Flexible electrode material as well as preparation method and application thereof

A flexible electrode, polyacrylonitrile fiber technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems such as inconvenience in use, and achieve the effects of good stability, excellent cycle performance, and excellent cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The invention provides a method for preparing a flexible electrode material, comprising the following steps:

[0074] Dissolving polyacrylonitrile fibers and manganese sulfate in a spinning solvent and then heat-treating to obtain a spinning solution; the spinning solvent is N,N-dimethylformamide and / or N,N-dimethylethane amides;

[0075] Spinning the spinning solution to obtain raw fibers;

[0076] performing pre-oxidation treatment on the raw fibers to obtain pre-oxidized fibers;

[0077] Under an inert atmosphere, the pre-oxidized fiber is carbonized to obtain a flexible electrode material.

[0078] In the invention, the polyacrylonitrile fiber and manganese sulfate are dissolved in a spinning solvent and then heated to obtain a spinning solution. The present invention has no special requirements on the mixing order of the polyacrylonitrile fiber, manganese sulfate and spinning solvent, and the three can be mixed in any order.

[0079] In the present invention, t...

Embodiment 1

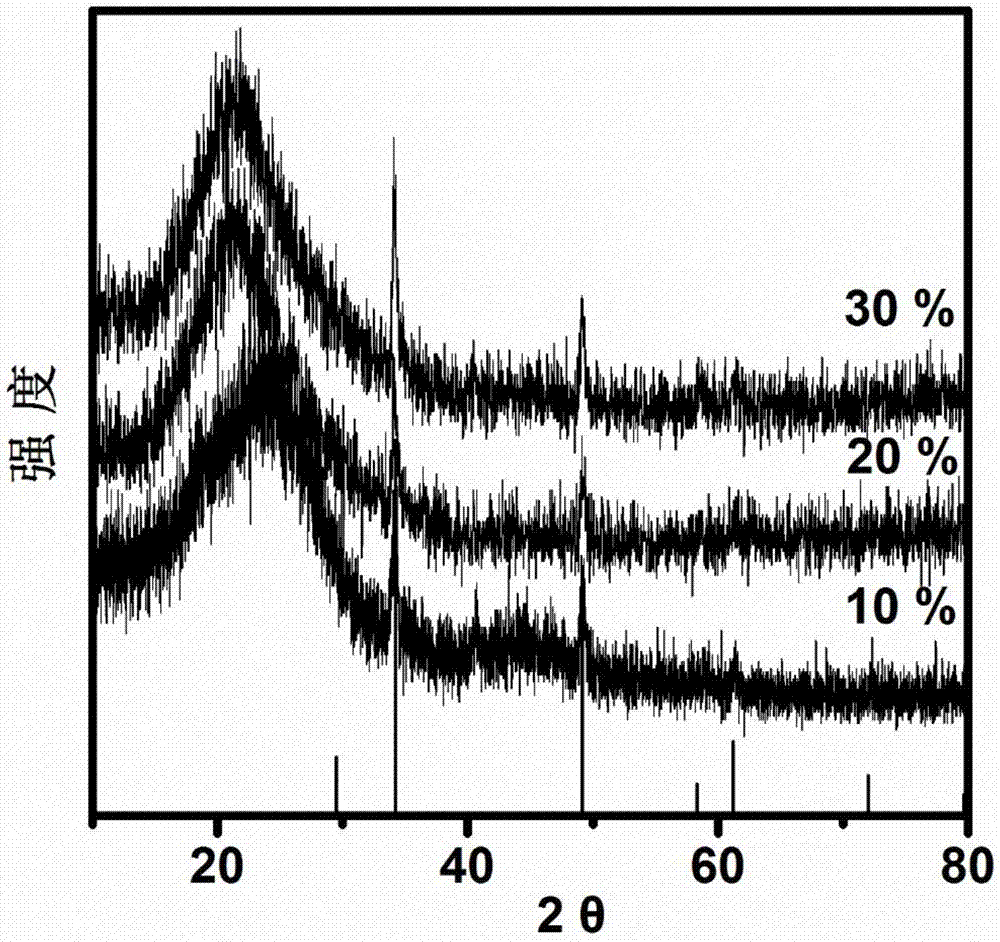

[0094] Put the polyacrylonitrile fibers into N,N-dimethylformamide so that the concentration is 0.07g / mL, add manganese sulfate monohydrate with a mass of 10% relative to the polyacrylonitrile fibers in the spinning solution, and bathe in 80°C water, Stir for 12 hours to obtain a spinning solution.

[0095] The spinning solution is injected into a plastic syringe, and a stainless steel No. 7 needle is connected underneath. A receiving steel plate was placed at a vertical distance of 20 cm below the needle, a DC voltage of 15 KV was applied between the needle and the receiving plate, and the spinning flow rate was 0.3 mL / h.

[0096] The raw fibers obtained by spinning were placed in a muffle furnace at 280° C. for 5 hours. The pre-oxidized material was placed in a tube furnace at 700°C, kept under nitrogen protection for 2 hours for carbonization, and a flexible electrode material in the form of a paper sheet was obtained.

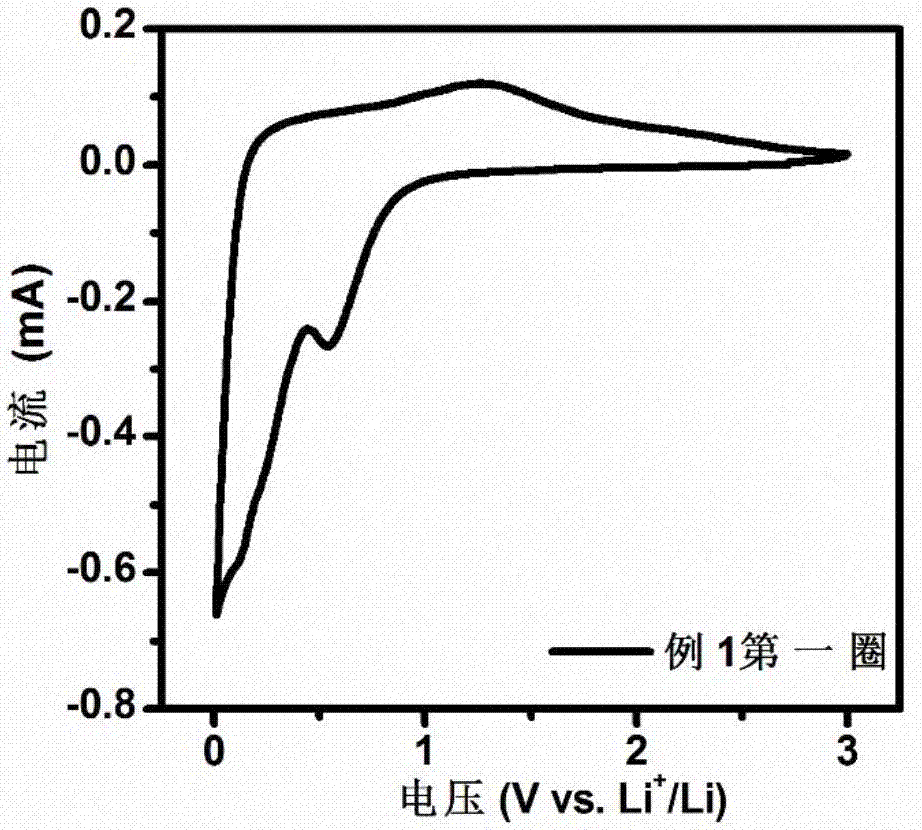

[0097] Cut the carbonized fiber cloth into small pi...

Embodiment 2

[0101] The scheme of embodiment 2 is the same as that of embodiment 1, the only difference is that 20% manganese sulfate monohydrate with respect to the mass of polyacrylonitrile fiber is added.

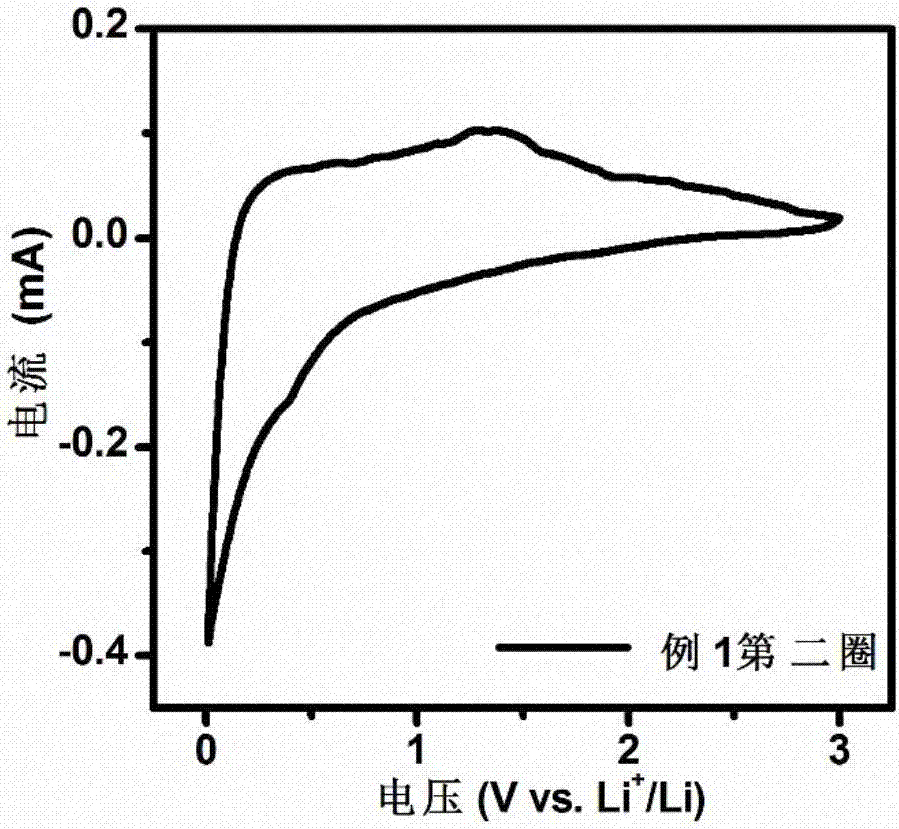

[0102] The present invention has carried out charge-discharge cycle test to the obtained lithium ion half battery, and its result is as follows: Figures 18-23 . in, Figure 18 It is the first circle CV diagram of the lithium-ion half-cell obtained in Example 2 of the present invention; Figure 19 It is the second circle CV diagram of the lithium-ion half-cell obtained in Example 2 of the present invention; Figure 20 It is the third circle CV diagram of the lithium-ion half-cell obtained in Example 2 of the present invention; Figure 21 It is the fourth circle CV diagram of the lithium-ion half-cell obtained in Example 2 of the present invention; Figure 22 It is the fifth circle CV diagram of the lithium-ion half-cell obtained in Example 2 of the present invention; Figure 23 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com