Patents

Literature

182results about How to "Good high temperature performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound sulphonic acid albany grease and method for producing the same

ActiveCN101153239AImprove performanceImprove water resistanceLubricant compositionAntioxidantManufacturing enterprises

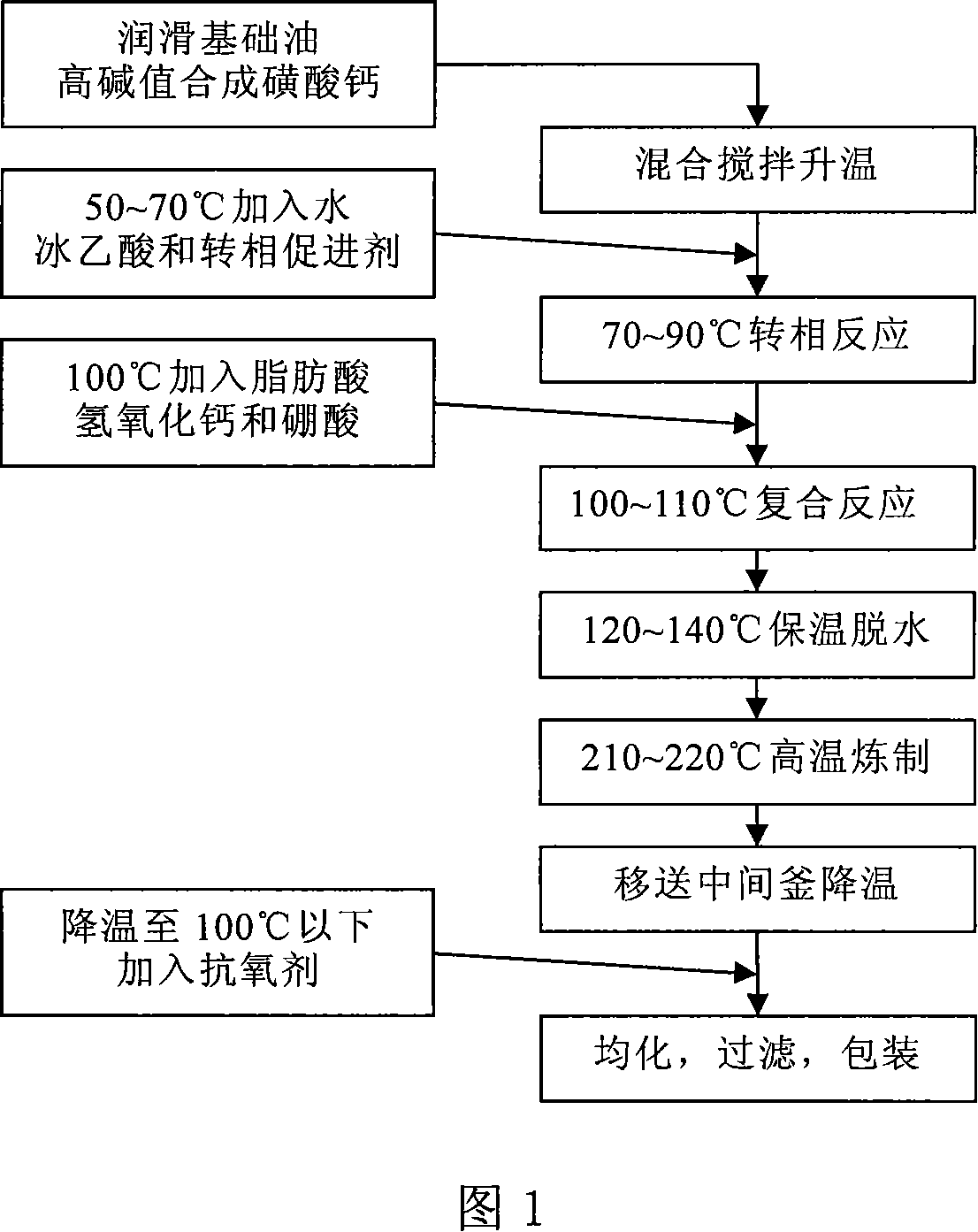

The invention relates to calcium sulfonate complex grease and a manufacture method thereof, in particular to grease producing the thickening agent by synthetic reaction with super-high base value. At first, the lubricating base oil and the calcium sulfonate are added into an opening reaction kettle to be stirred, the phase inversion promoter, the glacial acetic acid and the water are added into the kettle to boost the temperature to make the insulating reaction until the materials are thickened, then the calcium hydroxide, the aliphatic acid and the boric acid are added into make an insulating reaction, a temperature rise, an insulating dehydration and a refining in turn, then the materials are moved into an intermediate kettle, the antioxidant is added to disperse and homogenize, and the finished product is produced after the filtering. The invention has excellent anti-spray performance, excellent high temperature performance, good extreme pressure anti-abrasion performance, prominent anti-shear performance, good pumping performance, anti-rust performance and water adding shear stability; has apparent phase inversion effect and good product performance, decreases the grease exchange times under the same working condition and increases the service life of the equipment, which is proved by the trial applications of a plurality of appliance manufacture enterprises, steel works, paper mills and so on.

Owner:无锡中石油润滑脂有限责任公司

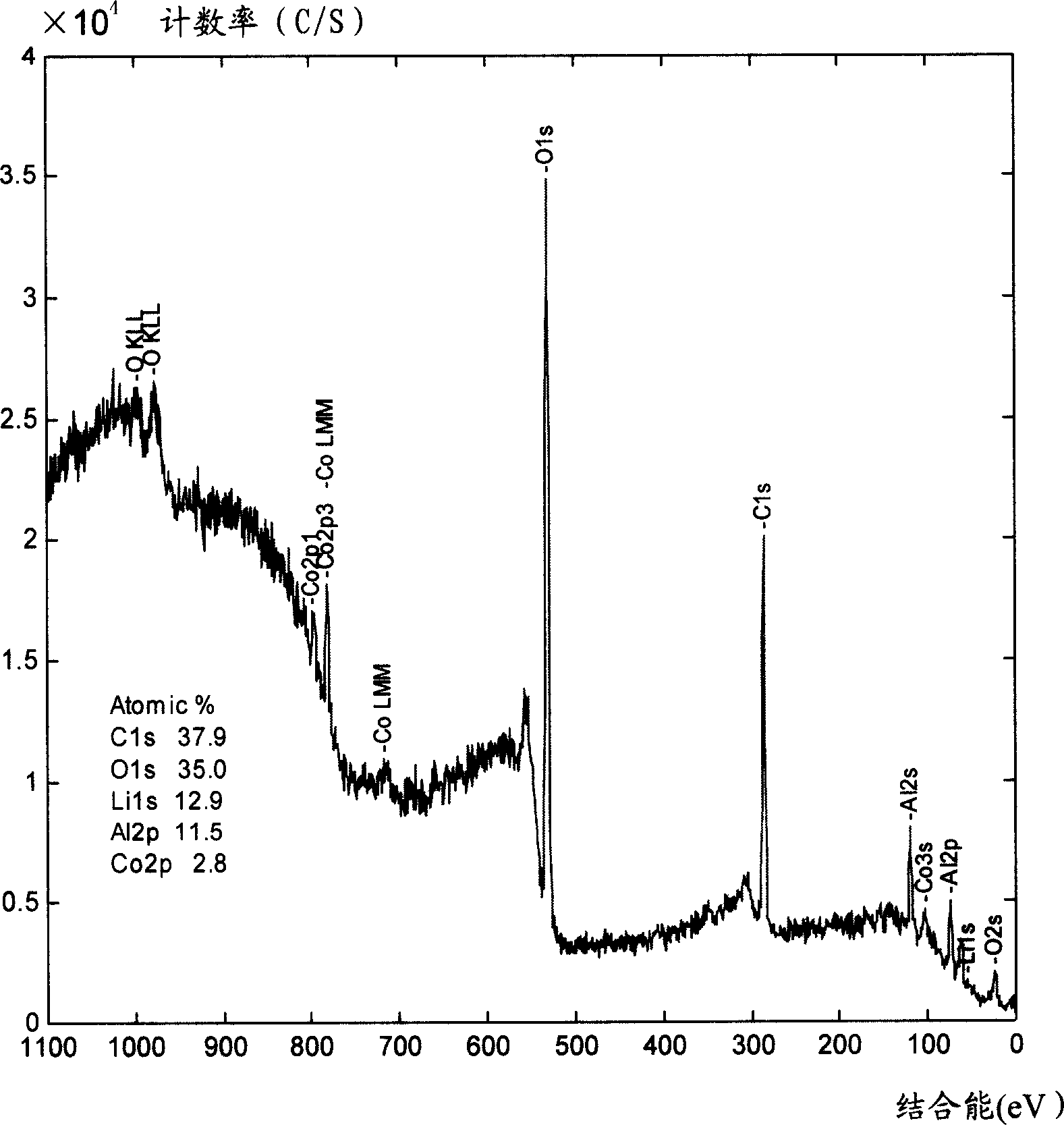

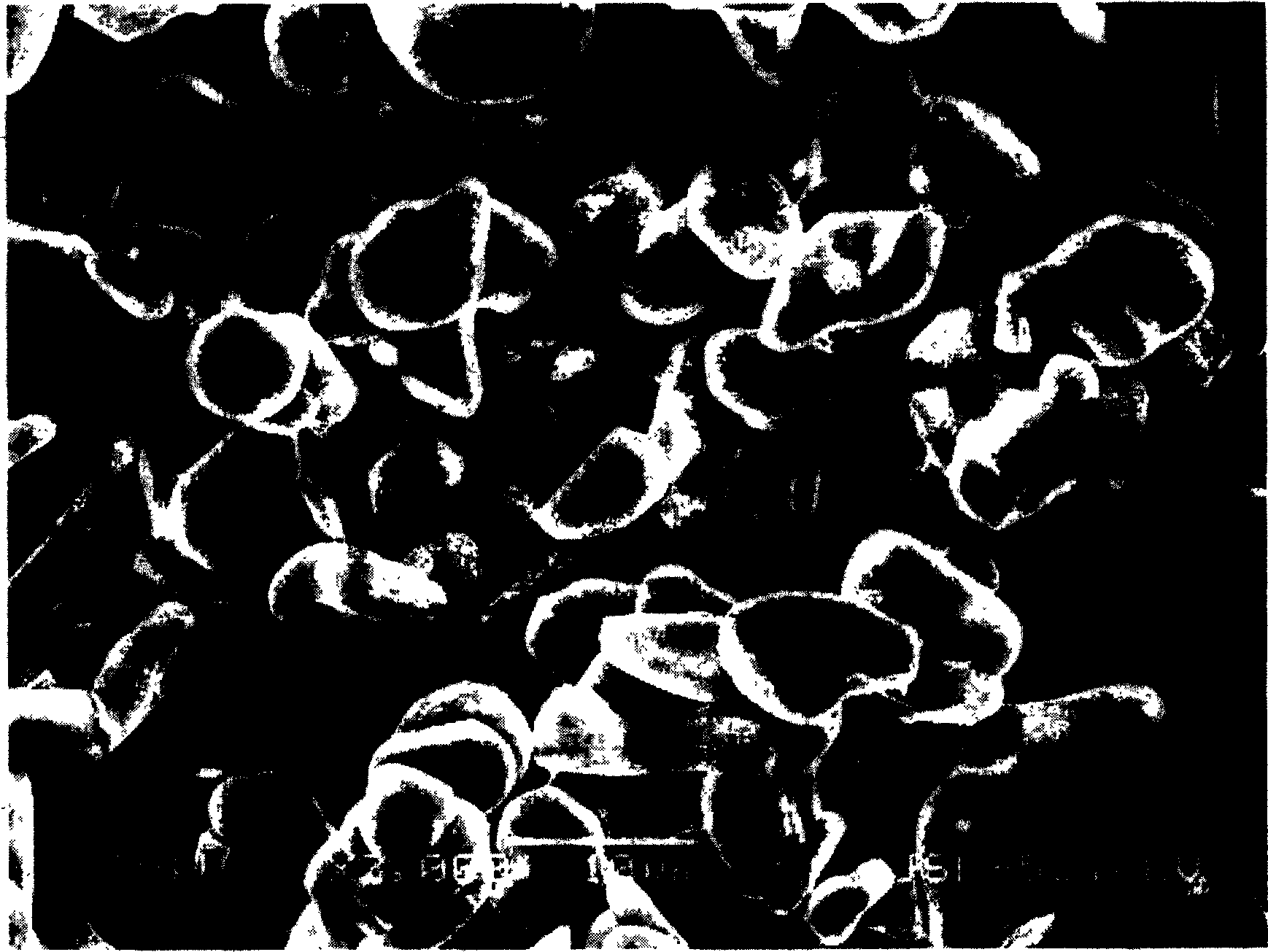

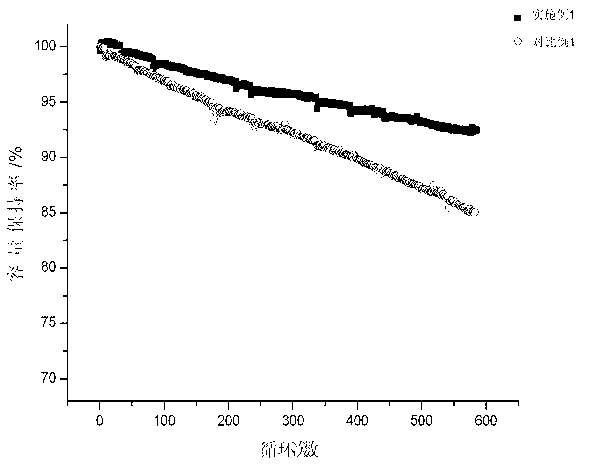

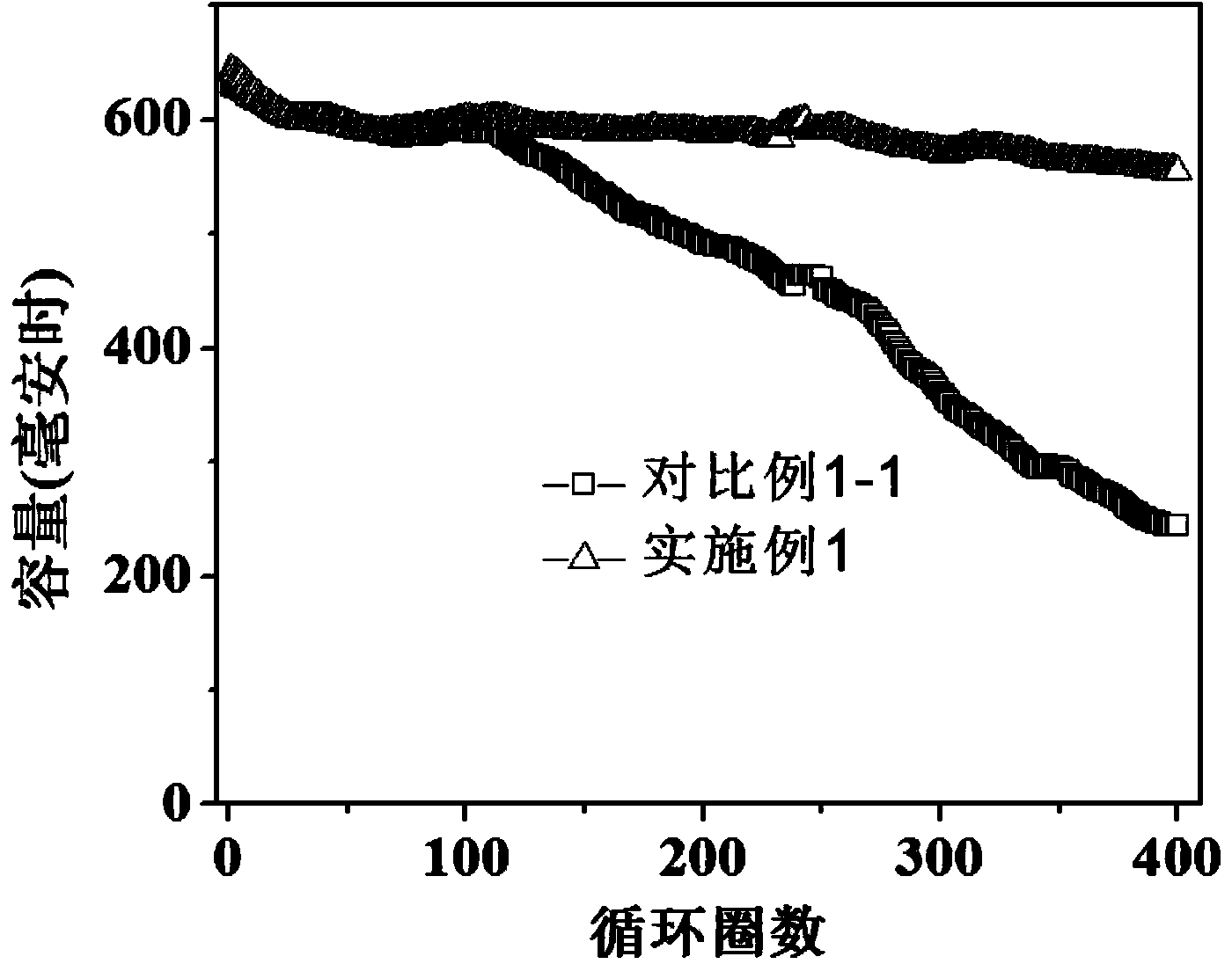

Anode material of lithium ion cell and preparation method

InactiveCN1627550AGood cycle performanceGood high temperature performanceElectrode thermal treatmentActive material electrodesAnodeMetallurgy

The anode material is prepared from oxidation material layer of covering surface of at least one anode active material among LiCoO2, LiNi1-xCOxO2, LiNi1 / 3Mn1 / 3O2 and LiMn2O4. Weight of non-oxygen element in oxidation material layer can be 0.01-10 weight% of anode active material. Advantages of the anode material are: good cycle performance, favorable high temp property and high power discharge property, and anti over change property as well as simple technique and easy of production.

Owner:BYD CO LTD

Preparation method of lamellar lithium manganese battery

ActiveCN101964428ALow costGood high temperature performanceFinal product manufactureCell electrodesLithium electrodeCooking & baking

Owner:BTR NEW MATERIAL GRP CO LTD

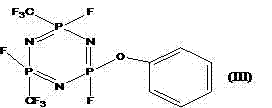

Lithium ion battery with nickel-based cathode, and electrolyte therefor

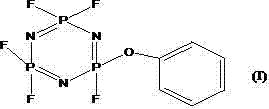

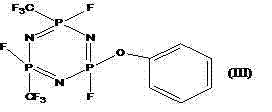

ActiveCN103208653AGood high temperature performanceGood low temperatureSecondary cellsElectrolytic agentOrganic solvent

The invention belongs to the technical field of lithium ion batteries and particularly relates to electrolyte for a lithium ion battery with a nickel-based cathode. The electrolyte comprises non-aqueous organic solvent, lithium salt, boron-containing lithium salt additive, cyclic ether compound and cyclic phosphonitrile compound. The cyclic phosphonitrile compound is hexaphenoxycyclotriphosphazene or cyclic phosphonitrile derivative. Compared with the prior art, the electrolyte is provided with the boron-containing lithium salt additive capable of improving high temperature performance of the lithium ion secondary battery with nickel-based cathode material, the cyclic phosphonitrile compound, and the cyclic ether compound, and the addition of the cyclic phosphonitrile compound and the cyclic ether compound enables the battery to be fine in high temperature performance, low temperature performance and cycle performance. In addition, the invention discloses the lithium ion battery comprising the electrolyte.

Owner:DONGGUAN AMPEREX TECH

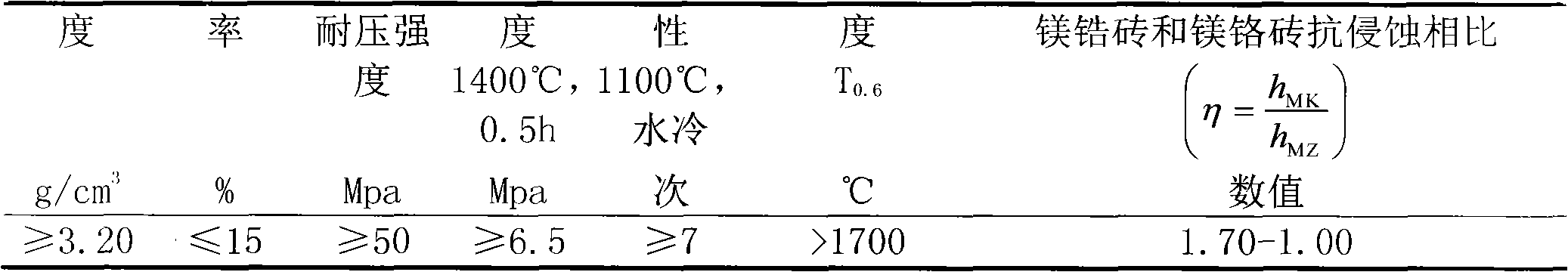

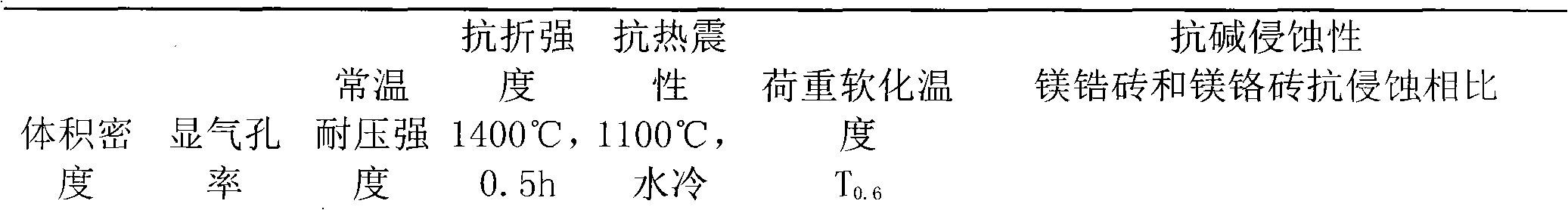

Magnesium-zirconium brick with high erosion resistance and thermal shock resistance for RH furnace and production technology thereof

The invention relates to a magnesium-zirconium brick with high erosion resistance and thermal shock resistance for an RH furnace and a production technology thereof. The brick comprises the following components by weight percent: 76-90% of MgO and 5-21% of ZrO2; and the firing temperature of the brick is 1680-1840 DEG C. The production technology comprises the following steps: pretreating magnesia and zirconia, synthesizing the magnesia and zirconia into magnesium-zirconium sand; crushing synthesized magnesium-zirconium sand and fused magnesia to 5-3mm, 3-1mm and 1-0mm particles; homogenizing under strong force and mixing the granular materials, 150-200 mesh magnesia and magnesium-zirconium sand powder, 200-250 mesh zirconia powder, additives CaO and Y2O3 and binder paper pulp water liquid and performing compression moulding; baking at 120 DEG C for 24-72 hours; and heating to 1680-1840 DEG C and maintaining the temperature for 3-5 hours. The linear change of the finished brick is within the range of + / -0.5%; and after being baked, the brick has no surface chap defect caused by the phase change of zirconia and has excellent refinery cinder erosion resistance and thermal shock resistance.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

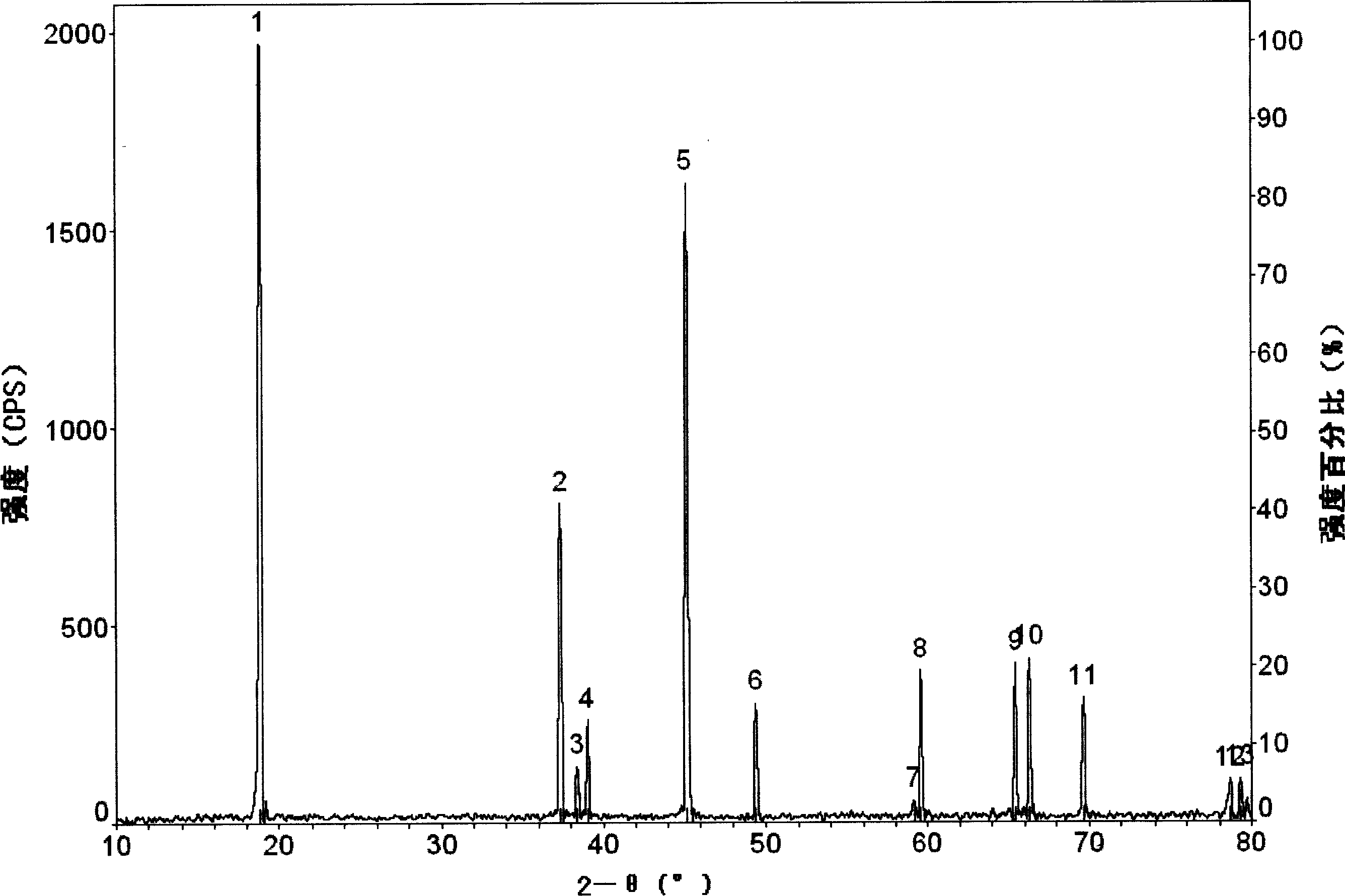

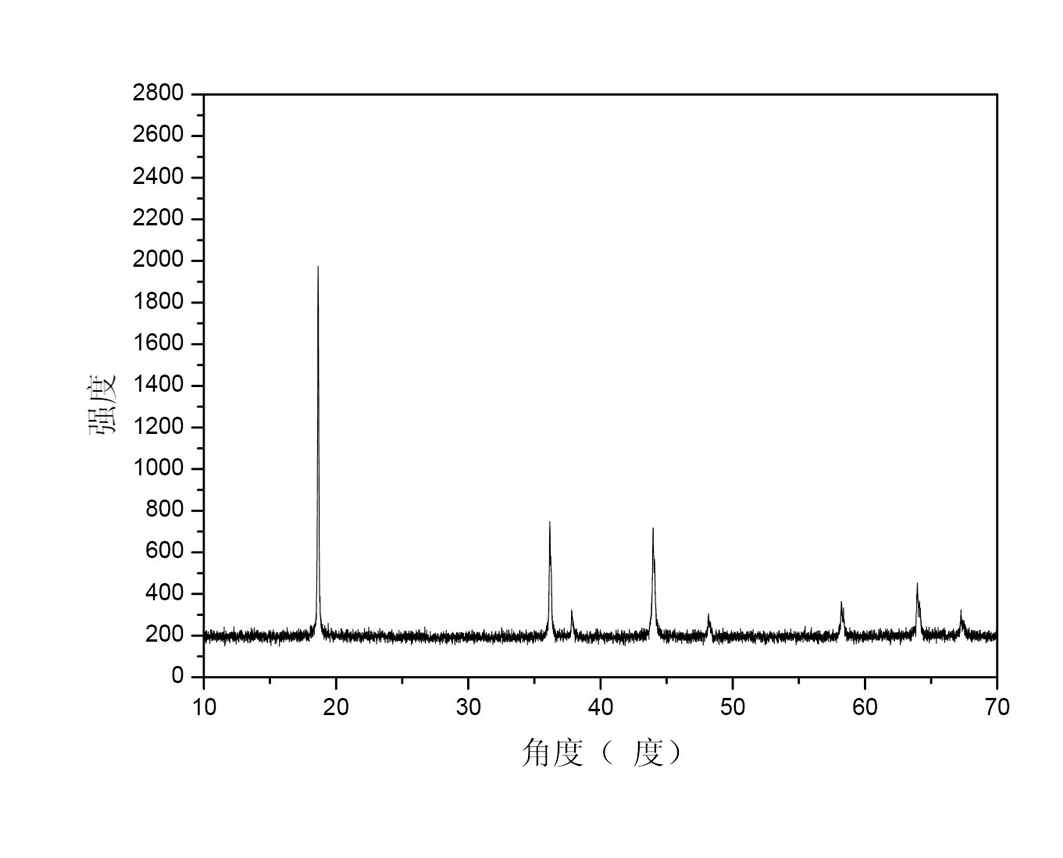

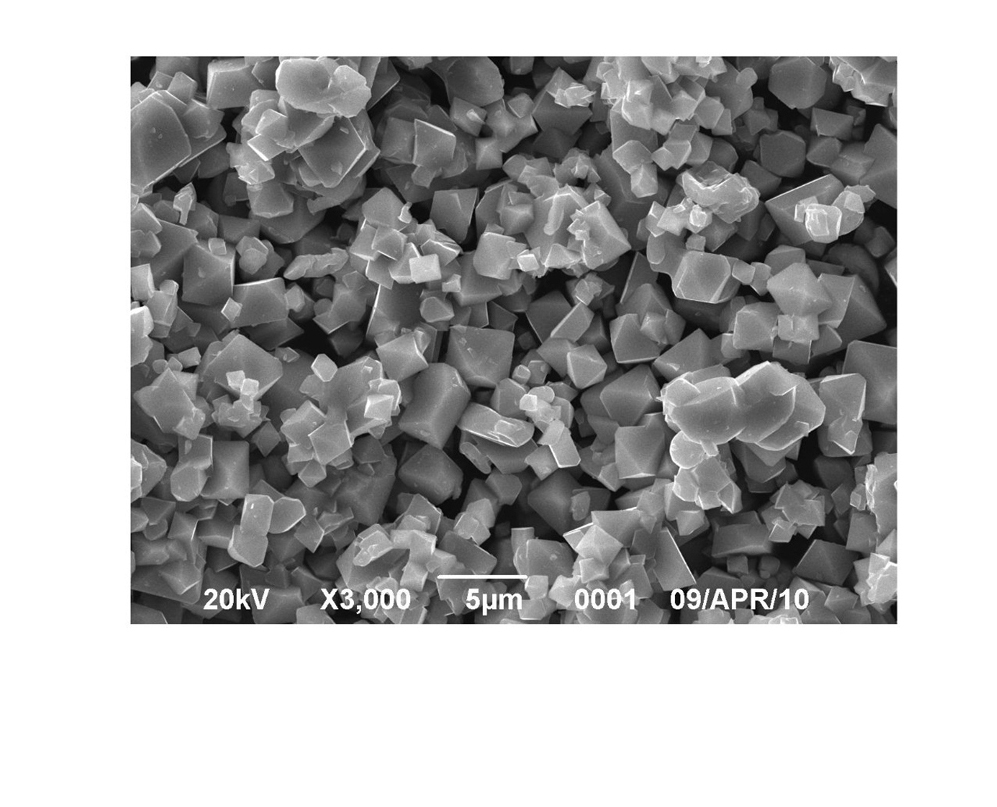

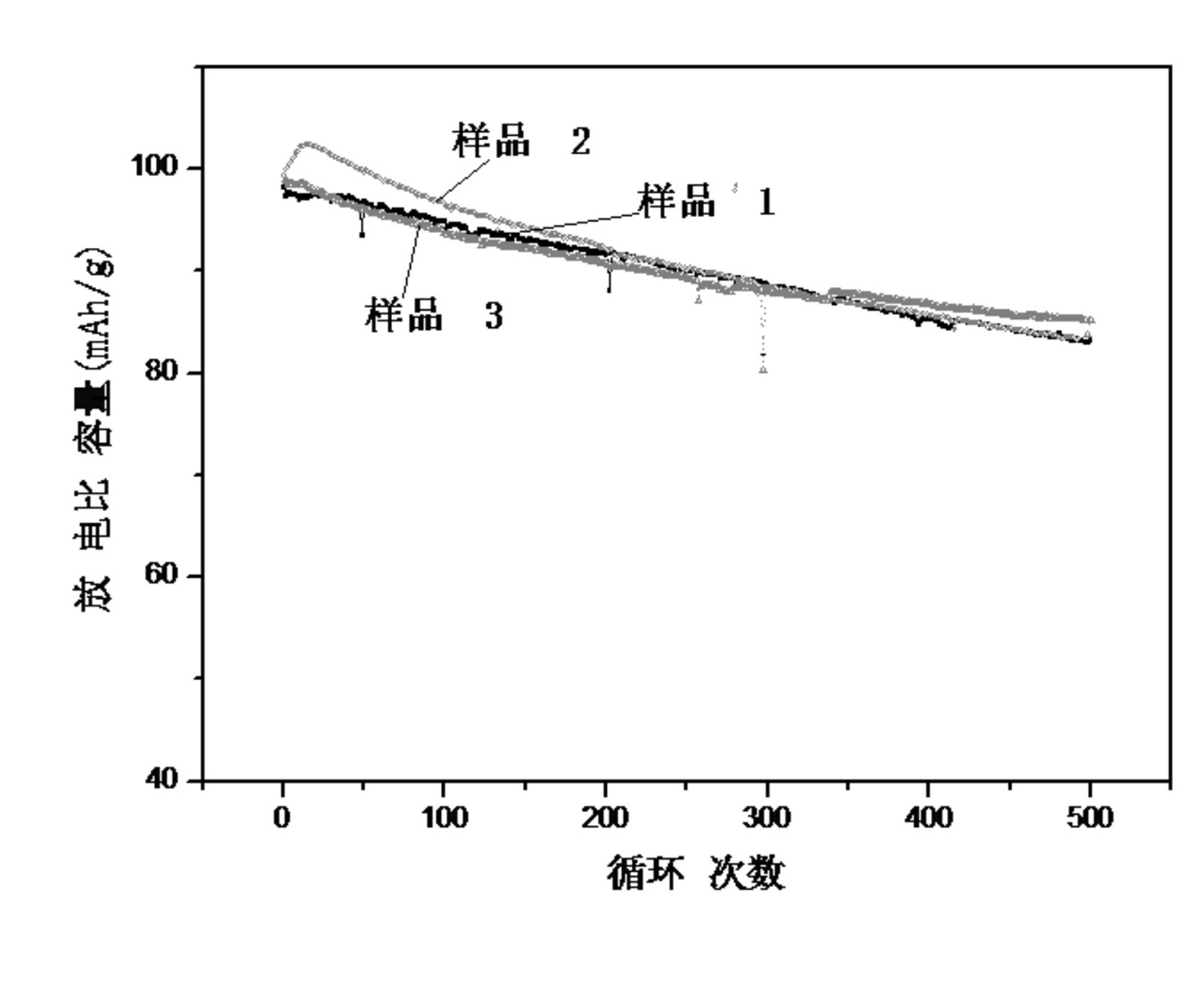

Preparation method of lithium ion battery anode material lithium manganate and automobile lithium ion battery

InactiveCN101964416AUniform bulkGood crystallizationCell electrodesSecondary cellsElectrical batteryManganate

The invention relates to a preparation technology of a battery anode material and a related automobile battery and particularly discloses a preparation method of lithium ion battery anode material lithium manganate. The method comprises the following steps: using lithium source, Mn3O4 and nanoscale doping metal additive as raw materials for proportioning, then presintering Mn3O4 or the Mn3O4 processed by ball milling, mixing the presintered Mn3O4 with the mixture of lithium source and metal additive; performing the first sintering and second sintering to the mixed raw material; and finally classifying and screening the sintering product to obtain the spinel lithium manganate product with the required grain size. The invention also discloses an automobile lithium ion battery which is assembled by using the spinel lithium manganate prepared by the method of the invention as anode and using graphite as cathode. The preparation method of the invention has simple operation and environmental friend; and the prepared lithium manganate product has excellent product performance.

Owner:HUNAN CHANGYUAN LICO CO LTD

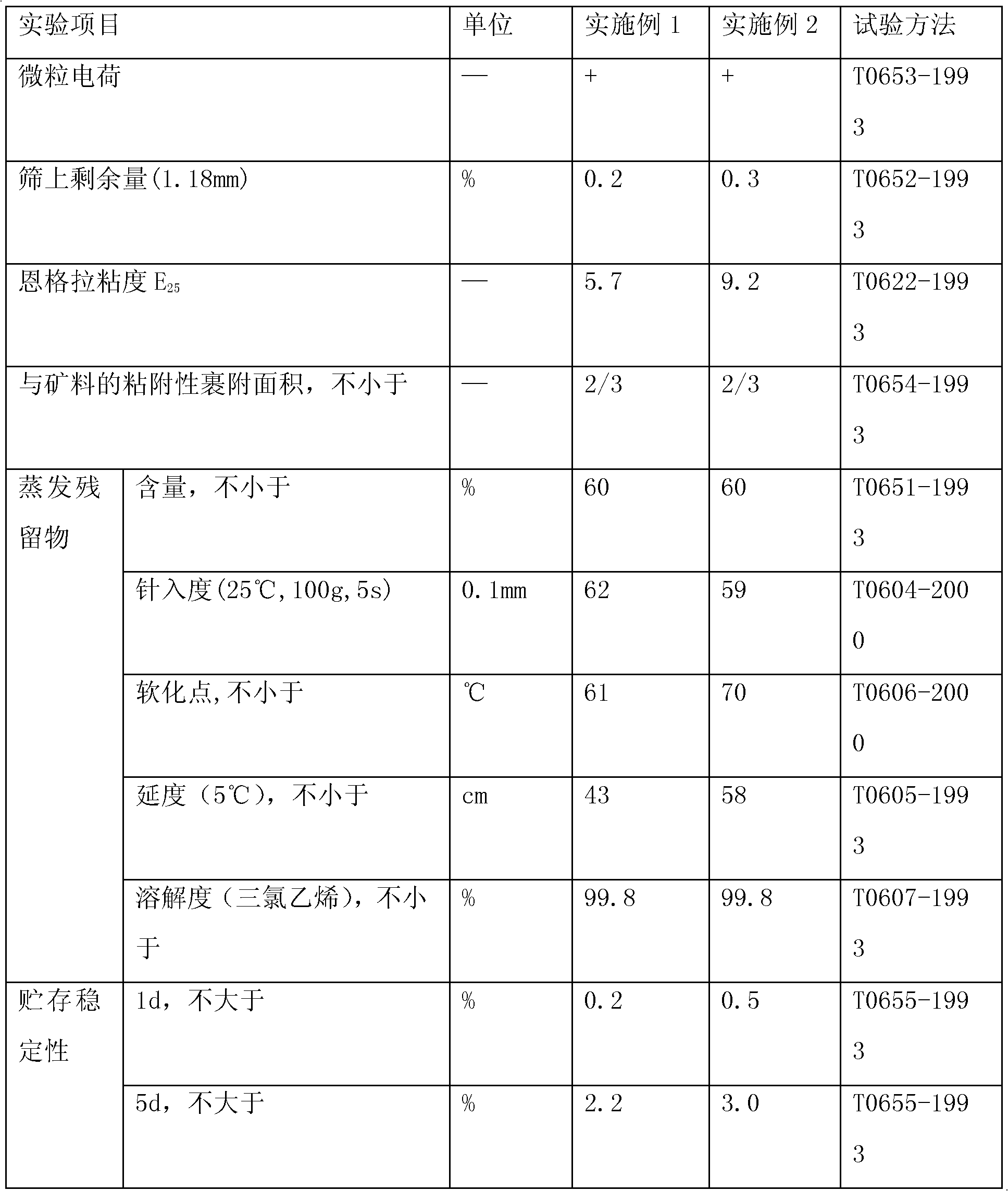

SBS polymer modified emulsified asphalt and preparation method

The invention belongs to the modified emulsified asphalt field, and more specifically relates to a SBS polymer modified emulsified asphalt and a preparation method, the SBS polymer modified emulsified asphalt is prepared by the following raw materials by mass percentages: 40-65% of SBS polymer modified emulsified asphalt, 25-50% of water, 2-10% of cation asphalt emulsifier, 0.1-2.0% of composite emulsified stabilizing agent and 0.2-2.0% of acid, wherein SBS polymer modified asphalt is prepared by mixing and reacting a SBS polymer modifier and matrix asphalt, and the mass of the SBS polymer modifier accounts for 3.5%-5.5% of that of the SBS polymer modified asphalt. The prepared SBS polymer modified emulsified asphalt has stable property, and can be used as a cement asphalt mortar layer and the like for a road tack coat, a seal layer, surface treatment, a slurry seal layer and a high speed railway plate-type ballastless track.

Owner:CHINA PETROLEUM & CHEM CORP

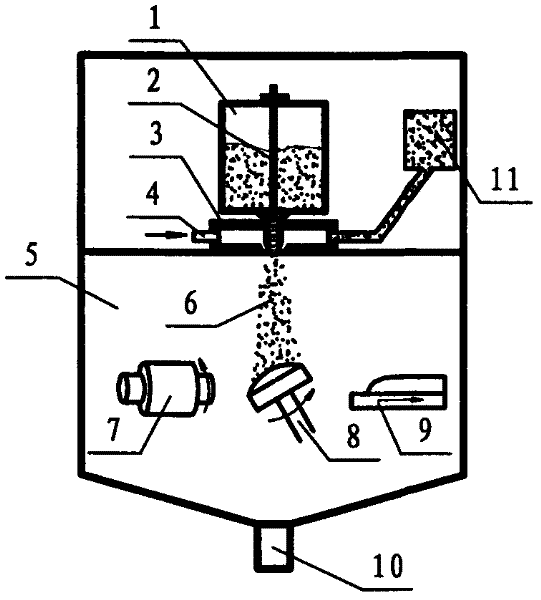

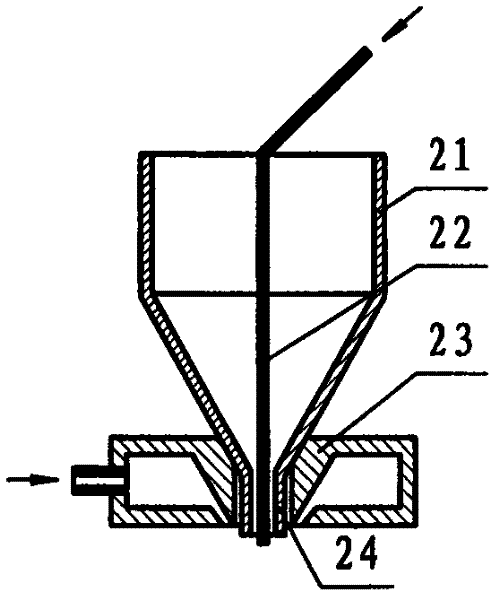

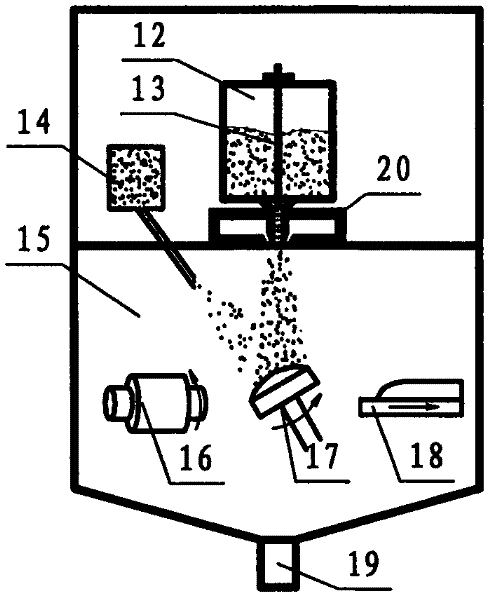

Method and system for preparing particle-reinforced metal-based composite material through injection molding

The invention relates to a method and system for preparing a particle-reinforced metal-based composite material through injection molding. Ceramic reinforced particles and high-pressure inert gas are uniformly mixed in an acceleration nozzle to be used as an atomizing medium, thereby improving the density, momentum and impact force of the atomizing medium, obviously enhancing the atomization effect and reducing the inert gas consumption as compared with the atomization based on the single use of inert gas. After atomization is completed, the ceramic particles are uniformly dispersed in atomized molten drops, and the molten metal drops doped with the reinforced particles are gradually solidified in the flying process and are ultimately deposited, solidified and molded on a receiver, thus obtaining the high-performance metal-based composite material of which the ceramic reinforced particles are uniformly distributed. In addition, the ceramic reinforcements used in the invention are prepared by a reaction and ball milling method, thereby ensuring that the reinforced particles better in strength, interface stability, high-temperature performance and other aspects can be prepared at a low cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

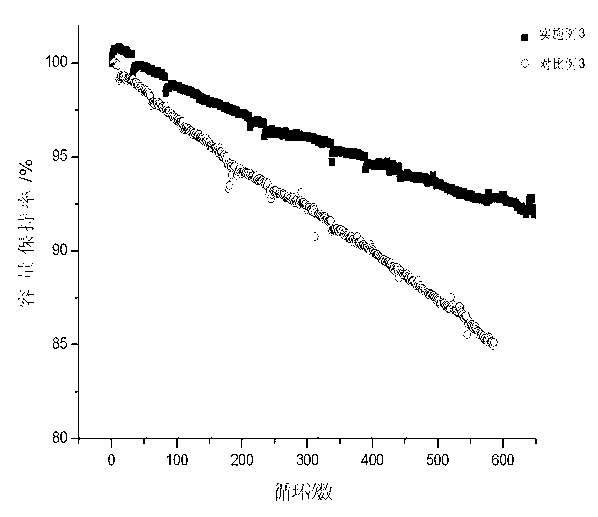

Lithium battery positive electrode slurry and preparation method thereof

ActiveCN103208631AGood high temperature performanceHigh capacity retentionNon-aqueous electrolyte accumulator electrodesOrganic solventSlurry

The invention discloses lithium battery positive electrode slurry. The lithium battery positive electrode slurry is a mixture of a positive electrode material and an organic solvent. The positive electrode material is composed of, by mass, 60-97% of a positive electrode active material, 1-30% of a binding agent, 0-10% of a conductive agent, 1-5% of a conductive reinforcing agent and 0.1-3% of a dispersing agent. A lithium battery prepared by the lithium battery positive electrode slurry provided by the invention has the advantages of excellent high temperature performance, high capacity conservation rate, good cycle performance, long service life and the like. The invention also provides a preparation method of the lithium battery positive electrode slurry, enabling solid materials such as the conductive reinforcing agent to be distributed in the organic solvent uniformly and stably and to be directly stirred and mixed in a common stirring apparatus, so that the operation is convenient and the method can realize large-scale production.

Owner:WANXIANG 123 CO LTD

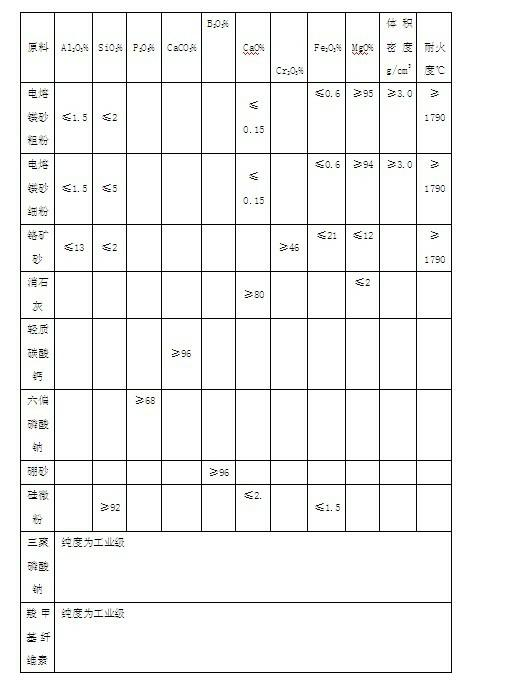

Novel RH gunning refractory

ActiveCN102659432AHigh bonding strengthGood high temperature performanceEnvironmental indexRefractory

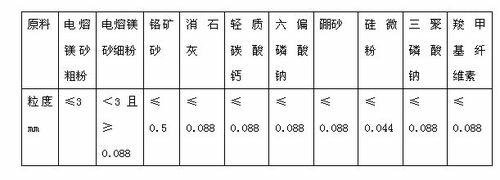

The invention relates to a novel RH gunning refractory belonging to the refractory material field. The gunning refractory comprises the following raw materials in weight percent: 50-60% of fused magnesite crude powder, 15-30% of fused magnesite fine powder, 10-255% of chrome ore, 0.5-2% of slaked lime, 1-5% of light calcium carbonate, 1-4% of sodium hexametaphosphate, 2-55% of borax, 2-4% of silica powder, 0.5-4% of sodium tripolyphosphate and 0.005-0.1% of carboxymethylcellulose; and the raw materials are evenly mixed in a stirring device to obtain a finished product. The RH gunning refractory prepared from the raw materials provided by the invention is low in production cost, resistant to erosion and good in impermeability; an RH insert tube after being subjected to gunning maintainmentcan be used more than 85 times and the RH insert tube can be used for 5-6 furnaces after every time of gunning maintainment; the service life of the RH insert tube is obviously prolonged and the production efficiency is greatly improved; and in the use process, no harmless gas gives out, no peculiar smell is produced and no thick smoke is generated; and therefore the novel RH gunning refractory completely meets specified environmental indexes and utilization requirements..

Owner:攀枝花市银江金勇工贸有限责任公司

Heat-resistant cast aluminum alloy and extrusion casting method thereof

ActiveCN104561689AGood high temperature performanceHigh hardnessMetallic materialsSolution treatment

The invention relates to a heat-resistant cast aluminum alloy and an extrusion casting method thereof, and belongs to the fields of metallic materials and metallurgy. The alloy consists of the following elements in percentage by weight: Si, Cu, Ni, Mg, Ti, RE, Mn, Fe and Al. The heat-resistant cast aluminum alloy is prepared by virtue of extrusion casting, and after performing solution treatment and artificial aging treatment on the alloy, the room temperature tensile strength sigma b of the alloy is more than or equal to 420MPa, the tensile strength sigma b at 300 DEG C is more than or equal to 220MPa, the tensile strength sigma b at 350 DEG C is more than or equal to 140MPa, the room temperature extensibility delta is more than or equal to 2.5%, the extensibility delta at 300 DEG C is more than or equal to 6.5%, and the extensibility delta at 350 DEG C is more than or equal to 14.5%. According to the alloy and the extrusion casting method thereof provided by the invention, the casting performance is improved, the room-temperature and high-temperature mechanical properties of the alloy are greatly improved, and the application range of Al-Si series cast aluminum alloys is expanded.

Owner:SHANGHAI JIAO TONG UNIV

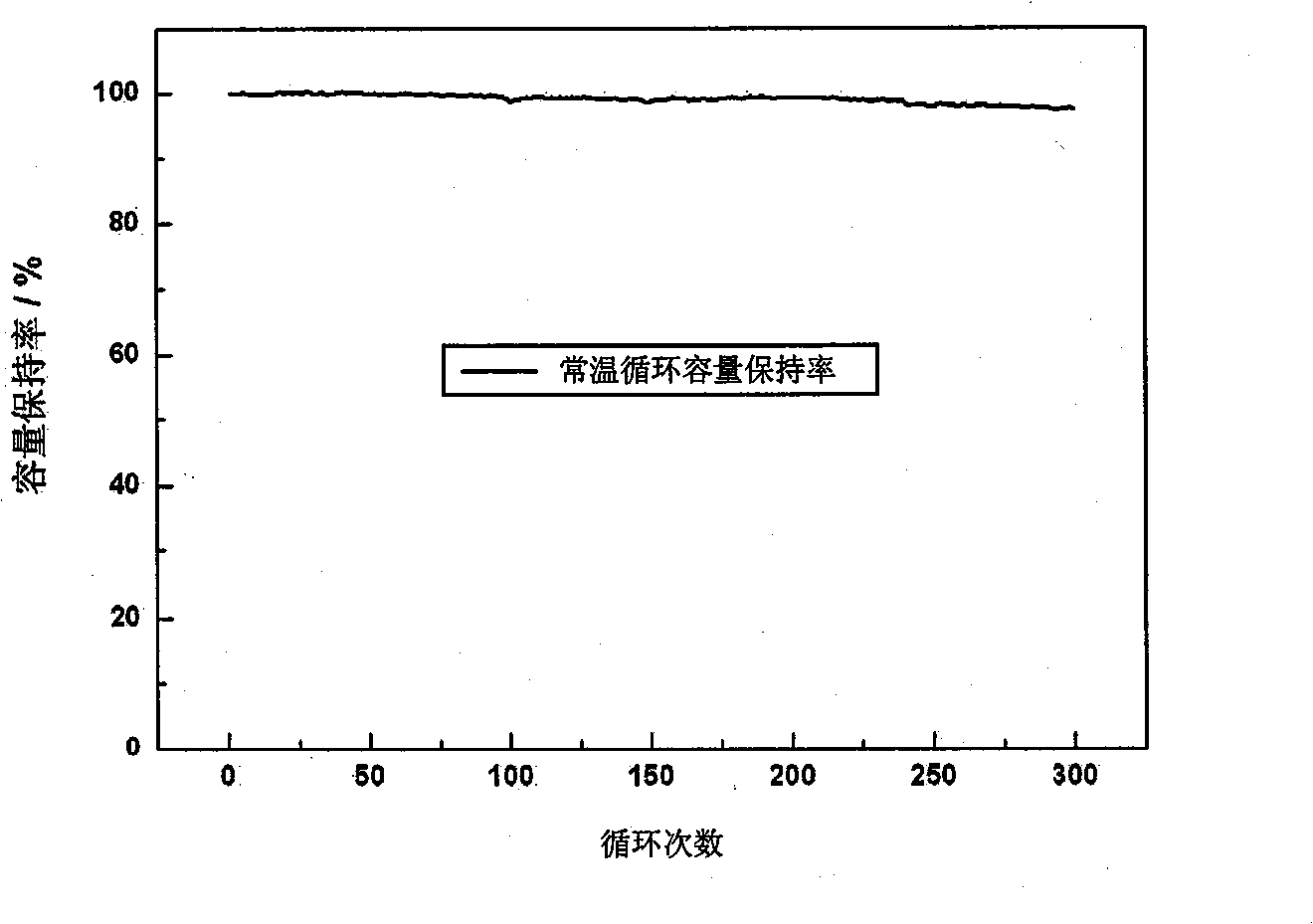

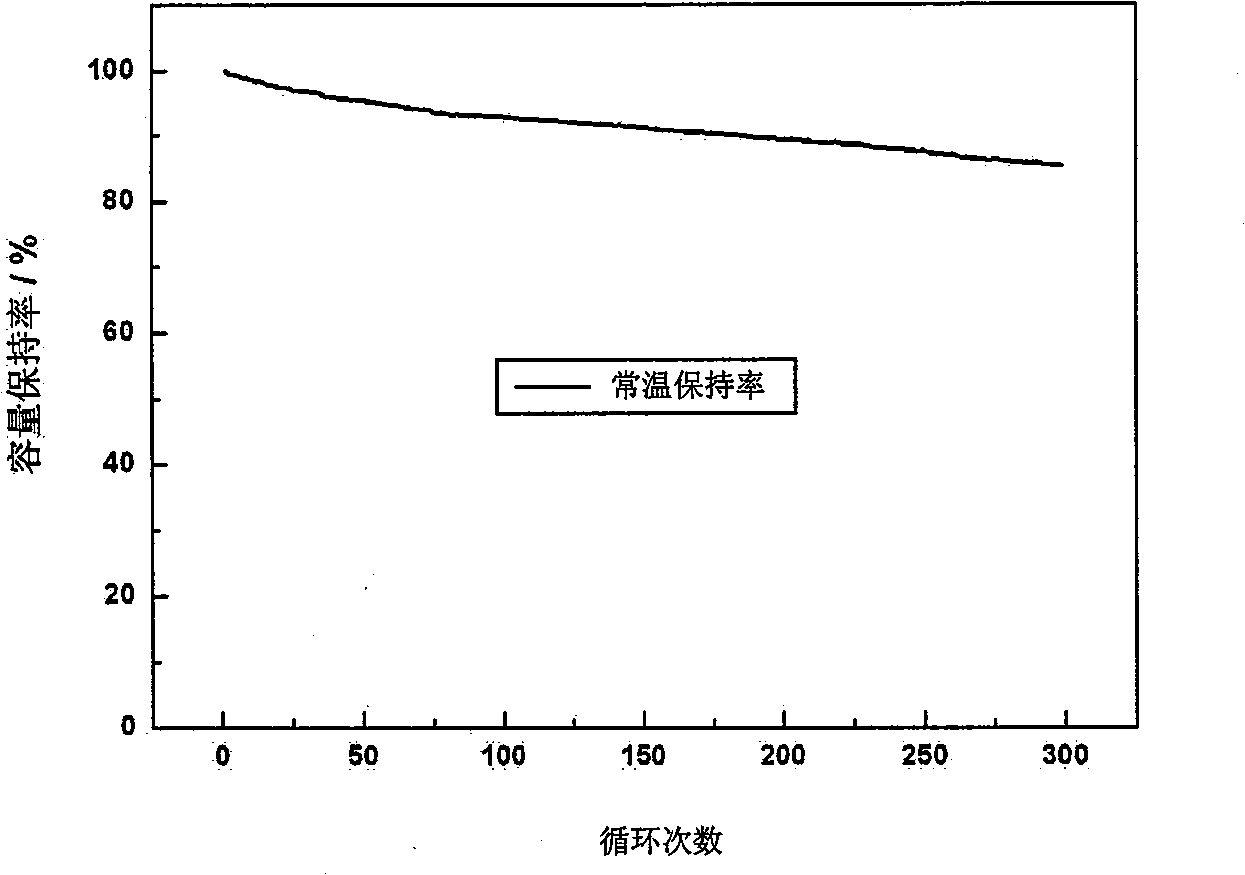

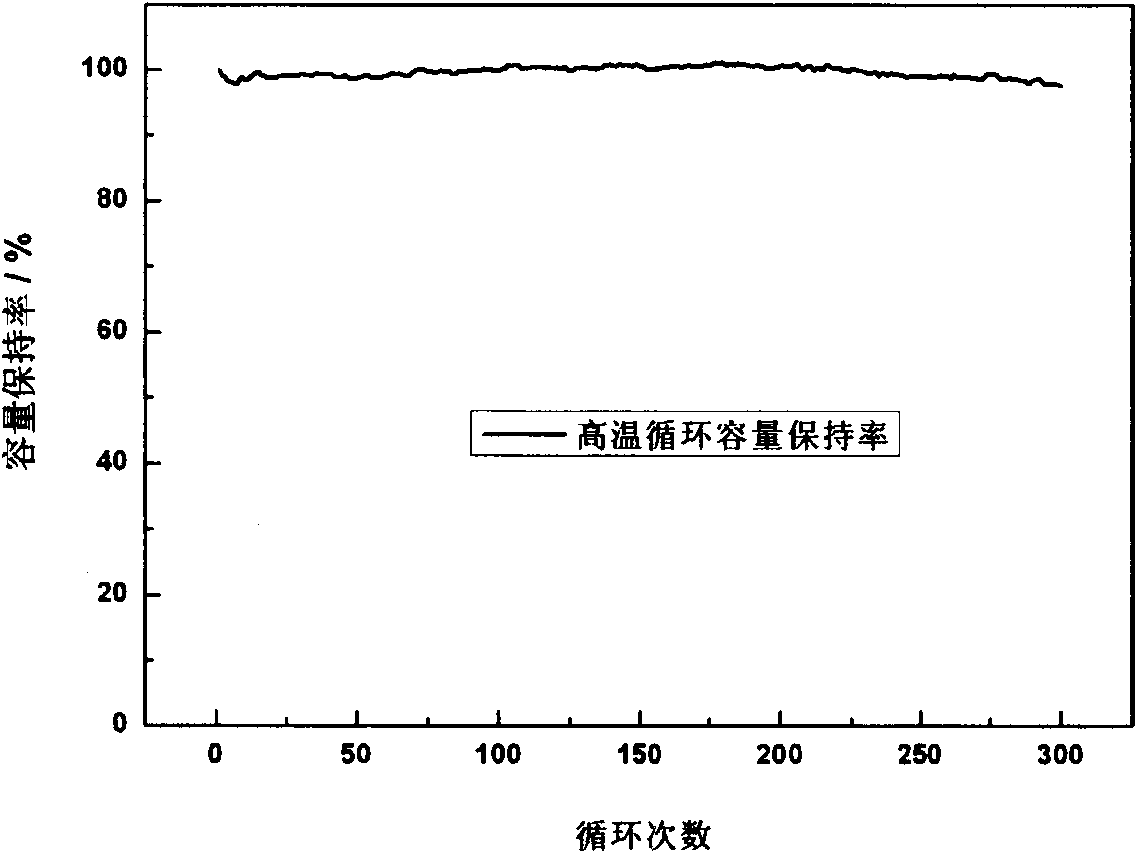

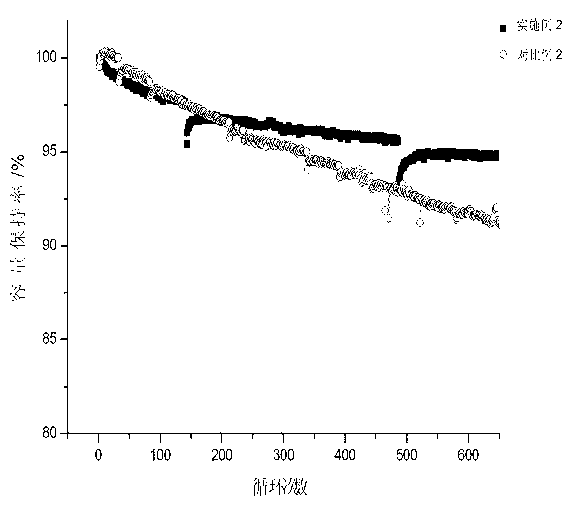

Functional additive for lithium ion battery electrolyte, lithium ion battery electrolyte and lithium ion battery

ActiveCN106848404AGood high temperature performanceImprove thermal stabilityFinal product manufactureElectrolyte accumulators manufactureOrganic solventPhosphate

The invention relates to a functional additive for a lithium ion battery electrolyte, the lithium ion battery electrolyte and a lithium ion battery and belongs to the technical field of lithium ion batteries. The functional additive is prepared from the components in parts by weight as follows: 0.5-3 parts of vinylene carbonate, 0.1-2 parts of lithium difluoro(oxalato) borate, 0.1-2 parts of lithium difluoro phosphate, 3-5 parts of fluorobenzene and 0.1-1 part of methylene methanedisulfonate. The electrolyte comprises lithium salt, an organic solvent and the functional additive, wherein the mass percents of the components of the functional additive in the electrolyte are as follows: 0.5%-3% of vinylene carbonate, 0.1%-2% of lithium difluoro(oxalato) borate, 0.1%-2% of lithium difluoro phosphate, 3%-5% of fluorobenzene and 0.1%-1% of methylene methanedisulfonate. The invention further relates to the lithium ion battery using the electrolyte. The high-temperature cycle performance of the lithium ion battery is significantly enhanced.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Preparation and heat treatment method of low-alloy heat-resistant high-strength steel memebers

InactiveCN102433513AReasonable optimization of componentsGood high temperature performanceSolid state diffusion coatingRoom temperatureHardness

The invention relates to a preparation and heat treatment method of low-alloy heat-resistant high-strength steel memebers, which is characterized in that on the basis of 15CrMo, the steel ingredients are reasonably optimized, the heat-resistant memebers with excellent high-temperature performance and little deformation quantity are prepared and obtained through controlling preparation process parameters, such as smelting, rolling, heat treatment and the like, the room-temperature tensile strength of the memebers is 610 MPa, the effective service life of the memebers is twice that of the 15CrMo through the stress test of 200 MPa under 600 DEG C, the use temperature of the heat-resistant steel is obviously improved, the surface hardness after the heat treatment is about 750 HV, in addition,the thickness of a hardening layer with the hardness exceeding 500 HV is 0.5mm, the deformation quantity is little, in addition, the weldability is also very excellent, and the performance of the memebers in all aspects exceeds that of 15CrMo products.

Owner:STATE GRID CORP OF CHINA +1

Extreme-pressure lubricating grease and preparation method thereof

ActiveCN101624549AGood high temperature performanceIncrease loading capacityLubricant compositionPolyureaAluminium

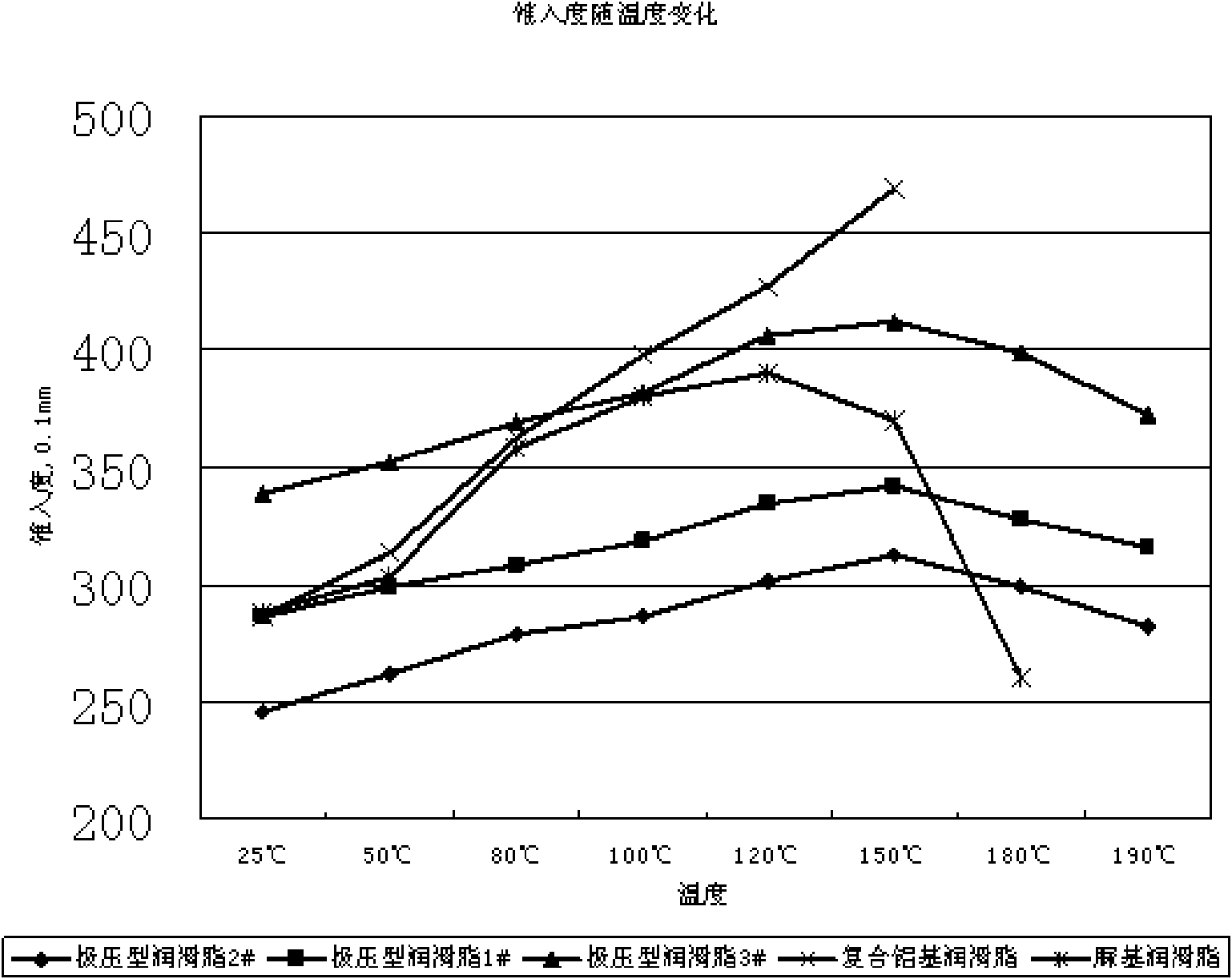

The invention relates to extreme-pressure lubricating grease and a preparation method thereof. The lubricating grease comprises the following components in percentage by weight: 80-92 percent of tempered oil taking mineral oil, synthetic oil or both the mineral oil and the synthetic oil as base oil, 5-13 percent of thickening agent, 0.5-1 percent of antioxidizer, 1-5 percent of extreme pressure agent and 1-1.5 percent of rust inhibitor. A one-step saponification campsite process is adopted. Due to the adoption of a proper raw material proportion, the lubricating grease has favorable high temperature performance, a drop point is larger than 235 DEG C, the thickness obviously becomes good along with the change of the temperature, and the requirement on use with wide temperature range is satisfied. The invention has the advantages of nonhardening at high temperature and low cost when compared with polyurea lubricating grease, also has favorable adhesiveness when being compared with composite aluminum, and improves the extreme-pressure performance and the load resisting capacity of the lubricating grease. The lubricating grease of the invention is prepared in one step by direct composite reaction, thereby ensuring simple process, saving the energy consumption and lowering the production cost; in addition, the quality of products produced by the process is also more stable.

Owner:CHINA PETROLEUM & CHEM CORP

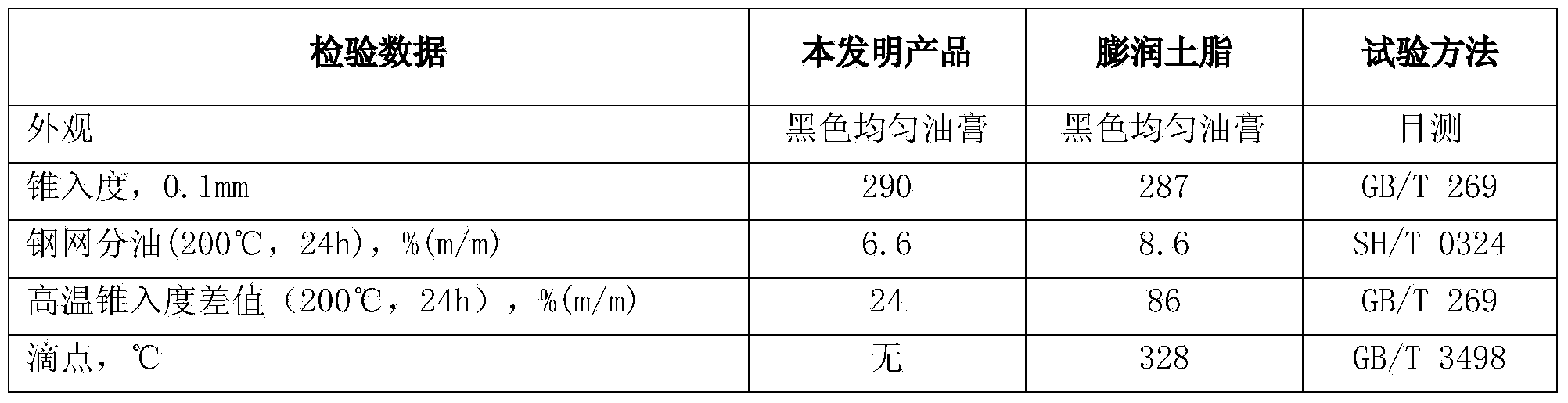

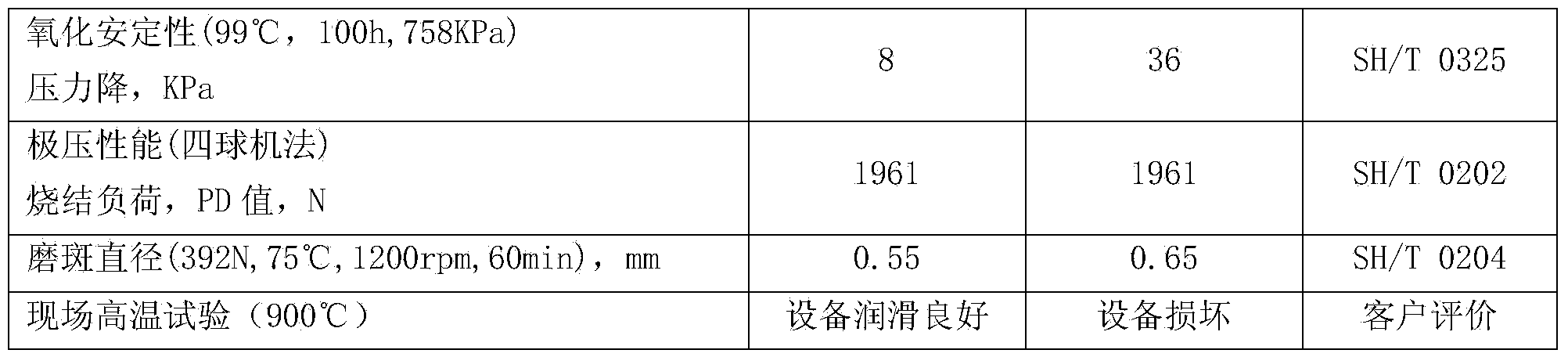

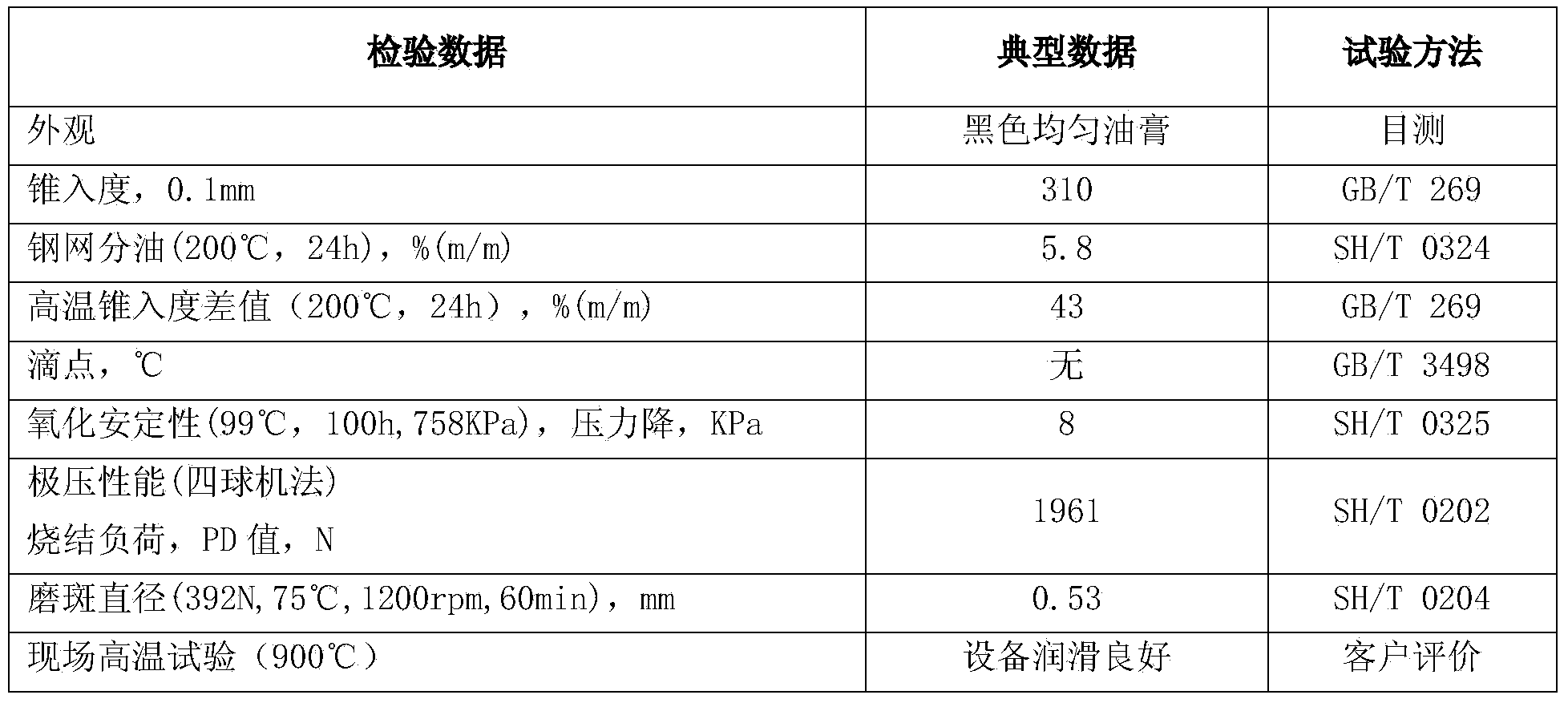

Synthetic high-temperature lubricating grease and preparation method thereof

ActiveCN101921653AGood high temperature performanceSmall oil separationLubricant compositionAntioxidantHydroxystearic Acid

The invention relates to synthetic high-temperature lubricating grease and a preparation method thereof, in particular to lubricating grease generated by taking high-base number compound calcium sulfonate as a thickening agent and high-viscosity synthetic oil as base oil. The synthetic high-temperature lubricating grease comprises the following components in percentage by mass: 30%-80% of the synthetic base oil, 15%-30% of high-base number compound calcium sulfonate, 2%-10% of 12-hydroxyl stearic acid, 1%-5% of boric acid, 1%-4% of acetic acid, 0.5%-2% of water, 1%-3% of calcium hydroxide and0.1%-0.5% of antioxidants. The produced high-temperature lubricating grease has the advantages of excellent high temperature and water spraying resistance, very well extreme pressure abrasion resistance, cutting safety, rust protection, and the like and is very suitable for the production parts of steel mills, cement plants, power plants, and the like, which have high temperature, heavy loads andlarge quantities of cooling water.

Owner:北京奥力助兴石化科技有限公司

Battery separator and preparation method thereof

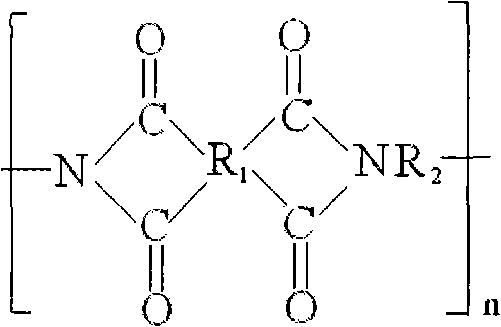

ActiveCN101355143AGood high temperature performanceImprove mechanical propertiesCell component detailsLithiumSubstance use

The invention provides a diaphragm for a battery, comprising a base material. The base material comprises through holes, wherein the base material contains polyimide and additives, and the additives are inorganic crystal whiskers and / or orthosilicate ester. The diaphragm prepared by the invention has excellent high-temperature performance, the heat shrinking property of the diaphragm is below 1.1 percent below 400 DEG C, and no cracking phenomenon occurs below 400 DEG C. The mechanical property of the diaphragm is excellent, the tensile-strength of the diaphragm is above 100 Mpa, while the tensile-strength of the diaphragm prepared by the prior art is only 90 Mpa. In addition, perforating substances used by the invention can effectively adjust the average diameter of a hole of the diaphragm within a better range of between 10 and 100 nanometers, thereby guaranteeing the smooth passing of lithium irons in the battery using the diaphragm, reducing the internal resistance of the battery, and having no short circuit.

Owner:BYD CO LTD

High-temperature lubricating grease composition and preparation method

InactiveCN103525513AGood high temperature performanceImprove high temperature performanceLubricant compositionColloid millLubrication

The invention provides a high-temperature lubricating grease composition and a preparation method. The preparation method comprises the following steps of adding boron nitride and an anti-wear reagent at extreme pressure into base oil according to a certain proportion, mixing, heating to 60-160 DEG C, carrying out pre-dispersion by mechanical stirring with the pre-dispersion time being 0.5-1 hour; carrying out pre-dispersion again on pre-dispersed materials by a colloid mill, adjusting the dispersing effect by adjusting the fineness of the colloid mill, and when the penetration is proper, carrying out filling. The lubricating grease provided by the invention has the advantages that due to selection of a thickening agent with high-temperature performance and the base oil with high-temperature performance and addition of a solid lubricating agent with good high-temperature performance as the anti-wear reagent at extreme pressure, the lubricating grease has excellent high-temperature performance, anti-wear performance at extreme pressure and oxidation stability and obtains better technical effects. The high-temperature lubricating grease composition provided by the invention can be applied to lubrication and protection of high-temperature mechanical equipment in the industries of ceramic, metallurgy and machining and the like.

Owner:CHINA PETROLEUM & CHEM CORP

MgO-SiC-C refractory material synthesized by forsterite-C and method

The invention relates to MgO-SiC-C refractory material synthesized by forsterite-C and a method. The technical proposal to be adopted is as follows: firstly, forsterite mineral powder and industrial carbon powder are blended according to molar ratio of 1: (1-5); and then the mixture is added with 4 to 10 wt% of bonding agent, stirred or mulled for 10 to 30 minutes, pressed to be formed and dried; and finally under the Ar gas condition, the mixture is sintered in the sintering temperature of 1530 to 1800 DEG C with heat preservation for 2 to 8 hours to obtain MgO-SiC-C refractory material synthesized by forsterite-C. The invention is characterized by comparatively simple processing technique, low producing cost, high producing efficiency, wide raw material source and being capable of reducing energy consumption of high temperature synthesis reaction. The prepared MgO-SiC-C refractory material has the advantages of excellent high temperature performance, anti-corrosion and good durability.

Owner:WUHAN UNIV OF SCI & TECH

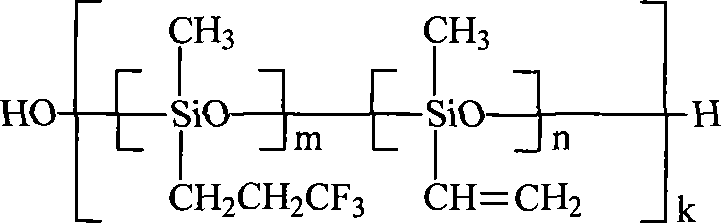

Method for preparing fluorine silicon rubber base glue

InactiveCN101177486AIncrease vinyl contentGood mechanical propertiesPolymer scienceMechanical property

The invention relates to a preparation method of fluorosilicone rubber base rubber, providing a preparation method of hydroxyl end capped fluorine silicon promoter with fluorine silicon structural unit and ethylene unit and certain polymerization degree, for preparing fluorosilicone rubber base rubber with excellent mechanical properties, high temperature properties and oil resistant properties. The invention prepares fluorine silicon promoter materials, materials of fluorine silicon promoter adopting open loop condensational procedure via general fluorine silicon monomer, vinyl silicone monomer, basic promoter and regulator, and obtains the needed fluorine silicon promoter; the fluorine silicon promoter and other promoters are added in the fluorine silicon raw rubber; the fluorine silicon raw rubber, the fluorine silicon promoter and the tetra butyl peroxy hexane are mixed uniformly for 5 to 60 minutes on a open mill or a internal mixer, thefluorosilicone rubber base rubber can be obtained after discharging. The invention prepares excellent fluorosilicone rubber base rubber with excellent mechanical properties, high temperature properties and oil resistant properties.

Owner:广东信力特种橡胶制品有限公司

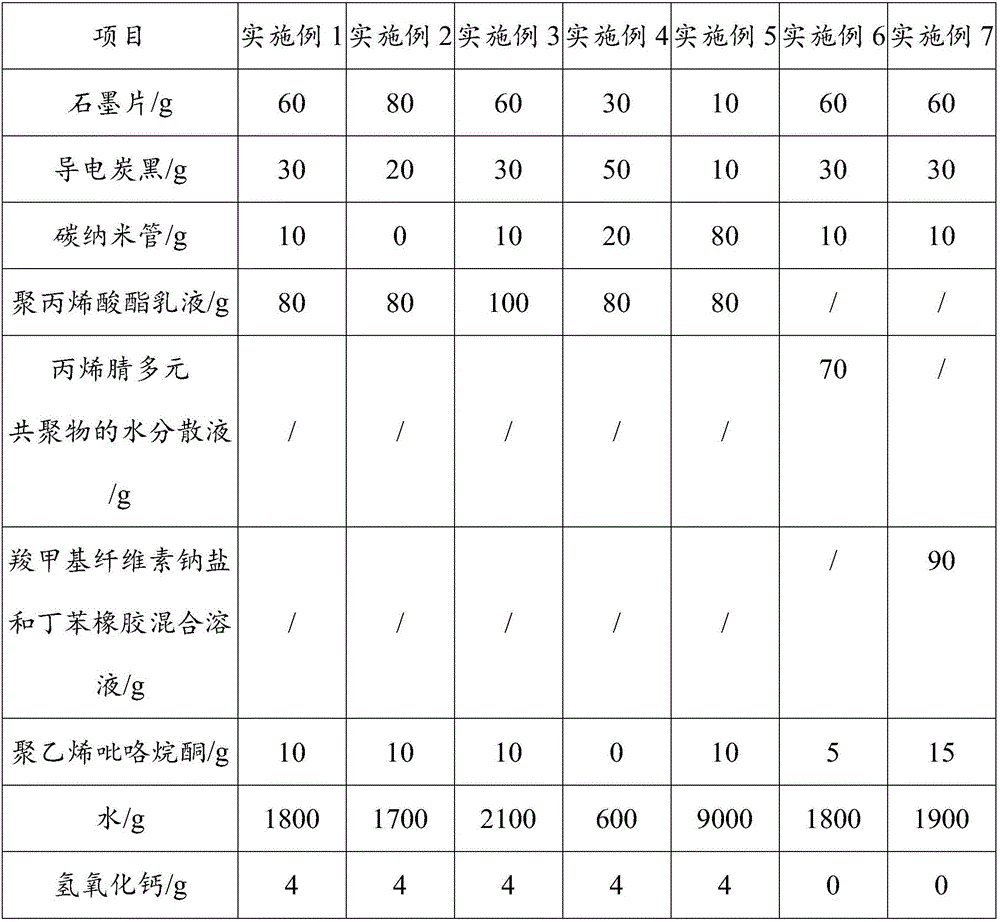

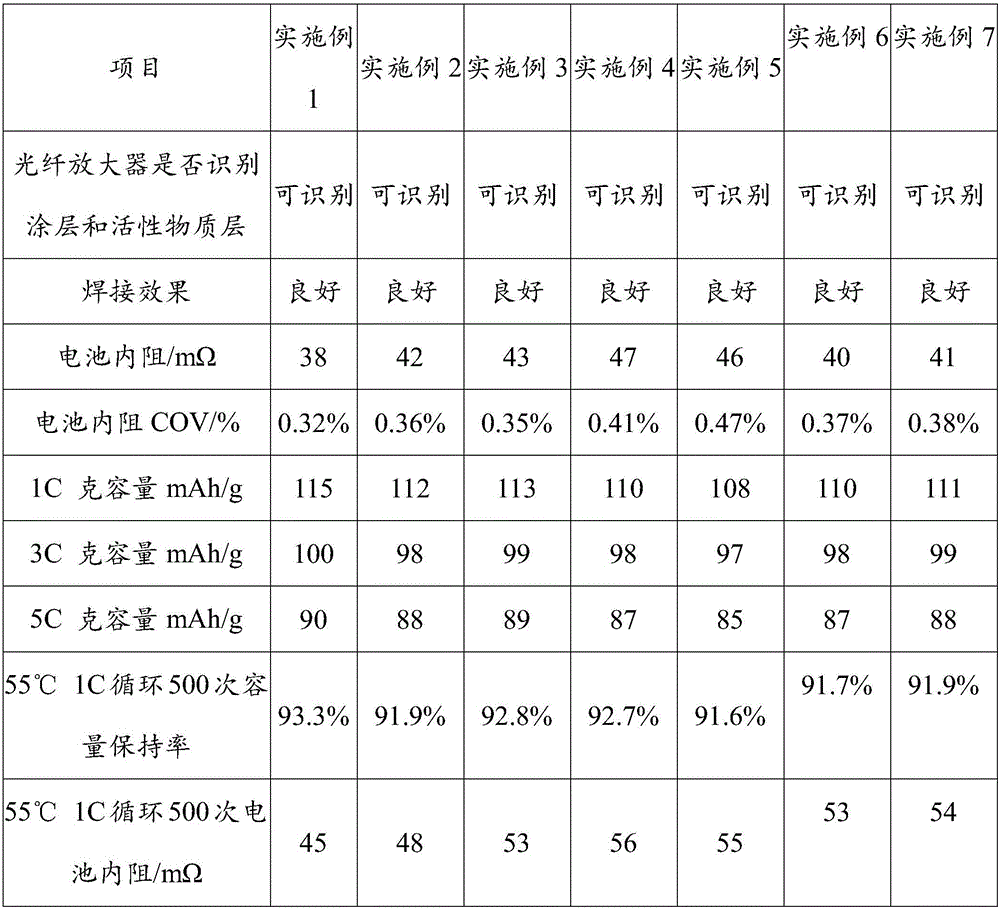

Silver conductive coating material of lithium ion battery, preparation method of silver conductive coating material and lithium ion battery

InactiveCN105895193AImprove stabilityHigh magnificationCell electrodesSecondary cellsInternal resistanceConductive coating

The invention provides a silver conductive coating material of a lithium ion battery. The conductive coating material comprises the following constituents by weight: 100 parts of conductive agent, 20-150 parts of binding agent, 0-30 parts of polyvinylpyrrolidone and 500-10,000 parts of water, wherein on the basis of 100 parts of conductive agent, graphite flakes account for 10-100 parts, conductive carbon black accounts for 1-50 parts, and a carbon nanotube accounts for 0-80 parts. The invention also provides a preparation method of the above silver conductive coating material and the lithium ion battery employing the conductive coating material. In the conductive coating material, different types of conductive agents are creatively used, and the paste stability can be improved; meanwhile, due to a synergistic effect of various conductive agents, the dynamic internal resistance increase of a battery core also can be further reduced, and the rate performance of the battery is improved; and moreover, a pole plate shows silver after a base coat of the conductive coating material is coated, the base conductive coating can be continuously achieved, and the requirements of various intermittent coating structured pole plates in different sizes are met.

Owner:深圳宇锵新材料有限公司

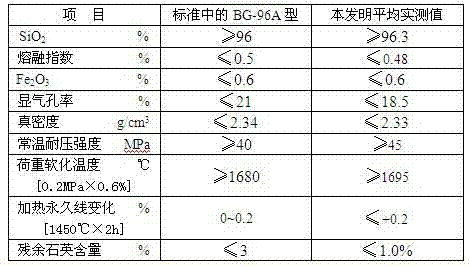

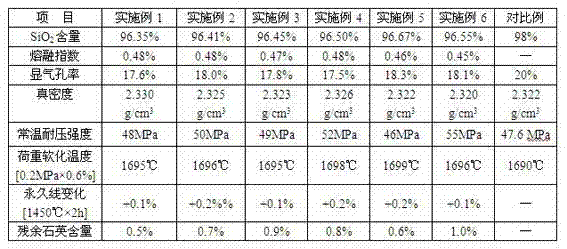

Silica brick for glass furnace

ActiveCN102515801ASmall volume expansionReduce crackingGlass furnace apparatusGlass productionPorosityBrick

The invention discloses a silica brick for a glass furnace, and belongs to the technical field of refractory materials. The silica brick for a glass furnace comprises: by weight, 30 to 45% of silica having particle sizes of 3 to 1.0mm, 5 to 25% of silica having particle sizes of 1.0 to 0.5mm, 30 to 50% of silica having particle sizes less than 0.5mm, an additive and a composite additive, wherein the weight of the additive is 5 to 15% of the total weight of the silica and the weight of the composite additive is 2 to 10% of the total weight of the silica. SiO2 content of the silica is great than or equal to 99%. Al2O3 content of the silica is less than or equal to 0.25%. Fe2O3 content of the silica is less than or equal to 0.45%. The additive is a waste silica material having SiO2 content great than or equal to 96%. The composite additive is a mixture of lime milk, mill scales and calcium lignosulphonate. The silica brick for a glass furnace has high SiO2 content, a high yield, low impurity content, low apparent porosity, good high-temperature performances and a long service life. A preparation technology of the silica brick for a glass furnace is simple and is suitable for large-scale production.

Owner:ZHEJIANG ZHAOSHAN SILICEOUS REFRACTORY MATERIAL

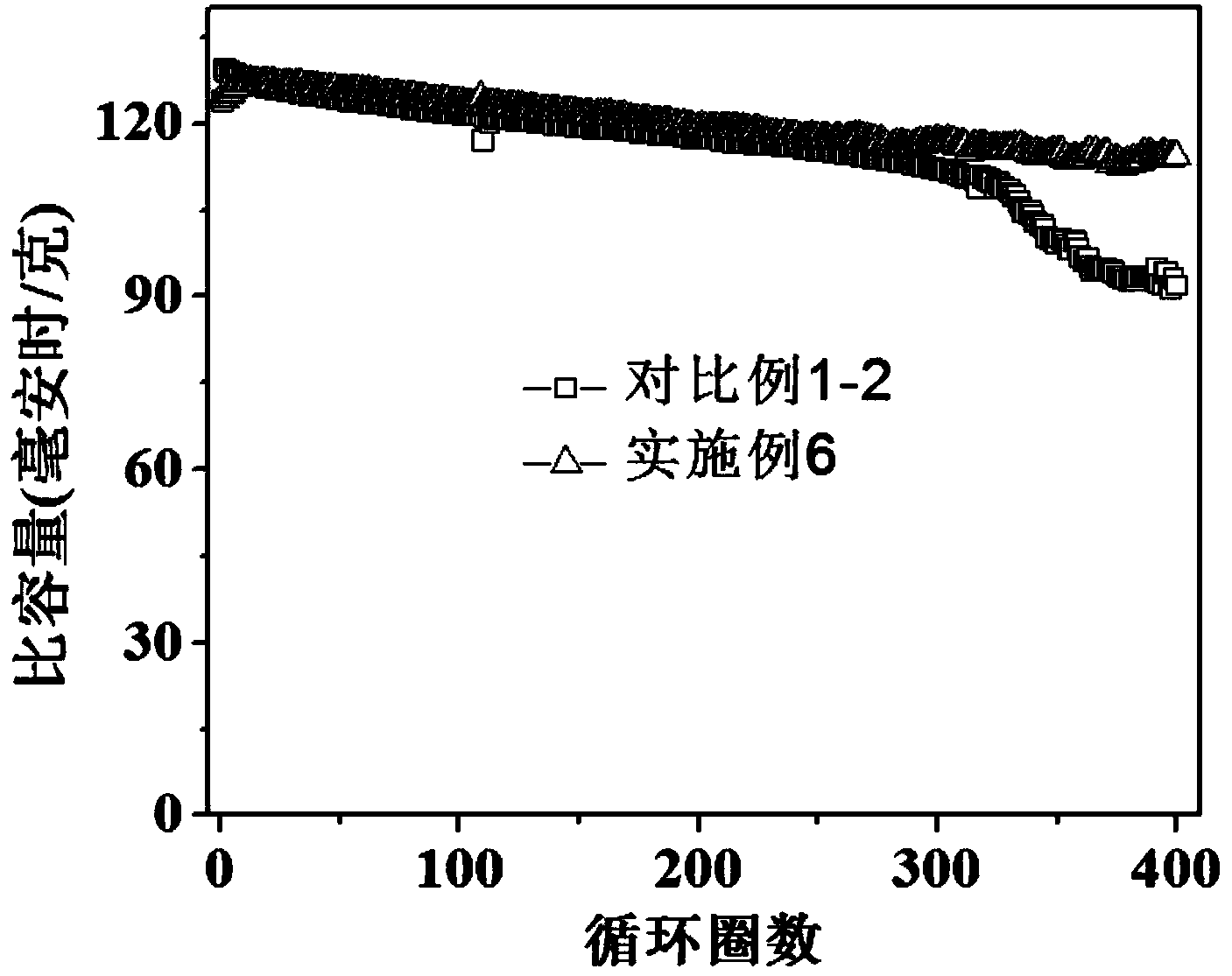

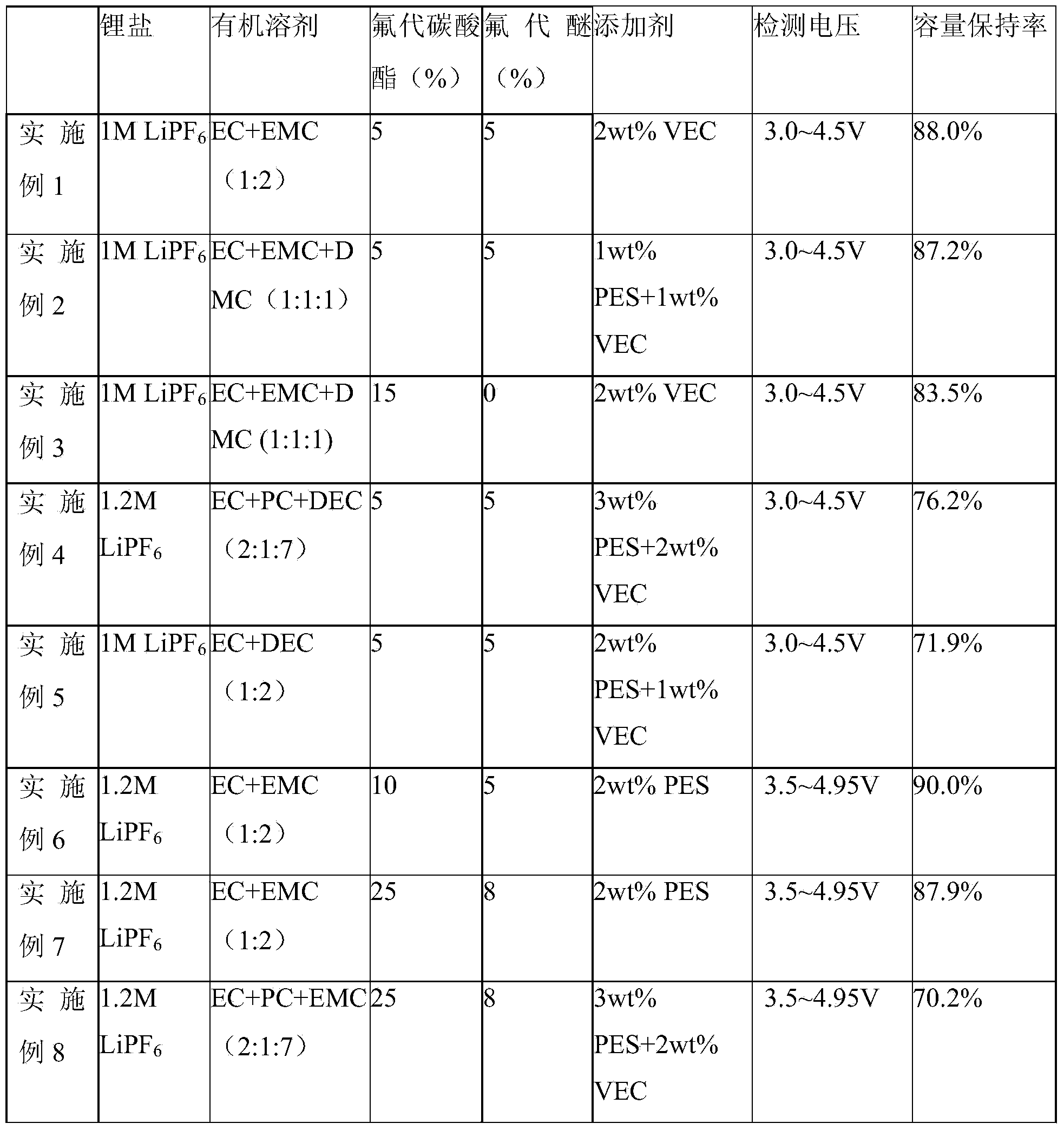

High-voltage lithium ion battery electrolyte, preparation method and application of electrolyte

InactiveCN103956517AReduce decompositionImprove high voltage performanceFinal product manufactureElectrolyte accumulators manufactureOrganic solventSolvent

The invention discloses high-voltage lithium ion battery electrolyte, a preparation method and application of electrolyte. The high-voltage lithium ion battery electrolyte comprises an organic solvent, conductive lithium salt and a functional additive, wherein the organic solvent is prepared from a cyclic carbonate solvent, a fluoro solvent and a linear carbonic ester solvent, the content of the fluoro solvent in the high-voltage lithium ion battery electrolyte is 0.1-40wt.%, the content of the functional additive is 0.01-5wt.%, and the concentration of the conductive lithium salt in the organic solvent is 0.8-1.5mol / L. According to the high-voltage lithium ion battery electrolyte, the interfacial property of the anode and the cathode of the battery and the electrolyte can be improved, and the stability of the electrolyte can be improved, so that the cycle life of the high-voltage lithium ion battery is prolonged, the high-temperature property of the high-voltage lithium ion battery is improved and the working voltage of the high-voltage lithium ion battery is increased to be above 4.5V.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Raw materials and preparation method of anti-corrosion mullite brick

The invention discloses raw materials for preparing an anti-corrosion mullite brick, comprising calcium hexaluminate, andalusite, sillimanite, alumina, cordierite, pyrophyllite, kaolin, refractory oxide, foaming agent and binding agent. The preparation method includes the following steps: the sillimanite, alumina, cordierite, pyrophyllite, kaolin, refractory oxide and binding agent are added into a grinding machine to be ground after material preparation, so as to obtain base material; the calcium hexaluminate and andalusite are added into a kollermill to be mixed and milled for 5-10 minutes, water is added until the surface is wetted, so as to obtain particle aggregate, and the base material is added into the kollermill to be mixed, milled and stirred with the particle aggregate, so as to obtain mixture; and water is injected into the mixture and stirring is carried out to form muddy mixture and green brick is obtained, and the green brick is placed into a kiln to be sintered into the anti-corrosion mullite brick finished product. The mullite brick prepared by the raw materials and preparation method has the advantages of low thermal conductivity, good thermal insulation property and strong corrosion resistance.

Owner:JIANGSU ZHONGLEI ENERGY SAVING TECH DEV CO LTD

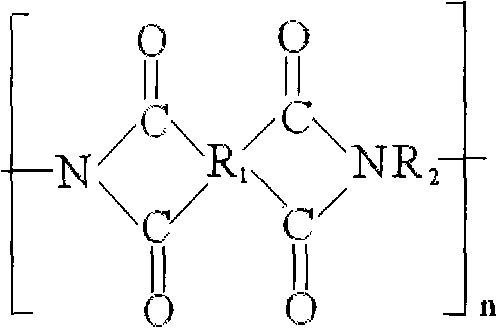

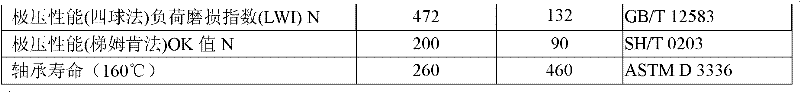

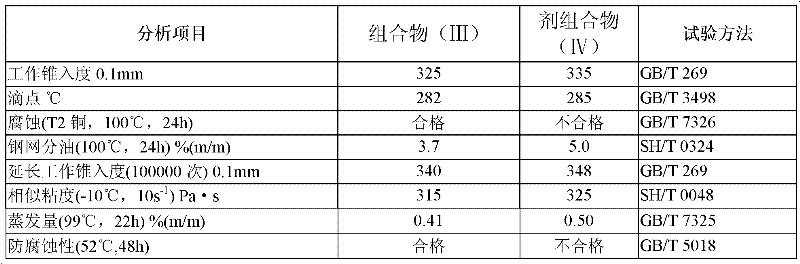

Polyurea-based grease additive composition

InactiveCN102504921AGood high temperature performanceImprove water resistanceLubricant compositionAntioxidantPolymethyl methacrylate

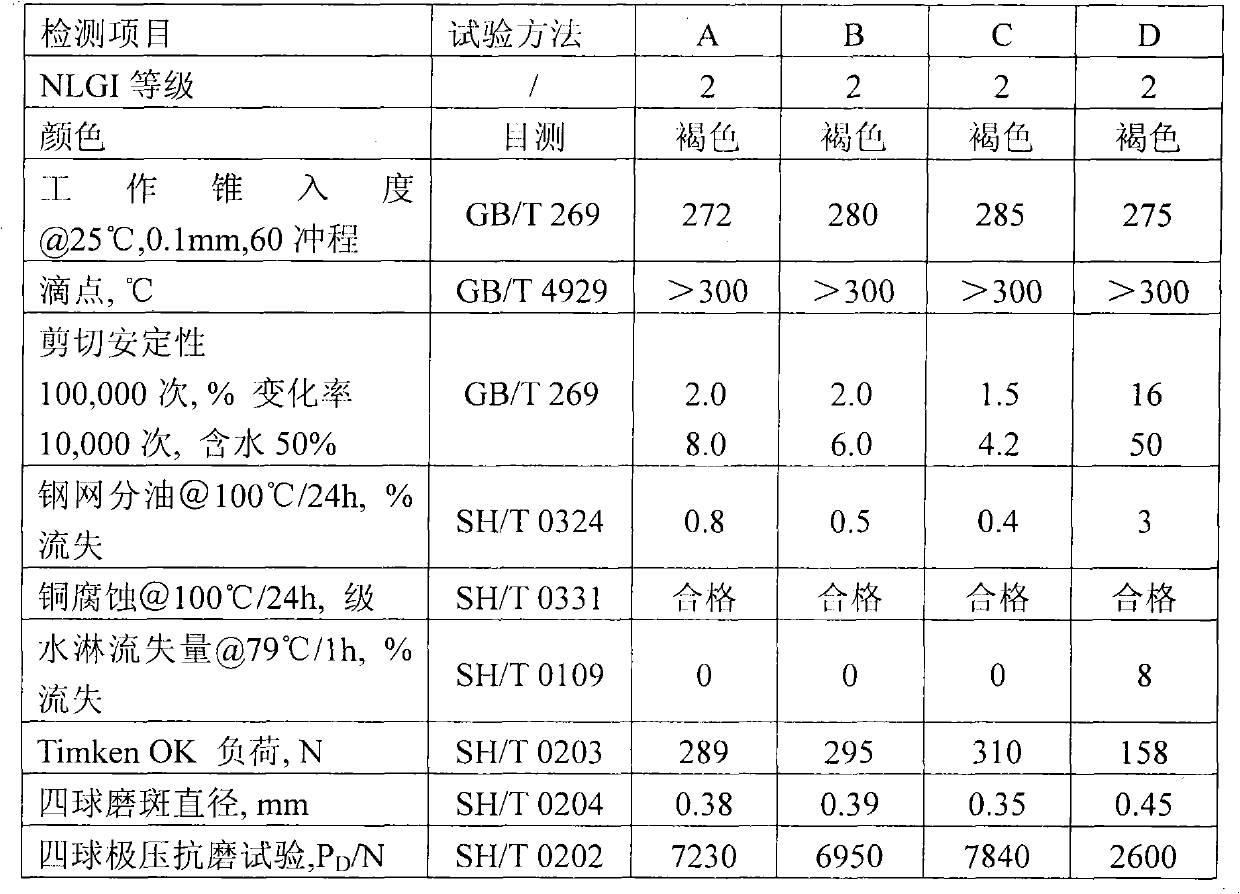

The invention relates to a polyurea-based grease additive composition. Components and percentage content of the polyurea-based grease additive composition are that: base oil is mineral oil and synthetic oil or blending oil of the mineral oil and the synthetic oil, and the content of the base oil is from 71% to 91.5%; a thickening agent is composed of a common reactant of isocyanate, fatty amine and alicyclic amine, and the content of the thickening agent is from 6% to 12%; an antioxidant uses amine antioxidants, and the total content of the antioxidant is from 0.5% to 3%; an extreme-pressure agent uses a mixture of sulfurized isobutylene, dialkyl group dithiophosphate and dialkyl group dithiocarbamic acid, and the total content of the extreme-pressure agent is from 0.5% to 5%; the content of an antirusting agent is from 0.5% to 3%; an antiwear agent is triphenyl thiophosphate and thiophosphoric acid ester or a mixture of the triphenyl thiophosphate and the thiophosphoric acid ester, and the total content of the antiwear agent is from 0.5% to 3%; and tackifier is polyisobutene and polymethyl methacrylate or a mixture of the polyisobutene and the polymethyl methacrylate, and the total content of the tackifier is from 0.5% to 3%. Due to the fact that appropriate raw material proportion is selected and used, grease has good high-temperature performance, a dropping point is higher than 260 DEG C, and the polyurea-based grease additive composition has a good water-resisting property, high and low temperature resistance and extreme pressure anti-wear performance, and can be applied to lubrication of each key running part of a continuous casing machine.

Owner:CHINA PETROLEUM & CHEM CORP

Anti-agglomeration high-temperature resistant coating of furnace bottom roller

ActiveCN102650028AImprove high temperature lifeGood high temperature performanceMolten spray coatingTemperature resistanceCermet

The invention provides an anti-agglomeration high-temperature resistant coating of a furnace bottom roller. The coating comprises a substrate, wherein the substrate includes the following components by weight: 35-63 percent of Co, 20-30 percent of Cr, 10-20 percent of Ta, 5-10 percent of Al and 2-5 percent of y. According to the invention, a metal-ceramic material is coated on a furnace bottom roller body in a spraying manner by adopting an explosion method, thus the characteristics of the surface of the furnace bottom roller body is changed, a better prevention of the agglomeration of the furnace bottom roller body is achieved, and further the high-temperature resistance of the furnace bottom roller is enhanced.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Manufacture method of high porosity and high strength yttrium-silicon-oxygen porous ceramics

The invention relates to the porous ceramics material field, and concretely relates to a method for manufacturing high porosity and high strength yttrium-silicon-oxygen porous ceramics material through a foaming injection coagution process. According to the method, yttrium oxide and silicon oxide mixed power can be taken as a raw material, water is taken as a disperse medium, polyethyleneimine or ammonium citrate is selected as a dispersant, acrylamide or N-methylolacrylamide is taken as a monomer, a cross-linking agent N,N'-methylene bisacrylamide is added, a foaming agent sodium dodecyl sulfate, a peeling inhibitor polyoxyethylene, a catalyst N, N, N',N'-tetramethyl ethylenediamine and an initiator ammonium persulfate are added after stirring, and then injection mold solidification is carried out, drying is carried out for 24-48 hours at room temperature after demoulding, and then drying is carried out for 24-36 hours under the temperature of 60-90 DEG C, high temperature reaction sintering is carried out for 1.5-2.5 hours under the temperature of 1500-1550 DEG C finally, and the gamma-Y2Si2O7 porous ceramics can be finally manufactured. The manufactured gamma-Y2Si2O7 porous ceramics material having a multi-layer pore structure has controllable porosity with high porosity (75-85%) and high strength (3-8MPa).

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Heat-resistant cast aluminum alloy and pressure casting method thereof

The invention relates to a heat-resistant cast aluminum alloy and a pressure casting method thereof. The aluminum alloy consists of the following elements according to certain weight percentage: Si, Cu, Ni, Mg, Ti, RE, Mn, Fe and the balance of Al. After pressure casting of the heat-resistant cast aluminum alloy provided by the invention, the tensile strength (sigma)b of the alloy at room temperature is greater than or equal to 400MPa, the tensile strength (sigma)b at 300 DEG C is greater than or equal to 210MPa, and the tensile strength (sigma)b at 350 DEG C is greater than or equal to 130MPa; and the elongation delta at room temperature is greater than or equal to 2.0%, the elongation delta at 300 DEG C is greater than or equal to 6.0%, and the elongation delta at 350 DEG C is greater than or equal to 14.0%. By comparing the alloy and pressure casting preparation method thereof provided by the invention with the existing Al-Si cast aluminum alloy and the pressure casting preparation method thereof, the casting performance is improved, the room-temperature and high-temperature mechanical properties of the alloy are remarkably improved, and the application range of the Al-Si cast aluminum alloy is widened.

Owner:SHANGHAI JIAO TONG UNIV

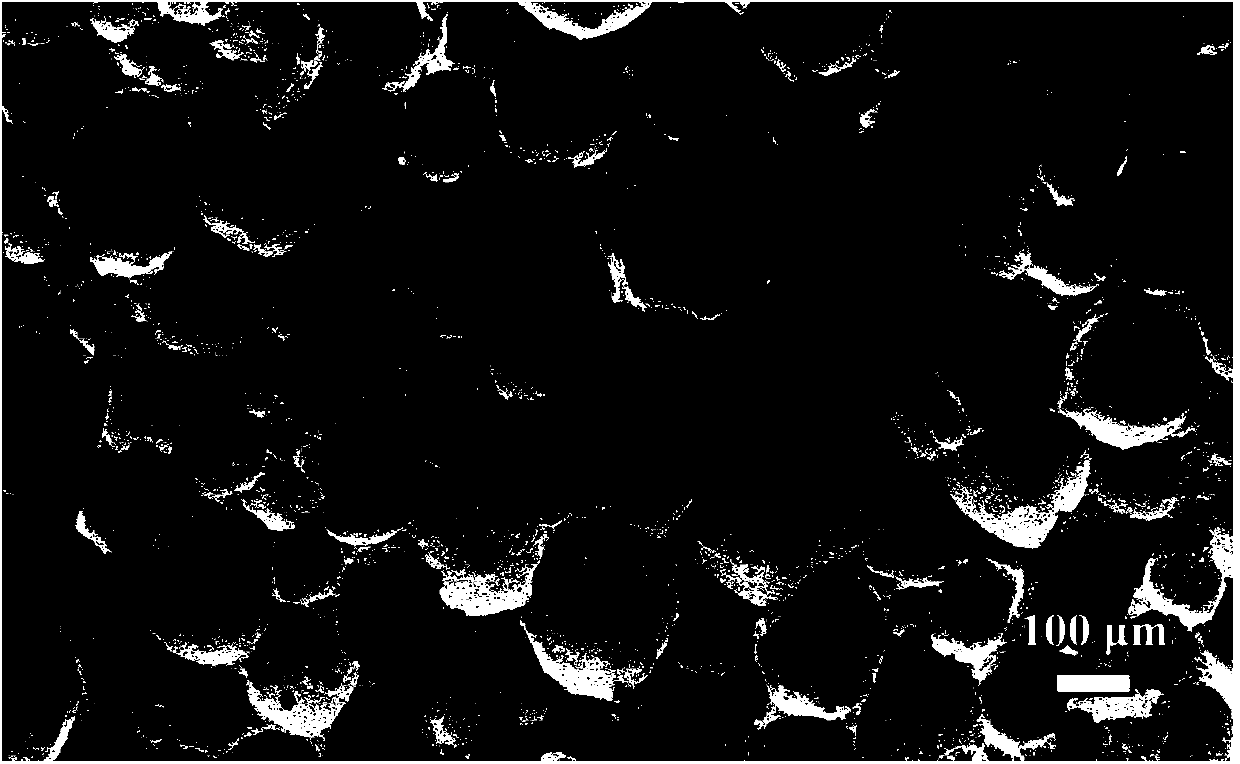

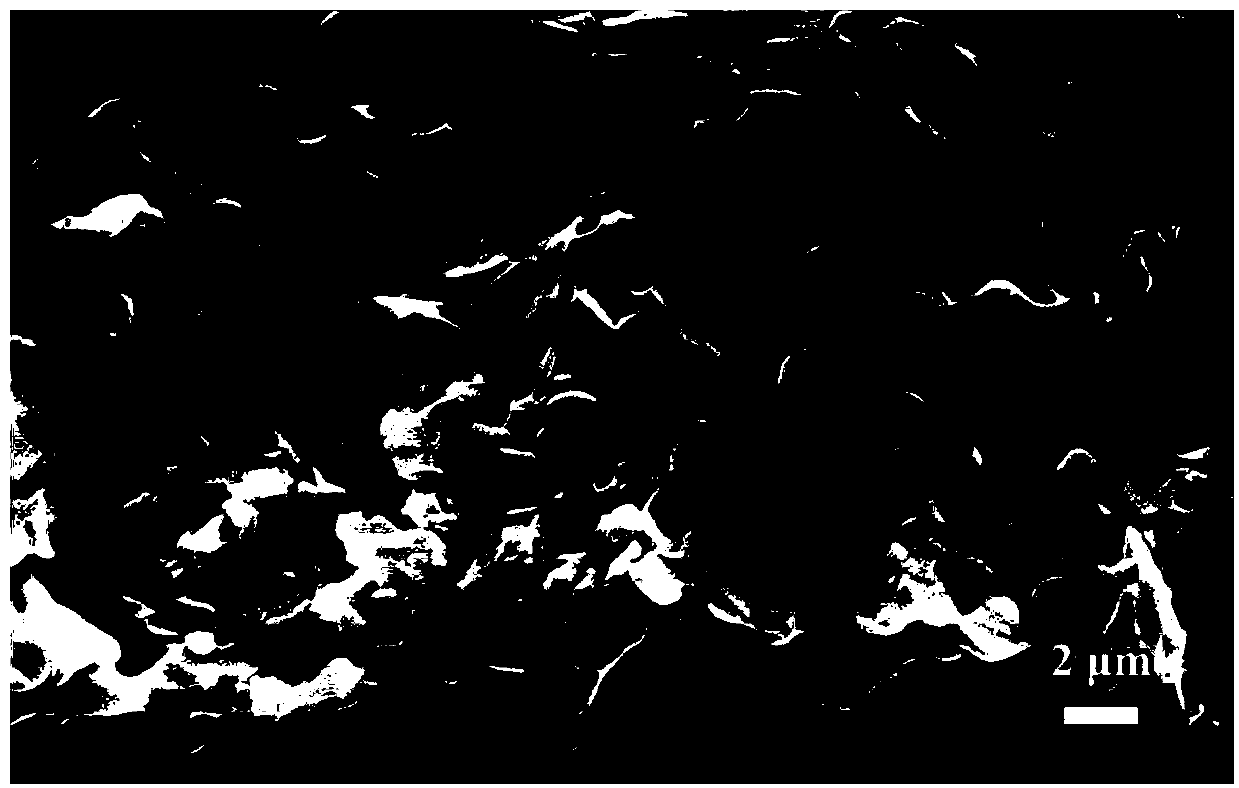

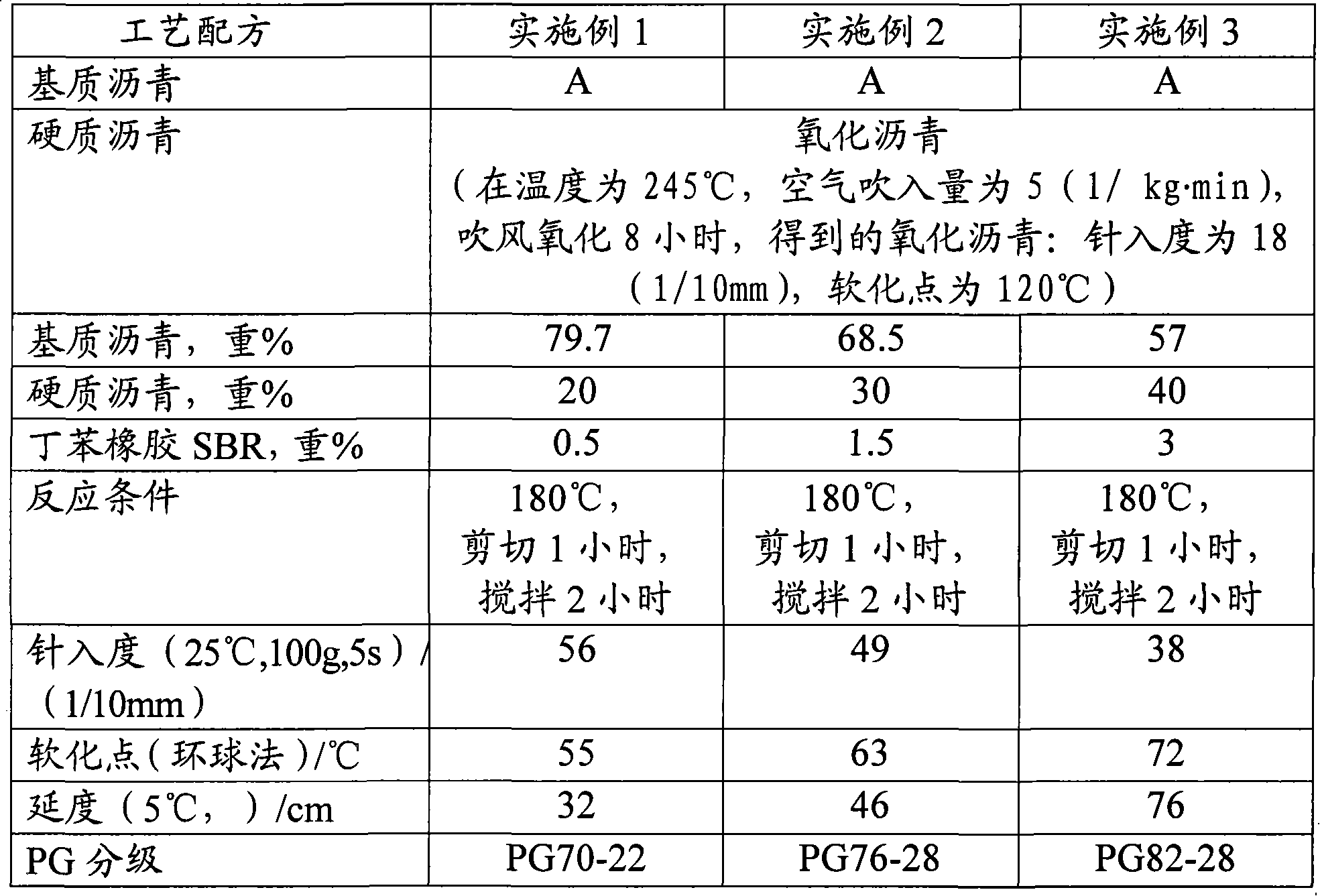

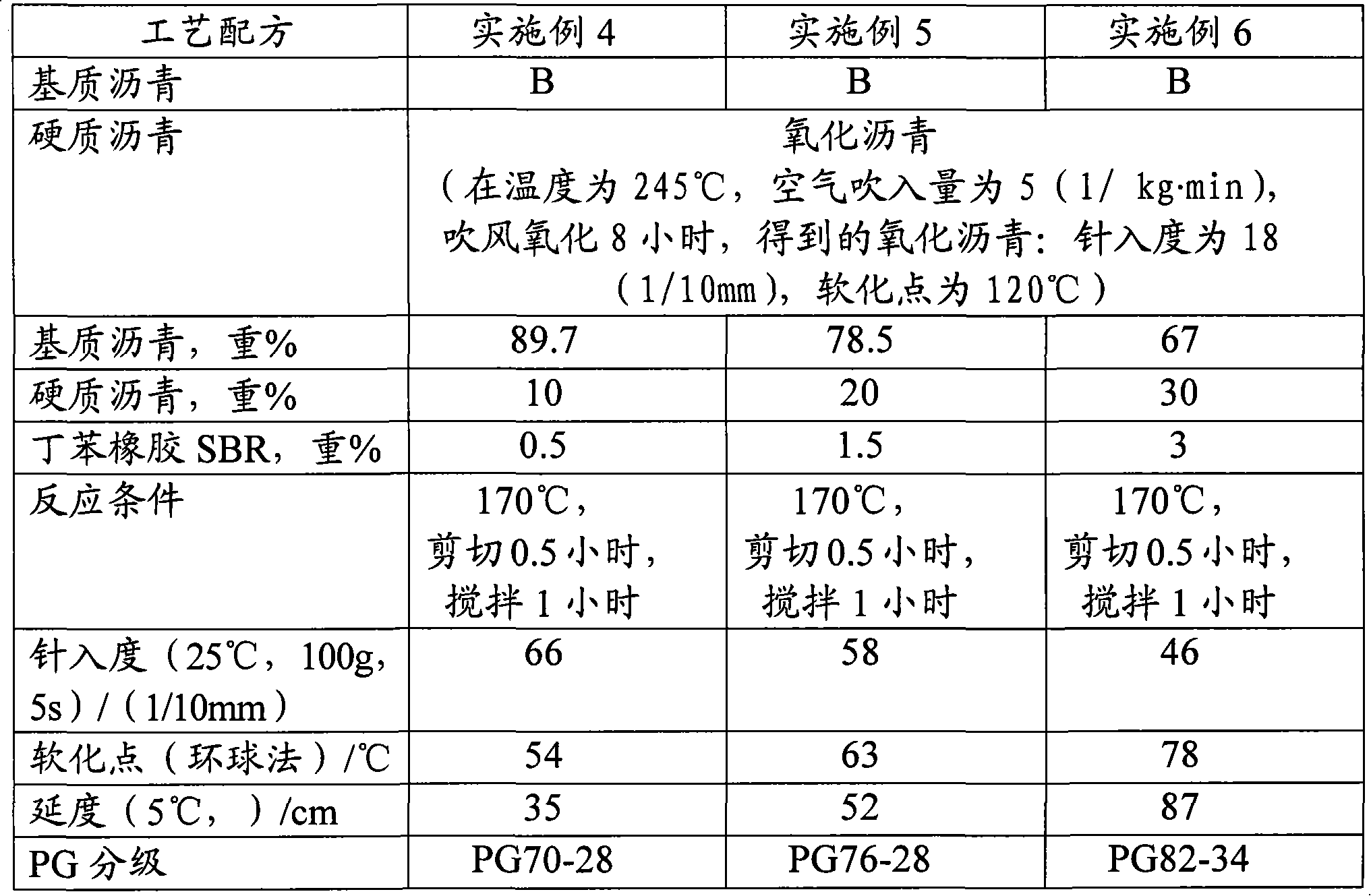

Composite modified bitumen and preparation method thereof

ActiveCN101608069AImprove high temperature performanceGood high temperature performanceBuilding insulationsRoad surfacePolymer

The invention relates to composite modified bitumen and a preparation method thereof. The preparation method comprises the following steps: mixing 50 to 89.9 weight percent of bitumen, 10 to 49.9 weight percent of hard bitumen and 0.1 to 5 weight percent of polymer according to the proportion; and then shearing and stirring for 0.1 to 3 hours at a temperature between 80 and 240 DEG C so as to obtain the composite modified bitumen. The composite modified bitumen has the advantages of outstanding high-temperature and low-temperature performances, good temperature sensibility, wide use temperature range and PG grade reaching or exceeding PG 76-28; therefore, the bitumen can be widely used for road surface paving of roads, bridges, airfield runway, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

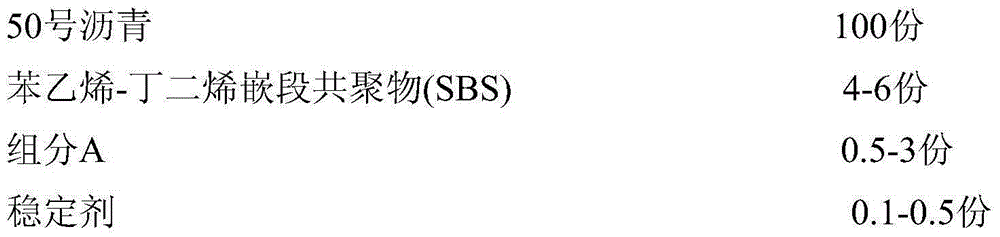

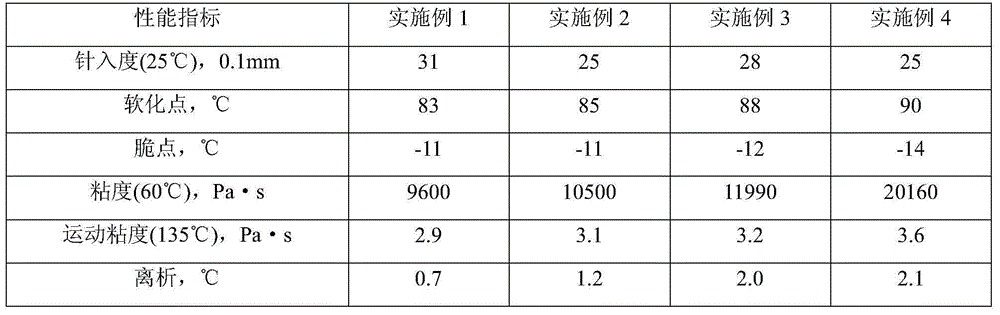

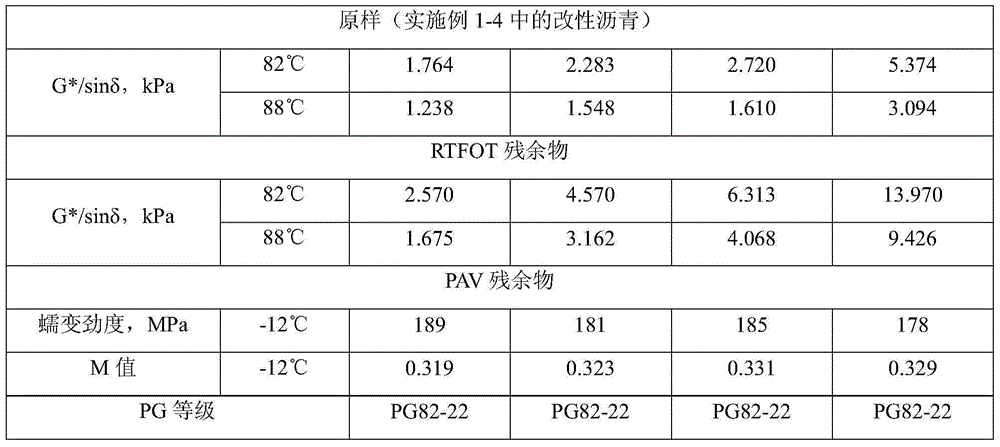

Modified asphalt meeting PG 82-22 grade, and preparation method thereof

ActiveCN105176110AExcellent anti-rutting performance at high temperatureImprove water stabilityBuilding insulationsPhosphoric acidButadiene-styrene rubber

The present invention discloses a modified asphalt and a preparation method thereof, wherein the modified asphalt comprises, by mass, 100 parts of 50# asphalt, 4-6 parts of a styrene-butadiene block copolymer, 0.5-3 parts of a component A, and 0.1-0.5 part of a stabilizer, wherein the component A is selected from polyethylene or polyphosphoric acid. The preparation method comprises: sequentially carrying out shear treatment and stirring development so as to obtain the modified asphalt. According to the present invention, the PG high temperature grade of the asphalt product is improved with the selection of the 50# asphalt, the high temperature performance of the modified asphalt is improved with the selection of the PE or polyphosphoric acid, the penetration degree of the obtained modified asphalt is low, the softening point of the obtained modified asphalt is high, the PG grade can achieve PG 82-22, the high temperature performance is good, and the high temperature rutting resistance is good.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Nickel chromium alloy for sealing face of nuclear power valve

InactiveCN101629256ALess affected by heatHigh bonding strengthMetallic material coating processesPlasma jetNuclear power

The invention discloses a nickel chromium alloy for a sealing face of a nuclear power valve. The nickel chromium alloy comprises the following components in percentage by weight: 26.0-28.0 percent of chrome, 2.0-2.5 percent of silicon, 1.1-1.3 percent of boron, 4.5-5.5 percent of molybdenum, 3.0-4.0 percent of tungsten, 0.9-1.1 percent of carbon and the balance of nickel. Meanwhile, a coating layer is prepared by a laser cladding technology so as to obtain a sealing face coating layer of a nickel-based alloy nuclear power valve, which has the following relevant parameters: the rigidity is HRC 42-46 which is slightly higher than HRC39-43 of a Stellite-6 cobalt-based alloy coating layer; the tissue grain fineness number of the coating layer is 11-12 grades which is superior to 9-10 grades of a general plasma jet welding layer and 8-9 grades of a flame resurfacing welding layer; and the width of a combination band of the coating layer and a basal body is 10-30 micrometers which is superior to 80-120 micrometers of a plasma jet welding combination band and 200-300 micrometers of a flame resurfacing welding combination band.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com