Motor-driven electronic hydraulic braking system

A technology of hydraulic braking and motor drive, which is applied in the direction of brakes, brake transmissions, transportation and packaging, etc., can solve the problems of high-pressure accumulator nitrogen leakage, reliability and safety hazards, etc., and achieve fast response speed, Good braking feeling and reduced risk of system failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

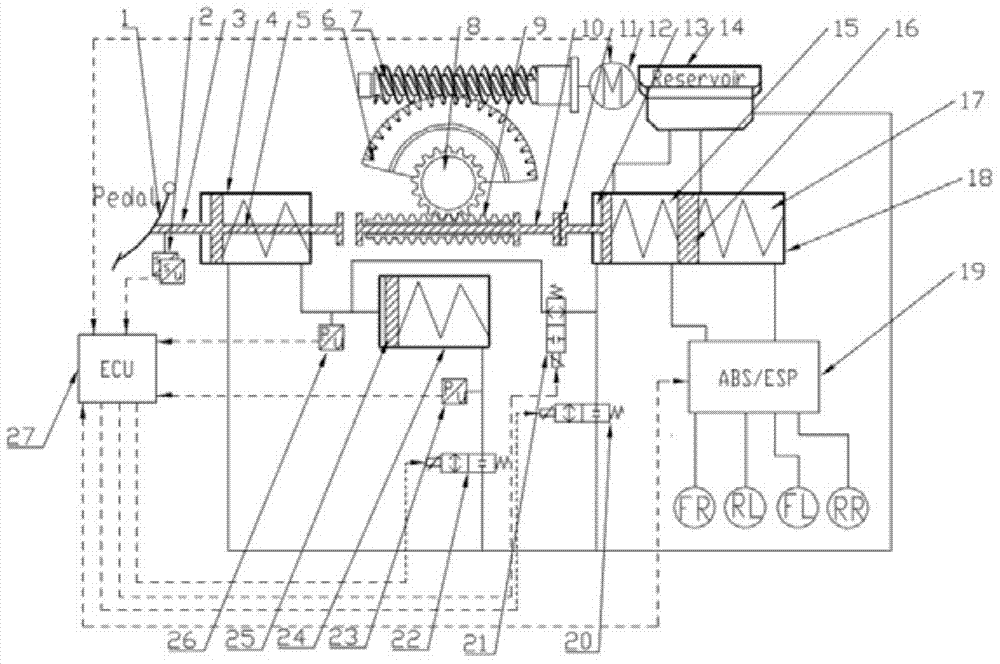

[0035] like figure 1 As shown, the electro-hydraulic braking system driven by a motor mainly includes a brake pedal 1, a secondary master cylinder 3, a pedal simulator 24, a decoupling valve 21, a motor 12, a worm gear 6, a worm screw 7, a master cylinder 18, and a pedal displacement Sensor 2, hydraulic pressure sensor 26, solenoid valves 20, 22.

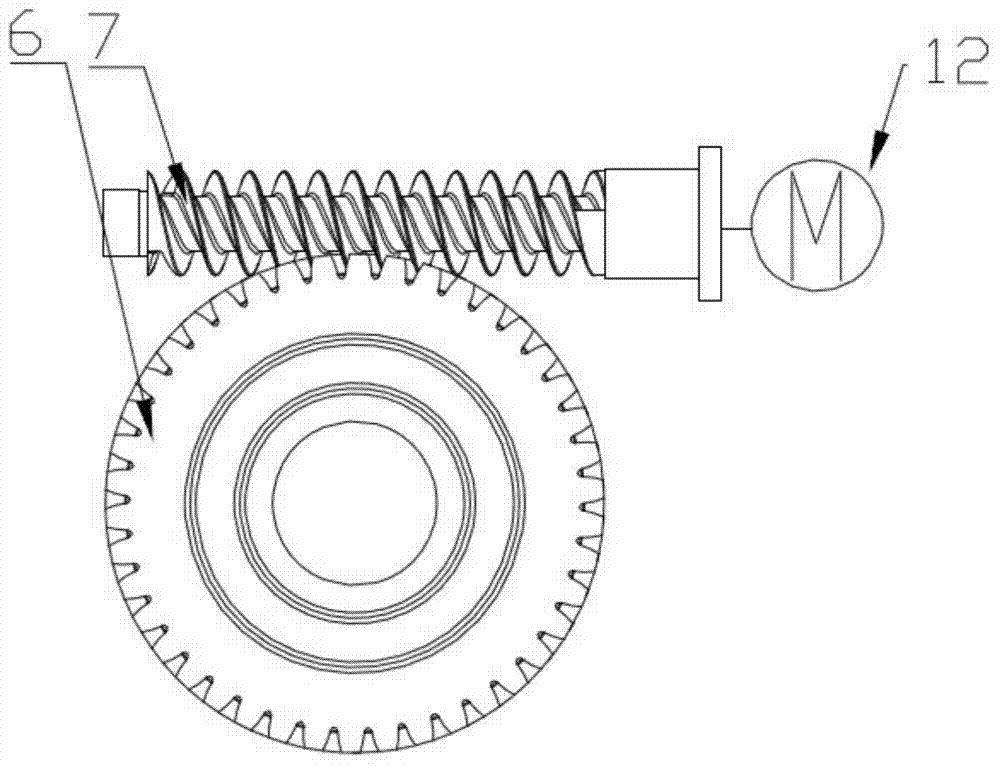

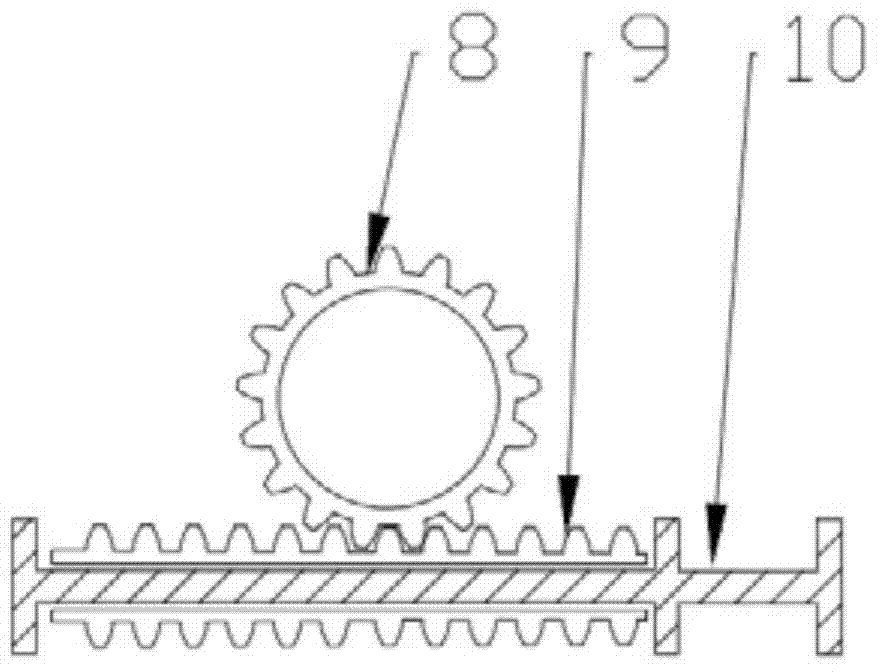

[0036] In this embodiment, the electronically controlled linear motion module includes an electronic control unit ECU27, a motor 12, a reduction mechanism (worm gear 6, worm 7), and a linear motion mechanism (gear 8, rack 9). The motor 12 is connected with the electronic control unit ECU27 through the control circuit, and controls the linear motion mechanism according to the motor torque signal transmitted by the electronic control unit. figure 1 Shown in is a preferred electronically controlled linear motion module, the motor 12 is a rotary motor, the reduction mechanism is a worm gear mechanism, and the linear motion mechanism is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com