Patents

Literature

74results about How to "Good cycle performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

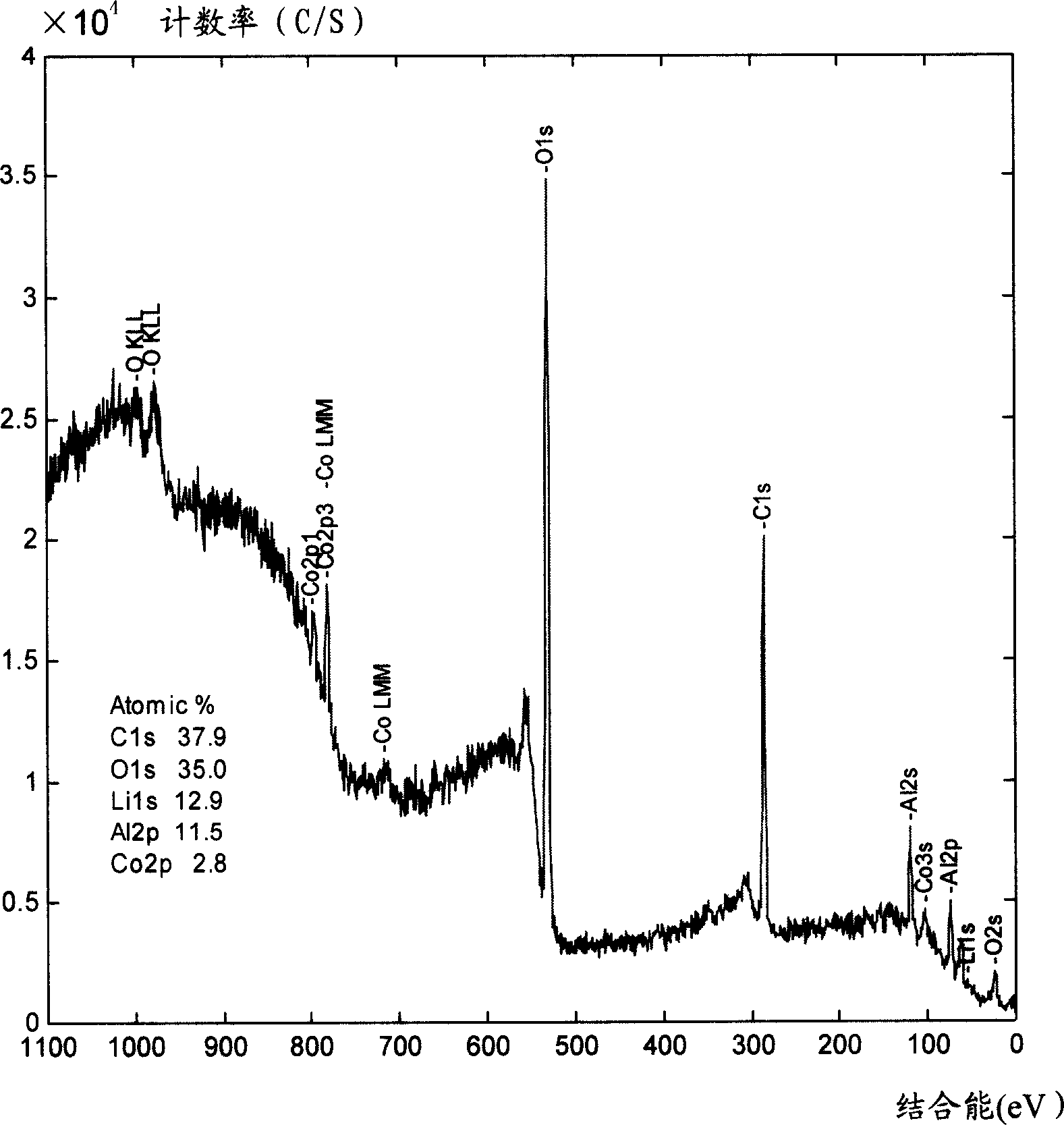

Anode material of lithium ion cell and preparation method

InactiveCN1627550AGood cycle performanceGood high temperature performanceElectrode thermal treatmentActive material electrodesAnodeMetallurgy

The anode material is prepared from oxidation material layer of covering surface of at least one anode active material among LiCoO2, LiNi1-xCOxO2, LiNi1 / 3Mn1 / 3O2 and LiMn2O4. Weight of non-oxygen element in oxidation material layer can be 0.01-10 weight% of anode active material. Advantages of the anode material are: good cycle performance, favorable high temp property and high power discharge property, and anti over change property as well as simple technique and easy of production.

Owner:BYD CO LTD

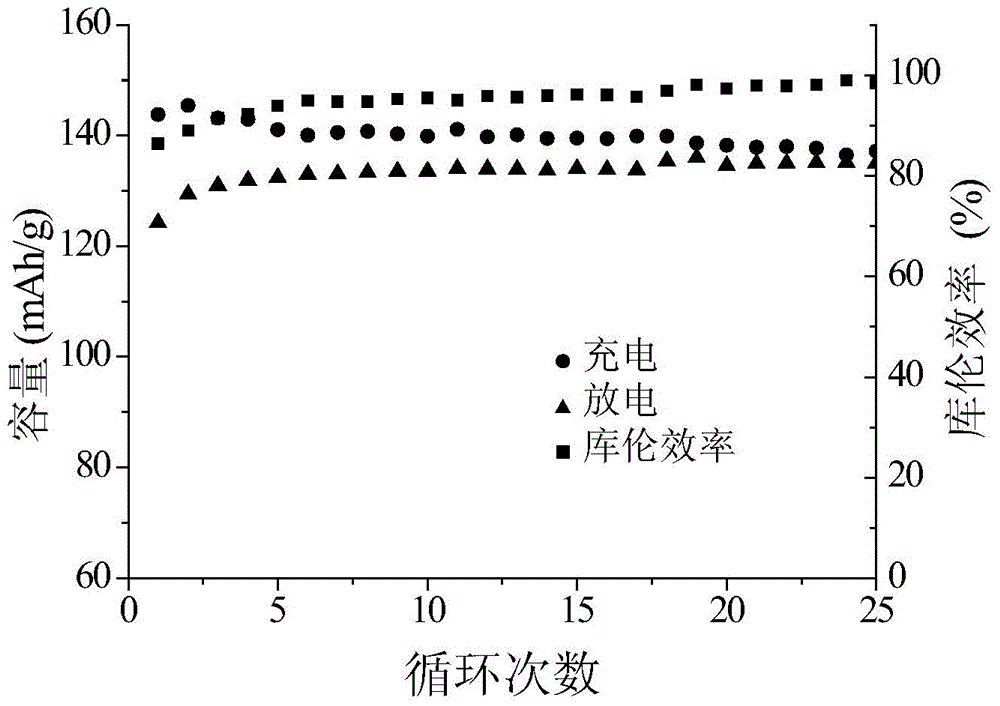

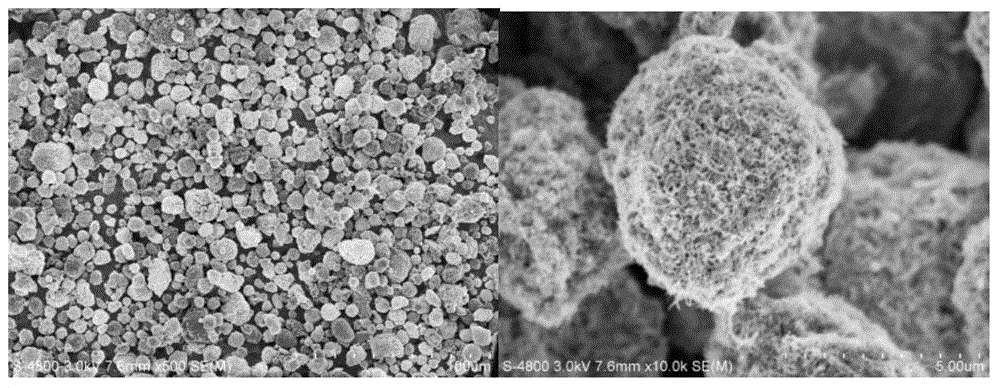

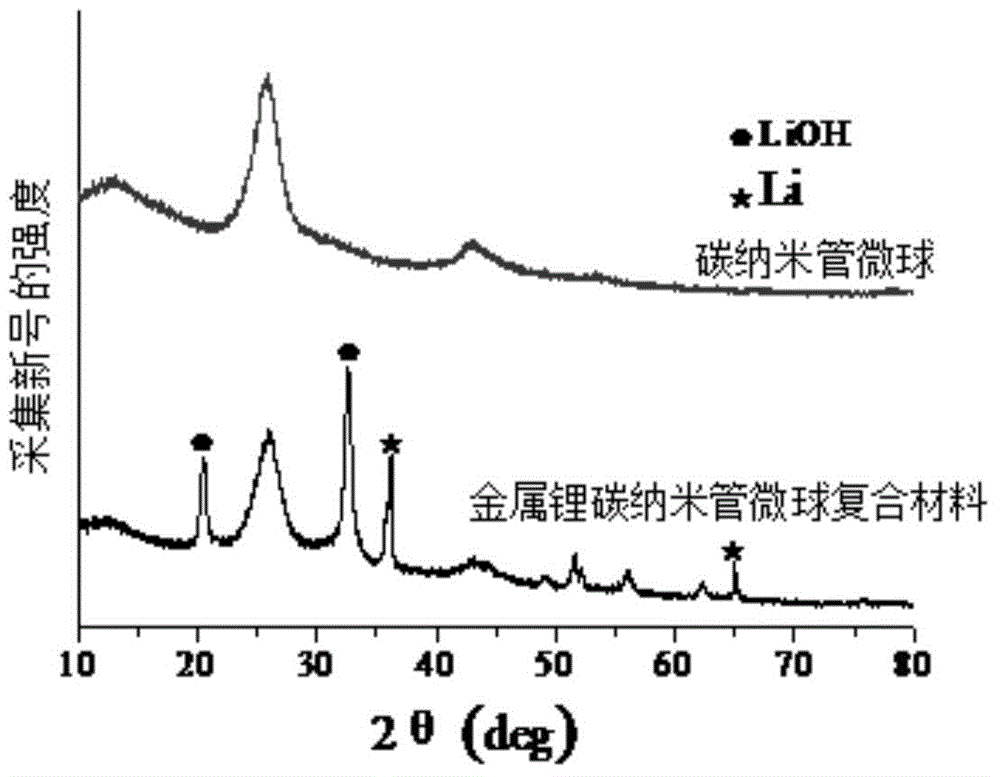

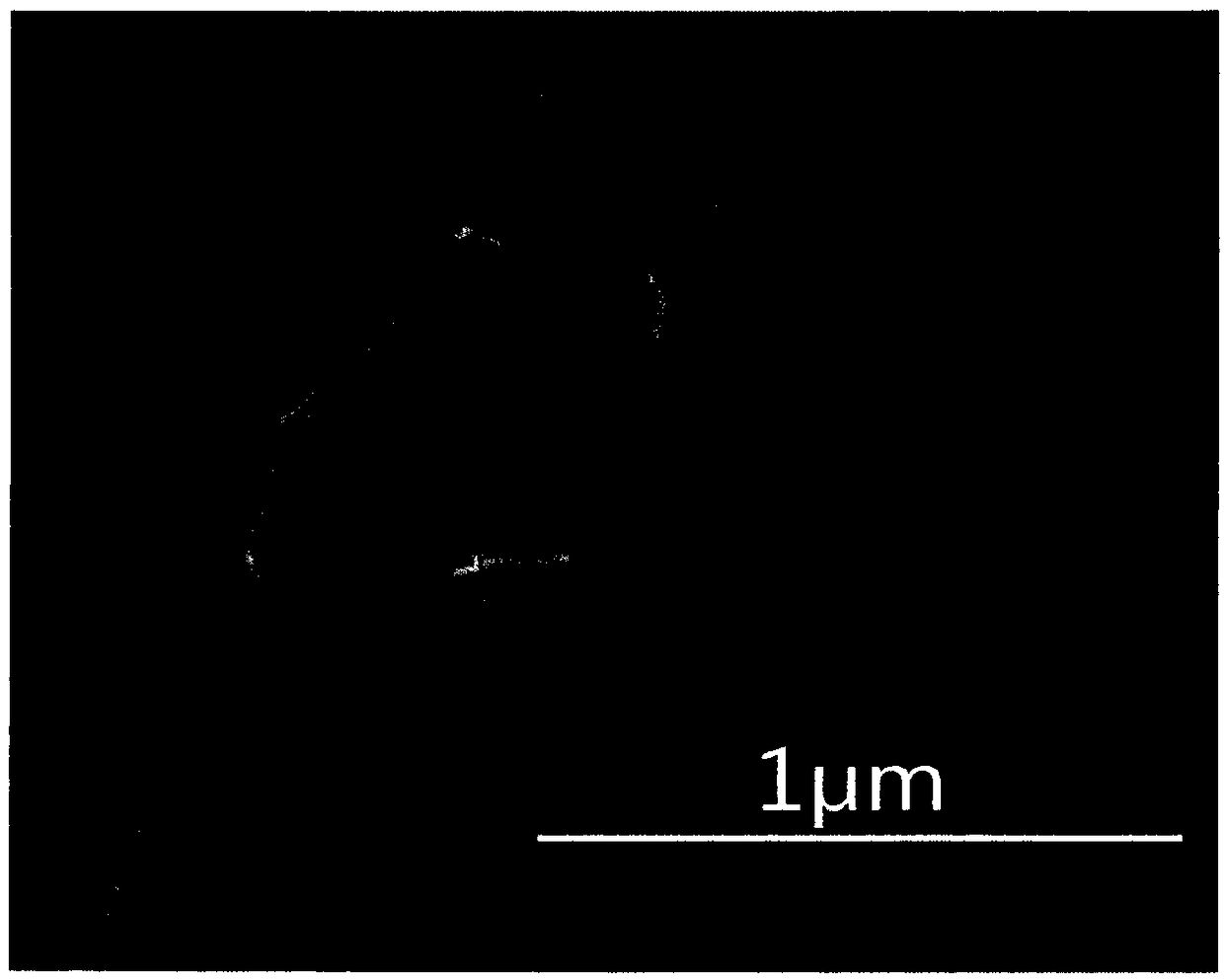

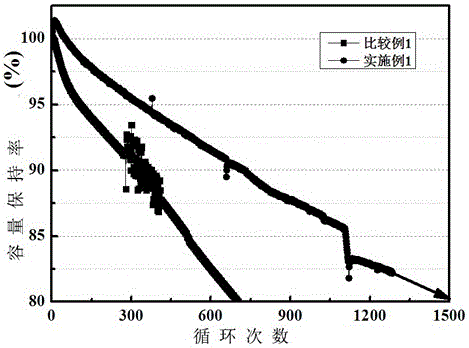

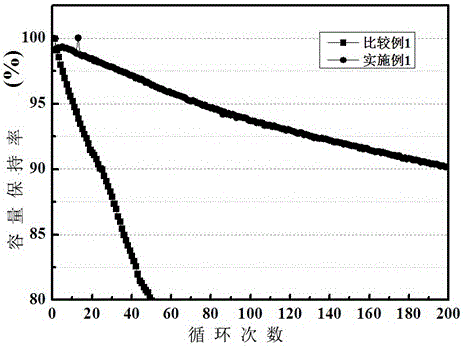

Metal lithium-framework carbon composite material and preparation method thereof, negative electrode and secondary battery

ActiveCN105374991AHigh specific capacityGood cycle performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesMetallic lithiumComposite material

The present application discloses a metal lithium-framework carbon composite material preparation method, which comprises: uniformly mixing metal lithium having a molten state and a porous carbon material carrier, and cooling to obtain the metal lithium-framework carbon composite material. The invention further discloses a metal lithium-framework carbon composite material, a secondary battery negative electrode, a secondary battery and a metal-framework carbon composite material. According to the present invention, with the prepared metal lithium-framework carbon composite material, the dendritic crystal formation can be inhibited, the whole property of the battery can be improved, and the high specific capacity and the good cycle performance are provided.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

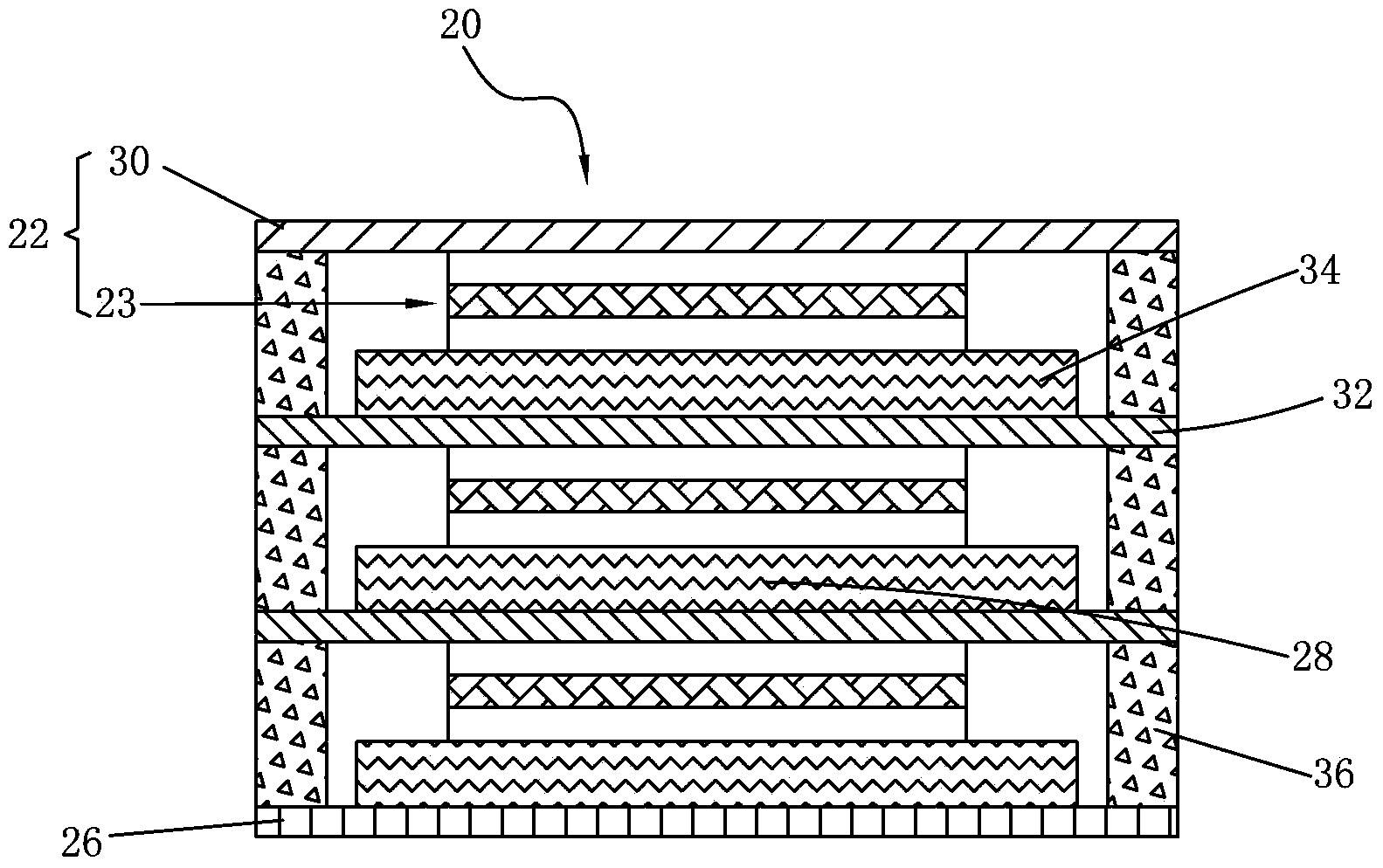

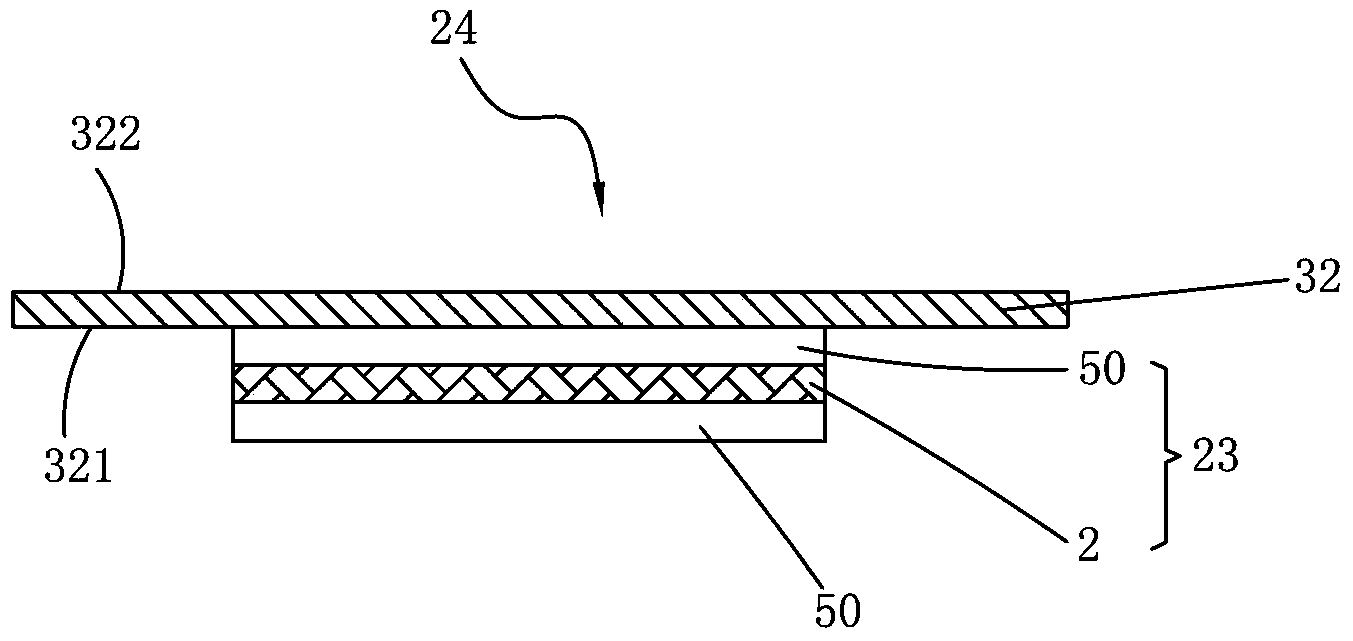

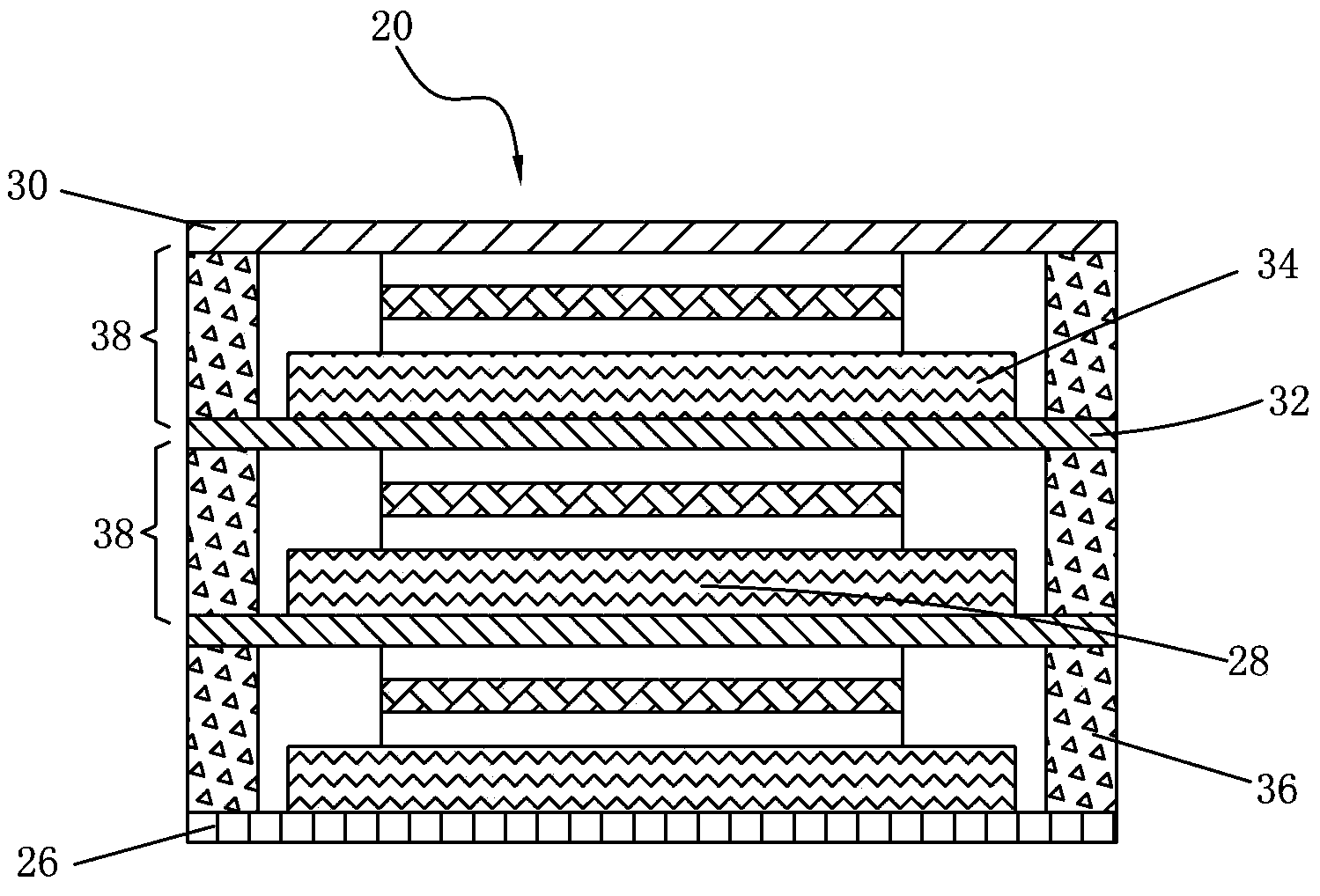

Battery

InactiveCN104253283ALow priceGood cycle performanceFinal product manufactureSecondary cells manufactureIonCurrent collector

The invention discloses a battery, which includes an anode, a cathode and an aqueous electrolyte solution. The anode comprises a composite current collector and an anode sheet. The composite current collector comprises an anode current collector and a conductive film coating the anode current collector. The anode sheet includes an anode active substance, which can realize reversible prolapse and embedding of ions. The cathode is a metal, alloy or carbon based material. The aqueous electrolyte solution includes an electrolyte, which can at least ionize active ions. The active ions are reduced and deposited at the cathode to form a cathode active substance during charging, and the cathode active substance is oxidized and dissolved in the aqueous electrolyte solution during discharging. The battery provided by the invention has good cycle performance and high energy, and is hopeful to be widely applied in large energy storage, power grid peak shaving and other fields.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD +1

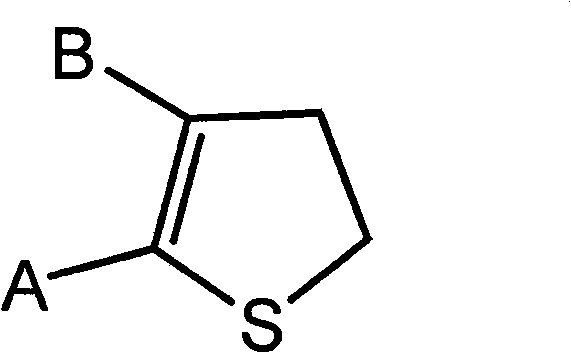

Non-aqueous electrolyte solution and lithium ion battery using same

InactiveCN102332606AGood cycle performanceGood low temperature performanceSecondary cellsHalogenAqueous electrolyte

The invention provides non-aqueous electrolyte solution and a lithium ion battery using the same. The non-aqueous electrolyte solution contains lithium salt, organic solvent and additives. The additives are one or several kinds of hydrogen thiophene with the following structure as shown in the accompanying drawing, wherein A and B are respectively and independently selected from one of amino group, alkyl group, halogen and ester group. The invention additionally provides the lithium ion battery, which comprises a cell, non-aqueous electrolyte solution and a shell, wherein the cell comprises an anode, a cathode and an isolating membrane which is arranged between the anode and the cathode, the cell and the non-aqueous electrolyte solution are contained in the shell and the electrolyte solution is the non-aqueous electrolyte solution provided by the invention.

Owner:BYD CO LTD

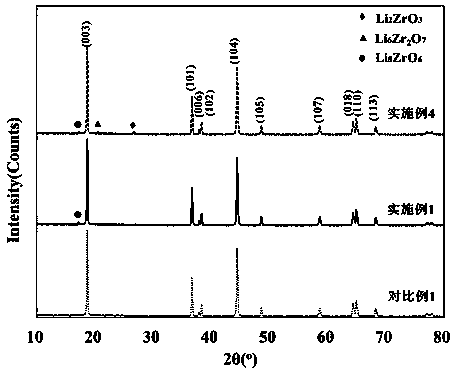

High-energy-density multi-element positive electrode material and preparation method thereof

ActiveCN109461928AGood structural stabilityGood cycle performanceCell electrodesComposite oxideHigh energy

The invention provides a high-energy-density multi-element positive electrode material and a preparation method thereof. The positive electrode material is composed of a substrate with a chemical formula Li1+a[(Ni1-2xCoxMnx)1-yMy]1-zM'zO2, and Li8ZrO6 and a lithium ion conductor LiuM''vOw which coat the surface of the substrate, wherein a is greater than or equal to -0.5 and is less than or equalto 0.3, M and M' are at least one element in La, Cr, Mo, Ca, Fe, Hf, Ti, Zn, Y, Zr, Si, W, Nb, Sm, V, Mg, B and Al, M'' is at least one element in Zr, Ti, Al, Si, Mn and Sn, and the total coating amount of a composite oxide is 0.01-3% of the molar weight of the substrate. The positive electrode material disclosed by the invention has relatively high energy density and cycling stability, and can beused for a lithium ion power battery. The preparation method of the material is simple in process, low in cost and suitable for large-scale production.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

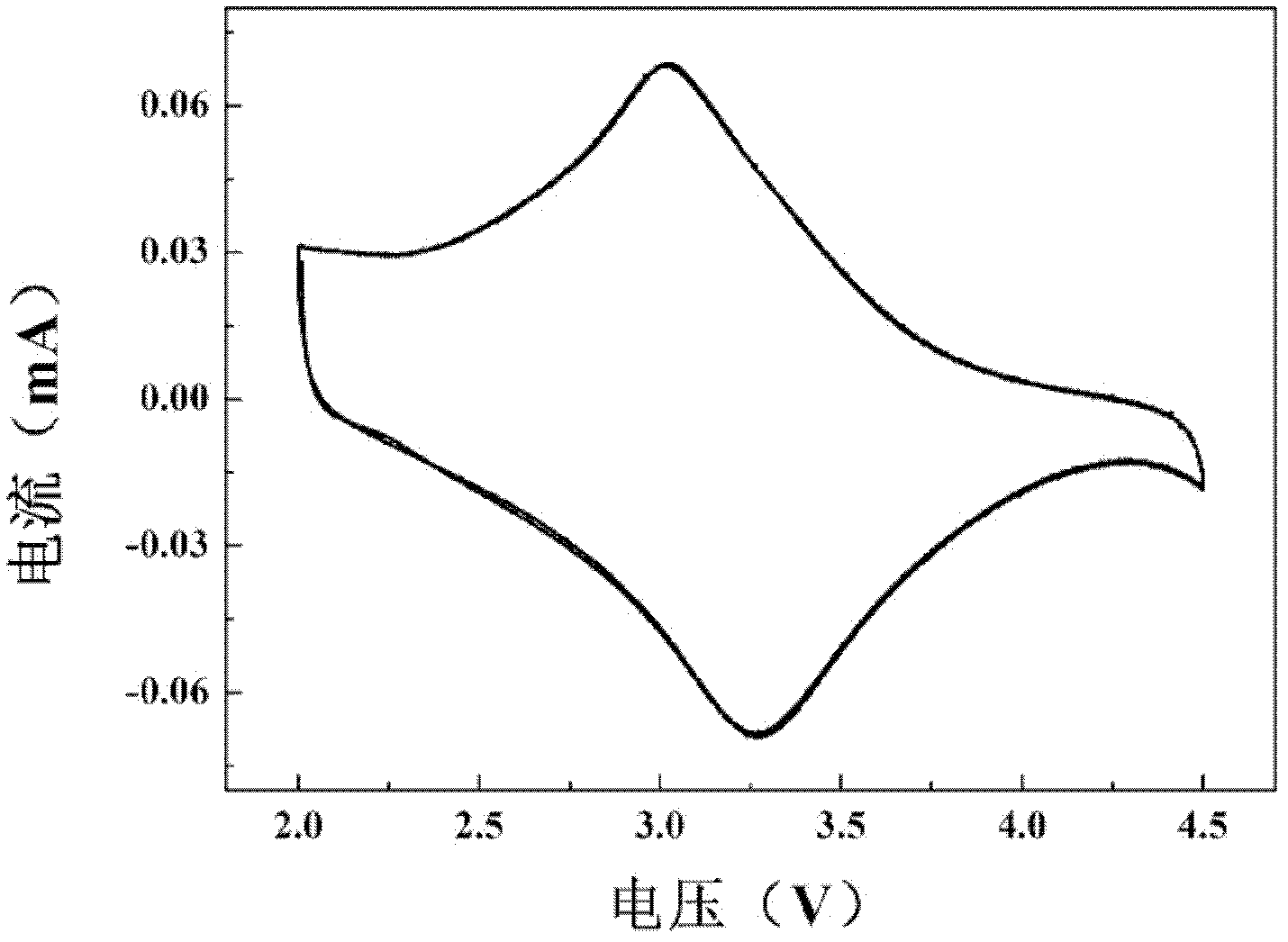

Metal fluoride cathode material for lithium secondary battery and preparation method thereof

ActiveCN102299328AGood cycle performanceImprove Coulombic efficiencyCell electrodesCell materialCathode material

The invention discloses a metal fluoride cathode material of a lithium secondary battery and a preparation method of the cathode material, which belong to the fields of green secondary batteries and related energy materials, particularly the field of multi-electron lithium secondary battery materials, and solve the problem of high energy consumption and risk of the conventional preparation methodof metal fluoride. The chemical composition of the cathode material is MFa(H2O)b, wherein a is more than or equal to 1 and less than or equal to 3, and b is more than or equal to 0 and less than or equal to 4 and is an integer. The preparation method of the cathode material comprises the following steps of: (1) reacting alkali with soluble metal salt to obtain metal hydroxide or metal oxide; (2) reacting the metal hydroxide or metal oxide obtained in the step (1) with hydrofluoric acid to obtain solution; and (3) drying the solution obtained in the step (2) to obtain the cathode material. Thecathode material has high electrochemical property and is environment-friendly; and the preparation method is simple, the energy consumption in the preparation process is low, reaction conditions areeasy to implement, and raw materials are easy to obtain.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method of nitrogen-doped silicon/carbon core-shell structure lithium-ion battery negative electrode material

InactiveCN108539140AExcellent specific capacityGood cycle performanceCell electrodesSecondary cellsElectrospinningAir atmosphere

The invention provides a preparation method of a nitrogen-doped silicon / carbon core-shell structure lithium-ion battery negative electrode material. The preparation method comprises the following steps: dissolving a nitrogen-containing substance and polyacrylonitrile into an N,N-dimethylformamide solvent to obtain sheath liquid; dissolving nano silicon powder and polyvinylpyrrolidone into the N,N-dimethylformamide solvent to obtain core liquid; putting injection syringes filled with the core liquid and the sheath liquid on two injection pumps of an electrostatic spinning device respectively and carrying out coaxial electrostatic electric spinning; collecting precursor fibers sprayed by the electric spinning on a rolling shaft; putting the obtained precursor fibers into an air atmosphere muffle furnace and carrying out pre-oxidization; then carbonizing under a protection atmosphere of inert gas and at the carbonization temperature of 700 to 1000 DEG C, so as to obtain a nitrogen-doped inner carbon net communicated silicon@carbon / carbon nano-fiber core-shell structure lithium-ion battery negative electrode material. The nitrogen-doped silicon / carbon core-shell structure lithium-ion battery negative electrode material obtained by the method provided by the invention has the characteristics of high capacity and good circulating stability.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Electrolyte of considering high temperature cycle performance and low temperature cycle performance of battery and lithium-ion battery

InactiveCN105789611AGood cycle performanceImproved high temperature cycle performance and low temperature cycle performanceCell electrodesSecondary cellsHalogenVinylene carbonate

The invention discloses a nonaqueous electrolyte, for a lithium-ion battery, of considering the high temperature cycle performance and the low temperature cycle performance of the battery and the lithium-ion battery employing the electrolyte. The electrolyte comprises a nonaqueous solvent, an additive and a lithium salt as shown in a general formula shown in the specification, wherein R1 and R2 are one of halogen elements; and the additive is one or more of vinylene carbonate, propylene sulfite, methylene methanedisulfonate and vinylethylene carbonate. By changing the lithium salt in the electrolyte for the lithium-ion battery and adding a certain amount of film-forming additive, the impedance of the battery in the cyclic process is reduced; and the stability of the electrolyte in a high temperature cycle and a low temperature cycle is improved, so that the high temperature cycle performance and the low temperature cycle performance of the battery are improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Lithium ion anode material SiO2@SnO2 with coated structure and preparation method and application thereof

ActiveCN105932253ASimple preparation processGood cycle performanceCell electrodesSecondary cellsLithiumAnode

The present invention belongs to the field of new energy, and discloses a lithium ion anode material SiO2@SnO2 with a coated structure and a preparation method and application thereof. The anode material is a composite material consisting of SnO2 and SiO2. SnO2 is wrapped and dispersed on the surface of SiO2 so as to form the coated structure. According to the preparation method, the lithium ion anode material SiO2@SnO2 with the coated structure is prepared by using a one-step hydrothermal method. The preparation method is simple, and the compounded composite anode material SiO2@SnO2 has the characteristics of good cycle performance and so on.

Owner:GUANGDONG UNIV OF TECH

Black-phosphorus-based composite negative electrode material and preparing method thereof

InactiveCN106025194AGood cycle performanceLow costCell electrodesSecondary cellsStructural stabilityGraphite

The invention relates to a black-phosphorus-based composite negative electrode material and a preparing method thereof, and belongs to the field of electrochemistry power supply materials. The black-phosphorus-based composite negative electrode material is prepared by combining black phosphorus, germanium oxide and graphite, flake-like germanium oxide particles are uniformly dispersed on the surface of the black phosphorus material, and the surface of germanium oxide / black phosphorus is coated with graphite, wherein the mass ratio of black phosphorus to germanium oxide is (0.25-2):1, and the mass percentage of graphite in the negative electrode material is 5-80%. The black-phosphorus-based composite negative electrode material is prepared through a two-step ball milling method with black phosphorus, germanium oxide and graphite as raw materials. The black-phosphorus-based composite negative electrode material is good in circulation performance, low in cost and stable in structure; the preparing method is simple in technological process, short in consumed time and high in yield, and has the advantages of being low in raw material cost and improving the structural stability of composites, and the problem that the circulation performance of a black-phosphorus-based composite is poor is solved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

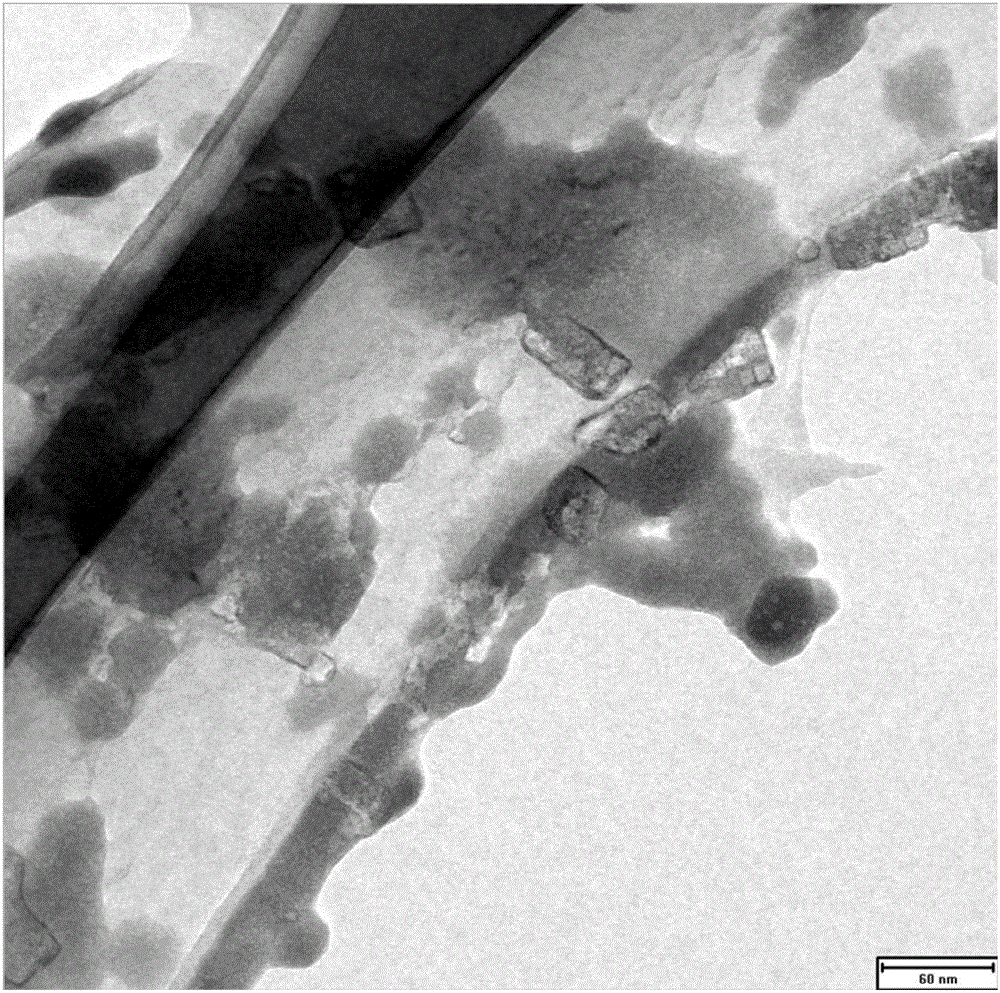

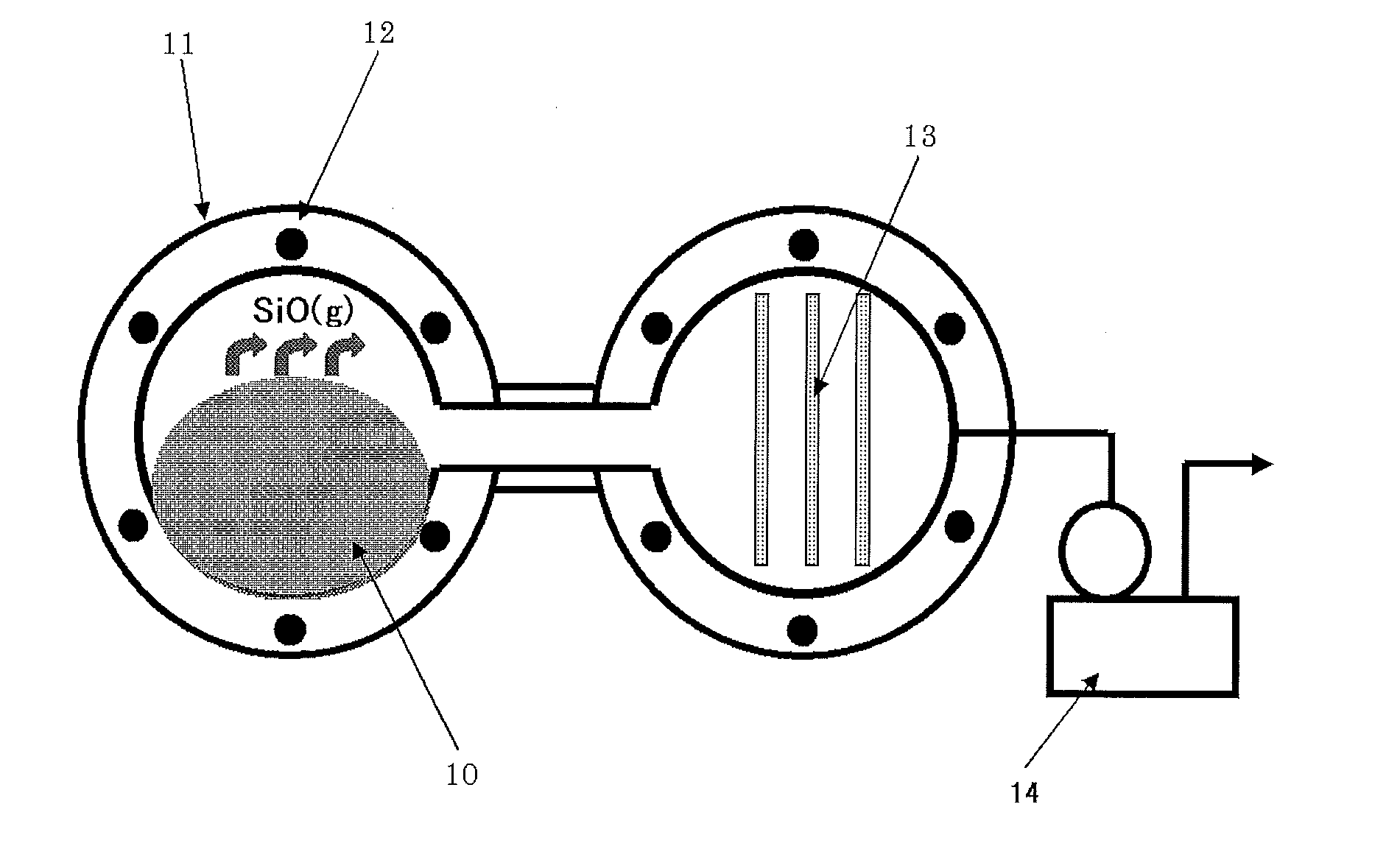

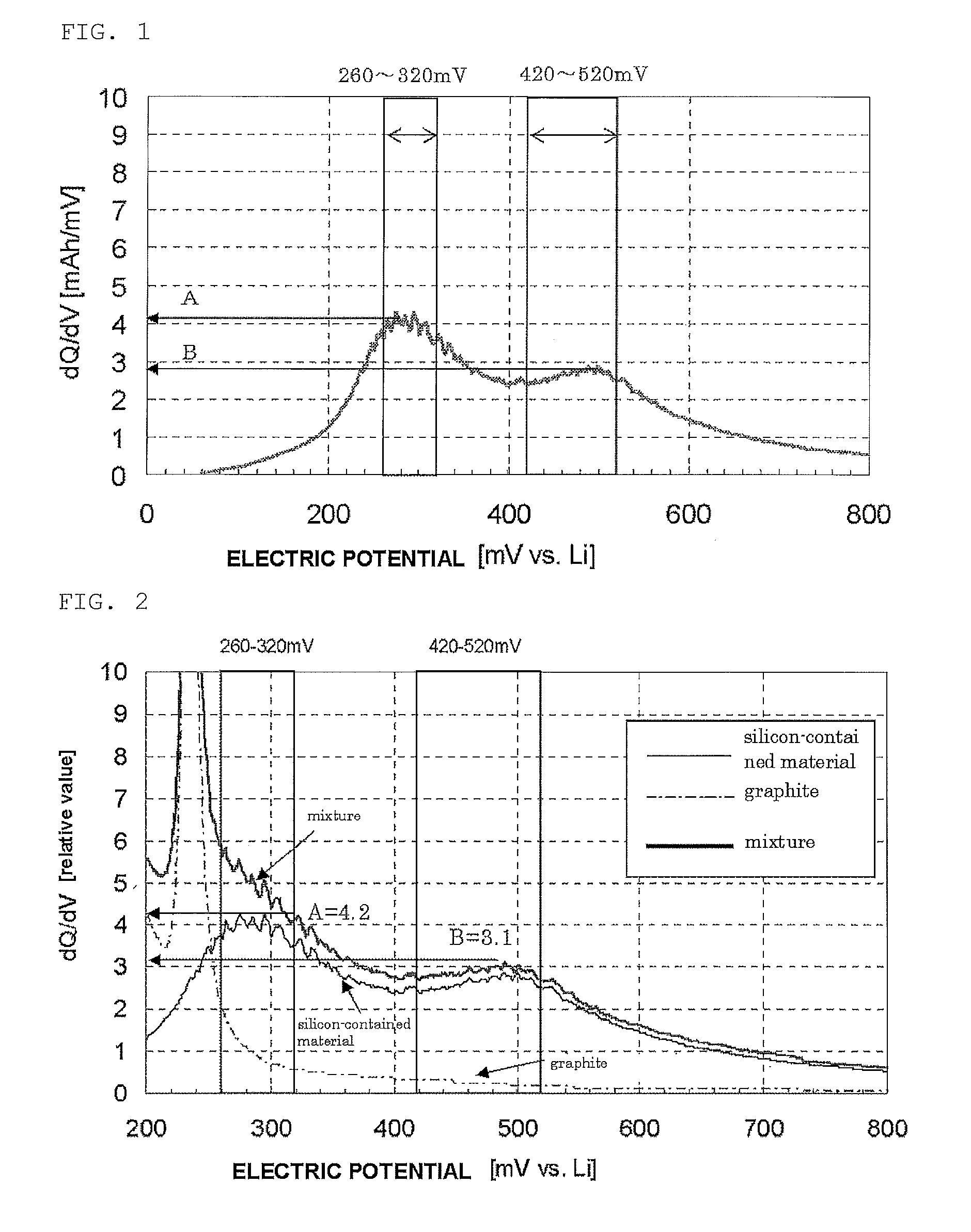

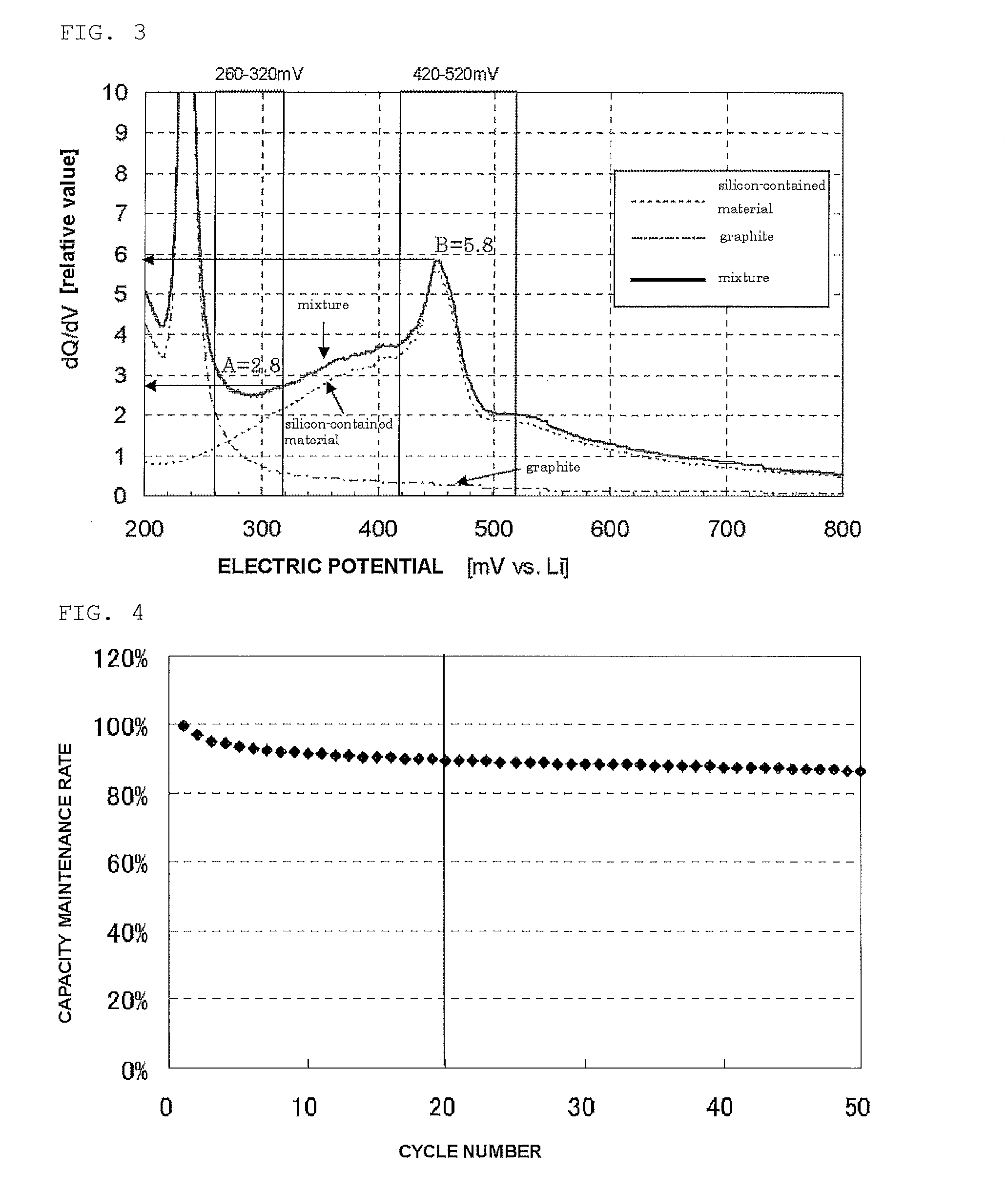

Silicon-contained material, negative electrode for use in non-aqueous electrolyte secondary battery, method of producing the same, non-aqueous electrolyte secondary battery, and method of producing the same

InactiveUS20160111711A1Good cycle performanceImprove cycle performanceElectrode thermal treatmentFinal product manufactureMetallic lithiumCharge and discharge

A silicon-contained material capable of being doped with lithium and de-doped, wherein when a three-electrode cell produced by using a working electrode including the silicon-contained material as an active material, a reference electrode made of metallic lithium, a counter electrode made of metallic lithium, and an electrolyte having lithium ionic conductivity is charged and discharged to graph a relationship between a derivative of a charging or discharging capacity with respect to an electric potential of the working electrode on the basis of the reference electrode and the electric potential, a ratio B / A is 2 or less while current flows in a direction in which the lithium of the silicon-contained material is de-doped in the discharge, A being the derivative maximum value with respect to a potential range from 260 to 320 mV, and B is the derivative maximum value with respect to a potential range from 420 to 520 mV.

Owner:SHIN ETSU CHEM CO LTD

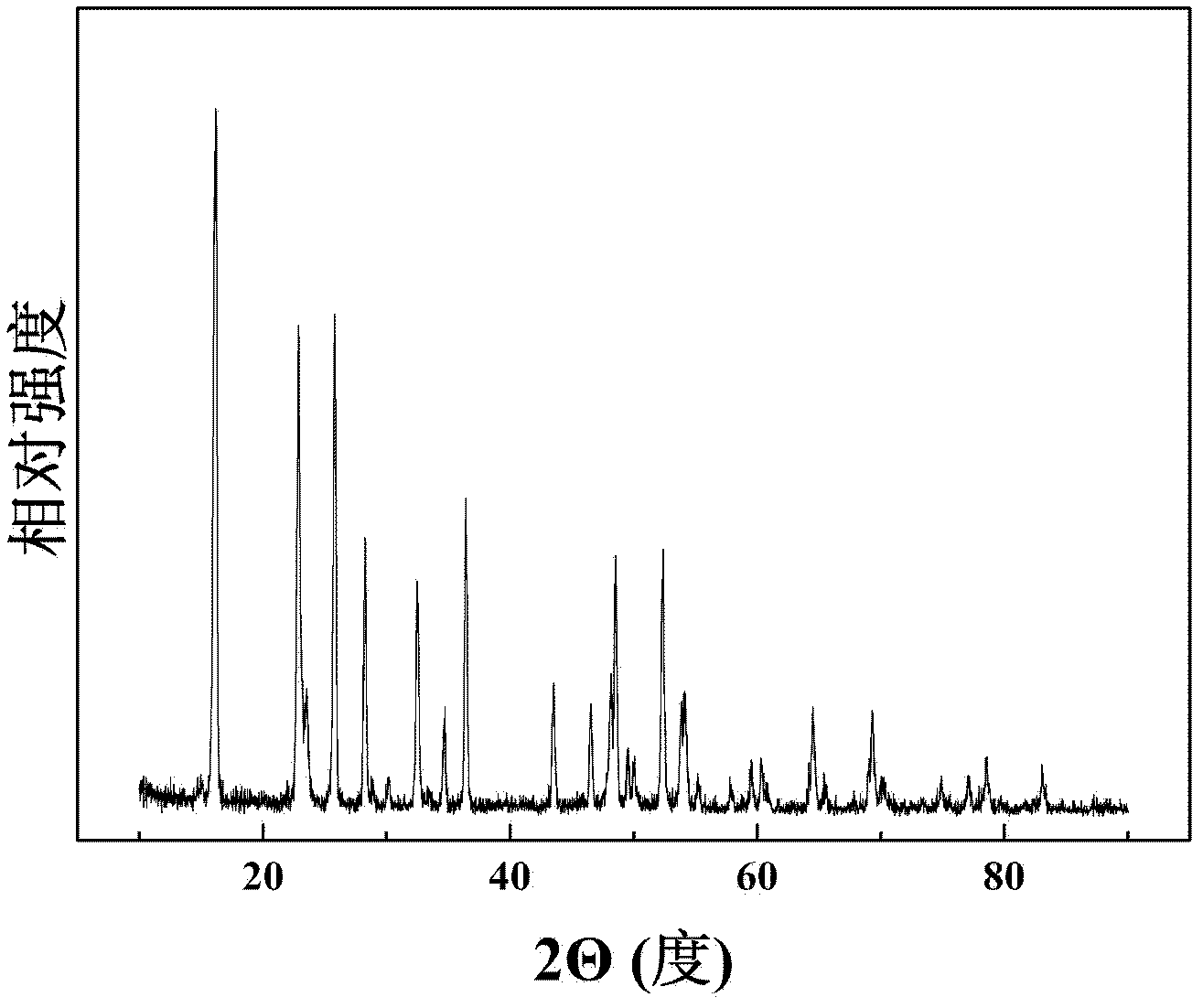

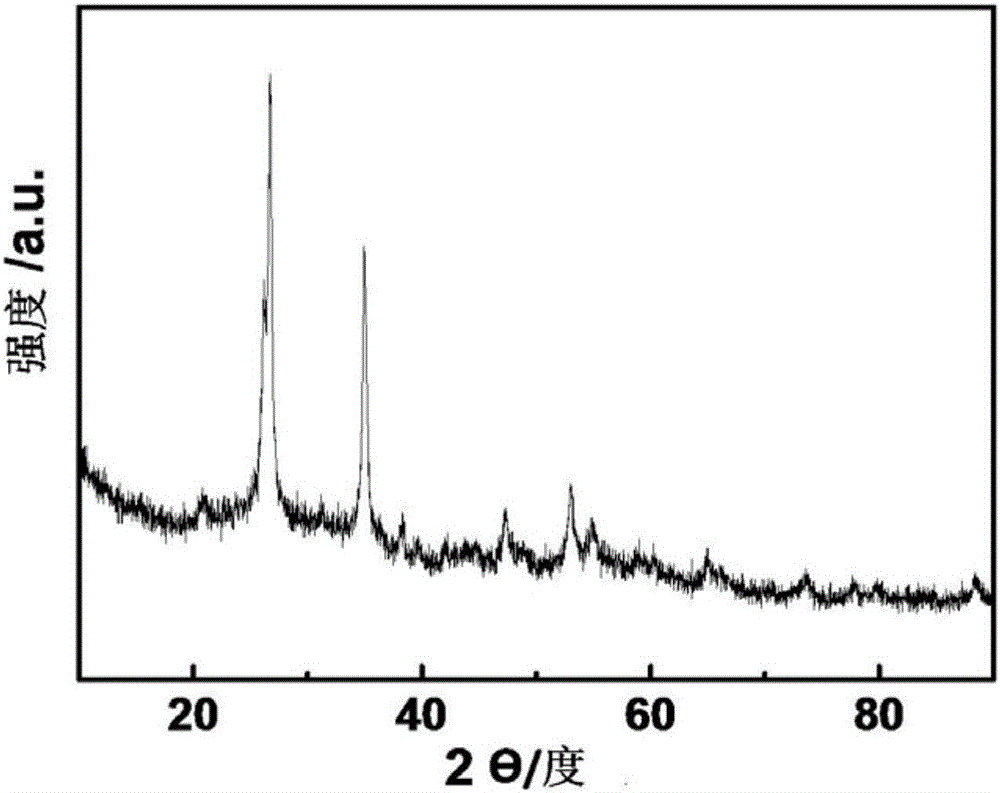

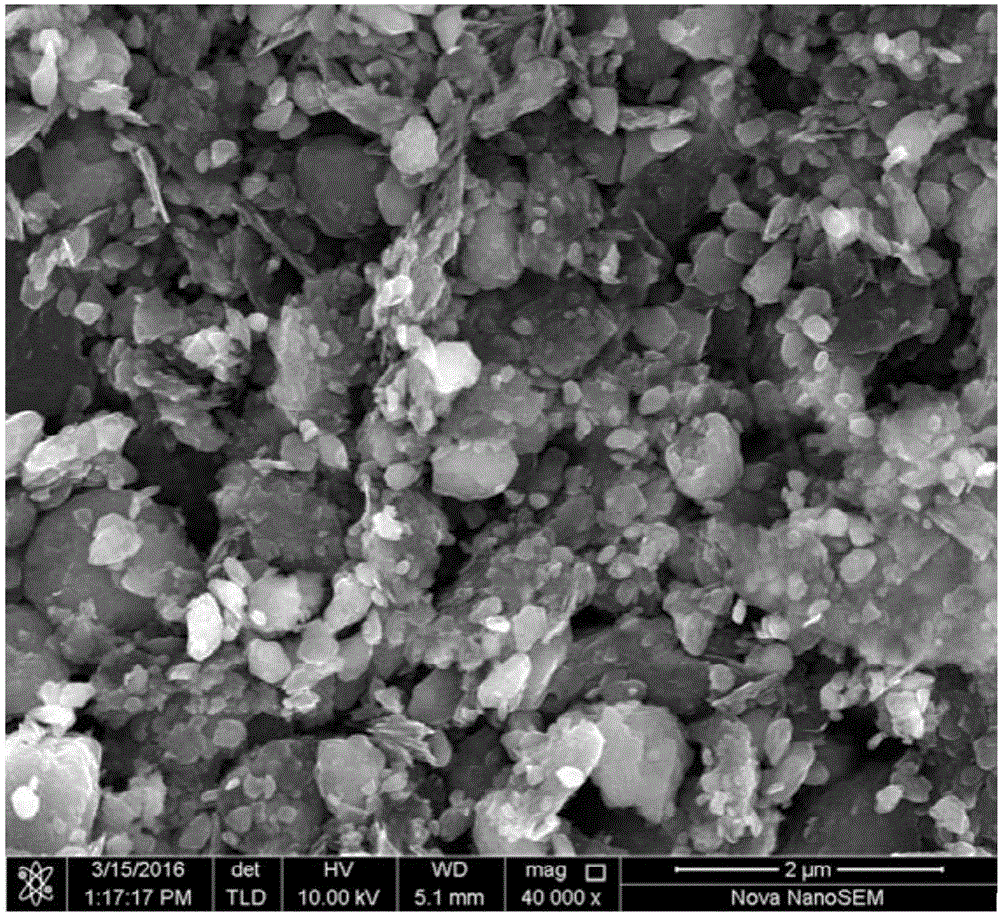

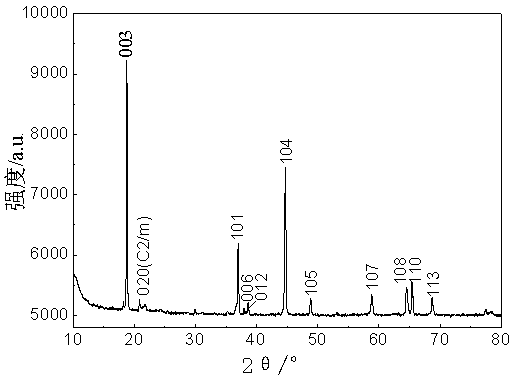

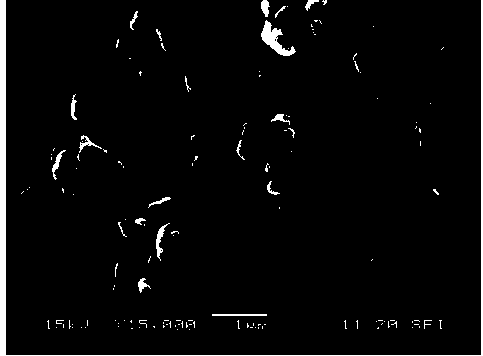

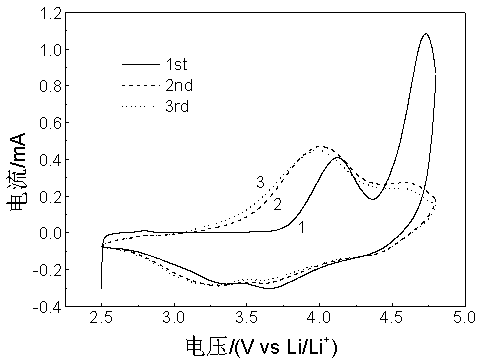

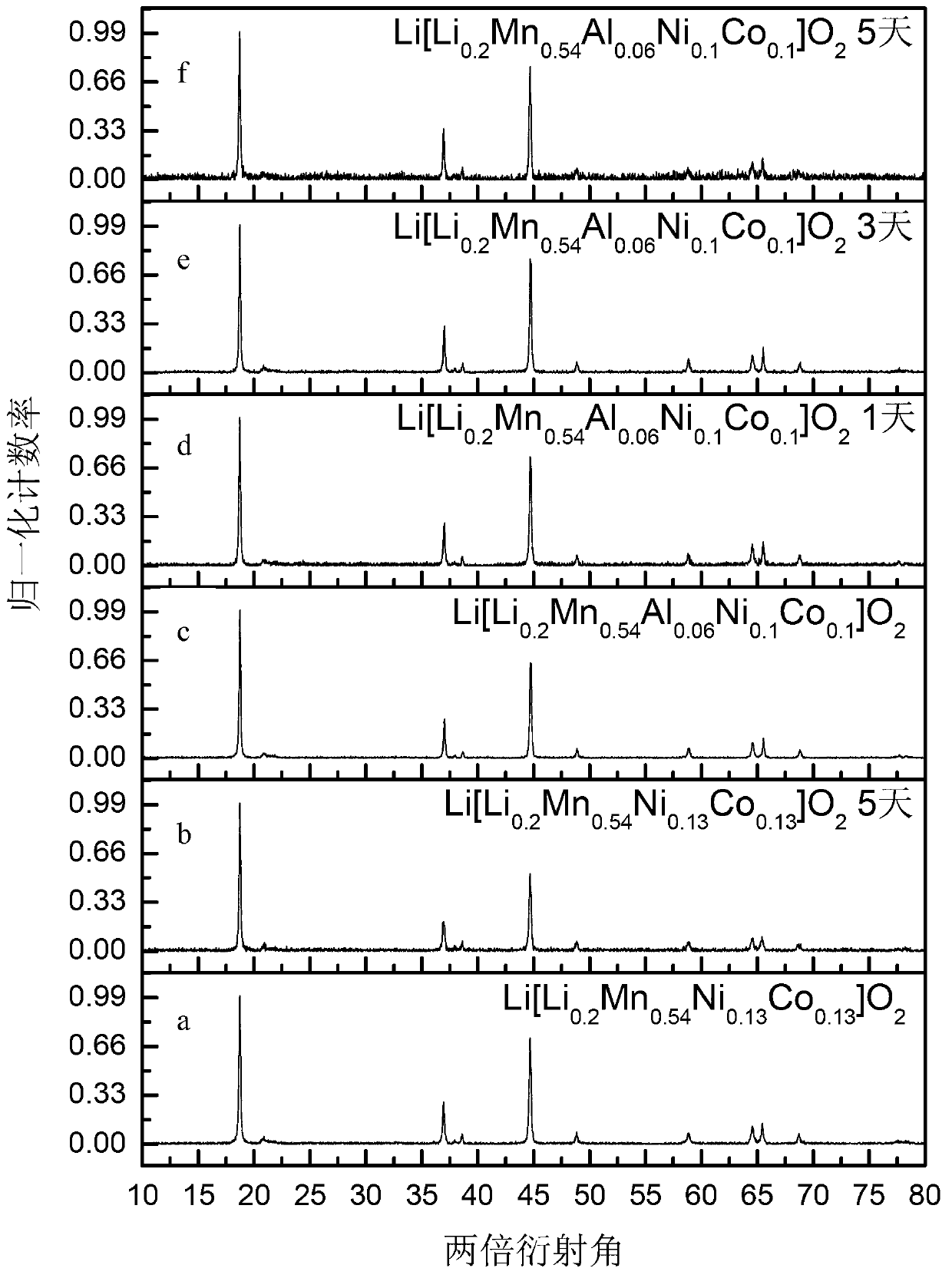

Mg-doped Li-rich anode material and preparation method for same

InactiveCN103441238AGood cycle performanceGood cycle performance and rate performanceCell electrodesCOBALTOUS ACETATEMagnesium nitrate

The invention discloses an Mg-doped Li-rich anode material and a preparation method for the same, wherein the molecular formula of the Mg-doped Li-rich anode material is Li(Li0.2Ni0.13Co0.13Mn0.54)0.98Mg0.02O2. The preparation method comprises the following steps of: dissolving lithium acetate, cobaltous acetate, nickel acetate, manganese acetate and magnesium nitrate in deionized water in a molar ratio of Li to Co to Ni to Mn to Mg being 1.196: 0.1274: 0.1274: 0.5292: 0.02 to obtain solution 1; adding citric acid in deionized water to obtain solution 2 in a ratio of the molar weight of the citric acid to the total molar weight of Ni, Co, Mn and Mg being 1: 1; and adding the solution 2 in the solution 1, adjusting the pH value to be 9, stirring at 80 DEG C until a purple gel is formed, sequentially performing drying, ball-milling, segmented calcination and grinding, and thus obtaining the Mg-doped Li-rich anode material which is high in specific discharge capacity, good in circulation performance, and excellent in rate performance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

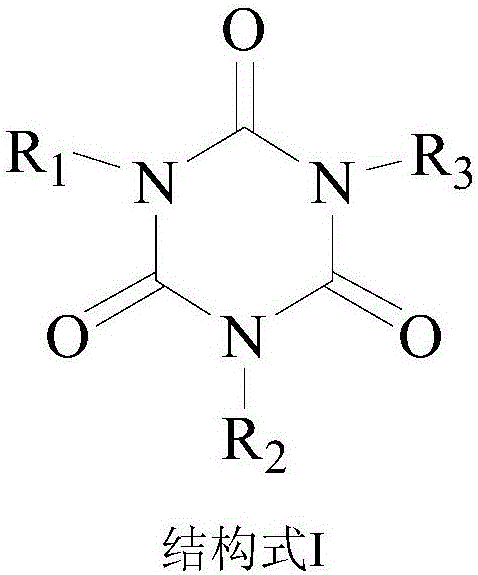

High-voltage lithium-ion battery with Si/C composite anode

InactiveCN106450432AGood cycle performanceImprove high temperature cycle performanceSecondary cells servicing/maintenanceOrganic electrolytesLithium electrodeOxide

The invention discloses a high-voltage lithium-ion battery with a Si / C composite anode. The high-voltage lithium-ion battery comprises a cathode, an anode as well as a separator and a non-aqueous electrolyte placed between the cathode and the anode, wherein the active substance of the cathode is lithium transition metal oxide; the active substance of the anode is a Si-based substance; the separator is a ceramic separator; the non-aqueous electrolyte comprises a non-aqueous organic solvent, lithium salt and an additive, the additive comprises FEC (fluoroethylene carbonate) and isocyanurate compounds in the mass ratio being (6-36):1. Compared with the prior art, the lithium-ion battery using the electrolyte has excellent normal-temperature cycle performance, high-temperature cycle performance and high-temperature storage life, and the gas output in the high-temperature storage process can be remarkably reduced.

Owner:GUANGZHOU TINCI MATERIALS TECH

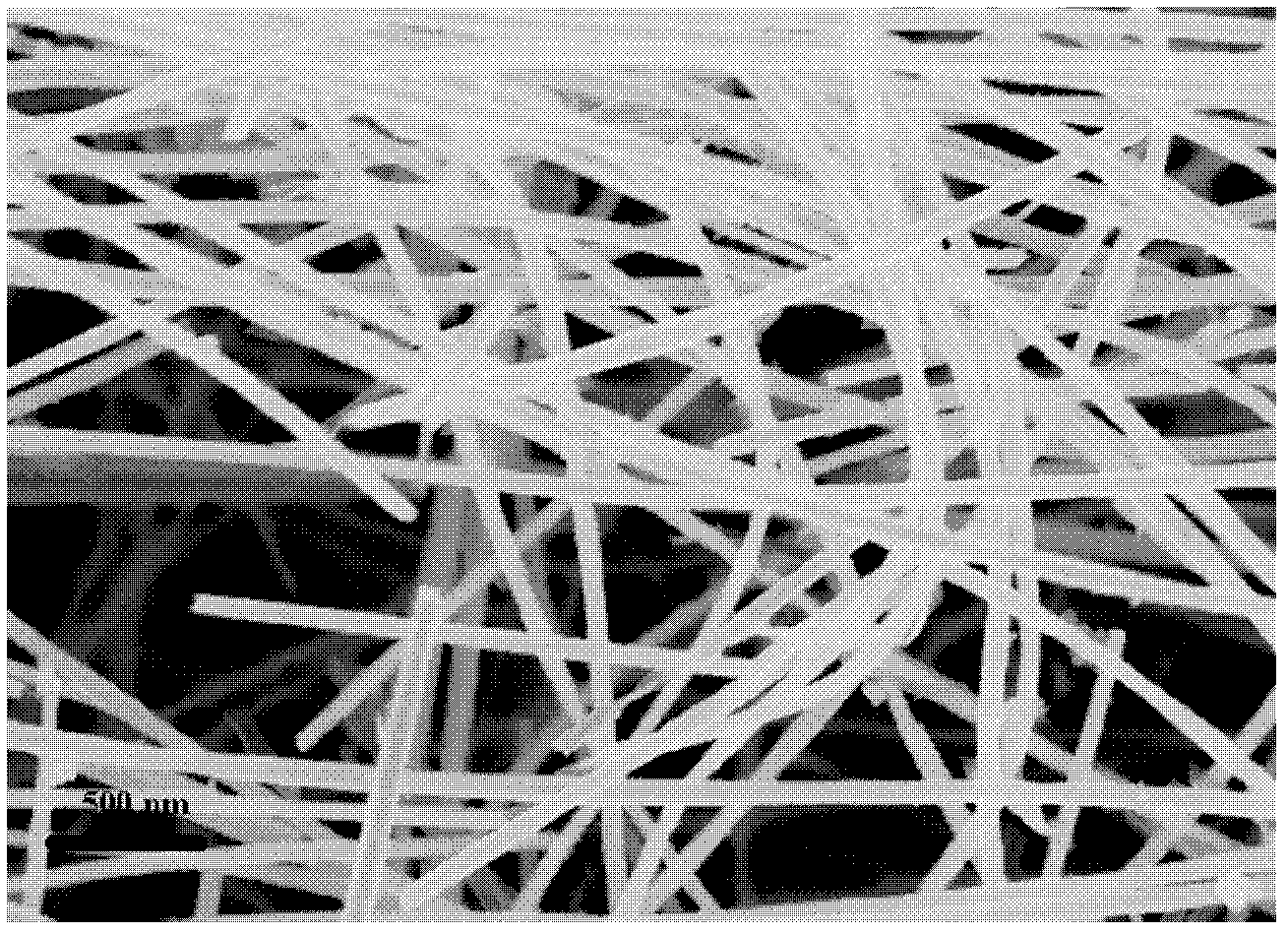

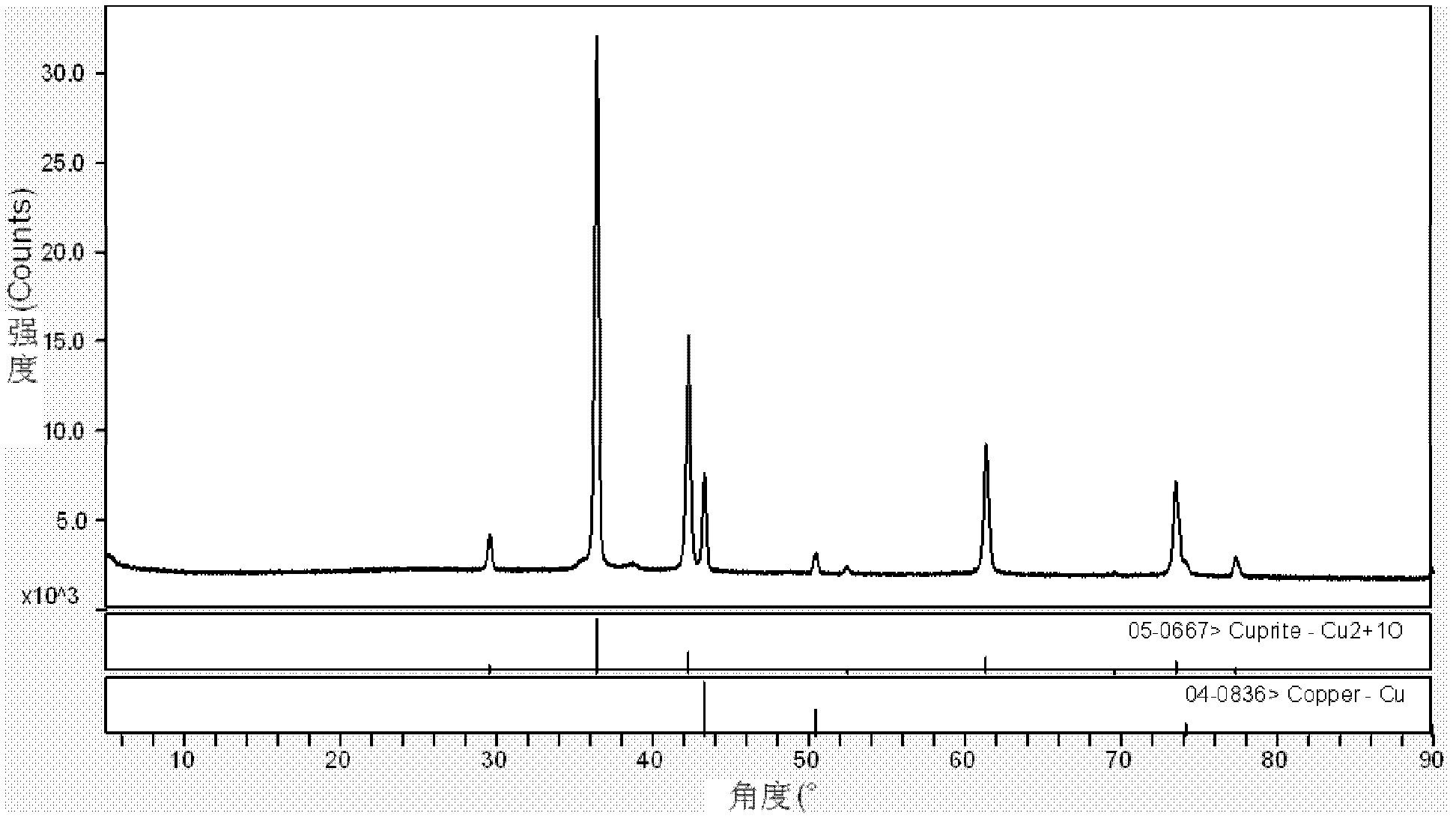

Preparation method of Cu2O/Cu/PPy nanowire composite lithium ion battery negative material

ActiveCN102629685AHigh specific capacityGood cycle performanceCell electrodesPyrroleLithium electrode

The invention relates to a preparation method of a Cu2O / Cu / PPy nanowire composite lithium ion battery negative material. The preparation method comprises the following steps of: (1) preparing pyrrole monomer solution and copper acetate solution and performing ultrasonic treatment to uniformly disperse the solution; (2) mixing the pyrrole monomer solution and the copper acetate solution obtained by the step (1) according to a volume ratio of 1:13-1:3 and transferring into a hydrothermal reaction kettle; (3) placing the hydrothermal reaction kettle in a drying oven to react for 10-20 hours, wherein the temperature of the drying oven is 120-180 DEG C; and (4) centrifugally separating a product obtained by the reaction, washing and then drying to obtain the Cu2O / Cu / PPy nanowire composite lithium ion battery negative material. Compared with the prior art, the material obtained by the invention has higher specific capacity compared with that of the lithium ion battery negative material and has good cycle performance.

Owner:浙江长芯光电科技有限公司

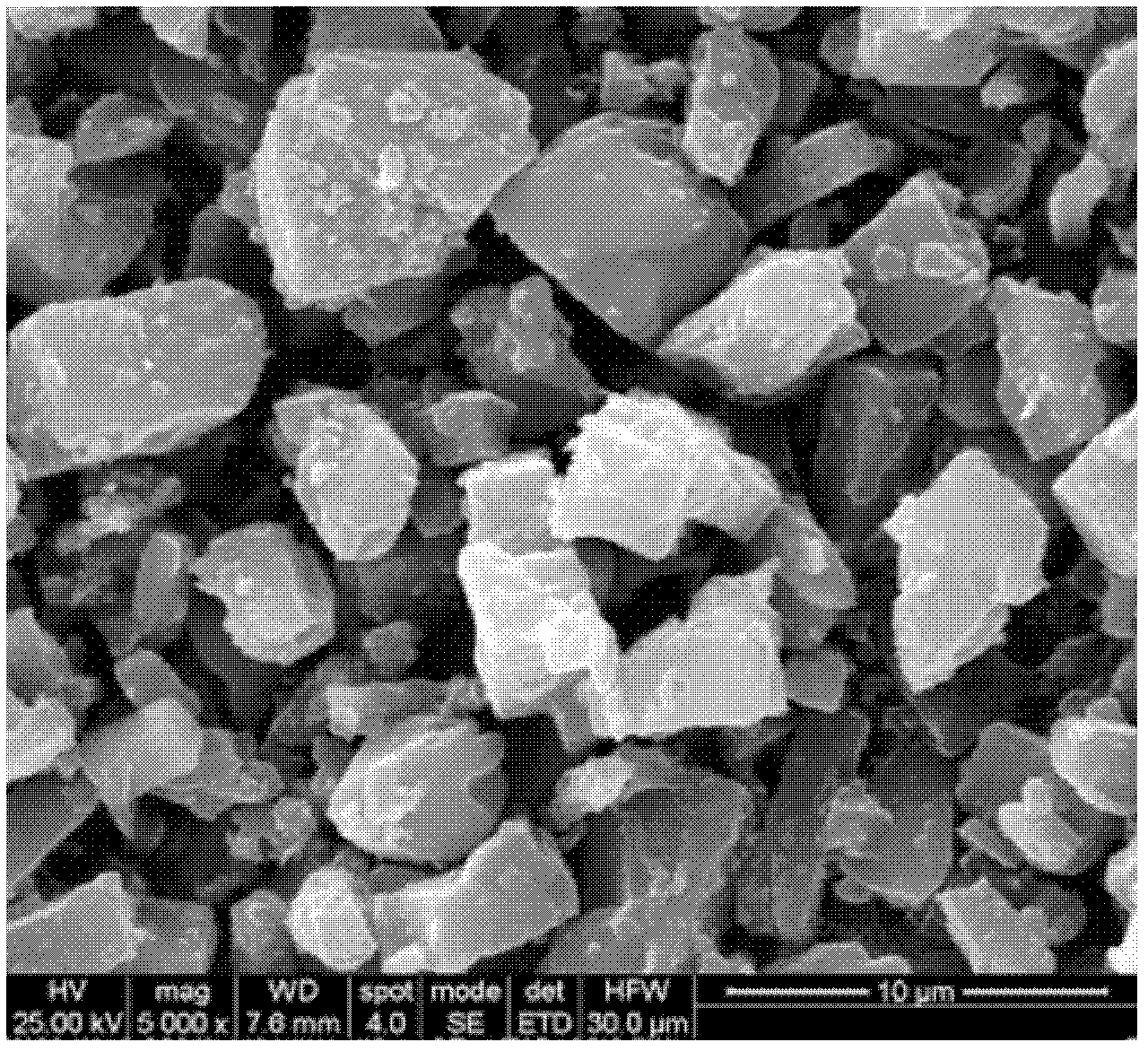

Multi-mixed and coated high compaction density silicon carbon anode material and preparation method thereof

ActiveCN109360946AIncrease compaction densityGood cycle performanceCell electrodesSecondary cellsActivated carbonActive carbon

The invention discloses a Multi-mixed and coated high compaction density silicon carbon anode material and a preparation method thereof, overcomes the defects that the surface of a silicon carbon material at the present is non-uniformly coated and is hardly intact, and solves the problem that the compaction density of a silicon carbon anode is hard to increase by means of a simple method. The silicon carbon anode material comprises primary particles and secondary particles, wherein the primary particles are porous silicon carbon materials; porous silicon is uniformly dispersed in activated carbon, and the surfaces of the porous silicon and the activated carbon are coated with a pyrolytic carbon coating layer having a thickness of 3 to 50 nm; the porous silicon accounts for 5 to 50 percentby mass of the primary particles, and the activated carbon accounts for 20 to 30 percent by mass of the primary particles; the pyrolytic carbon accounts for 20 to 75 percent by mass of the primary particles; the secondary particles are agglomerates formed by uniformly dispersing the primary particles and graphite in the pyrolytic carbon, and have a particle size of 5 to 100 [mu]m; the total carboncontent of the silicon carbon anode material is 80 to 90 percent; and the compaction density is 1.1 to 1.7 g / cm<3>.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

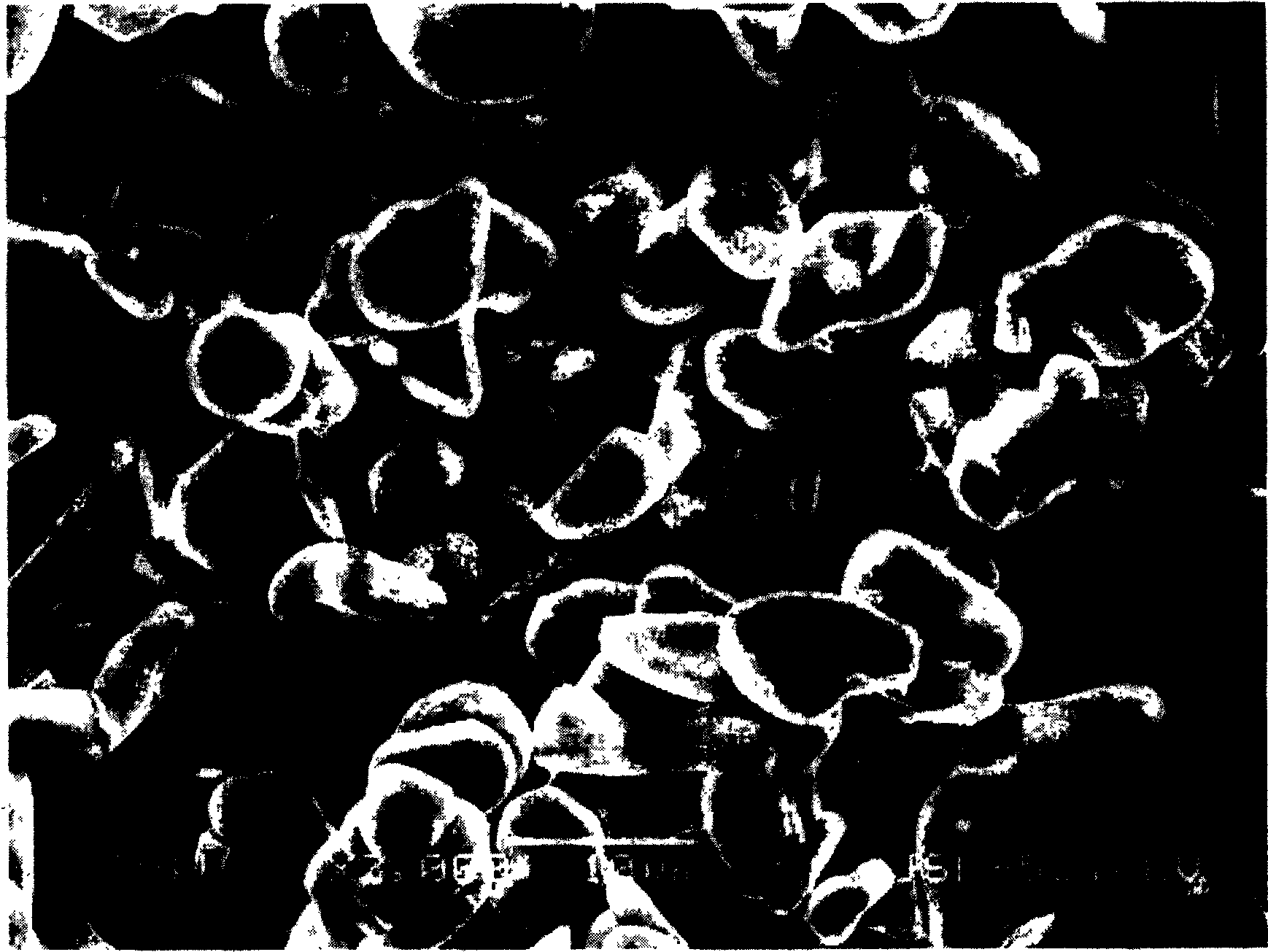

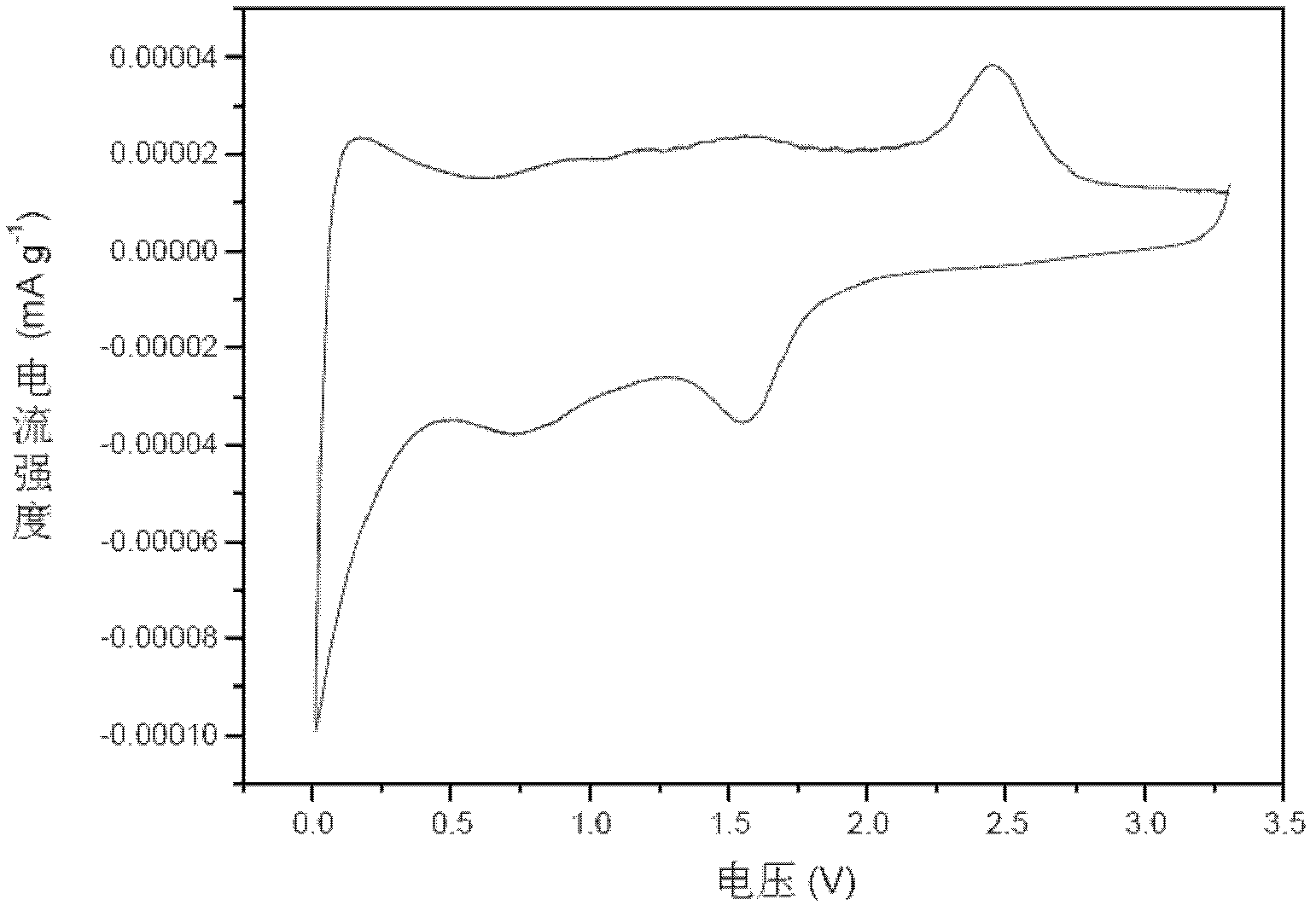

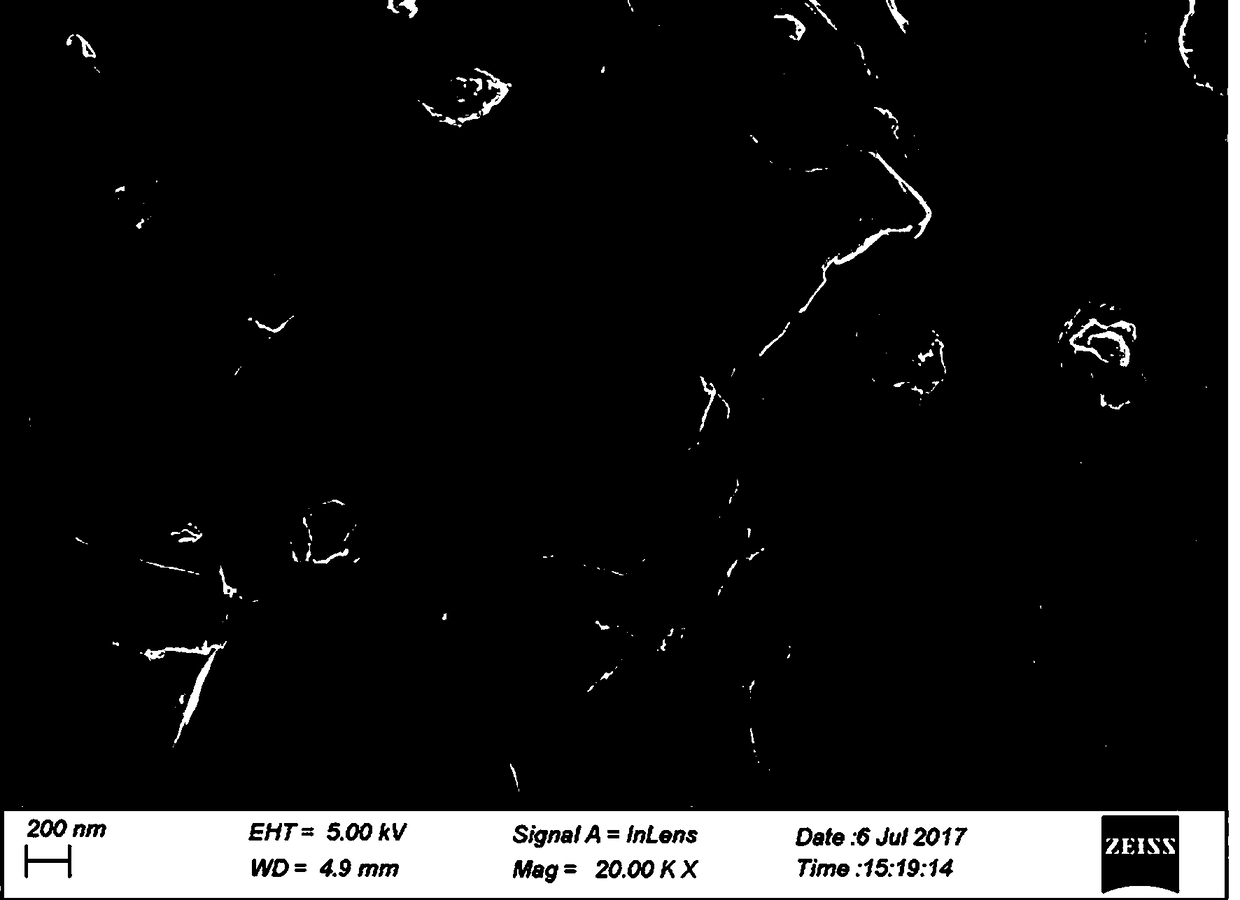

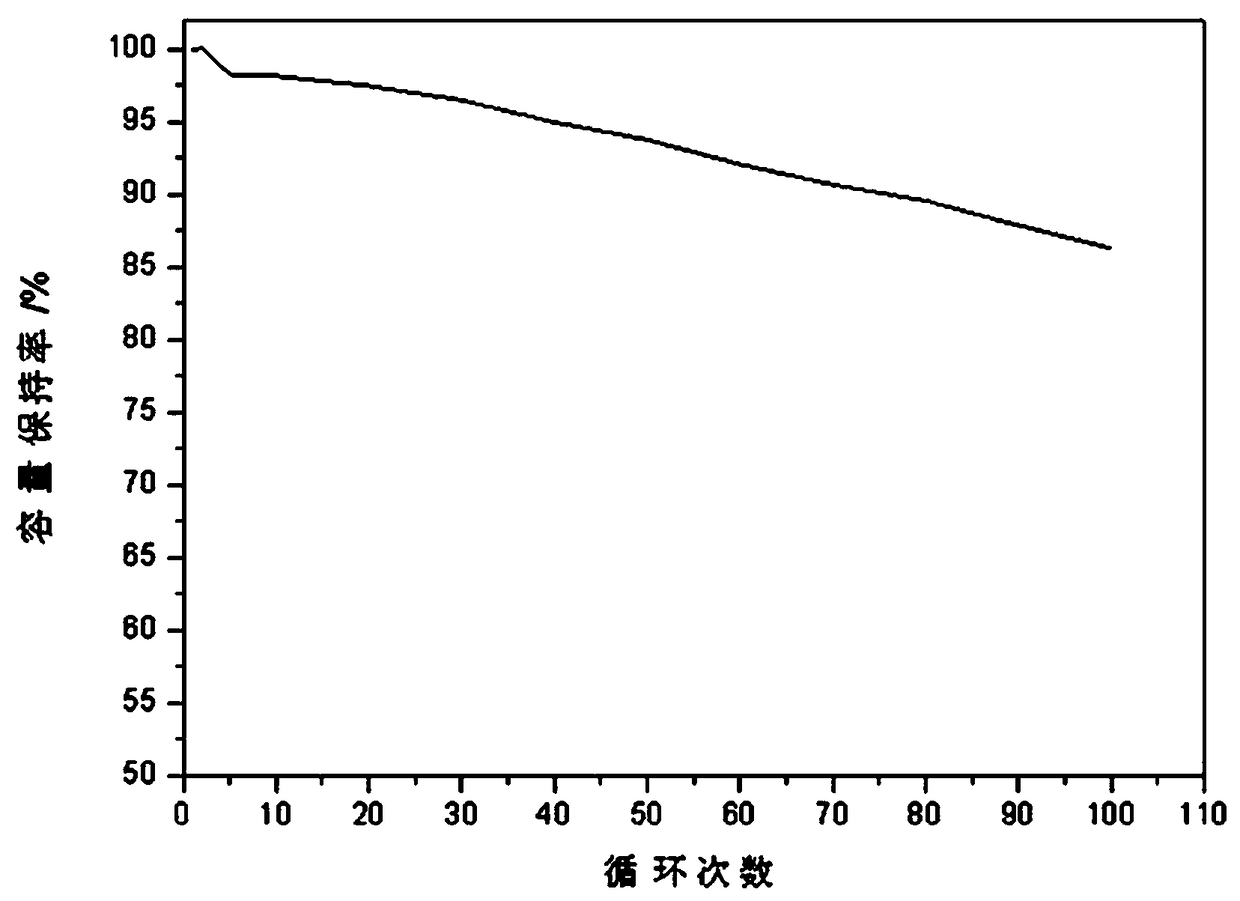

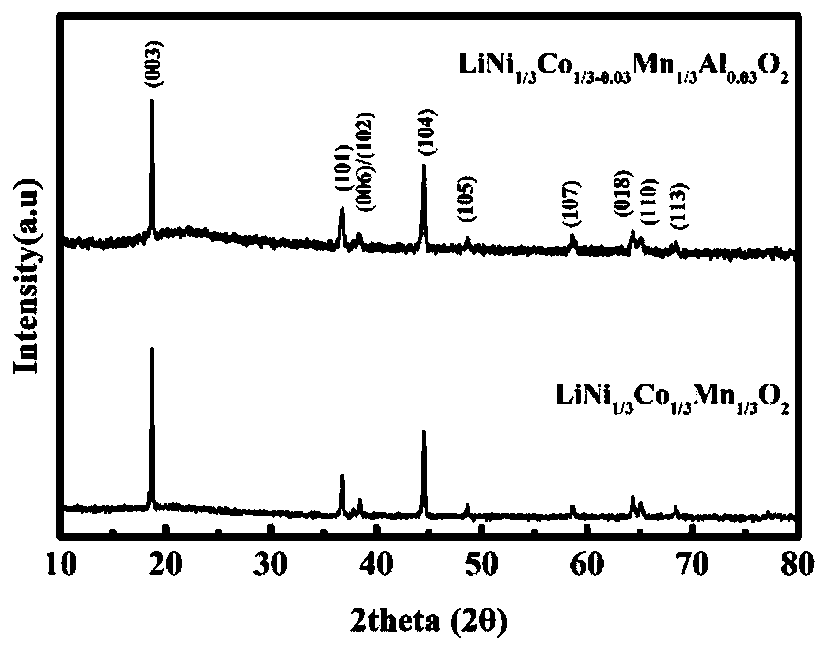

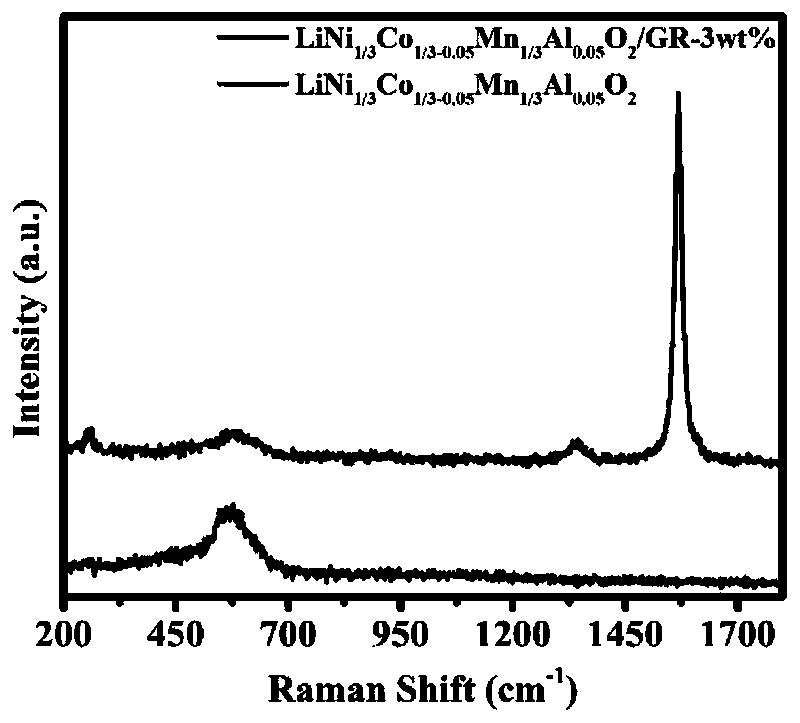

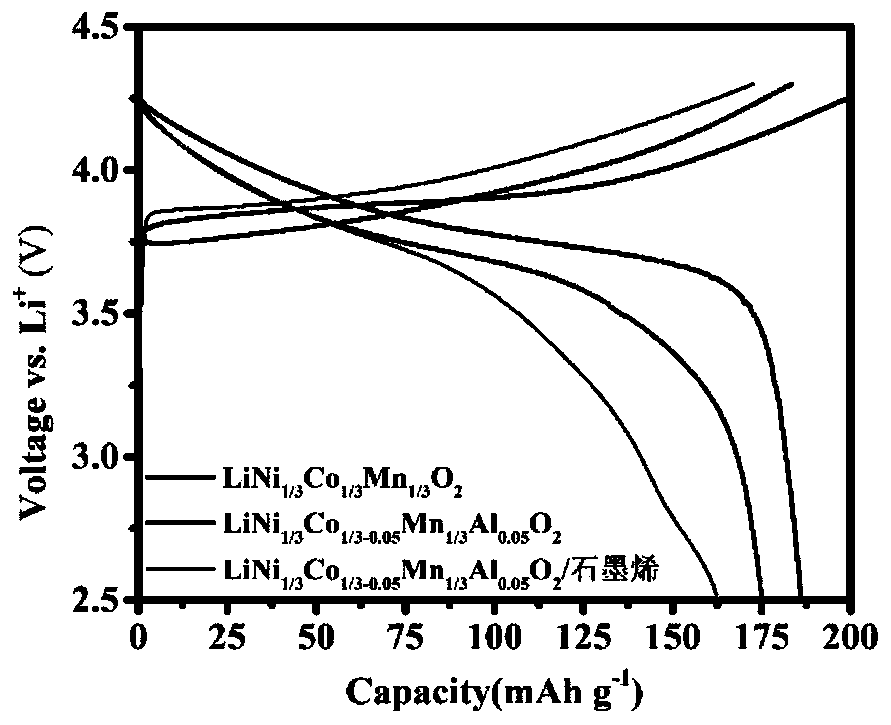

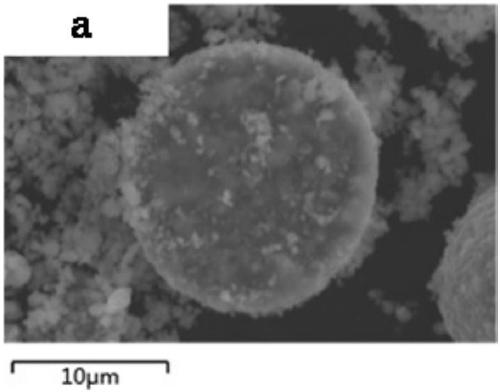

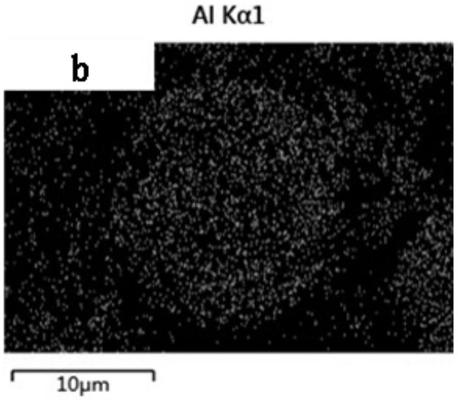

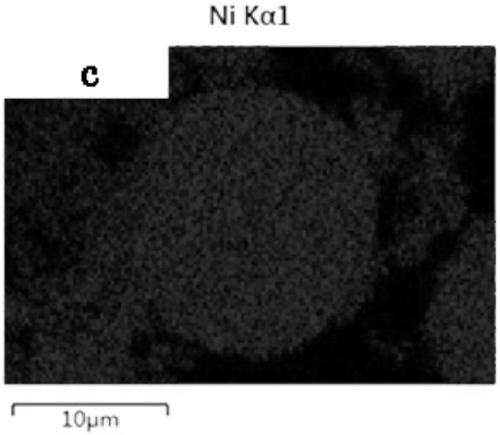

Lithium-ion battery graphene composite ternary anode material and preparation method thereof

ActiveCN109873140AGood cycle performanceGood magnification performanceCell electrodesSecondary cellsIonCvd graphene

The invention discloses a lithium-ion battery graphene composite ternary anode material and a preparation method thereof. According to the anode material, first, a template method is used to synthesize an aluminum-doped nickel-cobalt-manganese-lithium oxide anode material; second, the aluminum-doped nickel-cobalt-manganese-lithium oxide anode material and graphene are added into deionized water and stirred uniformly, a hydrothermal reaction is performed, and the aluminum-doped nickel-cobalt-manganese-lithium oxide anode material / graphene composite anode material is obtained through centrifugation after cooling, washing and drying. According to the method, the advantages of the two materials can be integrated through compositing, so that electron conductivity and ion conductivity are improved, output power density of a battery is increased, the structural stability of the ternary material can be improved, and therefore the composite anode material with good circulation performance, highcapacity and large energy density is obtained.

Owner:HEFEI UNIV OF TECH

In-situ preparation method of CuO electrode material of ultracapacitor by adopting foamed nickel

InactiveCN102129914AEasy to prepareHigh specific capacityElectrolytic capacitorsActivated carbonSupercapacitor

The invention provides an in-situ preparation method of a CuO electrode material of an ultracapacitor by adopting foamed nickel, which comprises the following steps of: firstly uniformly mixing 0.1-0.3mol / L of Cu(NO3)2 solution and 25-30 wt.% ammonia water; stirring the mixture for 15-30min to form a dark blue mixed solution; preheating the dark blue mixed solution for 2h at a temperature of 90 DEG C, and then adding 1-4cm<2> of the foamed nickel into the preheated dark blue mixed solution; heating for 5-8 hours at a temperature of 80-95 DEG C; and taking out and drying the foamed nickel to obtain the CuO electrode material prepared from the foamed nickel in an in-situ manner, wherein the specific surface area of the foamed nickel is 300-350g / m<2>. The essence of the invention is such that the electrode of the ultracapacitor is prepared by using a foamed nickel in-situ CuO preparation method to replace the method of mixing CuO powder, active carbon and a binding agent and pressing the mixture on the foamed nickel, by adopting the structure of the ultracapacitor. In the invention, the preparation method is simple, the specific capacity is high, and the circulation performance is good.

Owner:HARBIN ENG UNIV

Preparation method for silicon/graphite/solid electrolyte composite negative electrode material

ActiveCN110858642AGood cycle performanceImprove conductivitySecondary cellsNegative electrodesCarbon nanofiberGraphite

The invention discloses a preparation method for a silicon / graphite / solid electrolyte composite negative electrode material. The preparation method comprises the following steps of: firstly, mixing silicon powder, graphite, a binder, a conductive agent and a solid electrolyte to prepare a dispersion liquid, and then performing spray granulation and drying; and adding asphalt for kneading, sintering at high temperature, crushing, sieving and demagnetizing to obtain the silicon / graphite / solid electrolyte composite negative electrode material. According to the material prepared by the method, a conductive network is formed by utilizing conductive agents such as carbon nanotubes, carbon nanofibers and graphene, so that the conductivity of the material is improved; a high temperature-resistantsolid electrolyte is added, the effect of partial electrolyte can be replaced, an ionic conductance medium is achieved when the electrolyte enters the active material, the use amount of the electrolyte is reduced, and when an SEI film is heated and decomposed, the solid electrolyte can still exist stably, the ionic conductance effect is achieved, and the stability and the safety performance of thesilicon / graphite / solid electrolyte composite negative electrode material are improved.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

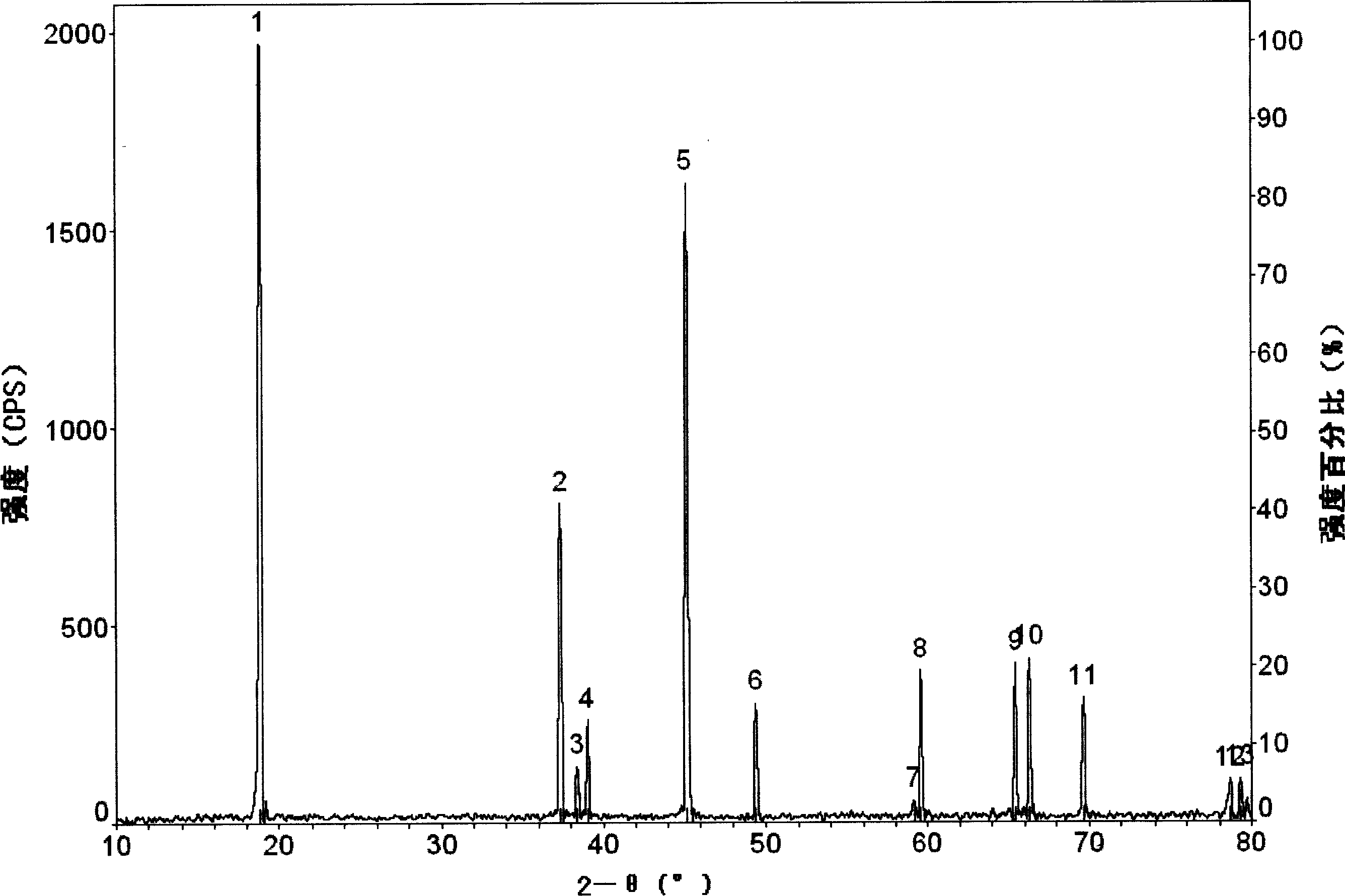

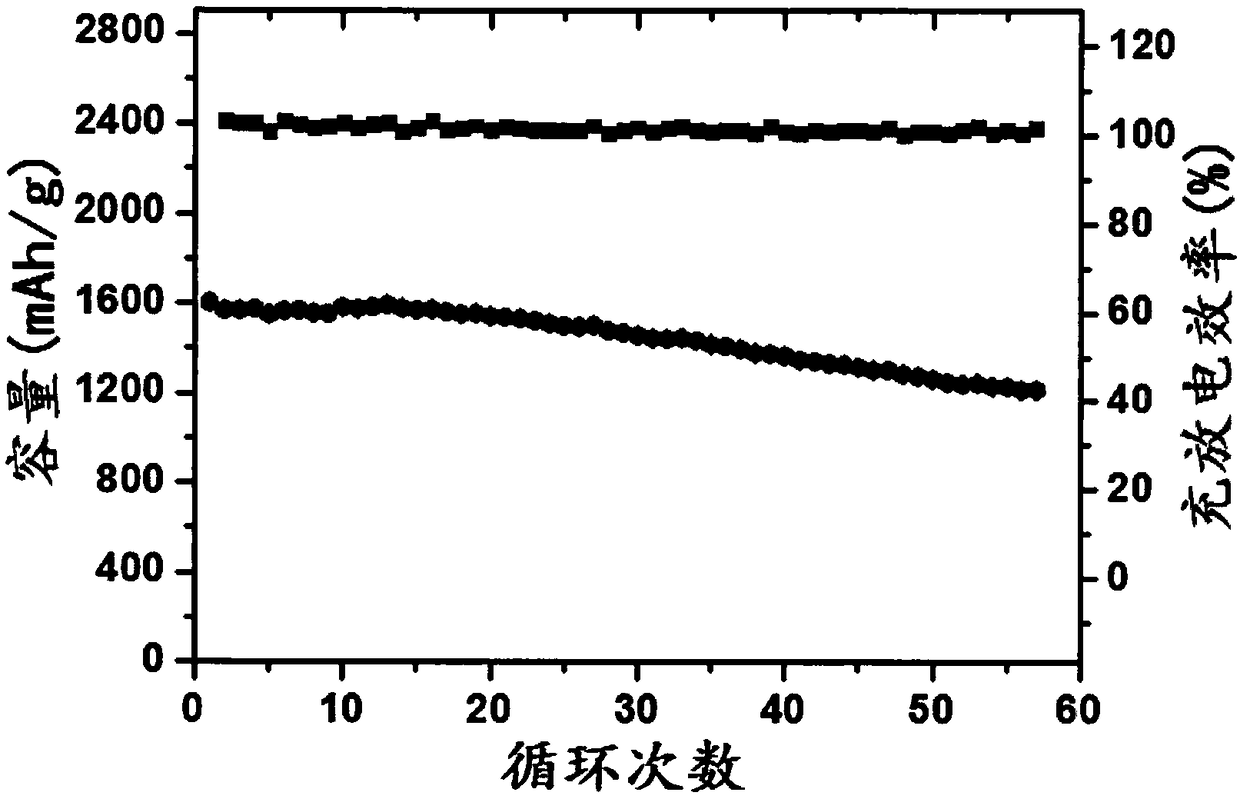

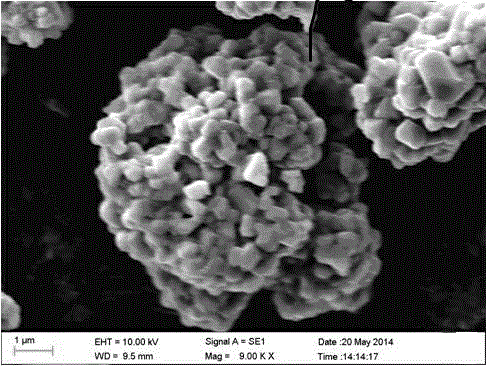

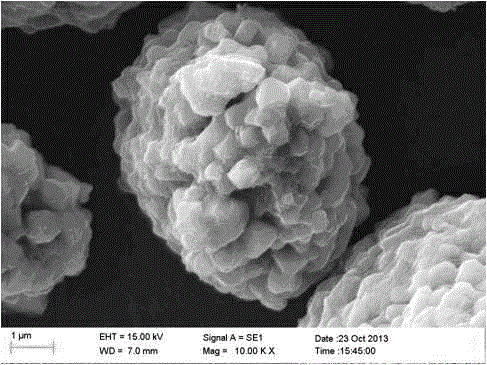

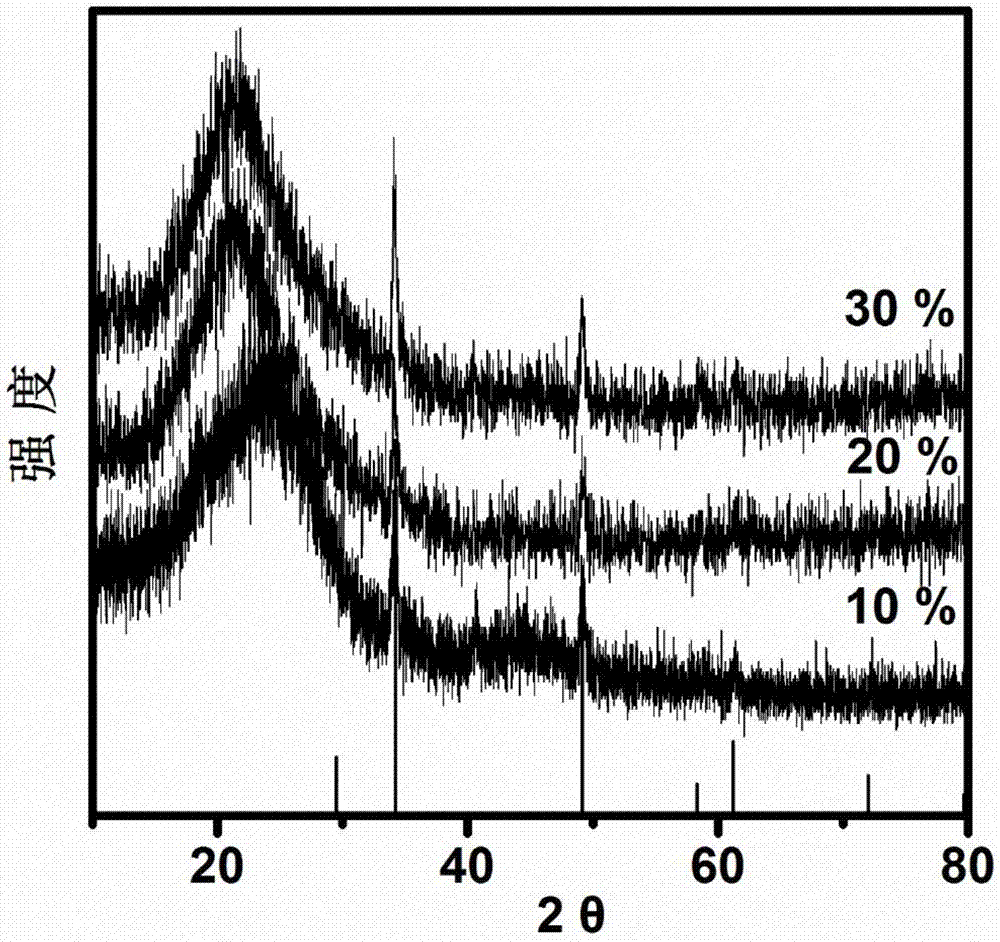

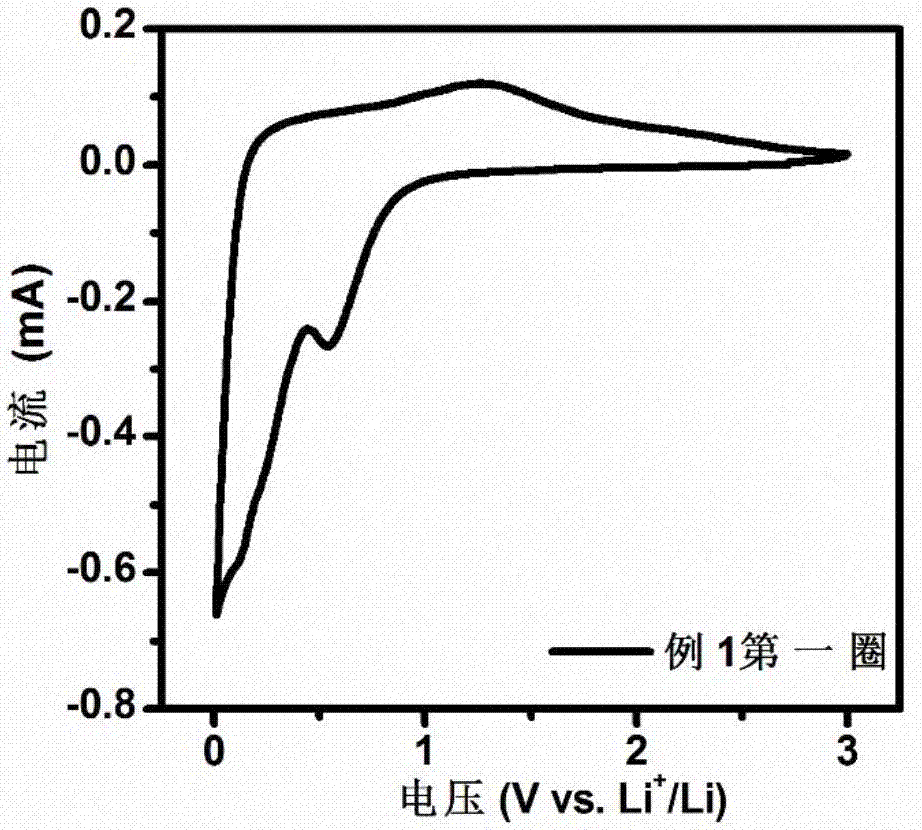

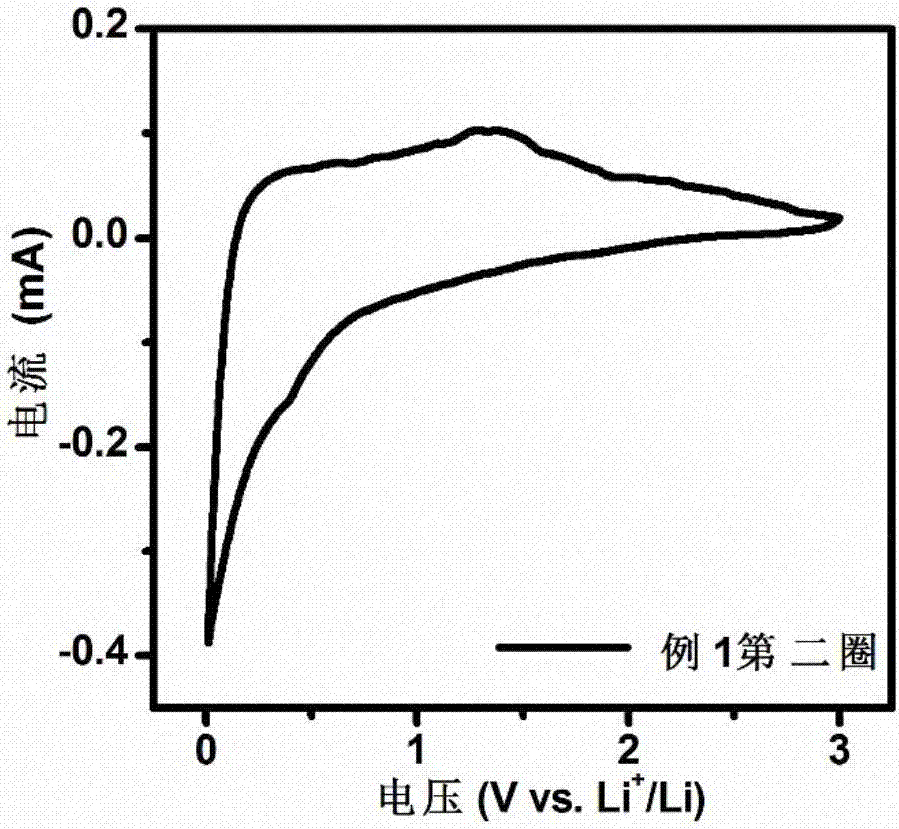

Method for preparing lithium ion secondary battery positive electrode material LiNi0.5Co0.2Mn0.3O2 by adding high-polymer saccharides as forming media

InactiveCN104577100AHigh specific capacityGood cycle performanceCell electrodesSecondary cellsNitrogen atmosphereLithium

The invention relates to a method for preparing a LiNi0.5Co0.2Mn0.3O2 positive electrode material with good sphericity degree by adding saccharides to promote the forming of a lithium ion secondary battery LiNi0.5Co0.2Mn0.3O2 precursor. According to the adopted technical scheme, the method comprises the following steps: dissolving NCM salts into water to prepare an NCM salt solution, sequentially adding ammonia water and sodium hydroxide solution into the NCM salt solution by taking ammonia water as a complexing agent and sodium hydroxide as a precipitator under the conditions of nitrogen atmosphere and water bath of 30-70DEG C, stirring during reaction, adding carbonhydrate, filtering a reaction solution obtained in the last step, to obtain an NCM precursor, performing microwave drying, and then drying for 5 hours in a vacuum drying oven; mixing the precursor and lithium salt at proper ratio, and adding the obtained mixture into a wet-process mechanical ball mill for ball-milling and mixing; and performing high-temperature sintering on the mixture, obtained from the last step, at the temperature of 700-850DEG C, and grinding the sintered materials and screening with a 325-mesh sieve, to obtain a final product.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Method for surface modification of AB3 type hydrogen storage alloy by means of graphene

The invention discloses a method for surface modification of AB3 type hydrogen storage alloy by means of graphene. Metal powder with purity being 99% or more is weighed according to a target product molar ratio, AB3 type hydrogen storage alloy is prepared with the vacuum induction melting method under the protection of argon, and the AB3 type hydrogen storage alloy is pulverized and then screened with a 200-mesh screen to obtain an alloy product; graphene is prepared with the graphene oxide chemical reduction method, and graphene powder is obtained through filtration drying and grinding in sequence; 1-5% parts by mass of graphene powder is mixed with the alloy product and then subjected to ball milling according to the ball-material ratio of 20:1, the rotating speed of a ball mill is 150-200 rpm, ball milling time is 0.5-1.0 h, and then surface modification of the AB3 type hydrogen storage alloy is achieved by means of graphene. According to the method, operation is easy, the AB3 type hydrogen storage alloy is modified by graphene, alloy electrodes with high cycling performance are obtained, and the corrosion resistance of the electrodes is improved remarkably.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Flexible electrode material as well as preparation method and application thereof

ActiveCN107275577AGood cycle performanceGood stabilitySecondary cellsMonocomponent synthetic polymer artificial filamentIonElectrical battery

The invention provides a preparation method of a flexible electrode material. The preparation method of the flexible electrode material, provided by the invention, can be realized only through steps of mixing liquid, spinning, pre-oxidizing and carbonizing, and is convenient and rapid. The invention further provides the flexible electrode material; the flexible electrode material can be independently used for preparing a lithium-ion battery and a sodium-ion battery, and does not need to be combined with any adhesive and carbon black to use. Moreover, the flexible electrode material provided by the invention also has an excellent circulating performance. According to records of the embodiment, after the flexible electrode material provided by the invention is used for preparing the lithium-ion battery and the sodium-ion battery, the batteries have an excellent charging / discharging circulating performance and good stability; wherein, after the lithium-ion battery is circulated for 100 circles, the capacity still can keep at 450mAh / g or more; after the sodium-ion battery is circulated for 100 circles, the capacity still can keep at 200mAh / g or more.

Owner:JILIN UNIV

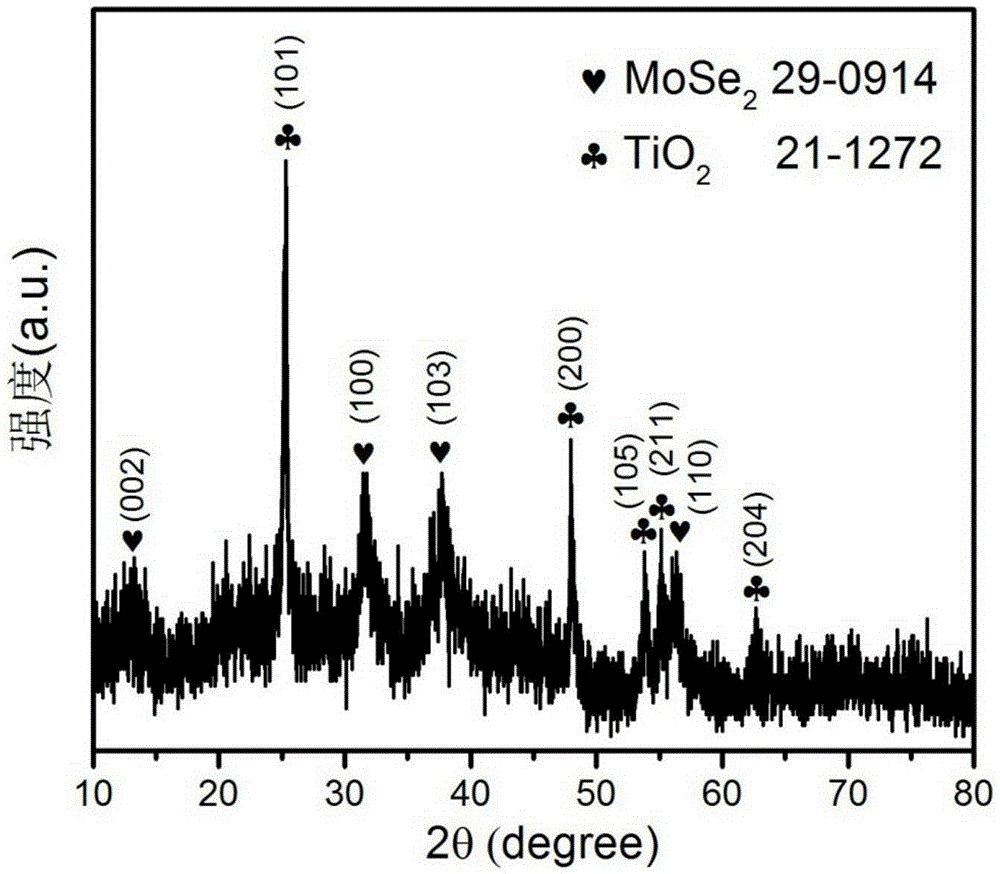

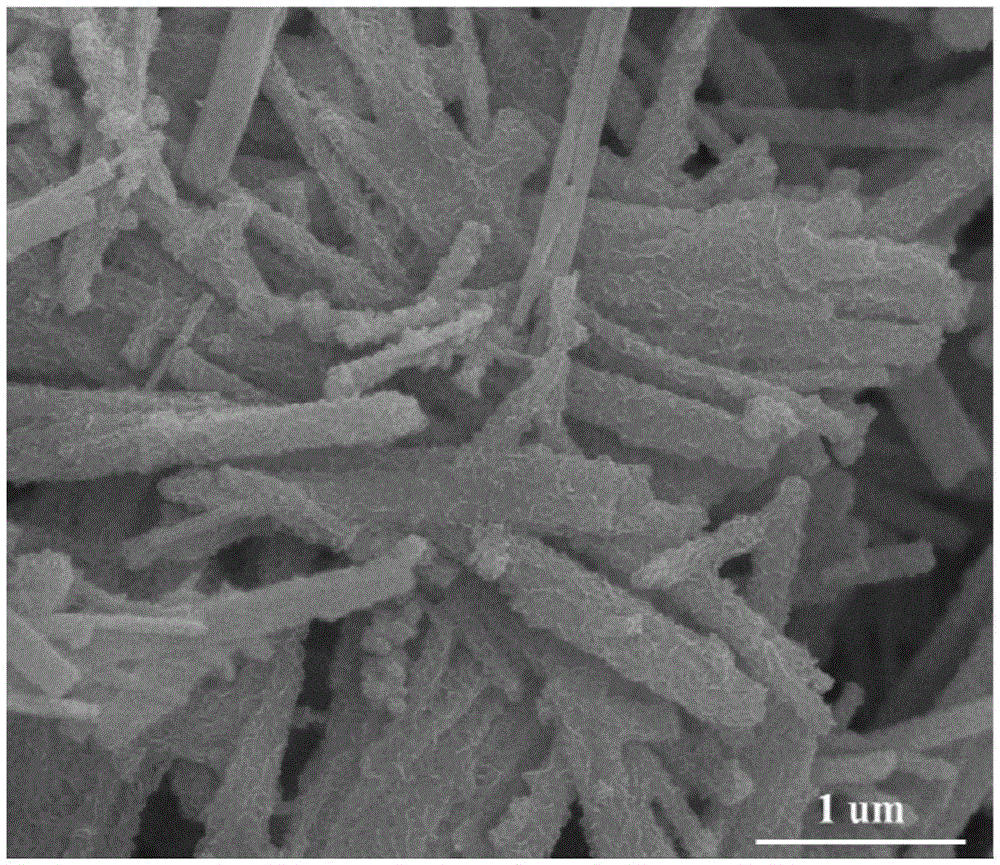

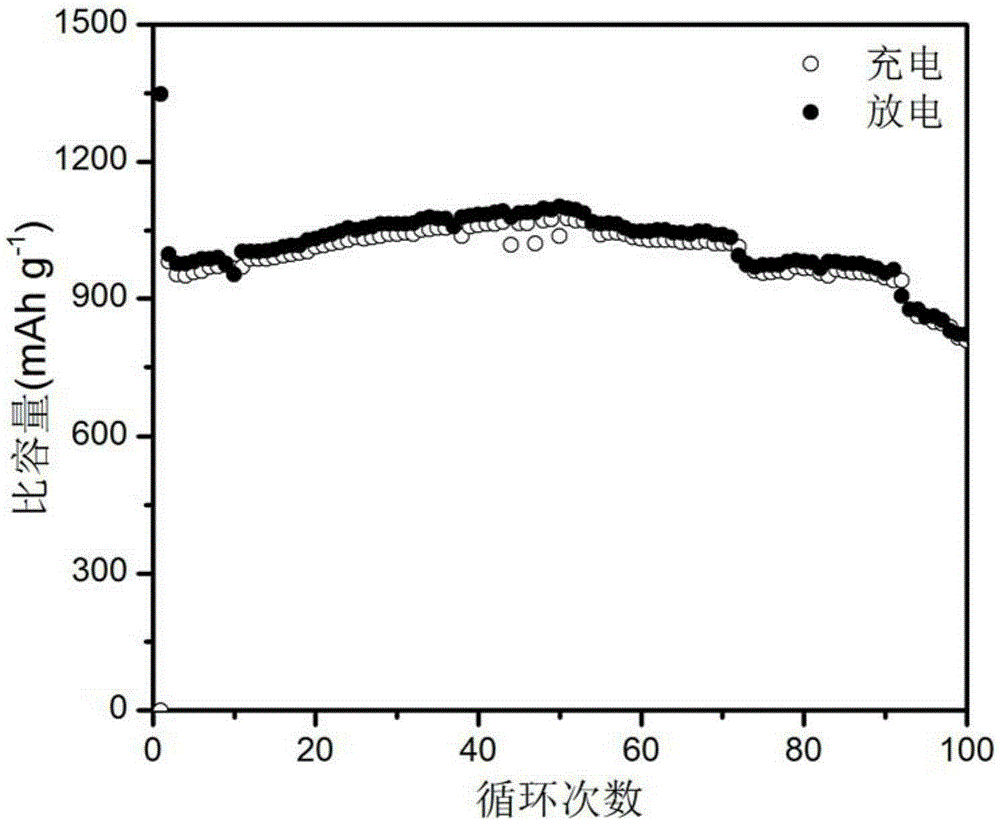

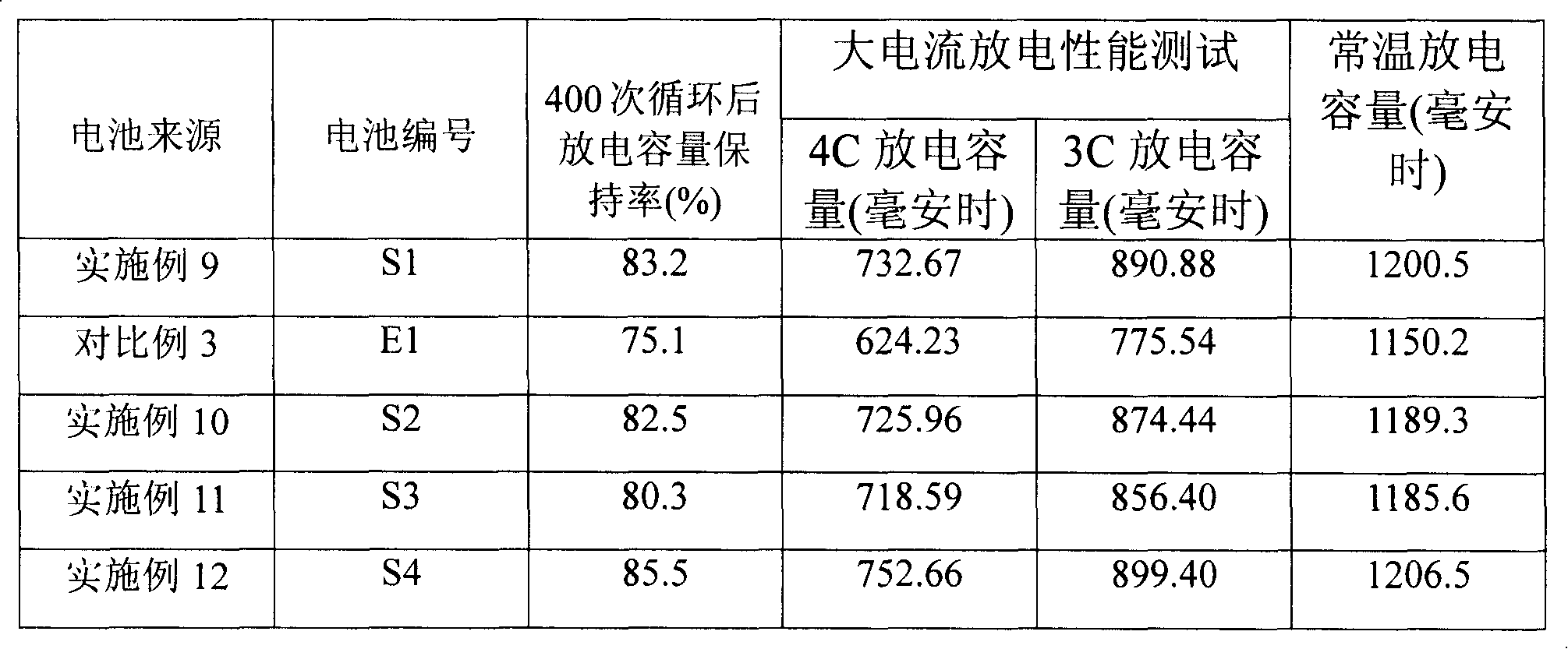

Molybdenum diselenide/titanium dioxide composite material and preparation method and application therefor

ActiveCN105375017AGood cycle performanceExcellent rate performanceCell electrodesBattery electrodeThermal reaction

The invention relates to a molybdenum diselenide / titanium dioxide composite material and a preparation method and an application therefor, and belongs to the technical field of battery electrode material development and design. According to the designed molybdenum diselenide / titanium dioxide composite material, the molar ratio of the titanium dioxide to molybdenum diselenide is 2.1-2.3:1; the titanium dioxide is distributed in the composite material in a nanoribbon form; the titanium dioxide is coated with the molybdenum diselenide that is in a nanosheet form; the preparation method comprises the steps of uniformly mixing a supernatant solution A containing Se with turbid liquid containing the titanium dioxide nanoribbon and the Mo source, performing a hydrothermal reaction at the temperature of 190-210 DEG C and then performing solid liquid separation; cleaning and drying the obtained solid, and calcining the solid under a protective atmosphere at the temperature of 600-700 DEG C to obtain the molybdenum diselenide / titanium dioxide composite material. The designed and prepared molybdenum diselenide / titanium dioxide composite material can be widely applied to the battery electrode materials. The preparation method is simple and easy, high in repeatability and wide in the application prospects.

Owner:CENT SOUTH UNIV

Non-aqueous electrolyte and Li-ion secondary battery, and method for producing them

InactiveCN101212061AGood cycle performanceGood high temperature storage performanceFinal product manufactureElectrolyte accumulators manufactureFree acidNon aqueous electrolytes

The invention relates to a non-aqueous electrolyte which contains lithium salt and organic solvent which are taken as electrolyte, wherein, the electrolyte also contains weak acid salt of lithium. By adding the weak acid salt of lithium into the non-aqueous electrolyte, the invention can remarkably reduce the content of free acid in the electrolyte and can control the content of the free acid in the electrolyte within 30 ppm. Besides, hydrofluoric acid is unlikely to repeatedly generated due to water entering even when the invention is stored for a long time. In addition, a cell manufactured by adopting the electrolyte provided by the invention has good cycle performance and high-temperature storage performance. The invention also presents improved discharge performance of large current and discharge capacity under normal temperature.

Owner:BYD CO LTD

Battery diaphragm and preparation method thereof

InactiveCN109524598AIncrease specific energyGood cycle performanceCell component detailsCharge and dischargeLithium electrode

The invention belongs to the technical field of lithium ion batteries and particularly relates to a battery diaphragm and a preparation method thereof. The preparation method of the battery diaphragmcomprises the steps of putting battery diaphragm fiber filaments into a textile machine, and weaving by virtue of the textile machine, so as to obtain the battery diaphragm, wherein the battery diaphragm fiber filaments are electronically insulated battery diaphragm fiber filaments which do not react with electrolyte, and the diameters of the battery diaphragm fiber filaments are 5-40 microns. Theinvention aims at providing the battery diaphragm with uniform small pore diameter and high porosity, so that dendritic crystals are produced in the charging and discharging processes of the battery,and the cycle performance of the battery is improved.

Owner:GUANGDONG UNIV OF TECH

Tremella-like V2O5 lithium ion battery cathode material adopting hollow core-shell structure and preparation method of cathode material

InactiveCN108110244AHigh reversible capacityGood cycle performanceMaterial nanotechnologyCell electrodesHollow coreTremella

The invention relates to the technical field of lithium ion cathode materials and discloses a tremella-like V2O5 lithium ion battery cathode material adopting a hollow core-shell structure and a preparation method of the cathode material. The tremella-like V2O5 lithium ion battery cathode material adopting the hollow core-shell structure is prepared from raw materials including ethyl orthosilicate, m-dihydroxybenzene, formaldehyde, ammonium metavanadate and the like with a simple hydrothermal method. The electrical conductivity and stability of the existing V2O5 cathode material are greatly improved by the tremella-like hollow core-shell structure C@V2O5 with the special morphology, so that the electrochemical performance of the cathode material is significantly improved. The specific surface area is enlarged and the electrochemical performance is improved due to the tremella-like morphology. The electrical conductivity of the material is improved due to existence of hollow carbon spheres. The stability of the material is greatly improved by the hollow structure.

Owner:HUNAN UNIV OF TECH

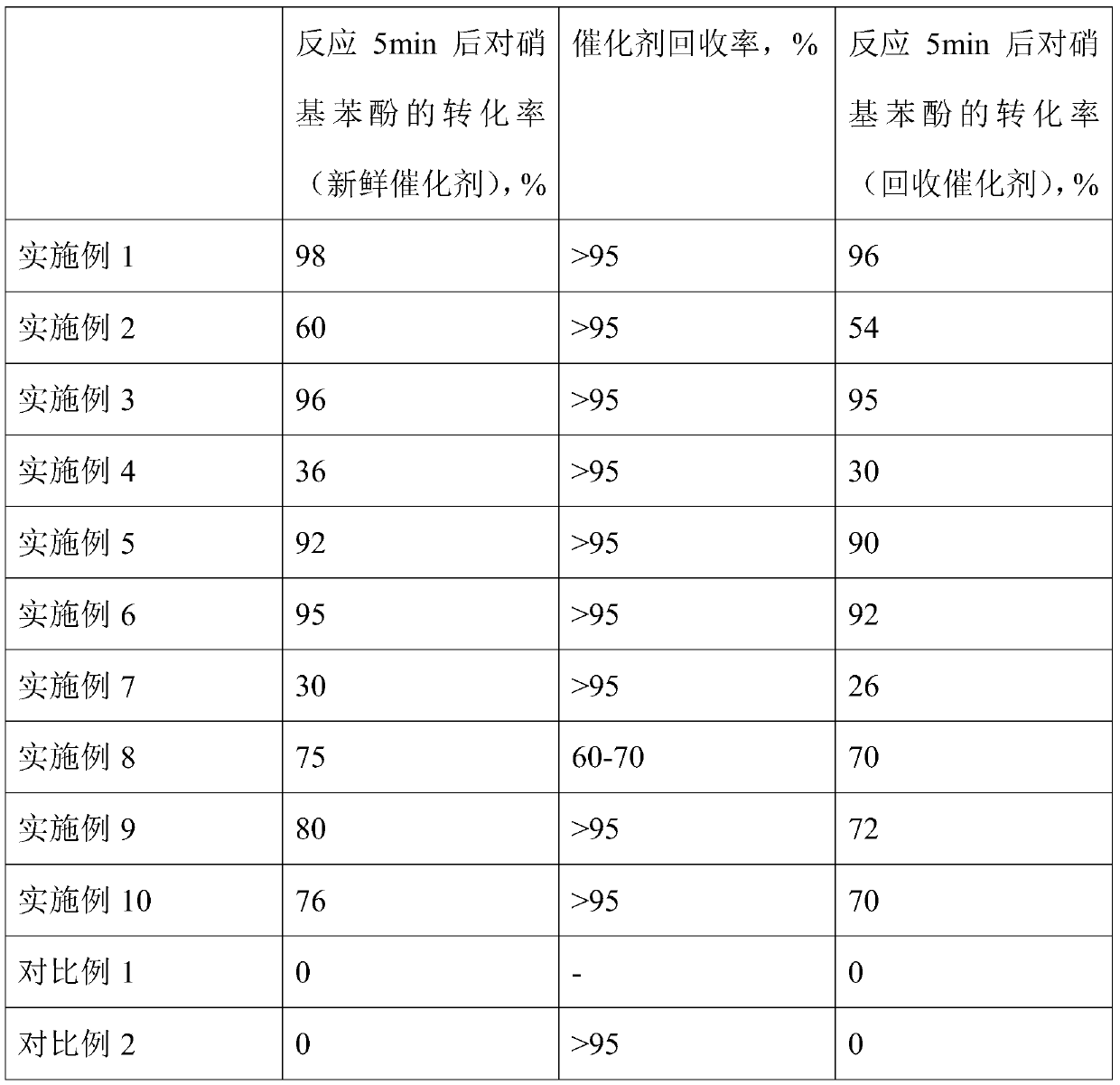

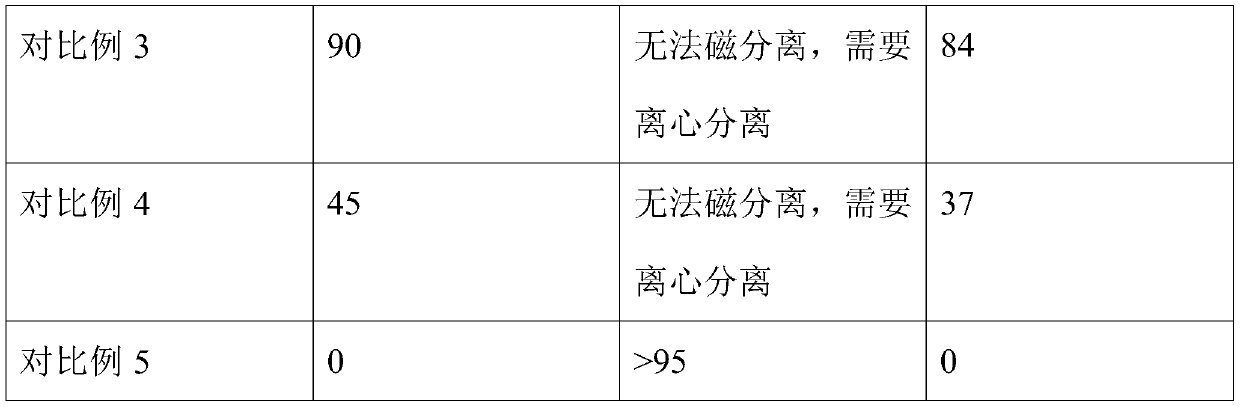

Application method of magnetic molybdenum-based catalyst in catalysis of p-nitrophenol

ActiveCN110227479AImprove efficiencyGood cycle performanceOrganic compound preparationChemical recyclingP-AminophenolMolybdenum

The invention relates to an application method for a magnetic molybdenum-based catalyst in the catalysis of p-nitrophenol. The method comprises that a catalytic reduction reaction is carried out by mixing p-nitrophenol, the magnetic molybdenum-based catalyst and a reducing agent to obtain p-aminophenol. The method has high efficiency for catalytic reduction of p-nitrophenol. The magnetic molybdenum-based catalyst used in the reaction process can be recovered by utilizing magnetic properties of the catalyst after the reaction is completed, so that the catalyst can be recycled and reused, and efficiency decline of the catalyst is relatively low after being recycled and reused.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

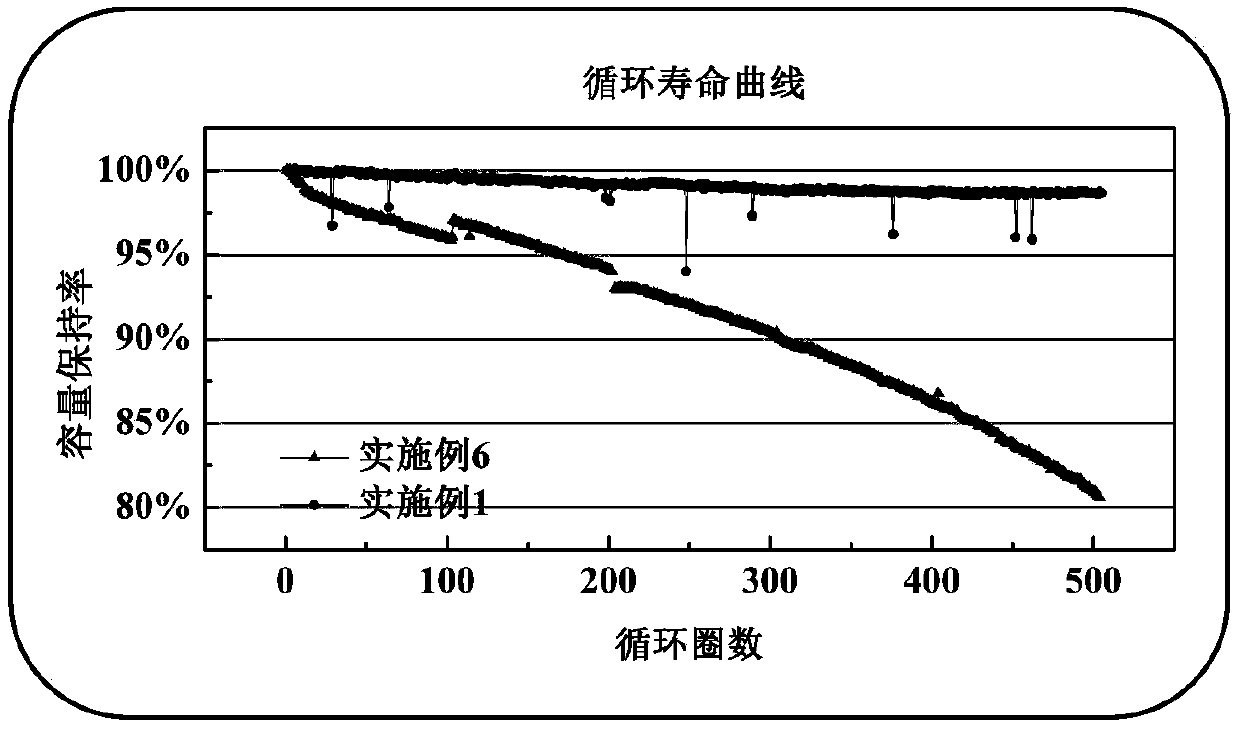

High-performance composite binary positive electrode material, preparation method thereof and lithium ion battery

PendingCN111200121AIncrease capacityGood cycle performanceSecondary cellsPositive electrodesLithium sulfideComposite material

The invention provides a high-performance composite binary positive electrode material, a preparation method thereof and a lithium ion battery. The composite binary positive electrode material comprises a binary lithium nickel aluminate material and a coating layer coating the surface of the binary lithium nickel aluminate material, wherein the coating layer is mainly composed of an aluminum-containing compound and lithium sulfide. The preparation method comprises the steps of 1) mixing hydroxide of nickel with an aluminum source, and carrying out first sintering to obtain nickel oxide doped with an aluminum element; 2) mixing the nickel oxide doped with the aluminum element with a lithium source, and carrying out secondary sintering in an oxidizing atmosphere to obtain a binary lithium nickel aluminate material; and 3) mixing the binary lithium nickel aluminate material with an aluminum source, and carrying out third sintering in a hydrogen sulfide atmosphere to obtain the composite binary positive electrode material. The composite binary positive electrode material provided by the invention realizes cobalt-free treatment, the capacity of the composite binary positive electrode material can reach 215mAh / g or above, and the cycle performance is that the capacity retention rate of the composite binary positive electrode material can reach 95% or above when the composite binary positive electrode material is circulated for 50 cycles at 0.5C / 1C.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Three-dimensional nickel hydroxide-graphene composite material, and preparation method and application thereof

InactiveCN107611379AGood cycle performanceImprove conductivityCell electrodesNickel accumulatorsMacroporeHigh conductivity

The invention provides a three-dimensional nickel hydroxide-graphene composite material. The three-dimensional nickel hydroxide-graphene composite material consists of a three-dimensional-structured conductive network and nickel hydroxide loaded on the conductive network; the three-dimensional conductive network of the composite material consists of graphene oxide nanosheets, and comprises pore structures of macropores, micropores and mesoporous; the nickel hydroxide loaded on the three-dimensional conductive network is 50 nanometers to 500 microns in dimensions; and the mass of nickel hydroxide accounts for 50-95% of the composite material. The invention also provides a preparation method of the composite material. The three-dimensional nickel hydroxide-graphene composite material provided by the invention has high conductivity, excellent toxic resistance and high cycle stability, and is a very ideal positive electrode material of a zinc nickel battery, and can be widely applied to the fields of various kinds of portable electronic equipment, electric vehicles, aerospace and the like; and in addition, the composite material can be prepared from the low-cost raw materials through aprocess with high repetition, simple process and low time consumption, so that the composite material is applicable to industrial production.

Owner:BEIHANG UNIV

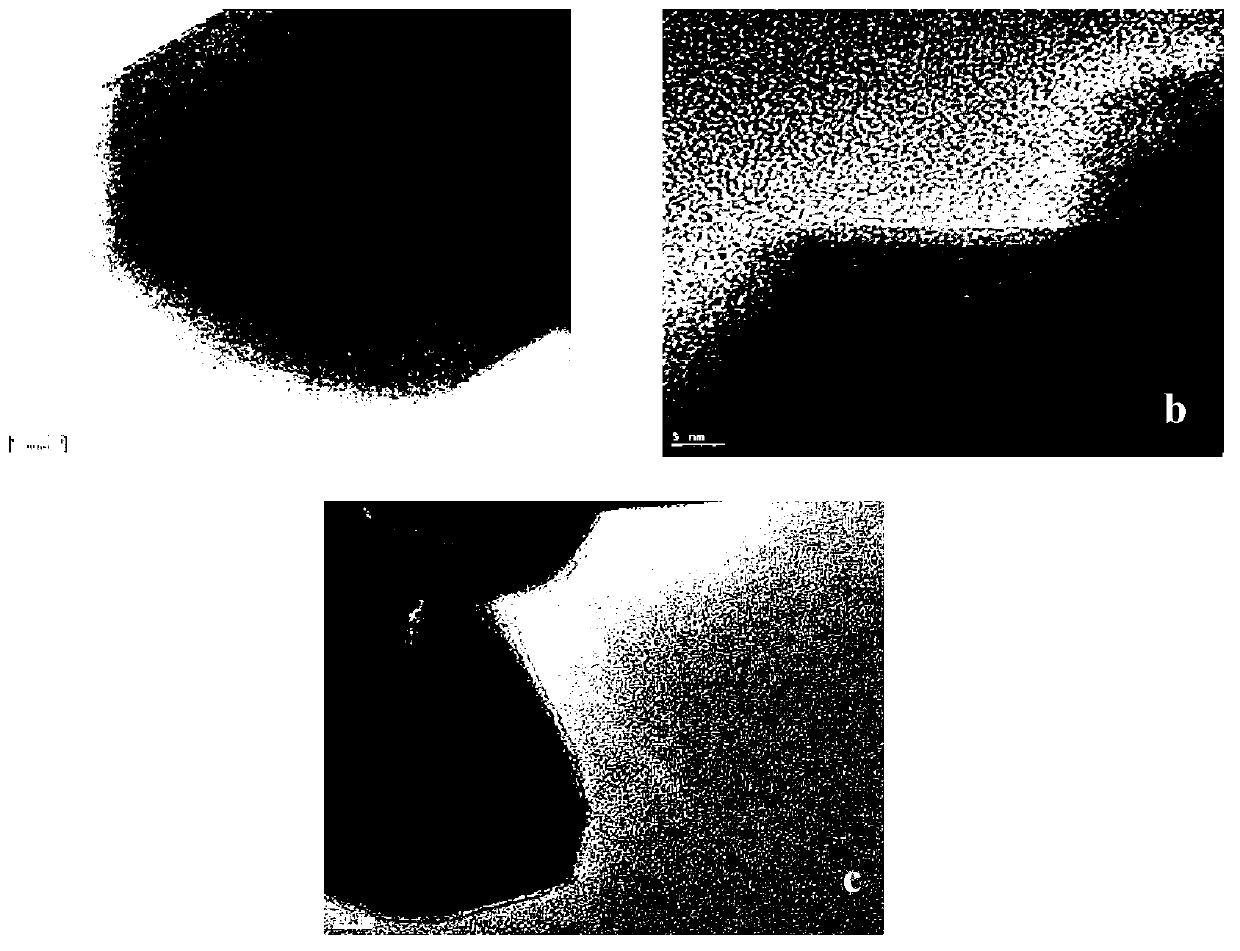

Method for preparing surface modification layer of lithium-rich material based on buffer solution system

The invention provides a method for preparing a surface modification layer of a lithium-rich material based on a buffer solution system. The method comprises the following steps of: adding the sieved lithium-rich material into a buffer solution with the pH value of 5.7 to 7.0, and reacting for 1 to 5 days; and performing washing, leaching and drying on obtained reaction products to obtain the surface-modified lithium-rich material. According to the method, a synthesized lithium ion positive electrode material is subjected to effective surface treatment by the buffer solution to form a uniform and unexposed coating layer on the surfaces of material particles; the material treated by using the method has relatively large discharge capacity and relatively good cycle performance under a relatively high rate; and the method is simple, the cost is low, the nontoxic and harmless performances can be realized, so that the method is suitable for large-scale industrial production.

Owner:PEKING UNIV

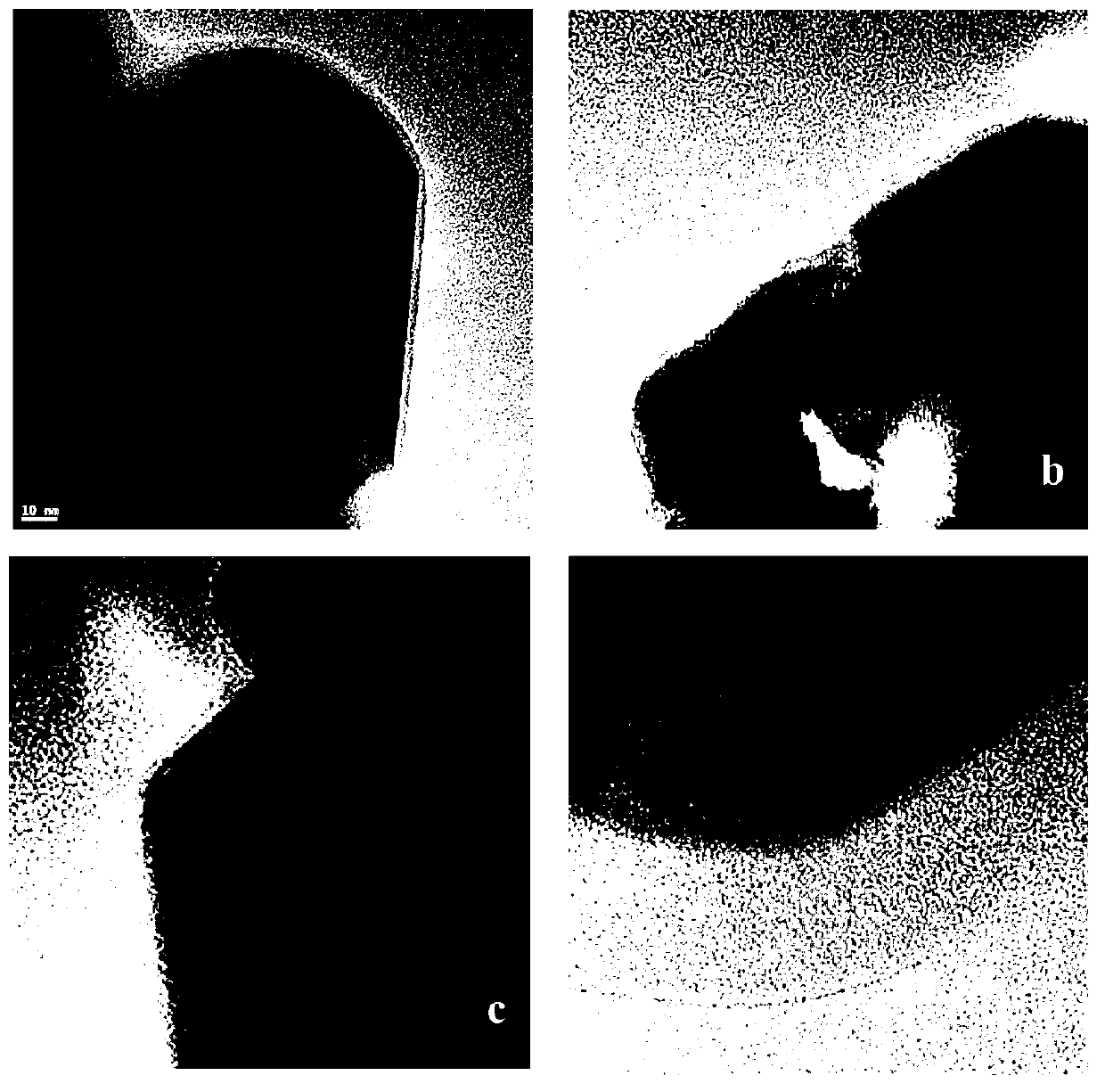

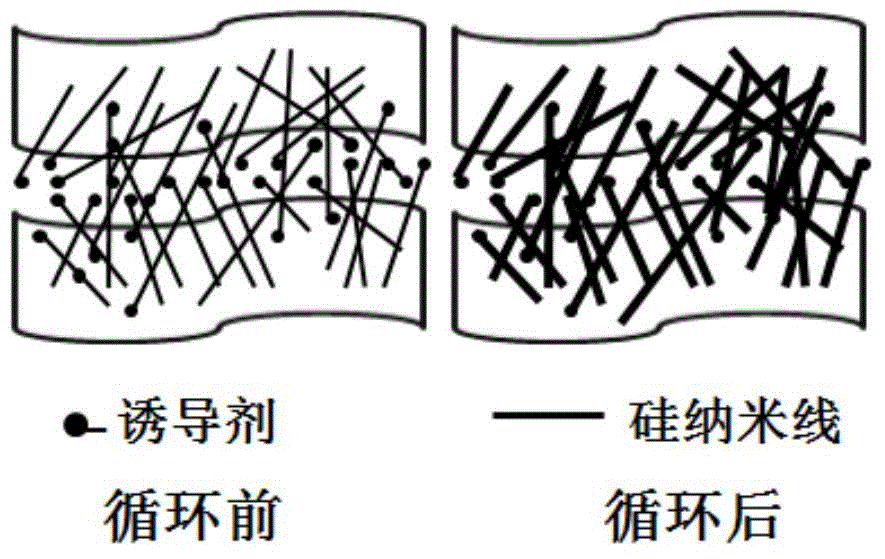

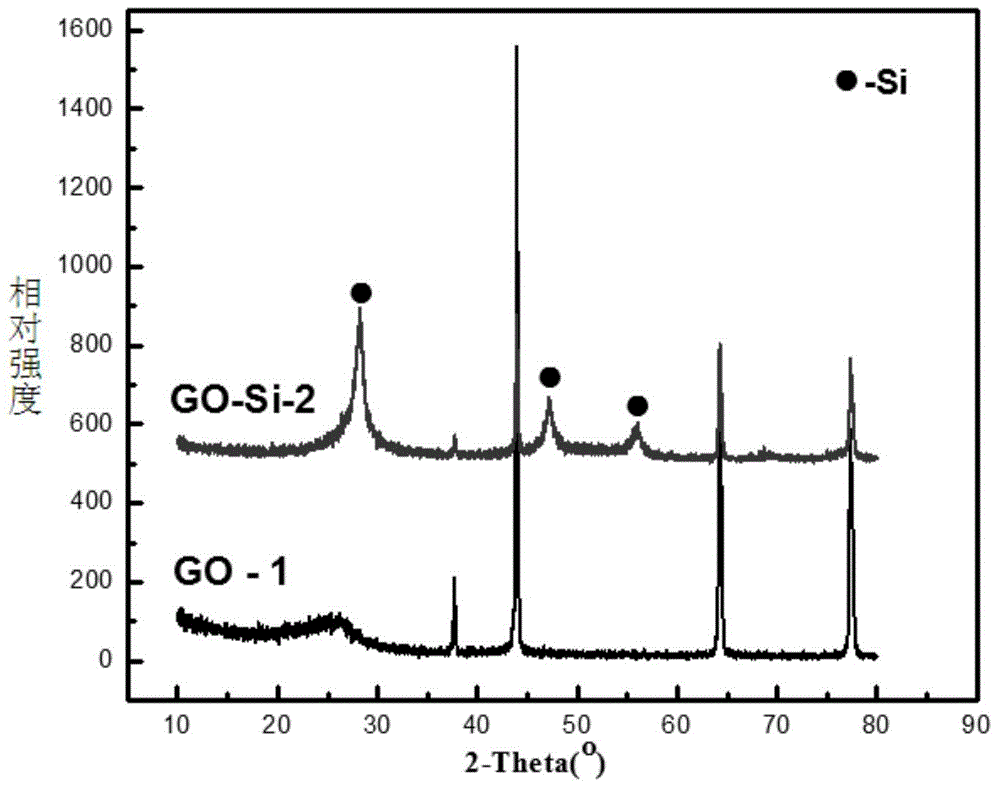

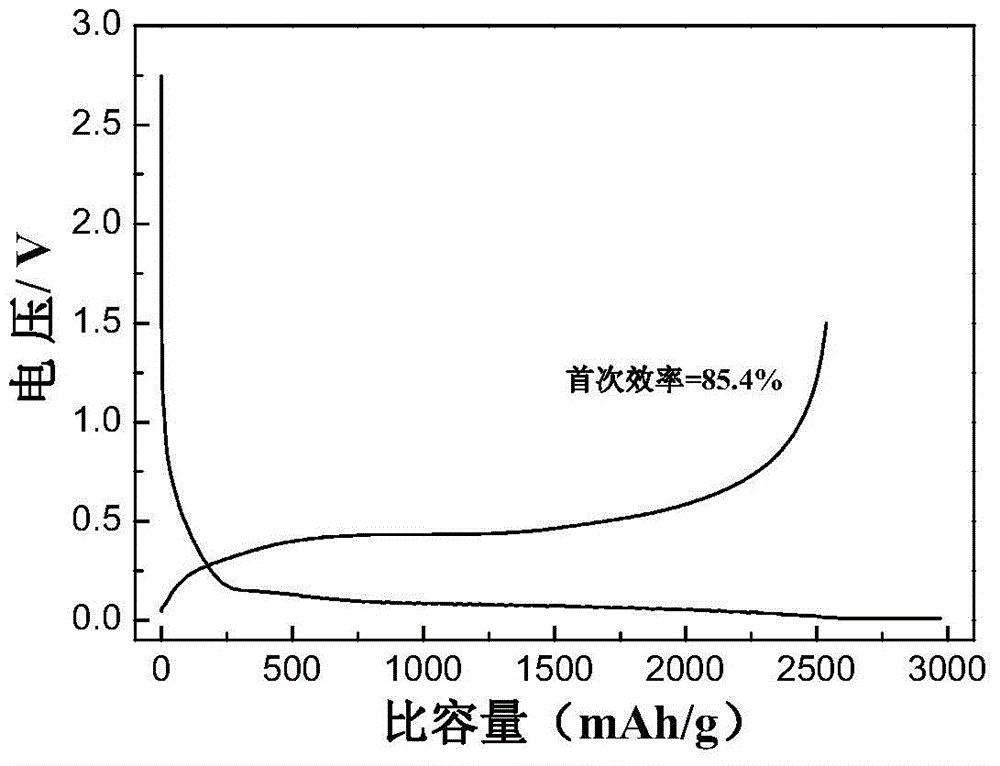

Graphene oxide silicon-intercalated nanowire composite material and preparation method thereof

ActiveCN105226243AHigh specific capacityGood cycle performanceMaterial nanotechnologyCell electrodesCarbon coatingSilicon nanowires

The invention is suitable for the field of lithium-ion battery anode materials, and provides a graphene oxide silicon-intercalated nanowire composite material and a preparation method thereof. The graphene oxide silicon-intercalated nanowire composite material comprises modified graphene oxide, silicon nanowire and a carbon coating layer, wherein the modified graphene oxide is the graphene oxide containing a catalyst on the surface; the silicon nanowire is deposited on the surface of the graphene oxide through induction of the catalyst; and the carbon coating layer coats the surface of the silicon nanowire.

Owner:王凤鸣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com