Patents

Literature

328results about How to "Will not short circuit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

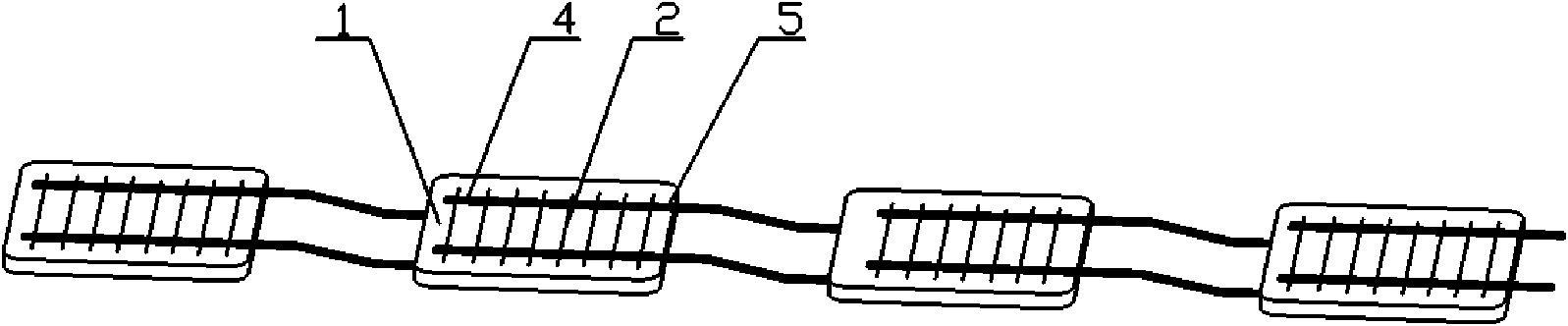

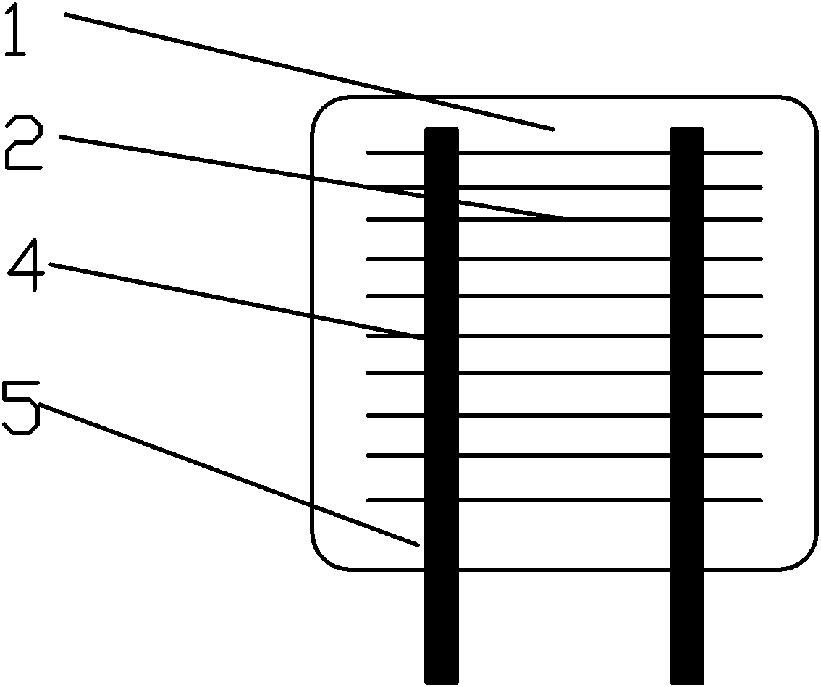

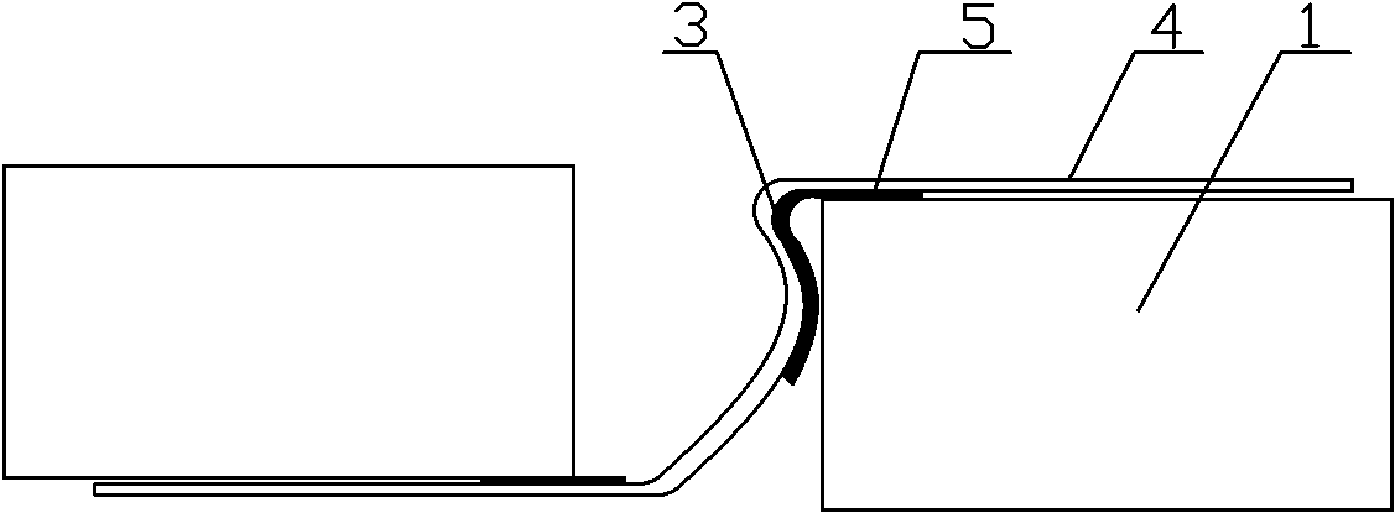

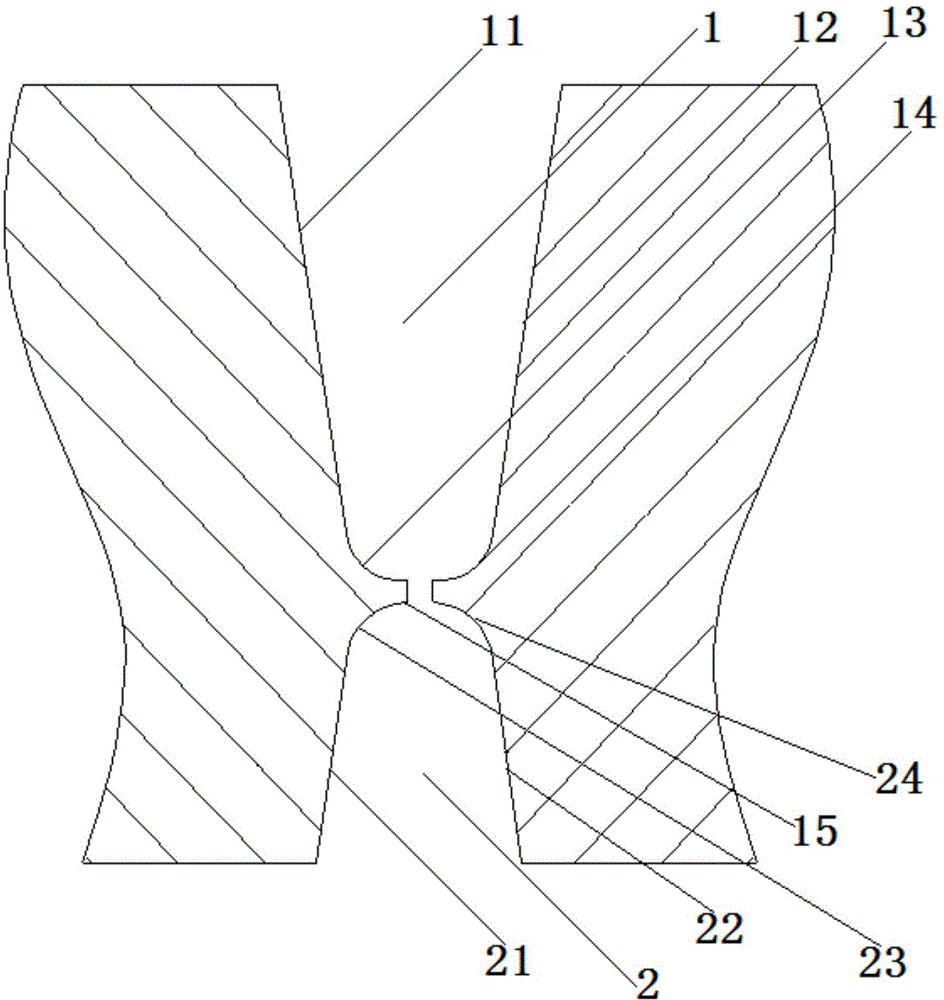

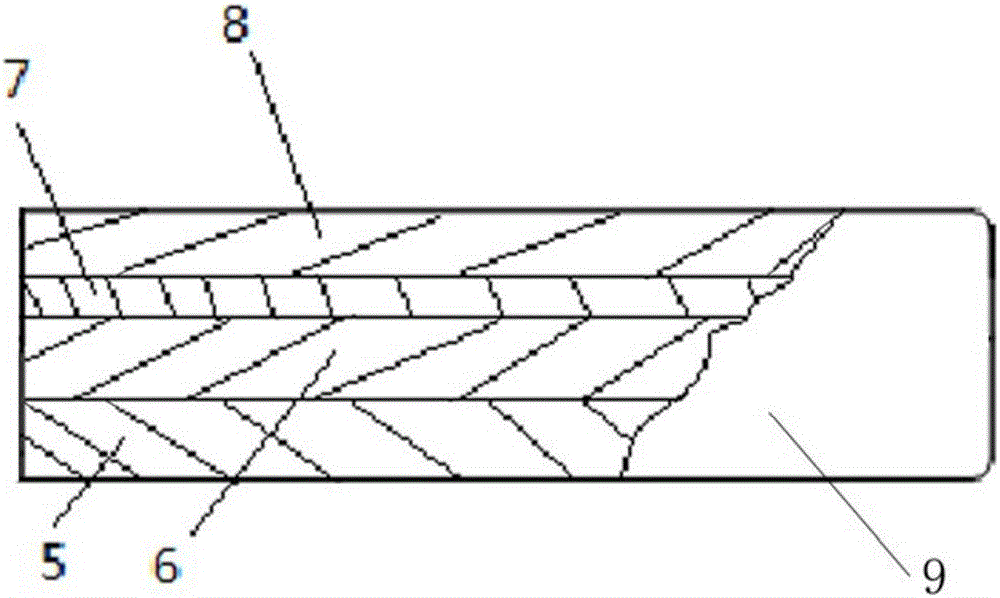

Solar photovoltaic component and welding process

InactiveCN101567402ASmall bridging stressImproved resistance to twistingSoldering apparatusPhotovoltaic energy generationAutomotive engineeringPressure resistance

A solar photovoltaic component and a welding process. The solar photovoltaic component comprises a group of solar cell plates. The front face of the solar cell plate is welded with the back face of the adjacent solar cell plate through a bus bar. A welding gap is arranged between the bus bar leading-off wire and the solar cell plate. The welding process comprises the following steps: preheating the welding bench, heating the electric iron; pasting the release paper on the bus bar; stably welding the front bus bar and the solar cell plate; putting the cell plate in a series welding platform; firstly welding the front bus bar leading-off wire, then welding the back bus bar. The invention effectively controls the welding start position and the welding direction by setting the welding gap on the structure and pasting the release paper in the welding process, reduces the bridge stress of the front face of the cell plate and the adjacent back face of the cell plate after welding, ensures the PN junction will not short out in the welding process, improves the wind resistance and static pressure resistance so as to enhance the solar photovoltaic component service life.

Owner:恒基光伏电力科技股份有限公司

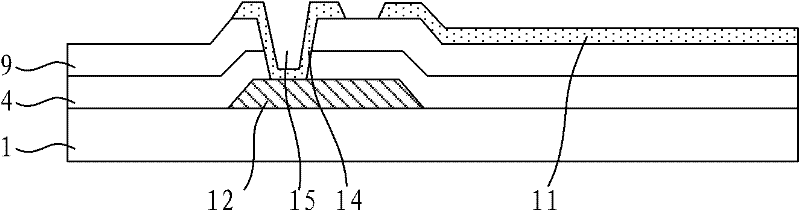

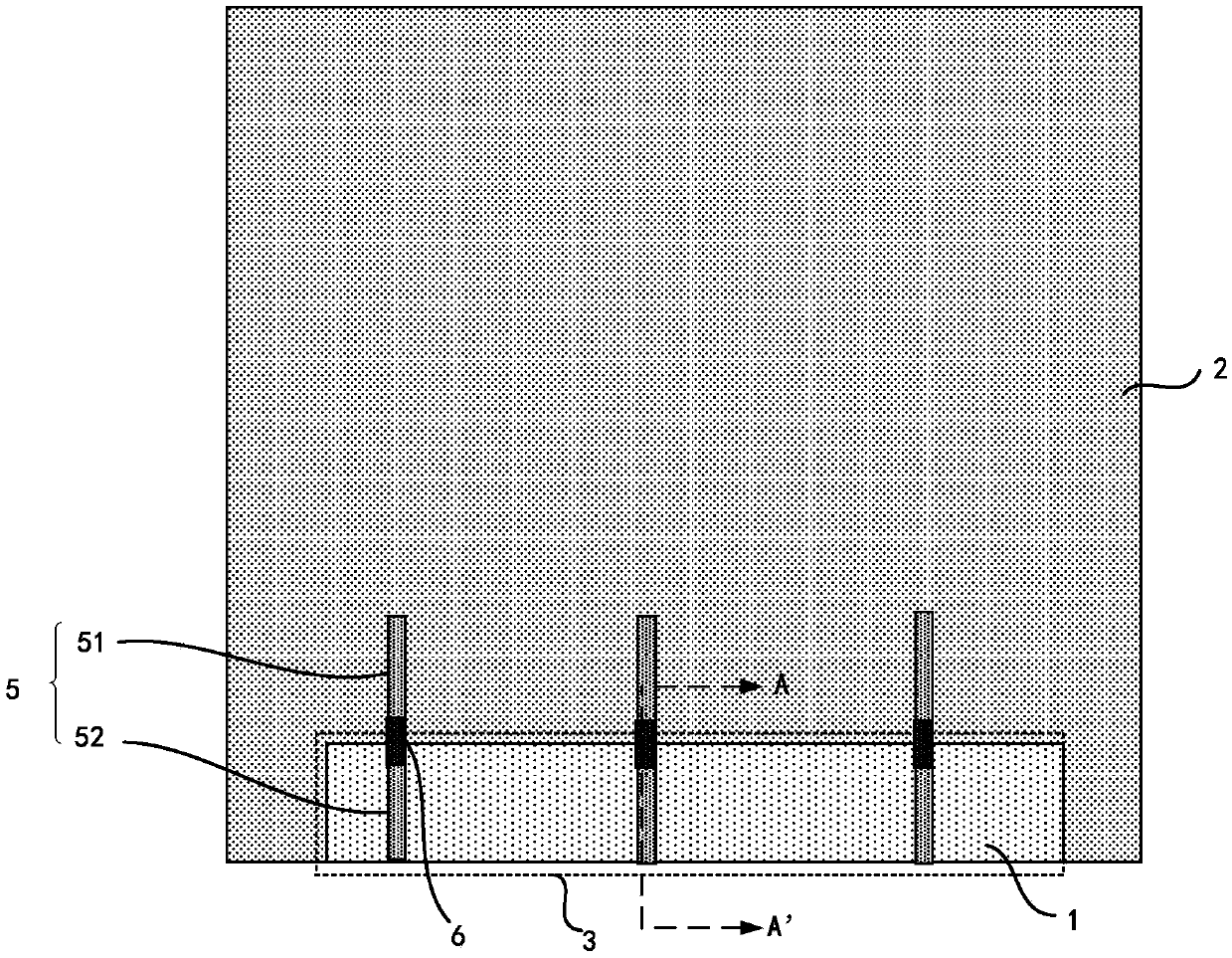

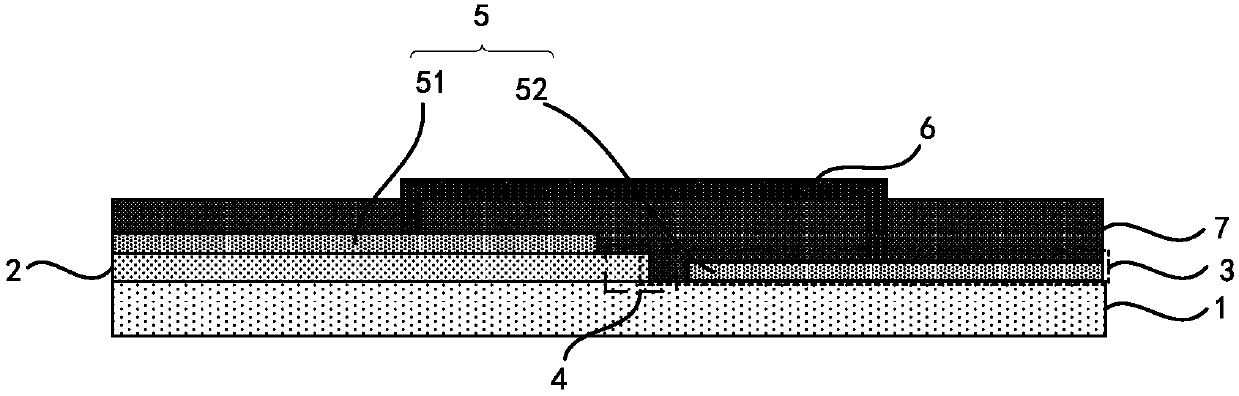

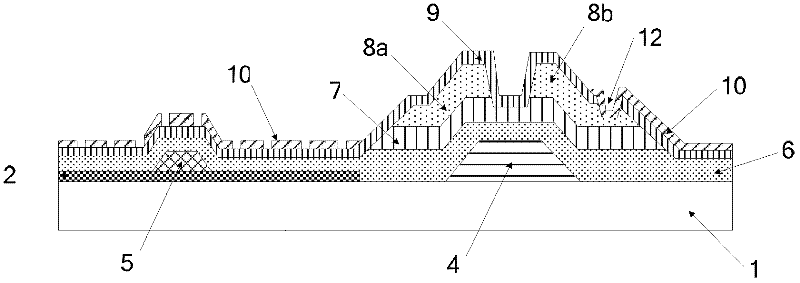

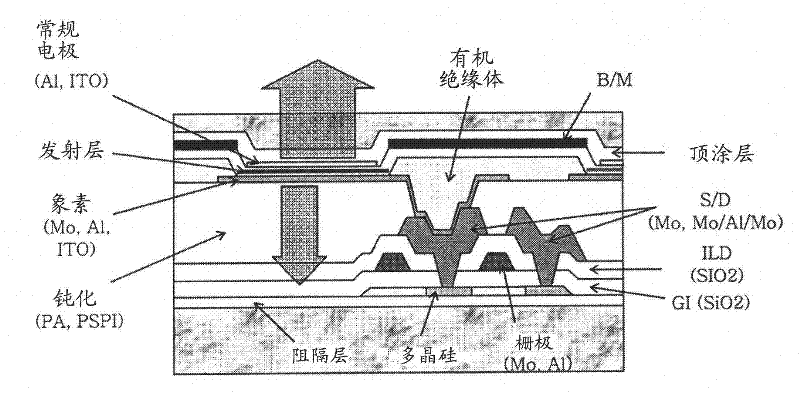

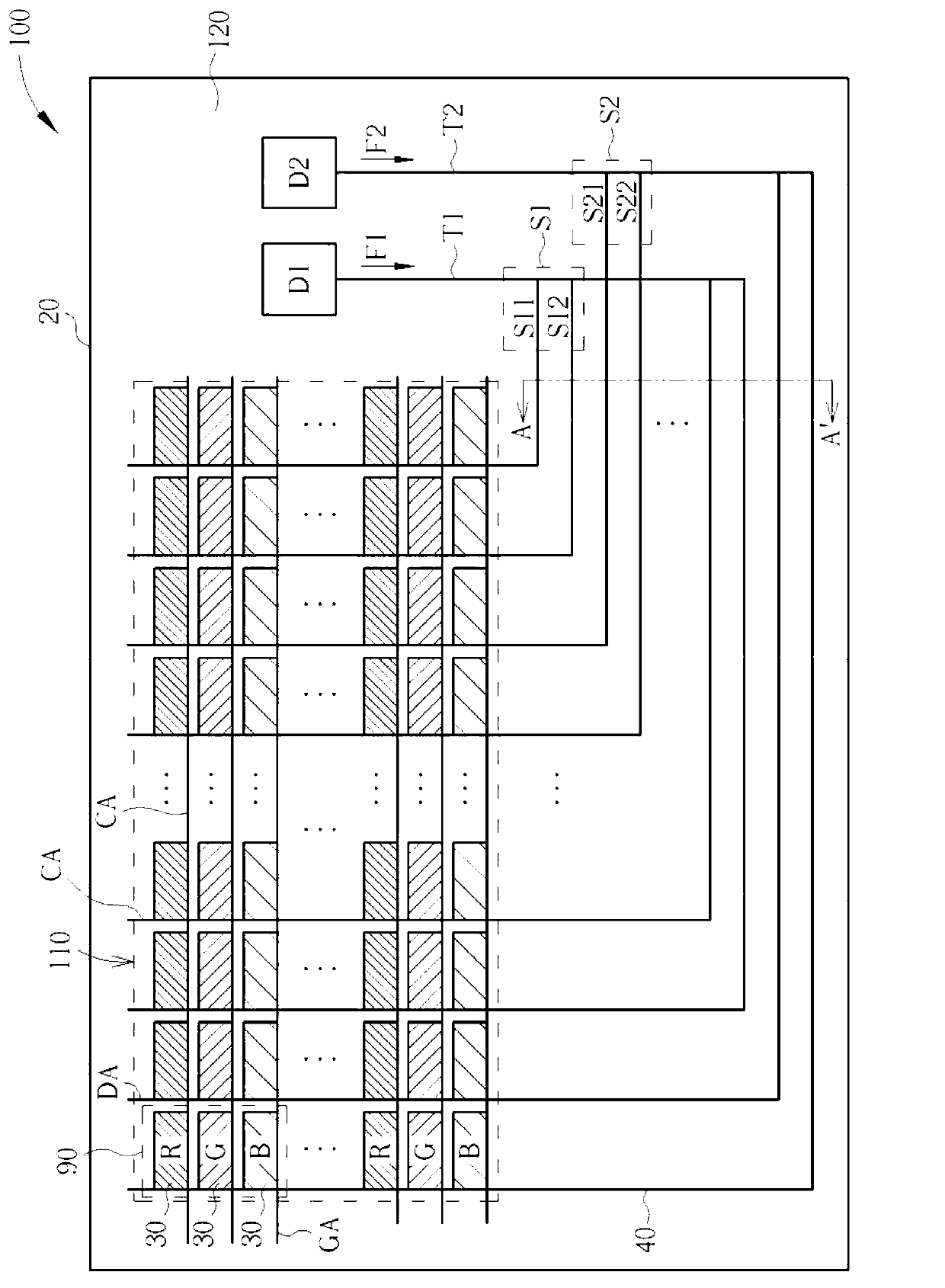

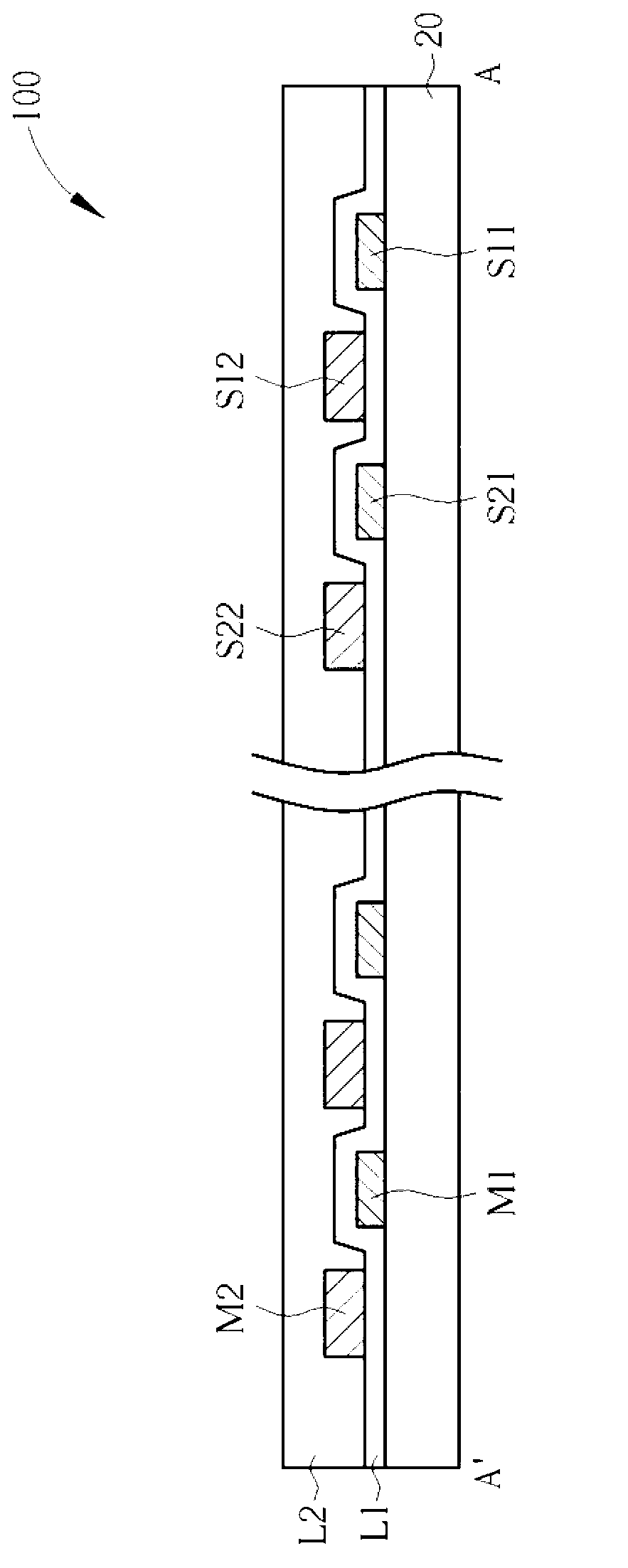

Array substrate and method for manufacturing same and liquid crystal display

InactiveCN102468308ASolve the problem of short circuitWill not short circuitSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

The invention discloses an array substrate and a method for manufacturing the same and a liquid crystal display. The method for manufacturing the array substrate comprises the steps of forming conductive patterns and an insulating layer on a substrate base plate, wherein the conductive patterns at least comprise a grid line, a grid electrode, an active layer, a source electrode, a drain electrode, a data line, a pixel electrode and public electrodes, the public electrodes on the array substrate are communicated through a public electrode connecting line, and a blocking block and a blocking groove are arranged between the public electrode connecting line and the pixel electrode. The blocking block and the blocking groove are formed according to the following steps of: forming patterns containing the blocking block on the substrate base plate formed with the grid line, the public electrodes, the grid electrode and the insulating layer by a patterning process; and forming patterns containing the blocking groove on the substrate base plate formed with the patterns by the patterning process. With the adoption of the array substrate and the method for manufacturing the same, the problem of short circuit of the pixel electrode and the public electrodes caused by material residue of the pixel electrode can be solved, and the qualified rate is improved.

Owner:BOE TECH GRP CO LTD

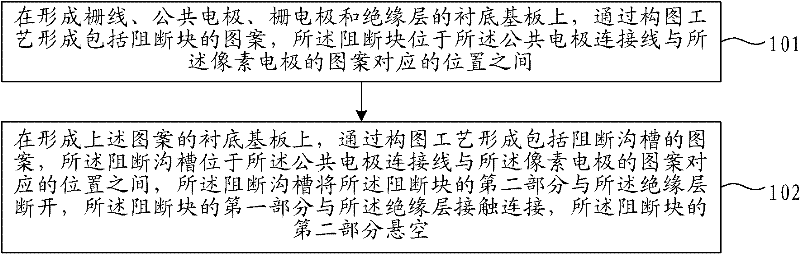

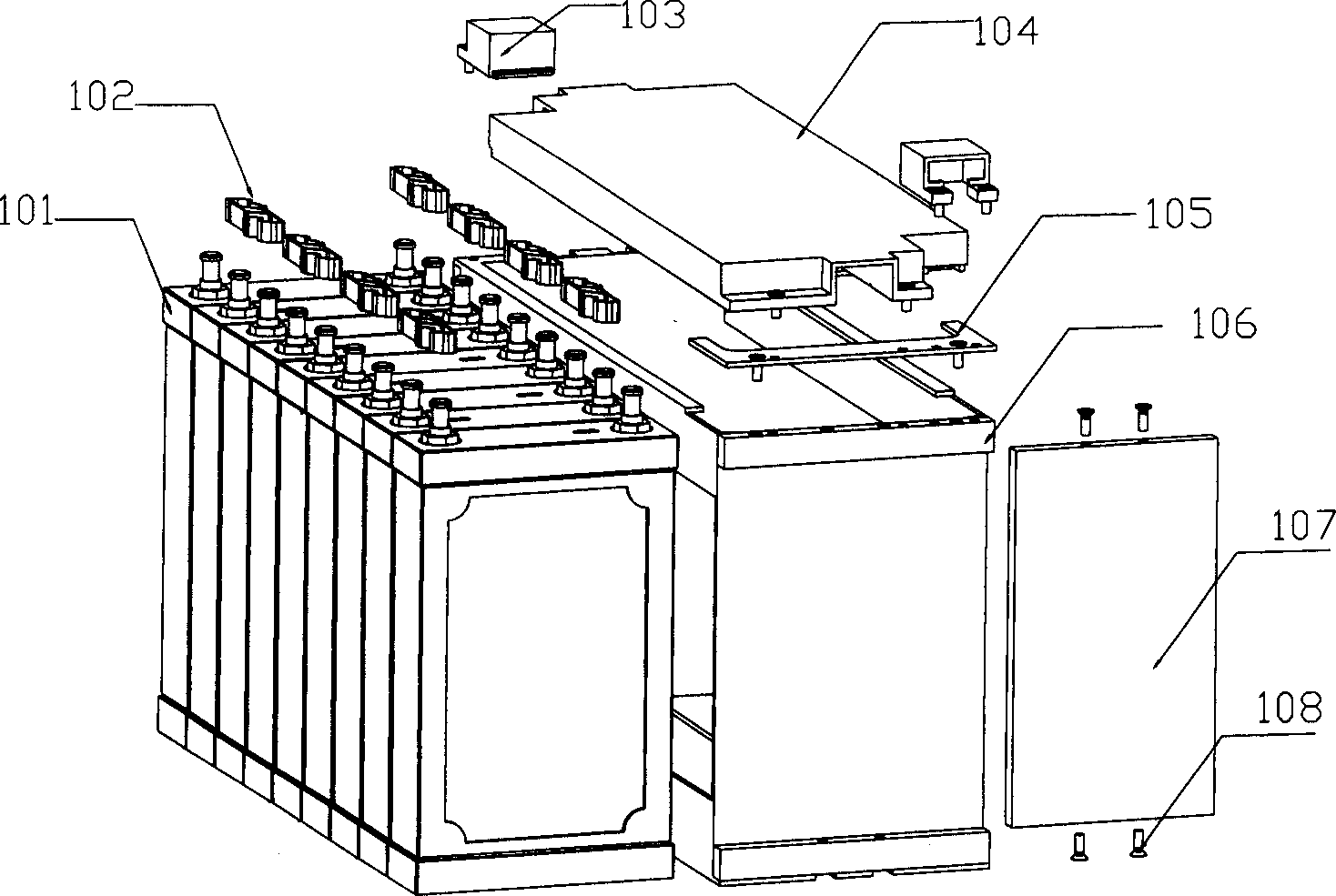

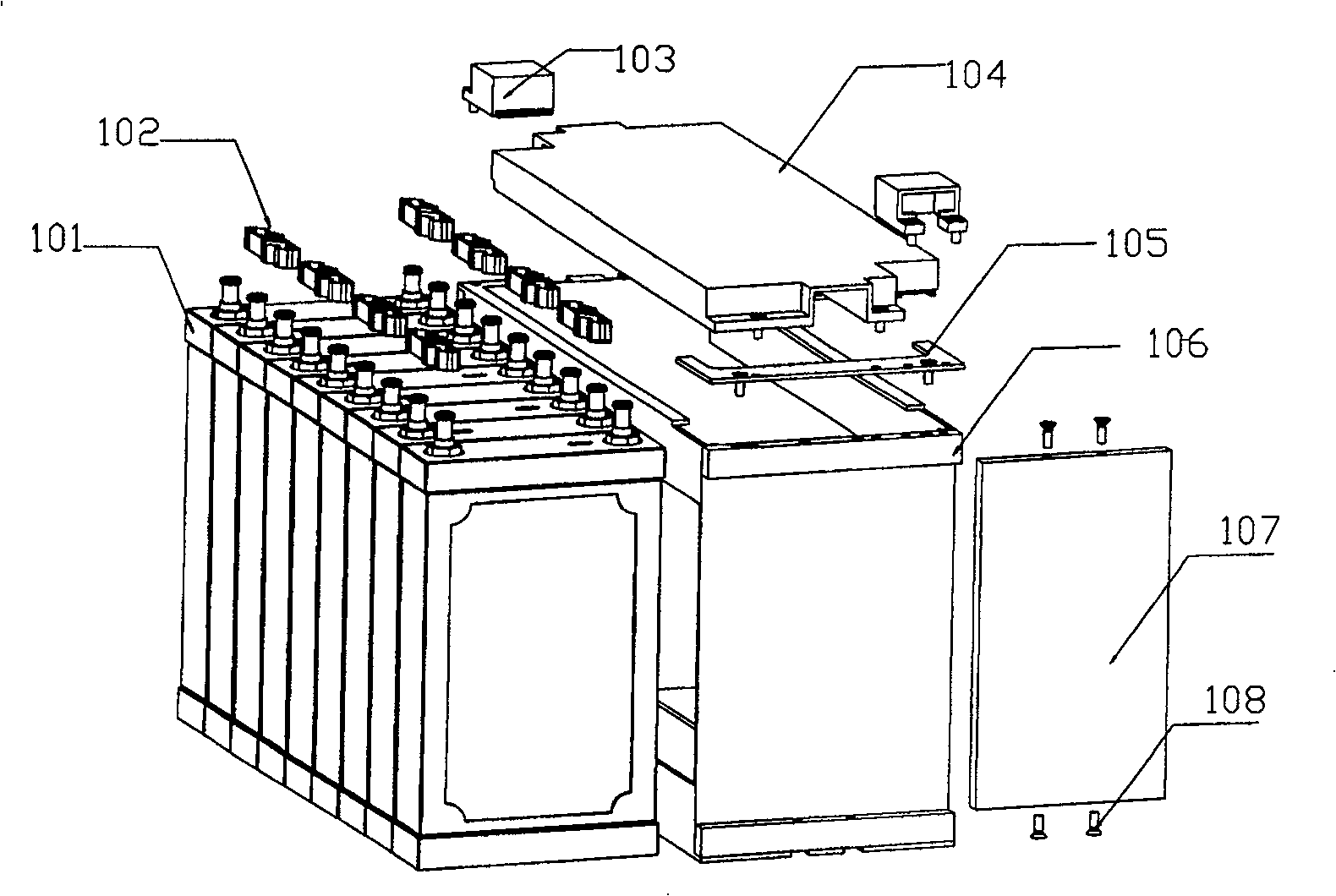

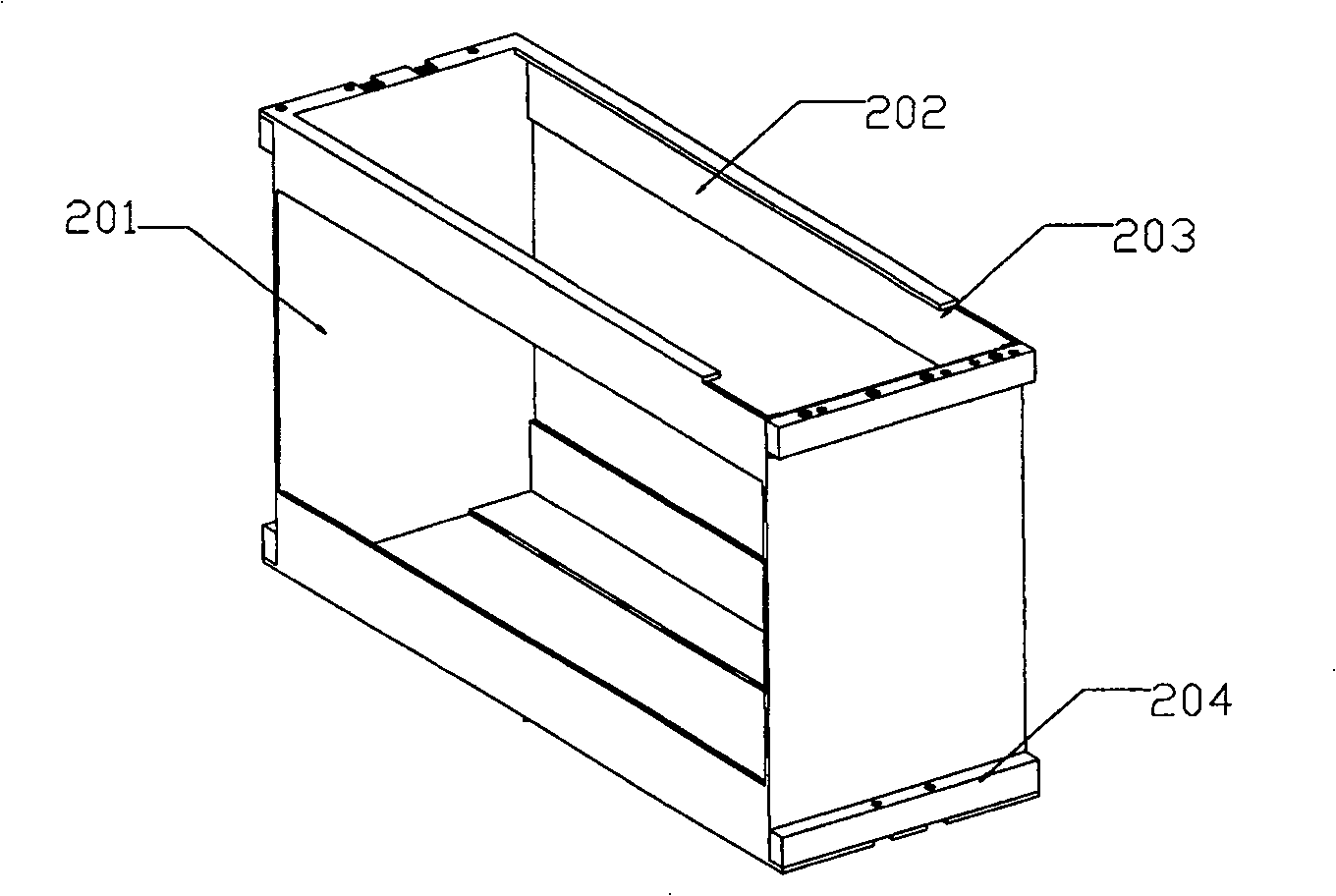

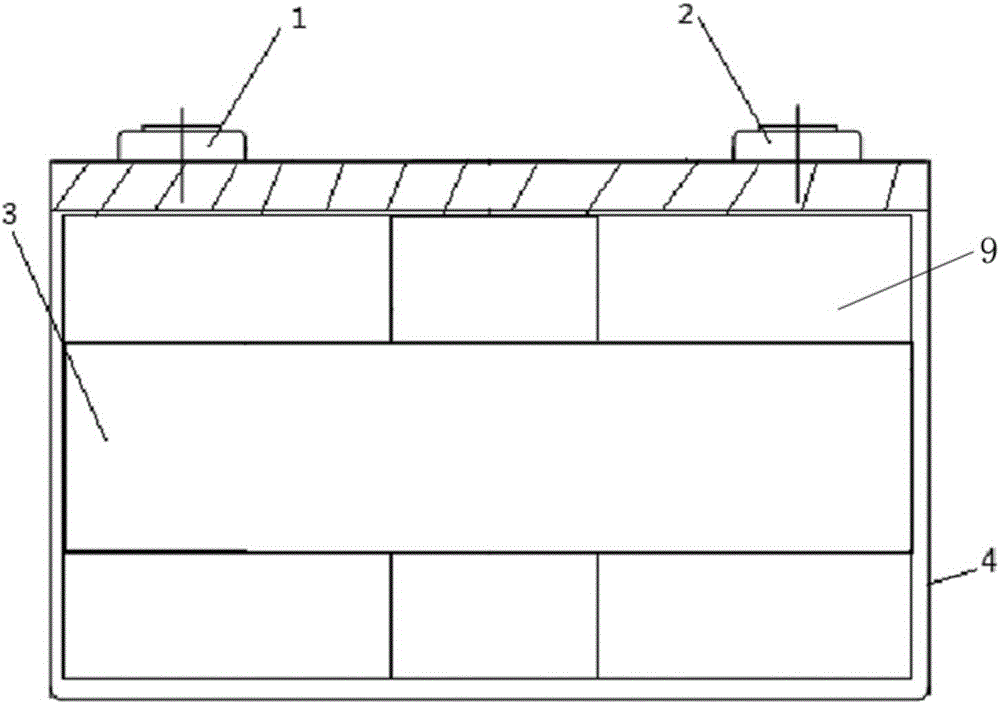

Battery pack of electric vehicle

ActiveCN1881654APole short circuitWill not short circuitCell lids/coversPropulsion by batteries/cellsBatch productionElectric vehicle

The invention relates to a battery pack of electric vehicle, which comprises a group of batteries and a box for containing said batteries, wherein said box has two pole protective sleeves made from insulated material at the positive and negative poles of battery. The invention uses pole protective sleeve to protect the poles of battery, to avoid short circuit of poles in accidence; in addition, the invention also comprises a connecting plate protective chamber, a voltage sampling wire channel, a temperature sensor compression block, a wire protective channel, and a seal compression bar, to improve efficiency and save cost in batch production. The invention can protect pole effectively, fix and protect the voltage sampling and temperature sampling wire, to simplify and structure and save cost.

Owner:BYD CO LTD

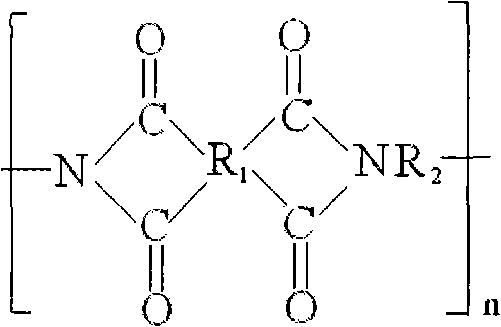

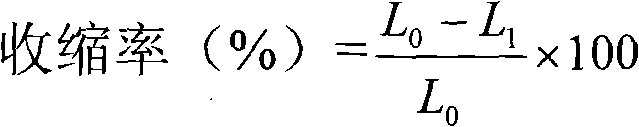

Battery separator and preparation method thereof

ActiveCN101355143AGood high temperature performanceImprove mechanical propertiesCell component detailsLithiumSubstance use

The invention provides a diaphragm for a battery, comprising a base material. The base material comprises through holes, wherein the base material contains polyimide and additives, and the additives are inorganic crystal whiskers and / or orthosilicate ester. The diaphragm prepared by the invention has excellent high-temperature performance, the heat shrinking property of the diaphragm is below 1.1 percent below 400 DEG C, and no cracking phenomenon occurs below 400 DEG C. The mechanical property of the diaphragm is excellent, the tensile-strength of the diaphragm is above 100 Mpa, while the tensile-strength of the diaphragm prepared by the prior art is only 90 Mpa. In addition, perforating substances used by the invention can effectively adjust the average diameter of a hole of the diaphragm within a better range of between 10 and 100 nanometers, thereby guaranteeing the smooth passing of lithium irons in the battery using the diaphragm, reducing the internal resistance of the battery, and having no short circuit.

Owner:BYD CO LTD

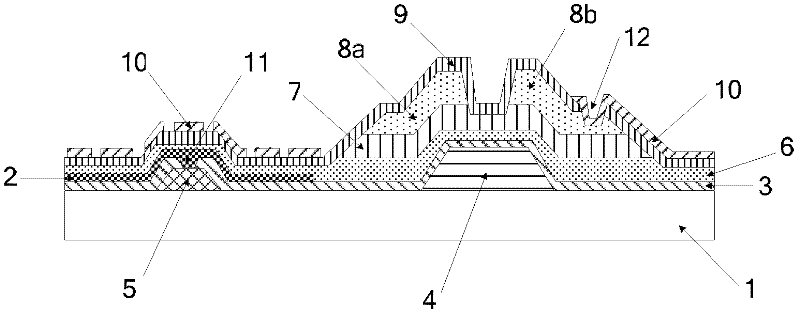

Display panel and display apparatus

Embodiments of the invention provide a display panel and a display apparatus. The display panel comprises a substrate, a first film layer, a first metal wire, and a bridge crossing metal wire, whereinthe first film layer is positioned on the substrate; the first film layer has an opening, and the opening comprises a bottom surface and a side wall; the upper surface, the side wall and the bottom surface, far from one side of the substrate, of the first film layer form a stage; the first metal wire is arranged on the upper surface of the first film layer and in the opening; the stage where thefirst metal wire is located is disconnected; the first end of the bridge crossing metal wire is electrically connected with a first trace wire through a via hole which runs through an insulating layer; and the second end of the bridge crossing metal wire is electrically connected with a second trace wire. By virtue of the abovementioned design, the stage where the first metal wire is located is disconnected, so that short circuit of the first metal wire is not caused by non-even photoresist thickness in the stage in the first metal wire manufacturing process through a patterning process, or bymetal residue in the stage after the patterning process is completed.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

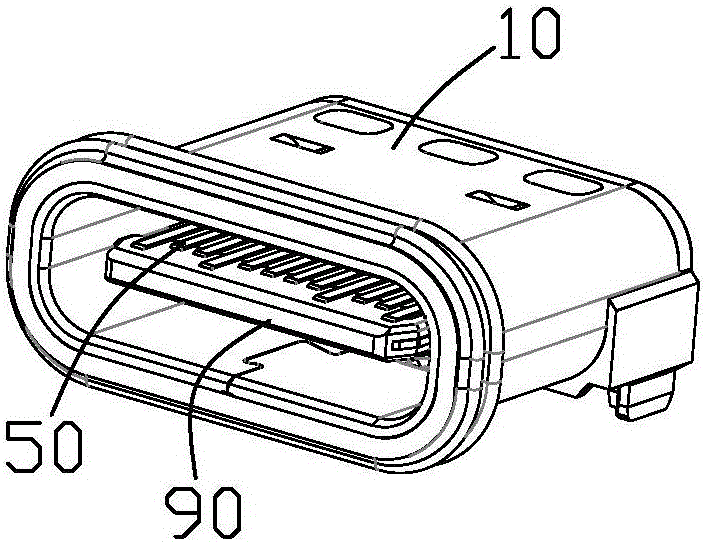

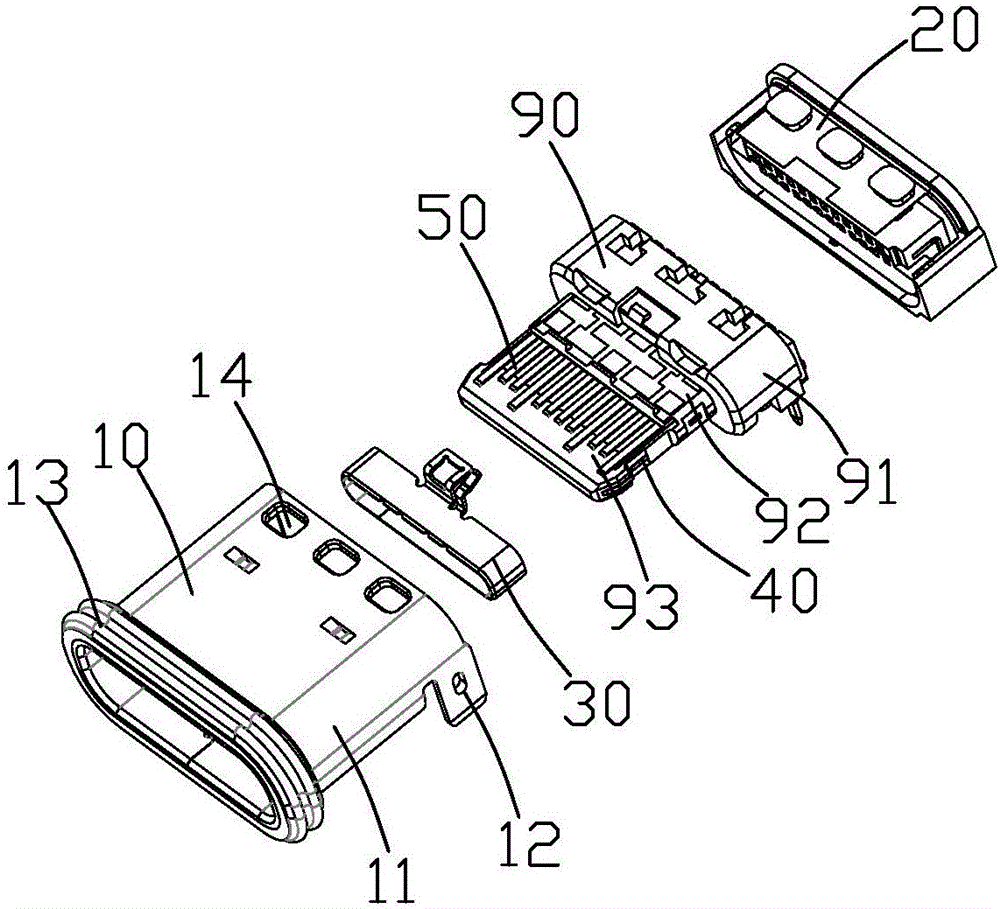

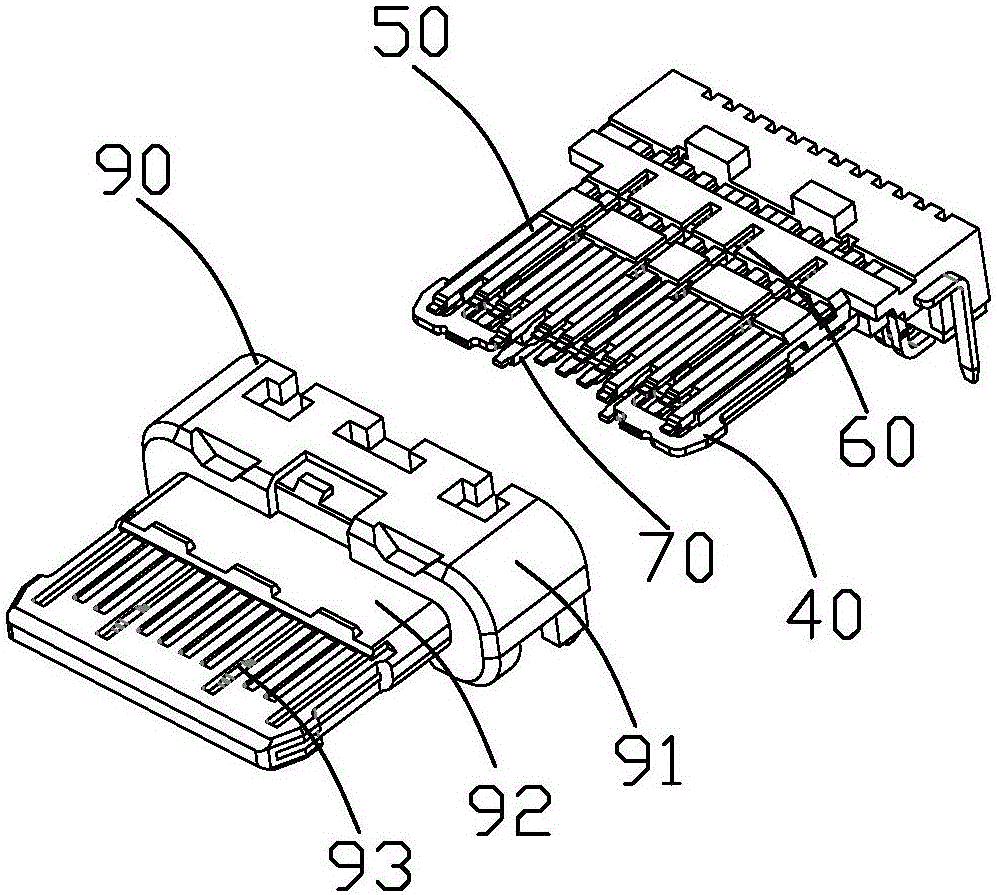

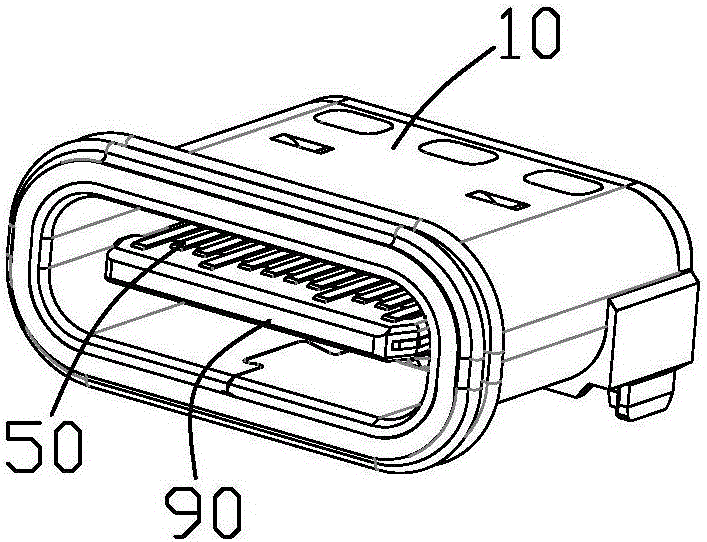

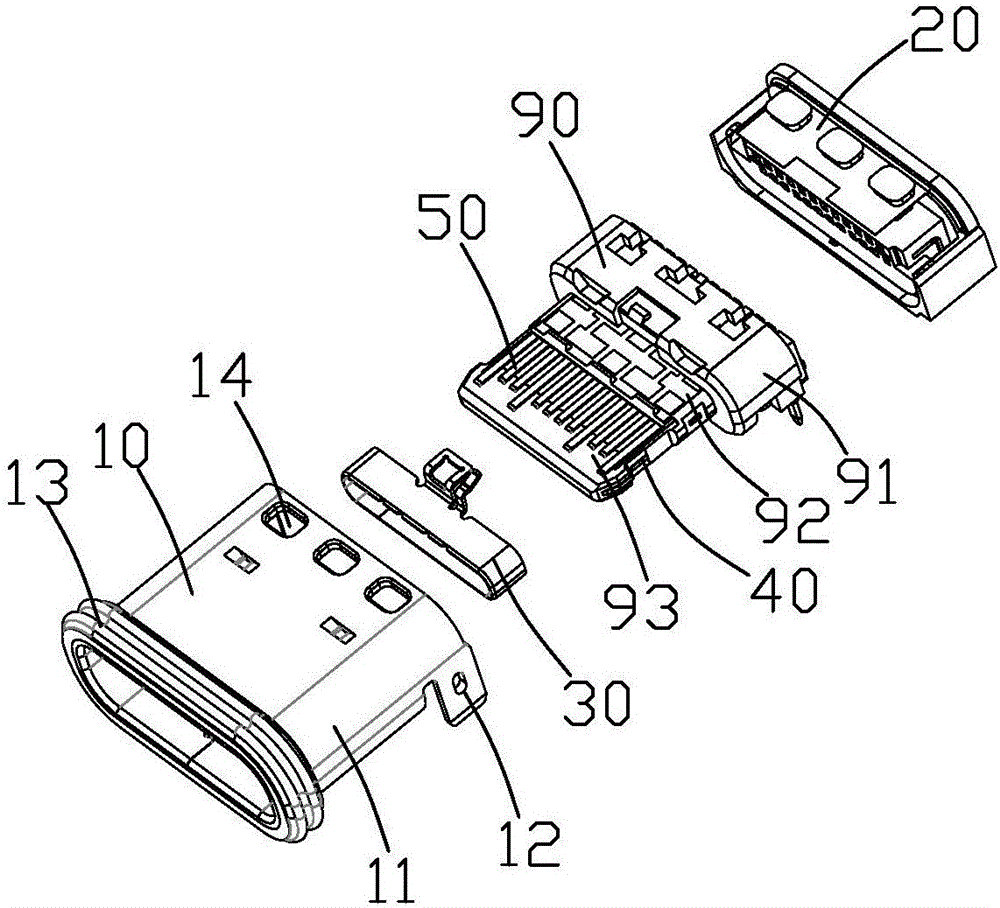

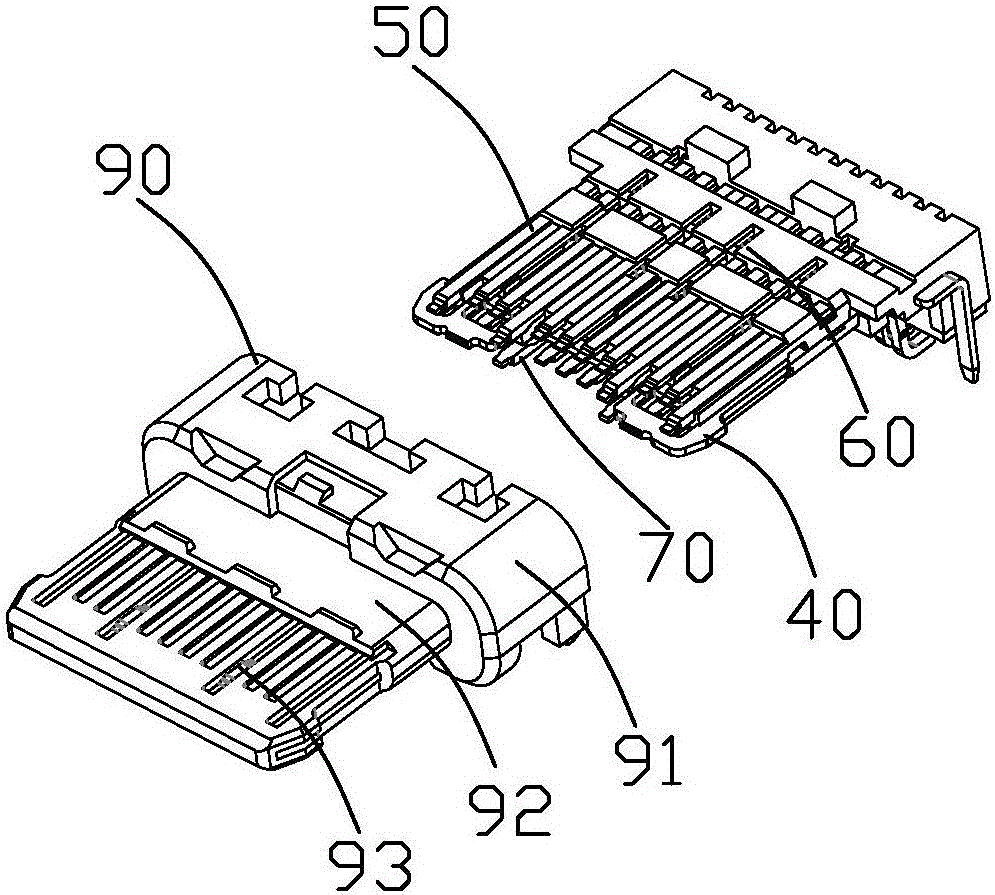

High-current USB Type C socket and manufacturing method thereof

ActiveCN106025638ALower impedanceEnhanced current flowSecuring/insulating coupling contact membersCoupling contact membersUSBHigh current

The invention relates to a high-current Type C socket, which comprises a metal medium plate, a first terminal group, a second terminal group and an insulating body, wherein the metal medium plate is provided with a main body portion, the first terminal group and the second terminal group are respectively located at the upper side and the lower side of the metal medium plate in a symmetrical manner, and the first terminal group, the second terminal group and the metal medium plate are molded into an integral whole by the insulating body. The first terminal group and the second terminal group respectively comprise two first grounding terminals, two second grounding terminals, a plurality of first signal terminals, two first power supply terminals, a plurality of second signal terminals and two second power supply terminals, wherein the two first grounding terminals and the two second grounding terminals are located at the outmost side, the plurality of first signal terminals and the two first power supply terminals are located between the two first grounding terminals, the plurality of second signal terminals and the two second power supply terminals are located between the two second grounding terminals, the thickness of the first power supply terminals and the second power supply terminals is greater than the thickness of the first signal terminals and the second signal terminals, and the main body portion of the metal medium plate is provided with strip-shaped holes at the positions corresponding to the first power supply terminals and the second power supply terminals. The high-current USB Type C socket can effectively support high-current charging.

Owner:SHENZHEN EVERWIN PRECISION TECH

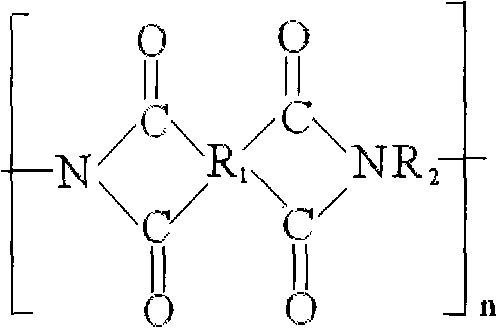

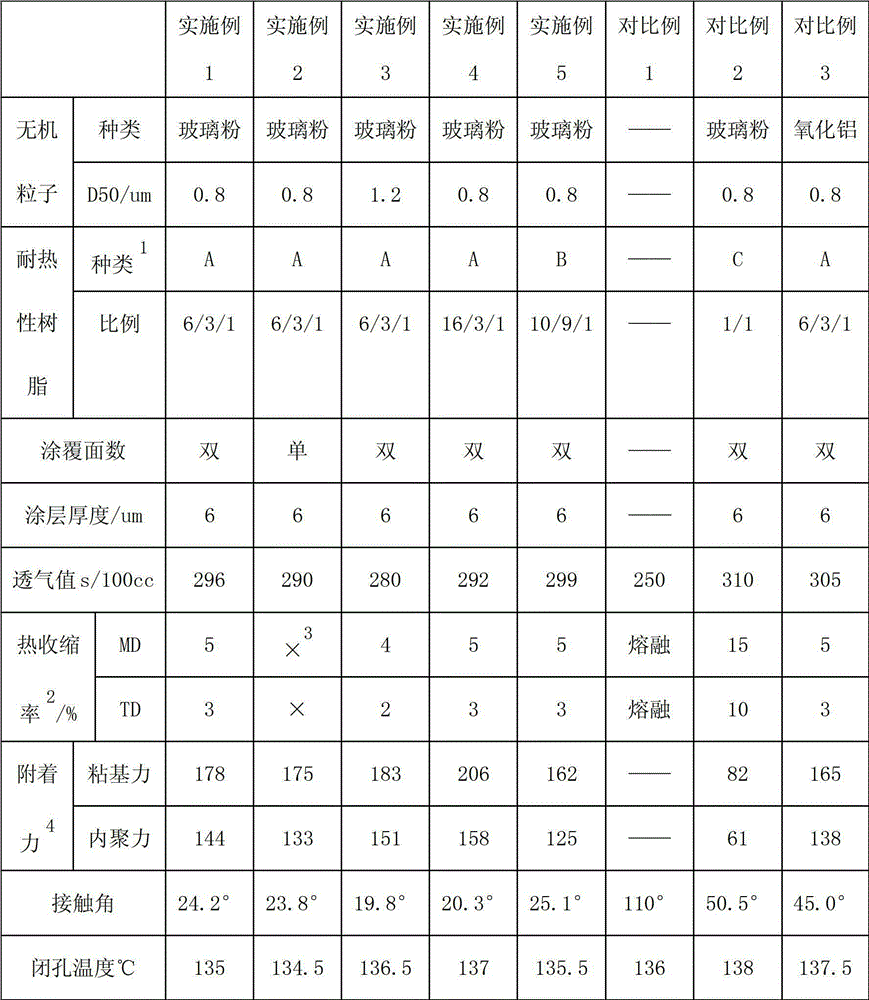

Coating composite for lithium ion secondary battery membrane and method for manufacturing membrane

ActiveCN102942831AHigh temperature resistantLow densityCell seperators/membranes/diaphragms/spacersSecondary cellsCoated surfaceLithium

The invention discloses a coating composite for a lithium ion secondary battery membrane and a method for manufacturing the membrane. The coating composite comprises heat resistant resins and inorganic non-conducting insulation particles, molecular chains of the heat resistant resins comprise oleophylic structural units, hydrophilic structural units and functional group structural units, and a thermal decomposition temperature is larger than 250 DEG C. The inorganic non-conducting insulation particles have the advantages of being high temperature resistant, low in density, rigidity and water absorption and the like; composite micro porous membranes prepared through the coating composite has the advantages of being low in hole closing temperature, high in membrane breaking temperature, low in thermal shrinkage rate, high in combining force between a heat resistant coating and a substrate, good in wettability of the heat resistant coating surface and the like simultaneously; and the membrane used for manufacturing a lithium ion secondary battery has good comprehensive properties and reliable safety performances.

Owner:河南惠强新能源材料科技股份有限公司

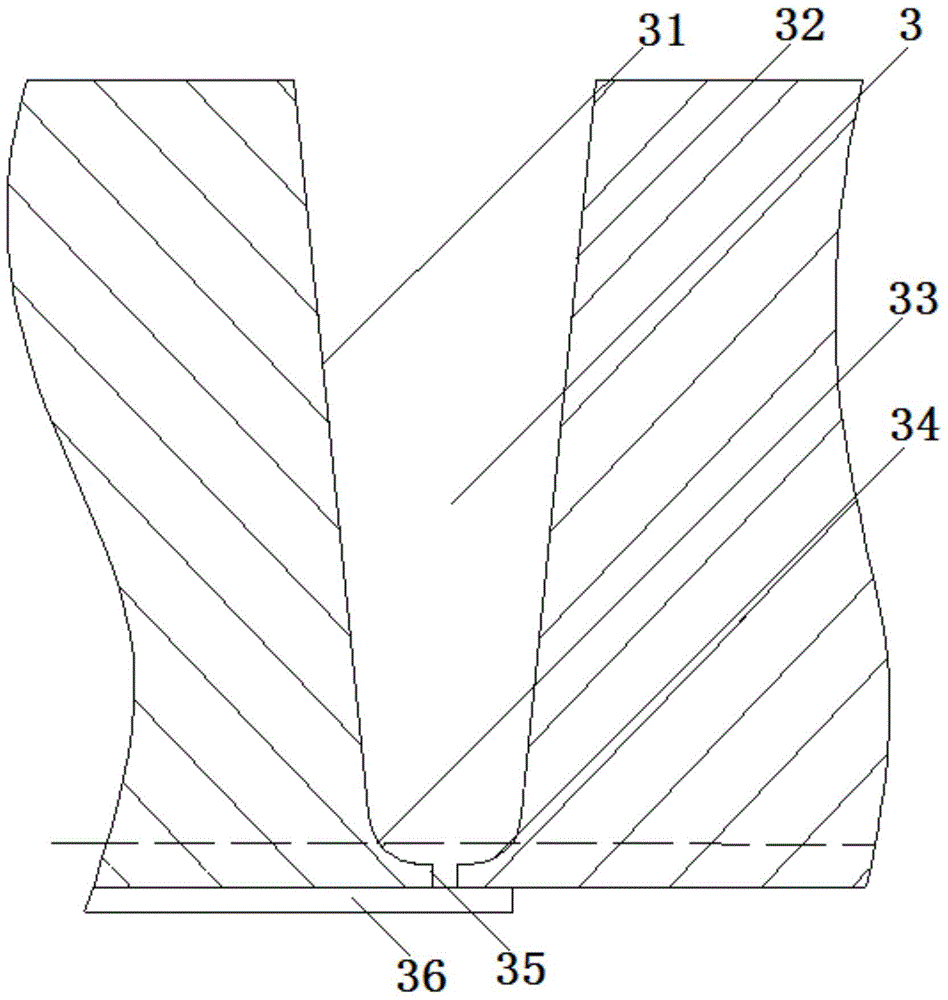

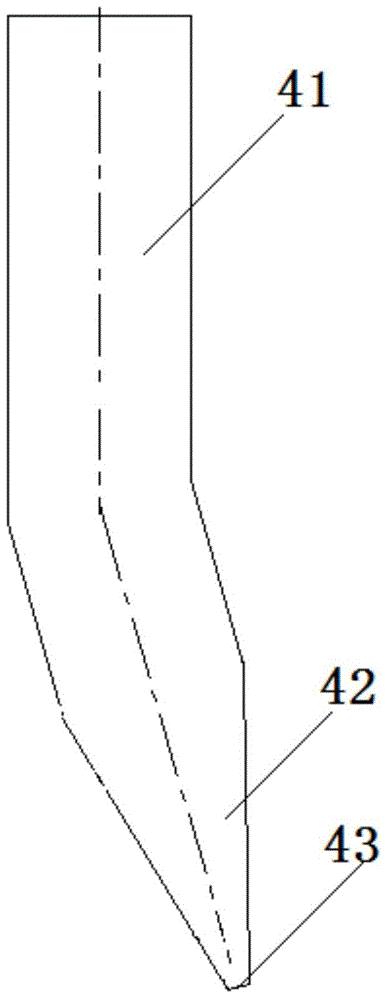

Full-position connecting pipe and safety end circular seam welding method achieved through tungsten electrode inert gas arc welding

ActiveCN104084678AImprove welding efficiencyReduce welding distortionArc welding apparatusWorkpiece edge portionsSpin weldingArchitectural engineering

The invention discloses a full-position connecting pipe and safety end circular seam welding method achieved through tungsten electrode inert gas arc welding. According to the method, nickel base alloy serves as an isolating layer to carry out machining on a connecting pipe and a safety end so that a welding groove can be formed by the connecting pipe and the safety end during assembling, and the welding groove is welded. A plurality of weld beads are welded during welding, the bottom end of a part to be welded is arced during welding, spin welding is carried out along one side of the part to be welded to the top end of the part to be welded, arcing is stopped, the bottom end of the part to be welded is arced again, spin welding is carried out along the other side of the part to be welded to the top end of the part to be welded, and arcing is stopped. When the welding groove is a double-faced U-shaped narrow gap groove, an outer groove is welded but not completely welded, back chipping and complete welding are carried out on an inner groove, and then complete welding is carried out on the outer groove. When the welding groove is a single-faced narrow gap groove, the groove is completely welded, a cushion plate is removed, and back chipping is carried out.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

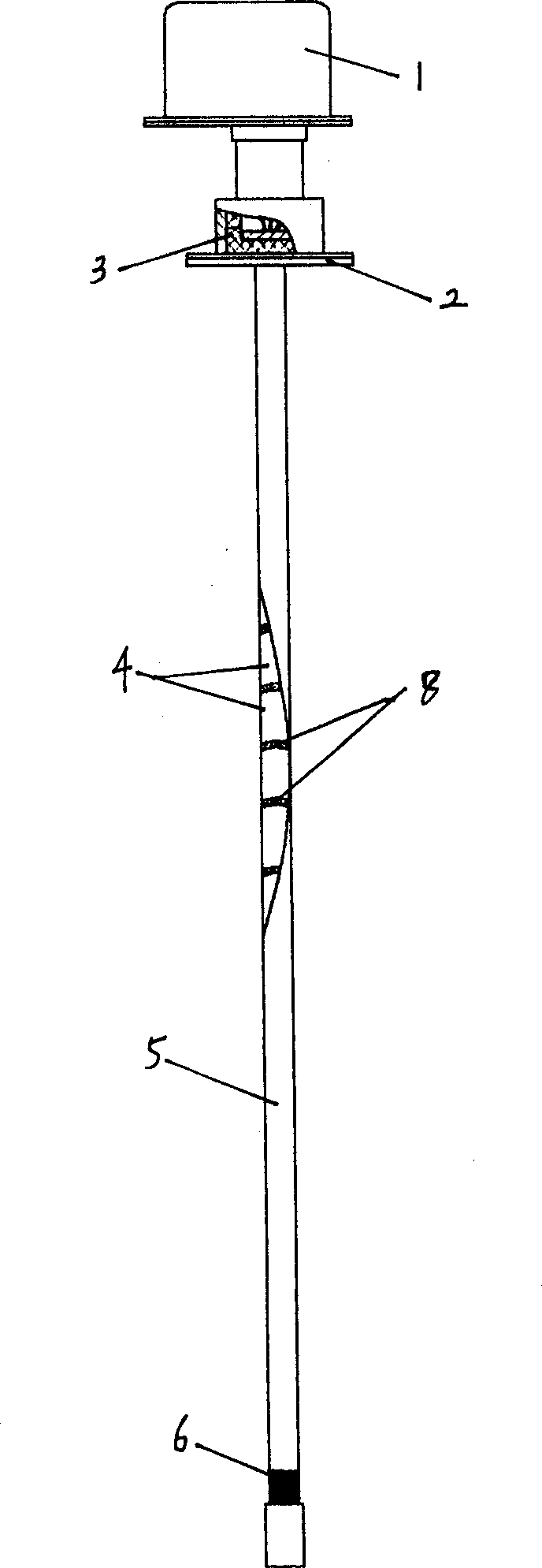

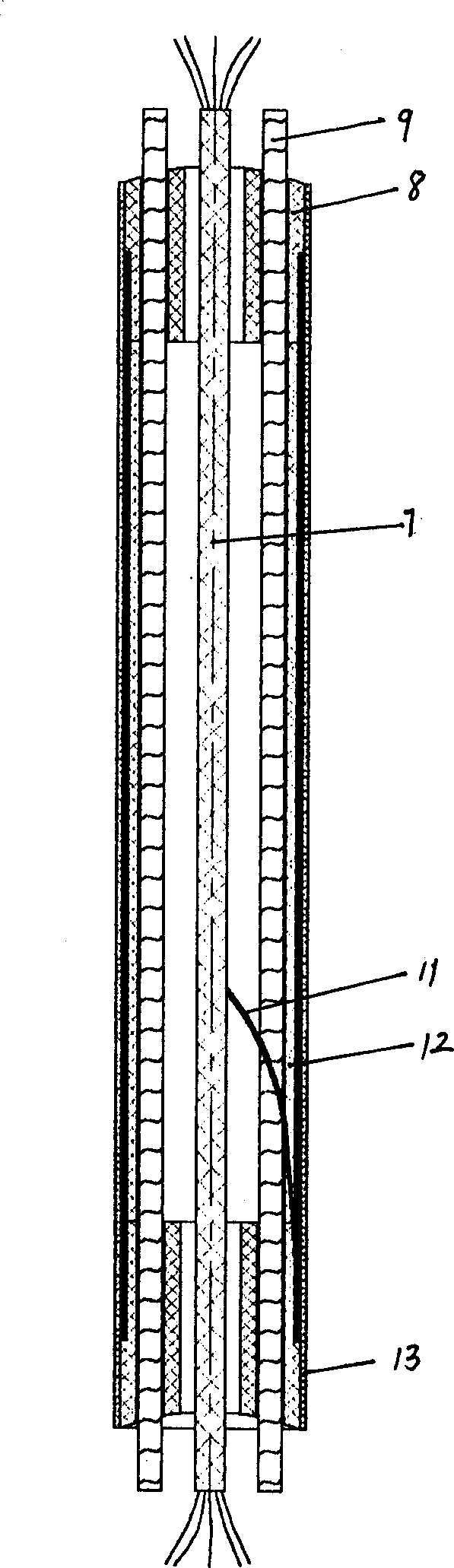

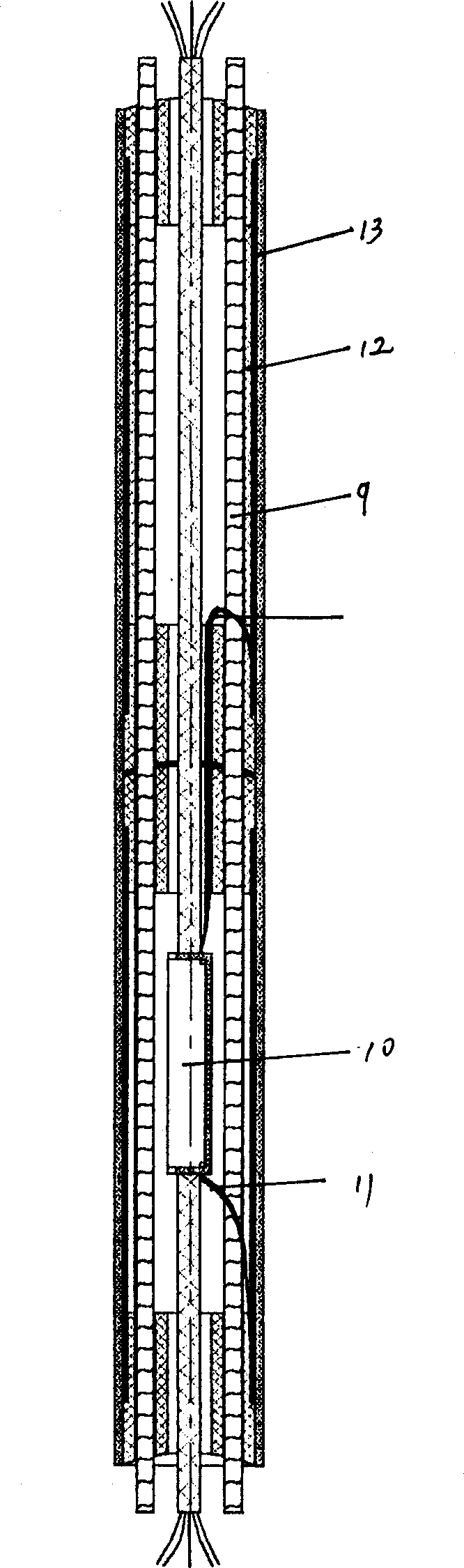

Multiphase material level sensor

InactiveCN1375435AAccurate measurementReal-time measurementLarge containersLevel indicators by physical variable measurementLevel sensorOil water

The multiphase material level sensor can be used not only for measuring oil-water interface position, but also for accurately measuring material levels of crude oil, sewage and mud-sand. Said sensor has a capacitor transmitter and a connection body, which is technically characterized by that the outer side of said connection body is equipped with an internal insulating cover, and the outer side of said insulating cover is equipped with multisectional tubular metal branch electrodes, between two adjacent branch electrodes an insulating layer is set, outer side of every branch electrode is equipped with an external insulating cover, internal cavity of the connection body is equipped with cable, and the branch electrode is connected with the capacitor transmitter electrically by means of cable.

Owner:威海万成电子科技有限公司

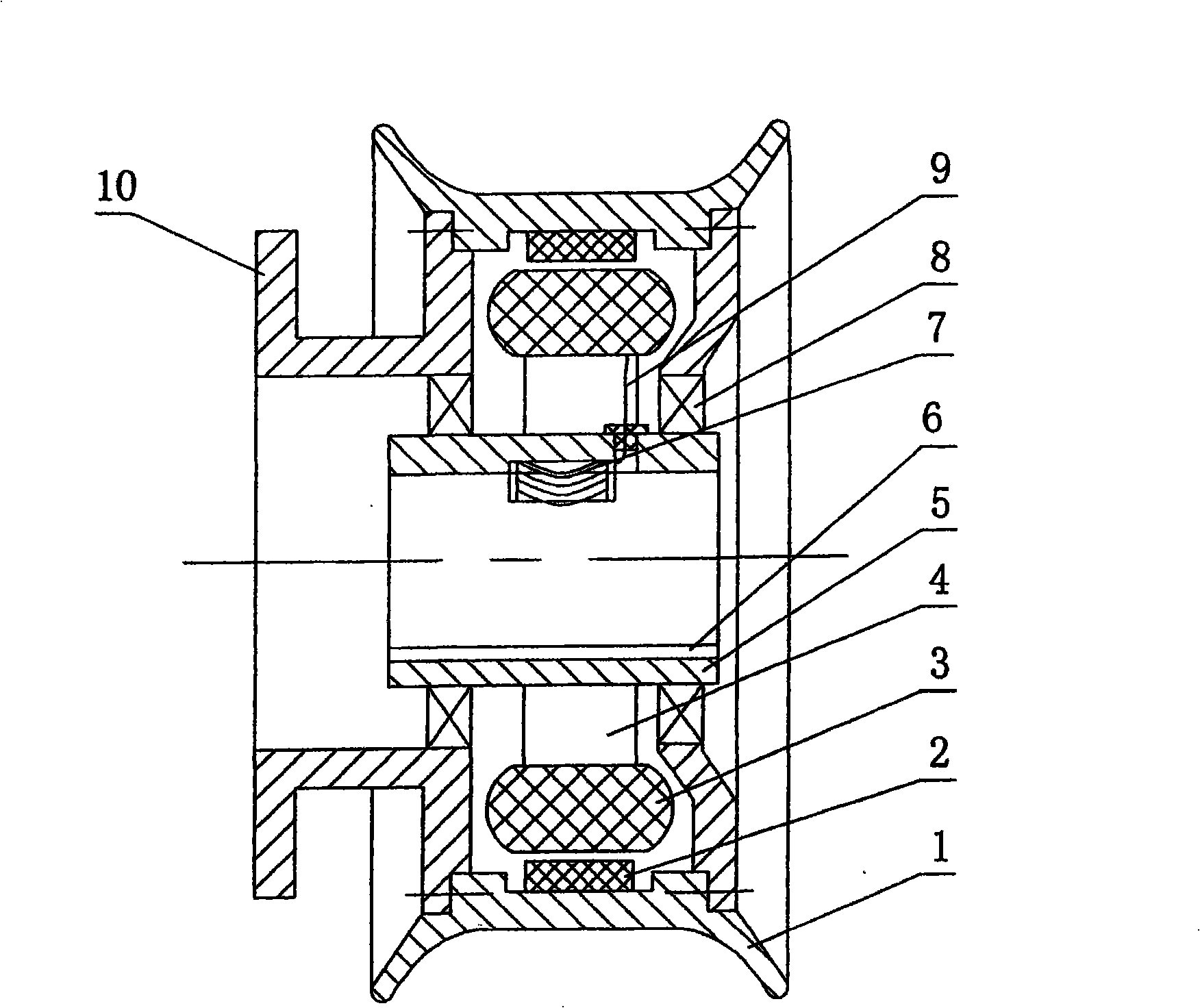

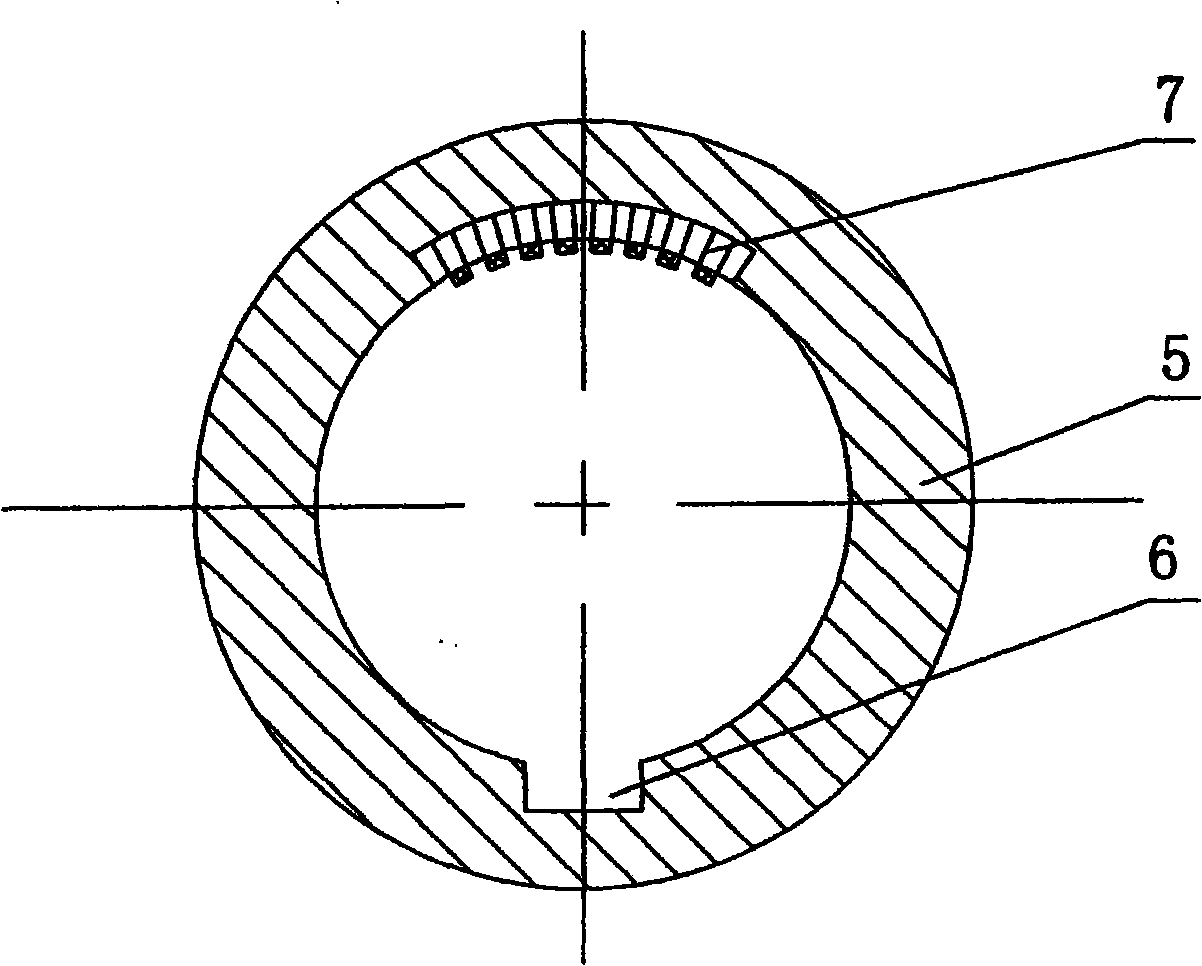

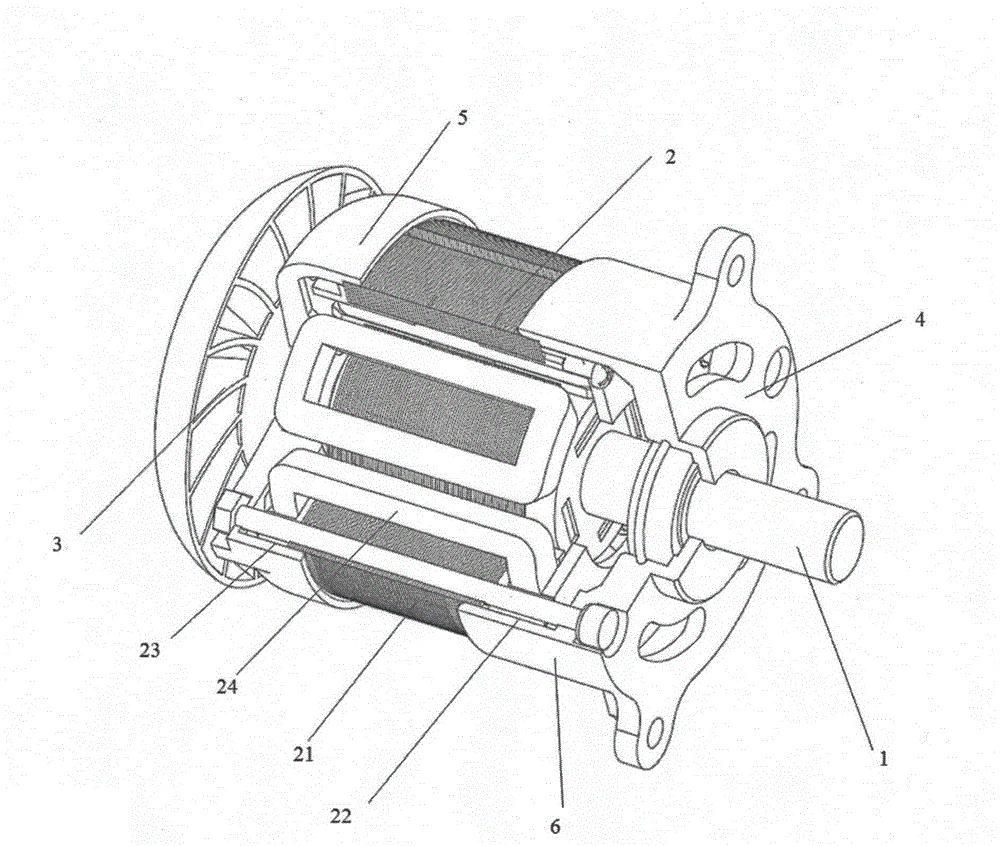

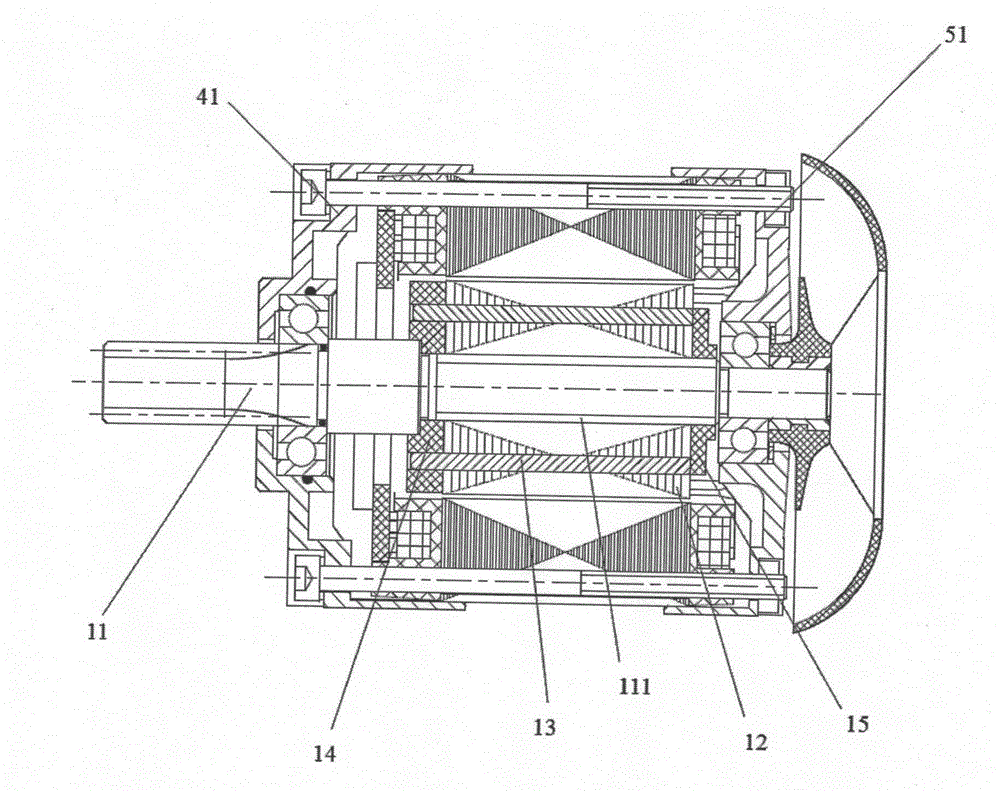

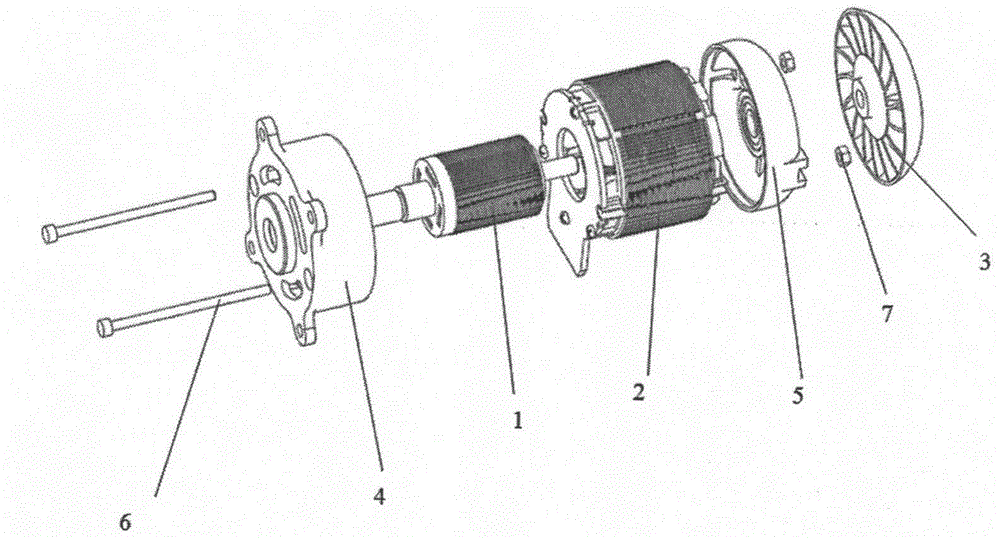

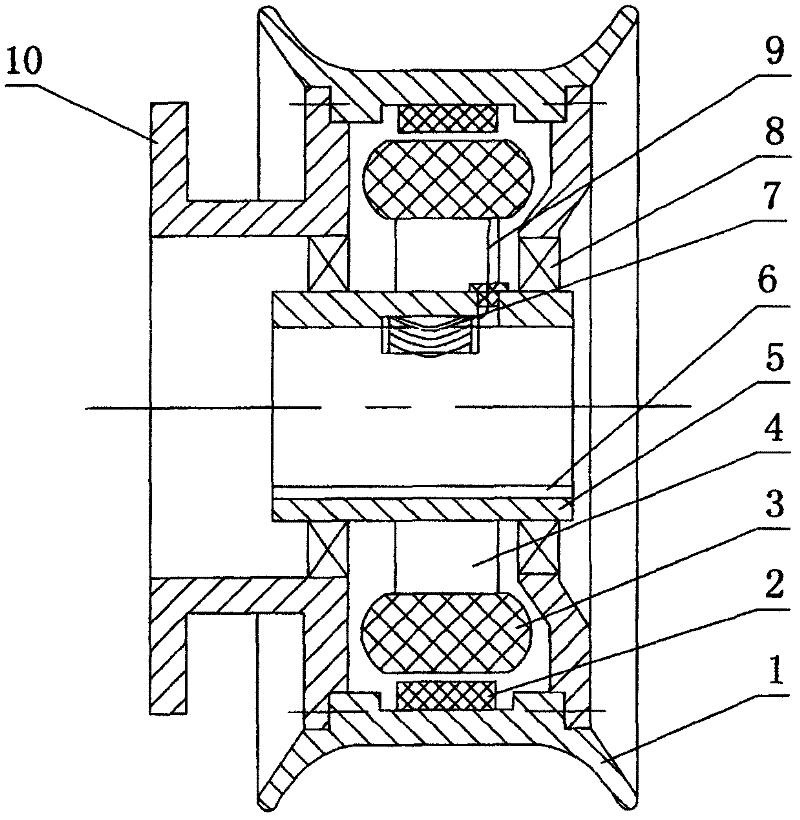

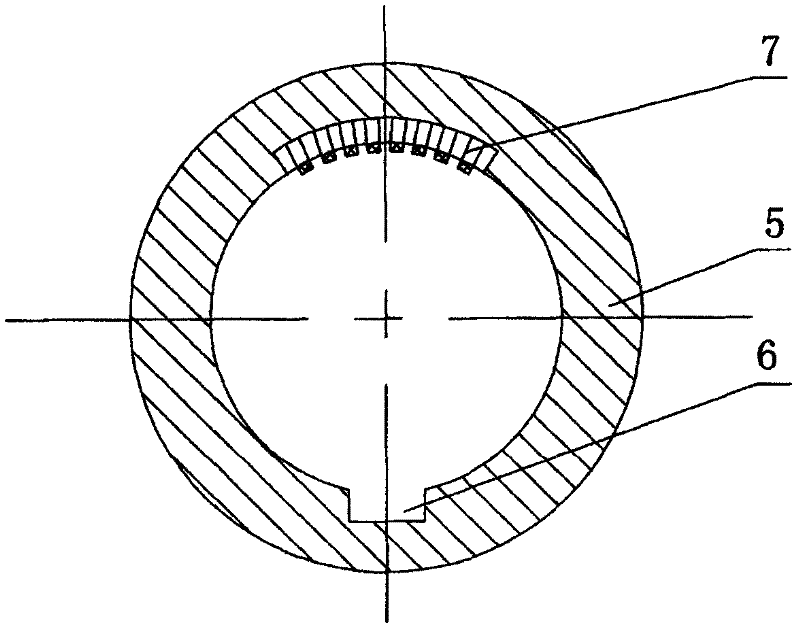

Insert shaft type hub electric motor and electric automobile

ActiveCN101257233AEasy loading and unloadingSuitable for useElectric propulsion mountingElectric machinesElectricityDrive wheel

The invention relates to an inserting shaft type hub motor and an electric automobile using the motor. The inserting shaft type hub motor includes an axle sleeve, a stator is fixedly installed on the ektexine of the axle sleeve, bearings are respectively provided on both sides of the ektexine of the axle sleeve, a hub rotor is installed on the bearings, and a driving wheel is inserted and installed at the corresponding position of the axletree through the bearings. The inner wall of the axle sleeve is provided with key grooves run-through axial direction and first elastic electrically connecting terminals electrically connected with the motor coils, the axletree is correspondingly provided with keys matched with the key grooves and second elastic electrically connecting terminals electrically connected with the automobile controller, the first and second electrically connecting terminals are automatically electrically connected after the driving wheel is installed at the axletree, thereby the circuit connecting the motor rotor coil and the automobile controller allows the circuit connection to be simple and credibility, and allows the assemble and unassemble, use and maintaining of the hub motor and driving wheel on the electric automobile.

Owner:董建国

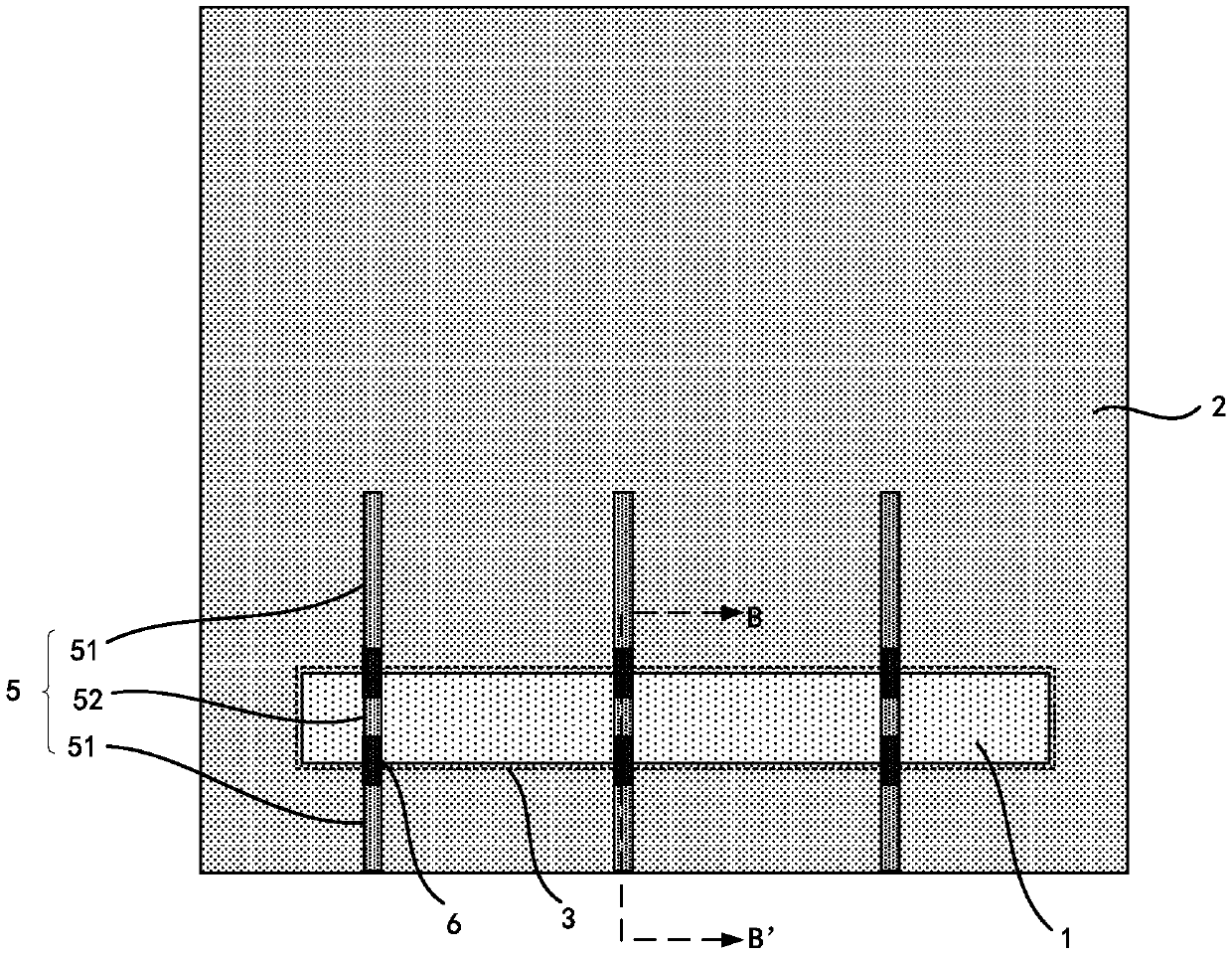

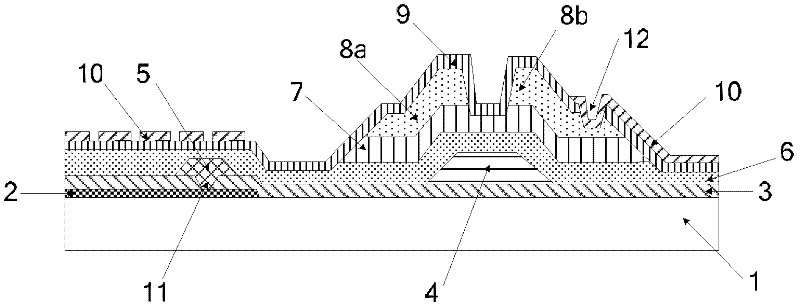

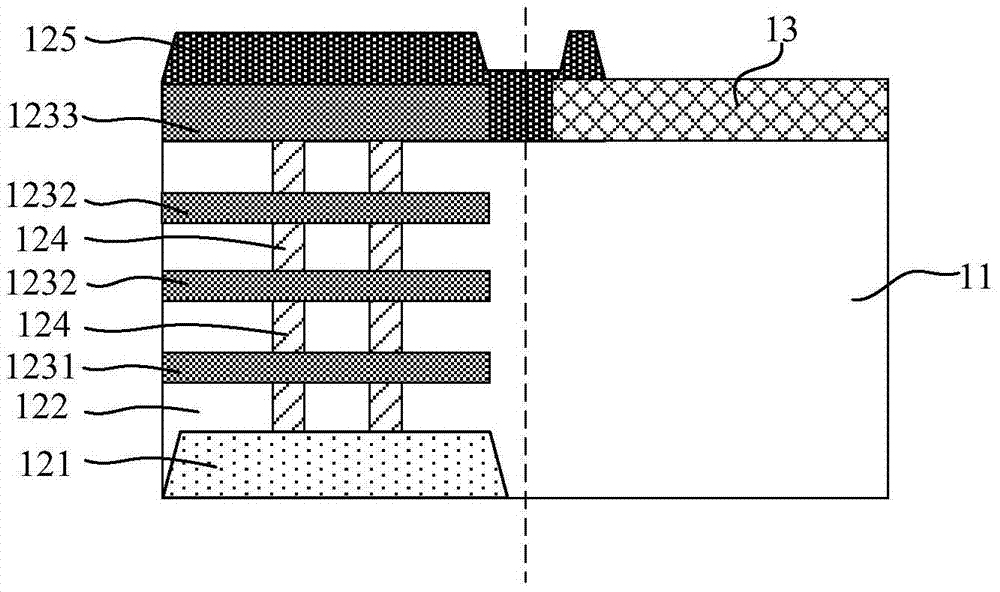

Array substrate and manufacturing method thereof as well as display equipment

ActiveCN102654703AWill not short circuitShorten the horizontal distanceSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsActive layer

The invention provides an array substrate, comprising a substrate, a common electrode and a pixel electrode which are sequentially formed on the substrate and are mutually insulated, a thin film transistor, a common electrode wire and an insulating layer, wherein the thin film transistor comprises a gate electrode, an active layer, a source electrode and a drain electrode; the drain electrode is electrically connected with the pixel electrode, the common electrode wire is arranged at the same layer of the gate electrode, the insulating layer is arranged between the gate electrode and the common electrode and is used for isolating the gate electrode from the common electrode, and the common electrode is connected with the common electrode wire by virtue of a through hole of the insulating layer. Accordingly, the invention provides a manufacturing method of the array substrate and display equipment adopting the array substrate. The array substrate disclosed by the invention can overcome the defect that the aperture ratio of unit pixel is lower in the prior art.

Owner:BOE TECH GRP CO LTD +1

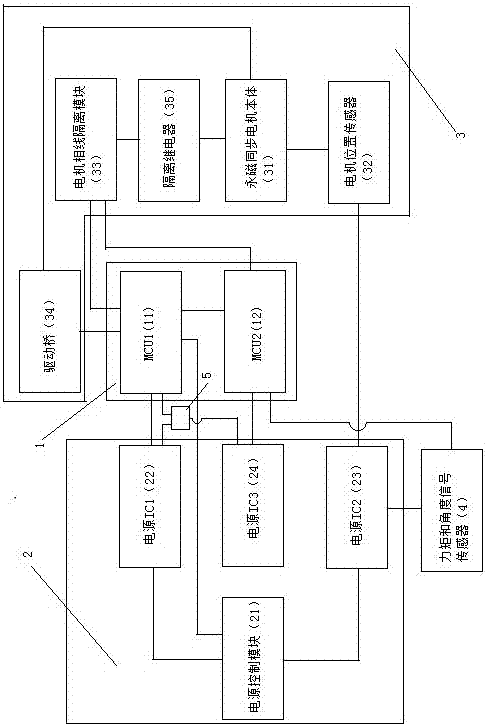

Brushless electric steering control unit and method based on functional safety design

ActiveCN106945720AGuaranteed reliabilityWill not short circuitElectrical steeringElectric machinePermanent magnet synchronous motor

The invention discloses a brushless electric steering control unit based on functional safety design. The brushless electric steering control unit comprises an EPS controller, a power redundancy module, a torque and angle signal sensor and a permanent magnet synchronous motor module. The power redundancy module comprises a power control module, a power source IC1, a power source IC2 and a power source IC3. The EPS controller comprises an MCU1 and an MCU2. The permanent magnet synchronous motor module comprises a permanent magnet synchronous motor body and a motor position sensor which are connected with each other. The power control module is connected with the power source IC1 and the power source IC2 at the same time. The power source IC1 is connected with the MCU1. The power source IC2 is connected with the torque and angle signal sensor and the motor position sensor at the same time. The power source IC3 is connected with the MCU2. The power redundancy module can continuously keep the working power sources of the EPS control module in the high-speed driving process of a vehicle under the condition that a rigid line IG signal or a CAN IG signal is lost, and an EPS can continuously provide the assistance to enable the vehicle to run safely.

Owner:浙江航驱汽车科技有限公司

High voltage power type lithium ion chargeable battery

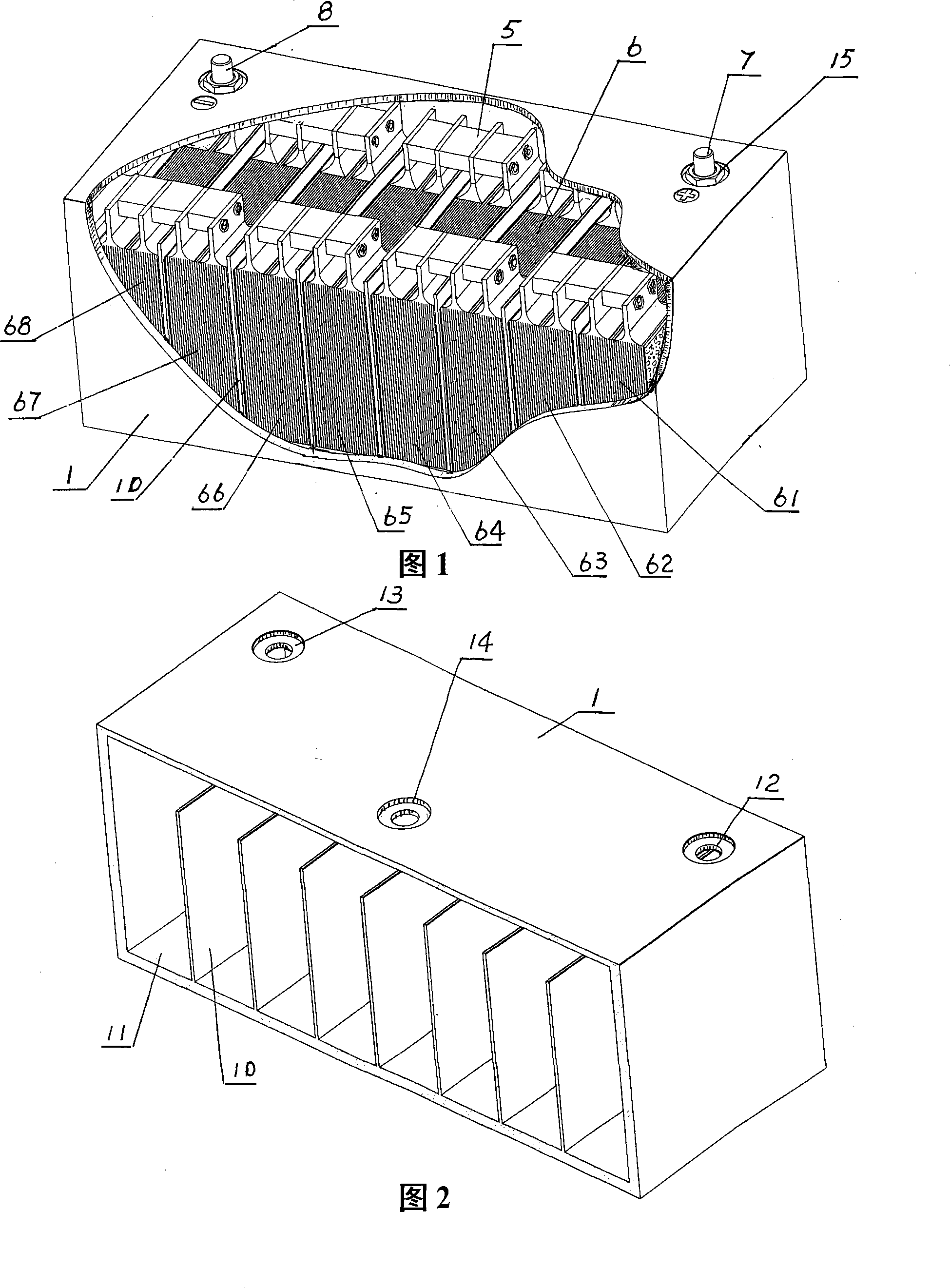

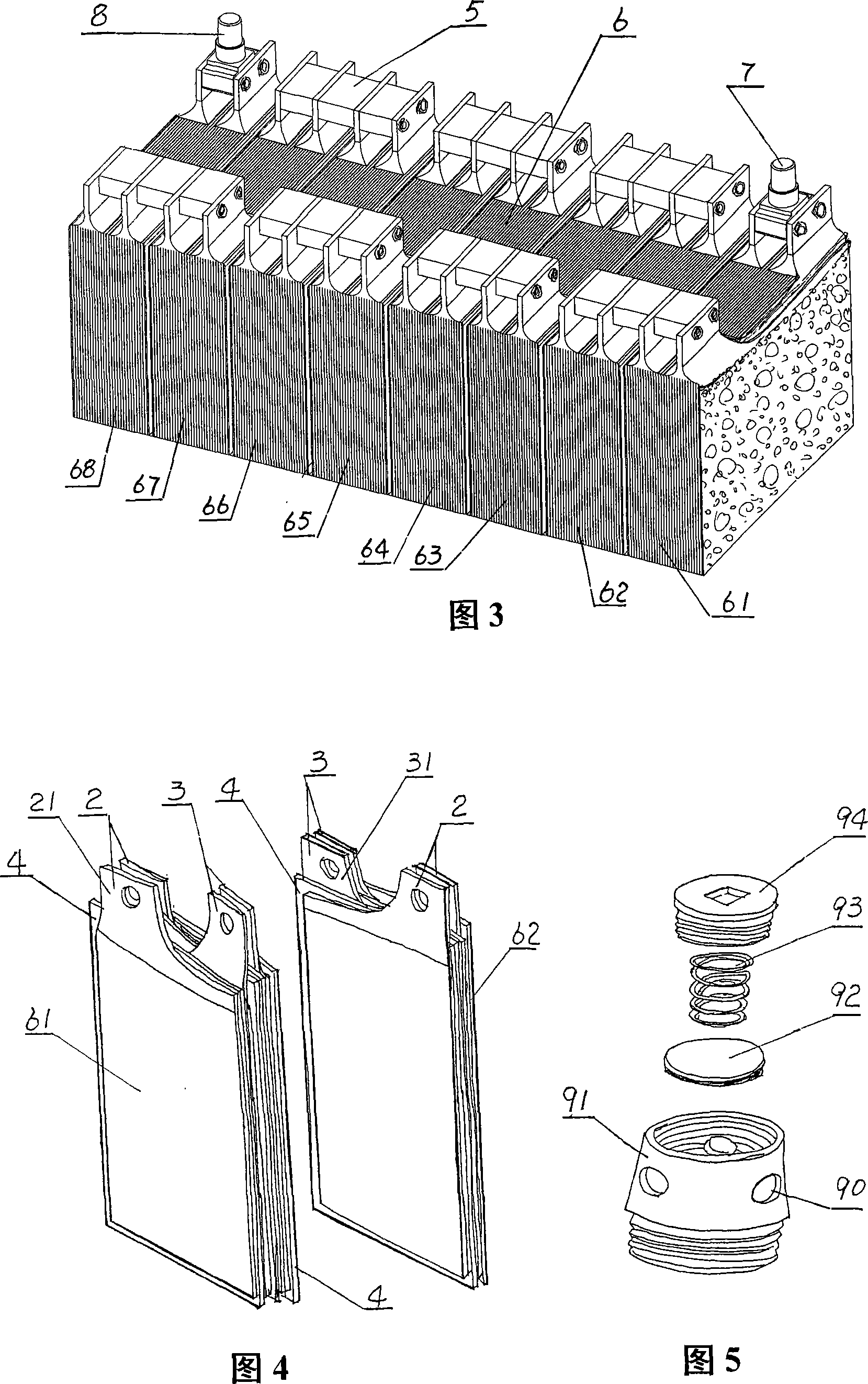

InactiveCN101141010ADesign scienceIngenious structureSmall-sized cells cases/jacketsVent arrangementsSodium-ion batteryEngineering

A high voltage dynamic lithium ion built-in battery is provided, which comprises a shell filled with electrolyte and at least two battery cells inside the shell. The positive and negative electrodes of each of the lithium ion battery cells are connected in series to form a battery cells body that will be wholly encapsulated into a shell. The invention is characterized in separately placing each of the said battery cells connected in series in each battery cell cabin. The invention is scientifically designed with refined and reasonable structure. Based on the characteristics of the invention, the said invention greatly improves its structure and lowers the possible damage due to the rise in temperature when using the battery. The structure can possibly increase the monomeric voltage of the lithium ion battery from 2.0V to hundreds of V, and brings better property of recharge cycles, meeting the requirement in various fields and under different loading conditions.

Owner:雷天电池技术有限公司

Chip protection ring, semiconductor chip, semiconductor wafer and packaging method

ActiveCN106898580AImprove protectionWill not short circuitSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipProtection ring

The invention provides a chip protection ring, a semiconductor chip, a semiconductor wafer and a packaging method. Through breaking a metal ring in the topmost layer of the protection ring near each bonding pad and reducing the size of a metal ring in the second topmost layer, a conductive plug in the topmost layer is not contacted with the metal ring in the second topmost layer and the rest below metal rings, the metal ring in the topmost layer is thus isolated and suspended, short circuit does not happen to bonding wires even if the bonding wires are contacted with the metal ring in the topmost layer in the case of packaging and bonding, and while short circuit between the bonding wires can be prevented, a protection role of the protection ring can still be ensured.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Large-current USB Type C type socket and manufacturing method thereof

ActiveCN106252932AAvoid short circuit problemsLower impedanceContact member manufacturingContact member assembly/disassemblyUSB

Provided is a large-current USB Type C type socket, which comprises a metal middle plate provided with a main body portion; a first terminal group and a second terminal group, which are symmetrically arranged at the upper and lower sides of the metal middle plate; and an insulation body for enabling the first and second terminal groups to be integrated with the metal middle plate. The first terminal group comprises two outermost first grounding terminals, a plurality of first signal terminals, which are arranged between the two first grounding terminals, and two first power terminals; and a second terminal group comprises two outermost second grounding terminals, a plurality of second signal terminals, which are arranged between the two second grounding terminals, and two second power terminals. The thickness of the first power terminal and the thickness of the second power terminal are larger than the thickness of the first signal terminal and the thickness of the second signal terminal respectively; the main body portion of the metal middle plate is provided with strip holes in the positions corresponding to the first power terminals and the second power terminals respectively. The large-current USB Type C type socket can effectively support large-current charging.

Owner:SHENZHEN EVERWIN PRECISION TECH

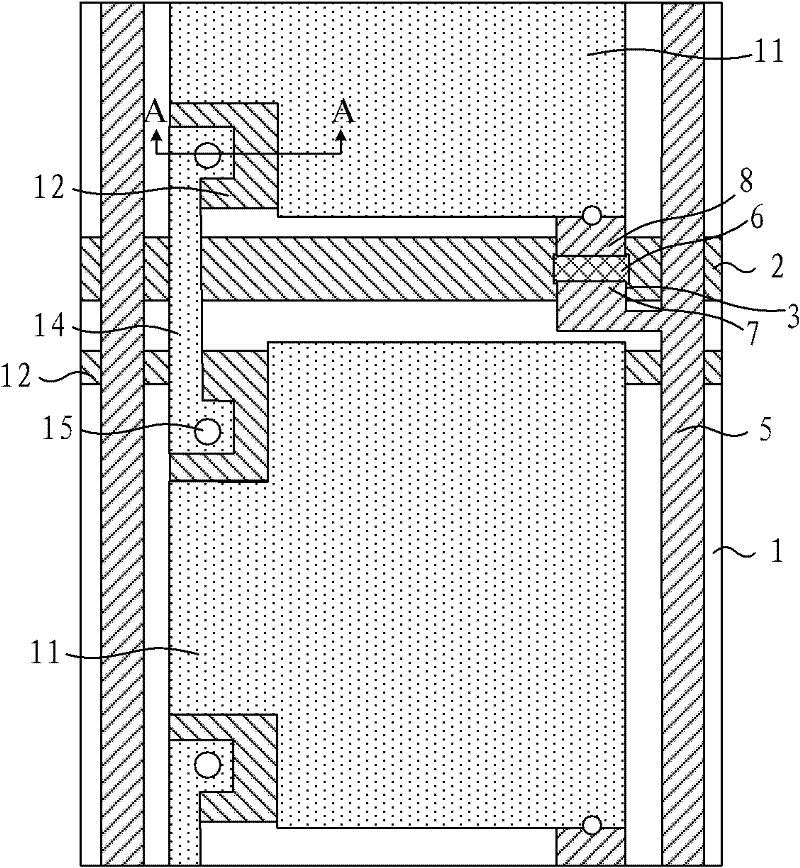

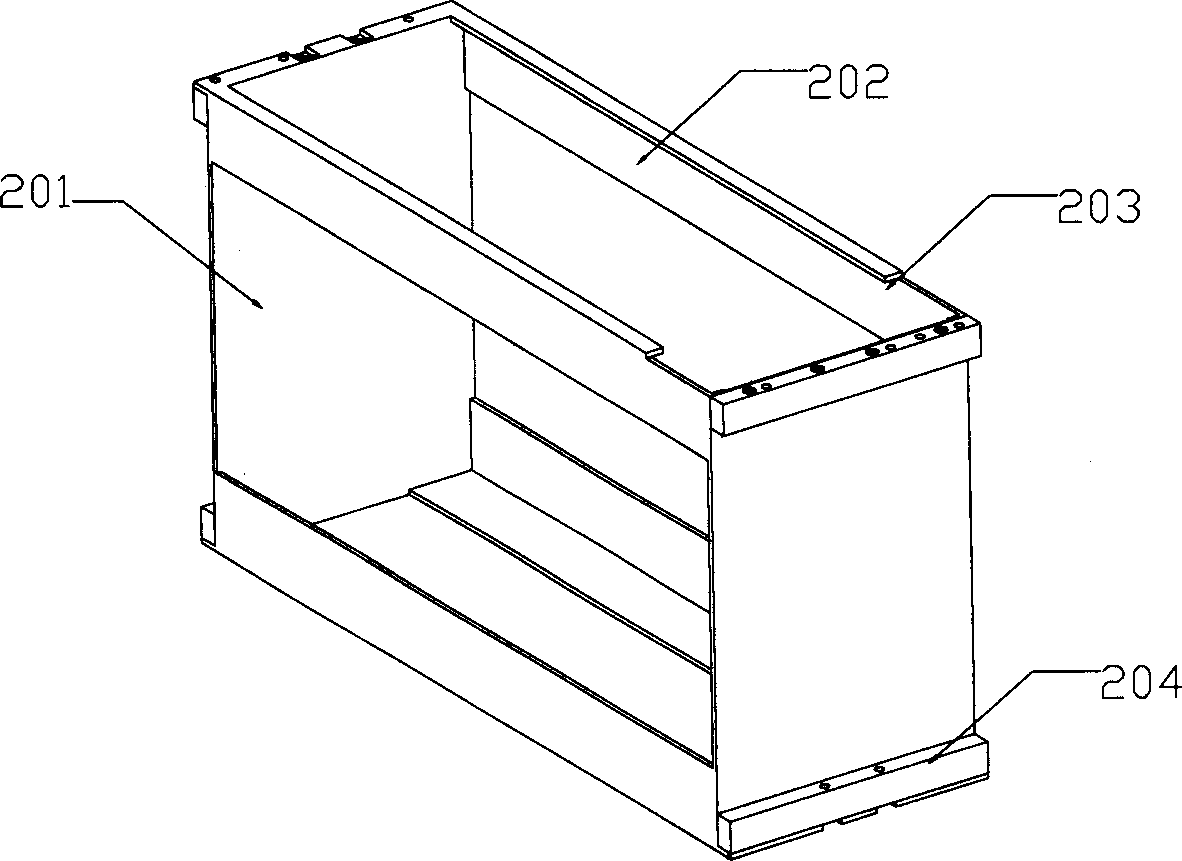

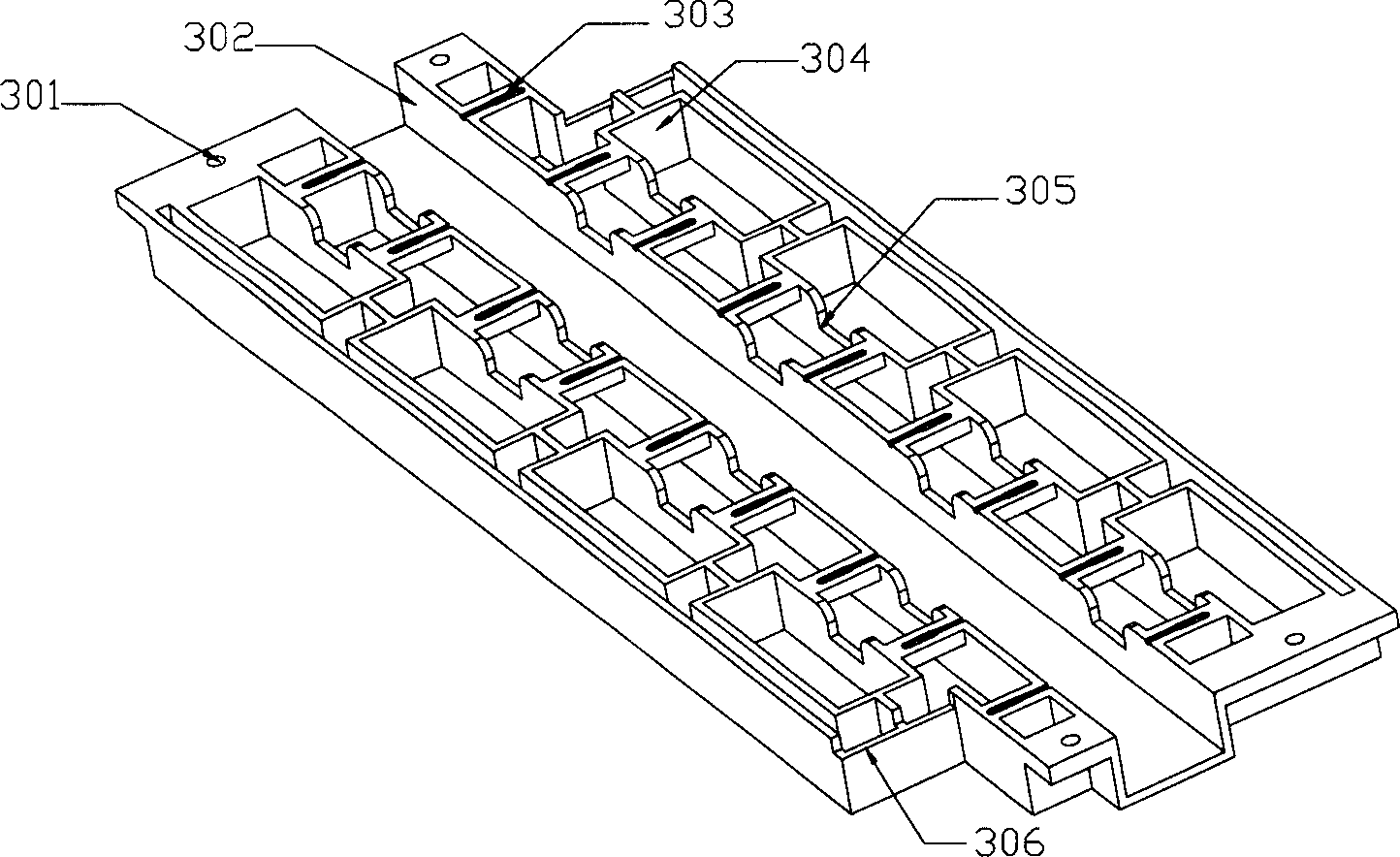

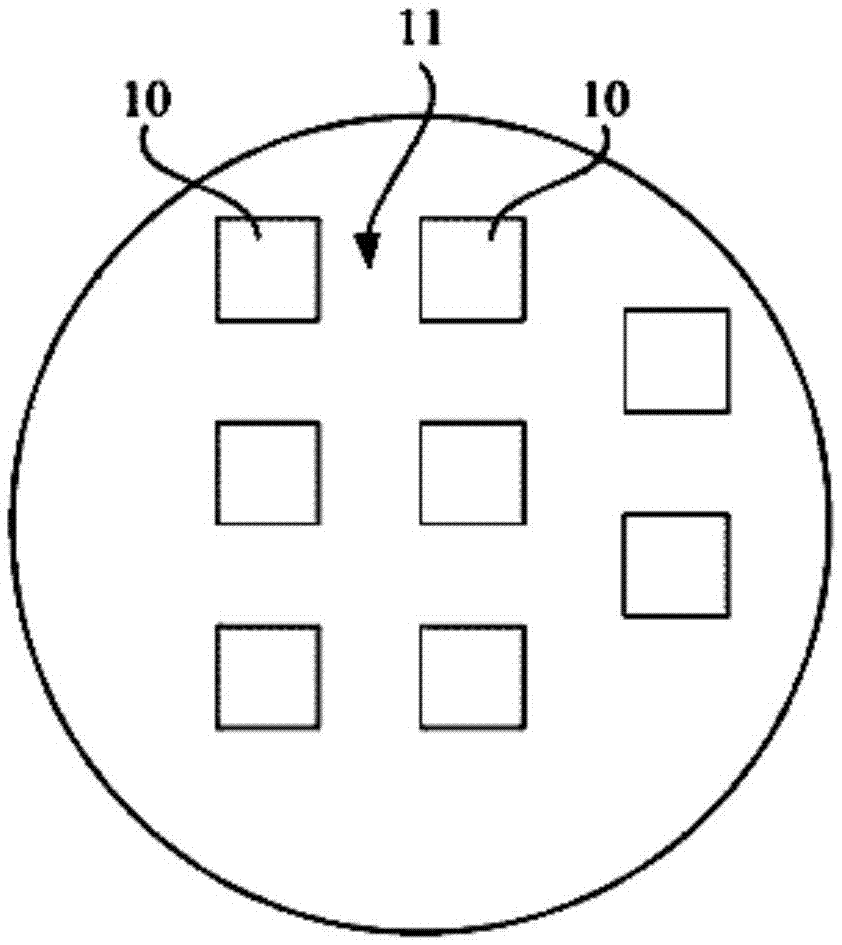

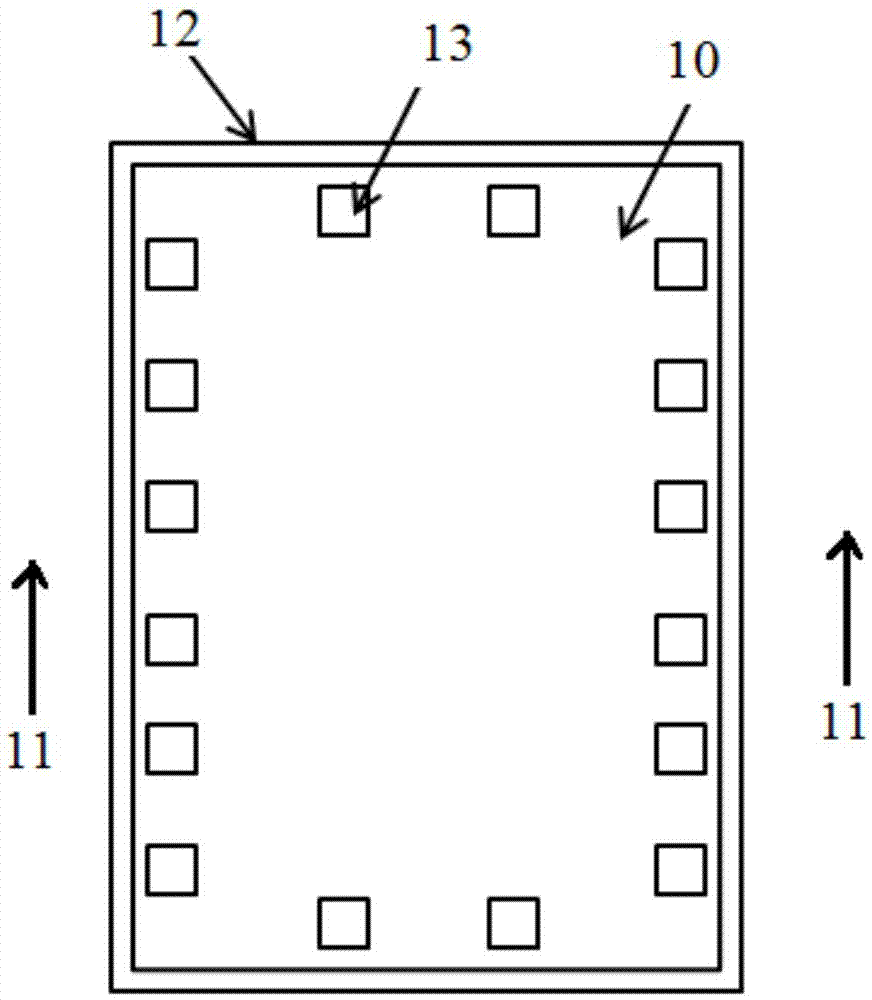

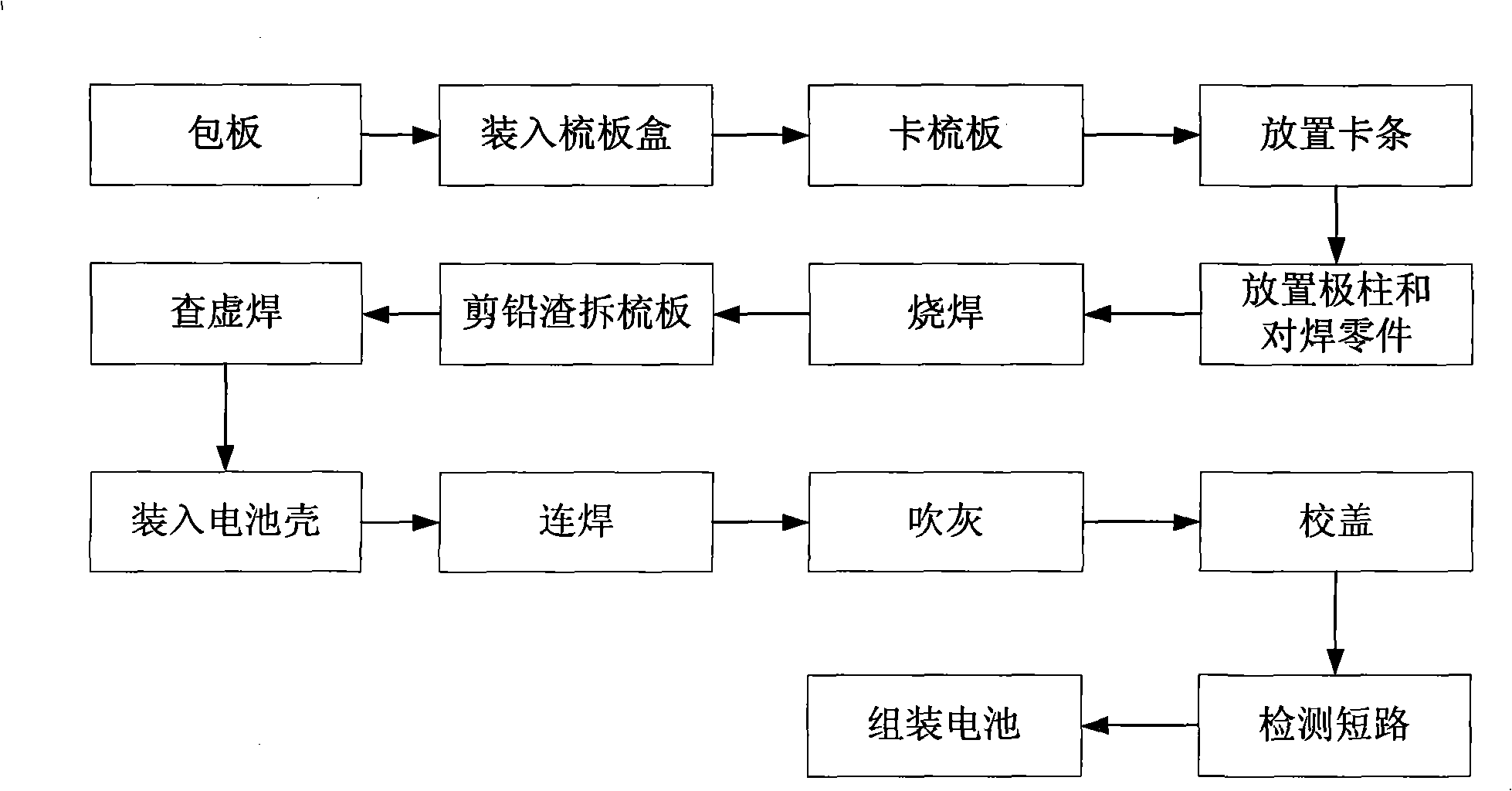

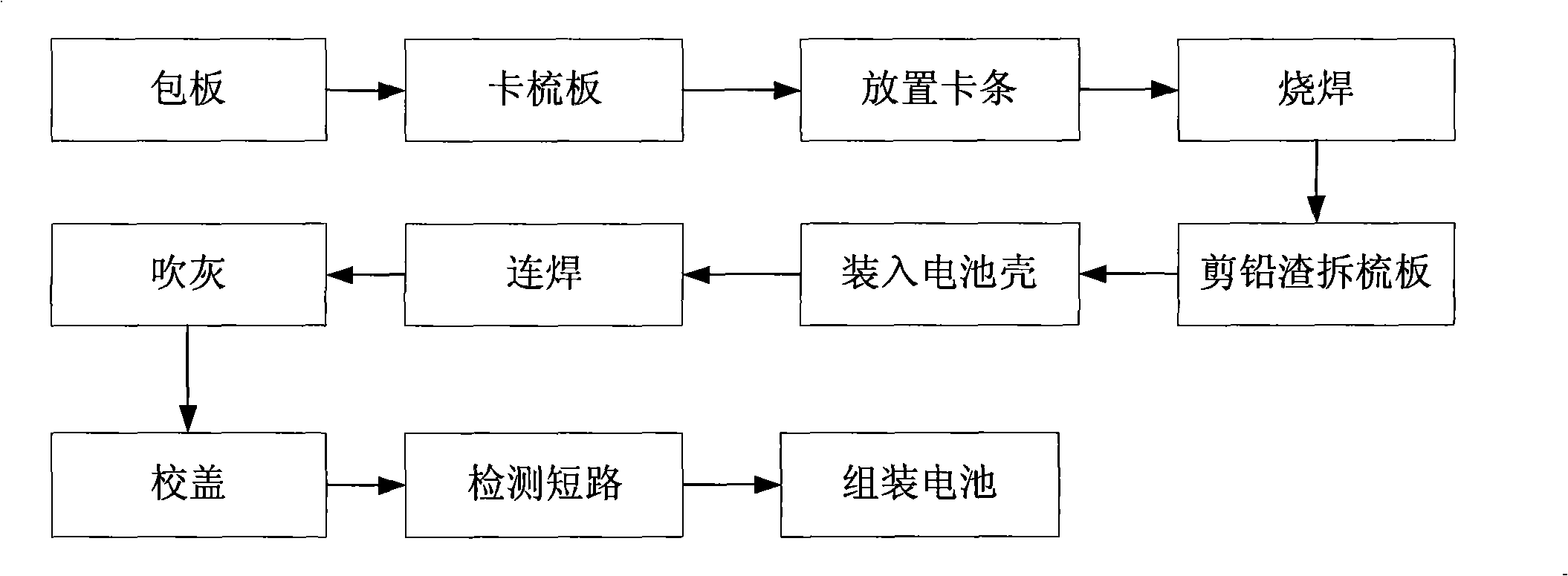

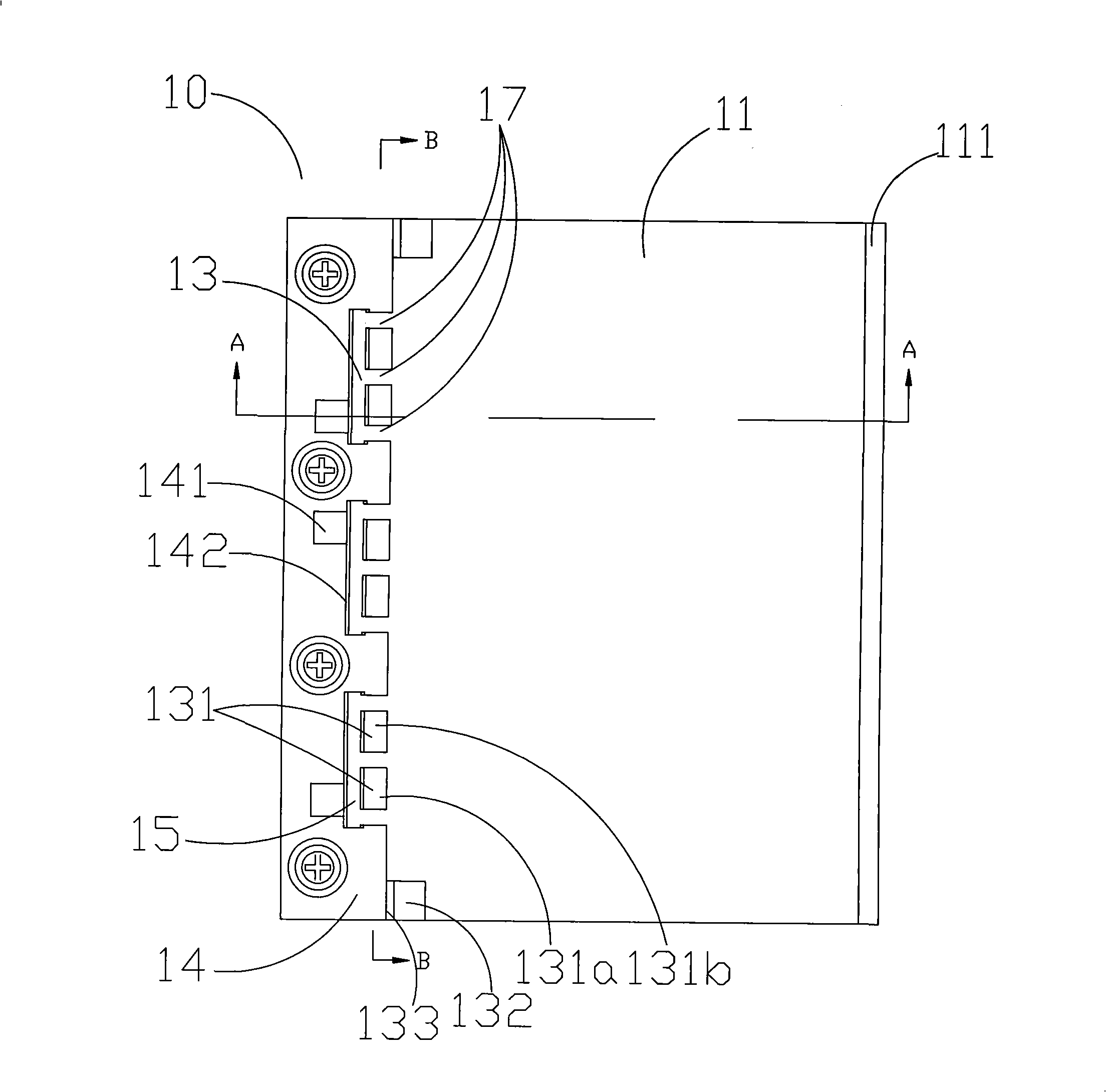

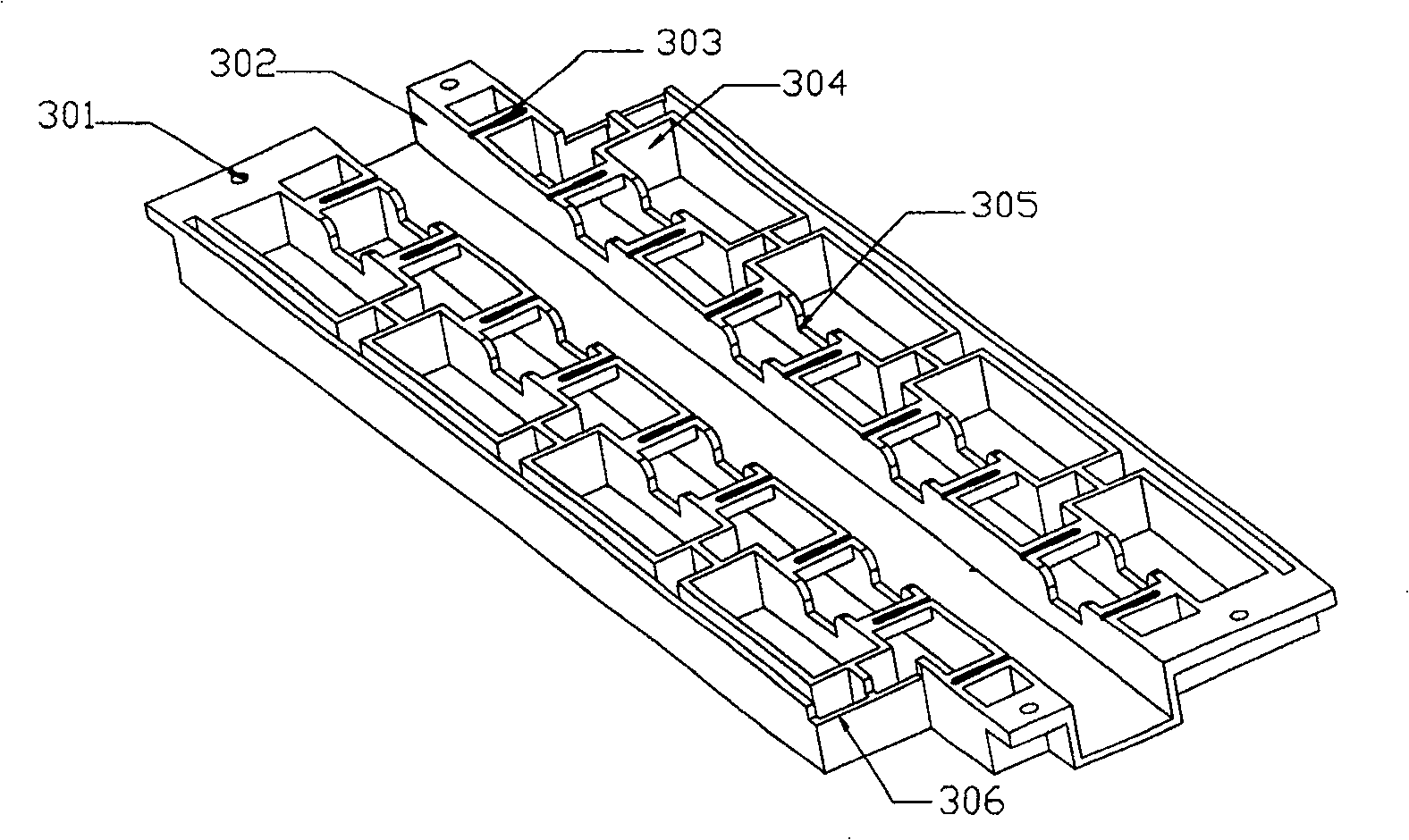

Sealed lead sour accumulator welding clamp and welding process thereof

InactiveCN101342652AThickness is easy to controlReduce processWelding/cutting auxillary devicesAuxillary welding devicesButt weldingBusbar

The invention discloses a sealed lead acid battery welding fixture and a welding process; the welding fixture comprises two welding comb plates, a positive welding comb plate and a negative welding comb plate, which comprise a vacant comb plate groove, a vacant comb plate tooth, a column and a locating plate. The vacant comb plate groove is arranged on the vacant comb plate tooth. The vacant comb plate is connected with the locating plate through the column. A busbar, a designed detail part and a tab seam matched with the tab of the plate are formed between the comb plate groove and the vacant comb plate tooth. The sealed lead acid battery welding fixture also comprises a locking strip. The locking strip is provided with a bayonet which is corresponding to the tab seam of the two welding comb plates. The welding process comprises plate wrapping, comb plate locking, locking strip arranging, flow welding, lead ash cutting and comb plate disassembling, battery shell setting, joint welding, soot blowing, cap checking, short circuit checking and battery assembling. The traditional processe of comb plat box setting, polar post arranging and parts butt welding, and the step of false welding checking are avoided. The production efficiency is improved.

Owner:SHENZHEN SUNNYWAY BATTERY TECH

Battery pack of electric vehicle

ActiveCN100429806CStrong anti-corrosion propertiesClose contactPropulsion by batteries/cellsCell component detailsFiberElectric-vehicle battery

The battery package for electric vehicle comprises a group of batteries and a box made of FRP (Fiber Reinforced Plastics) material to protect pole column and prevent short circuit or more damage. This invention has well physical and chemical features, and reduces mass and production cost.

Owner:BYD CO LTD

Photosensitive resin composition containing polyimide resin and novolak resin

InactiveCN102099741AEasy to control side angleEasy to manufacturePhotosensitive material processingPhotosensitizerOrganic solvent

Provided is a specified resin composition, the photosensitive-heat resistant resin composition comprising a) an alkali-soluble polyimide resin, b) an alkali-soluble novolak resin, c) a photosensitizer, and d) an organic solvent. When the photosensitive heat-resistant resin composition is used, the difference of development between an exposed portion and an unexposed portion in forming patterns is great, and sensitivity, resolution, heat resistance and adhesive properties are very excellent. Especially, the angle of the lateral sides of patterns can be easily controlled by a composition ratio of the resins. Thus, the resin composition can be used in forming a pattern circuit on an insulating layer of an OLED.

Owner:LG CHEM LTD

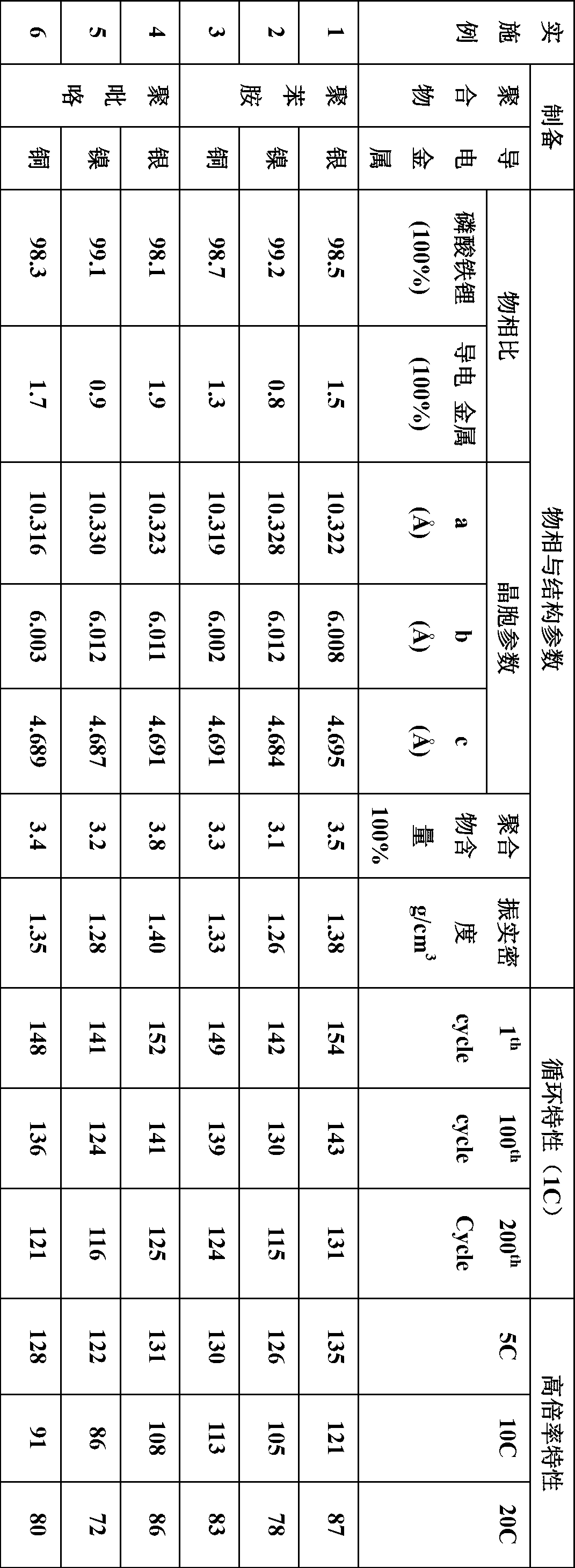

Preparation method of lithium iron phosphate anode material co-coated by conducting polymer/nanometer metal particles

ActiveCN102983329ACapable of deintercalating lithiumEasy accessCell electrodesWater bathsConductive polymer

The invention discloses a preparation method of a lithium iron phosphate anode material co-coated by conducting polymer / nanometer metal particles. The preparation method comprises the following steps of: (1) sufficiently diffusing a polymer monomer and lithium iron phosphate powder in an acid solution, so as to obtain a mixed solution A, wherein the polymer monomer is one or a combination of more than one of aniline, pyrrole, thiophene and 3,4-ethylenedioxythiophene; (2) adding a metallic compound in the mixed solution, and sufficiently diffusing to obtain a mixed solution B, wherein the metallic compound is one of silver nitrate, nickel nitrate, nickel sulfate, copper nitrate, copper sulfate, chloroauric acid and chloroplatinic acid; and (3) adding an oxidant in the mixed solution B, carrying out ultrasonic water bath on the obtained reaction mixtures at a temperature of 0-30 DEG C for 1-4 hours; standing for 1-2 hours at the room temperature, filtering, washing and drying so as to obtain the lithium iron phosphate anode material co-coated by the conducting polymer / nanometer metal particles by. The material provided by the invention has the advantages of high material capacity and good rate capability.

Owner:嘉善县国创新能源研究院

Integral high-speed permanent-magnet brushless direct-current motor for electric tool

ActiveCN104393733AEasy to assembleShorten the lengthMagnetic circuit rotating partsCooling/ventillation arrangementCooling effectEngineering

The invention discloses an integral high-speed permanent-magnet brushless direct-current motor for an electric tool, and the motor comprises a rotor and a stator sleeved outside the rotor, wherein front and rear ends of the rotor and stator are respectively provided with a front end cover and a rear end cover, a screw passes through the front end cover and the rear end cover and fits with nuts to integrally assemble the rotor, the stator, the front end cover and the rear end cover, and a fan blade is arranged outside the rear end cover or the front end cover and connected with the rotor to be together rotated. The motor has the advantages of simple process, easy assembly, excellent cooling effect, steady operation and long service life, and a solenoid coil cannot be in short circuit due to being damaged.

Owner:上海电动工具研究所(集团)有限公司

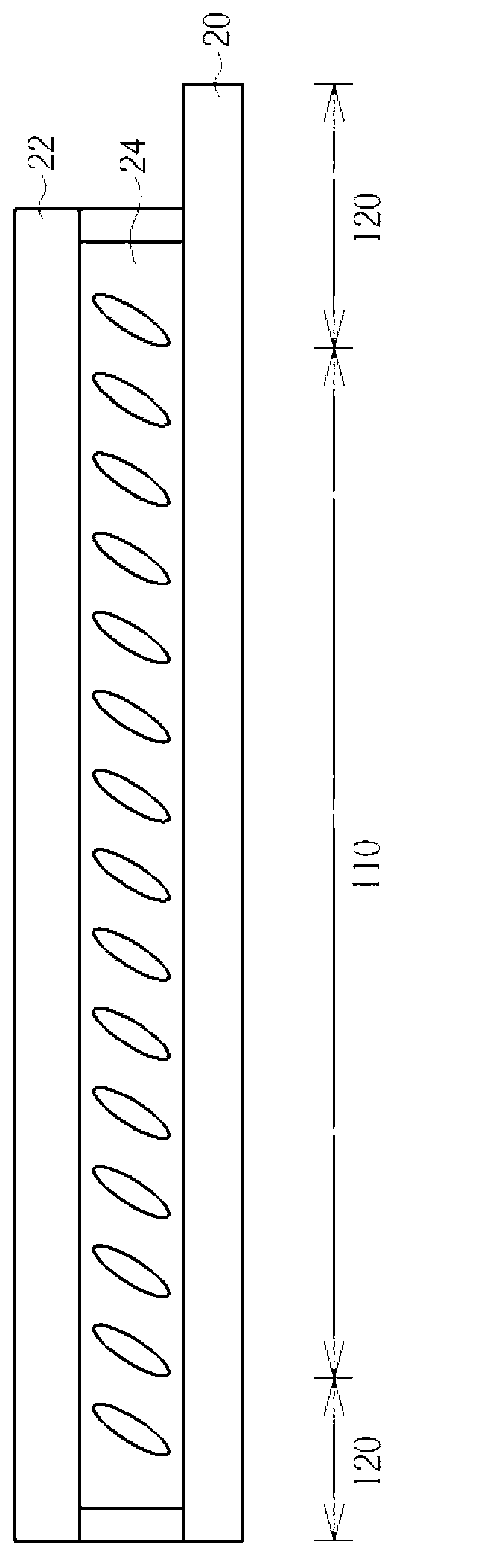

Display panel and detection method thereof

ActiveCN103106858AImprove pass rateWill not short circuitStatic indicating devicesElectrical testingEngineeringPeripheral zone

A display panel comprises a first substrate, a plurality of pixel unit, a plurality of first signal lines, a first test line and a second test line. The first signal lines are disposed on a peripheral zone and respectively correspondingly electrically connected with the pixel units, the first signal lines comprise a plurality of first groups of sub-signal lines and a plurality of second groups of sub-signal lines in an alternating arrangement. Each group of sub-signal lines and each group of sub-signal lines are respectively provided with first sub-signal lines and second sub-signal lines, and the first sub-signal lines and the second sub-signal line are different layers. The first test line is electrically connected with the first group of sub-signal lines, and the second test line is electrically connected with the second group of sub-signal lines.

Owner:AU OPTRONICS CORP

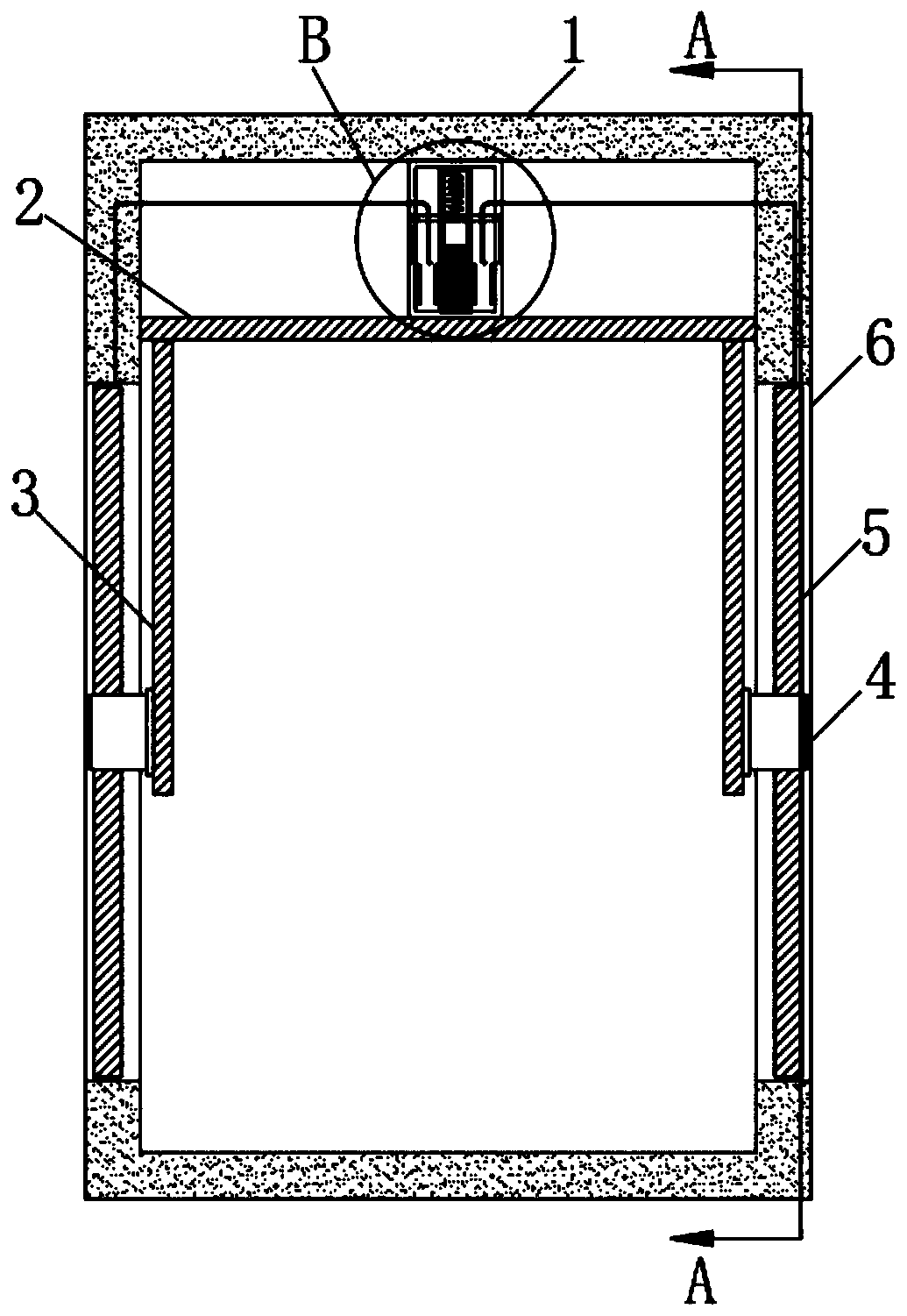

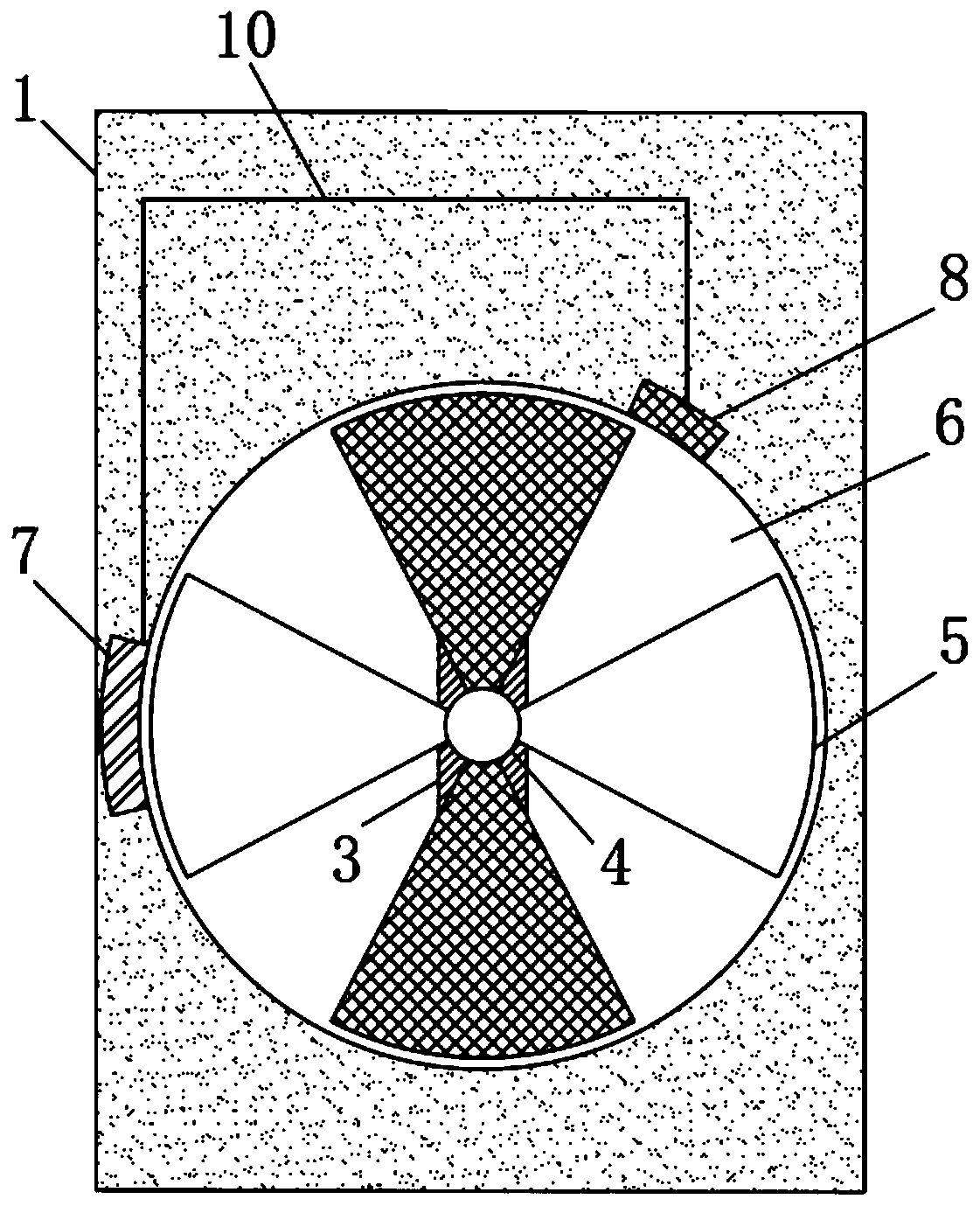

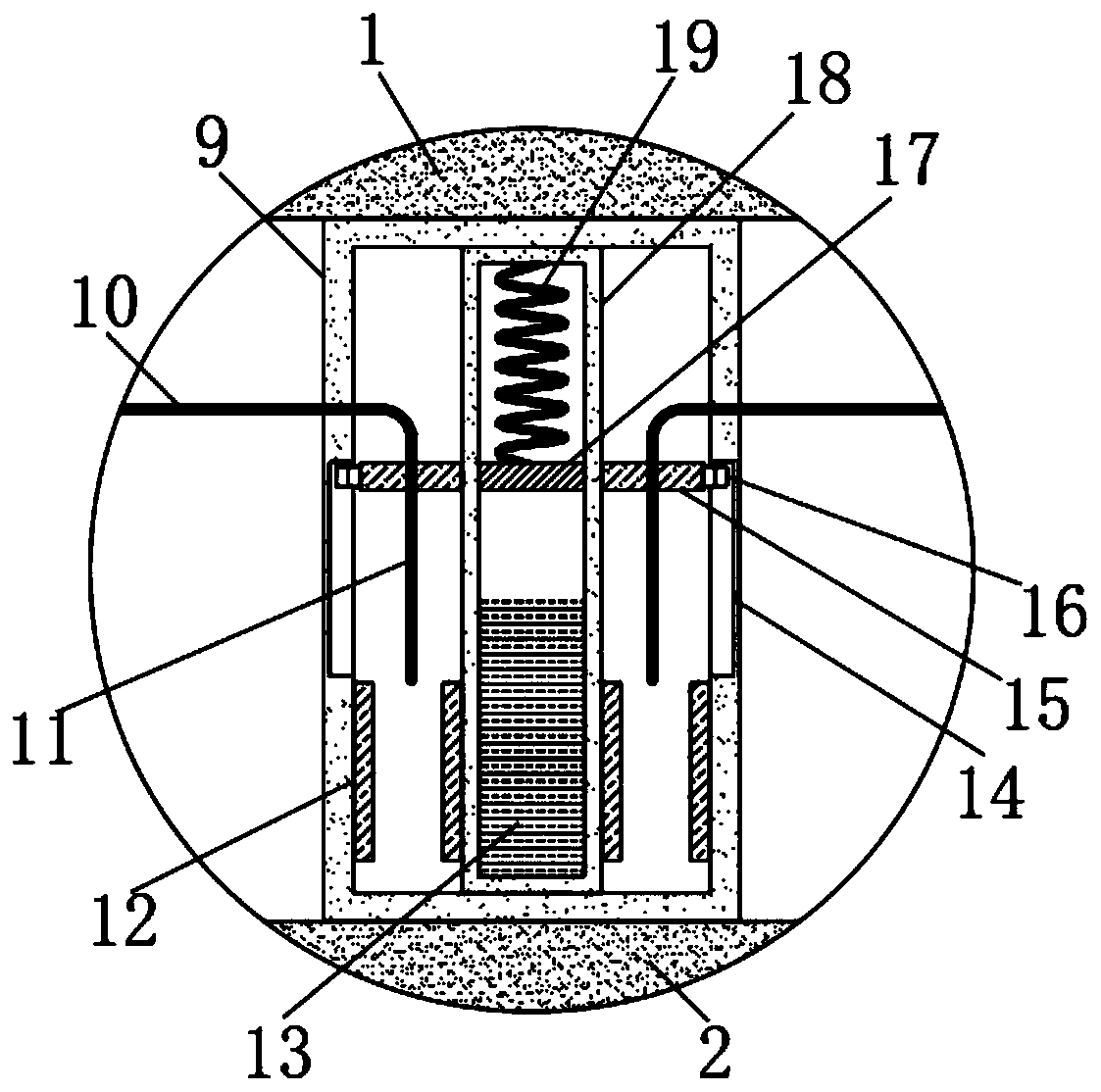

Distribution cabinet

ActiveCN110601025ASpeed up the air flowPrevent rainwater from entering the cabinetSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsPower componentMagnet

The invention discloses a distribution cabinet, which includes a cabinet body, wherein a heat dissipation mechanism is disposed in the cabinet body and includes a fixing plate fixedly connected to aninner wall of the cabinet body close to the upper end. A mounting box is fixedly connected to the upper wall of the fixing plate. A placing box is fixedly connected to the inner bottom of the mountingbox. The placing box is filled with a cooling liquid. A magnetic sliding plate is elastically connected to the upper inner wall of the placing box through a first memory metal sheet. Two permanent magnets that attract the magnetic sliding plate by opposite poles are slidably connected with the inner wall of the mounting box. Copper frames are fixedly inserted into the side walls of the two permanent magnets. The opposite side walls of the mounting box and the placing box are fixedly connected with two magnetic plates attracting each other by opposite poles. The inside of the distribution cabinet can be automatically cooled according to a temperature change, so as to ensure that power components in the cabinet body cannot be damaged by high temperature, and prevent rainwater from enteringthe cabinet body to ensure that the power components in the cabinet body cannot be short circuited.

Owner:深圳市奥通自动化有限公司

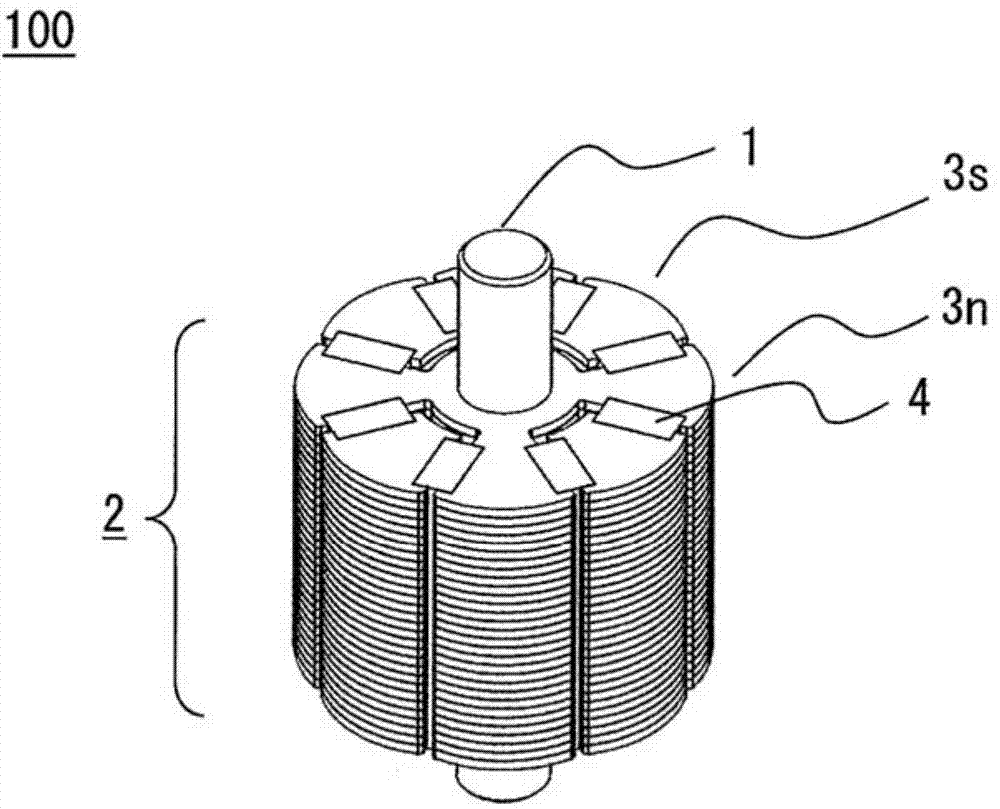

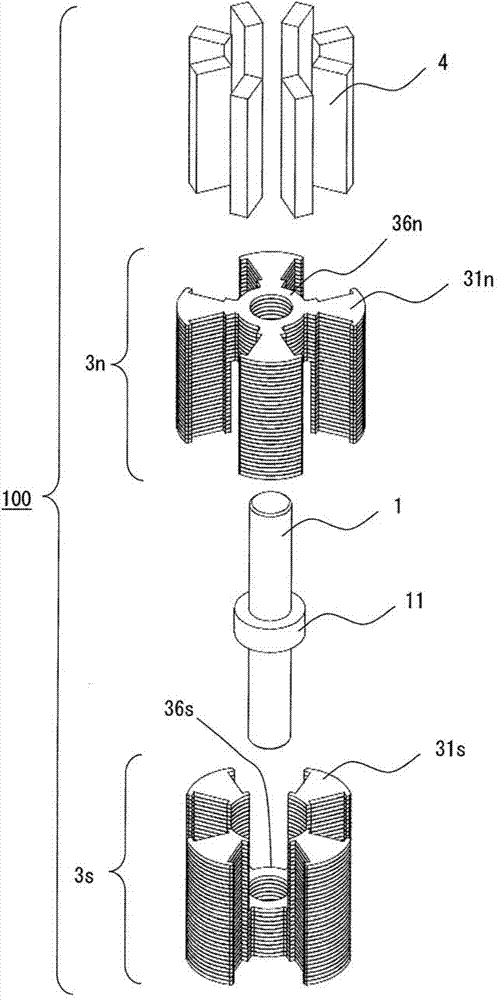

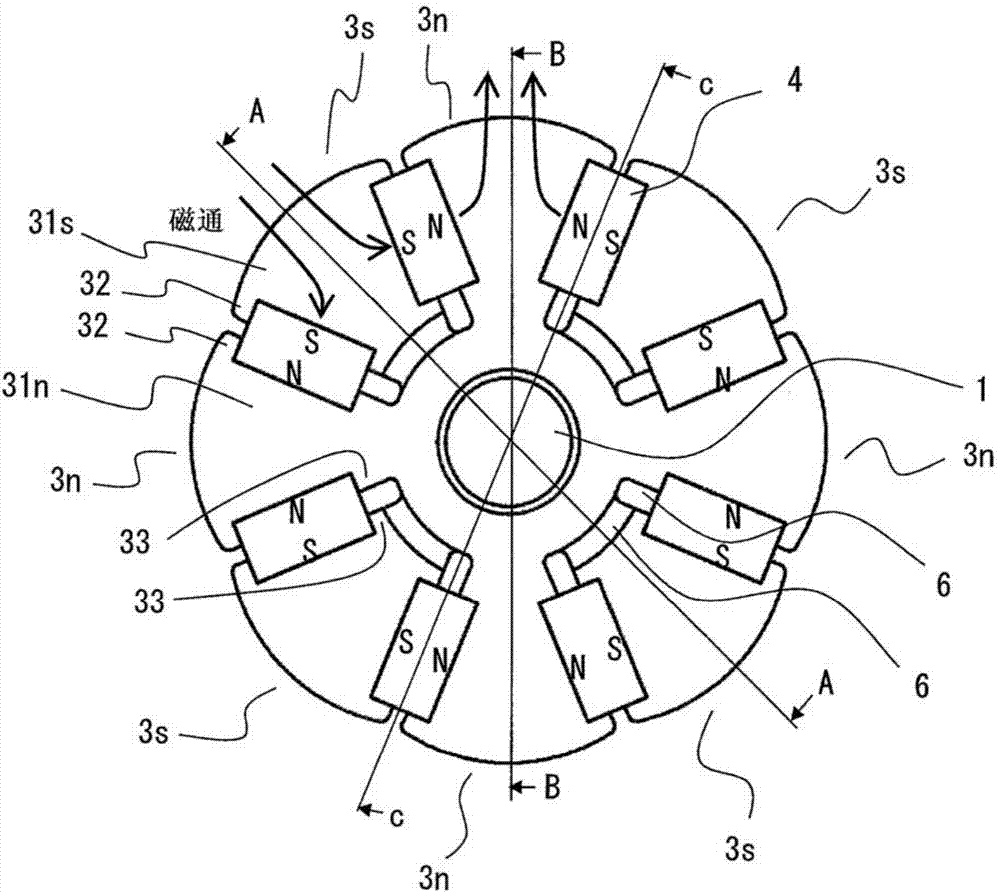

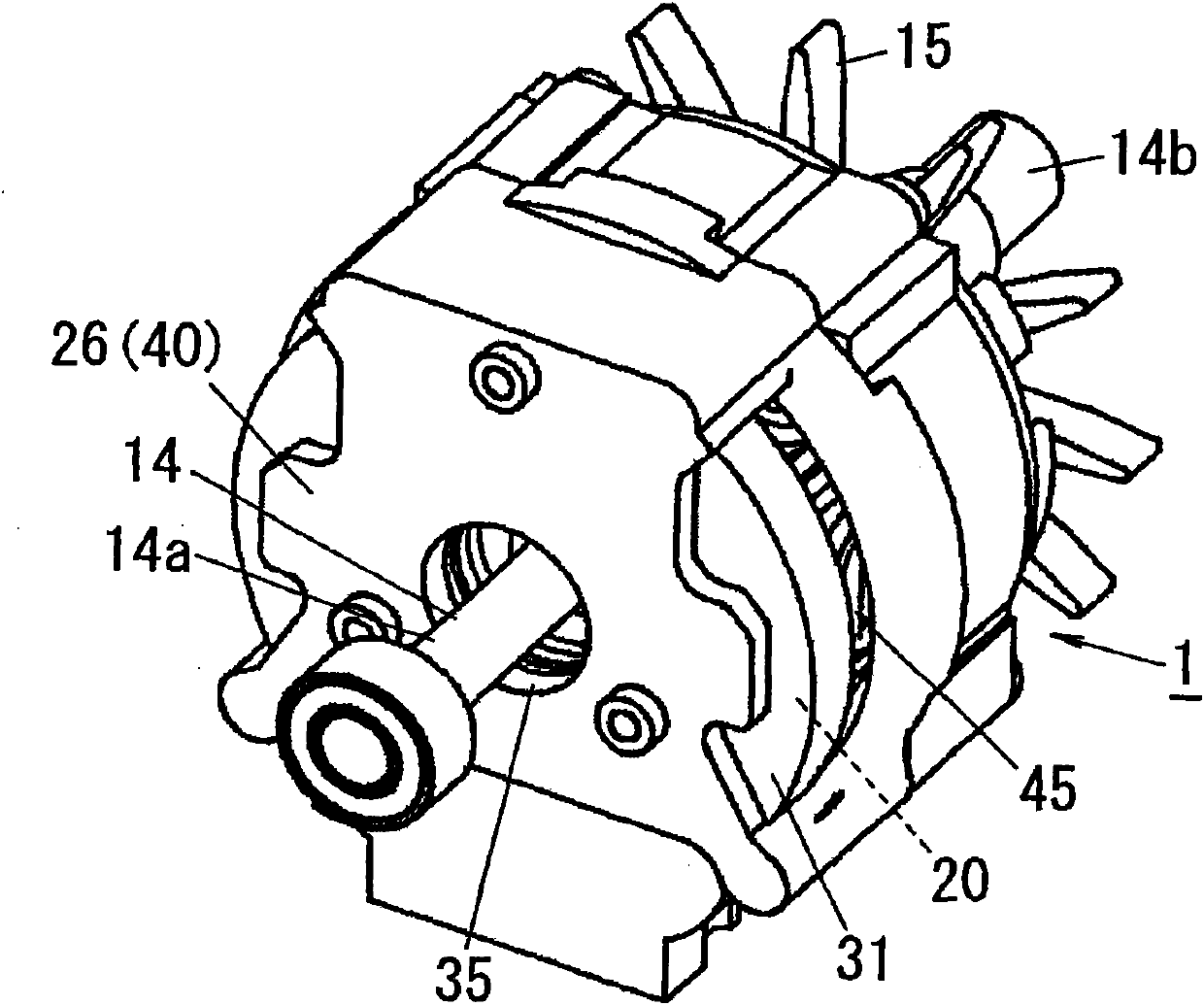

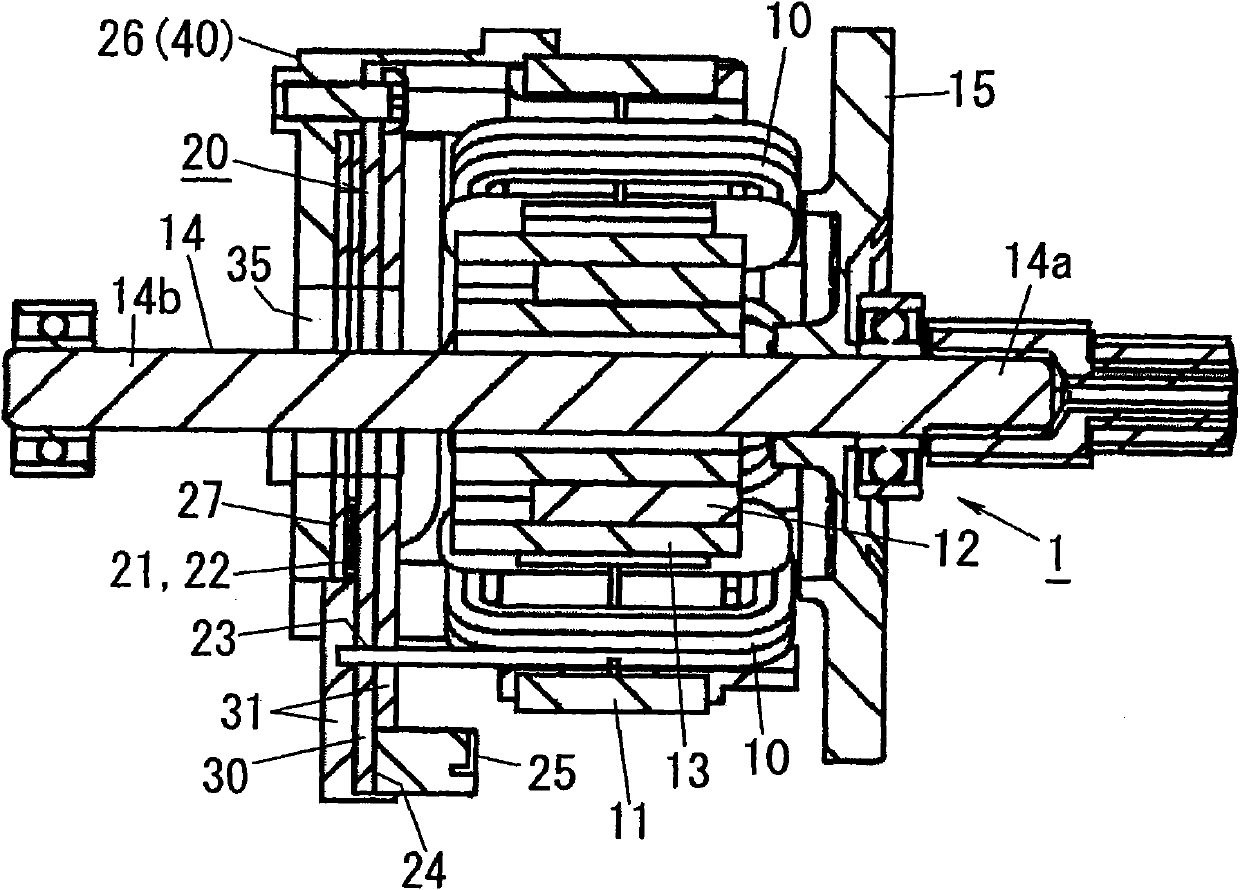

Rotor for rotating electric machine, rotating electric machine, and method for manufacturing rotor for rotating electric machine

InactiveCN104335454AWill not short circuitImprove coaxialityMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectric machineEngineering

Provided is a rotor for a rotating electric machine which includes: an N pole integrally-stacked core in which a plurality of stacked tooth portions that contact with N pole side portions of adjacent ones of first permanent magnets are integrated with each other; and an S pole integrally-stacked core in which a plurality of stacked tooth portions that contact with S pole side portions of adjacent ones of the first permanent magnets are integrated with each other, and in which the N pole integrally-stacked core and the S pole integrally-stacked core are disposed around a rotation shaft having a non-magnetic outer circumferential surface so as to dispose the first permanent magnets and a gap therebetween.

Owner:MITSUBISHI ELECTRIC CORP

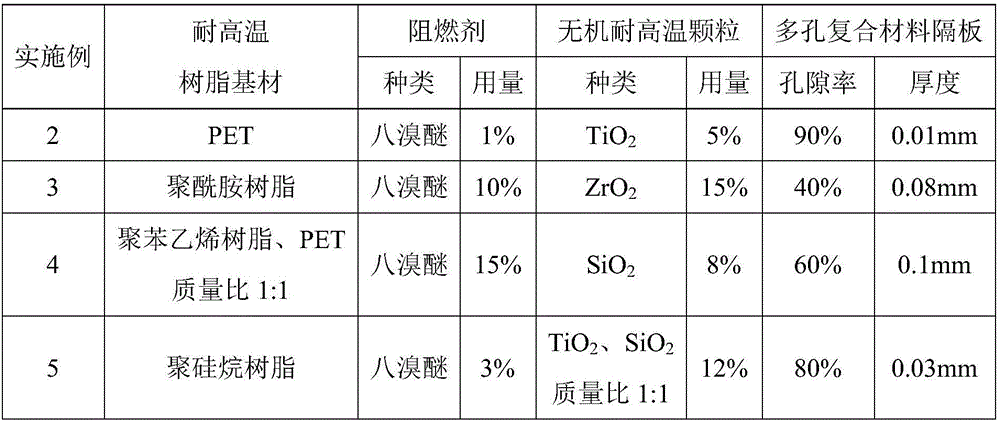

Porous composite material partition and preparation method thereof, composite-structure cell and lithium ion battery

ActiveCN106450105AGuaranteed performanceEasy to useCell seperators/membranes/diaphragms/spacersSecondary cellsPolyethylene terephthalate glycolPolystyrene

The invention discloses a porous composite material partition and a preparation method thereof, a composite-structure cell and a lithium ion battery. The partition comprises a high-temperature-resistant resin substrate, a flame retardant and inorganic high-temperature-resistant particles, wherein the high-temperature-resistant resin substrate is composed of any one or more of a polyamide resin, a polyethylene terephthalate resin, a polyamide resin, a polystyrene resin and a polysilane resin; the flame retardant accounts for 1-15 wt% of the high-temperature-resistant resin substrate; the inorganic high-temperature-resistant particles are at least one of Al2O3, TiO2, ZrO2 and SiO2; and the inorganic high-temperature-resistant particles account for 5-15 wt% of the high-temperature-resistant resin substrate. The porous composite material partition can resist the high temperature of more than 200 DEG C, and has the advantages of flame retardancy, high temperature resistance, corrosion resistance and impact resistance. The porous composite material partition is independently formed, does not need to be applied to a pole piece or diaphragm, can not influence the pole piece or diaphragm in the forming process, and ensures the self performance and service performance of the pole piece and diaphragm.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

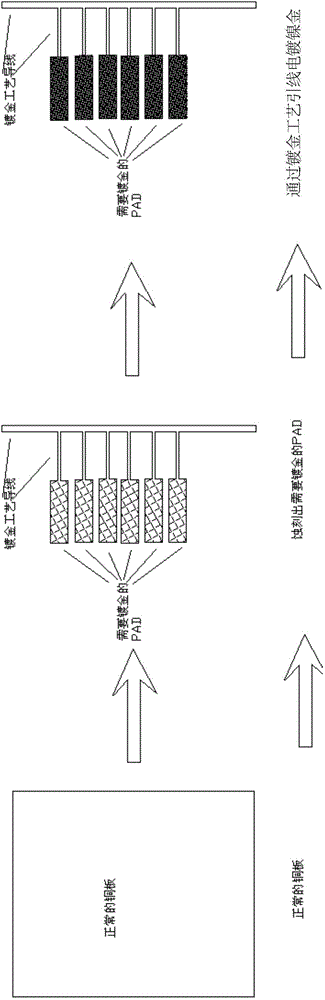

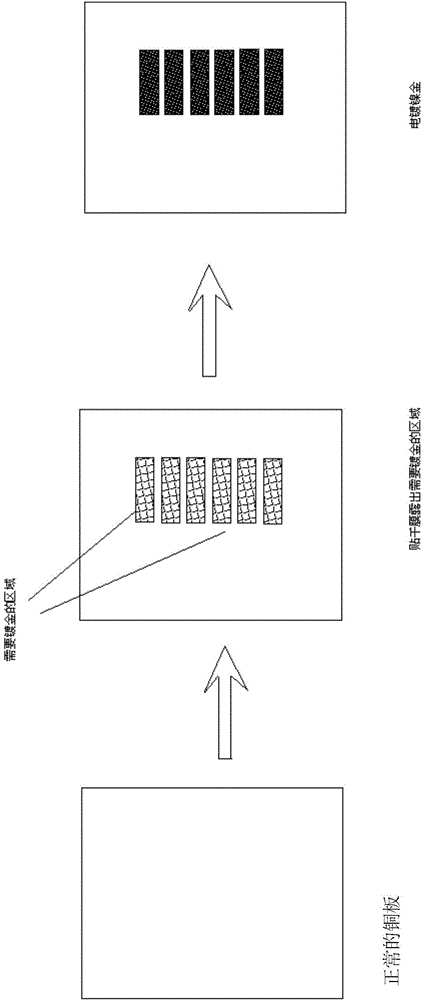

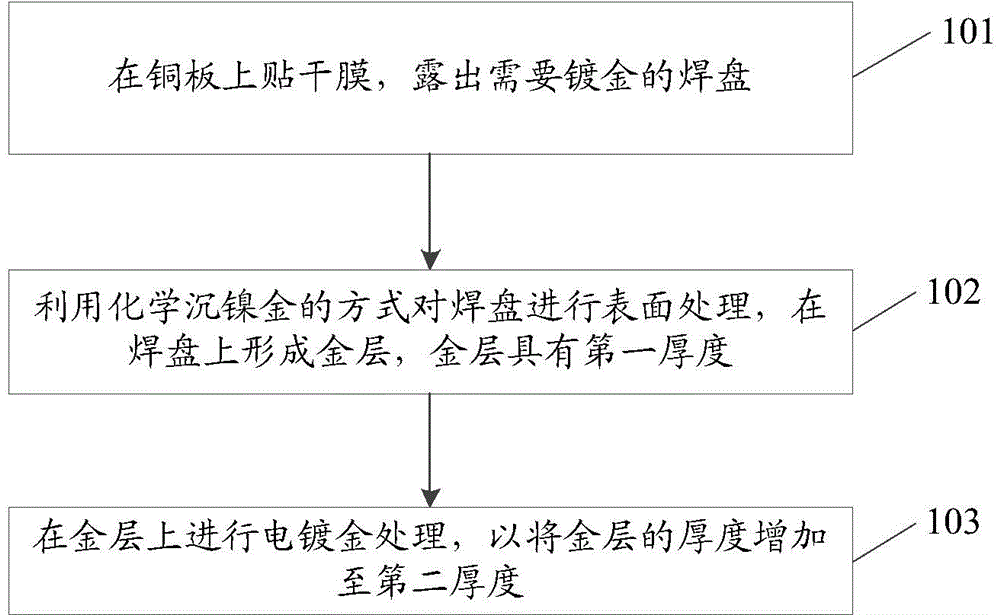

Circuit board and gilding method thereof

ActiveCN104582299AIncreasing the thicknessReduce the temperaturePrinted circuit aspectsConductive pattern reinforcementPower flowCopper

The invention discloses a circuit board and a gilding method thereof. The gilding method of the circuit board comprises the following steps: pasting a dry film on a copper plate to expose welding plate to be gilded; processing the surface of the welding plate through chemical nickel gold immersion to form a gold layer on the welding plate, wherein the gold layer has first thickness; electrogilding the gold layer so as to increase the thickness of the gold layer to second thickness, wherein the thickness current is 0.2-0.6A.

Owner:CHONGQING FOUNDER HI TECH ELECTRONICS +1

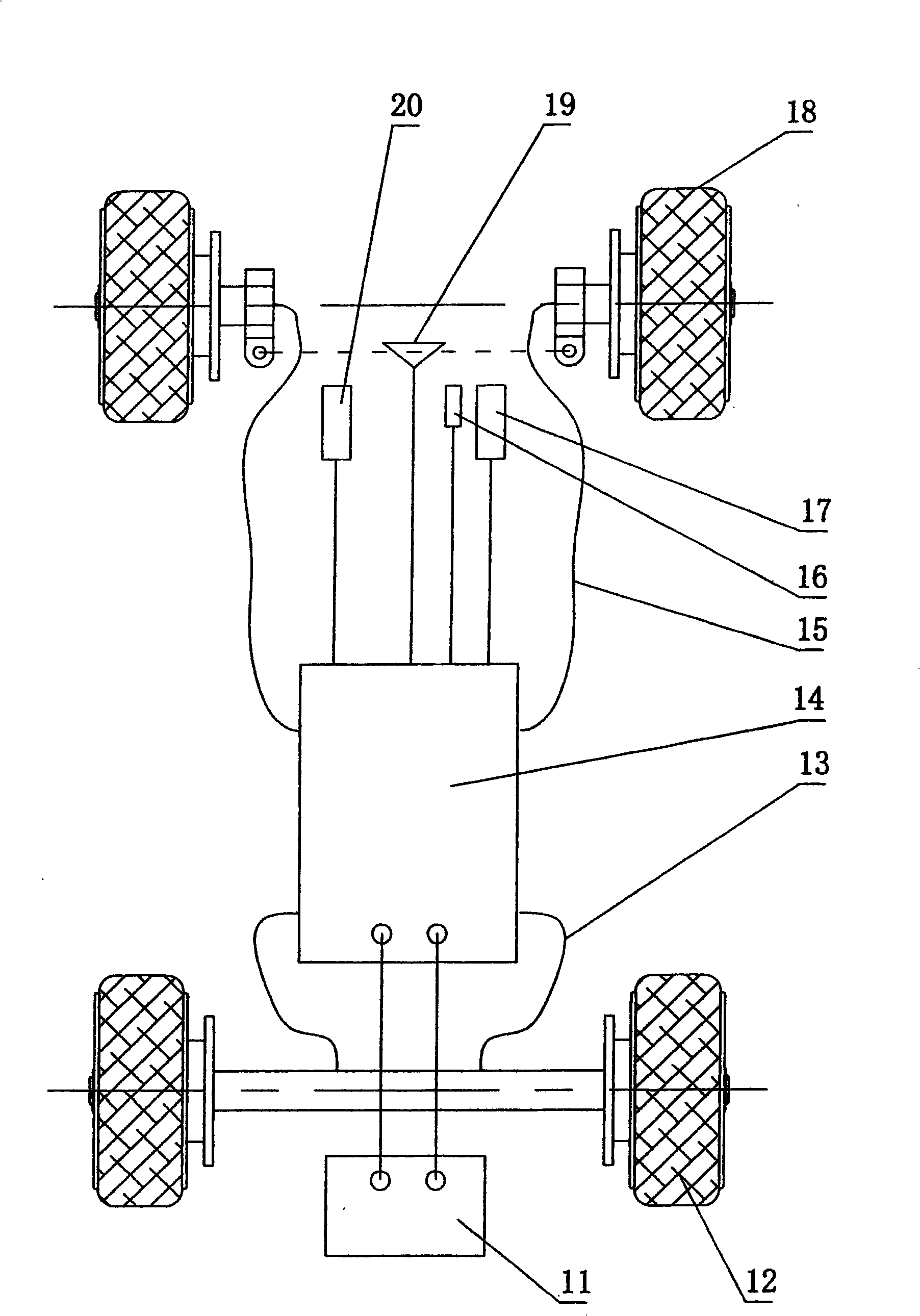

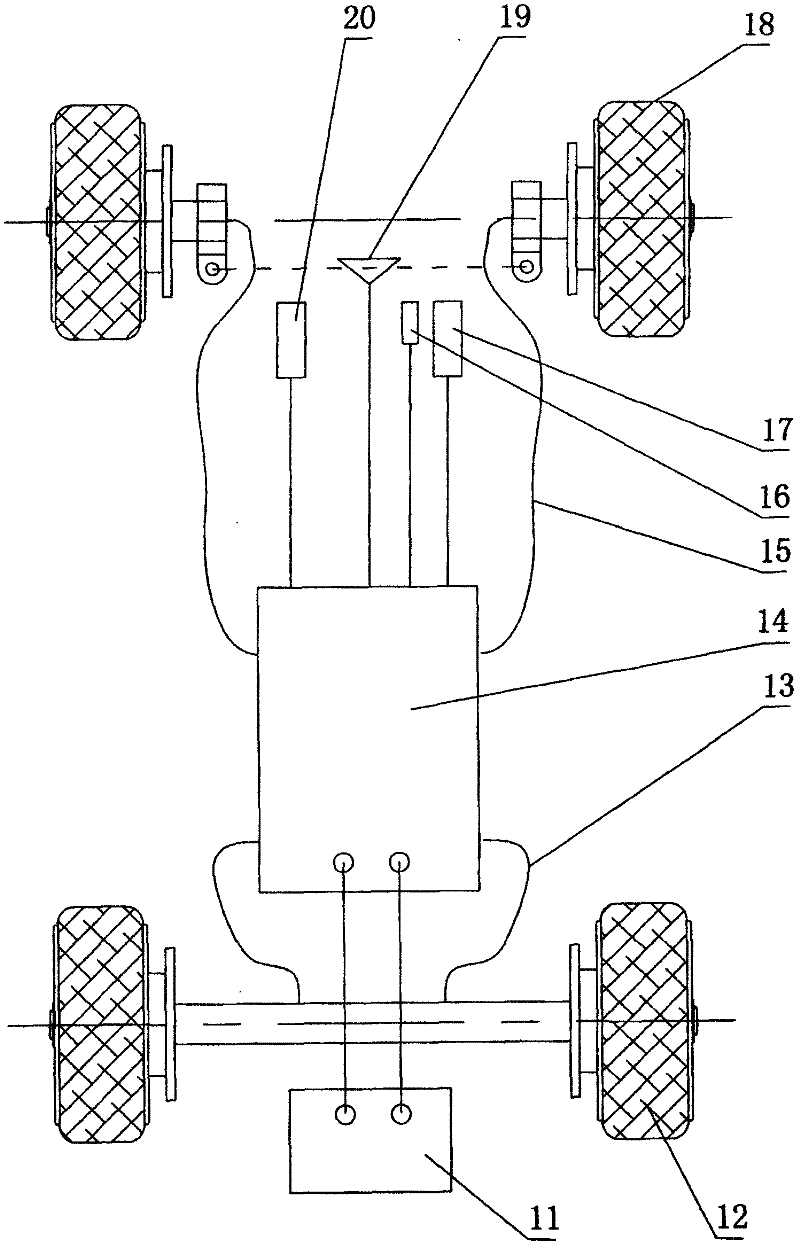

Electric automobile chassis of employing live axle hub motor as driving wheel

InactiveCN102390253AEasy to produceEasy to installMotor depositionControl devicesDrive wheelElectric machinery

The invention relates to an electric automobile chassis of employing a live axle hub motor as a driving wheel, comprising a battery pack, a controller, a hub motor and an axle, wherein the hub motor further comprises axle sleeves; stators are fixedly arranged on the outer walls of the axle sleeves; bearings are arranged on the outer walls of the axle sleeves on two sides of each stator, respectively; hub rotors are arranged on the bearings; the driving wheel is inserted into corresponding position of the axle through the axle sleeves; the inner walls of the axle sleeves are provided with a key slot which axially penetrates, and a first elastic electric connection terminal which is electrically connected with a motor coil; the axle is provided with a key in coordination with the key slot and a second elastic electric connection terminal which is electrically connected with the controller correspondingly; the first elastic electric connection terminal and the second elastic electric connection terminal are electrically connected automatically after the driving wheel is installed at proper position so that the circuit becomes simple and reliable, and simultaneously the electric automobile chassis is conveniently produced, installed, used and overhauled.

Owner:河南超微电动汽车有限公司

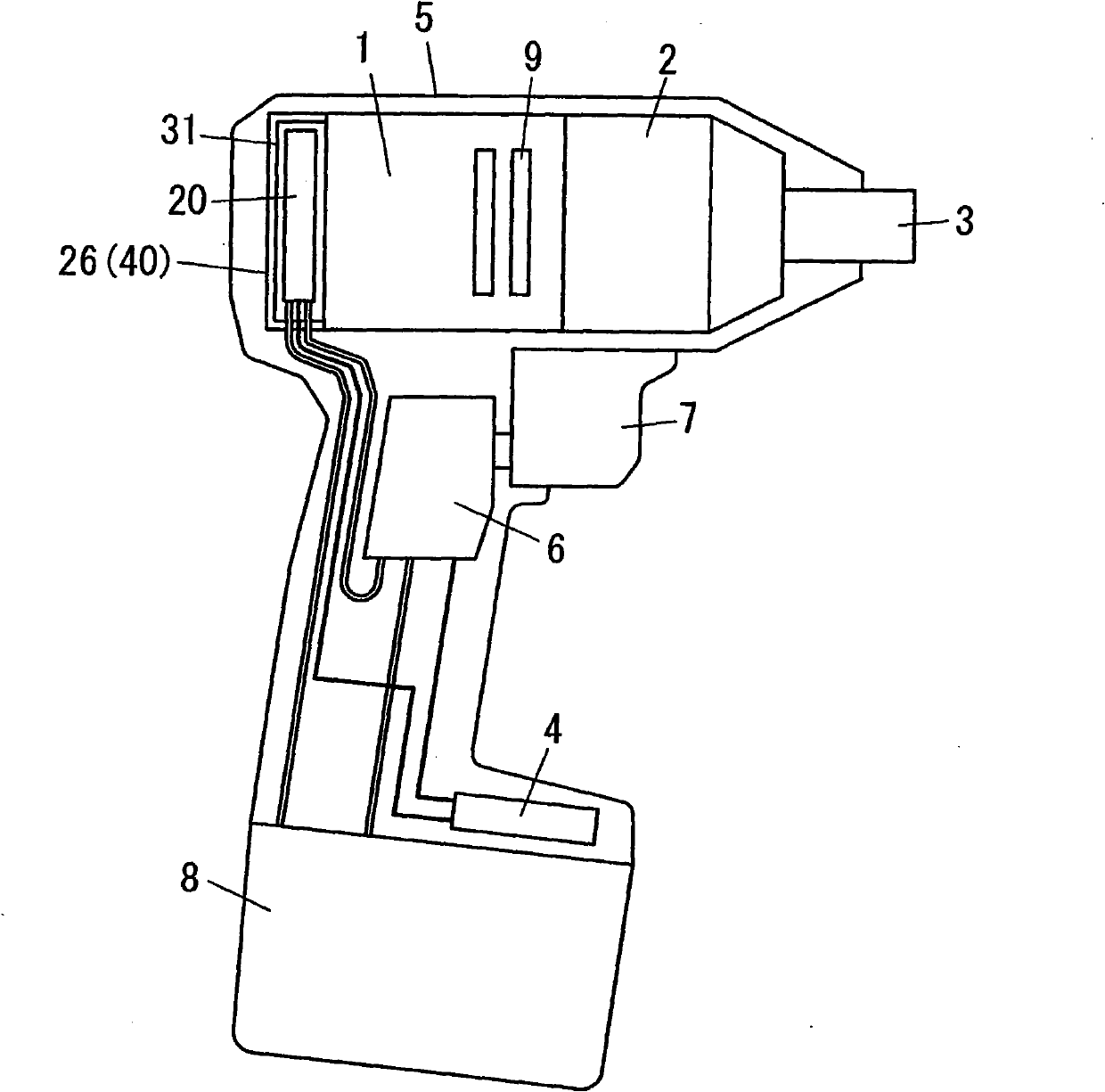

Electric power tool

ActiveCN102019611AImprove cooling effectWill not short circuitAssociation with control/drive circuitsPortable power-driven toolsElectric power systemElectric machine

An electric power tool includes a motor, a speed reduction mechanism, a power output unit, a control circuit unit, and a housing. The housing provided with an air supply-exhaust hole. The motor includes a stator core wound with coils, a rotor core and an electronic circuit unit. The electronic circuit unit includes a circuit board, electronic components arranged in the circuit board and including a switching element, coil connection portions arranged in the circuit board and connected to the coils and a control circuit connection portion arranged in the circuit board and connected to the control circuit unit. The motor further includes a radiator member for dissipating heat generated in the switching element of the electronic circuit unit and an insulating cover member molded to cover the electronic components, the coil connection portions, the control circuit connection portion, the circuit board and the radiator member.

Owner:PANASONIC CORP

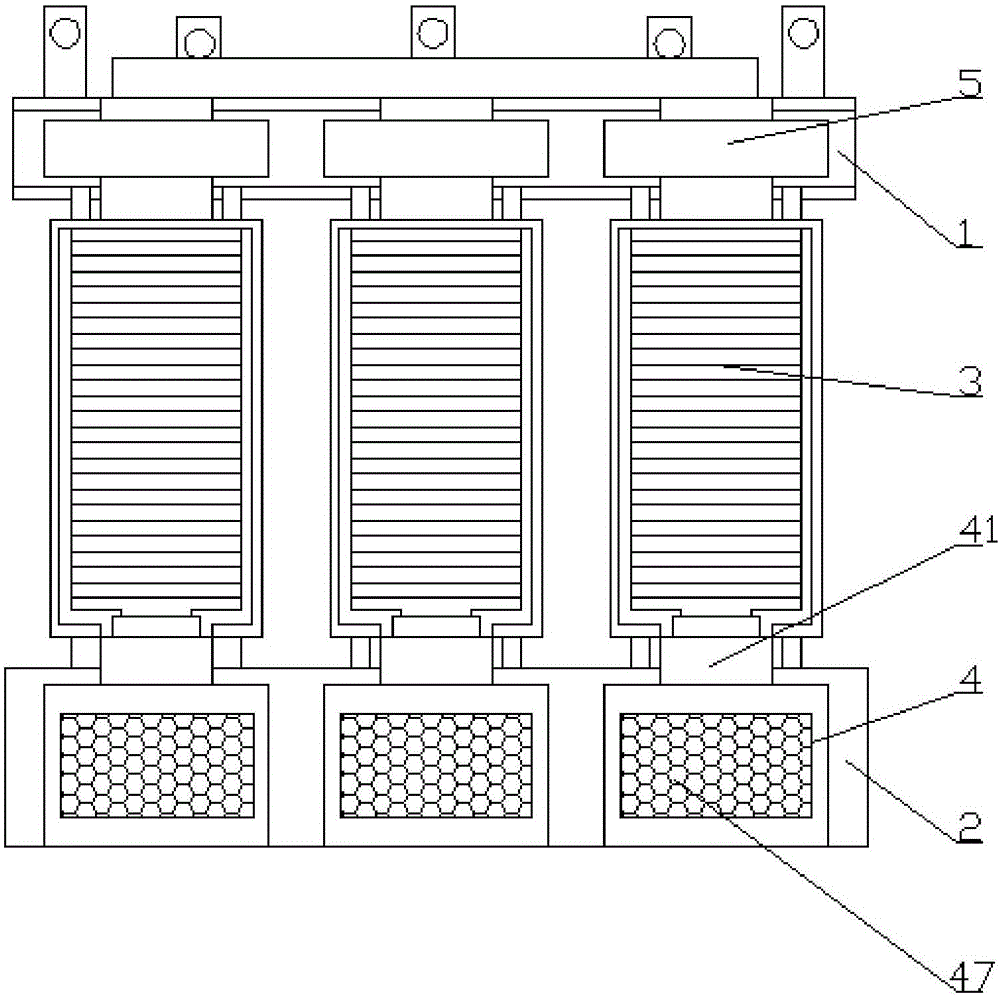

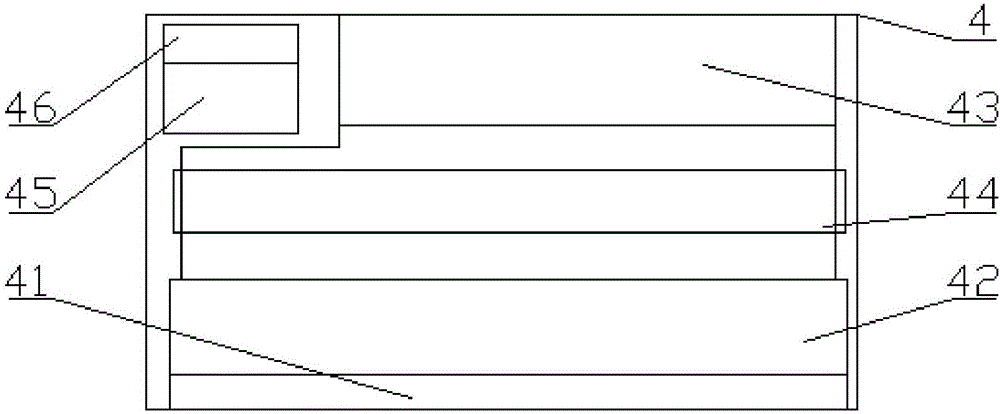

Air-cooled dry-type transformer

ActiveCN106098324AHigh and low voltage winding short circuitWill not short circuitTransformers/inductances coolingTransformers/inductances coils/windings/connectionsMetallurgyTransformer

The invention discloses an air-cooled dry-type transformer which at least comprises an upper steel body, a lower steel body, three high and low voltage windings, three dehumidifying and cooling devices and exhaust fans. The upper steel body and the lower steel body are fixedly installed at the upper ends and the lower ends of the three high and low voltage windings respectively, the upper steel body and the lower steel body are each internally provided with a cavity, the dehumidifying and cooling devices are installed in the cavity of the lower steel body, air inlets of the dehumidifying and cooling devices are formed in the front face of the lower steel body, an exhaust outlet of each dehumidifying and cooling device is connected and communicated with an air inlet of the corresponding high and low voltage winding, and an exhaust outlet of each high and low voltage winding is connected and communicated with an air inlet of the corresponding exhaust fan arranged in the inner cavity of the upper steel body; according to the air-cooled dry-type transformer, air blast cooling is conducted on the interior of the transformer through the dehumidifying and cooling devices, dehumidifying and dedusting are conducted on air entering the transformer simultaneously, and it is guaranteed that the high and low voltage windings of the transformer cannot be subjected to short circuit caused by water vapor and dust.

Owner:苏州华安普电力科技股份有限公司

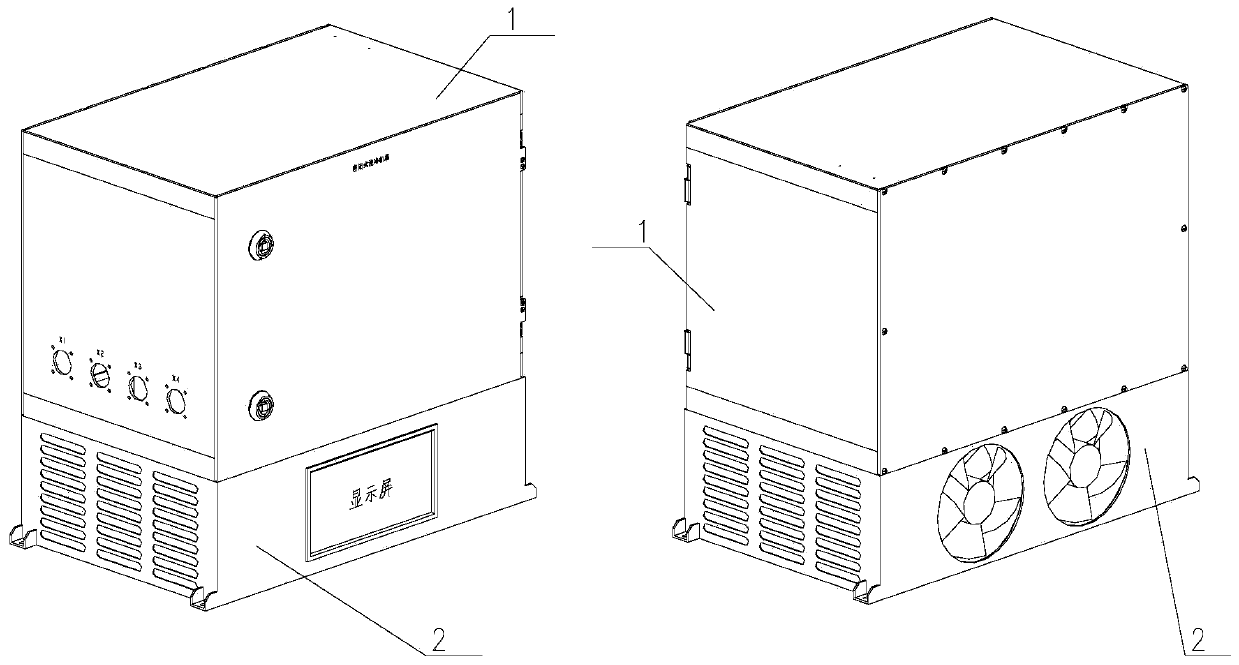

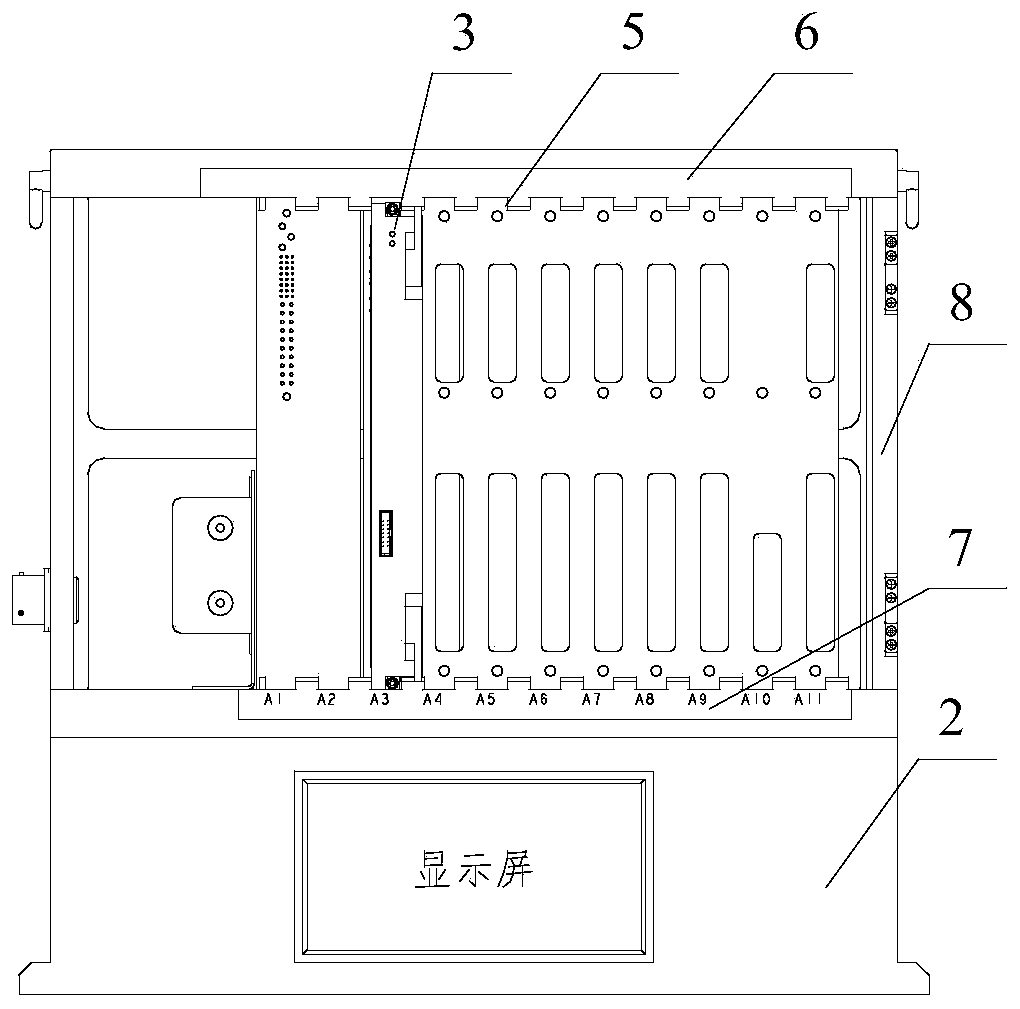

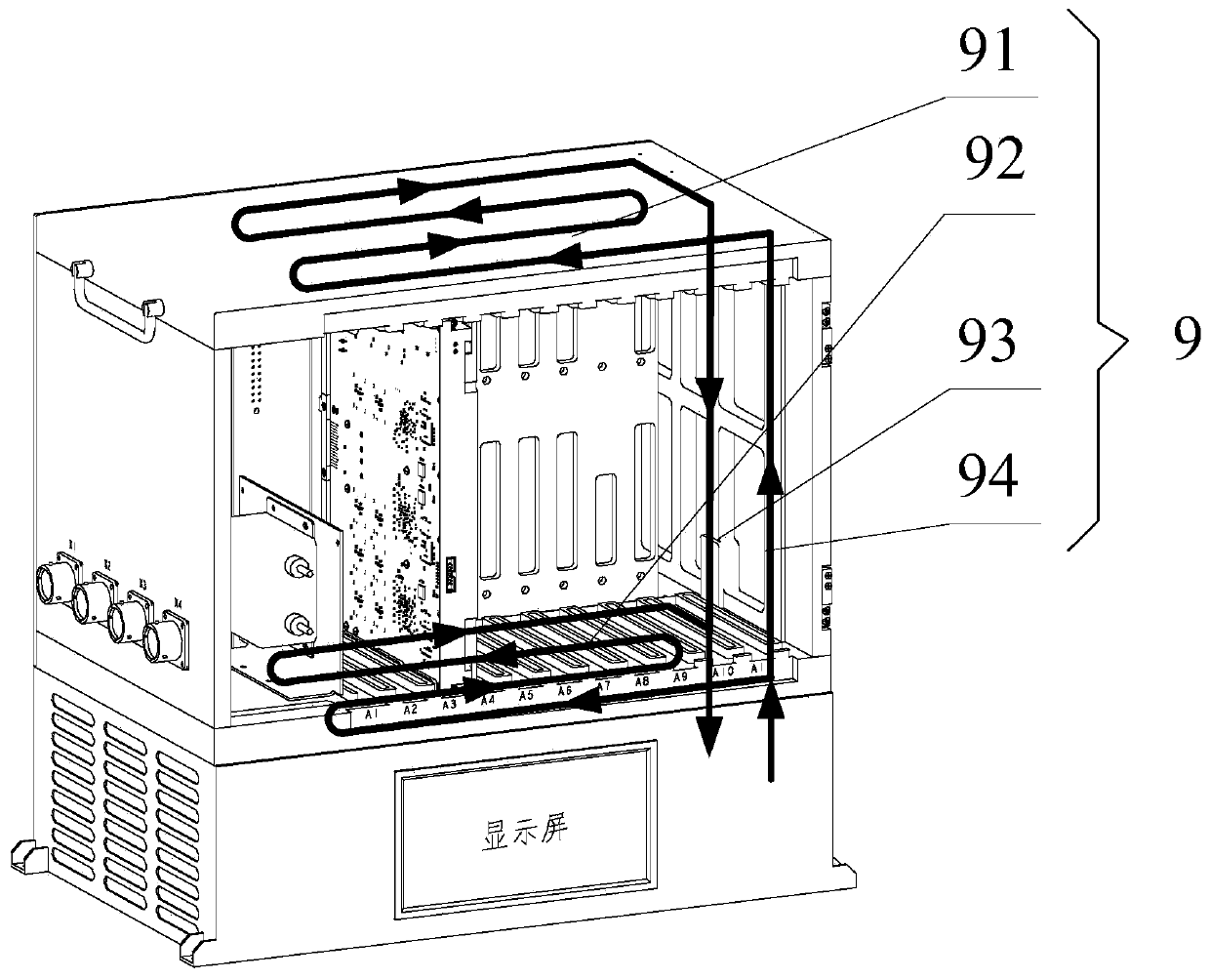

Integrated liquid cooling machine box based on two-phase heat transfer and two-phase heat transfer method thereof

InactiveCN110213942AImprove heat transfer efficiencyGood isothermModifications using liquid coolingSingle phaseIntegrated circuit

The invention relates to an integrated liquid cooling machine box based on two-phase heat transfer and a two-phase heat transfer method thereof. The integrated liquid cooling machine box comprises a machine box shell, a two-phase liquid cooling source and a plug-in cold guide plate, wherein flow channels which are communicated with each other are arranged in the top wall and the bottom wall of themachine box shell; the upper end and the lower end of the plug-in cold guide plate are fixedly connected with the top wall and the bottom wall of the machine box shell respectively, and are used forfixing electronic plug-in components; the two-phase liquid cooling source is fixedly connected with the machine box shell; and each flow channel has a flow channel inlet and a flow channel outlet which are communicated with the two-phase liquid cooling source through pipelines. The two-phase liquid cooling source is fixedly connected with the machine box shell and does not need to depend on an external liquid cooling source. The two-phase liquid cooling source is adopted, and a working medium is subjected to liquid state and gaseous state conversion in a pipeline system; the cooling working medium absorbs the heat of electronic equipment in the flow channels and is changed from the liquid state into the gaseous state, so that heat exchange efficiency is far higher than that of single-phasefluid heat exchange; and the cooling working medium phase change is performed in an isothermal process, so that the isothermal performance of the top wall and the bottom wall of the machine box shellis superior to that of the single-phase fluid heat exchange.

Owner:BEIJING INST OF RADIO MEASUREMENT

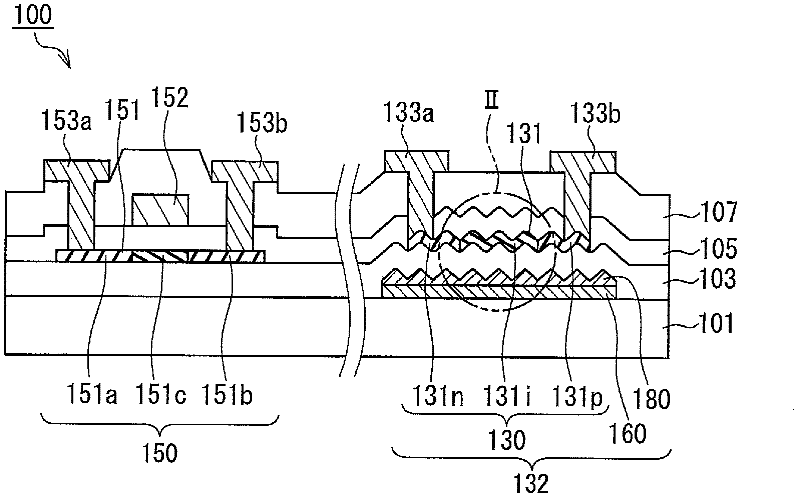

Optical sensor, semiconductor device, and liquid crystal panel

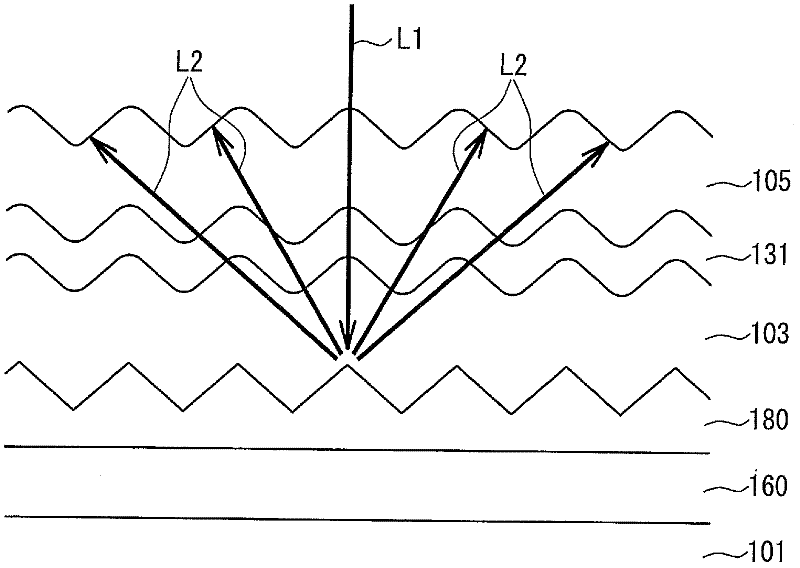

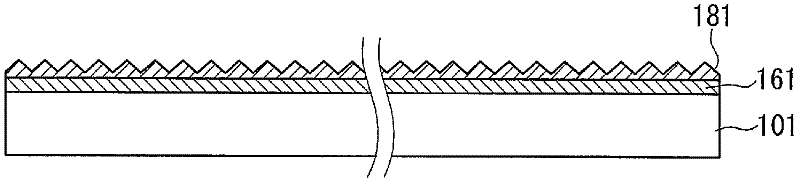

InactiveCN102473716AInsulationContact holes preventTransistorSolid-state devicesThin-film diodeBlocking layer

Disclosed is an optical sensor, wherein the light detection sensitivity of a thin film diode is improved by improving the light use efficiency, even if semiconductor layer of the thin film diode is thin, and by means of a light blocking layer, the electrode of the thin film diode is prevented from being short-circuited. On one side of a substrate a substrate (101), the thin film diode (130) having a first semiconductor layer (131) that includes at least an n-type region (131n) and a p-type region (131p) is provided, and the light blocking layer (160) is provided between the substrate and the first semiconductor layer. On the light blocking layer surface facing the first semiconductor layer, a metal oxide layer (180) is formed. On the metal oxide layer surface facing the first semiconductor layer, recesses and protrusions are formed, and the first semiconductor layer has recesses and protrusions that match the recesses and protrusions of the metal oxide layer.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com