Patents

Literature

2889results about How to "Improve braking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Braking mechanisms

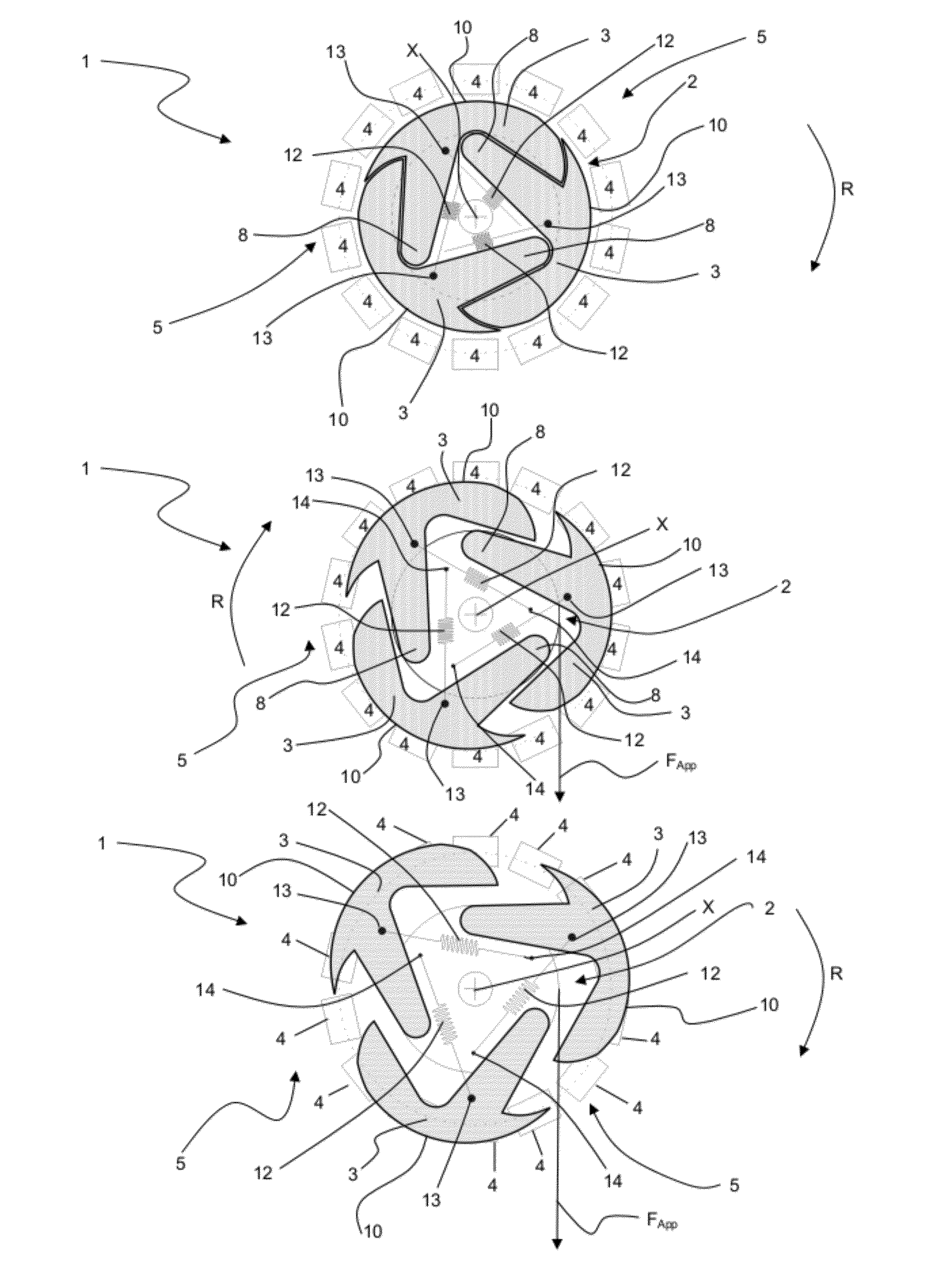

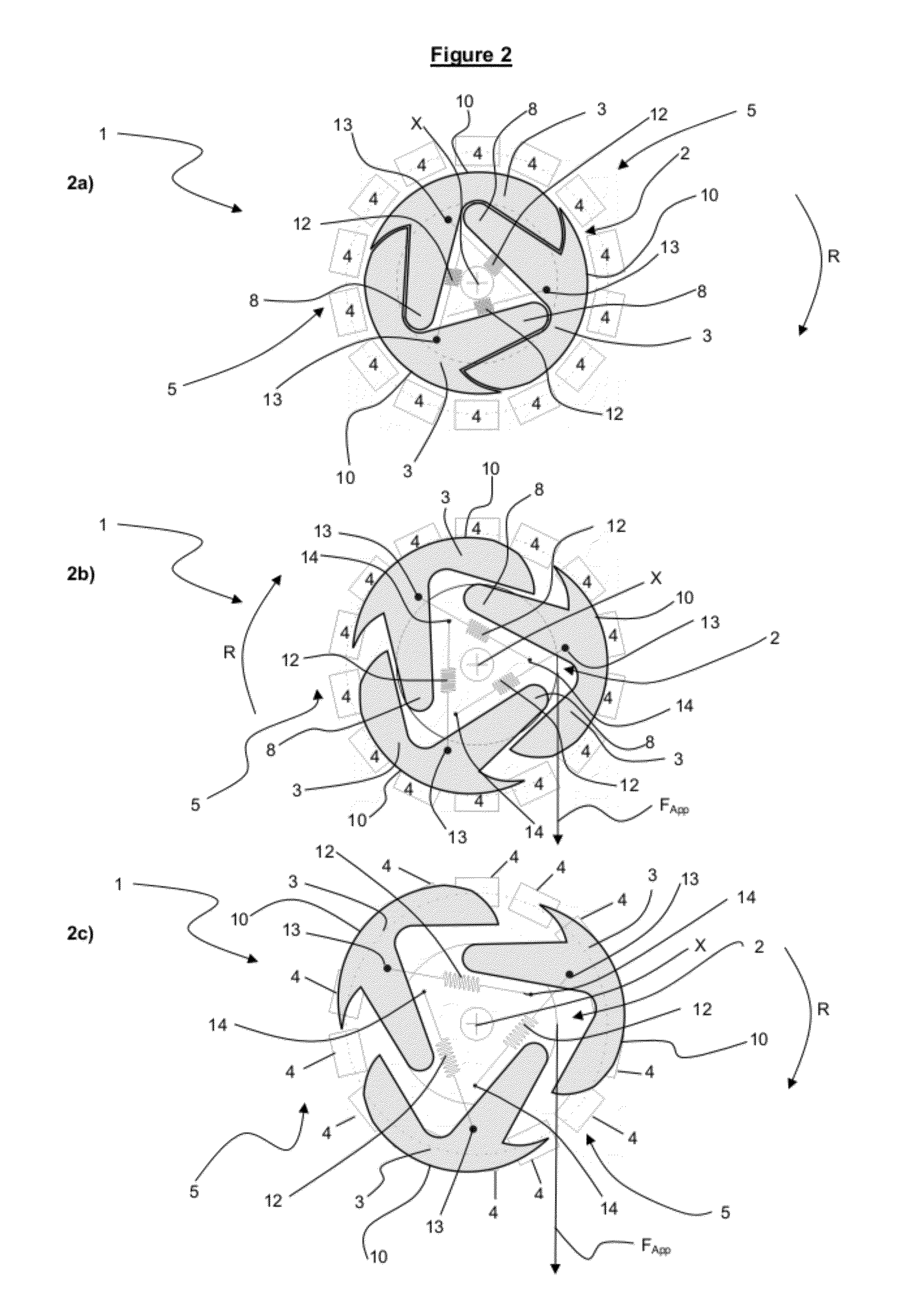

ActiveUS20120055740A1Improve braking effectEffective meanSafety beltsSelf acting brakesEngineeringEddy current

An eddy-current braking mechanism including a rotor, rotatable about a rotor axis; at least one electrically conductive member coupled to the rotor for rotation therewith; at least one magnet configured to apply a magnetic field extending at least partially orthogonal to the plane of rotation of the conductive member, and characterised in that upon rotation of the rotor, the conductive member is configured to move at least partially radially from the rotor axis into the applied magnetic field.

Owner:EDDY CURRENT PARTNERSHIP

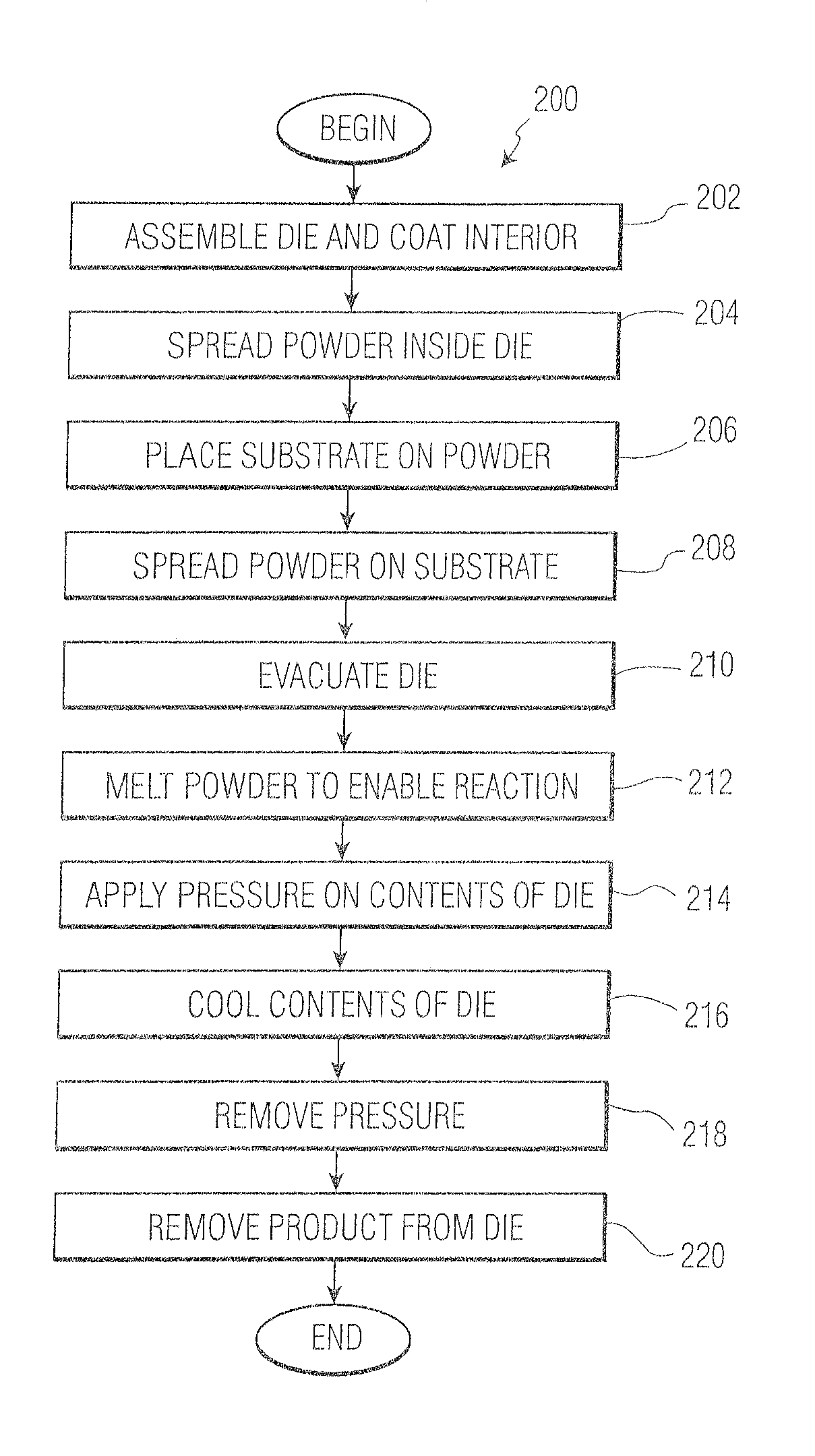

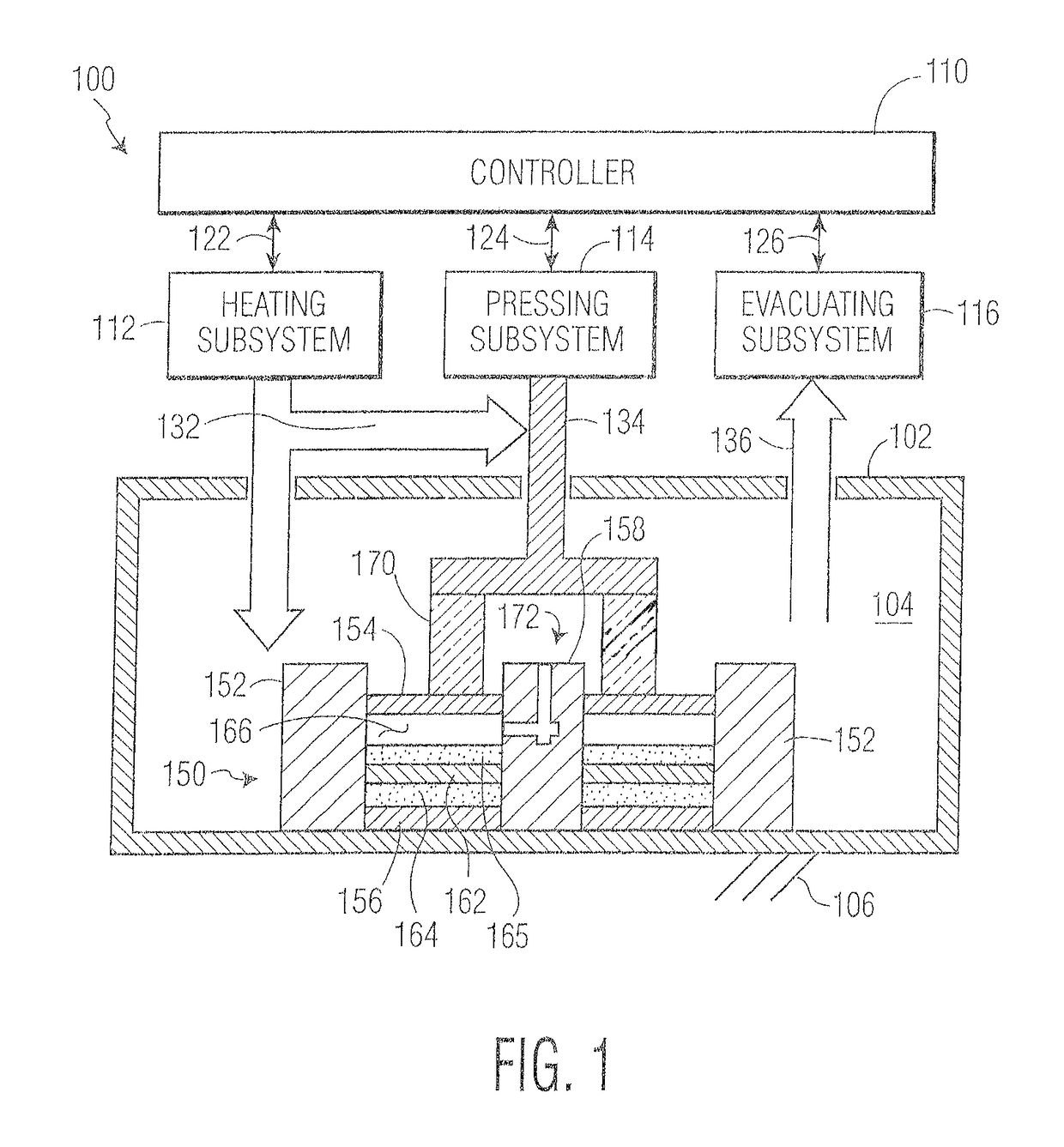

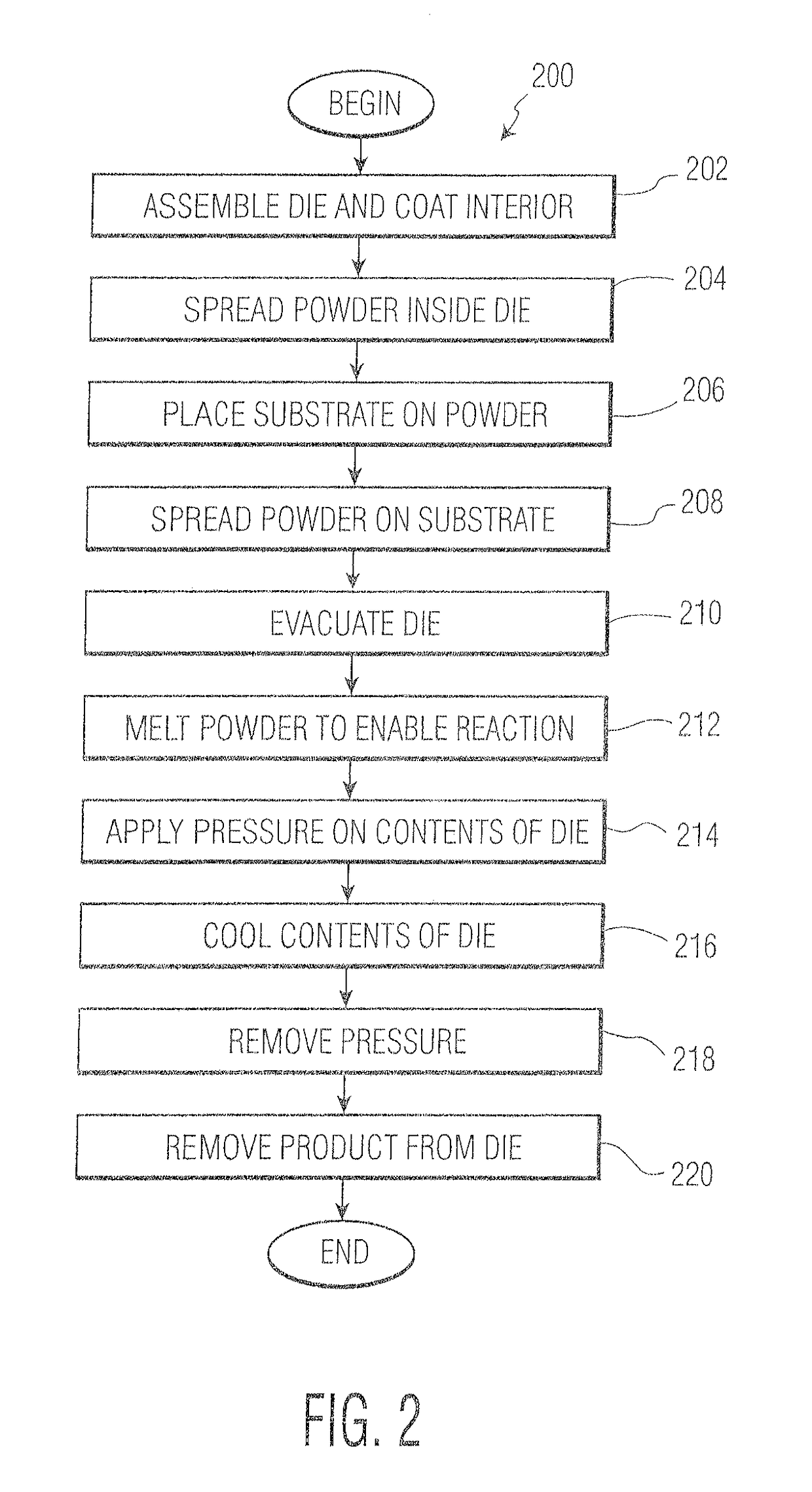

Systems and methods for forming a layer onto a surface of a solid substrate and products formed thereby

InactiveUS9933031B2Increase capacityImprove the overall coefficientBlade accessoriesBraking discsMetal matrix compositeSolid substrate

A method for forming a vehicular brake rotor involving loading a shaped metal substrate with a mixture of metal alloying components and ceramic particles in a dieheating the contents of the die while applying pressure to melt at least one of the metal components of the alloying mixture whereby to densify the contents of the die and form a ceramic particle-containing metal matrix composite coating on the metallic substrate; and cooling the resulting coated product.

Owner:ATS MER LLC

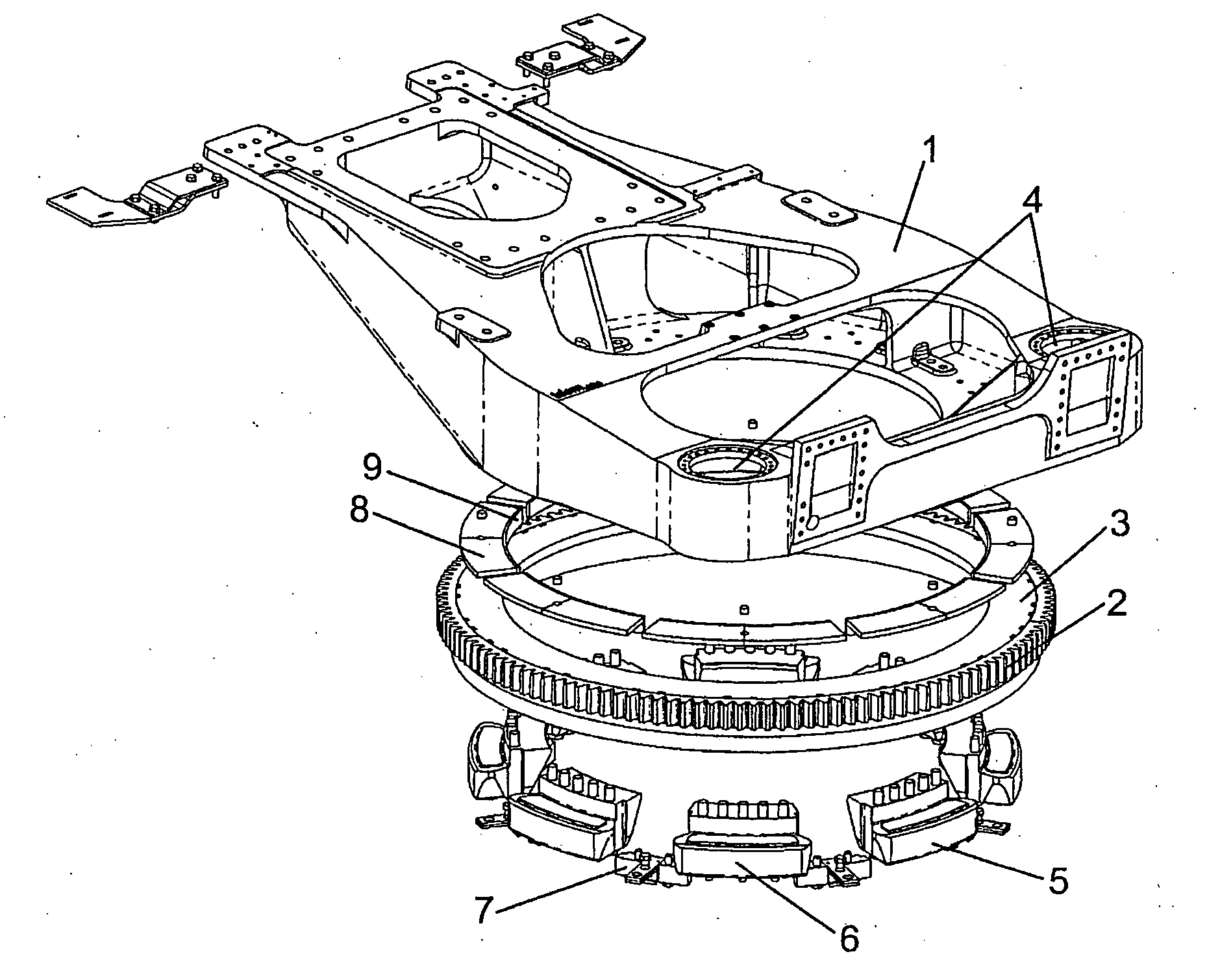

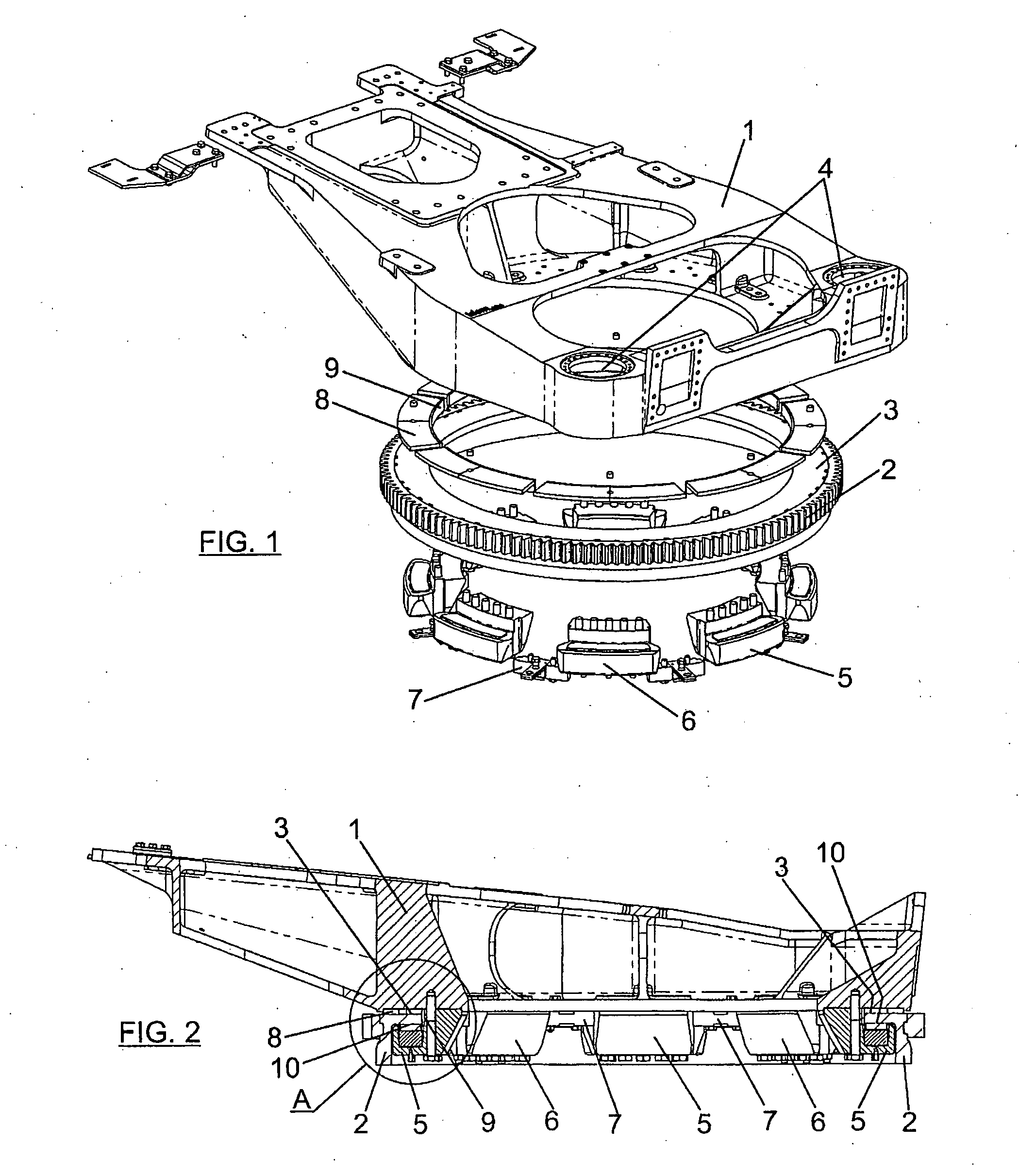

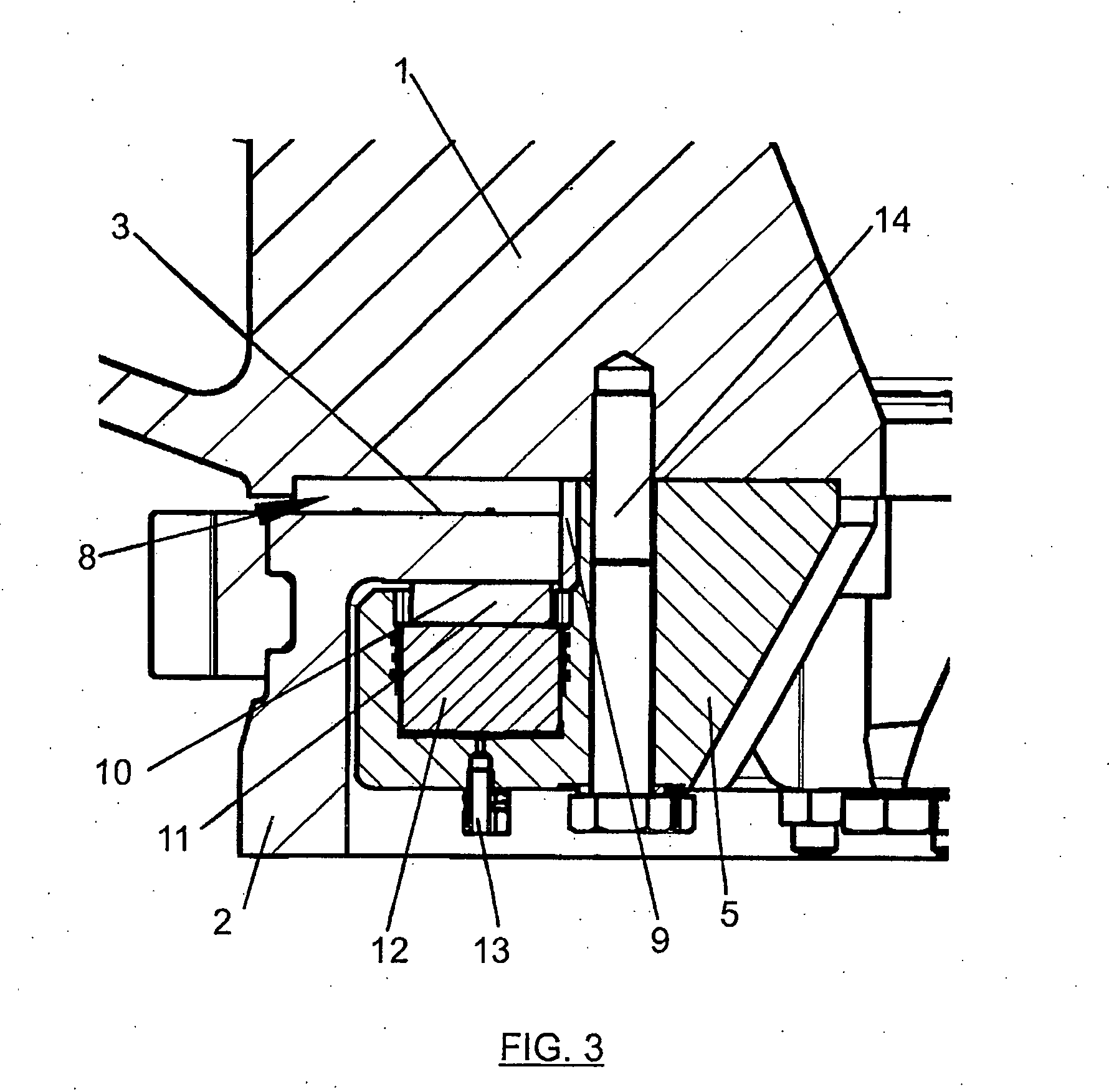

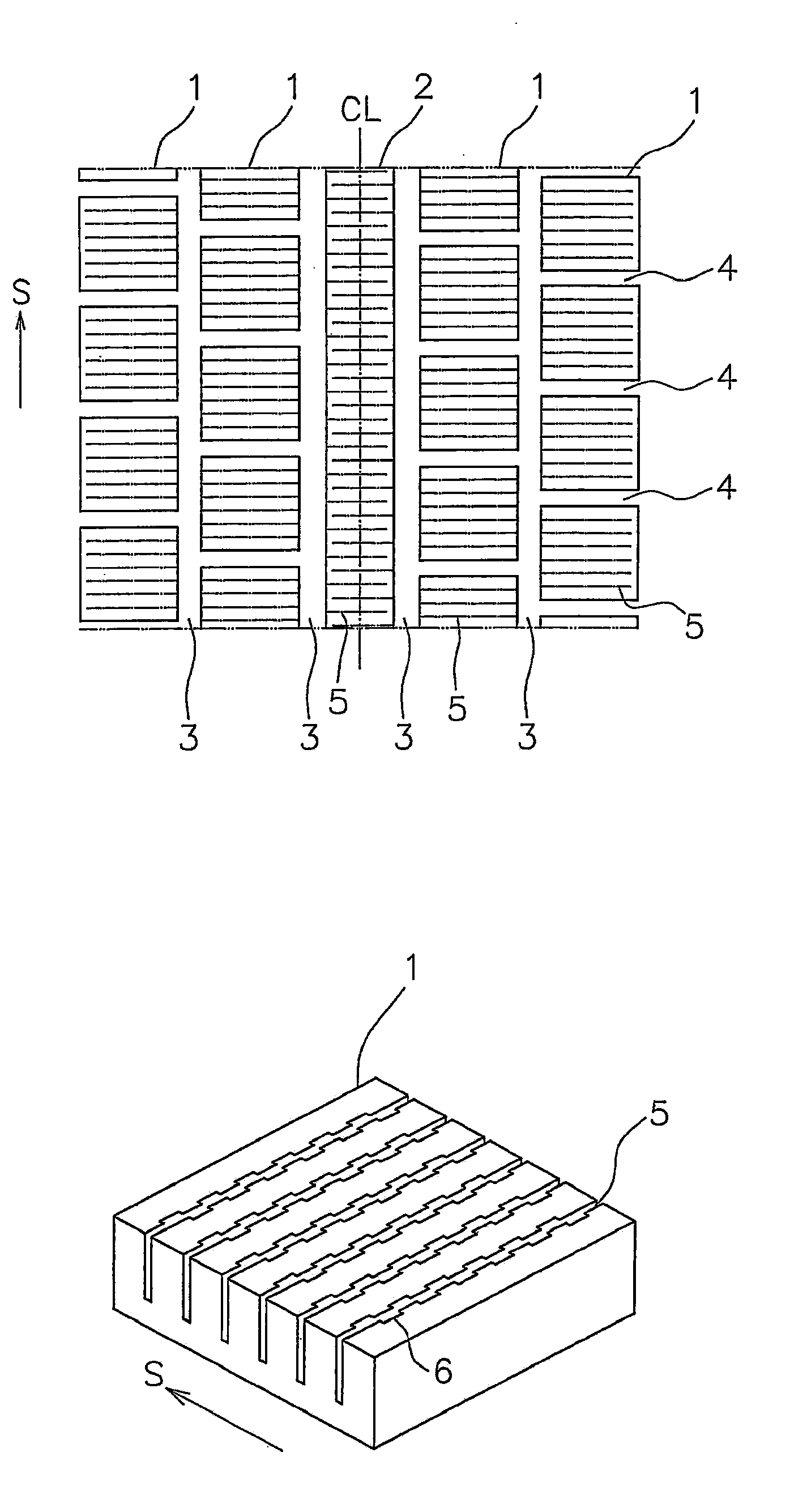

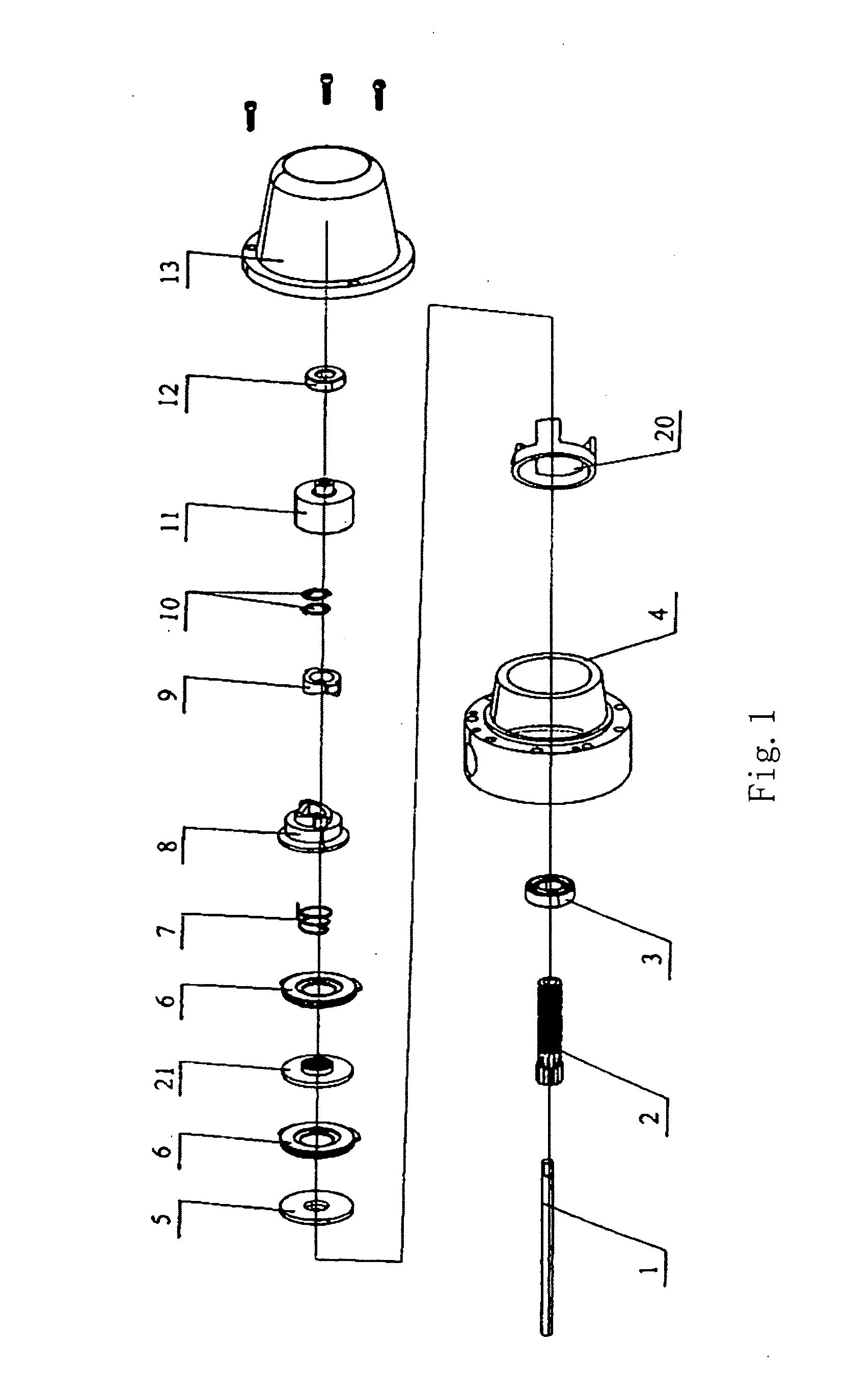

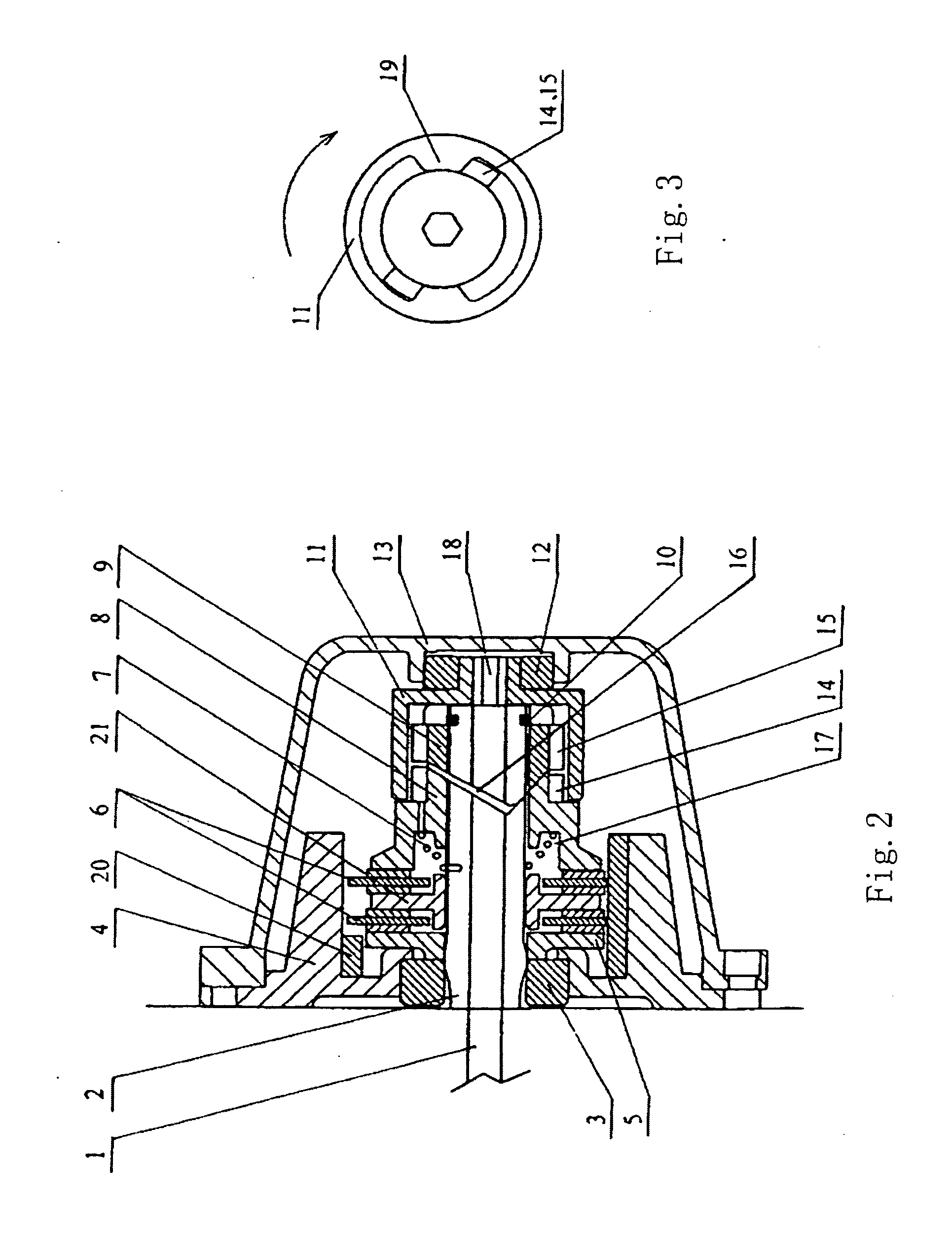

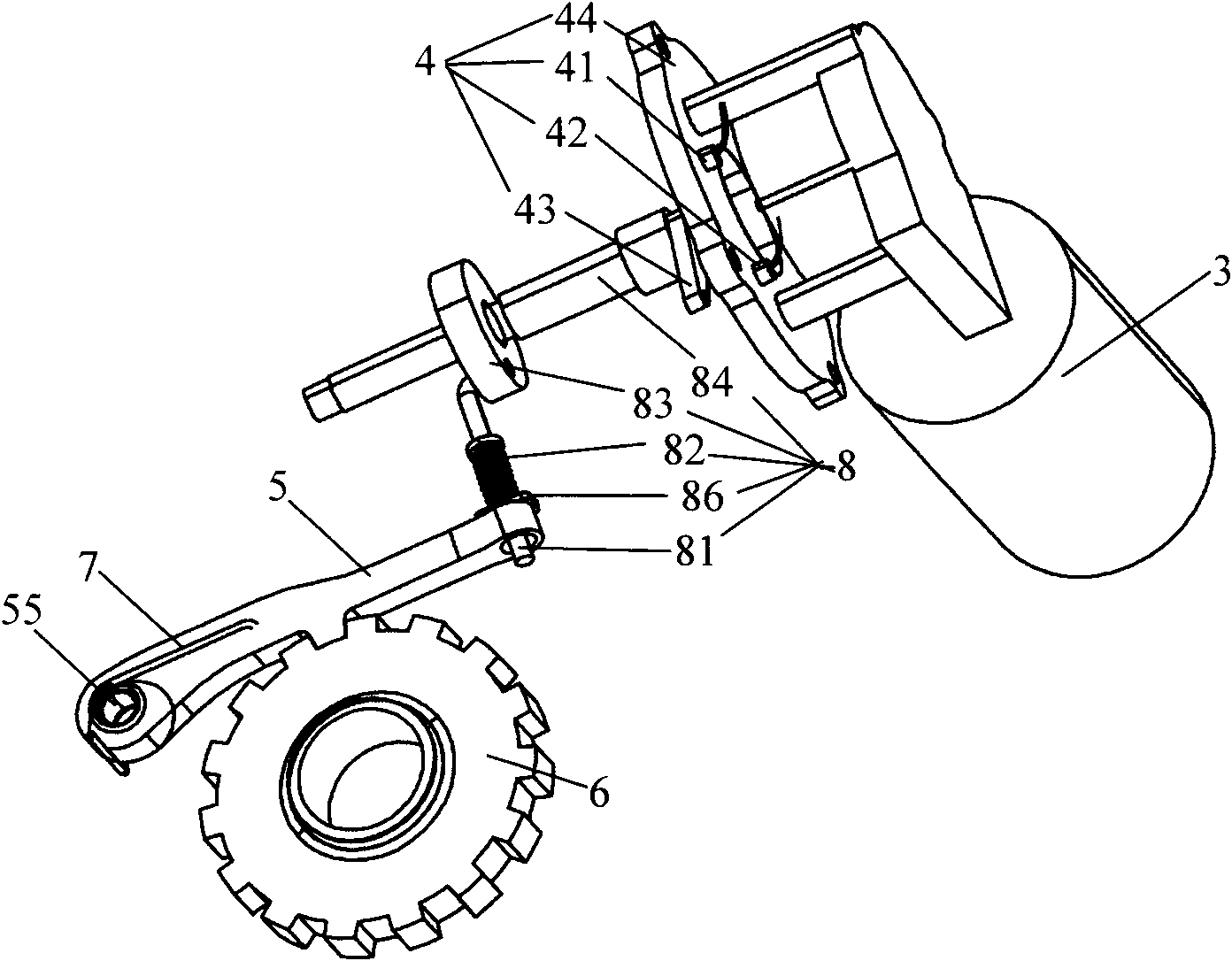

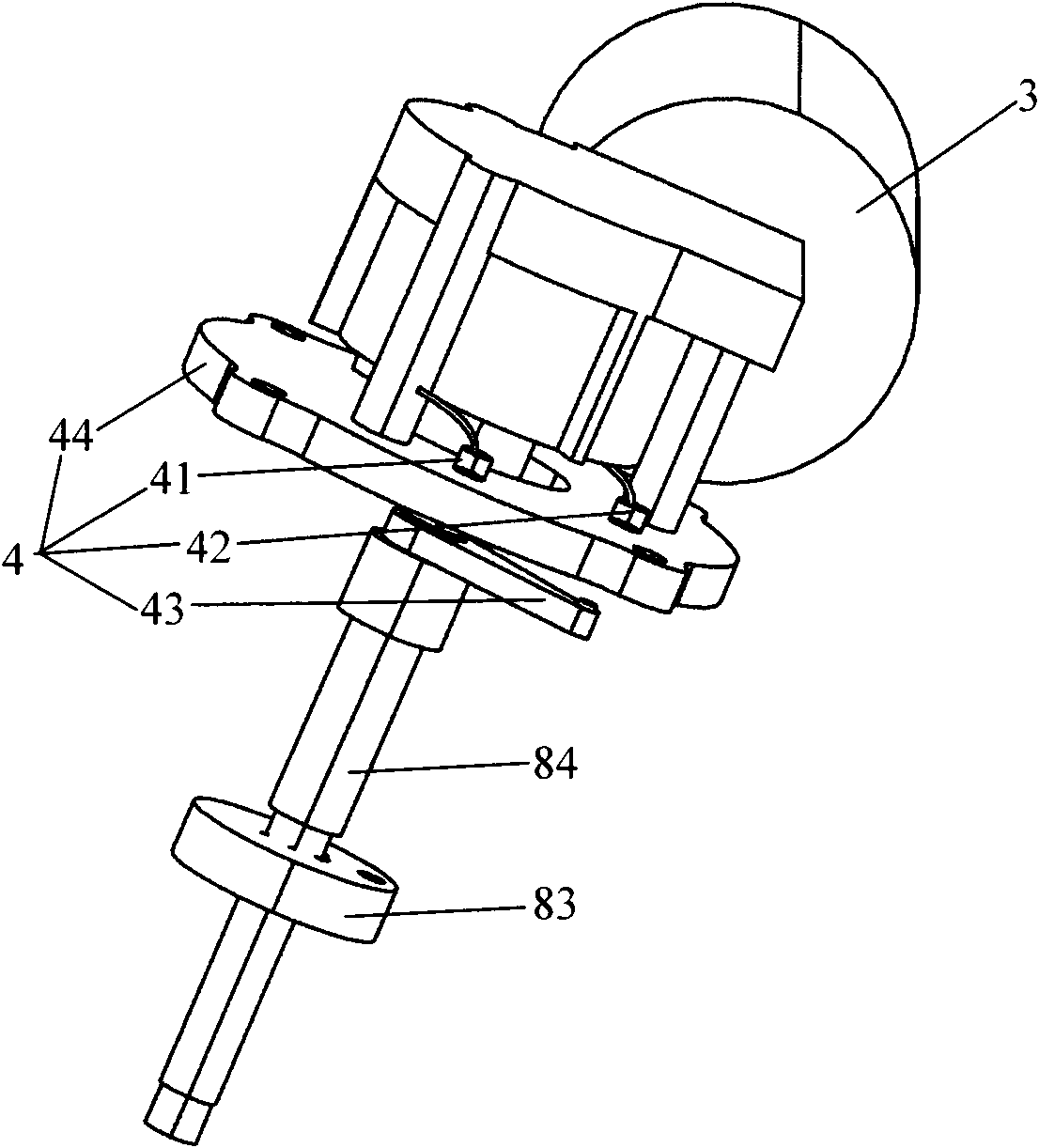

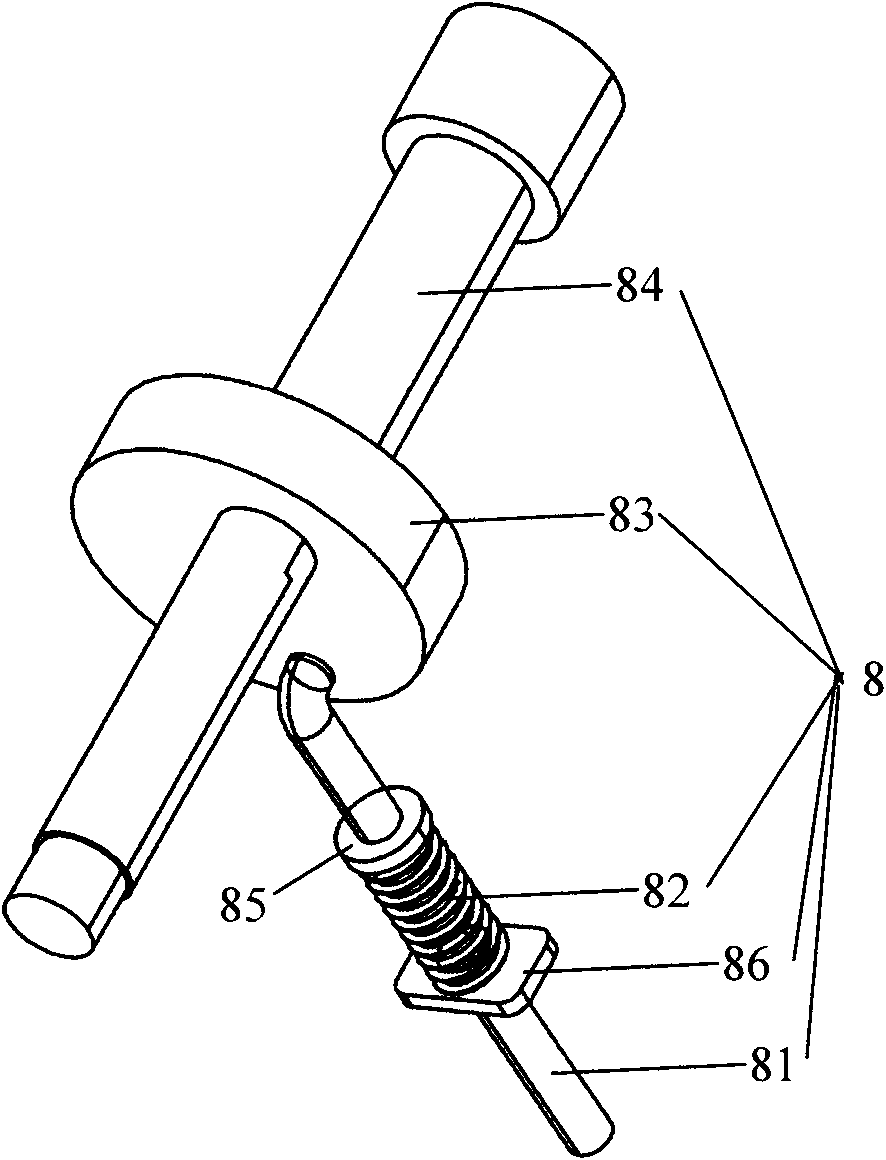

Wind turbine yawing system, wind turbine and yawing process

InactiveUS20050196280A1Improve braking effectEasily replaced in repairPropellersWind motor controlGear wheelTower

A yawing system for a wind turbine, the wind turbine comprising a tower fixed to the ground and a frame (1) housing an electric power generator, the tower and the frame (1) being joined by the yawing system which allows the orientation of the frame (1) with respect to the tower according to the direction of the wind. The yawing system comprises: a gear ring (2) fixed to the tower, the gear ring having a sliding track (3) on which the frame (1) rests and slides in its yawing movement, at least one geared motor fixed to the frame (1), meshed with the gear ring (2) through a gear wheel, at least one active braking module (5), and at least one passive braking module (6). The invention further comprises a sliding track (3) and a friction track on the gear ring, this friction track (10) being different from the sliding track (3), and the active braking modules (5) and passive braking modules (6) comprising a friction plate (11) acting on the friction track (10) of the ring. The frame (1) rests on the gear ring (2) by means of horizontal plates (8) and radial plates (9) made of a sliding material, and are kept in their position by separating parts (7). Furthermore, the gear ring (2) is divided into gear-toothed circular segments to favor its repair. Other aspects are a wind turbine with the previous yawing system and a yawing process of a turbine by means of the previous yawing system.

Owner:GAMESA INNOVATION & TECH SA

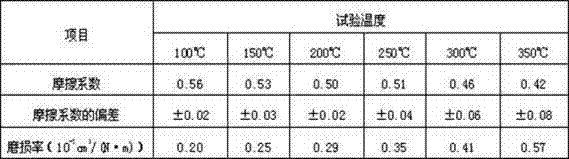

Formula of ceramic radical friction material for automobile braking friction facing

InactiveCN101113204AImprove braking effectImprove yieldFriction liningFilling materialsMaterials processing

The invention discloses a prescription of a ceramic-based friction material used in a vehicle braking friction pad, comprising the components (by weight): adhesives 5 percent-15 percent, intensifier 23.5 percent-33.5 percent, grinding aid 0 percent-7 percent anti-wearing lubricant 11.3 percent-21.3 percent, elastic toughening agent 5.7 percent-15.7 percent and filling material 27.5 percent-37.5 percent. The total amount of the components is 100 percent. The materials of the invention can be processed and molded into the vehicle braking pad that is applicable to friction braking on a vehicle braking device. The anti-wearing performance of the pad can be greatly enhanced, thereby reducing noise pollution and promoting the performance of the braking system of the vehicle.

Owner:SHAANXI LIZHIQUAN IND TRADE

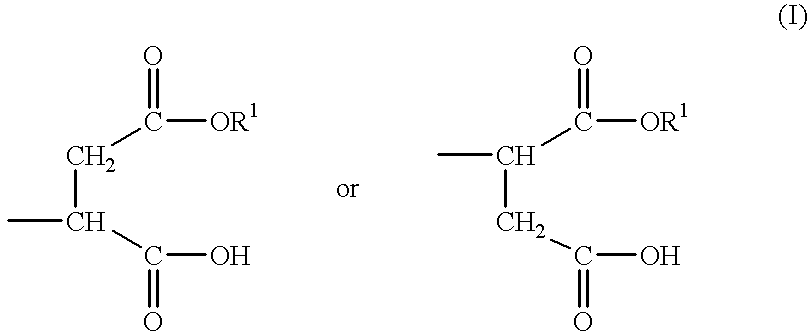

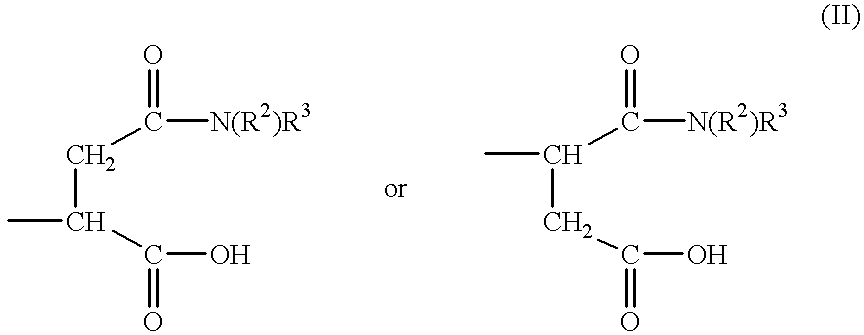

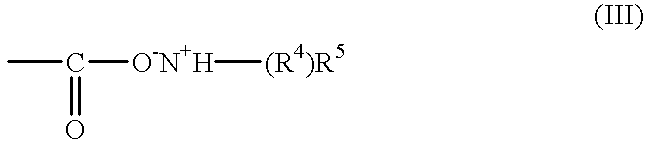

Polymer containing isobutylene as repeating unit and rubber composition containing the same

A modified polybutene(polyisobutylene) containing isobutylene repeating units and having, in the main chain, at the ends, and / or at the side chains of the polymer chain thereof, free radicals stable at a room temperature and in the presence of oxygen, or having a half-ester structure, amide structure, onium salt structure, or imide structure or acid anhydride residual group, as well as a rubber composition containing the same.

Owner:THE YOKOHAMA RUBBER CO LTD

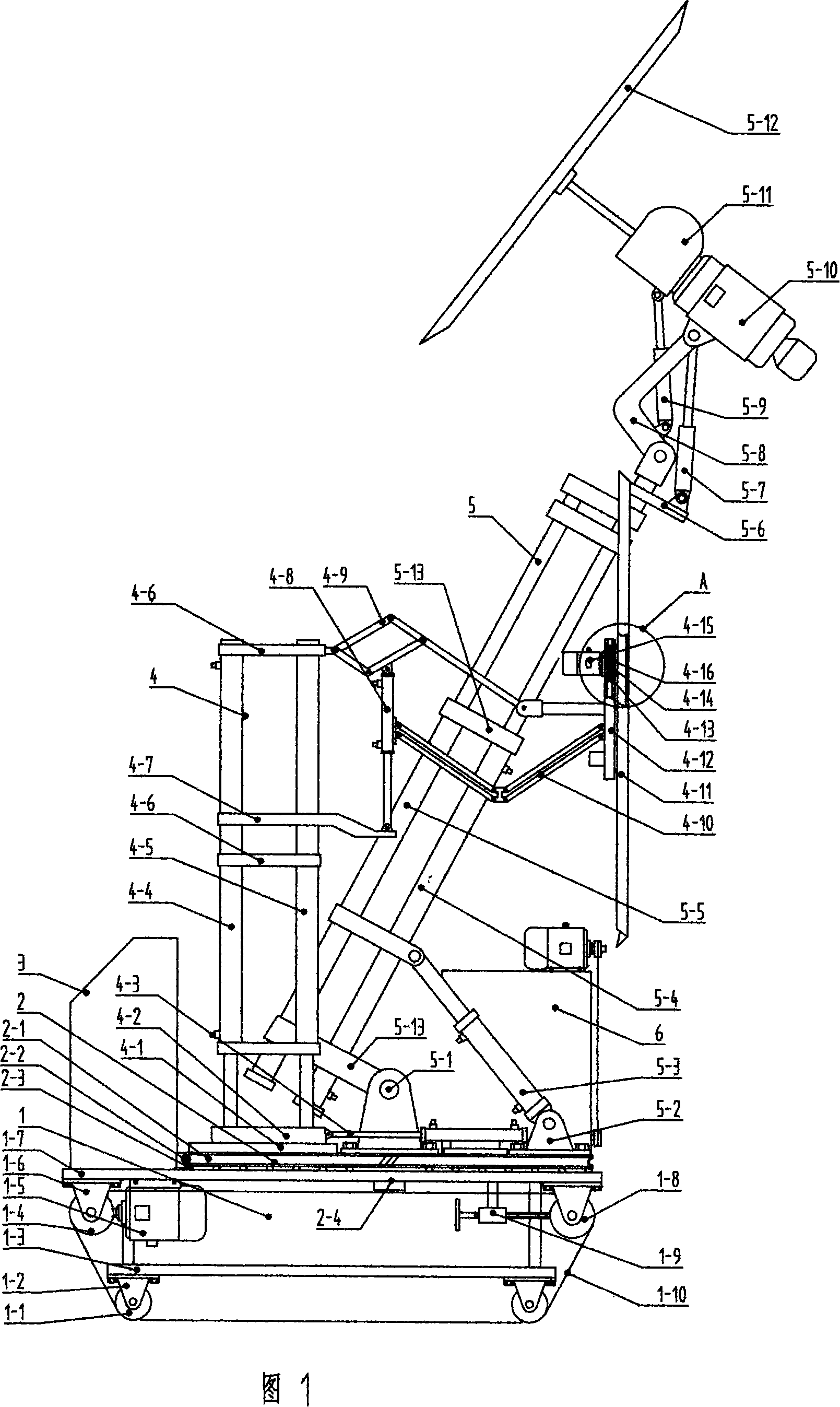

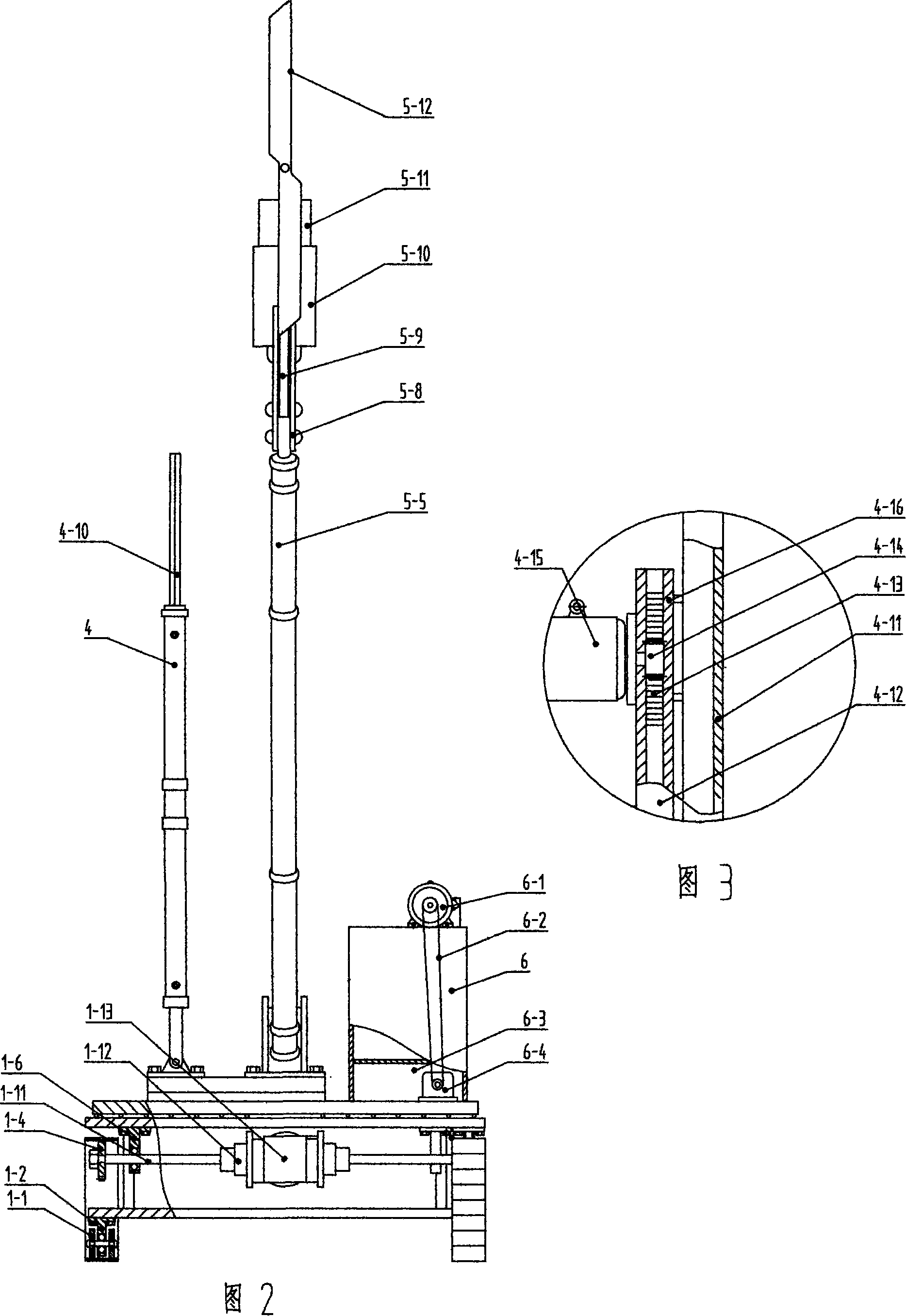

Wall rendering robot

InactiveCN101144324AStraightness is easy to guaranteeQuality improvementBuilding constructionsElectromagnetic clutchDrivetrain

The invention relates to an improved equipment on the basis of an original patent wall side plastering machine (the patent number: ZL01218090.4), and the invention is that two groups of mutually independent plane plastering devices and reentrant and outside corners plastering devices are arranged on the revolution support of a crawler belt chassis. Improvement is done to a power driving system of the crawler belt chassis, and a half axis and an electromagnetic clutch are added. The revolution support adopts a gear worm to drive. The weight of a complete machine is reduced, in order to ensure that the whole mechanization is realized for the work of the complete machine such as the plastering, the roughening, the treatment of the reentrant and outside corners during the construction, the labor strength is greatly reduced, the production efficiency is improved, and the maintenance expense is reduced, as well as the service life is prolonged.

Owner:赵呈为 +1

Pneumatic Tire

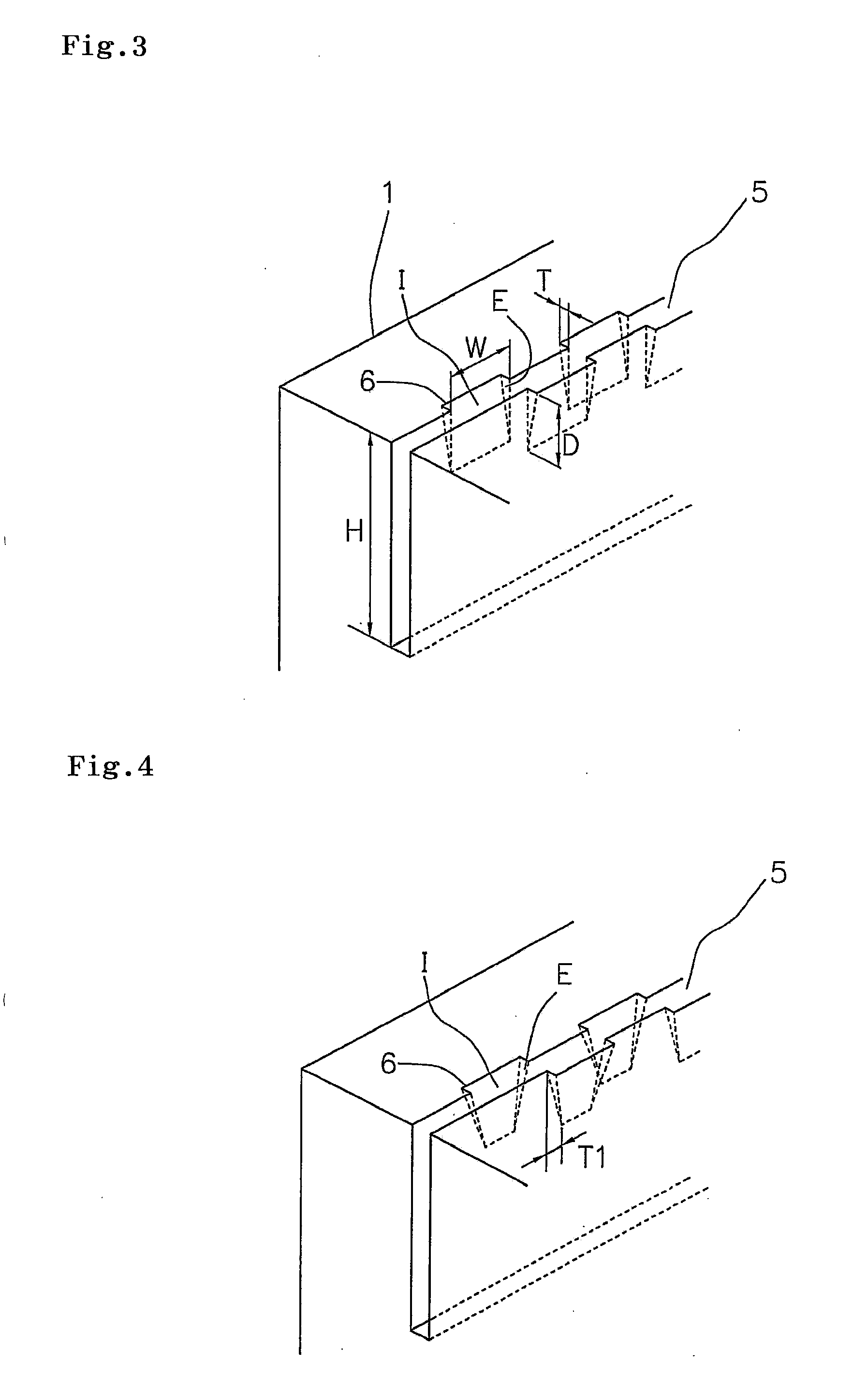

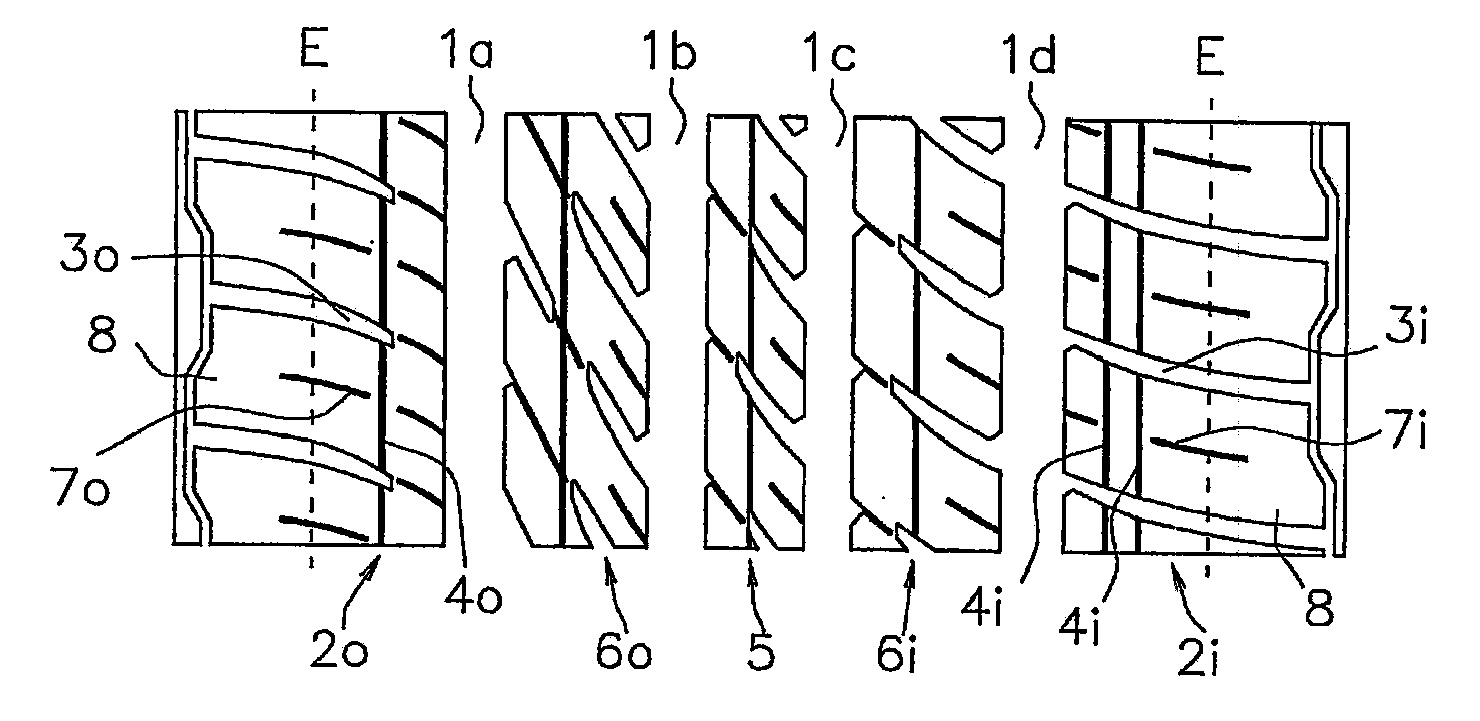

InactiveUS20100084062A1Increasing dry steering stability performanceImprove rigidityTyre tread bands/patternsNon-skid devicesRoad surfaceEngineering

An object of the present invention is to provide a pneumatic tire capable of ensuring both of the ice braking performance and the ice turning performance while increasing the dry steering stability performance. To achieve the above object, a sipe extending in a width direction of the tire is formed a land portion, the sipe having: pluralities of wide portions each having an inclined plane that begins from the tread surface of a road surface, and terminates in the half way of a sipe wall while inclining so that a sipe width decreases toward the groove bottom of the sipe, and a pair of side faces connecting the inclined plane and the sipe wall therebetween, wherein the pluralities of wide portions are located alternately on both sipe walls along a longitudinal direction of the sipe.

Owner:TOYO TIRE & RUBBER CO LTD

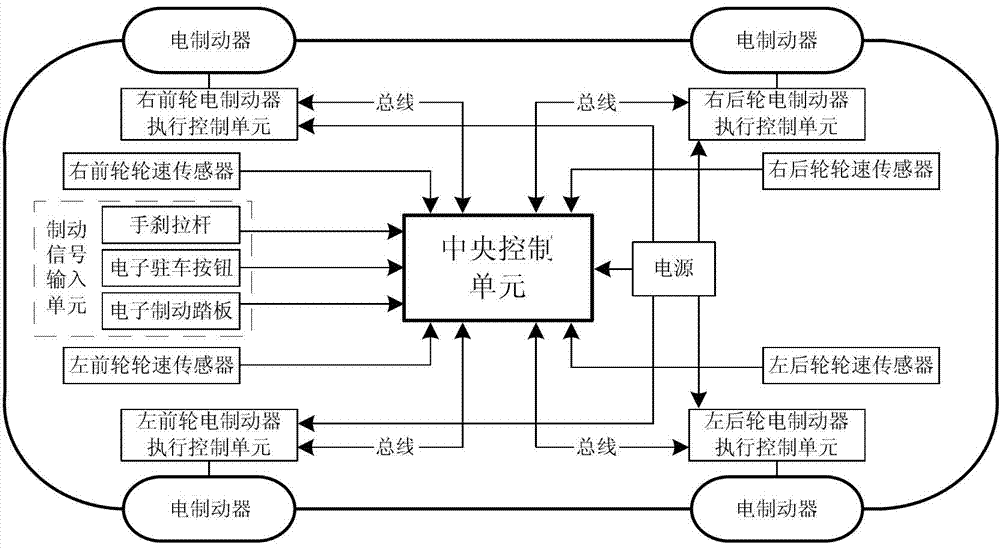

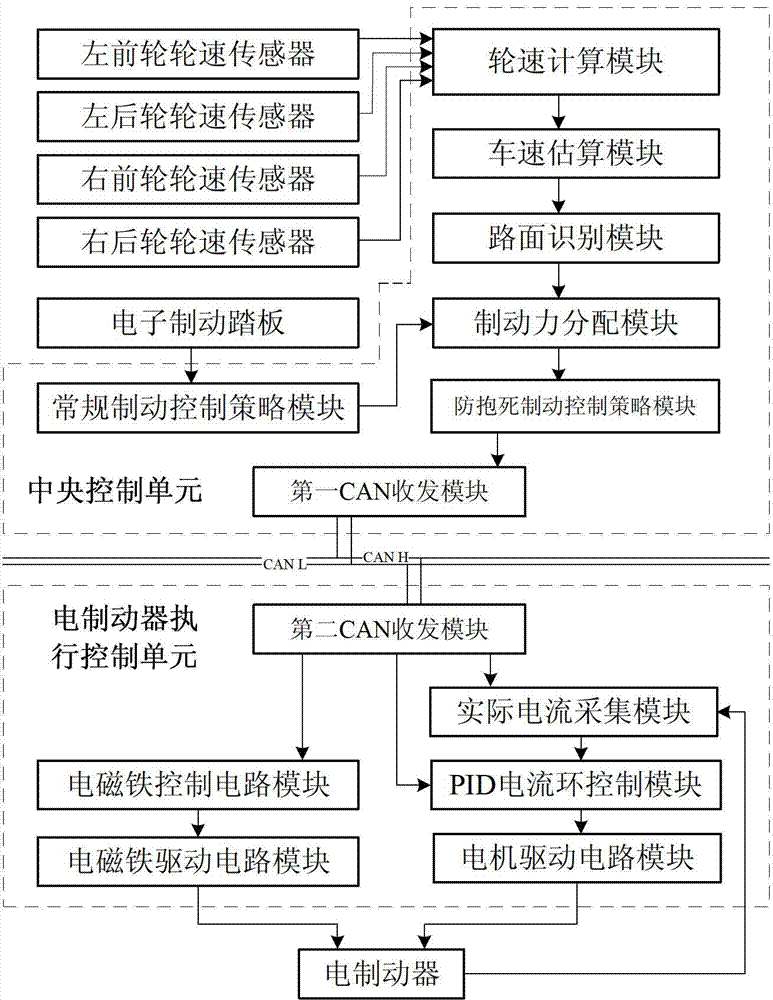

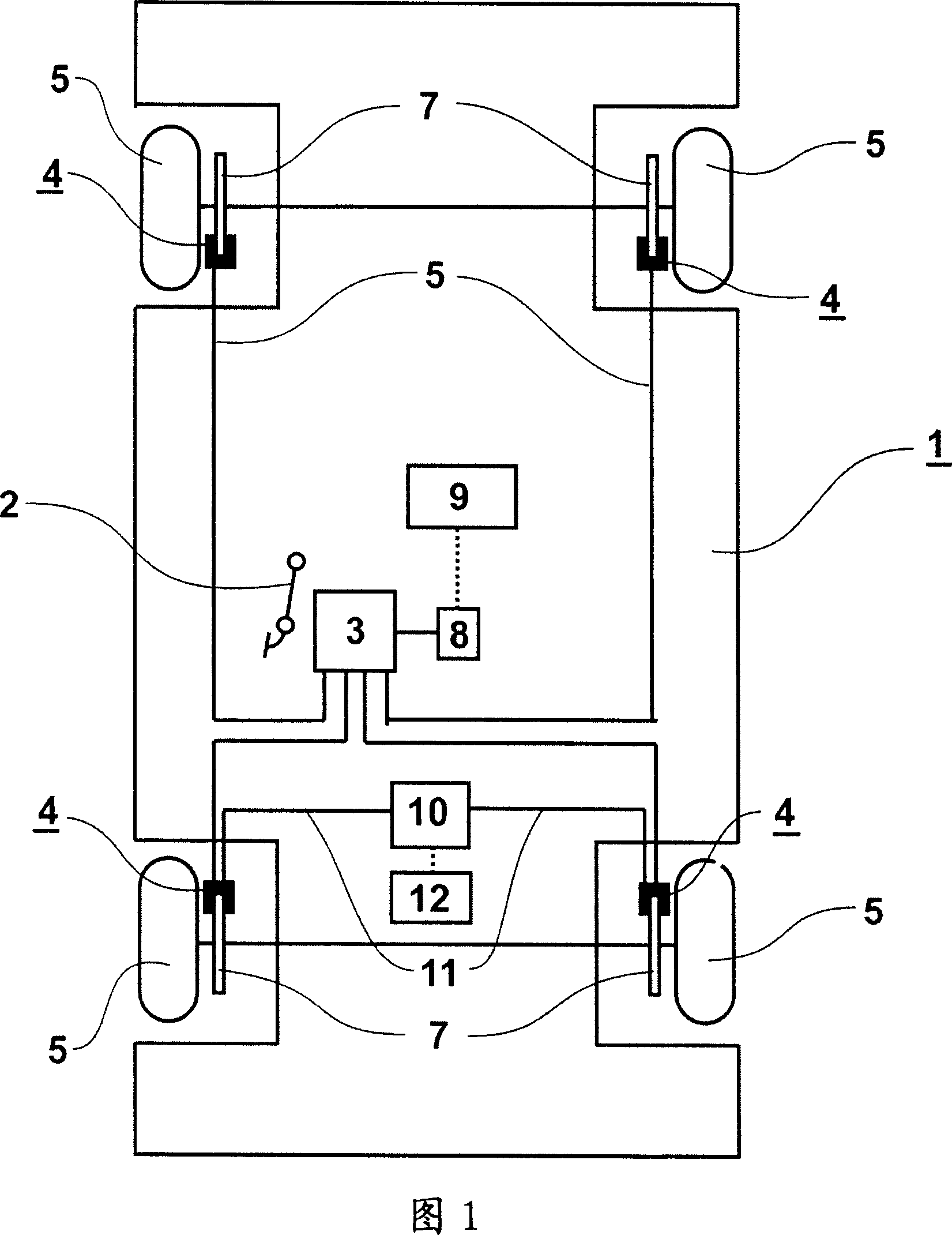

Electromechanical brake system based on automobile bus and automobile

The invention provides an electromechanical brake system based on an automobile bus. The electromechanical brake system based on the automobile bus comprises a brake signal input unit, a central control unit, a plurality of electric brake execution control units and a plurality of electric brakes, wherein the brake signal input unit is used for receiving brake signals and outputting the brake signals to the central control unit in real time; the central control unit is used for outputting multiple paths of brake motor target current signals to corresponding electric brake execution control units in real time according to the received brake signals; the electric brake execution control units are used for respectively driving and controlling corresponding electric brakes in real time according to the received brake motor target current signals; and the electric brakes are used for braking corresponding wheels. Correspondingly, the invention additionally provides an automobile with the brake system. The electromechanical brake system provided by the invention has the advantages of simple structure, small size, convenience in installation, low cost, quick brake response, good stability when used for braking , no pollution and the like.

Owner:CHERY AUTOMOBILE CO LTD

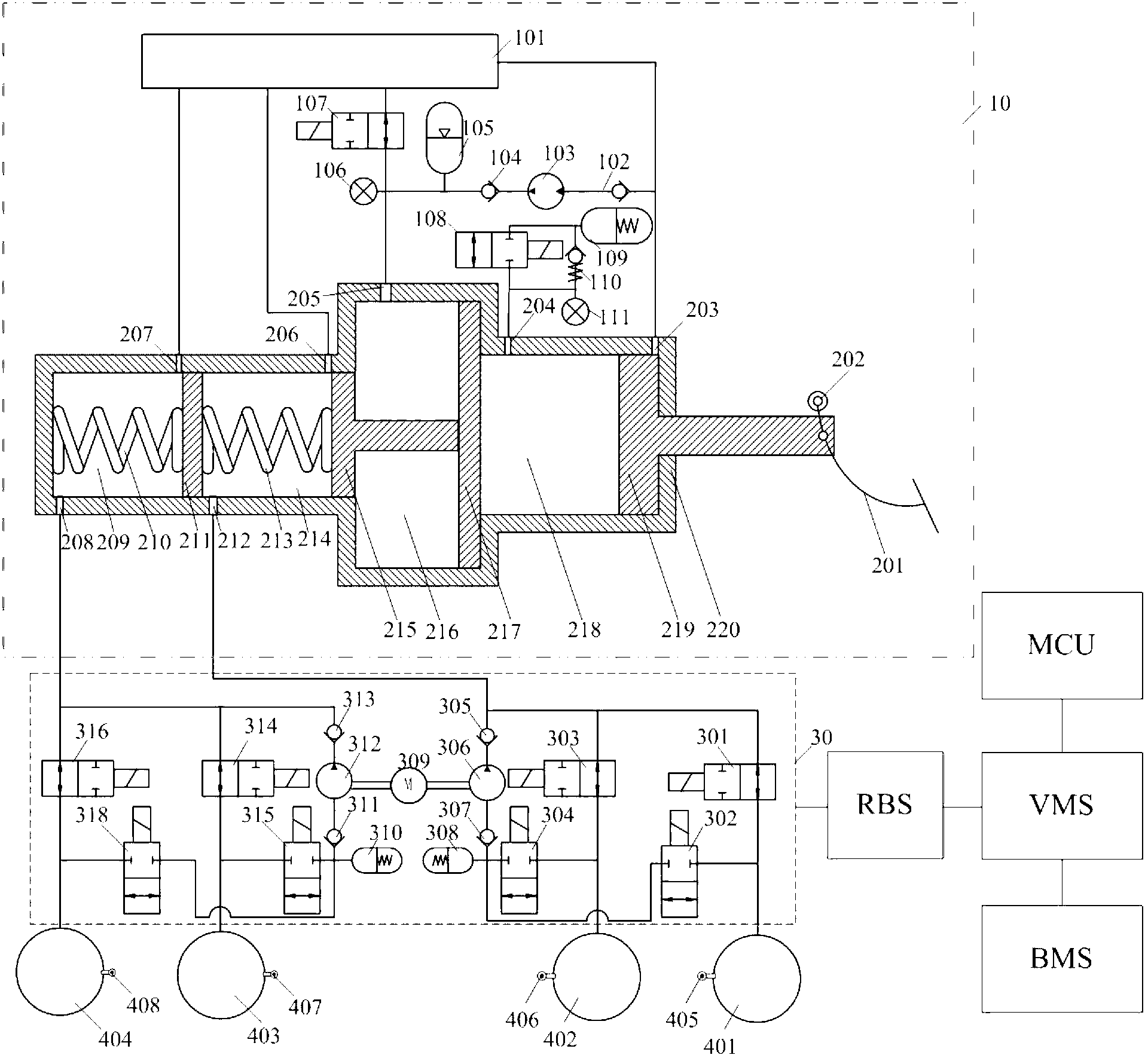

Pedal decoupling type electro-hydraulic composite braking system for integrated pedal displacement measurement

ActiveCN103253146AHighly integratedEase of difficulty and costBraking action transmissionElectrodynamic brake systemsElectro hydraulicAutomotive engineering

The invention relates to a pedal decoupling type electro-hydraulic composite braking system for integrated pedal displacement measurement. The pedal decoupling type electro-hydraulic composite braking system for the integrated pedal displacement measurement comprises a hydraulic braking subsystem and a motor regenerative braking subsystem, wherein an integrated type braking master cylinder assembly of the hydraulic braking subsystem is composed of an integrated type braking master cylinder and a high-pressure oil source. The integrated type braking master cylinder integrates a braking master cylinder pressure generation function, a pedal feeling imitation function and a positive and passive hydraulic assistance function. A high-pressure oil outlet of the high-pressure oil source is connected with the integrated type braking master cylinder, and provides stable and continuous braking energy for the braking process. A pressure sensor is installed on the integrated type braking master cylinder to achieve measurement of displacement of a braking pedal, and decoupling of the braking pedal is achieved. The pedal decoupling type electro-hydraulic composite braking system for the integrated pedal displacement measurement is compact in structure, easy to implement and high in integration degree, improves feeling of the braking pedal of a vehicle, has a positive hydraulic assistance function in a normal braking condition, has a passive hydraulic assistance function in an ineffective condition, effectively ensures braking safety of the vehicle, can be applied to a traditional vehicle line control braking system, and can be widely applicable to all-electric cars, hybrid electric cars and fuel cell cars.

Owner:TONGJI UNIV

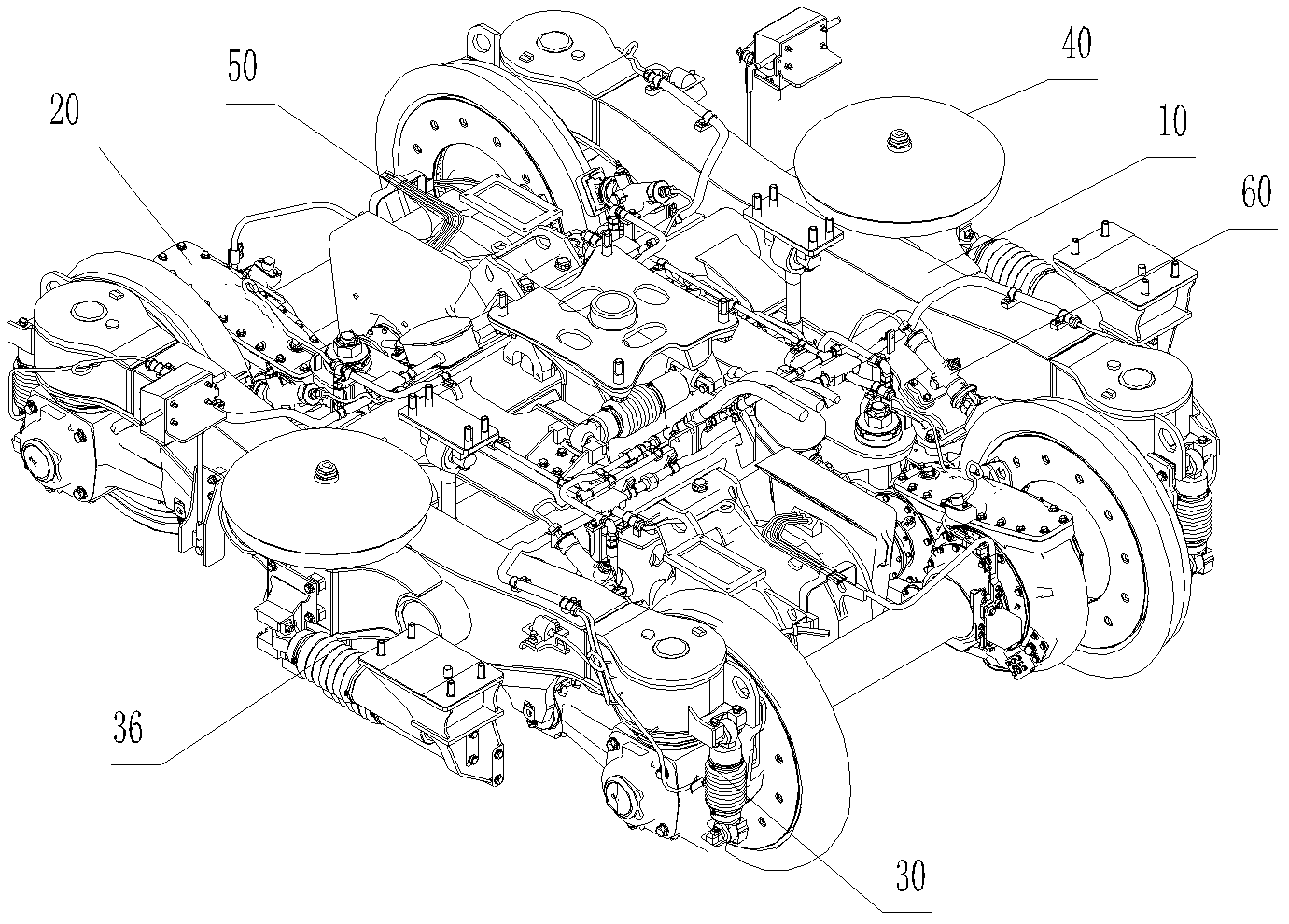

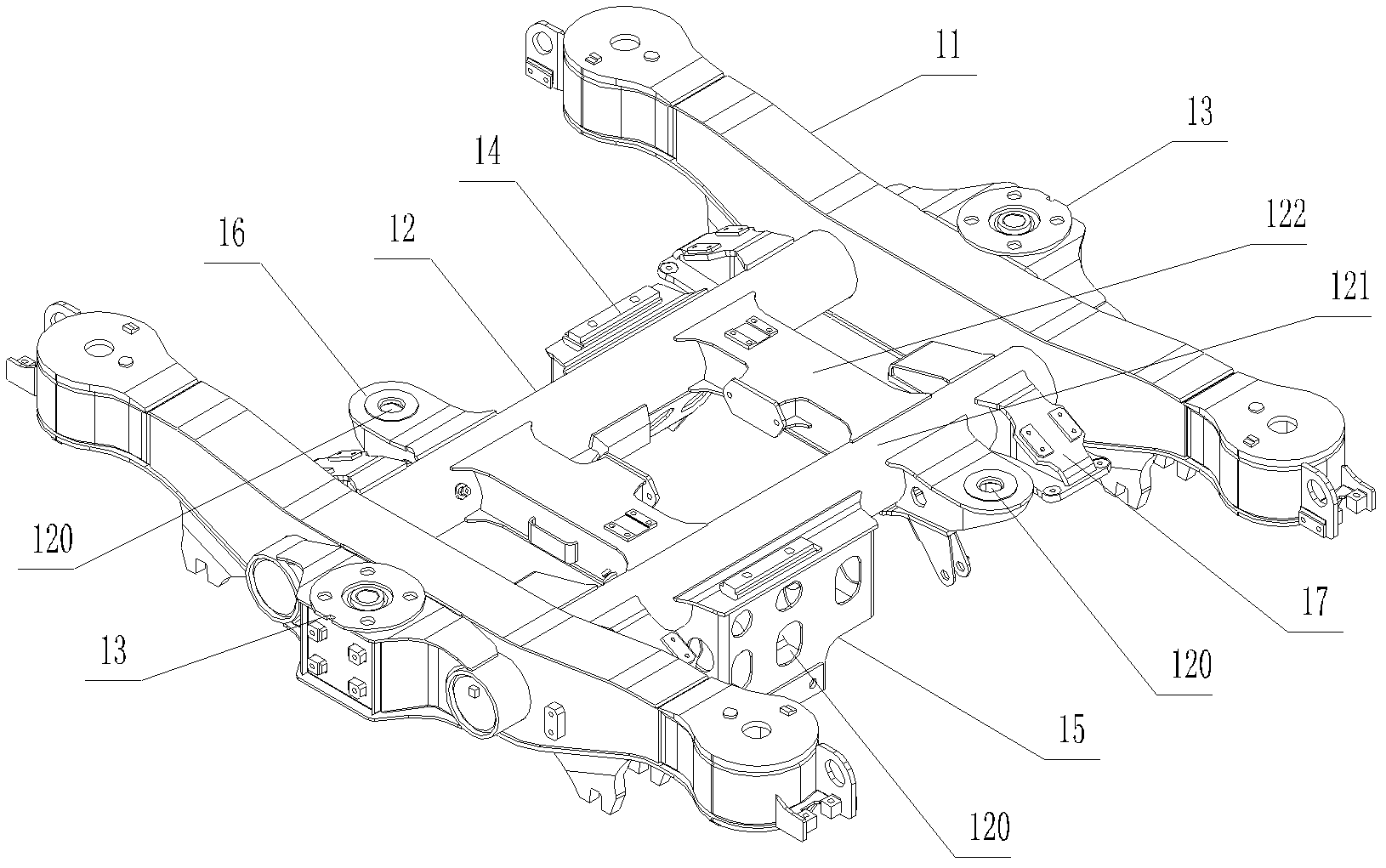

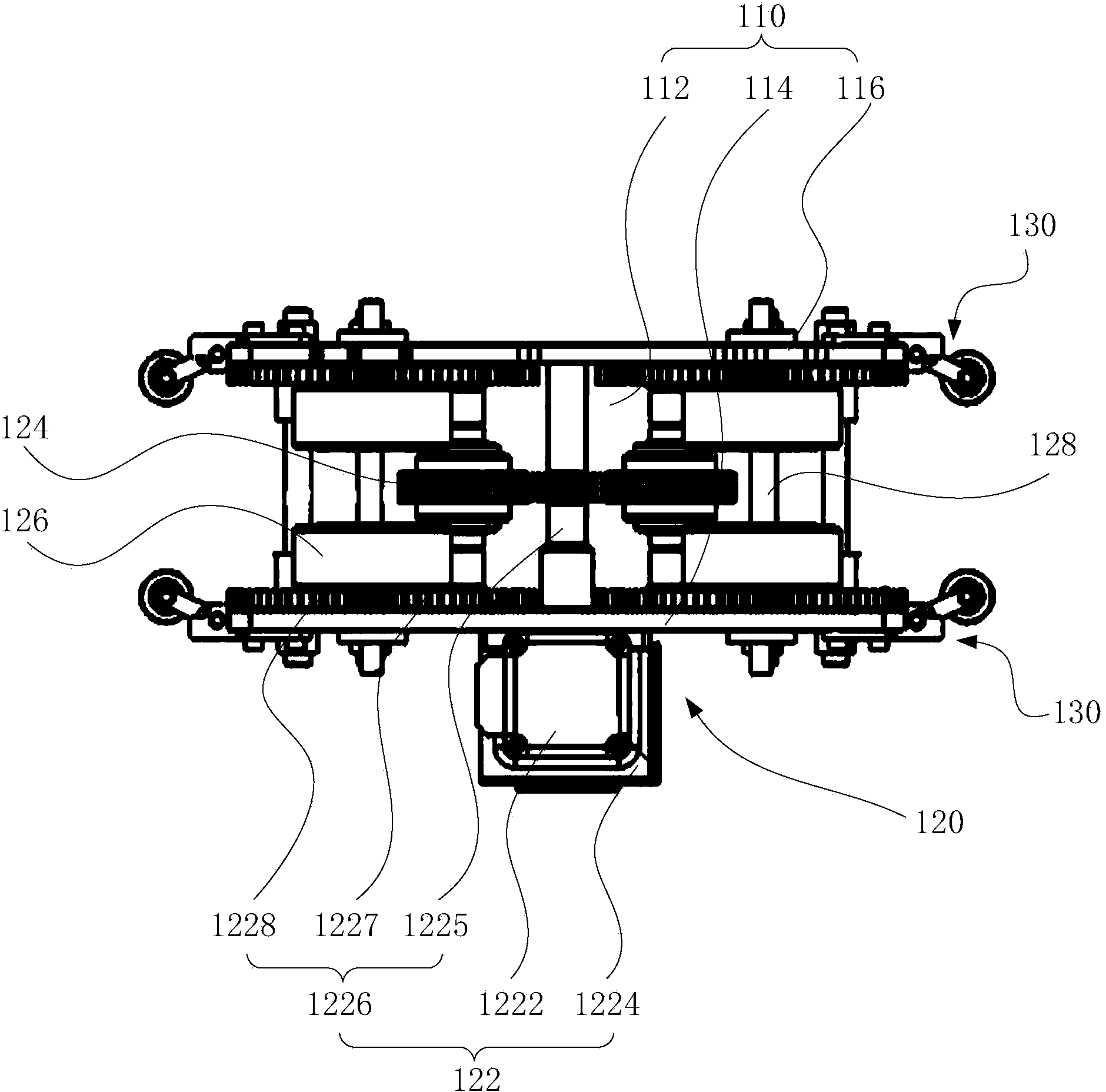

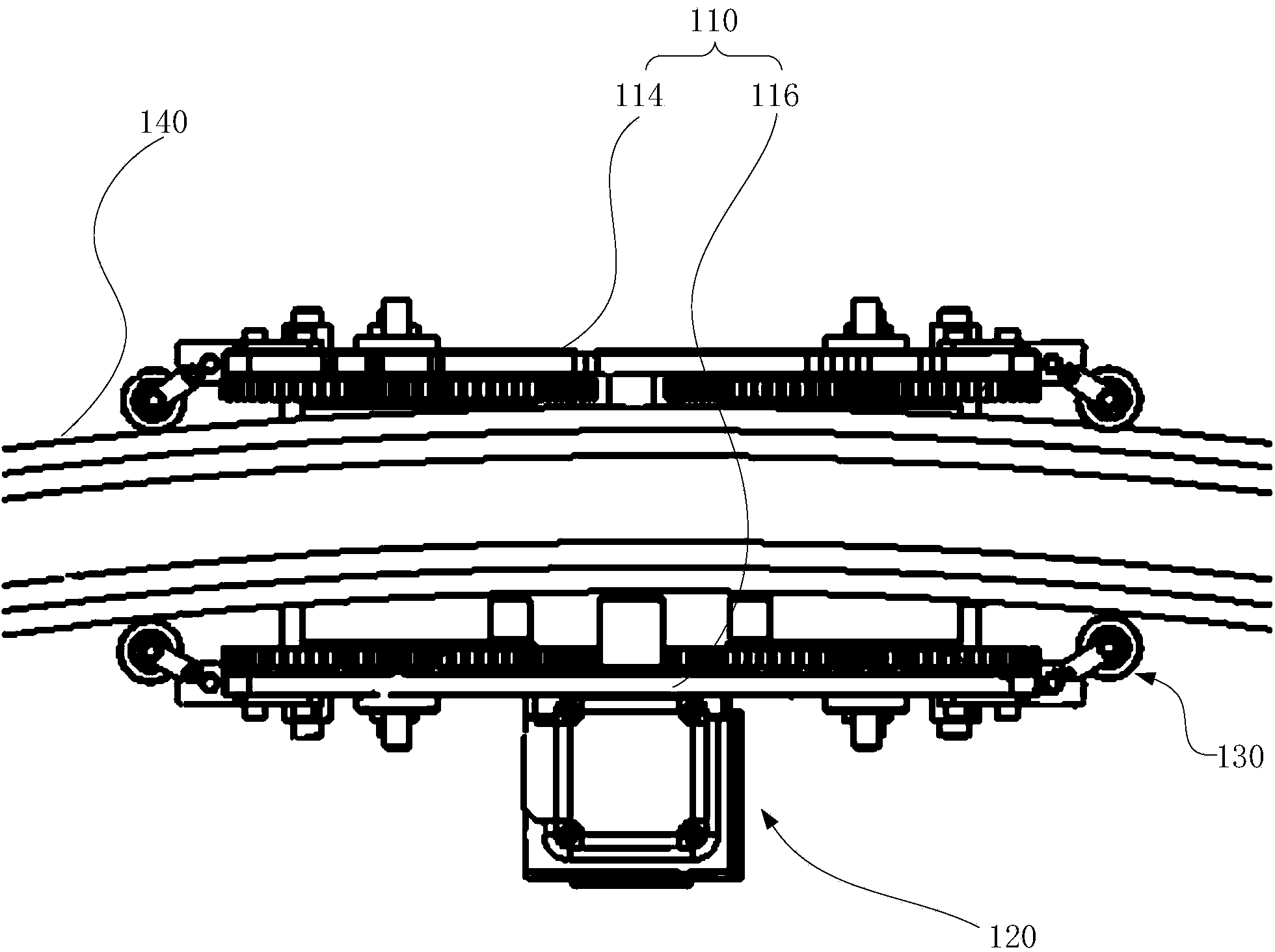

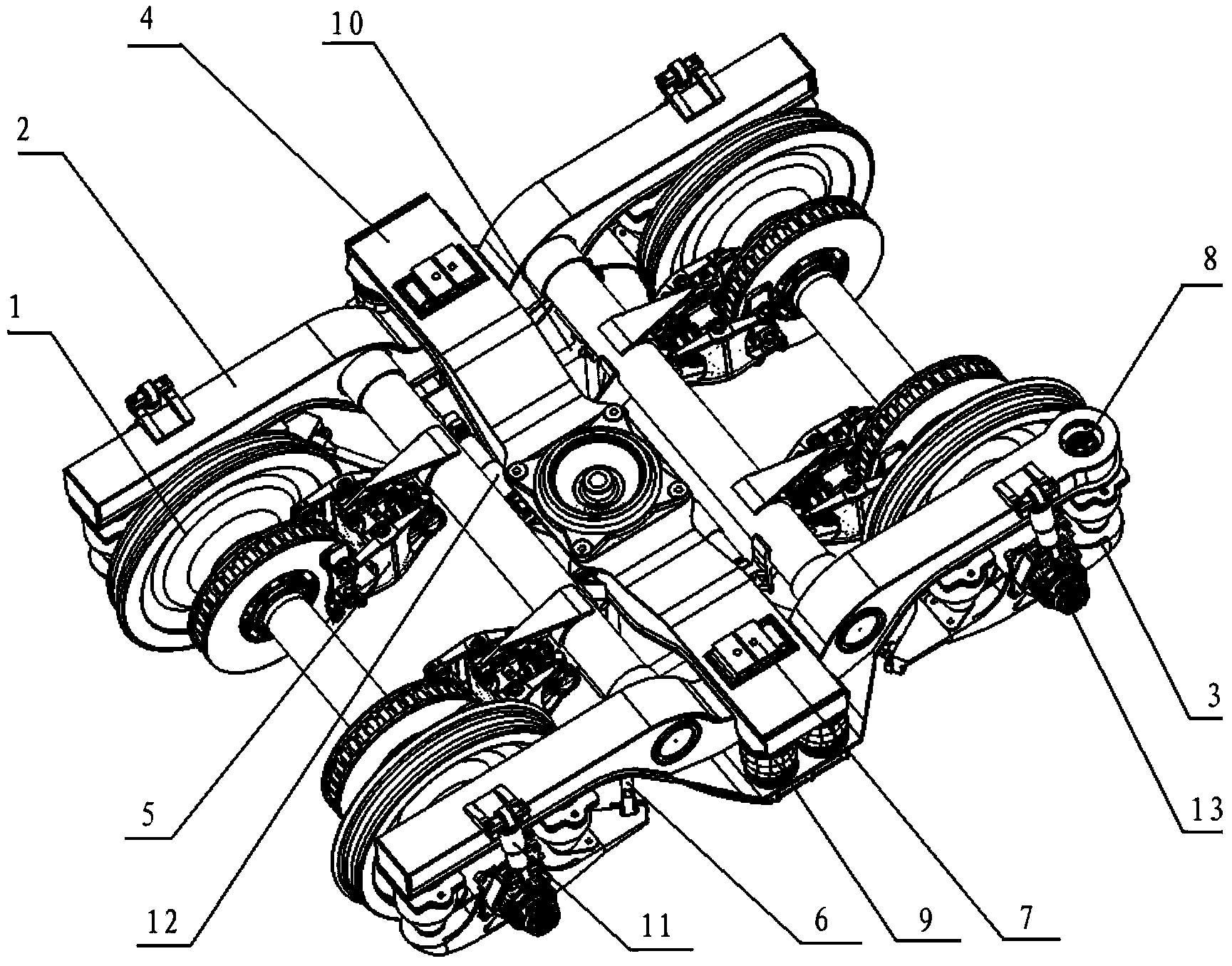

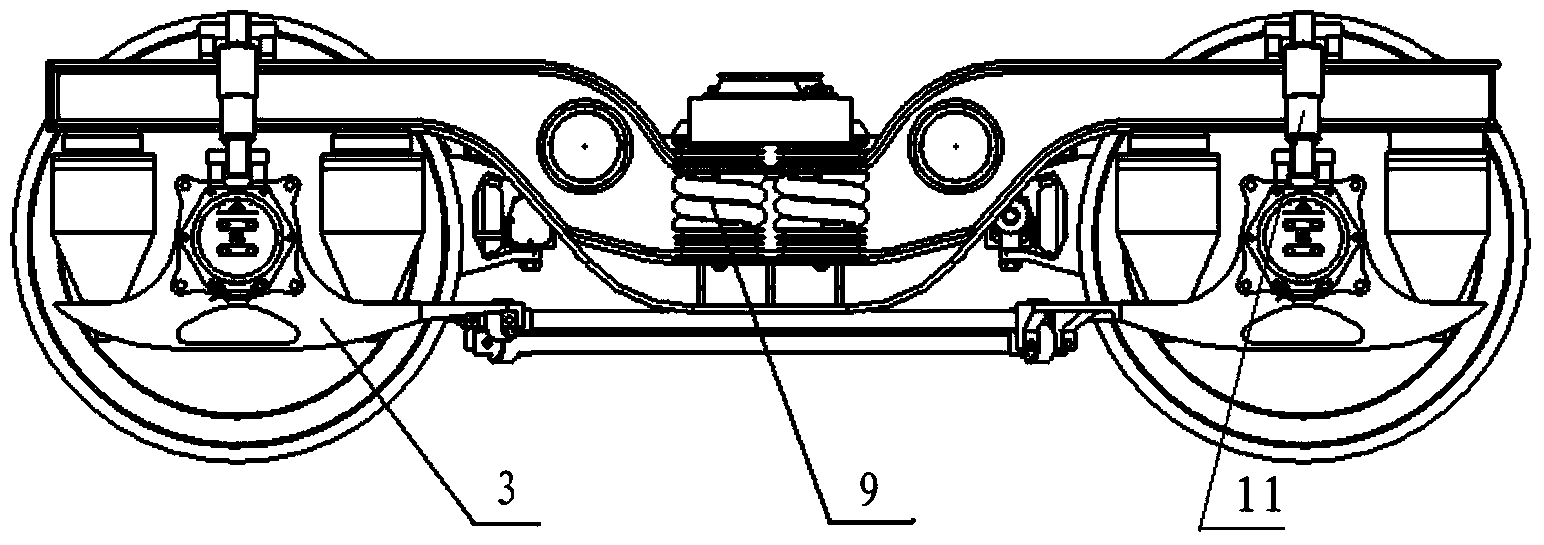

Bogie of high-speed motor train unit

InactiveCN102923153AAchieve lightweight designGuaranteed stabilityBogiesWheel-axle combinationsBogieAir spring

The invention discloses a bogie of a high-speed motor train unit. By adopting a brand-new bogie structure and a hanging connection and traction mode, overall lightweight design is realized, the unsprung weight of the bogie is reduced, and the hanging parameter between the bogie and a body is optimized. On the basis that the high-speed running speed is met, stability when the bogie passes through a big corner and good traction and braking performance are expected. The bogie comprises a framework, two groups of wheel set travelling devices, a linear motor, a first hanging device, a second hanging device, a traction device and a foundation brake device. The framework comprises a pair of side beam assemblies and a pair of cross beam assemblies which are connected with each other; each side beam assembly has a hollow box body structure, and comprises a pair of upper and lower cover plates and a pair of lateral web plates which are welded; each cross beam assembly comprises a pair of hollow steel pipes penetrating the lateral web plates and welded with the lateral web plates; and a pair of air spring supporting beams is welded at two ends of a steel pipe and outside the lateral web plates.

Owner:CRRC QINGDAO SIFANG CO LTD

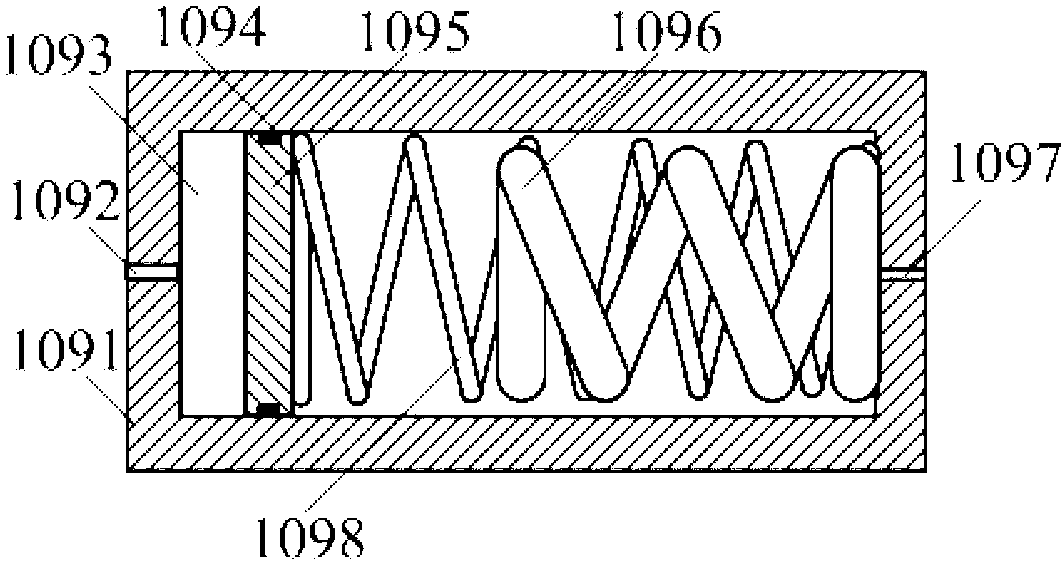

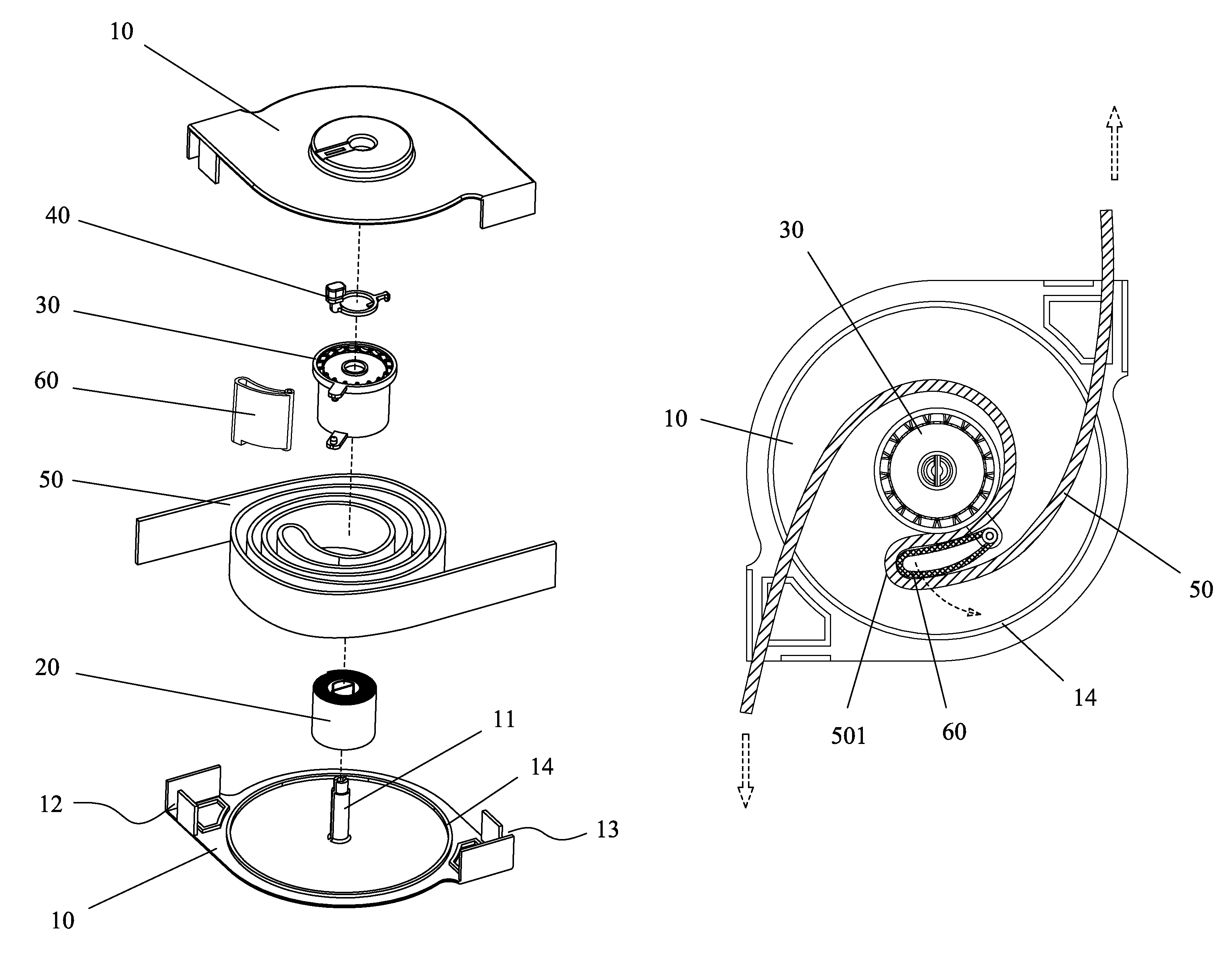

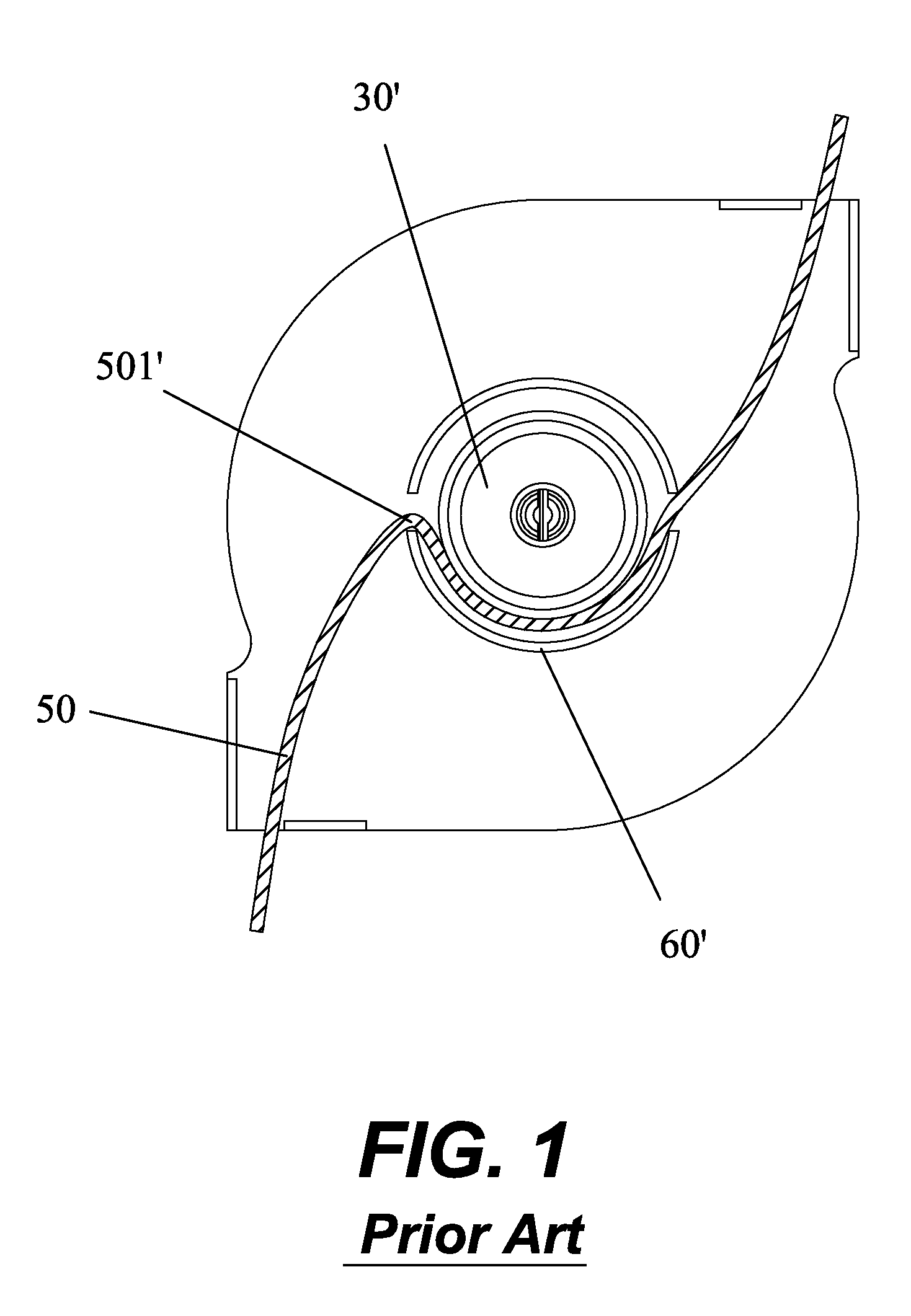

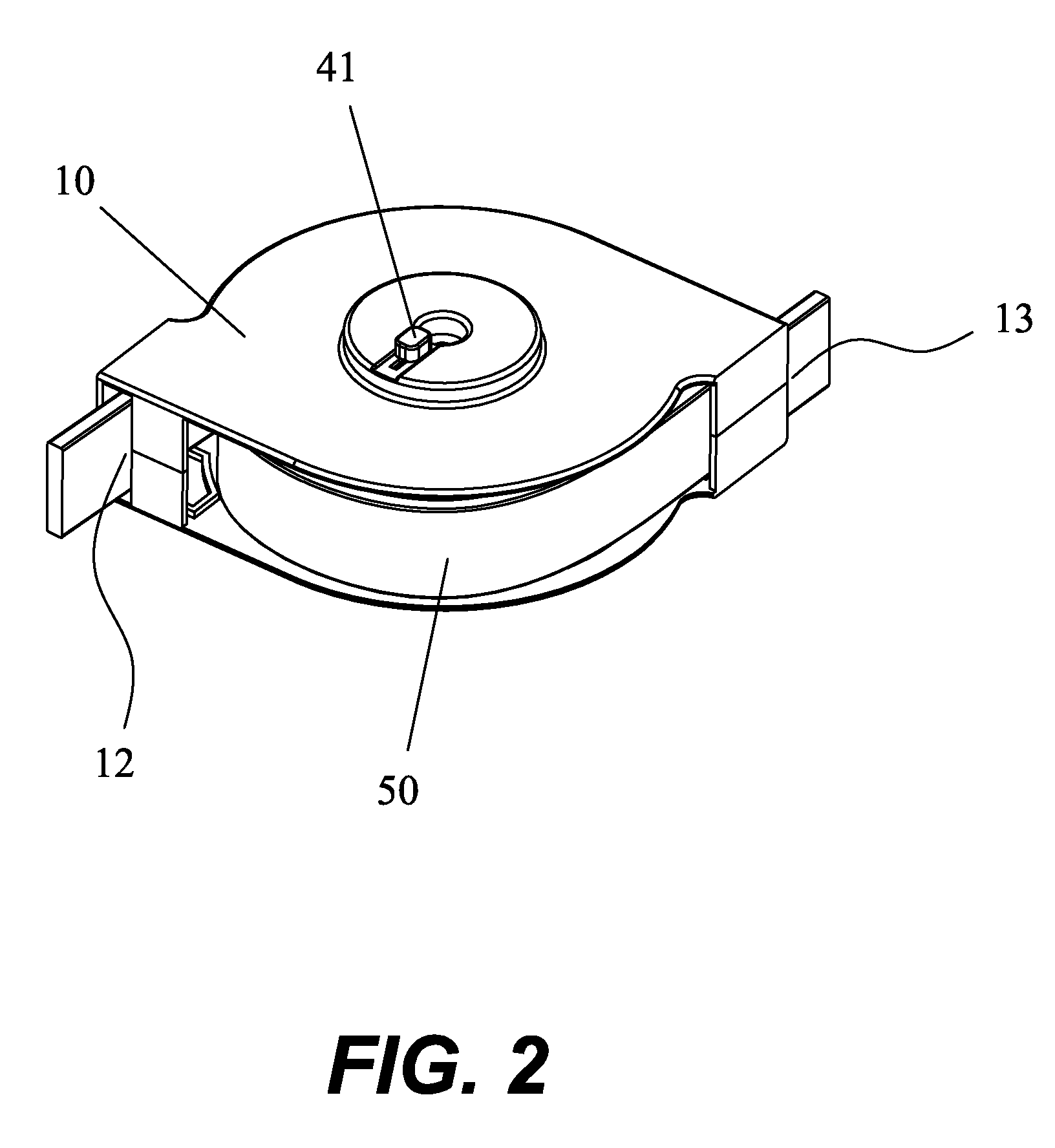

Retractable cable device having protecting function

InactiveUS7900863B1Improve fastening structureAvoid inferior quality of productCoil springEngineering

A retractable cable device having protecting function mainly comprises a housing, a spiral spring, a spool disk, an arresting system, and a communication cable. The spool disk pivoted on a shaft within the housing is wound by the communication cable. The spiral spring provides the spool disk with a reeling force to reel in the communication cable. The rotation of the spool disk flexibly controlled by the arresting system decides the protruding length of the communication cable. A swaying member installed on the spool disk is utilized to replace the conventional immovable clip for fixing the communication cable. Whereby, when the entire communication cable is drawn out, the communication cable at a second end of the swaying member presents a larger bent angle. Therefore, the communication cable is subjected to bending with less sharp degree, thence protecting the communication cable, especially for the core, by preventing it from damage.

Owner:CHENG CHI WEN

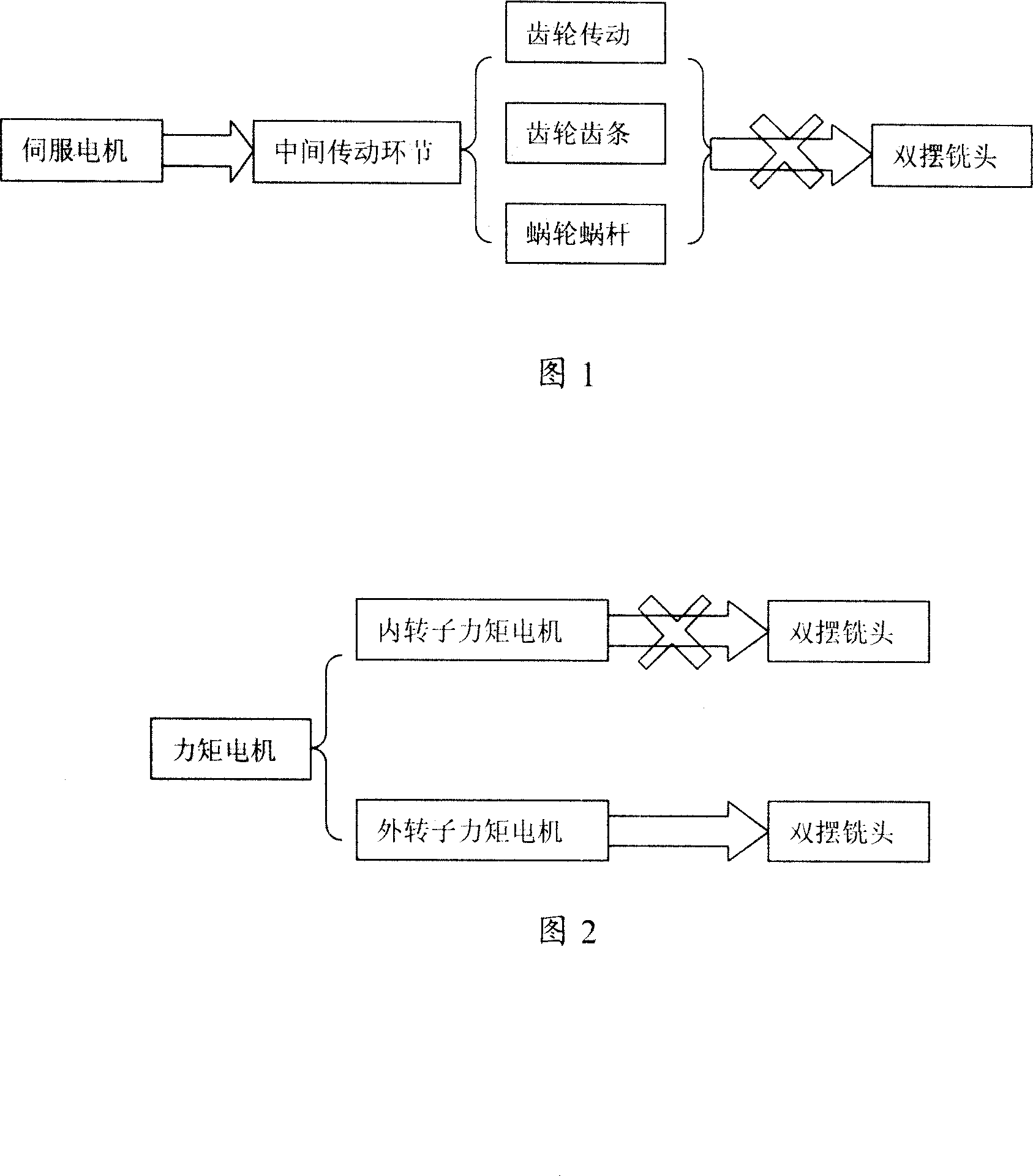

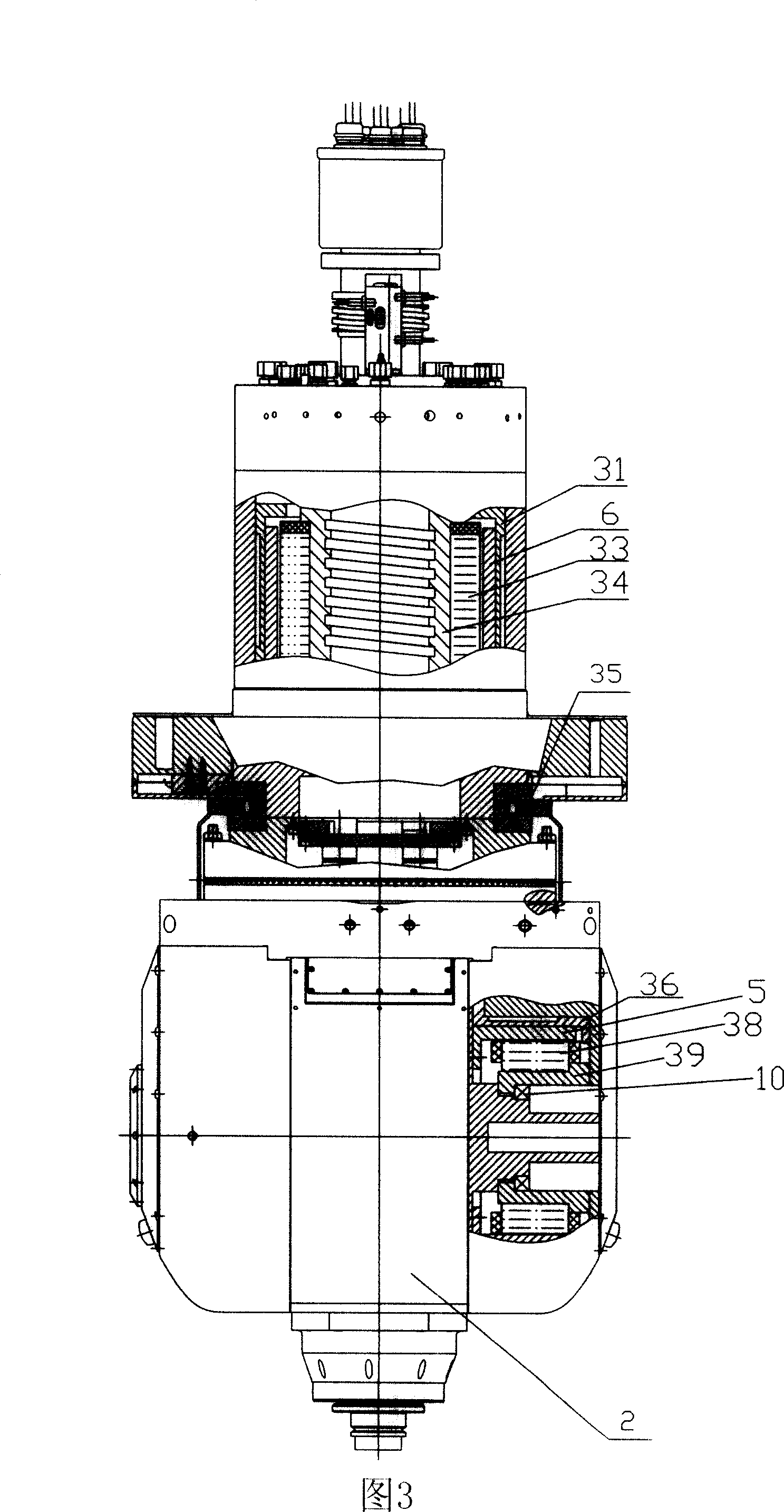

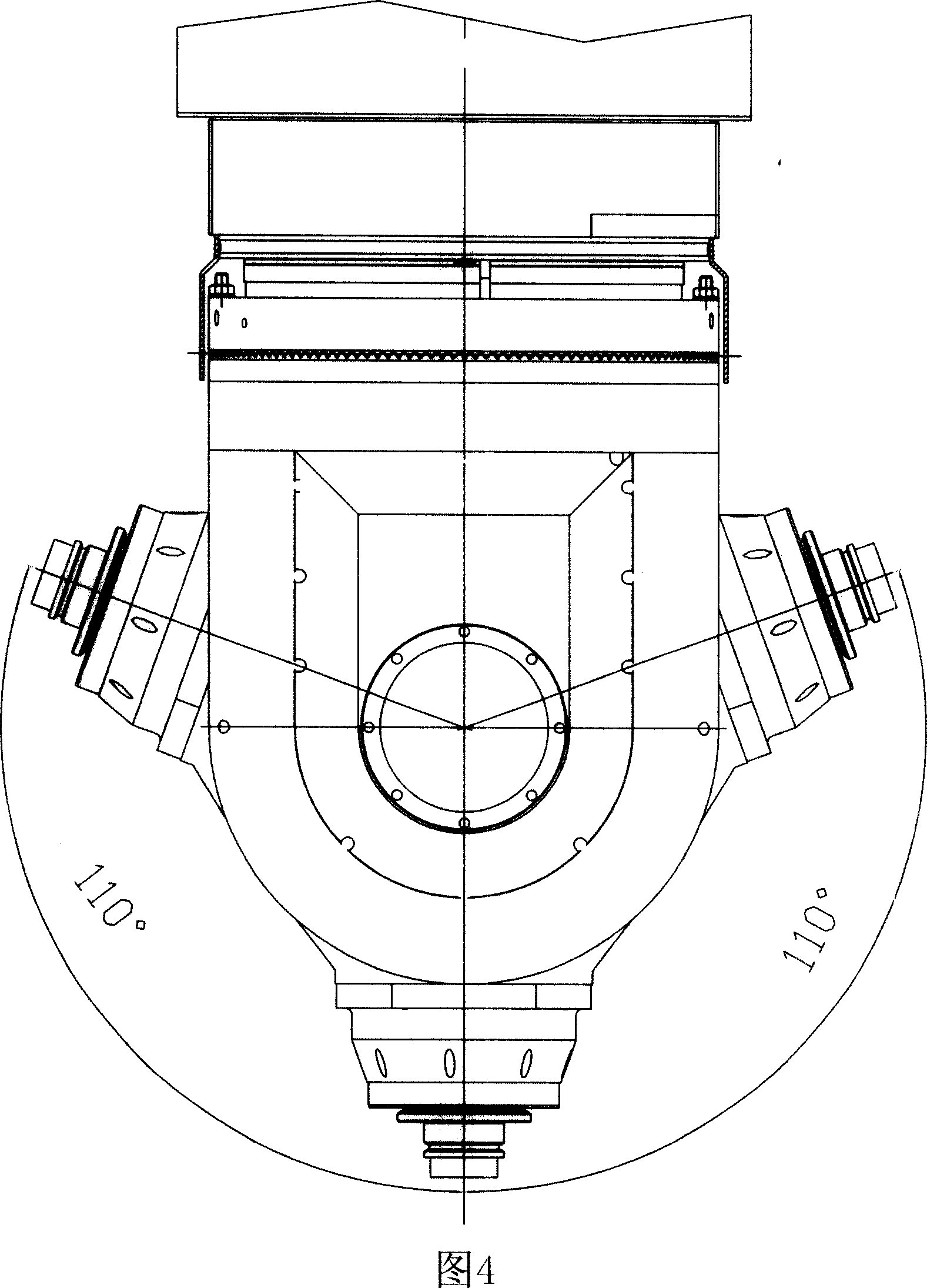

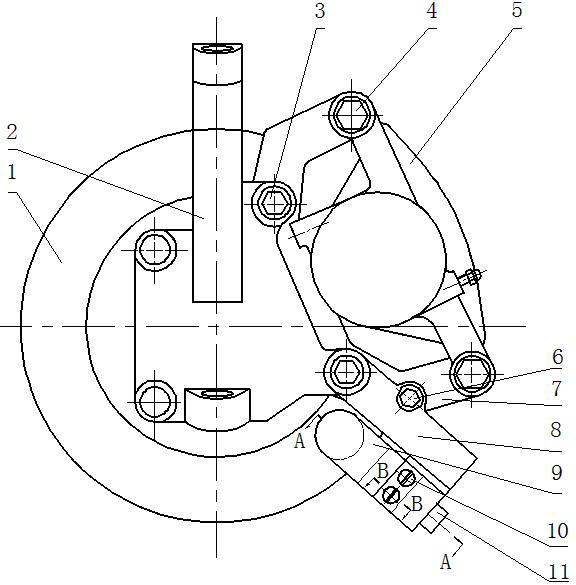

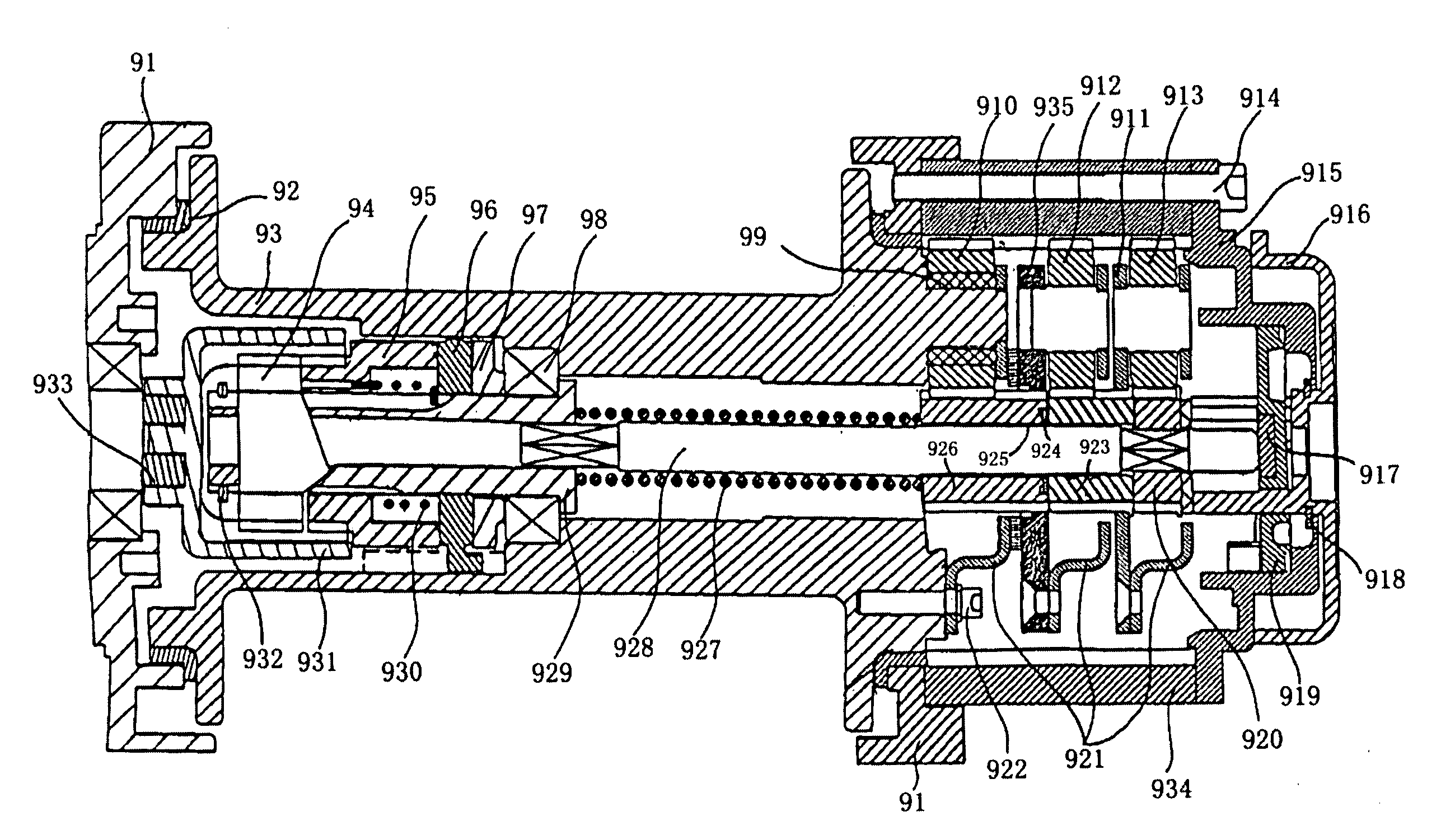

Double pendulum milling head of AC permanent magnetic synchronization external-rotor-type force moment motor drive

ActiveCN101011795AImprove running accuracyImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectricityNumerical control

The double pendulum milling head driven by the AC permanent syntactic rotor torque motor having a cross hollow shaft, whose both ends fixed on the rotor of the horizontal torque motor at both ends of the A shaft. Acting as an integral, they are fixed on the rotor of the vertical torque motor of C shaft. In this way, vertical motor driving the milling head to rotate around C shaft, and A shaft horizontal motor driving the pendulum of milling head around A shaft. It complete the complex machining of the working piece through compound motion in two directions matching the high speed revolution of the shaft itself. It is compact in structure, simple of drive, good in rigidity, smaller in mechanical components quantity, higher reaction sensitivity, free from wear and reverse gap, being able to machining for a five-face body with high precision.

Owner:KEDE NUMERICAL CONTROL CO LTD

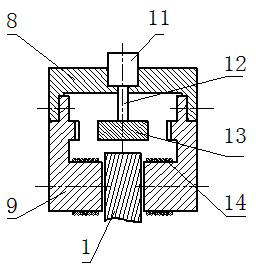

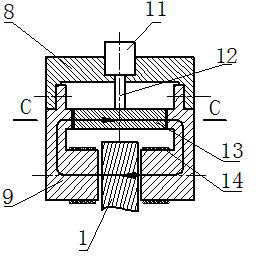

Electromagnet and friction composite disc type brake and brake method

InactiveCN102128227AShort duration of actionReduce usage intensityAxially engaging brakesBrake actuating mechanismsFriction reductionElectromagnetic field

The invention provides an electromagnet and friction composite disc type brake and a brake method. Both a steering knuckle and a brake caliper bracket are fixedly connected with an electromagnet brake fixing device, and the electromagnet brake fixing device is fixedly connected with magnet cores. The magnet cores are symmetrically arranged on the two sides of a brake disc, and coil windings are wound on the magnet cores. Permanent magnet bodies and the magnet cores are oppositely arranged, and air gaps are arranged between the permanent magnet bodies and the magnet cores. When an automobile brakes, electromagnet fields distributed on the axes of the coil windings are generated after the coil windings are electrified, and the directions of the electromagnet fields generated by the coil windings on the two sides of the brake disc are consistent. The permanent magnet bodies rotate 90 DEG, the directions of the permanent magnet fields of the permanent magnet bodies are consistent with the directions of the electromagnet fields of the coil windings, and the brake disc is braked by the superposition of the electromagnet fields and the permanent magnet fields. The size of the brake force is adjusted by adjusting the different rotating angles of the permanent magnet bodies or the size of electrifying current in the coil windings. The action time of the brake is shortened, the brake efficiency is enhanced, the use strength of the friction brake is reduced, the abrasion of brake pads is alleviated, and the brake force is easy to control.

Owner:JIANGSU UNIV

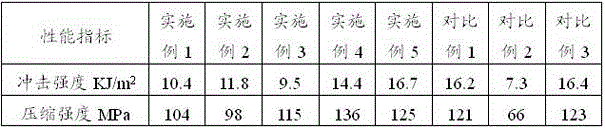

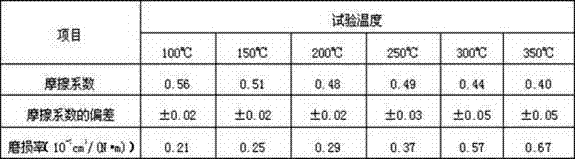

Reinforced wear-resistant automobile brake composite material and preparation method thereof

ActiveCN103059504AImprove wear resistanceLow costOther chemical processesFriction liningWear resistantCoupling

The invention discloses a reinforce wear-resistant automobile brake composite material which is prepared from the following components in parts by weight: 85-100 parts of resin matrix, 100-150 parts of composite reinforcing fiber, 80-120 parts of filler, 25-40 parts of toughening material, 6-10 parts of curing agent, 4-6 parts of curing accelerator, 30-85 parts of frictional property regulator, 30-40 parts of noise reducer and 4.5-6 parts of releasing agent. The resin matrix is reinforced by the composite reinforcing fiber and matched with proper frictional property regulator, filler, toughening material and noise reducer to display the synergic coupling actions among the resin matrix, reinforcing fiber, filler and frictional property regulator, thereby obtaining the novel automobile brake composite material which has the advantages of stable friction factor, small wear rate, high heat fade resistance, favorable braking effect, shock absorption, noise reduction, high mechanical strength, low cost, long service life and favorable braking property at different temperatures.

Owner:江苏裕铭铜业有限公司

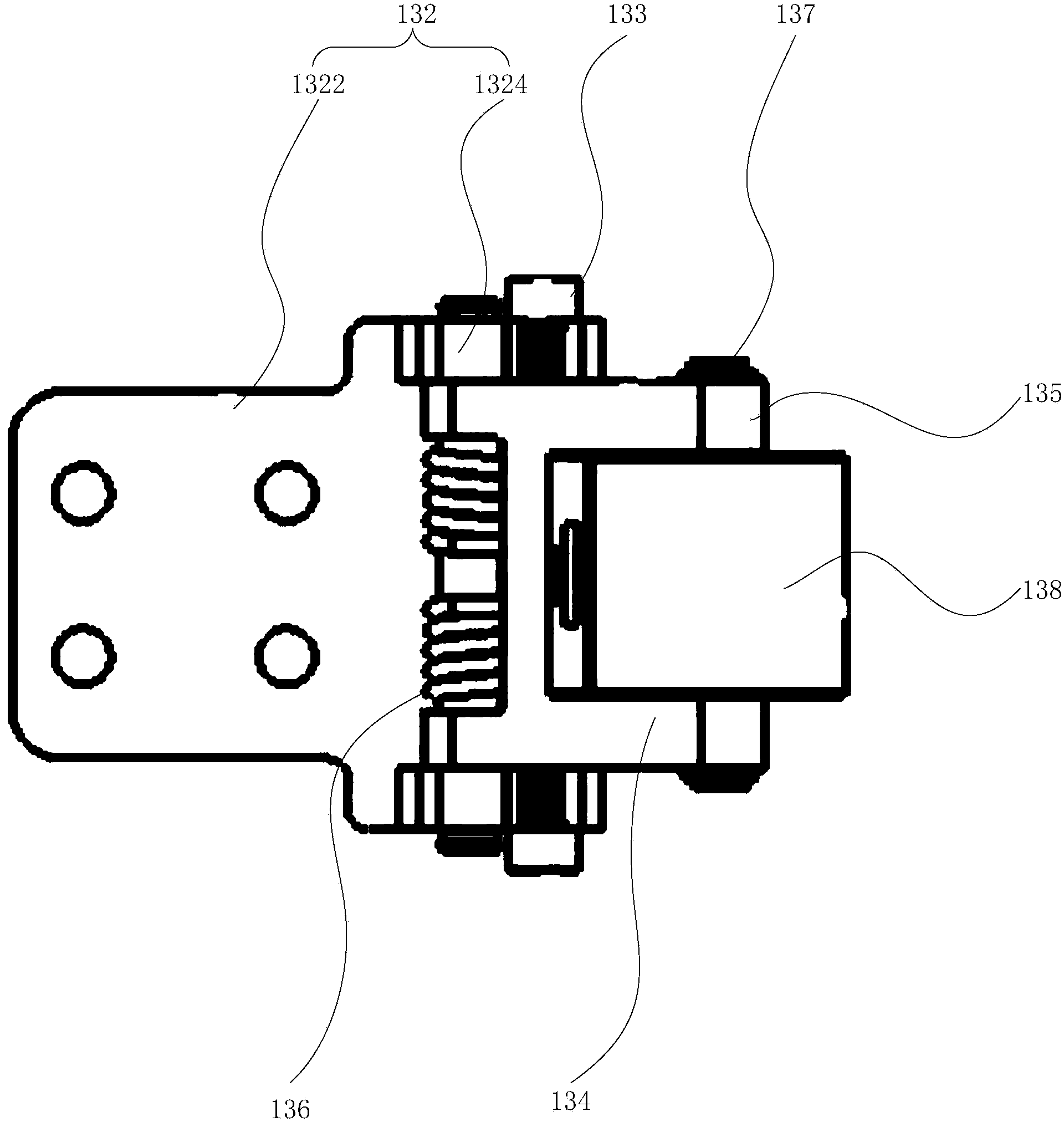

Inspection robot

ActiveCN103802086AAvoid repeated positioning difficultiesGuaranteed uptimeManipulatorCushioningEngineering

An inspection robot comprises a supporting frame body, a driving mechanism and a guiding wheel mechanism closely stuck to the orbital wall, wherein the driving mechanism comprises a driving device with adjustable actuating speed, a differential mechanism and at least two groups of marching wheels. The driving device is connected with the differential mechanism in a transmission mode, the differential mechanism is arranged between the marching wheels and is connected with the marching wheels in a transmission mode, and the driving device, the differential mechanism and the marching wheels are all arranged on the supporting frame body respectively. The guiding wheel mechanism closely stuck to the orbital wall comprises at least two groups of guiding wheel components which are arranged on the supporting frame body. According to the inspection robot, the driving device drives the differential mechanism and the differential mechanism drives the marching wheel so that multi-driving can be achieved, uphill slipping and difficulty in repeated positioning can be avoided, braking performance can be improved and turning capability can be improved, and the guiding wheel mechanism is closely stuck to the orbit so that waggle in the robot can be avoided, shock absorption and cushioning function which absorb goggling and shaking of the robot caused by unflatness of the orbital wall can be achieved, and stability and security in the operation of the inspection robot can be improved.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD +1

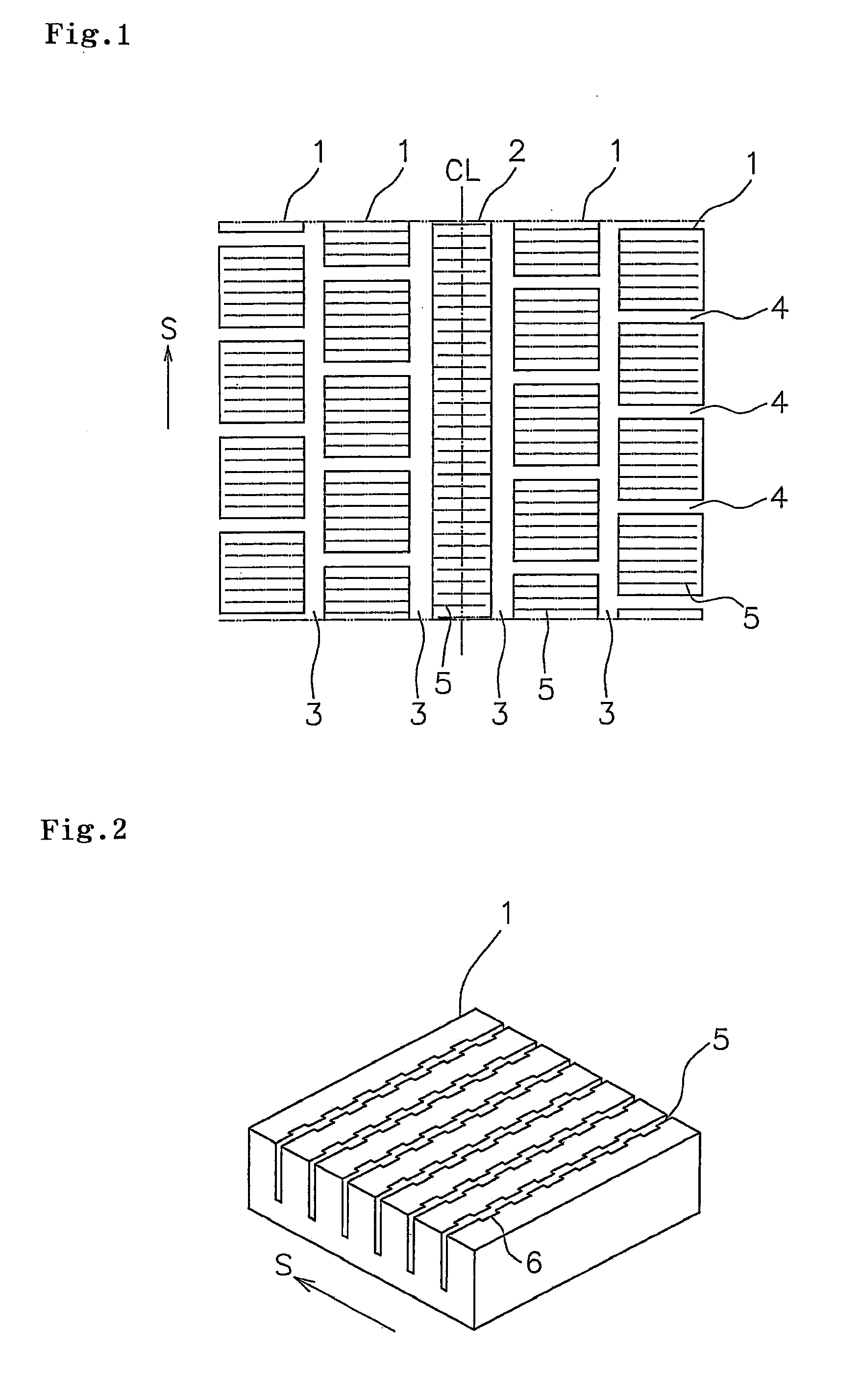

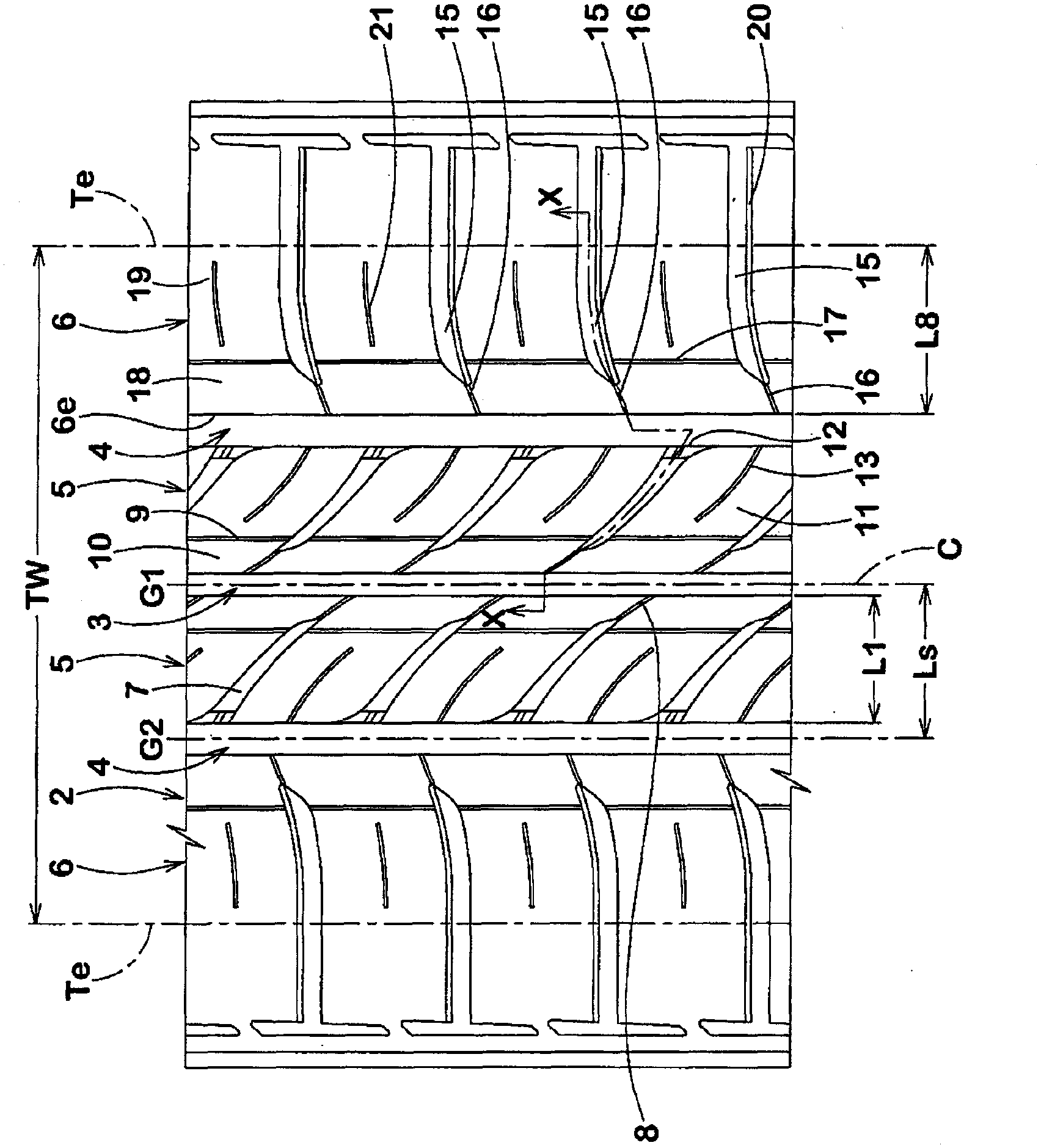

Pneumatic Tire

ActiveUS20100116393A1Improve rigidityImprove braking effectTyre tread bands/patternsNon-skid devicesTreadAutomotive engineering

A pneumatic tire has a tread pattern including a plurality of main grooves extending along a tire circumferential direction, and a shoulder land portion constructed by a rib or a block row formed in an outer side in a tire width direction of the main groove positioned in an outermost side. A circumferential sipe is provided in each of the shoulder land portions in both sides in the tire width direction. The number of the circumferential sipes provided in the shoulder land portion in a vehicle inner side is larger than the number of the circumferential sipes provided in the shoulder land portion in a vehicle outer side.

Owner:TOYO TIRE & RUBBER CO LTD

Method for preparing brake pad friction material by using rice and wheat straws

InactiveCN103820078AAbundant resourcesReduce recycling costsOther chemical processesFriction liningFiberAtmospheric pollution

The invention discloses a method for preparing a brake pad friction material by using rice and wheat straws and relates to the technical field of composite materials. The brake pad friction material has the following formula: 15 percent of toughened fibers, 16 percent of modified resin, 14 percent of a friction increase agent, 9 percent of sulfur and tin powder, 1.6 percent of carbon black, 2.5 percent of zinc oxide, 8.9 percent of barium sulfate, 10 percent of rice and wheat straw carbon powder, 6 percent of aluminum hydroxide, 14 percent of modified li beads and 3 percent of zinc stearate. The materials are uniformly mixed and stirred, pressed in a mold and subjected to machining such as grinding and chamfering according to a technical requirement to obtain a braking pad. According to the method, the rice and wheat straws are used as raw materials to prepare carbon powder which replaces graphite in a friction material formula, so that the atmospheric pollution caused by severe combustion of straws in each year is alleviated, the production cost of the brake pad is reduced, and the brake performance and the braking effect are enhanced; the friction coefficient is stable; the brake pad is simple in structure, low in brake noise, environment-friendly and pollution-free.

Owner:YANCHENG XINHAO MACHINERY

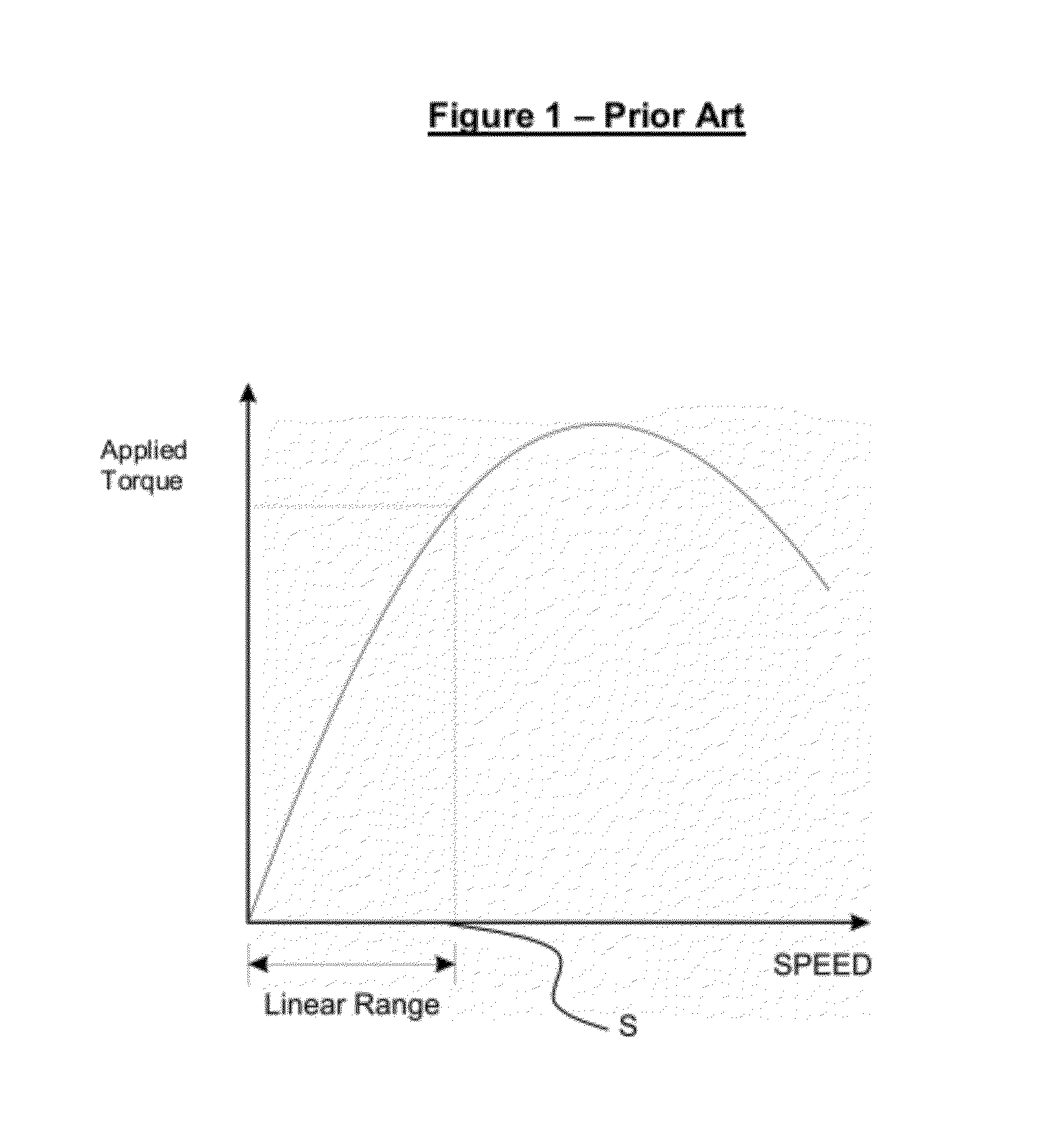

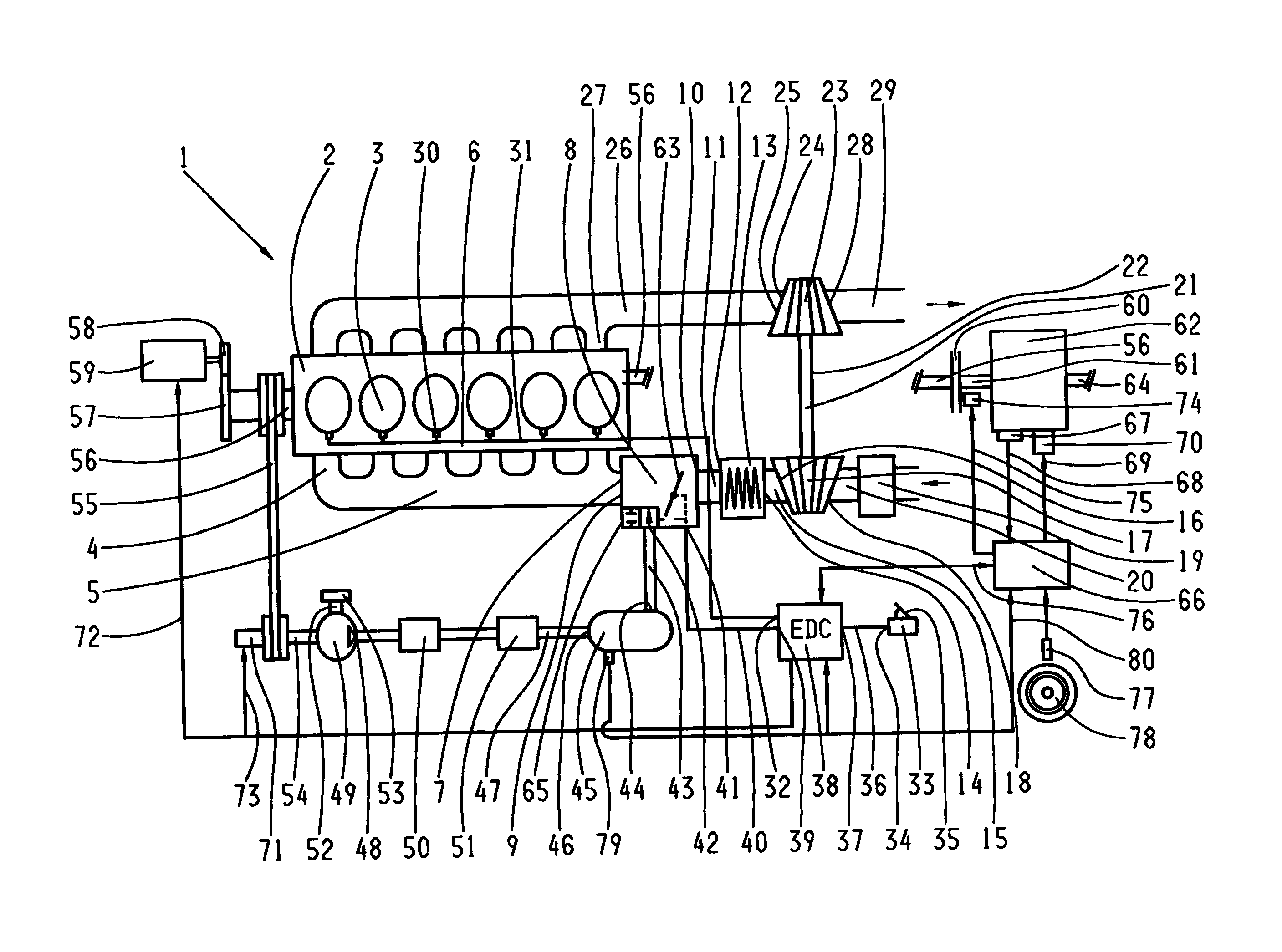

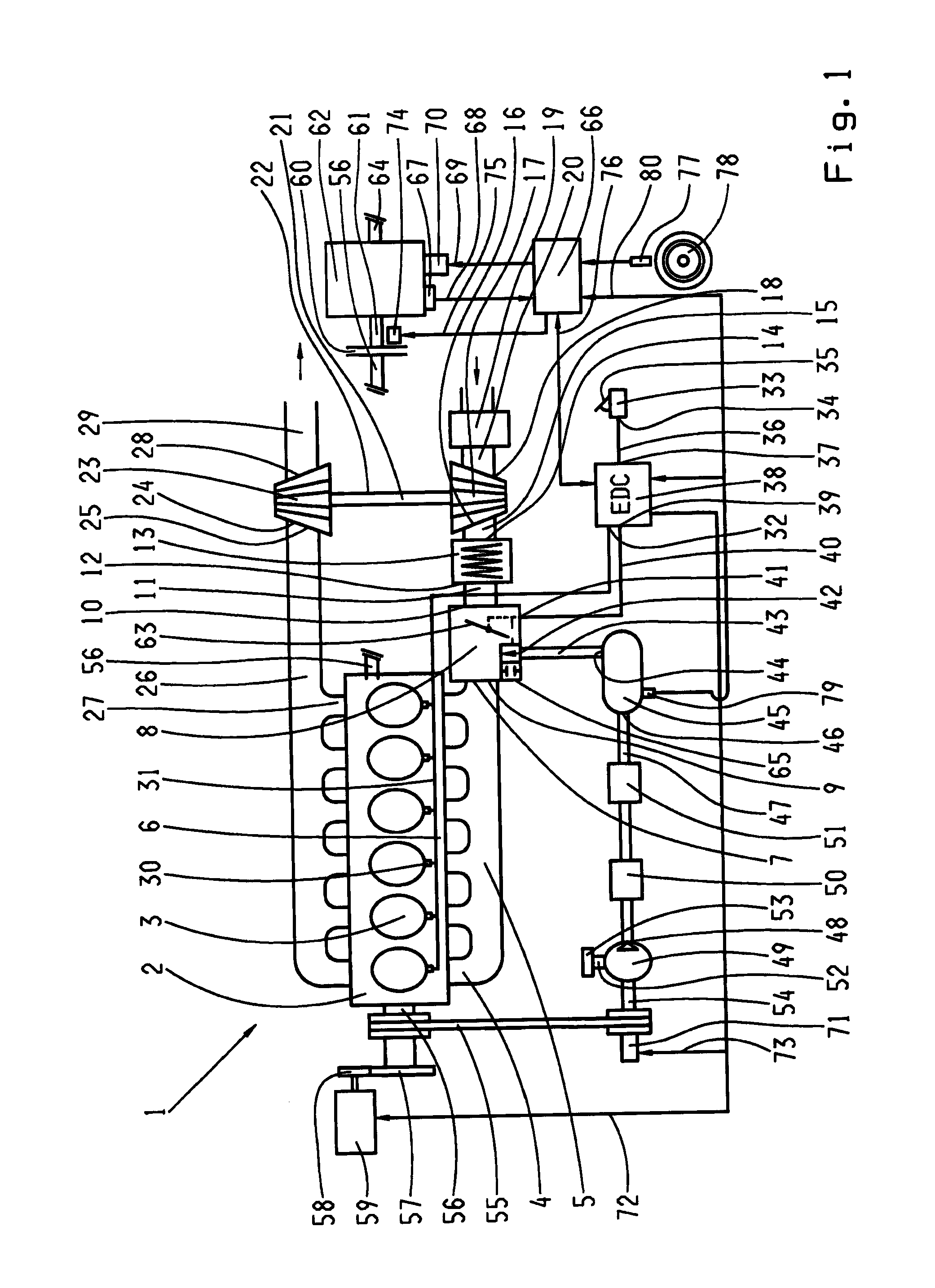

Method for controlling the compressed air supply of an internal combusion engine and transmission

InactiveUS20100318268A1Maximum and available torqueHigh torqueAnalogue computers for vehiclesElectrical controlCombustionEngineering

A method to operate a vehicle drive train comprising a combustion engine, a turbo charger assigned to the combustion engine, a mechanism for injecting additional compressed air into an air intake system of the combustion engine and a transmission. The method enables practical use of a compressed air injection mechanism, in the drive train, and comprises the step of controlling the time, the duration, the pressure and / or the volume of the additional compressed air, to be injected into the air intake system of the combustion engine, depending upon the performance request of the driver, the actual rotational speed and load condition of the combustion engine, the speed of the vehicle, and the procedures of the gear ratio change of the transmission.

Owner:ZF FRIEDRICHSHAFEN AG

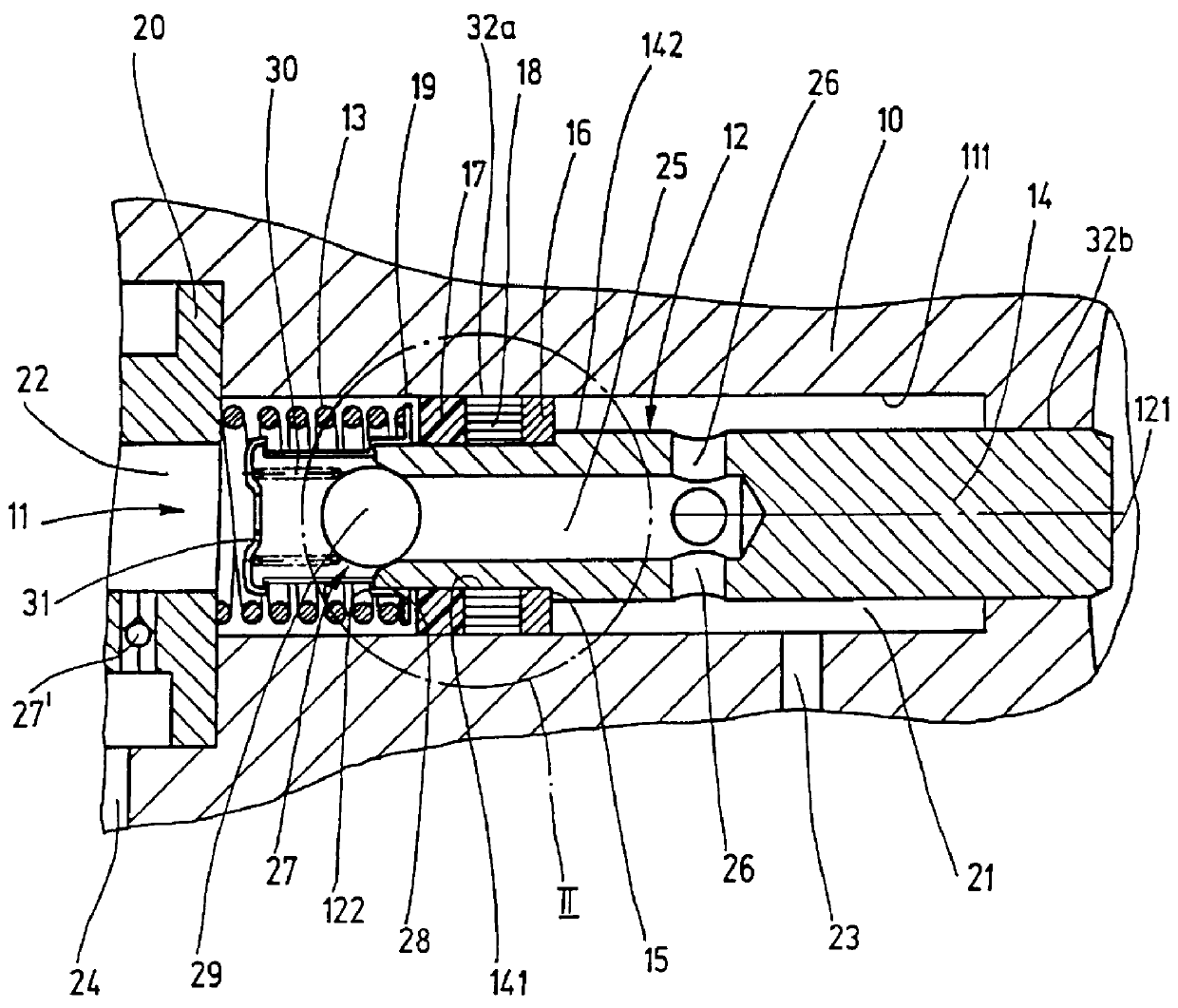

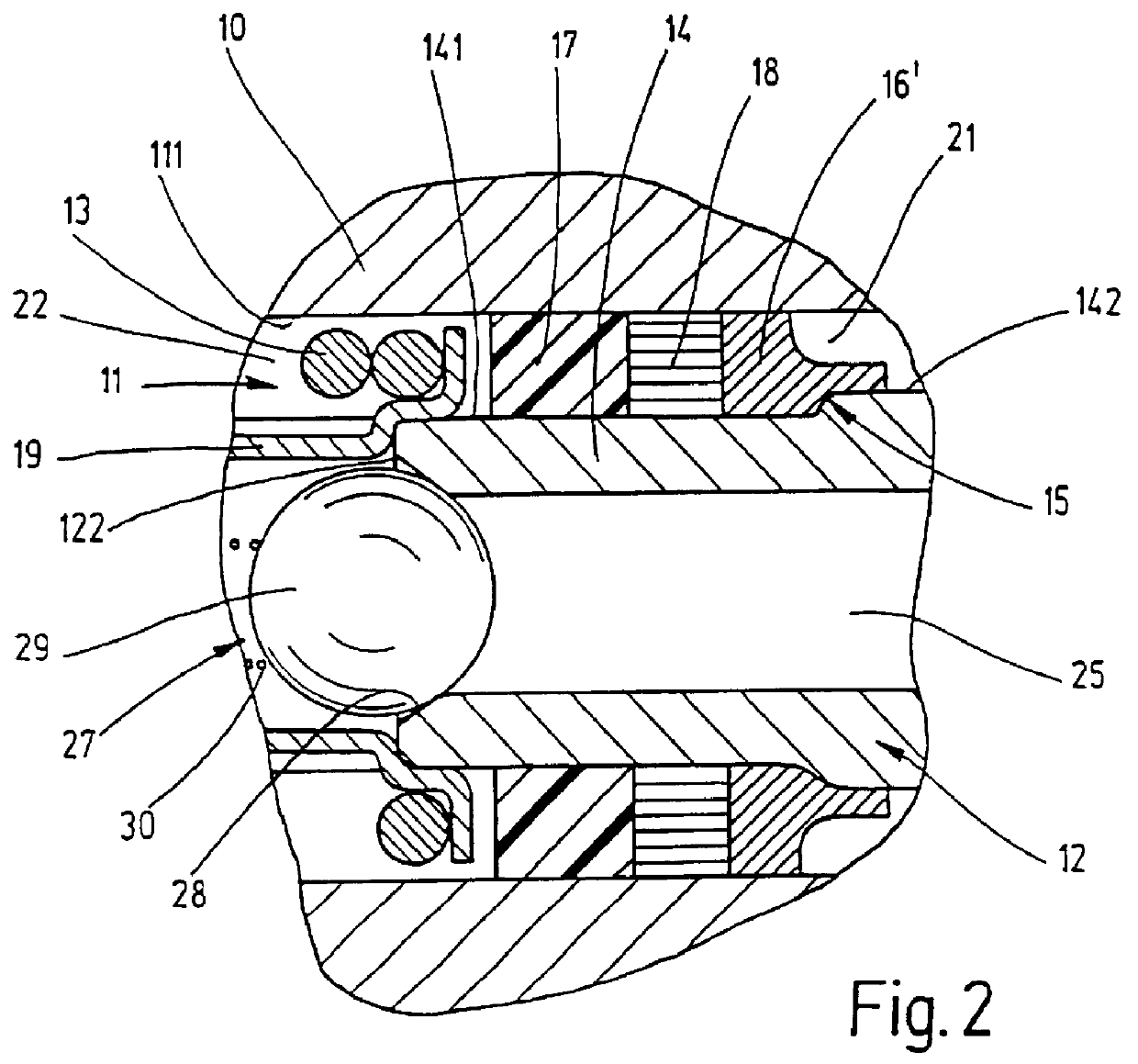

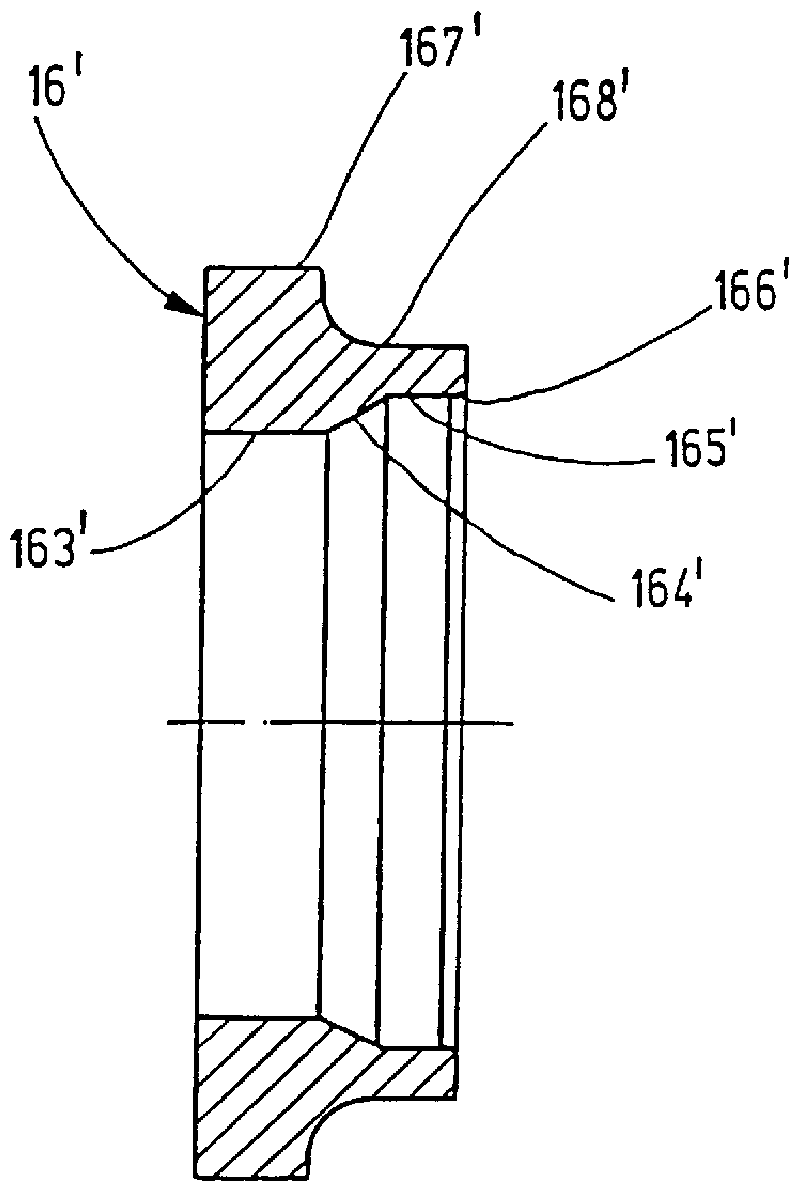

Piston pump

InactiveUS6109896AProduced economicallyCost advantagePositive displacement pump componentsPlungersElastomerPump chamber

PCT No. PCT / DE97 / 01101 Sec. 371 Date May 18, 1998 Sec. 102(e) Date May 18, 1998 PCT Filed Jun. 3, 1997 PCT Pub. No. WO98 / 12434 PCT Pub. Date Mar. 26, 1998A piston pump for pumping hydraulic fluid, especially for vehicle brake systems having a stepped piston axially displaceable in a pump space. The stepped piston in order to reduce the production costs comprises a cylinder of substantially constant outer diameter and a bush which is held axially nondisplaceably on the cylinder, by being press-fitted onto the cylinder. An elastomer seal is slipped onto a cylinder portion defined by the bush seals off the cylinder from the wall of the pump space and divides the pump space into two pump chambers of variable chamber volume.

Owner:ROBERT BOSCH GMBH

Brake device for a vehicle with an electric parking brake system and corresponding control method

ActiveCN1989034AAvoid or minimize lossesReduce loadBraking action transmissionBrake control systemsElectric parking brakeMaster cylinder

The invention relates to a brake device for a vehicle comprising a hydraulic service brake system with a power supply unit, which builds up a brake pressure inside a brake master cylinder of the service brake system according to a pressure demand, this brake pressure being transferred to at least one wheel brake, and comprising an electric parking brake system. The inventive brake device is characterized in that during the operation of the service brake system, a control unit verifies whether a defect exists in the service brake system on the basis of a comparison of the pressure demand with the brake pressure in at least one wheel brake and / or on the basis of a comparison between a recorded vehicle acceleration and an acceleration of the vehicle expected due to the pressure demand, and that the control unit activates the electric parking brake system when the existence of a defect is established. The invention also relates to a method for controlling the brake system of a vehicle.

Owner:CONTINENTAL AUTOMOTIVE SYST SHANGHAI

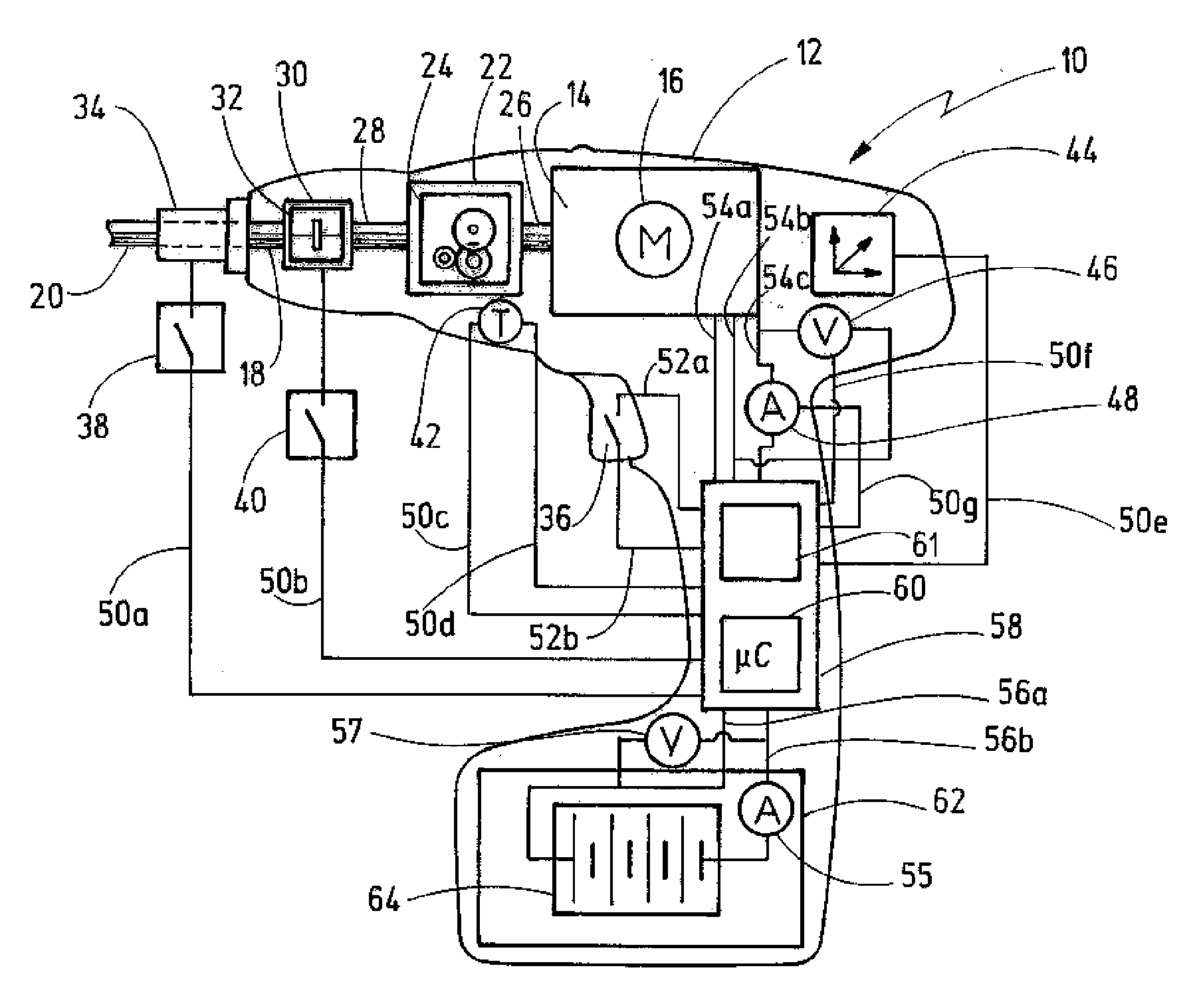

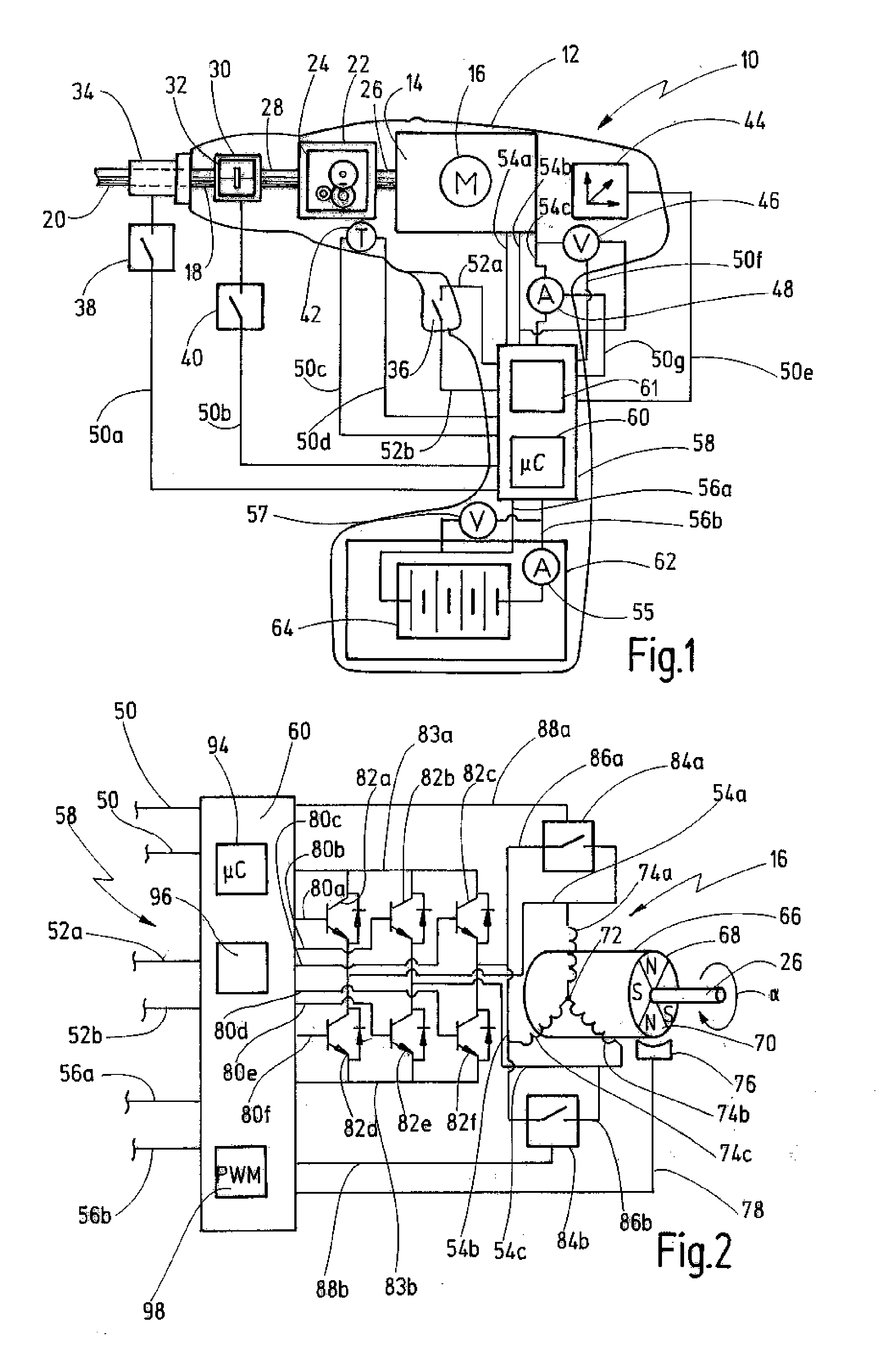

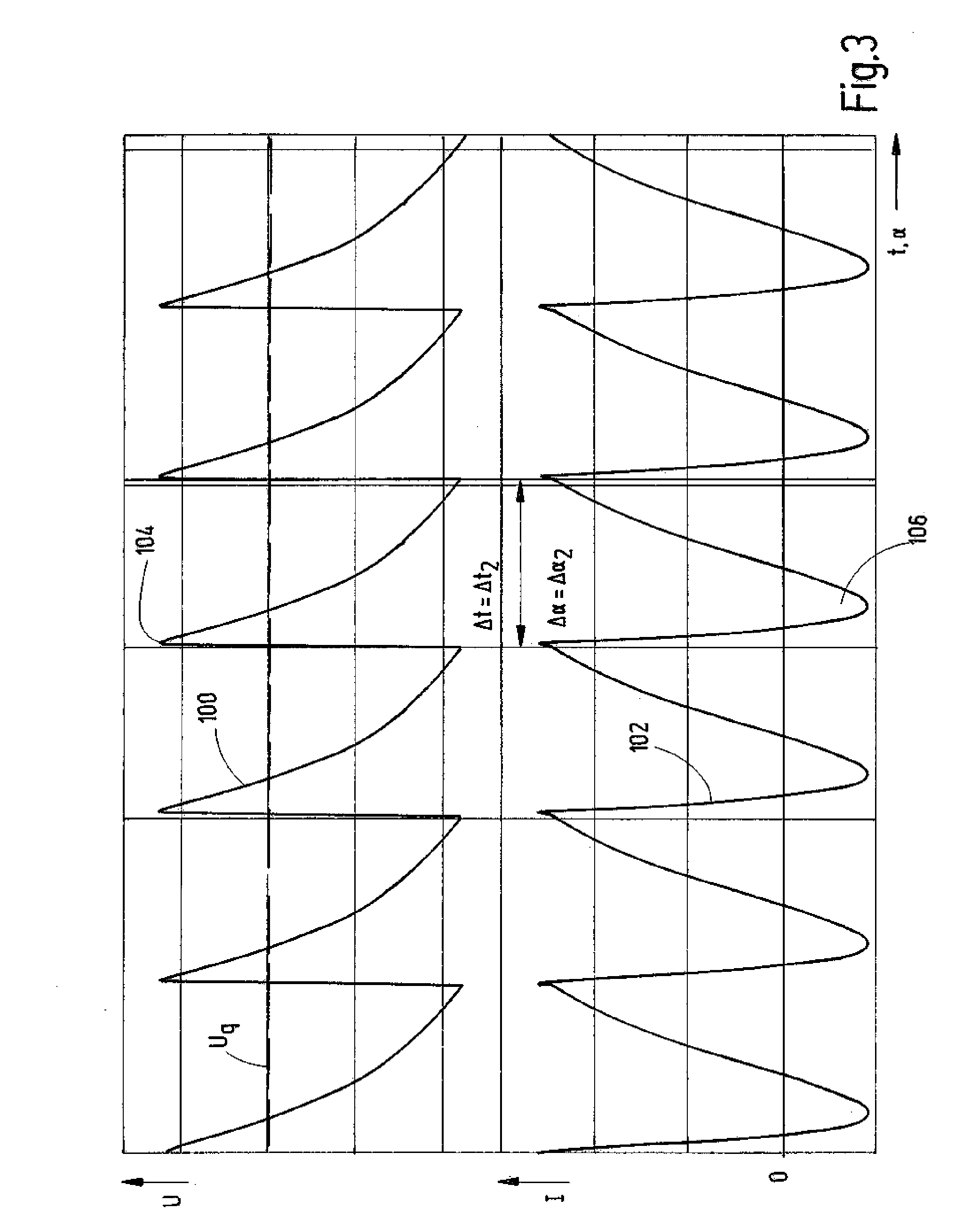

Power Tool Having An Electric Brake

ActiveUS20120019177A1Uncontrollable operate state and intrinsic movement be avoidHigh kinetic energySynchronous motors startersAC motor controlPower toolSupply energy

The invention relates to a method for decelerating a drive movement of a power tool and to a power tool suitable for carrying out the method, having a drive driven by a motor, an energy supply device for the provision of electrical energy, a controller having a motor controller for activating the motor and an operating-state recognition module which is to detect at least one operating-state variable and, as a function of this, to output a brake signal, the controller being designed to initiate, as a function of the brake signal, a braking procedure in which brake cycles are provided which have a first time segment, in which the motor is short-circuited, and a second time segment in which current is fed to the motor opposite to its original direction of rotation.

Owner:C & E FEIN

Non-asbestos friction material

ActiveUS20080156226A1Improve braking effectAvoid problemsOther chemical processesFriction liningHeavy metal compoundGraphite

A non-asbestos friction material not containing a heavy metal and a heavy metallic compound as the blending ingredients of the friction material is provided with graphite and coke in total from 5 to 25 vol % in volume of friction material. A volume ratio of the graphite / coke is preferably from 2 / 1 to 7 / 1. An average particle size of the coke is preferably from 150 to 400 μm.

Owner:AKEBONO BRAKE IND CO LTD

Plane braking device for electric winches and electric winch

The present invention discloses a plane braking device for electric winches and electric winch which disposes a section of hollow gear shaft, a section of core shaft, a fixing ring, a wedge shape support, a stopping piece, a braking plate, an elastic element, a wedge shape piece B, a wedge shape piece A, a braking clutch base and so on in a gear box of an electric winch. When a motor works, the section of core shaft of the motor drives the braking clutch base and the wedge shape pieces A, B to rotate, until a gap is formed between the adjacent braking plate and stopping piece between the braking clutch base and the wedge shape piece B, so that the braking effect disappears. When the motor stops suddenly, a heavy load lifted by a tight wire drum provides a reverse pulling force so that the wedge shape piece B produces a reverse thrust force to push the friction planes of the braking plate and the stopping piece, so the plane braking effect is achieved quickly. Based on the plane braking plate, the present invention can increase the braking area and the braking force and achieve safe braking. Furthermore, when there is wear of parts in long usage, so it only needs to replace the braking plate made of friction materials, which can simplify maintenance, reduce the parts costs and ensure service life of the gear box.

Owner:XIE YUZHI +1

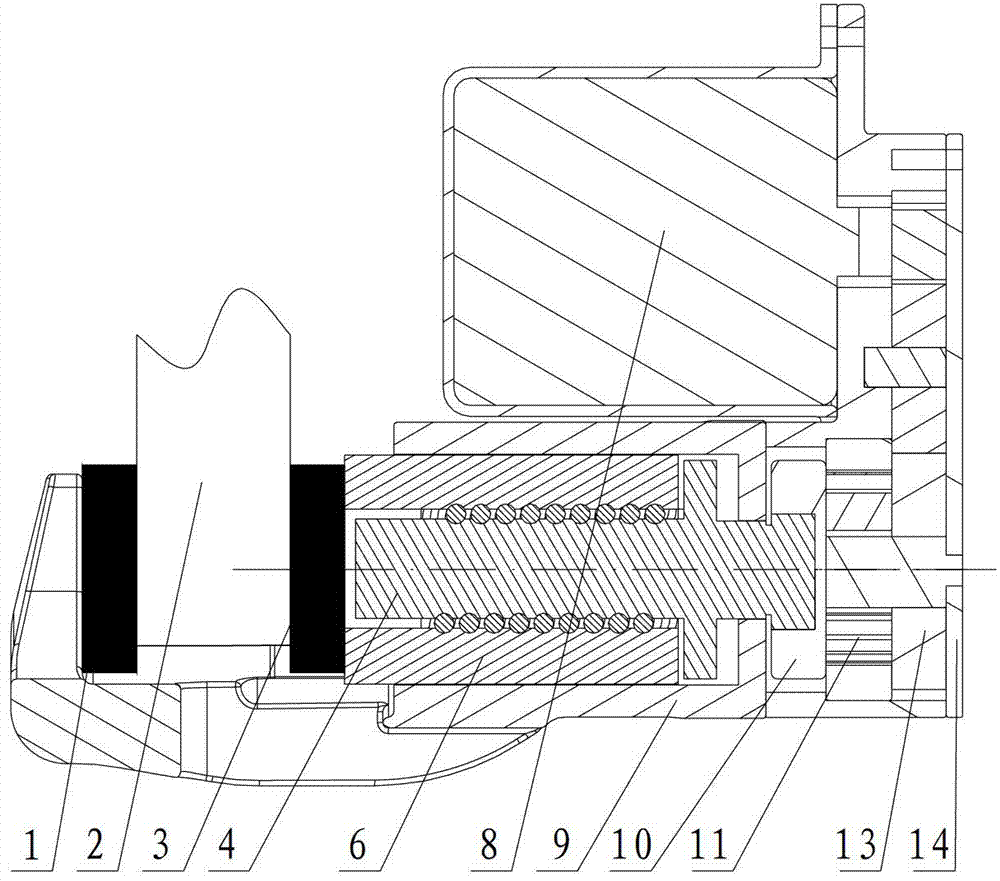

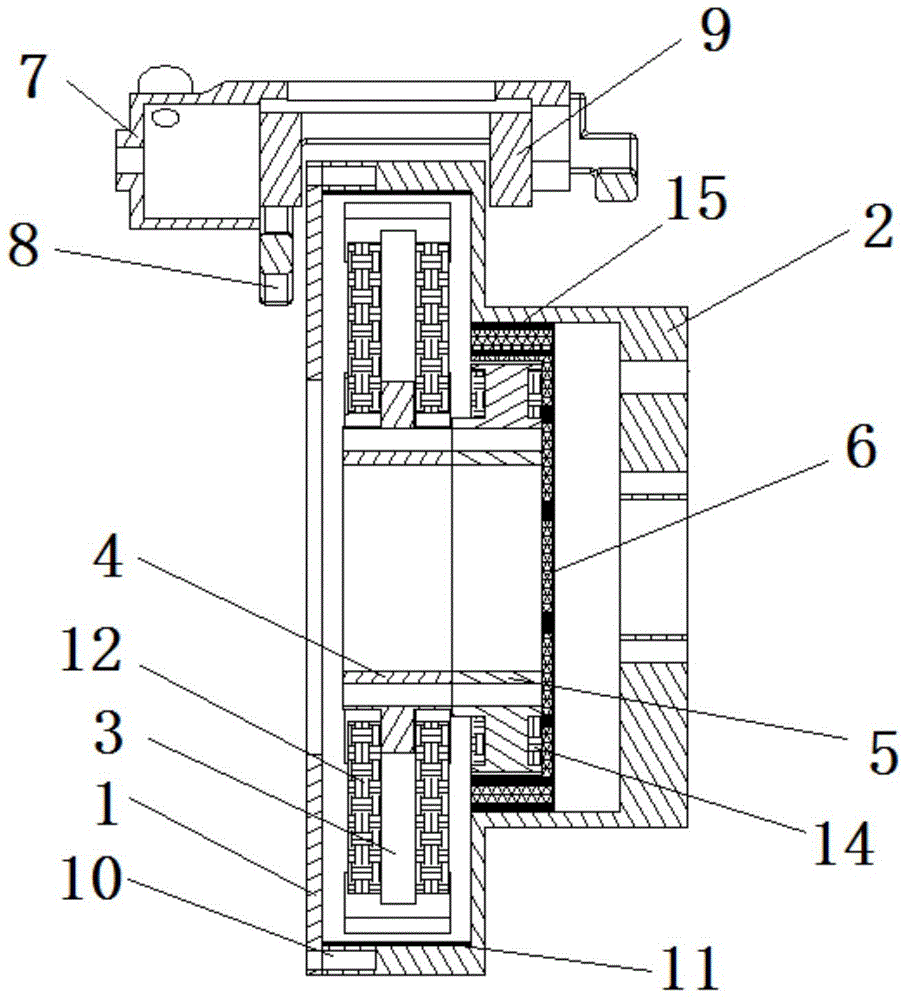

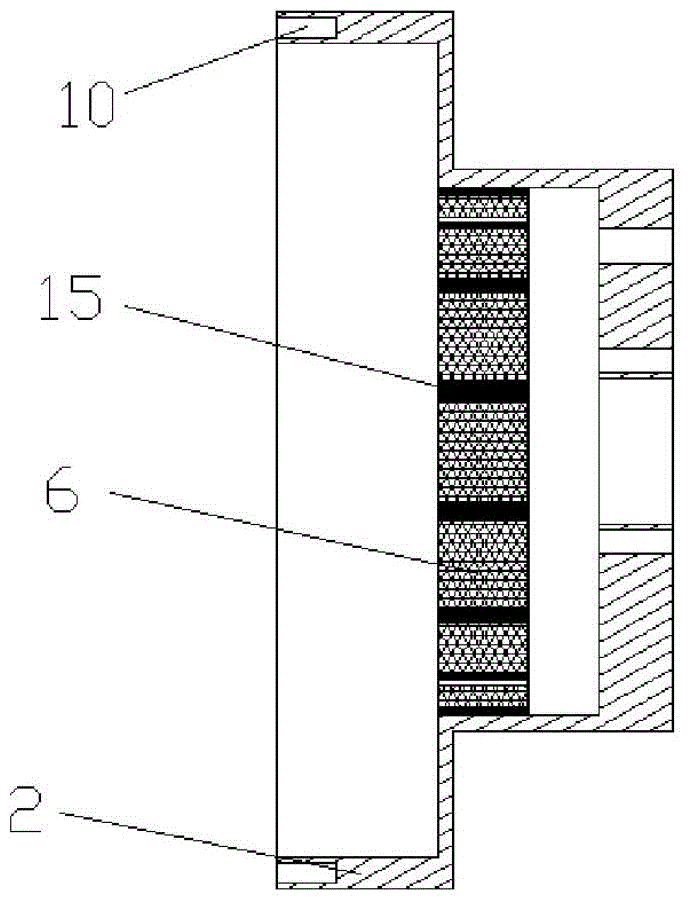

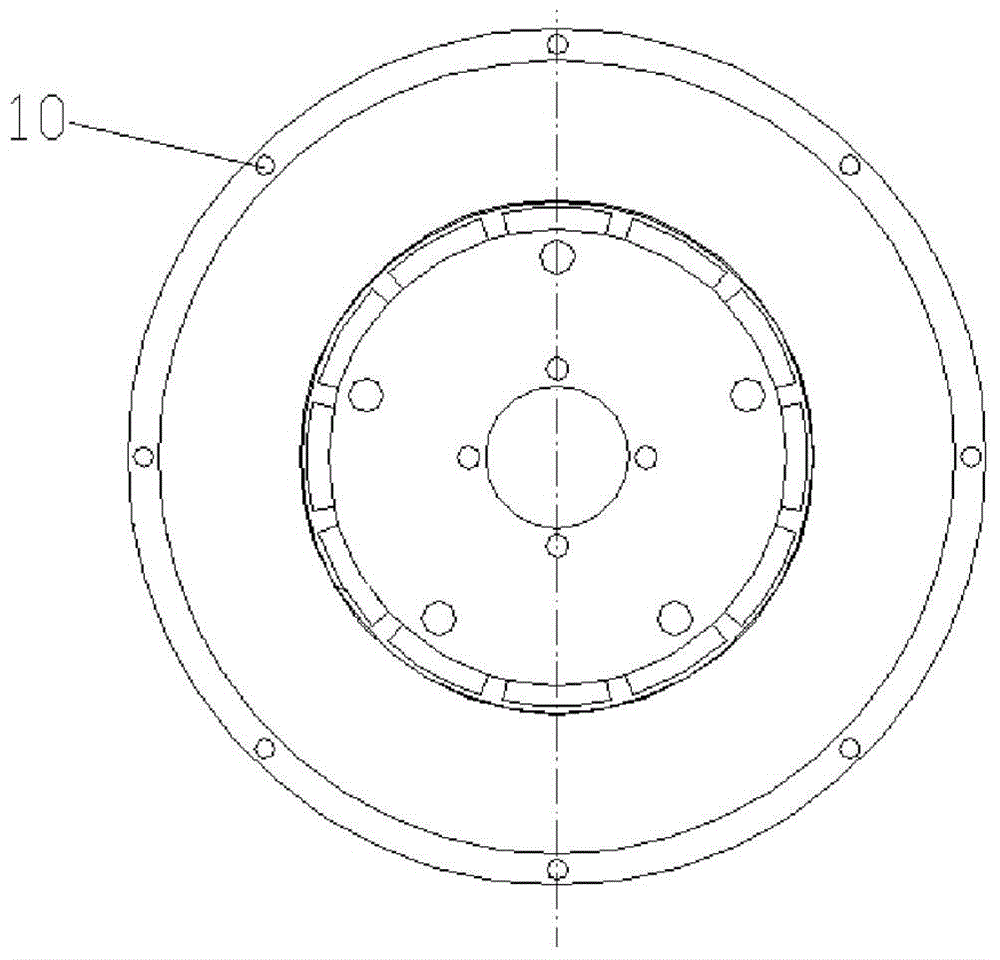

Electromagnetic and friction integrated brake system and control method thereof

ActiveCN104482080AImprove braking effectReduce axial sizeBrake actuating mechanismsElectricityIntegrated controller

The invention provides an electromagnetic and friction integrated brake system and a control method thereof. The electromagnetic and friction integrated brake system comprises a friction brake, an electromagnetic brake, a permanent magnet generator, a vehicle-mounted battery and an integrated controller. The inside friction disk and the outside friction disk of the disk-type friction brake are manufactured separately and connected by use of a bolt. The electromagnetic brake is of a rotary drum type and composed of an electromagnetic brake stator and a rotor for generating electrical vortex; the electromagnetic brake stator is located between the inside friction disk and the outside friction disk and fixedly connected with a steering joint support or suspension. The permanent magnet generator is located between the electromagnetic brake and the outside friction disk, and comprises a permanent magnet and a generator stator; the generator stator is connected with the electromagnetic brake stator by use of a bolt. The electromagnetic and friction integrated brake system has the advantages that the frequency of use of the friction brake is reduced, the heat of the brake system is scattered, the stability of the braking efficiency of the vehicle is improved, partial braking energy is recovered, and the braking noise is reduced and the consumption of energy of the whole vehicle during running is also reduced.

Owner:JIANGSU UNIV

P step actuating mechanism of electric control mechanical automatic variable-speed device for electrically-operated car and control system

The invention relates to a P step actuating mechanism of an electric control mechanical automatic variable-speed device for an electrically-operated car and a control system, comprising a P step position detection device of a gearshift handle, a P step electronic control device, a driving device, a position detection device of the driving device, a pawl and a ratchet wheel, wherein the P step electronic control device is electrically connected with the P step position detection device of the gearshift handle, the driving device and the position detection device of the driving device, the position detection device of the driving device and the driving device are arranged in a matching way for detecting the rotation position of a driving shaft of the driving device, the driving device, the pawl and the ratchet wheel are arranged in a matching way so as to drive the pawl to lock the ratchet wheel by the driving device, and the pawl is driven by the driving device or an elastic component to unlock the ratchet wheel. Preferably, the driving shaft drives the pawl by a transmission mechanism, and the P step electronic control device also is electrically connected with a car speed detection device. The invention has skillful design and convenient use, has very good braking effect for electric cars, increases the braking reliability of the electrically-operated cars greatly and is suitable for large-scale popularization and application.

Owner:SHANGHAI ZHONGKE SHENJIANG ELECTRIC VEHICLE

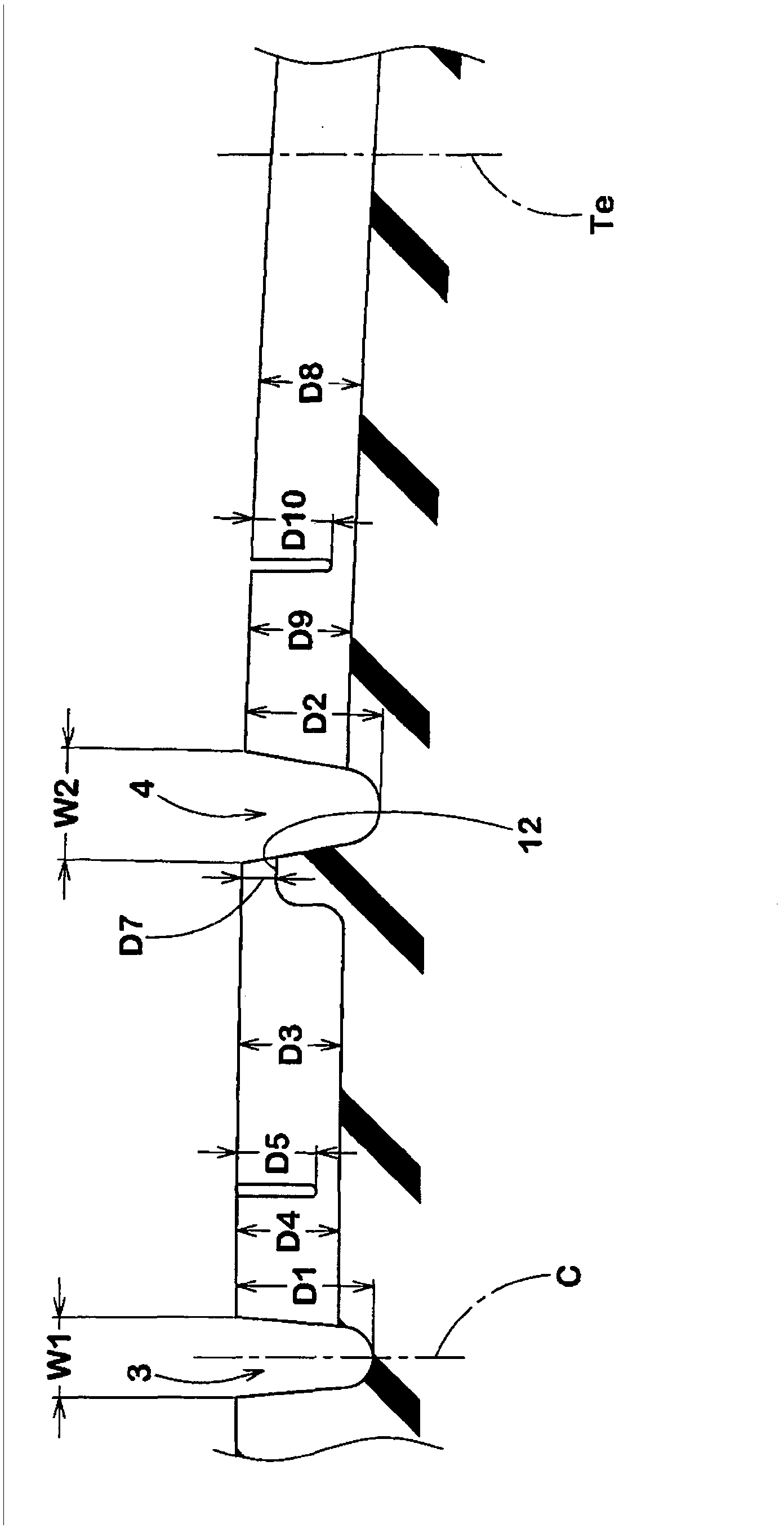

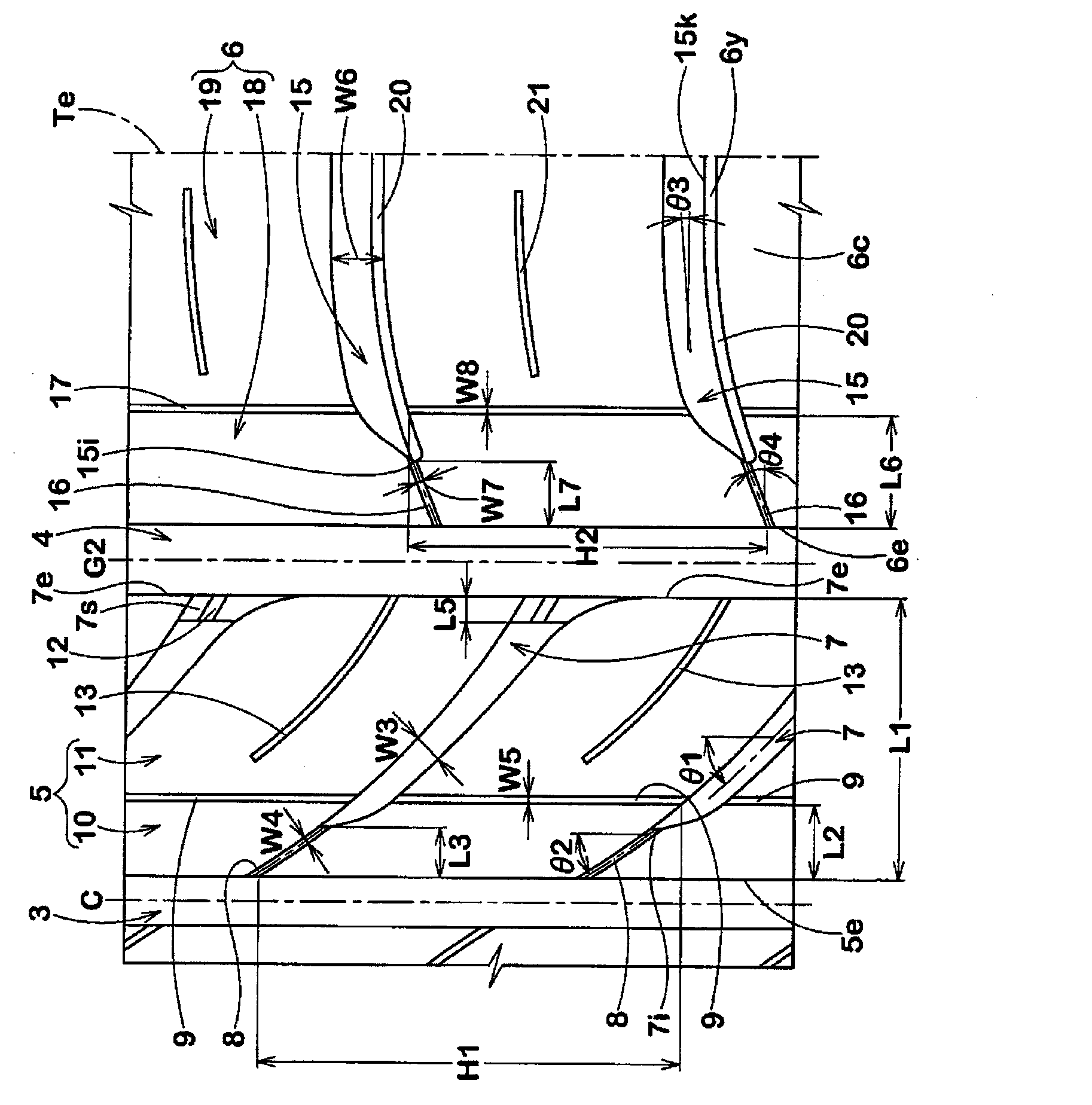

Pneumatic tire

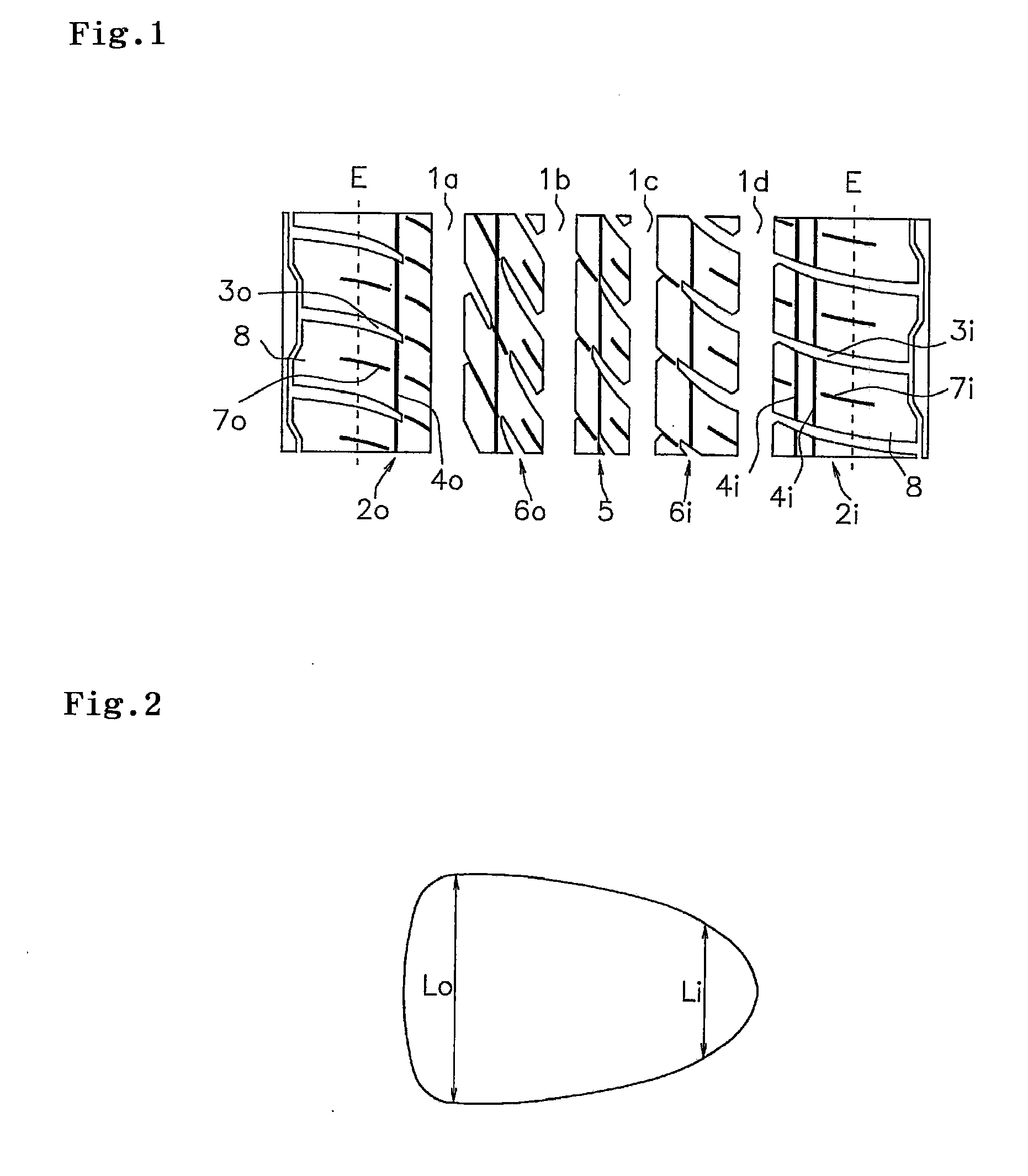

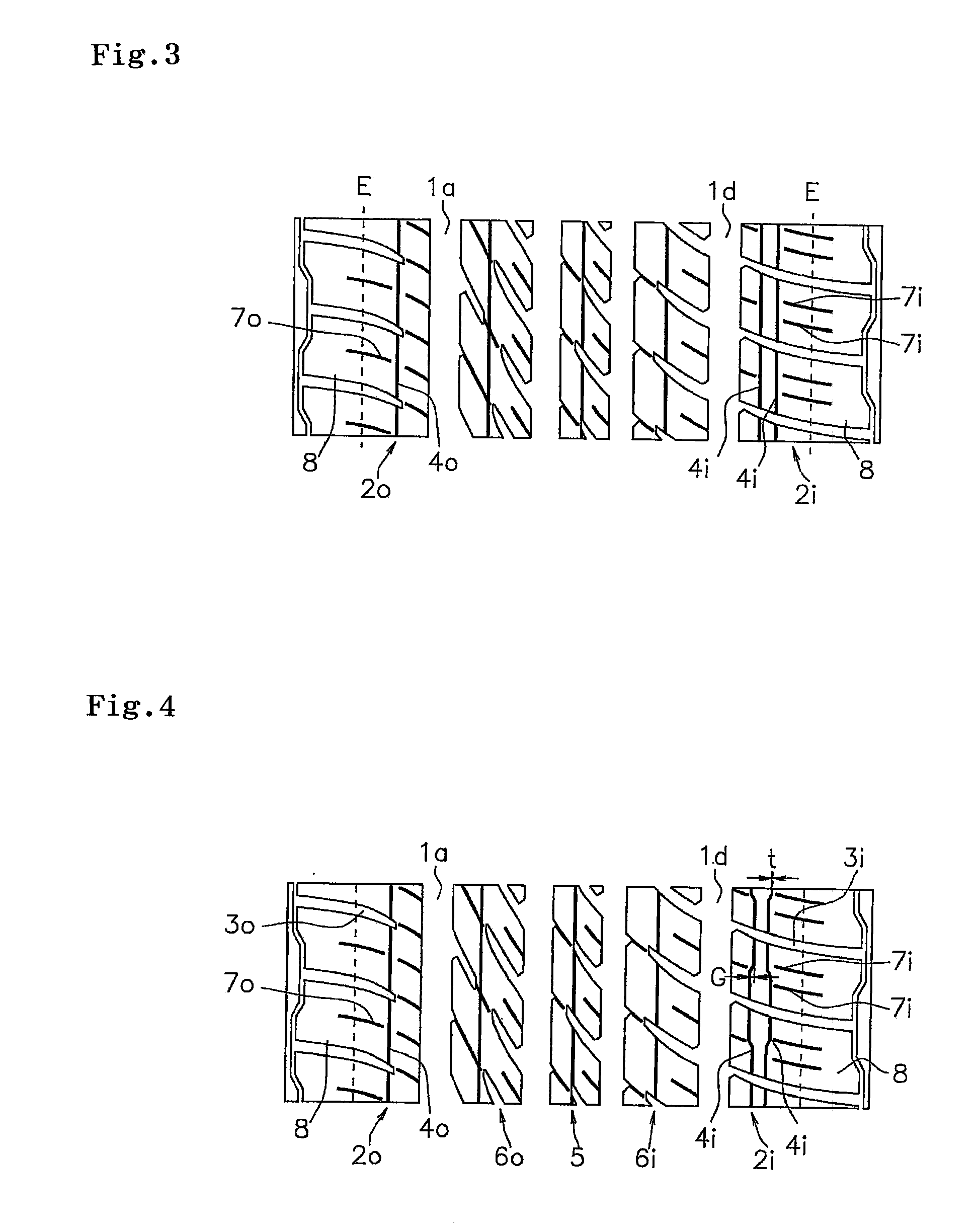

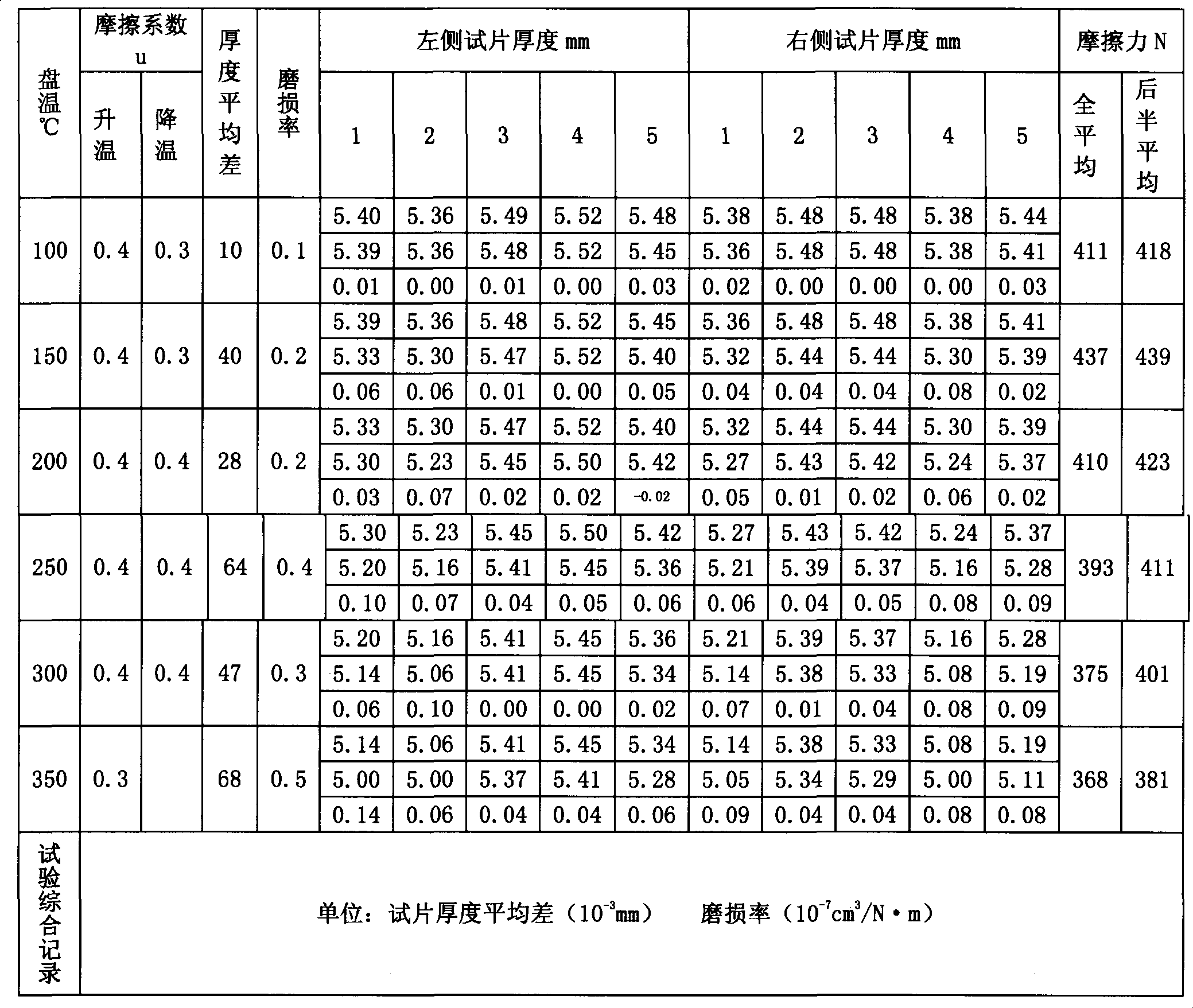

ActiveCN103182905AImprove rigidityImprove braking effectTyre tread bands/patternsEngineeringAxial distance

The invention provides a pneumatic tire in which the braking performance on wet road can be improved while maintaining the steering stability and wear resistance. The pneumatic tire (1) comprising a tread portion (2) provided with center portions (5) and shoulder portions (6). wherein each said center portion is provided with: a plurality of center lateral grooves (7) each of which extends from the shoulder main groove (4) toward the axially inside (C) of the tire without reaching the center main groove so as to have an axially inner end thereof on the center portion, and has an angle (theta 1) of from 35 to 65 degrees with respect to an axial direction of the tire; a plurality of center lateral sipes (8) each of which extends from the axially inner end (7i) of the center lateral groove to the center main groove and has the same inclination direction with the center lateral groove having an angle (theta 2) of from 35 to 65 degrees with respect to an axial direction of the tire; and a center longitudinal sipe (9) which connects between circumferentially adjacent center lateral grooves and is separated from an axially inner edge (5e) of the center portion in a first axial distance in a range of from 20 to 40 % of a width (L1) of the center portion.

Owner:SUMITOMO RUBBER IND LTD

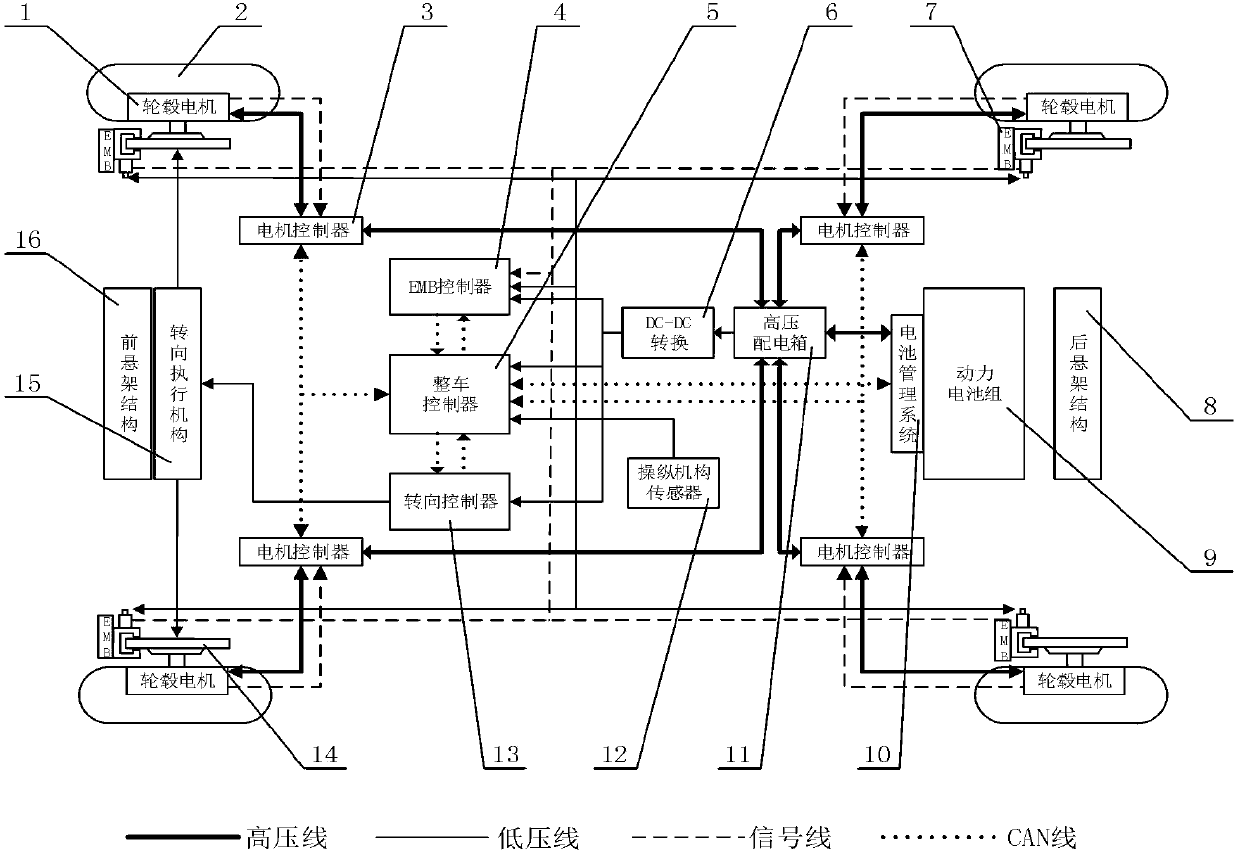

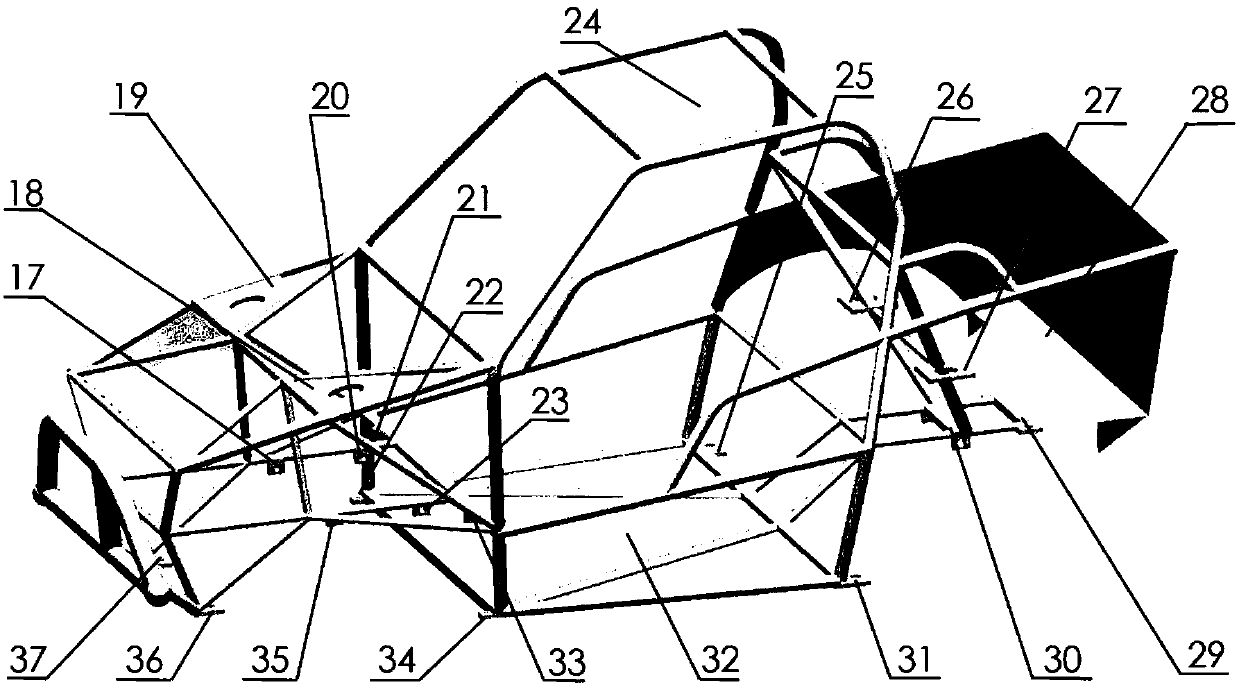

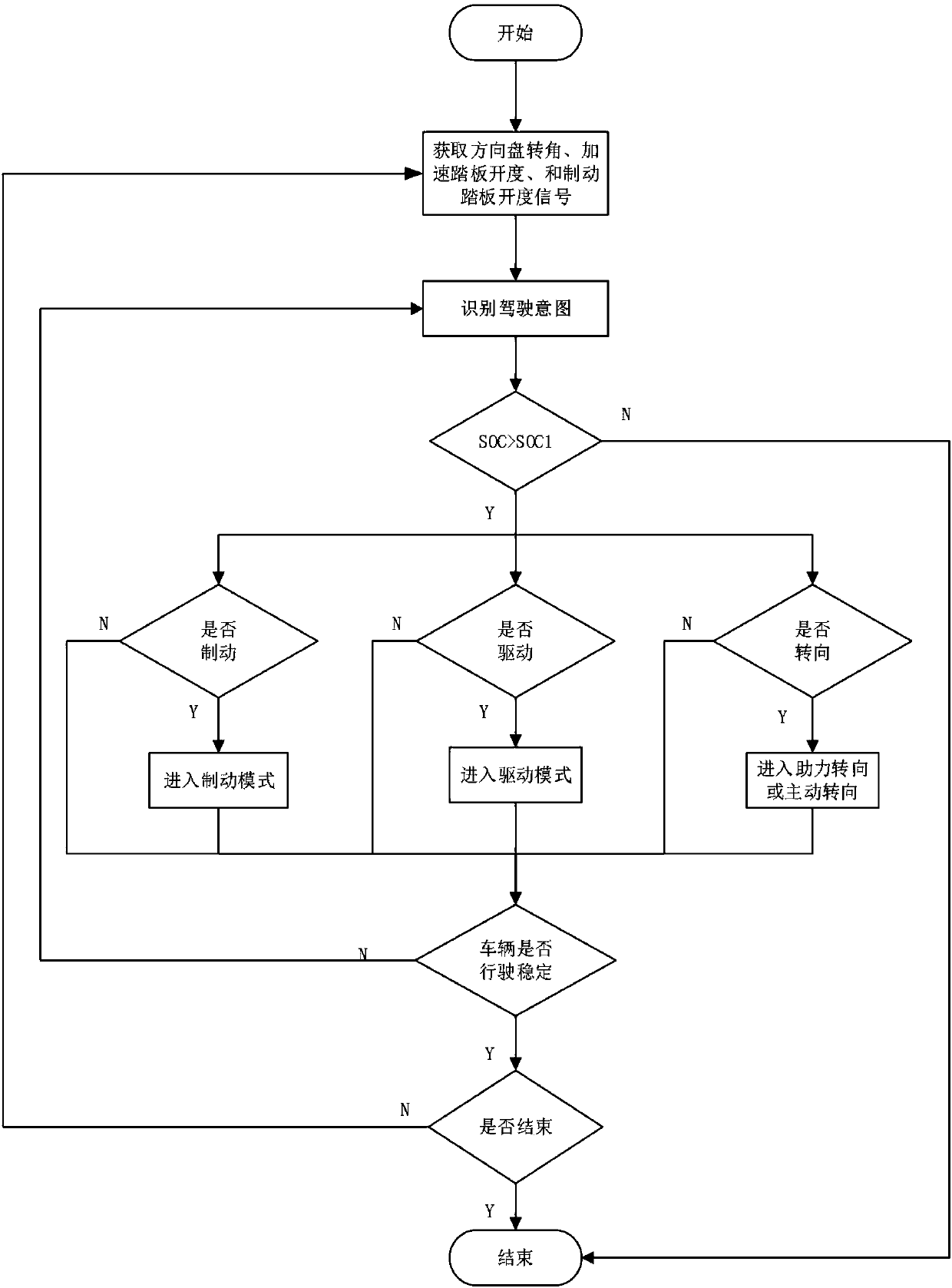

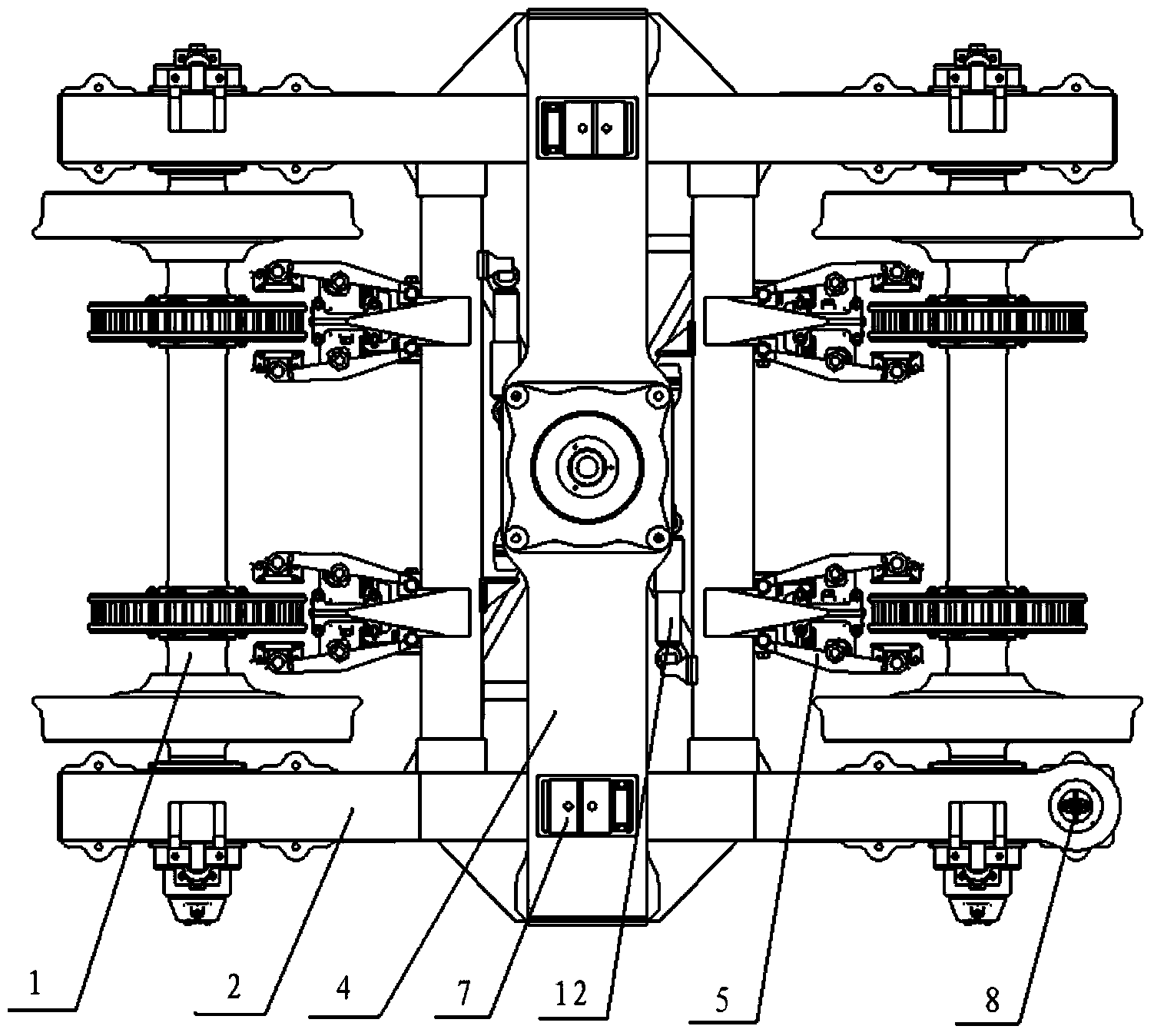

Hub motor driving automobile integrative design and cooperative control test platform and implementation method

ActiveCN108036953ARealize integrated designRealize collaborative controlVehicle testingSensori motorVehicle frame

The invention provides a hub motor driving automobile integrative design and cooperative control test platform and an implementation method. The platform comprises a whole vehicle control system, an active distributed driving system, an EMB electronic mechanical braking system, an active steering system, a power battery pack, a battery management system, a whole vehicle frame structure and a suspension module; the whole vehicle control system comprises a whole vehicle controller, a control mechanism sensor and a communication system; the active distributed driving system comprises four motor controllers, four hub motors, four wheels, an accelerator pedal and a hub motor sensor; the EMB electronic mechanical braking system comprises an EMB controller, four EMB brakes, a brake pedal sensor,a wheel cylinder pressure sensor and an EMMB brake angle and displacement sensor; the active steering system comprises a steering system control mechanism, a steering execution structure, a steering controller, and a steering knuckle angle and torque sensor. The whole vehicle frame is simple in structure, simple in process and high in expansibility.

Owner:YANSHAN UNIV

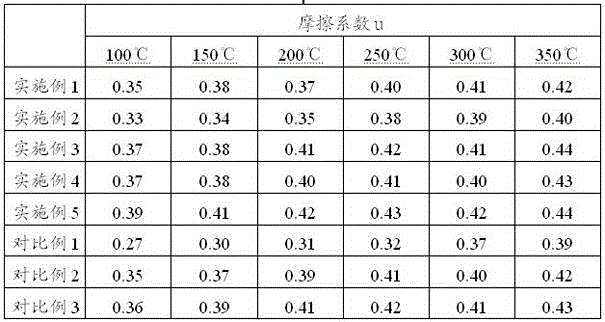

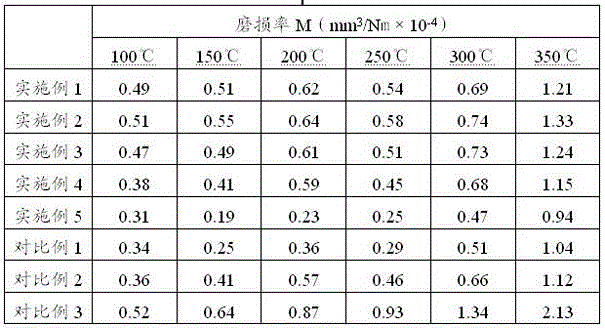

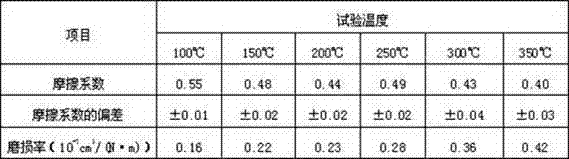

Formula and manufacturing method for car soft magnetic brake pad

ActiveCN103939511AEasy to prepareImprove braking effectOther chemical processesFriction liningFiberThermal treatment

The invention discloses a formula and manufacturing method for a car soft magnetic brake pad. The formula comprises, by weight, 6-18 parts of organic binding agents, 15-45 parts of reinforced fibers, 10-50 parts of friction performance conditioners, 3-10 parts of packing and 5-30 parts of soft magnetic materials. The manufacturing method comprises porphyrization, material mixture, thermo-compression formation, thermal treatment, surface processing and other processes. The formula and manufacturing method for the car soft magnetic brake pad have the advantages that the soft magnetic materials are added into an original car brake pad, so that the friction coefficient is increased, the abrasion rate is lowered, friction stability is improved, and the car soft magnetic brake pad well adapts to various complex braking conditions of a car; as the added soft magnetic materials are ferromagnetic substances, the car soft magnetic brake pad has high magnetic conductivity and saturation magnetic induction intensity, and the most basic material conditions are provided for magnetic field control in the brake friction process. The manufacturing method for the car soft magnetic brake pad is simpler, magnetism does not need to be charged in advance, and the friction action can be regulated and controlled in the braking process by regulating the magnitude of the magnetism through an external magnetic field.

Owner:CHINA UNIV OF MINING & TECH

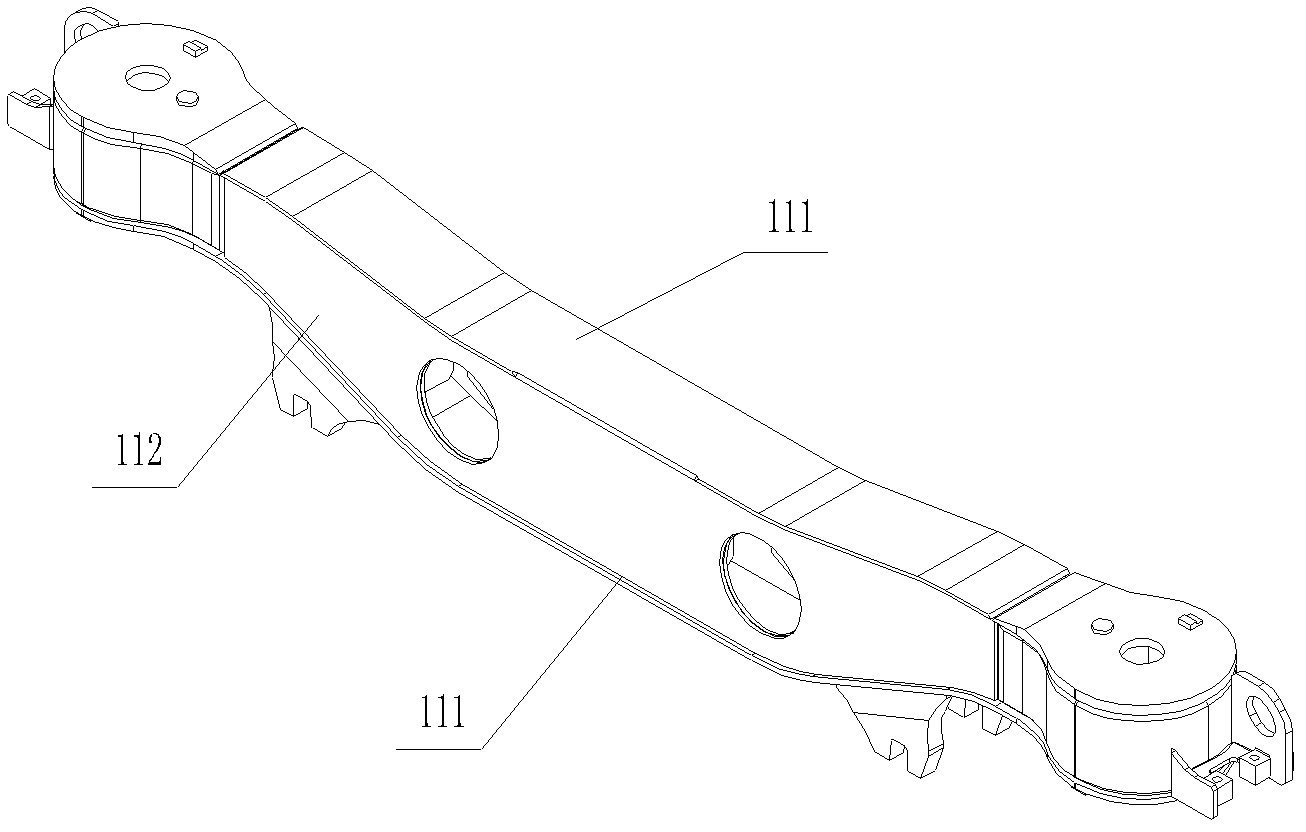

Rapid freight car radial bogie

InactiveCN103661464AReduce forceReduce lateral vibration accelerationBogie-underframe connectionsAxle-boxes mountingBogieTruck

The invention discloses a rapid freight car radial bogie. The rapid freight car radial bogie comprises an axle assembly, a frame, a swing bolster, a braking device, central suspension devices, a radial device, a side bearing device arranged on the swing bolster and an axle box suspension device, wherein the frame is installed on the axle assembly through the axle box suspension device, the two ends of the swing bolster are fixedly installed in the middle of the frame respectively through the central suspension devices, the frame is composed of two side beams and parallel cross beams connected with the side beams, and bearing platforms where the central suspension devices are installed are arranged outside the middle portions of the side beams. The rapid freight car radial bogie structure obviously reduces wheel-rail wear and wheel-rail noise, reduces wheel-rail acting force, reduces vehicle transverse vibration acceleration and improves vehicle operation lateral stability, straight line stability and curve line negotiating capacity. The unsprung mass of the bogie is reduced, the speed of the bogie is high, vehicle braking performance is improved, wheel-rail wear and wheel-rail noise are small, vehicle operation stability is good, and stability and safety are high.

Owner:CRRC MEISHAN

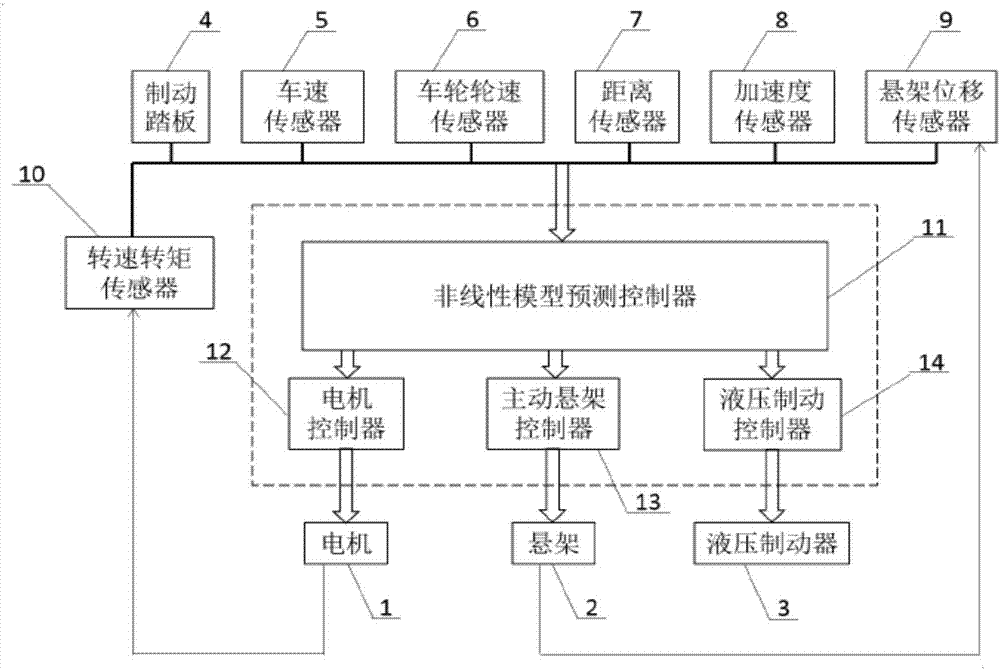

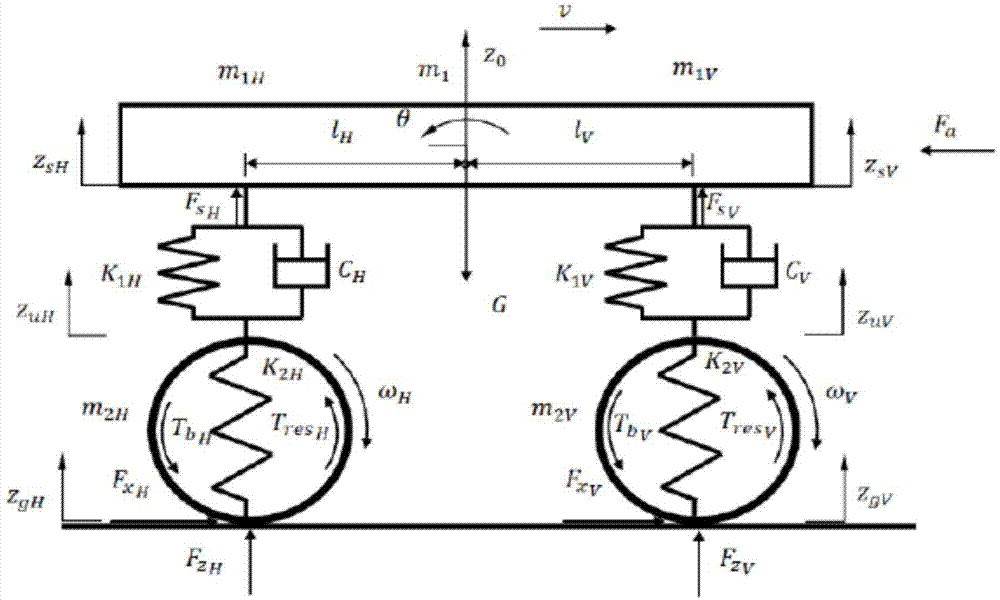

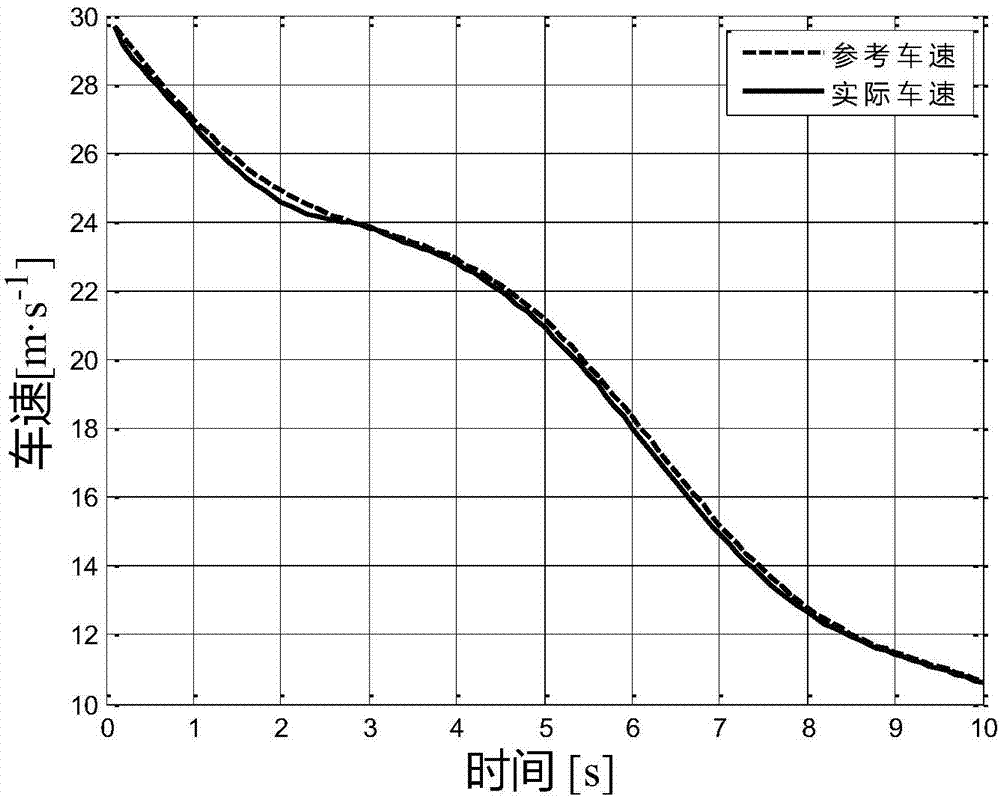

Nonlinear model prediction control method of regenerative braking of electric vehicle

InactiveCN103921786AAvoid loss of controlHigh precisionExternal condition input parametersDriver input parametersRegenerative brakeControl system

The invention relates to the field of vehicle control, in particular to a nonlinear model prediction control method of regenerative braking of an electric vehicle. The method adopts a nonlinear model prediction control strategy of a rapid system, on the basis of establishing an electric vehicle regenerative braking nonlinear model, subsystem operating state signals, acquired by sensors, of the entire vehicle, wheels, suspensions and motors in the braking process of the electric vehicle are acquired, and multiple purposes, namely controlling speed accurately, guaranteeing vehicle stability, improving driving smoothness and regenerative braking energy recovering efficiency, in the braking process are controlled coordinately. The control system is mainly applied into the driving and braking processes of traditional vehicles and electric vehicles, especially the multipurpose controlling process of strong nonlinear systems.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com