Patents

Literature

979 results about "Third phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Third phase is the term for a stable emulsion which forms in a liquid–liquid extraction when the original two phases (aqueous and organic) are mixed. The third phase can be caused by a detergent (surfactant) or a fine solid. While third phase is a term for an unwanted emulsion, a stable emulsion is wanted in emulsion polymerization all the things which can be used to make a stable 'emulsion' for a latex synthesis can prove to encourage a third phase to form.

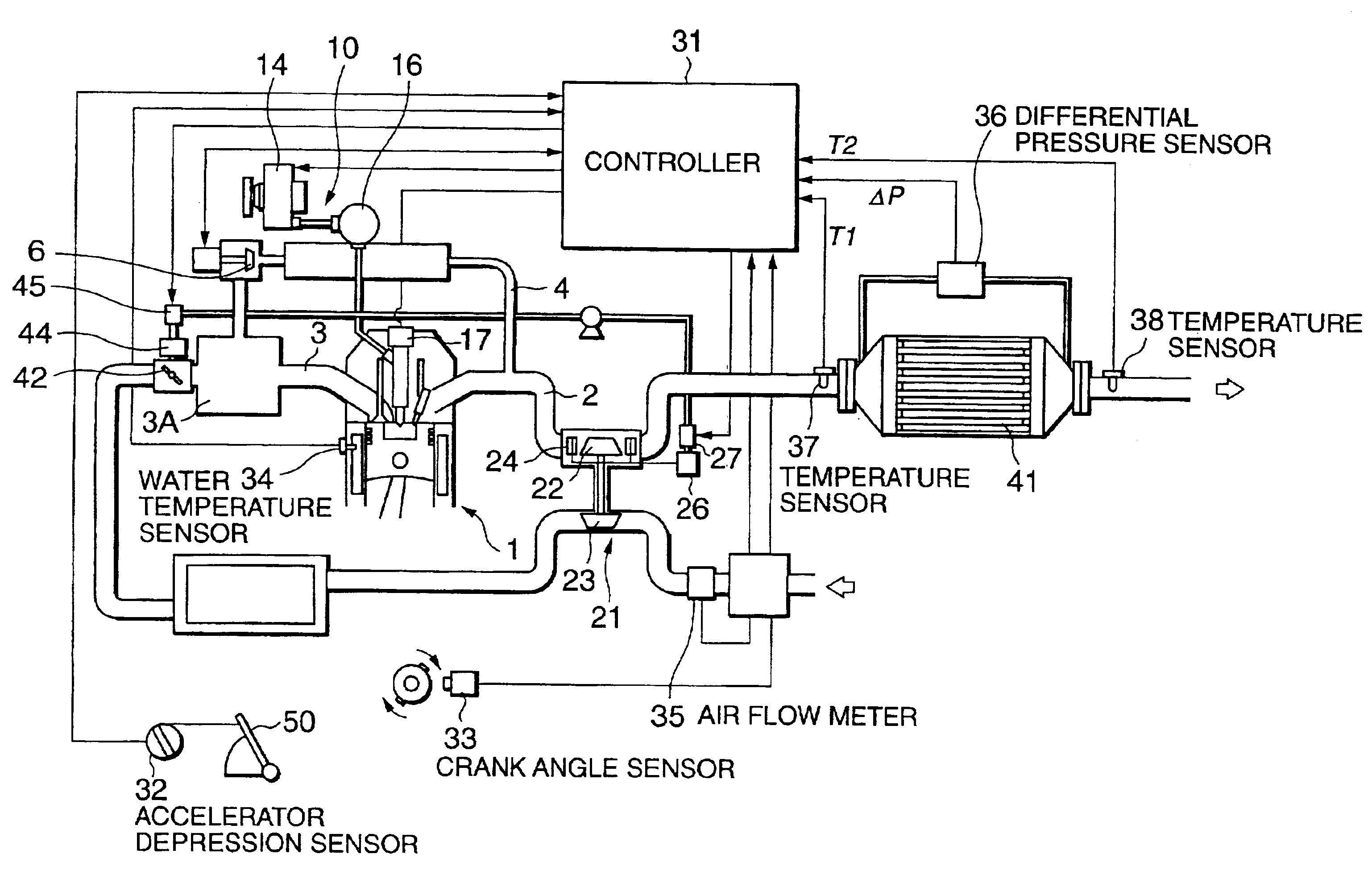

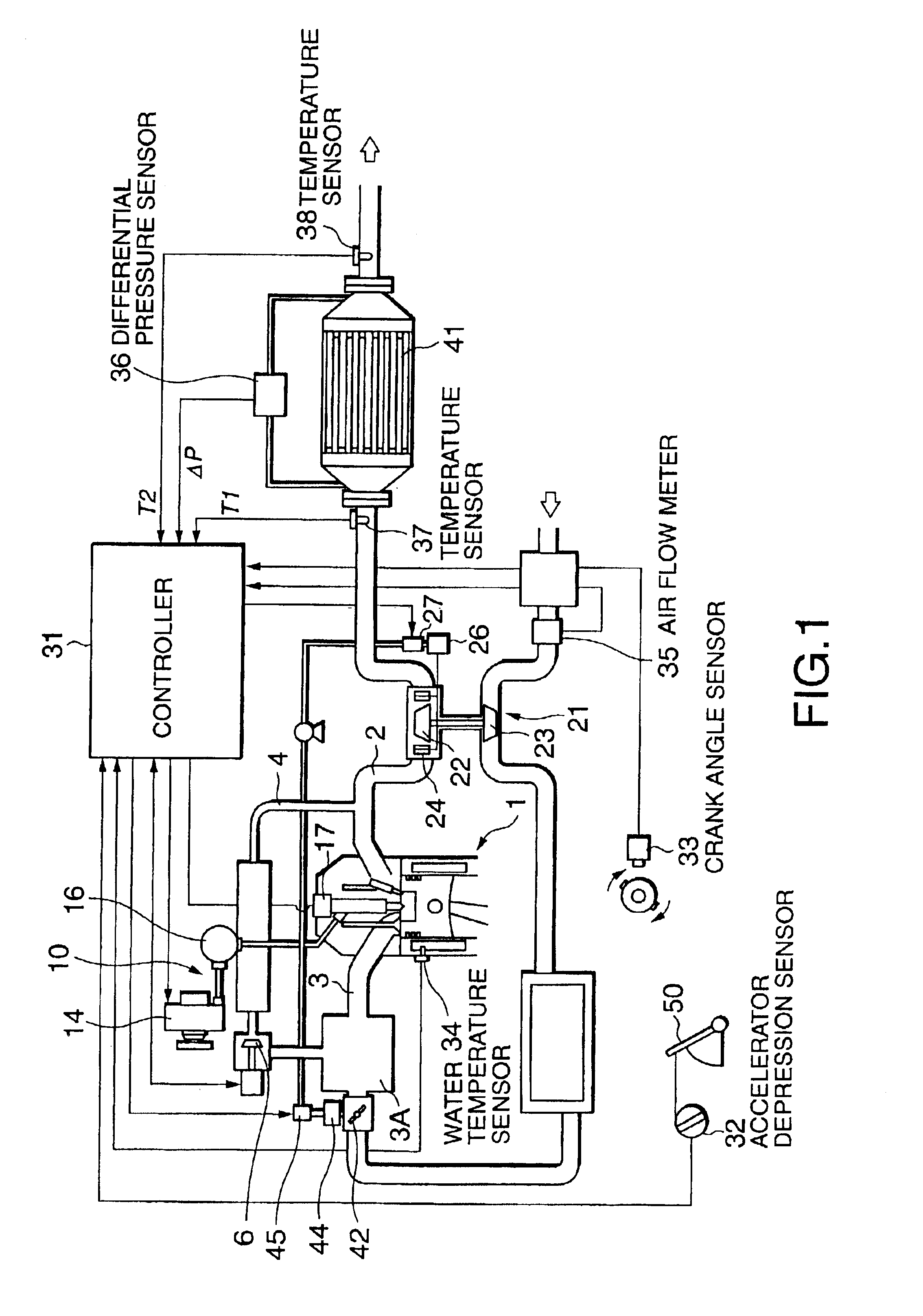

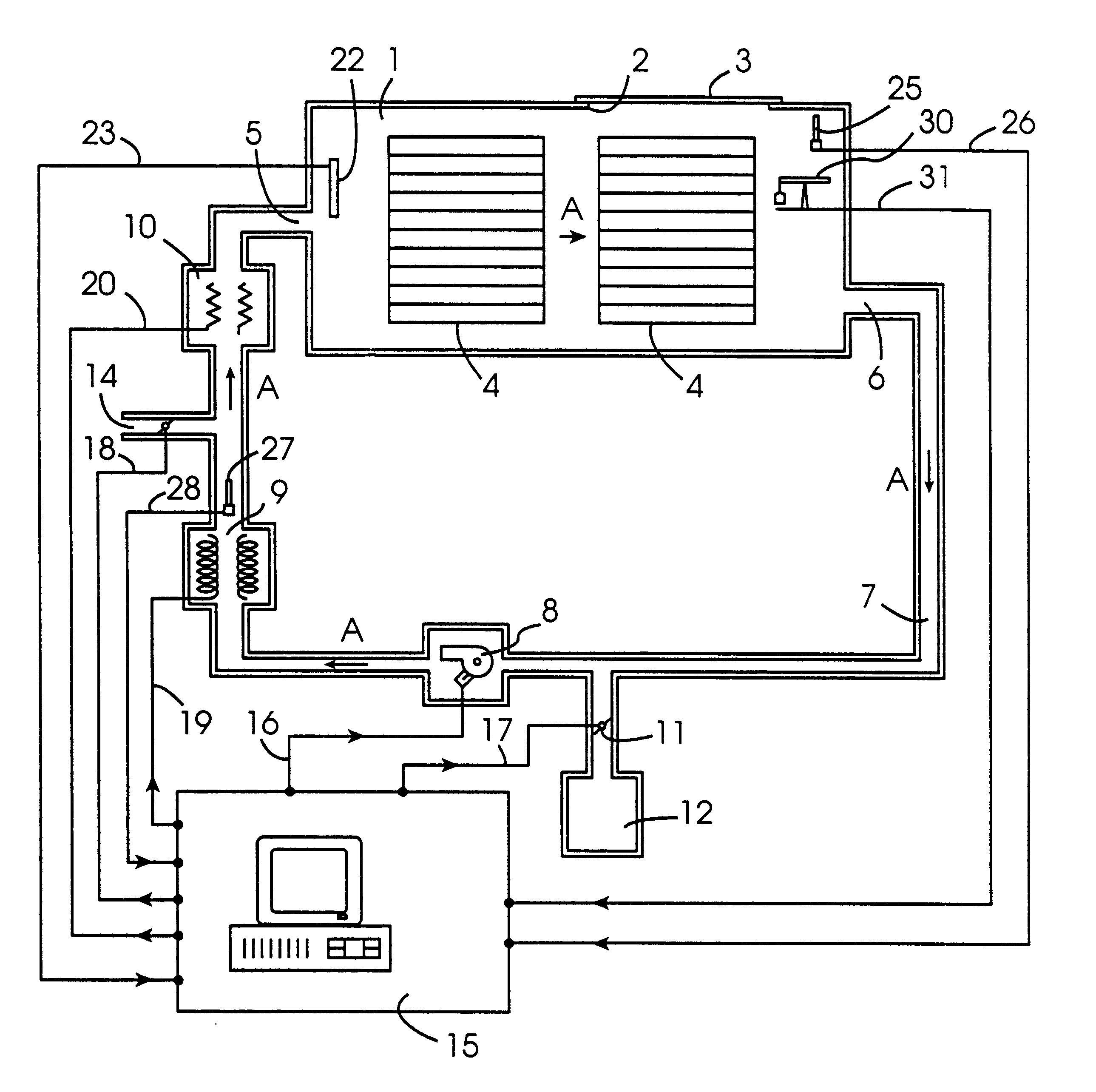

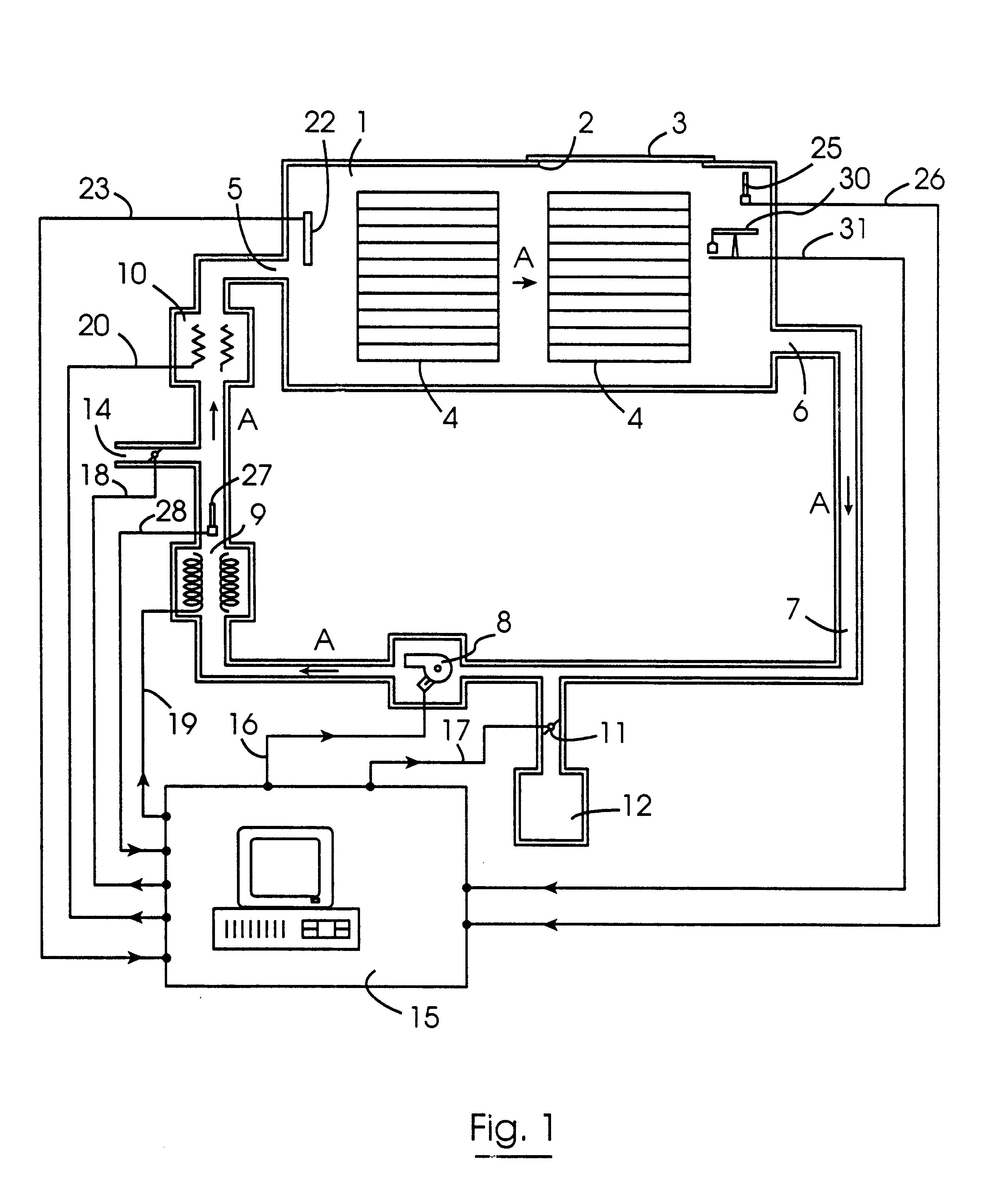

Regeneration of particulate filter

InactiveUS6851258B2Inhibit deteriorationShorten the overall cycleElectrical controlNon-fuel substance addition to fuelParticulatesCombustion

An exhaust passage (2) of a diesel engine (1) is provided with a filter (41) for trapping particulate matter. Regeneration of the filter (41) is divided into first to third phases. In the first phase the filter temperature is raised to the combustion temperature of the particulate matter in a short period of time through control of the exhaust gas temperature. In the second phase, the oxygen concentration of the exhaust gas is held at a predetermined low level while the filter temperature is maintained so as to prevent excessive combustion of particulate matter. In the third phase, wherein the amount of trapped particulate matter has been reduced, the oxygen concentration of the exhaust gas is held at a predetermined high level while the filter temperature is maintained so as to complete the combustion of the trapped particulate matter.

Owner:NISSAN MOTOR CO LTD

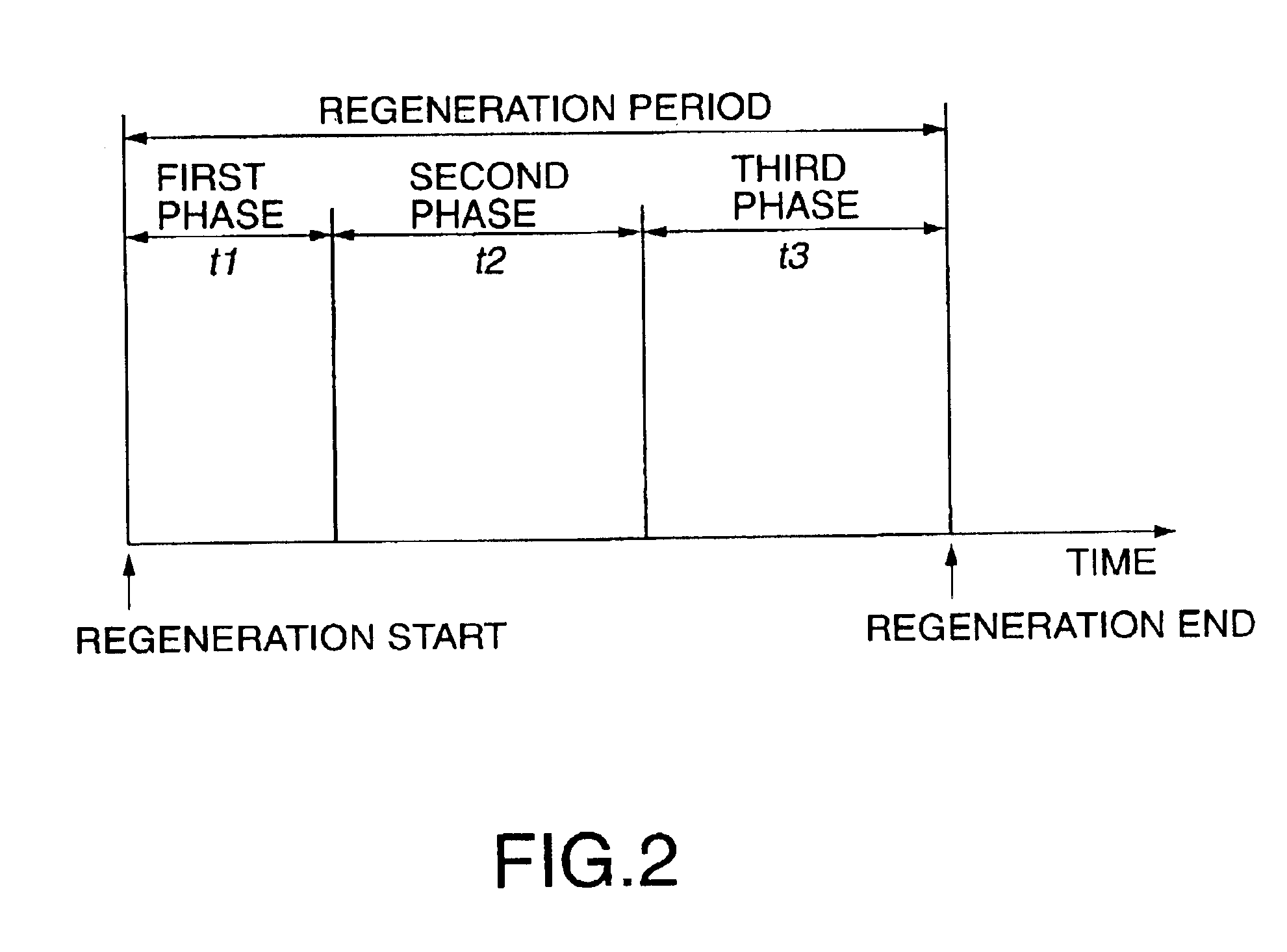

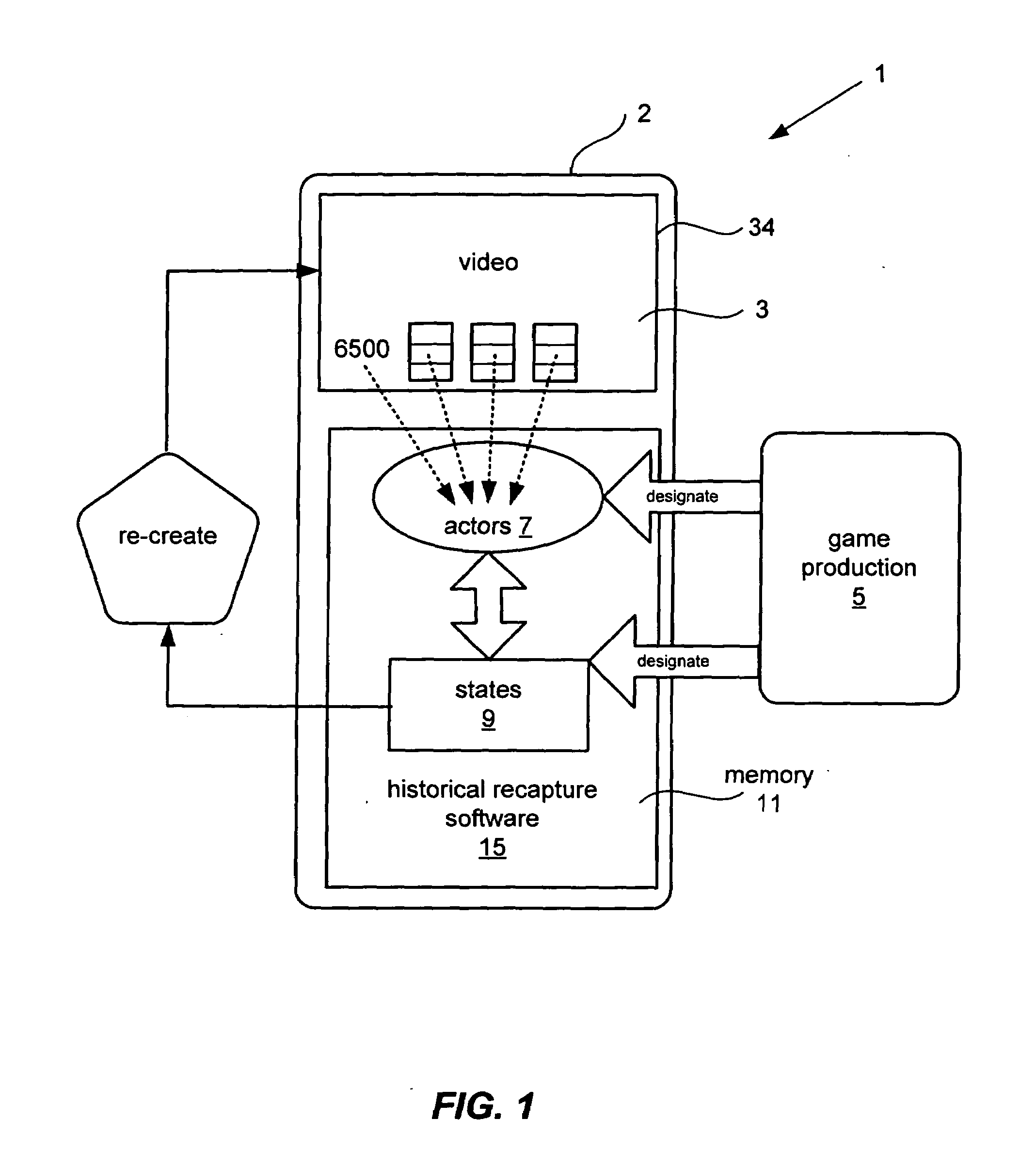

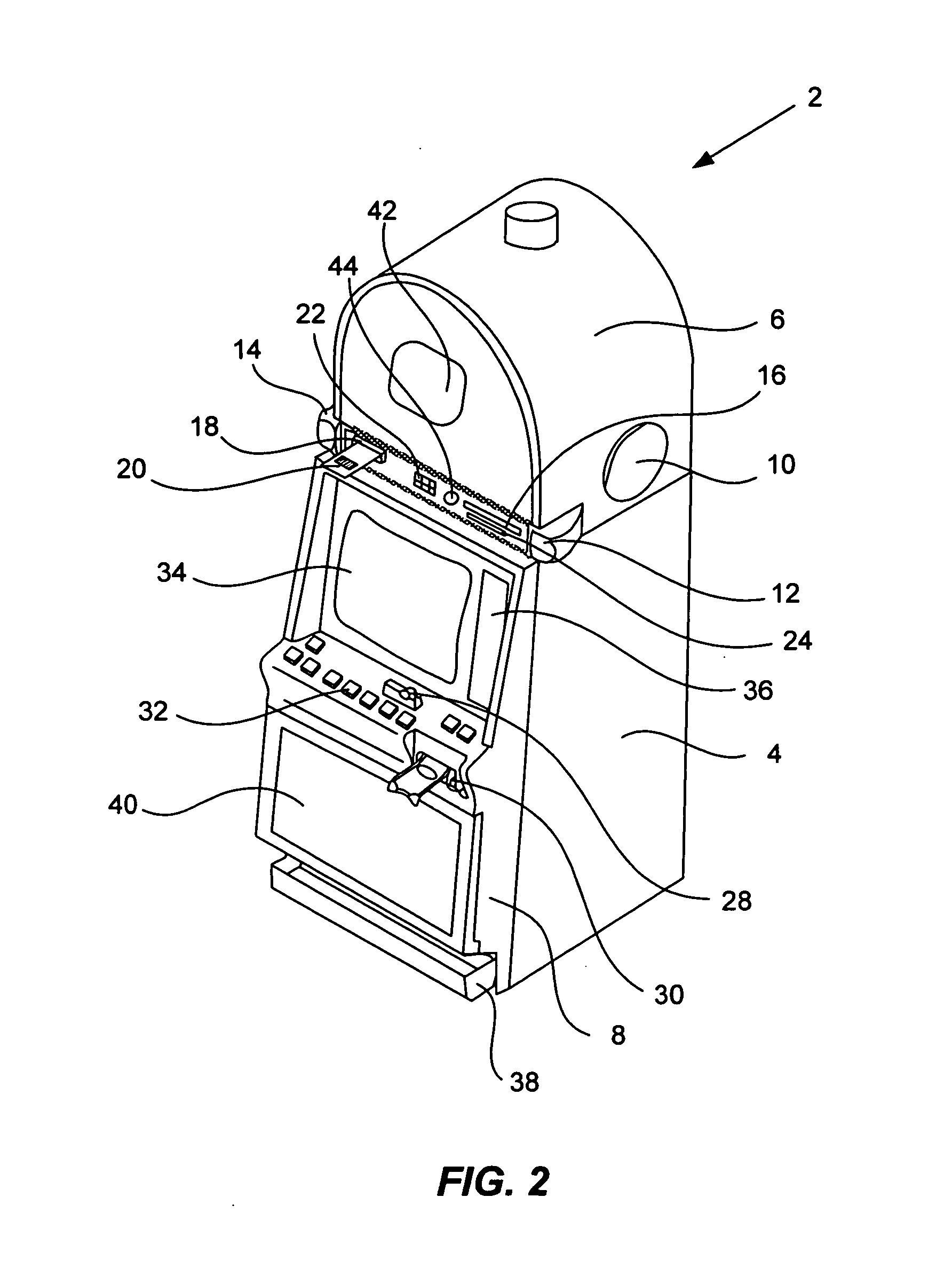

Gaming machine systems and methods with memory efficient historical video re-creation

InactiveUS20080076546A1Improves historical captureImproves video playbackApparatus for meter-controlled dispensingVideo gamesGame playMulti phase

The present invention provides employs a multi-phase process that improves historical capture and video playback on gaming machines. The first phase occurs during game creation and production, where video data required for video re-creation and playback is identified for each scene or frame in a game where a designer seeks playback capability. The second phase occurs during game play. Historical game re-creation software on the gaming machine knows what data in each frame is needed for historical video re-creation of the frame, and saves this data. The third phase occurs during re-capture and playback, where the data is recalled from memory to enable video playback at the particular instance of interest.

Owner:IGT

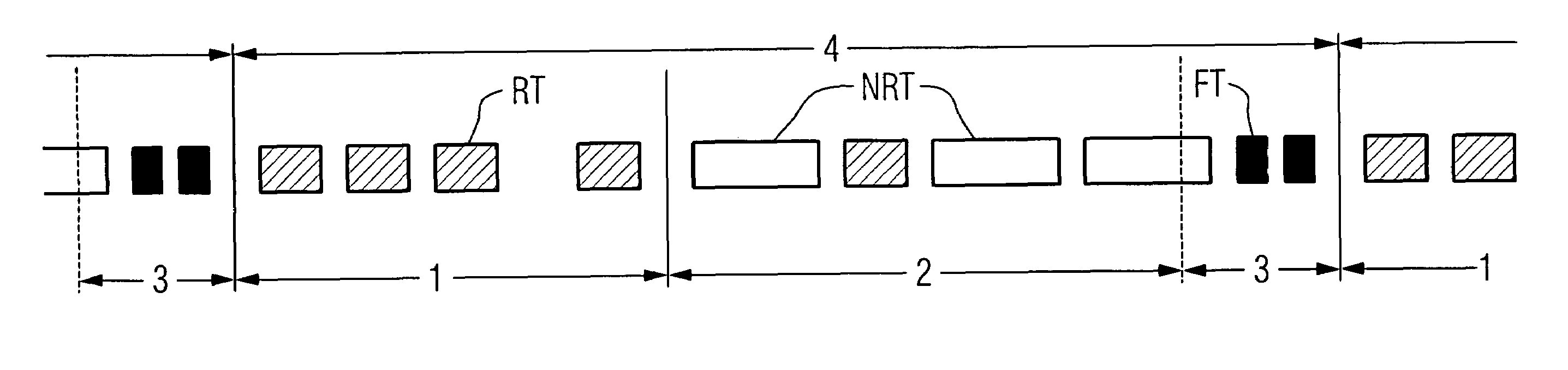

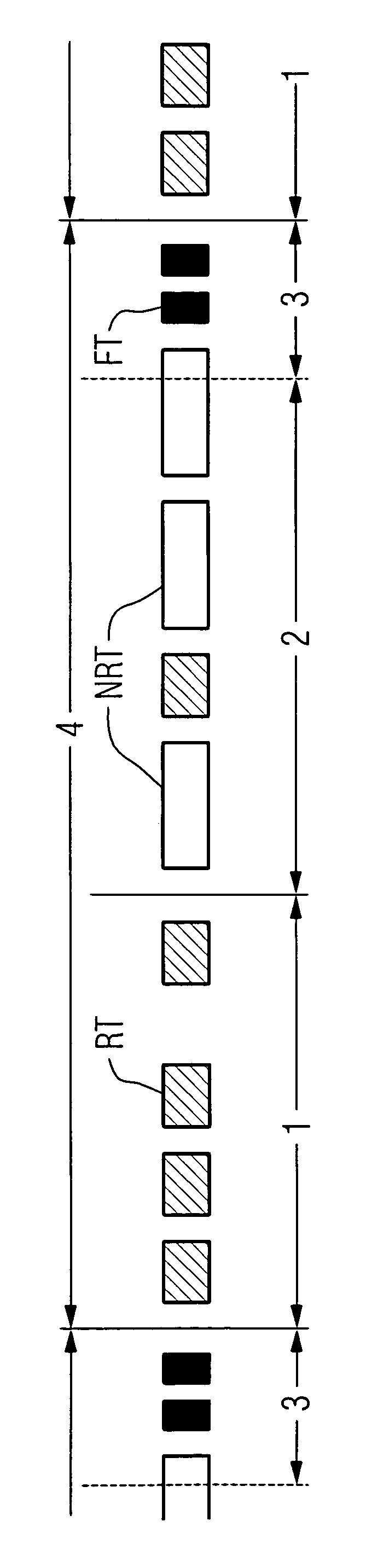

Scheduling of realtime communication in switched networks

ActiveUS7486681B2Utilization capacityHigh acceptanceTime-division multiplexData switching by path configurationReal-time dataExchange network

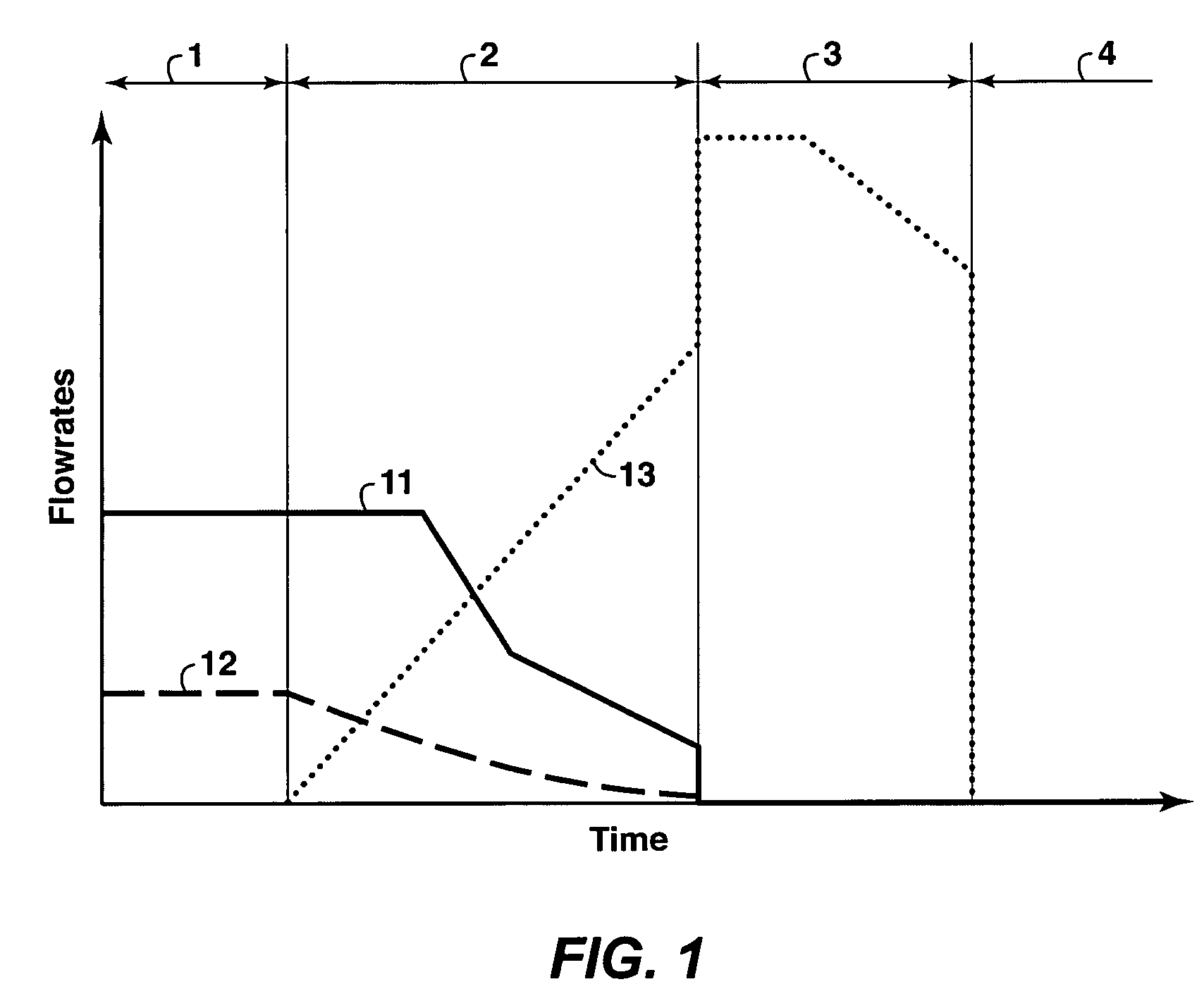

A method and a switching router for simple scheduling of realtime data telegrams with calculable load-insensitive cycle times. A transmission cycle (4) is subdivided into three phases. In a first phase (1), only realtime data telegrams are sent; in a second phase (2), realtime and non-realtime data telegrams are sent; and in a third phase (3), the transmission of long non-realtime data telegrams is suppressed. Short filler telegrams can be sent during the phase (3). This ensures that data transmission of the realtime data telegrams will proceed smoothly. Transmission in certain phases is regulated by the priorities assigned to the data telegrams.

Owner:SIEMENS AG

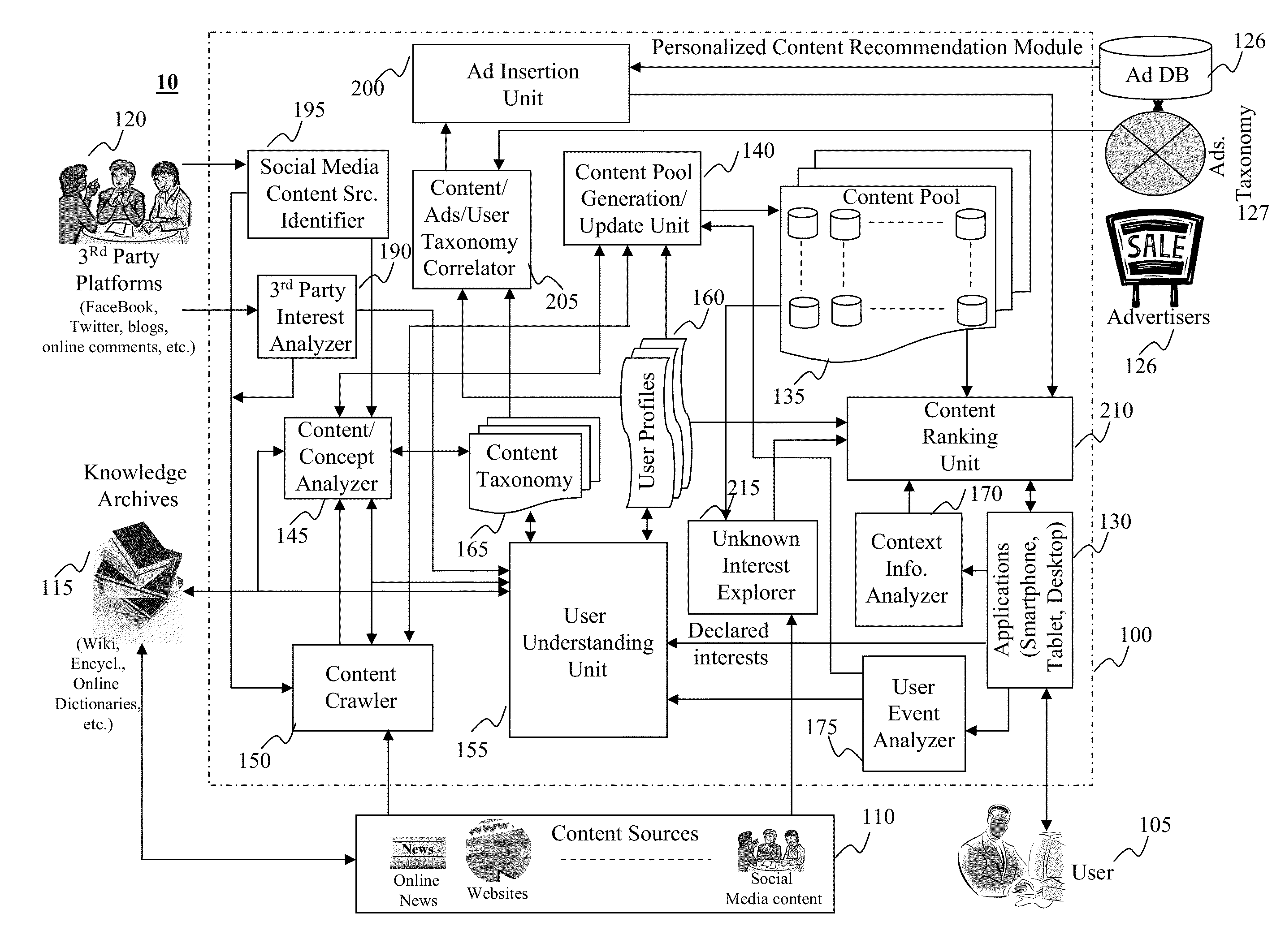

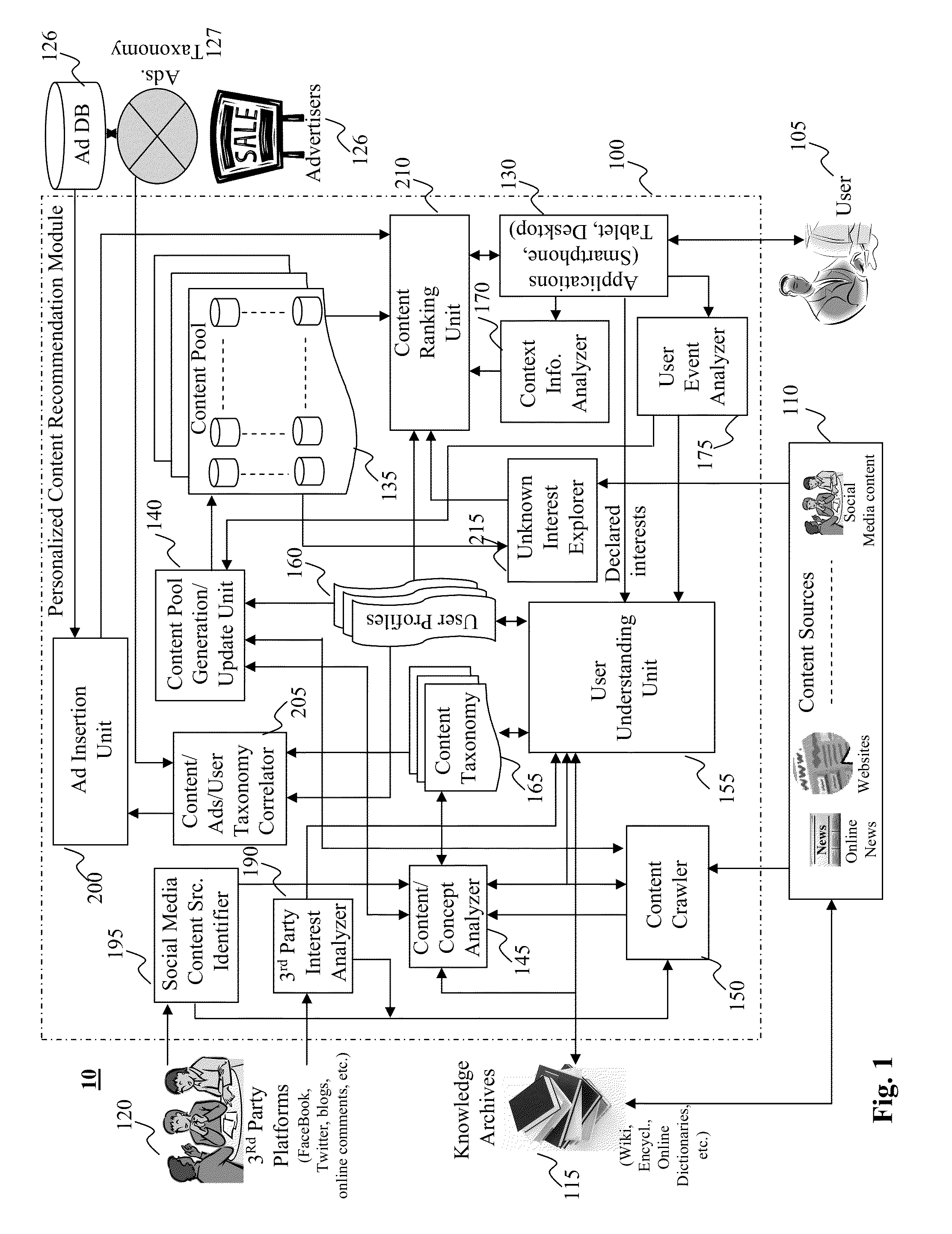

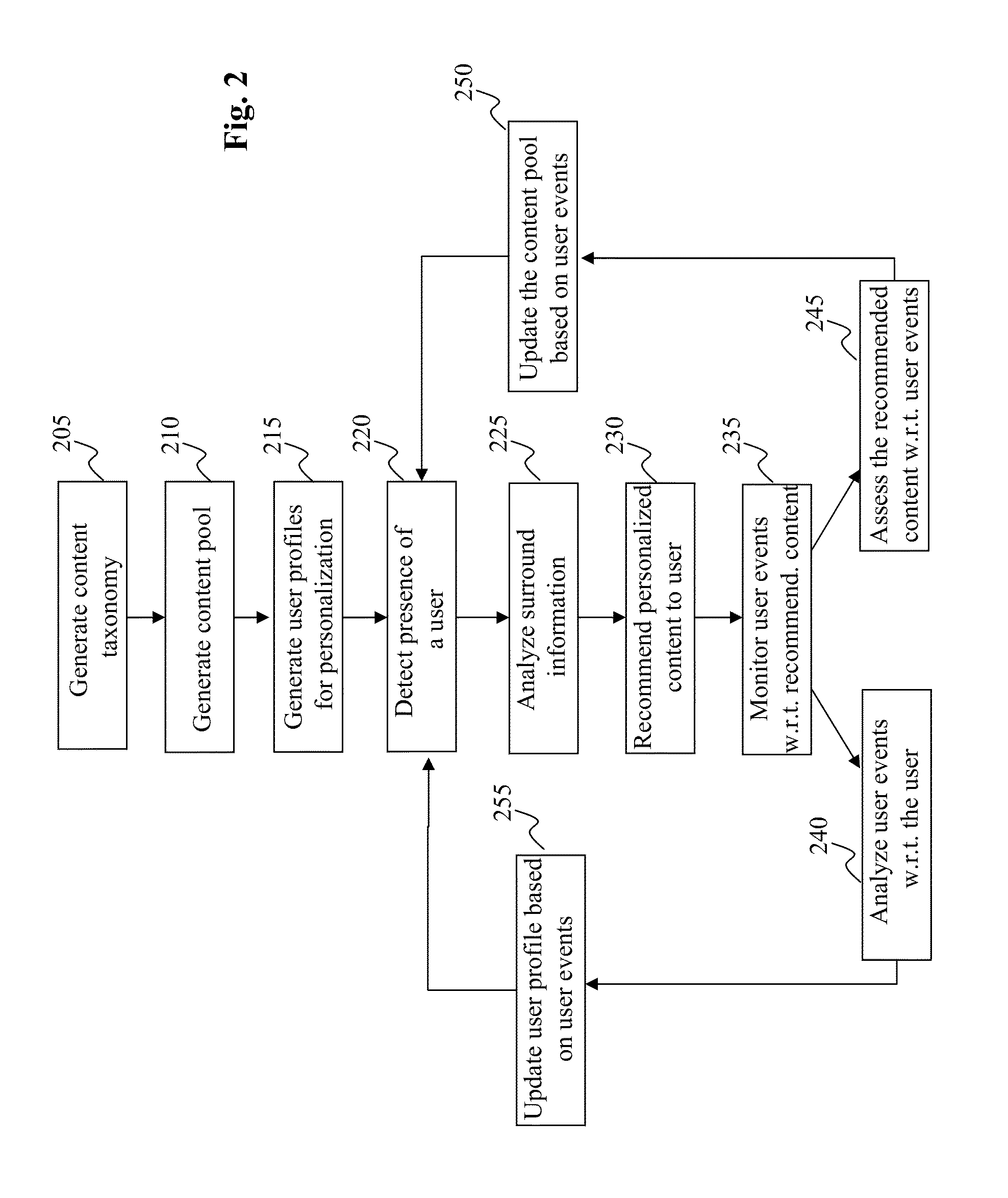

Method and system for multi-phase ranking for content personalization

Embodiments of the present teachings disclose method, system, and programs for a multi-phase ranking system for implementation with a personalized content system. The disclosed method, system, and programs utilize a weighted AND system to compute a dot product of the user profile and a content profile in a first phase, a content quality indicator in the second phase and a rules filter in a third phase.

Owner:YAHOO AD TECH LLC

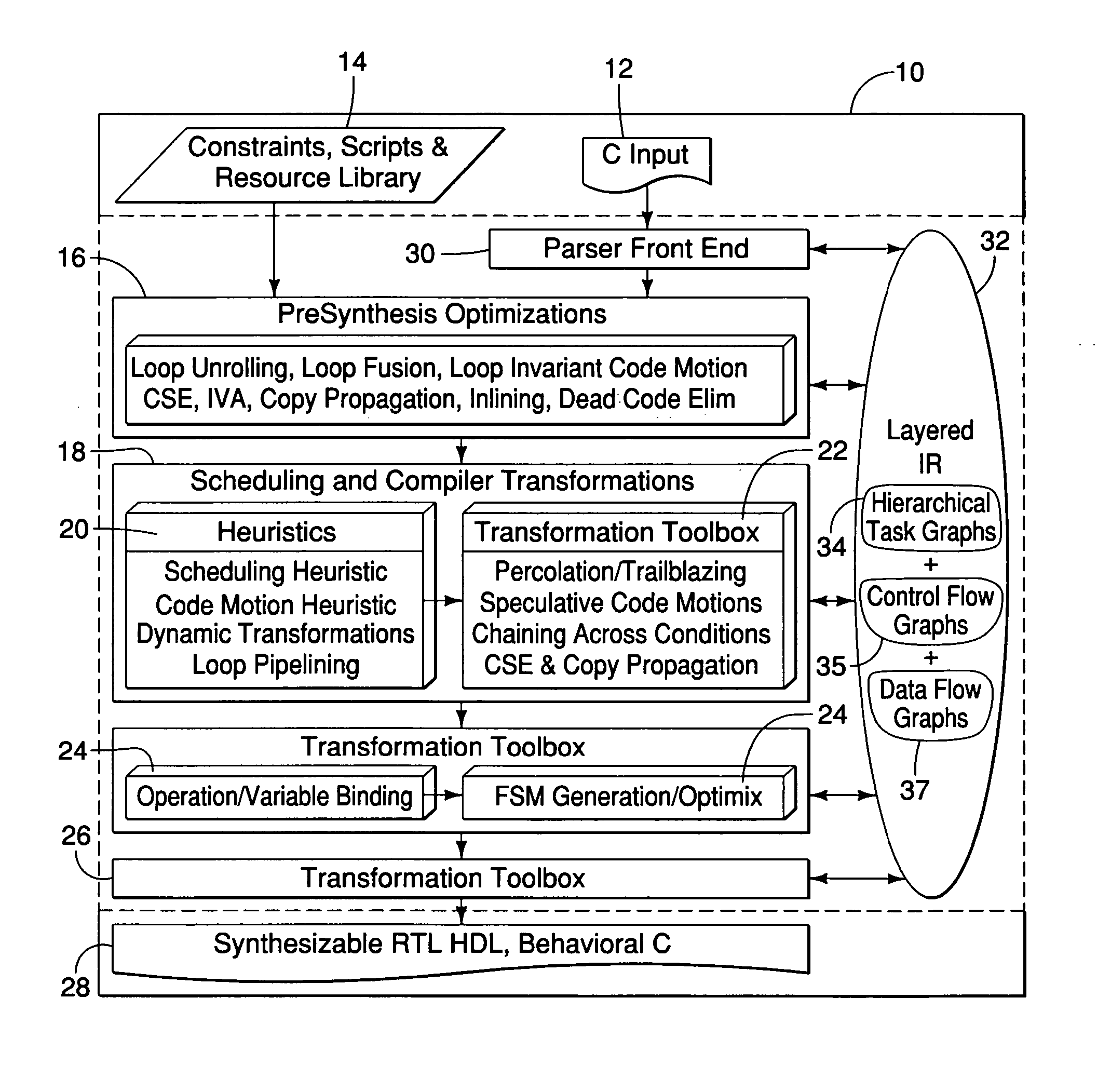

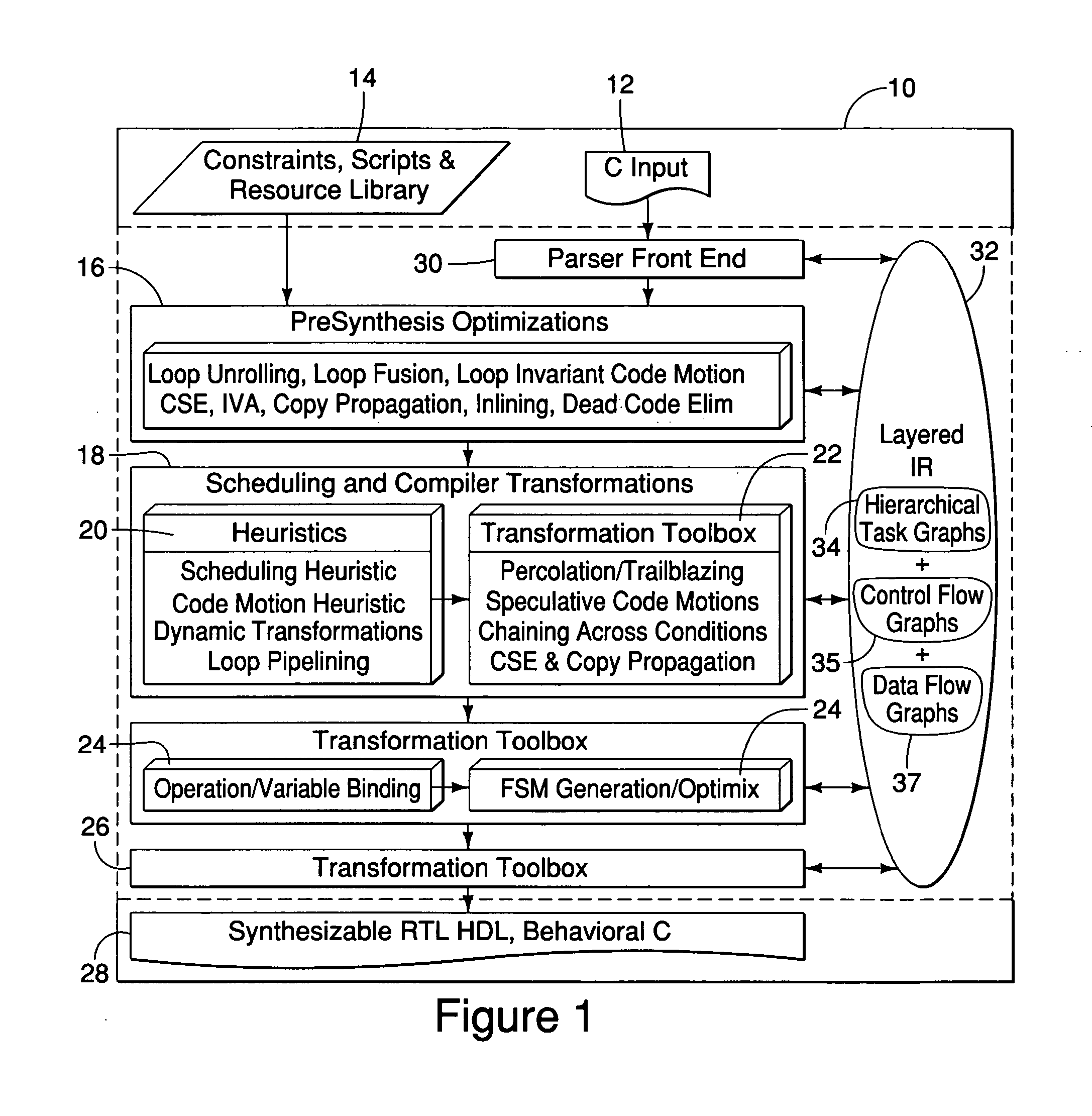

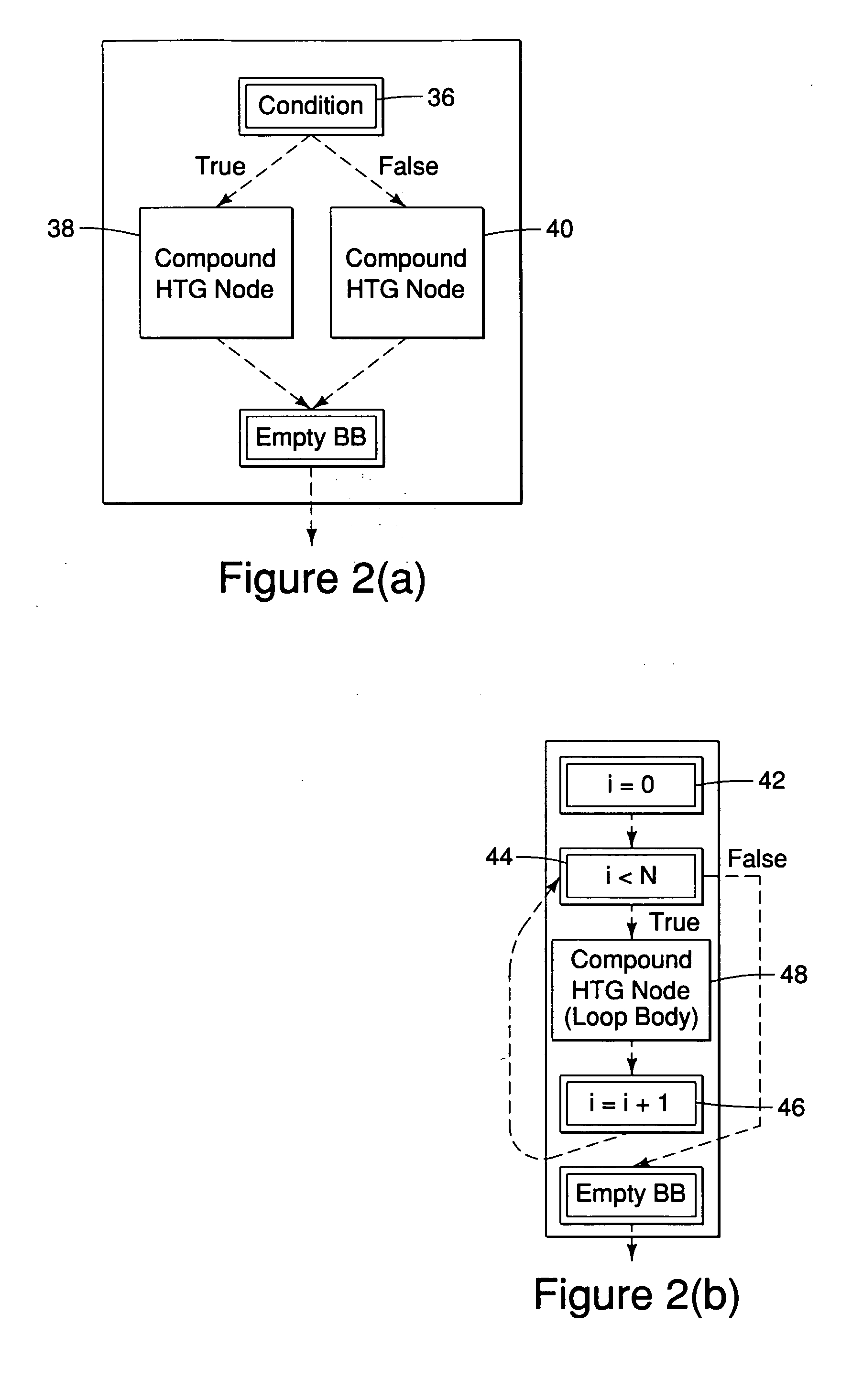

Method and apparatus for designing circuits using high-level synthesis

InactiveUS20050193359A1CAD circuit designSpecial data processing applicationsComputer architectureThird phase

A method for performing high-level synthesis (HLS) of a digital design includes a first phase for performing transformations on a behavioral description of the design, and a second phase for selecting a transformation from a plurality of transformations for transforming the behavioral description. The method further includes a third phase for implementing the transformed behavioral description using lower level primitives, and a fourth phase for generating implementation codes for the design.

Owner:RGT UNIV OF CALIFORNIA

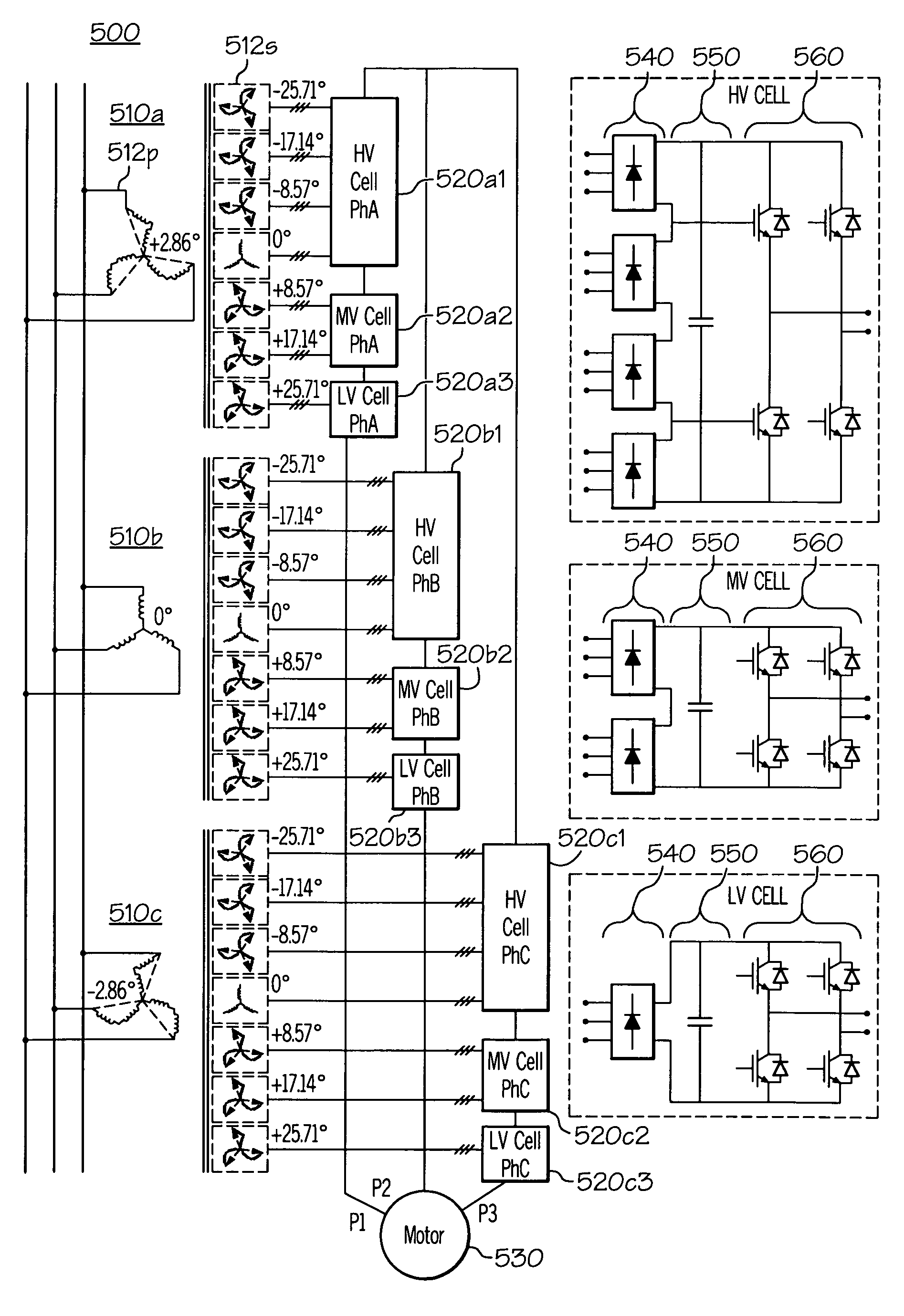

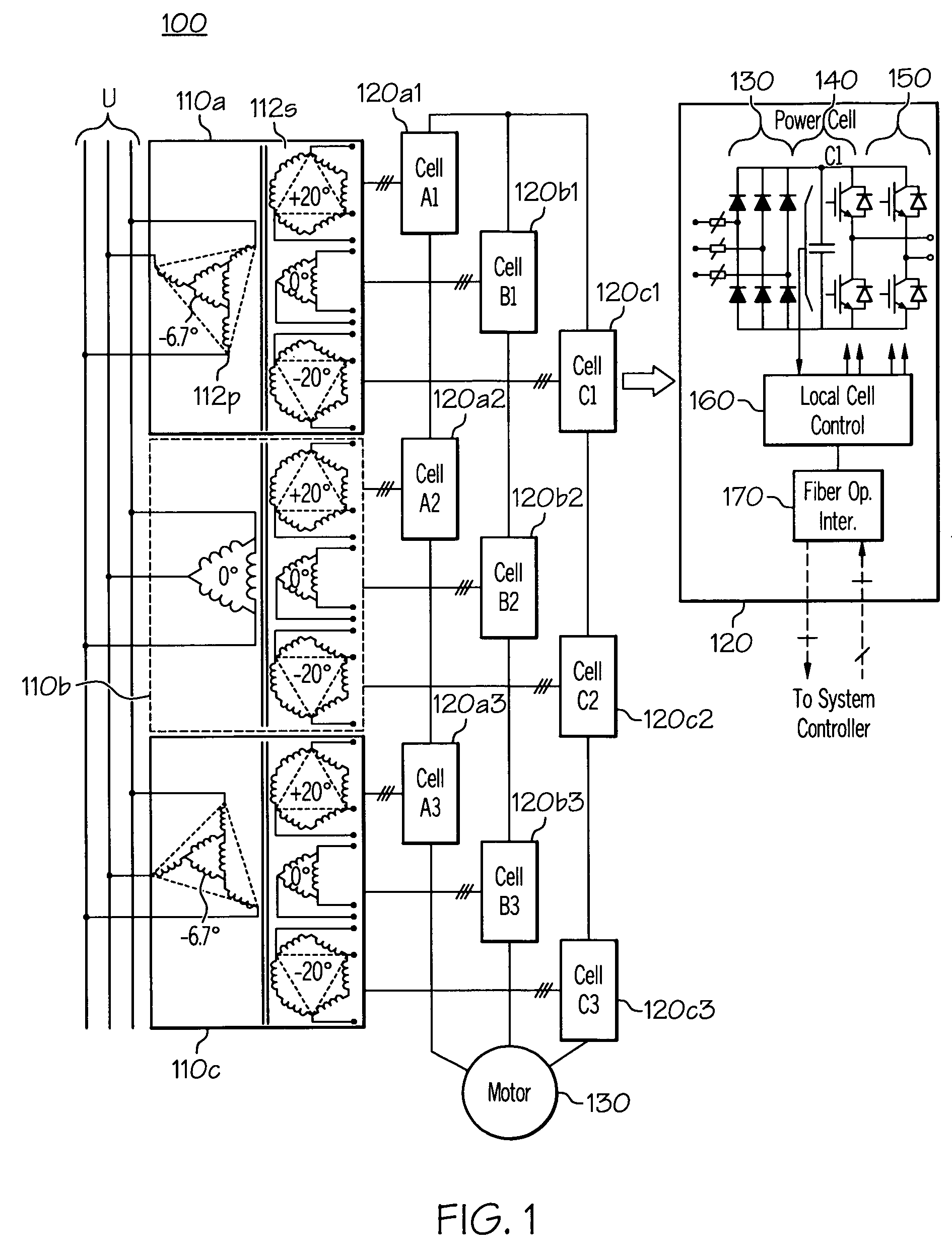

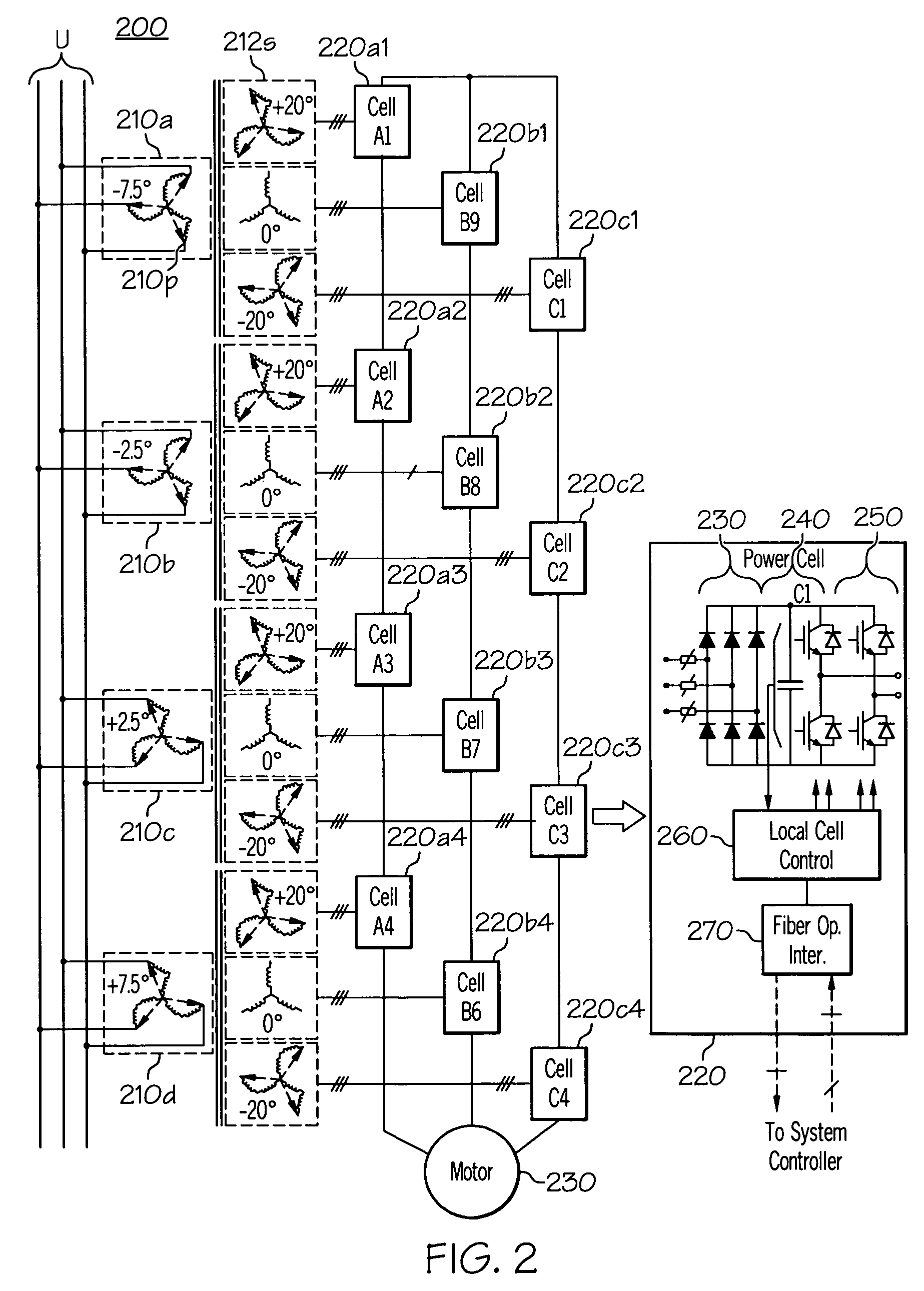

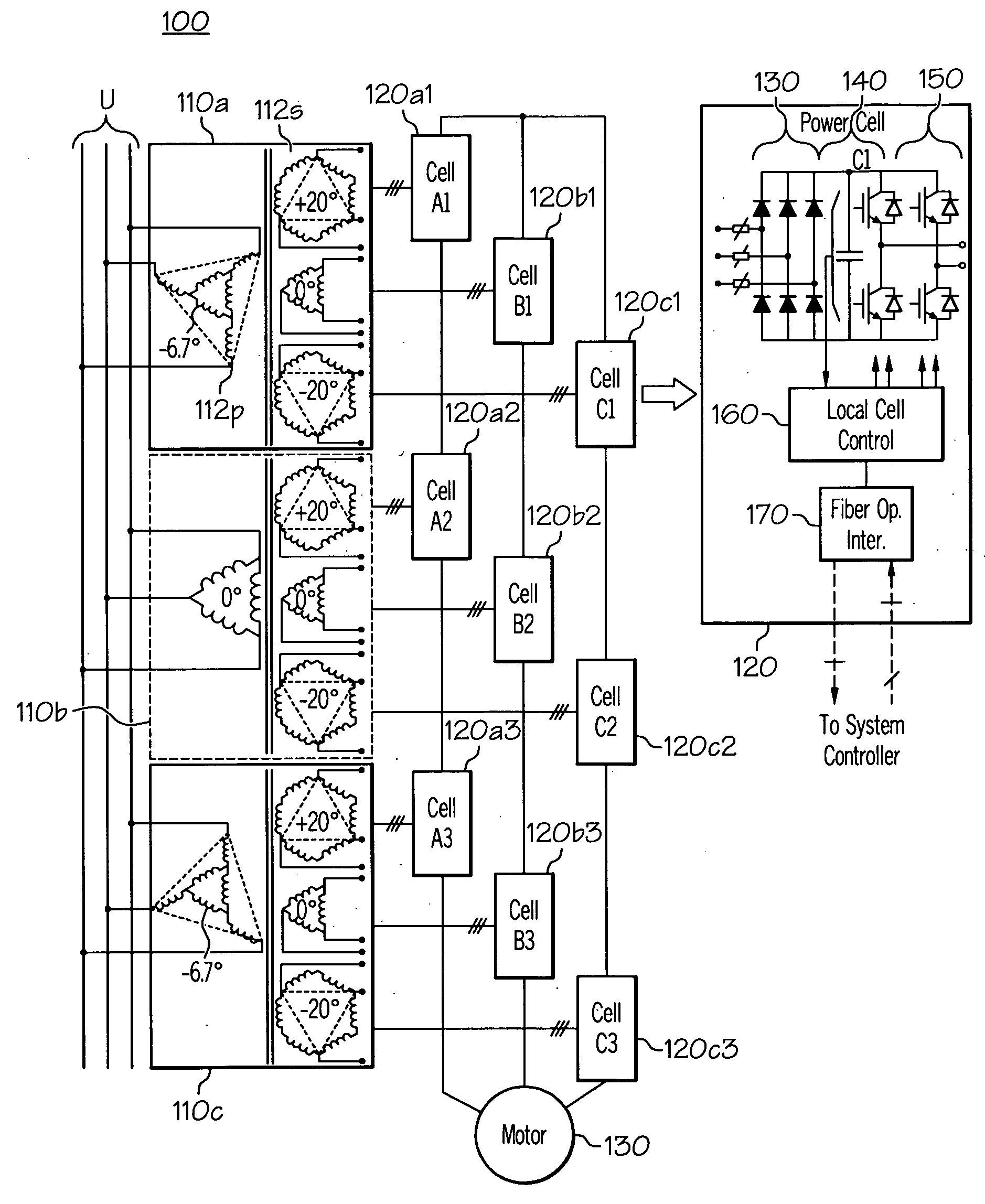

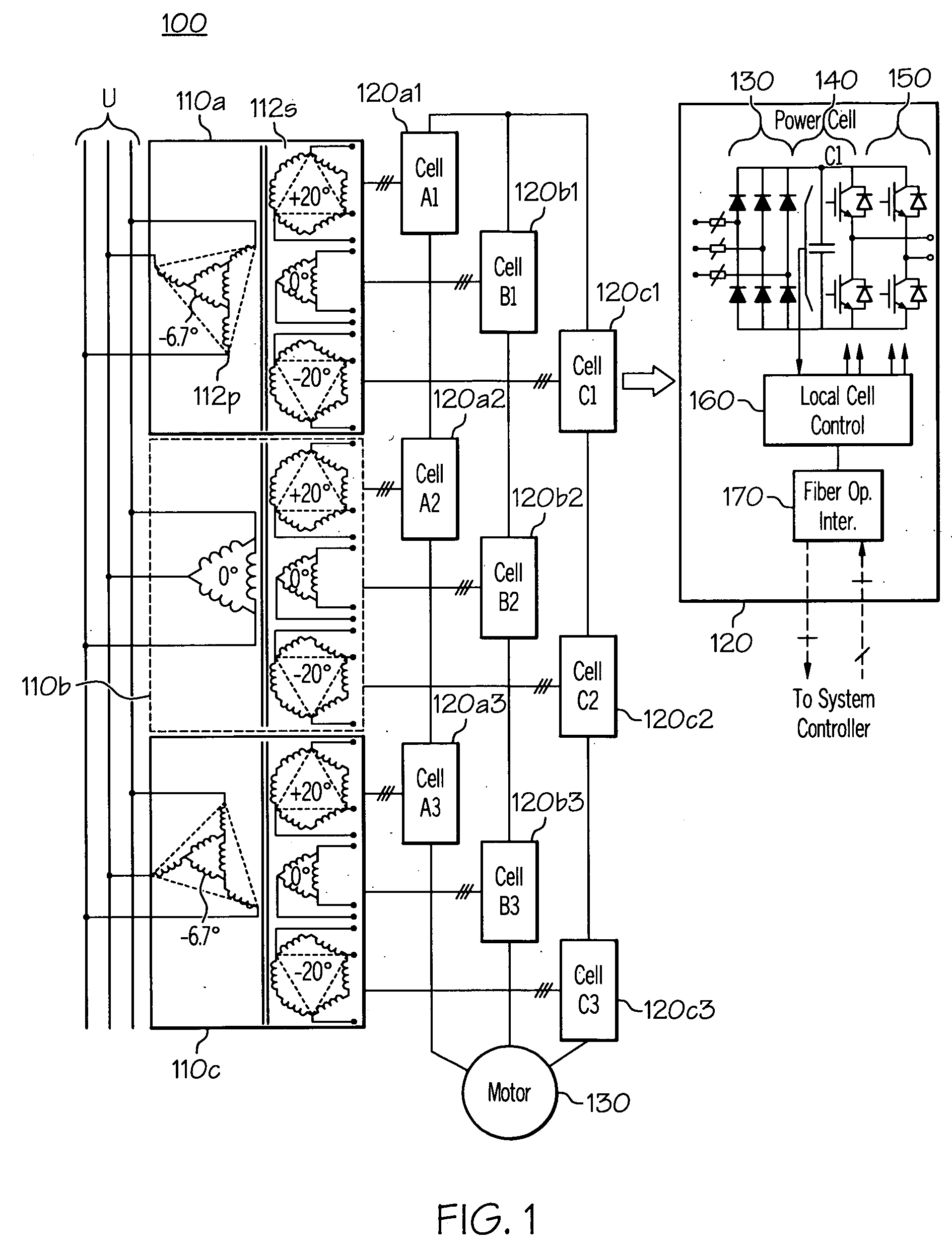

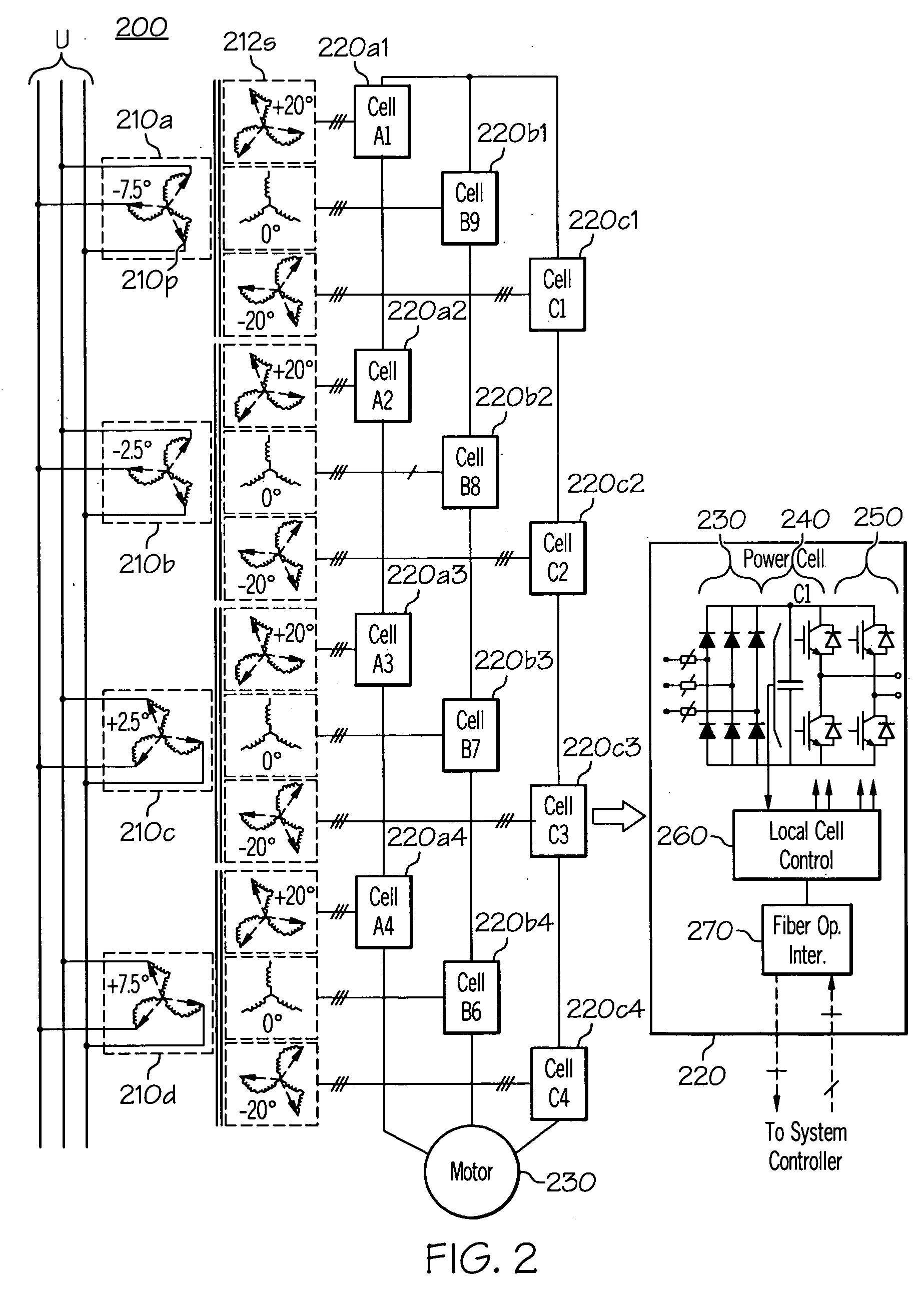

Modular multi-pulse transformer rectifier for use in asymmetric multi-level power converter

ActiveUS7830681B2Conversion with intermediate conversion to dcDc source parallel operationPhase shiftedComputer module

In one embodiment, the present invention includes a system having multiple modular transformers each including a phase-shifted primary winding coupled to an input power source and phase-shifted secondary windings each coupled to a power cell. The system further includes different phase output lines coupled to a load. These lines may include first, second and third phase output lines.

Owner:TECO WESTINGHOUSE MOTOR

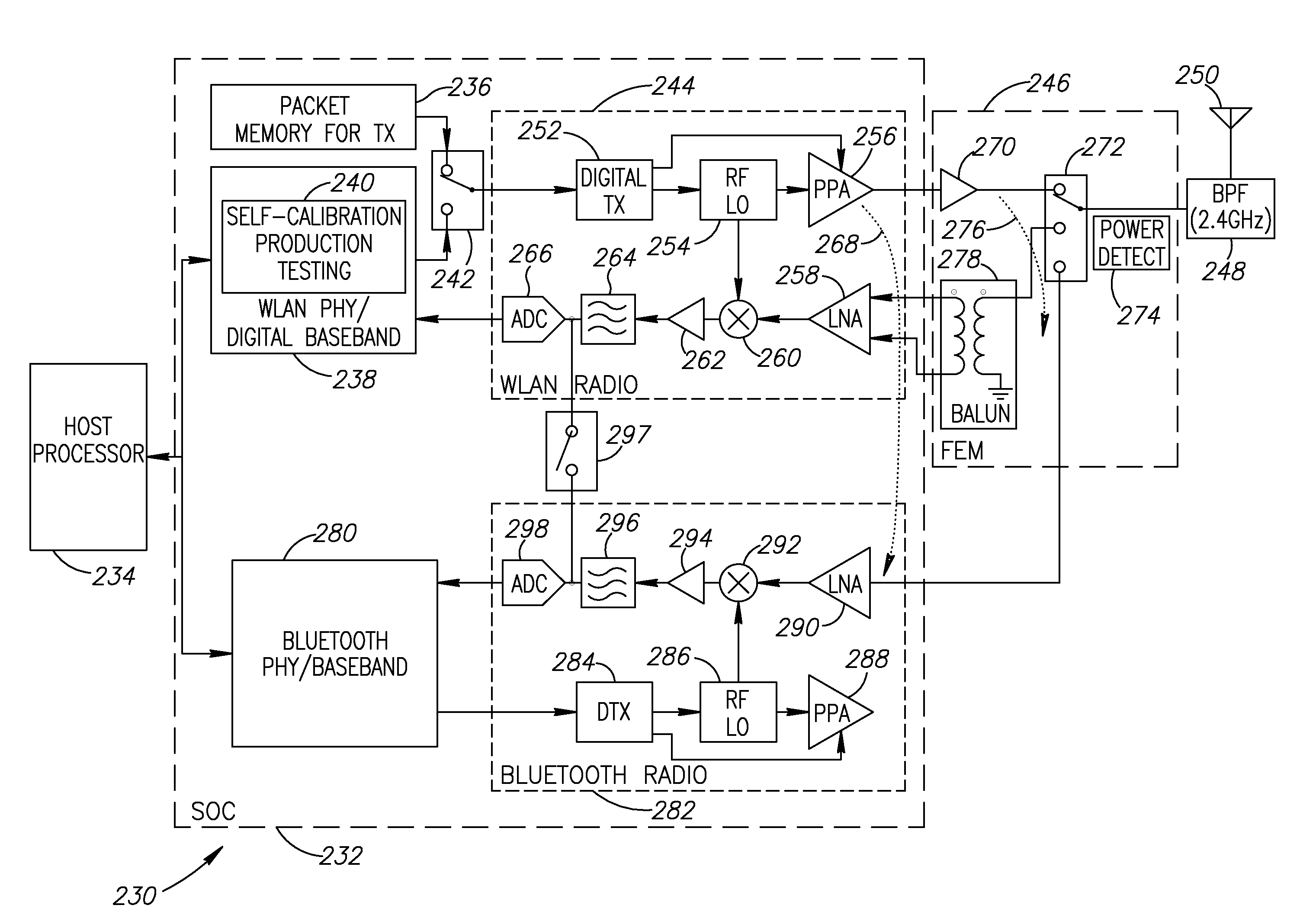

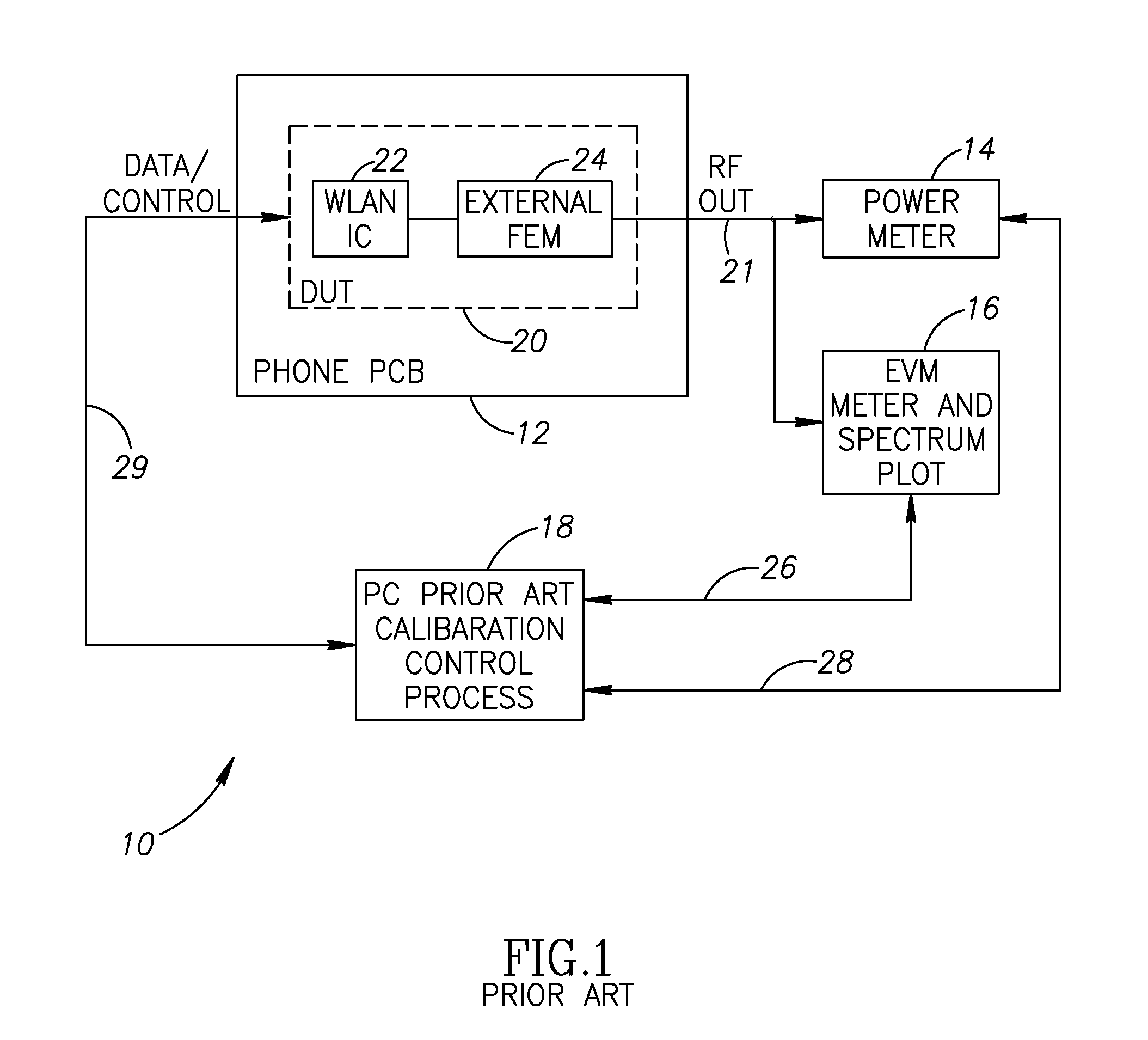

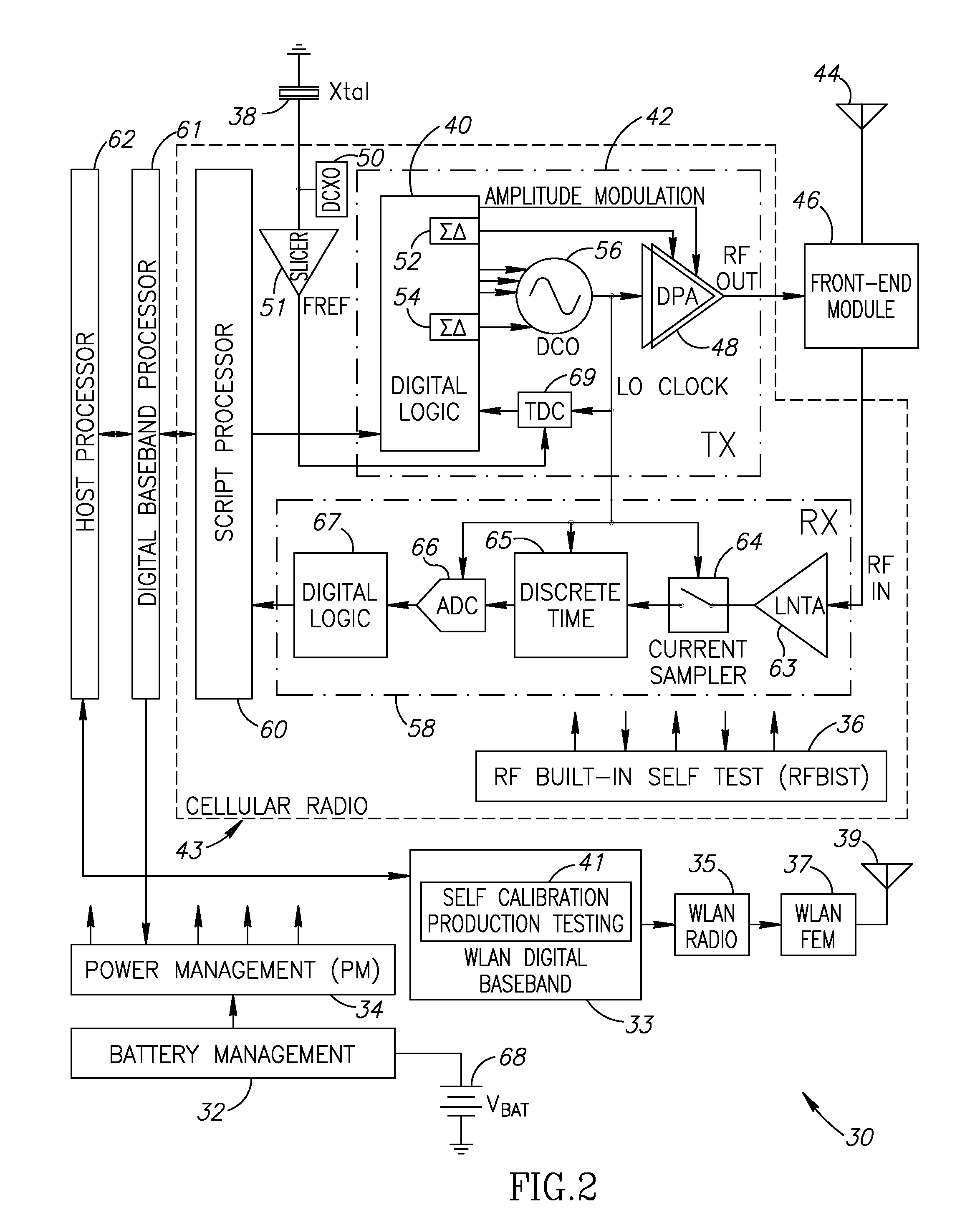

Transmitter built-in production line testing utilizing digital gain calibration

ActiveUS20080144707A1Easy to implementSuitable for useTransmitters monitoringResonant long antennasProduction lineAudio power amplifier

A novel and useful self-calibration based production line testing mechanism utilizing built-in closed loop measurements in the radio to calibrate the output power of an external power amplifier coupled to a SoC radio. The mechanism is applicable during production line testing and calibration which is performed on each SoC and associated external power amplifier after assembly at the target PCB of the final product. The mechanism calibrates the TX output power in three phases based on loopback EVM measurements. In a first phase, the PPA in the radio (SoC) is calibrated and gain versus output power is stored in a gain table in on-chip NVS. In a second phase, the maximum PPA TX power is determined using closed loop EVM measurements. The external PA is calibrated in a third phase and the maximum PA power is determined. During this third phase, the maximum power of the device is calculated, compared to the requirements of the particular standard and a pass / fail determination is thereby made.

Owner:TEXAS INSTR INC

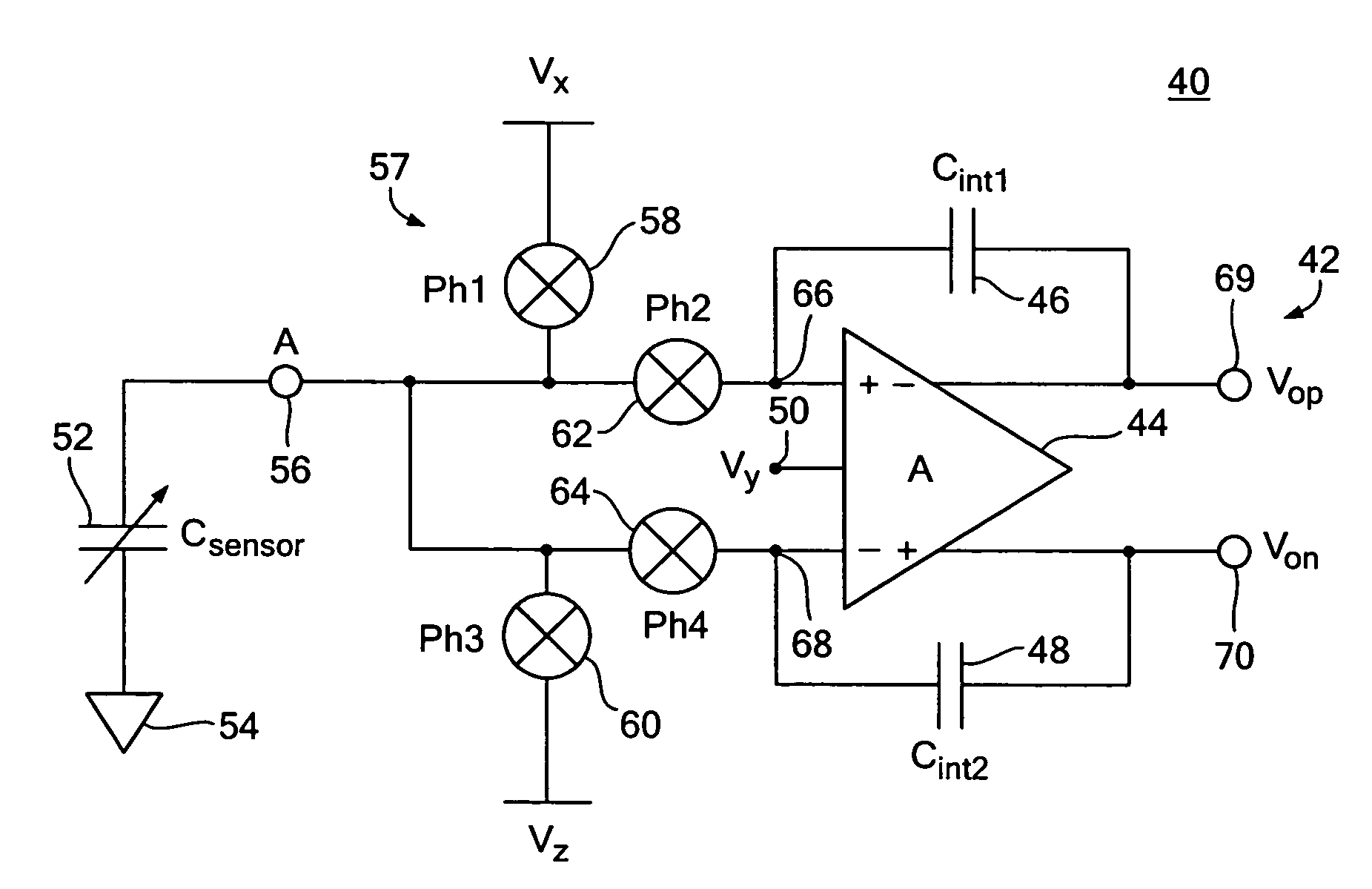

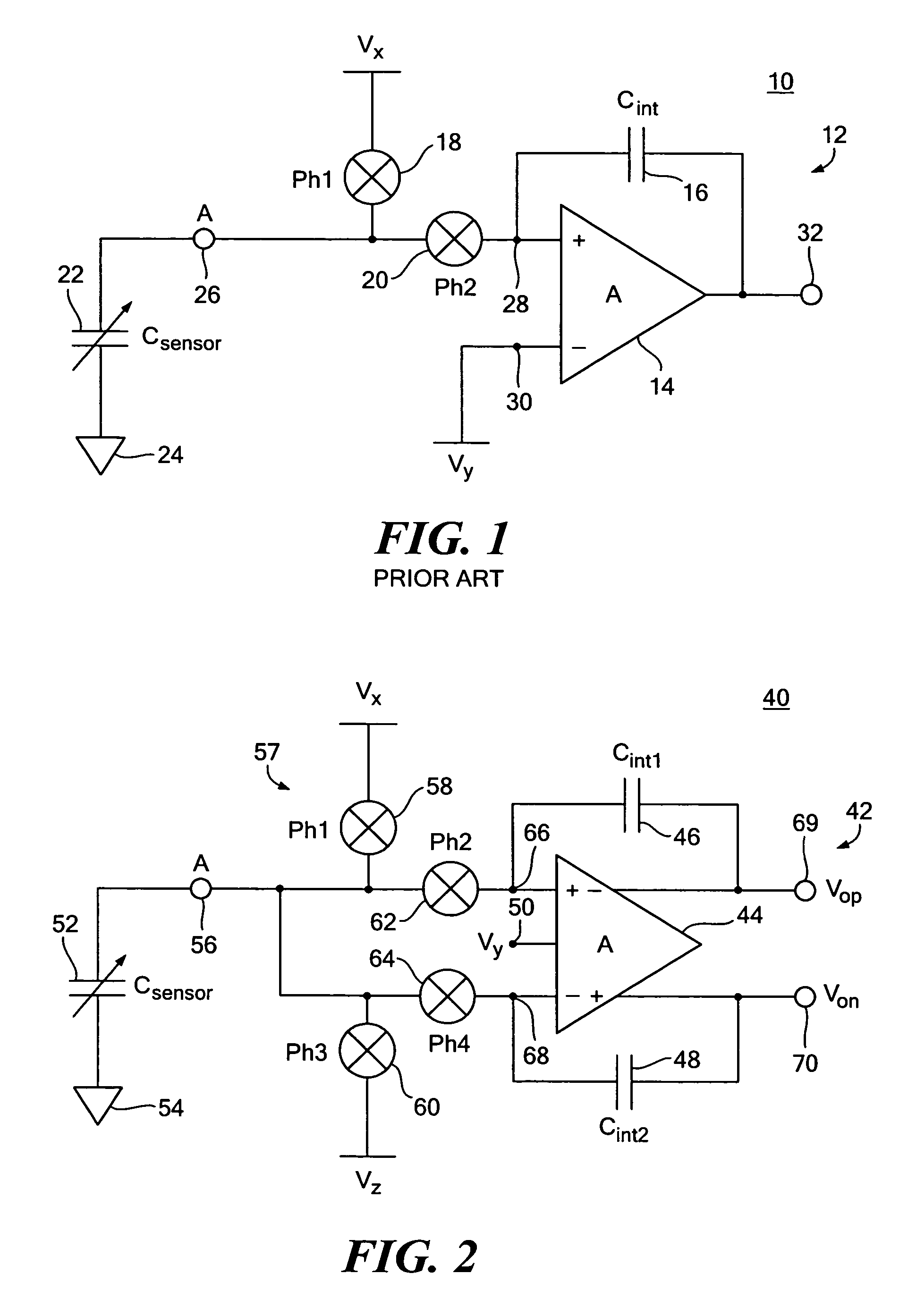

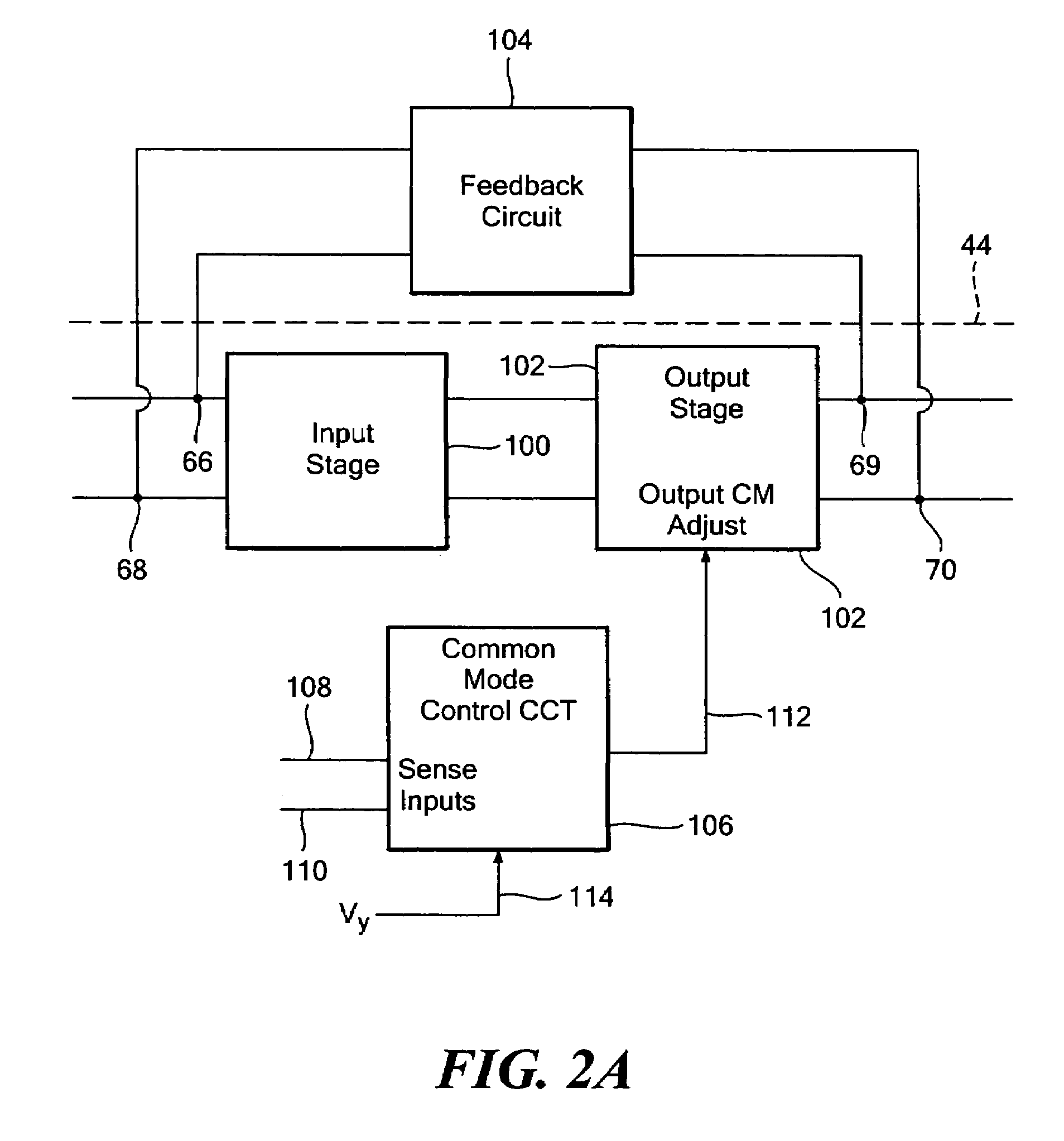

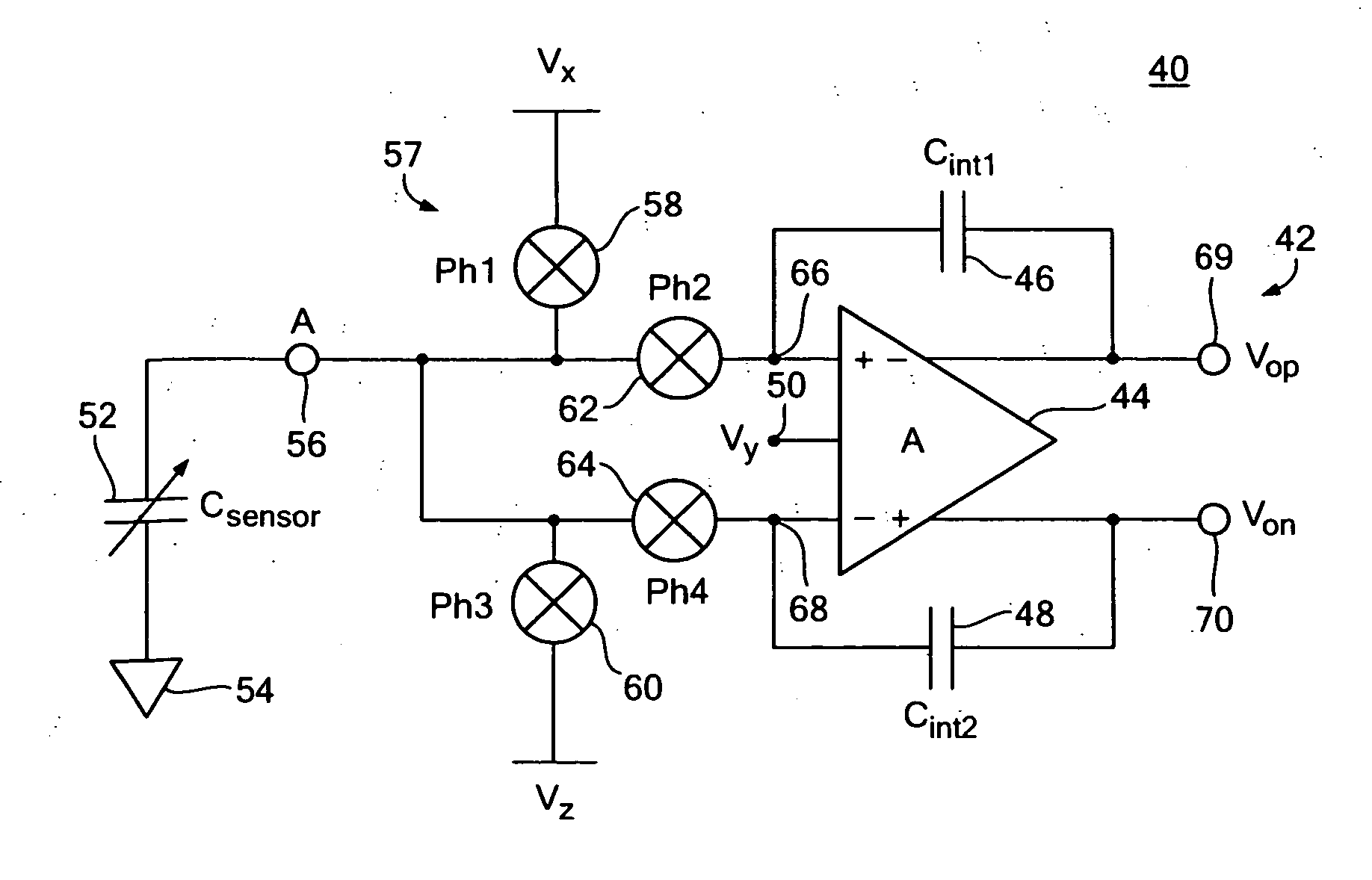

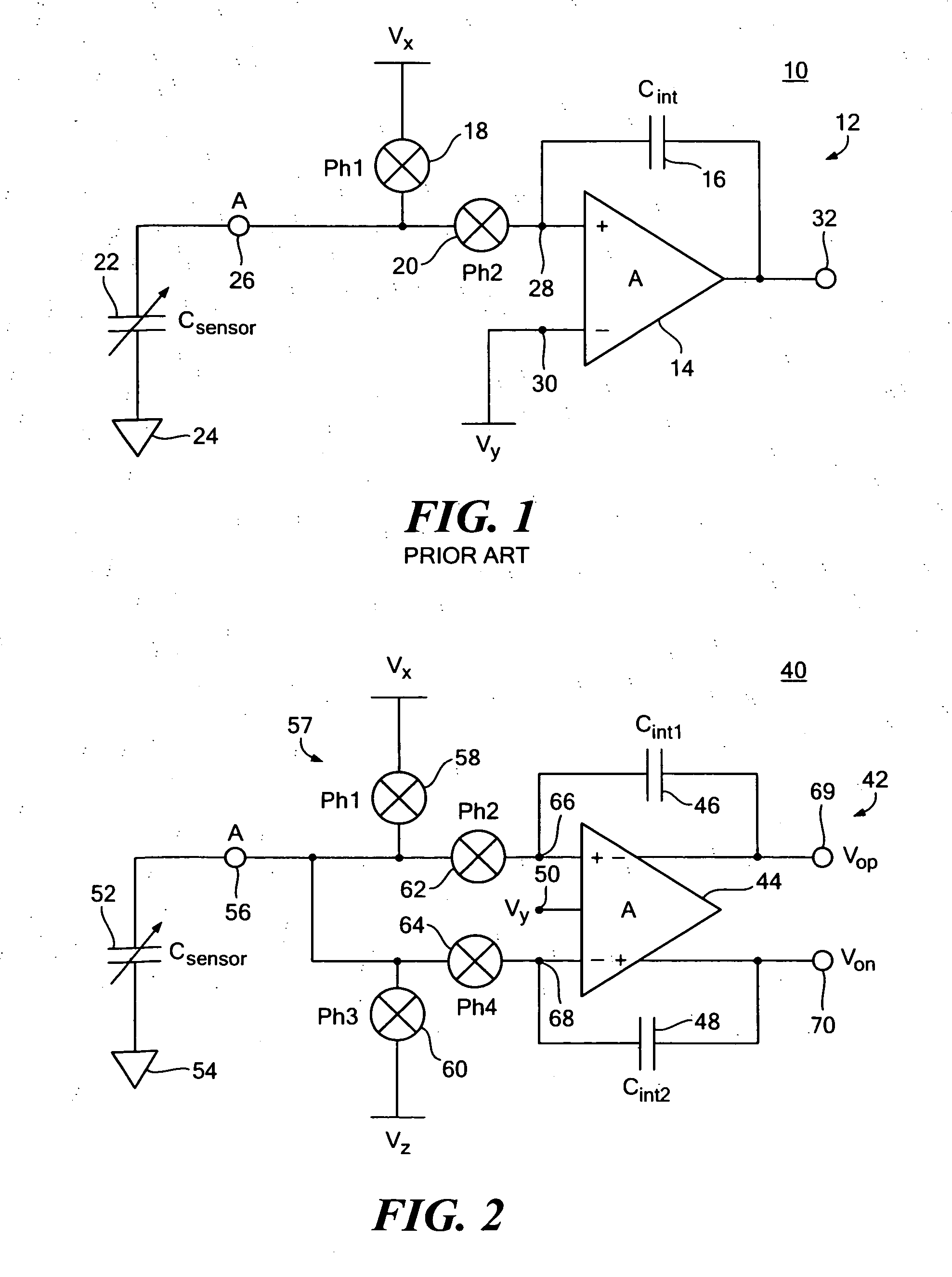

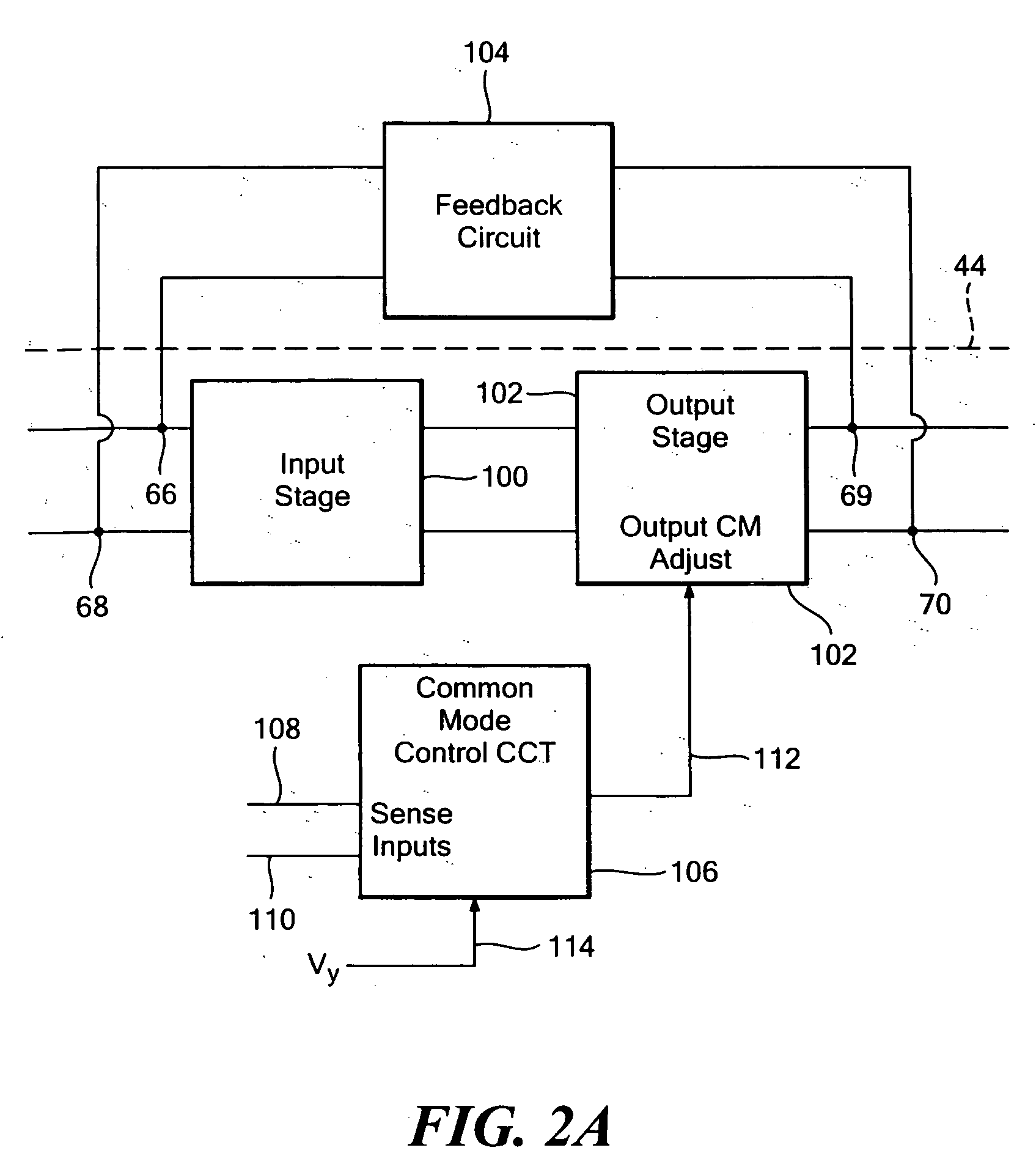

One terminal capacitor interface circuit

ActiveUS7235983B2Offset errorLow frequency noiseResistance/reactance/impedenceAnalogue conversionCapacitanceSecondary stage

A one terminal capacitor interface circuit for sensing the capacitance of a capacitor includes a differential integrating amplifier having an input common mode voltage and two summing nodes whose voltage is substantially equal to the input common mode voltage, a switching circuit for charging the capacitor to a first voltage level in a first phase, connecting, in a second phase, the capacitor to one of the summing nodes of the differential amplifier to provide a first output change substantially representative of the difference between the first voltage level and the input common mode voltage, and also representative of the capacitor; charging the capacitor to a second voltage level in a third phase, and connecting, in a fourth phase, the capacitor to the other summing node of the differential amplifier to provide a second output change substantially representative of the difference between the second voltage level and the input common mode voltage, and also representative of the capacitor; the combined first and second output changes representing the capacitance of the capacitor substantially independent of the input common mode voltage.

Owner:ANALOG DEVICES INC

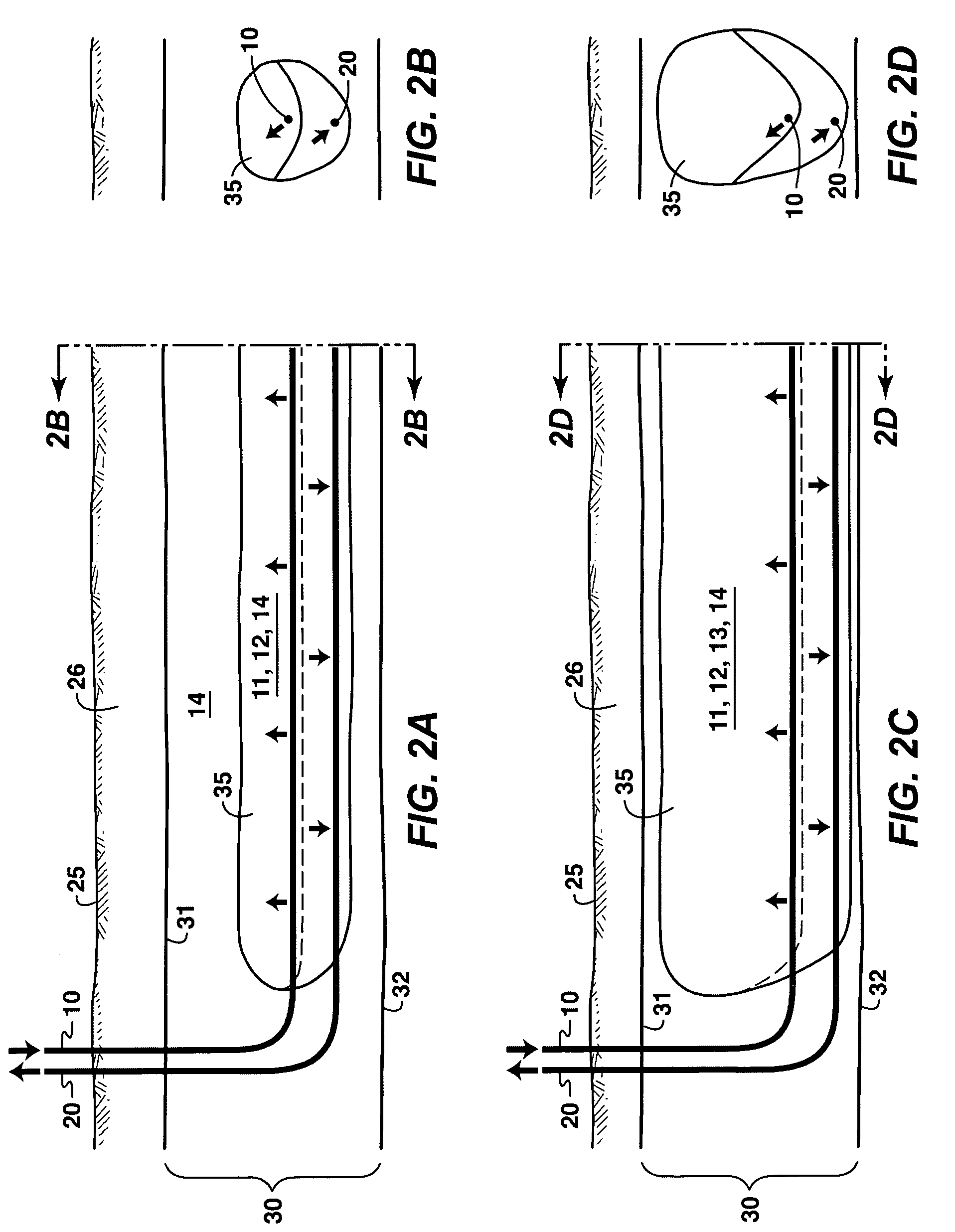

Process for in situ recovery of bitumen and heavy oil

A process is described for in situ recovery of bitumen or heavy oil from a reservoir having a horizontal injection well and a horizontal production well. The process includes a first phase in which steam and a heavy hydrocarbon solvent are injected into the reservoir, a second phase in which the steam and heavy hydrocarbon injections are transitioned to a light hydrocarbon solvent injection, and a third phase in which a light hydrocarbon solvent is injected without further steam or heavy hydrocarbon injection. A displacement gas may be added during any of the phases, and production of hydrocarbons continues throughout all phases. The process employs a high-production start-up phase, followed by lower cost phases which progress a depletion chamber within the reservoir.

Owner:EXXONMOBIL UPSTREAM RES CO

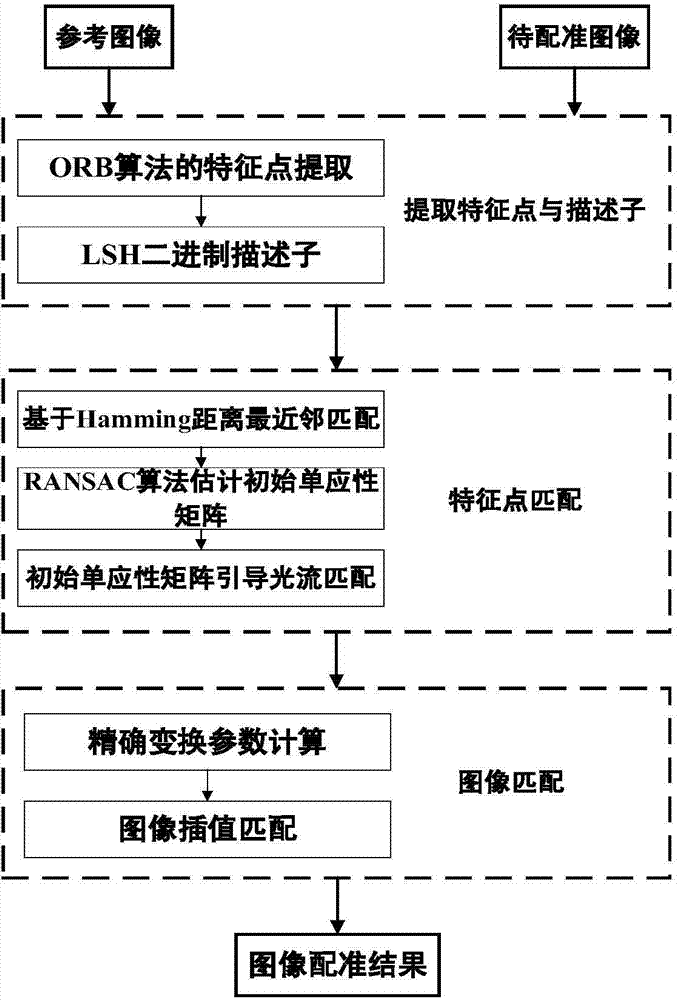

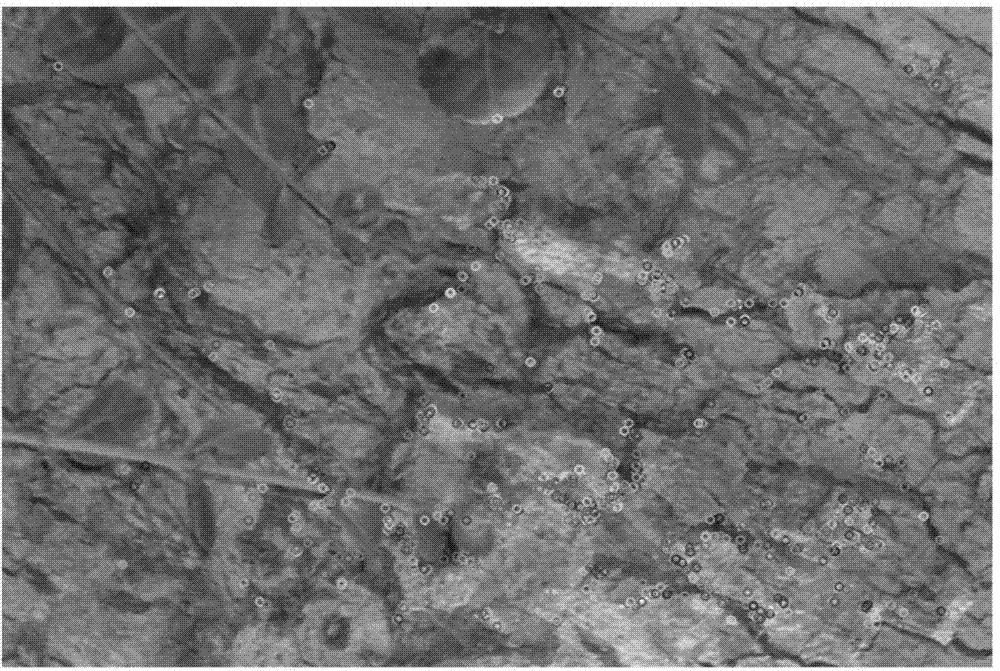

ORB (oriented brief) image feature registration method based on LK (Lucas-Kanade) optical flow constraint

InactiveCN104751465ASimple calculationReduce computationImage analysisImaging processingImaging Feature

The invention relates to an ORB (oriented brief) image feature registration method based on LK (Lucas-Kanade) optical flow constraint. The method includes three phases; in the first phase, ORB feature matching, ORB feature points in an image are extracted and matched to obtain a homography matrix; in the second phase, LK optical-flow precision matching, local optimal points are searched for by means of multiple iterations by the LK sparse optical flow method and used as optimal matching points, subjected to precision matching; in the third phase, image interpolation registration, two images are subjected to precision matching using the renewed homography matrix by means of bilinear interpolation. The method has the advantages that images of different scenes or images acquired by different sensors are automatically matched by means of image processing, registration precision directly determines quality of following image fusion, the high precision matching is maintained, and an algorithm is enabled to meet the demand for timely processing is met.

Owner:UNIV OF SCI & TECH OF CHINA

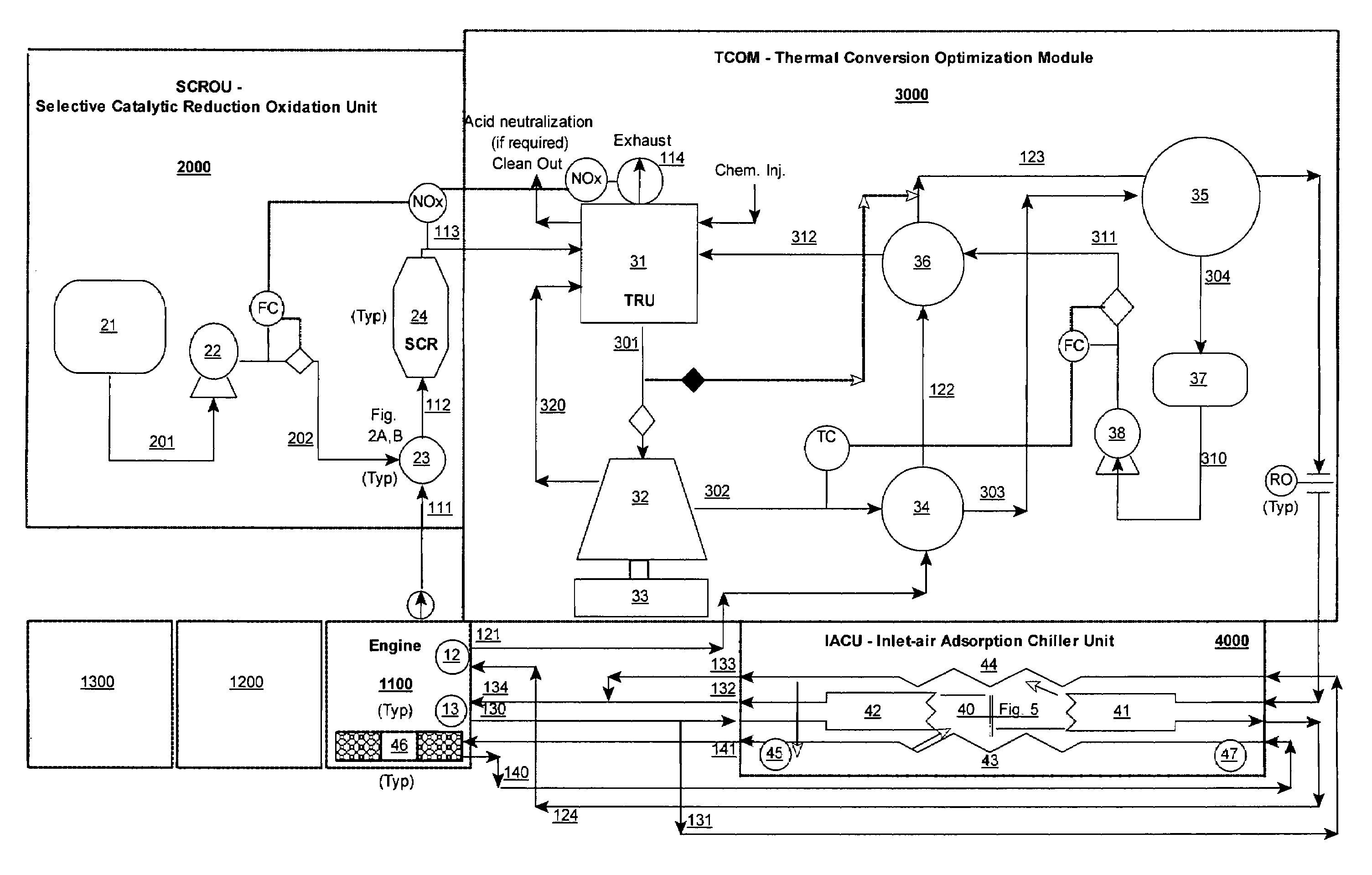

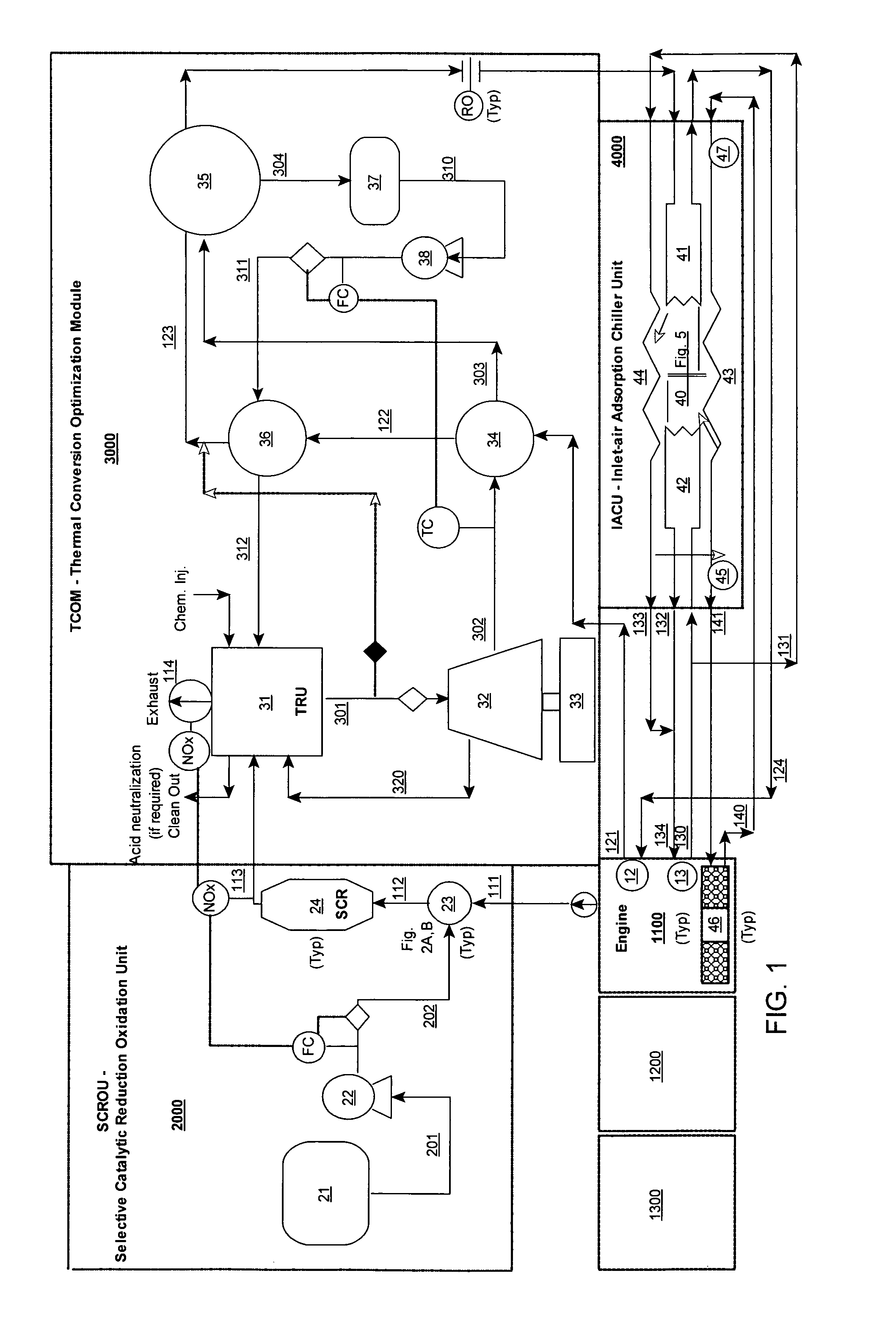

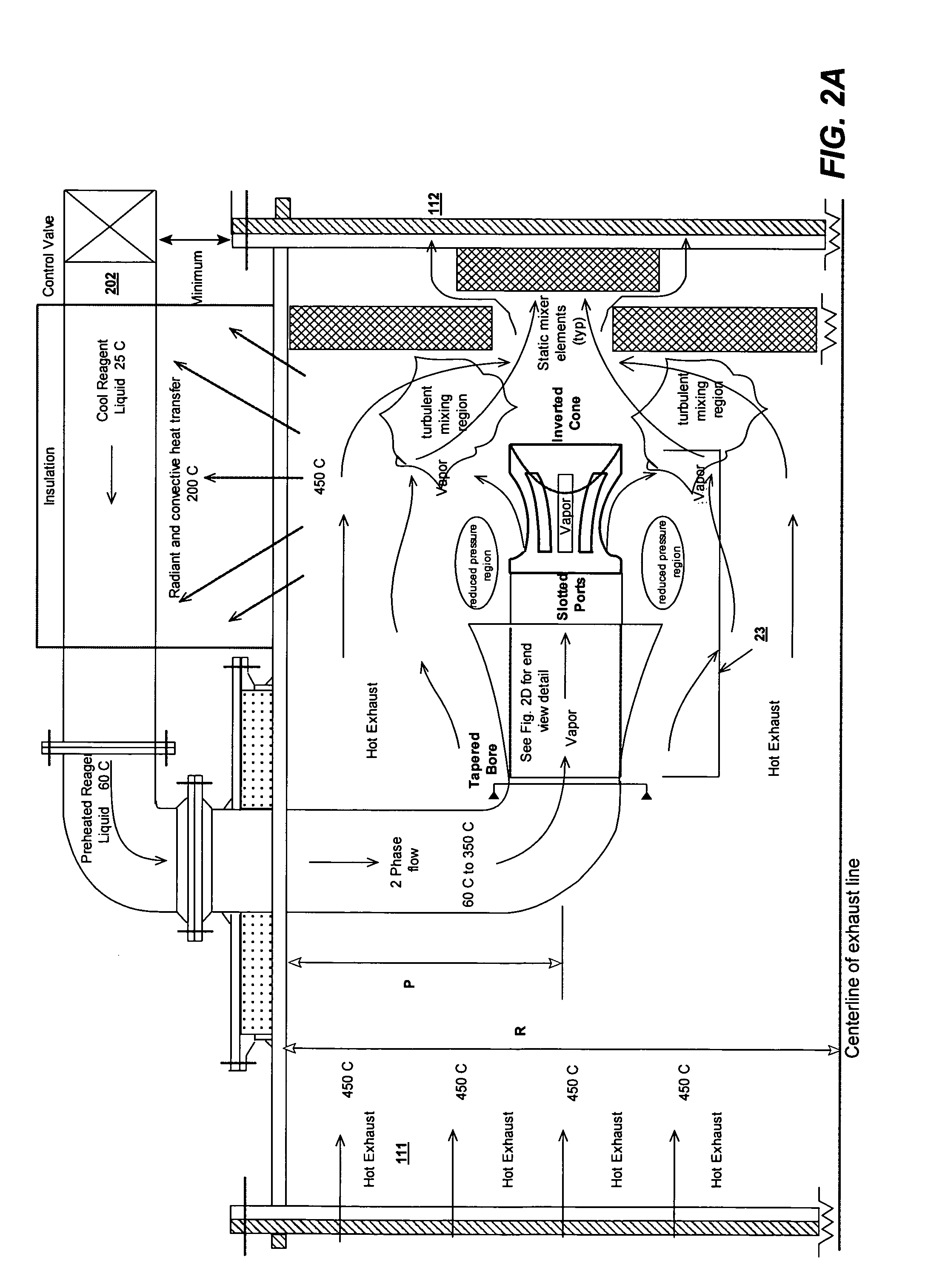

Energy recovery from waste heat sources

InactiveUS7469540B1Emission reductionResist acidic corrosionInternal combustion piston enginesExhaust apparatusThermal energyEngineering

In some embodiments, three integrated phases may be used to reduce emissions, convert thermal energy into electricity, and cool inlet combustion air. An ammonia injection system may be designed to eliminate extraneous equipment and hazardous re-circulation lines by directly vaporizing, injecting, and mixing ammonia using a specially designed nozzle. The second phase may include using a preheat / vaporizer / superheater exchanger to convert ammonia liquid into a superheated vapor that is then passed through a turbo-expander / generator to produce power. In some embodiments, the third phase may include inlet combustion air chilling.

Owner:KNAPTON BRENT WILLIAM +1

Dried product and a drying process

InactiveUS6268012B1Minimize impactNot to damageFruits/vegetable preservation by dehydrationMeat/fish preservation by dryingWater activityFresh air

A dried fruit or vegetable has a water content in the range 4% to 7%, and has a water activity of 0.4. Substantially all of the cells of the dried product are undamaged. An air drying process is gentle and contains four phases, during which the temperature of the drying air is maintained at 60° C. In a first phase the relative humidity of the drying air is allowed to rise to between 50% and 55%, and is maintained substantially constant at this value during a second phase by maintaining exchange of the drying air with fresh air substantially constant. In a third phase of the process, the relative humidity of the drying medium is permitted to decrease relatively rapidly until the fourth phase commences, at which stage the relative humidity is permitted to asymptotically approach a predetermined relative humidity value. During the drying process, excessive temperature differences and relative humidity differences between the temperature and relative humidity, respectively of the drying medium and the product are avoided in order to minimize damage to the cellular structure of the product.

Owner:DTL

Modular multi-pulse transformer rectifier for use in asymmetric multi-level power converter

In one embodiment, the present invention includes a system having multiple modular transformers each including a phase-shifted primary winding coupled to an input power source and phase-shifted secondary windings each coupled to a power cell. The system further includes different phase output lines coupled to a load. These lines may include first, second and third phase output lines.

Owner:TECO WESTINGHOUSE MOTOR

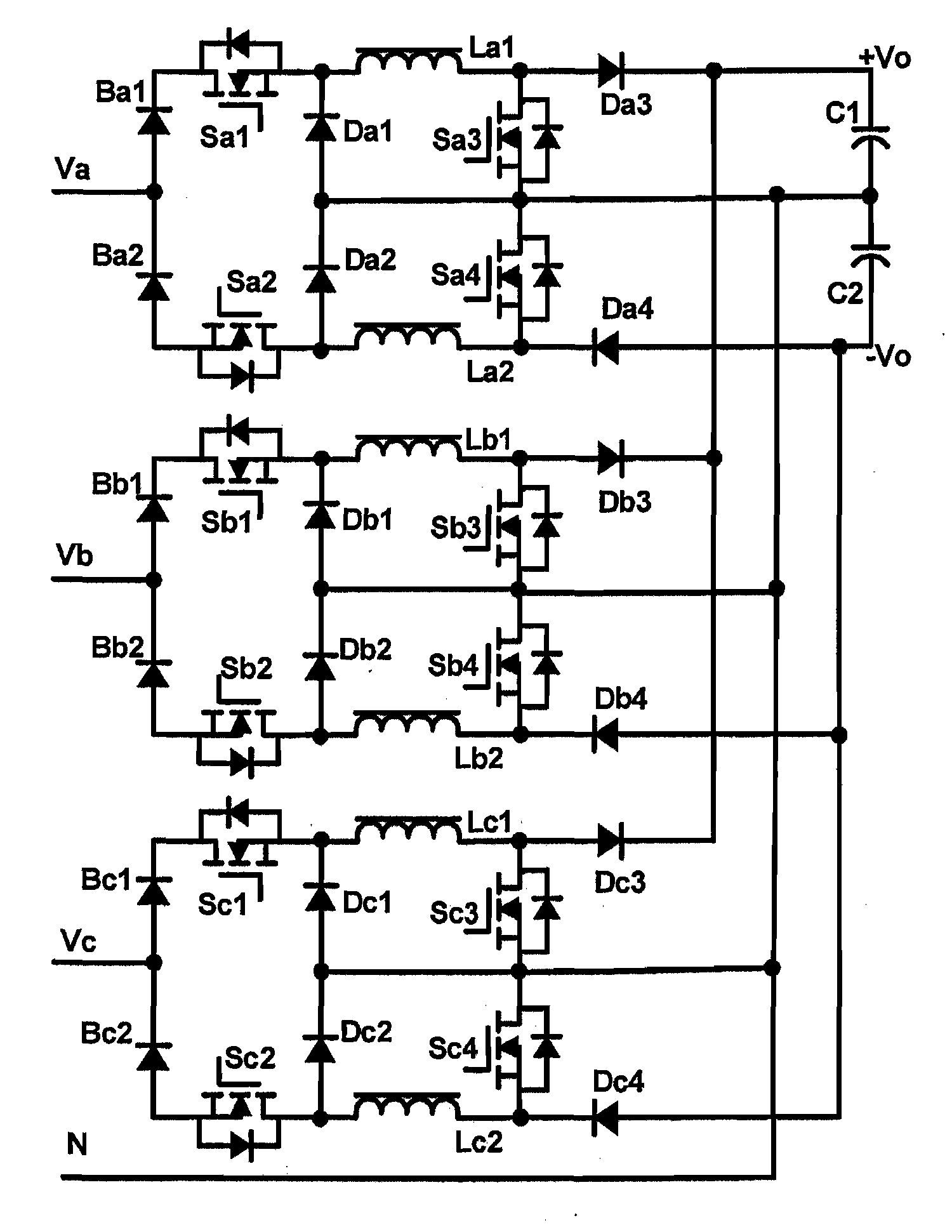

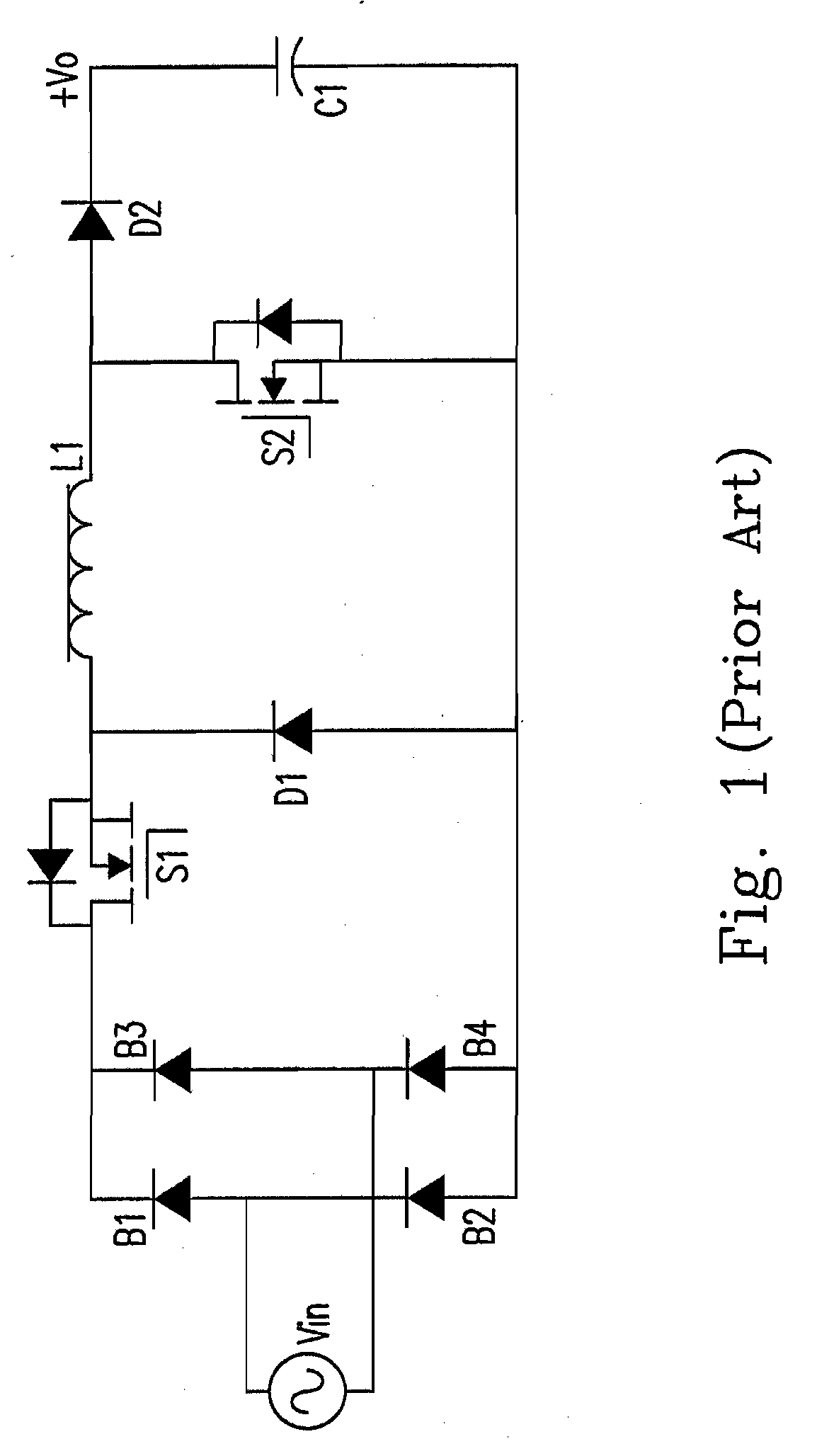

Three-phase buck-boost power factor correction circuit and controlling method thereof

ActiveUS20090268496A1Improve efficiencyReduce in quantityAc-dc conversion without reversalEfficient power electronics conversionThree-phaseNeutral line

The configurations of a three-phase buck-boost power factor correction (PFC) circuit and a controlling method thereof are provided in the present invention. The proposed circuit includes a first single-phase buck-boost PFC circuit receiving a first phase voltage and having a first and a second output terminals and a neutral-point for outputting a first and a second output voltages, a second single-phase buck-boost PFC circuit receiving a second phase voltage and coupled to the first and the second output terminals and the neutral-point, a third single-phase buck-boost PFC circuit receiving a third phase voltage and coupled to the first and the second output terminals and the neutral-point, a first and a second output capacitors coupled to the first and the second output terminals respectively, and to the neutral-point also and a neutral line coupled to the neutral-point.

Owner:DELTA ELECTRONICS INC

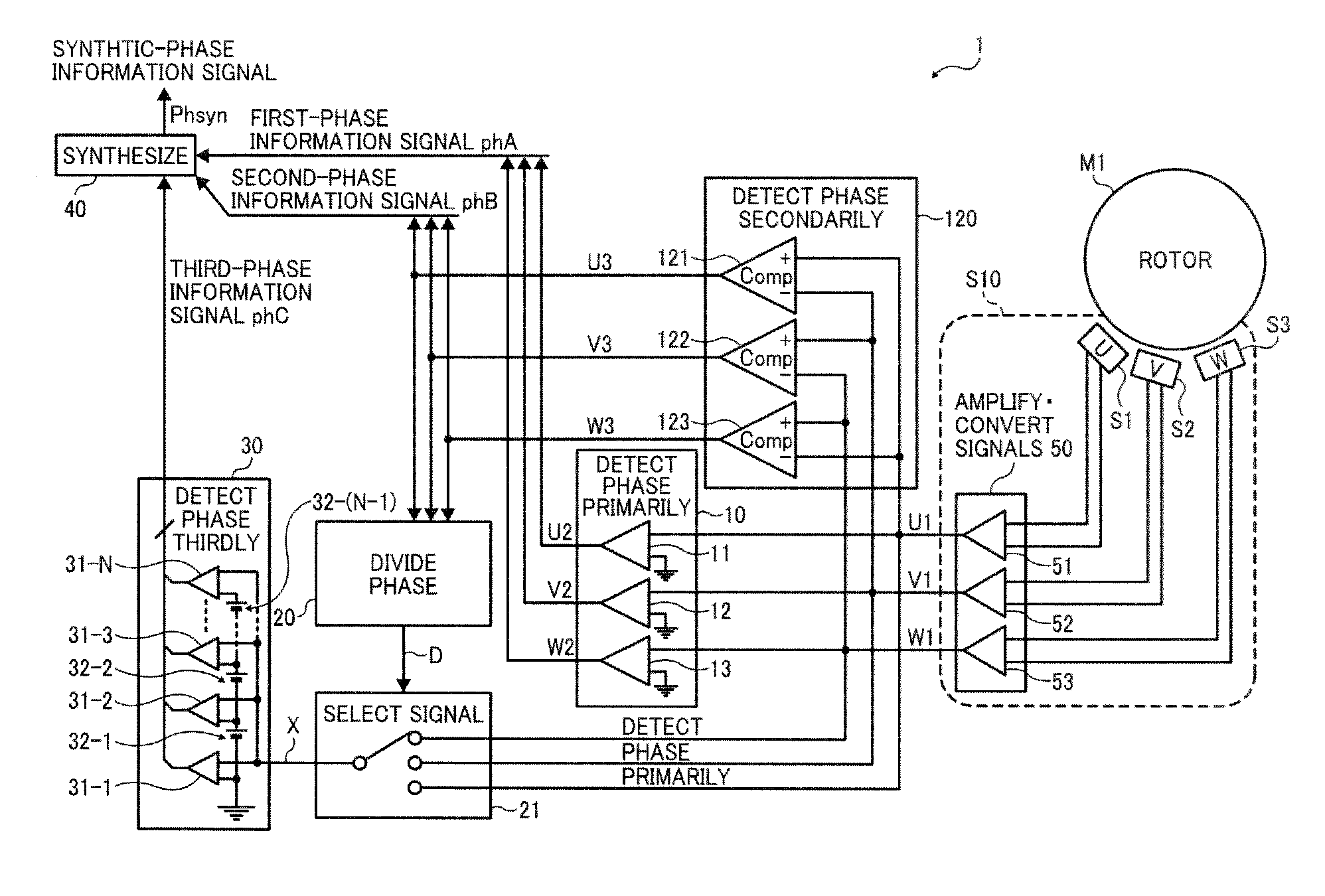

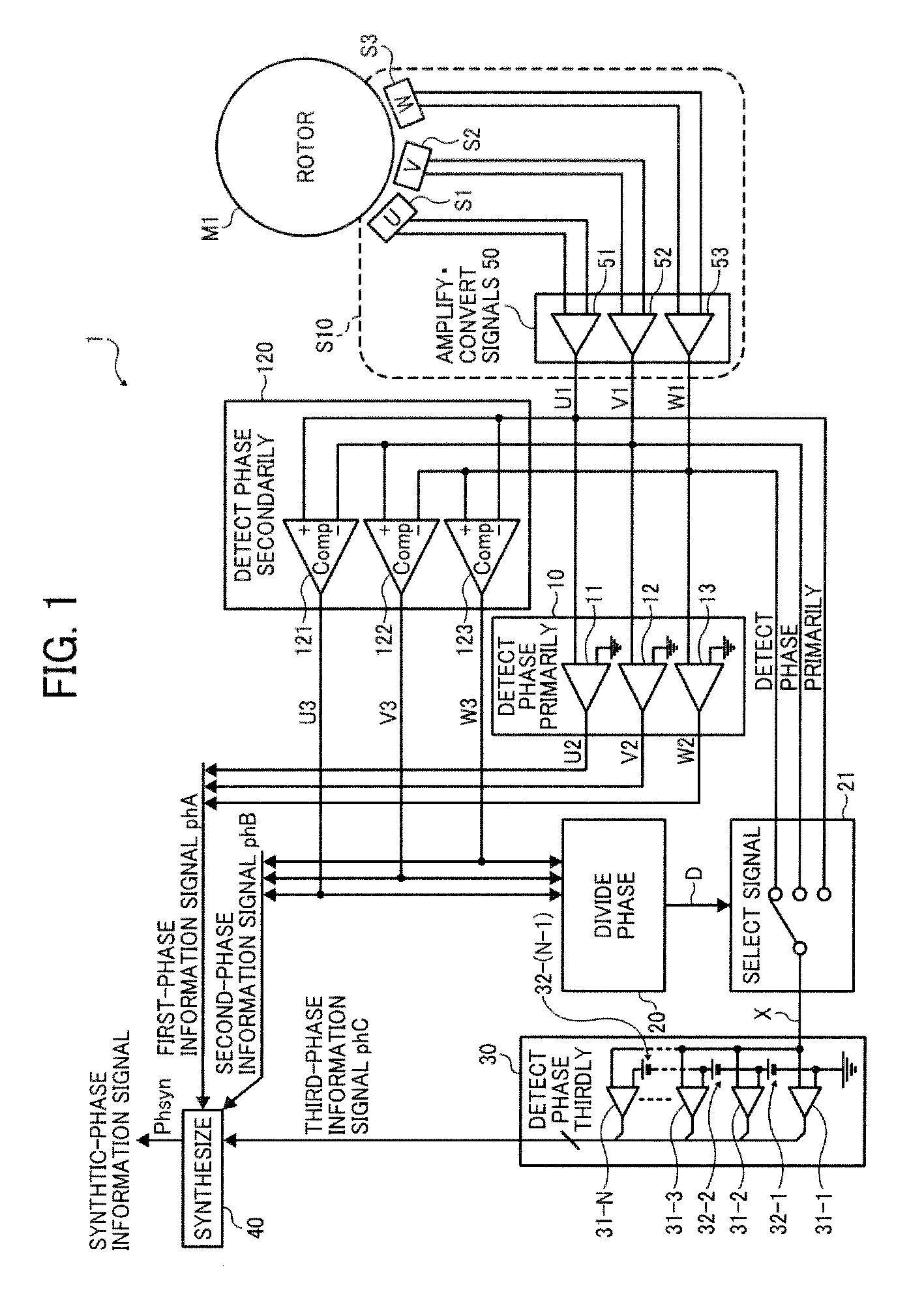

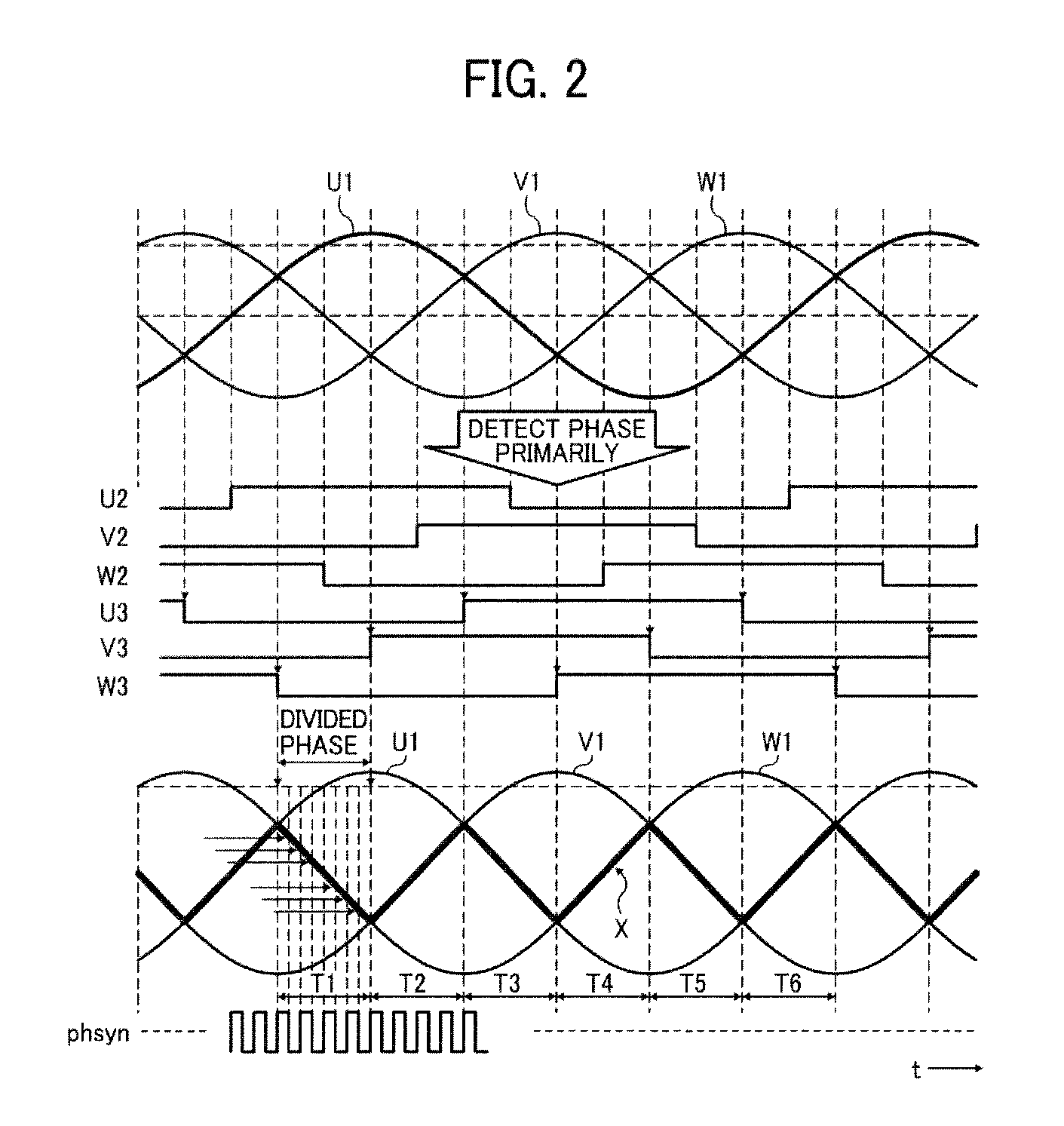

Motor drive controller and control method

A motor drive controller to control a motor via multiple sensors includes a first phase detector to compare respective differential pairs of the sensor signals from the same sensor to detect phases of the rotor, and output a first phase information signal; a second phase detector to compare a respective one of the multiple sensor signals with another sensor signal from the different sensor to detect the phases and output a second phase information signal; a phase divider to divide the phases, detected by the first and second phase detectors, into multiple predetermined phase intervals; a signal selector to select one of the multiple sensor signals in the multiple predetermined phase intervals; and a third phase detector to detect whether the signal selected by the signal selector reaches a predetermined threshold level corresponding to a predetermined phase of the rotor, and output a third phase information signal.

Owner:RICOH KK

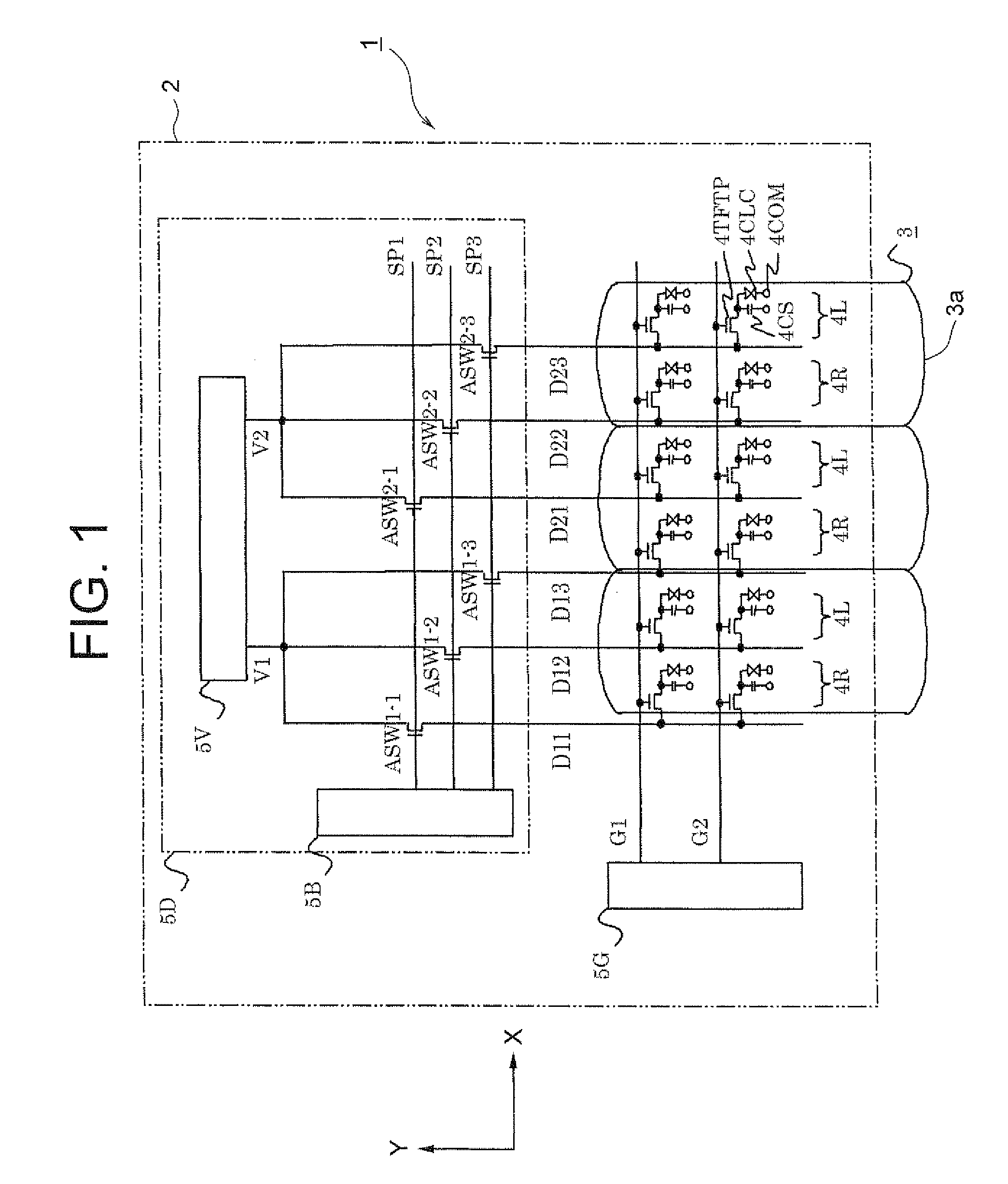

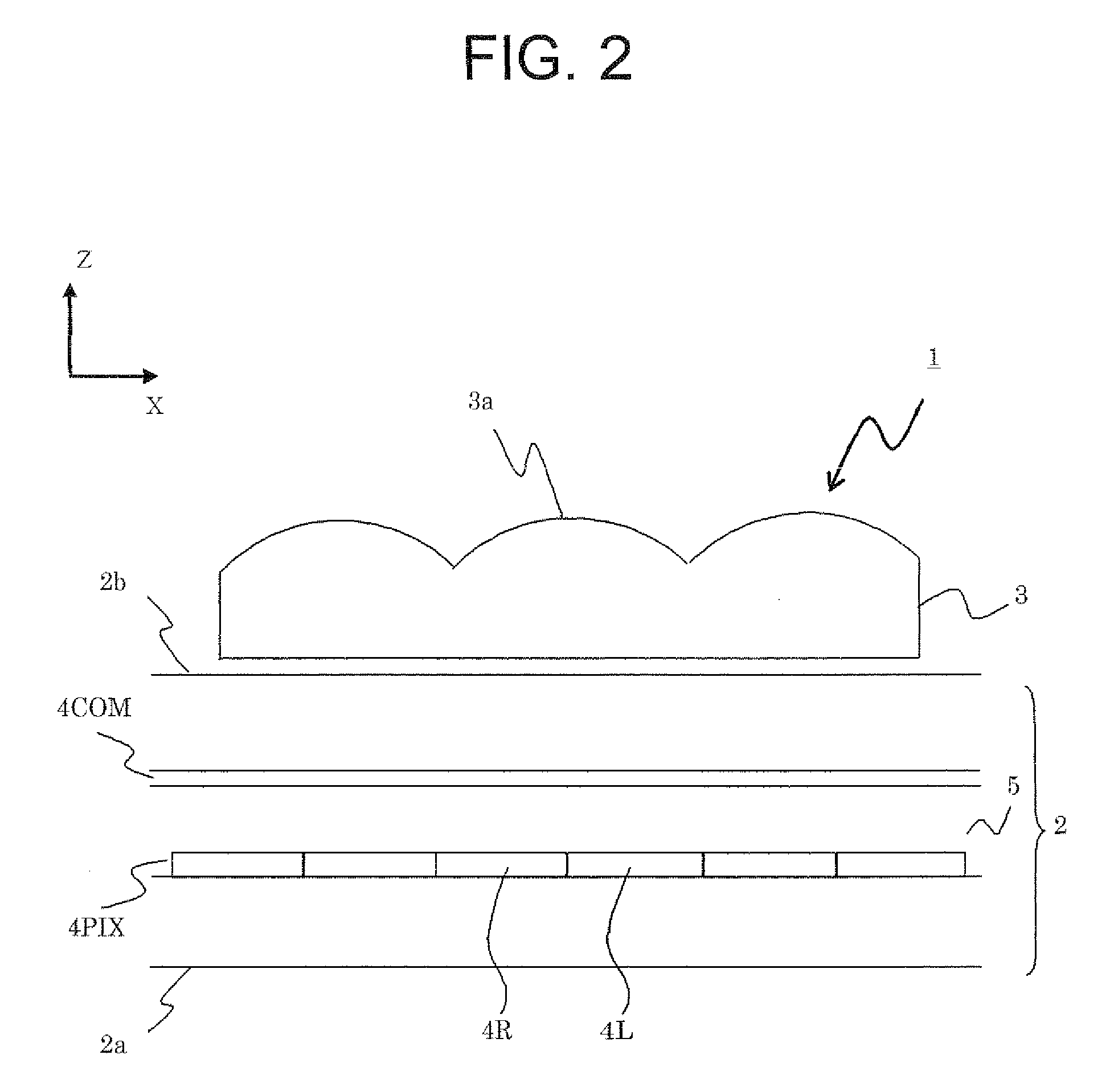

Display device, terminal device, display panel, and display device driving method

ActiveUS20090096726A1Improve image qualityInhibit deteriorationCathode-ray tube indicatorsSteroscopic systemsImaging qualityComputer graphics (images)

To provide a plural-viewpoint display device having an image separating optical element such as a lenticular lens or a parallax barrier, which is capable of achieving a high image quality by suppressing deterioration in the display image quality caused when a block division driving method is employed, and to provide a terminal device, a display panel, and a driving method thereof, which can be preferably used for those devices. A pixel group configured with pixels for displaying a right-eye image includes a pixel connected to a data line phase-deployed in the first phase of a block division driving method, and a pixel connected to a data line phase-deployed in the third phase, and a pixel connected to a data line phase-deployed in the second phase. In this manner, it is designed to have no deviation in the phase deployment orders in the pixel groups for each viewpoint.

Owner:NEC LCD TECH CORP

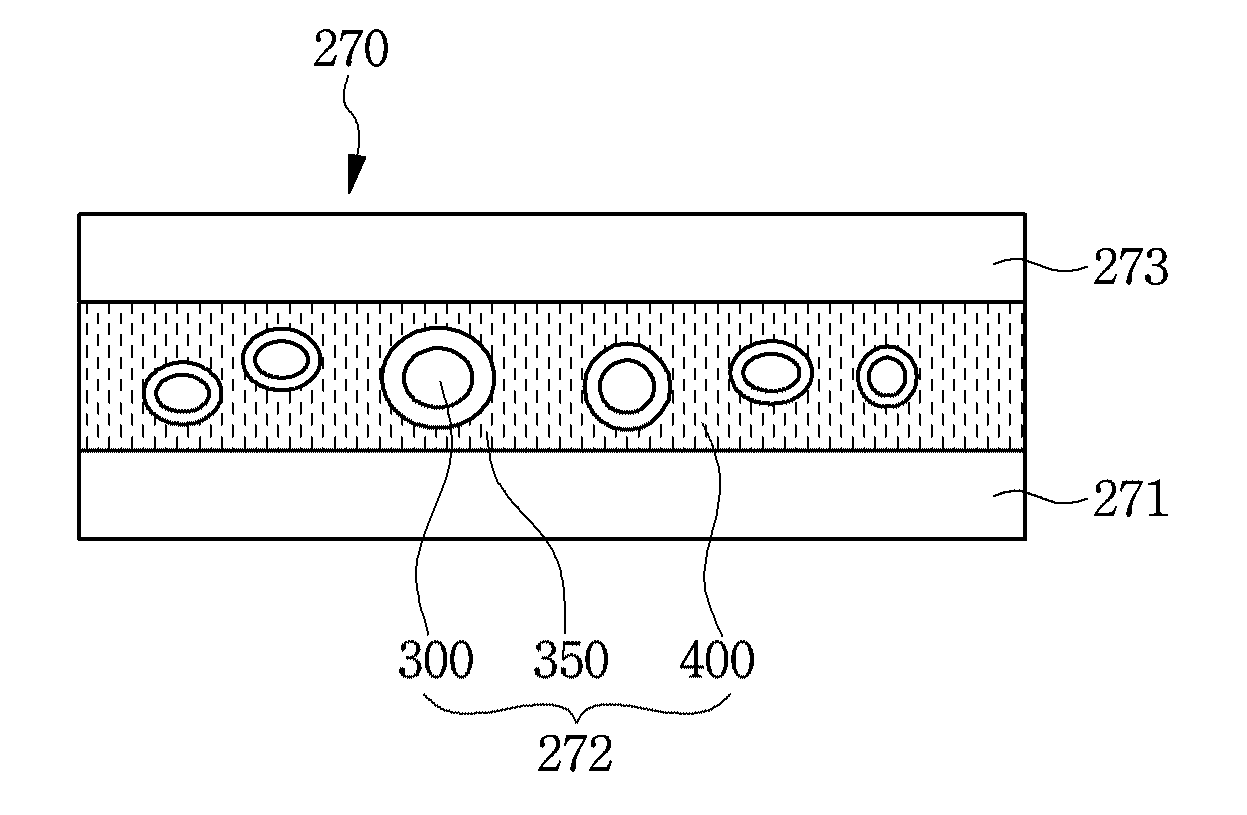

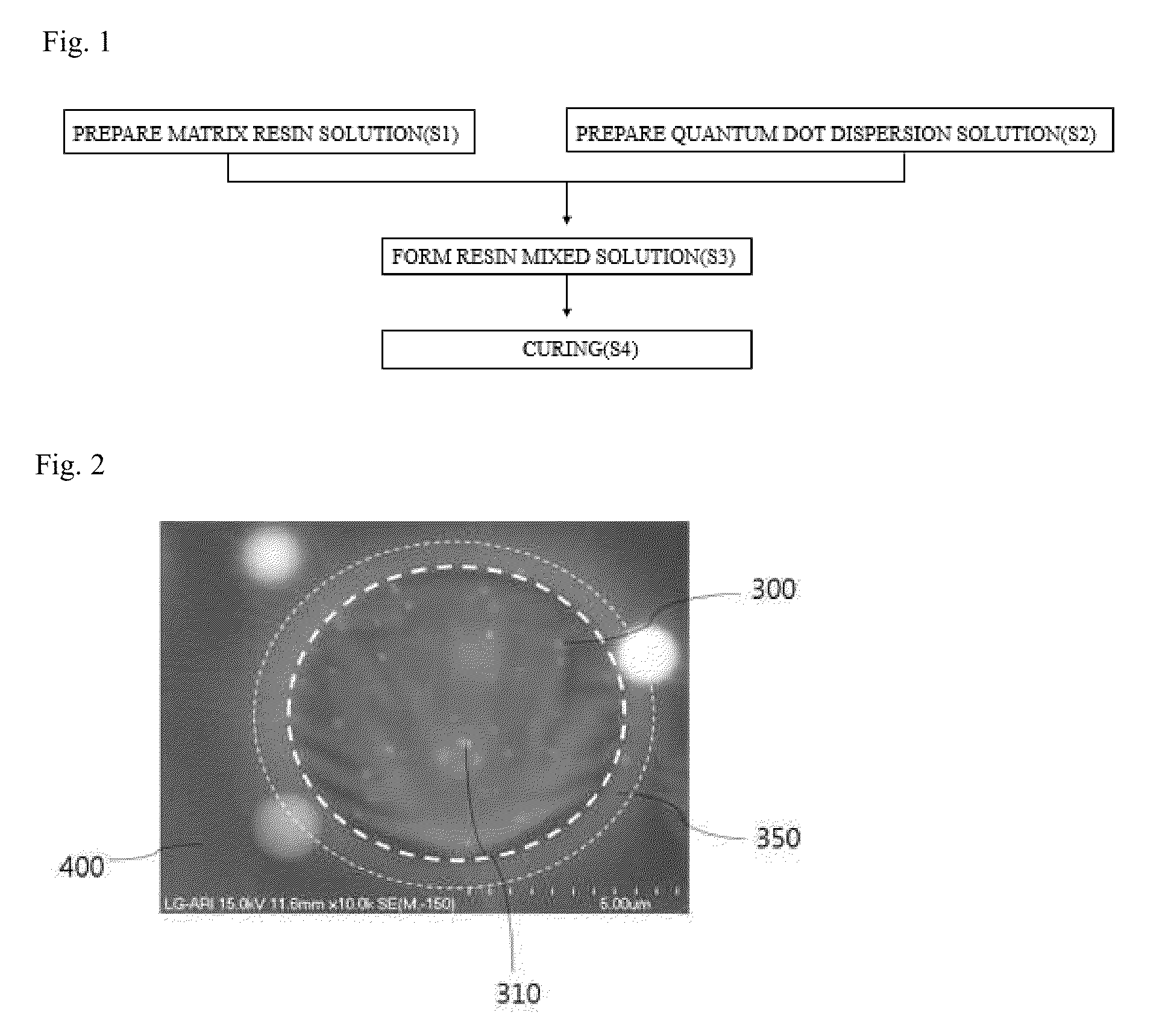

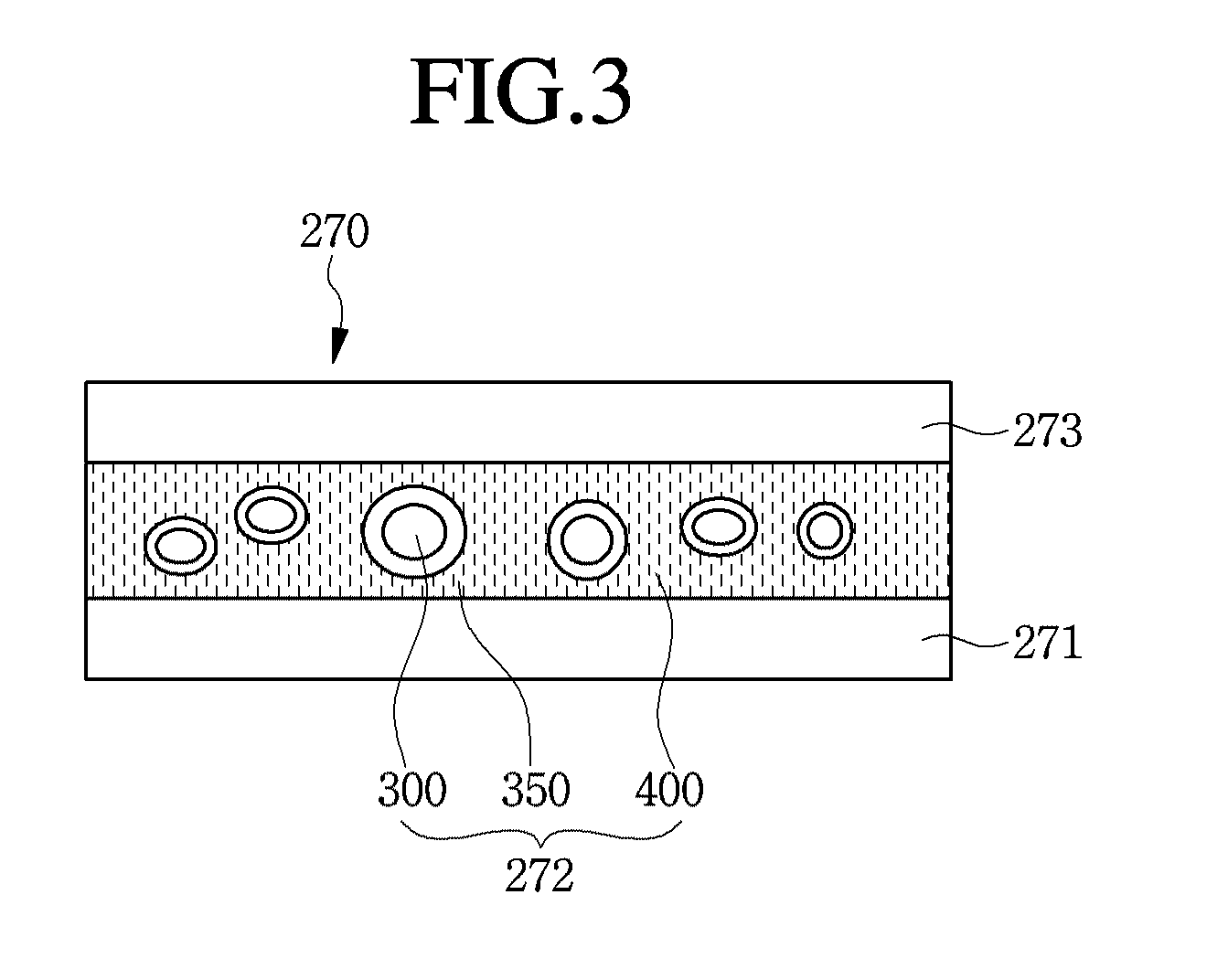

Method for preparing quantum dot-polymer complex, quantum dot-polymer complex, light conversion film, backlight unit and display device having the same

ActiveUS20160161066A1Uniform thicknessReduce degradationPoint-like light sourceSynthetic resin layered productsDisplay deviceQuantum dot

A quantum dot-polymer complex and a method for preparing the same. The quantum dot-polymer complex includes a first phase formed of a matrix resin, a globular second phase dispersed in the first phase, the second phase including a quantum dot therein, and a third phase disposed along a surface of the second phase between the first and second phases.

Owner:LG ELECTRONICS INC

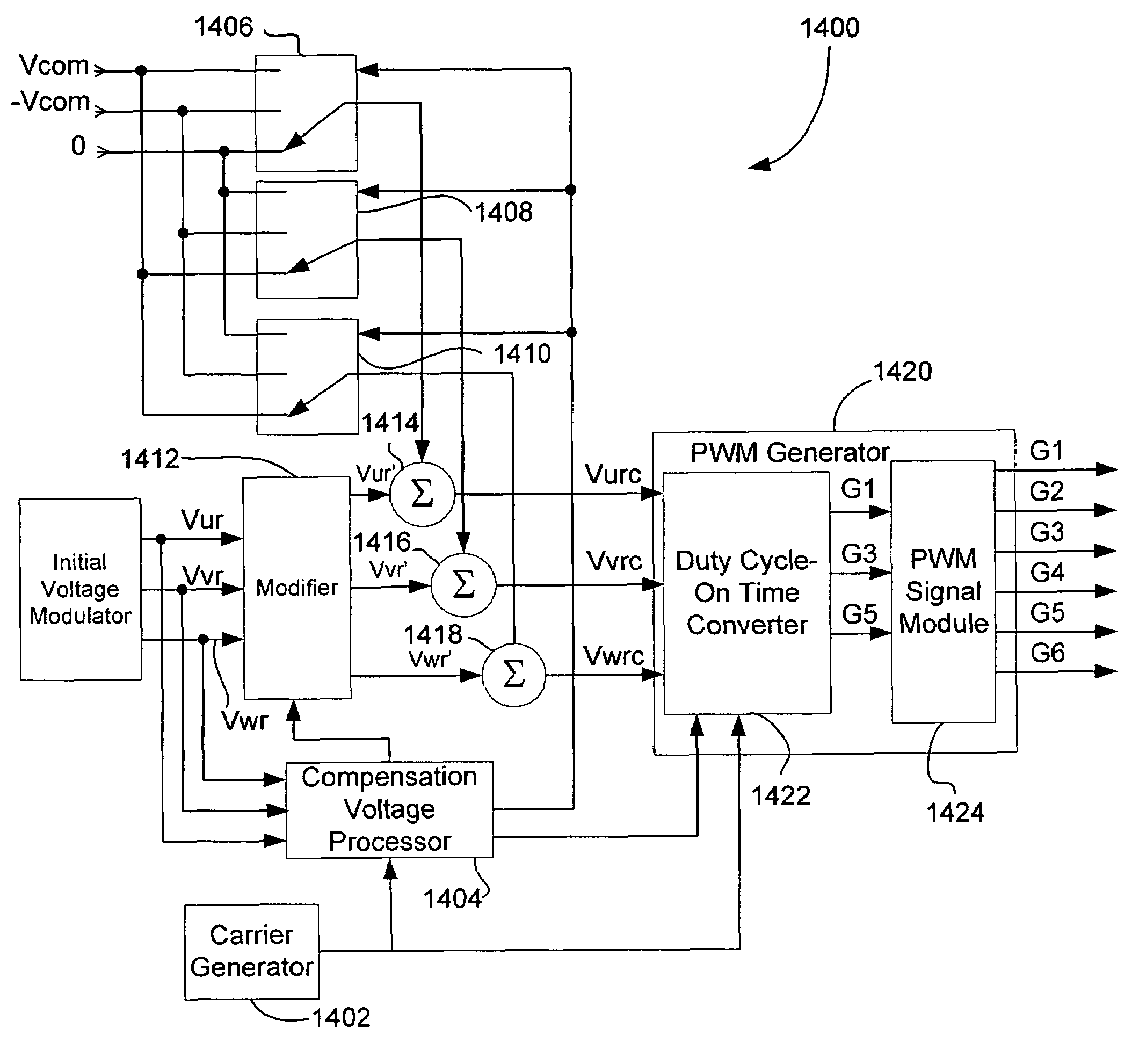

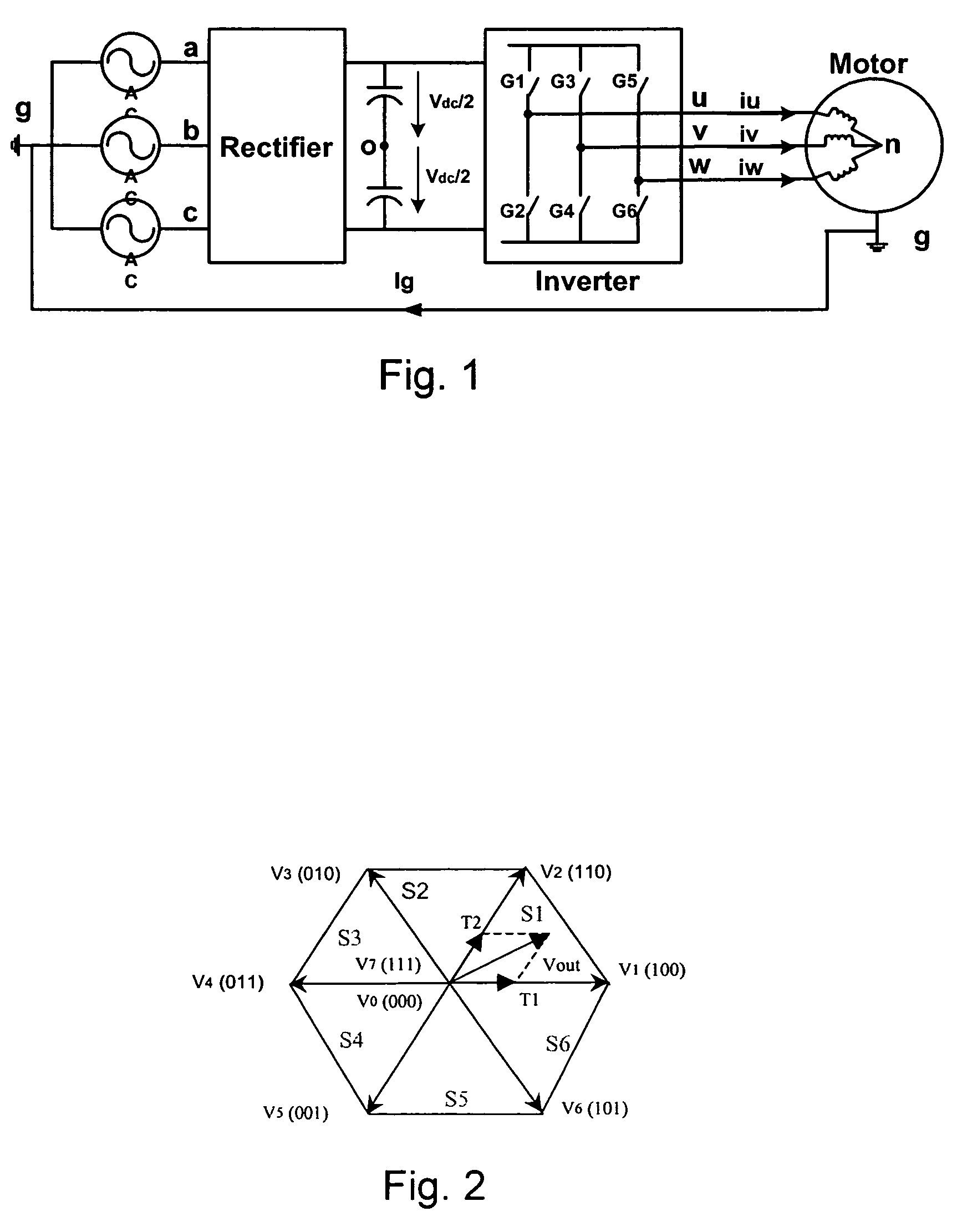

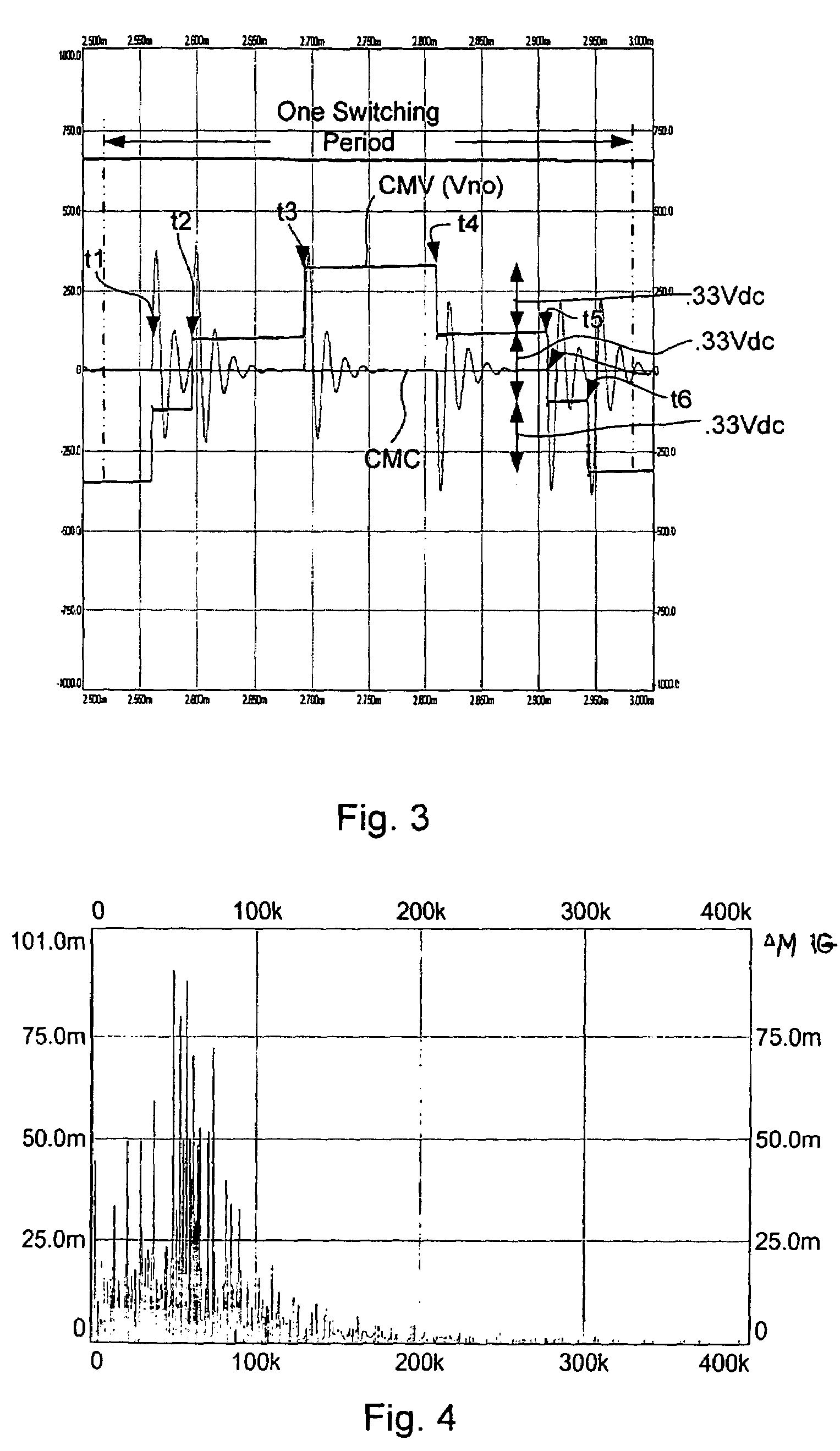

Modulation methods and apparatus for reducing common mode noise

ActiveUS7400518B2Reduce common mode noiseMinimize impactAC motor controlAc-dc conversionWave shapeCarrier signal

A method and apparatus for reducing common mode noise in a three phase pulse width modulated (PWM) system the method comprising the steps of receiving modulating waveforms, identifying a first of the modulating waveforms that is instantaneously the maximum of the modulating waveforms, identifying a second of the modulating waveforms that is instantaneously the minimum of the modulating waveforms, for a first phase associated with at least one of the first and second identified waveforms, substituting a first substitute waveform for the one of the first and second waveforms, for the first phase, modifying at least one of the first substituted waveform and duty cycle signals generated by comparing the first substituted waveform with the carrier signal as a function of a first rule set to substantially minimize the effects of turn on delays and for at least one of the second and third phases, modifying at least one of the associated modulating waveform and duty cycle signals generated by comparing the modulating waveform with the carrier signal as a function of a second rule set to substantially eliminate the effects of turn on delays where the second rule set is different than the first rule set.

Owner:ROCKWELL AUTOMATION TECH

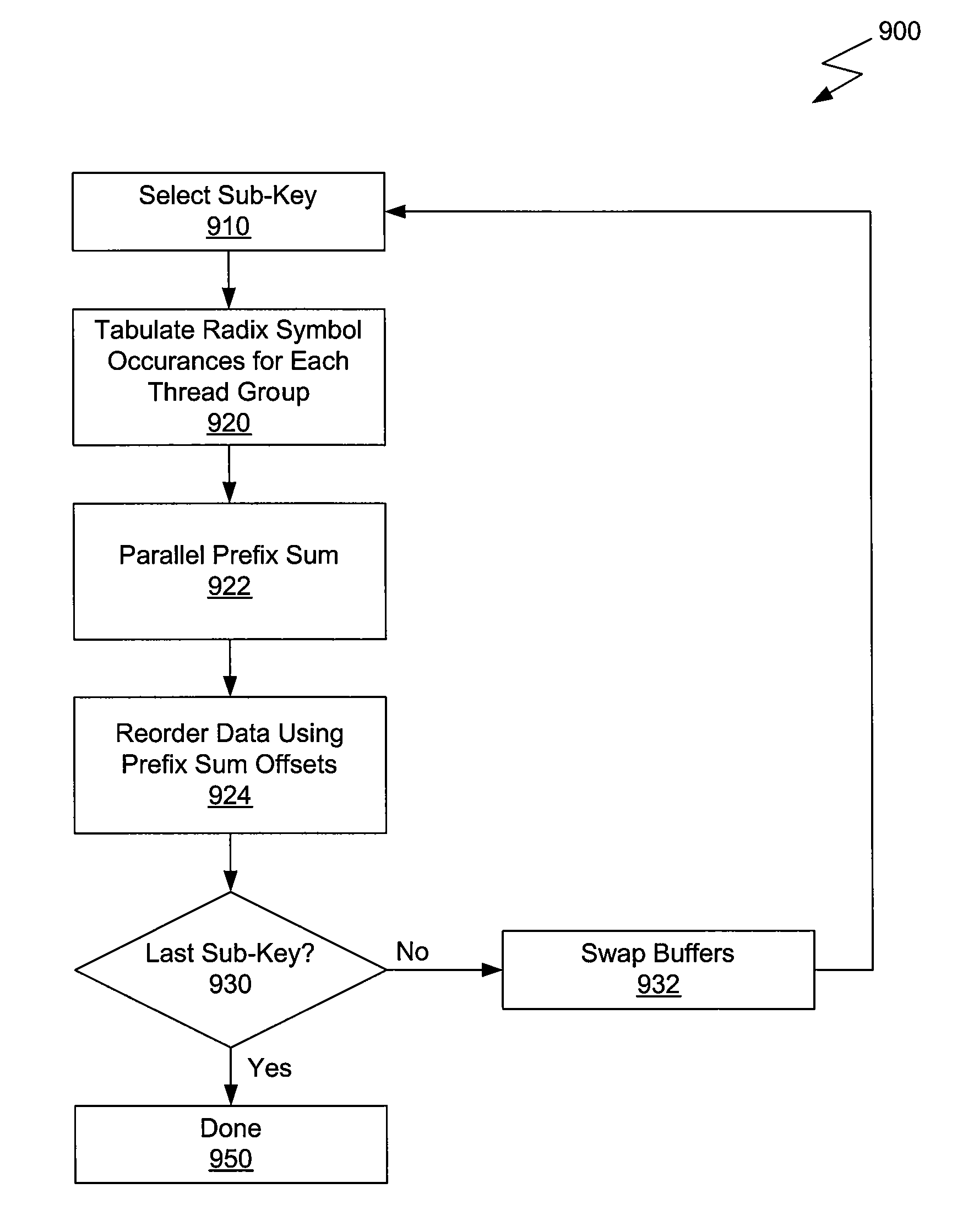

Performing an occurence count of radices

One embodiment of the present invention sets forth a technique for efficiently performing a radix sort operation on a graphics processing unit (GPU). The radix sort operation is conducted on an input list of data using one or more passes of a series of three processing phases. In each processing phase, thread groups are each associated with one segment of input data. In the first phase, occurrences of each radix symbol are counted and stored in a list of counters. In the second phase, the list of counters is processed by a parallel prefix sum operation to generate a list of offsets. In the third phase, the list of offsets is used to perform re-ordering on the list of data, according to the current radix symbol. To maintain sort stability, the one or more passes proceed from least significant data to most significant data in the sort key.

Owner:NVIDIA CORP

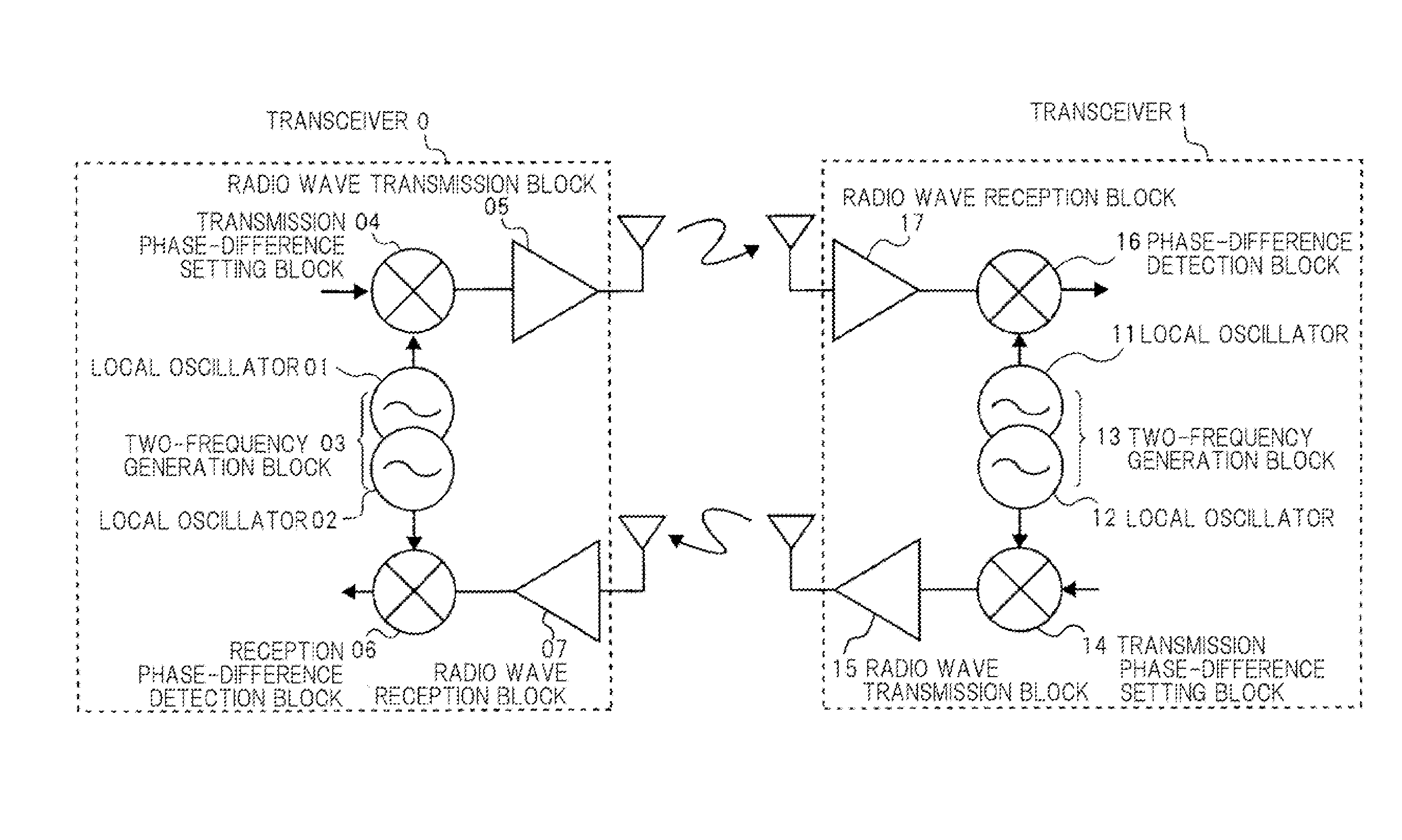

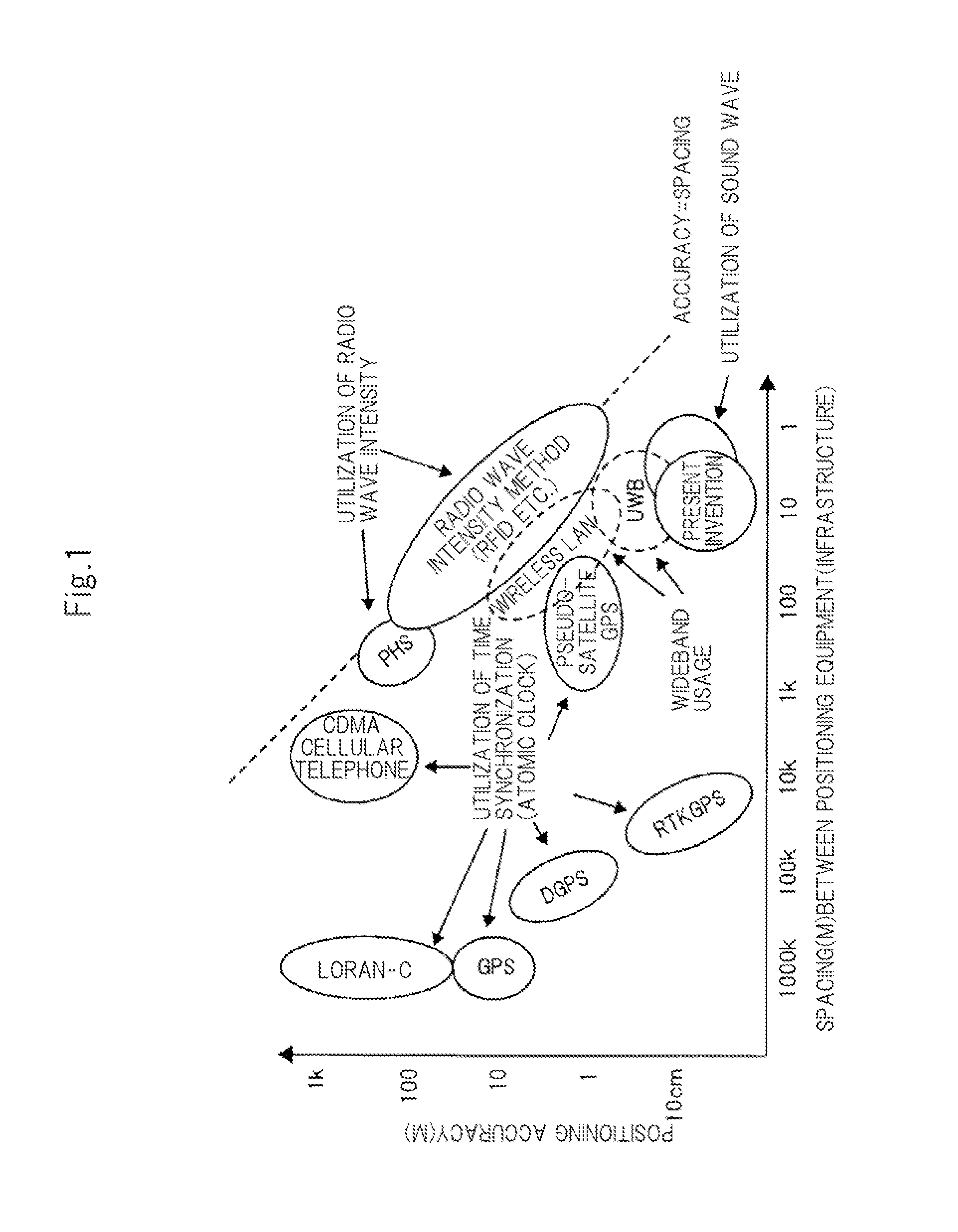

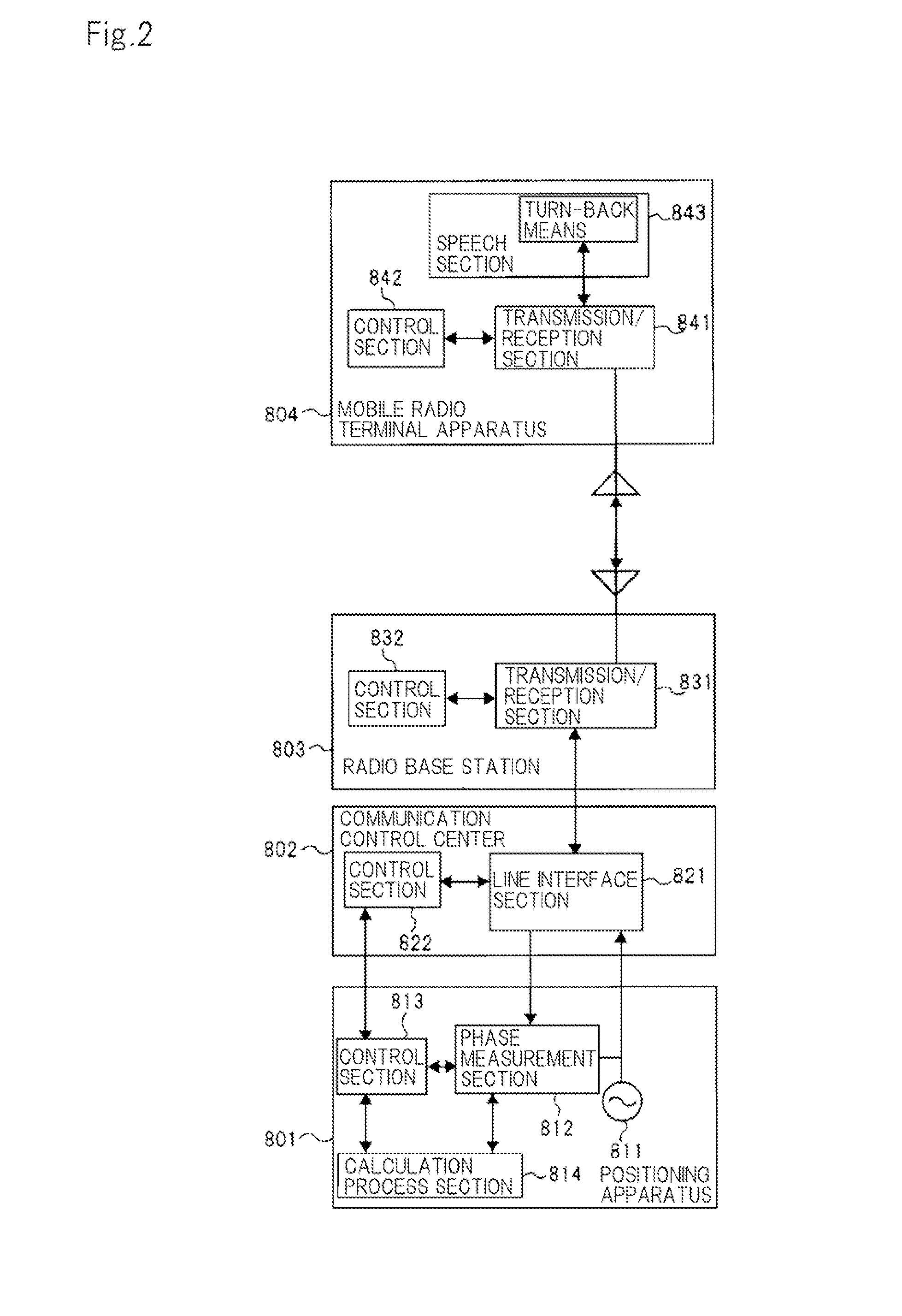

Multiband transceiver and positioning system using the transceiver

ActiveUS20100321245A1Possible to performLow costDirection finders using radio wavesTransmissionTransceiverPhase difference

The present invention comprising: a first local oscillator for generating a first frequency; a second local oscillator for generating a second frequency; phase-difference setting means for setting a first phase difference between a transmission signal and an output of the aforementioned first local oscillator; phase-difference detection means for detecting a second phase difference which is the phase difference between a reception signal and an output of the aforementioned second local oscillator, and calculation means for calculating a distance to a communication counterpart from a third phase difference and a fourth phase difference which are notified by the communication counterpart, and from the aforementioned first phase difference and second phase difference, wherein the third phase difference is set to the second frequency by the communication counterpart, and the fourth phase difference is set to the first frequency by the communication counterpart.

Owner:NEC CORP

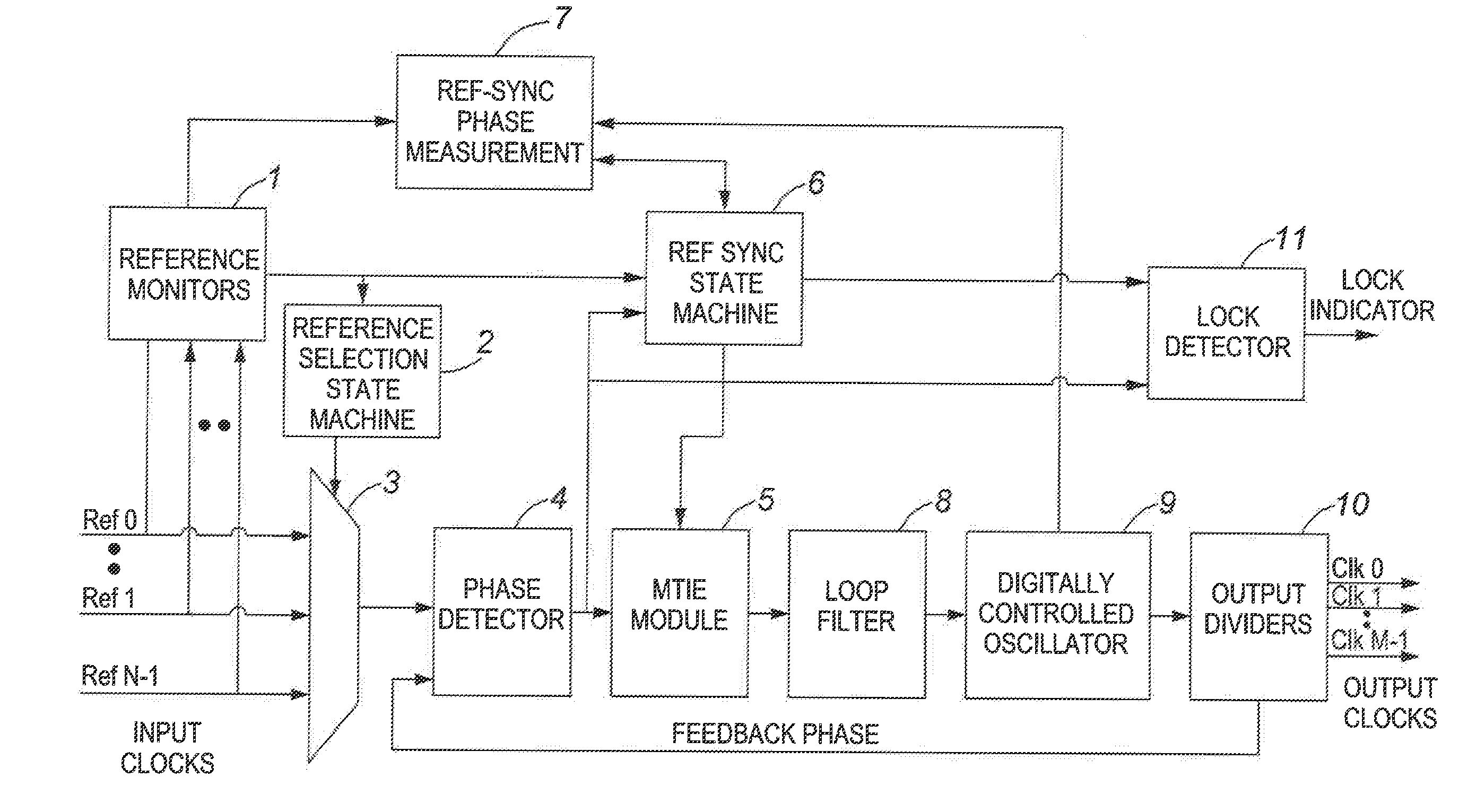

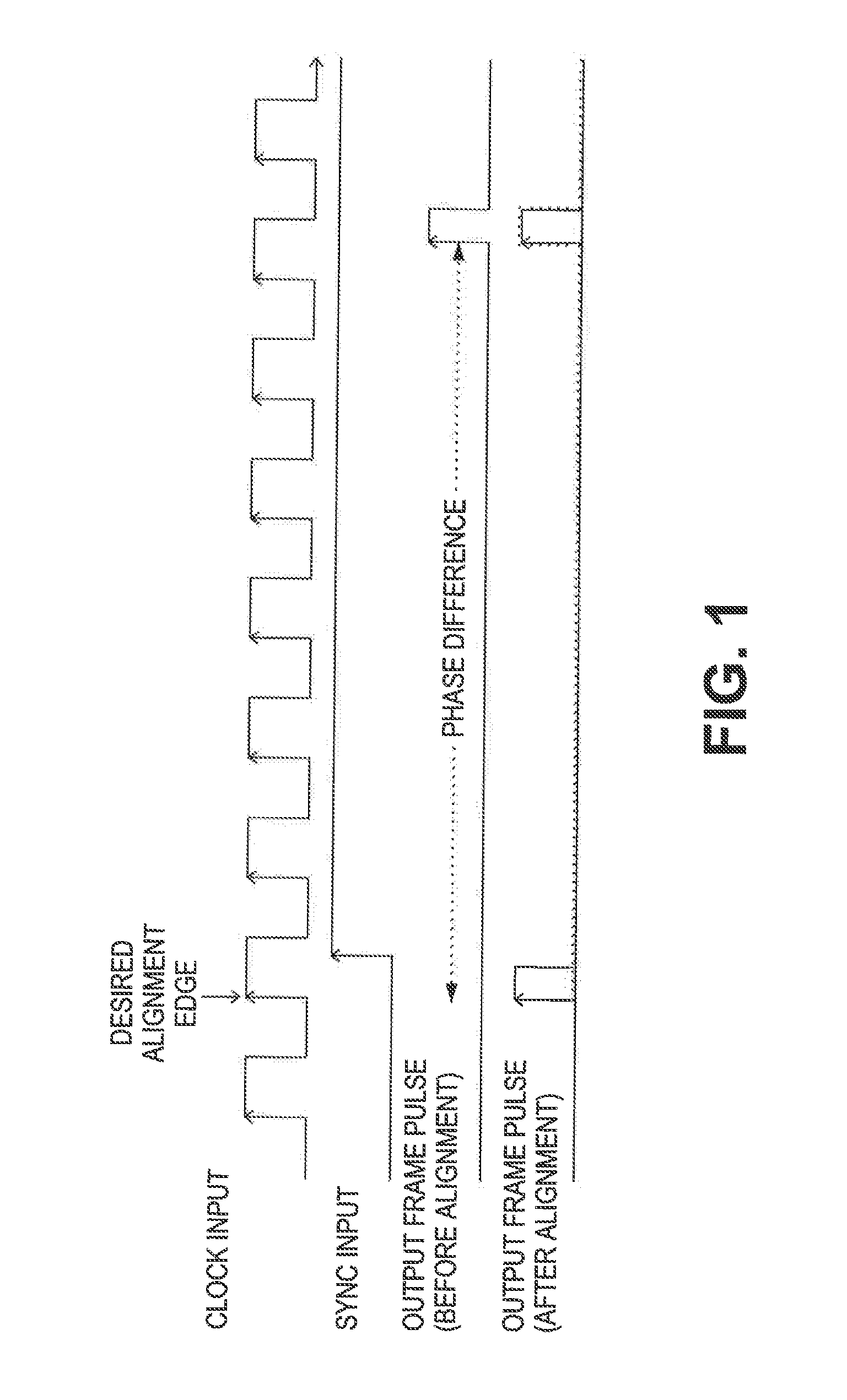

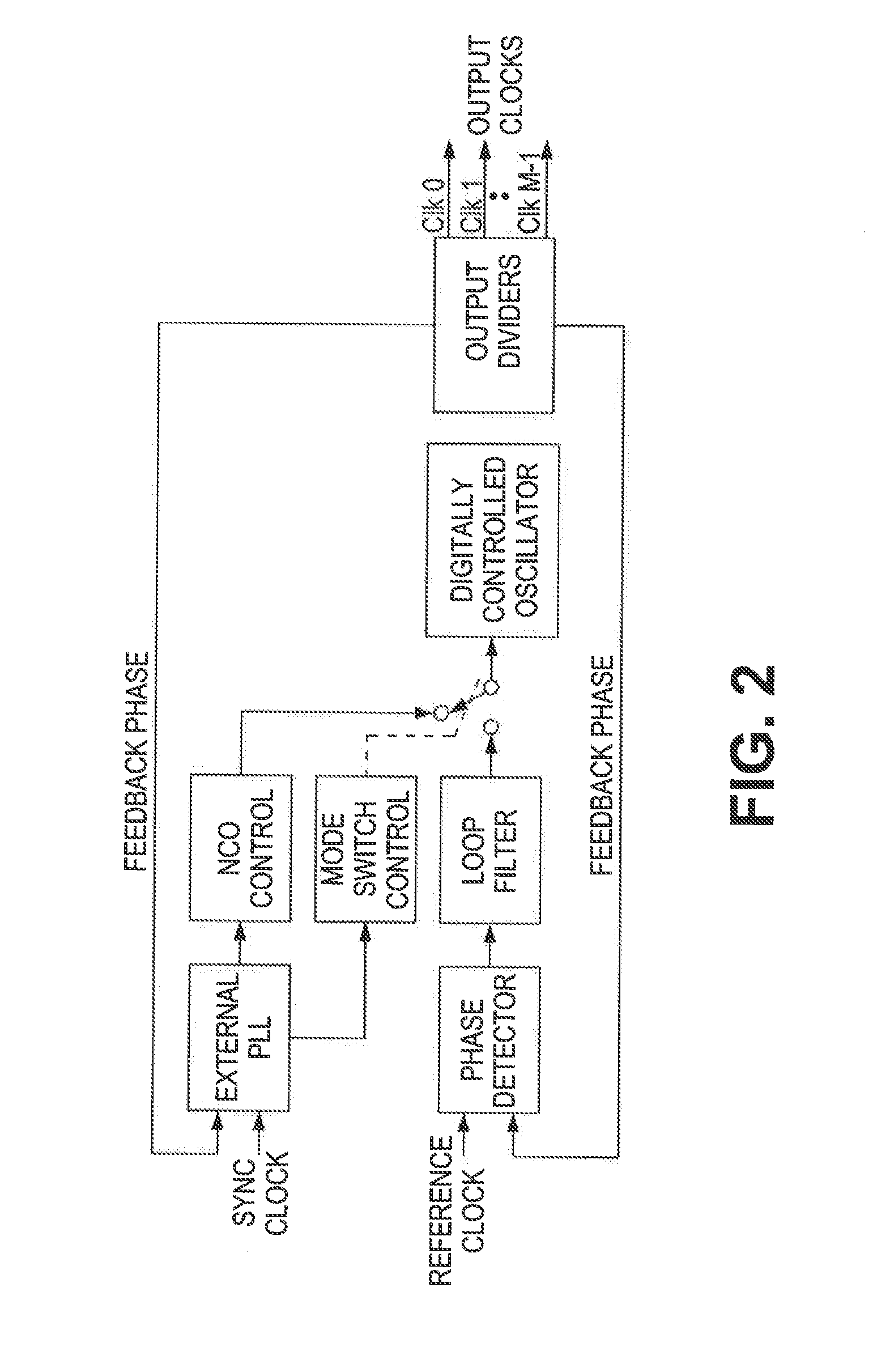

Phase locked loop with simultaneous locking to low and high frequency clocks

ActiveUS20140320181A1Accurate samplingEasy to implementPulse automatic controlHigh ratePhase difference

A phase-locked loop to is simultaneously synchronized to high and low frequency clocks by (i) locking an output of the phase-locked loop to a high-frequency reference clock, (ii) measuring at a high rate a first phase difference between the high-frequency reference clock and the output of the phase-locked loop, (iii) measuring at a high rate a second phase difference between a low-frequency reference clock and the output of the phase-locked loop; (iv) computing at a low rate from said first and second phase differences a third phase difference between the high-frequency and low frequency clocks; (v) combining at a low rate said third phase difference with said second phase-difference to obtain a total phase difference; and (vi) adjusting the output of the phase-locked loop at a low rate to reduce the obtained total phase difference.

Owner:MICROSEMI SEMICON

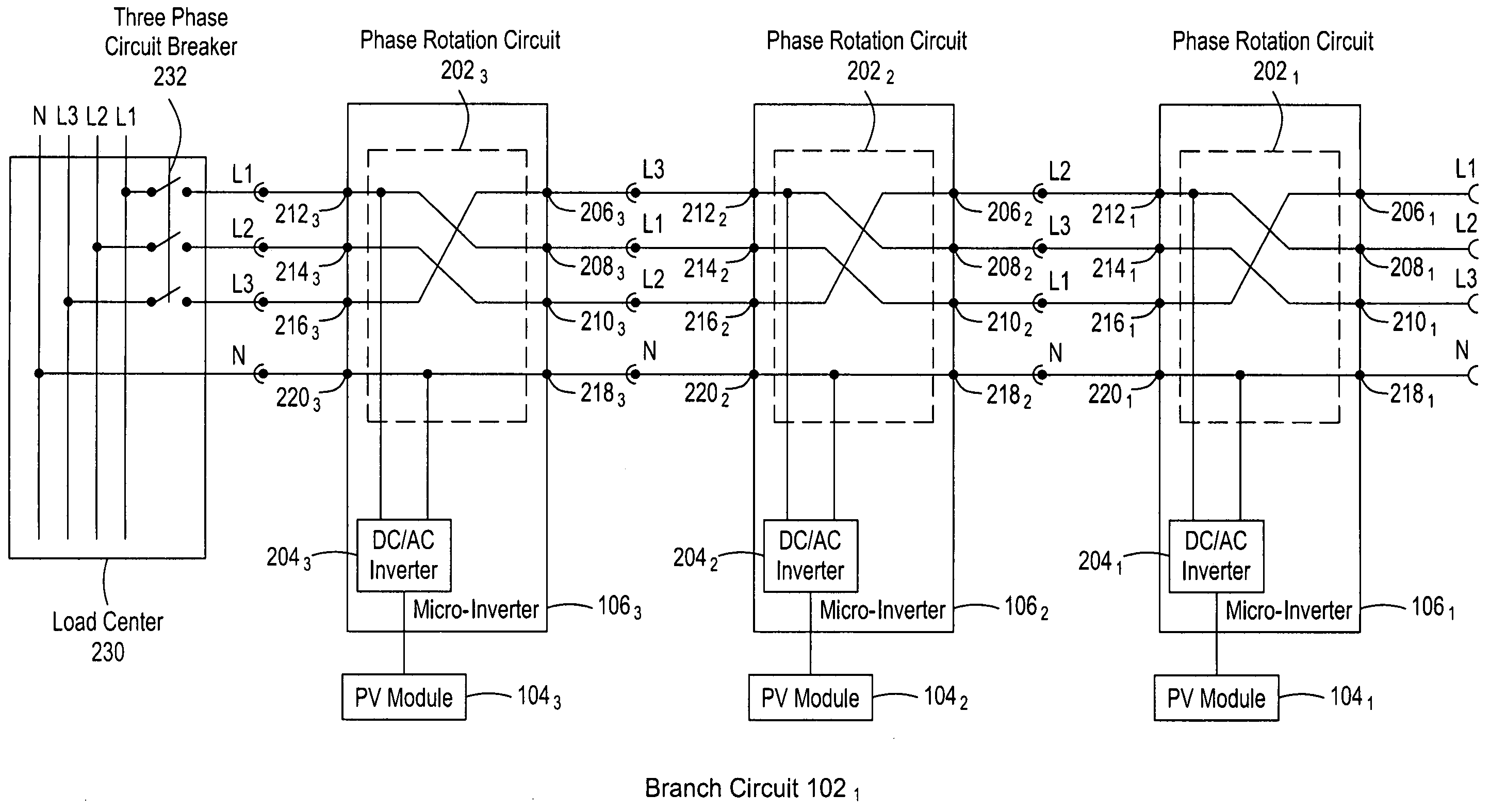

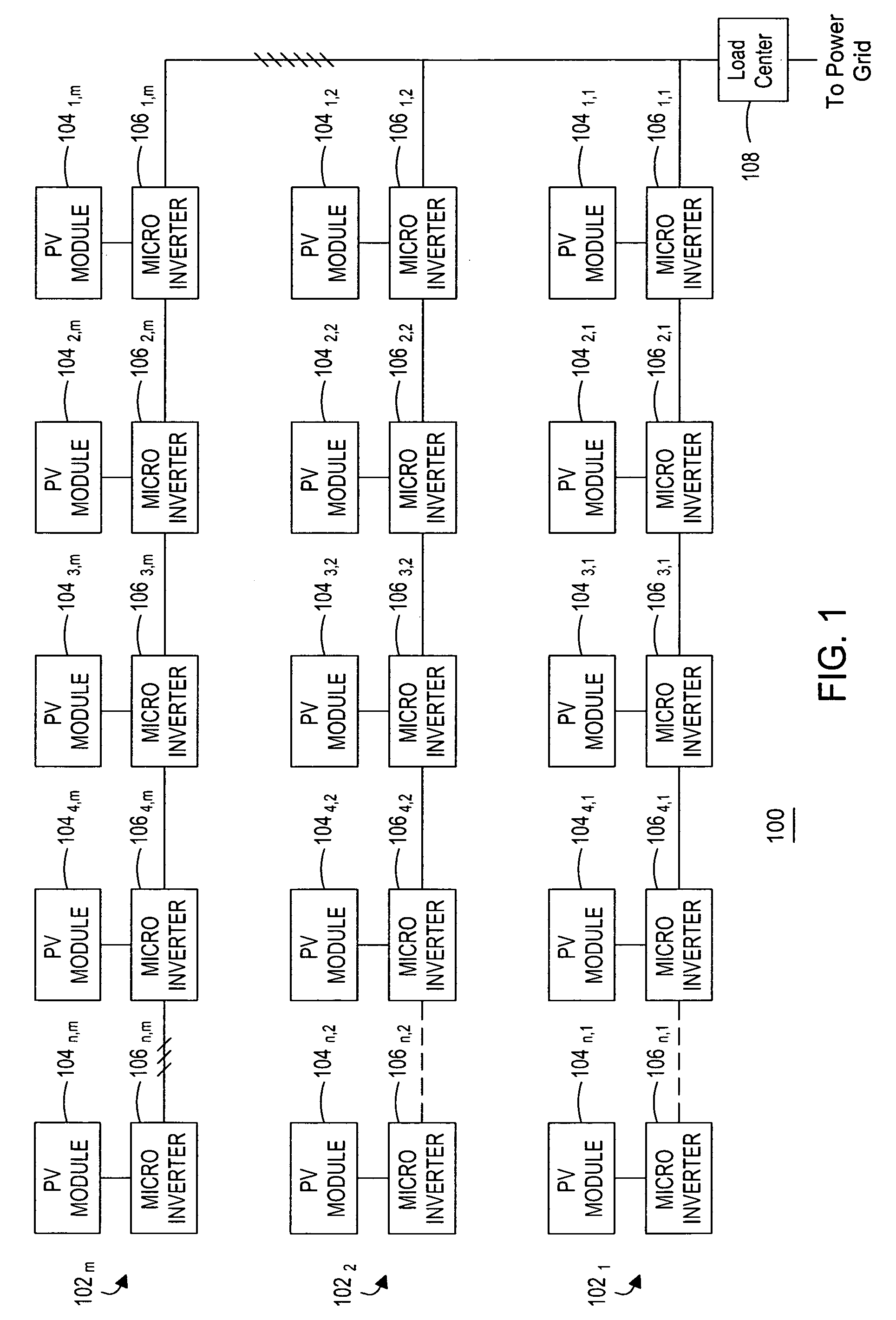

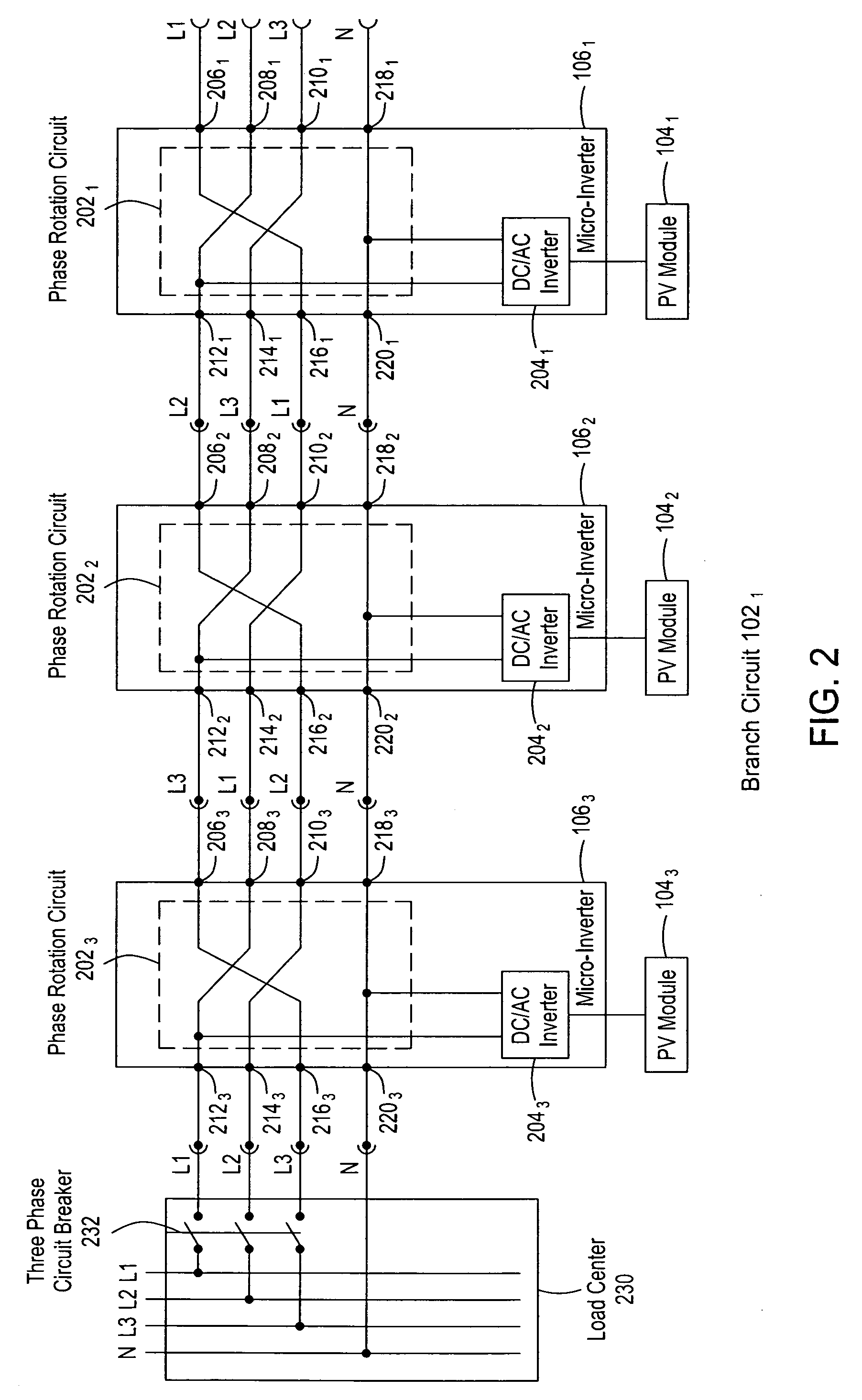

Apparatus for phase rotation for a three-phase AC circuit

An apparatus for providing phase rotation for a three-phase AC circuit. The apparatus comprises three phase input terminals and three phase output terminals, where a first phase input terminal is coupled with a third phase output terminal; a second phase input terminal is coupled with a first phase output terminal; and a third phase input terminal is coupled with a second phase output terminal.

Owner:ENPHASE ENERGY

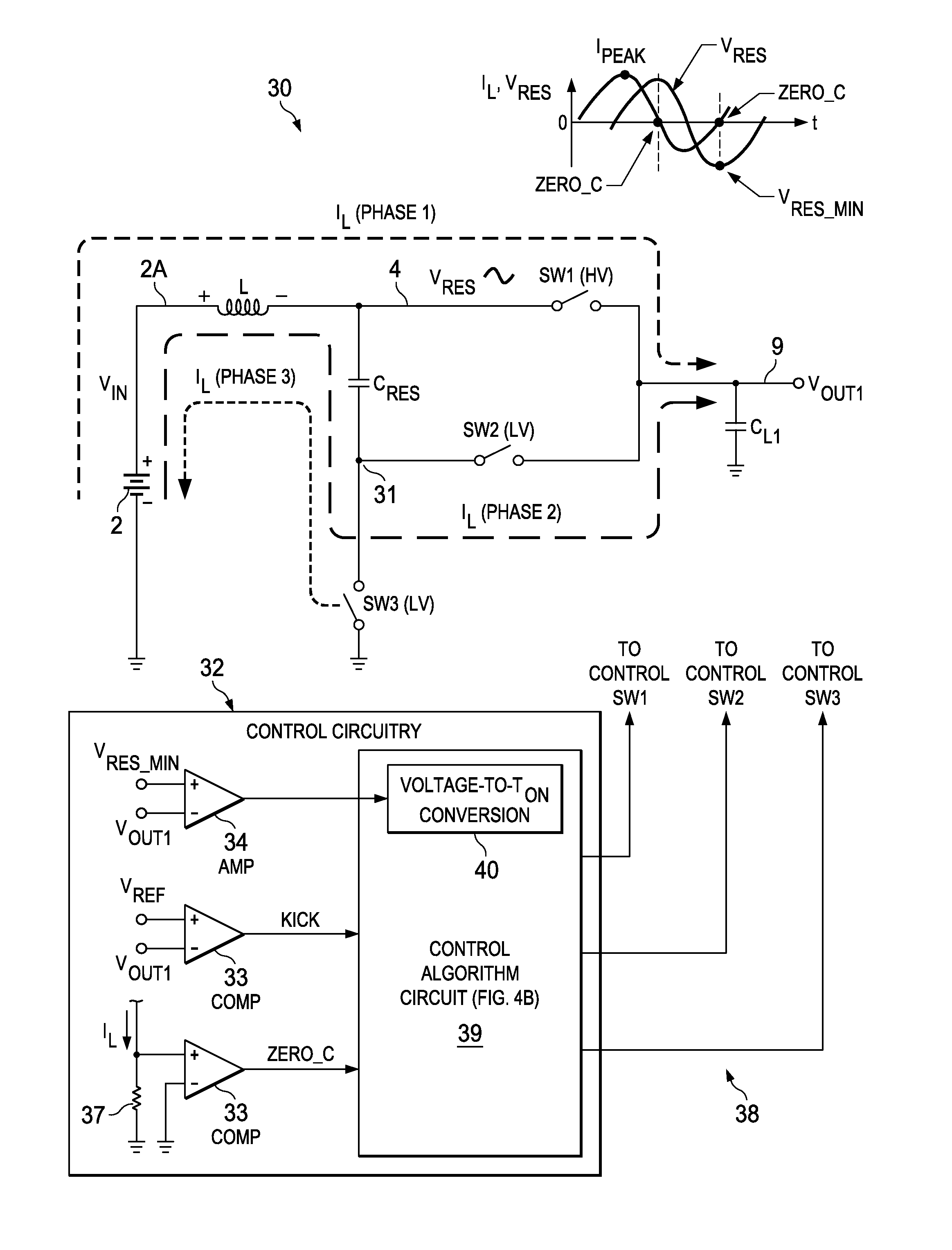

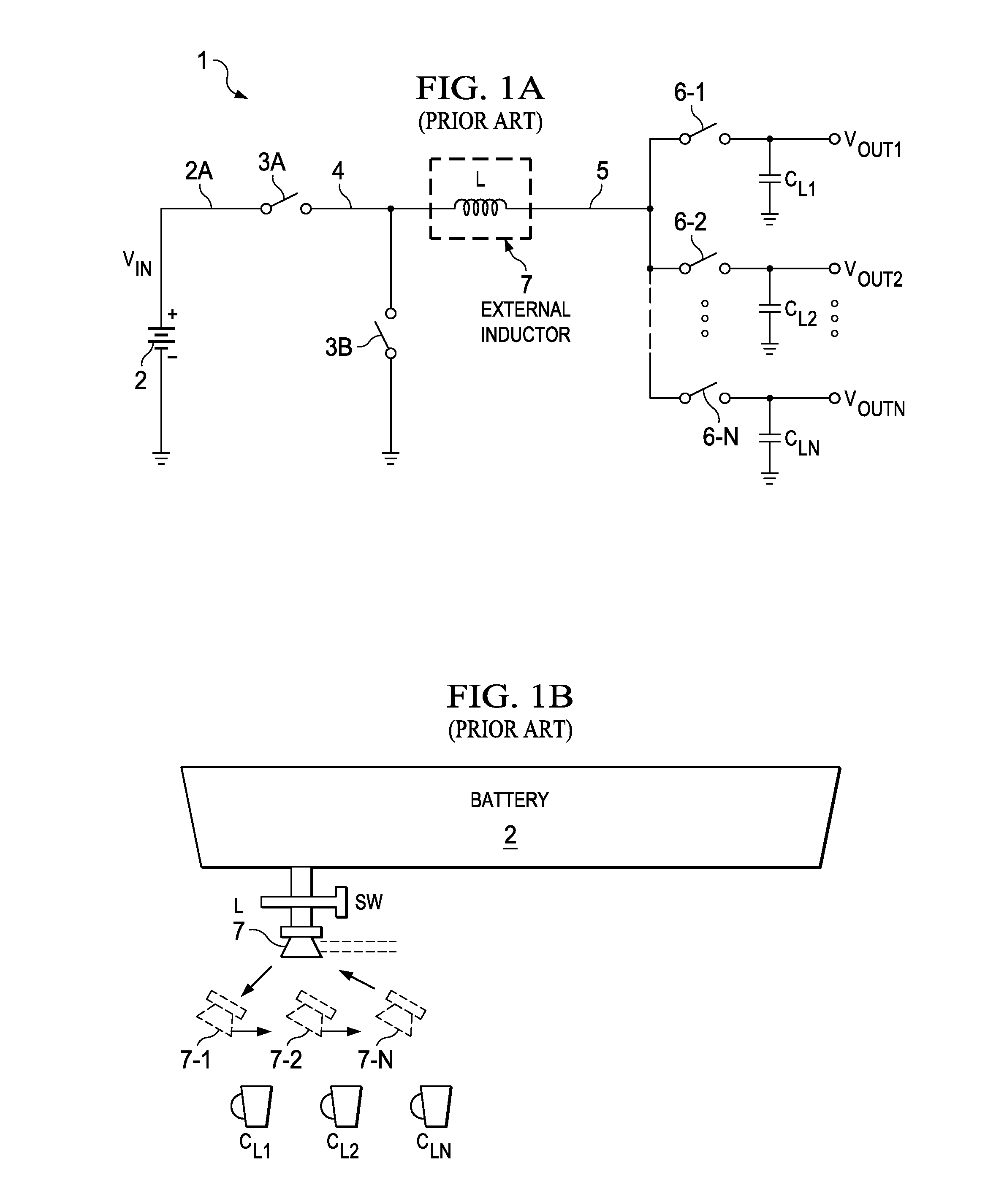

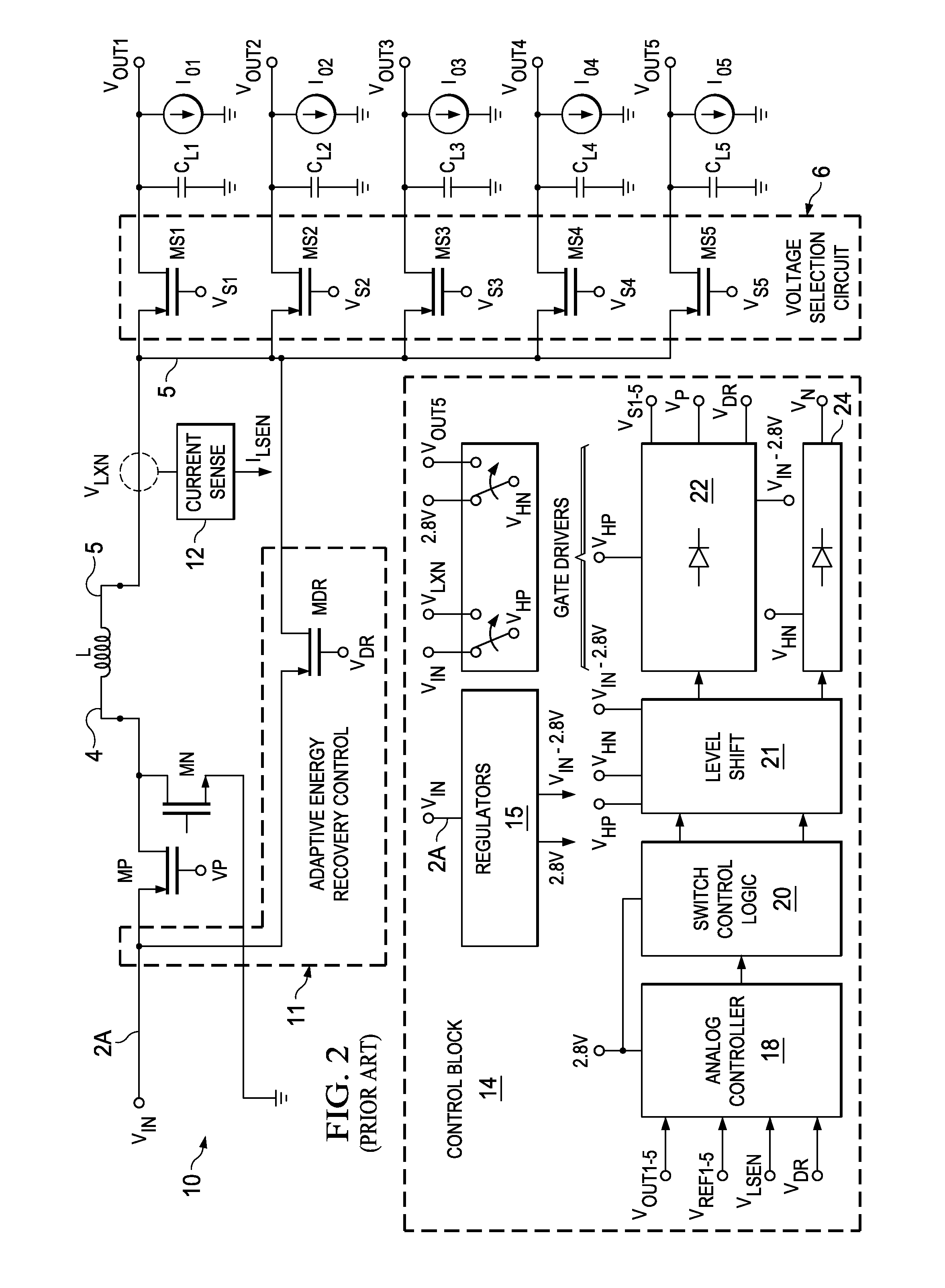

Resonance-based single inductor output-driven dc-dc converter and method

ActiveUS20140232359A1High system power efficiencyReduce system costEfficient power electronics conversionApparatus without intermediate ac conversionDc dc converterElectrical conductor

A resonance-based DC-DC converter for converting a DC input voltage to a first DC output voltage (VOUT1) on a output conductor (9) includes an inductor (L) having a first terminal connected to a source (2) of a DC input voltage (VIN) and a second terminal coupled to a first conductor (4) and a capacitor (CRES) having a first terminal coupled to the first conductor. A first switch (SW1) is coupled between the resonance conductor and the output conductor to conduct inductor current (IL) into the output conductor during a first phase (Phase1). A second switch (SW2) is coupled between a second terminal of the capacitor and the output conductor to conduct inductor current through the capacitor into the output conductor (9) during a second phase (Phase2). A third switch (SW3) is coupled between the second terminal (31) of the capacitor and a first reference voltage (GND) to conduct inductor current from a source of the first reference voltage through the capacitor to the input voltage (VIN) during a third phase (Phase3).

Owner:TEXAS INSTR INC

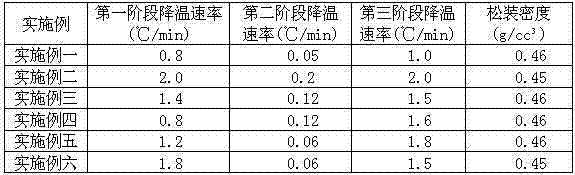

Preparation method of nylon powder for selective laser sintering

ActiveCN104497323ADestroy the regularity of the shapeRegular shapeSelective laser sinteringOrganic solvent

The invention provides a preparation method of nylon powder for selective laser sintering. The preparation method comprises the steps of adopting a precipitation method, and finally separating out solid powder through the processes of dissolution, cooling and precipitation. The method is characterized by being carried out under the condition of the presence of an organic solvent, wherein the cooling process is carried out in three phases, and rapid cooling is carried out to achieve a temperature which is 10 DEG C below than the separation temperature in the first phase; slow cooling is carried out to achieve the separation temperature in the second phase; rapid cooling is carried out to achieve a normal temperature in the third phase. The method is simple and feasible, low in cost, and capable of preparing the nylon powder with regular morphology, good part performance and suitable for SLS sintering.

Owner:HUNAN FARSOON HIGH TECH CO LTD

Halogen-free flame-proof static resistant polycarbonate composition and method for producing the same

The invention discloses a halogen-free flame retardant antistatic polycarbonate composition and a preparation method thereof. The composition comprises the components based on parts by weight: 50-70 parts of polycarbonate, 5-20 parts of polymer which can form a third phase, 8-15 parts of impact modifier, 3-15 parts of phosphonium flame retardant, 0.2 part of fluoro-polyolefine additive, 1-10 parts of conducting material and 0.1-1 part of other accessory ingredient. When in operation, the polymer which can form the third phase, the phosphonium flame retardant, the conducting material and other accessory ingredient are firstly melted and extruded by a double screw extruder to prepare intermediate composition; after being melted and extruded by the double screw extruder, the intermediate composition, the polycarbonate, the impact modifier and the fluoro-polyolefine additive are pelleted and then dried. The composition prepared by the invention does not contain chlorine and bromine, has excellent antistatic property, flame retardance, impact resistance and formability and needs a little conductive filler.

Owner:SOUTH CHINA UNIV OF TECH

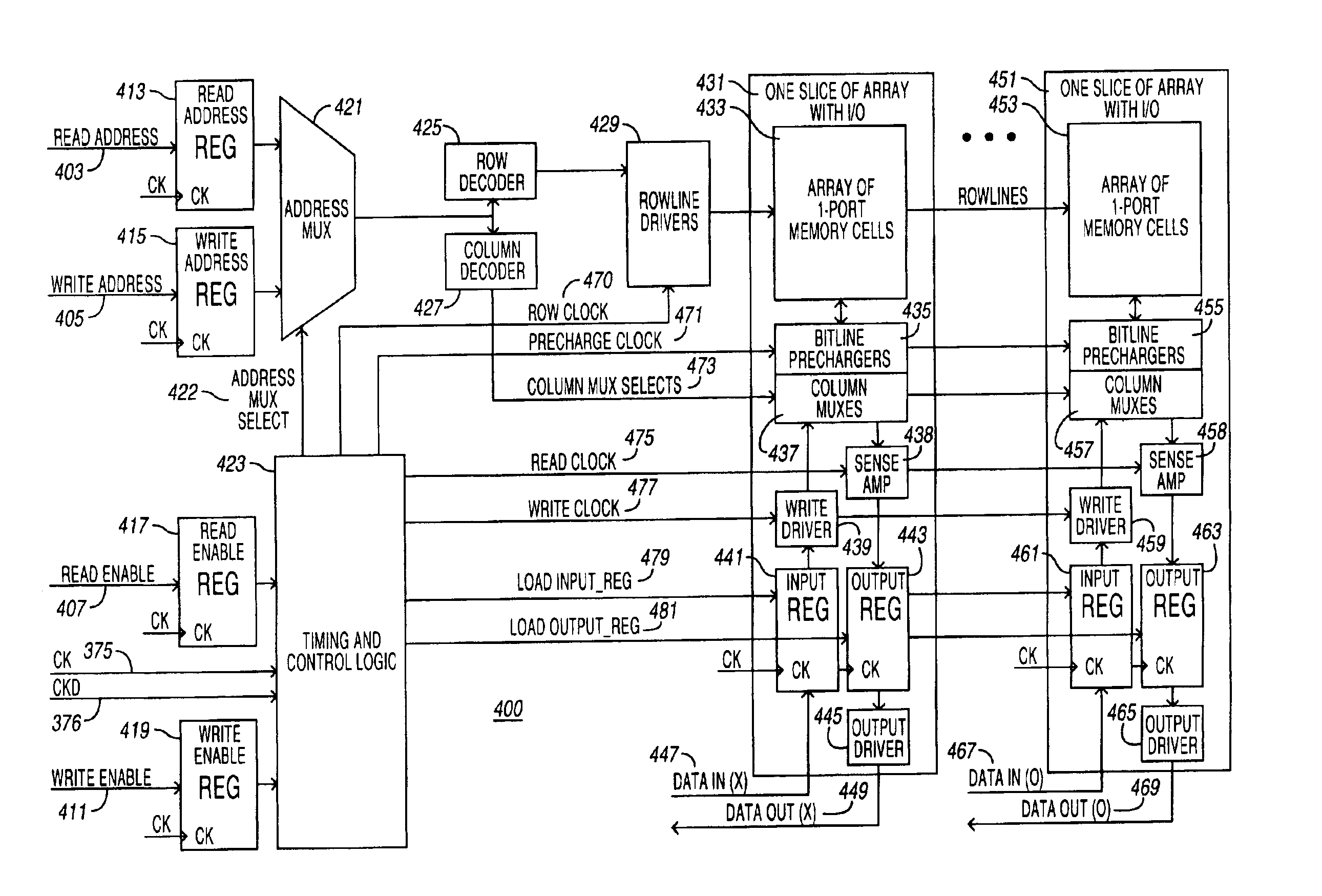

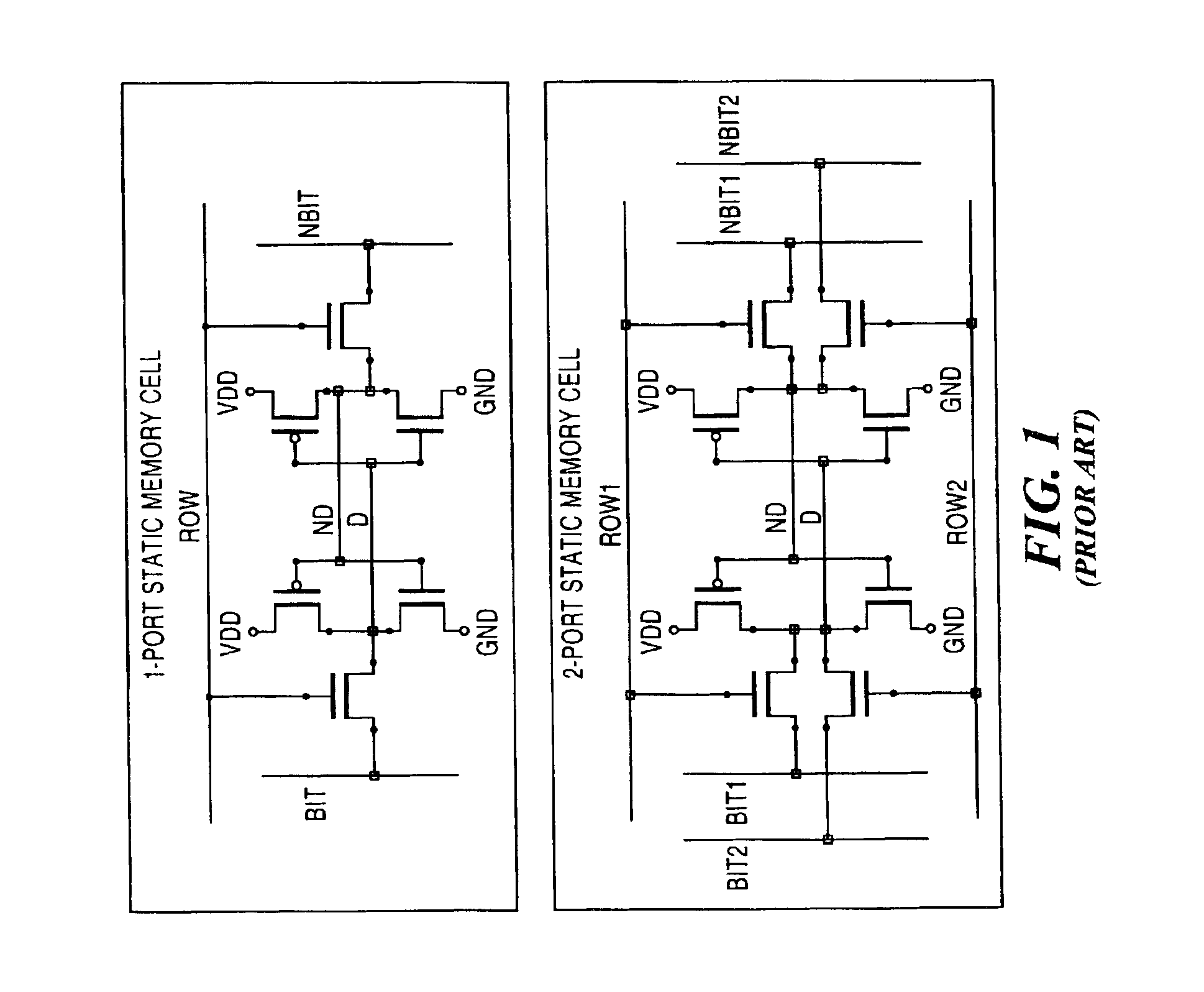

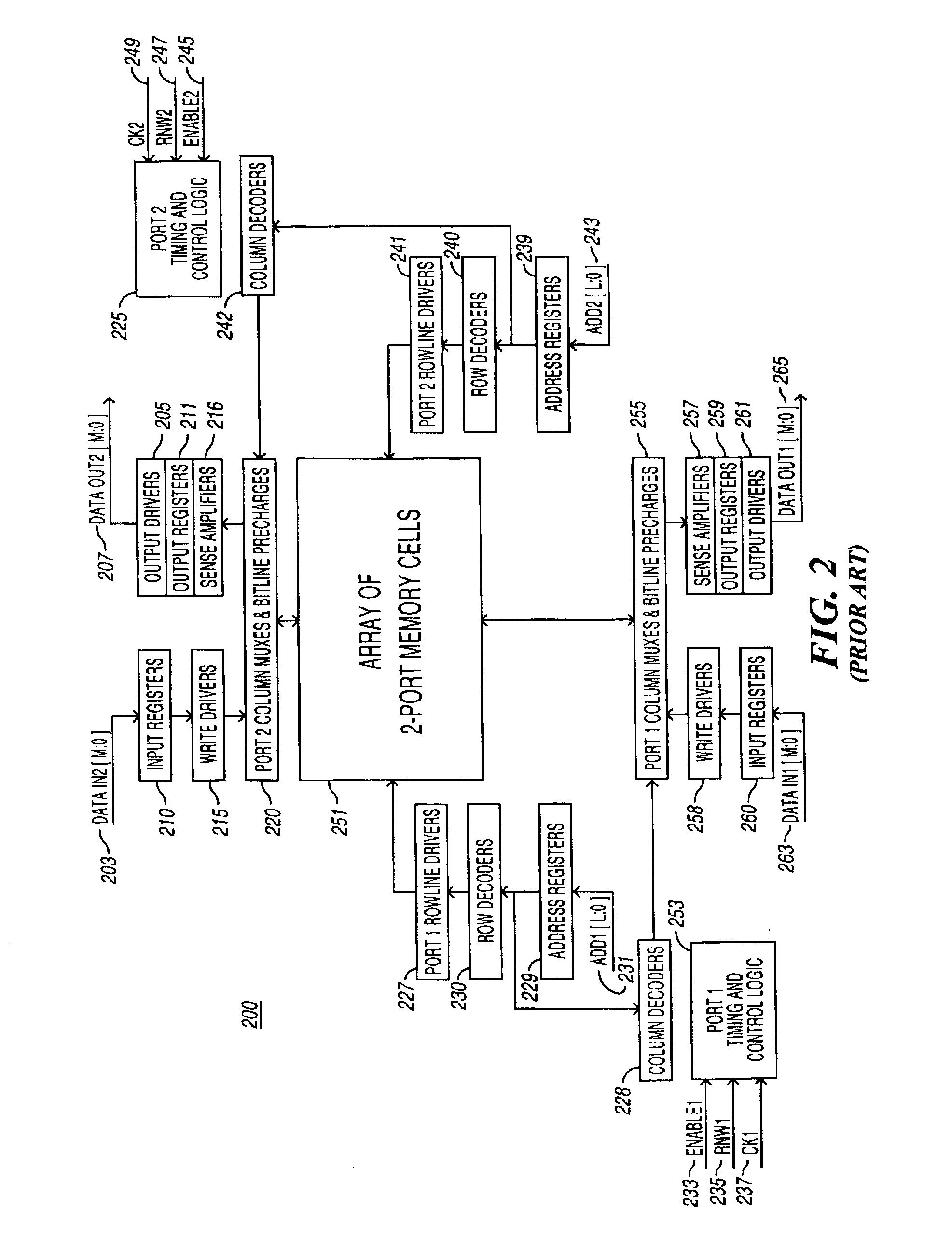

Method and apparatus for providing pseudo 2-port RAM functionality using a 1-port memory cell

A method and apparatus operable to provide pseudo 2-port RAM functionality using 1-port memory cells. A pseudo 2-port RAM functionality is provided using an array of 1-port memory cells to perform read and write operations during a single clock cycle. Control logic is used to determine when the read and write operations occur. The pseudo 2-port RAM uses the control logic to divide the clock cycle into four phases in accordance with a preferred embodiment. The first phase is used to set up the addresses and register values, the second phase is used to prepare for the read operation, the third phase is used to perform the read operation and prepare for the write operation, and the fourth phase performs the write operation.

Owner:BROADCOM INT PTE LTD

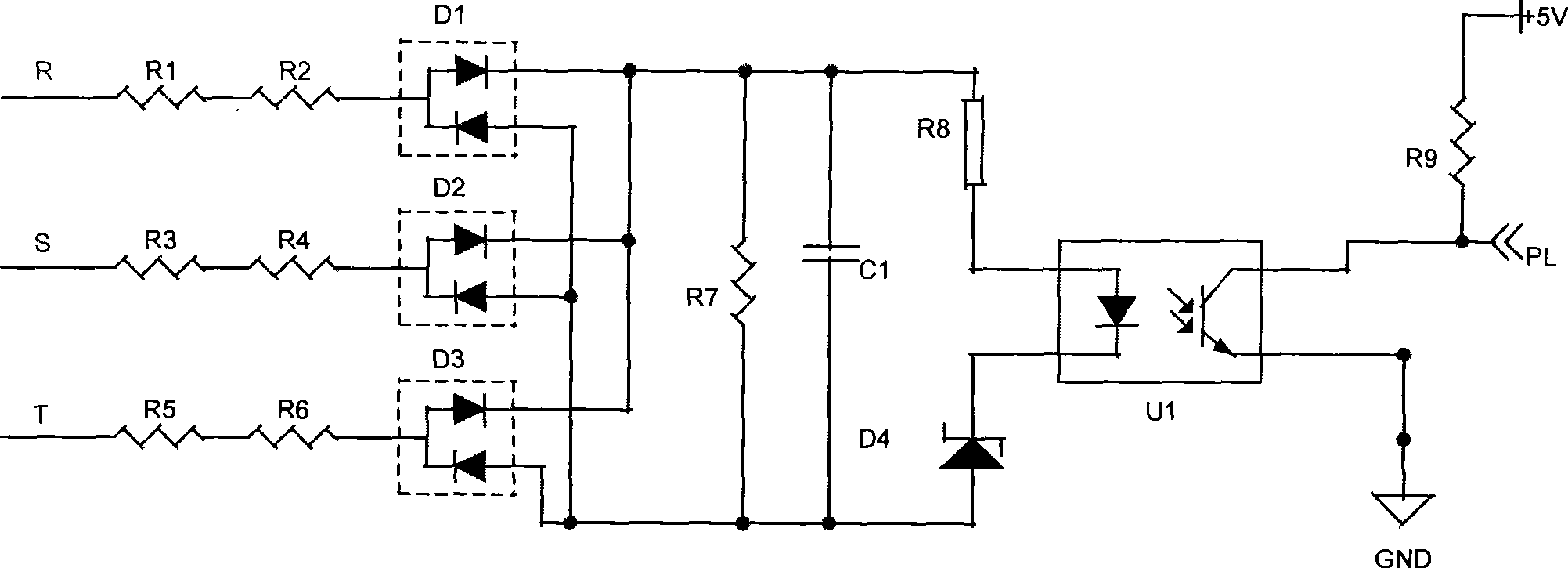

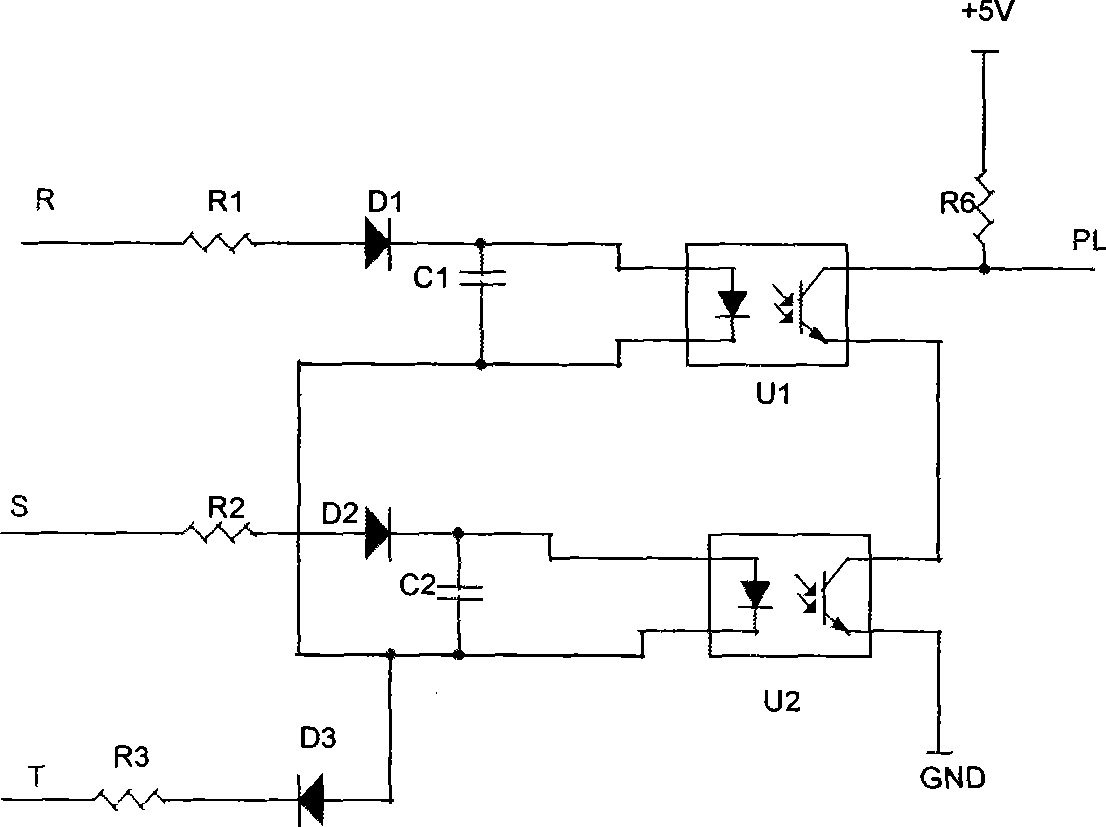

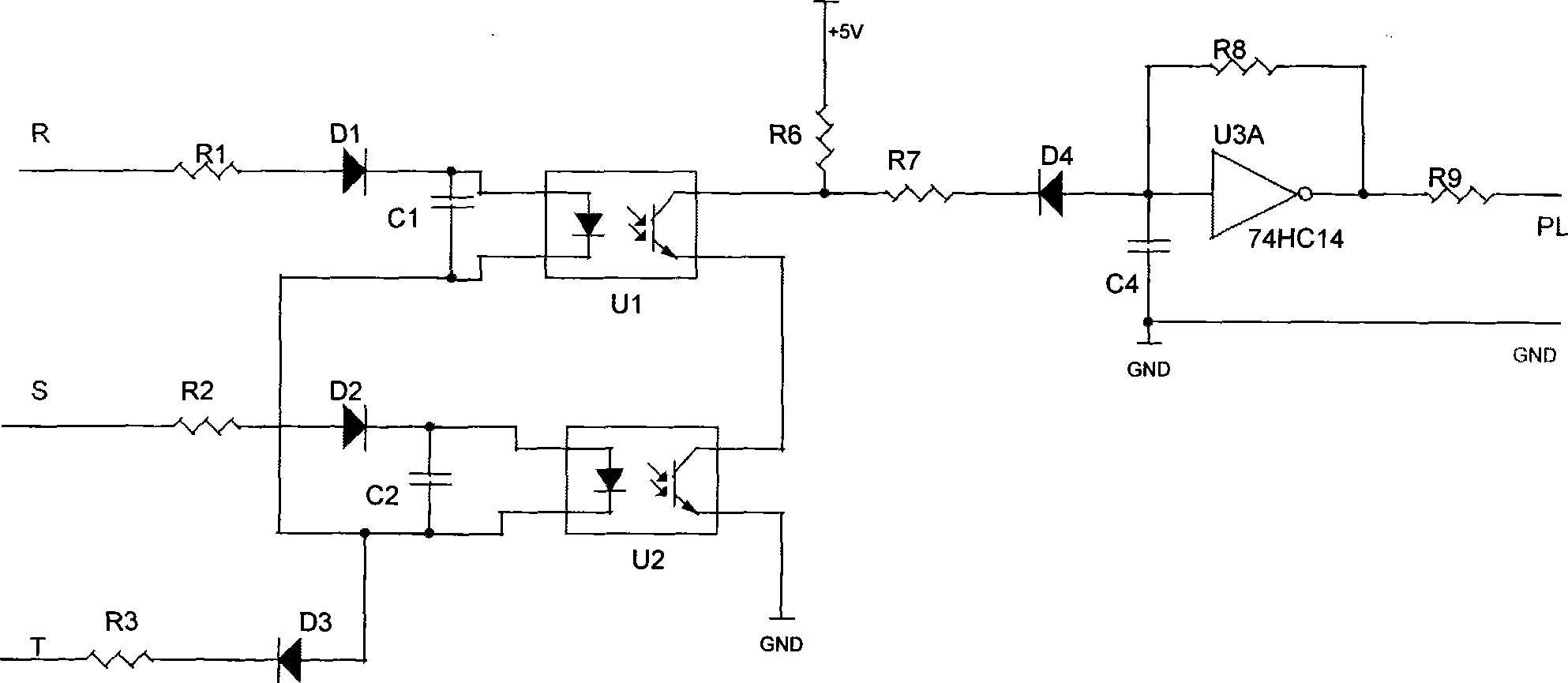

Three-phase power input phase lack detection circuit

ActiveCN101413975AImprove anti-interference abilityReduce lossPower supply testingPolyphase network asymmetry measurementsCapacitanceCircuit reliability

The invention relates to an input lack-phase detection circuit of a three-phase power supply, comprising a first current-limiting resistor, a second current-limiting resistor and a third current-limiting resistor which are respectively connected to a first phase line, a second phase line and a third phase line, the input lack-phase detection circuit also comprises a pull-up resistor, a third diode with a cathode which is connected to the third current-limiting resistor, a first optocoupler and a second optocoupler with output ends which are connected in series between the pull-up resistor and signal ground, a first diode which is connected with an input end of the first optocoupler in series between the first current-limiting resistor and an anode of the third diode, a second diode which is connected with the input end of the second optocoupler in series between the second current-limiting resistor and the anode of the third diode, a first capacitor which is connected with the input end of the first optocoupler in parallel and a second capacitor which is connected with the input end of the second optocoupler in parallel, and the pull-up resistor is connected to the output end of the lack-phase detection circuit. The input lack-phase detection circuit reduces the loss on the current-limiting resistors, so the current-limiting resistors are difficult to damage due to small heat, the reliability of the circuit is improved and the service life is prolonged.

Owner:SHENZHEN INOVANCE TECH

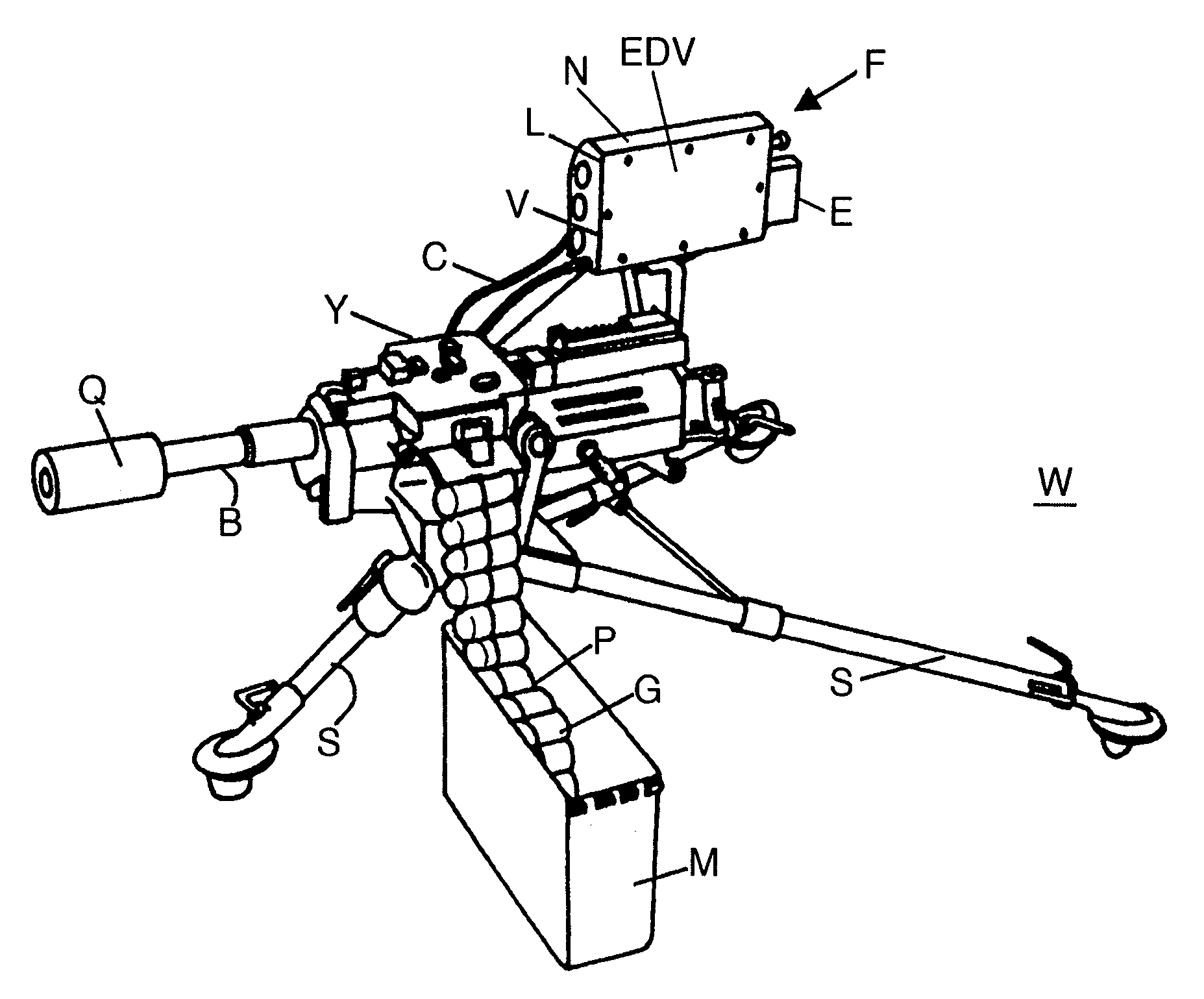

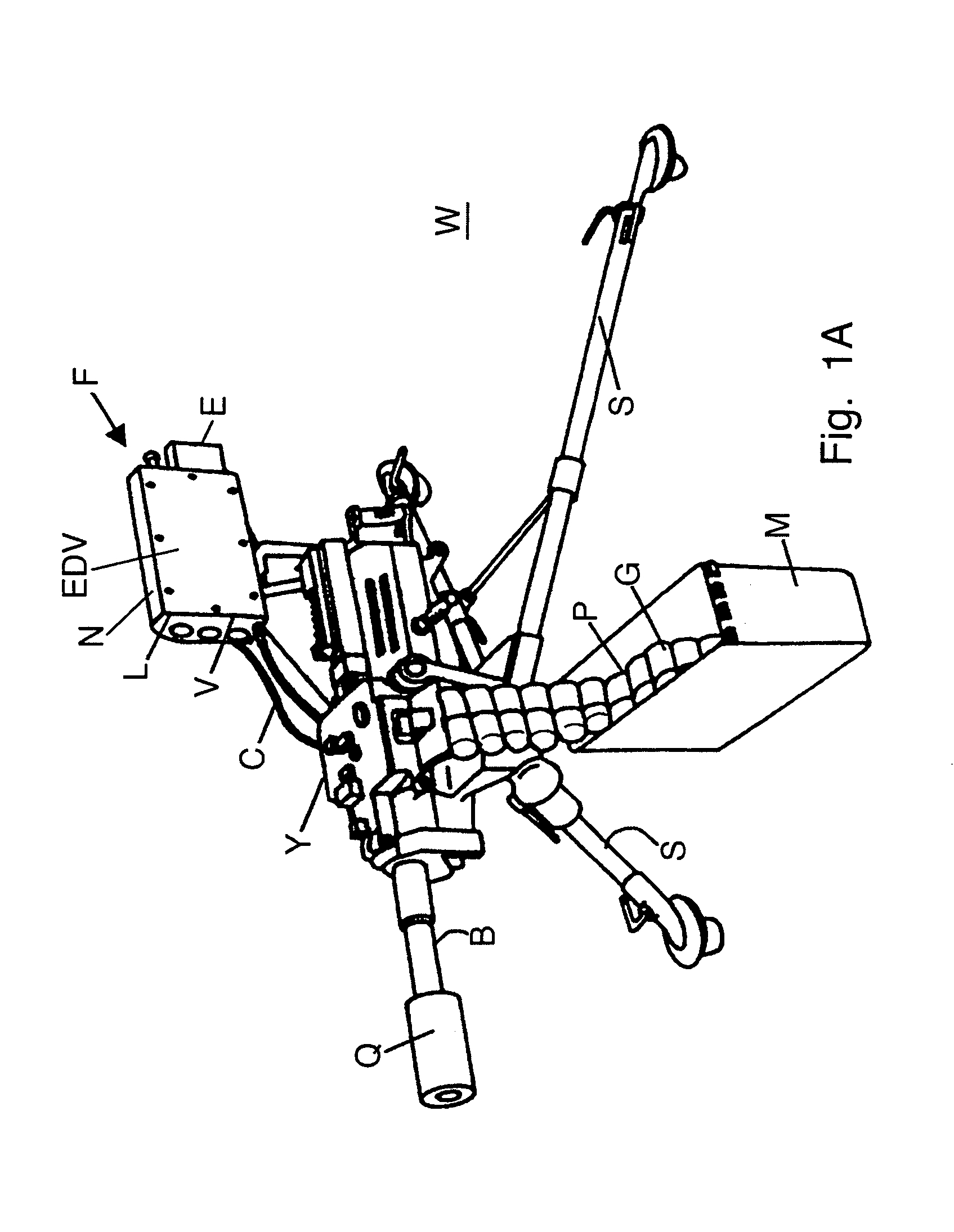

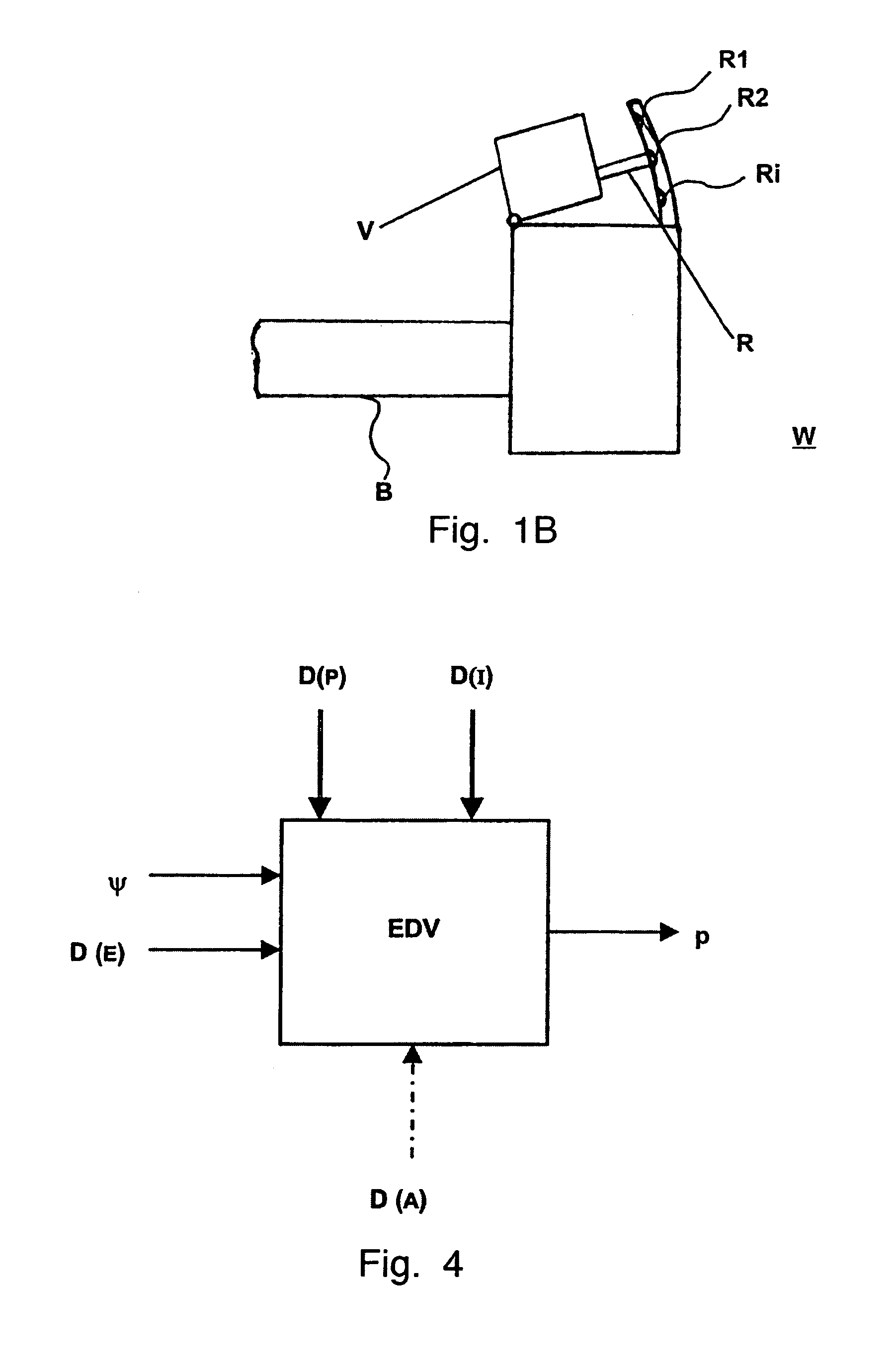

Method and device for aiming a weapon barrel and use of the device

InactiveUS7089845B2Easy to replaceDistortion and eliminated and minimizedSighting devicesWeapon control systemsComputer graphics (images)Fire control

A method for aiming a weapon barrel [B], wherein a target image [Z*] and a target marker [X] are displayed with the aid of an image visualization unit M. The rough aiming of the weapon barrel [B] is performed in a first phase, in a second phase, with the weapon barrel [B] stationary, sighting by sighting the target image [Z*] by means of the image visualization unit [V] is performed, wherein the target image [Z*] and the target marker [X] are brought into coincidence as closely as possible, and fine aiming of the weapon barrel [B] in a third phase. The device for executing the method comprises a device for setting an initial gun sight angle [ψo] an image visualization unit [V], the latter displays a target image [Z*] and a target marker [X] representing the end of an imaginary projectile trajectory [p]. The device contains a fire control device, with the image visualization unit [V], an angle measuring device [Y] for measuring angular changes [Δψ] and a data processing unit [EDV] for performing a ballistics calculation, in which the angular change [Δψ] and the interior ballistics can be taken into consideration, as well as for issuing a signal determining the target marker [X]. The device is suitable for infantry weapons.

Owner:CHARTERED AMUNITION IND PTE LTD +1

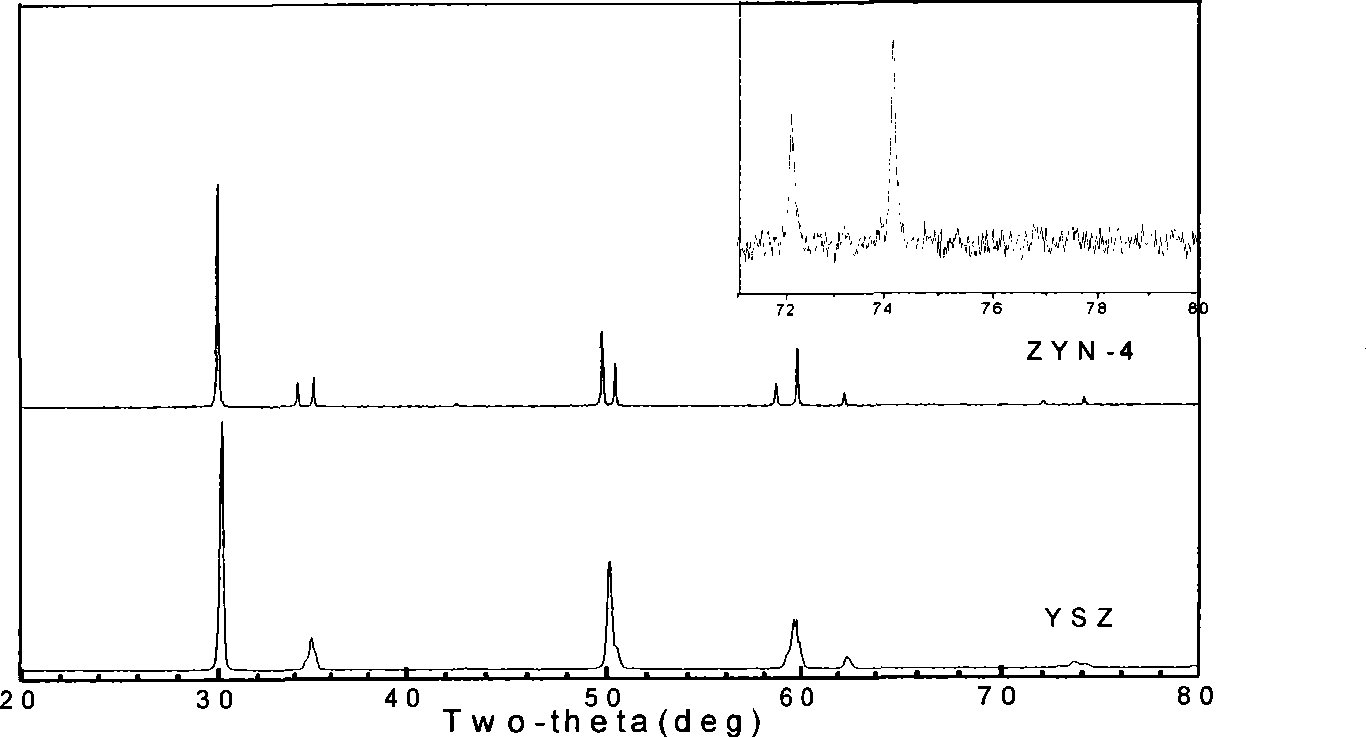

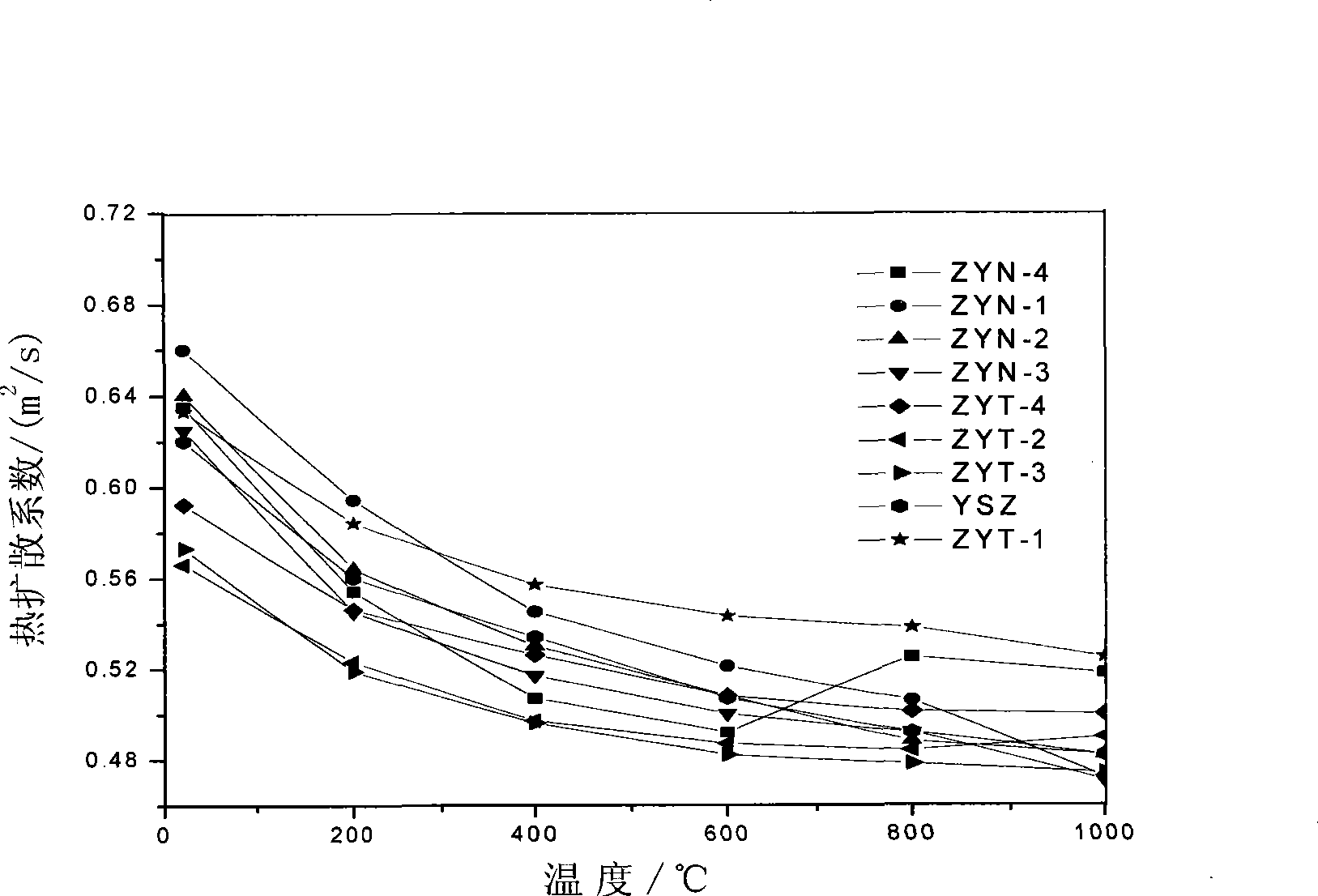

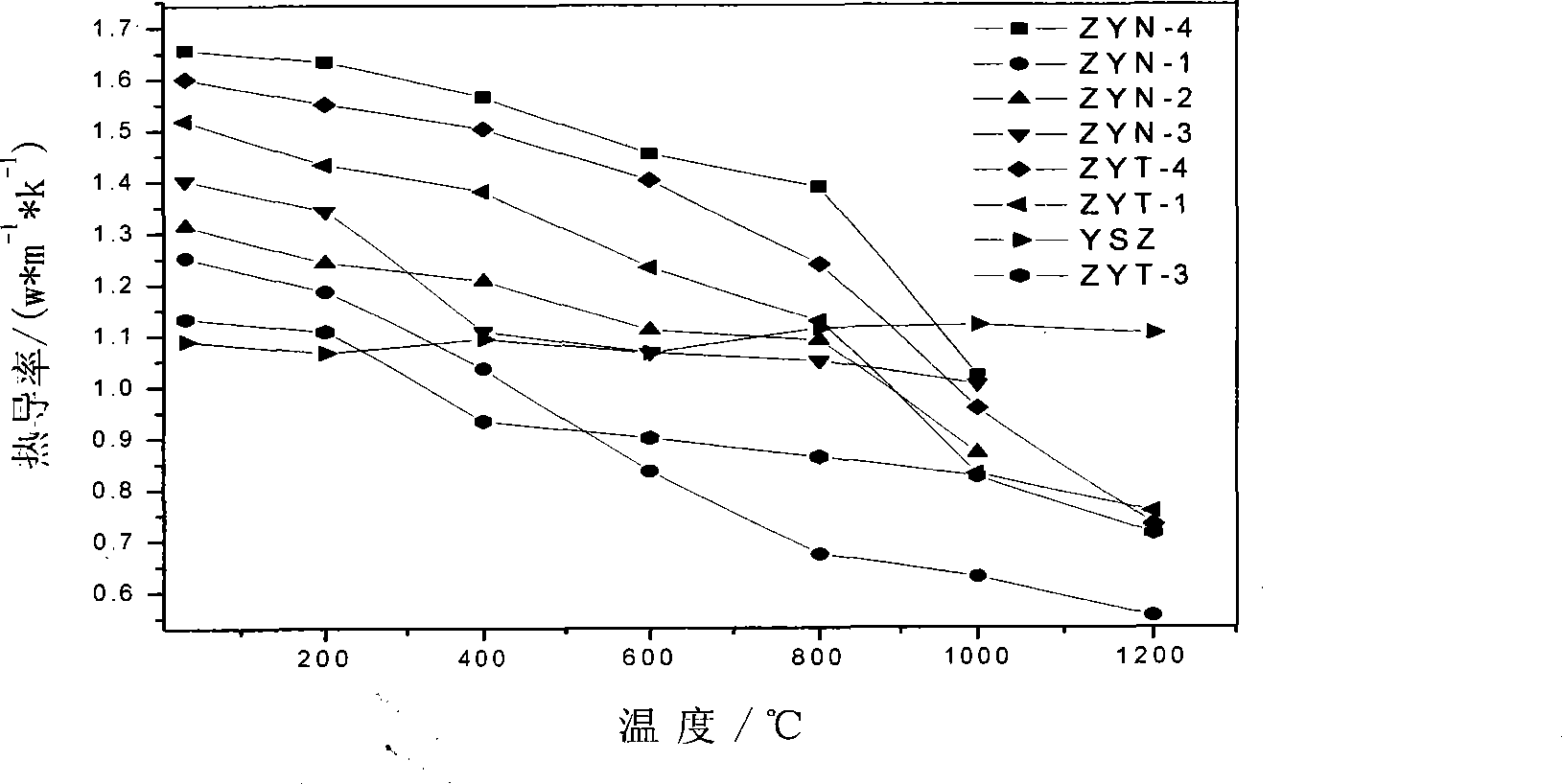

Multi-element co-stabilizing zirconia of heat barrier coat material and preparation method

The invention relates to a multivariant co-stable zirconia thermal barrier coating material and a preparation method which belong to the field of materials. The multivariant co-stable zirconia thermal barrier coating material is characterized by consisting of the following materials according to mole fractions: zirconia, yttria, niobium oxide or tantalum oxide and rare earth oxide. The preparation method comprises the following steps: a zirconia ball is ground by wet process, dried and molded; a pre-burnt block is obtained by pre-burning; the pre-burnt block is smashed and further carried out with the wet ball milling to obtain slurry; the slurry is dried, granulated and mould pressed to obtain a green body, the green body is sintered to obtain the multivariant co-stable zirconia thermal barrier coating material; the ceramic material can be used as a target material for preparing a thermal barrier coating by using the EB-PVD method. A third phase of Nb2O5 / Ta2O5 is introduced in YSZ to develop the stable existence interval of t-ZrO2 to further obtain non-transition t'-ZrO2, and the rare earth oxide is added to increase the defects to further improve the phonon or photon scattering on the basis, thereby improving the using temperature of the ZrO2 thermal barrier coating and reducing the thermal conductivity of the material.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

One terminal capacitor interface circuit

ActiveUS20070247171A1Offset errorLow frequency noiseResistance/reactance/impedenceAnalogue conversionCapacitanceAudio power amplifier

A differential capacitor one terminal capacitor interface circuit for sensing the capacitance of first and second capacitors includes a differential integrating amplifier having first and second summing nodes and an input common mode voltage; and a switching circuit for charging a first capacitor of said differential one terminal capacitor to a first voltage level and a second capacitor of said differential one terminal capacitor to a second voltage level in a first phase, in a second phase connecting said first capacitor to said first summing node and said second capacitor to said second summing node of said amplifier to provide first and second output changes substantially representative of the difference between said first and second voltage levels and said input common mode voltage, in a third phase charging said first capacitor to said second voltage level and said second capacitor to said first voltage level, and in a fourth phase connecting said first capacitor to said second summing node and said second capacitor to said first summing node of said amplifier to provide third and fourth output changes substantially representative of the difference between said first and second voltage levels and said input common mode voltage, the combined first, second, third and fourth changes representing the capacitance of said first and second capacitors substantially independent of said input common mode voltage.

Owner:ANALOG DEVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com