Patents

Literature

2599results about How to "Regular shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Infrared touch screen and its multi-point touch positioning method

InactiveCN101071356ANo additional costImplement multi-touch positioningInput/output processes for data processingLocation detectionTouchscreen

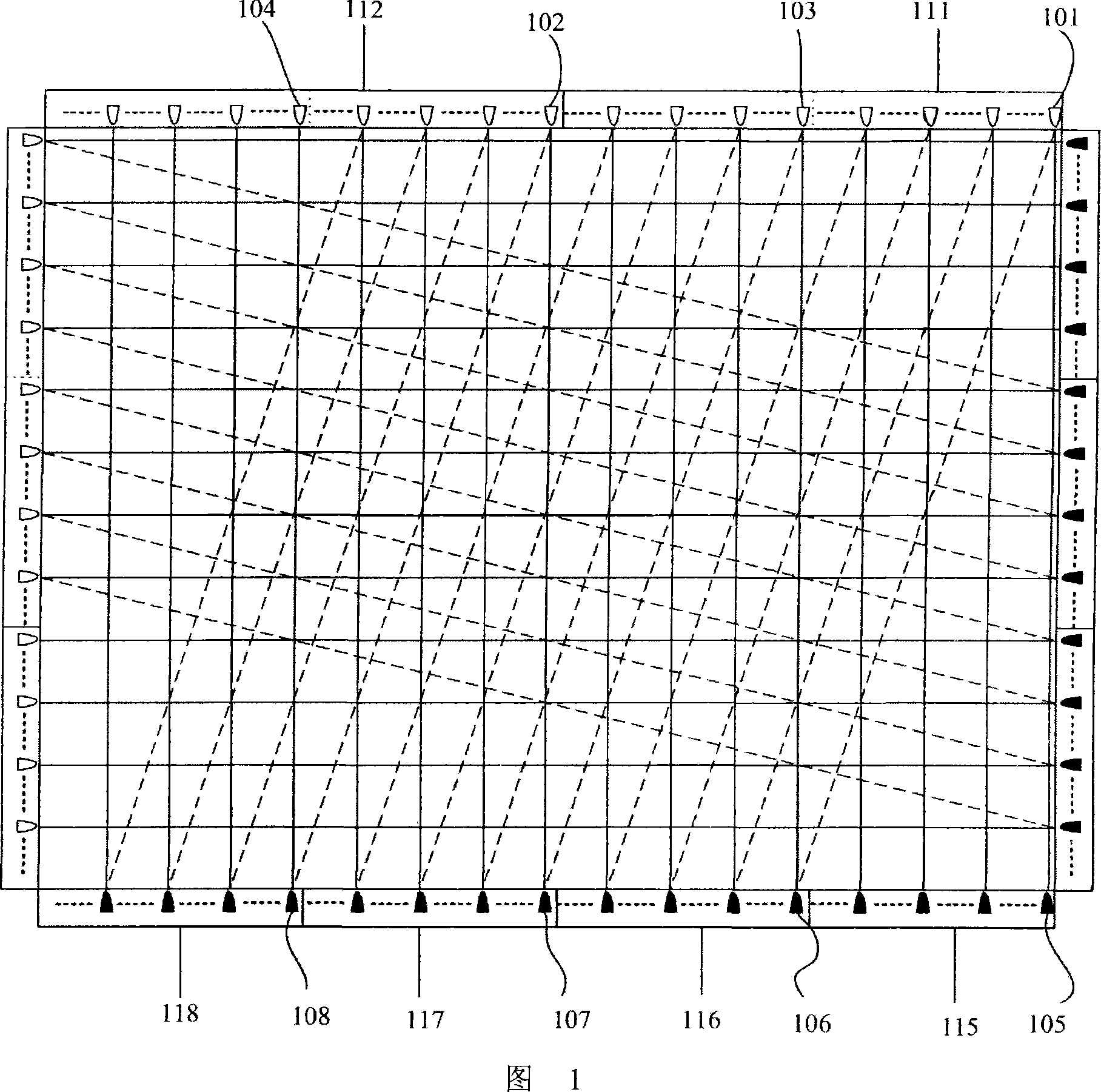

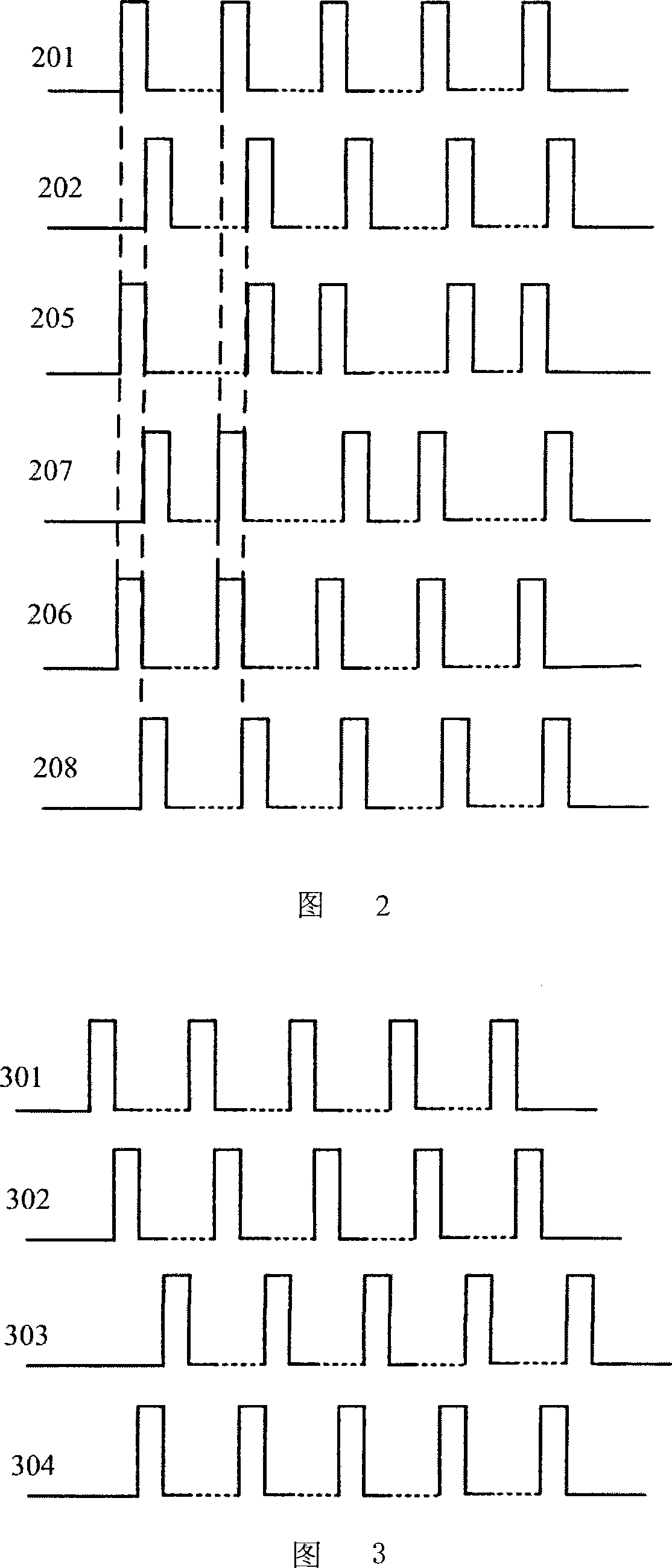

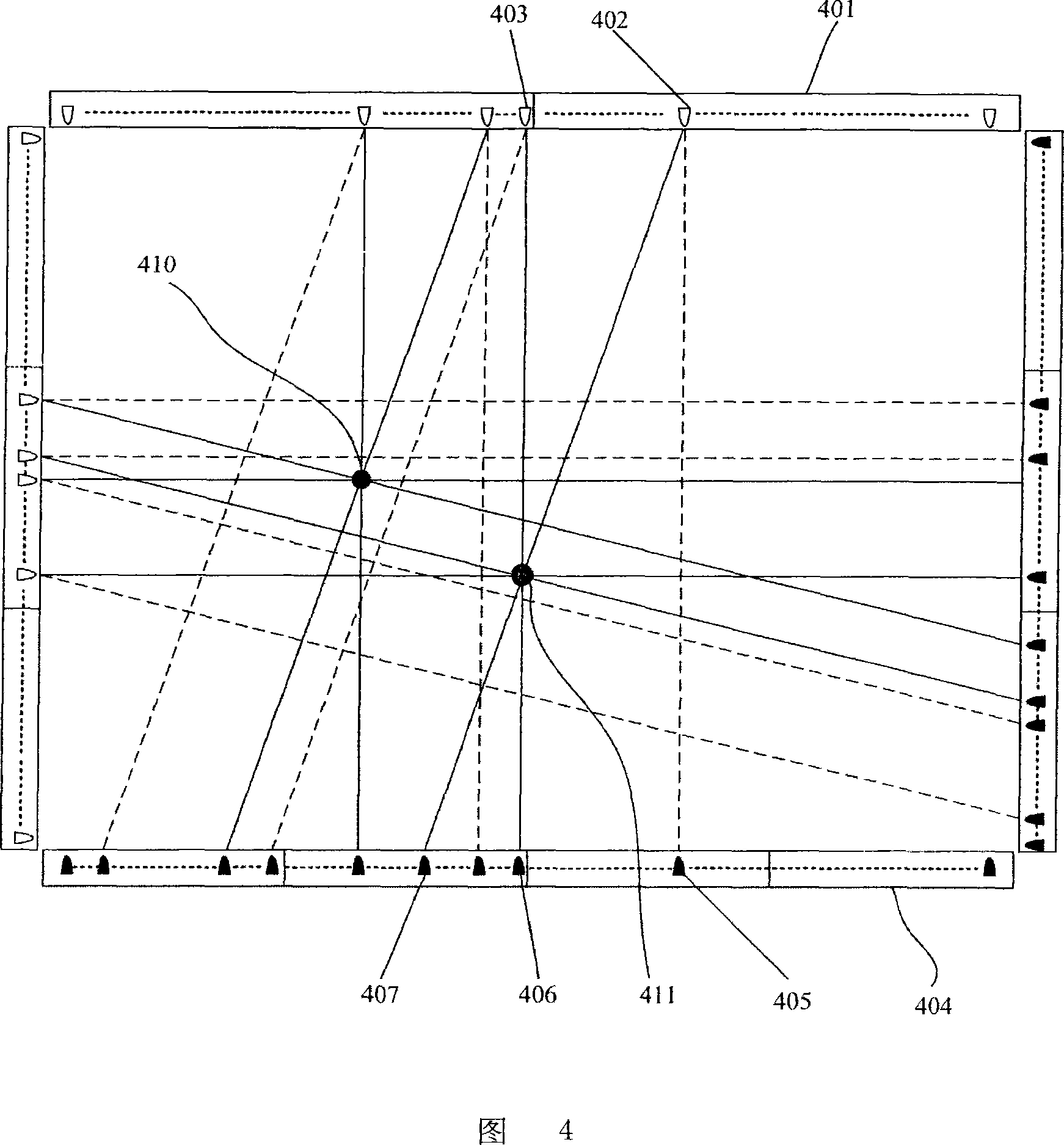

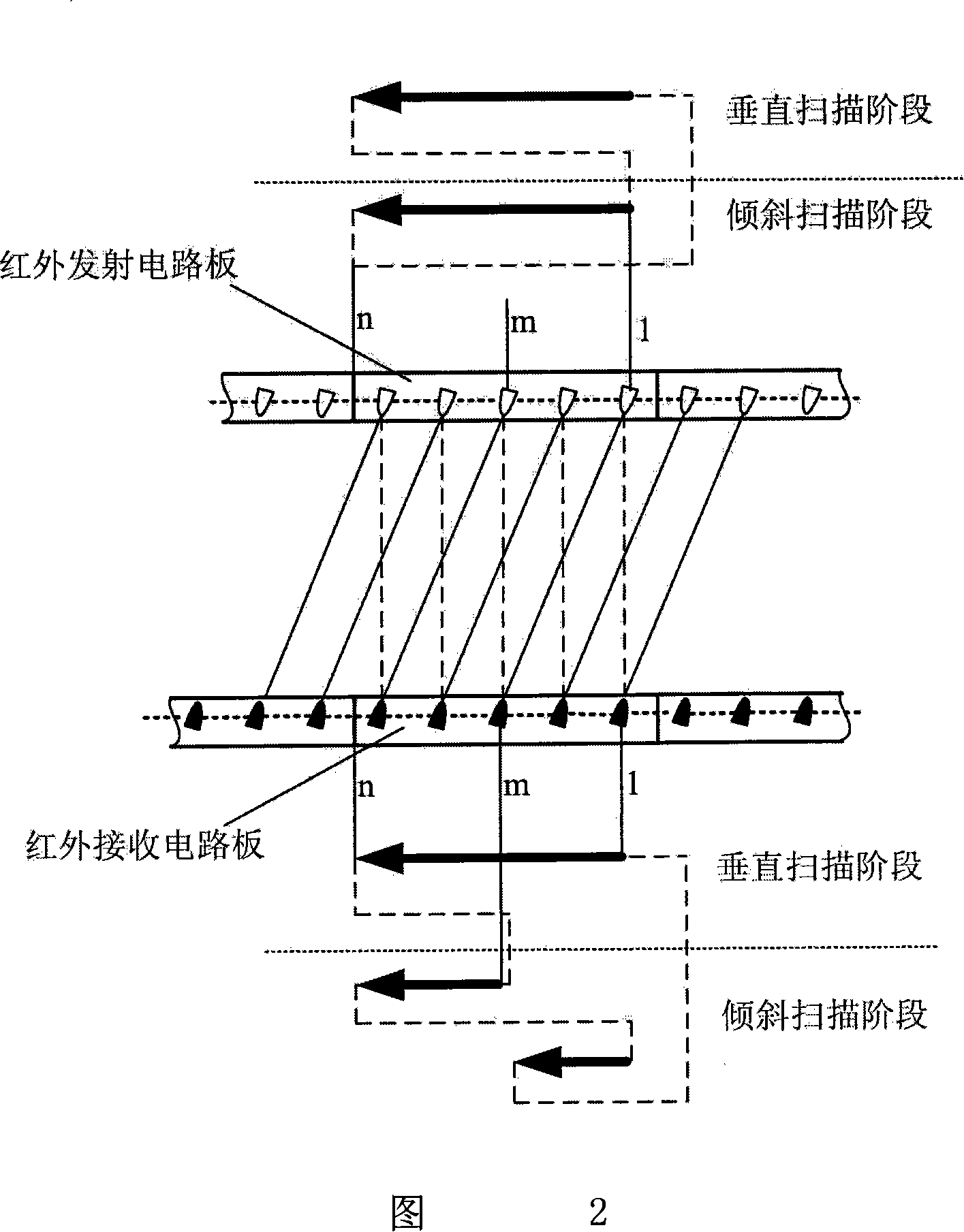

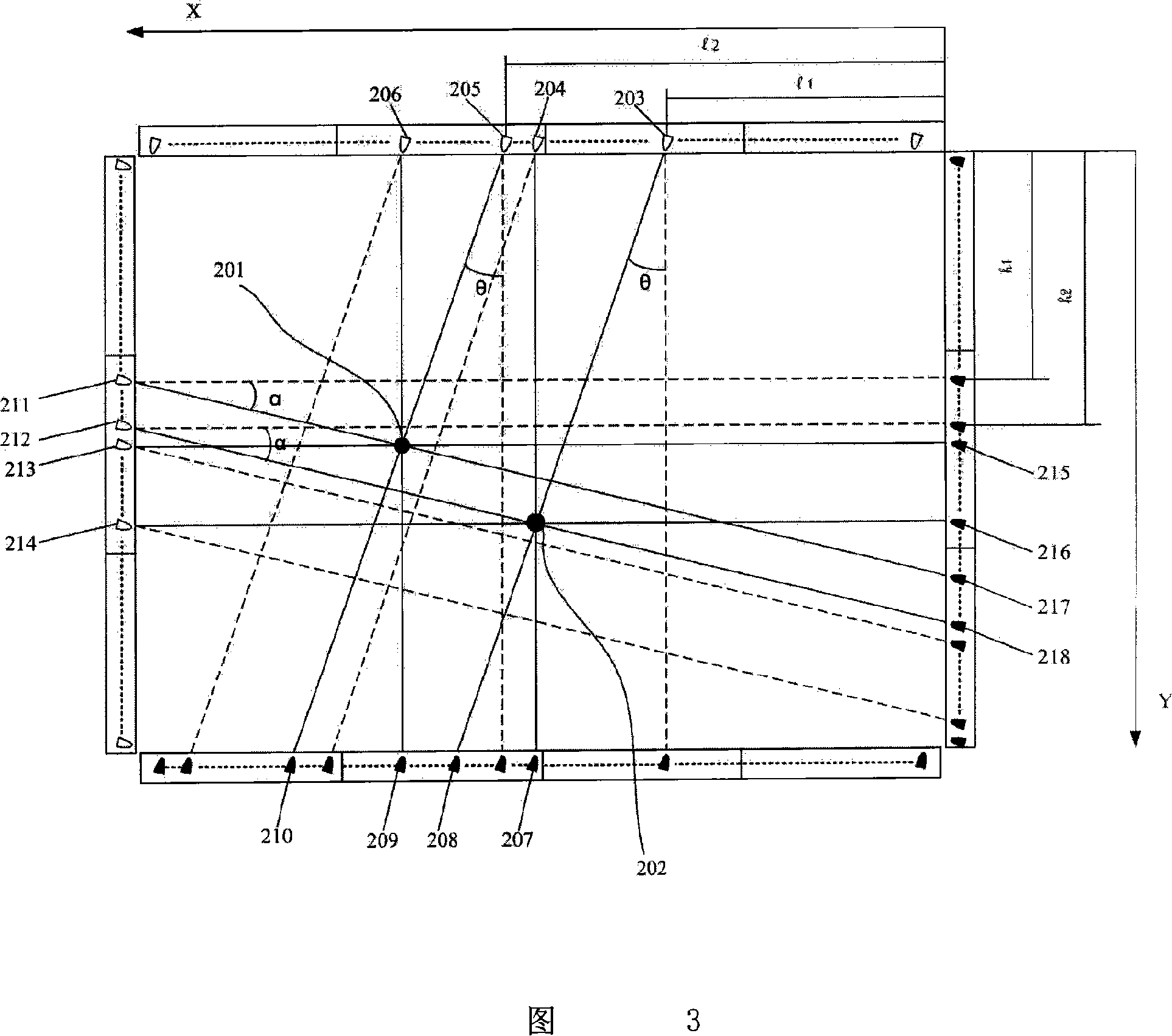

The invention discloses an infrared touch screen and multi-point touch positioning method. That is, at least one touch-screen direction detection, a set of infrared emission scanning circuit corresponding two infrared receiver scanning circuit; a set of infrared emission scanning circuit of an infrared launching the beam of light emitted by the components of a scanning infrared receiver circuit in an infrared receiver components of the receiver at the same time, in the receiving area also receive another set of infrared scanning circuit components of the receiver to receive an infrared detection in infrared touch screen The algorithm process that could be used to determine in advance the scope of touch point touch-point detection algorithm module. The present invention generally use the touch position detection algorithm is a touch location coordinates point to touch another pre-detection algorithm to determine touch point in the region, in combination with detection algorithm is usually the touch location coordinates. The invention can identify two or more touch operation, while more effective identification can touch position.

Owner:GUANGDONG VTRON TECH CO LTD

Infra red touch screen and multiple point touching positioning method

InactiveCN101149656ANo additional costImplement multi-touch positioningInput/output processes for data processingInfraredMultiple point

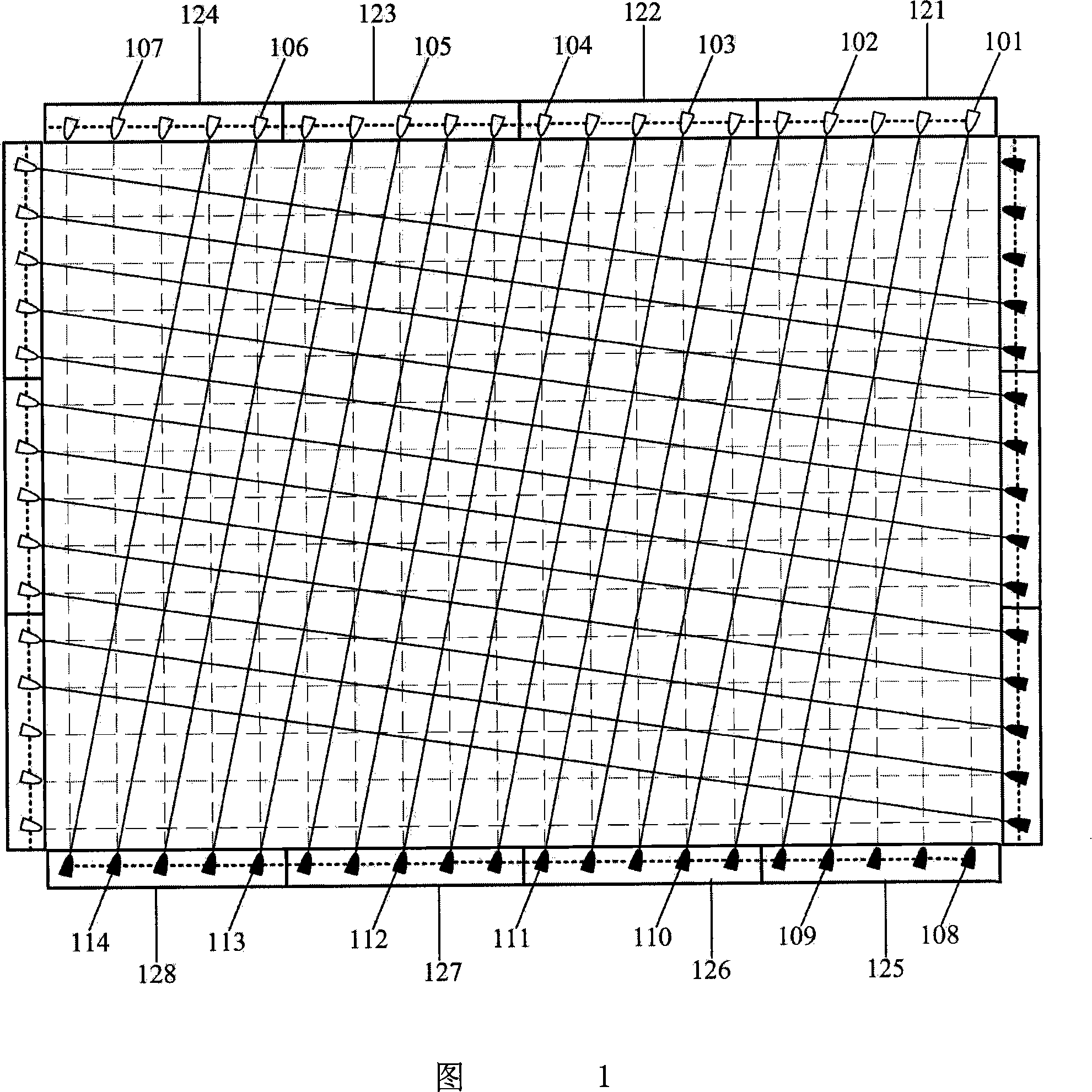

This invention discloses an infrared touching screen and the multi-spot touching localization method, in an examination direction, the ray of light send out by the infrared emission part on the infrared emission sweep circuit not only can be received at least by one infrared sweep circuit's infrared receive part which is vertical to the part's position, but may also be received by another inclined relative infrared receive sweep circuit's infrared receive part at least which is deviated vertical to the part's position. Thus, in a scanning period, the ray of light send out by an infrared emission part may be received by two different position infrared receive parts in the different time, through a checking calculation between touching possible coordinate figure and location parameter, then may determine each touching position data, this invention realizes the multi-spot localization scanning examination method to be simple, the touching position data computation convenient, accurate, reliable, the circuit wafer type is few, the shape is rule, easy to realize the large scale production, does not have the complex succession corresponding relationships, easy to realize.

Owner:GUANGDONG VTRON TECH CO LTD

Multifunctional pressure cooker

The invention discloses a multifunctional pressure cooker. The multifunctional pressure cooker comprises a cooker body and a cooker cover, the cooker cover comprises an upper cover body and an inner cover body, and the upper cover body is provided with a water injection port for injecting cooling water to the inner cover body; the multifunctional pressure cooker further comprises a water tank anda shielding cover; the multifunctional pressure cooker has a water-cooled cooking state in which the water tank is installed and a normal cooking state in which the shielding cover is installed, whenthe water tank is installed on the cooker cover, the water tank discharges water to the water injection port, and when the shielding cover is installed on the cooker cover, the shielding cover shieldsthe water injection port. The multifunctional pressure cooker can be used as a water-cooled pressure cooker by installing the water tank and used as a normal pressure cooker without installing the water tank.

Owner:JOYOUNG CO LTD

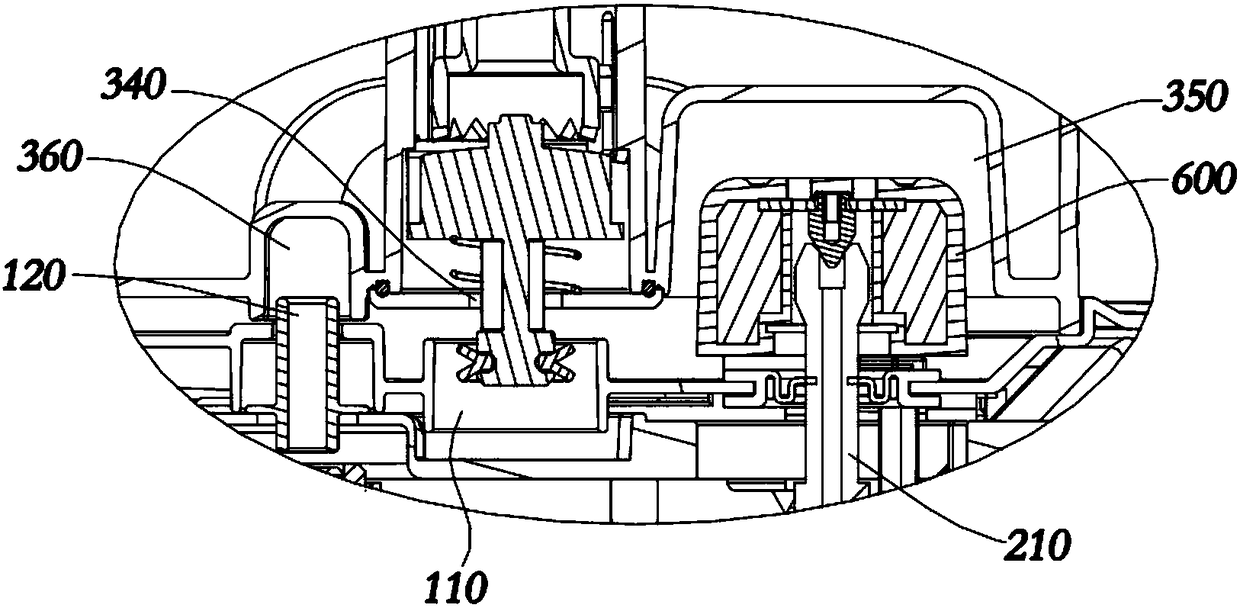

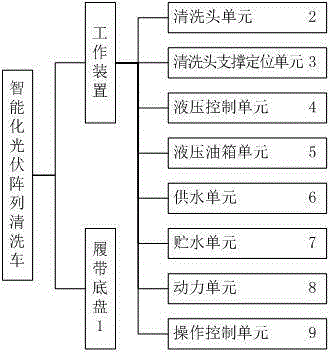

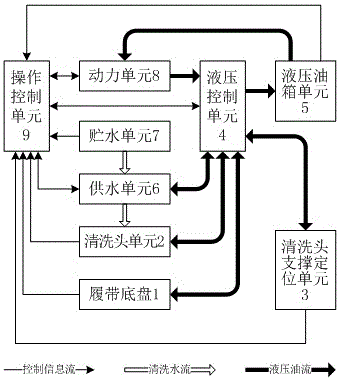

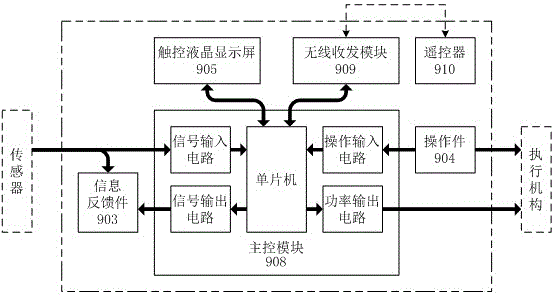

Intelligent photovoltaic array washing car

ActiveCN105107772AFunction increaseRegular shapeCleaning using toolsCleaning using liquidsWater storageHydraulic control unit

The invention provides an intelligent photovoltaic array washing car used for washing photovoltaic arrays of a large-scale ground photovoltaic power station. A washing head supporting and locating unit and a power unit are arranged on the head portion and the tail portion of a crawler base respectively, a water storage unit is arranged adjacent to the power unit, and a washing head unit is provided with range finder sensors used for measuring the distance between the washing head unit and solar cell panels; the washing head supporting and locating unit comprises a movable base capable of rotating and transversely moving and a working arm set provided with a main arm and an end arm, wherein the main arm and the end arm can pitch respectively; a water pump of a water supply unit is driven by a hydraulic motor; a computer is used as a control kernel of a main control module of an operation control unit; a pair of proportional directional valves of the hydraulic control unit controls two base crawler traveling motors, and other directional valves are electromagnetic directional valves controlled by the main control module. According to the intelligent photovoltaic array washing car, the position and the posture of the washing head unit relative to photovoltaic array panels and the position and the posture of a car body relative to the photovoltaic arrays can be automatically controlled, and the intelligent photovoltaic array washing car is intelligent, efficient, flexible in operation, high in adaptability, easy and convenient to operate, concise in structure and good in washing effect.

Owner:CSIC HAIWEI ZHENGZHOU HIGH TECH CO LTD

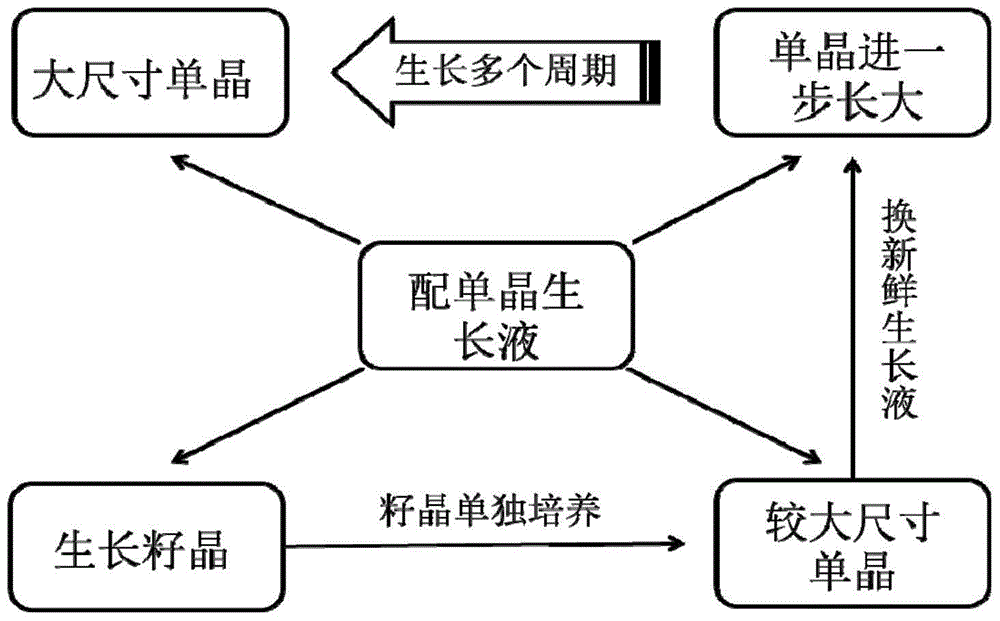

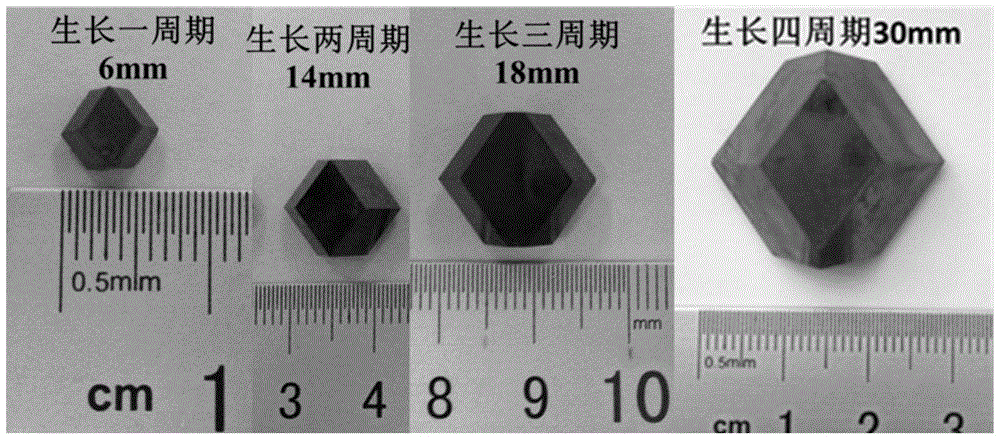

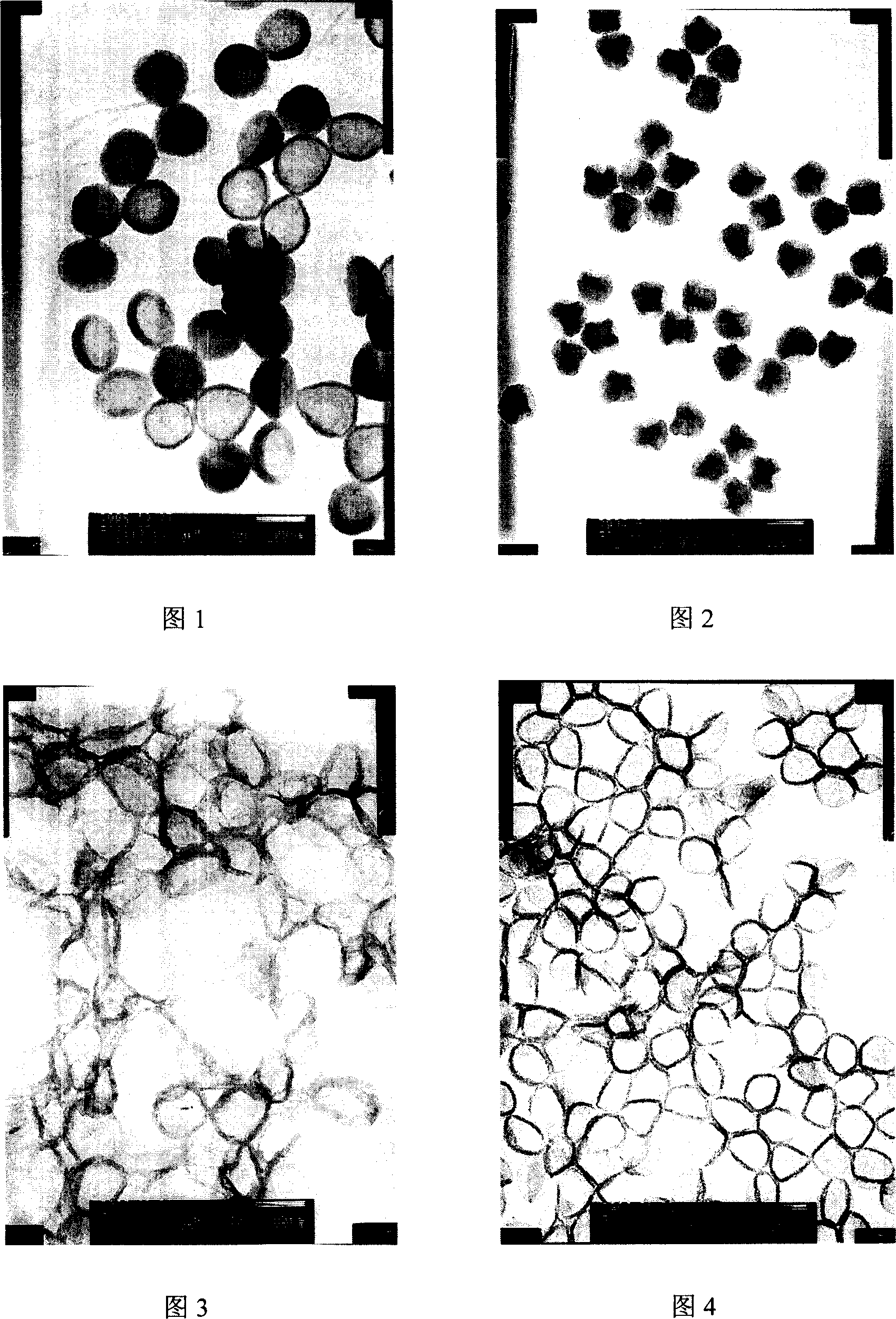

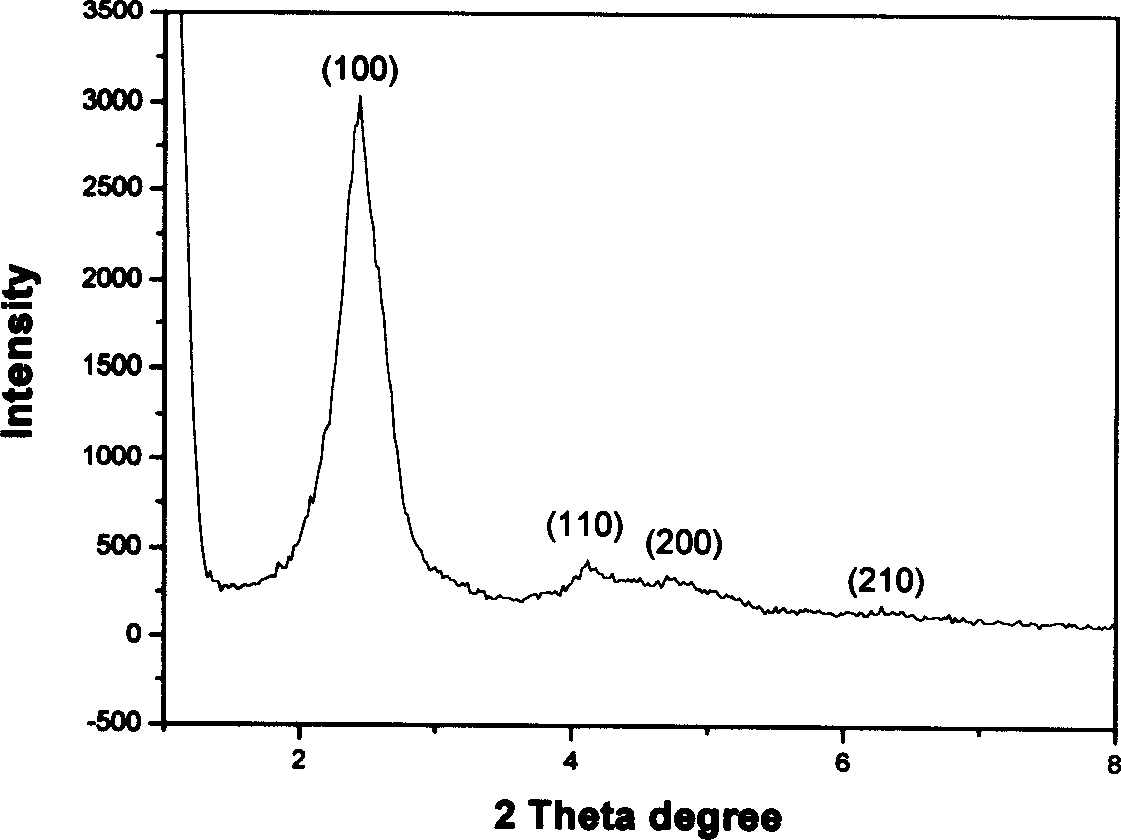

Method for growing ABX3 perovskite single crystals in low-temperature solution

ActiveCN104911705ARegular shapeModerate shapePolycrystalline material growthFrom normal temperature solutionsPhotodetectorSingle crystal growth

The invention provides a method for growing ABX3 perovskite single crystals in a low-temperature solution. According to the invention, a continuous growing method is adopted, and the ABX3 perovskite single crystals are rapidly grown in the low-temperature solution continuously with multiple periods and different stages. The concentration of the solution is high, and the raw materials required by growing are uniformly dissolved. Growing periods are added, and growing conditions are finely controlled, such that ABX3 perovskite single crystals with large sizes, regular shapes and high quality can be easily obtained. The method has the advantages of simple process, high operability, mild growing conditions, low required temperature, low energy consumption, low equipment requirement, low cost, high success rate, fast single crystal growth speed, fewer defects, good stability, large single crystal size (>10mm)*(>10mm)*(>10mm), and the like. Therefore, basic mechanism theoretical researches on perovskite materials and related optoelectronic devices (including solar cell, photodetector, LED and laser) are promoted.

Owner:SHAANXI NORMAL UNIV

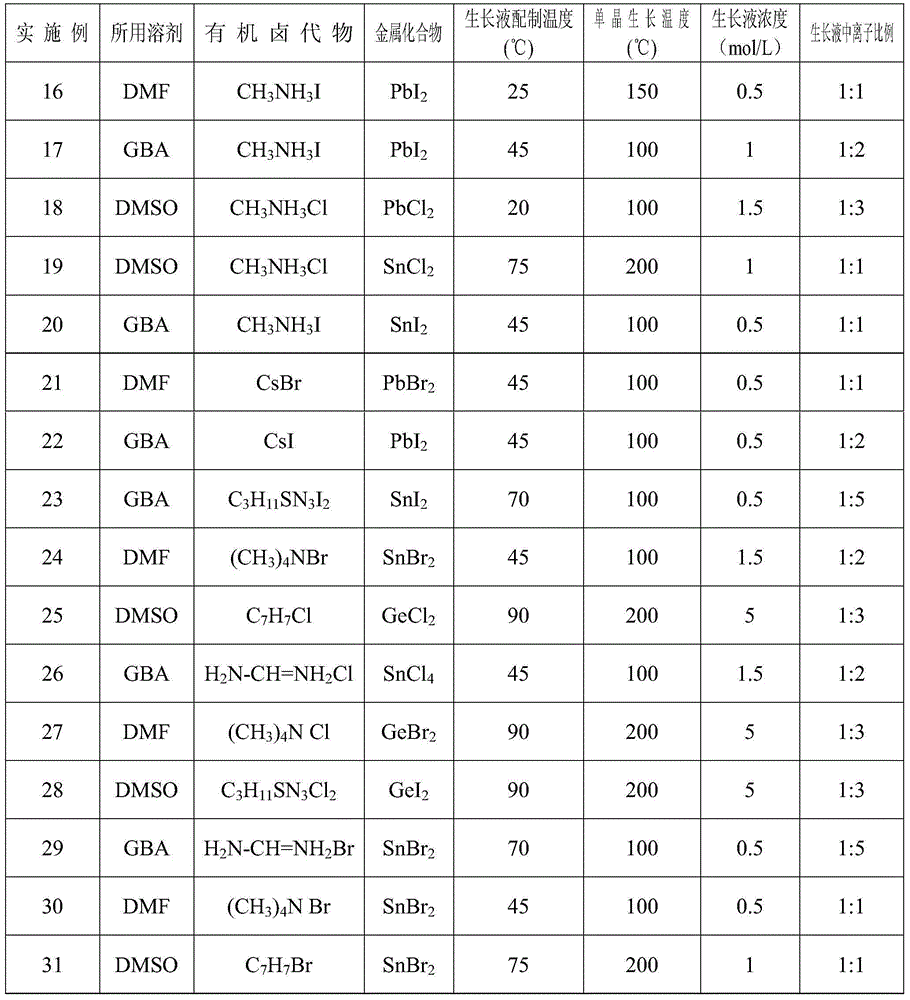

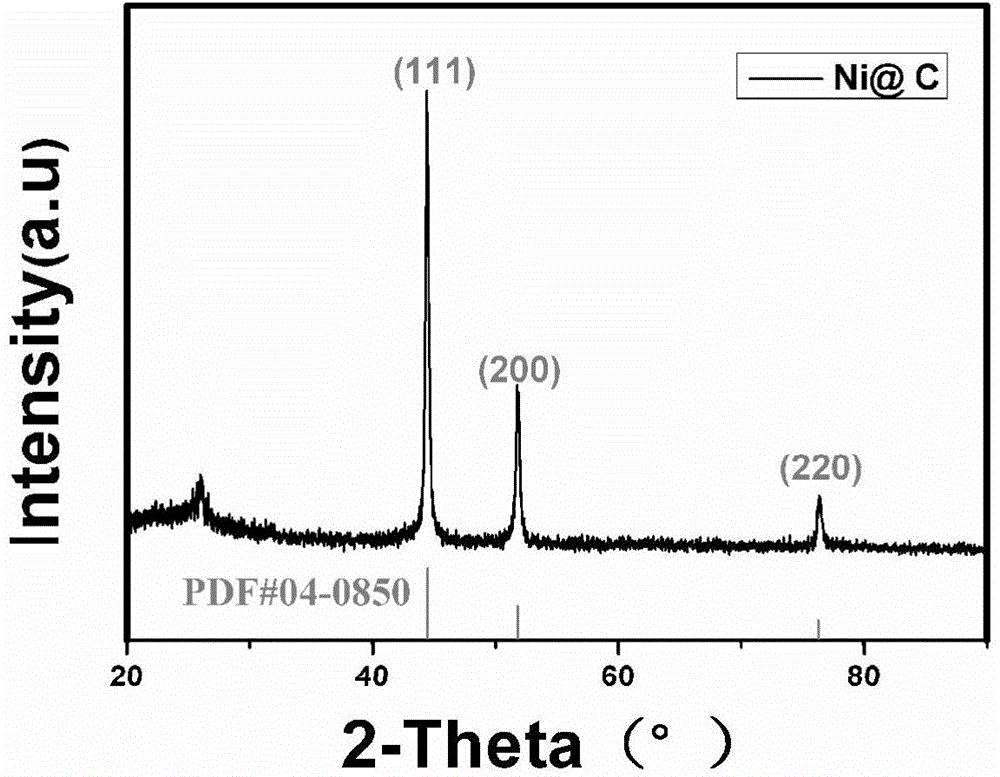

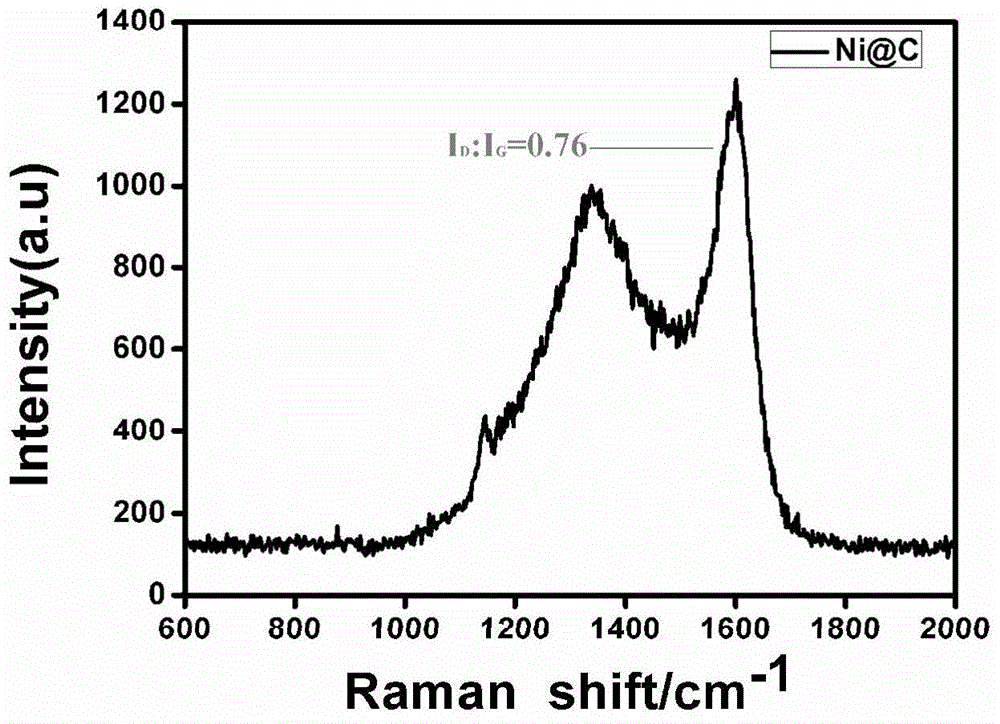

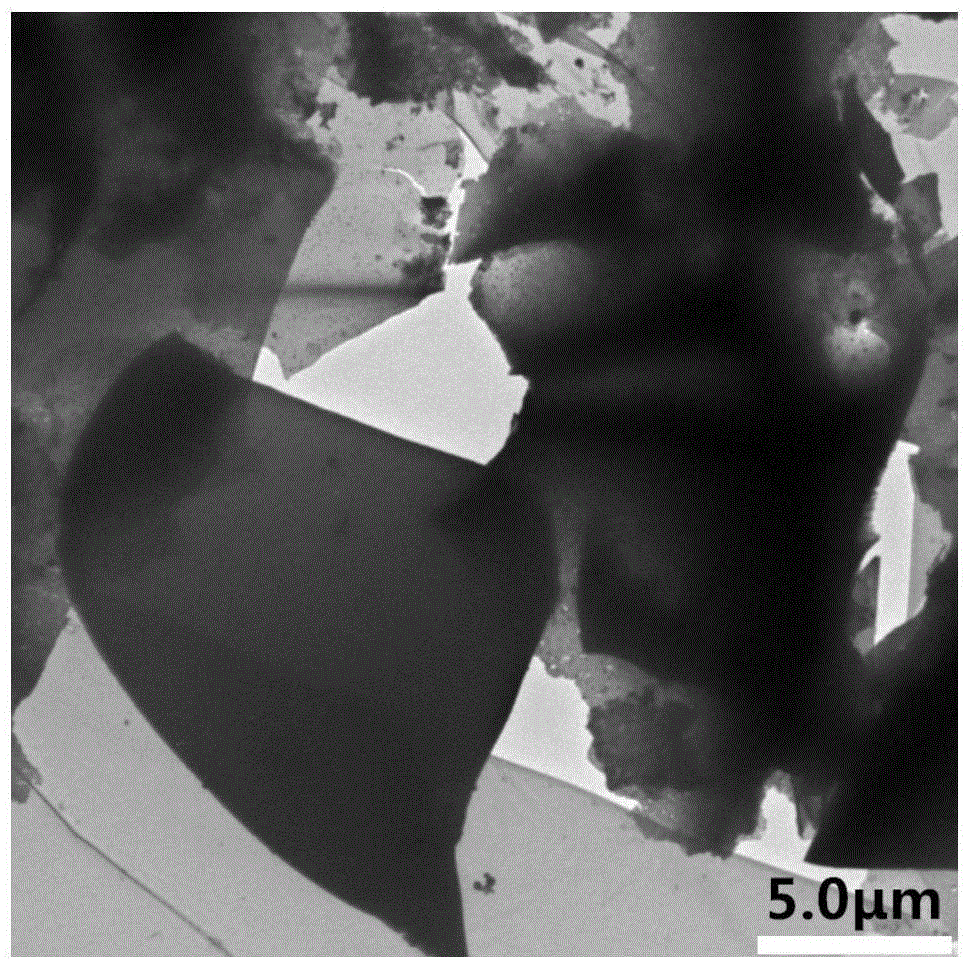

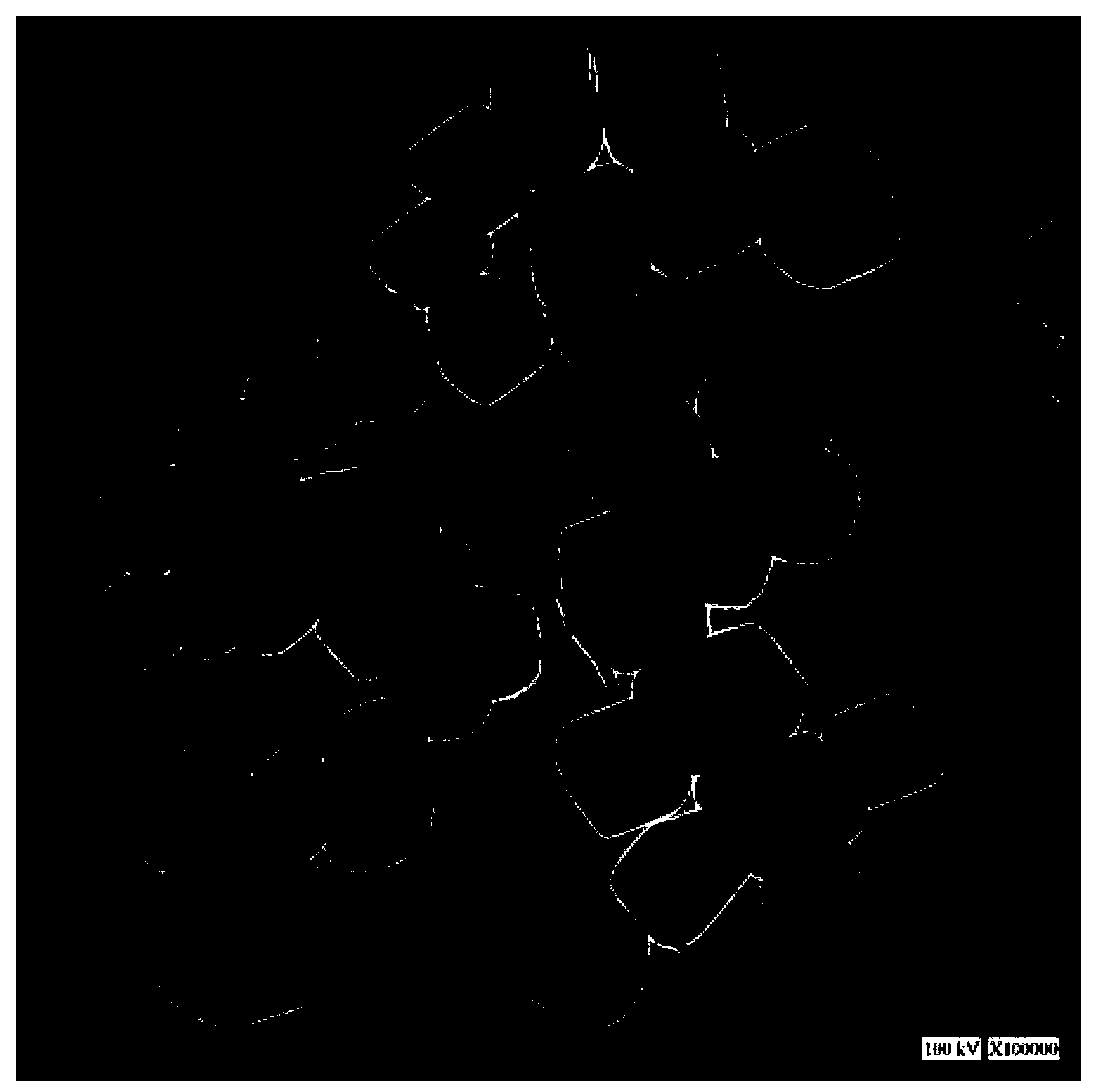

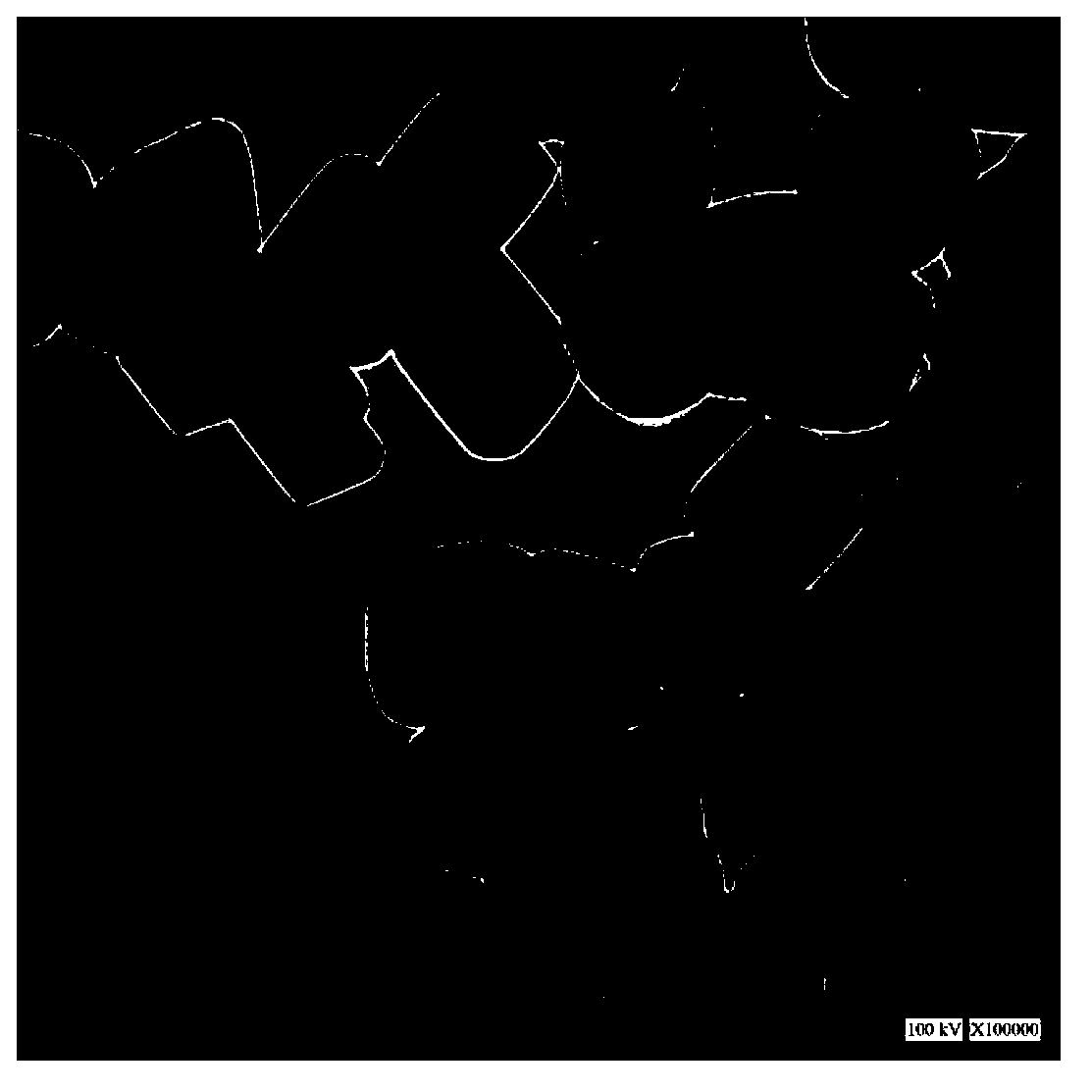

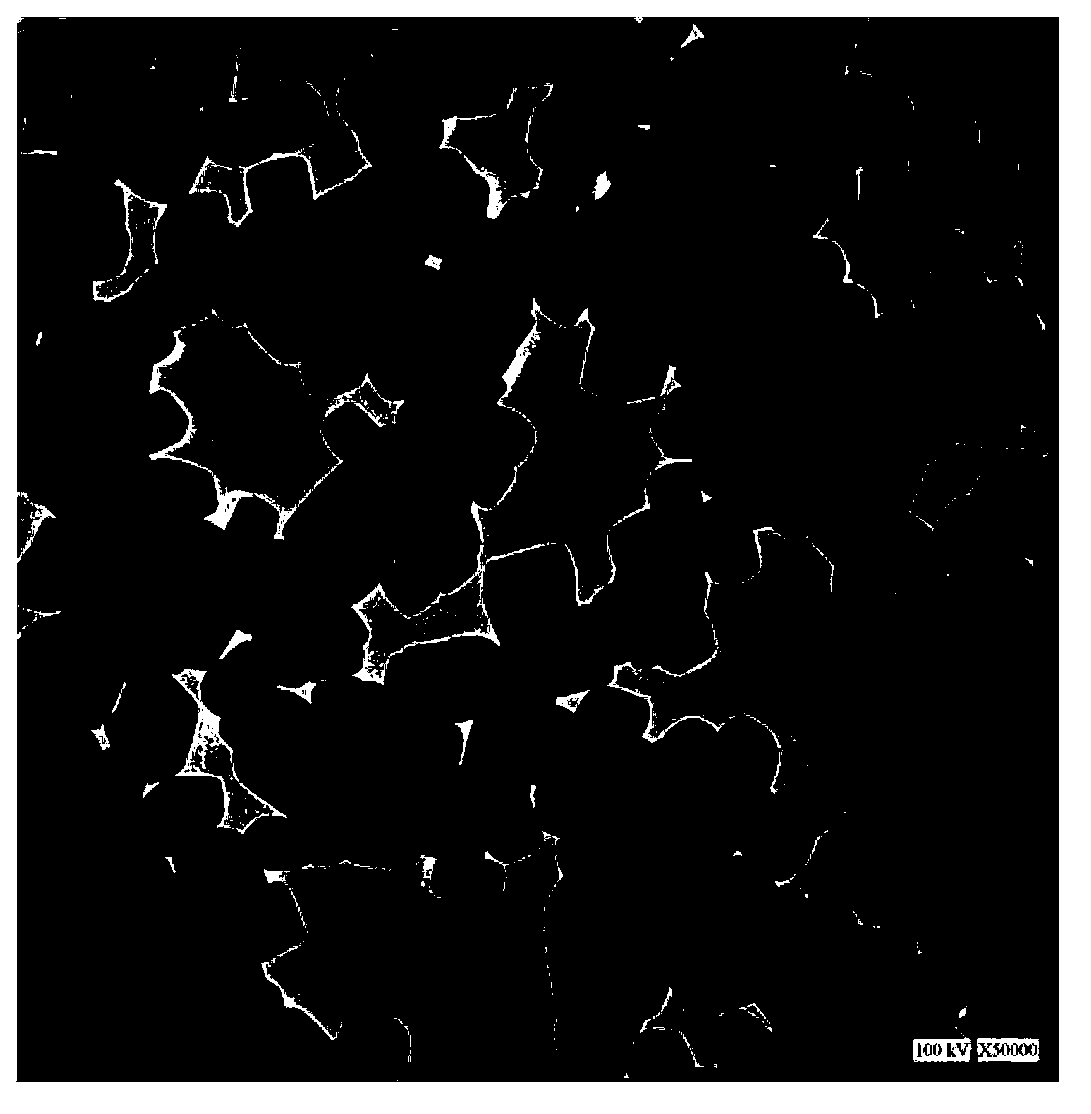

Lithium ion battery cathode material embedded nano metal loaded carbon nanosheet as well as preparation method and application thereof

InactiveCN104538595AUniform sizeRegular shapeMaterial nanotechnologyCell electrodesChemistryCarbon source

The invention discloses a lithium ion battery cathode material embedded nano metal loaded carbon nanosheet as well as a preparation method and an application thereof. By taking sugar (chitosan, cane sugar, fructose and glucose) as a carbon source, nitrate of transitional metals (Fe, Co and Ni) as a metal source and a catalyst and inert salts (sodium sulfate, sodium chloride, potassium chloride and cesium chloride) as a template and a dispersant, a two-dimensional carbon nanosheet which uniformly loads embedded nickel (or iron or cobalt) nanoparticles is prepared by a pyrolytic method in one step. The two-dimensional carbon nanosheet which uniformly loads embedded nickel (or iron or cobalt) nanoparticles prepared by the method is high in degree of graphitization, relatively high in specific surface area and high in conductivity, uniform in distribution and easy to separate, and the surface of the nanosheet is in a porous structure. The nanosheet as the lithium ion battery cathode material has relatively good circulating and rate performances.

Owner:NANJING NORMAL UNIVERSITY

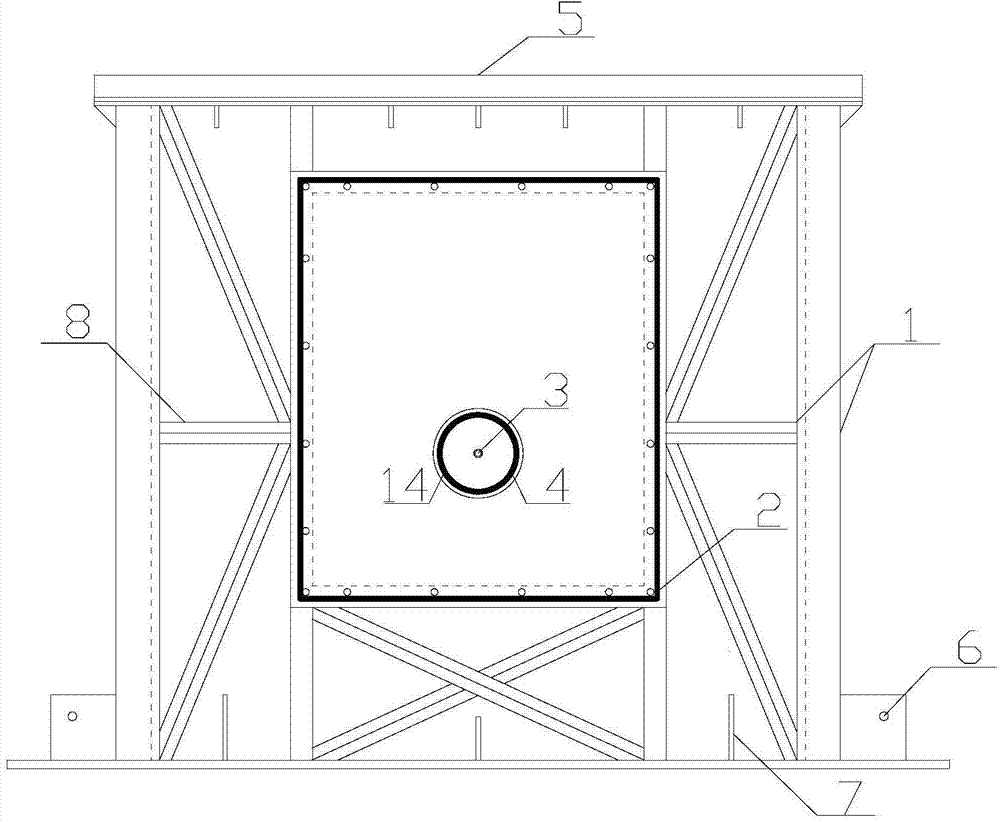

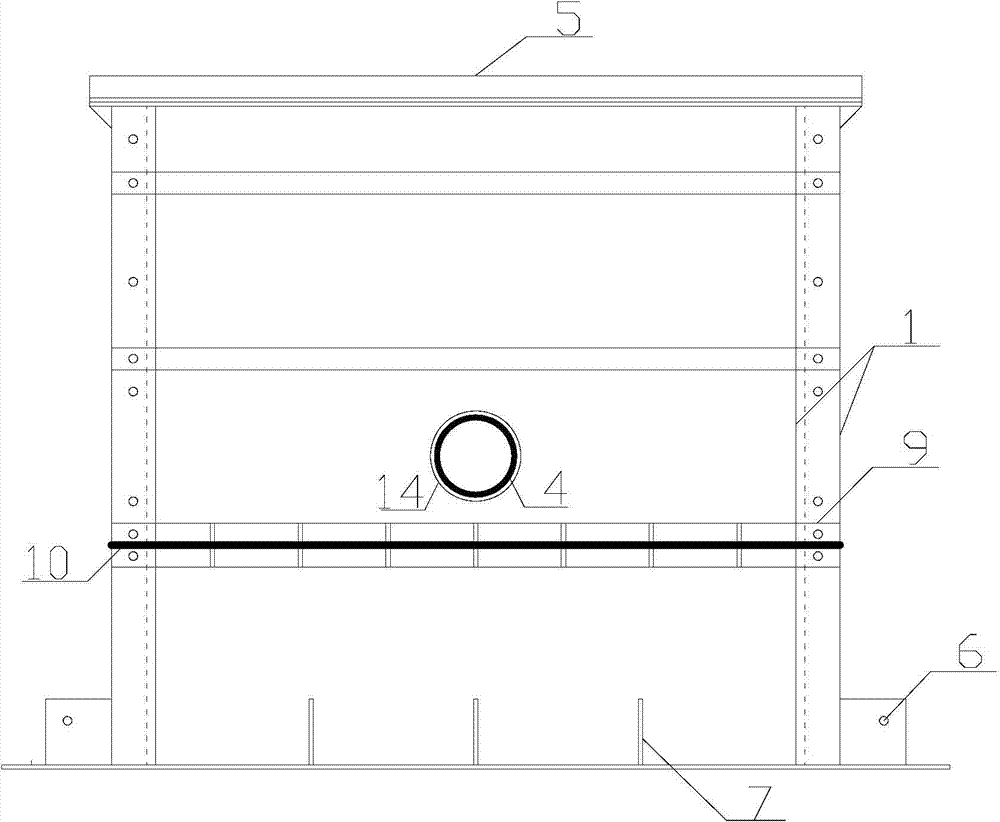

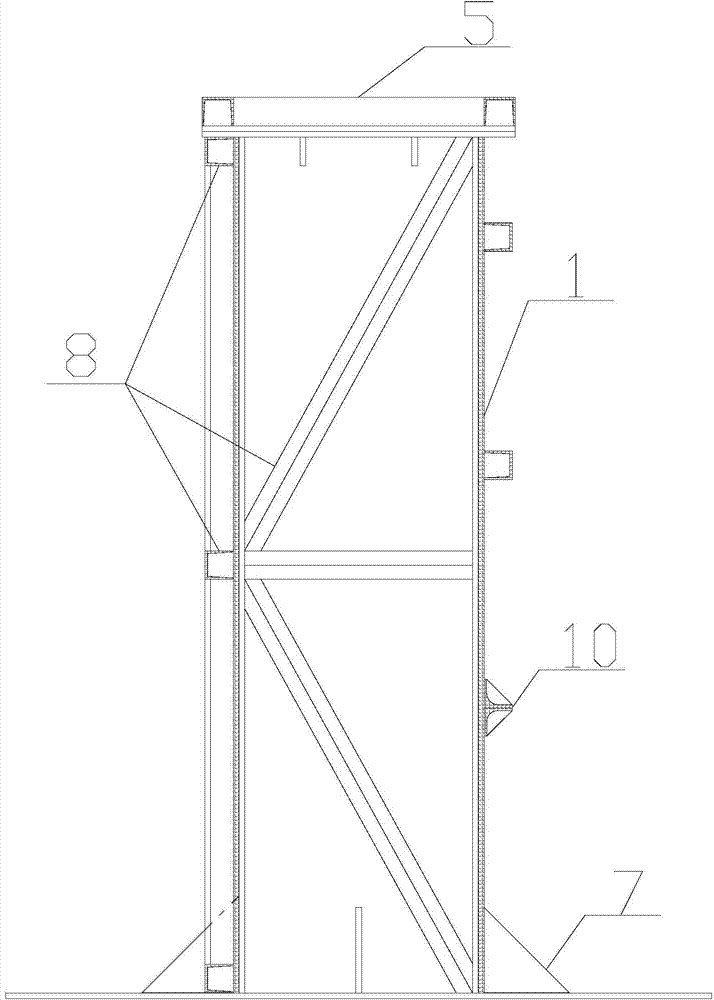

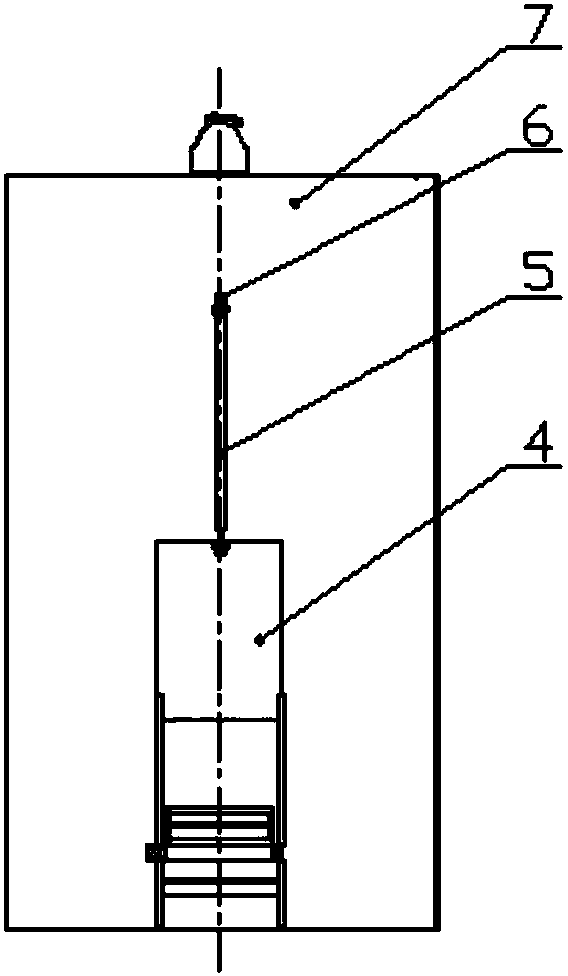

Model test apparatus for stimulating tunnel excavation process

ActiveCN104713987ARegular shapeReduce the level of disturbanceMaterial analysisThin walledEnvironmental geology

The invention discloses a model test apparatus for stimulating a tunnel excavation process, and belongs to the field of underground engineering test. Prototaxic sandy soil is adopted as a stratum condition, a lining structure adopts a stress similar galvanized iron thin wall cylinder, a non-contact strain displacement measurement and analysis system is adopted to observe the stratum deformation in the excavation process in a whole course real time manner, and an airbag loading system is adopted to simulate different embedded depths of a tunnel. A model opening mode is a loading and opening mode; and the test apparatus can be used to stimulate the excavation processes of an unlined tunnel and a lining structure possessed tunnel under different embedded depths. The stress similar galvanized iron thin wall cylinder is adopted to stimulate the lining structure, a built-in water capsule system is adopted to stimulate the excavation process and measure force and deformation, and the pressure of soil on the lining structure and the development rule of the pressure under different embedded depths are analyzed. The apparatus provides scientific understanding for the pressure change of surrounding rocks and the deformation mechanism of the stratum in the tunnel excavation process, and provides theoretic bases for tunnel design and construction.

Owner:BEIJING UNIV OF TECH

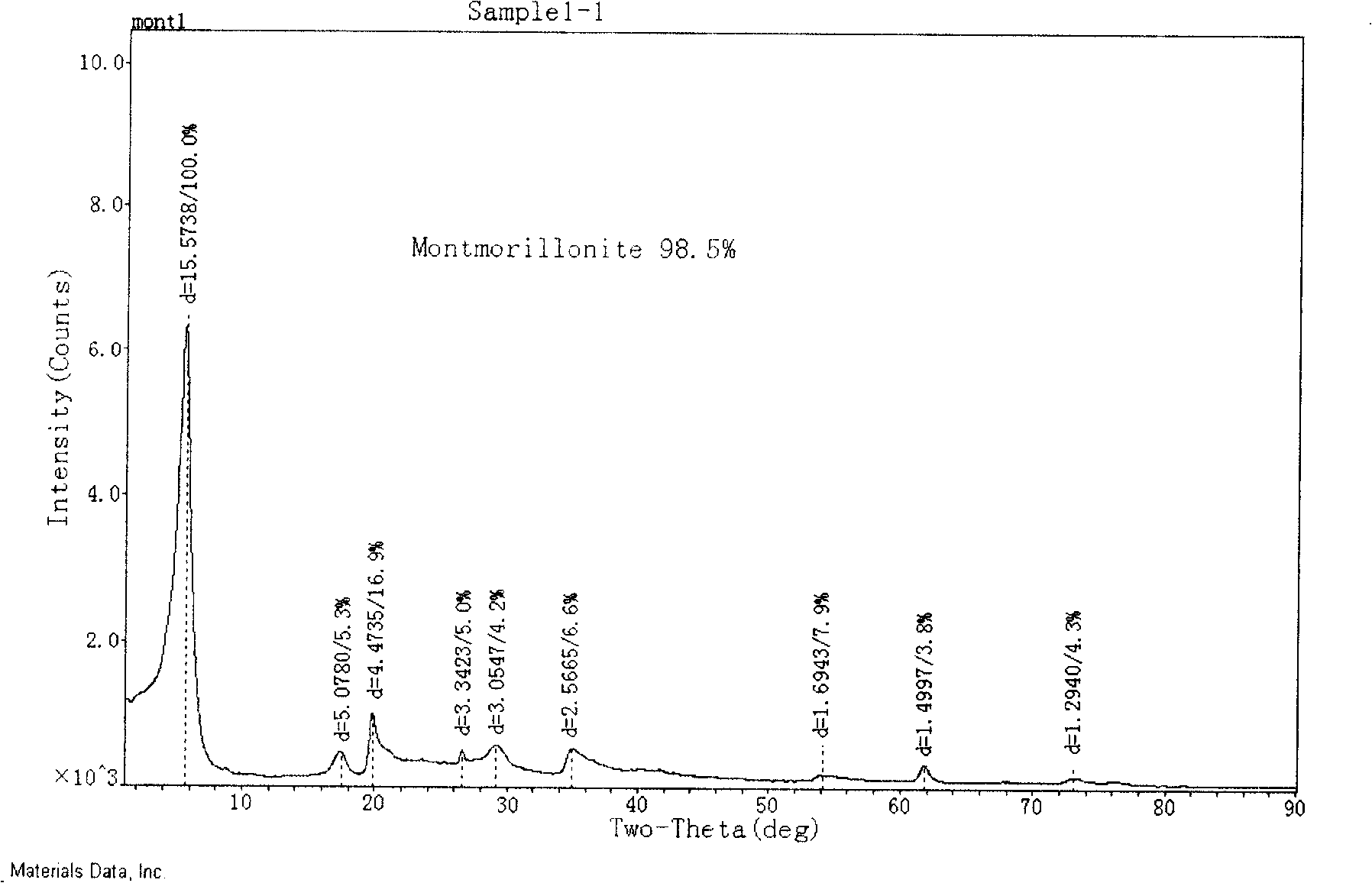

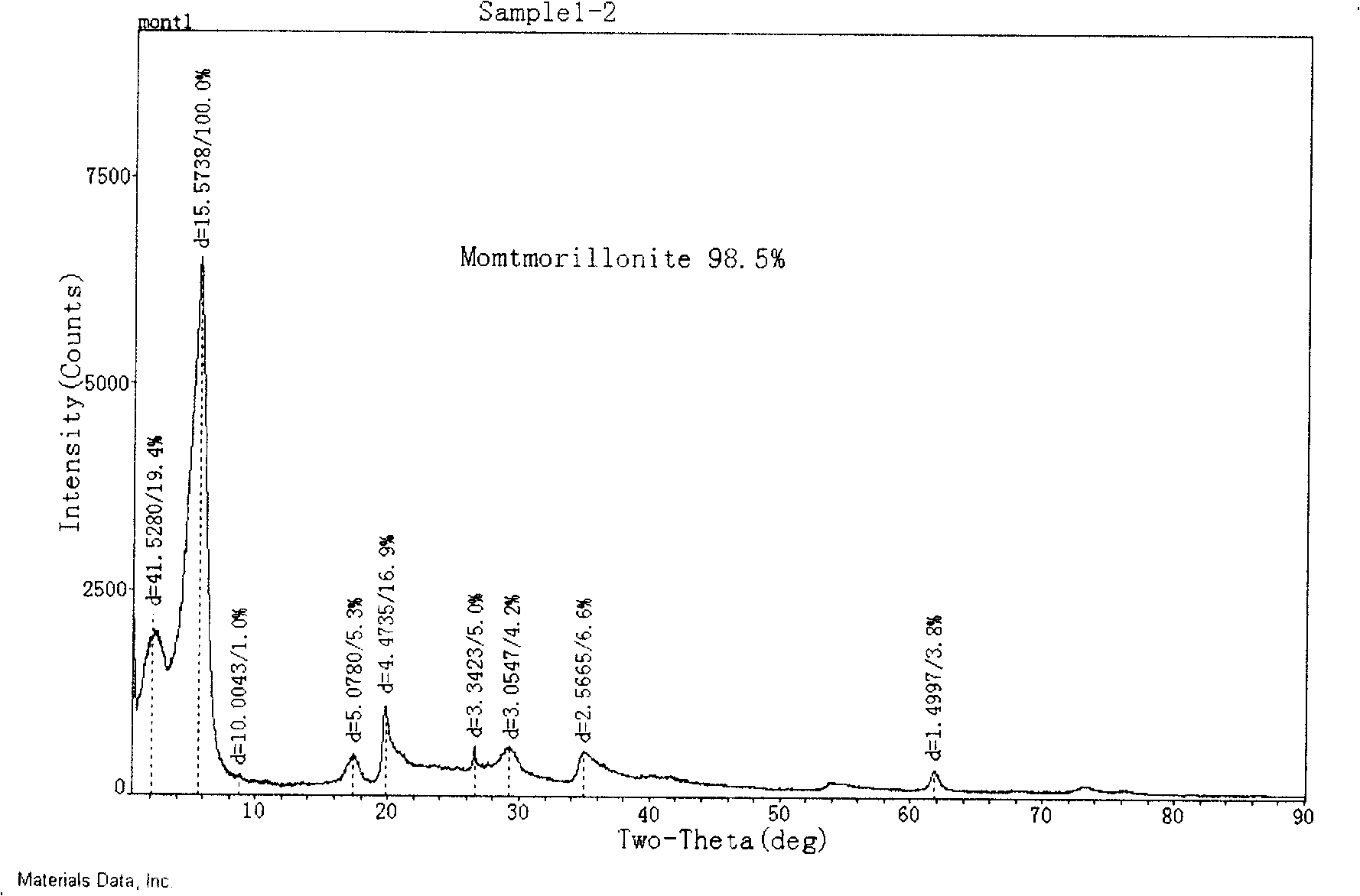

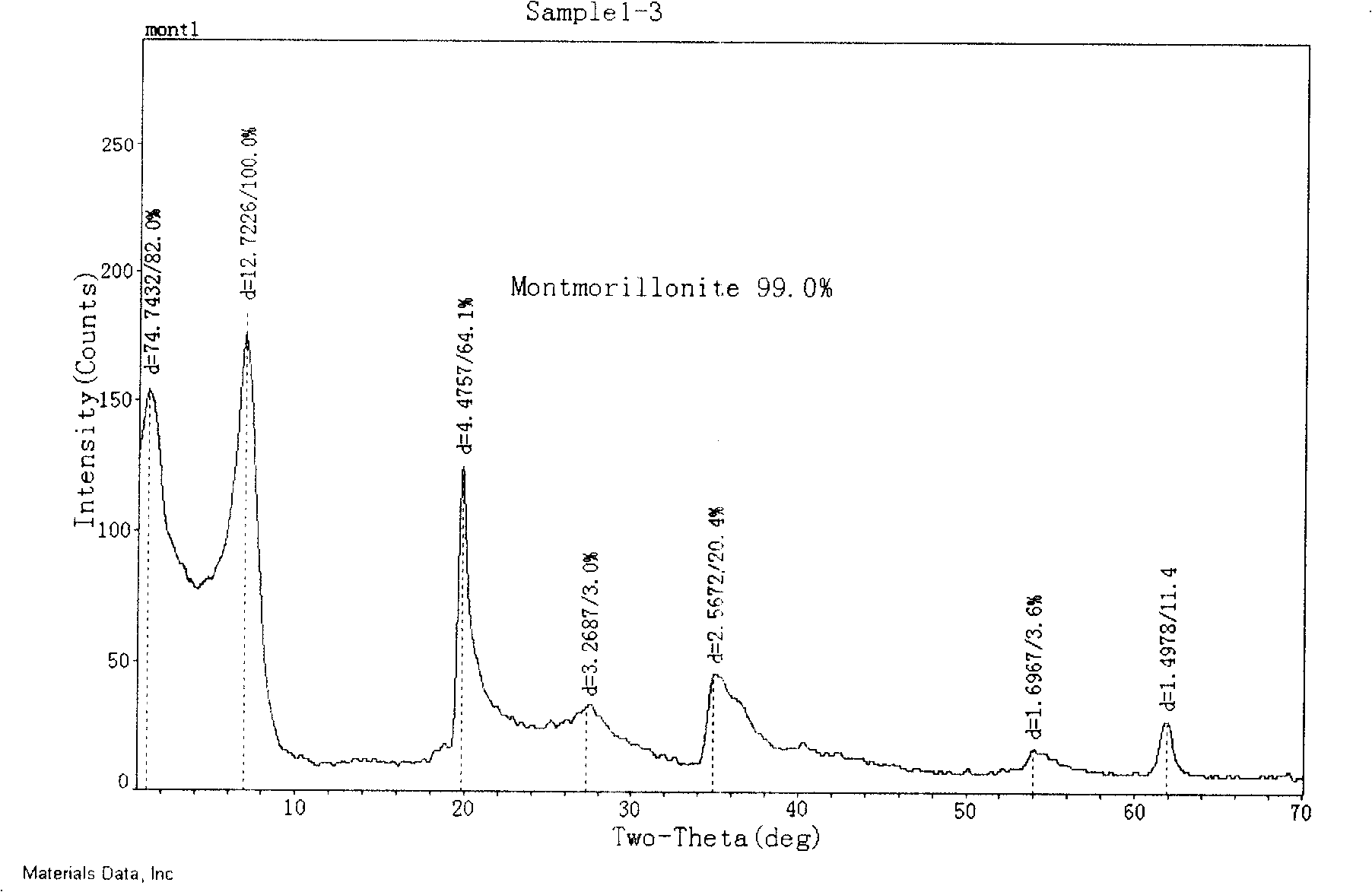

Modified smectite and method for producing the same and its application

ActiveCN101272986ANot easy to raise dustReduce moisture contentCosmetic preparationsOther chemical processesChemical compositionMontmorillonite

Disclosed is an inorganic medicine, particularly modified montmorillonite, method for preparing the same and use thereof. The said modified montmorillonite means that dioctahedron of natural montmorillonite is not destroyed and basic chemical composition for the same is not changed, and the microstructure stacked from dioctahedron layer is changed to decrease the thickness of stacking layer and to expose and increase the end face charge and the interlayer charge of montmorillonite, thereby resulting in its lower degree of C axis order. The present medical use of montmorillonite is thus significantly strengthened, particularly the reversal treatment effect on chronic atrophic gastritis. Also disclosed are a medicine composition containing modified montmorillonite and the reversal treatment effect of natural montmorillonite on chronic atrophic gastritis.

Owner:ZHEJIANG HAILISHENG PHARM CO LTD

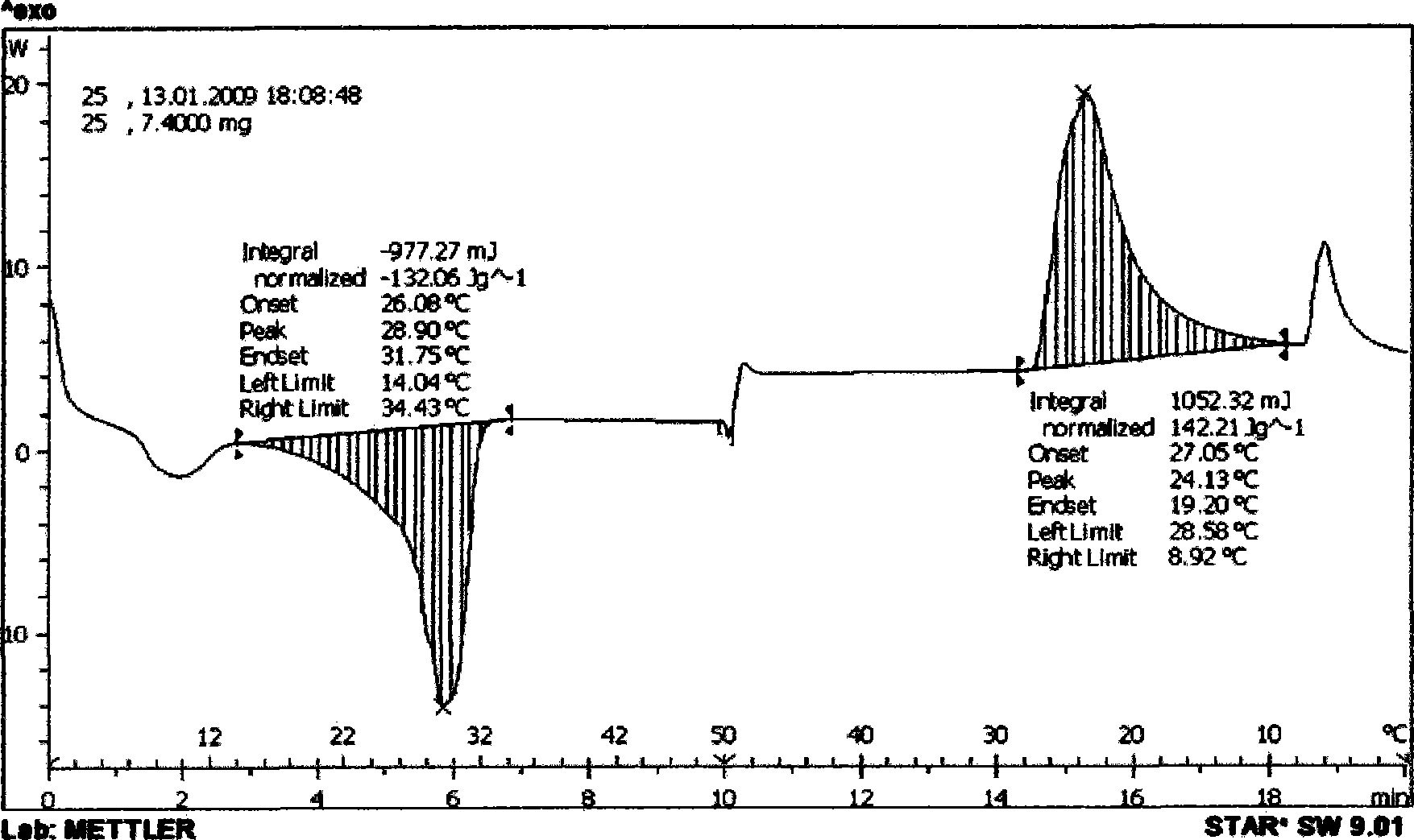

Preparing method for phase transited stored energy microcapsule covered with an organic polymer material

InactiveCN101530772ALess light fastnessSmall smellHeat-exchange elementsMicroballoon preparationPolymer chemistryPhase-change material

A preparing method for phase transited stored energy microcapsule covered with an organic polymer material adopts the following steps: (1) mixing the 10 weight organic phase transited material and 0.5-2.5 weight nonionic surfactant under the condition of heating and blending; (2) picking the organic polymer material monomer A, B 2-3 weight to add to 40-60 weight water, blending and mixing as the water phase; (3) adding the oil phase to the water phase, blending the material as the creaming liquid at 30-50 centigrade, adding the free radical to the initiator for the poly-reaction 1-8h at 35-90 centigrade; then adjusting the low temperature as blending the material and adding the cross linker, filtering, washing and drying to obtain the finished products. The organic polymer material achieves the phase transited capsule envelopment via the creaming polymer reaction of the wall material; the microcapsule is the spherical; the granule is distributed evenly; the polymer wall material has a stable intensity, great tightness and great mechanical performance.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Preparation method of cubic ultra-fine calcium carbonate particles

ActiveCN103663527AParticle size controllableNarrow rangeCalcium/strontium/barium carbonatesNanotechnologySodium bicarbonateSucrose

The invention provides a preparation method of cubic ultra-fine calcium carbonate particles. The method comprises the following steps: (1) adding a nucleation promoter to calcium hydroxide suspension liquid, wherein the nucleation promoter is selected from more than one of glucose, sucrose or sodium citrate; (2) carbonizing by introducing carbon dioxide until the pH value is 8-12, adding a crystal modifier and ageing for 0.5-10 hours, wherein the crystal modifier is selected from one of sodium chloride, sodium carbonate, sodium bicarbonate or sodium hydroxide; (3) further introducing carbon dioxide and carbonizing until the pH value is 6.5-7.0; (4) coating by adding a coating agent, filtering and drying to obtain a product, wherein the coating agent is selected from a resin acid, a resin acid alkali metal salt, a fatty acid or a fatty acid alkali metal salt. According to the calcium carbonate particles, the particle sizes are 90-180nm, the calcium carbonate particles are in a cubic shape, and the specific surface area is 10-18m<2> / g. Thus, the cubic ultra-fine calcium carbonate particles can be used as functional fillers in coating, rubber, plastic and sealant industries.

Owner:建德华明科技有限公司

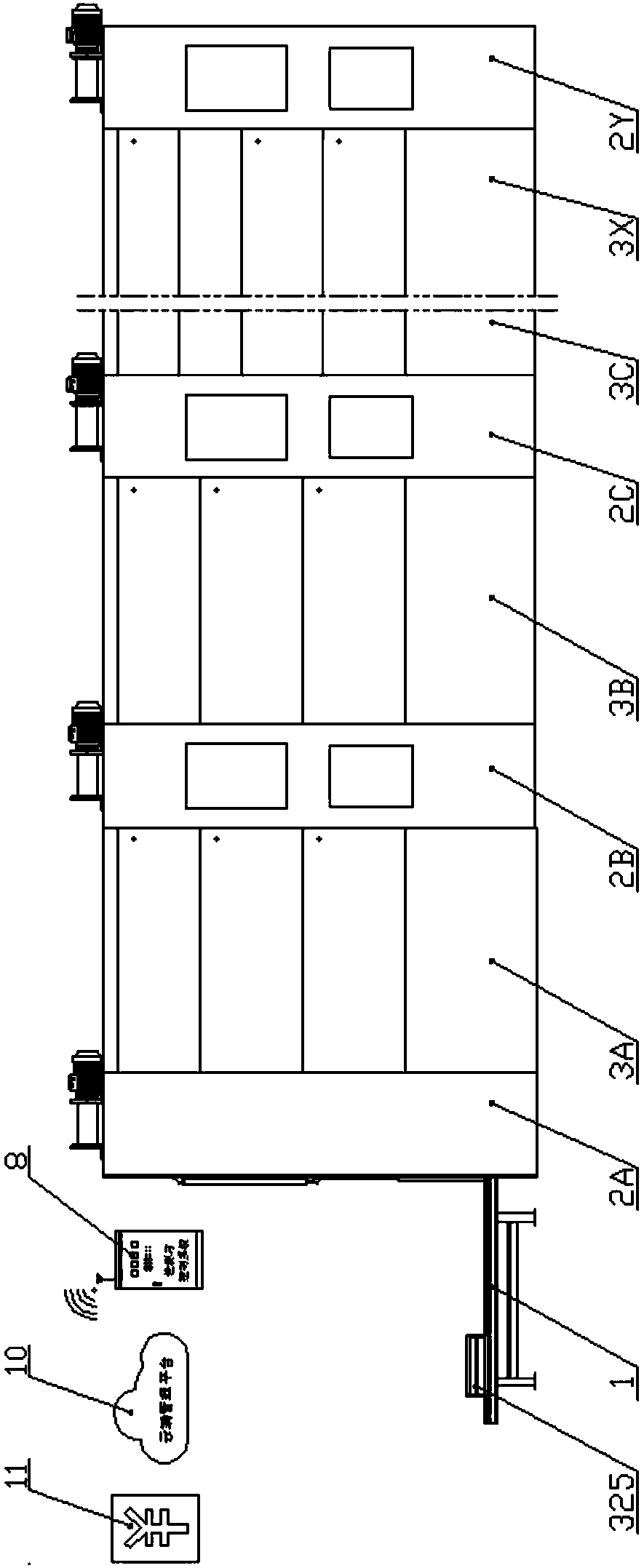

Caterpillar vending machine and automatic vending method

ActiveCN107945378AImprove adaptabilityReduce manual laborAcutation objectsCoin-freed apparatus detailsPayment systemIndustrial engineering

The invention provides a caterpillar vending machine. The caterpillar vending machine comprises a goods replenishing unit, m transshipment units, n container units, a detection control unit, a cloud side management platform and a payment system; the goods replenishing unit, the transshipment units and the container units are connected in sequence, and the integrated caterpillar vending machine isformed, wherein m and n are both natural numbers except 0, when n=1, m=1, and when n>1, m=n+1; regarding the m transshipment units and the n container units, when n>1 and m=n+1, the transshipment units and the container units are connected in an alternated and arranged mode, and the last unit is the transshipment unit; when n=1 and m=1, the transshipment units and the container units are of an integrated structure. The caterpillar vending machine solves the problem of a traditional vending machine that manual work is relied on to replenish goods, goods replenishing is troublesome, time and labor are wasted, and the adaptability of vended commodities are poor.

Owner:HUNAN SCIENTOP AUTOMATIC EQUIP SHARES +1

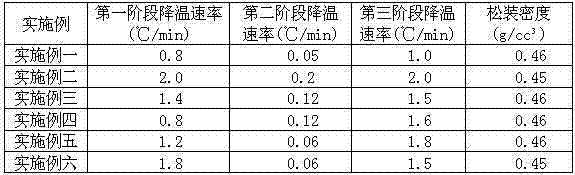

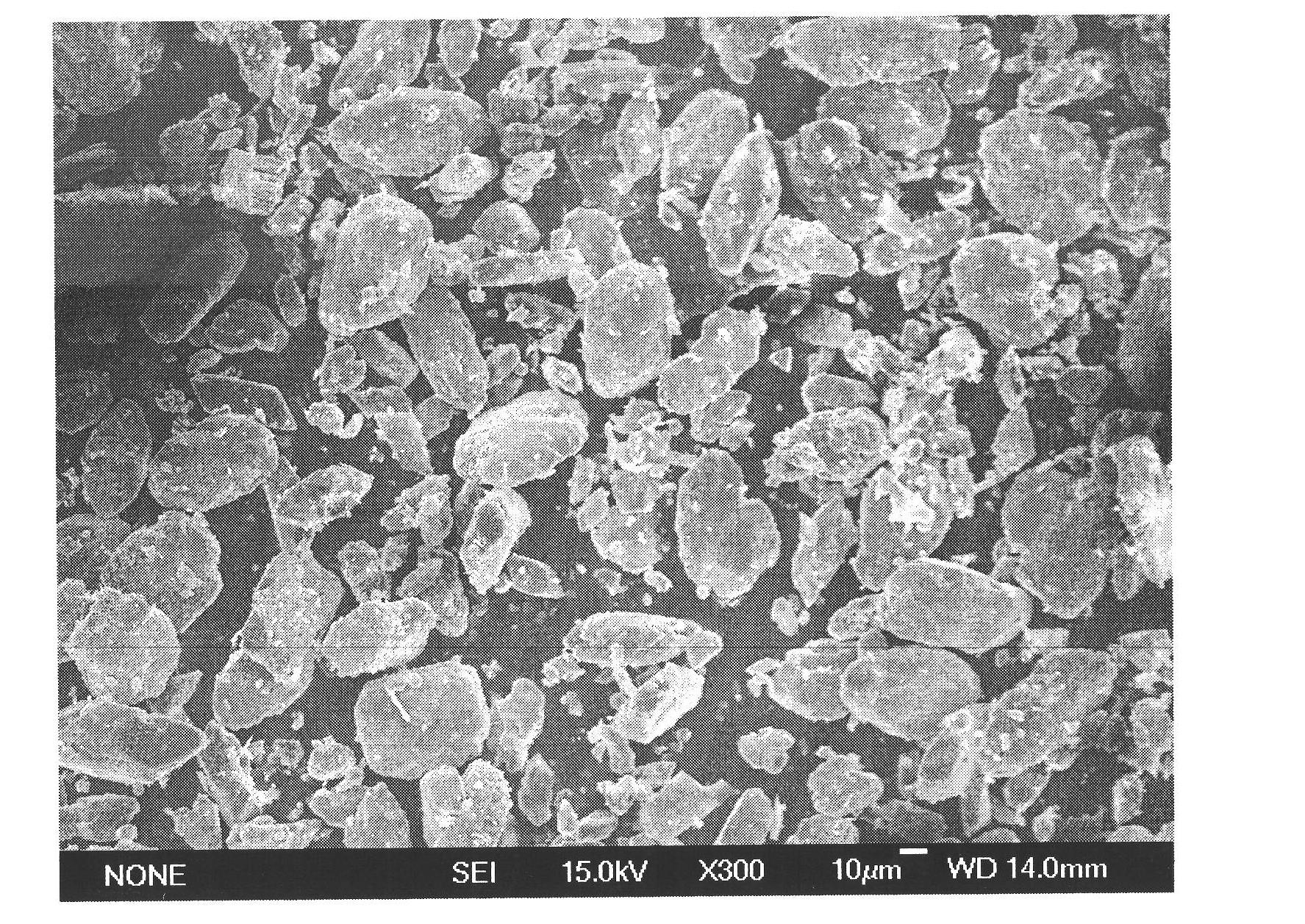

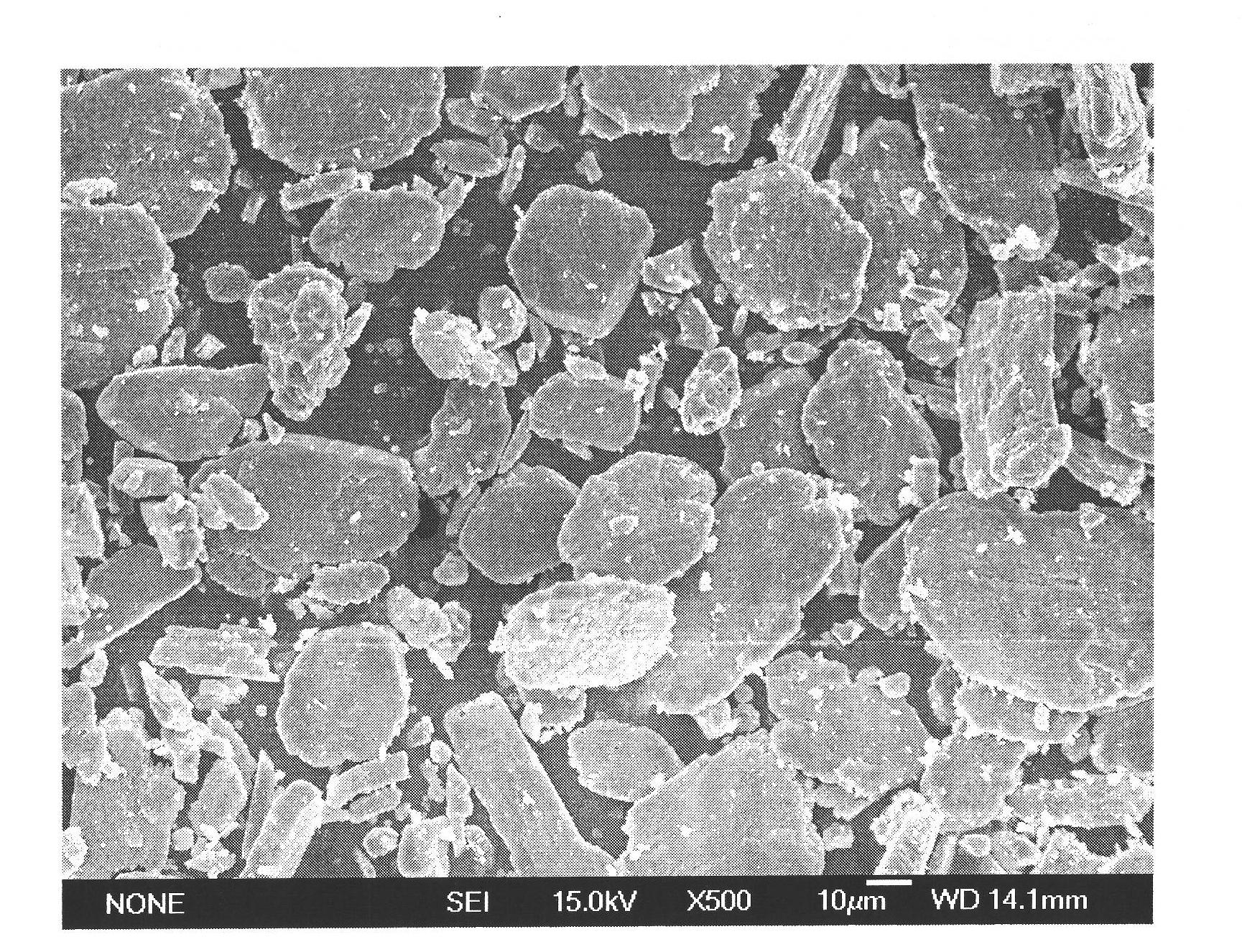

Preparation method of nylon powder for selective laser sintering

ActiveCN104497323ADestroy the regularity of the shapeRegular shapeSelective laser sinteringOrganic solvent

The invention provides a preparation method of nylon powder for selective laser sintering. The preparation method comprises the steps of adopting a precipitation method, and finally separating out solid powder through the processes of dissolution, cooling and precipitation. The method is characterized by being carried out under the condition of the presence of an organic solvent, wherein the cooling process is carried out in three phases, and rapid cooling is carried out to achieve a temperature which is 10 DEG C below than the separation temperature in the first phase; slow cooling is carried out to achieve the separation temperature in the second phase; rapid cooling is carried out to achieve a normal temperature in the third phase. The method is simple and feasible, low in cost, and capable of preparing the nylon powder with regular morphology, good part performance and suitable for SLS sintering.

Owner:HUNAN FARSOON HIGH TECH CO LTD

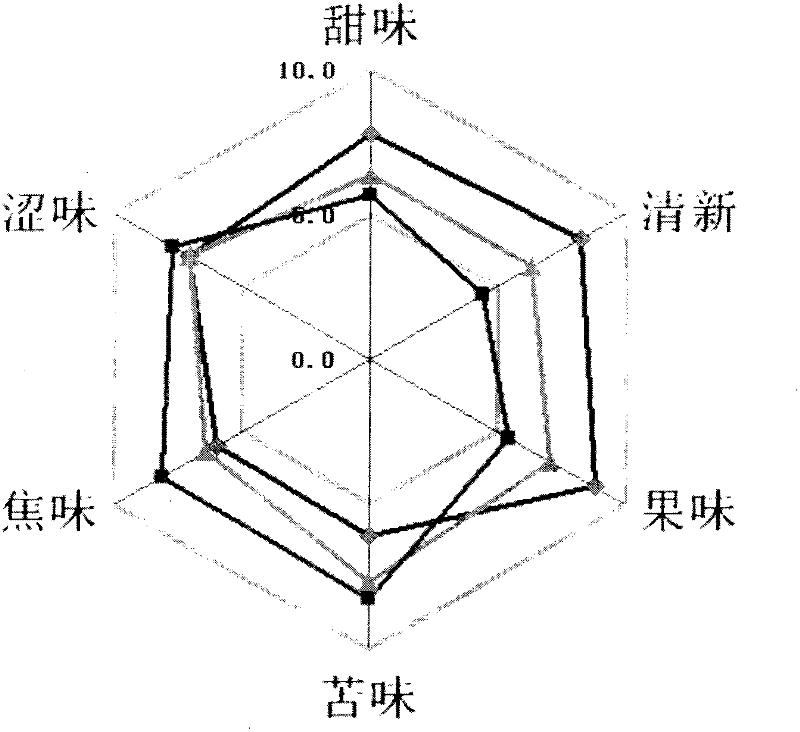

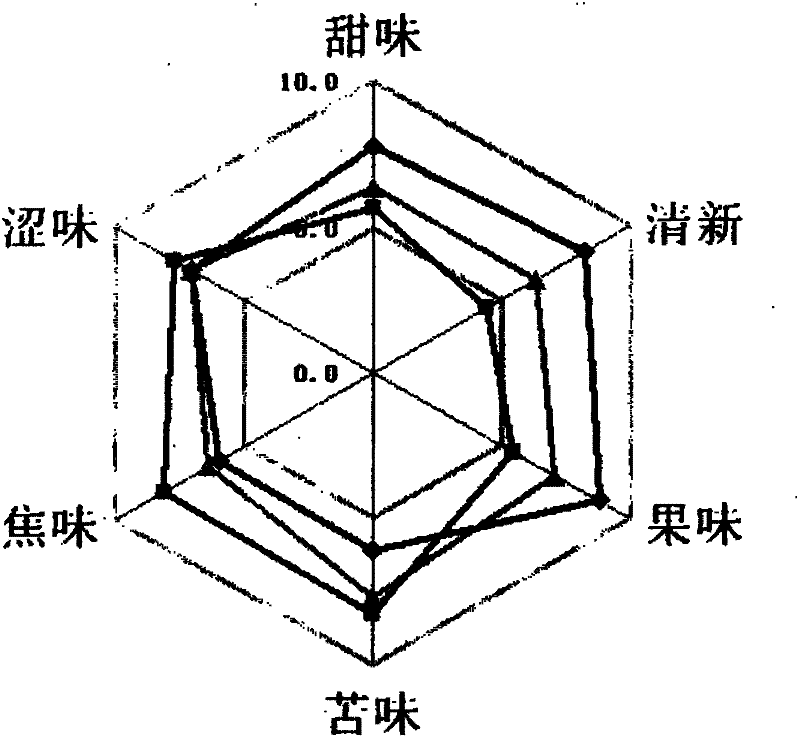

Method for performing microwave drying on grosvener siraitia and grosvener siraitia dried by same

ActiveCN102125248ARegular shapeFruit shape is beautifulDigestive systemRespiratory disorderNavelMogroside V

The invention discloses a method for performing microwave drying on grosvener siraitia and the grosvener siraitia dried by the same. The method comprises the following steps of: washing the grosvener siraitia completely and performing green-removing; punching a small hole on the top of the grosvener siraitia and the corresponding fruit navel at the bottom of the grosvener siraitia respectively; placing the punched grosvener siraitia into microwave drying equipment to dry for 8 to 10 minutes under the conditions of 2,400 to 2,500 MHz or 915 MHz and the temperature of between 50 and 60 DEG C; taking out the grosvener siraitia; placing the grosvener siraitia into the microwave drying equipment to dry for 8 to 10 minutes under the same conditions; taking out; cooling the grosvener siraitia at the temperature of between 0 and 4 DEG C for 3 to 5 minutes; and repeating the drying and cooling processes for 5 to 6 times to obtain grosvener siraitia. Compared with the prior art, the method has the advantages of simple and easily controlled process, short drying time and low energy consumption. The obtained dried grosvener siraitia has a complete and attractive fruit shape, green color, good mouthfeel and high retention rate of mogrosides V.

Owner:GUILIN NATURAL INGREDIENTS CORP

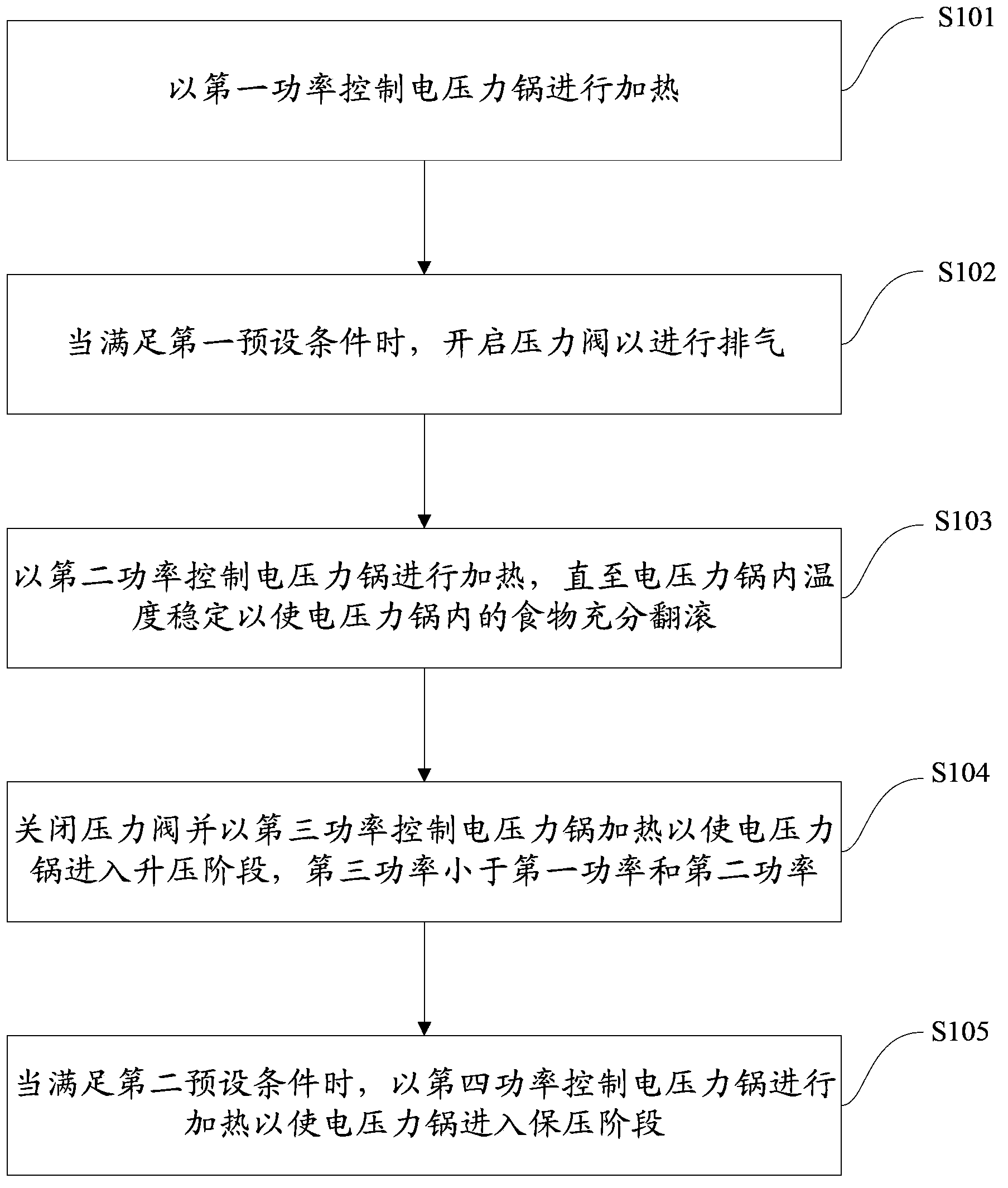

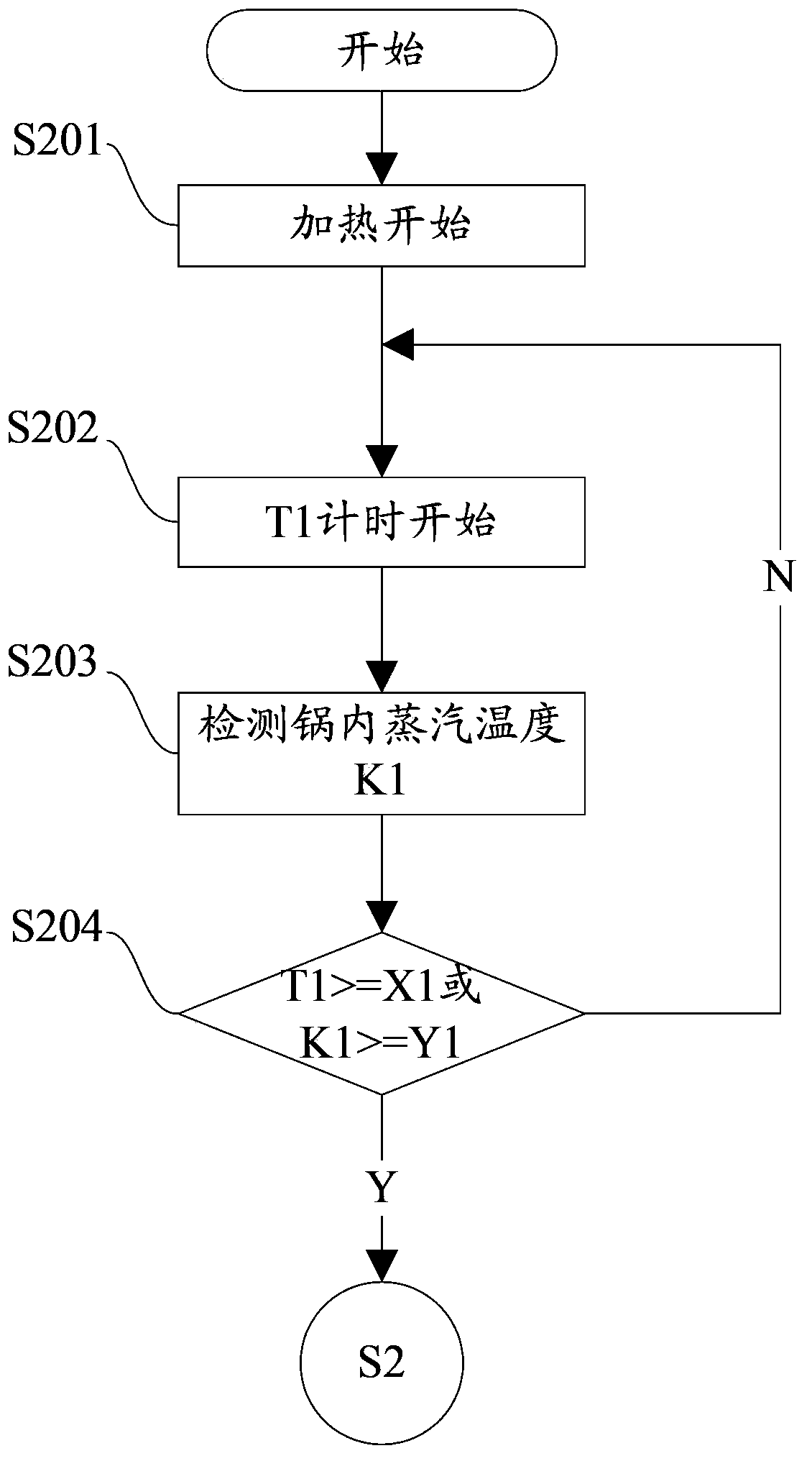

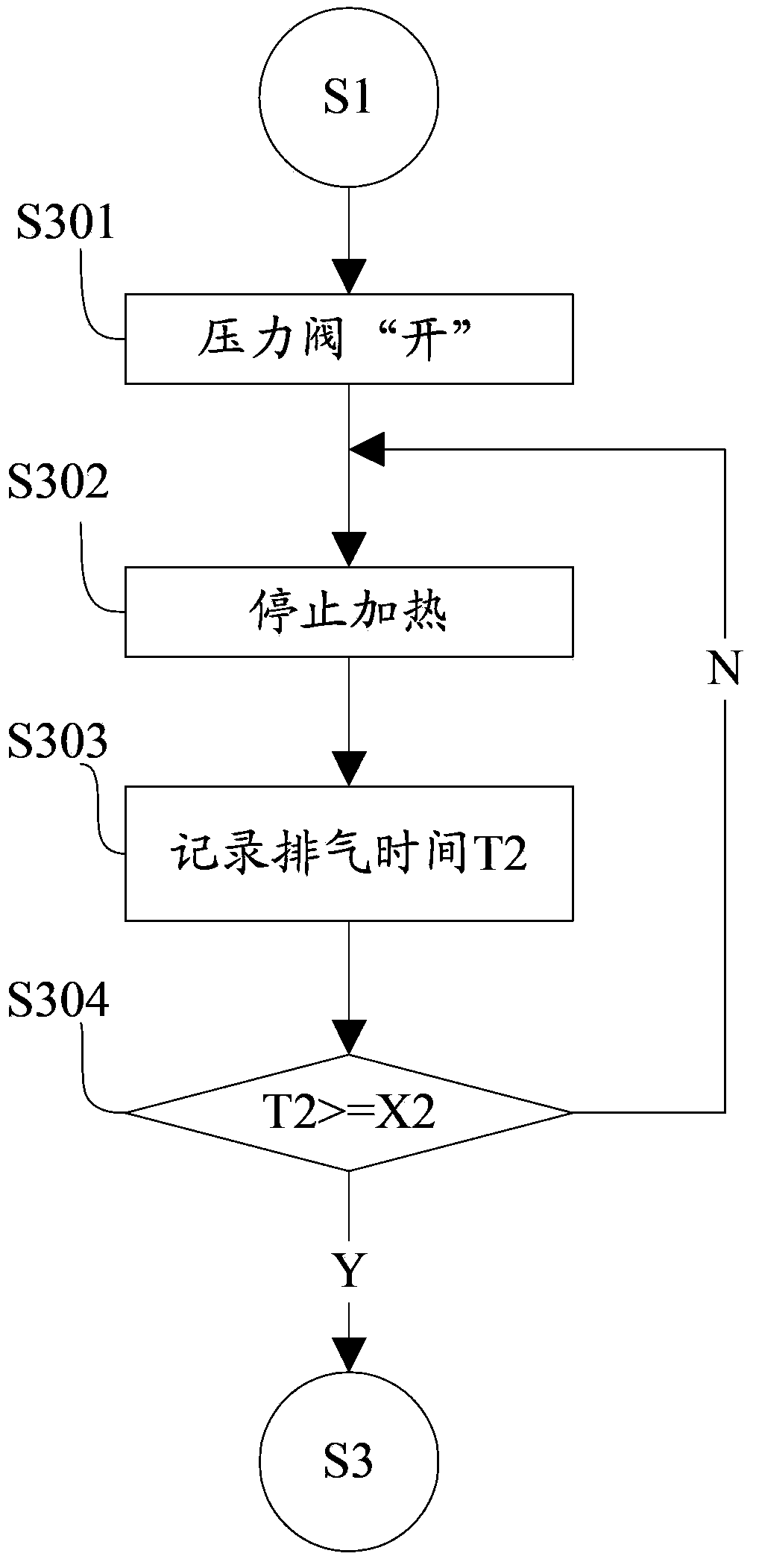

Electric pressure cooker control method and electric pressure cooker

ActiveCN103654373AUniform surface hardnessSufficient flexibilityPressure-cookersEngineeringCooked food

The invention provides an electric pressure cooker control method which comprises the following steps that an electric pressure cooker is controlled to heat with first power; when a first preset condition is met, a pressure valve is opened, so that air is discharged; the electric pressure cooker is controlled to heat with second power until the temperature in the electric pressure cooker is stable and food in the electric pressure cooker is made to be turned over completely; the pressure valve is closed and the electric pressure cooker is controlled to heat with third power, so that the electric pressure cooker enters a boosting stage, and the third power is smaller than the first power and the second power; when a second preset condition is met, the electric pressure cooker is controlled to heat with fourth power, so that the electric pressure cooker enters a pressure maintaining stage. According to the electric pressure cooker control method, the cooked food is complete, moisture is sufficient, the hardness is even, the taste is good, and the cooked food is prevented from pasting the bottom of the cooker and overflowing out of the cooker. The invention further provides the electric pressure cooker.

Owner:MIDEA GRP CO LTD

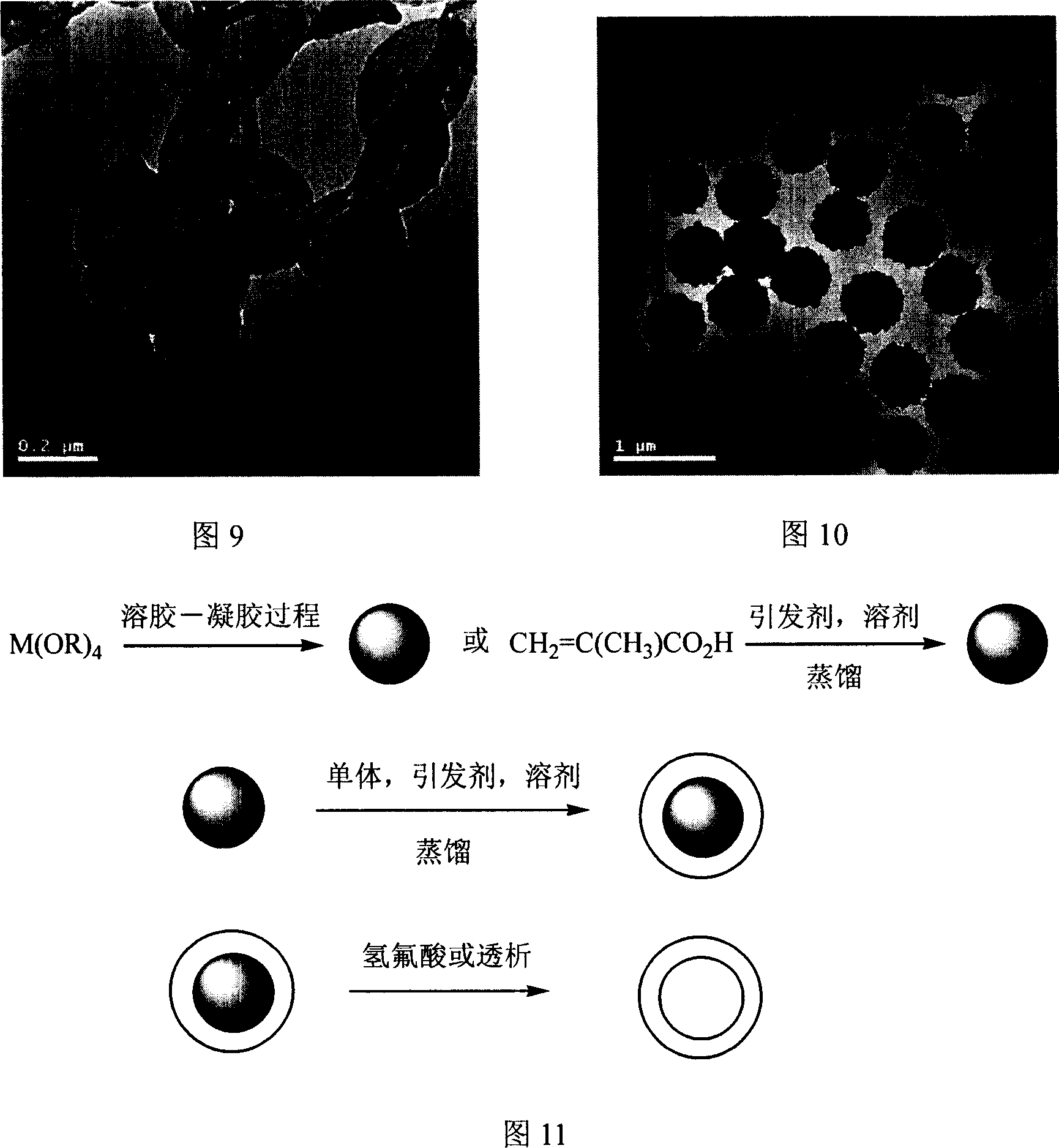

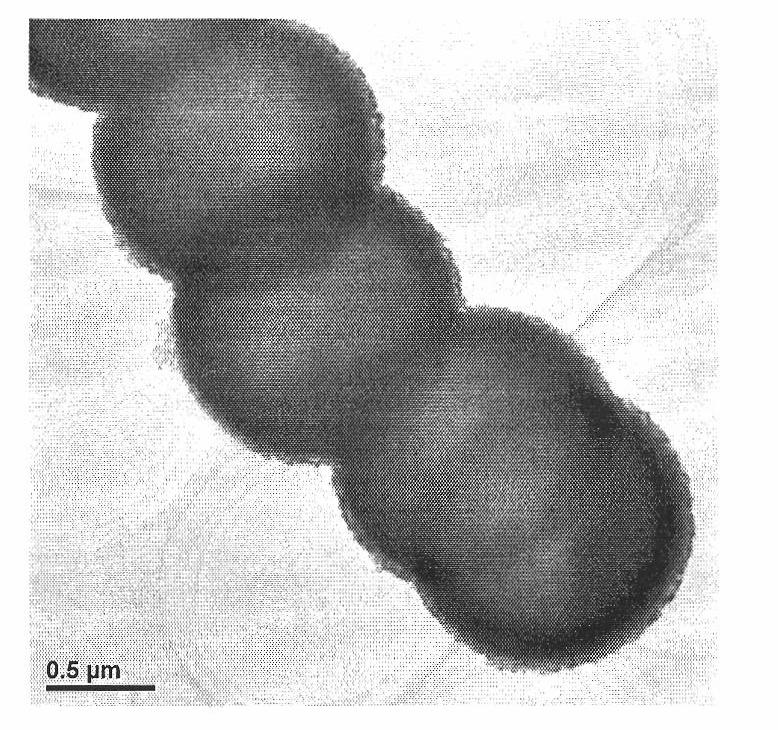

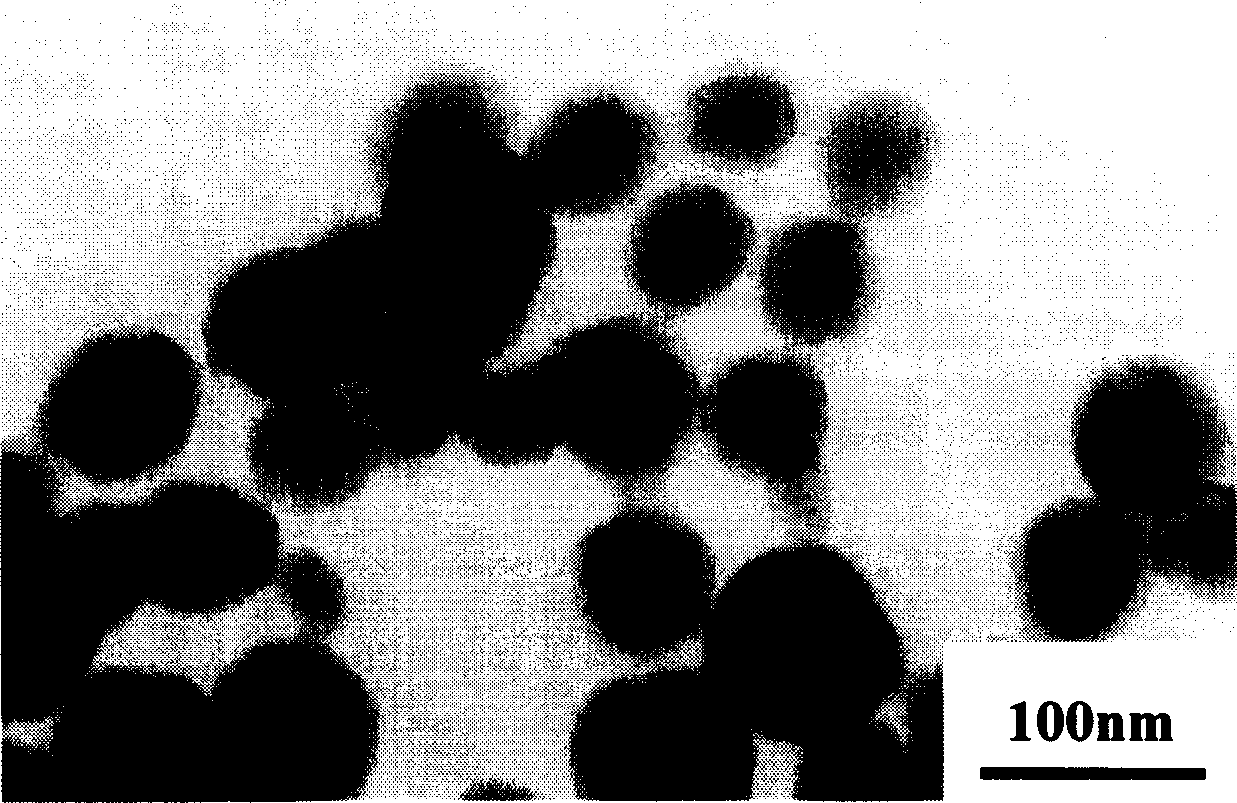

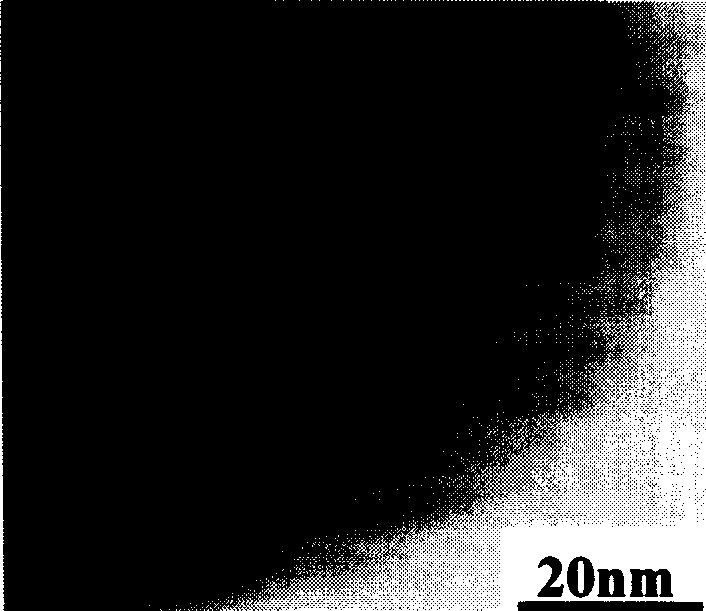

Mono-dispersed nano/micron polymer hollow microsphere resin and method for synthesizing the same

The invention relates to a preparation method of isodisperse nano / micron polymer hollow microsphere. The hollow microsphere with 10 nano-10 micron inner diameter and 10 nano-200 nano wall thickness is polyene type monomer homopolymer or copolymer (20-100 percent crosslinking) of polyene type monomer and other functional monoene type monomer. The polyene type monomer or the polyene type monomer and other functional monoene type monomer are distilled with the existence of a template to prepare a series of sodisperse sodisperse hollow microsphere with different inner diameters and wall thicknesses after precipitation polymerization. The invention has the advantages of simple conditions, easy operation, pure products and being easy to get raw materials and environment protective and so on. The nano / micron polymer hollow microsphere of the invention can be applied to systems with controllable transportation and release such as dyes, cosmetics, medicine, enzymes, proteins, etc. as well as light fillings, nano micro vessels, low dielectric constant materials, catalyst carrier and has very important application value in aspects such as artificial cell, disease diagnosis, biological material separation, etc.

Owner:NANKAI UNIV

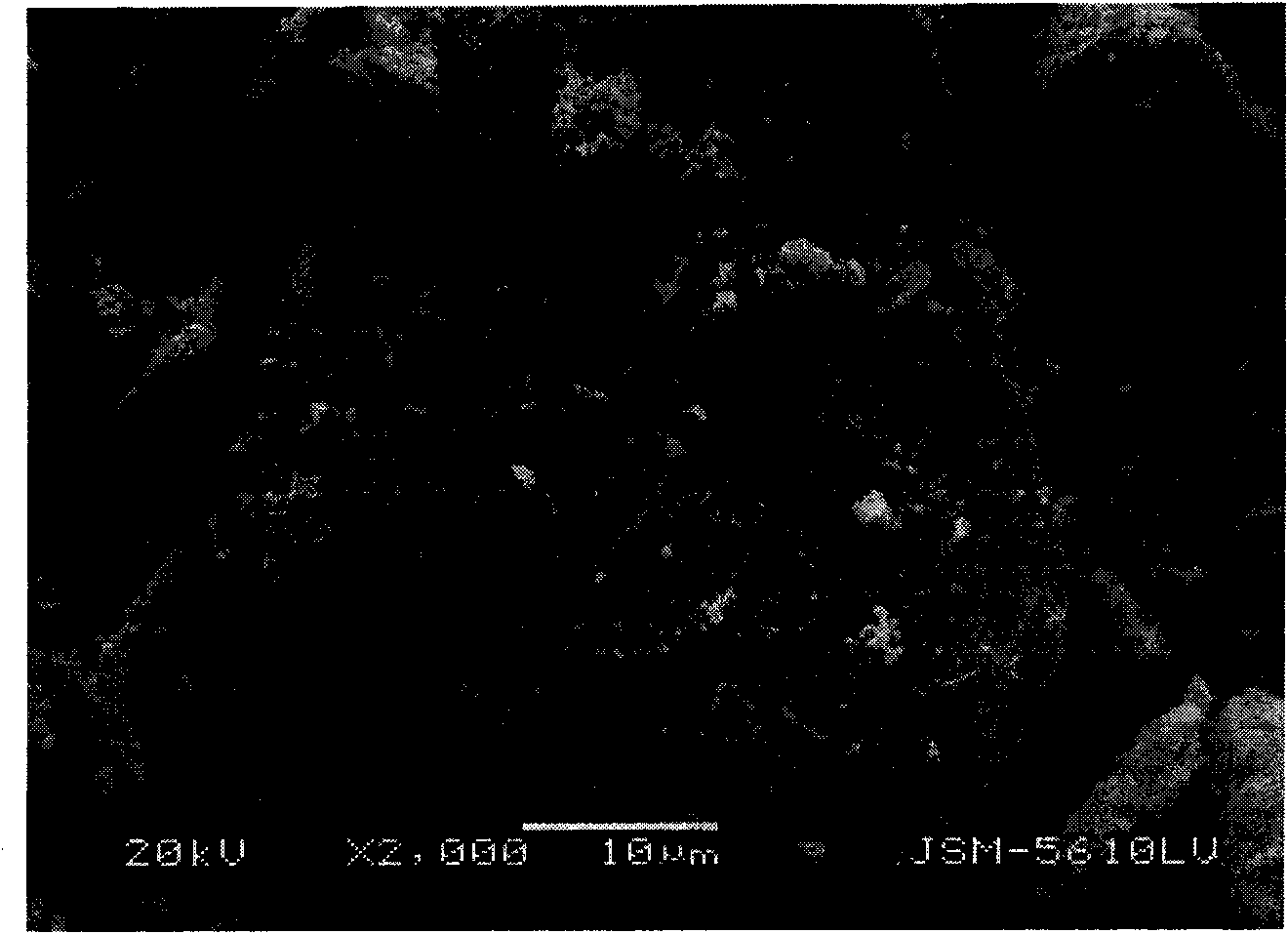

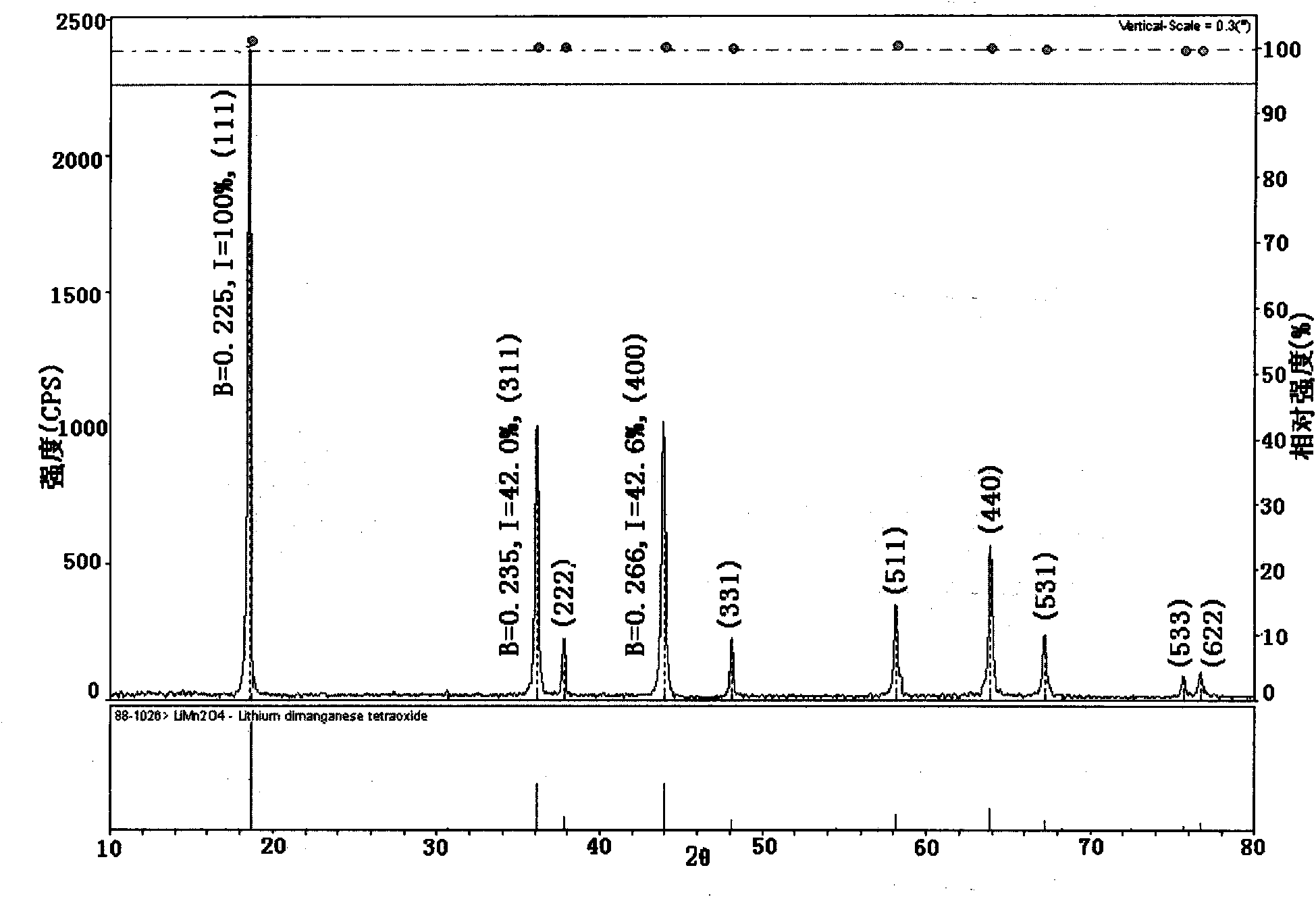

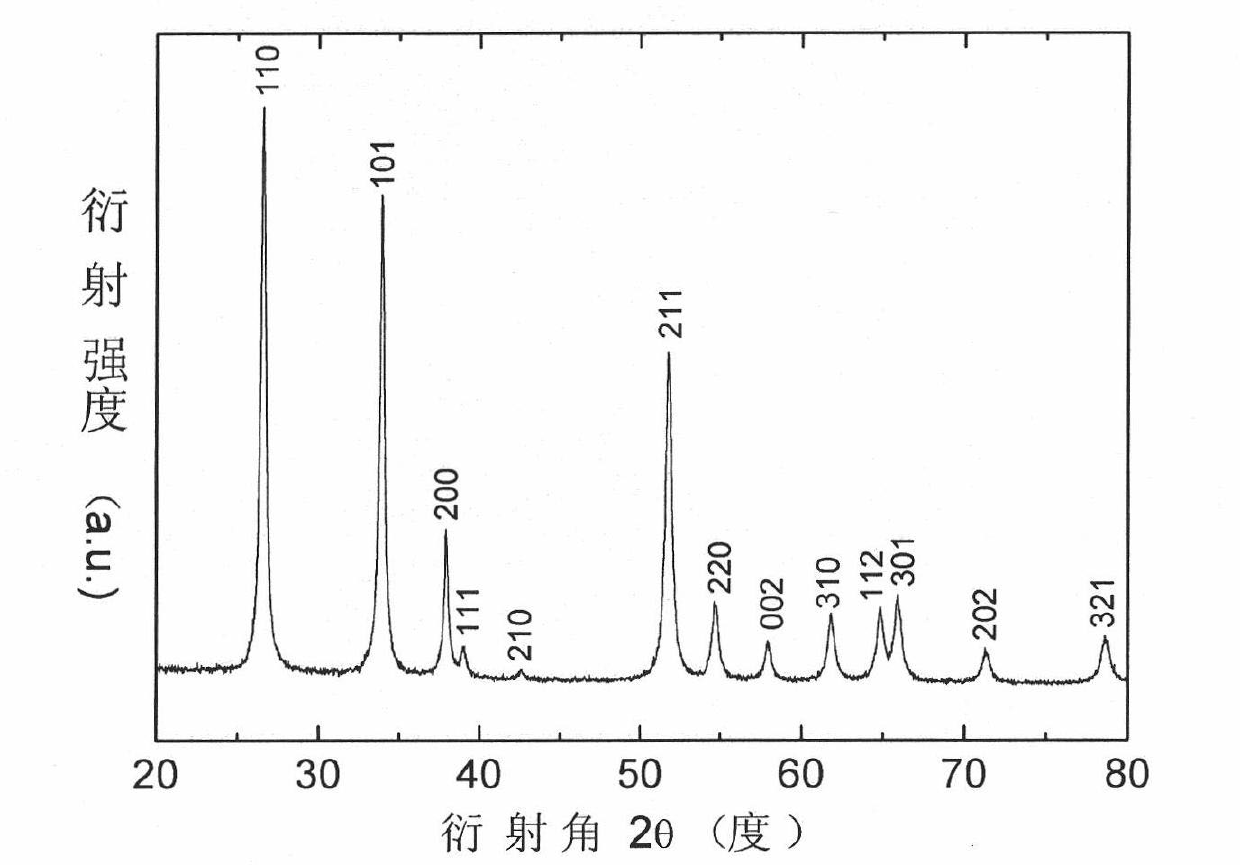

Spinel Li1+xMyMn2-x-yO4, preparation method thereof and lithium-ion secondary battery

InactiveCN101780983ARegular shapeGood consistencyFinal product manufactureLead-acid accumulators constructionLithium ion intercalationCrystallinity

The invention provides a lithium manganese oxide material, i.e. a spinel Li1+xMyMn2-x-yO4, wherein x is less than 0.1 and more than 0, y is less than 0.1 and more than 0, and M is selected from one or a plurality of Mg, Na, Co and Al; the ratio of the 400 crystal face diffraction peak strength I400 to 311 crystal face diffraction peak strength I311 of the Li1+xMyMn2-x-yO4 is 1.05-1.25; the atomic arrangement in crystal of the material is more ordered; the crystallinity degree of the material is higher, and fewer oxygen defects in a crystal lattice exist, thereby being more favourable for the lithium ion intercalation and deintercalation process in the crystal lattice and effectively inhibiting the Jahn-Teller effect to obviously improve the cycle performance of the material; and meanwhile, the invention also provides a preparation method of the material and is simple and easy to realize process. The invention also provides a lithium-ion secondary battery using the material, and the lithium-ion secondary battery has higher specific capacity and cycle performance, especially the high-temperature cycle performance, and satisfies the requirements of the existing battery development.

Owner:BYD CO LTD

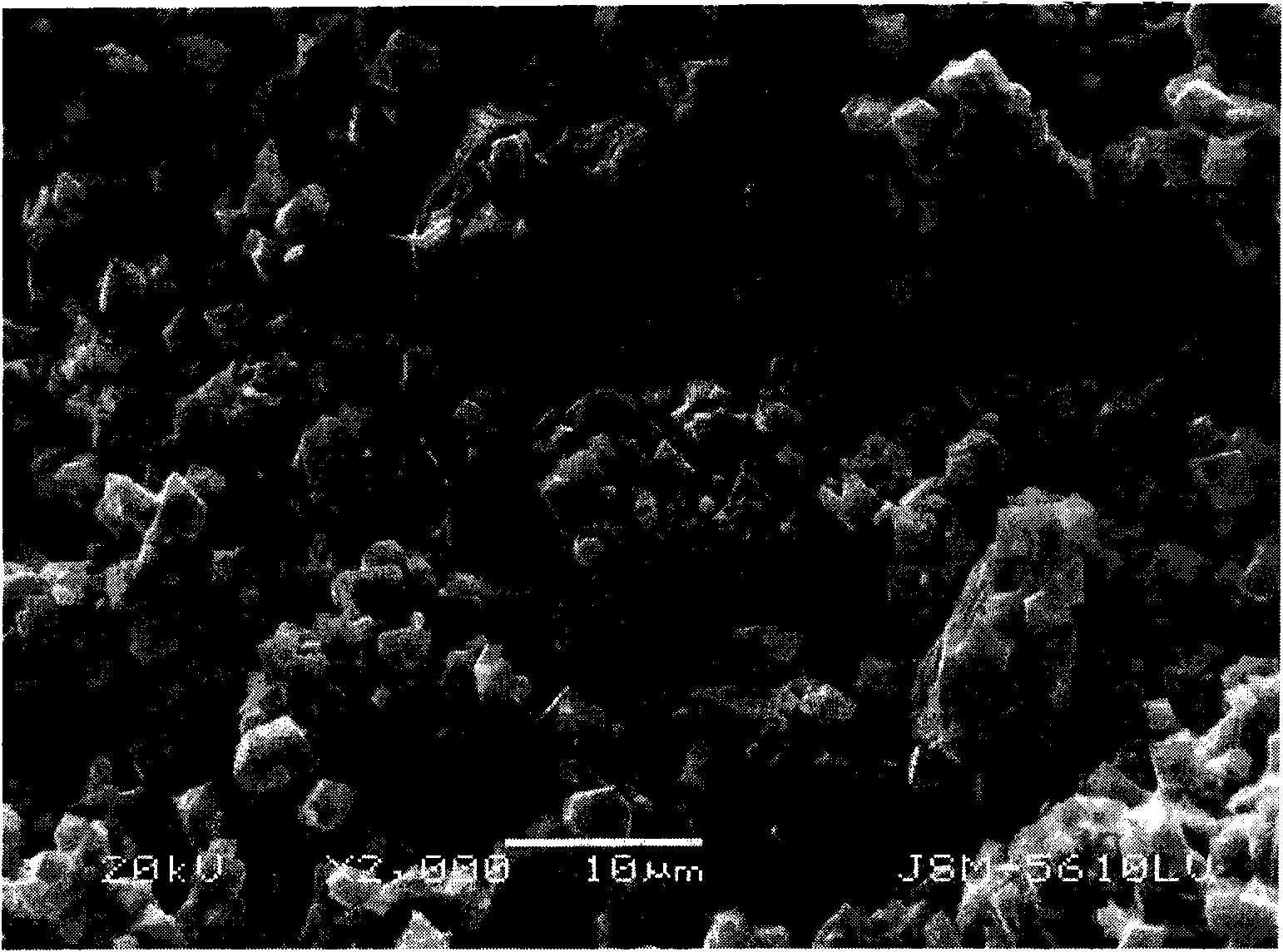

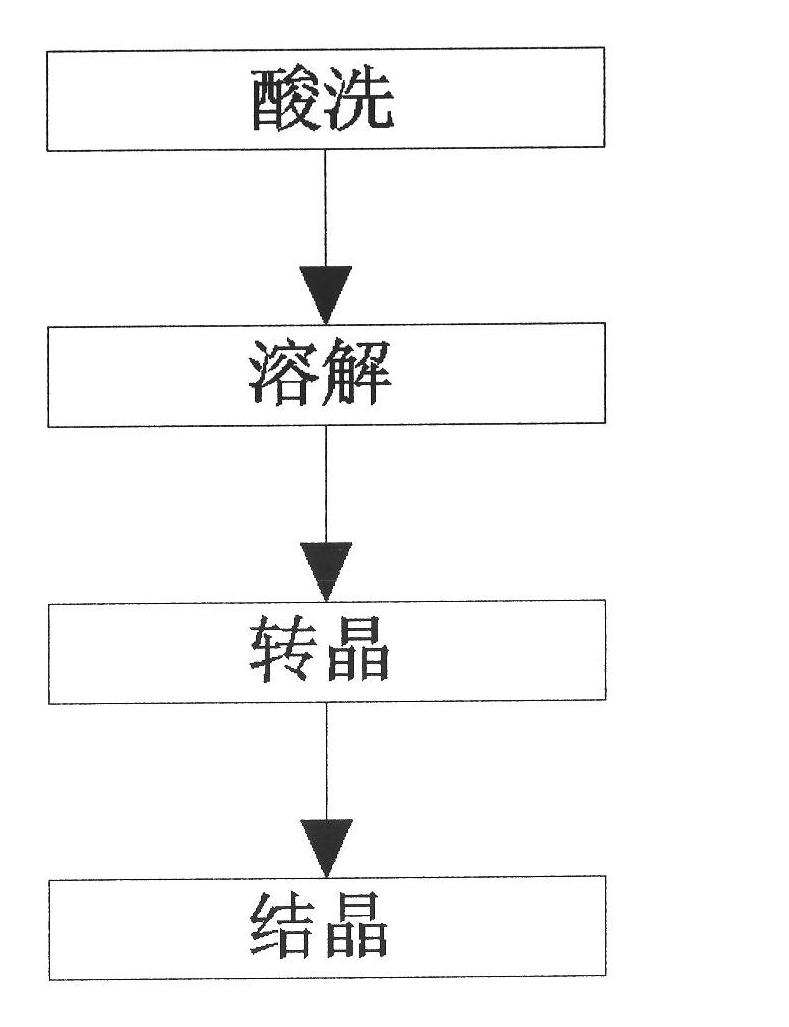

Method for preparing calcium sulfate crystal whiskers from desulfurized gypsum under normal pressure

ActiveCN102352535ASimple manufacturing processEasy to implementPolycrystalline material growthFrom normal temperature solutionsDispersityCalcium sulfate crystals

The invention discloses a method for preparing calcium sulfate crystal whiskers from desulfurized gypsum under normal pressure. The method comprises the following steps: 1) pickling; 2) dissolving; 3) rotating crystal; and 4) crystallizing, after crystallizing, carrying out solid-liquid separation, washing filter cake with water, and drying to obtain calcium sulfate crystal whiskers. The method disclosed by the invention has the advantages that: the preparation process is simple and is easy to achieve, and the production efficiency is high; higher-purity and higher-whiteness calcium sulfate crystal whiskers are prepared by adopting a normal-pressure recrystallization method, controlling related process conditions and utilizing the characteristic that the dissolubility of main component calcium sulfate dihydrate of desulfurized gypsum in specific solution changes obviously along with the temperature; obtained calcium sulfate crystal whisker product has regular morphology, low agglomeration and good dispersity; and in addition, inorganic acid solution used for recrystallization can be recycled, and inorganic acid solution is not consumed in the reaction process, thereby creating better economic benefit, environmental benefit and social benefit, reducing the burden of coal-fired power plant and increasing enterprise benefits.

Owner:上海大学浙江嘉兴新兴产业研究院

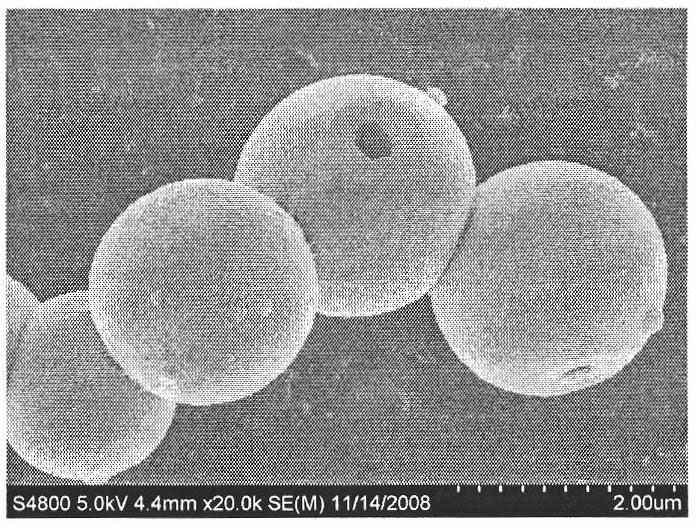

Method for preparing hollow spherical stannic oxide nano powder

InactiveCN102086044AAvoid destructionEasy to makeNanostructure manufactureTin oxidesTin dioxidePrill

The invention provides a method for preparing hollow spherical stannic oxide nano powder and belongs to the technical field of preparation of nano materials. The preparation method mainly comprises the steps of: respectively preparing tin salt and an alkali source into solution; uniformly dripping the solution of the alkali source into the solution of tin salt with stirring of a magnetic force, and stirring to obtain uniform precursor solution; performing hydrothermal treatment on the precursor solution in a reaction kettle; washing and drying the hydrothermal product to obtain the hollow spherical powder consisting of nano SnO2 particles. The prepared SnO2 hollow spheres have uniform size, regular shape, good crystallization and uniform thickness of a spherical shell. In the method, an expendable template is not needed, the process is simple and reaction conditions are mild, and the method has the characteristics of short preparation period, high product quality, high yield, low costand the like, and is an environmentally-friendly synthesis method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

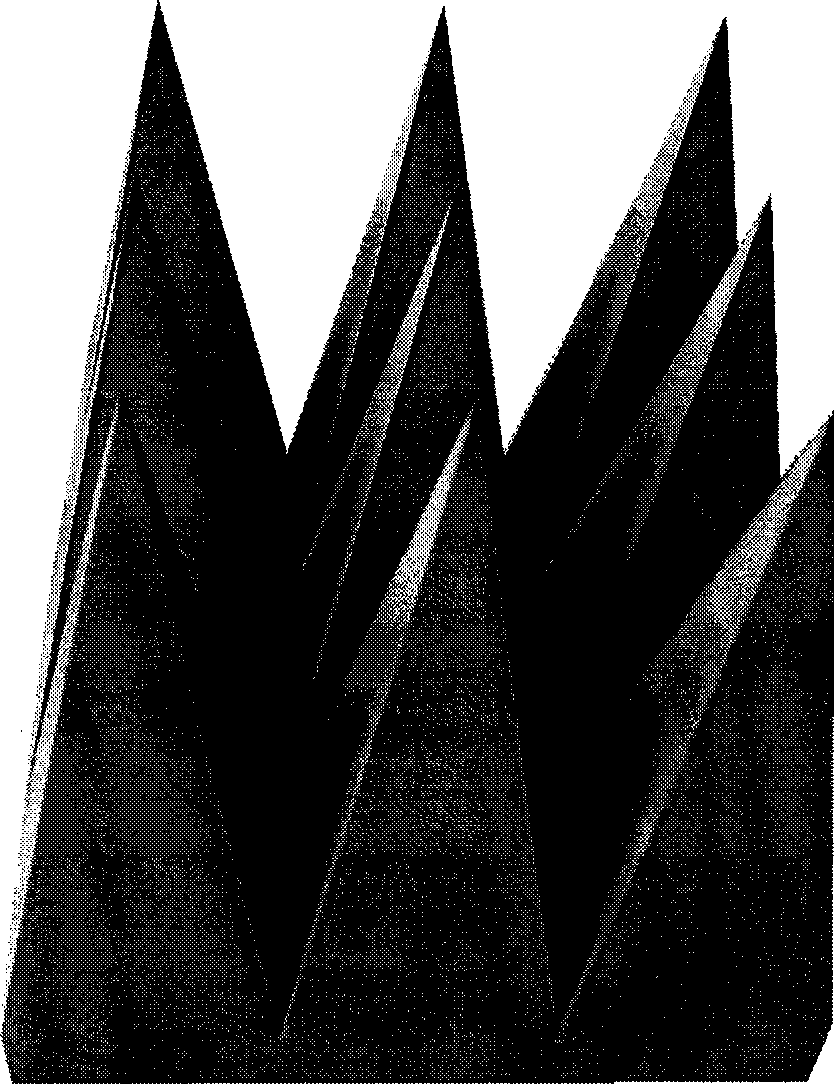

Foamed high resilience polyurethane wave-absorbing material and preparation method thereof

InactiveCN101519487AThe shape of the material is regularThe size of the bottom surface is accurate and consistentPliabilityFire retardant

The invention relates to a foamed high resilience polyurethane wave-absorbing material and a preparation method thereof. In the foamed high resilience polyurethane wave-absorbing material, a foamed combining material takes 4,4'-diphenylmethane diisocyanate and polyether glycol as main reaction substances, and is added with a conventional blowing promoter. The foamed high resilience polyurethane wave-absorbing material is characterized in that the foamed combing material also comprises substances such as an absorbent, a flame retardant and the like. The material is applied to full-anechoic chambers and semi-anechoic chambers, not only can achieve the effect of absorbing electromagnetic waves, but also has the characteristics of good environmental protection, flexibility, and dimensional uniformity, good mounting matrix property, beautifulness and consistency, and is particularly suitable for clean experiment environment.

Owner:NANJING BOPING ELECTRONICS TECH CO LTD

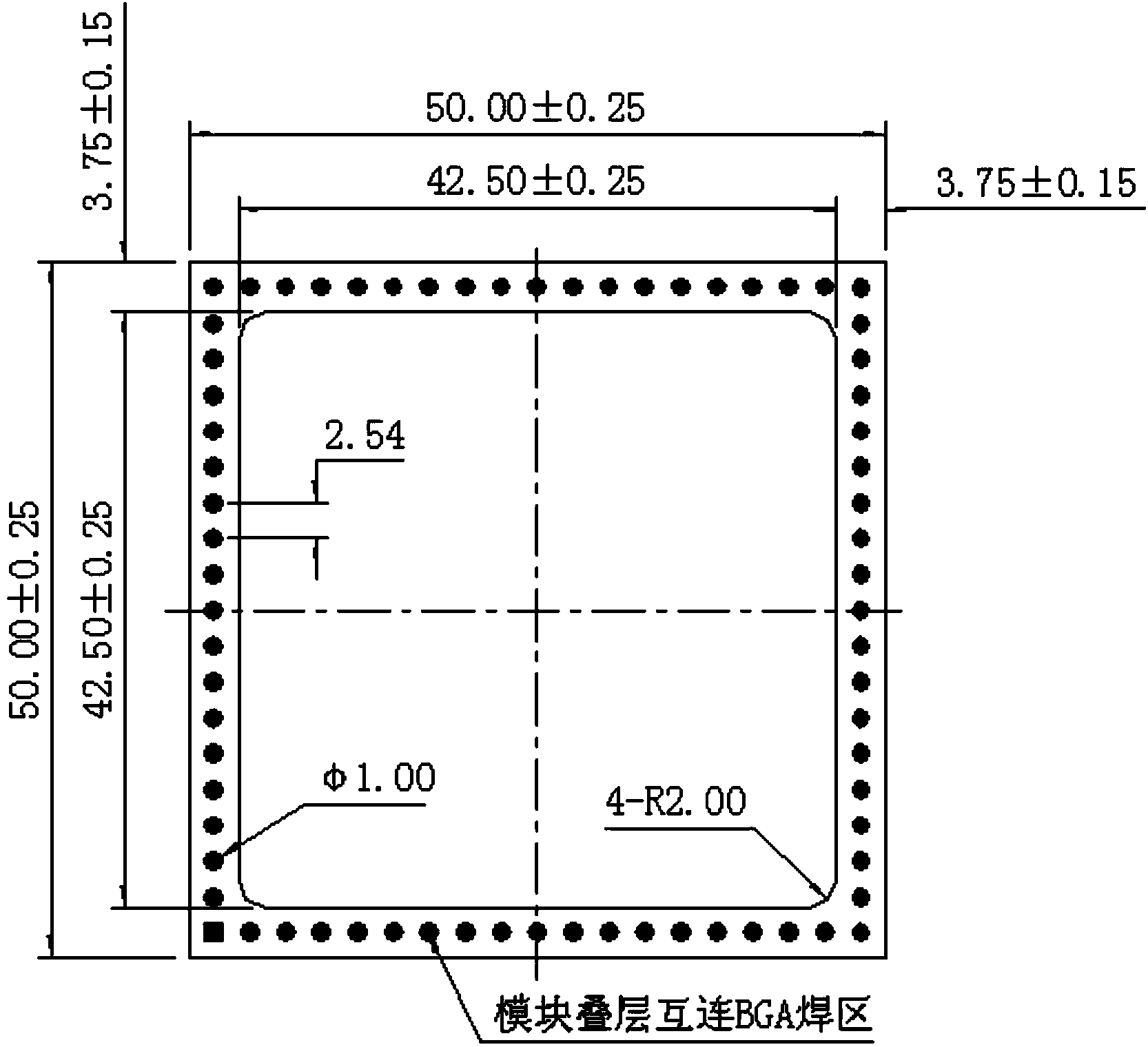

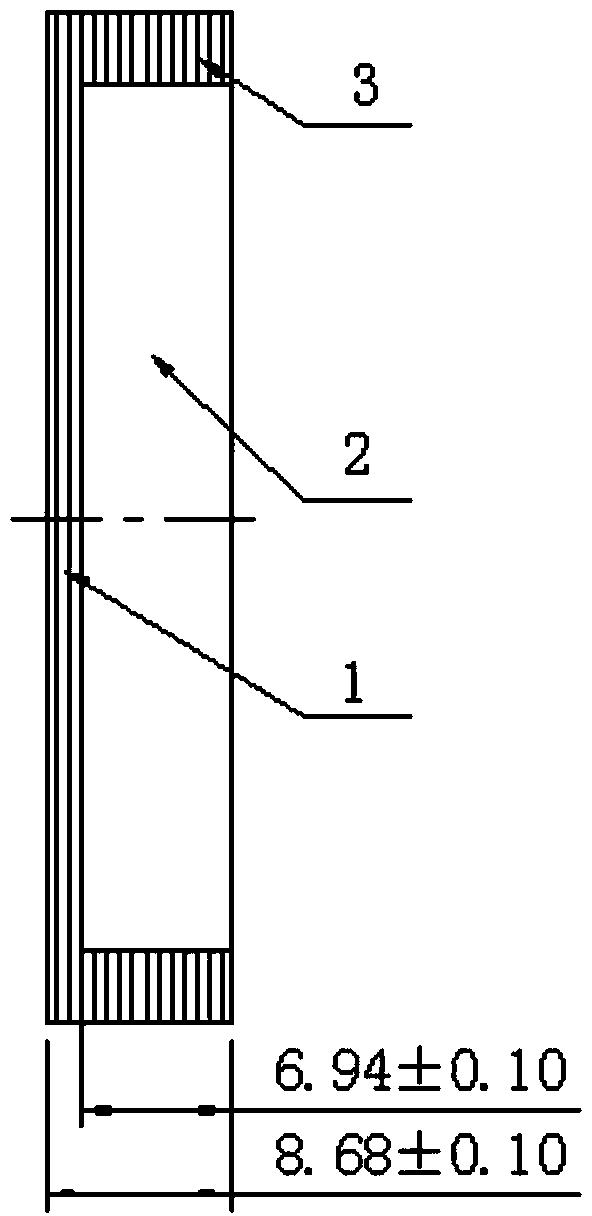

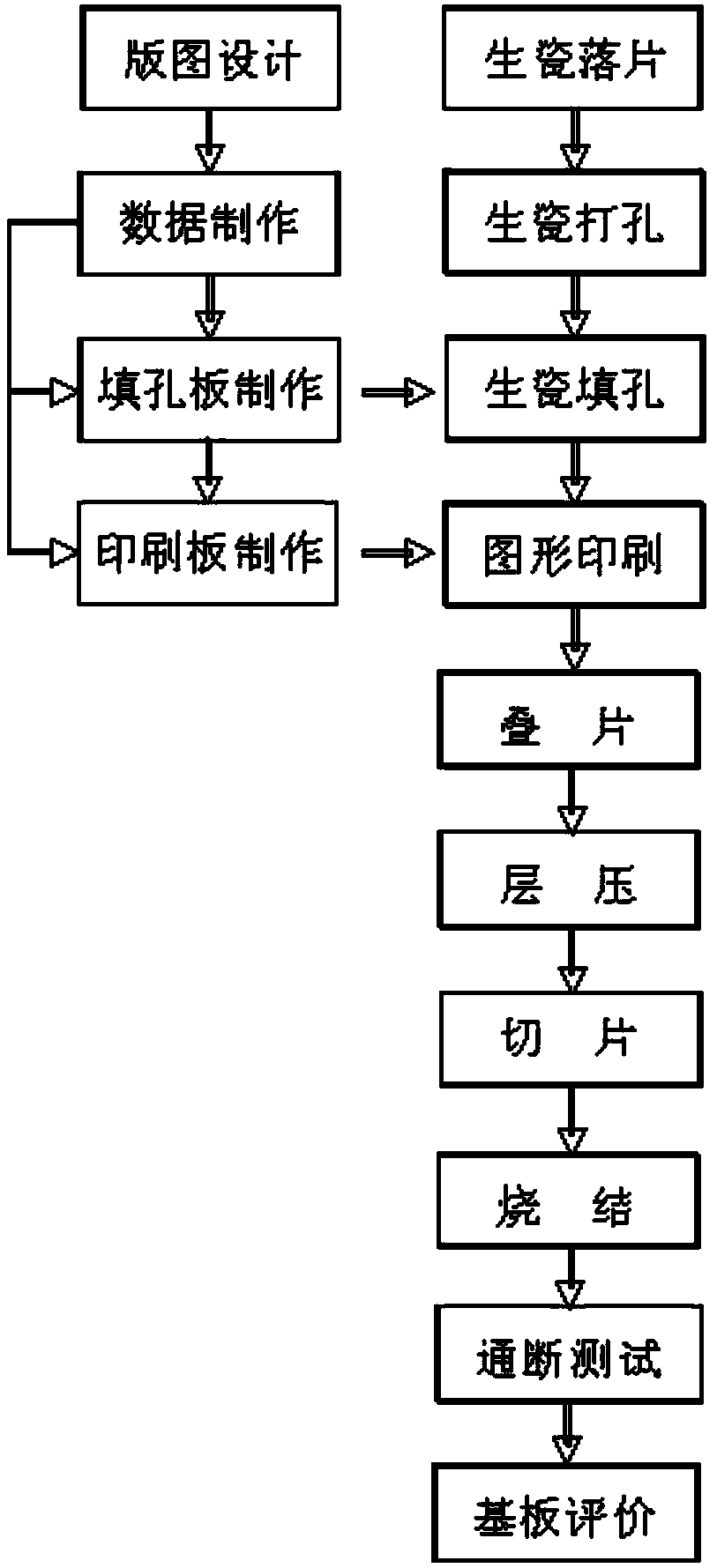

Ultra-multi-layer ultra-deep-cavity LTCC substrate manufacturing technology

ActiveCN104284534AAchieve preparationEasy to operateMultilayer circuit manufacturePrinted element electric connection formationScreen printingManufacturing technology

The invention discloses an ultra-multi-layer ultra-deep-cavity LTCC substrate manufacturing technology. A conventional solid flat plate LTCC substrate machining technology is broken through, after hole filling and screen printing, a cavity window in an unglazed porcelain layer is formed in a laser-cutting-up mode, the non-operability problem of hole filling and screen printing technologies on a large-size window unglazed porcelain piece is avoided, and the contraction amount and the unevenness of an unglazed porcelain piece obtained after filling and printing before piece stacking are lowered. After cofiring, an abrasive wheel cuts a ripe porcelain plate in a rotating mode, and the fact that an LTCC substrate which is regular in shape, accurate in size, thin in wall and ultra-deep in cavity is machined is guaranteed. Network multi-through-hole connecting is used in an ultra-deep-cavity ultra-multi-layer unglazed porcelain side wall, and the connecting pass rate is guaranteed through redundancy. Through a lamination tool set and an optimized overlying technology method, the lamination and stacking technology of the deep-large-cavity ultra-thick LTCC substrate is guaranteed. An abrasive wheel dicing saw is used for opposite cutting of a ripe porcelain body LTCC substrate from the bottom face and the top face of the ultra-thick substrate, and the problem that the maximum thickness can only reach 5 mm during blade unglazed porcelain hot cutting and abrasive wheel ripe porcelain rotating cutting is solved.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

Method for planting strawberry

InactiveCN102217467ARegular shapeUniform colorBio-organic fraction processingFertilising methodsFragariaGreenhouse

The invention relates to a method for planting strawberry. The method is characterized by comprising the following steps of: (1) cultivating strong seedlings generally at the end of March to the beginning of April; (2) measuring soil, applying a fertilizer, deeply turning the soil, leveling the soil, and mixing uniformly; (3) finely making ridges, and absorbing water till saturation; (4) performing cultivation and detoxification on the strawberry seedlings; (5) performing transplantation generally at the end of August to the beginning of September; (6) spreading weeping pipes in October, covering a mulching film and a greenhouse film, and controlling the temperature of a greenhouse to be between 25 and 28 DEG C at the budding stage, between 24 and 26 DEG C at the flowering and fruiting stage and not less than 5 DEG C at night; (7) reasonably performing topdressing, and introducing bees at the beginning of flowers to pollinate; (8) fermenting rice chaff in the soil, and preventing and controlling diseases and insect pests; and (9) picking when 80 to 90 percent of strawberry fruits are red. The strawberry planting method is reasonable and scientific, has remarkable prevention effect on strawberry cultivation, and can increase the yield of the strawberry.

Owner:HAIMEN CHANGLE TOWN CULTIVATE STRAWBERRY COOP

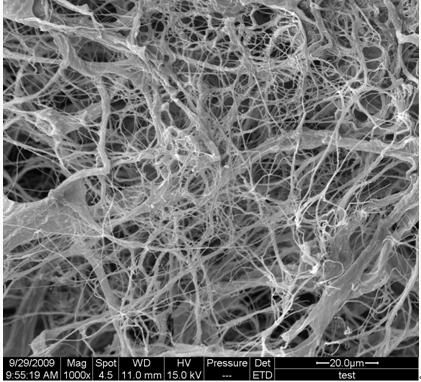

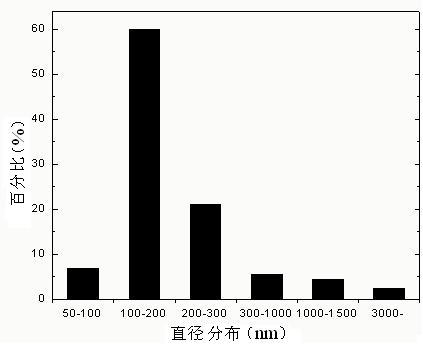

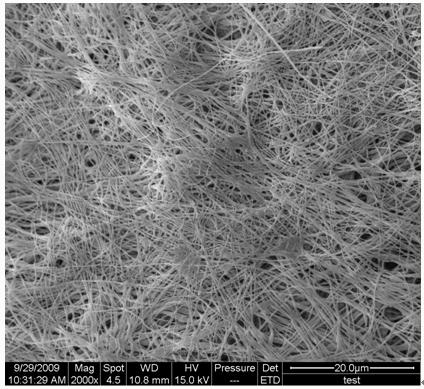

Method for preparing nanometer cellulose fiber through combining ultrasound and high-pressure homogenization treatment

InactiveCN101851801AUniform fibrillationRegular shapeArtificial filaments from cellulose solutionsBenzeneAlcohol

The invention provides a method for preparing nanometer cellulose fiber through combining ultrasound and high-pressure homogenization treatment, which relates to a preparation method of nanometer cellulose fiber. The invention solves the problems of short length, nonuniform fiber diameter distribution and easy interweaving between fiber into cluster nanometer fiber of the nanometer cellulose fiber prepared by the existing method only using mechanical high-pressure homogenization treatment. The method of the invention comprises the following steps that: 1. biomass fiber is extracted by an alcohol benzene solution; 2. the treatment by acidified sodium chlorite is carried out; 3. alkali liquor gradient treatment is carried out; 4. an ultrasonic cell crushing machine is used for treatment; and 5. high-pressure homogenization treatment is carried out, and nanometer cellulose fiber is obtained after being dried. The fiber diameter distribution is uniform, the length is longer than or equal to 150 mum, the slenderness ratio is larger than or equal to 600, and the fiber is mutually interwoven into a reticular winding structure. The method of the invention is applicable to the preparation of nanometer cellulose fiber from wood pulp, papermaking pulp materials, wood materials, bamboo materials and crop straws.

Owner:NORTHEAST FORESTRY UNIVERSITY

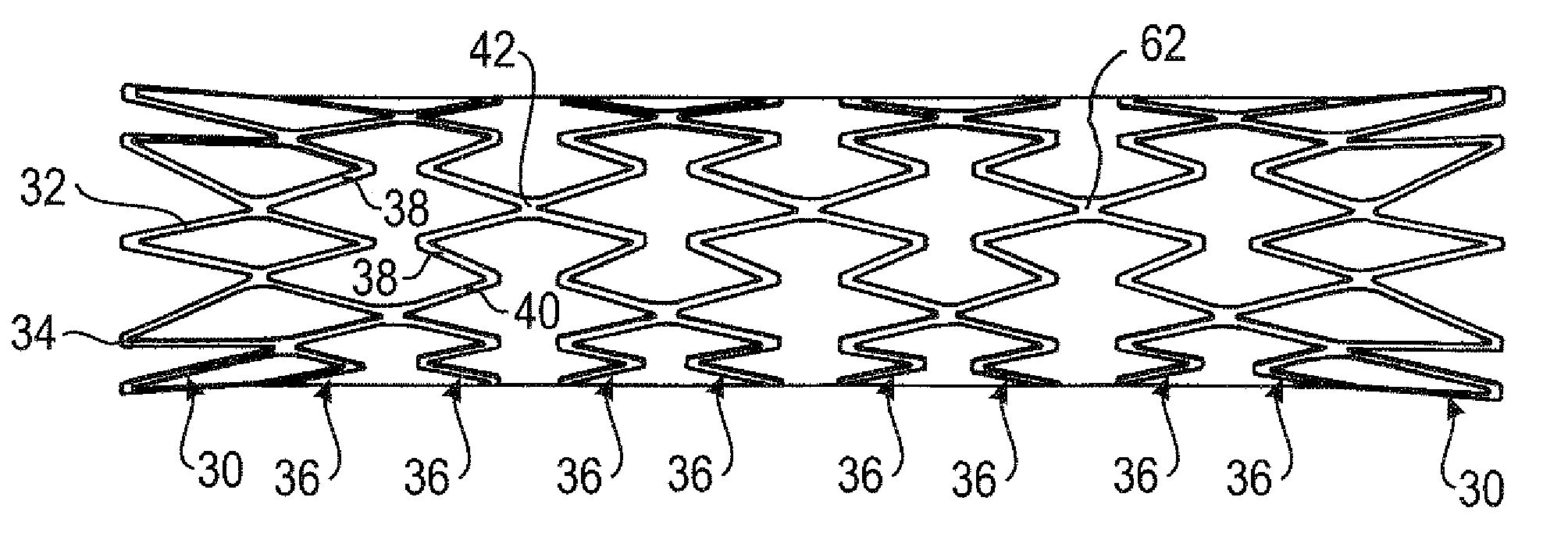

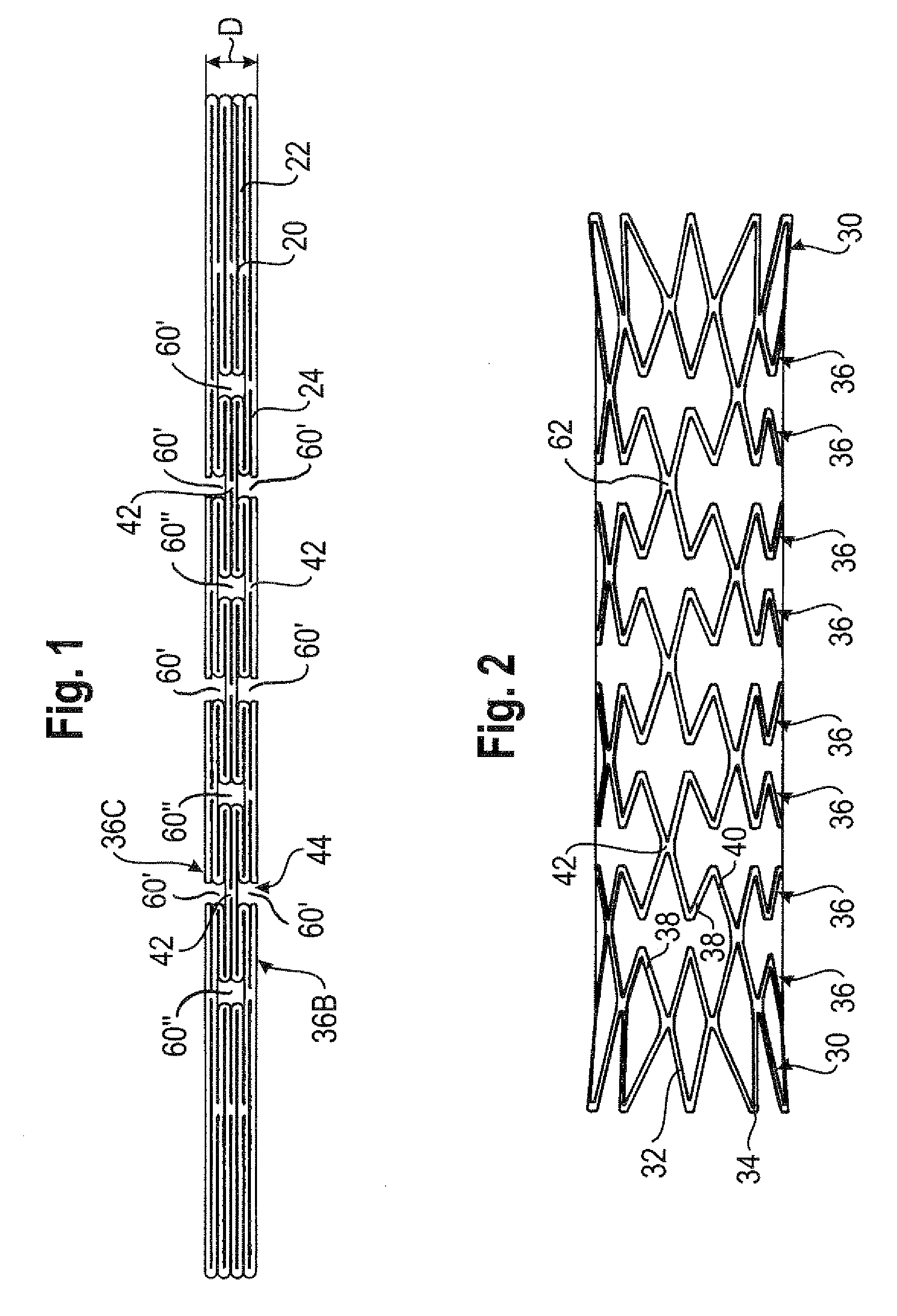

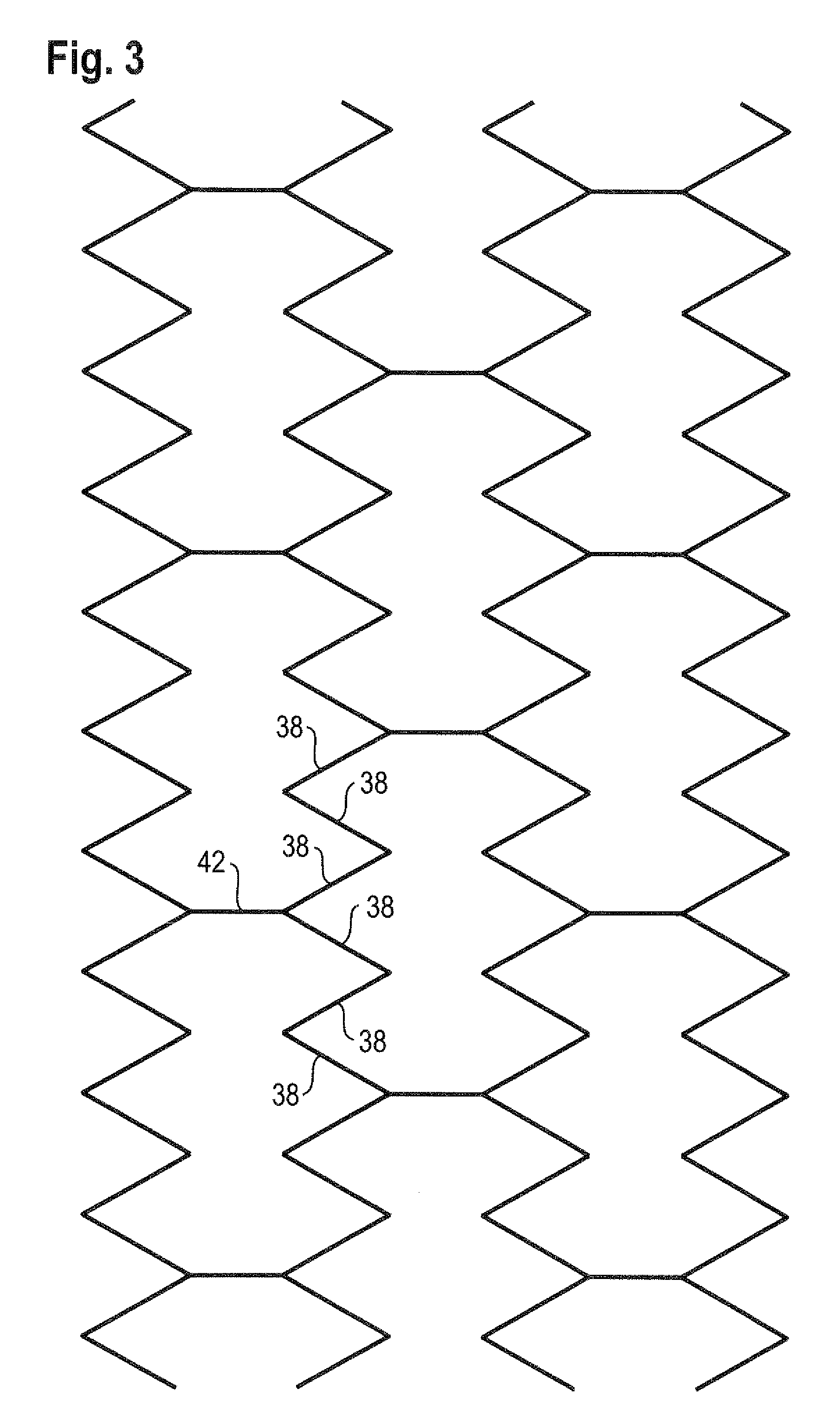

Bend-capable stent prosthesis

Normally, when stents are bent, inside the body of the stented patient, there is head-to-head collision between facing V-points on the inside of the bend. However, by alternating between two whole numbers the number of struts between successive connectors around the circumference of each of the stenting rings, the V-points are caused to veer circumferentially in opposite directions as they approach each other on the inside of the bend, so allowing them to pass by each other without collision, thereby allowing in the same stent both close packing of the ring stack, and an enhanced ability to tolerate severe bending, after placement in the body.

Owner:CR BARD INC

Preparation method and application of carbon-based copper-cobalt oxide nanosheet catalyst

InactiveCN107442125ARegular shapeLarge specific surface areaCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsWater basedFiber

The invention discloses a preparation method of a carbon-based copper-cobalt oxide nanosheet catalyst and application to oxygen evolution by electrolyzing water based on the catalyst, and belongs to the technical fields of nano catalysis, nano materials and metal-organic framework (MOF) materials. The preparation method comprises the following main steps of blending an aspartic acid alkaline solution with a copper nitrate-cobalt nitrate solution at a room temperature, generating a sediment at the room temperature, carrying out suction filtration, and drying, so that a Cu-MOF nano fiber loaded Co(II) ion, namely a CuCo-MOF nano fiber, is prepared; heating the CuCo-MOF nano fiber in an air atmosphere, so that the carbon-based copper-cobalt oxide nanosheet catalyst is prepared. The cost of raw materials used for the preparation of the catalyst is low; the preparation process is simple; the reactive energy consumption is low; the carbon-based copper-cobalt oxide nanosheet catalyst has an industrial application prospect. The catalyst is used for efficiently catalyzing and hydrolyzing the water for the oxygen evolution and has favorable oxygen-evolution electrocatalytic activity and electrochemical stability.

Owner:UNIV OF JINAN

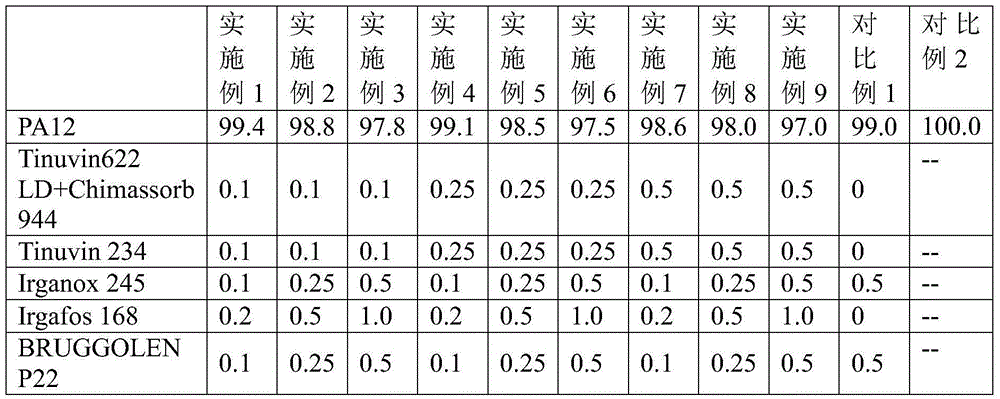

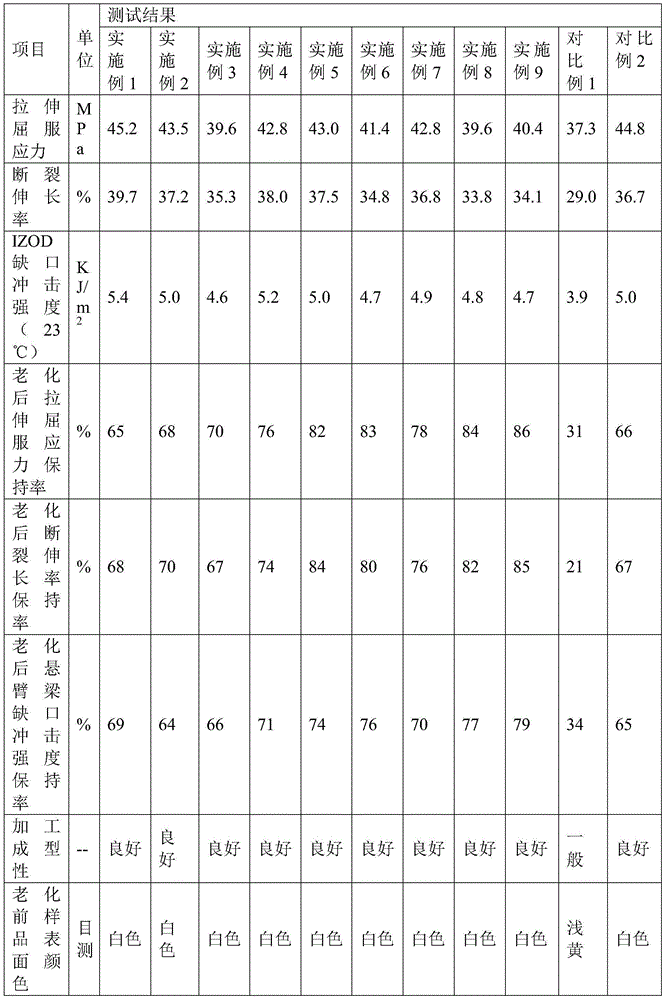

3D printing weather-resistant nylon powder composite material and preparation method thereof

The invention discloses a 3D printing weather-resistant nylon powder composite material and a preparation method thereof. The 3D printing weather-resistant nylon powder composite material is characterized by being prepared from the following components in percentage by mass: 97-99.4wt% of nylon, 0.1-0.5wt% of a hindered amine light stabilizer, 0.1-0.5wt% of an ultraviolet light absorber, 0.1-0.5wt% of a hindered phenol antioxidant, 0.2-1.0wt% of a phosphite ester antioxidant and 0.1-0.5wt% of other additives, wherein the other additives comprise one or combination of multiple components of a dispersing agent, a nucleating agent and a lubricant. With the combination of the hindered amine light stabilizer, the ultraviolet light absorber, the hindered phenol antioxidant and the phosphite ester antioxidant, the 3D printing weather-resistant nylon powder composite material prepared through spray-drying is excellent in weather resistance and small in mechanical property change before and after being modified, can be recycled and reused for multiple times, is narrow in spherical granule distribution, good in flowing property, free of layering or powder dropping, and moreover is high in preparation efficiency, small in energy consumption and simple and easy to process.

Owner:QINGDAO UNIV OF SCI & TECH +2

Method for preparing zinc sulfide nanospheres

The invention discloses a method for preparing zinc sulfide nanospheres, which comprises the following steps: 1) preparing a solution A by dissolving zinc acetate and a surfactant in deionized water, and preparing a solution B by dissolving thioacetamide in deionized water; and 2) mixing the solution A and the solution B to obtain a reaction solution, reacting the reaction solution in a water bath and obtaining zinc sulfide nanospheres, wherein the particle size of the zinc sulfide nanospheres can be kept between 90 and 120 nanometers by controlling reaction conditions. The method has the characteristics of readily available raw material, simple equipment, easy operation, high efficiency, high speed and the like; and the prepared zinc sulfide nanospheres with regular form, high dispersity, controllable size, high yield and high stability are suitable for mass industrial production. The zinc sulfide nano material prepared by the method has a great application prospect in fields of fluorescent lamps, field emission flat-panel displays, light-emitting diodes, electroluminescent devices, solar cells and the like.

Owner:SOUTHWEST UNIVERSITY

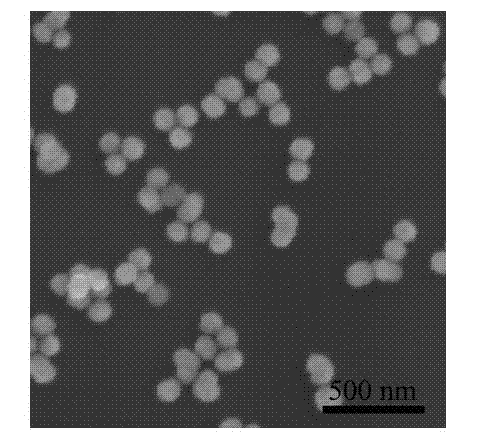

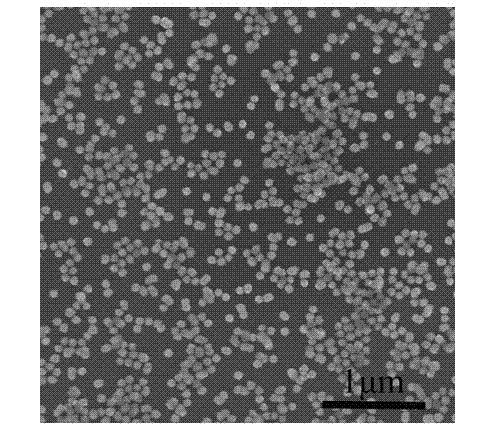

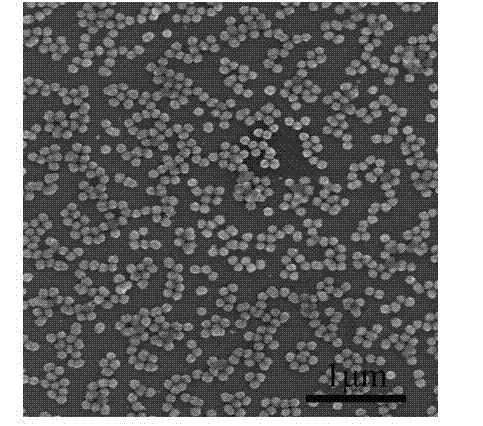

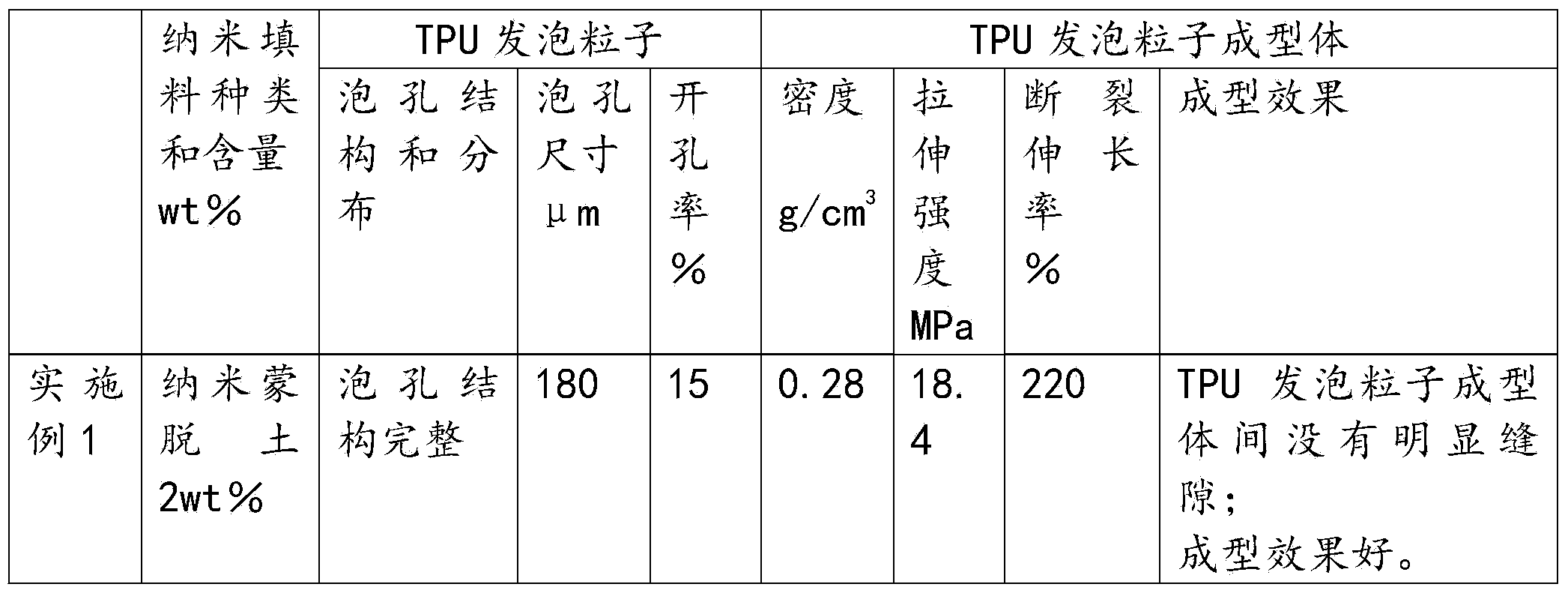

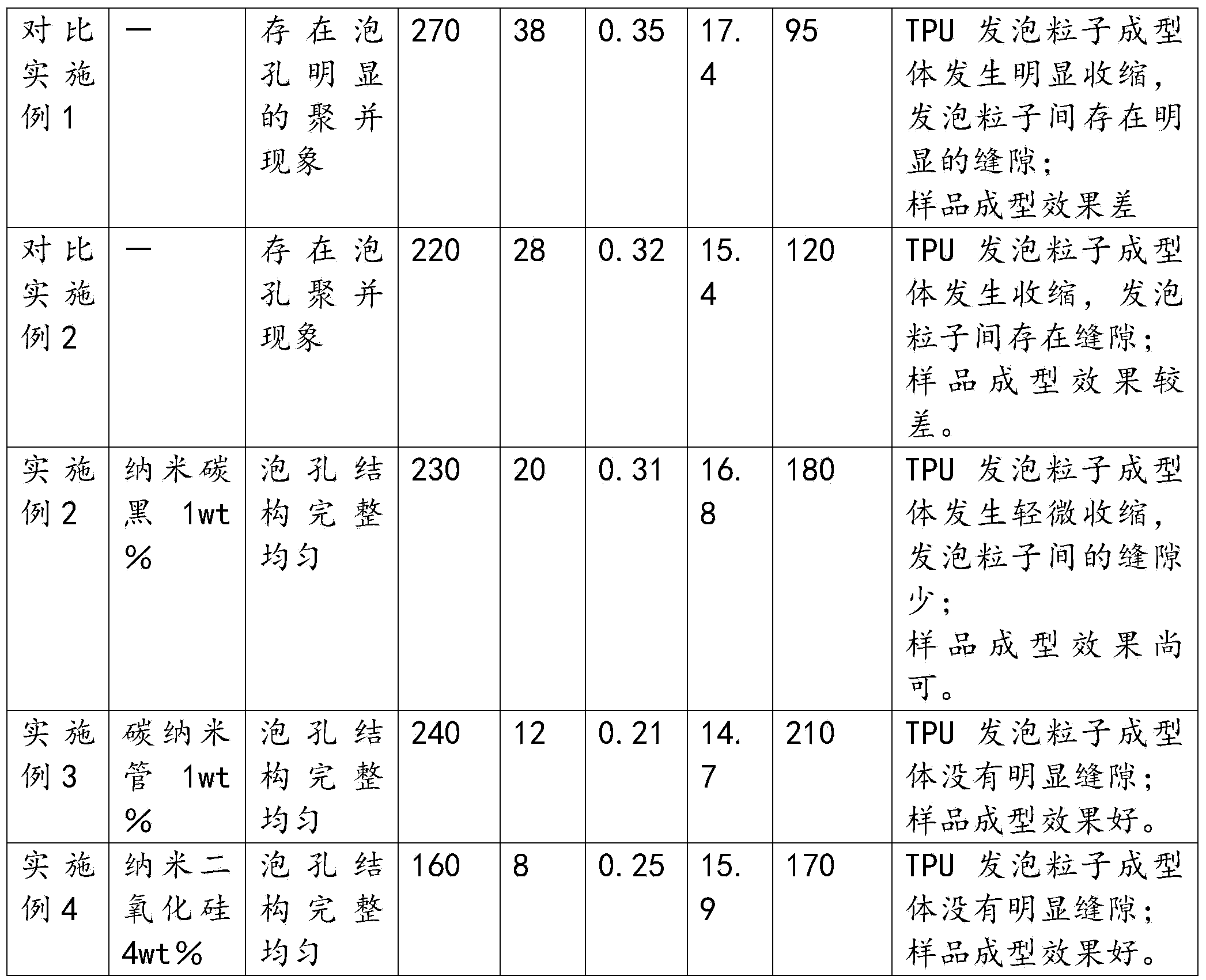

Method for preparing TPU foamed beads by continuous extrusion foaming

The invention discloses a method for preparing TPU (Thermoplastic Polyurethane) foamed beads by continuous extrusion foaming. The method comprises the steps of (1) mixing TPU particles with inorganic nano-particles which are organically modified, adding the mixed TPU particles into a material barrel of a first extruder, melting the TPU particles into a polymer melt by screw heating, and injecting a supercritical fluid into the tail end of the first extruder to mix the supercritical fluid with the polymer melt; (2) injecting a mixed polymer / high-pressure fluid melt into a second extruder through a melt pump, and gradually reducing the temperature of a heating area of the second extruder to obtain a polymer / supercritical fluid melt which is cooled and uniformly mixed; (3) extruding the polymer / supercritical fluid melt from an opening mold of the second extruder, and performing underwater ring cutting to obtain TPU foamed particles. According to the method, a TPU foamed particle molding body material which enables the foamed particles to be well bonded after steam molding can be quickly prepared.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Lithium ion battery anode material and preparation method thereof

InactiveCN101859886ARegular shapeUniform particle size distributionNon-aqueous electrolyte accumulator electrodesCarbon coatingCarbon composites

The invention discloses a lithium ion battery anode material, which is characterized in that a carbon coating layer is coated on a silicon / carbon composite material. The invention also discloses a preparation method of the lithium ion battery anode material. The carbon shell layer of the carbon-coated silicon / carbon composite material prevents exposed silicon on the surface of the composite material from directly contacting with electrolyte, and a stable SEI film is formed on the surface of the carbon-coated silicon / carbon composite material, thereby improving the initial charge-discharge efficiency and the cycle stability.

Owner:HUBEI SANJUN BATTERY

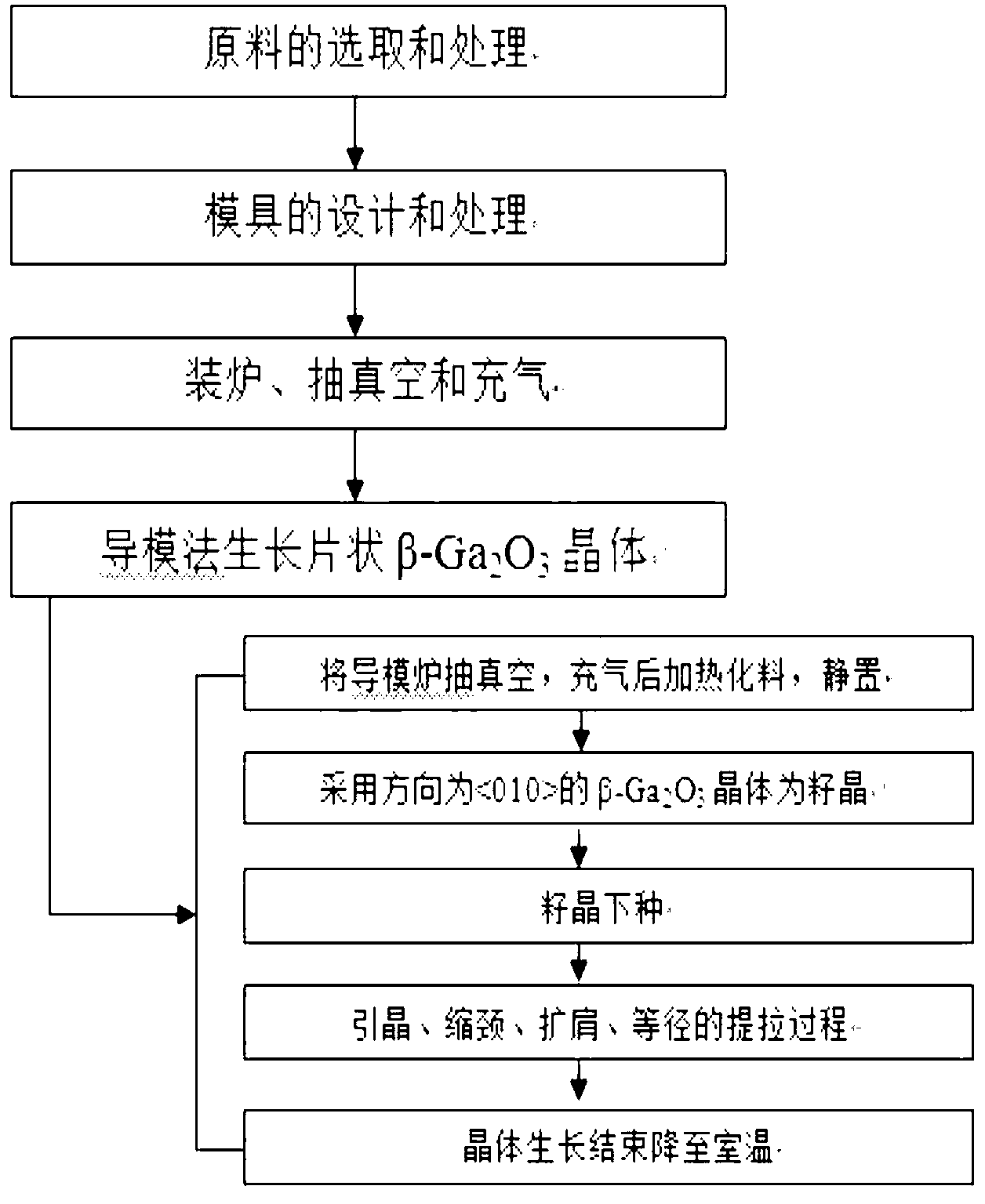

Method for growing tabular gallium oxide crystals through edge-defined film-fed growth process

InactiveCN103290471AOvercome bubblesOvercoming polycrystalline problemsPolycrystalline material growthBy pulling from meltSurface finishIridium

The invention discloses a method for growing tabular gallium oxide crystals through an edge-defined film-fed growth process. The method comprises the following steps of: by taking high-purity gallium oxide powder as a raw material, selecting an iridium die with the top end having such a surface smoothness so that mirror face effect is achieved; by selecting beta-Ga2O3 single crystals with an end-face normal direction (010) as seed crystals and taking a (100) surface as a main growth surface, melting the material in a high-purity CO2 atmosphere for growing, increasing the temperature to the range from 10 to 20 DEG C after melting of the material is finished, keeping the temperature constant for 1-2 hours and then entering a growth stage; dividing the whole crystal growth into four parts: seeding, necking down, shouldering and isodiametric growth; employing different technical parameters at different growth stages until the whole growth process is completed, thereby obtaining tabular beta-Ga2O3 crystals. The tabular beta-Ga2O3 crystals prepared by the method provided by the invention has the characteristics of regular appearance, flat surface, no bubbles, no polycrystal and no stress fringes.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Prepn of mesoporous spherical nano Sio2 particle

The preparation process of mesoporous spherical nano SiO2 particle includes mixing deionized water, CTAB, tetraethyl metasilicate, water solution or ammonia water solution of sodium hydroxide and alcohol solvent in certain proportion; heating reaction of the mixture inside PTFE reactor with protecting stainless steel casing and set in stove with blower; filtering of the reacted solution; washing and high temperature roasting to obtain mesoporous spherical nano SiO2 particle with homogeneous size. The process of the present invention is simple, low in cost and short in production period, and the prepared mesoporous spherical nano SiO2 particle is homogeneous in size, regular in appearance and ordered in pore channel.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com