Method for detecting optical alignment prism mounting accuracy deviation calibration of platform system

An optical aiming and detection method technology, applied in the field of measurement, can solve the problems of installation accuracy affecting aiming and missile drop point accuracy, and achieve the effects of wide application range, easy implementation, and improved detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

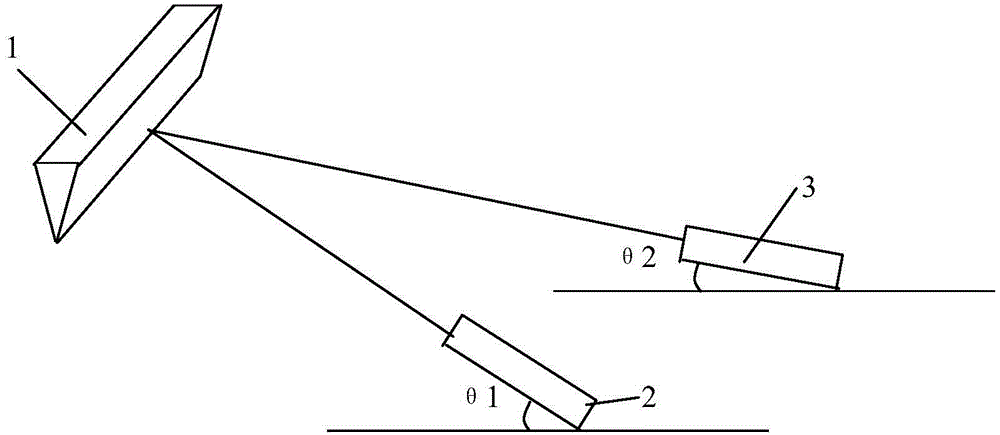

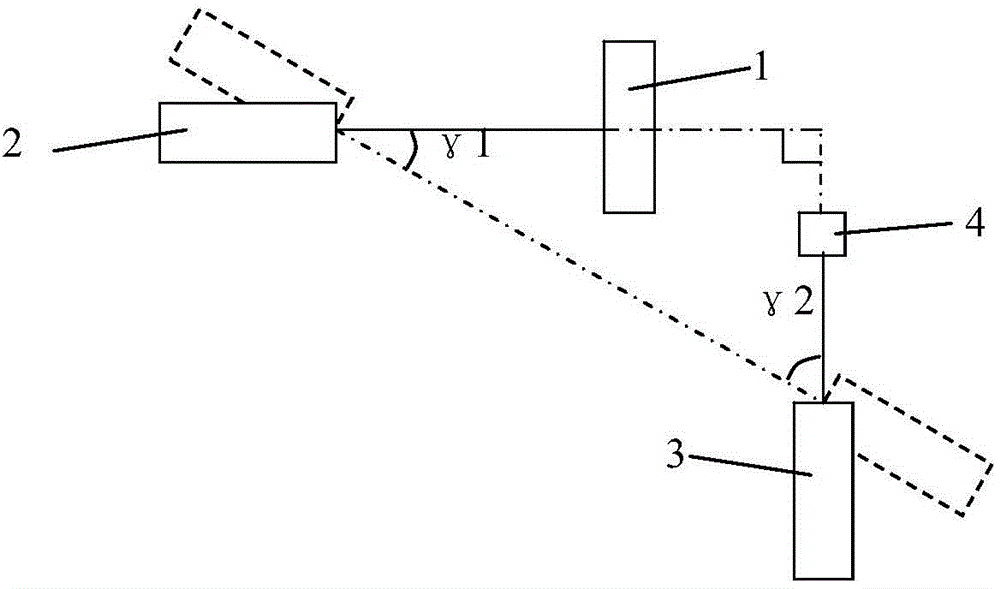

Method used

Image

Examples

Embodiment

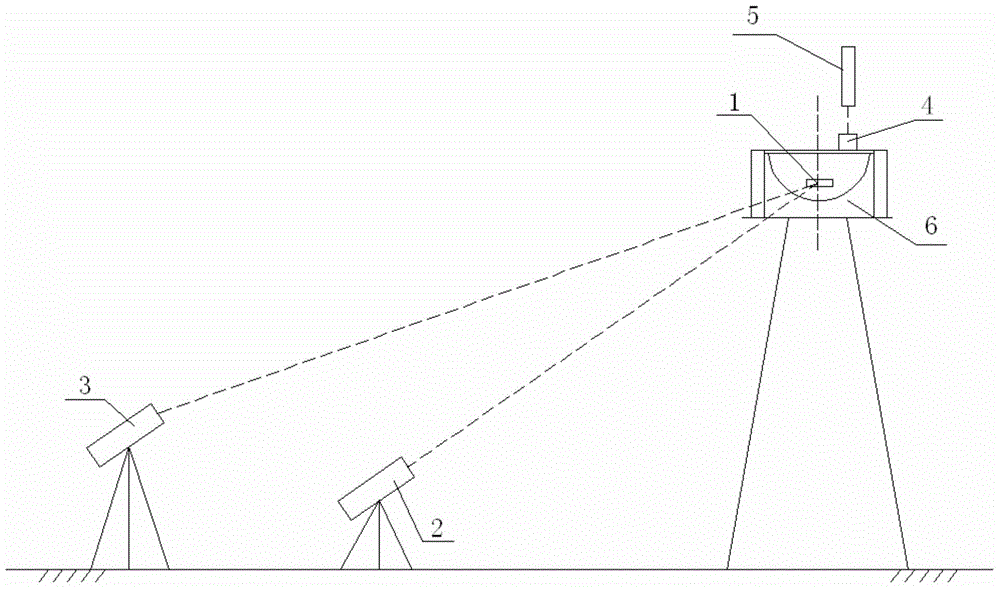

[0076] 1 Optical sighting prism level detection

[0077] (1) Press image 3 As shown, the height of 6 platforms is about 2.5 meters. Align the optical axis of the autocollimator 5 to the local vertical direction, and the alignment accuracy is not greater than 3".

[0078] (2) Adjust the regular hexahedron 4 with the autocollimator 5 to keep the regular hexahedron 4 horizontal.

[0079] (3) Set up the first theodolite 2 at an elevation angle of 30.9337° to the center of the aiming prism 1 of the platform 6 about 3.3 meters away from the platform 6, and set up the second theodolite 3 on a tripod at an elevation angle of 16.6917° at an elevation angle of 16.6917° at a distance of about 4.8 meters from the platform 6 The aiming prism 1 center. After the two theodolites are aligned with the aiming prism 1, the position of the theodolite is fine-tuned so that the optical axes of the two theodolites after aiming at the aiming prism 1 are in the same plane. After adjustment, fix the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com