Patents

Literature

2682 results about "Welding torch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for fabricating or repairing a part

InactiveUS7020539B1Improve accuracyHigh geometric accuracyAdditive manufacturing apparatusTool changing apparatusMulti axisMachining

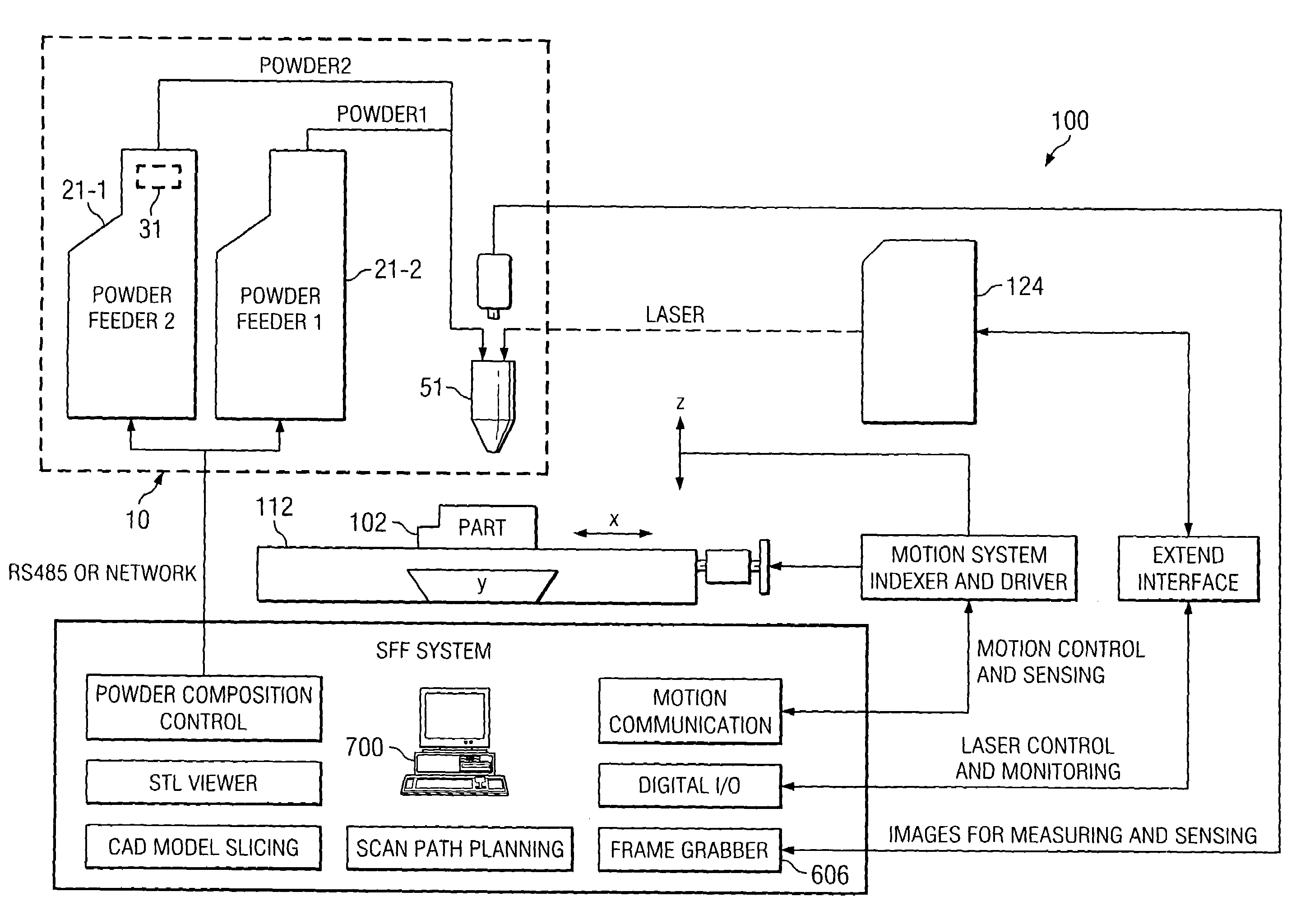

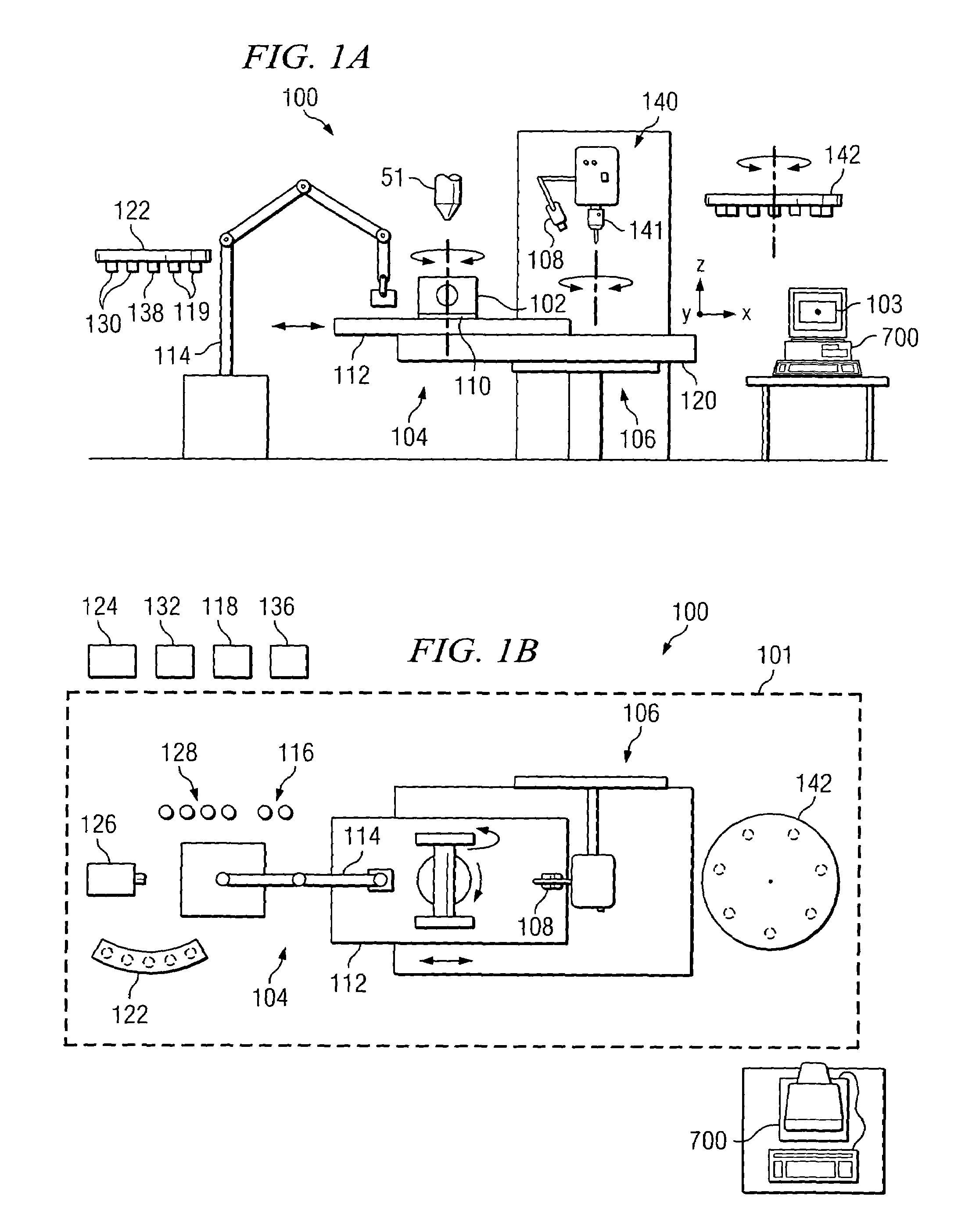

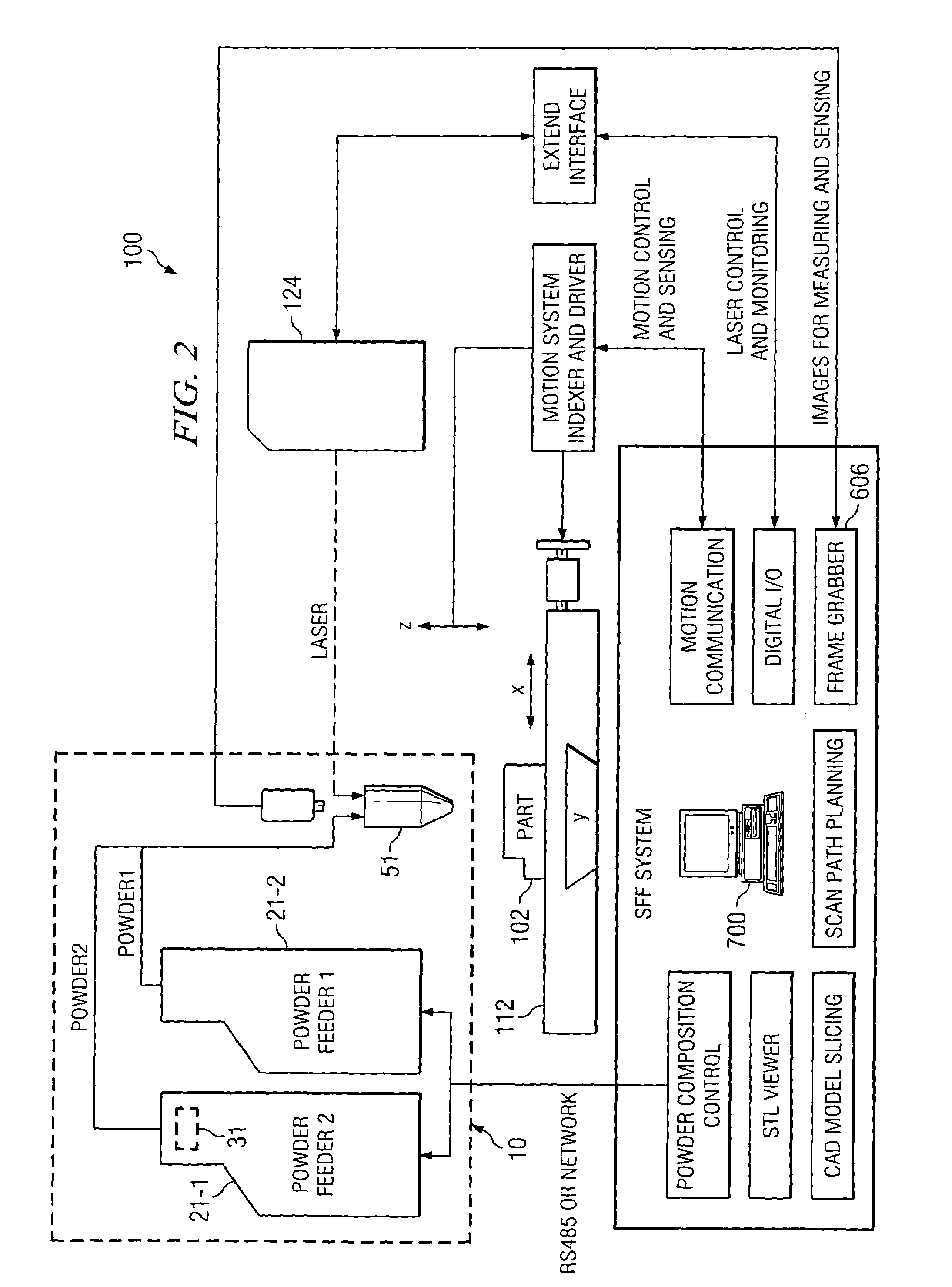

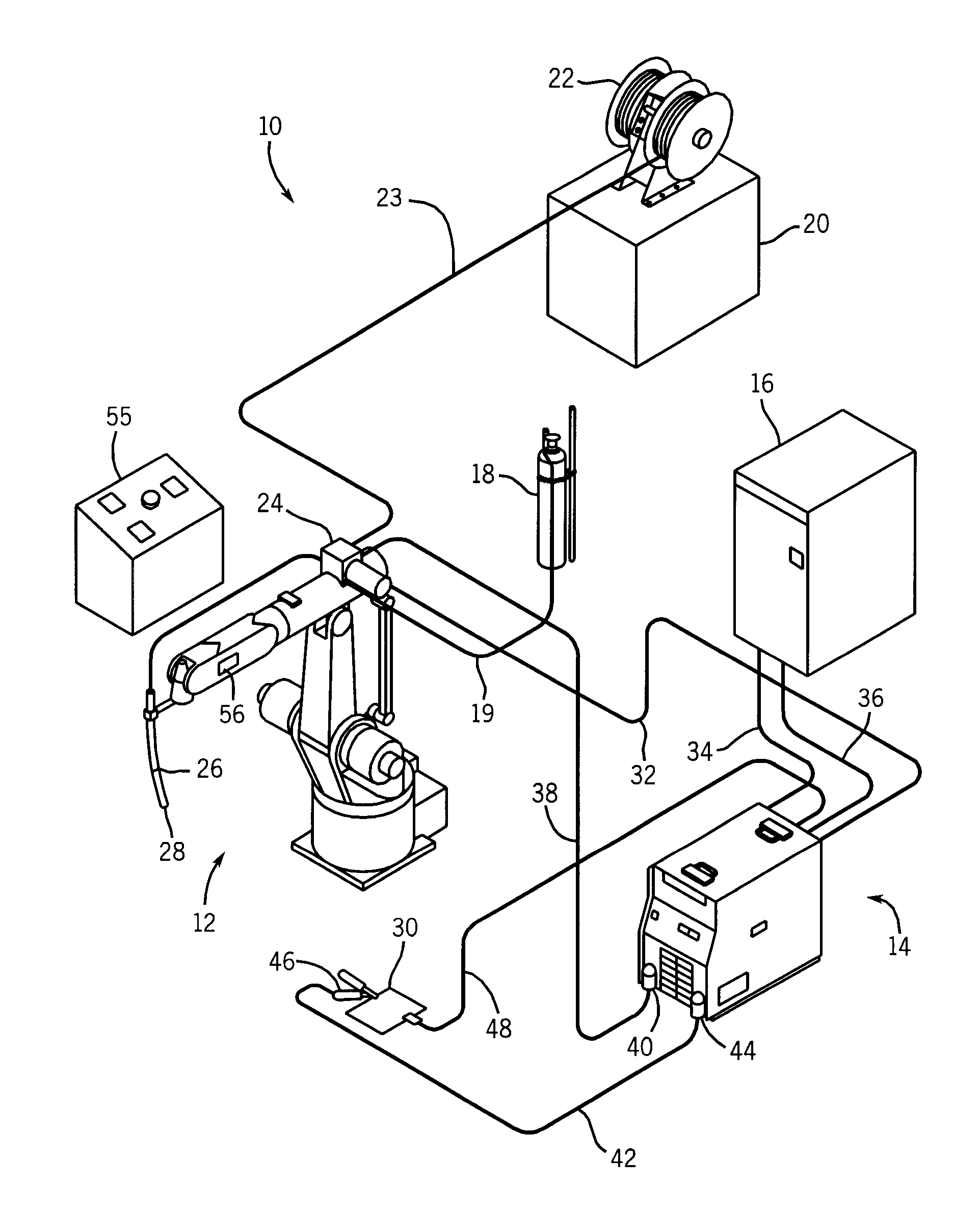

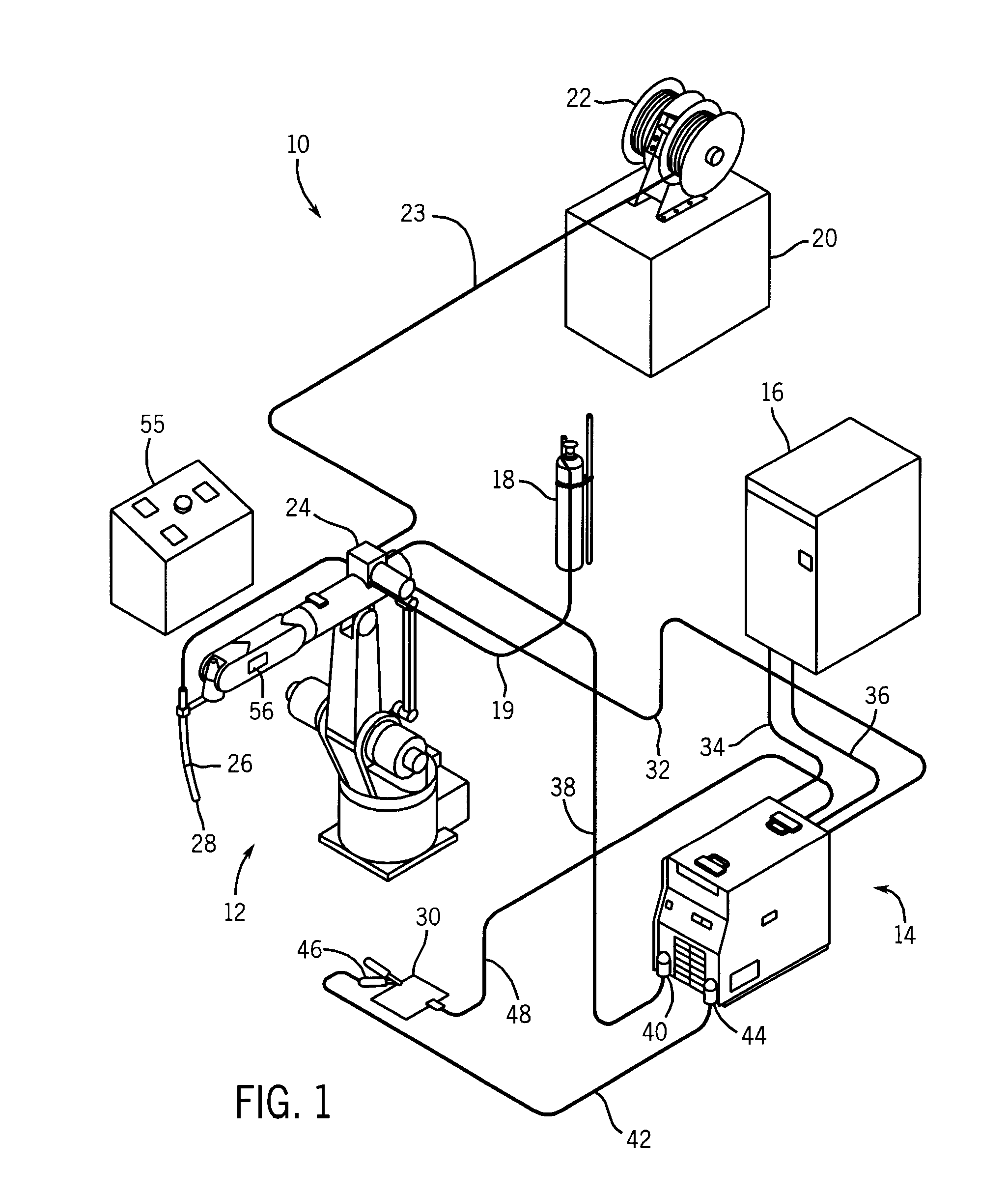

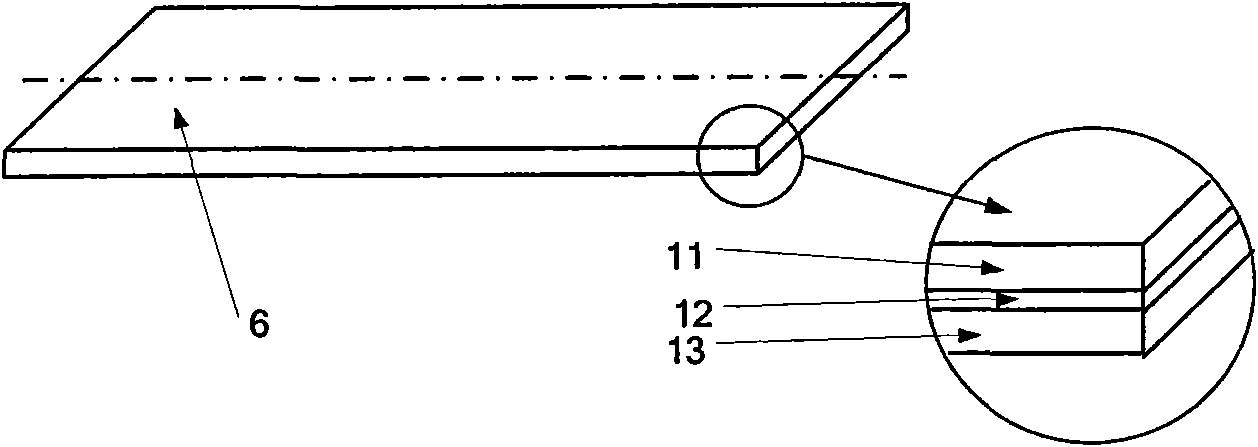

According to one embodiment of the invention, a system for fabricating a part includes a computer operable to control the fabrication of a three-dimensional part using a solid CAD model, a deposition station operable to deposit successive two-dimensional layers of material to fabricate the three-dimensional part, and a machining station operable to remove at least a portion of one or more of the deposited two-dimensional layers of material. The deposition station includes a substrate on which to fabricate the three-dimensional part, a welding-based deposition system having a welding torch, a laser-based deposition system having a laser head, a plasma powder cladding system having a plasma torch, and a multi-axis robot operable to, when directed by the computer, utilize one of the welding-based deposition system, laser-based deposition system, and plasma powder cladding system to deposit any of the two-dimensional layers of material. The machining station includes a multi-axis milling machine and an automatic tool changer. The milling machine is operable to, when directed by the computer, select from a plurality of machining tools associated with the automatic tool changer for use in the milling machine.

Owner:SOUTHERN METHODIST UNIVERSITY

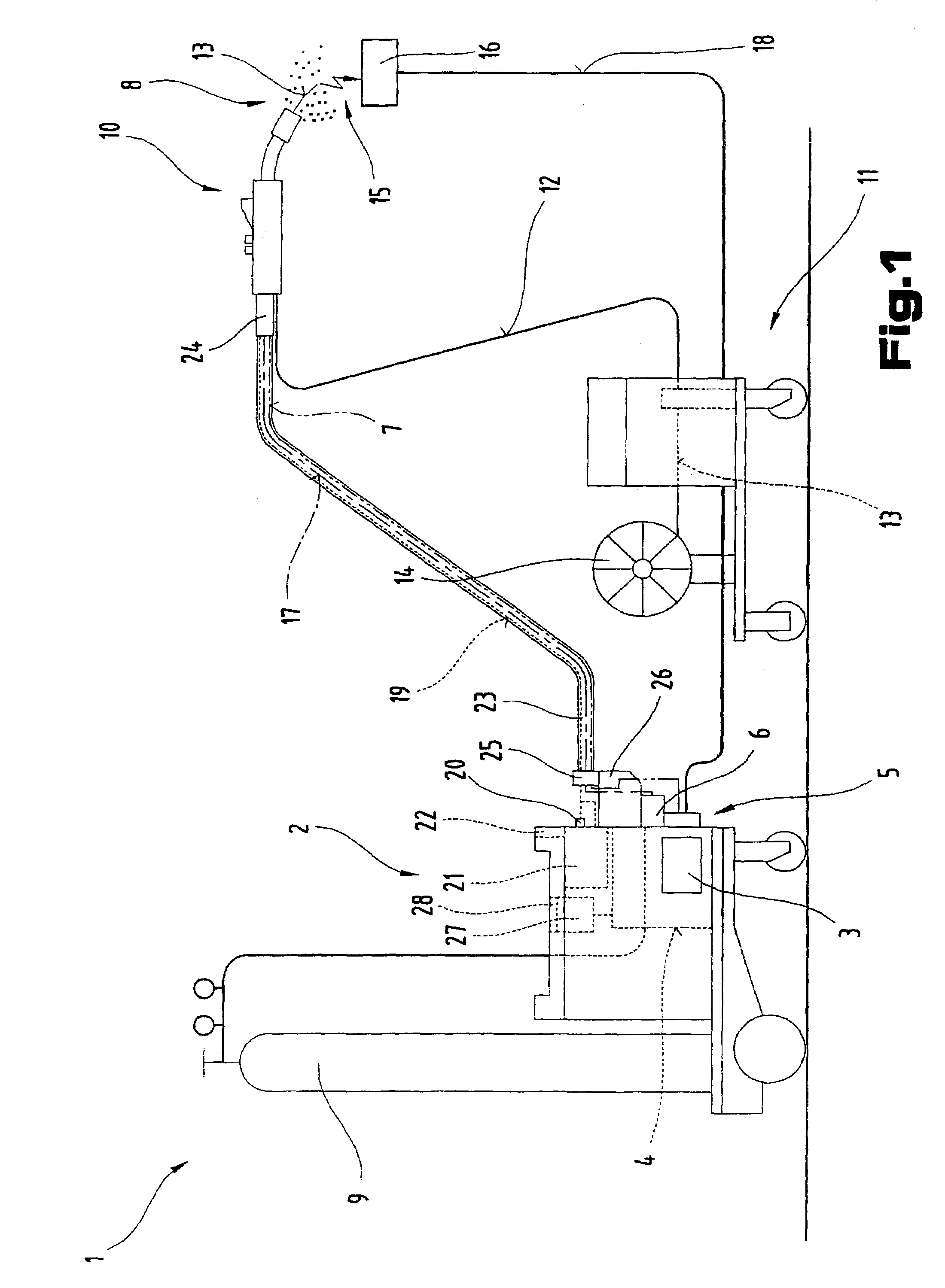

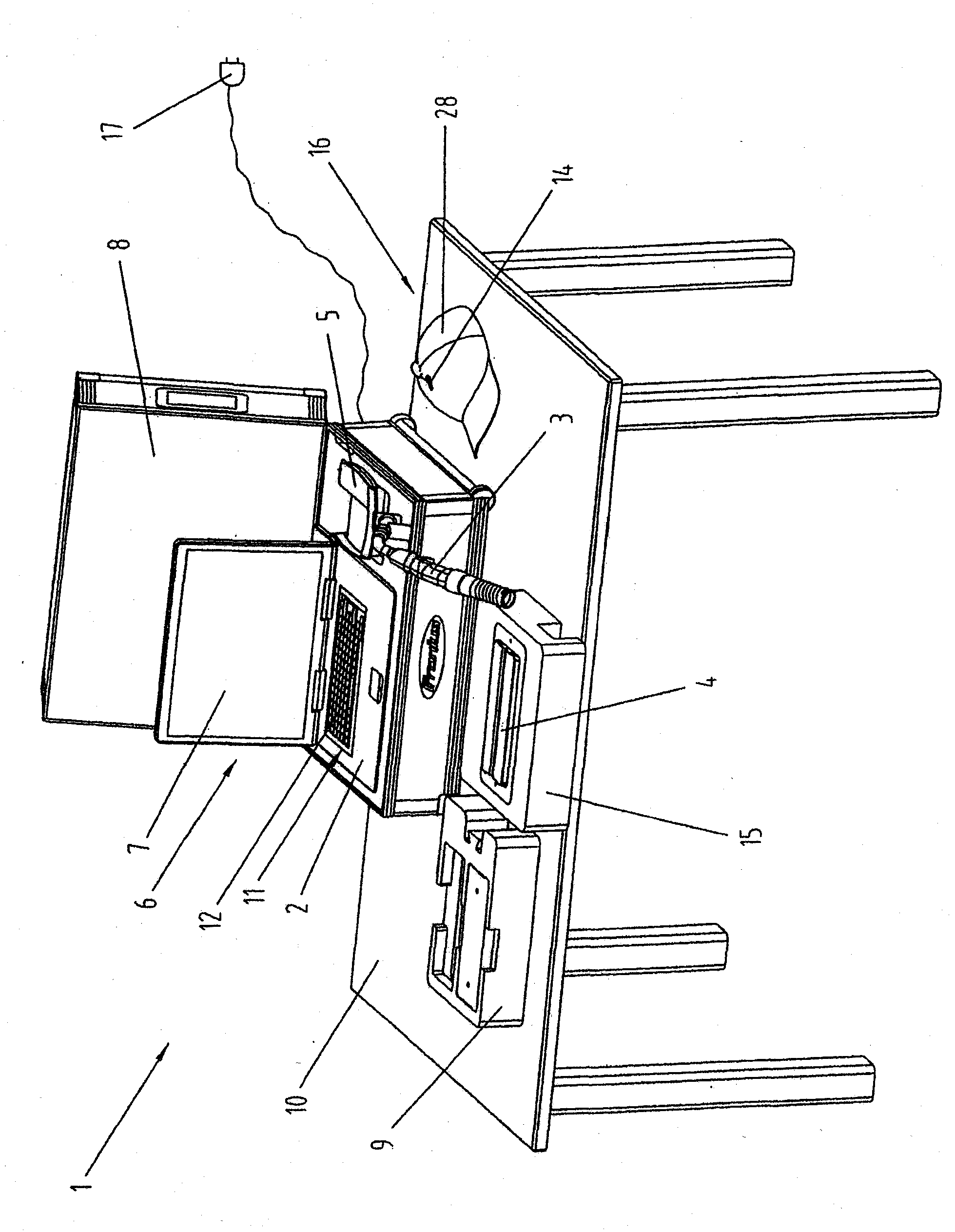

Assessing and/or determining of user authorizations using a transponder, a finger print recognition routine or the like

InactiveUS7523069B1Easy to carryUser identity/authority verificationUnauthorized memory use protectionControl systemEngineering

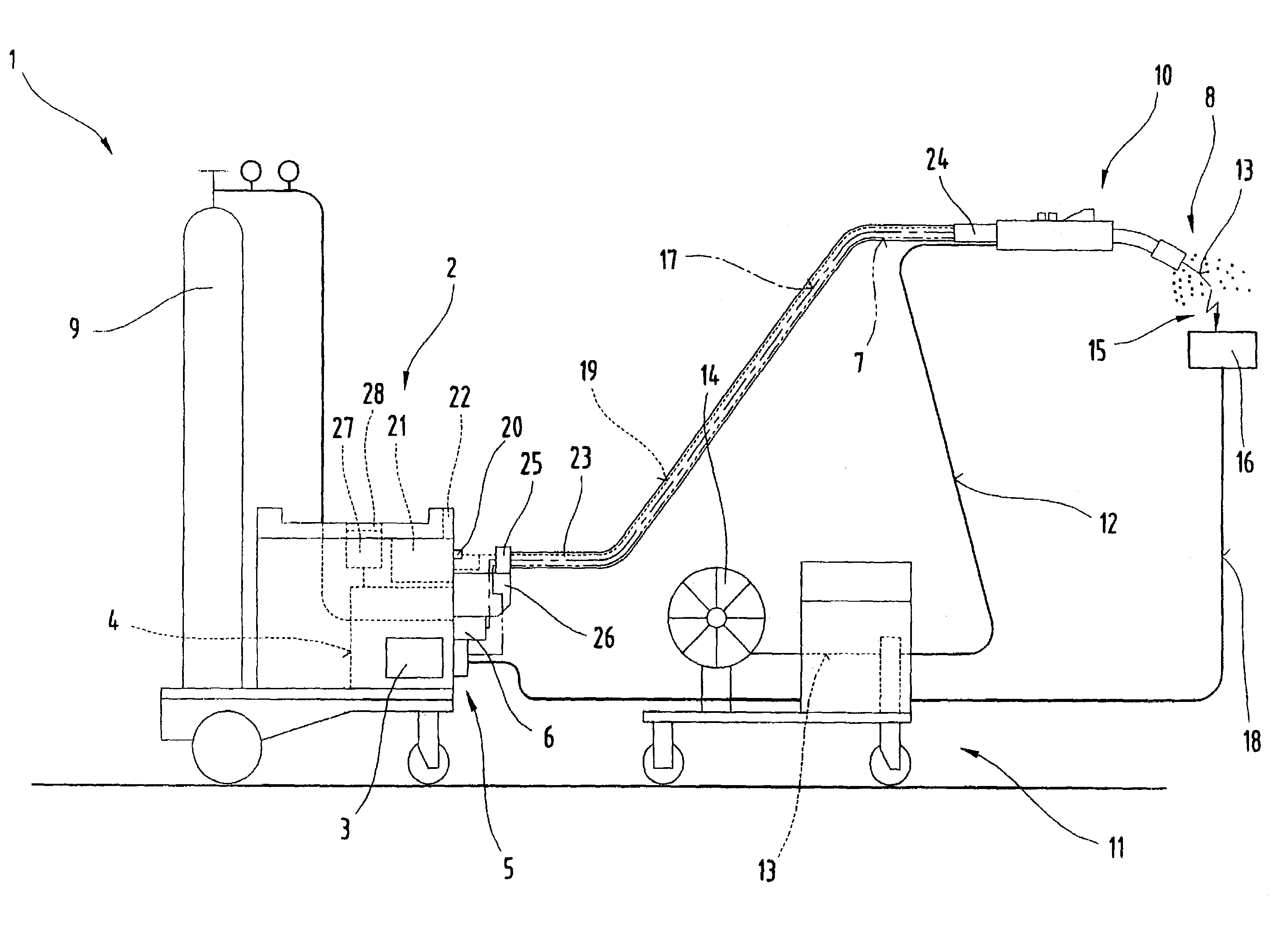

The invention describes a welding device (1) or a current source (2), with a control system (4), preferably comprising a microprocessor controller with a memory unit, a power component (3), in particular a current-inverting source, and additional components such as a welding torch (10), a wire feed device (11), etc., which are connected to the welding device (1) or the current source (2) via appropriate interfaces. An add-on module (27) is connected to the control system (4) or to the current source (2) for identifying a person by means of biometric physical characteristics such as an electronic fingerprint, voice recognition, iris recognition, recognition of a facial shape, recognition of writing, etc. or alternatively a transponder code via a transponder system.

Owner:FRONIUS INTERNATIONAL GMBH

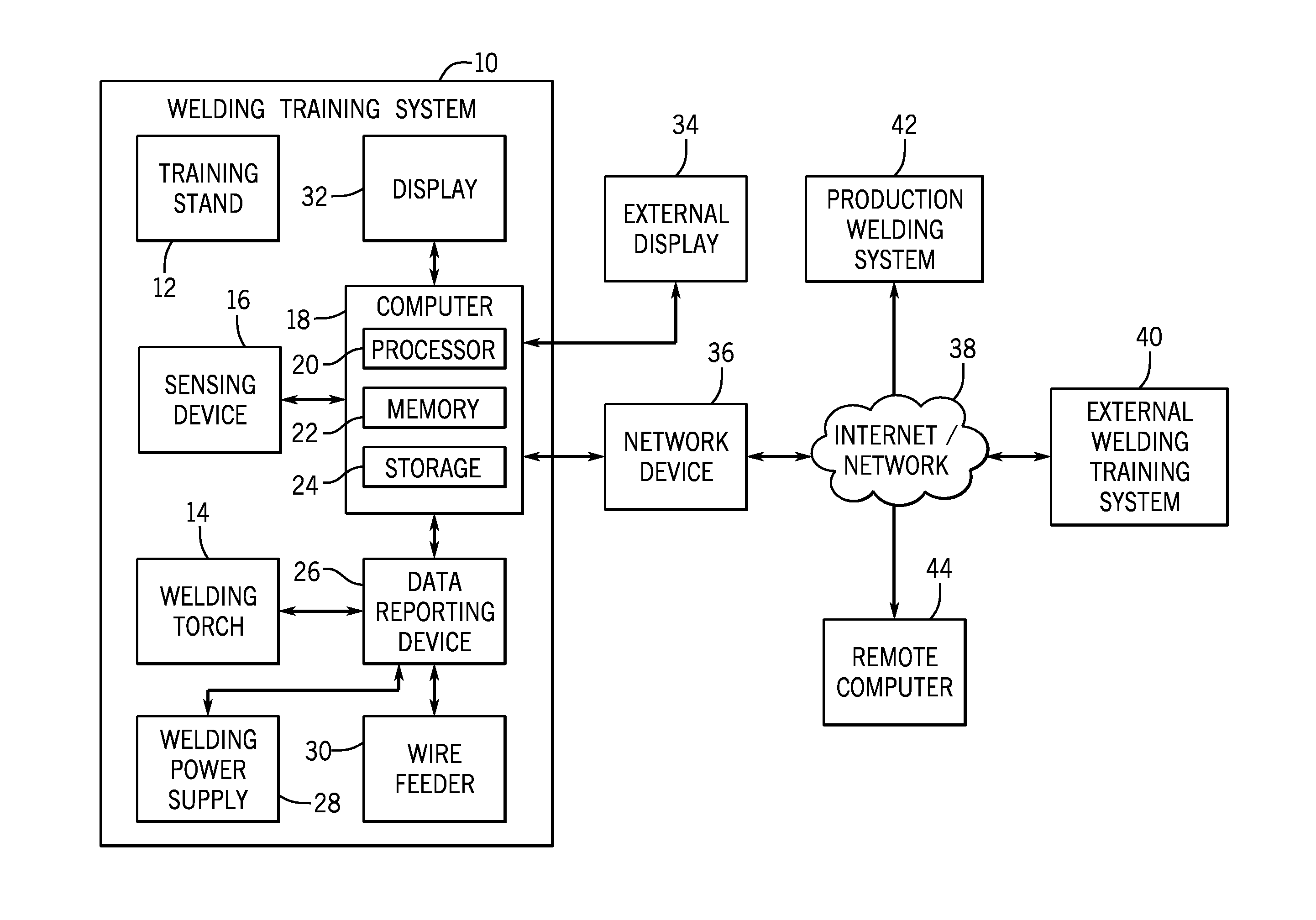

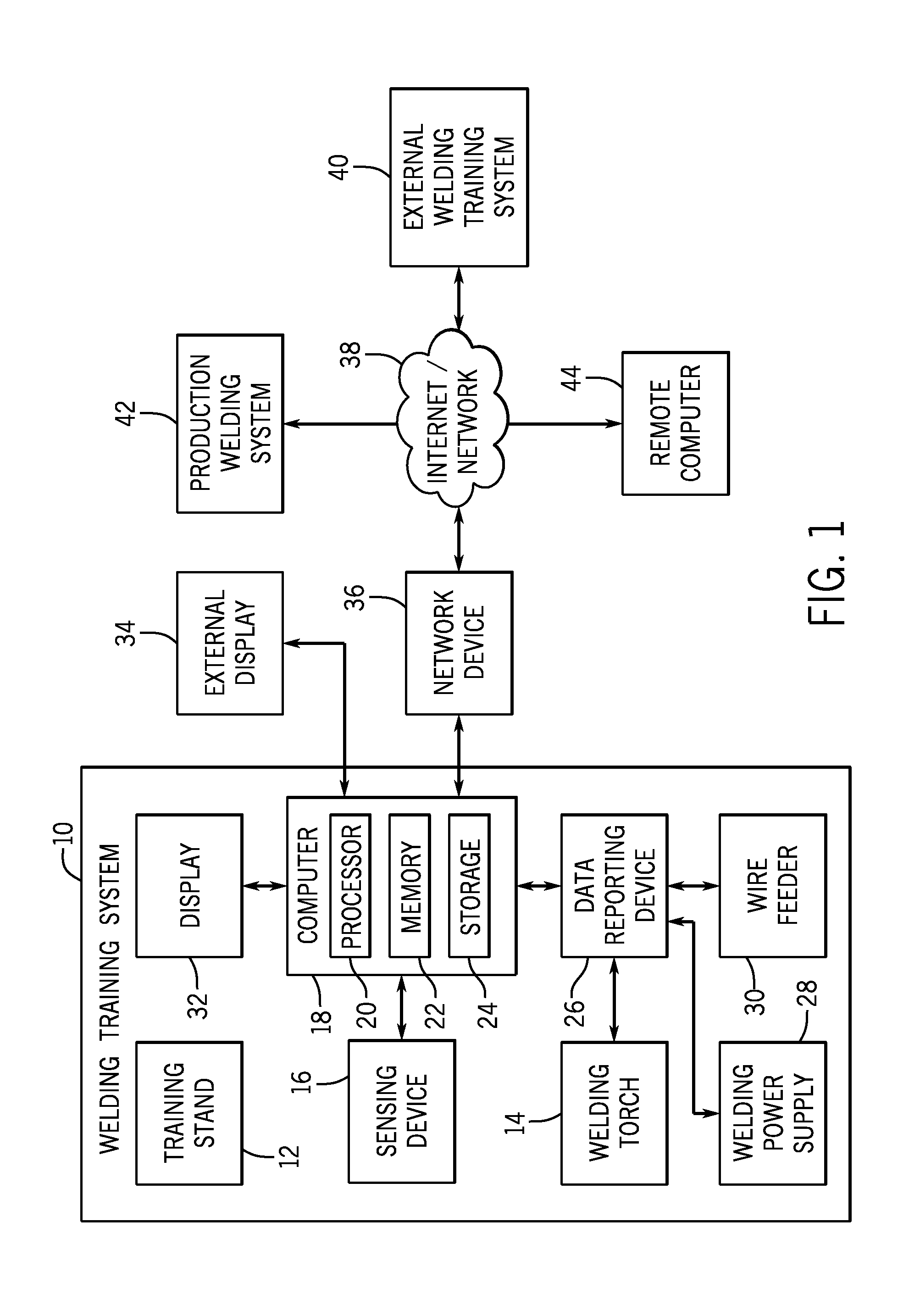

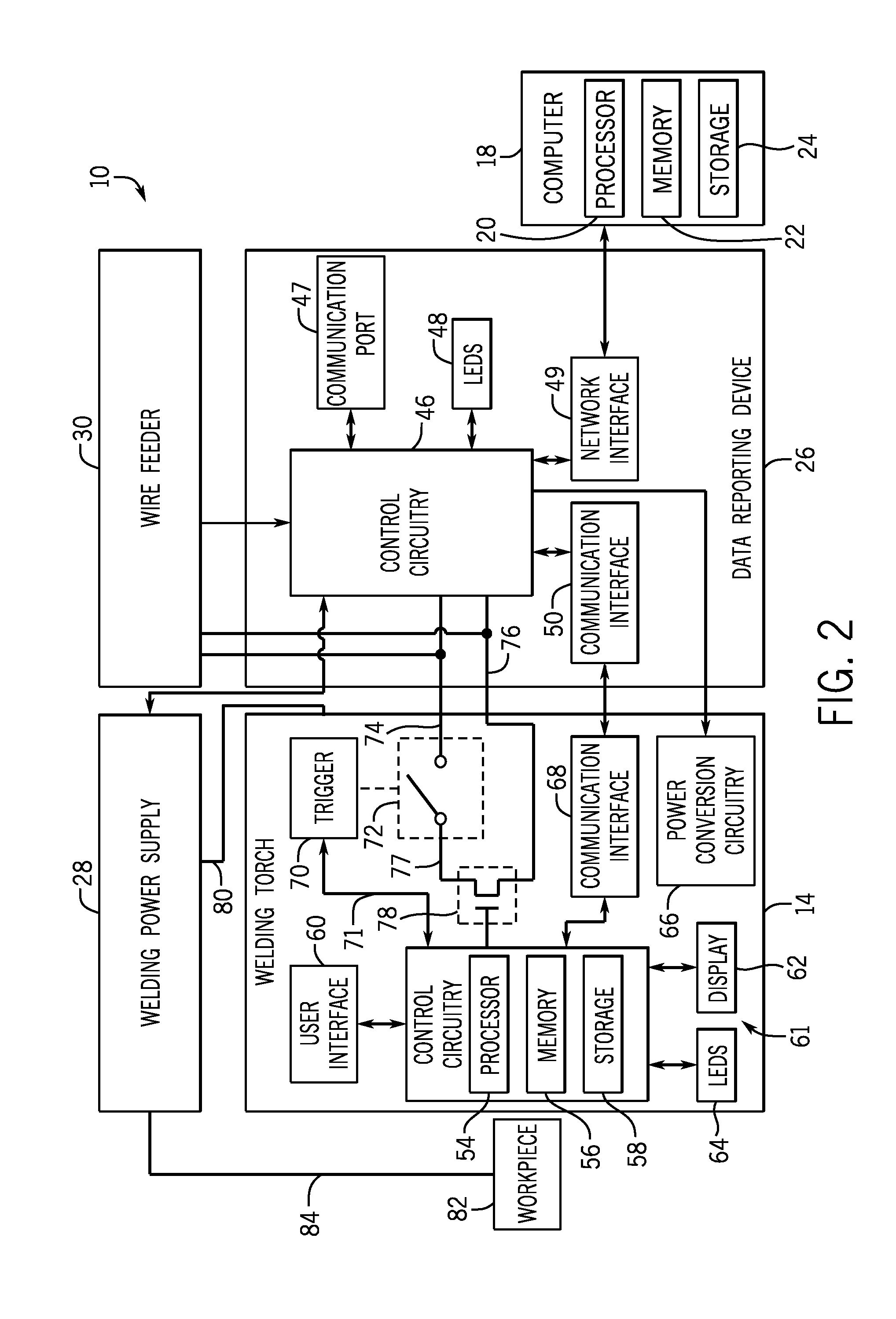

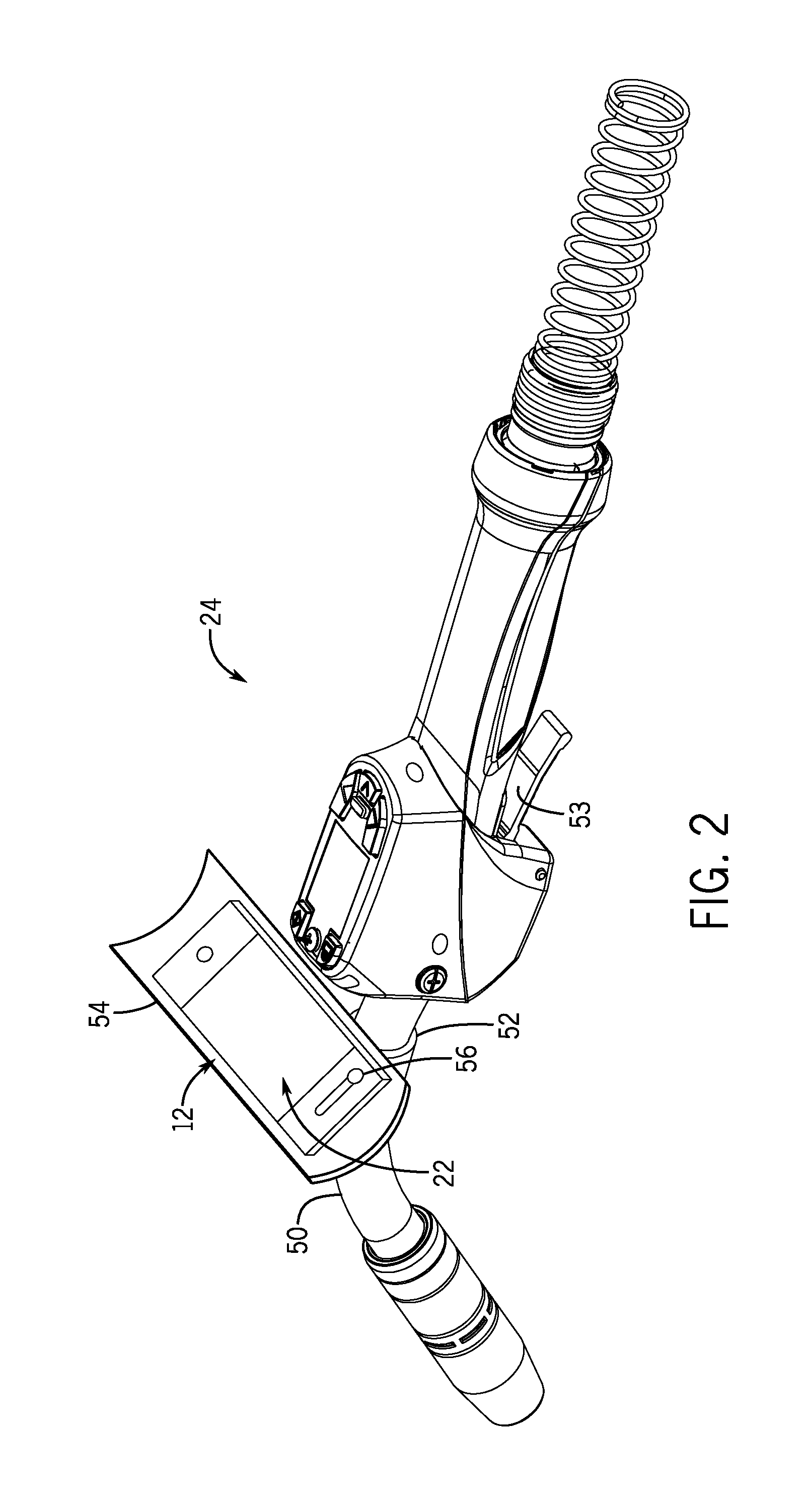

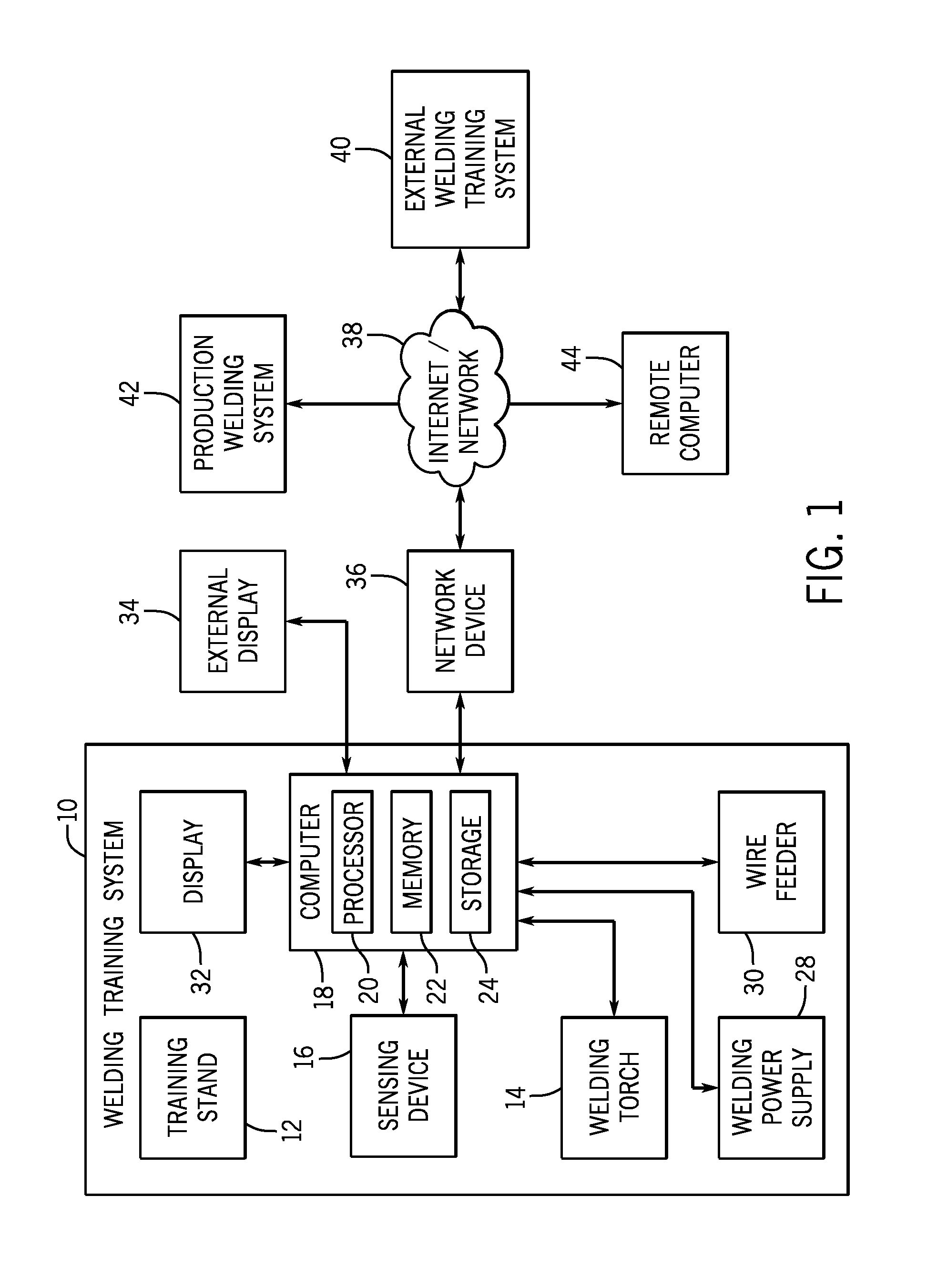

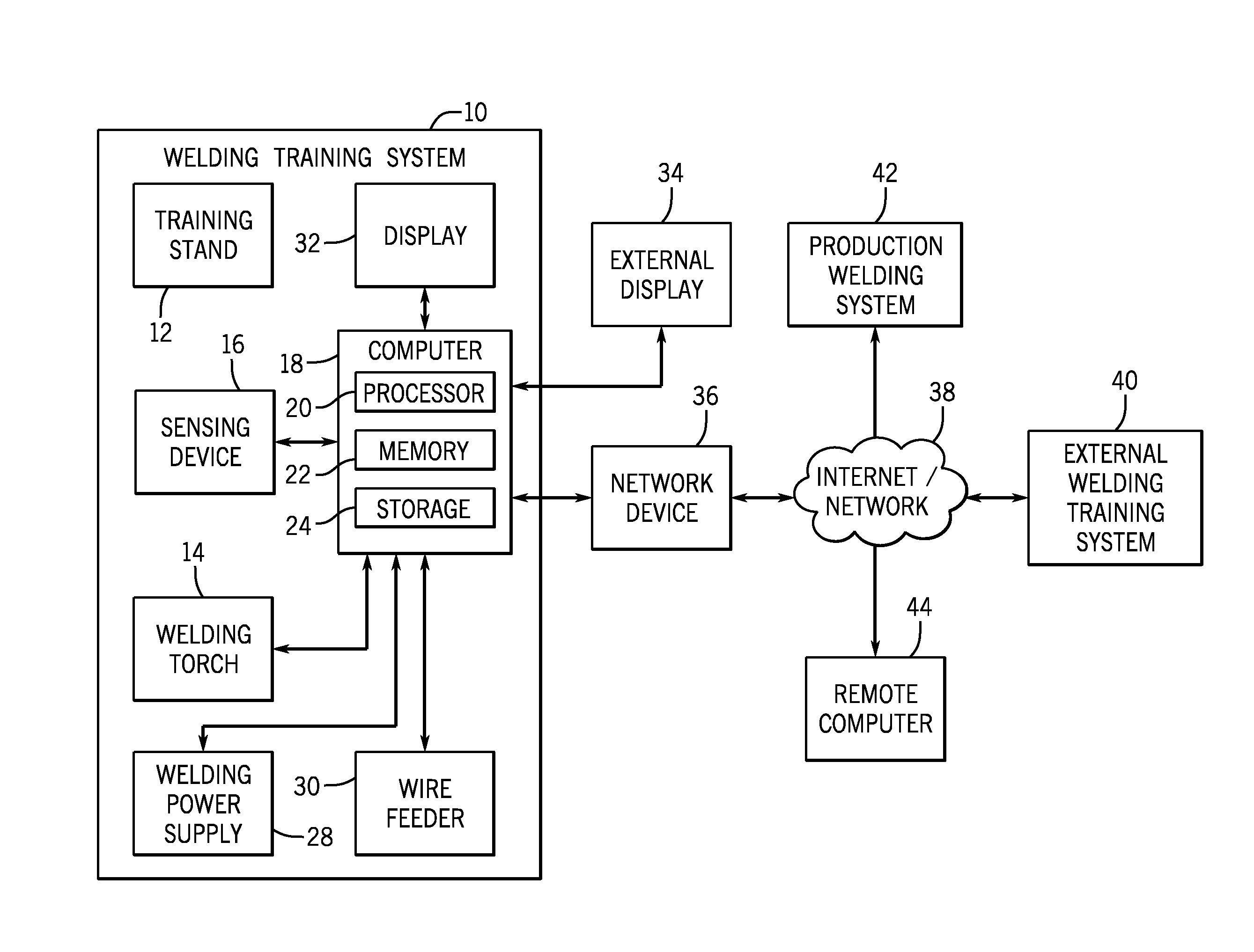

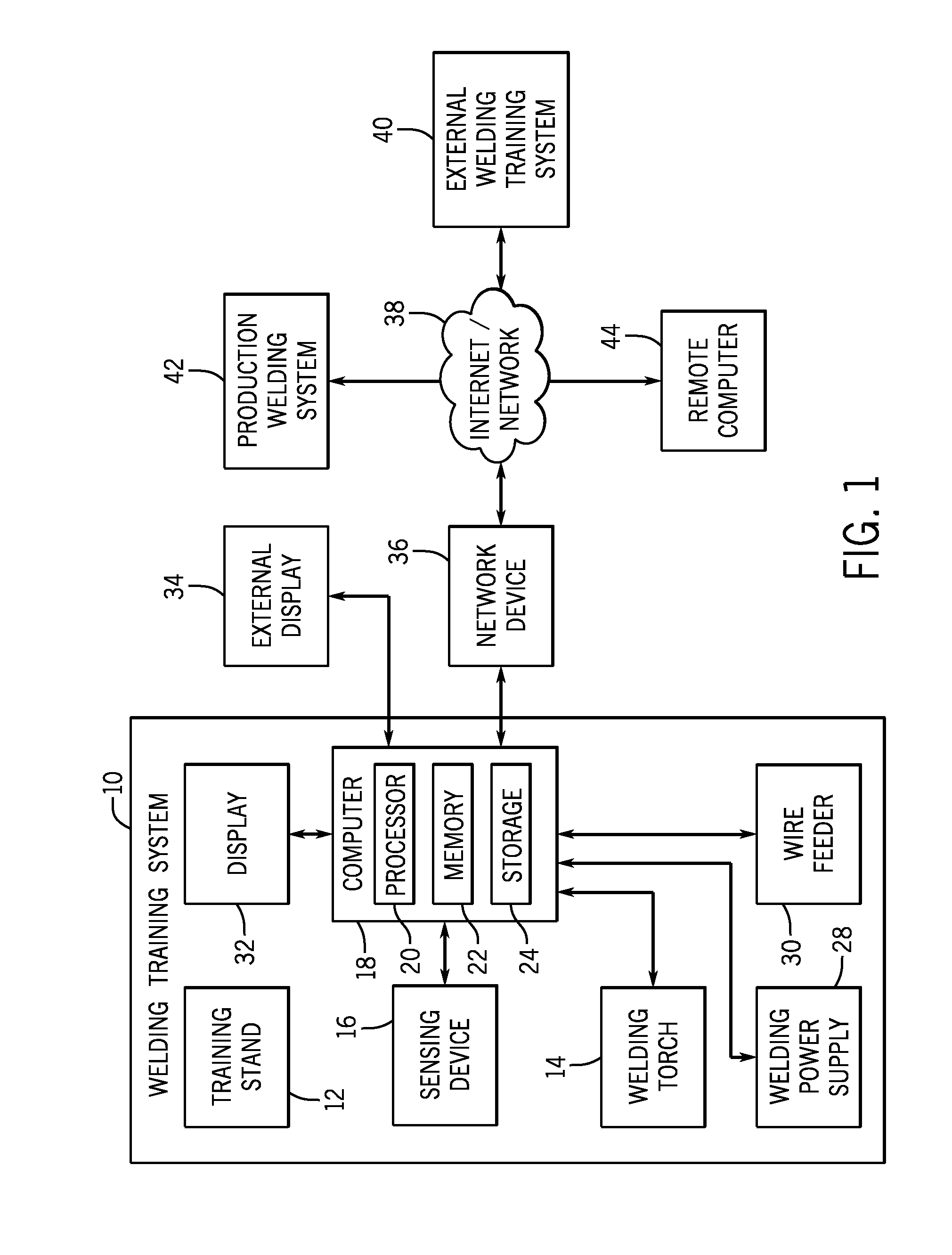

Welding training systems and devices

A welding tool includes a first handle and a second handle. The welding tool also includes a torch nozzle holder configured to hold a nozzle of a welding torch therein, and to block the nozzle from extending therethrough. The welding tool includes a blade assembly positioned a predetermined distance from the torch nozzle holder. The blade assembly is configured to cut welding wire extending through the blade assembly to calibrate wire stickout from the welding torch to the predetermined distance.

Owner:ILLINOIS TOOL WORKS INC

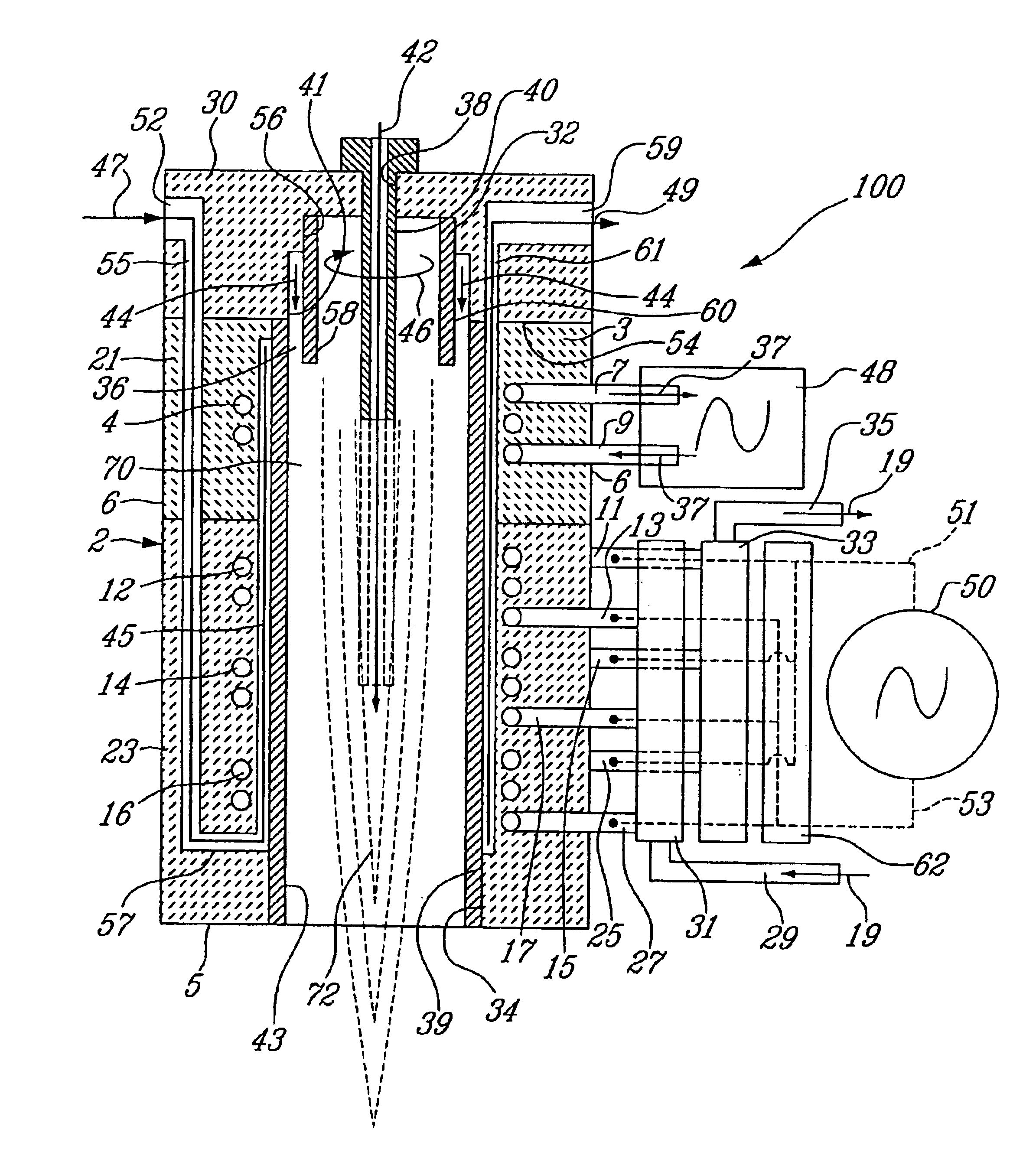

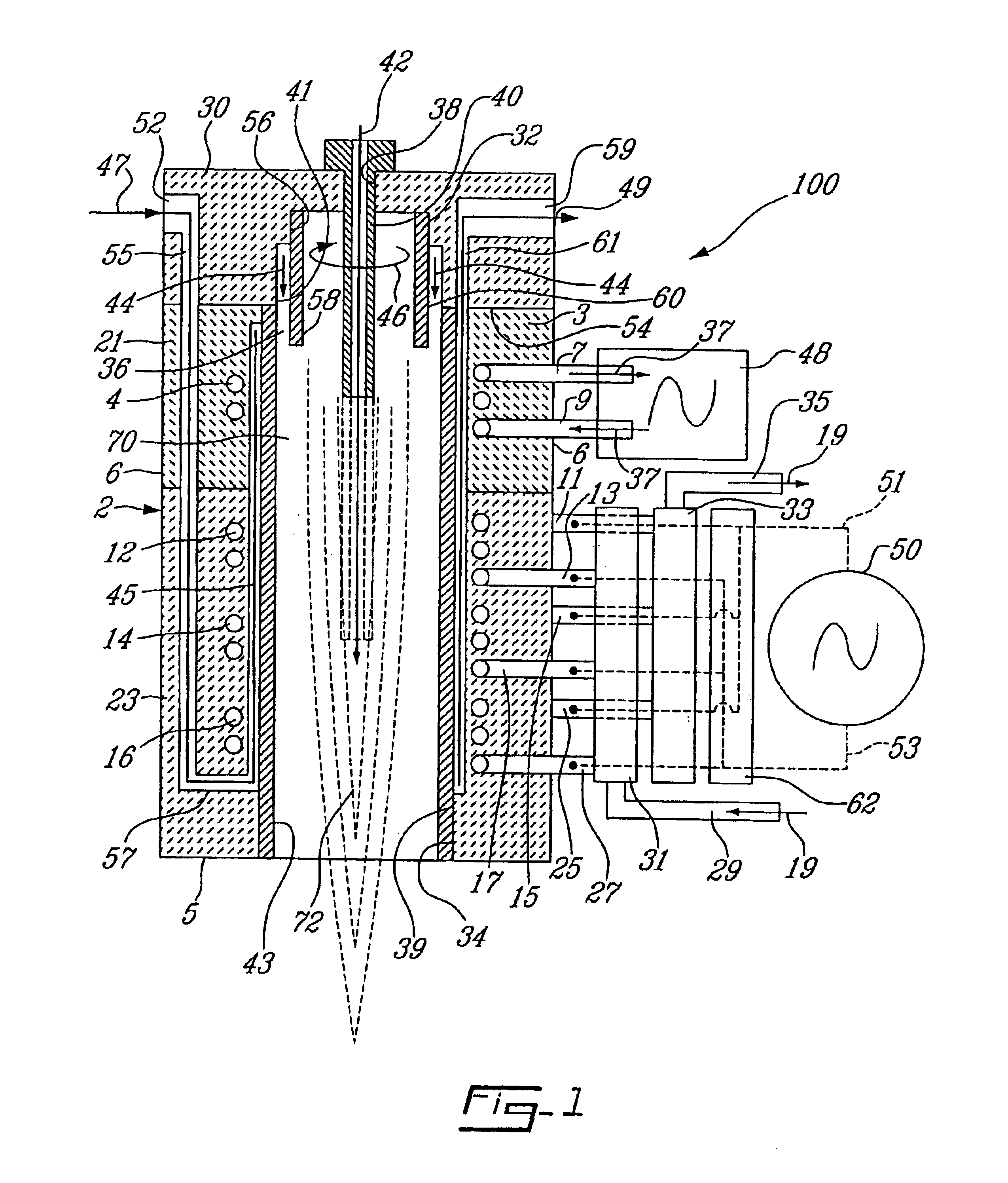

Multi-coil induction plasma torch for solid state power supply

InactiveUS6919527B2Efficient heatingImprove thermal conductivityElectric discharge tubesElectric arc lampsHigh frequency powerInduction plasma technology

Owner:TEKNA PLASMA SYST INC

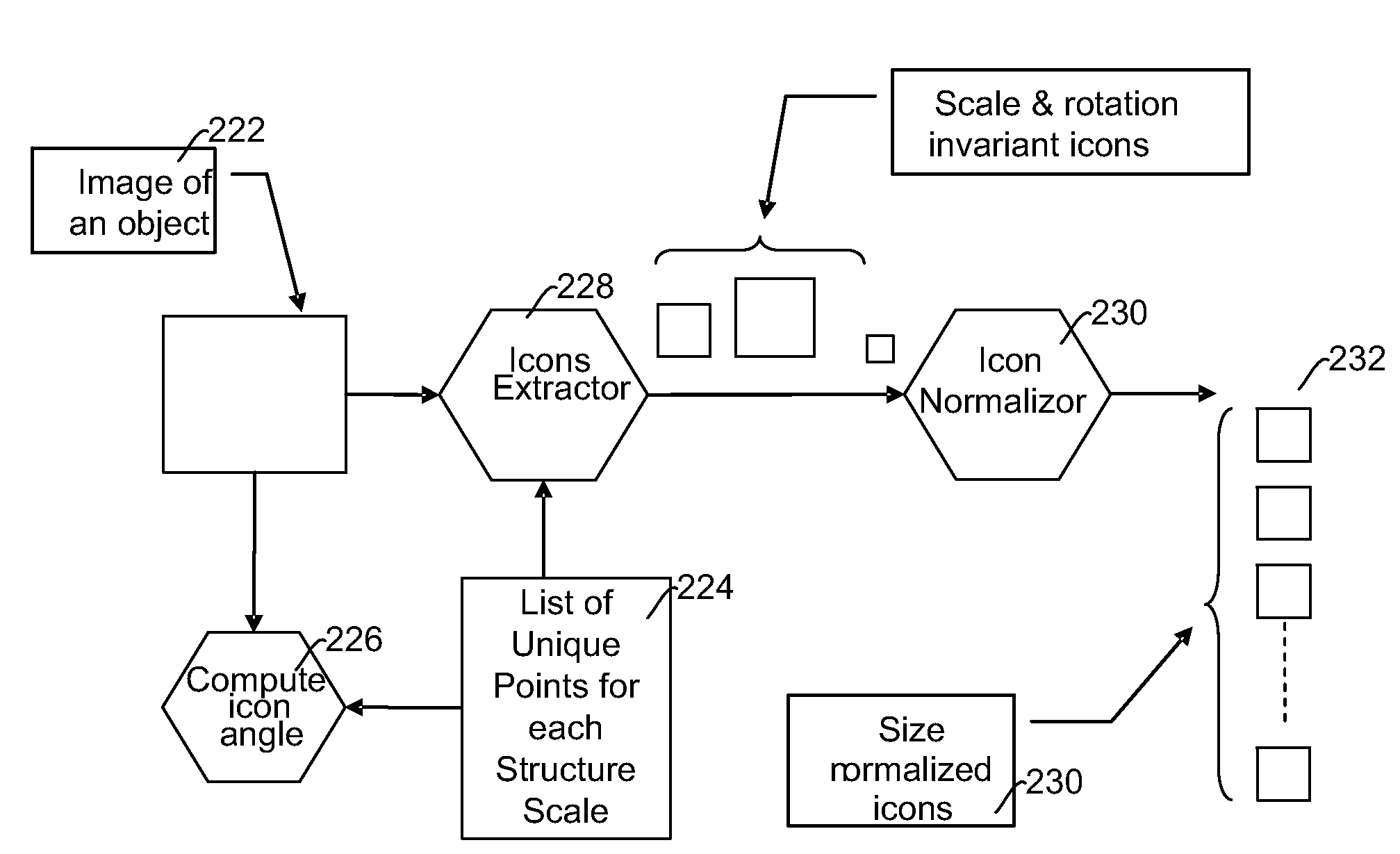

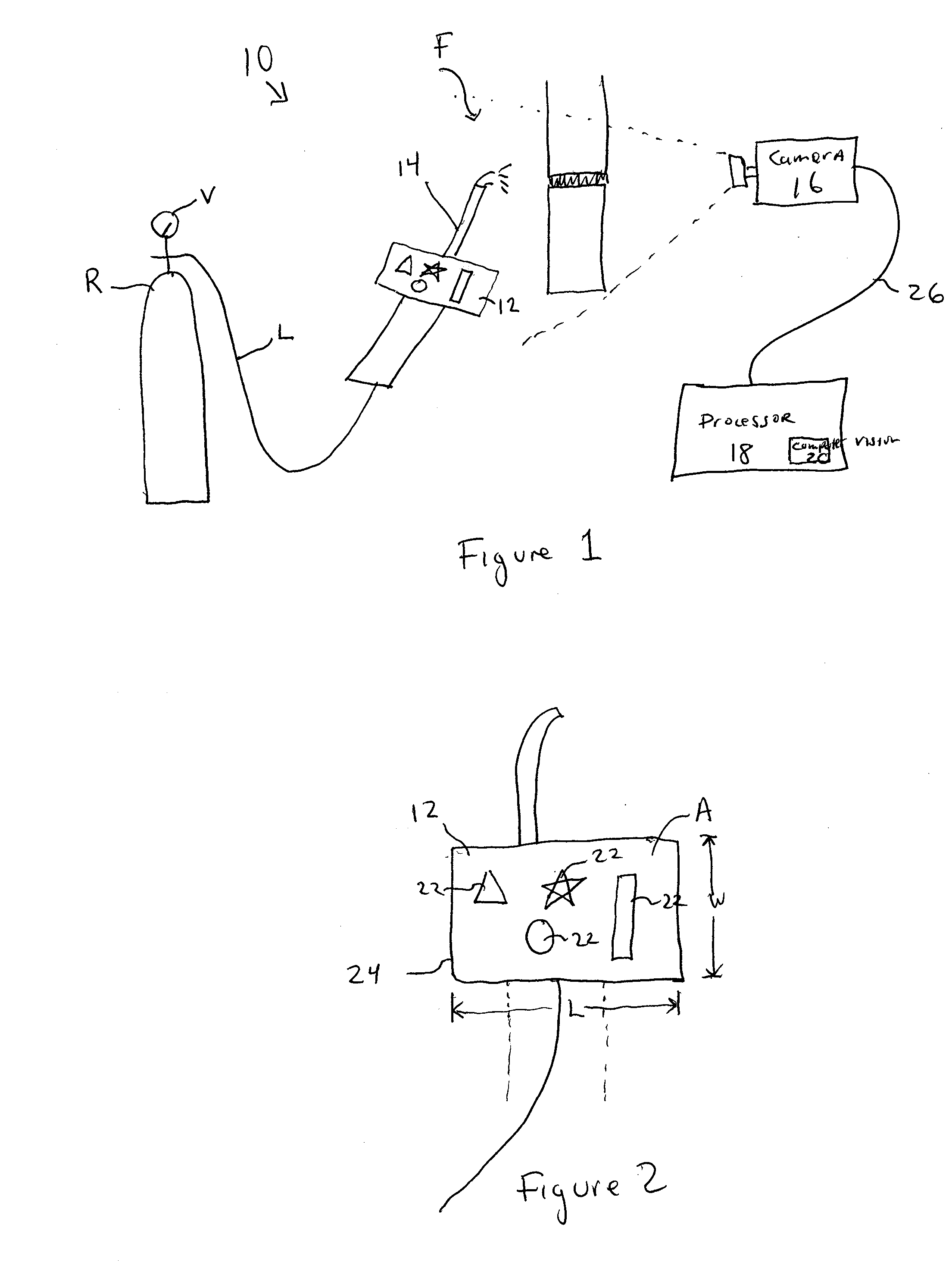

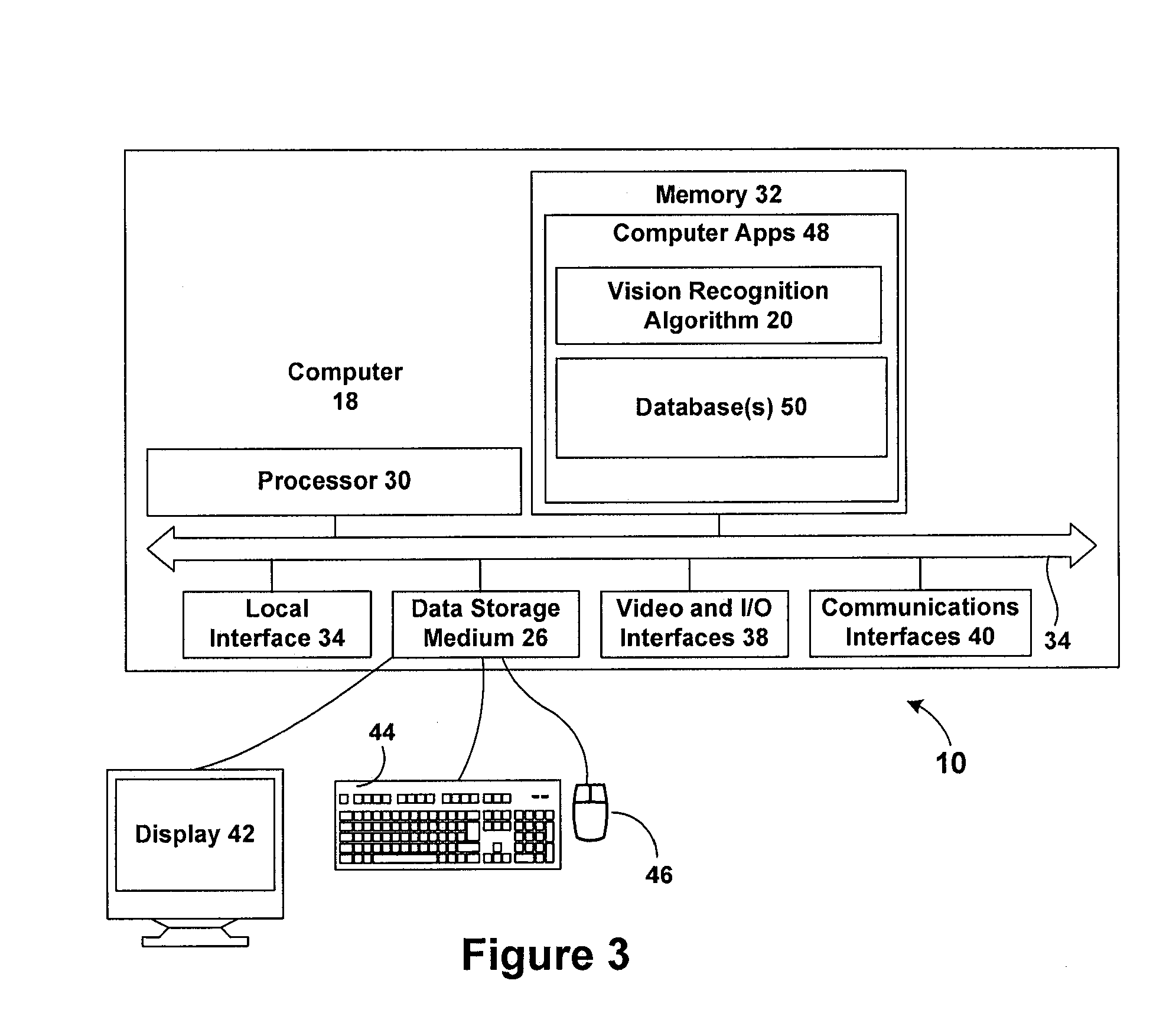

Work piece tracking system and method

A system and method of visual monitoring of a work implement (e.g., a welding torch) while a task is being performed (e.g., forming a welding joint) to train workers (e.g., apprentices, inexperienced workers) in proper welding technique, for example) and / or to evaluate the worker's use of a particular work implement (e.g., to determine if the welding torch was held in a desired relationship to the items being welded together, determine if the welding torch formed the joint at the current speed, etc.). In general, one or more cameras may acquire images of a target secured to and / or formed on the work implement. The images may be analyzed to provide feedback to the user, to be evaluated for weld integrity purposes; and / or may be used to compare the performance of a task (e.g., forming a welding joint) with a database of one or more profiles made by experienced and / or expert craftsmen.

Owner:VISUAL MATHEMATICS LLC

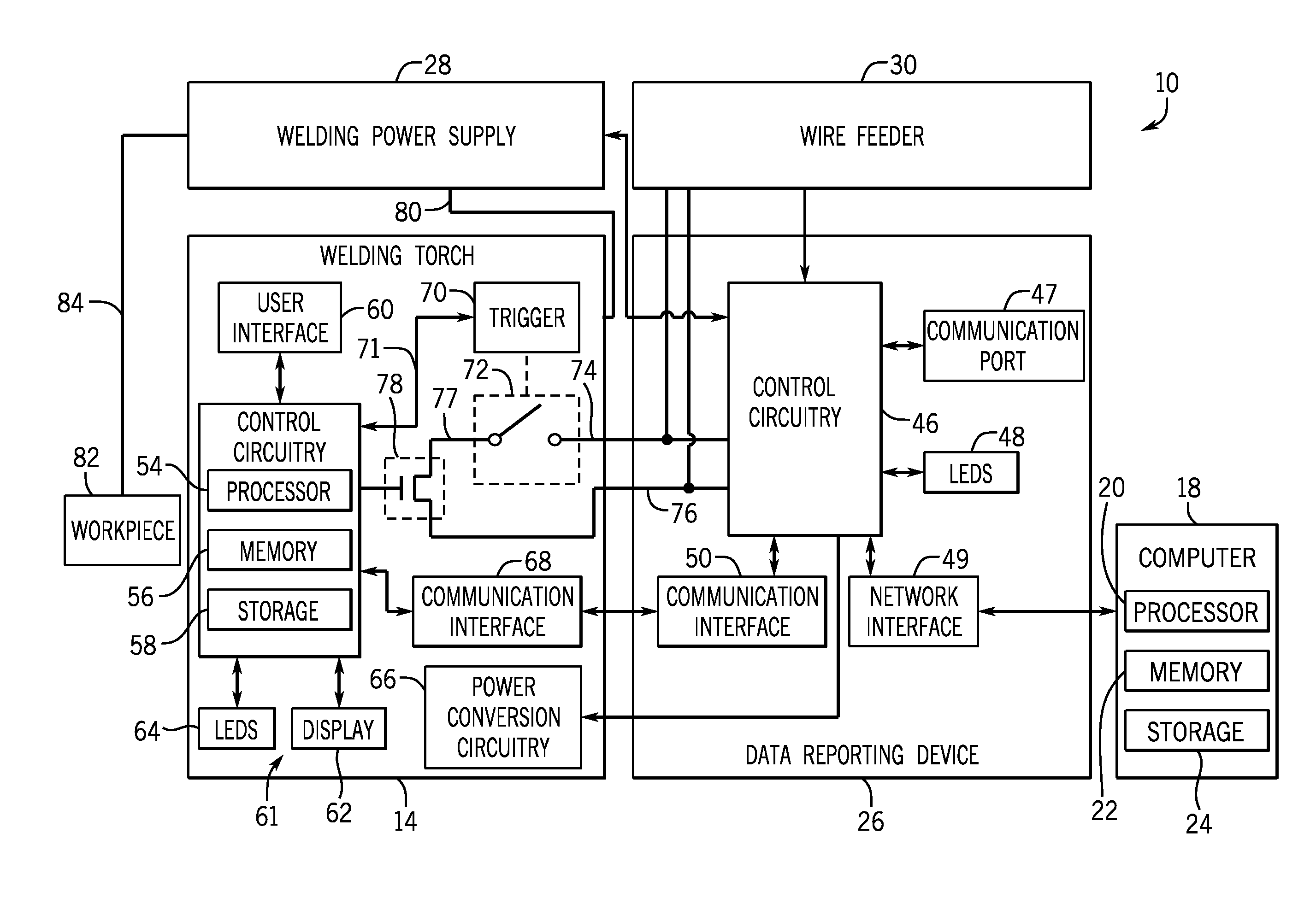

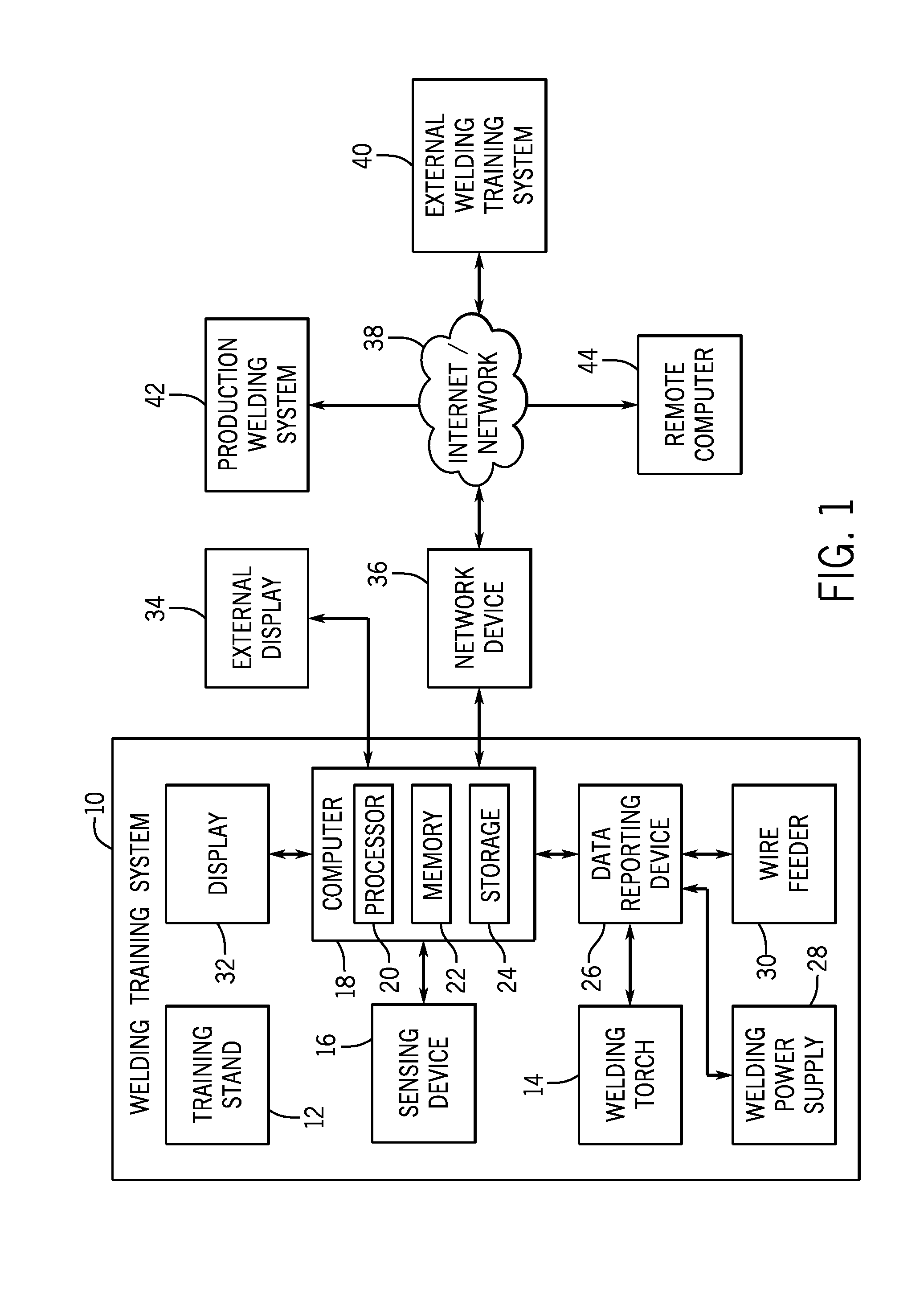

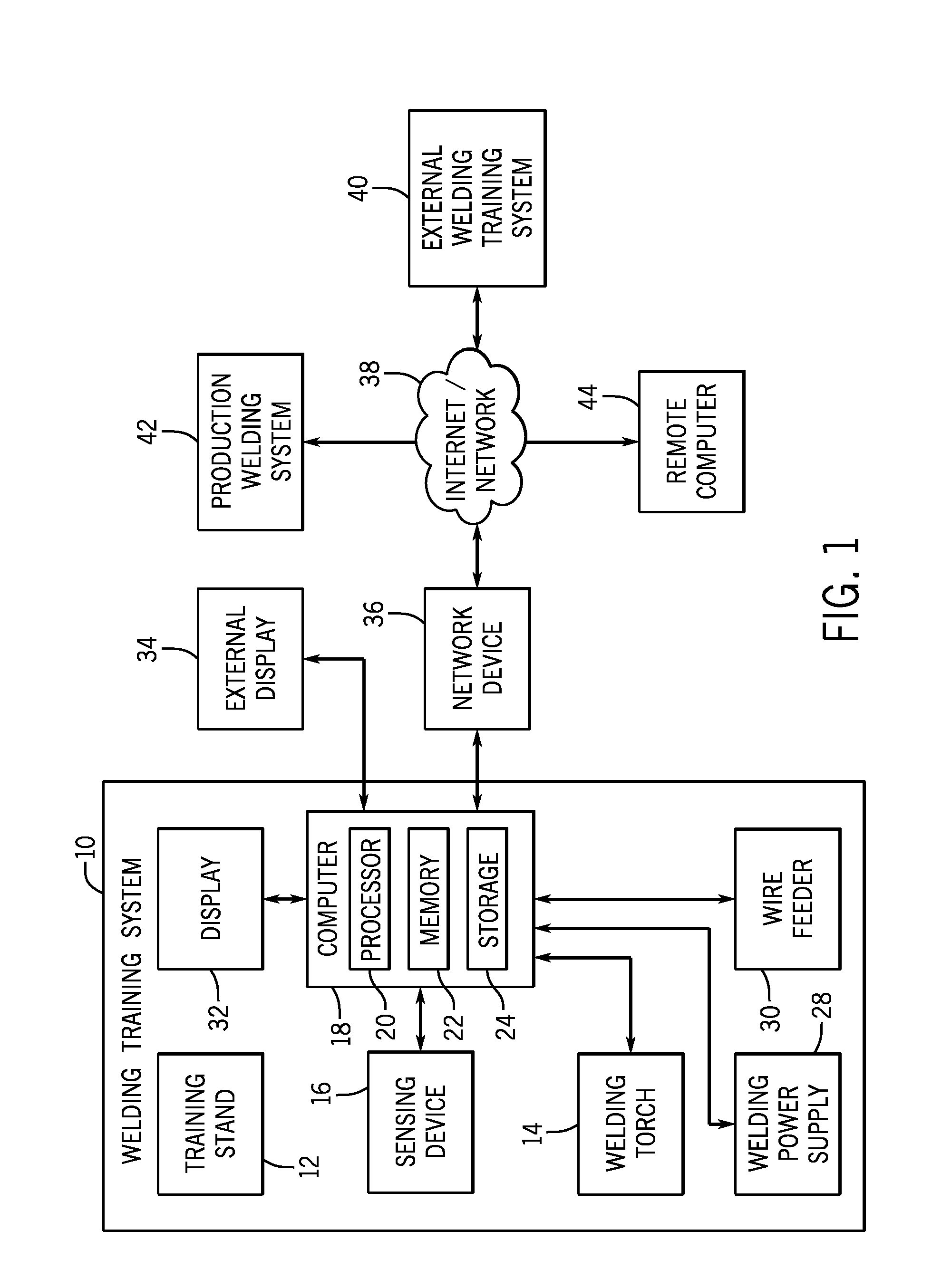

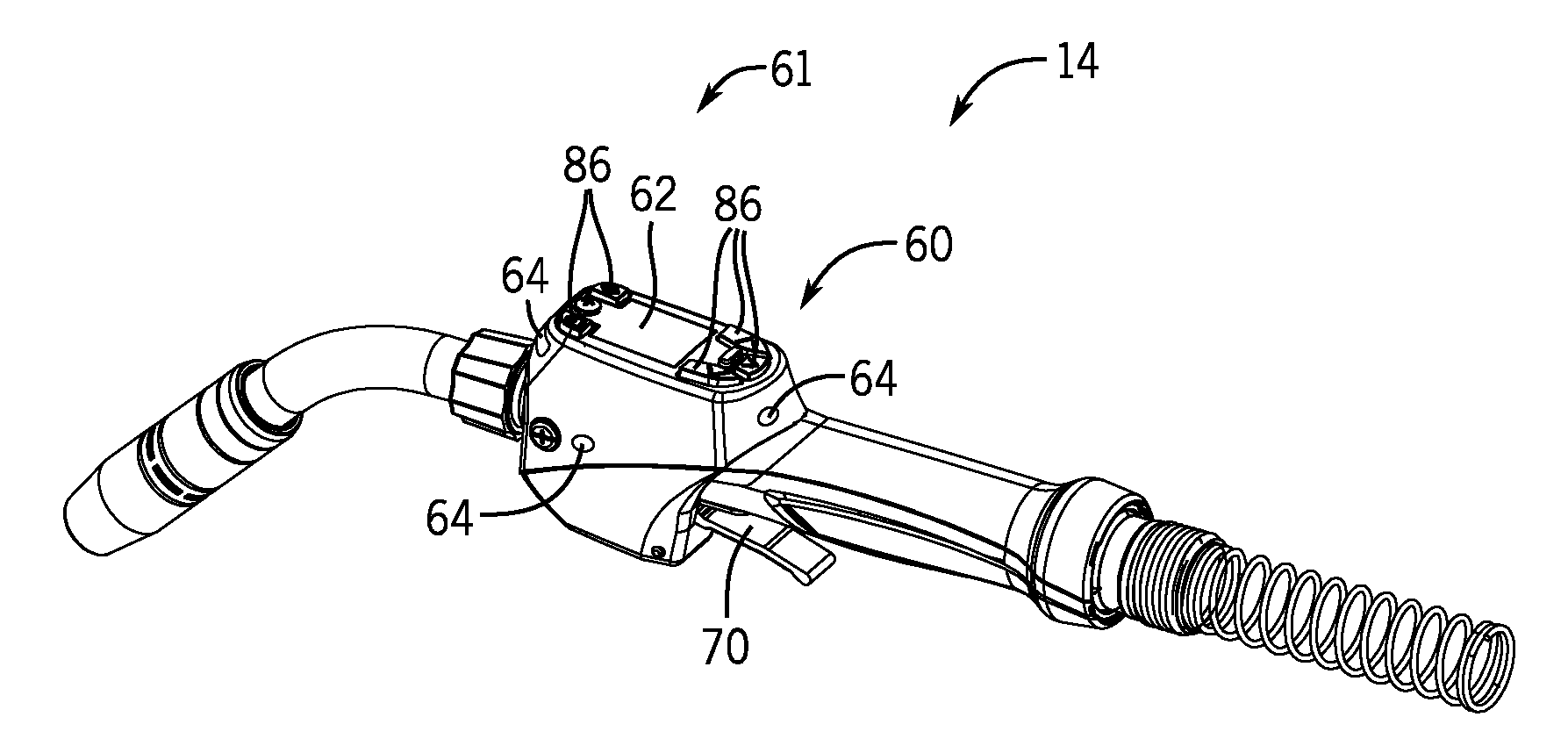

Welding torch for a welding training system

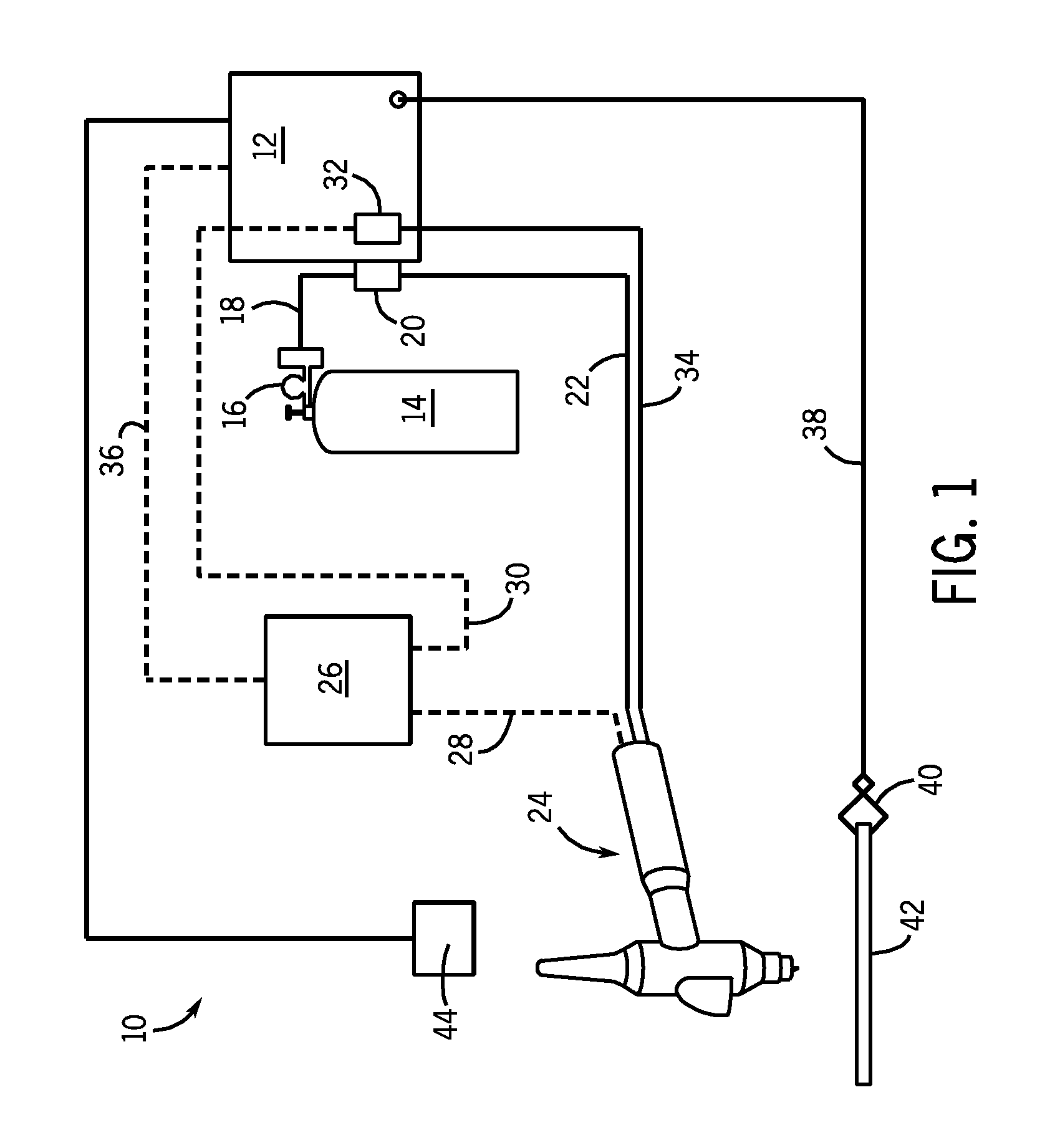

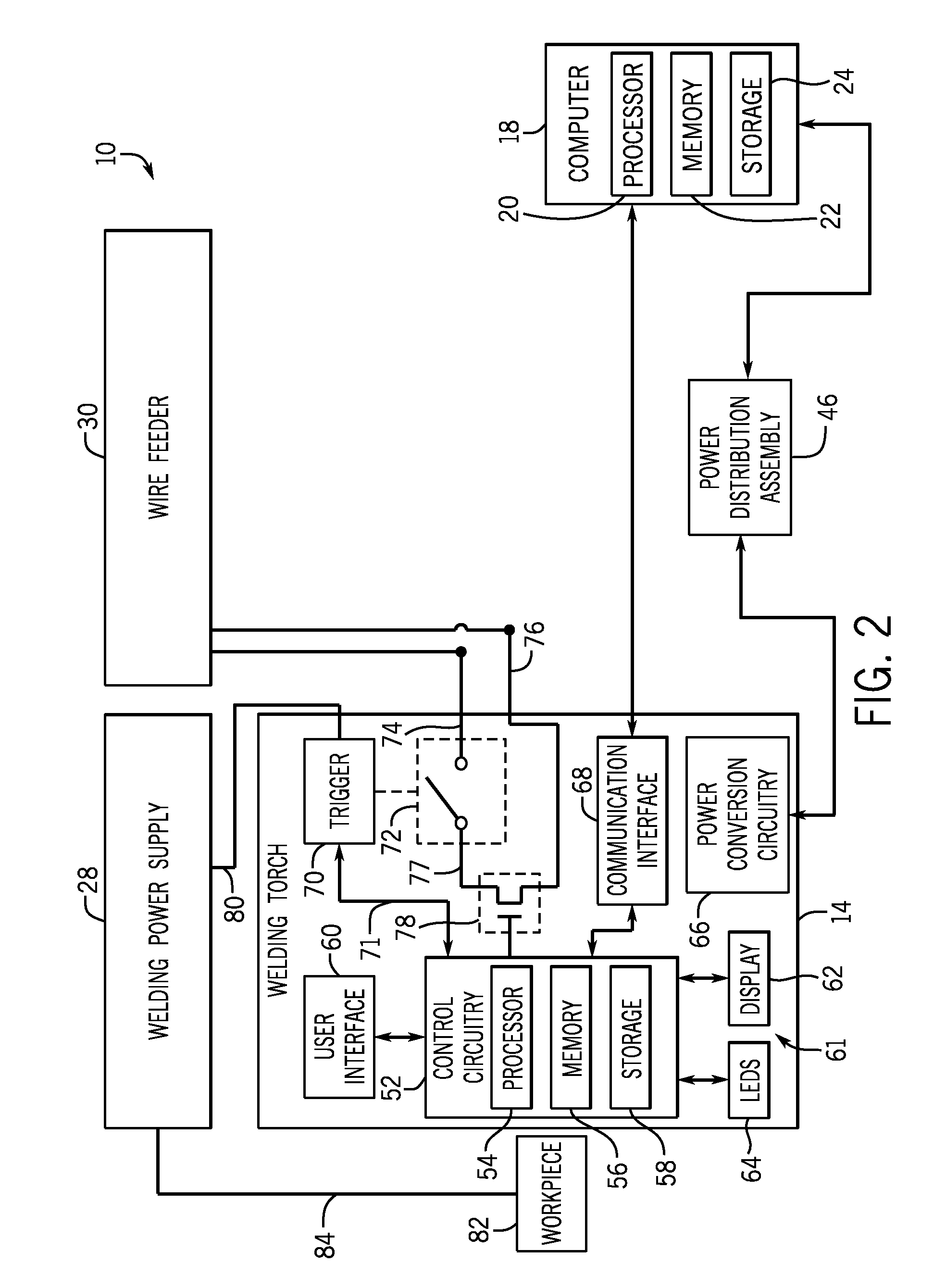

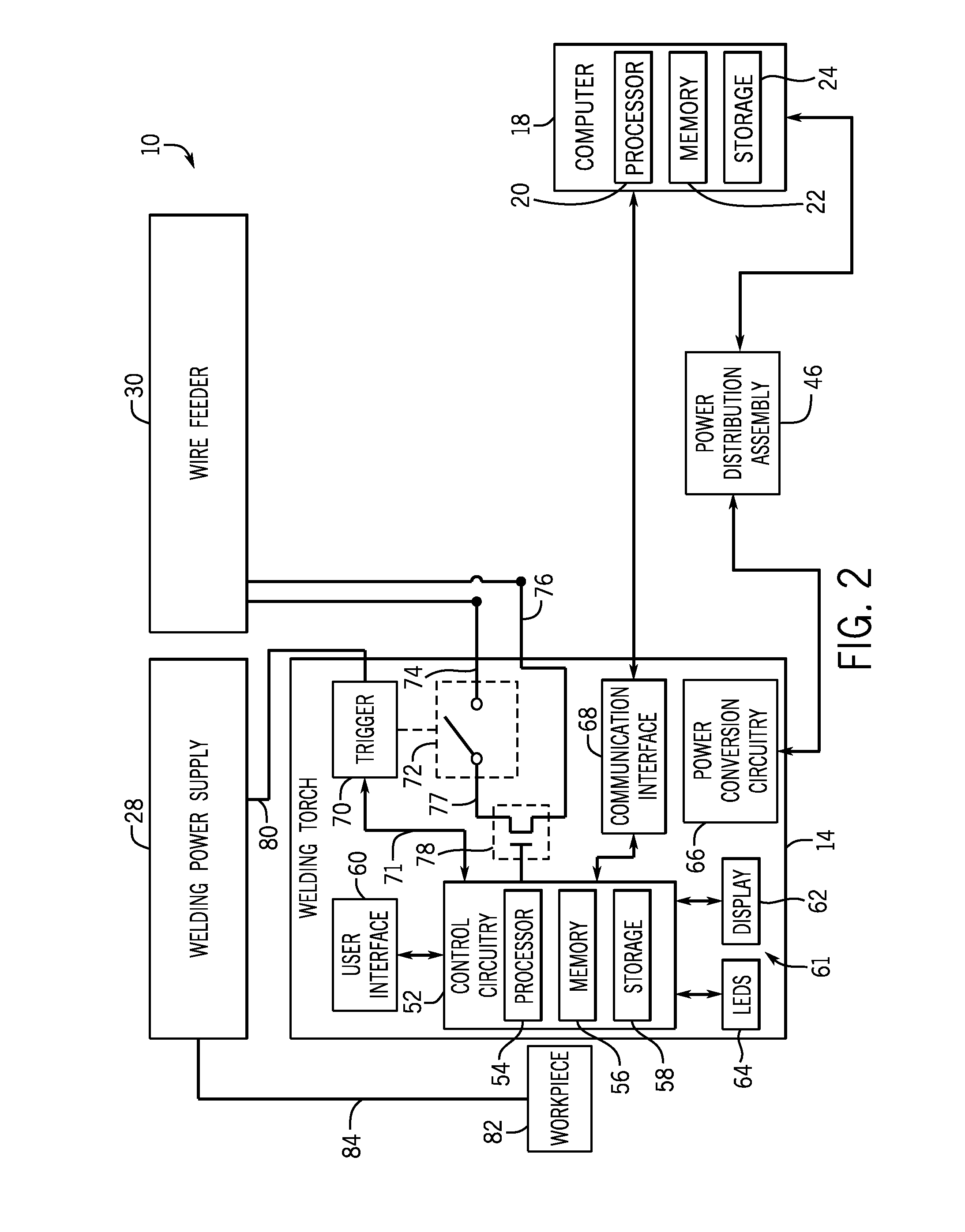

A welding training system includes a welding training software having a first training mode configured to simulate a welding arc and a second training mode configured to use a live welding arc. The welding training system is configured to block welding power flow between a welding power supply and a welding torch while the welding training software is in the first training mode. The welding training system is also configured to enable the welding power to flow between the welding power supply and the welding torch while the welding training software is in the second training mode.

Owner:ILLINOIS TOOL WORKS INC

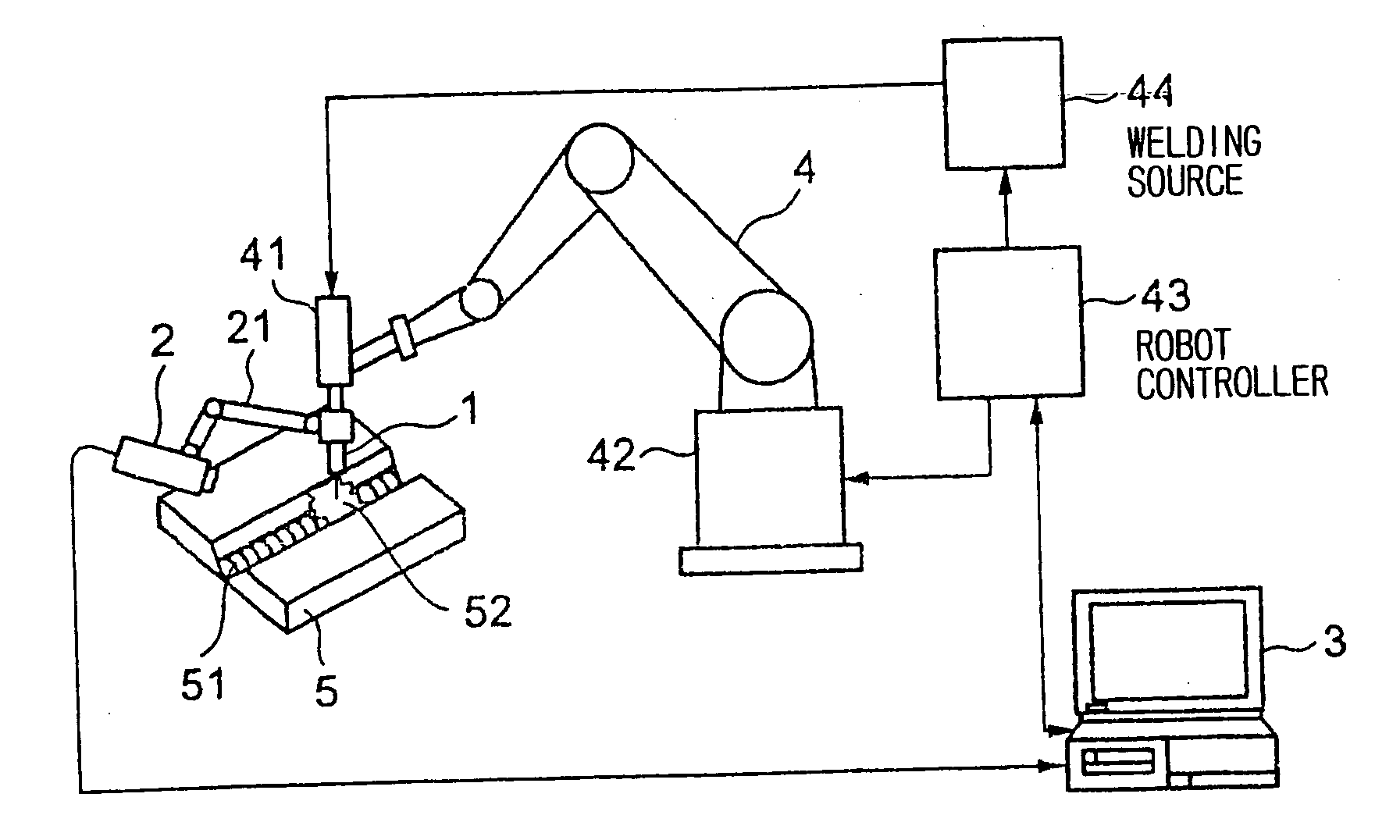

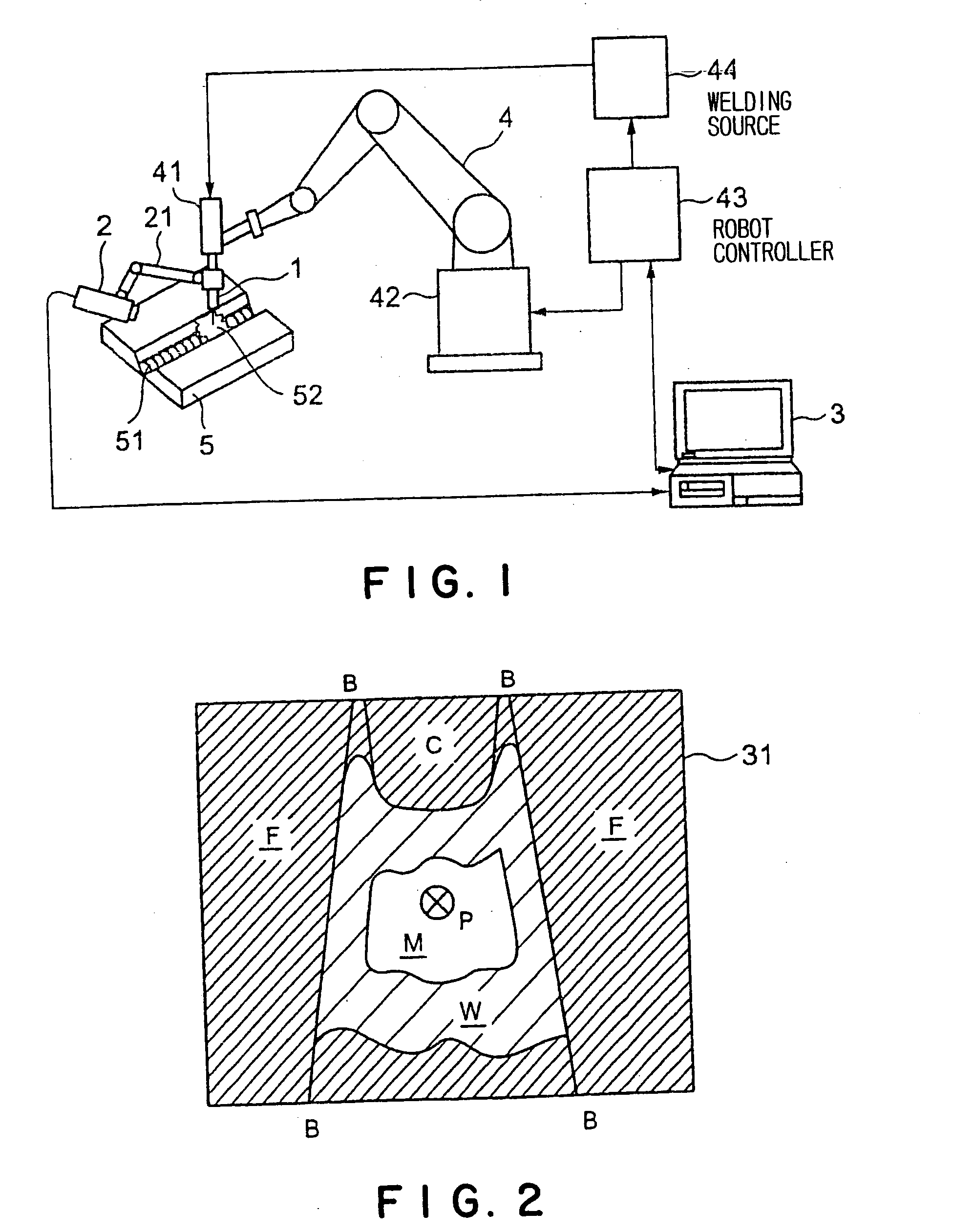

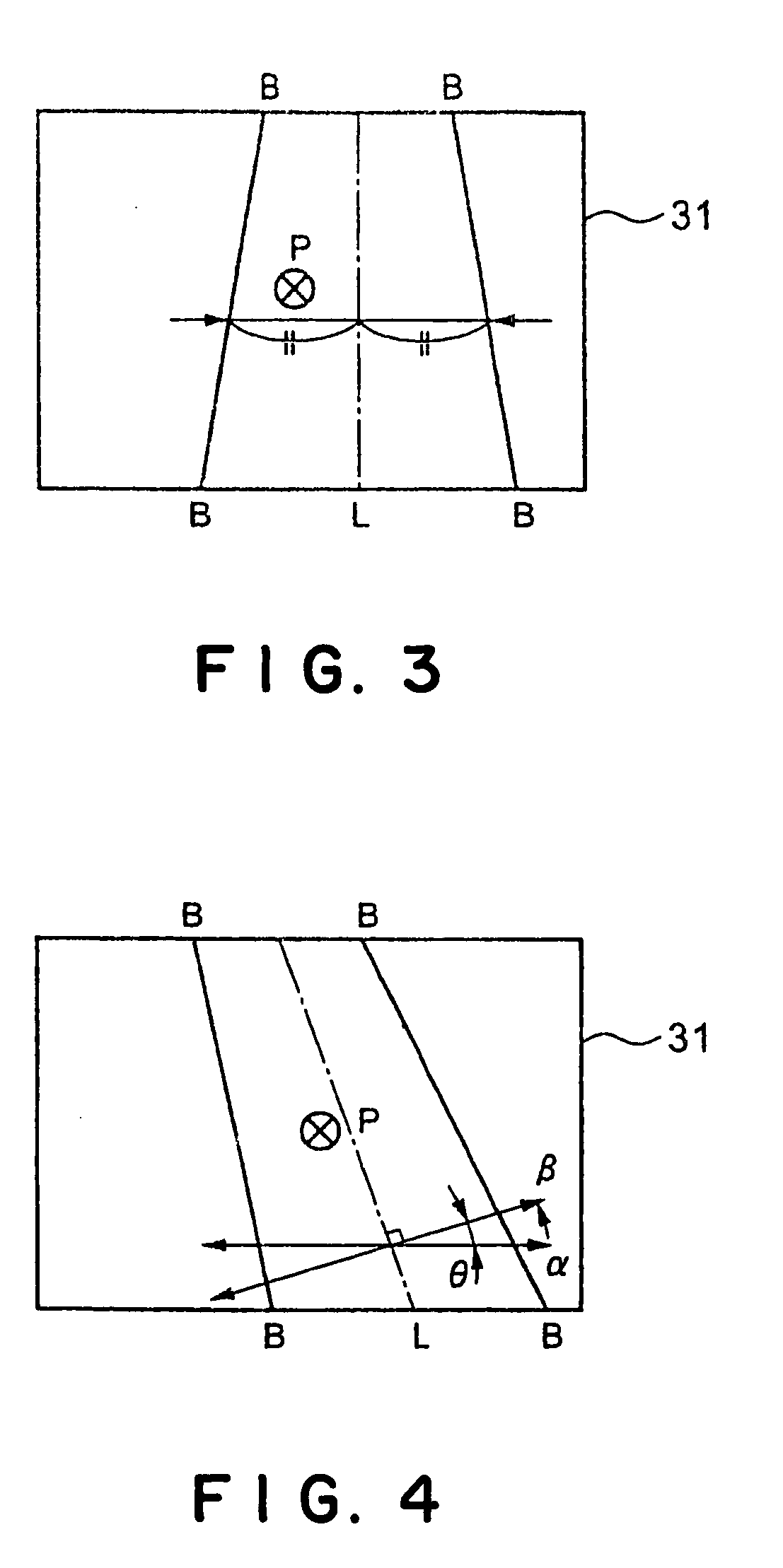

Automatic groove copy welder and welding method

InactiveUS20050103766A1Accurate control operationAccurately carry-outArc welding apparatusEngineeringCcd camera

An automatic groove-tracing welding system is capable of carrying out a welding operation, particularly, a welding operation involving weaving, without requiring monitoring even if conditions of a groove is different from design conditions of the groove. An image processor 3 receives an image signal representing an image of a weld zone 52 including the tip of a welding wire from a camera head 2 provided with a CCD camera, processes the image of the weld zone 52 to determine the position of a groove, calculates the positional relation of the groove with a welding torch 1, and sends a position correction for correcting the position of the welding torch 1 so that the welding path of the tip of the welding torch 1 may coincide with a predetermined middle part in the groove to a robot controller 43 for controlling a welding robot. When the automatic groove-tracing welding system performs a welding operation involving weaving, the image processor 3 receives a weaving phase signal representing phases of weaving from the robot controller 43, calculates the positional relation between the groove and the welding torch on the basis of the phase of weaving, and sends a weaving width correction signal to the robot controller 43.

Owner:KAWASAKI HEAVY IND LTD

System and method for identifying welding consumable wear

A system and method for determining a wear condition of a welding consumable includes a welding torch having a consumable component and a wire delivery system configured to deliver wire to the welding torch during a welding process. The welding system also includes a power source configured to deliver power to the welding torch to perform the welding process. A controller is included that is configured to monitor at least one operational characteristic of the delivery of wire to the welding torch over a selected period, determine a wear condition of the consumable component from the at least one operational characteristic, and generate a signal indicating detection of the wear condition.

Owner:ILLINOIS TOOL WORKS INC

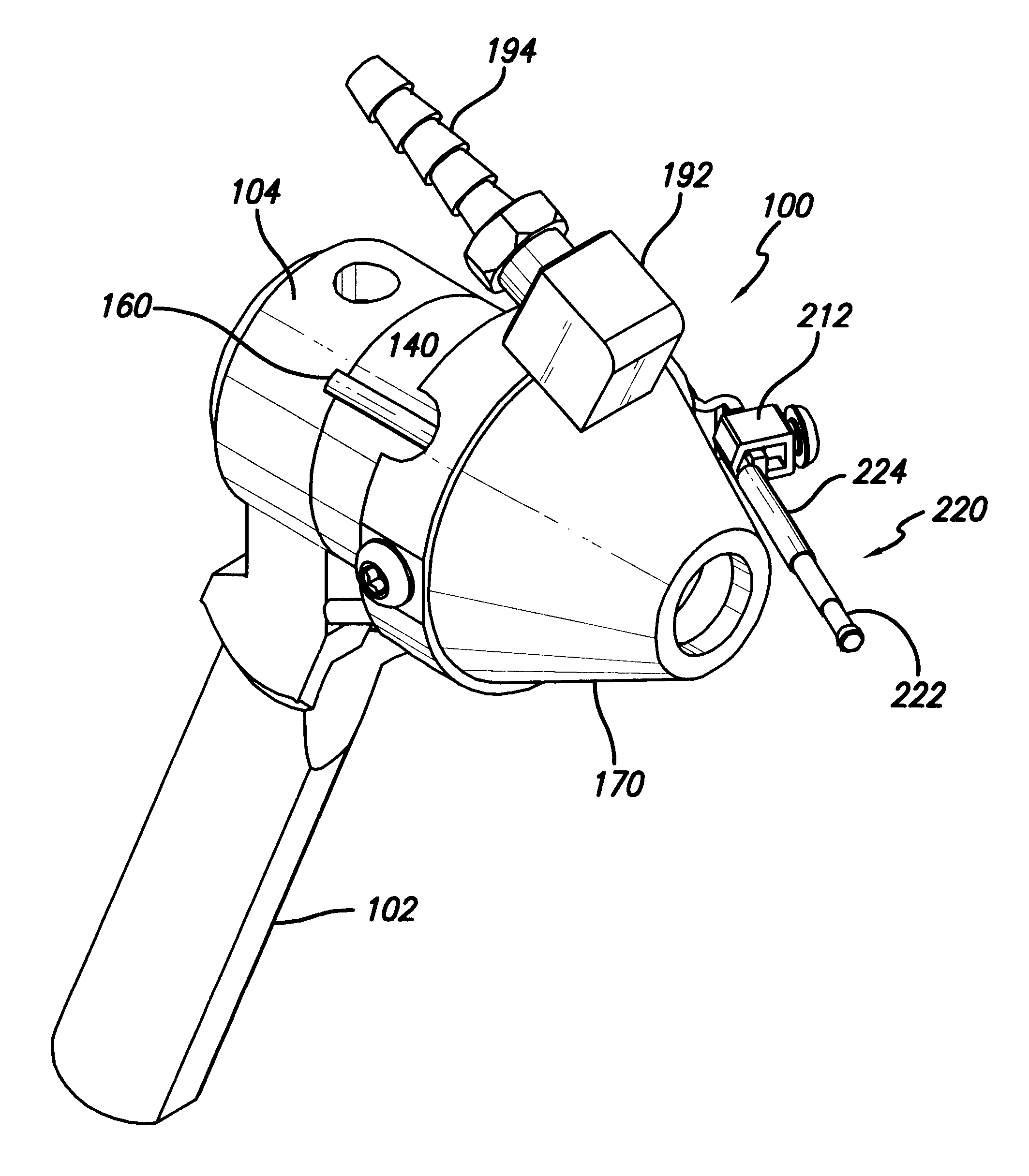

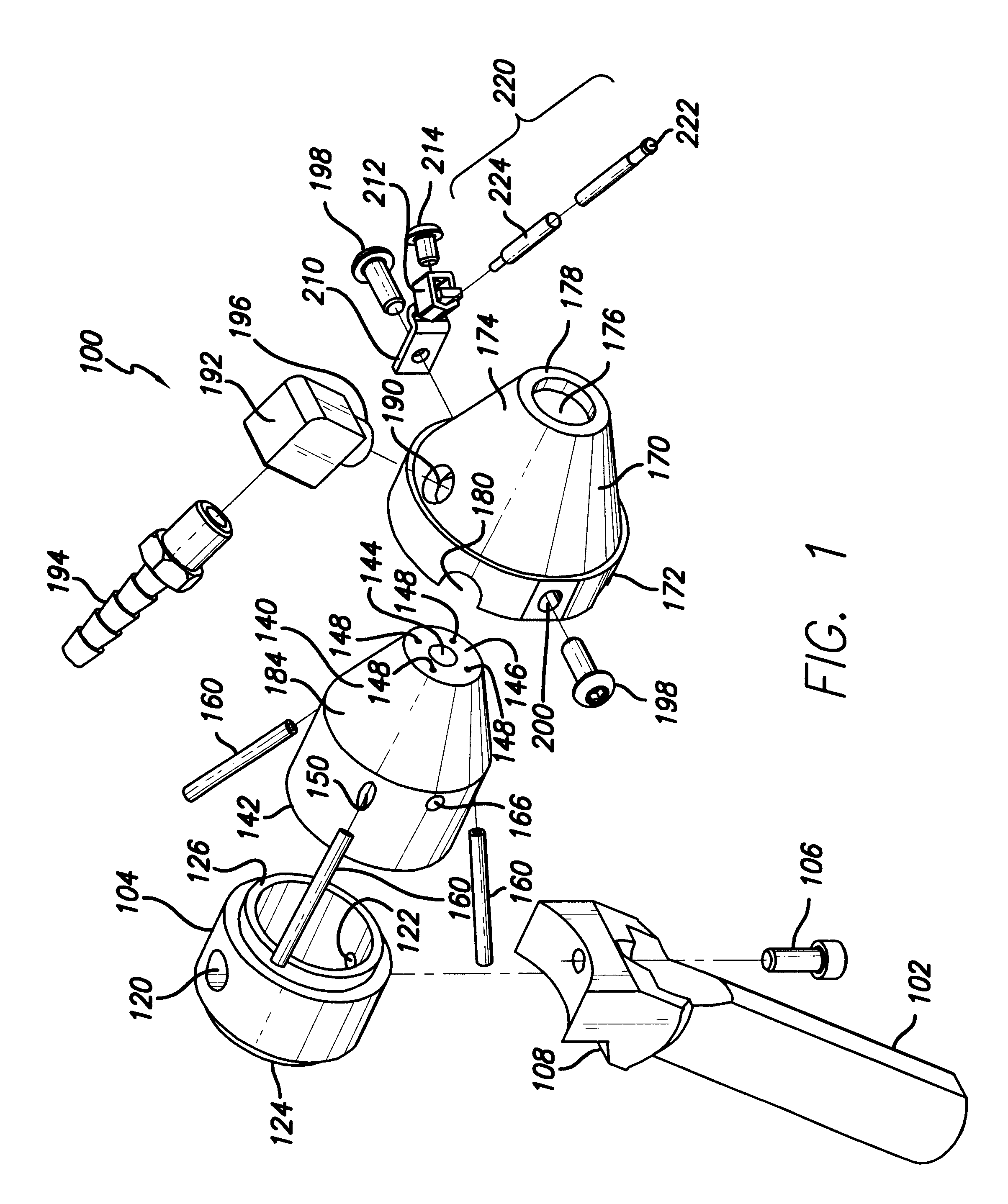

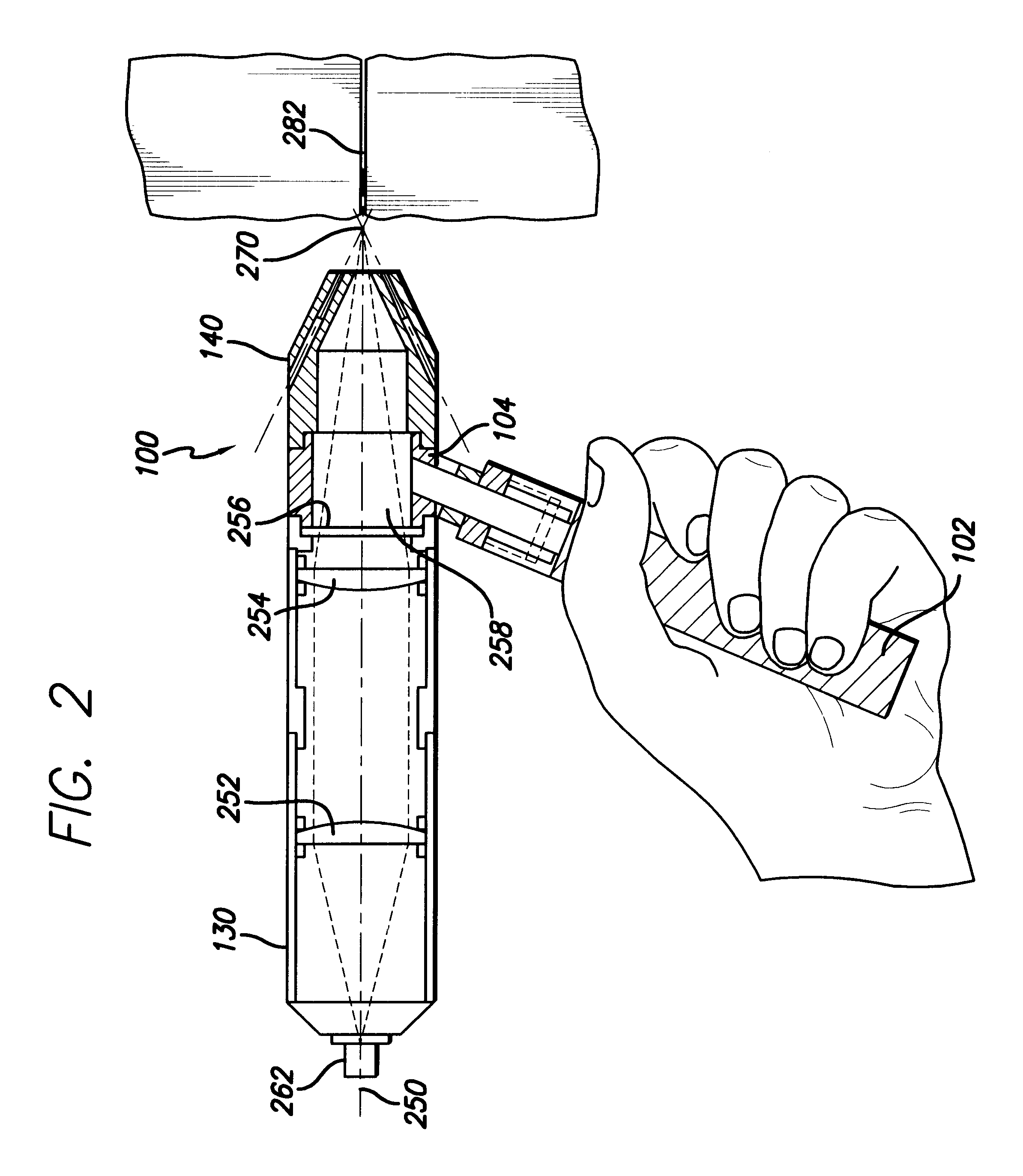

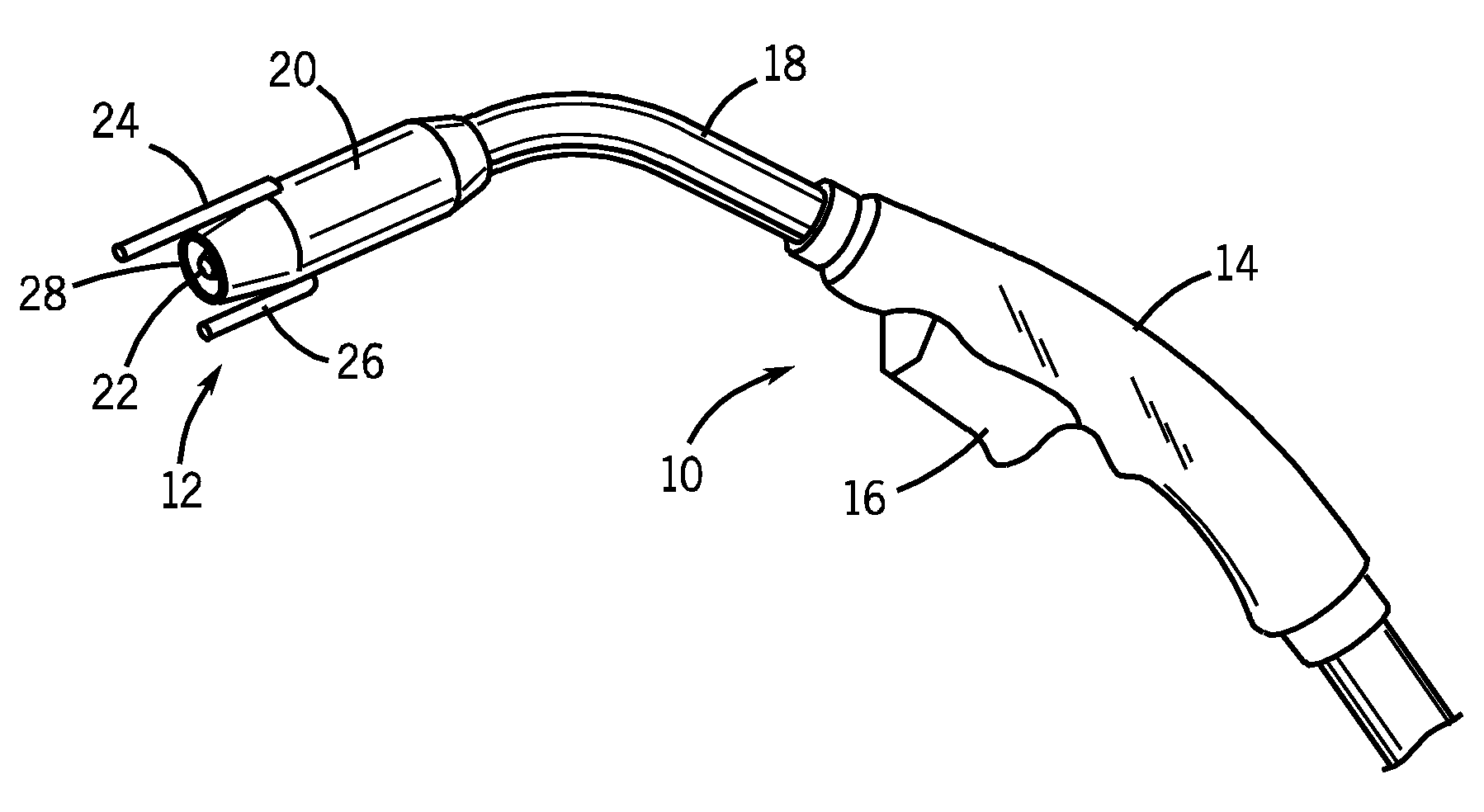

Hand held powder-fed laser fusion welding torch

A novel and inventive hand held powder-fed laser fusion welding torch providing manual flexibility for laser welding with powder-fed material. The hand held laser includes a body, handle, and nozzle assembly. The nozzle may be shrouded by a cover that is slightly spaced apart from the nozzle. The gap between the two may provide space through which inert gas may flow. Laser light from a remote source shines through the nozzle's central aperture. The nozzle aperture may be circumscribed by powder channel outlets aligned upon a working focal point coincident with the laser beam to treat a workpiece. A proximity sensor may enable selective welding torch operation according to the presence of a workpiece.

Owner:HONEYWELL INT INC

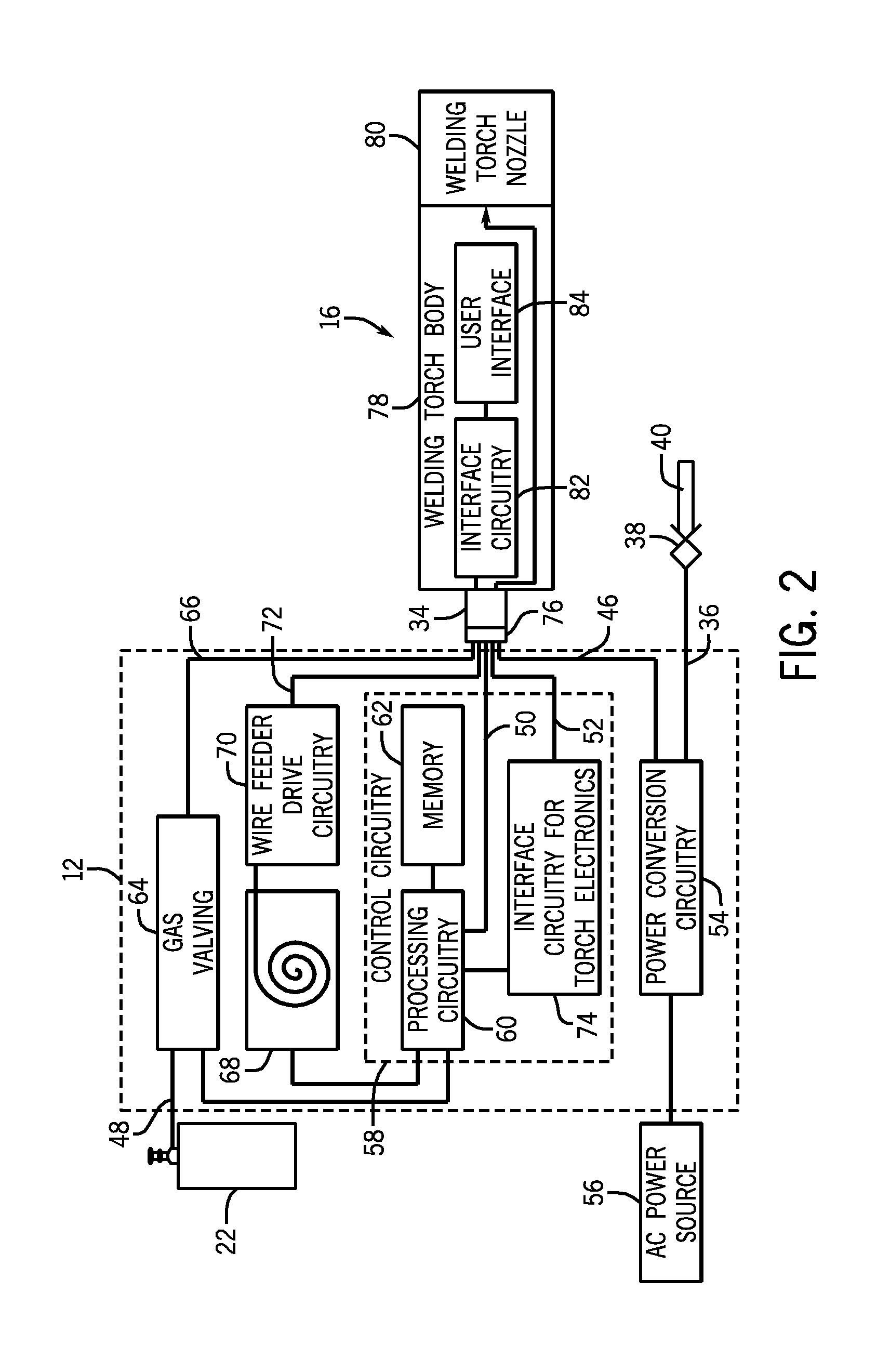

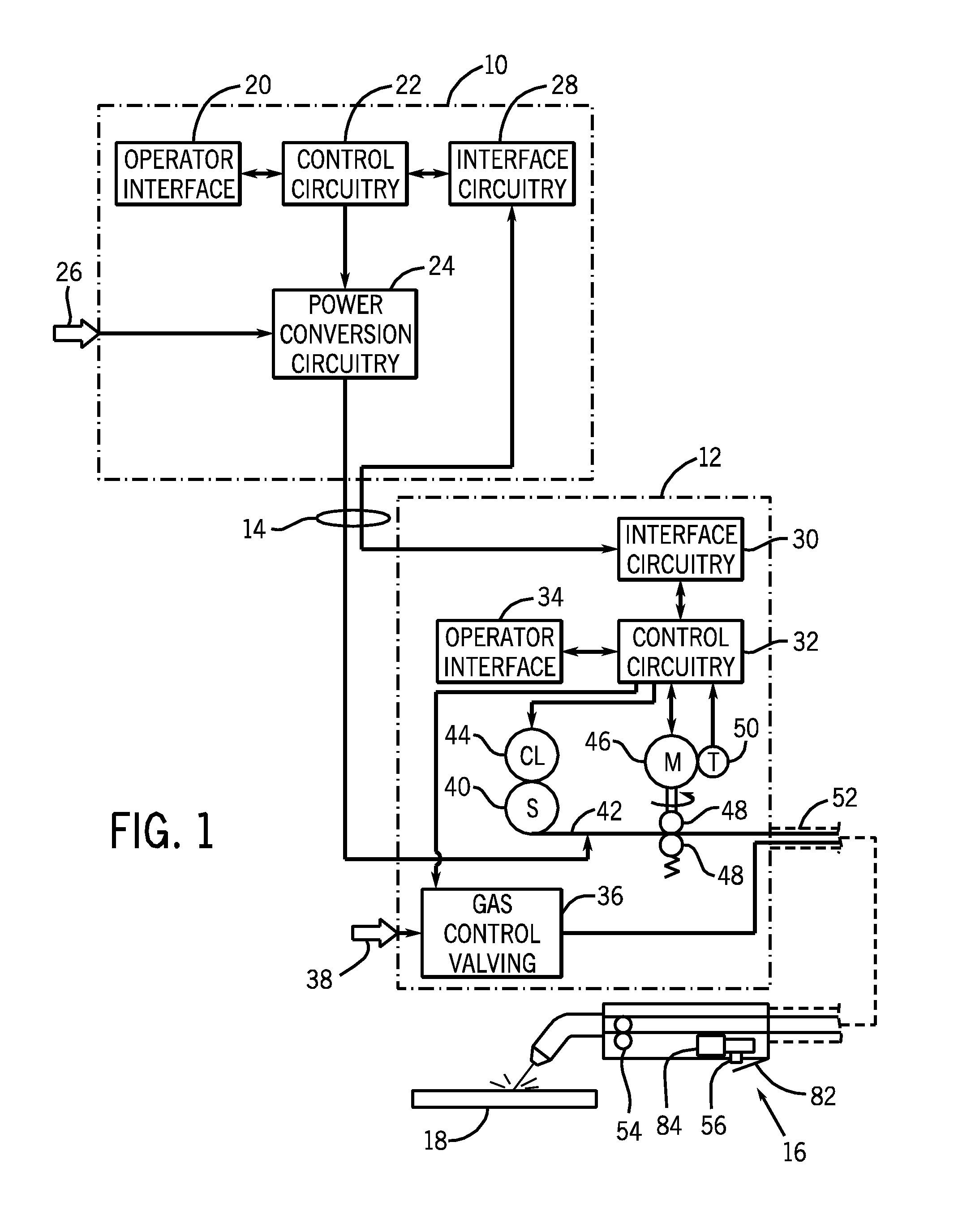

Welding device with integral user interface

InactiveUS20110220616A1Arc welding apparatusWelding/cutting media/materialsGraphical user interfaceWelding power supply

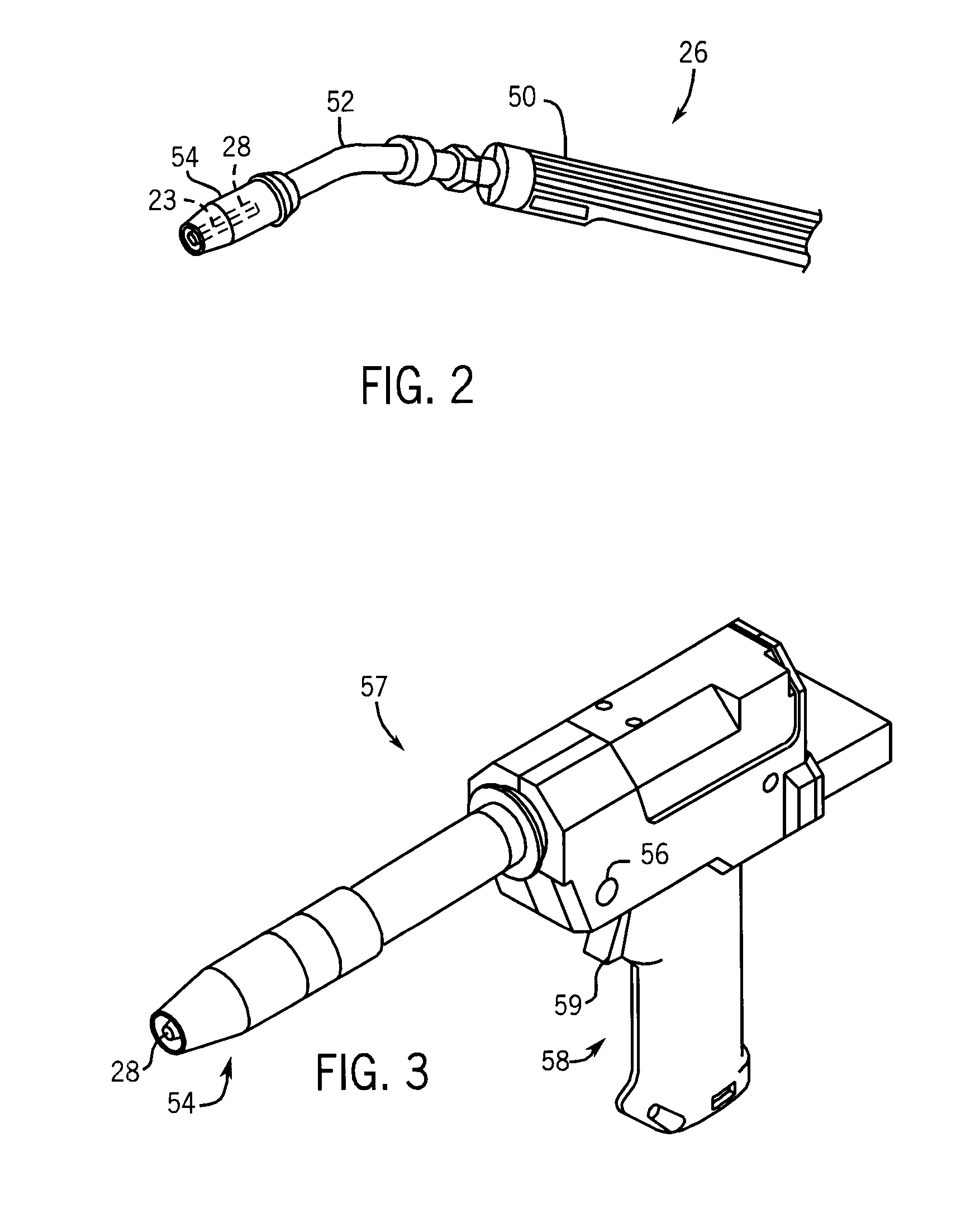

Welding torch assemblies including a torch body having a user interface module integrally formed therewith, a welding nozzle, and a torch lead assembly are provided. The user interface module may enable a user to control one or more parameters of a welding operation. The welding nozzle may be coupled to a first end of the torch body. The torch lead assembly may be coupled to a second end of the torch body opposite the first end and may include a weld power lead and a weld control lead.

Owner:ILLINOIS TOOL WORKS INC

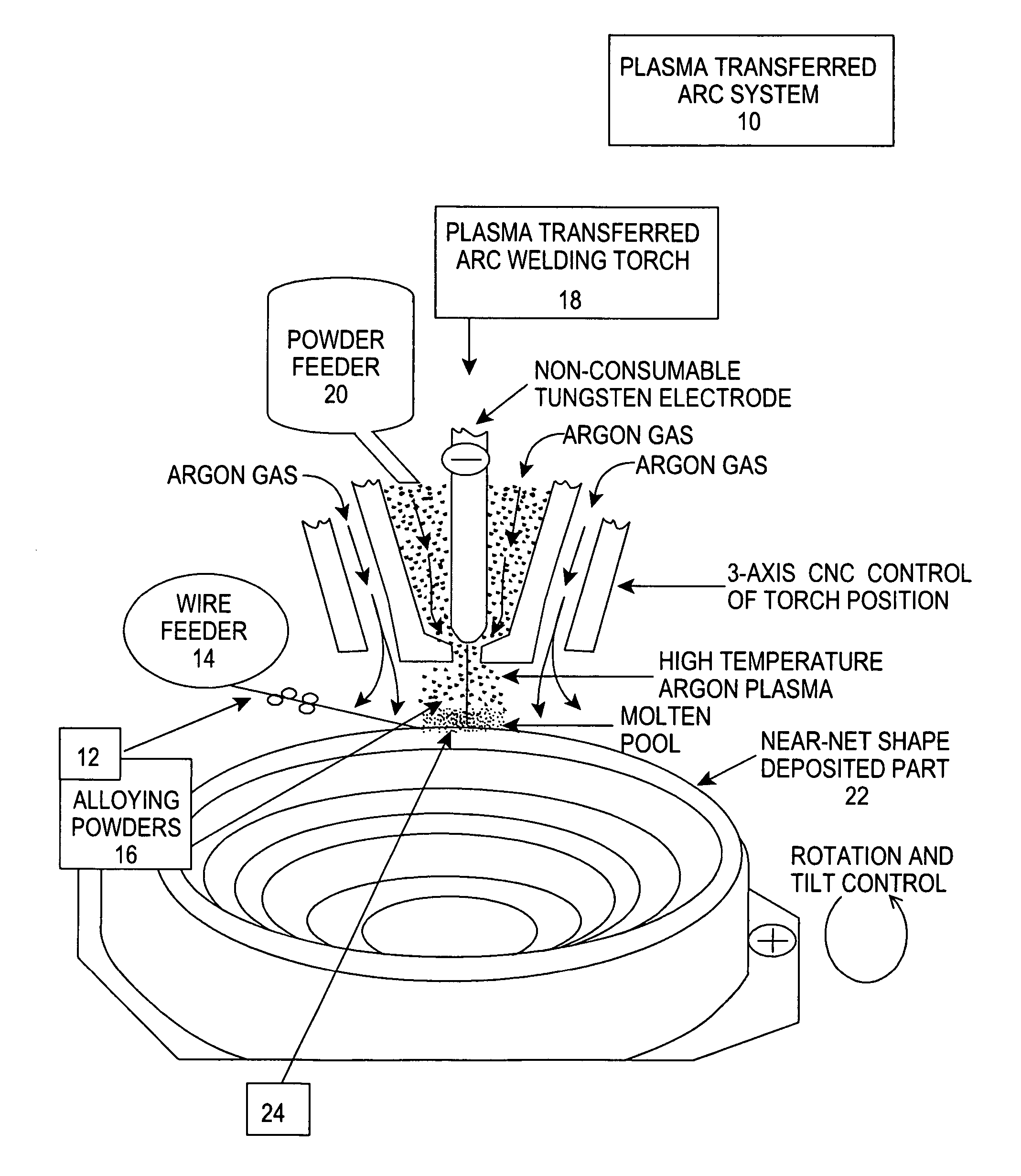

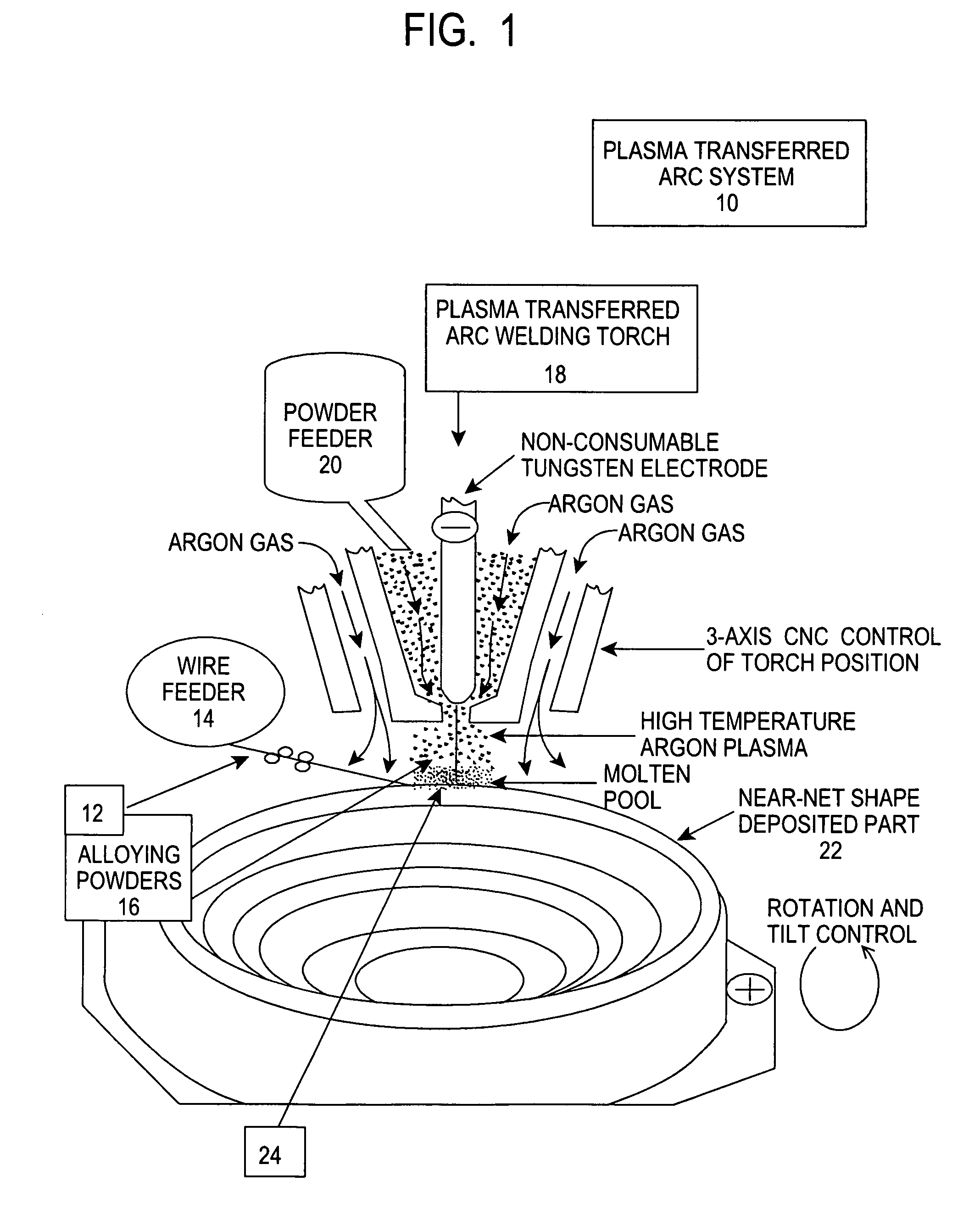

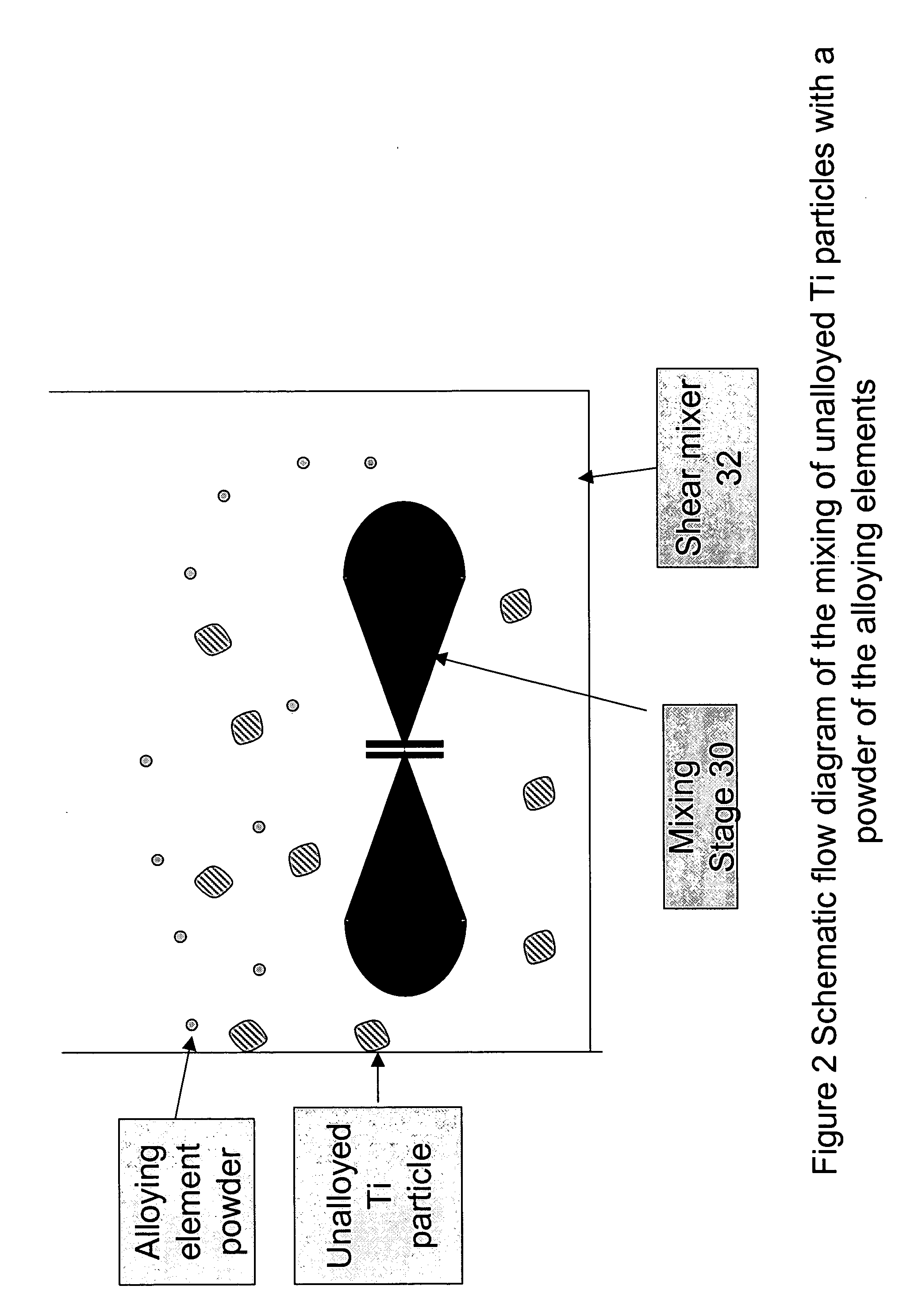

Low cost process for the manufacture of near net shape titanium bodies

InactiveUS20060185473A1Low costAdditive manufacturing apparatusArc welding apparatusHigh energyTitanium

Owner:ATS MER LLC

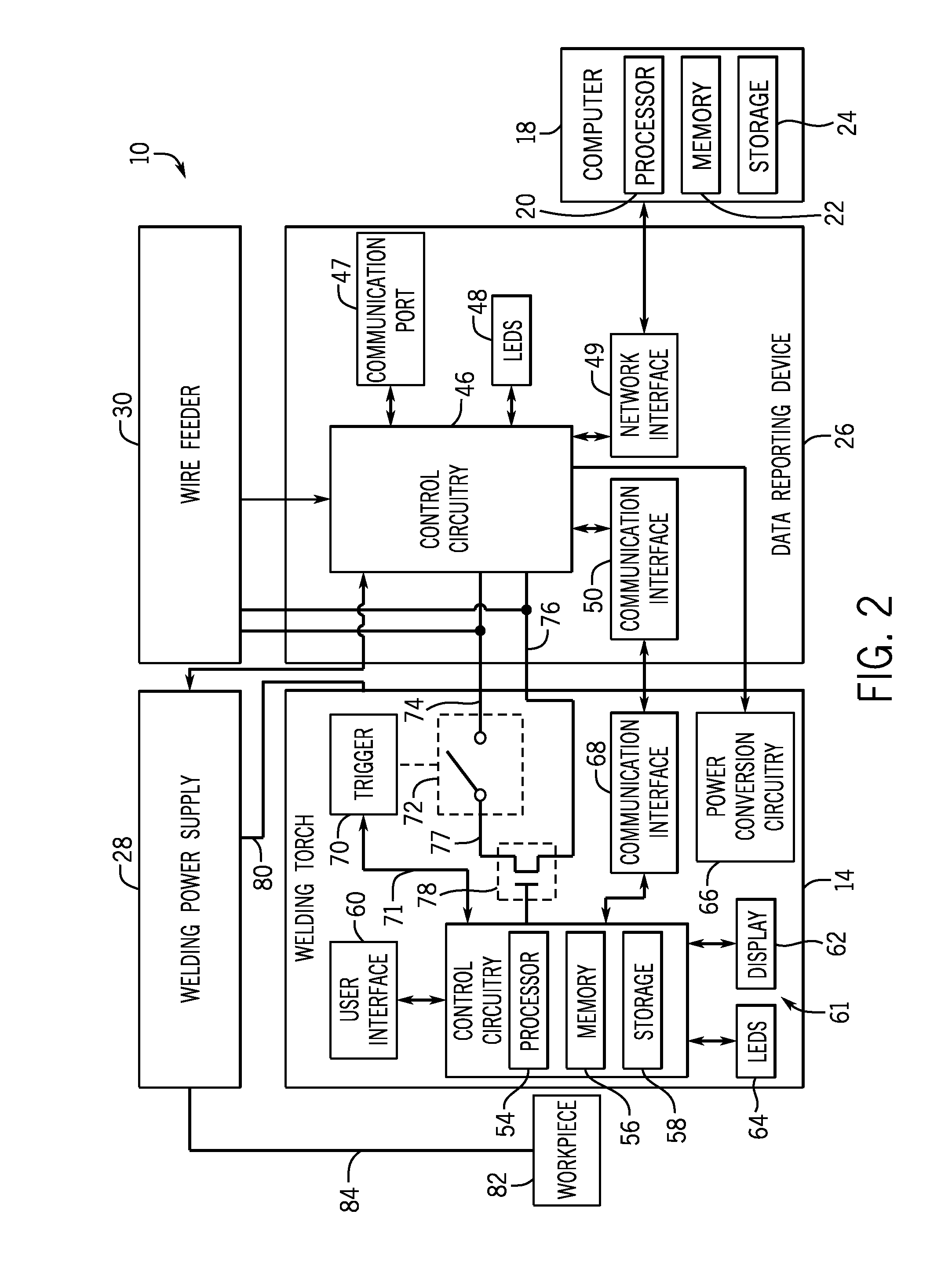

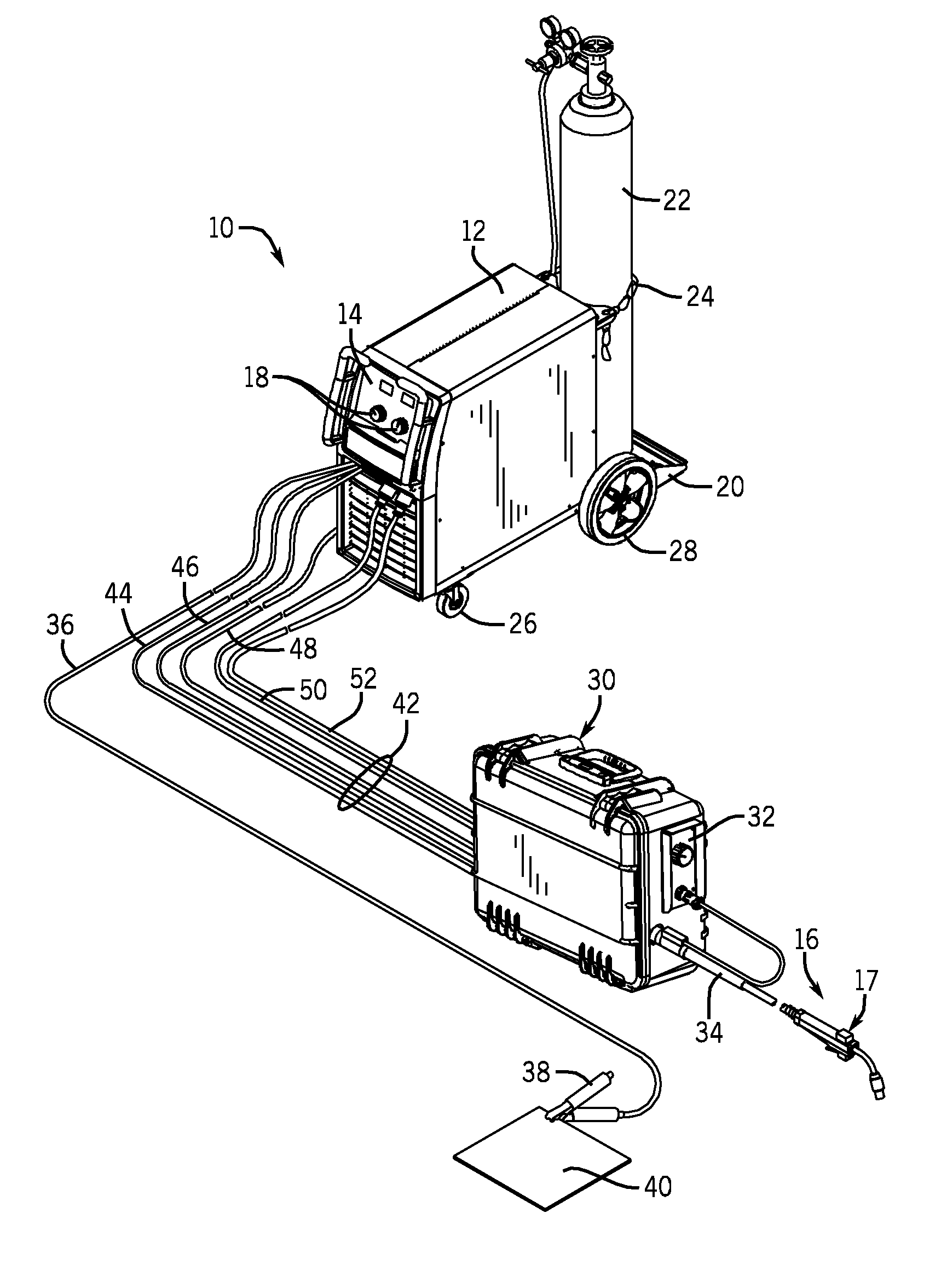

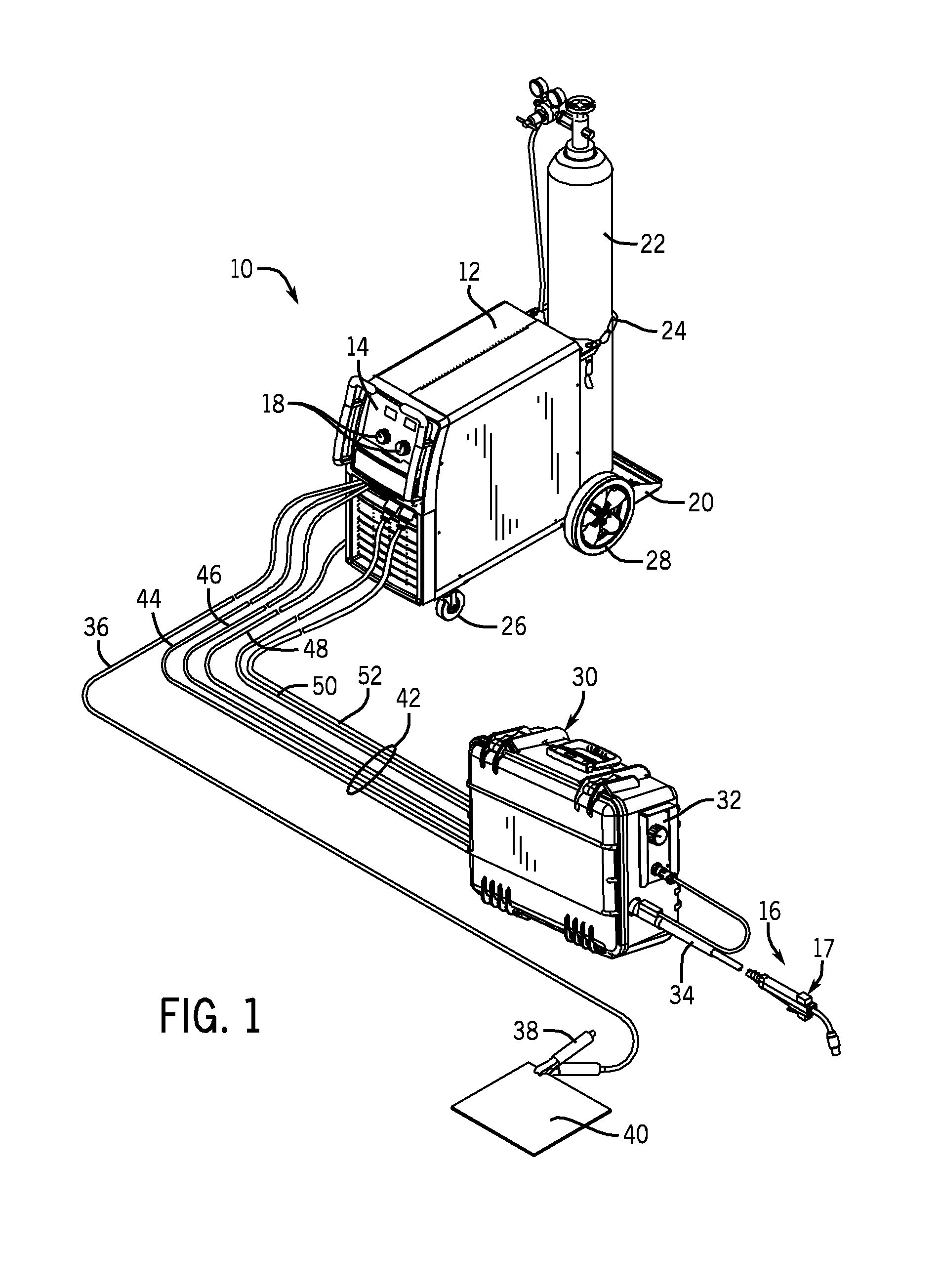

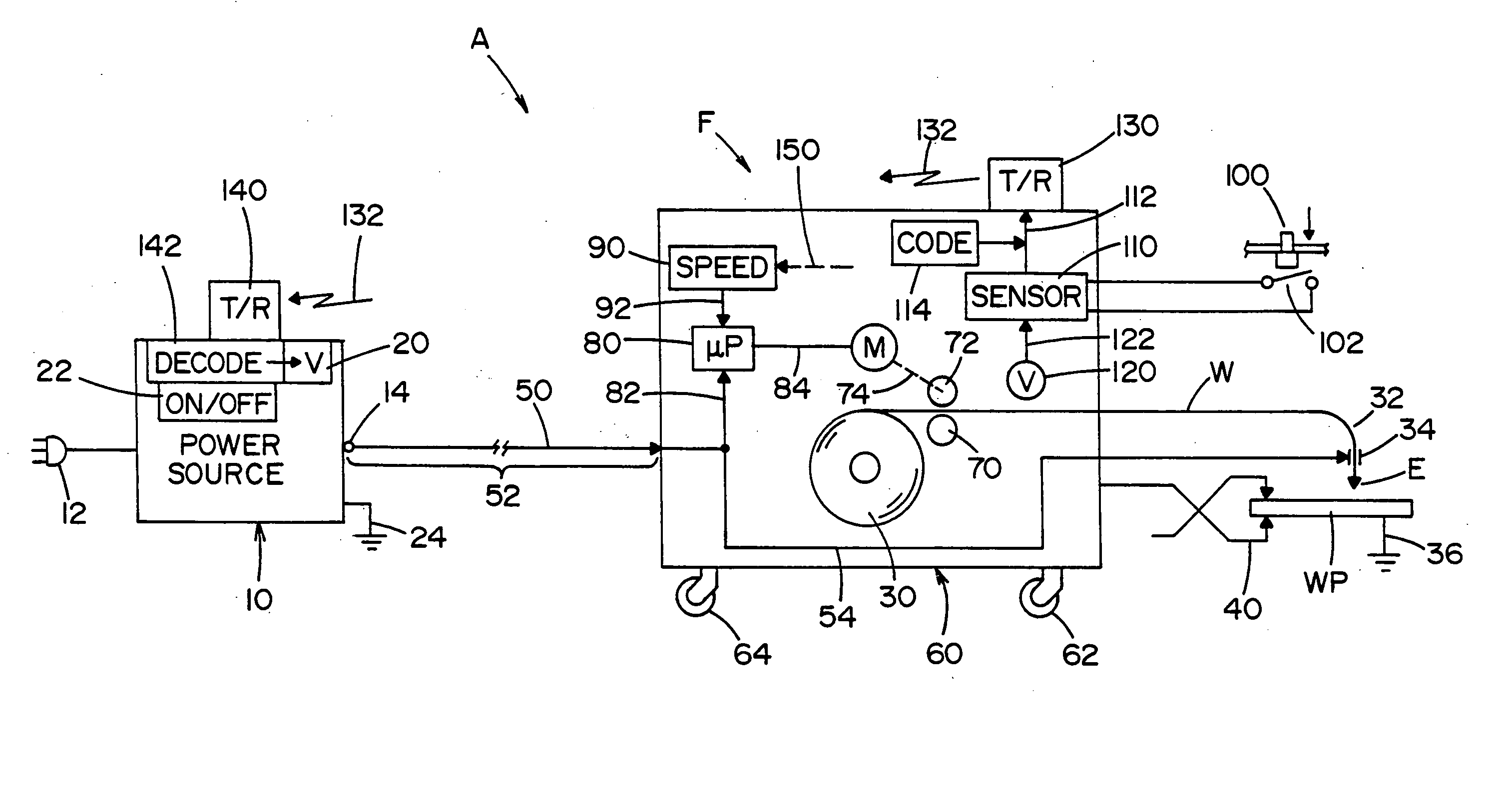

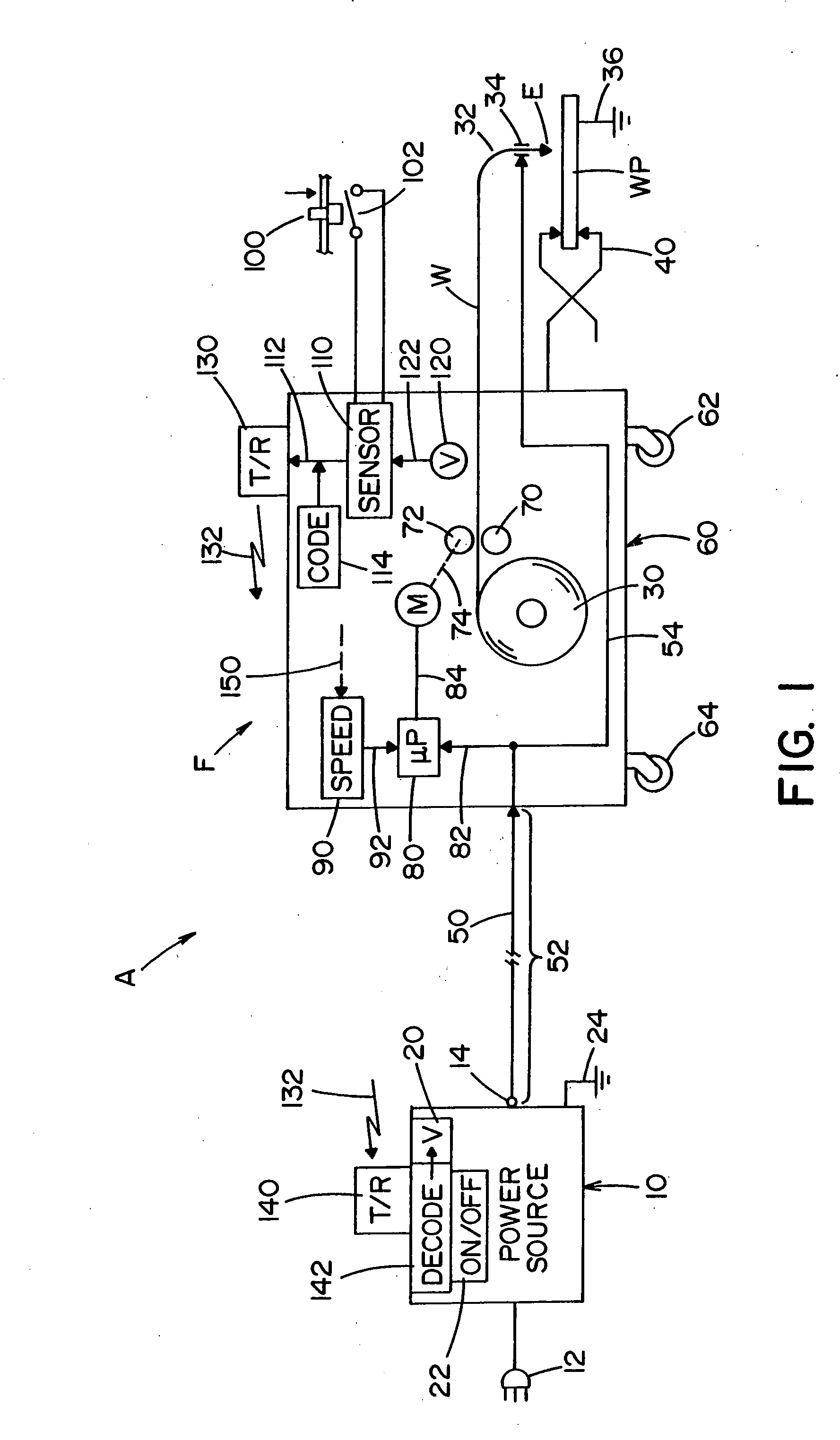

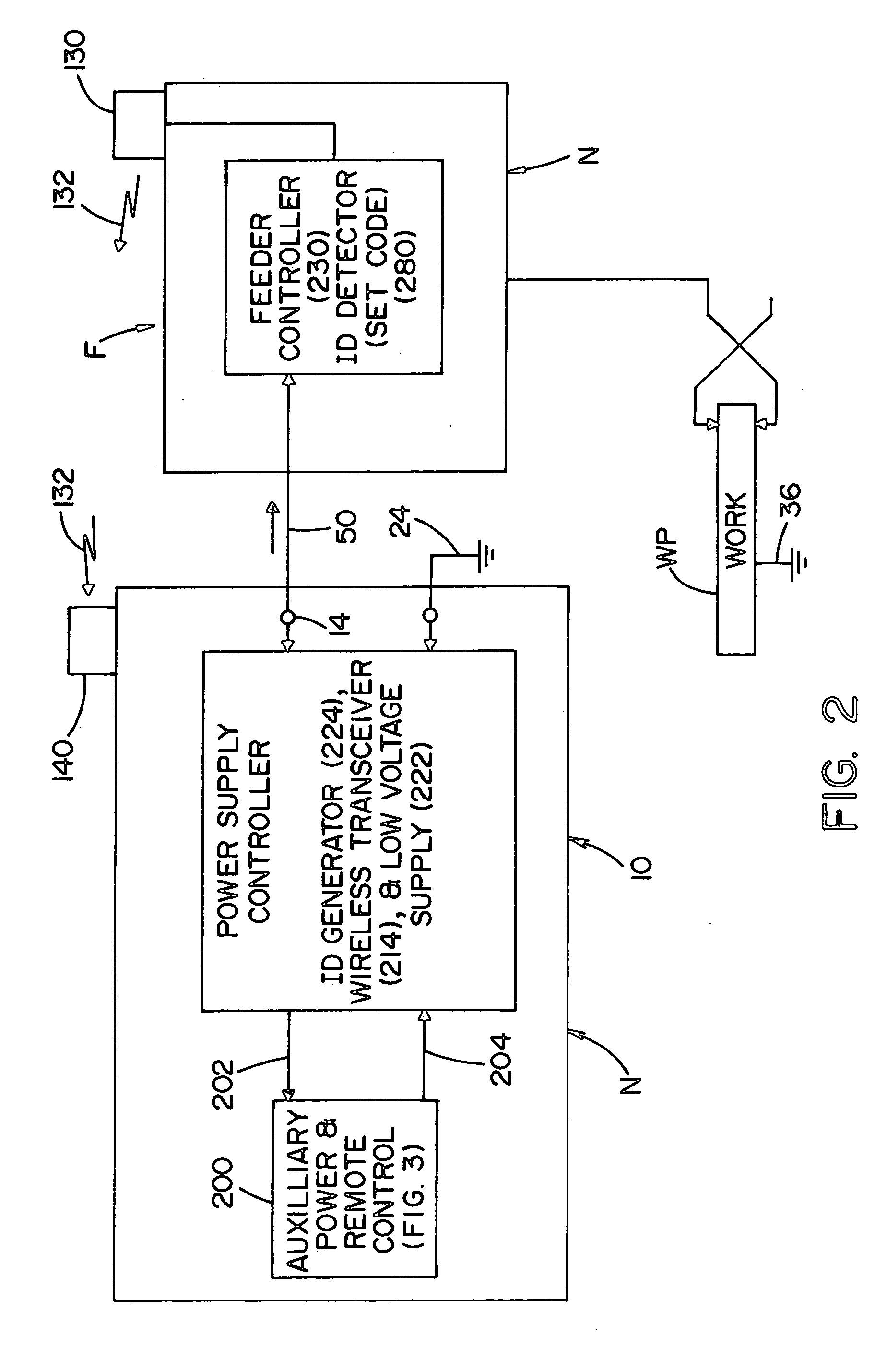

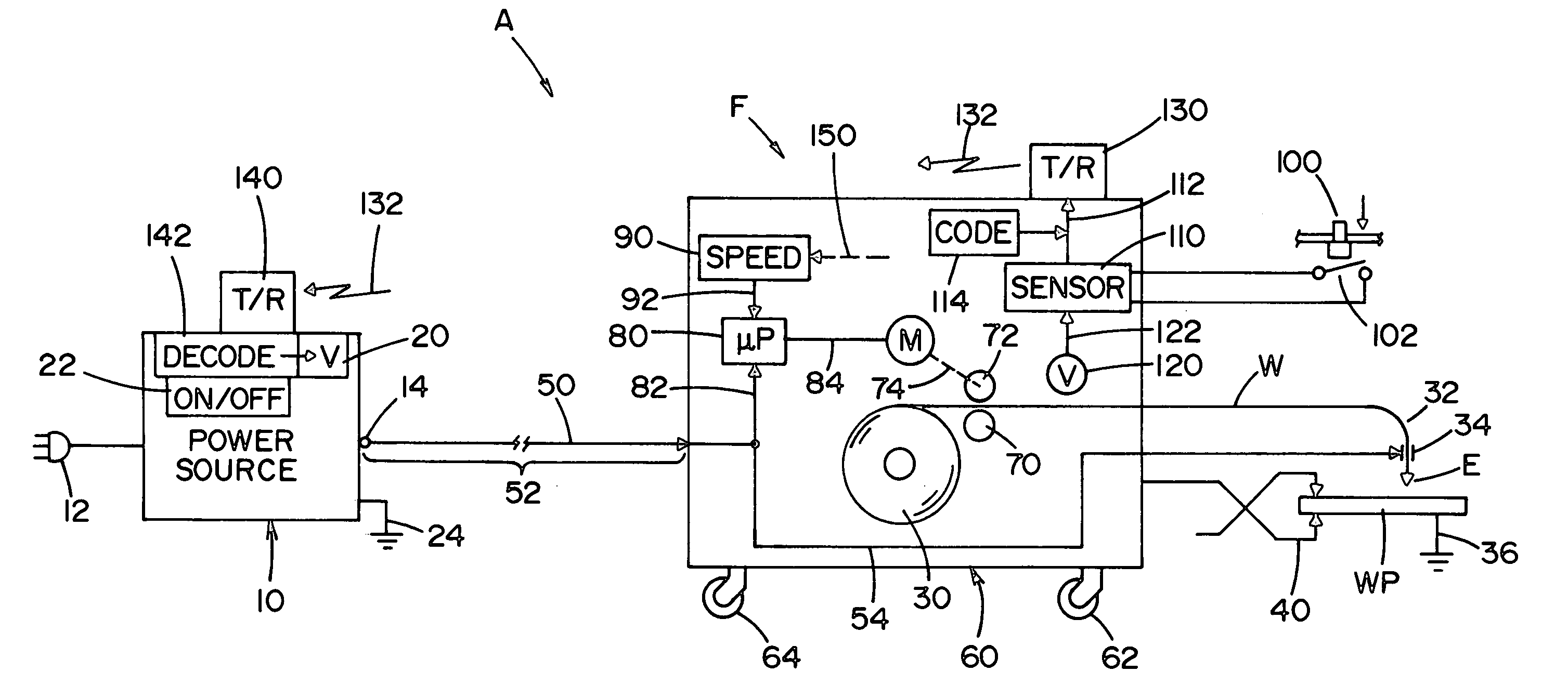

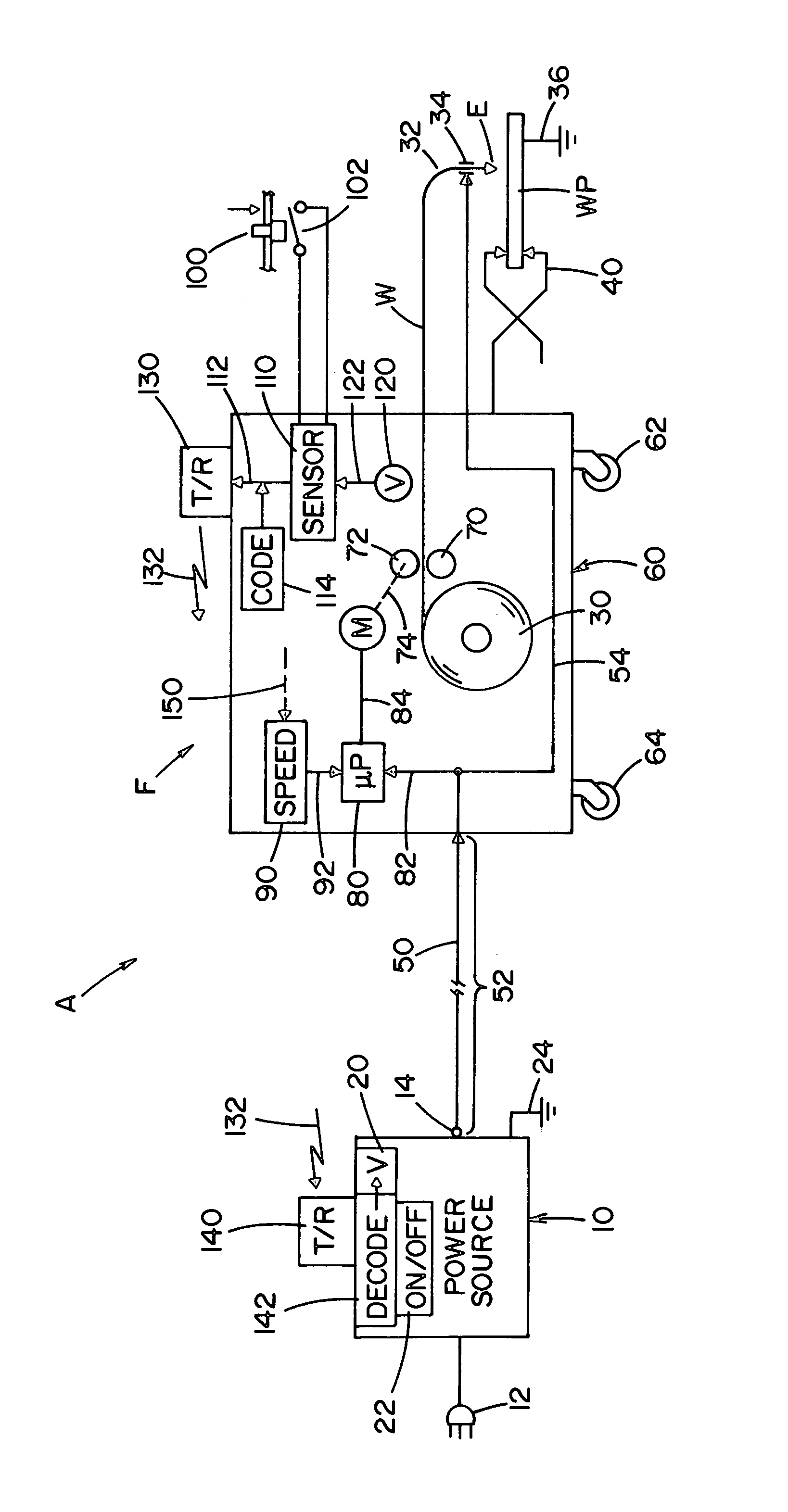

Remote wire feeder

ActiveUS20050199605A1High currentHigh power cyclingElectric discharge heatingArc welding apparatusMotor driveElectric machinery

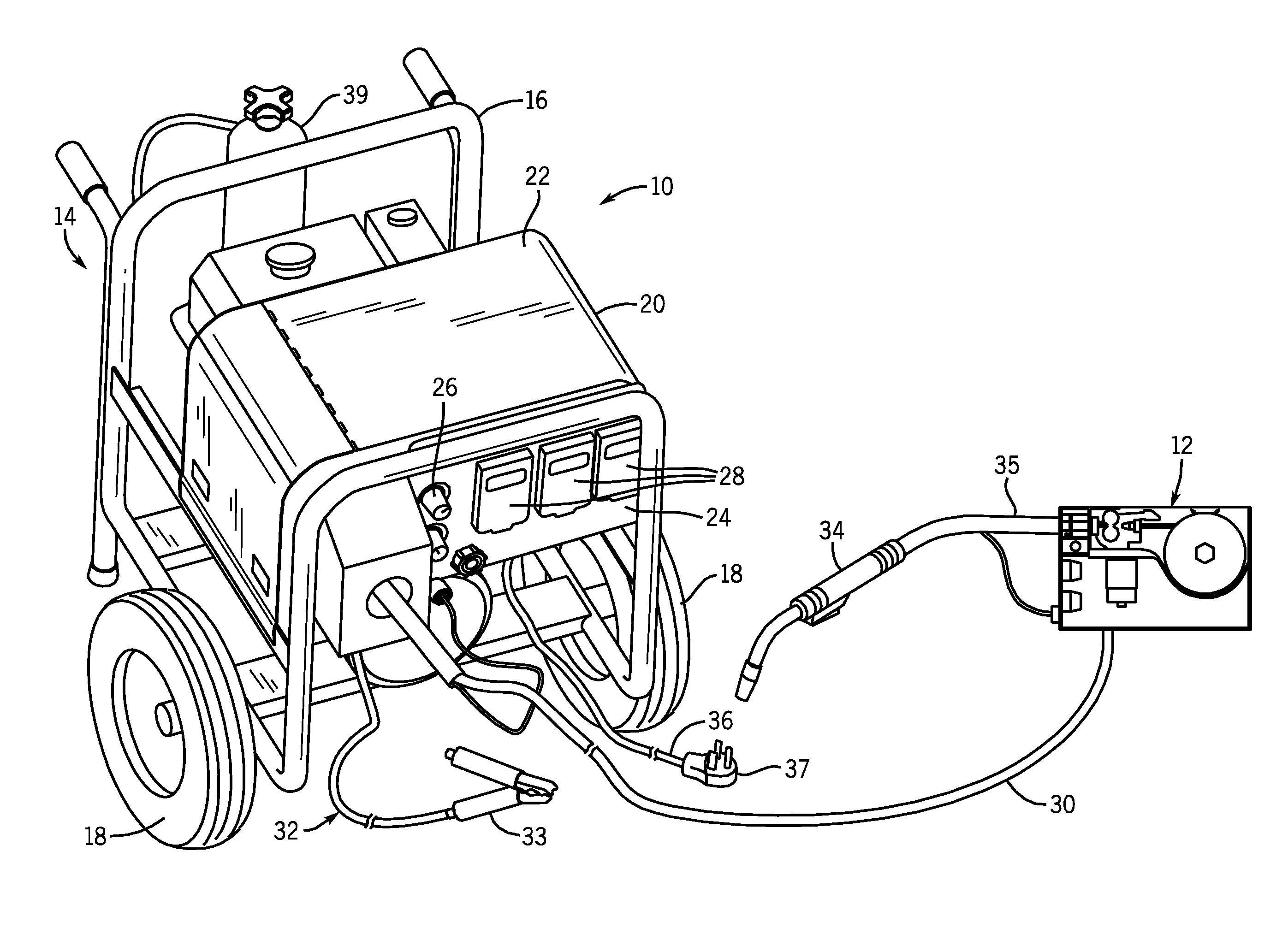

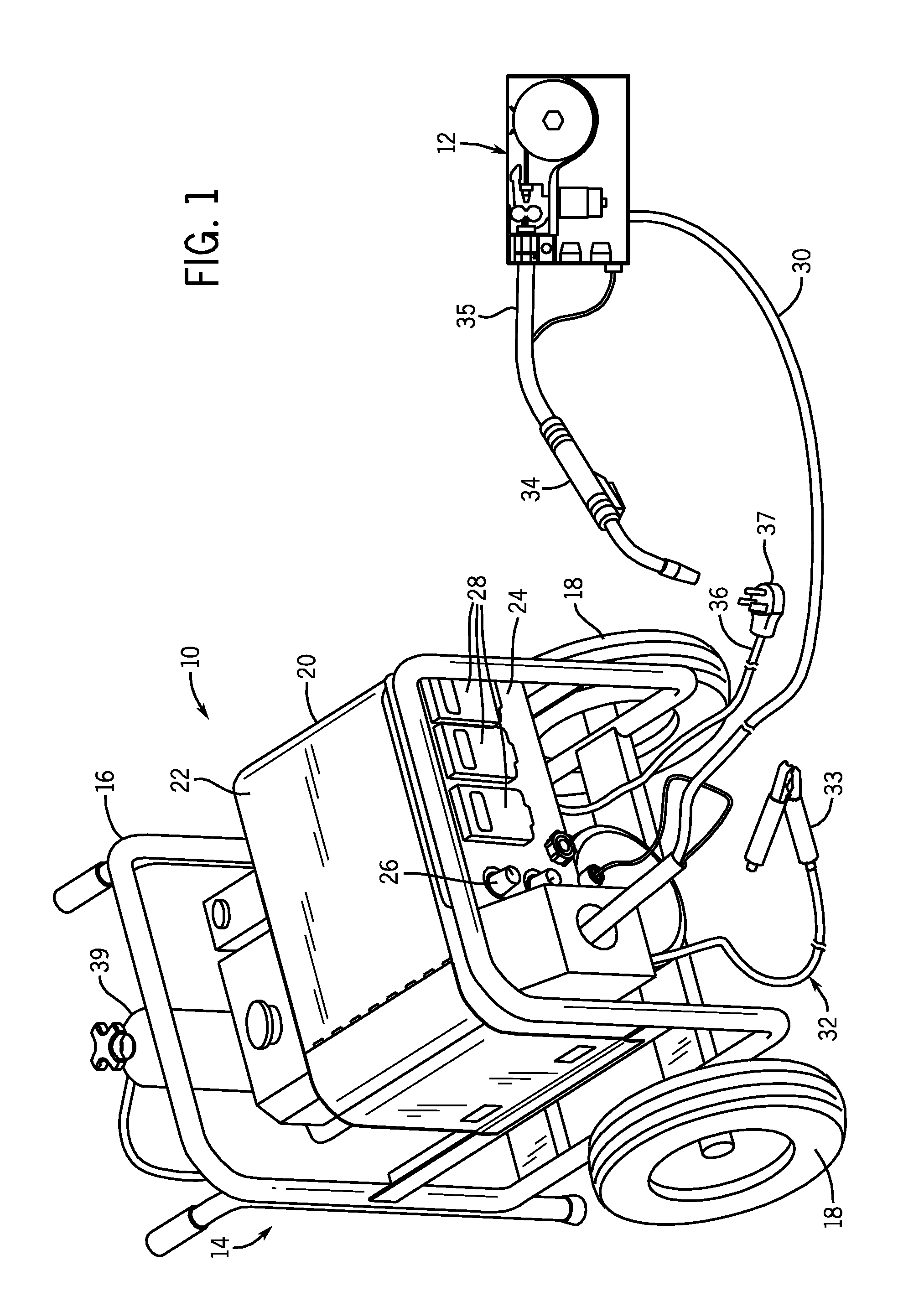

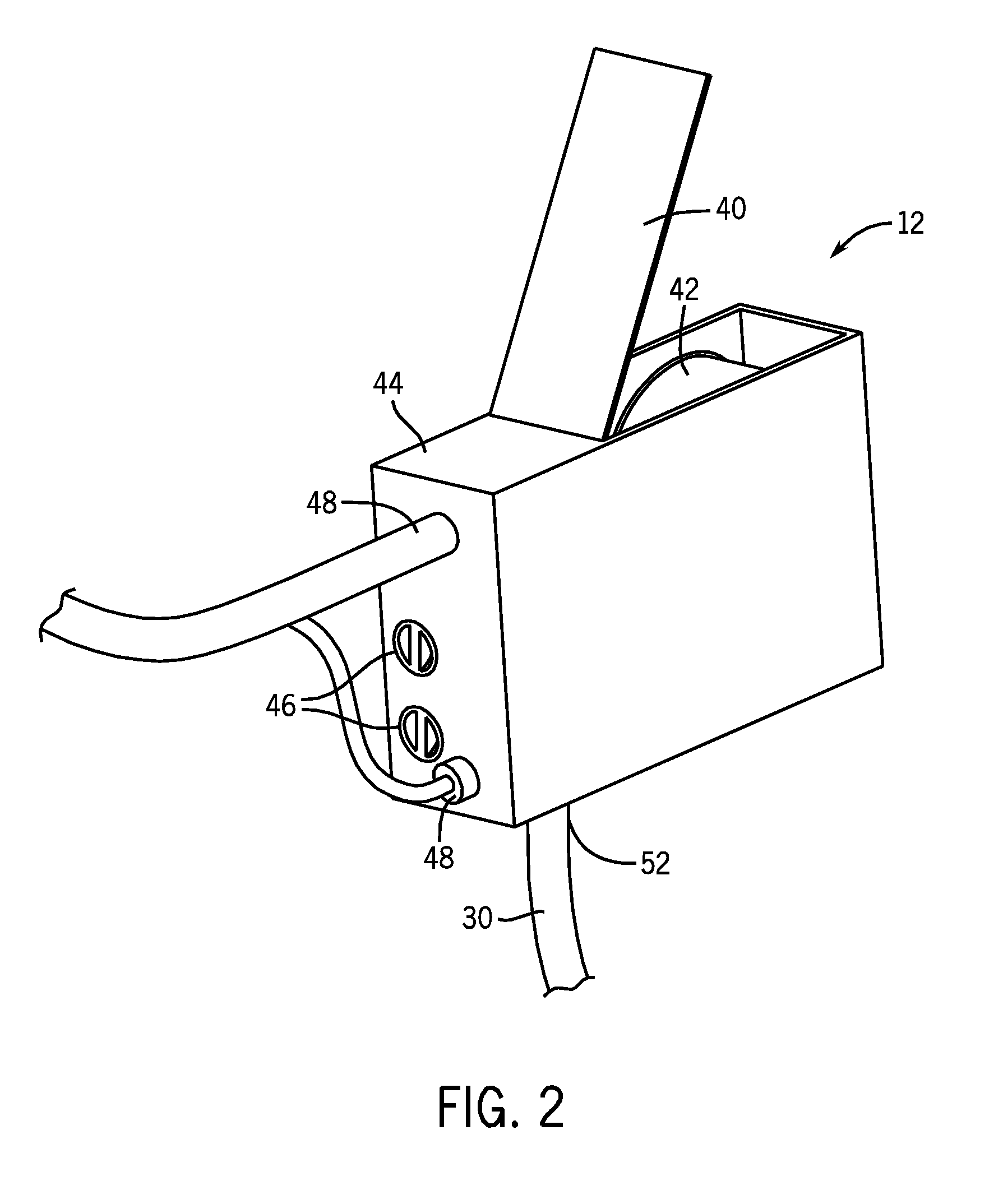

A wire feeder including a motor driving a set of feed rolls to force a welding wire from a spool through a welding torch to a welding operation. The wire feeder has an input lead to be connected to the output lead of one of a plurality of remotely located power sources, each having a signal receiver for receiving transmitted signal with a code unique to one of the power sources. The receiver having an output for controlling a parameter or condition of the one power source in accordance with a received signal with the unique code. A transmitter on each of said plurality of power sources for transmitting on its output lead a coded signal specific to the power source. A signal receiver on said wire feeder to receive a unique code from the specific power source actually connected to the wire feeder and a circuit on the wire feeder for transmitting command signals from the wire feeder, which command signals each have the unique code specific to the power source connected to said wire feeder.

Owner:LINCOLN GLOBAL INC

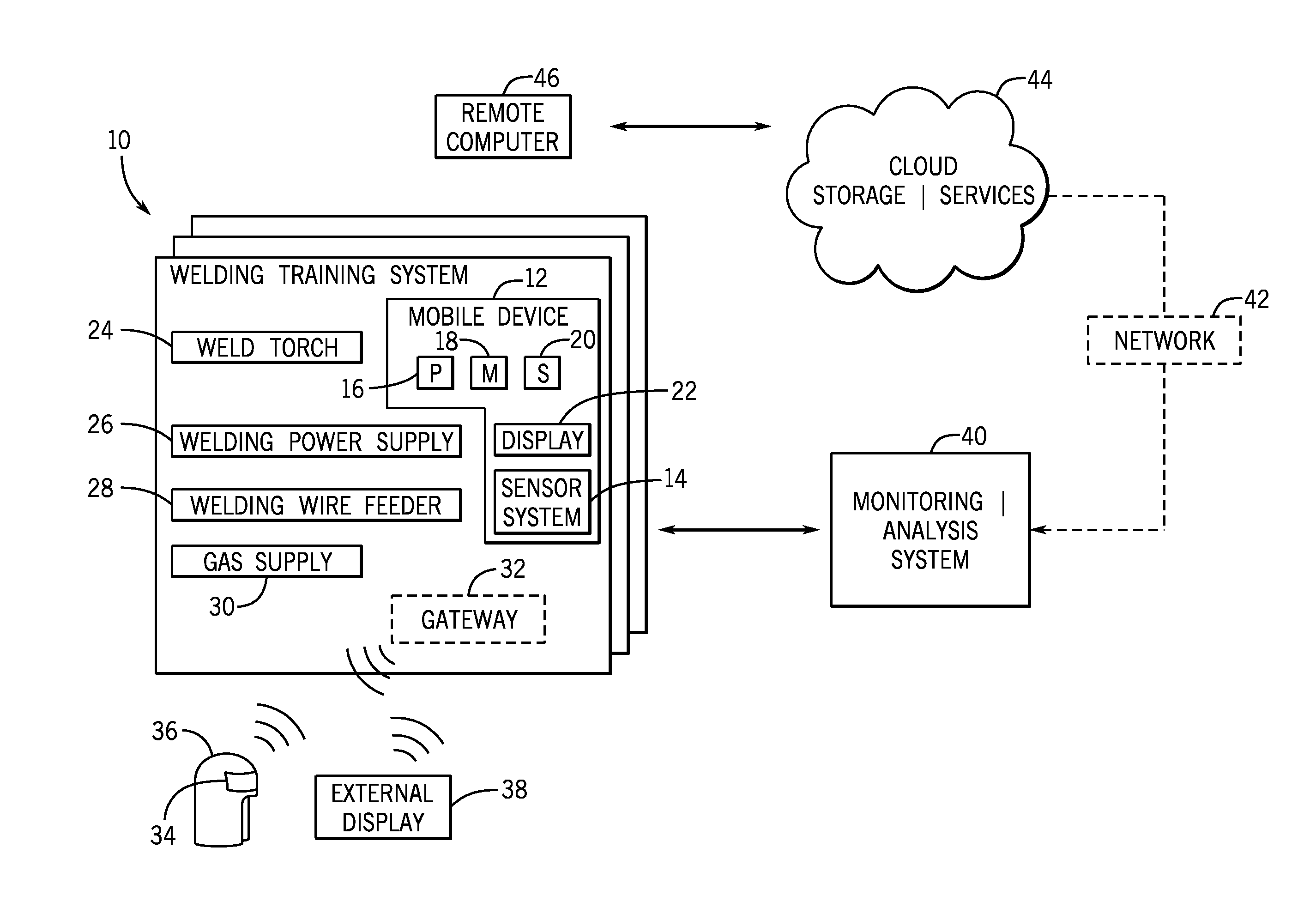

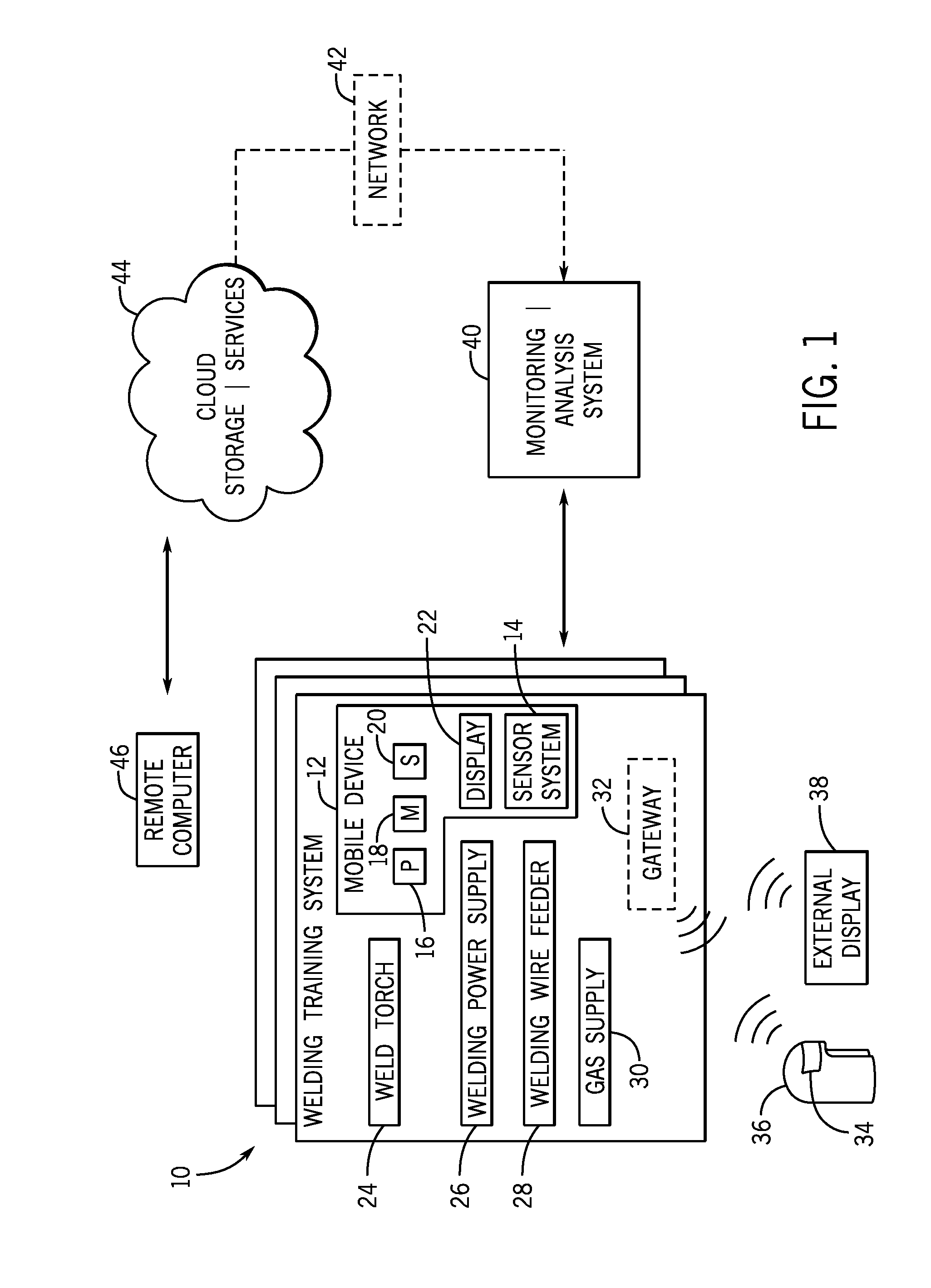

Systems and methods for a weld training system

A weld training system is provided. The weld training system includes a welding torch configured to perform a welding procedure and a mobile device coupled to the welding torch. The mobile device is configured to detect, via one or more sensors, dynamic position or orientation information of the welding torch during the welding procedure to determine one or more operating parameters of the welding procedure. The mobile device is also configured to display a welding environment based at least in part on the one or more operating parameters.

Owner:ILLINOIS TOOL WORKS INC

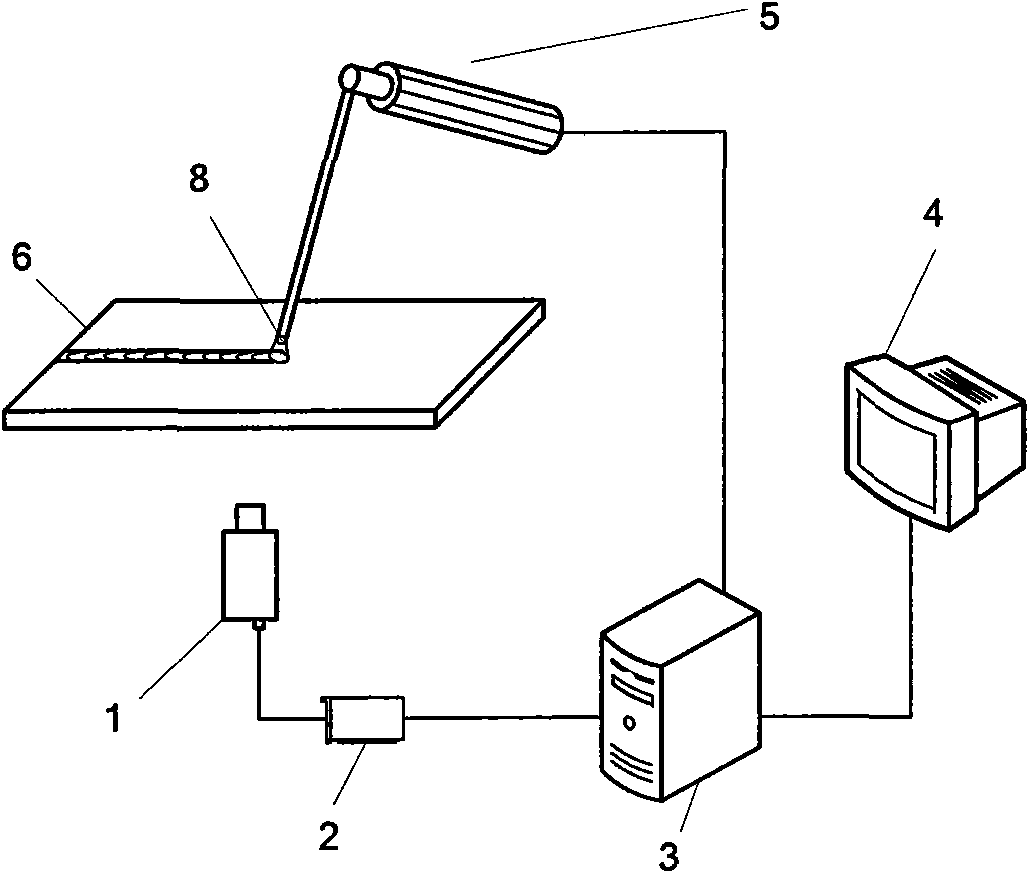

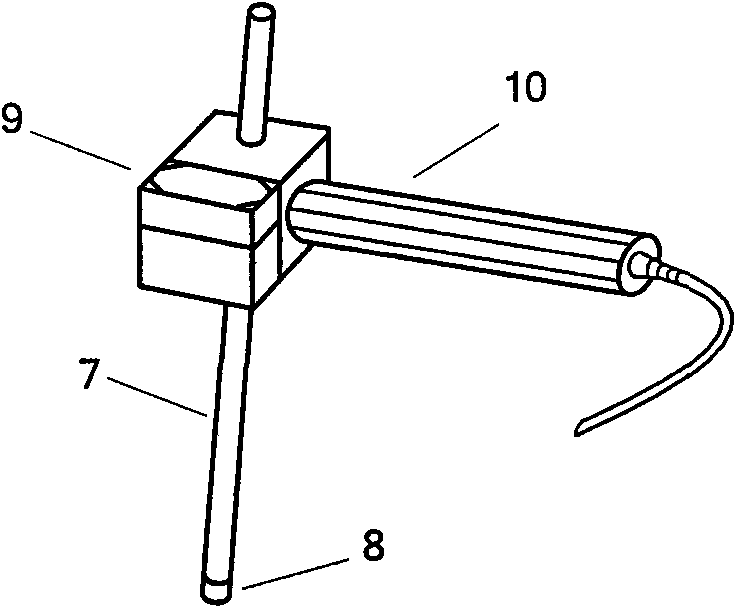

Simulation training device for manual arc welding rod-moving operation, and arc welding rod-moving detection method

InactiveCN101587659ARealize high-precision detectionImprove learning efficiencyUsing optical meansTeaching apparatusShielded metal arc weldingImage detection

The invention provides a simulation training device for manual arc welding rod-moving operation, and an arc welding rod-moving detection method, which is used for the introduction, improvement and enhancement training of welders in welding rod-moving operation. The device comprises a simulated welding torch, a simulated test plate, an image detection module, a dip-angle sensor, a master control computer and an evaluation system. Through the reasonable choice and layout of sensors and efficient data processing, high-precision detection and evaluation of real-time positions of simulated welding rods operated by the welders are realized. The device can record the arc striking, rod moving, ending and a series of operation of welding students during operation, and allows operation tracks to reappear after the operation is completed so as to improve learning efficiency and learning effects.

Owner:XI AN JIAOTONG UNIV

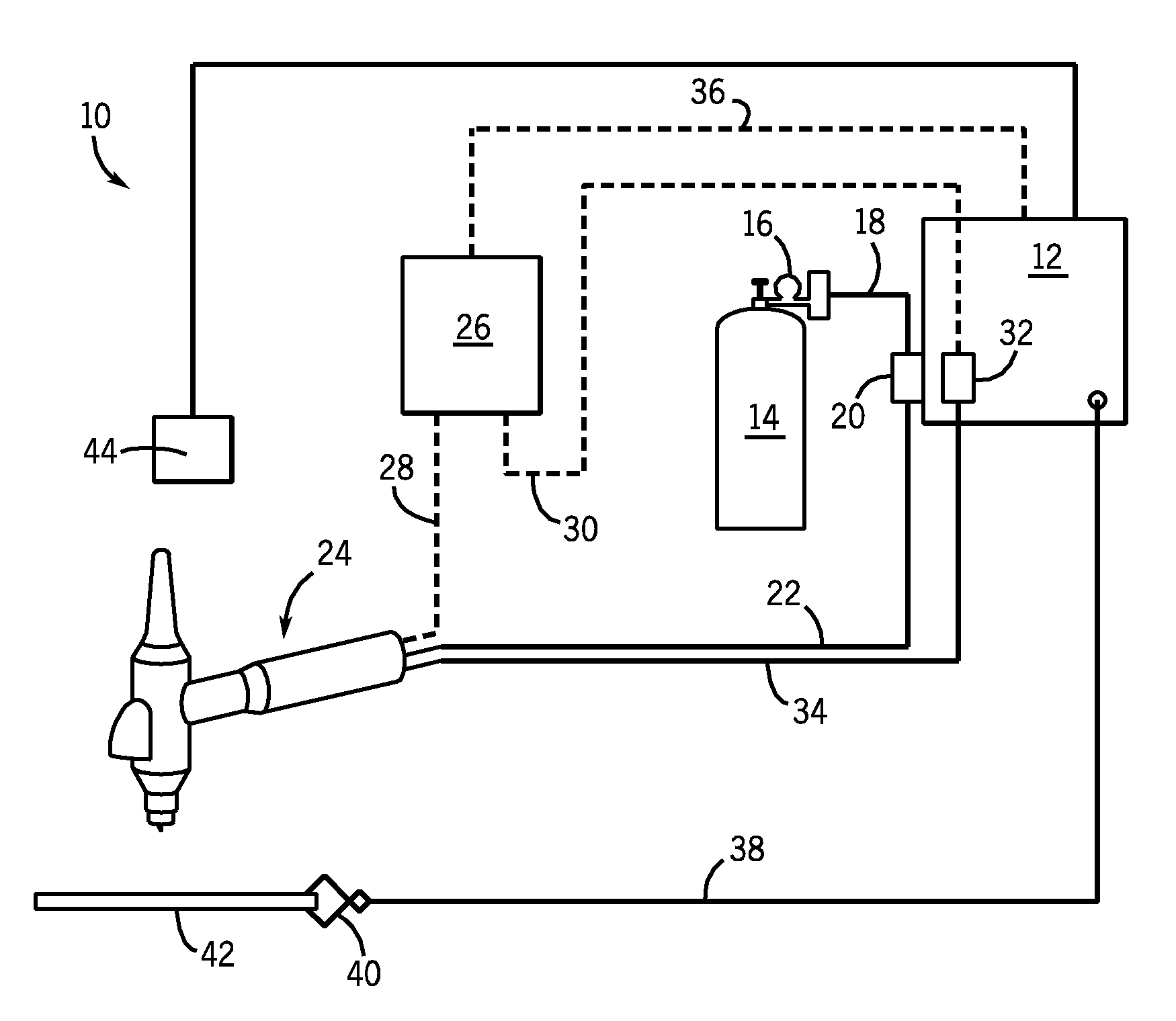

Portable welding wire feed system and method

A welding system is provided that includes a wearable wire feeder having a wire drive motor that is responsive to a control signal received directly from a power unit. Another welding system is provided that includes a wearable wire feeder that is configured to couple to a constant voltage power unit and does not include a voltage sensor. Another welding system is provided that includes a power unit, a wearable wire feeder separate from the power unit, a cable extending directly from the power unit to the wearable wire feeder and a welding torch coupled to and separate from the wire feeder. A method is provided that includes receiving a control signal from a power unit at a wearable wire feeder and driving a welding wire from the wearable wire feeder to a welding torch in response to the control signal, wherein the wearable wire feeder is separate from the torch.

Owner:ILLINOIS TOOL WORKS INC

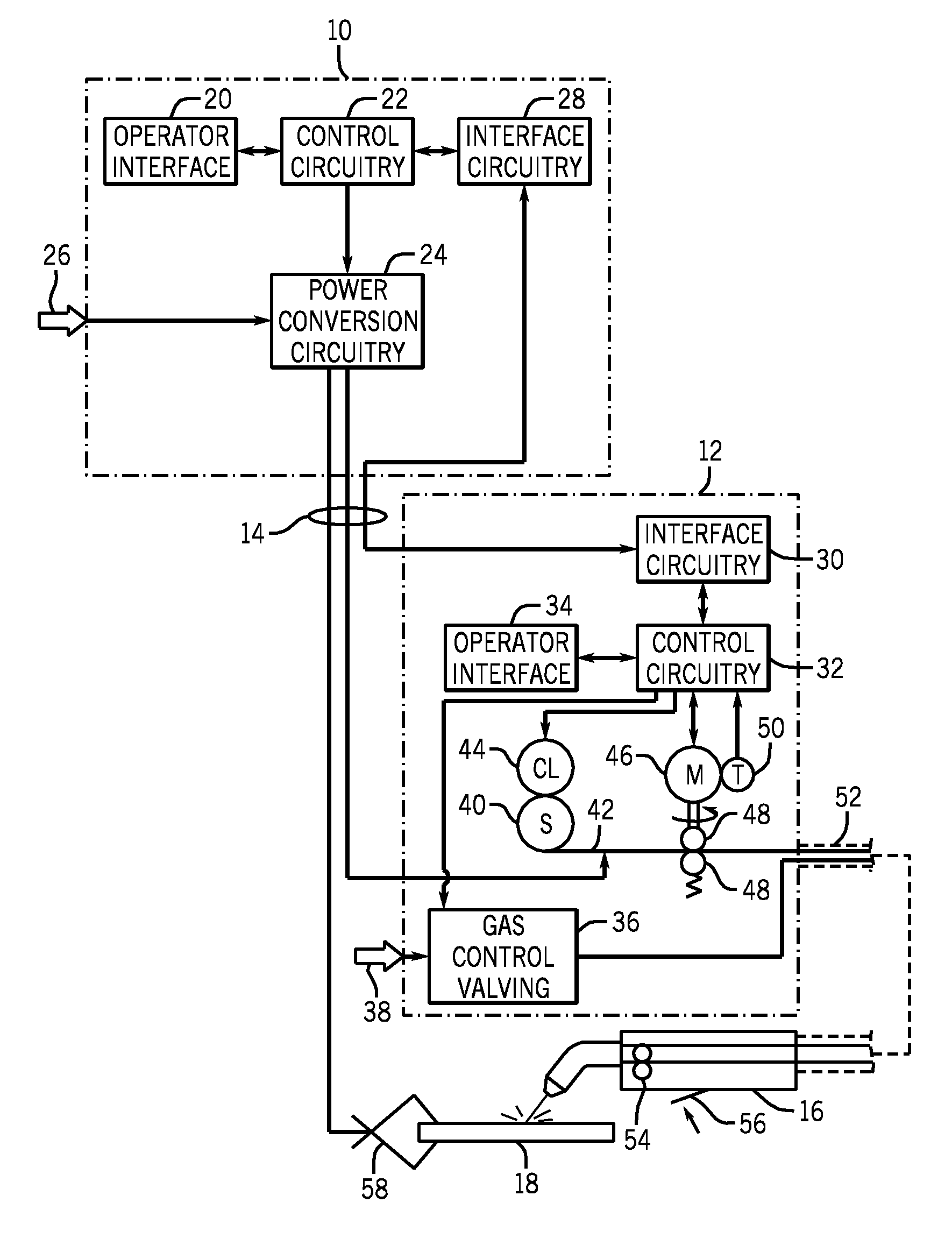

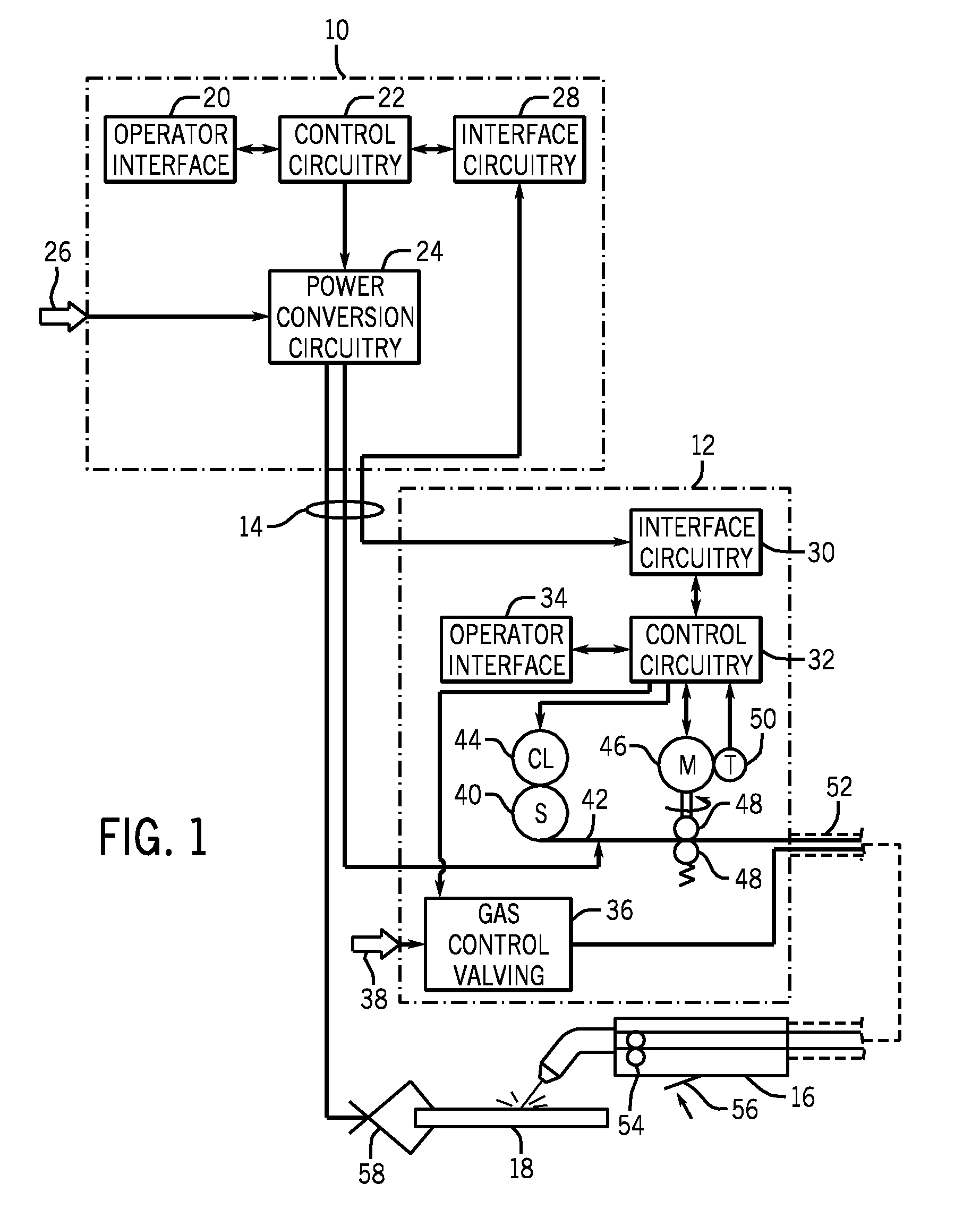

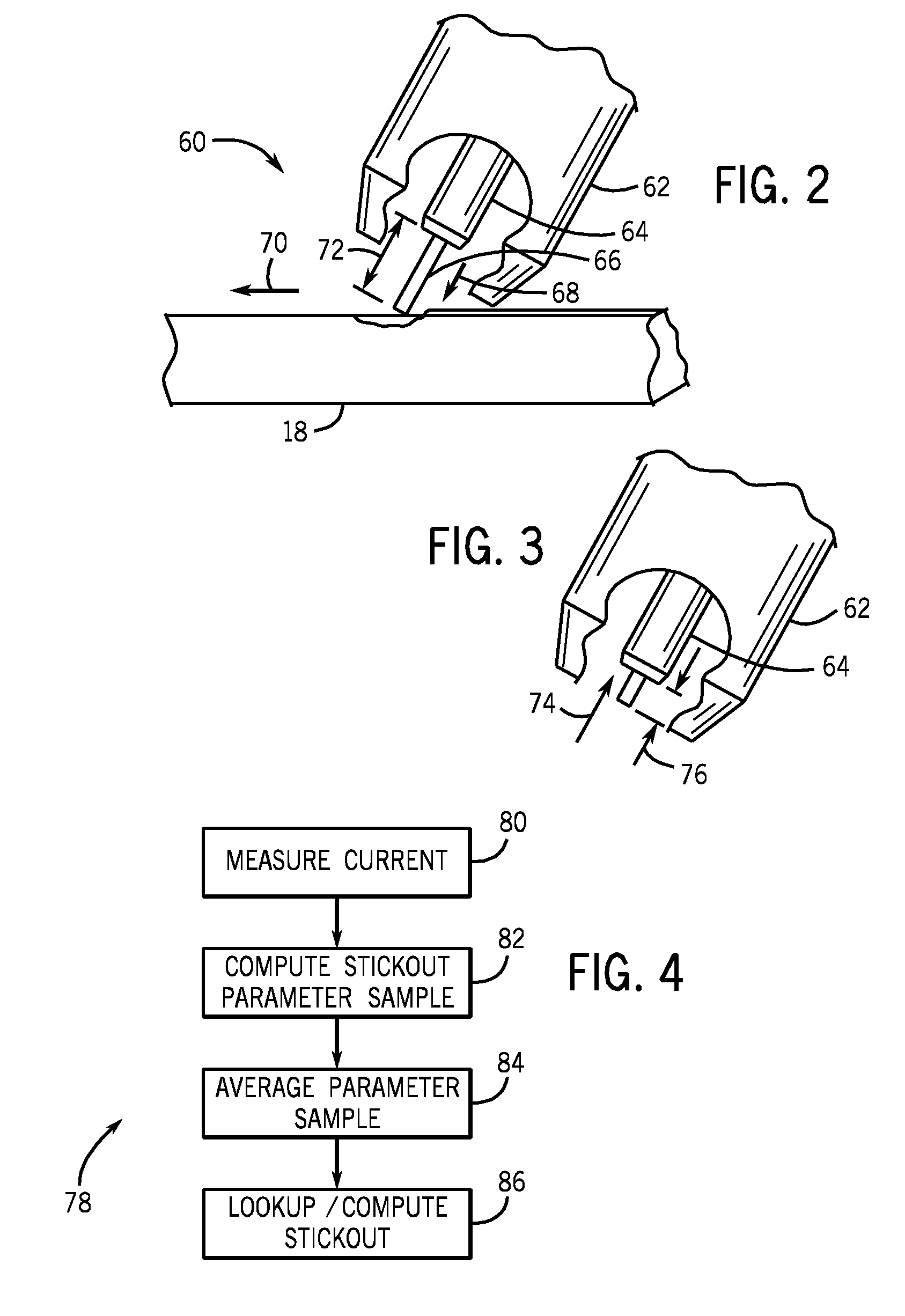

Welding electrode stickout monitoring and control

Stickout of a welding electrode wire from a welding torch is determined during welding, and based upon a welding parameter, such as welding current. Different relationships are used for the determination depending upon whether the welding wire is in a short-circuit condition or an arc condition. The stickout may be converted to a standardized unit of measure to make it readily understandable to an operator. The stickout may be logged and associated with other parameters and information, such as workpiece, operator, welding system, date and time. The stickout may be used as the basis for an alarm or a disabling operation. Moreover, the stickout may be provided on a readout for the operator. It may also be used as a basis for controlling a wire feeding apparatus that retracts the welding wire to a desired stickout following a weld.

Owner:ILLINOIS TOOL WORKS INC

Lighted welding torch

Provided is system for aiding a welding operator in positioning a welding device. The system includes a welding device and a light source coupled to the welding device, wherein the light source is configured to generate a focused beam of light that is configured to illuminate a weld location. The configuration of the light source's illumination may provide for aligning and positioning of the welding device relative to a work piece or other surface.

Owner:ILLINOIS TOOL WORKS INC

Welding software for detection and control of devices and for analysis of data

ActiveUS20150194073A1Quality be determineProgramme controlComputer controlAnalysis dataWelding software

A method used in a welding system includes detecting multiple markers on a welding torch. The markers are detected using one or more cameras. The method also includes blocking live welding using the welding torch while the one or more cameras are unable to detect at least one of the multiple markers on the welding torch.

Owner:ILLINOIS TOOL WORKS INC

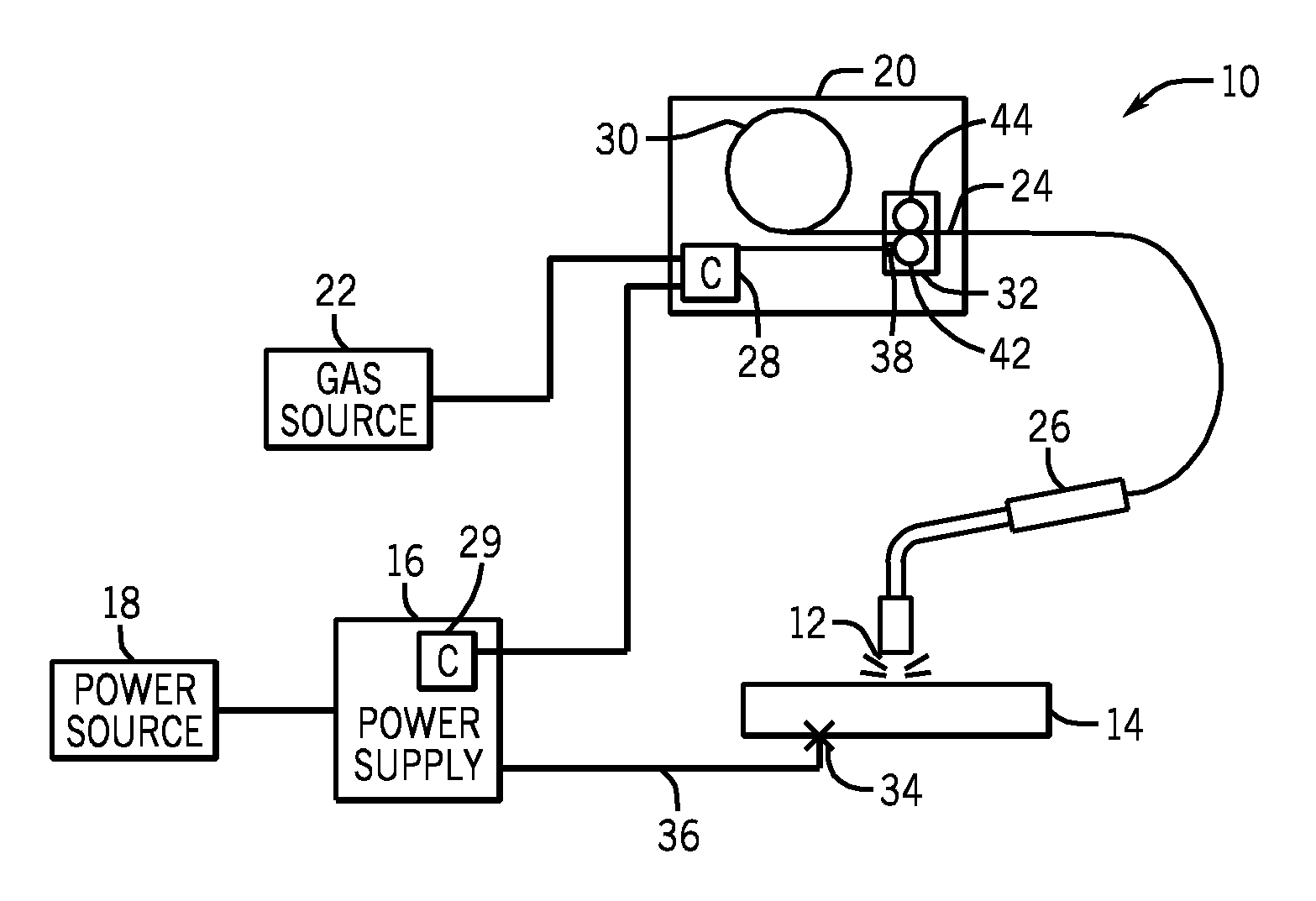

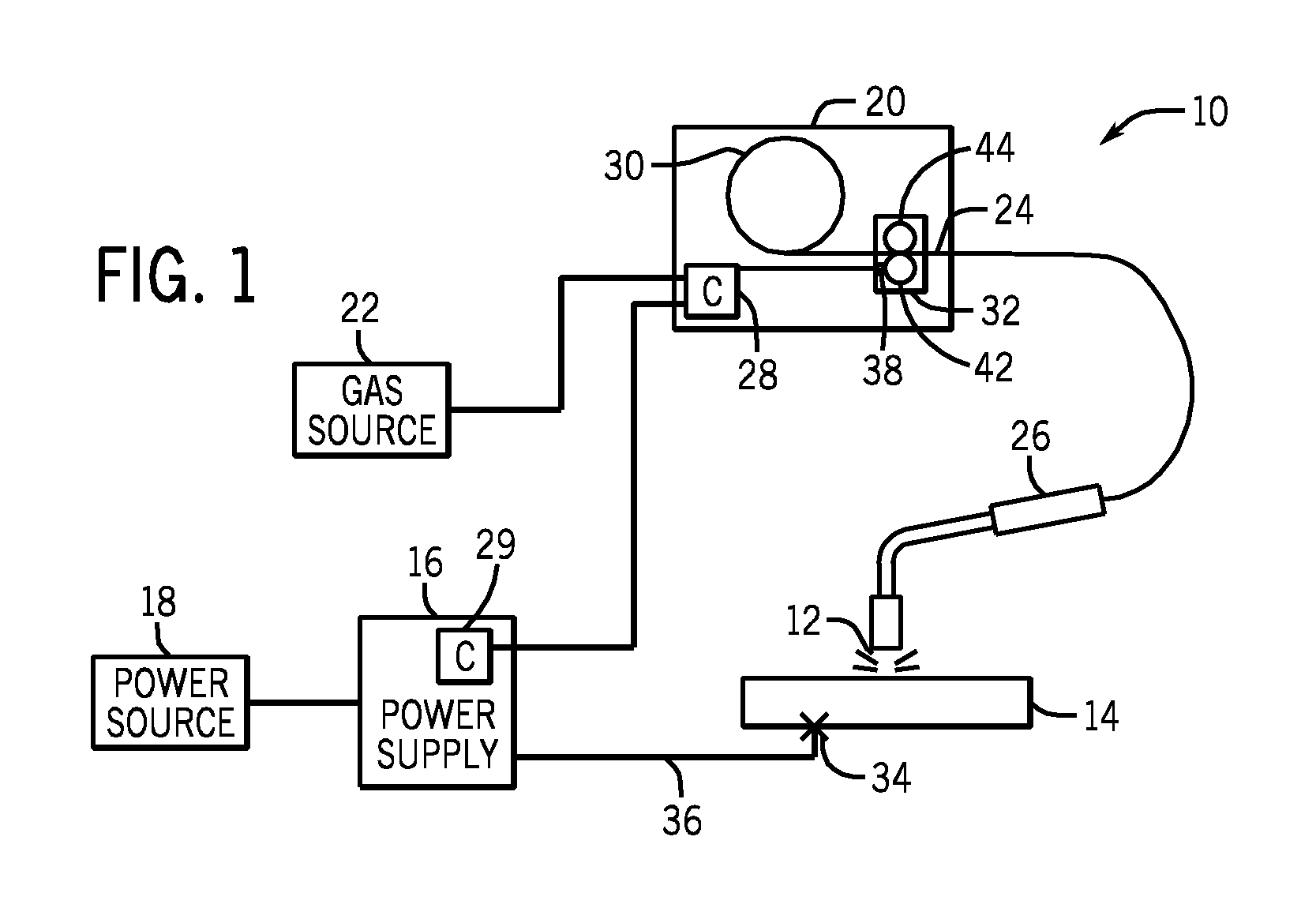

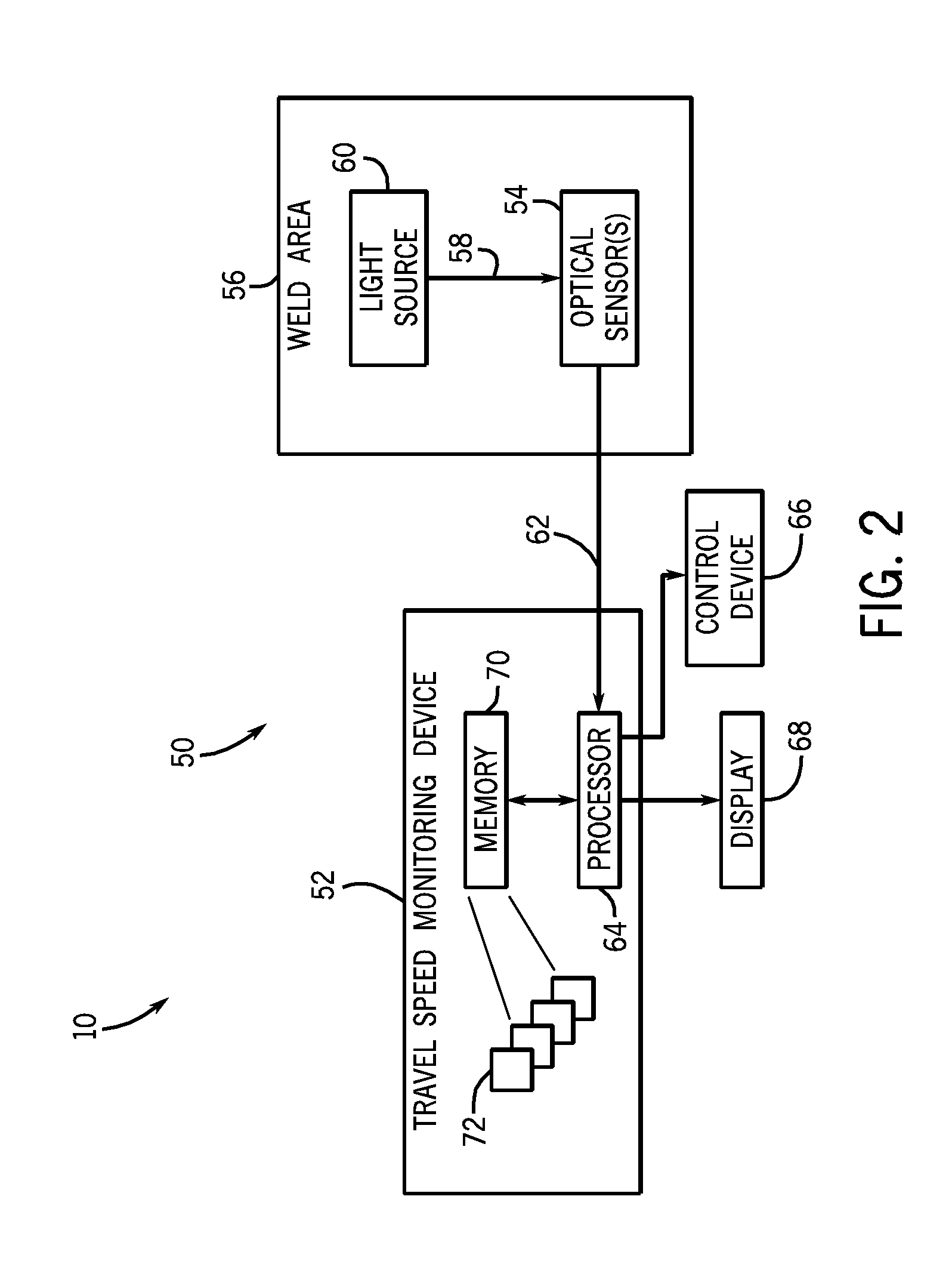

Optical-based weld travel speed sensing system

A travel speed sensing system includes an optical sensor configured to be coupled to a welding torch. The optical sensor is configured to sense light incident on the optical sensor, and the travel speed sensing system is configured to determine a travel speed of the welding torch, a direction of the welding torch, or both, based on the sensed light.

Owner:ILLINOIS TOOL WORKS INC

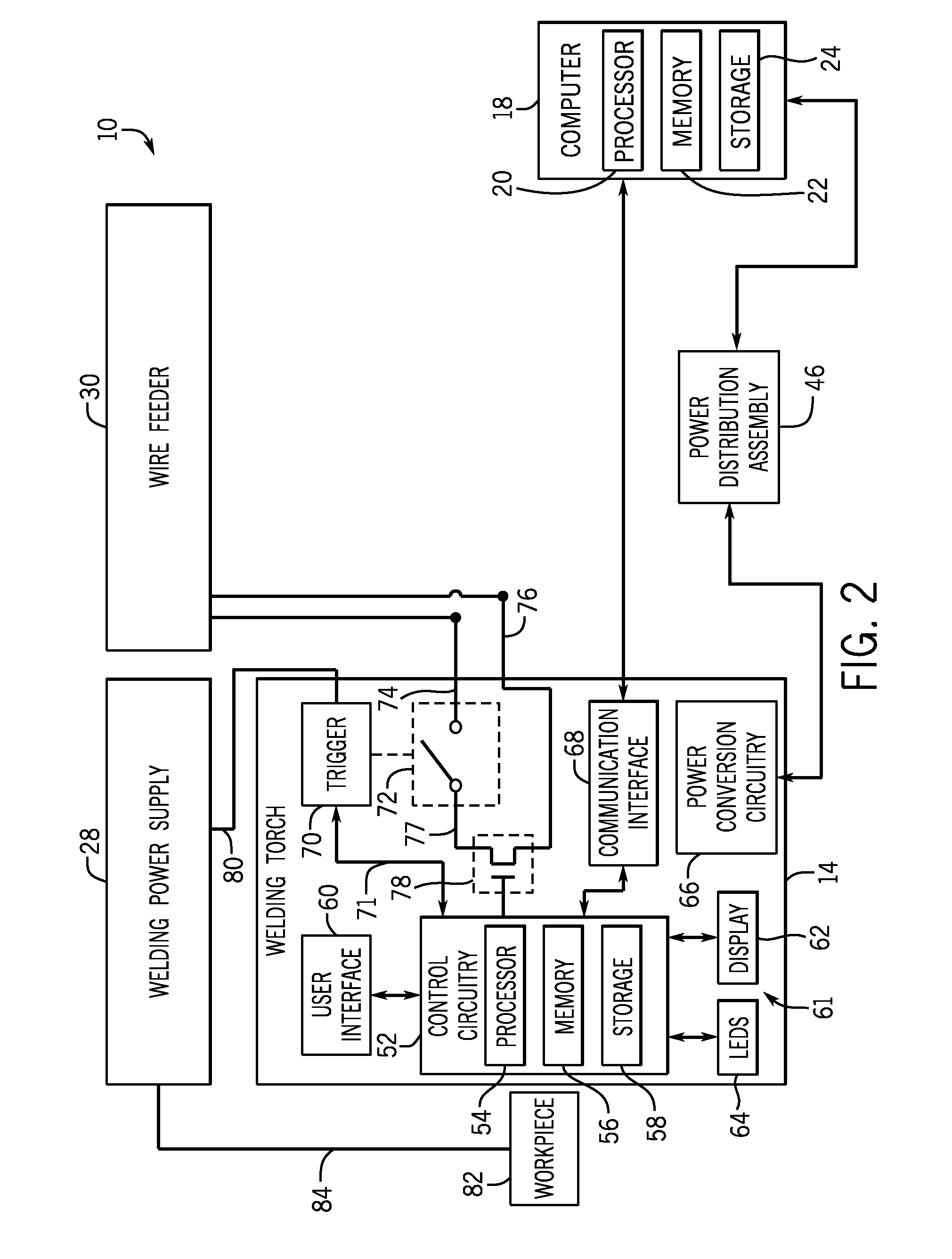

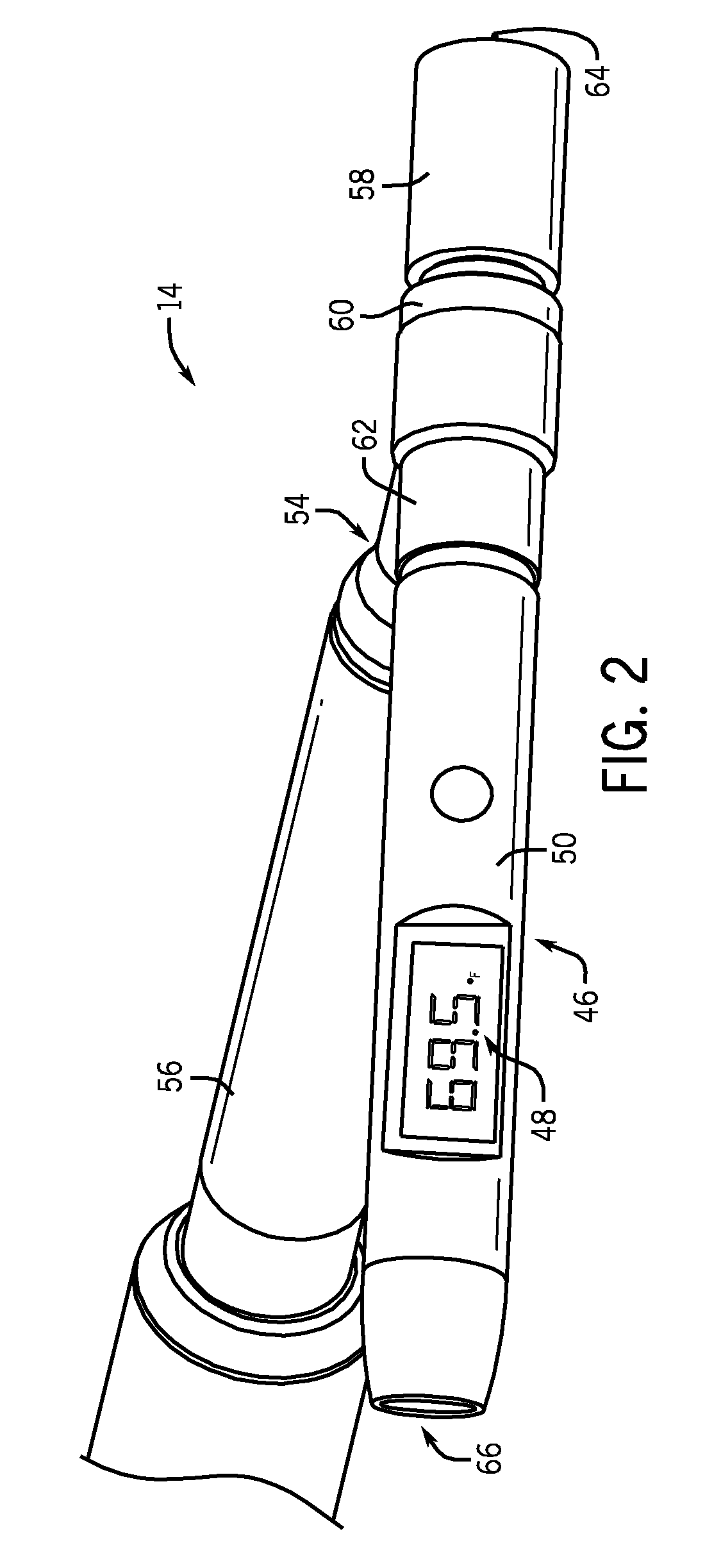

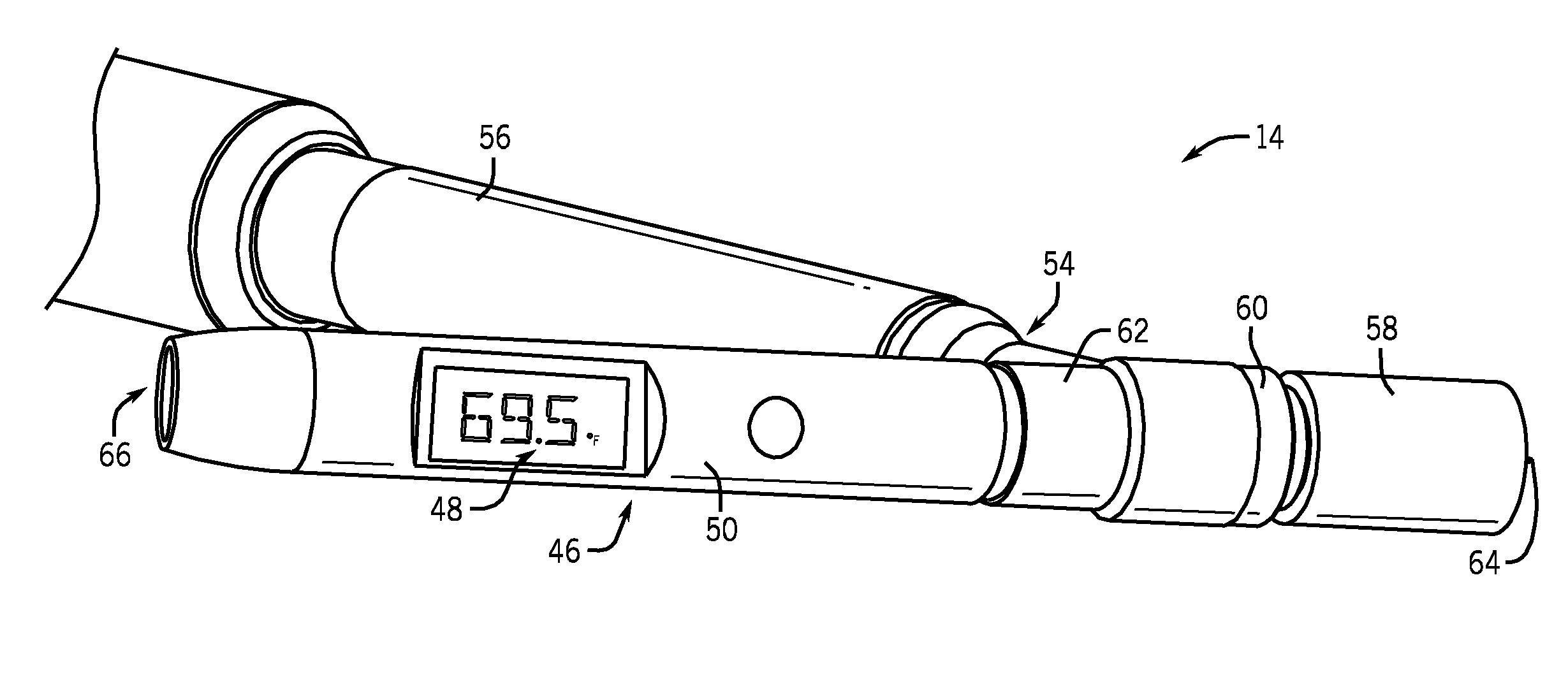

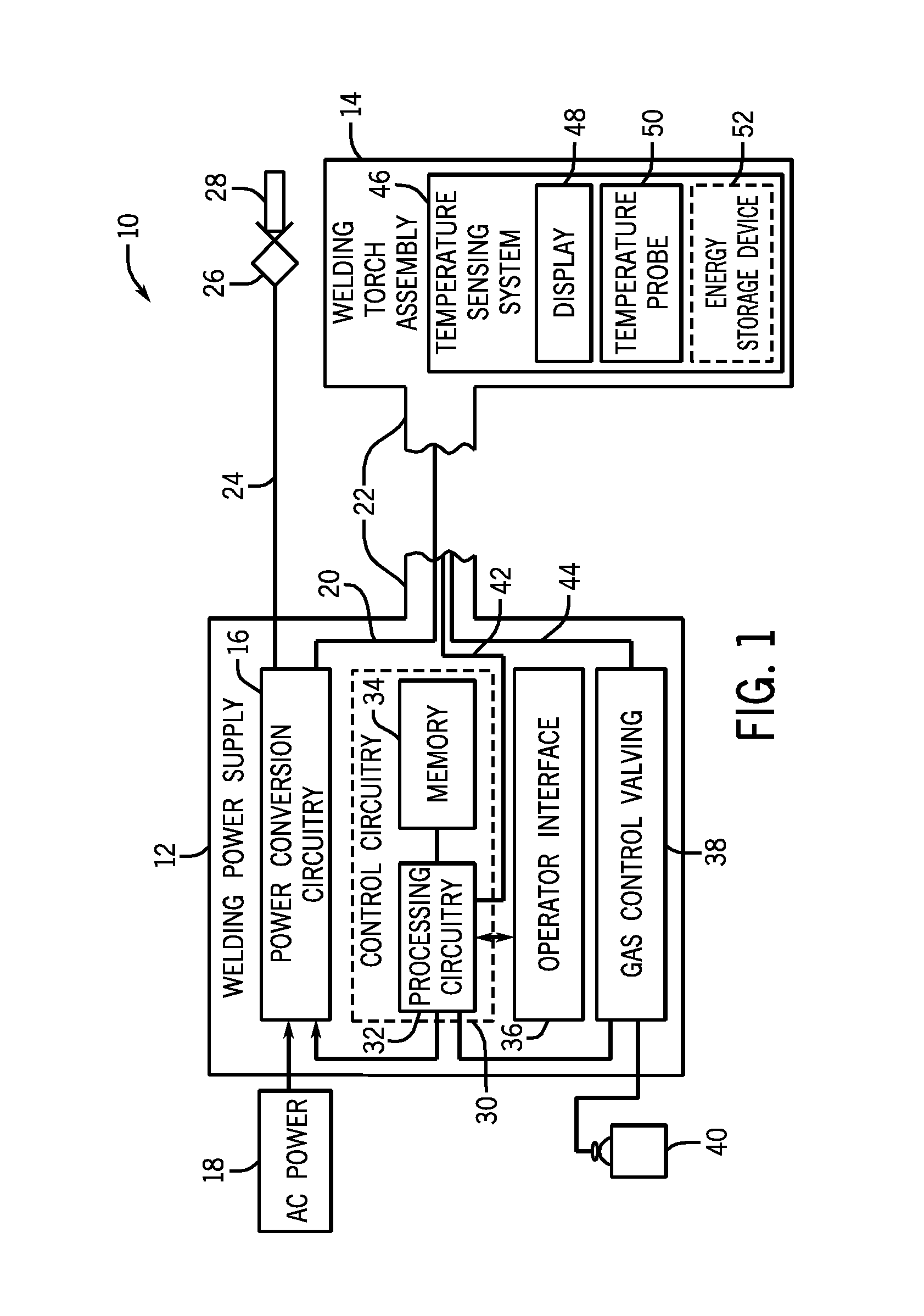

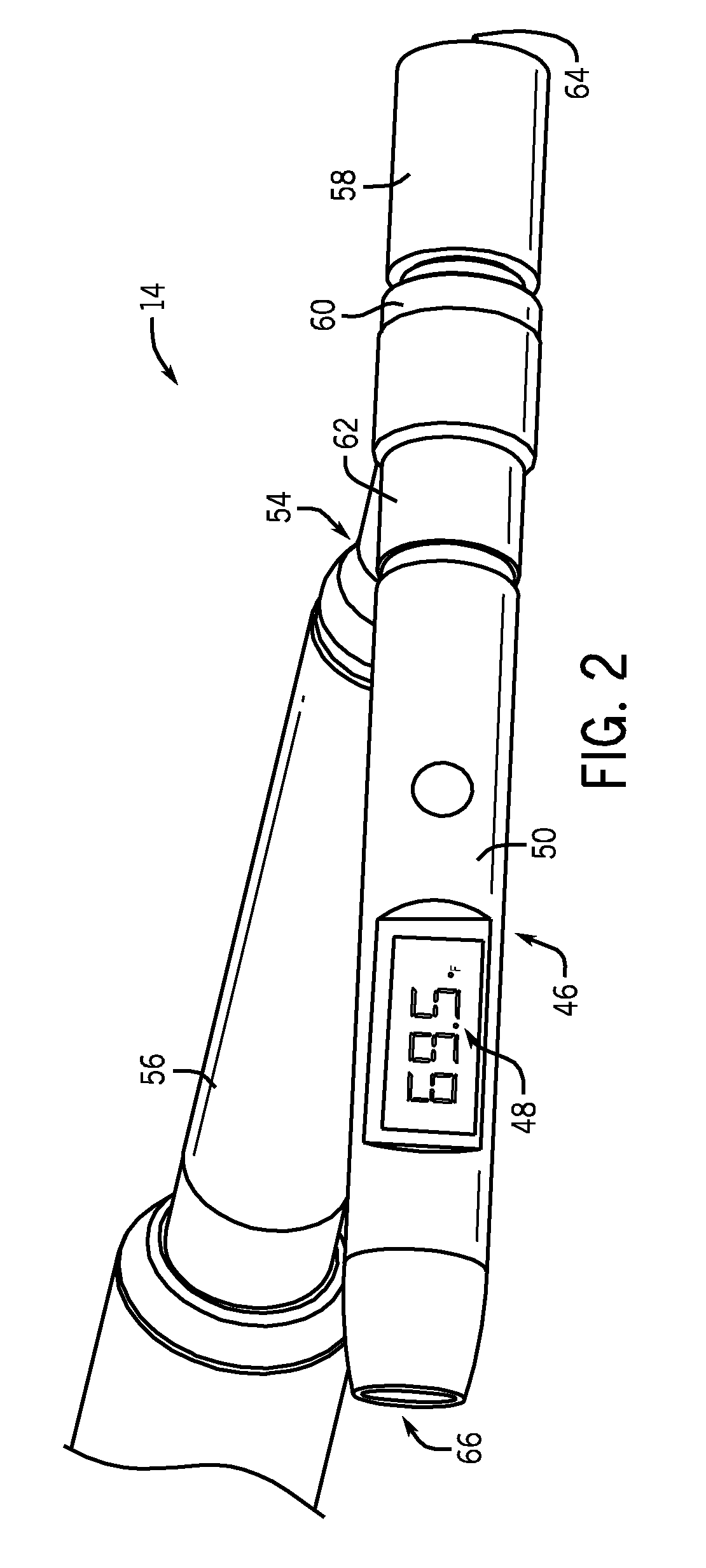

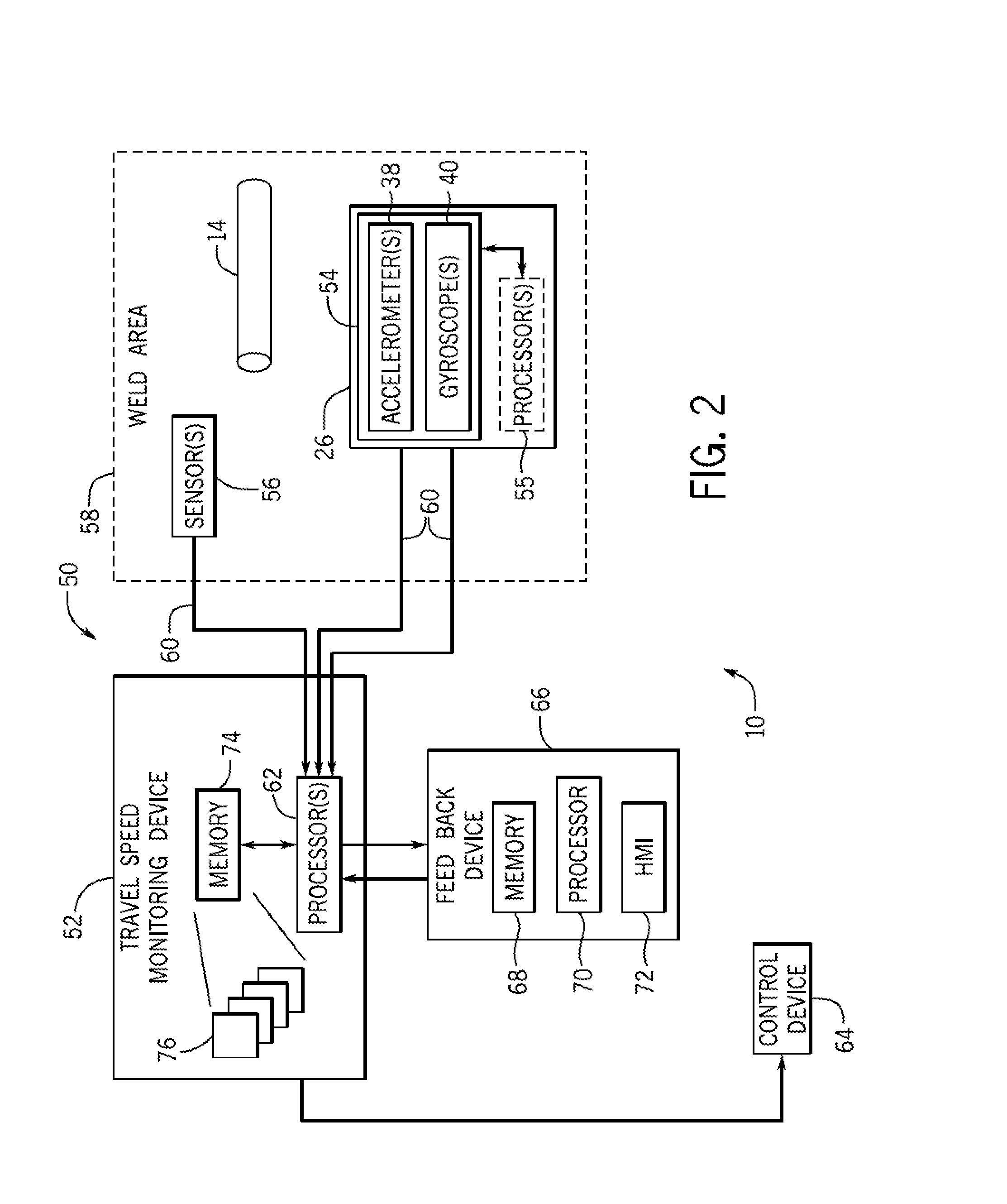

Feedback from a welding torch of a welding system

ActiveUS20150194072A1Electrode vibration holdersCosmonautic condition simulationsDisplay deviceEngineering

A welding system includes a welding torch. The welding torch includes a sensor configured to detect a motion associated with the welding torch, a temperature associated with the welding torch, or some combination thereof. A display of the welding torch is activated, a determination is made that the welding torch has been involved in a high impact event, live welding using the welding torch is disabled, a software selection is made, or some combination thereof, based on the motion, the temperature, or some combination thereof.

Owner:ILLINOIS TOOL WORKS INC

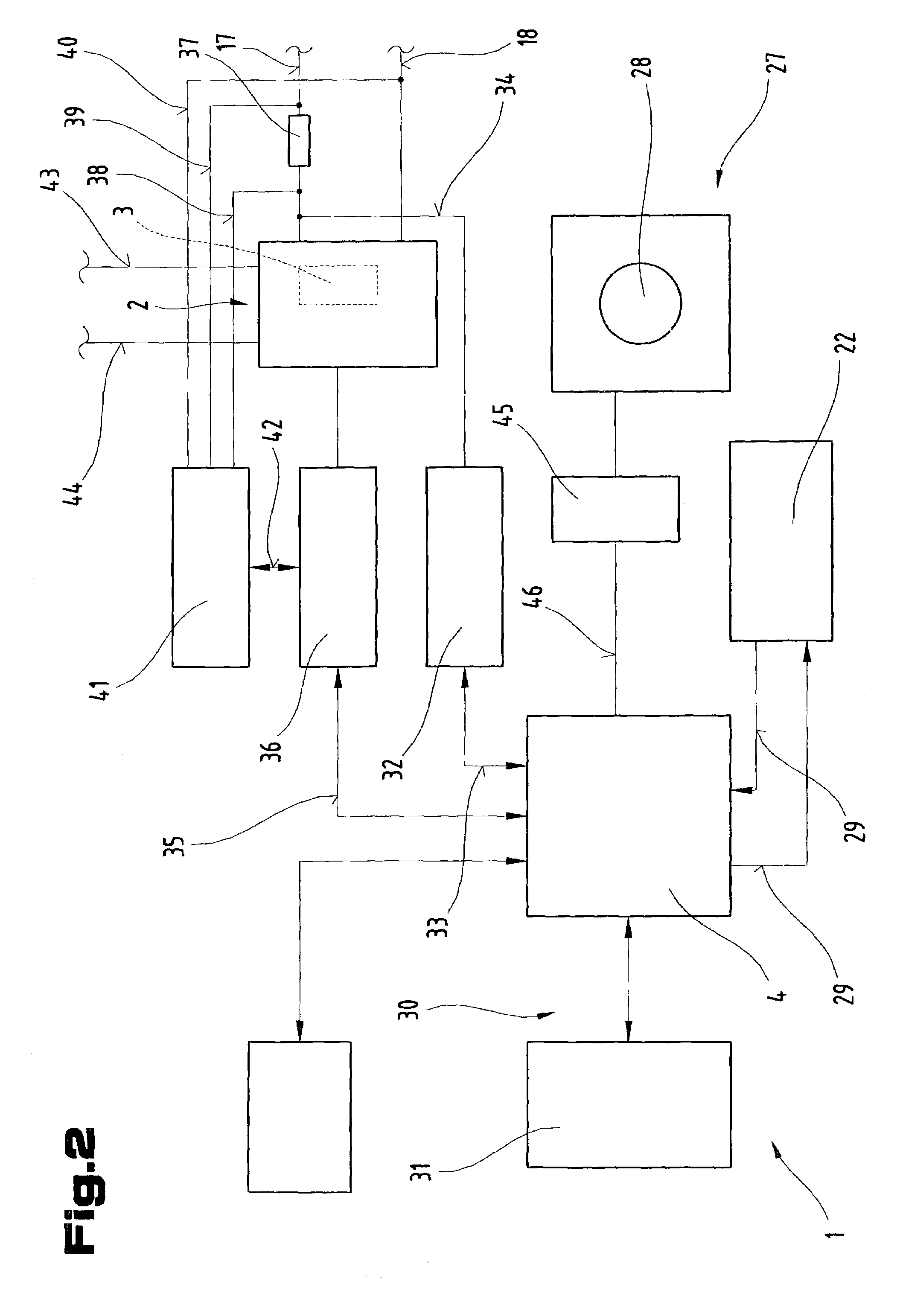

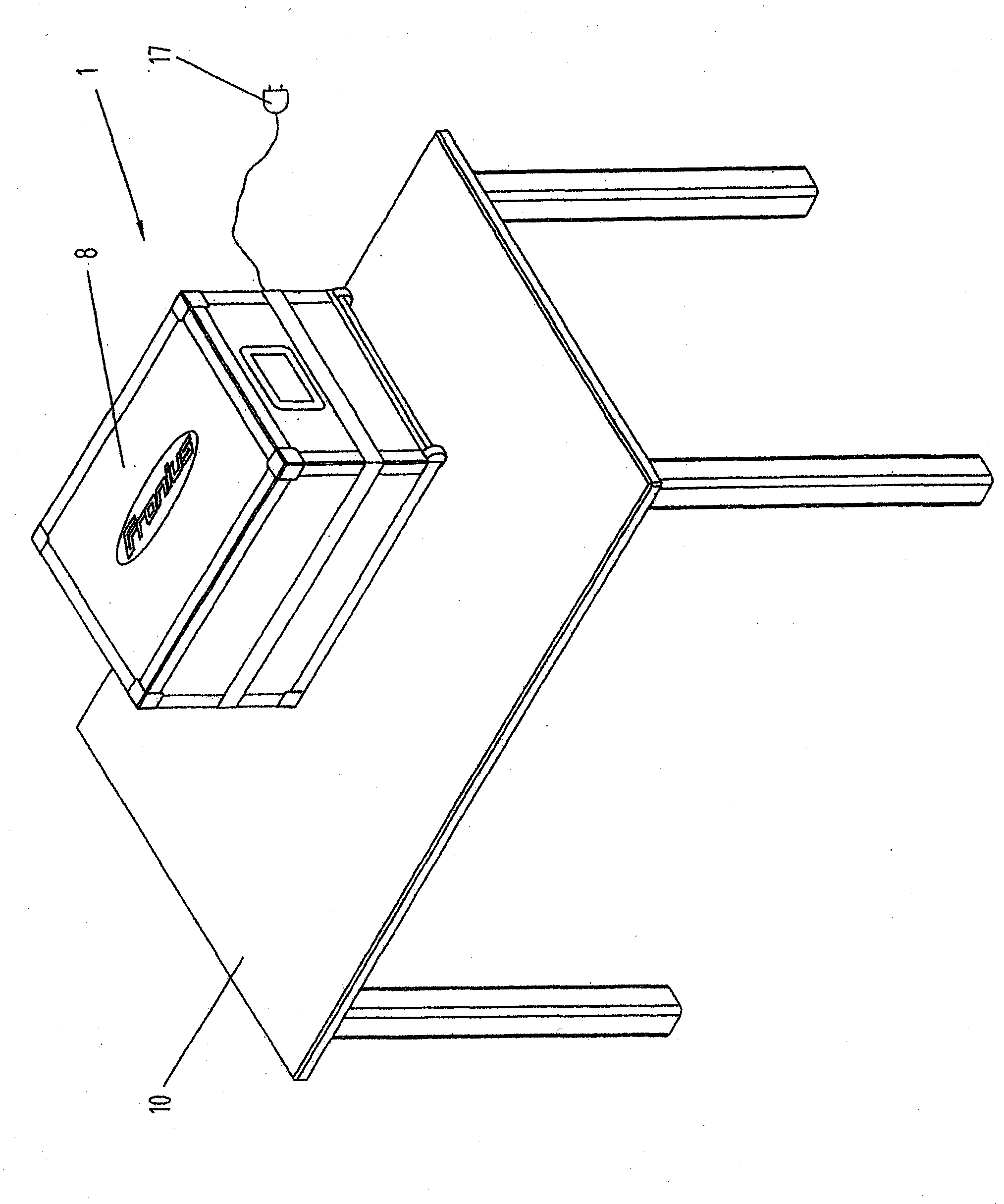

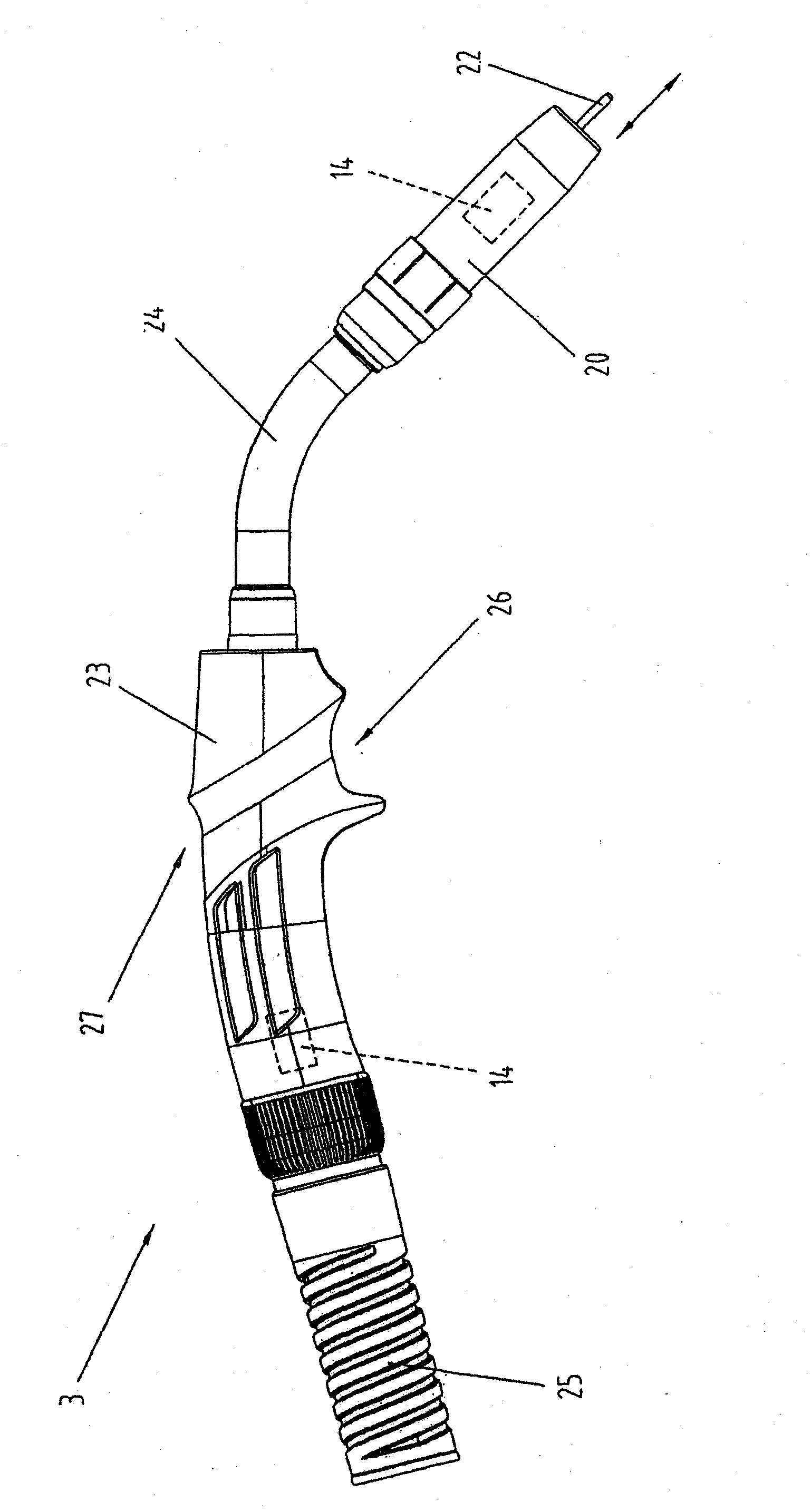

Device and method for simulating a welding process

ActiveCN102083580AAutomatic recognition and automatic realizationImprove user friendlinessWelding/cutting auxillary devicesArc welding apparatusOutput deviceTransmitter

The invention relates to a device (1) and a method for simulating a welding process. The device comprises a computer (2) having an input device (11) and an output device (6), a welding torch (3), a magnetic position monitoring device (5) having at least one transmitter (13) and a plurality of sensors (14), a retaining device (15) for a workpiece (4) used for the simulation and a visualization device (16) for generating a two- or three-dimensional image (29) on the output device (6). The retaining device (15) has a recess (18) into which the workpiece (4) can be inserted, at least one transmitter (13) of the position monitoring device (5) being arranged below the recess (18) at as small a distance from the workpiece (4) as possible, and the retaining device (15) being designed as a small, portable box (19) to be placed on a table (10).

Owner:FRONIUS INTERNATIONAL GMBH

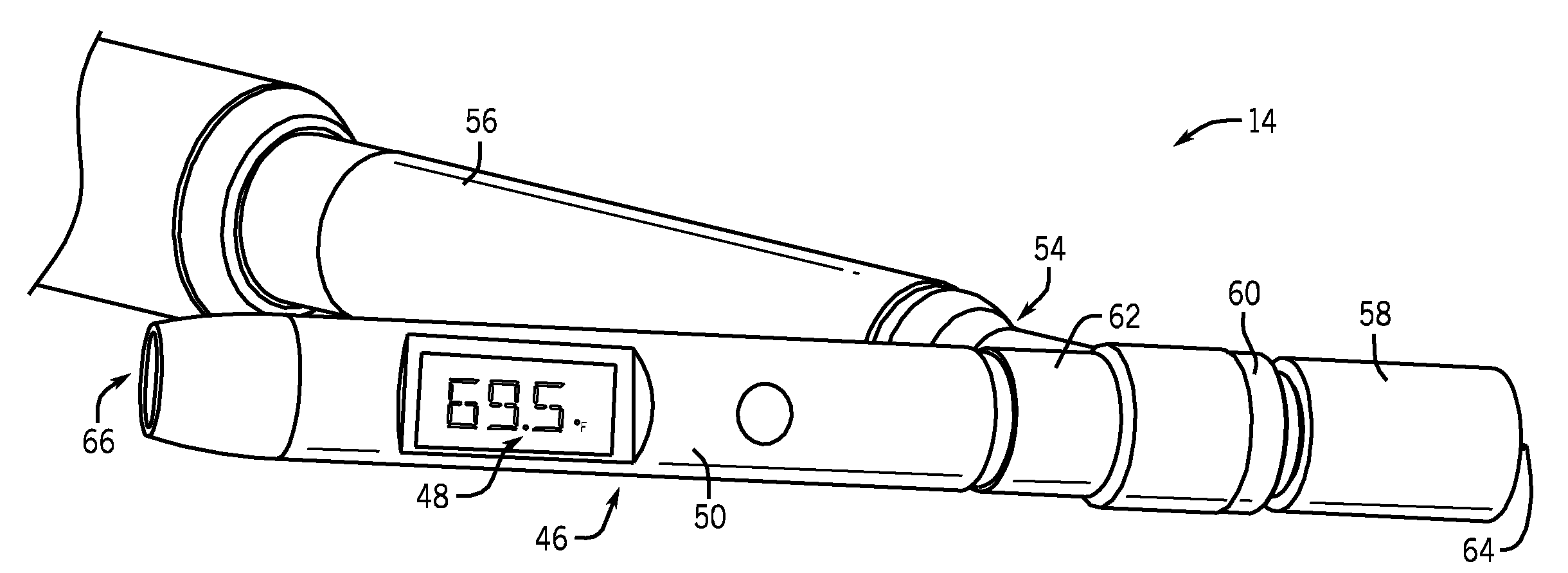

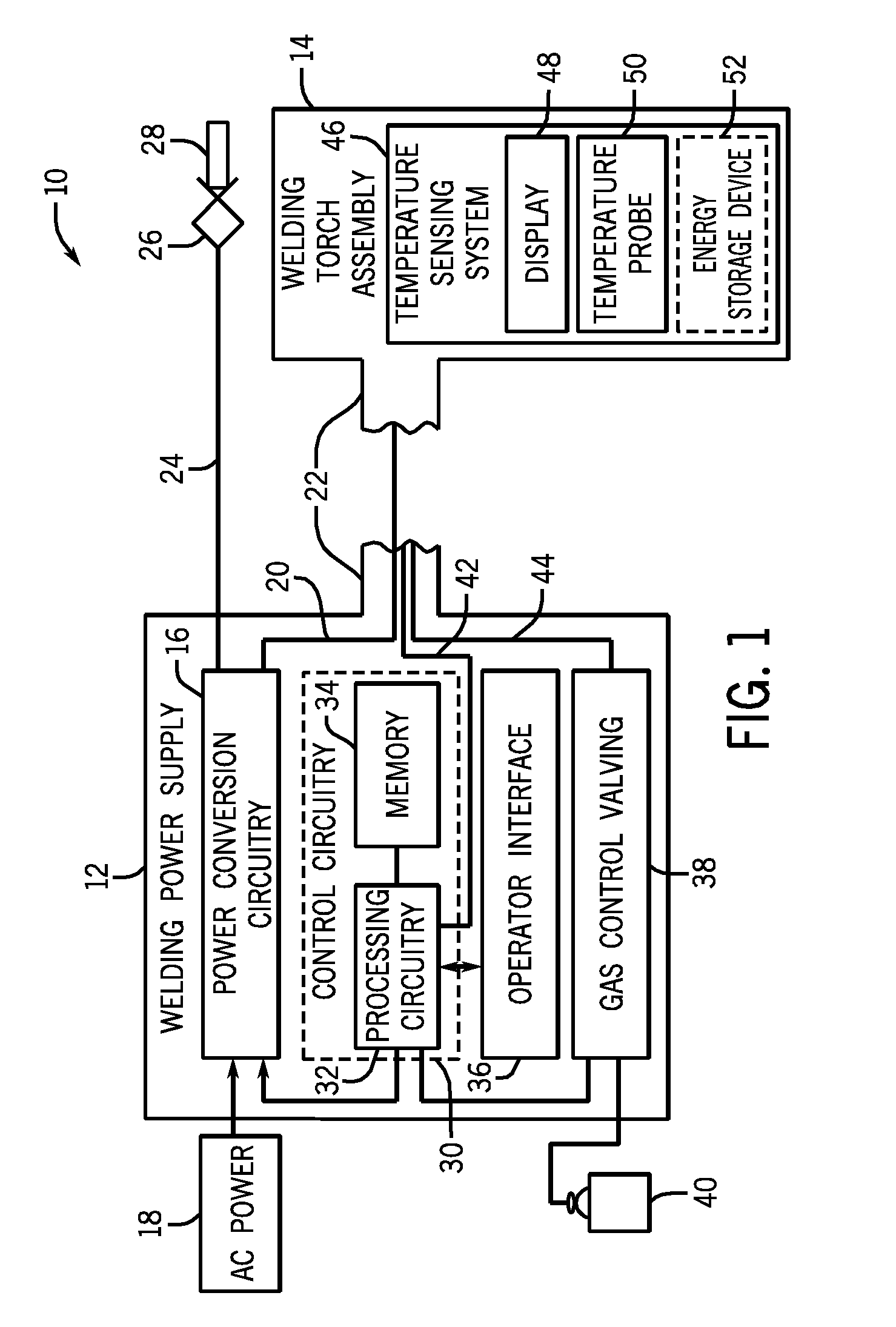

Welding systems having non-contact temperature measurement systems

ActiveUS20130264322A1Pyrometry using electric radation detectorsWelding accessoriesShielding gasCarbon Dioxide / Helium

Welding systems including welding torch assemblies are provided. The welding torch assembly may include a welding torch adapted to be utilized in a welding operation to establish a welding arc between the welding torch and a workpiece. Shielding gas may be supplied to the welding torch for establishment of a gas shielding area around a weld pool. The welding torch assembly may also include a temperature sensing system having a non-contact temperature sensor coupled to the welding torch and adapted to sense a temperature of the workpiece at a location outside of the molten weld pool.

Owner:ILLINOIS TOOL WORKS INC

Weld viewing

InactiveUS20090161212A1View effectivelyEconomical and compact and transportable solutionMirrorsPlasma welding apparatusComputer scienceWelding torch

A mirror may have hole(s) in or passing through its viewing surface. A video remote may be associated with the mirror, especially as configured with the hole(s). A gas, typically an inert gas, may be passed about or through the mirror system, for example, through one or more of the hole(s) through the viewing surface. The mirror may be part of a mirror system, which can be combined with a welding torch. Obscured sites may be inspected and / or welded therewith.

Owner:GOUGH YUMA E

Feedback from a welding torch of a welding system

A method includes displaying, on a display of a welding torch, a welding parameter in relation to a predetermined threshold range for the welding parameter, a target value for the welding parameter, or some combination thereof as a position of the welding torch changes, an orientation of the welding torch changes, a movement of the welding torch changes, or some combination thereof, to enable a welding operator to perform a welding operation with the welding parameter within the predetermined threshold range, at the target value, or some combination thereof. The welding parameter is associated with the position of the welding torch, the orientation of the welding torch, the movement of the welding torch, or some combination thereof.

Owner:ILLINOIS TOOL WORKS INC

Remote wire feeder

Owner:LINCOLN GLOBAL INC

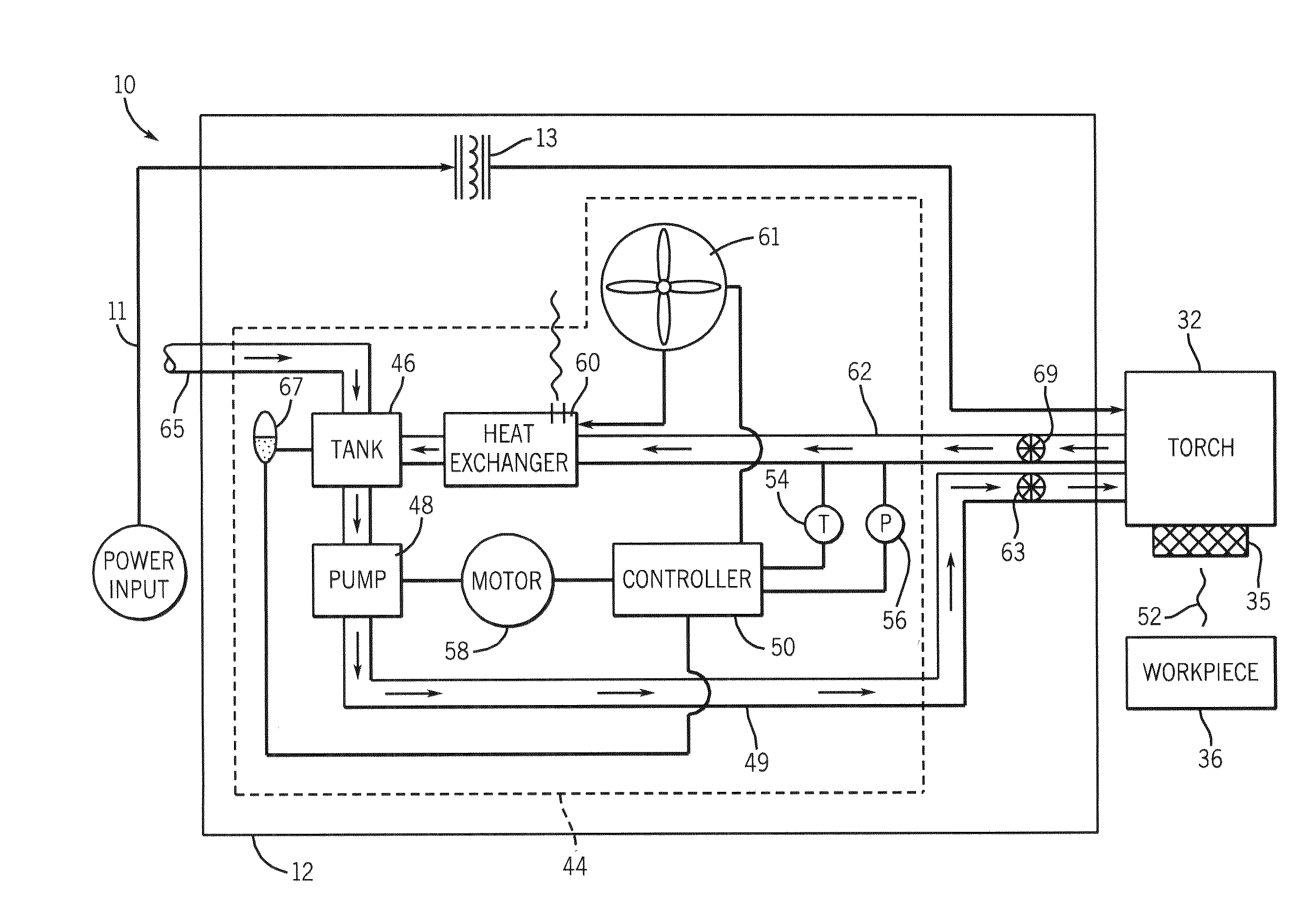

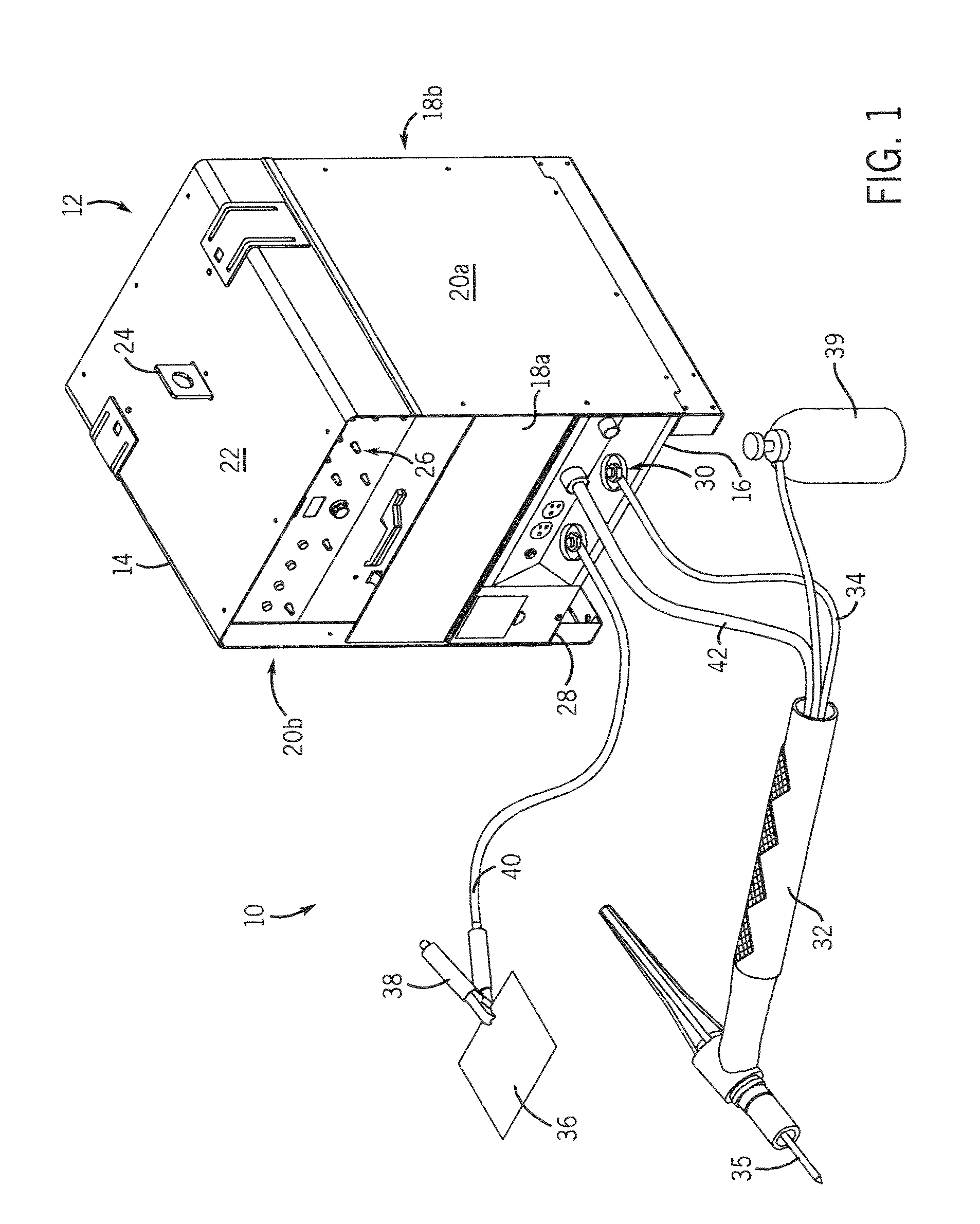

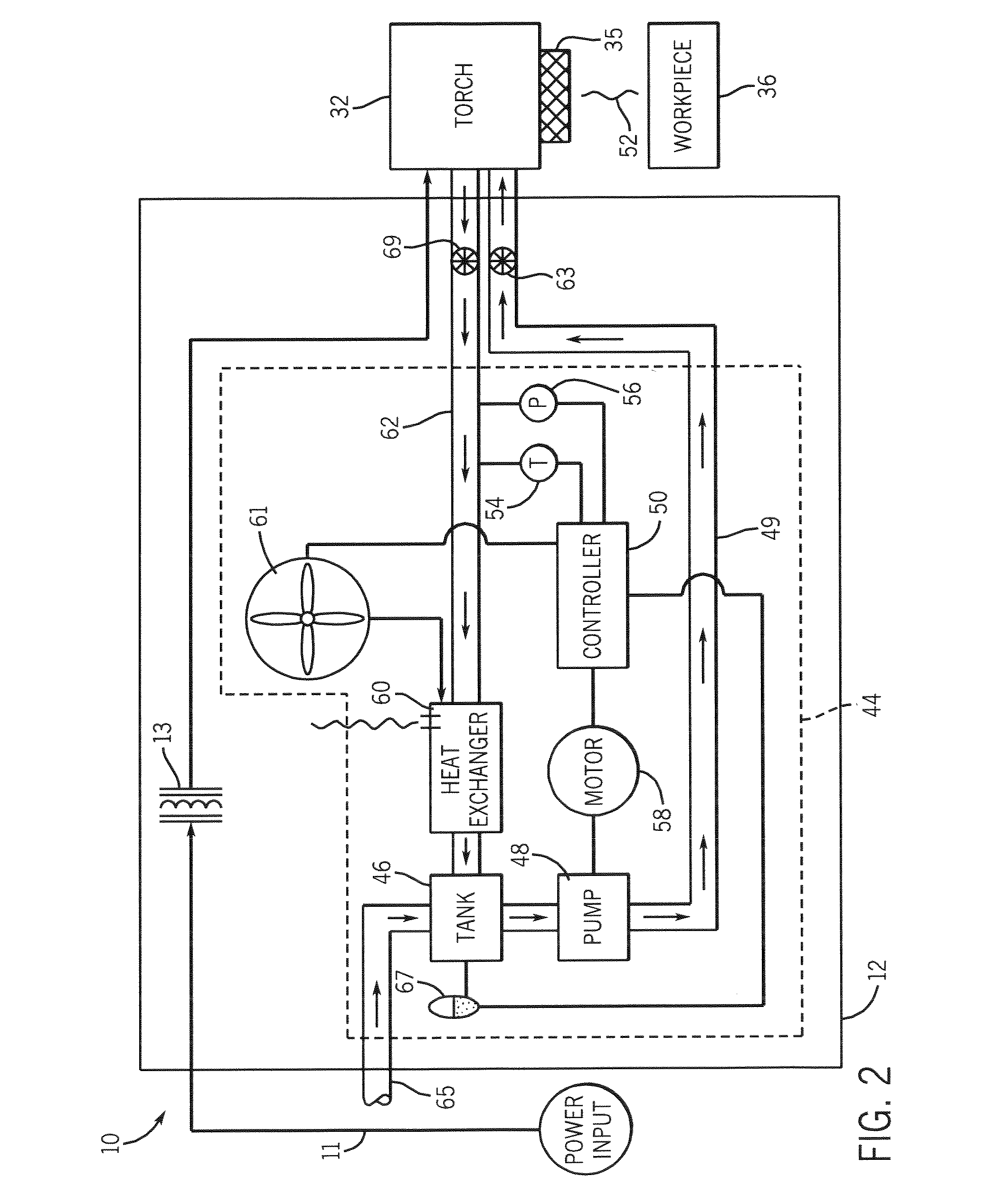

Method and apparatus to adaptively cool a welding-type system

ActiveUS20050016979A1Support devices with shieldingCooled electrode holdersEngineeringBiological activation

A cooling system connected to provide coolant to a welding-type component automatically circulates coolant through the welding component upon activation of the welding component. A controller is configured to regulate the cooling system such that upon activation of the welding-type component coolant is caused to at least flow through the welding-type component and circulate after deactivation of the welding torch until a temperature of the coolant falls below a certain value or a specified time period has expired.

Owner:ILLINOIS TOOL WORKS INC

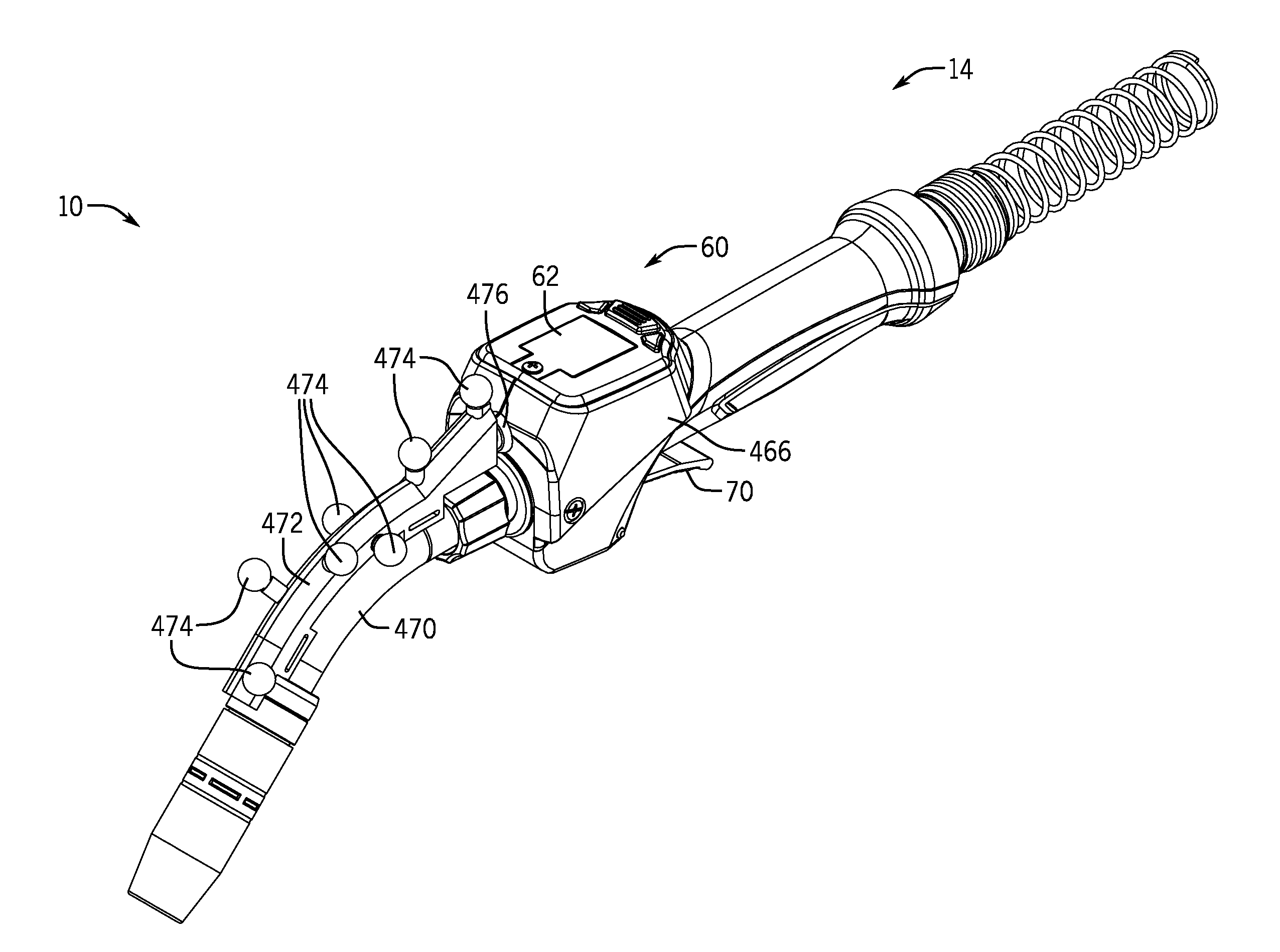

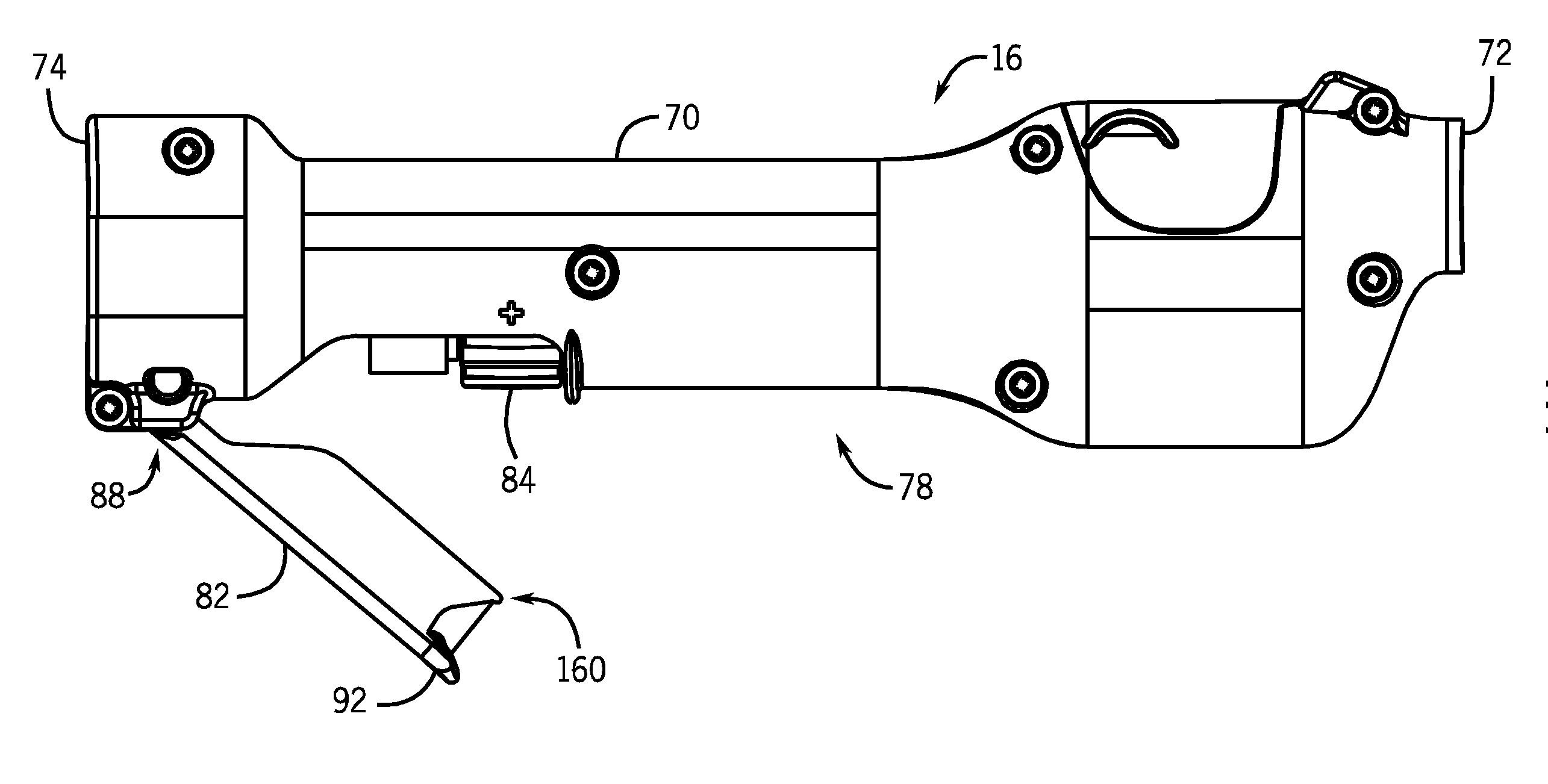

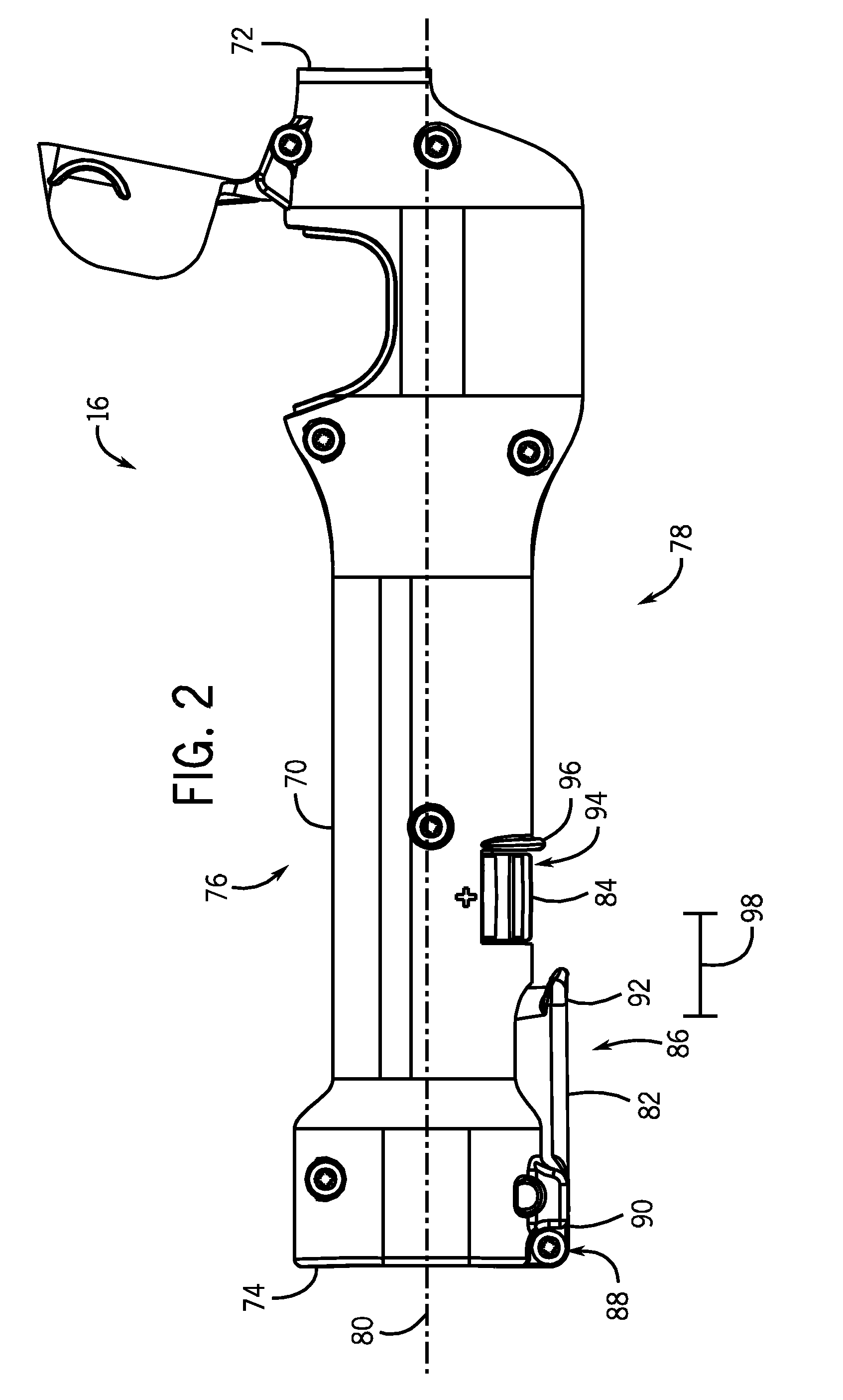

Welding torch with wire feed speed control

A welding torch has a torch handle. A wire drive assembly is disposed in the torch handle and includes a drive motor and a drive roller. The wire drive assembly contacts the welding wire and is configured to drive the welding wire from a wire feeder to a welding operation. In addition, the welding torch has a trigger and a wire feed speed adjustment assembly. The trigger is disposed near a rear end of the torch handle and is configured to be depressed by an operator for initiating feed of the welding wire. The adjustment assembly is positioned near the rear end of the handle adjacent to the trigger and on the same side of the handle as the trigger. The adjustment assembly allows operator adjustment of a feed speed of the welding wire.

Owner:ILLINOIS TOOL WORKS INC

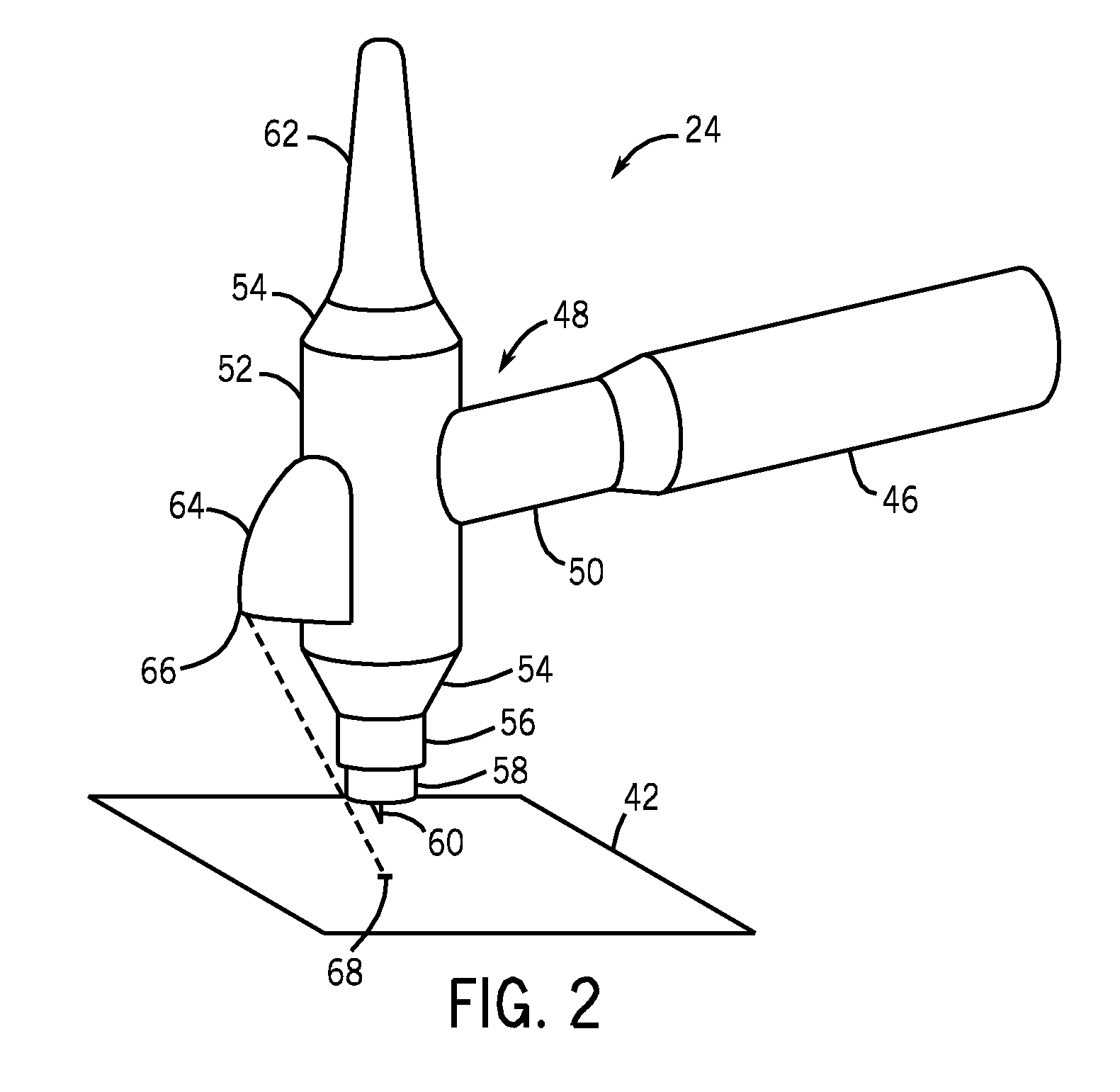

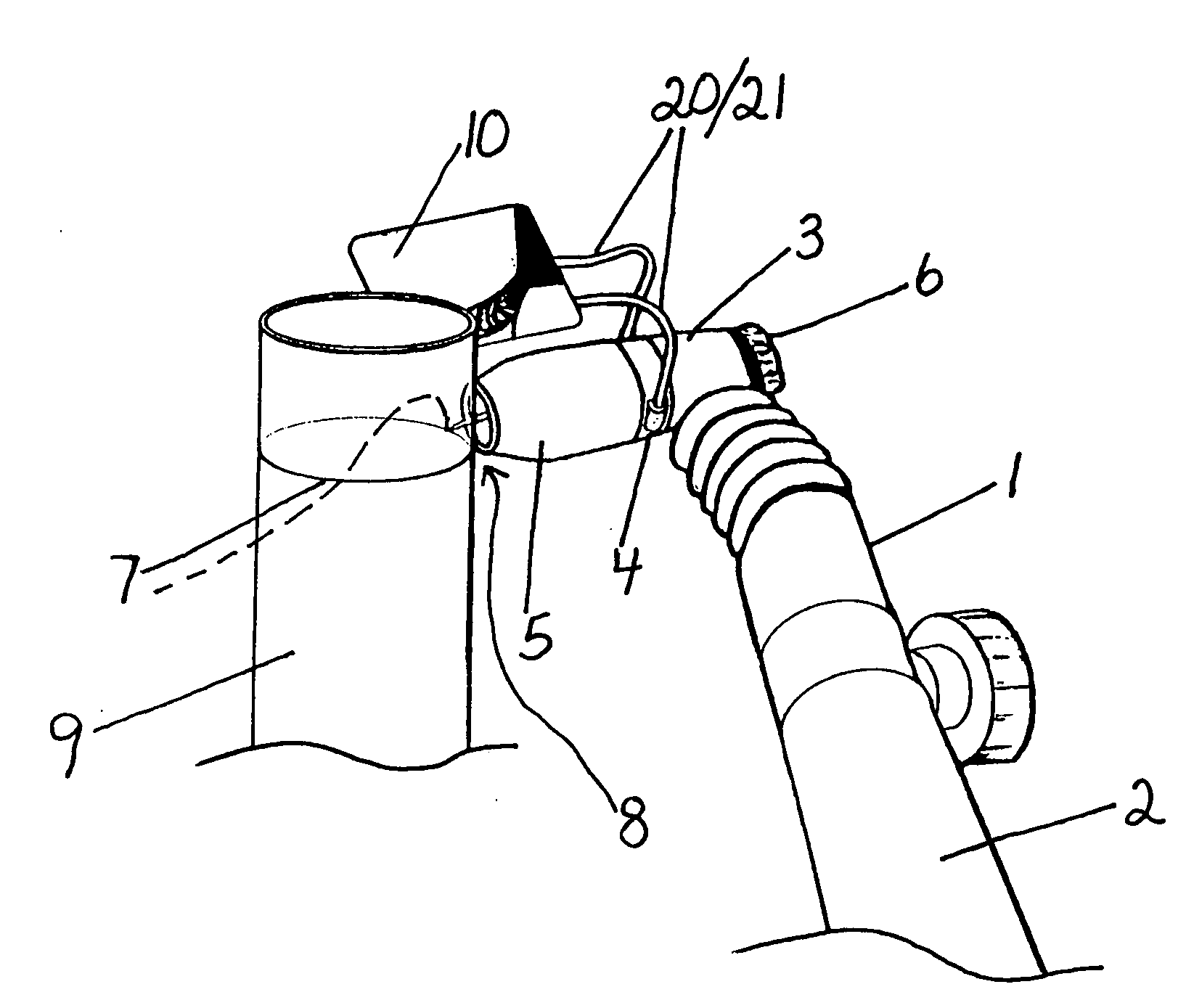

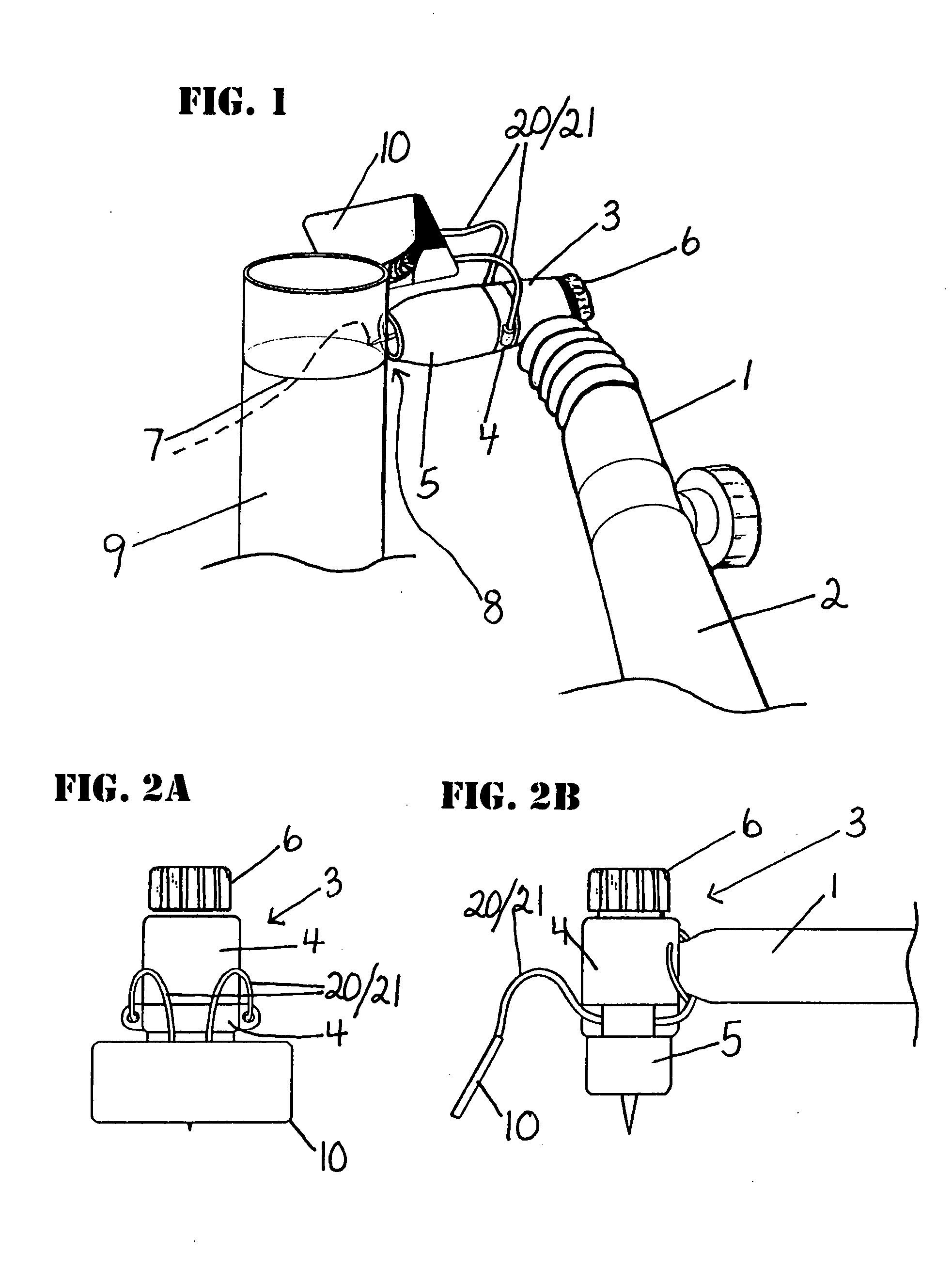

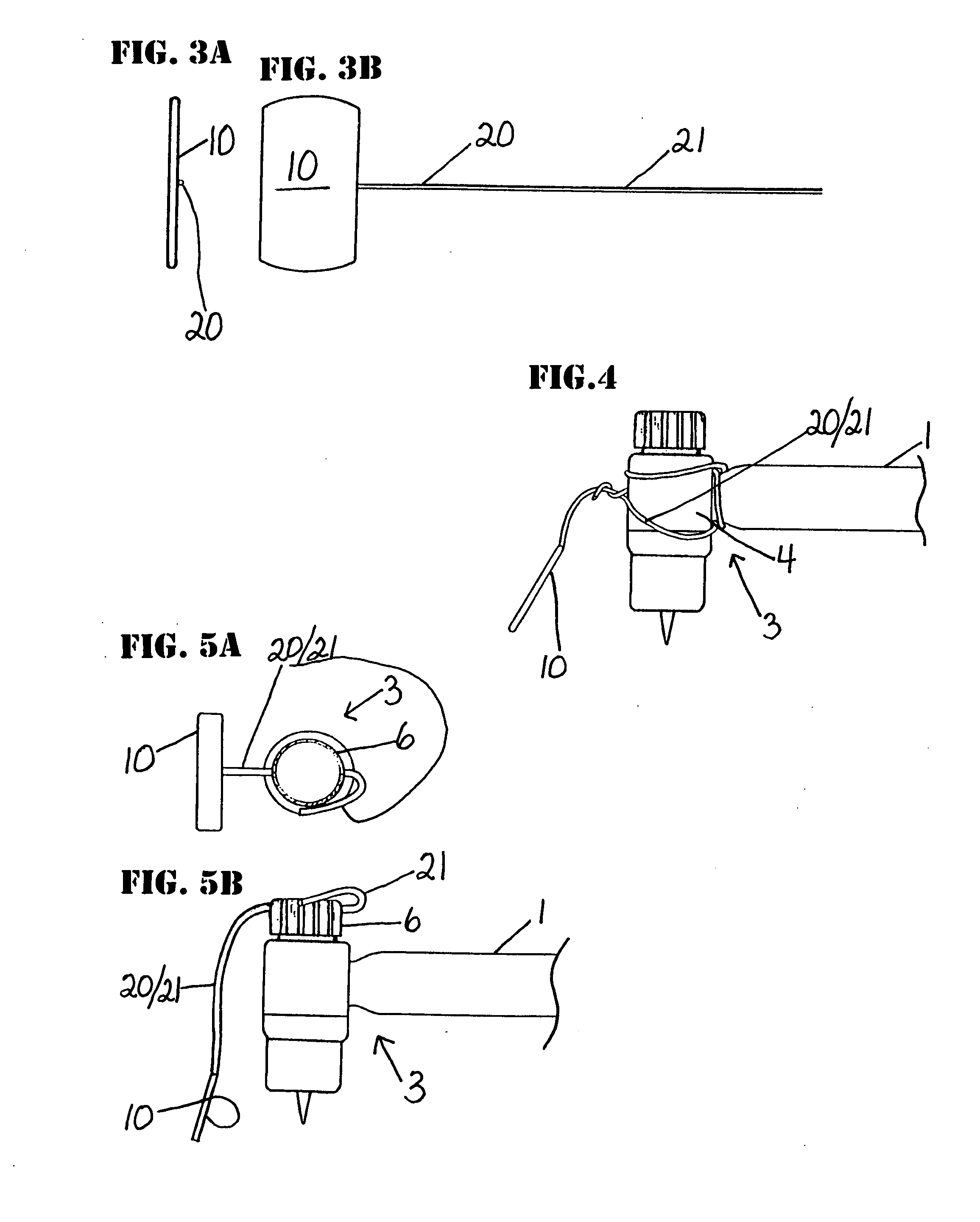

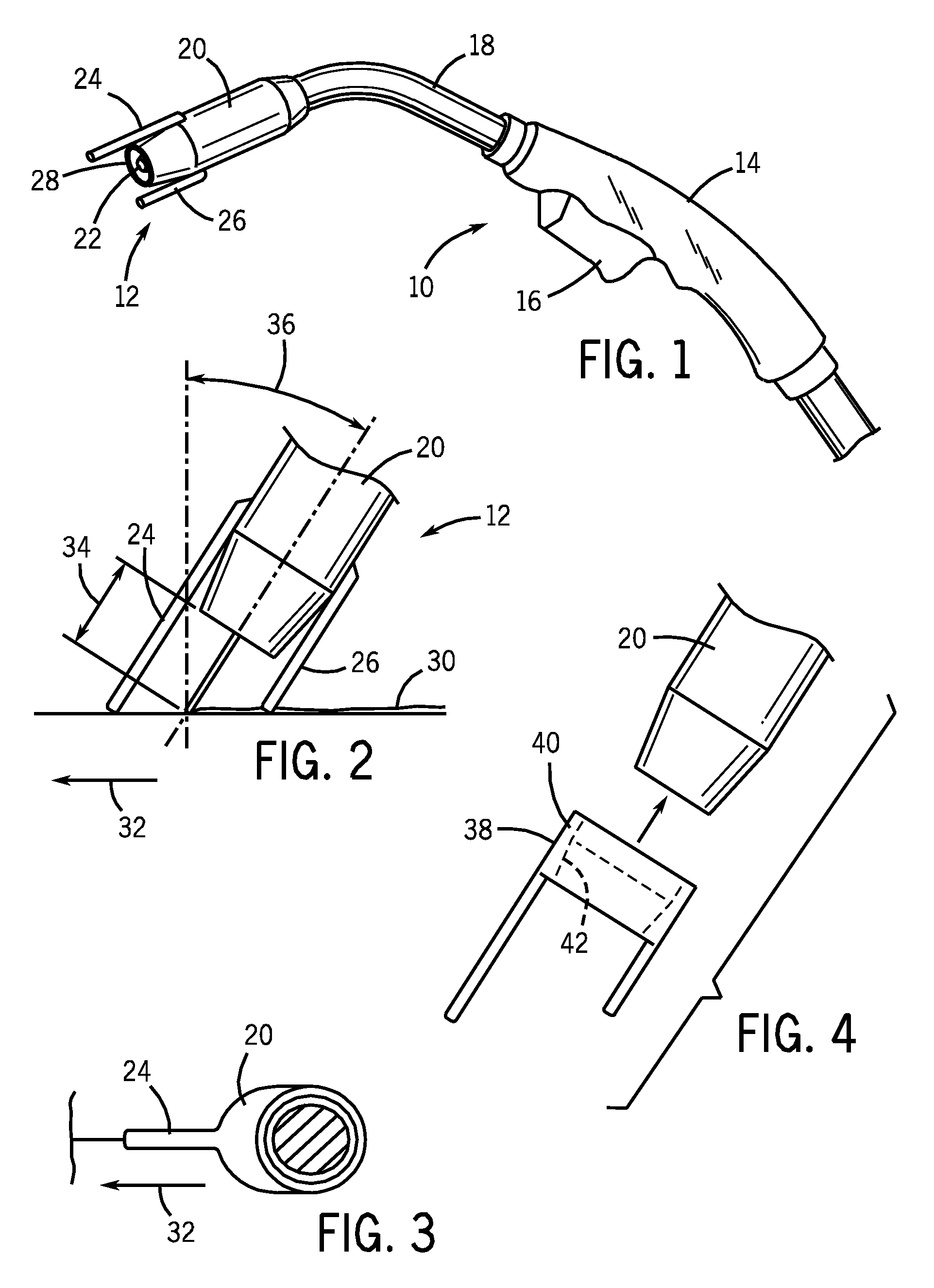

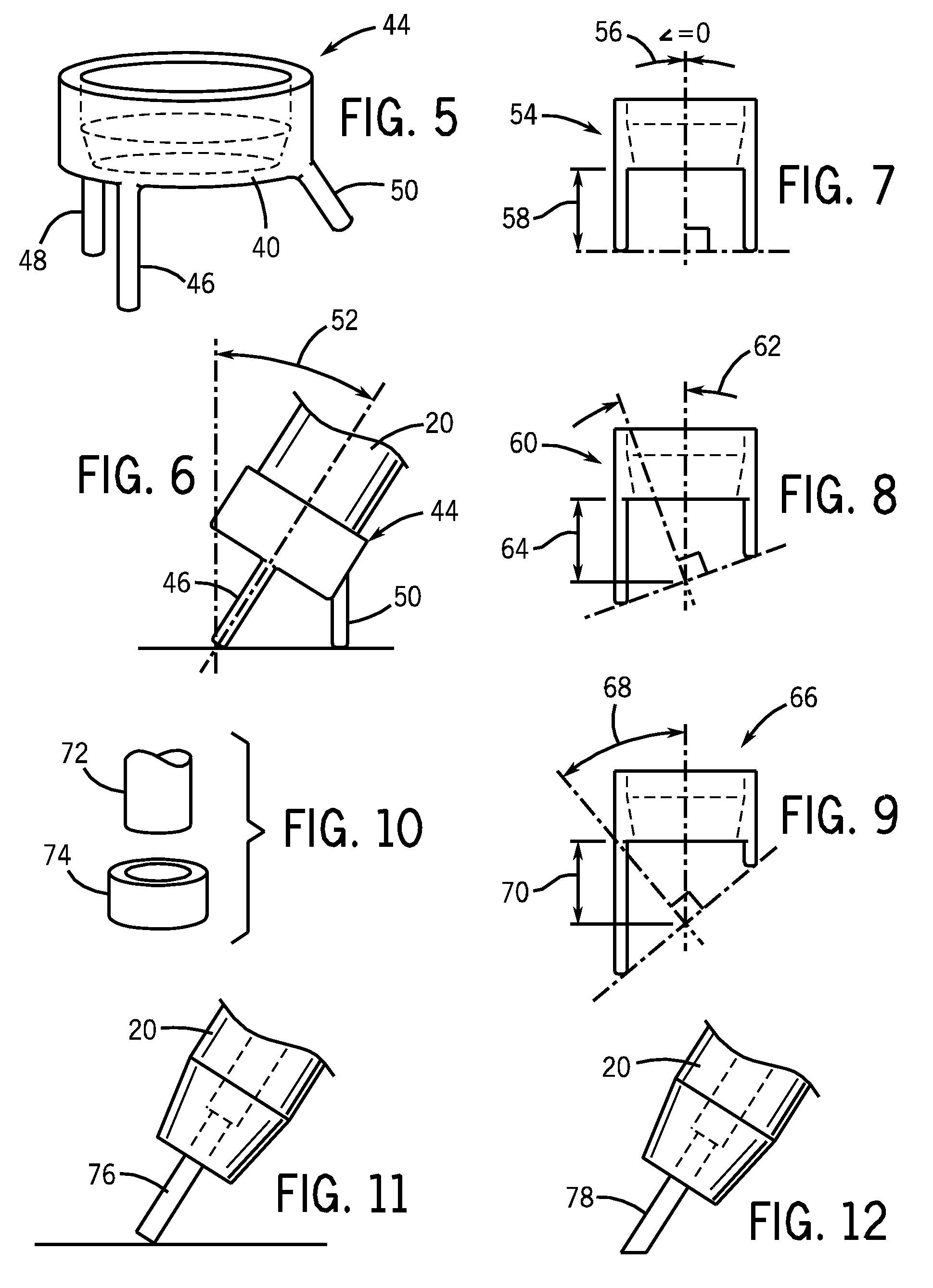

Positioning attachment for a welding torch

InactiveUS20090230107A1Welding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

A positioning attachment for definition of torch angle and torch to workpiece distance during welding and / or training is provided. The positioning attachment includes one or more legs of equal or varied lengths capped with a tip, which contacts the workpiece, and a body, which may be permanently attached or removably secured to the welding torch nozzle. Certain embodiments may be made of heat resistant metals or ceramic to withstand high temperatures during welding. The positioning attachment may be mounted on the welding torch nozzle or provided as an extension of the contact tip.

Owner:ILLINOIS TOOL WORKS INC

Welding torch with a temperature measurement device

Various welding systems including a welding torch assembly are provided. The welding torch assemblies may include a welding torch adapted to be utilized in a welding operation to establish a welding arc between the welding torch and a workpiece. The welding torch assemblies may also include a temperature sensing system integral with the welding torch and adapted to sense a temperature of the workpiece.

Owner:ILLINOIS TOOL WORKS INC

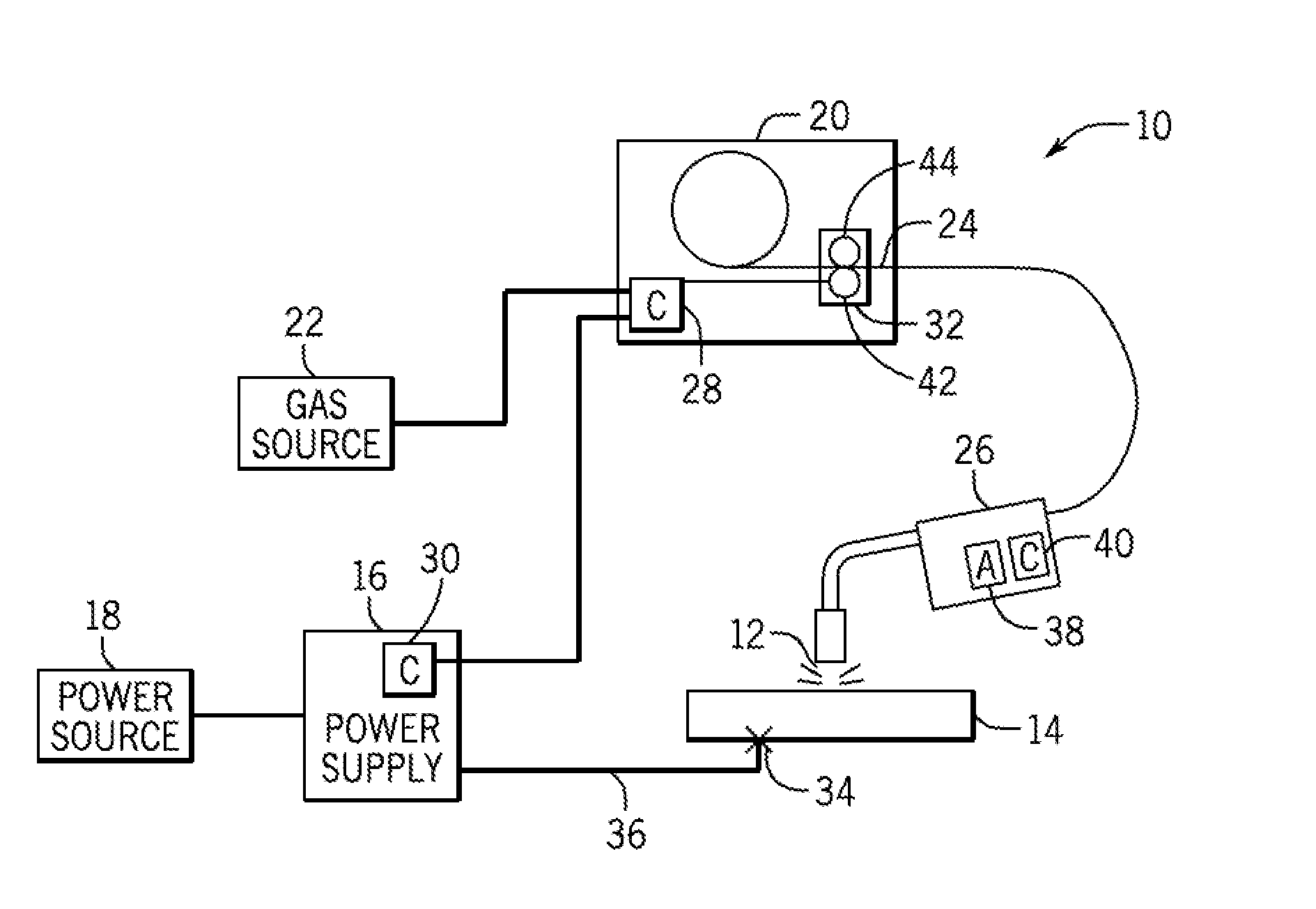

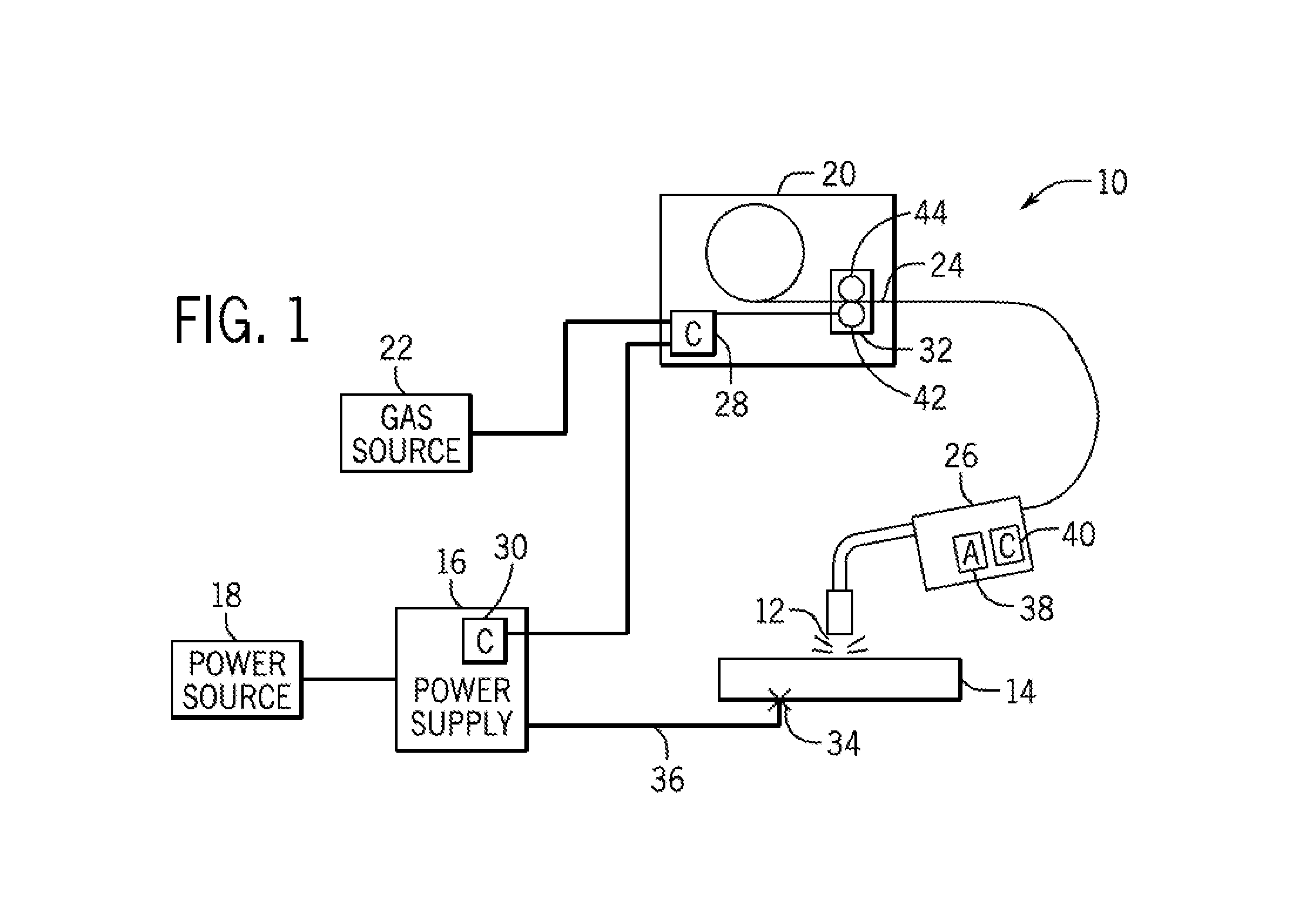

Gravity-based weld travel speed sensing system and method

A welding system includes an orientation sensing system associated with a welding torch and is configured to sense a welding torch orientation relative to a direction of gravity. The welding system also includes a processing system communicatively couple to the orientation sensing system and configured to determine an angular position of the welding torch relative to a pipe based at least in part on the sense welding torch orientation.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com