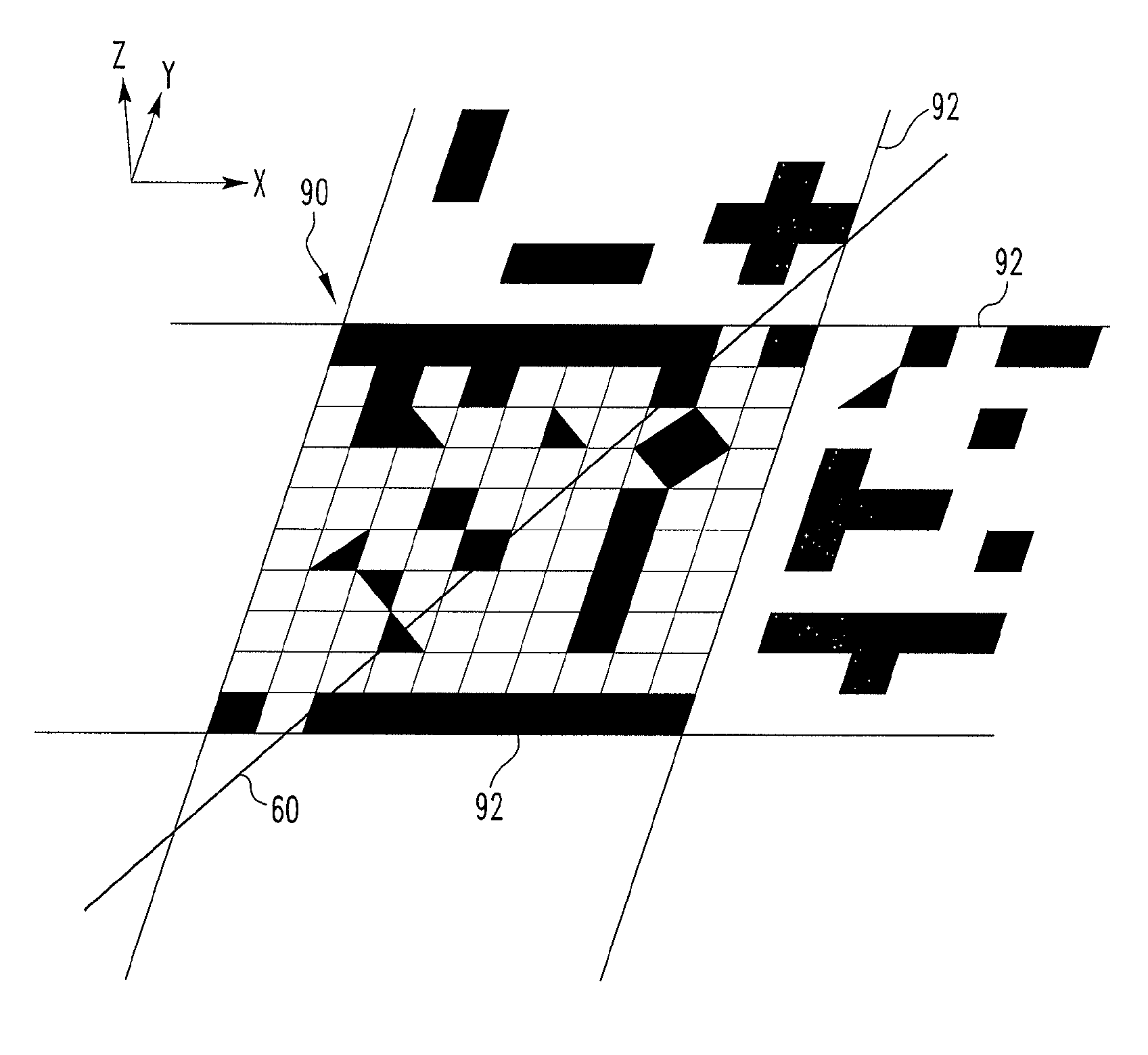

An improved dimensional detection system is portable and can be used to characterize a workpiece. The dimensional detection system employs as few as a single focused light source and as few as a single camera along with a calibration data set to convert the illuminated pixels of an image of a beam on the workpiece into a cloud of real world points in space on an outer surface of the workpiece. The cloud of points can be processed to characterize the workpiece, such as by determining the right hexahedron that would encompass all of the real world points in space and which could be used to determine a dimensional weight of the workpiece.

Owner:LTS SCALE CO LLC

Dimensional detection system and associated method

InactiveUS8134717B2Clear visionSafety devices for lifting equipmentsCharacter and pattern recognitionData setLight beam

An improved dimensional detection system is portable and can be used to characterize a workpiece. The dimensional detection system employs as few as a single focused light source and as few as a single camera along with a calibration data set to convert the illuminated pixels of an image of a beam on the workpiece into a cloud of real world points in space on an outer surface of the workpiece. The cloud of points can be processed to characterize the workpiece, such as by determining the right hexahedron that would encompass all of the real world points in space and which could be used to determine a dimensional weight of the workpiece.

Owner:LTS SCALE CO LLC

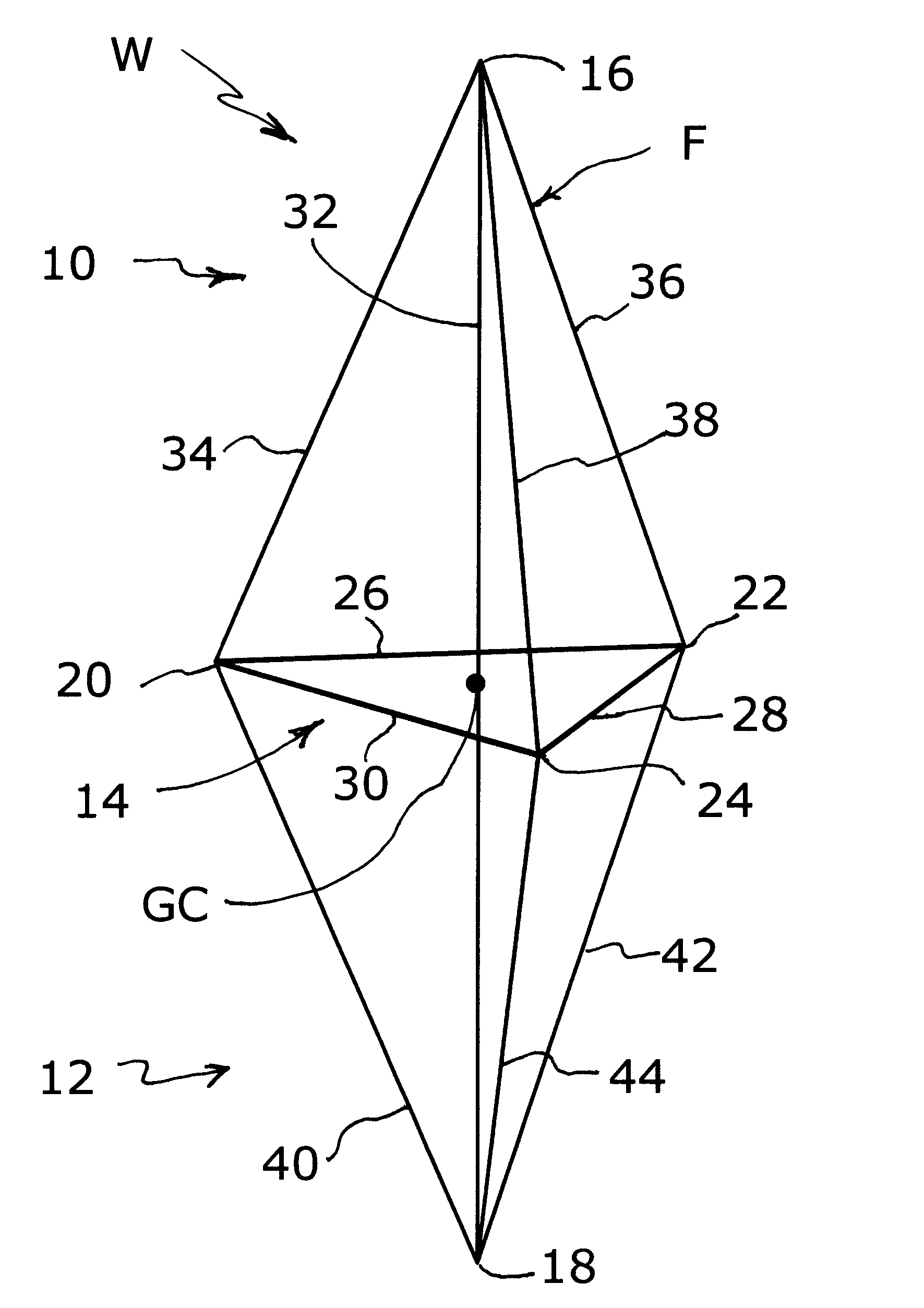

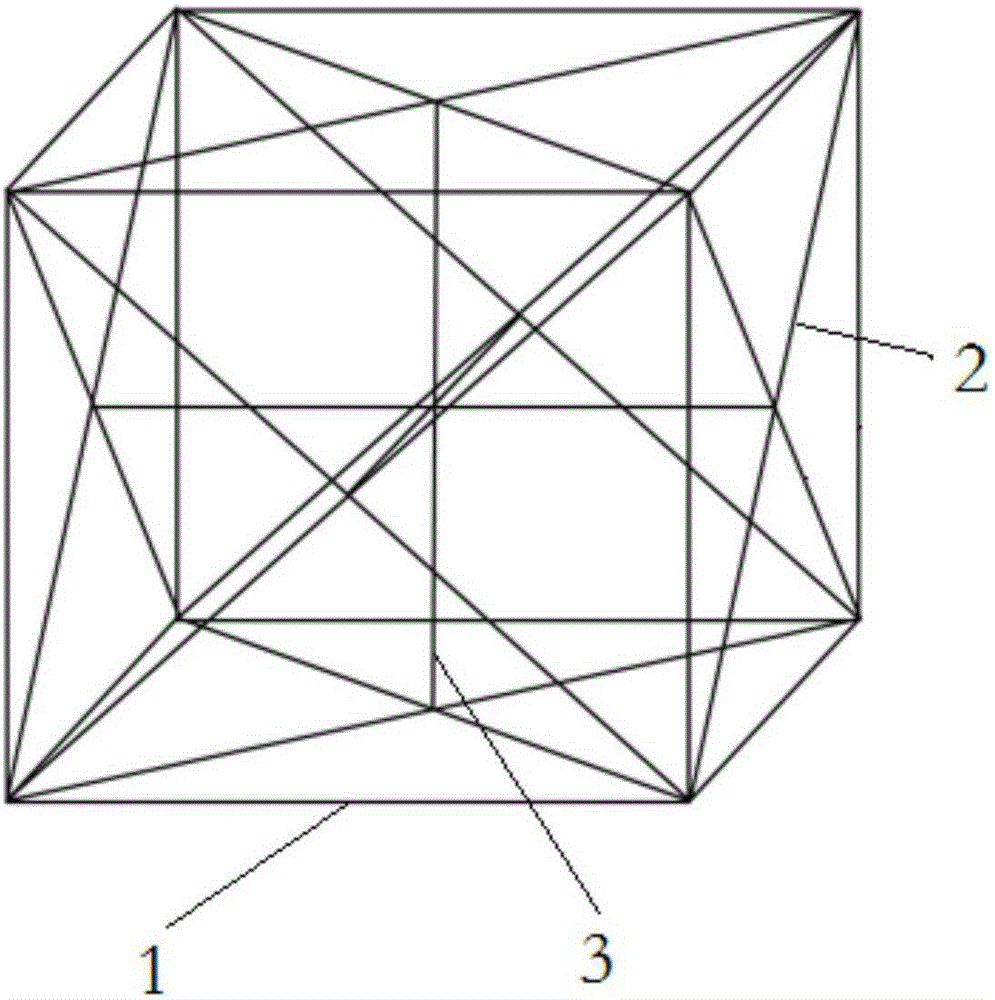

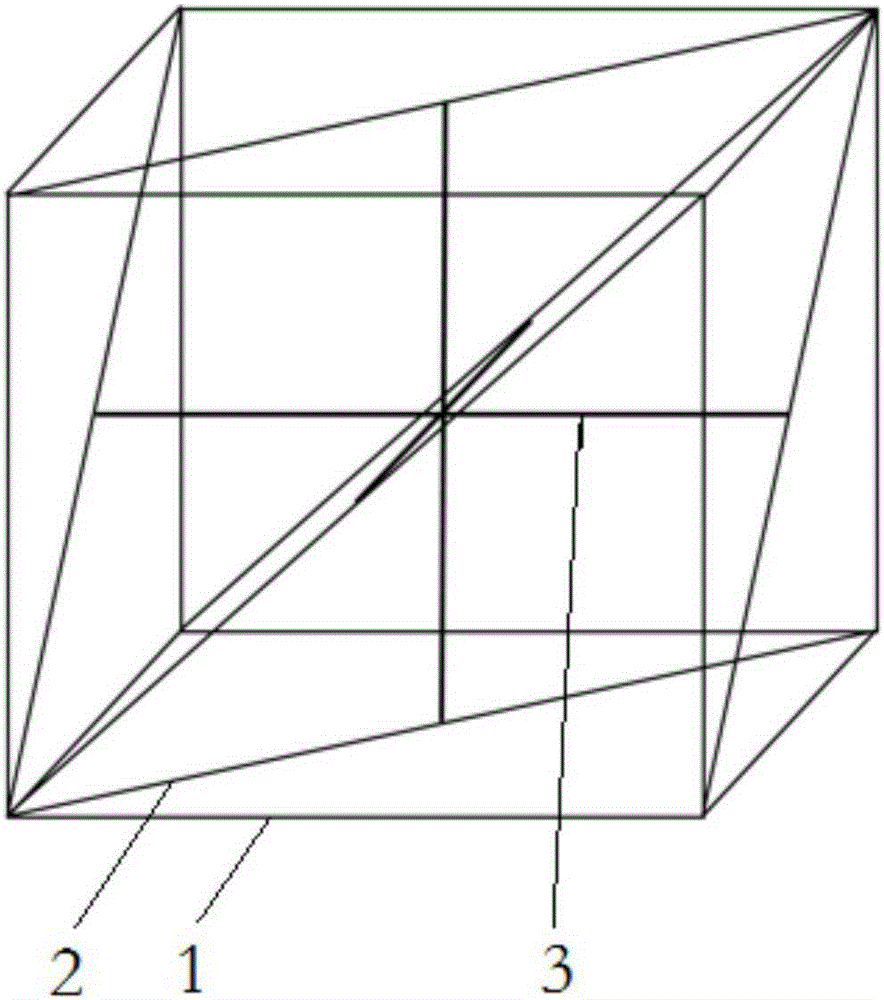

Web structure and method for making the same

InactiveUS6931812B1Strong and stable structureStable and strongLayered productsTowersWeb structureEngineering

A web structure includes a generally hexahedron-shaped frame having a plurality of points or vertices oriented in a manner that no more than three points lie in a common plane. Each pair of the points is connected by a line or frame segment and a plane includes three of the points. One line or frame segment passes through the plane and has first and second ends that are generally equidistant from the plane.

Owner:LIPSCOMB STEPHEN LEON

Storage medium having information processing program stored therein, information processing apparatus, information processing system, and information processing method

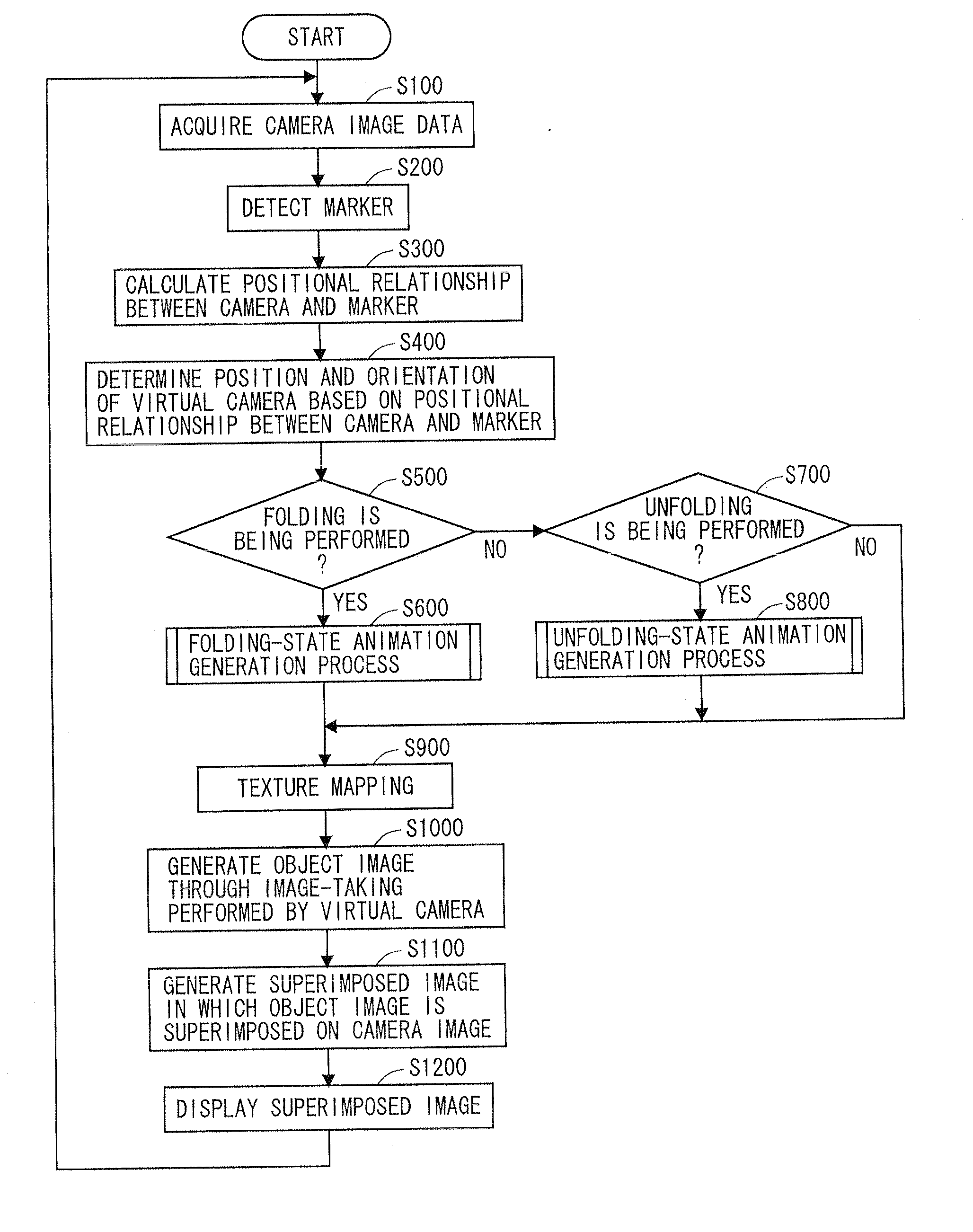

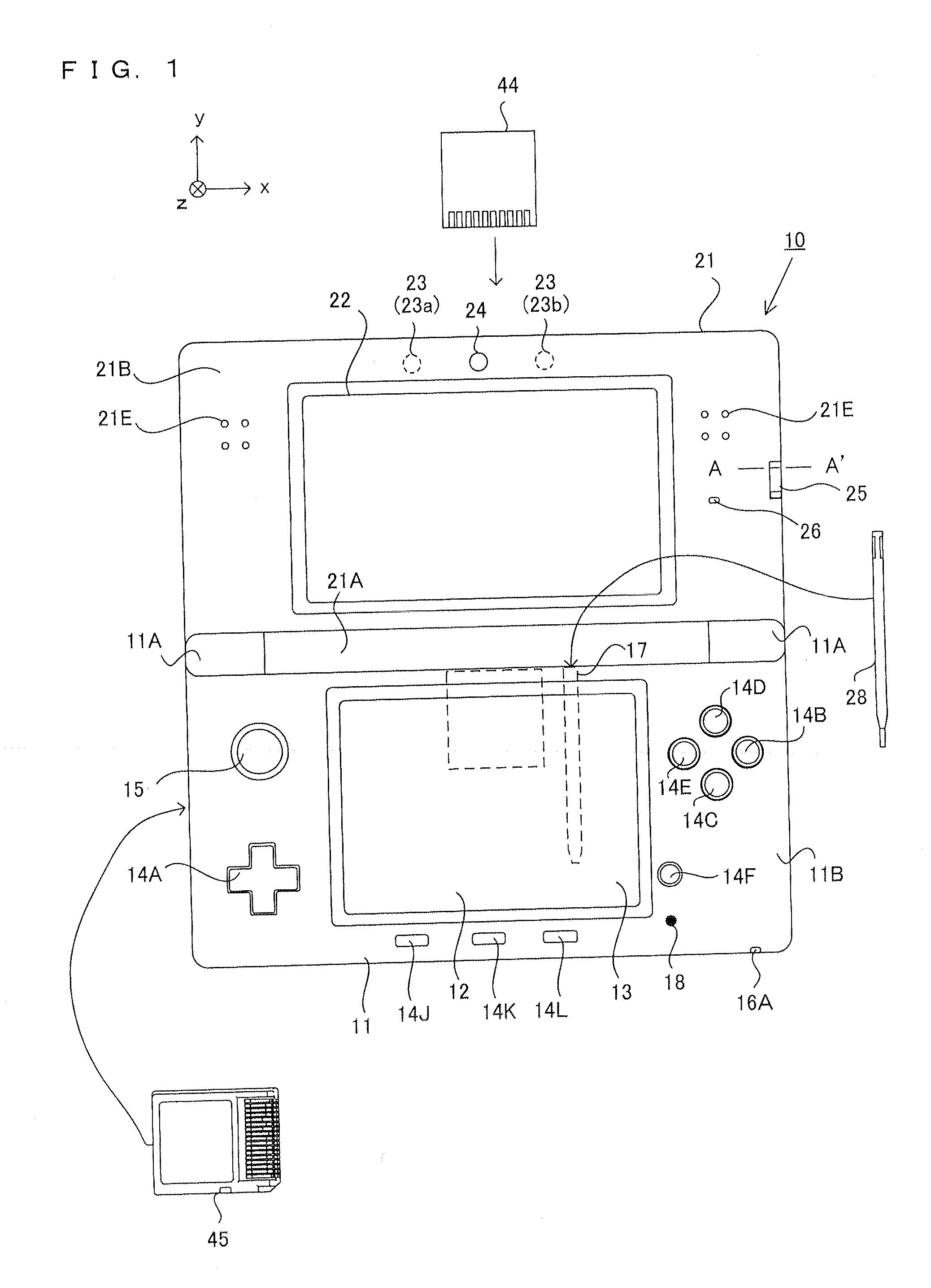

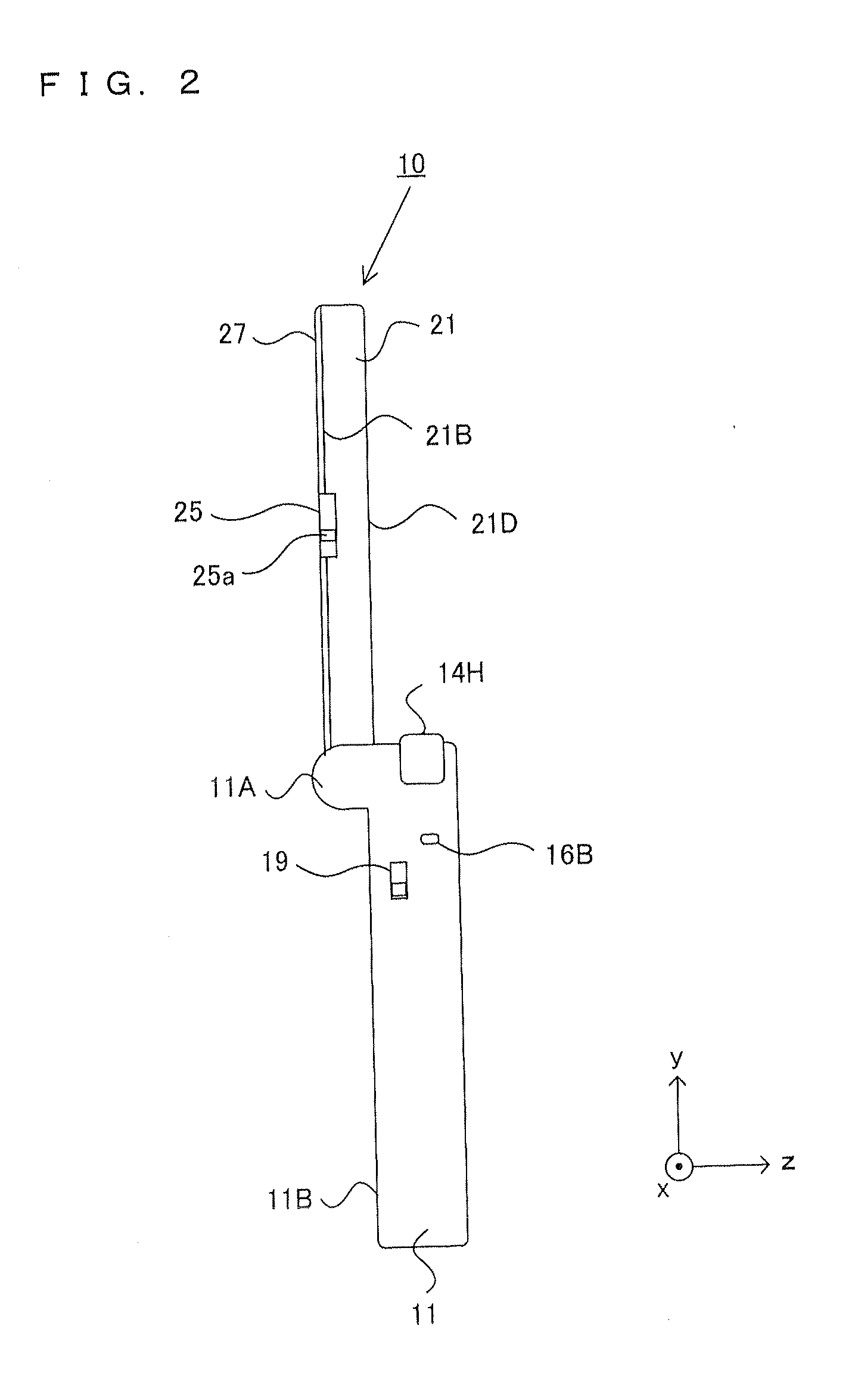

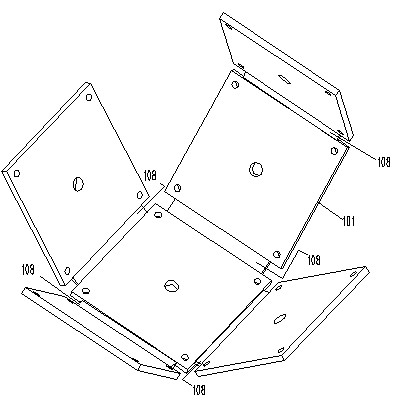

An information processing section of a game apparatus executes a program for implementing a step S100 of acquiring a camera image; a step S200 of detecting a marker; a step S400 of calculating a position and an orientation of a virtual camera; a step S600 of generating an animation in which layed-flat surfaces of a hexahedron appear, and the hexahedron is folded so as to confine virtual objects representing targets therein when a stage is cleared; a step S800 of generating an animation in which the folded hexahedron is unfolded so as to position different virtual objects thereon; a step S900 of mapping the photographed image on objects; a step S1000 of taking an image of the objects by means of the virtual camera; and a step S1100, S1200 of displaying the camera image and an object image which is superimposed on the camera image.

Owner:NINTENDO CO LTD +1

Computer process for prescribing second-order tetrahedral elements during deformation simulation in the design analysis of structures

InactiveUS6044210AComputation using non-denominational number representationDesign optimisation/simulationElement modelEngineering

A computer implemented process prescribes second-order tetrahedral elements during simulation in the design analysis of structure. The computer implemented process includes the steps of defining a finite element model for an element including at least one tetrahedral element, and defining the at least one tetrahedral element as a combination of hexahedral sub-elements. The computer implemented process also includes the steps of executing the simulation, and evaluating the structure for structural integrity responsive thereto.

Owner:DASSAULT SYSTEMES SIMULIA CORP

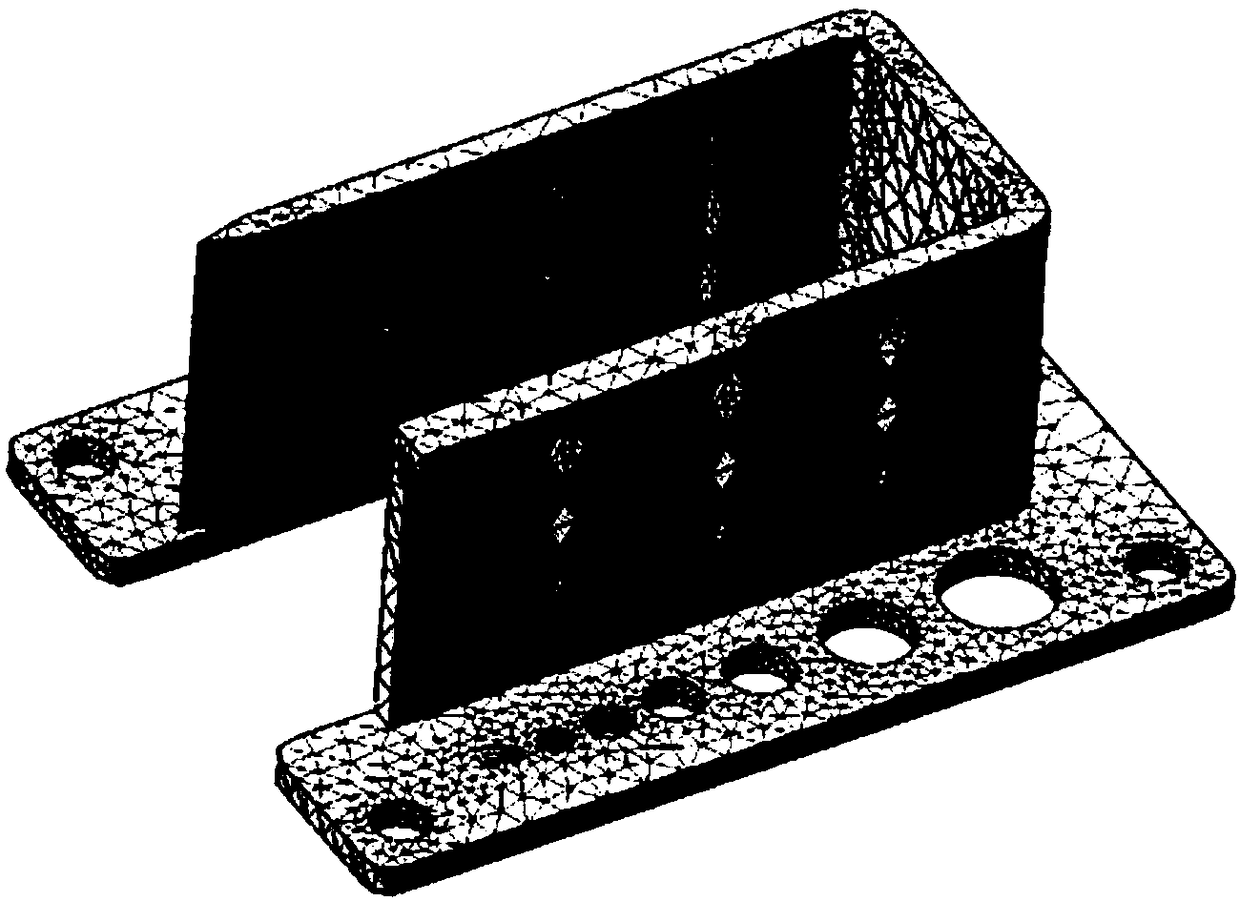

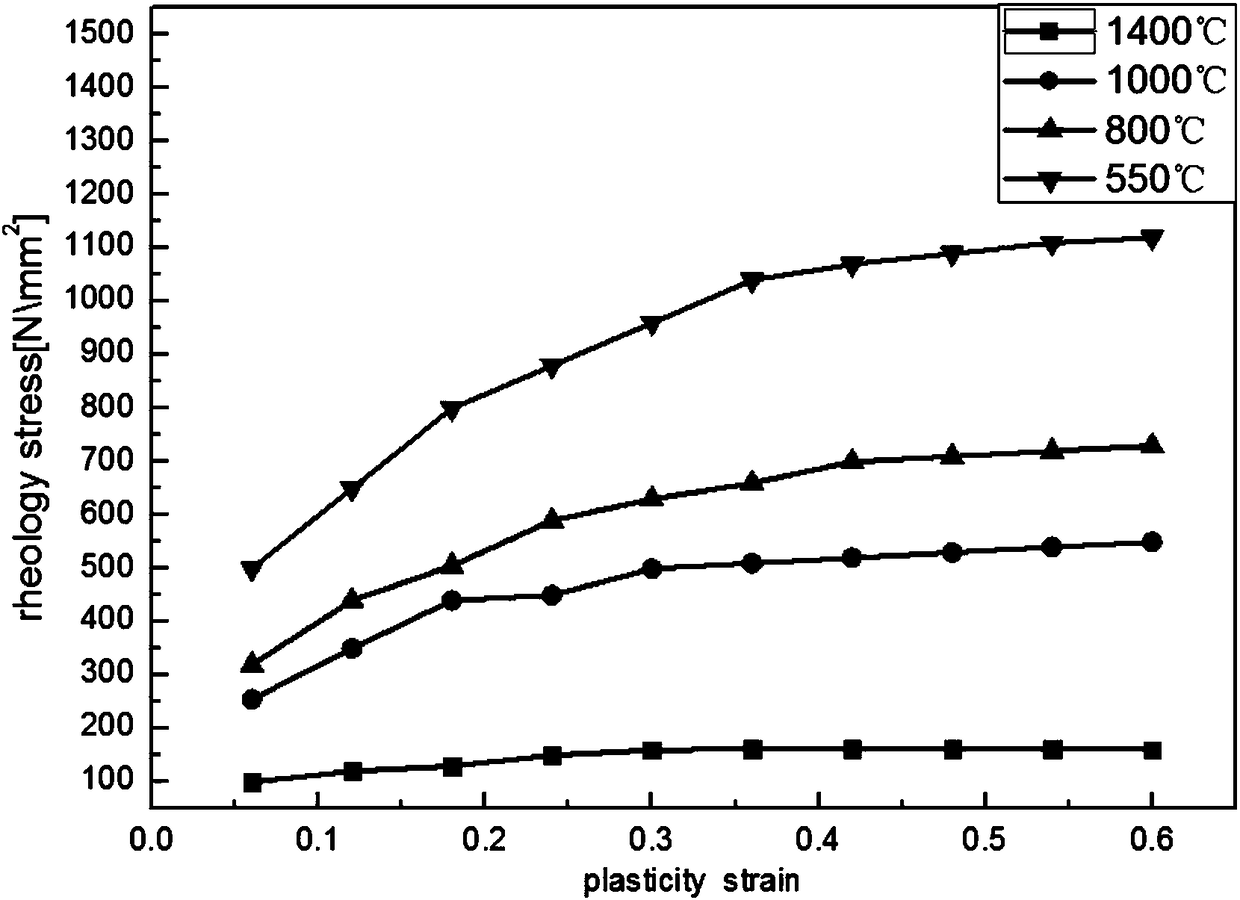

Numerical simulation method for selective laser melting process

InactiveCN108062432APrevent cracks and other phenomenaOptimize printing parametersDesign optimisation/simulationSpecial data processing applicationsSelective laser meltingElement model

The invention discloses a numerical simulation method for a selective laser melting process. The method comprises a first step of establishment of a finite element model of additive manufacturing process simulation; a second step of meshing on the finite element model of the additive manufacturing process, wherein full-hexahedron meshing is adopted; a third step of definition of printing powder material properties and thermal physical performance parameters which must be determined for temperature field analysis in the additive manufacturing process; a fourth step of loading of a control equation of a mobile heat source; and a fifth step of analysis of thermal stress field and total deformation changes in the additive manufacturing process and after sintering is finished. Through the numerical simulation method for the selective laser melting process, printing parameters can be optimized, and warping and deformation of parts can be prevented; and the method provides effective guidancefor supporting structural design and a printing strategy (speed and direction), lowering the rejection rate and realizing ''success at a time''.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

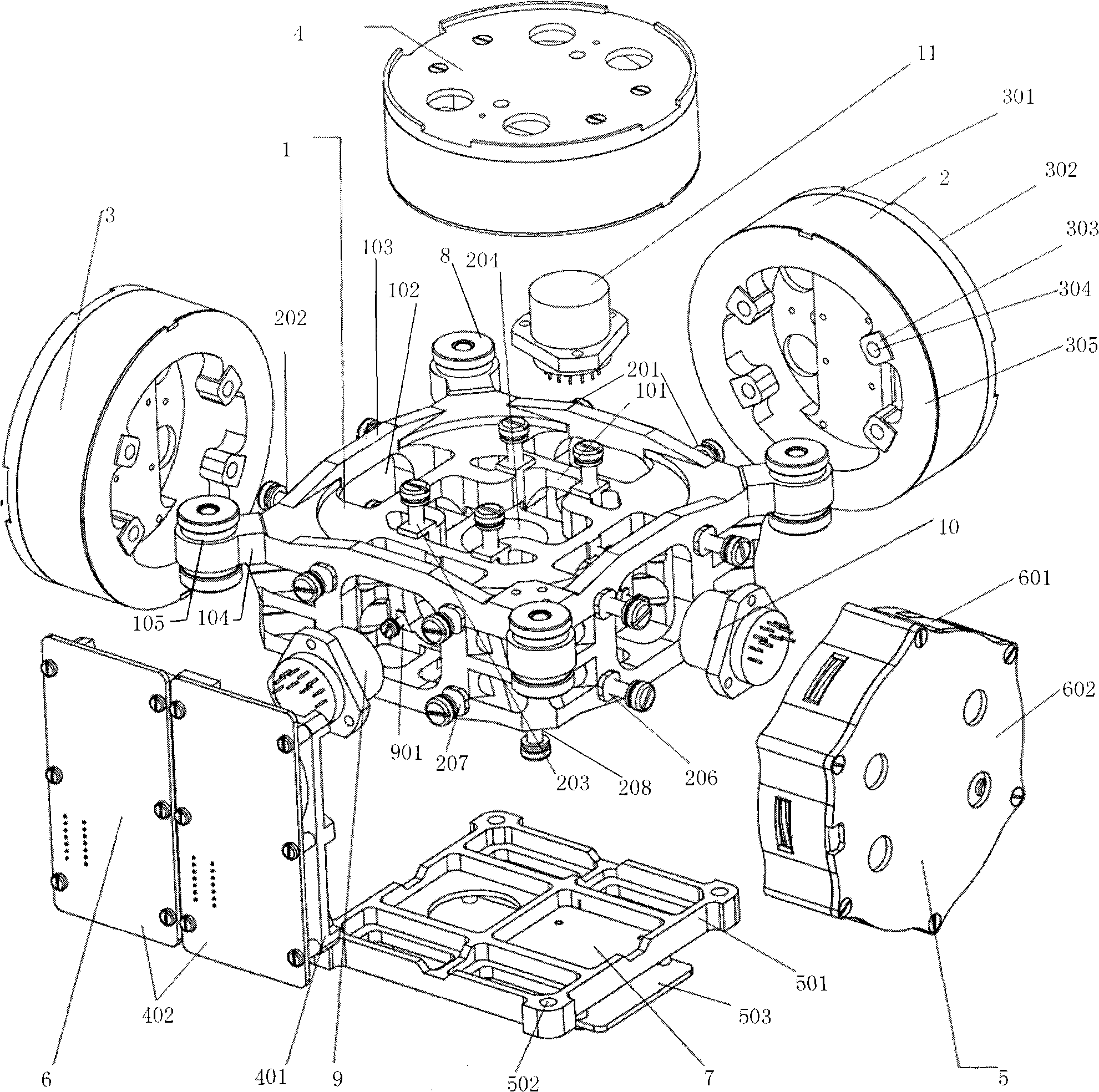

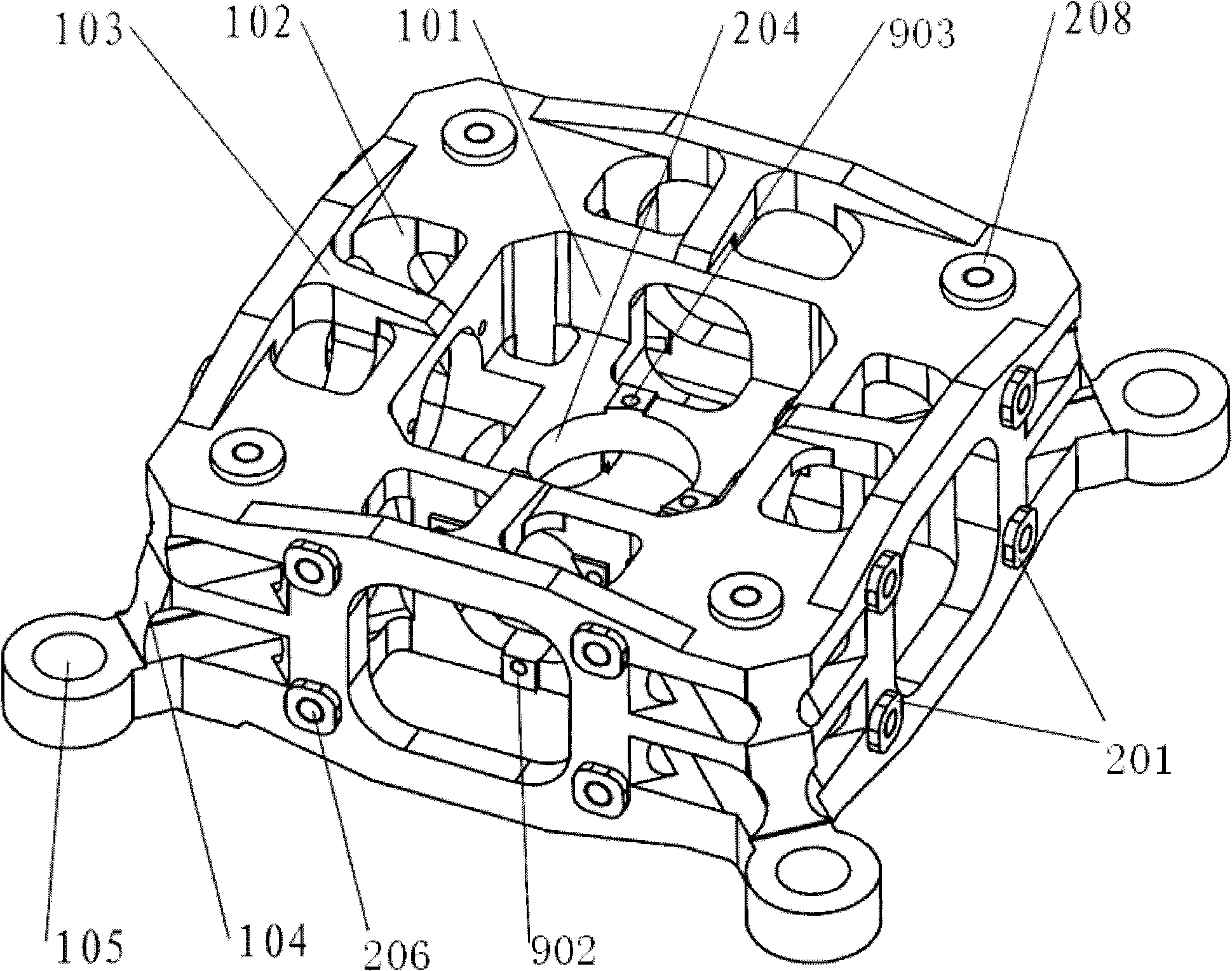

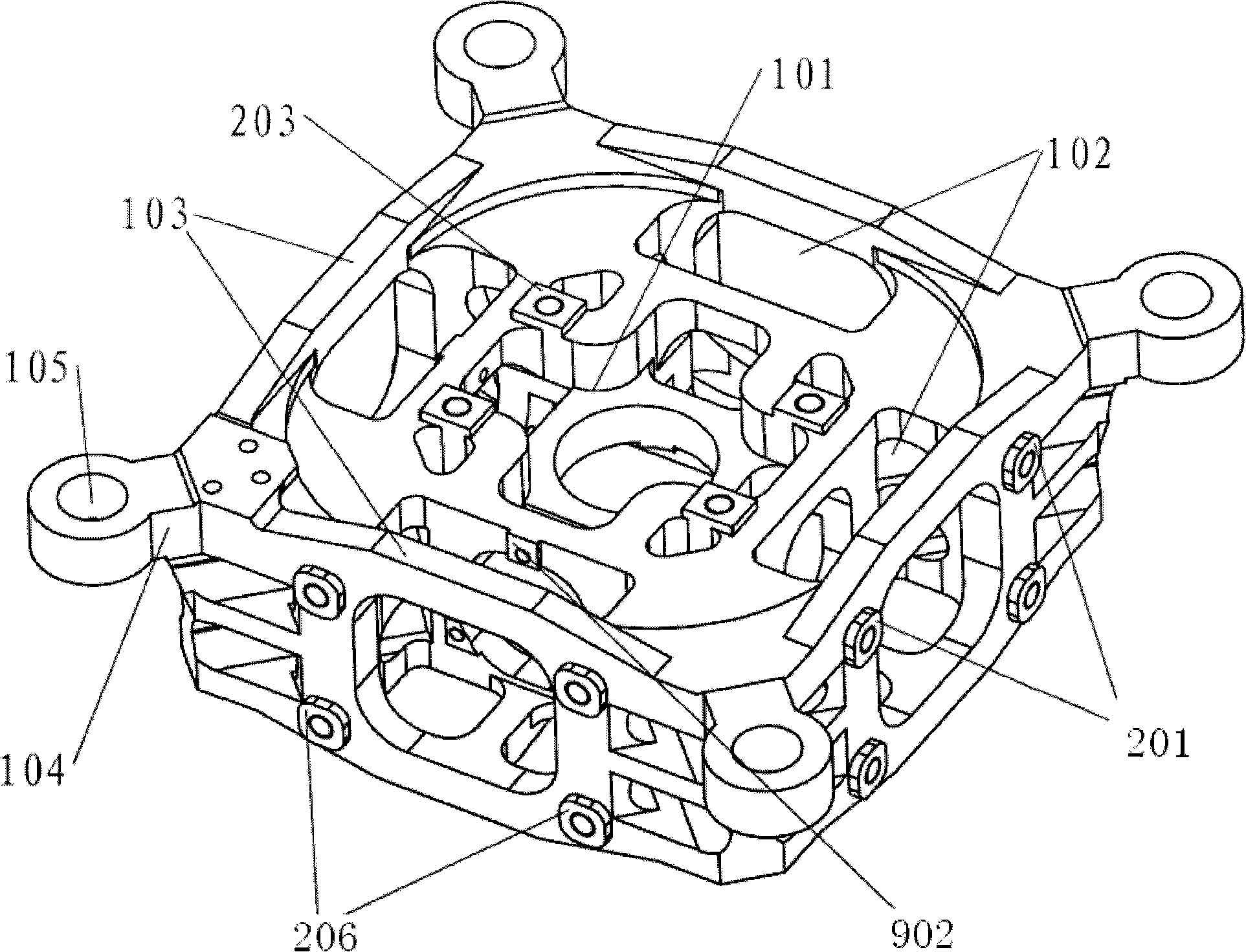

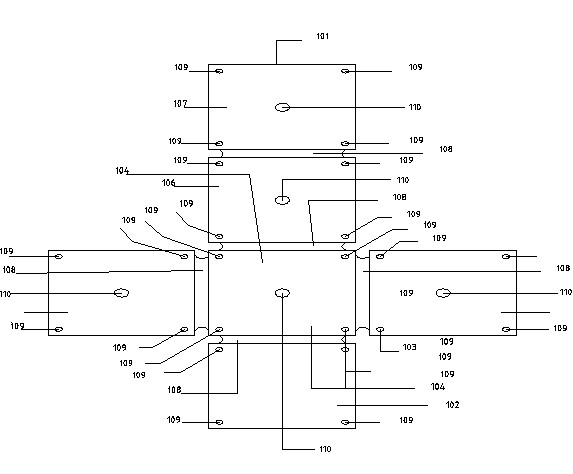

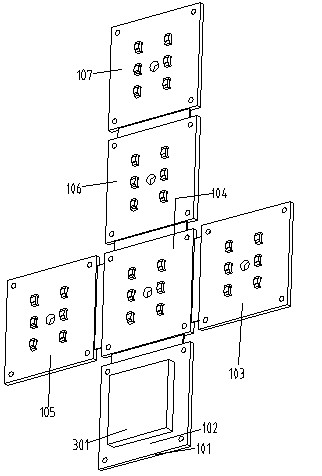

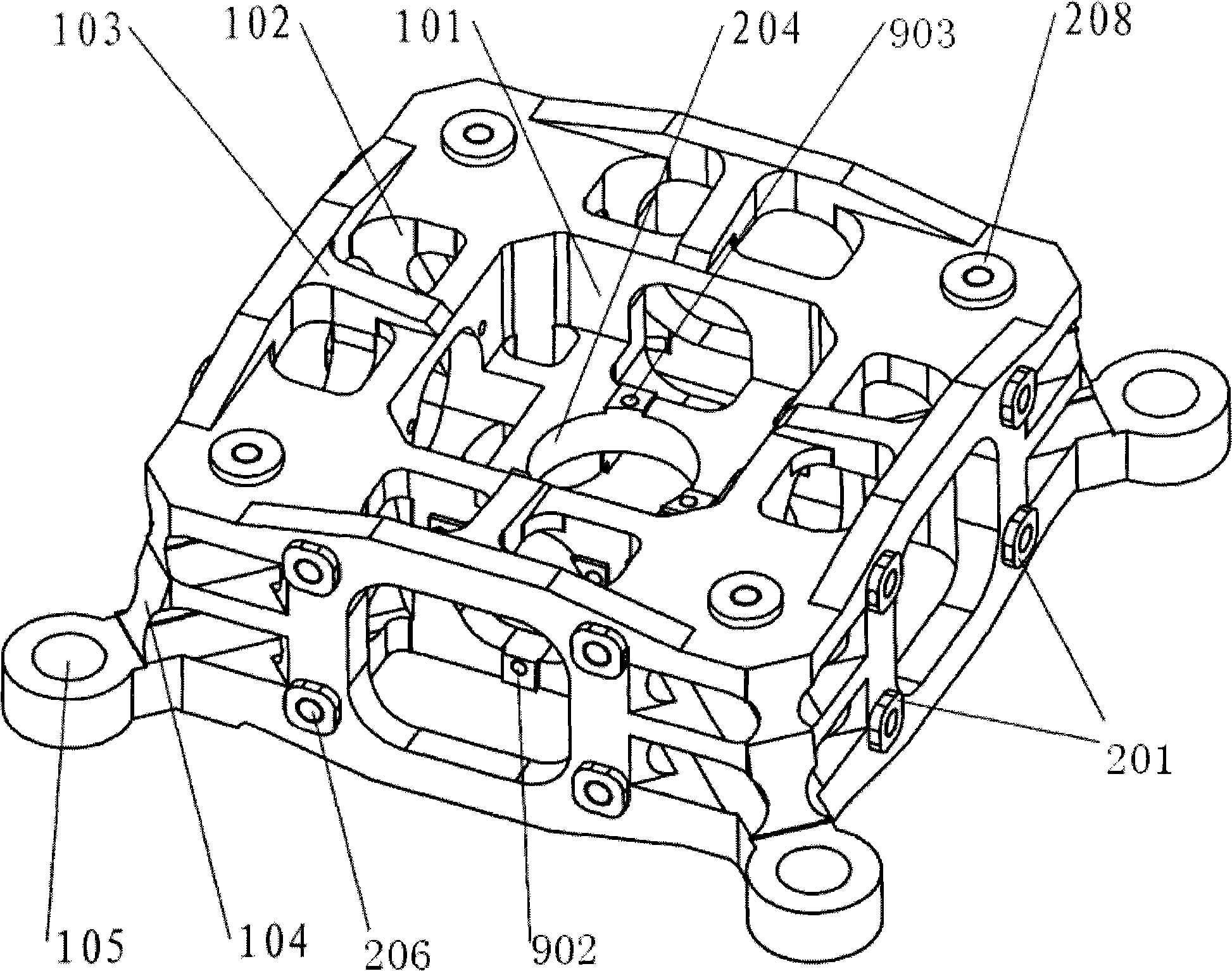

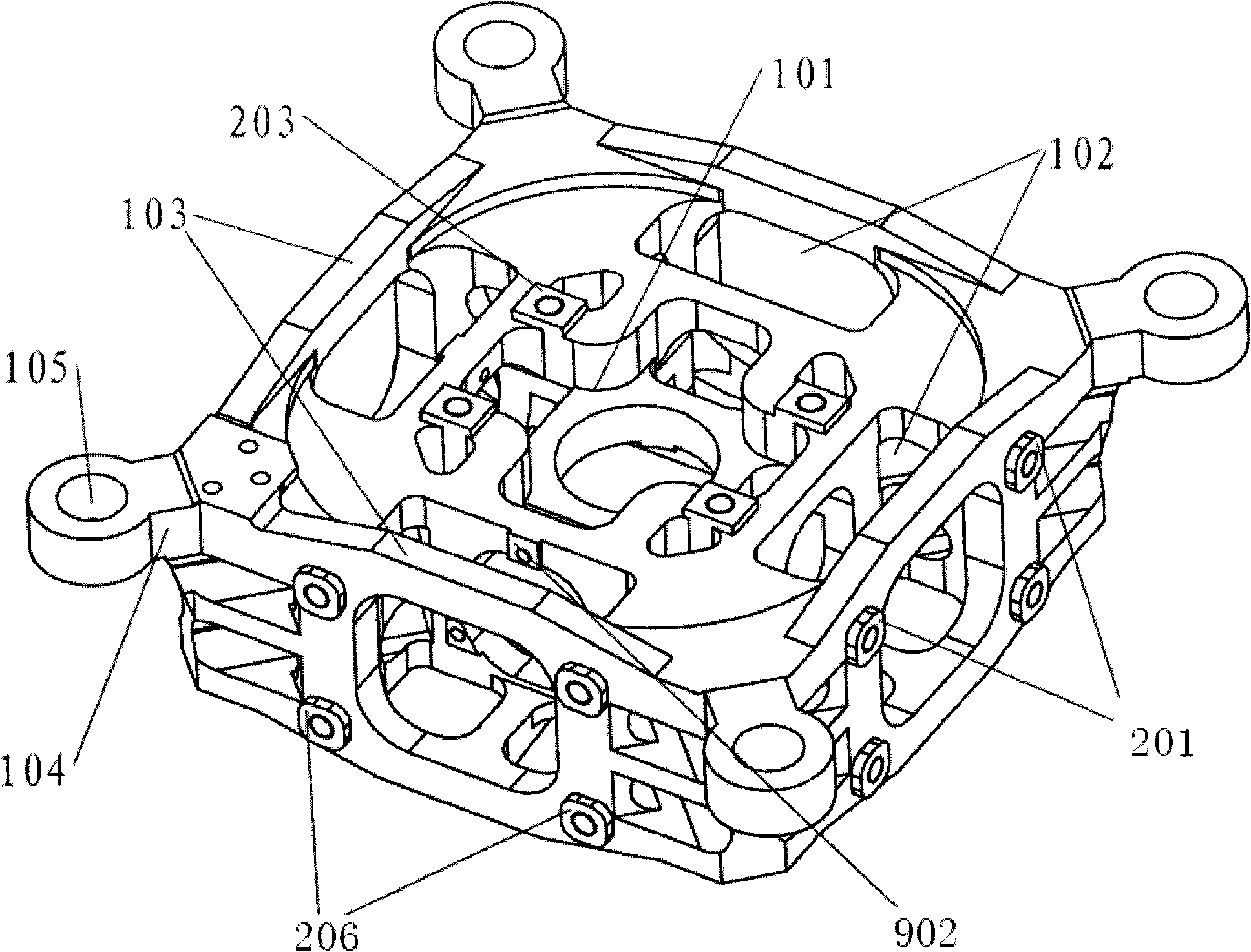

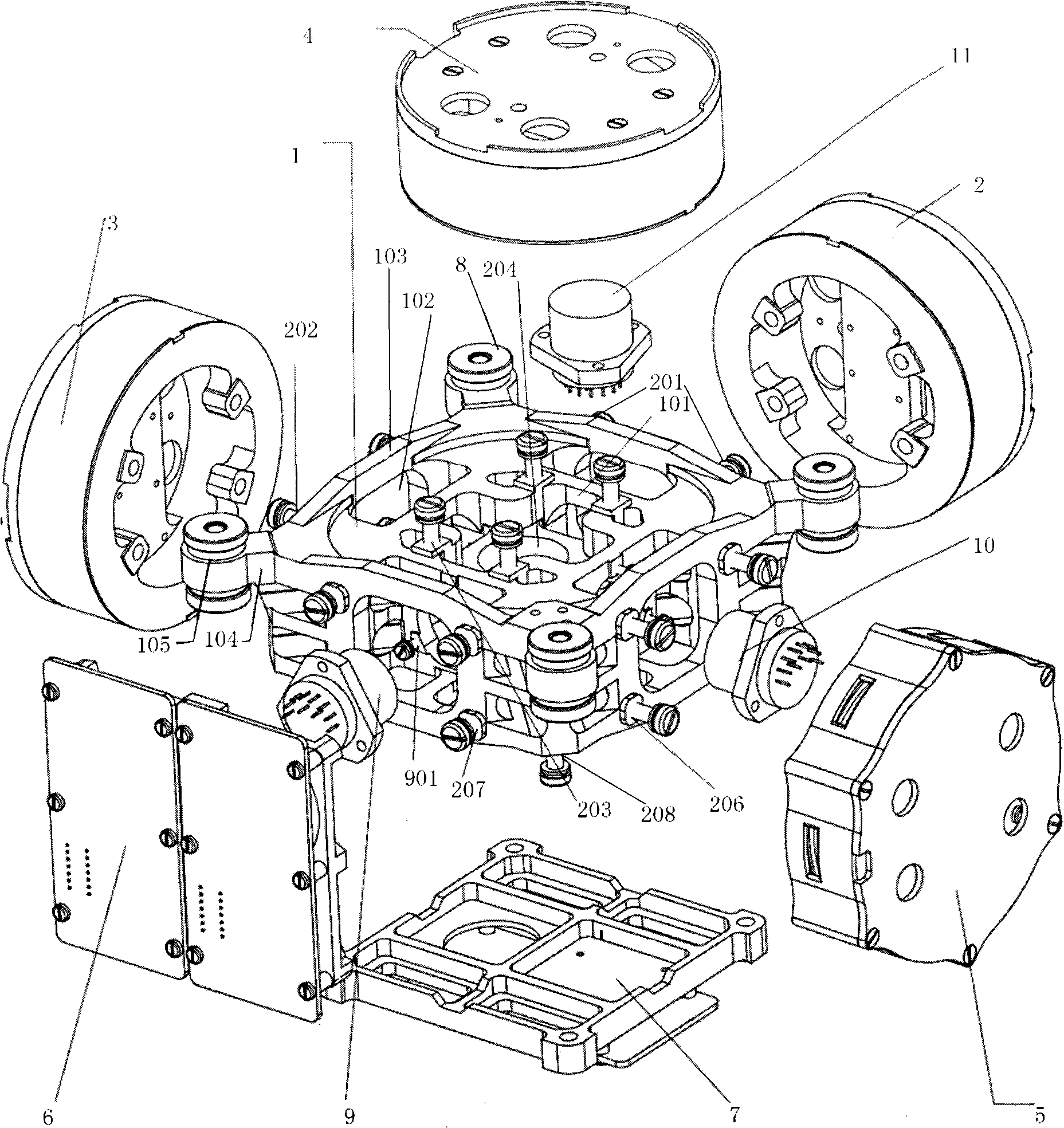

Three axis optical fibre gyroscope inertia measurement unit integral structure

The invention relates to an integral structure of a triaxial optical fiber gyro inertia measuring unit, which comprises a mounting skeleton, three fiber optic gyro scopes, three accelerometers, a light source, a circuit board and a vibration damper. The mounting skeleton adopts a hollow hexahedron frame structure, each group of mounting holes are symmetrically arranged, and mounting lug bosses are arranged on the positioning end surface of the mounting holes. Three fiber optic gyro scopes form mutual space and are orthogonally arranged on the outer surface of the mounting skeleton, the light source and the circuit board are respectively arranged on the outer surface of the mounting skeleton which is corresponding to the three fiber optic gyro scopes, the three accelerometers form the mutual space and are orthogonally arranged on the inner surface of the mounting skeleton which is corresponding to the three fiber optic gyro scopes and near the geometric center of the mounting skeleton, and the vibration damper is arranged on the outer surface of the mounting skeleton. The measuring unit has the advantages that the quality is light; the degree of deviation between the mass center of an inertia measuring unit and the geometric mounting center is very small; the dynamic testing precision is high; the temperature field distribution of the inertia measuring unit is beneficial for the temperature compensation and control of each component, and the like.

Owner:BEIHANG UNIV

Three-dimensional finite-element code for electrosurgery and thermal ablation simulations

ActiveUS7467075B2Ultrasonic/sonic/infrasonic diagnosticsAnalogue computers for chemical processesGraphicsFinite element code

A system and method for performing a simulation of an electrosurgical procedure are disclosed. The method includes the steps of generating a three-dimensional medium, which includes one or more material regions representing a physical object. The method also includes the steps of dividing the medium into multiple hexahedron elements to generate a three-dimensional conformal mesh and assigning each element to the material region. The method further includes the steps of calculating an electrical energy solution and a thermal transport solution and generating graphical representations illustrating one or more aspects of the electrical energy and the thermal transport solutions.

Owner:COVIDIEN AG

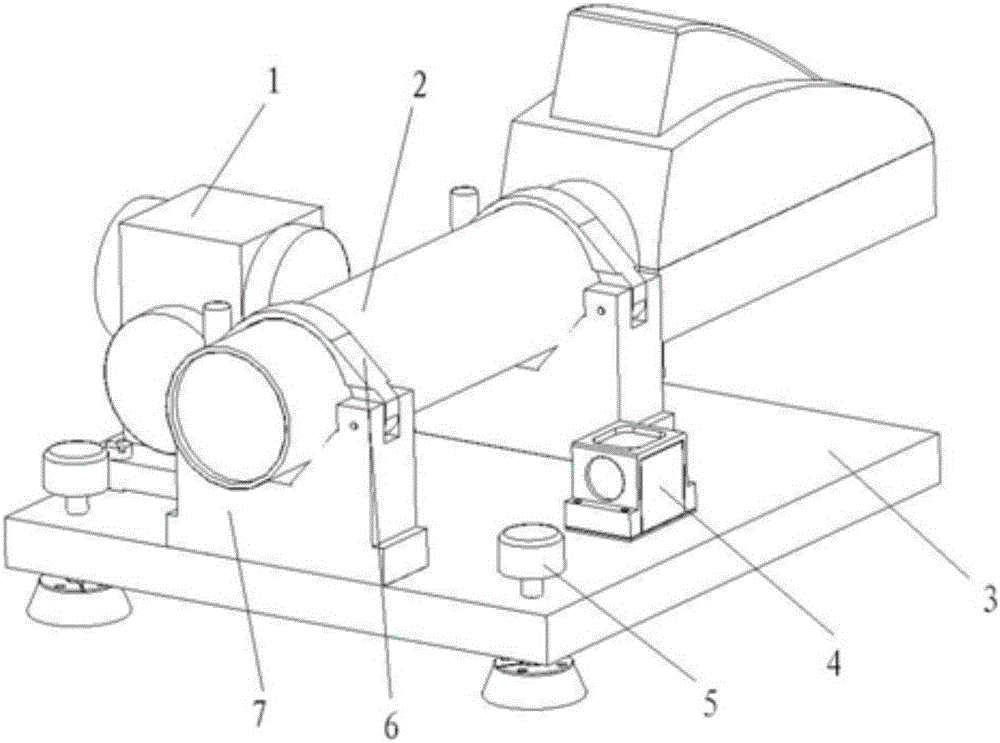

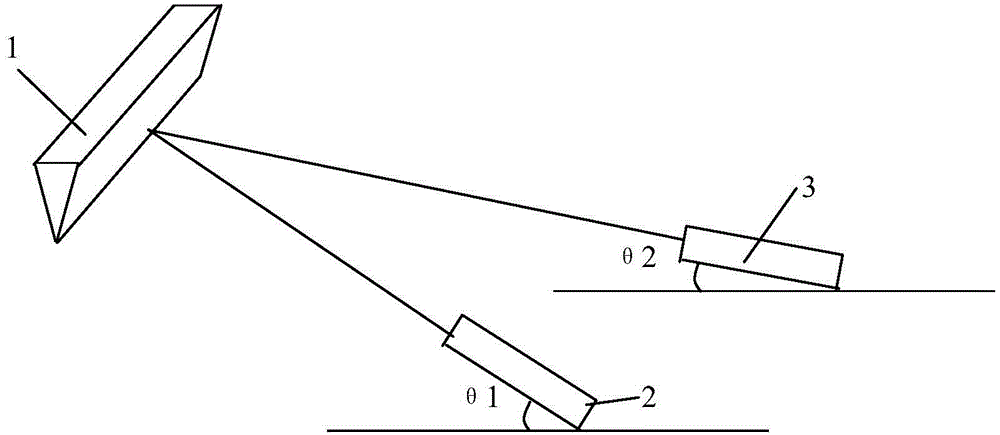

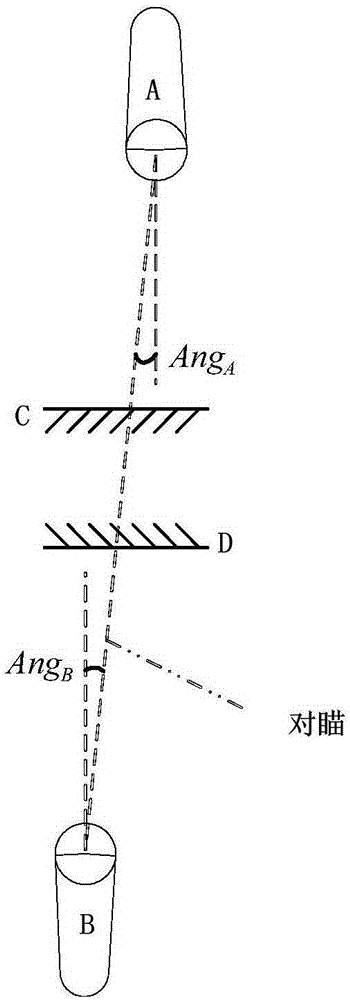

Attitude testing apparatus and method based on autocollimator

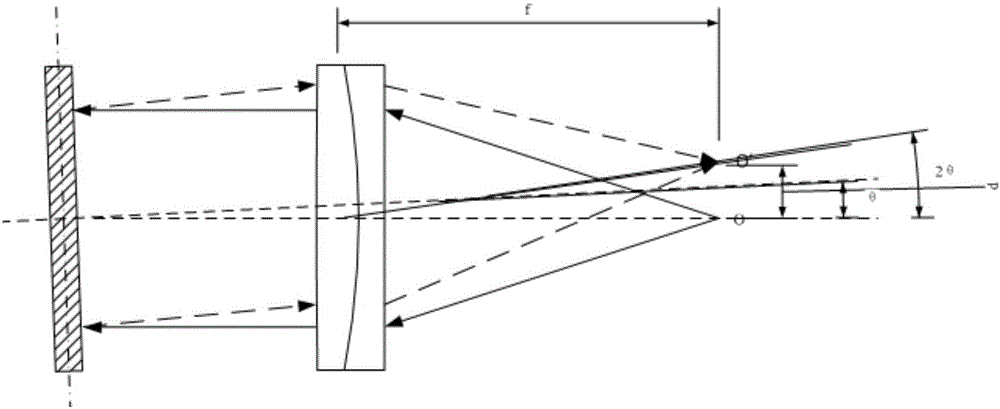

ActiveCN105021211AContinuous attitude measurementMeet measurement needsMeasurement devicesAttitude testingAutocollimation

The invention relates to an attitude testing apparatus and method based on an autocollimator. The apparatus mainly comprises the autocollimator, an optical hexahedron, a double-shaft electronic level meter and a pedestal with a leveling function. The method comprises the following steps: putting the attitude testing apparatus on a firm base, allowing the autocollimator to collimate a reflecting surface of an object, then collimating the optical hexahedron with an autocollimation gyro theodolite and measuring the included angle between the apparatus and a true north azimuth reference; starting the autocollimator for recording and retrieving of continuous data of the attitude of the reflecting surface of the object and starting the double-shaft electronic level meter for recording and retrieving of continuous data of horizontal attitude; and after completion of recording and retrieving of the data, processing the data of the autocollimator and the double-shaft electronic level meter by using a data processing method for the attitude testing apparatus so as to eventually obtain continuous changes of the attitude of the reflecting surface of the object in a geographic coordinate system, thereby meeting demands of continuous absolute measurement.

Owner:TIANJIN NAVIGATION INSTR RES INST

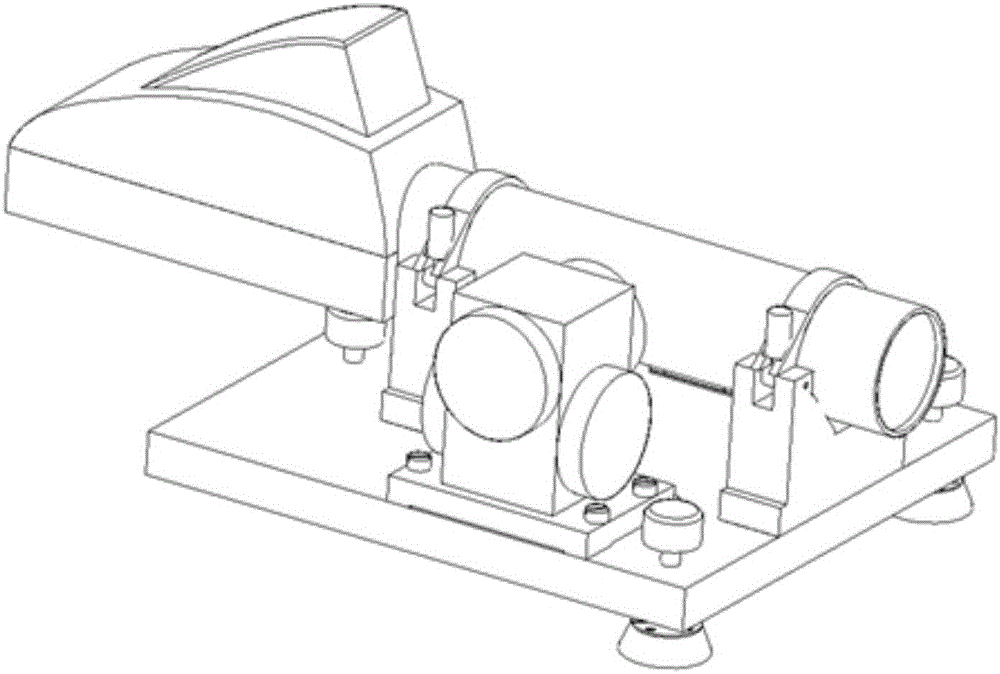

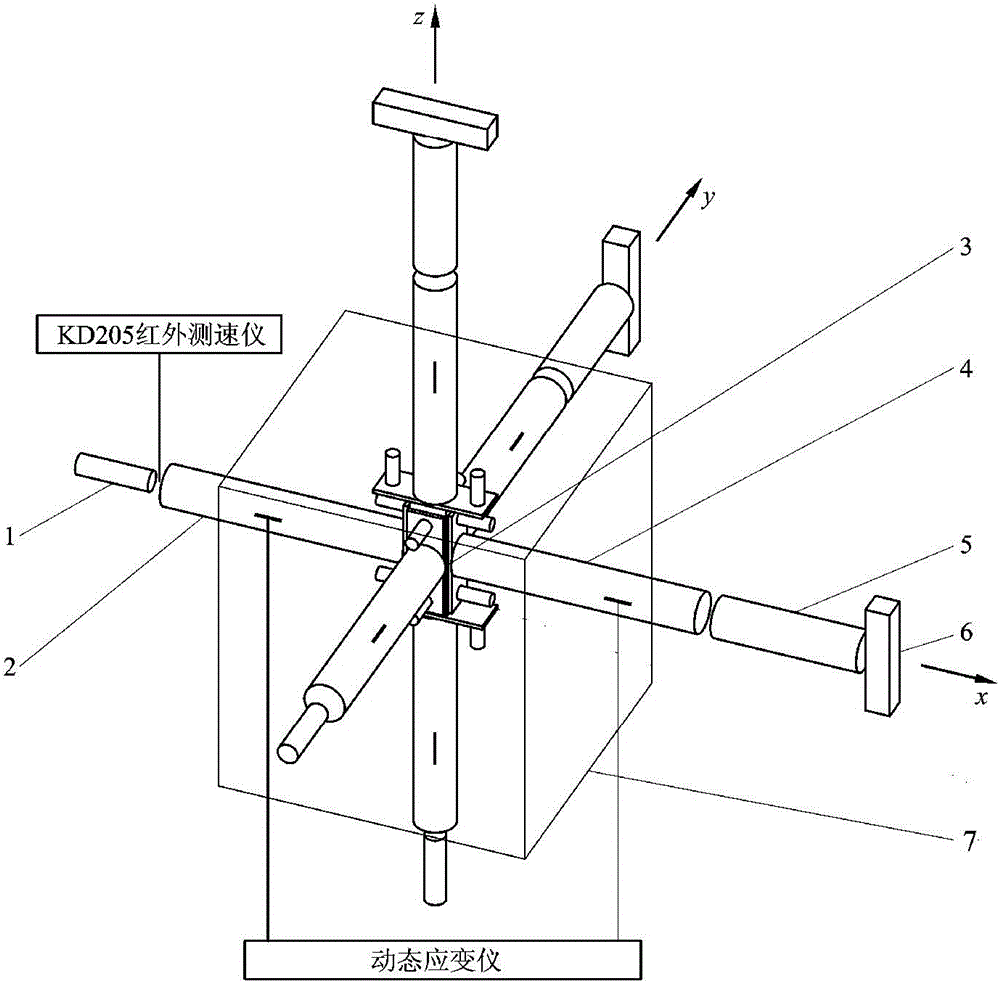

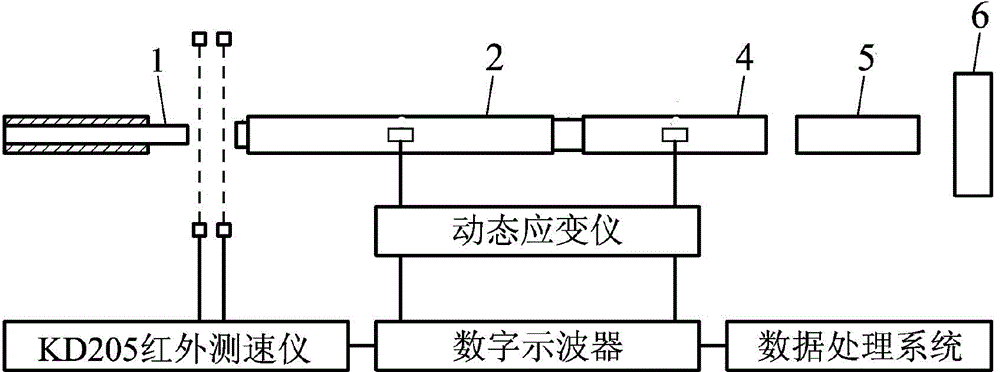

True triaxial multi-field multi-phase coupling dynamic test system and method

The invention discloses a true triaxial multi-field multi-phase coupling dynamic test system and method. One end of an incident rod and one end of a transmission rod are fixed to the two ends of a triaxial loading device respectively; the triaxial loading device is a hexahedron, comprises three pressure device sets opposite to each other in pairs and is capable of separately controlling over compression and unloading of all faces of rock samples and changing the prestress loading value of six oil cylinders freely, both the incident rod and the transmission rod are provided with strain gages beneficial for measuring mechanical property of the rock samples when the rock samples are impacted; furthermore, a temperature effect test system and a chemical effect test system are additionally arranged, the temperature field and chemical field where the rock samples are located are changed by adjusting the temperature of the system and injecting different chemical solvents and various gas, meanwhile, the stress field borne by the rock samples is combined, the mechanical characteristics of the rock samples under the multi-field multi-phase coupling action of the stress field, the temperature field, the chemical field, solid, liquid, gas and the like, and data and theoretical supports are provided for follow-up studies.

Owner:CHINA UNIV OF MINING & TECH

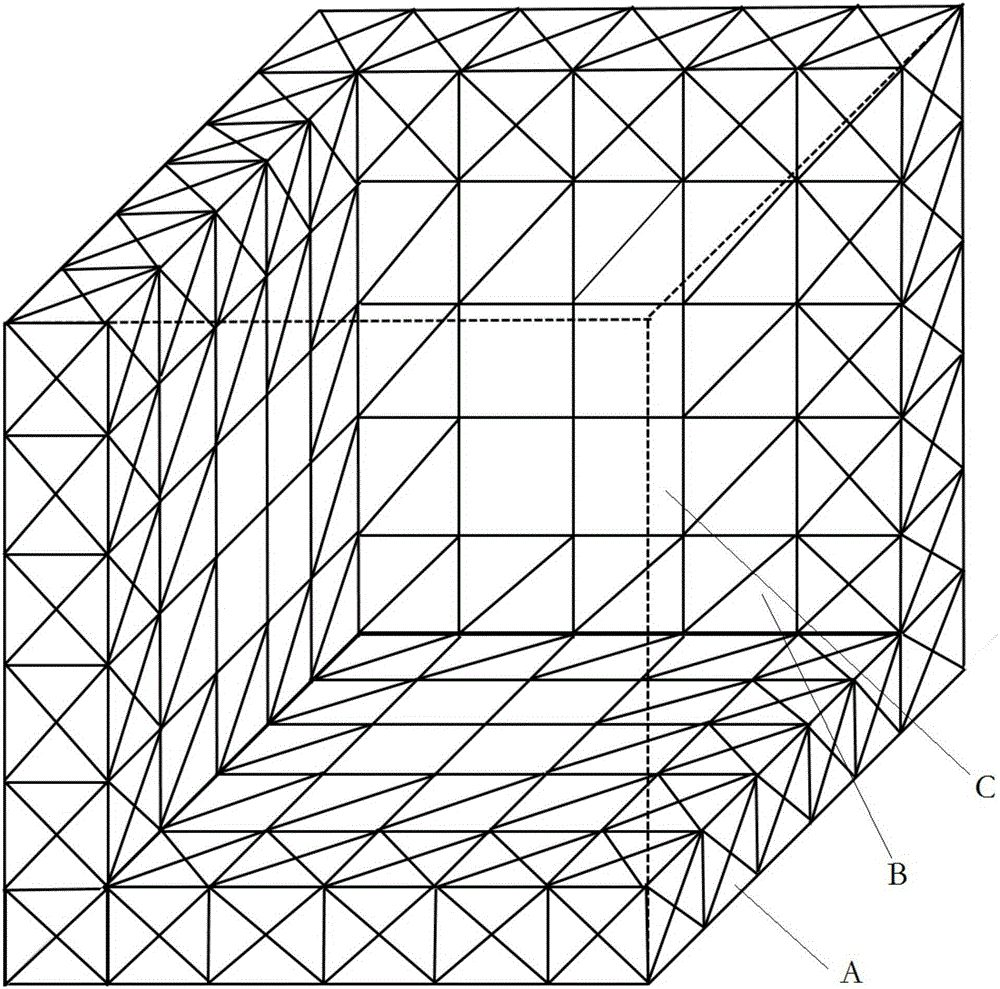

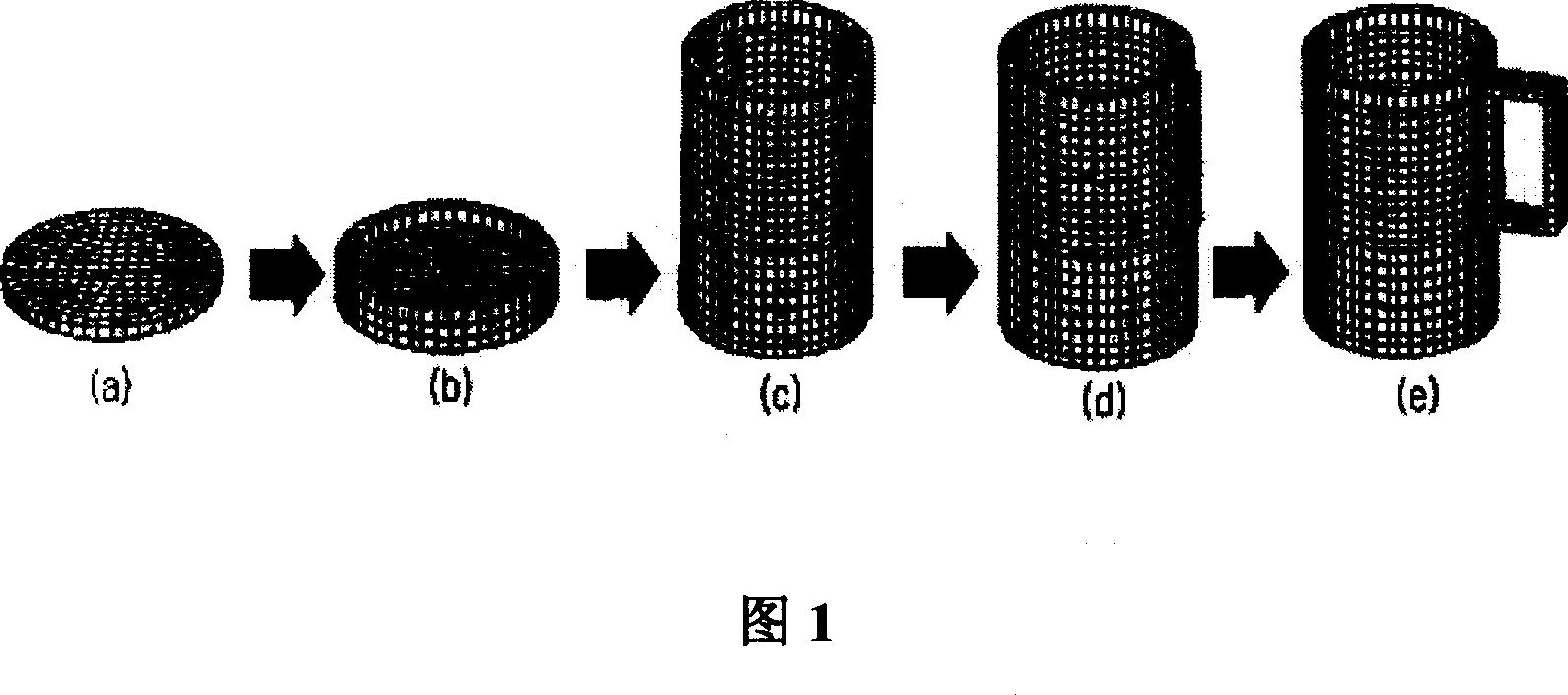

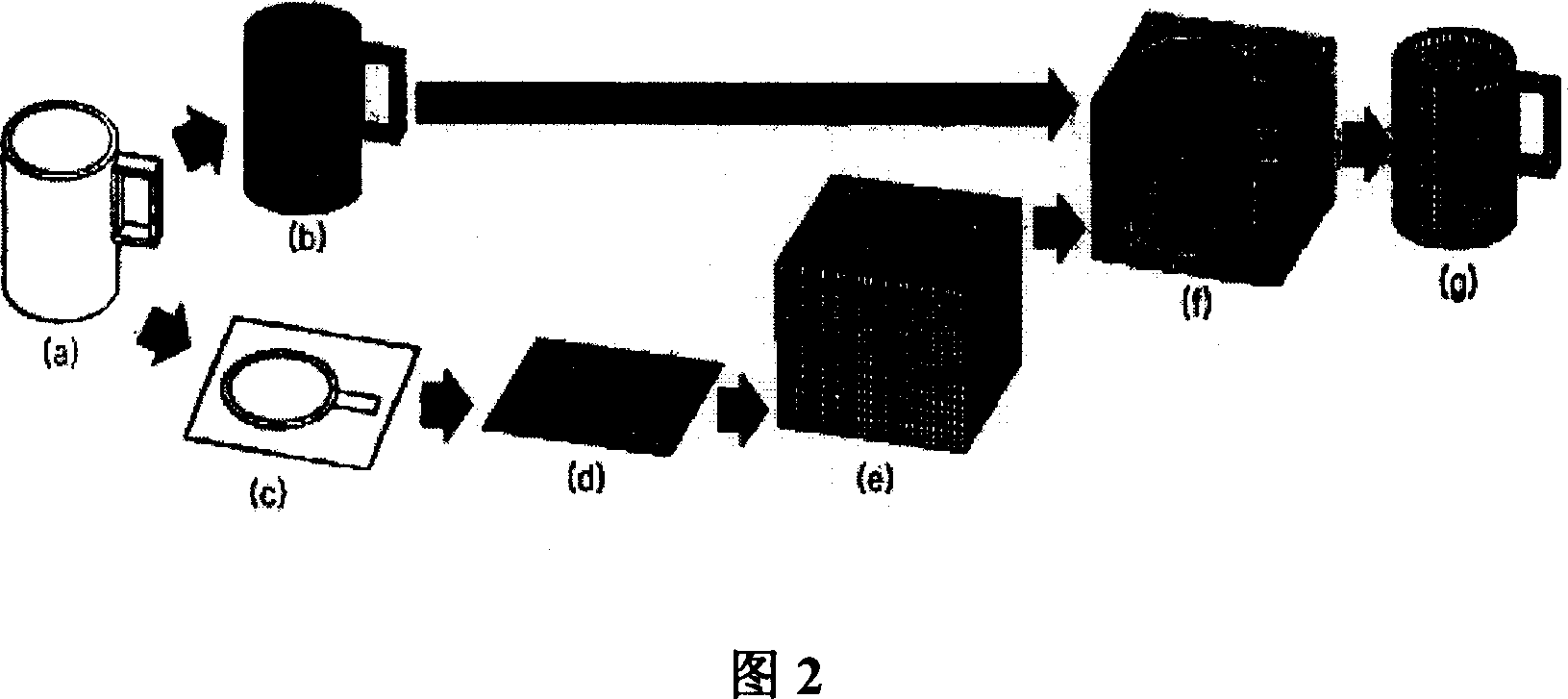

3D-printed gradient-diameter medical porous metal bone tissue scaffold

The invention discloses a 3D-printed gradient-diameter medical porous metal bone tissue scaffold and aims to solve the problems that a single repeated microporous structure in the prior art is adverse to bone tissue ingrowth and a bone tissue implant has difficulty in bony healing with self-bones. The scaffold is in a hexahedron structure as a whole, and comprises components A, components B and components C in tight arrangement, wherein the components A are arrayed on an outermost layer of the hexahedron structure; the components B are arrayed on a secondary outer layer; and the components C are arrayed on the innermost layer; all the components A, B and C are in a hexahedron frame structure; the pore diameter of the components A is greater than that of the components B; and the pore diameter of the components B is greater than that of the components C. Through the reinforcing structural design, the gradient-pore tissue engineering bone scaffold is produced; through regulating the ingrowth of bone tissues, fibroblasts and the like by gradient-change pores, the optimal bone healing can be achieved finally.

Owner:JILIN UNIV

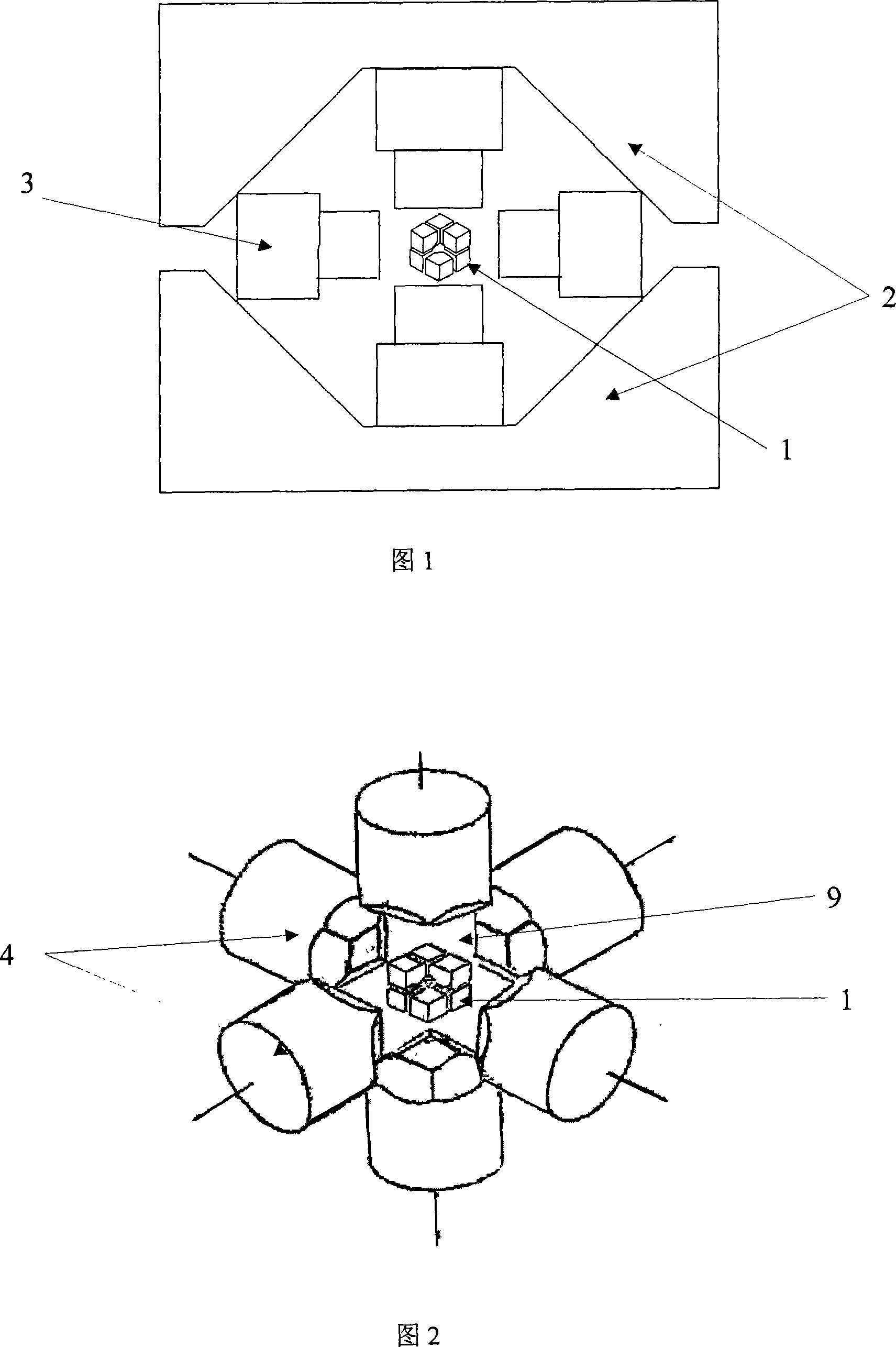

New type equipment for producing super high pressure

ActiveCN101091895ANo collisionImprove performanceUltra-high pressure processesUltra high pressureOctahedron

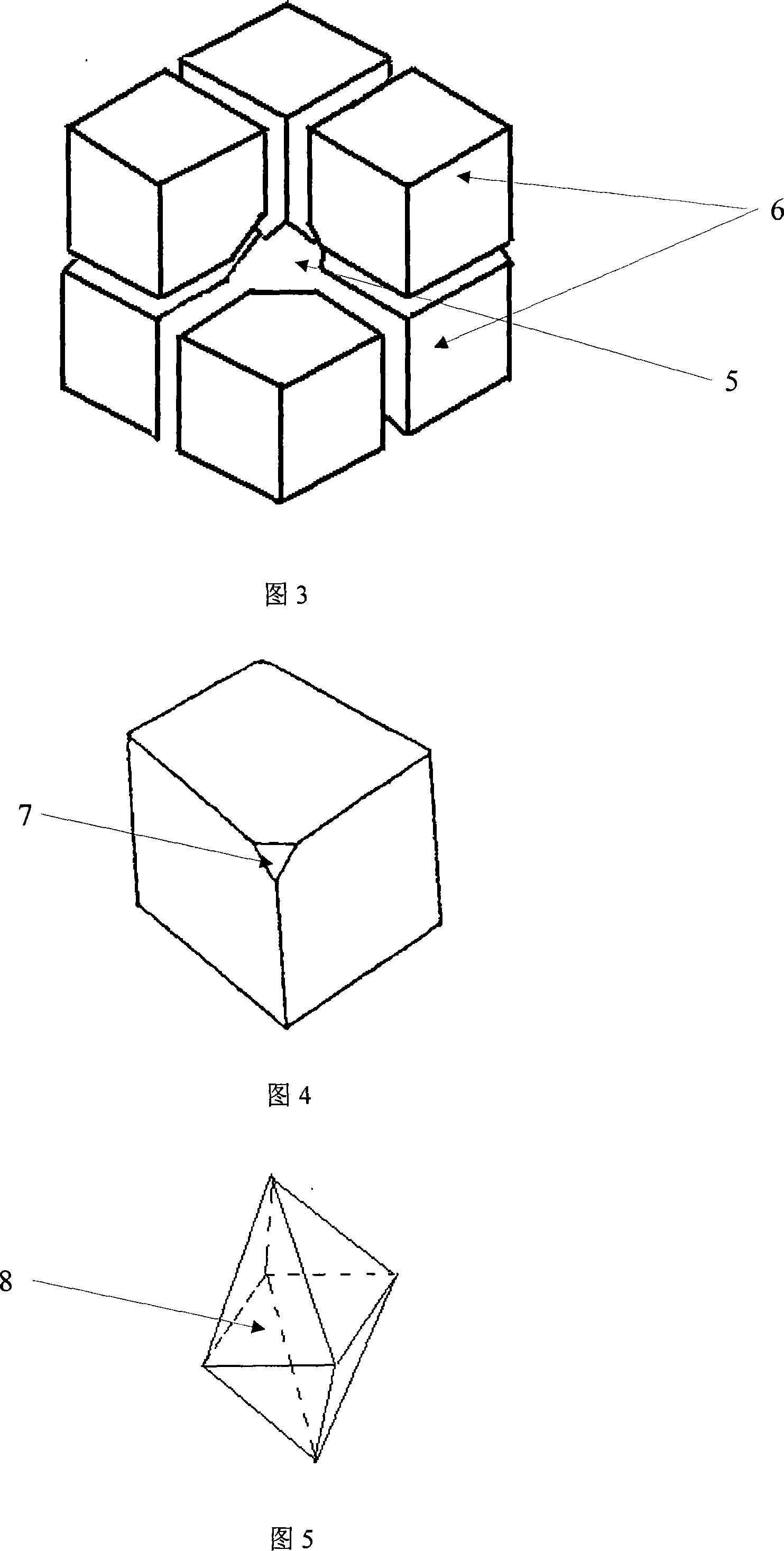

The invention relates to a new installment for having ultrahigh voltage. It includes 6 hammer heads (4) of 6 sides presser synchronization drive, supercharging unit (1) composed of 8 cubes (6) which cutting one corner each and octahedron synthesis blocks (8) used for holding the synthesis raw material in the internal. Thereinto, putting the turbo-charged unit (1) into the hexahedron high pressure octahedron cavity (9) made of cubes (6) which matches with the unit, and putting the octahedron synthesis block (8) into the octahedron high pressure cavity made of cubes which matches with the block, the deformation strutting whose hardness is smaller than the tangential angle cube is filled among the eight cubes (6) which compose the turbo-charged unit. Composed to the second-level six - octahedron static high pressure installment based on two sides skeleton heads in existence, it is simple structure, high intensity of pressure transfer ratio, few energy consumption of the movement, few service work load and so on.

Owner:SICHUAN UNIV

Fan blade based on hollow metal/composite material structure

InactiveCN101649844AFully reflect the superioritySimple processPump componentsPumpsHigh energyEngineering

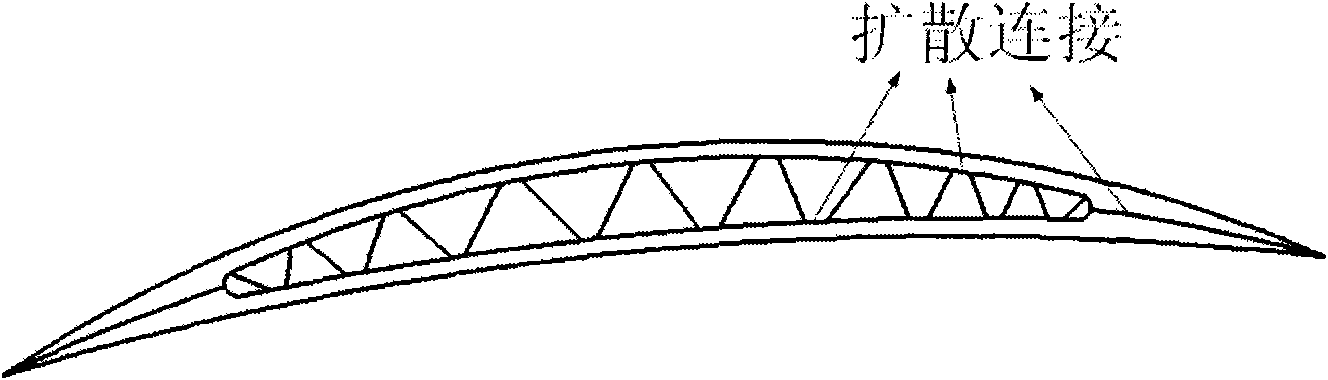

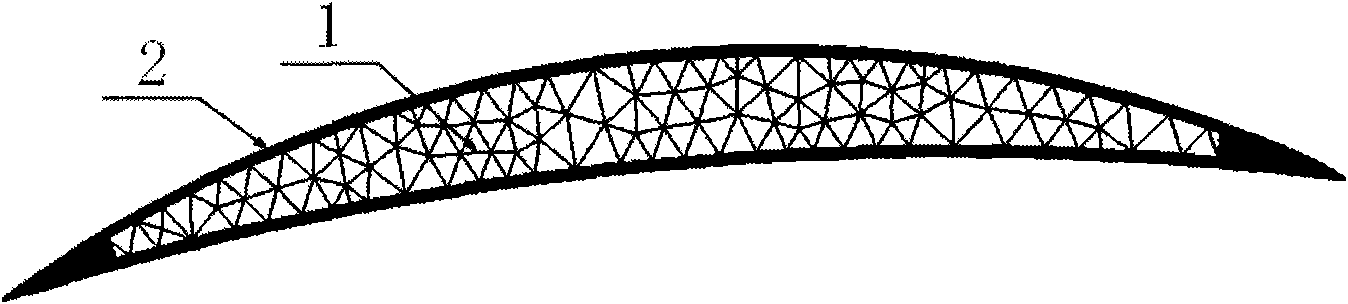

The invention discloses a fan blade based on a hollow metal / composite material structure. The inner base body of the fan blade is in a rib structure with discrete space. The fan blade comprises a hollow metal / composite material structure; the structure comprises a rib structure and inner holes; the rib structure is formed by combining and optimizing arbitrary space structures; the hole ratio is directly displayed by the space arranging mode of ribs and the rib diameter distribution; the rib structure and the surface of the blade are fixedly connected into a whole; the rib structure can be combined and optimized by a diamond structure, a tetrahedron unit structure, a hexahedron unit structure, a honeycomb structure or other arbitrary space structures; in regard to the space arrangement modeof the ribs and the rib diameter distribution, the rib diameters are gradually reduced and the space arrangement is gradually sparse following the radial increase of the blade along the radial direction of the blade; the thickness of the surface of the blade is controlled by pneumatic loads and technological conditions and the blade of the metal structure can be formed and processed quickly by high energy beams. The fan blade is directly and quickly formed and has simple technology. The structure shape has strong design performance.

Owner:BEIJING DAINUOXINSI POWER TECH

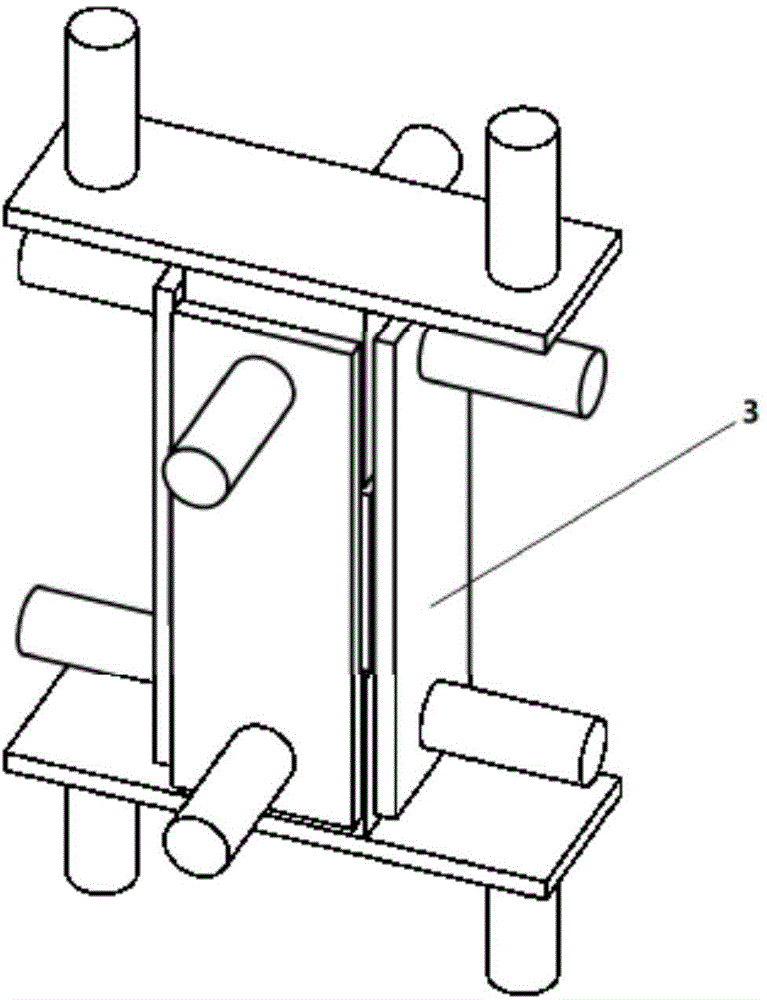

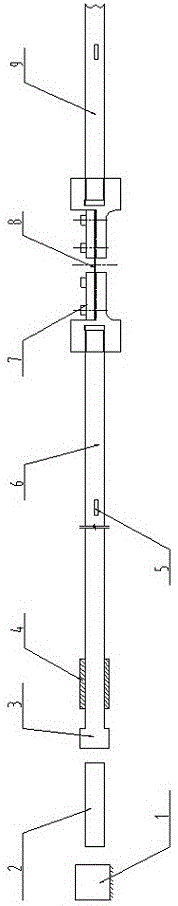

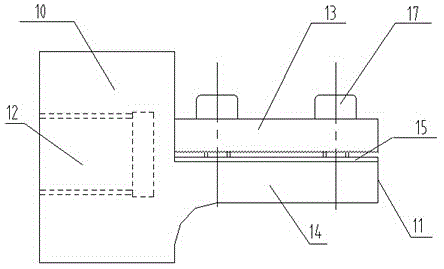

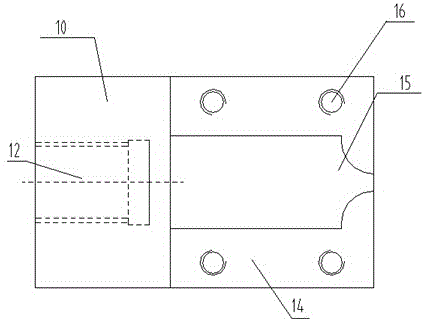

Clamping device and experiment method for split Hopkinson torsion bar test piece

InactiveCN105424470ANo need to disassembleConnectors are versatileMaterial strength using tensile/compressive forcesFibrous compositesScrew thread

The invention discloses a clamping device and an experiment method for a split Hopkinson torsion bar test piece, and belongs to the field of impact dynamics experiments. The clamping device comprises a connector and a clamping part. The connector is of a cylinder structure, a circular blind hole is formed in the connector, an internal thread is arranged in the hole, and the connector is connected with an incidence bar or a transmission bar through the thread. The clamping part comprises a pressing block and a base, the pressing block is arranged above the base in a buckled mode, the base and the connector are fixed into a whole, a groove is formed in the upper surface of the base and is of a flat structure, the body of the groove is square, the end of the groove is in a horn shape, the pressing block is of a hexahedron structure, the upper surface of the pressing block is parallel with the lower surface of the pressing block, screw holes are formed in the periphery of the pressing block, screw holes are formed in the portion, corresponding to the pressing block, of the base, and the pressing block and the base are connected and fixed through screws. By means of the clamping device and the experiment method for the split Hopkinson torsion bar test piece, the problems of difficulty of thread machining of a composite and nonuniformity in the high-strength adhesive bonding process are avoided, and a powerful foundation is laid for studying the constitutive relation of a fiber composite under dynamic tension.

Owner:TAIYUAN UNIV OF TECH

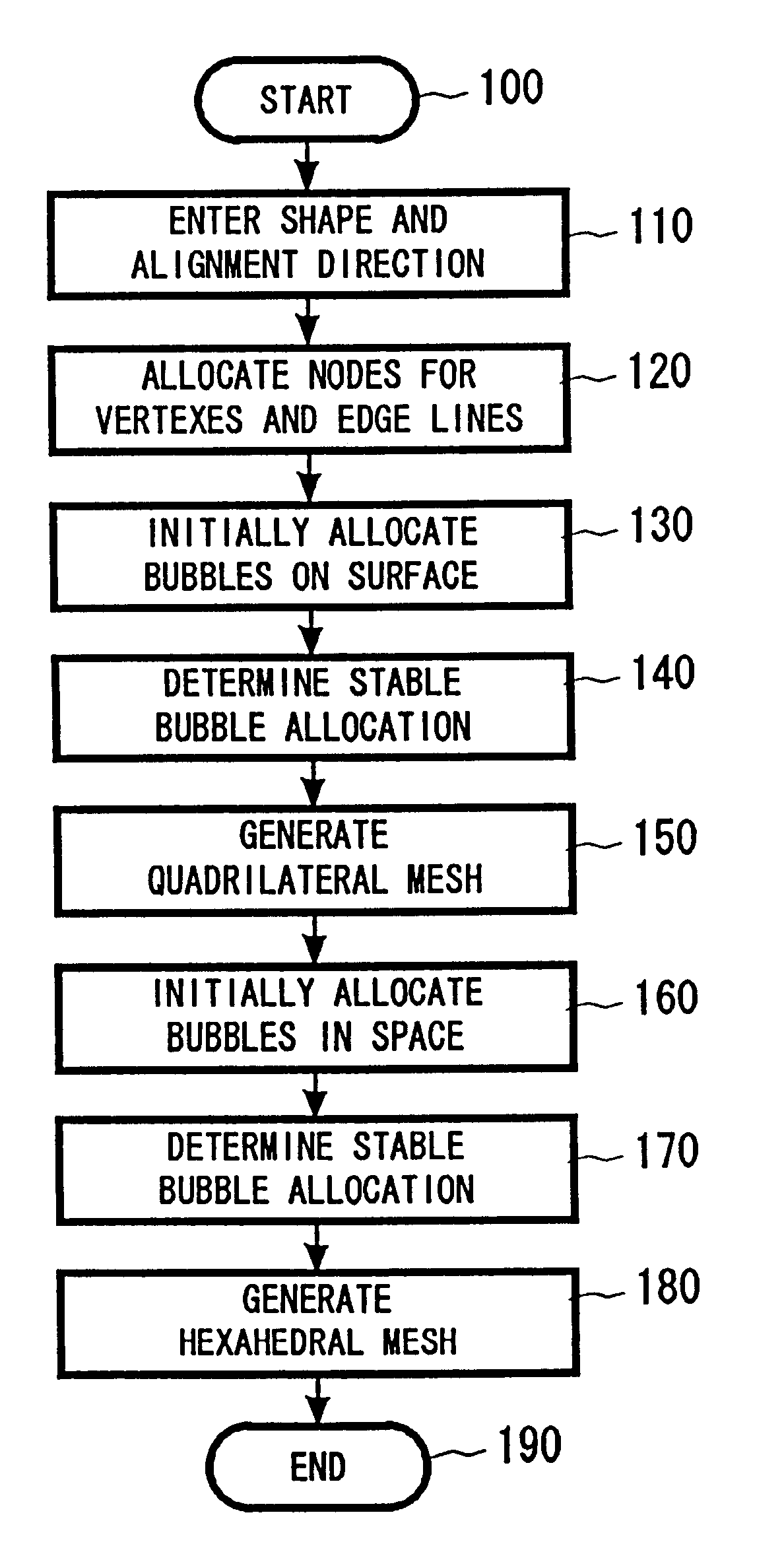

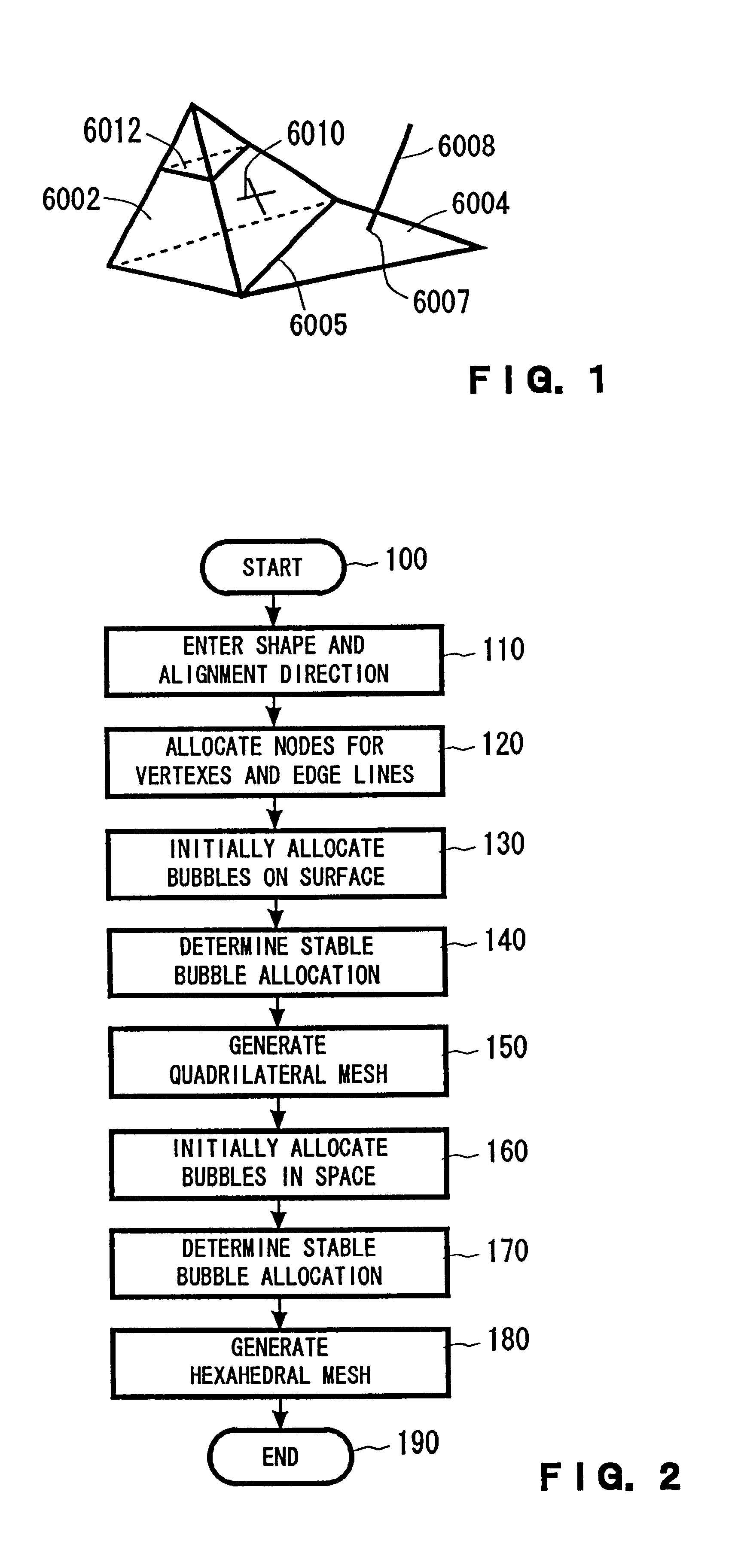

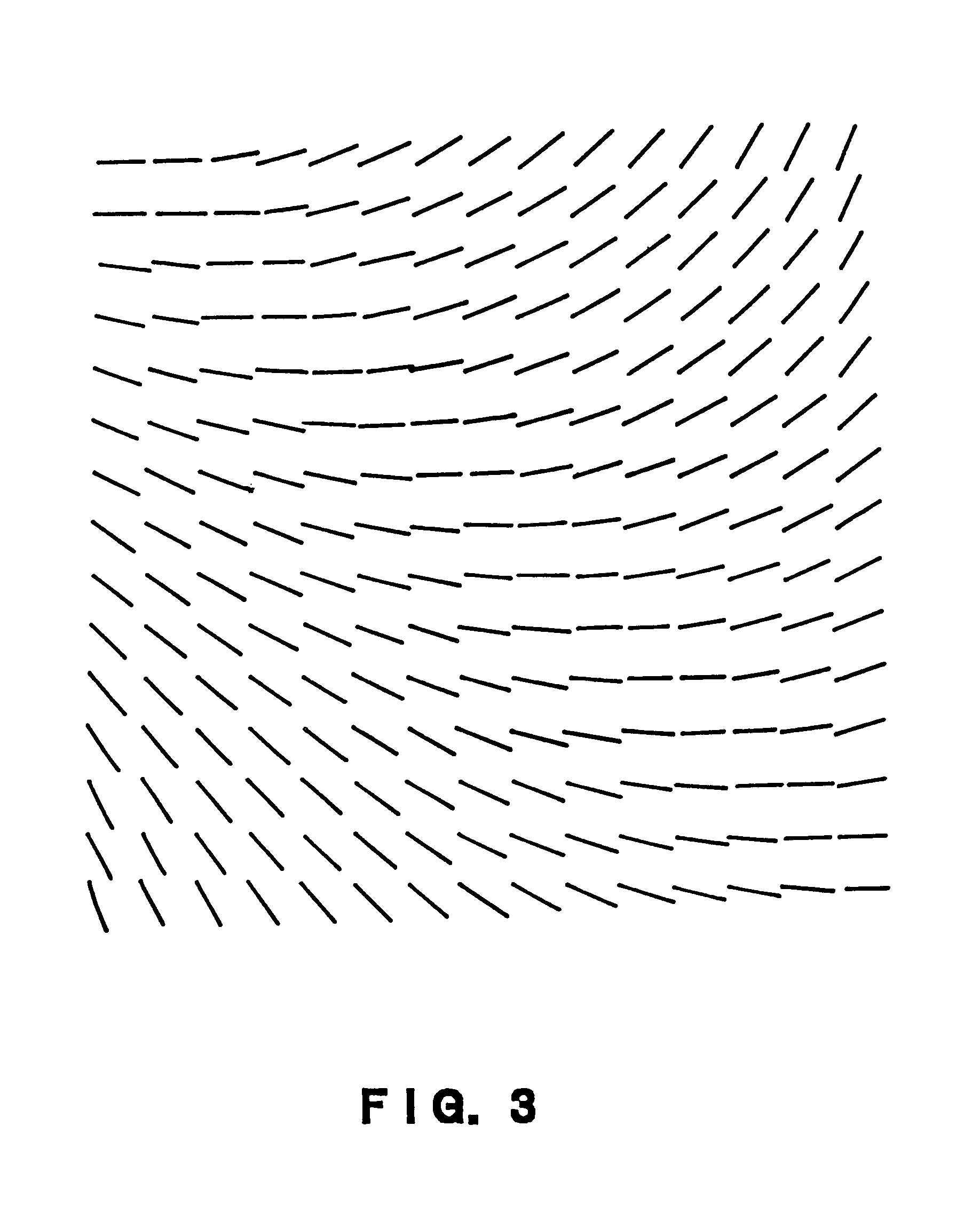

Meshing method and apparatus

InactiveUS6259453B1Less distortionDigital computer detailsSpecial data processing applicationsPotential fieldQuadrilateral meshes

A method for automatically generating a mesh (e.g., a quadrilateral mesh, a hexahedral mesh, and the like) includes inputting a geometric model to be meshed, generating a plurality of bubbles within a region of the geometric model, determining a stable allocation of the bubbles by moving the bubbles using a force defined by a potential field provided for the bubbles and controlling a number of the bubbles, and generating the mesh by connecting centers of adjacent bubbles.

Owner:IBM CORP

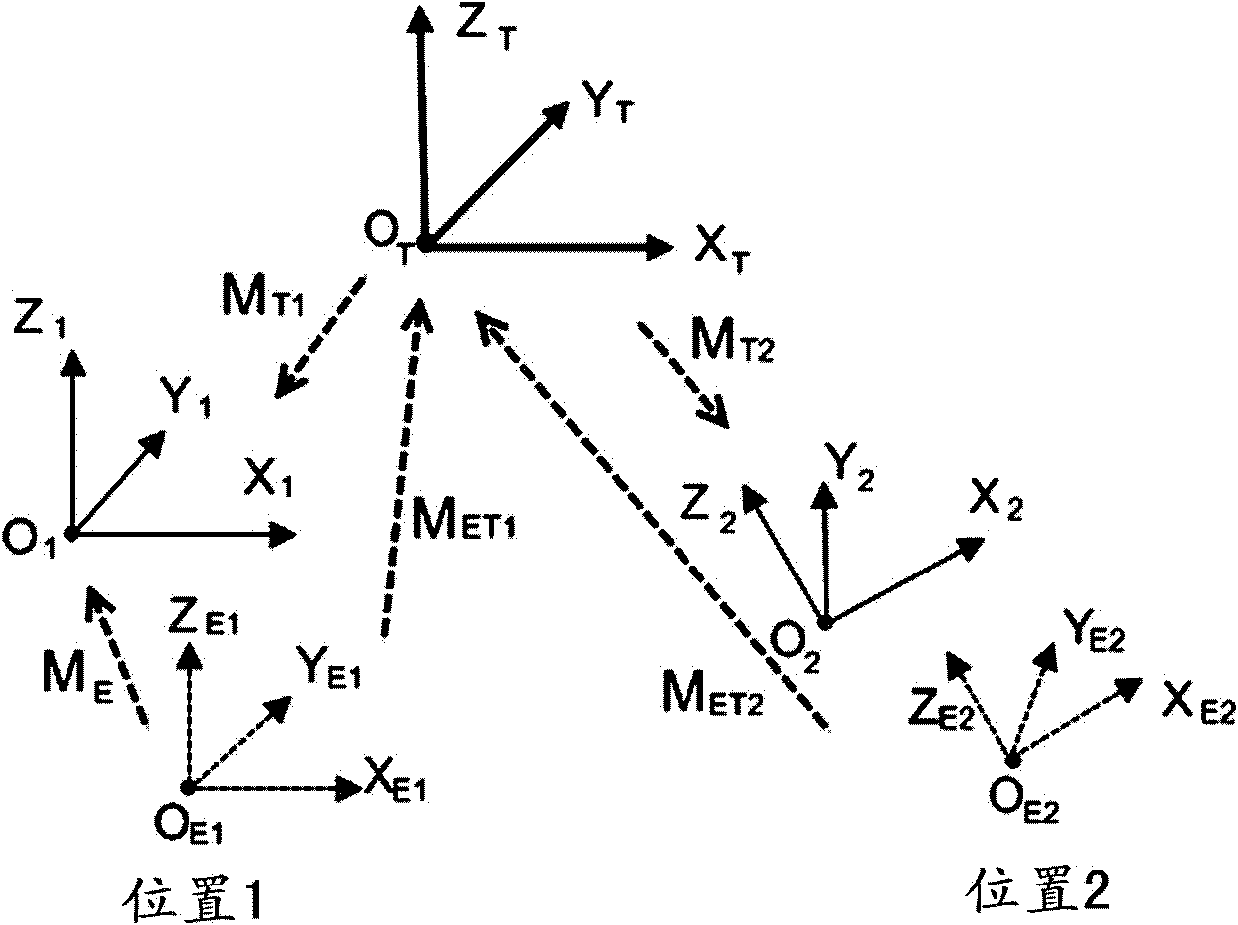

Solid target for binocular vision positioning and tracking system

InactiveCN102155940AHigh positioning accuracyPrevent occlusionMeasuring points markingComputer scienceFrustum

The invention discloses a solid target for binocular vision positioning and tracking system. The solid target comprises nine trapezoid-shaped blocks forming a regular hexahedron. Each trapezoid-shaped block comprises a base and a regular quadrangular frustum. The trapezoid-shaped blocks from first to fourth are respectively positioned at the right upper top point, the right lower top point, the left upper top point and the left lower top point of the back surface of the regular hexahedron, the trapezoid-shaped blocks from fifth to eighth are respectively positioned on the right upper top point, the right lower top point, the left upper top point and the left lower top point of the front surface of the regular hexahedron, and the ninth regular hexahedron is positioned in the center of the back surface of the regular hexahedron. The two adjacent trapezoid-shaped blocks are supported and fixed by a connecting rod. Marking points are uniformly distributed on the right lateral faces of the regular quadrangular frustums of the first and second trapezoid-shaped blocks and on the left lateral faces of the regular quadrangular frustums of the third and fourth trapezoid-shaped blocks, on the upper lateral faces of the regular quadrangular frustums of the first and third trapezoid-shaped blocks, and on the top faces of the regular quadrangular frustums of the ninth trapezoid-shaped block.

Owner:BEIJING INFORMATION SCI & TECH UNIV

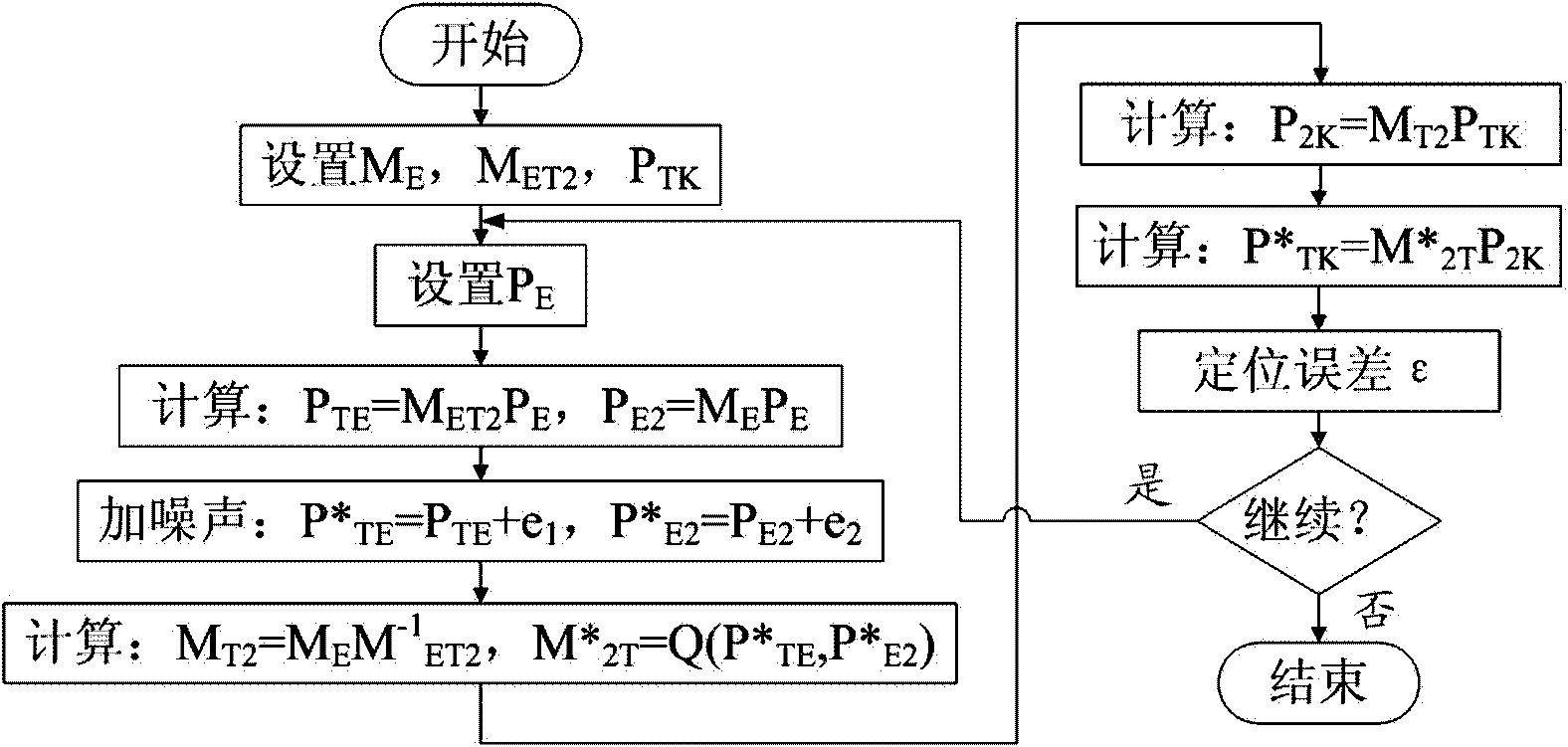

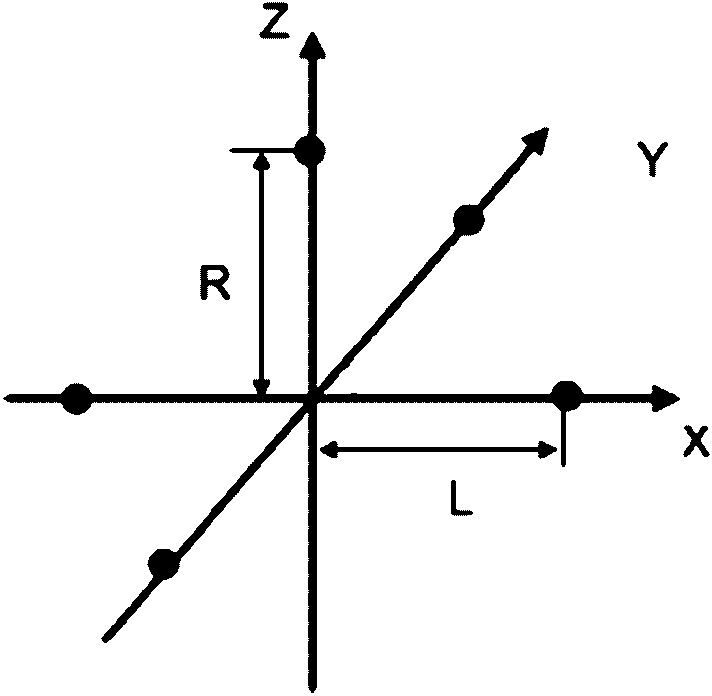

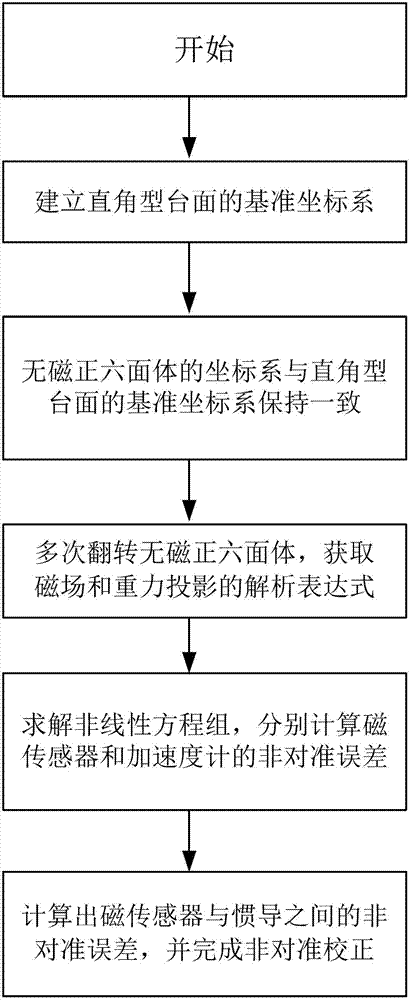

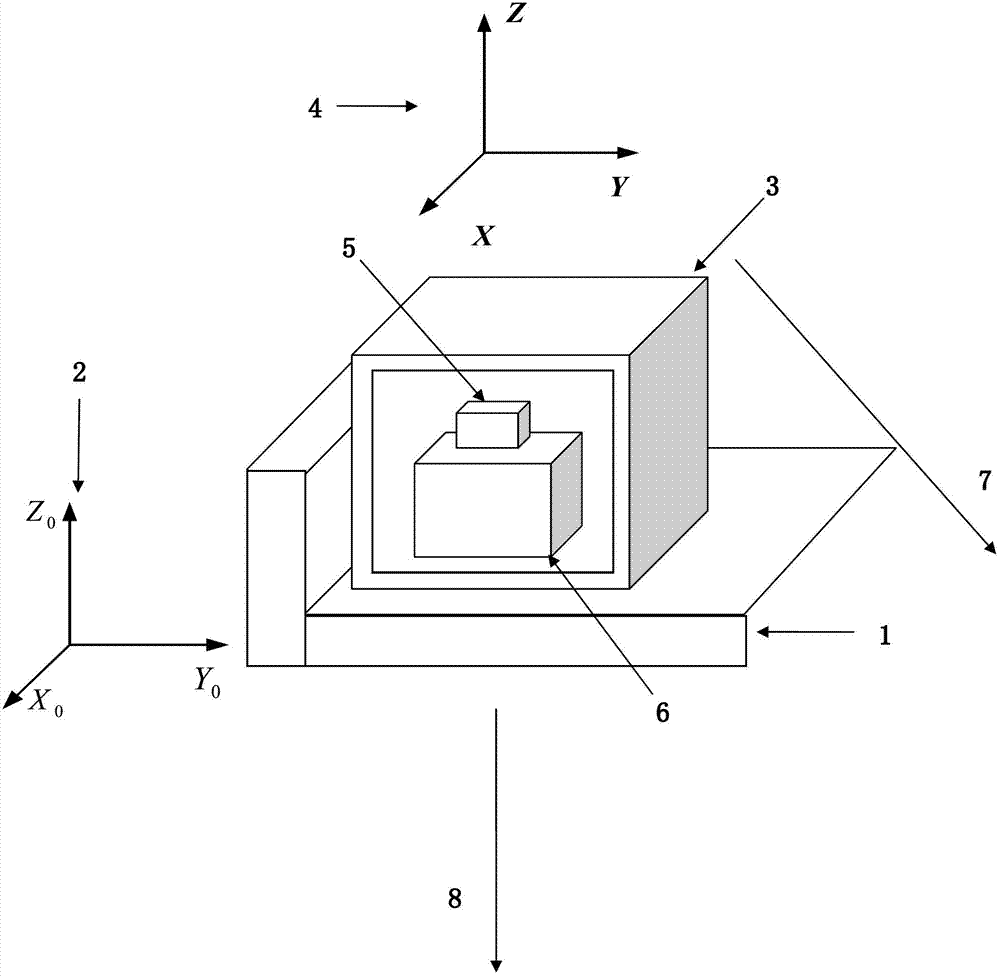

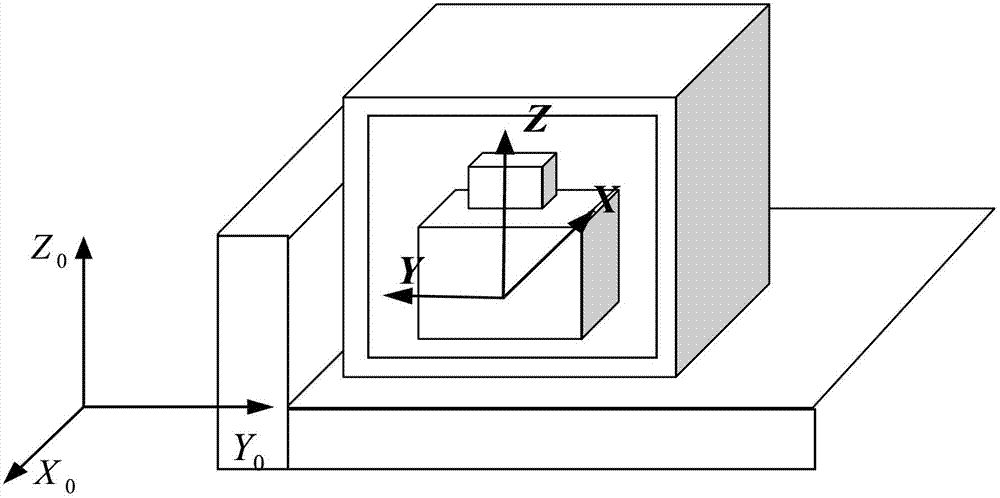

Non-alignment error correction method used for geomagnetic element measuring system

The invention discloses a non-alignment error correction method used for a geomagnetic element measuring system, which comprises the following steps: (1) a rectangular table-board is arranged and a reference coordinate system for the rectangular table-board is established; (2) a magnetic sensor of the geomagnetic element measuring system and an accelerometer are encapsulated together in a non-magnetic regular hexahedron; two surfaces of the non-magnetic regular hexahedron are attached to two vertical surfaces of the rectangular table-board; and a regular hexahedron coordinate system is established for the non-magnetic regular hexahedron; (3) the non-magnetic regular hexahedron is turned for multiple times, and after multiple times of turning, the non-magnetic regular hexahedron is still attached to the rectangular table-board; (4) multiple sets of measurement values of the non-magnetic regular hexahedron and the accelerometer during the process of multiple times of turning are utilized, and through solving multiple non-linear equations simultaneously, the non-alignment error of the magnetic sensor and the non-alignment error of the accelerometer are calculated; (5) the non-alignment error between the magnetic sensor and an inertial navigation is indirectly calculated to correct the non-alignment error of the measurement value of the magnetic sensor. The method has the advantages of simple principle, facilitation of realization and operation, higher correction accuracy, etc.

Owner:NAT UNIV OF DEFENSE TECH

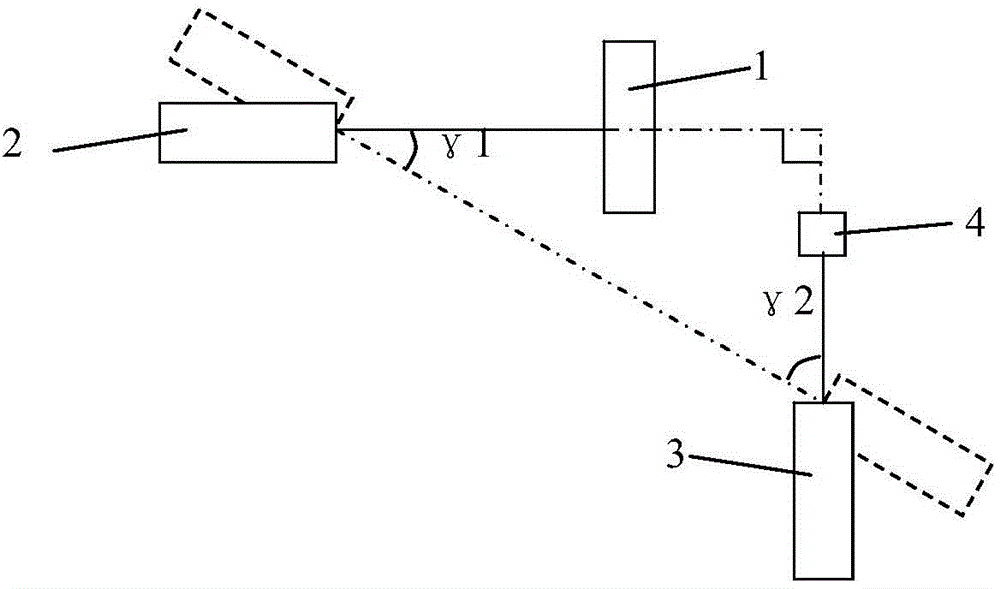

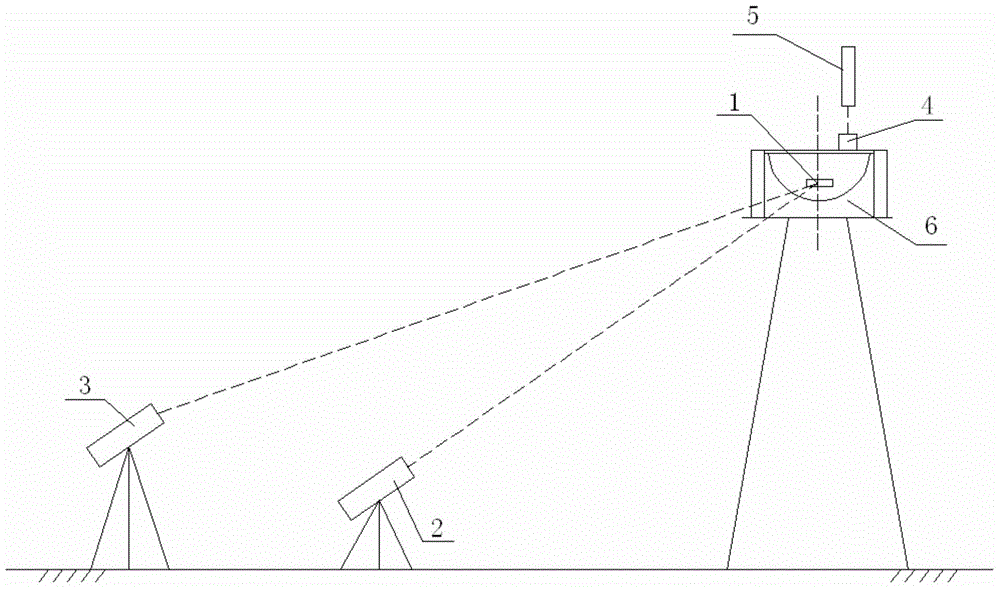

Method for detecting optical alignment prism mounting accuracy deviation calibration of platform system

ActiveCN104697747ALarge swing angleLarge elevation differenceOptical apparatus testingTheodolitesTheodolitePrism

A method for detecting optical alignment prism mounting accuracy deviation calibration of a platform system includes a non-levelness calibration method of an alignment prism and a non-perpendicularity calibration method of the alignment prism, optical alignment prism mounting accuracy deviation calibration of the platform system can be detected by the aid of a regular hexahedron, an autocollimator and two theodolites, and the technological gap of the method is filled. A large swinging angle of a detected object is allowed, namely, a large elevation difference exists, a ground horizontal plane serves as a reference, the reference does not need to be converted through a standard hexahedron, the detecting accuracy of optical alignment prism mounting accuracy deviation calibration is improved, and the method is simple to operate, high in efficiency and detecting accuracy and easy to implement.

Owner:北京兴华机械厂有限公司

Micro attitude and heading reference system based on 3D stereoscopic packaging technology

ActiveCN102313548AReduce volumeReduce non-orthogonal errorNavigational calculation instrumentsNavigation by speed/acceleration measurementsAttitude and heading reference systemTriaxial accelerometer

The invention discloses a micro attitude and heading reference system based on 3D stereoscopic packaging technology. The system provided by the invention comprises a 3D integrated pedestal which is positioned in a core and is shaped as a hexahedron; the external surface of the 3D integrated pedestal is tightly covered with multilayer rigid-flexible PCB; one side of the multilayer rigid-flexible PCB is equipped with a microprocessor, and other five sides are respectively provided with three single-shaft gyroscopes, a triaxial accelerometer and a triaxial magnetic sensor; one side of the 3D integrated pedestal is equipped with a main device slot, and the microprocessor is embedded inside the main device slot; set screws are mounted at four corners of each surface of the 3D integrated pedestal and are also fixedly connected with corresponding positions of the multilayer rigid-flexible PCB; the 3D integrated pedestal is moulded at one step, and each shaft of the sensor is respectively parallel to each other and mutually orthogonal; various sensors are installed by the adoption of multilayer printed circuit boards so as to minimize the volume of the whole pedestal; the microprocessor is introduced to reach independent operational and data processing functions.

Owner:威海中宏微宇科技有限公司

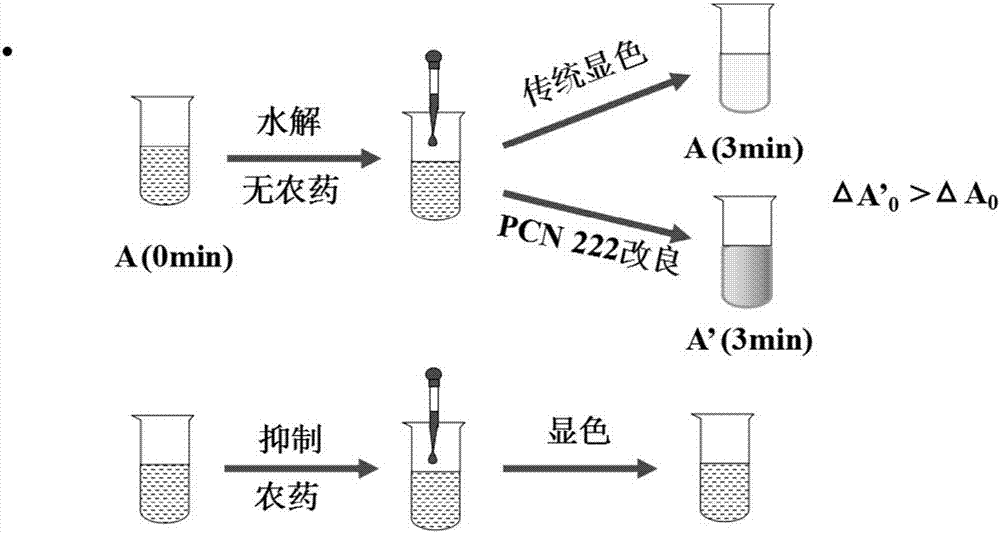

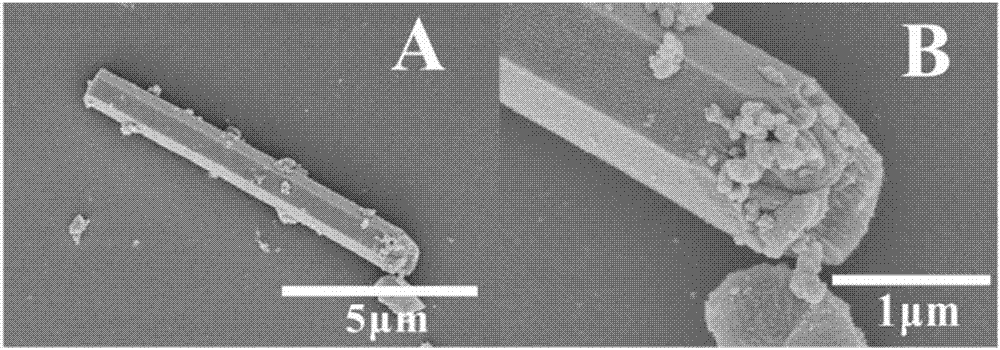

PCN (Porous Coordination Network) 222 metal organic framework material as well as preparation method and application thereof

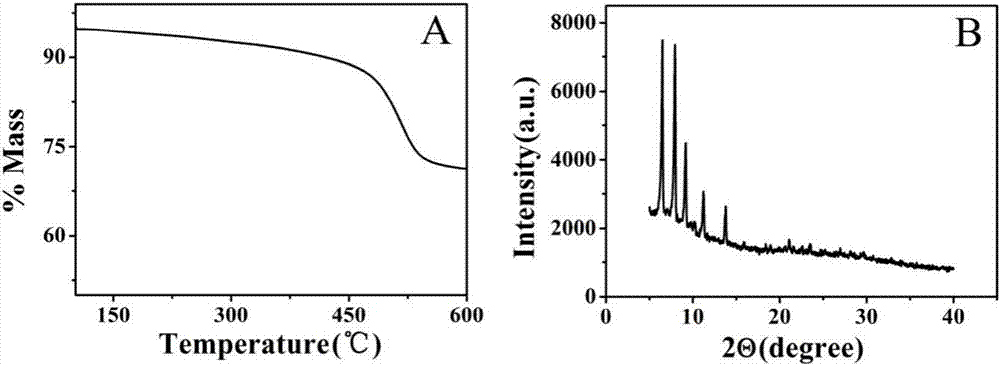

ActiveCN106959279AEfficient detectionHigh sensitivityColor/spectral properties measurementsBenzoic acidN dimethylformamide

The invention discloses a PCN (Porous Coordination Network) 222 metal organic framework material as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing porphyrin, zirconium chloride and benzoic acid with N,N-dimethylformamide under the ultrasonic condition to obtain a mixed solution; carrying out hydrothermal reaction on the mixed solution, and carrying out ethanol washing, centrifuging and drying to obtain the PCN 222 metal organic framework material. The microtopography of the material is of a rod-like structure, and a crystal spindle is a hexahedron; the PCN 222 metal organic framework material has good thermal stability and can be used for enhancing the sensitiveness of a pesticide residue detection enzymatic inhibition method; the method disclosed by the invention has the advantages of simplicity, quickness and low cost and provides a practical tool for determining organophosphorus pesticide in a complex sample matrix.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

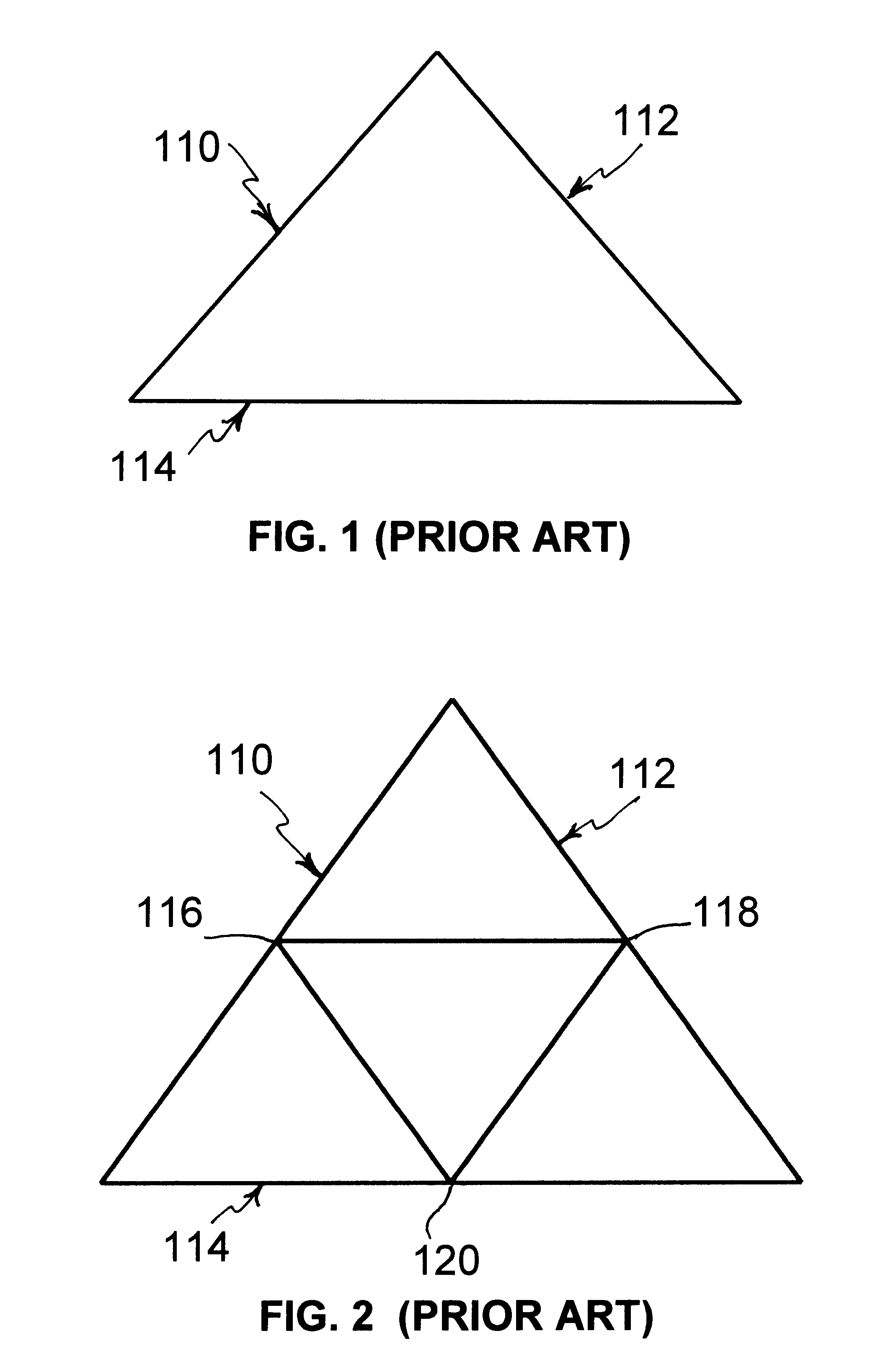

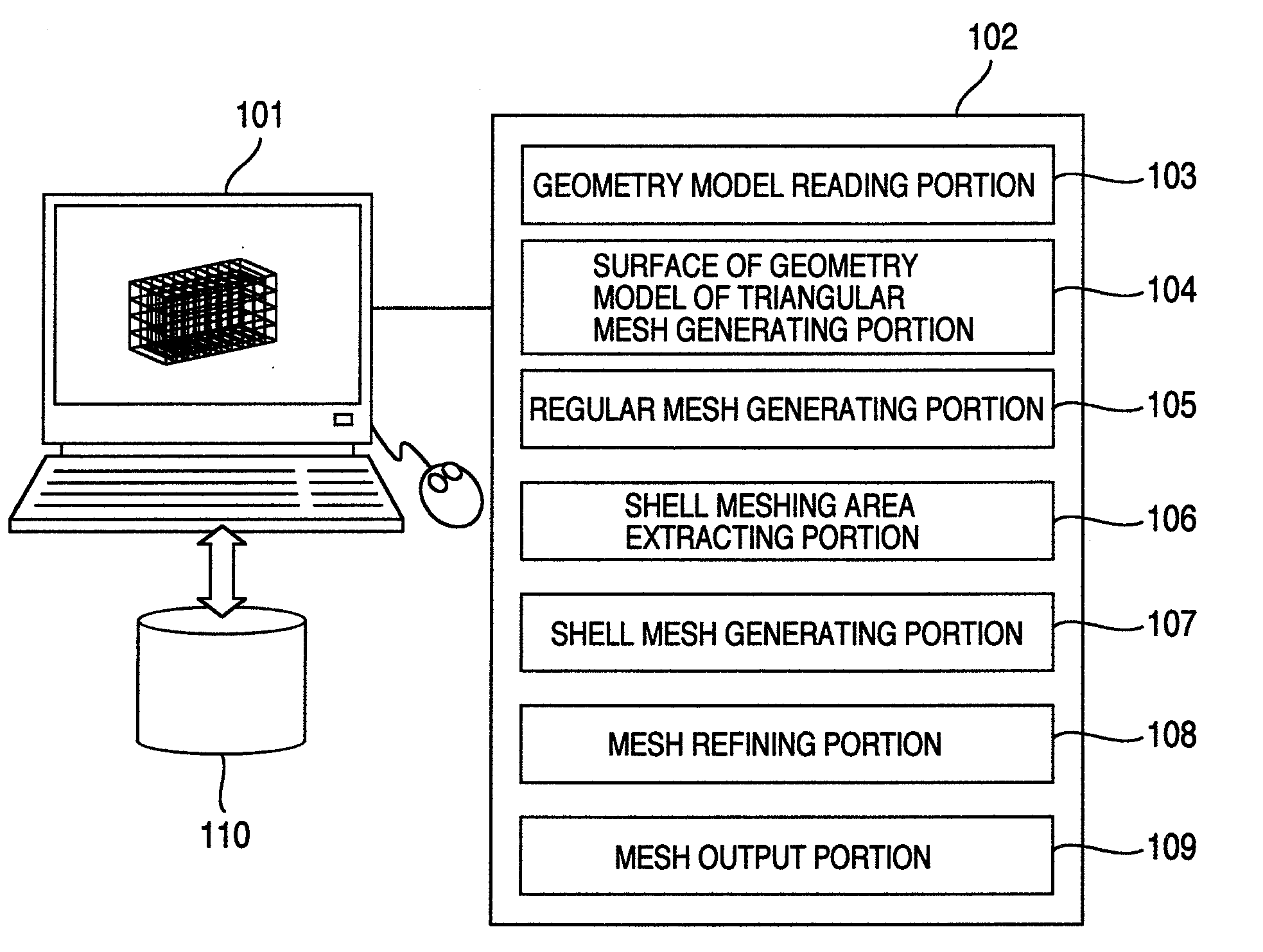

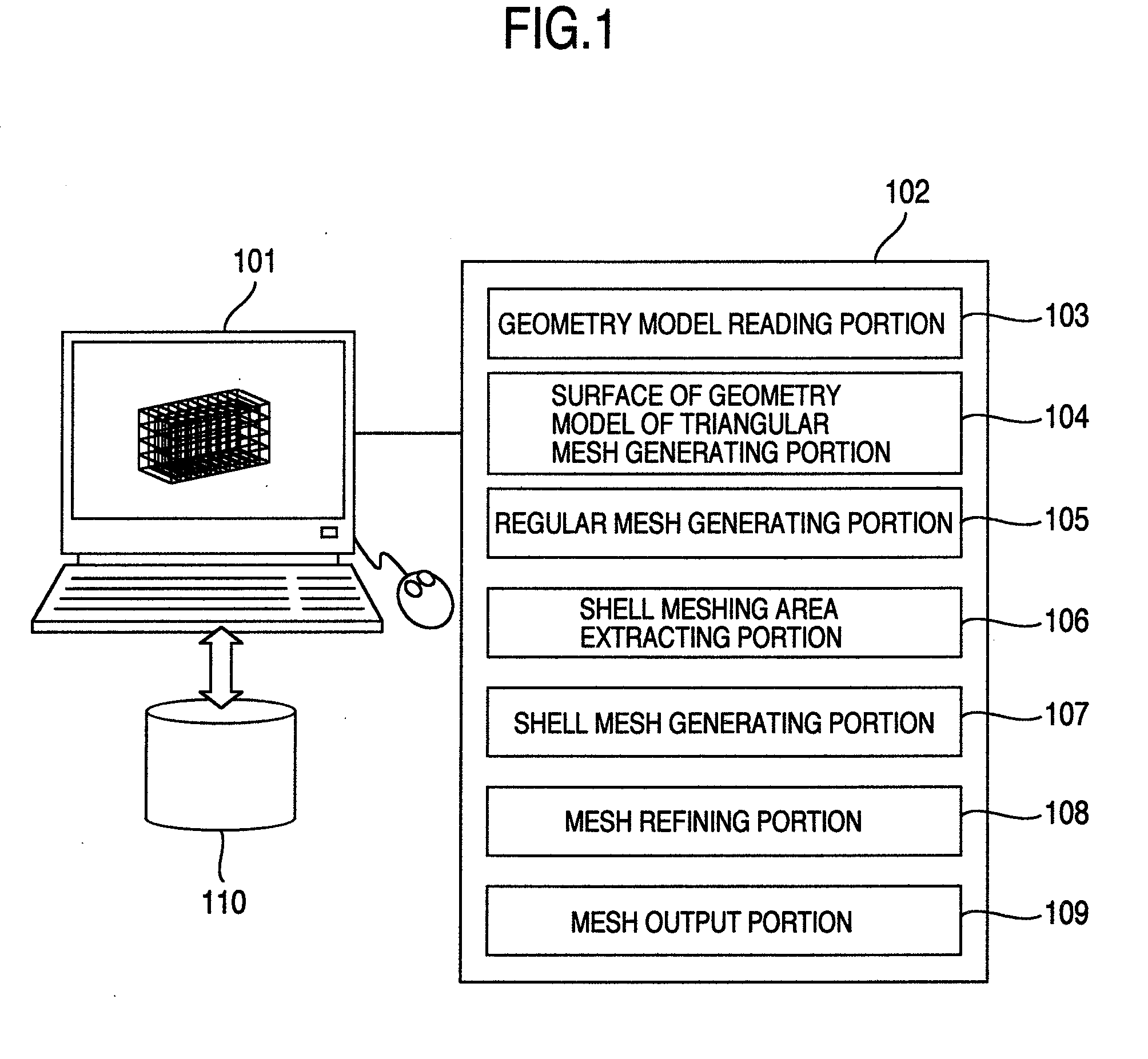

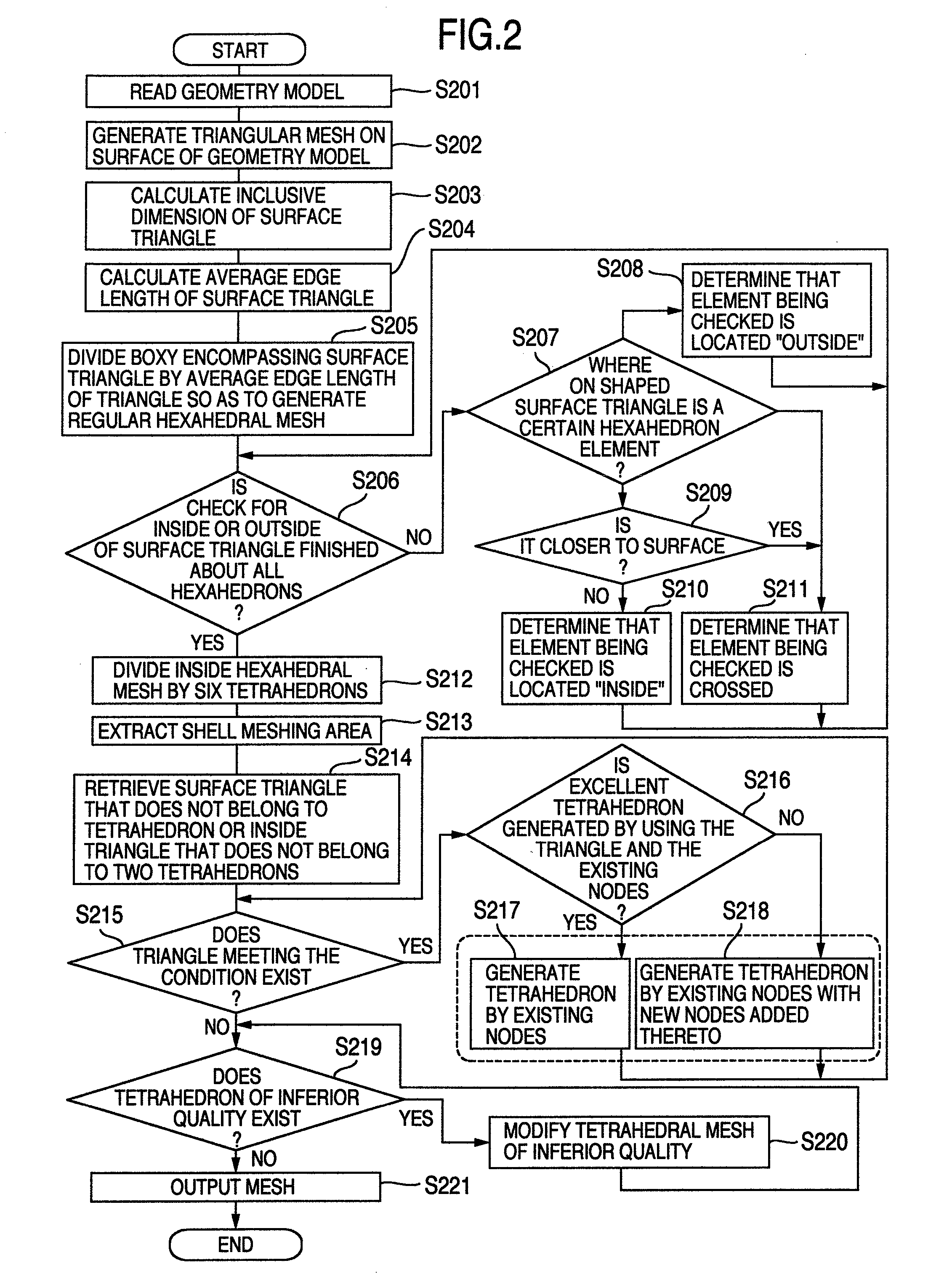

Method for creating three-dimensional finite element mesh

ActiveCN1991846AQuality improvementShorten the timeSpecial data processing applicationsCalculation errorComputer image

The invention belongs to fields of computer image processing; a method of generating three-dimensional finite element grid is disclosed that includes steps as following: 101. Two-dimension surface grid is divided on surface of the three-dimensional model of object noumenon; 102. The noumenon basic grid which encompasses the three-dimensional model is generated by the noumenon basic grid built by projection borderline; 103. The Two-dimension surface grid is inserted into the back of the noumenon basic grid, eliminating the noumenon grid which is out of the noumenon surface grid; the noumenon three-dimensional grid needed is obtained. Because said technical project is adopted, the Two-dimension surface grid and the noumenon basic grid are obtained easily, for adopting the penetration algorithm, the time of generating final noumenon grid is decreased than traditional approach, quantity of work in several months can be accomplished within several days even several hours. At the same time, because the three-dimensional noumenon grid generated is hexahedron grid, the quantity of grid id higher, the calculation error can be improved greatly.

Owner:靖江德方科技服务有限公司

Three axis optical fibre gyro system integrated mounting cage

InactiveCN101290226AReduce processing difficultyReduce processing costsSagnac effect gyrometersFiberAccelerometer

The invention relates to an integral mounting skeleton of a triaxial fiber optic gyro scope system. A plurality of groups of mounting holes are arranged on the mounting skeleton, each group of mounting holes are respectively used to install fiber optic gyro scopes, an accelerometer, a light source, a circuit board and a vibration damper. The fiber optic gyro scopes are three, form mutual space, and are orthogonally arranged on the outer surface of the mounting skeleton, the mounting skeleton adopts a hollow hexahedron frame structure, each group of mounting holes are symmetrically arranged, and mounting lug bosses are arranged on the positioning end surface of the mounting holes. An accelerometer hole is arranged in the mounting skeleton. The quality of the mounting skeleton is very small when enough rigidity and strength are guaranteed; the degree of deviation between the mass center of an inertia measuring unit and a geometric mounting center is very small; simultaneously the temperature compensation and the control scheme of each component of the inertia measuring unit are enabled to be executed; and the manufacturing cost is lowered.

Owner:BEIHANG UNIV

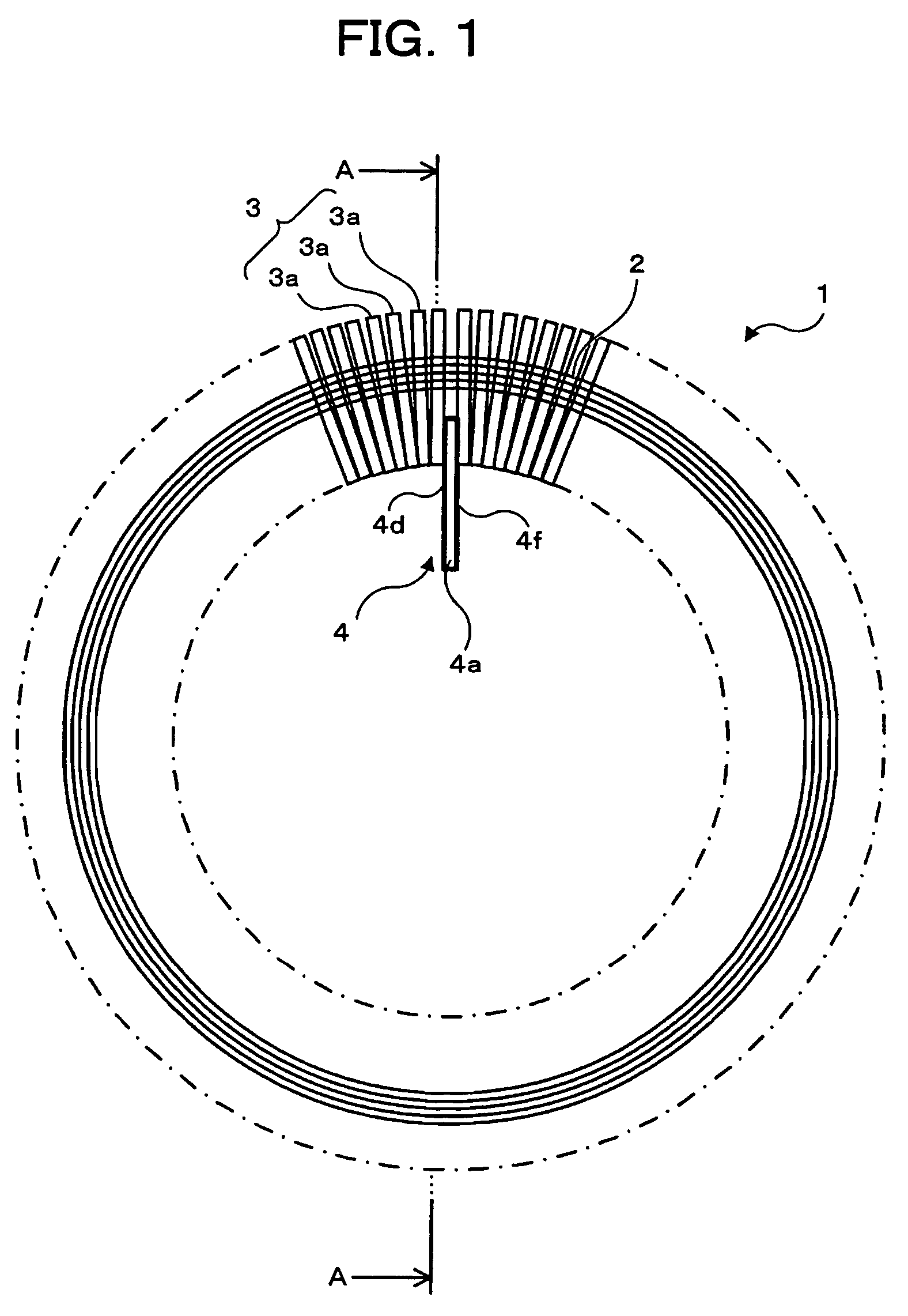

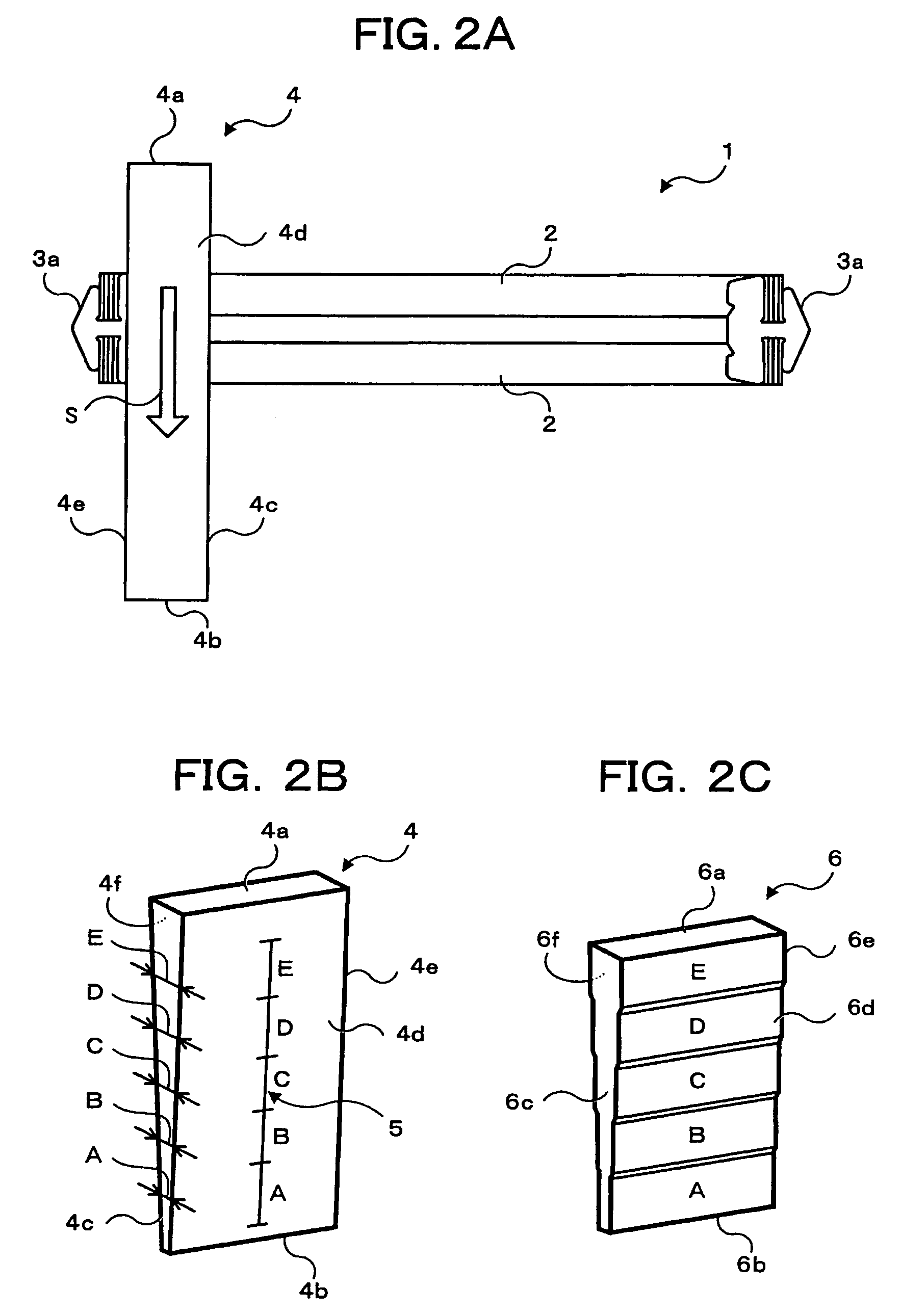

Continuously variable transmission belt inspection device

An inspection device designed for a large number of consecutively attached metal elements punched and processed into a specified shape and for inspecting clearance between said metal elements of a continuously variable transmission belt which are assembled to support a laminated band of a metal stepless belt; a wedge-shaped inspection jig, for example, used for inspecting quantitatively the clearance value with an inspection jig structure of a modified hexahedron having six surfaces containing an upper surface and a lower surface opposing four side surfaces of which both of two side surfaces are a rectangle and the remaining two side surfaces are a wedge-shape which becomes gradually narrower in width from an upper part to a lower part.

Owner:JATCO LTD

Numerical analysis mesh generating method and apparatus

InactiveUS20080246766A1Reducing meshing timeMemory capacity3D-image rendering3D modellingRegular gridComputer graphics (images)

Owner:HITACHI LTD

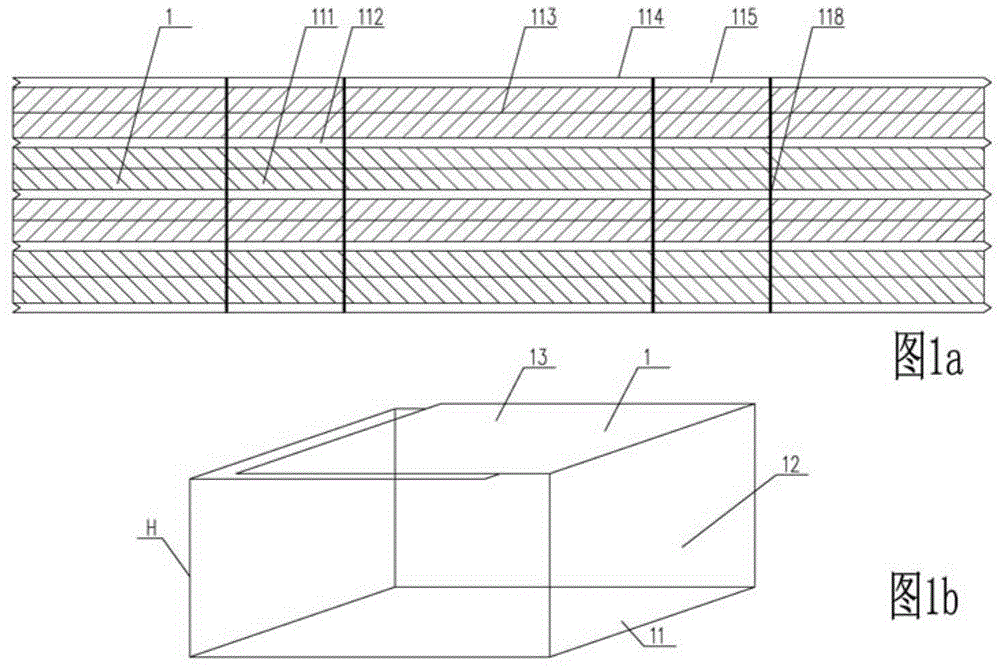

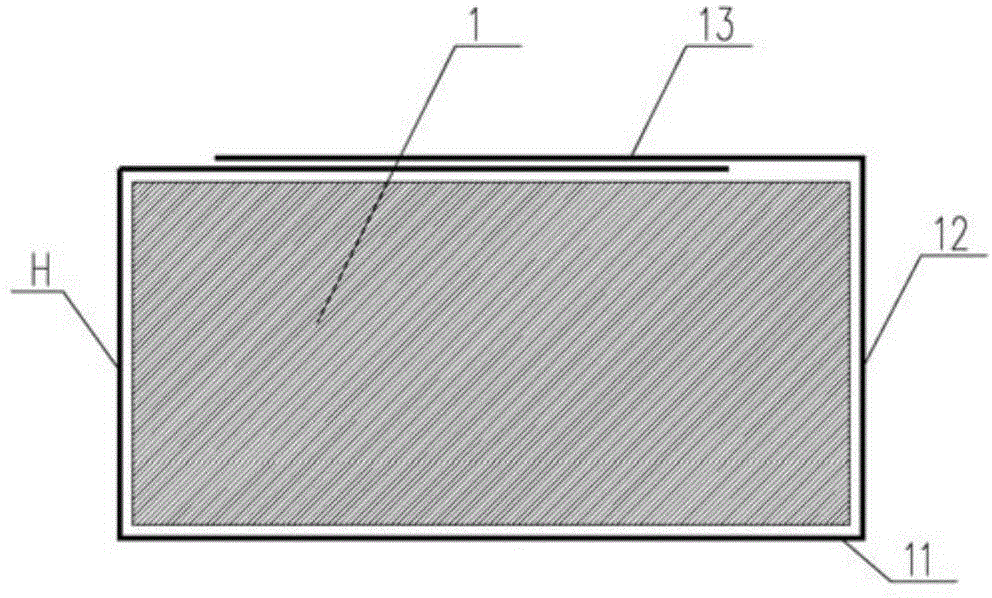

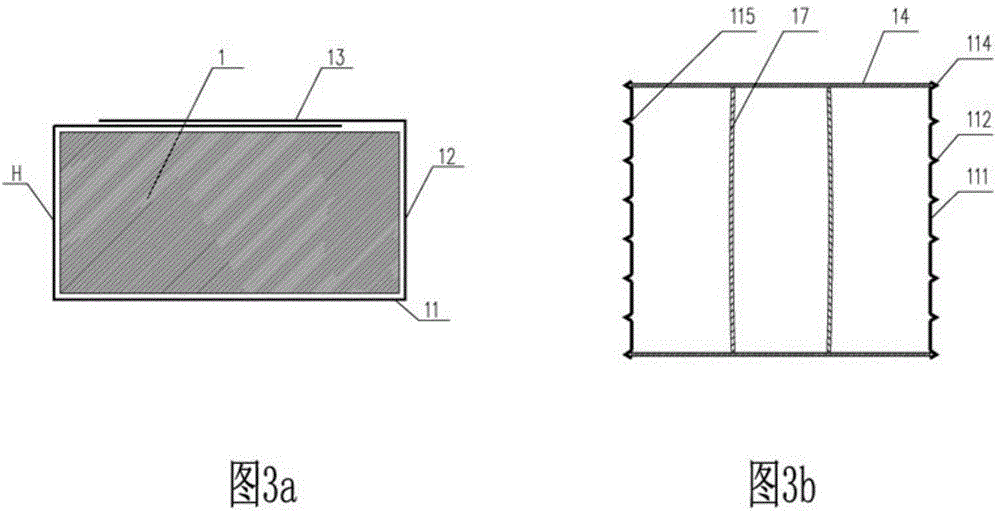

Hollow floor using steel mesh and thin plate combination for hole forming

InactiveCN104631679ARealize multifunctional applicationReinforced top surface against construction loadsFloorsCalcium silicateThin slab

A hollow floor using steel mesh and thin plate combination for hole forming comprises columns, beams, flange plates, and a cavity component formed by steel meshes and thin plates, wherein the beams are reinforced concrete beams or steel reinforced concrete combined beams; the flange plates are I-shaped section plates or T-shaped section plates; the cavity component is formed by the steel meshes and the thin plates which acts on each other; the steel meshes form the overall forming tetrahedron of the top plate, the bottom plate and two lateral walls of the hexahedron cavity component; the head and tail ends of the steel meshes overlap on one optional face of the tetrahedron; the thin plates include calcium silicate plates, plastic plates, composite plates, gypsum plates or corrugated plates; the thin plates form the other two lateral wall plates of the cavity component and the support plates between the top plate and the bottom plate of the cavity component; the two lateral wall plates formed by the thin plates are placed in edge reinforcing rib grooves at two edges of the steel meshes; in-situ concrete pouring is performed on the columns, the beams and the flange plates.

Owner:王本淼 +2

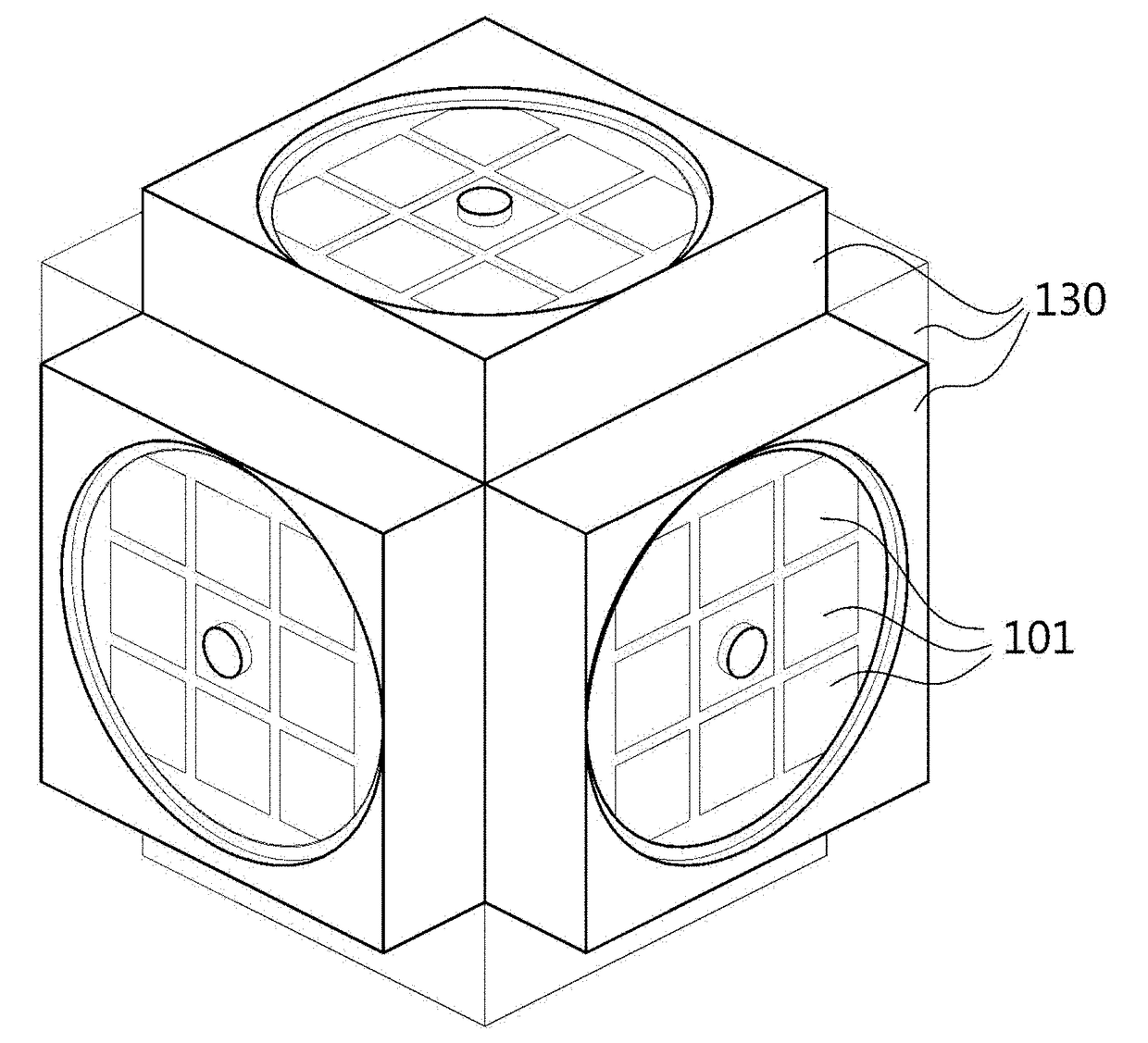

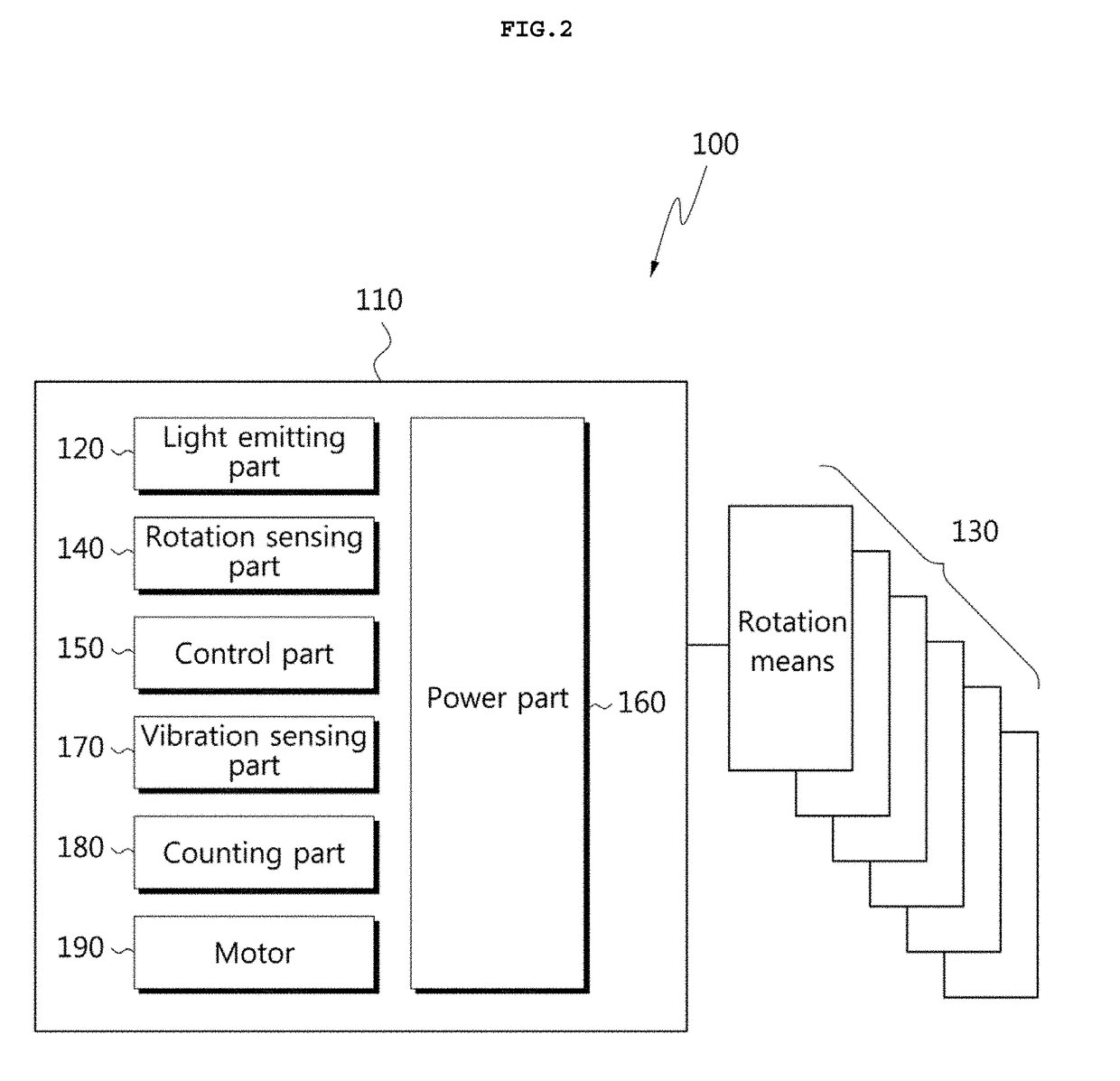

Smart magic cube and operation method thereof

ActiveUS20180311566A1Exciting games with fairness secured can be inducedIndoor gamesEngineeringHexahedron

The present invention relates to a smart magic cube providing a cube game by changing lights of respective cells constituting a magic cube while the cells are fixed, and an operation method thereof. A smart magic cube of the present invention includes: a regular hexahedron housing in which each surface is divided by N×N cells; a light emitting part formed inside each cell and emitting at least one type of light externally through a surface of the cell; six rotation means formed in a rotatable manner; a rotation sensing part sensing a rotation direction and a rotation angle of the rotation means; and a control part controlling the light emitting part to change and emit lights such that border cells of a surface where the rotated rotation means is formed, and cells of four different surfaces adjacent to the border cells output lights changed according to a preset rule.

Owner:SMARTCUBELABS

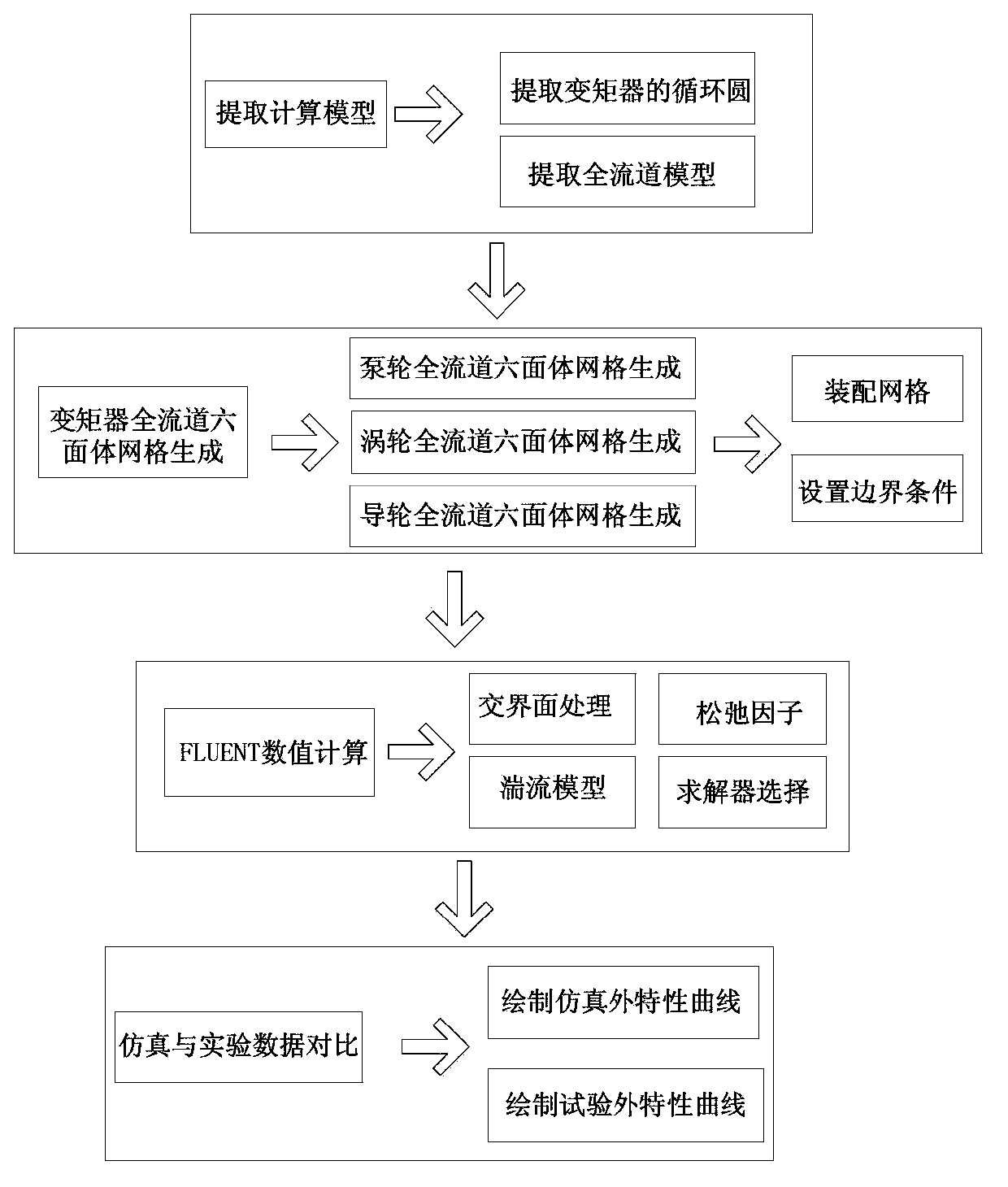

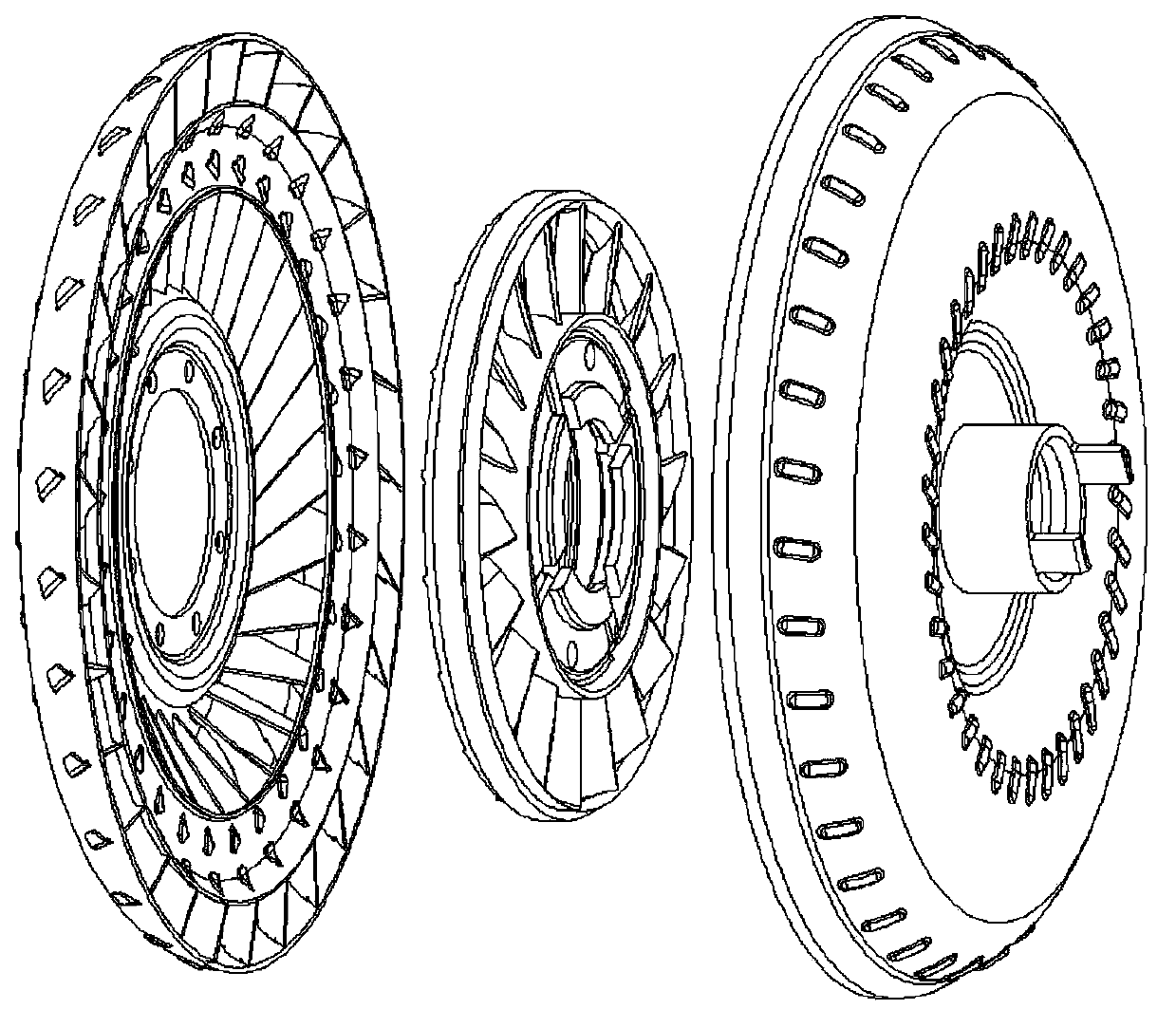

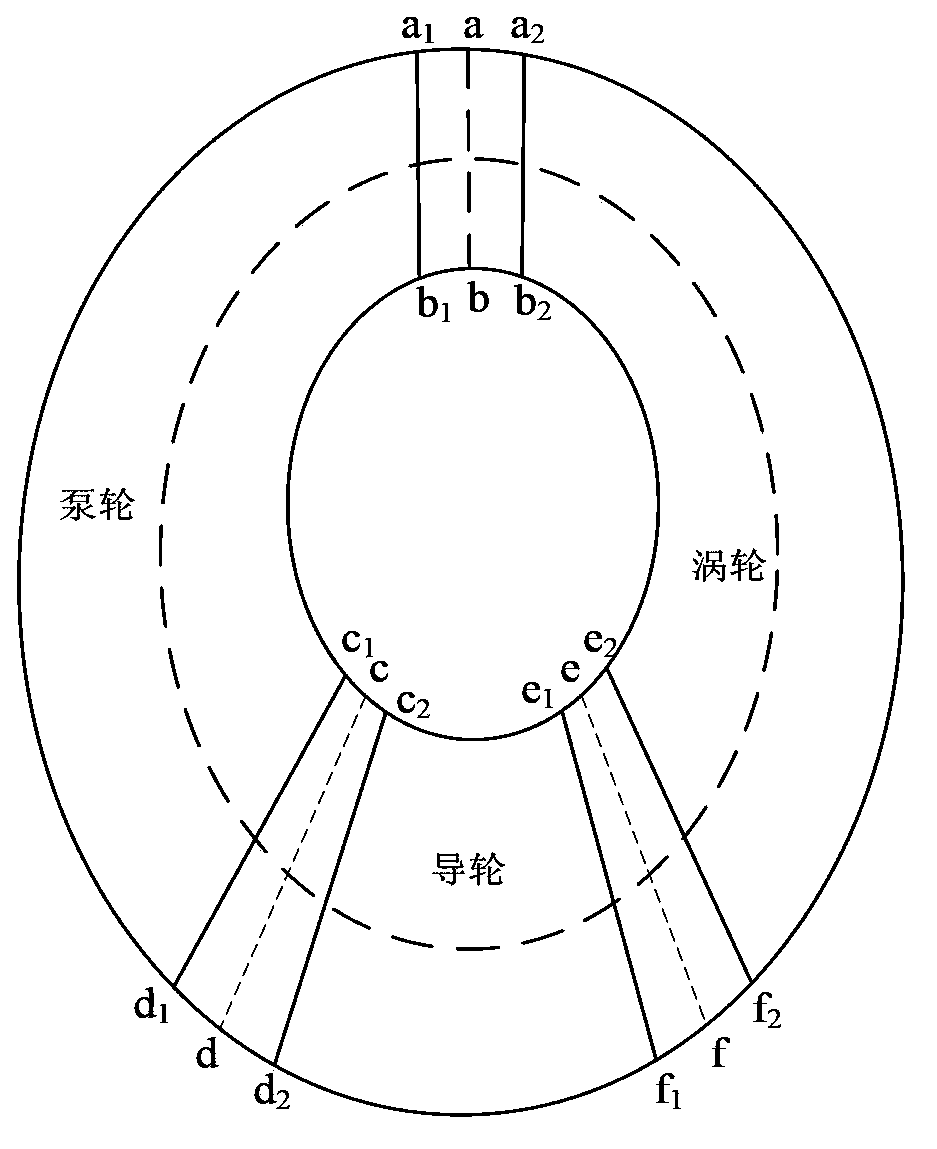

Method for predictingperformance of hydraulic torque converter through simulation

InactiveCN103366067ACreate quickly and accuratelyHigh precisionSpecial data processing applications3D modellingEngineeringTurbine

The invention discloses a method for predicting the performance of a hydraulic torque converter through simulation and aims to solve the problems of low accuracy, numerous grids and large calculated amount for predicating the performance of the hydraulic torque converter. The method for predicting the performance of the hydraulic torque converter through simulation comprises the following steps: 1, extracting calculation models, namely extracting a circulating circle of the hydraulic torque converter, extracting a full passage model of thehydraulic torque converter and extracting a single passage model of the hydraulic torque converter; 2, generating full passage hexahedral mesh models of the hydraulic torque converter, namely generating a guide wheel full passage hexahedral mesh model and a pump wheel and turbine full passage hexahedral mesh model, assembling a mesh, namely sequentially importing the generated pump wheel and turbine full passage hexahedral mesh model and guide wheel full passage hexahedral mesh model into a computational fluid dynamics pre-processing software for assembly, and setting boundary conditions; 3, performing numerical calculation by using Fluent, namely performing numerical solution by importing the assembled hydraulic torque converter full passage mesh file into commercialcomputational fluid dynamics software Fluent; and 4, comparing the simulation with experimental data.

Owner:JILIN UNIV

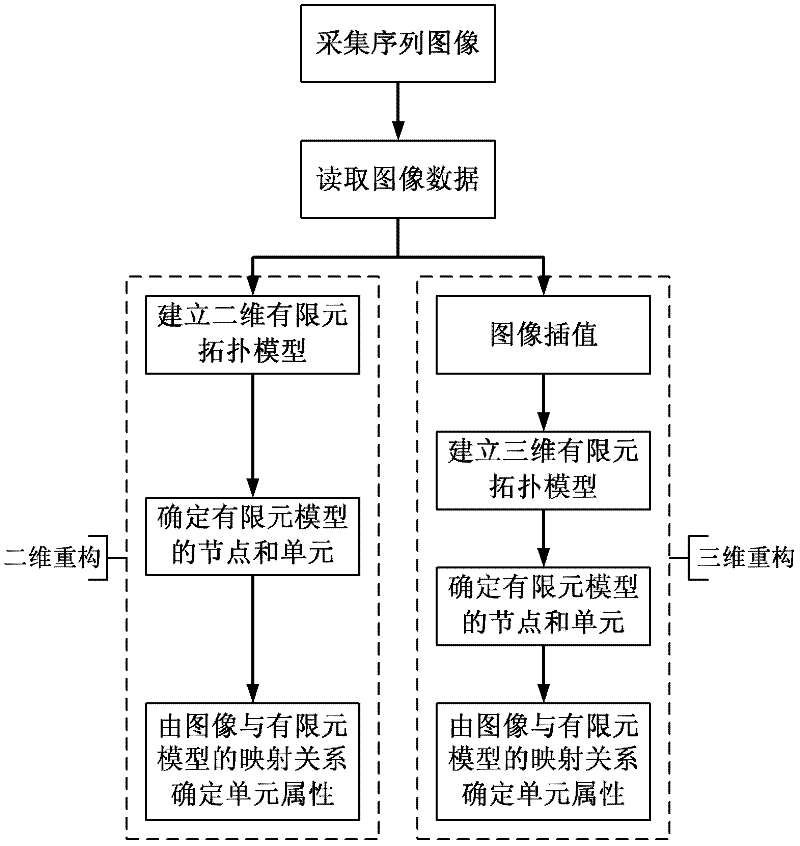

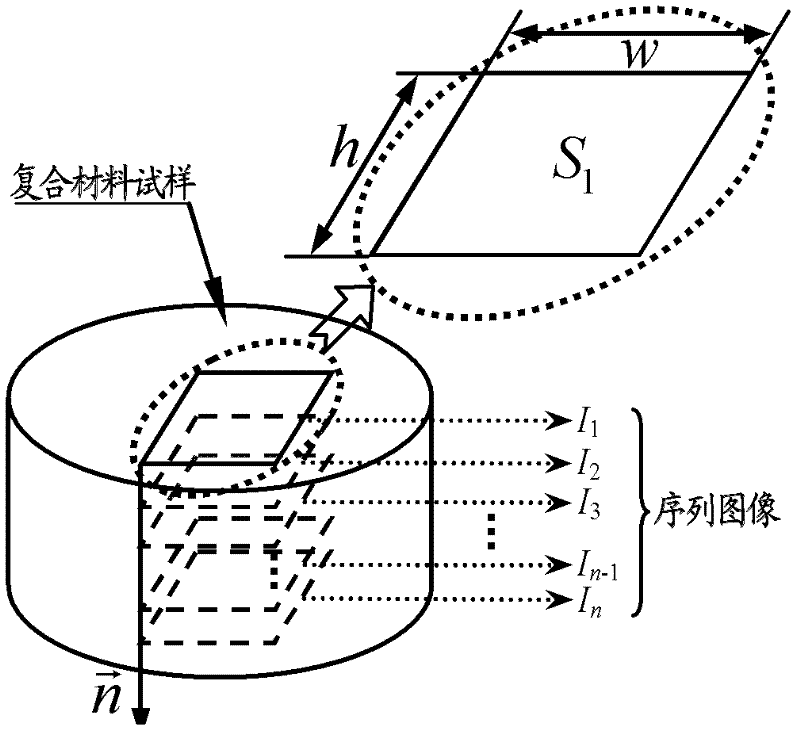

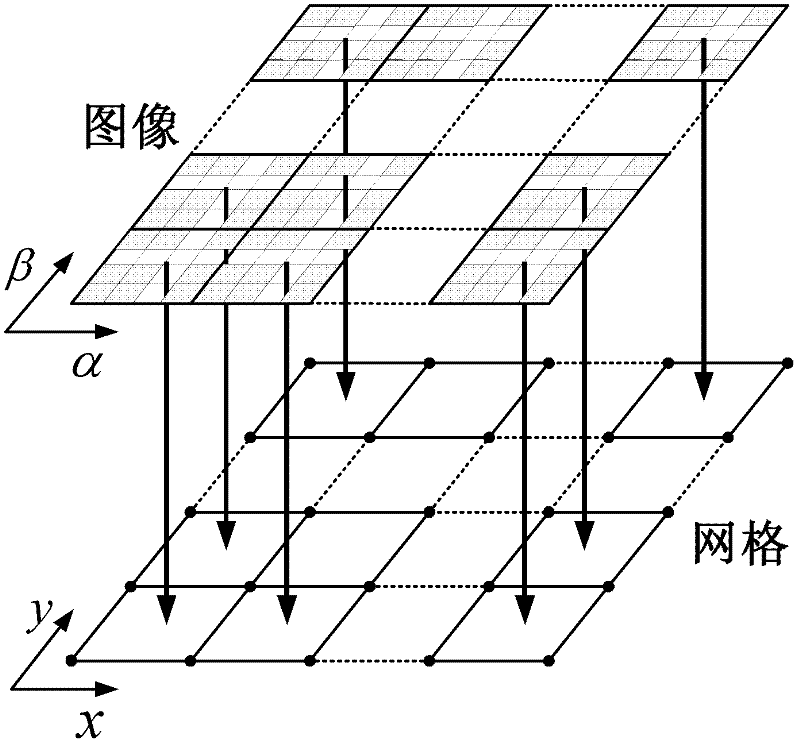

Method for reconstructing micro structure finite element of multiphase material based on sequence image

InactiveCN102236737AReliable Mesomechanics Theory2D-image generationSpecial data processing applicationsMicro structureElement model

The invention provides a method for reconstructing a micro structure finite element of a multiphase material based on a sequence image, comprising the following steps of: on the basis of collecting, reading and interpolating the sequence image of the material, establishing a finite element topology model forming a mapping relation with the sequence image; using configuration information of the image and a topology structure of the model to determine a node and unit information; and then using a statistical average value of colour information in the image to determine material attributes of each unit of the finite element model. The method disclosed by the invention not only can be used for reconstructing a two-dimensional quadrangular finite element model reflecting a real structure of a material section through a single image, but can also be used for directly reconstructing a three-dimensional hexahedral finite element model reflecting the real structure of the material through the sequence image. By means of the invention, error accumulation in the links of reconstructing, grid dividing and the like in the current geometrical reconfiguration method can be avoided; the reconfiguration time is greatly saved; and the reconfiguration efficiency is improved. The method disclosed by the invention can be widely used in the fields, such as macro-micro cross scale research, optimization design and preparation of the multiphase material.

Owner:XI AN JIAOTONG UNIV

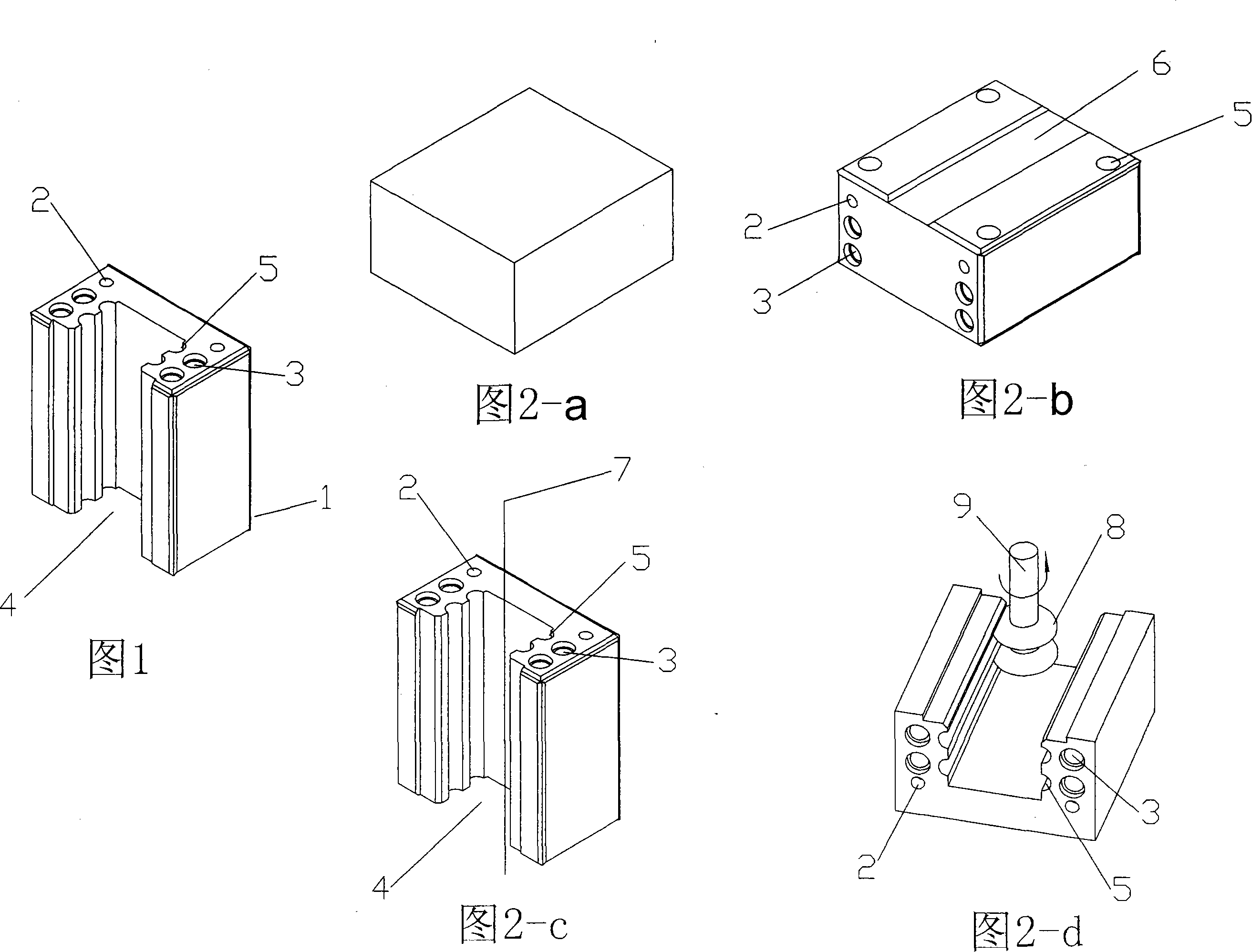

Straight-line rolling slipper block and method of manufacture

InactiveCN101235847AImprove compactnessStable and precise upper and lower contactLinear bearingsSEMI-CIRCLESteel bar

The invention relates to a linear rolling slider, which comprises a rolling steel ball which is arranged in the slider, an upper raceway groove and a lower raceway groove which are parallel are arranged on the inner walls of the two sides of an inner concave slider, and a raceway cavity which is reversely connected with the upper raceway groove and the lower raceway groove is horizontally arranged on the inner walls of the two sides of the inner concave slider. The method for preparation comprises that a round steel bar is thermally forged into a square green body, the square green body is milled and processed into cut angle end surfaces which are mutually vertical, and relative surfaces are hexahedron which are mutually parallel. The hexahedron is flatly ground and processed to achieve the required precision of parallelism and reference location, the hexahedron is cut and processed into a concave slider body by a wire electrical discharge, and an upper semi-circle raceway groove and a lower semi-circle raceway groove which are parallel and are arranged on the two sides of the inner concave slider are ground in high speed. A steel ball in the raceway groove not only operates in high speed not to block, but also is not bore in long time operation and not produces frictional heating. The friction coefficient is capable of being reduced to fiftieth of the original friction coefficient, the instantaneous speed is increased for 10 times, the linear rolling slider uses a double-row raceway groove, thereby being capable of greatly increasing carrier loads, achieving steady operation, and prolonging the service life.

Owner:宁波恒力汽配轴承有限公司

Double-strap-down inertial set orientation deviation calibration device and method of rocket launcher

ActiveCN105222806ALower requirementCalibration operation is simpleMeasurement devicesTheodoliteControl system

The invention provides a double-strap-down inertial set orientation deviation calibration device of a rocket launcher. A double-strap-down inertial set of the rocket launcher comprises two strap-down inertial sets which are installed on one integrated support in parallel so that a complete strap-down inertial set can be formed; the two strap-down inertial sets are movably placed on a horizontal flat plate calibration table; a standard hexahedron and right-angle prisms of the two strap-down inertial sets are arranged at equal height; the standard hexahedron and the strap-down inertial sets are alternately located in the view fields of a first theodolite and a second theodolite as a whole; the first theodolite and the second theodolite are arranged on the two sides of the flat plate calibration table respectively. Meanwhile, a calibration method of the calibration device is provided. The calibration device and the calibration method of the calibration device achieve the purpose that after double-strap-down inertial measurement combination main and salve redundancy is adopted for a control system of the rocket launcher, the orientation deviation of the two strap-down inertial sets is determined. After the main strap-down inertial set is aimed at at the initial orientation in front of the rocket launcher, the orientation of the slave strap-down inertial set is determined through the calibration deviation, the initial alignment and launching process of the rocket launcher provided with the redundant strap-down inertial sets can be simplified, and engineering practicability is high.

Owner:SHANGHAI XINYUE METER FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com