Patents

Literature

11180results about How to "Uniform thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

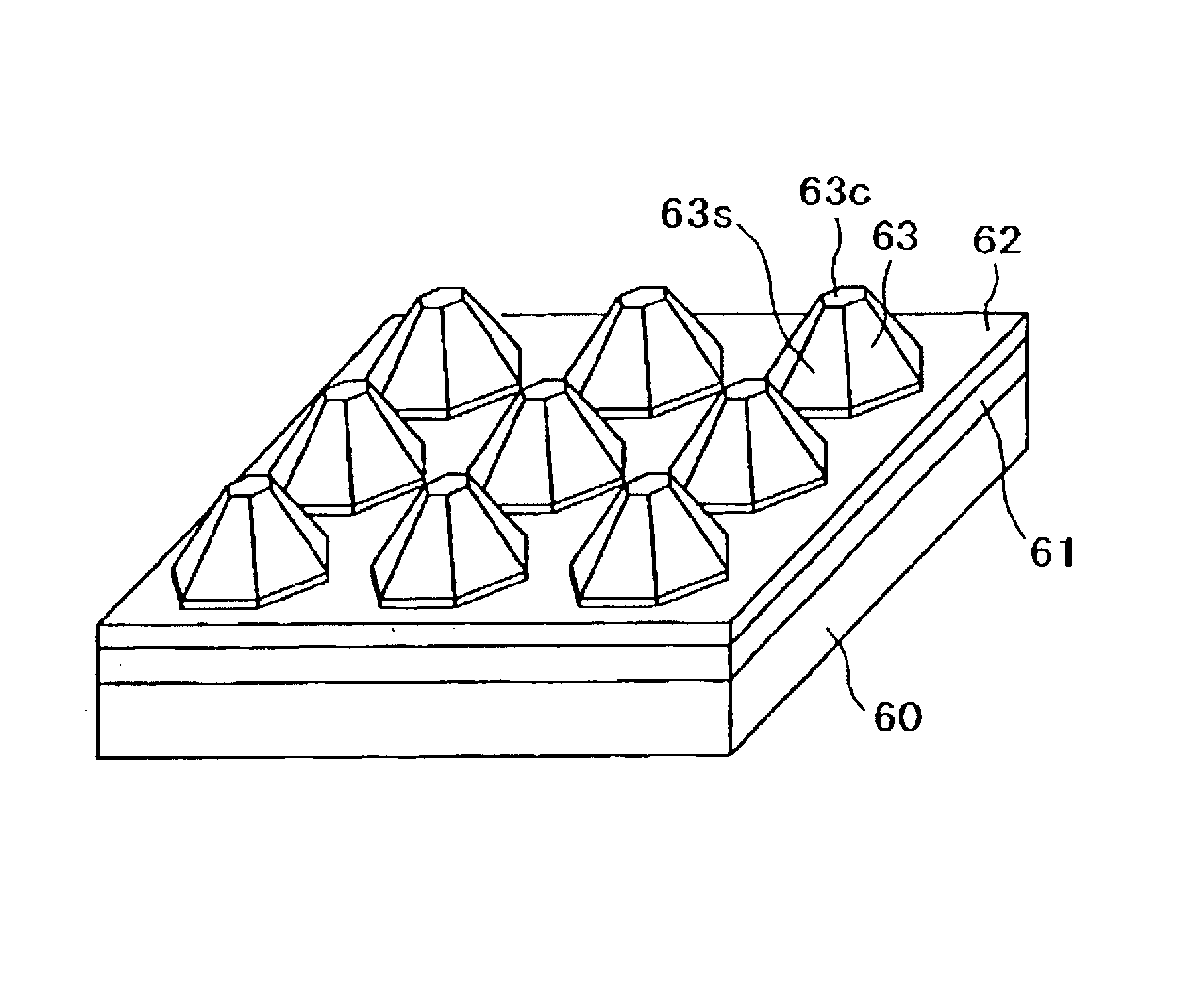

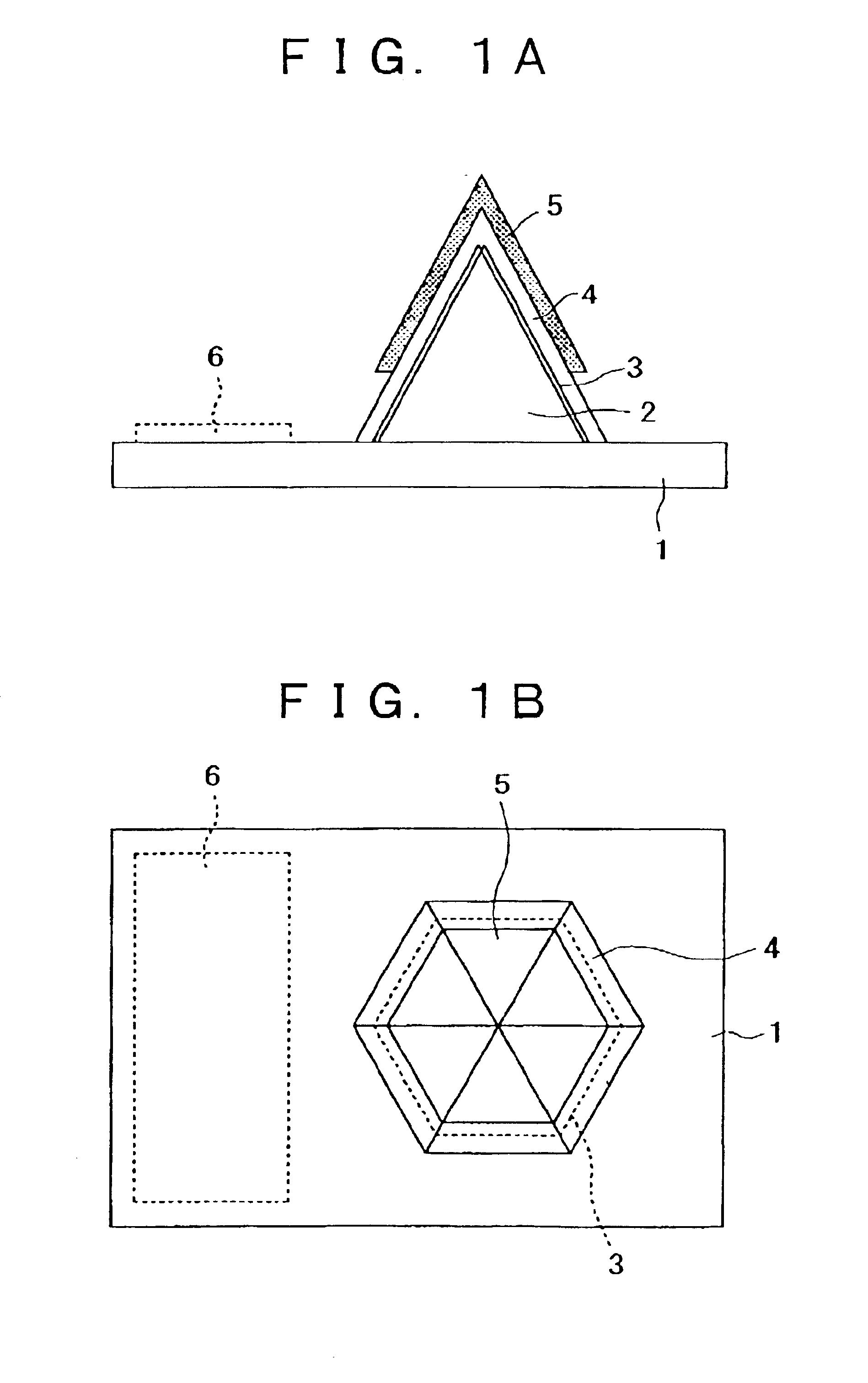

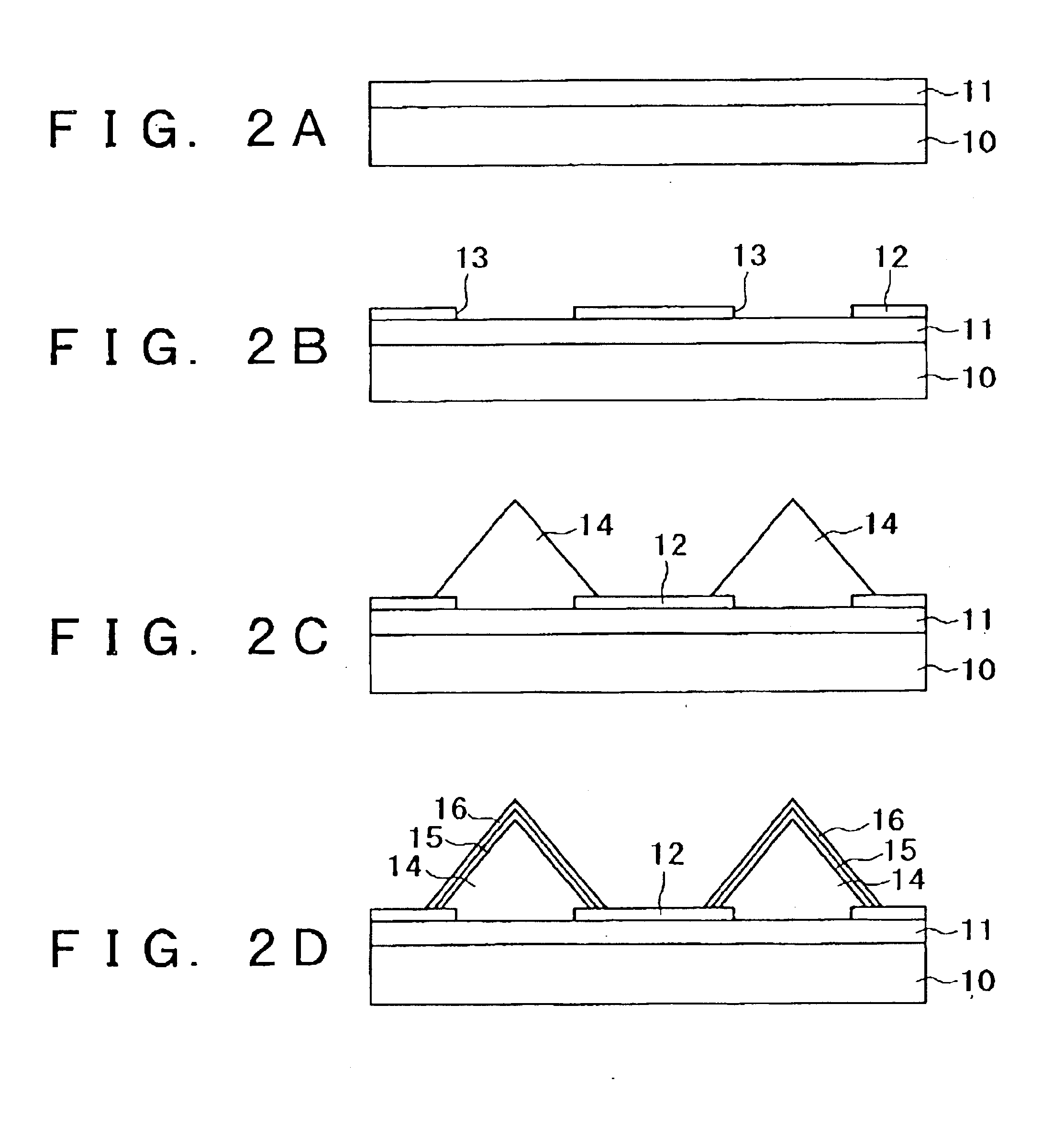

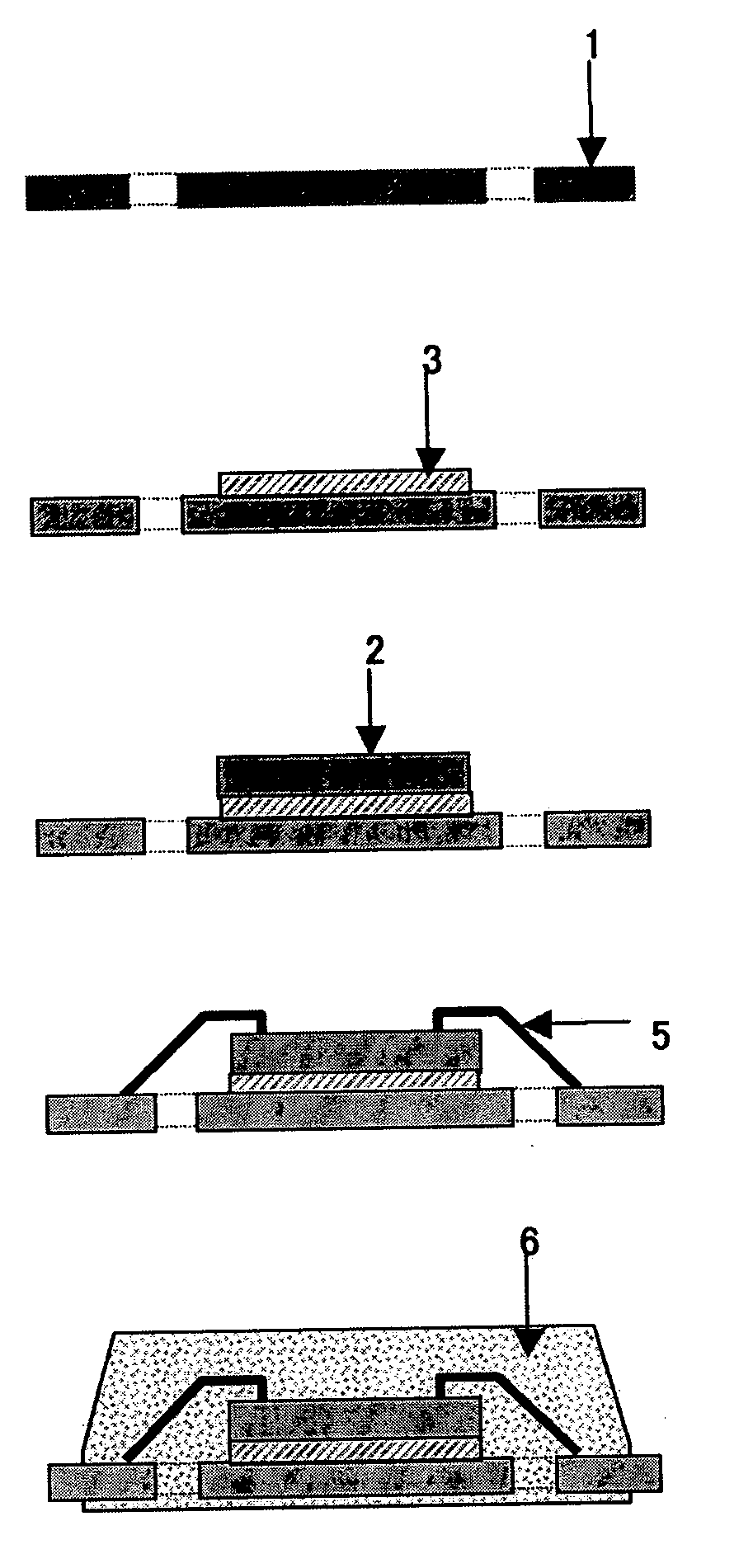

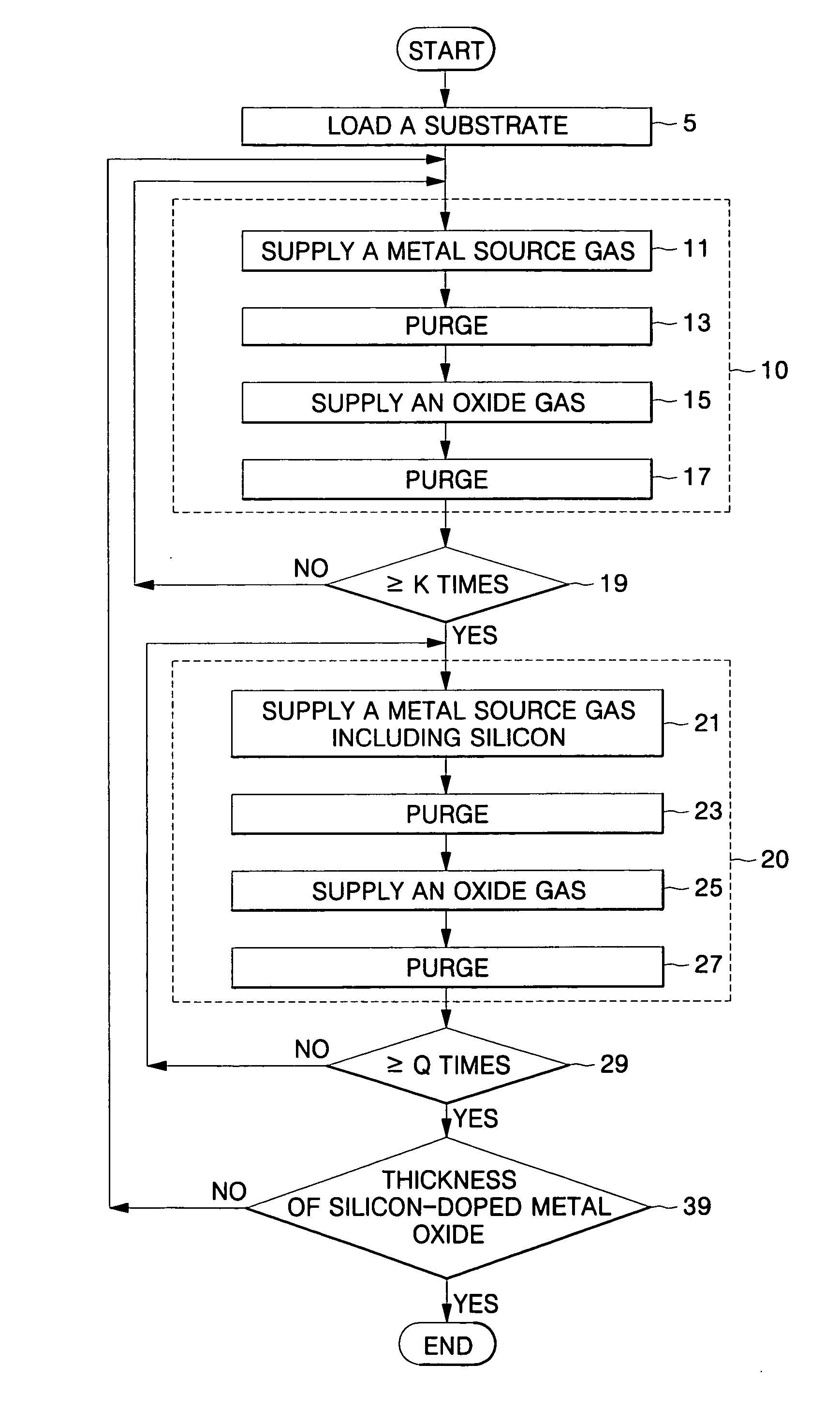

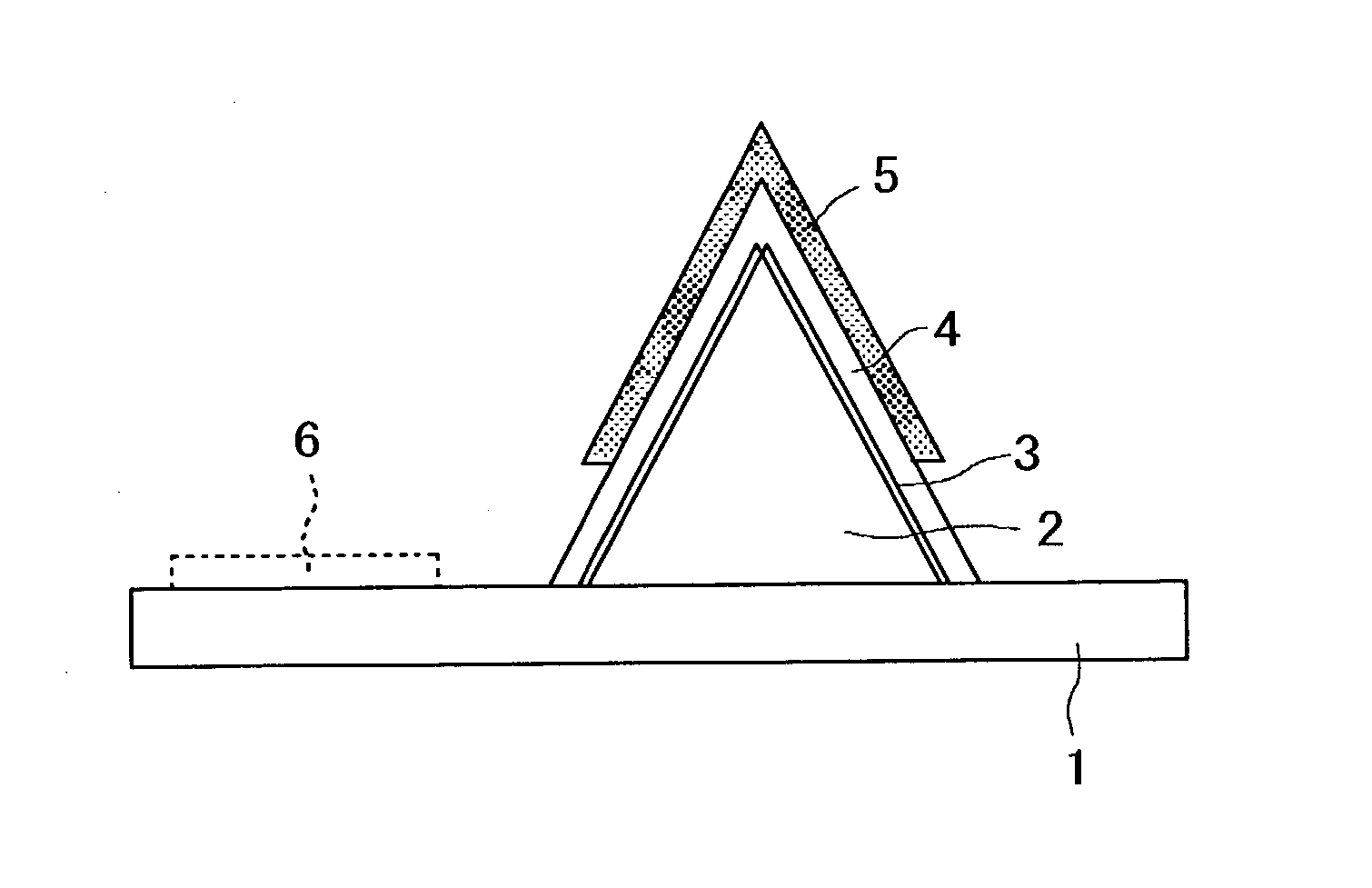

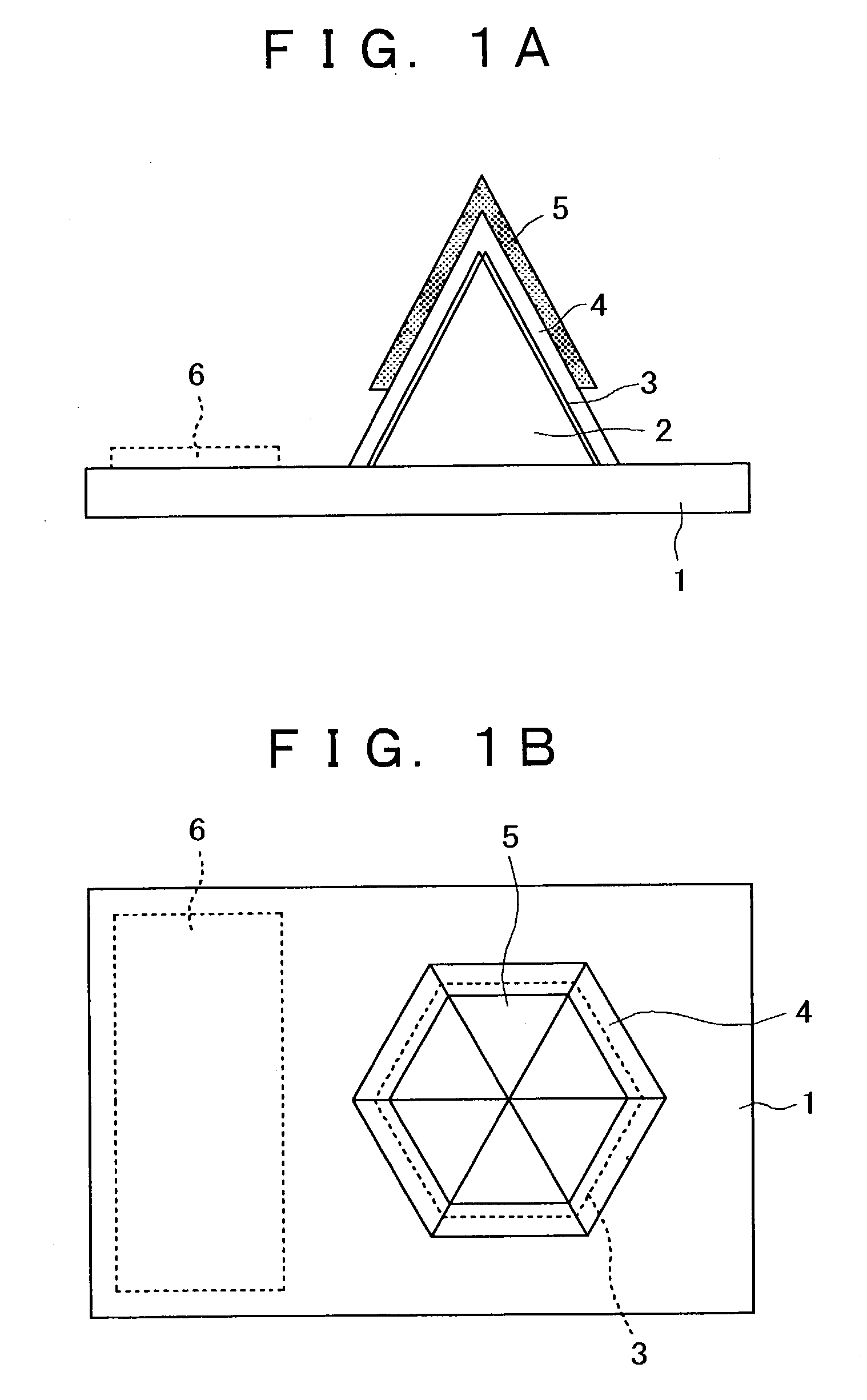

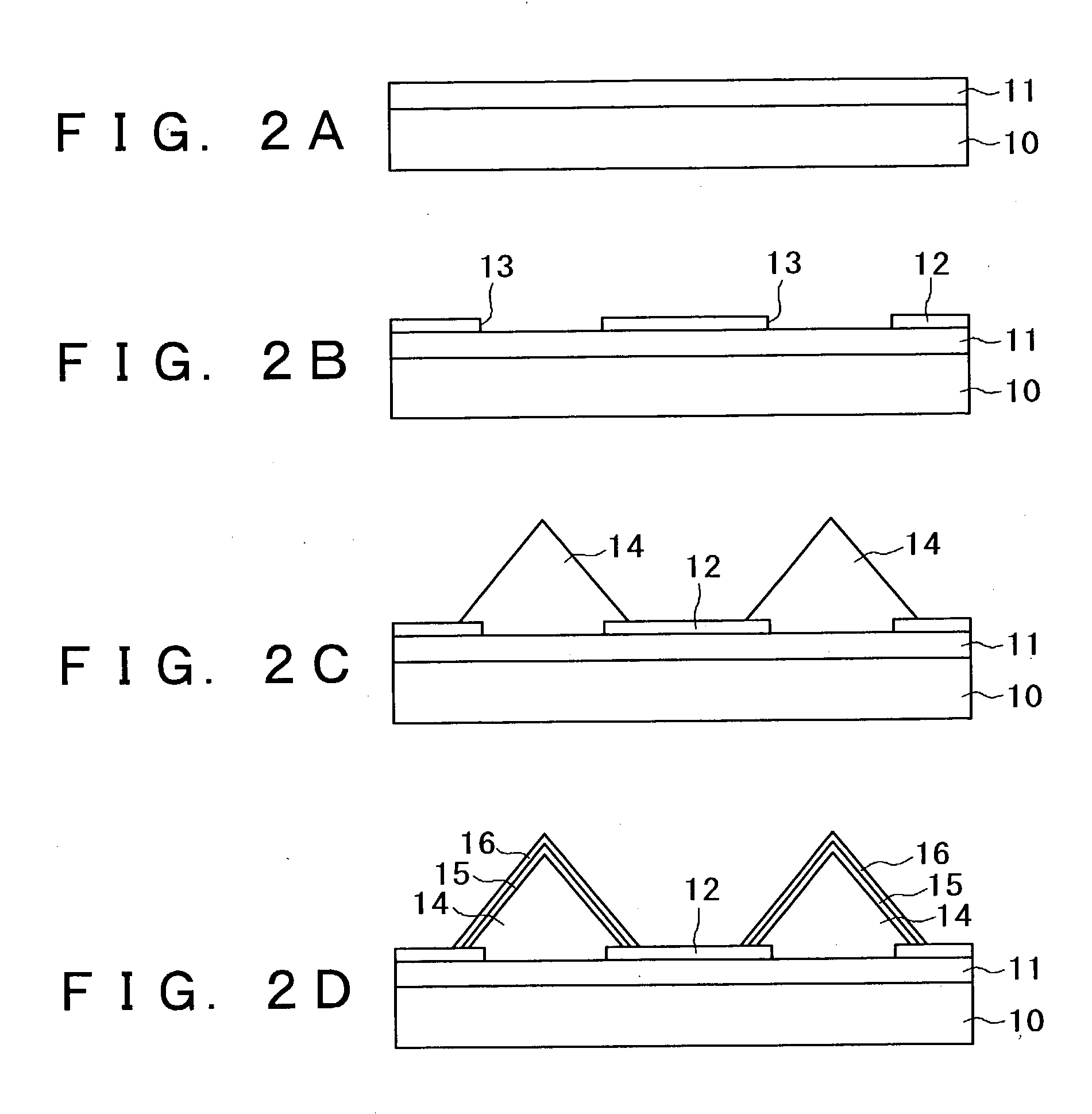

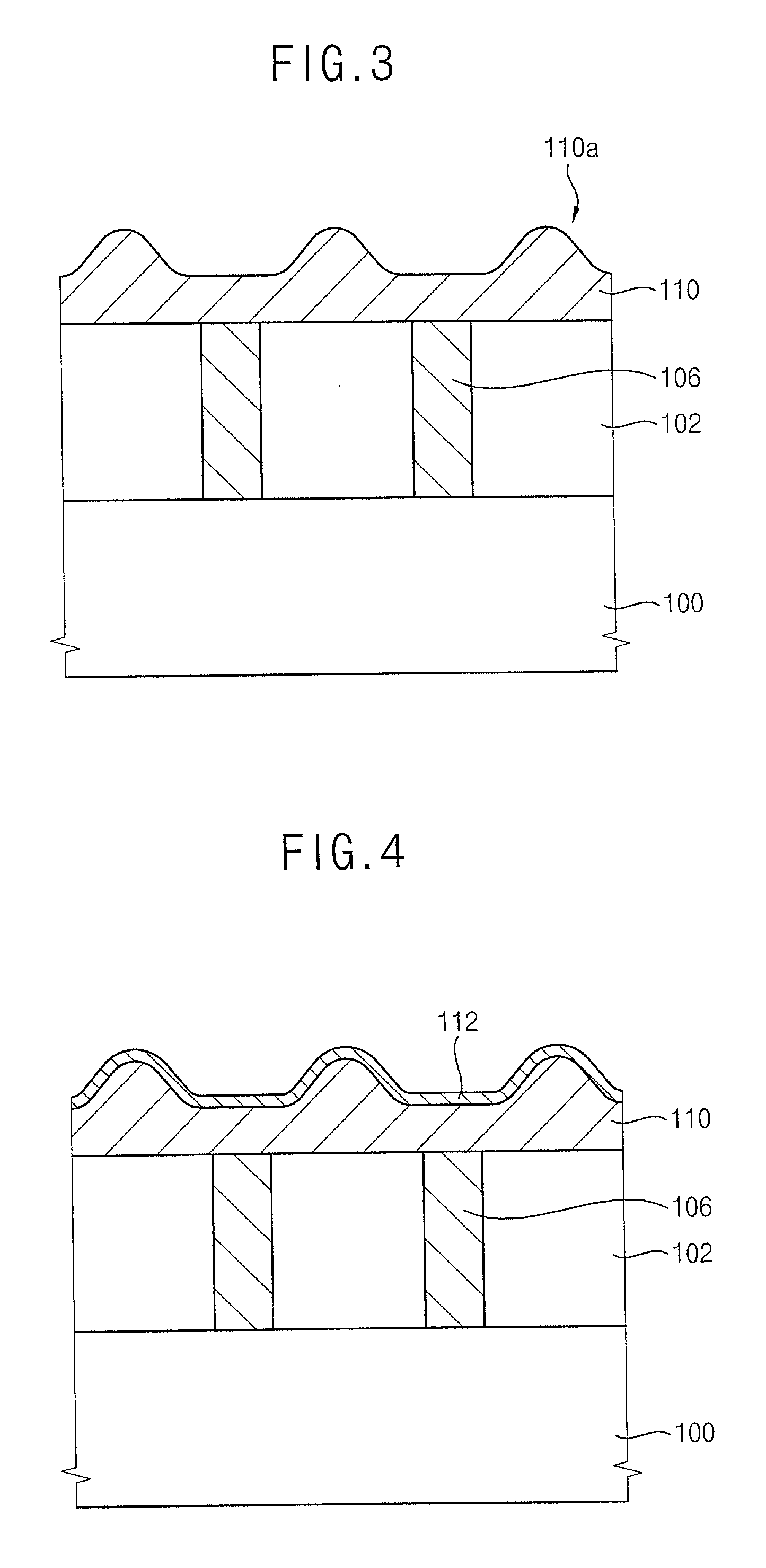

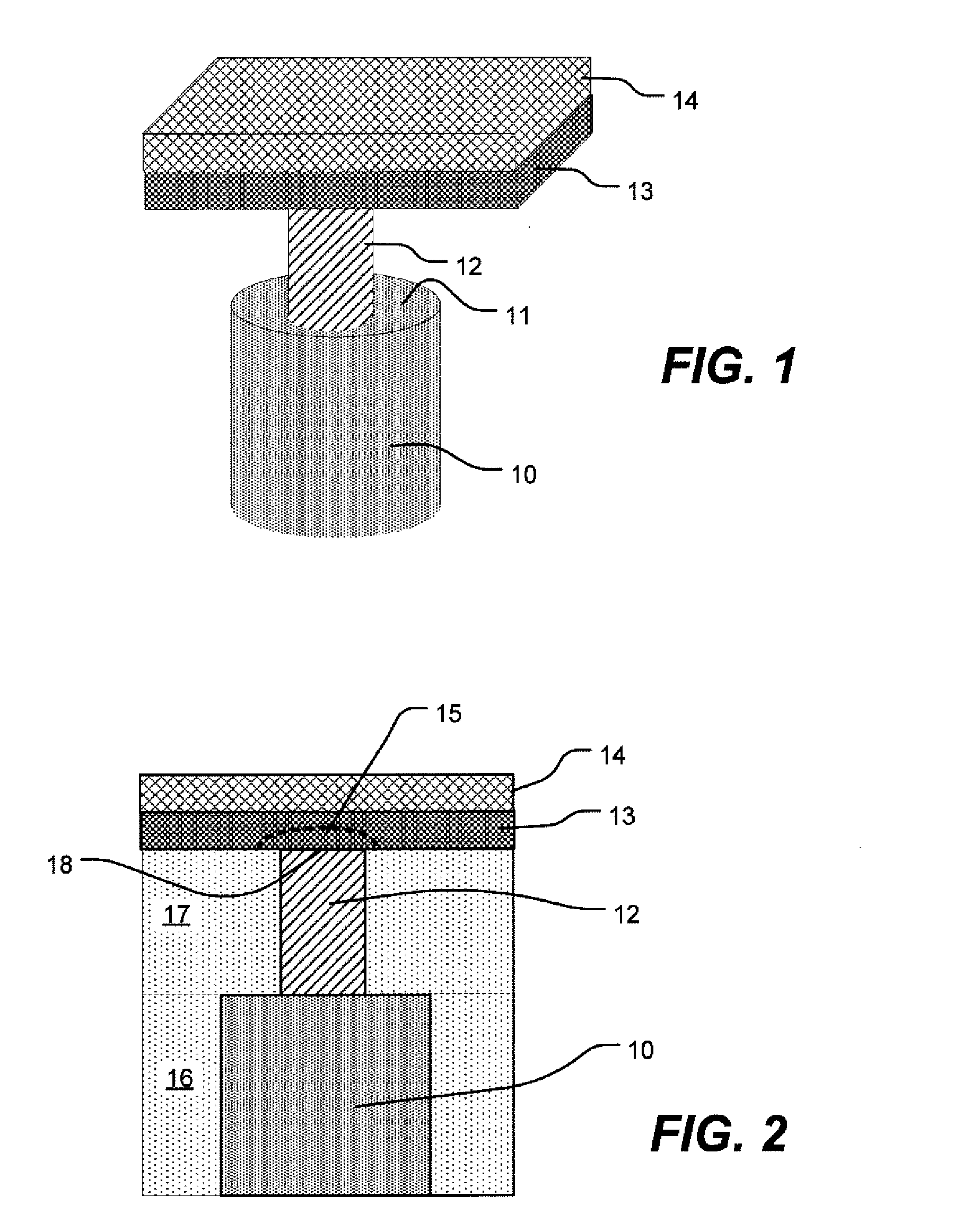

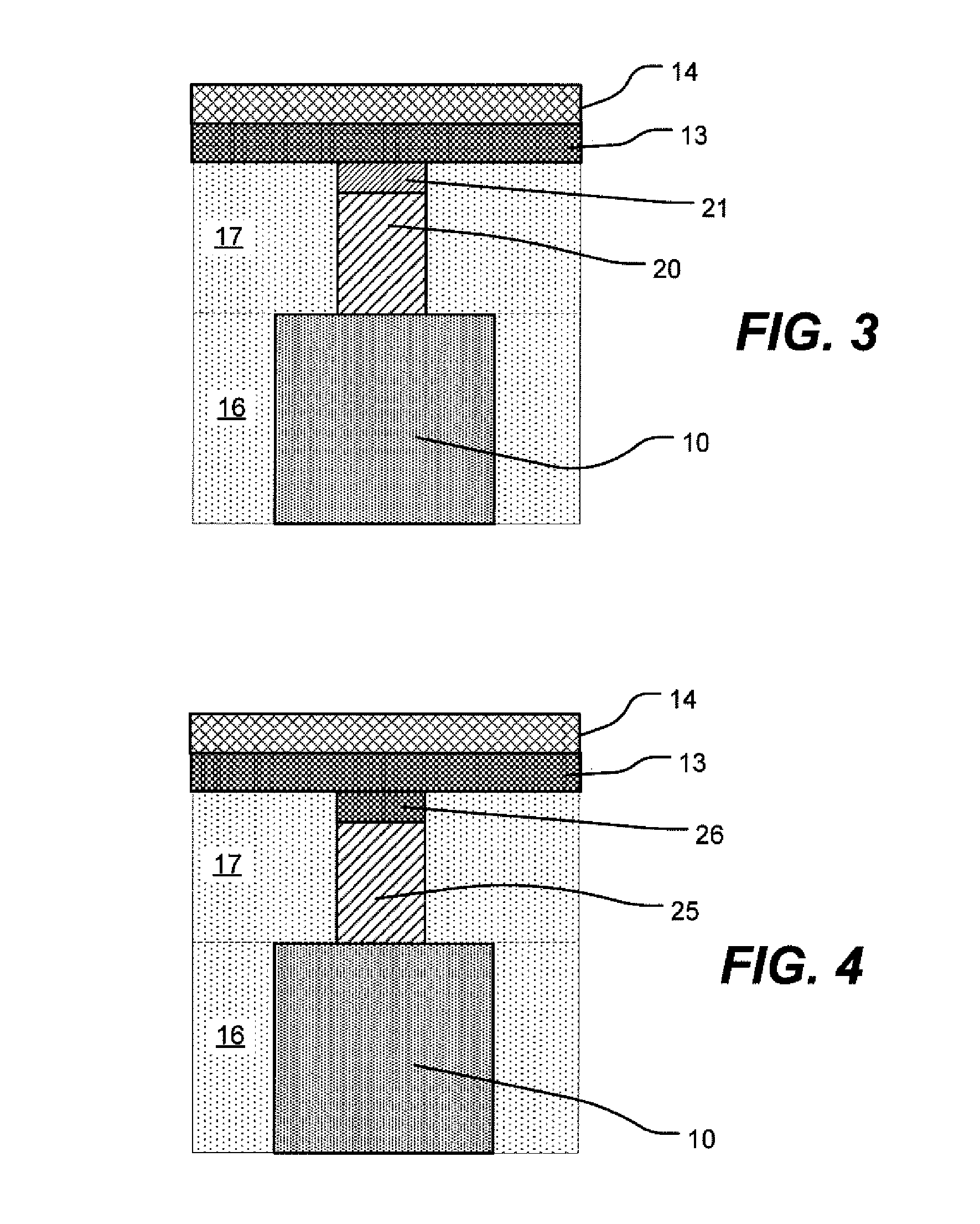

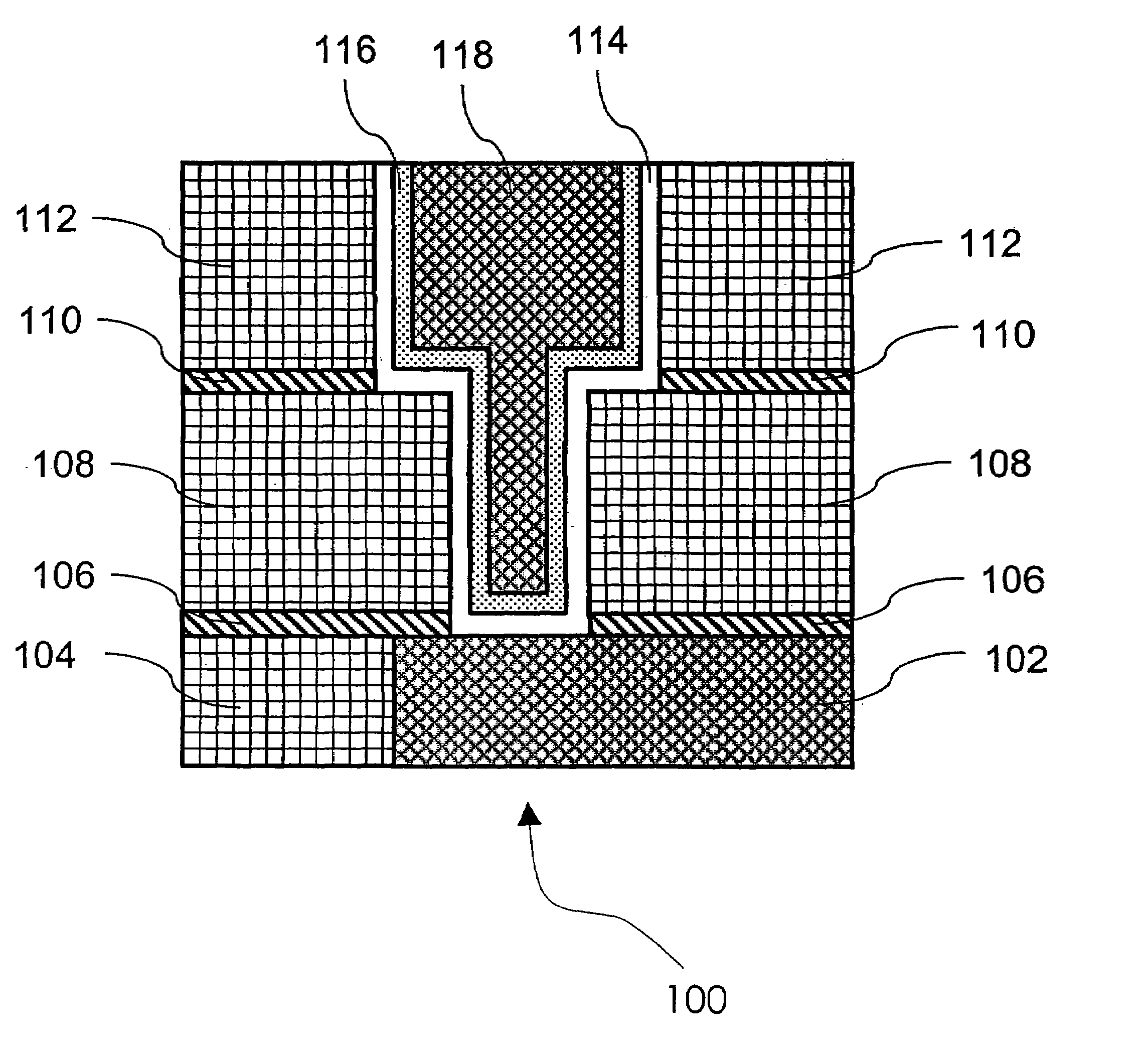

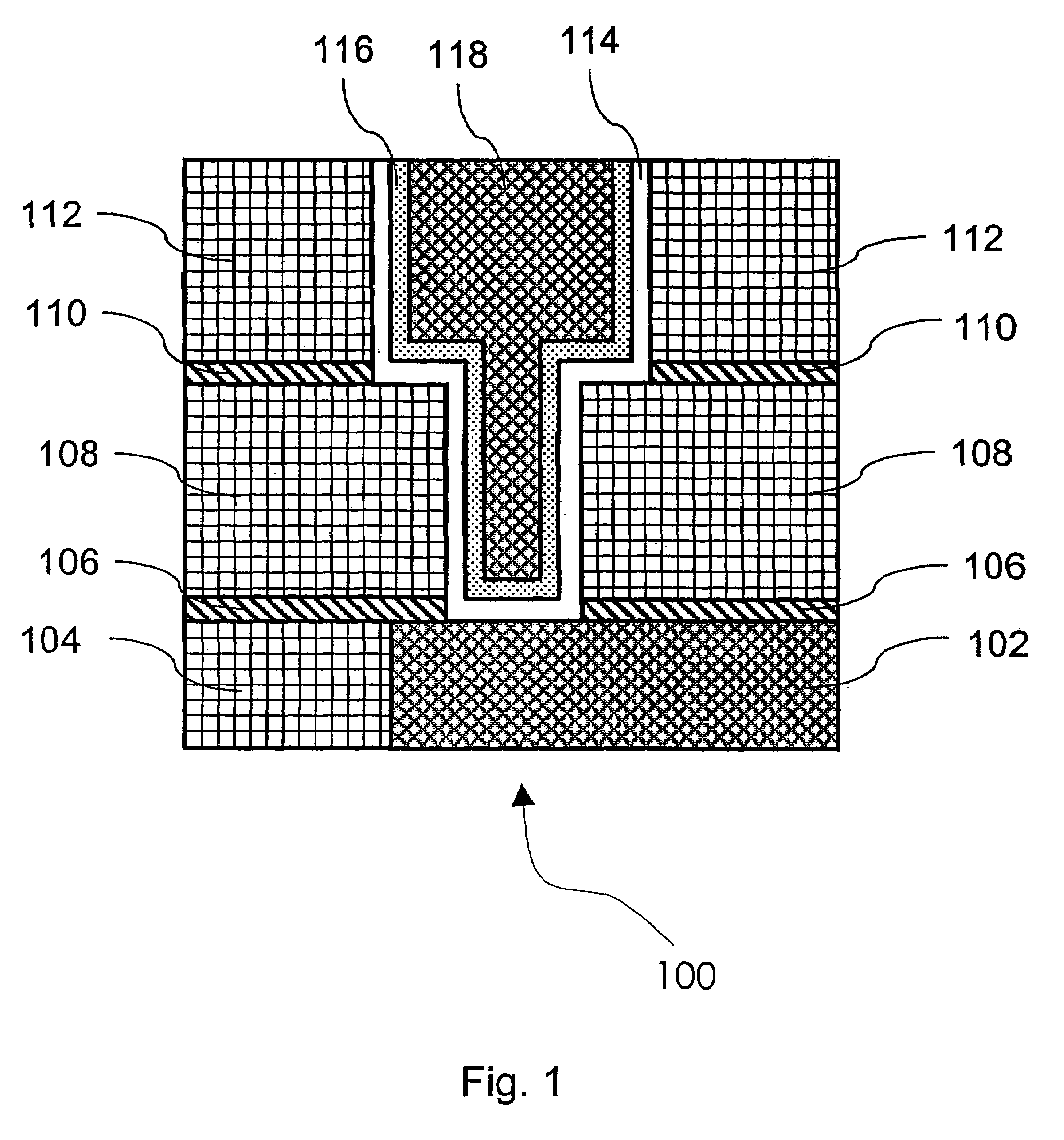

Selective growth method, and semiconductor light emitting device and fabrication method thereof

InactiveUS6858081B2Improve featuresReduce widthPolycrystalline material growthSemiconductor/solid-state device manufacturingThree dimensional shapeActive layer

In a selective growth method, growth interruption is performed at the time of selective growth of a crystal layer on a substrate. Even if the thickness distribution of the crystal layer becomes non-uniform at the time of growth of the crystal layer, the non-uniformity of the thickness distribution of the crystal layer can be corrected by inserting the growth interruption. As a result of growth interruption, an etching rate at a thick portion becomes higher than that at a thin portion, to eliminate the difference in thickness between the thick portion and the thin portion, thereby solving the problem associated with degradation of characteristics due to a variation in thickness of the crystal layer, for example, an active layer. The selective growth method is applied to fabrication of a semiconductor light emitting device including an active layer as a crystal layer formed on a crystal layer having a three-dimensional shape by selective growth.

Owner:SAMSUNG ELECTRONICS CO LTD

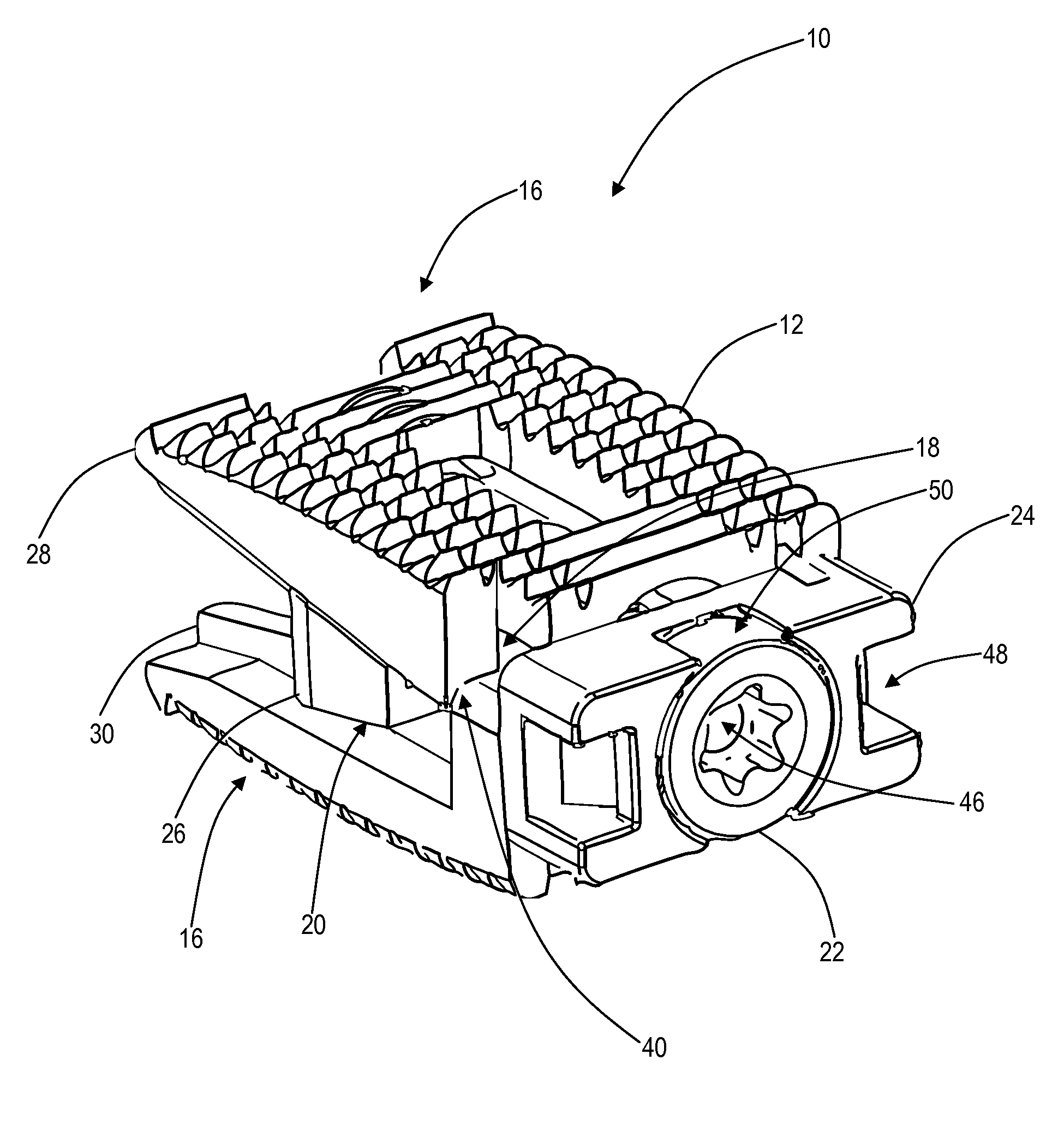

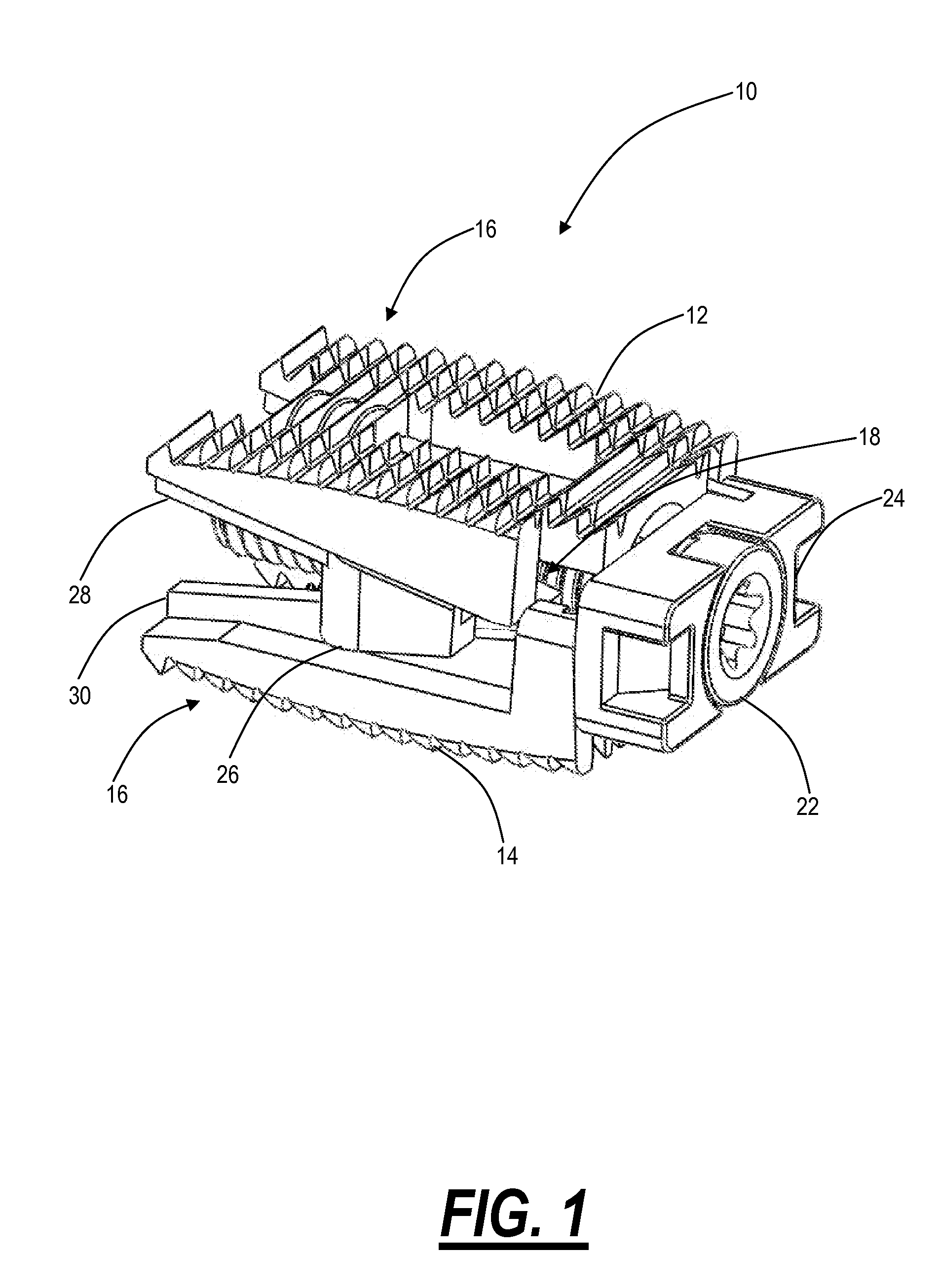

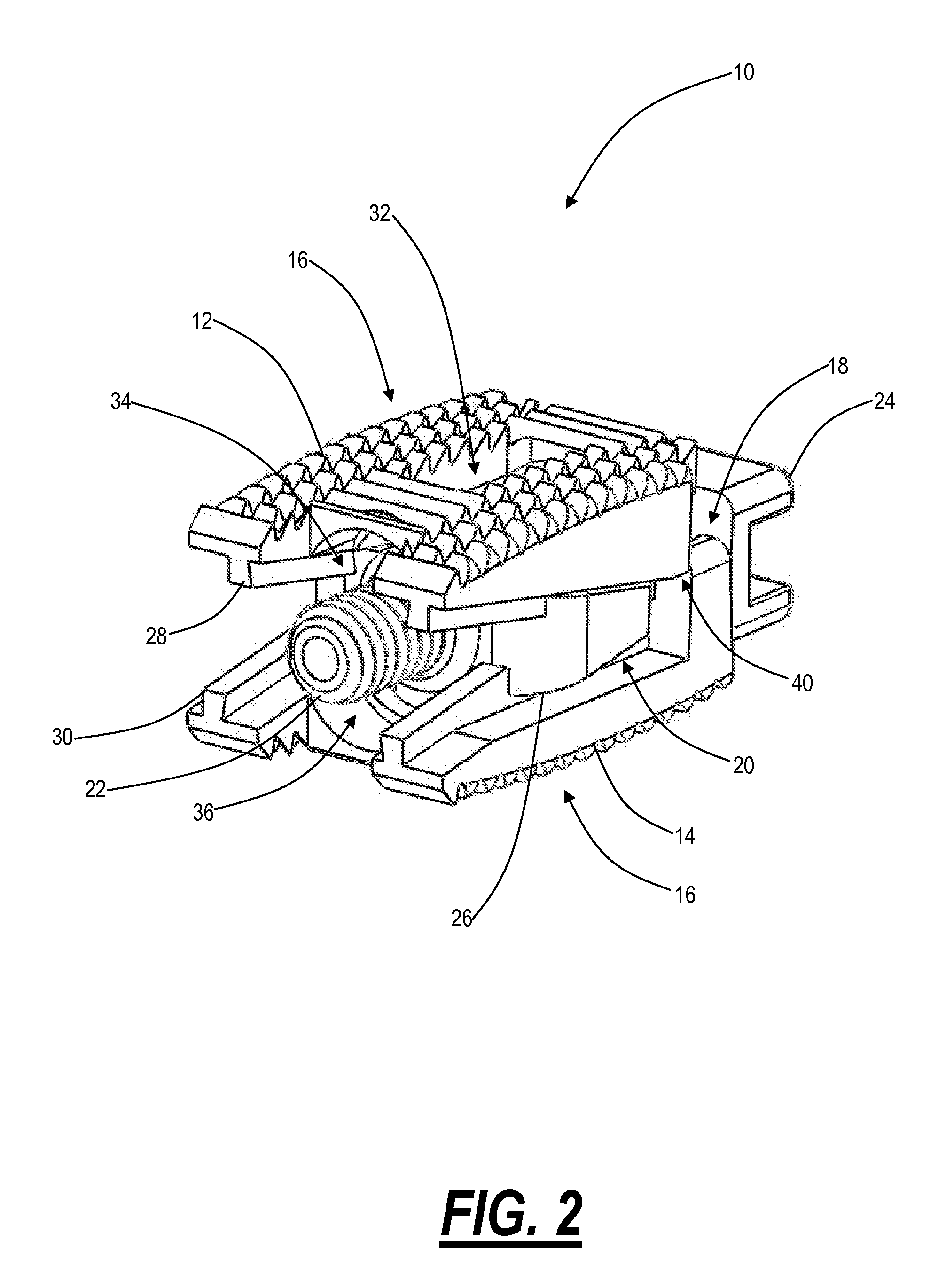

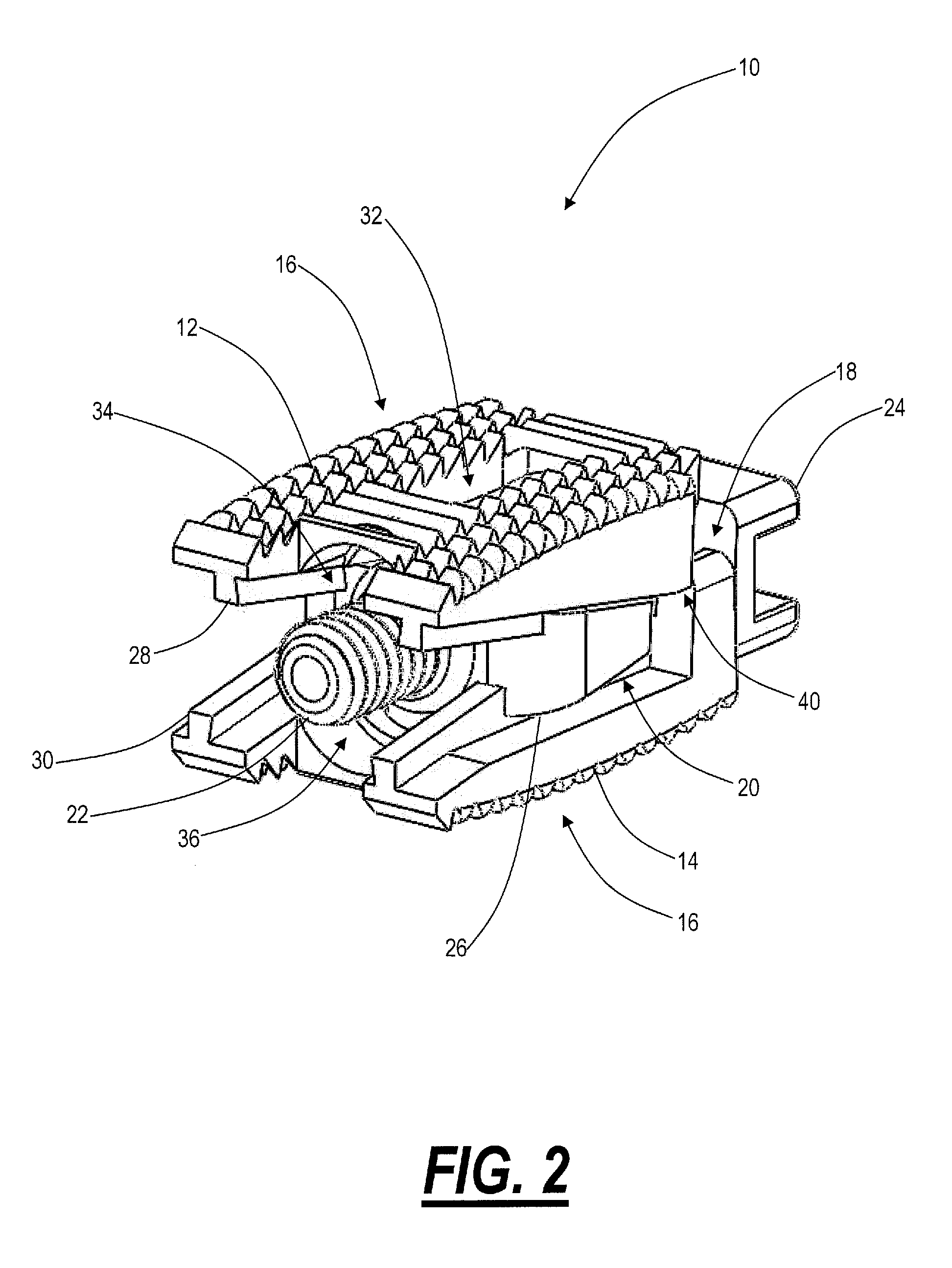

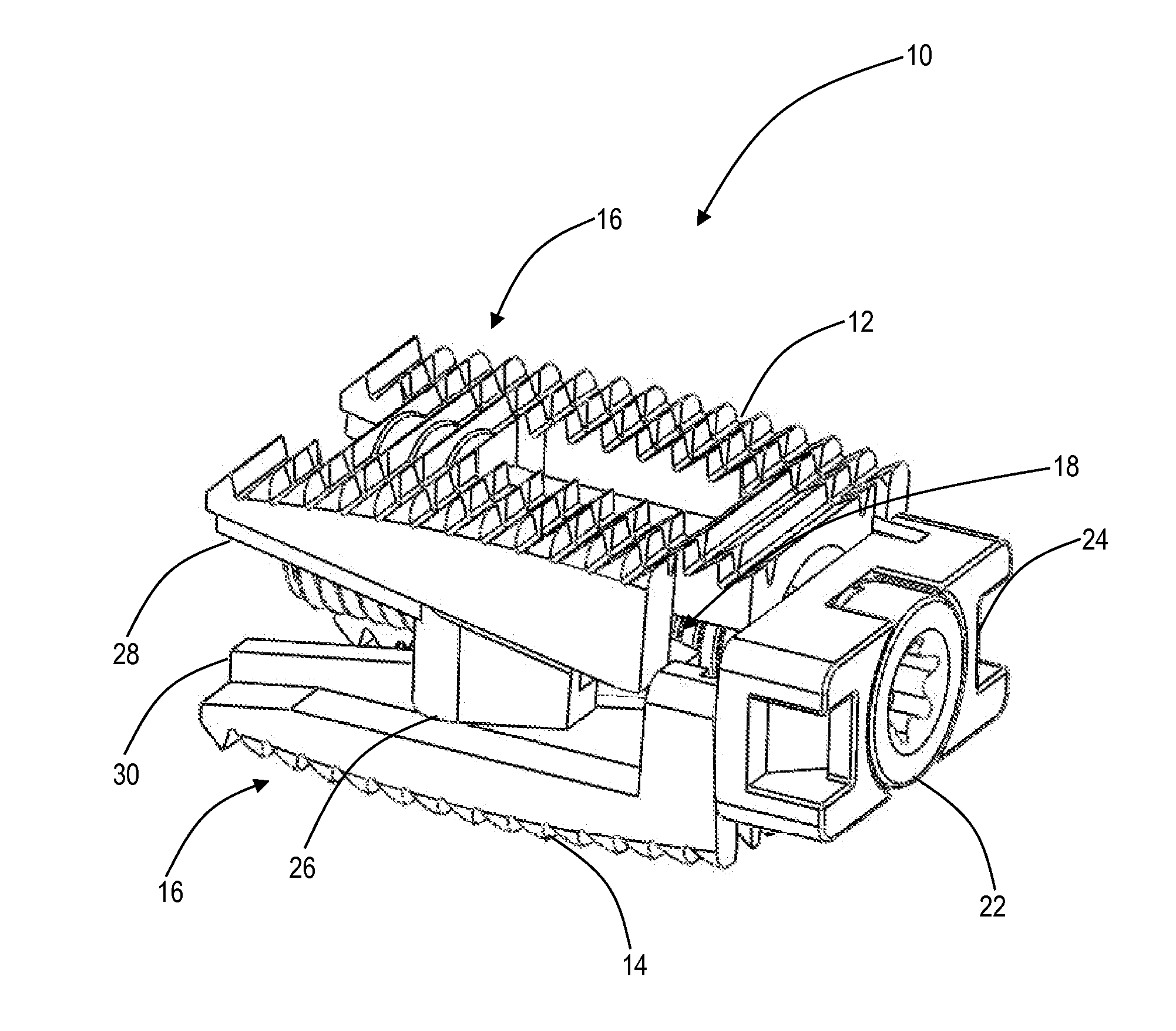

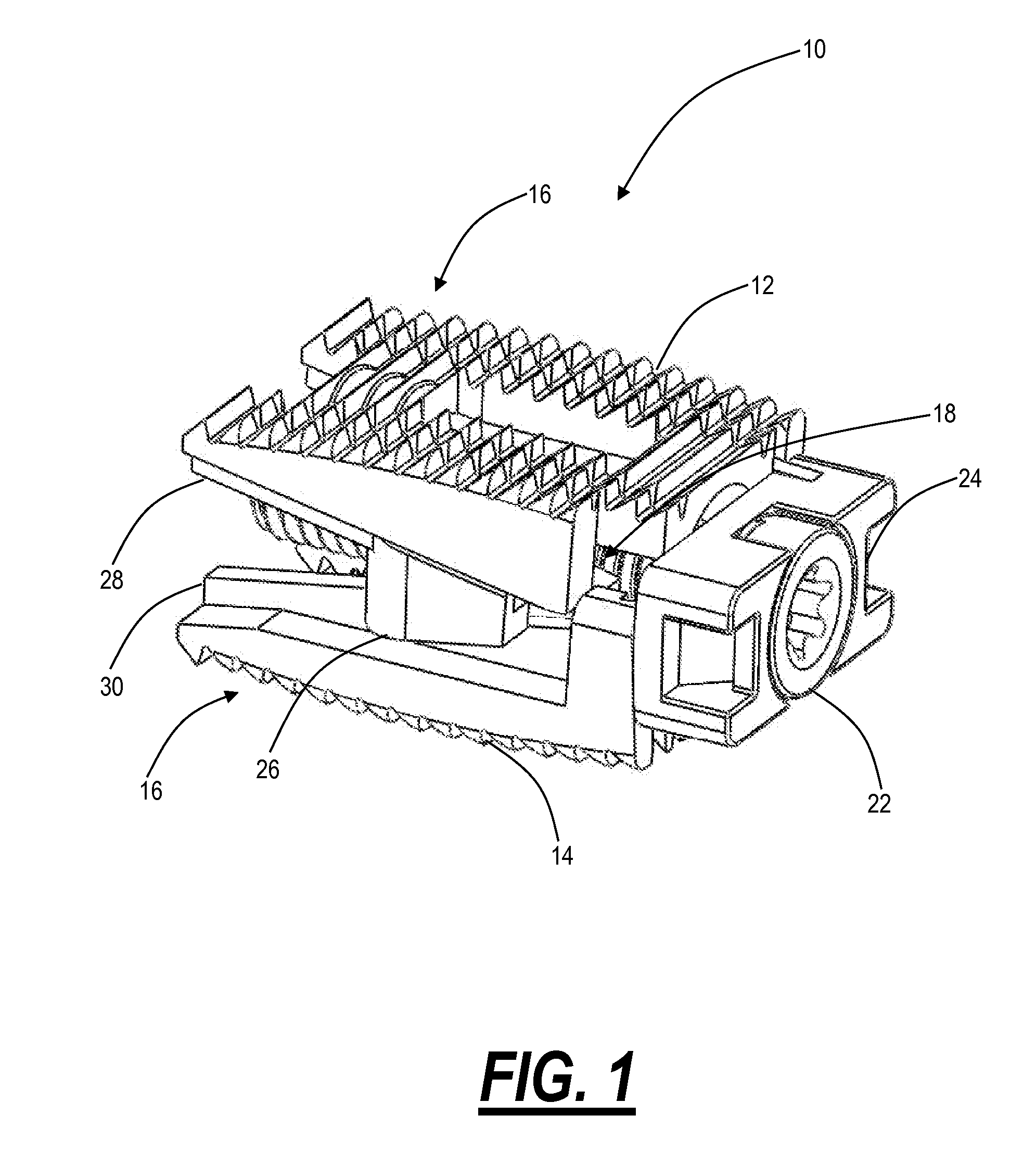

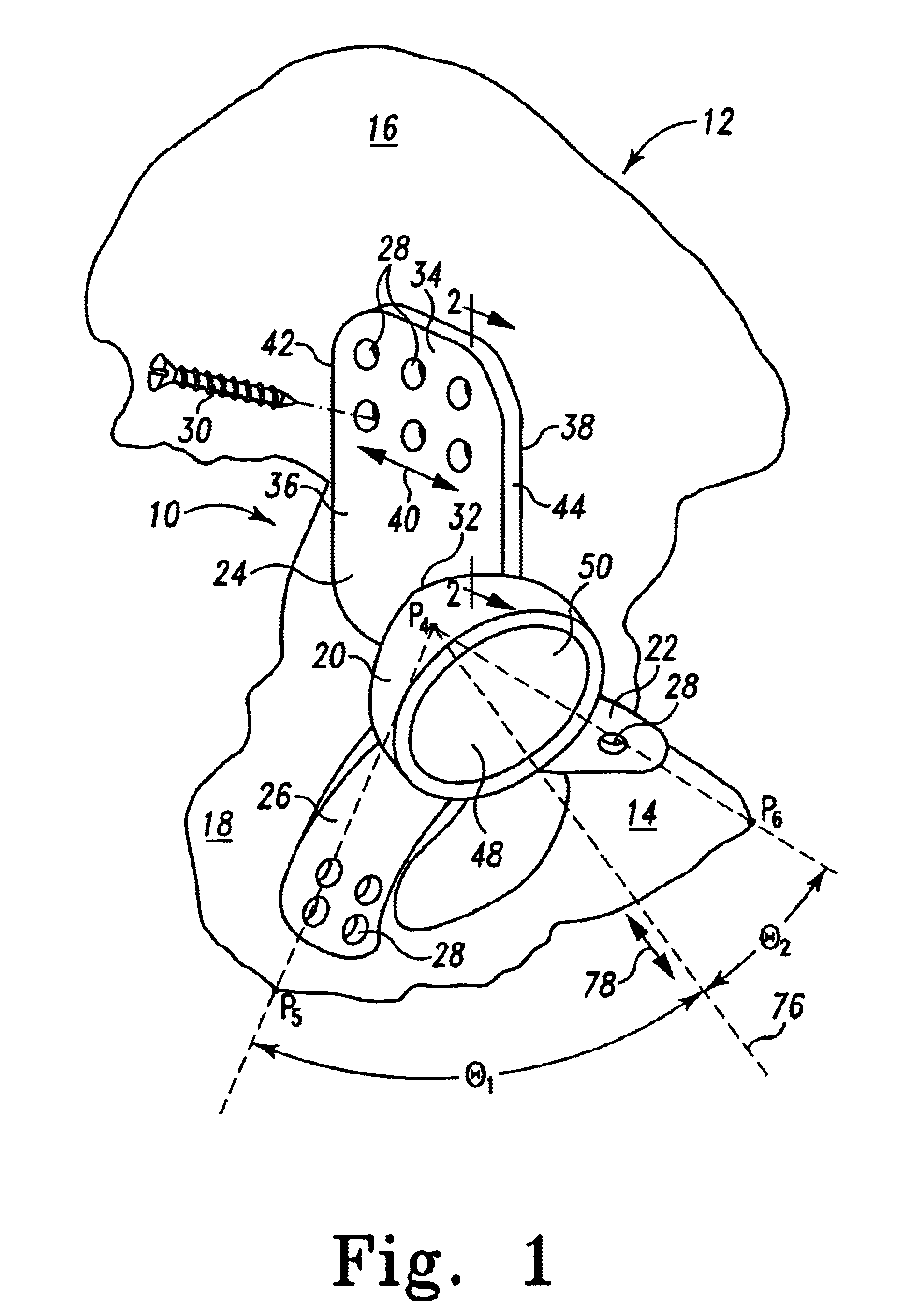

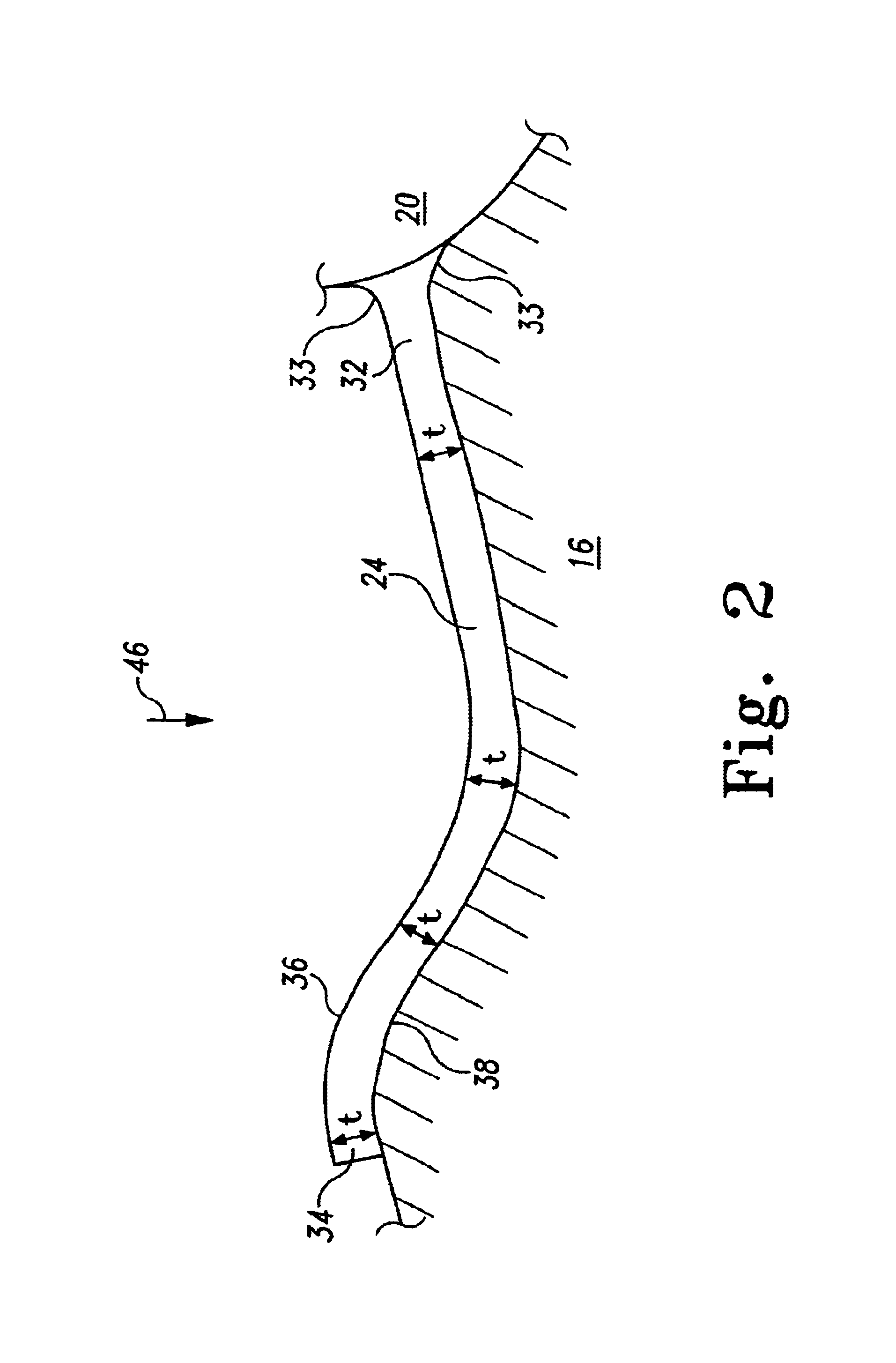

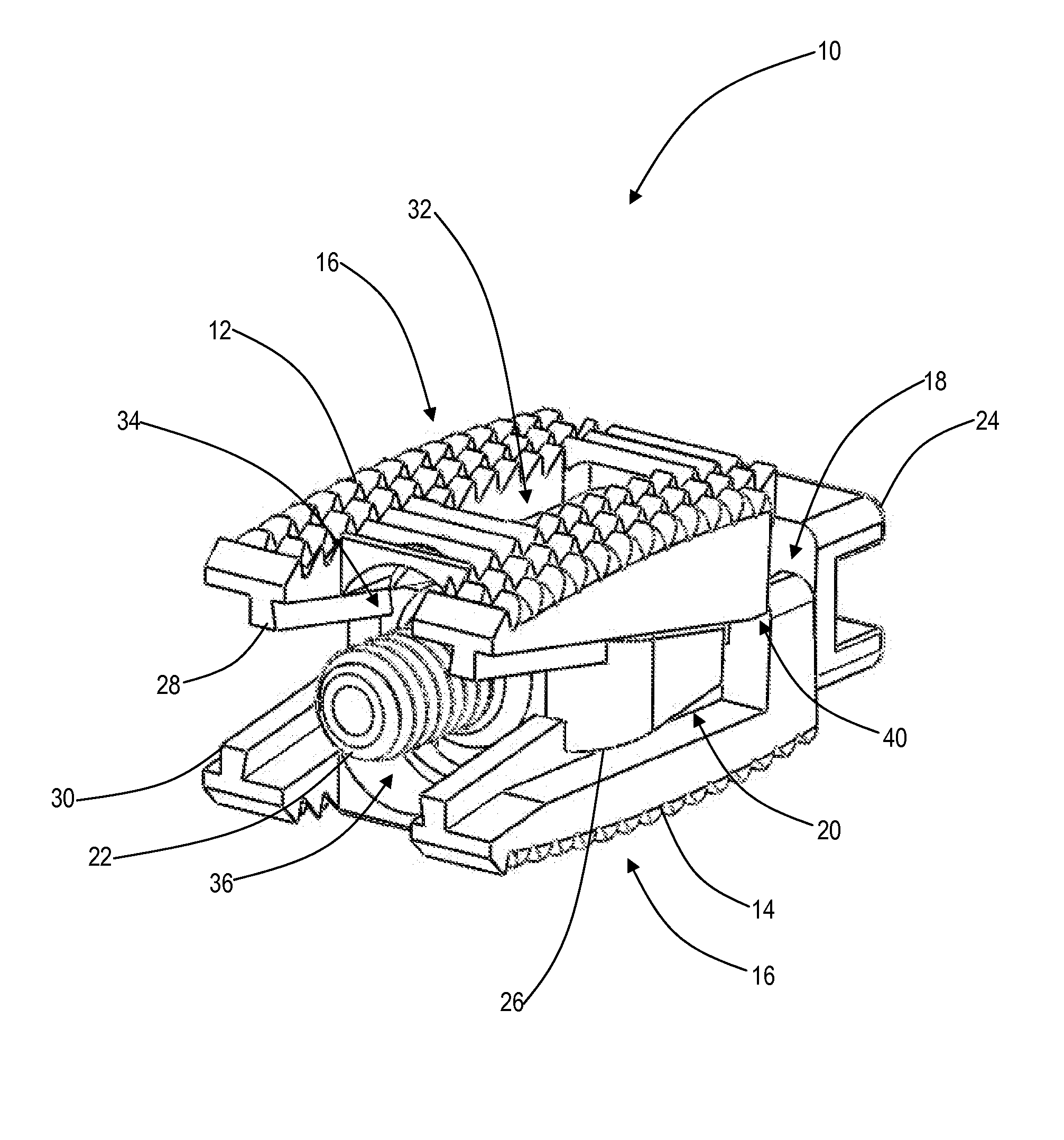

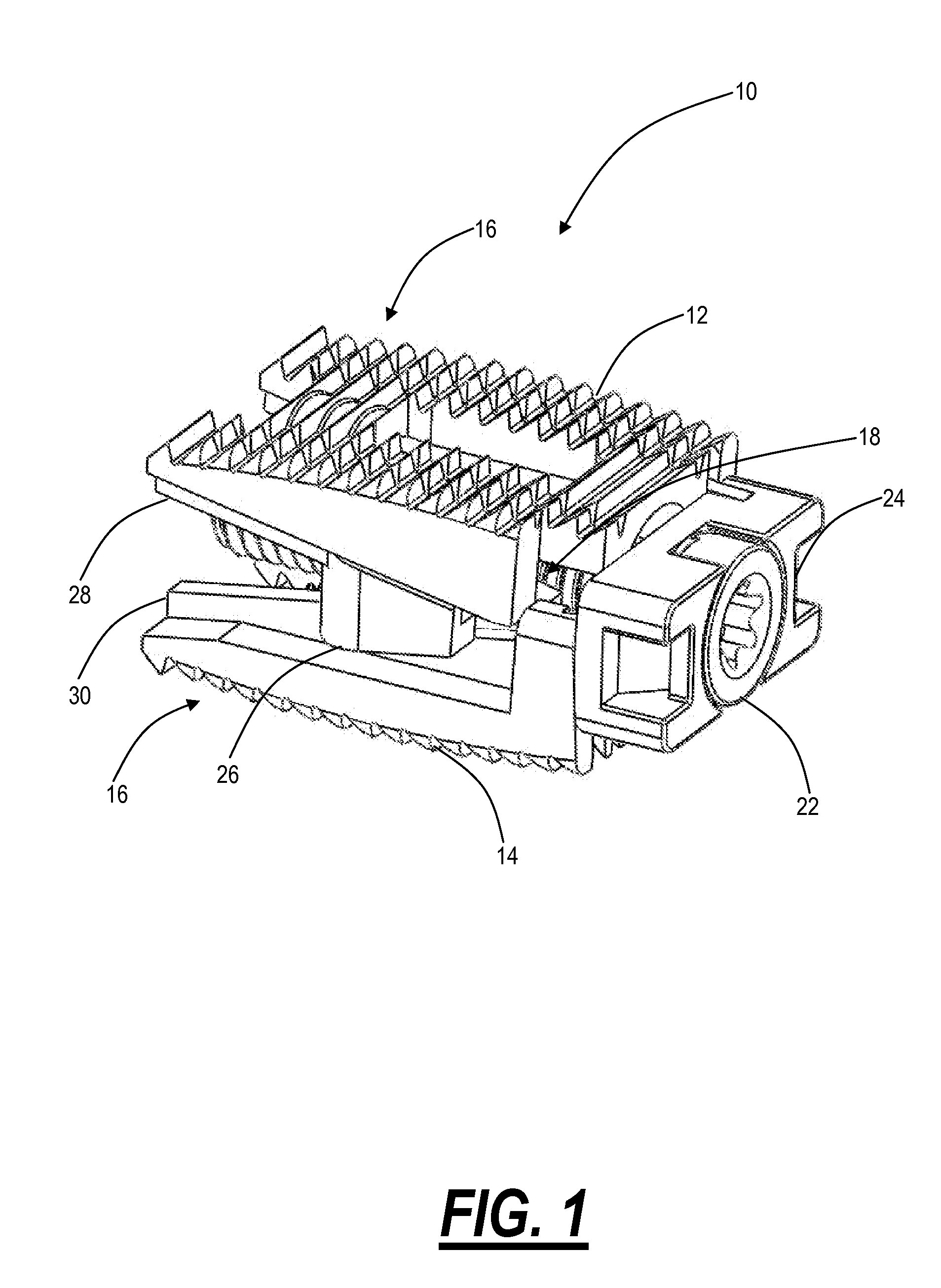

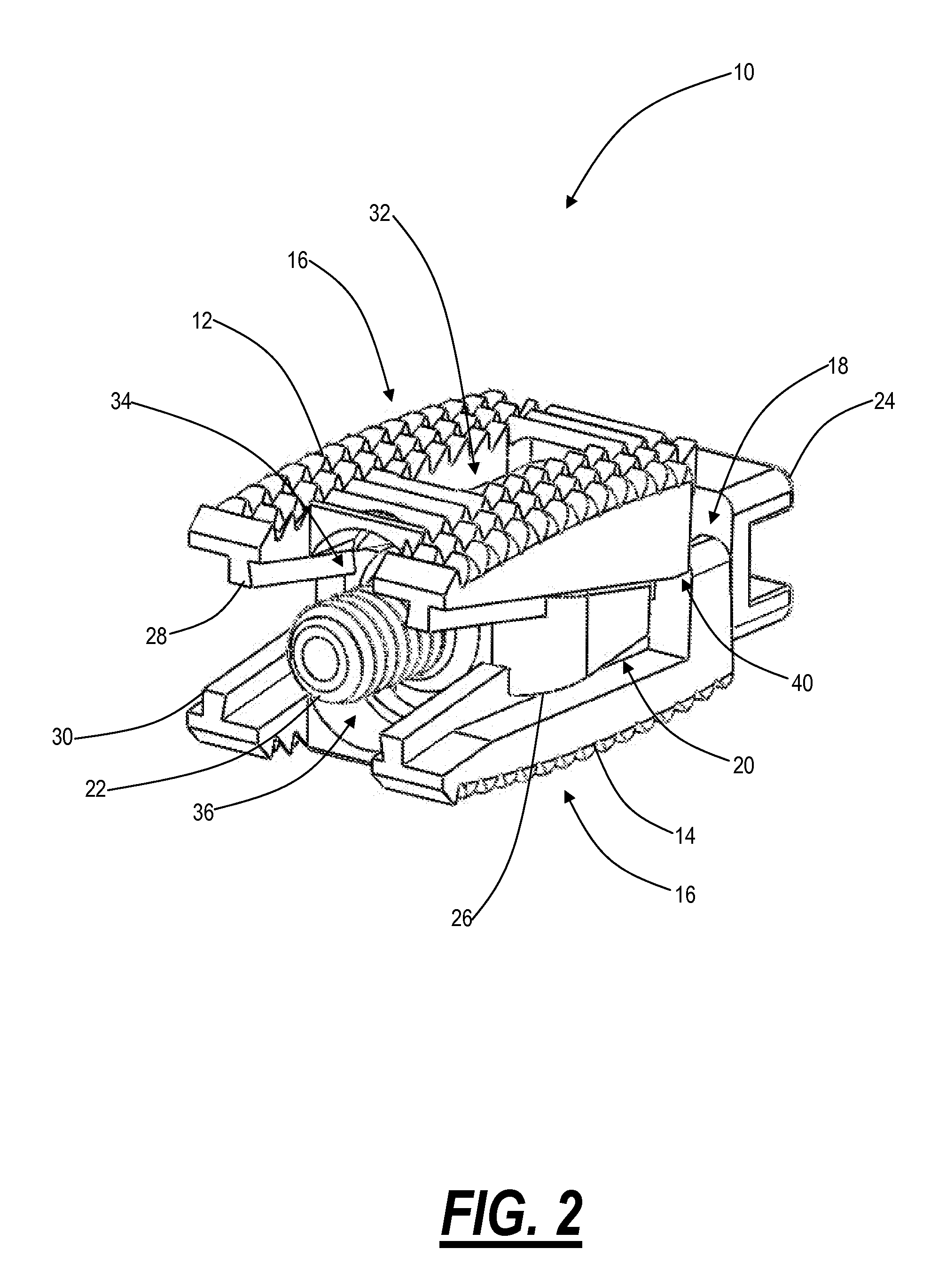

Expandable intervertebral implant and associated surgical method

The present invention provides an expandable intervertebral implant that is selectively disposed in the intervertebral space and deployed, thereby in-situ distracting, realigning, and / or stabilizing or fusing a portion of the spine of a patient in the treatment of injury, disease, and / or degenerative condition. The expandable intervertebral implant includes a superior member and an inferior member, each of which has a partially or substantially wedge or prismatic shape and a partially or substantially convex or other-shaped surface that is suitable for engaging the substantially concave surfaces of the associated bony superior and inferior intervertebral endplates. Once disposed in the intervertebral space, the expandable intervertebral implant is actuated and deployed, with the superior member and the inferior member moving apart from one another, seating against the associated intervertebral endplates, and distracting, realigning, and / or stabilizing them to a desired degree. The external surface of each of the superior member and the inferior member is provided with a plurality of ridges or other friction structures, providing purchase with the associated intervertebral endplates.

Owner:INNOVA SPINAL TECH

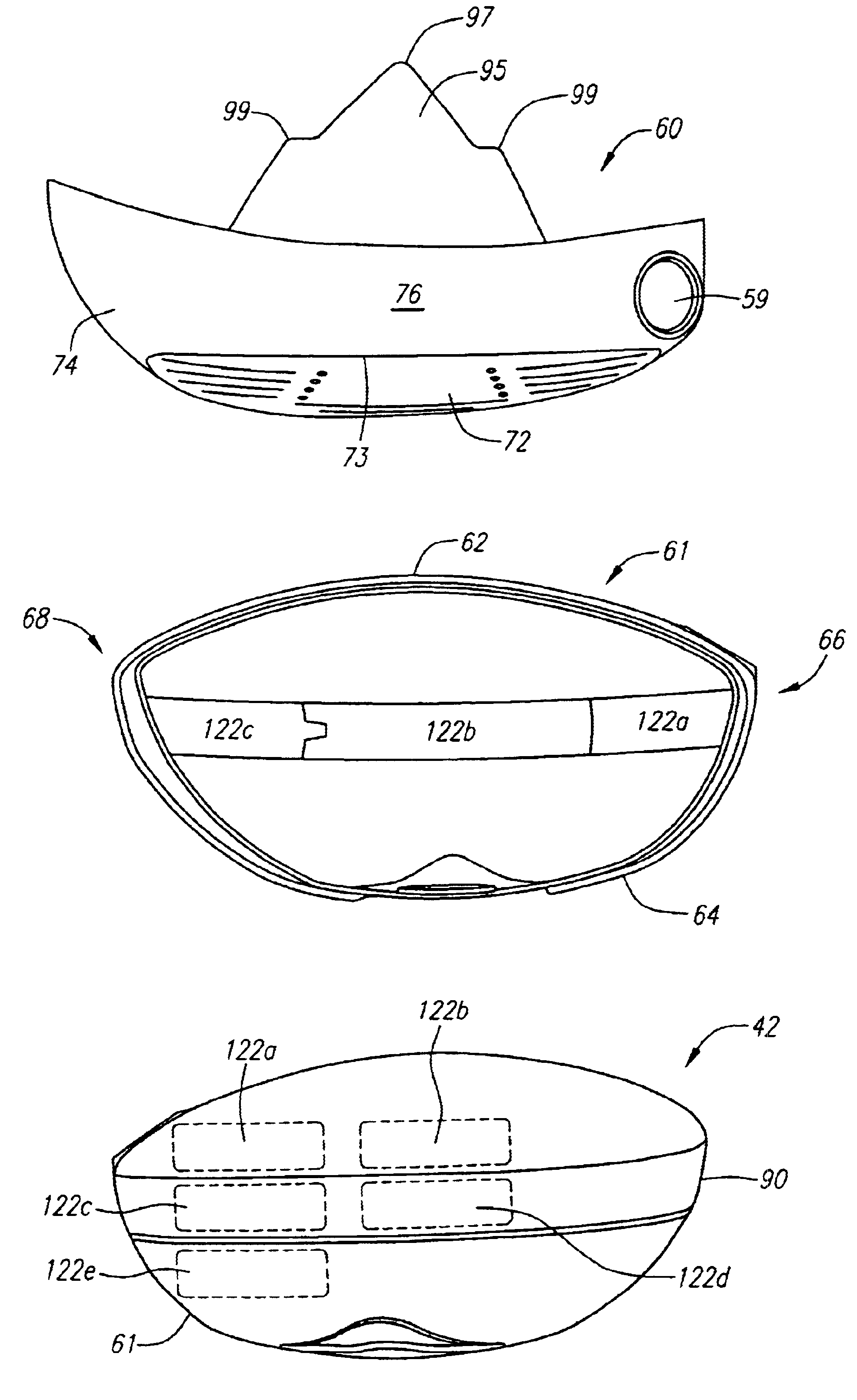

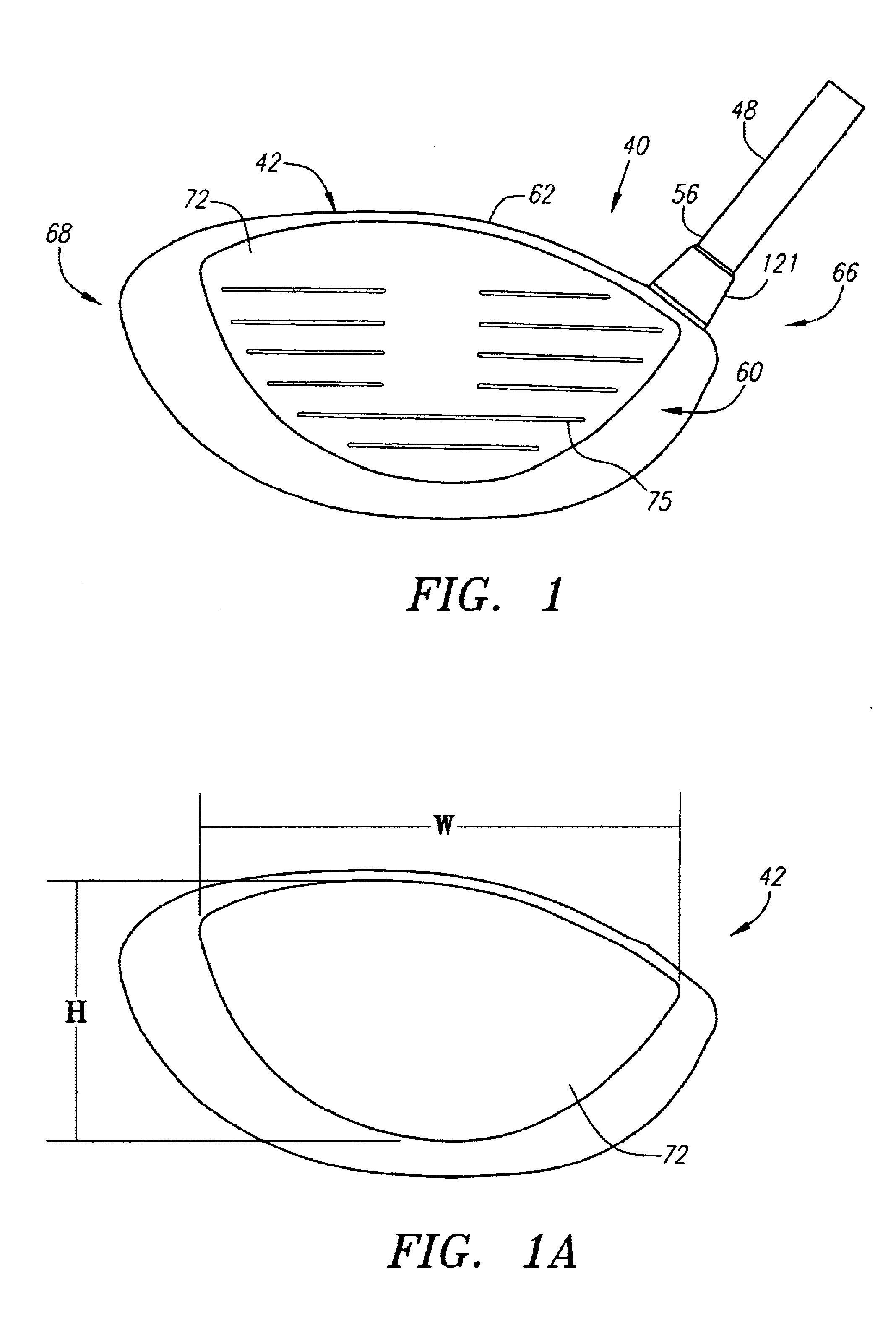

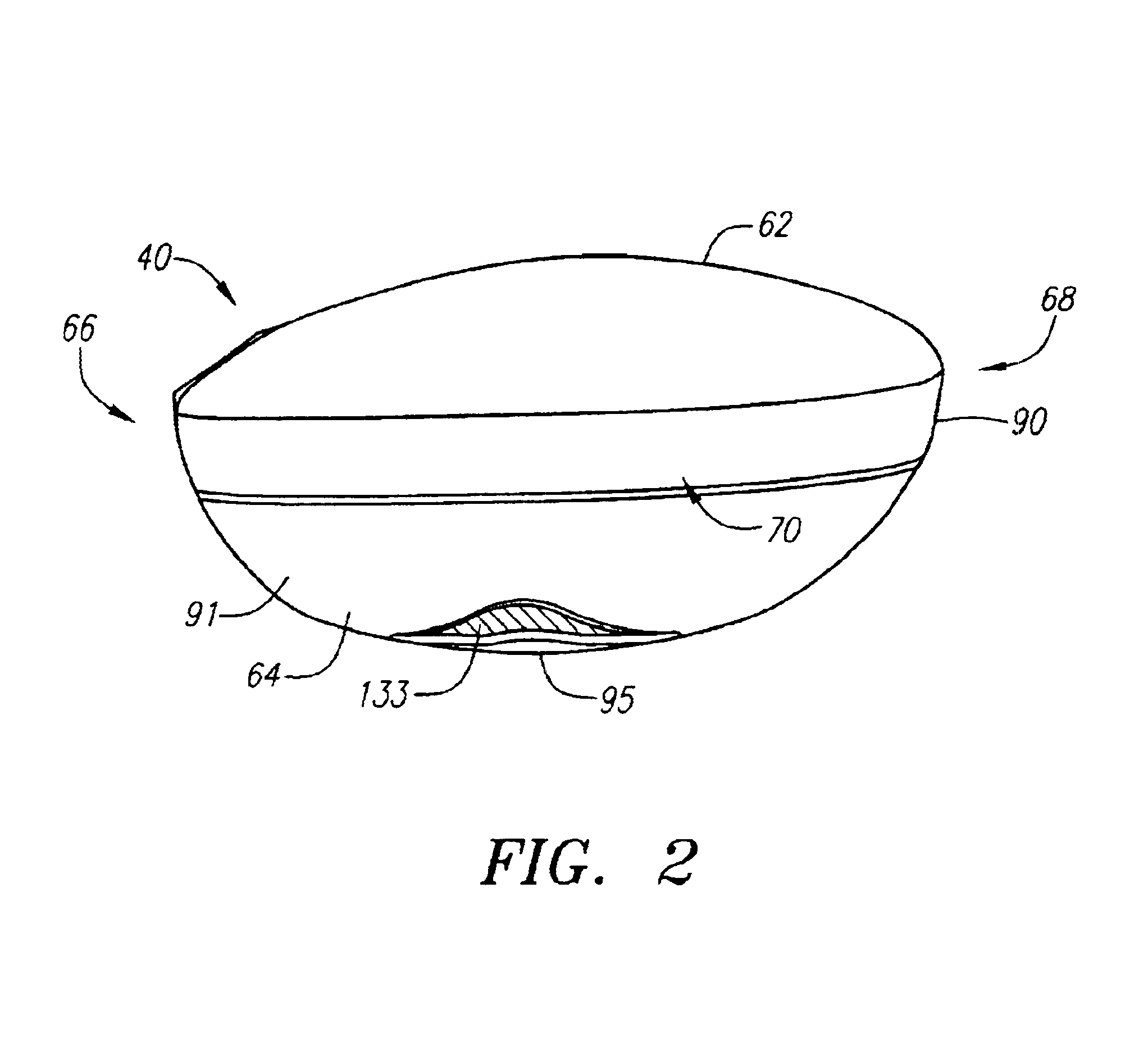

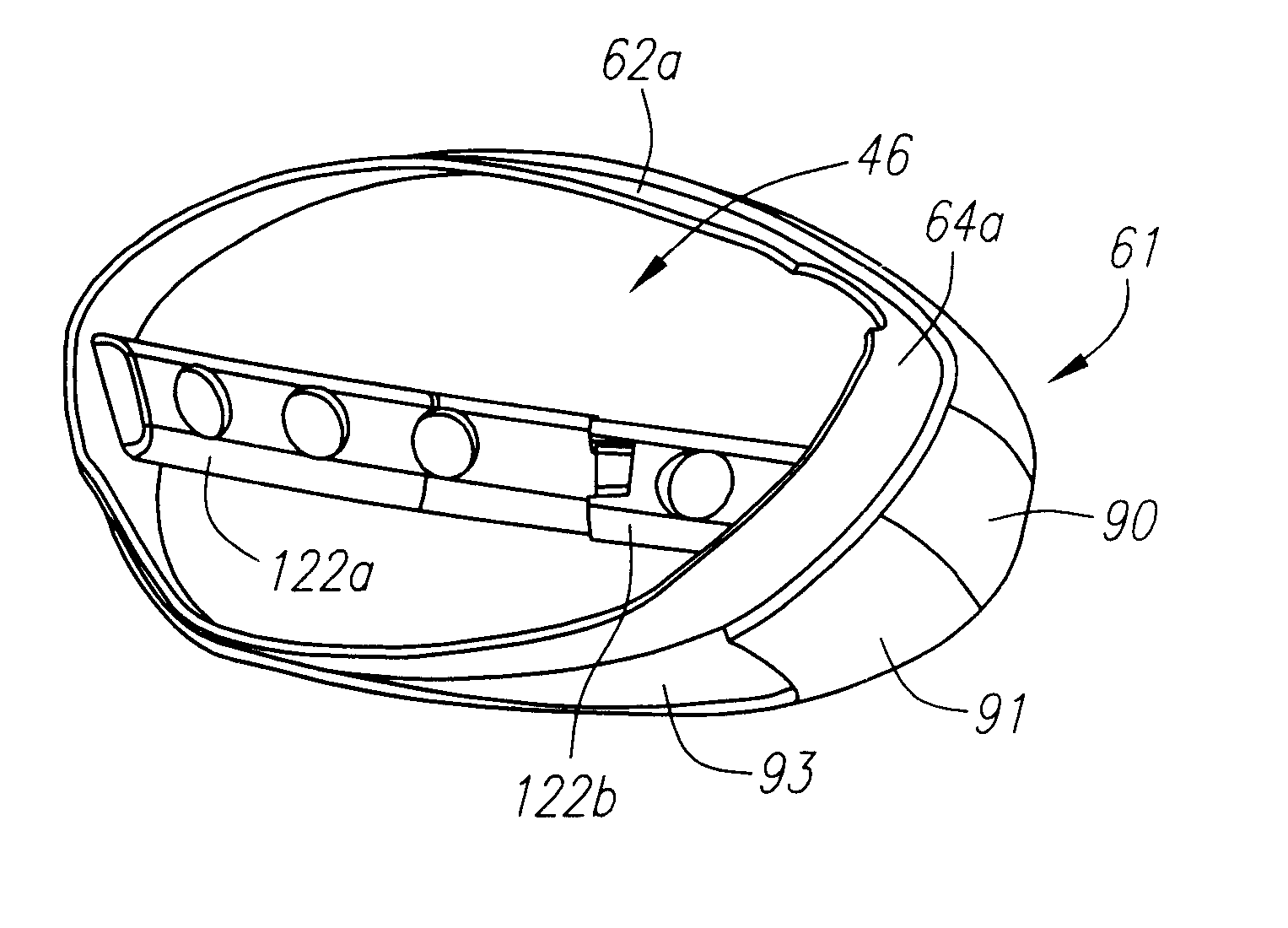

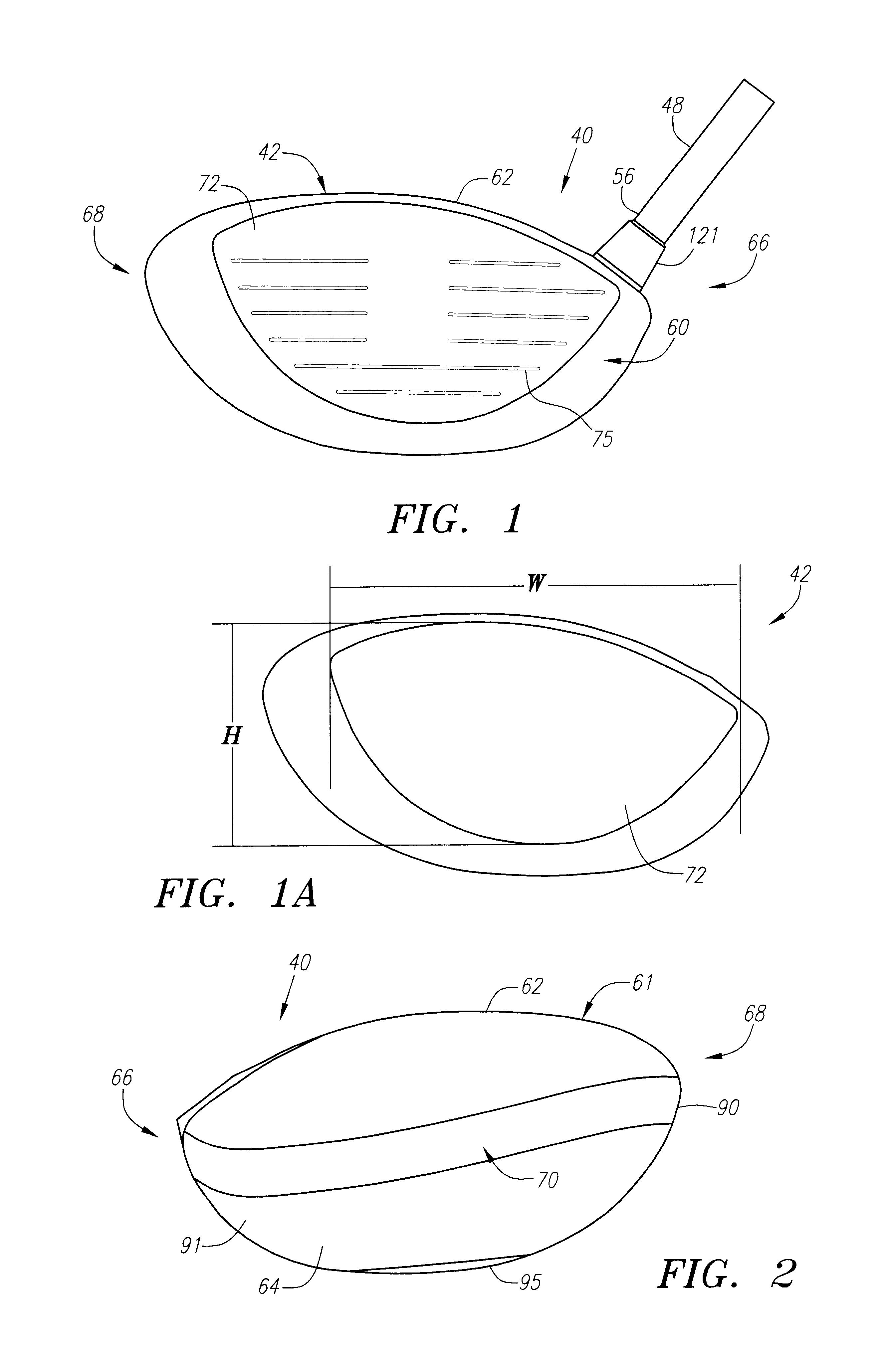

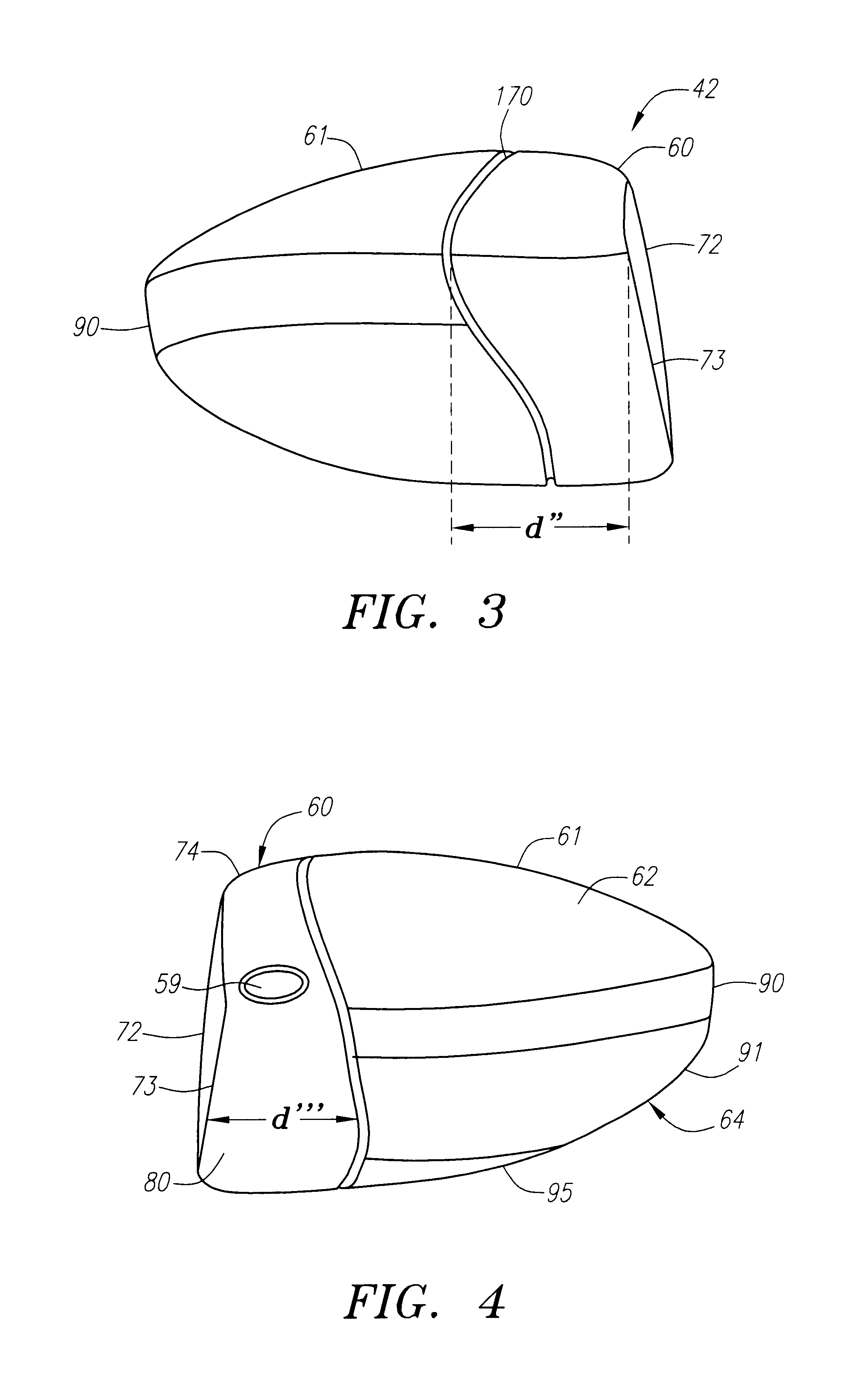

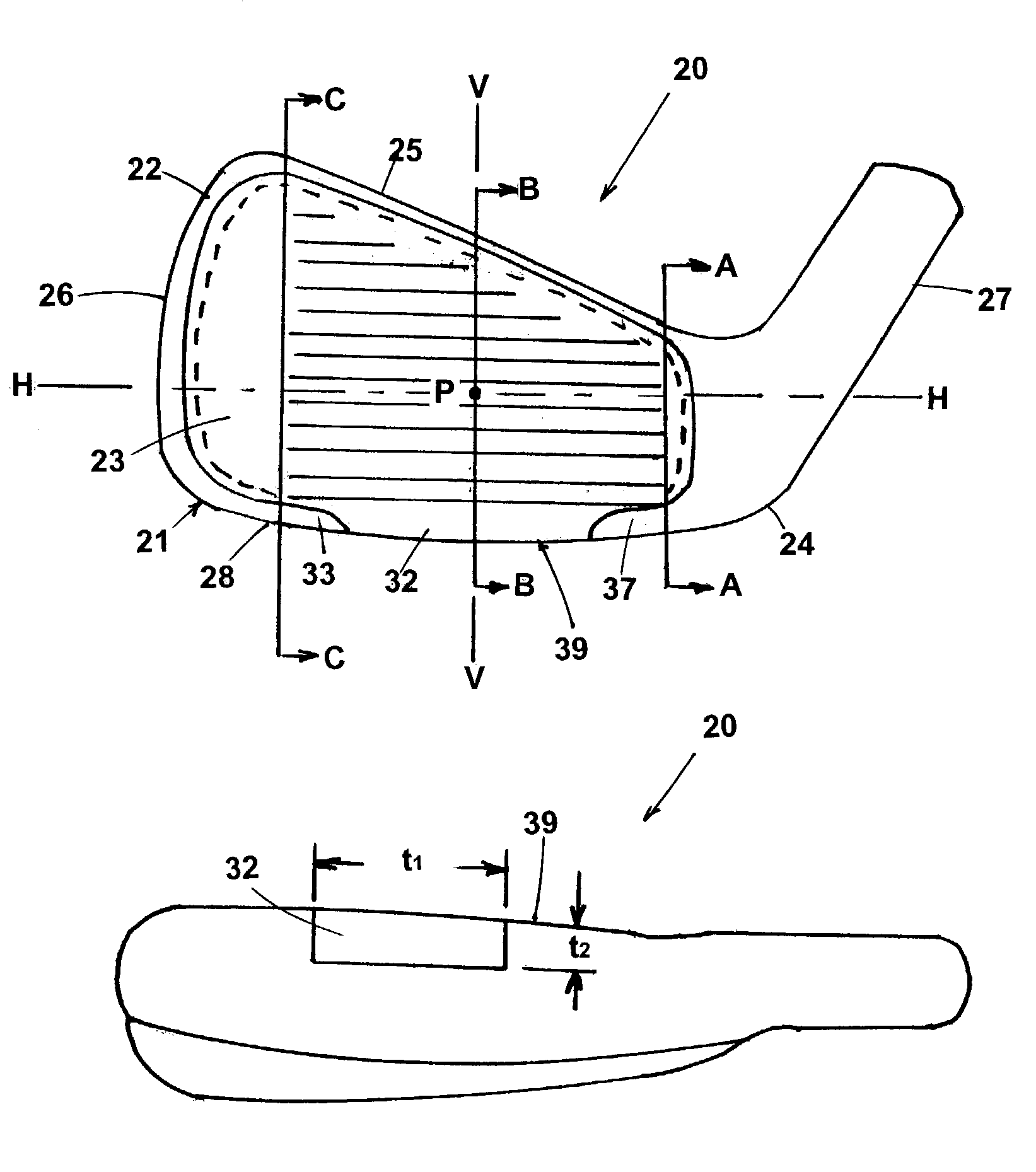

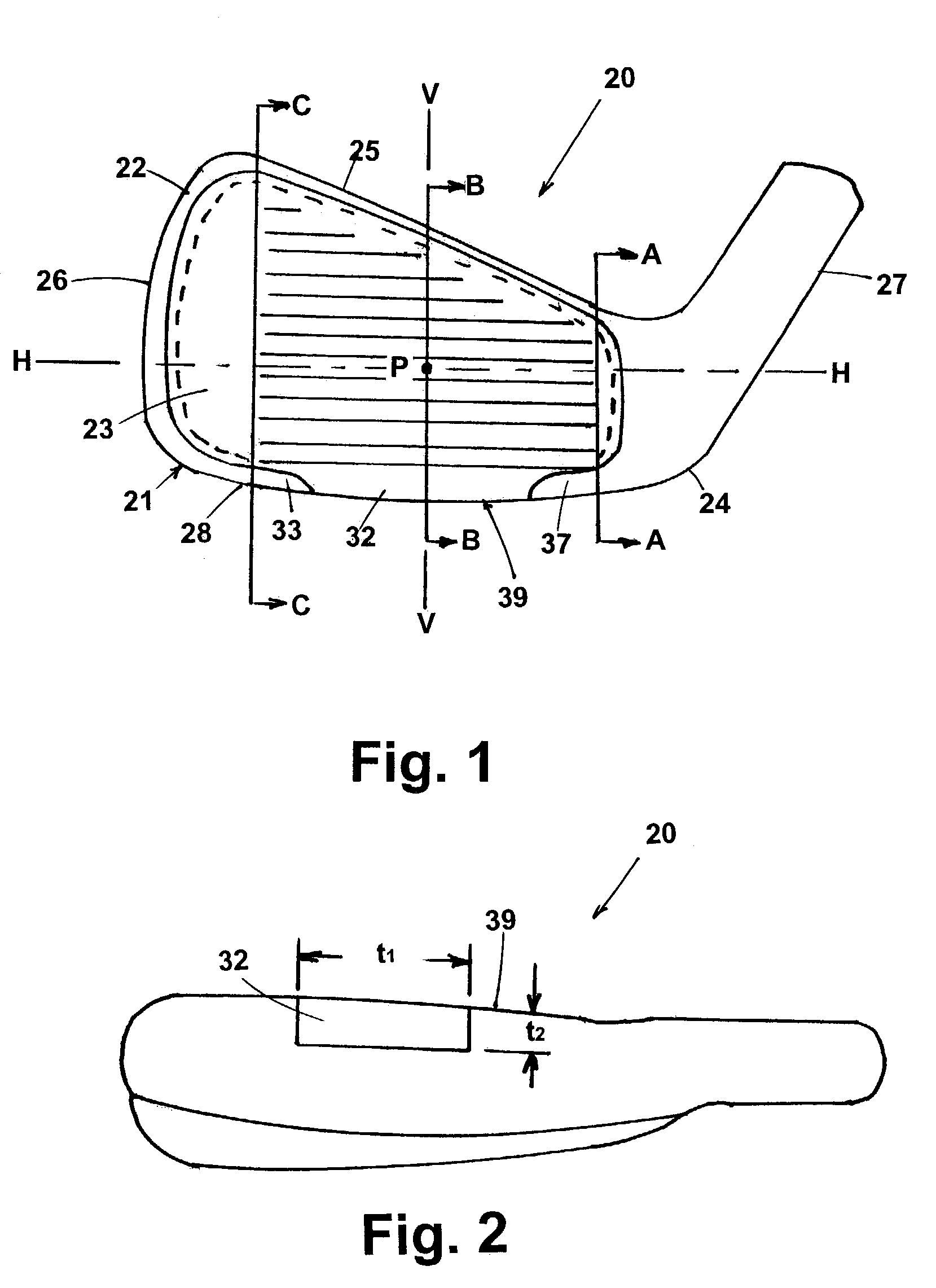

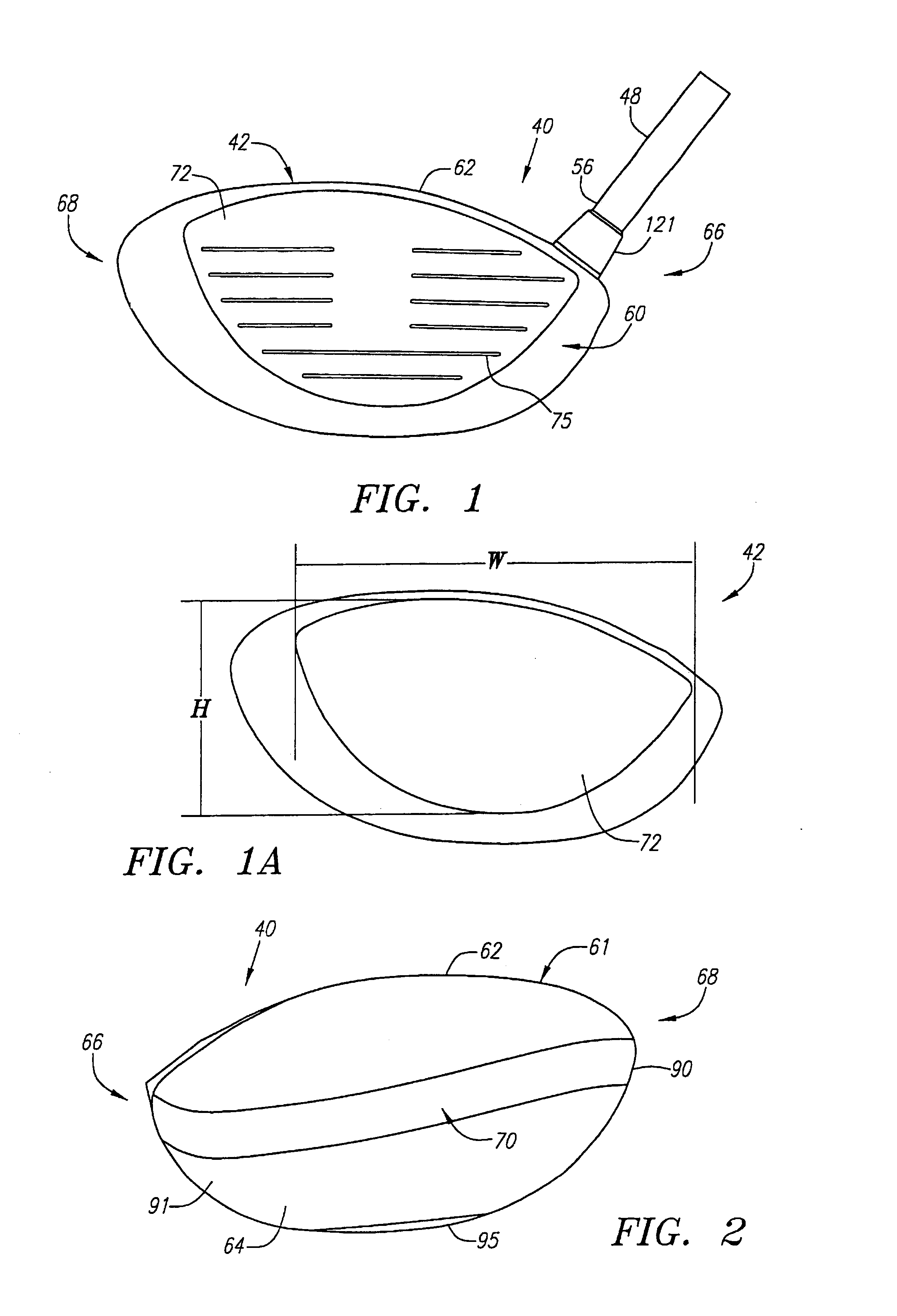

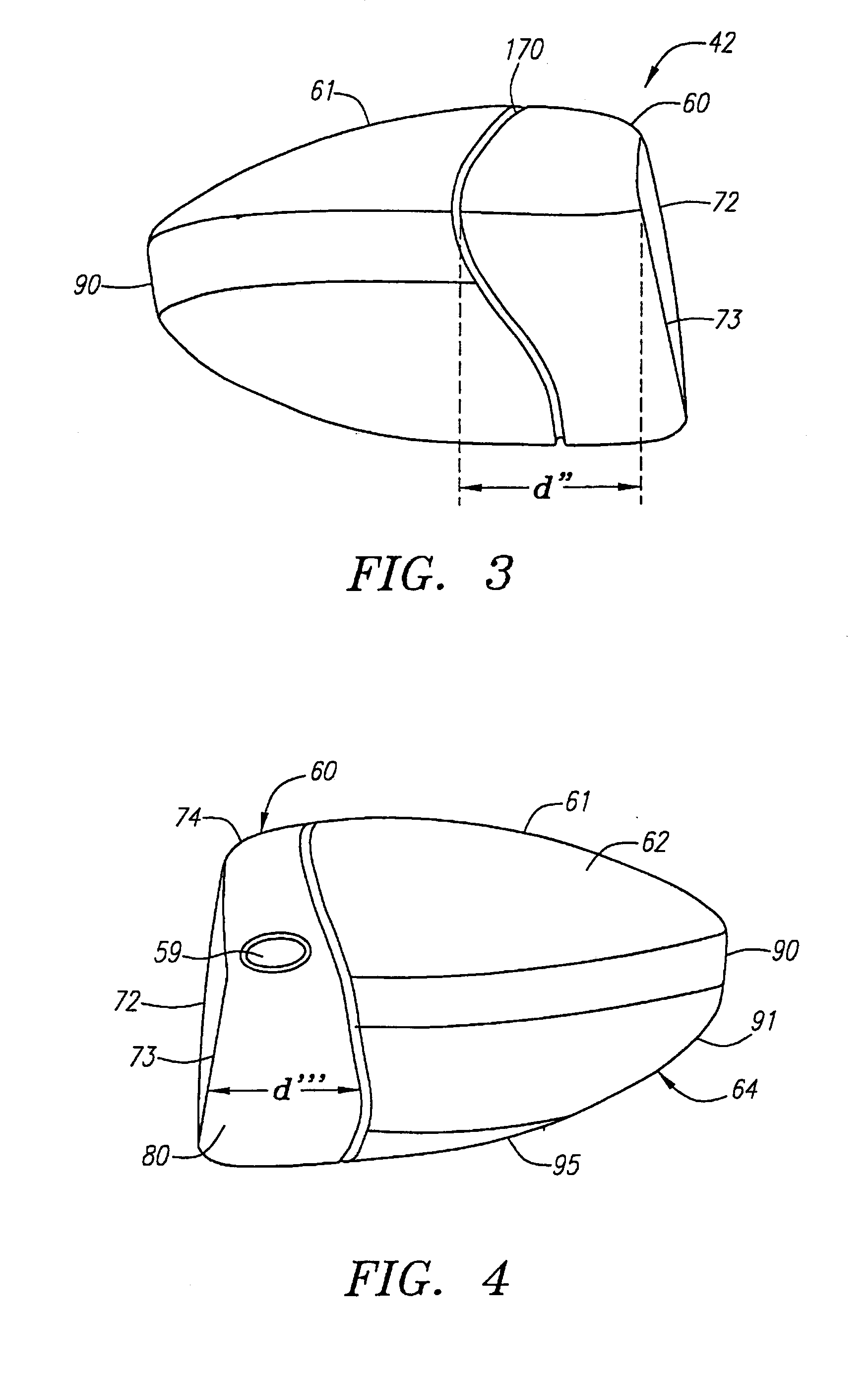

Golf club head with customizable center of gravity

InactiveUS6739983B2Improve matchHigher golf ball trajectoryMetal-working apparatusGolf clubsEngineeringGravity center

A golf club (40) having a club head (42) with a face component (60) and an interchangeable aft body (61) is disclosed herein. The face component (60) has a striking plate portion (72) and a return portion (74). The aft-body (61), which is attached to the return portion (74) of the face component (60), is selected from a plurality of aft-bodies, each having a different center of gravity location. Each of the aft-bodies (61) is composed of a crown portion (62), a sole portion (64), and at least one weight member (122) for adjusting location of the center of gravity. An aft-body (61) is selected from the plurality of aft-bodies (61) based on its center of gravity location, so as to provide the club head (40) with a center of gravity location suited to a particular golfer.

Owner:TOPGOLF CALLAWAY BRANDS CORP

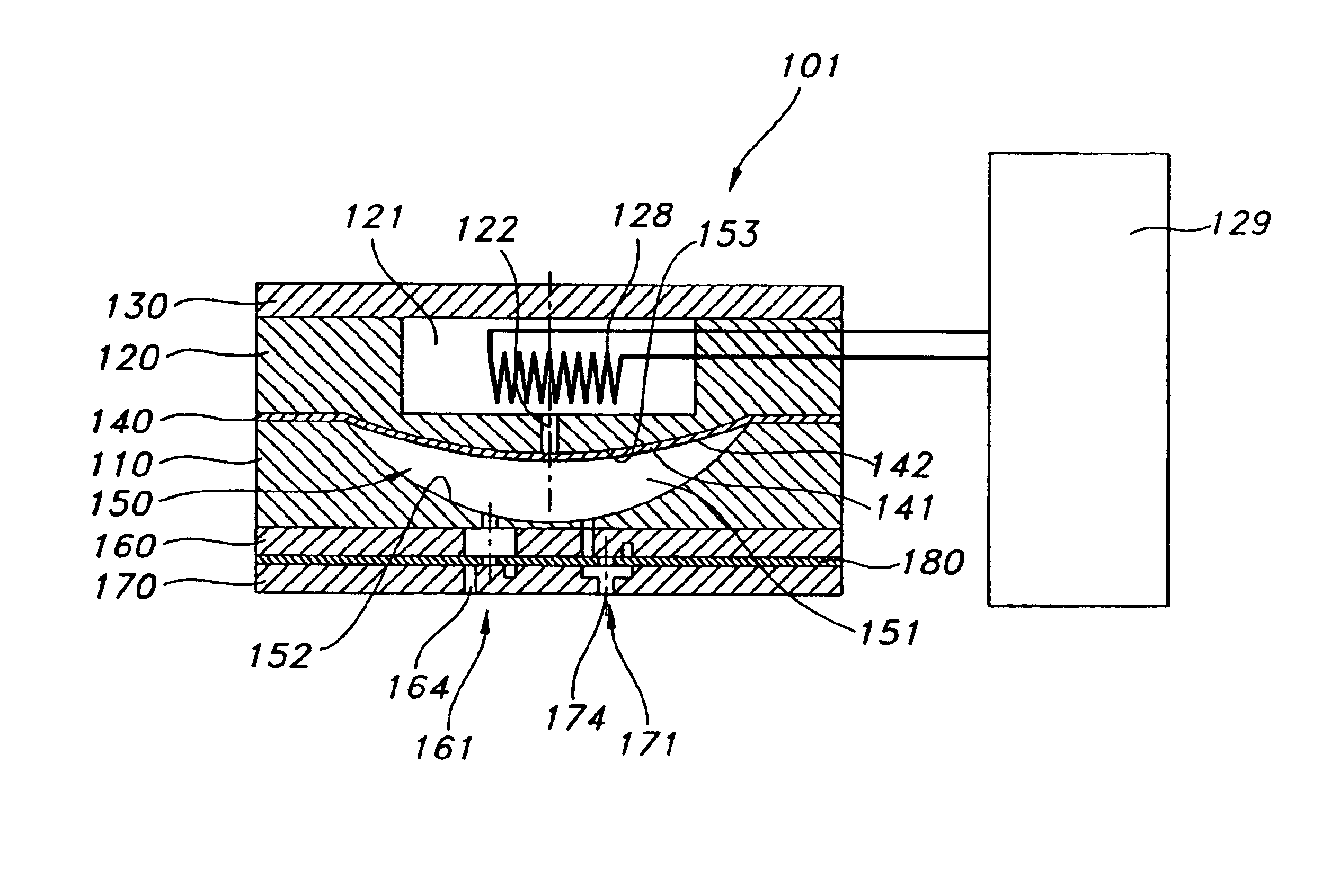

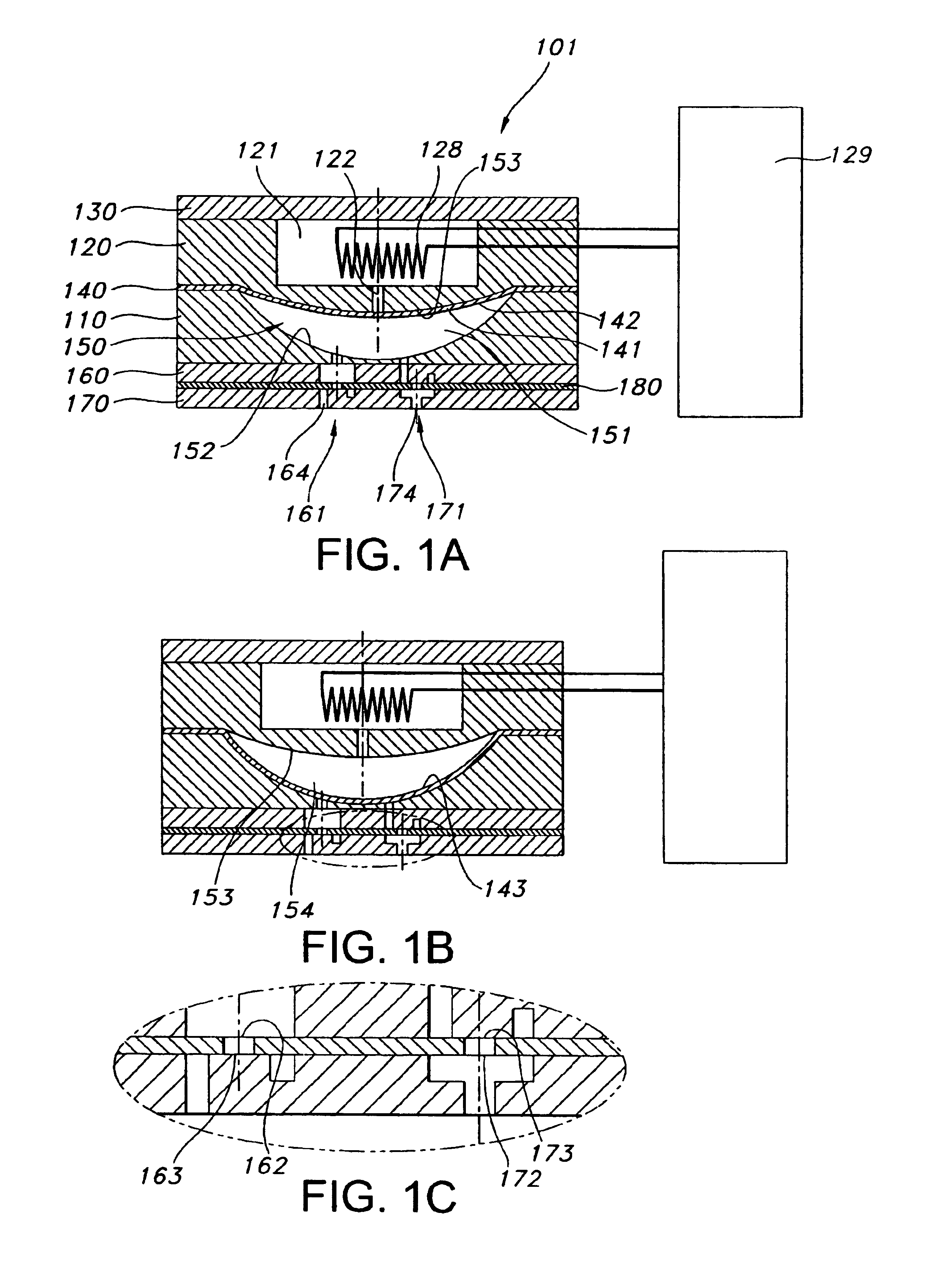

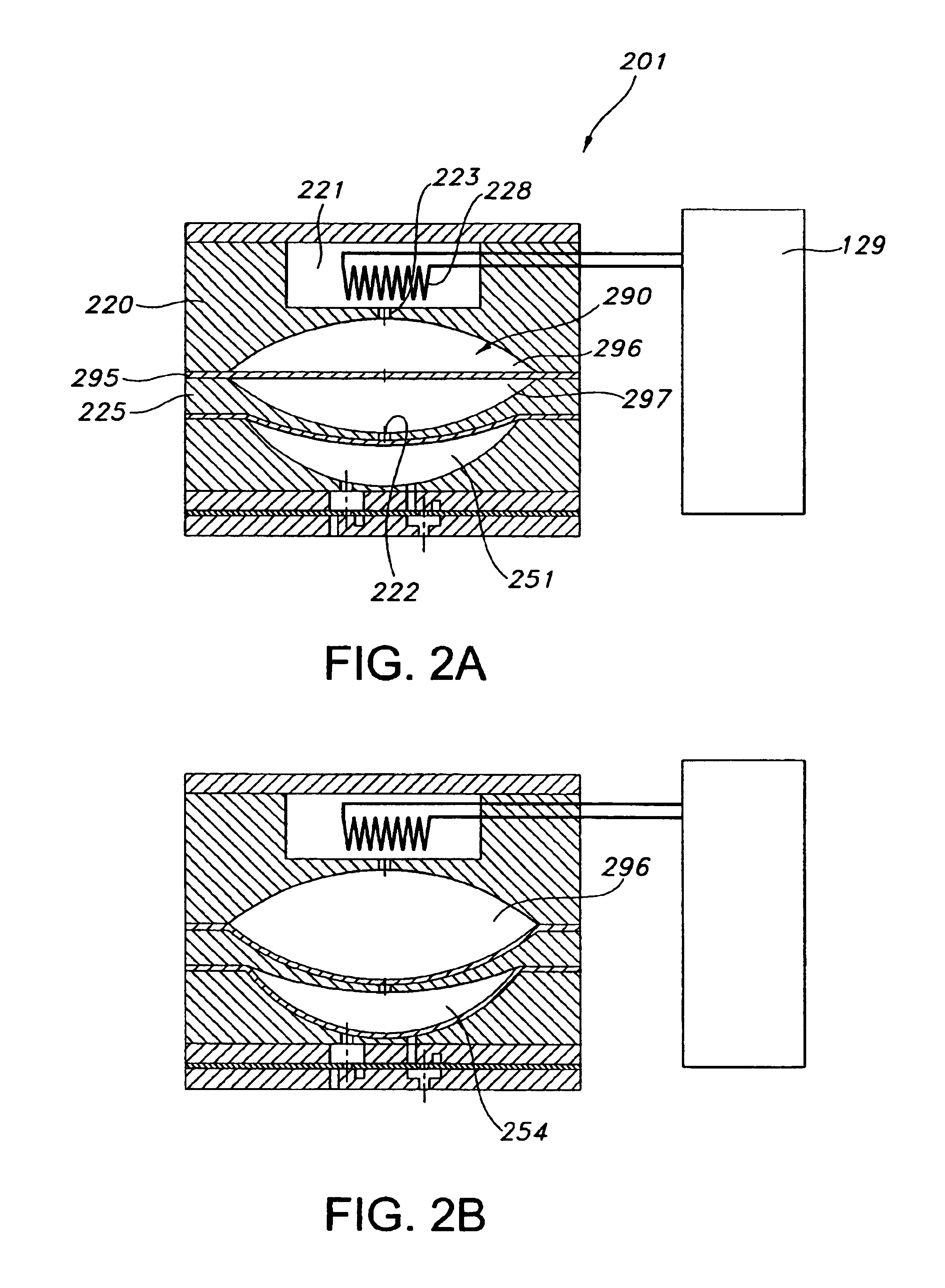

Membrane pump with stretchable pump membrane

InactiveUS6948918B2Stiff systemImprove accuracyValve arrangementsPositive displacement pump componentsPump chamberInlet valve

The invention relates to membrane pumps for delivering liquids. More specifically, a pump is provided having a pump housing with a pump cavity formed between first and second wall portions thereof, and an pump membrane pump membrane having first and second membrane surfaces arranged within the pump cavity, whereby a pump chamber is provided between the first wall portion and the first membrane surface, and an actuation chamber is provided between the second wall and the second membrane surface. Inlet means comprising an inlet valve in fluid communication with the pump chamber, and outlet means comprising an outlet valve in fluid communication with the pump chamber are provided. The pump membrane has a maximum volume position, and a drained volume position in which the first membrane surface in a stretched state abuts the first wall. To drive the membrane, actuating means for periodically shifting the pump membrane between the maximum volume position and the drained volume position is provided, thereby, in a situation of use, providing a flow of fluid.

Owner:NOVO NORDISK AS

Conductive adhesive agent and process for manufacturing article using the conductive adhesive agent

ActiveUS20060038304A1Fully curedUniform thicknessSemiconductor/solid-state device detailsConductive materialPolymer scienceFluid viscosity

The present invention provides a conductive adhesive agent capable of being diluted with a solvent to give good coating workability and allowing formation of a conductive joint excellent in both thermal conductivity and electrical conductivity by inhibiting a gas generated when a binder resin is heat-cured after attachment of a part. The conductive adhesive agent according to the present invention is a conductive adhesive agent wherein, based on 100 parts by weight of silver powder having an average particle diameter of micrometers, which is used for a conductive medium, e.g. as a main component, 1 to 10 parts by weight of silver fine particles having an average particle diameter of nanometers is used in combination therewith and 5 to 15 parts by weight of thermosetting resin as a binder resin component and 10 parts or less by weight of solvent for adjustment of a fluid viscosity are blended therein as essential components, and by selection of such a blending ratio, generation of a gas component during heating and curing of the thermosetting resin to prevent formation of voids, and at the same time, fabrication of a conductive joint excellent in thermal conductivity and electrical conductivity is achieved.

Owner:HARIMA CHEM INC +1

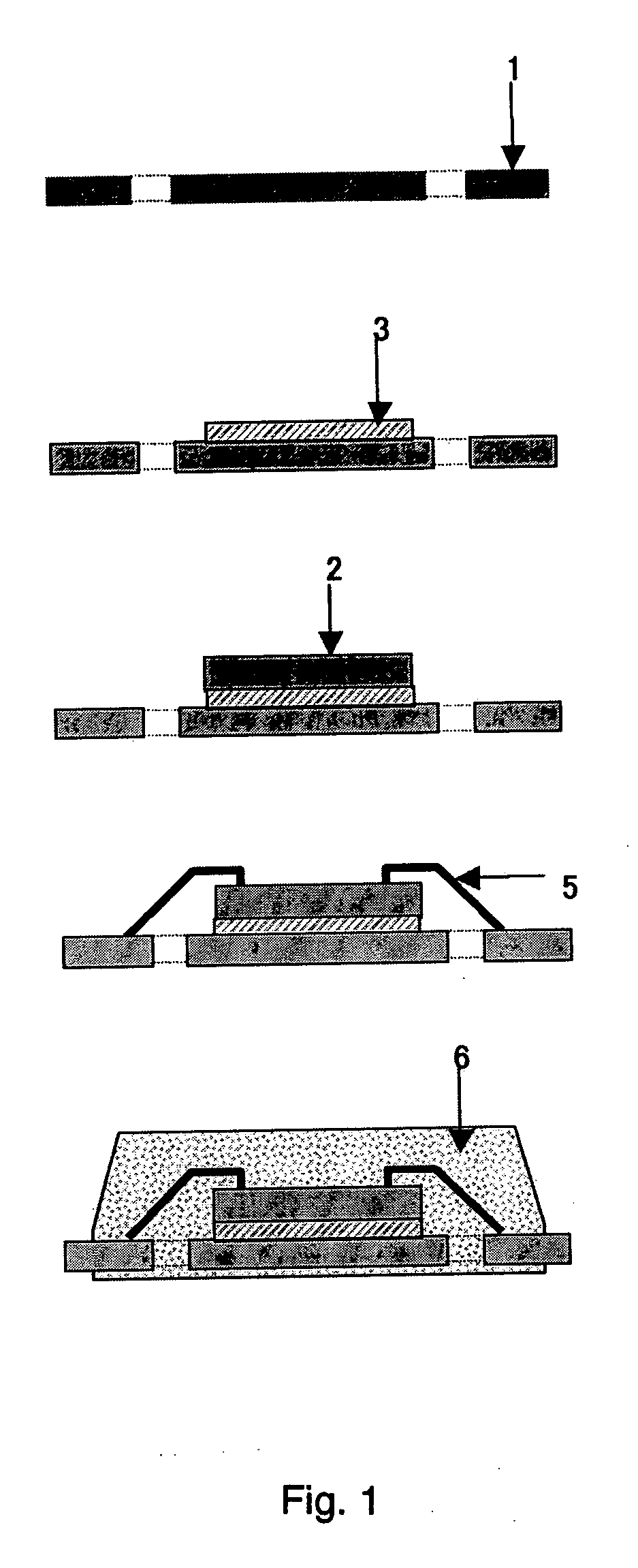

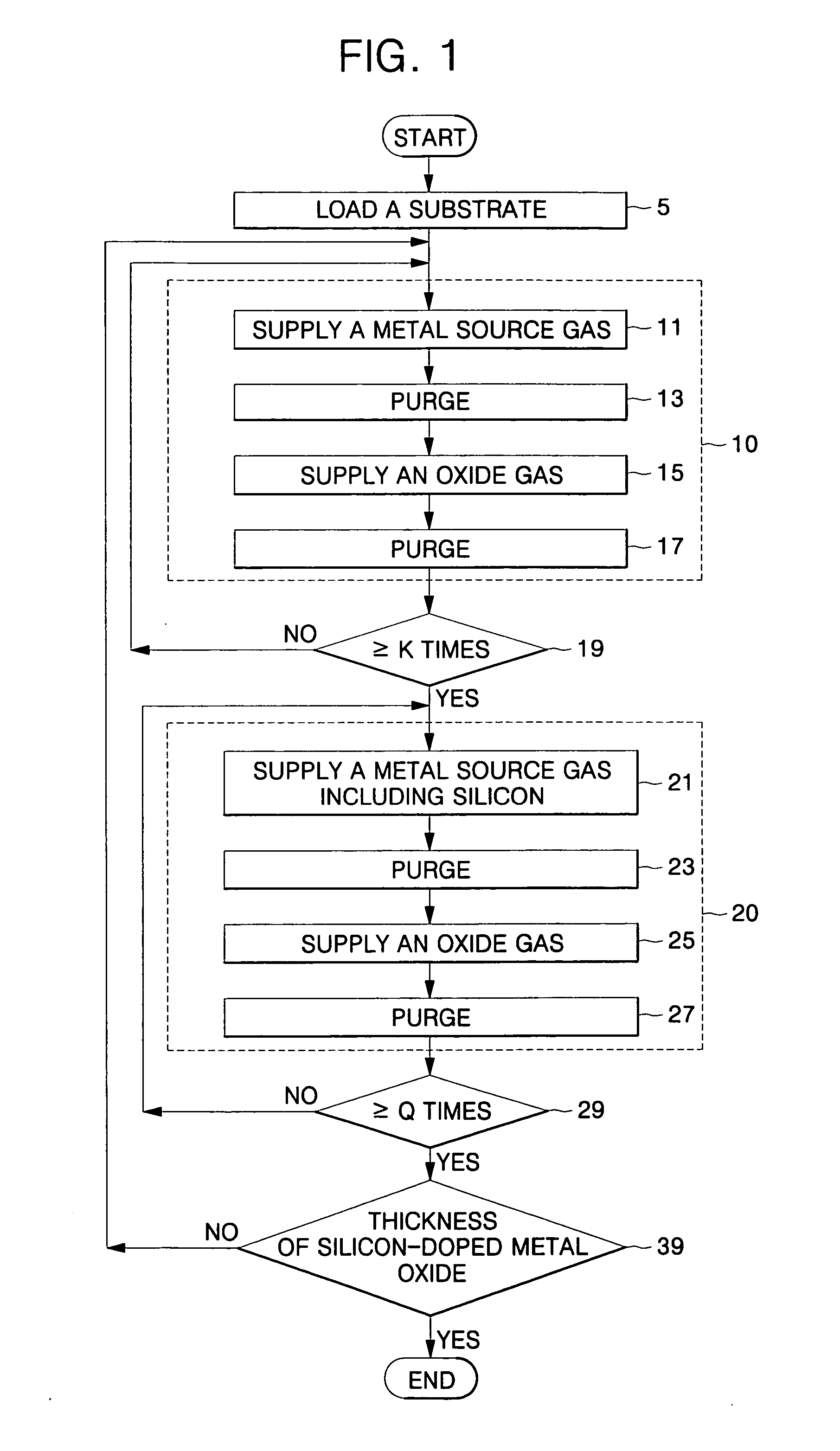

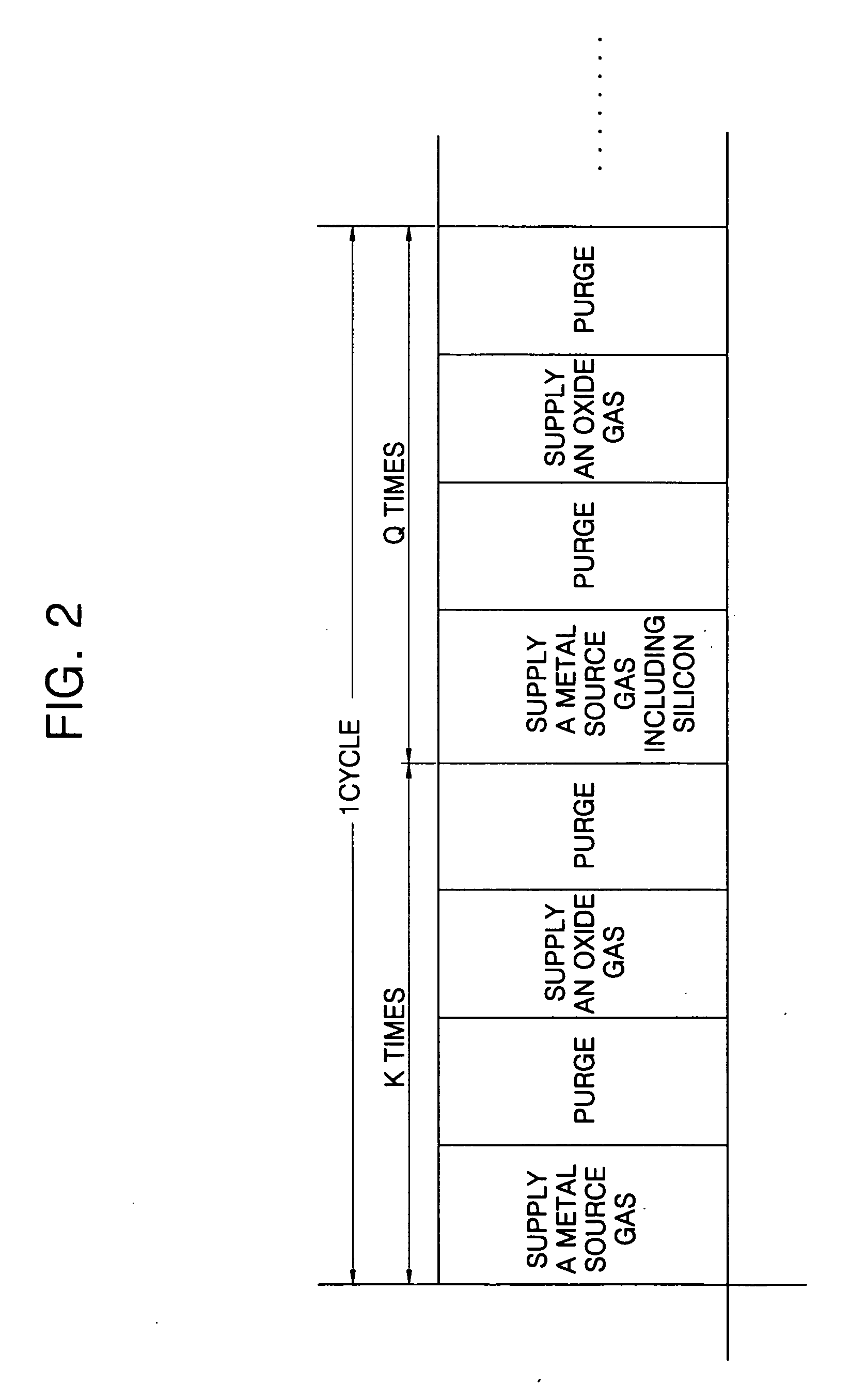

Method of fabricating silicon-doped metal oxide layer using atomic layer deposition technique

InactiveUS20060257563A1Uniform thicknessAccurate thicknessChemical vapor deposition coatingHafnium oxideOxide

There are provided methods of fabricating a silicon-doped metal oxide layer on a semiconductor substrate using an atomic layer deposition technique. The methods include an operation of repeatedly performing a metal oxide layer formation cycle K times and an operation of repeatedly performing a silicon-doped metal oxide layer formation cycle Q times. At least one of the values K and Q is an integer of 2 or more. K and Q are integers ranging from 1 to about 10 respectively. The metal oxide layer formation cycle includes the steps of supplying a metal source gas to a reactor containing the substrate, and then injecting an oxide gas into the reactor. The silicon-doped metal oxide layer formation cycle includes supplying a metal source gas including silicon into a reactor containing the substrate, and then injecting an oxide gas into the reactor. The sequence of operations of repeatedly performing the metal oxide layer formation cycle K times, followed by repeatedly performing the silicon-doped metal oxide layer formation cycle Q times, is performed one or more times until a silicon-doped metal oxide layer with a desired thickness is formed on the substrate. In addition, a method of fabricating a silicon-doped hafnium oxide (Si-doped HfO2) layer according to a similar invention method is also provided.

Owner:SAMSUNG ELECTRONICS CO LTD

Vapor deposition of silicon dioxide nanolaminates

ActiveUS20050112282A1Easy to produceUniform thicknessMaterial nanotechnologySemiconductor/solid-state device manufacturingPorosityElectrical conductor

This invention relates to materials and processes for thin film deposition on solid substrates. Silica / alumina nanolaminates were deposited on heated substrates by the reaction of an aluminum-containing compound with a silanol. The nanolaminates have very uniform thickness and excellent step coverage in holes with aspect ratios over 40:1. The films are transparent and good electrical insulators. This invention also relates to materials and processes for producing improved porous dielectric materials used in the insulation of electrical conductors in microelectronic devices, particularly through materials and processes for producing semi-porous dielectric materials wherein surface porosity is significantly reduced or removed while internal porosity is preserved to maintain a desired low-k value for the overall dielectric material. The invention can also be used to selectively fill narrow trenches with low-k dielectric material while at the same time avoiding deposition of any dielectric on the surface area outside of the trenches.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

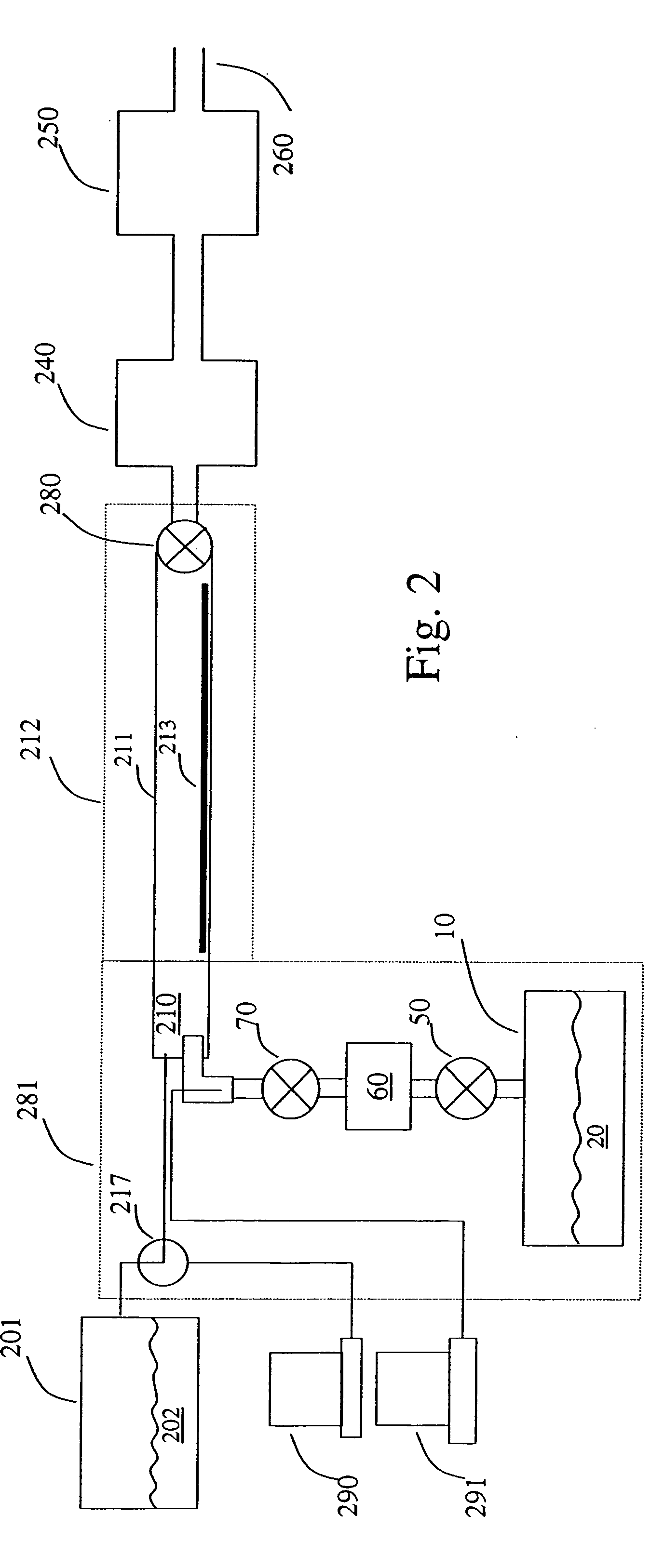

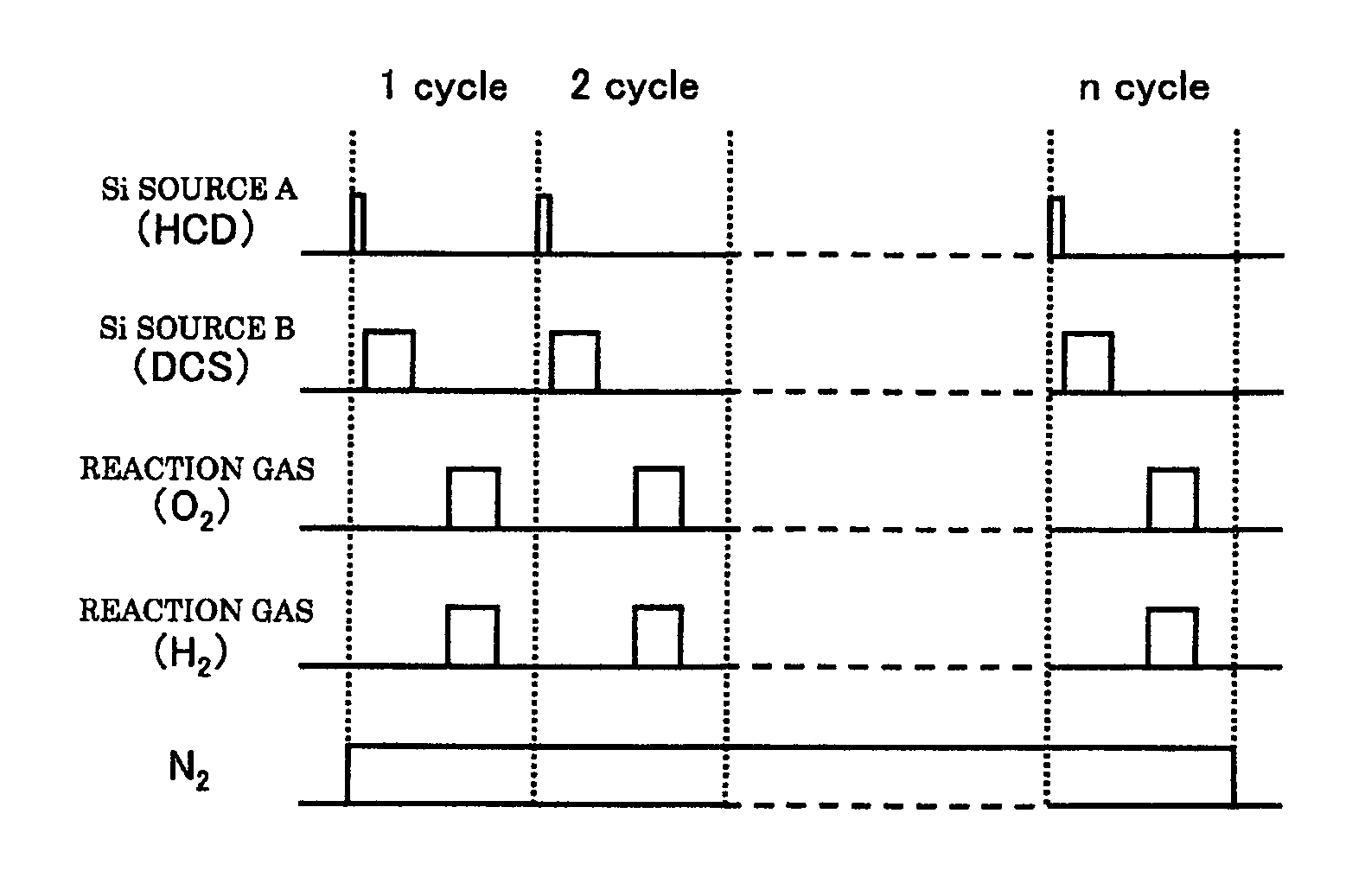

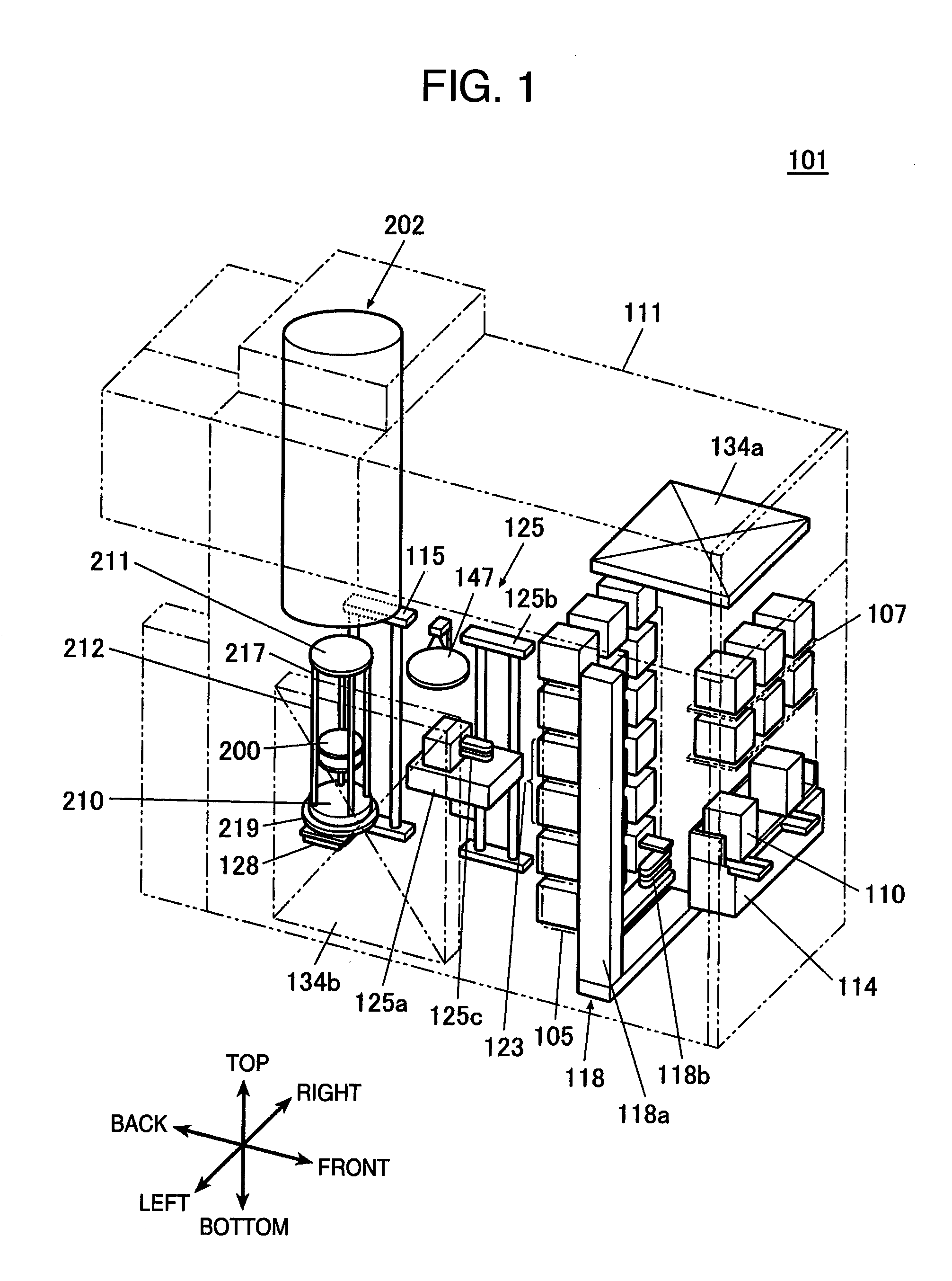

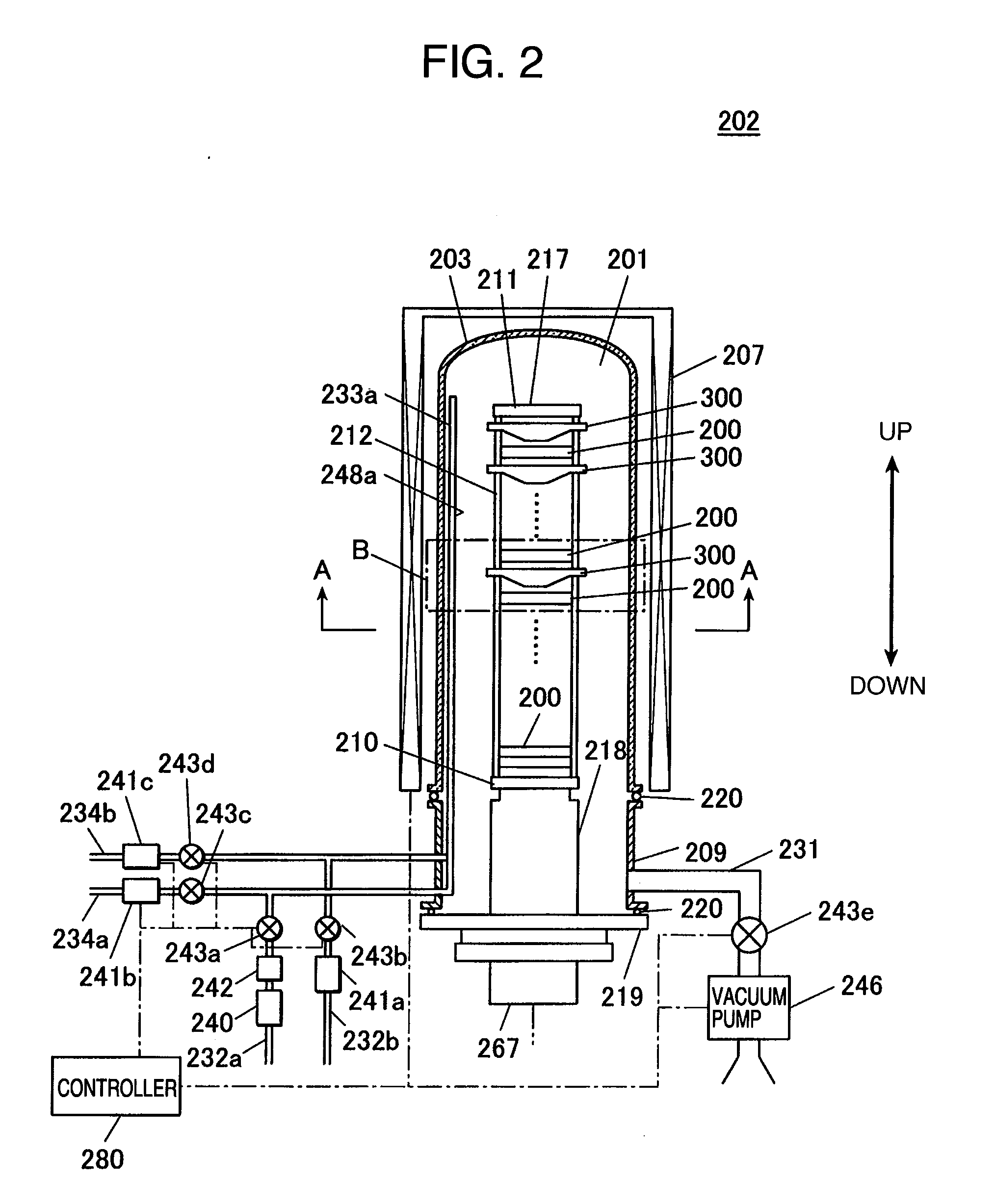

Method of manufacturing semiconductor device, method of processing substrate and substrate processing apparatus

ActiveUS8076251B2Increase probabilityLow costSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialPhysical chemistry

Provided is a method of manufacturing a semiconductor device. The method includes: loading a substrate into a process vessel; performing a process to form an oxide, nitride, or oxynitride film on the substrate by alternately repeating: (a) forming a layer containing an element on the substrate by supplying and exhausting first and second source gases containing the element into and from the process vessel; and (b) changing the layer containing the element into an oxide, nitride, or oxynitride layer by supplying and exhausting reaction gas different from the first and second source gases into and from the process vessel; and unloading the substrate from the process vessel. The first source gas is more reactive than the second source gas, and an amount of the first source gas supplied into the process vessel is set to be less than that of the second source gas supplied into the process vessel.

Owner:KOKUSA ELECTRIC CO LTD

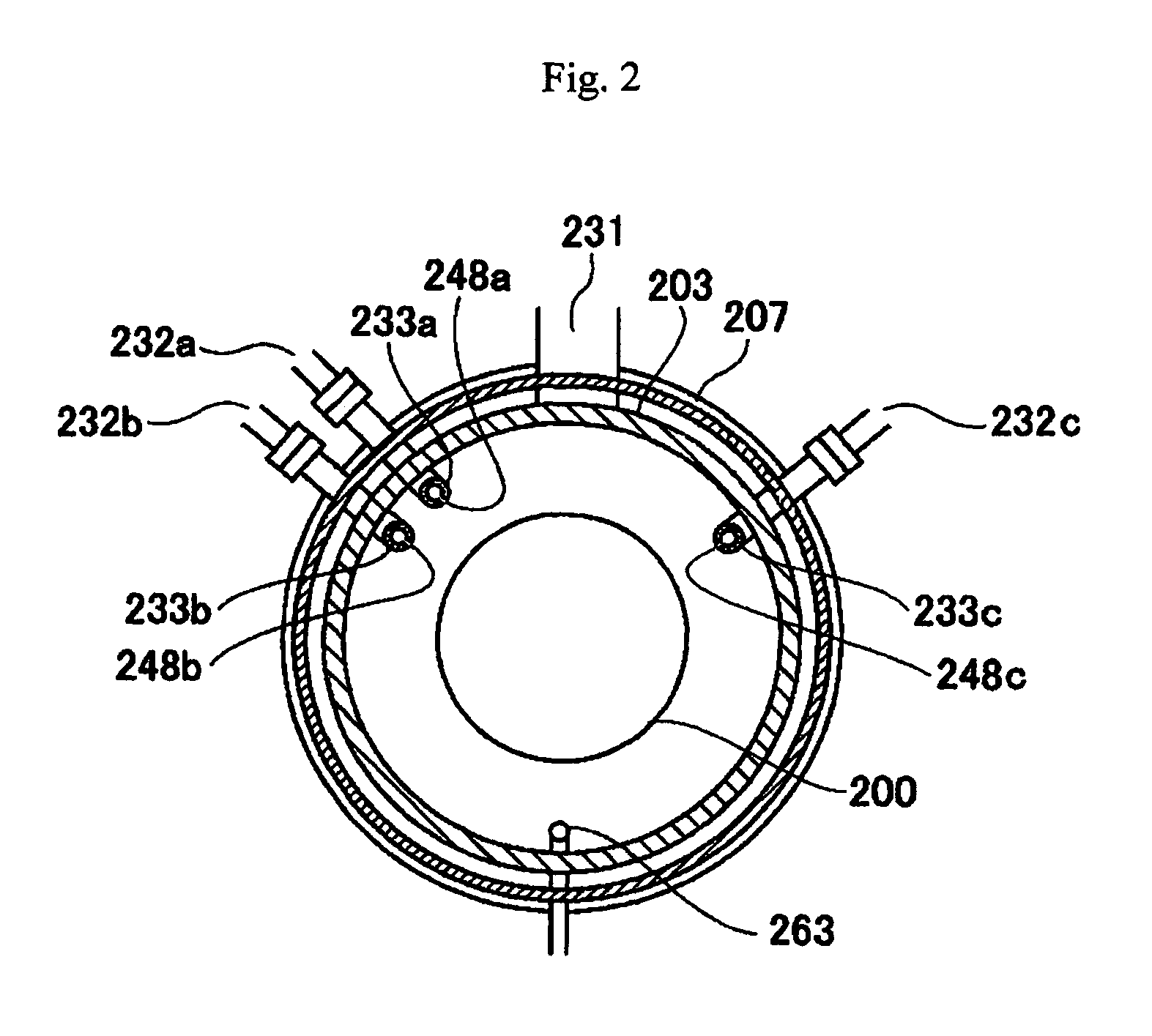

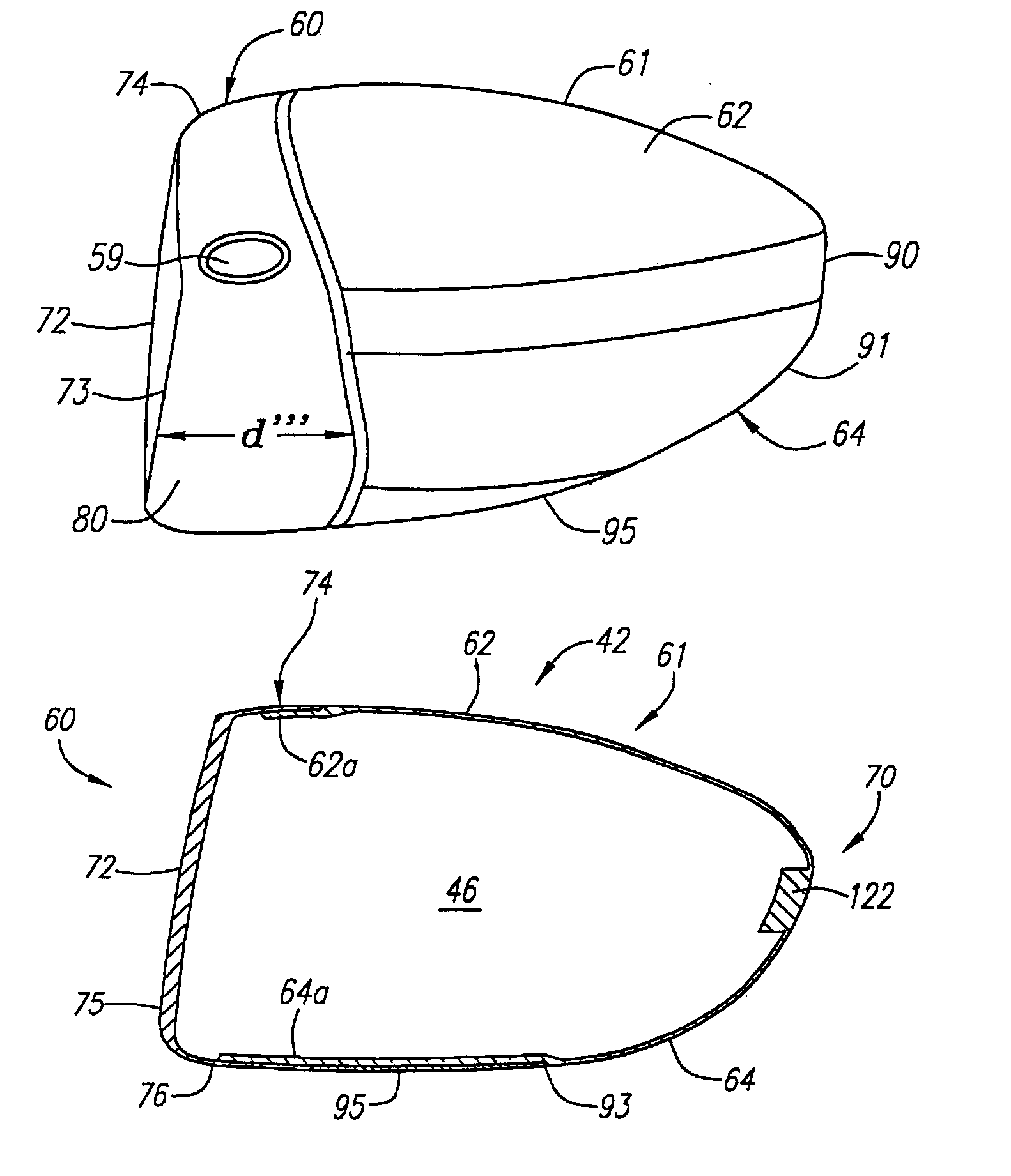

Multiple material golf club head

InactiveUS6582323B2Increase flexibilityGood coefficientMetal-working apparatusGolf clubsGramMetallic materials

A golf club (40) having a club head (42) with a face component (60) and an aft body (61) is disclosed herein. The face component (60) has a striking plate portion (72) and a return portion (74). The aft-body (61) is composed of a crown portion (62), a sole portion (64) and optionally a ribbon section (90). The face component (60) is composed of a metal material, and the aft-body (61) is composed of a non-metal material such as a composite material or a thermoplastic material. The striking plate portion (72) preferably has an aspect ratio less than 1.7. The striking plate portion (72) preferably has concentric regions of thickness with the thickness portion in the center (102). The club head (42) has a volume in the range of 290 cubic centimeters to 600 cubic centimeters, a weight in the range of 165 grams to 300 grams, and a striking plate portion (72) surface area in the range of 4.00 square inches to 7.50 square inches. The golf club head (42) has a coefficient of restitution greater than 0.81 under test conditions such as the USGA test conditions specified pursuant to Rule 4-1e, Appendix II, of the Rules of Golf for 1998-1999.

Owner:TOPGOLF CALLAWAY BRANDS CORP

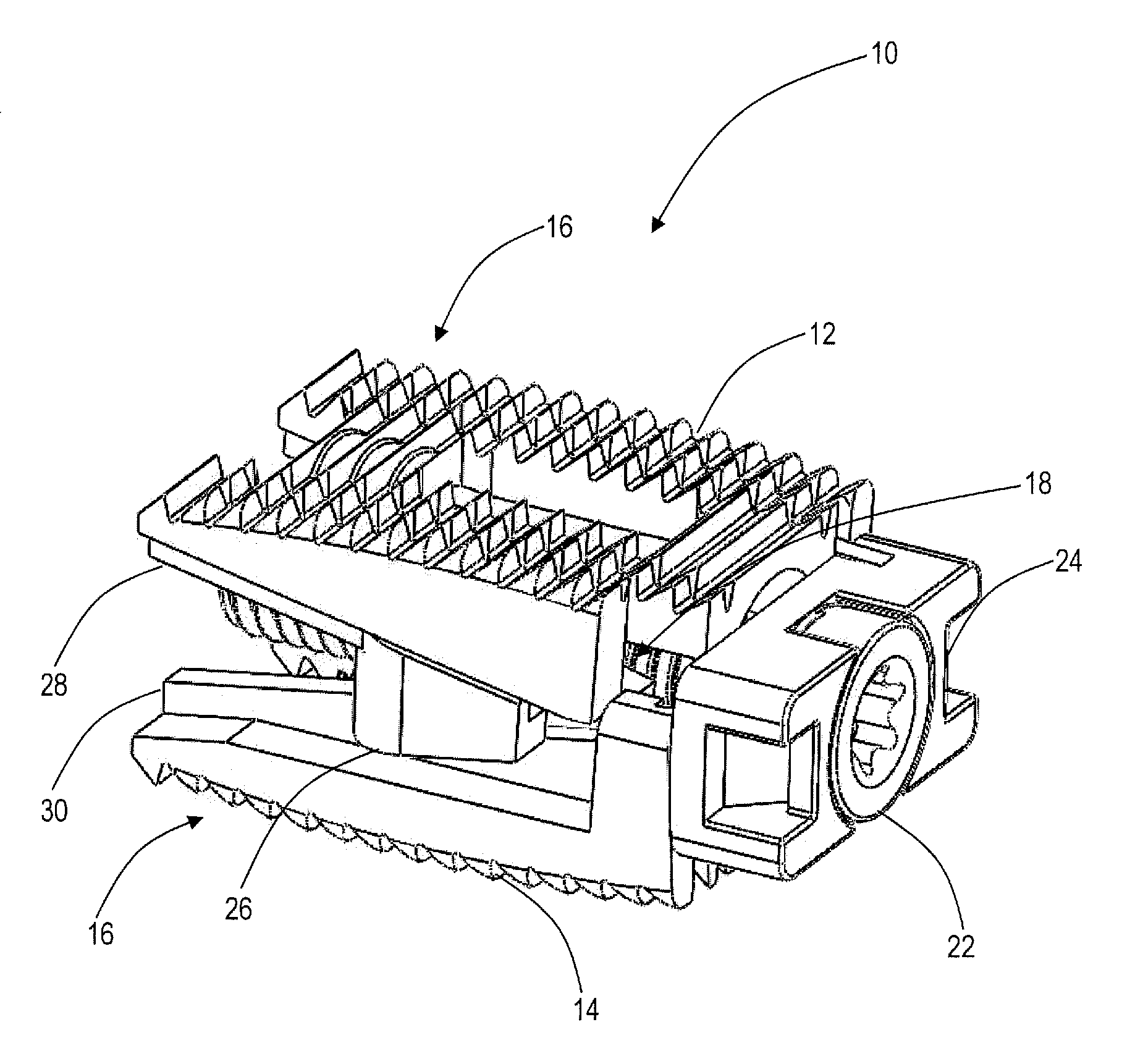

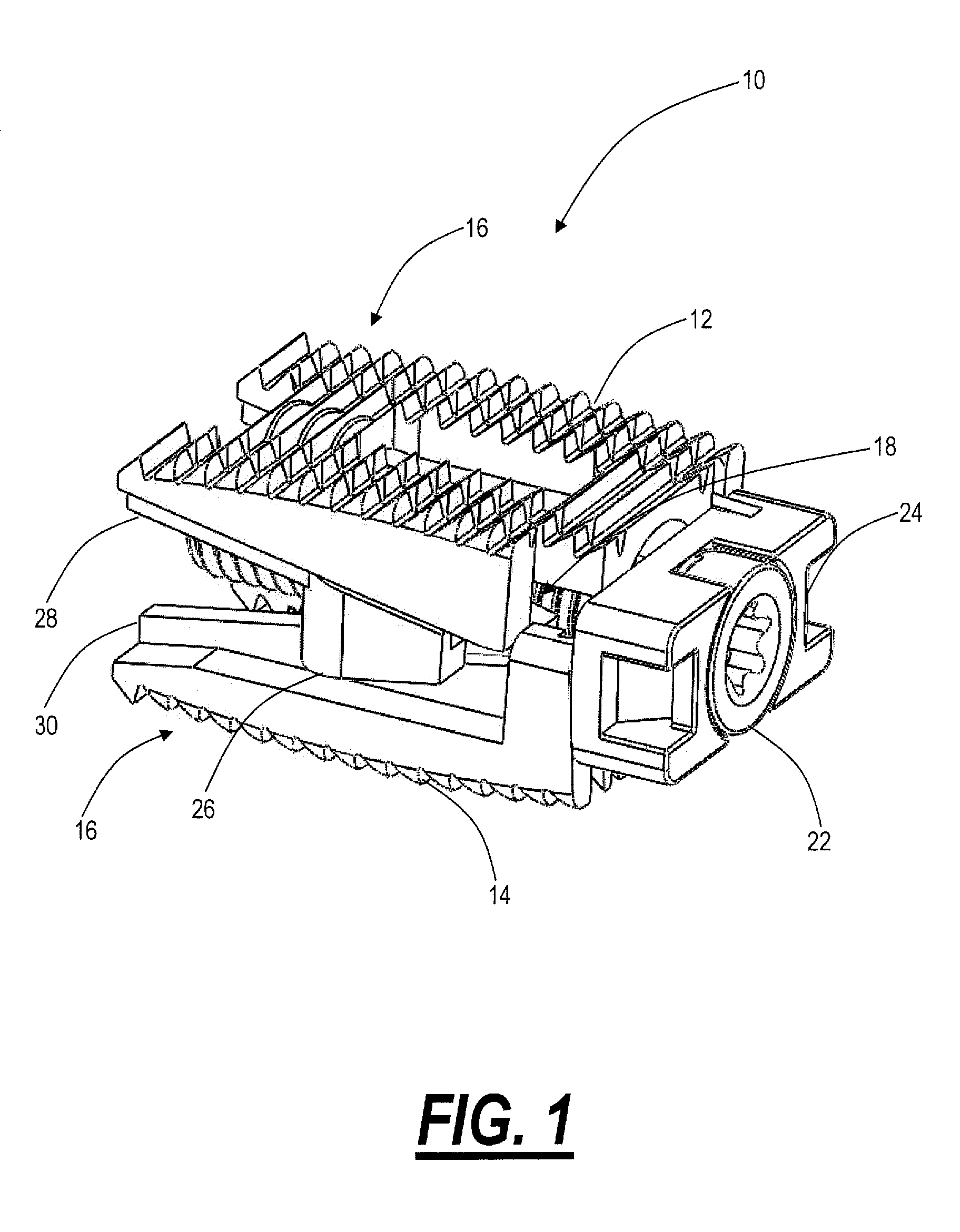

Expandable intervertebral implant and associated surgical method

ActiveUS20120185049A1MiniaturizationUniform thicknessSpinal implantsBiomedical engineeringSuperior member

The present invention provides an expandable intervertebral implant, including: a superior member configured to engage a superior intervertebral body; an inferior member configured to engage an inferior intervertebral body; and an expansion mechanism disposed between the superior member and the inferior member configured to selectively adjust a separation of the superior member from the inferior member; wherein the expansion mechanism includes a proximal wedge structure and a distal wedge structure that are relatively translated between the superior member and the inferior member, wherein the proximal wedge structure and the distal wedge structure are each coupled to the superior member and the inferior member by a plurality of aligned and / or staggered (i.e. nested) track structures and rail structures.

Owner:INNOVA SPINAL TECH

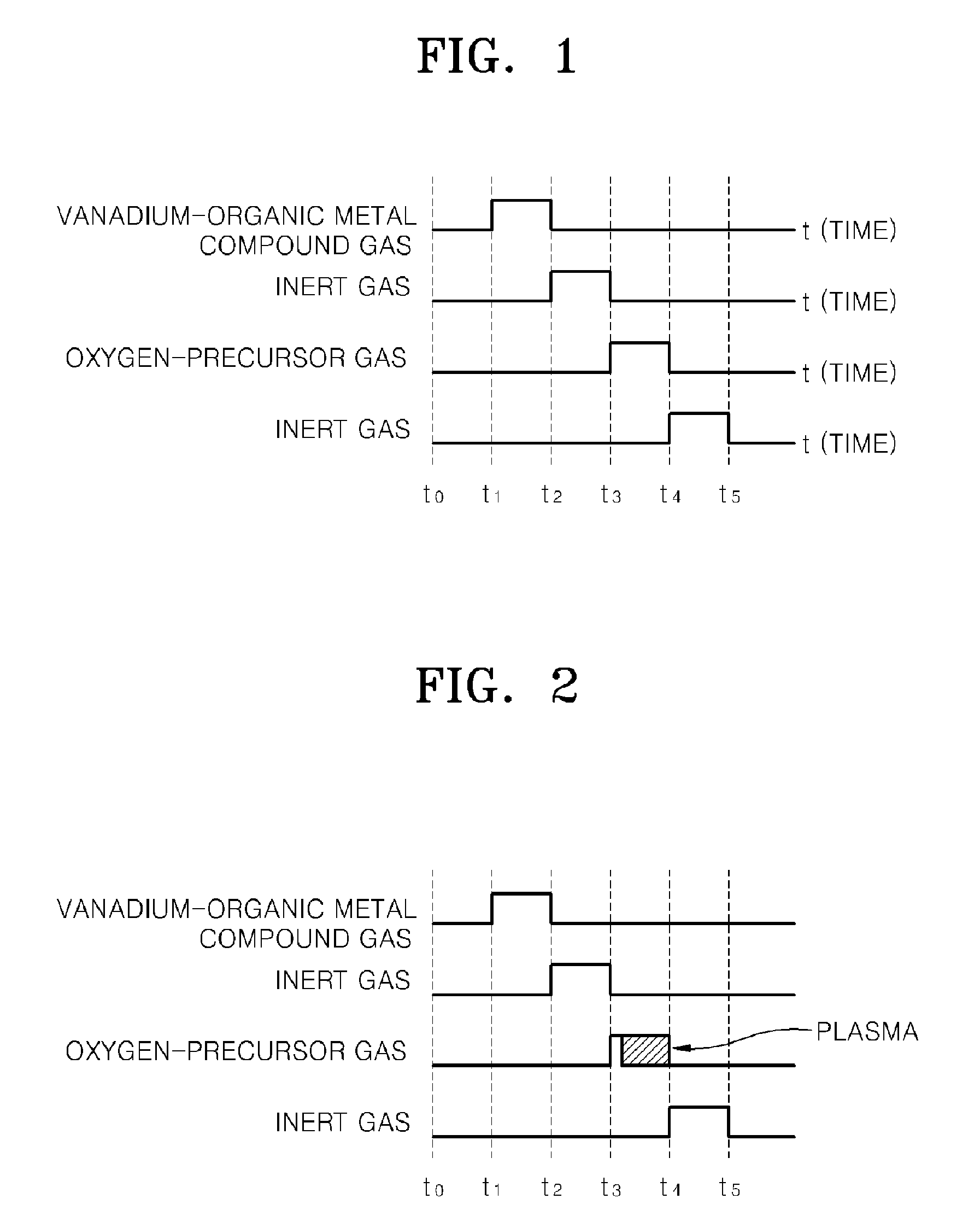

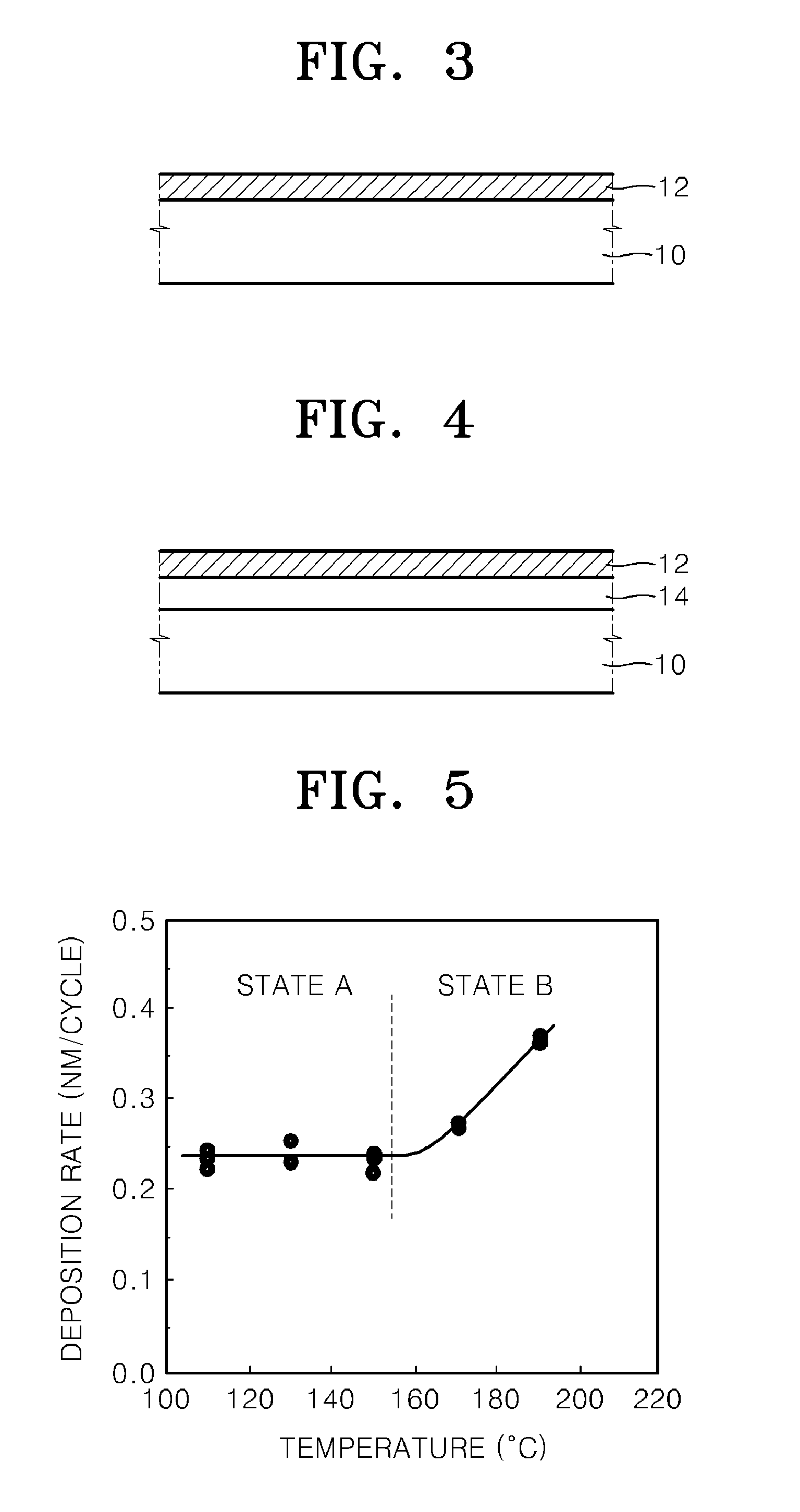

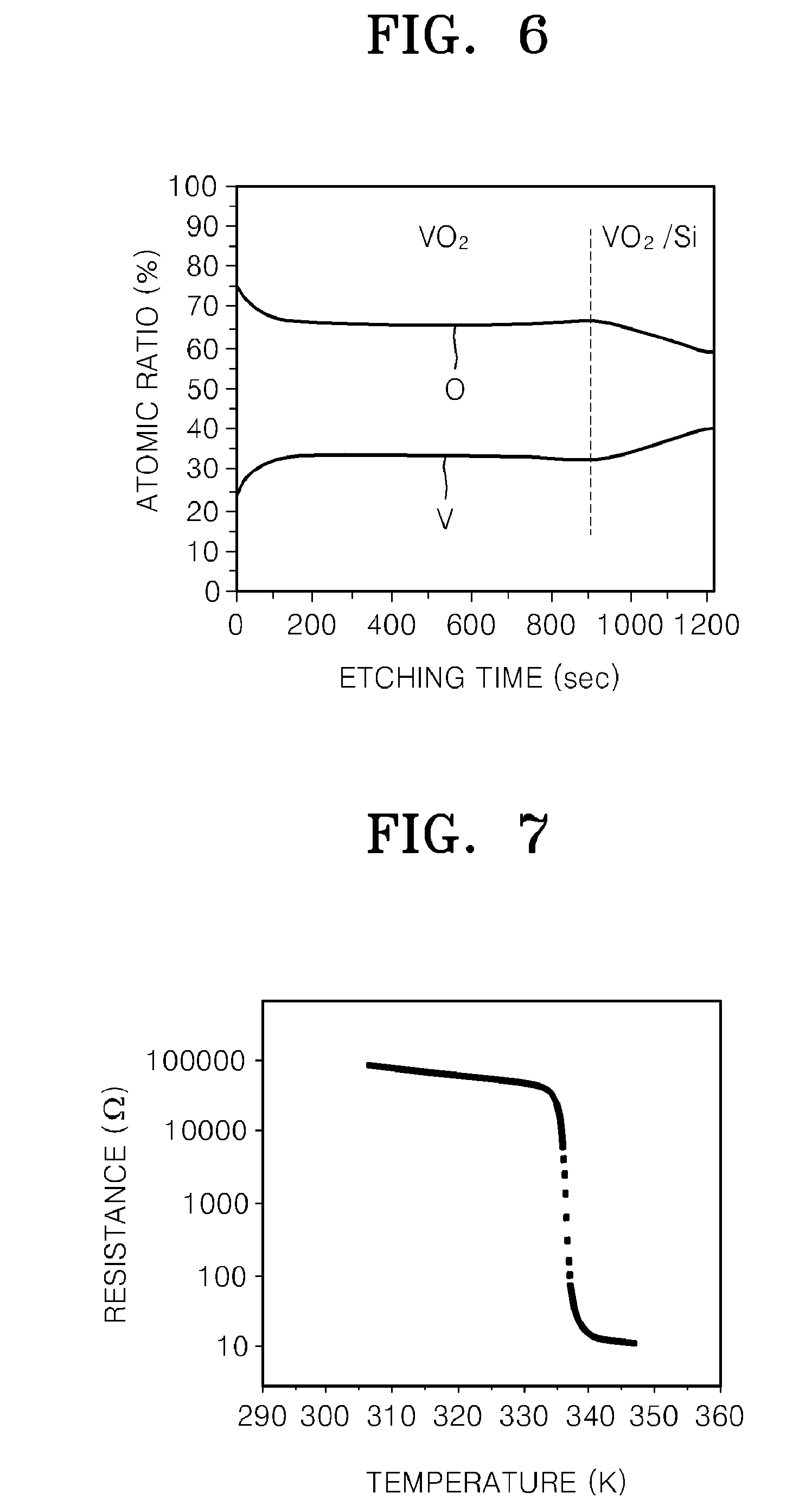

Method of Manufacturing Vanadium Oxide Thin Film

InactiveUS20090011145A1Uniform thicknessComposition is stableChemical vapor deposition coatingPlasma techniqueOxygenMaterials science

Provided is a method of manufacturing a large-sized vanadium oxide thin film having a uniform surface, uniform film thickness and stable composition. According to the method, a vanadium-organometallic compound gas is injected into a chamber to form adsorption layer where molecules of the vanadium-organometallic compound are adsorbed on the surface of a substrate. After that, an oxygen precursor is injected into the chamber and thus allowed to accomplish surface-saturation reaction with the adsorbed materials to fabricate a vanadium oxide thin film.

Owner:ELECTRONICS & TELECOMM RES INST

Expandable intervertebral implant and associated surgical method

ActiveUS20120226357A1Uniform thicknessSecurely holdSpinal implantsBiomedical engineeringSuperior member

The present invention provides an expandable intervertebral implant, including: a superior member configured to engage a superior intervertebral body; an inferior member configured to engage an inferior intervertebral body; and an expansion mechanism disposed between the superior member and the inferior member configured to selectively adjust a separation of the superior member from the inferior member; wherein the expansion mechanism includes a proximal wedge structure and a distal wedge structure that are relatively translated between the superior member and the inferior member, wherein the proximal wedge structure and the distal wedge structure are each coupled to the superior member and the inferior member by a plurality of aligned and / or staggered (i.e. nested) track structures and rail structures; and wherein a load-bearing portion of a bottom surface of the superior member is configured to mate vertically with a load-bearing portion of a top surface of the inferior member when the expansion mechanism is undeployed via conformal protruding and recessed features.

Owner:INNOVA SPINAL TECH

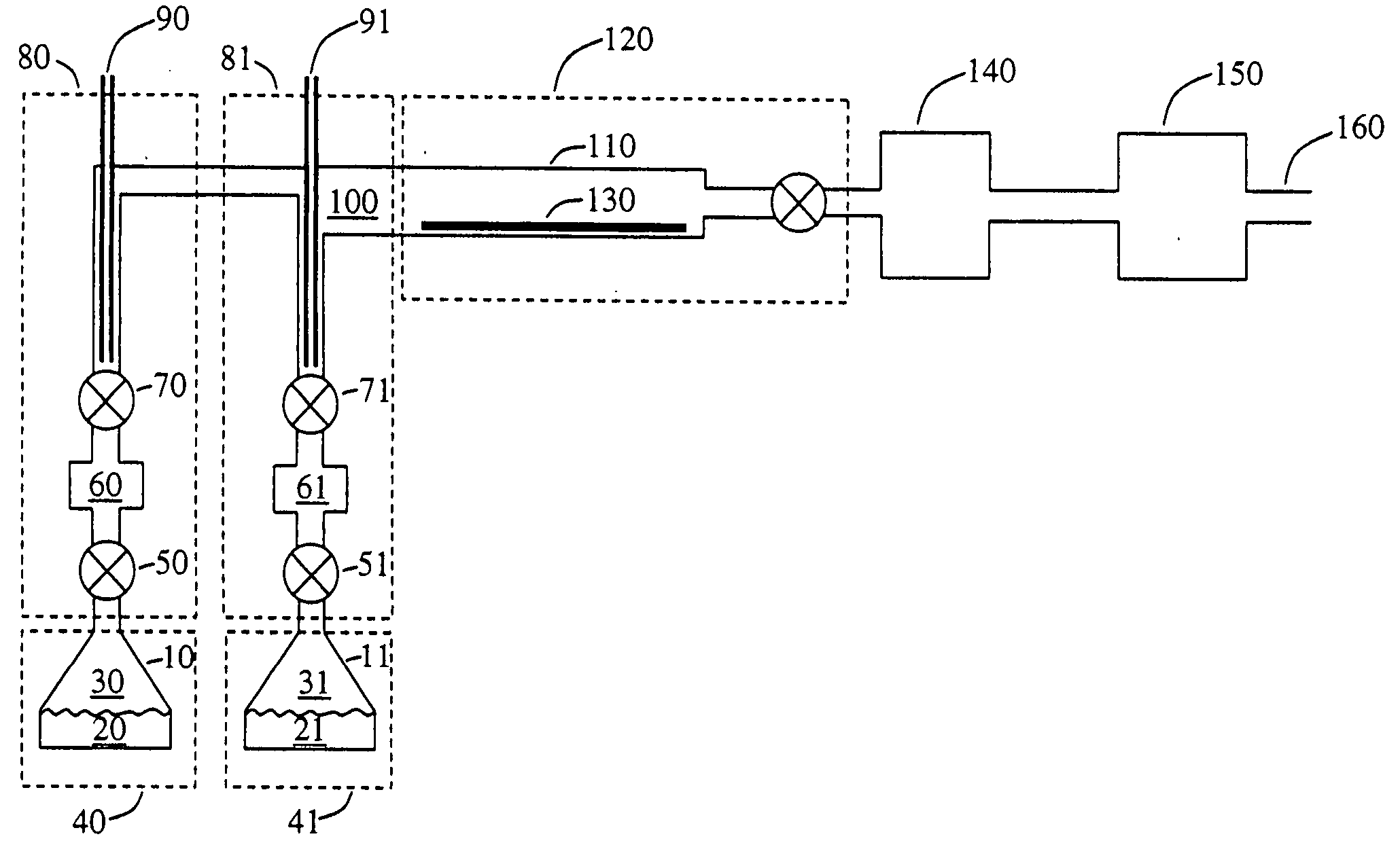

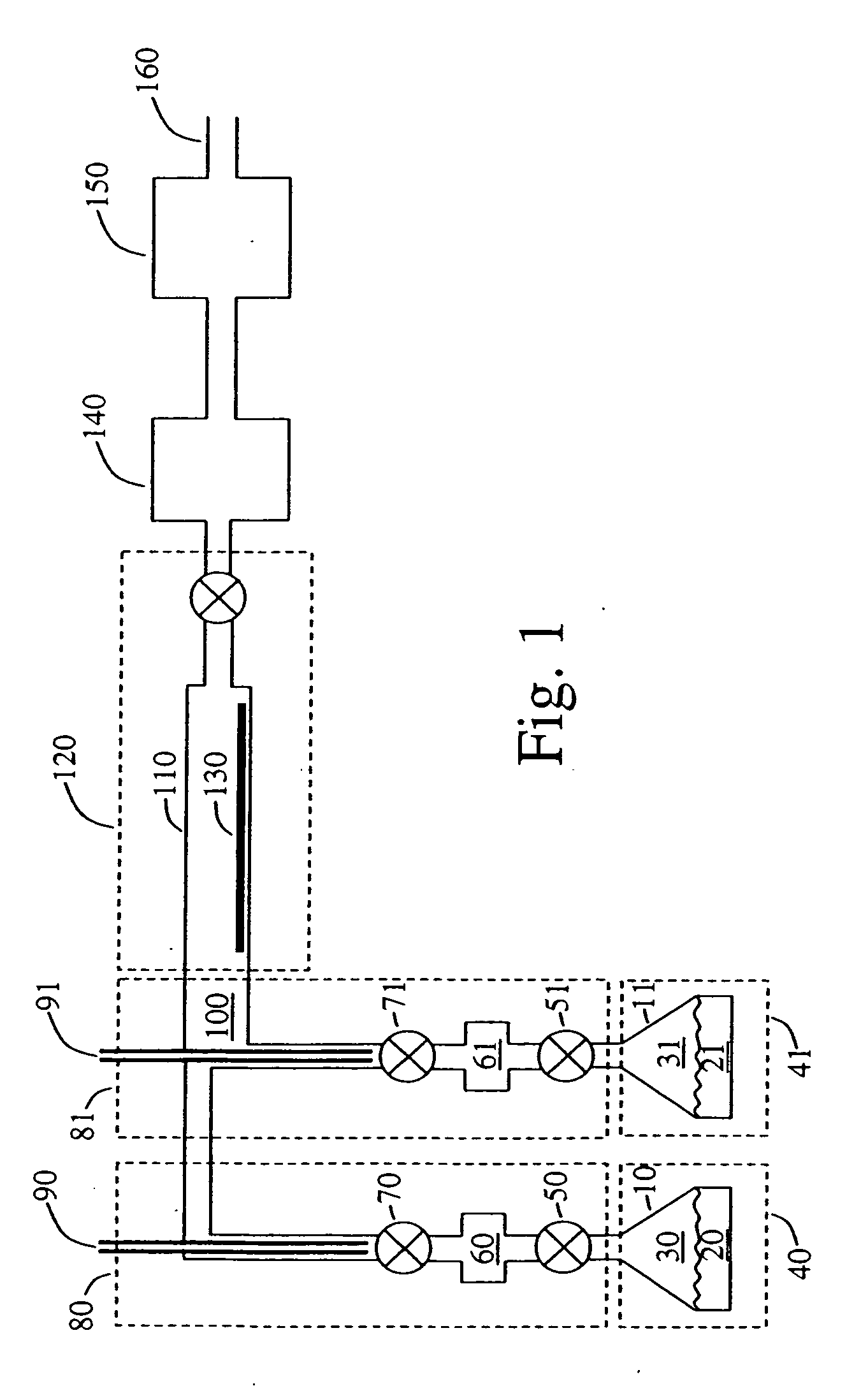

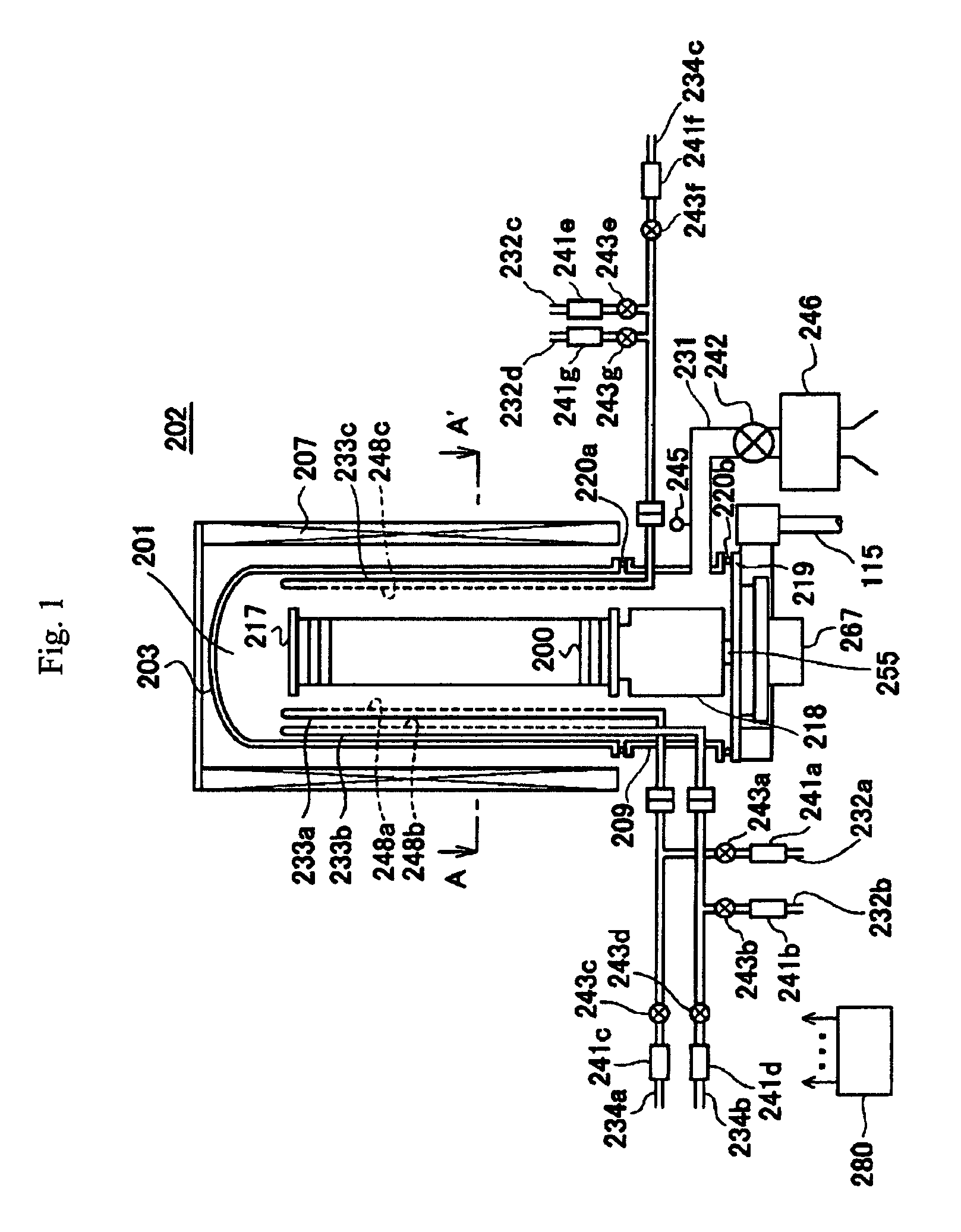

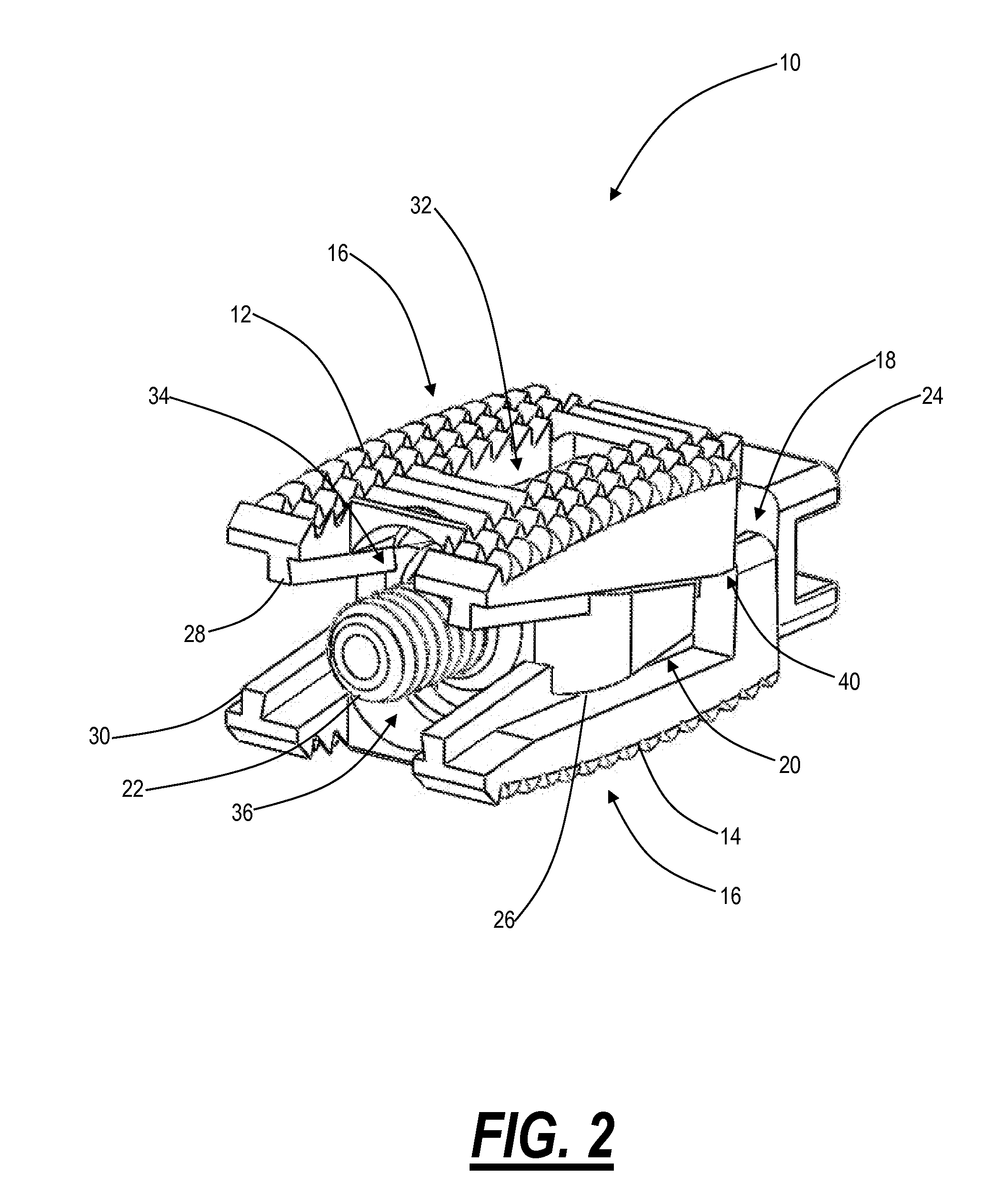

Substrate processing apparatus

InactiveUS20080216742A1Little changeUniform thicknessSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringGas supply

A substrate processing apparatus having a support for holding a wafer, a processing chamber for accommodating the wafer, a gas supply hole for supplying desired processing gas in a parallel direction to the surface to be processed of the wafer to be accommodated in said processing chamber, an adjustment plate to be arranged with facing the surface to be processed of the wafer accommodated in the foregoing processing chamber, and an exhaust means for exhausting atmosphere in said processing chamber. A substrate processing apparatus wherein distance between the surface to be processed of wafer and the center part of the adjustment plate is narrower than distance between the surface to be processed of wafer and the circumference part and the midway part of the adjustment plate, in a direction perpendicular to a supply direction of processing gas.

Owner:KOKUSA ELECTRIC CO LTD

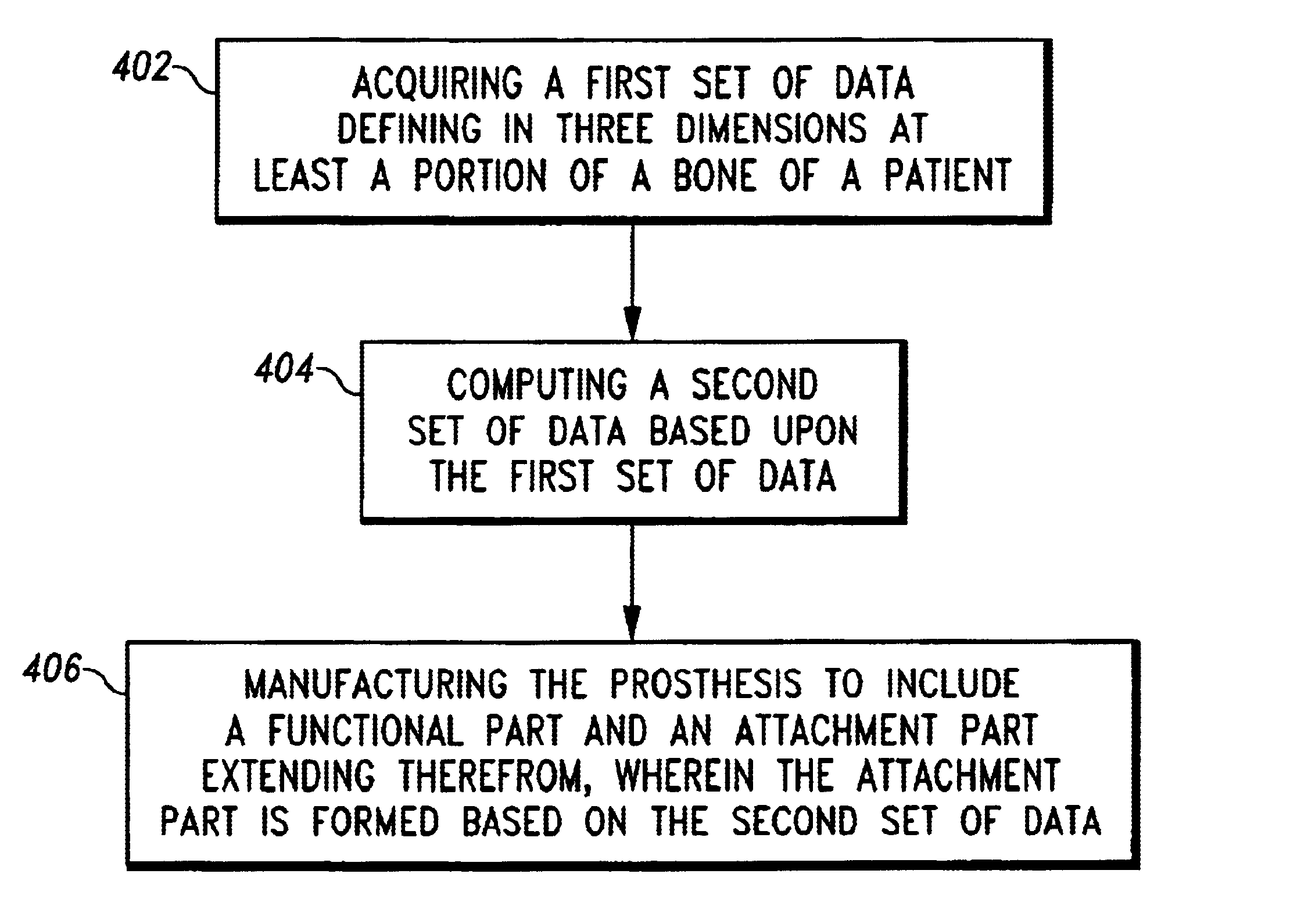

Customized prosthesis and method of designing and manufacturing a customized prosthesis by utilizing computed tomography data

InactiveUS6944518B2Uniform thicknessFast preparationMedical simulationProgramme controlProsthesisComputing tomography

A method of making an acetabular prosthesis includes acquiring a first set of data defining in three dimensions at least a portion of a bone of a patient. A second set of data is computed based upon the first set of data. The prosthesis is manufactured to include an acetabular cup and an attachment part extending therefrom. The manufacturing step includes the step of forming the attachment part based on the second set of data.

Owner:DEPUY PROD INC

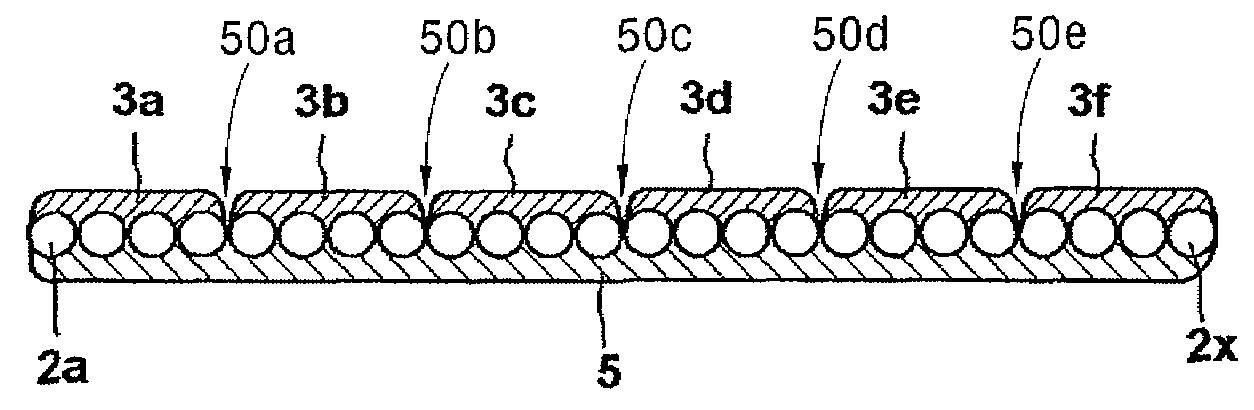

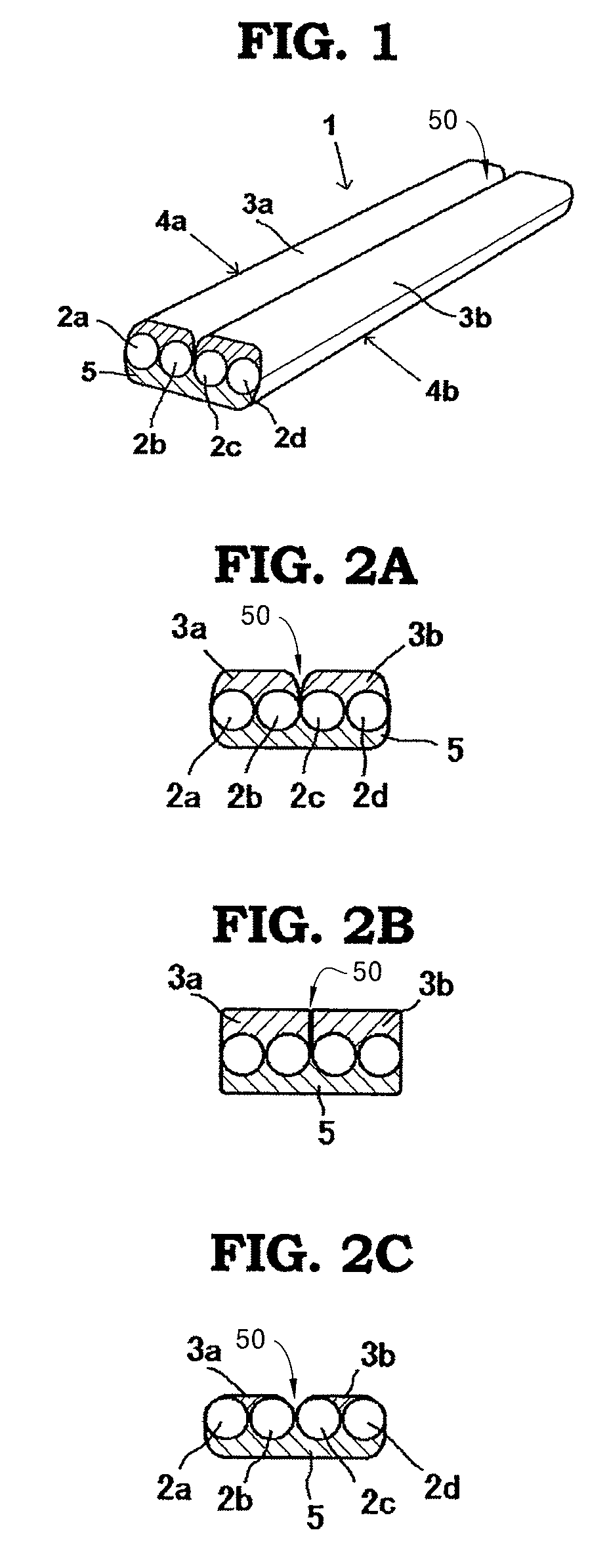

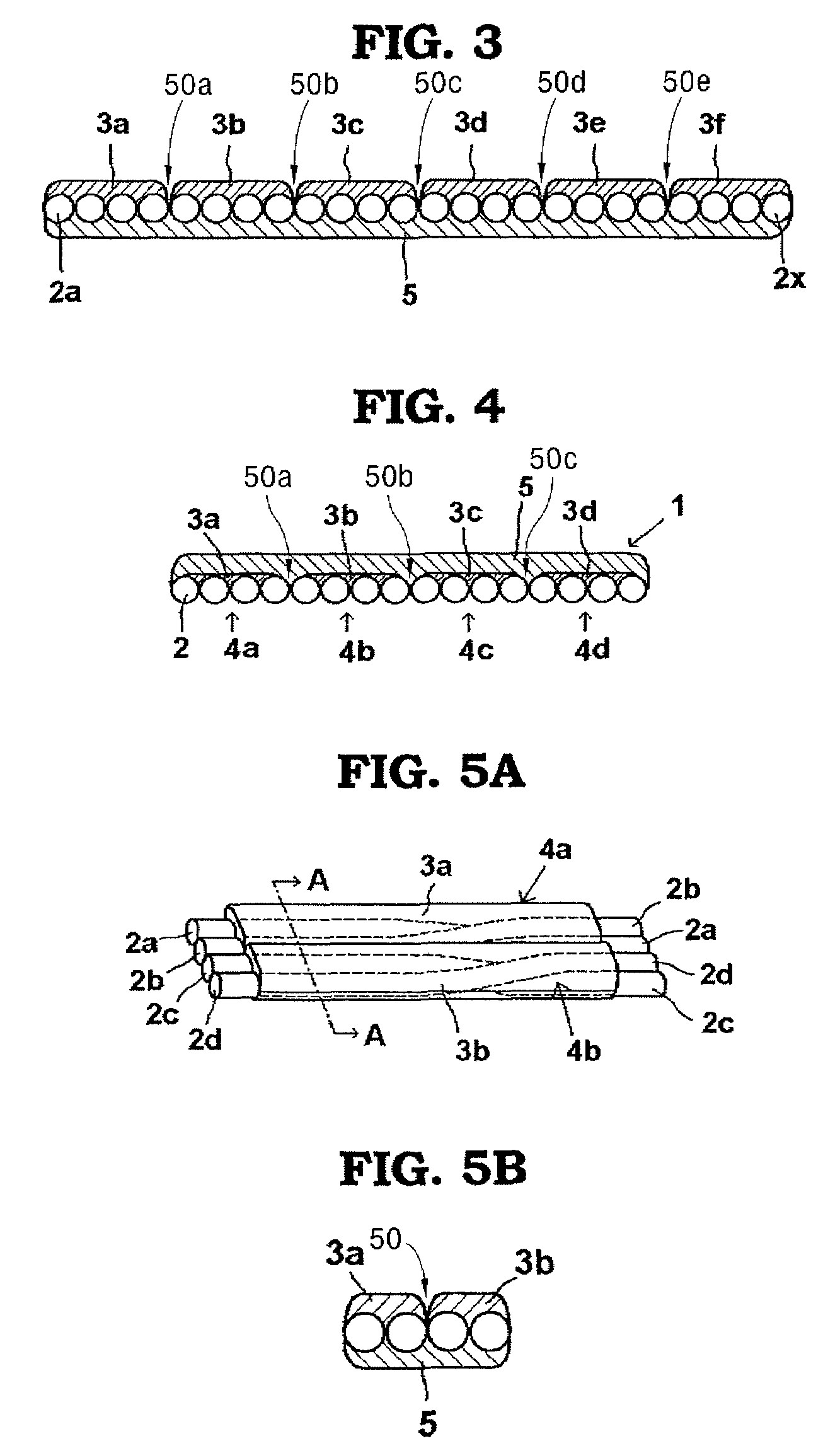

Optical fiber structure and method of manufacturing same

InactiveUS7509009B2Easily branchedPromote divisionGlass optical fibreFibre mechanical structuresEngineeringUltimate tensile strength

The present invention provides an optical fiber structure that allows for reliable and easy branching of optical fibers, as well as a method of manufacturing such optical fiber structure. The optical fiber structure proposed by the present invention is characterized by a structure wherein multiple optical fiber units, each comprising multiple optical fibers that are aligned two-dimensionally in such a way that one side is covered by a first covering body, are aligned so that the covered surfaces face the same direction, and the covered or uncovered surfaces of the multiple optical fiber units are integrally covered by a second covering body. The second covering body should preferably be made of silicone rubber having a tearing strength of 29 kgf / cm or below.

Owner:TOMOEGAWA PAPER CO LTD

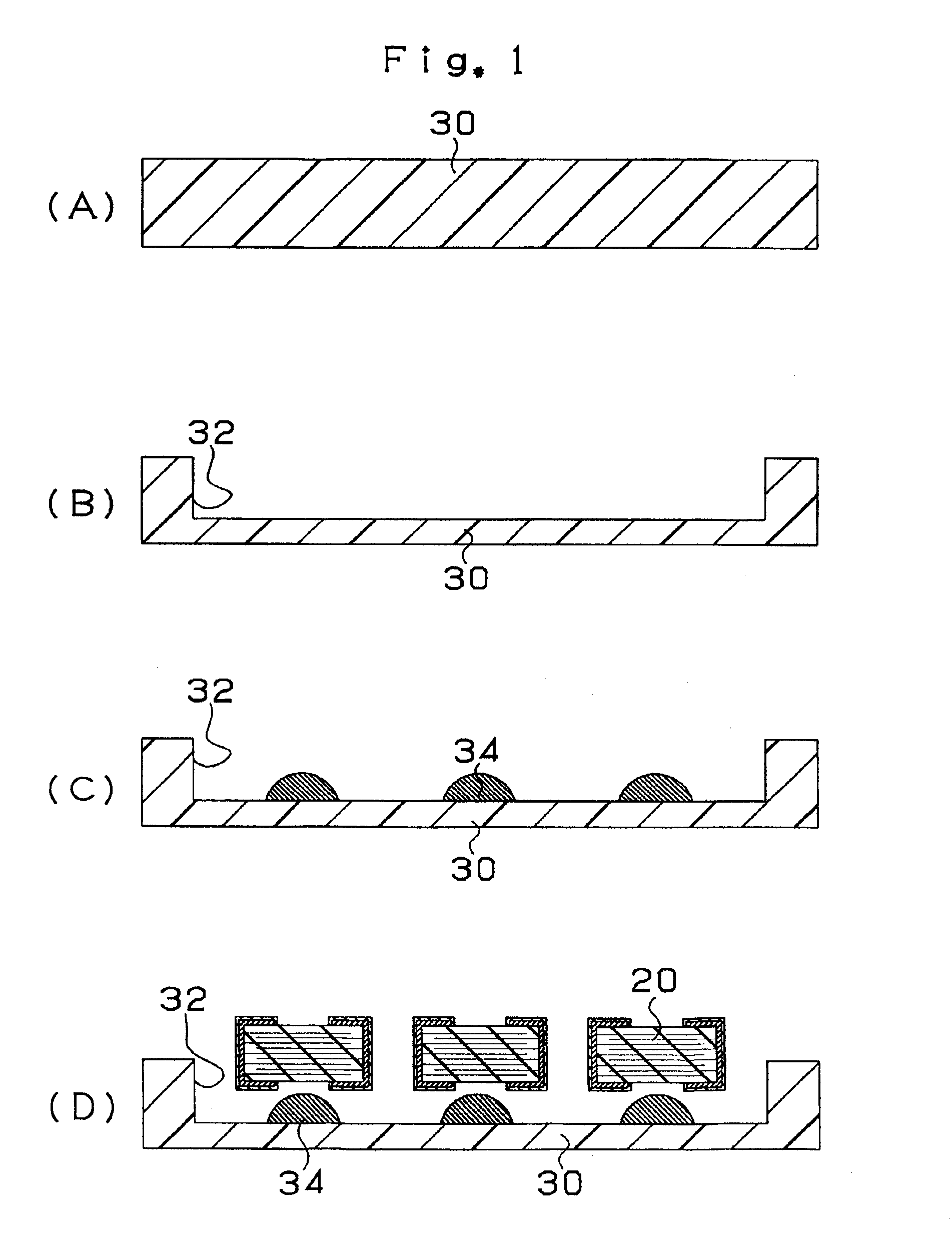

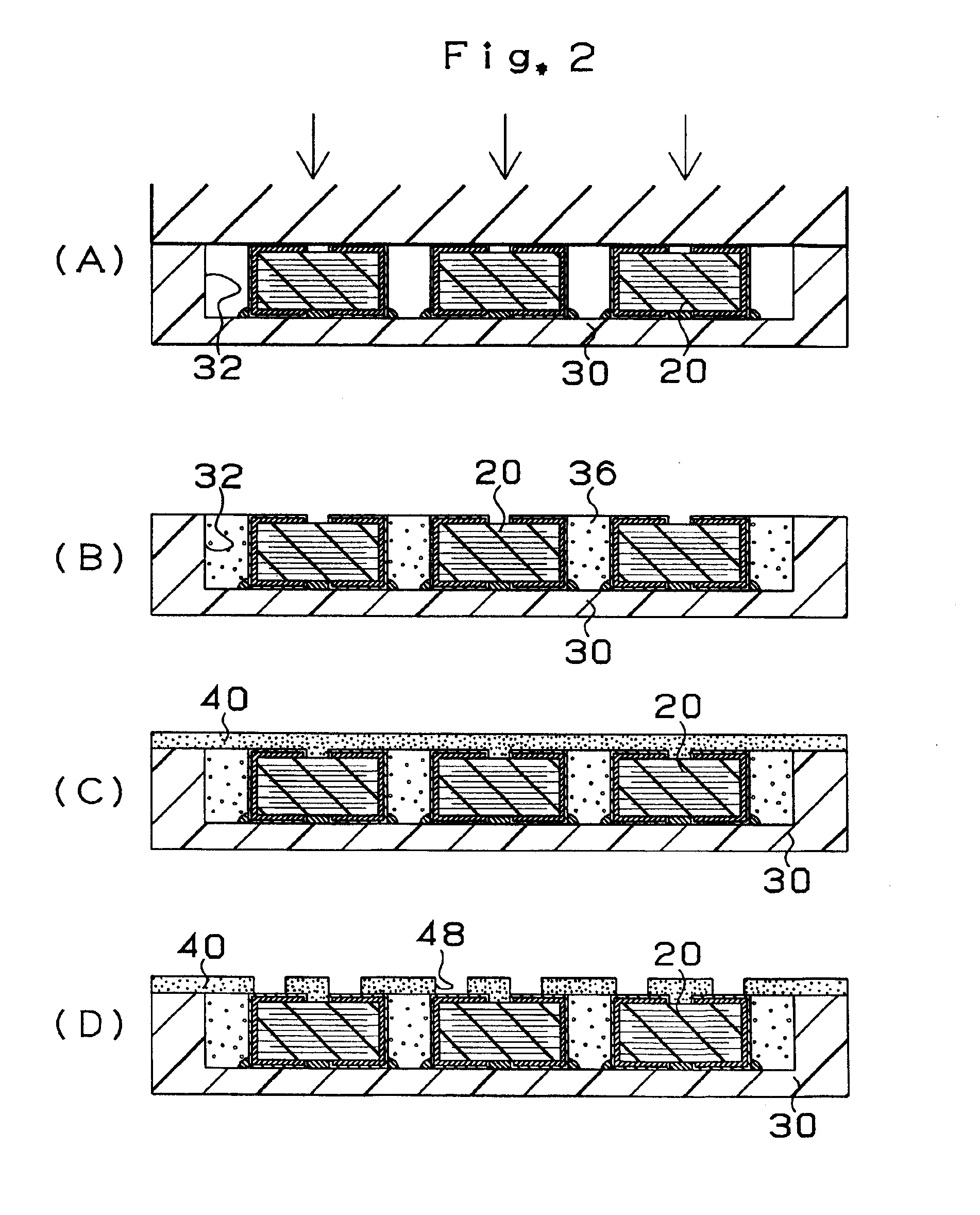

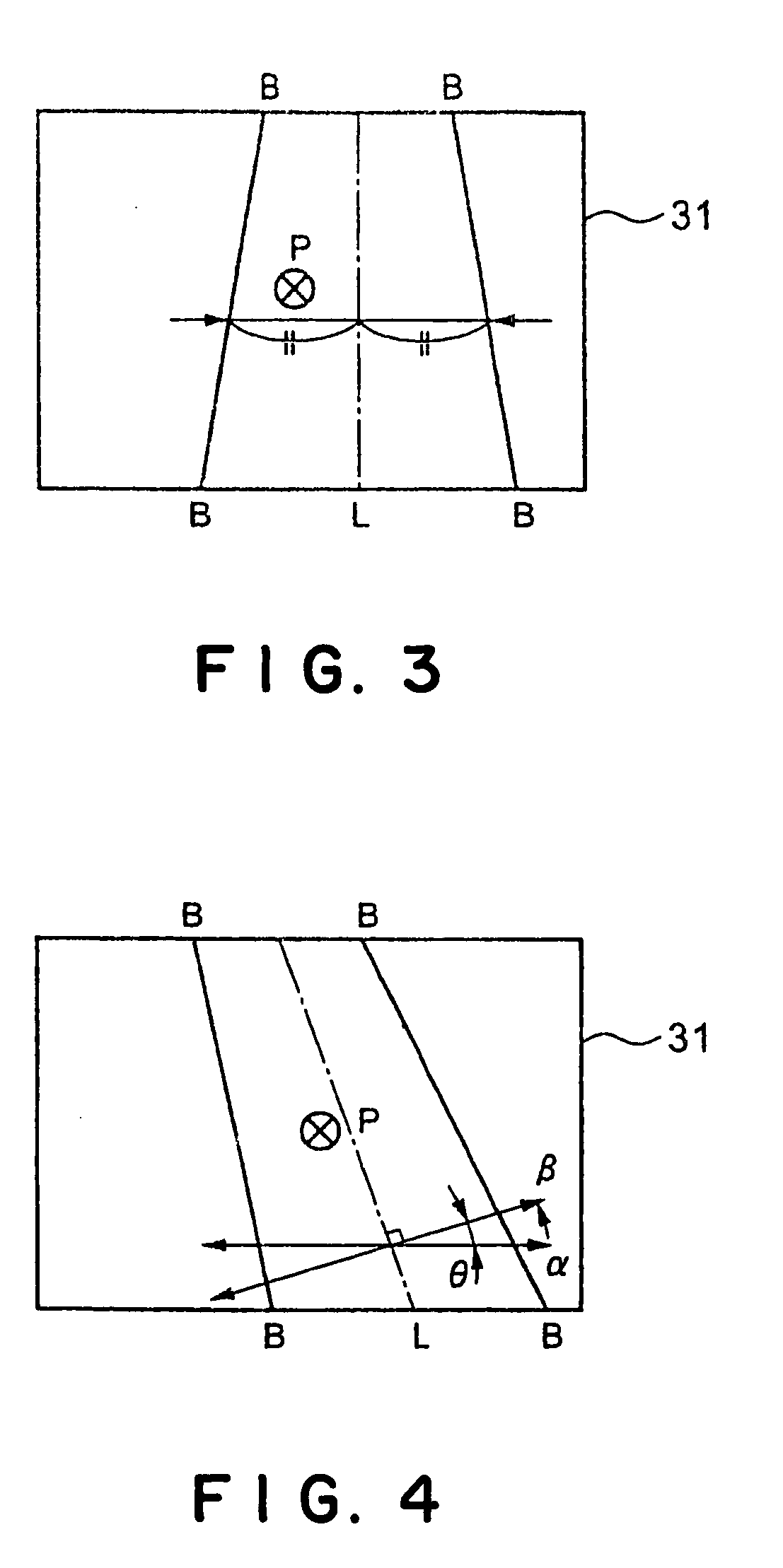

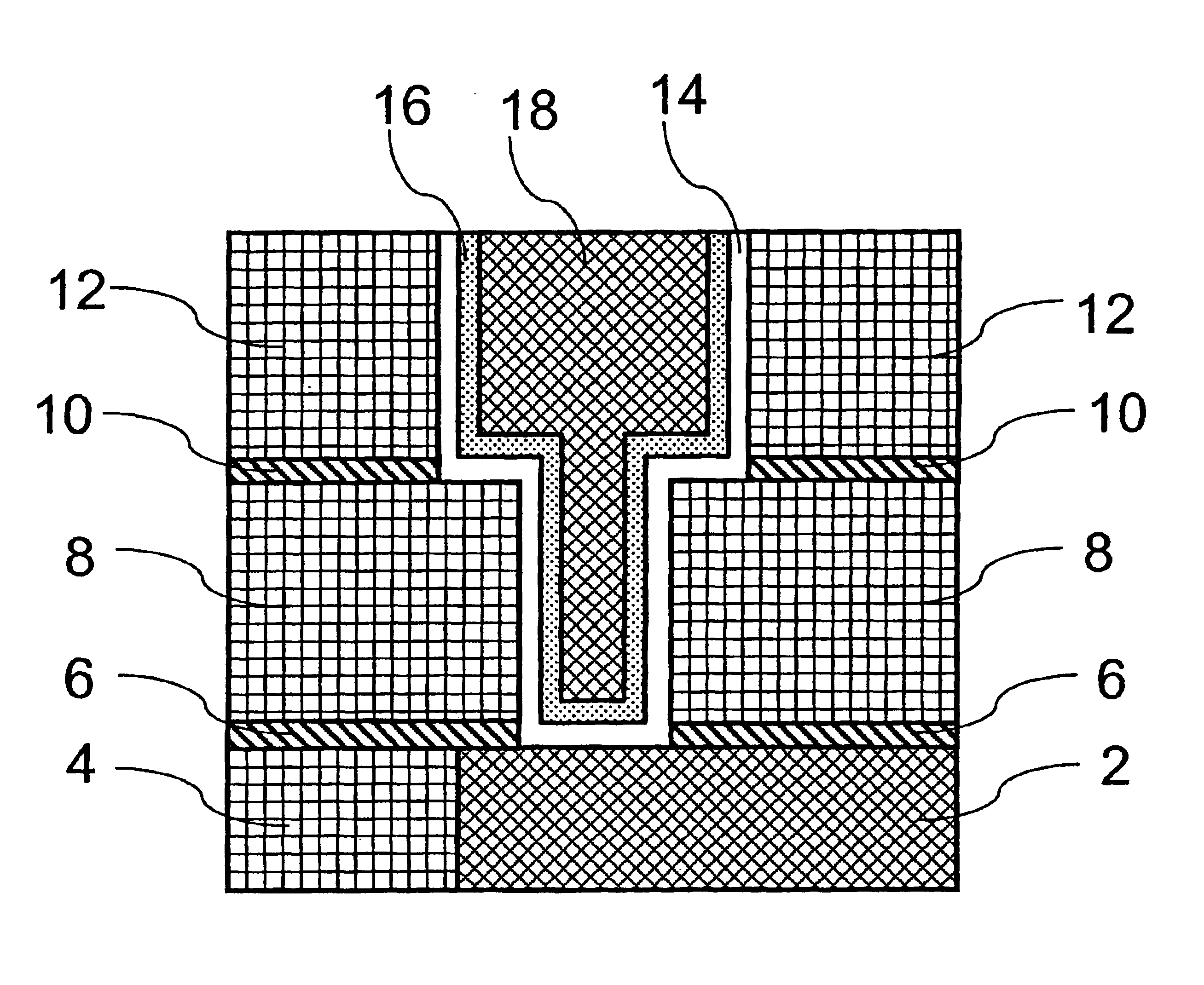

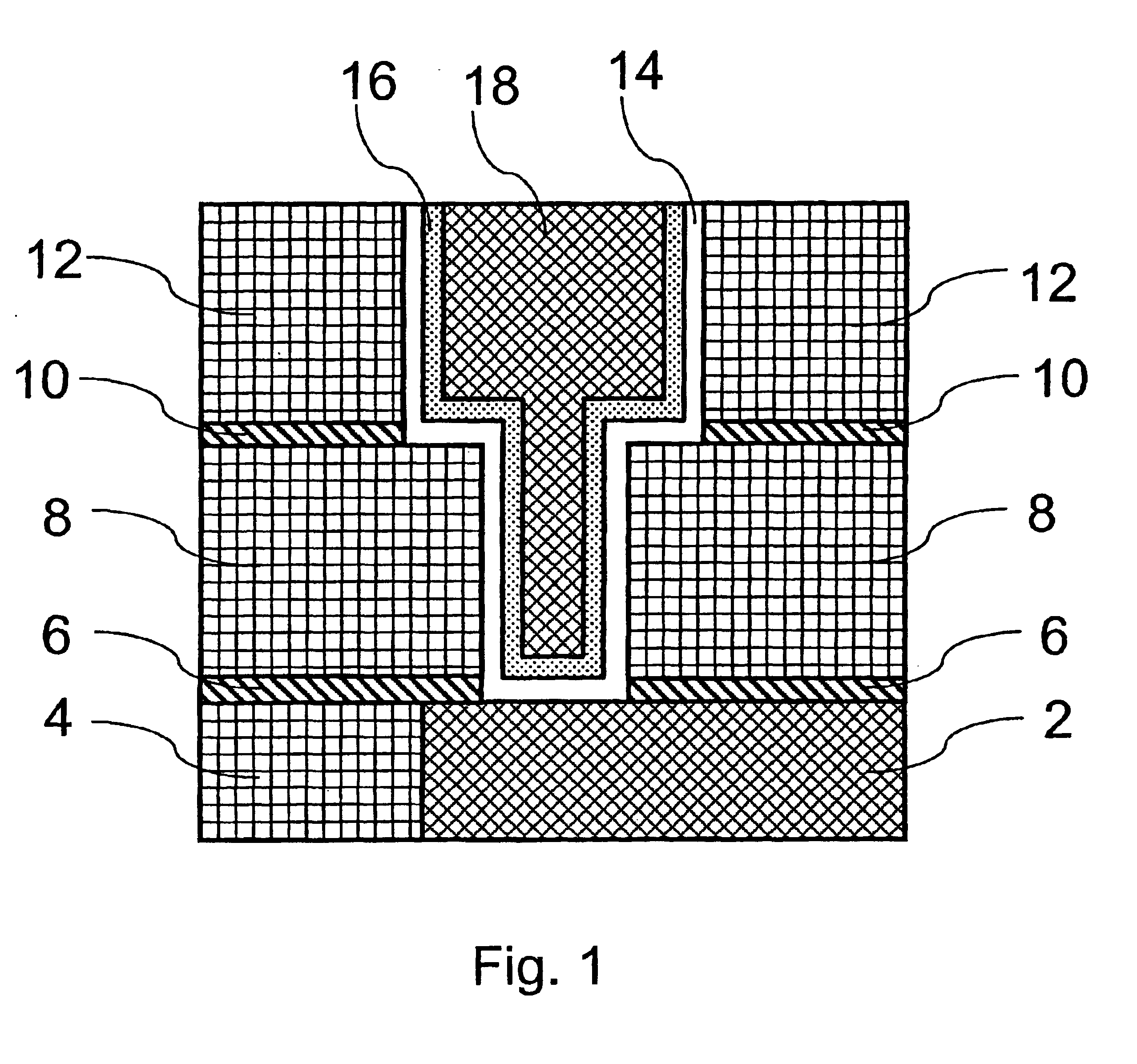

Selective growth method, and semiconductor light emitting device and fabrication method thereof

InactiveUS20030140846A1Improve featuresReduce widthPolycrystalline material growthSemiconductor/solid-state device manufacturingThree dimensional shapeActive layer

In a selective growth method, growth interruption is performed at the time of selective growth of a crystal layer on a substrate. Even if the thickness distribution of the crystal layer becomes non-uniform at the time of growth of the crystal layer, the non-uniformity of the thickness distribution of the crystal layer can be corrected by inserting the growth interruption. As a result of growth interruption, an etching rate at a thick portion becomes higher than that at a thin portion, to eliminate the difference in thickness between the thick portion and the thin portion, thereby solving the problem associated with degradation of characteristics due to a variation in thickness of the crystal layer, for example, an active layer. The selective growth method is applied to fabrication of a semiconductor light emitting device including an active layer as a crystal layer formed on a crystal layer having a three-dimensional shape by selective growth.

Owner:SAMSUNG ELECTRONICS CO LTD

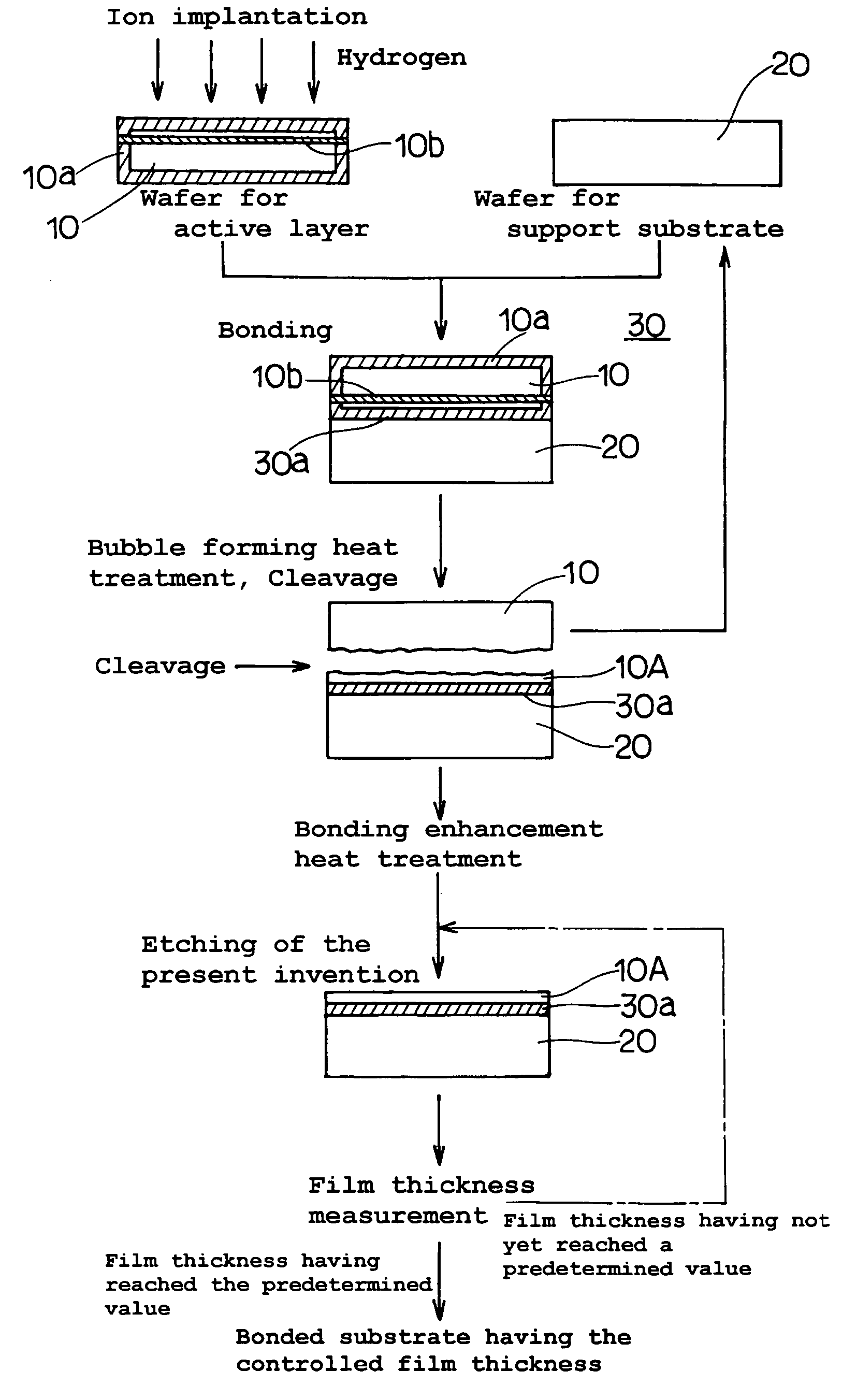

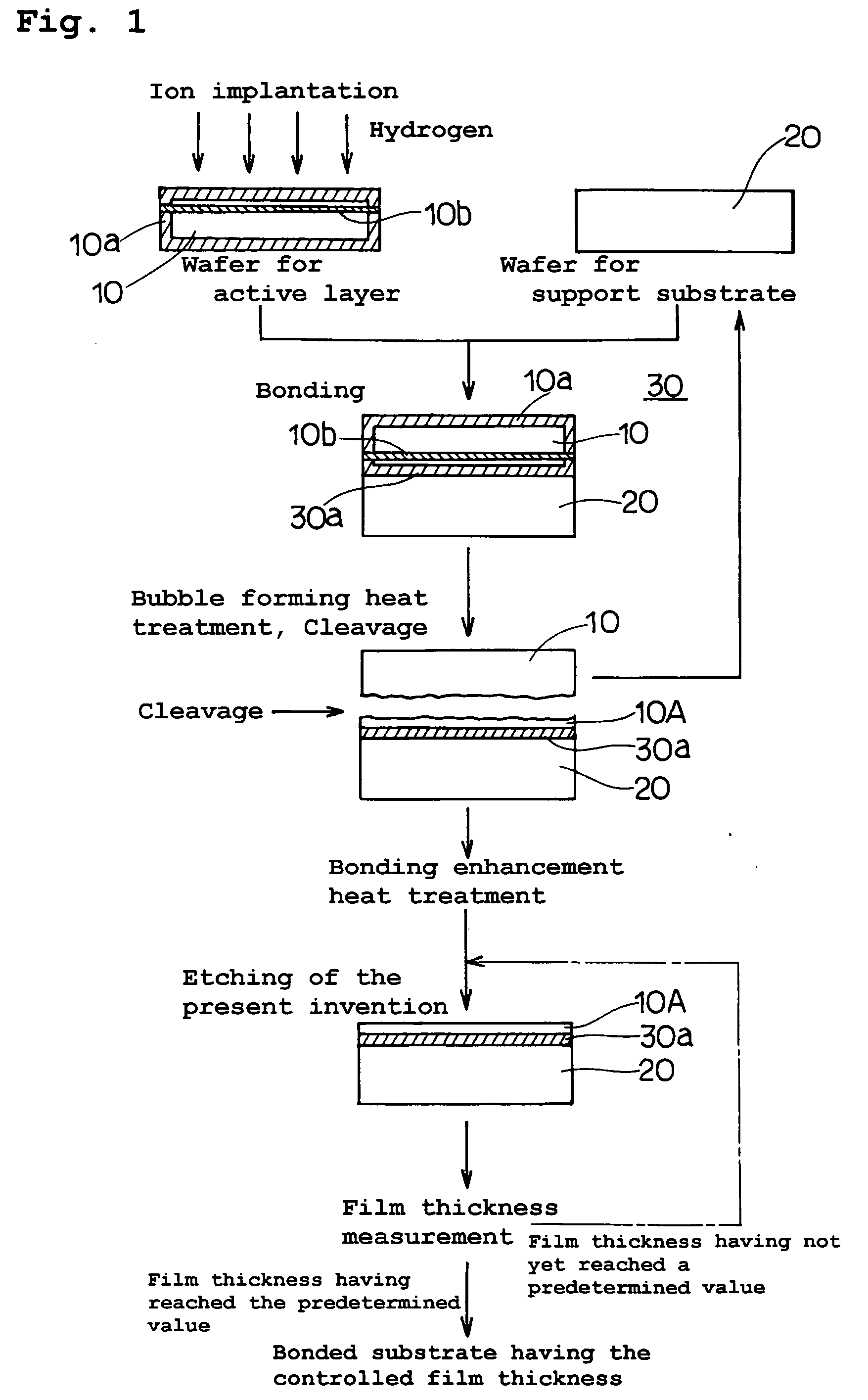

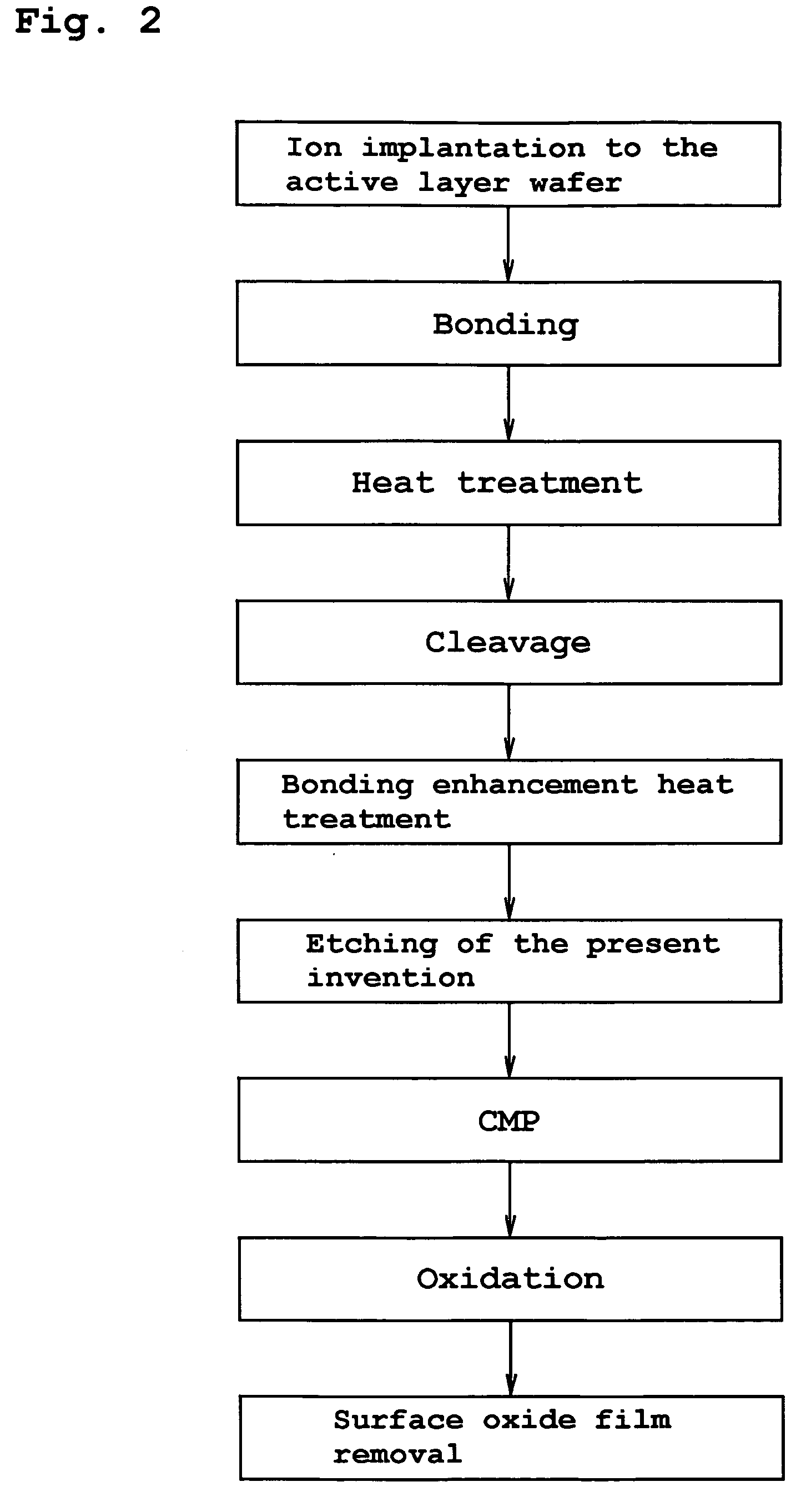

Laminated semiconductor substrate process for producing the same

InactiveUS20060118935A1Simple processReduce surface roughnessDecorative surface effectsSemiconductor/solid-state device detailsEtchingSurface roughness

The present invention provides a bonded substrate fabricated to have its final active layer thickness of 200 nm or lower by performing the etching by only 1 nm to 1 μm with a solution having an etching effect on a surface of an active layer of a bonded substrate which has been prepared by bonding two substrates after one of them having been ion-implanted and then cleaving off a portion thereof by heat treatment. SC-1 solution is used for performing the etching. A polishing, a hydrogen annealing and a sacrificial oxidation may be respectively applied to the active layer before and / or after the etching. The film thickness of this active layer can be made uniform over the entire surface area and the surface roughness of the active layer can be reduced as well.

Owner:SUMCO CORP +1

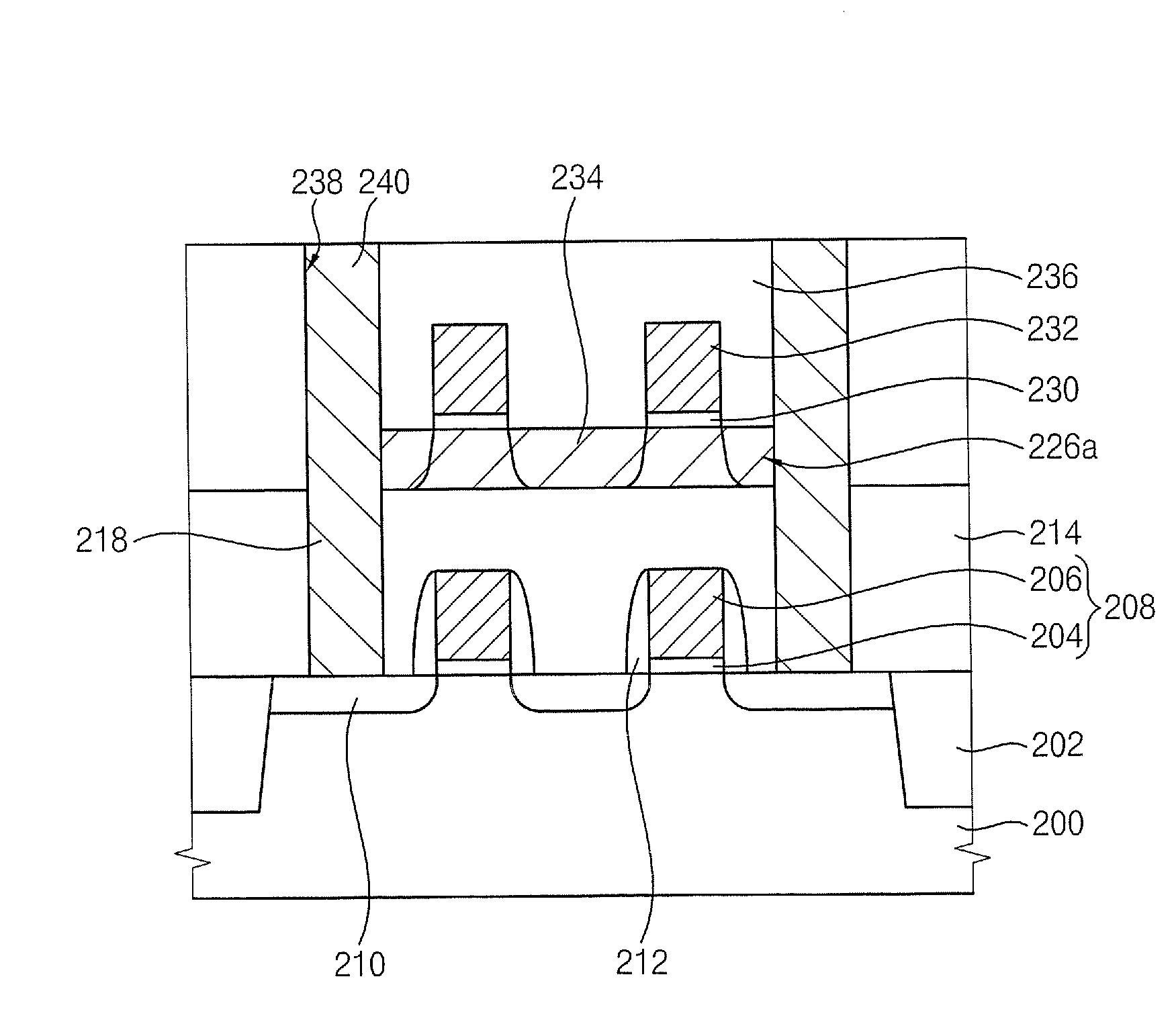

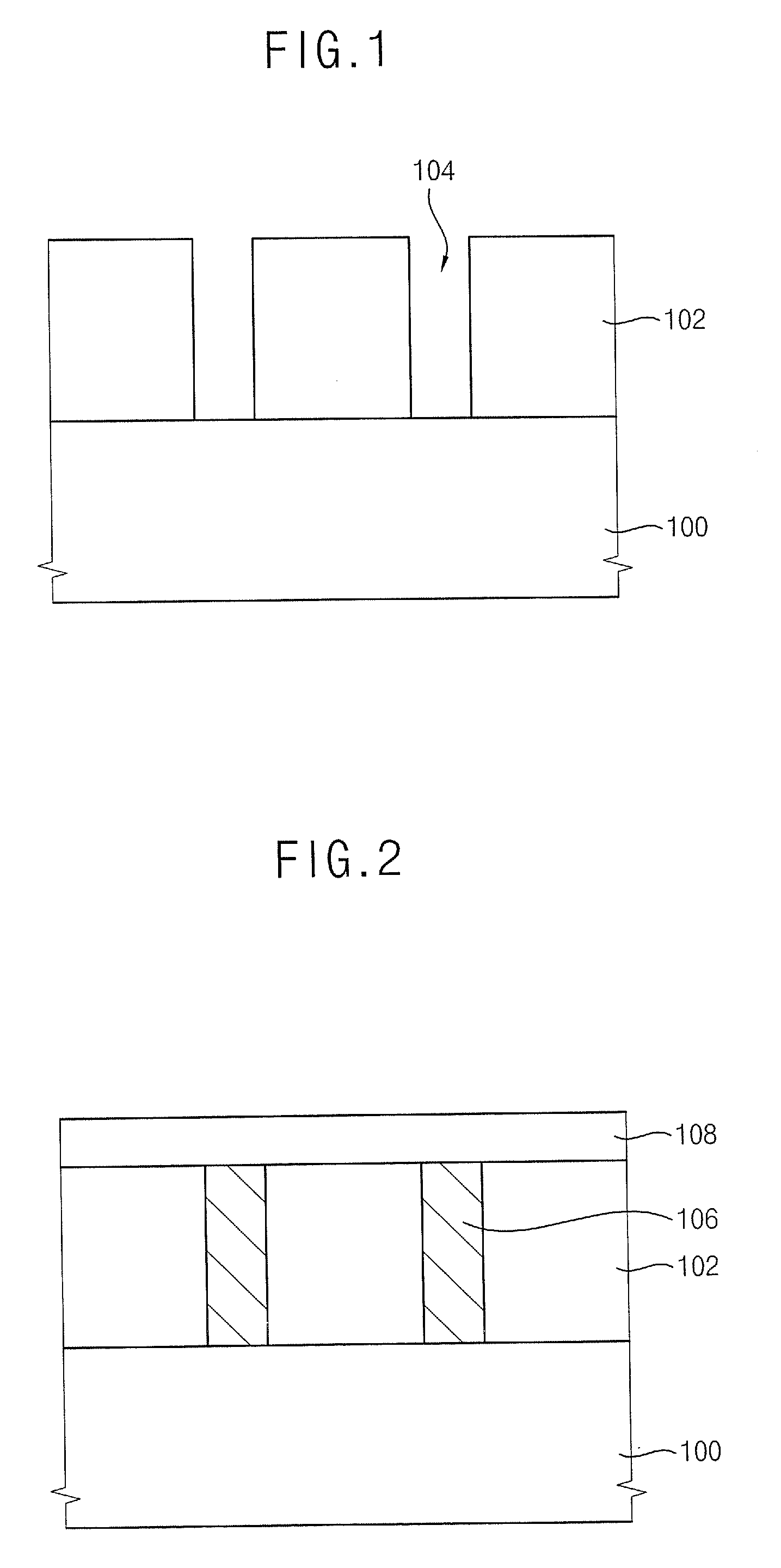

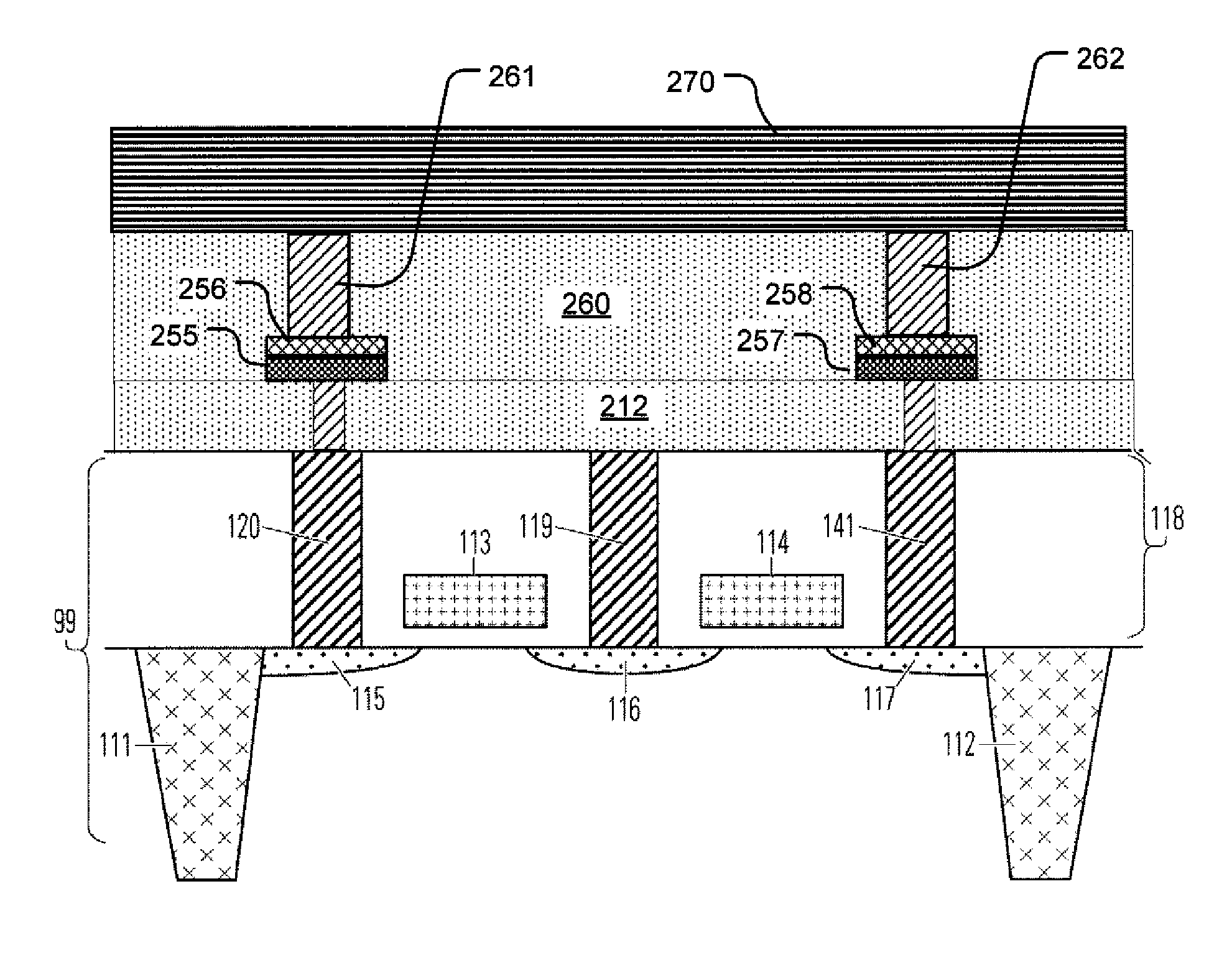

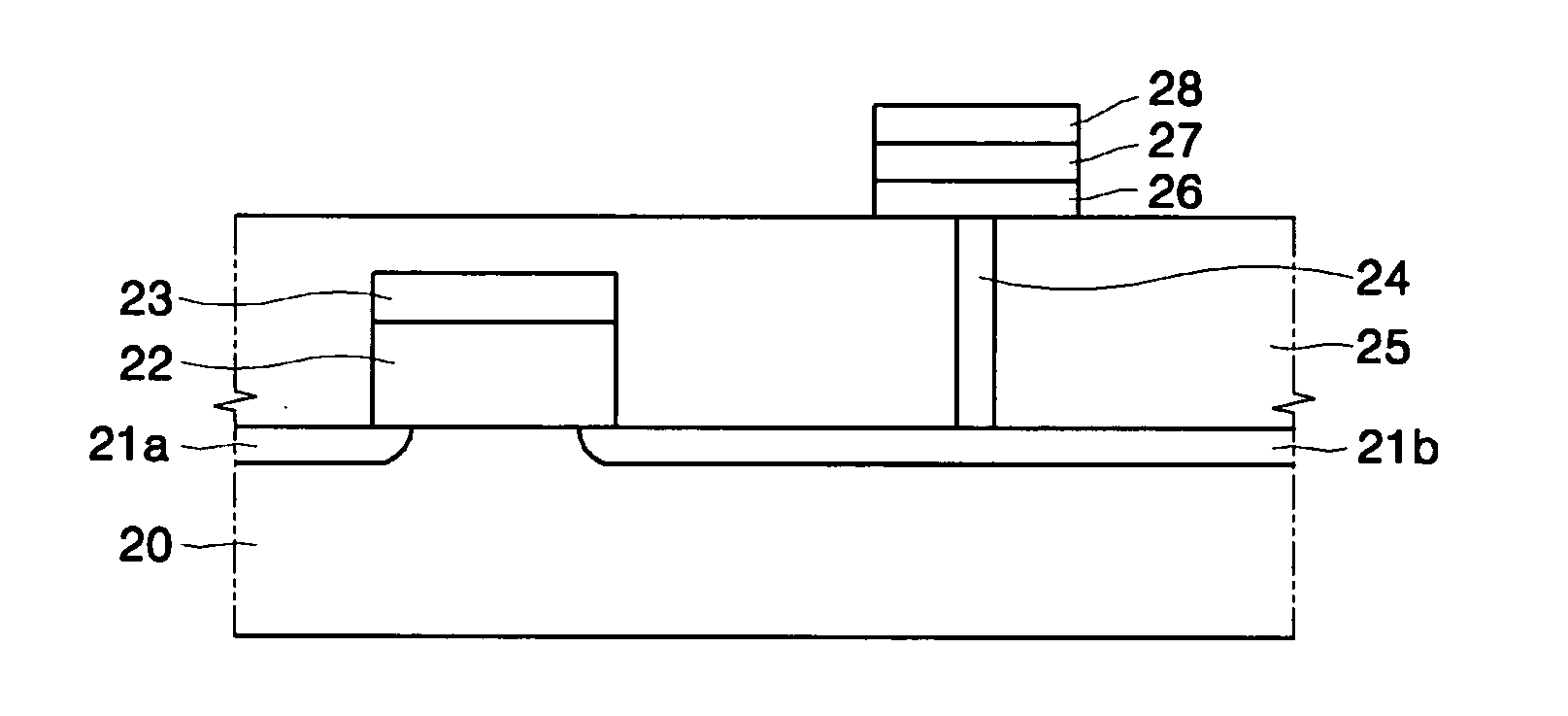

Methods of fabricating semiconductor devices including channel layers having improved defect density and surface roughness characteristics

ActiveUS20080160726A1Improved surface roughness characteristicUniform thicknessSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingSurface roughnessSingle crystal

A method of fabricating a semiconductor device including a channel layer includes forming a single crystalline semiconductor layer on a semiconductor substrate. The single crystalline semiconductor layer includes a protrusion extending from a surface thereof. A first polishing process is performed on the single crystalline semiconductor layer to remove a portion of the protrusion such that the single crystalline semiconductor layer includes a remaining portion of the protrusion. A second polishing process different from the first polishing process is performed to remove the remaining portion of the protrusion and define a substantially planar single crystalline semiconductor layer having a substantially uniform thickness. A sacrificial layer may be formed on the single crystalline semiconductor layer and used as a polish stop for the first polishing process to define a sacrificial layer pattern, which may be removed prior to the second polishing process. Related methods of fabricating stacked semiconductor memory devices are also discussed.

Owner:SAMSUNG ELECTRONICS CO LTD

Expandable intervertebral implant and associated surgical method

ActiveUS8795366B2Uniform thicknessSecurely holdJoint implantsSpinal implantsLamina terminalisIntervertebral space

The present invention provides an expandable intervertebral implant that is selectively disposed in the intervertebral space and deployed, thereby in-situ distracting, realigning, and / or stabilizing or fusing a portion of the spine of a patient in the treatment of injury, disease, and / or degenerative condition. The expandable intervertebral implant includes a superior member and an inferior member, each of which has a partially or substantially wedge or prismatic shape and a partially or substantially convex or other-shaped surface that is suitable for engaging the substantially concave surfaces of the associated bony superior and inferior intervertebral endplates. Once disposed in the intervertebral space, the expandable intervertebral implant is actuated and deployed, with the superior member and the inferior member moving apart from one another, seating against the associated intervertebral endplates, and distracting, realigning, and / or stabilizing them to a desired degree. The external surface of each of the superior member and the inferior member is provided with a plurality of ridges or other friction structures, providing purchase with the associated intervertebral endplates.

Owner:INNOVA SPINAL TECH

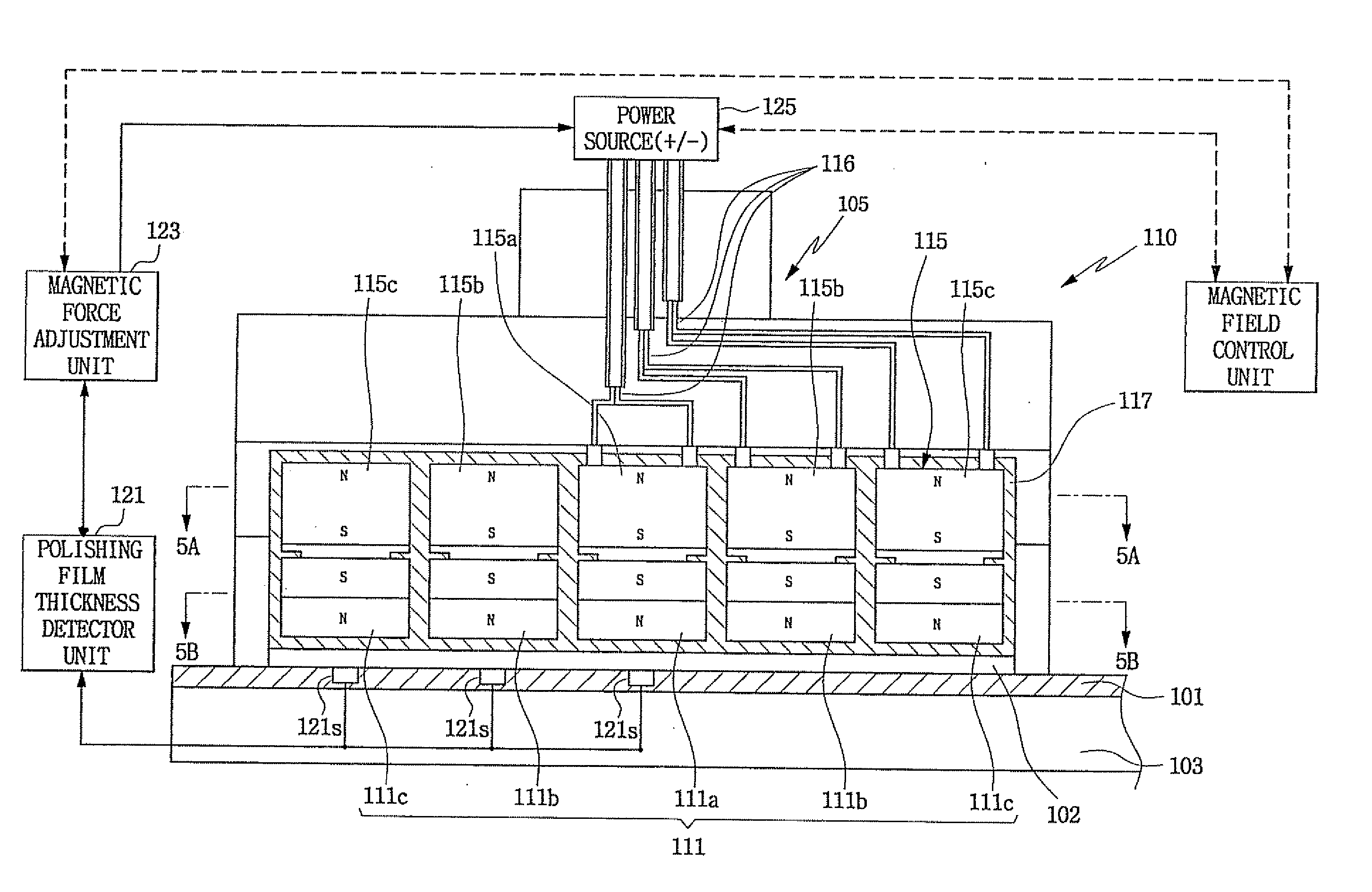

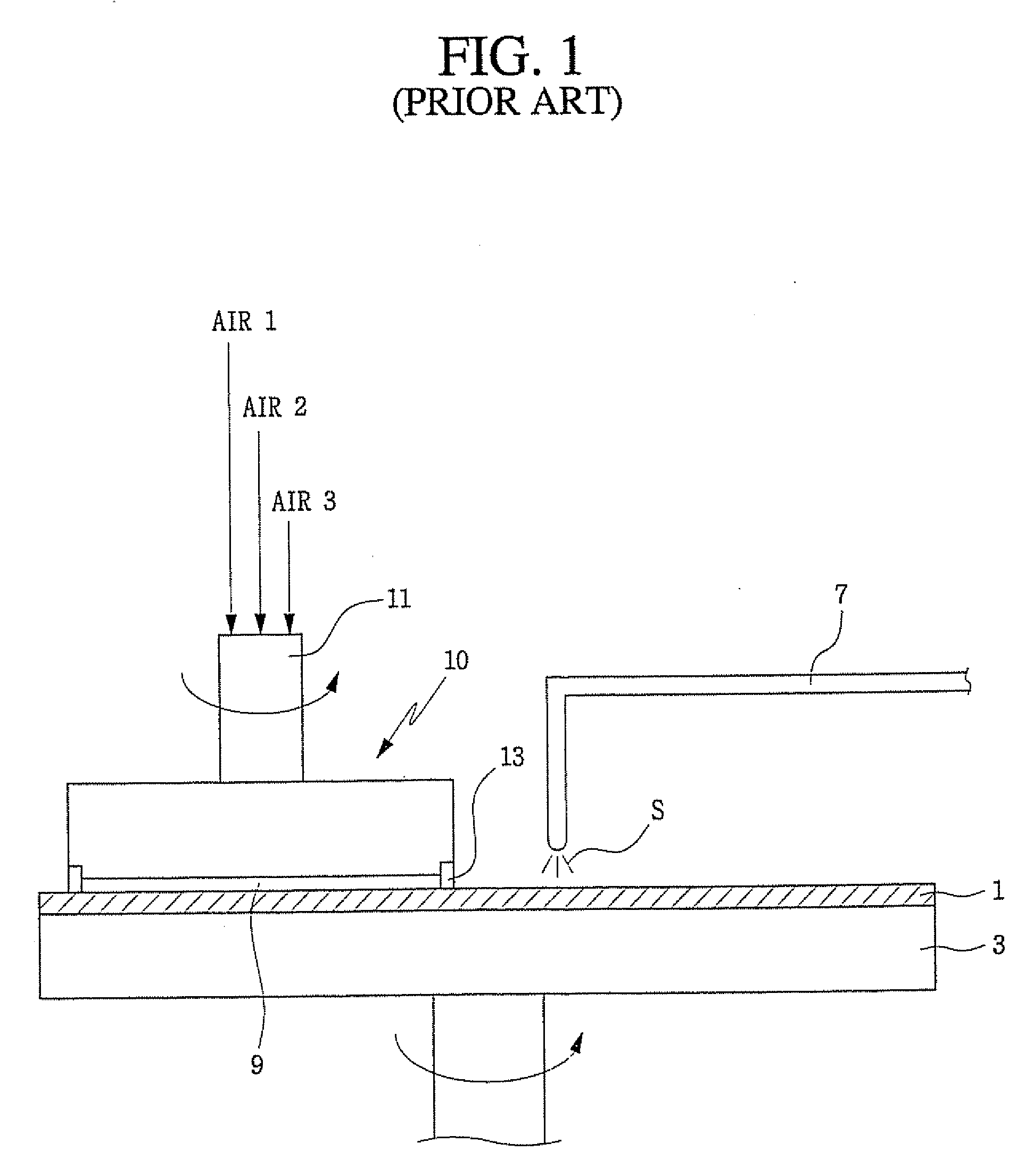

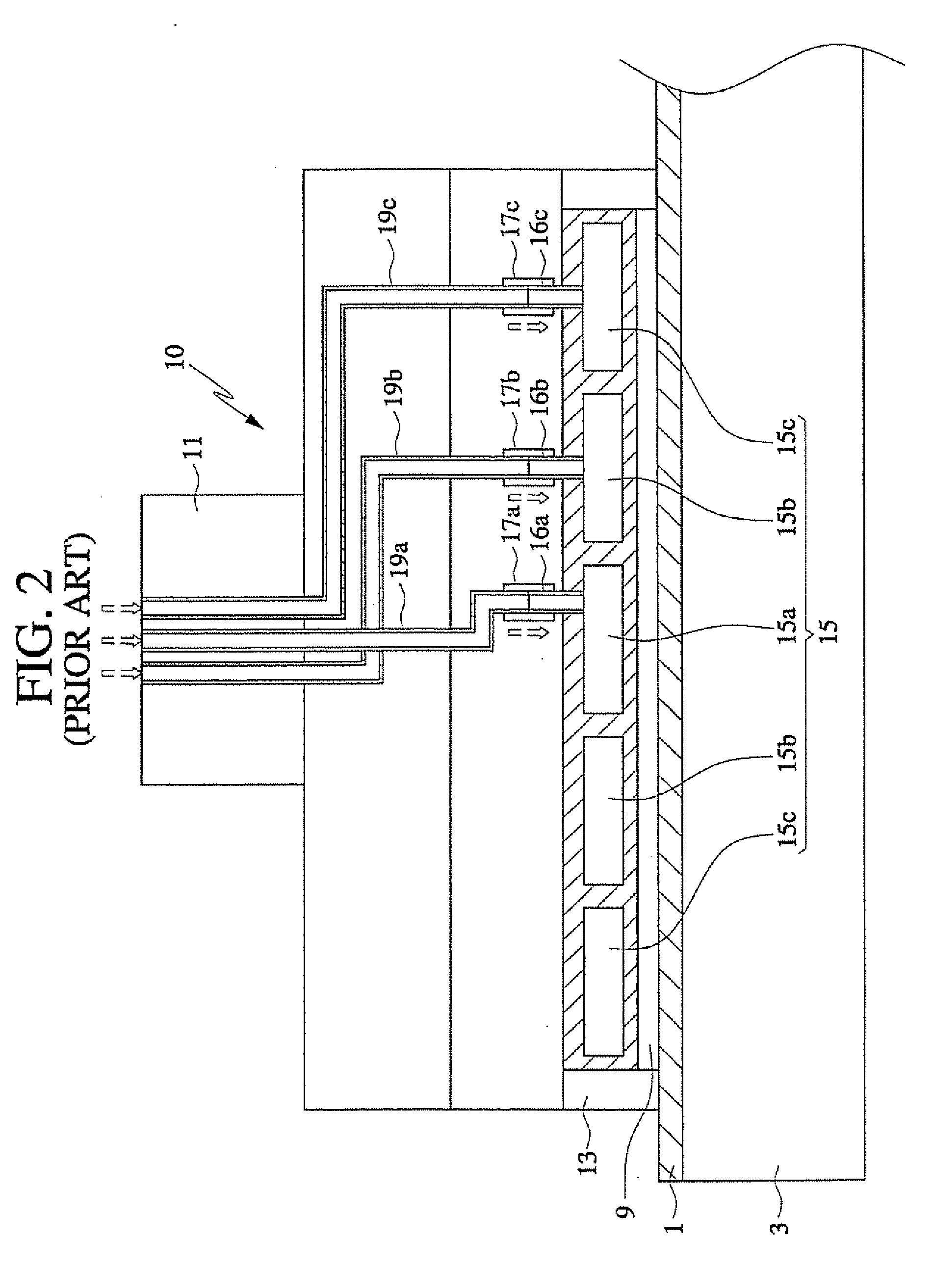

Polishing apparatus and related polishing methods

InactiveUS20060189259A1Uniform thicknessPolishing machinesRevolution surface grinding machinesEngineeringMagnetic field

Polishing apparatus and related methods employ aligned first and second magnetic field sources to adjust the compressive force and / or pressure applied by a carrier head against a target workpiece (such as a wafer) by selectively and controllably generating a repellant or attractive force between the two magnetic field sources.

Owner:SAMSUNG ELECTRONICS CO LTD

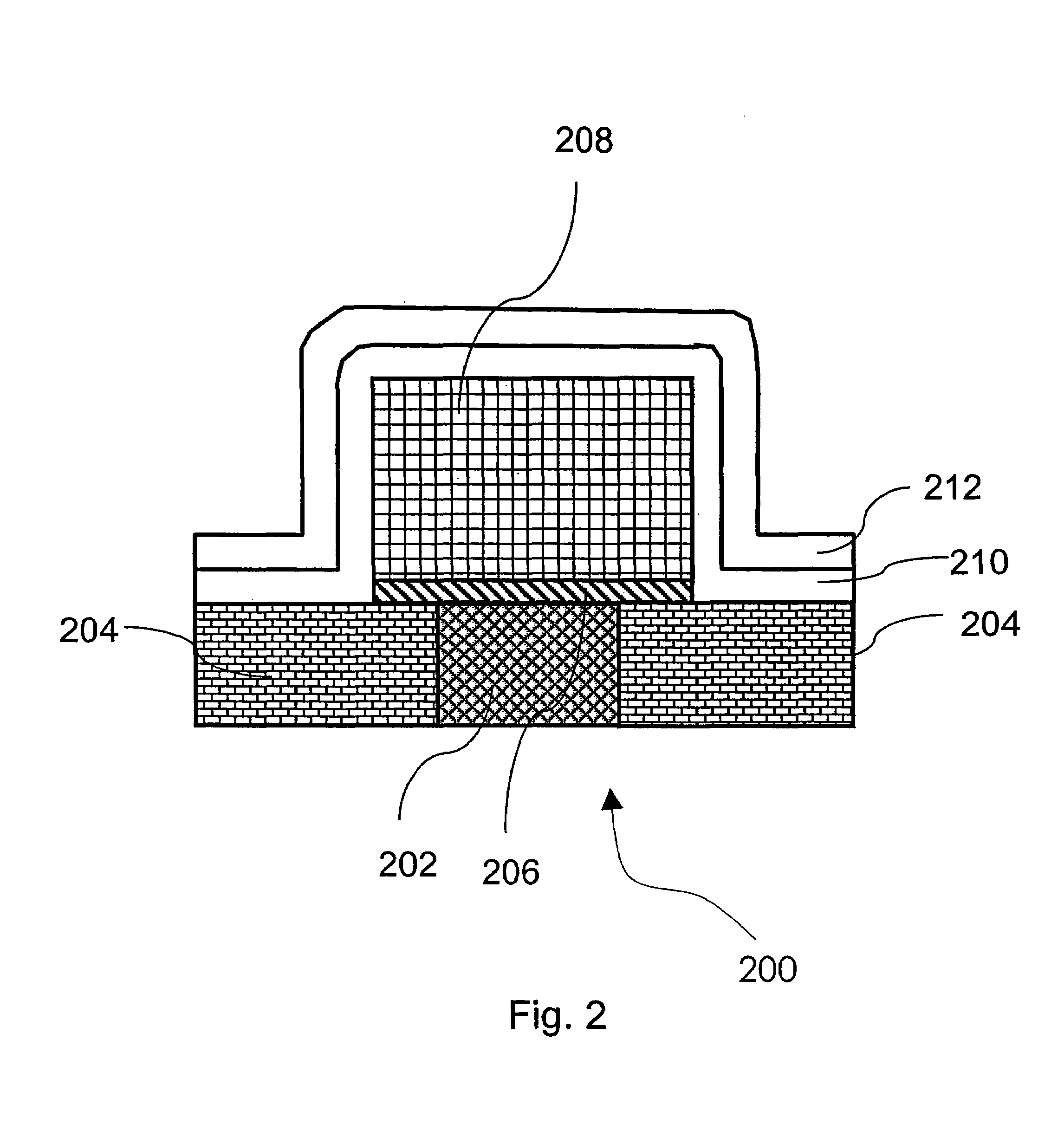

Method for manufacturing a phase change memory device with pillar bottom electrode

ActiveUS20080191187A1Improve operationHigh densitySolid-state devicesSemiconductor/solid-state device manufacturingChalcogenidePhase-change material

A method for manufacturing a mushroom-cell type phase change memory is based upon manufacturing a pillar of bottom electrode material upon a substrate including an array of conductive contacts in electrical communication with access circuitry. A layer of electrode material is deposited making reliable electrical contact with the array of conductive contacts. Electrode material is etched to form a pattern of electrode pillars on corresponding conductive contacts. Next, a dielectric material is deposited over the pattern and planarized to provide an electrode surface exposing top surfaces of the electrode pillars. Next, a layer of programmable resistive material, such as a chalcogenide or other phase change material, is deposited, followed by deposition of a layer of a top electrode material. A device including bottom electrode pillars with larger bottom surfaces than top surfaces is described.

Owner:GLOBALFOUNDRIES US INC +2

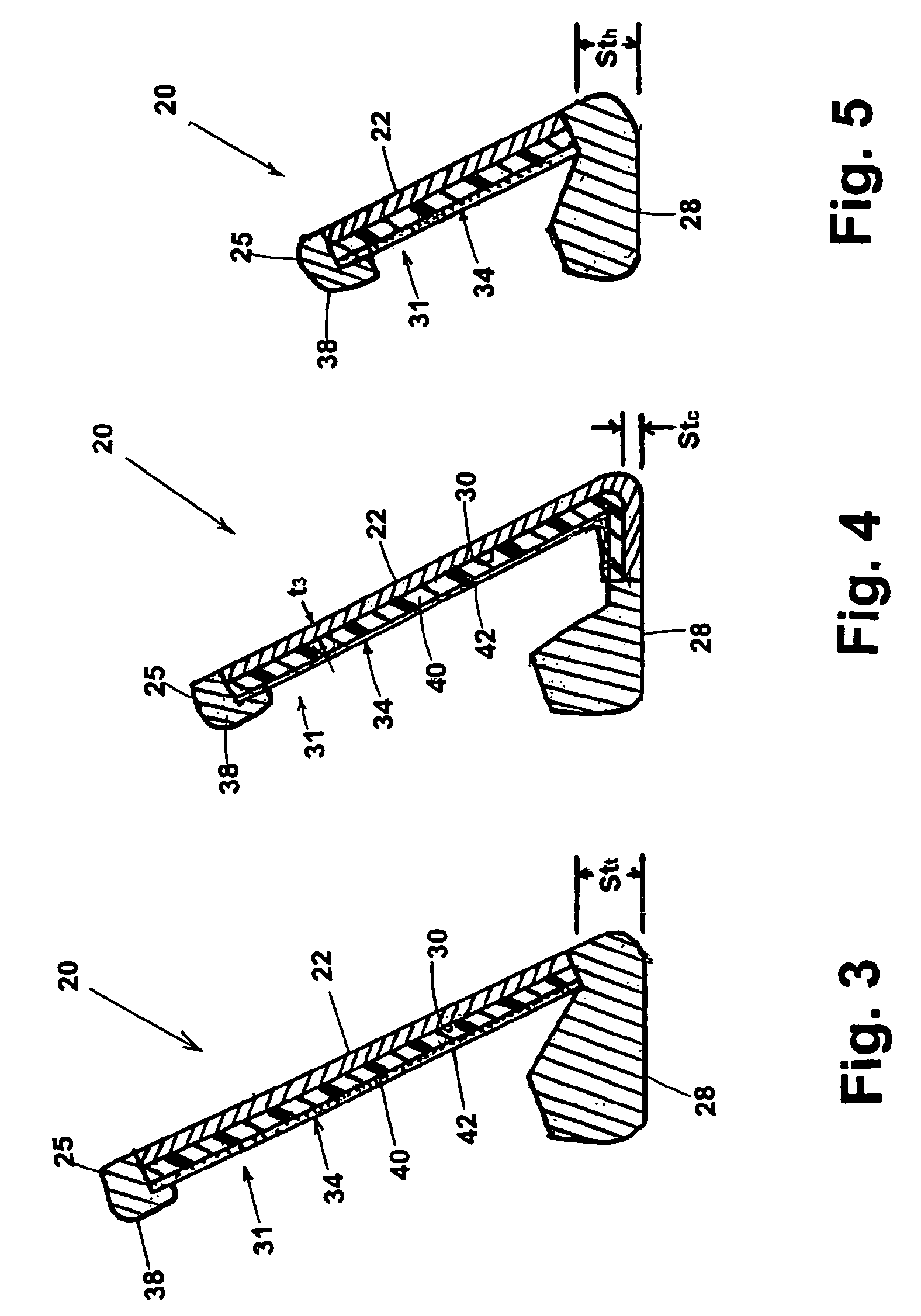

Golf club iron

An iron golf club head having a thin (less than 0.12 inches) first section that has an expanded unsupported front face region. The first section including a central portion forming part of a leading edge and wrapping around a sole section of the club, to create an increase the coefficient of restitution of the club head to greater than 0.8. The club head utilizes a rear insert that in addition to providing support for the front face, also allows for the fine tuning of swing weights with no change in geometry or size of the club head. This is accomplished this by the utilization of weight adjustment inserts that impregnate tungsten loaded plastic into sheets of carbon graphite and epoxy. The percentage of tungsten creating a weight range without any size change in the sheets.

Owner:ACUSHNET CO

Bonded joint design for a golf club head

A golf club (40) having a club head (42) with a face component (60) and an aft body (61) is disclosed herein. The face component (60) has a striking plate portion (72) and a return portion (74). The aft-body (61) is composed of a crown portion (62), a sole portion (64) and optionally a ribbon section (90). The face component (60) is composed of a metal material, and the aft-body (61) is preferably composed of a non-metal material such as a composite material or a thermoplastic material. The face component (60) is bonded to the aft-body (61) with a leading edge (180) of an undercut portion (62a and 64a) of the aft-body positioned a distance of 0.100 inch to 0.500 inch from the interior surface (60a) of the face component (60) in order to reduce the stress on the bonded joint of between the face component (60) and the aft-body (61). The club head (42) has a volume in the range of 290 cubic centimeters to 600 cubic centimeters, a weight in the range of 165 grams to 300 grams, and a striking plate portion (72) surface area in the range of 4.00 square inches to 7.50 square inches.

Owner:TOPGOLF CALLAWAY BRANDS CORP

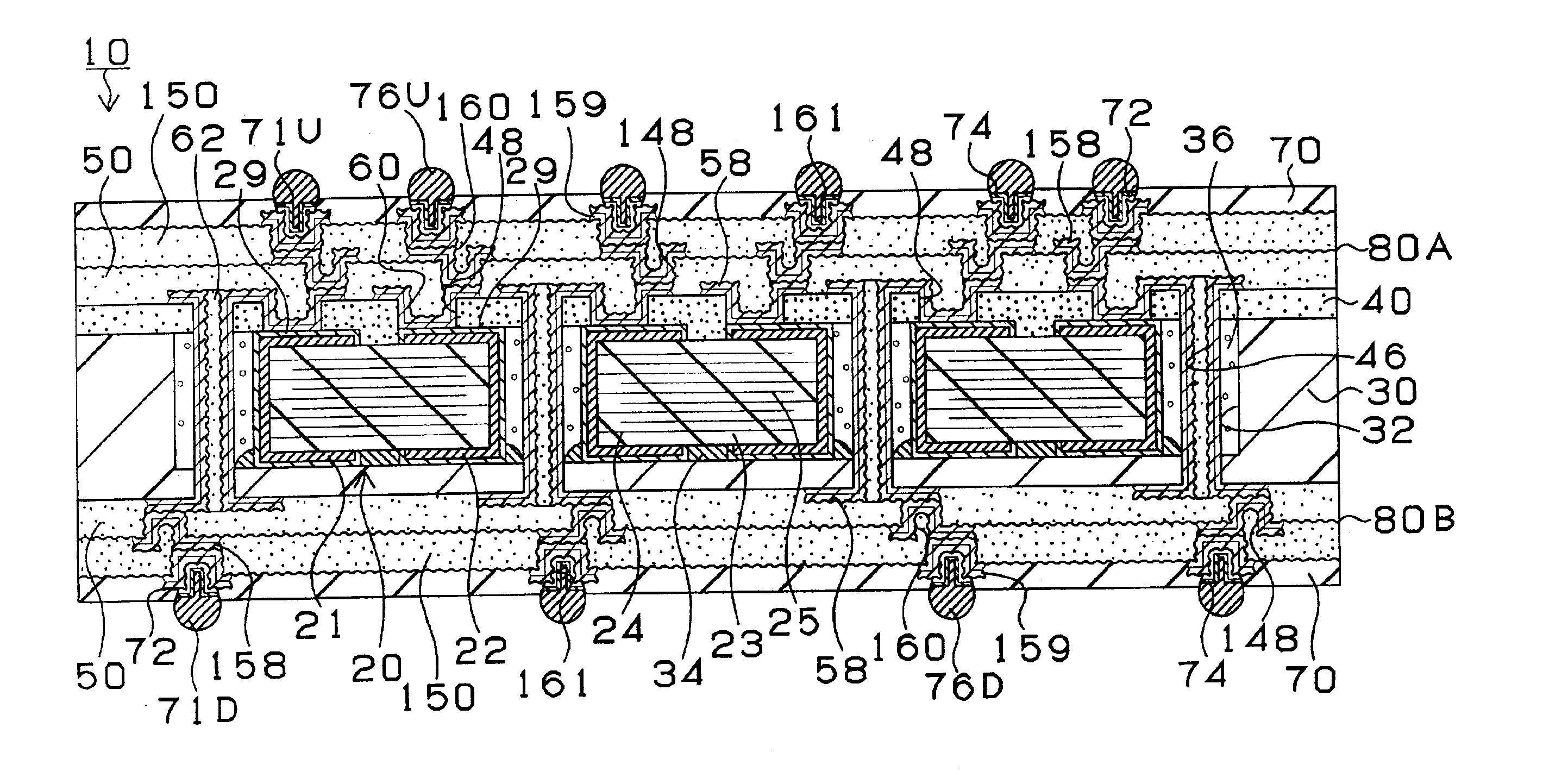

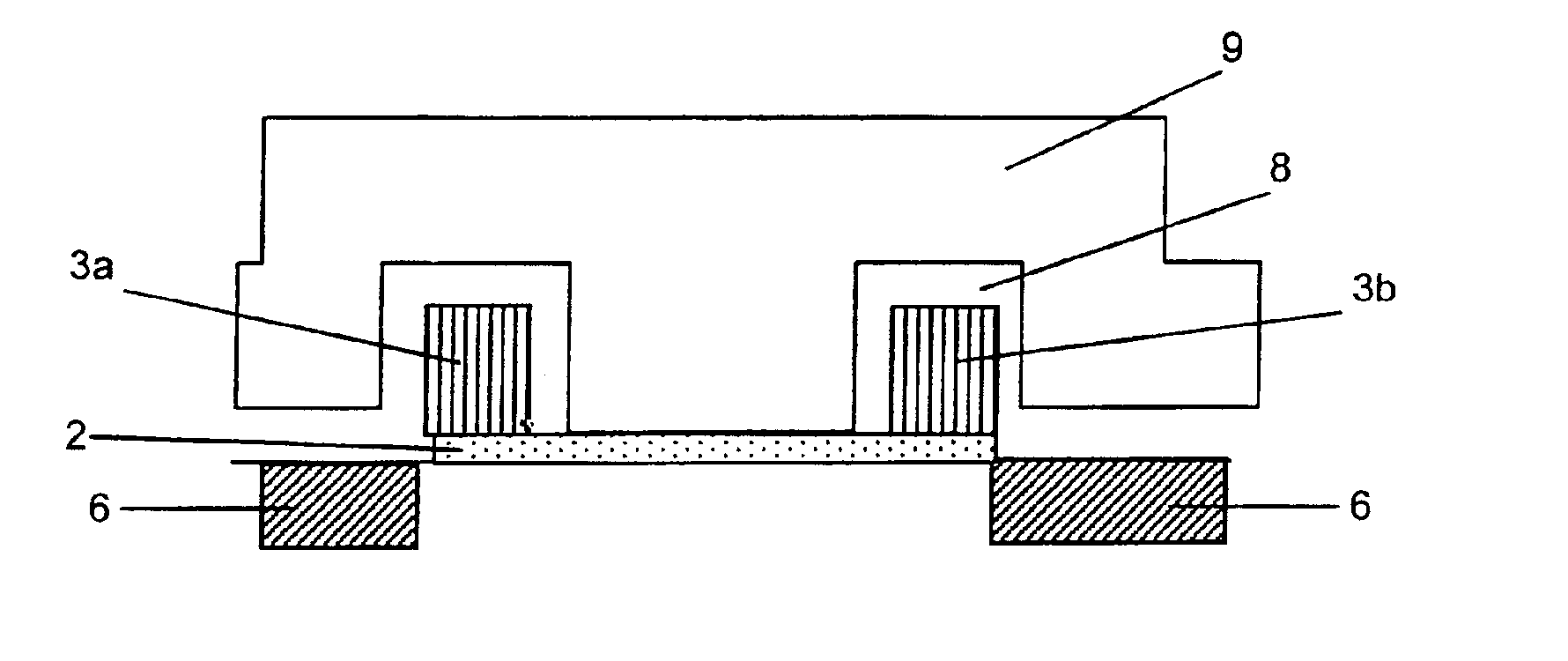

Printing wiring board and method of producing the same and capacitor to be contained in printed wiring board

InactiveUS6876554B1Improve reliabilityFlat surfaceFinal product manufactureSemiconductor/solid-state device detailsEngineeringPrinted circuit board

Chip capacitors 20 are provided in a printed circuit board 10. In this manner, the distance between an IC chip 90 and each chip capacitor 20 is shortened, and the loop inductance is reduced. In addition, the chip capacitors 20 are accommodated in a core substrate 30 having a large thickness. Therefore, the thickness of the printed circuit board does not become large.

Owner:IBIDEN CO LTD

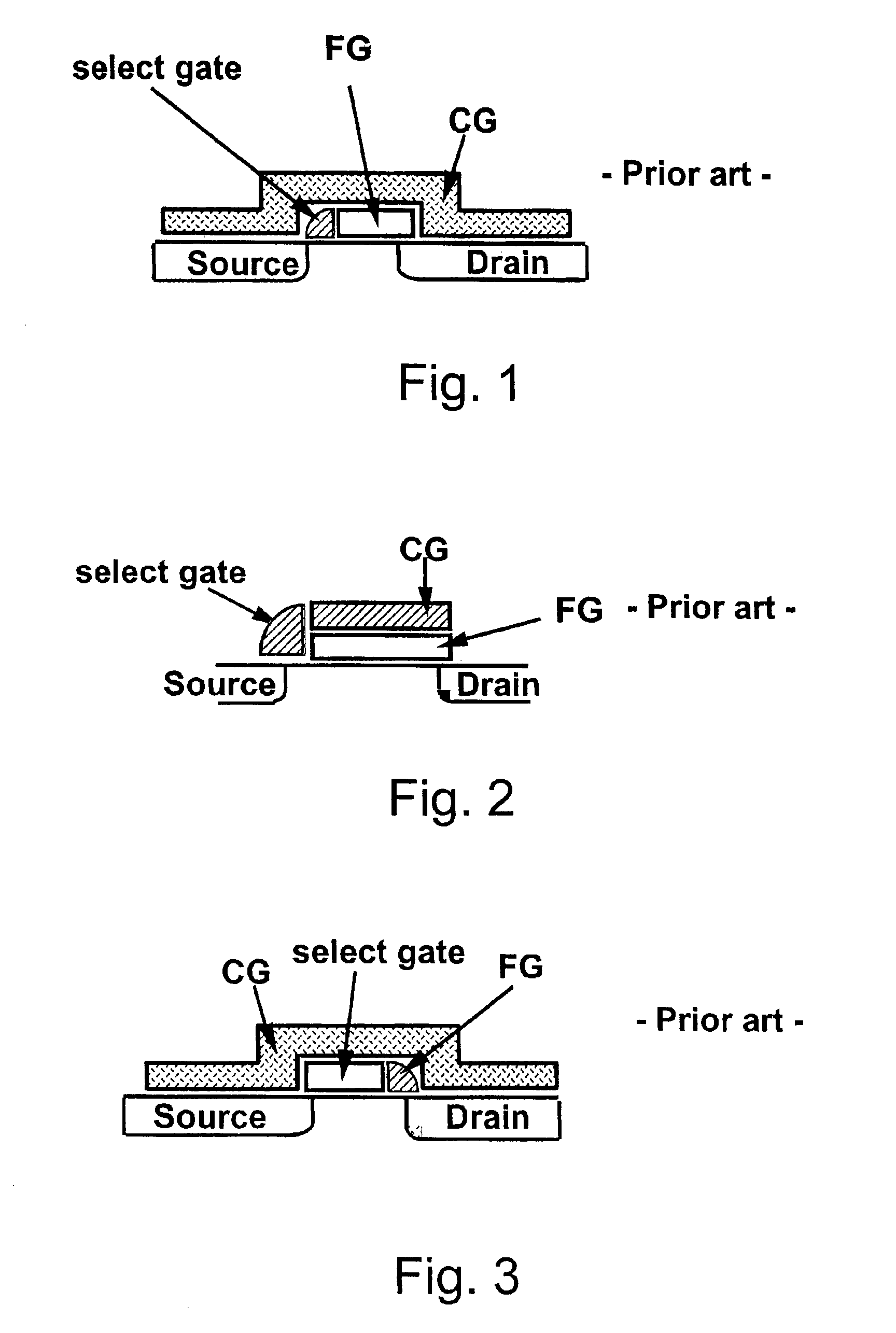

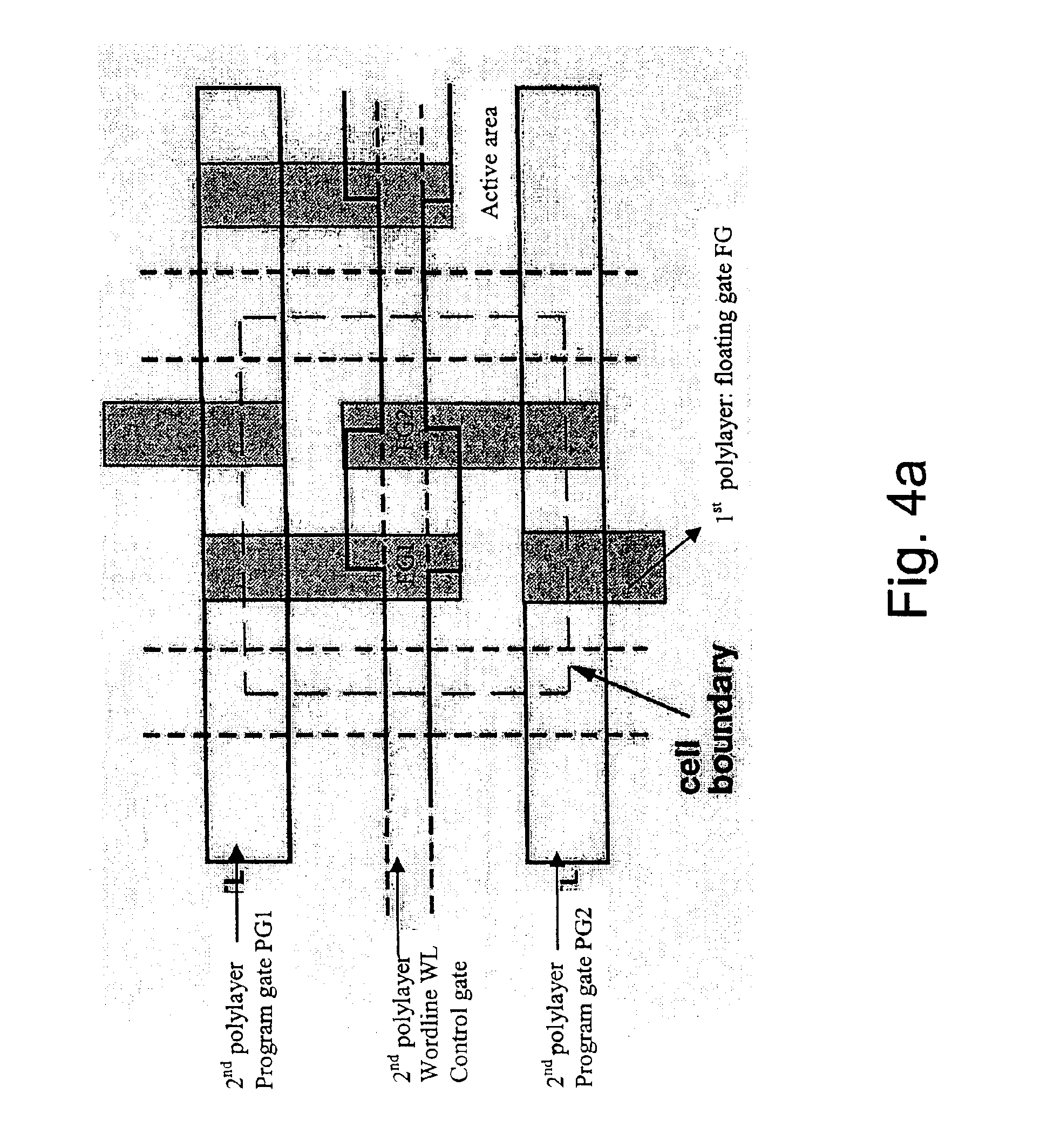

Multibit non-volatile memory and method

A memory is described having a semiconductor substrate of a first conductivity type, a first and a second junction region of a second conductivity type, whereby said first and said second junction region are part of respectively a first and a second bitline. A select gate is provided which is part of a wordline running perpendicular to said first and said second bitline.Read, write and erase functions for each cell make use of only two polysilicon layers which simplifies manufacture and each memory cell has at least two locations for storing a charge representing at least one bit.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

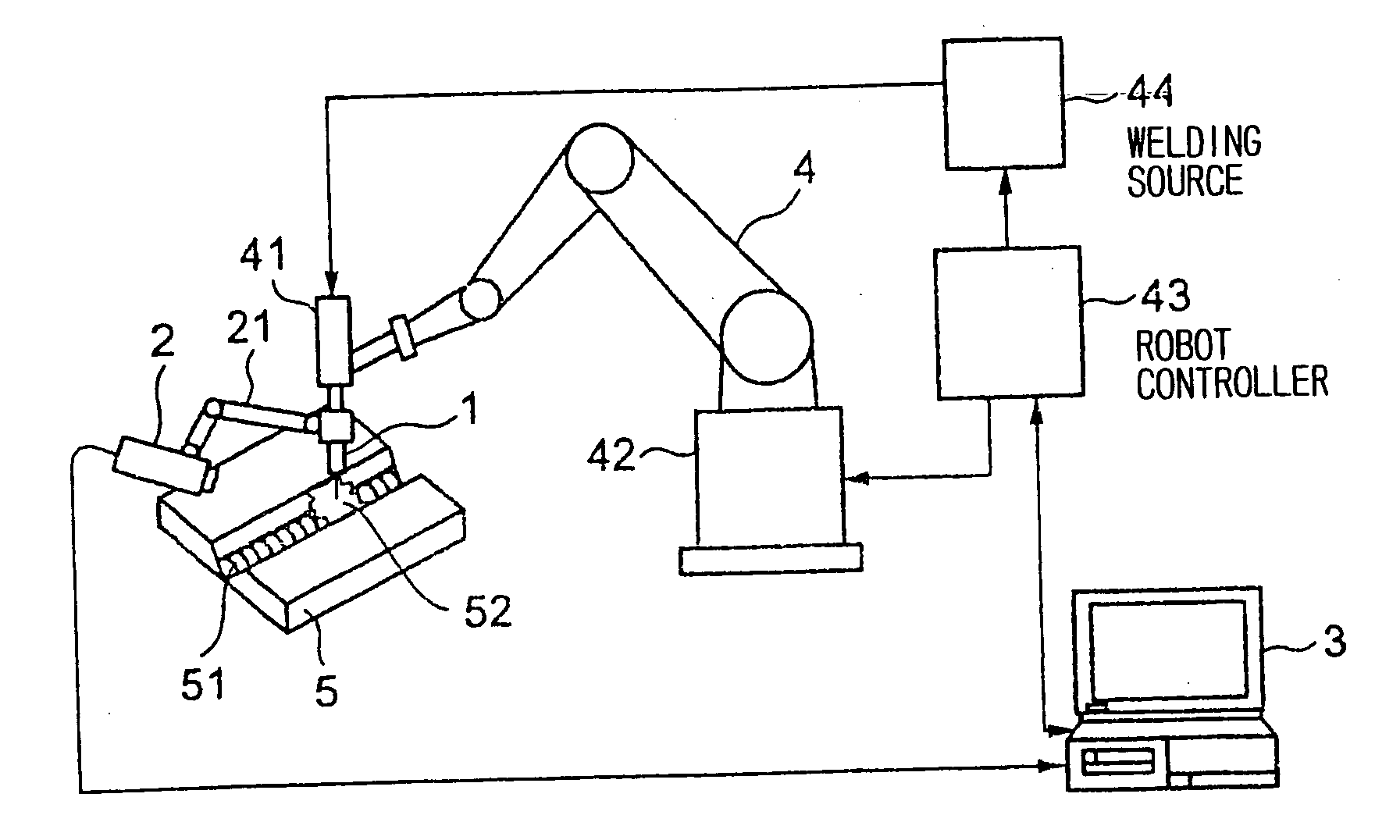

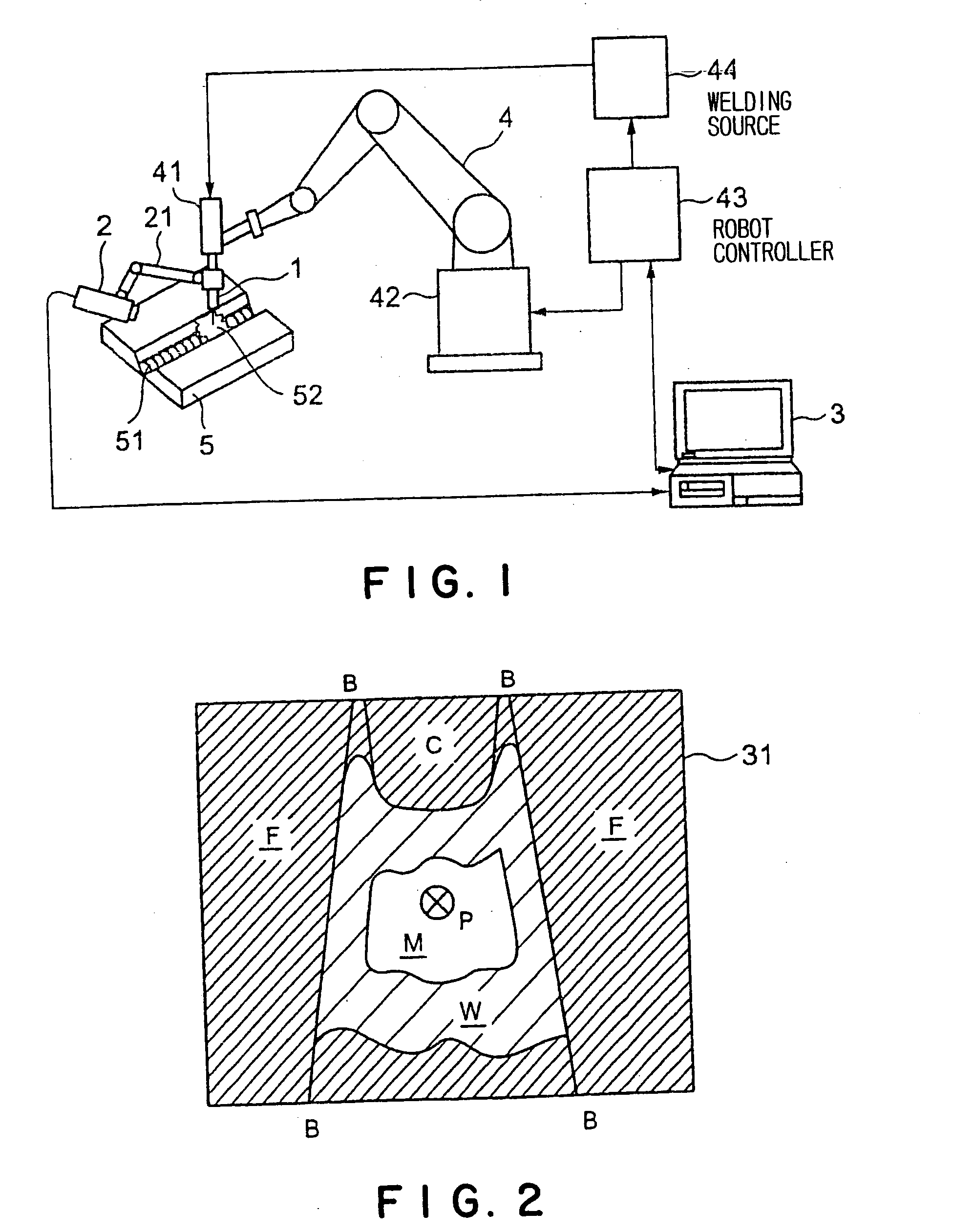

Automatic groove copy welder and welding method

InactiveUS20050103766A1Accurate control operationAccurately carry-outArc welding apparatusEngineeringCcd camera

An automatic groove-tracing welding system is capable of carrying out a welding operation, particularly, a welding operation involving weaving, without requiring monitoring even if conditions of a groove is different from design conditions of the groove. An image processor 3 receives an image signal representing an image of a weld zone 52 including the tip of a welding wire from a camera head 2 provided with a CCD camera, processes the image of the weld zone 52 to determine the position of a groove, calculates the positional relation of the groove with a welding torch 1, and sends a position correction for correcting the position of the welding torch 1 so that the welding path of the tip of the welding torch 1 may coincide with a predetermined middle part in the groove to a robot controller 43 for controlling a welding robot. When the automatic groove-tracing welding system performs a welding operation involving weaving, the image processor 3 receives a weaving phase signal representing phases of weaving from the robot controller 43, calculates the positional relation between the groove and the welding torch on the basis of the phase of weaving, and sends a weaving width correction signal to the robot controller 43.

Owner:KAWASAKI HEAVY IND LTD

Method of growing electrical conductors

InactiveUS6887795B2Quality improvementGood step coverageSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorCompound (substance)

This invention relates to manufacturing of integrated circuits (ICs) and especially conductive layers suitable for use in an IC. According to the preferred method a metal oxide thin film is deposited on a substrate surface and reduced thereafter essentially into a metallic form with an organic reducing agent. The metal oxide is preferably deposited according to the principles of atomic layer deposition (ALD) using a metal source chemical and an oxygen source chemical. The reduction step is preferably carried out in an ALD reactor using one or more vaporized organic compounds that contain at least one functional group selected from the group consisting of —OH, —CHO and —COOH.

Owner:COLOR ACCESS +1

Method of growing electrical conductors

ActiveUS7067407B2Quality improvementGood step coverageSemiconductor/solid-state device manufacturingCapacitorsElectrical conductorAtomic layer deposition

Owner:ASM INTERNATIONAL

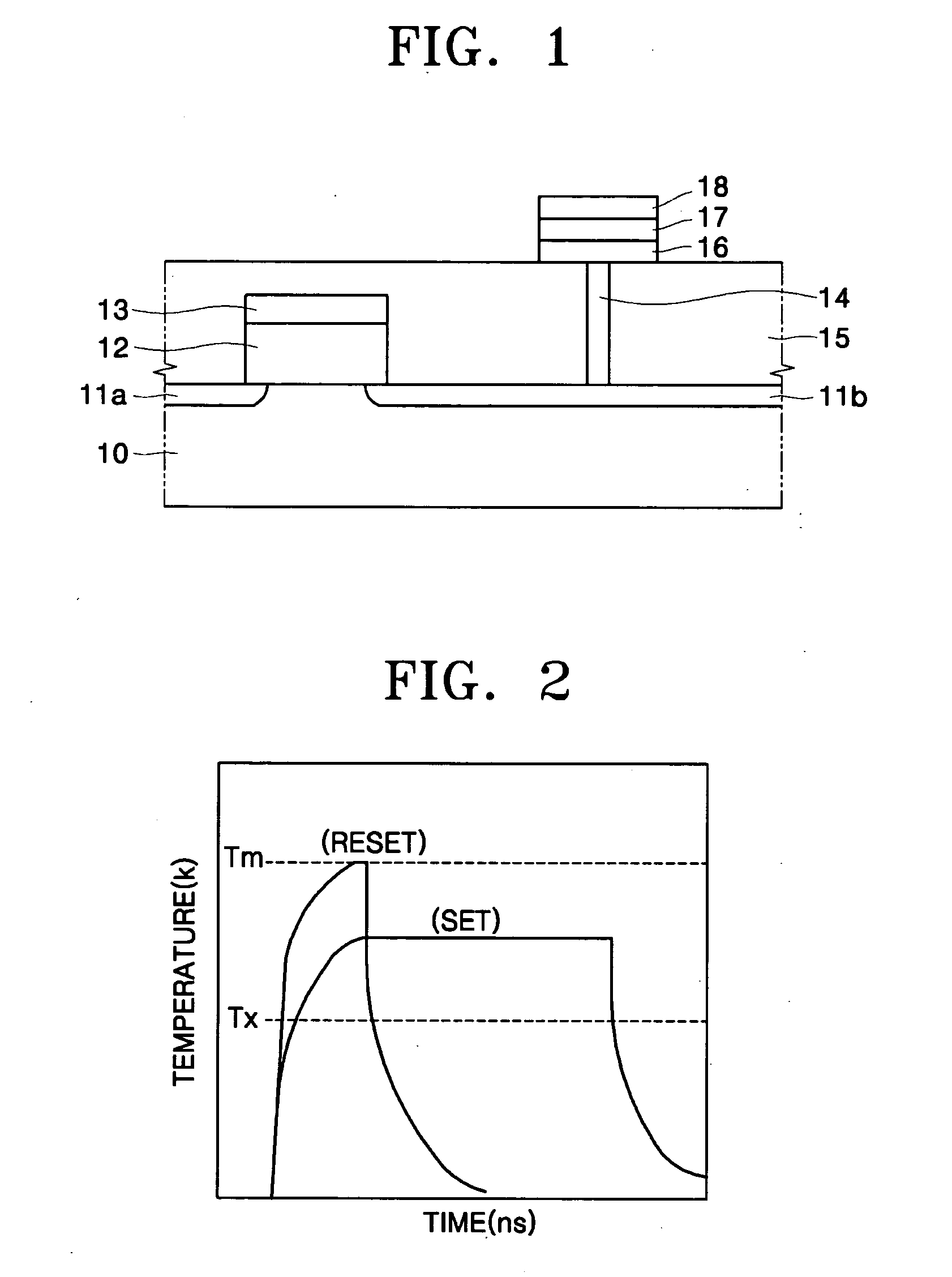

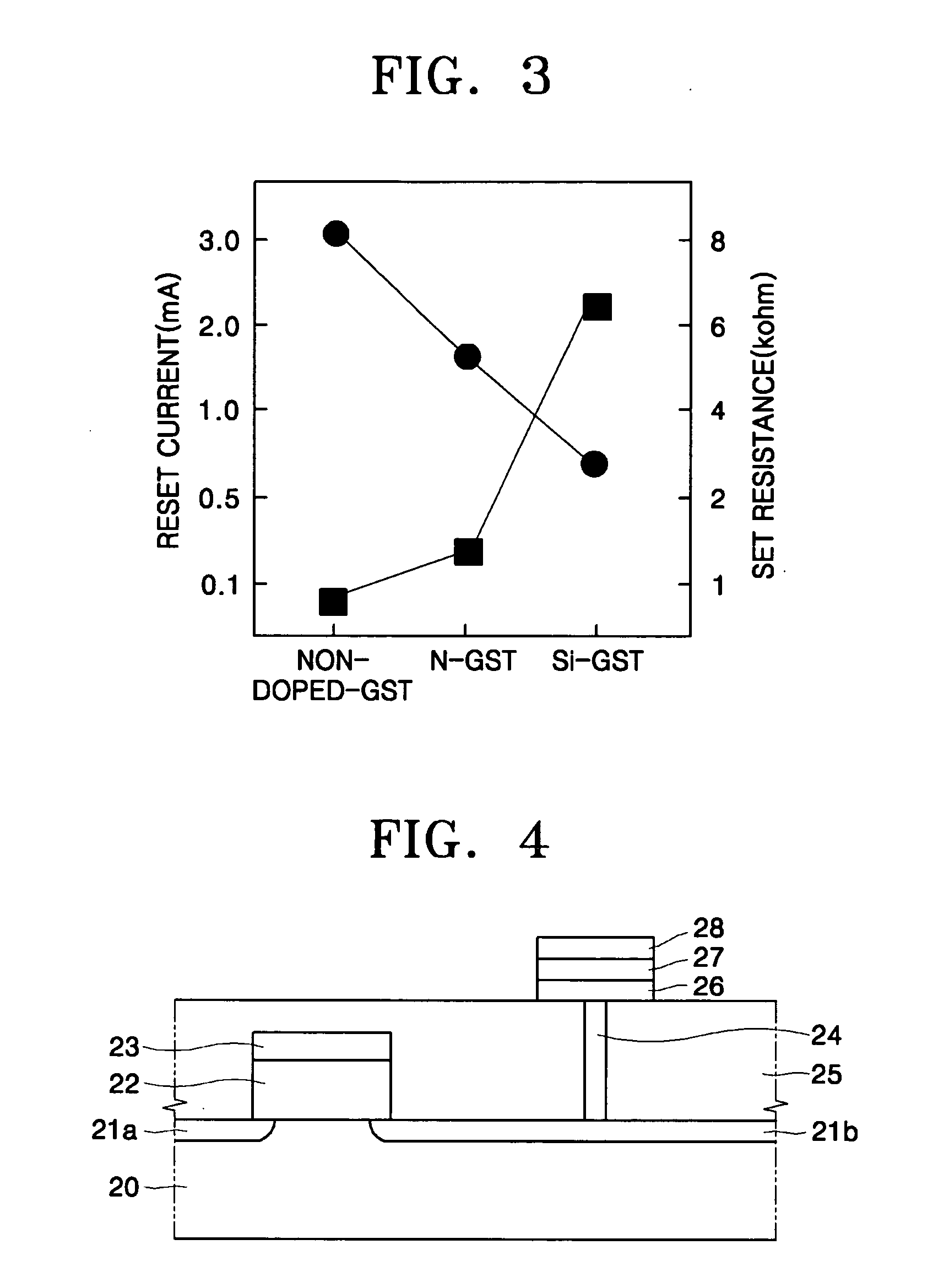

Ge precursor, GST thin layer formed using the same, phase-change memory device including the GST thin layer, and method of manufacturing the GST thin layer

ActiveUS20060138393A1Uniform thicknessImproved performance characteristicsSolid-state devicesGermanium organic compoundsLow temperature depositionPhase-change memory

Provided are a Ge precursor for low temperature deposition containing Ge, N, and Si, a GST thin layer doped with N and Si formed using the same, a memory device including the GST thin layer doped with N and Si, and a method of manufacturing the GST thin layer. The Ge precursor for low temperature deposition contains N and Si such that the temperature at which the Ge precursor is deposited to form a thin layer, particularly, the GST thin layer doped with N and Si, can be low. In addition, during the low temperature deposition, H2 plasma can be used. The GST phase-change layer doped with N and Si formed from the Ge precursor for low temperature deposition has a low reset current. Therefore, a memory device including the GST phase-change layer doped with N and Si can be highly integrated, have a high capacity, and can be operated at a high speed.

Owner:SAMSUNG ELECTRONICS CO LTD

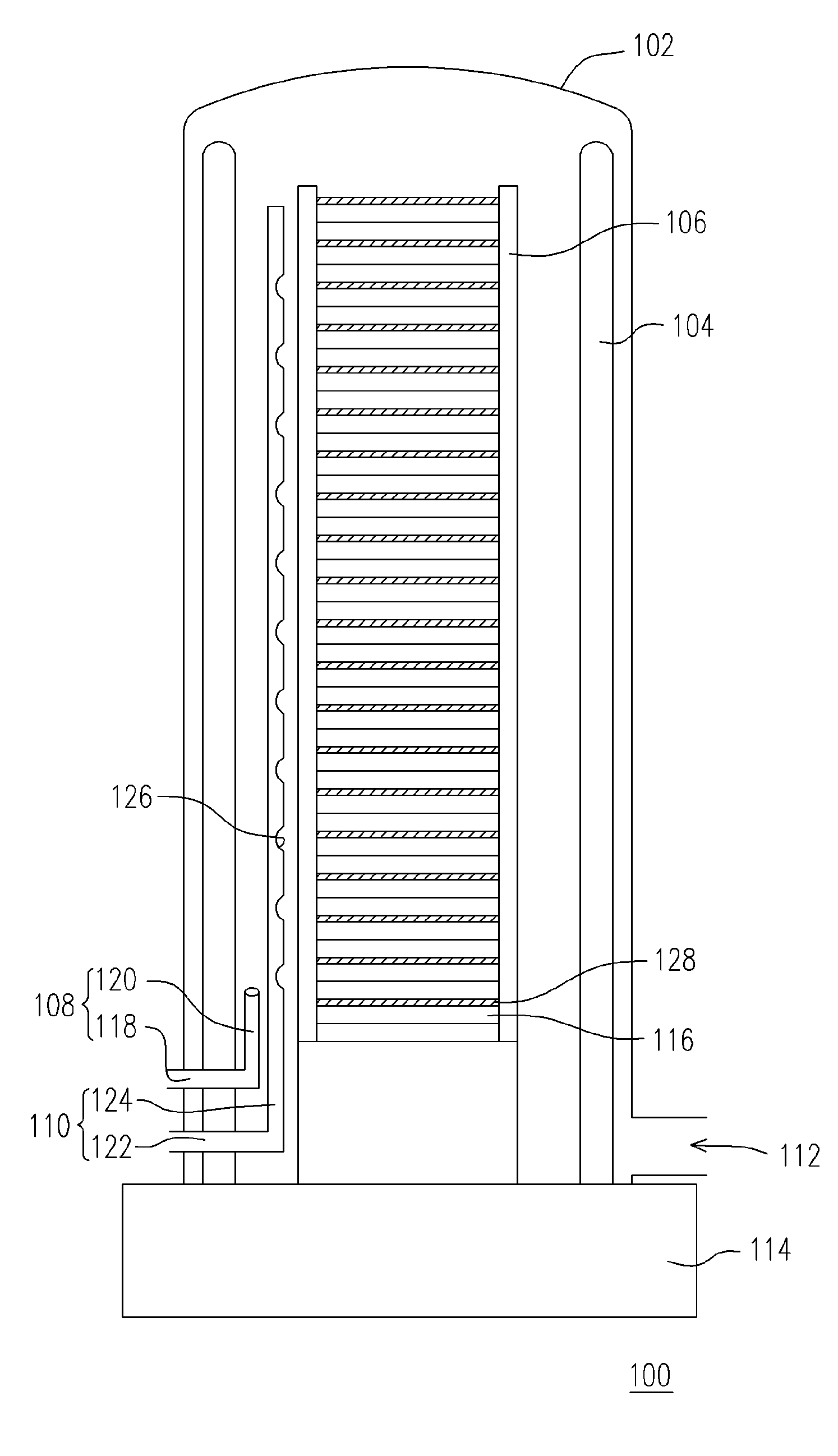

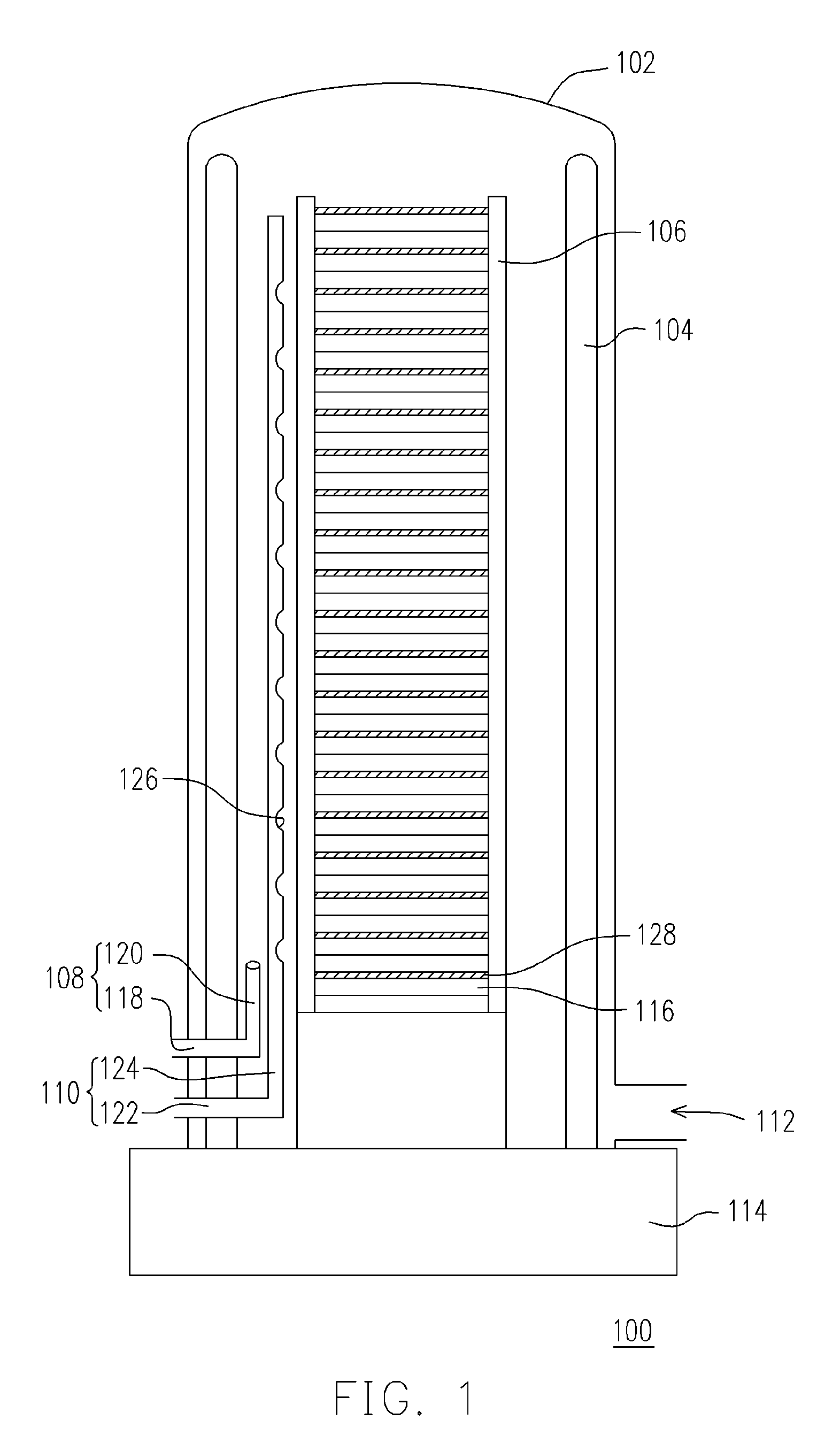

Method of forming a silicon nitride layer

ActiveUS7229502B2Uniform thicknessReduce internal stressVacuum evaporation coatingSputtering coatingNitrogenEngineering

A method of forming a silicon nitride layer is provided. A deposition furnace having an outer tube, a wafer boat, a gas injector and a uniform gas injection apparatus is provided. The wafer boat is positioned within the outer tube for carrying a plurality of wafers. The gas injector is positioned between the outer tube and the wafer boat. Similarly, the uniform gas injection apparatus is positioned between the outer tube and the wafer boat. Gas injected into the uniform gas injection apparatus is uniformly distributed throughout the entire deposition furnace. To form a silicon nitride layer on each wafer, a silicon-containing gas is passed into the deposition furnace via the gas injector and a nitrogen-mixed carrier gas is passed into the deposition furnace via the uniform gas injection apparatus.

Owner:MACRONIX INT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com