Patents

Literature

3465 results about "Master cylinder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In automotive engineering, the master cylinder is a control device that converts force (commonly from a driver's foot) into hydraulic pressure. This device controls slave cylinders located at the other end of the hydraulic system.

Hydraulic braking system for automobiles

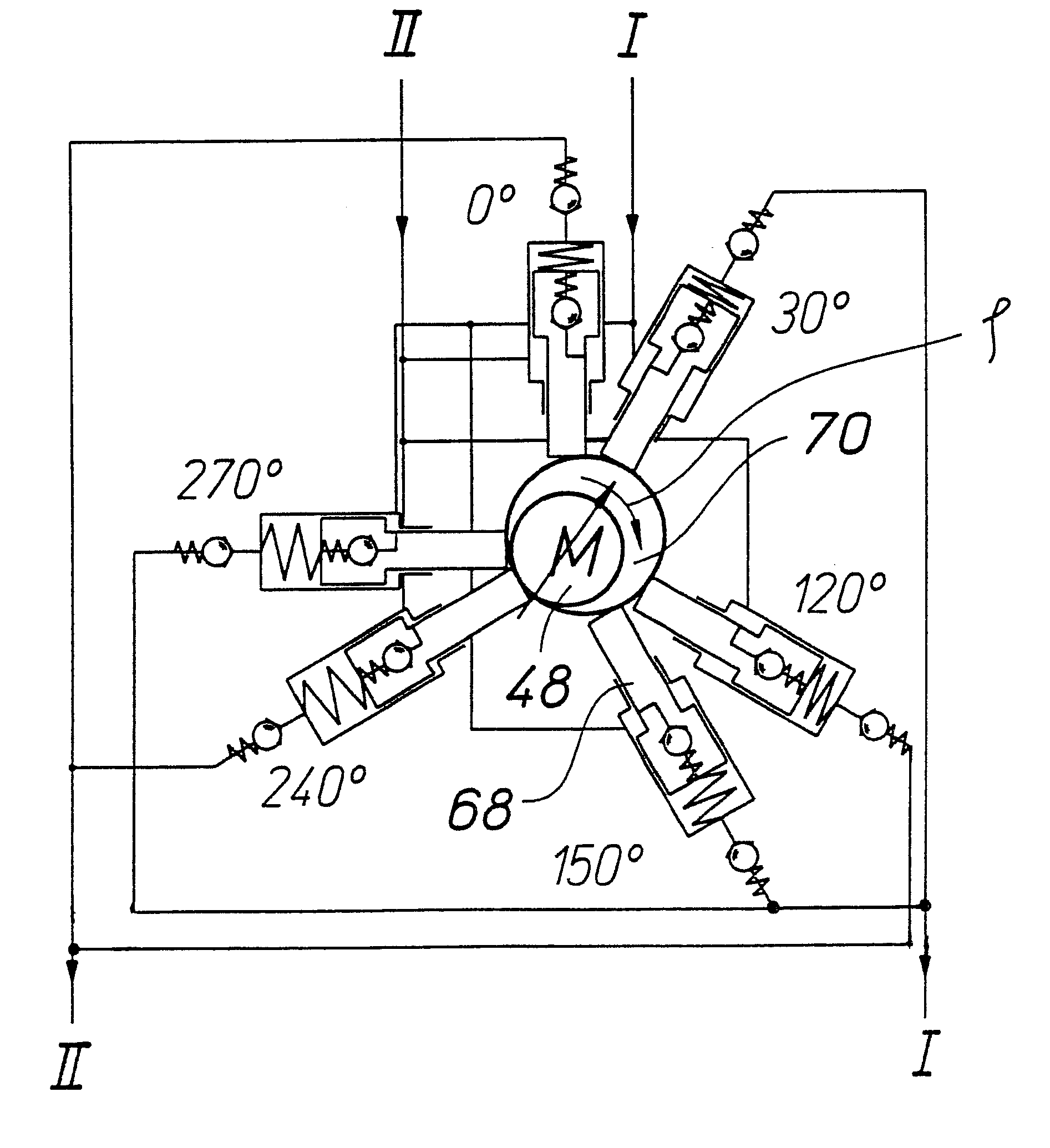

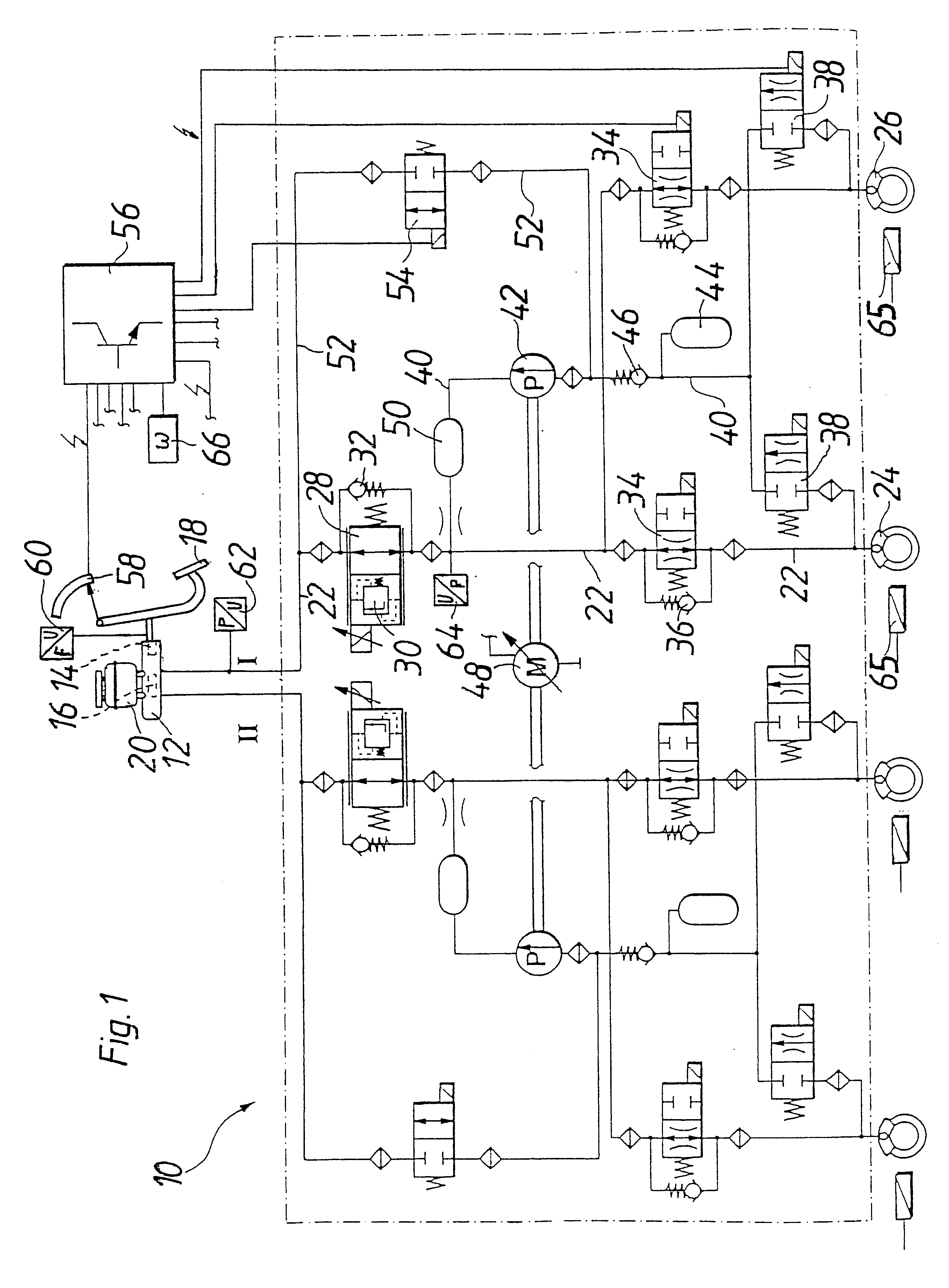

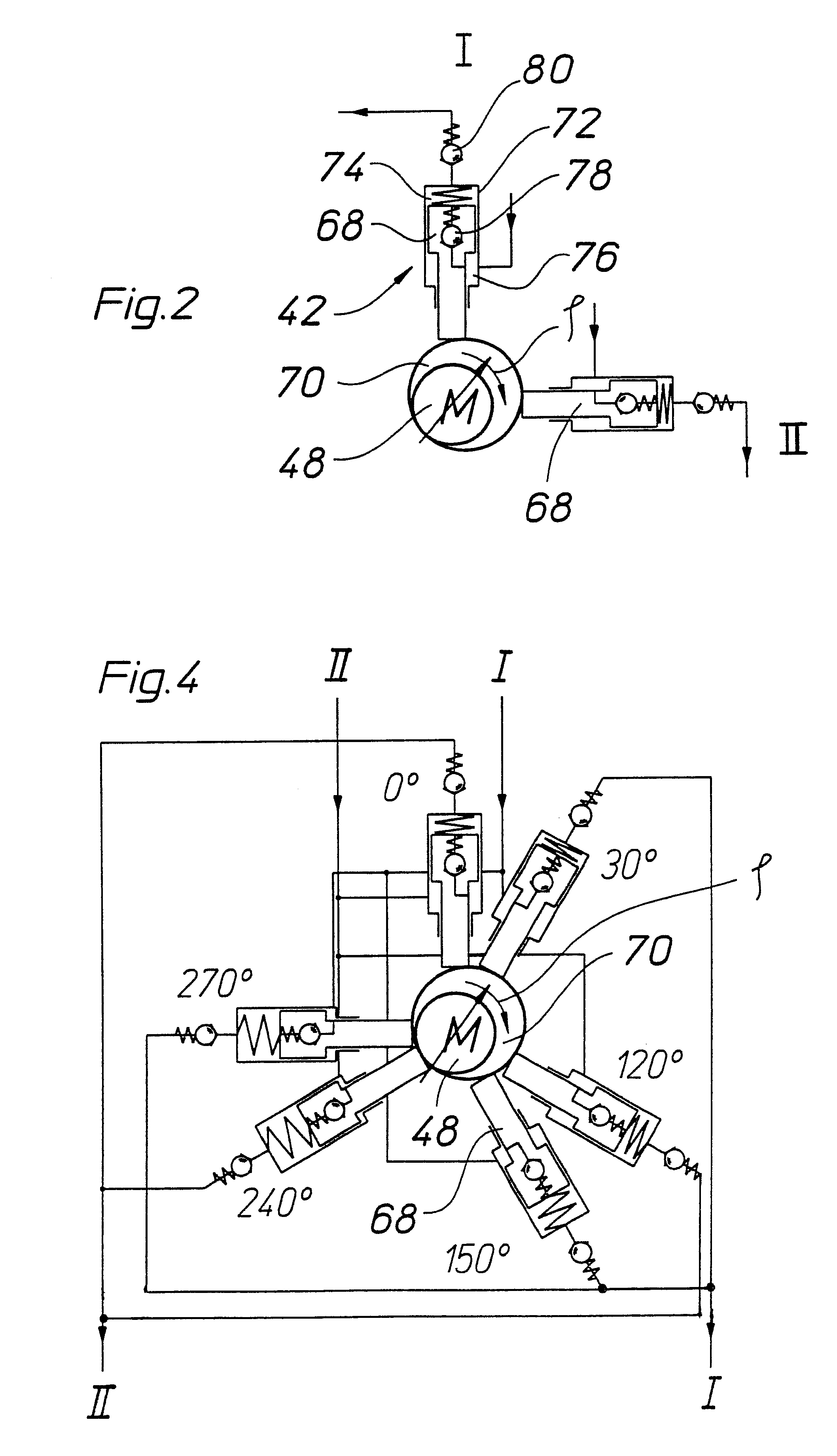

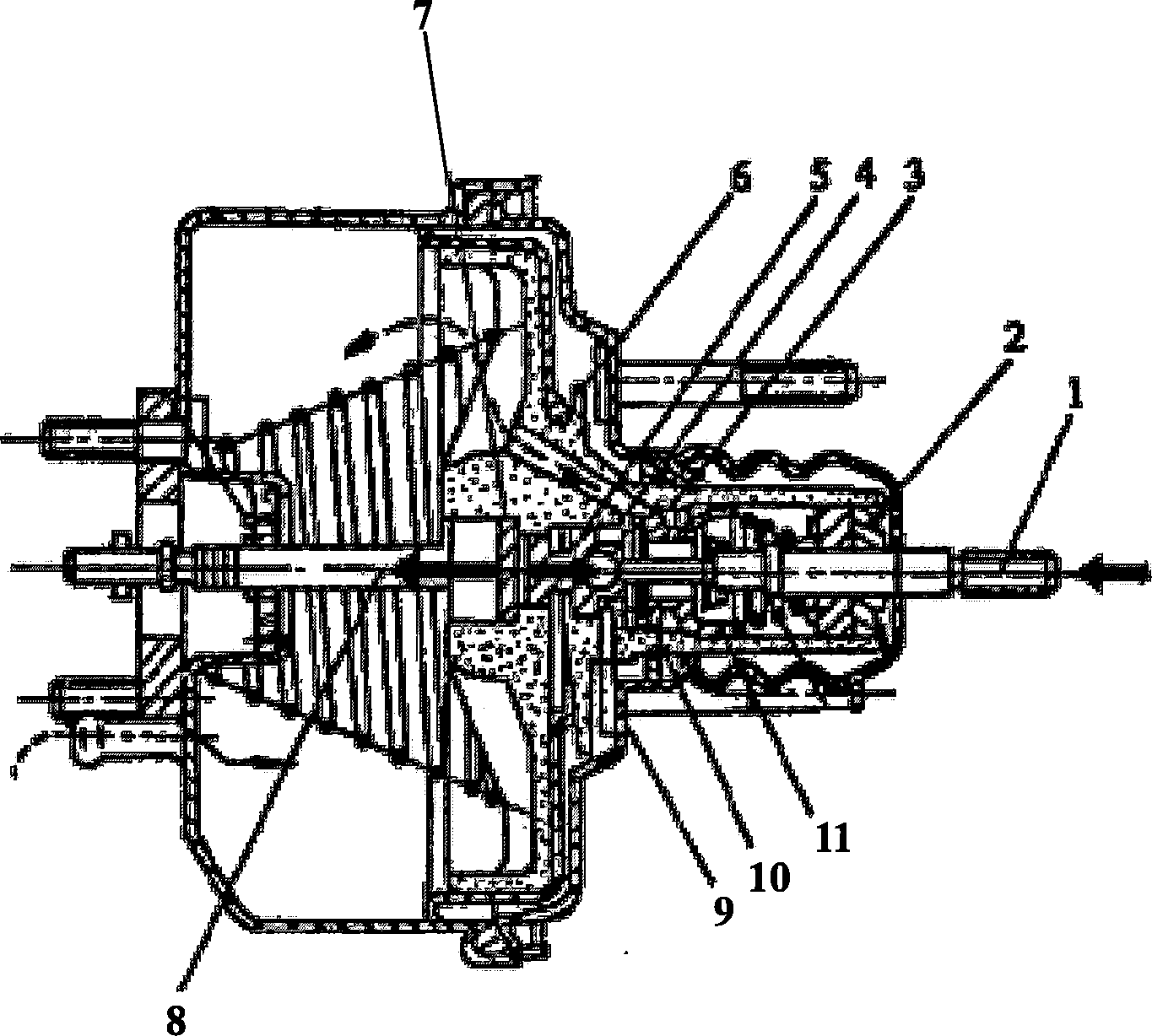

The invention relates to a vehicle hydraulic brake system with electrohydraulic brake boosting by a piston pump. In order to reduce pressure pulsations on an intake side of the multi-piston pump, the brake system embodies a multi-piston pump, for example, as a six-piston pump with stepped pistons that are driven with an alternating phase shift of 30° and 90° in relation to one another. The phase shift of the drive of the stepped pistons is selected so that the intake volume flows have a uniform phase shift, by which the total intake volume flow of the multi-piston pump has a reduced amplitude of the pressure pulsation, which reduces the repercussions on a master cylinder.

Owner:ROBERT BOSCH GMBH

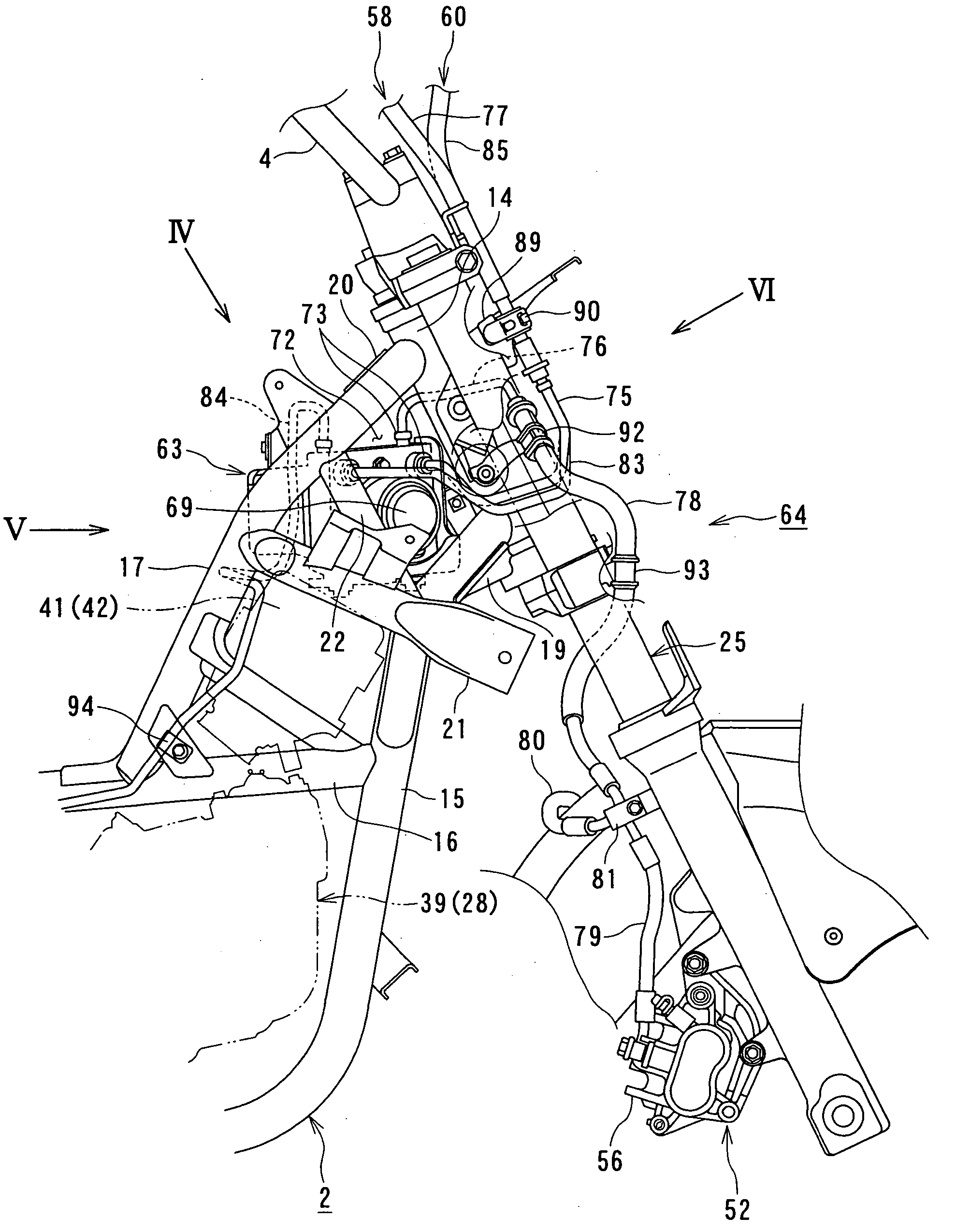

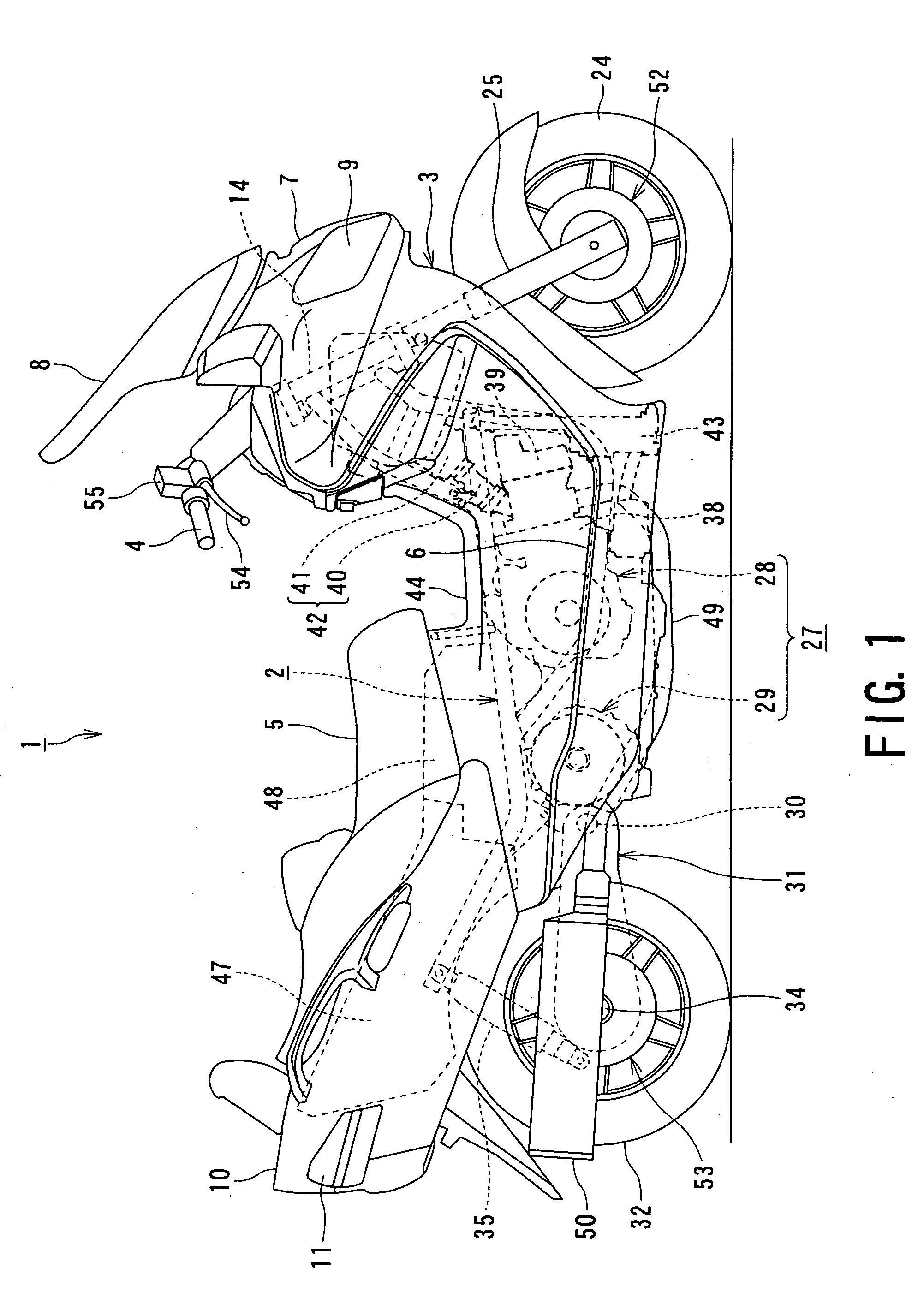

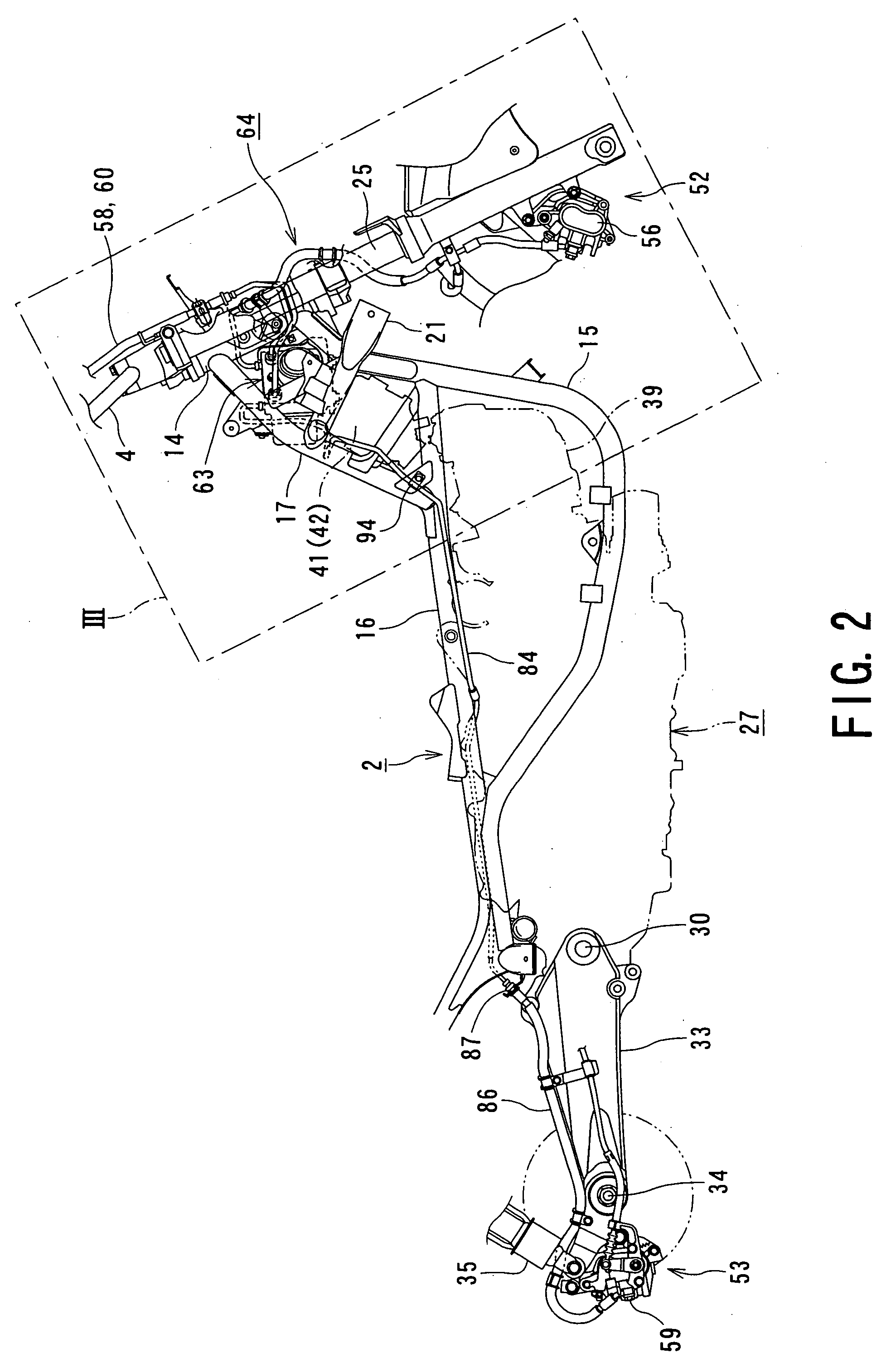

Motorcycle with antilock brake system

ActiveUS20050134114A1Improve braking performanceImprove engine performanceElectric propulsion mountingGas pressure propulsion mountingMaster cylinderEngineering

In a motorcycle provided with an antilock brake system, a front fork supporting a front wheel of a motorcycle is supported to be rotatable by a head pipe which is located at the front end portion of a body frame of a motorcycle, a handle-bar is secured to an upper end portion of the head pipe, master cylinders attached to the handle-bar are connected to hydraulic wheel brakes, respectively, via brake pipes. An antilock brake system includes an ABS-unit for antilock control disposed in an intermediate portion of the brake pipes. The ABS-unit is disposed immediately behind the head pipe and between a pair of body frame components disposed on both lateral sides of the motorcycle body and extending, from the head pipe, obliquely downward and backward, while extending outward in directions opposite to each other in the width direction of the motorcycle body.

Owner:SUZUKI MOTOR CORP

Operating a vehicle with high fuel efficiency

InactiveUS7607503B1Increase fuel consumptionReduce fuel consumptionAuxillary drivesRailway vehiclesCombustionEngine efficiency

High vehicle fuel efficiency is achieved by reducing fuel consumption during driving both in the city and on the highway. During driving in the city, the system accumulates the energy derived from vehicle motion during braking, and uses it to assist in vehicle propulsion at a later time. The energy can be stored either in a compressed-air reservoir or in an electric battery. During cruising on the highway, the engine operates in a two-stage gas-expansion cycle. The engine has primary and secondary cylinders. Only primary cylinders operate in internal-combustion mode. After expansion in primary cylinders, combustion gas is subjected to a second stage of expansion in secondary cylinders. This substantially improves the engine efficiency. Whenever heavy engine load is needed, all cylinders operate in internal-combustion mode.

Owner:SCHECHTER MICHAEL MOSES

Regulatable hydraulic machine with up and down both double moving

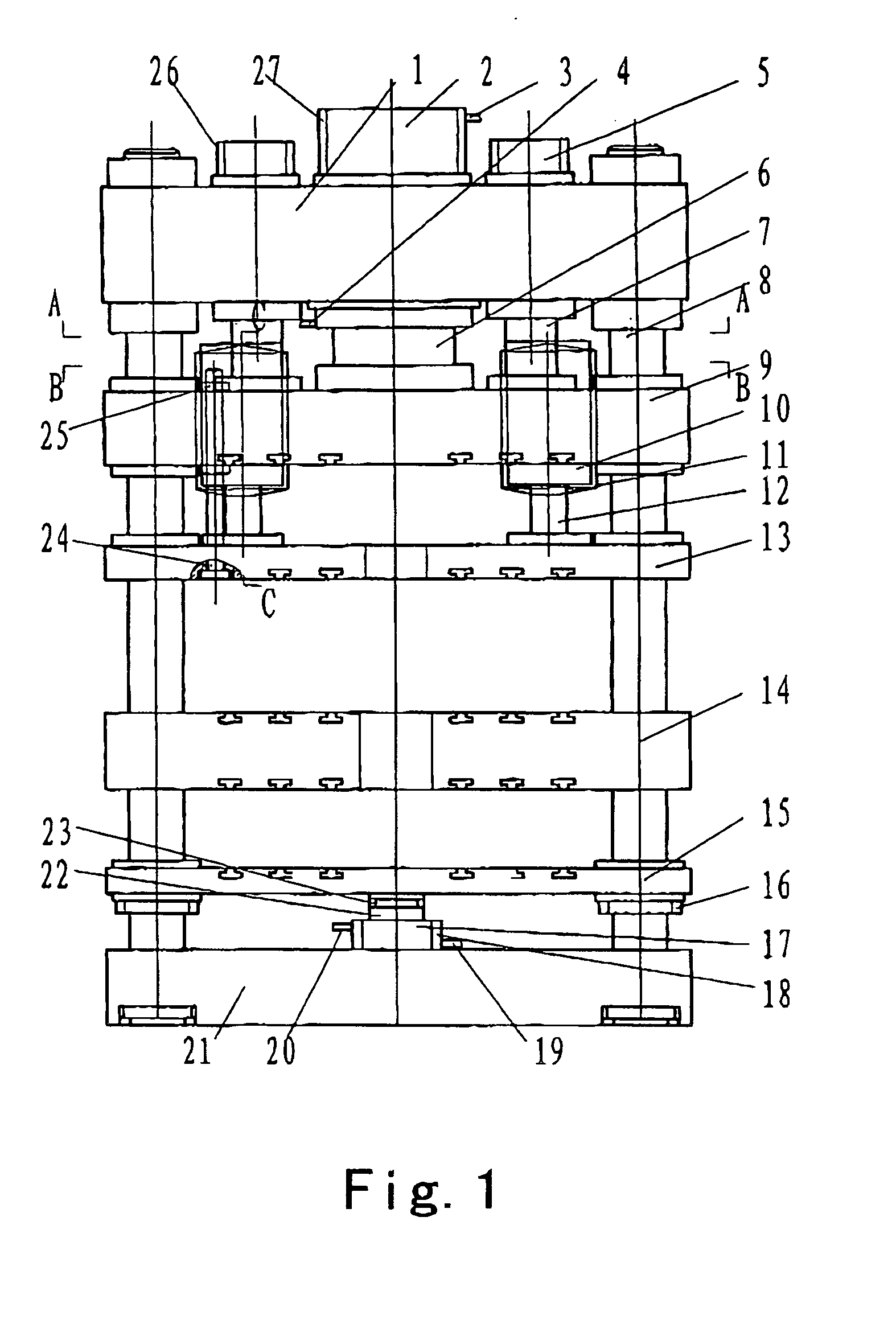

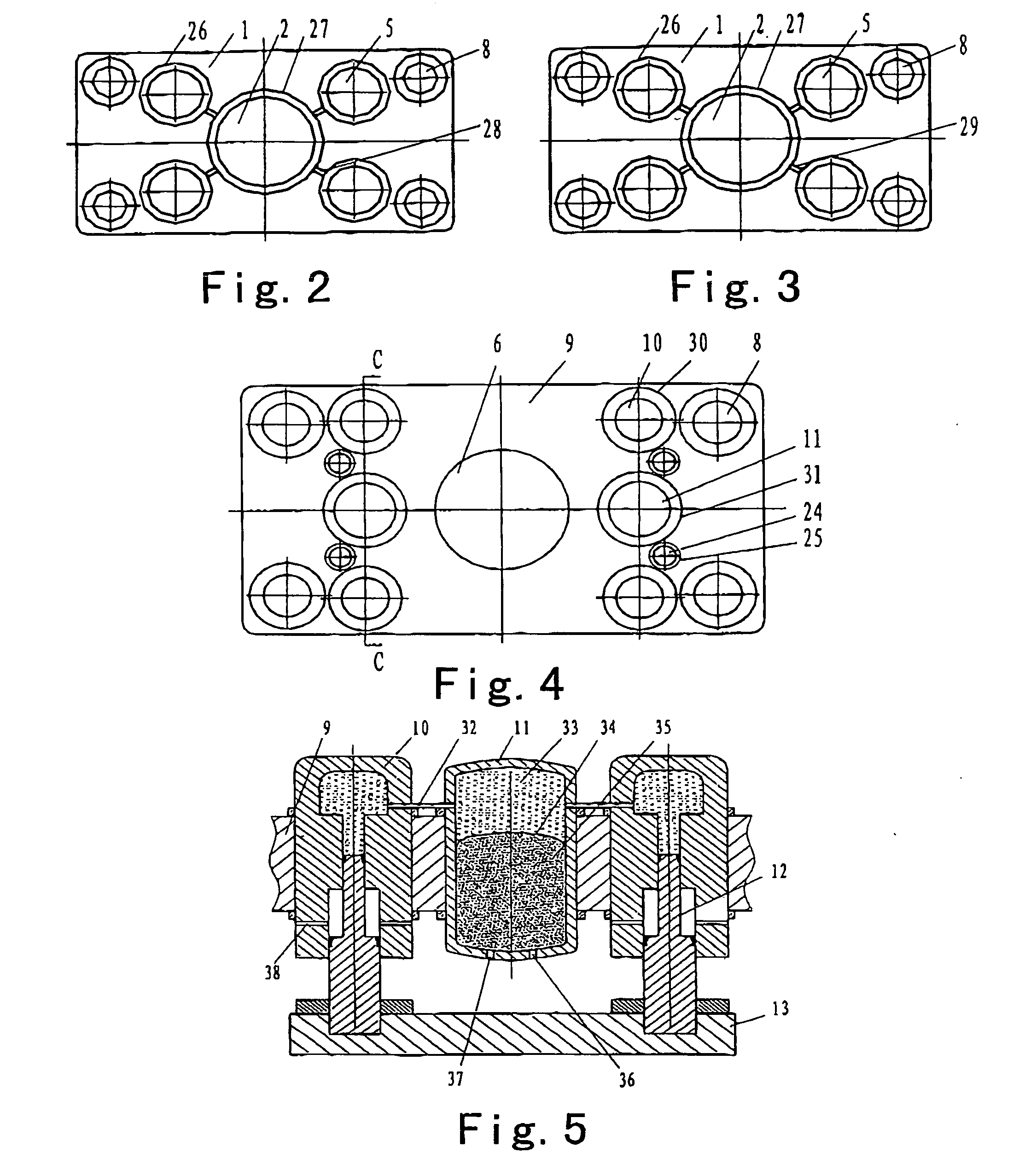

InactiveCN1559792AInnovative designSimple structureForging press drivesPress ramMarine engineeringMaster cylinder

An adjustable hydraulic press with movable upper and lower units is composed of vertical columns, upper transverse beam, primary slide block, the slide block for pressing edge, bench, floating bench, lower transverse beam, the primary and secondary cylinders fixed to upper transverse beam, and a push-up cylinder fixed to lower transverse beam for driving said floating bench.

Owner:JILIN UNIV

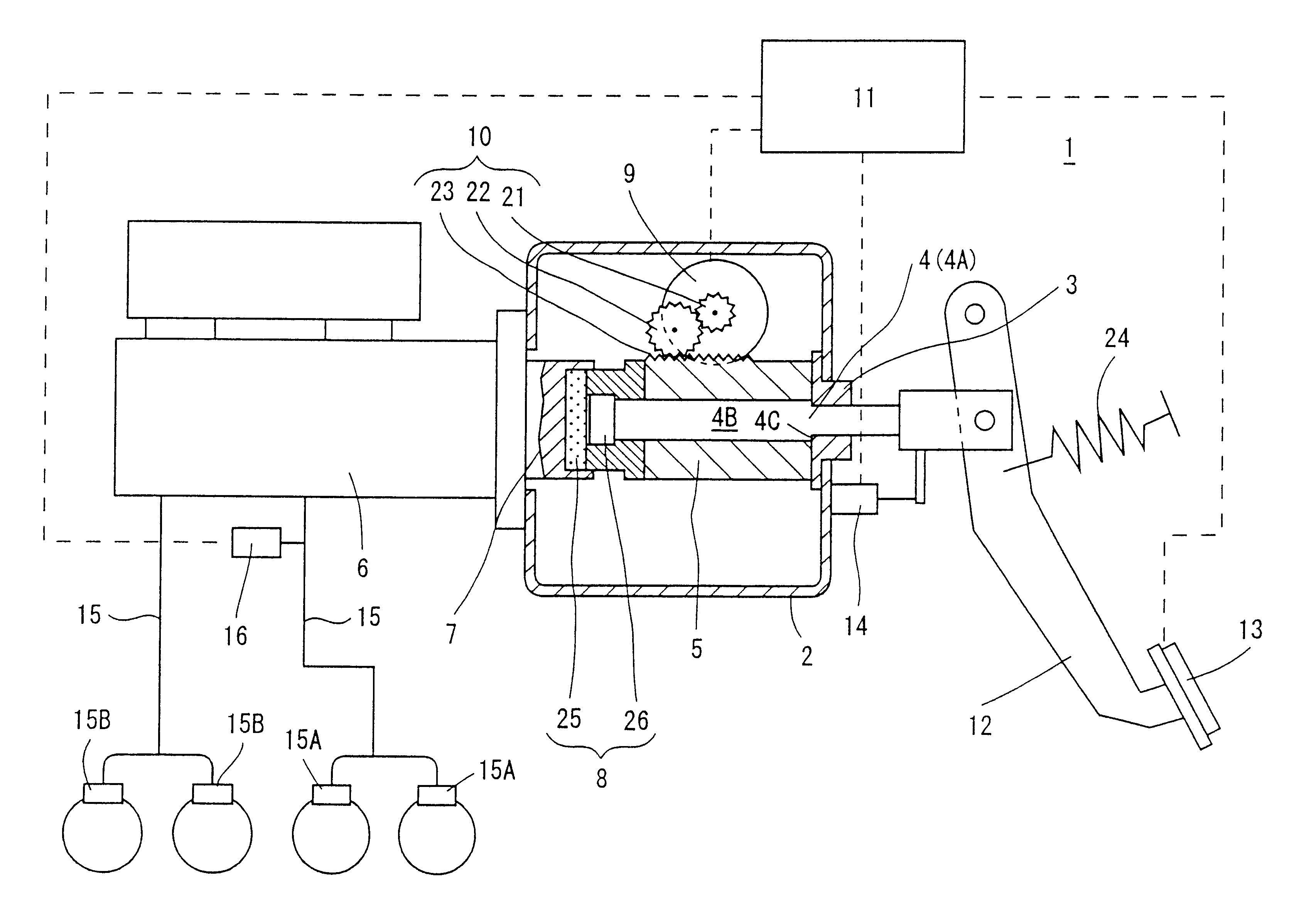

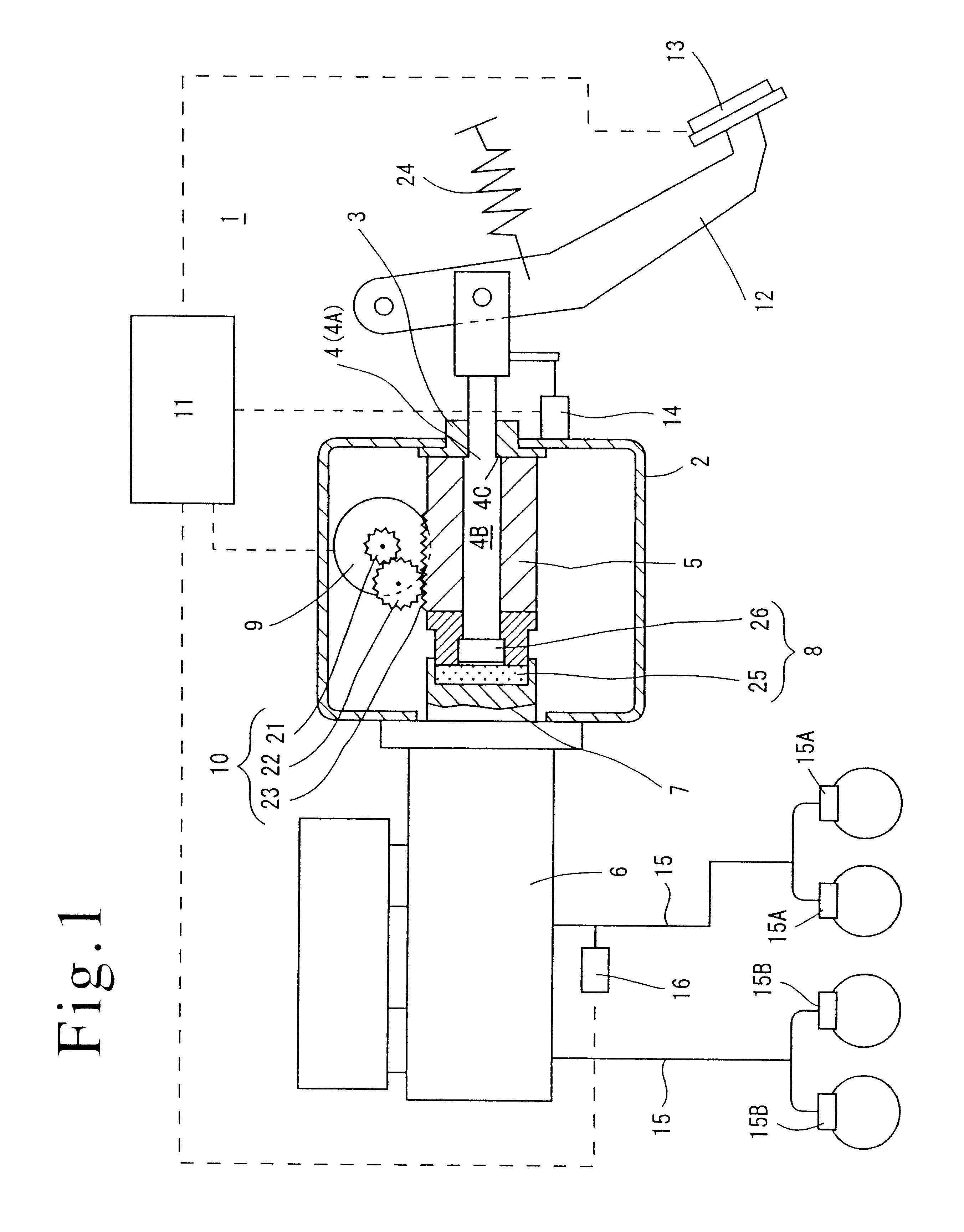

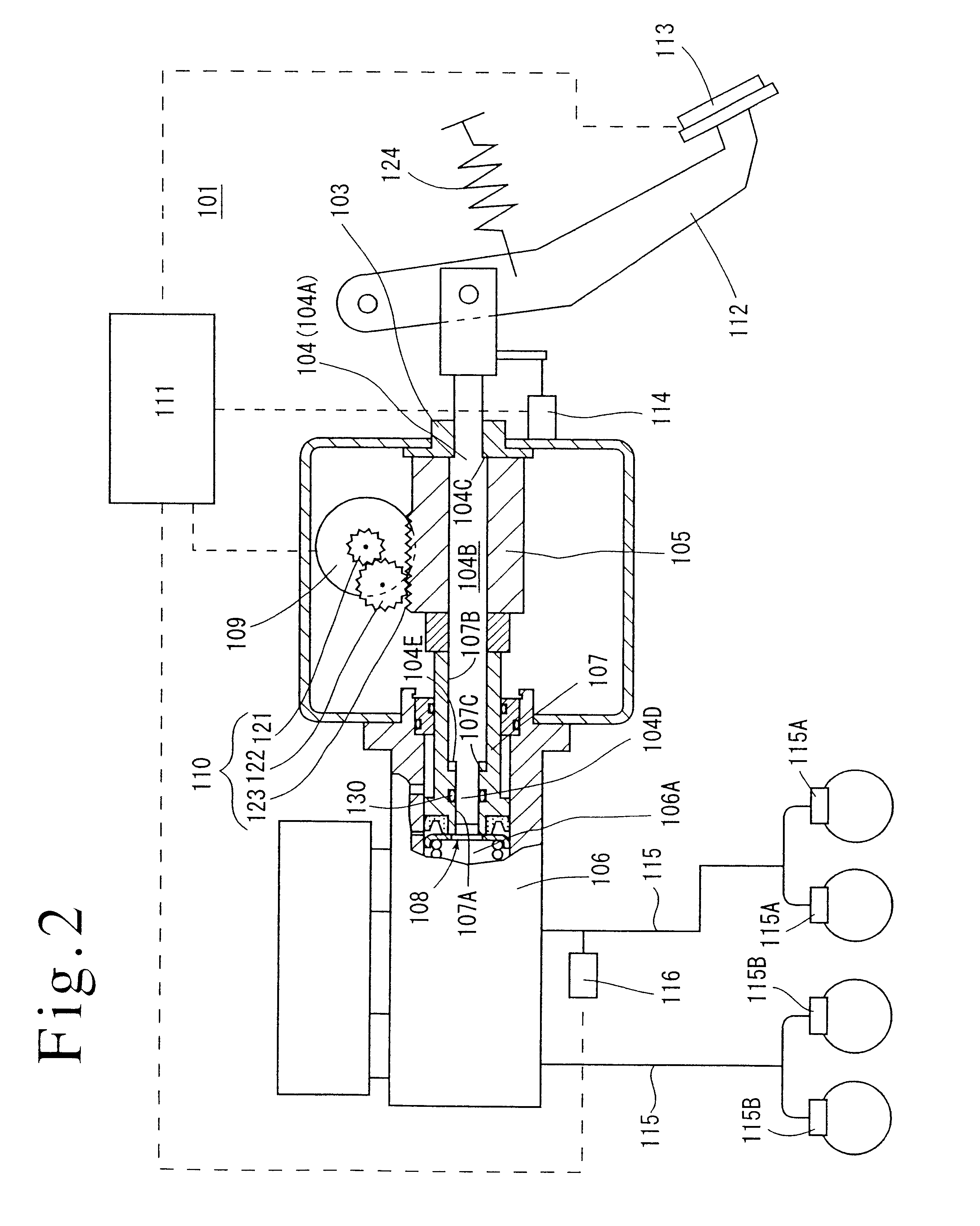

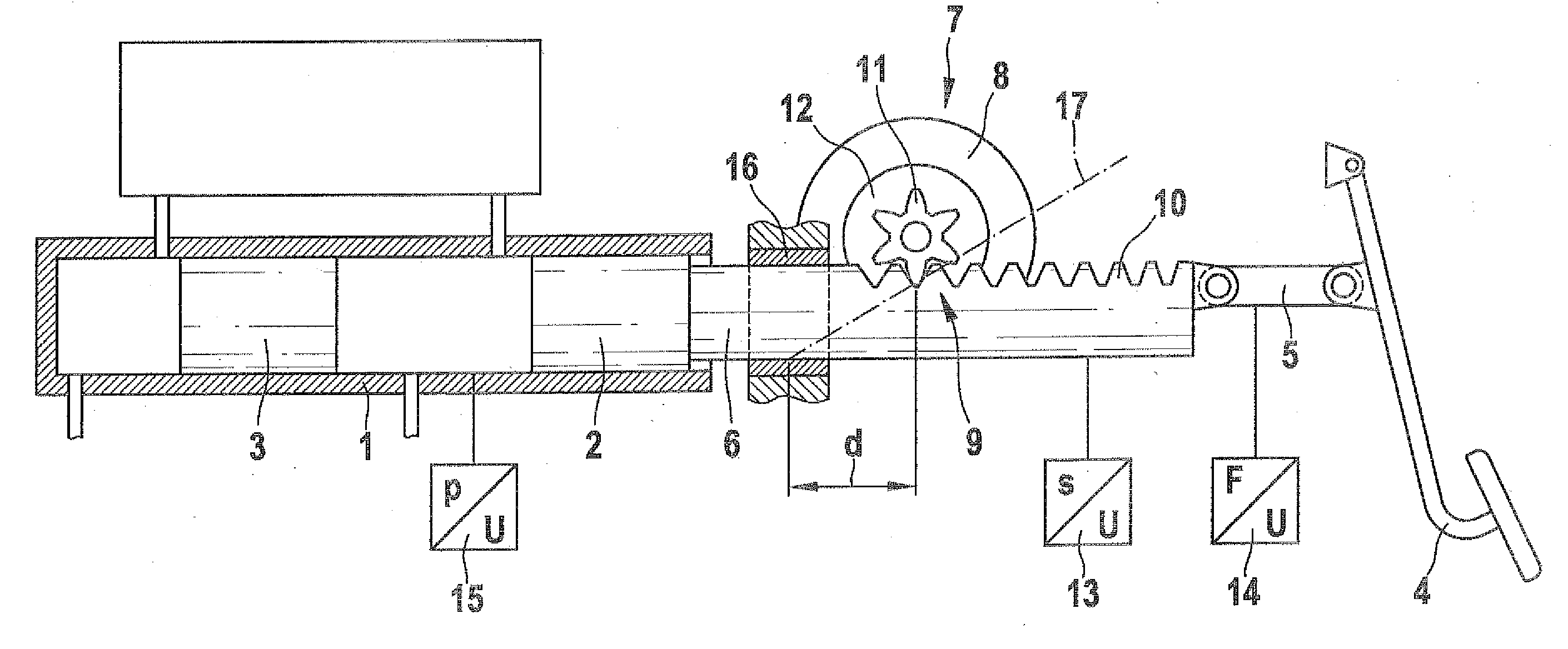

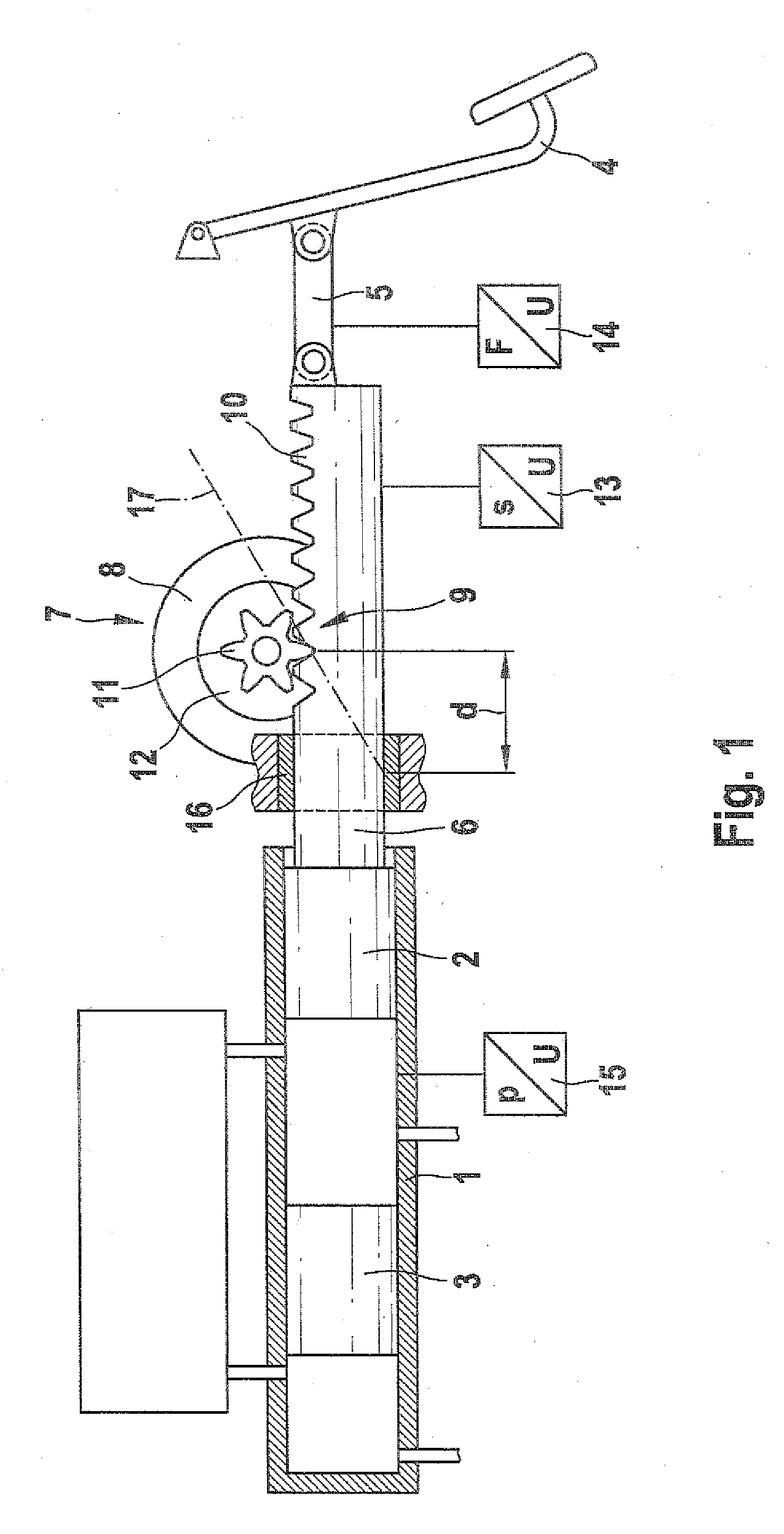

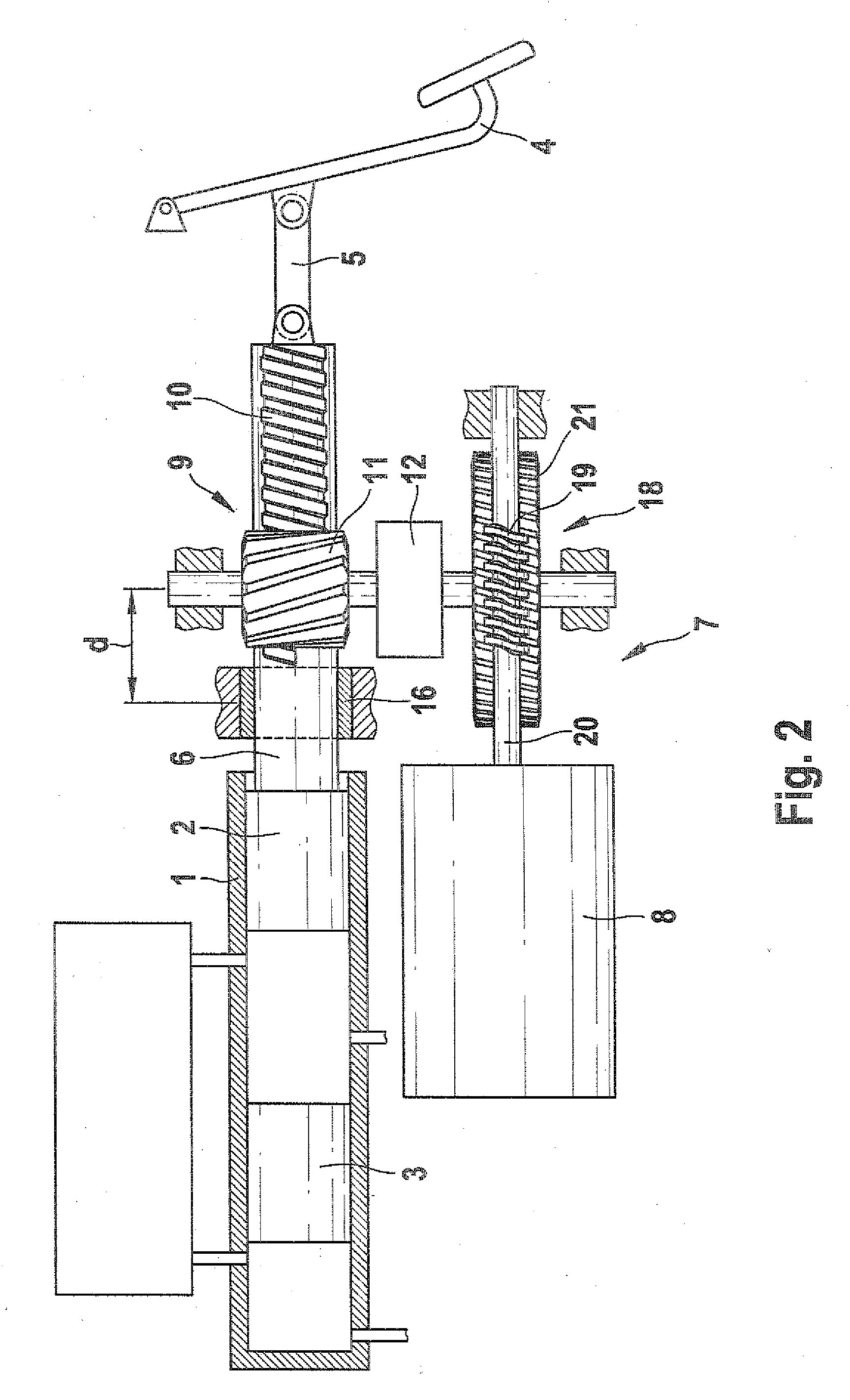

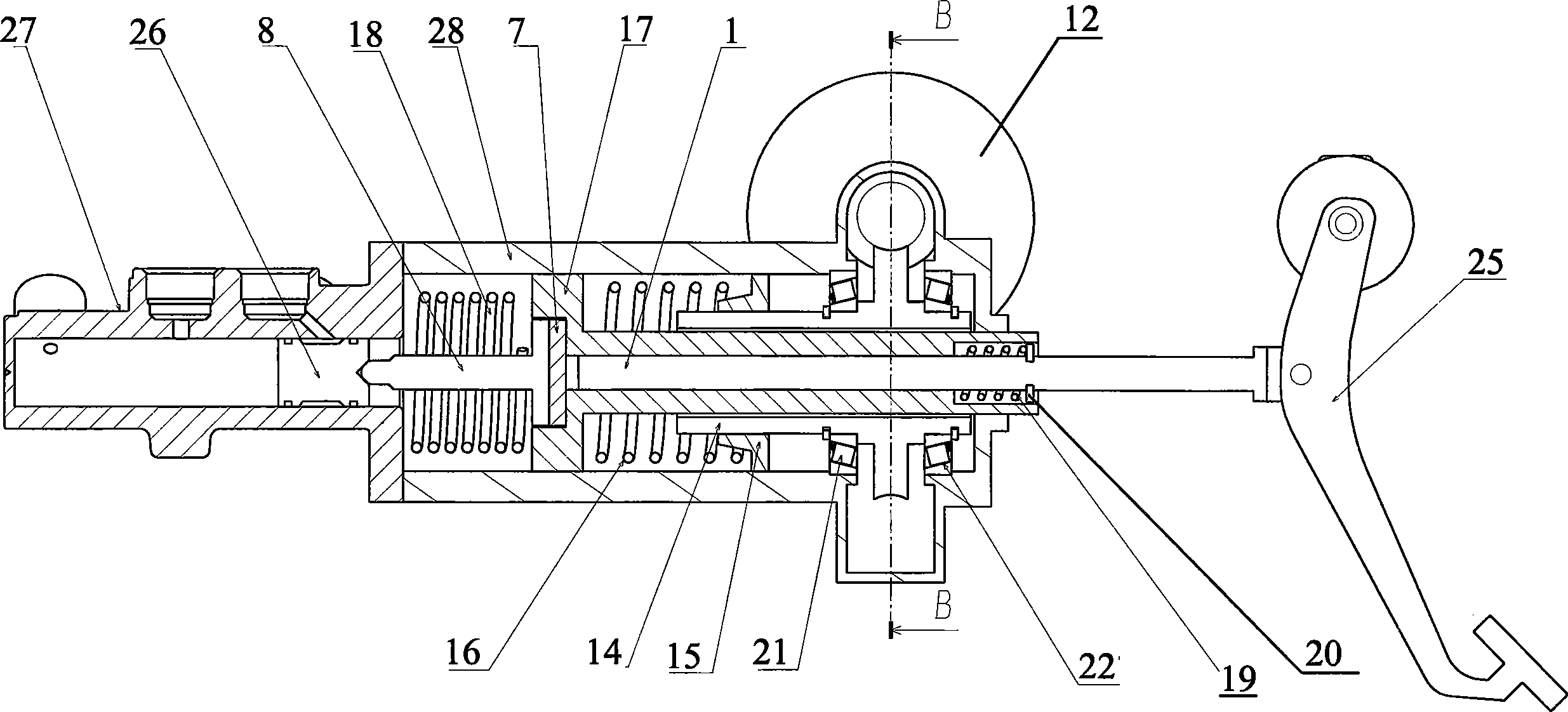

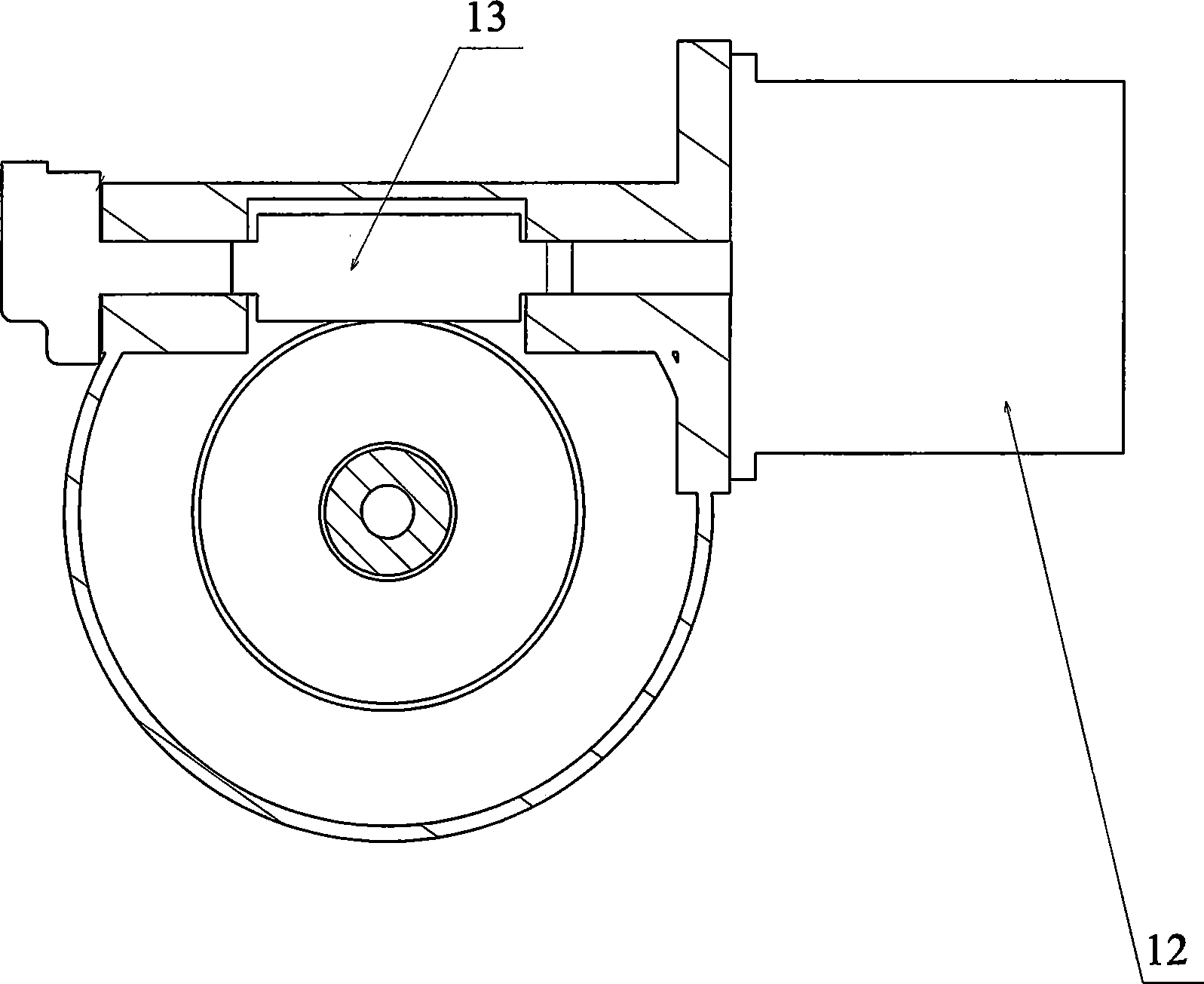

Electrically driven brake booster

InactiveUS6634724B2Reduce weightEasy constructionServomotor componentsRotary clutchesLinear motionMaster cylinder

An electrically driven brake booster (1) includes an input member (4) disposed in operative association with a brake pedal (12), an output member (5) disposed in operative association with the master cylinder (6), and drive transmitting device (10) for translating a rotating motion of a motor (9) into a linear motion to be transmitted to the output member (5). The drive transmitting device (10) comprises a rack (23) formed on the output member (5), and pinions (21, 22) disposed in operative association with the motor (9) and in meshing engagement with the rack (23). Also, reaction transmitting device (8) which transmits a brake reaction to the input member (4) and the output member (5) at a given proportion is provided. In comparison to conventional drive transmitting device, the drive transmitting device (10) of the present invention has a simple construction, a reduced weight and a better transmission efficiency. The provision of reaction transmitting device allows a correct brake control to be achieved on the basis of a brake reaction.

Owner:DIESEL KIKI CO LTD

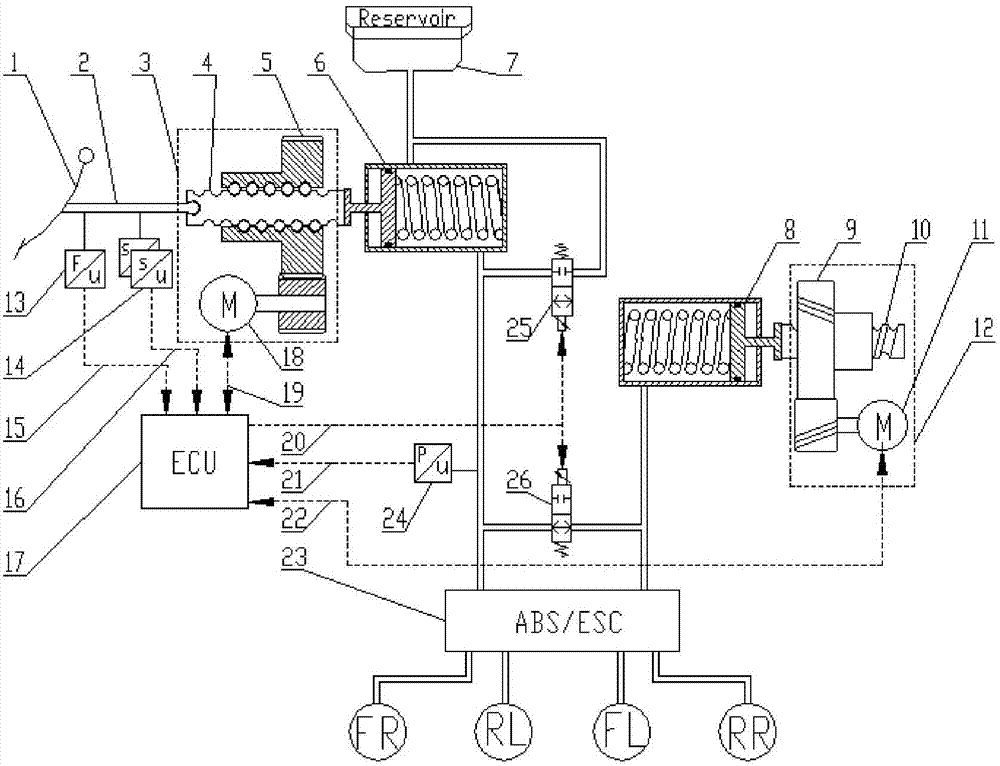

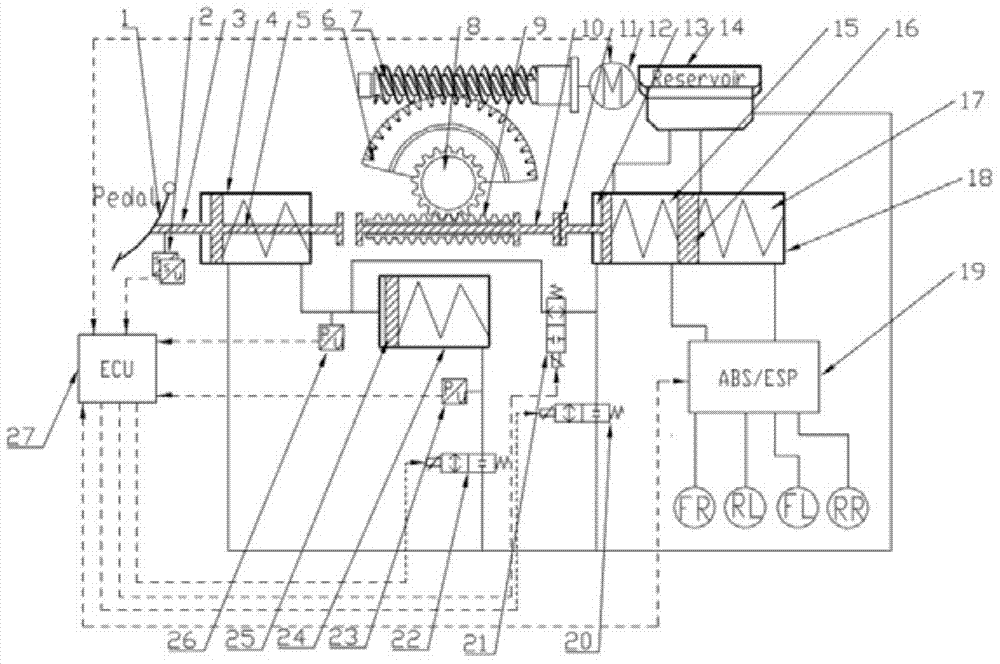

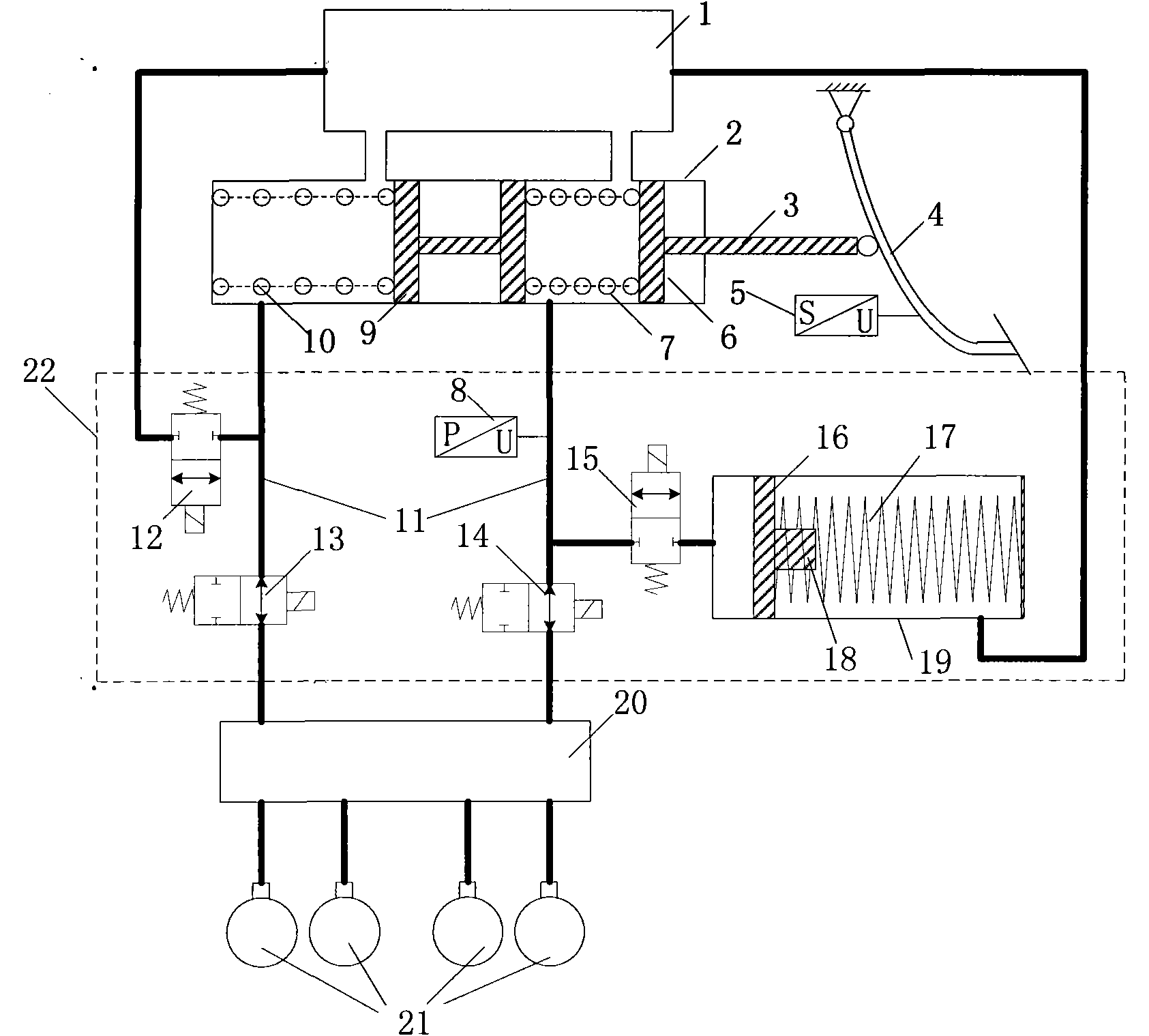

Double-motor driving type electronic hydraulic brake system capable of actively simulating pedal feeling

InactiveCN104760586AMeet braking requirementsImprove securityBraking action transmissionEnergy recoveryElectric control

A double-motor driving type electronic hydraulic brake system capable of actively simulating pedal feeling comprises a brake pedal, a fluid storage tank used for storing brake fluid, a pedal displacement sensor, a pedal force sensor, a hydraulic force sensor, an electronic control unit, an electromagnetic valve, an electronic stability control module, a brake master cylinder and a secondary master cylinder. An electric control linear movement module comprises a rotating motor and a speed reduction and moment increasing mechanism which converts the rotating movement of the motor into linear movement to achieve the active control over system hydraulic brake force and pedal force. The pedal force of a driver can be fully used for reducing pressure. While the active control over the pedal force is achieved, a pedal force simulator of a complex structure is omitted, the feeling of a brake pedal is guaranteed, and the accurate automobile brake condition is fed back to the driver. The active control over the hydraulic force is achieved, and the brake requirement for automatic driving vehicles is met; maximum braking energy recovery is achieved, control is precise, and the response speed is high; double-loop braking is achieved, failure protection is considered thoroughly, and the safety is good.

Owner:TONGJI UNIV

Motor-driven electronic hydraulic braking system

ActiveCN103754210AQuick responsePrecise control of hydraulic braking forceBraking action transmissionSystems designLinear control

A motor-driven electronic hydraulic braking system comprises a brake pedal, a pedal displacement sensor, a secondary master cylinder, a pedal simulator pressure sensor, a pedal simulator, pedal simulator solenoid valves, a push rod, an electrically-controlled linear movement module, a brake master cylinder and an ABS / ESP (anti-skid brake system / electronic stability program) module. The electrically-controlled linear movement module drives the push rod to move by means of driving a movement regulating mechanism through a motor, the motor is controlled through a displacement signal, and linear control on braking pressure is realized. The brake master cylinder passes the ABS / ESP module to be hydraulically coupled with vehicle wheel brakes. The ABS / ESP module can passively regulate pressure transmitted from the master cylinder to the wheel brakes, and can actively regulate the pressure of the brake of each wheel. The motor-driven electronic hydraulic braking system has the advantages of rapid response, accurate control on brake fluid pressure, capabilities of well simulating brake pedal feeling of a driver and maximally recovering braking energy, and the like; meanwhile, the system is designed with a dual failure protection mode, thereby having high safety and reliability.

Owner:上海同驭汽车科技有限公司

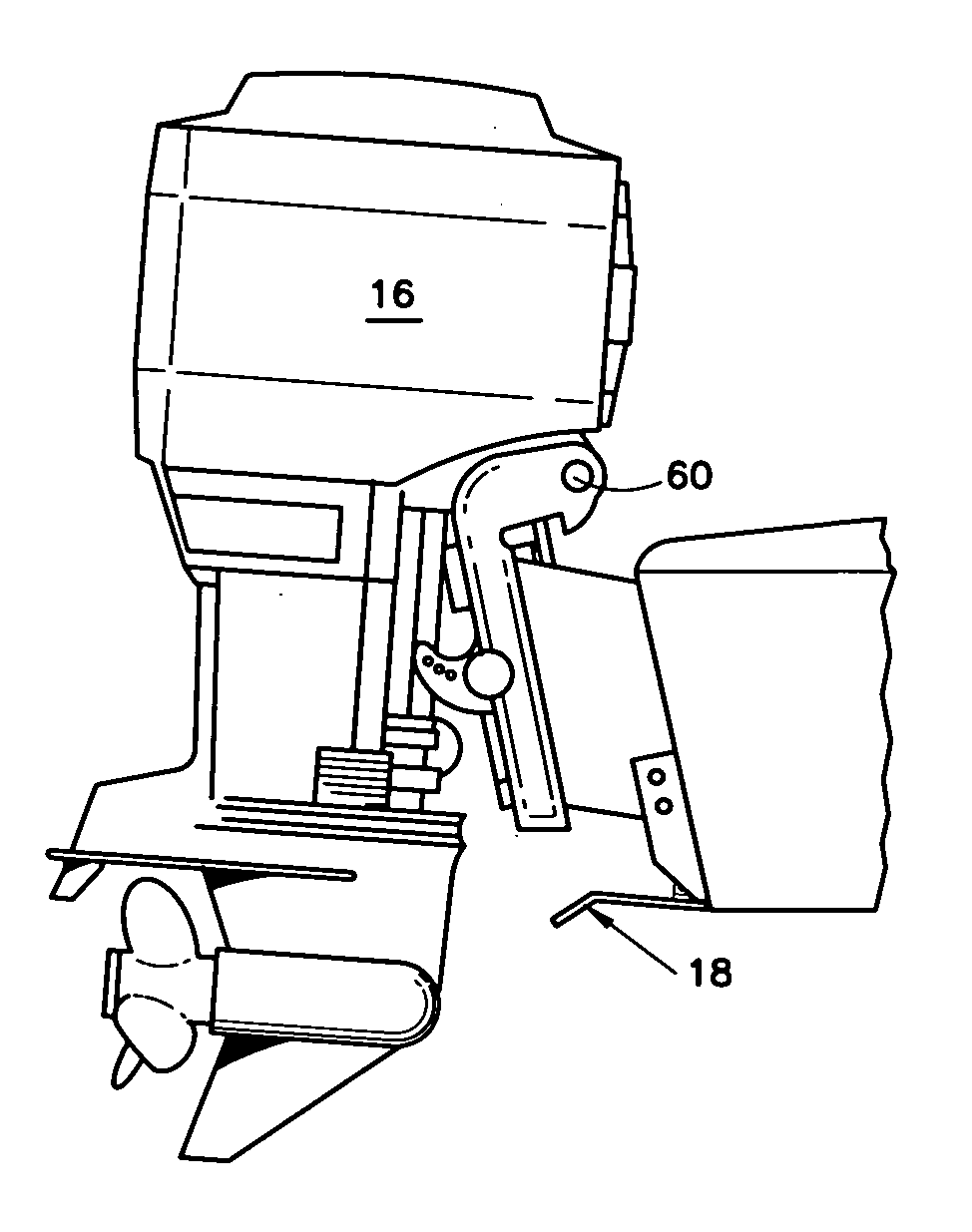

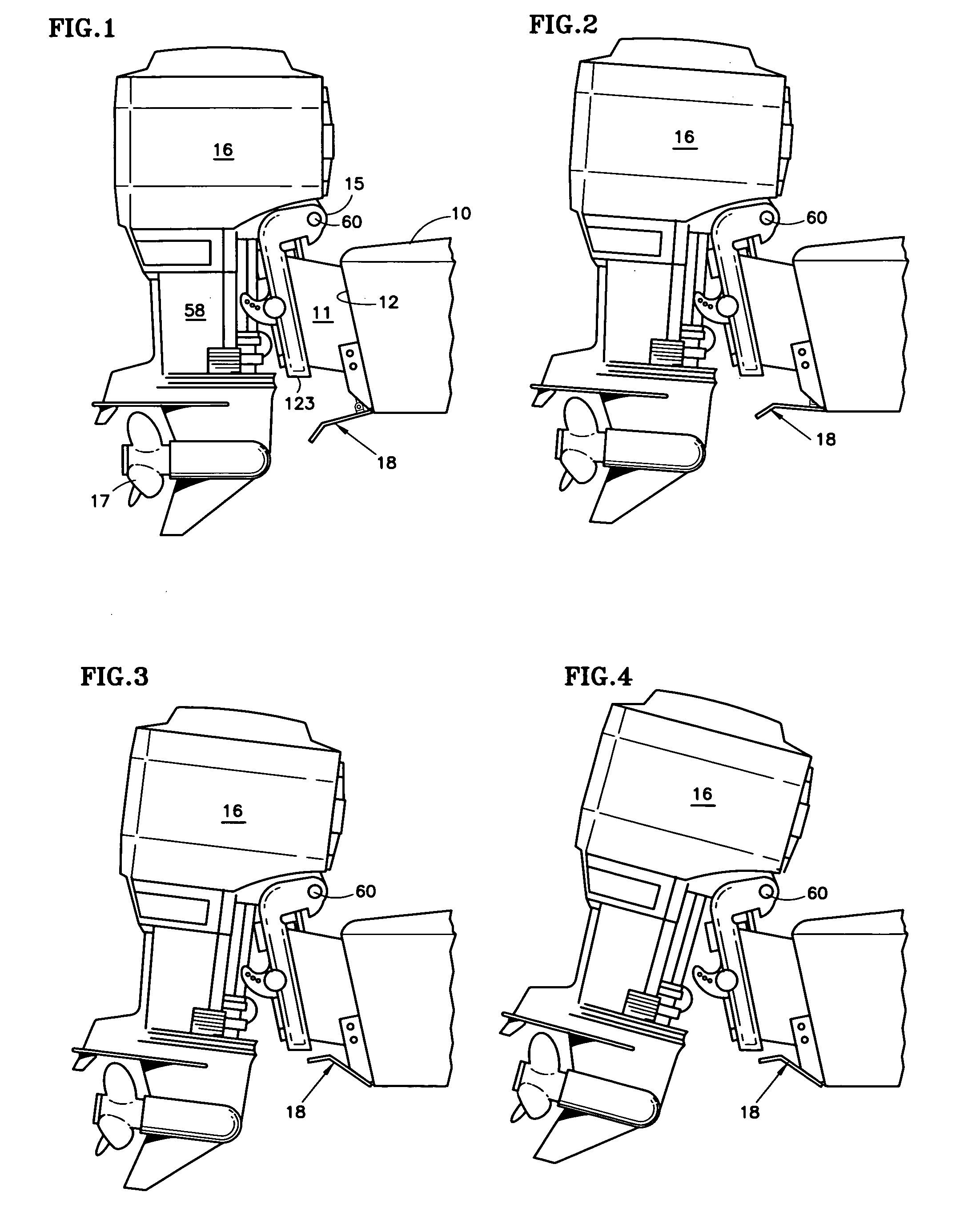

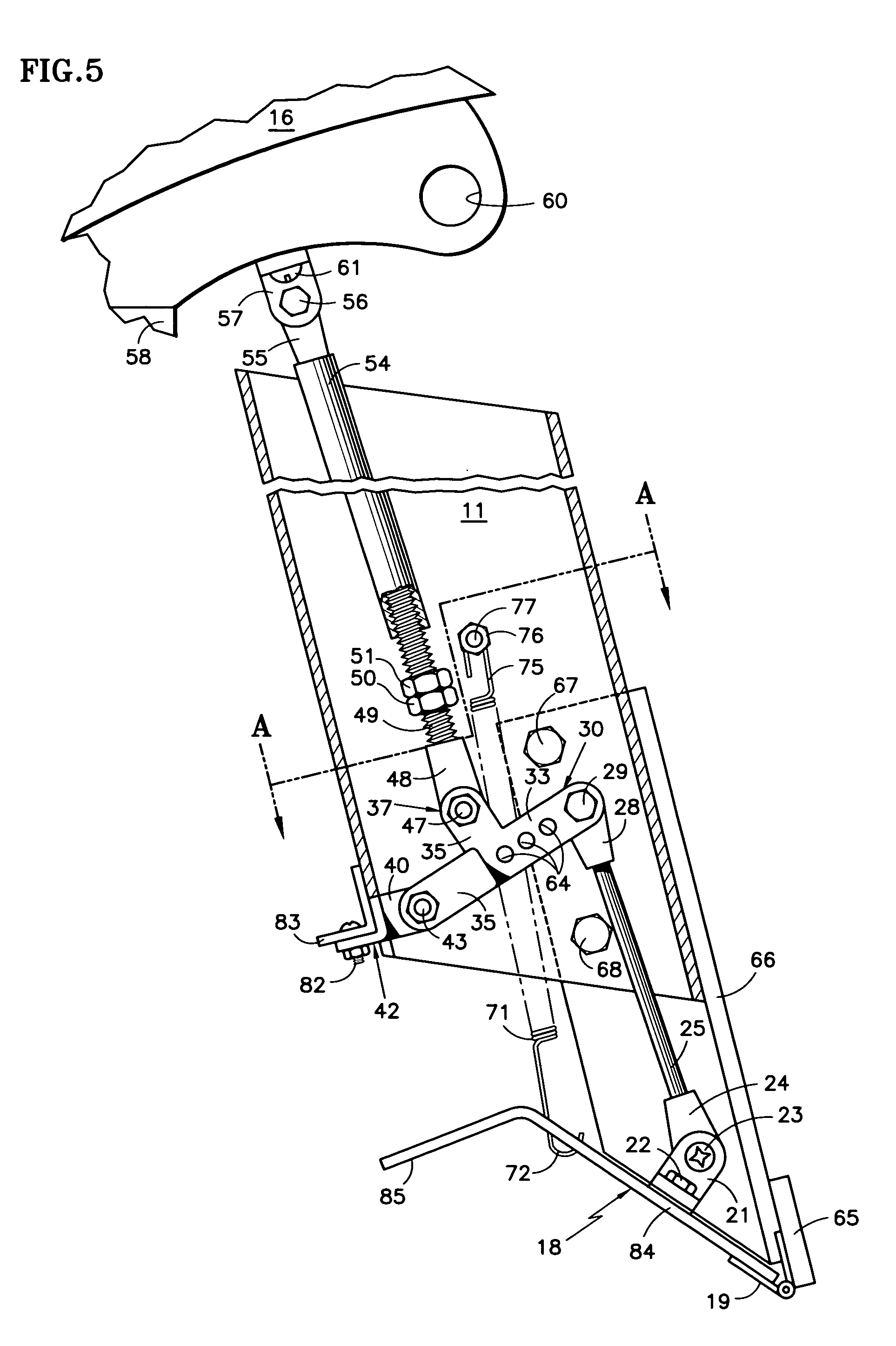

Automatic trim for power boats

InactiveUS6923136B1No resistanceEasy to adaptPropulsion power plantsOutboard propulsion unitsTrim tabMaster cylinder

A trim tab (18, 204) hinged (19) at the bottom edge of a boat transom (12, 179) is rotated into a position below the boat when the drive (58, 186) is in a lowest-most trim position, and is raised up, when the drive is above a selected pickup trim position. A push tube (58) connected to the motor (16) operates a push rod (49) and a trim tab (18). A push bar (96, 97) is moved by the drive, causing pieces (104, 105) to rotate trim tabs (18a). A fluidic slave cylinder (142) is operated by a master cylinder (134) or by a pump (148) responding to a position detector (150). Levers (164, 167) may be connected by a cable (155). A hydraulic master cylinder (195) is disposed on a part (186) of an outdrive that rotates for trim, its cylinder rod (200) contacting a fixed part (184), driving fluid to a slave cylinder (201) mounted on a fixed part (183) with its piston rod (202) moving a trim tab (204).

Owner:FOUND FOR ADVANCEMENT OF INT SCI

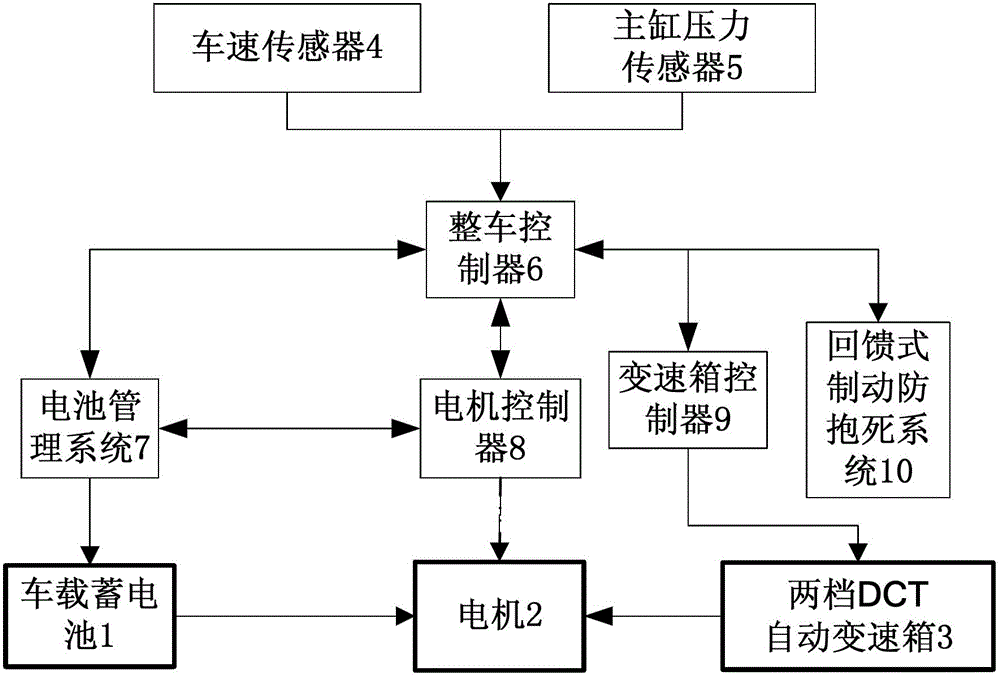

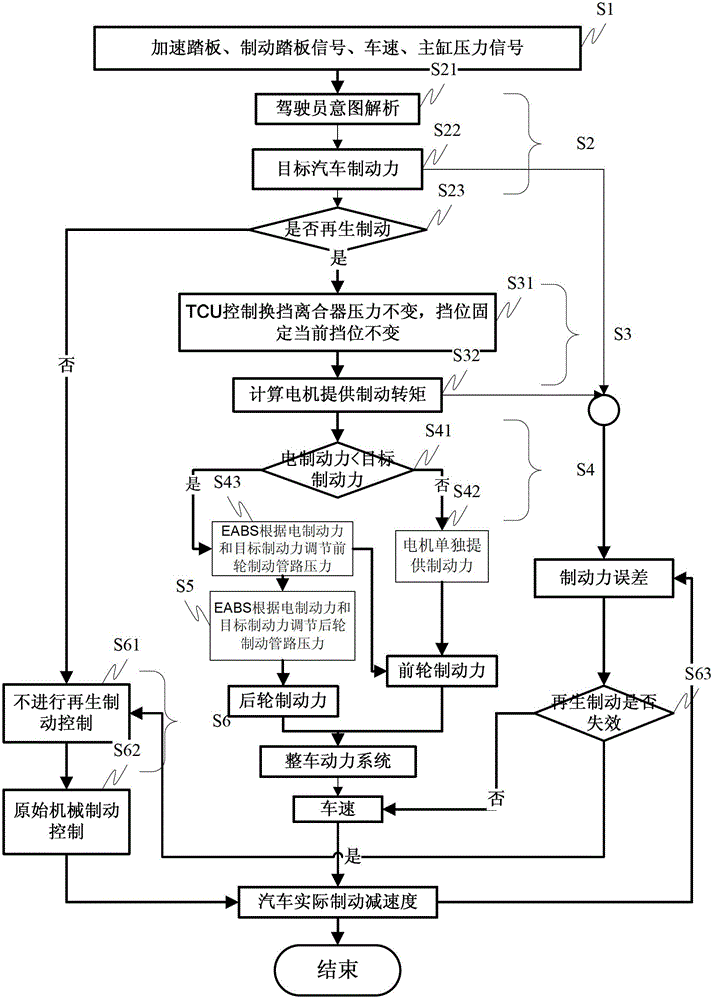

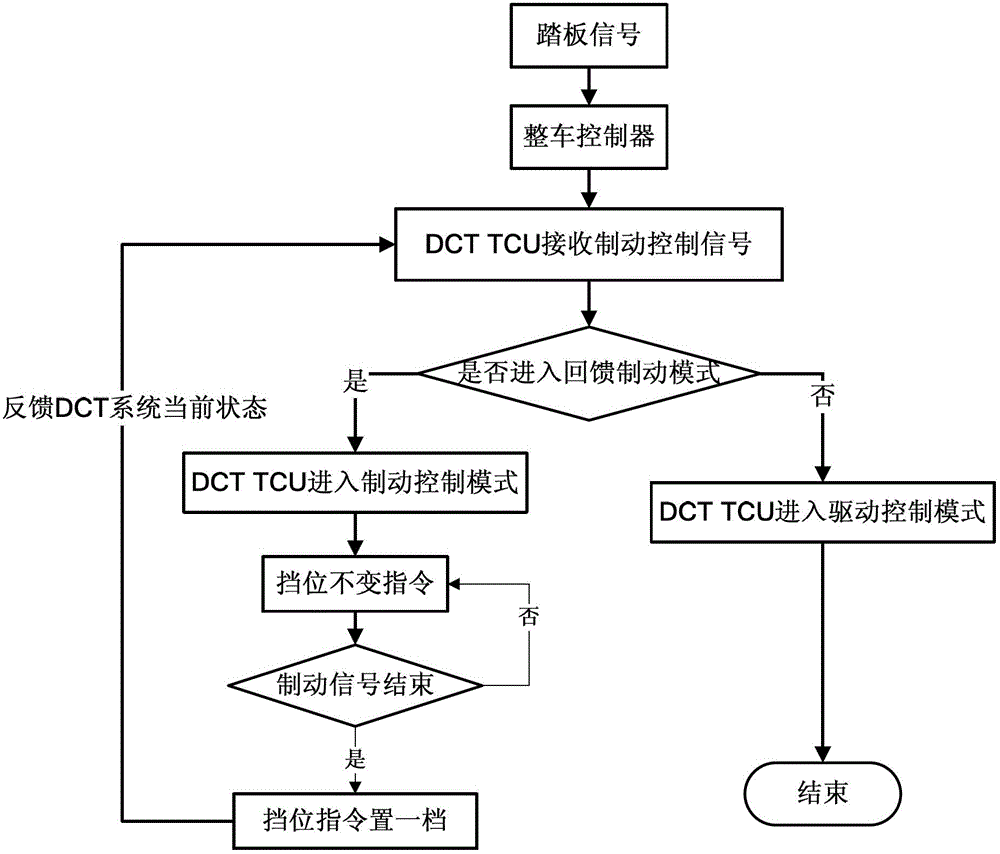

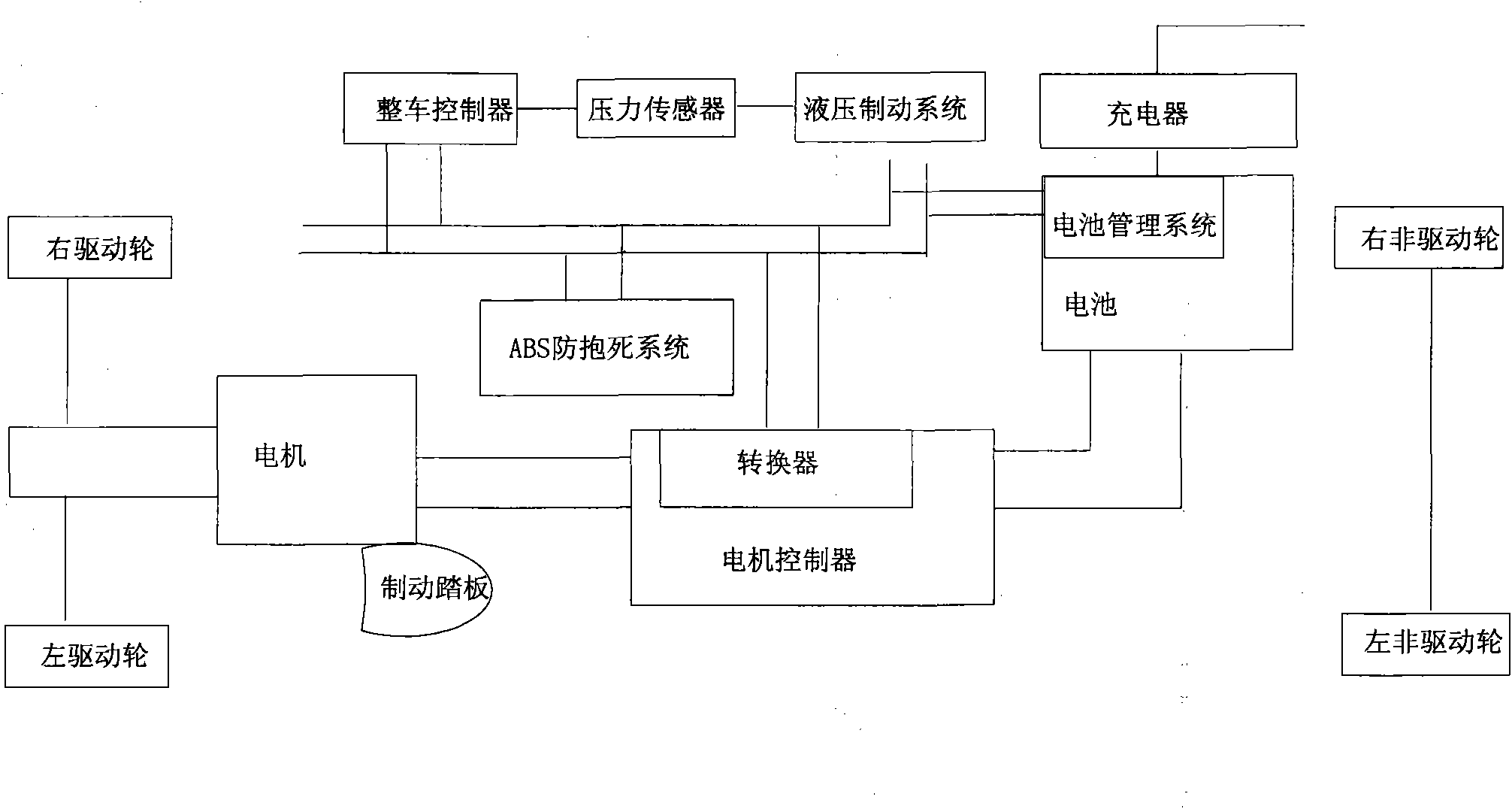

Pure electric vehicle braking energy recovery control system and method based on DCT (Data Communication Terminal)

InactiveCN102717714AGood progressive feelingGood brake force distributionElectrodynamic brake systemsElectric vehicle charging technologyElectrical batteryControl system

The invention discloses a pure electric vehicle braking energy recovery control system and method based on a DCT (Data Communication Terminal), relating to the technical field of electric vehicles. The control system comprises a vehicle-mounted storage battery, a motor, a two-gear DCT automatic gearbox, a vehicle speed sensor, a master cylinder pressure sensor, a vehicle control unit, a battery management system, a motor controller, a gearbox controller and a feedback type brake anti-lock system, wherein the vehicle-mounted storage battery supplies power for the motor, and the motor is mechanically connected with the DCT automatic gearbox; and the vehicle control unit, the battery management system, the motor controller, the gearbox controller, the feedback type brake anti-lock system, the vehicle speed sensor and the master cylinder pressure sensor carry out information communication and instruction issue through a network and hard wires. The invention also discloses the pure electric vehicle braking energy recovery control method based on the DCT. The energy utilization and the driving mileage of the vehicles are increased.

Owner:BEIJING ELECTRIC VEHICLE

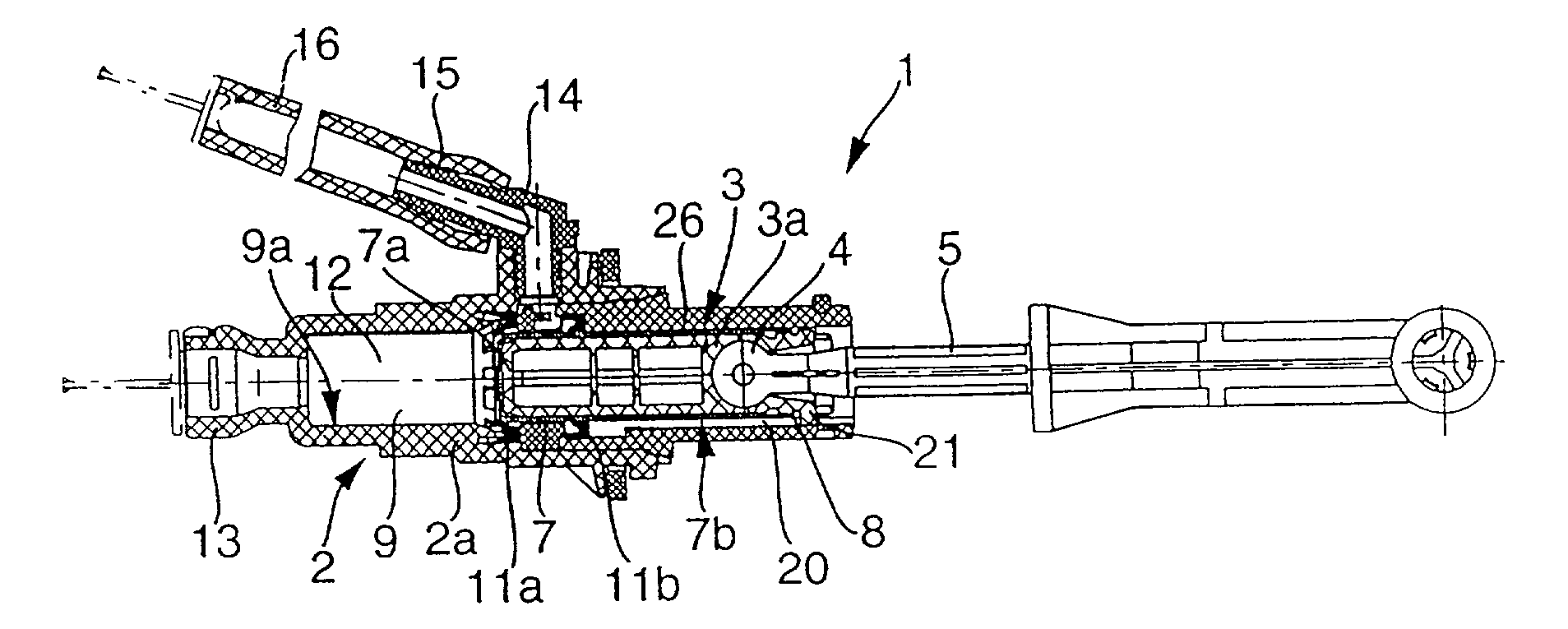

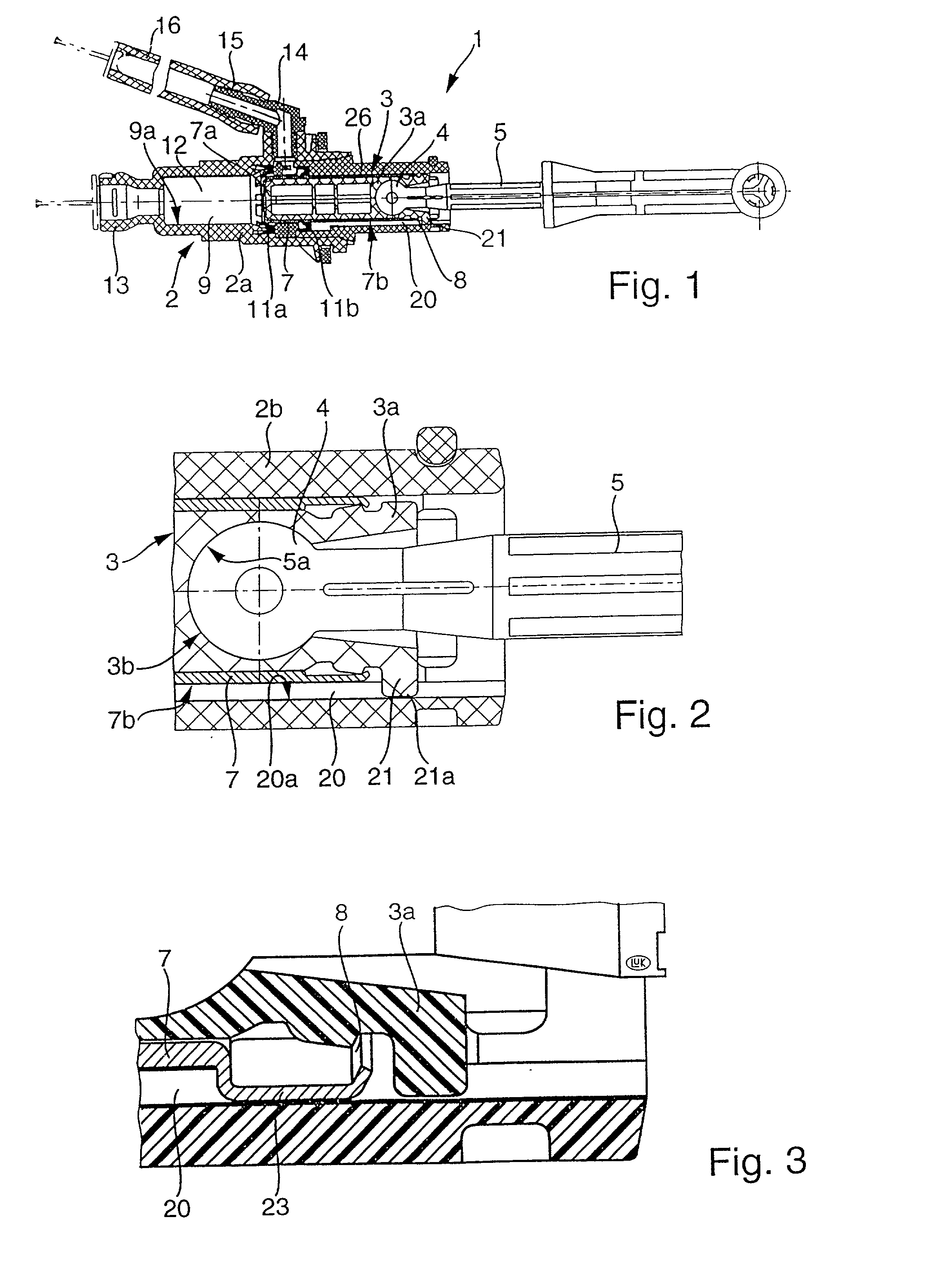

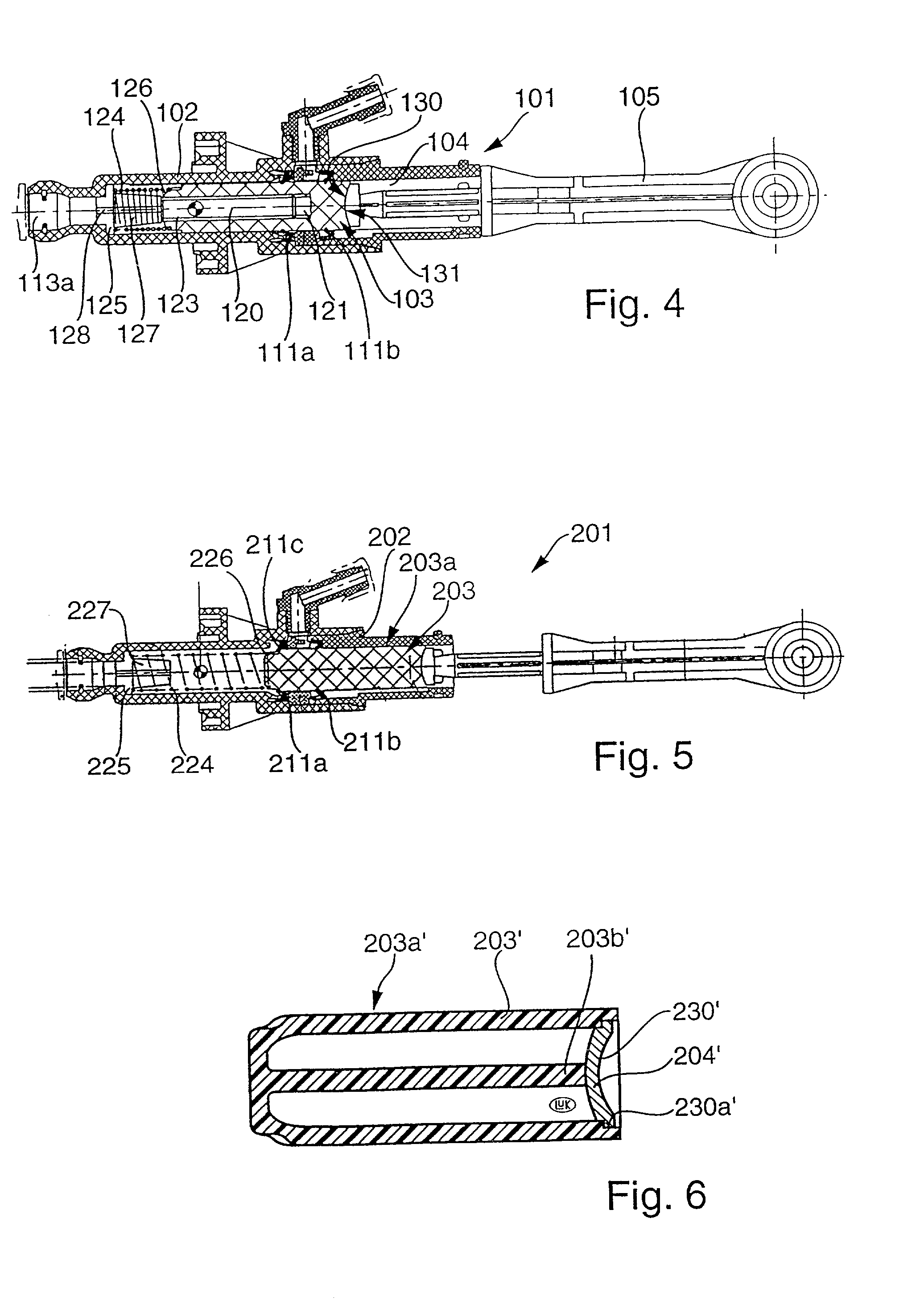

Master cylinder for use in power trains of motor vehicles

InactiveUS20020116924A1Satisfactory operationAvoid spreadingPiston ringsRotary clutchesMaster cylinderControl theory

A master cylinder for use in the power train of a motor vehicle to actuate the brakes or the friction clutch is designed to avoid the generation of screeching noise and / or the transmission of stray movements to the piston rod in response to shifting of the piston relative to the housing and relative to the sealing element(s) between the piston and the housing. This can be accomplished by causing the piston to turn relative to the housing and the sealing element(s) during axial movement in the housing and / or by installing one or more dampers between the piston and the housing and / or between the piston and the piston rod. The dampers can constitute separately produced parts and / or specially configured and / or finished surfaces provided on the piston and contacting the housing and / or the sealing element(s). The invention also relates to improvements in the configuration and / or the material(s) of the piston.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

Brake System for Motor Vehicles. and Method for Operating the Brake System

A motor vehicle brake system actuated in brake-by-wire and fallback operating modes, having a brake master cylinder, brake circuits, a pressure medium storage vessel, a brake pedal, a separating valve for separating the brake circuit into a first section connected to the separating valve the master cylinder, and a second section connected to the separating valve and the wheel brakes. A first pressure provision device has a piston actuated by an actuator, a simulation device connected by a simulator release valve to the master cylinder for a pleasant brake pedal feel in the brake-by-wire operating mode. A first electronic control and regulating unit actuates the first pressure provision device, the separating valves and the simulator release valve. A second pressure provision device has a suction connector and a pressure connector per brake circuit being connected to the inlet of the separating valve.

Owner:CONTINENTAL TEVES AG & CO OHG

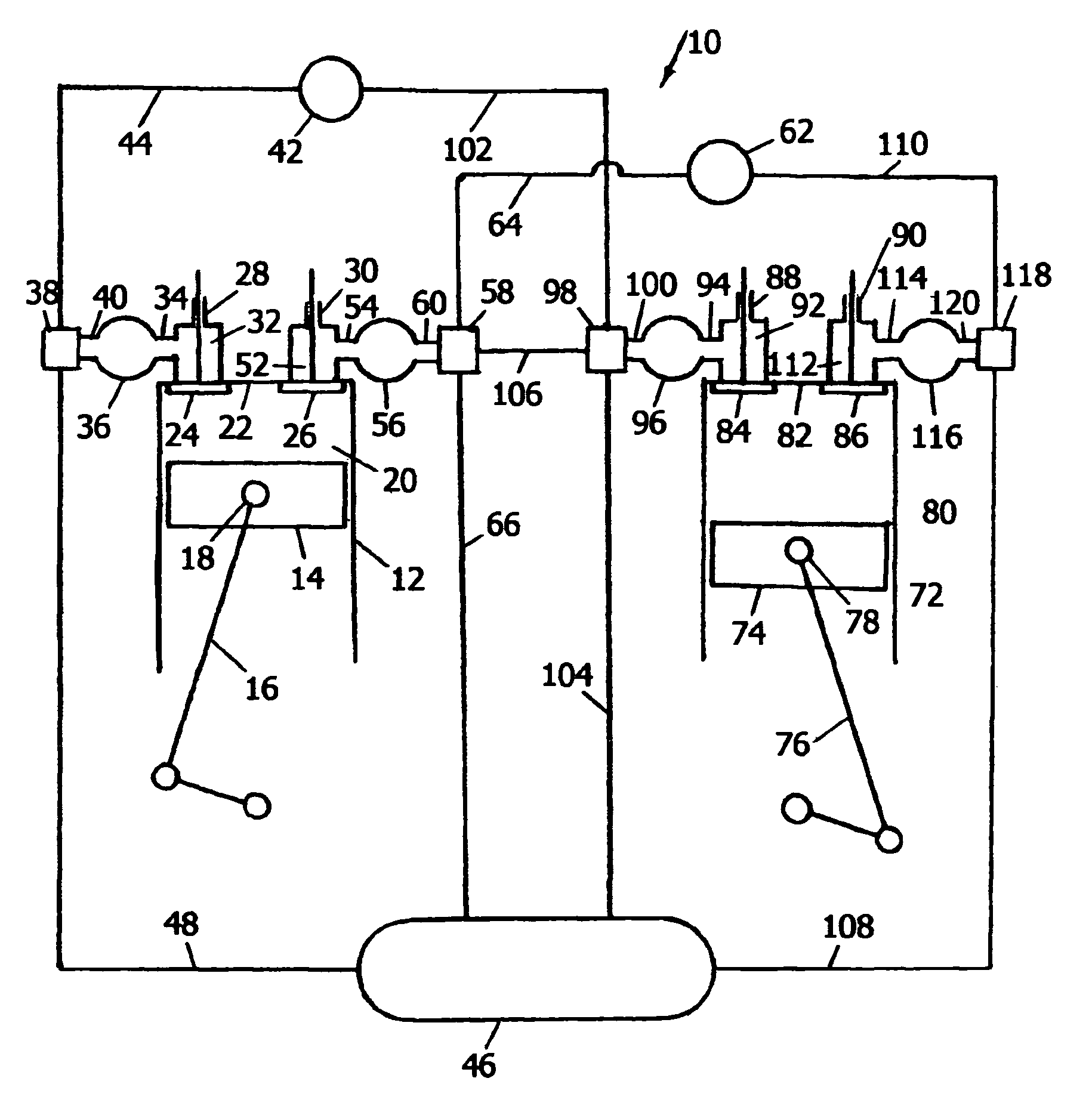

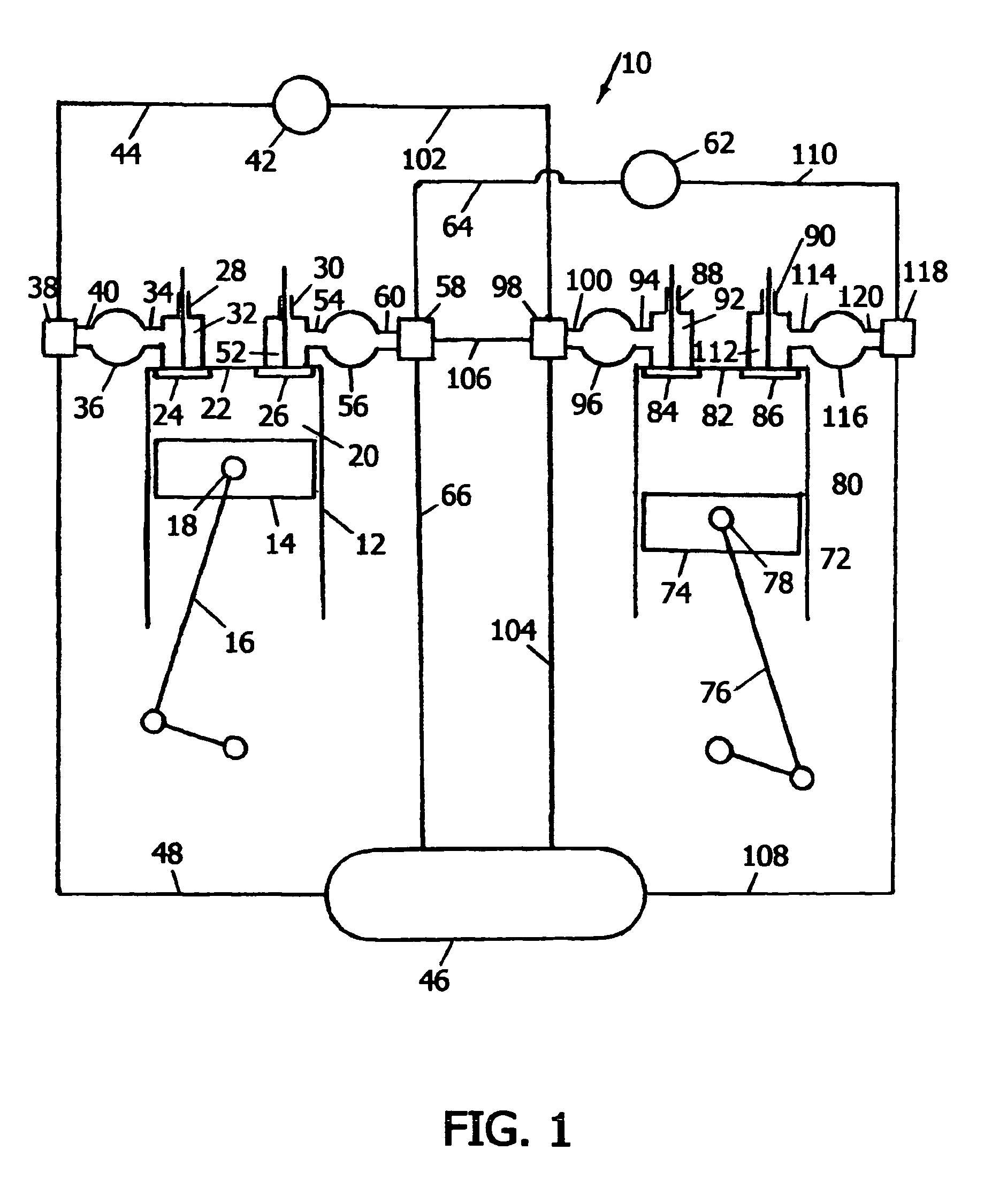

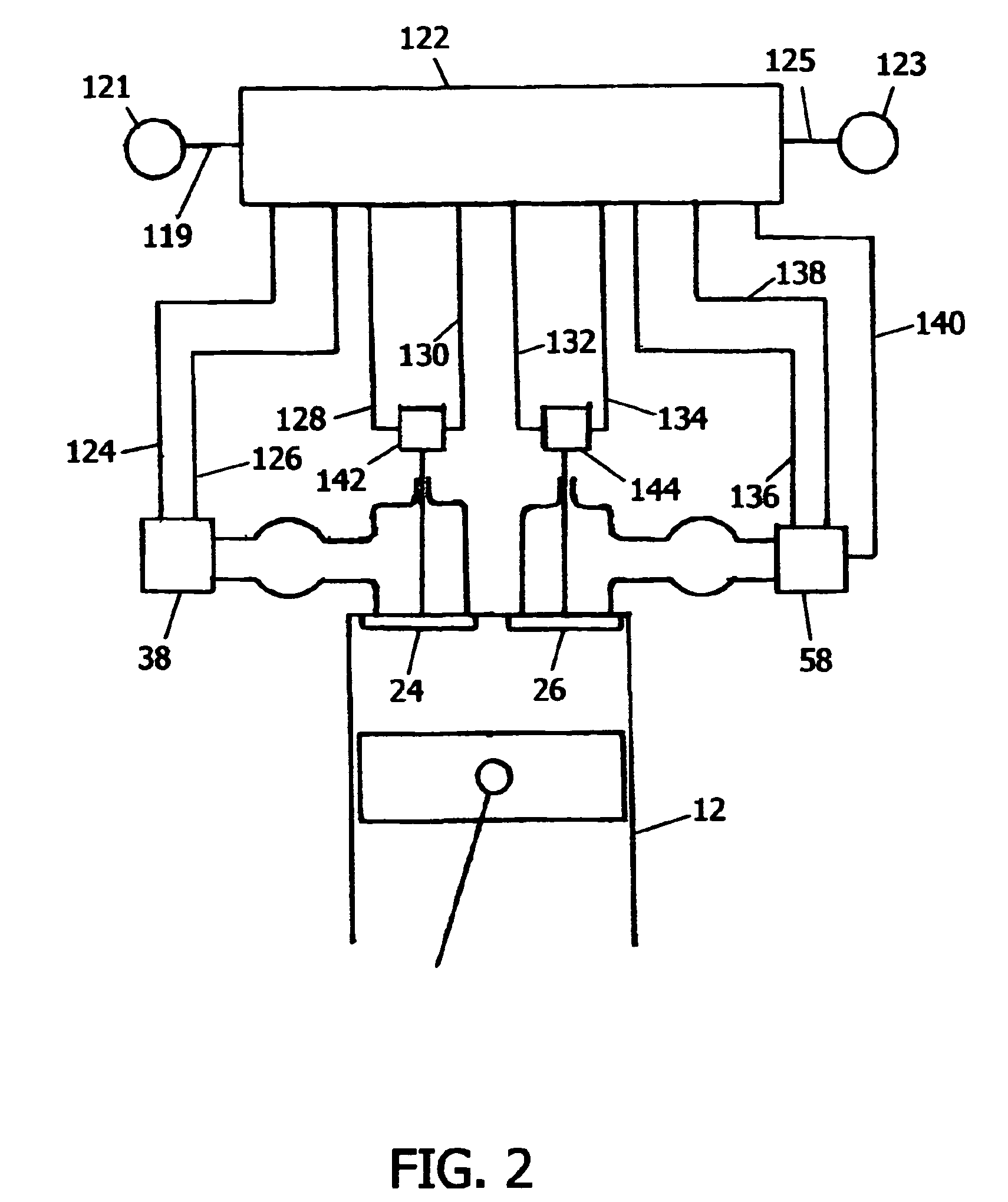

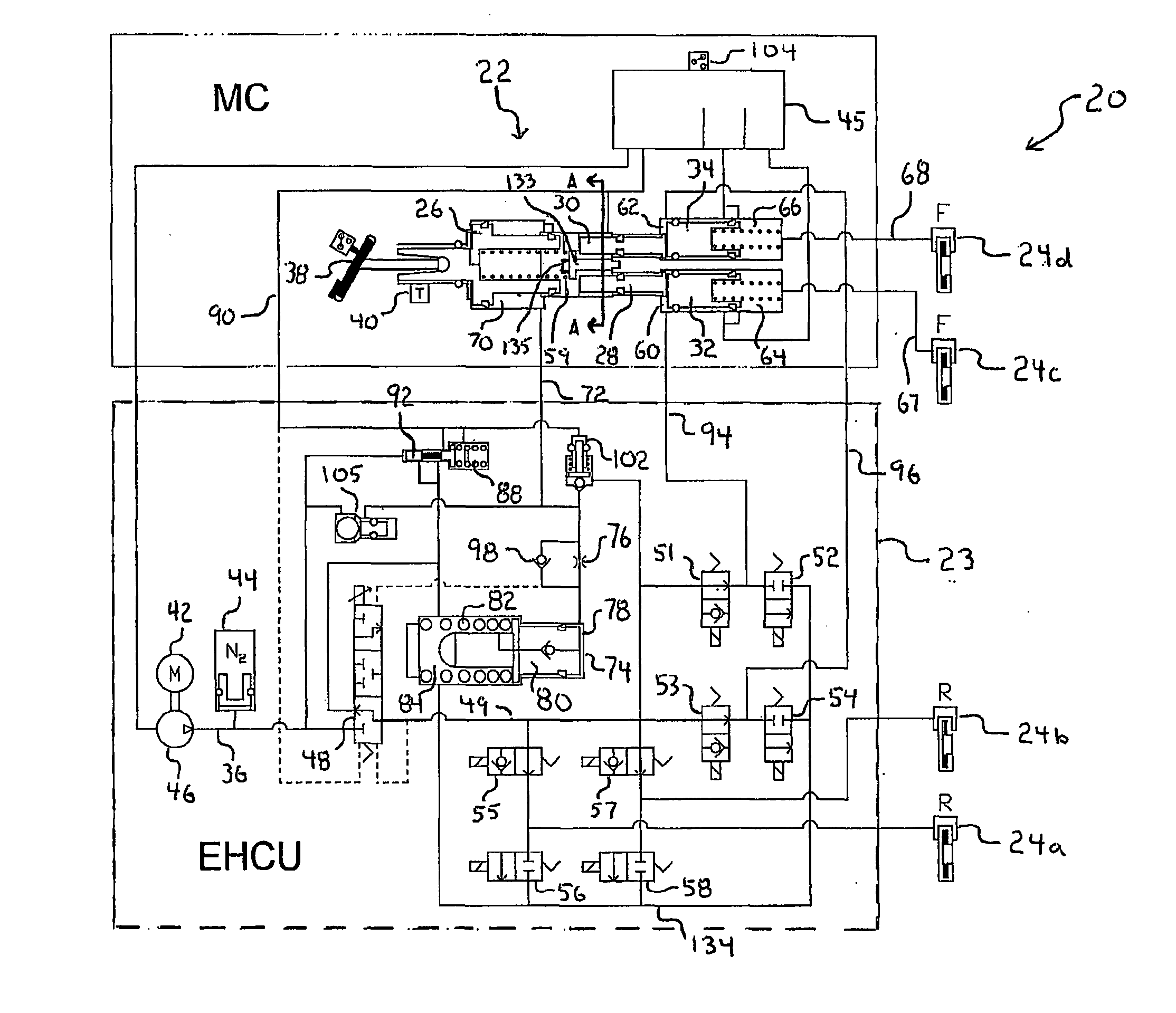

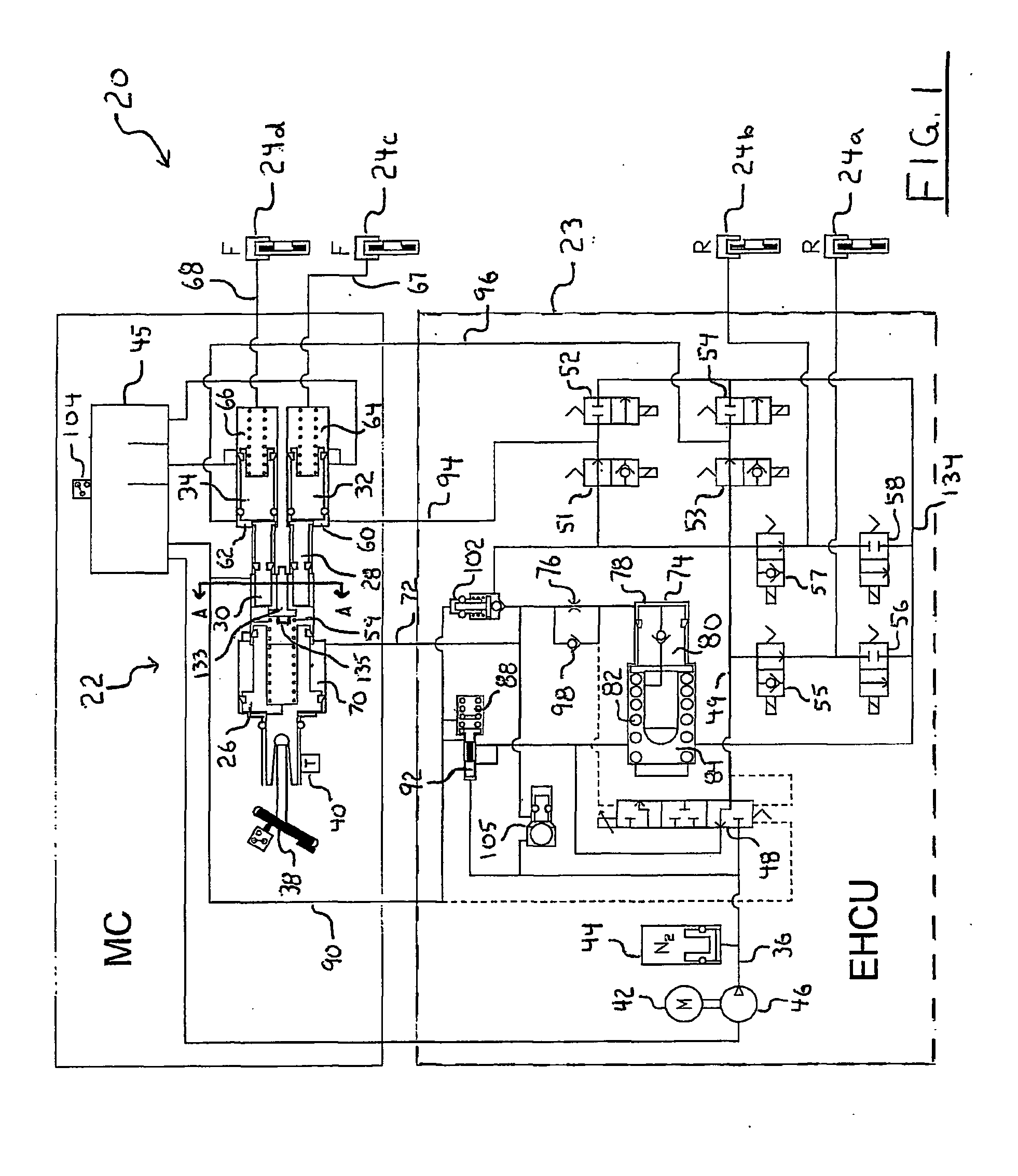

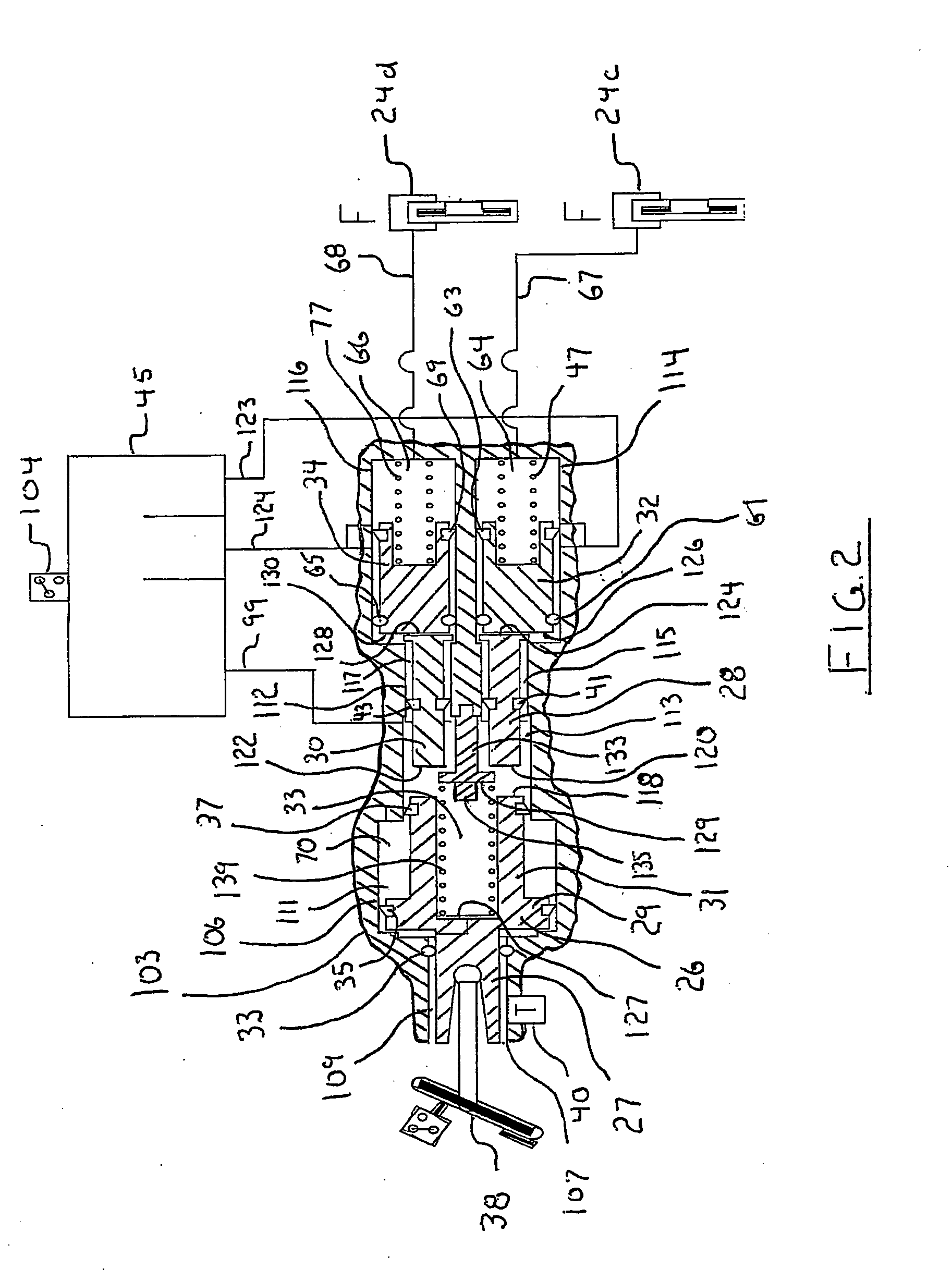

Slip Control Boost Braking System

A braking system is provided for applying pressurized hydraulic brake fluid to a plurality of vehicle brakes. The system includes a source of pressurized brake fluid, a first brake fluid circuit, and a boost valve for controlling a flow of brake fluid from the source to the first circuit. A first brake actuator is actuated by brake fluid from the first circuit and a second brake actuator operated by an application of brake fluid from the first circuit. The system further includes a second brake fluid circuit and a third brake fluid circuit. A third brake actuator is actuated by brake fluid from the second circuit. A fourth brake actuator actuated by brake fluid from the third circuit. A master cylinder includes a primary piston, a first secondary piston, and second secondary piston. The first and second secondary pistons are capable of being each independently operably displaced by an application of pressurized fluid from the first circuit to pressurize brake fluid in, respectively, the second circuit to operate the third brake actuator and the third circuit to operate the fourth brake circuit.

Owner:KELSEY HAYES CO

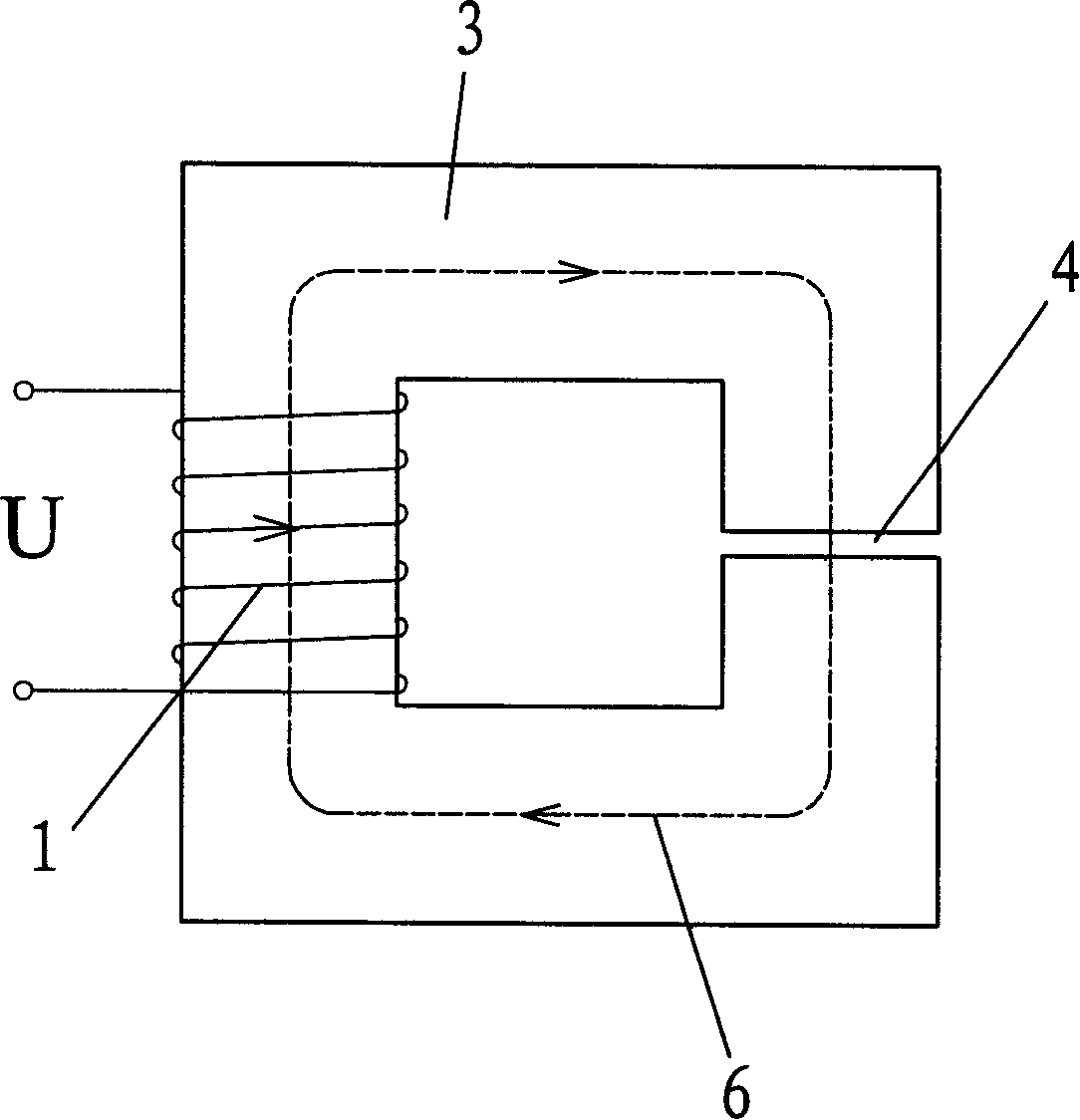

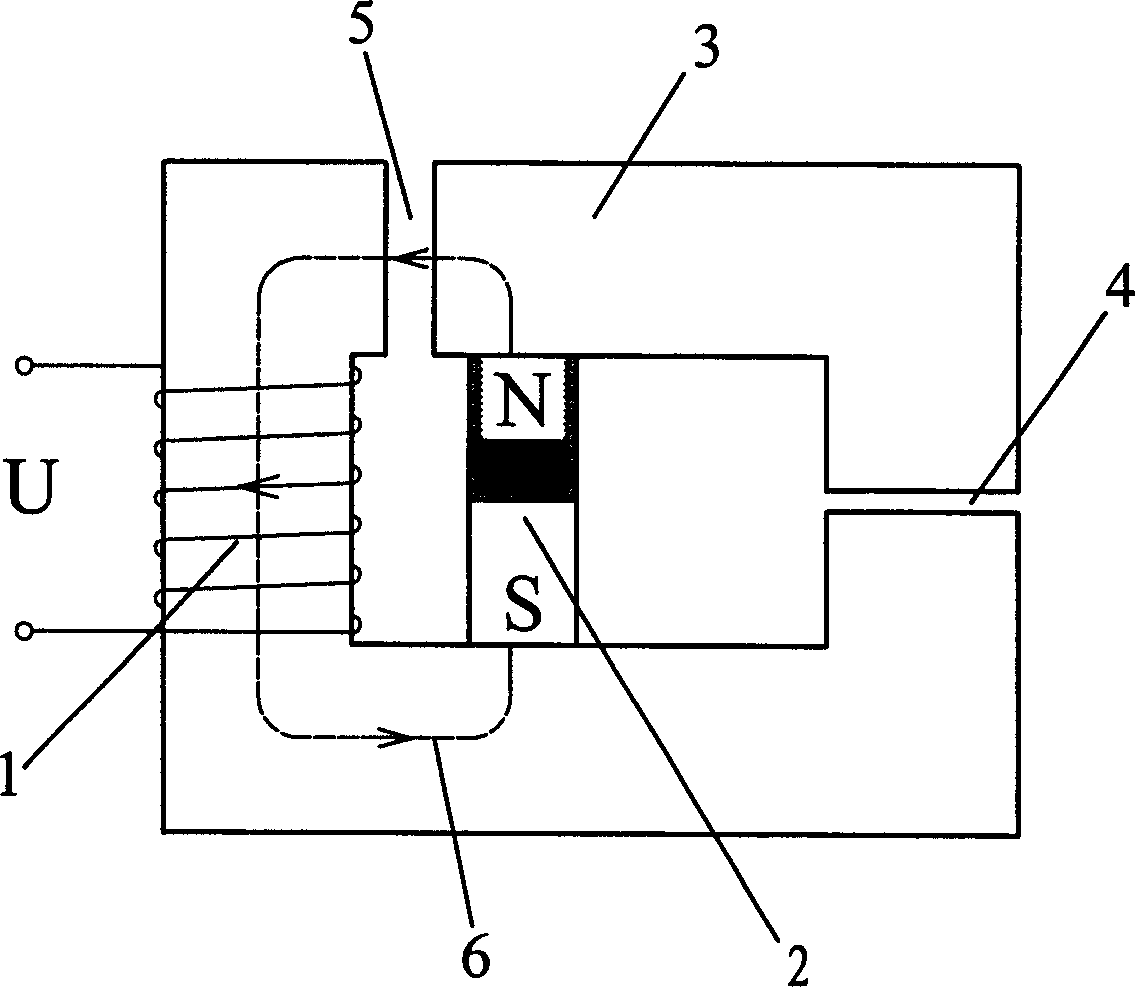

Inverse type magnetic flow damper

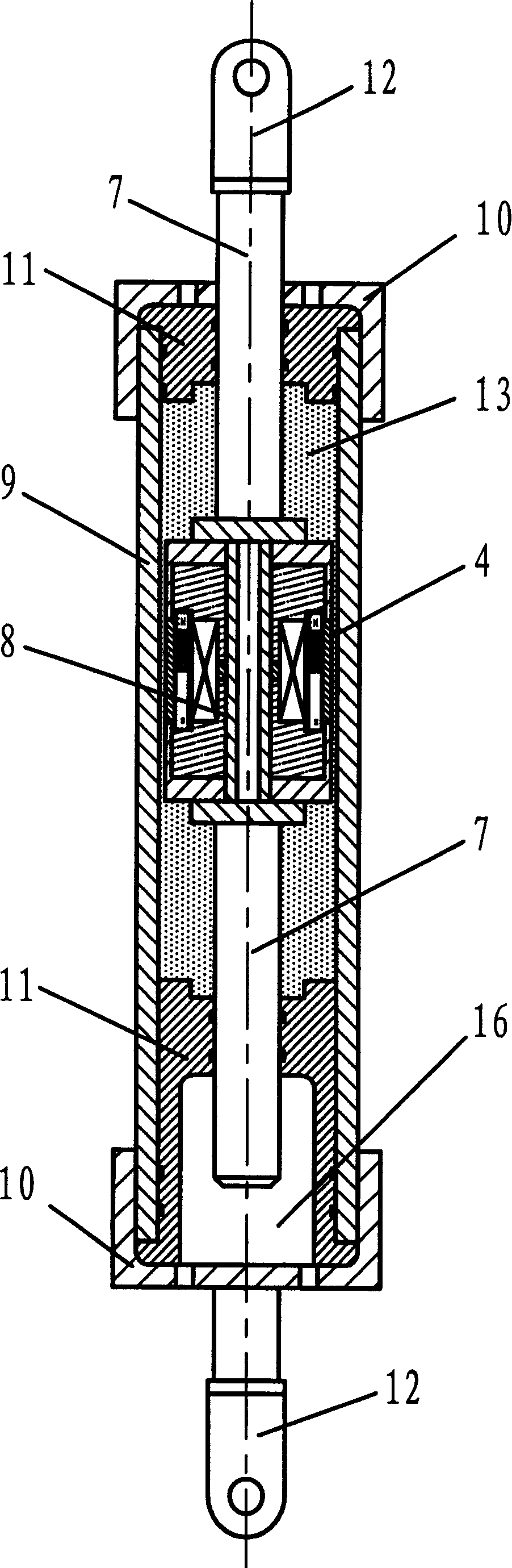

InactiveCN1587738AGuaranteed to workSpringsNon-rotating vibration suppressionMagnetic currentMaster cylinder

A kind of inversion magnetic current alter amortisseur,which has application in the absorption of vibration of the building structure and the locomotive cars. It includes the cylinder body,the piston, the piston rod which connected to it, the confinement gasoline device of the both sides of the cylinder body and the cylinder cap, there has magnetic current alternative liquid in the void of the cylinder body, and institutes the magnetizer that generates the magnetic field and the energizing coil and the electromagnet magnetic circuit component which is unitized of the running void, the cylinder body is composed of the master cylinder, or the master cylinder and the set jar, or the master cylinder and bypass jar, its character is:Institutes both the energizing coil and the permanent magnet magnetic circuit, composes the compounded magnetic circuit with the energizing coil and the permanent magnetic field, and also institutes the administer void in the electromagnet circuit, and when the power is cut, the most of the permanent magnetic field that generated by the permanent magnet will pass through the running void, so the amortisseur can work at the great amortization condition. The component of the electromagnet circuit may set at the pertinent position in terms of the different cylinder body. This kind of amortisseur can joint with the controlled structure, fulfills the semiactivly controlled with the absorption of vibration.

Owner:BEIJING UNIV OF TECH

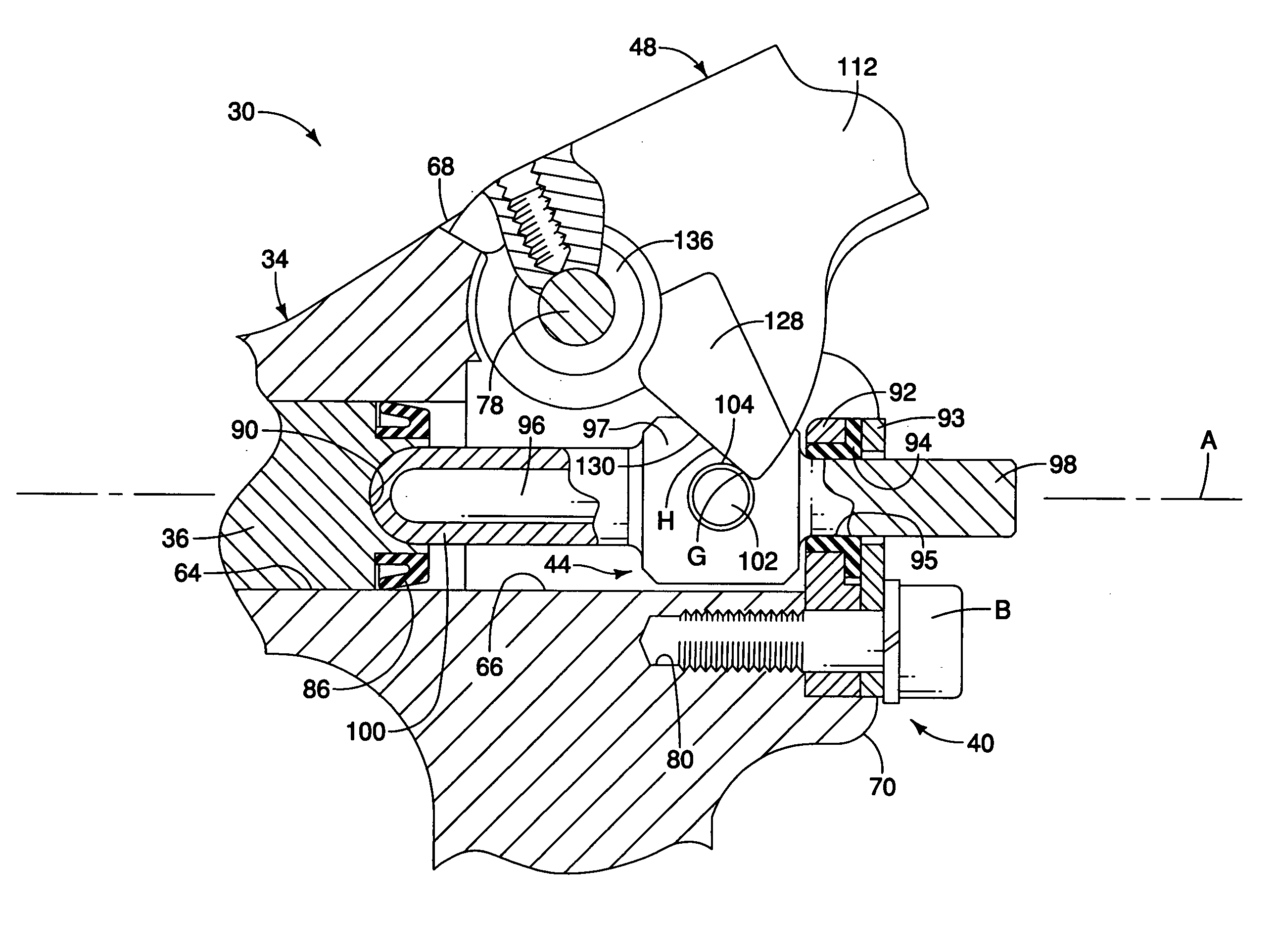

Eccentric cam brake booster

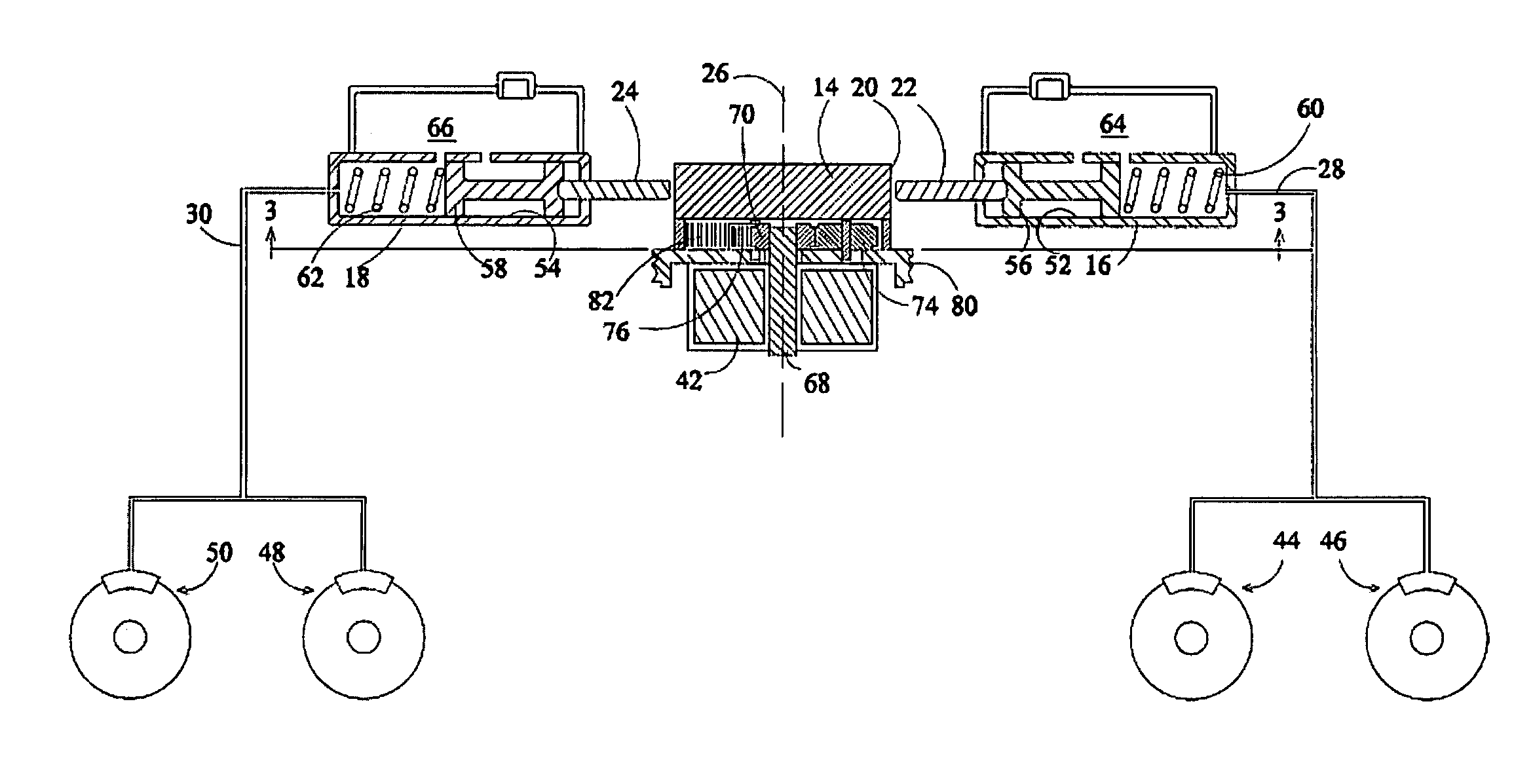

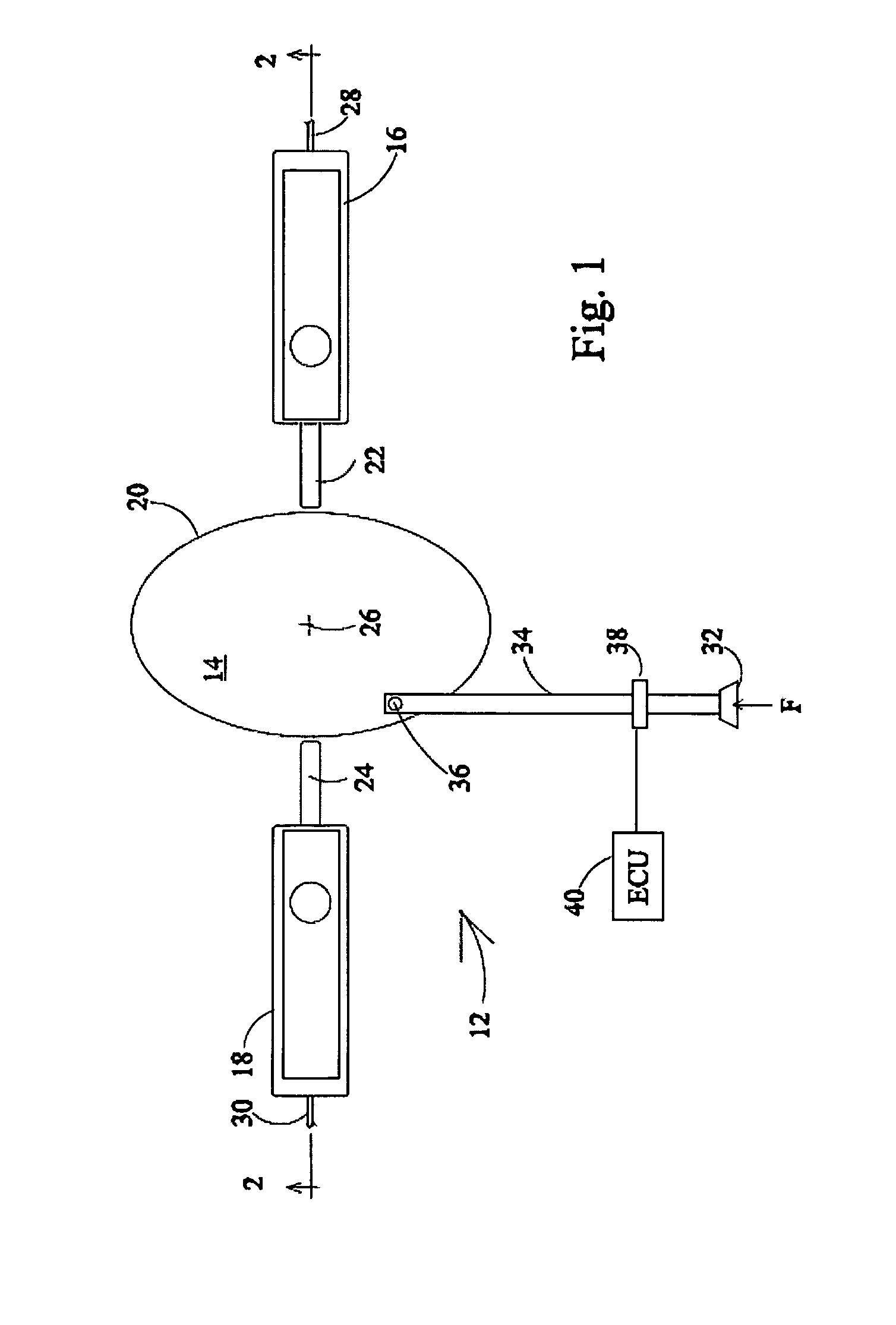

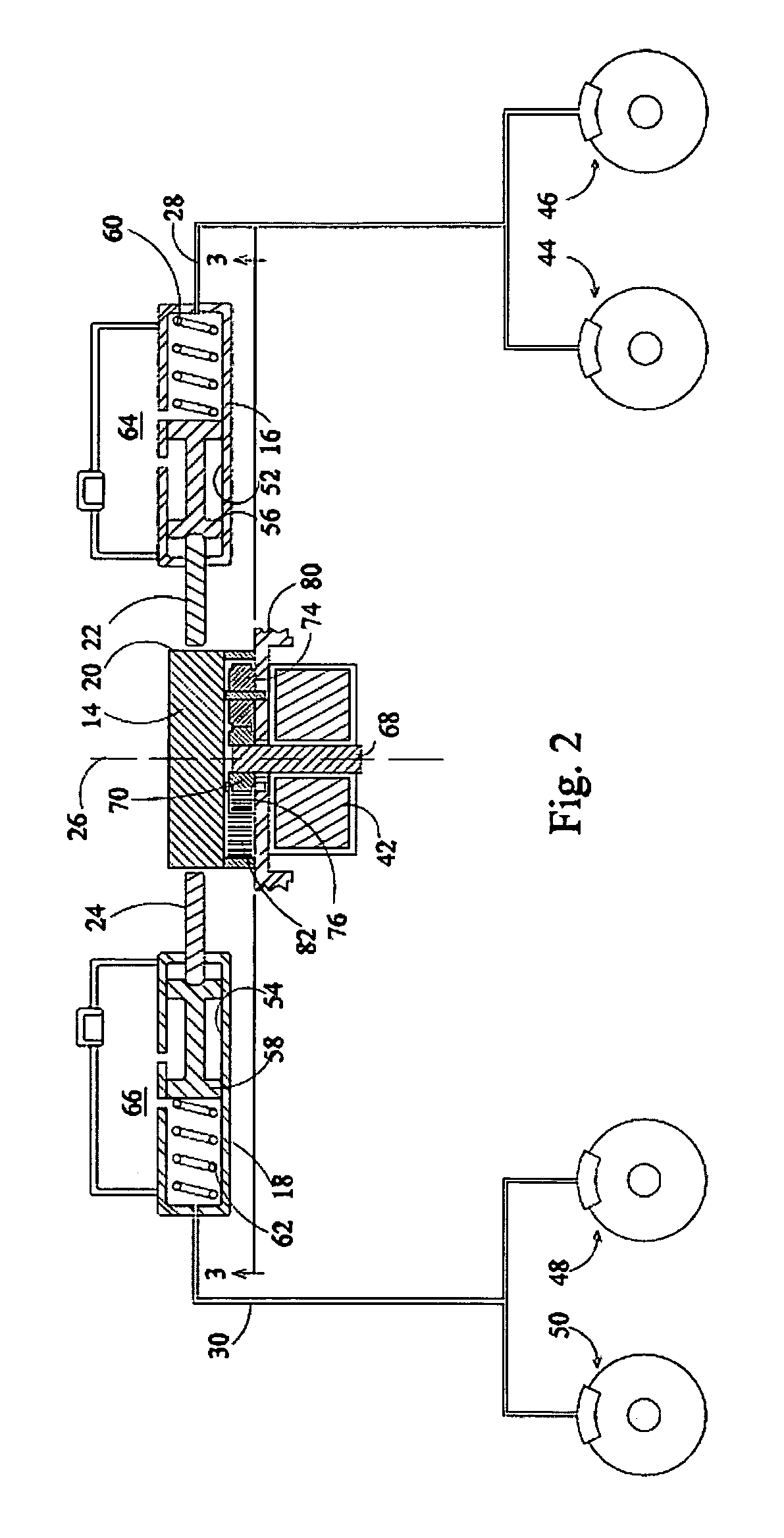

ActiveUS8069662B1Reduce noiseIncrease buff effectRotary clutchesFoot actuated initiationsPower flowMaster cylinder

An electric power booster (12) where driver command is monitored by a transducer (38) on an input rod (34). This signal is converted to the appropriate voltage / current and operates an electric motor (42). The motor output shaft (68) is connected to a planetary gear reducer (72) appropriately sized to provide no more than + / −1 / 4 turn of an eccentric cam (14). Two master cylinders (16, 18) power piston rods (22, 24) ride diametrically opposed on the cam surface (20). As the cam rotates the piston rods are forced out pressurizing the respective hydraulic circuits and thereby providing fluid to each brake circuit (28, 30). In the event of power failure as well as to augment the output of the motor, the input rod is mechanically linked directly to the cam offset from the center allowing the driver to manually rotate the cam thereby pressurizing the brake circuits.

Owner:ROBERT BOSCH CORP +1

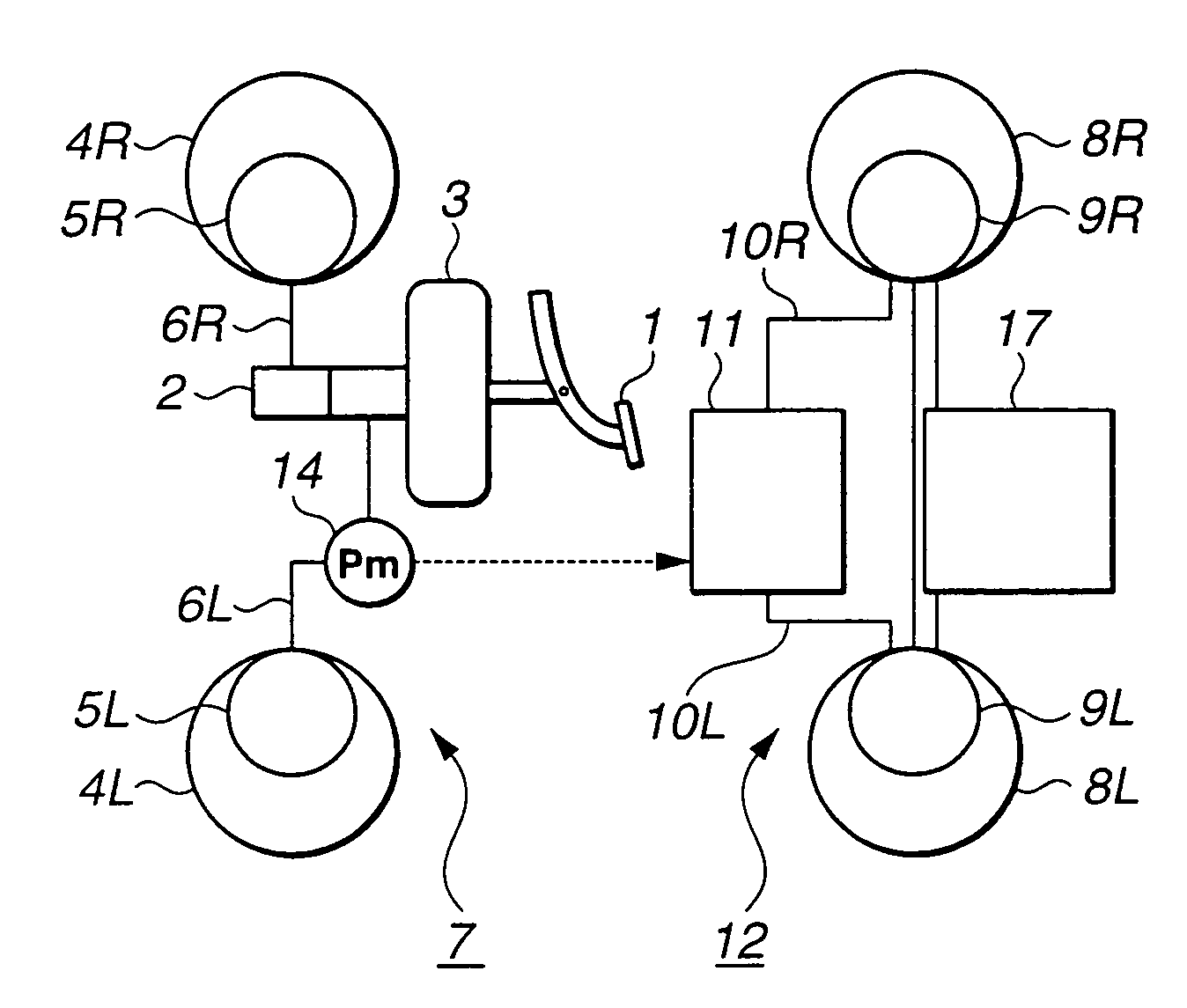

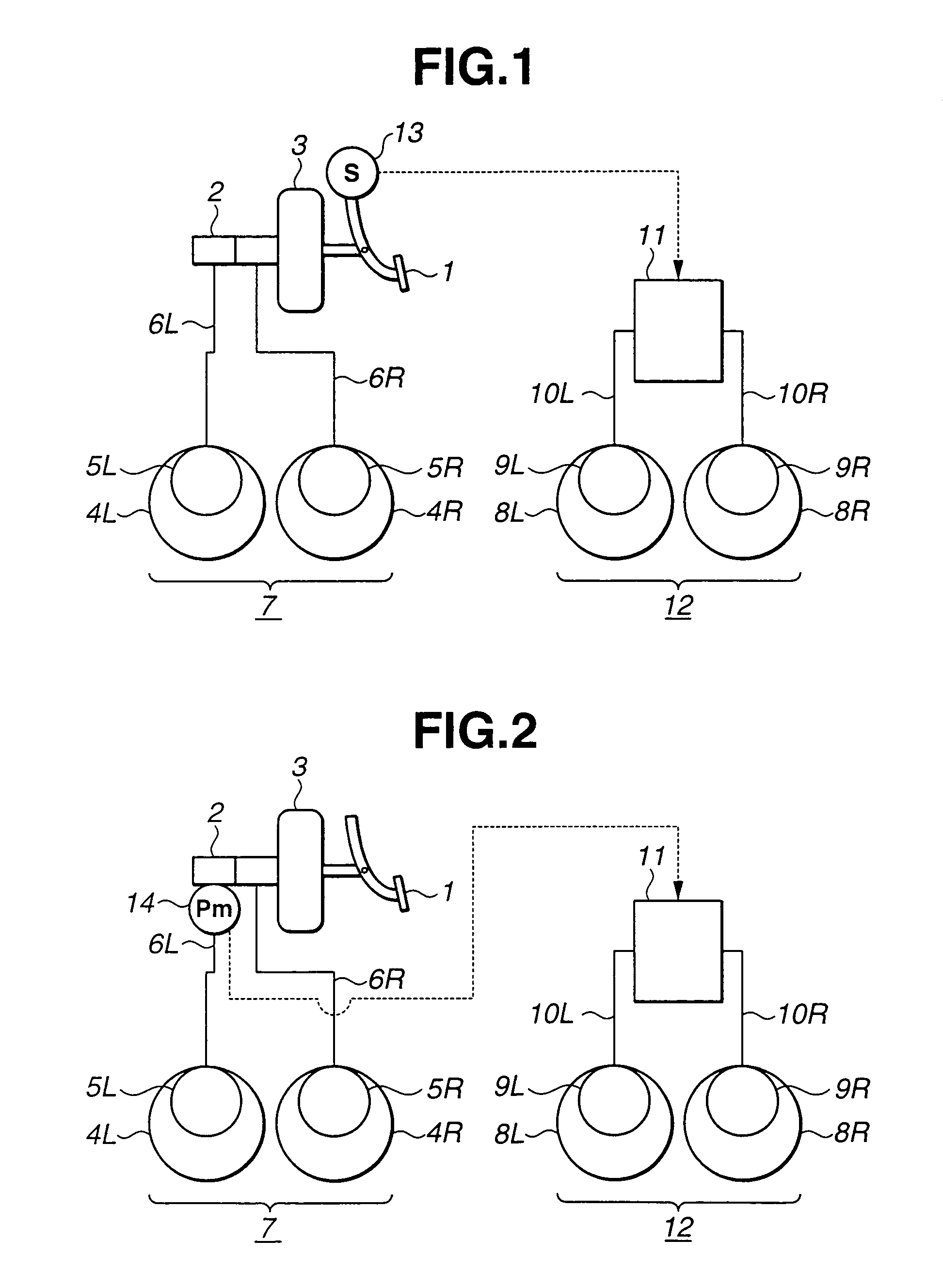

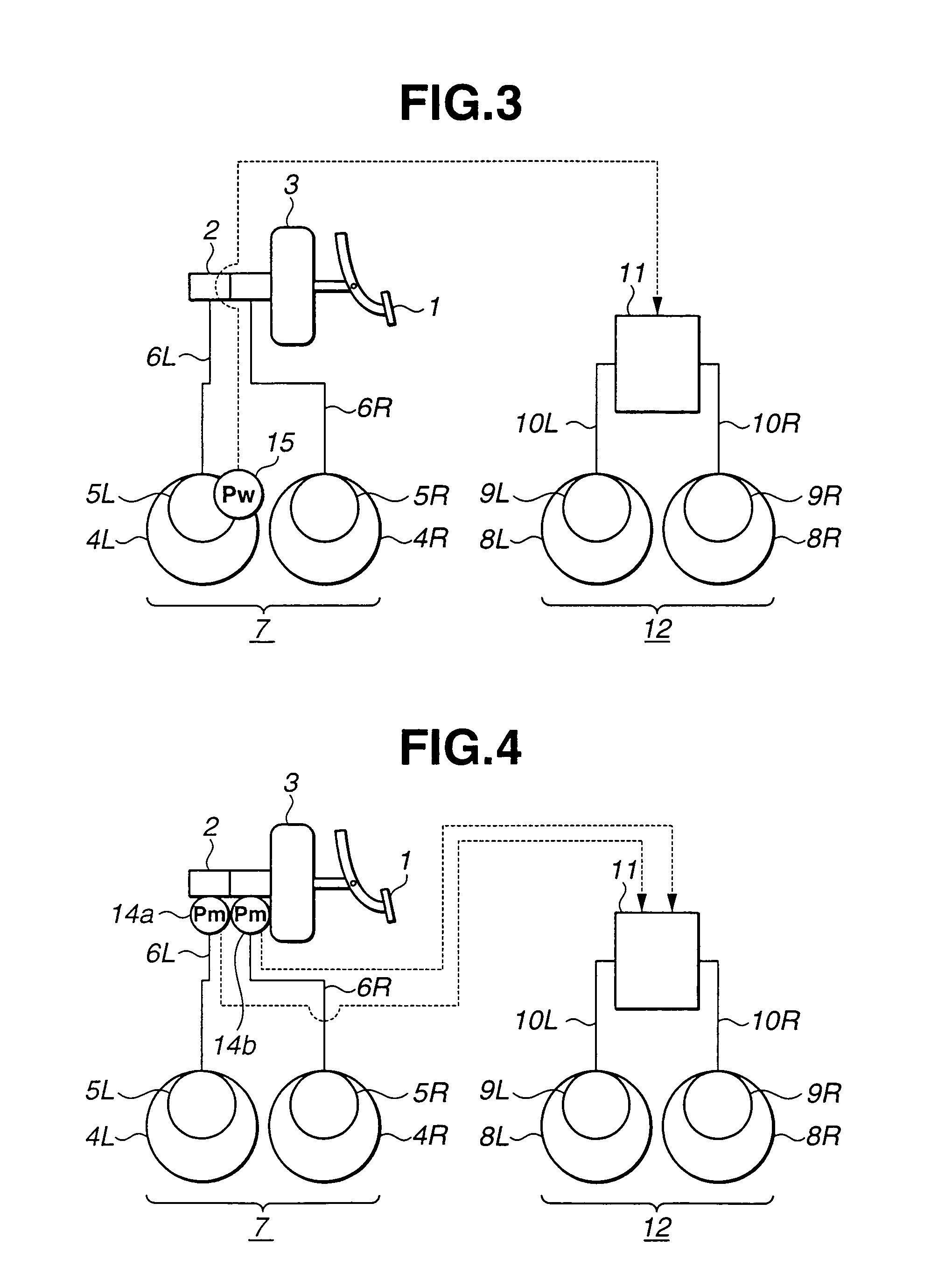

Vehicle brake system

InactiveUS7059691B2Increase production costAvoid using forceBraking element arrangementsBraking action transmissionDriver/operatorMaster cylinder

A brake system for a vehicle is comprised of a first brake system that mechanically applies a braking force to wheels according to a master cylinder hydraulic pressure outputted from a master cylinder which receives a brake manipulation force of a driver, and a second brake system that apply a braking force to other wheels according to at least a braking state of the first brake system.

Owner:NISSAN MOTOR CO LTD

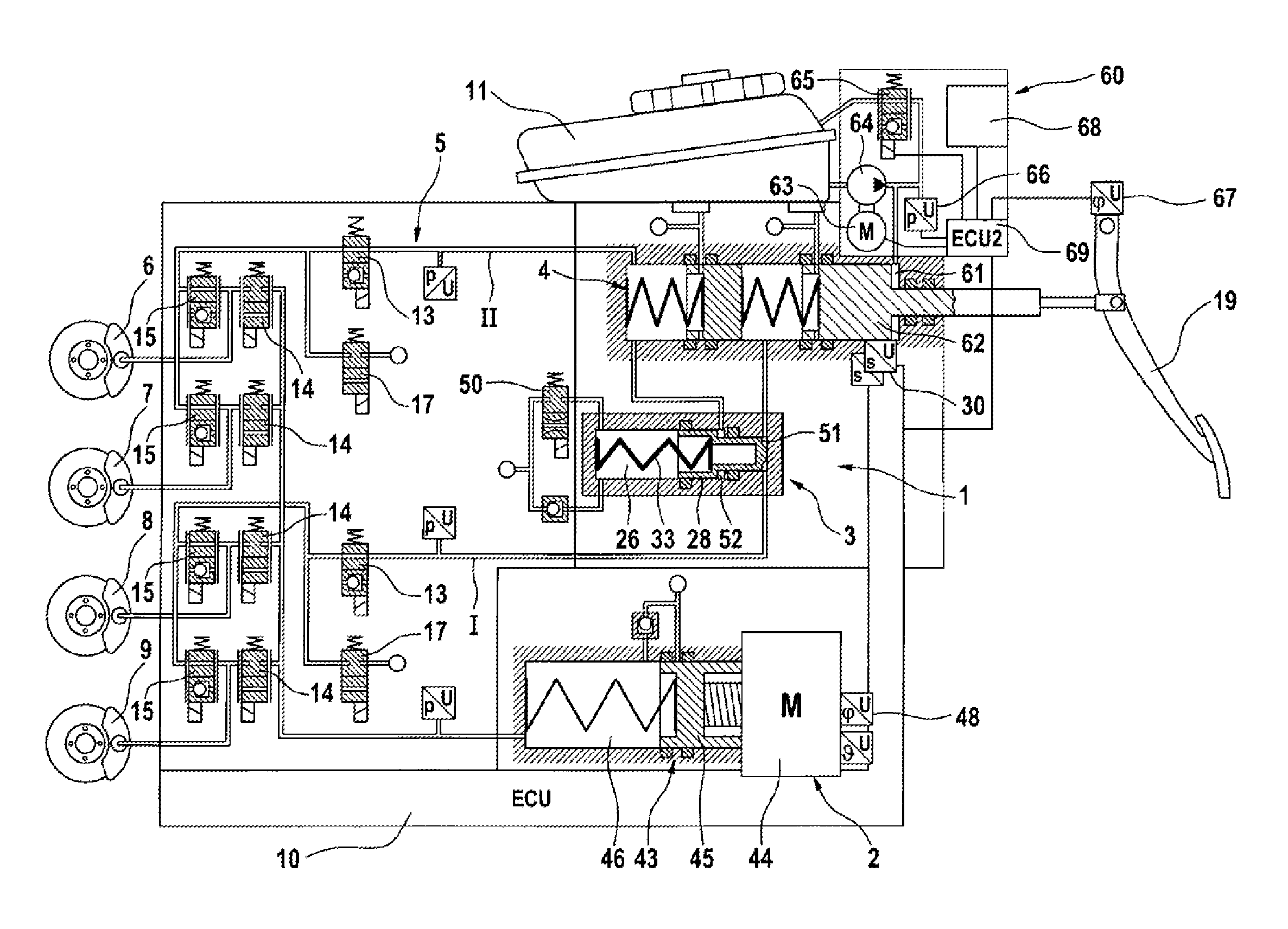

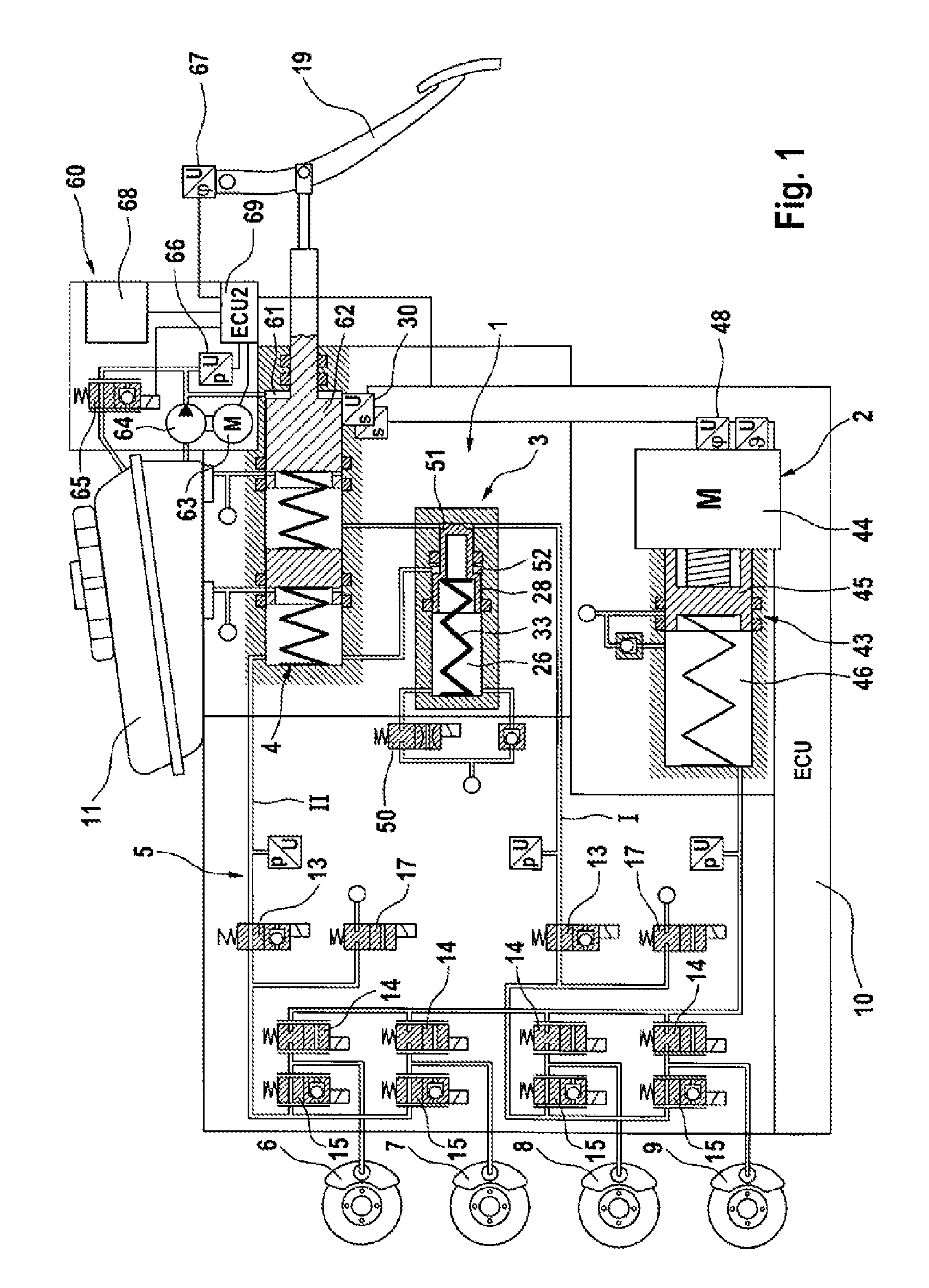

Brake System for Motor Vehicles and Method for Operating the Brake System

InactiveUS20140225425A1Braking action transmissionBrake action initiationsElectricityMaster cylinder

A brake system includes a brake pedal for actuating a master cylinder having two pistons and corresponding pressure chambers, where the system can be operated in a brake-by-wire mode and also a fallback mode. The system also includes a first electrically controllable pressure source and a second electrically controllable pressure source. The first and second electrically controllable pressure sources each have corresponding output flows that are connected together. The second electrically controllable pressure source can therefore provide output volume flow in the event the first electrically controllable pressure source fails.

Owner:CONTINENTAL TEVES AG & CO OHG

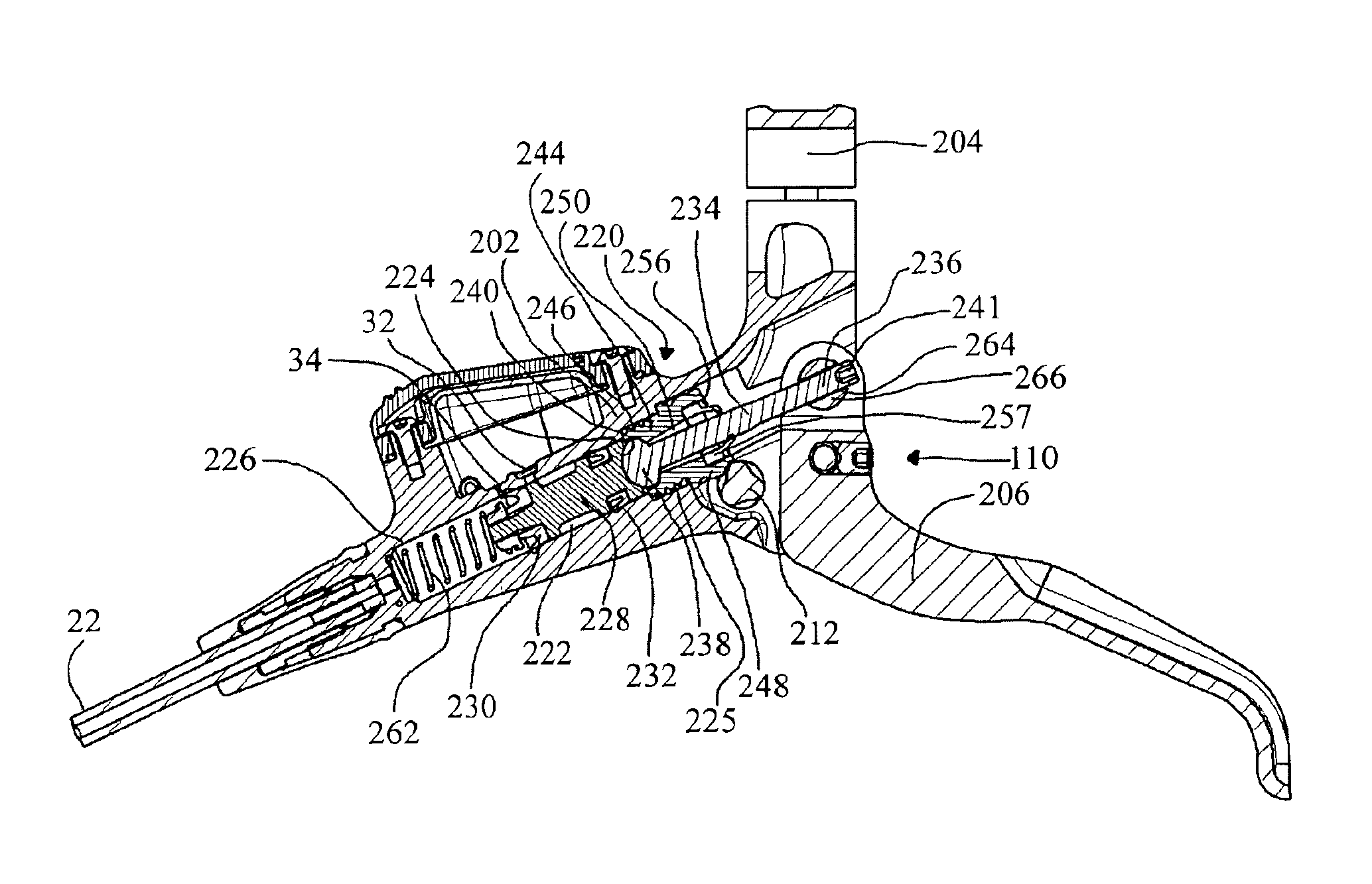

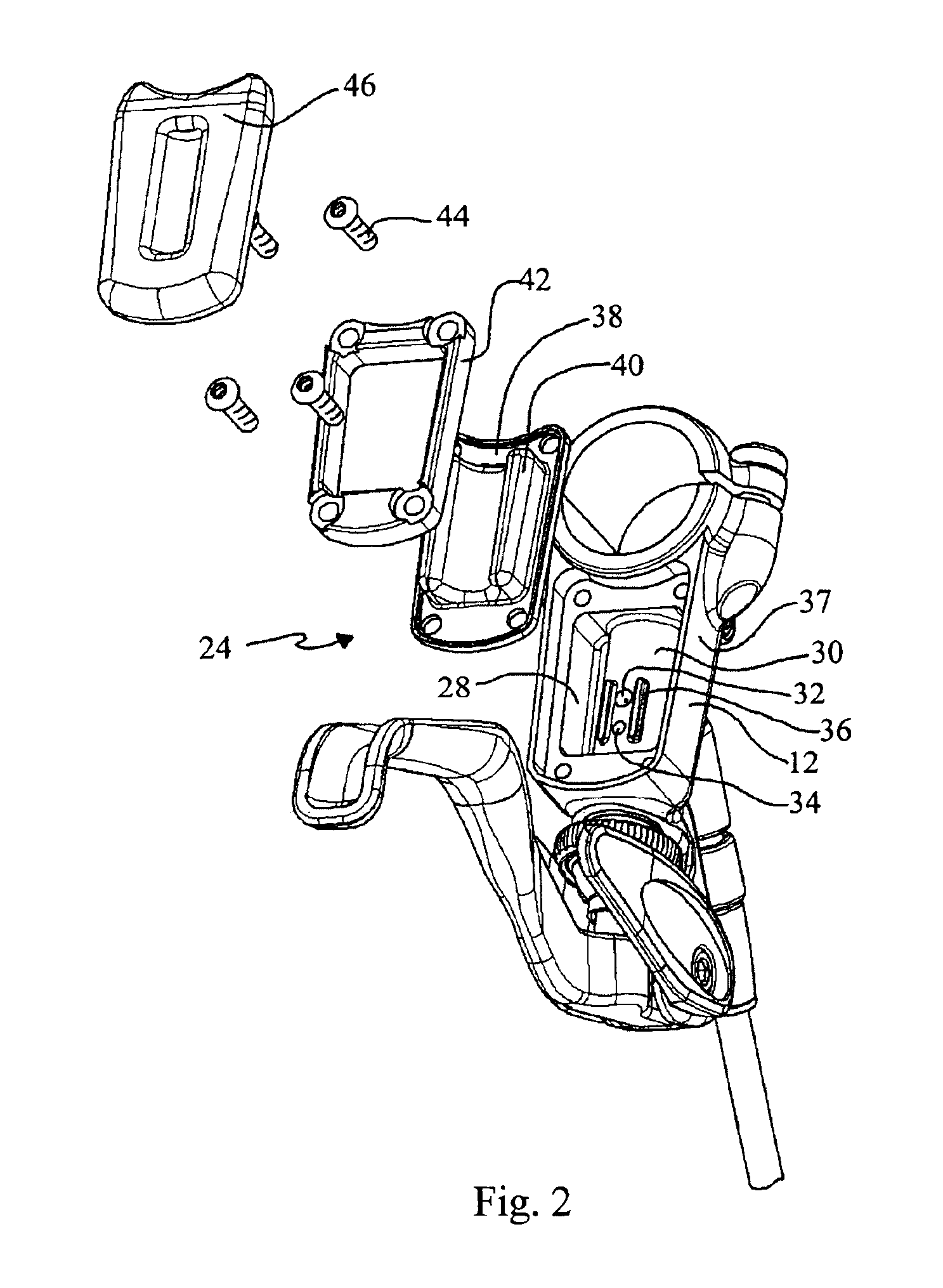

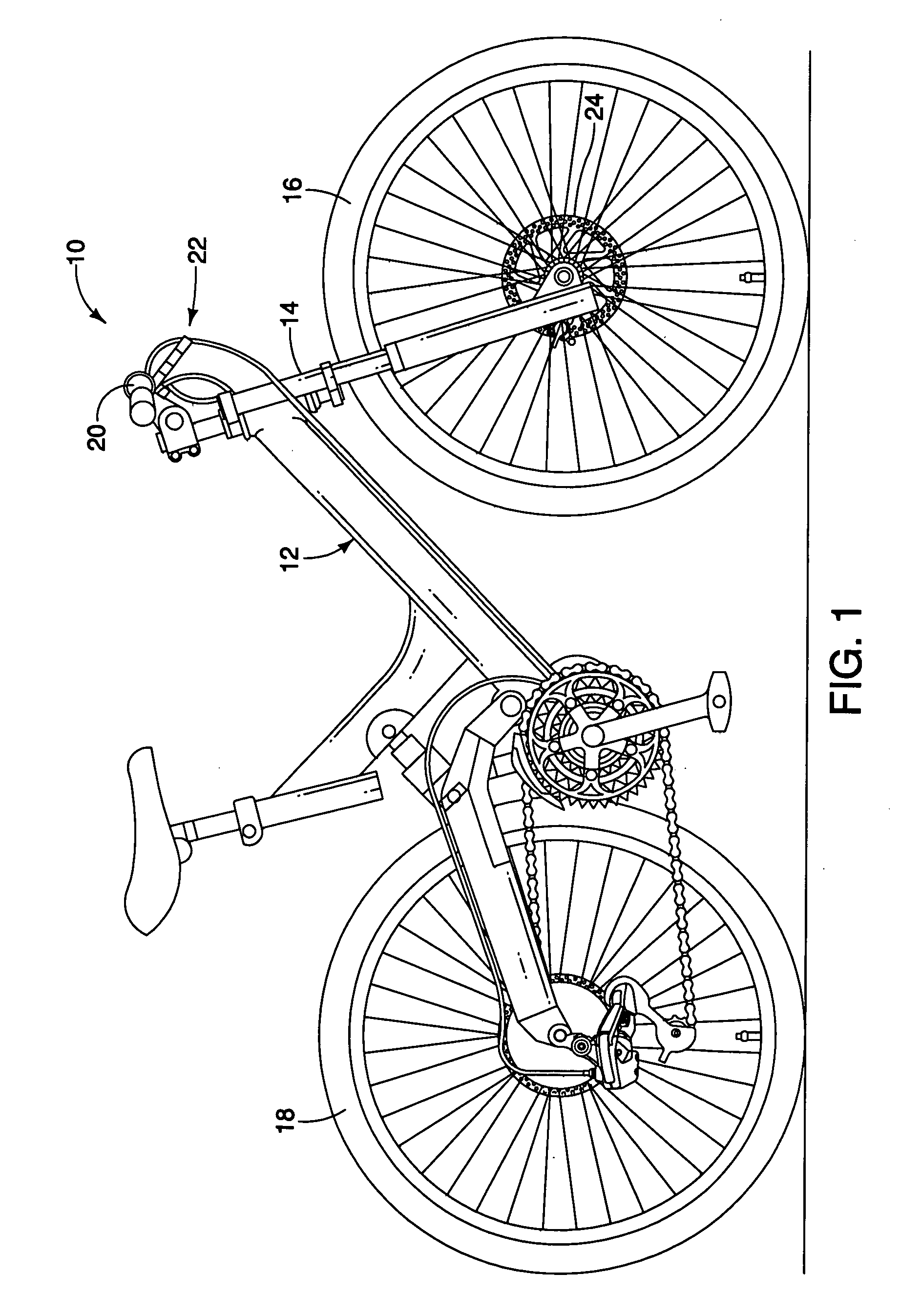

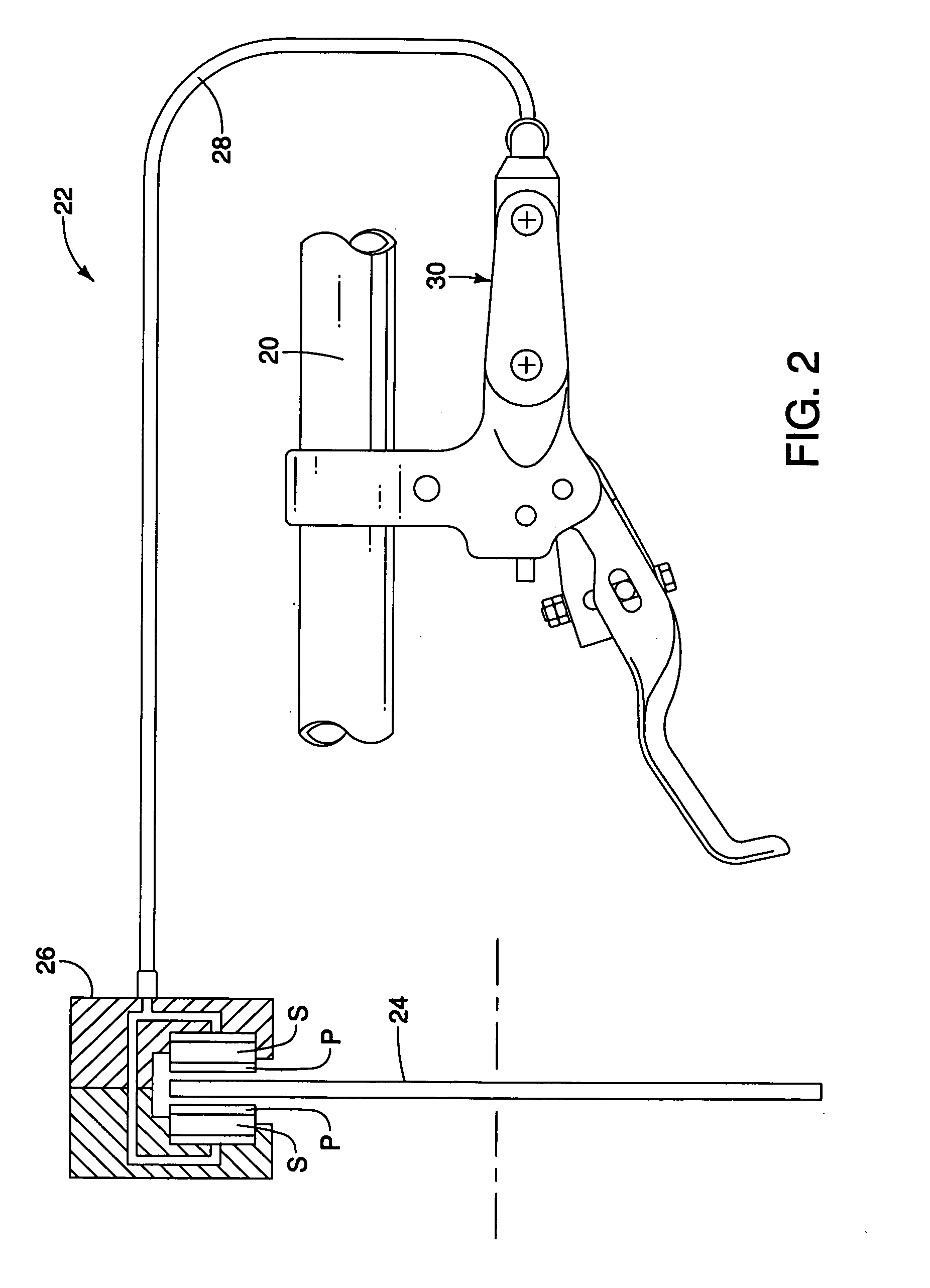

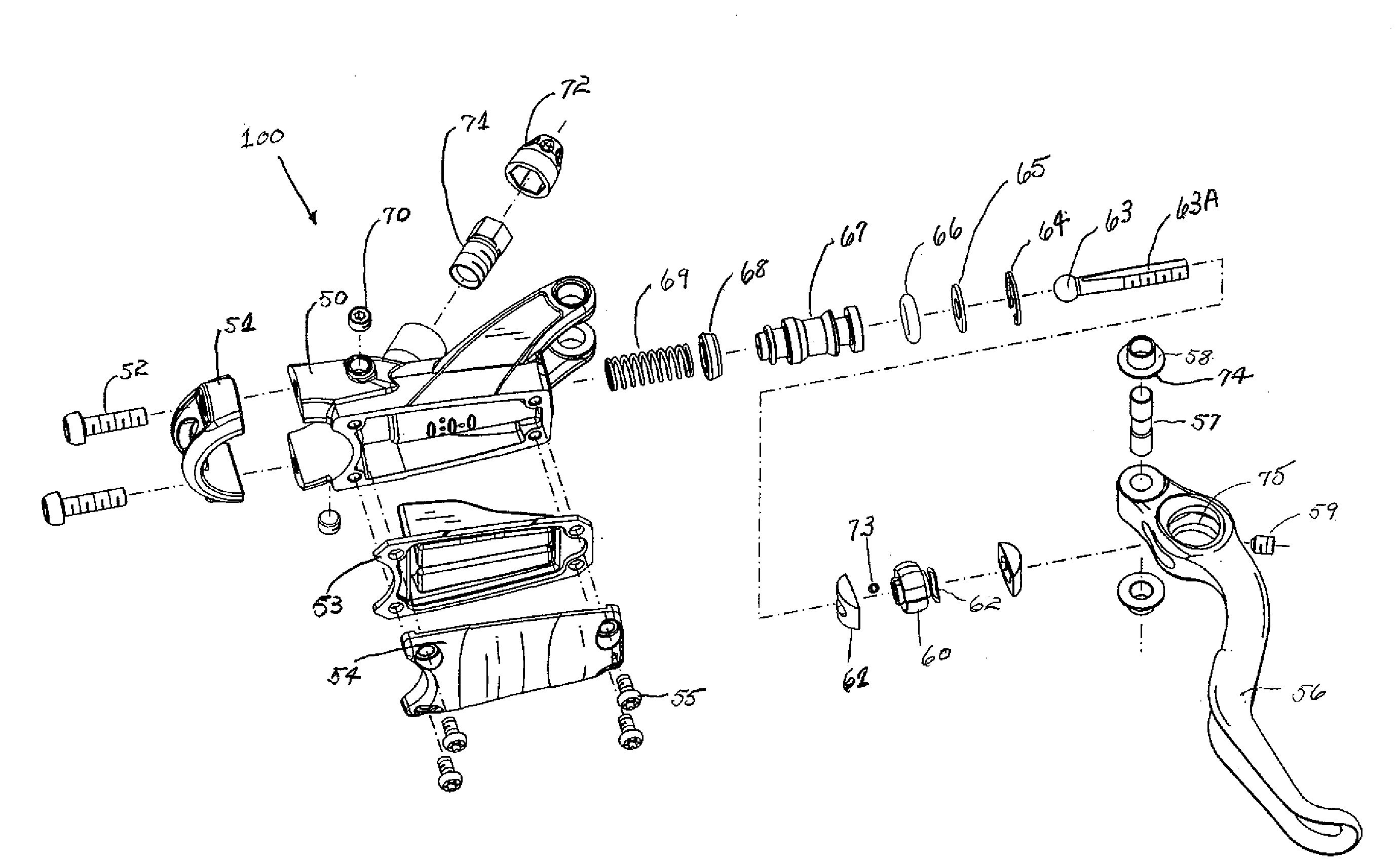

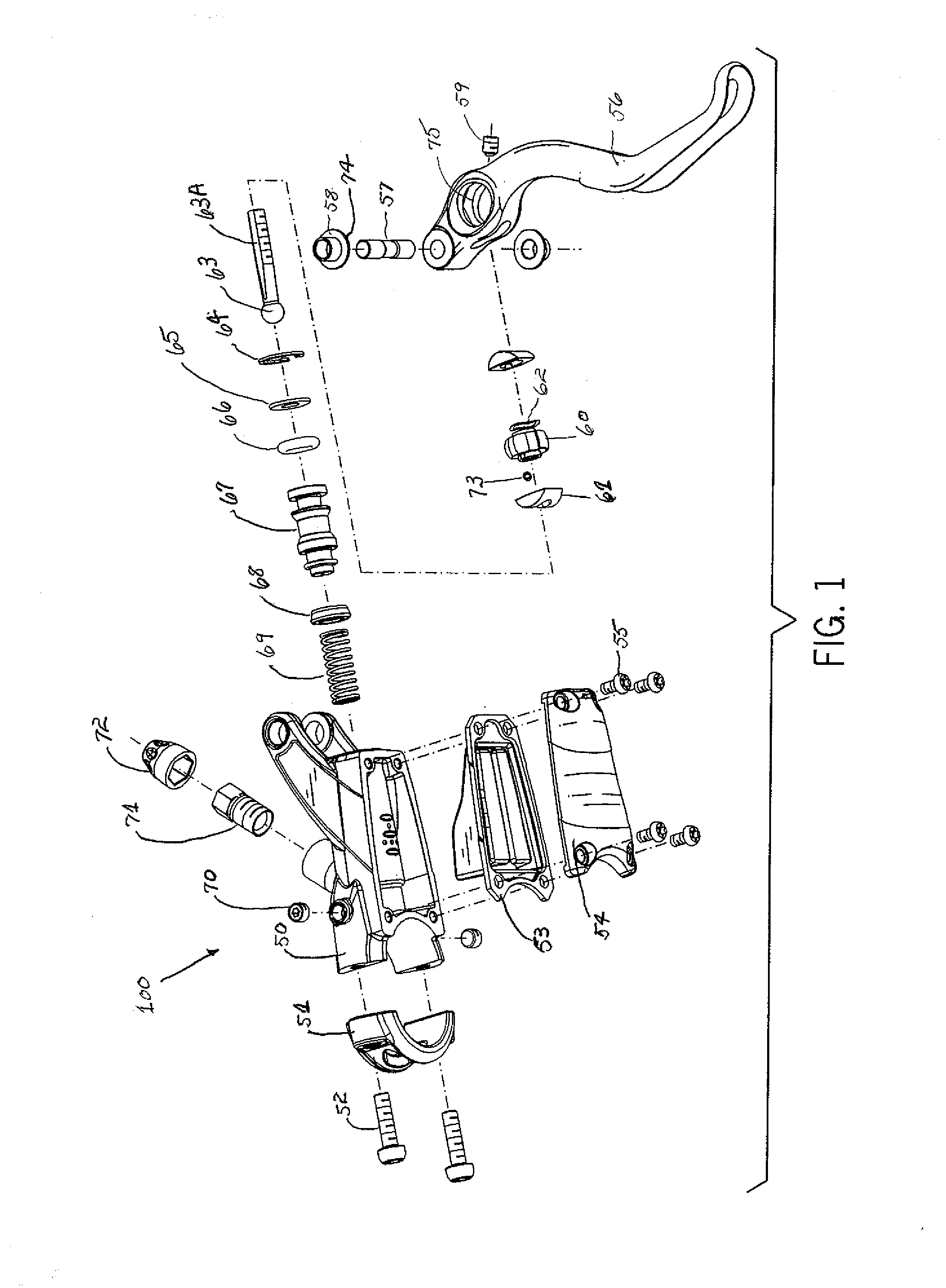

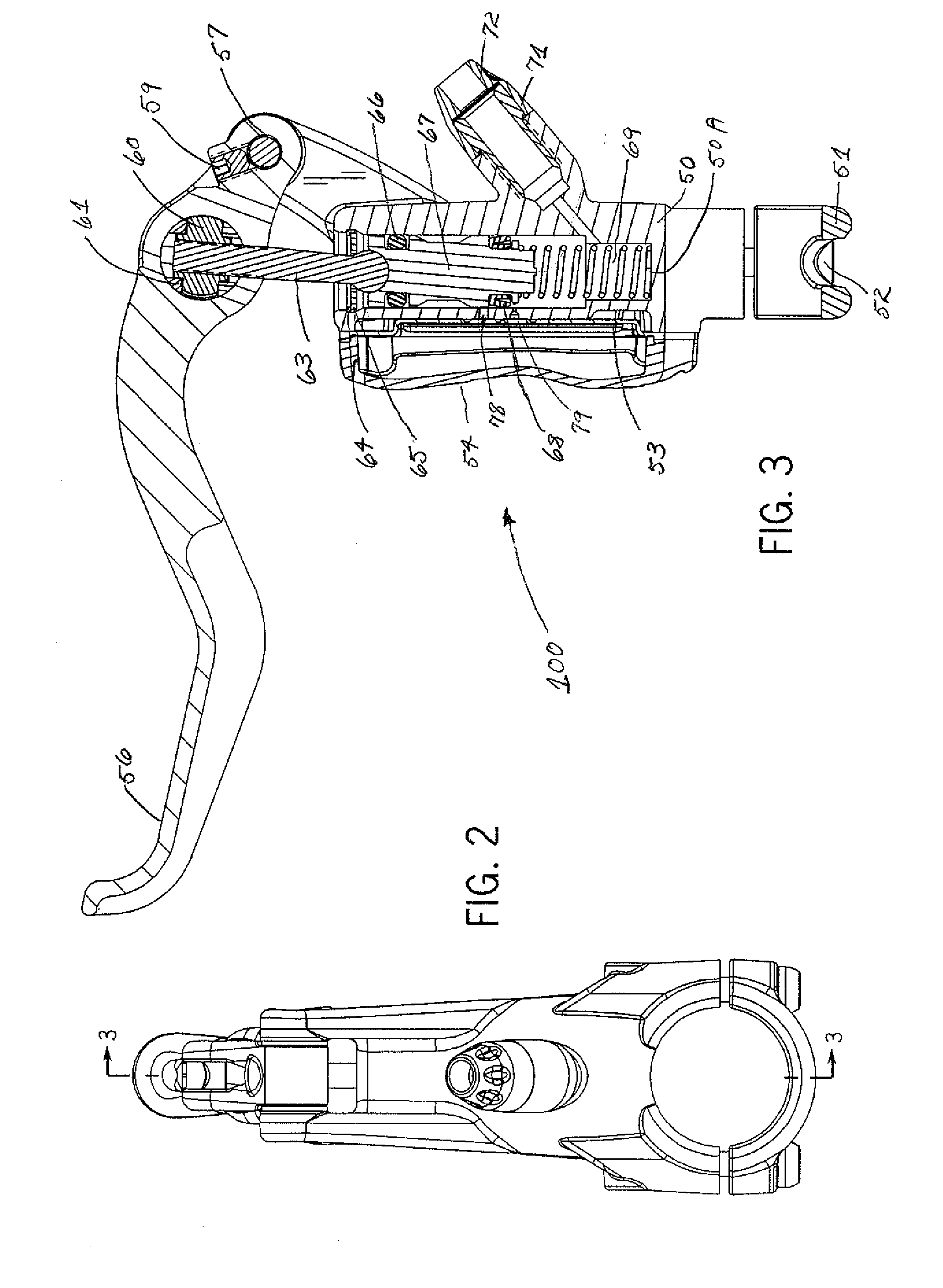

Reach adjustment mechanism for a master cylinder lever of a hydraulic disc brake

InactiveUS6957534B2Prevent unwanted changesIncreasing costControlling membersRotary clutchesRest positionMaster cylinder

A master cylinder for a hydraulic disc brake includes a housing defining a cylinder, the cylinder having a first and second end along its axis. A piston is received in the cylinder and has a radial seal between the piston and the cylinder. A lever is pivotably associated with the housing for pivoting between a rest position and an actuated position relative to the housing. A push rod is operatively associated with the piston and the lever to move the piston axially within the cylinder as the lever is actuated between the rest and actuated positions. A threaded engagement between a first end of the push rod and the lever is configured to cause movement of the rest position of the lever relative to the housing when a rotating force is applied to the push rod causing axial rotation of the push rod. An indexing structure is operatively associated with the push rod for providing index axial rotation of the push rod upon application of the rotating force to the push rod causing axial rotation of the push rod.

Owner:SRAM CORPORATION

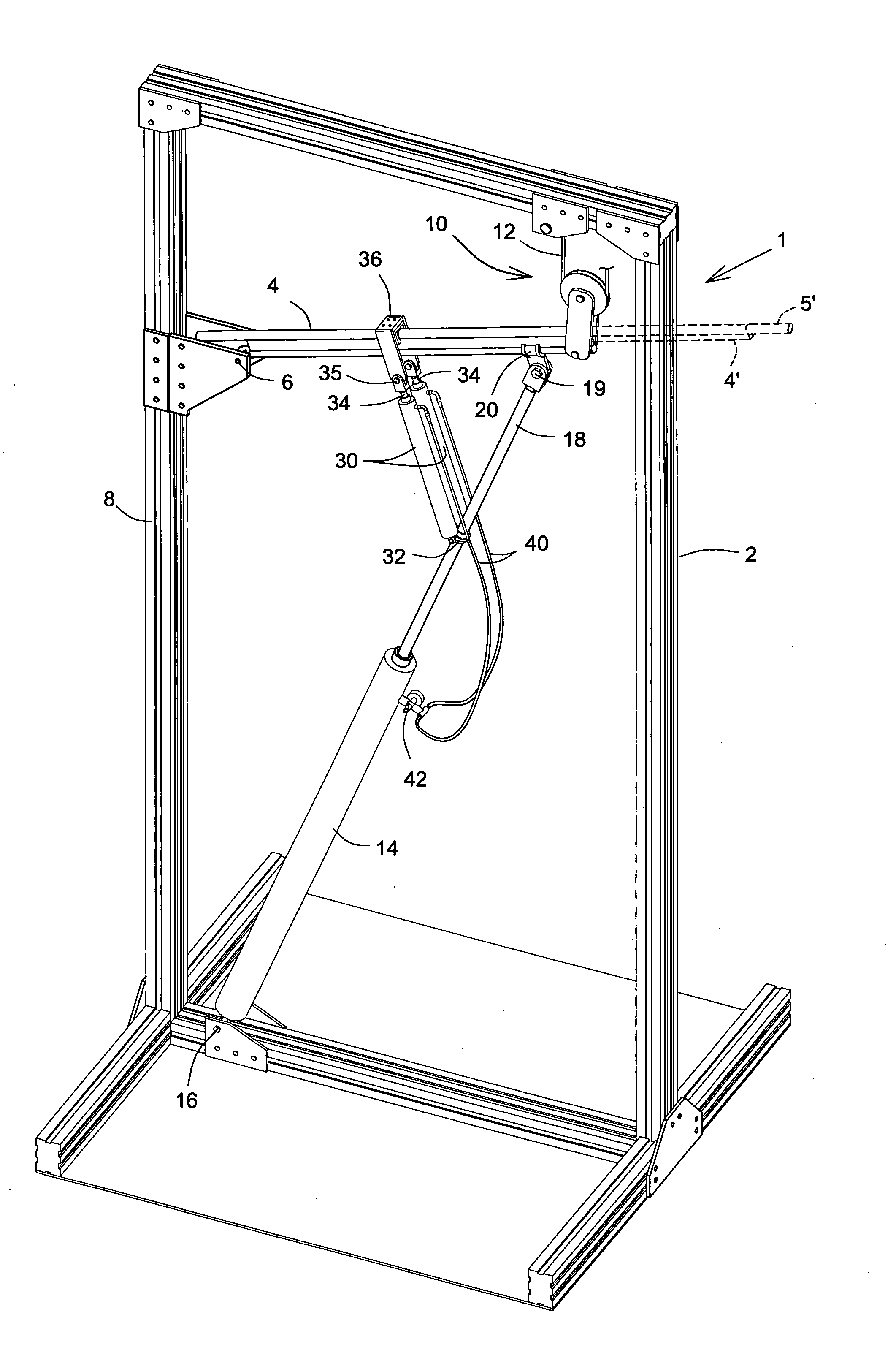

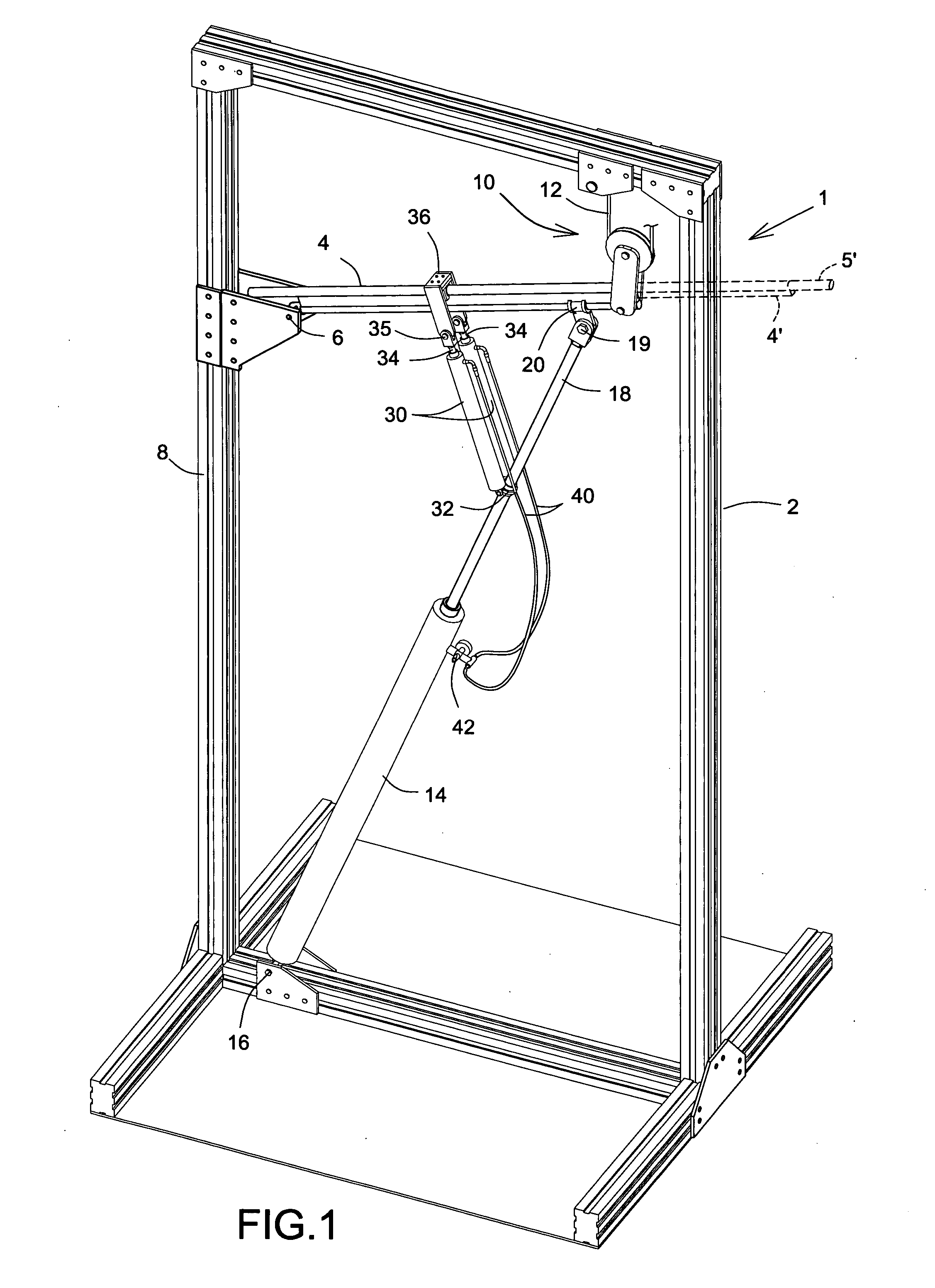

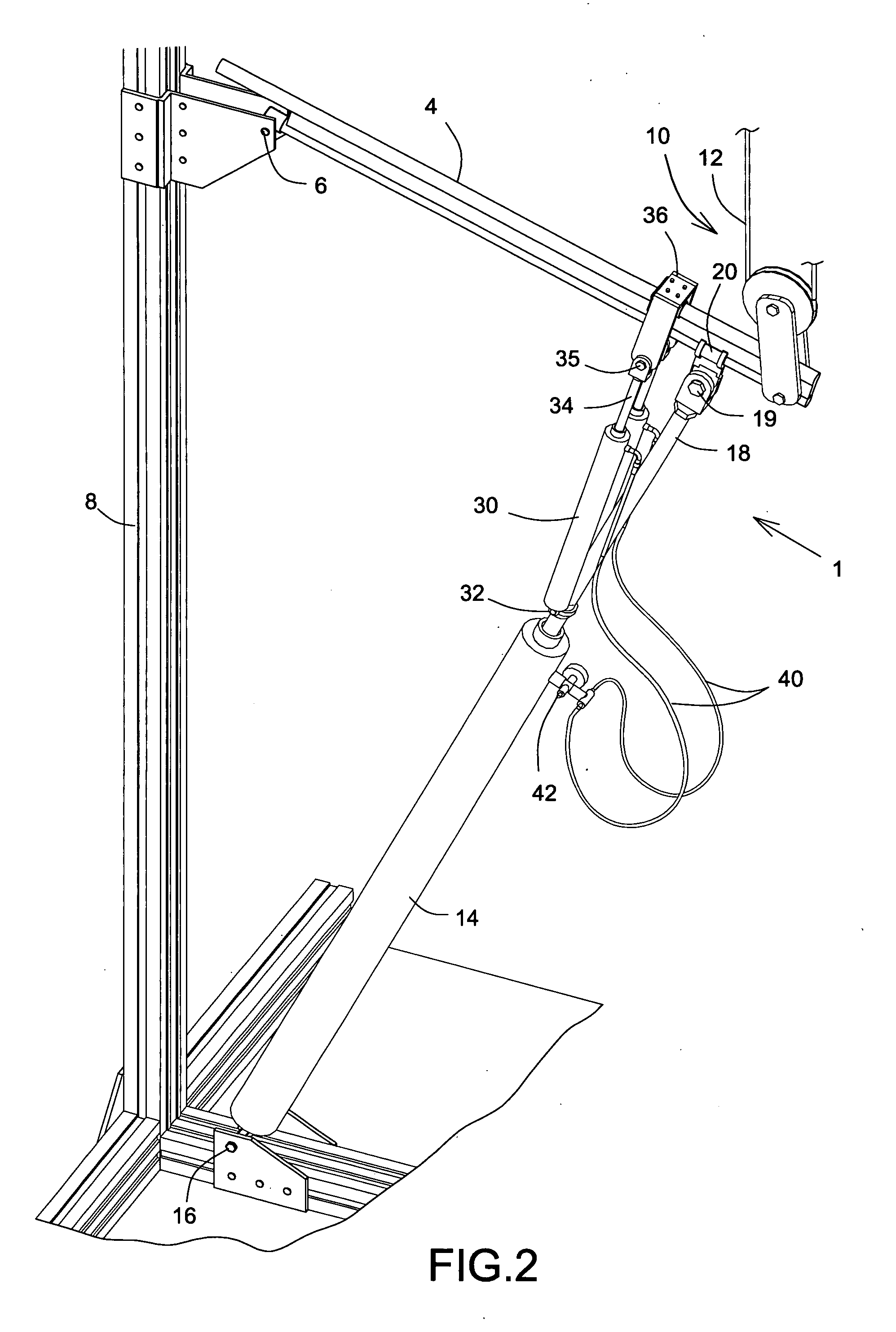

Weight lifting simulator apparatus

ActiveUS20070142187A1Enhanced inertia effectCompact designMuscle exercising devicesWeight liftingFixed position

Weight lifting simulator apparatus includes a primary pneumatic cylinder providing the principal resistance for simulating weight lifting exercise with at least one secondary cylinder in free fluid interconnection with the primary cylinder whereby constant and balanced loading is achieved, with provisions for dynamic simulation of weight inertia effect, and control thereof, as in lifting a real weight. The primary and the secondary cylinders are associated with a guideway, the primary cylinder being fixed to the guideway and the secondary cylinder being slidable relative to the guideway and pivotable relative to the piston rod of the primary cylinder. Variation of the securement position of the primary cylinder on the guideway is available and valving is provided in the fluid interconnection.

Owner:KOLOMEIR

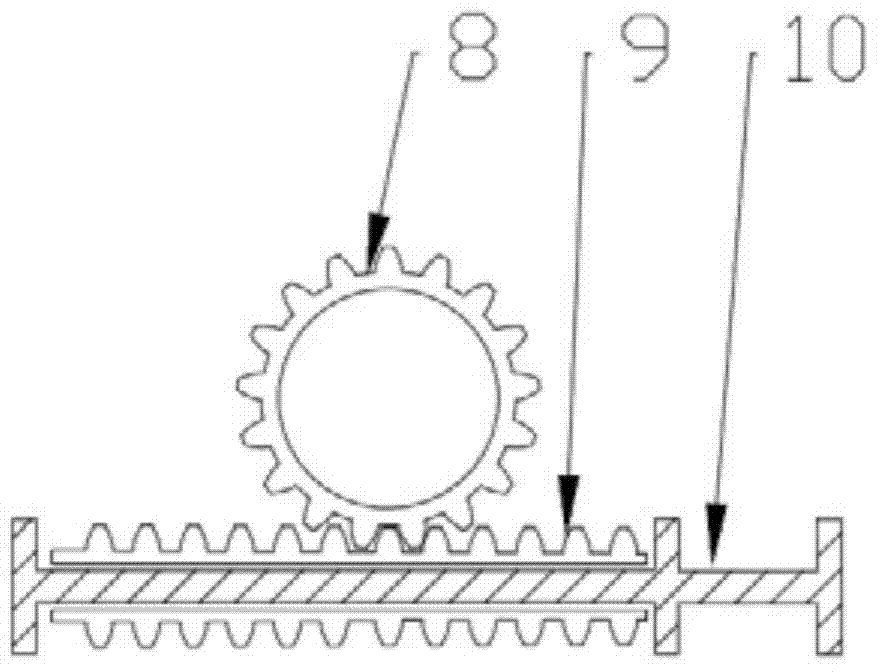

Electromechanical brake booster

InactiveUS20100126167A1Little strengthReduce the risk of injuryBraking action transmissionRotary clutchesFreewheelMaster cylinder

The invention relates to an electromechanical brake booster for a master brake cylinder of a hydraulic vehicle braking system. The invention provides to configure the brake booster such that it preferably includes a switchable freewheel, which enables an actuation of the master brake cylinder without any movement of the electric motor of the brake booster. The invention further provides to configure the brake booster such that it includes a mechanical gear having a variable transmission ratio, which has a high path transmission at the beginning of an actuation of the master brake cylinder, and a force transmission that rises with increasing actuation. A variable gear ratio is possible using a rack and pinion gear, the toothed rack of which has a soothing with a pitch that changes across the length of the toothed rack. A further possibility of a mechanical gear having a variable ratio is a toggle lever mechanism.

Owner:ROBERT BOSCH GMBH

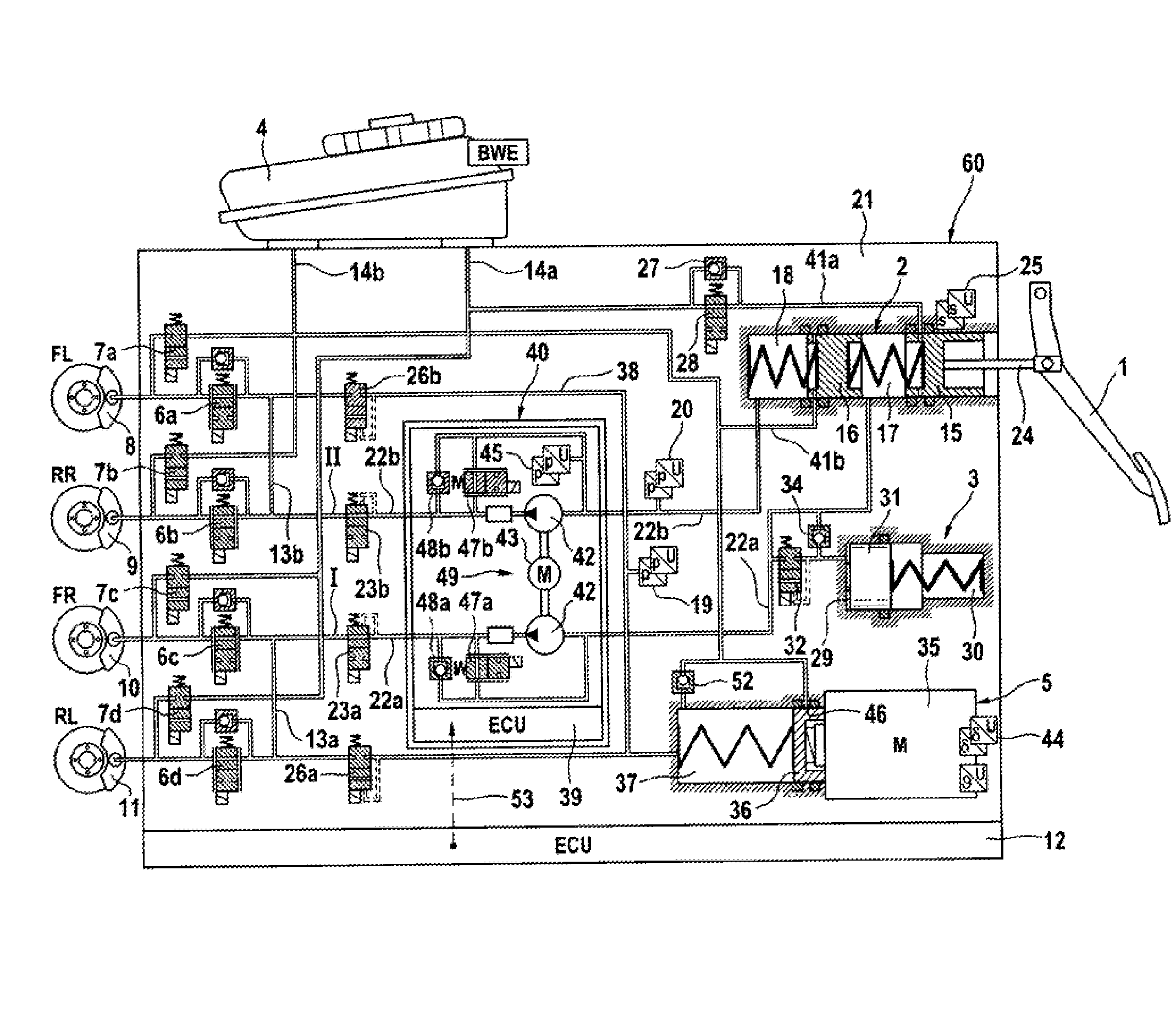

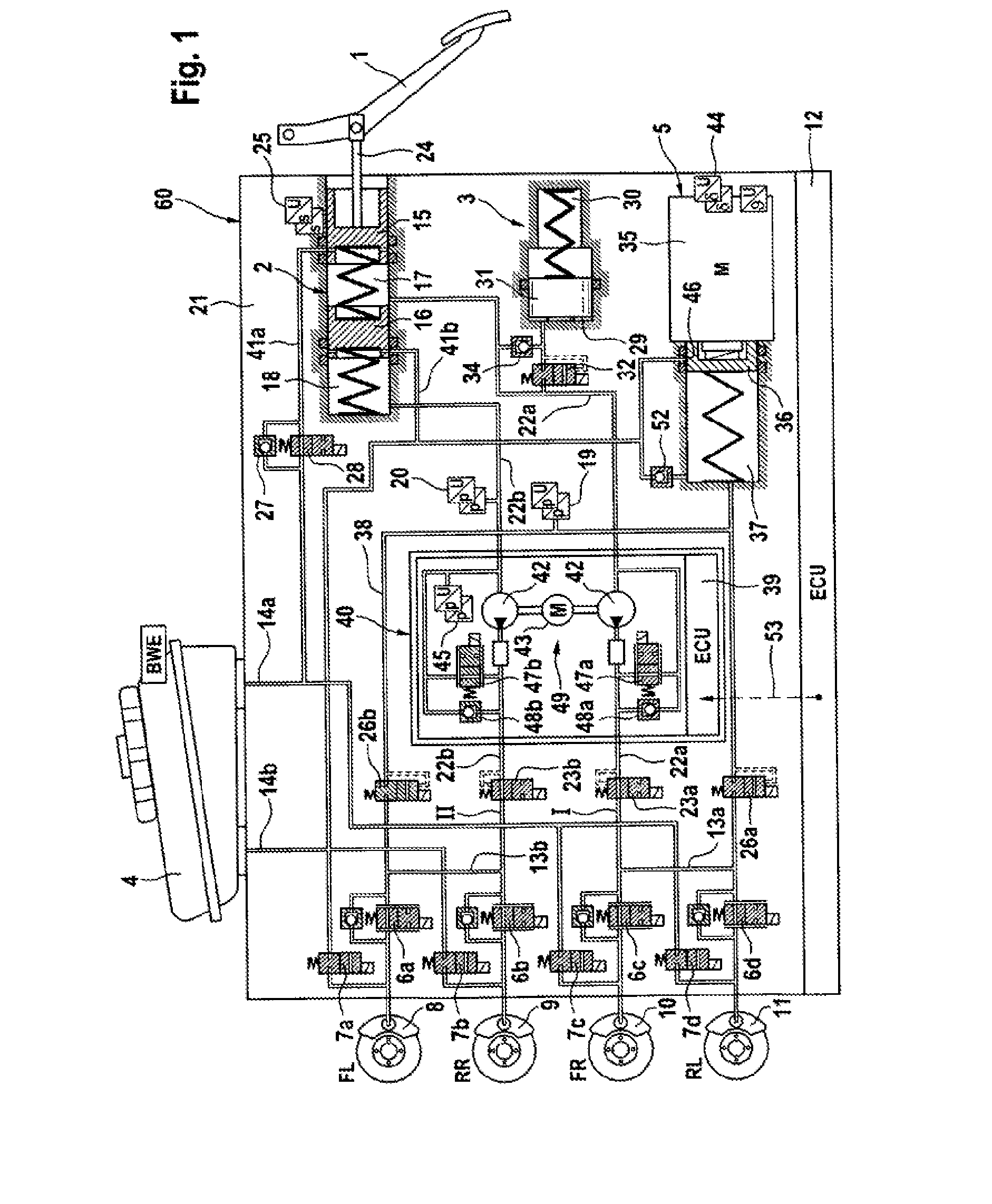

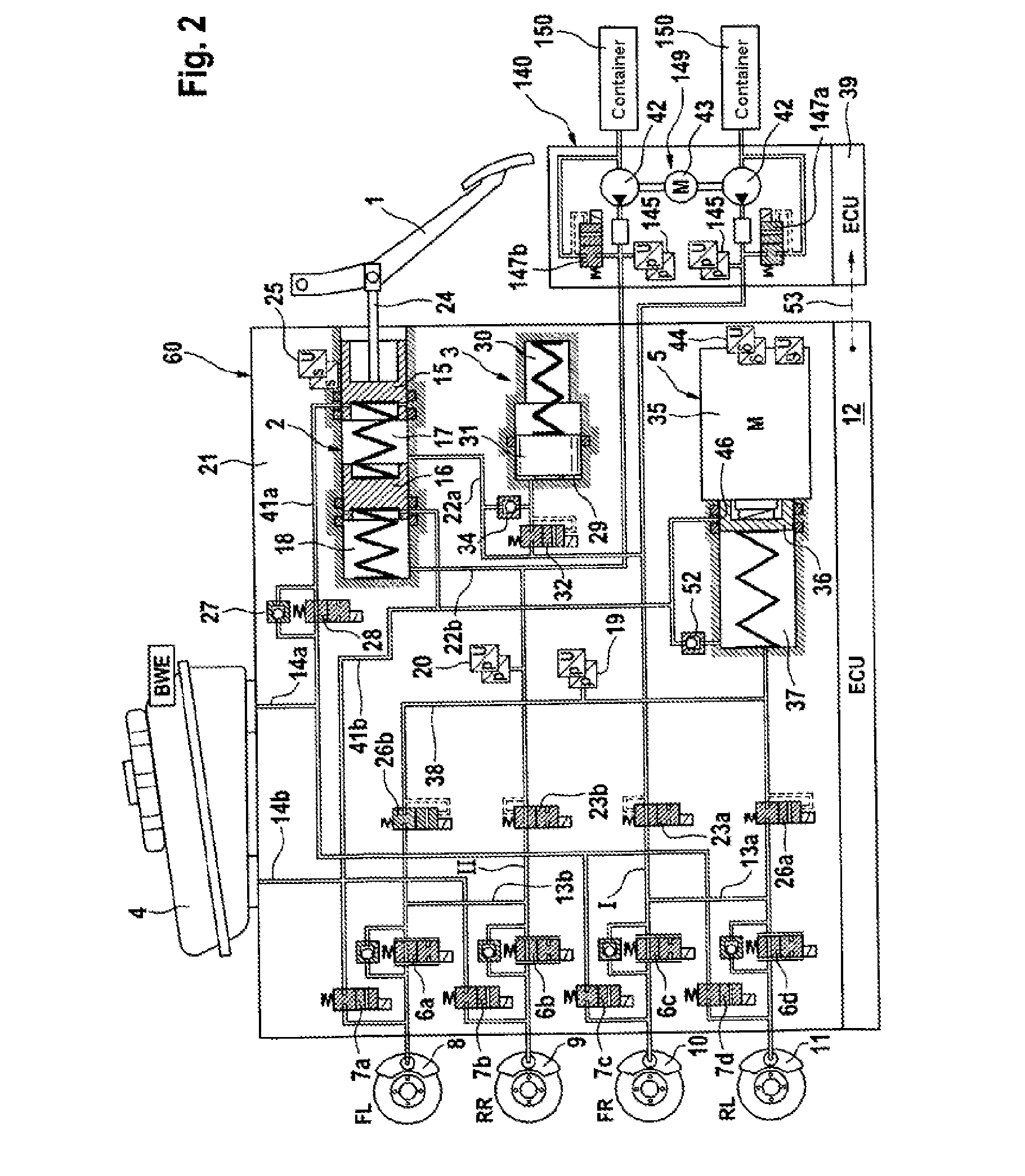

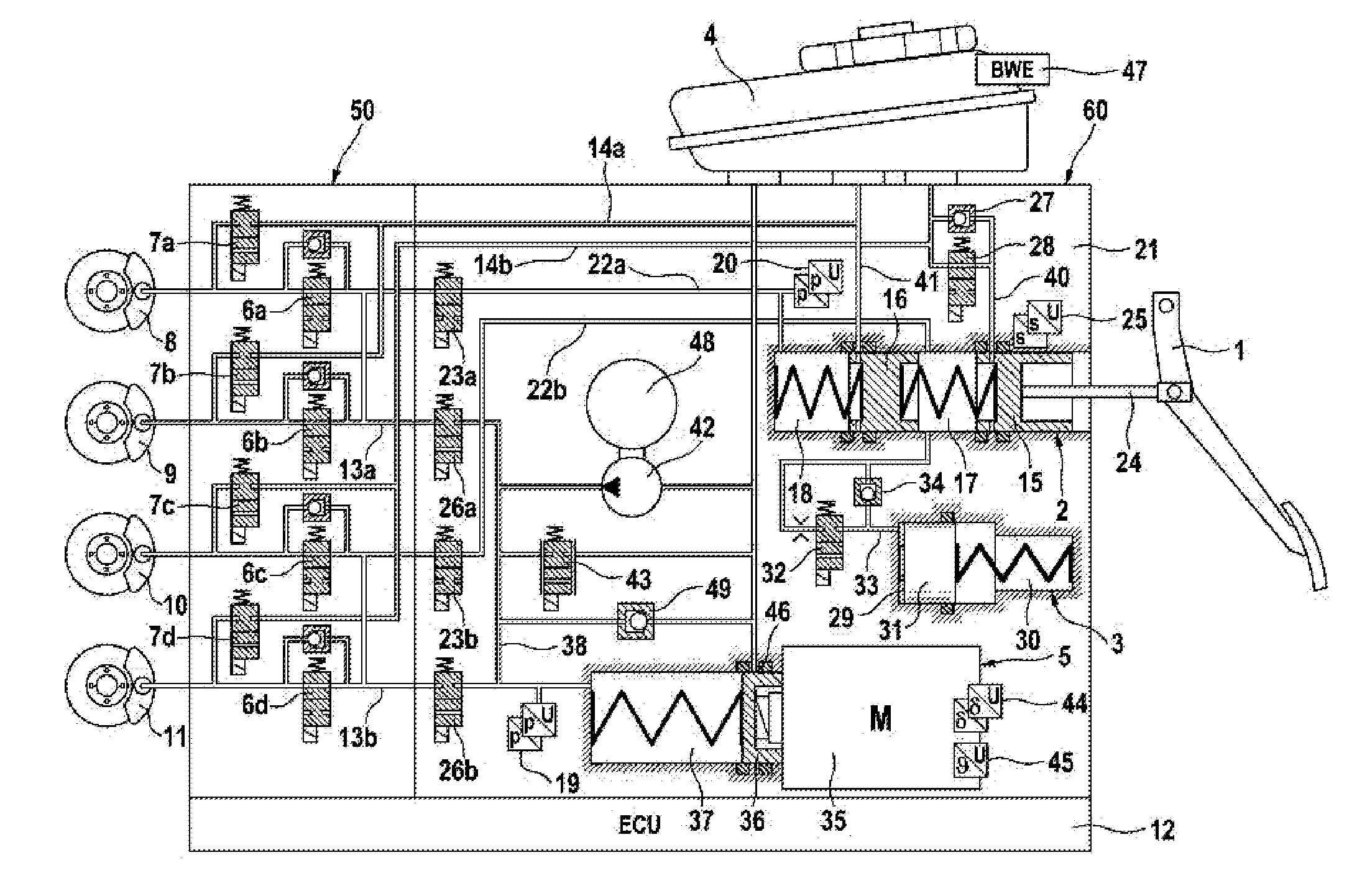

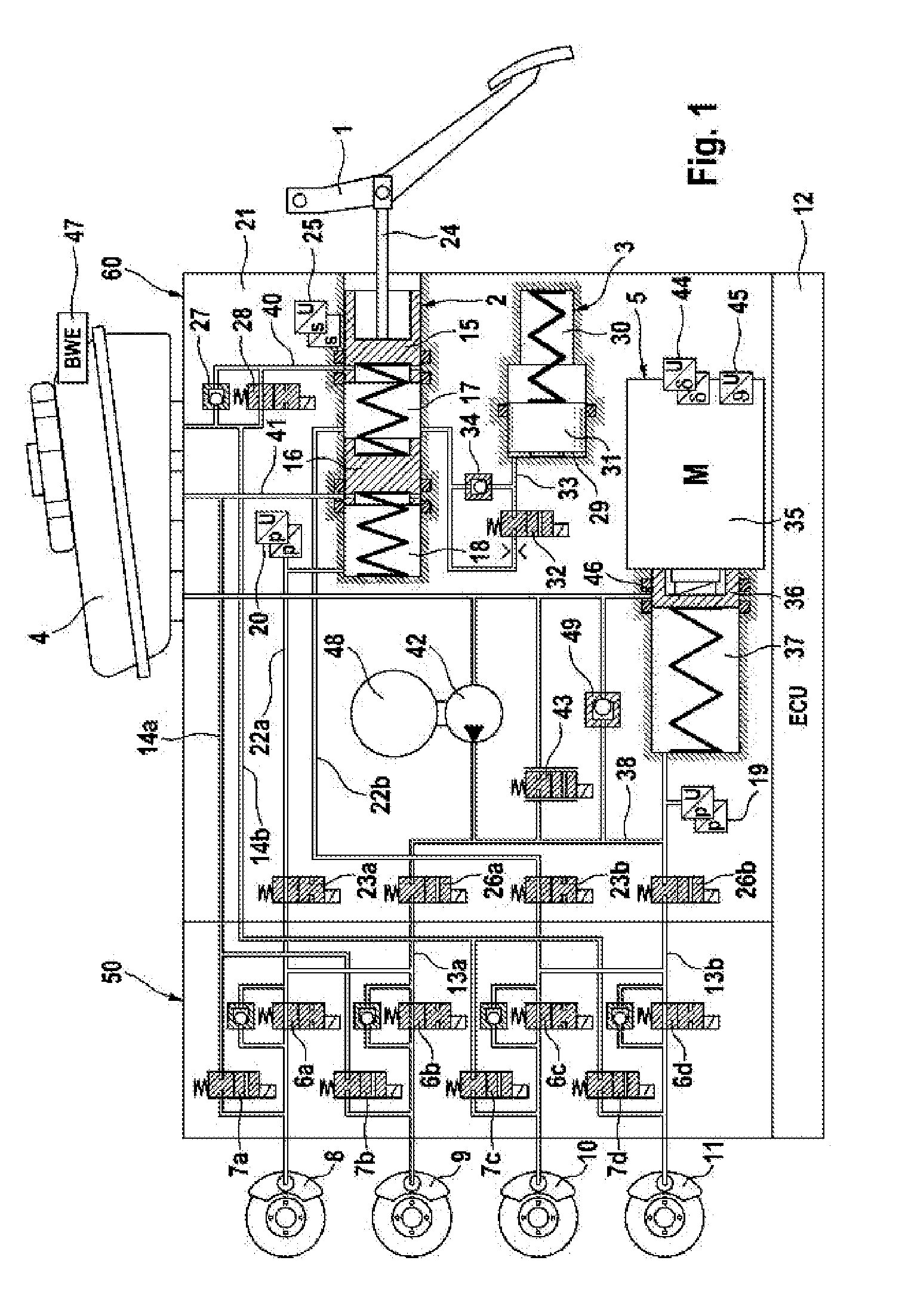

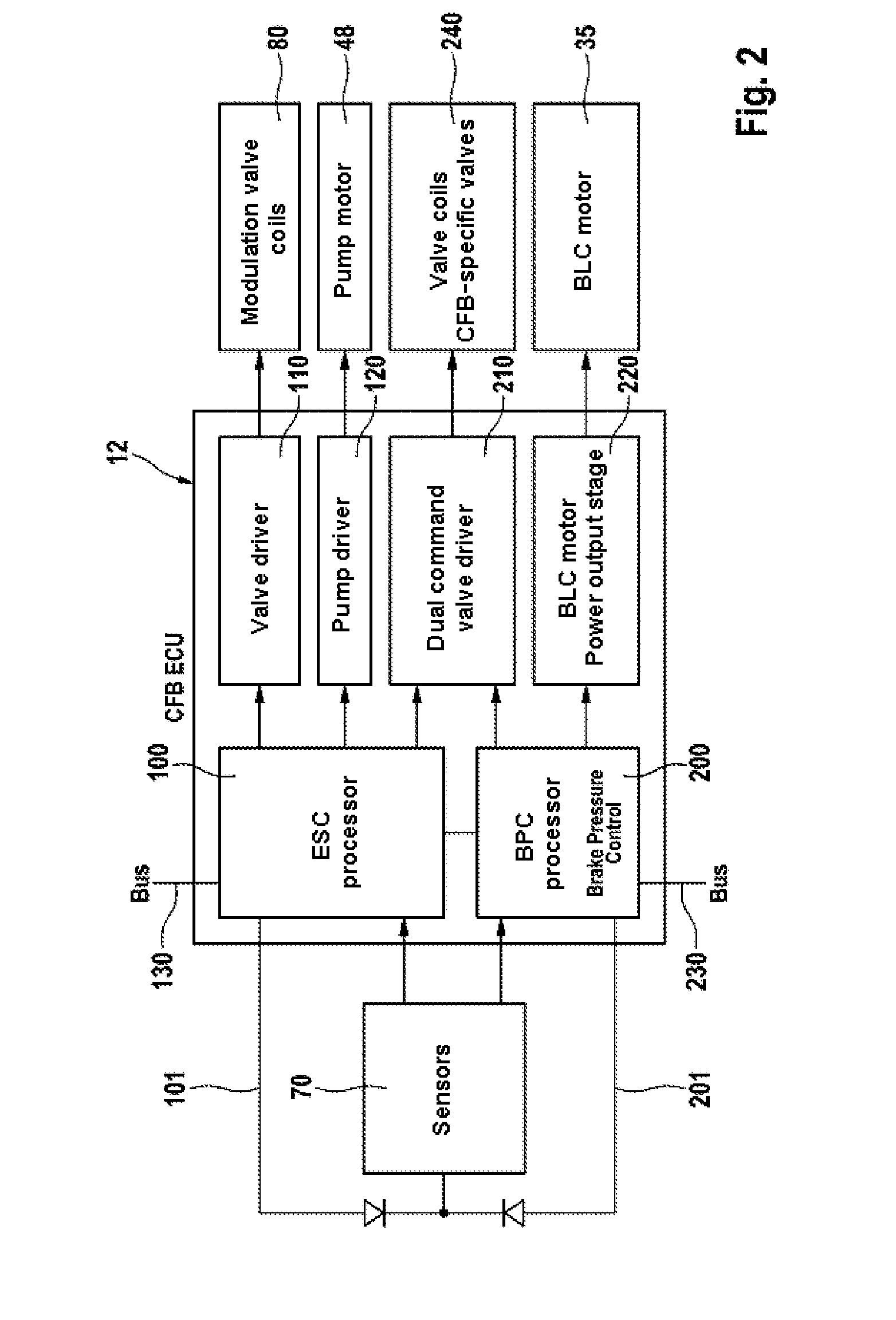

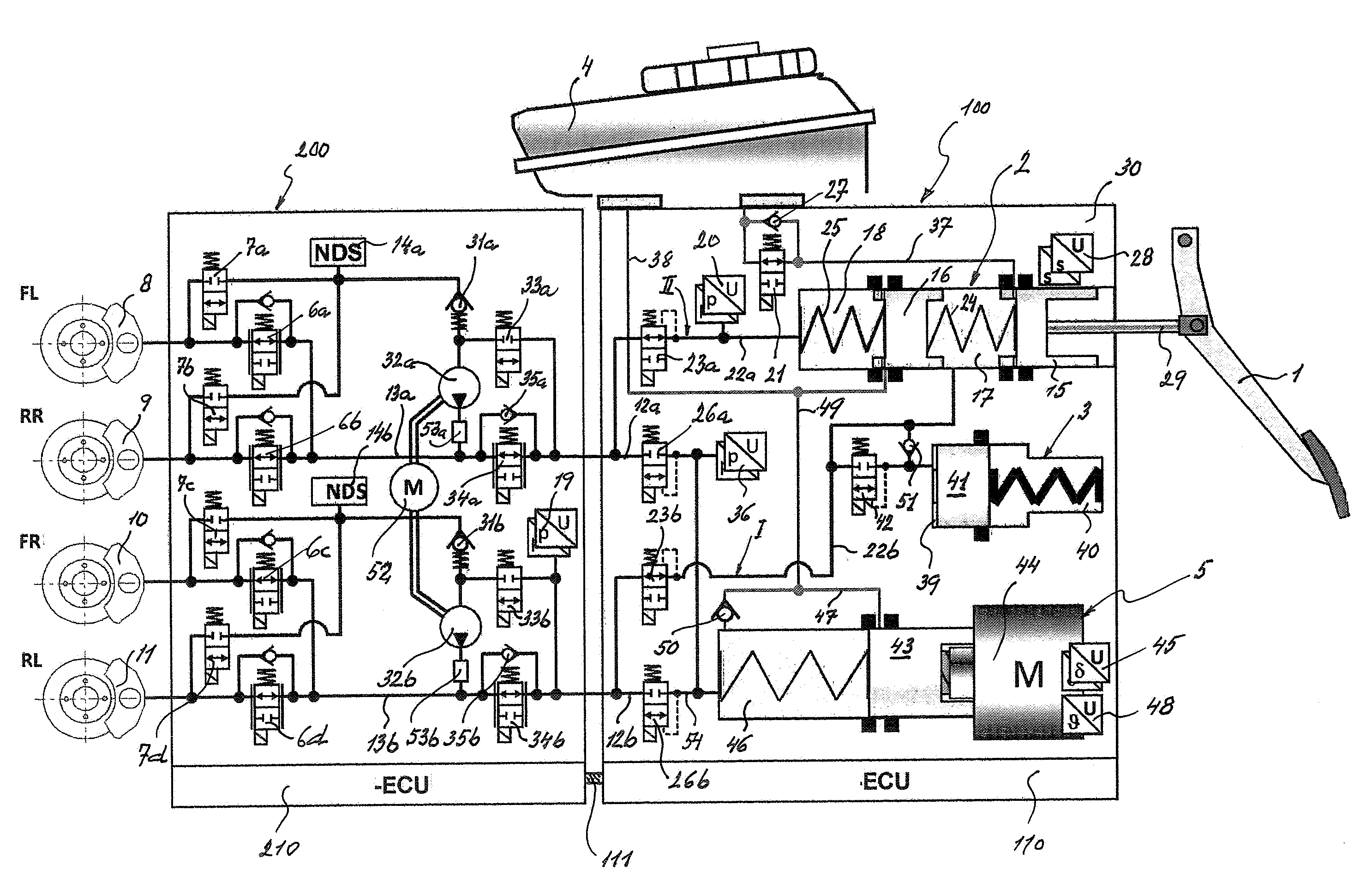

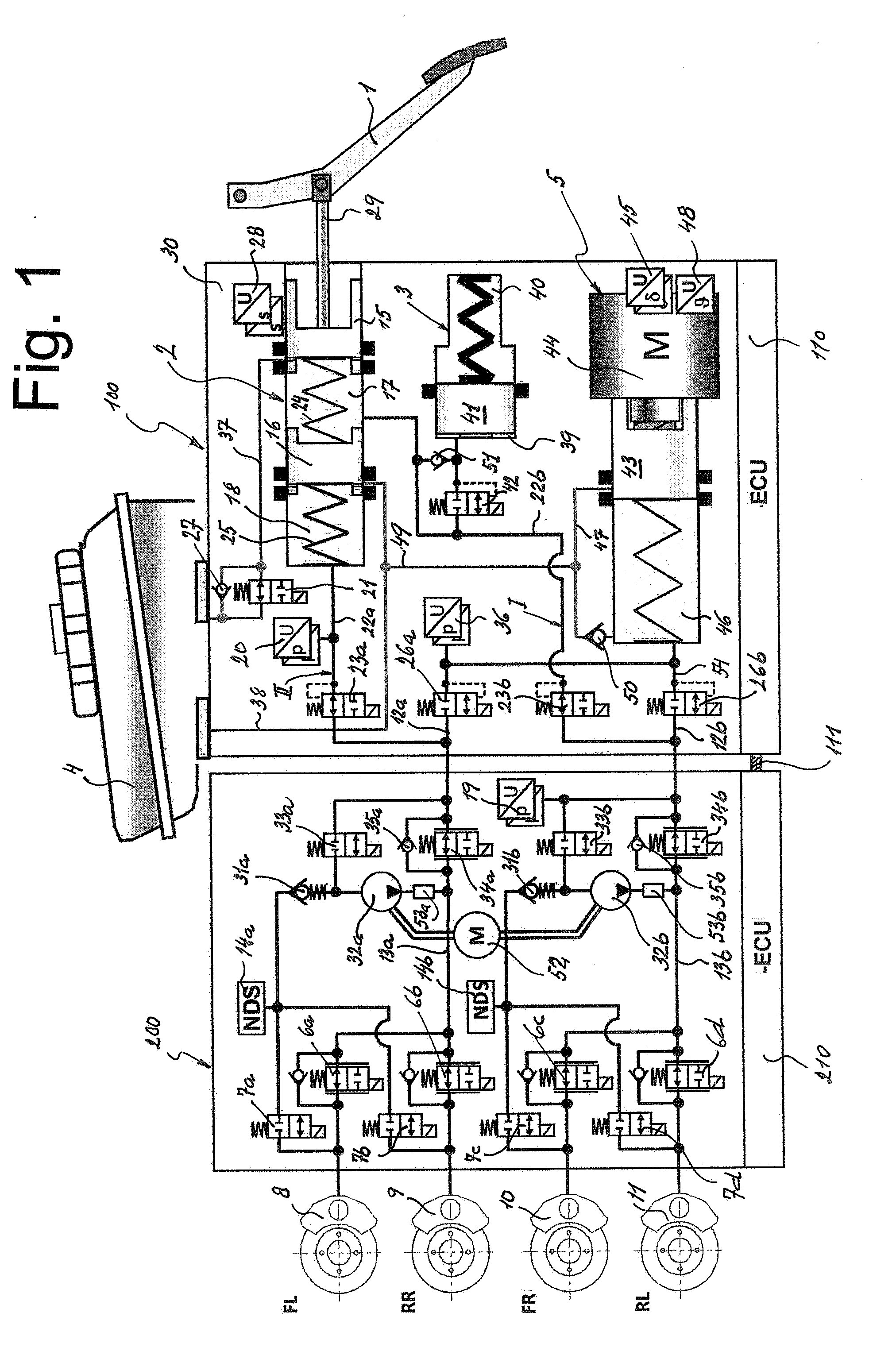

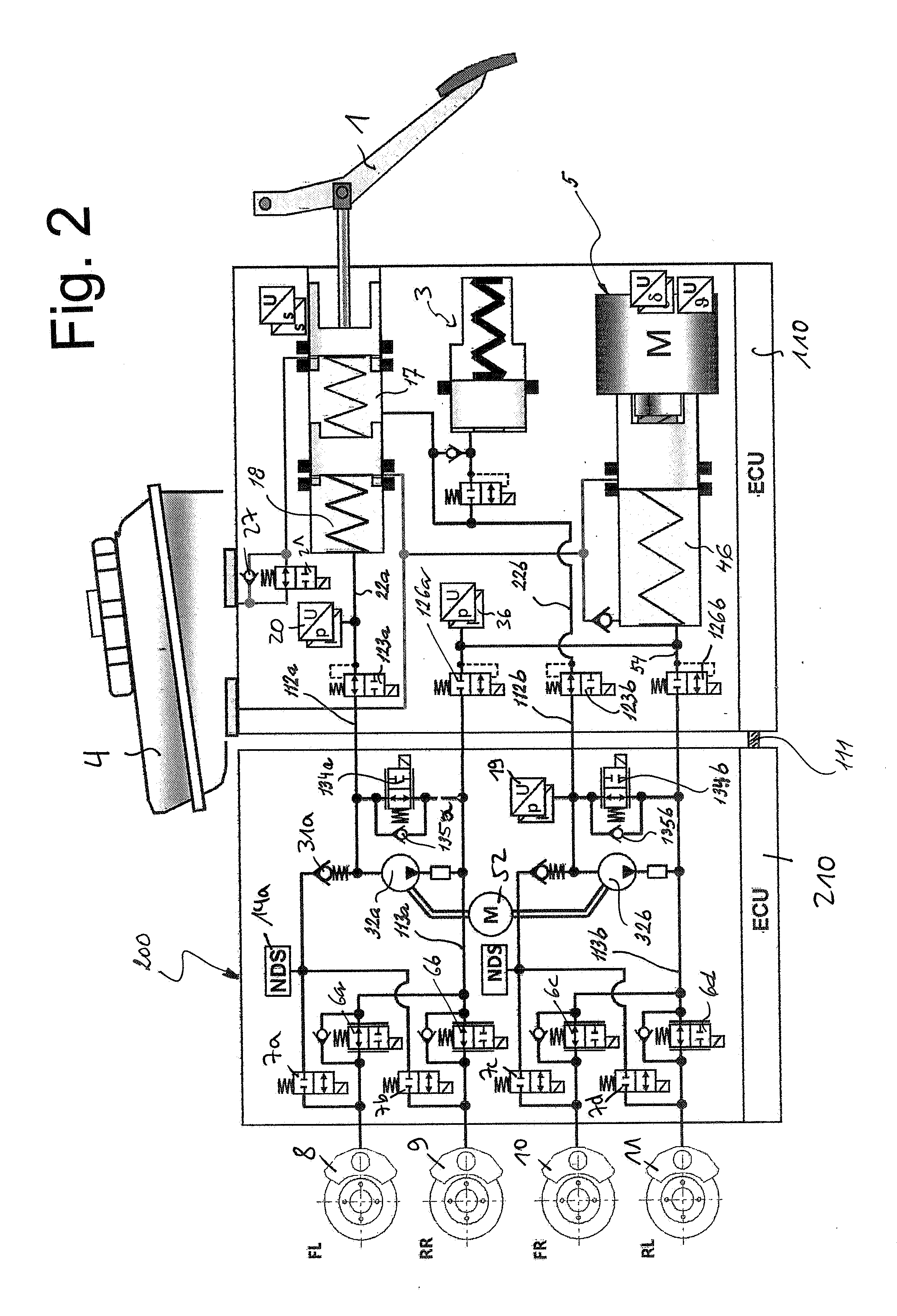

Brake System for Motor Vehicles

A motor vehicle brake system operable in a brake-by-wire and fallback modes. The system includes a brake pedal (1), a master cylinder (2), a reservoir (4), a travel simulator (3), an electrically controllable pressure source (5), isolation valves (23a, 23b) pumps (32a, 32b) and a low-pressure accumulator (14a, 14b), an inlet valve (6a-6d) and an outlet valve (7a-7d) for each wheel brake (8, 9, 10, 11), valves (34a, 34b; 134a, 134b) connected to the pumps (32a, 32b), and a control and regulation unit (110, 210). A valve arrangement (23a, 23b) establishes for each brake circuit (I, II) a connection from the pressure chamber (17, 18) of the master cylinder (2) to the modulator admission pressure line (13a, 13b; 113a, 113b) and disconnects the connection when unenergized, the valve arrangement (23a, 23b) preventing the pressure source (5) from being subjected to pressure from the pressure chambers (17, 18).

Owner:CONTINENTAL TEVES AG & CO OHG

Brake System for Motor Vehicles

ActiveUS20130147259A1Sufficient forceEasy to manufactureFoot actuated initiationsFluid braking transmissionMobile vehicleMaster cylinder

A brake system for motor vehicles comprising a brake master cylinder which can be activated by means of a brake pedal and to which wheel brakes are connected. The brake system also comprises an electrically controllable pressure-generating device, a pressure-regulating valve arrangement to regulate a wheel brake pressure set at a wheel brake, a first electronic control and regulating unit which controls at least one of the pressure-generating device, the pressure-regulating valve arrangement, and an electrically controllable auxiliary pressure-generating device by means of which the brake master cylinder can be activated by means of which a pressure in an intermediate chamber of the brake master cylinder can be controlled or regulated.

Owner:CONTINENTAL TEVES AG & CO OHG

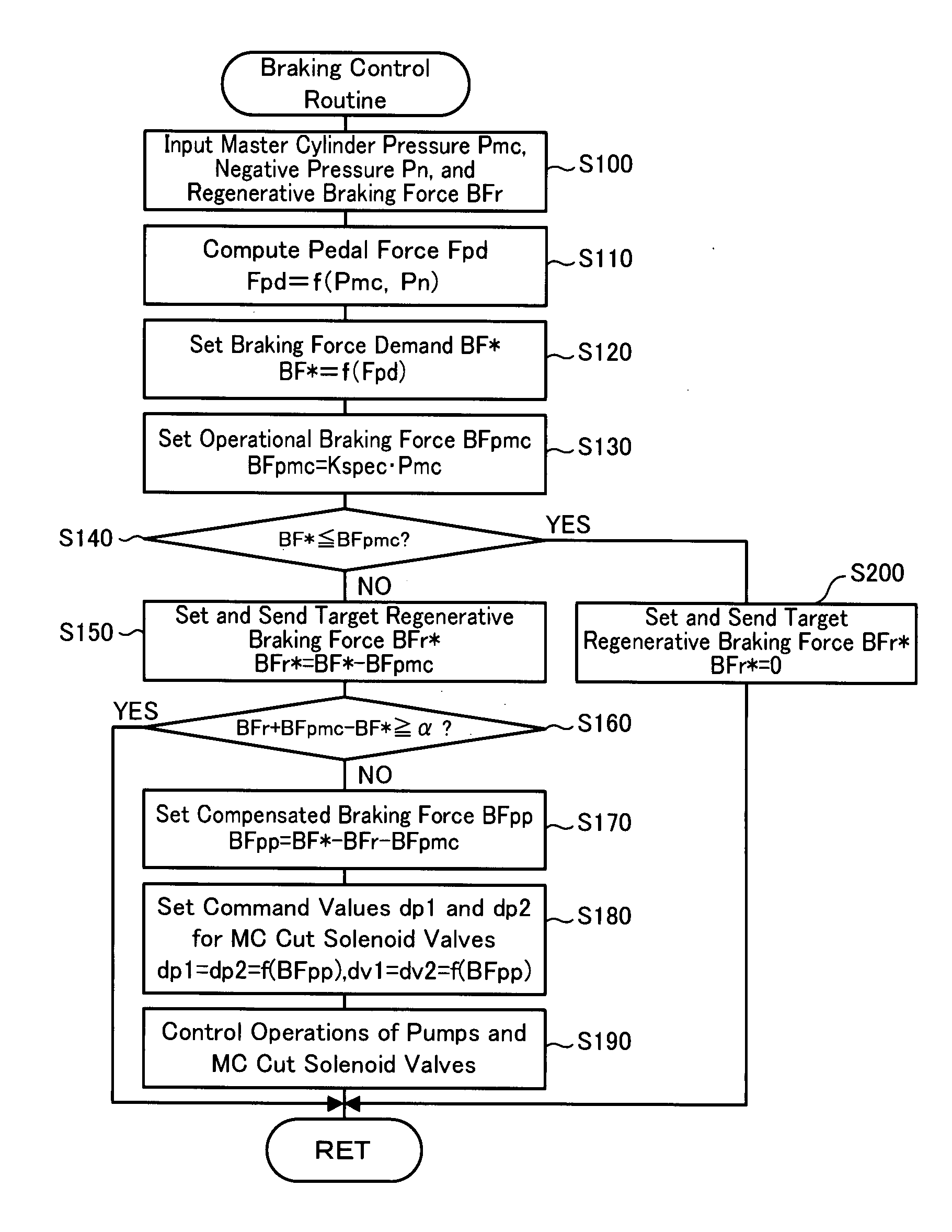

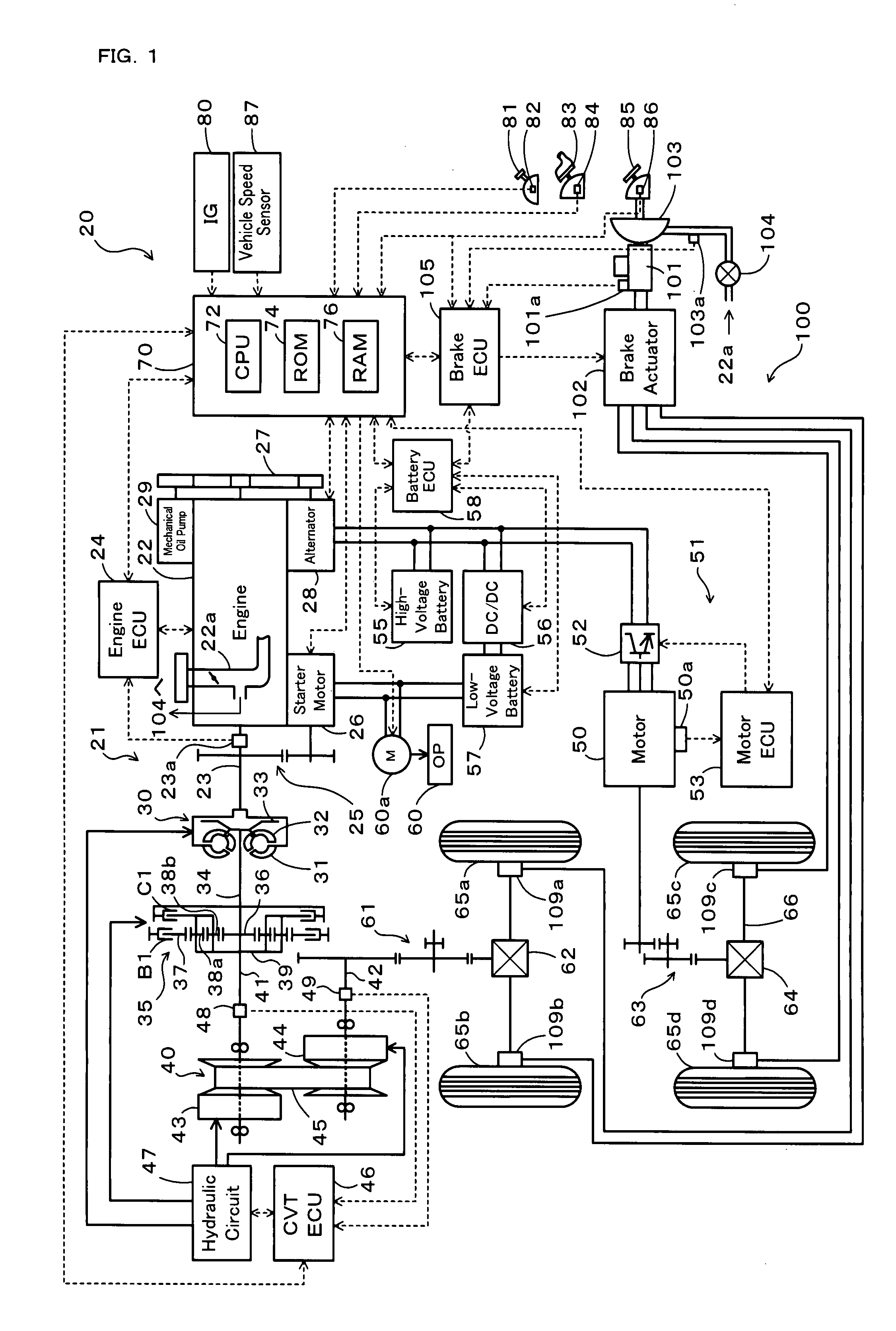

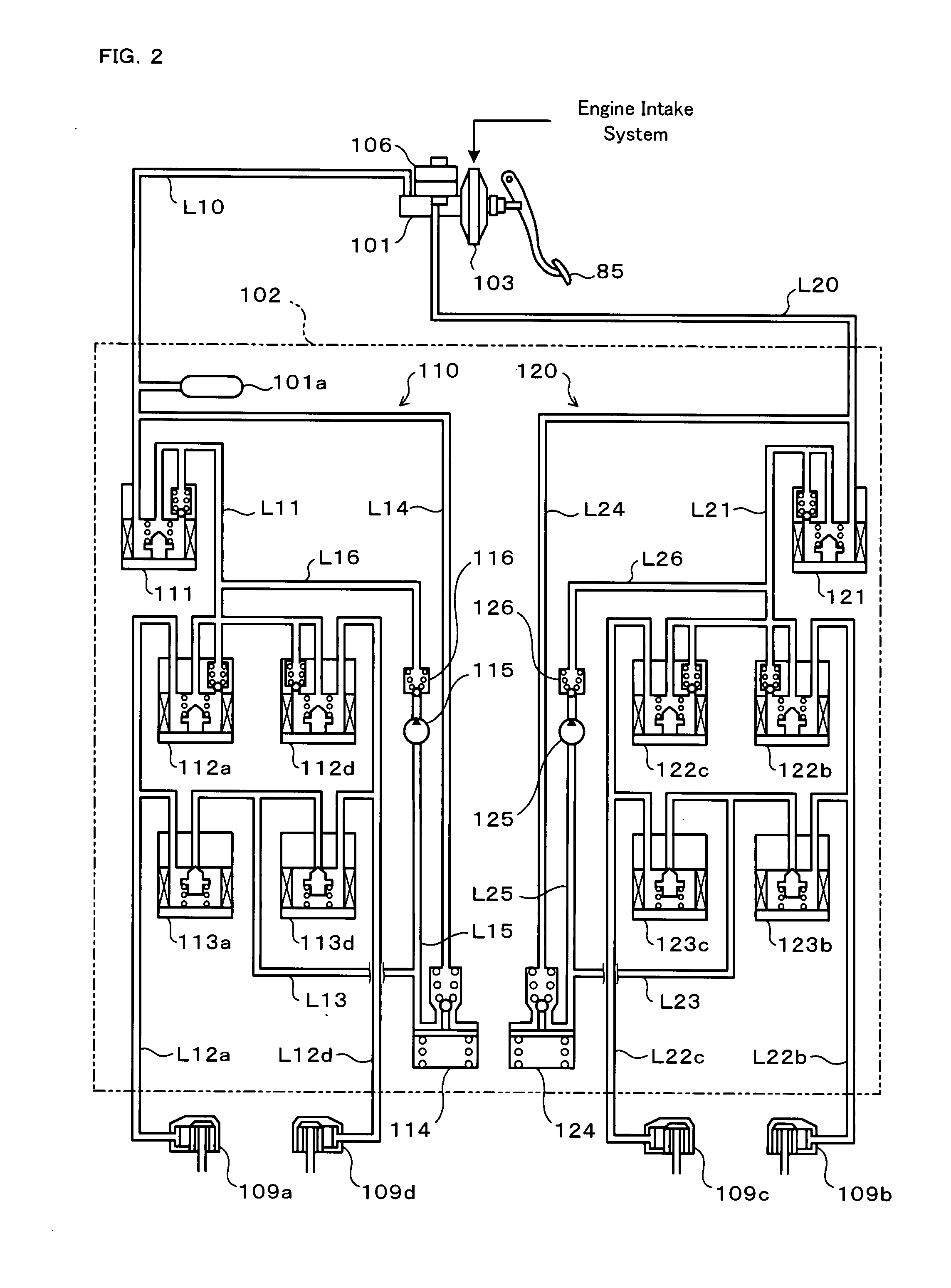

Vehicle and control method of vehicle

InactiveUS20070273204A1Reduce potential differenceAvoid discomfortBrake control systemsPlural diverse prime-mover propulsion mountingDriver/operatorMaster cylinder

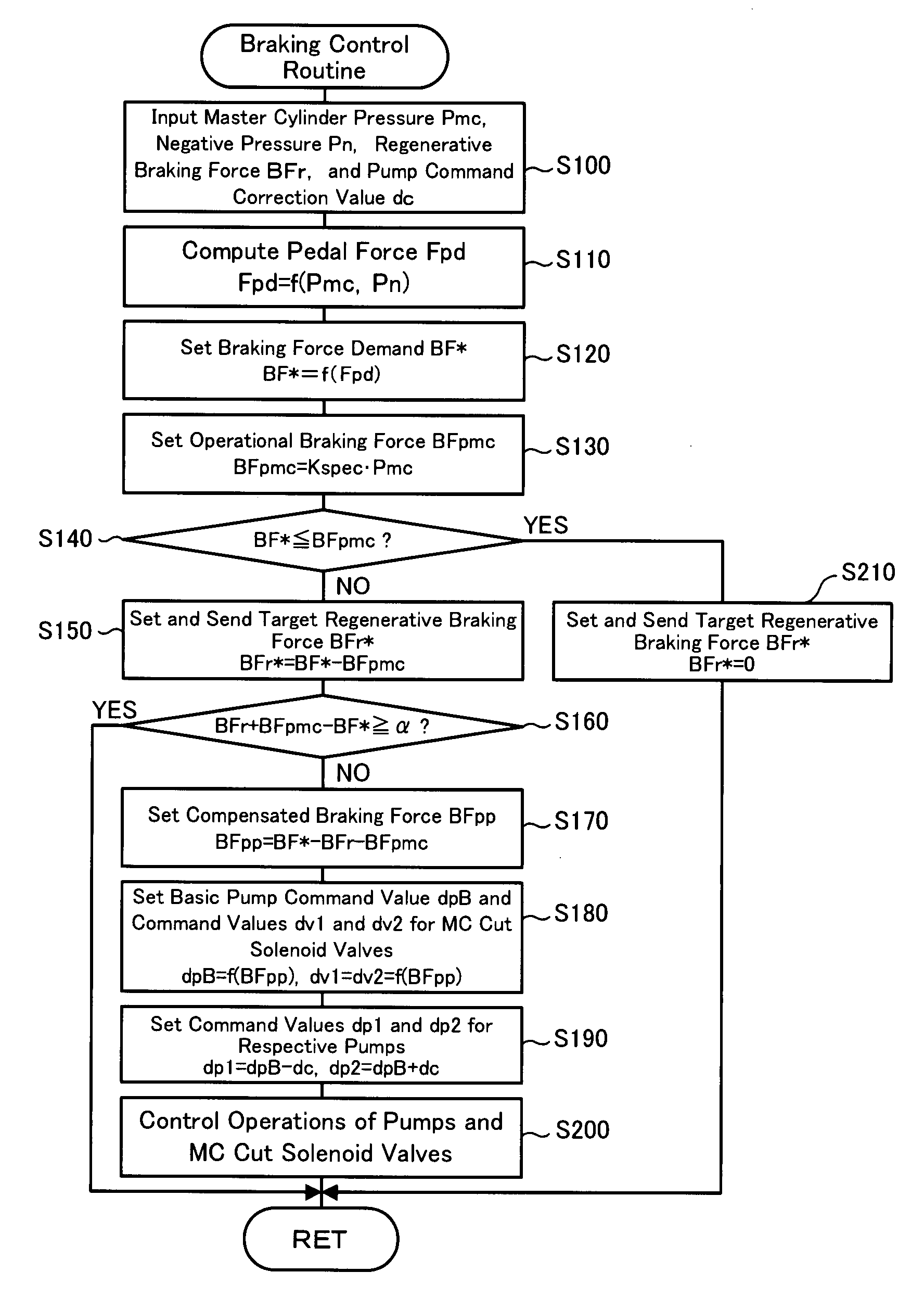

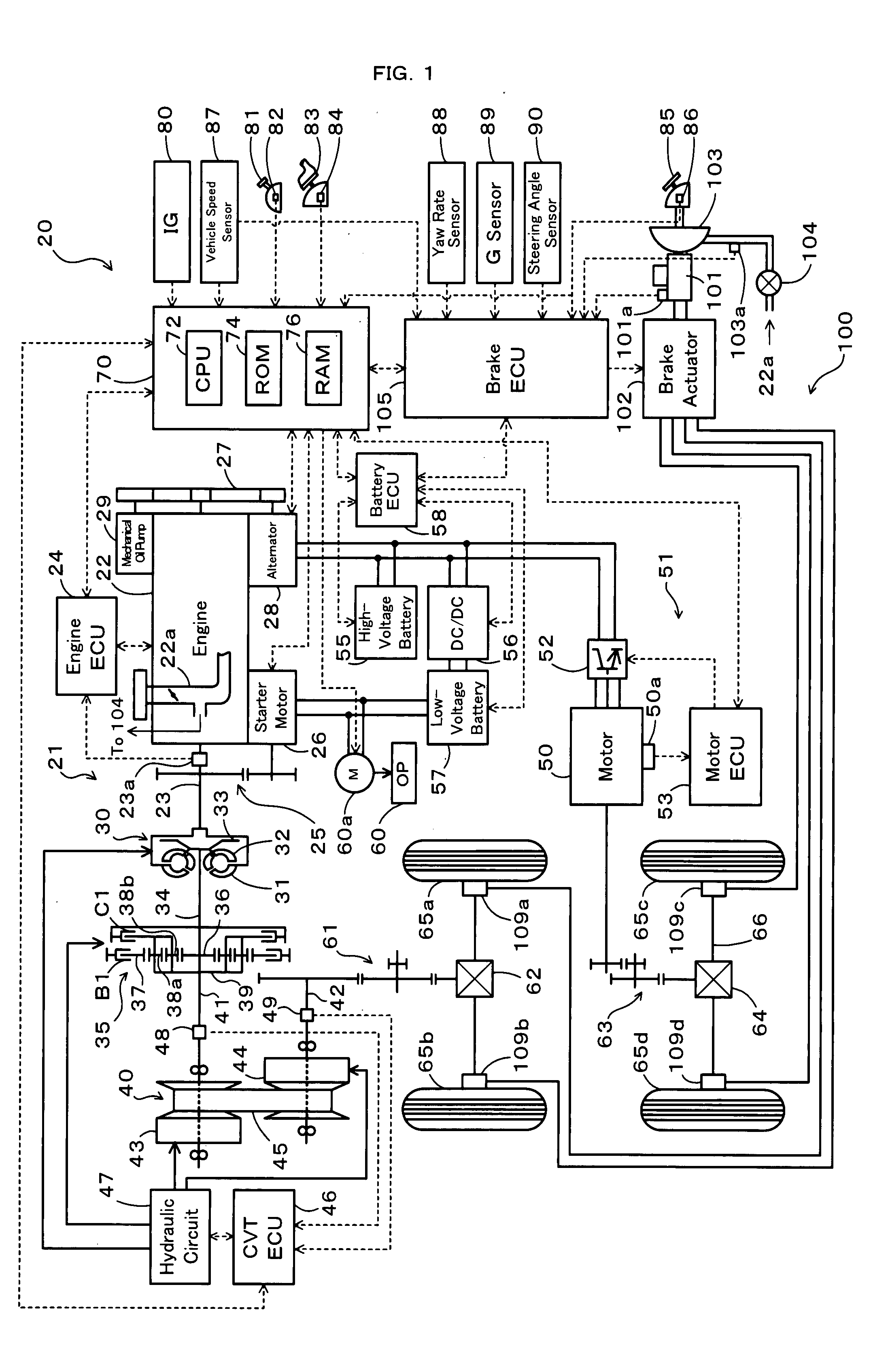

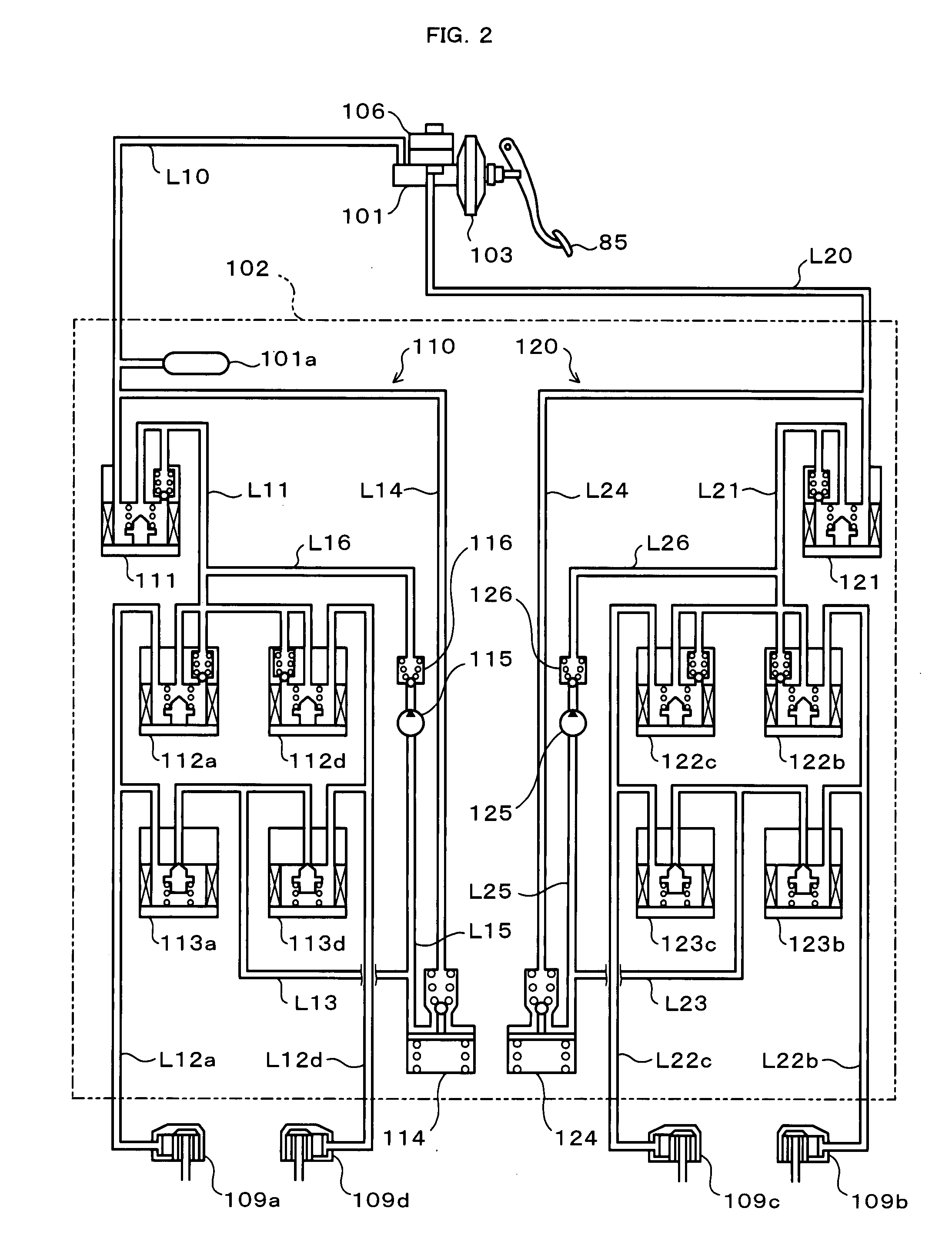

In response to the driver's depression of a brake pedal, the hybrid vehicle of the invention utilizes both a master cylinder pressure Pmc and a pressure increase by two pumps included in two different braking systems of a brake actuator in an HBS to satisfy a braking force demand BF* required by the driver. In this case, the braking control of the invention corrects a basic pump command value dpB for the respective pumps with a pump command correction value dc (step S190), which is set according to a detected behavior of the hybrid vehicle in a braking state, and controls the brake actuator in the HBS to satisfy the braking force demand BF* (steps S170 to S200).

Owner:TOYOTA JIDOSHA KK

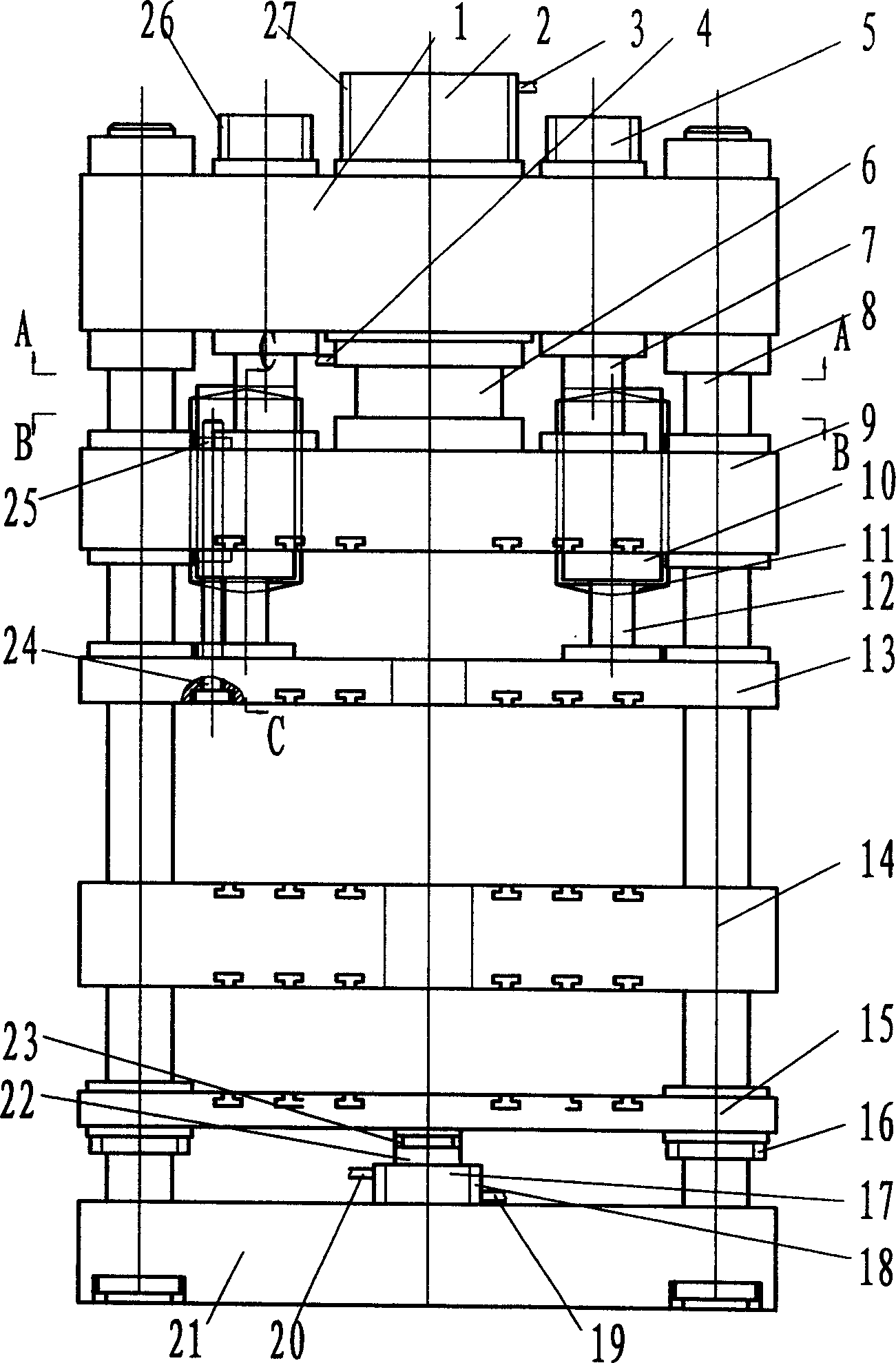

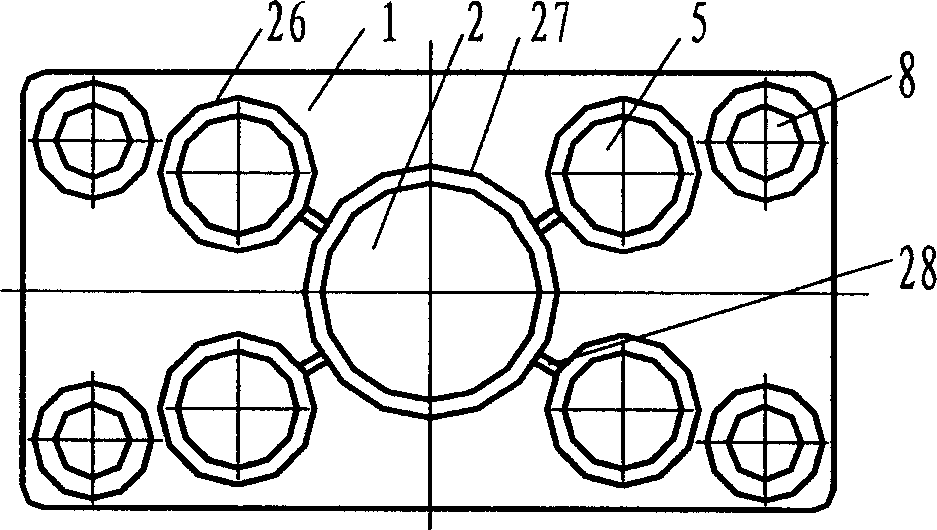

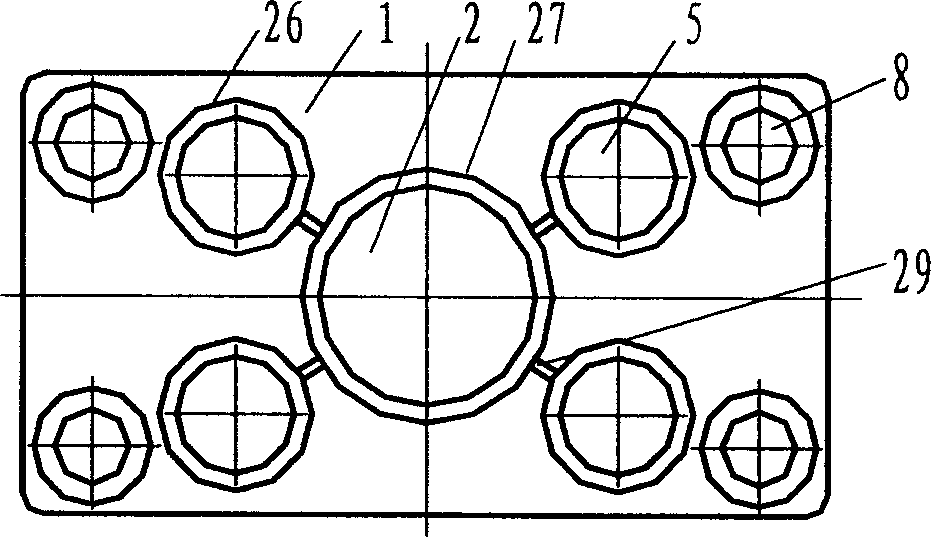

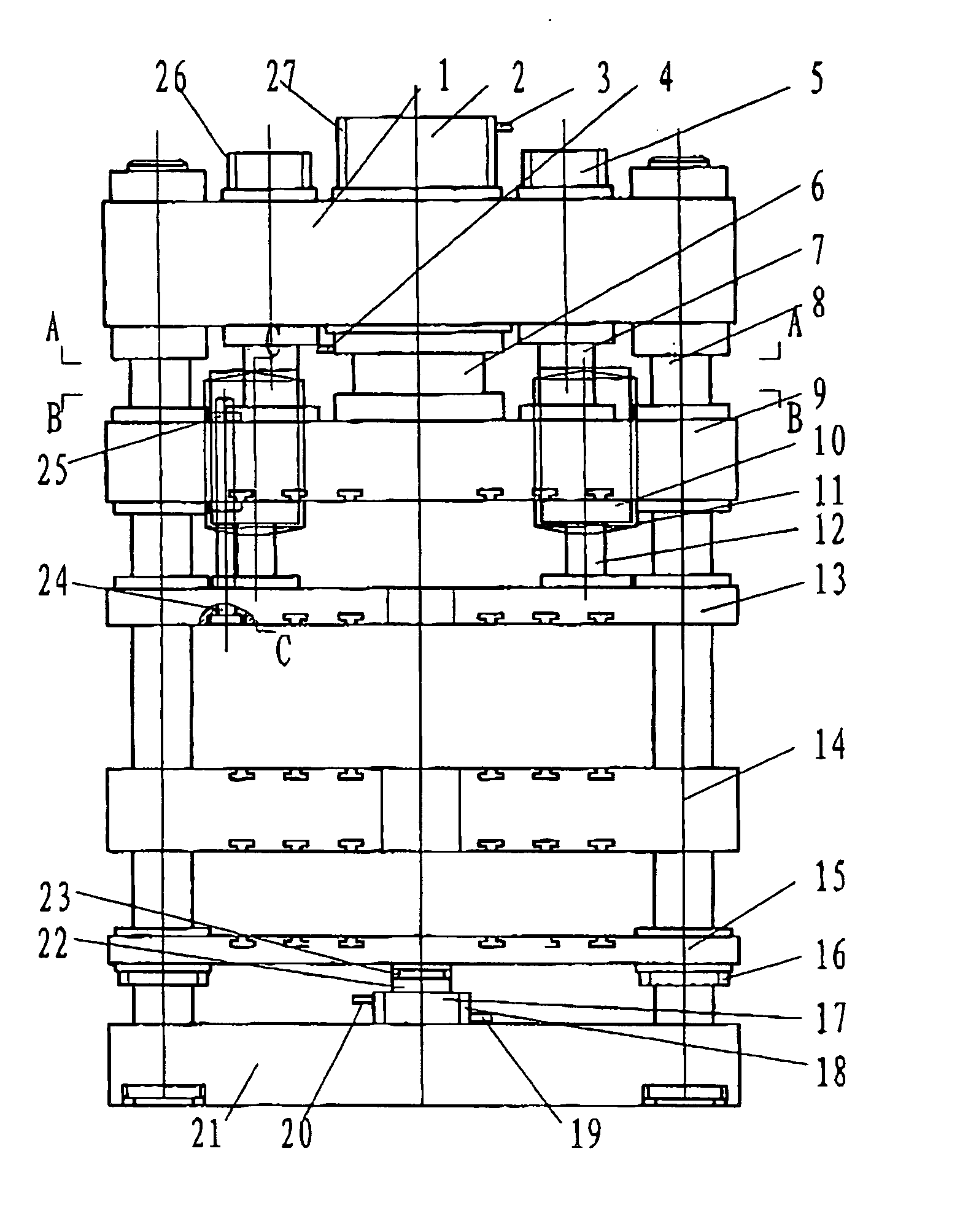

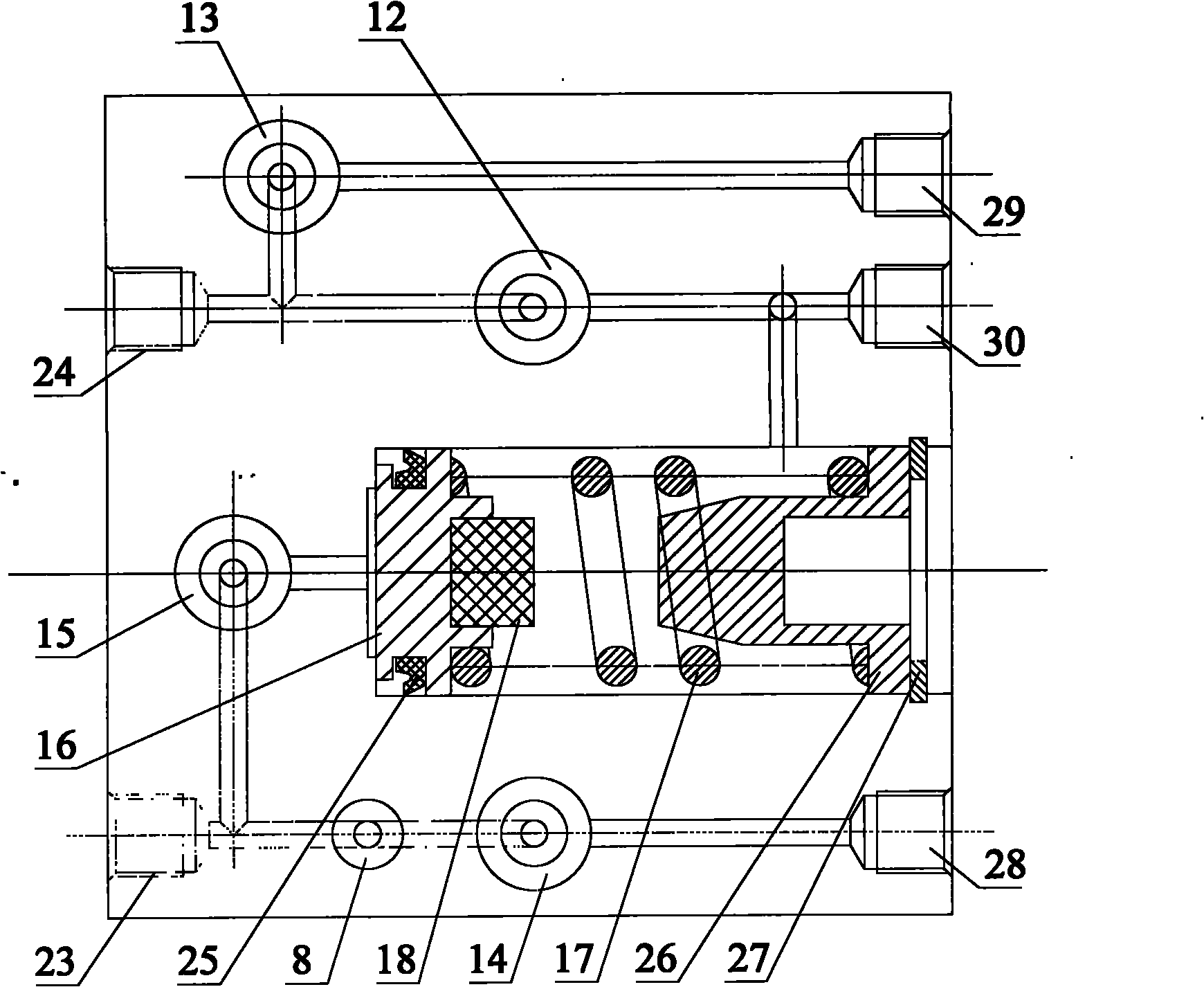

Adjustable Hydraulic Press With Both Upper And Lower Double Action

ActiveUS20080098908A1Innovative designSimple structureShaping toolsForging/hammering/pressing machinesMetal formingGear wheel

The present invention discloses an adjustable hydraulic press with both upper and lower double action, specially suitable for the cylindrical gear formed by stamping or expanding, closed forging and the metal cold forming or metal hot forming of punching, finishing, flanging and drawing of sheet materials. The press comprises four columns, an upper beam, a main slide block, a hold down slide block, a fixing worktable, a floating worktable and a lower beam. The hydraulic chamber of master cylinder fixed in the upper beam communicates to the hydraulic chamber of the auxiliary cylinder, the plunger of master cylinder is connected to the main slide block and drives it. The hydraulic chamber of gas-liquid power accumulator fixed in the main slide block communicates to the hydraulic chamber of hold down cylinder, the plunger of hold down cylinder is connected to the hold down slide block and drives it. The plunger of ejecting cylinder fixed in the lower beam is connected to the floating worktable and drives it. The hydraulic press of the invention simplifies the hydraulic system of the existing hydraulic, improves utilization rate of energy, production efficiency and working accuracy of workpiece.

Owner:JILIN UNIV

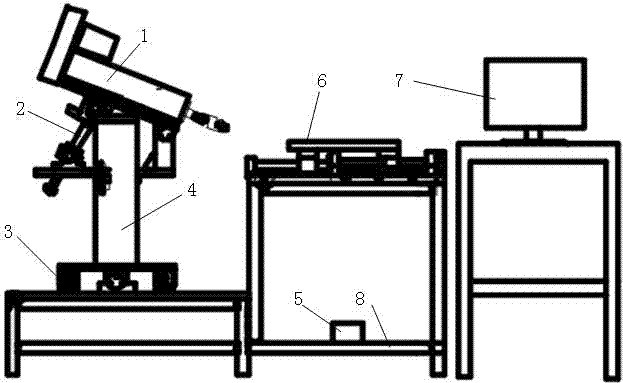

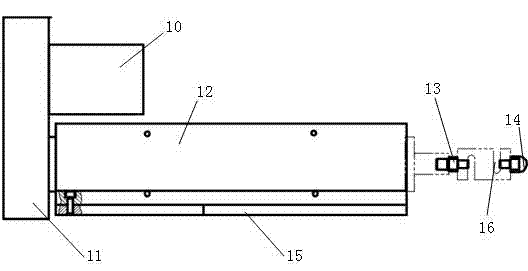

Automobile pedal operating mechanism assembly performance test board

ActiveCN102353544AShorten the development and trial production cycleReduce test costsVehicle testingMachine gearing/transmission testingElectricityControl system

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

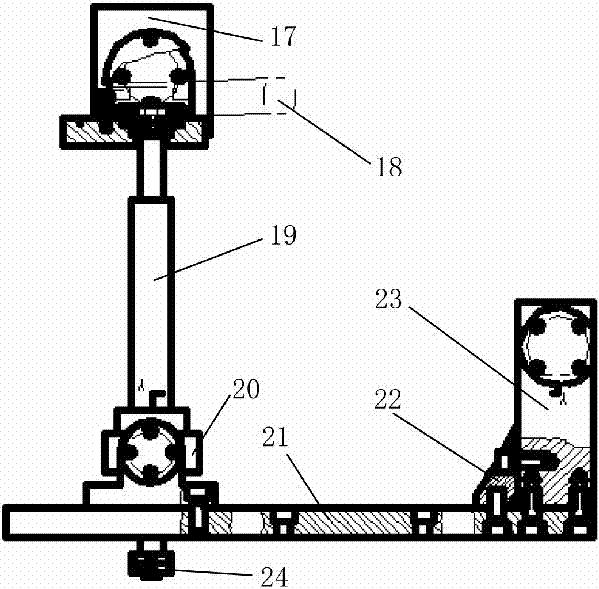

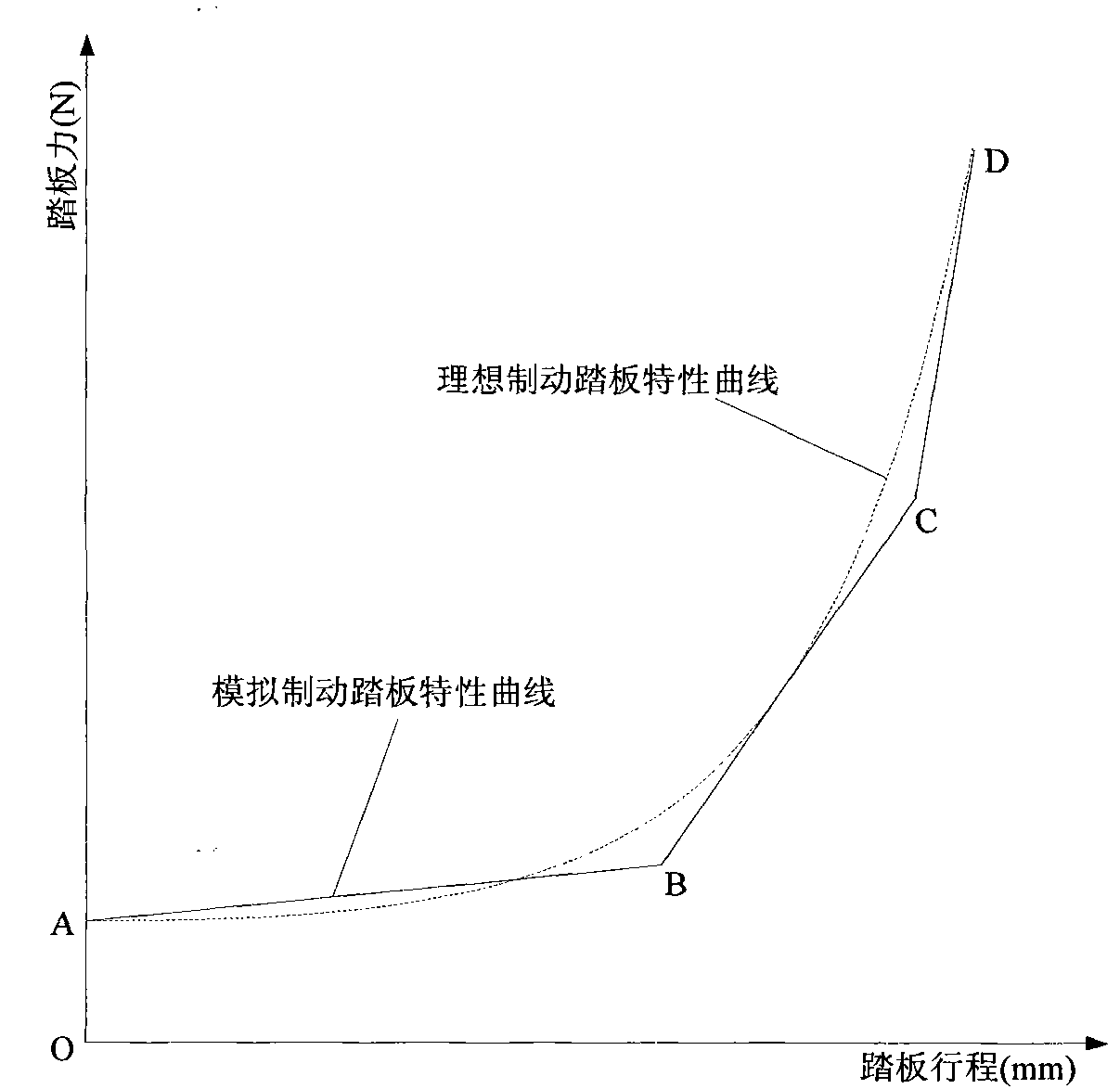

Simulator for feeling automobile brake pedal

ActiveCN101879891ASimple structureSimple designFoot actuated initiationsDriver/operatorMaster cylinder

The invention discloses a simulator for feeling an automobile brake pedal, comprising an oil storage cup, a brake master cylinder and a brake pedal which is provided with a pedal stroke sensor; a simulator valve block is connected between the first chamber and second chamber of the brake master cylinder and an ABS valve block; the hydraulic oil in the first chamber of the brake master cylinder is accessed into the simulator valve block and then is divided into two paths after passing a pressure sensor; one path of the hydraulic oil in series connection with a third electromagnetic valve is connected with the ABS valve block, the other path in series connection with a fourth electromagnetic valve is connected with stimulator-free spring chamber of a stimulator cylinder body; the hydraulic oil in the second chamber of the brake master cylinder is accessed into the simulator valve block and then is divided into two paths; one path of the hydraulic oil in series connection with a second electromagnetic valve is connected with the ABS valve block, the other path in series connection with a first electromagnetic valve is connected with the oil storage cup; and the stimulator spring chamber of the stimulator cylinder body is connected with the oil storage cup. The simulator has simple structure, is convenient for being installed in an automobile, can accurately obtain the brake intention of a driver and truly feed back the feeling of the driver stamping the pedal, and can realize emergent brake function of an electronic control braking system; and the property of the pedal is stable.

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

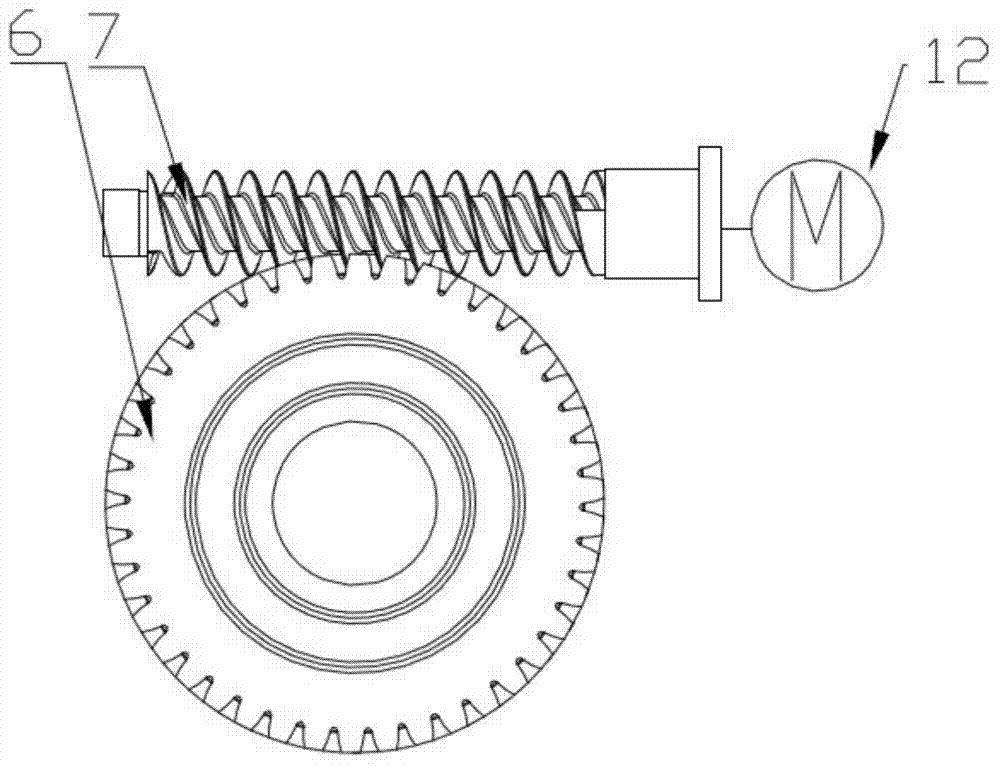

Force aid system for braking

ActiveCN1872599ASimple structureCompact structureBraking action transmissionMaster cylinderSystem structure

A boosting system for the braking of electric car or the car with mixed power system is composed of the push rod of pedal, reactive rubber disc, the push rod of master cylinder, braking pedal, casing, electric motor, worm-gear set, nut, spring, piston, restoring springs, baffle ring and bearings.

Owner:BYD CO LTD

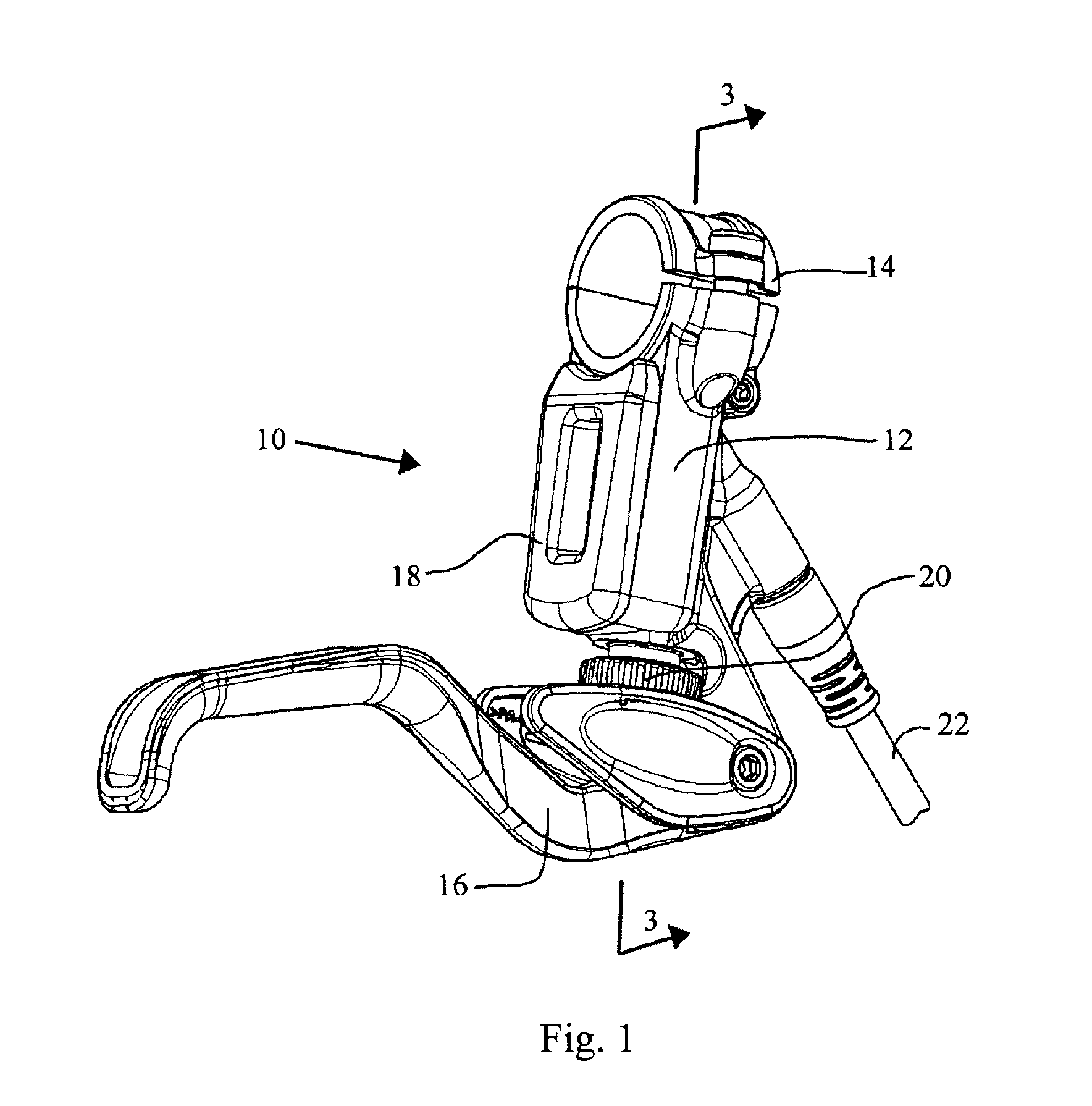

Bicycle hydraulic brake accentuate device

ActiveUS20070283692A1Improved master piston movement responseImproved brake responseRotary clutchesTelemotorsRest positionMaster cylinder

A bicycle hydraulic brake actuation device includes a hydraulic master cylinder housing having a bore and a push rod guide surface, a master piston and a radial seal received in the bore, a push rod and a lever. The push rod is supported by the push rod guide surface for sliding movement within the hydraulic master cylinder housing. The push rod is configured to move the master piston and the radial seal from a neutral position to a braking position. The lever is pivotally attached to the housing for pivotal movement between an at rest position and a brake actuation position. The lever is also configured and arranged to move the push rod and the master piston from the neutral position toward the braking position as the lever is pivoted between the at rest position and the brake actuation position.

Owner:SHIMANO INC

Hydraulic Brake Master Cylinder

A hydraulic brake master cylinder is provided that is compact and light in weight. The master cylinder has a reservoir shape that provides increased reservoir expansion volume. The master cylinder also provides gear shifter operation clearance and a comfortable lever that allows easy adjustment without the use of tools. The lever has defined increments of adjustment which make it easy to use. The invention also includes a method of bleeding air from the system without requiring reorientation of the master cylinder. The retention methods for the various lever embodiments shown allow for easy and inexpensive retention of the lever and also provide for reduced overall weight and cost.

Owner:HAYES BICYCLE GROUP

Vehicle and control method of vehicle

InactiveUS20070272457A1Reduce negative pressureAccurate settingAuxillary drivesBraking element arrangementsRegenerative brakeMaster cylinder

In the hybrid vehicle of the invention, when the sum of a regenerative braking force BFr produced by a motor and an operational braking force BFpmc based on a master cylinder pressure Pmc is insufficient for a braking force demand BF* required by the driver in response to the driver's depression of a brake pedal, the motor and a brake actuator of an HBS are controlled to satisfy the braking force demand BF* by the total of the regenerative braking force BFr of the motor, the master cylinder pressure Pmc-based operational braking force BFpmc, and a compensated braking force BFpp based on a pressure increase by two pumps included in the brake actuator (steps S170 through S190).

Owner:TOYOTA JIDOSHA KK

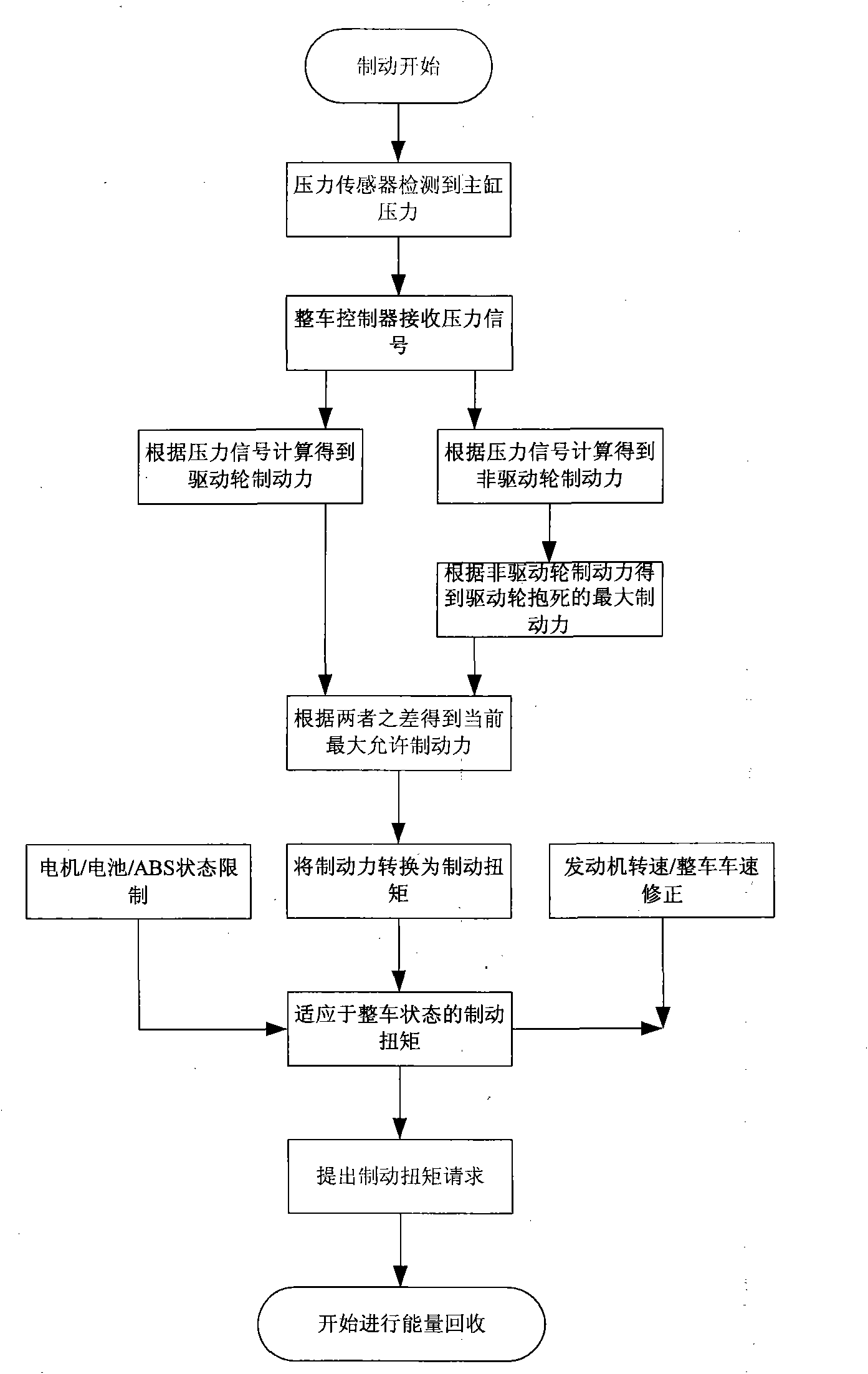

Electric vehicle energy recovery system and control method thereof

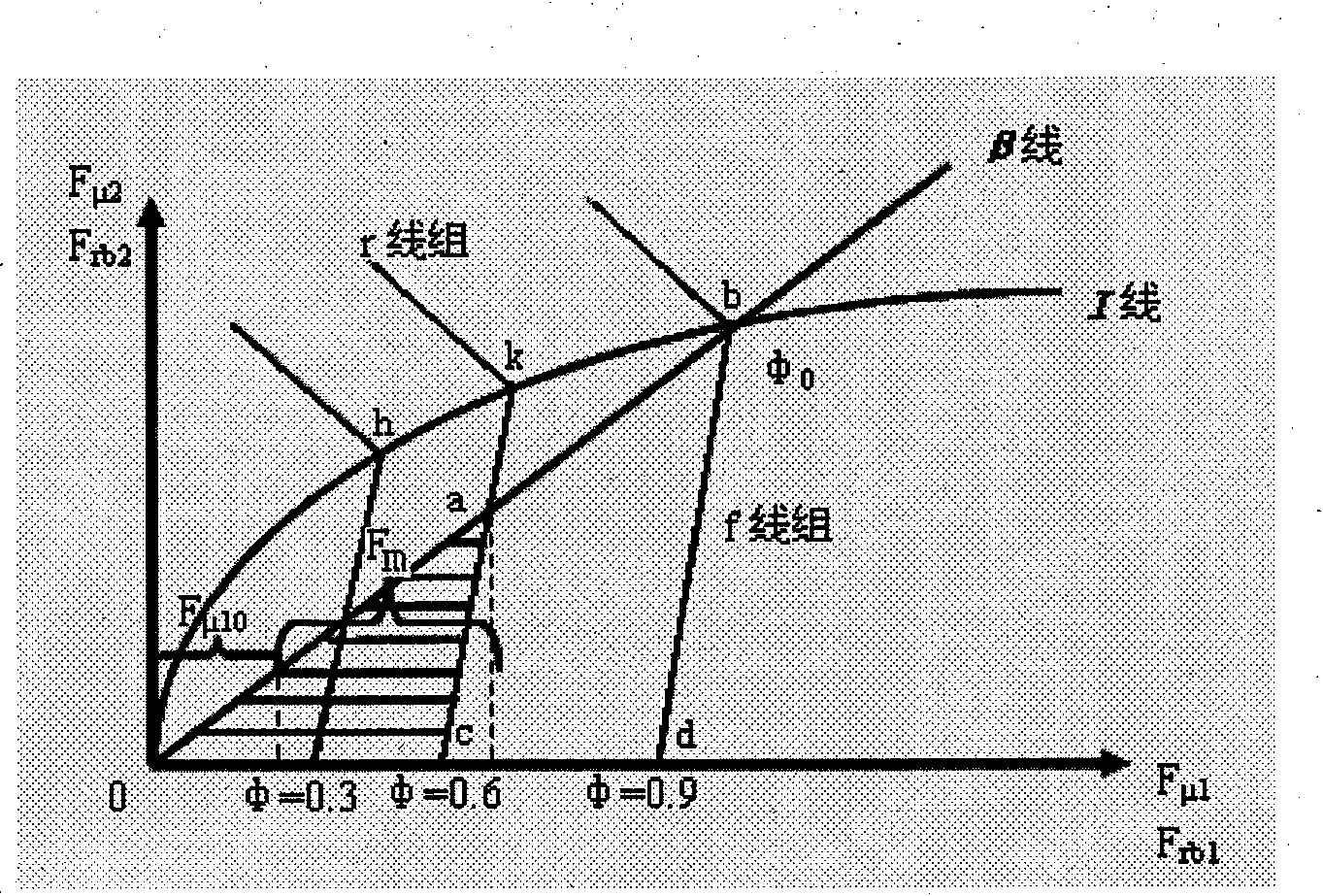

ActiveCN101979259AMaximum recoverySatisfy securitySpeed controllerElectrodynamic brake systemsAdhesion coefficientBrake torque

The invention discloses an electric vehicle energy recovery system and a control method thereof. On the basis of the pressure of a brake master cylinder of an electric vehicle, a maximal brake force Fm which is allowed to be applied to a current driving wheel is obtained by calculating according to a brake force distribution curve in an electric vehicle brake system design and a driving wheel locking curve when the electric vehicle travels on a road surface with an ideal synchronous surface adhesion coefficient; and the Fm is converted into a torque, namely a maximal motor brake torque which can be applied currently so that the overall vehicle energy of the electric vehicle can be recovered to the maximum. Simultaneously, the calculated brake torque is corrected according to the requirements on the drivability and the safety of a vehicle, so that brake energy can be recovered to the maximum on the premise of ensuring the drivability and the safety of the electric vehicle.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com