Patents

Literature

5338results about "Friction lining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

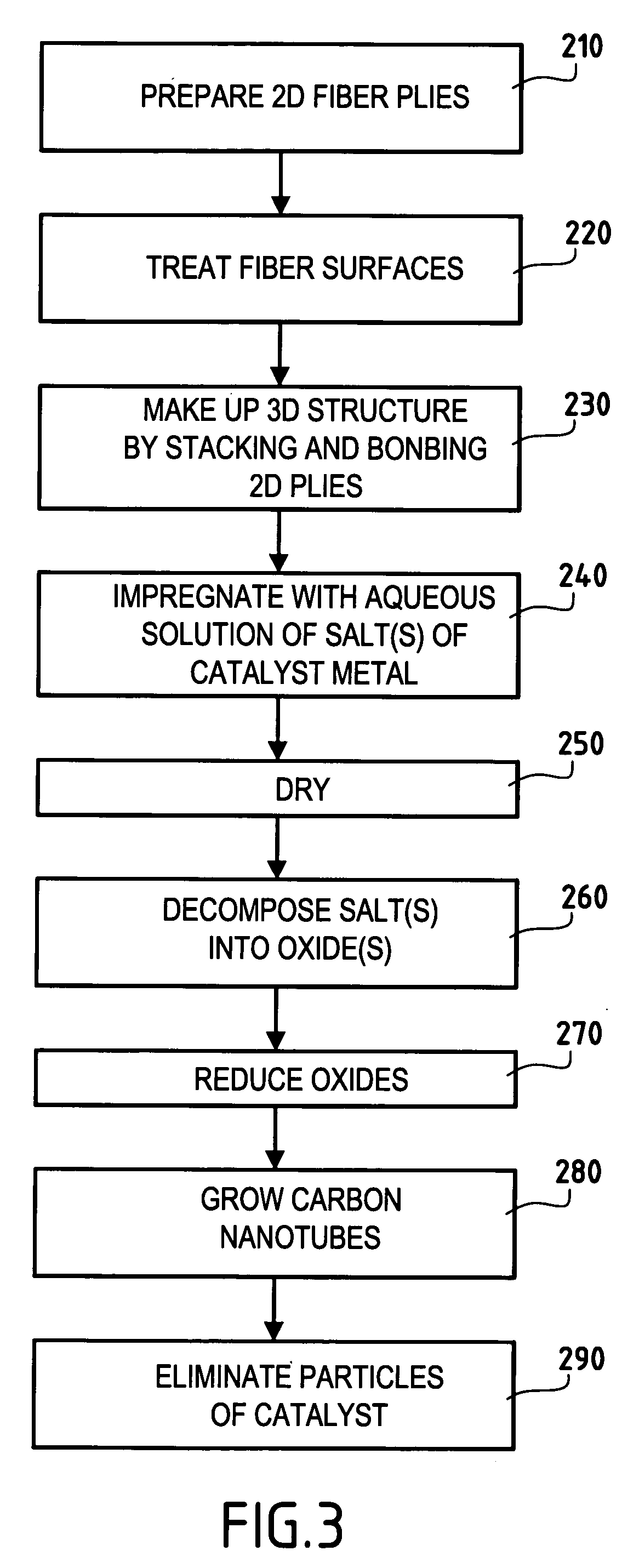

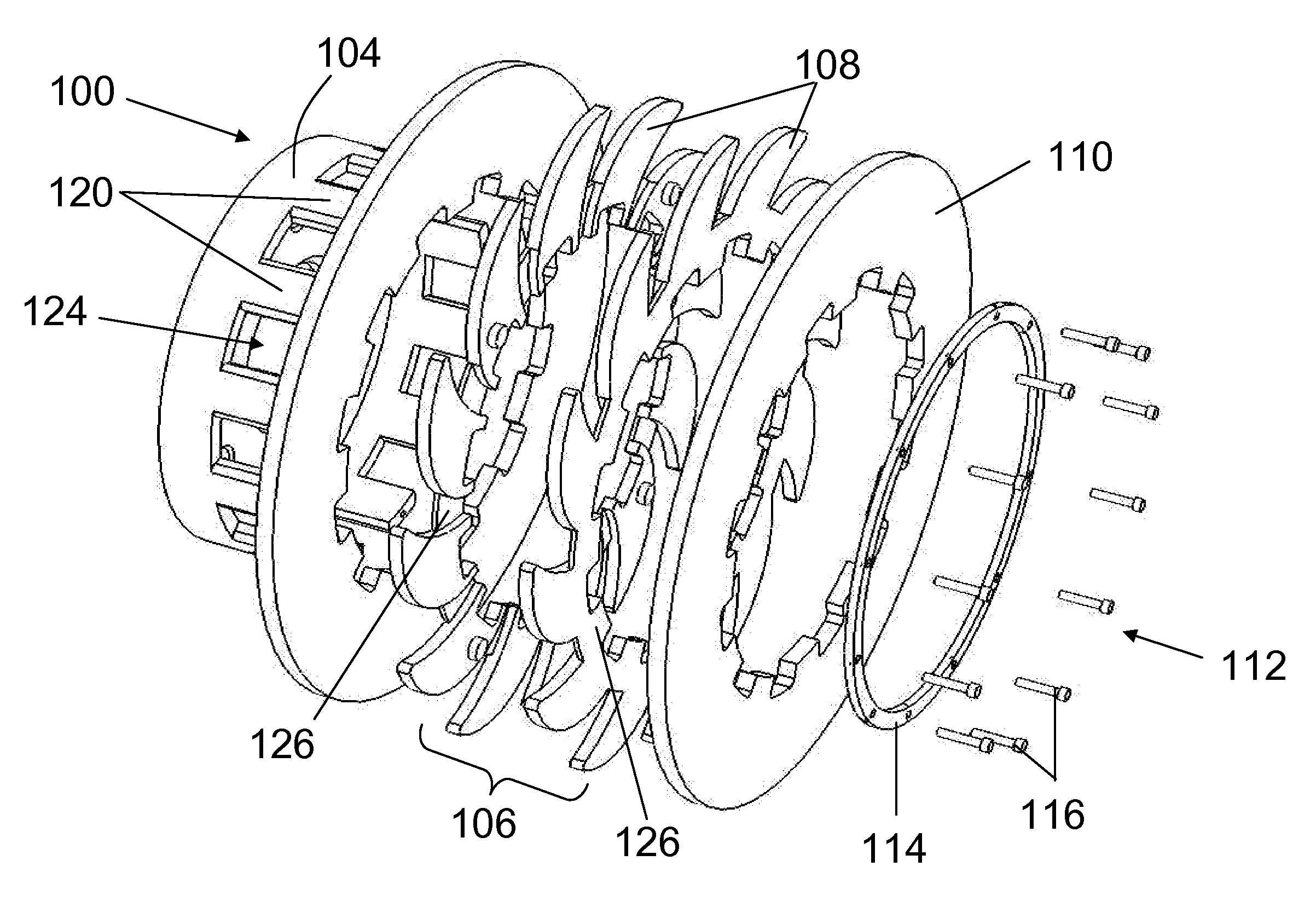

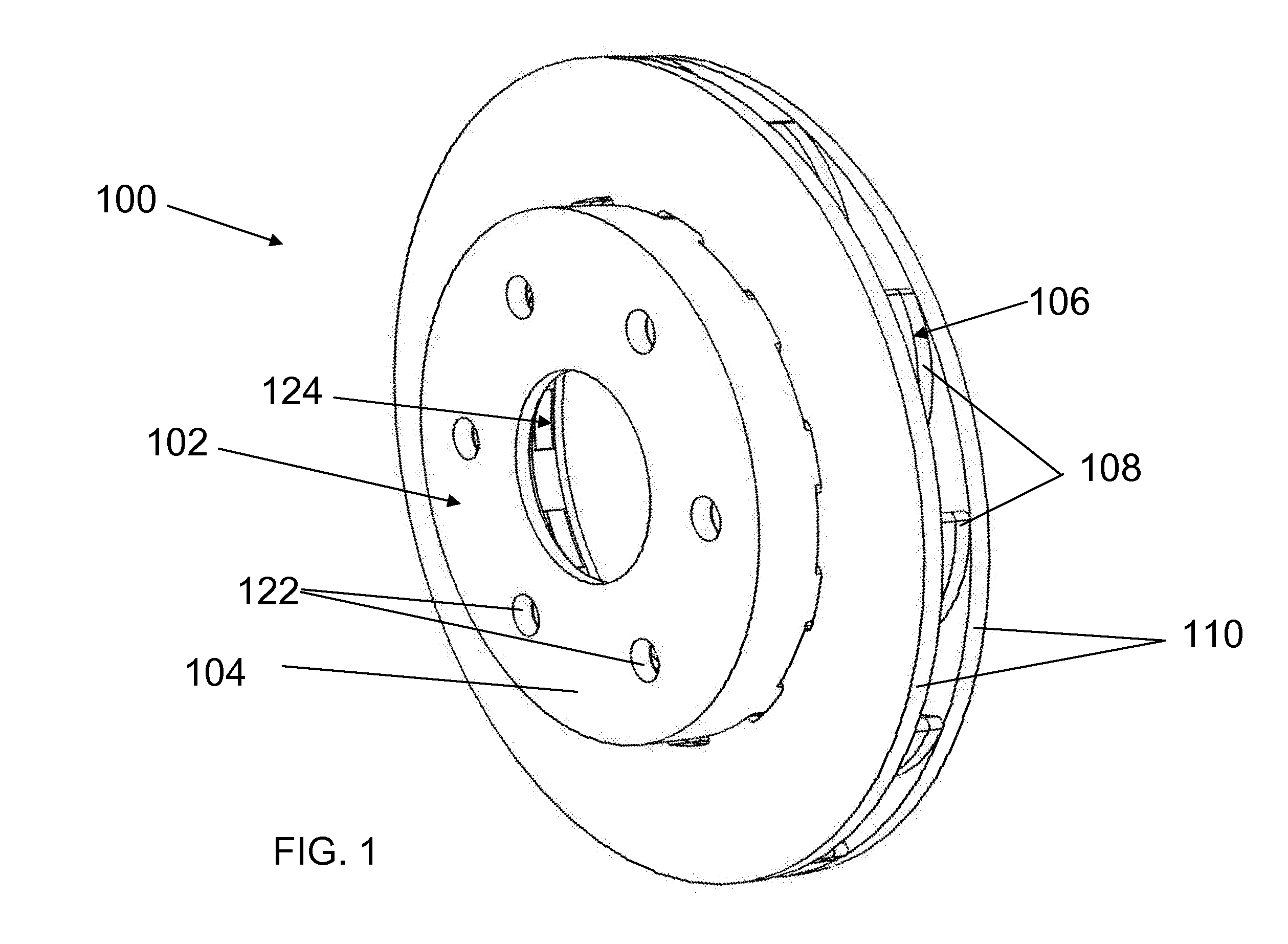

Disc brake rotor assembly and method for producing same

InactiveUS20050183909A1Improve thermal conductivityOptimize acoustic frequency transferBraking element arrangementsNoise/vibration controlAdhesiveMetal alloy

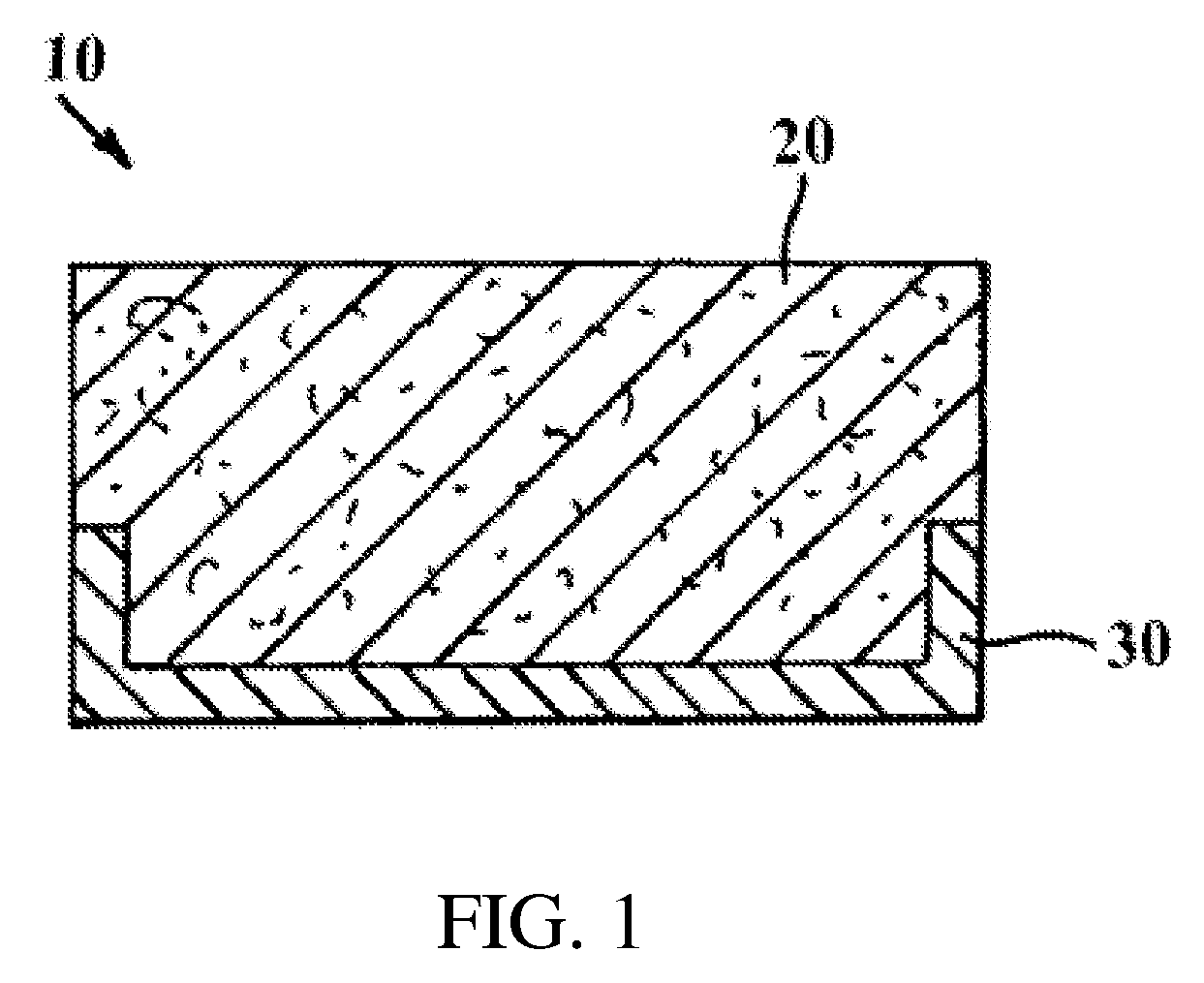

Novel composite disc brake rotor assemblies are provided, along with novel and efficient methods for manufacturing them. Preferably, the rotor assemblies comprise annular wear plates formed of particle reinforced aluminum-based metal matrix composite (MMC), ceramic matrix composite (CMC), or of ‘carbon graphite foam.’ The wear plates, made of a first material, are attached to annular surfaces of a central rotor, made of a second material, by fusing bonding layers between the wear plates and the rotor surfaces. The bonding layers are comprised of at least one of a metal alloy having a melting temperature lower than that of either the first or second materials, and a high-temperature adhesive. Preferably, the wear plates comprise projections that are positioned within adjacent receiving recesses in the center rotor. The bonding layers and projections enhance thermal and acoustical transference between the wear plates and the center rotor section. Carbon graphite foam provides for substantially enhanced heat transference. Use of the fusable binding layer, or adhesive provides for an efficient, low cost method of manufacturing for composite disc brake rotor assemblies.

Owner:BENMAXX

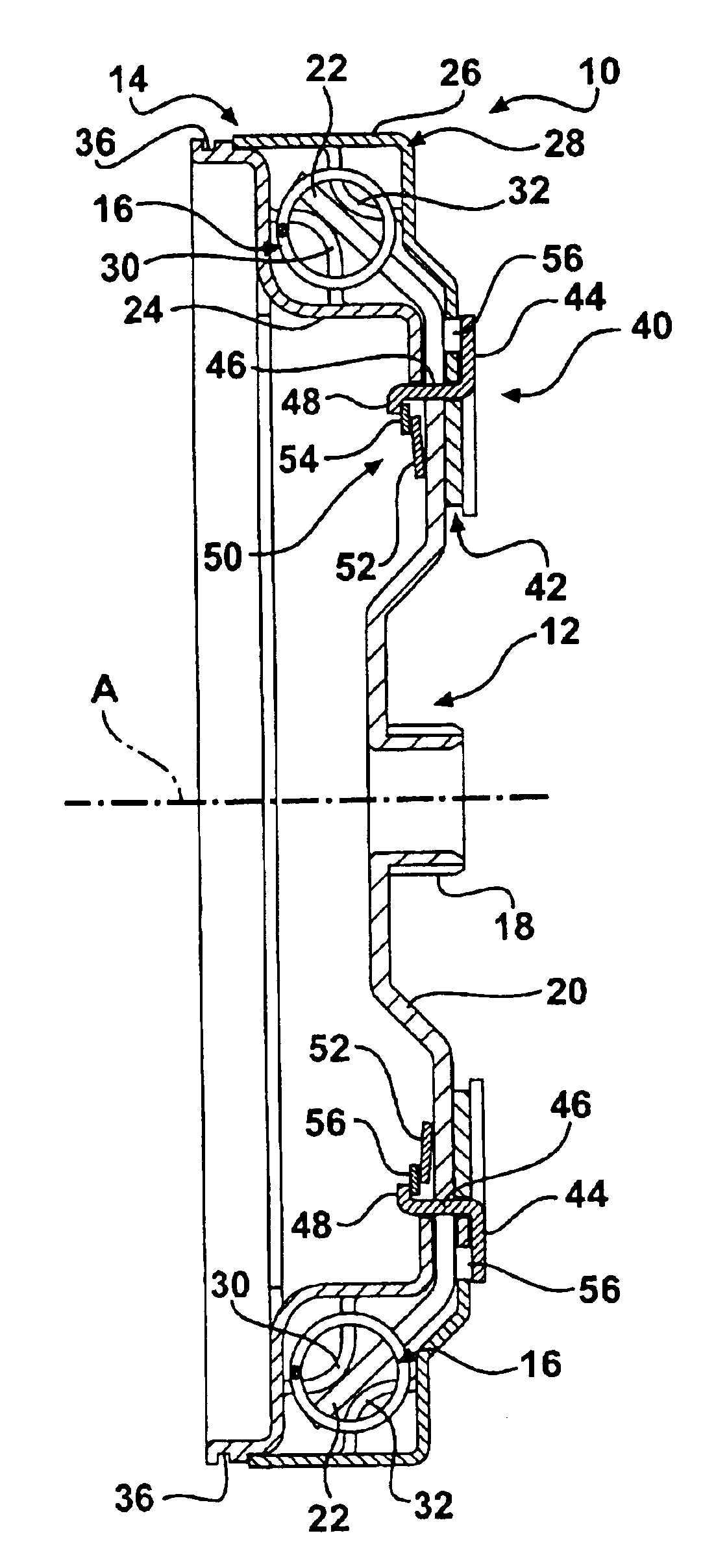

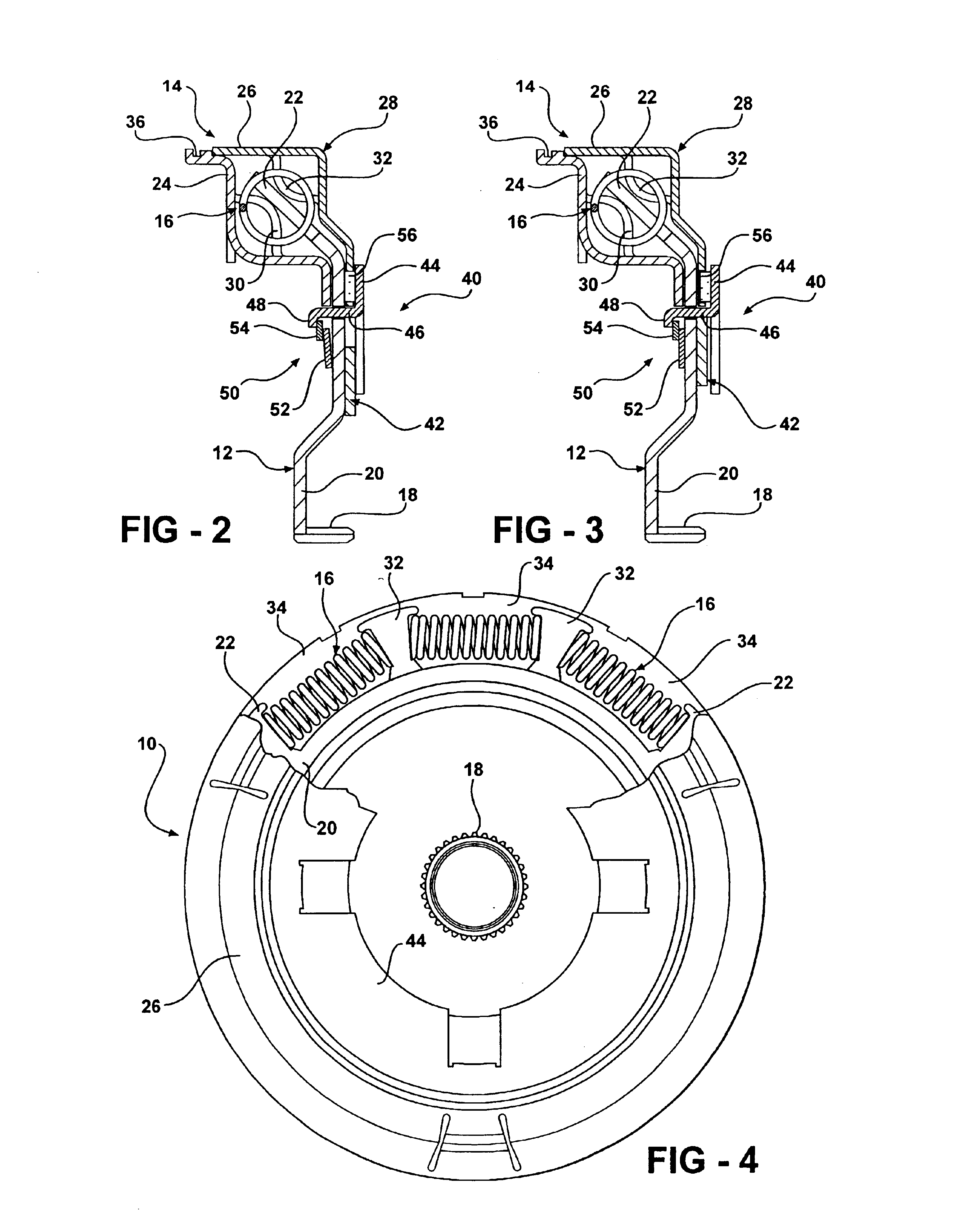

Torsional damper having variable bypass clutch with centrifugal release mechanism

InactiveUS6854580B2Restraint torsionReduce torqueYielding couplingRotary clutchesCentrifugal forceControl theory

A torsional damper (10) rotatably supported for translating torque between a prime mover and the input of a transmission including a torque input member (12) that is operatively connected for rotation with the power take-off of a prime mover, an output member (14) operatively connected for rotation with the input to a transmission and a plurality of damping elements (16) interposed between the input member and the output member. The damping members (16) act to translate torque between the input and output members and to dampen torsional forces generated between the prime mover and the transmission. A bypass clutch (40) acts to translate torque directly between the input and output members thereby providing a path for partial torque translation that bypasses the damping elements at low rotational speeds of the input and output members. In addition, the torsional damper (10) includes a clutch release mechanism (42) that is responsive to centrifugal forces acting on the torsional damper to disengage the bypass clutch (40) to reduce the torque translated directly between the input and output members at high rotational speeds.

Owner:BORGWARNER INC

Friction material and method of mix-fibrillating fibers

A friction material comprising a fibrous reinforcement, a friction modifier and a binder, characterized by being free from asbestos fiber and containing, as the organic fibrous reinforcement, a mixture of a dry aramid pulp with at least one member selected from the group consisting of a wet aramid pulp, a woodpulp and an acrylic pulp.

Owner:AKEBONO BRAKE IND CO LTD +1

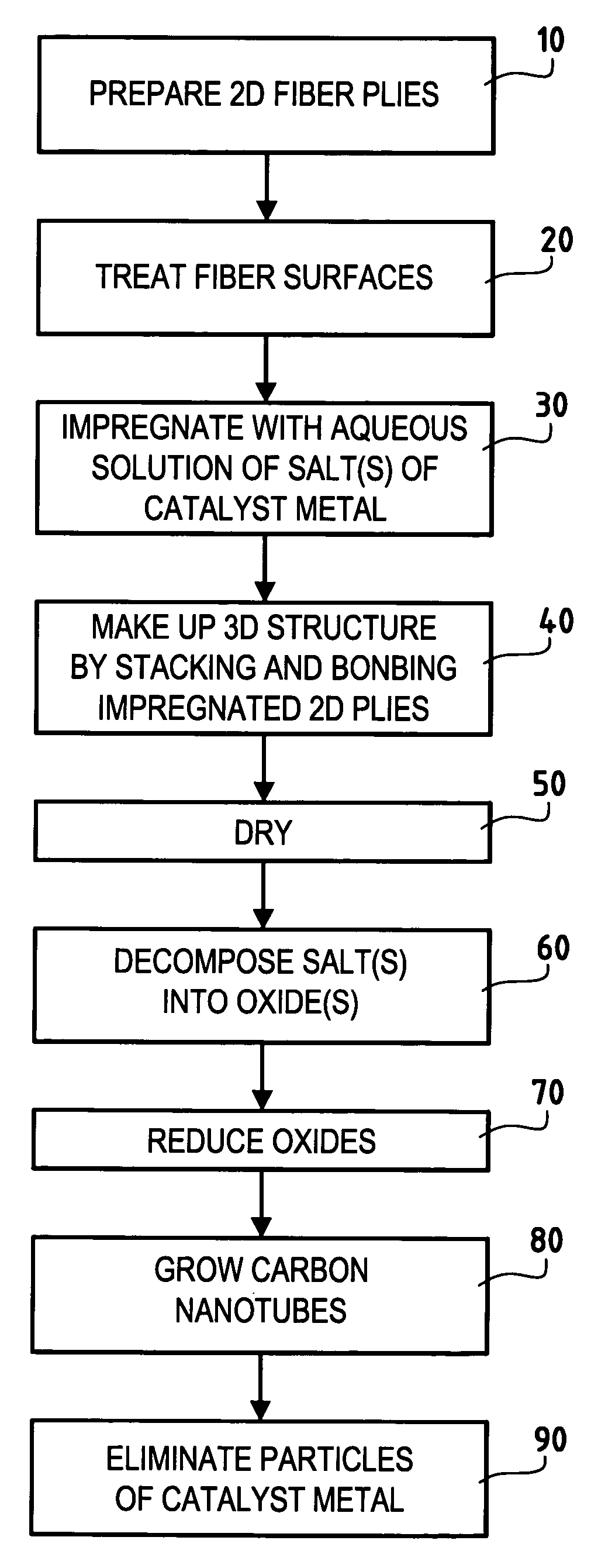

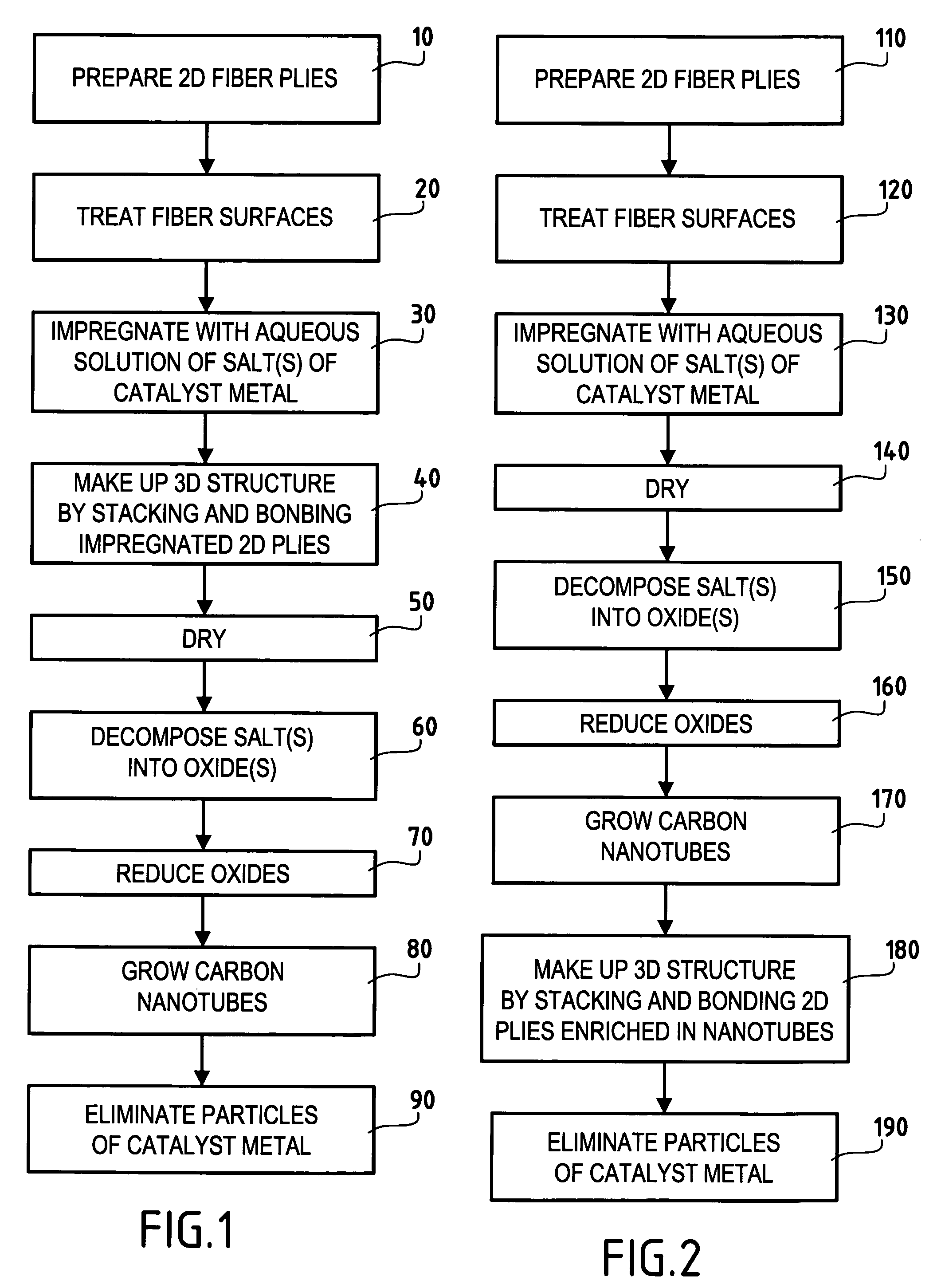

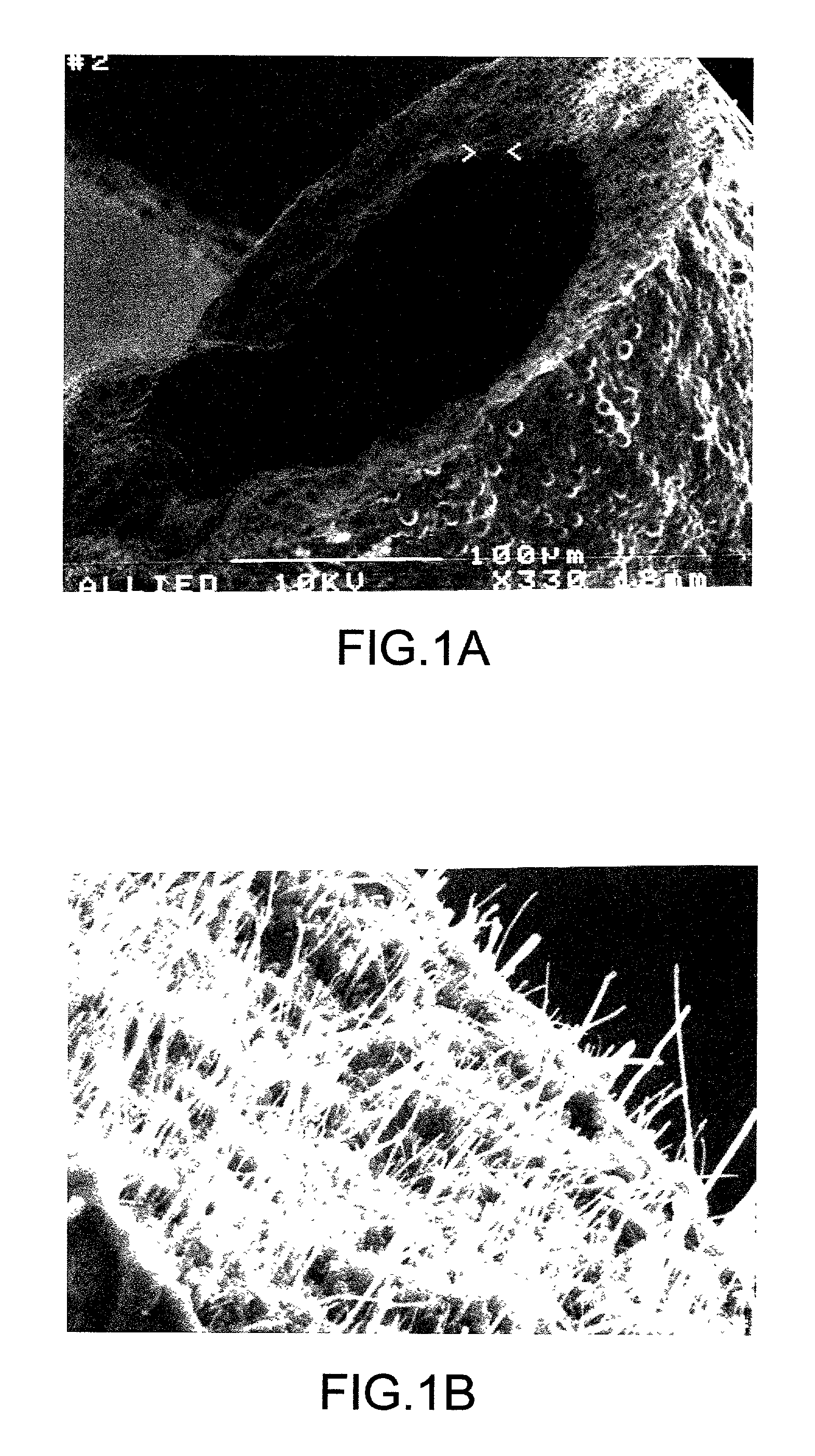

Three-dimensional fiber structure of refractory fibers, a method of making it, and thermostructural composite materials, in particular friction parts, made therefrom

ActiveUS20050176329A1Improve propertiesEasy to prepareMaterial nanotechnologyCarbon fibresMetallurgyCarbon nanotube

Carbon nanotubes are incorporated in the fiber structure by growing them on the refractory fibers of the substrate so as to obtain a three-dimensional substrate made of refractory fibers and enriched in carbon nanotubes. The substrate is densified with a matrix to form a part of composite material such as a friction part of C / C composite material.

Owner:CENT NAT DE LA RECHERCHE SCI

Method for preparing C/SiC composite material through low-cost fused silicon impregnation method

The invention relates to a method for preparing a C / SiC composite material through a low-cost fused silicon impregnation method, which comprises the following steps: performing calcining pretreatment on a carbon felt or graphite felt at 400-600 temperature; immersing the pretreated carbon felt or graphite felt in a melamine and boric acid solution, thus coating a boron nitride protective layer; immersing in a carbon / silicon carbide slurry water solution, performing impregnation to ensure that pores of the carbon felt or graphite felt are fully filled with carbon / silicon carbide, placing in a sintering furnace, and performing primary fused silicon impregnation treatment at 1600-1800 DEG C; immersing in liquid phenolic resin, and performing carbonization treatment under the protection of an inert atmosphere at 800-1000 DEG C to ensure that all the resin is carbonized; and finally, performing secondary fused silicon impregnation treatment to ensure that carbon produced by carbonization of the resin totally reacts with silicon to generate silicon carbide, thus obtaining the C / SiC composite material. The obtained C / SiC composite material is high in density, low in air pore and free silicon content, and favorable in material strength, toughness and frictional wear performance, and can be used for manufacturing of brake pads.

Owner:山东宝纳新材料有限公司

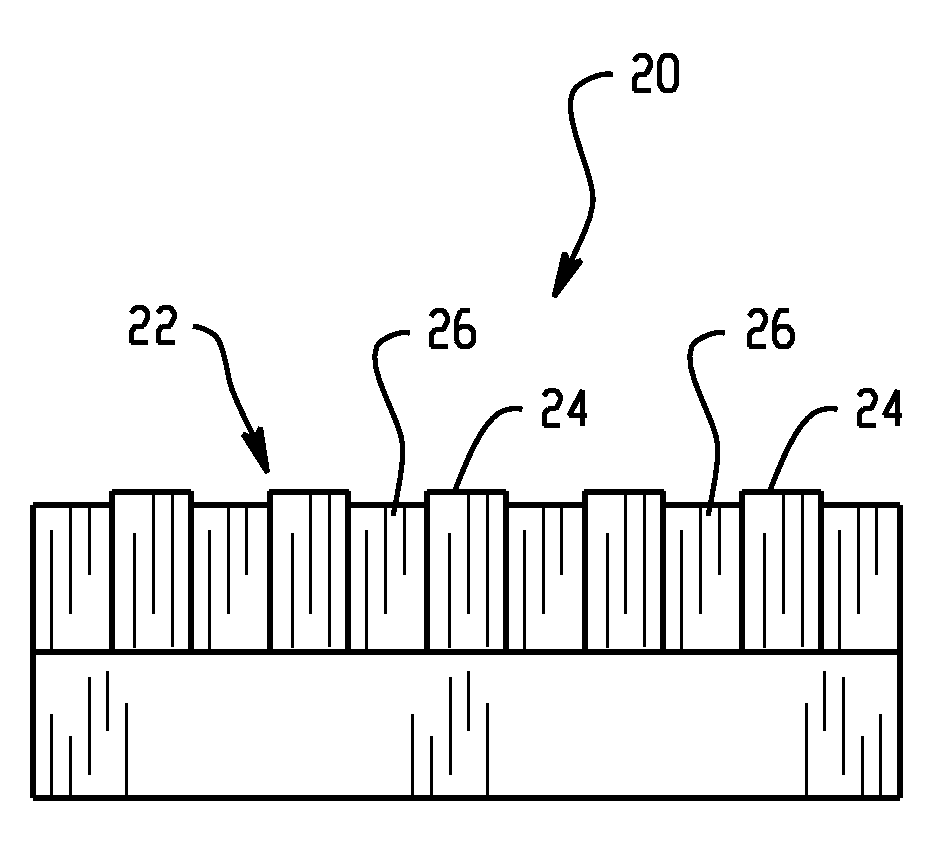

Backing plate with friction material retention members and method and apparatus for manufacturing same

A backing plate for a friction assembly includes a body having a first surface and a second surface and a thickness defined therebetween. One or more retention members are provided on the first surface for engaging a friction material mounted thereon. Each retention member has an extruded protrusion and an groove. The extruded protrusion has a generally constant width and a free curved distal end. The groove has a bottom wall having an inclined section and a flat section.

Owner:UTIL CANADA LIMITED

Composite material comprising oriented carbon nanotubes in a carbon matrix and process for preparing same

Fiber spinning of two polymer compositions wherein one of the compositions contains carbon nanotubes produces structures such as fibers, ribbons, yarns and films of carbon nanotubes. The polymers are removed and stabilization of the carbon nanotube material is achieved by post-spinning processes. The advances disclosed herein enable the carbon nanotube composites to be used in actuators, supercapacitors, friction materials and in devices for electrical energy harvesting.

Owner:HONEYWELL INT INC

Composite material comprising oriented carbon nanotubes in a carbon matrix and process for preparing same

Fiber spinning of two polymer compositions wherein one of the compositions contains carbon nanotubes produces structures such as fibers, ribbons, yarns and films of carbon nanotubes. The polymers are removed and stabilization of the carbon nanotube material is achieved by post-spinning processes. The advances disclosed herein enable the carbon nanotube composites to be used in actuators, supercapacitors, friction materials and in devices for electrical energy harvesting.

Owner:HONEYWELL INT INC

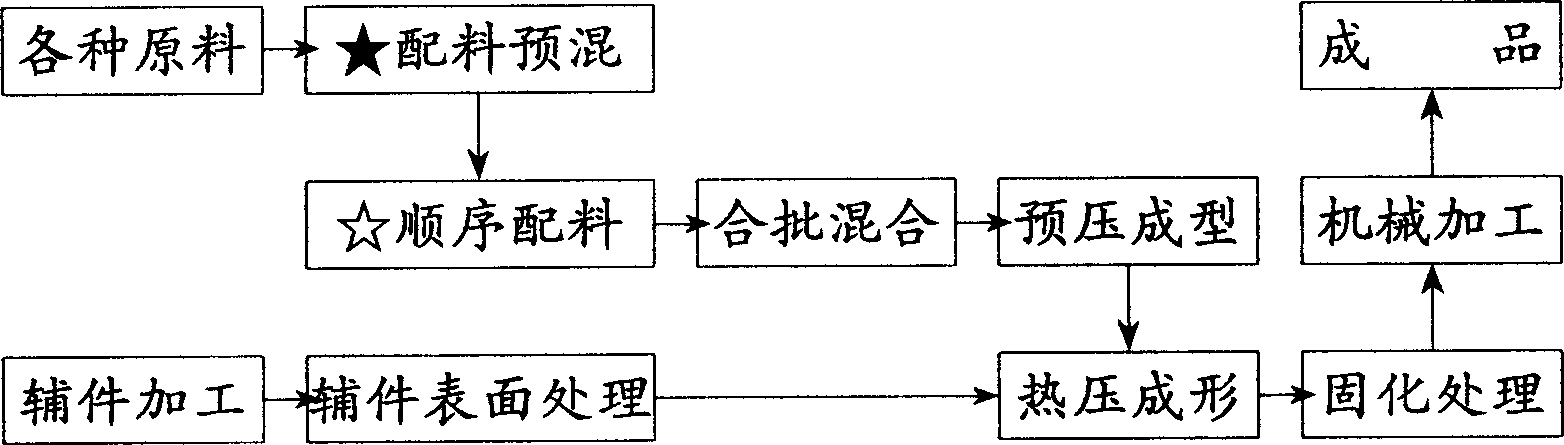

Environment-protection type high-performance automobile braking piece and making method

InactiveCN1814657AIncrease frictionOvercoming high temperature recession defectsFriction liningFiberAdhesive

This invention relates to a preparation technology for producing special products with plastic substances characterizing in mixing an adhesive agent, strengthened fibers, a regulator for friction performance and inorganic fillers in good match to process the surfaces of them with an anti-high temperature coupler to be hot-pressed to a format to get a high performance car brake plate of environmental protection, which replaces that made of asbestos fiber and overcomes the shortcoming of declining at high temperature of the asbestos car brake plates.

Owner:CENT SOUTH UNIV +1

Method for preparing nanoparticle-modified friction material

The invention discloses a method for preparing a nanoparticle-modified friction material, which comprises the following steps: dissolving a resin in a solvent to obtain solution of the resin, uniformly dispersing nanoparticles in the solution of the resin, soaking reinforcing fibers in the solution and adding surfactant to allow the resin, the nanoparticles and the reinforcing fibers to be tightly bonded and uniformly disperse; and mixing the resin-coated nanoparticles and the resin-coated reinforcing fibers with a friction performance regulator and a filler, uniformly stirring the mixture and drying the mixture. In the method, the flowability of the solution of the resin is used to coat the nanoparticles and the reinforcing fibers, so the uniform mixing of the nanoparticles, the fibers and the resin is realized; the bonding strength of the nanoparticles, the fibers and the resin is increased under the action of the surfactant; and the friction performance and the service life of a brake pad can be improved on the basis of reducing the dosages of the nanoparticles, the reinforcing fibers and the resin. The friction material of the invention can be widely used in the preparation of brake pads of motor vehicles, brakes of machine tools and electrodes, clutch liners and the like.

Owner:CHINA JILIANG UNIV

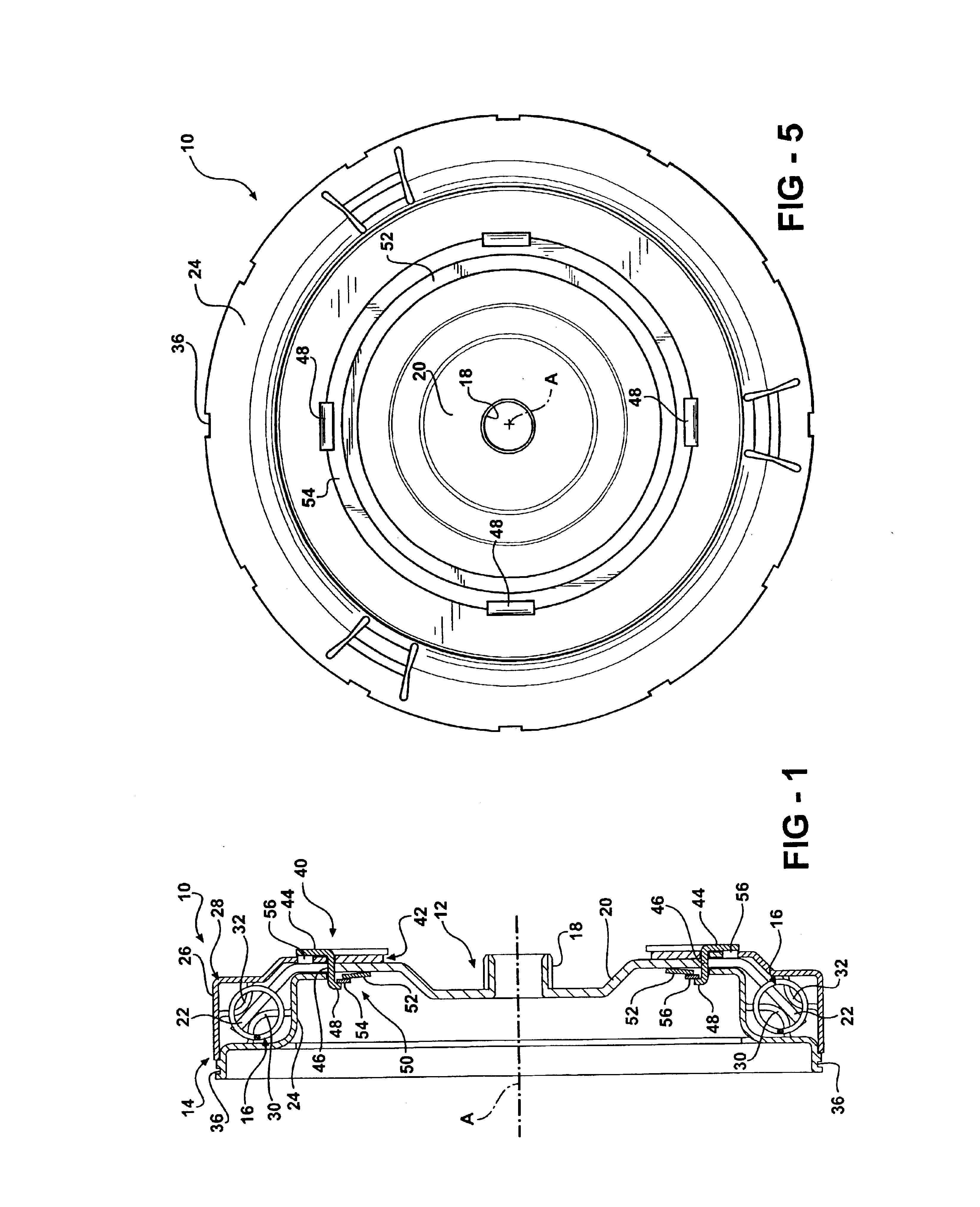

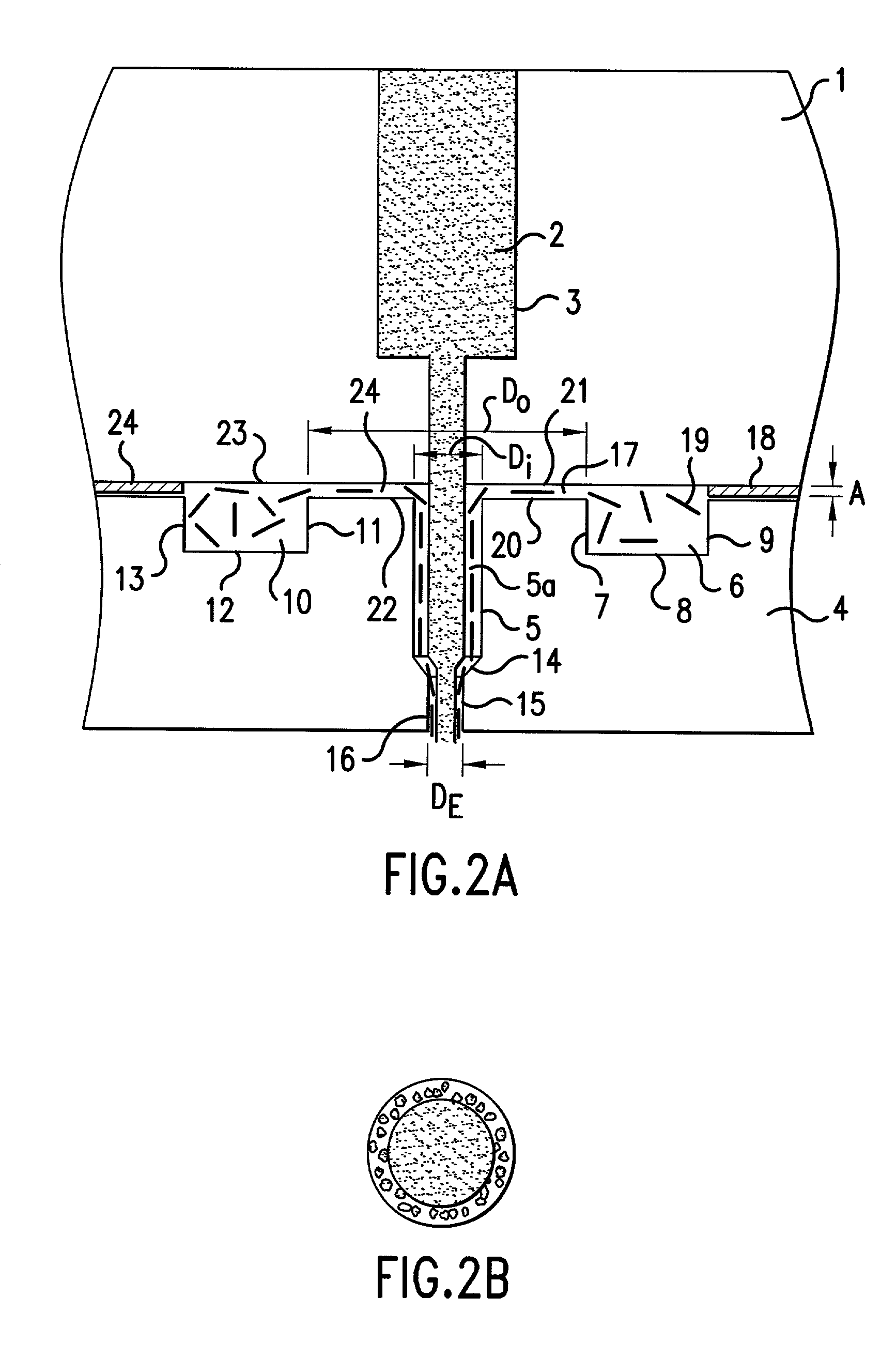

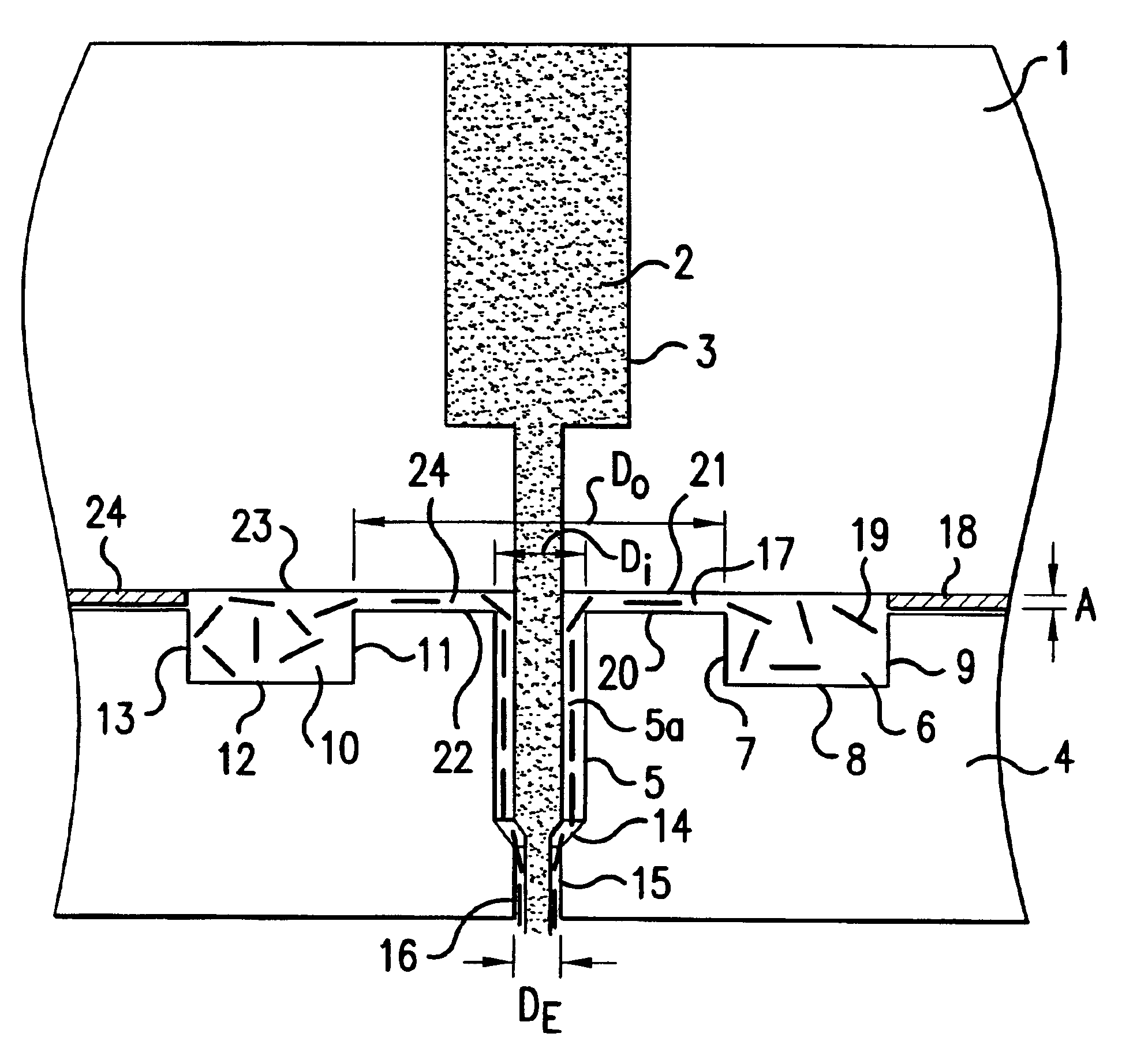

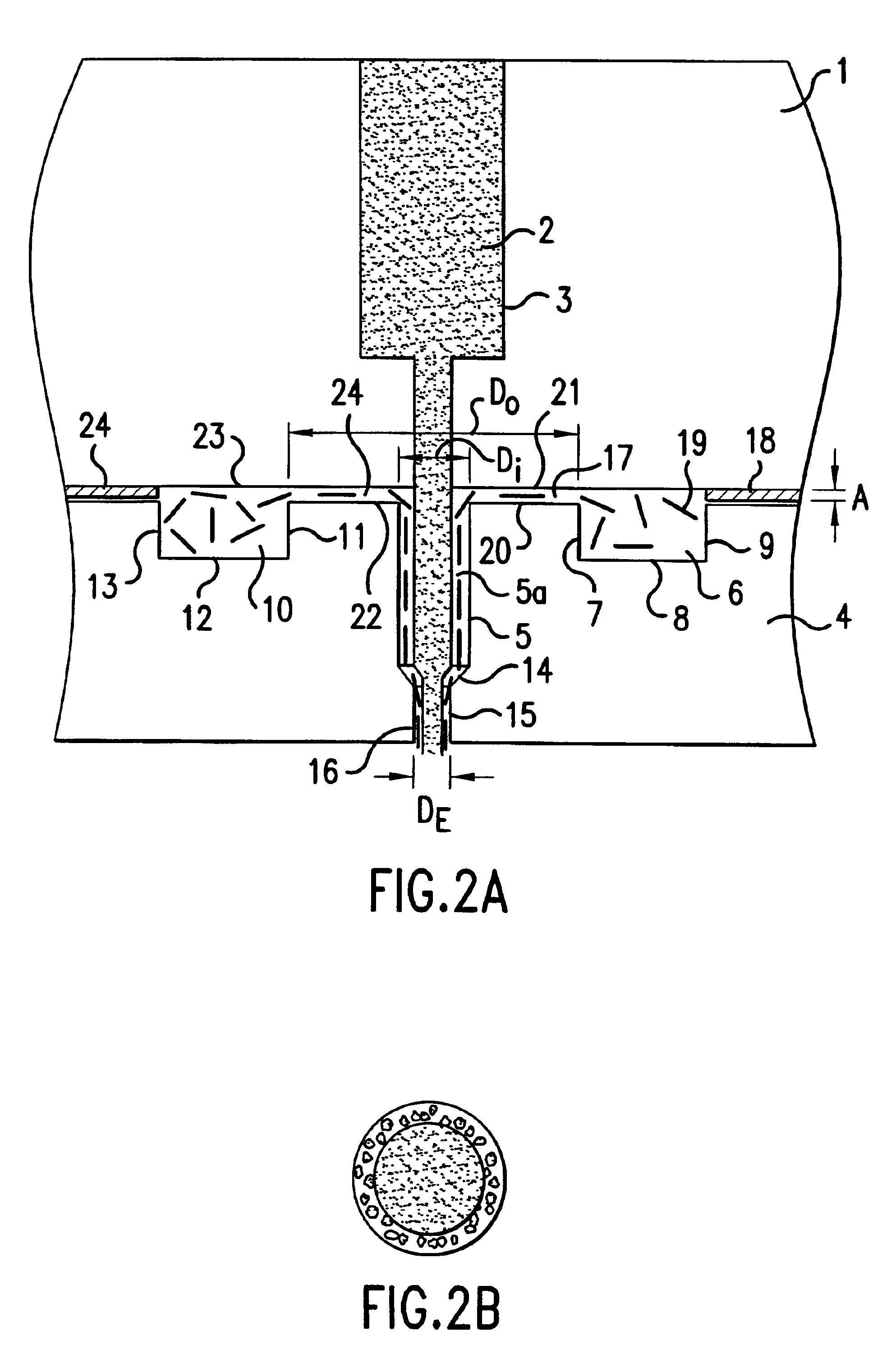

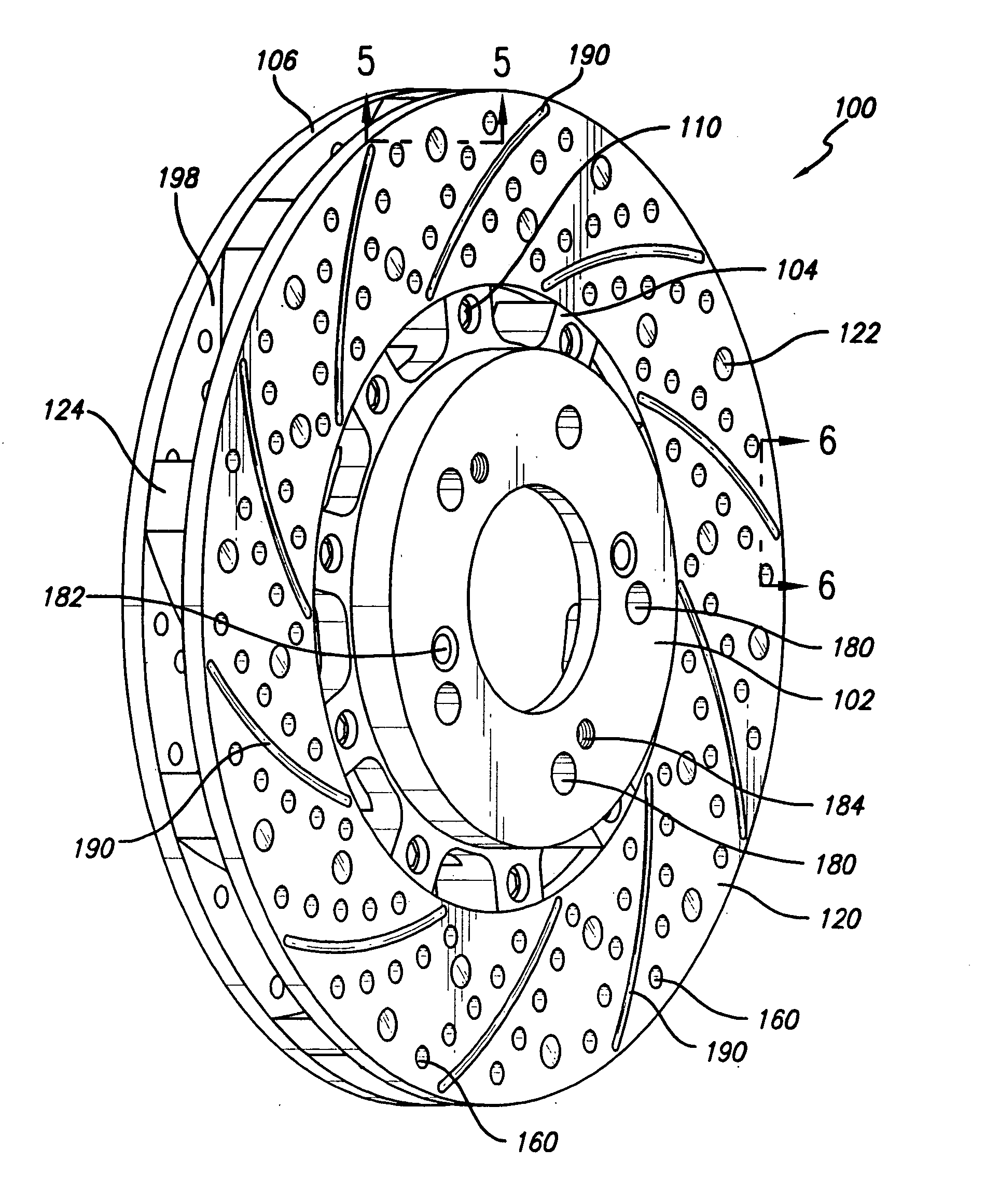

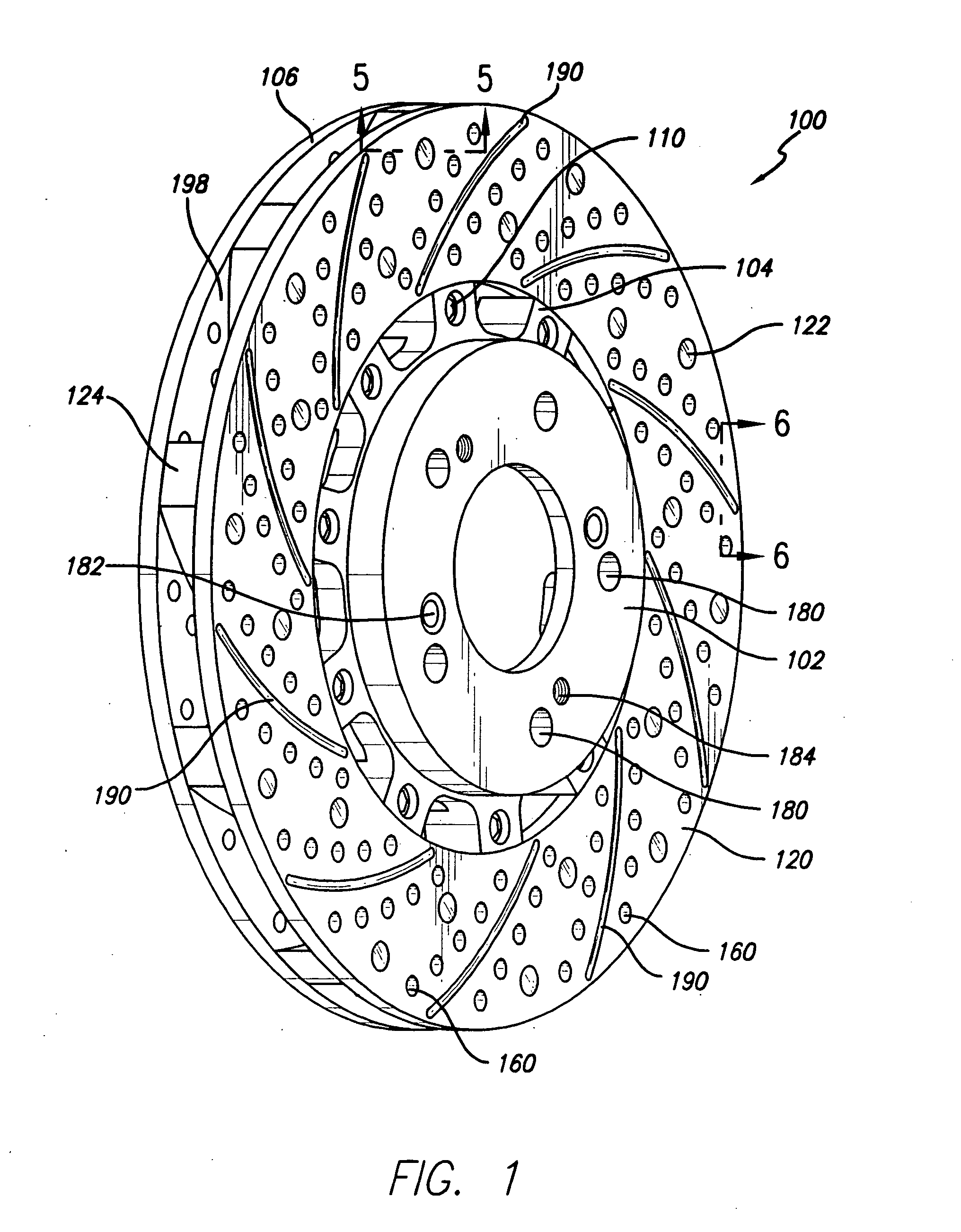

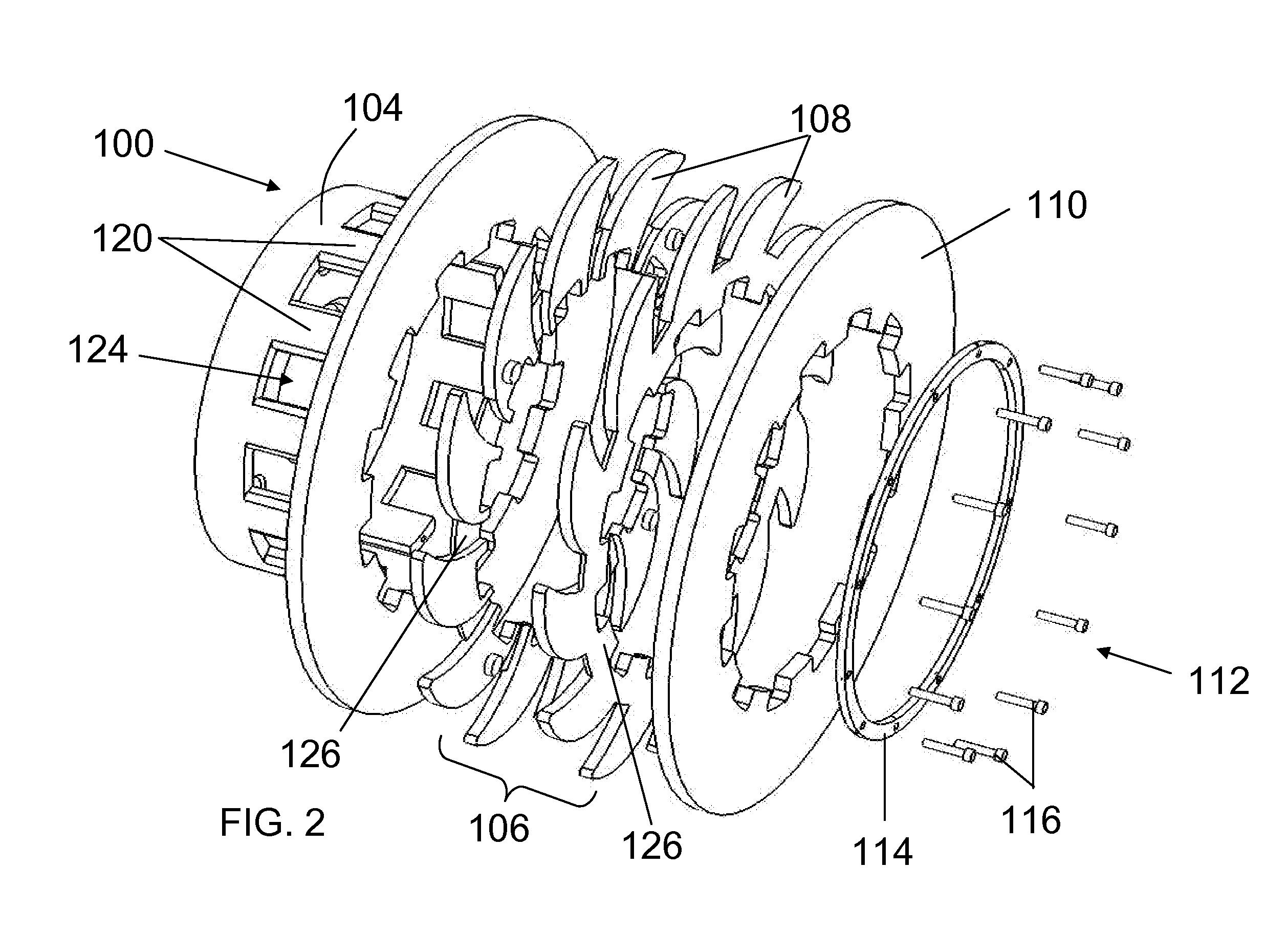

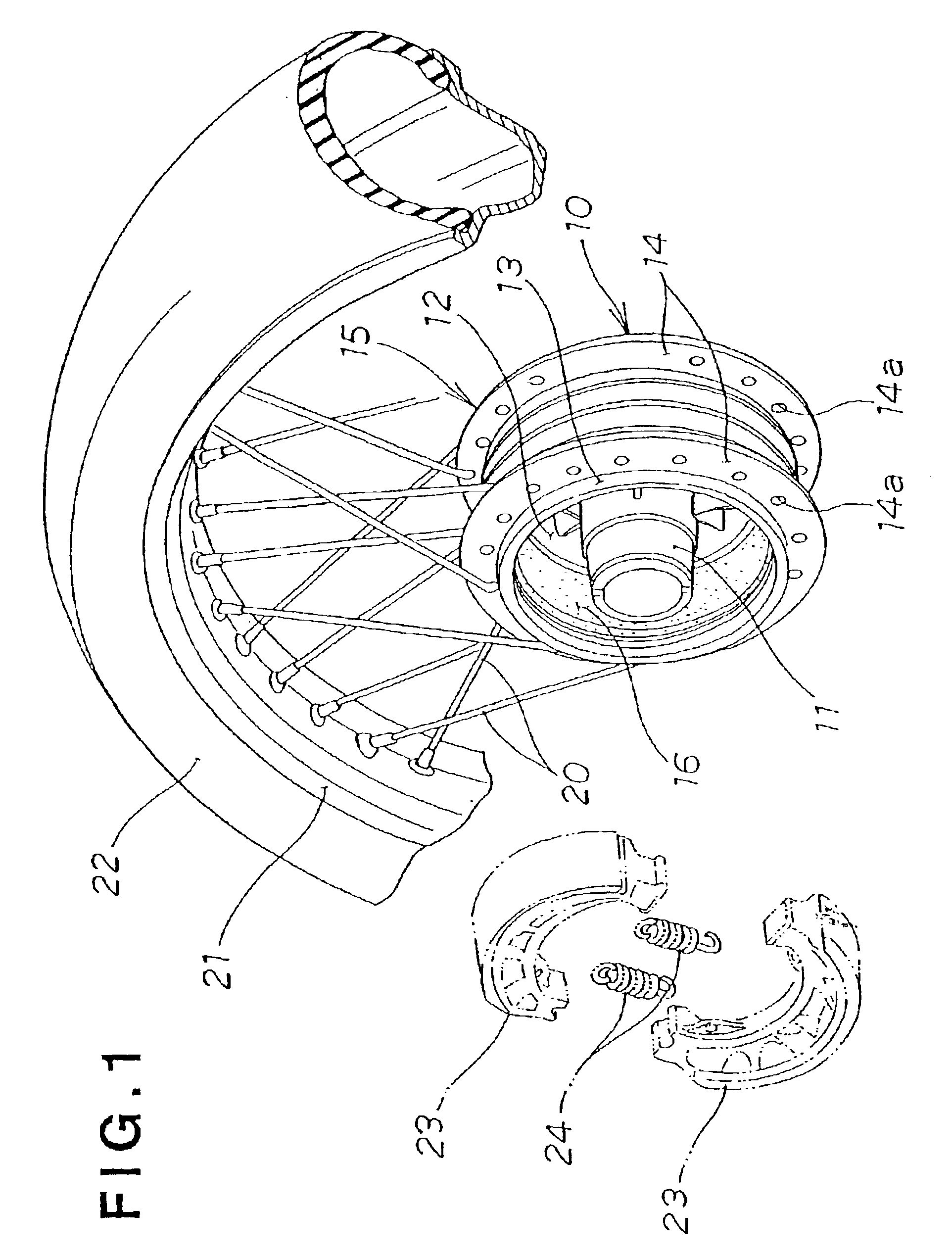

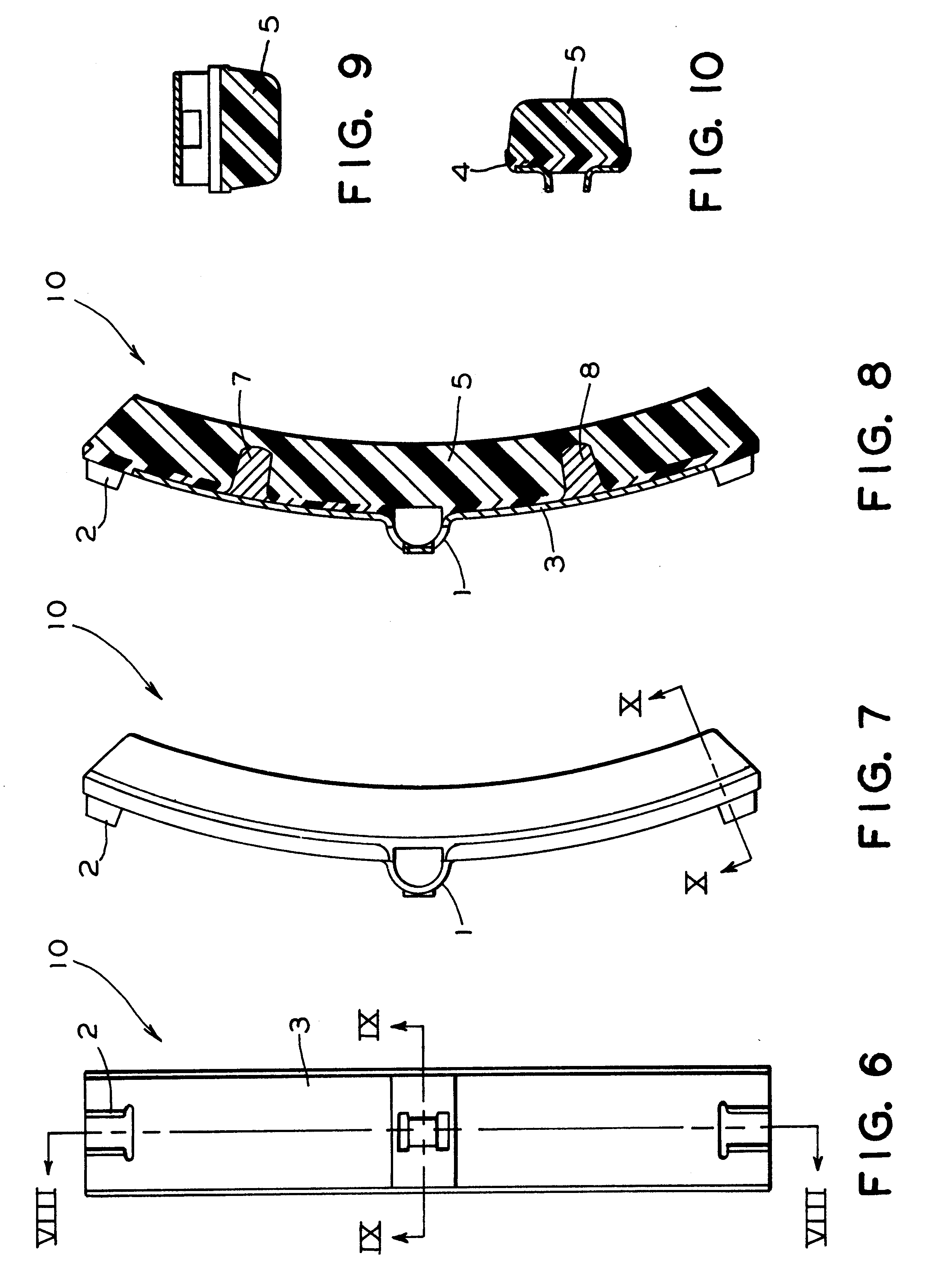

Air-cooled brake rotor system

InactiveUS20070181390A1Easy to replaceImprove cooling effectBraking discsFriction liningDisc brakeEngineering

An air-cooled brake rotor system defining an inter-rotor disk slot through which spacers in the form of turbine or fan vanes propel air when the brake rotor system is turned. An inner disk brake rotor plate is attached to a hub which in turn may be attached to an axle on a vehicle such as an automobile. Pins having ends of opposite threading are used to connect the inner rotor to the outer rotor. The outer rotor is spaced apart from the inner rotor by means of spacers which are shaped to propel air through the slots defined between the two rotors. The spacers are also configured so that compression of the two rotors by a caliper system always serves to have a spacer beneath the area engaged by the brake pad to provide mechanical support for the rotor system. Each rotor generally has defined in it venting holes and inscribed debris-channeling slots in an arcuate, volute, or turbinate manner. An enhanced braking system experiencing lower heat retention is thereby attained.

Owner:KORM KEVIN

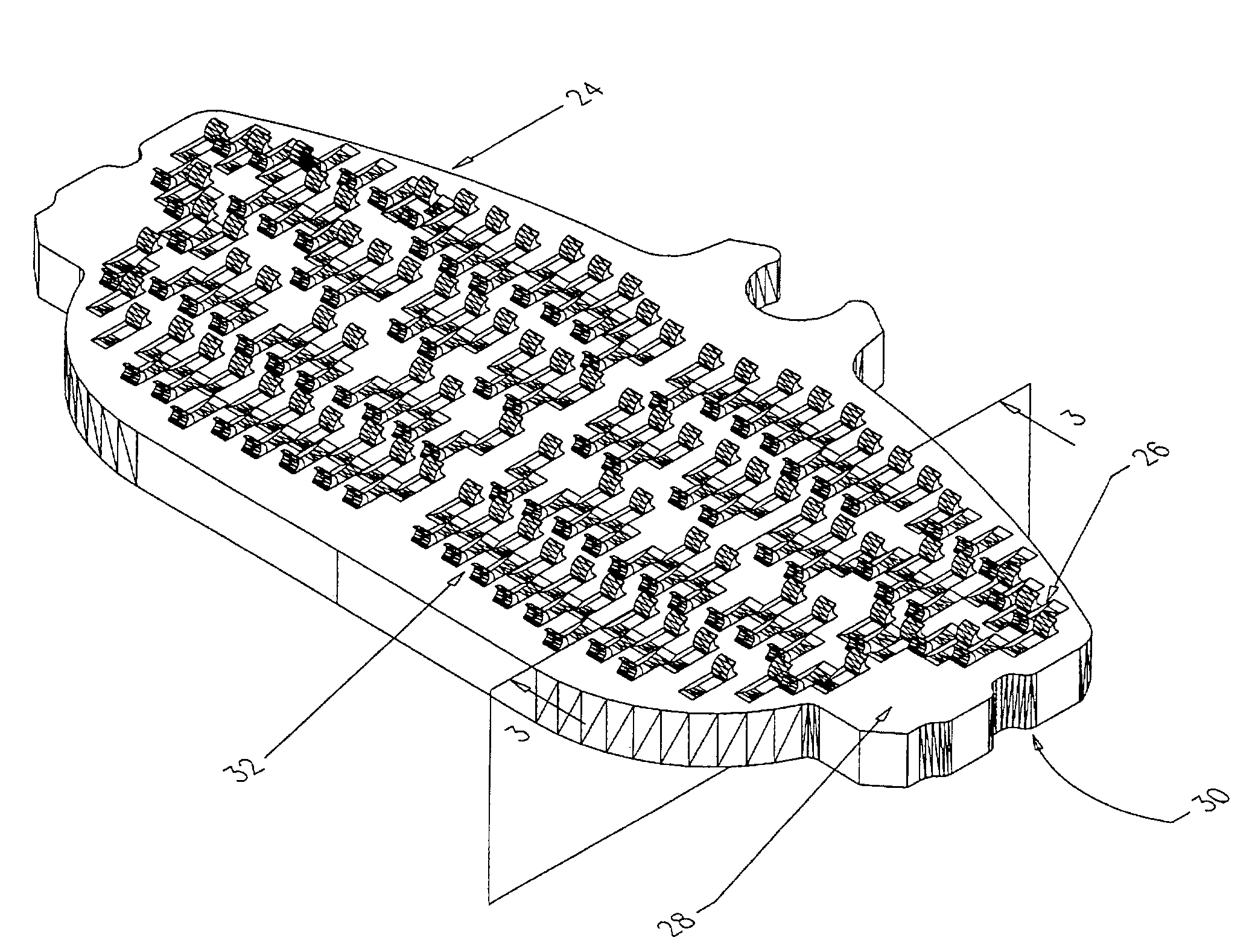

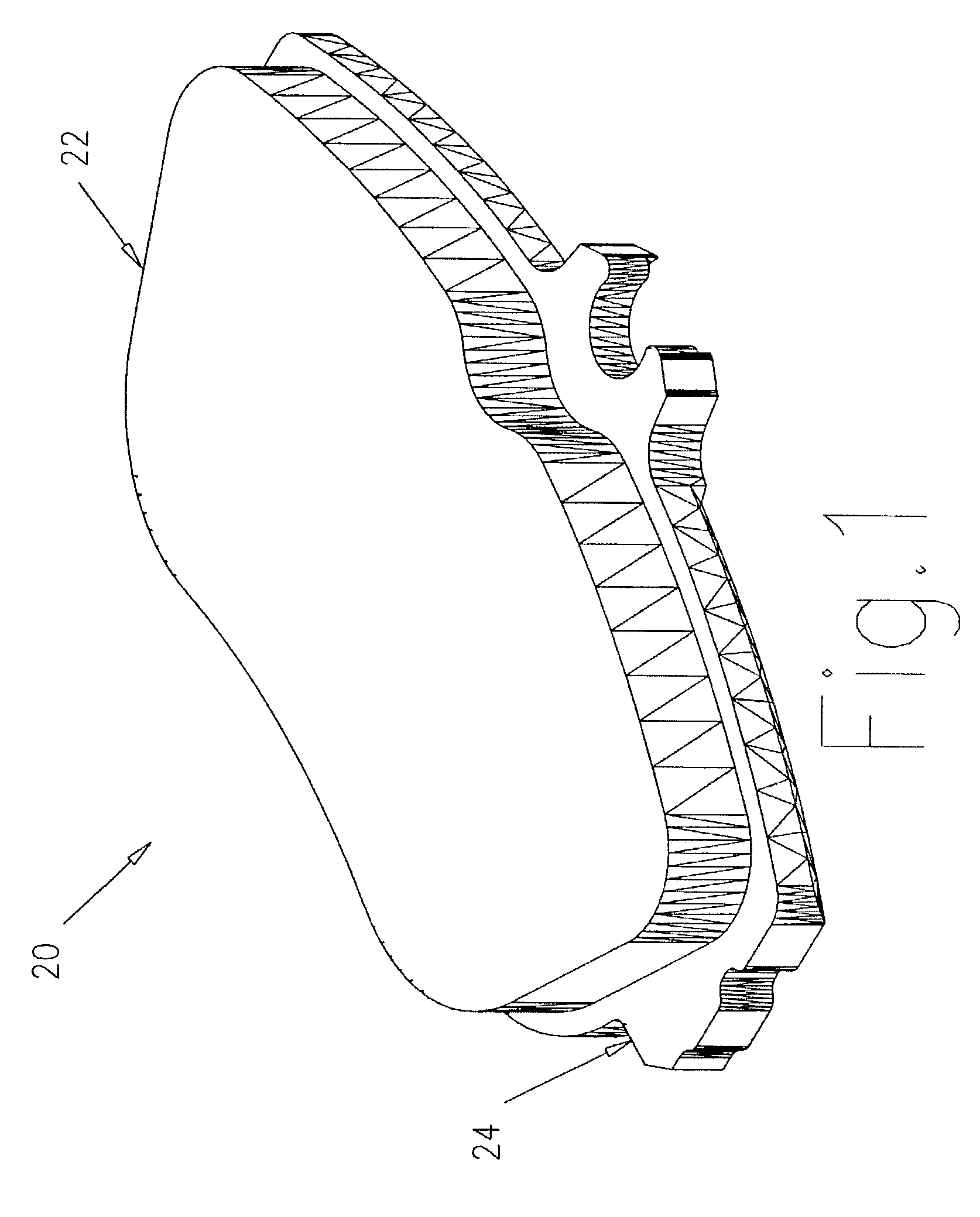

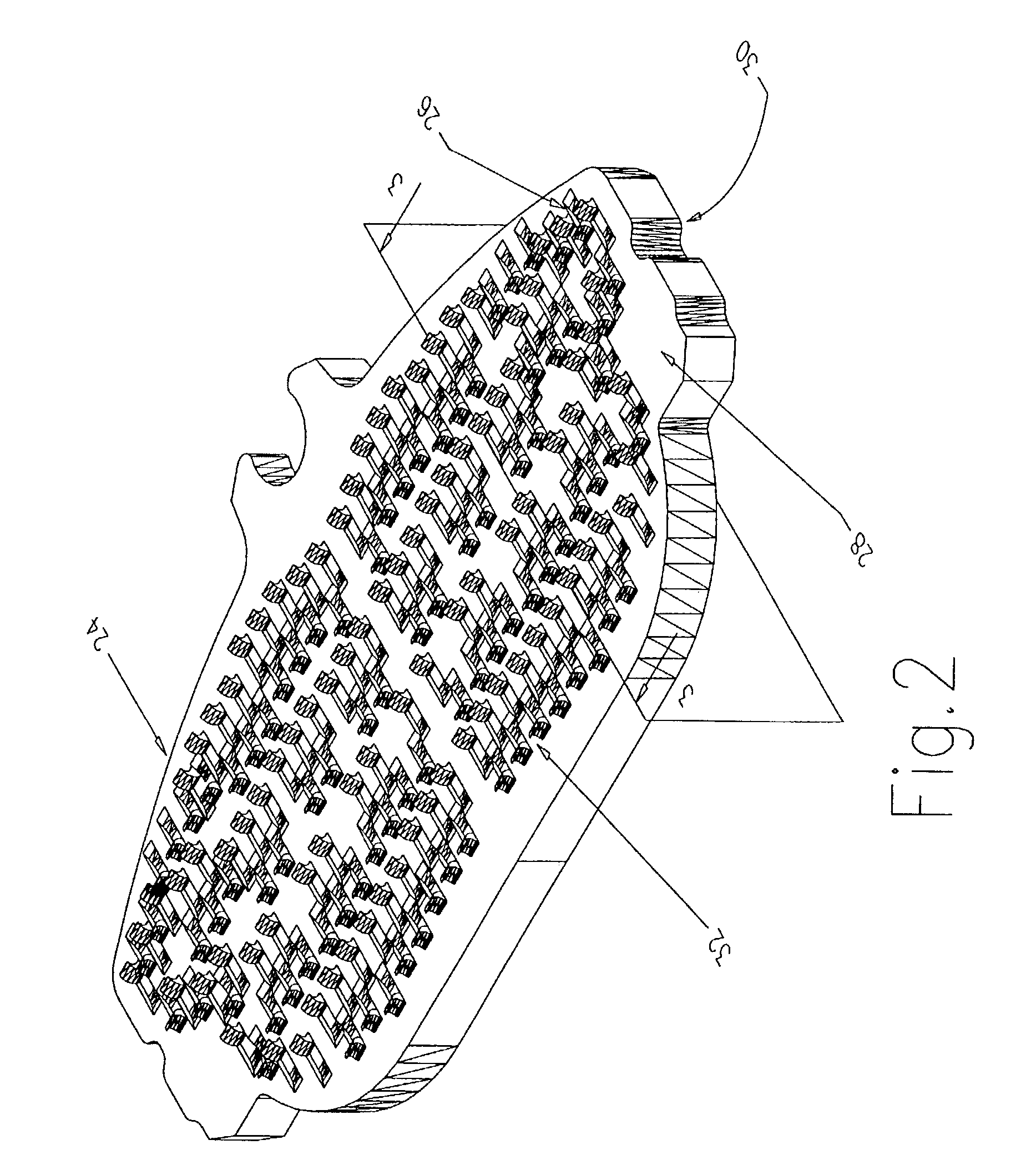

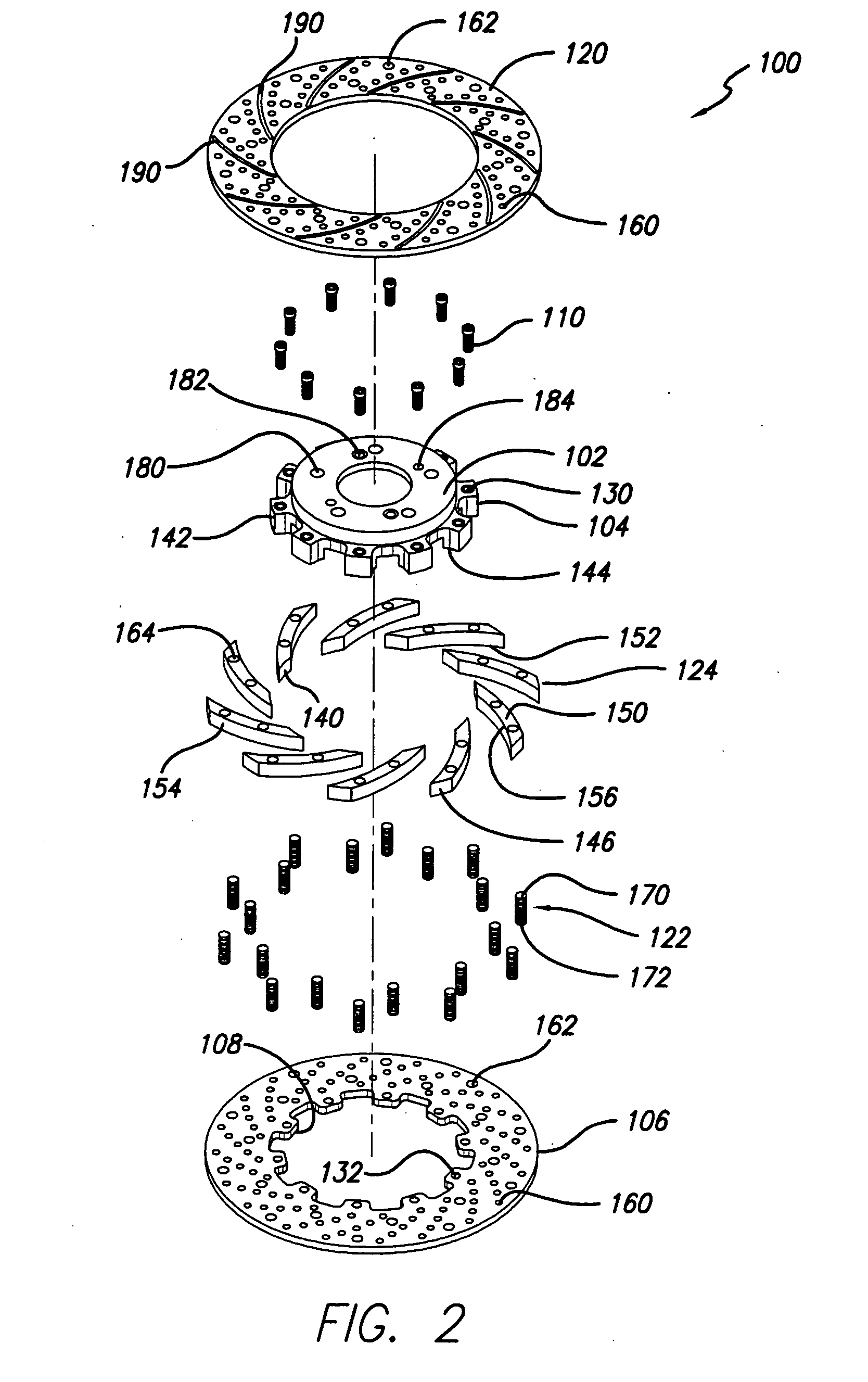

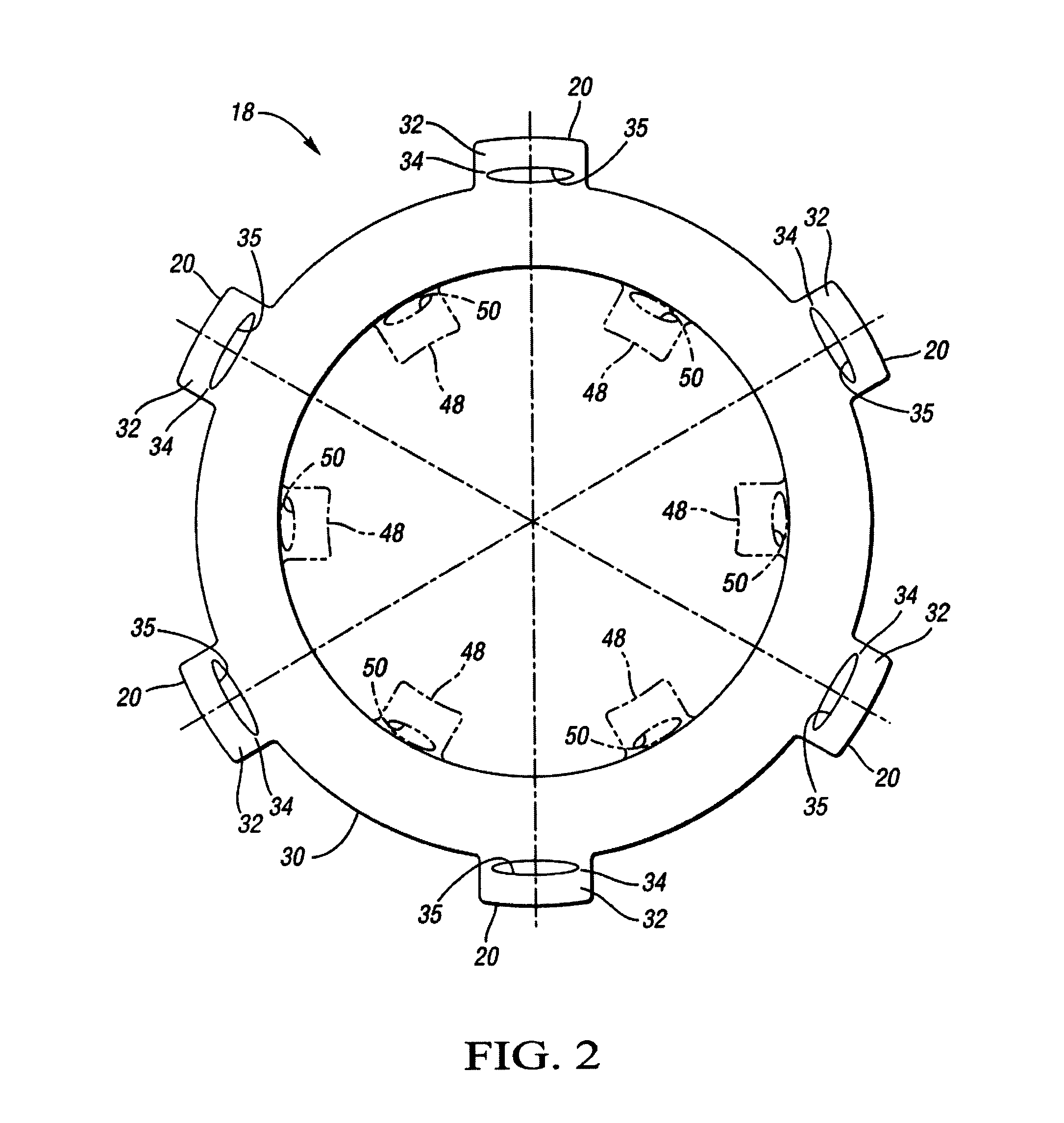

Brake rotor with ceramic matrix composite friction surface plates

The disclosure relates to structures and a method for providing an air cooled rotor with ceramic-metal composite friction surface plates, and in particular to a brake rotor including a rotor hat; a ventilation disc having a plurality of cooling vanes extending therefrom; a ceramic matrix composite (CMC) friction surface plate on each side of the ventilation disc; and a fastener for holding the CMC friction surface plates and the ventilation disc to the rotor hat.

Owner:STARFIRE SYST

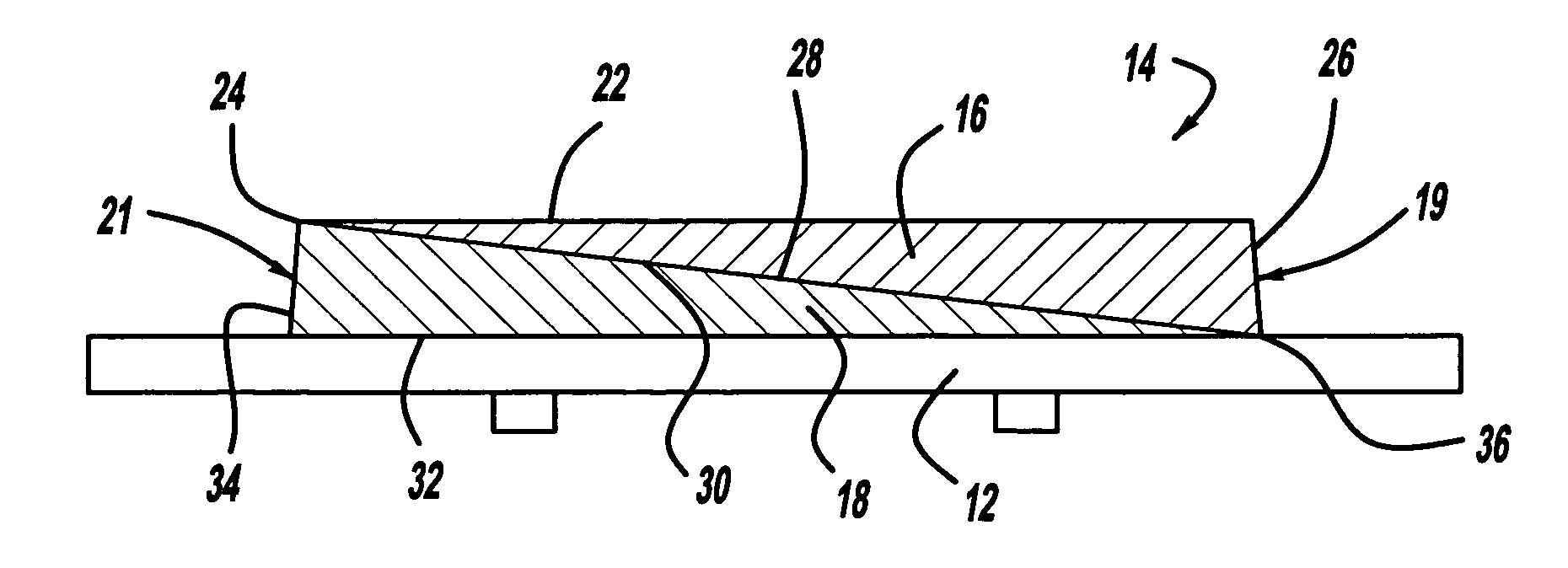

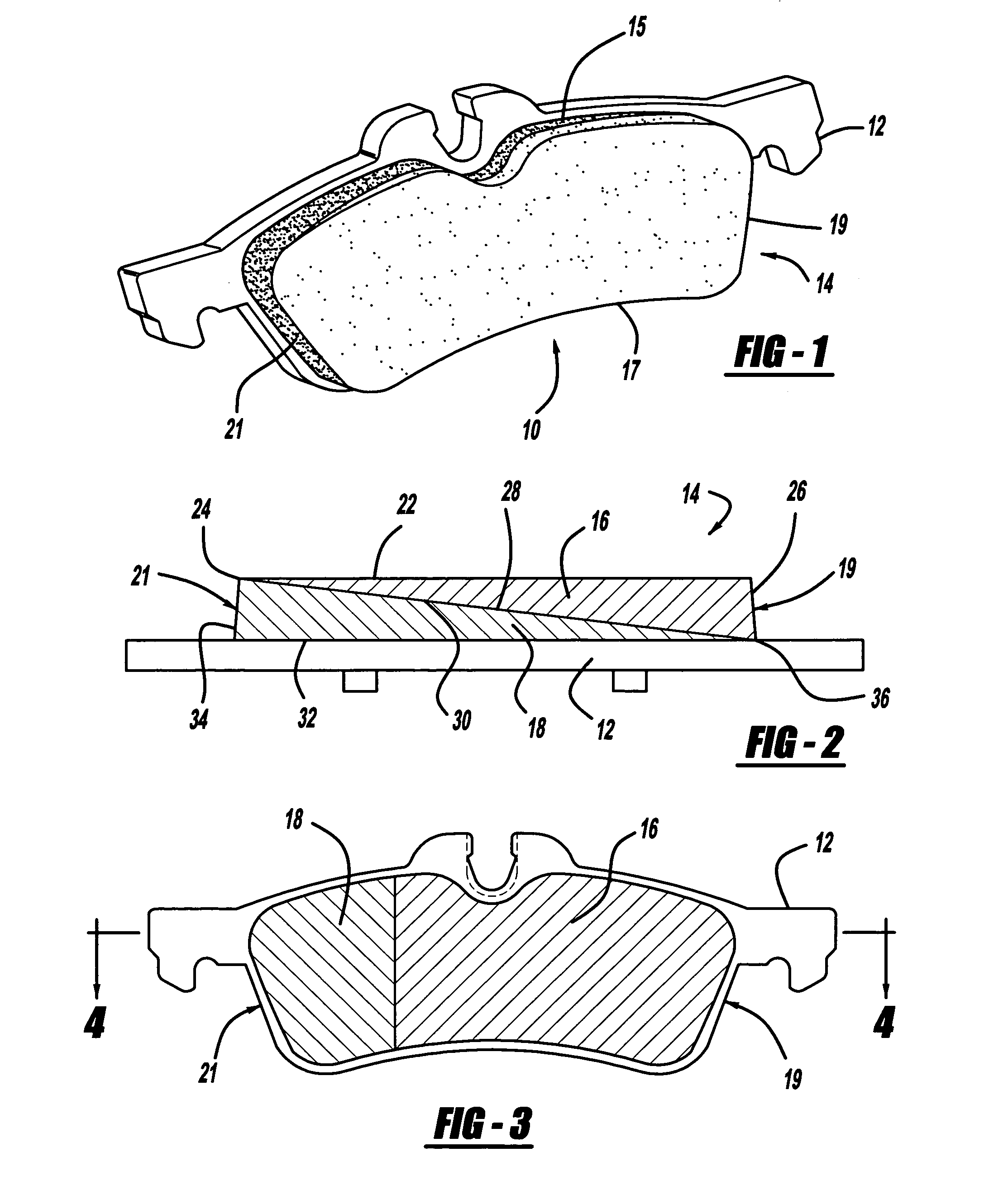

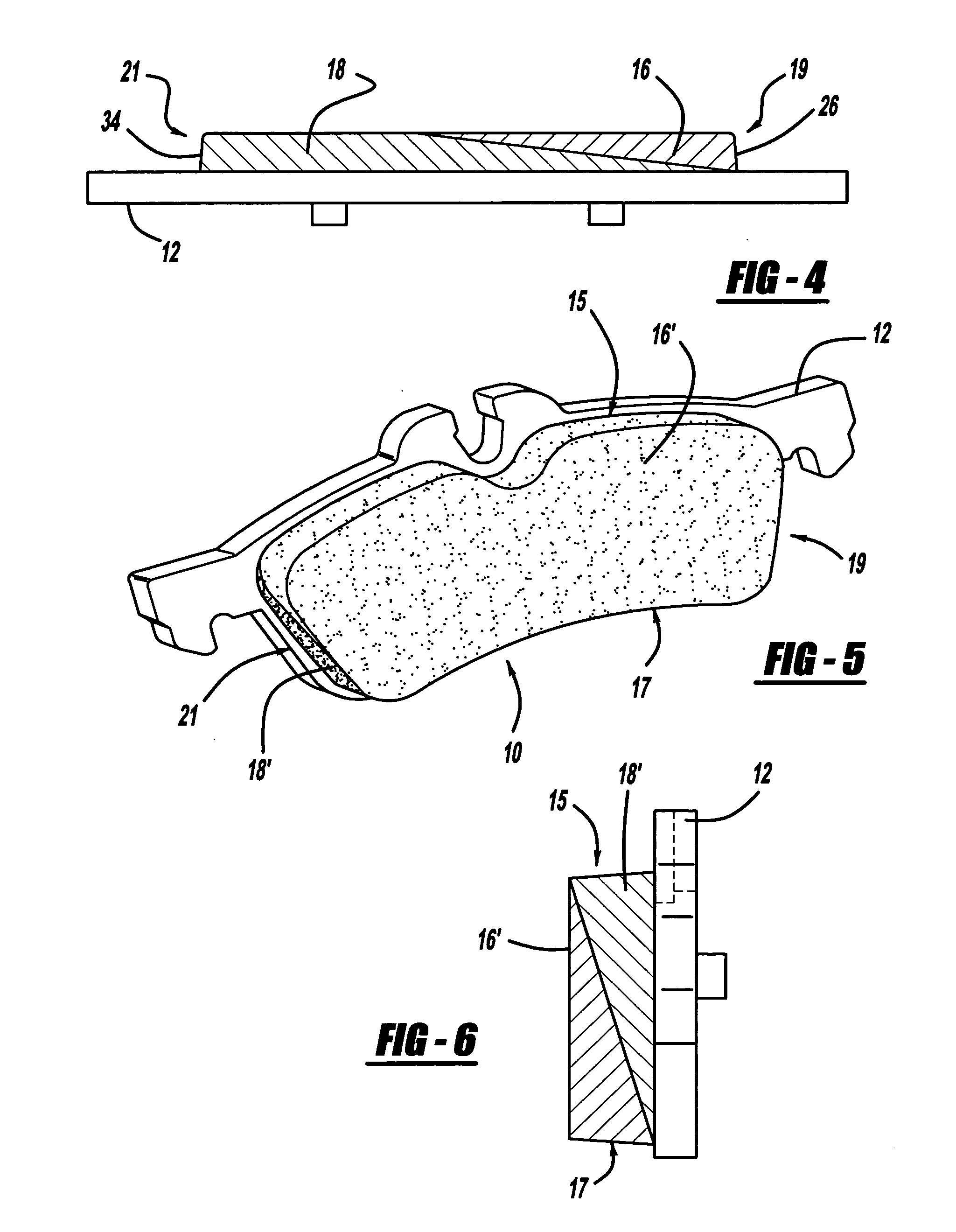

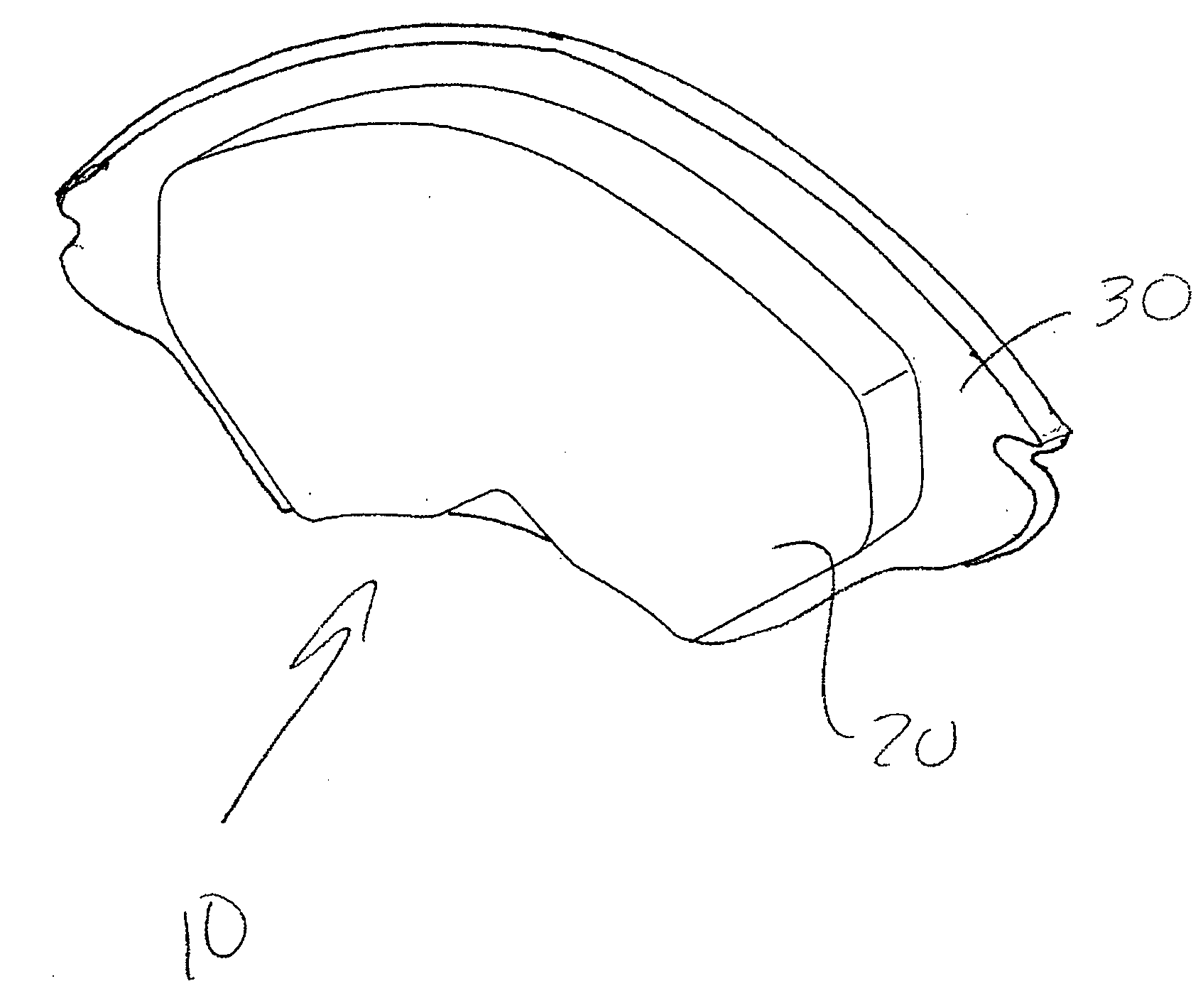

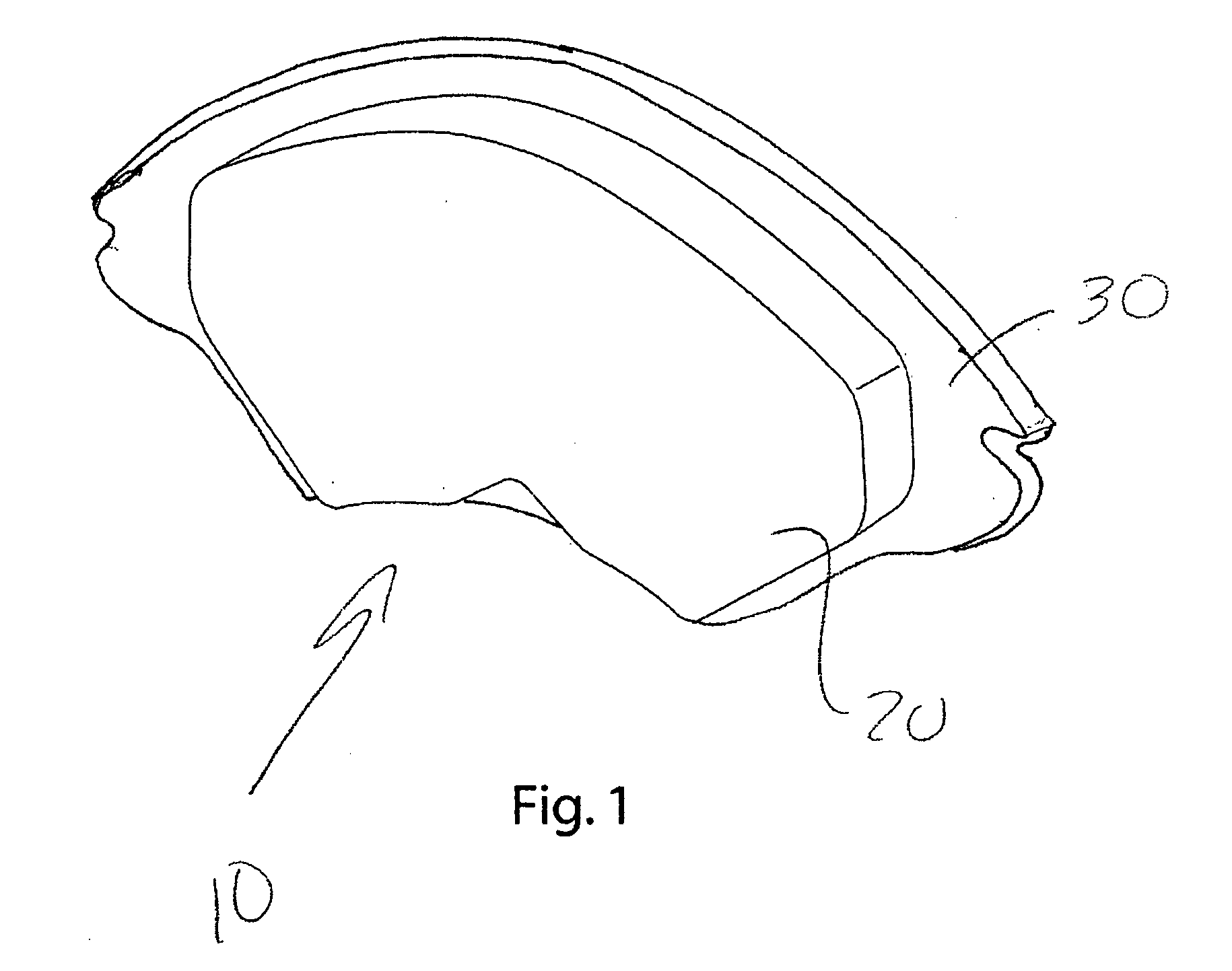

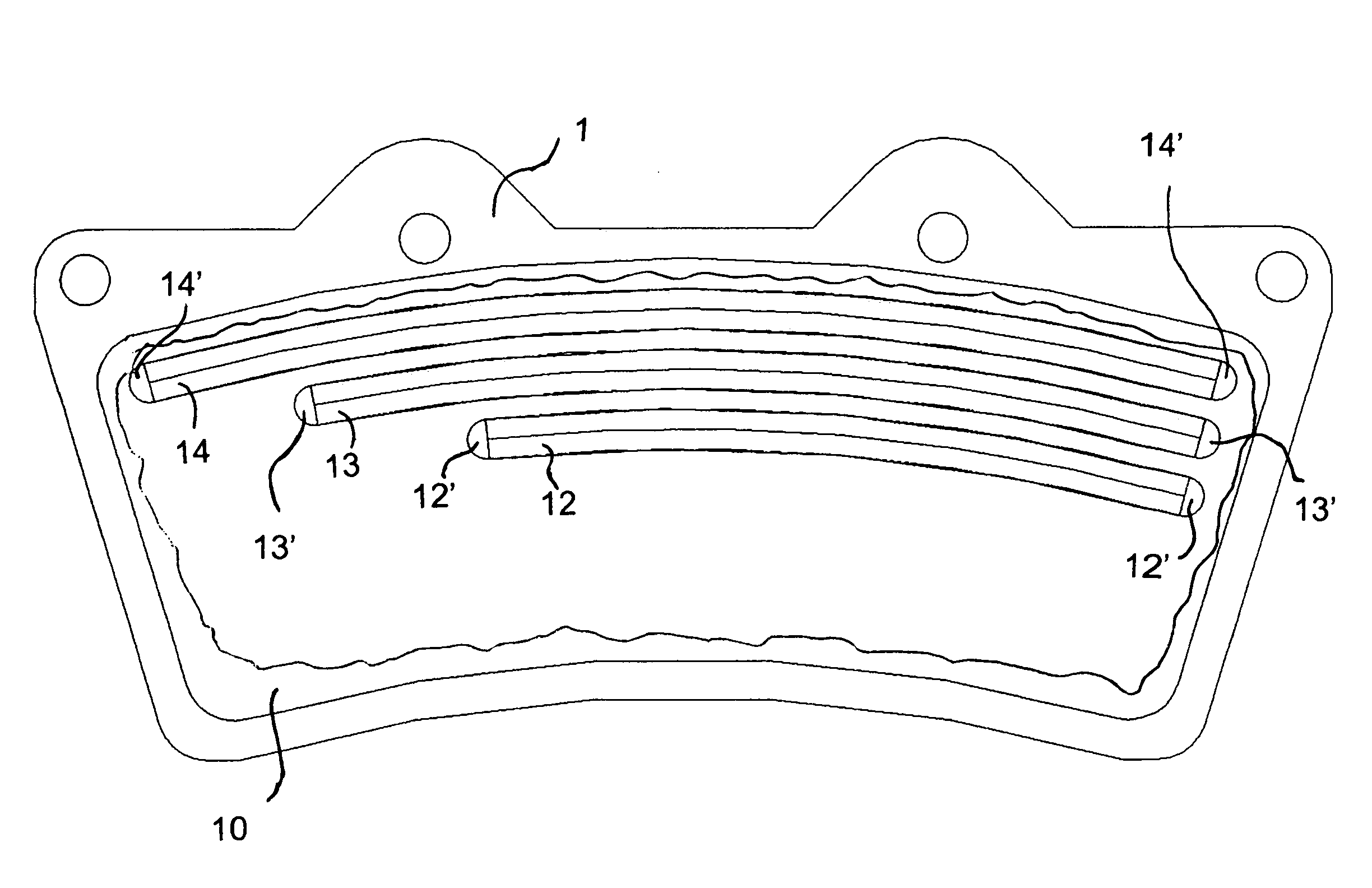

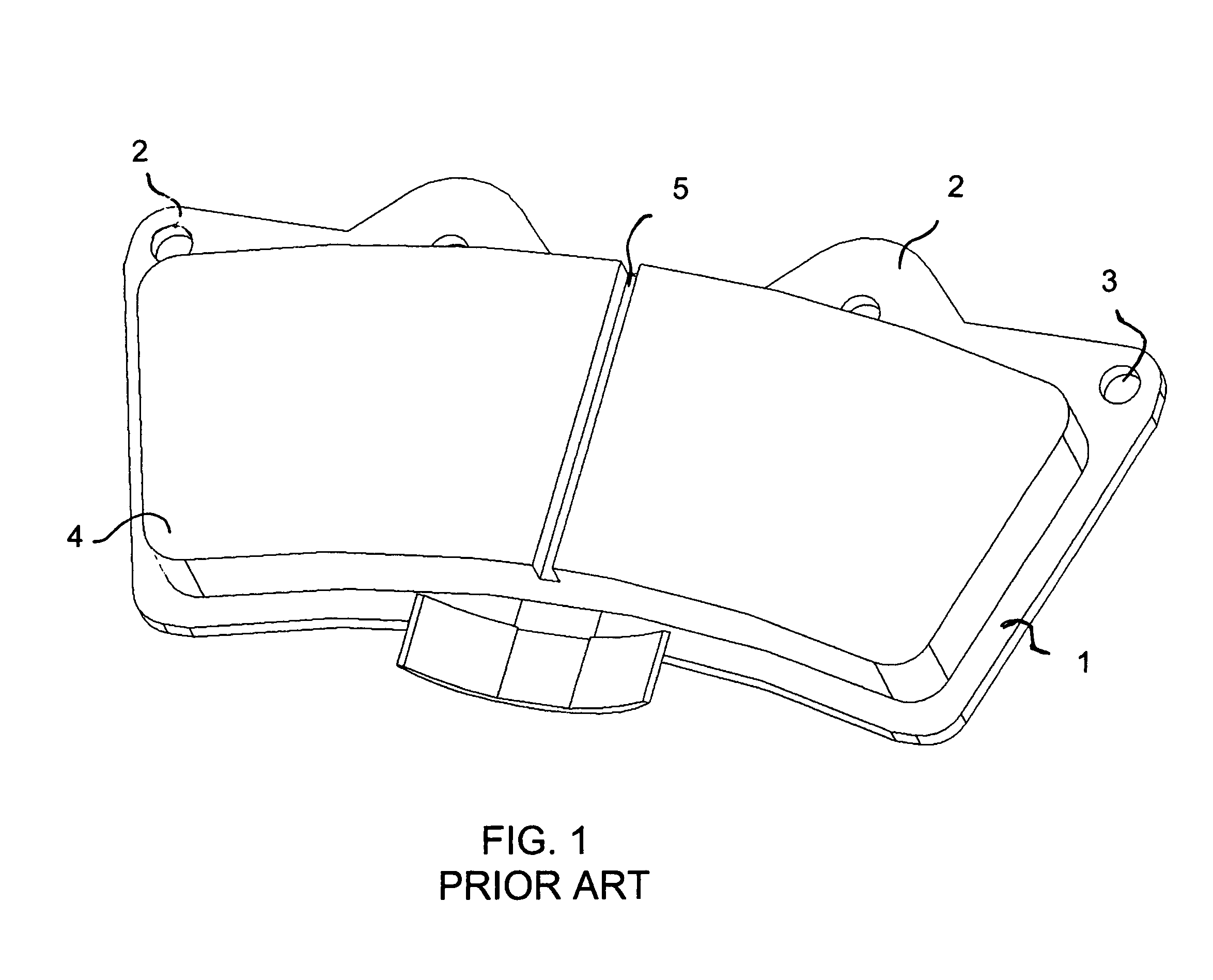

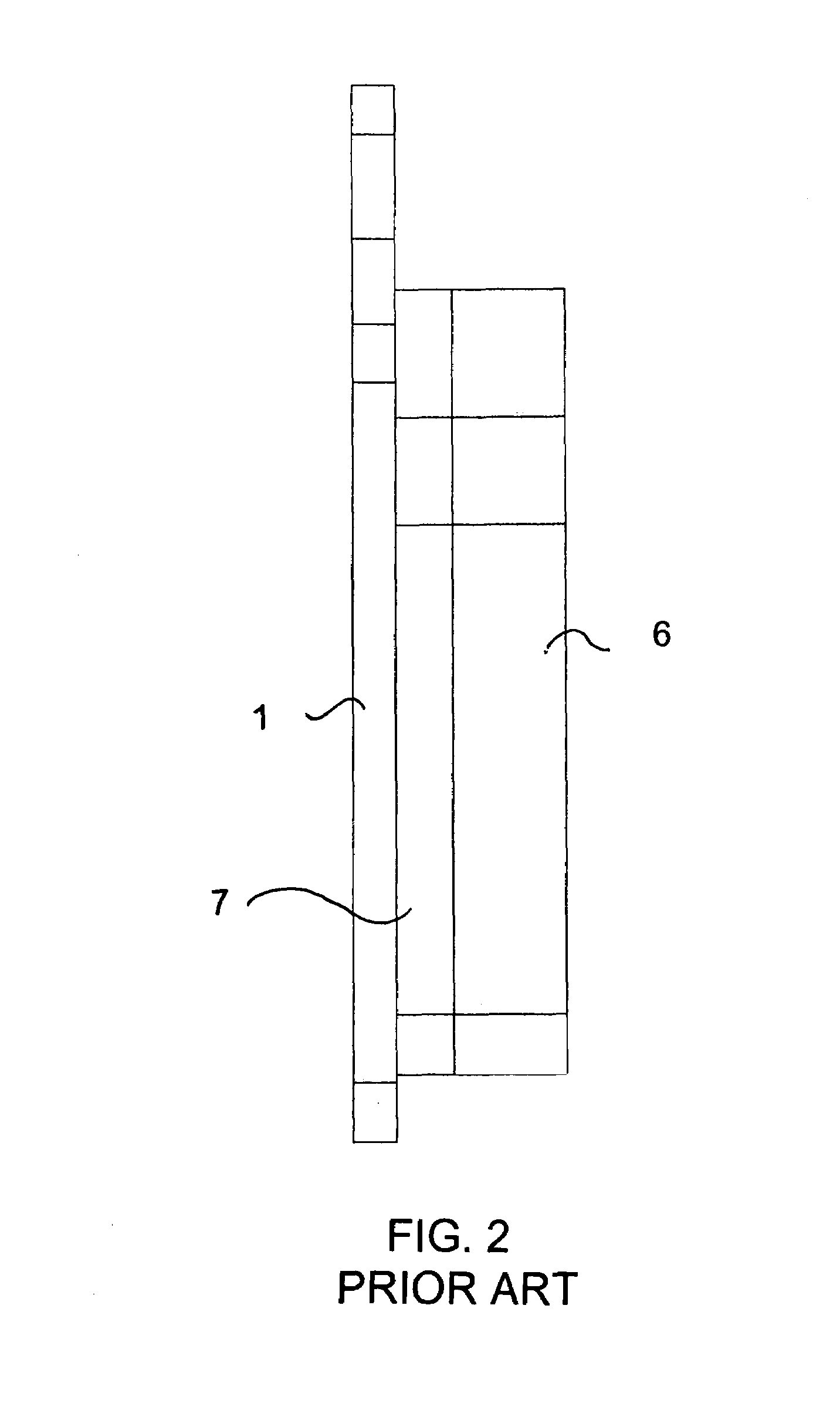

Multiple layer friction material brake pad

A brake pad has a backing plate and a friction pad. The friction pad is provided with a plurality of layers. Each layer is formed from a desired material such that at least two layers are formed from different materials. A first layer of said plurality of layers is adapted to contact a brake rotor. A second layer is covered by the first layer. At least one of said first and second layers has a tapered thickness from one edge of the friction pad to the other edge. As the first layer wears, the second layer gradually transitions into contact with the brake rotor.

Owner:AKEBONO CORP (NORTH AMERICA)

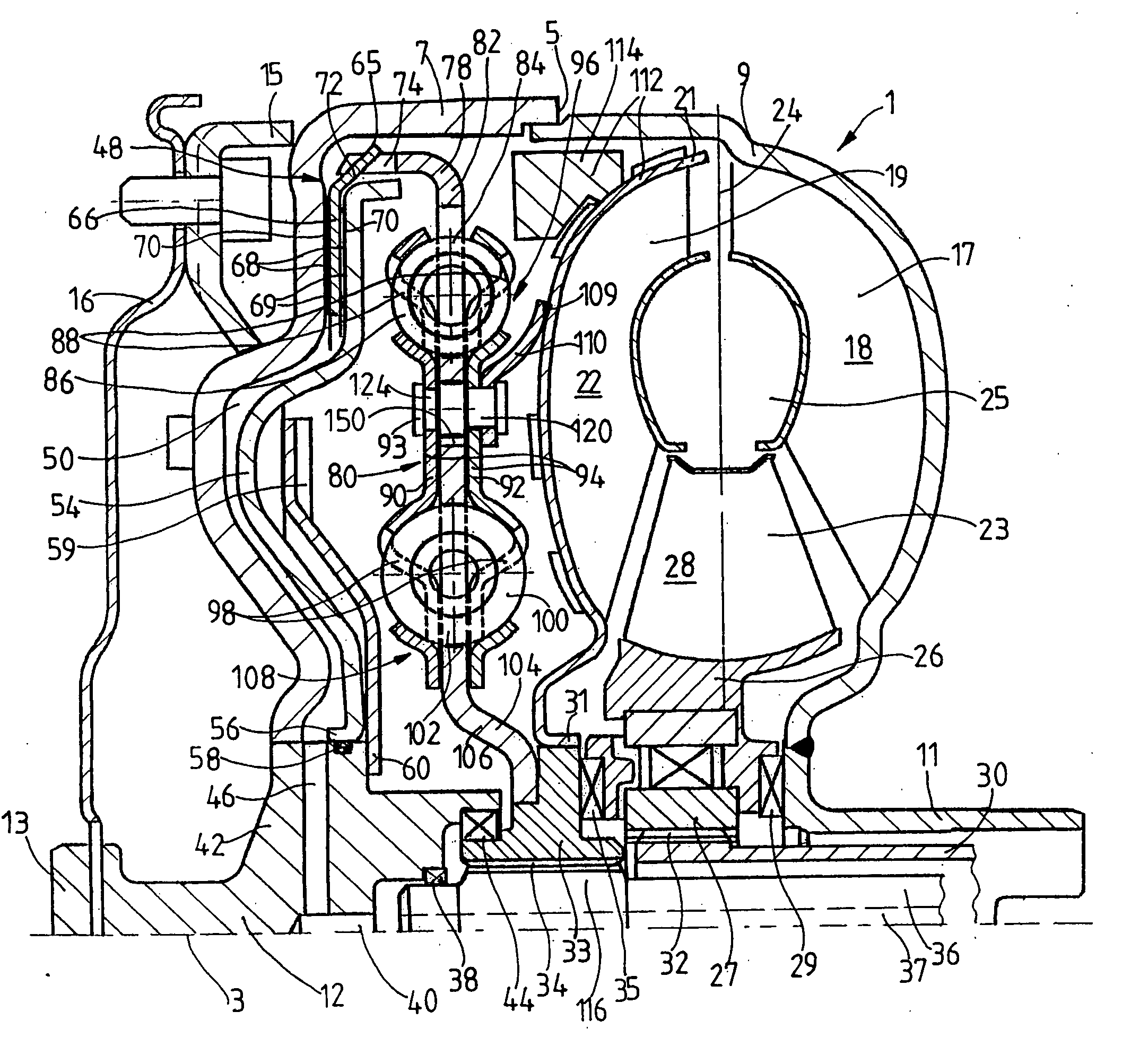

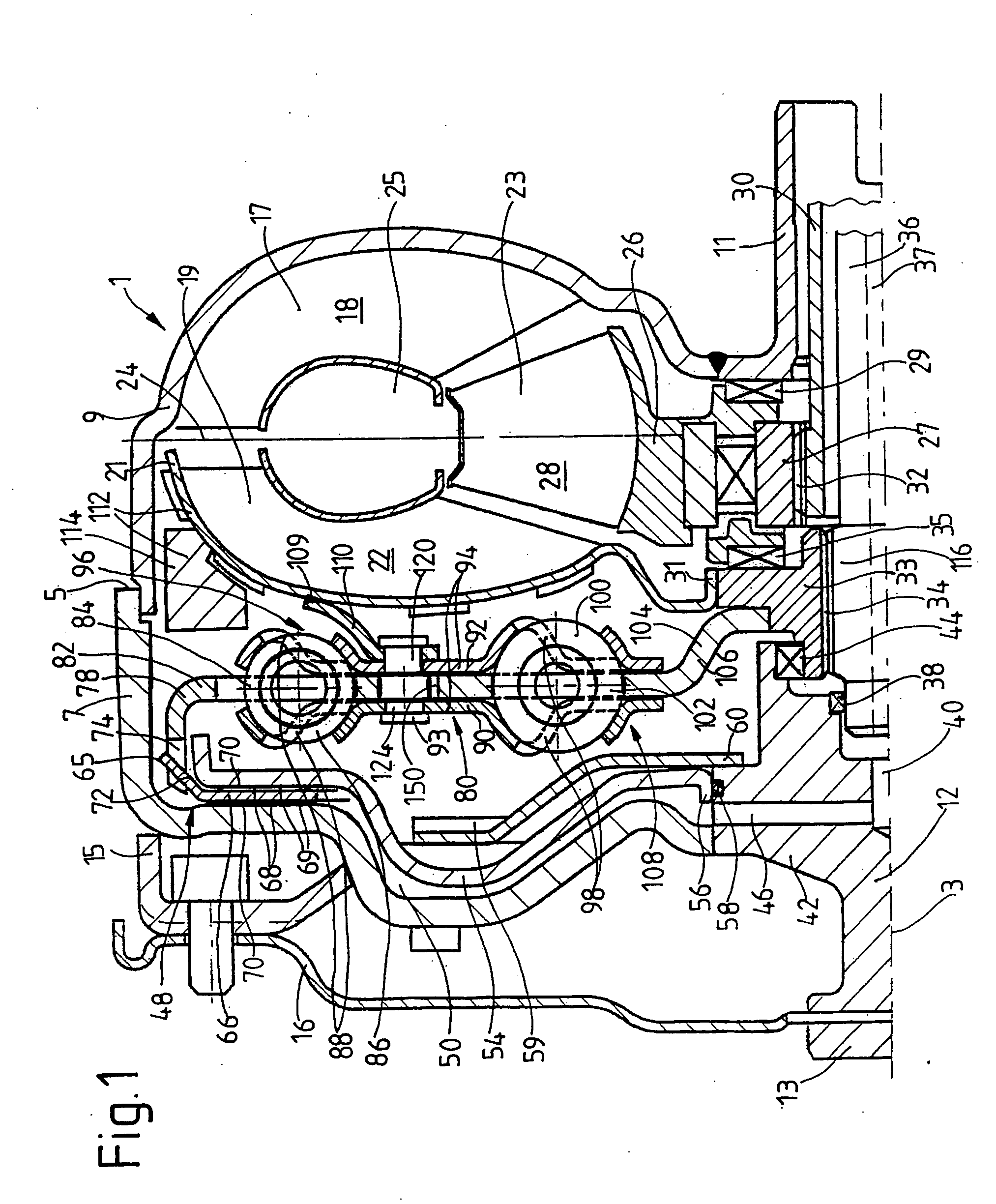

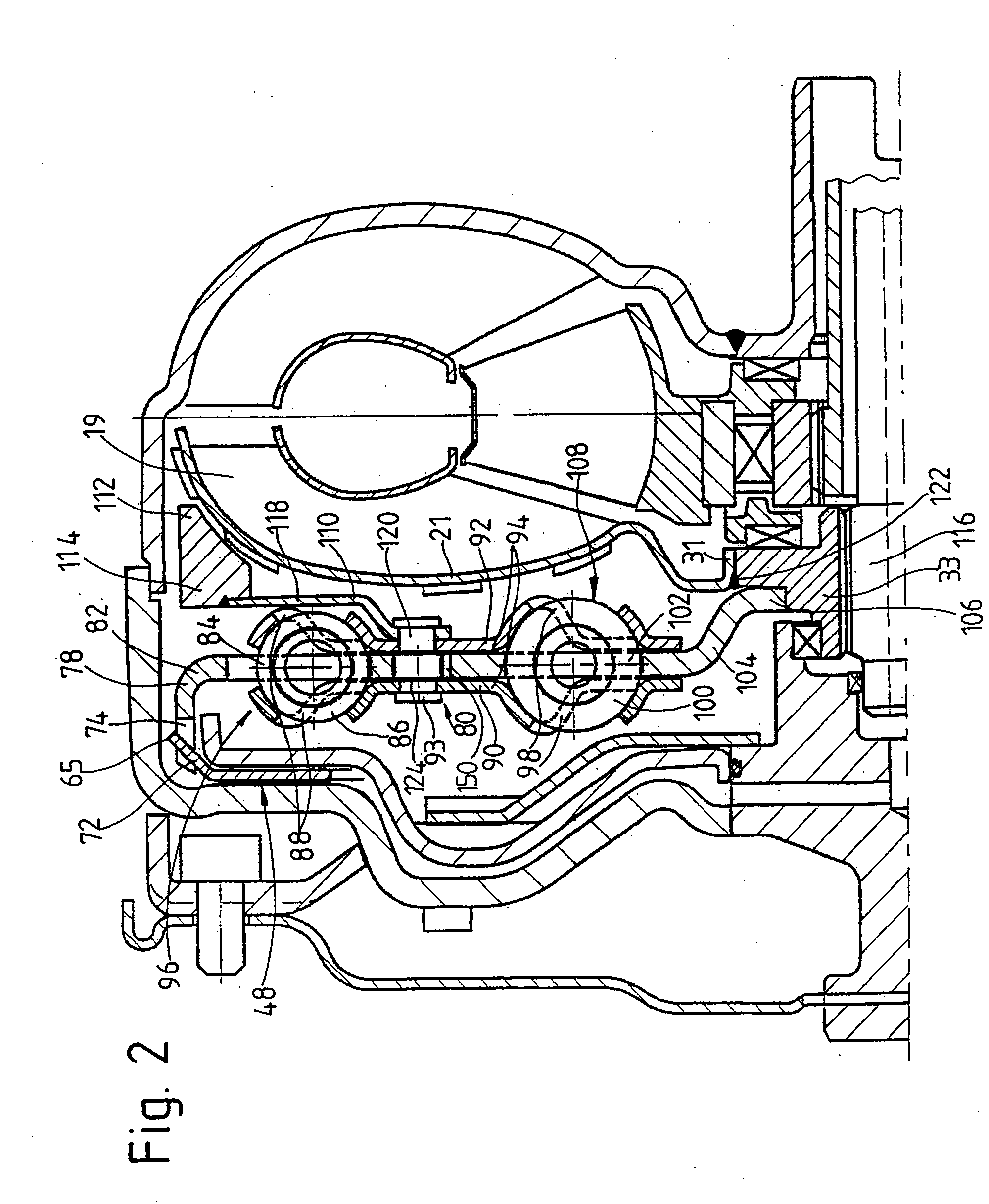

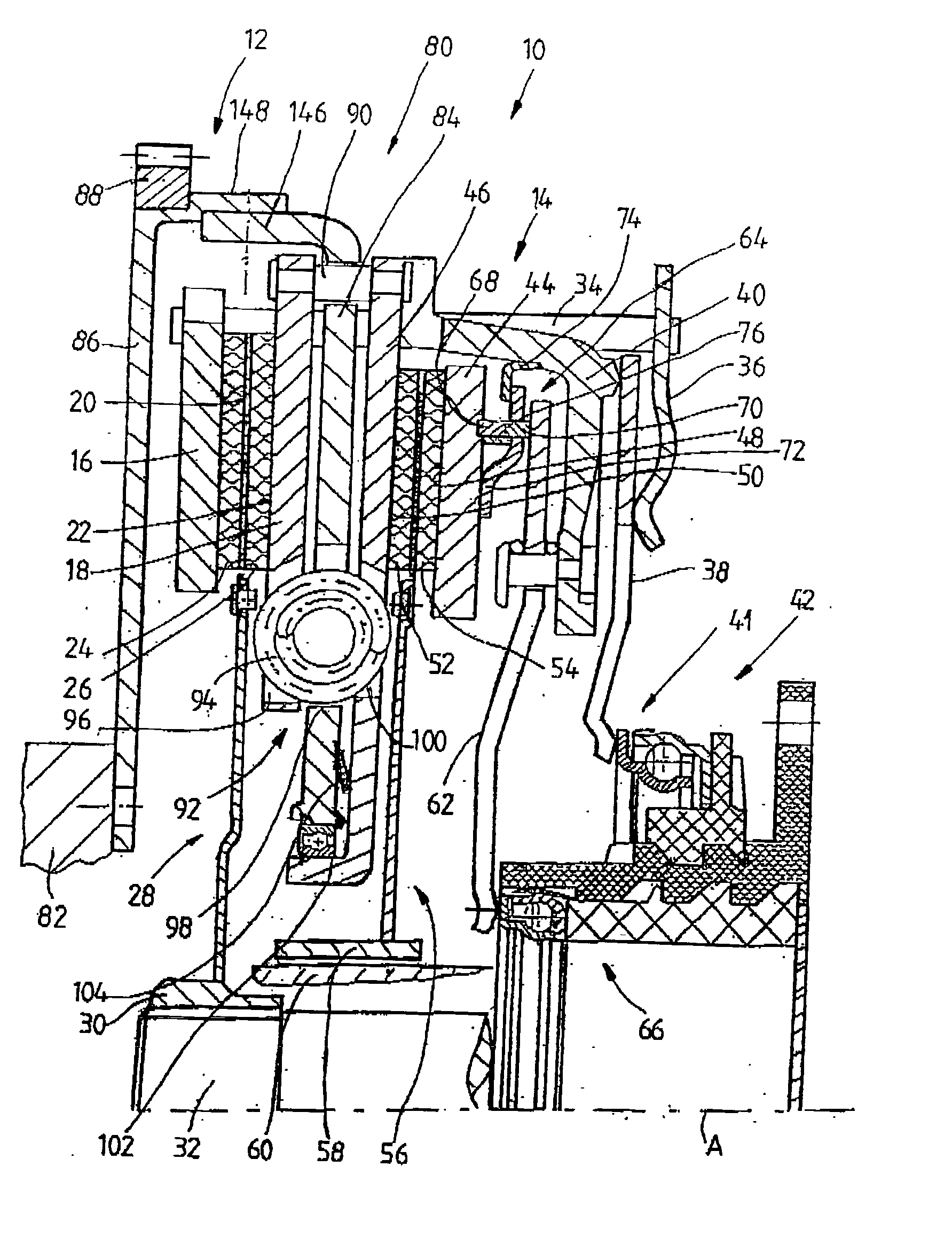

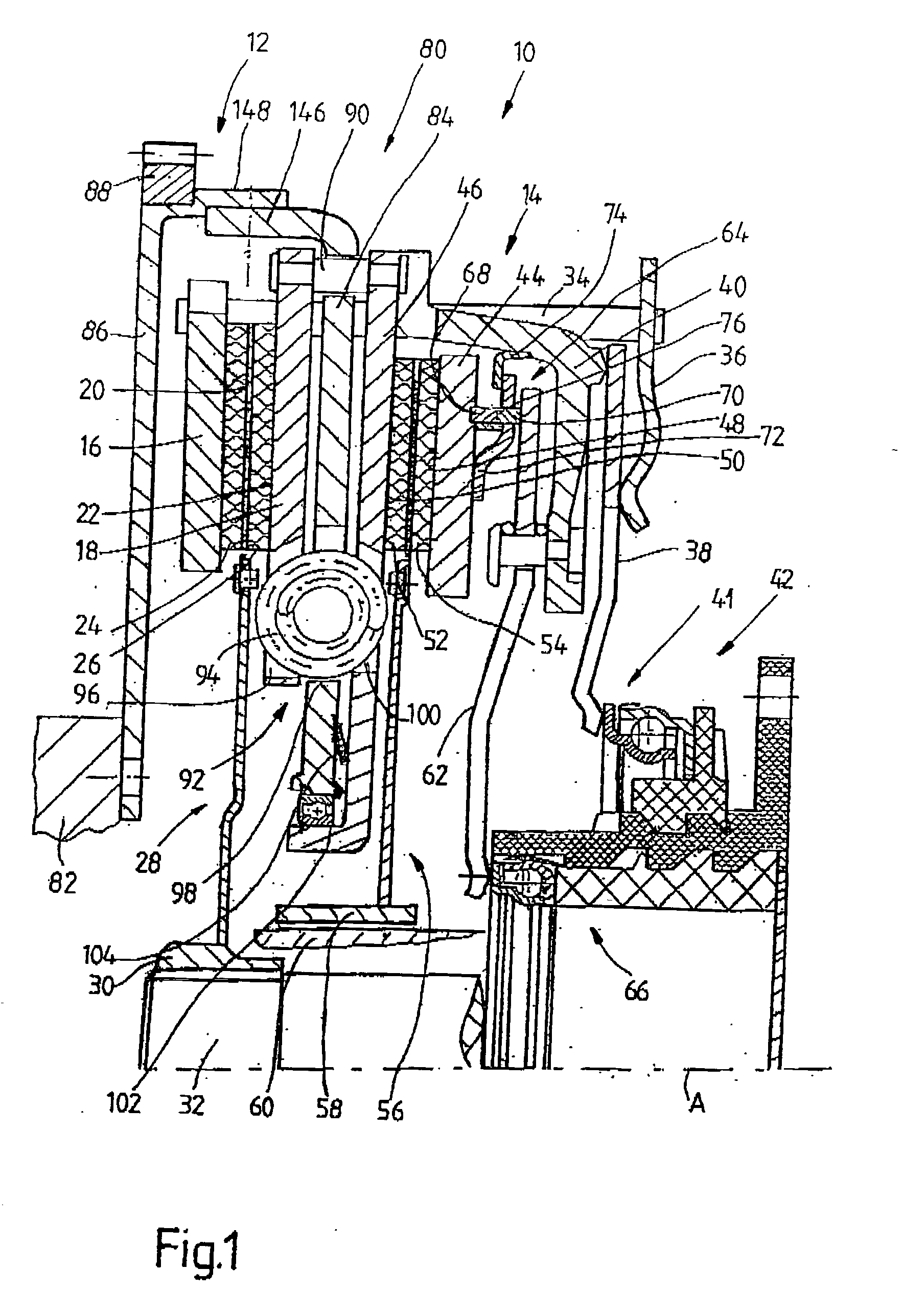

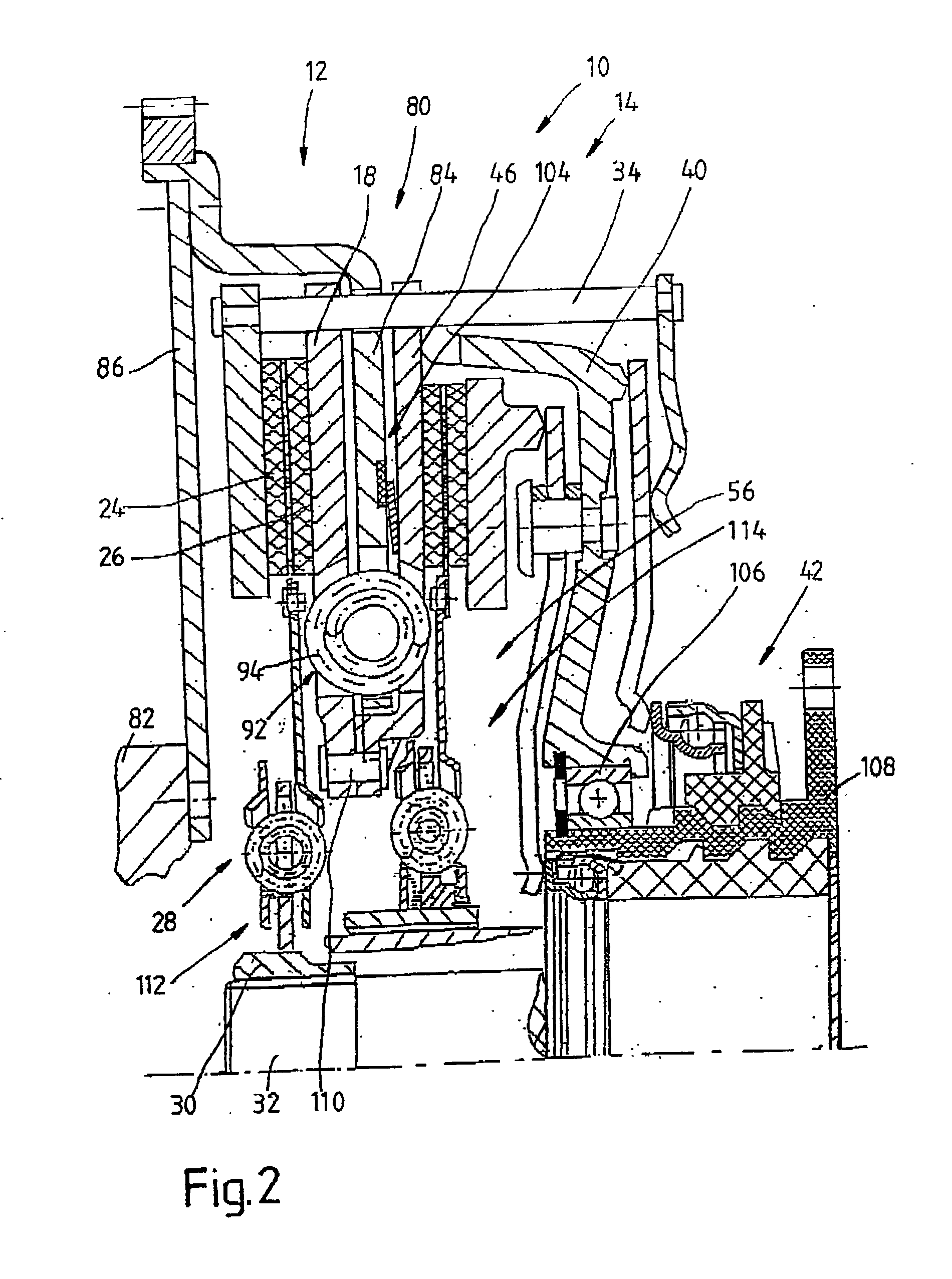

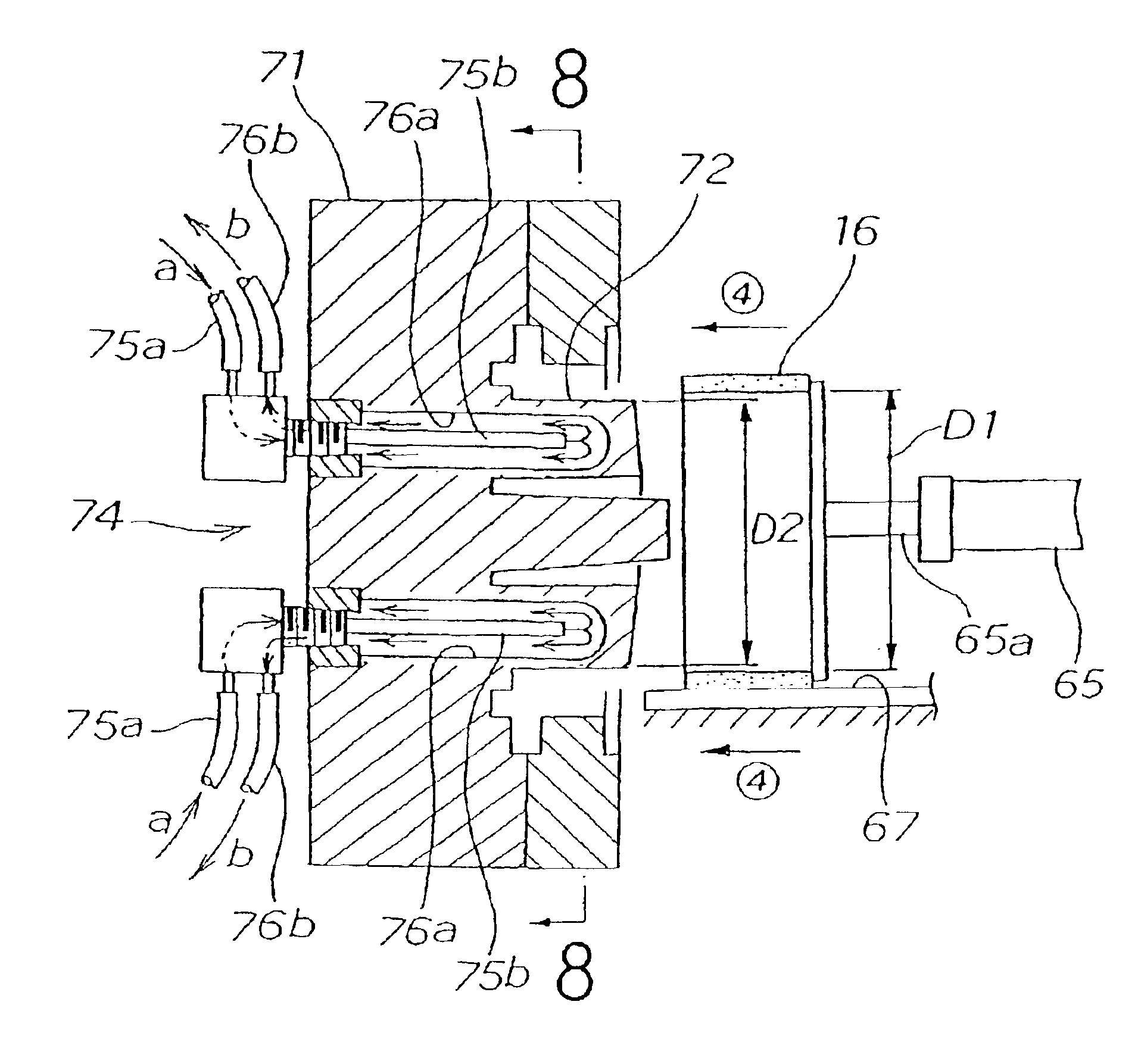

Torsional vibration damper

A torsional vibration damper on the bridging clutch of a hydrodynamic clutch arrangement has a first connecting device, which can be brought into working connection with the clutch housing and with a drive-side transmission element. The drive-side transmission element is connected via first energy-storage devices to an intermediate transmission element. The torsional vibration damper also has a second connecting device for establishing a working connection via second energy-storage devices between the intermediate transmission element and a takeoff-side transmission element, which is connected to a takeoff-side component of the hydrodynamic clutch arrangement. The intermediate transmission element accepts a mass element, located operatively between the two connecting devices.

Owner:ZF FRIEDRICHSHAFEN AG

Materials and methods for making ceramic matrix composites

Ceramic matrix composites and fiber reinforced ceramic matrix composite components of brake systems and other friction tolerant composite articles of this invention are made by providing a fiber preform, coating the fibers with an interface layer of carbon or ceramic, infiltrating the coated fiber preform with a composition comprising a liquid ceramic forming polymer including friction controlling additives, and pyrolyzing the polymer in the infiltrated preform to form a ceramic matrix around the fibers of the preform.

Owner:SHERWOOD WALTER J +1

Formula of ceramic radical friction material for automobile braking friction facing

InactiveCN101113204AImprove braking effectImprove yieldFriction liningFilling materialsMaterials processing

The invention discloses a prescription of a ceramic-based friction material used in a vehicle braking friction pad, comprising the components (by weight): adhesives 5 percent-15 percent, intensifier 23.5 percent-33.5 percent, grinding aid 0 percent-7 percent anti-wearing lubricant 11.3 percent-21.3 percent, elastic toughening agent 5.7 percent-15.7 percent and filling material 27.5 percent-37.5 percent. The total amount of the components is 100 percent. The materials of the invention can be processed and molded into the vehicle braking pad that is applicable to friction braking on a vehicle braking device. The anti-wearing performance of the pad can be greatly enhanced, thereby reducing noise pollution and promoting the performance of the braking system of the vehicle.

Owner:SHAANXI LIZHIQUAN IND TRADE

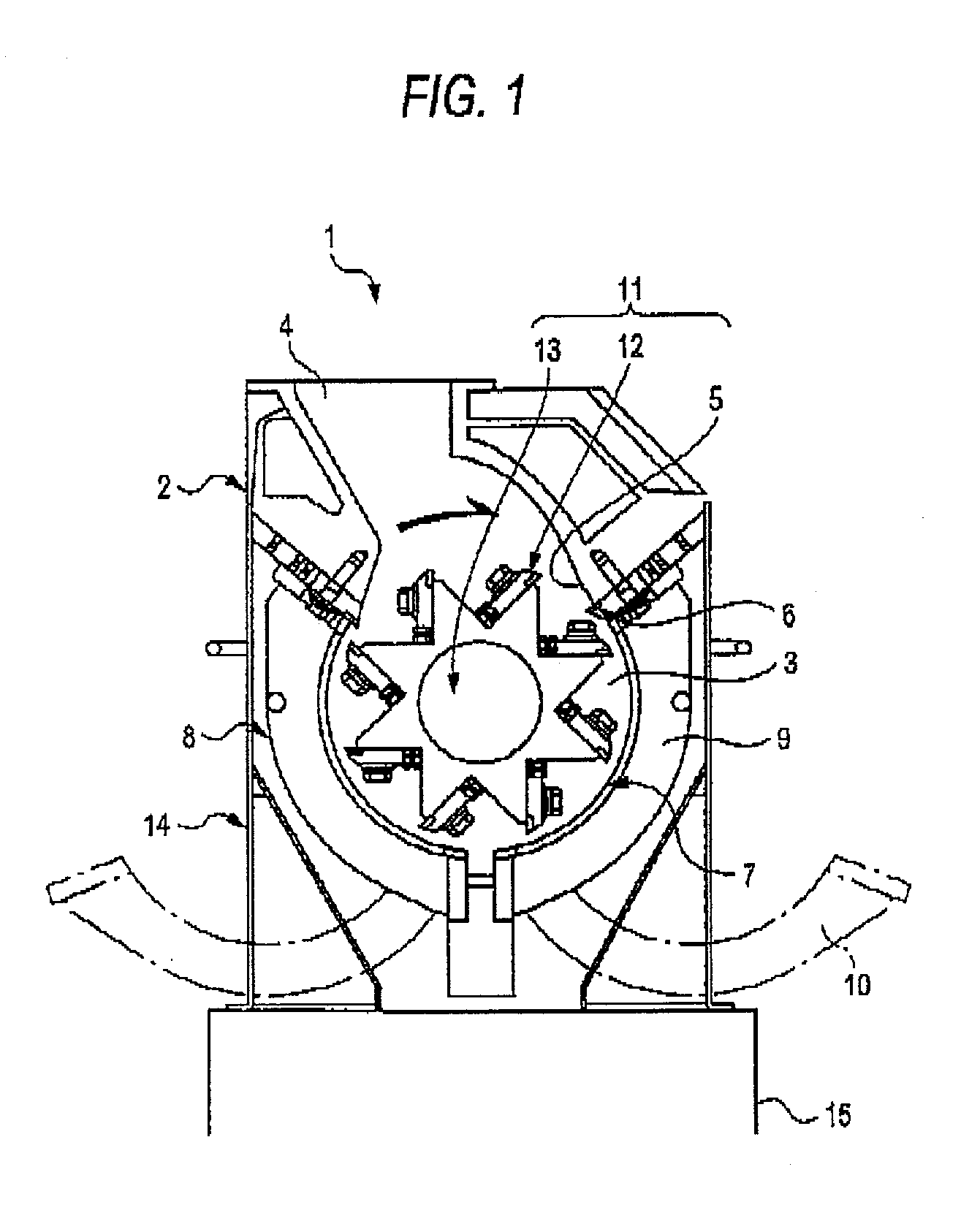

Multi-clutch arrangement

InactiveUS20030079953A1Large amount of space is occupiedIncrease in driving comfortYielding couplingFriction clutchesMobile vehicleEngineering

A multi-clutch arrangement, especially a dual clutch for motor vehicles, comprising a first clutch area with a first pressure plate arrangement, with a first opposing support arrangement, and with a first clutch disk arrangement , which can be clamped between the first pressure plate arrangement and the first opposing support arrangement to transmit torque via the first clutch area; and a second clutch area with a second pressure plate arrangement, with a second opposing support arrangement, and with a second clutch disk arrangement, which can be clamped between the second pressure plate arrangement and the second opposing support arrangement to transmit torque via the second clutch area. A torsional vibration damper arrangement is assigned to at least one of the clutch areas, and where-relative to an axis of rotation (A)-the torsional vibration damper arrangement is arranged at least partially in the axial area of the first clutch area and / or of the second clutch area.

Owner:ZF SACHS AG

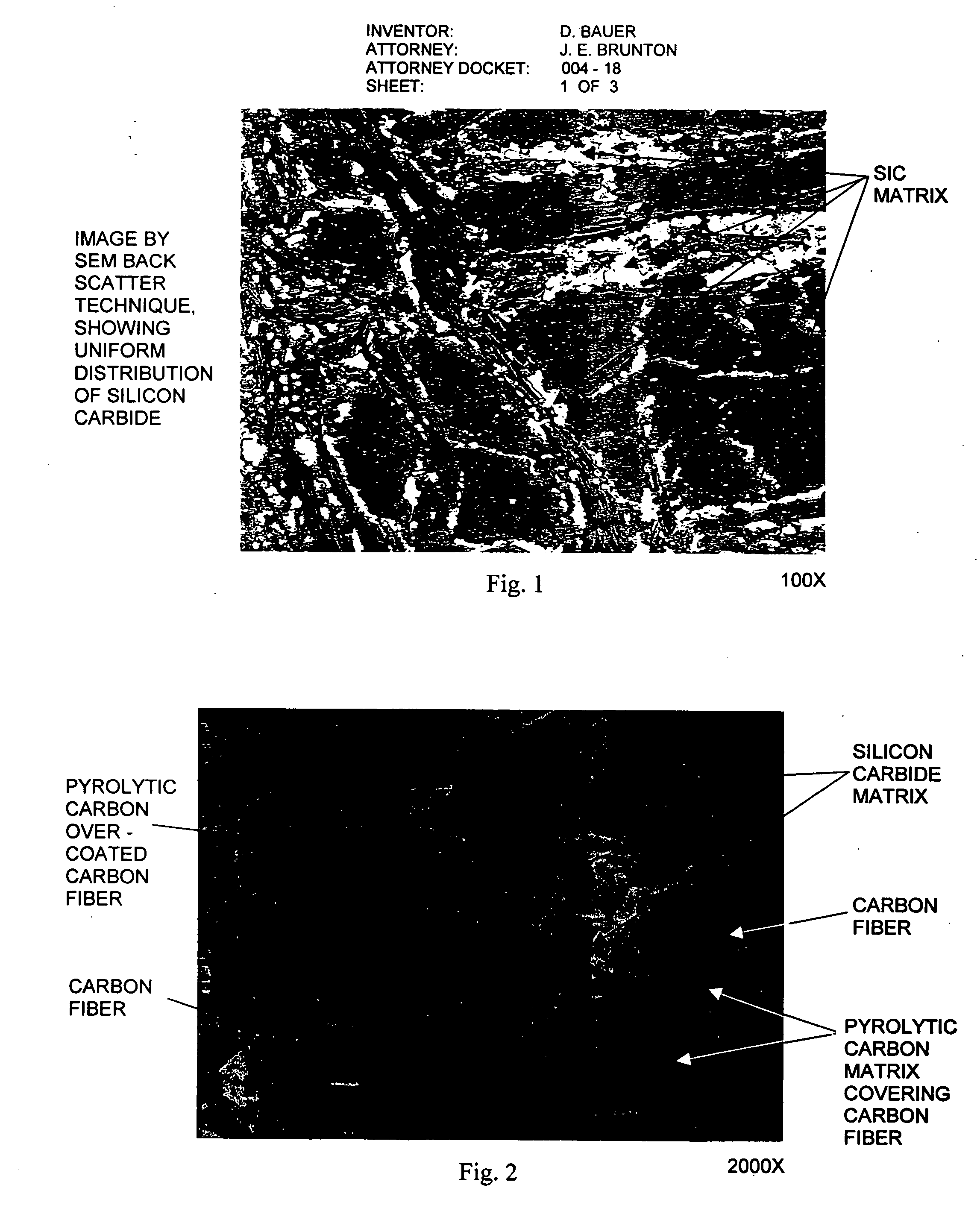

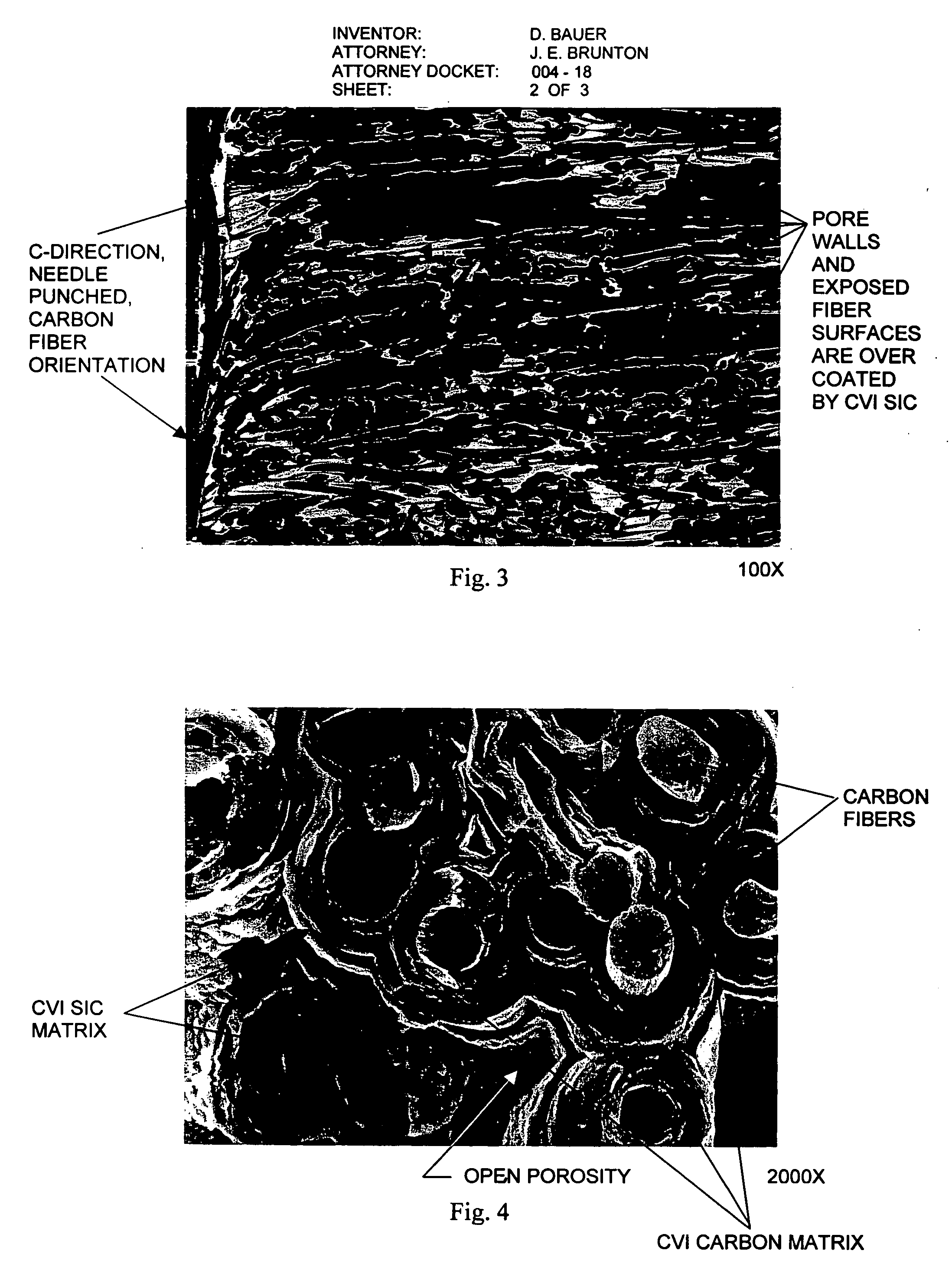

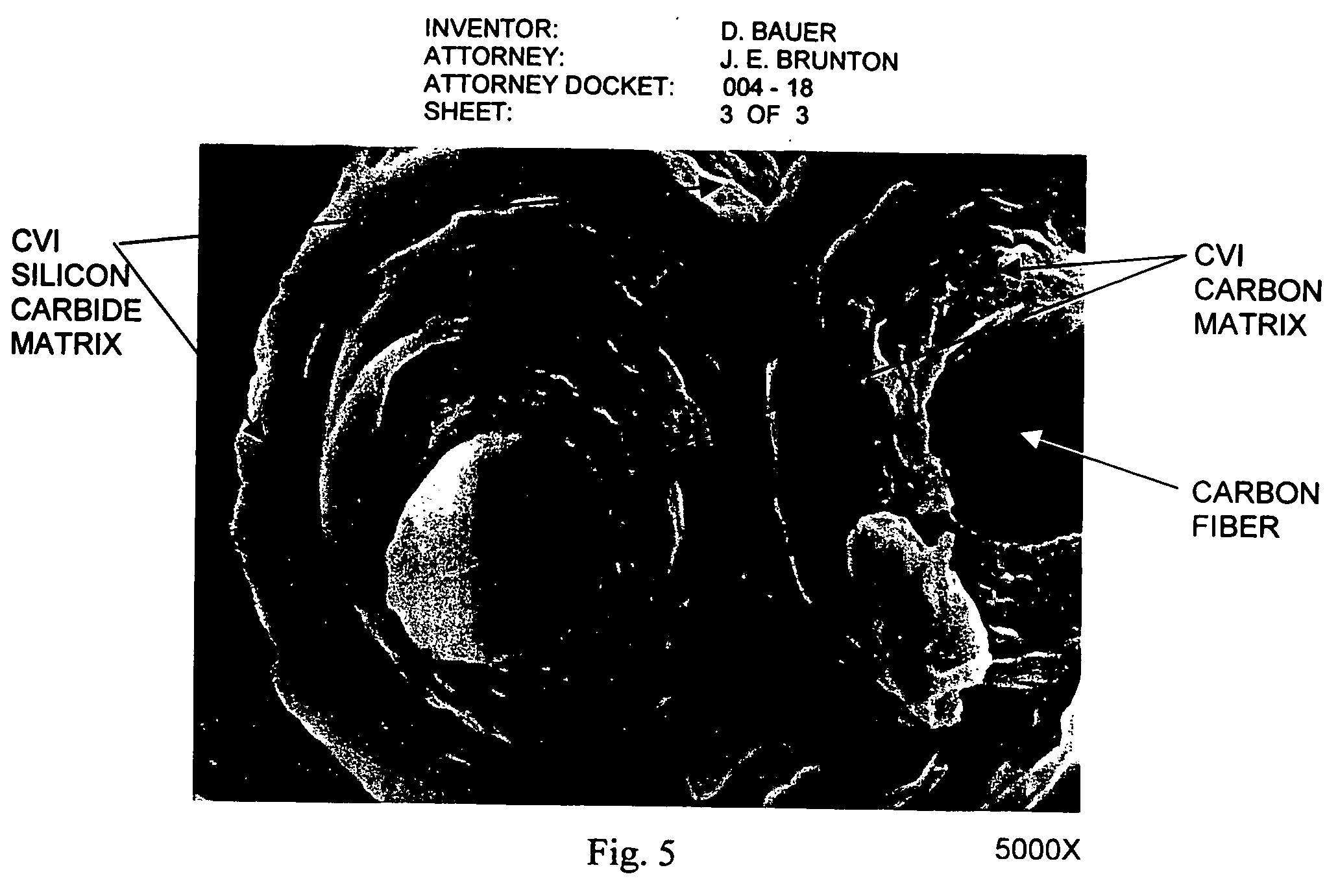

Carbon/ceramic matrix composites and method of making same

InactiveUS20060151912A1Improve performanceOptimization of coefficientWood working apparatusCeramic shaping apparatusCarbon compositesHeat treated

Owner:BAUER DIETER

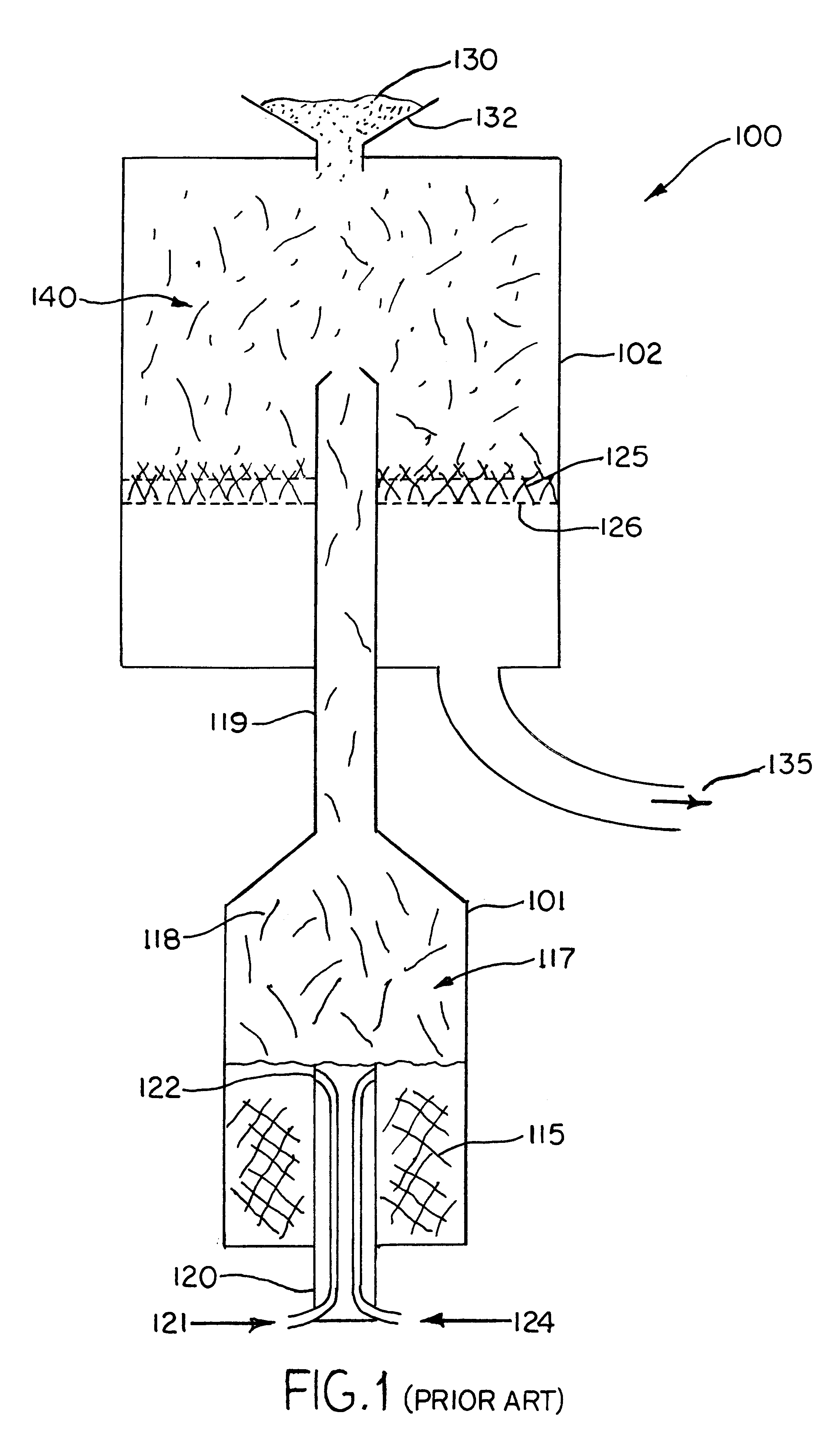

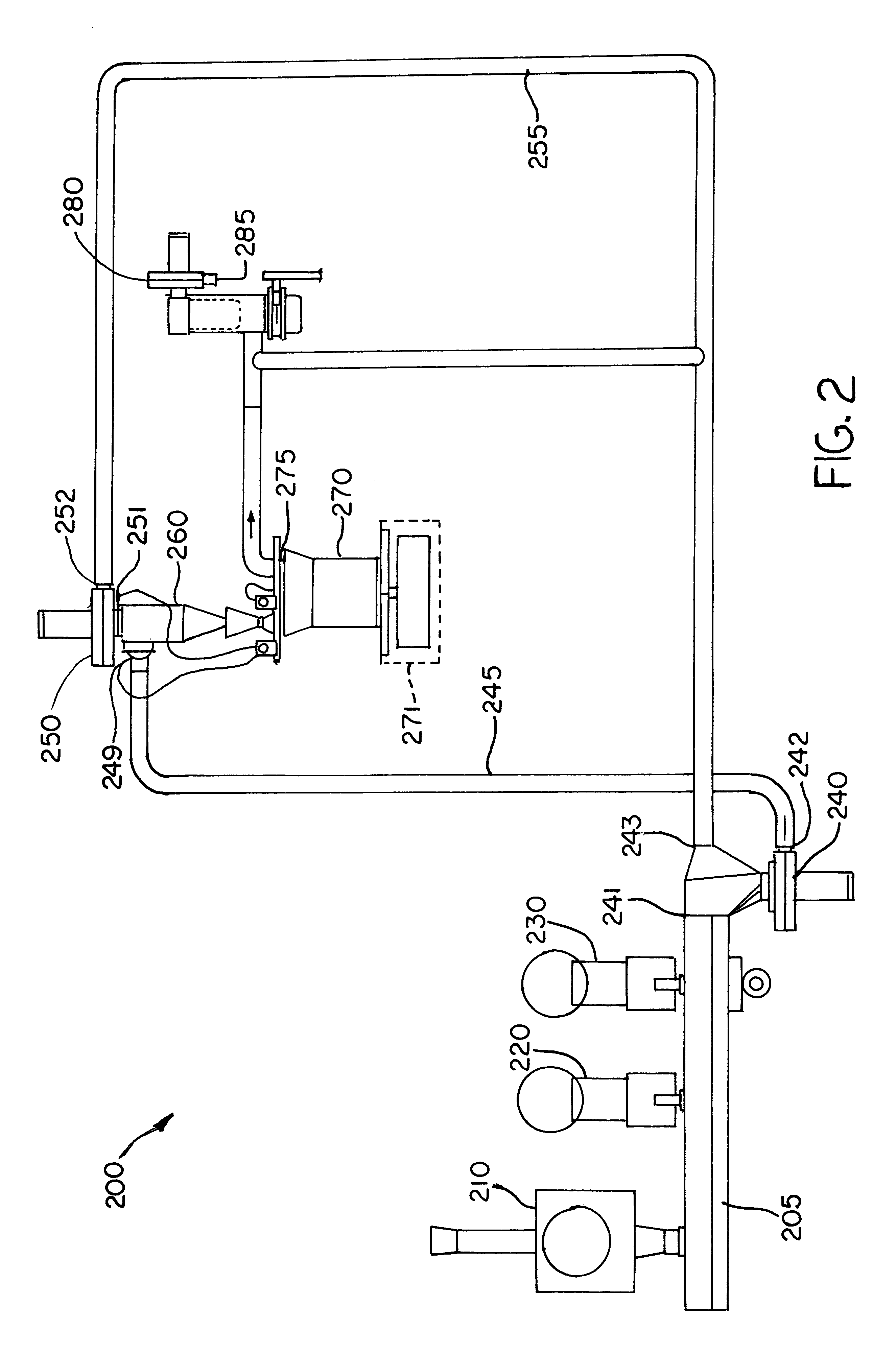

Method for forming fiber reinforced composite parts

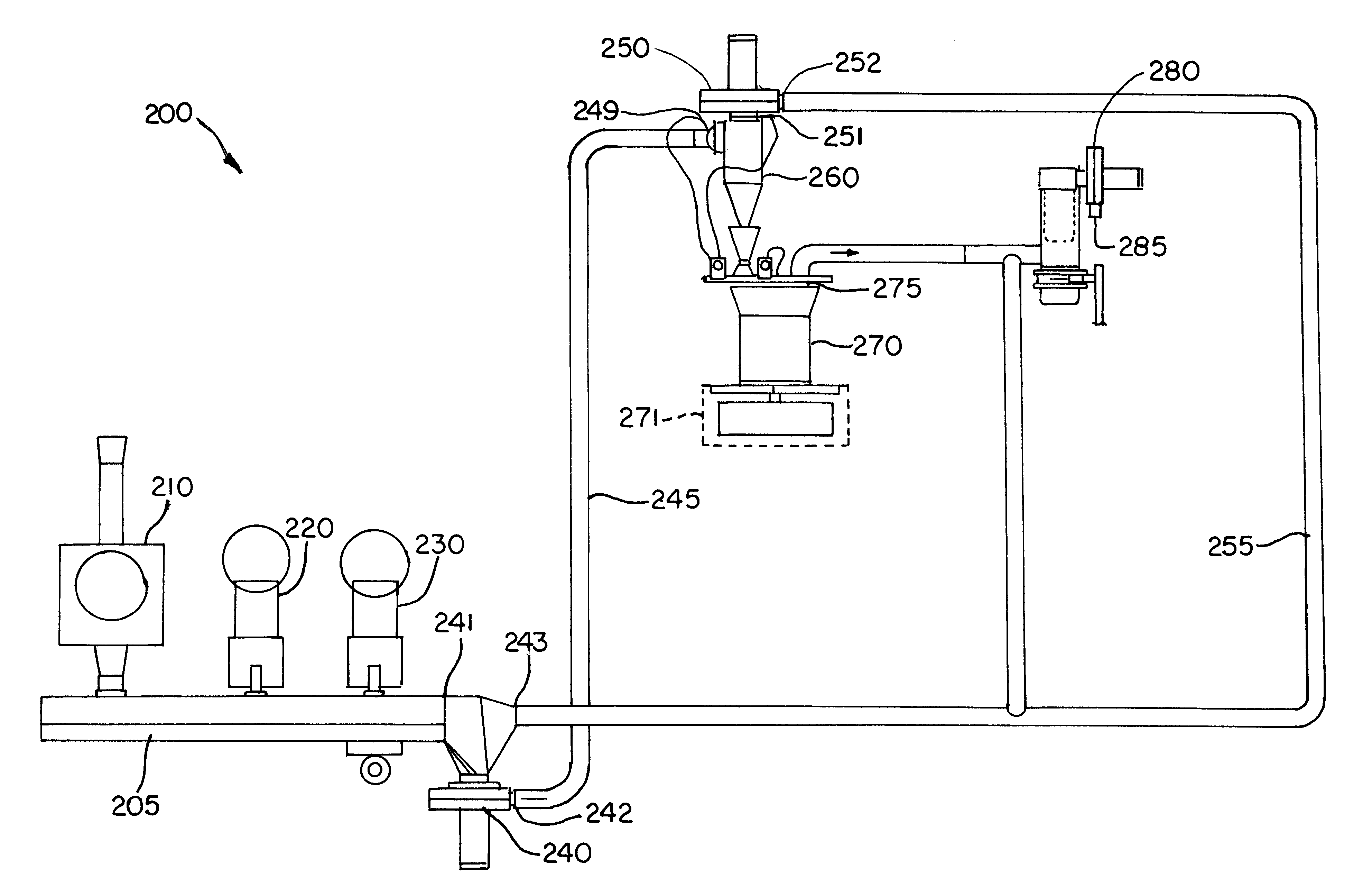

A method and apparatus for combining raw fibrous and binding materials in a single mixing step (Step S3), followed by consolidation (Step S5) so as to greatly shorten the overall cycle time to a finished fiber-reinforced composite part. Chopped fibrous materials and binder materials are deposited sequentially onto a belt conveyor (Step S2) so that the materials are successively layered, one on top of each other in a predetermined ratio, and subsequently mixed (Step S3) to achieve uniform dispersion throughout. The mixed materials are then deposited into a rotating mold (Step S4) to further ensure uniform dispersion of fibrous and binder materials. Impregnation of the fibrous materials with the binder material occur in-situ as the uniformly mixed materials are heated and subsequently compacted in the mold (Step S5) to obtain the desired shape of the fiber-reinforced composite part.

Owner:HONEYWELL INT INC

Brake drum and method for producing the same

Owner:HONDA MOTOR CO LTD

Friction material

InactiveUS20050004258A1Good brake feelingImprove effectivenessBraking element arrangementsOther chemical processesMohs scale of mineral hardnessHardness

A friction material is made by molding and curing a composition containing a fibrous base that includes stainless steel fibers but not other steel fibers, a binder, and a friction modifier that includes at least two types of hard particles having a large Mohs hardness, bronze powder and a specific amount of tin sulfide. The friction material has a excellent balance of properties, including a high strain linearity that provides a excellent brake feel, a high torque linearity and a excellent effectiveness, and also minimizes disc rotor attack, disc pad wear and metal pickup. Such friction materials are particularly suitable for automotive applications, such as disc pads.

Owner:NISSHINBO INDDUSTRIES

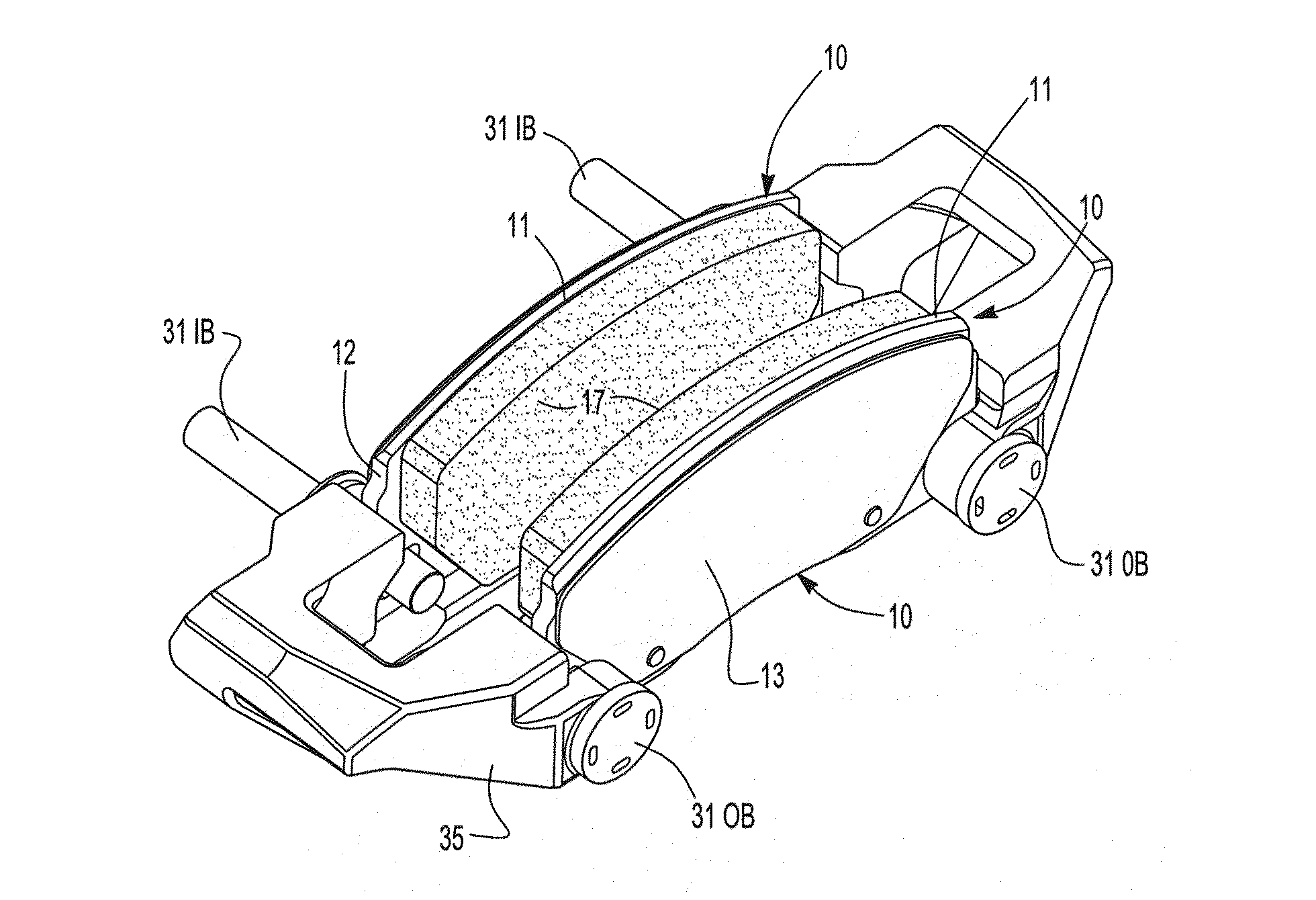

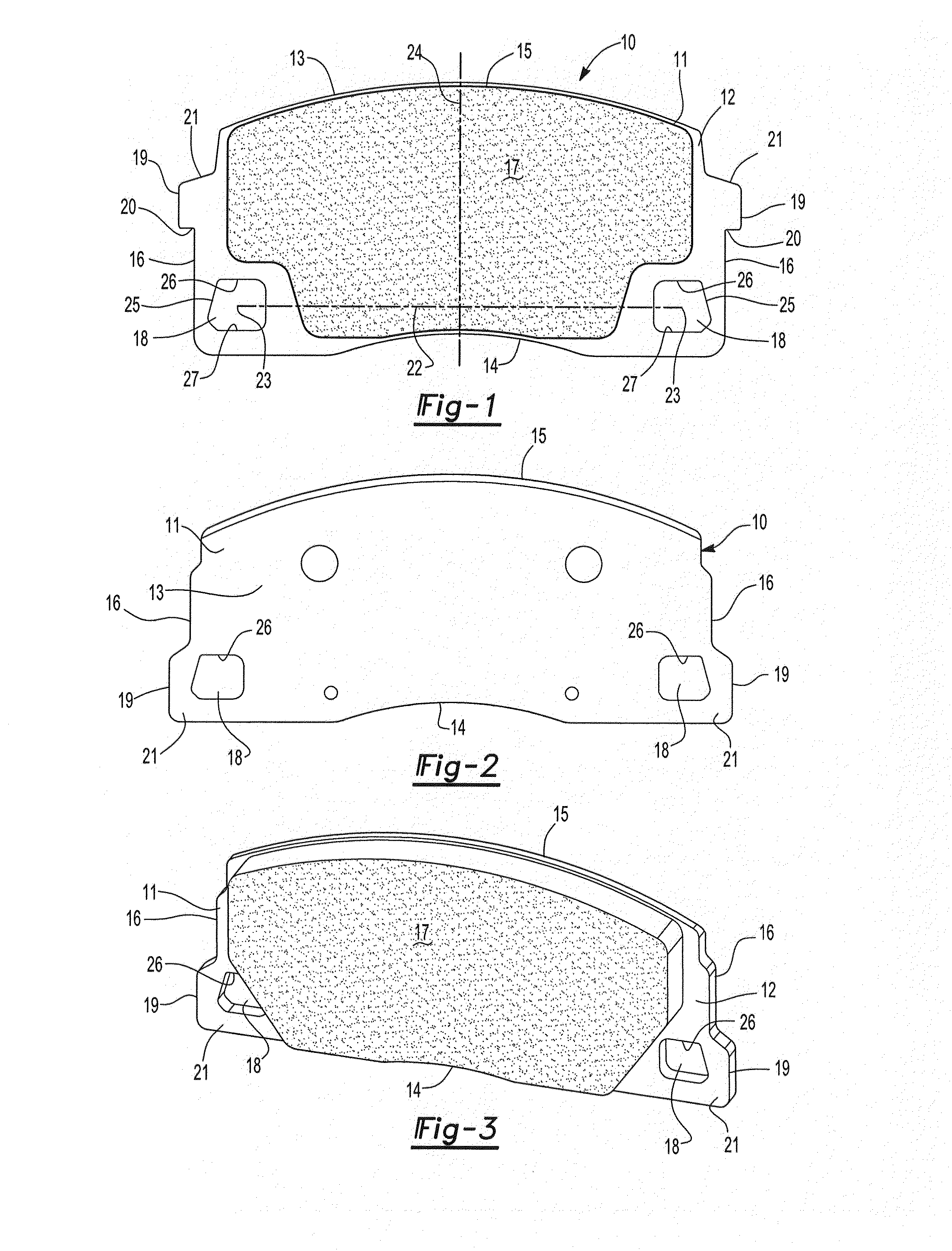

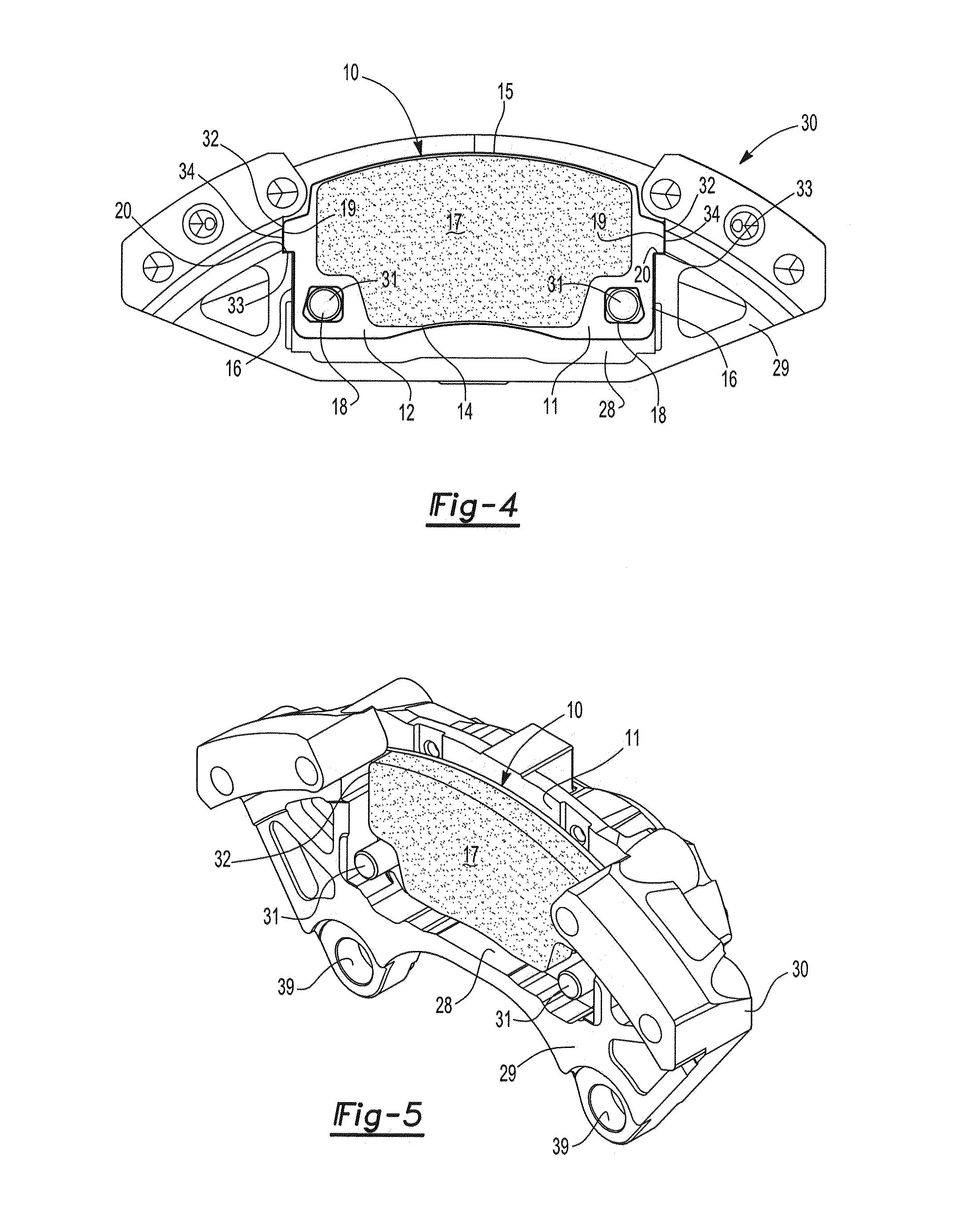

Brake systems, caliper assemblies and pads incorporating differential abutments

InactiveUS20120043168A1Transmission of forceImprove NVH performanceMechanically actuated brakesBraking membersPush pullEngineering

The present invention is directed to a unique solution for caliper assemblies, brake pads utilized in such caliper assemblies, support structures utilized in caliper assemblies and disc brake systems containing such caliper assemblies which utilize push pull or pull push abutment designs.

Owner:AKEBONO CORP (NORTH AMERICA)

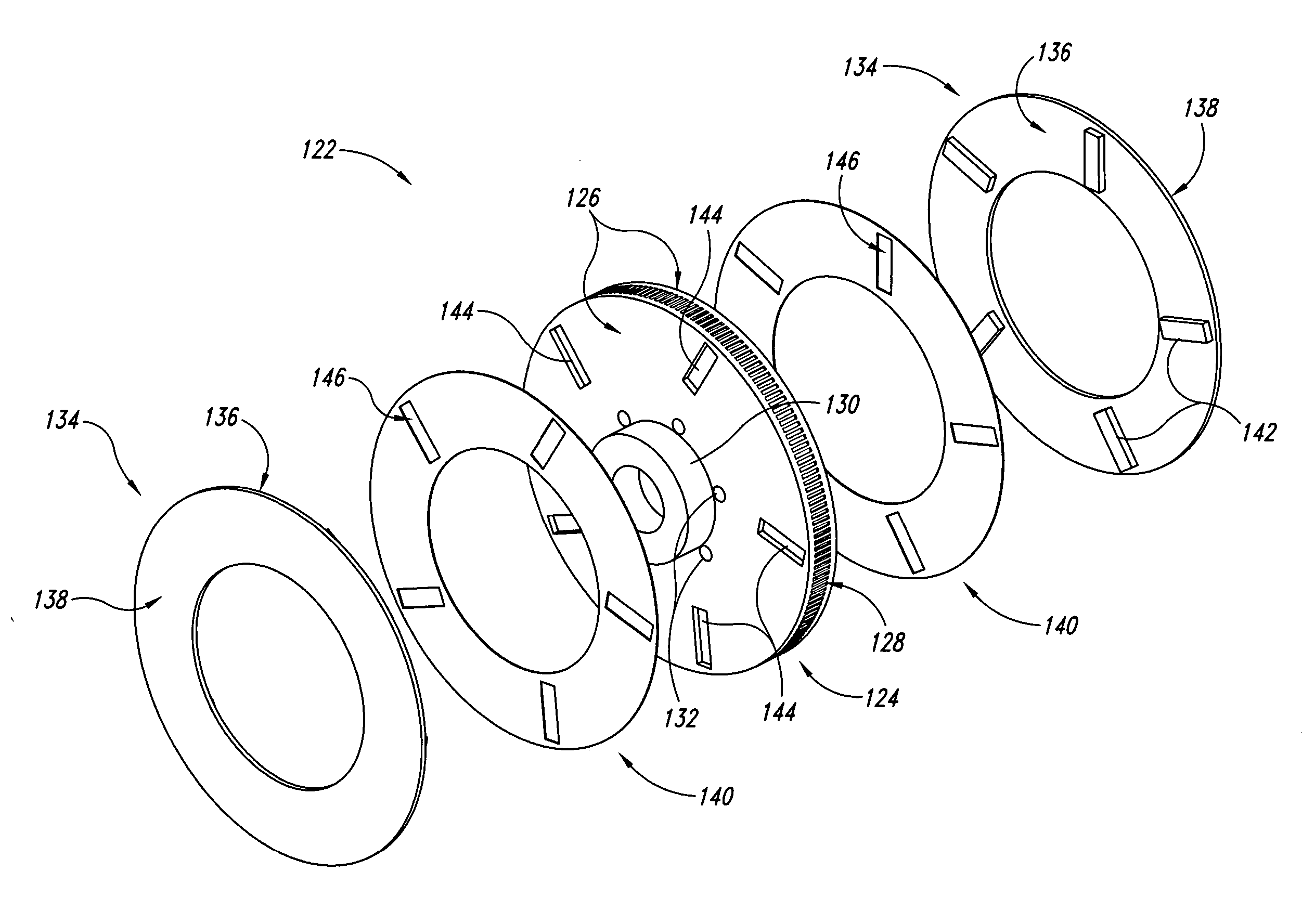

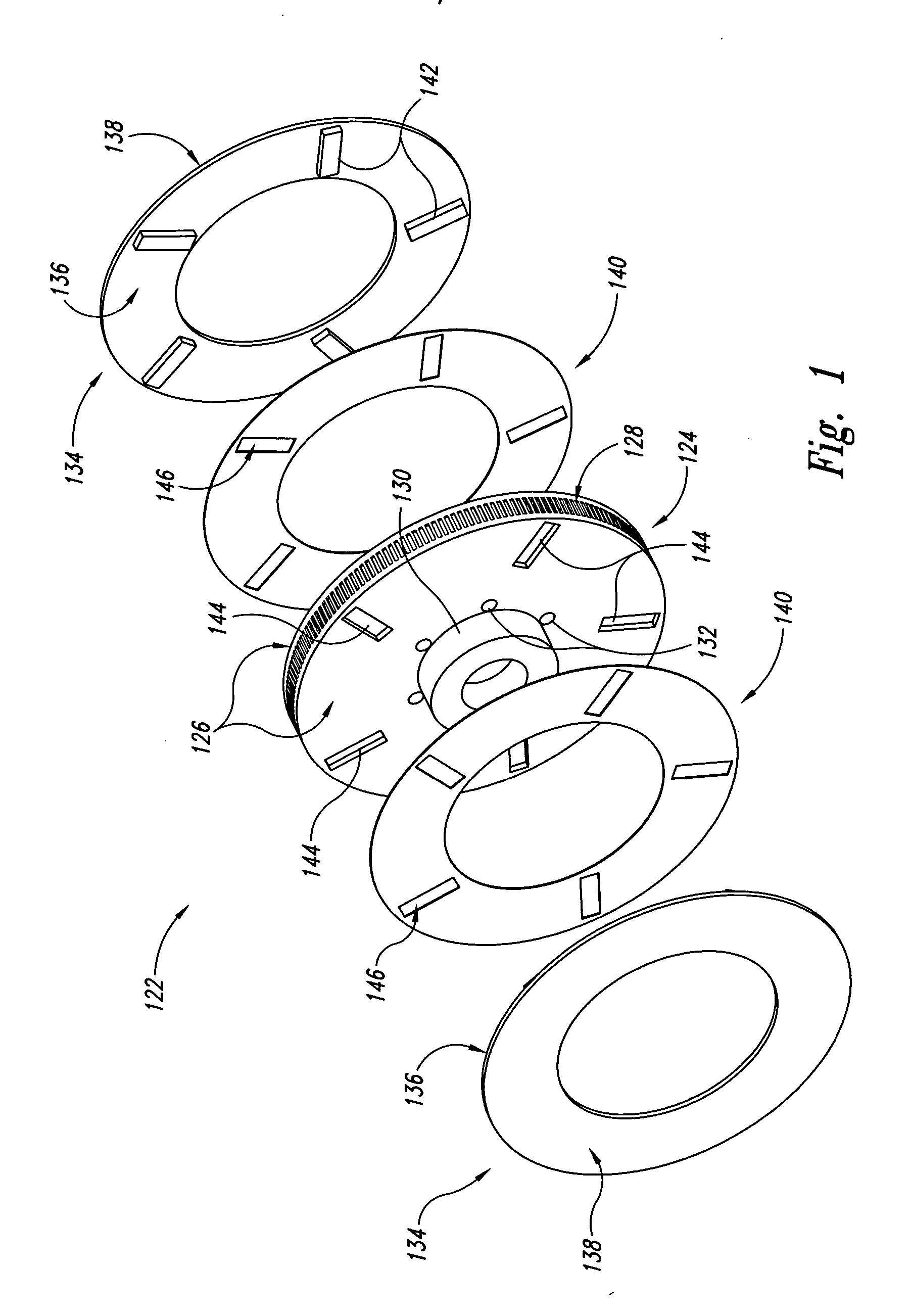

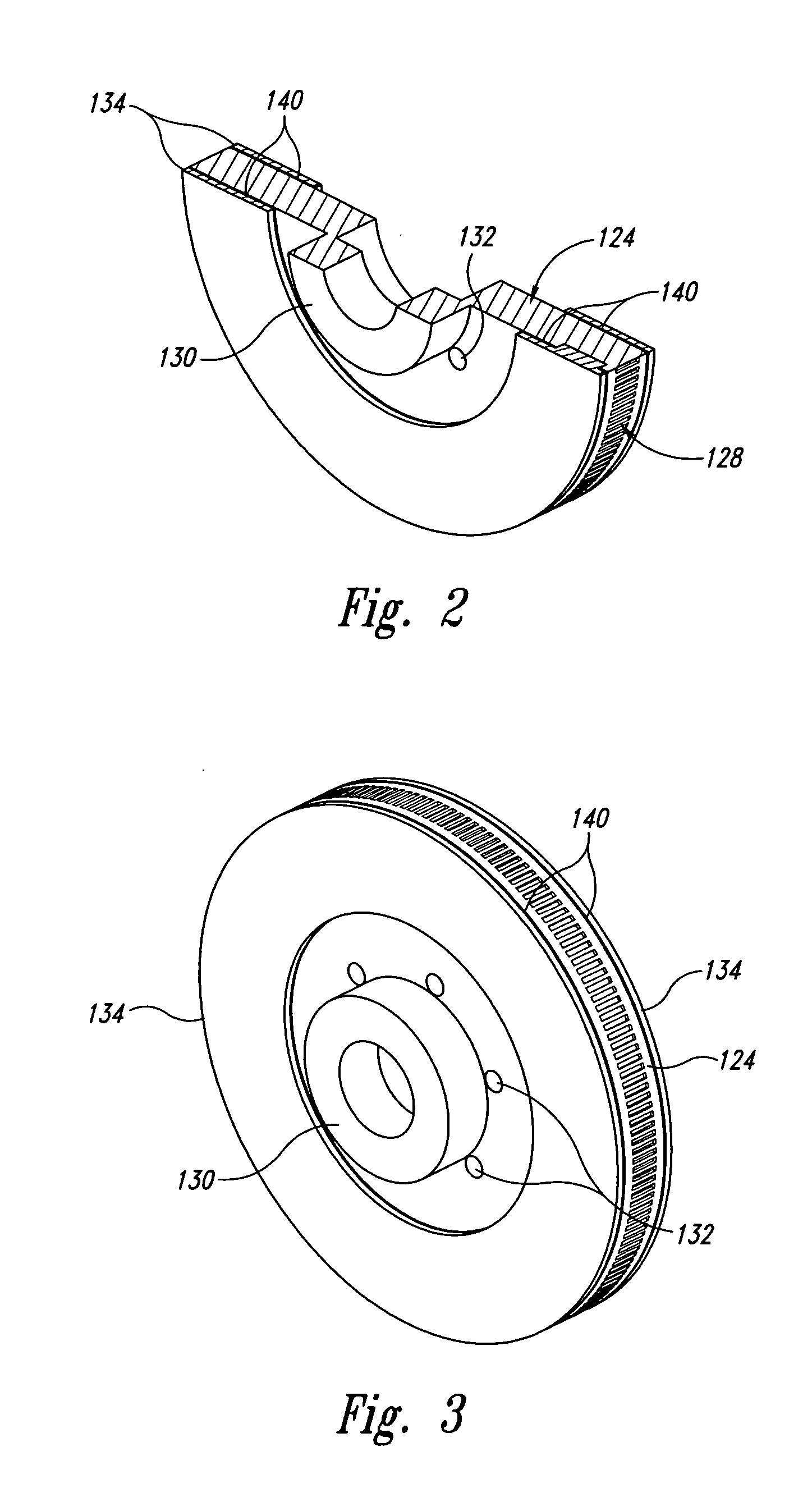

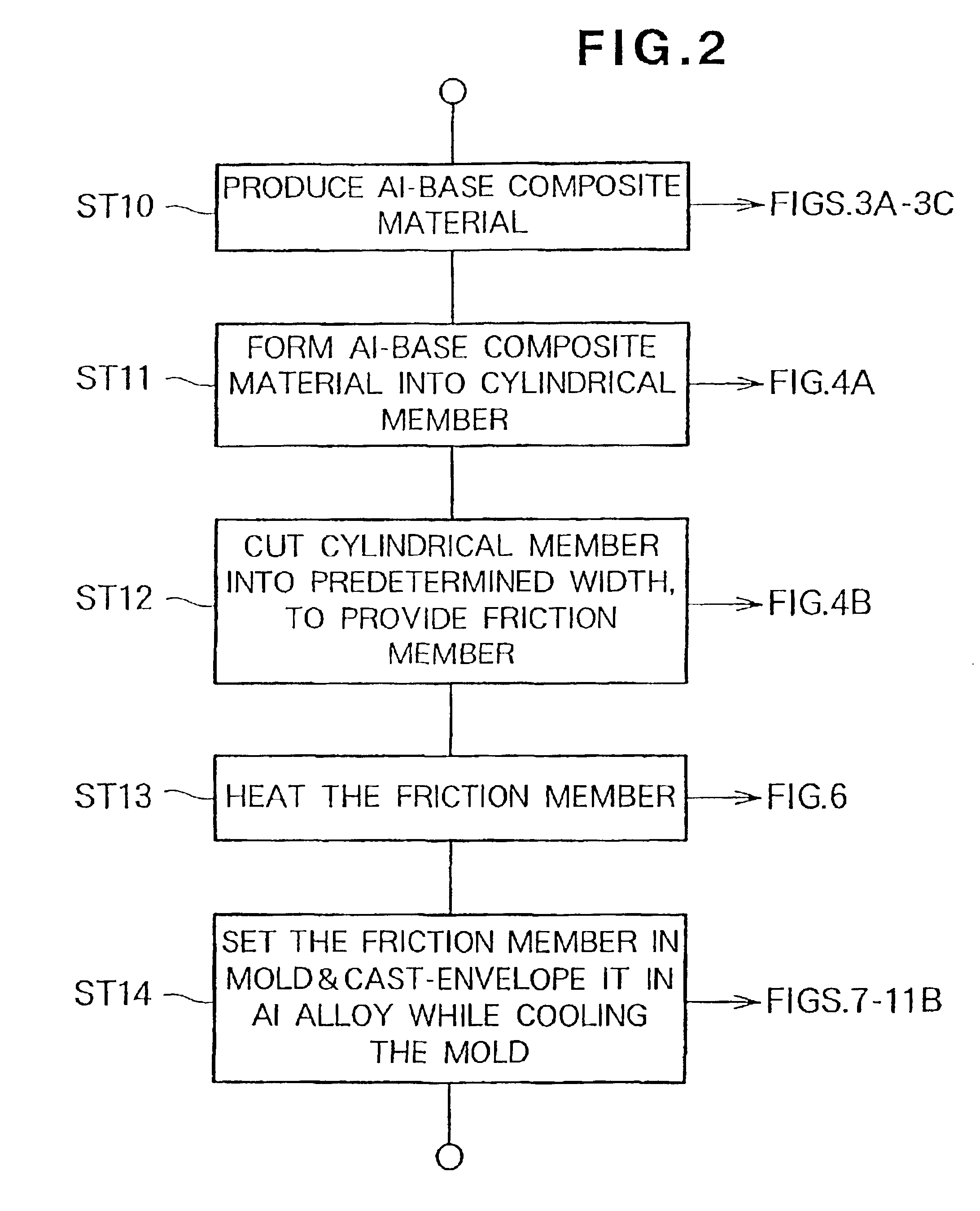

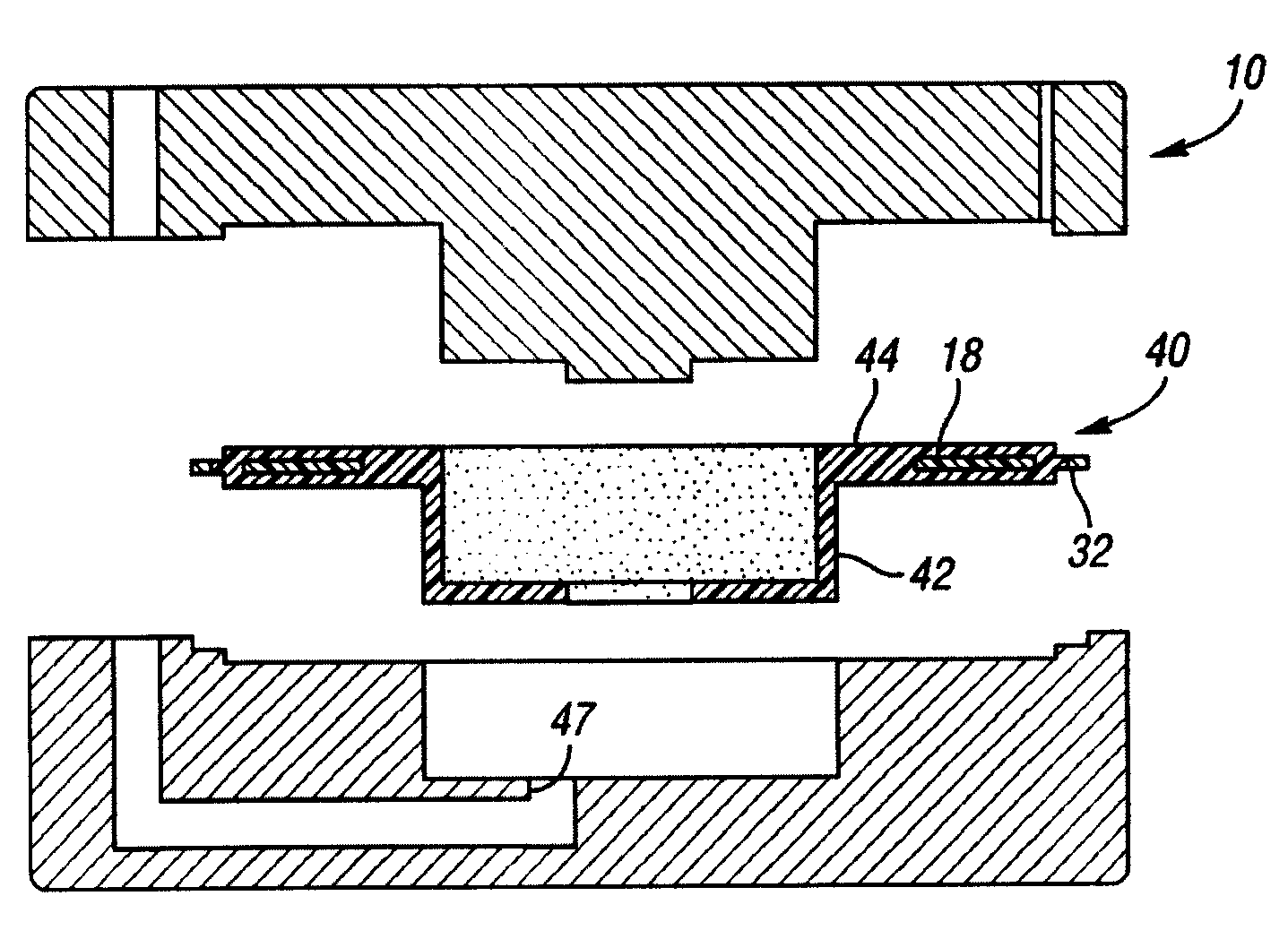

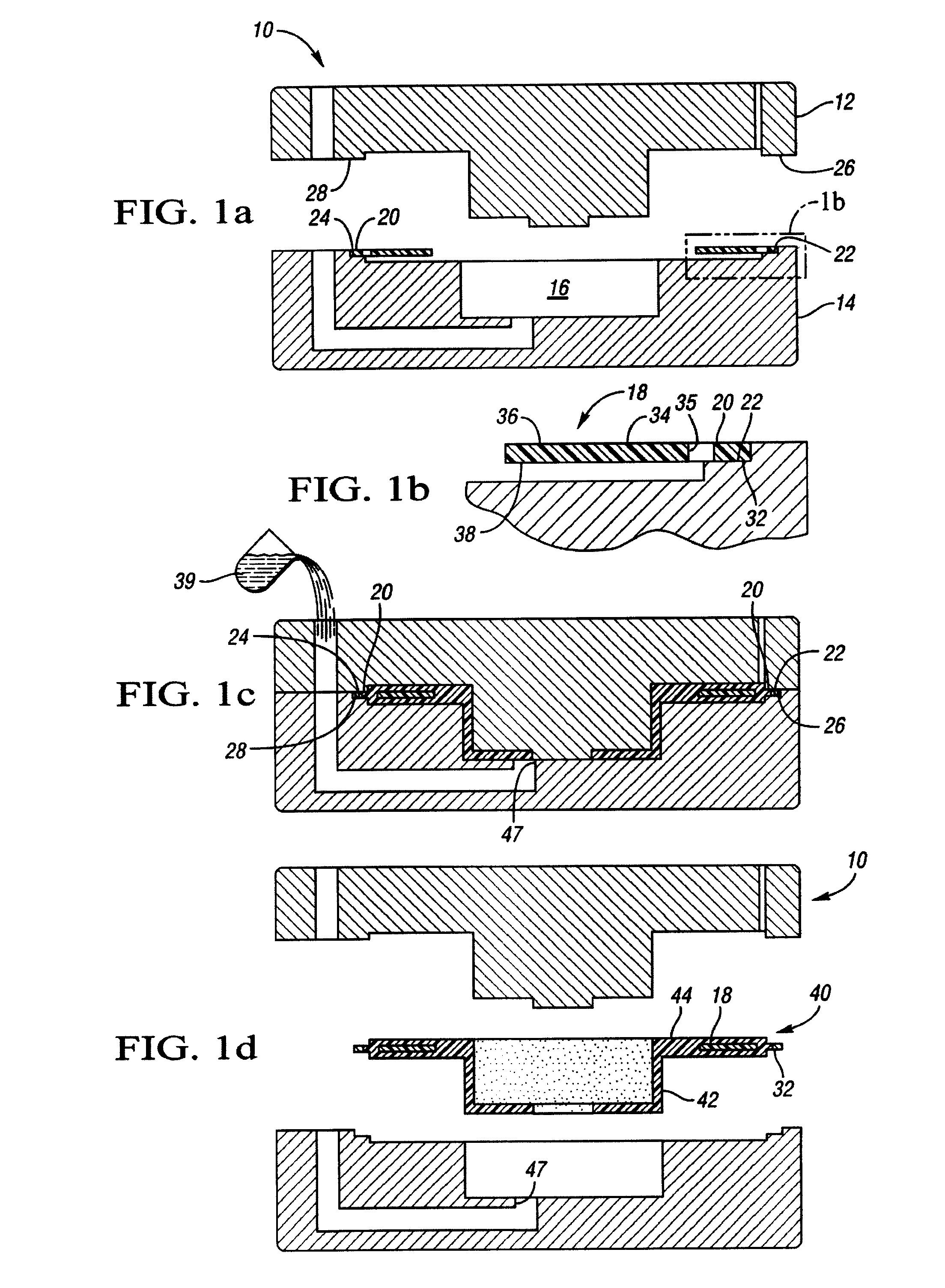

Coulomb damped disc brake rotor and method of manufacturing

InactiveUS20080099289A1Avoid bondingExternal exposure is reducedNoise/vibration controlBraking discsEngineeringMechanical engineering

The invention provides a method for manufacturing a coulomb damped disc brake rotor, including the steps of: (A) providing a mold having the general shape of the coulomb damped disc brake rotor; (B) placing a coulomb damper insert having a generally annular body and at least one tab extending generally radially from the generally annular body, wherein the at least one tab operates to locate the coulomb damper insert within the mold, and wherein the at least one tab at least partially defines an orifice with its major axis generally coincident with the periphery of the coulomb damped disc brake rotor; and (C) causing casting material to enter the mold to substantially encapsulate the coulomb damper insert with the casting material to form a rotor cheek of the coulomb damped disc brake rotor. A coulomb damper insert and coulomb damped disc brake rotor are also disclosed.

Owner:GM GLOBAL TECH OPERATIONS LLC

Brake pad with wear indicator

InactiveUS7424936B2Simple and reliable and effectiveBrake typesFriction liningMechanical engineeringBrake pad

A brake pad includes a backing plate and a friction material layer attached to the backing plate. At least one inner layer is disposed within the friction material layer. The inner layer has a color different than the friction material layer.

Owner:MCCLELLAN WILLIAM THOMAS

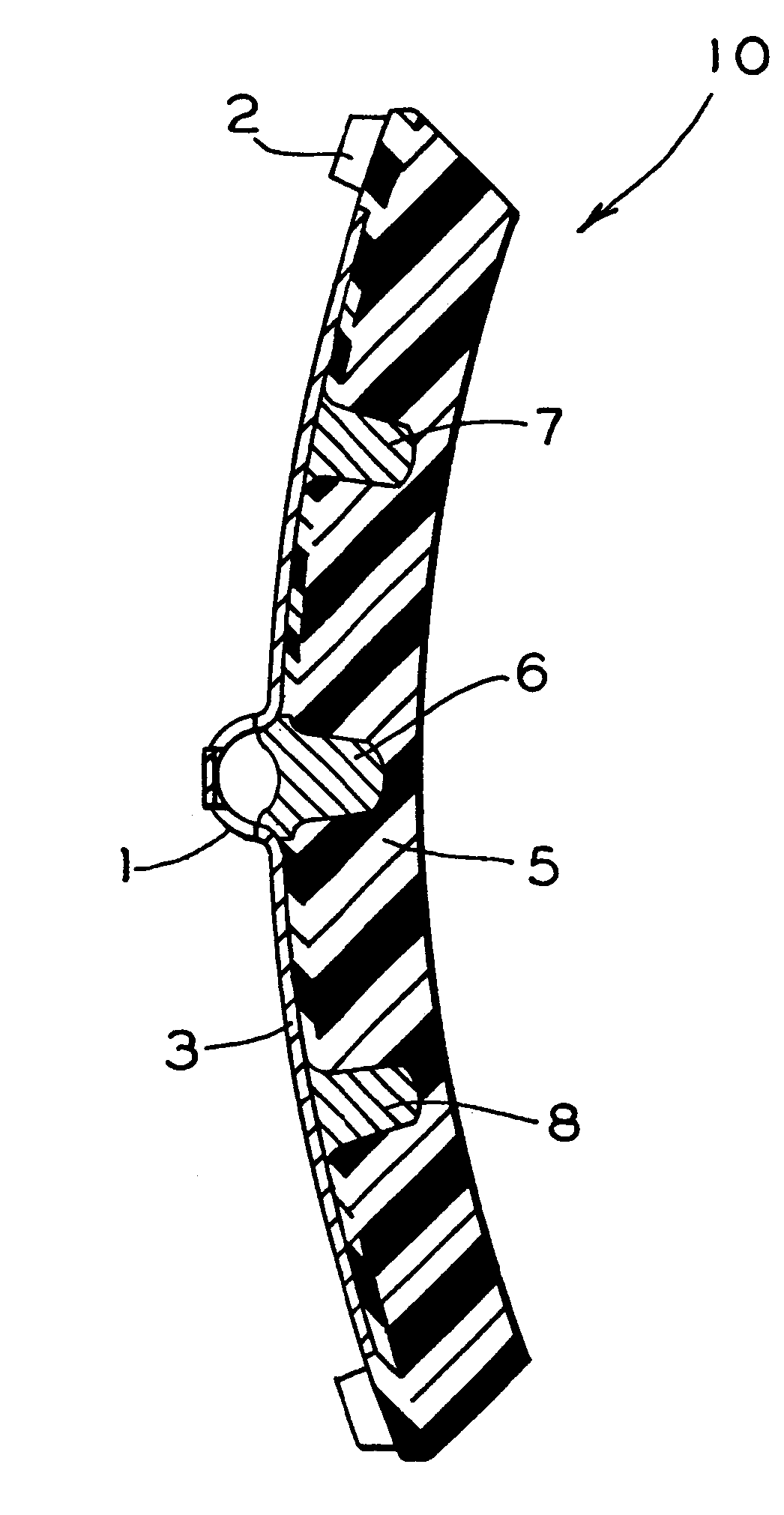

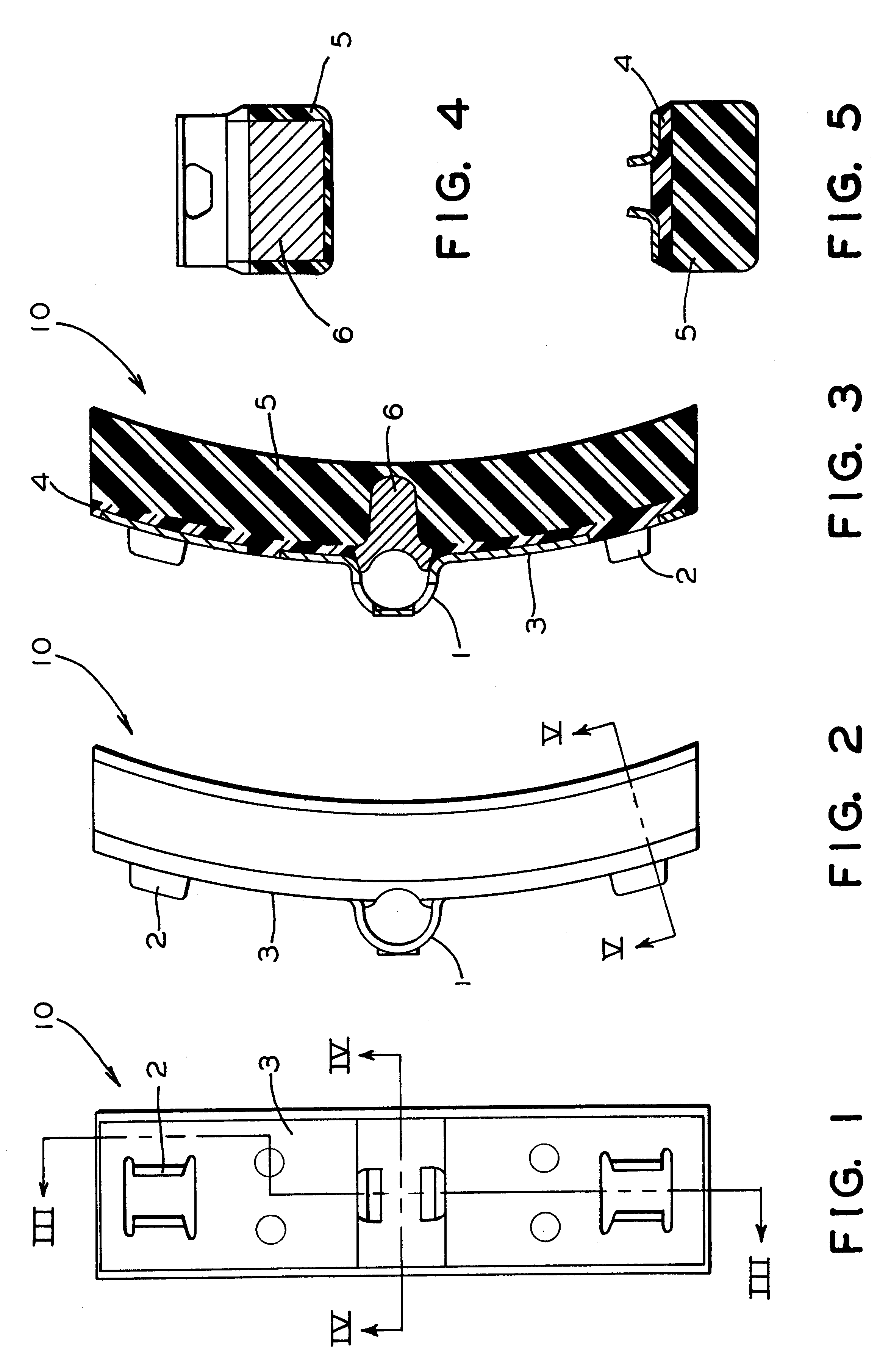

Brake shoe with insert bonded to backing plate

InactiveUS6241058B1Reduce defectsLightweight productionBraking membersFriction liningBrake shoeTread

A composition brake shoe for use on a railway vehicle for reconditioning a wheel tread surface during a normal braking application on such railway vehicle is provided. The composition brake shoe includes a backing plate having a stirrup and a brake surface having a predetermined configuration and a predetermined surface area. It further includes a first friction type composition material extending over the surface area of such brake surface of such composition brake shoe. The composition brake shoe further contains a second friction type material, formed as at least one discrete insert, having a predetermined shape and molded into such first friction type composition material. Such second friction type material initially being completely embedded within such first friction type composition material. One surface of such at least one discrete insert being incrementally exposed as such first friction type composition material is eroded away due to frictional engagement with such wheel tread surface during normal braking operations, such second friction type material exhibiting greater abrasive properties than such first friction type composition material. Such at least one discrete insert of such second friction type material is bonded to such backing plate.

Owner:RFPC HLDG CORP

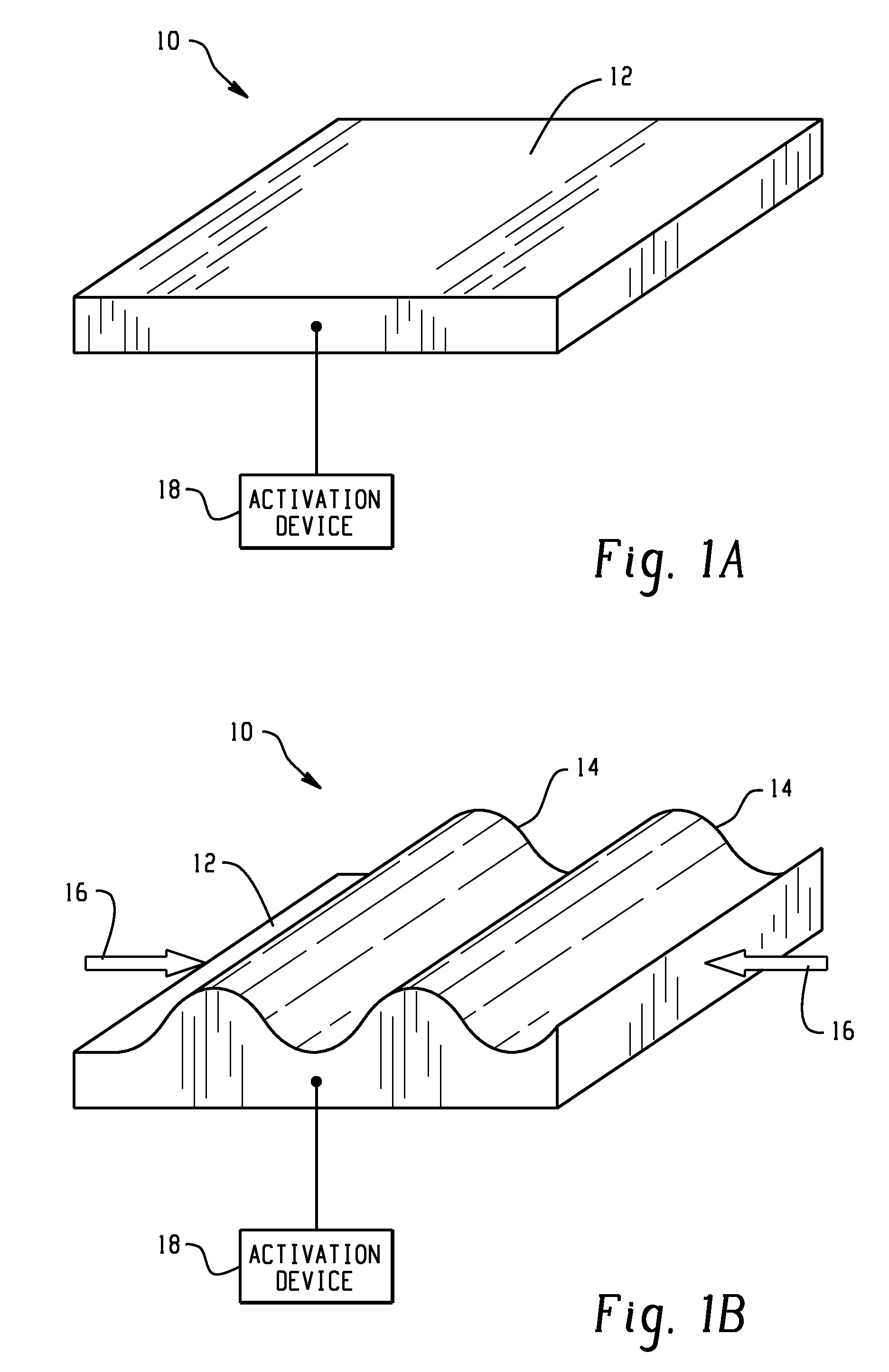

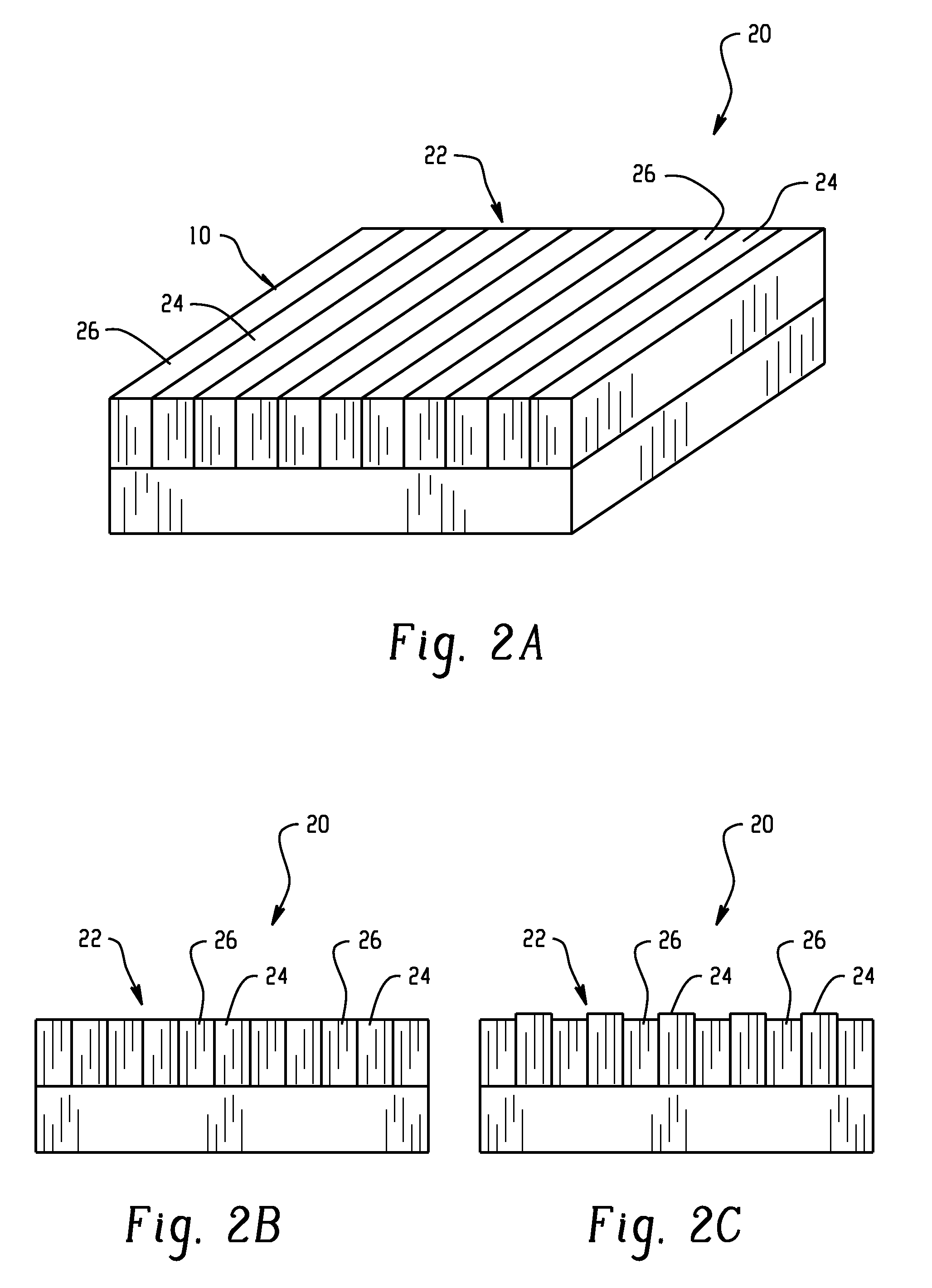

Active material based bodies for varying surface texture and frictional force levels

InactiveUS20090047197A1Efficient changeBacterial antigen ingredientsLavatory sanitoryEngineeringBiological activation

A device for selectively controlling and varying surface texture includes a body having at least one surface, and an active material in operative communication with the at least one surface, wherein the active material is configured to undergo a change in a property upon receipt of an activation signal, wherein the change in a property is effective to change a texture of the at least one surface.

Owner:GM GLOBAL TECH OPERATIONS LLC

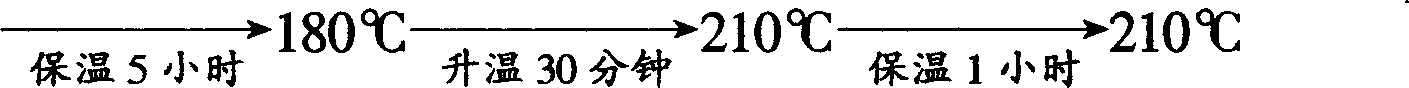

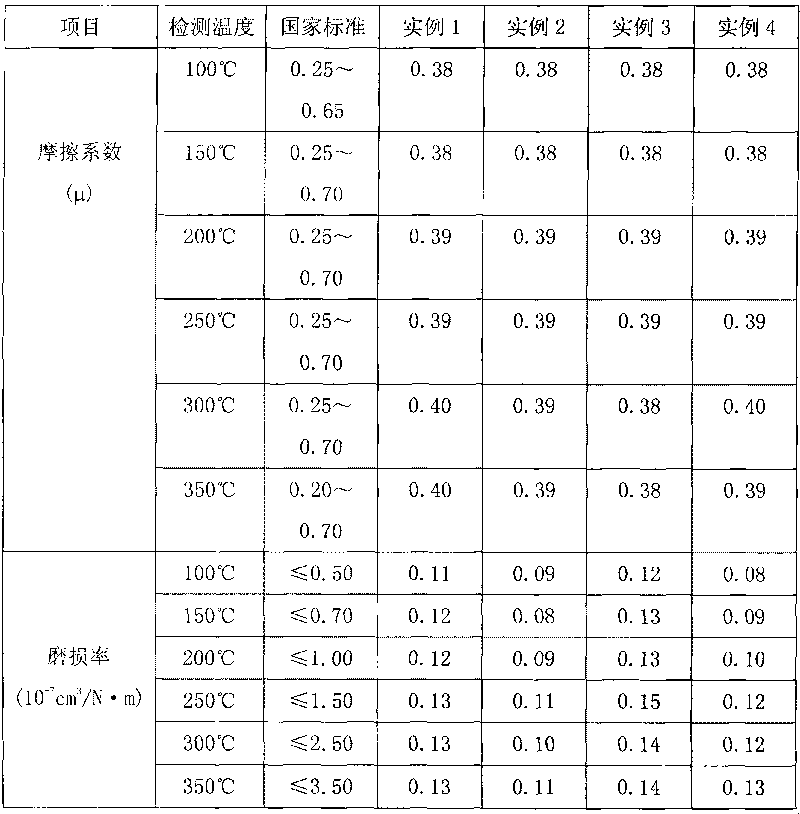

Environmental ceramic base friction material free of copper or metal and preparation method of material

InactiveCN103881657AGood mechanical skeleton performanceStable coefficient of frictionOther chemical processesFriction liningSulfurMetallic sulfide

The invention discloses an environmental ceramic base friction material free of copper or metal and a preparation method of the material. The environmental ceramic base friction material is characterized by comprising the following components by weight percent: 6-12% of phenolic resin, 2-10% of ceramic fiber, 2-8% of inorganic fiber, 2-10% of rubber, 4-12% of graphite, 10-25% of potassium titanate lamella, 3-15% of mineral fiber, 4-20% of metal sulfur compound, 6-20% of grinding aid and 5-20% of filler. The prepared friction material has excellent friction and wear properties, high heat-conducting property, excellent high-temperature decline property, stable friction coefficient, and excellent noise performance.

Owner:YANTAI SHENGRUI BRAKE SYST

Friction Material

InactiveUS20070219289A1Improve wear resistanceShort lifeFriction liningActuatorsFiberAlkaline earth metal

A friction material includes a binder, a reinforcement fiber, and a friction modifier which in turn includes flat layered titanate particles and baryte particles, wherein the baryte particles constitute less than 25% by volume of the friction material. The flat layered titanate particle may include alkali metal titanate particles, and more specifically potassium lithium titanate particles. Other flat layered titanates, including alkali metal alkaline earth metal titanates may also be used. The titanate particles may be used in an amount of 3-25% by volume of the friction material, and more specifically 5-15% by volume thereof. They may also have particle sizes ranging from 0.1-500 μm, and more specifically 1-30 μm, and even more specifically 15-30 μm. The friction material may include a binder or binders in an amount of about 8-31% by volume of the friction material. The friction material may also include reinforcement fibers in an amount of about 2-13% by volume of the friction material. These friction material may be used for any friction component including use in industrial machinery and vehicles, but are particularly useful as friction materials for use in various brake and clutch components.

Owner:FEDERAL MOGUL WORLD WIDE

Carbon-carbon composite article manufactured with needled fibers

InactiveUS20060177663A1Manufacturing EaseReduce layeringLayered productsTextiles and paperCarbon compositesCarbon fibers

Method of making a carbon-carbon composite article such as an aircraft brake disc. The method includes: selecting carbon fiber precursors, having limited shrinkage in the axial direction when carbonized, in the form of individualized chopped or cut fibers; placing the selected chopped or cut carbon fiber precursors into a preform mold configured in the form of a brake disc to form a fibrous matrix; and then needling the molded fibrous matrix to provide it with three-dimensional structural integrity and to reduce layering. The carbon fiber precursor matrix may subsequently be infused with liquid carbon matrix precursor, the impregnated matrix may be carbonized; e.g., at 600-1800° C. for 1-10 hours to provide a preform having a density of at least about 1.1 g / cc, and the carbonized preform may be further densified to a density of at least about 1.6 g / cc by known liquid resin infiltration techniques and / or by conventional CVI / CVD processing.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com