Patents

Literature

87results about "Electrode vibration holders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feedback from a welding torch of a welding system

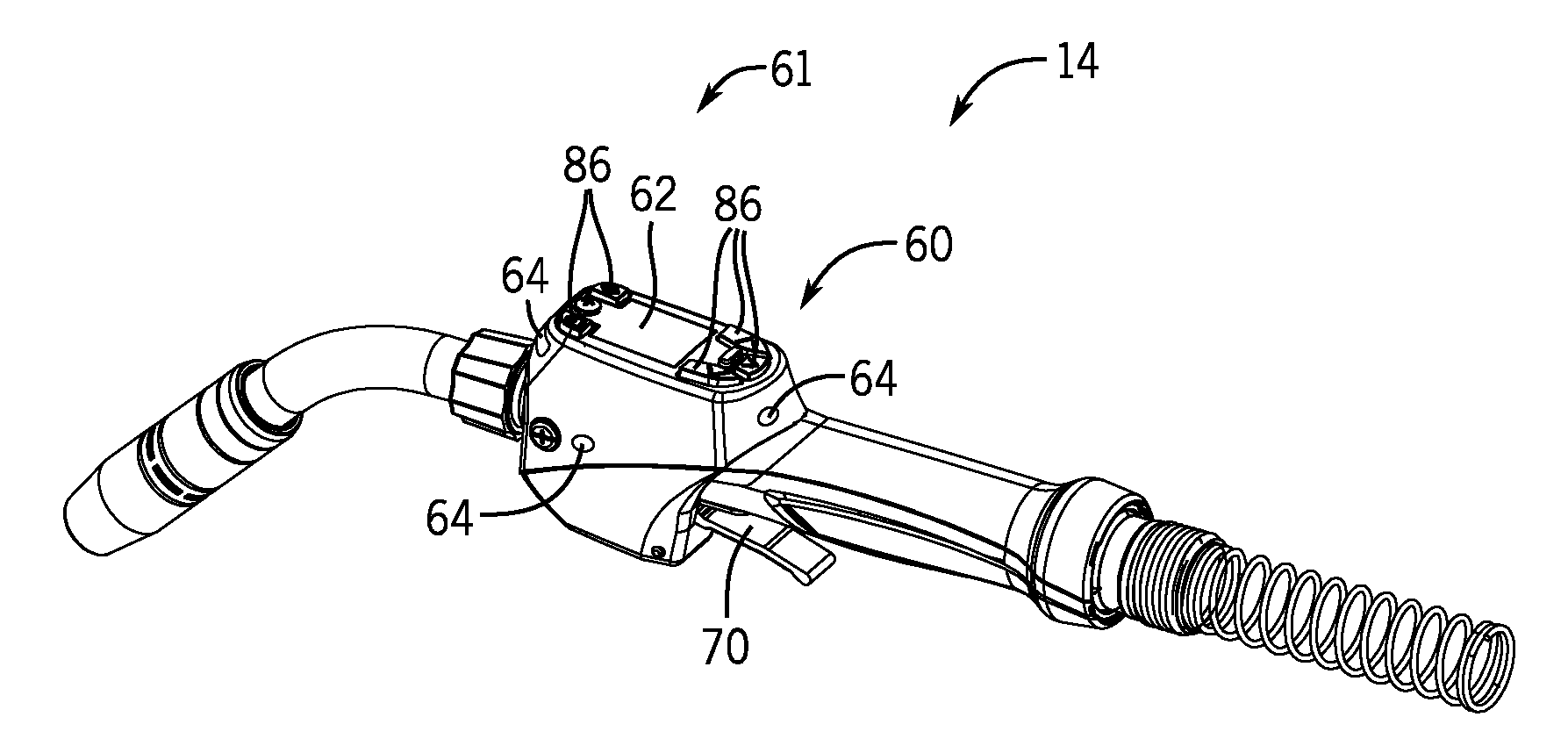

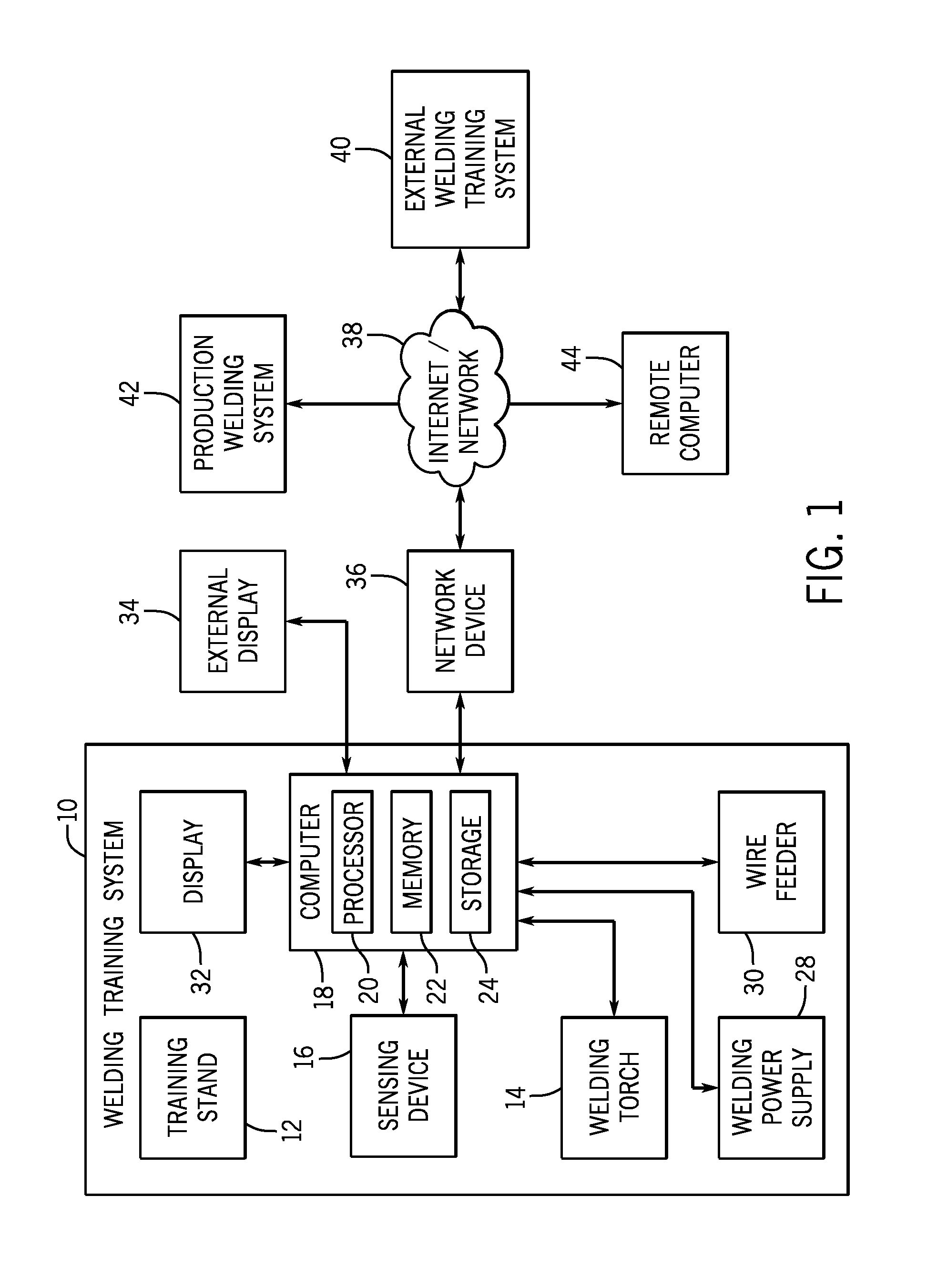

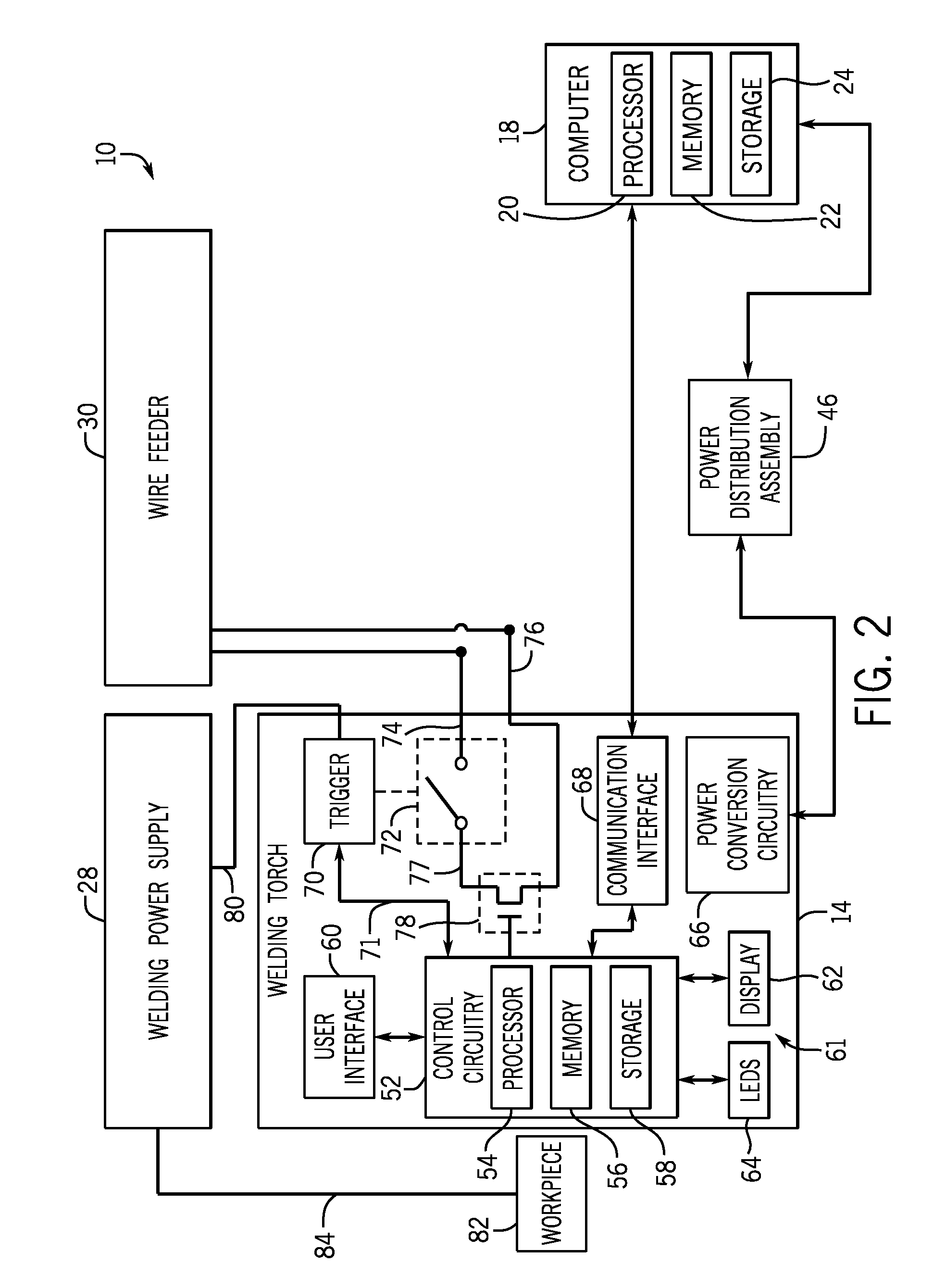

ActiveUS20150194072A1Electrode vibration holdersCosmonautic condition simulationsDisplay deviceEngineering

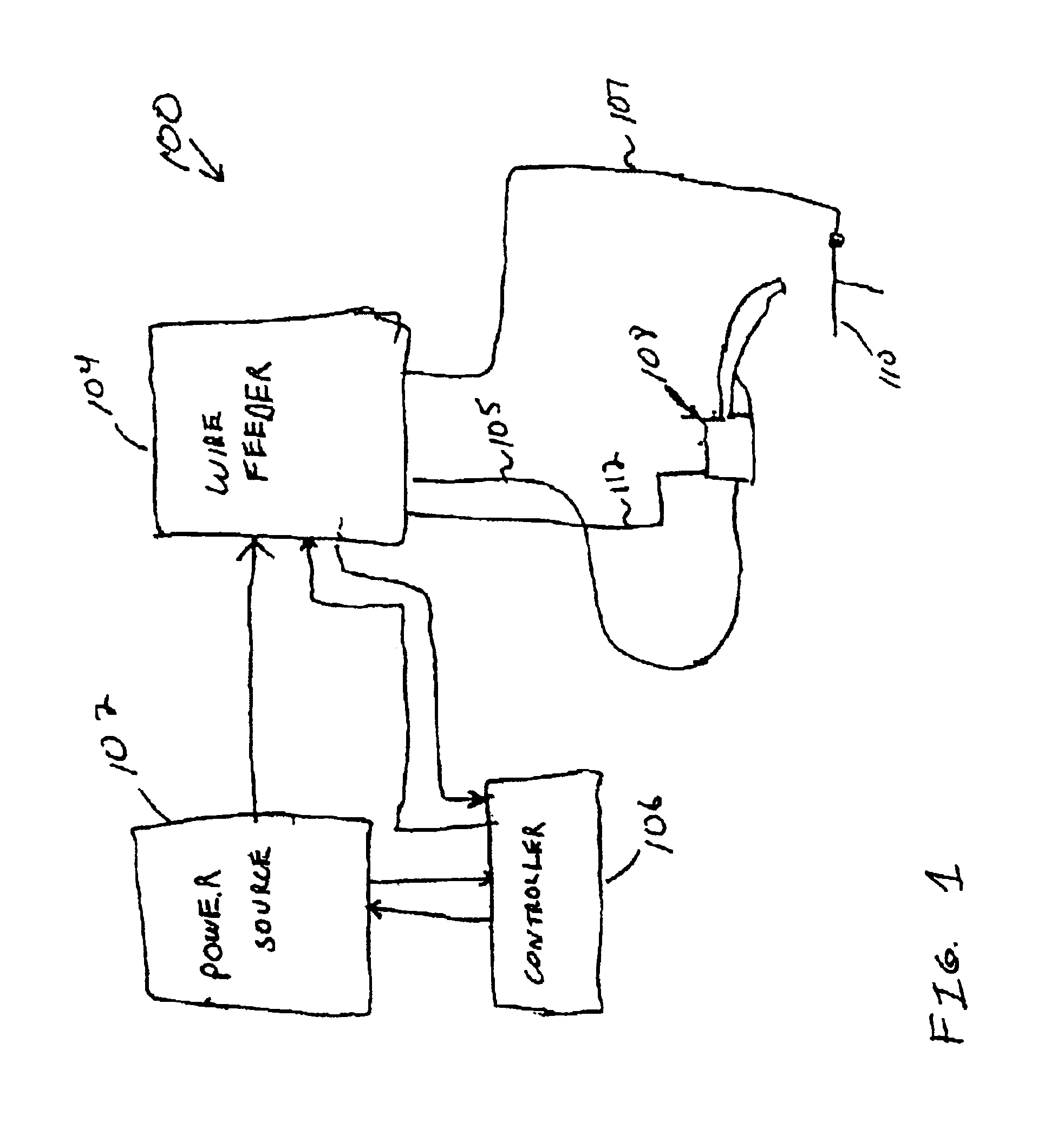

A welding system includes a welding torch. The welding torch includes a sensor configured to detect a motion associated with the welding torch, a temperature associated with the welding torch, or some combination thereof. A display of the welding torch is activated, a determination is made that the welding torch has been involved in a high impact event, live welding using the welding torch is disabled, a software selection is made, or some combination thereof, based on the motion, the temperature, or some combination thereof.

Owner:ILLINOIS TOOL WORKS INC

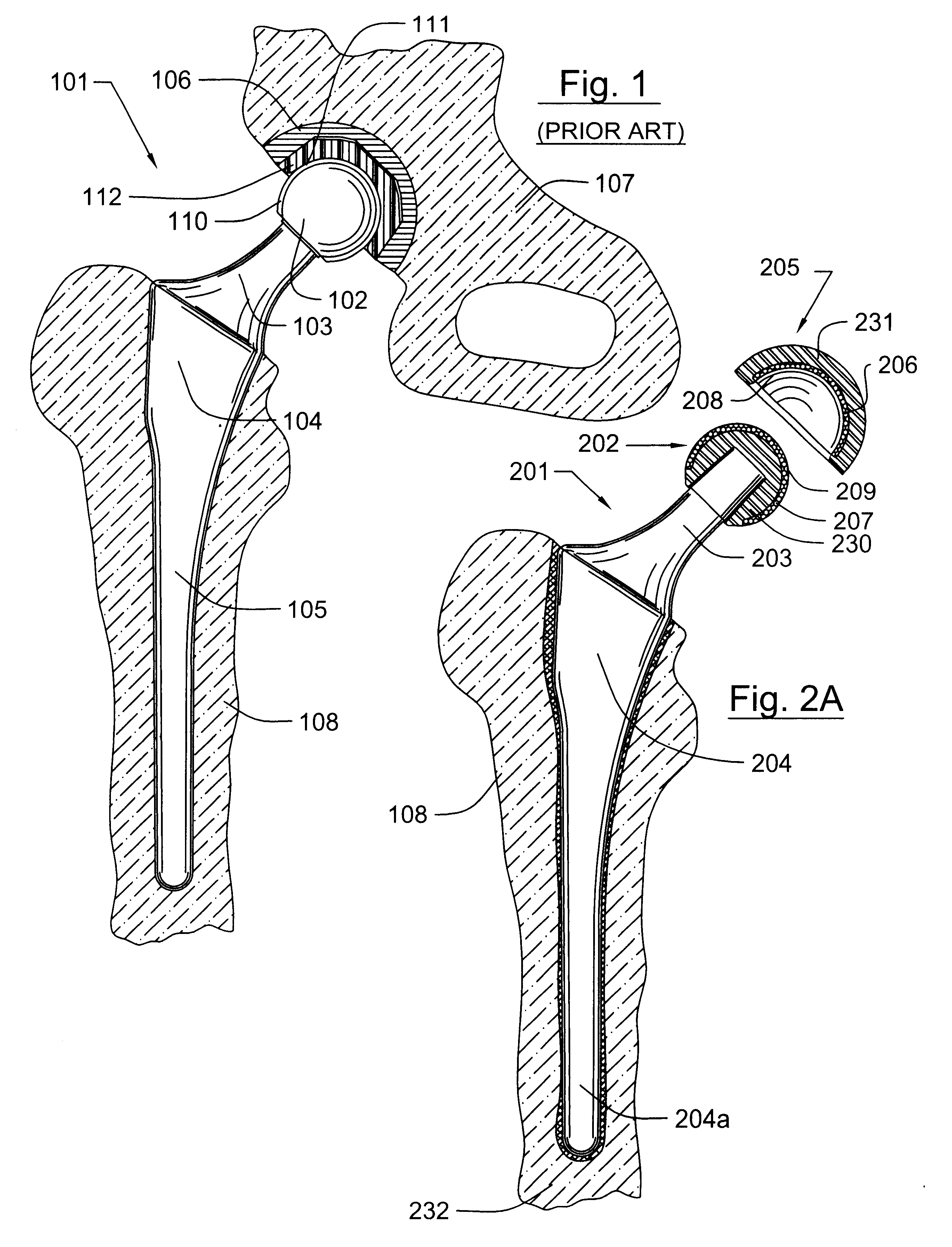

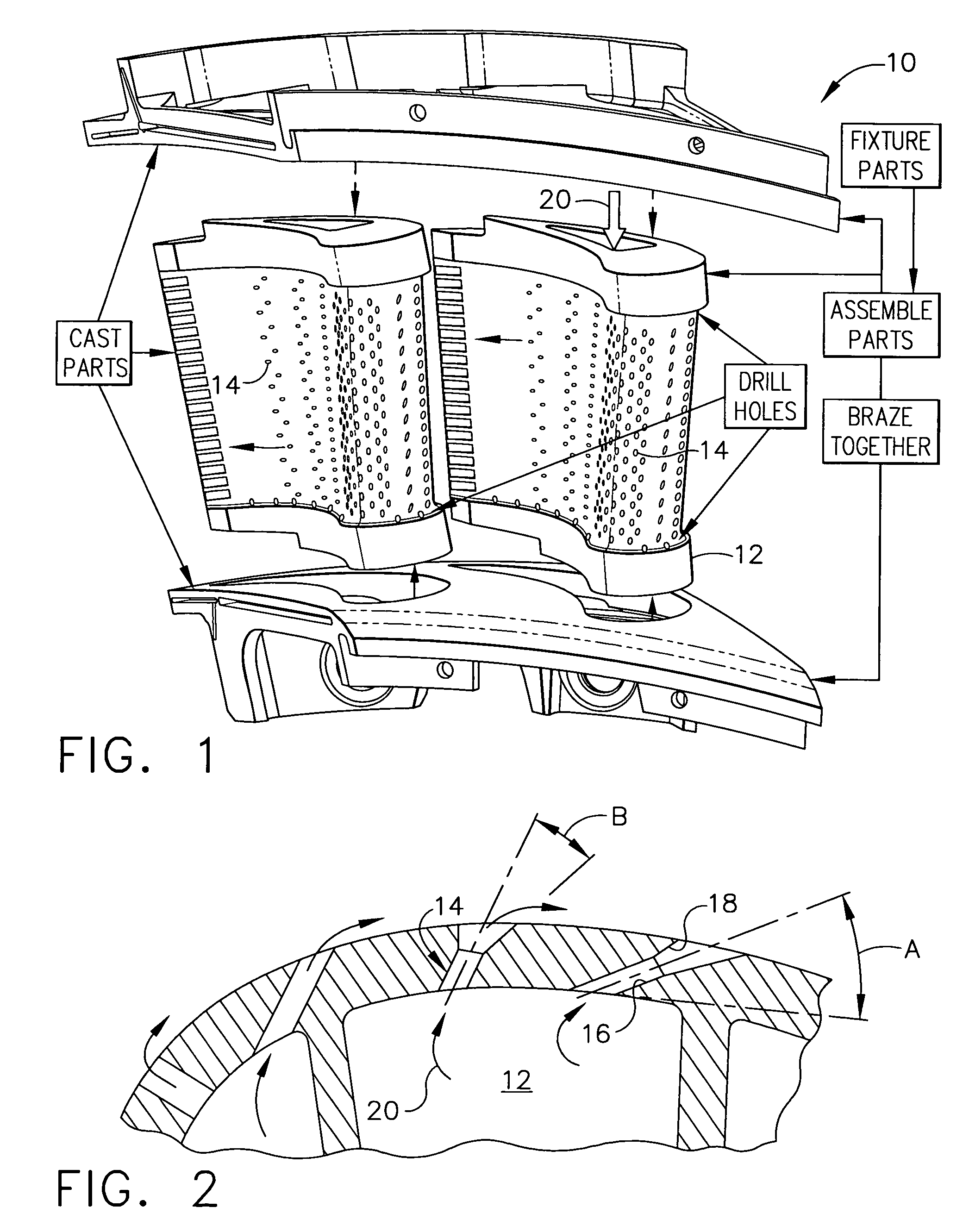

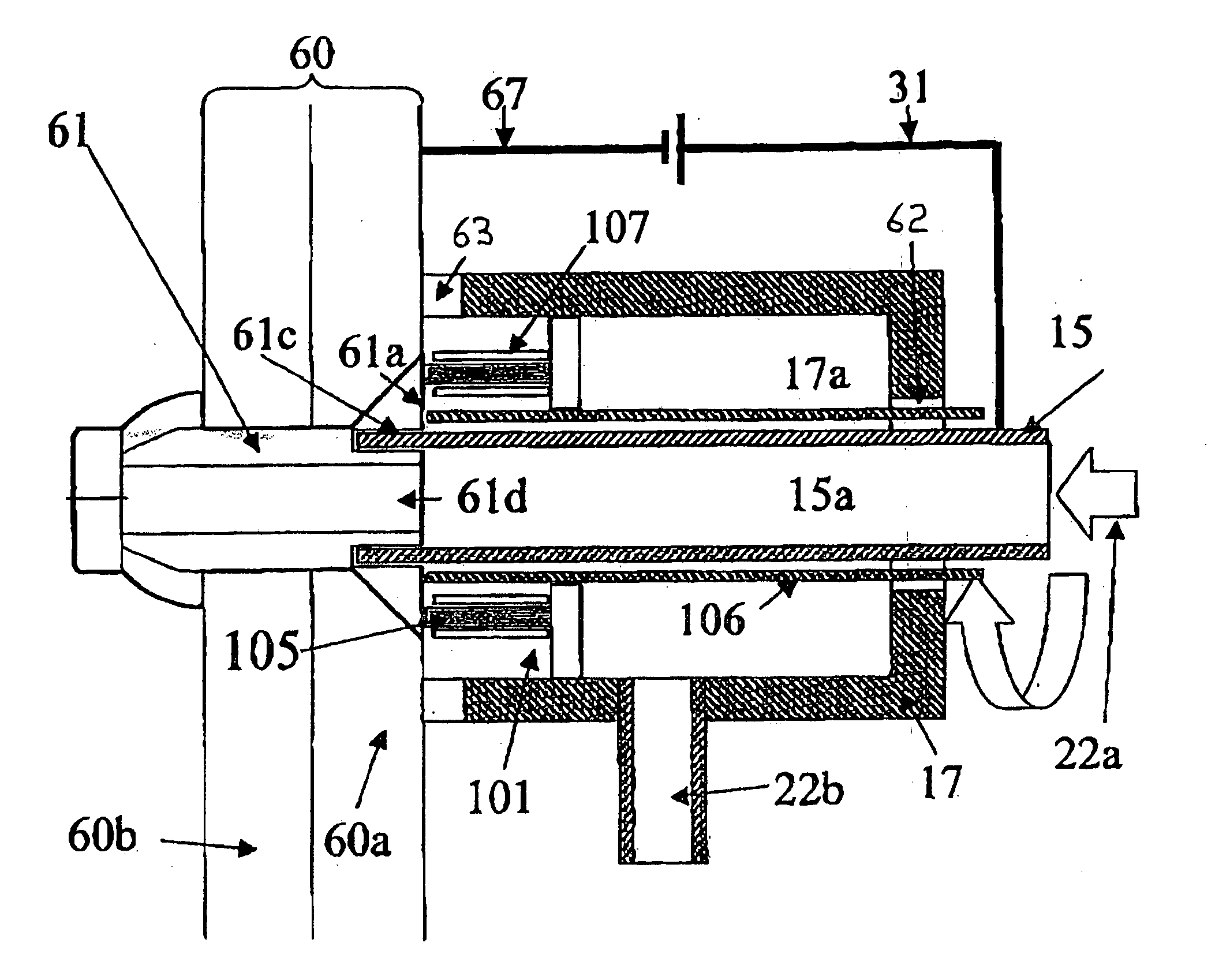

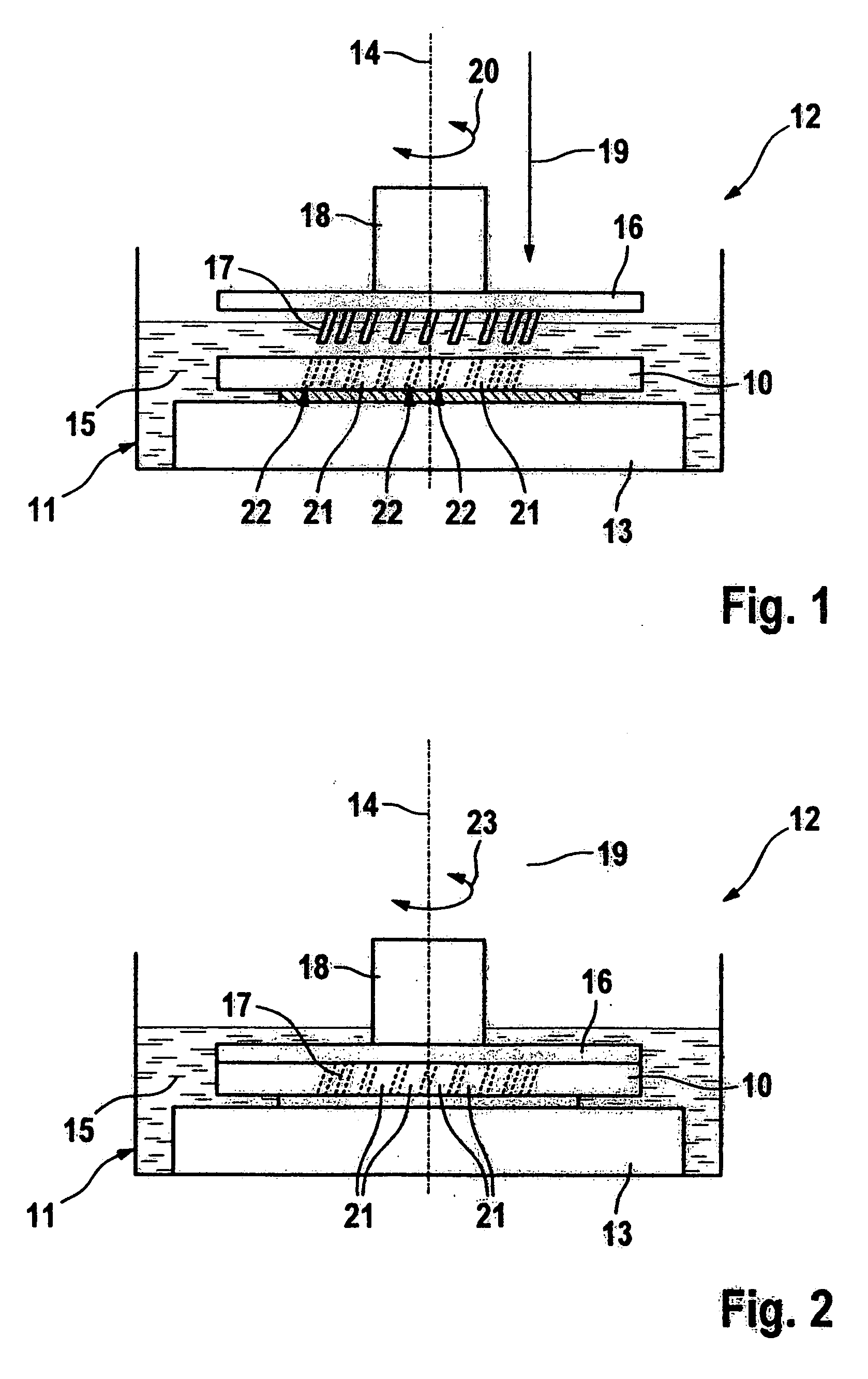

Methods for shaping and finishing prosthetic joint components including polycrystalline diamond compacts

InactiveUS6410877B1Less disruptiveImprove overall utilizationElectrode vibration holdersElectrical-based machining electrodesHeat-affected zoneElectric discharge

A method of rough shaping a prosthetic joint component that includes a generally spherical polycrystalline diamond compact by electric discharge machining is disclosed. The discharge machining electrode roughens a polycrystalline diamond compact sphere while the electrode and the sphere are rotating about different axes. By controlling the amount of discharge current, the depth and amount of the heat affected zone can be minimized. In the case of a polycrystalline diamond compact, the heat affected zone can be kept to about 3 to 5 microns in depth and is easily removable by grinding and polishing.

Owner:DIAMICRON

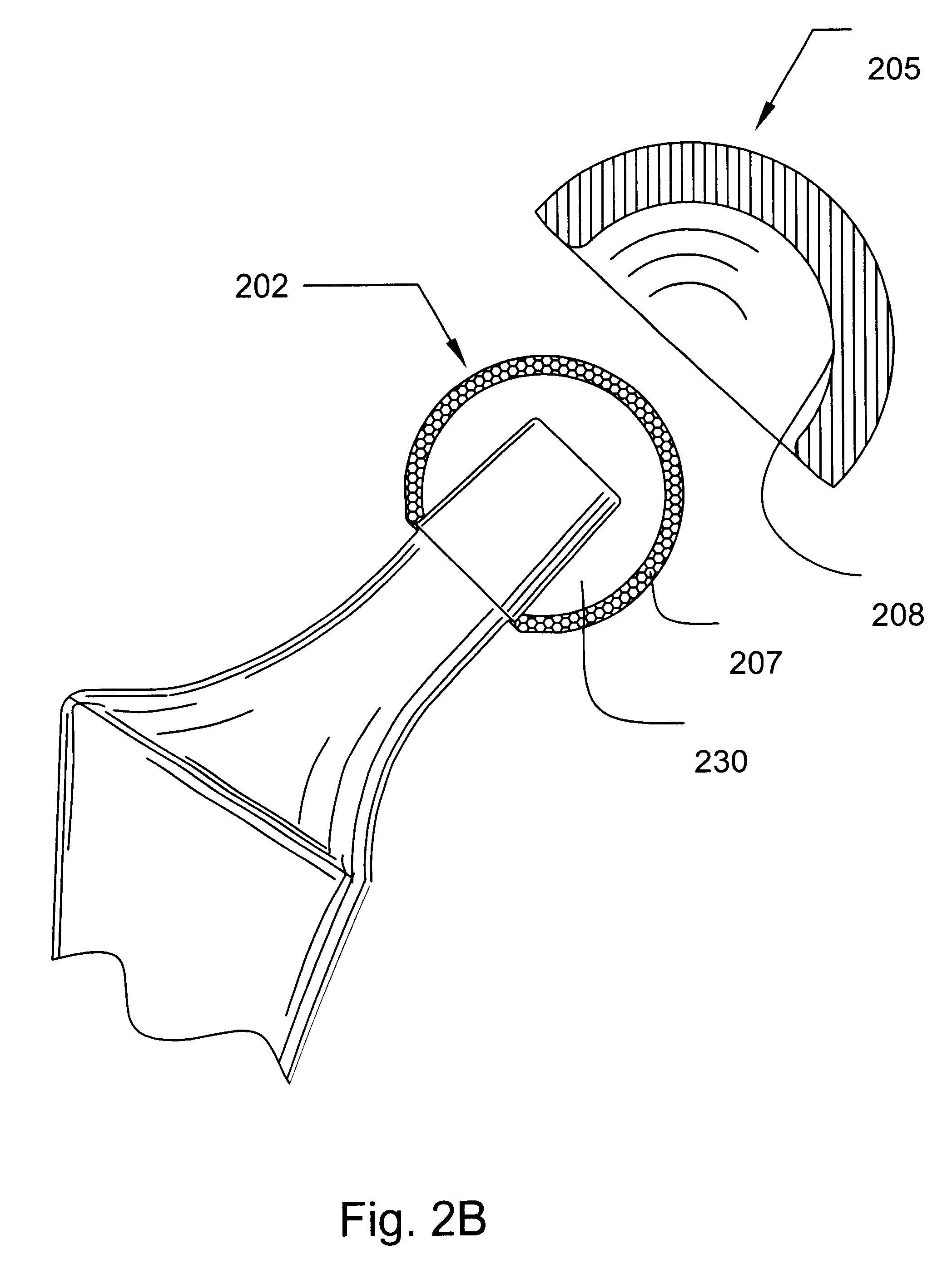

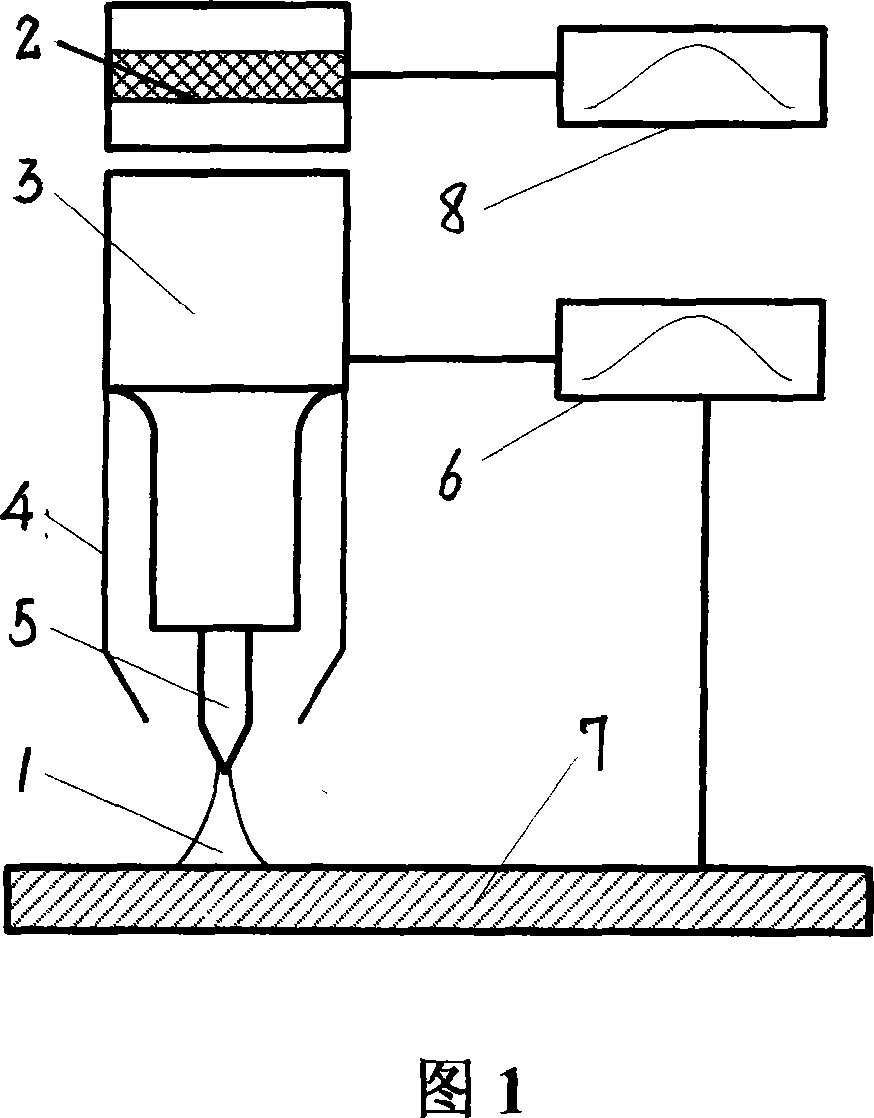

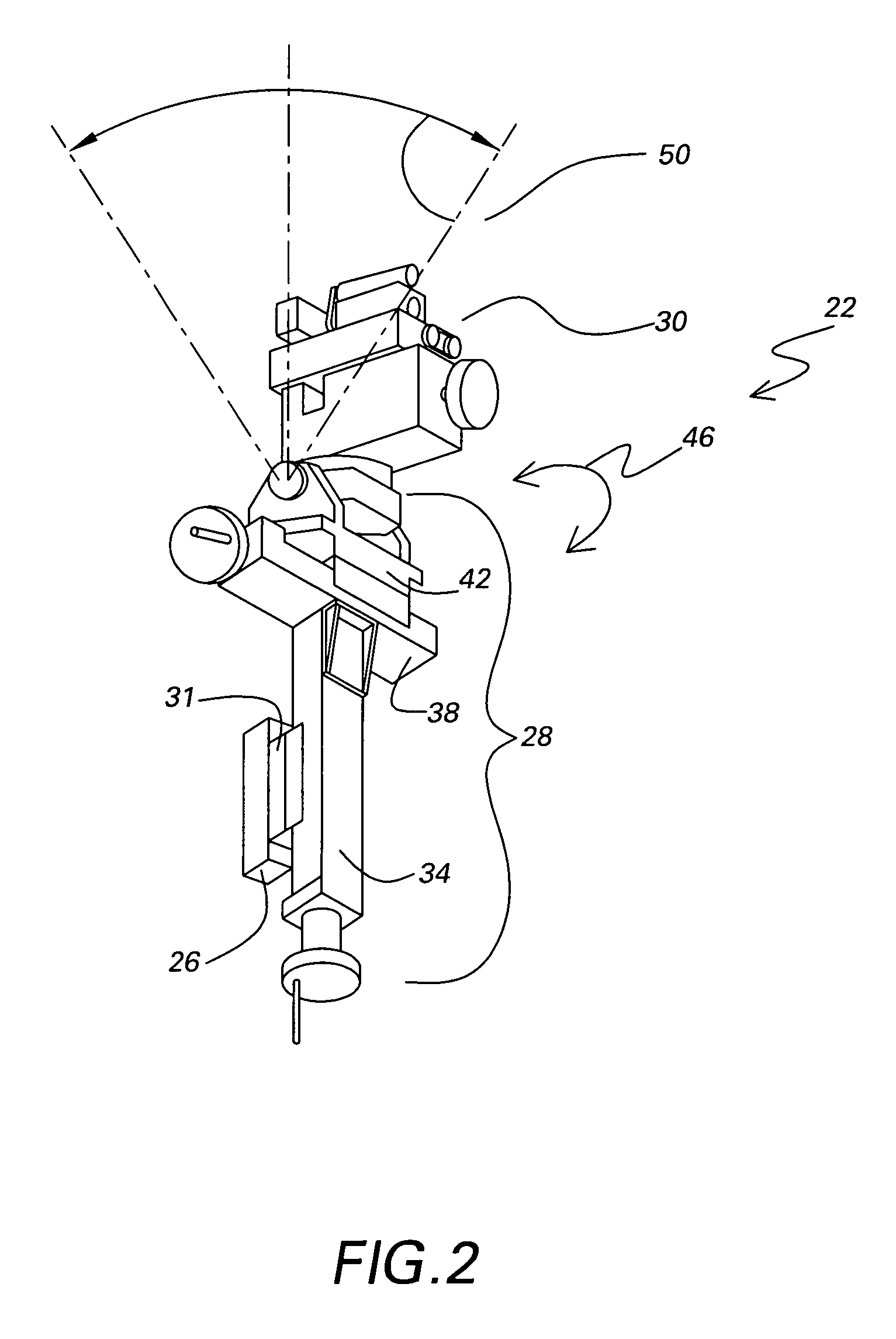

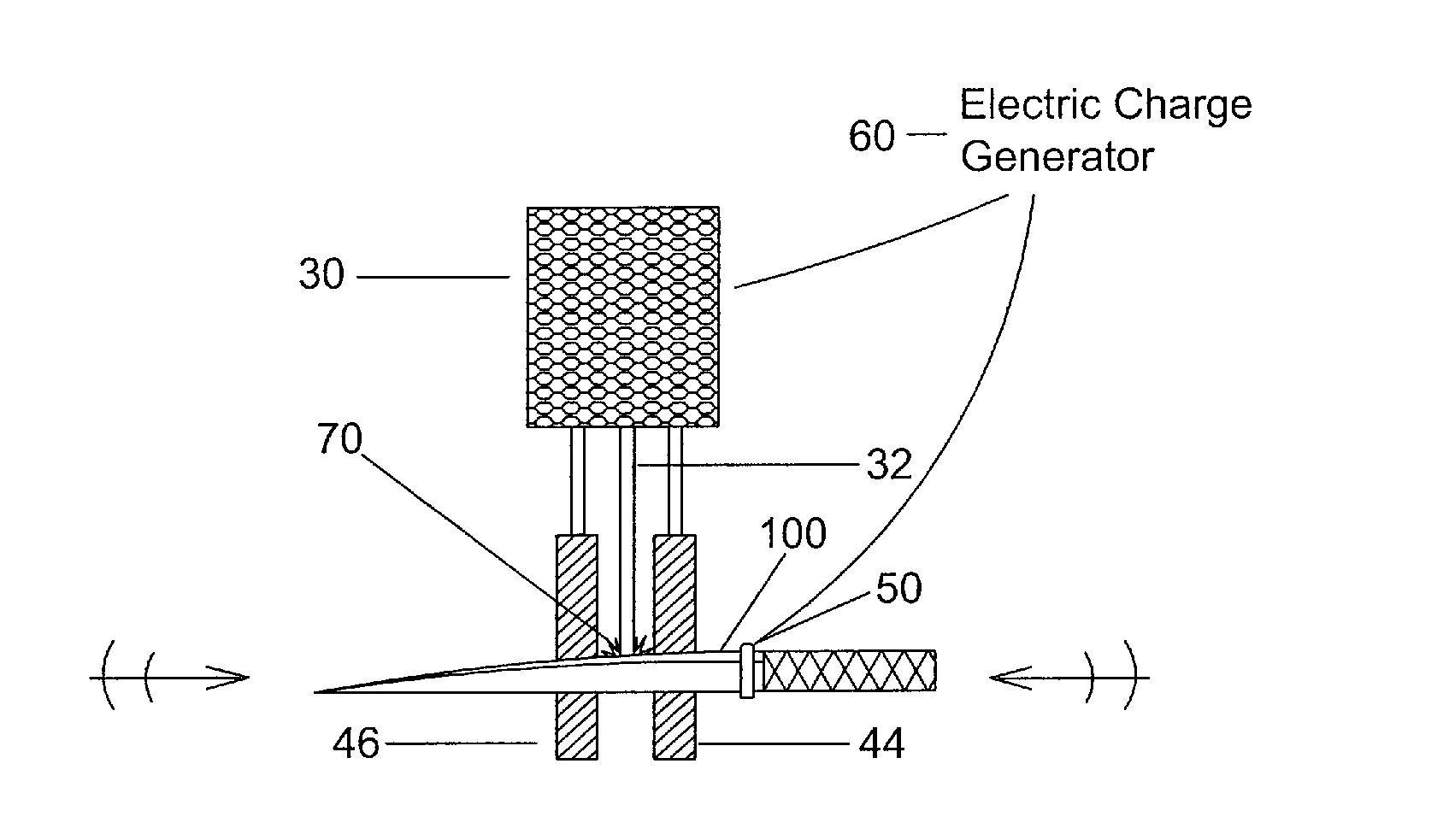

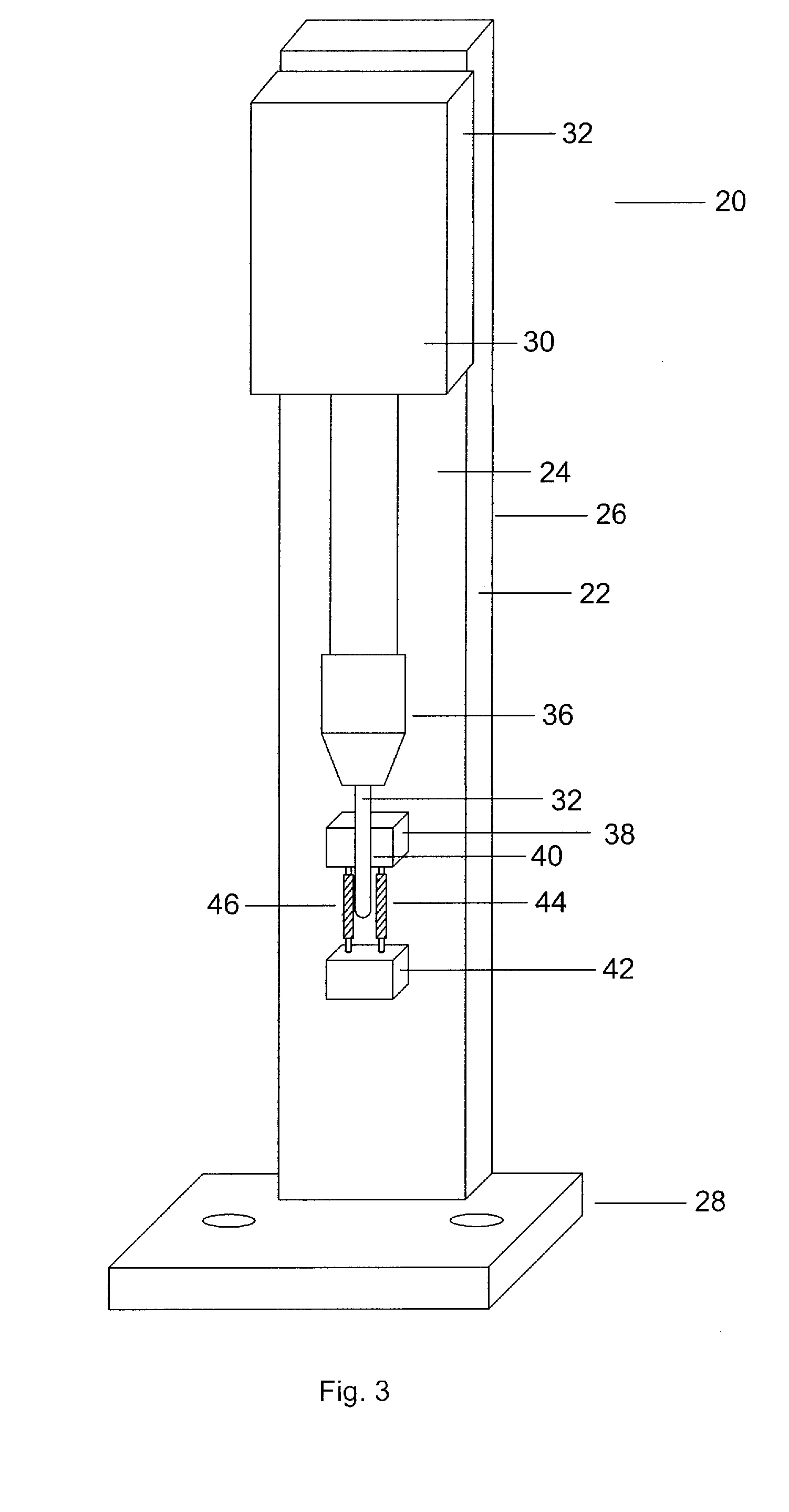

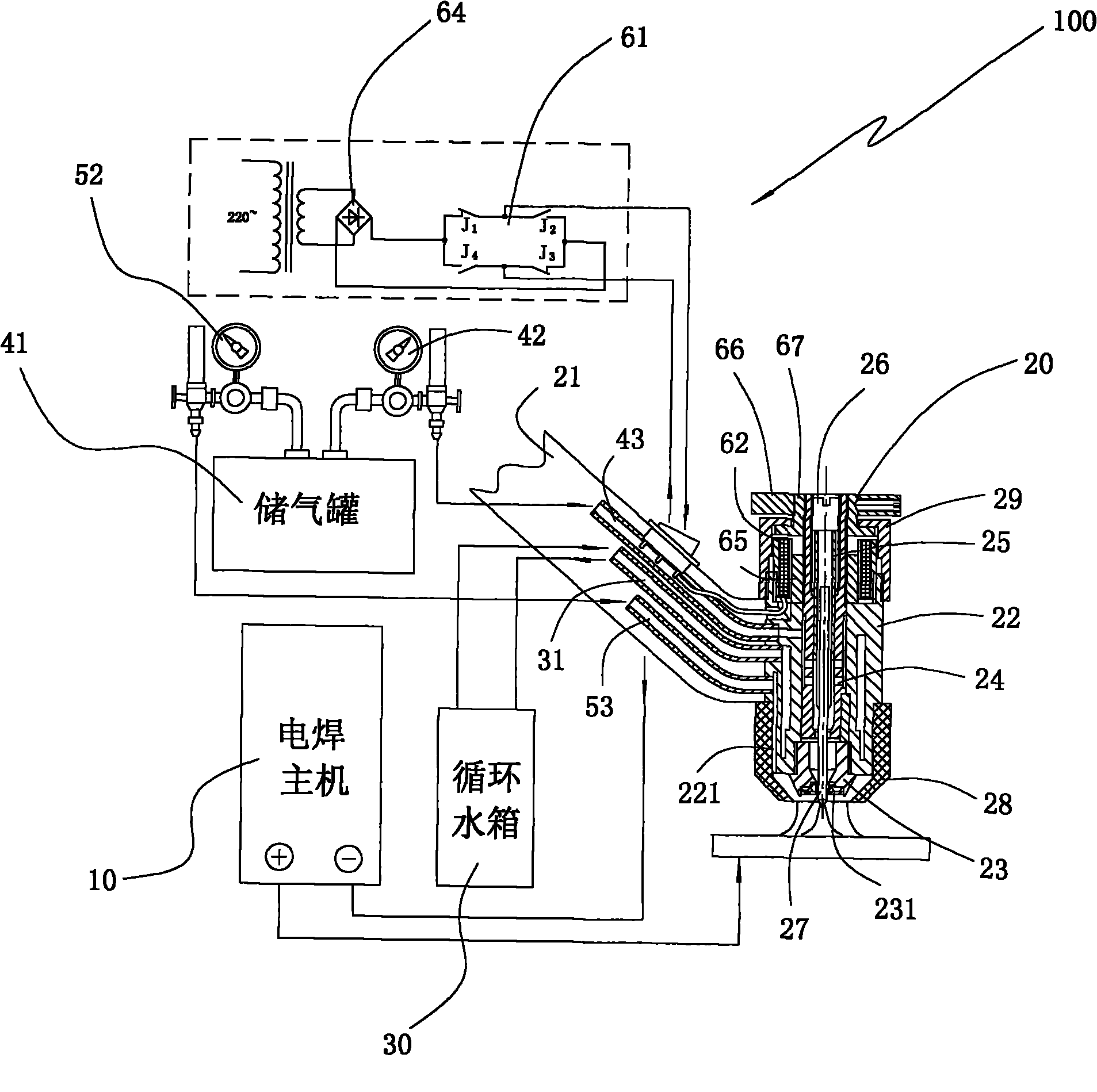

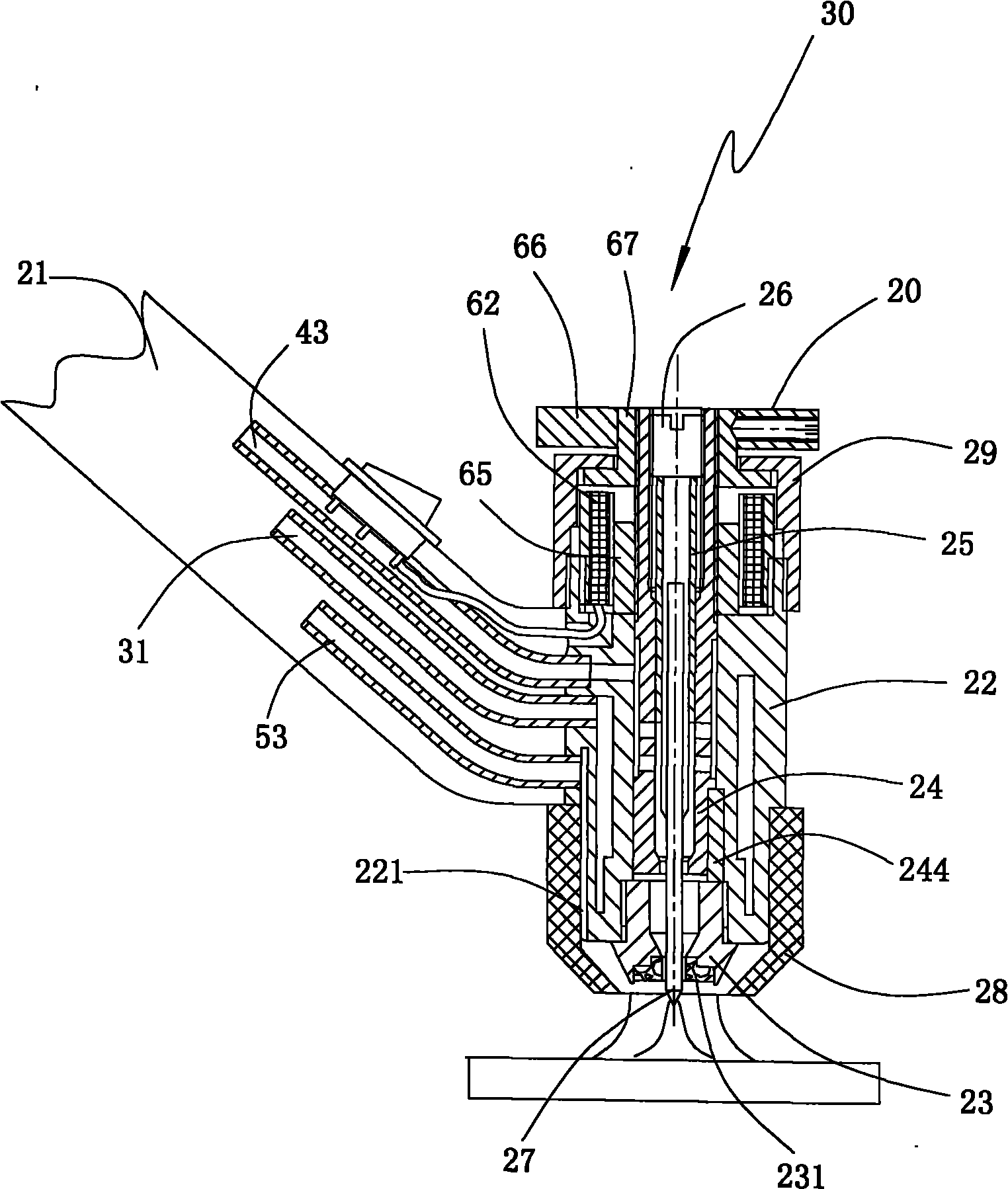

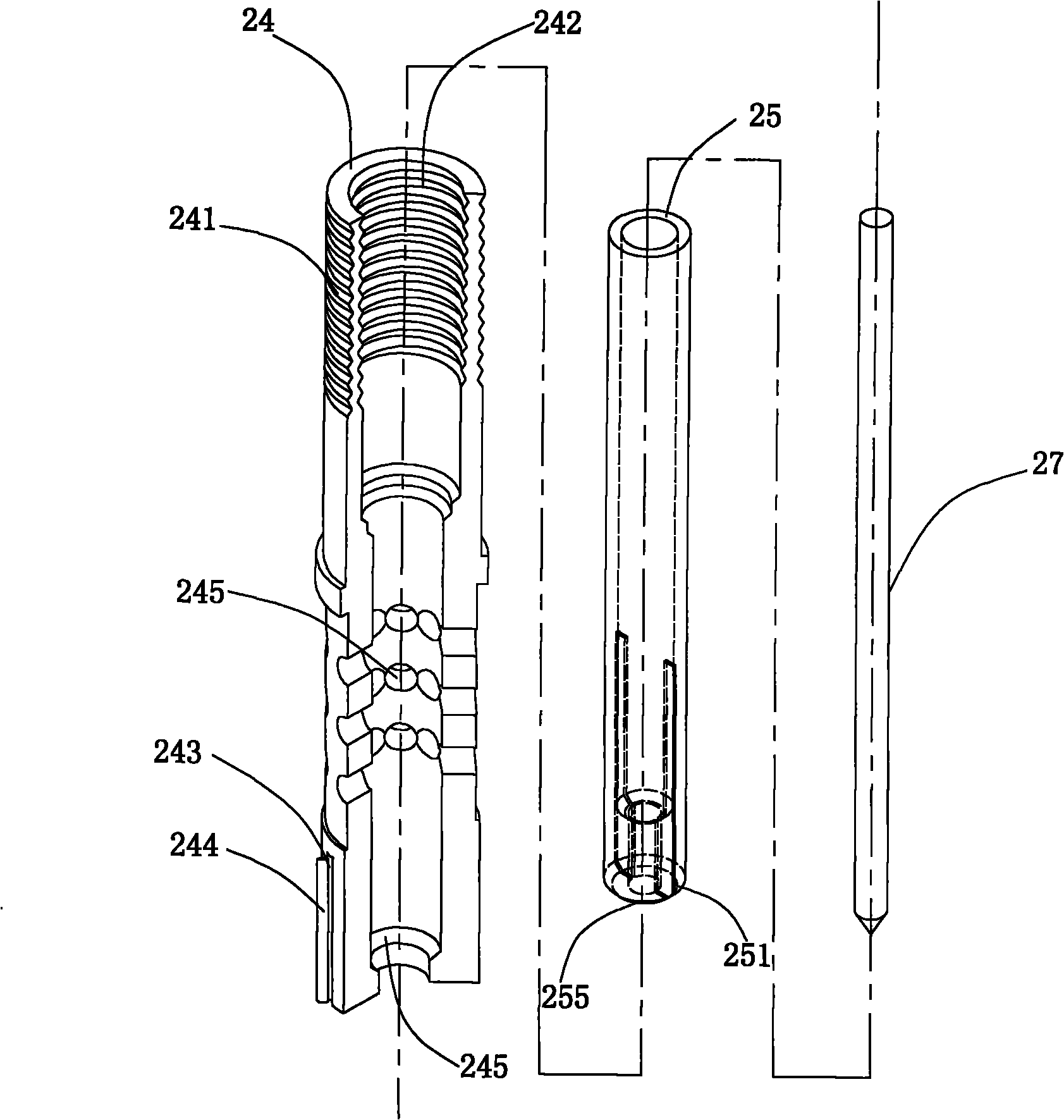

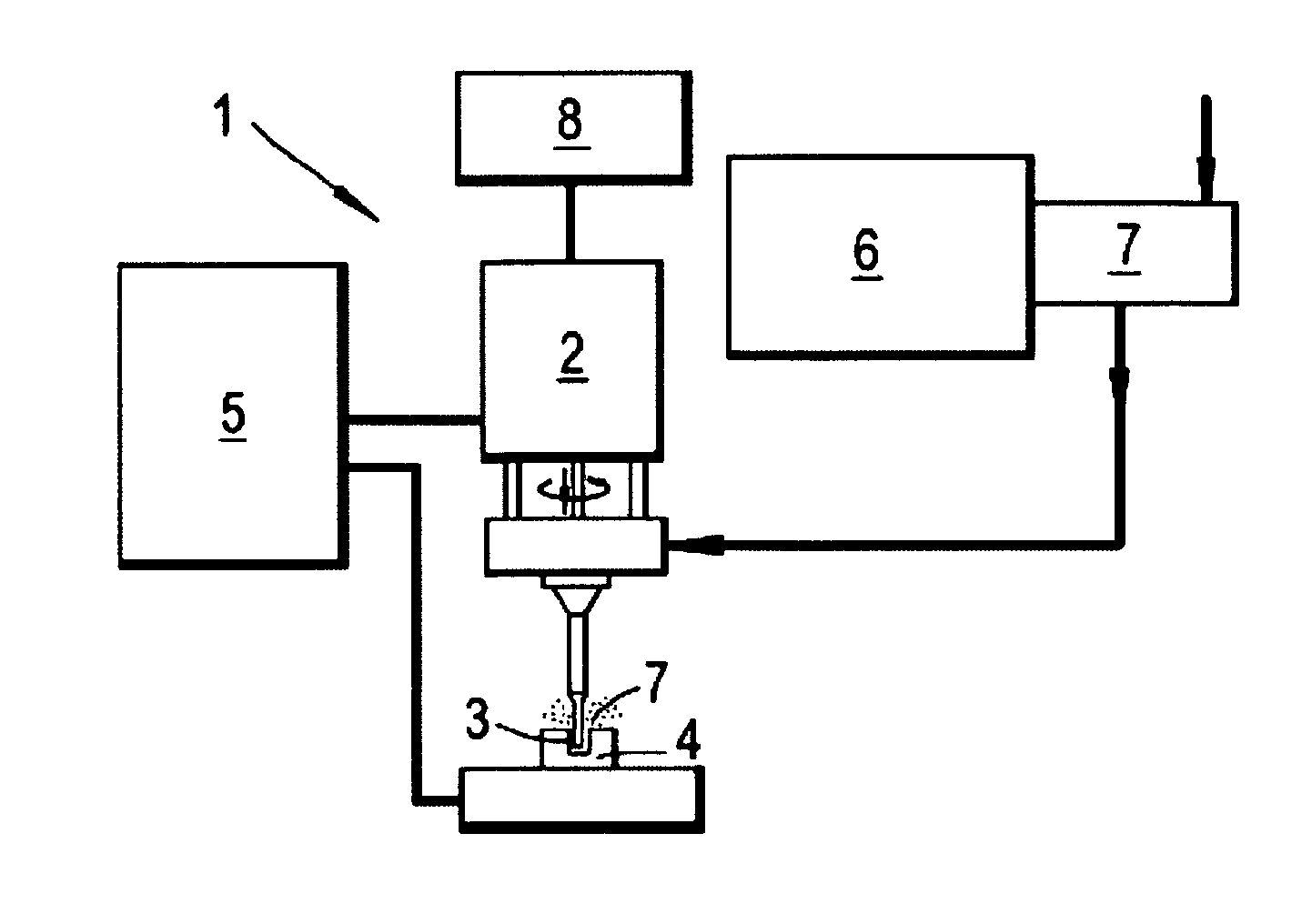

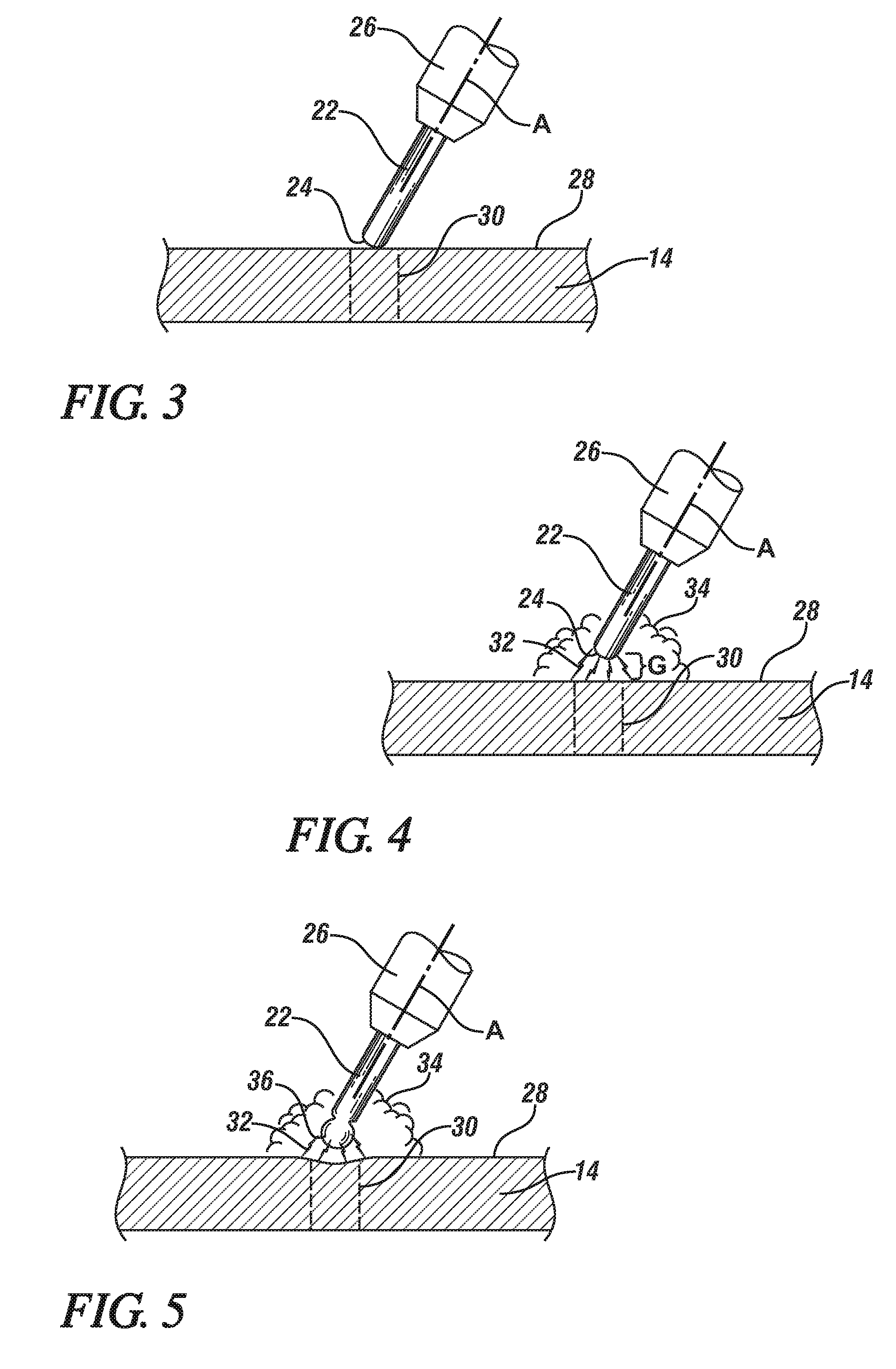

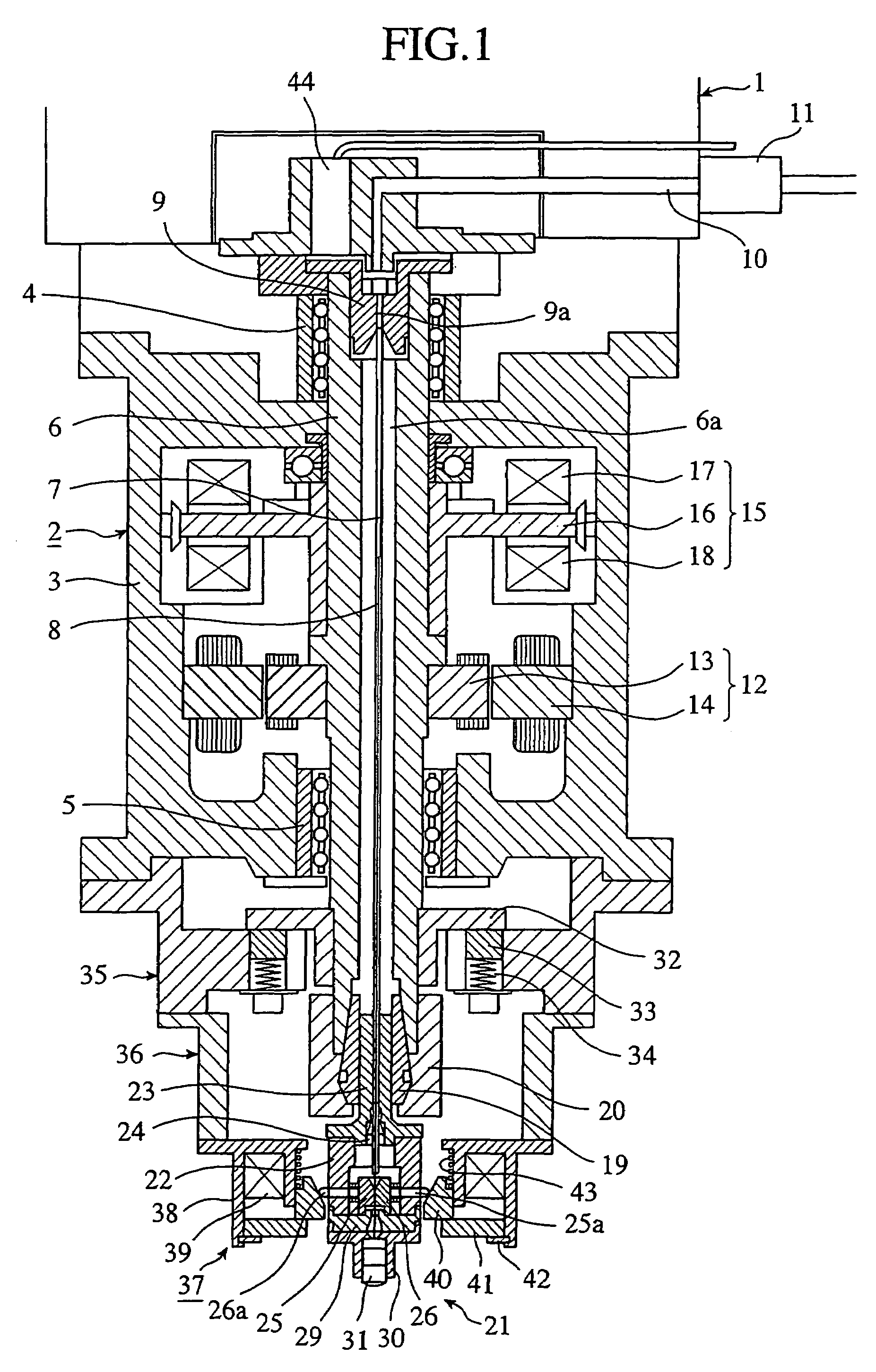

Ultrasound wave and melt pole electrical arc compound welding method

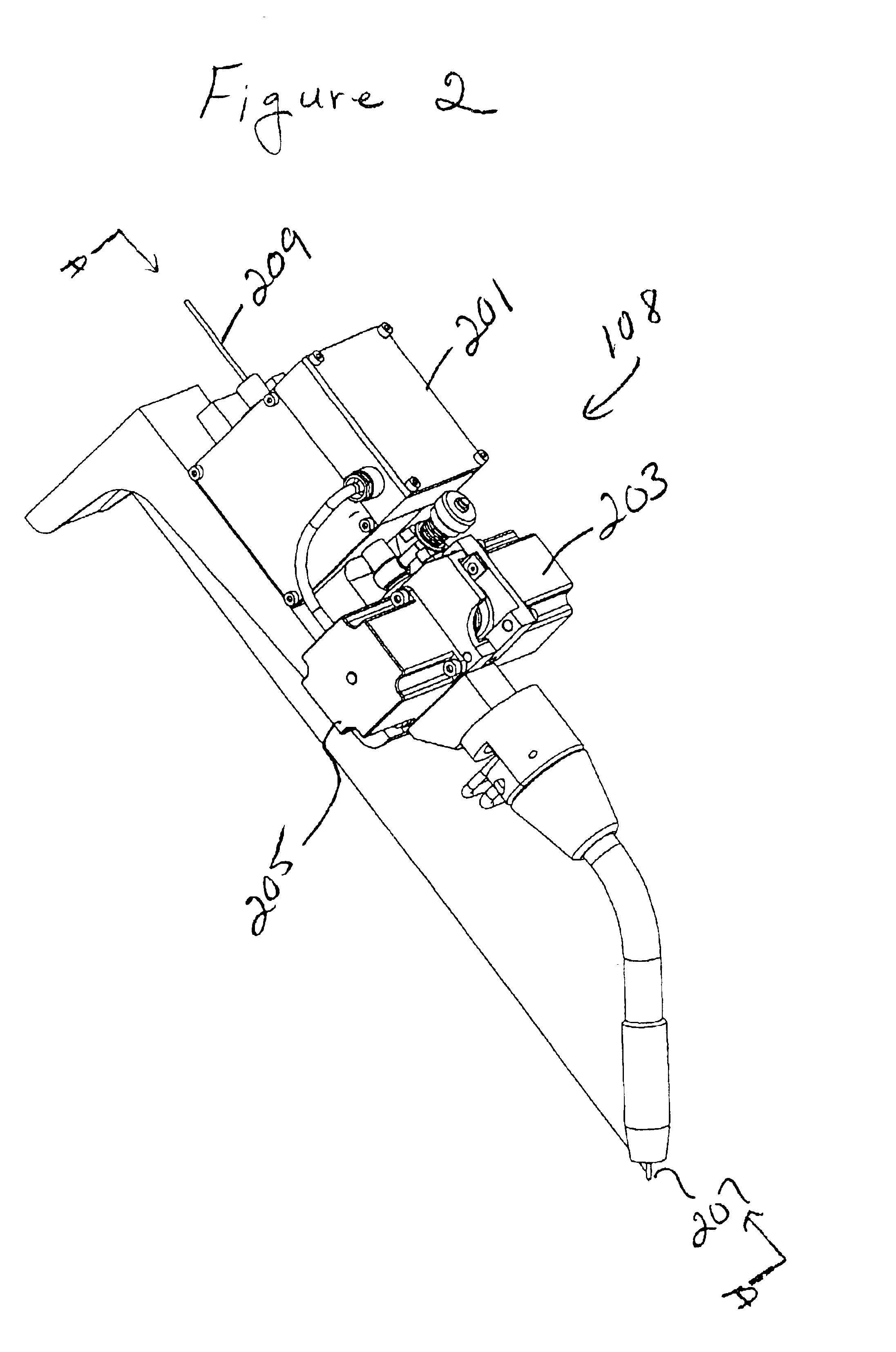

The invention provides a weld method compounding an ultrasonic and a gas metal arc welding so as to make use of the cavitation effect and the vibration effect of the ultrasonic to lead welding drops generated by the gas metal arc welding to be smoothly transmitted to a welding pool when the drops are still small. And when in welding, an electric arc shrinks under the effect of the ultrasonic and then the stiffness of the electric arc can be enhanced, which has a significant application value for welding of special positions such as a full-position welding, an overhead position welding, a flat position welding and a horizontal position welding, etc.. The invention includes the following steps: an ultrasonic generator is connected with an ultrasonic transducer 2 to convert ultrasonic energy into mechanical vibration; an ultrasonic transformer 3 enlarges amplitude; a conductive tip 5 is combined with the ultrasonic transformer; a protective gas nozzle 4 is fixed on the vibration node of the transformer; a welding wire 1 is connected with the conductive tip 5 to start a welding power supply 9 and then start an ultrasonic power supply after the electric arc becomes stable, then the transducer converts electrical energy into vibration and the ultrasonic transformer enlarges the ultrasonic amplitude which is transmitted to a melting electrode.

Owner:HARBIN INST OF TECH

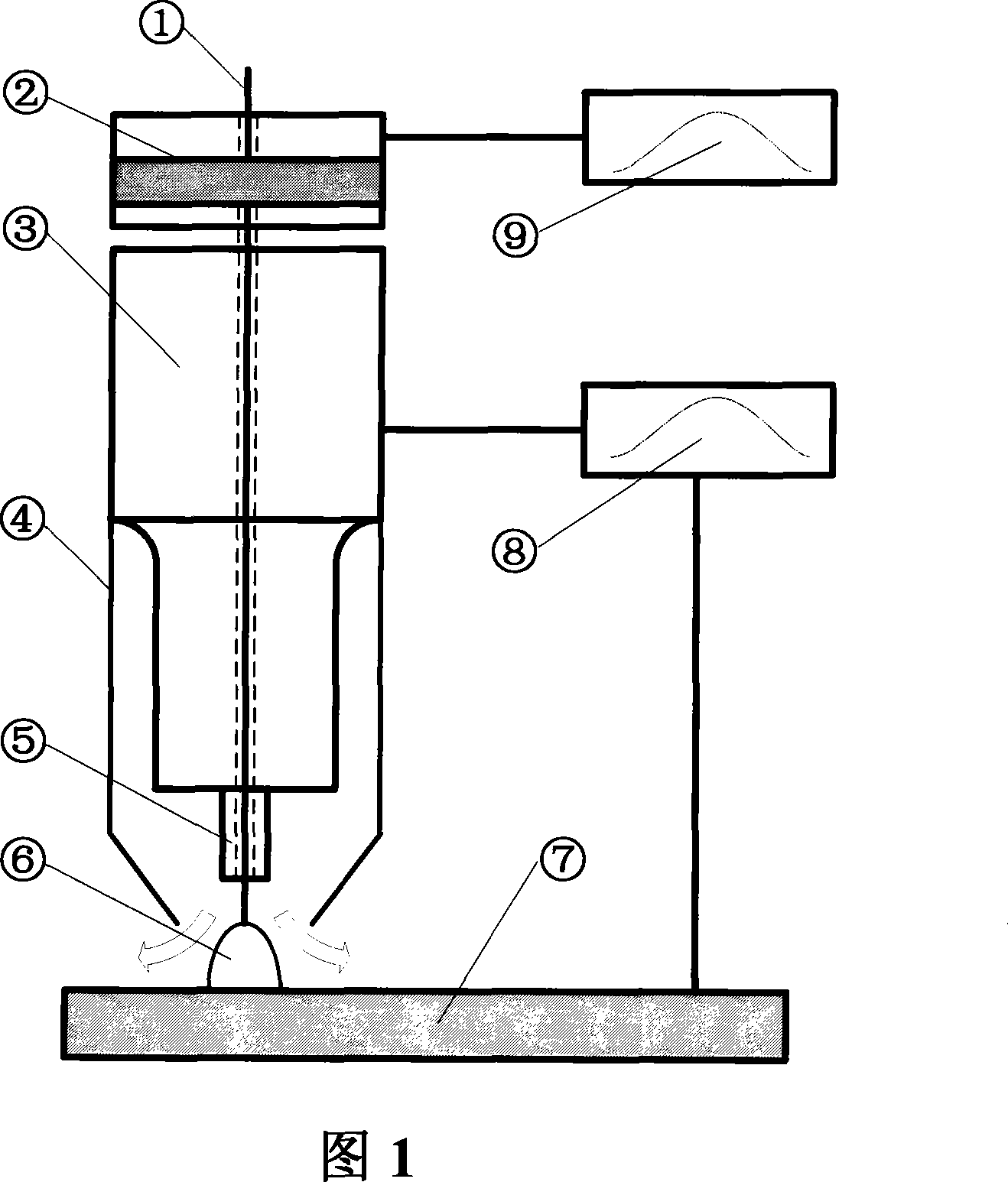

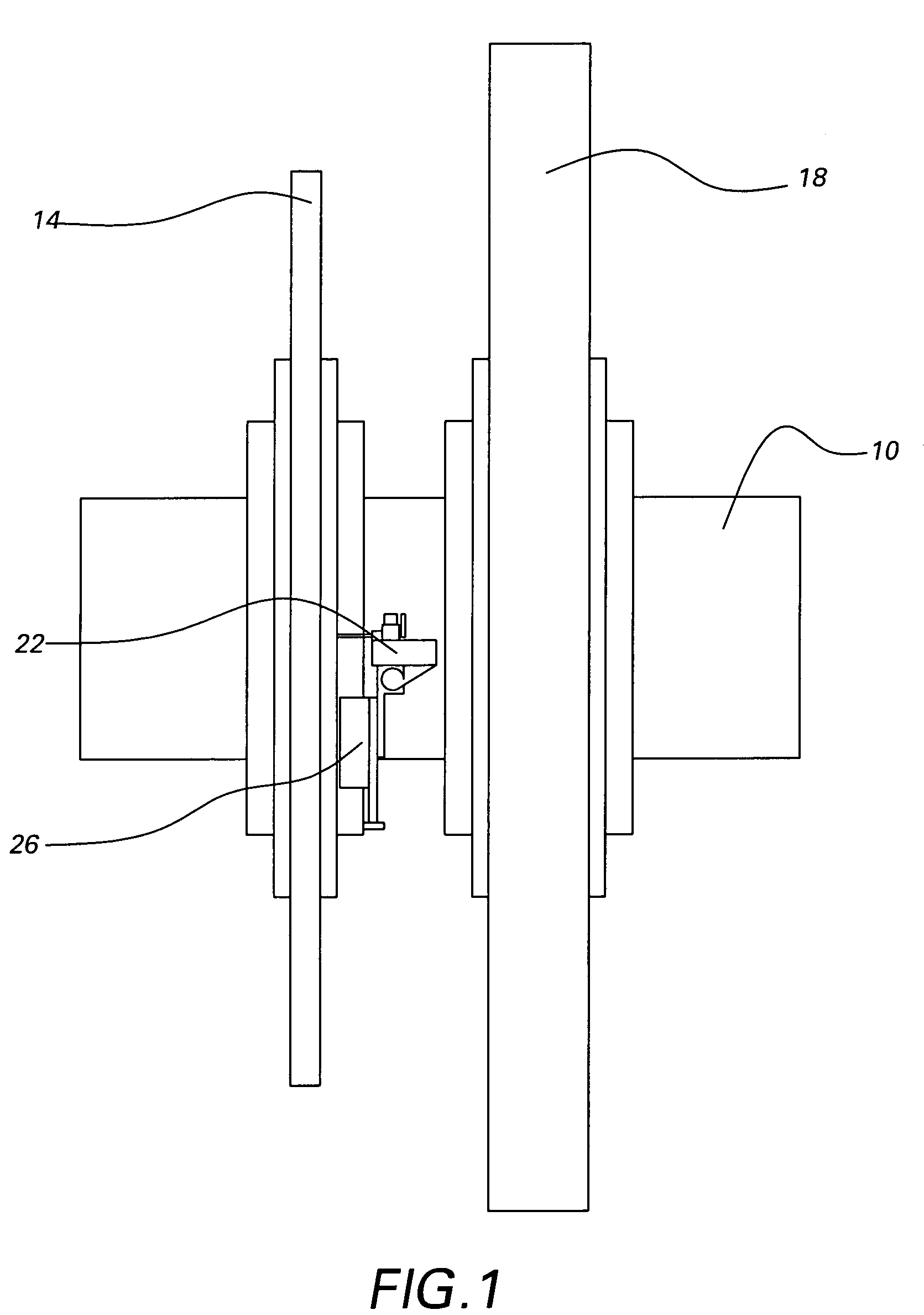

Method and apparatus for controlling a welding system

A method and apparatus for controlling a welding-type power supply includes providing a current wave form having an arc current portion and a short circuit current portion. An arc state is entered by retracting a welding wire, and a short circuit state is entered by advancing the wire. The current enters the arc current portion prior to the creation of the arc and the current enters the short circuit current portion prior to the creation of the short, by coordinating the wave form with the wire retraction. This may be preformed on a wire having a diameter of 2.4 mm or more to a weld and applying a welding current of less than 100 amps, or of less than 35 amps. One current waveform during the arc state includes at least three segments, and the last segment is entered into prior to the short circuit state being entered, and is the same current magnitude as the current magnitude at the start of the short circuit state. Penetration and / or bead formation may be controlled by controlling the advancement of the wire into the weld pool. The balance may be user set.

Owner:ILLINOIS TOOL WORKS INC

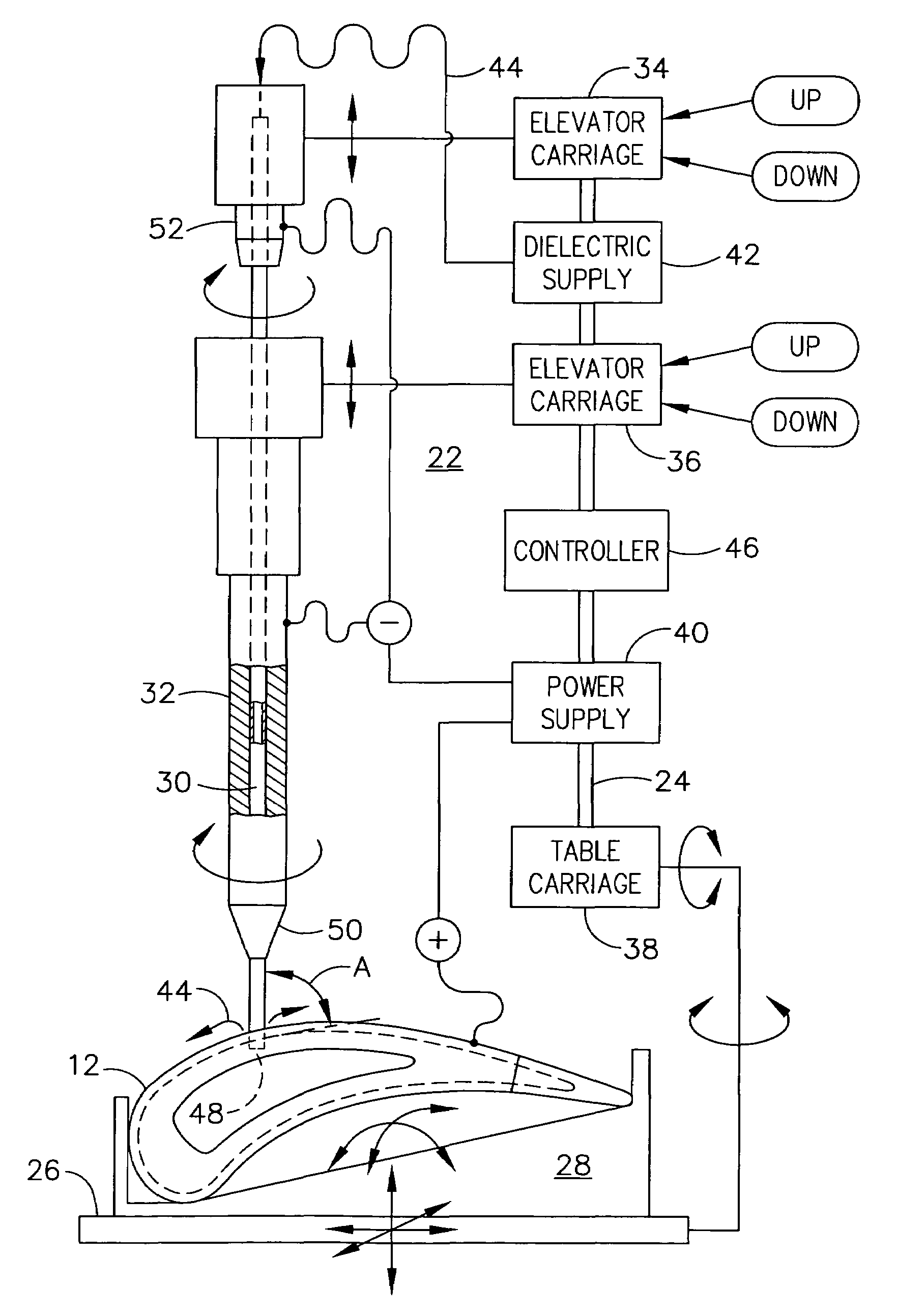

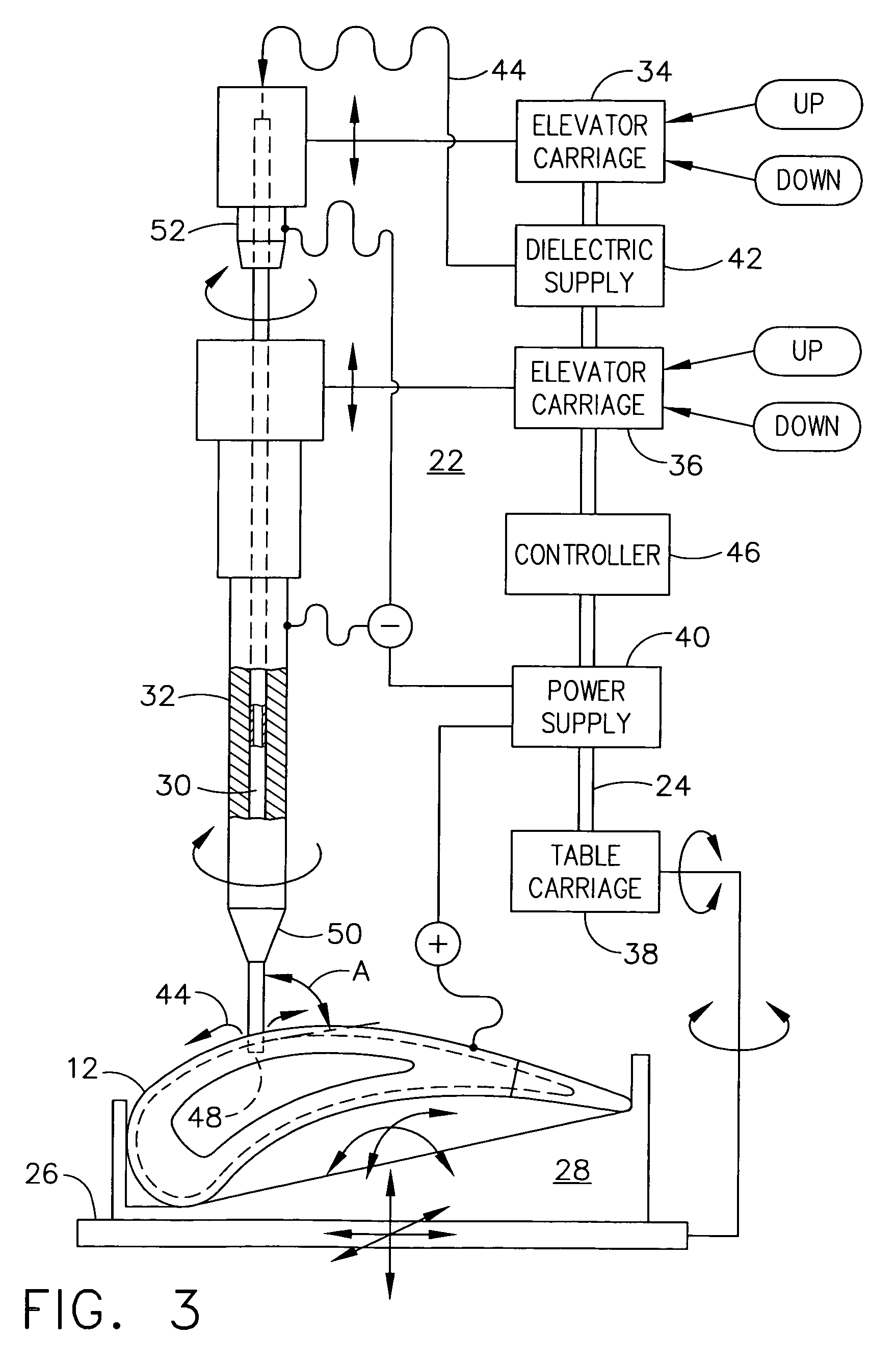

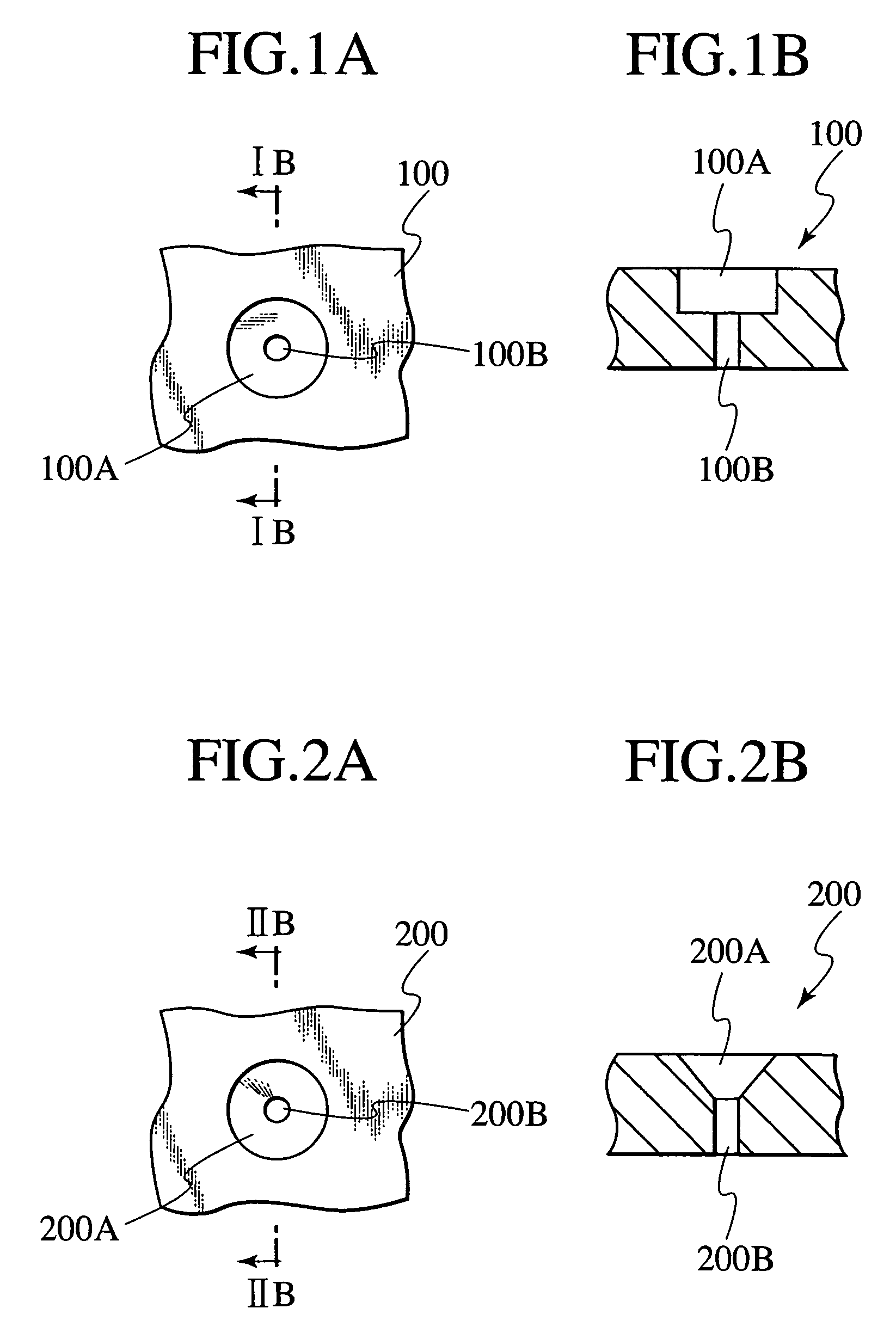

Duplex electrical discharge machining

ActiveUS7214901B1Electrode vibration holdersElectrical-based machining electrodesElectricityElectrical discharge machining

An electrical discharge machine includes first and second coaxial electrodes and corresponding carriages. A liquid dielectric is channeled between the electrodes and a workpiece which are suitably electrically powered for machining a duplex hole in the workpiece.

Owner:GENERAL ELECTRIC CO

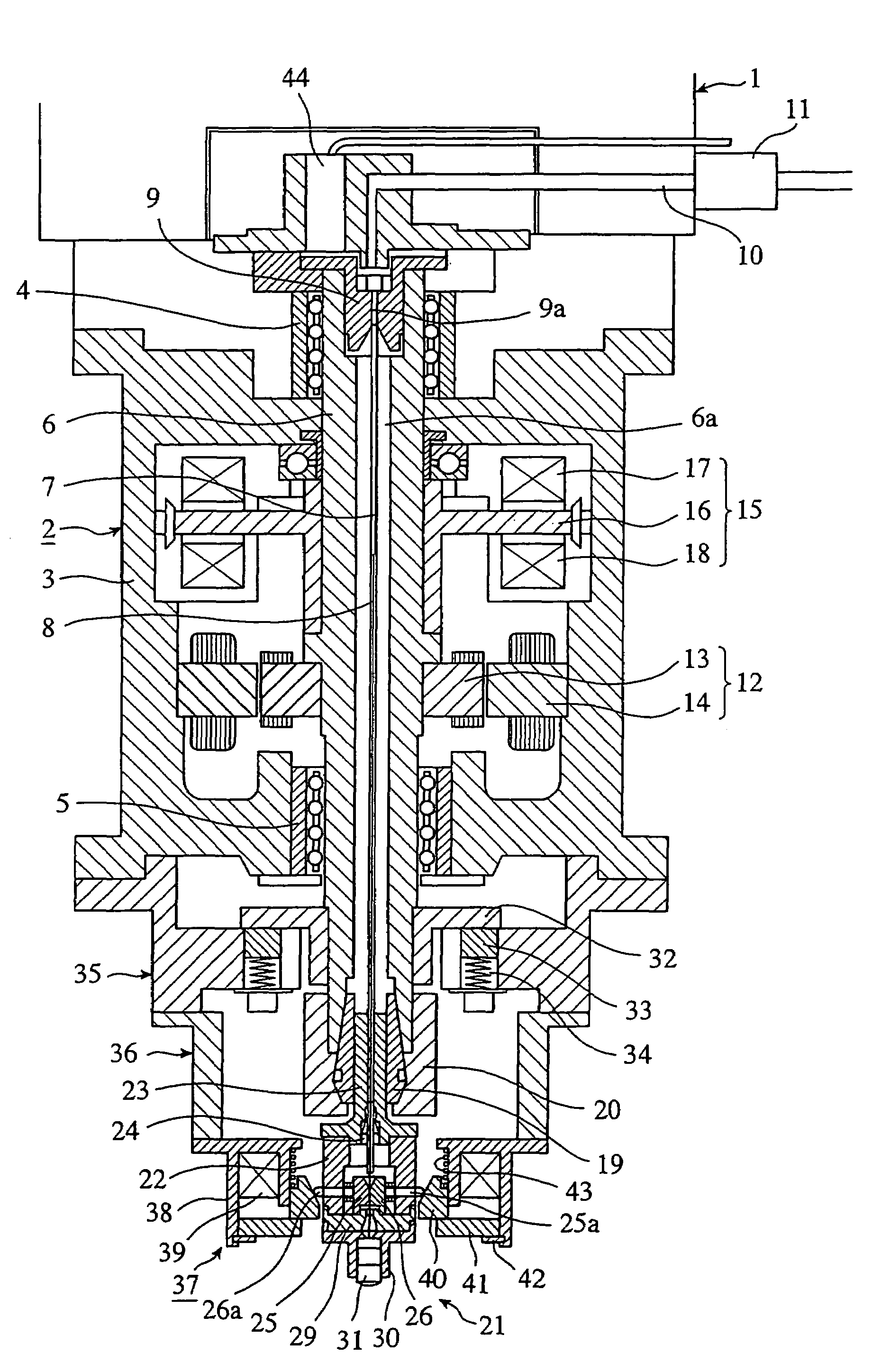

Composite welding method of ultrasound wave and non-melt pole electrical arc

InactiveCN101219499AImprove straightnessImproved arc stabilityElectrode vibration holdersTransformerEngineering

The invention discloses a welding method of compounding ultrasonic and nonconsumable electrode voltaic arc. Under the welding condition of protection of nonconsumable electrode gas, the ultrasonic is conducted into welding arc through the conductive electrode and the voltaic arc obviously contracts after ultrasound is carried on. The invention not only has the advantages of stable welding process and high welding and forming quality which normal TIG welding has, but also can improve weld penetration of single-pass welding and therefore the method can realize high quality welding under normal welding condition. The invention converts the high frequency electrical signals of ultrasound supply into mechanical vibration through an energy conversion device and the mechanical vibration is amplified by an amplitude transformer, and then is transmitted to an electrode studded in the amplitude transformer so as to generate supersonic vibration of corresponding frequency on the electrode. The input power of the ultrasound can be adjusted at will between 1W to 1000W and then welding is carried out by the method of normal gas metal arc welding. When voltaic arc is applied to processing pieces, the energy is concentrated, thereby effectively improving utilization ratio of voltaic arc during welding.

Owner:HARBIN INST OF TECH

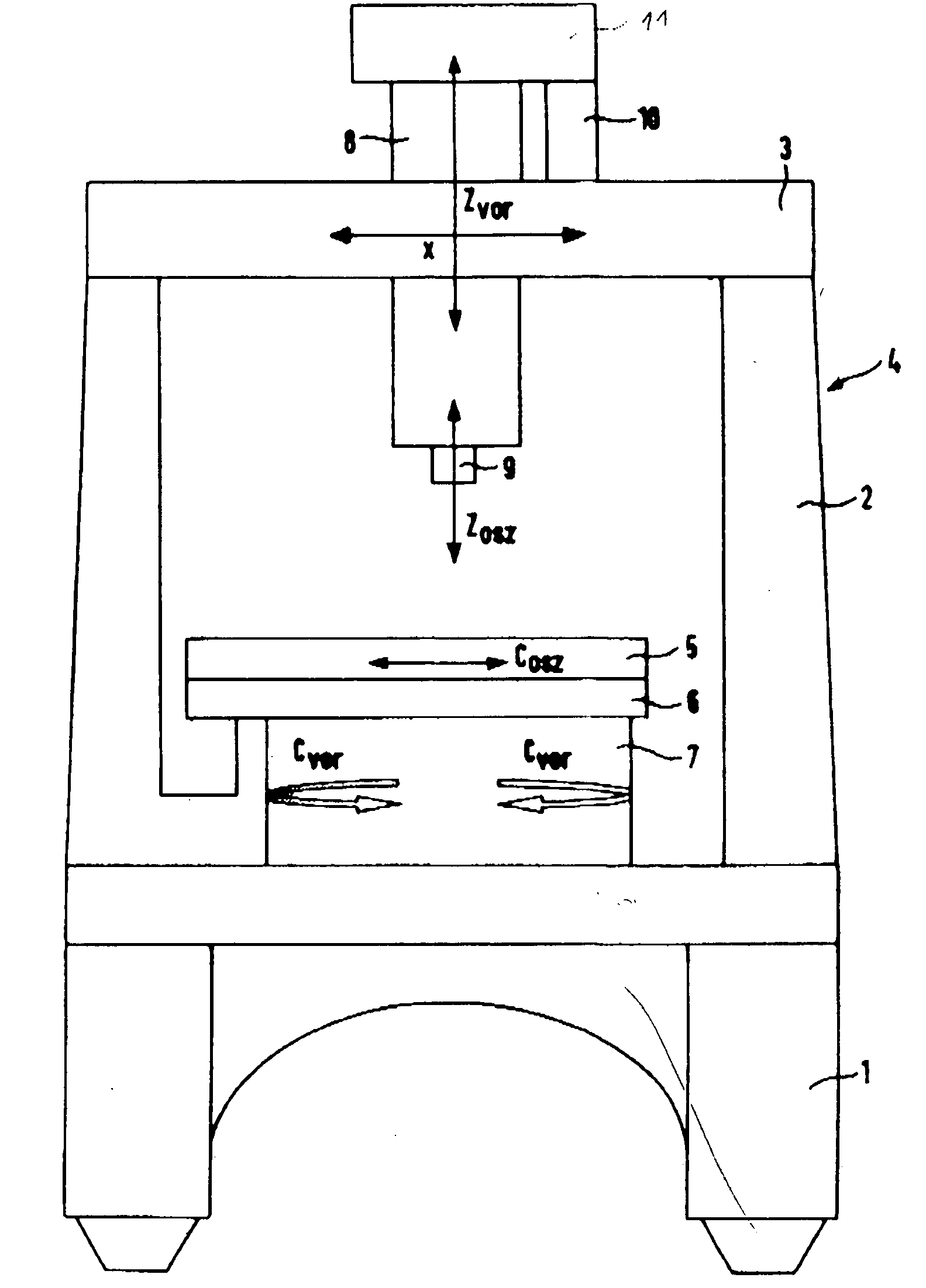

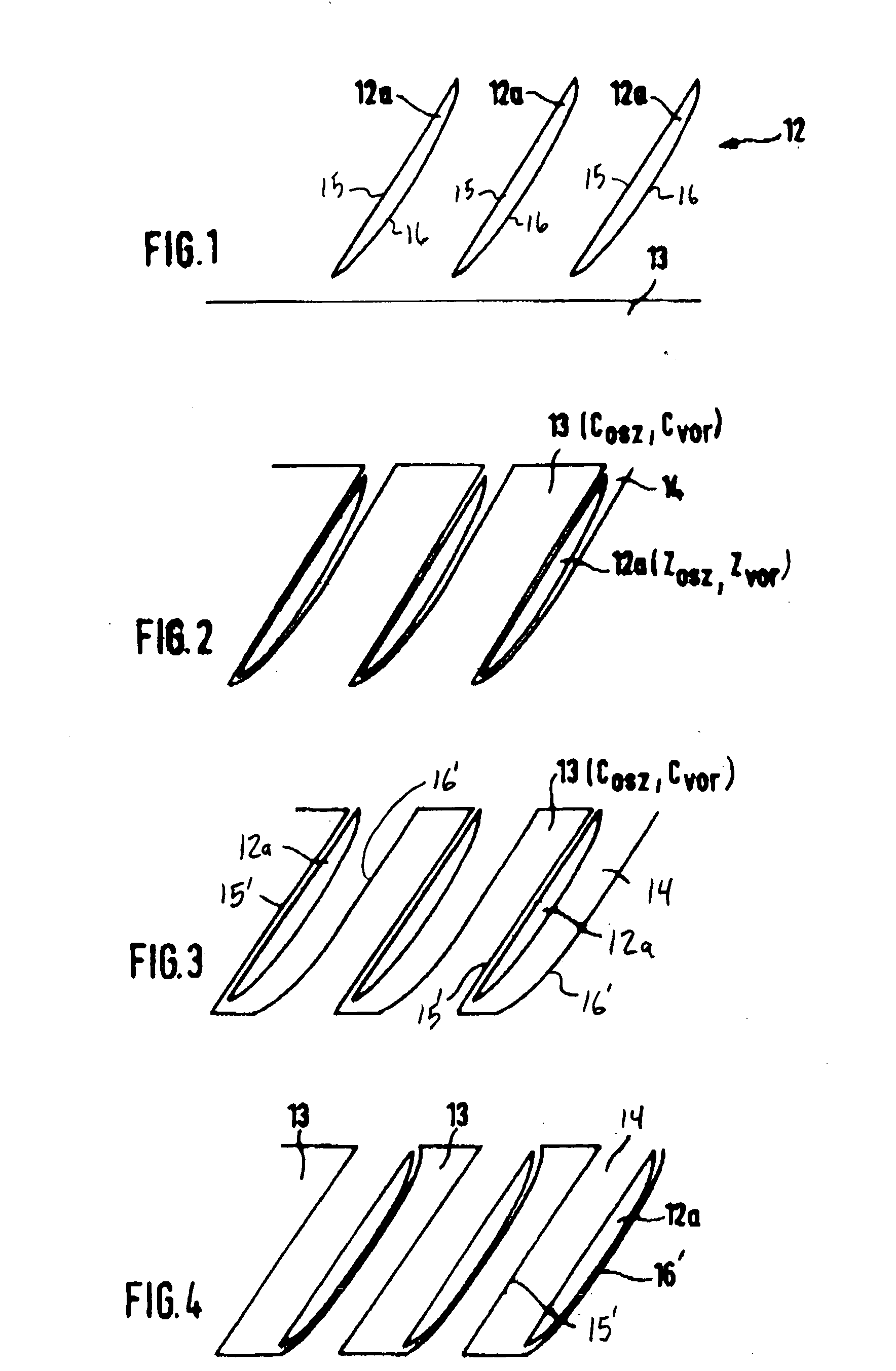

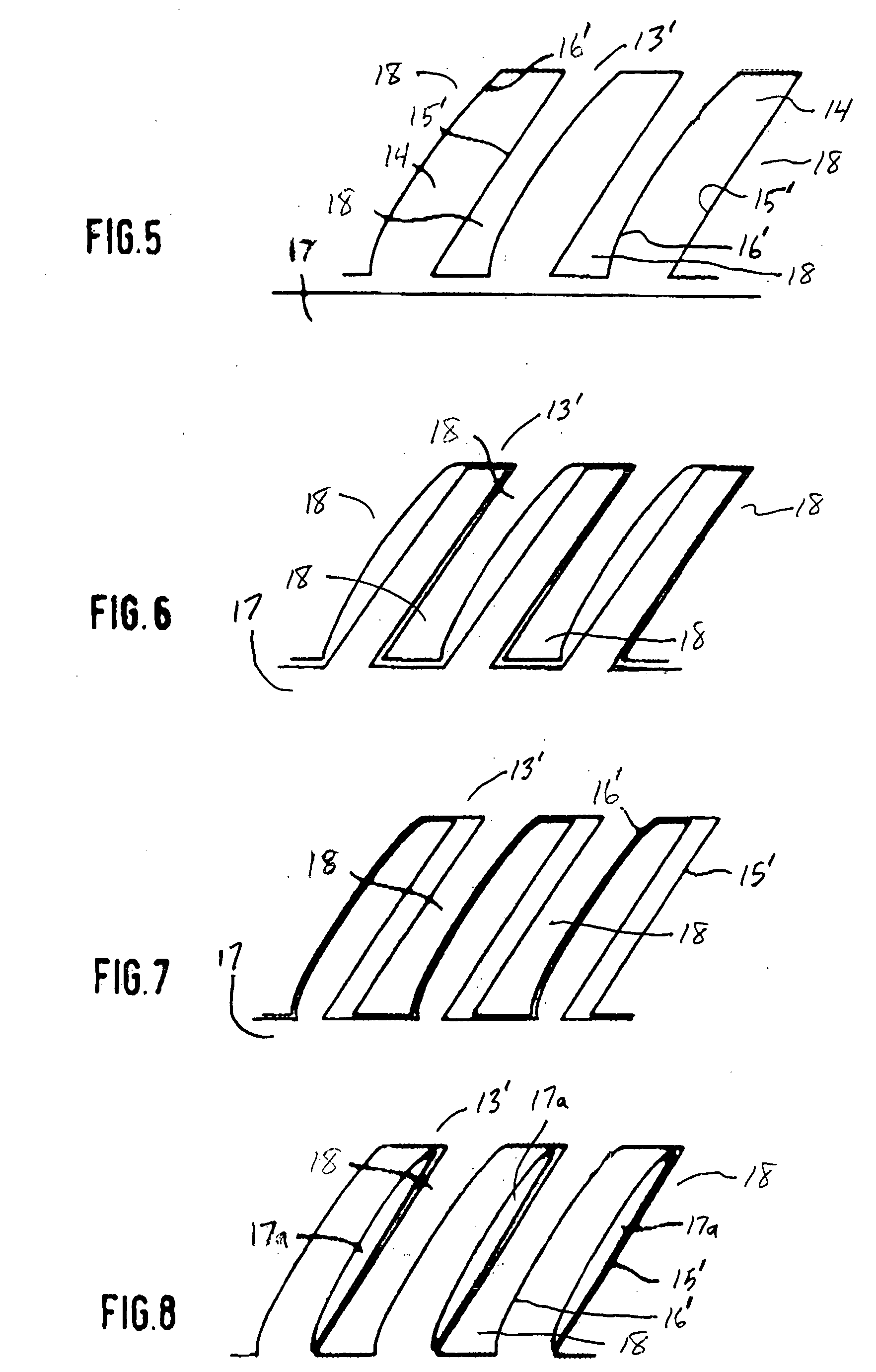

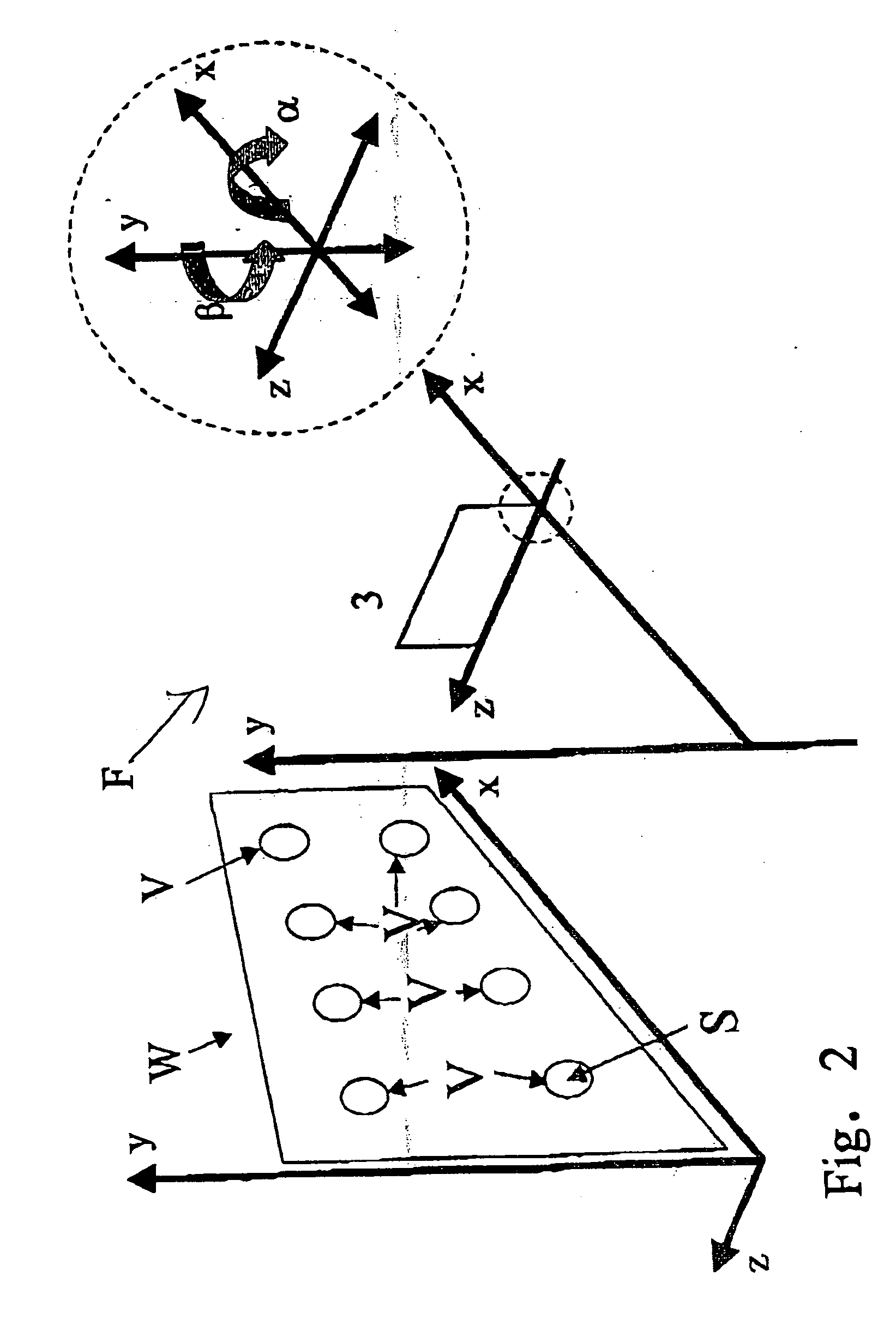

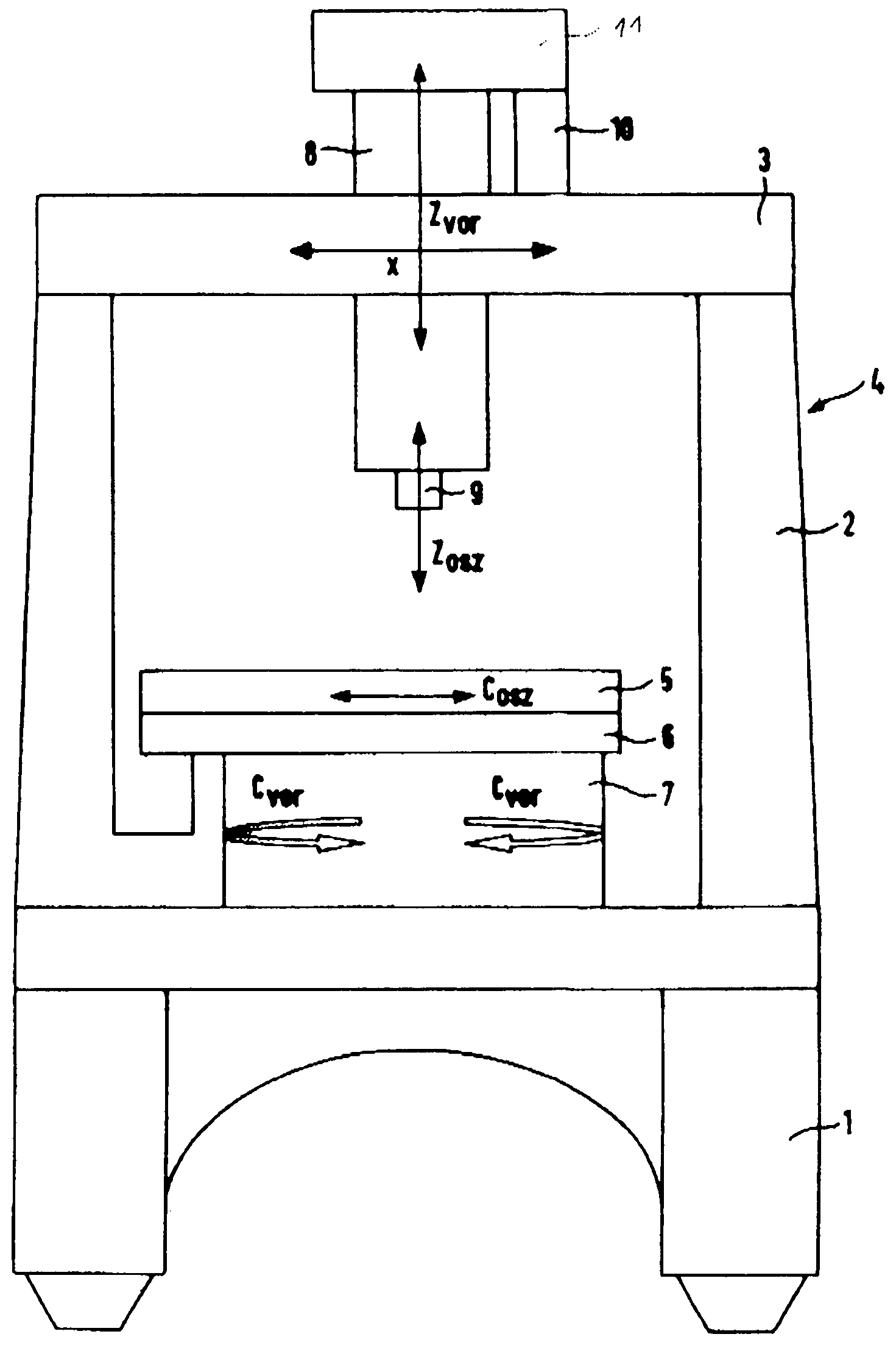

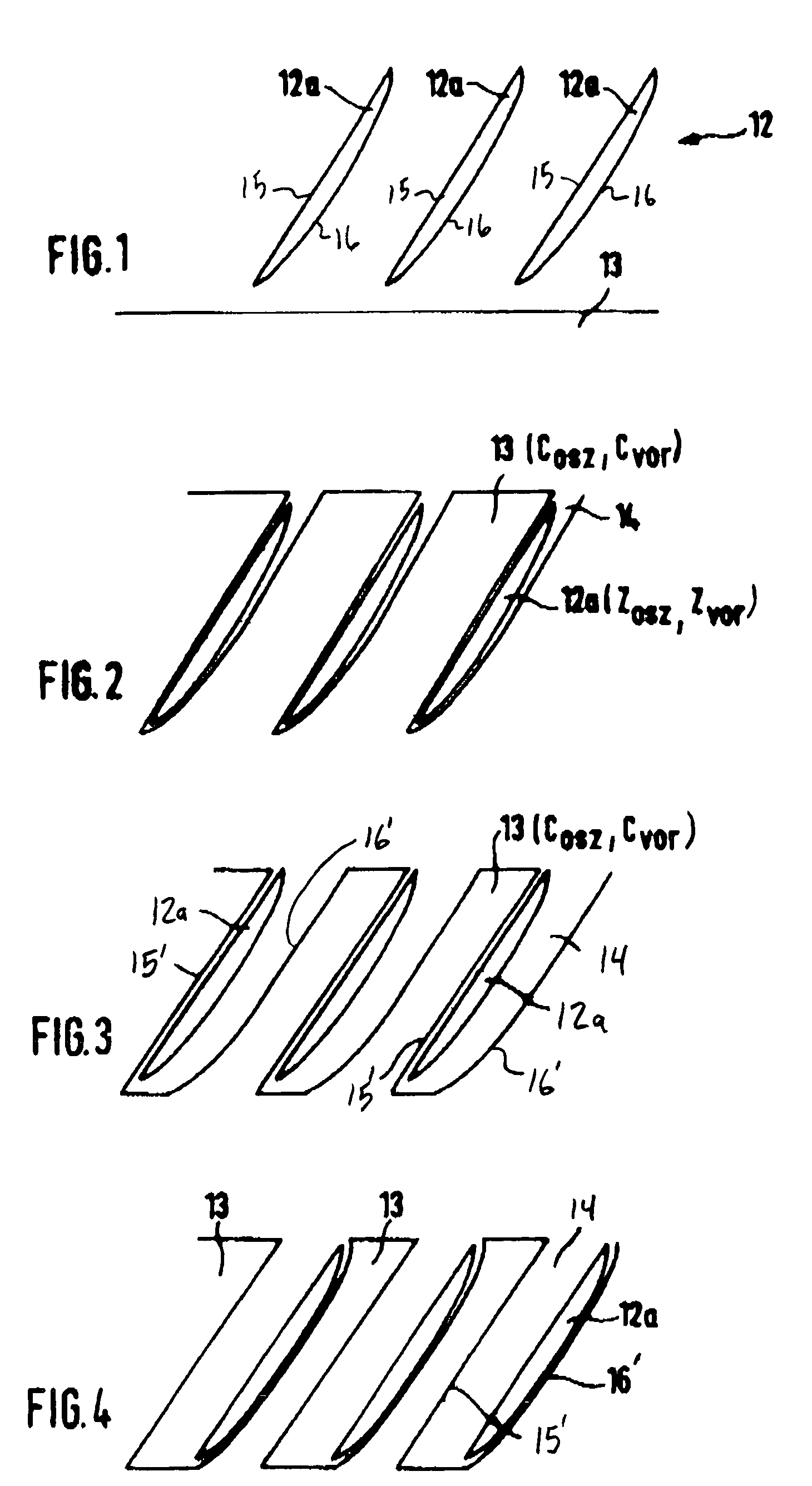

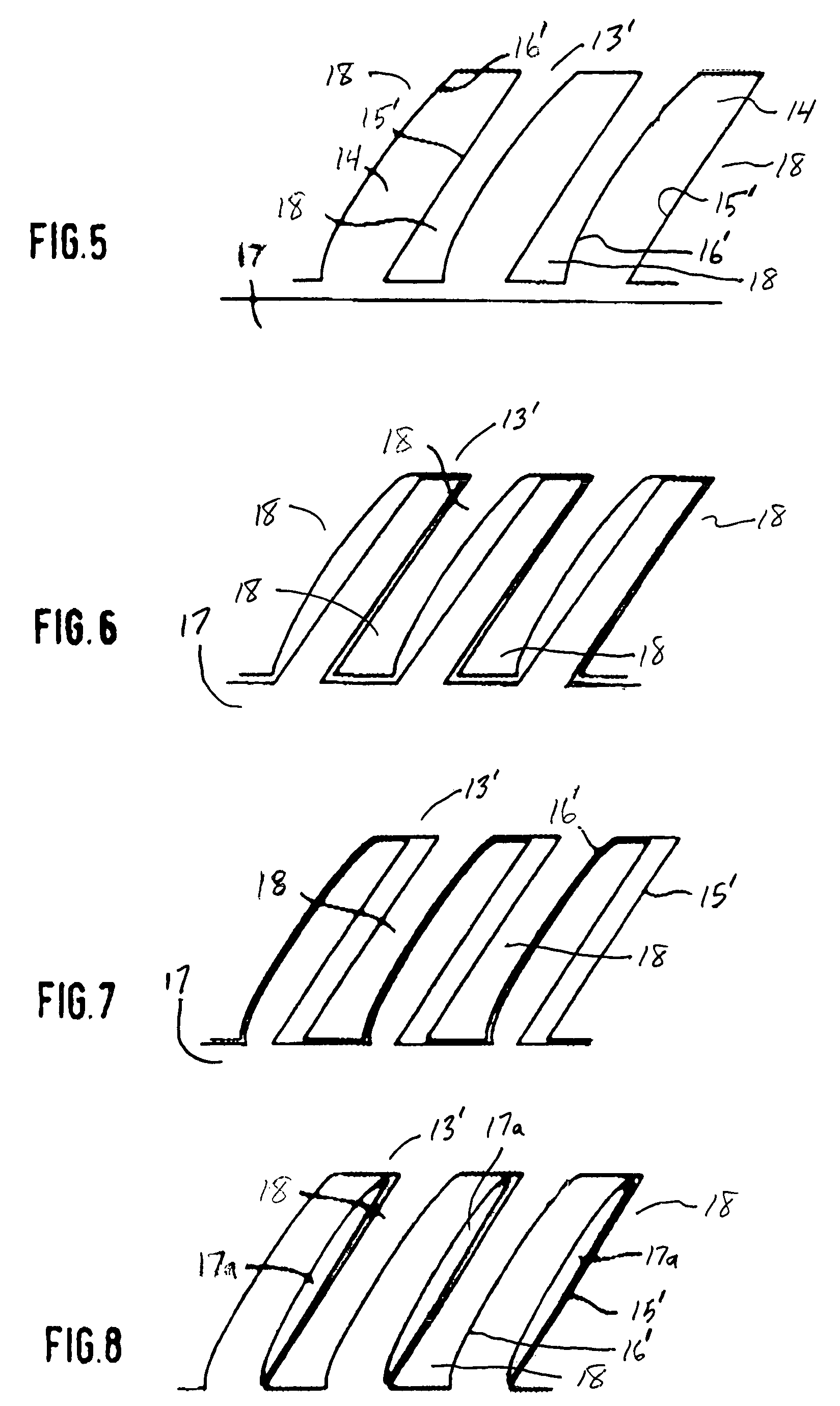

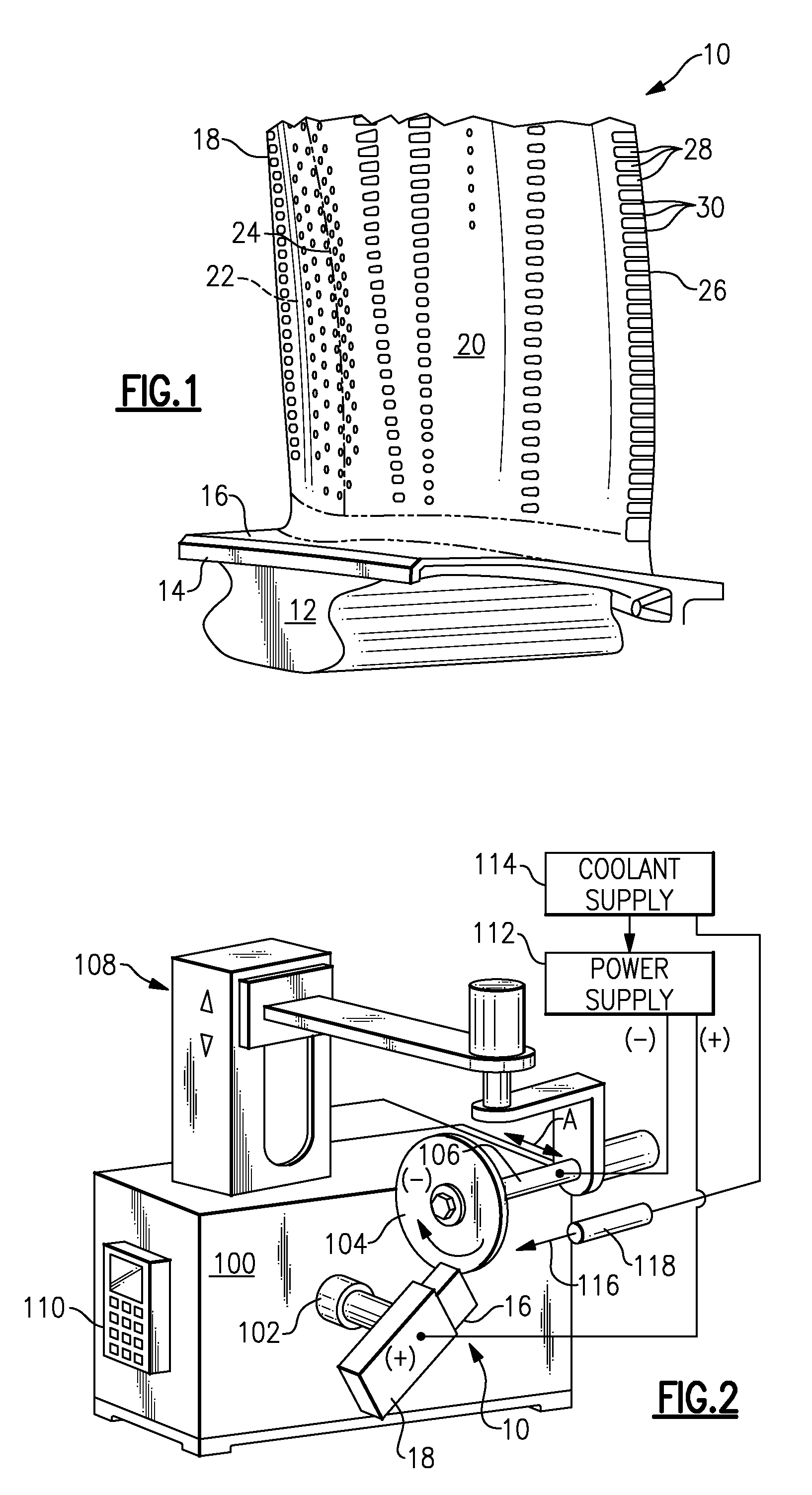

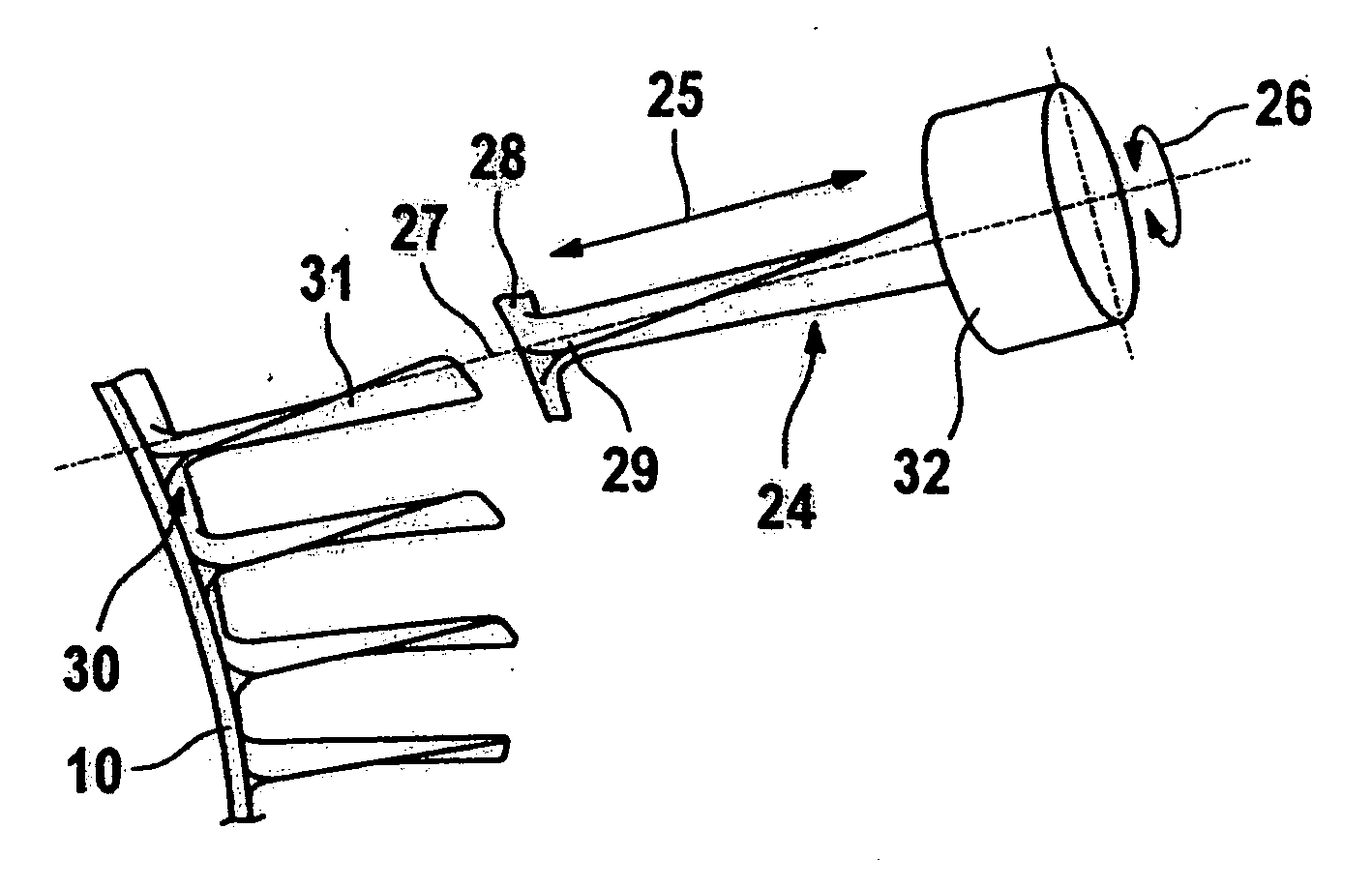

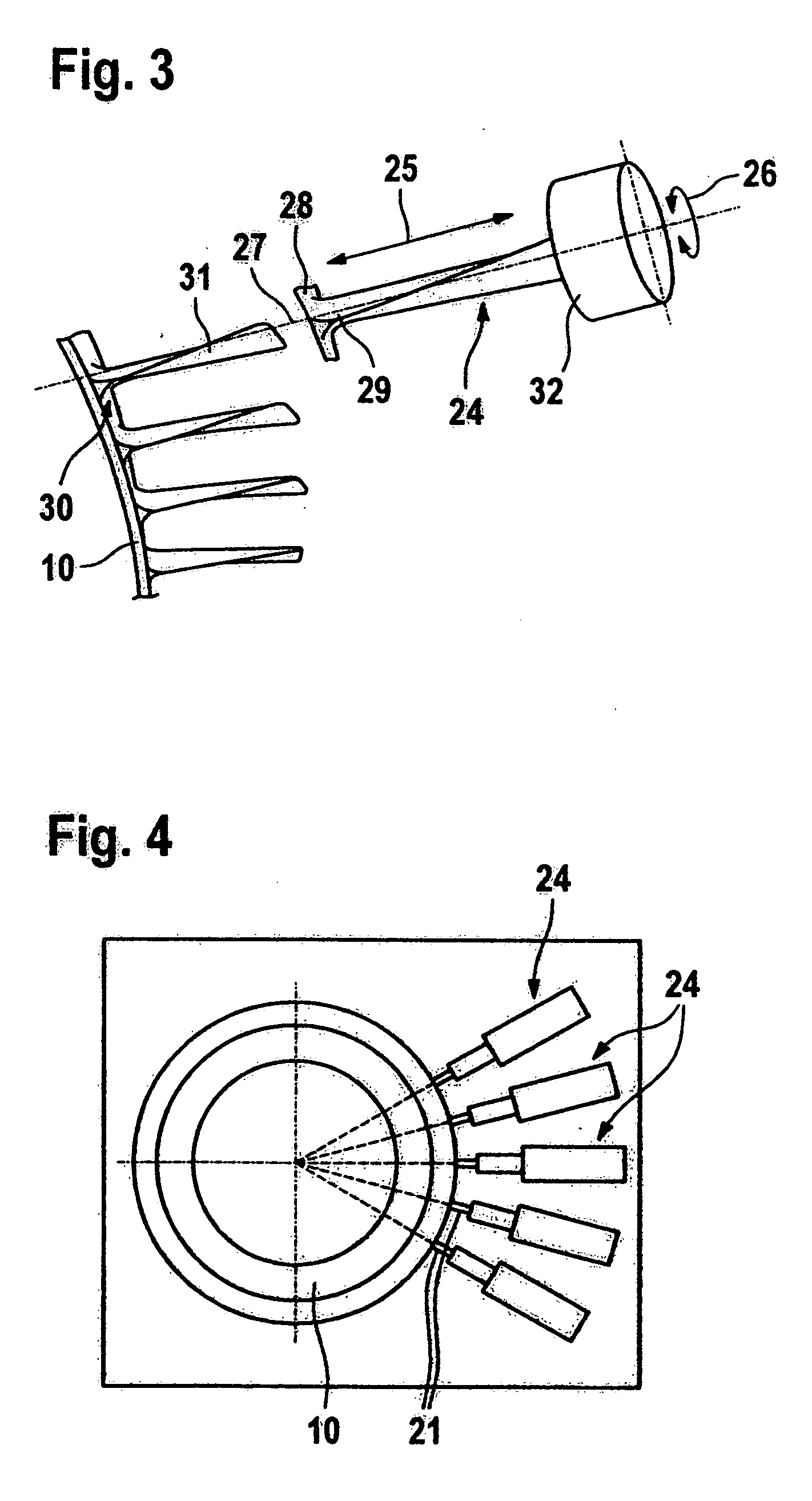

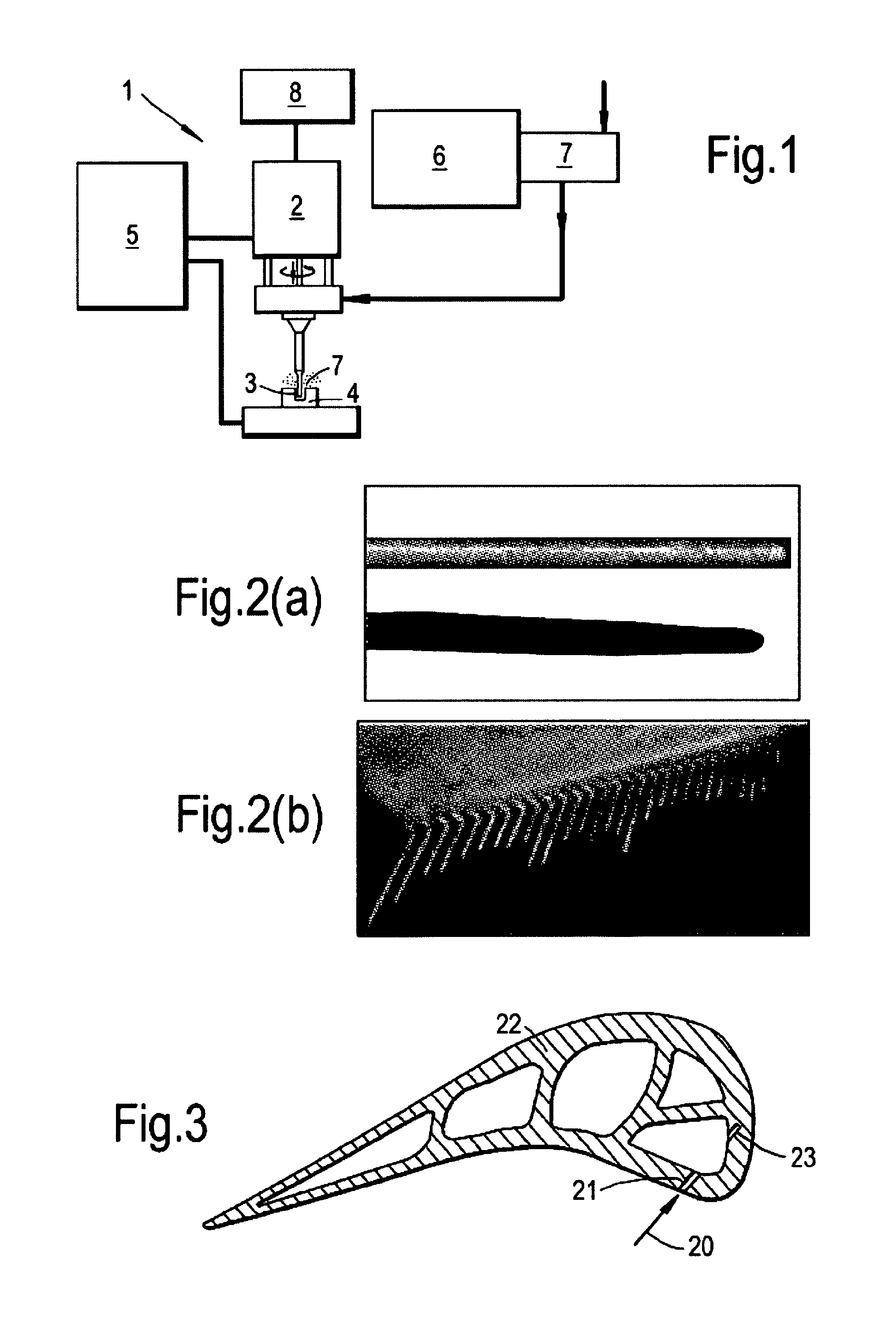

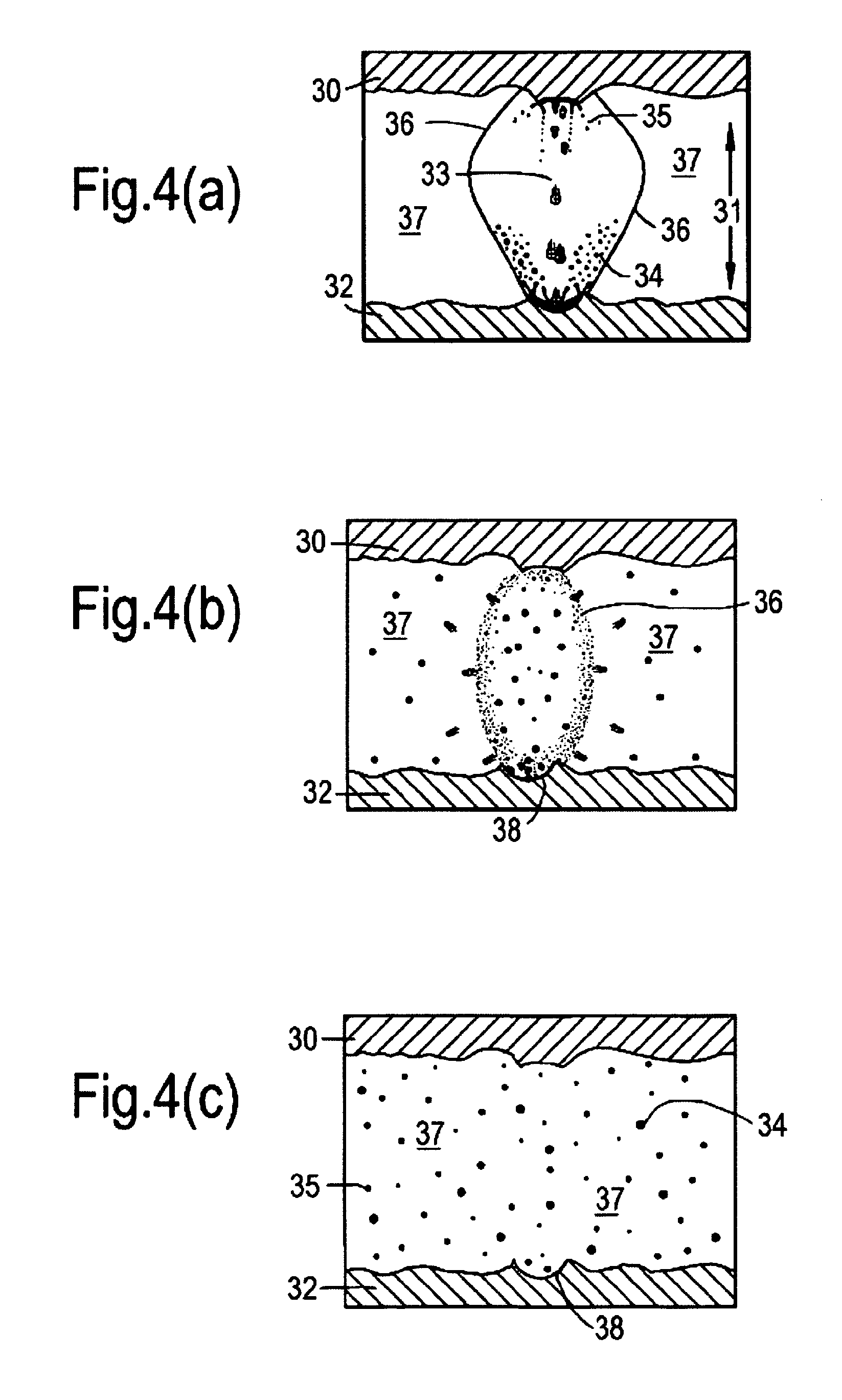

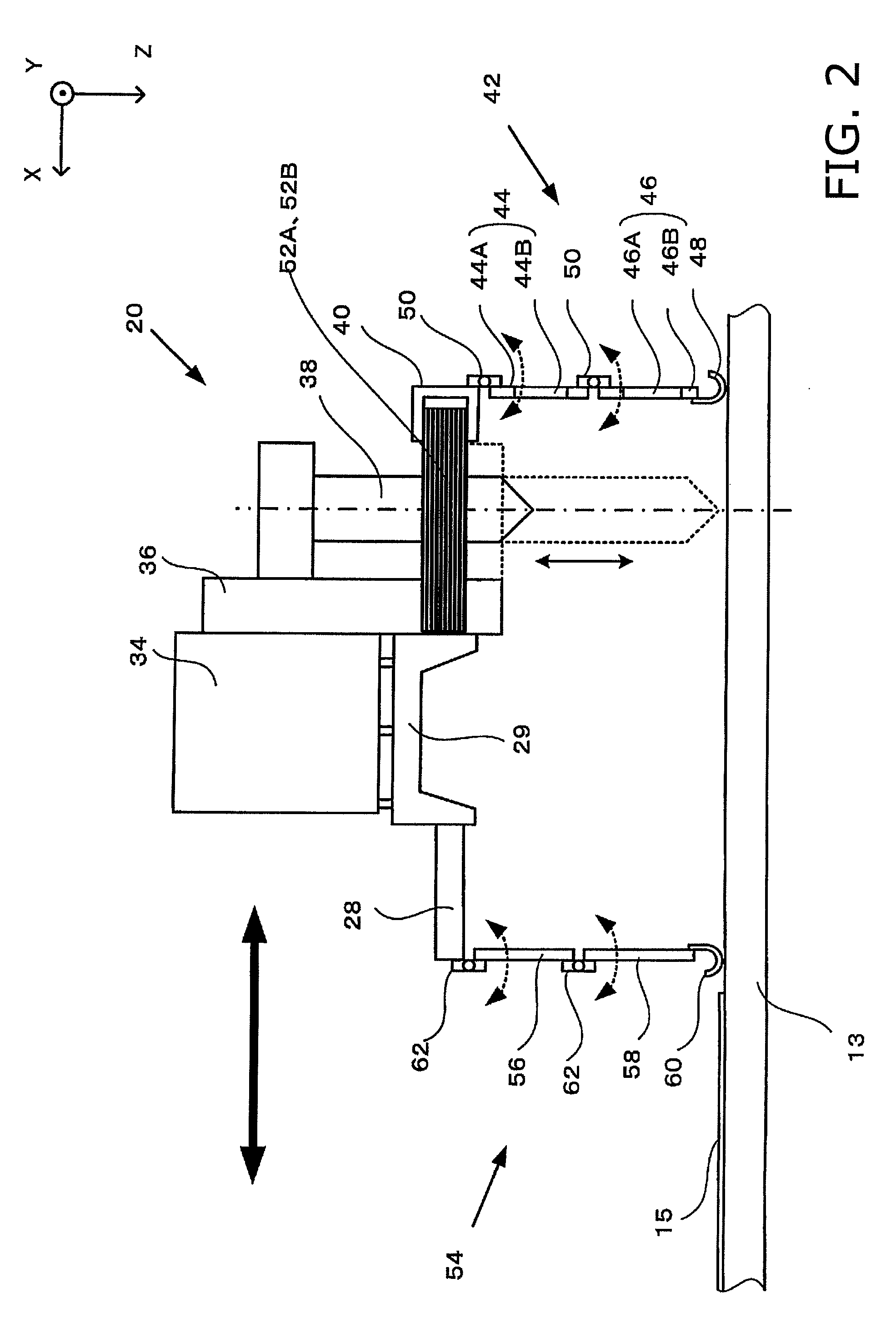

Method and apparatus for forming by electrochemical material removal

InactiveUS20060131184A1Low effortLow costMachining electrodesElectrode vibration holdersImpellerMaterial removal

When forming metallic components, in particular three-dimensionally curved blades, which constitute a single piece with the blading of turbomachine rotor wheels, the linear oscillation of the electrode acting as a tool is superimposed by a circular oscillation, enabling the electrode to turn into the workpiece conformally with its shape. Further forming is performed by circular oscillation with circular feed in the one and / or the other direction. An embodiment of the corresponding apparatus comprises an electrode holder (9) with linear feed (Zvor) and linear oscillation (Zosz) and a workpiece holder (5) with circular oscillation (Cosz) and circular feed (Cvor).

Owner:ROLLS ROYCE DEUT LTD & CO KG

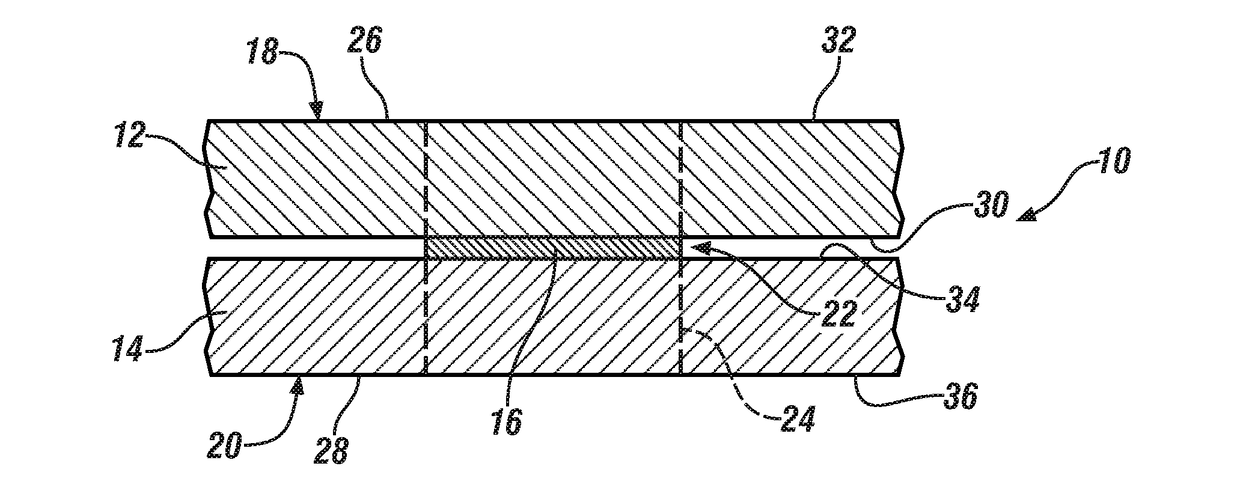

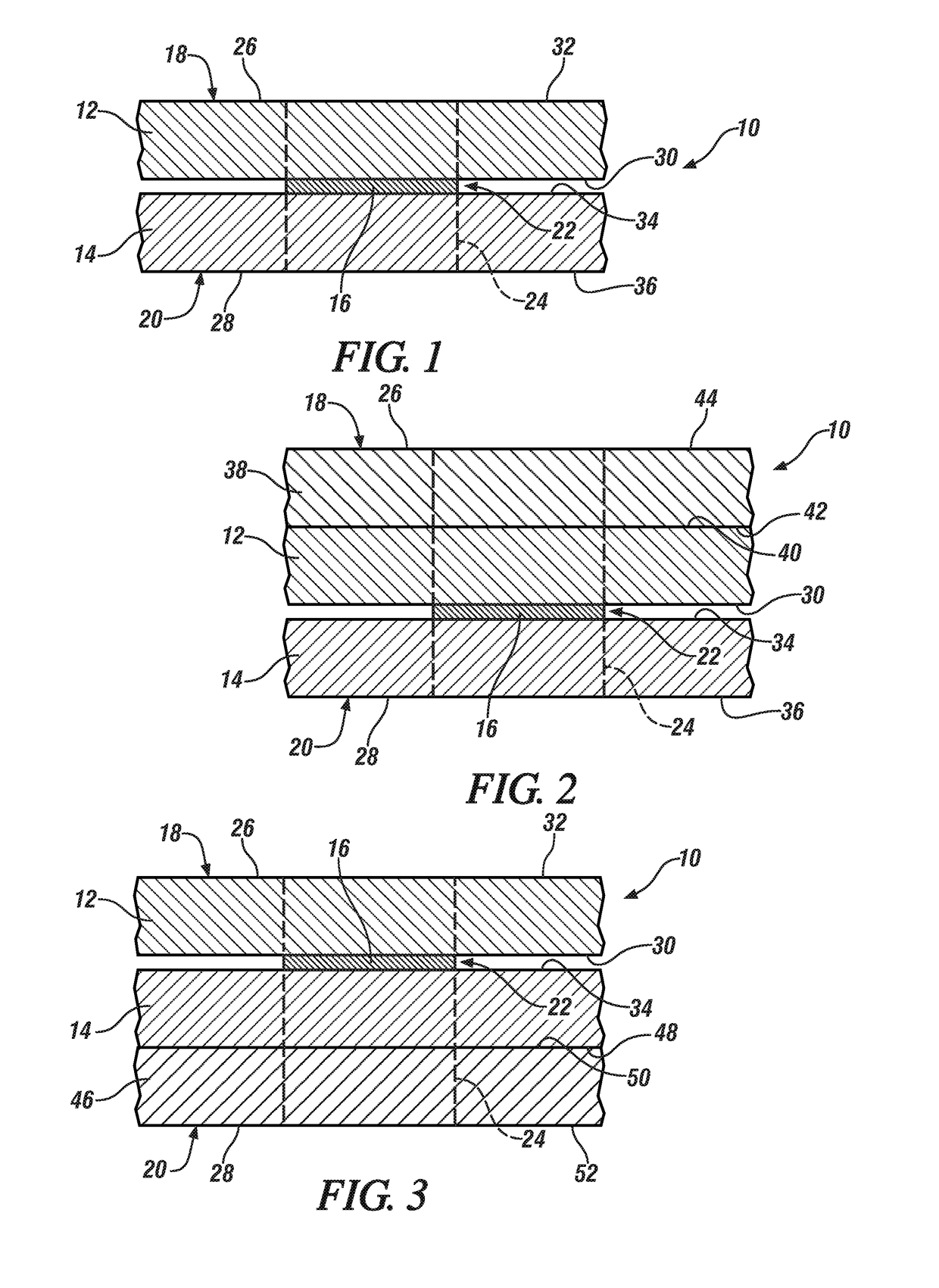

Method of joining aluminum and steel workpieces

InactiveUS20170297137A1Increase currentElectrode vibration holdersVehicle componentsBond interfaceMaterials science

A method of joining an aluminum workpiece and an adjacent overlapping steel workpiece by reaction metallurgical joining, and the resultant metallurgical joint formed between the two workpieces, are disclosed. The method involves compressing a reaction material located between the aluminum and steel workpieces and heating the reaction material momentarily to form a metallurgical joint that comprises bonding interface between the reaction material and the steel workpiece and a bonding interface between the reaction material and the aluminum workpiece. The reaction material is formulated to be able to interact with both aluminum and steel in order to establish the bonding interfaces of the metallurgical joint. Moreover, the practice of oscillating wire arc welding may be employed to deposit the reaction material in the form of a reaction material deposit onto the steel workpiece prior to assembling the steel and aluminum workpieces in a workpiece stack-up.

Owner:GM GLOBAL TECH OPERATIONS LLC

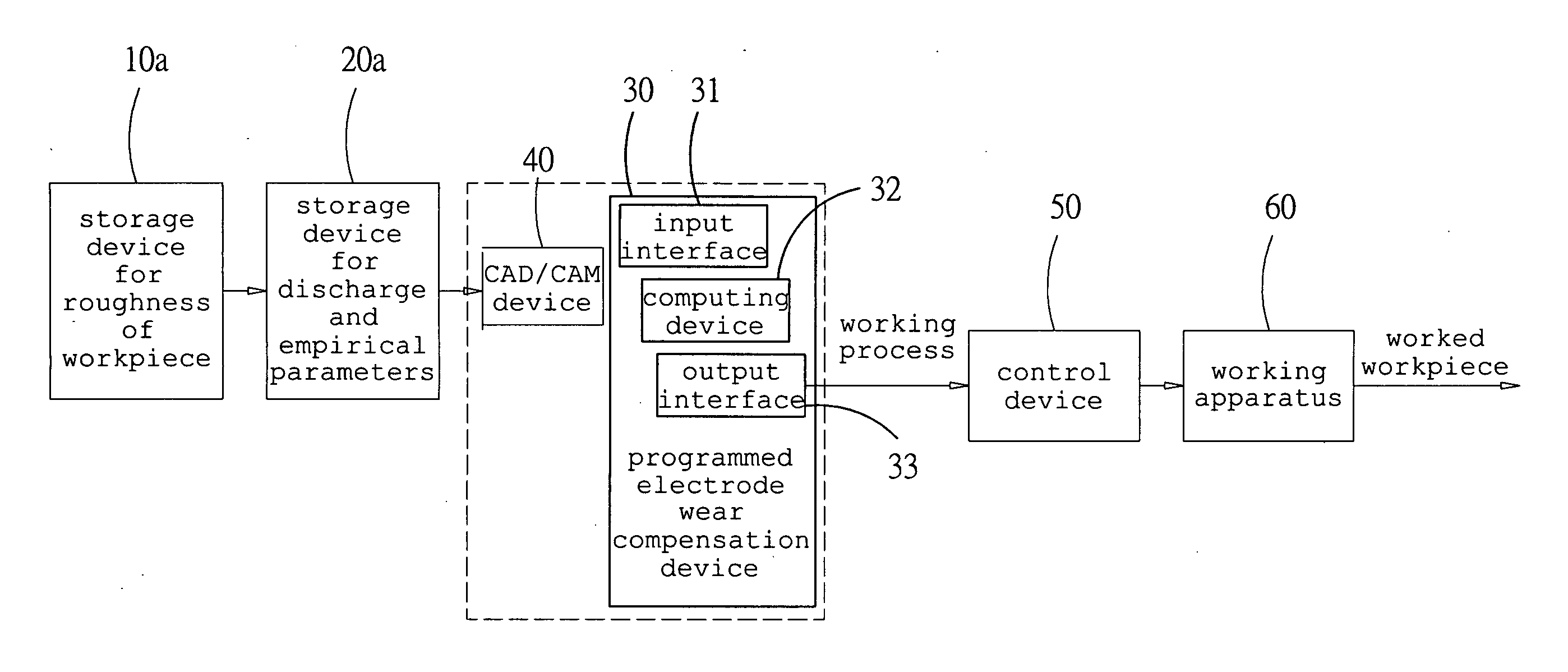

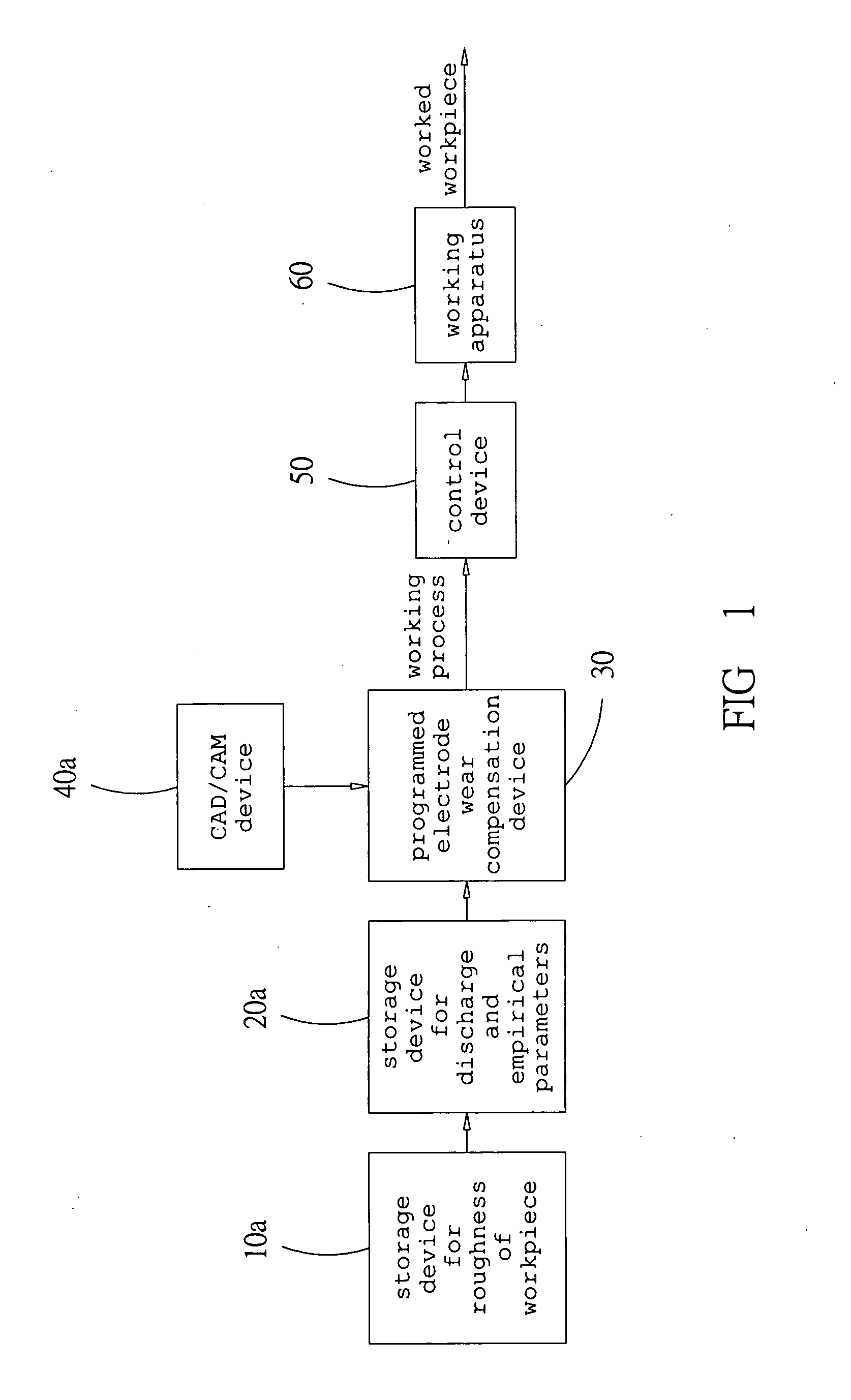

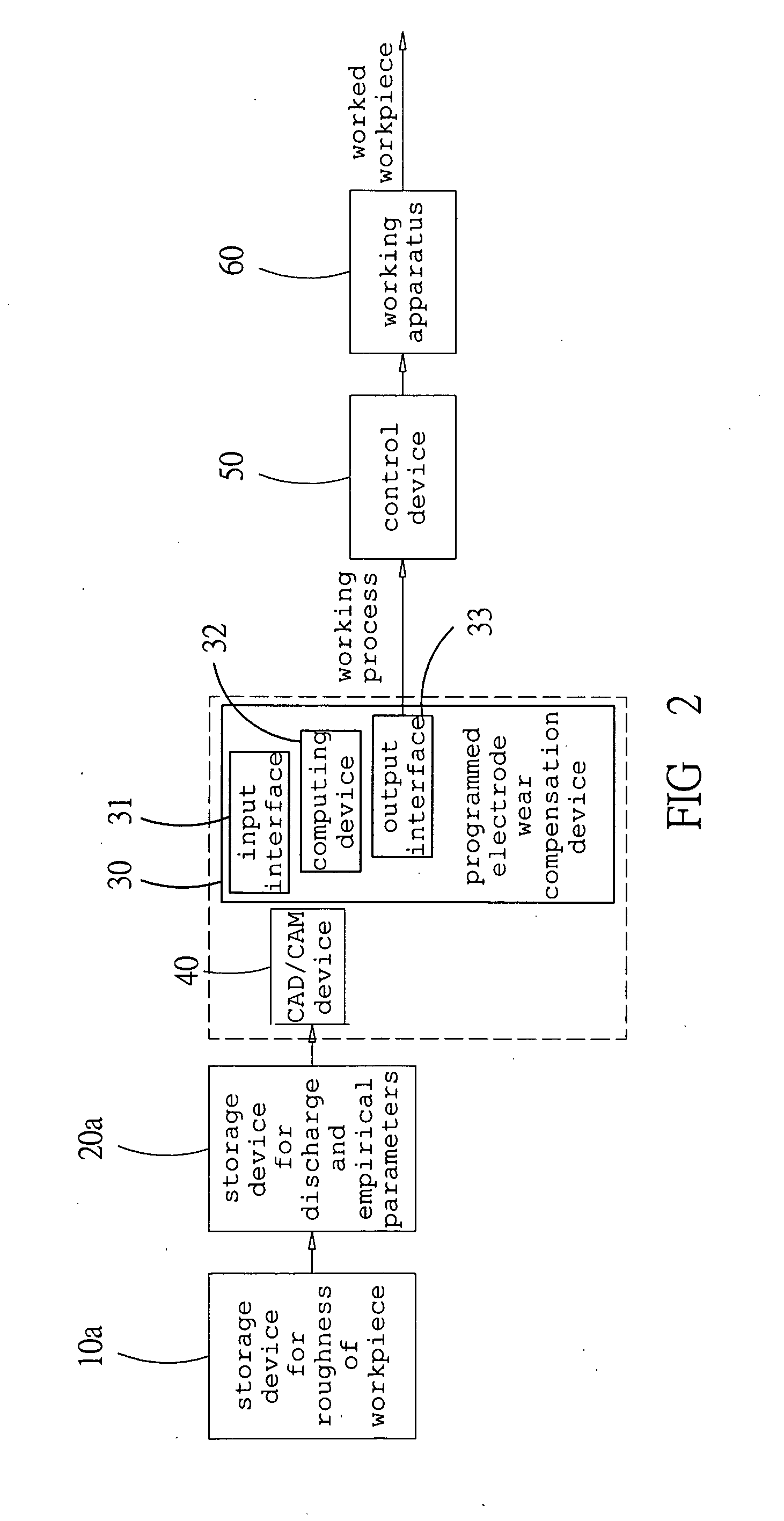

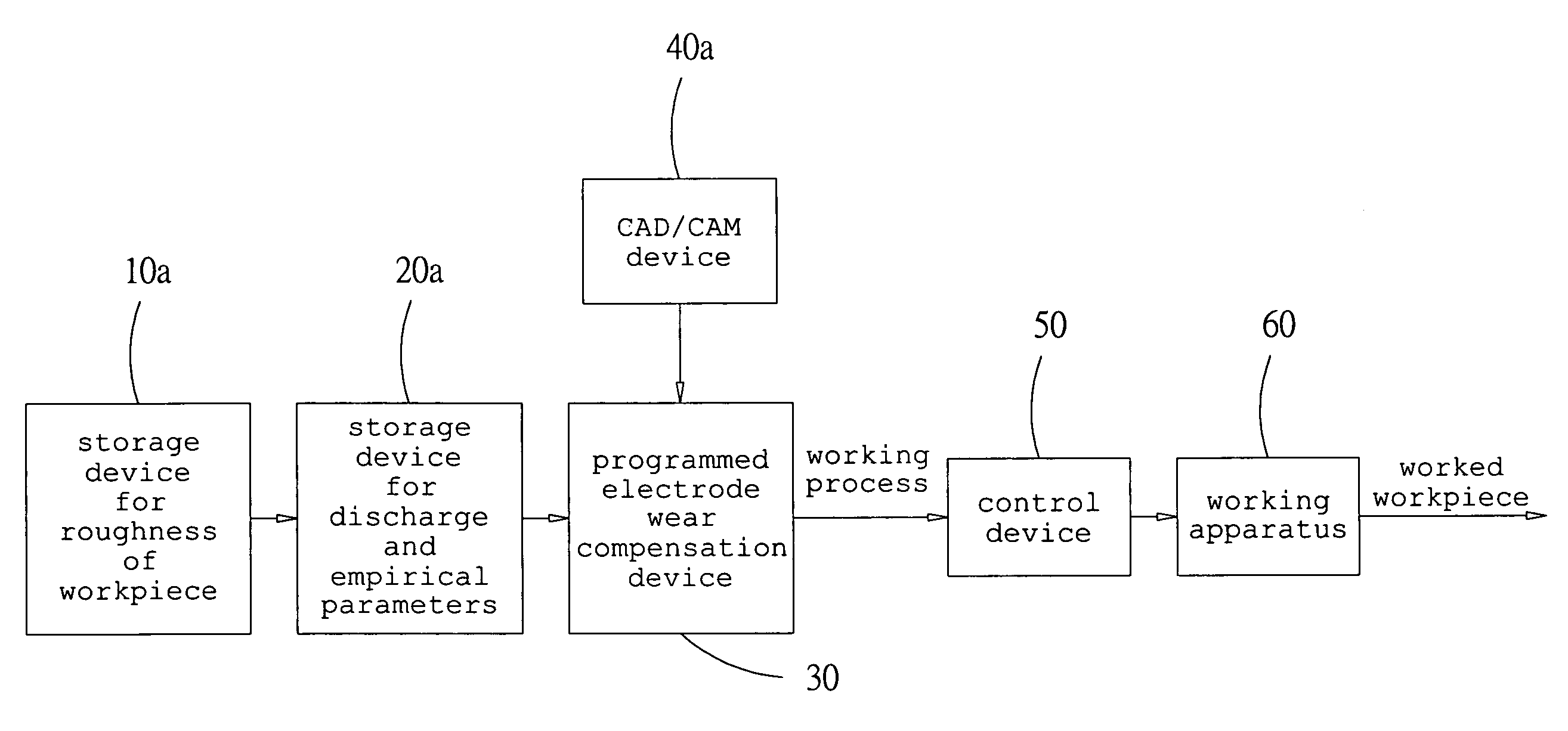

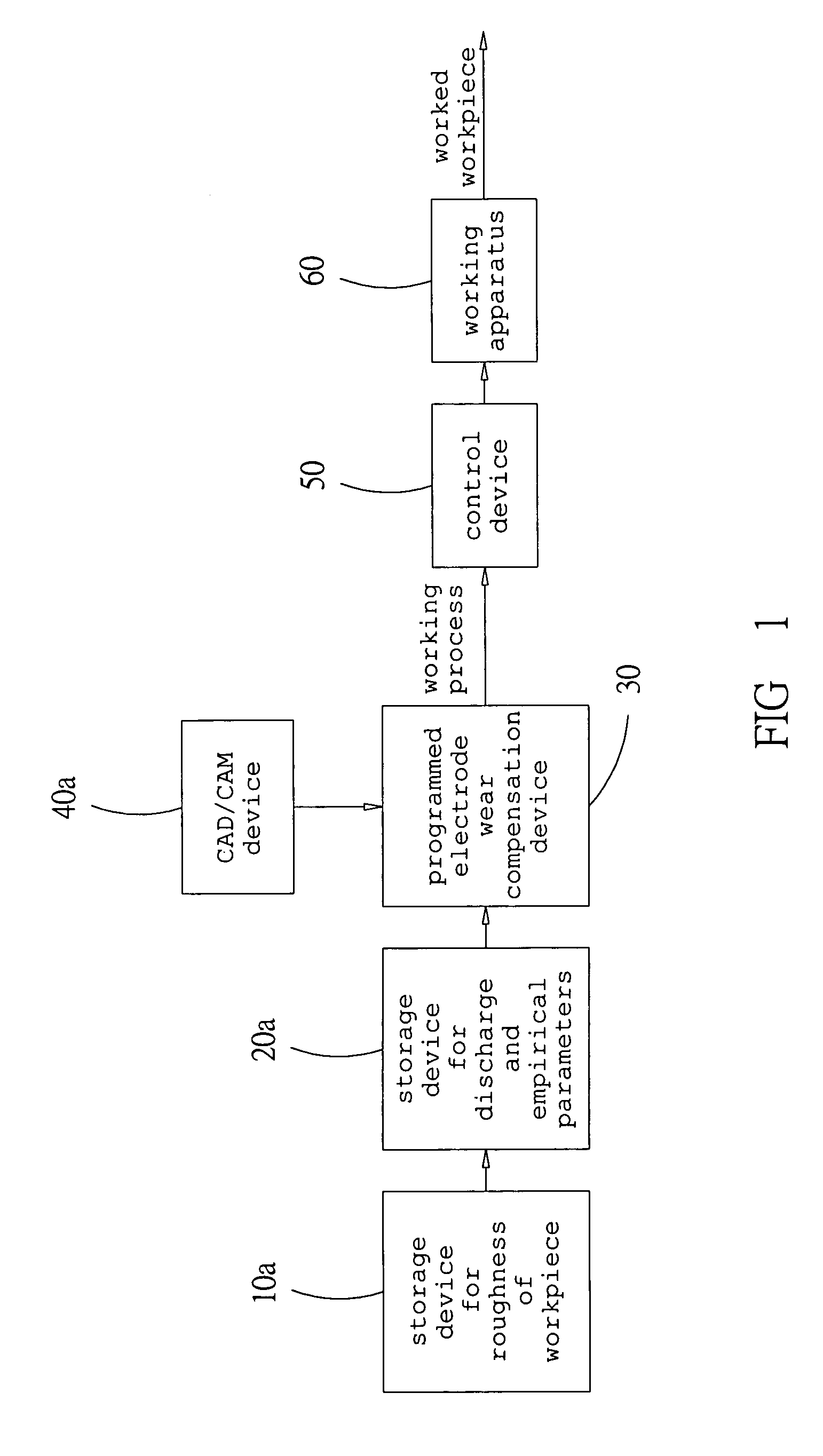

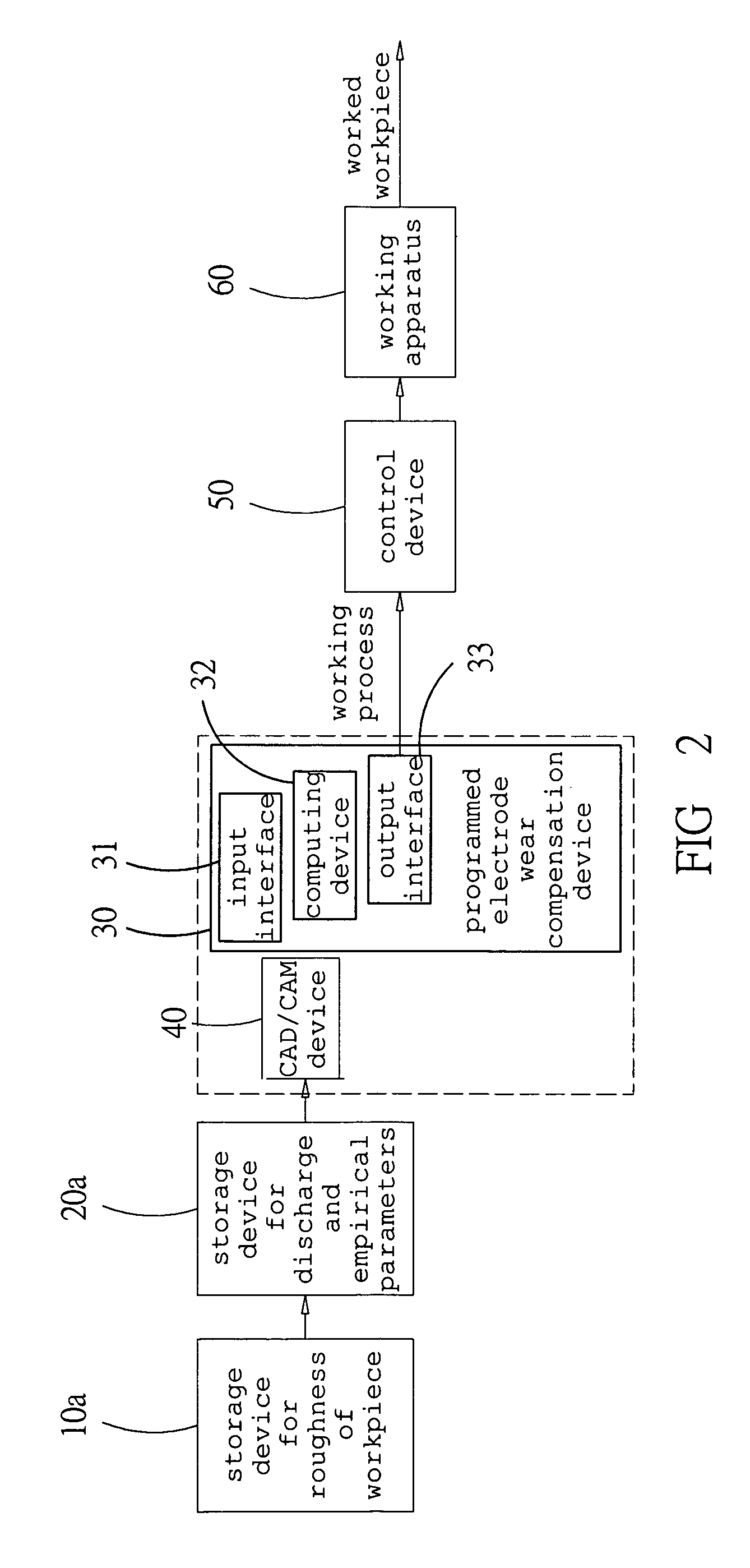

Programmed electrode wear compensation device and method for 3D EDM scanning apparatus

ActiveUS20060138092A1Overall shapeImprove smoothnessElectrode vibration holdersElectric circuitsElectric dischargeMachined surface

A programmed electrode wear compensation device and method for 3D EDM scanning apparatus has a compensation device which receives raw data about a working path of a working apparatus from a CAD / CAM device, calculates therefrom compensated data which take into account electrode wear and transmits the compensated data to a control device which controls the working apparatus, so that smoothness and shape of a machined surface are maintained during electric discharge.

Owner:IND TECH RES INST

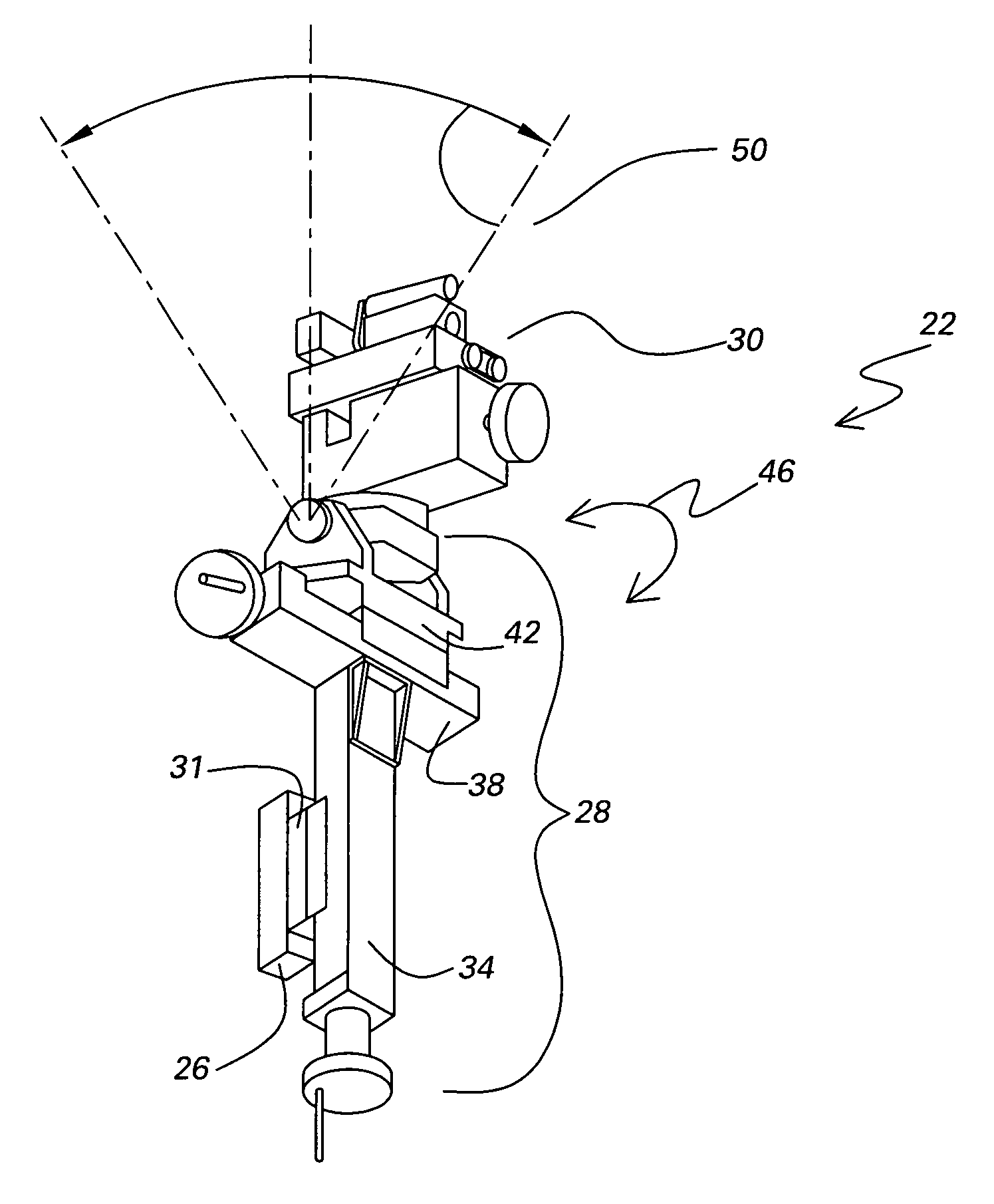

Apparatus and method for machining in confined spaces

A machining apparatus is provided. The machining apparatus includes a discharge machining head assembly and a slide assembly supporting the head assembly. The machining apparatus also includes an electromagnet configured to support the slide assembly in a position on a work piece to machine an area. The slide assembly permits linear displacement of the head assembly generally parallel to the supporting work piece surface.

Owner:GENERAL ELECTRIC CO

Erosion apparatus for the shaping machining of a metallic structural component or a metallic insert element in a structural component as well as an erosion method

ActiveUS20050184030A1Reduce processing timeReduced tool wearElectrode vibration holdersElectric circuitsElectricityElectrical connection

Apparatus and method for erosion machining a structure comprising one of a metallic structural component, a metallic insert element, and a connecting element, by way of erosion. The apparatus includes an eroding head including an electrode, a power supply, and a control device. The power supply and the control device produce an erosion current. A grounding device is arranged in an area of the eroding head and includes at least one contact element. When the eroding head is arranged to perform erosion machining, the at least one contact element contacts and forms an electrical connection with a surface of the structure, whereby an eroding electric circuit is formed via the electrode and the structure. The method includes arranging the erosion head in an area of the connecting element, sealing, with a seal, a flushing cage to the structural component, contacting a portion the connecting element with the electrode; and electrically connecting the at least one contact element and another portion of the connecting element. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:AIRBUS DEFENCE & SPACE

Method and apparatus for forming by electrochemical material removal

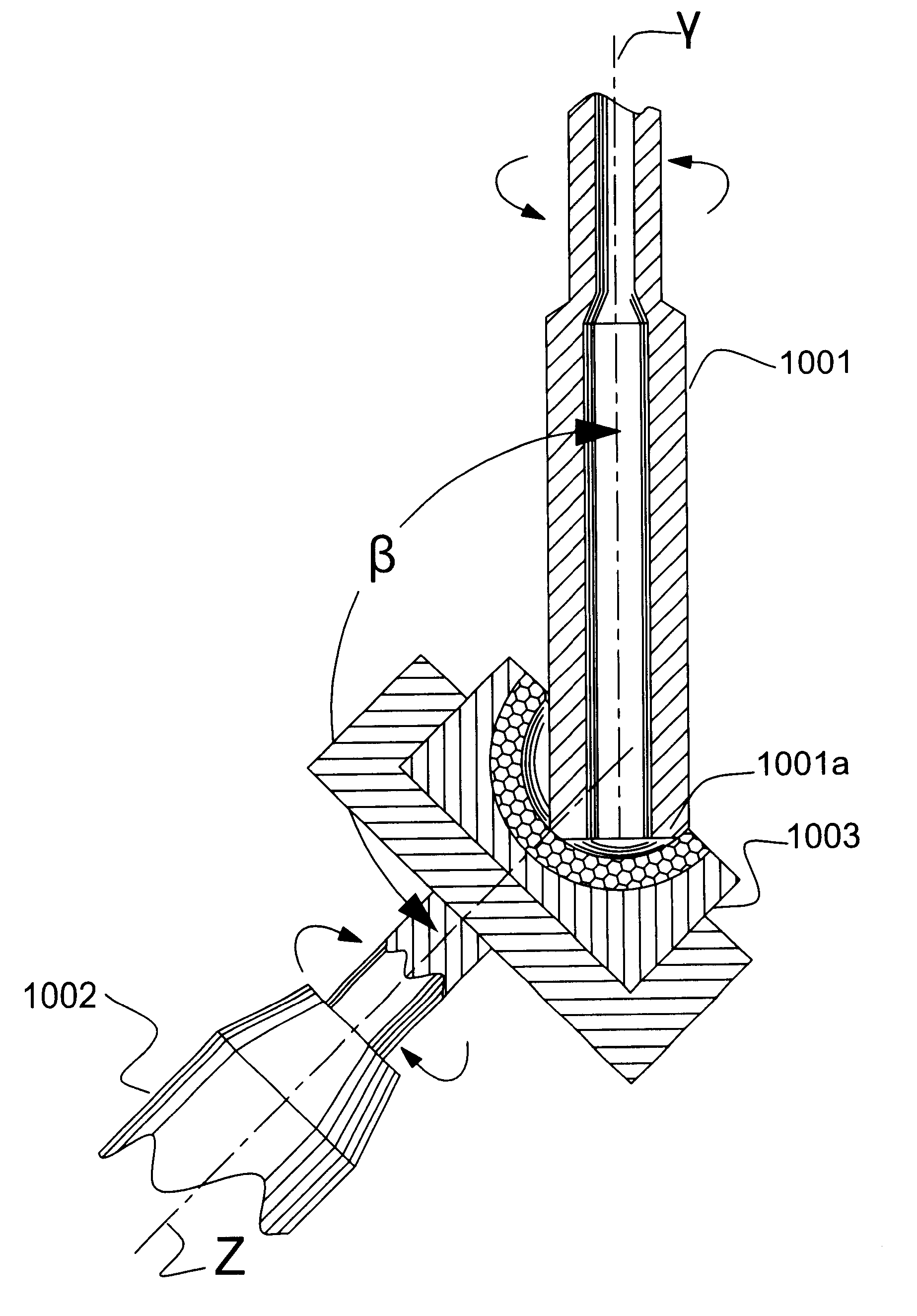

InactiveUS7462273B2Low effortLow costMachining electrodesElectrode vibration holdersMaterial removalEngineering

When forming metallic components, in particular three-dimensionally curved blades, which constitute a single piece with the blading of turbomachine rotor wheels, the linear oscillation of the electrode acting as a tool is superimposed by a circular oscillation, enabling the electrode to turn into the workpiece conformally with its shape. Further forming is performed by circular oscillation with circular feed in the one and / or the other direction. An embodiment of the corresponding apparatus comprises an electrode holder (9) with linear feed (Zvor) and linear oscillation (Zosz) and a workpiece holder (5) with circular oscillation (Cosz) and circular feed (Cvor).

Owner:ROLLS ROYCE DEUT LTD & CO KG

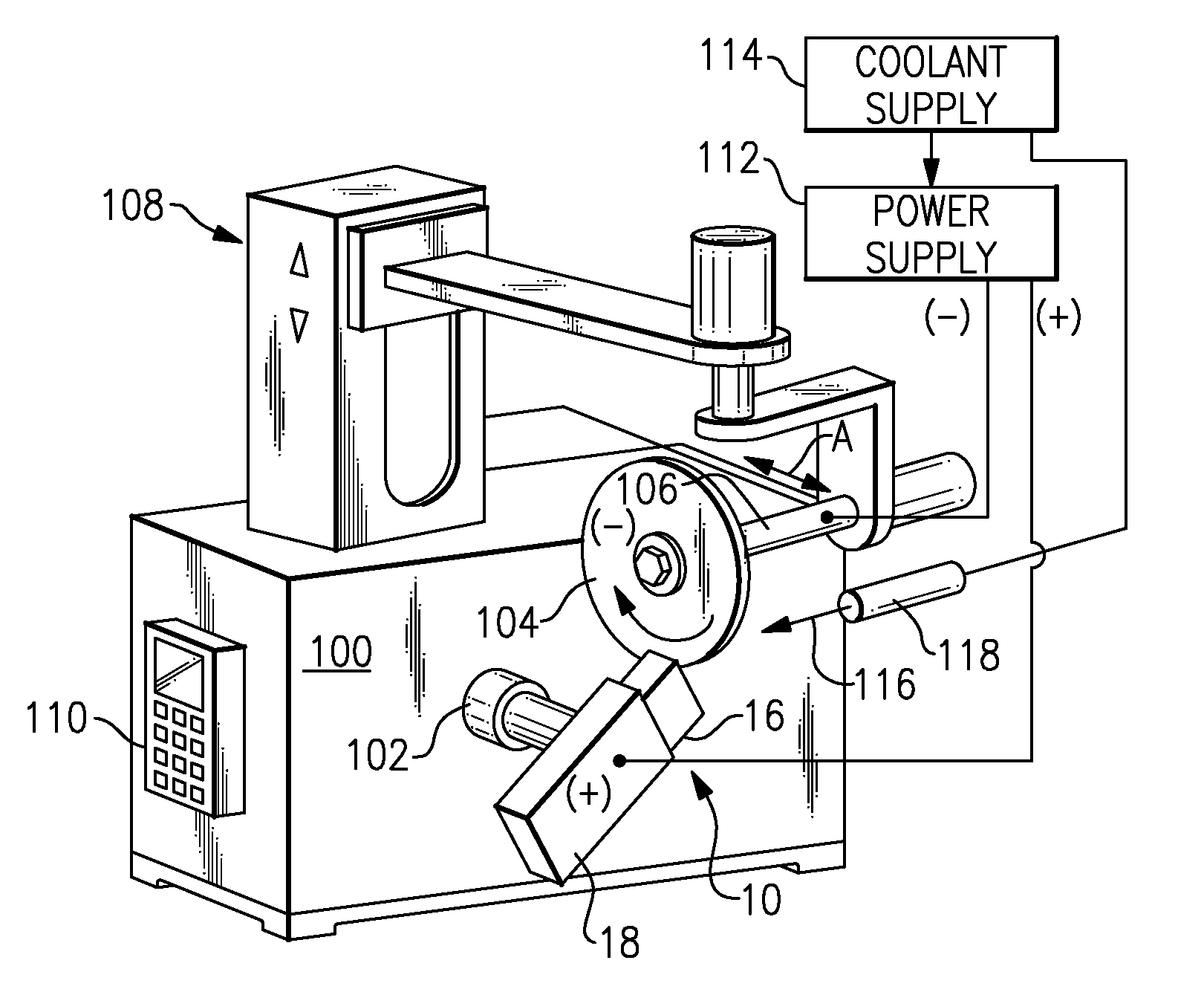

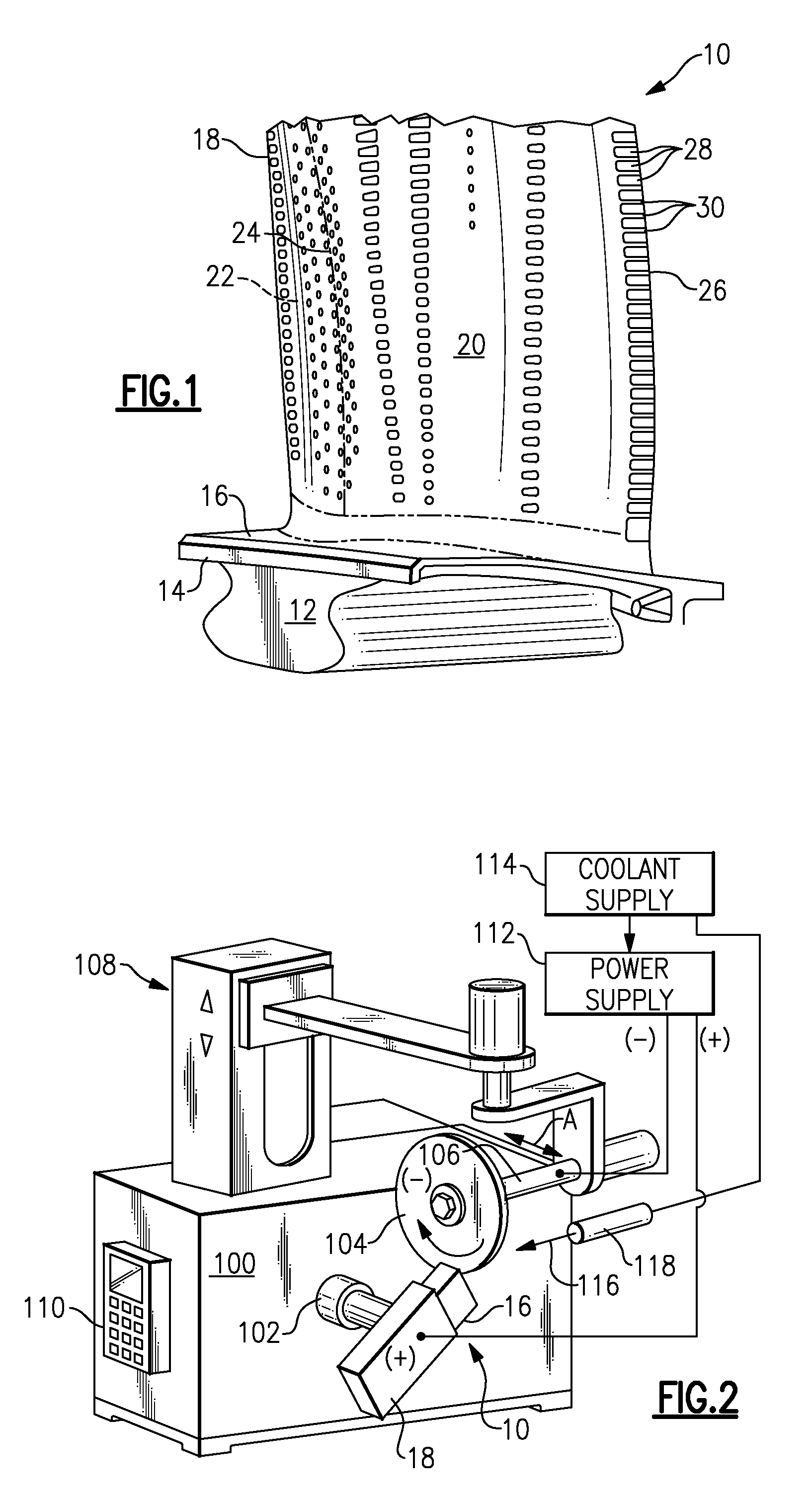

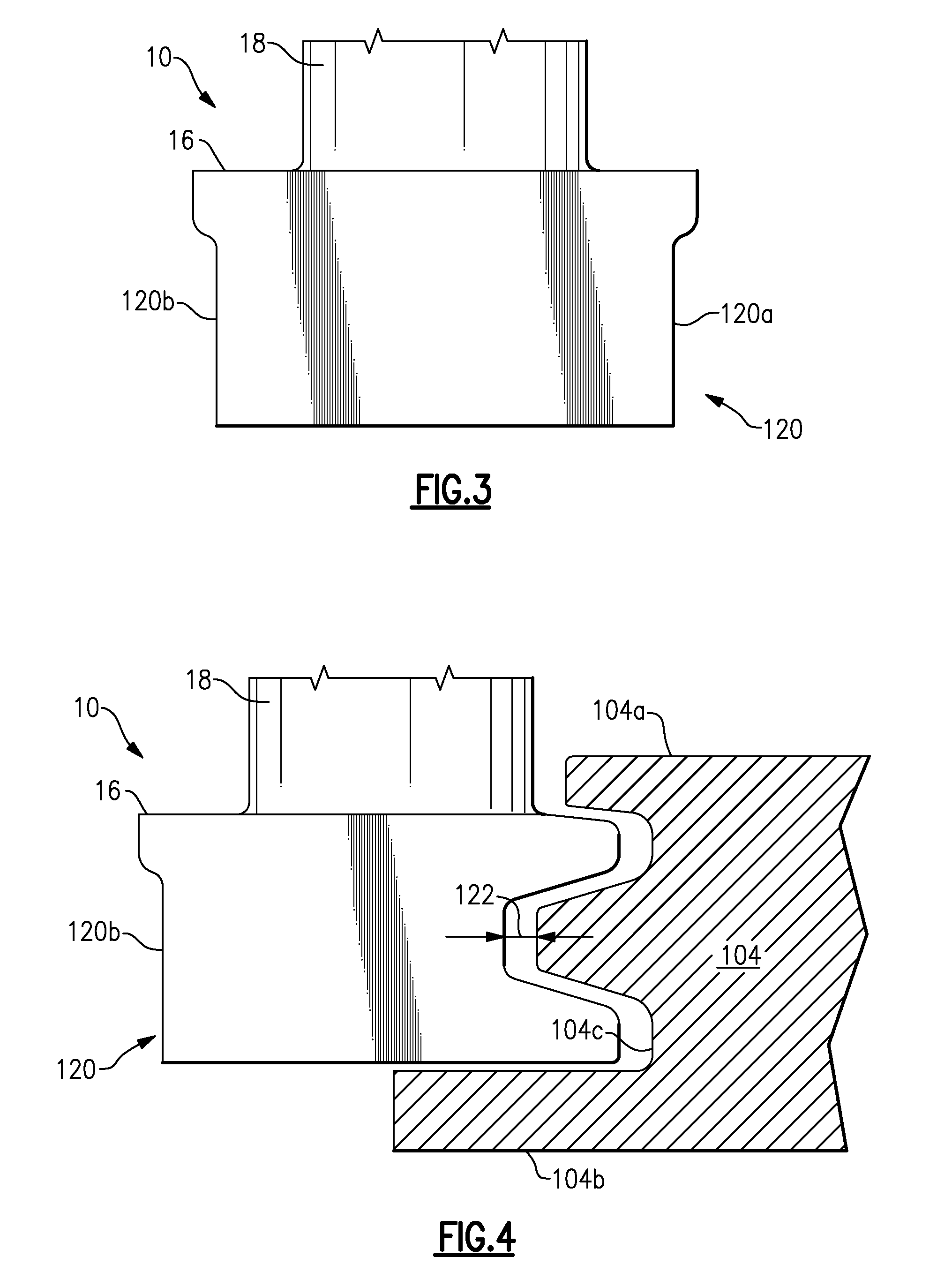

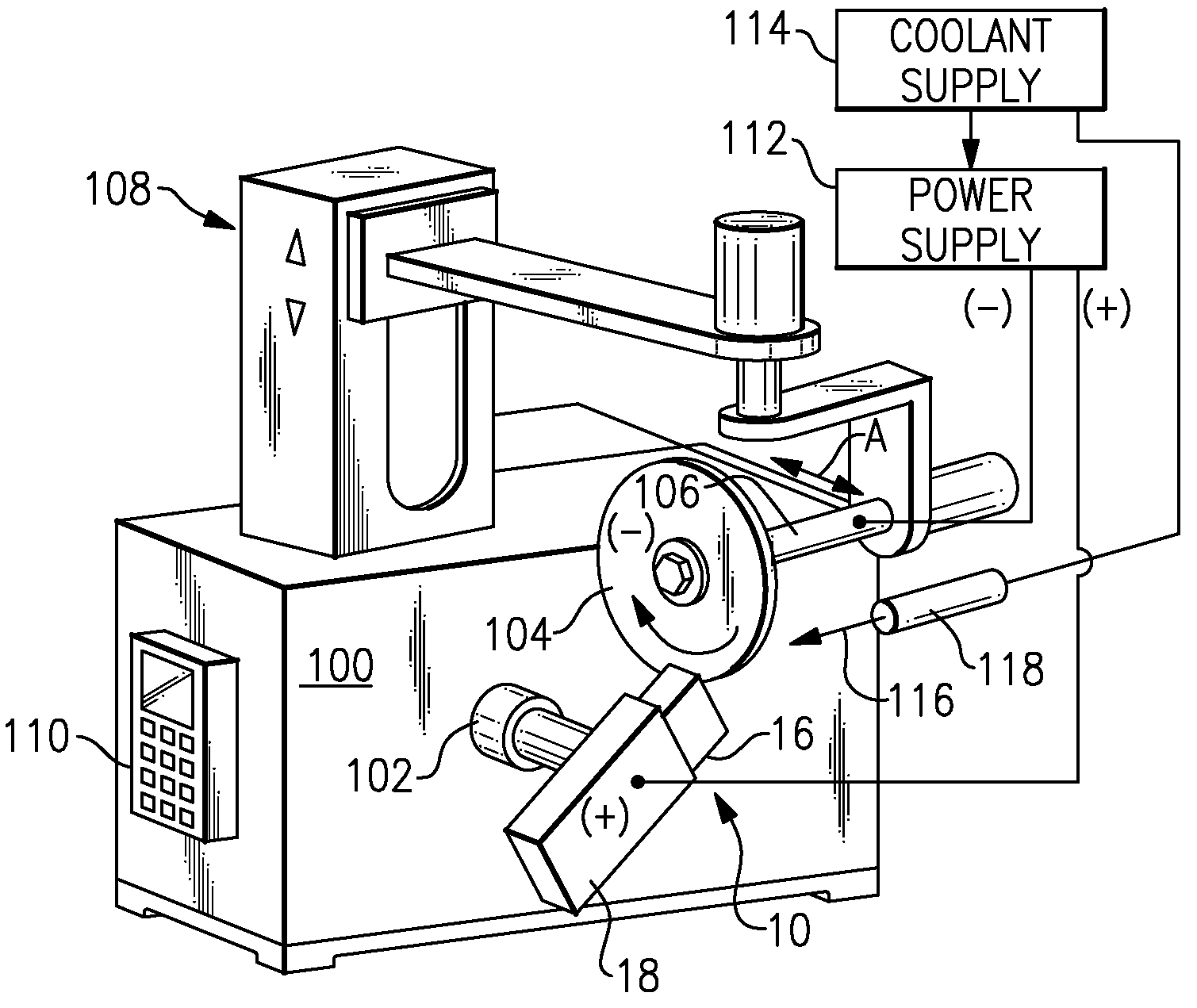

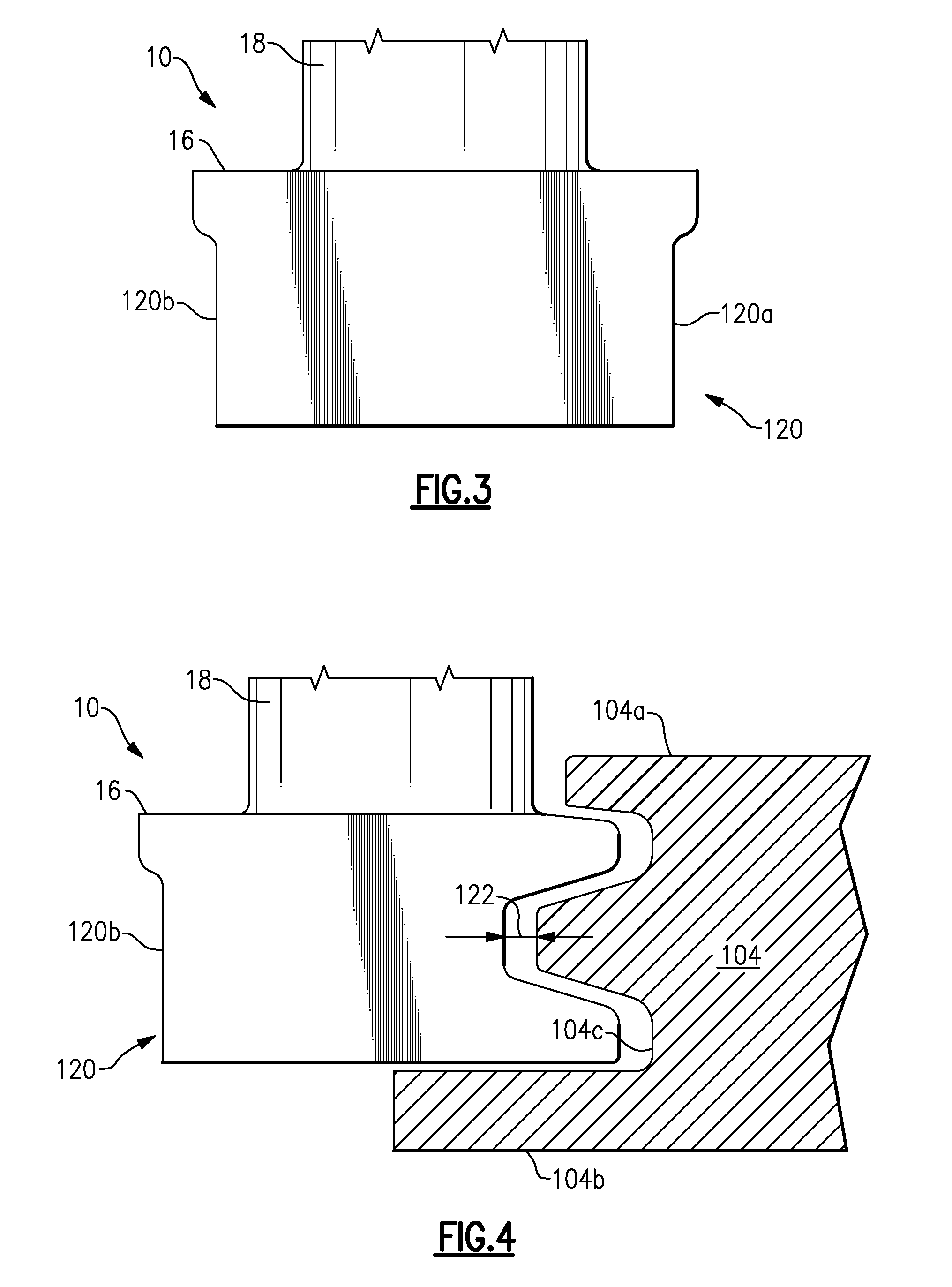

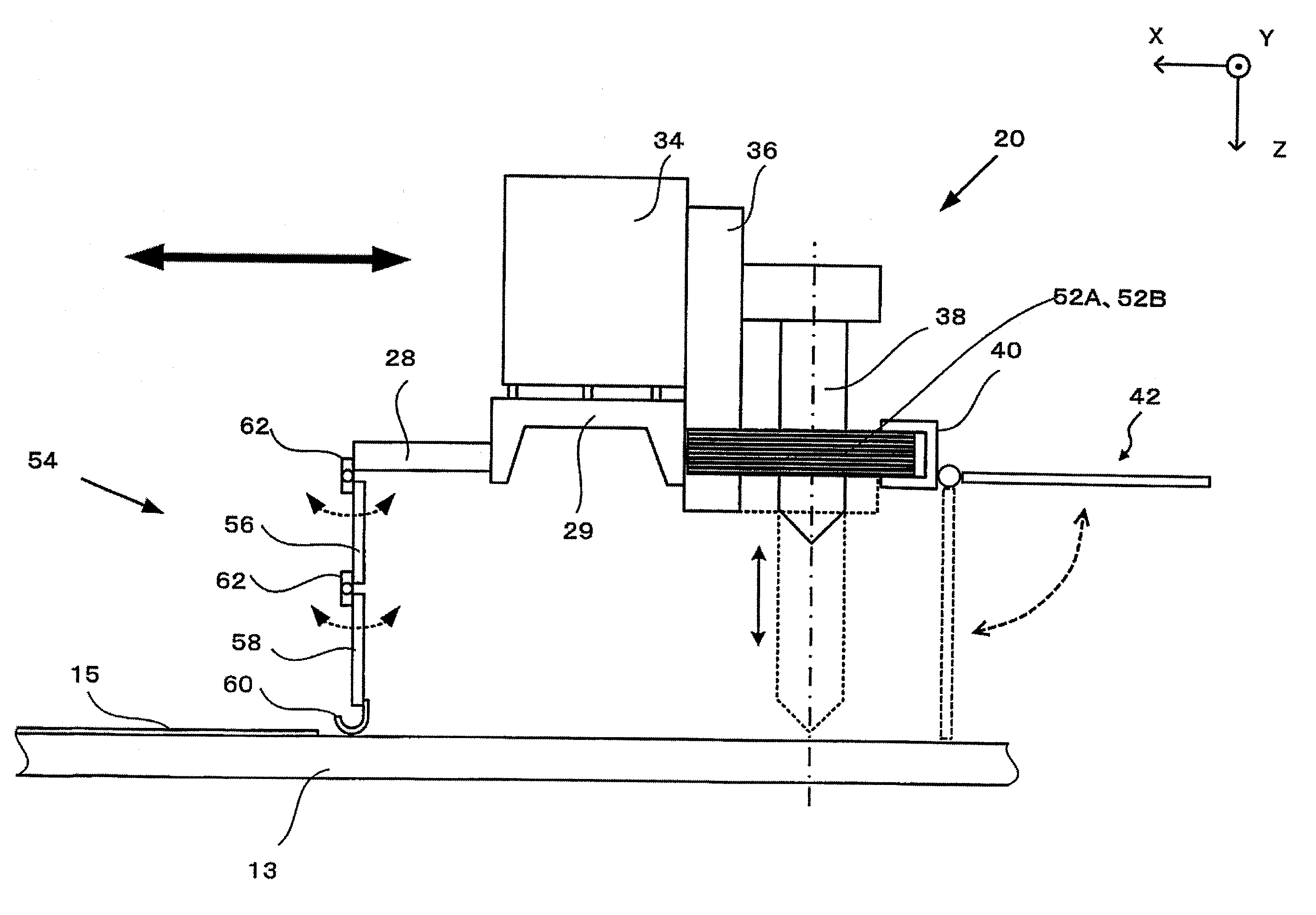

Apparatus and method for hybrid machining a workpiece

An apparatus and method for hybrid machining a workpiece is disclosed. The apparatus includes a mandrel for supporting the workpiece adjacent a cutter mounted on an arbor. A workpiece is powered as an anode and the cutter is powered as a cathode, and a cutting fluid or coolant is circulated therebetween. The cutter is made of a conductive material and a non-conductive abrasive material to maximize the amount of material removed from the workpiece. The coolant includes one or more additives to enhance the electrical discharge between the cutter and the workpiece. The cutter is moved relative to the workpiece to remove material from the workpiece at a predetermined depth of cut using an enhanced high-speed electro-erosion (HSEE) process in which both HSEE and abrasive machining processes are used. The workpiece may then be finish machined to a final shape of the titanium article, such as a dovetail of a turbine blade.

Owner:GENERAL ELECTRIC CO

Apparatus and method for hybrid machining a workpiece

An apparatus and method for hybrid machining a workpiece is disclosed. The apparatus includes a mandrel for supporting the workpiece adjacent a cutter mounted on an arbor. A workpiece is powered as an anode and the cutter is powered as a cathode, and a cutting fluid or coolant is circulated therebetween. The cutter is made of a conductive material and a non-conductive abrasive material to maximize the amount of material removed from the workpiece. The coolant includes one or more additives to enhance the electrical discharge between the cutter and the workpiece. The cutter is moved relative to the workpiece to remove material from the workpiece at a predetermined depth of cut using an enhanced high-speed electro-erosion (HSEE) process in which both HSEE and abrasive machining processes are used. The workpiece may then be finish machined to a final shape of the titanium article, such as a dovetail of a turbine blade.

Owner:GENERAL ELECTRIC CO

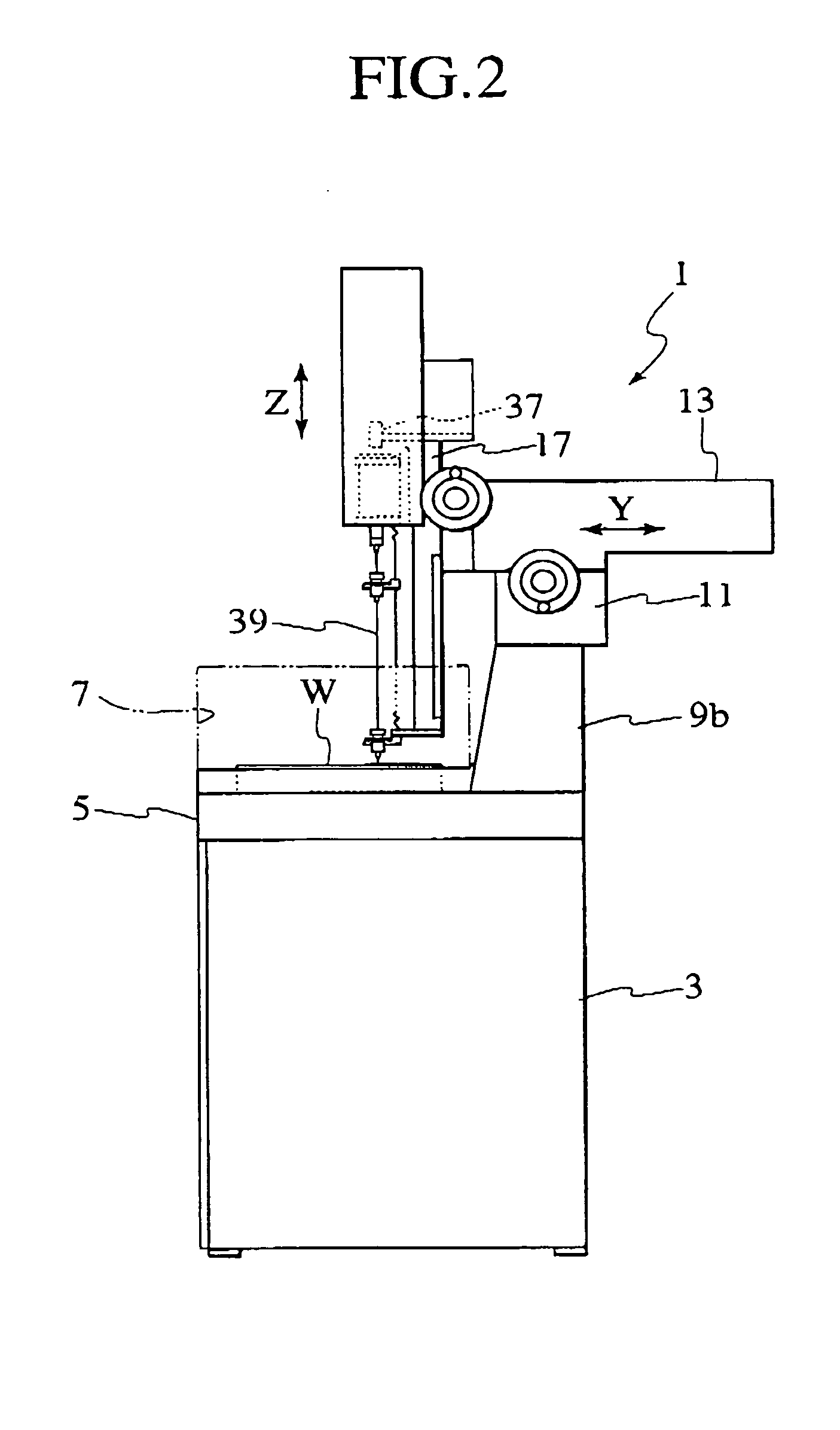

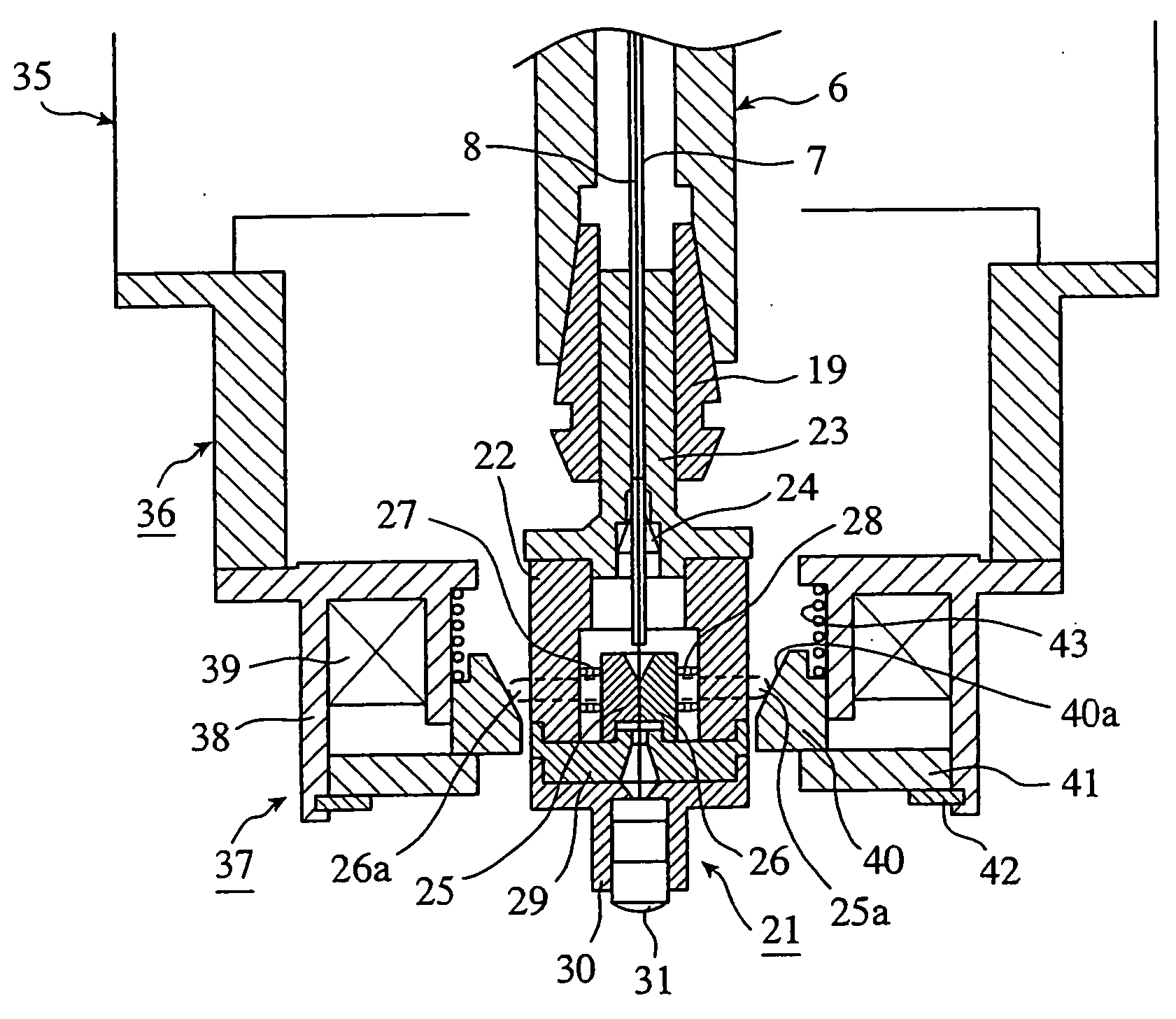

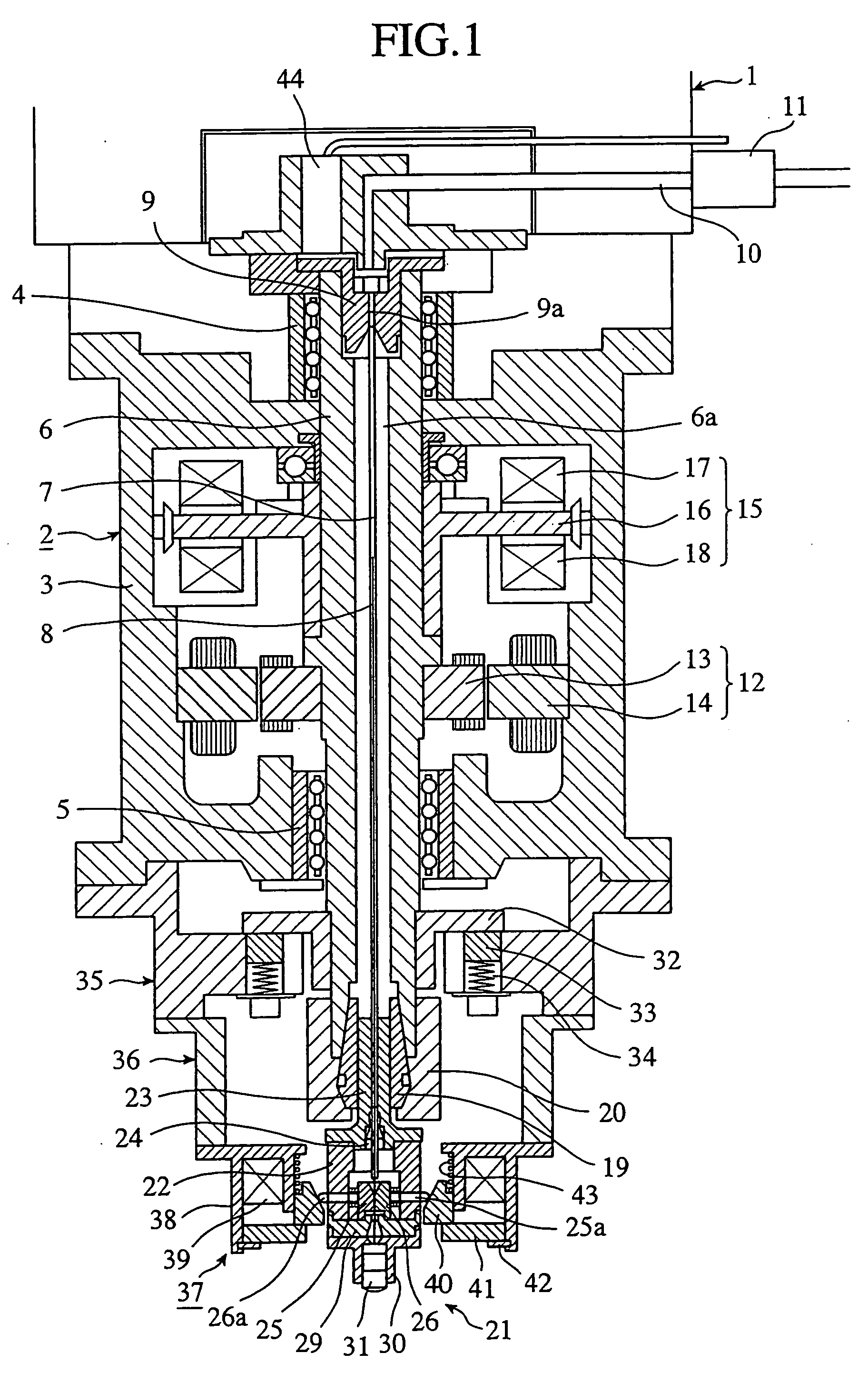

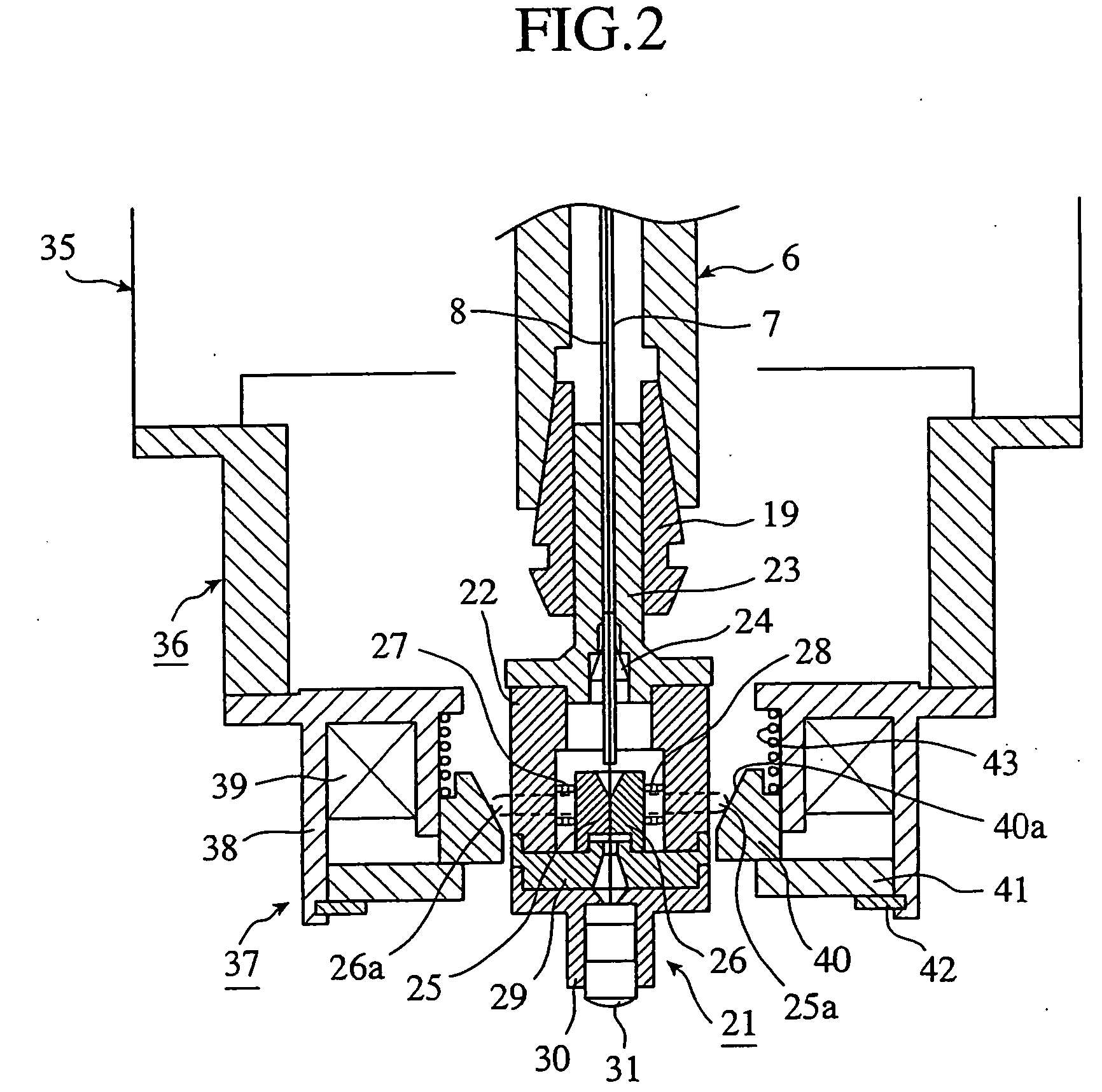

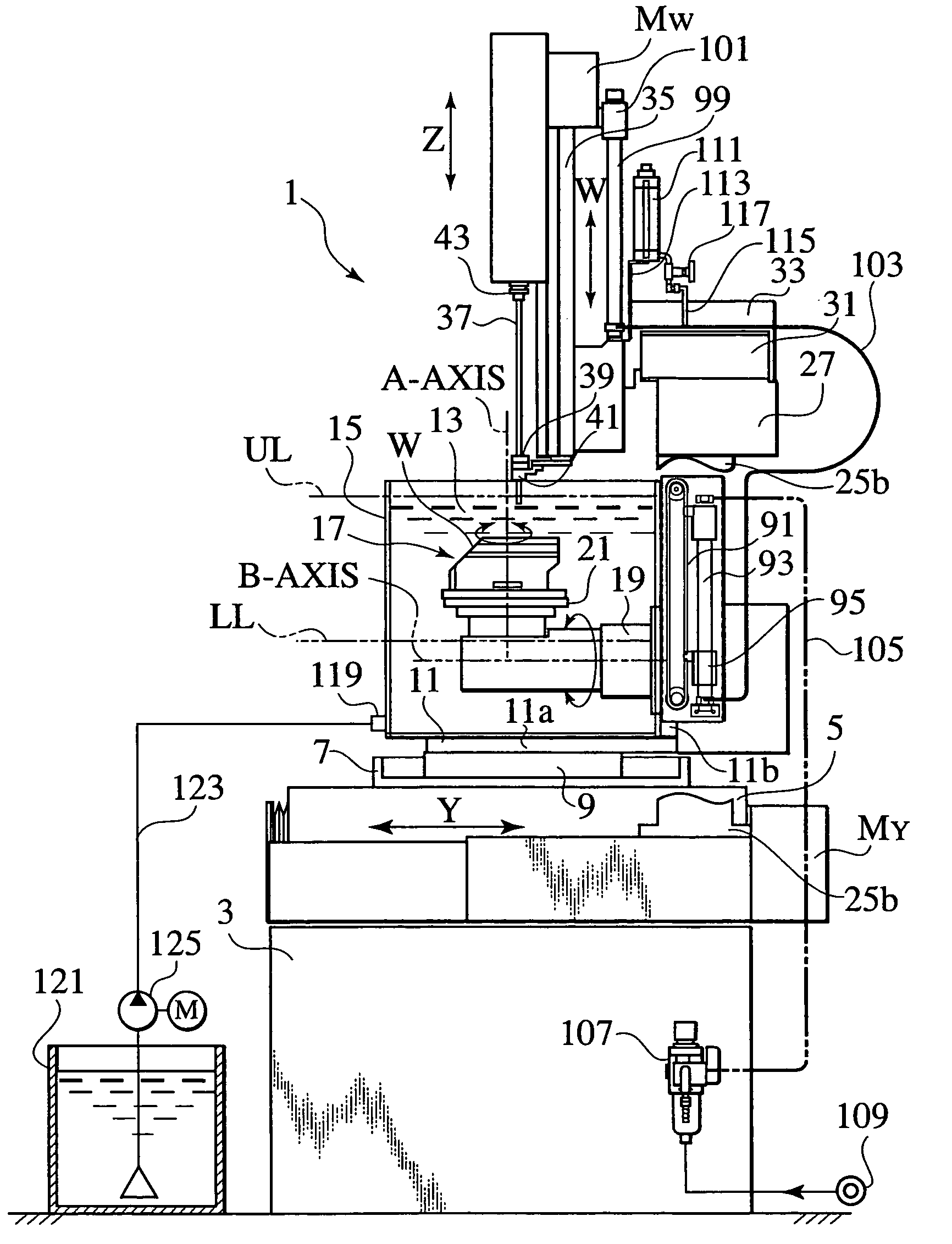

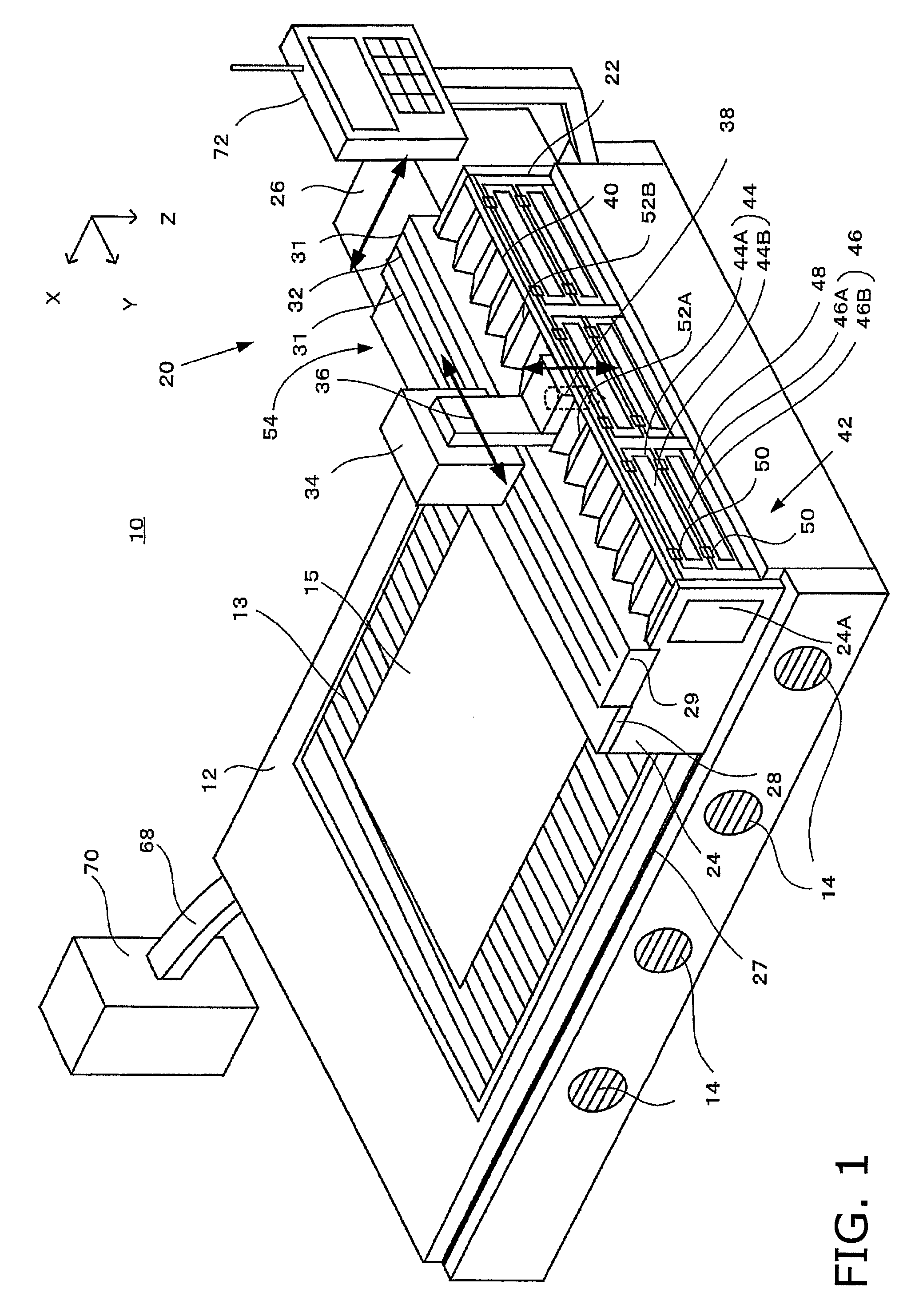

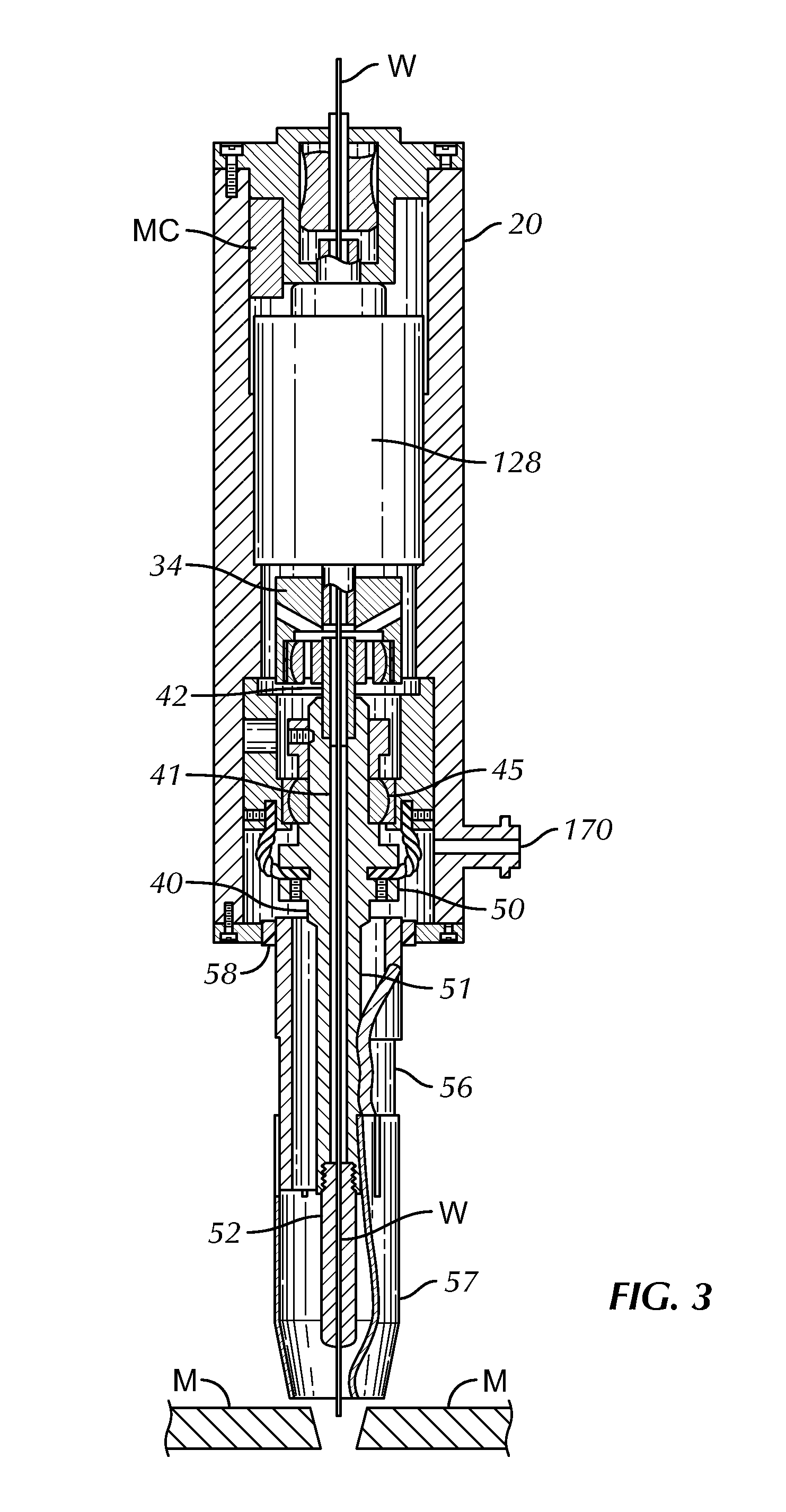

Small hole electrical discharge machining method and small hole electrical discharge machining apparatus and electrode inserting method and electrode inserting apparatus

ActiveUS20050077269A1Electrode vibration holdersElectrical-based machining electrodesEngineeringProduct gas

A small hole electrical discharge machining apparatus 1 is comprised of electrode holding 27 means for holding an upper part of an electrode 39, electrode guide means 41 for guiding a lower part of the electrode 39, a jet nozzle 73 injecting a water let (WJ) from the electrode holding means 27, and a fluid channel 97 which supplies a gas, such as air, to an electrode guide 75 of the electrode guide means. The electrode 39 is guided with the water jet (WJ) toward the workpiece (W), and small hole electrical discharge machining is performed while the gas is being released from the electrode guide 75 into a working liquid via the fluid channel 97.

Owner:ELENIX KK

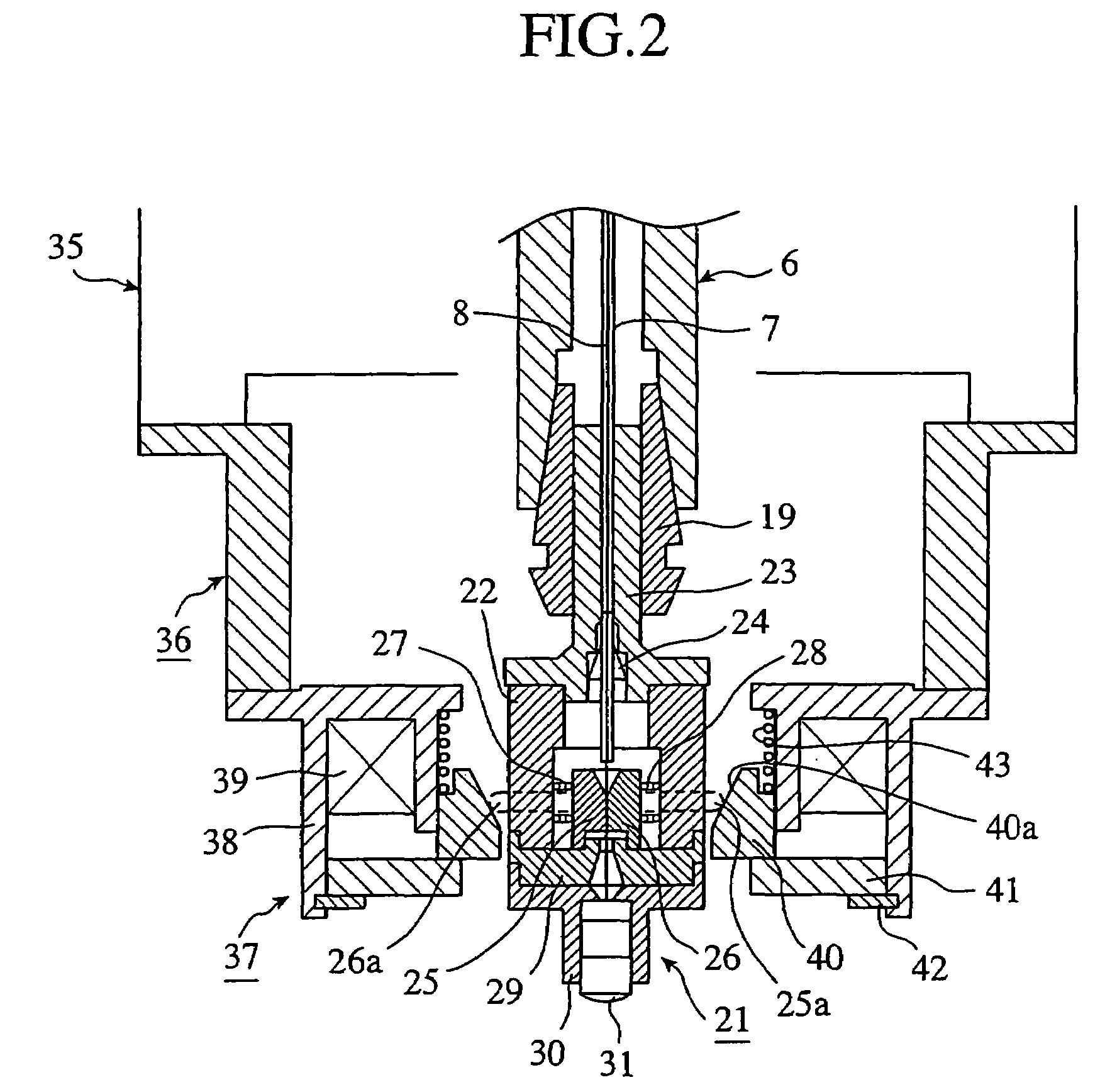

Electric discharge machining apparatus

InactiveUS20070102402A1Prevent bucklingAvoid vibrationElectrode vibration holdersElectrical-based machining electrodesEngineeringFluid supply

An electric discharge machining apparatus includes: a guide electrode (7) that is shaped like a hollow bar and receives a small-diameter wire electrode (8) for electric discharge machining in such a way that the small-diameter electrode can freely slide and; guide electrode holding means (9, 19, 20) that holds this guide electrode (7) at a specified position; pressurized fluid supply means (10, 11) that supplies pressurized fluid into the guide electrode (7) to feed out the small-diameter wire electrode (8) from inside the guide electrode (7) to an electric discharge machining side; and small-diameter wire electrode holding means (21) that automatically holds the small-diameter wire electrode (8) fed out of the guide electrode (7).

Owner:MITSUBISHI ELECTRIC CORP

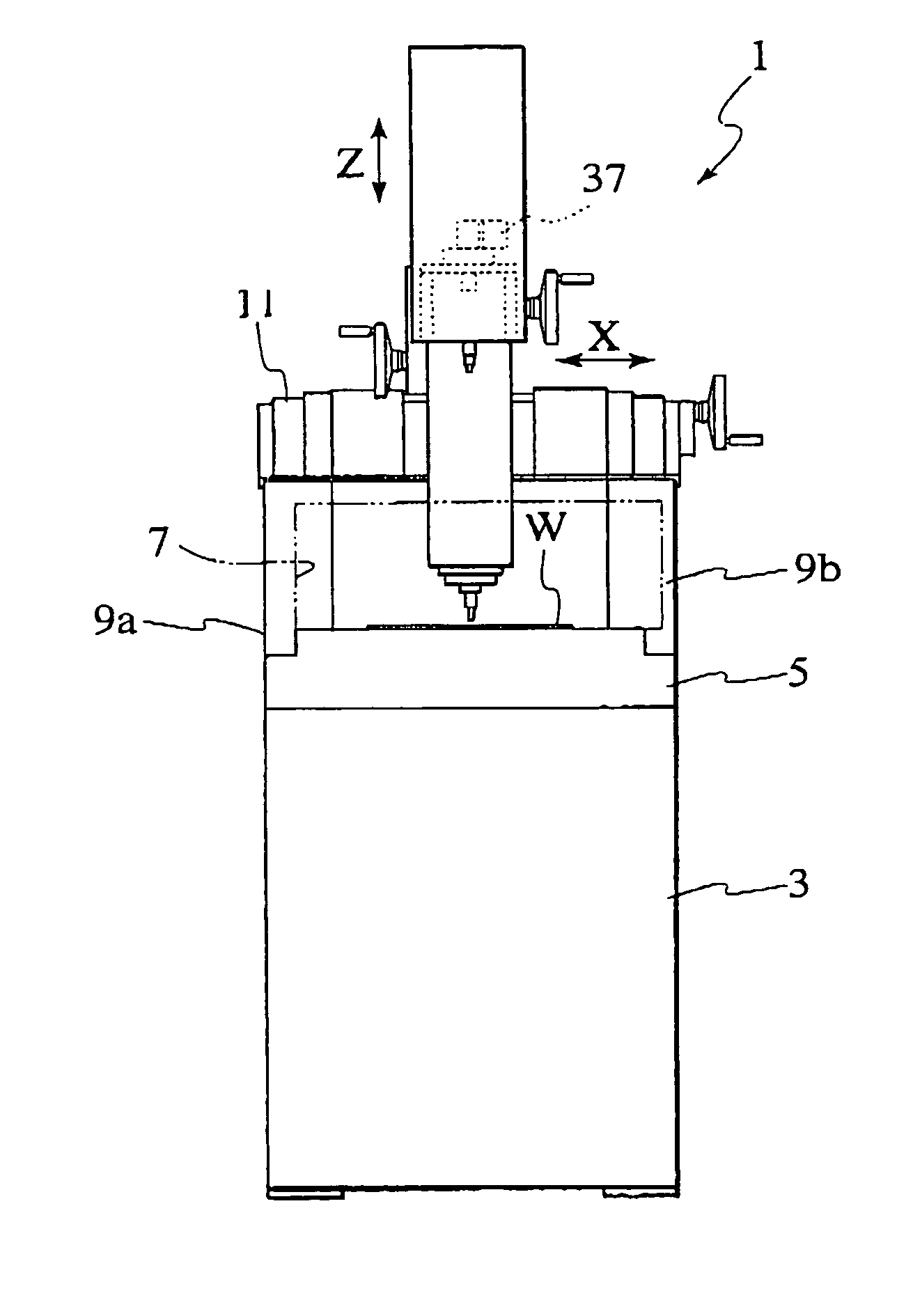

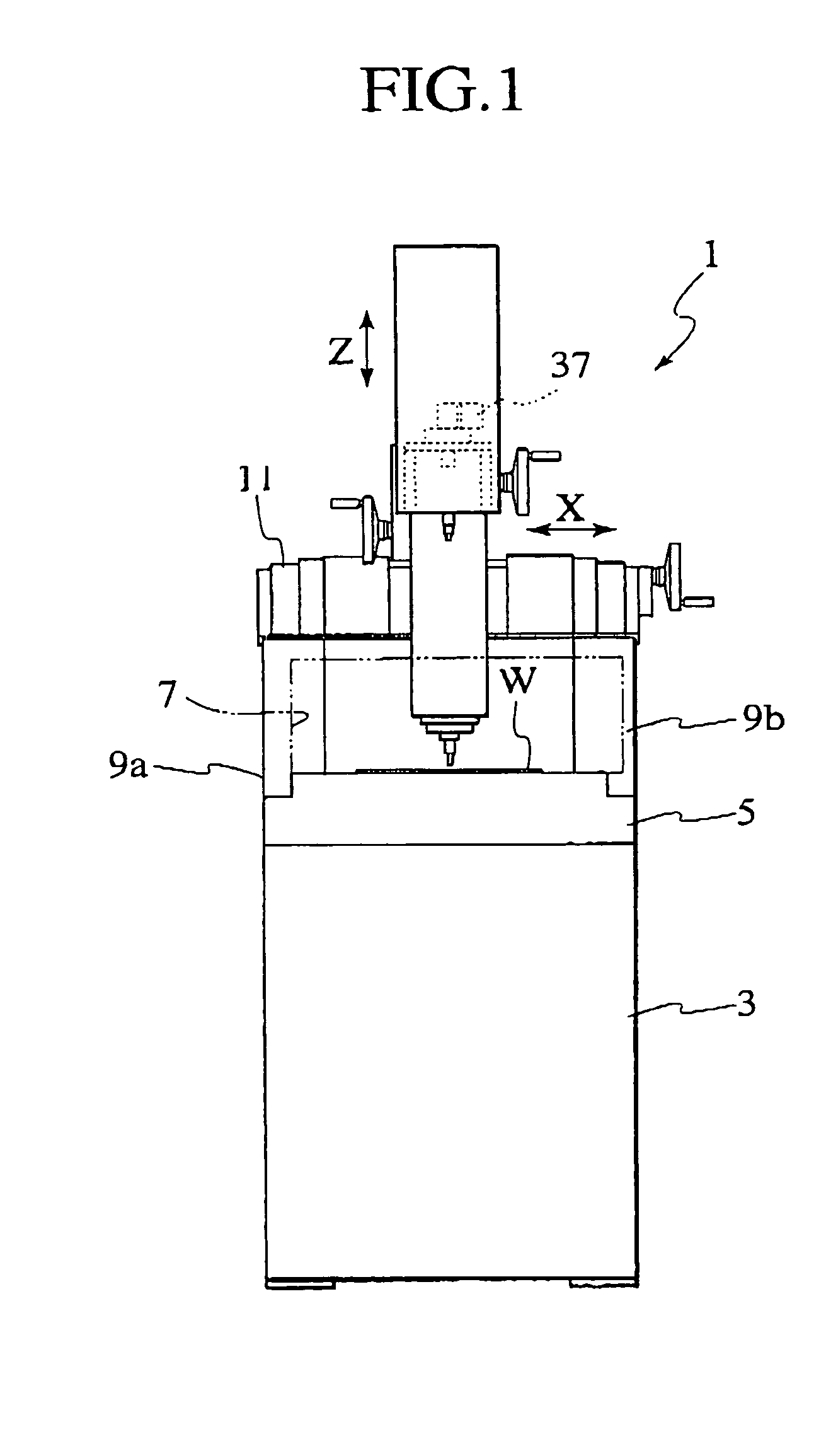

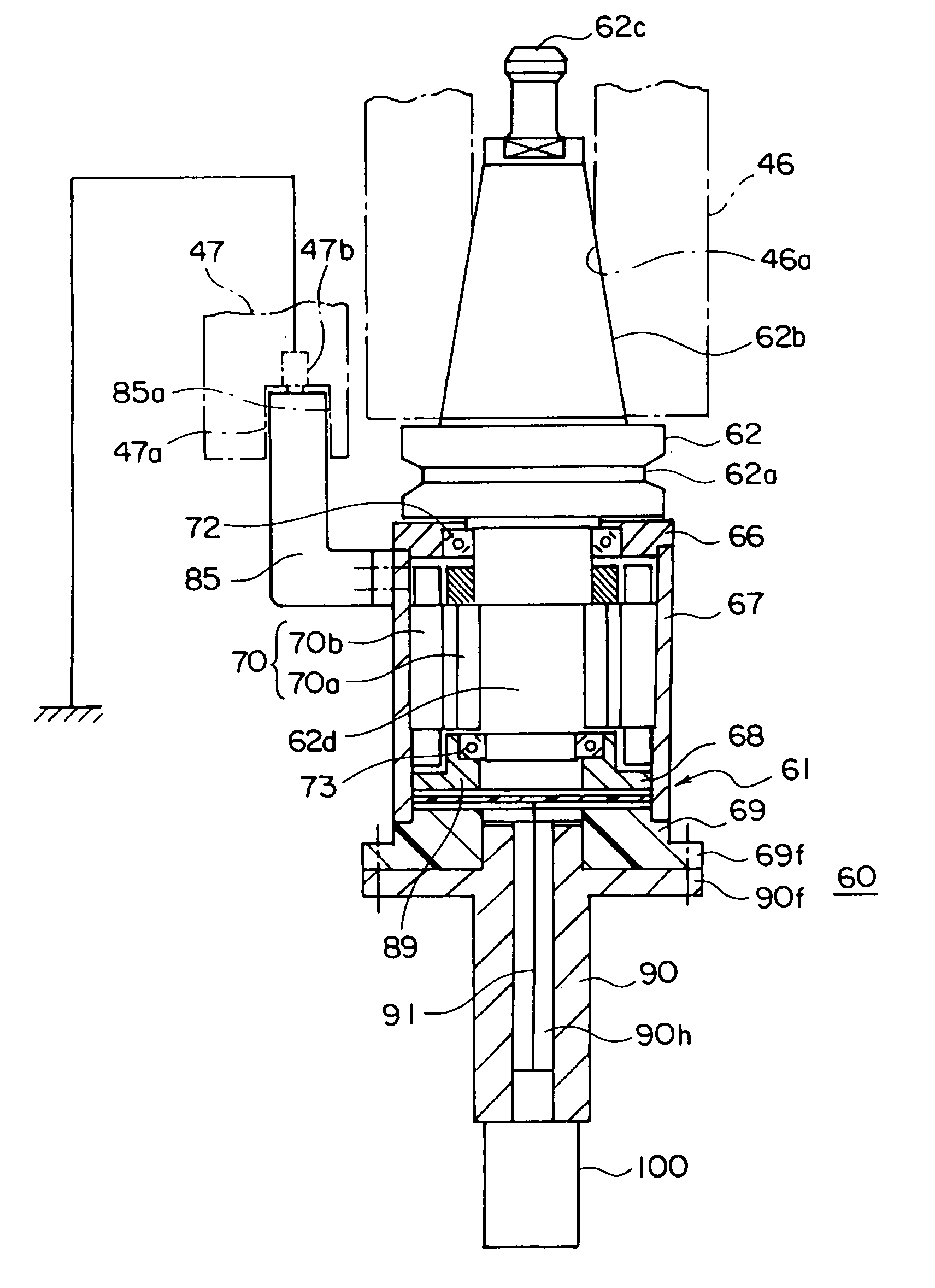

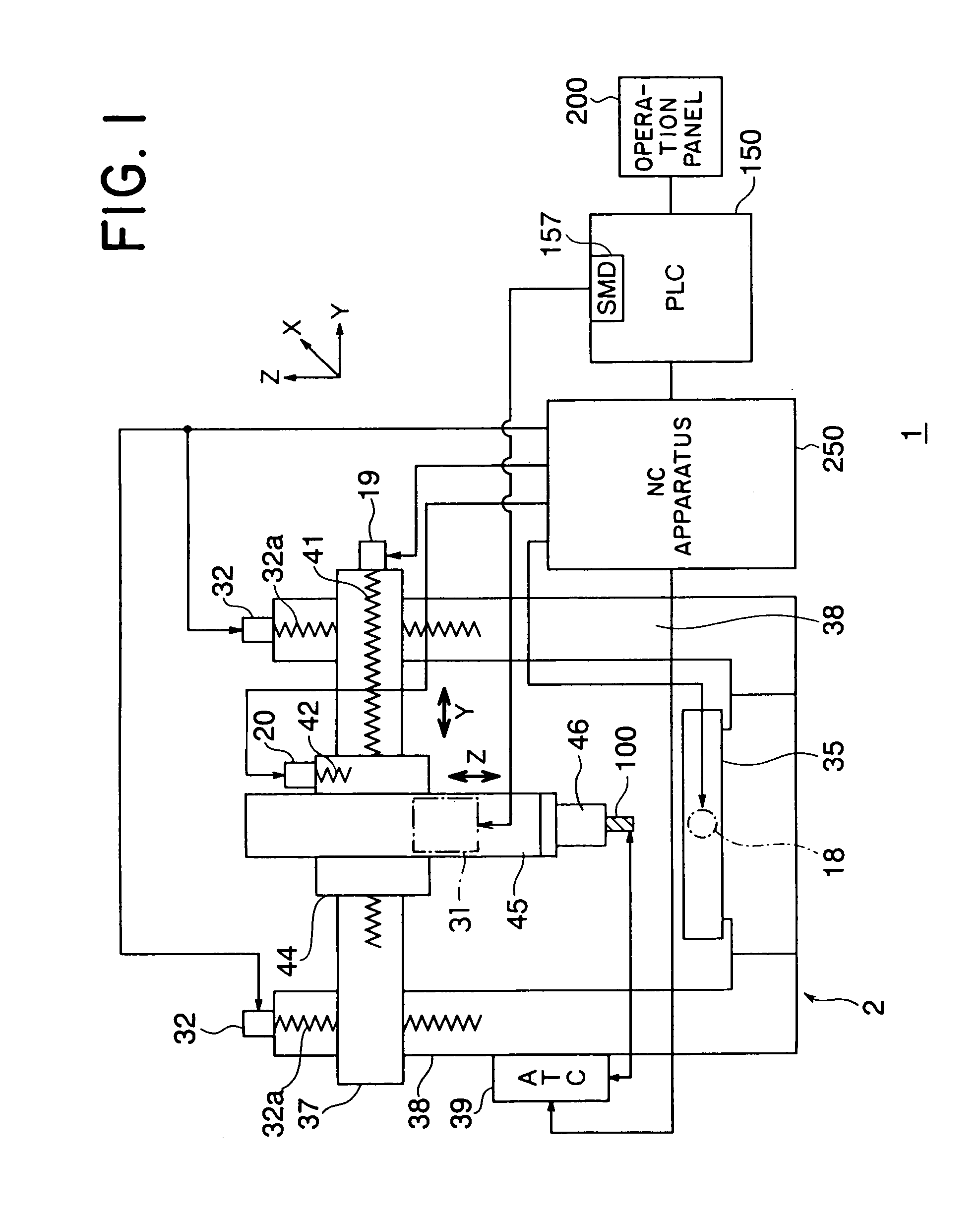

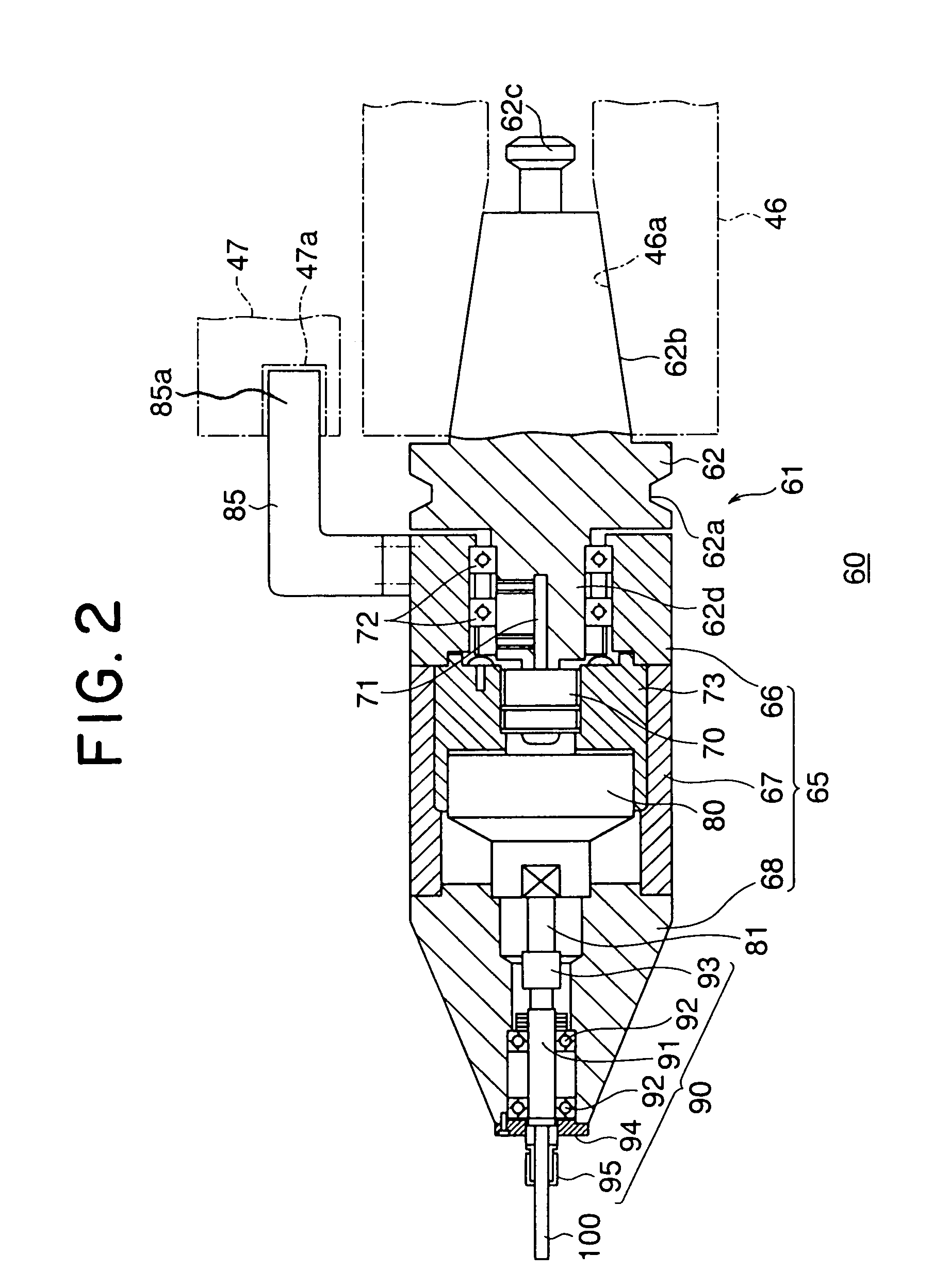

Tool, tool holder, and machine tool

InactiveUS7004693B2Inhibition effectMaintain propertiesElectrode vibration holdersAutomatic control devicesEngineeringMachine tool

A tool attachable to a spindle of a machine tool by an automatic tool changer in the same way as an ordinary tool, capable of being driven without connecting with an external power supply etc., and able to rotate at a rotational speed different from than that of the spindle of the machine tool without supply of electric power from the outside, provided with a machining tool for machining a workpiece, a motor connected with the machining tool and rotating the machining tool, and a generator to which rotary force is transmitted from the spindle of the machine tool and generating electric power to drive the motor, the shaft of the motor being arranged in an orientation different from the axial center of the spindle.

Owner:TOSHIBA MASCH CO LTD

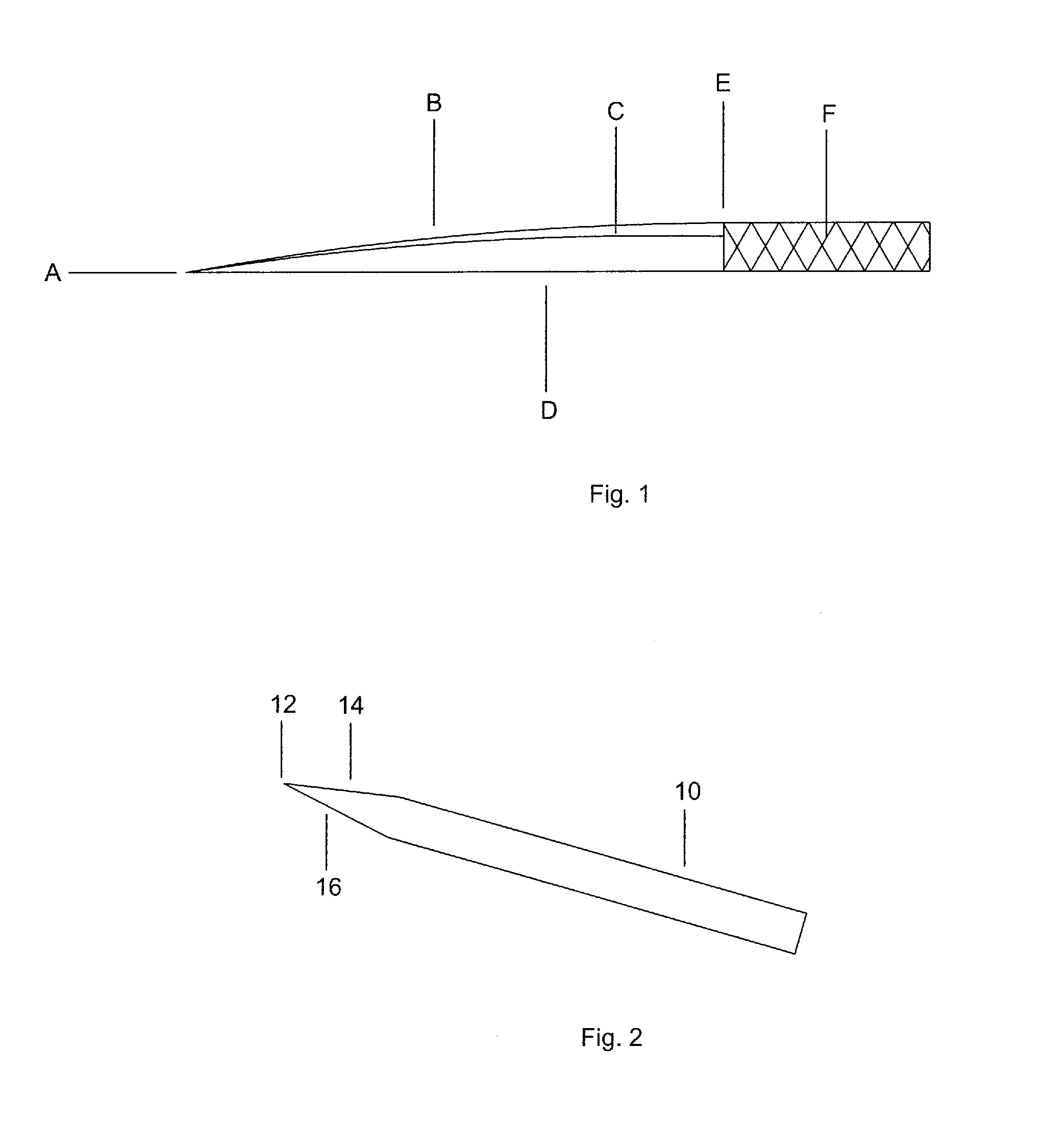

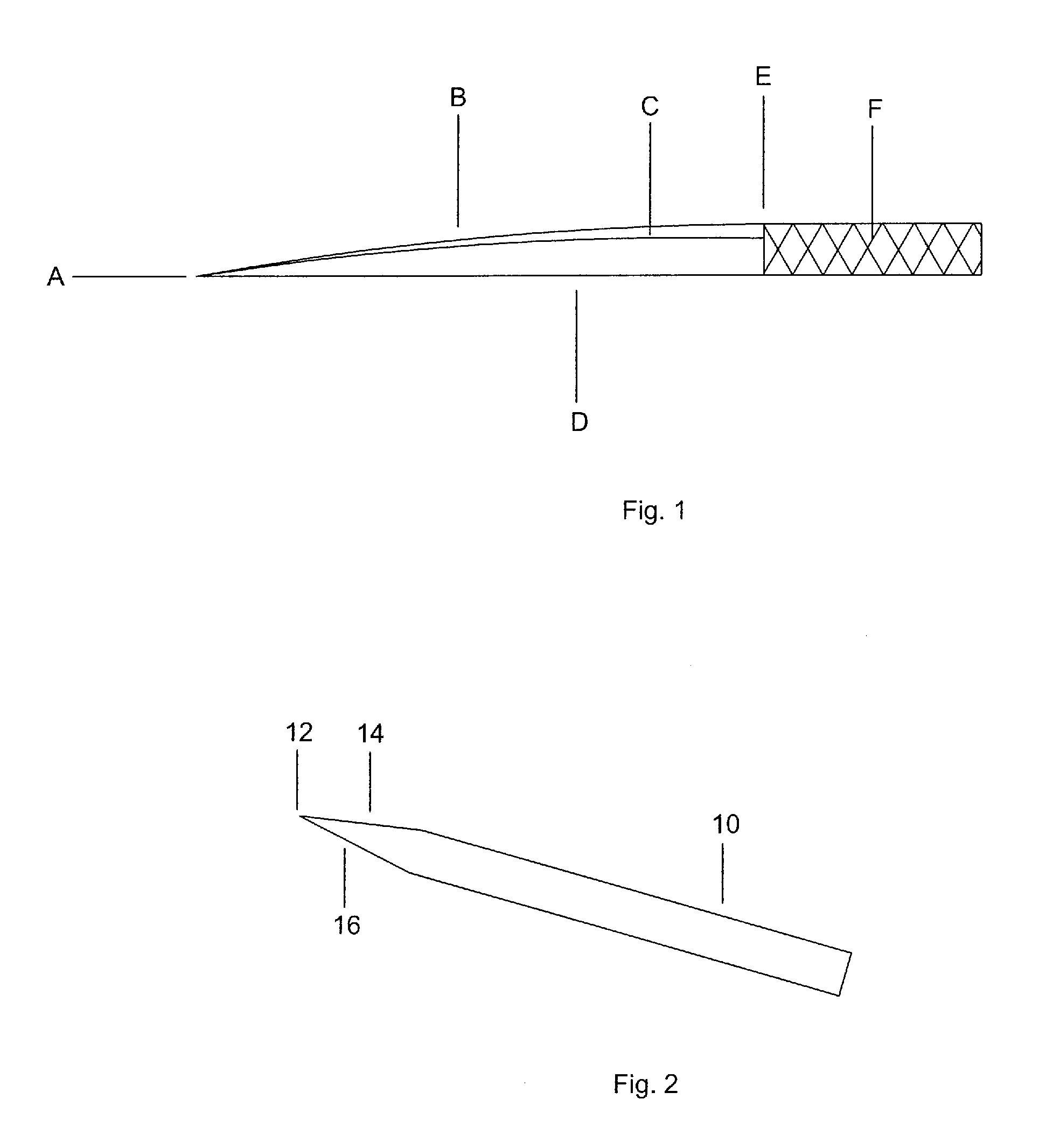

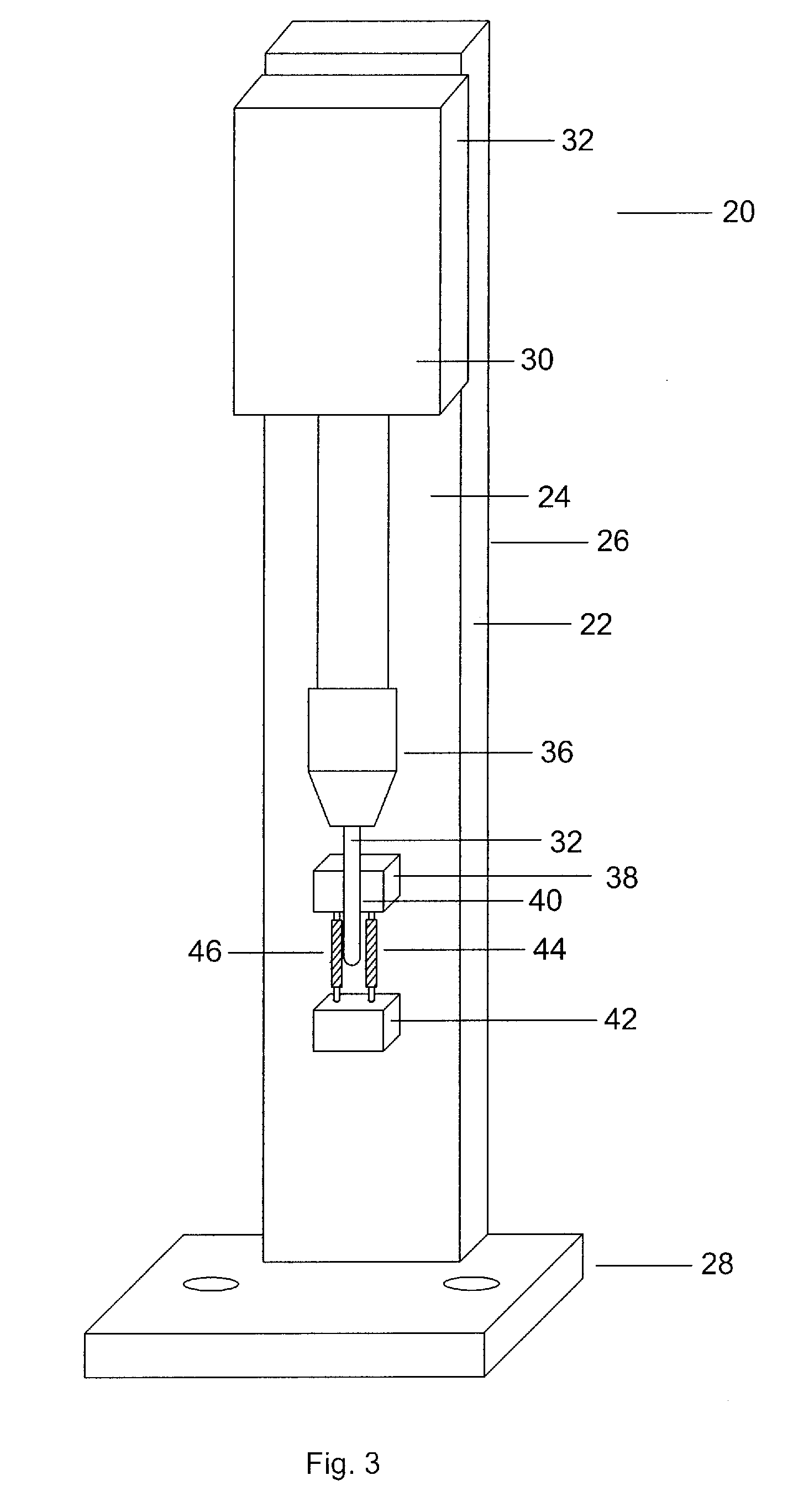

Apparatus and method of electronically impregnating a wear-resistant cutting edge

ActiveUS20110078909A1Improve cutting effectQuick wearElectrode vibration holdersOther manufacturing equipments/toolsCarbide coatingWear resistant

An apparatus and method for treating a cutting edge with a carbide coating to form a high endurance cutting edge that is self sharpening. The cutting edge has one side of its bevel treated with an electronically impregnated coating to create a wear resistant surface employing Tungsten, Titanium or Vanadium Carbide. The coating providing an abrasion resistant cutting edge and creates a differential hardness on the total cutting edge thereby extending its cutting ability through a wear-resistant surface on its treated face and a faster wear on the untreated surface causing the cutting edge to be self sharpening.

Owner:LAMBERT GEORGE H

Programmed electrode wear compensation device and method for 3D EDM scanning apparatus

ActiveUS7301116B2Overall shapeImprove smoothnessElectrode vibration holdersElectric circuitsMachined surfaceEngineering

Owner:IND TECH RES INST

Method and device for manufacturing integrally bladed rotors

ActiveUS20060085979A1Efficient preparationElectrode vibration holdersElectrolysis componentsEngineeringGas turbines

A method for manufacturing integrally bladed rotors (preferably gas turbine rotors) is provided. The method includes the steps of a) providing a basic rotor body; b) placing the basic rotor body into an electrolyte; c) electrochemically machining the basic rotor body by simultaneously manufacturing a plurality of unmachined blades; and d) subsequently machining the unmachined blades to provide hydrodynamic surfaces, in particular a suction side and a pressure side, in the area of each unmachined blade.

Owner:MTU AERO ENGINES GMBH

Inverter electric welding machine device with adjustable electric arc

InactiveCN101823176AImprove stabilityImprove practicalityElectrode vibration holdersShielding gasCompression screw

Owner:上海新亚电焊机有限公司

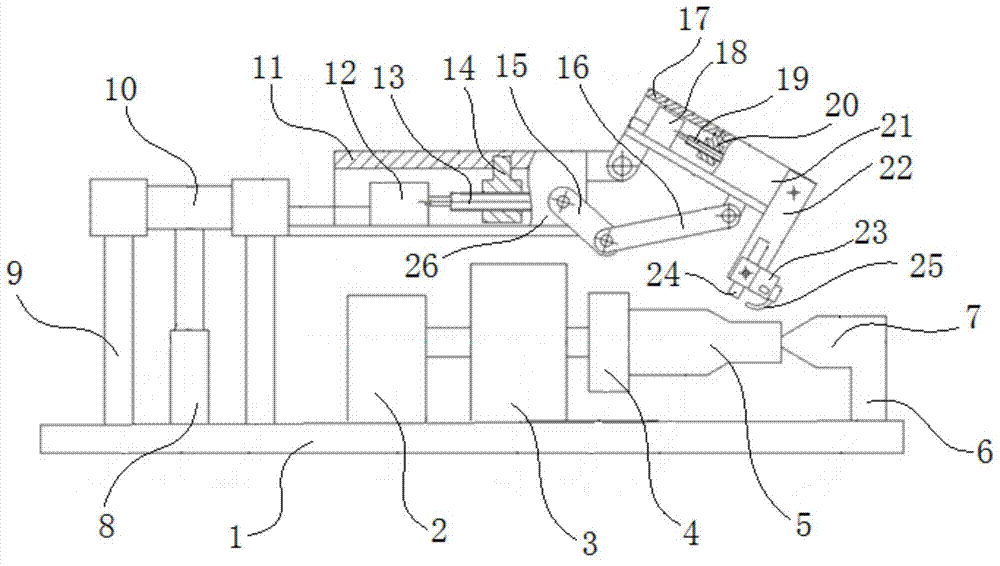

Build-up welding device for axis part with conical surface

InactiveCN104493331AReduce labor intensityHigh degree of mechanizationElectrode vibration holdersWelding/cutting auxillary devicesEngineeringConical surface

The invention discloses a build-up welding device for an axis part with a conical surface. The build-up welding device comprises a base, a tool, a horizontal guide rail, a horizontal sliding table, a swing guide rail, a feed sliding table, a connecting plate and a welding head, wherein the tool comprises a machine head, a chuck and a centre seat, wherein the machine head is arranged on the base, the chuck is arranged on the machine head, the centre seat is arranged on the base, and the upper end of the centre seat is provided with a centre; the horizontal guide rail is erected above the base through an elevator mechanism; the horizontal sliding table is arranged on the horizontal guide rail, and is driven by a horizontal driving mechanism; the left end of the swing guide rail is hinged to the right end of the horizontal sliding table, and the right end of the swing guide rail is hinged to one end of a first connecting rod; the other end of the first connecting rod is hinged to one end of a second connecting rod; the other end of the second connecting rod is connected with a swing motor; the feed sliding table is arranged on the swing guide rail; the upper end of the connecting plate is connected with the lower end of the feed sliding table; the welding head is arranged at the lower end of the connecting plate, and is provided with a welding gun and a wire feeding head. The build-up welding device disclosed by the invention can be used for performing mechanical build-up welding on the conical surface of the axial part with the conical surface, and is stable in welding quality and high in efficiency.

Owner:GUANGXI UNIV

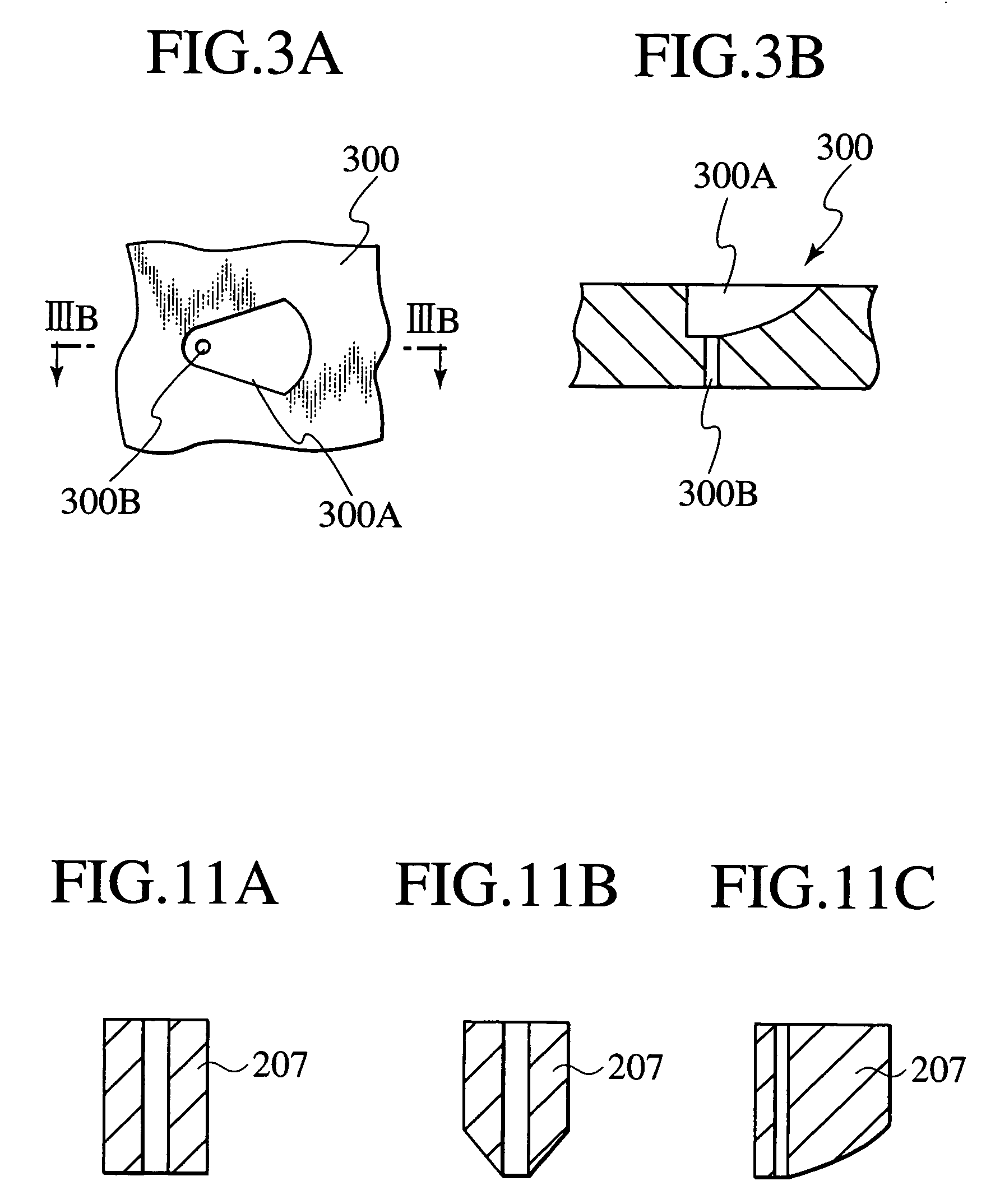

Electrical discharge machining

ActiveUS20130248495A1Large spark gap sizeEfficient removalElectrode vibration holdersElectrical-based auxillary apparatusLong axisEngineering

A method for electrical discharge machining a workpiece includes the steps of: presenting an elongate electrode to the workpiece with a spark gap therebetween; flowing a dielectric fluid in the gap; eroding the workpiece by electrical discharge between the tip of the electrode and the workpiece; displacing the electrode in a direction aligned with the long axis of the electrode to maintain the gap as the electrode wears and the workpiece is eroded; and simultaneously with the displacement, producing vibratory movement of the electrode, the vibratory movement being aligned with the long axis of the electrode.

Owner:ROLLS ROYCE PLC

Small-hole electrical discharge machining device and multiple diesinking-and-small-hole electrical discharge machining device, and method for multiple diesinking-and-small-hole electrical discharge machining with the same device

A small-hole electrical discharge machining device comprises a diaphragm which can be moved up and down along a notch window provided in a work tank for mounting a work in the work tank in which a working fluid can be filled or discharged, and adjusts the height of the working fluid; a W-axis slide which can be moved up and down, and having an electrode guide in the lower end portion; a master cylinder which is moved up and down corresponding to up-and-down movement of the W-axis slide; and a slave cylinder which is connected with the master cylinder through a pipeline and with a diaphragm driving mechanism, and wherein the diaphragm is moved up and down corresponding to up and down movement of the W-axis slide.

Owner:ELENIX KK

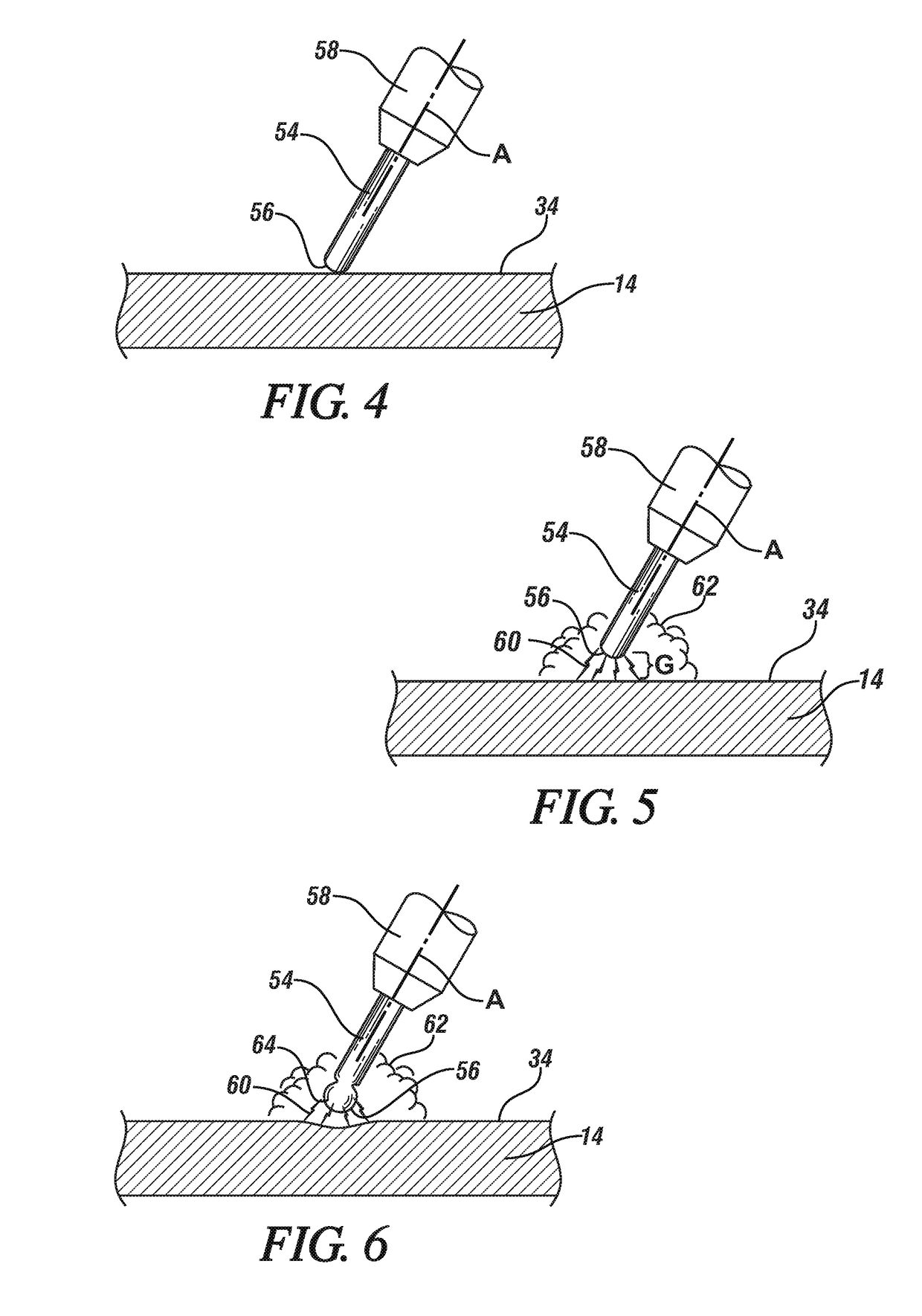

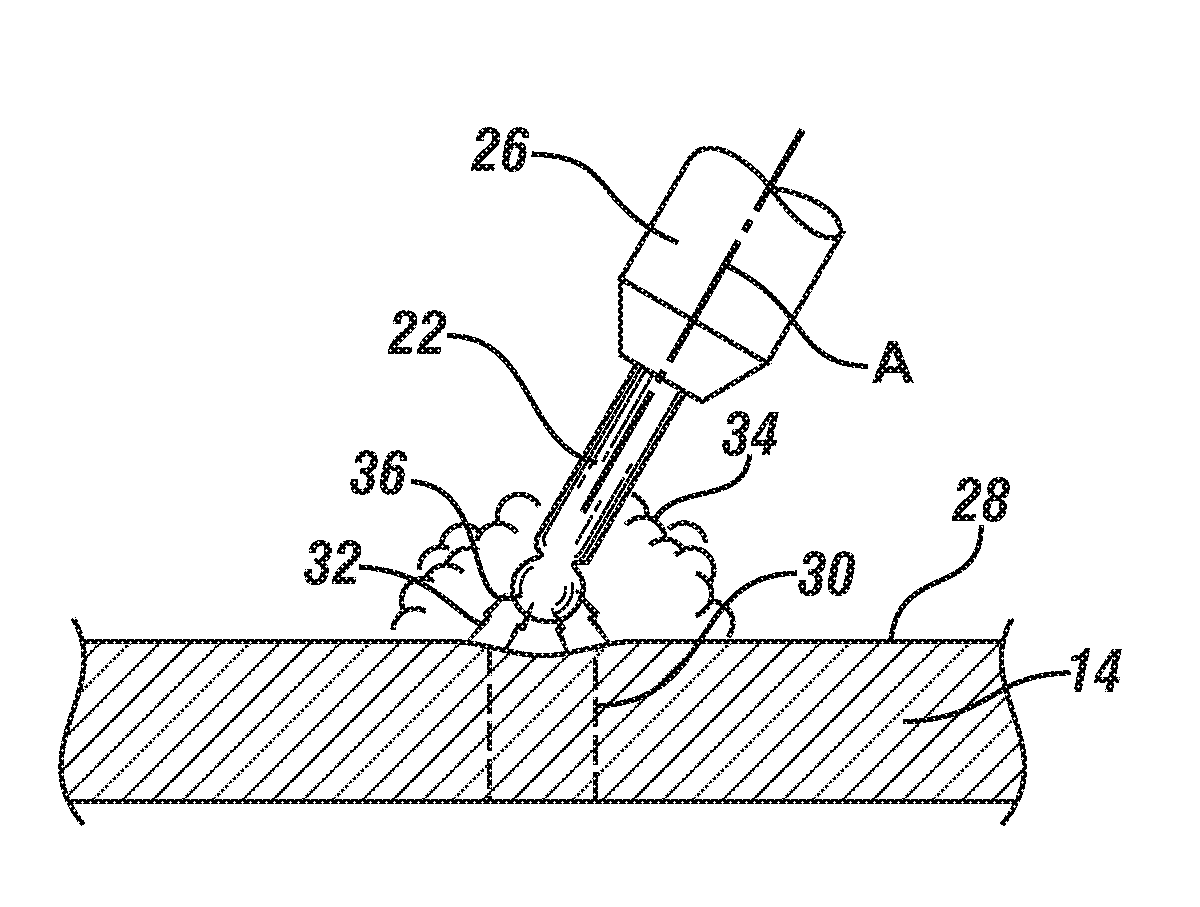

Reaction material pre-placement for reaction metallurgical joining

ActiveUS20160008911A1Quality improvementImprove efficiencyElectrode vibration holdersWelding/cutting media/materialsMetalElectrode

A method of pre-placing a reaction material onto a surface of a metal workpiece substrate involves the use of oscillating wire arc welding. The method involves depositing and adhering the reaction material from a consumable electrode rod. In doing so, the reaction material can be deposited at any time before the metal workpiece substrate is ready for joining by reaction metallurgical joining, and the size and shape of the reaction material deposit can be more easily controlled.

Owner:GM GLOBAL TECH OPERATIONS LLC

Apparatus and method of electronically impregnating a wear-resistant cutting edge

ActiveUS8592711B2Quick wearImprove cutting effectElectrode vibration holdersOther manufacturing equipments/toolsCarbide coatingWear resistant

An apparatus and method for treating a cutting edge with a carbide coating to form a high endurance cutting edge that is self sharpening. The cutting edge has one side of its bevel treated with an electronically impregnated coating to create a wear resistant surface employing Tungsten, Titanium or Vanadium Carbide. The coating providing an abrasion resistant cutting edge and creates a differential hardness on the total cutting edge thereby extending its cutting ability through a wear-resistant surface on its treated face and a faster wear on the untreated surface causing the cutting edge to be self sharpening.

Owner:LAMBERT GEORGE H

Thermal cutter with sound absorbent walls

InactiveUS9000321B2Mitigating fumeAvoid noiseElectrode vibration holdersElectric discharge heatingInterior spaceEngineering

Owner:KOMATSU IND CORP

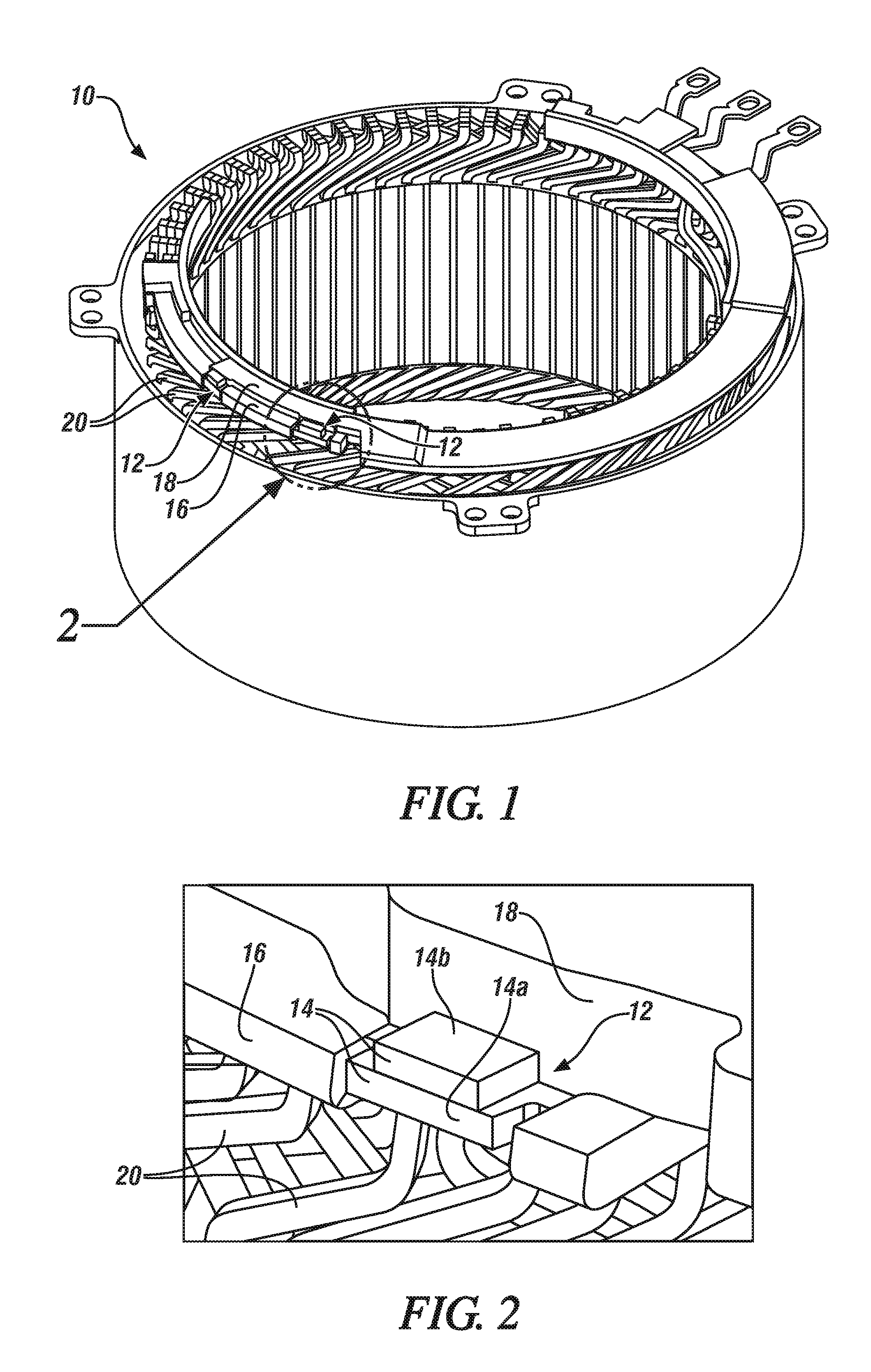

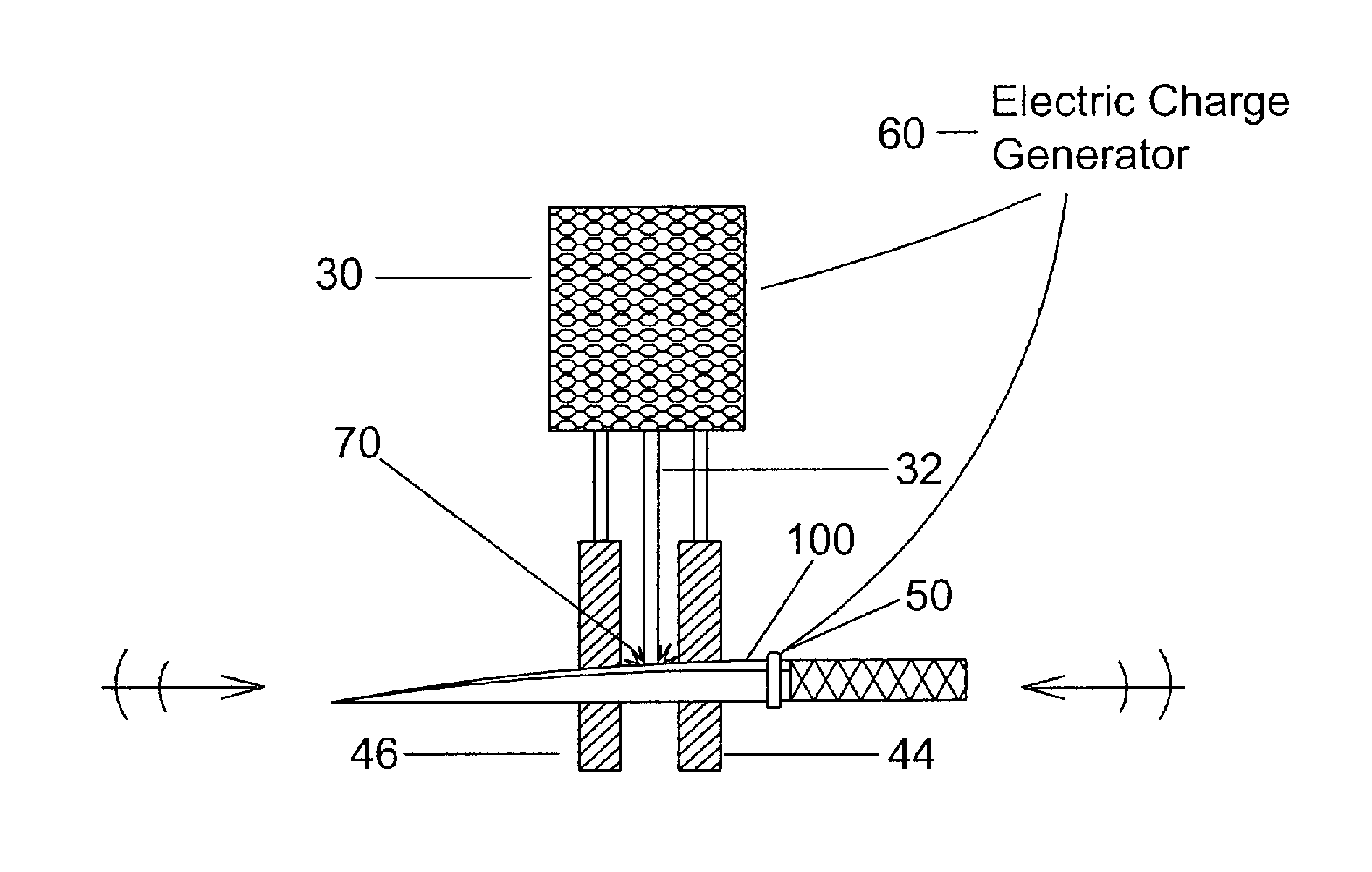

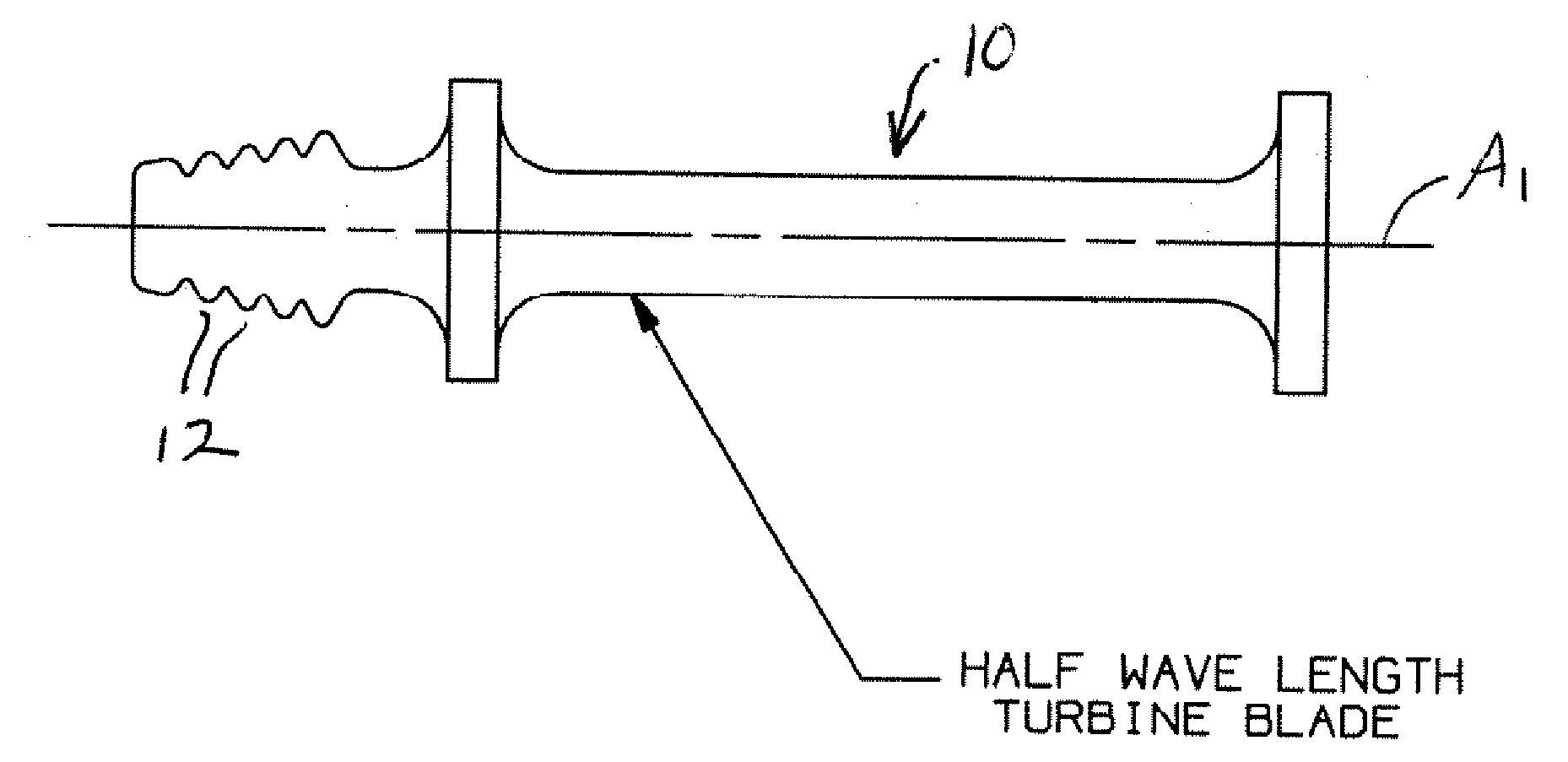

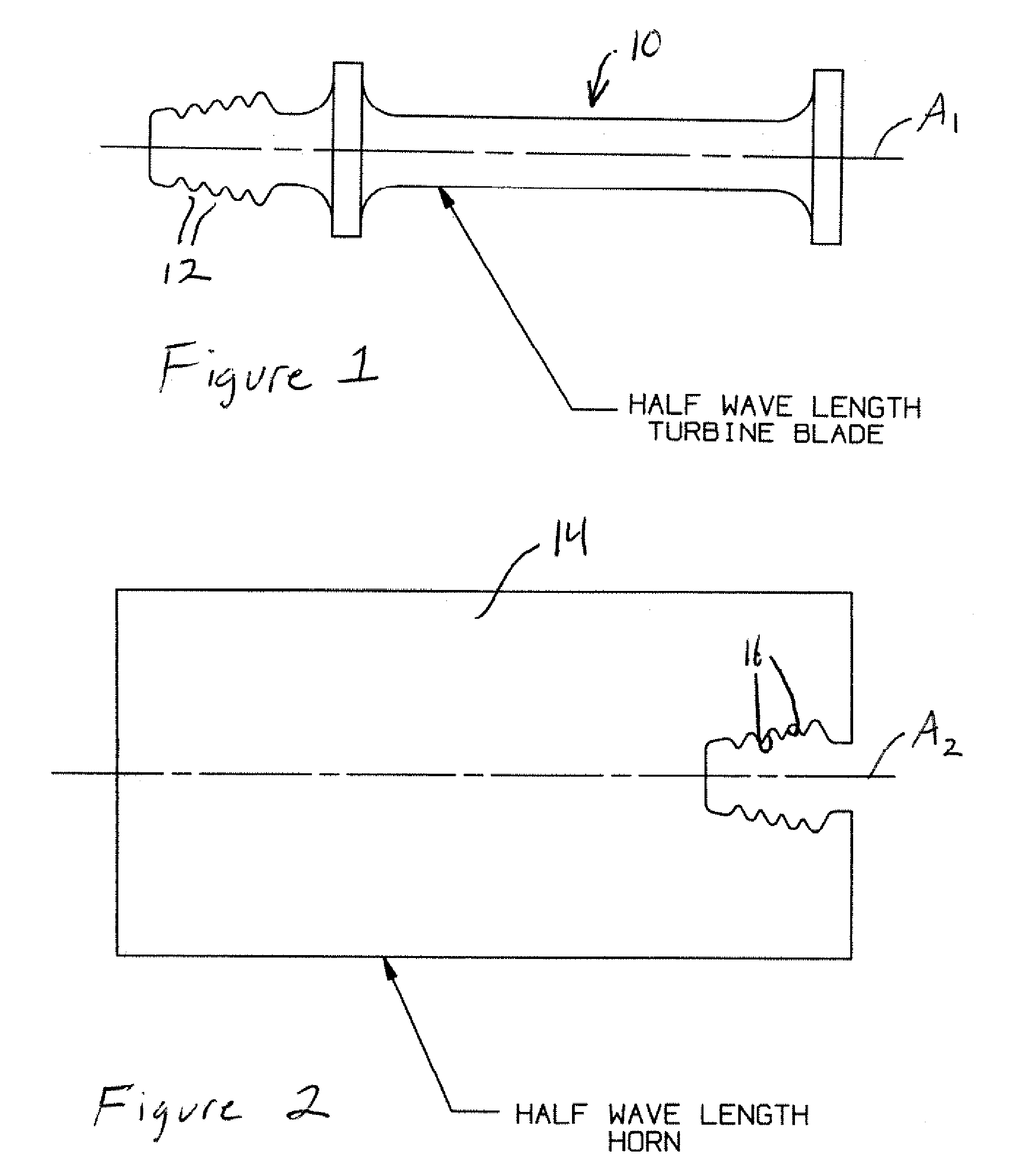

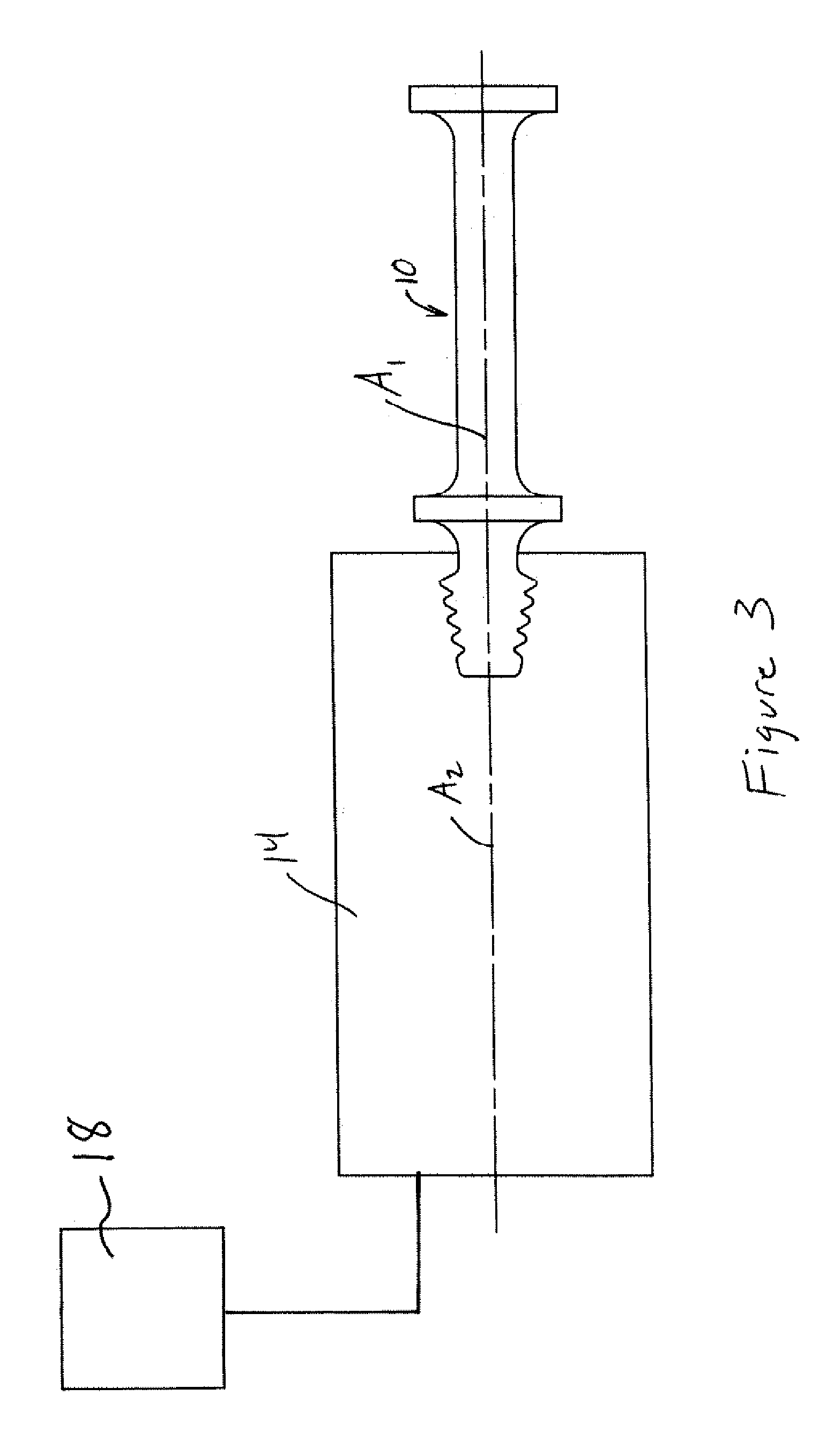

System and Method for Ultrasonic Assisted EDM Machining

ActiveUS20090166335A1Small dimensionElectrode vibration holdersElectrical-based auxillary apparatusUltrasonic assistedMachining system

A system for ultrasonic assisted electrical discharge machining of a component part having a longitudinal axis, a half wavelength resonant frequency along the longitudinal axis and an attachment portion, is provided. The system includes an ultrasonic horn having a longitudinal axis, a half wavelength resonant frequency along the longitudinal axis and an attachment portion. The half wavelength resonant frequency of the ultrasonic horn is the same as the half wavelength resonant frequency of the component part. Additionally, one of the attachment portion of the component part and the attachment portion of the ultrasonic horn is a male part and the other one of the attachment portion of the component part and the attachment portion of the ultrasonic horn is a female part sized and shaped to mate and engage one another when the component part and the ultrasonic horn are at generally the same temperature.

Owner:SONICS & MATERIALS

Electric discharge machining apparatus

InactiveUS7518081B2Preventing buckling and vibrationReduce protrusionElectrode vibration holdersElectrical-based machining electrodesElectric dischargeEngineering

An electric discharge machining apparatus includes a guide electrode that is tubular and receives a small-diameter wire electrode for electric discharge machining. The small-diameter wire electrode can freely slide within the guide electrode. A guide electrode holder holds the guide electrode at a specified position. Pressurized fluid is supplied into the guide electrode to feed the small-diameter wire electrode from the guide electrode. A small-diameter wire electrode holder automatically releases and grasps the small-diameter wire electrode in response to starting and stopping of the pressurized fluid supply, respectively.

Owner:MITSUBISHI ELECTRIC CORP

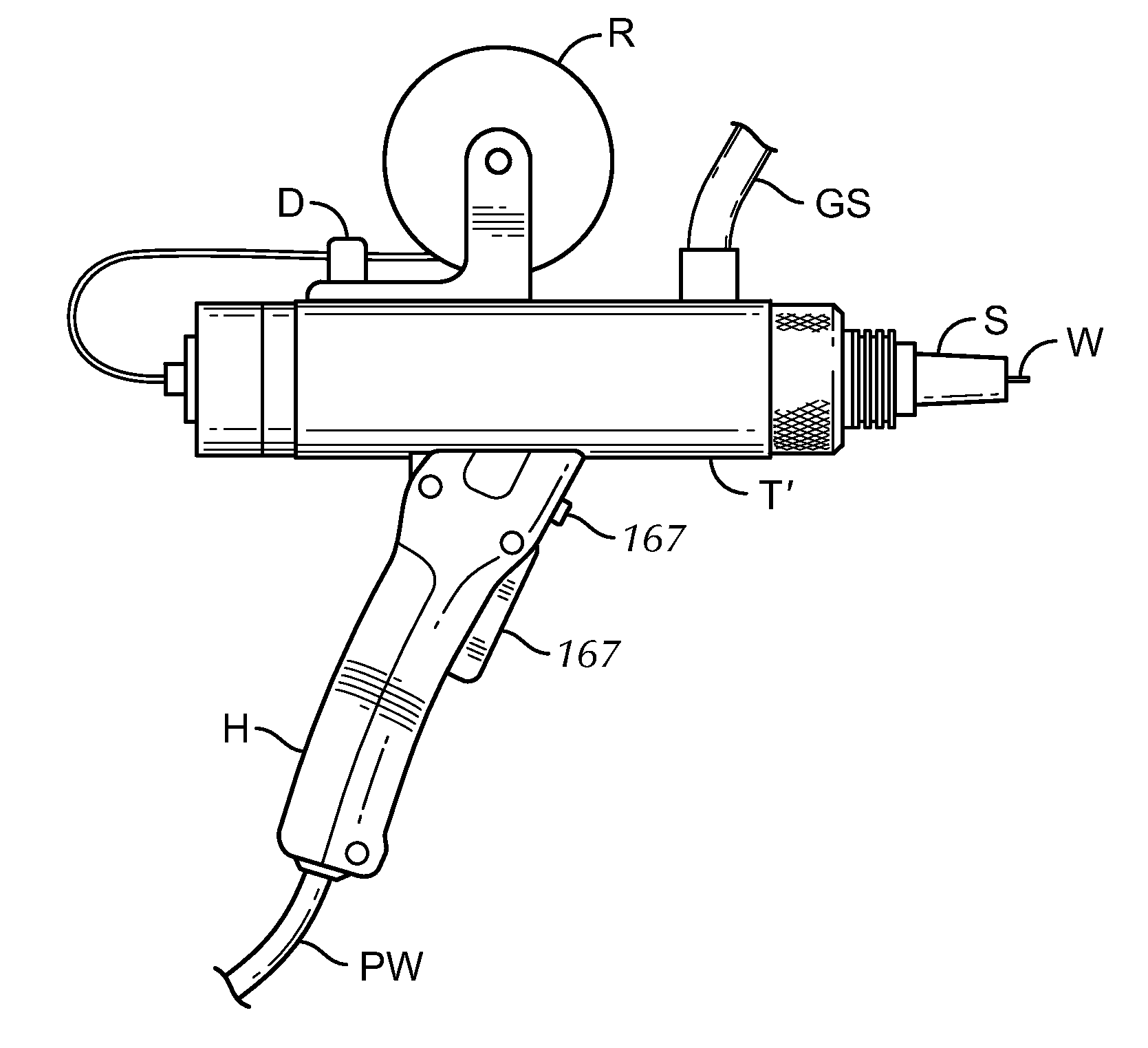

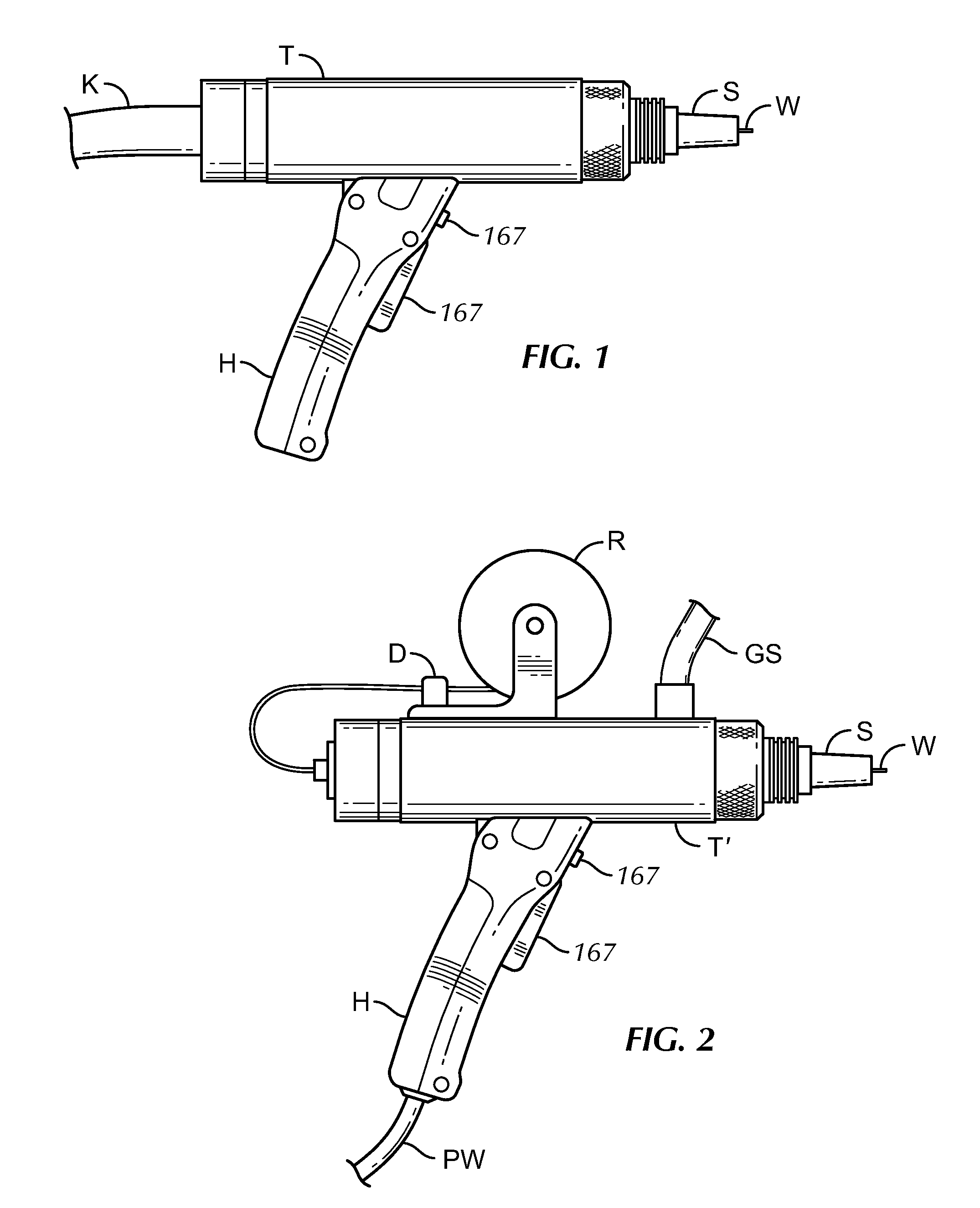

Apparatus and Method for use of Rotating Arc Process Welding

InactiveUS20150190878A1Electrode vibration holdersSupport devices with shieldingEngineeringCentrifugal force

An arc welding apparatus that imparts a rotational movement to the tip of the consumable electrode to cause molten metal to be thrown by centrifugal force against the sidewall of the slot between metal work pieces being welded. The welding apparatus being configurable to control speed, direction, and / or placement of the electrical arc in relation to the slot. The welding apparatus being configurable to pair with other similar devices and to be cooperatively operated in close proximity and\or on a single weld puddle to accomplish larger and / or complex welds in rapid, repeatable succession.

Owner:WELD REVOLUTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com