Patents

Literature

40results about How to "Good braking feel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

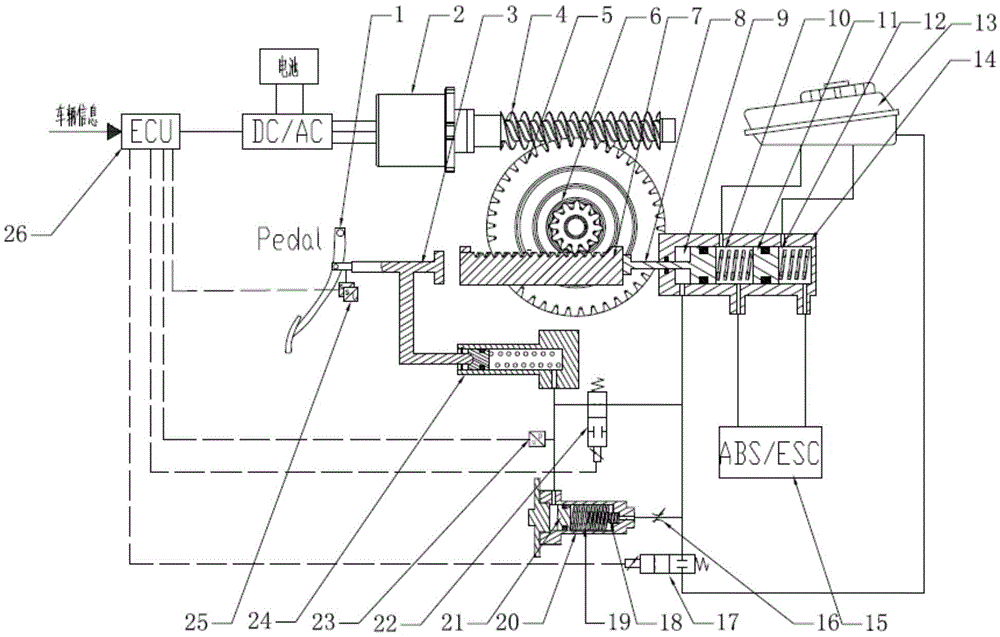

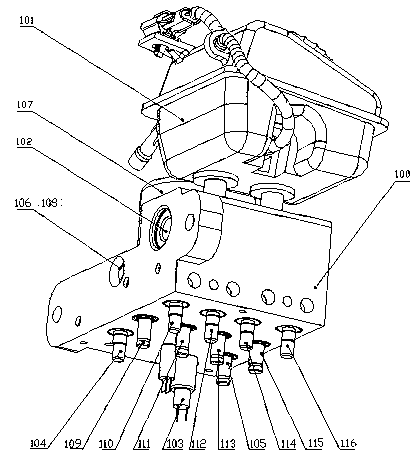

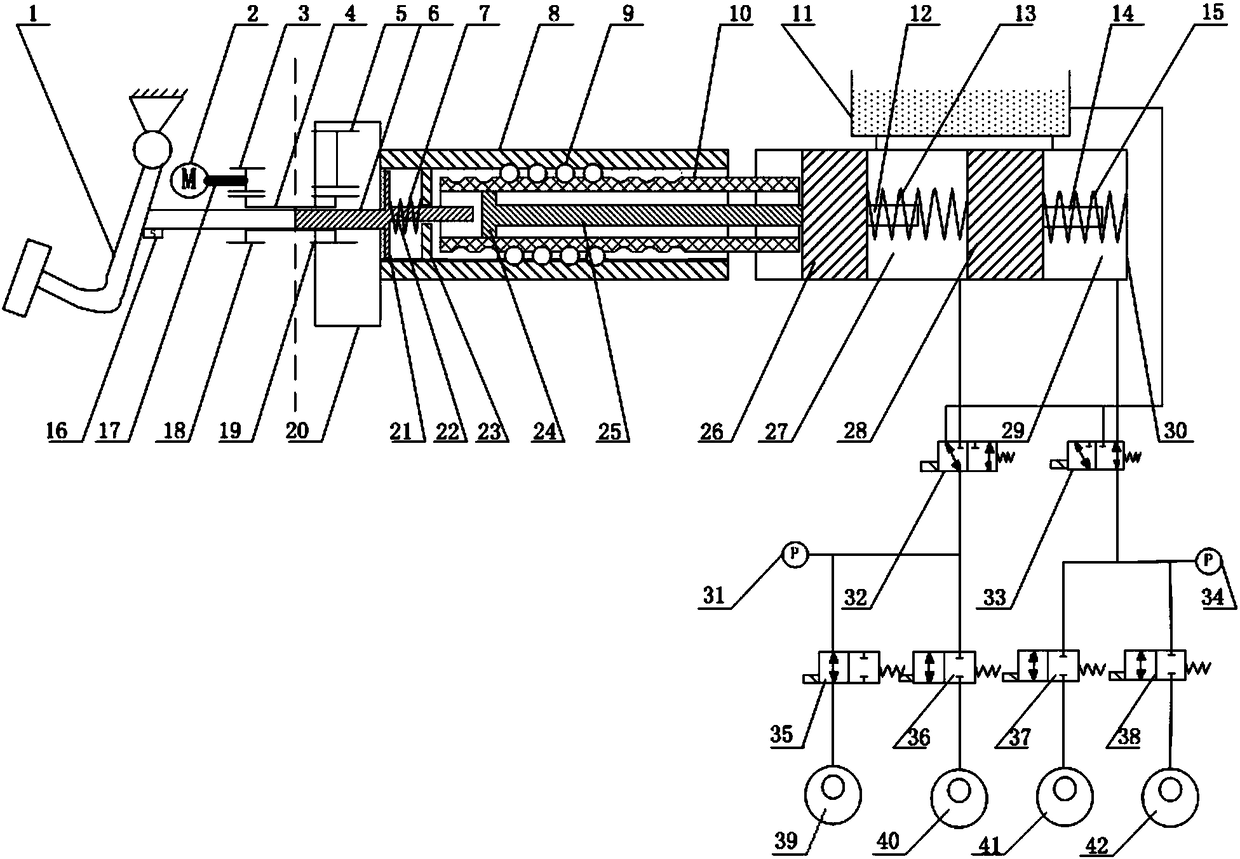

Motor-driven electronic hydraulic braking system

ActiveCN103754210AQuick responsePrecise control of hydraulic braking forceBraking action transmissionSystems designLinear control

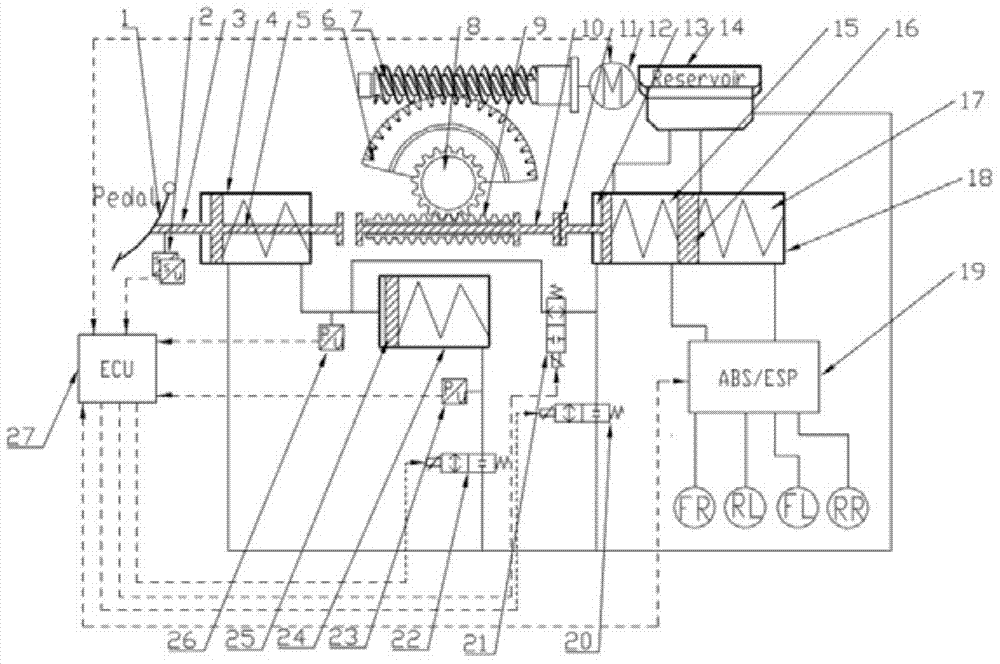

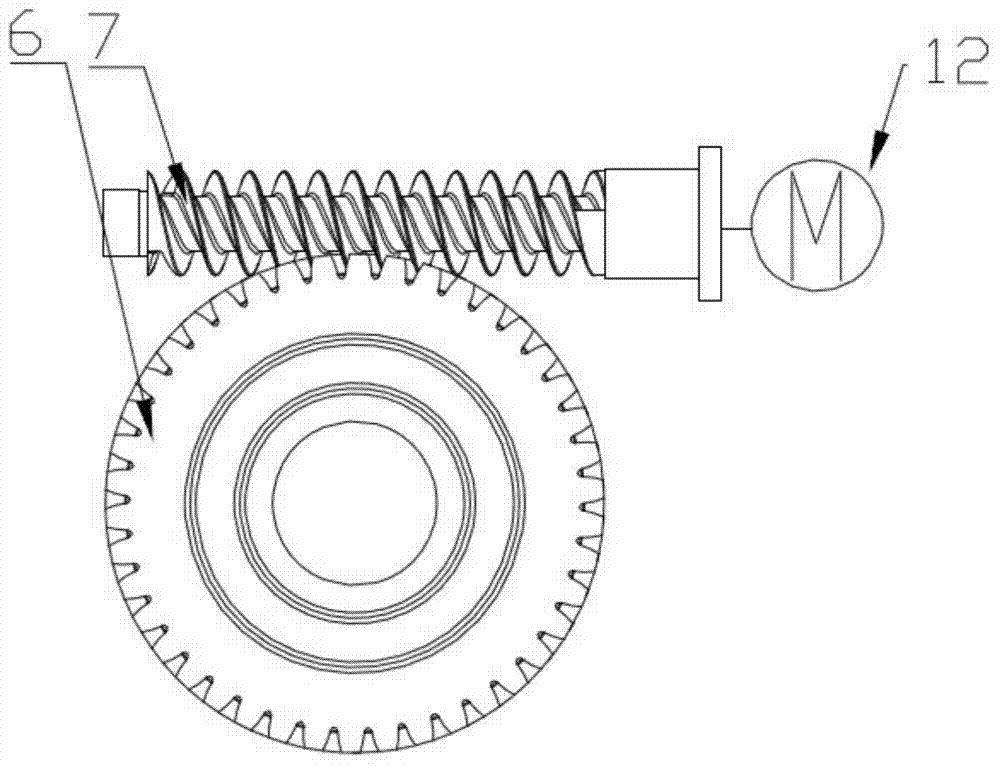

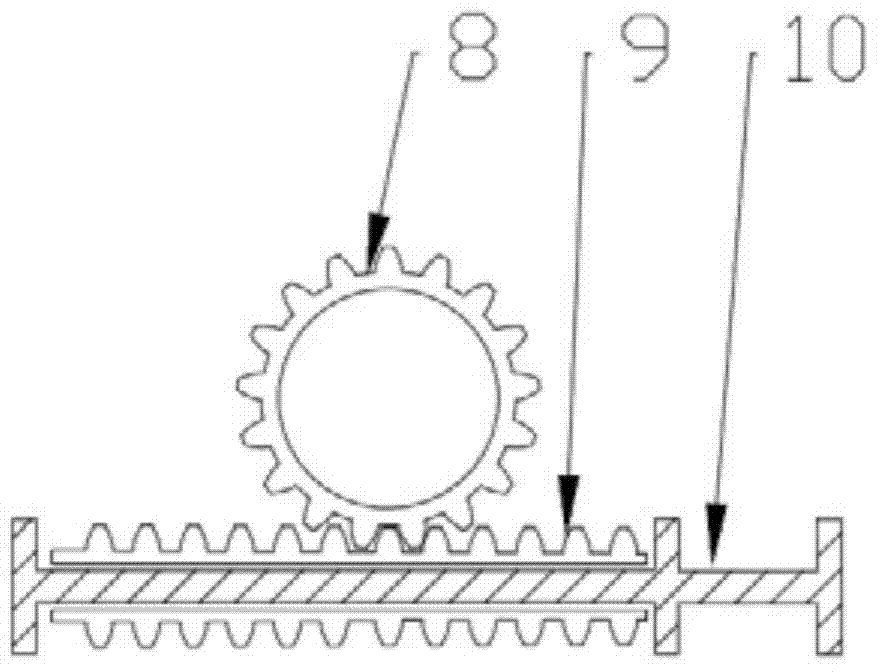

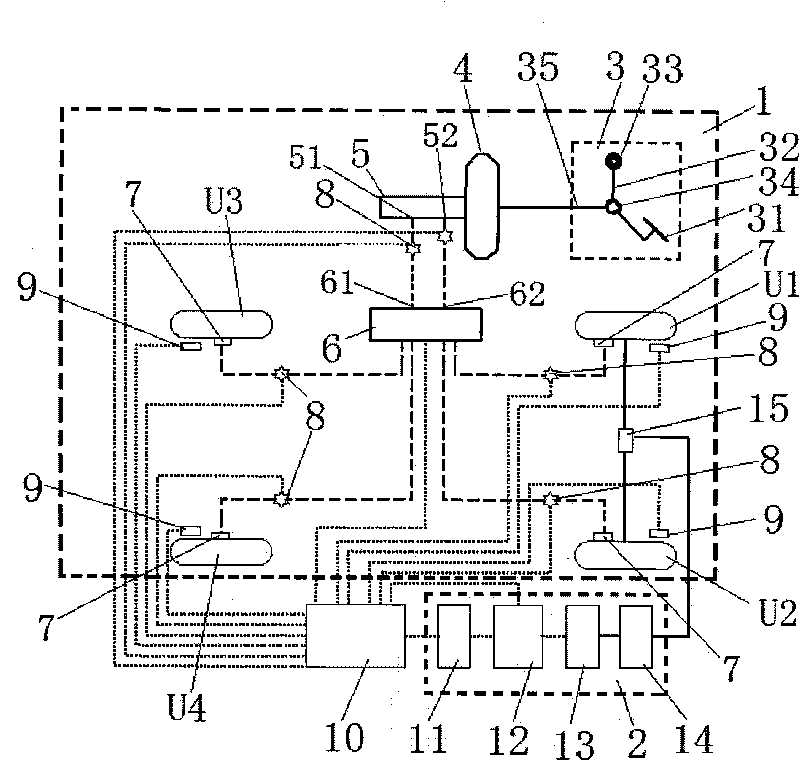

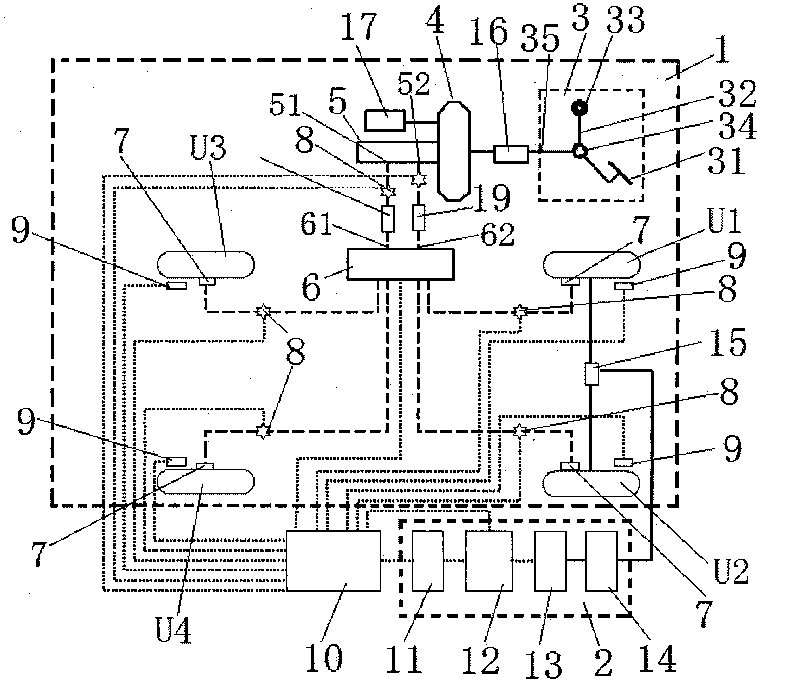

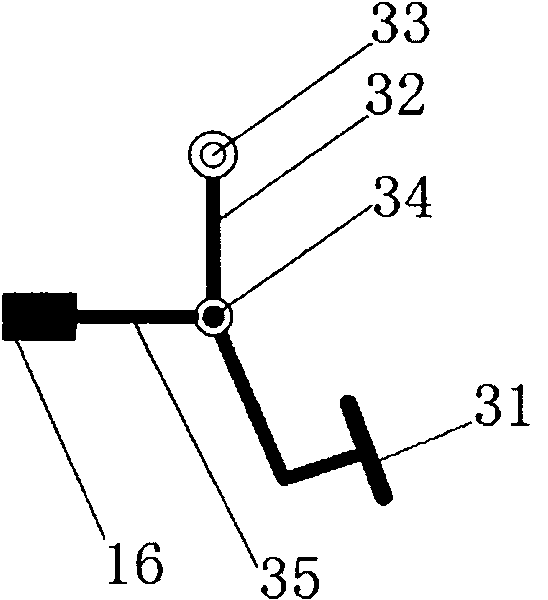

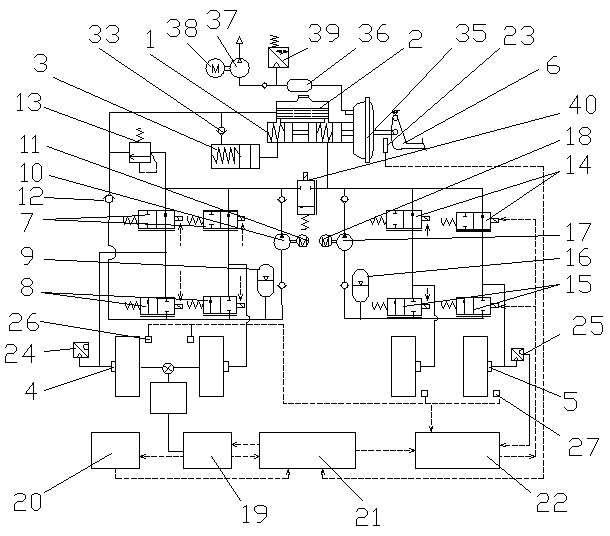

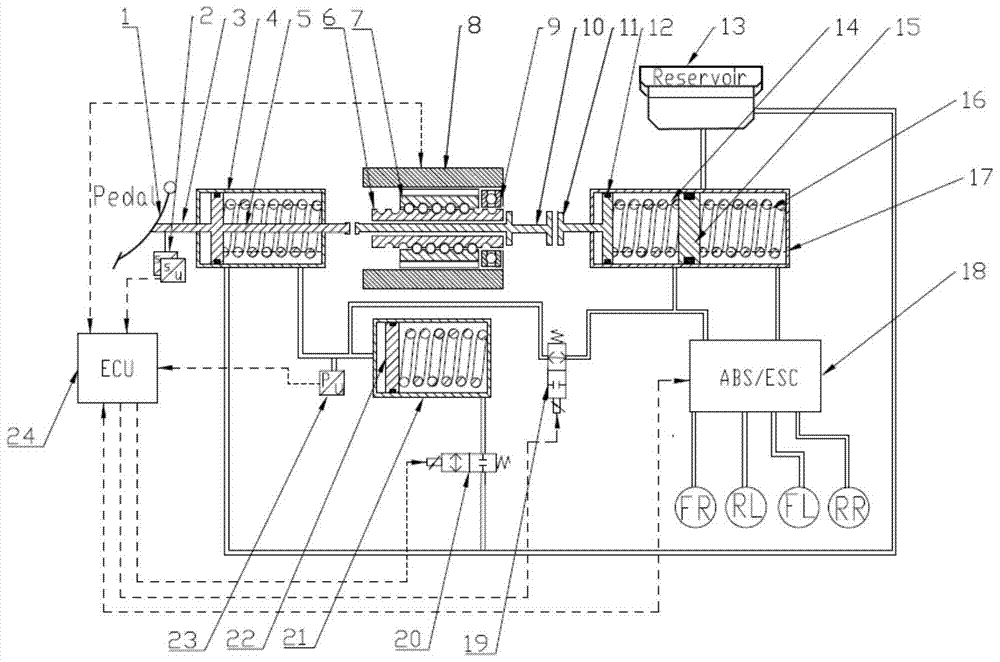

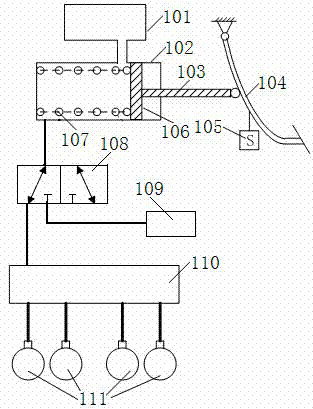

A motor-driven electronic hydraulic braking system comprises a brake pedal, a pedal displacement sensor, a secondary master cylinder, a pedal simulator pressure sensor, a pedal simulator, pedal simulator solenoid valves, a push rod, an electrically-controlled linear movement module, a brake master cylinder and an ABS / ESP (anti-skid brake system / electronic stability program) module. The electrically-controlled linear movement module drives the push rod to move by means of driving a movement regulating mechanism through a motor, the motor is controlled through a displacement signal, and linear control on braking pressure is realized. The brake master cylinder passes the ABS / ESP module to be hydraulically coupled with vehicle wheel brakes. The ABS / ESP module can passively regulate pressure transmitted from the master cylinder to the wheel brakes, and can actively regulate the pressure of the brake of each wheel. The motor-driven electronic hydraulic braking system has the advantages of rapid response, accurate control on brake fluid pressure, capabilities of well simulating brake pedal feeling of a driver and maximally recovering braking energy, and the like; meanwhile, the system is designed with a dual failure protection mode, thereby having high safety and reliability.

Owner:上海同驭汽车科技有限公司

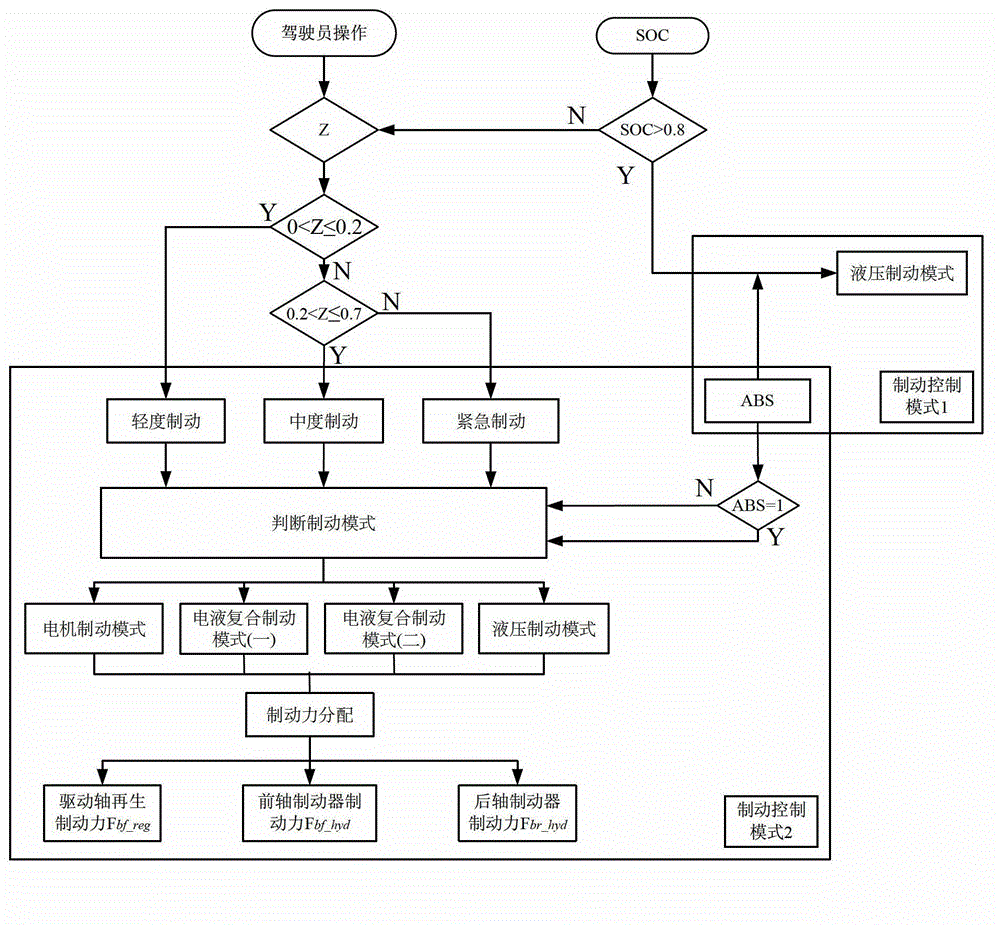

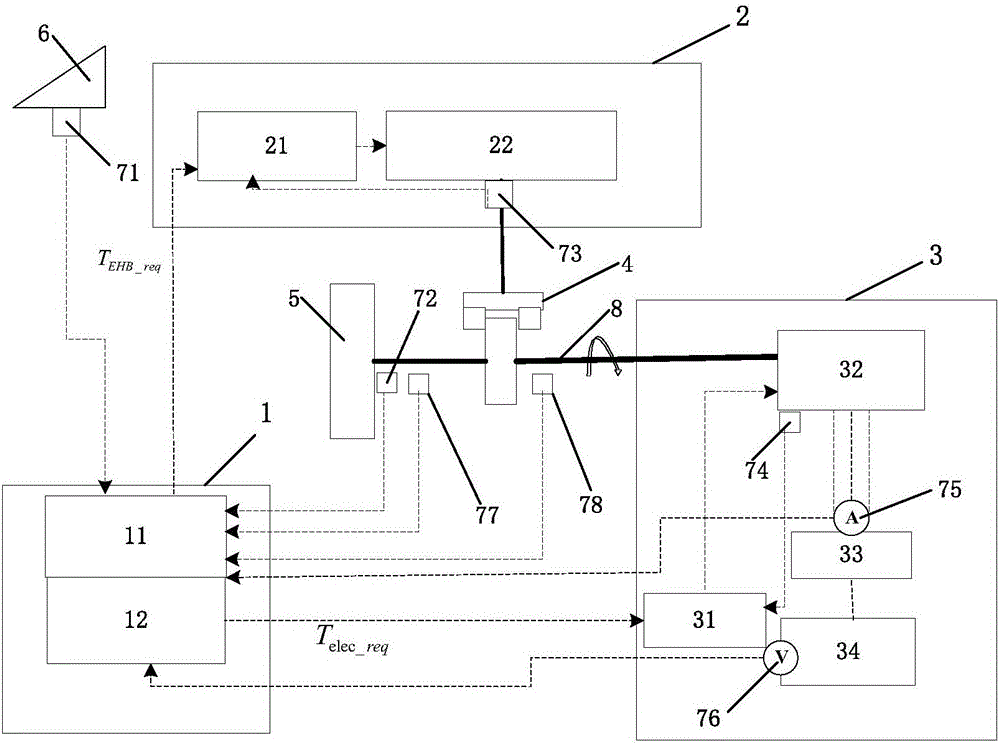

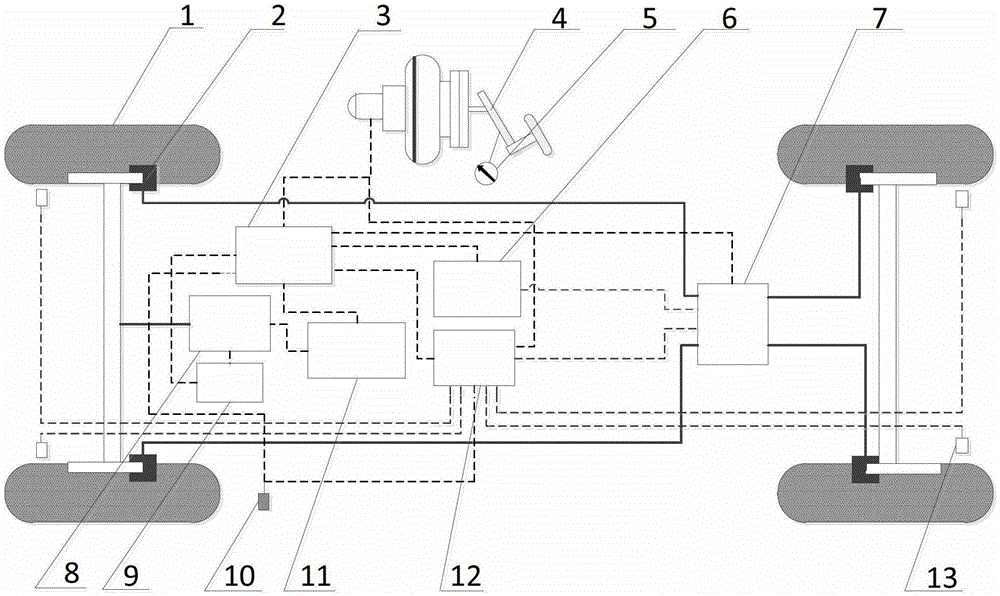

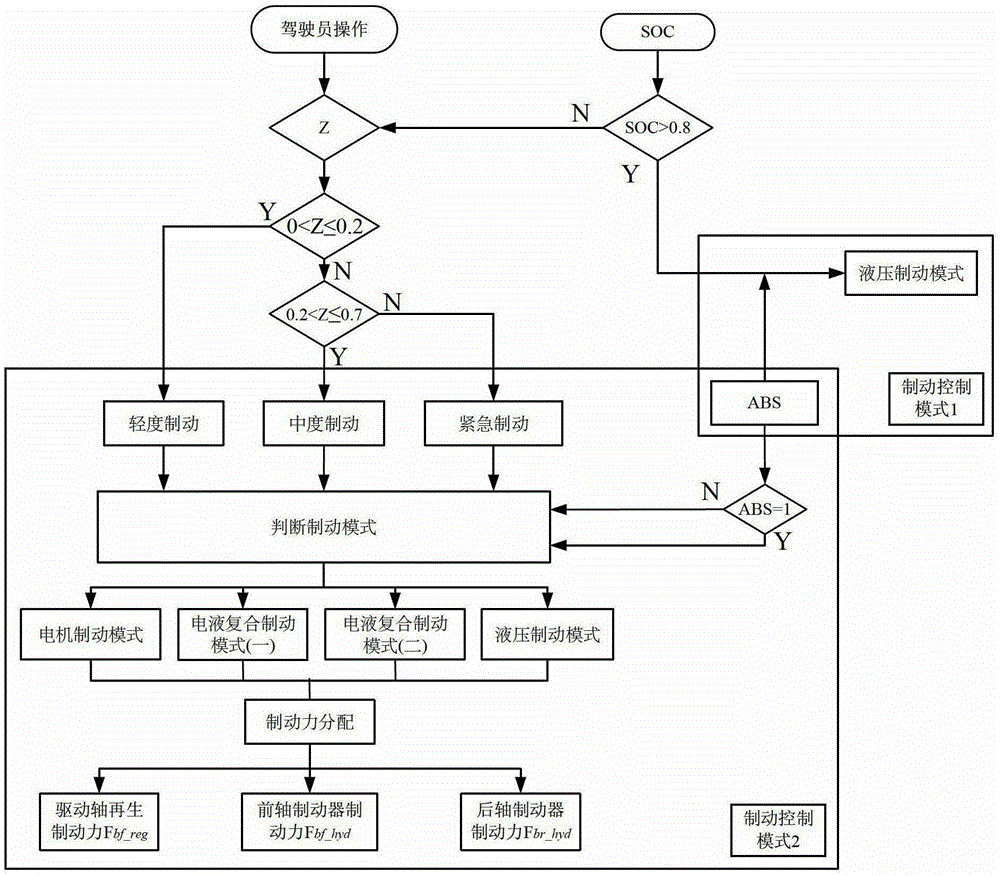

Electric-hydro complex brake control method for electric vehicle use and controlling device thereof

InactiveCN103332184AImprove utilization efficiencyGuaranteed braking effectBraking systemsRegenerative brakeWheel speed sensor

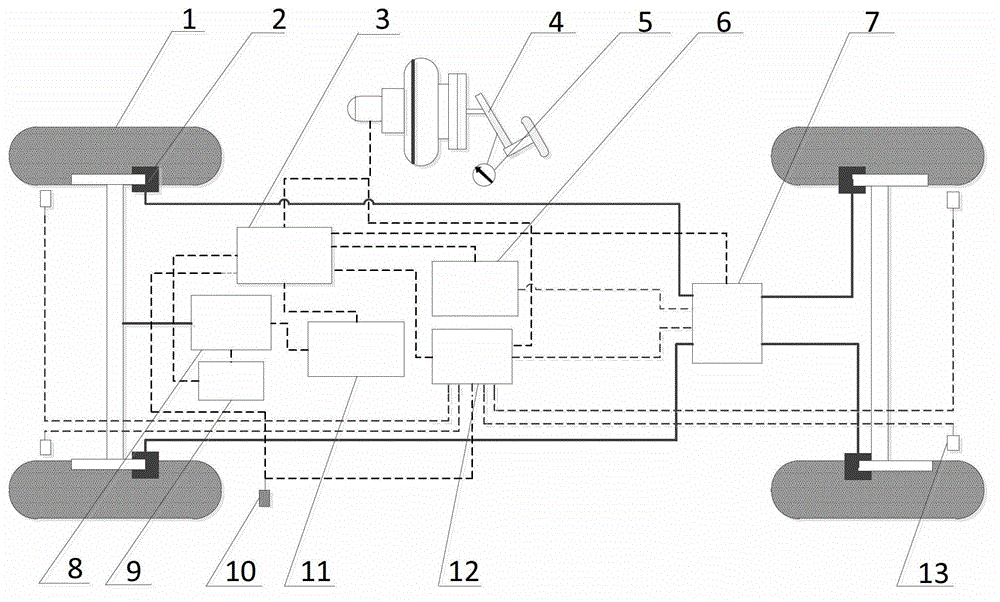

The invention discloses a brake control method for an electric vehicle use and a controlling device thereof, and belongs to the technical field of electric vehicles. The controlling device comprises wheels, wheel brakes, an electric-hydro complex brake ECU, a brake pedal, a brake pedal position sensor, a hydraulic control module, a hydraulic braking system, a motor, a battery, a vehicle speed sensor, a motor control module, an ABS control module, and wheel speed sensors. The method comprises the following steps: determining the braking purpose of a driver according to the driving state, the braking strength, and the state of the motor and the battery of the electric vehicle, determining and choosing a braking mode according to the braking purpose, the battery SOC value, and the state of the ABS, and conducting coordination control for the motor regenerative braking and the hydraulic braking to allow the electric vehicle to provide an excellent braking experience for the driver on the basis of guaranteeing the braking safety. Therefore, under the premise that the braking efficiency can be guaranteed, braking energies are recycled by utilizing the regenerative braking of the motor, and the energy utilization efficiency is improved.

Owner:BEIHANG UNIV

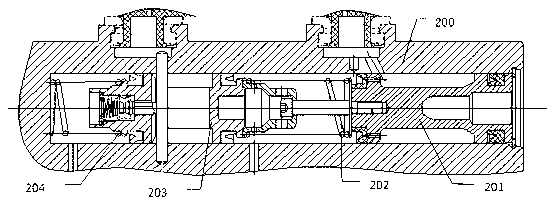

Electro-hydraulic brake system

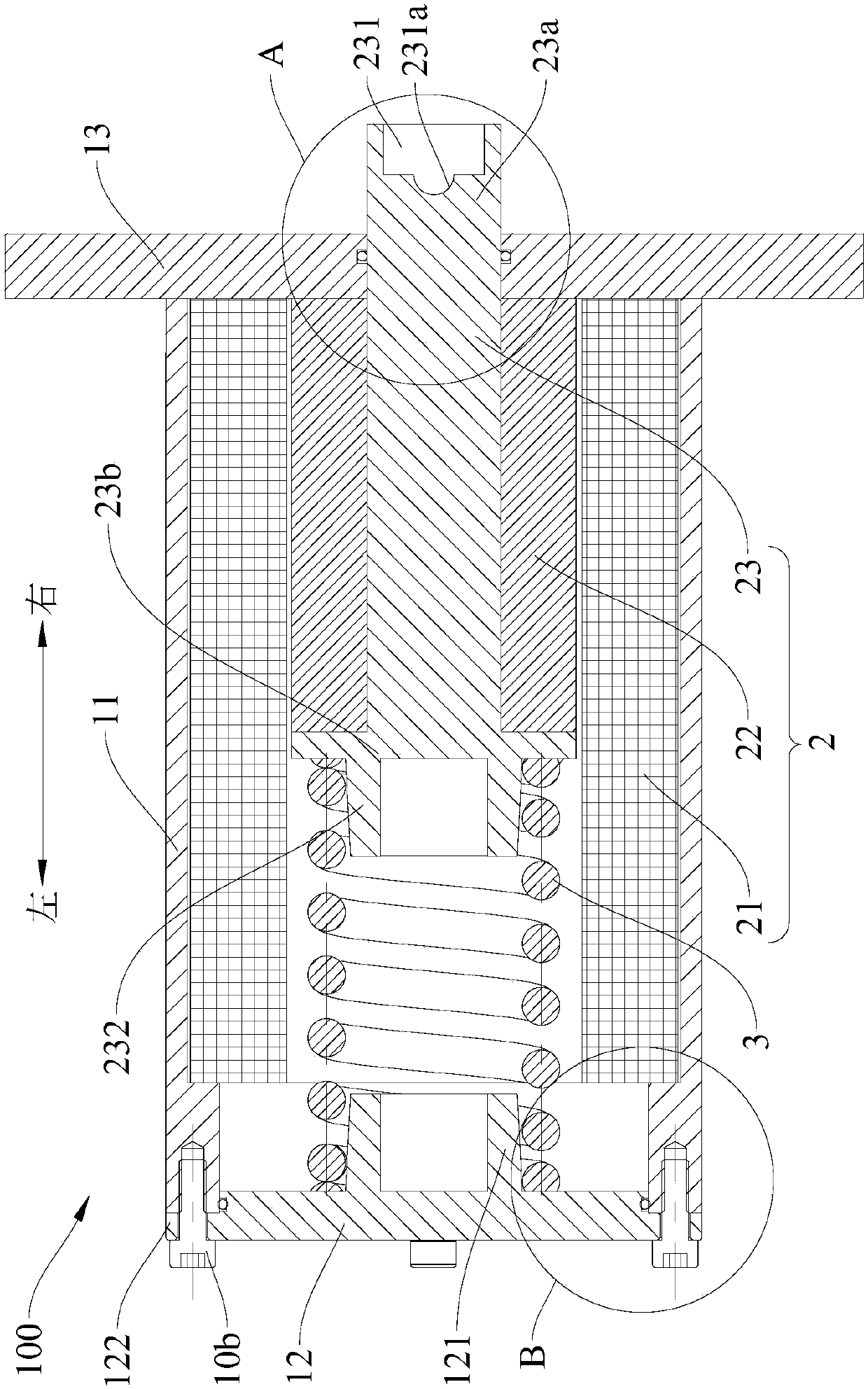

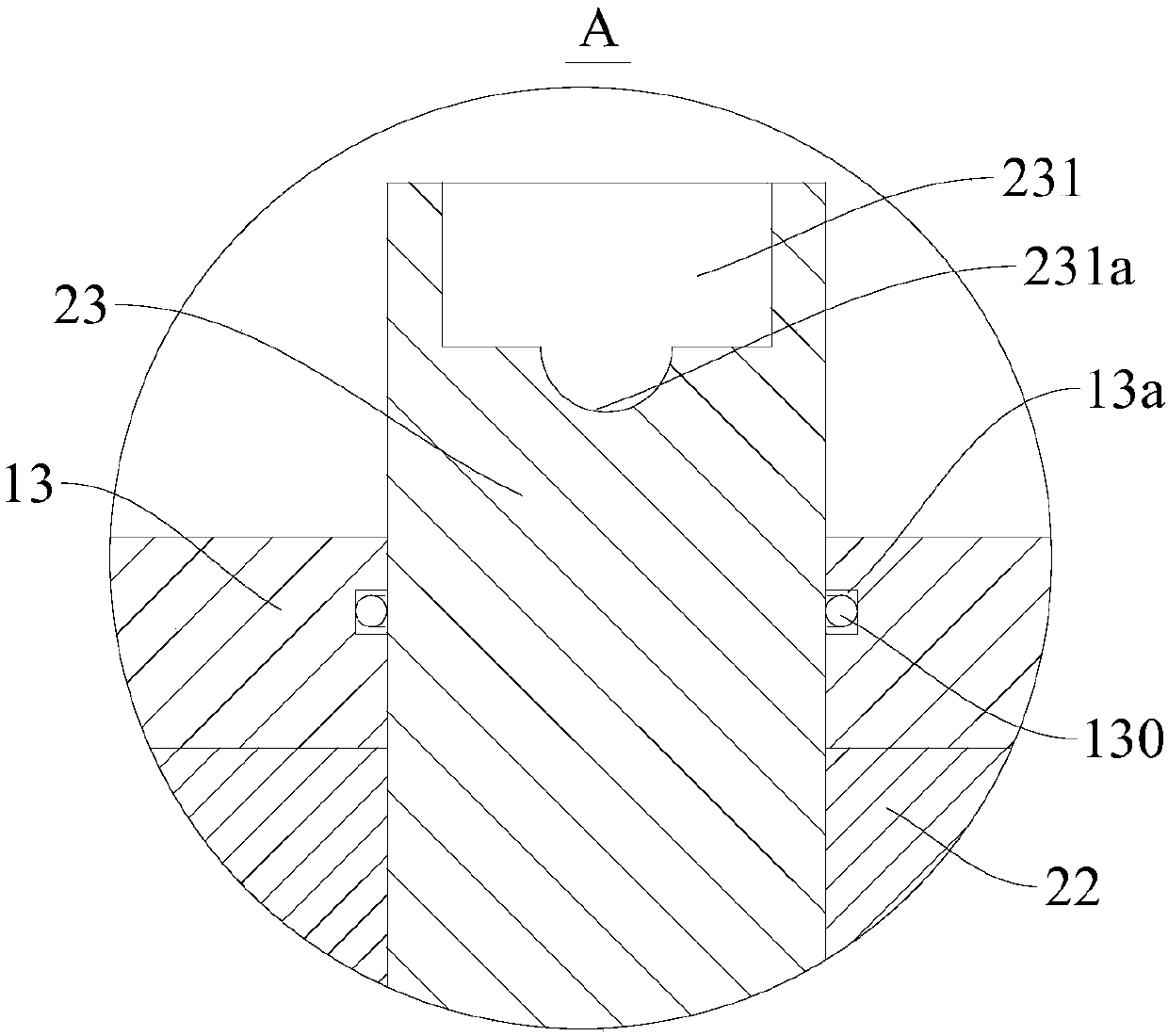

InactiveCN104309599AQuick responsePrecise control of hydraulic braking forceBraking action transmissionBrake control systemsLiquid storage tankElectric control

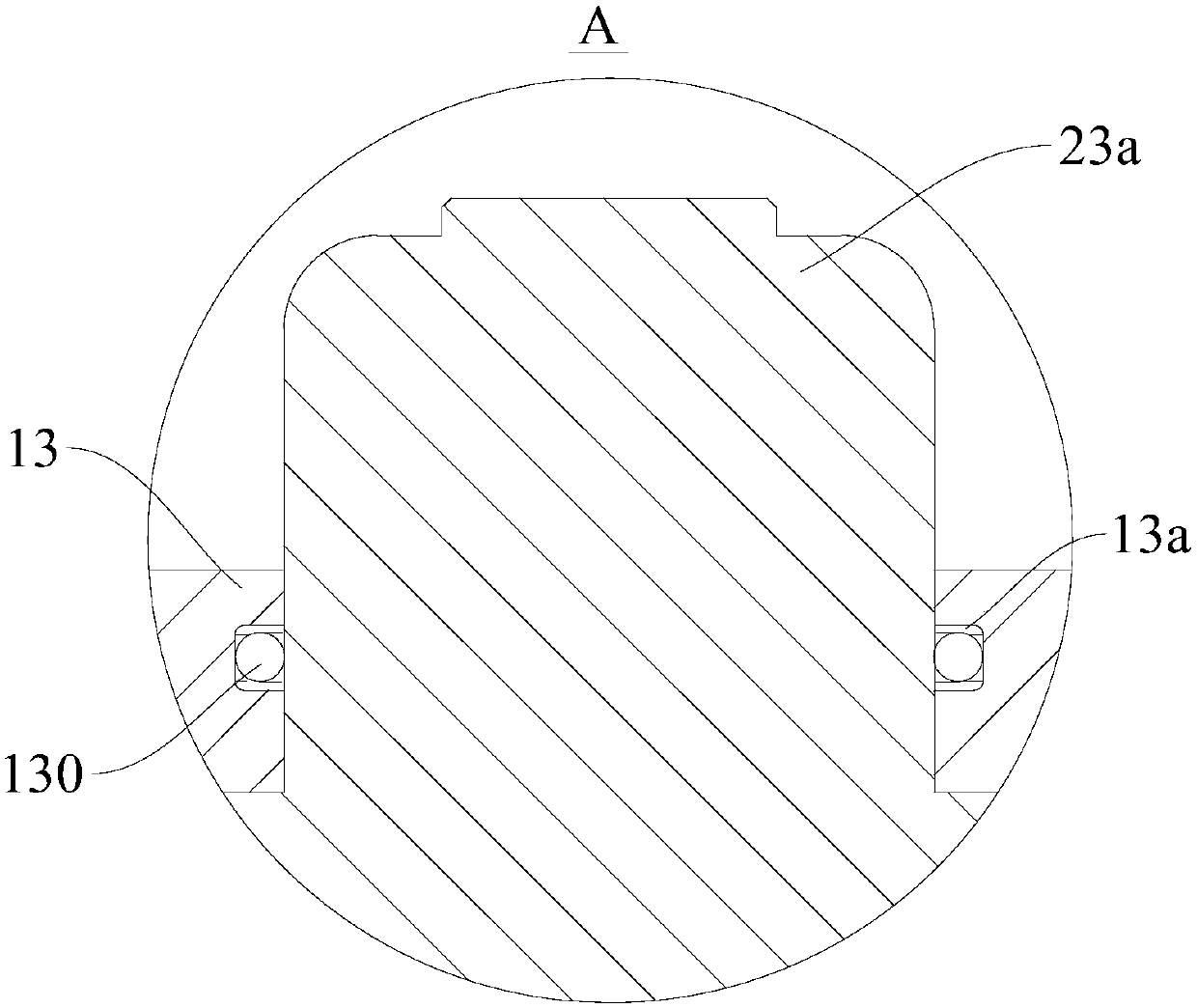

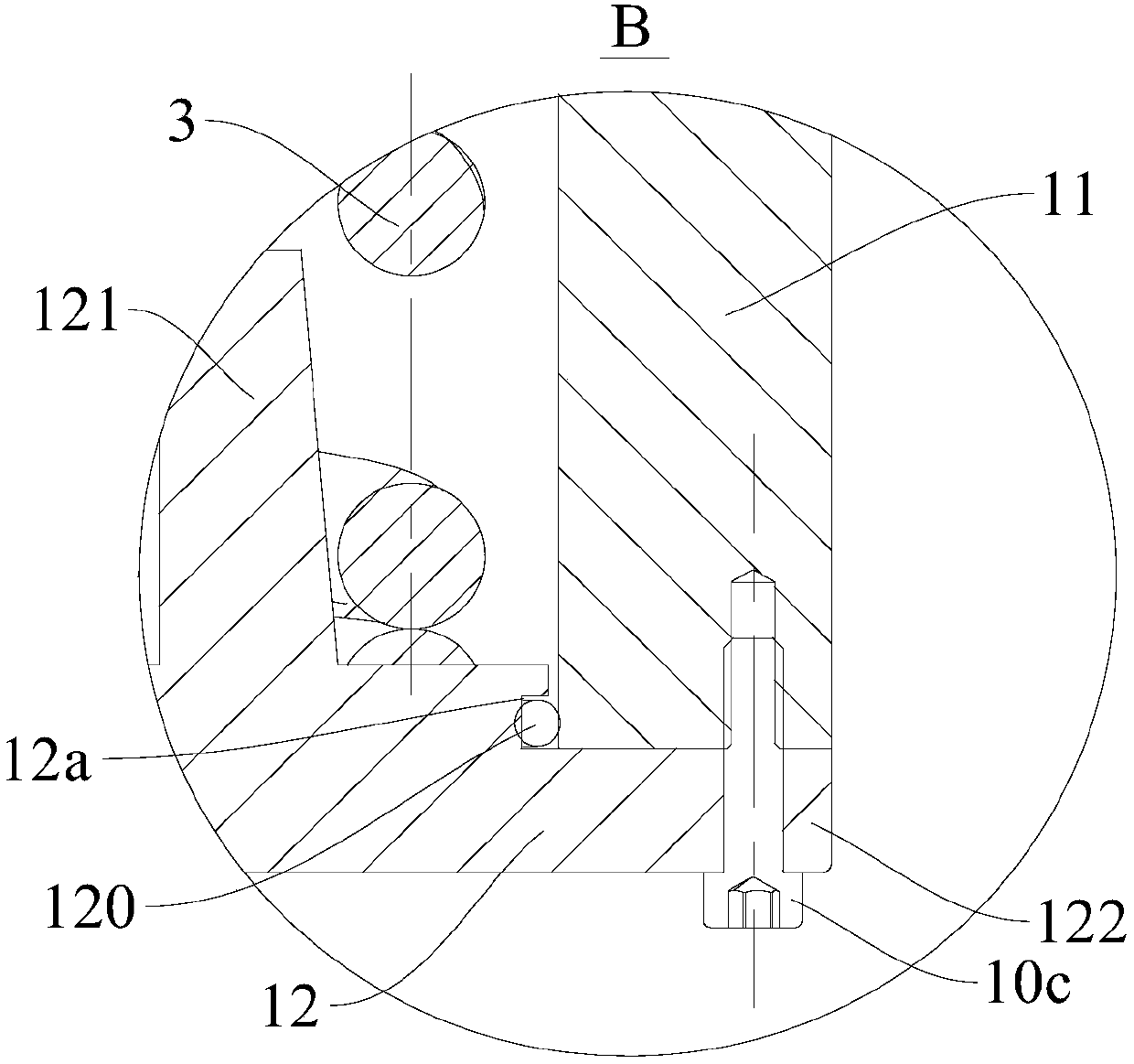

The invention discloses an electro-hydraulic brake system driven by a motor for a vehicle. The electro-hydraulic brake system comprises a brake pedal, a pedal displacement sensor, a hydraulic sensor, a pedal simulator, a pedal push rod with two branches, an electric control unit, an electric control linear motion module, a brake main cylinder, a secondary main cylinder and an ABS (anti-lock braking system) / ESC (electronic stability control) module; one branch of the pedal push rod is abutted against the linear motion mechanism, and is positioned in the same axis as the piston of the brake main cylinder; the other branch of the pedal push rod is connected with the piston of the secondary main cylinder; the brake main cylinder sequentially comprises a front cavity, a first cavity and a second cavity for the brake main cylinder; the front cavity is connected with the secondary main cylinder and a liquid storage tank respectively through a decoupling valve and a liquid supply valve; the first cavity and the second cavity are connected with a vehicle wheel brake through the ABS / ESC module; the secondary main cylinder is connected with the liquid inlet of the pedal simulator. The electro-hydraulic brake system is used for recycling brake energy, improving system response time and accurately controlling hydraulic brake force, well feeds the braking force back to a driver, and realizes active control over hydraulic force and pedal force of the system.

Owner:TONGJI UNIV

Composite braking system

ActiveCN101716890AReduce vibrationImproved braking feelElectrodynamic brake systemsElectricityWheel speed sensor

The invention relates to a composite braking system, which comprises a hydraulic braking system consisting of a brake pedal, a vacuum booster, a braking main cylinder, a hydraulic adjustment module, a braking wheel cylinder, a pressure sensor, a wheel speed sensor and a braking controller and a motor braking system, and is characterized in that: a push rod between the brake pedal and the vacuum booster is provided with a shock absorber; main valves are arranged on oil pipes on which two liquid inlets of the pressure hydraulic adjustment module are positioned respectively; the vacuum input end of the vacuum booster is provided and connected with a vacuum supply module; the vacuum supply module comprises a vacuum pump, a direct current motor, a pressure relay and a power supply; the output end of the vacuum pump is connected with both the vacuum input end of the vacuum booster and the reference pressure input end of the pressure relay through pipes; the output end of the pressure relay is connected with the input end of the direct current motor; the direct current motor is electrically connected with the vacuum pump; and the power supply supplies power to the direct current motor and the pressure relay. The system requires few changes in the hydraulic breaking system of an original vehicle, and can realize series braking energy recovery, guarantee a good brake pedal feel and be widely used in breaking energy recovery systems of electricity-driven vehicles.

Owner:TSINGHUA UNIV

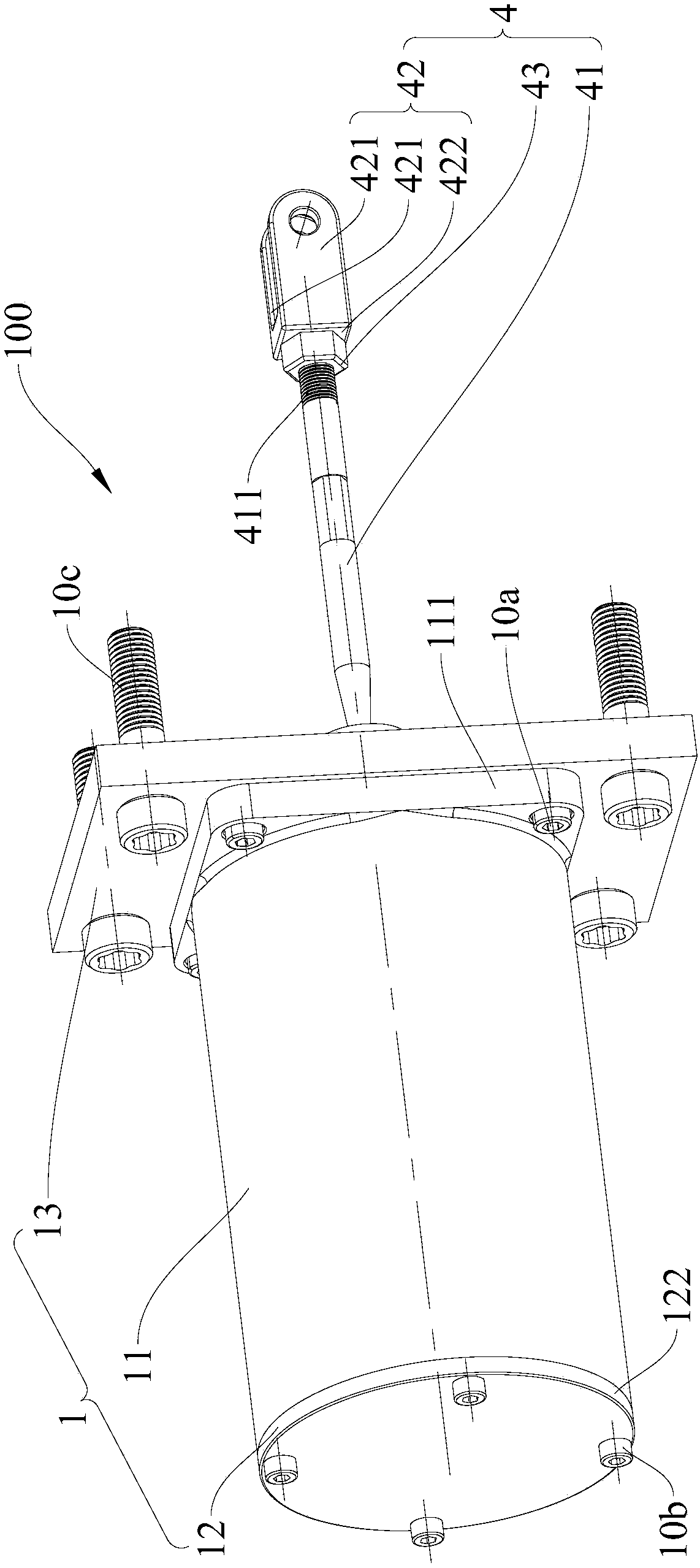

Electric brake apparatus for vehicle

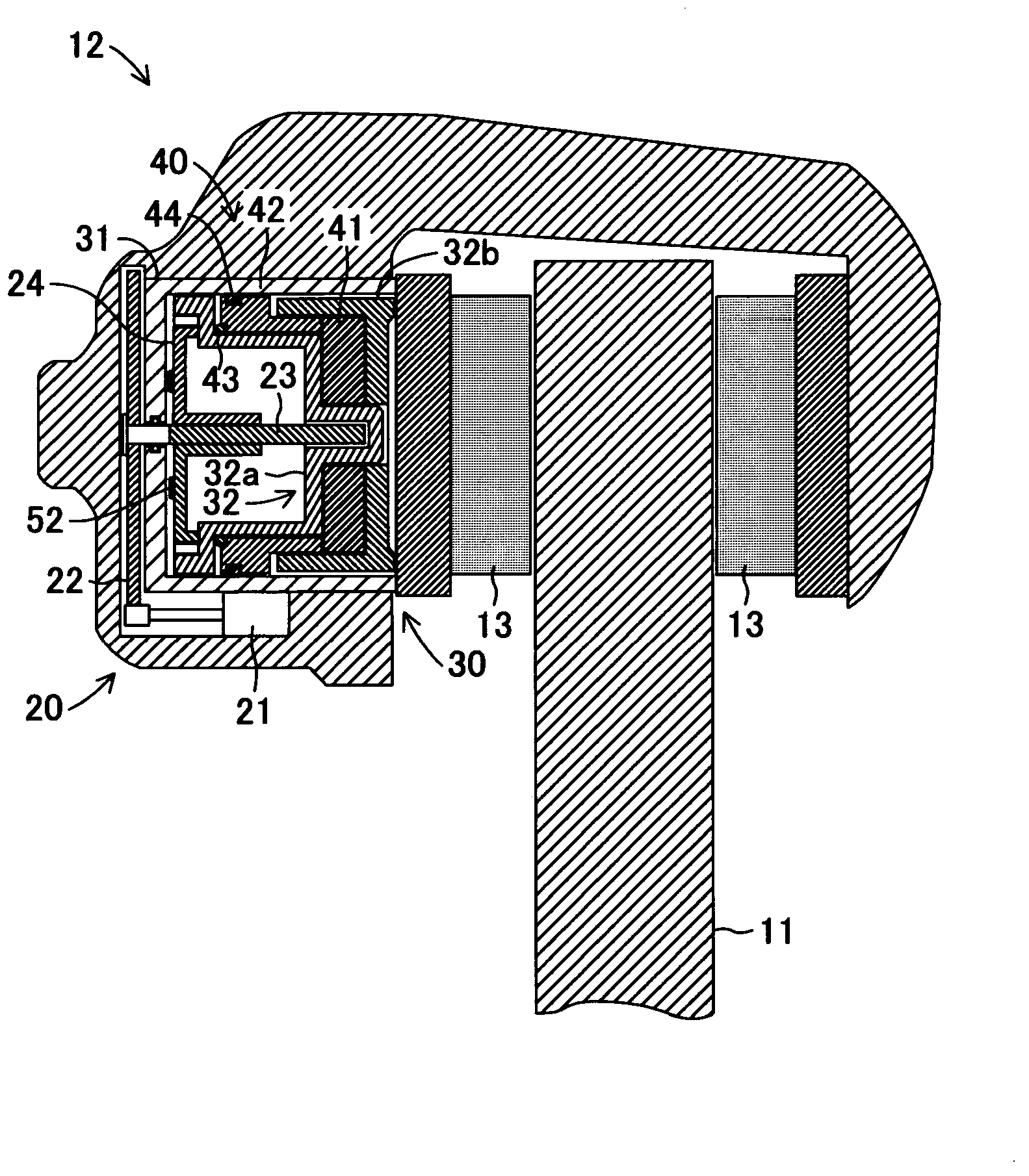

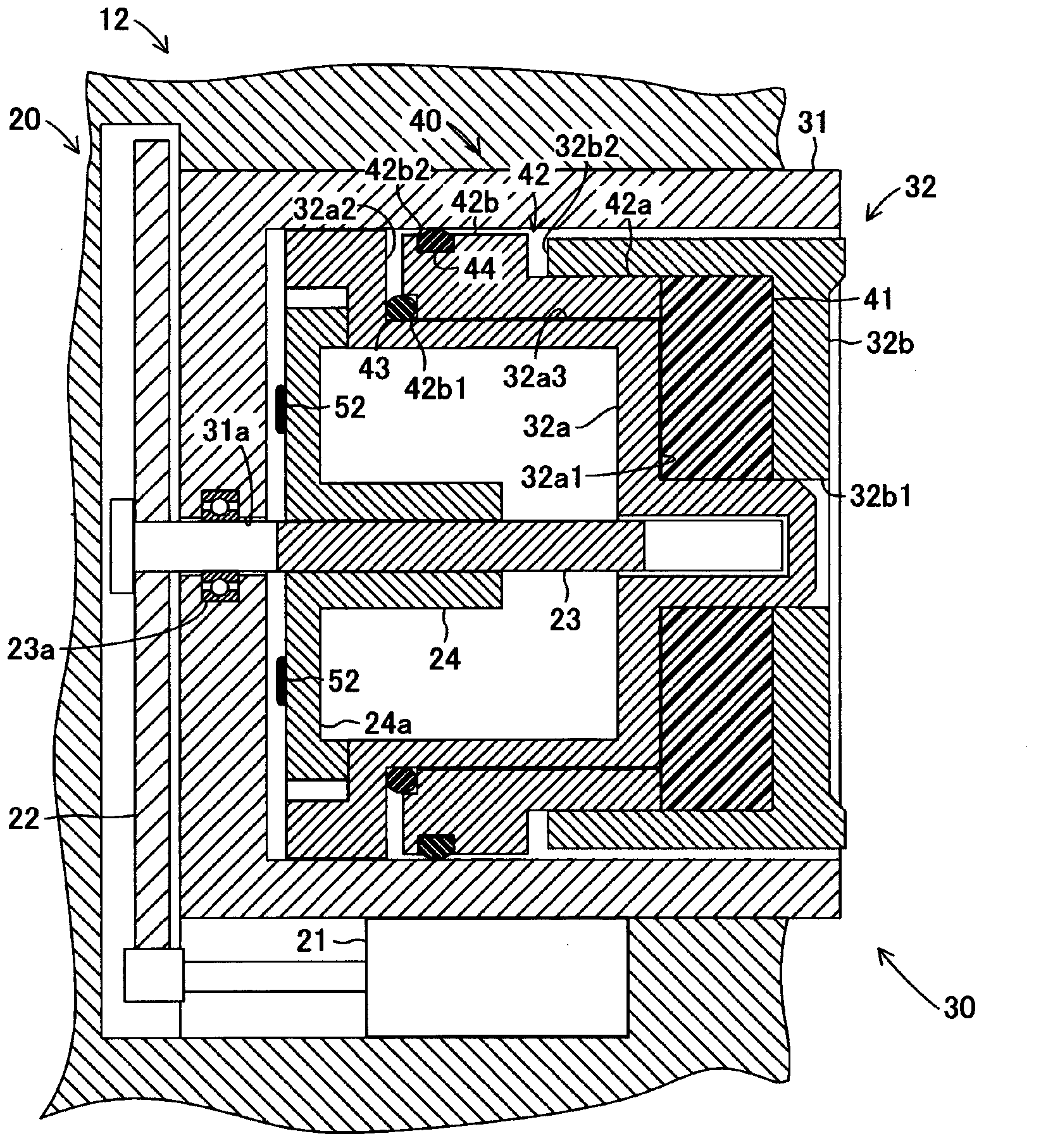

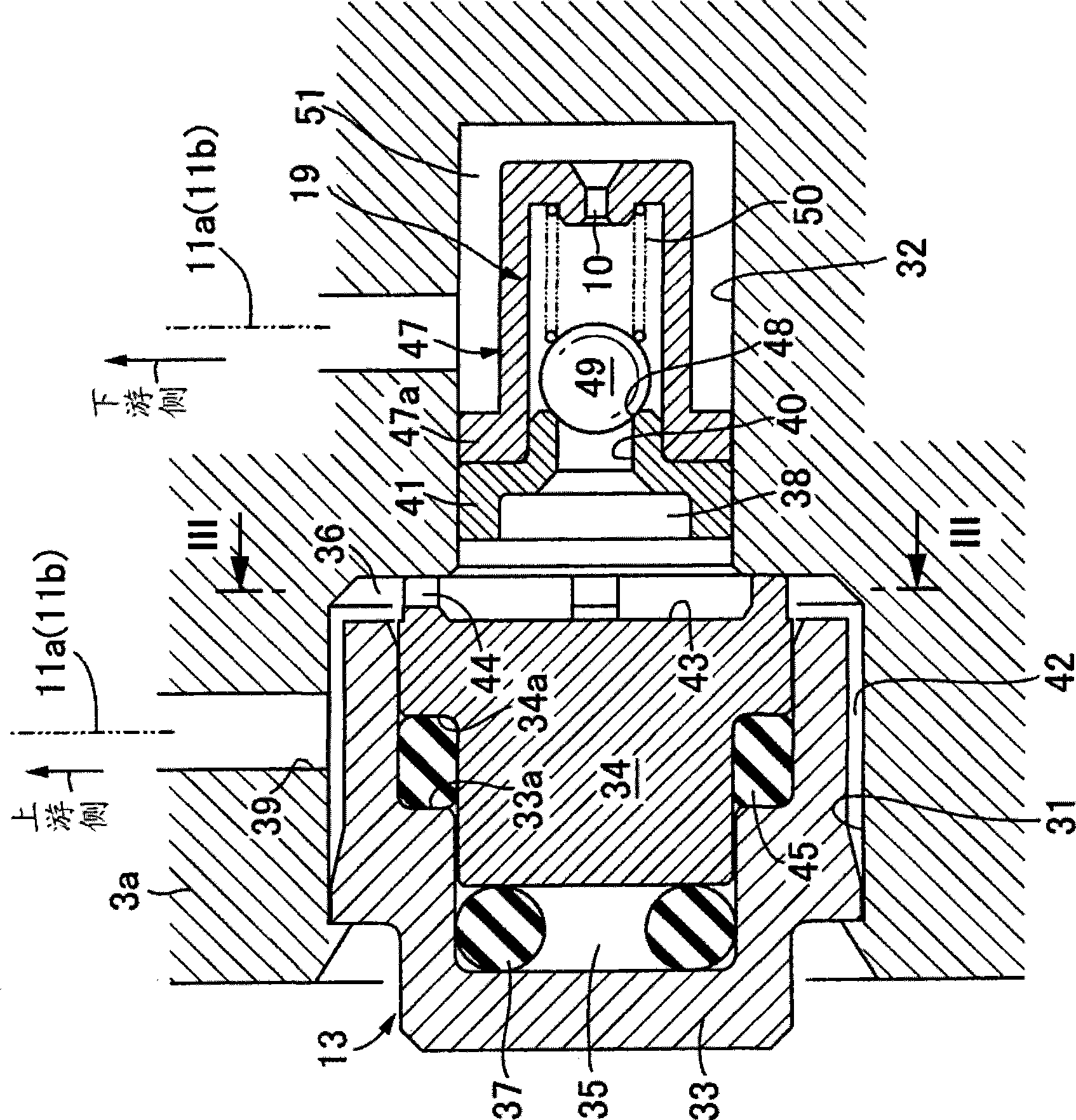

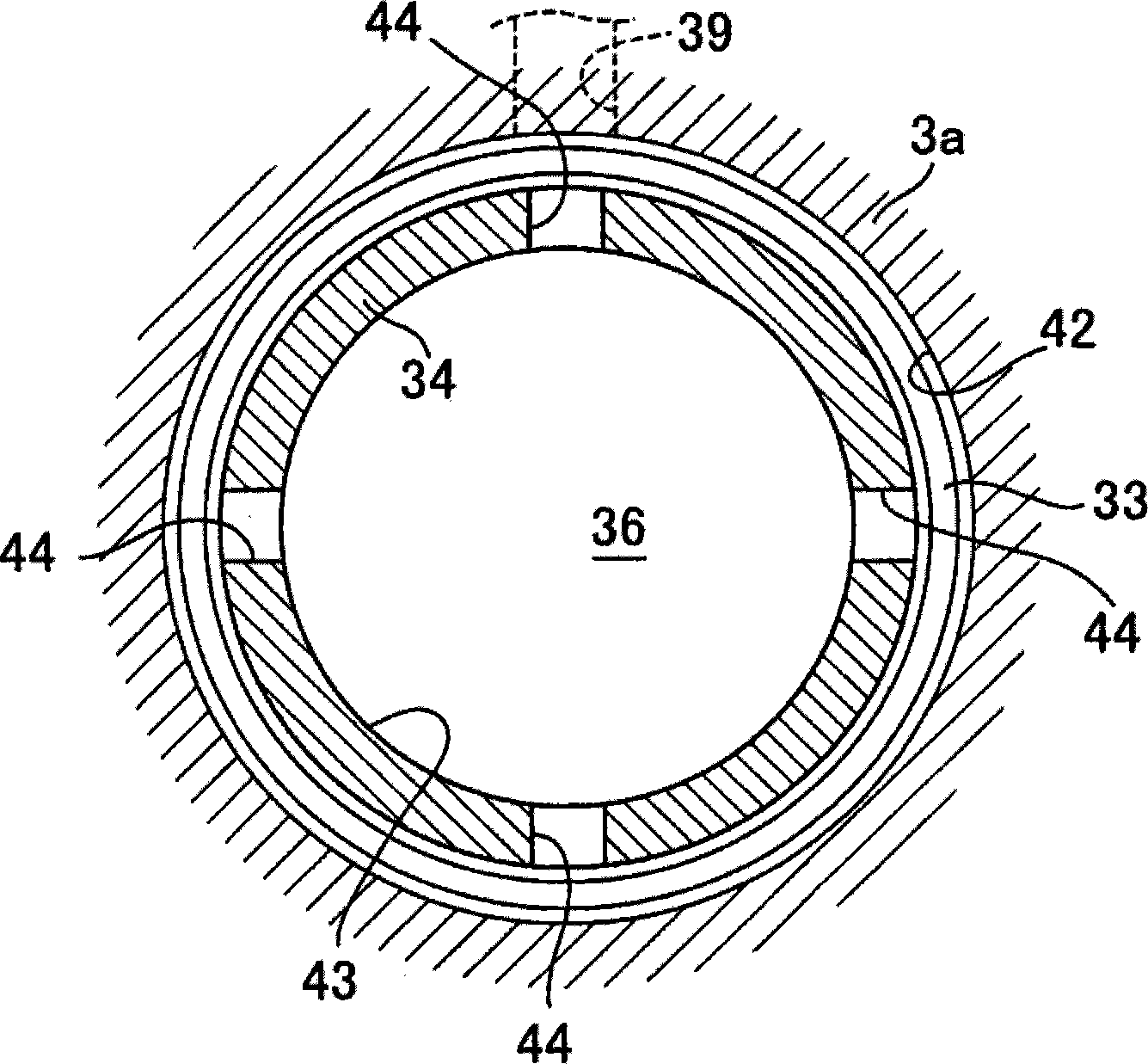

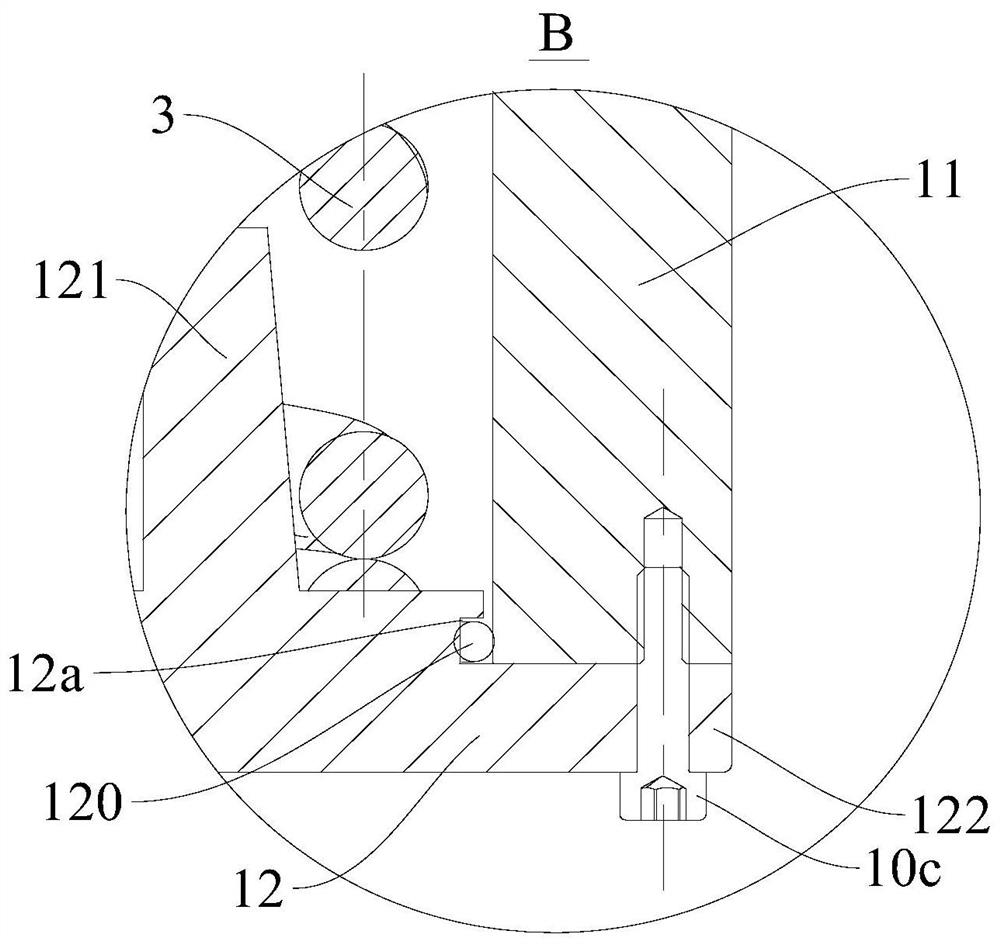

InactiveCN102933866AGood braking feelBraking action transmissionBrake actuating mechanismsFree rotationElectric drive

Disclosed is an electric brake apparatus for a vehicle, wherein an electric caliper (12) is provided with an electric drive mechanism (20) for generating a pressing force for pressing a friction pad (13) against a disk rotor (11), and a retraction mechanism (40) provided in a piston (32) of a pressing mechanism (30). The retraction mechanism (40) is provided with a reversing member (41) which is compressed by a power transmission portion (32a) and a pressing portion (32b) of the piston (32), to generate a reversing force. Furthermore, the retraction mechanism (40) is provided with a movable element (42) which relatively moves backward by the reversing force, and a first elastic member (43) which is compressed by the movable element (42) and the forward moving power transmission portion (32a), to apply a restoring force. Thus, in the retraction mechanism (40), the reversing member (41) generates a reversing force in conjunction with the forward movement of the power transmission portion (32a), and the movable element (42) relatively moves backward, to compress the first elastic member (43). When a free rotation (no-load rotation) of a brake motor (21) which is a component of a mechanism (20) is allowed, the restoring force generated by the compression of the first elastic member (43) is applied to the power transmission portion (32a), to move the piston (32) backward.

Owner:TOYOTA JIDOSHA KK

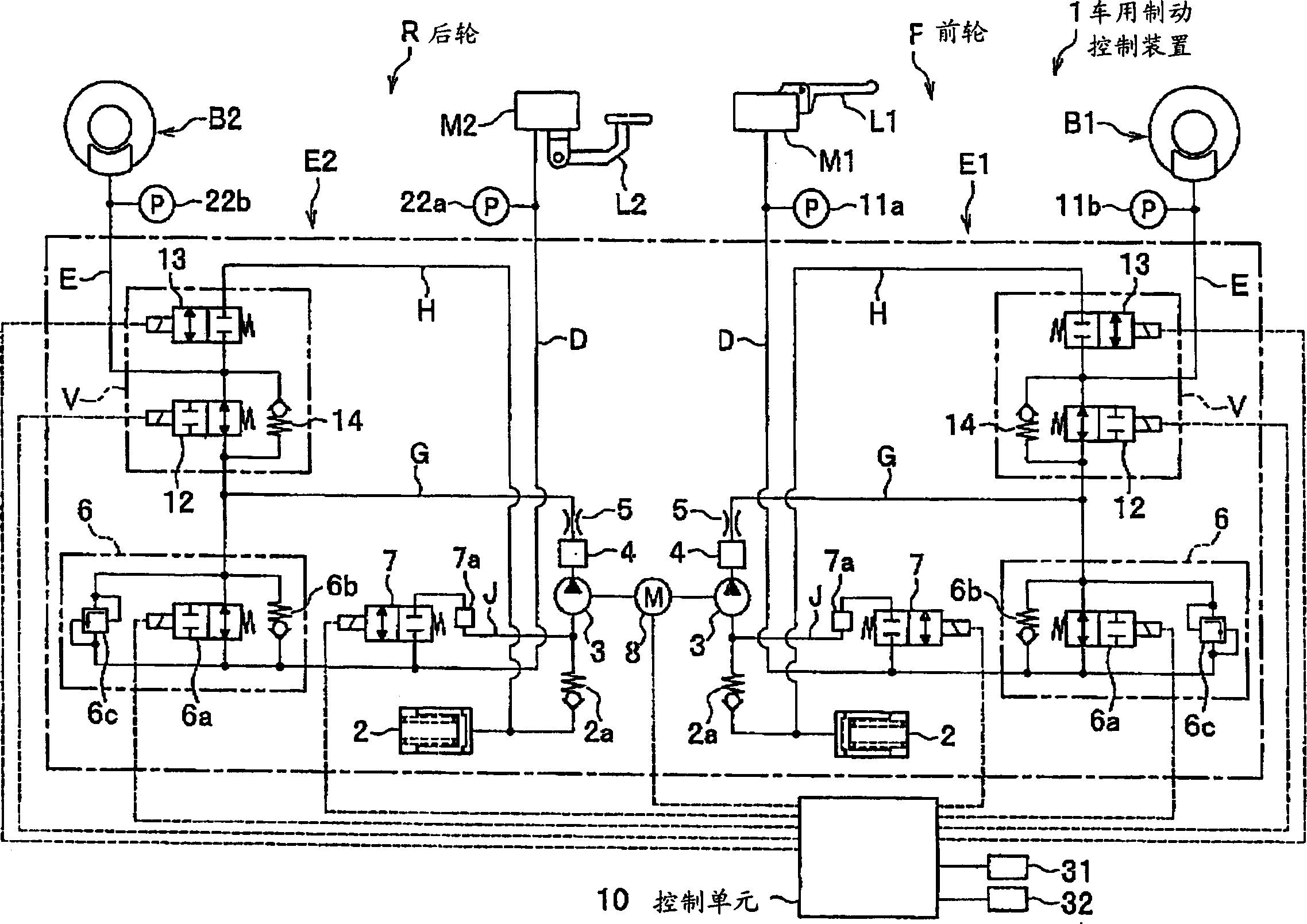

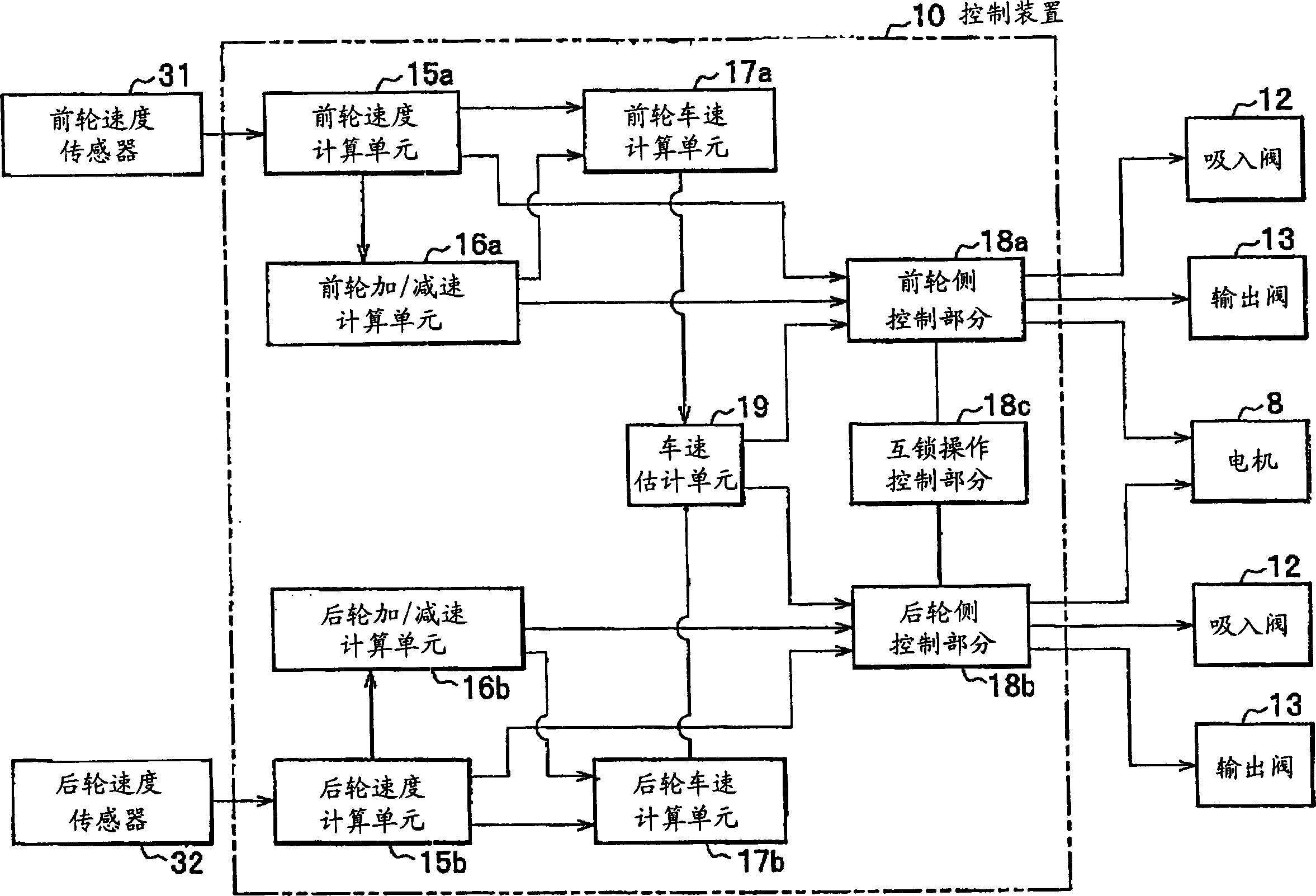

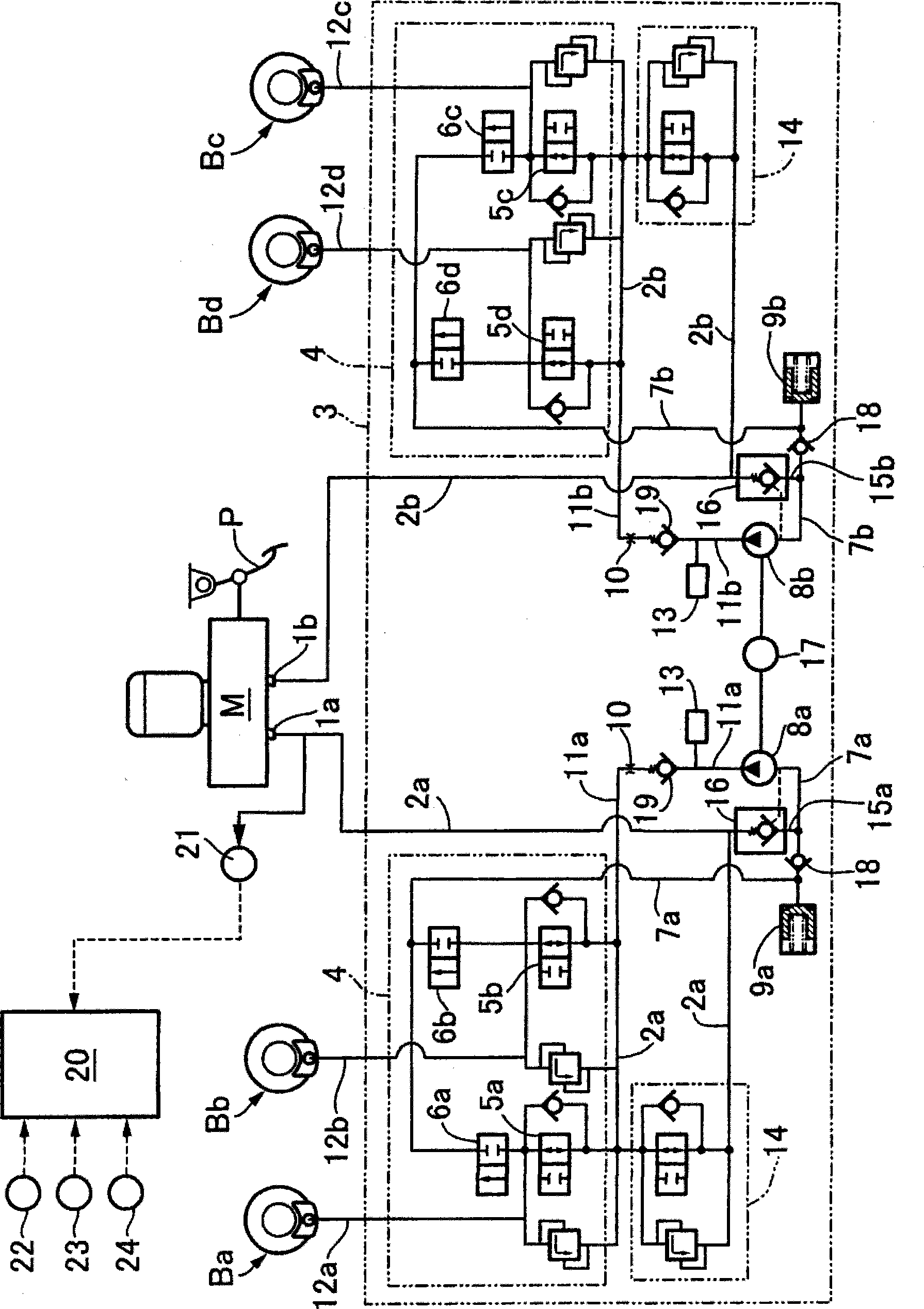

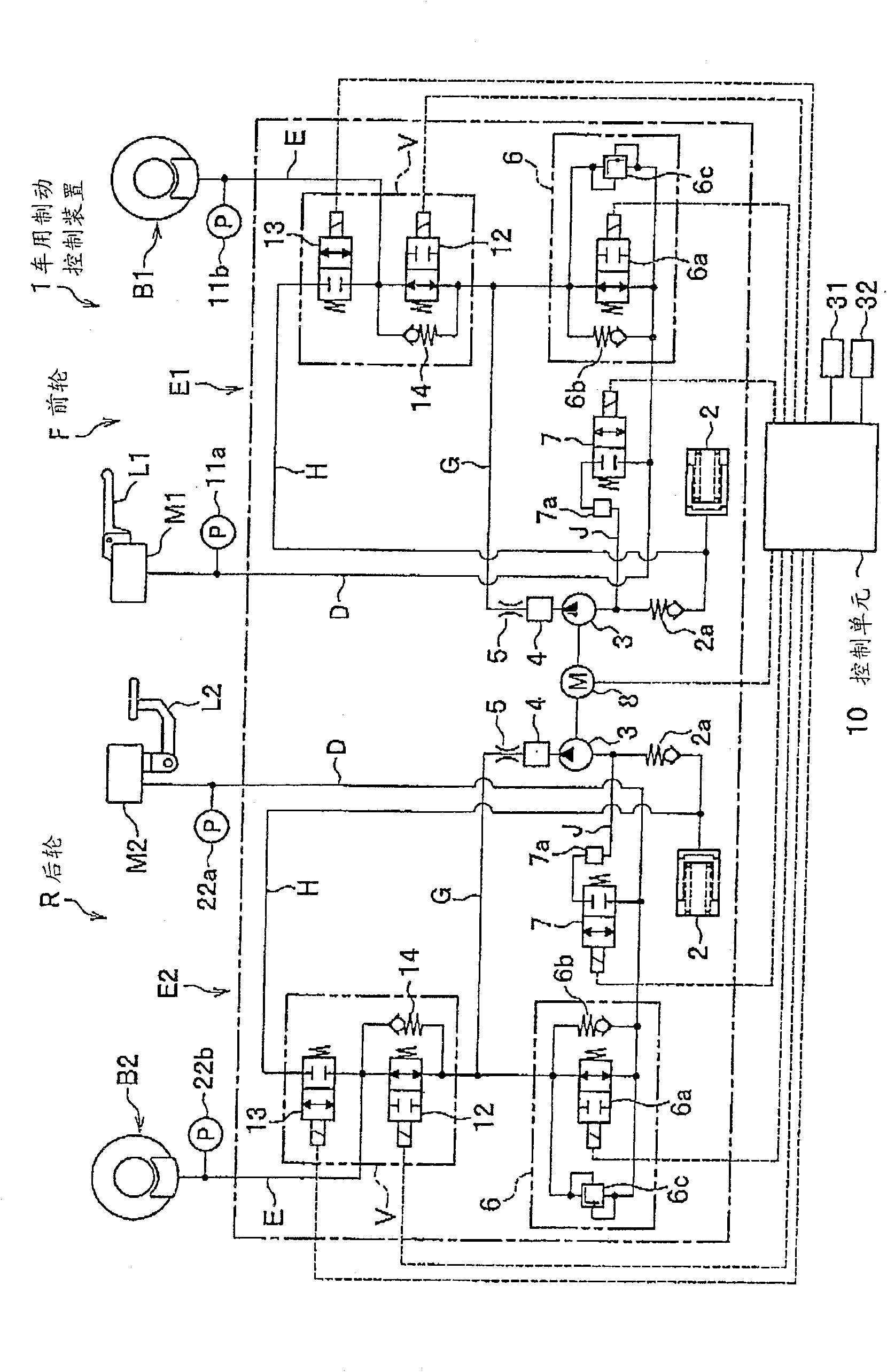

Vehicular brake control apparatus and control method therefor

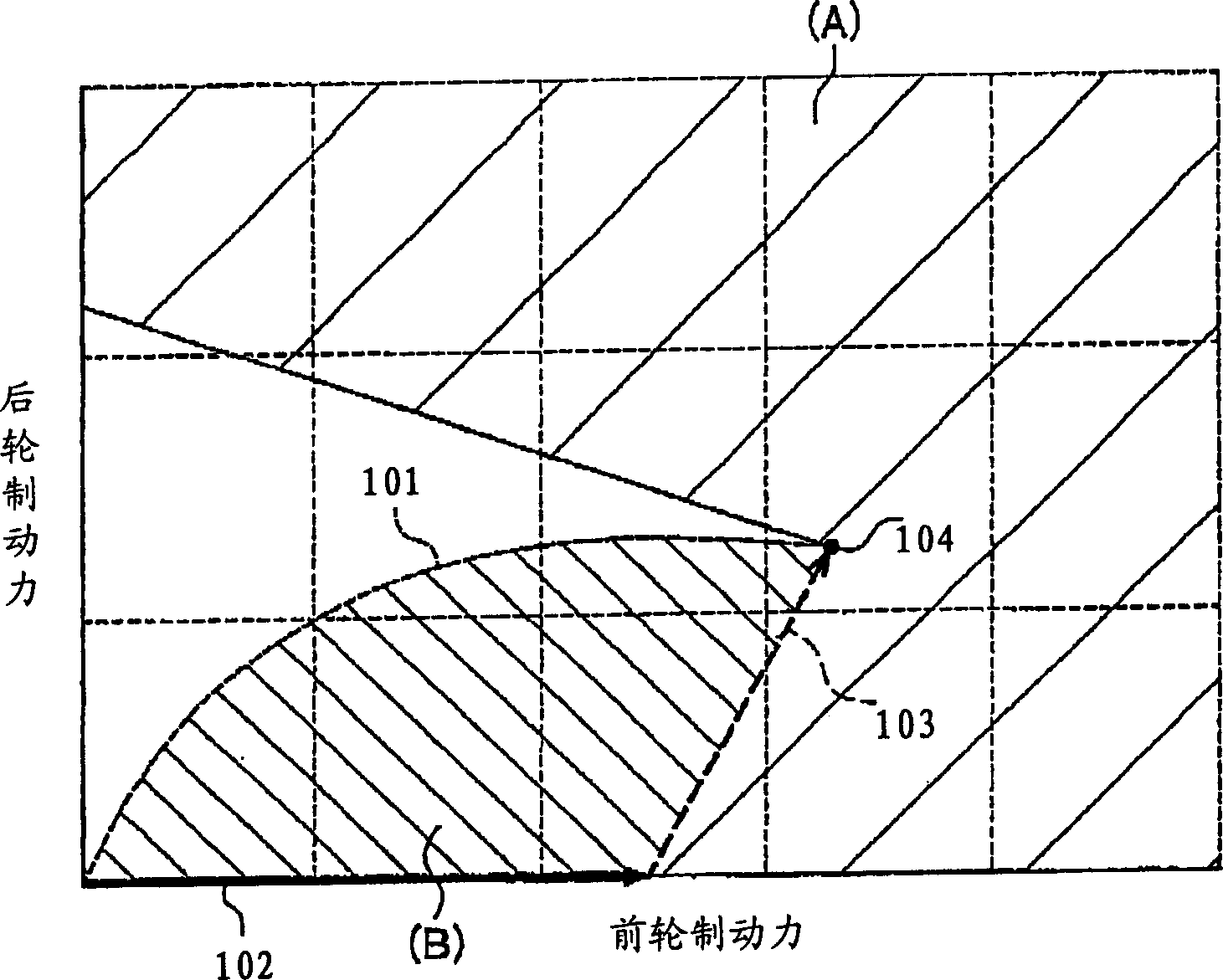

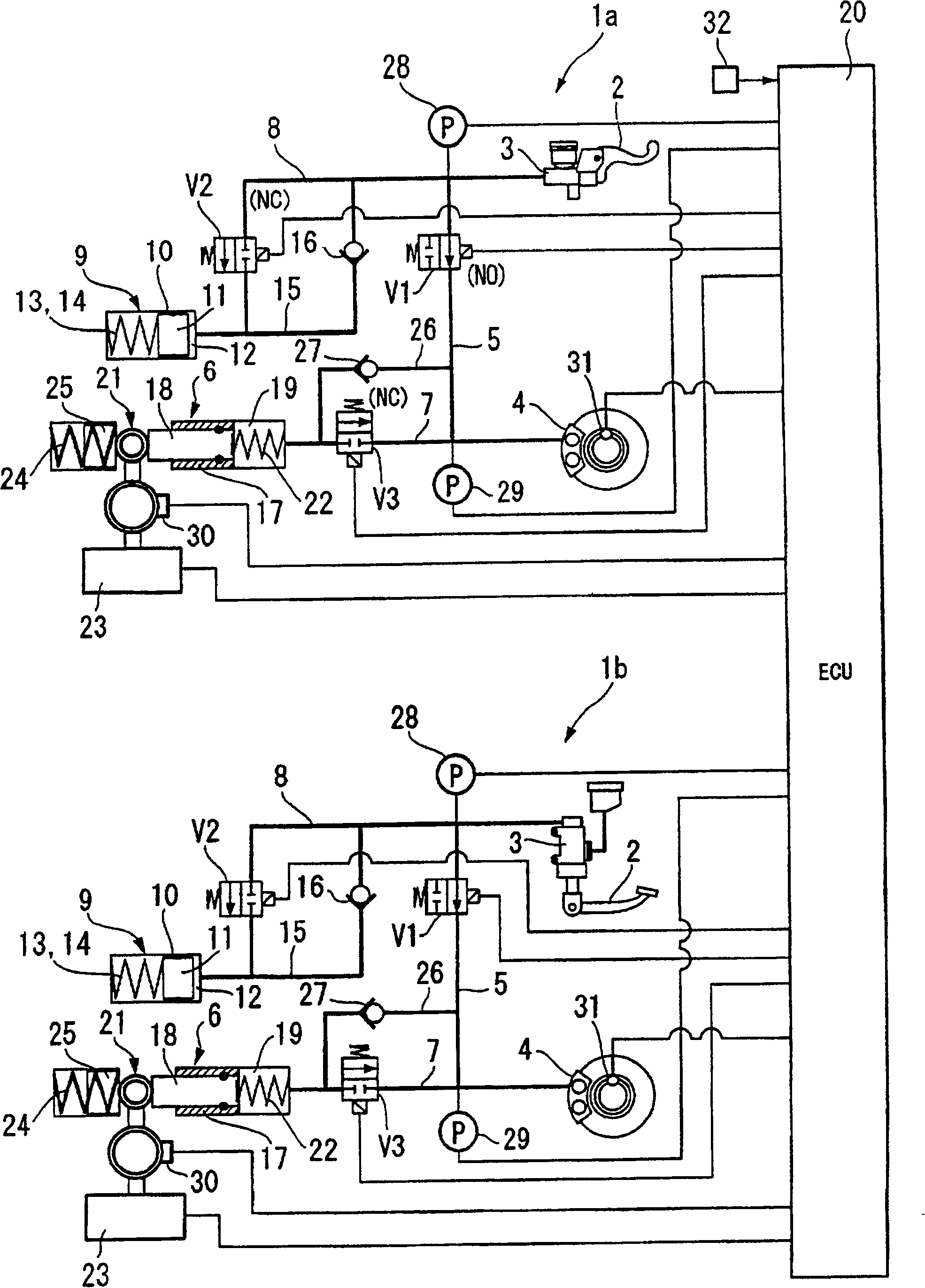

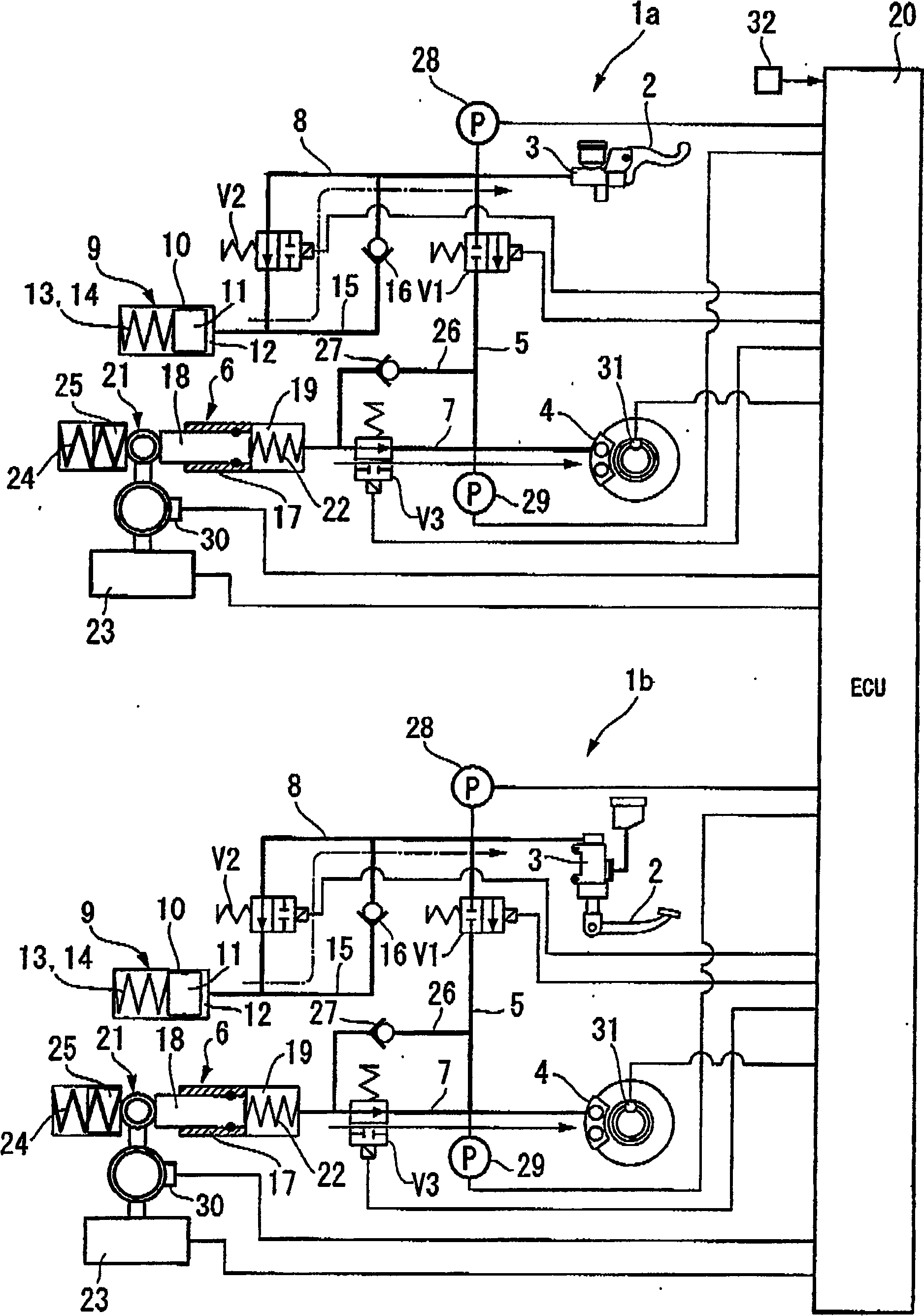

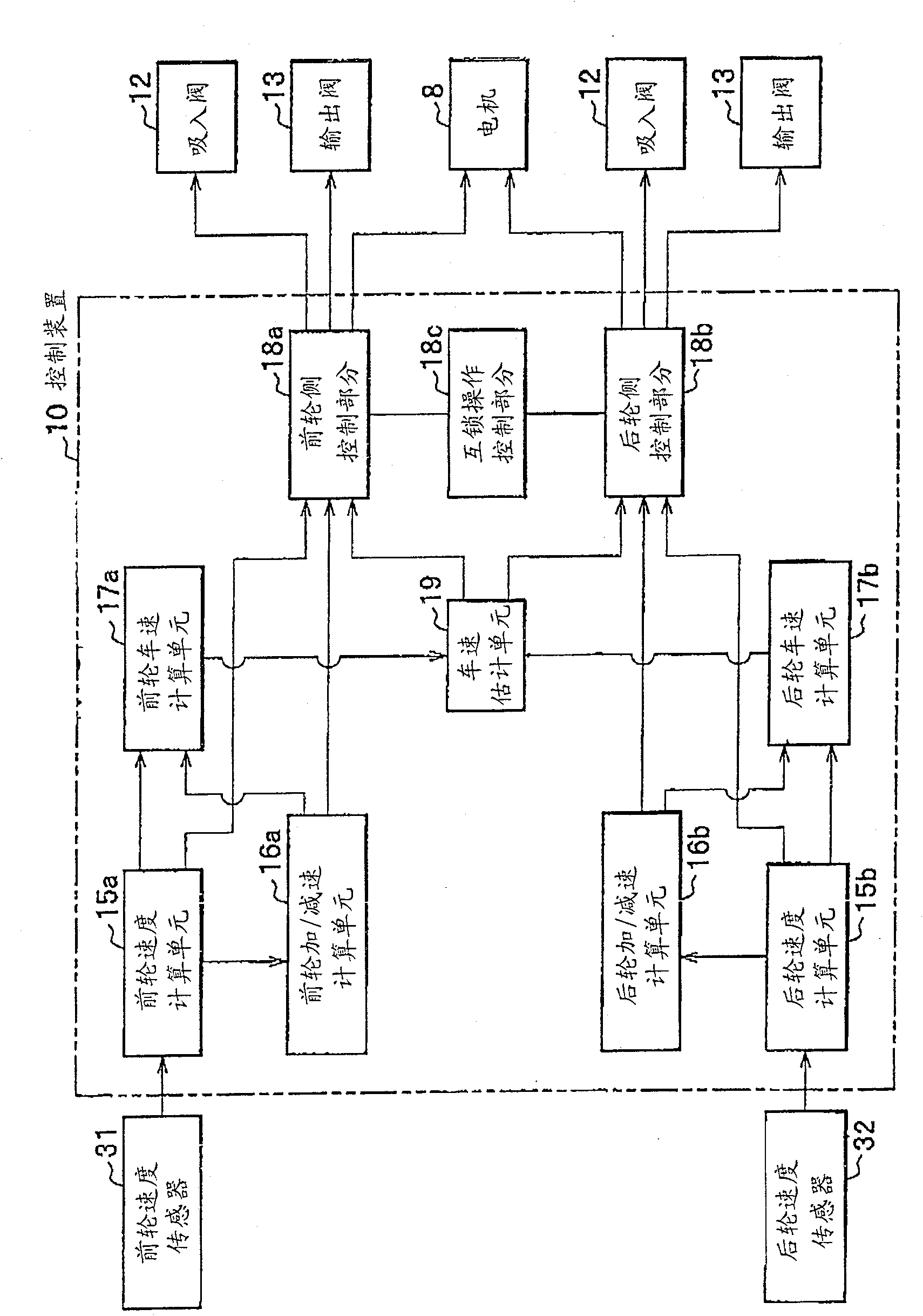

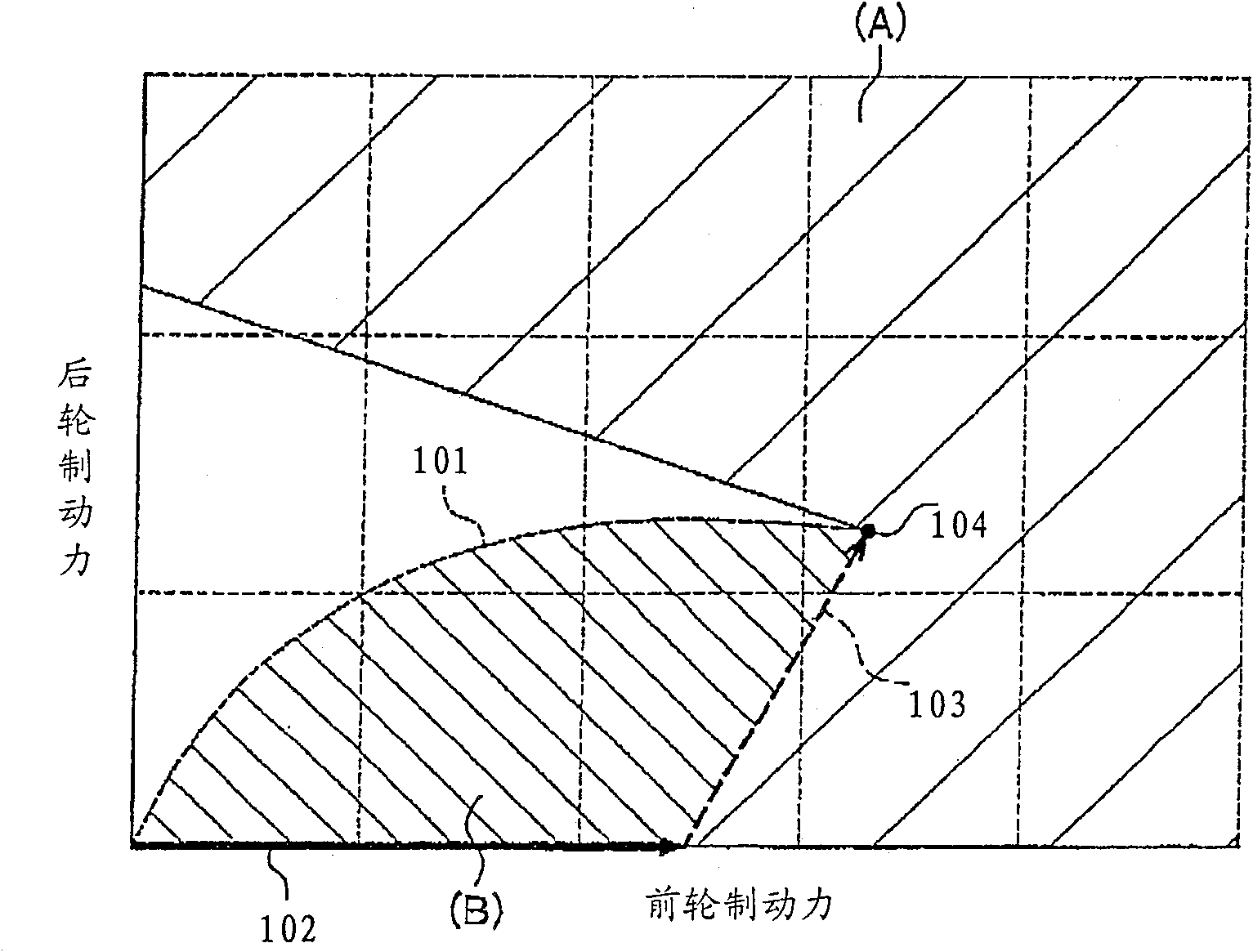

A control unit 10 controls brake forces of brake systems of a pair of brake operation elements L1, L2 operated independently to perform an anti-lock brake control for eliminating a locked state of a wheel. The control unit 10 applies the brake force to one of the wheel brakes B1, B2 of the brake system which differs from the brake system of the operated brake operation element when the brake operation elements L1, L2 is operated. When one or both of the brake operation elements L1, L2 are operated and so the wheel likely falls in a locked state, the control unit 10 performs an anti-lock brake control on the brake system of the wheel likely falling in the locked state and also performs a brake force application control on the other brake system which is different from the brake system of the wheel likely falling in the locked state.

Owner:NISSIN KOGYO CO LTD

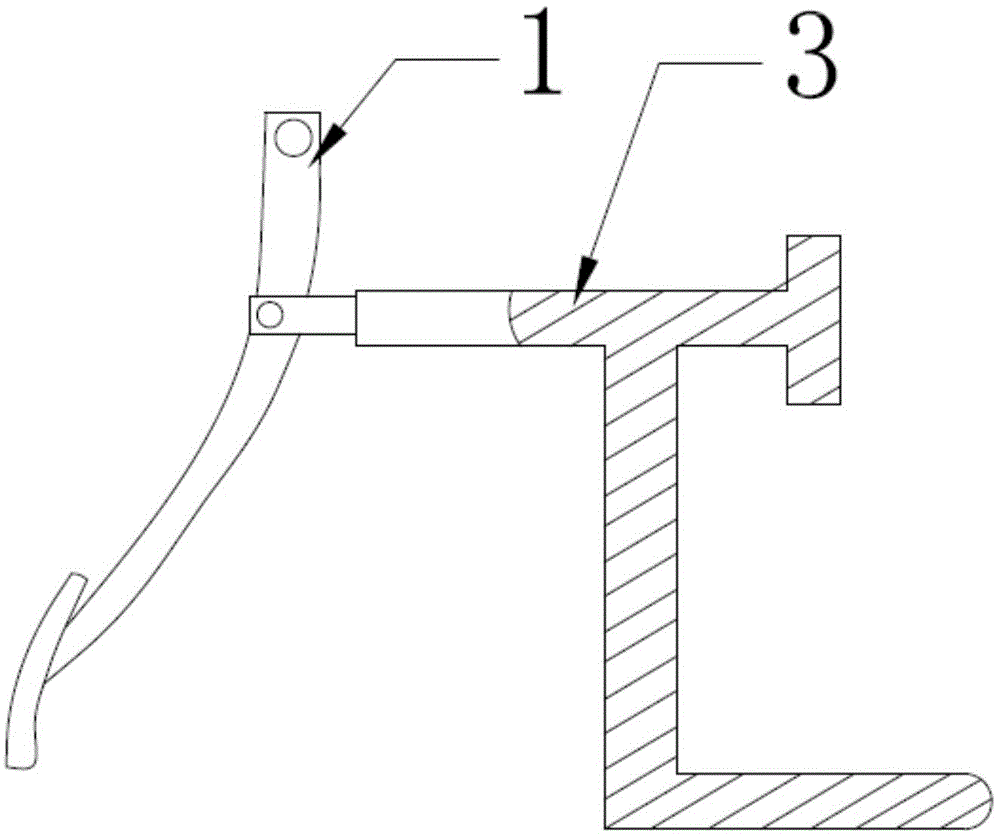

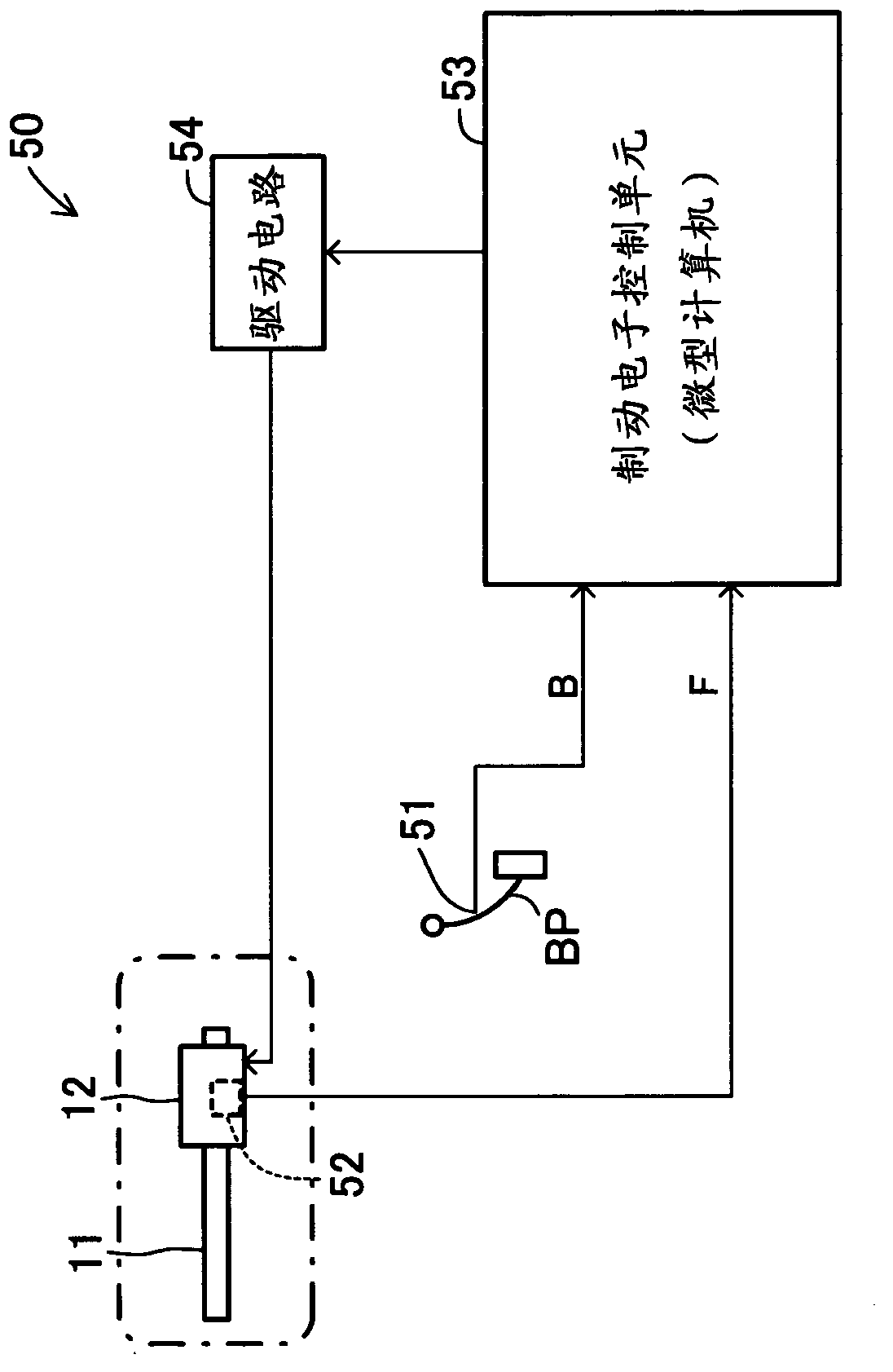

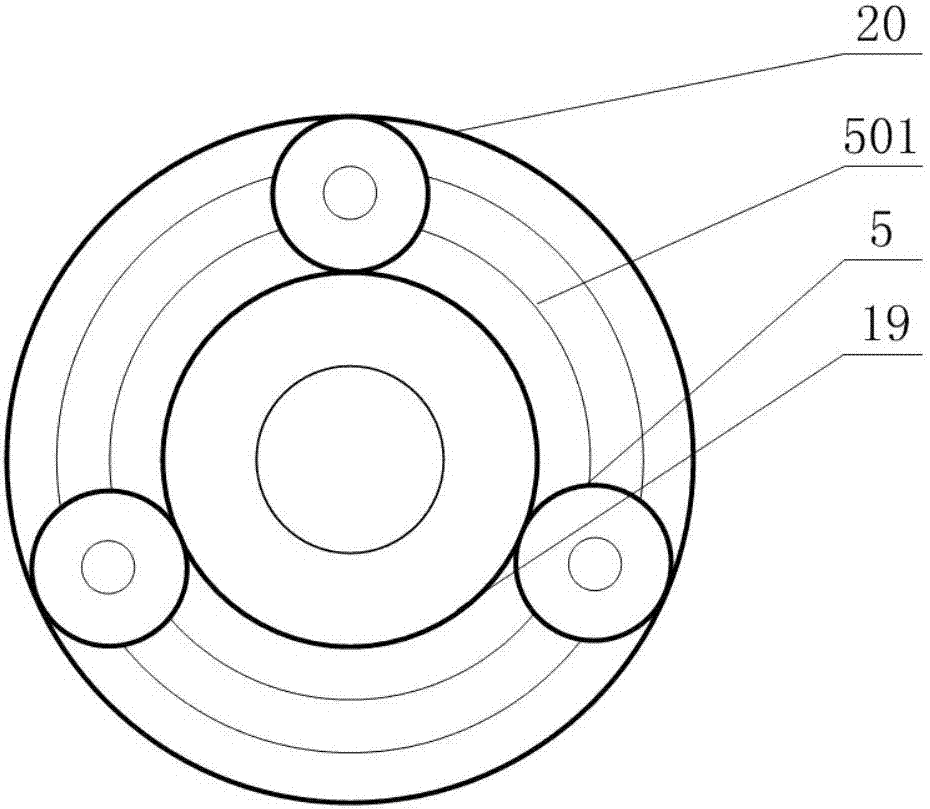

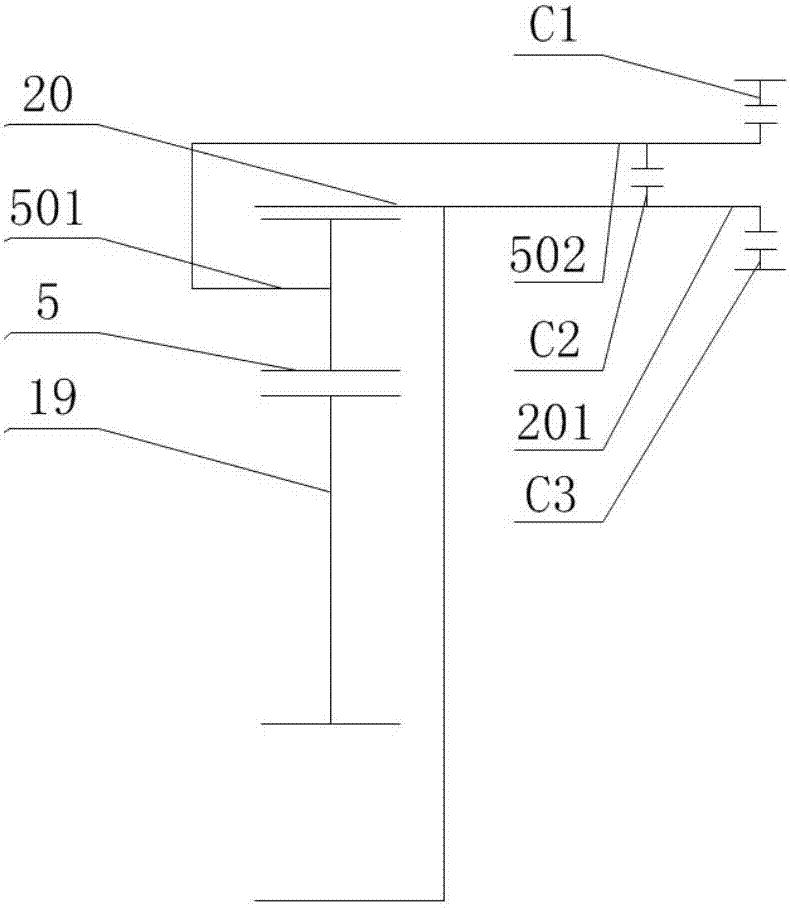

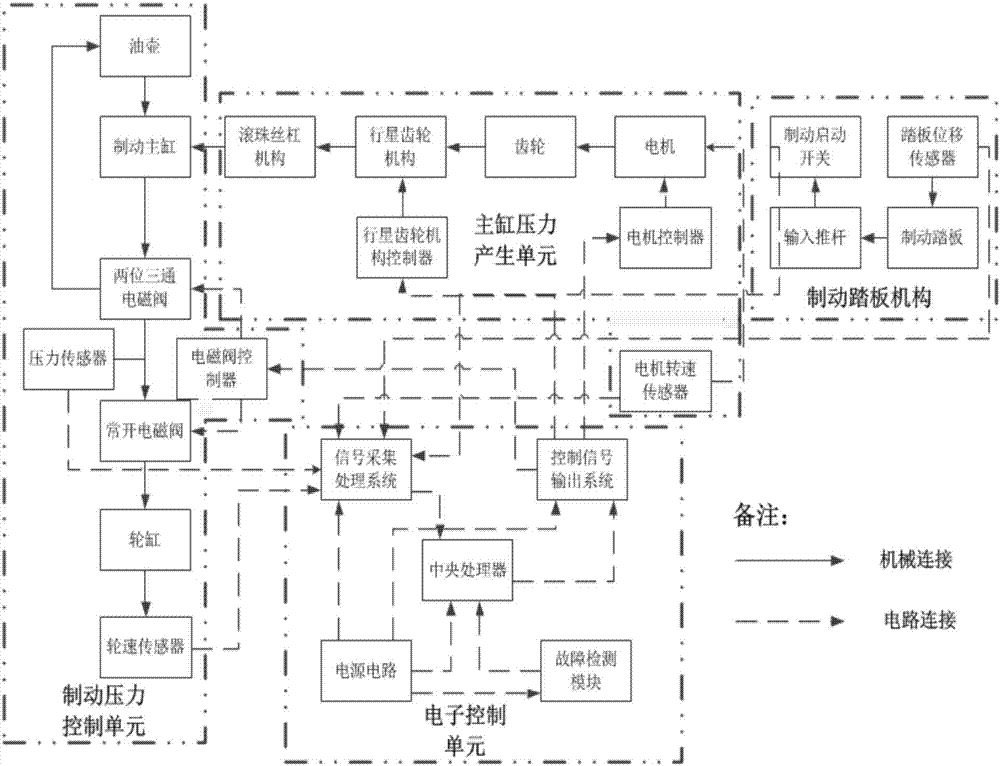

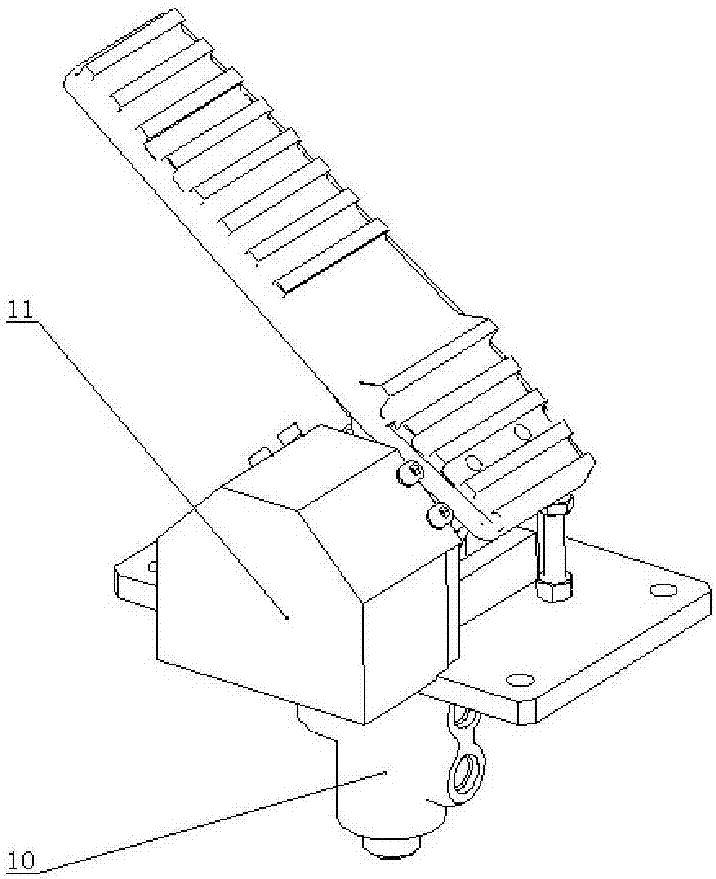

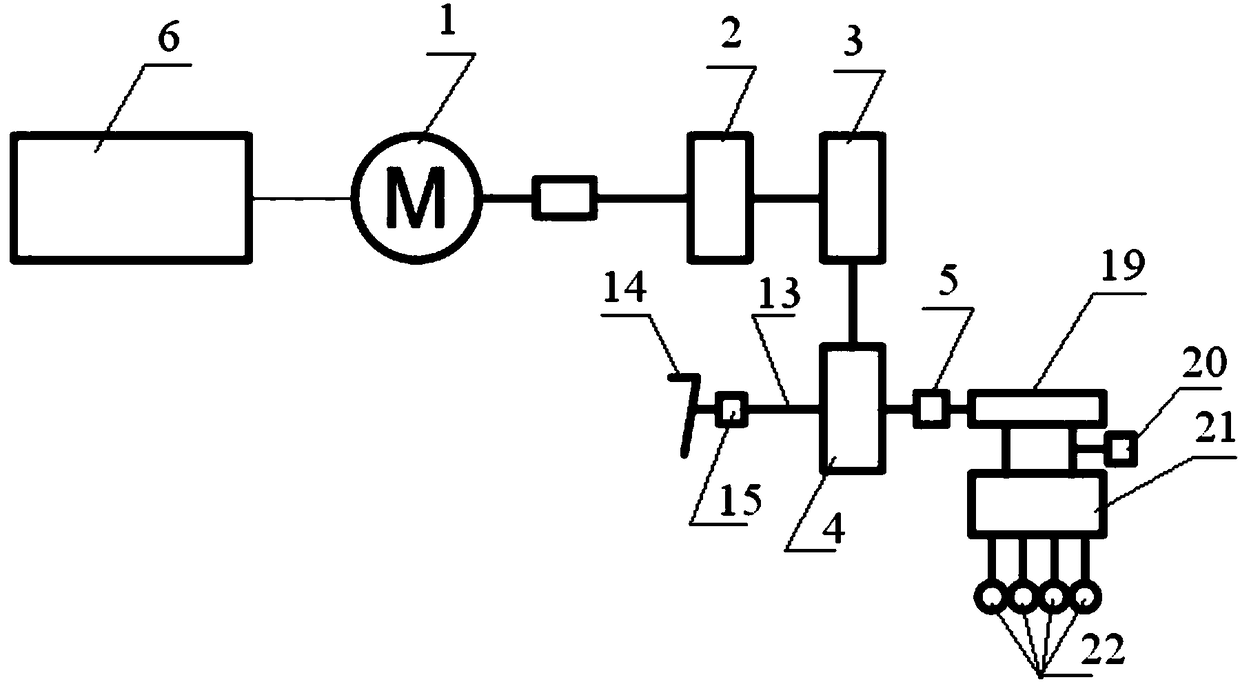

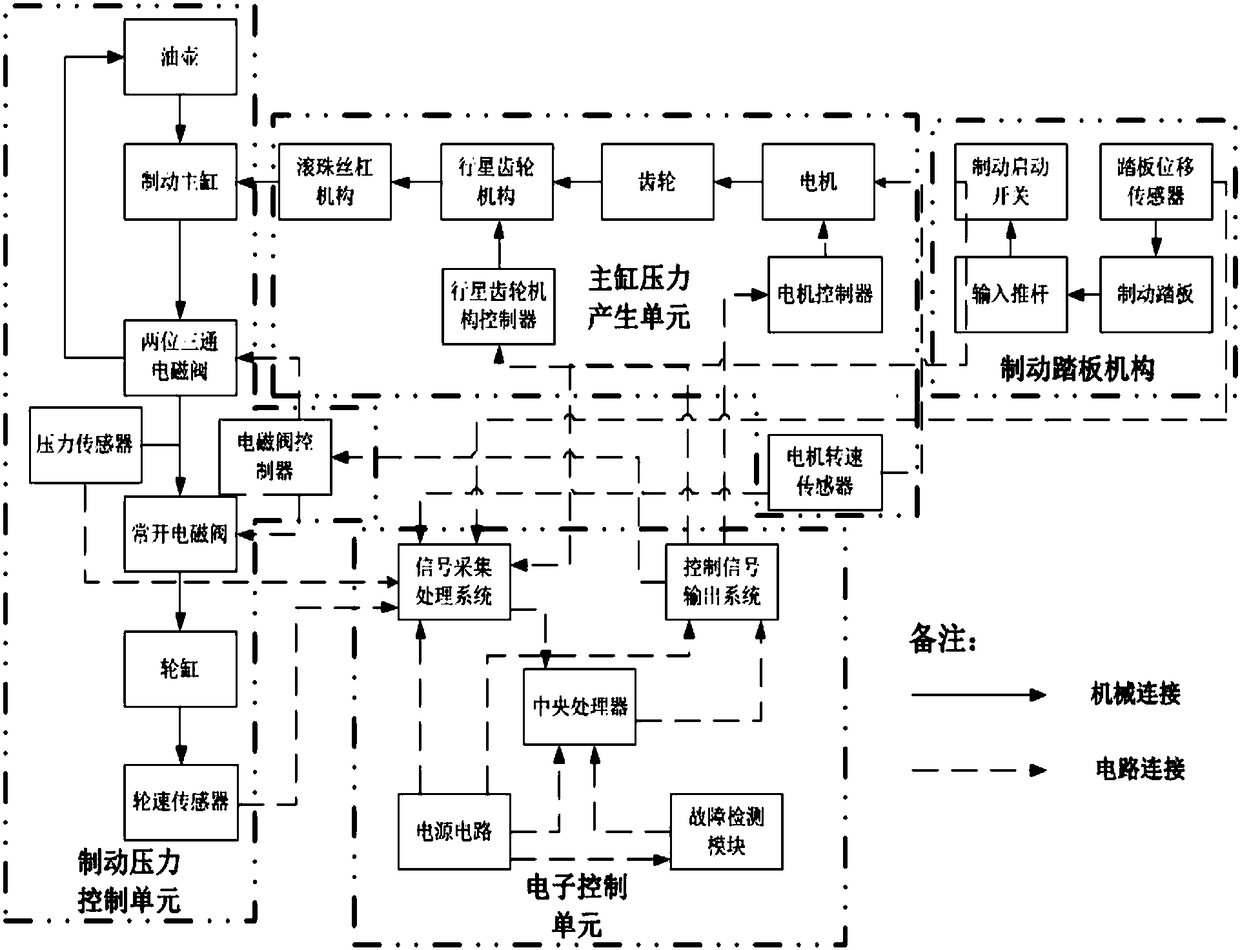

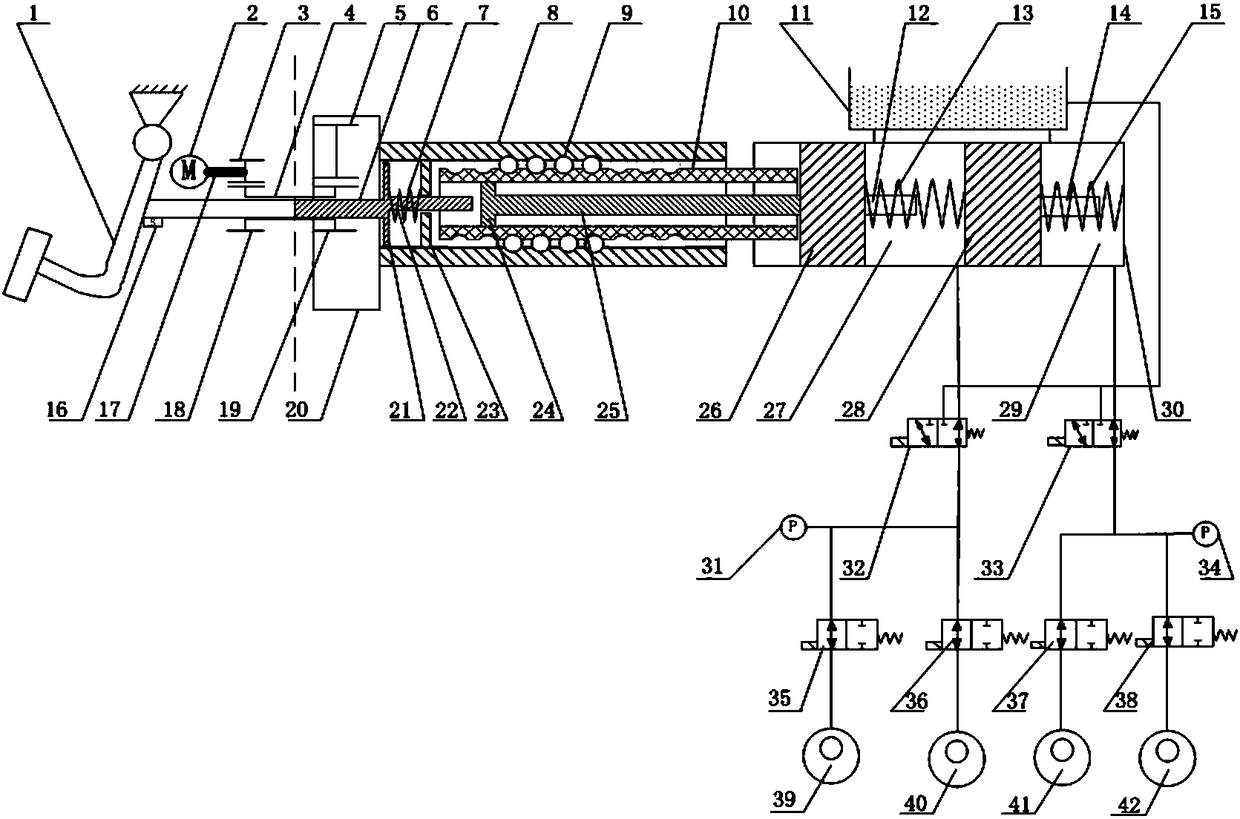

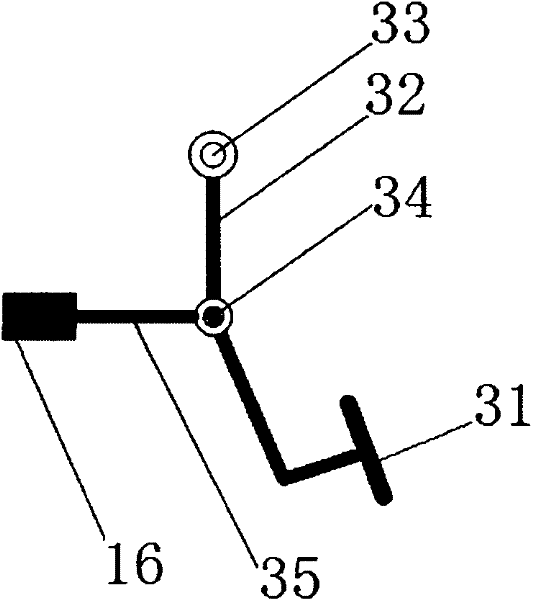

Motor-controlled hydraulic braking system

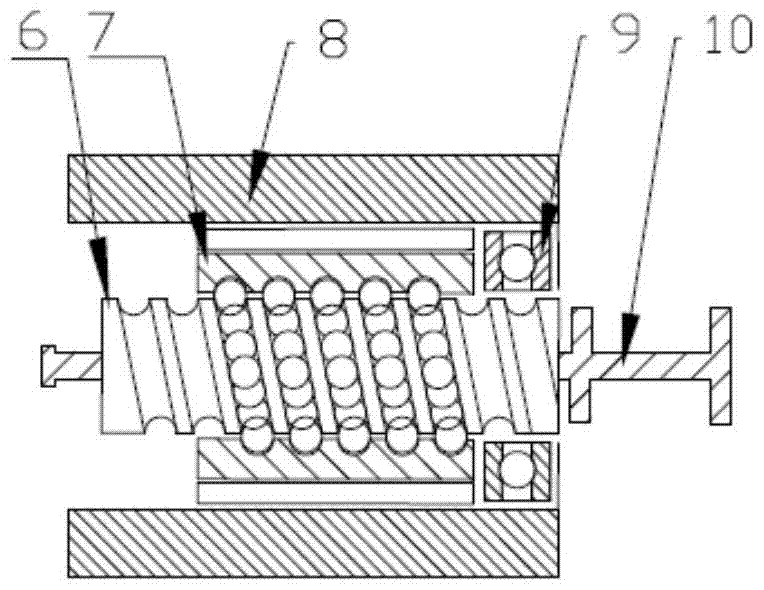

ActiveCN107054333AFast response timeFail safeBraking action transmissionFoot actuated initiationsHysteresisControl signal

The invention discloses a motor-controlled hydraulic braking system. The problem that the hysteresis influence caused by a motor during direction shifting and vertical movement caused by the condition that a brake pedal changes with pedal force are solved. The motor-controlled hydraulic braking system comprises a brake pedal mechanism, a master cylinder pressure generating unit, a brake pressure control unit and an electronic control unit. The brake pedal mechanism comprises an input push rod (6); the master cylinder pressure generating unit comprises a ball screw mechanism; the brake pressure control unit comprises a brake master cylinder; and the electronic control unit comprises a control signal output system and a signal collecting treatment system. The brake pedal mechanism is fixedly connected with an input push rod limiting plate (21) in the ball screw mechanism through the input push rod (6), the master cylinder pressure generating unit is fixedly connected with a master cylinder front cavity piston (26) in the brake master cylinder through a connecting shaft (25) in the ball screw mechanism, and the electronic control unit is connected with the brake pedal mechanism, the master cylinder pressure generating unit and the brake pressure control unit in an electric wire mode.

Owner:JILIN UNIV

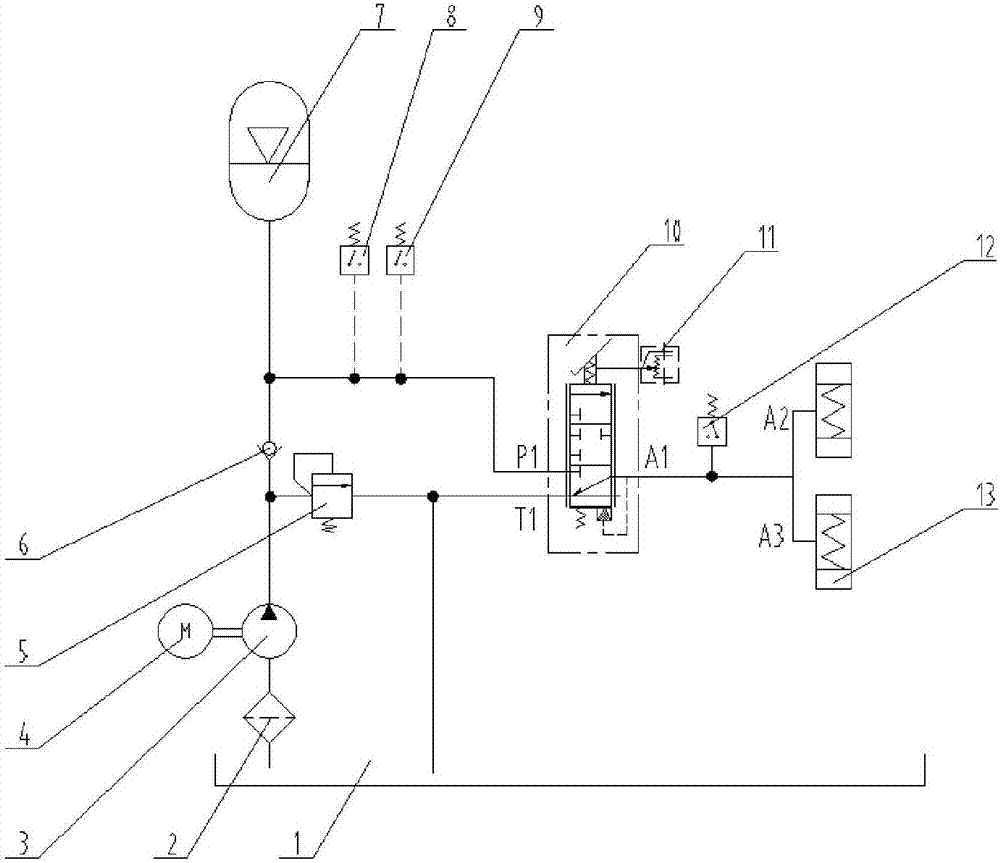

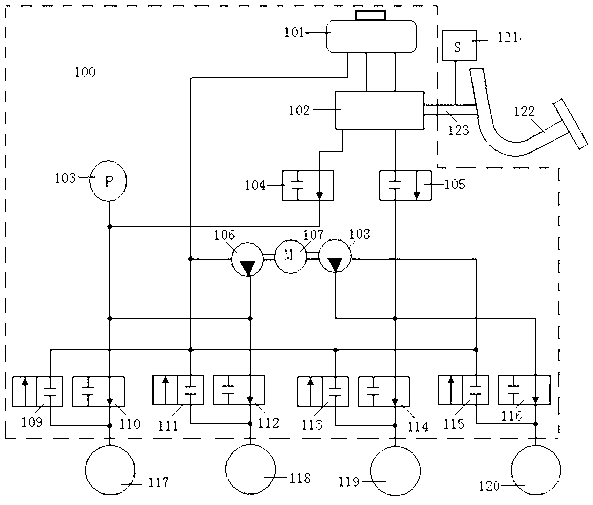

Electro-hydraulic compound brake system for recovering braking energy of electric fork-lift

PendingCN107344548AReduce wearIncrease profitBraking action transmissionElectrodynamic brake systemsRotational axisRegenerative brake

The invention relates to an electro-hydraulic compound brake system for recovering the braking energy of an electric fork-lift. The system comprises a suction filter, wherein the oil inlet of the suction filter extends into oil in a hydraulic oil tank, and the oil outlet of the suction filter is communicated with the oil inlet of a gear pump; the oil outlet of the gear pump is respectively communicated with the oil inlet of an overflow valve and the oil inlet of a one-way valve; the oil outlet of the overflow valve is respectively communicated with an oil return opening T1 of a three-position three-way full-hydraulic power brake valve and the hydraulic oil tank; the oil outlet of the one-way valve is respectively communicated with an energy accumulator and the oil inlet P1 of the three-position three-way full-hydraulic power brake valve; the oil outlet of the three-position three-way full-hydraulic power brake valve is connected with a service braking device; and a pedal angle sensor is connected with the brake pedal rotating shaft of the three-position three-way full-hydraulic power brake valve through a coupler. The electro-hydraulic compound brake system realizes maximized regenerating braking energyrecovery by coordinated control of electro-braking and hydraulic braking, so that braking safety is guaranteed, and energy utilization is improved.

Owner:ANHUI HELI CO LTD

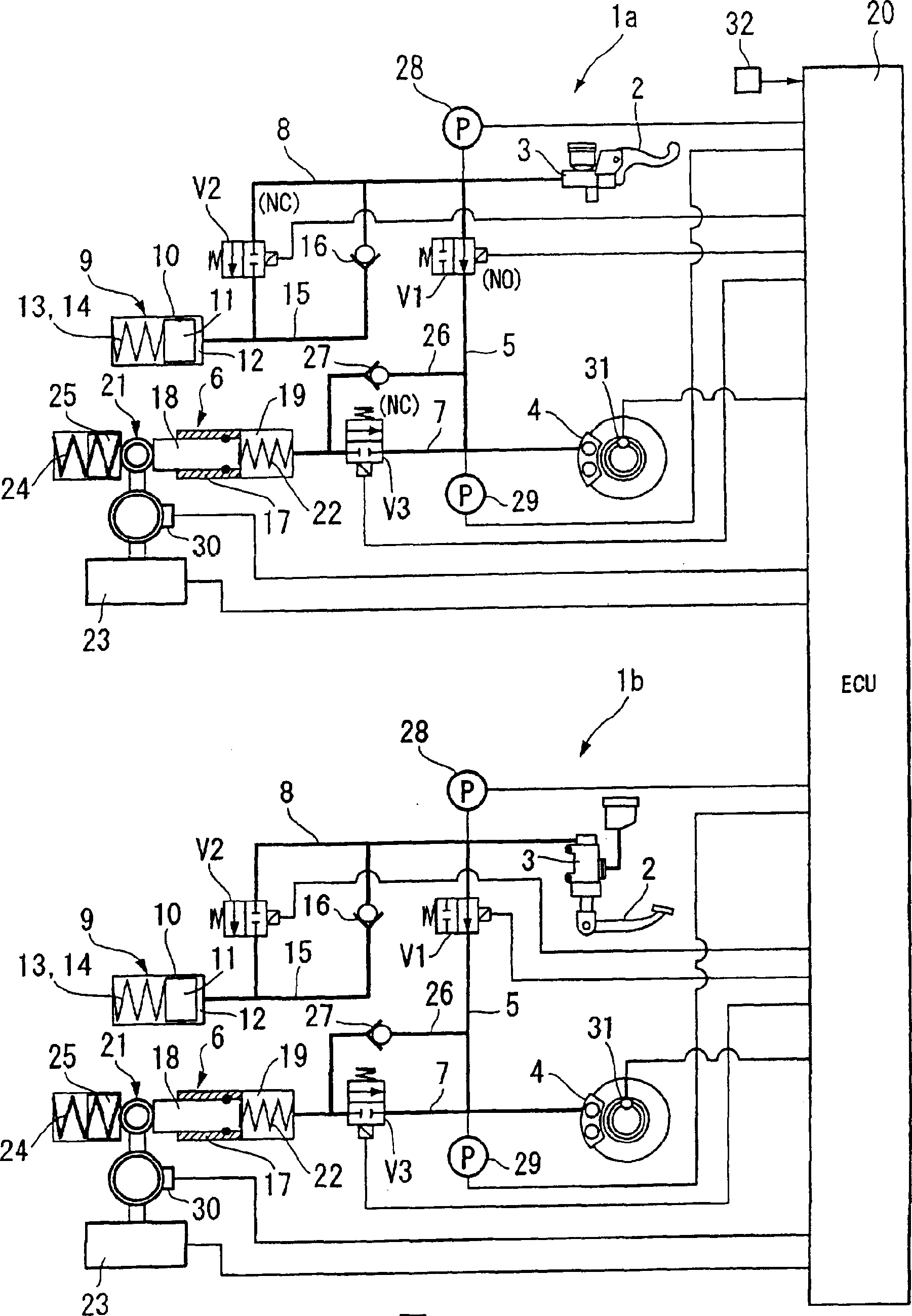

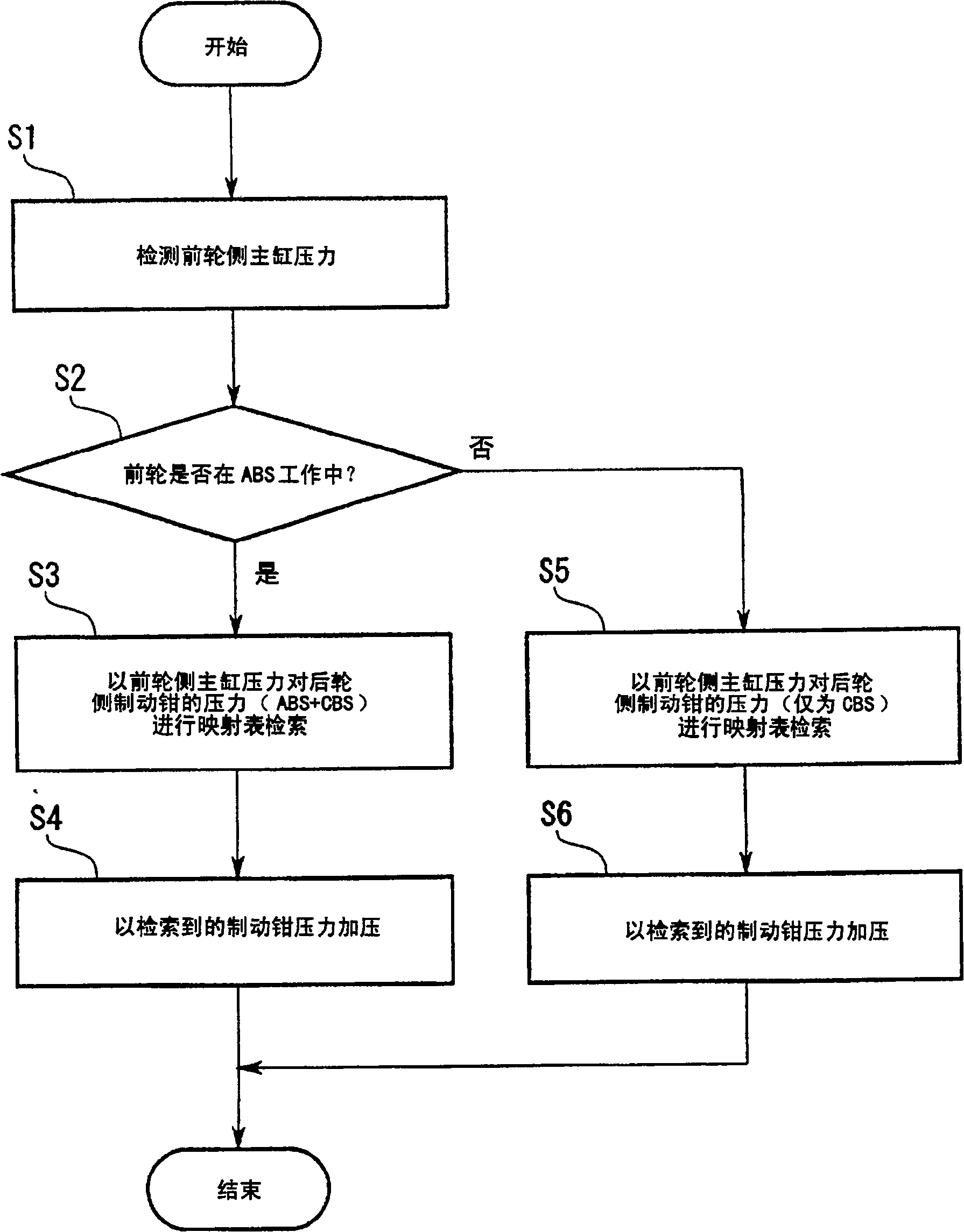

Motorcycle braking device

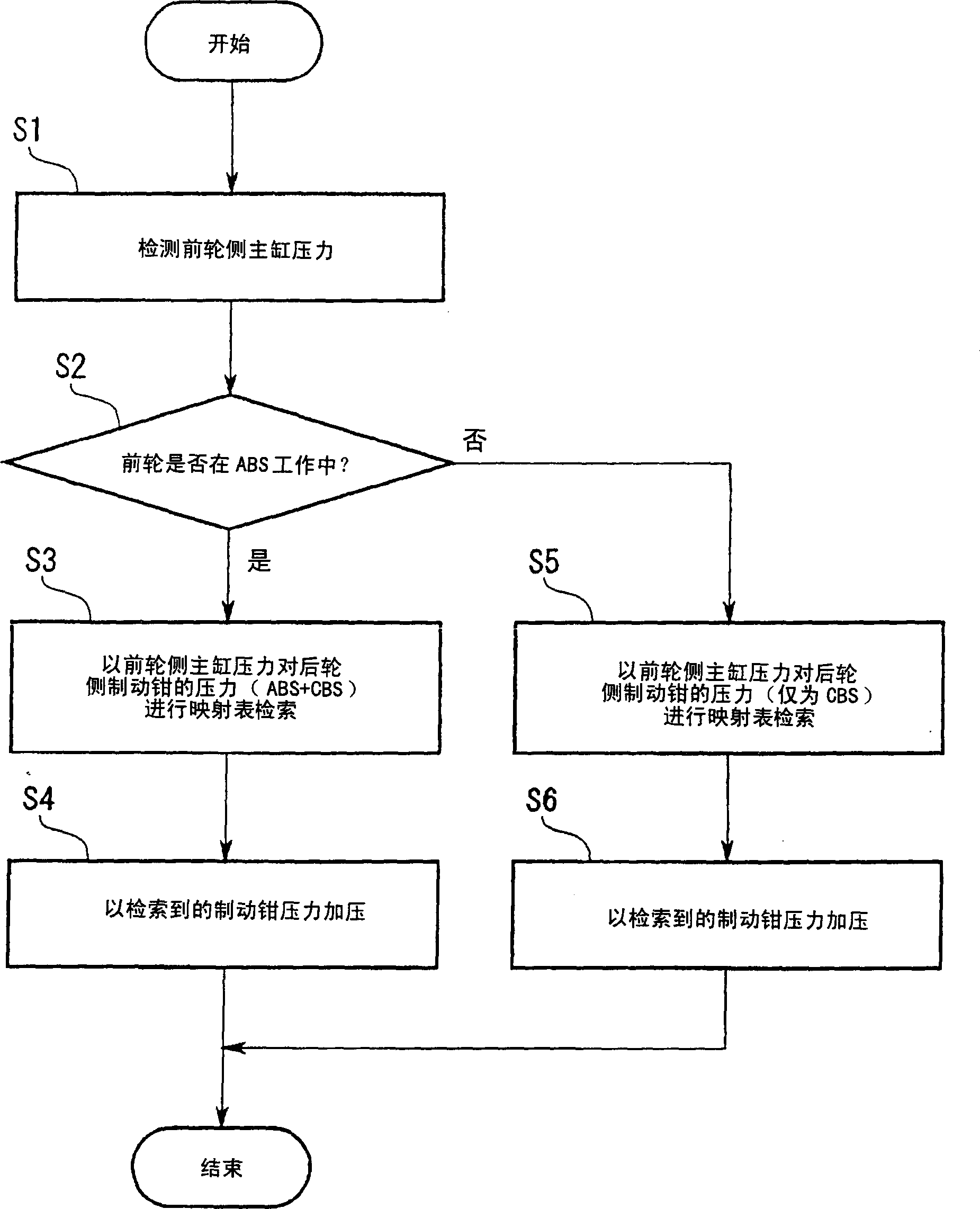

The utility model relates to a braking system of a motorcycle which adopts a front-rear linkage braking system and can make the braking feeling of the motorcycle better. In the braking device of a motorcycle equipped with ABS in which the brake caliper on the rear wheel side is linked to the brake operation on the front wheel side, when the front wheel braked by the brake operating part on the front wheel side When the ABS is activated, the ratio of the brake pressure of the brake calipers on the front wheel side and the rear wheel side can be changed compared to the case where the ABS is not activated.

Owner:HONDA MOTOR CO LTD

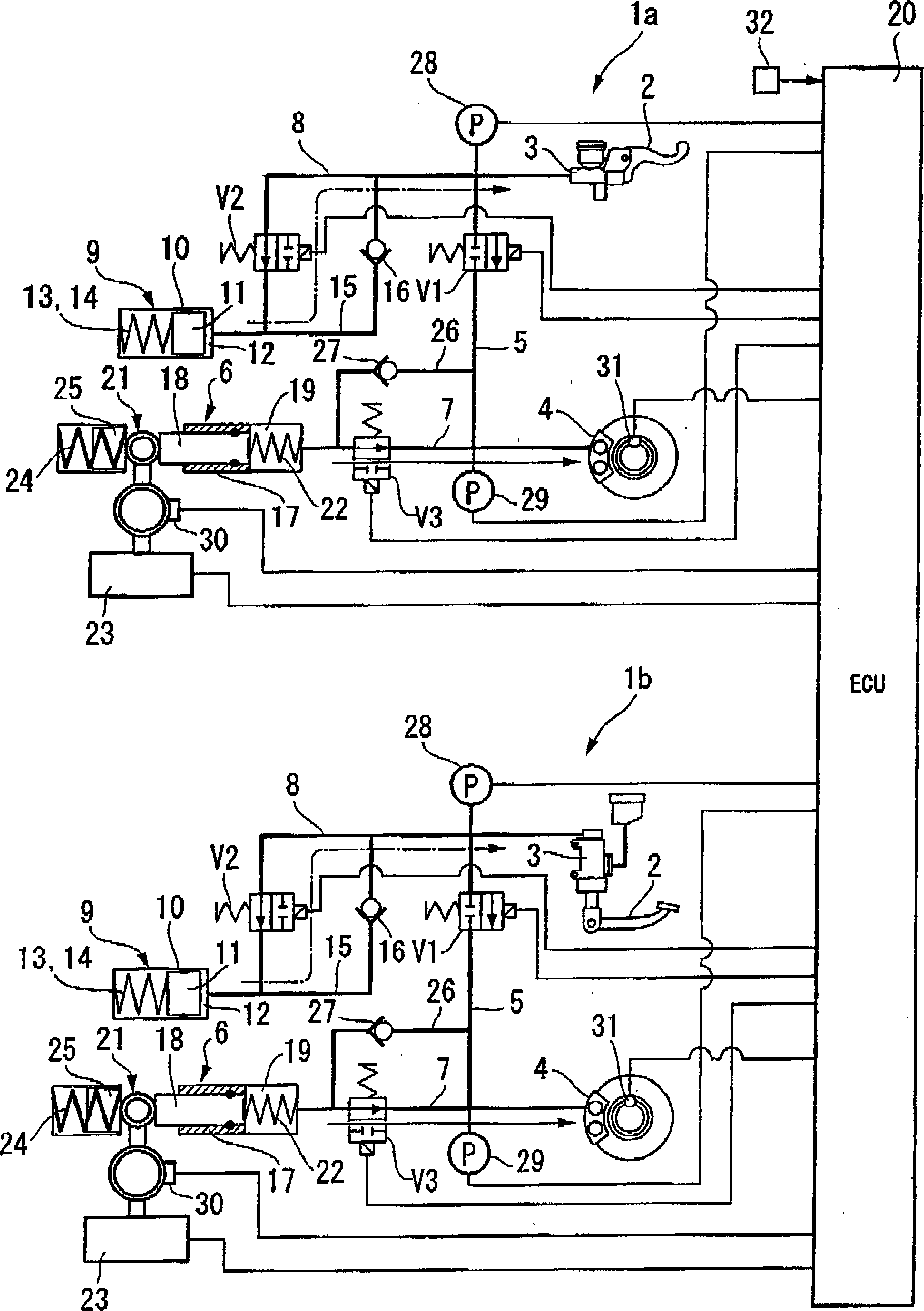

Vehicle brake apparatus

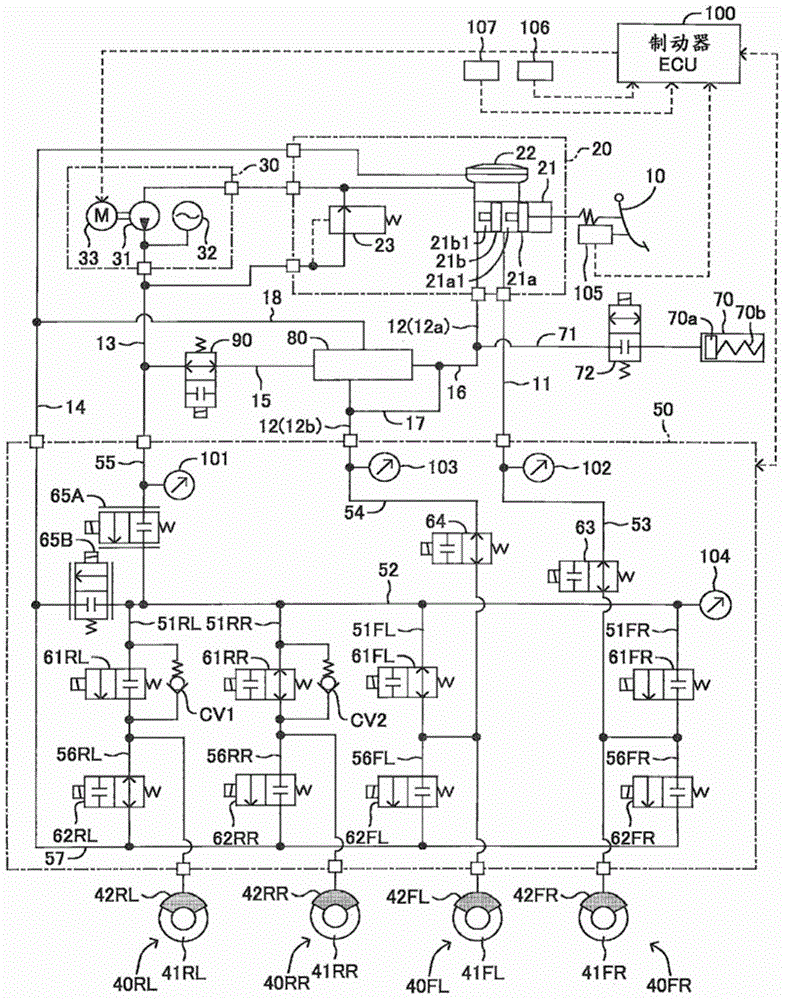

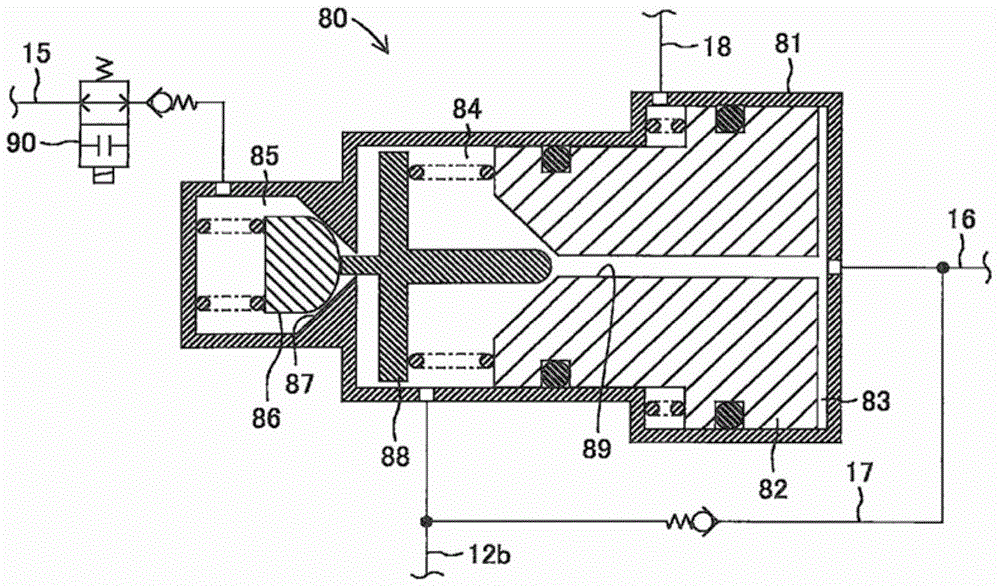

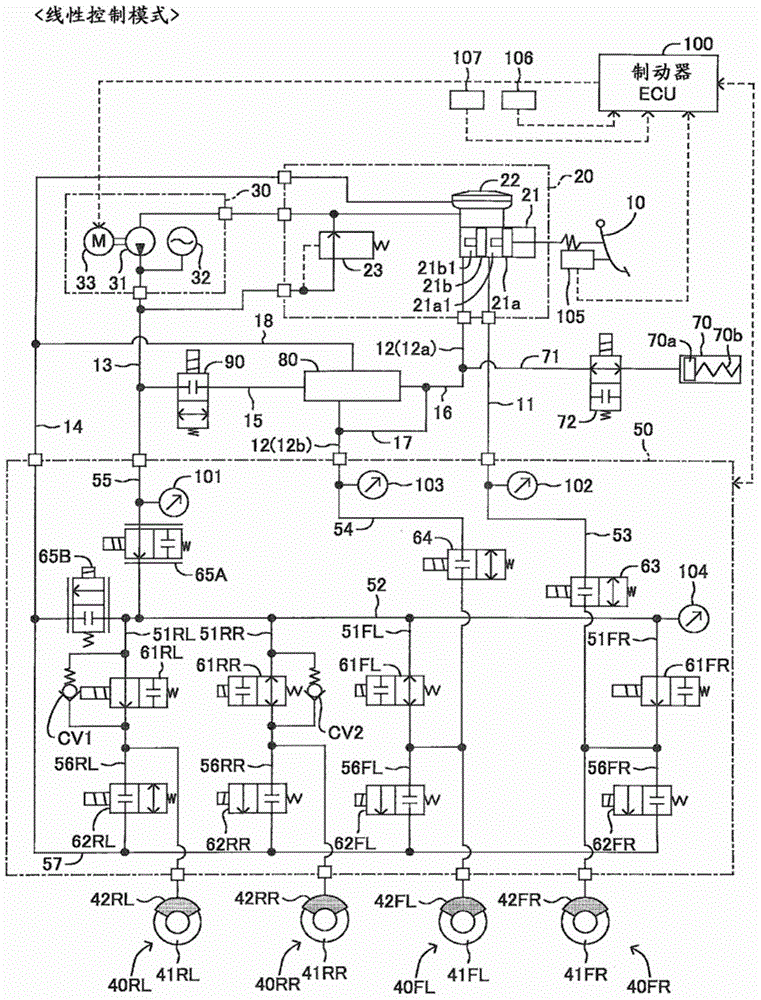

InactiveCN104602980ASuppress changesGood braking feelBrake control systemsBrake action initiationsWheel cylinderCheck valve

In individual flow passageways (51) connecting a main flow passageway (52) connected to an accumulator (32) of a power fluid pressure generation device (30) with wheel cylinders (42), holding valves (61) are disposed. The holding valves (61) permit communication between an upstream side and a downstream side in an open valve state to transmit a fluid pressure from the accumulator (32) to the wheel cylinders (42), while disconnecting the upstream side and the downstream side in a closed valve state. Of the holding valves (61), the holding valves (61RR, 61RL) disposed in left and right rear-wheel brake systems in which the fluid pressure on the main flow passageway (52) side (upstream side) to which the fluid pressure is transmitted from the accumulator (32) is not less than the fluid pressure on the wheel cylinder (42) side (downstream side) at all times are provided with check valves (CV1, CV2) in parallel for reducing the fluid pressure of the wheel cylinders (42) by permitting communication only from the downstream side to the upstream side.

Owner:TOYOTA JIDOSHA KK

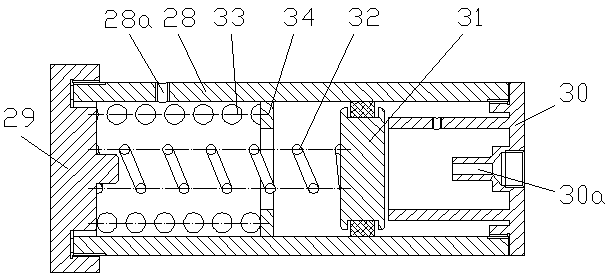

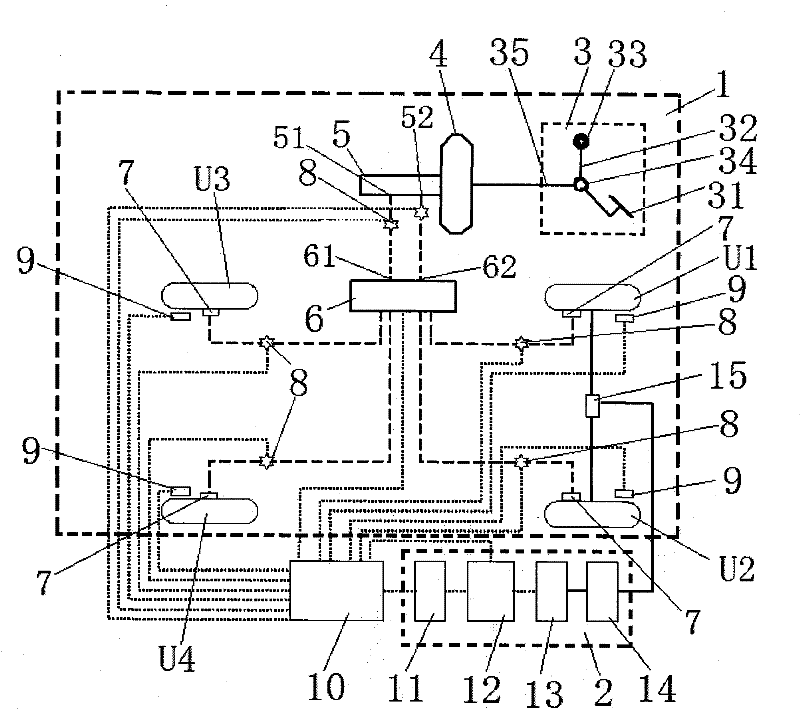

Hybrid electrical vehicle (HEV)/electrical vehicle (EV) regeneration brake pressure coordinate control system based on antilock brake system (ABS) hardware

ActiveCN102303597BAccurate braking forceAccurate brake strength signalBraking action transmissionElectrodynamic brake systemsDrive motorWheel cylinder

The invention discloses a hybrid electrical vehicle (HEV) / electrical vehicle (EV) regeneration brake pressure coordinate control system based on antilock brake system (ABS) hardware. The system comprises a hydraulic brake subsystem, a motor regeneration subsystem and a control system for controlling the hydraulic brake subsystem and the motor regeneration brake subsystem; and the hydraulic brake subsystem comprises a vacuum assistance system, a brake main cylinder, an oil storage tank, a travel simulator, a front wheel ABS pressure regulation system, a front wheel brake wheel cylinder, a rearwheel ABS pressure regulation system and a rear wheel brake wheel cylinder, and a working cavity I of the brake main cylinder is communicated with the travel stimulator. In the HEV / EV system regeneration brake pressure coordinate control system based on the ABS hardware, the working modes such as pure motor brake, electrohydraulic combined brake, pure hydraulic brake, antilock brake and the like can be flexibly selected according to specific conditions, and accurate brake force is provided; when a brake pedal is trampled, the travel simulator can produce good retardation brake feeling; and during pressurization, an overflow valve and a solenoid directional valve can protect an oil pump I driving motor to ensure that a system can work stably.

Owner:CHONGQING UNIV

Hydraulic unit for integrated automobile brake system

InactiveCN102795216ASimple structureReduce in quantityFluid braking transmissionNew energyHydraulic pump

The invention discloses a hydraulic unit for an integrated automobile brake system. The hydraulic unit comprises a hydraulic valve block and further comprises a brake master cylinder, a motor, two hydraulic pumps, two switch valves, a second switch valve, four pressure-increasing valves, four pressure-relieving valves, an oil storage chamber and a pressure sensor which are mounted on the hydraulic valve block, wherein a brake master cylinder body is integrated with the hydraulic valve block; a piston of the brake master cylinder is arranged in the brake master cylinder body; the piston of the brake master cylinder is connected with a brake pedal through a push rod; the motor is mounted on the hydraulic valve block and is connected with the hydraulic pumps; and the oil storage chamber which is connected with the hydraulic valve block is connected with two oil inlets of the brake master cylinder body through oil channels on the hydraulic valve block and also is connected with the outlets of the pressure-relieving valves and the oil inlets of the hydraulic pumps. The hydraulic unit for the integrated automobile brake system has the advantages of simple and compact structure, low cost, energy conservation and environmental protection, wide application scope, powerful function, high speed in establishing braking hydraulic pressure, benefit to the reduction of braking distance, and capability of increasing the driving safety. The hydraulic unit for the integrated automobile brake system can be applied to a traditional vehicle as well as a new energy vehicle.

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

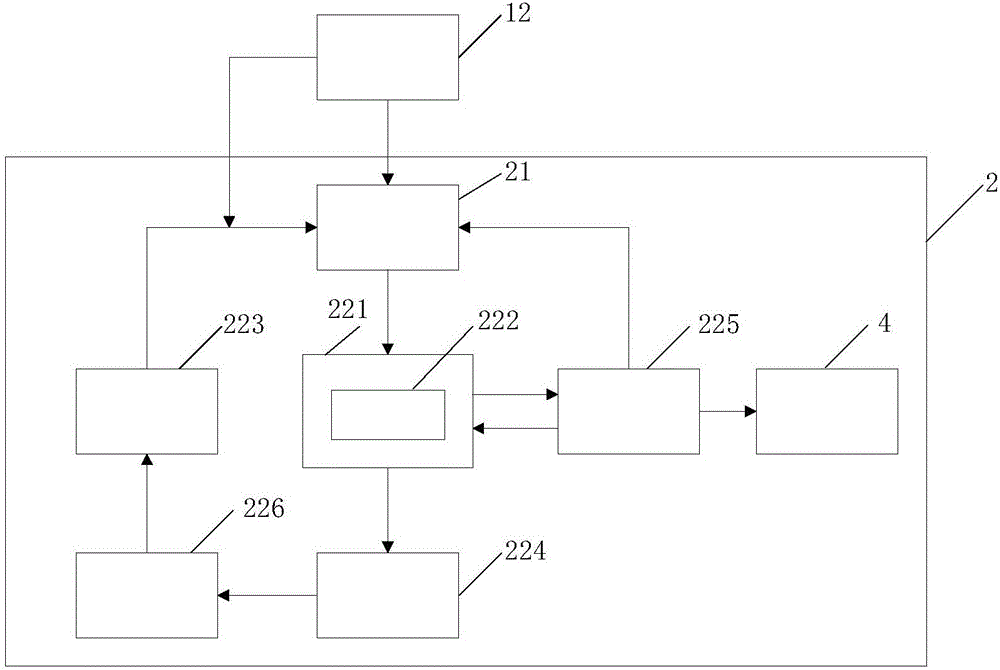

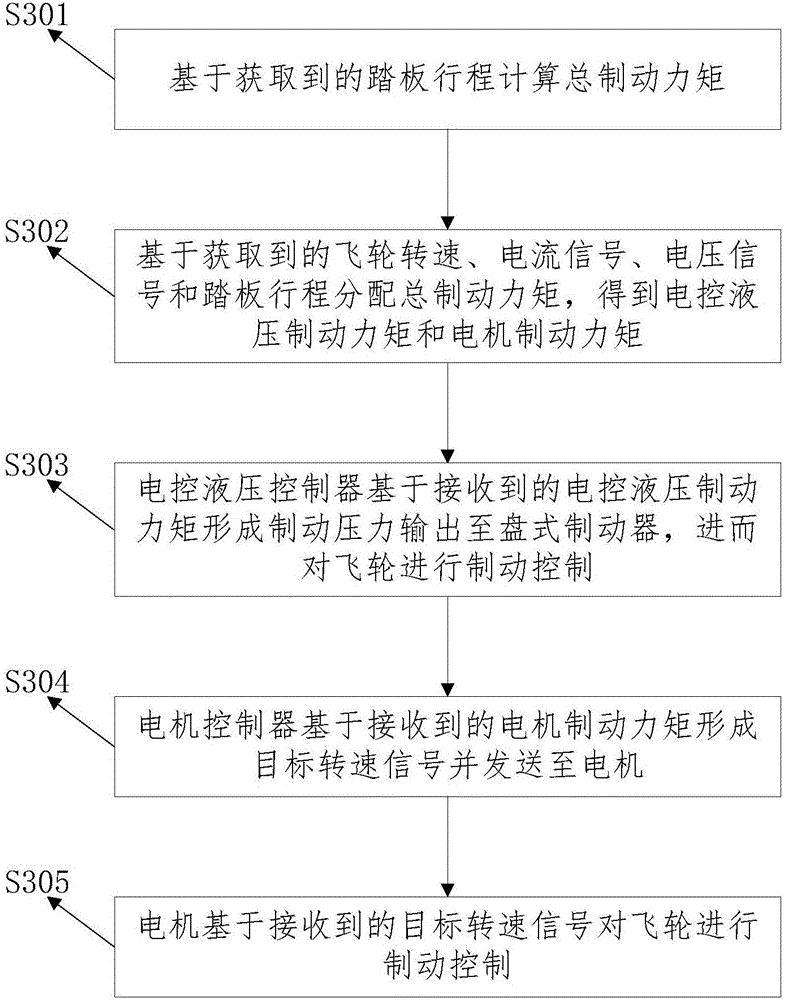

Coordination control method simulating automobile braking

InactiveCN106379178AGuaranteed stabilityImprove energy efficiencyHybrid vehiclesElectrodynamic brake systemsBrake torqueDisc brake

The invention discloses a coordination control method simulating automobile braking and belongs to the technical field of automobile braking control. The method includes the steps that based on the obtained pedal travel, the total braking torque is calculated; based on the obtained flywheel rotating speed, current signal, voltage signal and pedal travel, the total braking torque is distributed, the electronic control hydraulic braking torque and the motor braking torque are obtained; an electronic control hydraulic controller forms braking pressure based on the received electronic control hydraulic braking torque and outputs the braking pressure to a disc brake, and then braking control over a flywheel is conducted; a motor controller forms a target rotation speed signal based on the received motor braking torque and sends the target rotation speed signal to a motor; and the motor carries out braking control over the flywheel based on the received target rotation speed signal. The coordination control method simulating automobile braking can be used for realizing coordination control over an automobile.

Owner:JILIN UNIV

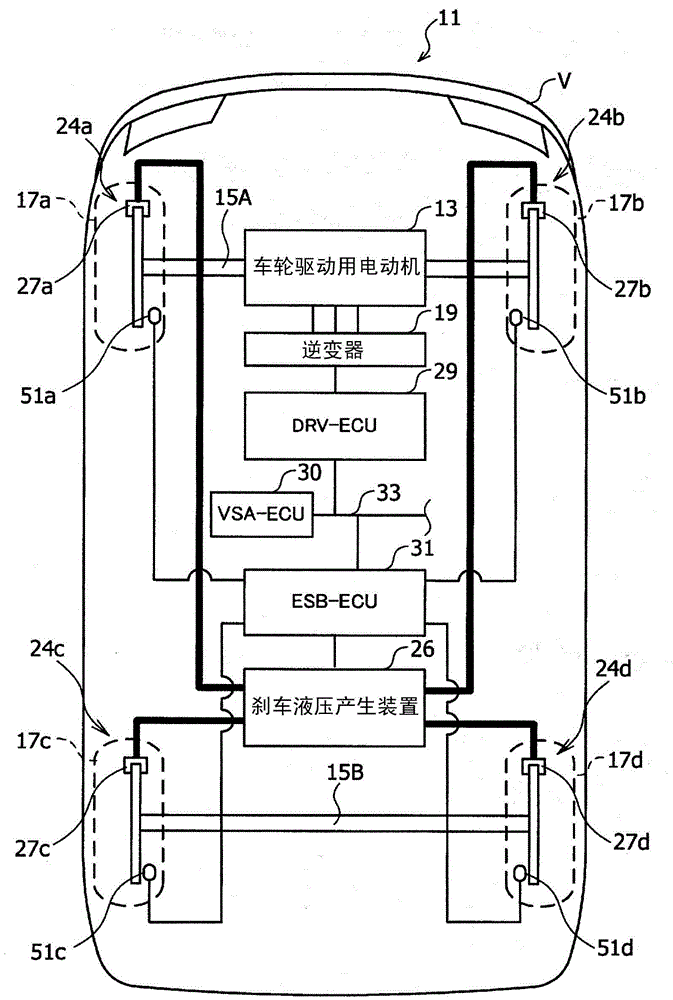

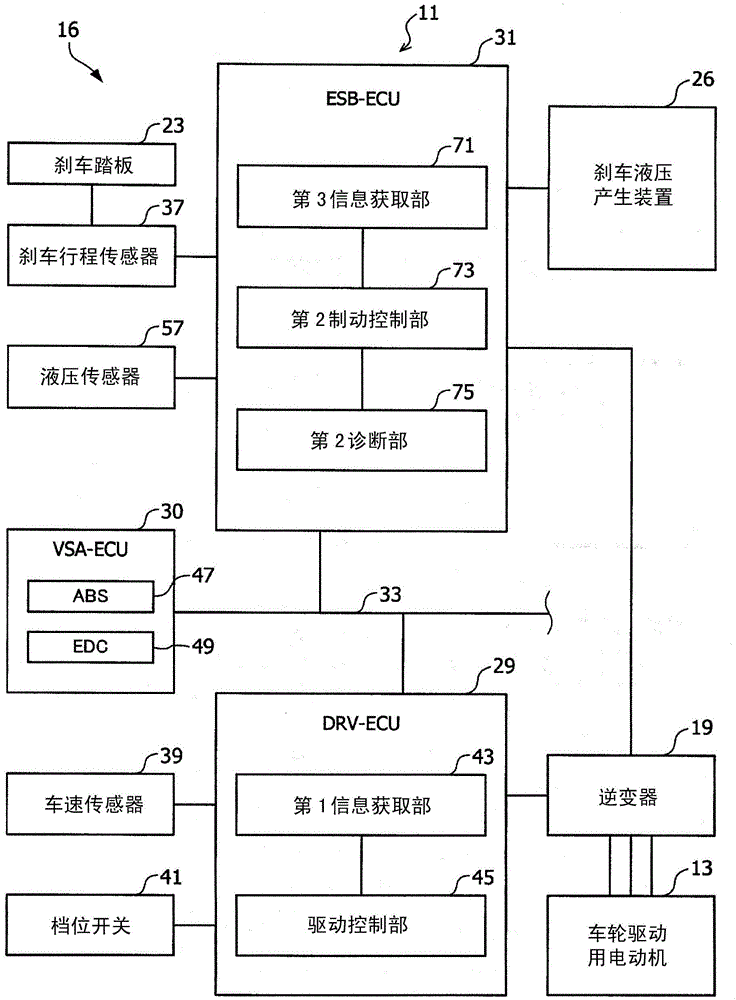

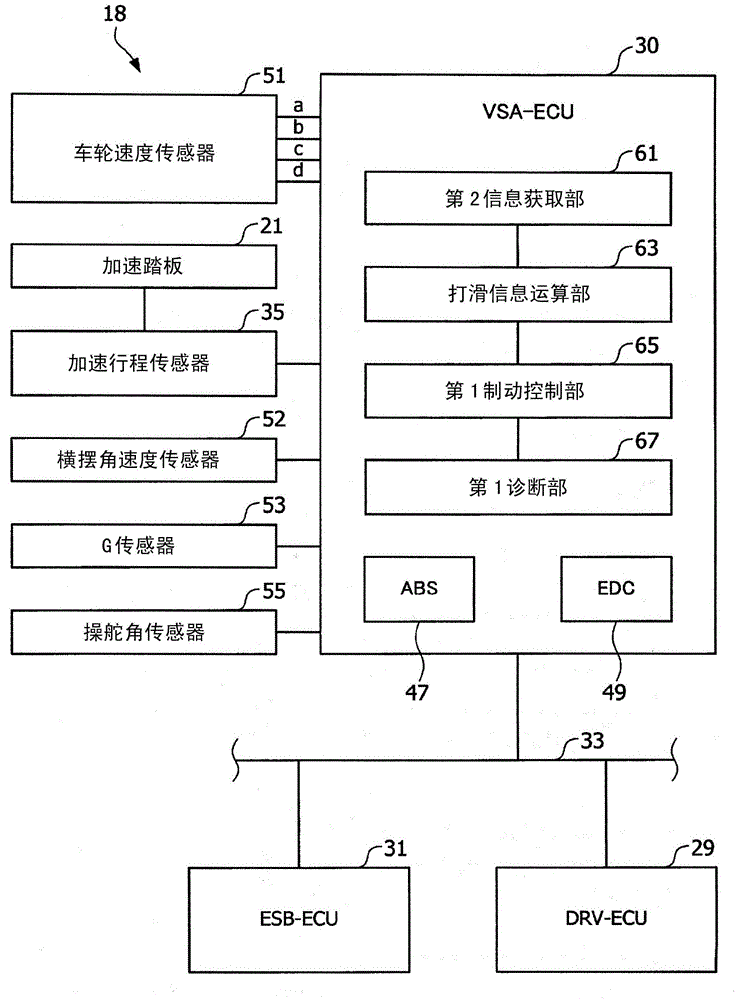

Vehicle brake force generation device

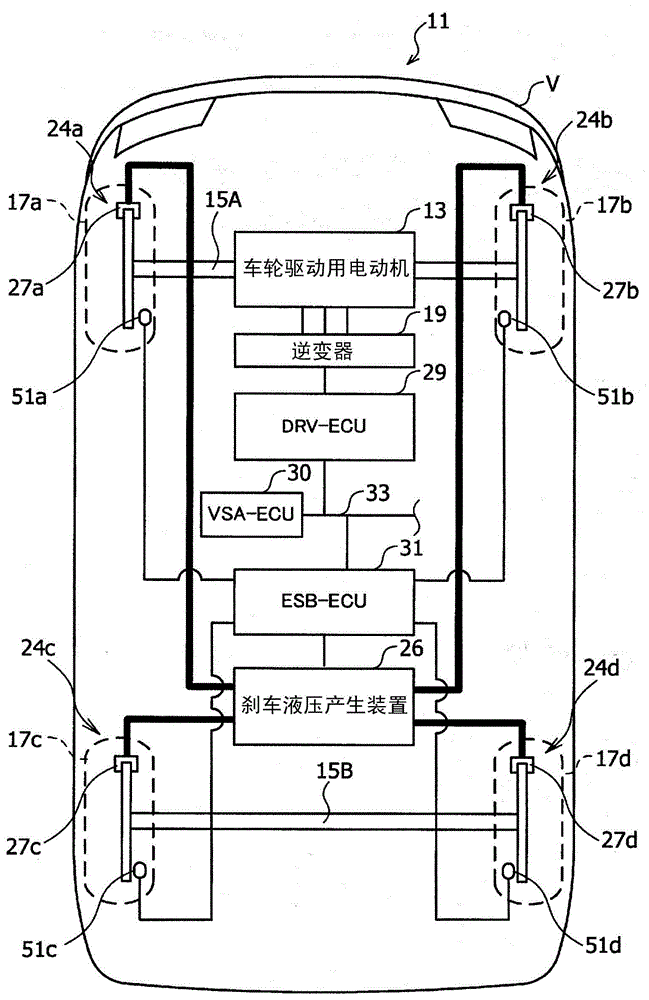

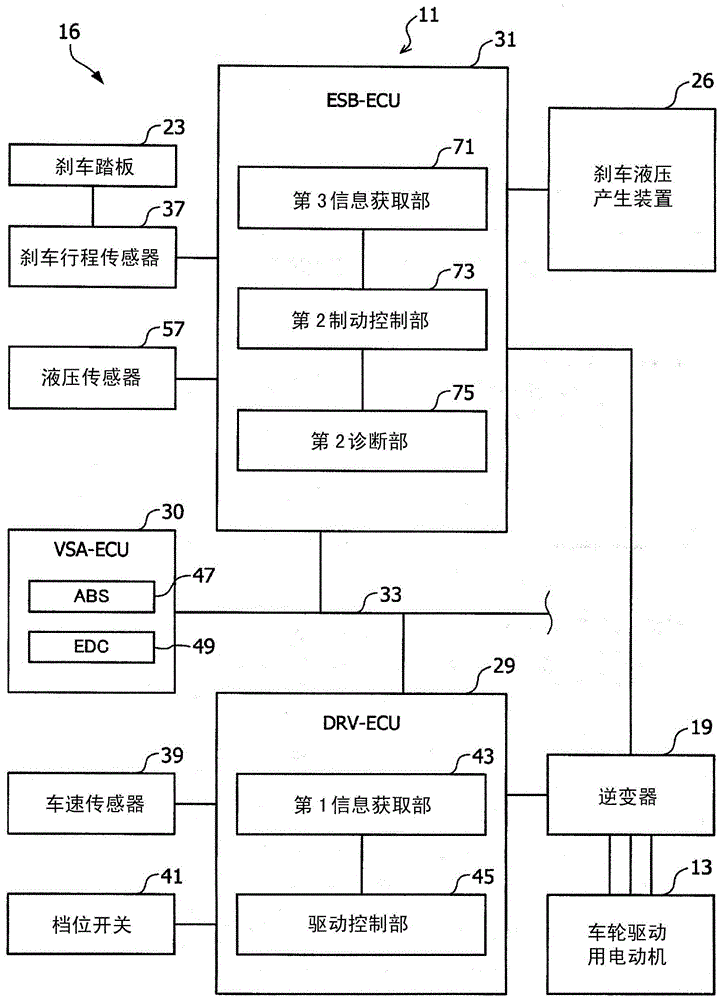

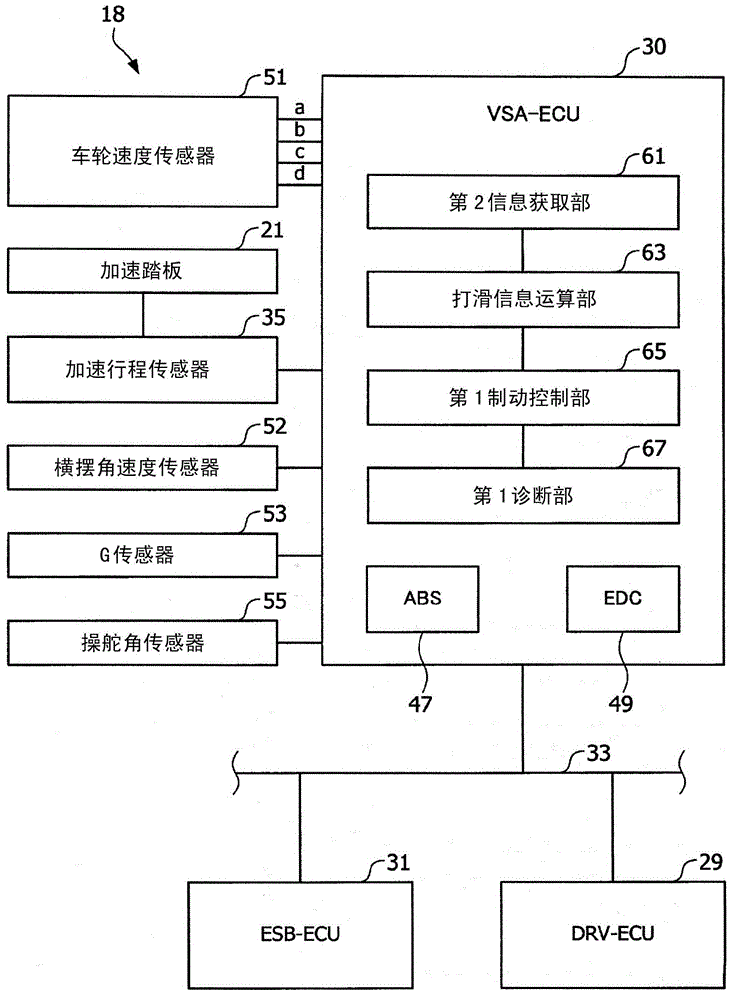

ActiveCN104428179AGood brake feelingAction stabilization performance improvedHybrid vehiclesSpeed controllerRegenerative brakeForce generation

A vehicle brake force generation device (11) is provided with an electric motor (13) for applying drive force and regenerative brake force to the wheels (17) of an electric vehicle (V), a brake hydraulic pressure generation device (26) for generating the brake hydraulic pressure to be applied to the calipers (27) of the electric vehicle (V), a slip information computation unit (63) for computing the slip information of the wheels (17), a VSA device (18) for controlling the friction braking of at least the brake hydraulic pressure generation device (26) such that the slipping of the wheels (17) is inhibited, a first diagnosis unit (67) for diagnosing the VSA device (18), and a brake control unit (65) for controlling the cooperative braking which includes controlling the regenerative braking of the electric motor (13) and / or controlling the friction braking of the brake hydraulic pressure generation device (26). The brake control unit (65) continues to control the regenerative braking of the electric motor (13) when a behavior stabilization assistance device (18) goes into an abnormal state while the regenerative braking of the electric motor (13) is being controlled.

Owner:HONDA MOTOR CO LTD

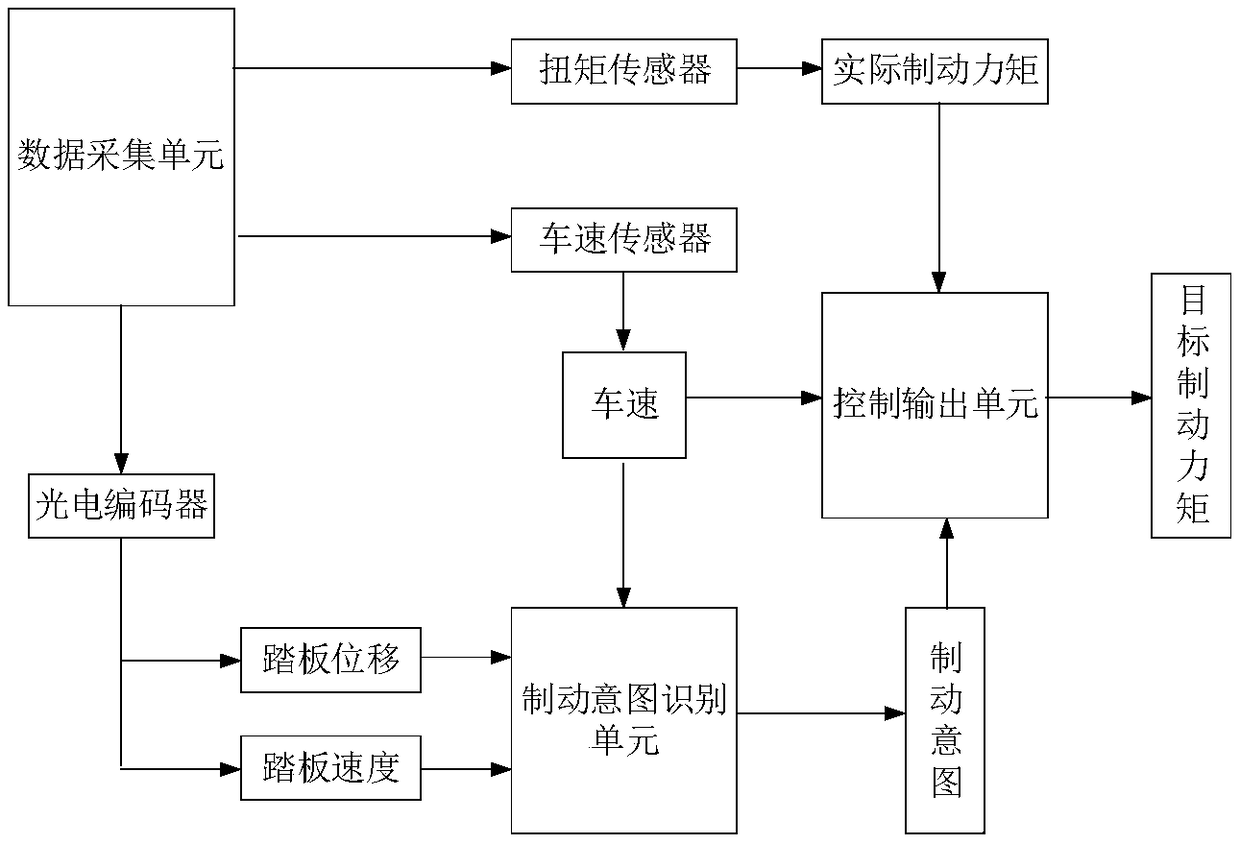

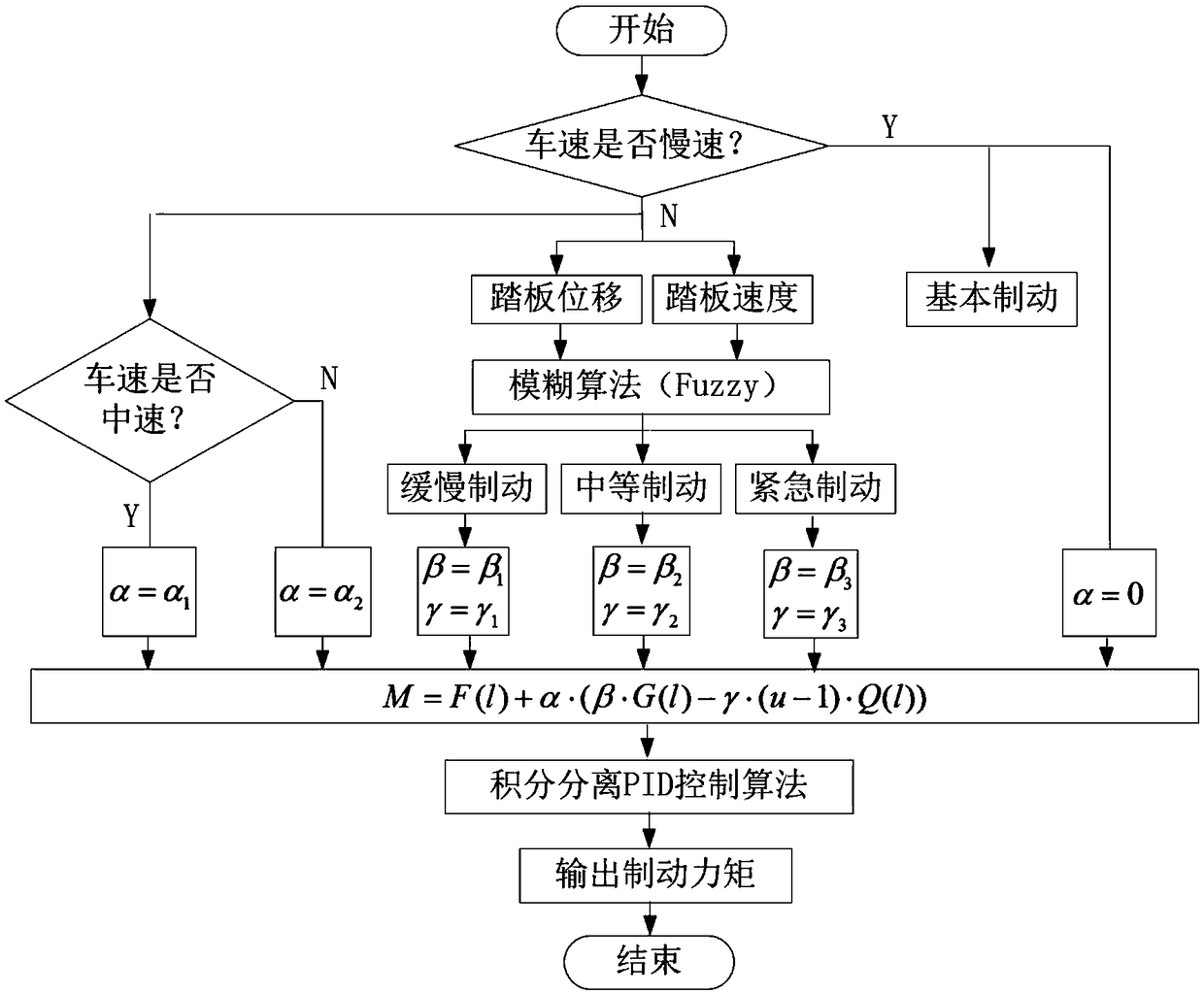

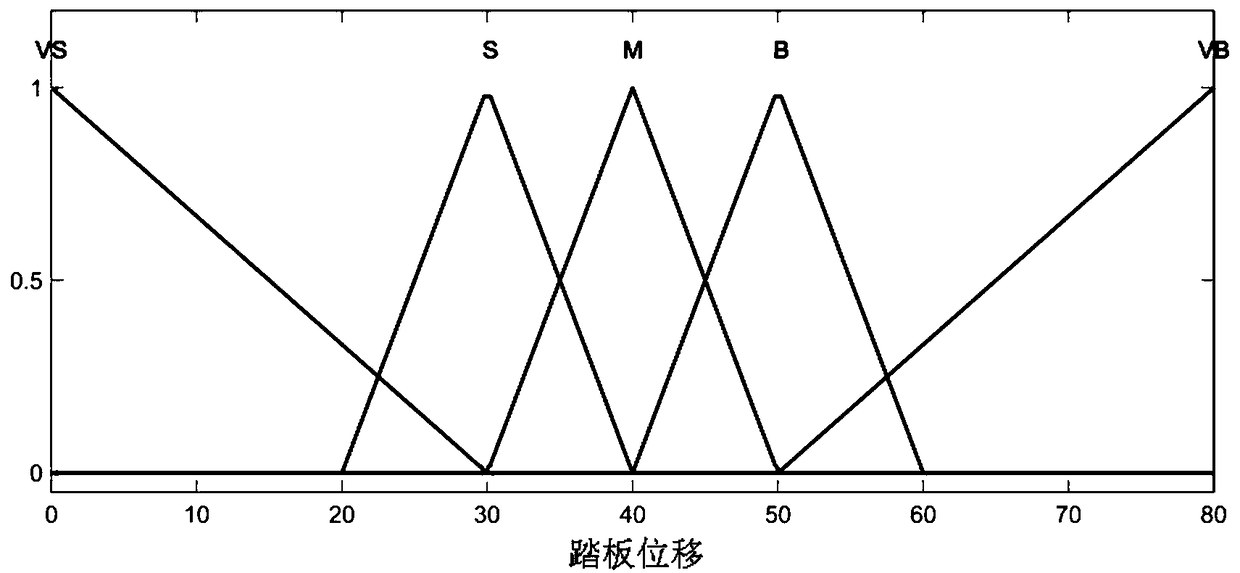

Control method of vehicle magnetorheological fluid braking system based on braking intention identification

ActiveCN109278563AAccurate outputStable outputLiquid resistance brakesElectrodynamic brake systemsBrake torqueMagnetorheological fluid

The invention relates to a control method of a vehicle magnetorheological fluid braking system based on braking intention identification. The control method of the vehicle magnetorheological fluid braking system based on braking intention identification comprises the following steps that vehicle speed is collected through a vehicle speed sensor; whether vehicle speed at this time is at slow speedor not is judged, if the vehicle speed is at a slow speed state, the braking intention is identified as basic braking; otherwise, values of pedal displacement and pedal speed are taken as input values, and the corresponding braking intention is identified by a fuzzy controller; a target braking torque is obtained according to a target braking torque generation algorithm in a control output unit; and through integral separation PID control, actual braking torque can be output accurately, stably and quickly. The control method of the vehicle magnetorheological fluid braking system based on braking intention identification can accurately, stably and quickly output braking torque while rapidly identifying the braking intention of a driver, braking time can be reduced, efficient braking effectcan be achieved, and loss of life and property is avoided.

Owner:HEFEI UNIV OF TECH

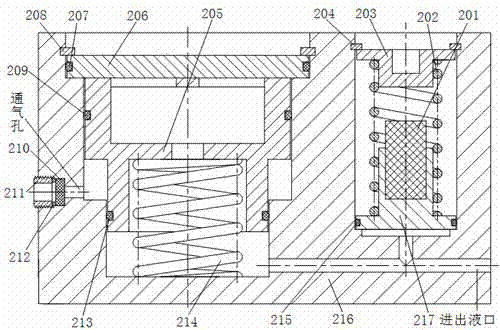

Pedal-feeling simulator for vehicle and vehicle with pedal-feeling simulator

The invention discloses a pedal-feeling simulator for a vehicle and the vehicle with the pedal-feeling simulator. The vehicle comprises a pedal, and the pedal-feeling simulator comprises a shell, a linear motor and an elastic part; and the linear motor comprises a motor primary part, a motor secondary part and a motor push rod, the motor primary part is fixed to the inner wall of the shell, the motor secondary part is arranged in the motor primary part, the motor secondary part is matched with the motor primary part so as to enable the motor secondary part to axially move relative to the motorprimary part, the motor secondary part sleeves the motor push rod to drive the motor push rod to move synchronously, the first end of the motor push rod extends out of the shell to be suitable for being connected with the pedal, and the elastic part is used for applying elastic force to the motor push rod. The pedal-feeling simulator for the vehicle is high in response speed, has a good braking effect, and meanwhile can provide a good 'brake feeling', especially a pedal braking feeling, for a driver.

Owner:BYD CO LTD

Vehicle brake hydraulic pressure control apparatus

ActiveCN104071144AStop the flowAvoid absorptionFluid braking transmissionDischarge pressureEngineering

A vehicle brake hydraulic control apparatus includes a reservoir, a hydraulic pressure pump, an orifice, a damper and a one-way valve. The reservoir absorbs an excess brake hydraulic pressure of a wheel brake. The hydraulic pressure pump suctions brake fluid absorbed by the reservoir and returns the suctioned brake fluid to a master cylinder through a return line. The orifice is provided in the return line. The damper is connected to the return line between the orifice and the hydraulic pressure pump and damps discharge pressure pulsation of the hydraulic pressure pump. The one-way valve is provided in the return line between the damper and the orifice and prevents a hydraulic flow from an orifice side to a damper side.

Owner:AUTOLIV NISSIN BRAKE SYST JAPAN CO LTD

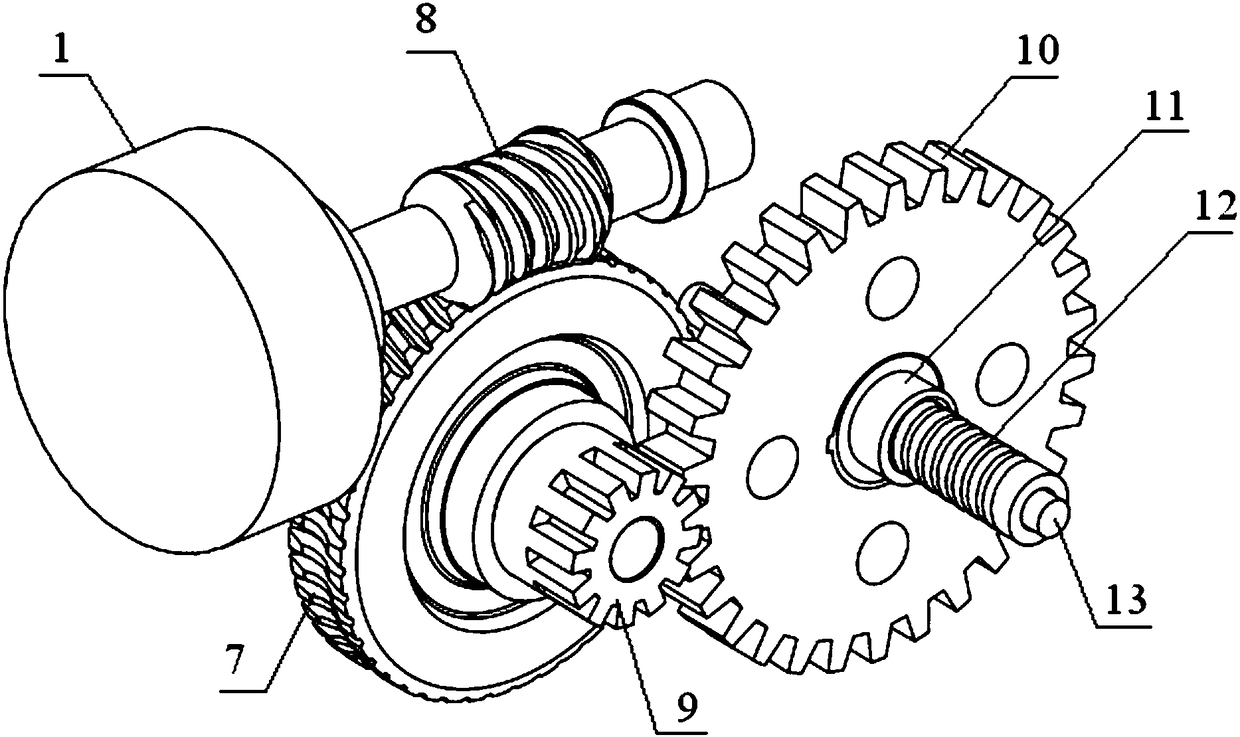

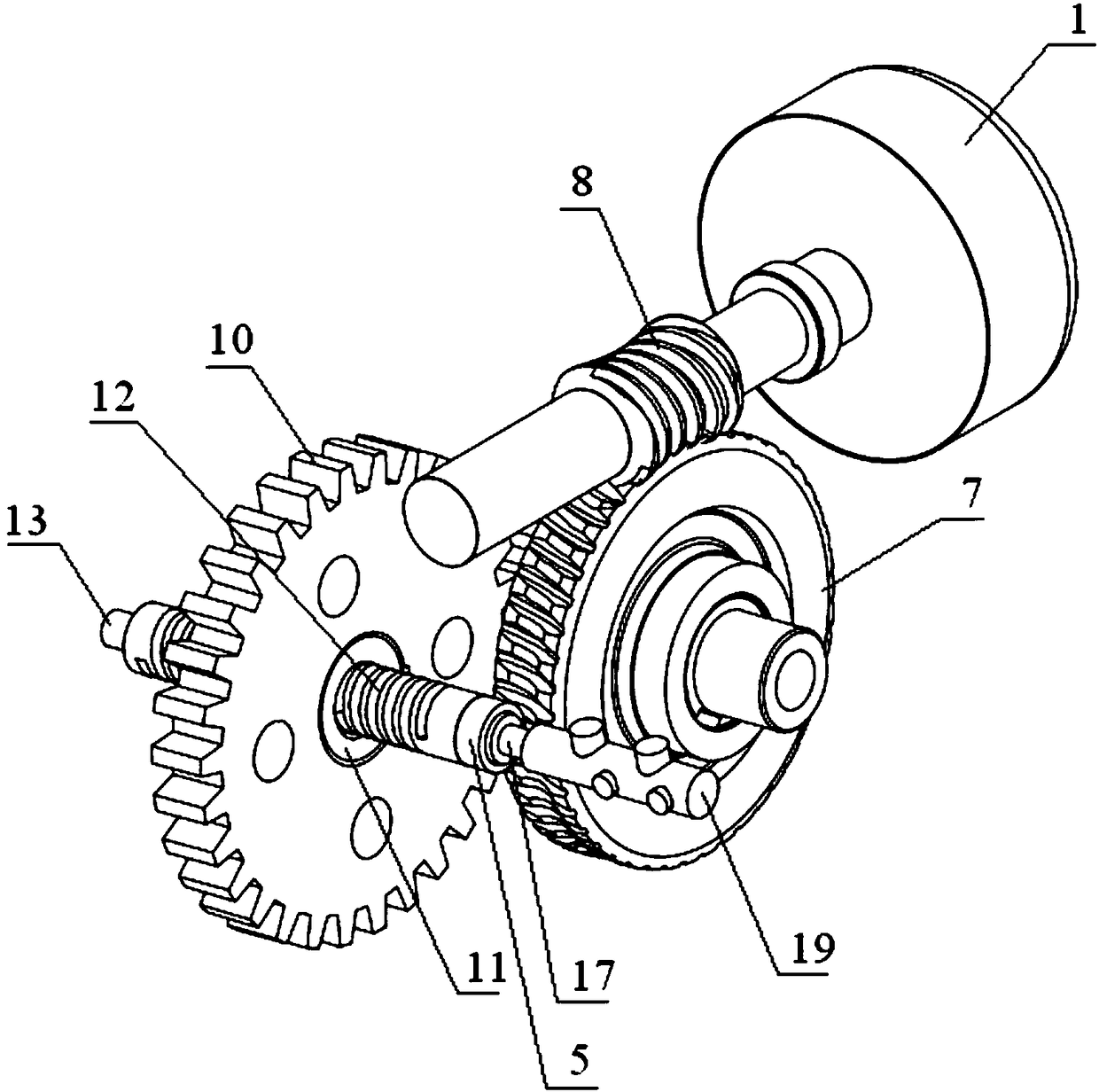

Electric power-assisted brake system with large transmission ratio

PendingCN108394393ATurn Up Response TimeTurn up the dynamic performanceBraking action transmissionPower couplingEffective solution

The invention discloses an electric power-assisted brake system with a large transmission ratio. The system comprises a motor, a first transmission pair, a second transmission pair, a third transmission pair and a power coupling mechanism, wherein the motor is connected with the first transmission pair and drives the first transmission pair to work, after the second transmission pair and the thirdtransmission pair are sequentially connected to the first transmission pair, the first transmission pair, the second transmission pair and the third transmission pair are driven by the motor to achieve linkage, and the power coupling mechanism is connected with the third transmission pair. The system has the advantages that the problems that due to the fact that the transmission ratio of an existing electric power-assisted brake system is low, maximum brake force is not large enough, and the current of the motor is excessively large are solved, and an effective solution is provided for intelligentization of a heavy vehicle brake system.

Owner:JILIN UNIV

Coordination control device for simulating automobile braking

InactiveCN106274872AEnsure braking safetyGuaranteed Coordinated ControlBraking action transmissionBrake control systemsBrake torqueControl system

The embodiment of the invention discloses a coordination control device for simulating automobile braking. The coordination control device comprises a pedal stroke collecting unit, an electronic control hydraulic braking system, an electric power system, a control system, a flywheel, a disc brake and a collecting unit arranged in the preset position. The control system is used for outputting initial torque and calculating total braking torque based on the pedal displacement change rate and is further used for distributing the total braking torque based on the total braking torque and all collected signals and outputting electronic control hydraulic braking torque and motor braking torque. The electric power system is used for driving a rotating shaft to rotate based on the received initial torque so that the initial speed of automobile braking can be simulated and is used for driving the rotating shaft to rotate based on the motor braking torque so that rotating speed control over the flywheel can be conducted. The electronic control hydraulic braking system is used for receiving the electronic control hydraulic braking torque and controlling the disc brake to brake the flywheel based on the electronic control hydraulic braking torque. According to the coordination control device for simulating automobile braking, coordination control can be conducted on automobile braking based on electronic control hydraulic braking and motor regenerative braking.

Owner:JILIN UNIV

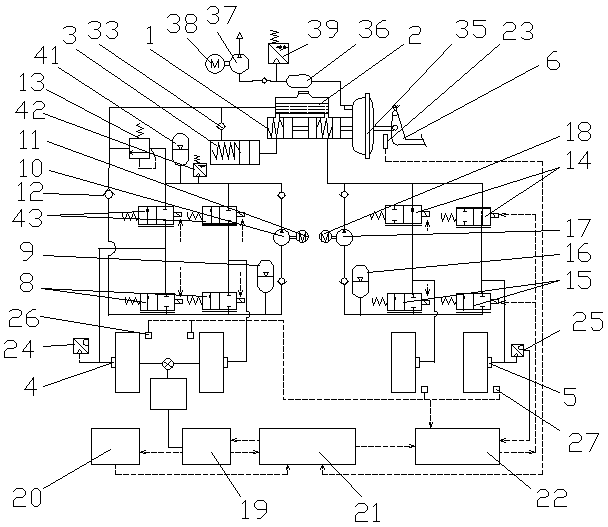

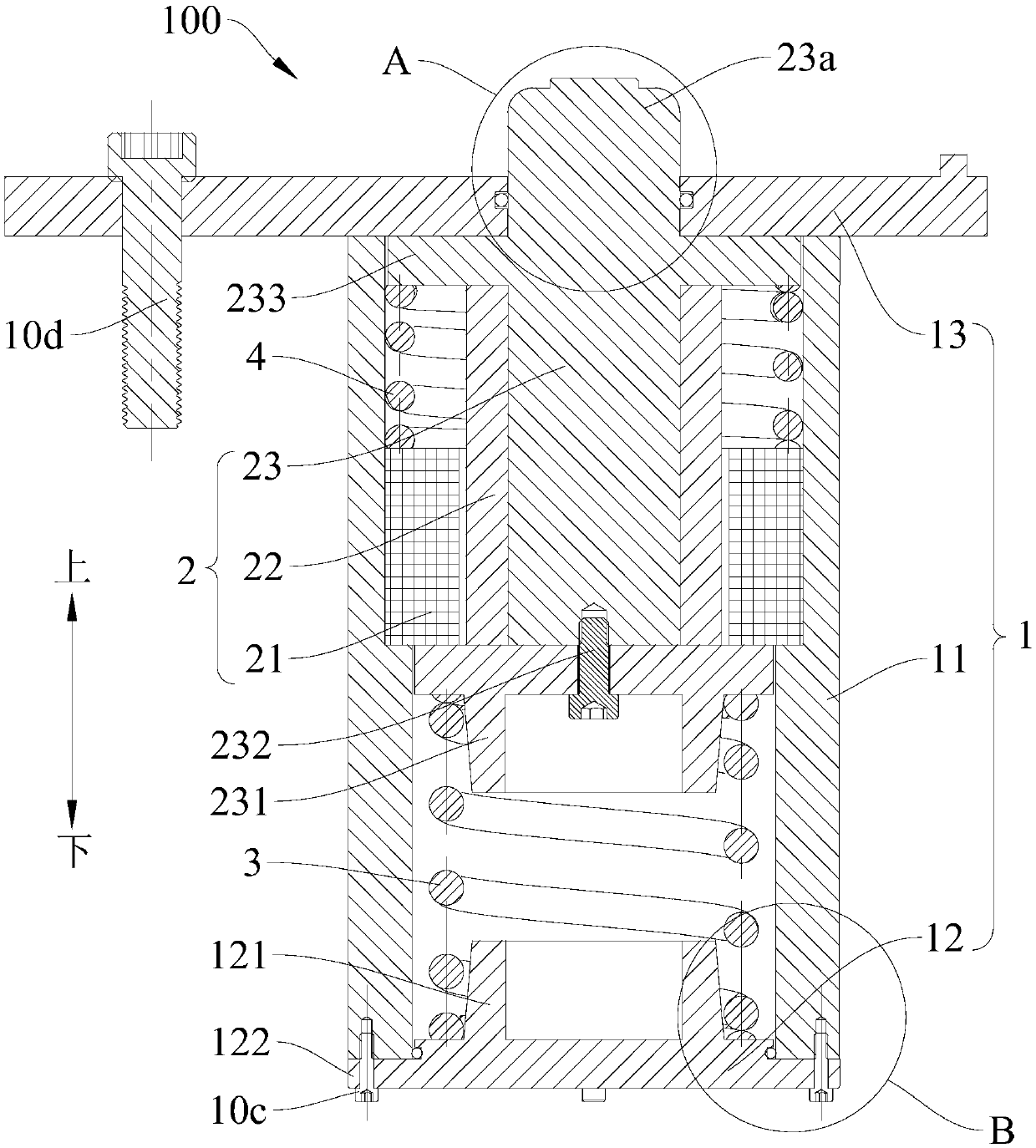

Pedal feel simulator for vehicle and vehicle having same

ActiveCN110027525BGood braking feelReasonable brake feelBraking action transmissionFoot actuated initiationsDriver/operatorSimulation

The invention discloses a pedal feel simulator for a vehicle and a vehicle having the same. The vehicle includes a pedal, the pedal feel simulator includes a casing, a linear motor, a first elastic member and a second elastic member, and the linear motor includes a motor primary, The motor secondary and the motor push rod, the motor secondary cooperates with the motor primary so that the motor secondary can move axially relative to the motor primary, the motor secondary drives the motor push rod to move synchronously, and the first end of the motor push rod protrudes out of the casing to fit It is connected with the pedal; the two ends of the first elastic part are matched with the inner wall of the shell and the second end of the motor push rod respectively; the second elastic part and the first elastic part are located on both sides of the primary axial direction of the motor, and the The two ends are fitted on the motor push rod and the motor primary respectively. According to the pedal feeling simulator for vehicles of the present invention, the response speed is fast, the braking effect is good, and at the same time, the driver can be provided with good "braking feeling", especially pedal braking feeling.

Owner:BYD CO LTD

Vehicle braking force generator

ActiveCN104428179BGood braking feelHybrid vehiclesSpeed controllerRegenerative brakeForce generation

The vehicle braking force generating device (11) includes: an electric motor (13), which provides driving force and regenerative braking force to the wheels (17) of the electric vehicle (V); V) The brake hydraulic pressure provided by the calipers (27); the skid information calculation unit (63), which calculates the skid information of the wheels (17); the VSA device (18), which at least performs The friction braking control of the wheel (17) is suppressed; the first diagnosis unit (67) performs the diagnosis of the VSA device (18); and the brake control unit (65) performs at least the electric motor ( 13) Coordinated braking control including at least one of the regenerative braking control and the friction braking control related to the brake fluid pressure generating device (26). During the regenerative braking control process involving the electric motor (13), if the behavior stabilization support device (18) falls into an abnormal state, the brake control unit (65) maintains the state of the regenerative braking control involving the electric motor (13) .

Owner:HONDA MOTOR CO LTD

Motorcycle braking device

The invention provides a braking system which improves the brake feeling on a motorcycle and which uses a front-rear interlocking brake system. In a motorcycle braking device in which a brake caliper for a rear wheel works in conjunction with brake operation for a front wheel and the ABS is equipped, when the ABS is active on the side of the front wheel which is braked by a front wheel brake controller, the braking pressure ratio between the brake caliper for the front wheel and the brake caliper for the rear wheel is different from that when the ABS is inactive.

Owner:HONDA MOTOR CO LTD

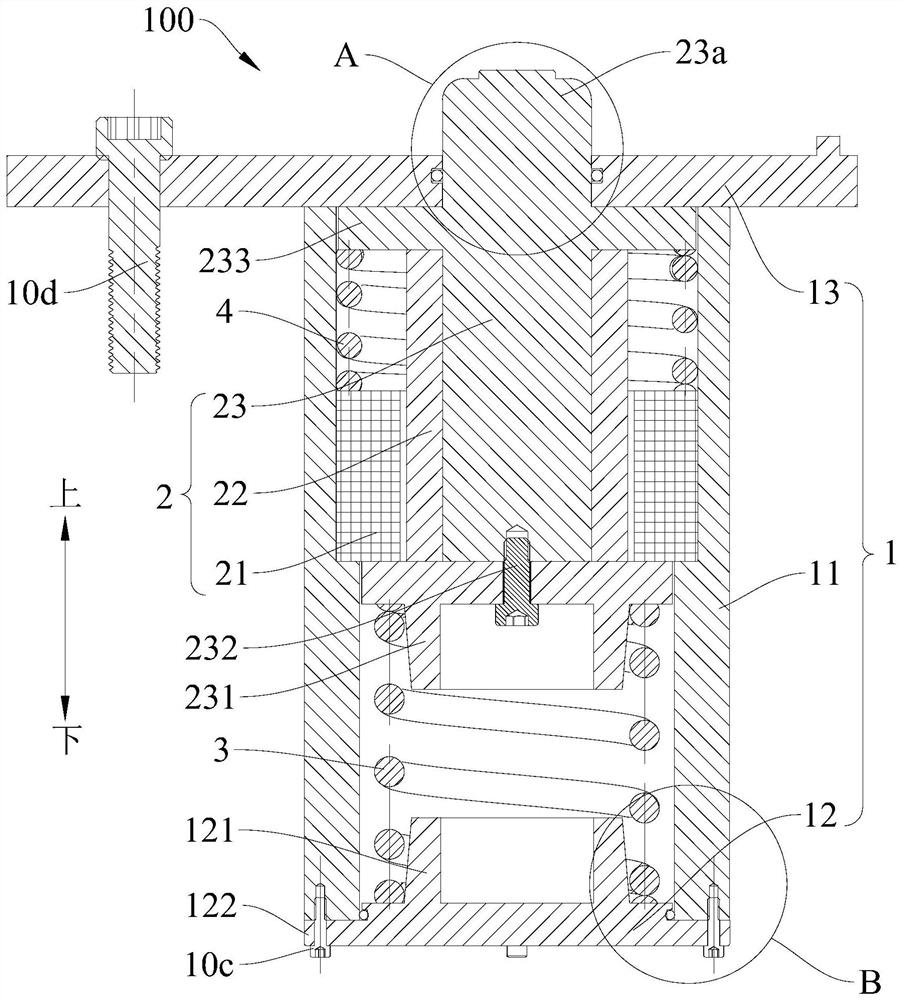

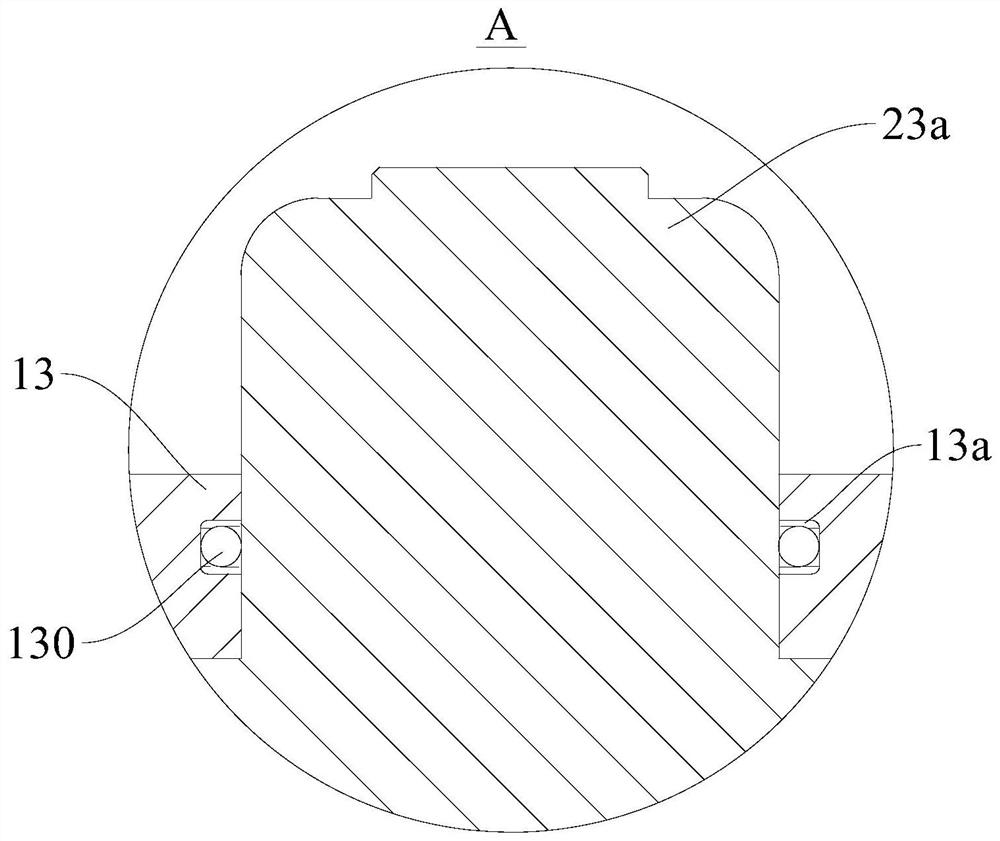

Pedal-feeling simulator for vehicle and vehicle with pedal-feeling simulator

ActiveCN110027525AGood braking feelReasonable brake feelBraking action transmissionFoot actuated initiationsLinear motorFootplate

The invention discloses a pedal-feeling simulator for a vehicle and the vehicle with the pedal-feeling simulator. The vehicle comprises a pedal, and the pedal-feeling simulator comprises a shell, a linear motor, a first elastic part and a second electric part; and the linear motor comprises a motor primary part, a motor secondary part and a motor push rod, the motor secondary part is matched withthe motor primary part so that the motor secondary part can axially move relative to the motor primary part, the motor secondary part drives the motor push rod to move synchronously, the first end ofthe motor push rod extends out of the shell to be suitable for being connected with the pedal, the two ends of the first elastic part are matched with the inner wall of the shell and the second end ofthe motor push rod correspondingly, the second elastic part and the first elastic part are located on the two axial sides of the motor primary part, and the two ends of the second elastic part are matched with the motor pushing rod and the motor primary part. The pedal-feeling simulator for the vehicle is high in response speed, has the good braking effect, and meanwhile can provide the good 'braking feeling', especially a pedal braking feeling, for a driver.

Owner:BYD CO LTD

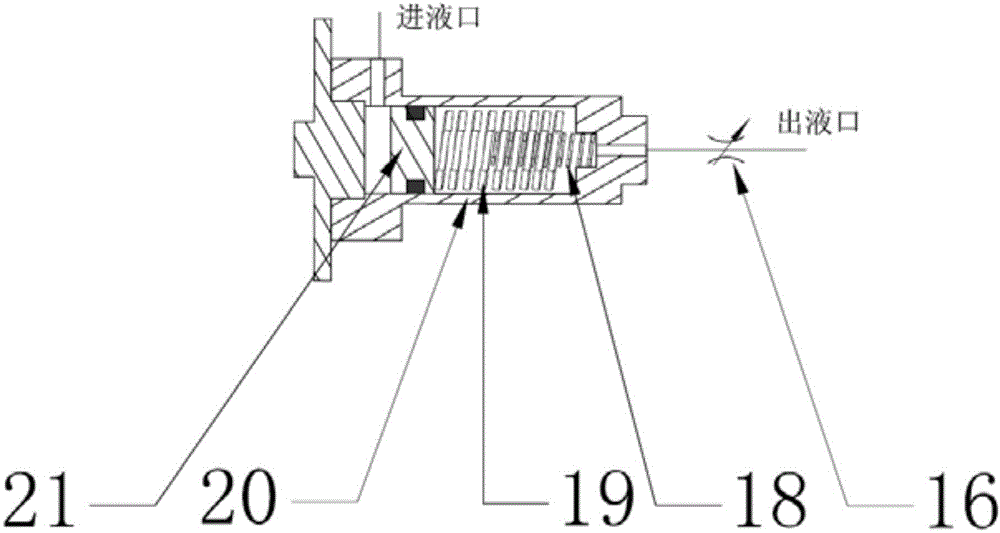

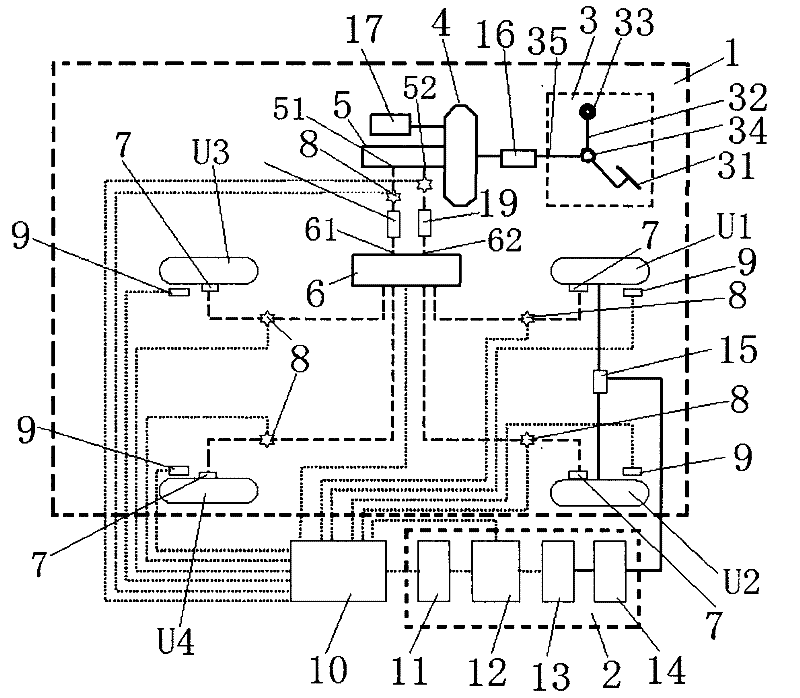

An Electro-hydraulic Braking System with Reduced Liquid Outlet of Master Cylinder

ActiveCN103950444BQuick responseEasy to completeBraking action transmissionBrake safety systemsLinear motionMotor drive

An electro-hydraulic braking system that reduces the liquid outlet of a master cylinder, including: a brake pedal and a pedal displacement sensor connected to the pedal; a secondary master cylinder with two through holes, the front through holes are directly connected to the reservoir The liquid tank is connected, and the rear end through hole is connected to two passages, one of which is connected to the pedal feeling simulator, and the other is connected to the front chamber of the master cylinder through the decoupling solenoid valve; at the same time, the left end of the secondary master cylinder piston is directly connected to the brake pedal , the right end is opposite to the central push rod of the electronically controlled linear motion module, and there is a gap; for the electronically controlled linear motion module, there is a push rod in the hollow part of the whole module, which drives the transmission mechanism through the motor to drive the push rod to move, thereby pushing the piston of the master cylinder The right end of the push rod is opposite to the first piston of the master cylinder, and there is a gap; the present invention has the characteristics of fast response, precise control of brake fluid pressure, better simulation of the driver's brake pedal feeling, and maximum recovery of braking energy. Contains dual fail-safe modes for high safety and reliability.

Owner:TONGJI UNIV

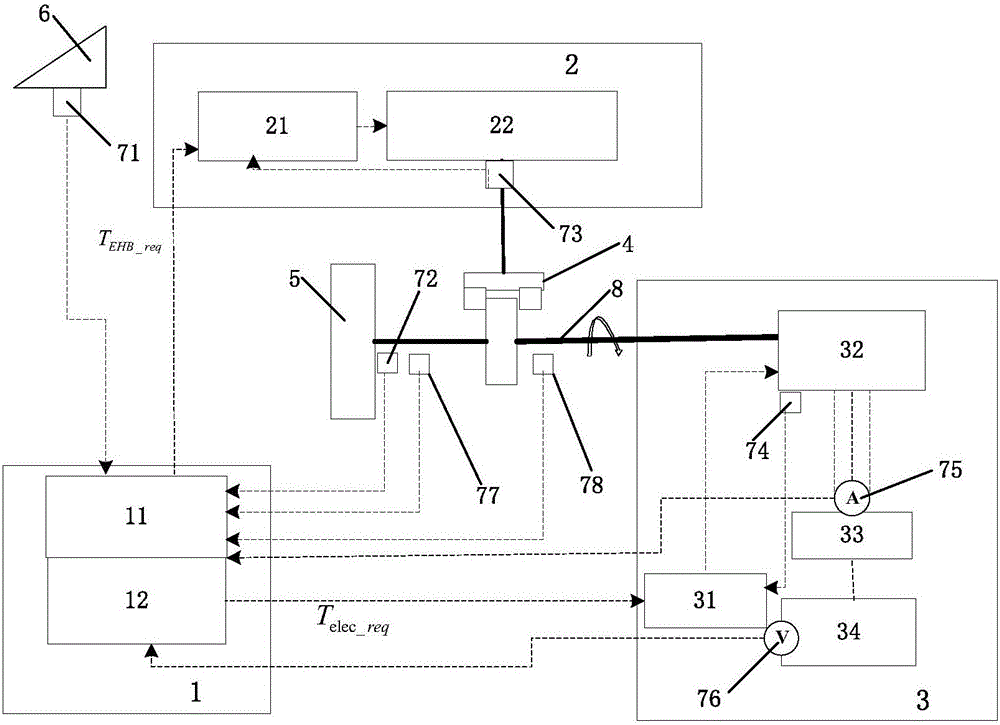

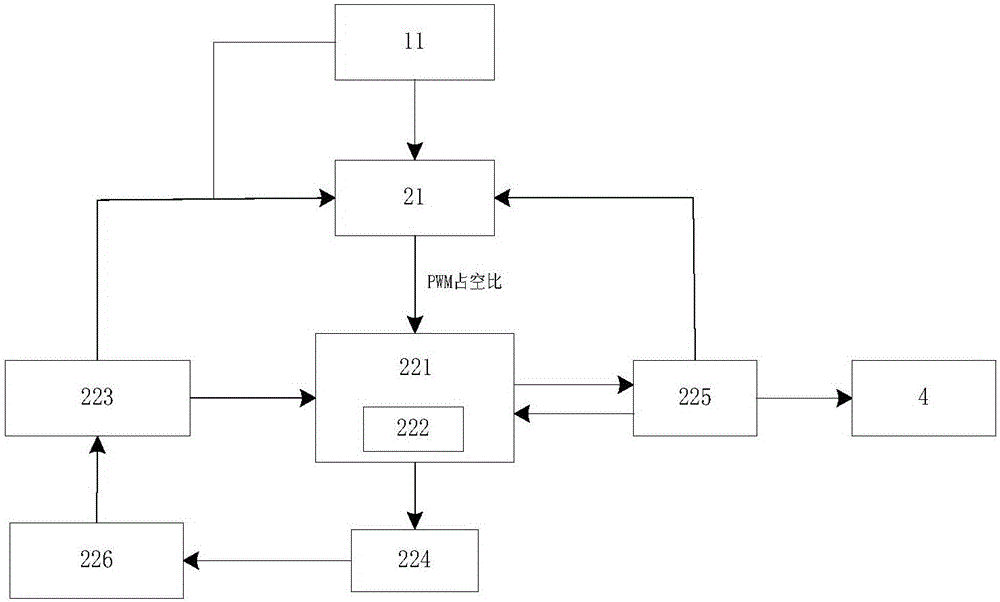

An electro-hydraulic composite braking control method and control device for an electric vehicle

InactiveCN103332184BImprove utilization efficiencyGood braking feelBraking systemsDriver/operatorWheel speed sensor

The invention discloses a brake control method for an electric vehicle use and a controlling device thereof, and belongs to the technical field of electric vehicles. The controlling device comprises wheels, wheel brakes, an electric-hydro complex brake ECU, a brake pedal, a brake pedal position sensor, a hydraulic control module, a hydraulic braking system, a motor, a battery, a vehicle speed sensor, a motor control module, an ABS control module, and wheel speed sensors. The method comprises the following steps: determining the braking purpose of a driver according to the driving state, the braking strength, and the state of the motor and the battery of the electric vehicle, determining and choosing a braking mode according to the braking purpose, the battery SOC value, and the state of the ABS, and conducting coordination control for the motor regenerative braking and the hydraulic braking to allow the electric vehicle to provide an excellent braking experience for the driver on the basis of guaranteeing the braking safety. Therefore, under the premise that the braking efficiency can be guaranteed, braking energies are recycled by utilizing the regenerative braking of the motor, and the energy utilization efficiency is improved.

Owner:BEIHANG UNIV

Motor-controlled hydraulic braking system

ActiveCN107054333BFast response timeFail safeBraking action transmissionFoot actuated initiationsHysteresisControl signal

The invention discloses a motor-controlled hydraulic braking system. The problem that the hysteresis influence caused by a motor during direction shifting and vertical movement caused by the condition that a brake pedal changes with pedal force are solved. The motor-controlled hydraulic braking system comprises a brake pedal mechanism, a master cylinder pressure generating unit, a brake pressure control unit and an electronic control unit. The brake pedal mechanism comprises an input push rod (6); the master cylinder pressure generating unit comprises a ball screw mechanism; the brake pressure control unit comprises a brake master cylinder; and the electronic control unit comprises a control signal output system and a signal collecting treatment system. The brake pedal mechanism is fixedly connected with an input push rod limiting plate (21) in the ball screw mechanism through the input push rod (6), the master cylinder pressure generating unit is fixedly connected with a master cylinder front cavity piston (26) in the brake master cylinder through a connecting shaft (25) in the ball screw mechanism, and the electronic control unit is connected with the brake pedal mechanism, the master cylinder pressure generating unit and the brake pressure control unit in an electric wire mode.

Owner:JILIN UNIV

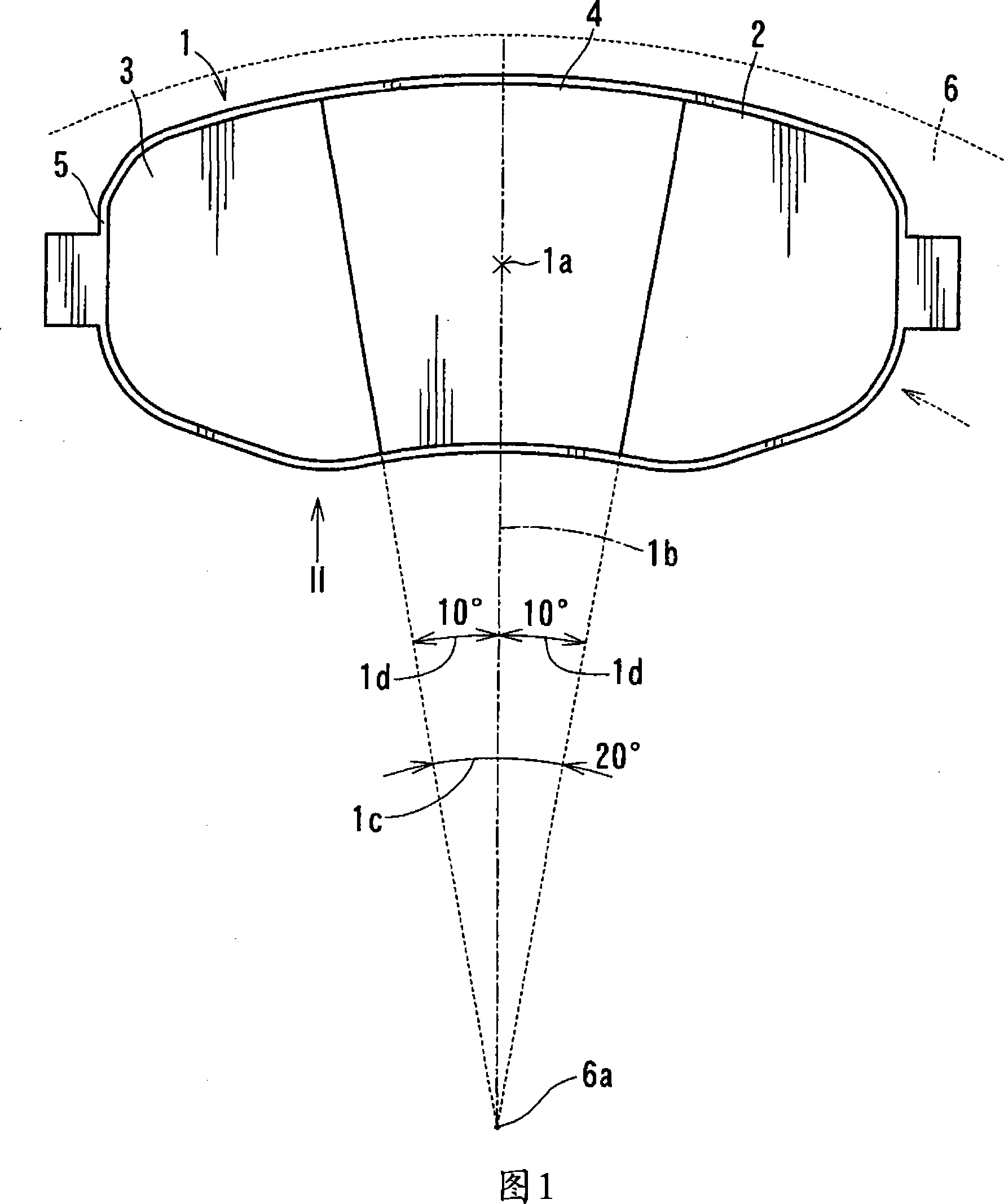

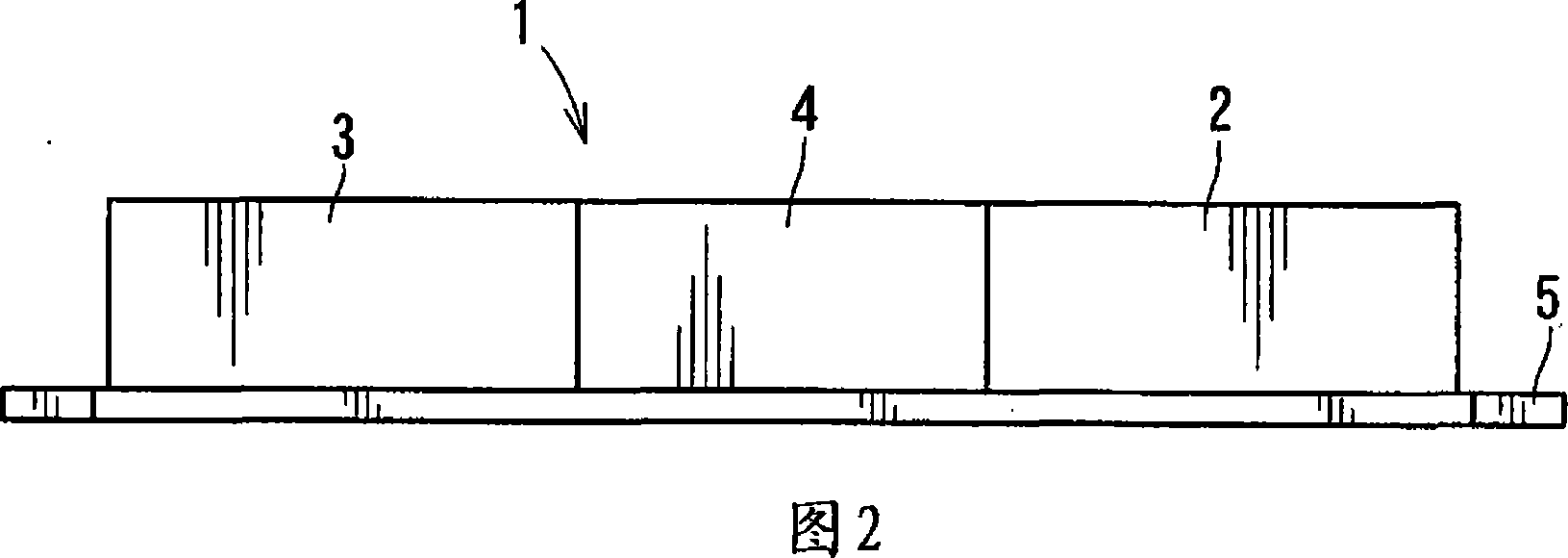

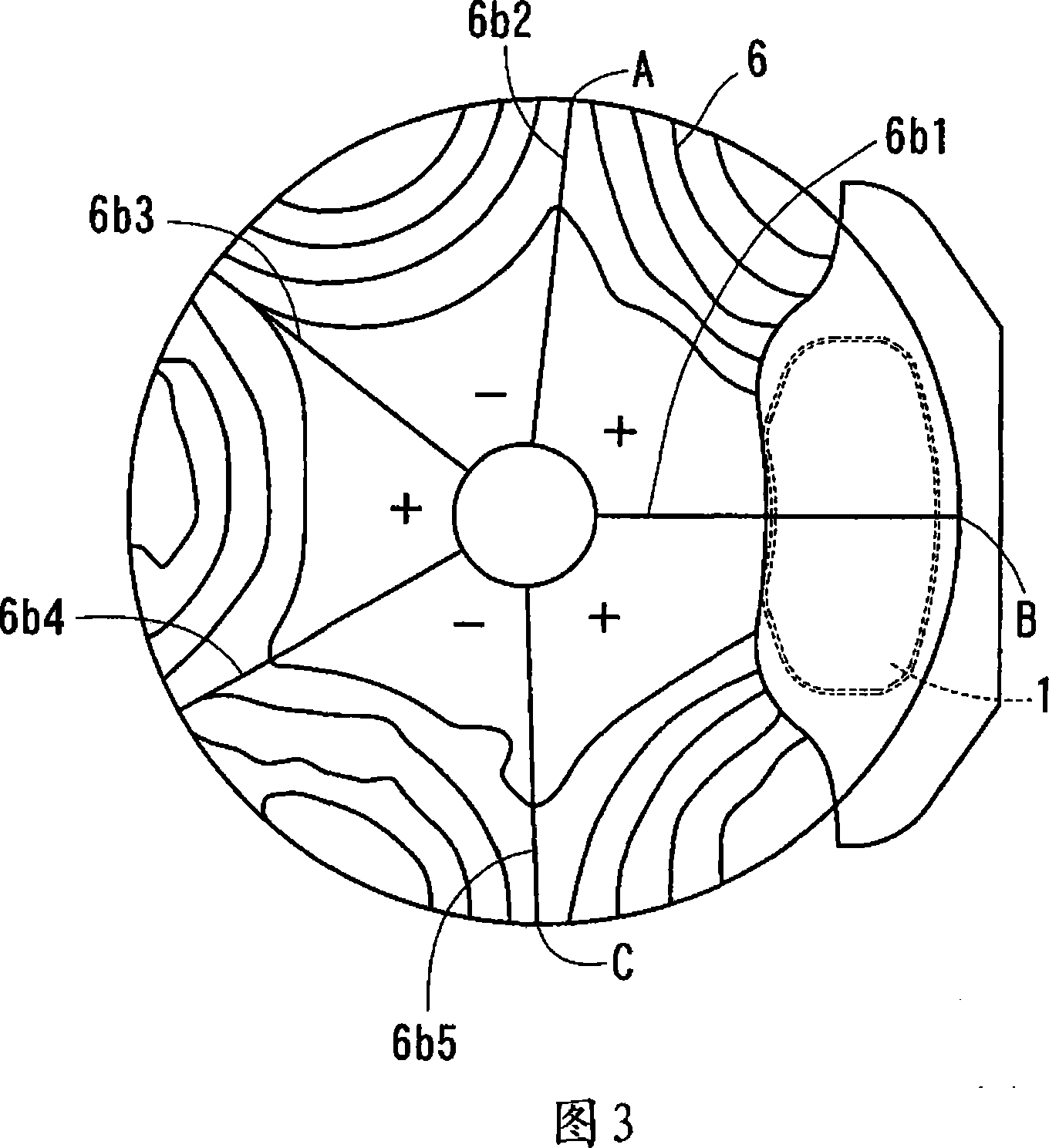

Hybrid pads for disc brakes

A hybrid pad for a disc brake has first friction members and a second friction member. The first friction members can be positioned at a rotor rotation inlet portion and at a rotor rotation outlet portion of the pad. The second friction member can be positioned at a central portion of the pad. The first friction members include a Young's modulus E1, a friction coefficient mu1 and a sum of the sliding areas A1 of the paired first friction members to come into sliding contact with the disc rotor. The second friction member has a Young's modulus E2, a friction coefficient mu2 and a sliding area A2 to come into sliding contact with the disc rotor. The mu2 is higher than the mu1, the E2 is higher than the E1, and (E2xA2) / (E1xA1) is 0.8 or more and 1.2 or less.

Owner:ADVICS CO LTD

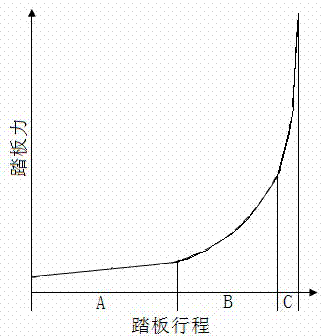

Sensation simulator of automobile brake pedal

ActiveCN102294997BAccurately obtain braking intentionInstant feedback on pedal feelFoot actuated initiationsFluid braking transmissionHydraulic control unitDriver/operator

The invention discloses a sensation simulator of an automobile brake pedal. The rod-free cavity of a main braking cylinder is provided with a piston return spring and is respectively communicated with an oil storage cup and the input end of a two-position three-way solenoid valve; the brake pedal is respectively connected with the push rod of the main cylinder braking piston and a pedal travel sensor; and two output ends of the two-position three-way solenoid valve are respectively connected with a hydraulic control unit (HCU) and a simulator valve block. According to the sensation simulator,the braking sensation of a driver can be accurately obtained, and the pedal feeling of the driver can be fed back. The traditional hydraulic braking system is improved slightly, and the sensation simulator is installed on the main braking cylinder or is integrated with the HCU. The sensation simulator has the advantages of small volume, low cost and small difficulty. Under the condition that a motor-driven hydraulic braking system fails, the traditional hydraulic braking system can be subjected to emergent braking. The sensation simulator of an automobile brake pedal and the HCU guarantee good braking feeling under the coordination control of an electronic control unit (ECU).

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

Vehicular brake control apparatus and control method therefor

The control unit 10 controls the braking forces respectively acting on a pair of independently working brake operating elements L1, L2, so as to perform anti-lock braking control and prevent the wheels from possibly being locked. When the brake operating elements L1, L2 are activated, the control unit 10 applies the braking force to one of the wheel brakes B1, B2 of a braking system different from the braking system operated by the brake operating element . When one or both of the brake operating elements L1 and L2 work, and the wheel may be in a locked state, the control unit 10 performs anti-lock control on the braking system of the wheel that is about to be in the locked state, and at the same time, the brake Power is applied to another braking system than the one that is about to be locked.

Owner:NISSIN KOGYO CO LTD

Composite braking system

ActiveCN101716890BReduce vibrationImproved braking feelElectrodynamic brake systemsElectricityWheel speed sensor

The invention relates to a composite braking system, which comprises a hydraulic braking system consisting of a brake pedal, a vacuum booster, a braking main cylinder, a hydraulic adjustment module, a braking wheel cylinder, a pressure sensor, a wheel speed sensor and a braking controller and a motor braking system, and is characterized in that: a push rod between the brake pedal and the vacuum booster is provided with a shock absorber; main valves are arranged on oil pipes on which two liquid inlets of the pressure hydraulic adjustment module are positioned respectively; the vacuum input endof the vacuum booster is provided and connected with a vacuum supply module; the vacuum supply module comprises a vacuum pump, a direct current motor, a pressure relay and a power supply; the output end of the vacuum pump is connected with both the vacuum input end of the vacuum booster and the reference pressure input end of the pressure relay through pipes; the output end of the pressure relay is connected with the input end of the direct current motor; the direct current motor is electrically connected with the vacuum pump; and the power supply supplies power to the direct current motor and the pressure relay. The system requires few changes in the hydraulic breaking system of an original vehicle, and can realize series braking energy recovery, guarantee a good brake pedal feel and be widely used in breaking energy recovery systems of electricity-driven vehicles.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com