Graphene oxide silicon-intercalated nanowire composite material and preparation method thereof

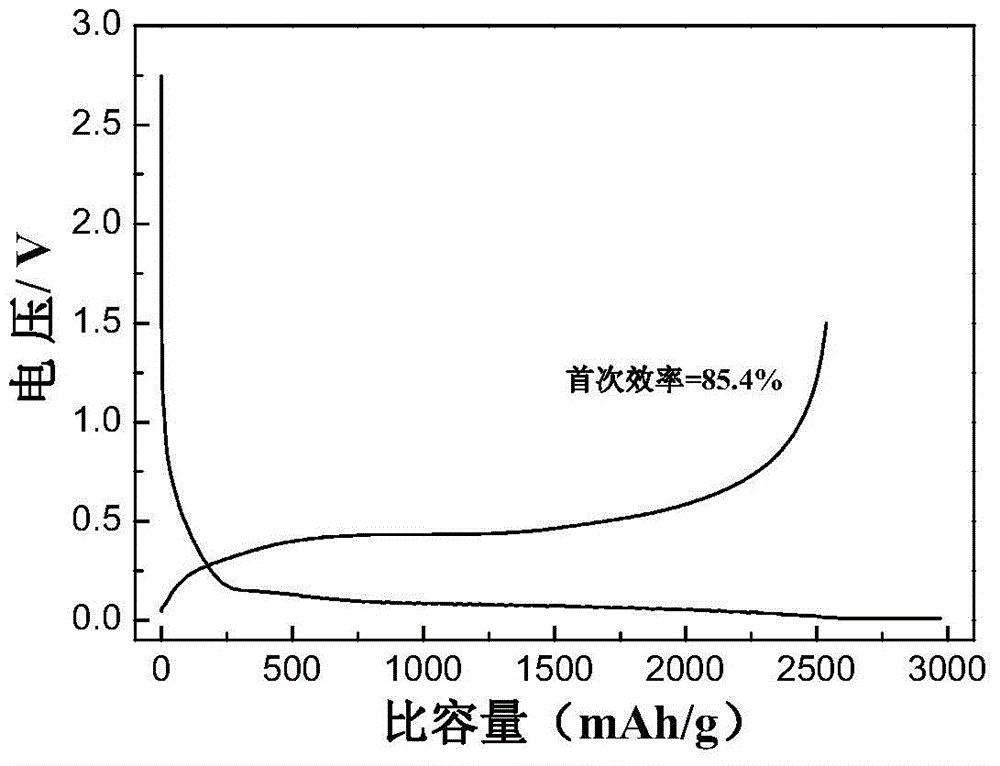

A technology of silicon nanowires and composite materials, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor electrical contact, high cycle performance and high specific capacity of the battery, Problems such as serious material pulverization, to achieve high specific capacity, good cycle performance, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Correspondingly, the embodiment of the present invention also provides a method for preparing a graphene oxide silicon-embedded nanowire composite material, comprising the following steps:

[0028] S01. Graphene oxide pretreatment: use thermal evaporation or magnetron sputtering to deposit a catalyst on the surface of graphene oxide to obtain modified graphene oxide;

[0029] S02. Silicon nanowire deposition: the modified graphene oxide is placed in a closed device, a silicon source and hydrogen are introduced under negative pressure conditions, and the modified graphene oxide is deposited to obtain a surface with silicon deposited on the surface. Modified graphene oxide of nanowires;

[0030] S03. Carbon coating: a carbon source is introduced, and the silicon nanowires are subjected to carbon precipitation treatment under normal pressure conditions to obtain a graphene oxide embedded silicon nanowire composite material.

[0031]Specifically, in the above step S01, in ...

Embodiment 1

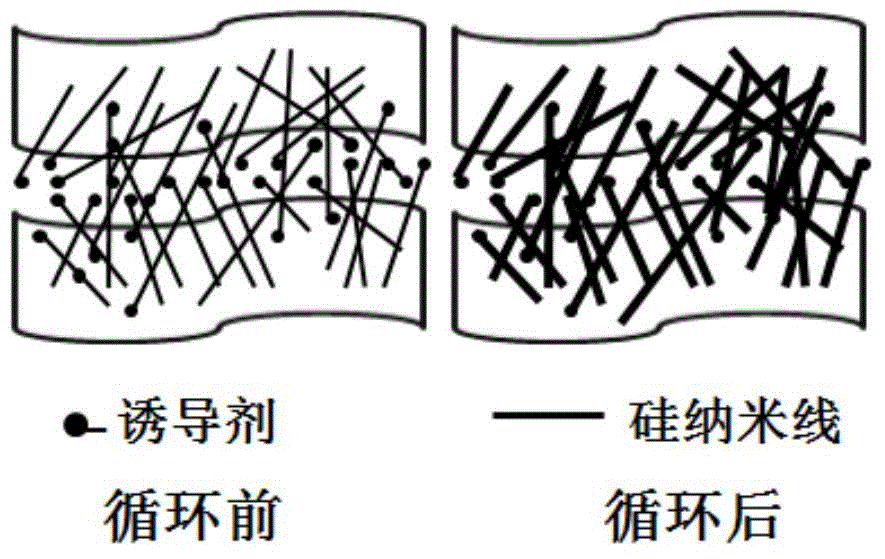

[0047] A graphene oxide silicon-embedded nanowire composite material, the graphene oxide silicon-embedded nanowire composite material includes modified graphene oxide, silicon nanowires and a carbon coating, wherein the modified graphene oxide is a surface Graphene oxide containing a catalyst, and the silicon nanowire is deposited on the surface of the graphene oxide through the catalyst, and the carbon coating layer is coated on the surface of the silicon nanowire.

[0048] The preparation method of described graphene oxide embedded silicon nanowire composite material comprises:

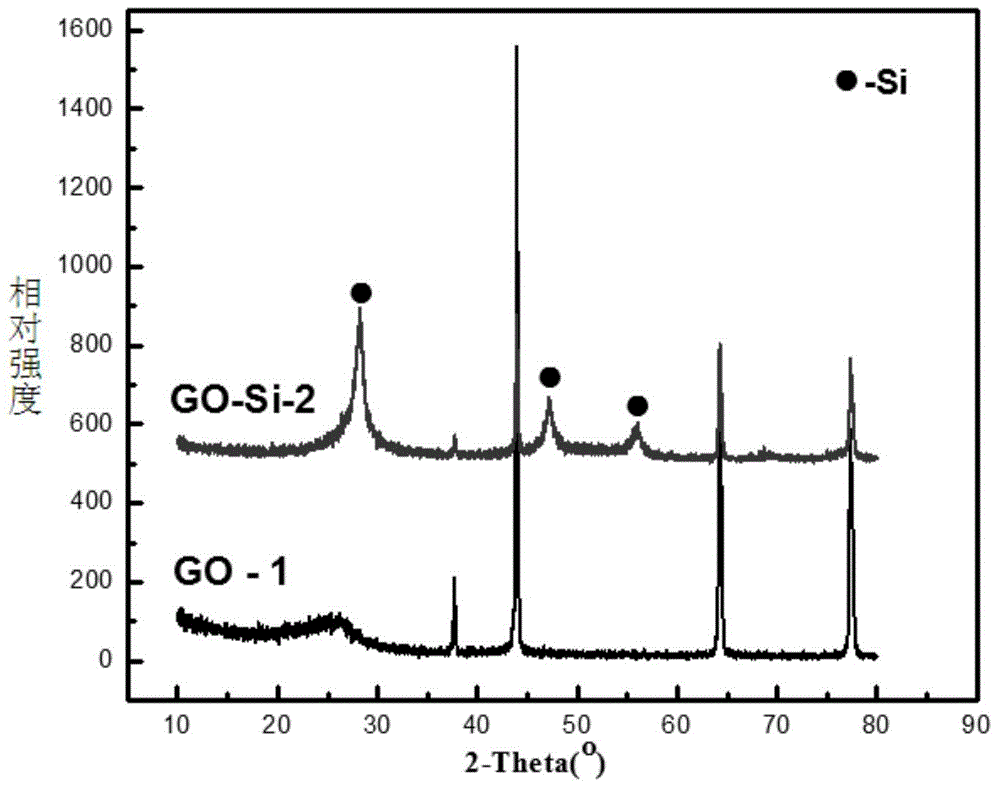

[0049] S11. Graphene oxide pretreatment: Take 0.5g of graphene oxide and put it into the sputtering equipment, the target material is Ti, and the vacuum degree is 1.4×10 -4 During stage sputtering, a small amount of Ti is deposited on the surface of the base material as a catalyst, and the sputtering time is 2 minutes;

[0050] S12. Silicon nanowire deposition: place the above-mentioned graphene ox...

Embodiment 2

[0055] A graphene oxide silicon-embedded nanowire composite material, the graphene oxide silicon-embedded nanowire composite material includes modified graphene oxide, silicon nanowires and a carbon coating, wherein the modified graphene oxide is a surface Graphene oxide containing a catalyst, and the silicon nanowire is deposited on the surface of the graphene oxide through the catalyst, and the carbon coating layer is coated on the surface of the silicon nanowire.

[0056] The preparation method of described graphene oxide embedded silicon nanowire composite material comprises:

[0057] S21. Graphene oxide pretreatment: Take 0.3g of graphene oxide and put it into the sputtering equipment. Deposit a small amount of Au as a metal catalyst with a sputtering time of 1 min;

[0058] S22. Silicon nanowire deposition: place the graphene oxide sputtered with Au on the surface in the tube furnace cavity, then close the flanges at both ends, vacuumize and fill with nitrogen gas for w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com