Patents

Literature

189results about How to "Improve heat storage effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Systems and methods for forming a layer onto a surface of a solid substrate and products formed thereby

InactiveUS9933031B2Increase capacityImprove the overall coefficientBlade accessoriesBraking discsMetal matrix compositeSolid substrate

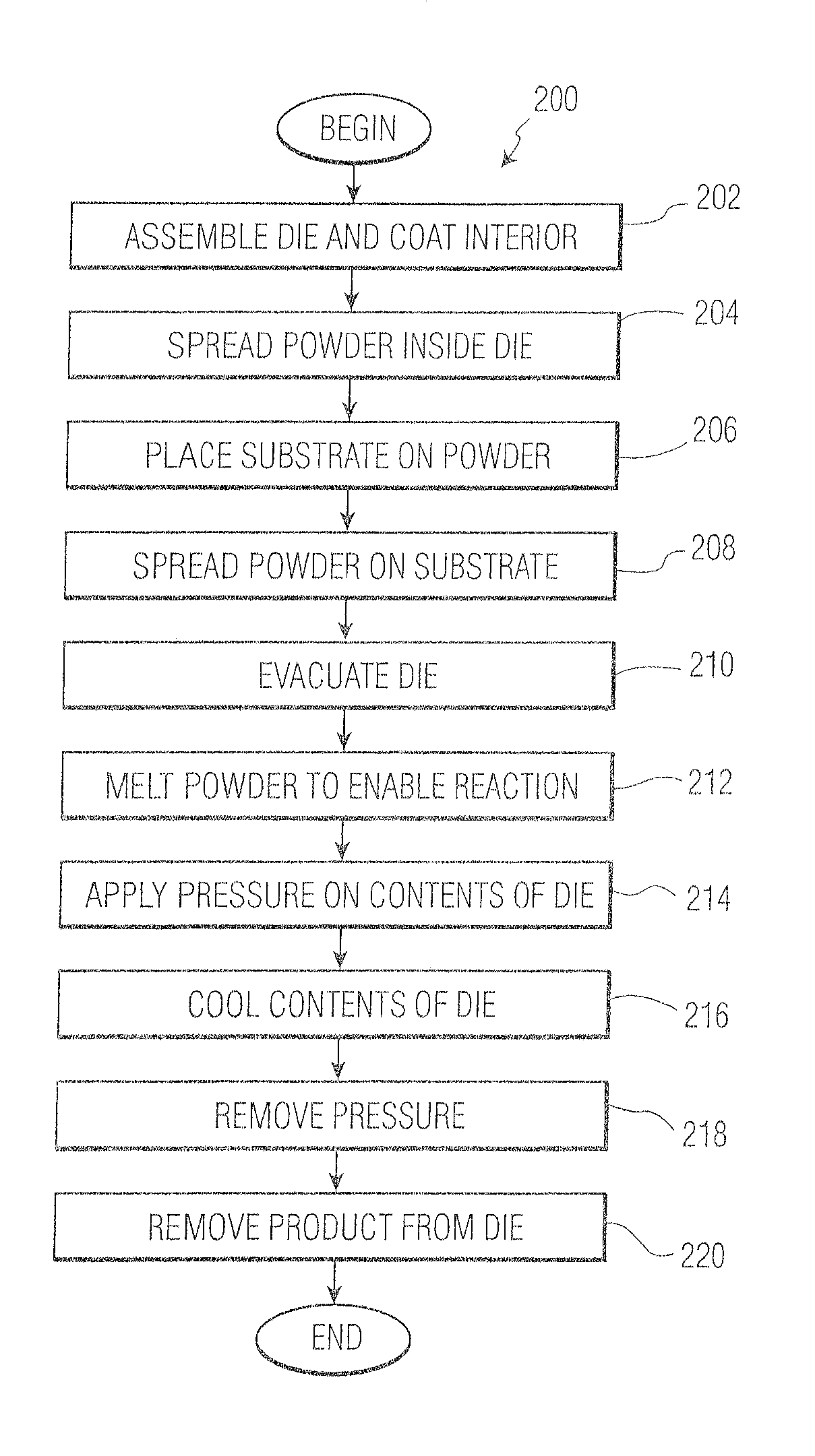

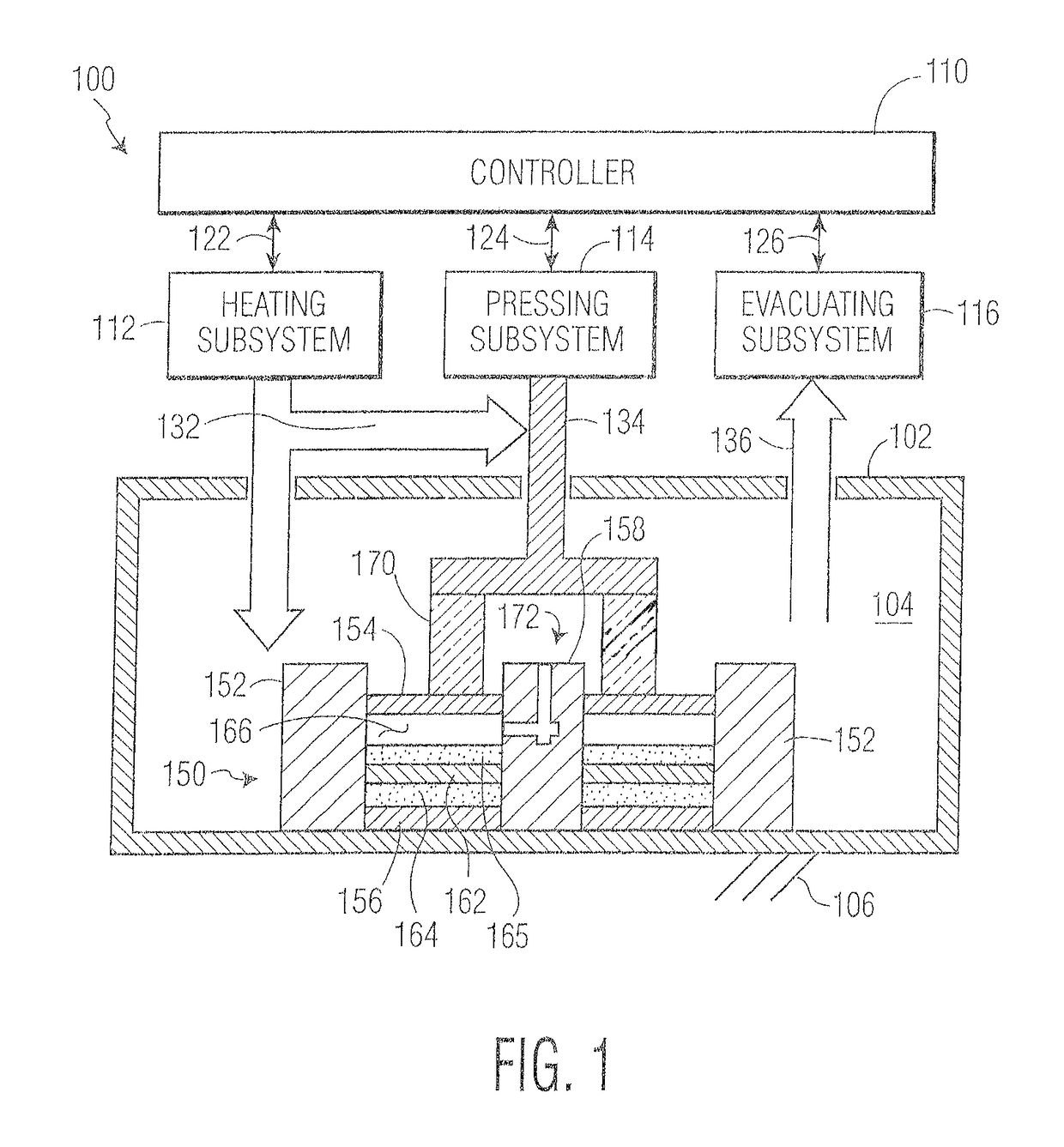

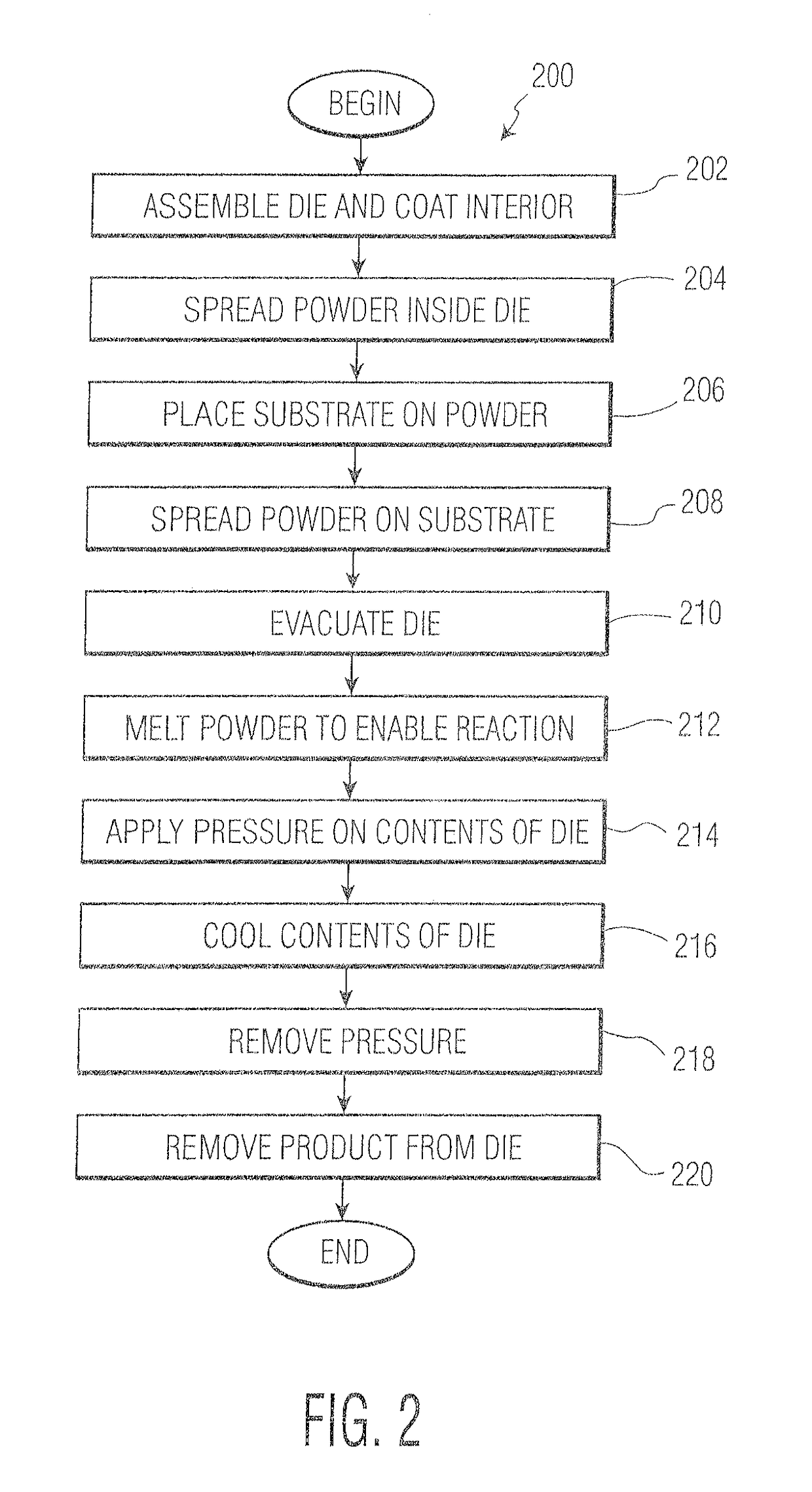

A method for forming a vehicular brake rotor involving loading a shaped metal substrate with a mixture of metal alloying components and ceramic particles in a dieheating the contents of the die while applying pressure to melt at least one of the metal components of the alloying mixture whereby to densify the contents of the die and form a ceramic particle-containing metal matrix composite coating on the metallic substrate; and cooling the resulting coated product.

Owner:ATS MER LLC

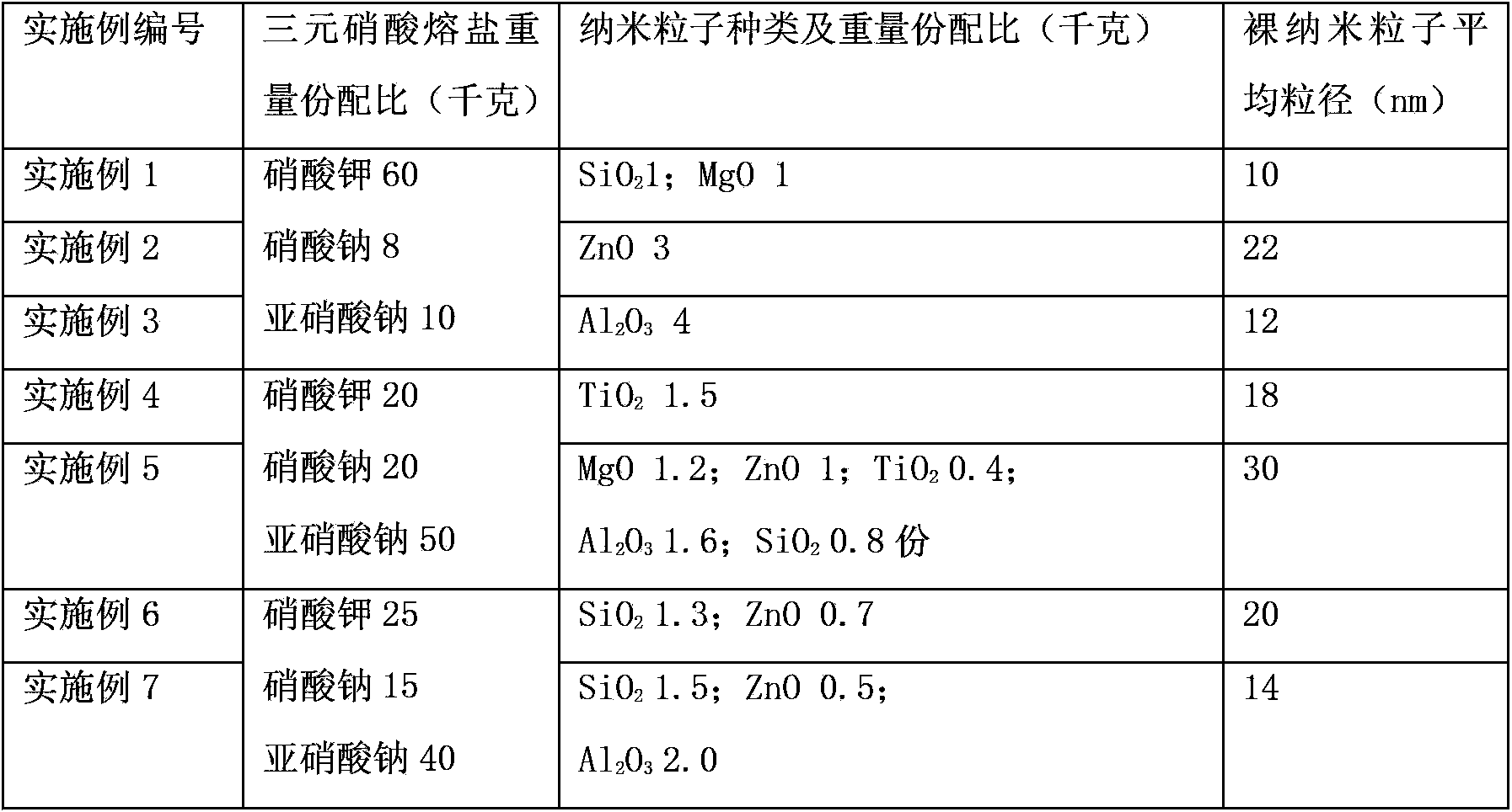

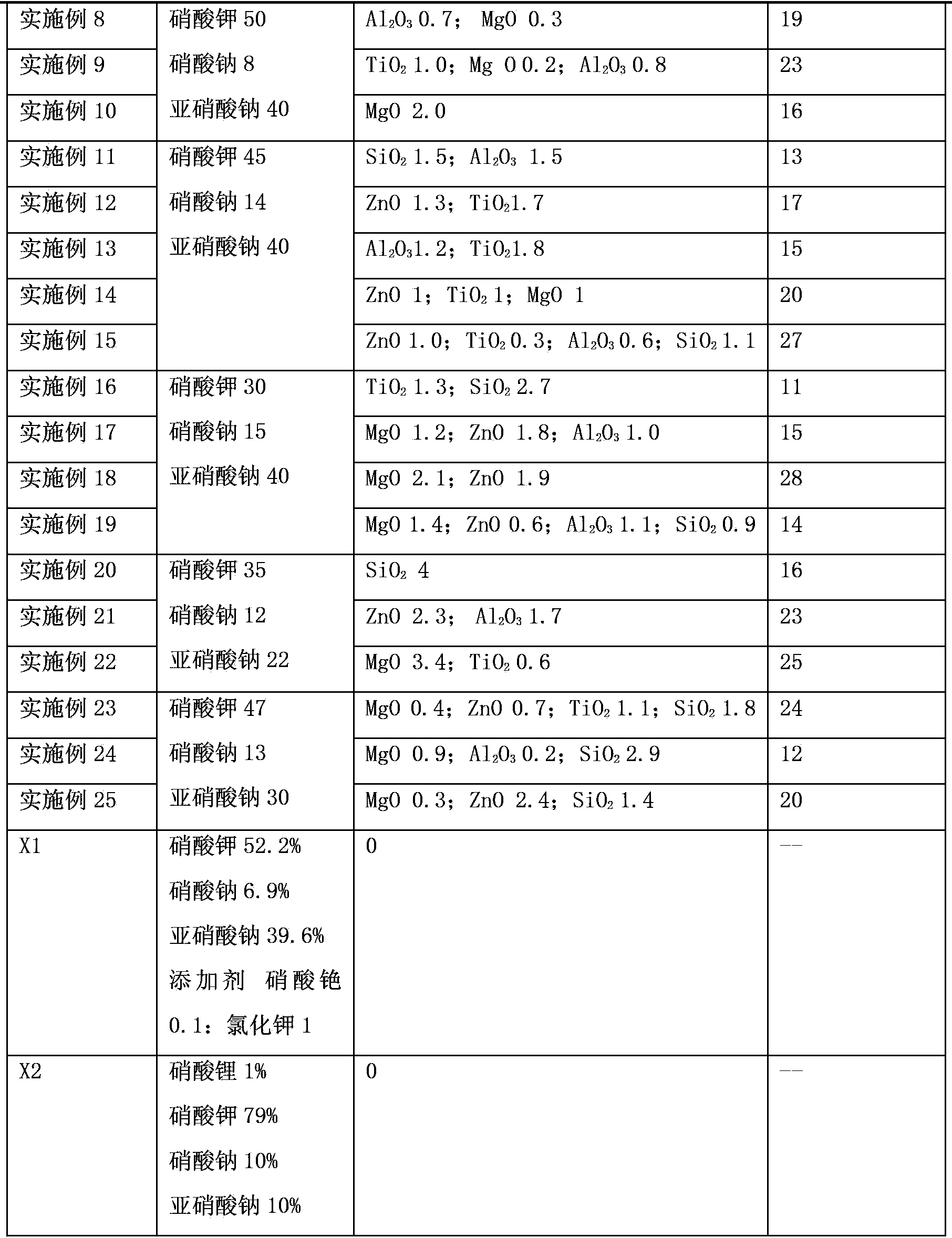

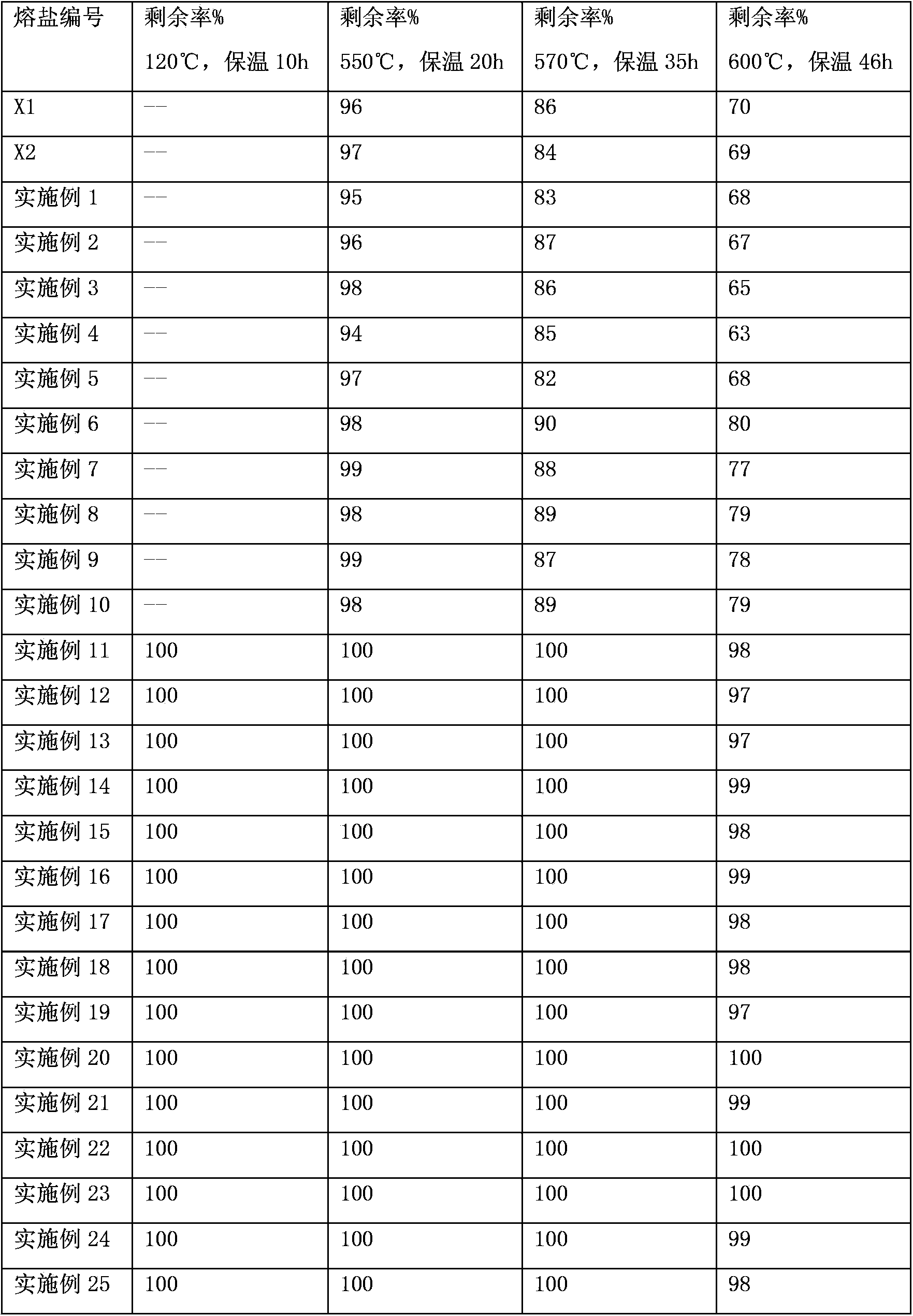

Ternary nitric acid nano-molten salt heat transfer and storage medium, preparation method and application thereof

InactiveCN103881662AOvercome solubilityOvercoming thermal conductivityHeat-exchange elementsMetal oxide nanoparticlesNanoparticles dispersion

Belonging to the technical field of heat storage and transfer, the invention provides a ternary nitric acid nano-molten salt heat transfer and storage medium, a preparation method and application thereof. The ternary nitric acid nano-molten salt heat transfer and storage medium contains a ternary nitric acid molten salt system formed by potassium nitrate, sodium nitrate and sodium nitrite. The ternary nitric acid nano-molten salt heat transfer and storage medium is characterized in that it also includes metal oxide nanoparticles and / or non-metal oxide nanoparticles. The nanoparticles are dispersed into the ternary nitric acid molten salt system to undergo compounding so as to form the ternary nitric acid nano-molten salt heat transfer and storage medium. The ternary nitric acid nano-molten salt involved in the invention has a low melting point, an upper limit use temperature up to 600DEG C, good thermal stability, and high heat conductivity, thus being very suitable for the heat storage and transfer system of industrial energy storage and solar-thermal power generation.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

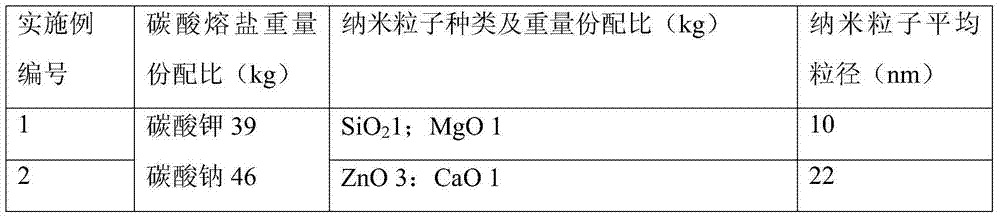

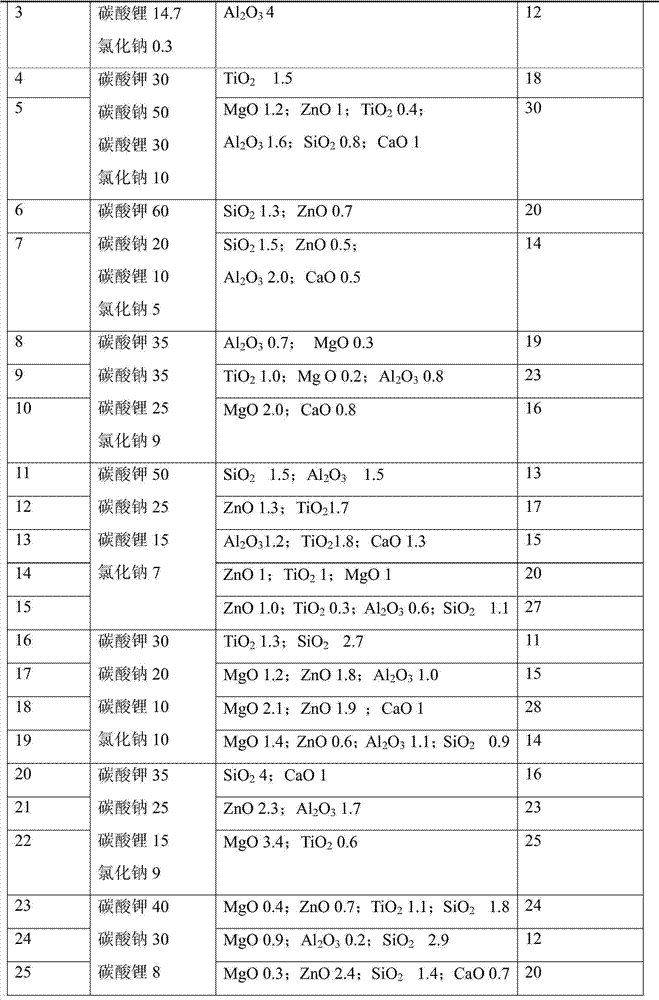

Molten nano-carbonate heat transfer and accumulation medium, and preparation method and application thereof

ActiveCN103923619AHigh safe use upper limit temperatureReduce volume shrinkage ratioHeat-exchange elementsHeat stabilityNanoparticles dispersion

The invention provides a molten nano-carbonate heat transfer and accumulation medium, and a preparation method and an application thereof, and belongs to the technical field of heat storage and transmission. The molten nano-carbonate heat transfer and accumulation medium contains a molten carbonate system formed by potassium carbonate, sodium carbonate, lithium carbonate and sodium chloride, nanoparticles are added into the molten carbonate system, and the nanoparticles are metal oxide and / or nonmetal oxide; and the nanoparticles are dispersed into the molten carbonate system, and the molten nano-carbonate heat transfer and accumulation medium is formed through compounding. The melting point of molten nano-carbonate is low, so the molten nano-carbonate heat transfer and accumulation medium has an upper limit use temperature of 800DEG C, has a good heat stability and a high heat conductivity, and is very suitable for the heat accumulation and transfer systems of industrial energy accumulation and solar photo-thermal power generation.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

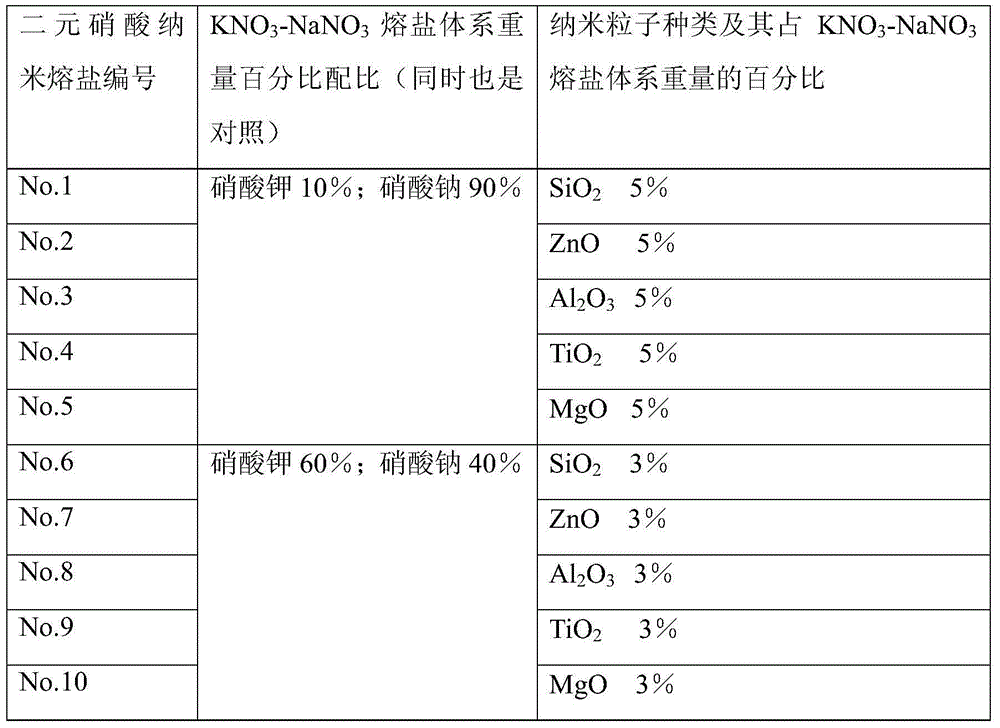

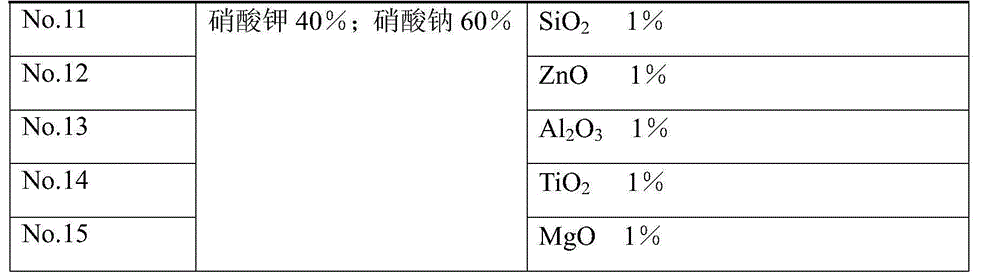

Nanometer molten binary nitrate heat-transfer heat-storage medium and preparation method thereof

ActiveCN103911121AImprove thermal conductivityImprove thermal stabilityFrom solar energySolar heat devicesMolten saltHeat stability

The invention relates to a nanometer molten binary nitrate heat-transfer heat-storage medium and a preparation method thereof and belongs to the field of solar photo-thermal electricity generation. The nanometer molten binary nitrate heat-transfer heat-storage medium is characterized in that nano-particles are dispersed in a KNO3-NaNO3 and KNO3-NaNO2 solid-liquid phase-change molten binary nitrate system at a high temperature so that the nanometer molten binary nitrate heat-transfer heat-storage medium is compounded, and the nano-particles comprise SiO2, ZnO, Al2O3, TiO2, CaO and / or MgO nanoparticles. The nanometer molten binary nitrate heat-transfer heat-storage medium solves the problem that the existing nanometer molten binary nitrate system has a low heat conductivity coefficient, poor heat stability and a narrow use temperature scope and can be widely used in the technical field of solar photo-thermal electricity generation.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

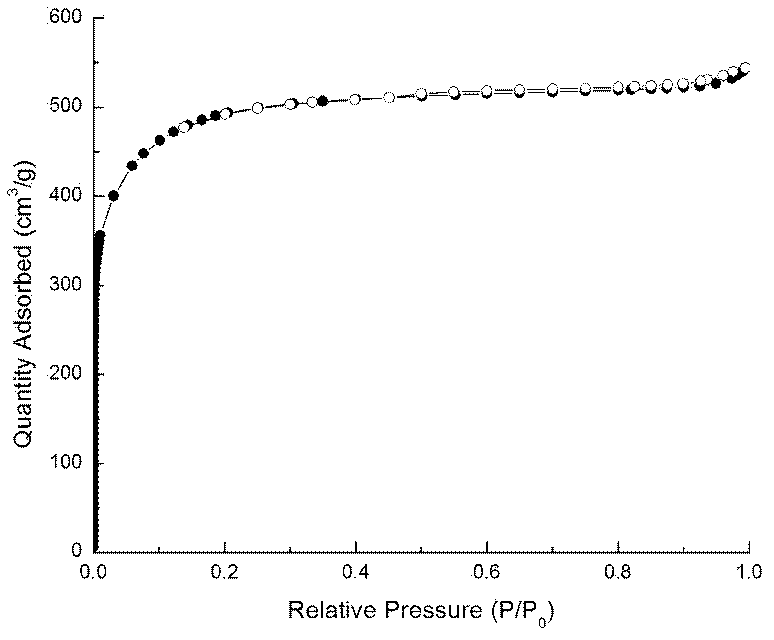

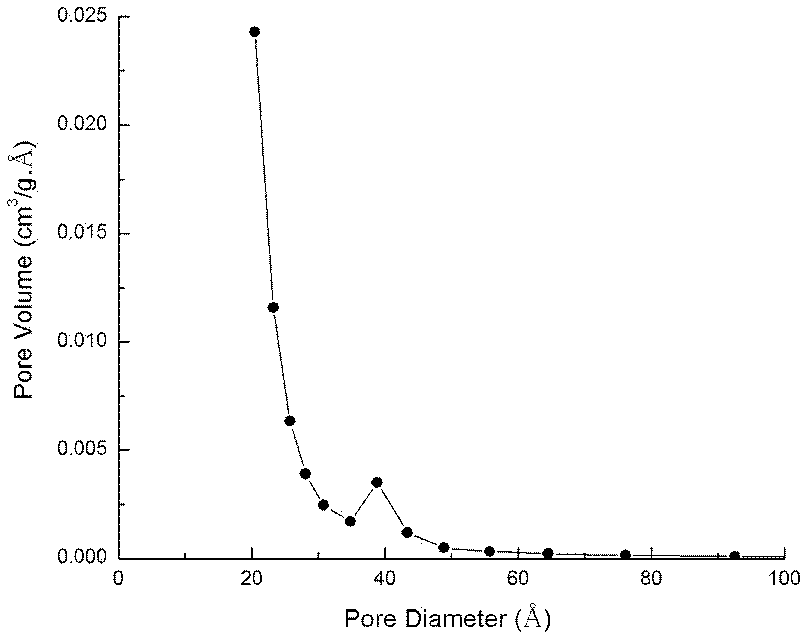

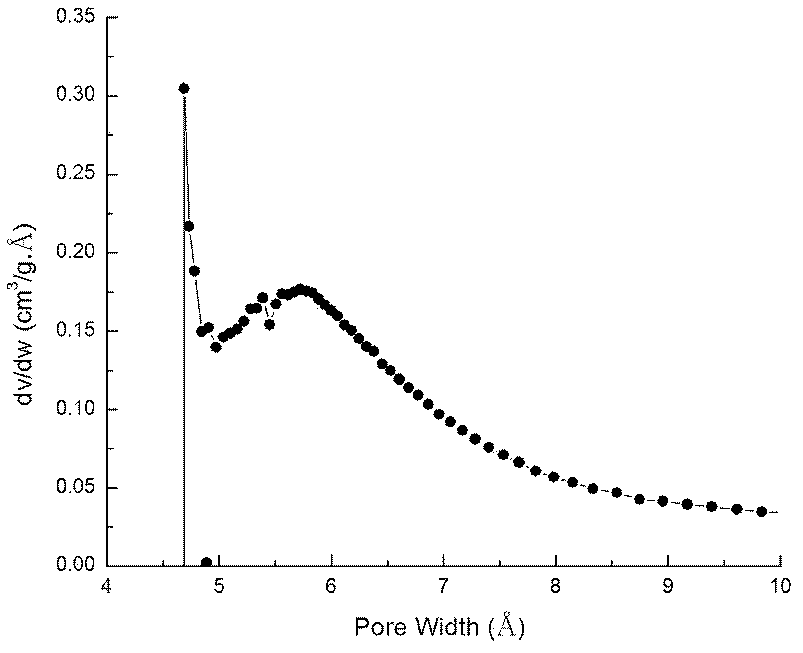

Method for preparing nutshell activated carbon by pyrolyzing activation technology and activated carbon

The invention provides a method for preparing nutshell activated carbon by a pyrolyzing activation technology and activated carbon. The method takes fragmented dry nutshells as raw materials, which are pyrolyzed under a pyrolysis temperature, and then pickled, washed, and dried so as to obtain activated carbon. Specifically, the raw materials are put in a ceramic pyrolysis reactor first, and the ceramic pyrolysis reactor is filled with air and sealed completely, then pyrolysis is carried out under a pyrolysis temperature of 700-1000DEG C for 1-10h. The prepared activated carbon has a specific surface area of 500-2300m<2> / g, a yield of 5-40%, and an iodine adsorption value of 470-1930mg / g. The one-step pyrolyzing activation method provided in the invention for preparing nutshell activated carbon with high adsorption performance needs no water vapor, phosphoric acid or zinc chloride and other activating agents. The prepared product has high yield and excellent adsorption performance. And the preparation technology is green, clean, and has short process as well as low cost.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Paraffin phase changed thermal mortar powder and preparing method thereof

A mortar powder containing paraffin wax for phase-change insulating is prepared from cement, light aggregate, fibres and paraffin wax through fusing paraffin wax or preparing the microcrystal powder of paraffin wax, and proportionally mixing it with others. Its advantages are low hydroscopicity and high water-proof performance and softening coefficient.

Owner:北京振利高新技术有限公司

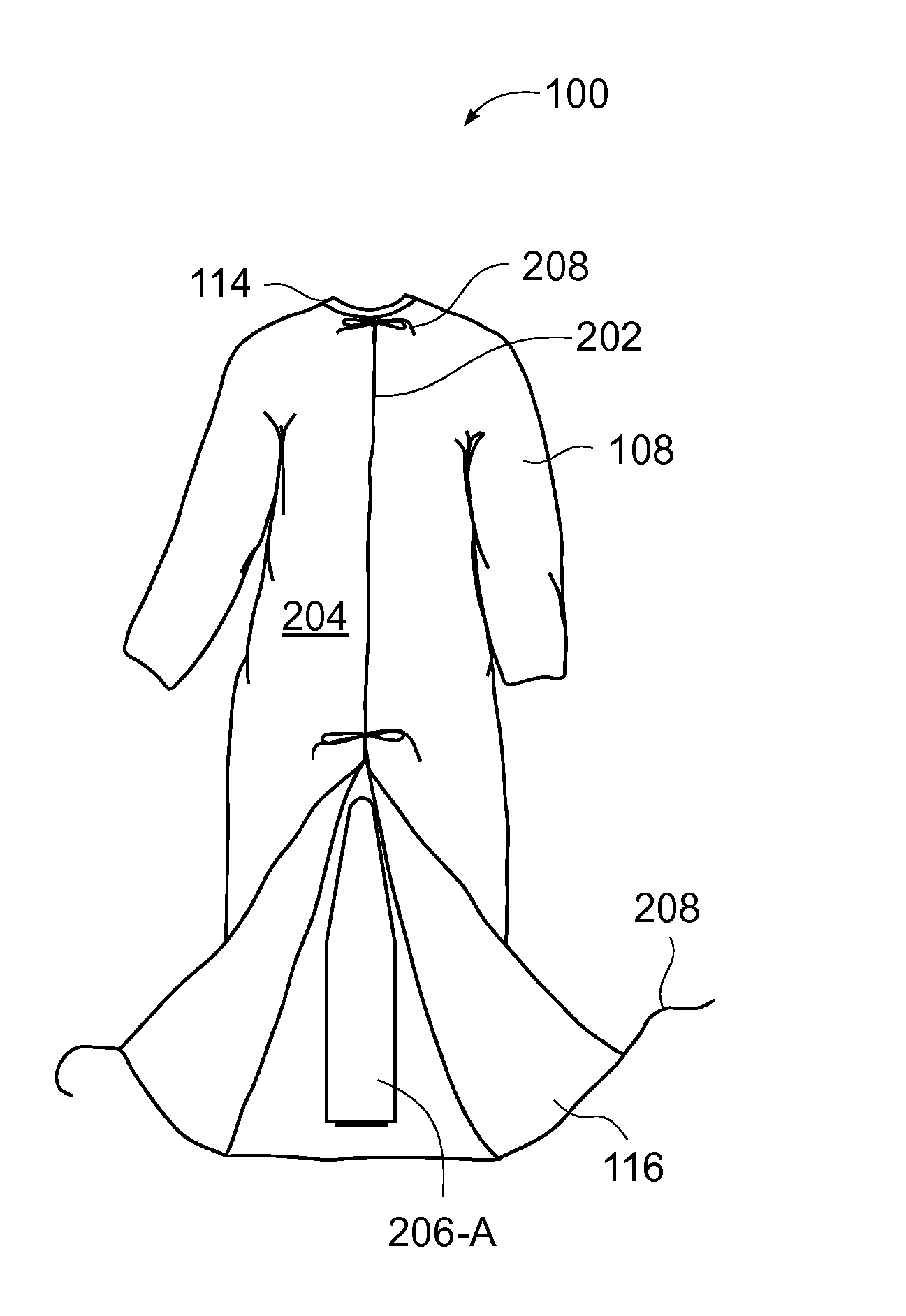

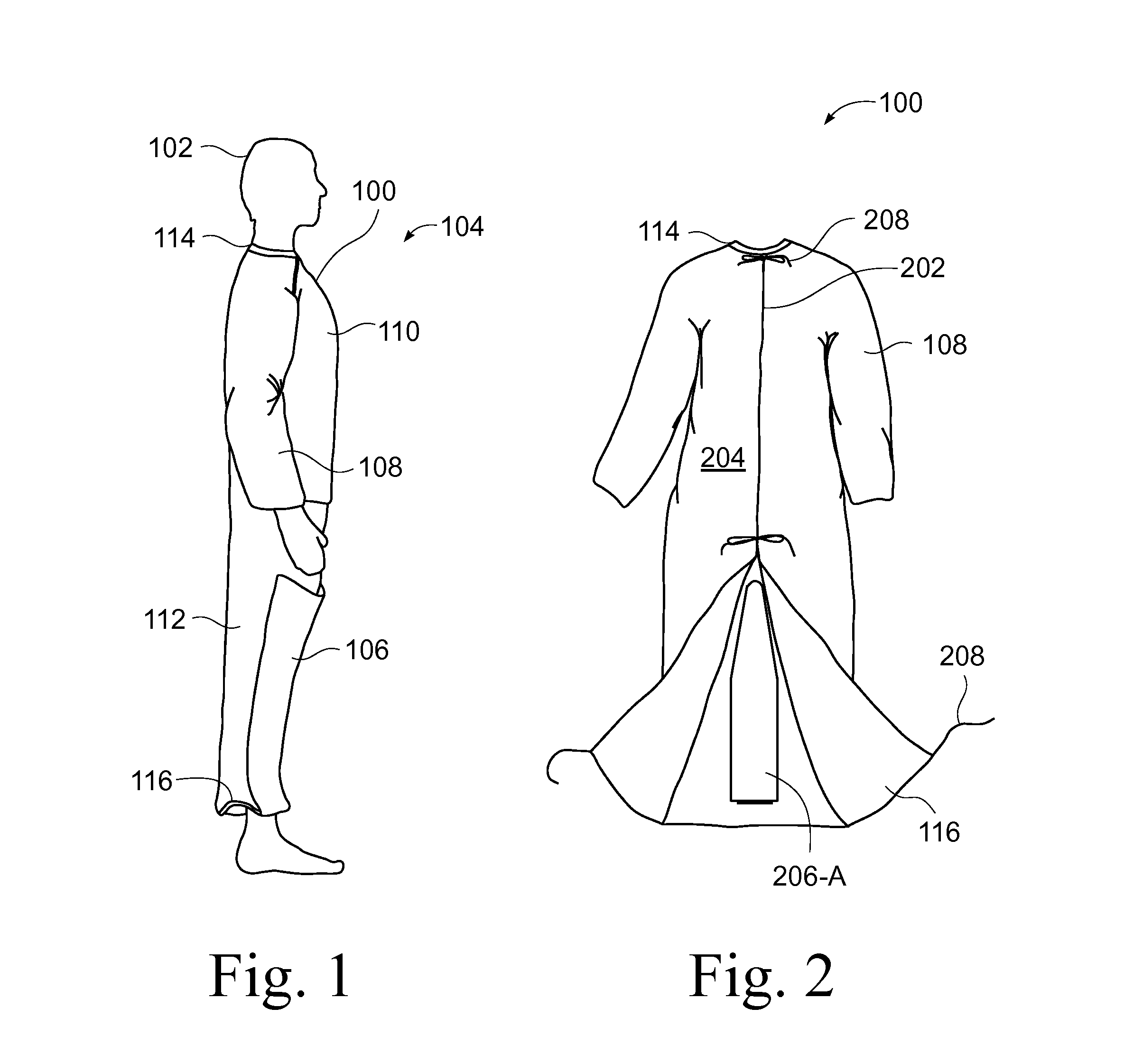

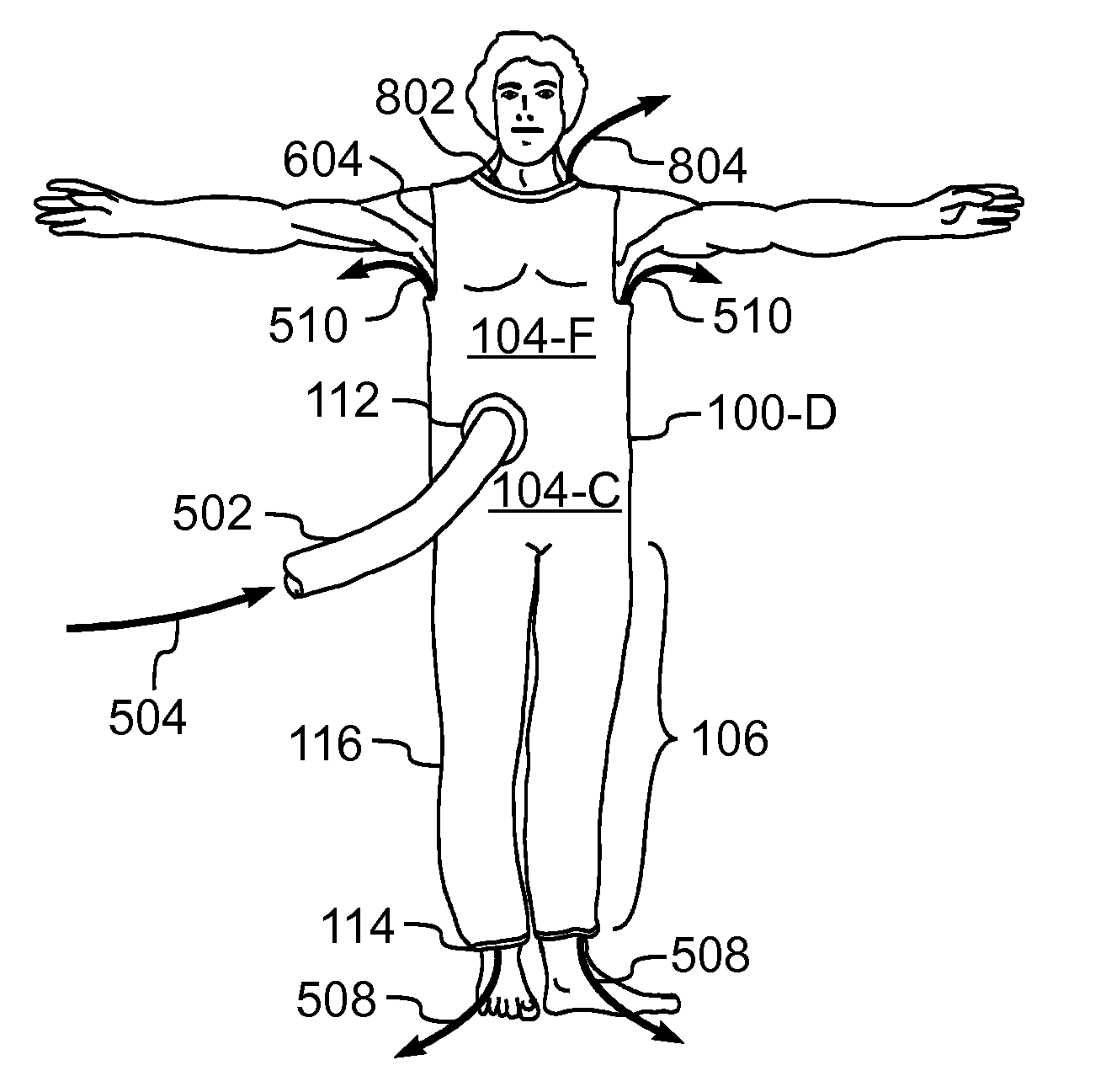

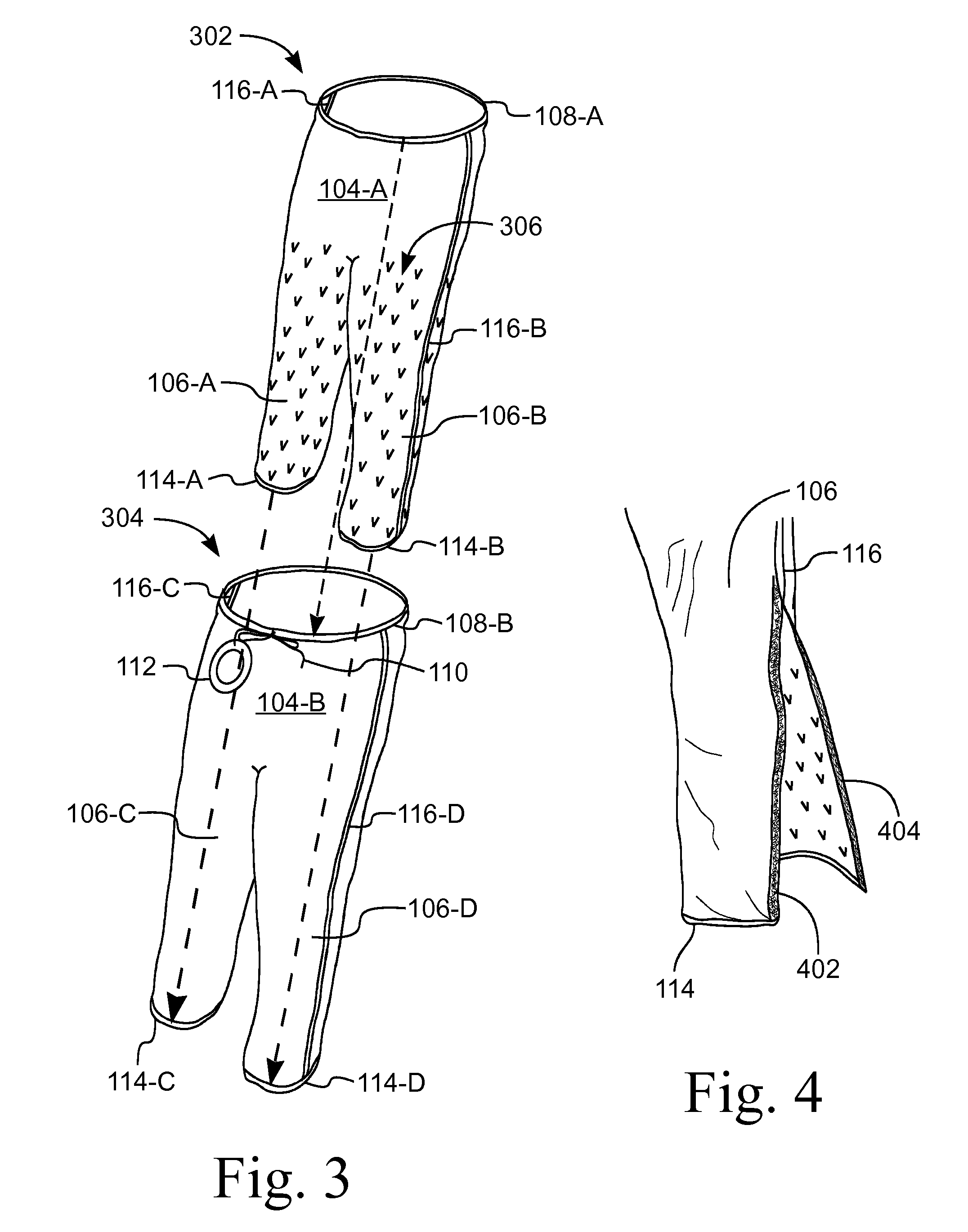

Prewarming Gown

ActiveUS20120047623A1Avoid areaMaintain air temperatureTherapeutic coolingPyjamasHuman bodyEngineering

A device for warming a human body. The device is a gown that has a body with a thorax portion and a leg portion. One embodiment prevents redistribution hypothermia with a distributor attached to the inside of the leg portion. The sleeves, leg portion, and posterior of the gown are heat reflective. The anterior of the thorax portion of the gown is non-reflective. The distributor inflates when heated air is supplied. The distributor exhausts air into the gown. Temperature is maintained at a desired level for the extremities, while preventing the thorax area from being elevated to an uncomfortable level. Another embodiment is a perioperative warming device. The device is a gown that has a thorax portion and a leg portion. Each portion has an independent air chamber and inlet. The two portions are releasably connected. The sleeves, leg portion, and anterior of the gown are heat reflective.

Owner:THE SURGICAL INT

Thermal storage oxygen carrier of core-shell structure and preparation method thereof

InactiveCN102925245AGood heat storage and oxygen carrying capacityHigh mechanical strengthFuel additivesMicroballoon preparationIonChemistry

The invention provides a thermal storage oxygen carrier of a core-shell structure and a preparation method thereof. The oxygen carrier is of a double-shell structure, namely a high-temperature phase change heat storage material. An inner shell is TiO2, and an outer shell is made of an oxygen carrier material. The method includes that the high-temperature phase change heat storage material is ground to nanoscale microballoons and dispersed in a mixed liquor of cetyl trimethyl ammonium bromide (CTAB) and ethanol to form turbid liquid, the turbid liquid and ammonia water parallelly flow and are dropped into tetra-n-butyl titanate (TBOT) slowly, a nitrate and aluminum nitrate solution is dropped into the turbid liquid gradually, stirring is conducted continuously in a dropping process, and sediment is generated; and then centrifugal processing is conducted, the sediment is washed through absolute ethyl alcohol and deionized water, the sediment is dried and baked, and the thermal storage oxygen carrier is obtained. The structure is favorable for protecting and fixing an inner-core thermal storage material becoming liquid at high temperature. Simultaneously, a frit reaction is prevented from happening between the inner-core thermal storage material and the outermost-layer oxygen carrier material, and the mechanical strength of the oxygen carrier is improved. The preparation method is simple and easy to control.

Owner:KUNMING UNIV OF SCI & TECH

Fluorine salt-based nano high temperature phase change heat storage composite material and preparation method thereof

InactiveCN101613593AImprove thermal conductivityLight in massSolar heat devicesHeat-exchange elementsMolten stateHeat conducting

The invention provides a fluorine salt-based nano high temperature phase change heat storage composite material, which is characterized by compounding nano material and fluorine salt material to form uniform and stable compound. The synthetic method comprises the following steps: stirring evenly fluorine salt and placing into a vacuum electric furnace; heating to a temperature which is above the phase change temperature by 50-100 DEG C; degassing and dehydrating to lead the fluorine salt in a melting state; adding nano metal particles which account for 1%-5% of the total mass to molten salt crystals; magnetically stirring the molten material for 10-60min with the heat preservation ultrasound of 10-120min; and preparing the uniform and stable fluorine salt-based nano high temperature phase change heat storage composite material. The prepared fluorine salt-based nano high temperature phase change heat storage composite material has the advantages of rapid heat storage and heat release, high heat storage density and good heat-conducting property, can be used in various fields like space station solar energy thermo-motive power generating system, solar power generation, high temperature residue heat recycling and the like, and is in particular applicable to a heat absorber of the space solar energy thermo-motive power generating system.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

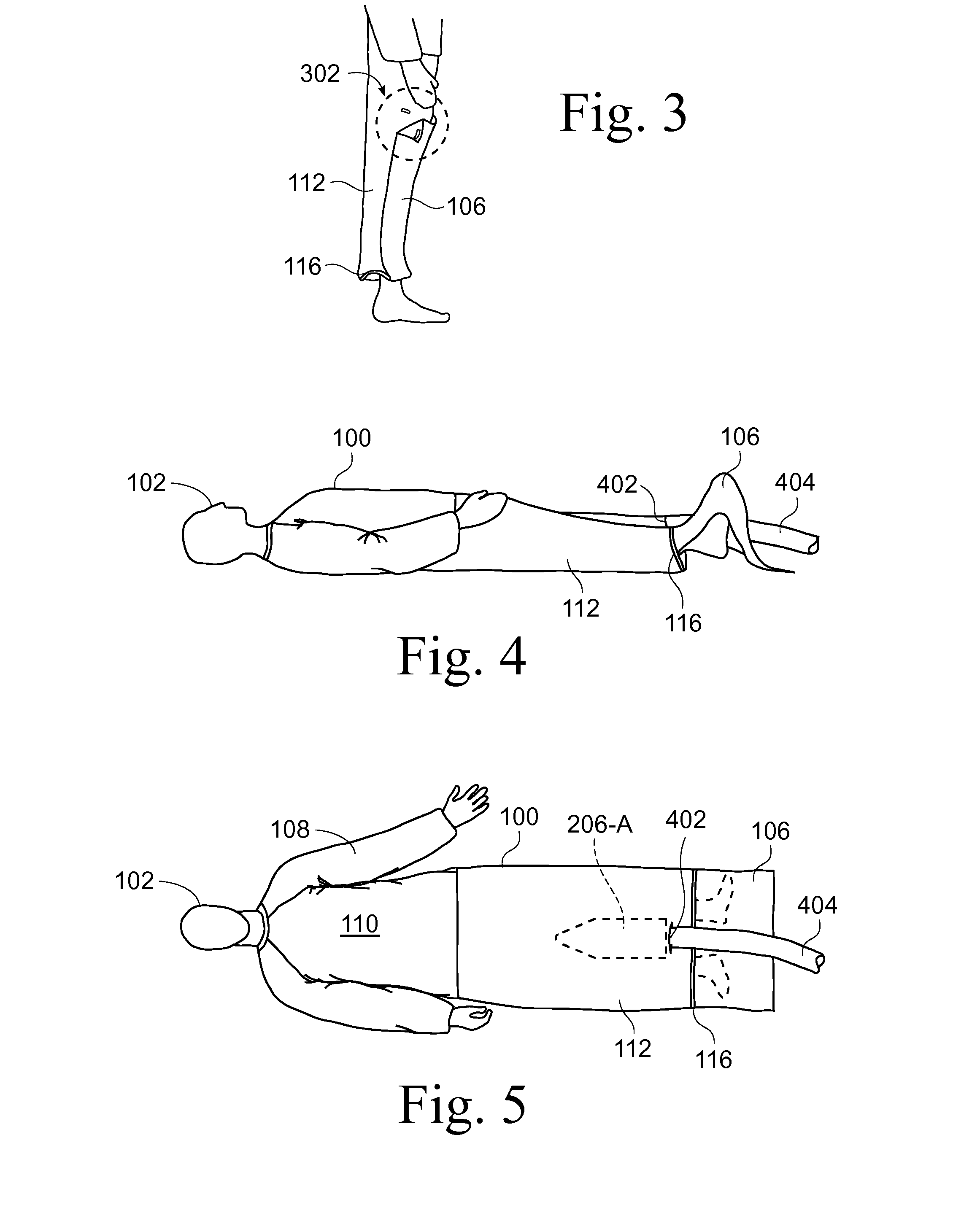

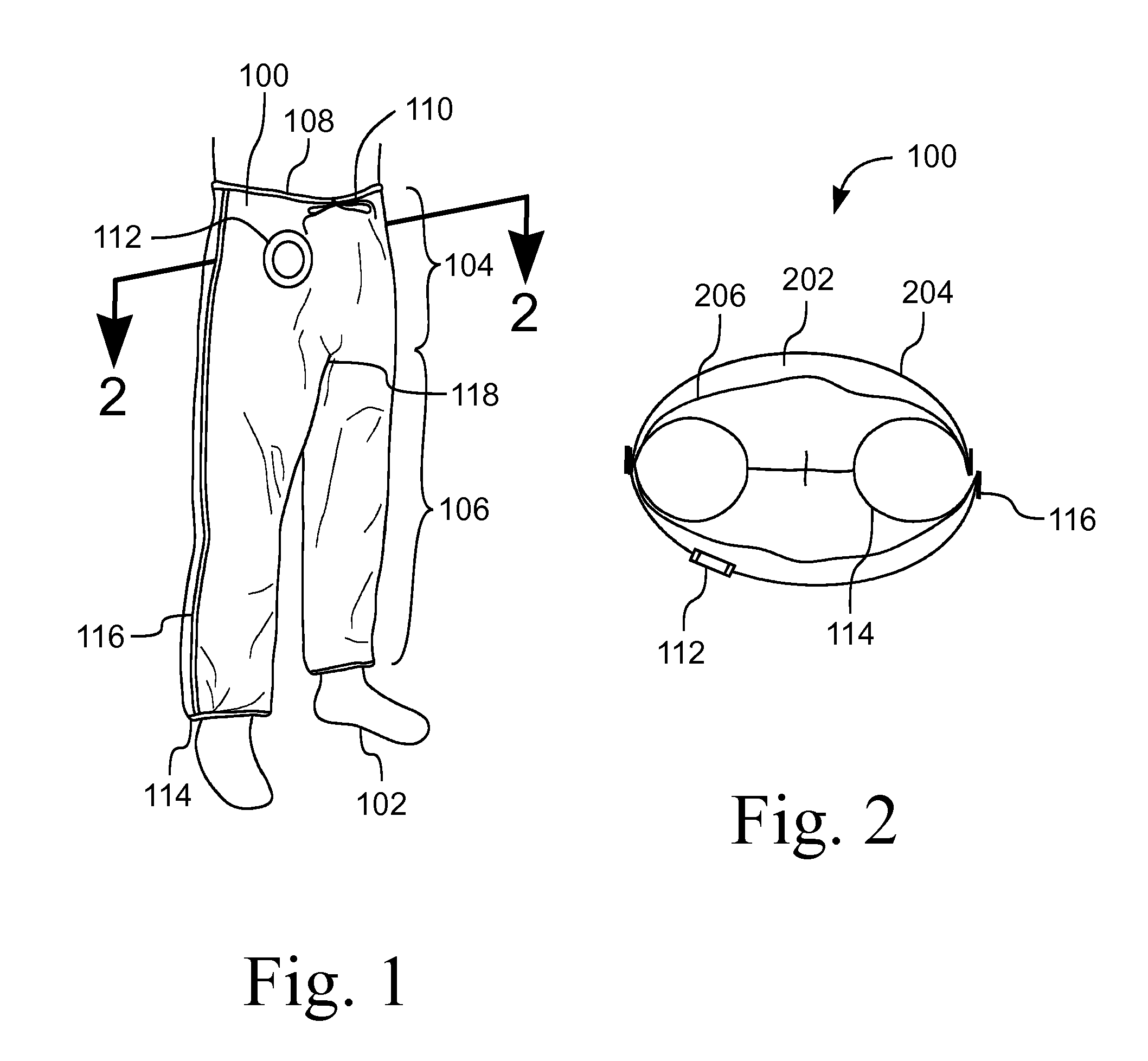

Garment For Preventing Redistribution Hypothermia

ActiveUS20120047622A1Prevent hypothermiaComfort levelChemical protectionHeat protectionEngineeringTemperature gradient

A thermal therapy garment that covers at least the lower extremities of a patient. The garment has an air impermeable outer layer and an air permeable inner layer. An inflatable air chamber is defined between the inner and outer layers. An inlet port connects to the chamber to allow inflation with conditioned air, which is exhausted through the inner layer over a selected region of the patient's lower body. A gown has a length sufficient to overlap a waist portion of the garment, The gown has an opening that coincides with the inlet port, thereby allowing a hose to pass through the gown and connect to the inlet port. In one embodiment, the gown has sleeves and / or a posterior portion that are heat reflective whereby the extremities are warmed to minimize the core to peripheral temperature gradient.

Owner:THE SURGICAL INT

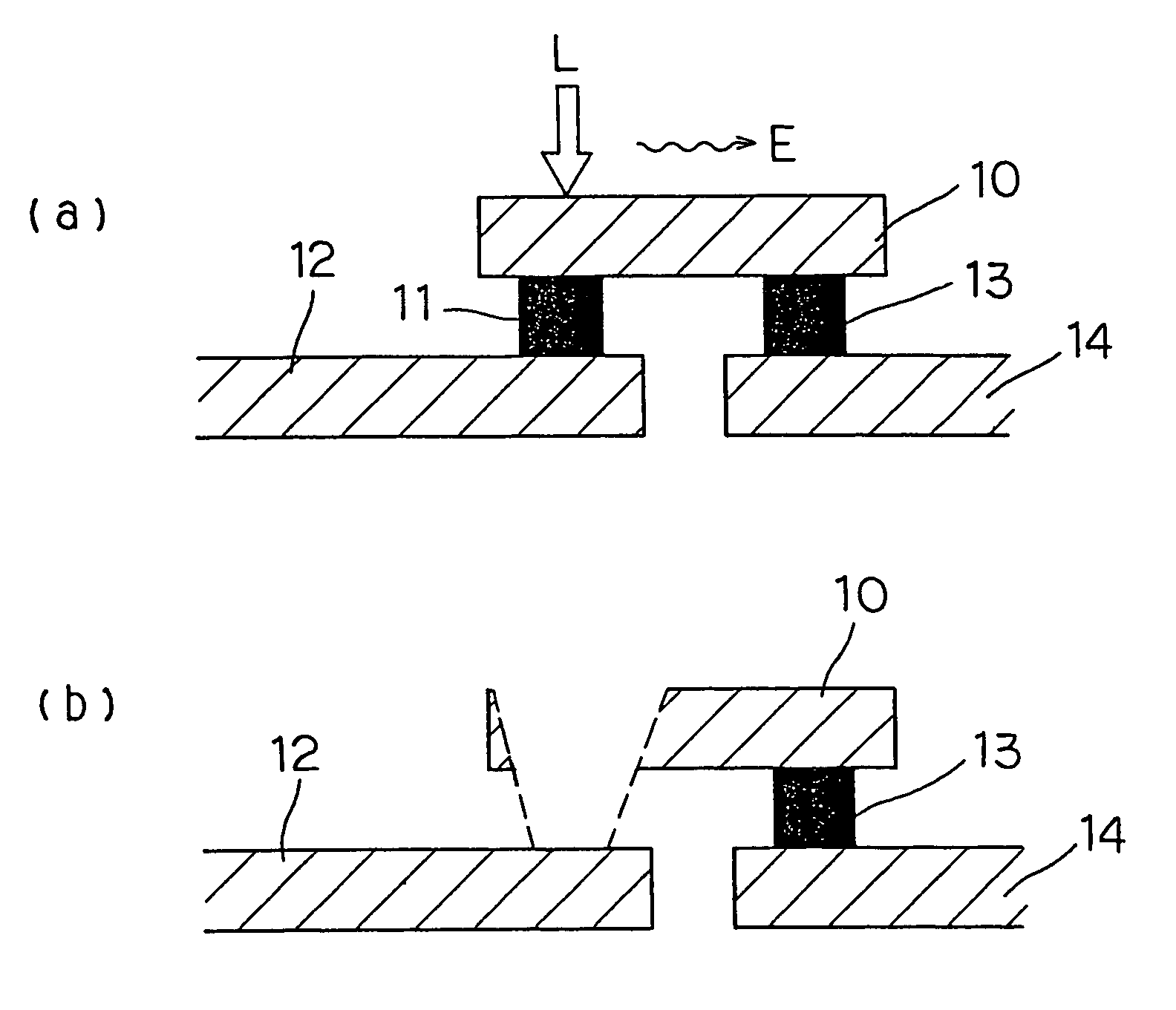

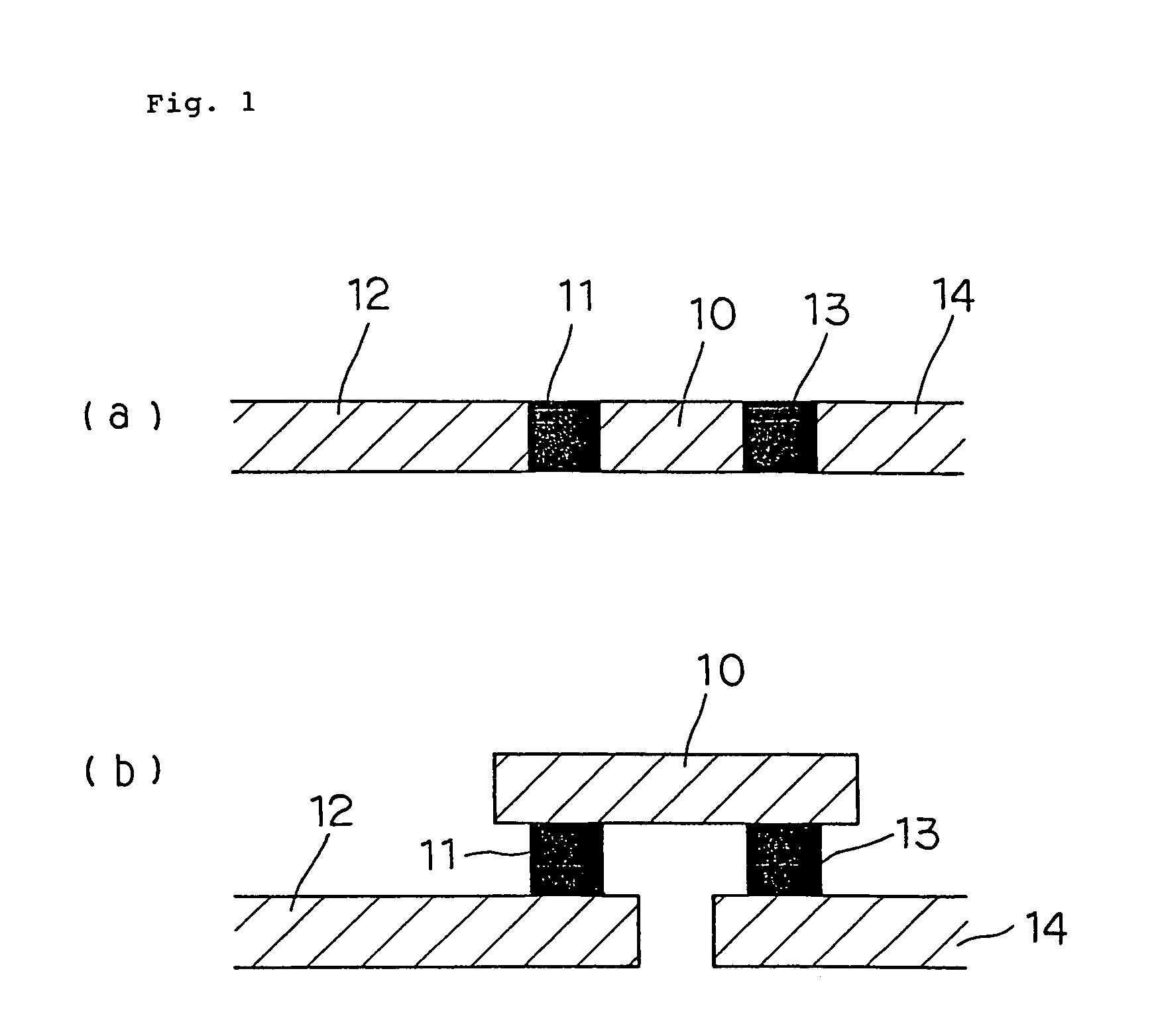

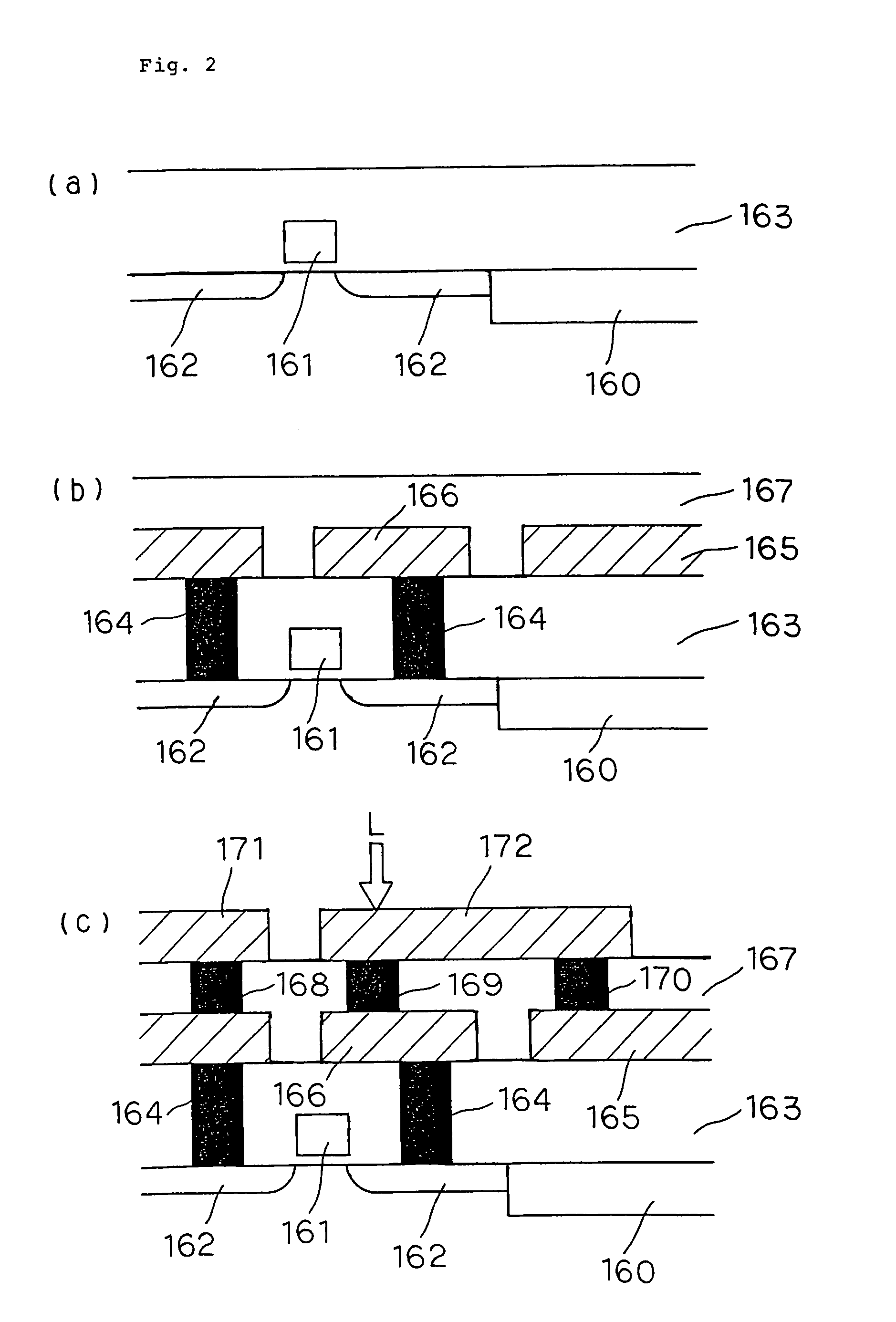

Semiconductor device having a fuse and a low heat conductive section for blowout of fuse

InactiveUS6972474B2Complete disconnectionAvoid heat dissipationSemiconductor/solid-state device detailsSolid-state devicesInterconnectionIrradiation

In a semiconductor device having a fuse 11 which makes connection between a first interconnection 10 and a second interconnection 12, and a first low heat-conductive section 13 which makes connection between the first interconnection 10 and a third interconnection 14 at a site of the first interconnection 10 where the fuse 11 is not connected, the first low heat-conductive section 13 is fabricated from a material having a heat conductivity lower than that of the material to form the first interconnection 10. When the fuse is blown with the laser beam irradiation, the heat dissipation through the heat conduction along the fuse and the interconnection is to be suppressed, and thereby a satisfactory disconnection at the fuse is to be achieved.

Owner:RENESAS ELECTRONICS CORP

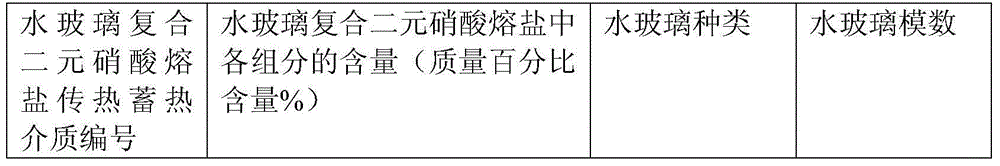

Sodium silicate-molten binary nitrate compounded heat-transfer heat-storage medium and its preparation method and use

ActiveCN103911122ARaise the upper limit of safe operating temperatureWide temperature rangeChemical industryHeat-exchange elementsCompound aPotassium nitrate

The invention discloses a sodium silicate-molten binary nitrate compounded heat-transfer heat-storage medium and its preparation method and use. The sodium silicate-molten binary nitrate compounded heat-transfer heat-storage medium is prepared by compounding a molten binary nitrate system and sodium silicate. The molten binary nitrate system mainly comprises potassium nitrate and sodium nitrate. The sodium silicate-molten binary nitrate compounded heat-transfer heat-storage medium has heat-transfer performances of the nitric acid molten salt, improves a safe work temperature upper limit of the system to 650 DEG C, and has a wide use temperature range and good thermal conductivity. The sodium silicate-molten binary nitrate compounded heat-transfer heat-storage medium has good heat absorption and heat-storage capability, solves the problem that the molten binary nitrate has poor thermal conductivity and easily produces local overheating, and can be widely used in the technical field of solar photo-thermal power generating.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

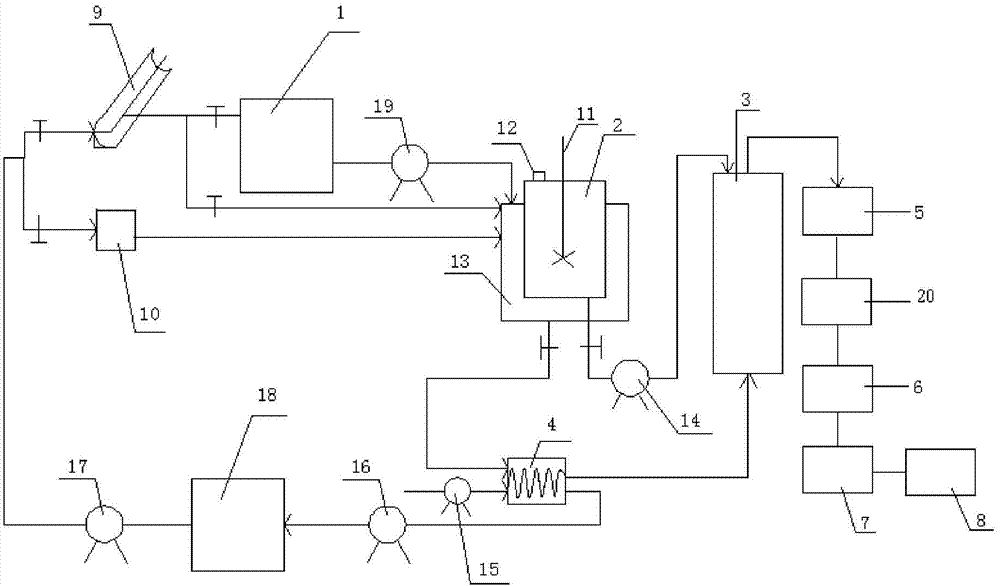

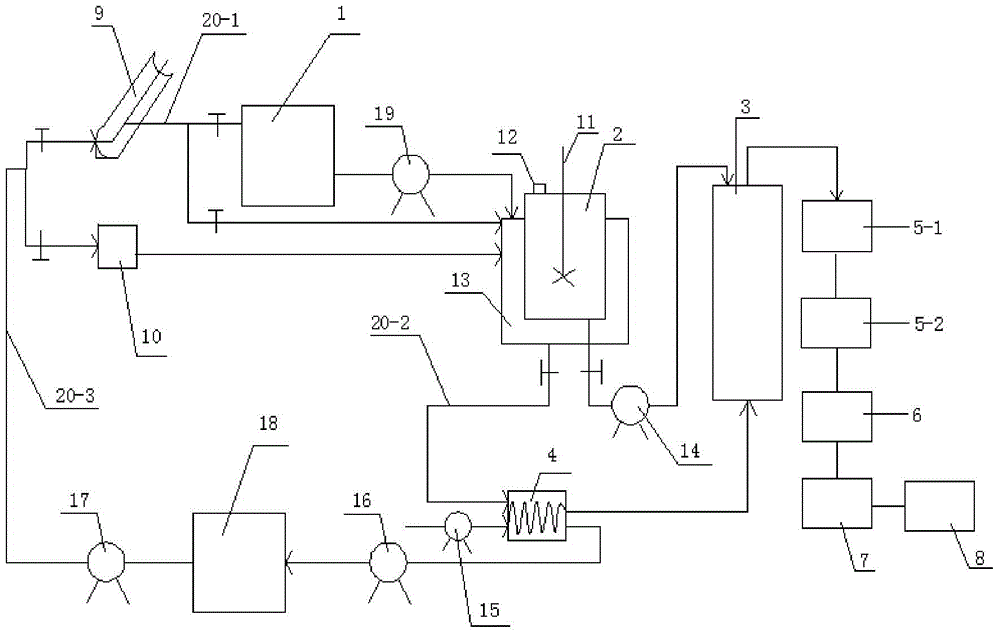

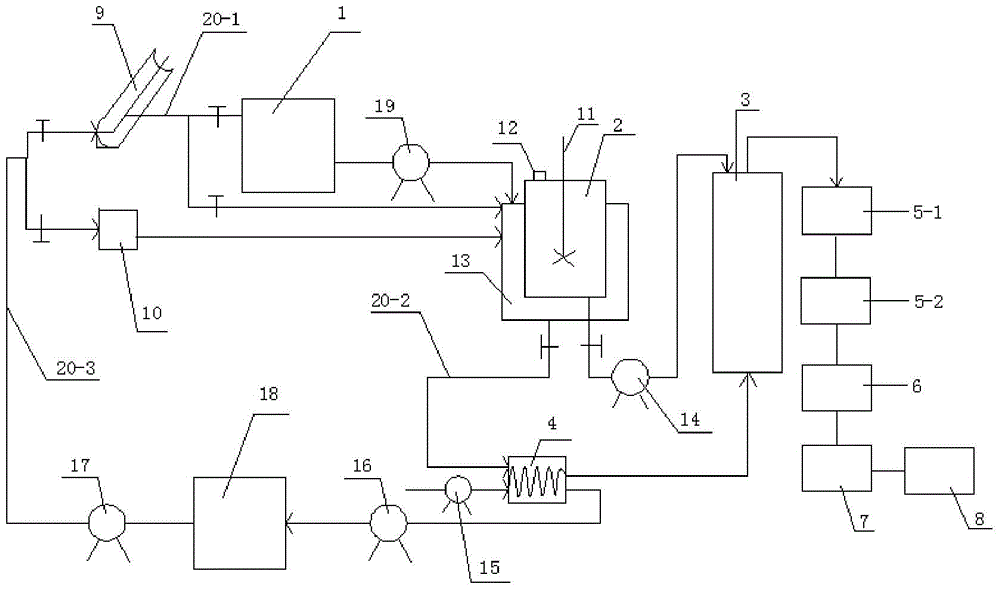

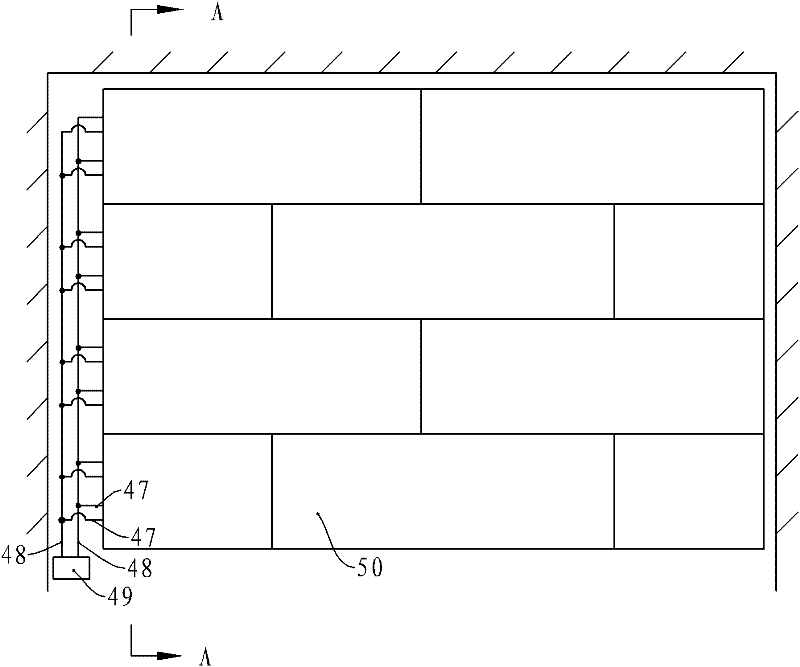

Novel solar heat tube heat collection and storage radiant heating system

InactiveCN103411262AGood energy saving effectStrong applicabilityIndirect heat exchangersSpace heating and ventilation detailsHeating systemEngineering

The invention discloses a novel solar heat tube heat collection and storage radiant heating system, and belongs to the field of solar energy utilization. The system comprises a heat insulation light transmitting cover, an internal heat tube group, an external heat tube group, a heat conduction external box, a fixing device and an indoor heat radiation device, wherein an evaporation end of the internal heat tube group can be provided with a selective coating, so that the system performance is enhanced; and heat exchange coil heating water can be placed in the heat conduction external box in summer, so that domestic hot water is provided. The system uses the unidirectional heat conduction characteristic of gravity assisted heat tubes, solar energy is absorbed at evaporation ends of the heat tubes, and heat is released from condensation ends, so that heat is transferred to the interior continuously, and radiant heating is realized through the indoor heat radiation device. The system is cheap and practical, requires no secondary cost, and also can be used as an auxiliary heating device and a main heating system.

Owner:NANJING NORMAL UNIVERSITY

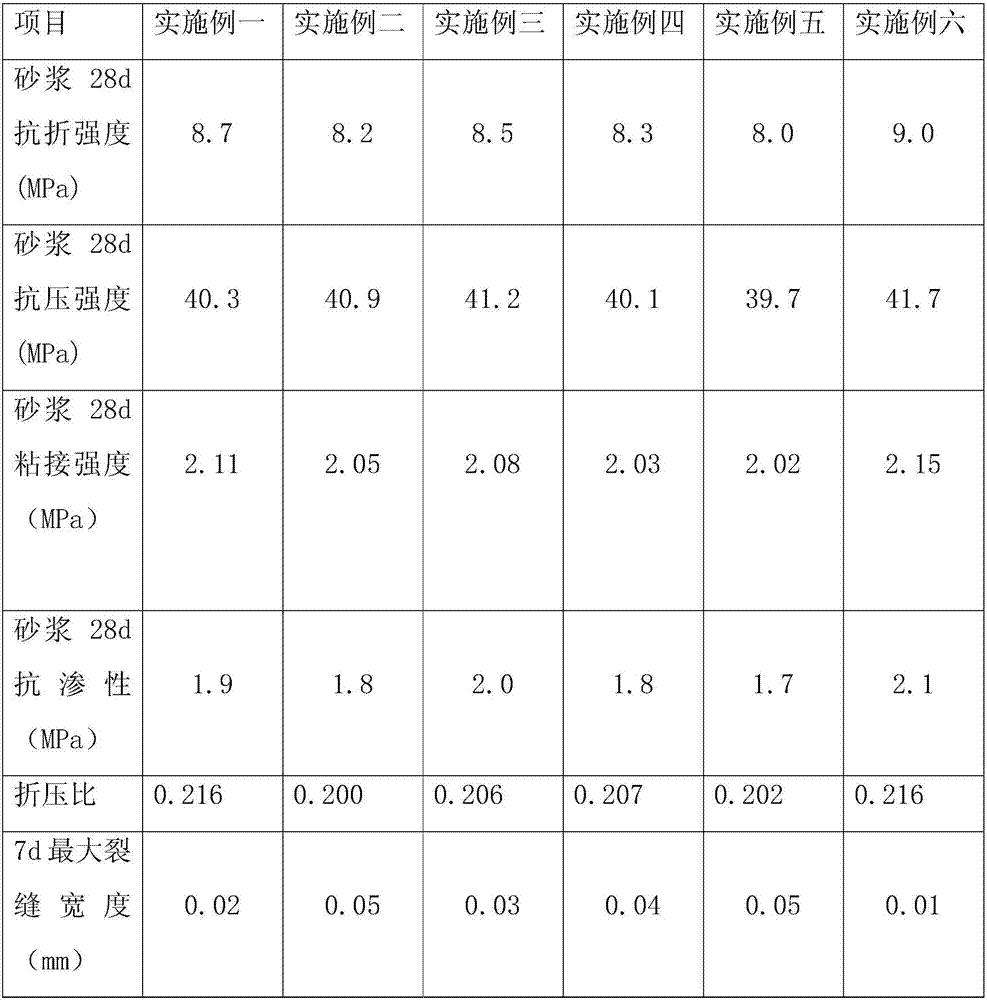

Dry mixing waterproof mortar with high crack resistance

The invention provides a dry mixing waterproof mortar with high crack resistance. The dry mixing waterproof mortar contains the following raw materials in parts by weight: 400-410 parts of cement, 1400-1450 parts of machine-made sand, 70-75 parts of coal ash, 0.8-4 parts of acrylic based emulsion powder, 0.8-4 parts of EVA emulsion powder, 3-12 parts of styrene-butadiene latex, 100-120 parts of modified towel gourd fiber, 100-120 parts of ramie fiber, 50-60 parts of bamboo charcoal fiber, 70-100 parts of seaweed meal, 0.8-1.0 part of organic silicon defoamer and 280-350 parts of water. According to the invention, all the raw material components are matched with one another and have a synergic effect, so that the prepared mortar has the advantages of high toughness, high rupture strength, high compressive strength and excellent anti-cracking ability and has a certain adsorptive property and a bactericidal ability; the matching relation of all the raw material components is reasonable; all the raw materials can be uniformly mixed; the dry mixing waterproof mortar is harmless to environment and conforms to the idea of low carbon, environmental protection and sustainable development.

Owner:CHONGQING JIAOTONG UNIVERSITY

Composite phase change energy storage material and preparation method thereof

InactiveCN101747868AImprove heat storage effectImprove thermal conductivityHeat-exchange elementsParaffin waxHalloysite

The invention discloses a composite phase change energy storage material and a preparation method thereof. The invention relates to an energy storage material and aims to provide the composite phase change energy storage material which has good energy storage thermal effect, low cost and good heat conductivity, and the preparation method for the composite phase change energy storage material. In order to realize the aim, the invention adopts a technical scheme that the composite phase change energy storage material comprises paraffin wax and halloysite which is a material compounded with the paraffin wax, wherein the content of the paraffin wax in percentage by weight is 30 to 80 percent. The composite phase change energy storage material and the preparation method thereof are used for heat accumulation materials.

Owner:HENAN NORMAL UNIV

Foam heat storage and method for preparing the same

ActiveCN101113323ATake advantage ofHigh compressive strengthHeat-exchange elementsHoneycomb structureHeat capacity

The invention discloses a foam heat storage regenerator and a preparation method thereof. The existing heat storage regenerators are all of direct type network structures or honeycomb structures, thereby having small surface area and non-ideal thermal storage effect, besides, due to the limitation of product forming, the shape of products cannot be too large, which has a higher requirement to application environment, therefore, the existing heat storage regenerators generally have the disadvantages of large difficulty of processing, high cost, low yield and narrow application range. The invention takes kaolin, aluminum oxide, spodumene and organic material as raw materials, the raw materials are first coated and adhered by polymer cavernous mode and then burnt and the finished products are produced. The invention has the advantages of large surface area, which is over 2000m2 / m3, good heat storage effect, large application efficiency, which is more than 90 percent, small product water absorption, which is less than 1 percent, high anti-pressure strength, large heat capacity, wide application, no limitation of system waste gas types, long service life, small processing difficulty and low cost and materials can be fully applied and comply with the environmental protection requirements.

Owner:刘光文

Paraffin phase changed thermal mortar powder and preparing method thereof

A mortar powder containing paraffin wax for phase-change insulating is prepared from cement, light aggregate, fibres and paraffin wax through fusing paraffin wax or preparing the microcrystal powder of paraffin wax, and proportionally mixing it with others. Its advantages are low hydroscopicity and high water-proof performance and softening coefficient.

Owner:北京振利高新技术有限公司

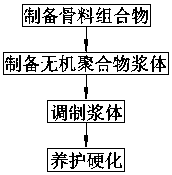

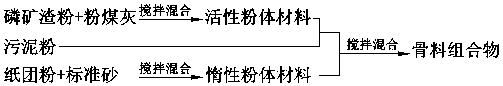

Inorganic polymer foaming material prepared from sludge and preparing method of inorganic polymer foaming material

ActiveCN108516755ASimple preparation stepsReduce pollutionSolid waste managementCeramicwarePorosityPolymer science

The invention relates to the field of preparation of inorganic polymer building materials, in particular to an inorganic polymer foaming material prepared from sludge and a preparing method of the inorganic polymer foaming material. The inorganic polymer foaming material comprises inorganic polymer slurry prepared by mixing an aggregate composition and an alkali activator. The aggregate composition comprises sludge powder and a powder material containing aluminum oxide and / or silicon oxide. The sludge powder is prepared by drying the sludge. The alkali activator comprises sodium hydroxide and / or sodium silicate. The good utilization approach is provided for sludge and industrial solid waste produced during urban sewage treatment, the labor and material consumption in the processing processis reduced, the environment pollution is reduced, and great economic environment-friendly benefits are achieved; meanwhile, through multiple times of stirring and standing treatment and fermenting oforganic mass in the sludge, bubbles in the slurry are increased to the maximum extent, and the prepared foaming material is high in porosity, high in water absorption rate and good in thermal insulation and heat storage effect.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

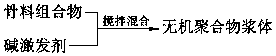

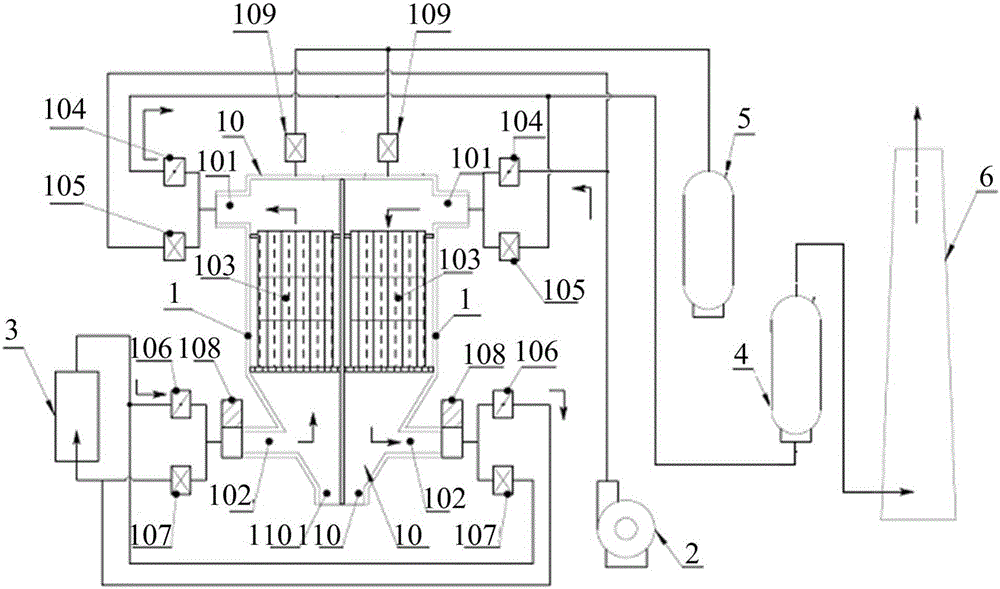

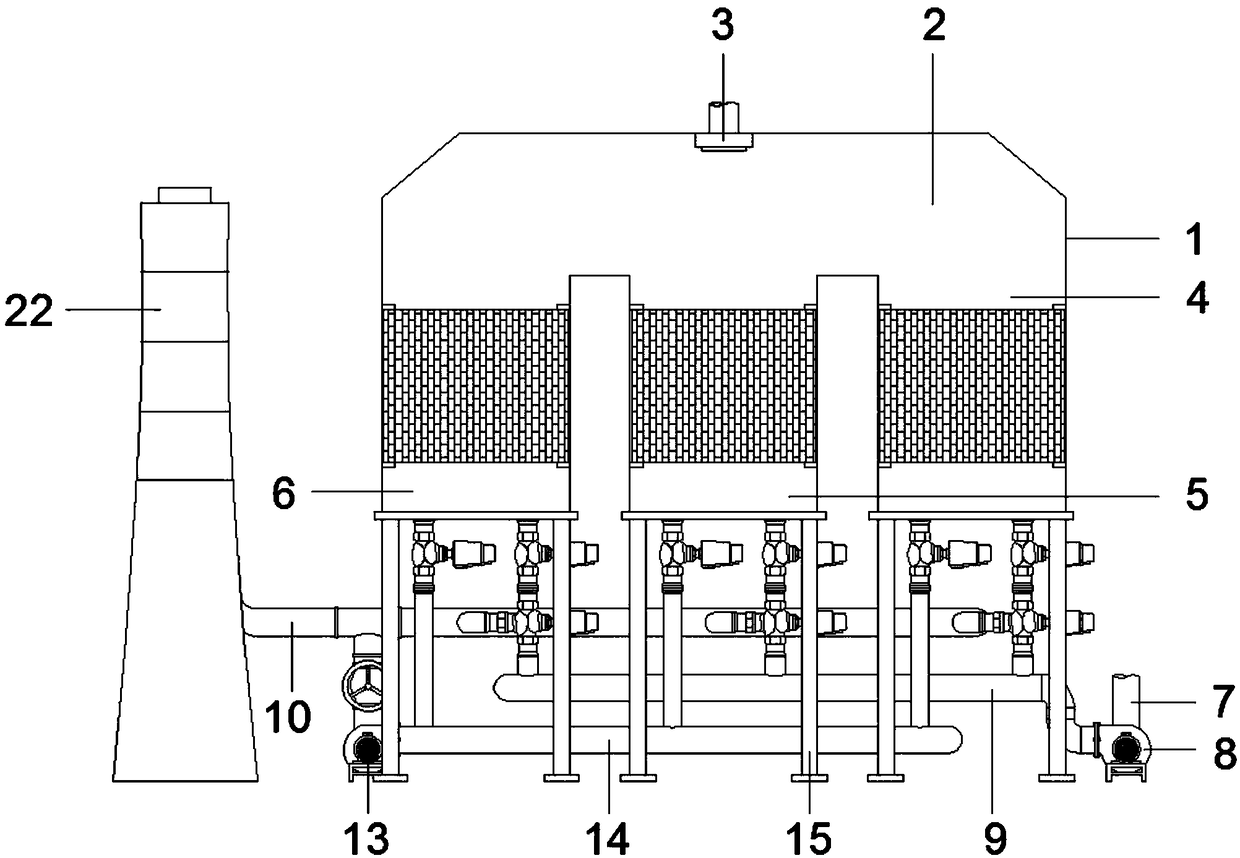

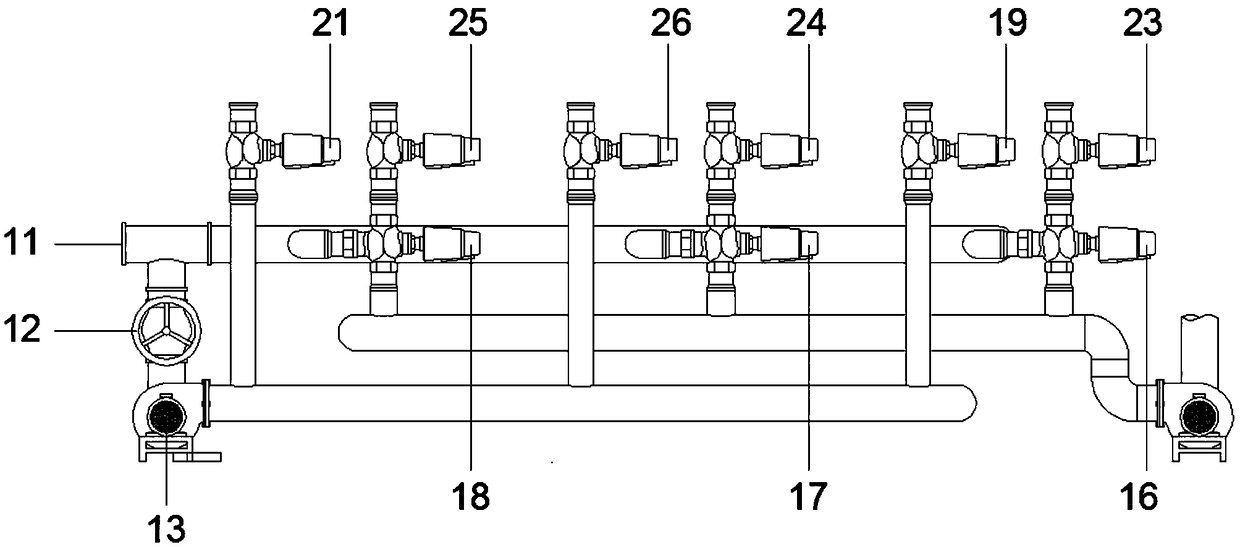

High-temperature wastewater dust removal filter device with waste heat recovery function

ActiveCN105999909AEasy to captureExcellent shooting down performanceDispersed particle filtrationHeat storage plantsWaste heat recovery unitCombustion

The invention provides a high-temperature wastewater dust removal filter device with a waste heat recovery function. The device used for removing dust in waste gas produced through combustion of a combustion furnace and guiding the waste gas into a denitration reaction tower for denitration. The device comprises at least two dust removal working chambers and a combustion fan. The dust removal working chambers are sequentially opened and closed according to preset rules. Each dust removal working chamber comprises an upper air through hole, a lower air through hole and a filter body, wherein the upper air through hole is made communicated with the denitration reaction tower, the lower air through hole is made communicated with the combustion furnace, and the filter body is arranged between the upper air through hole and the lower air through hole. The combustion fan is made communicated with the upper air through holes and injects combustion air into the combustion furnace according to a preset rule. The combustion air passes through the dust removal working chambers to bring heat of the dust removal working chambers to the combustion furnace. According to the high-temperature wastewater dust removal filter device with the waste heat recovery function, dust catching and knocking-down performance is excellent, and heat storage performance and waste water recovery performance are excellent.

Owner:德州奥深节能环保技术有限公司

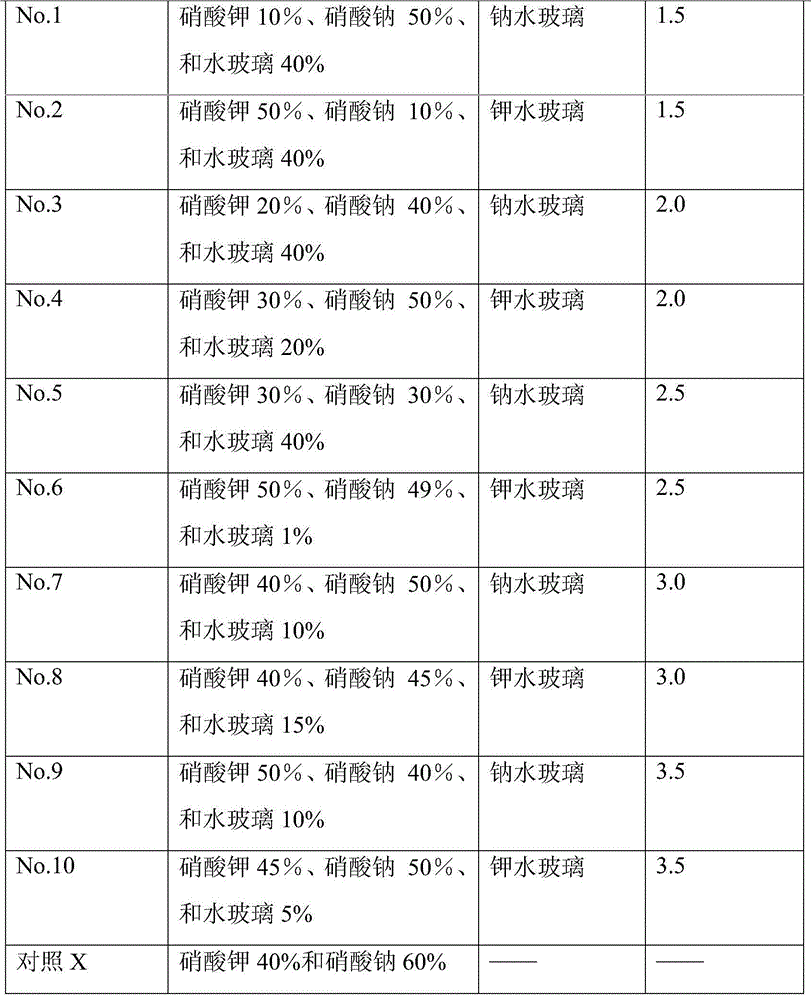

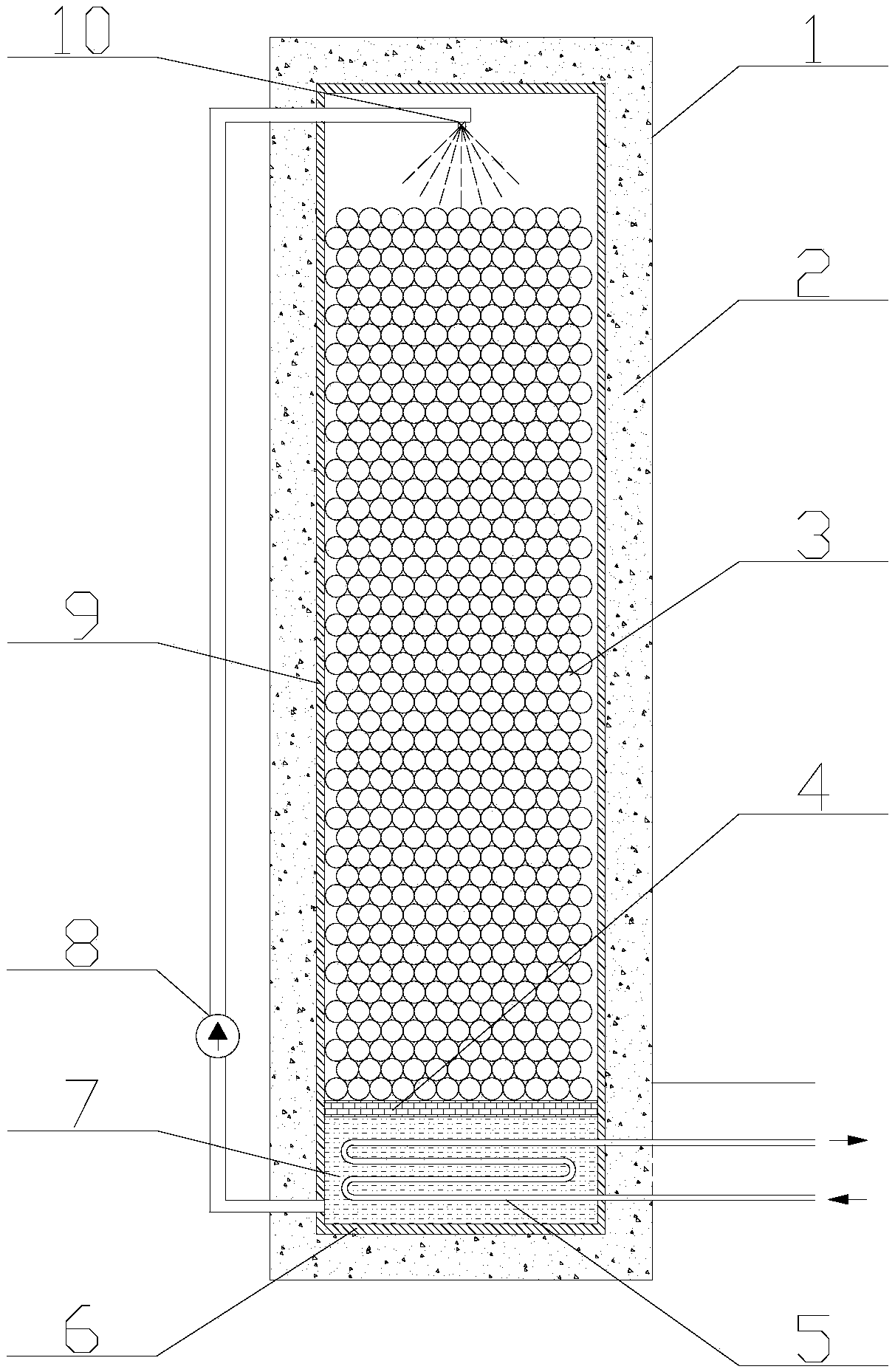

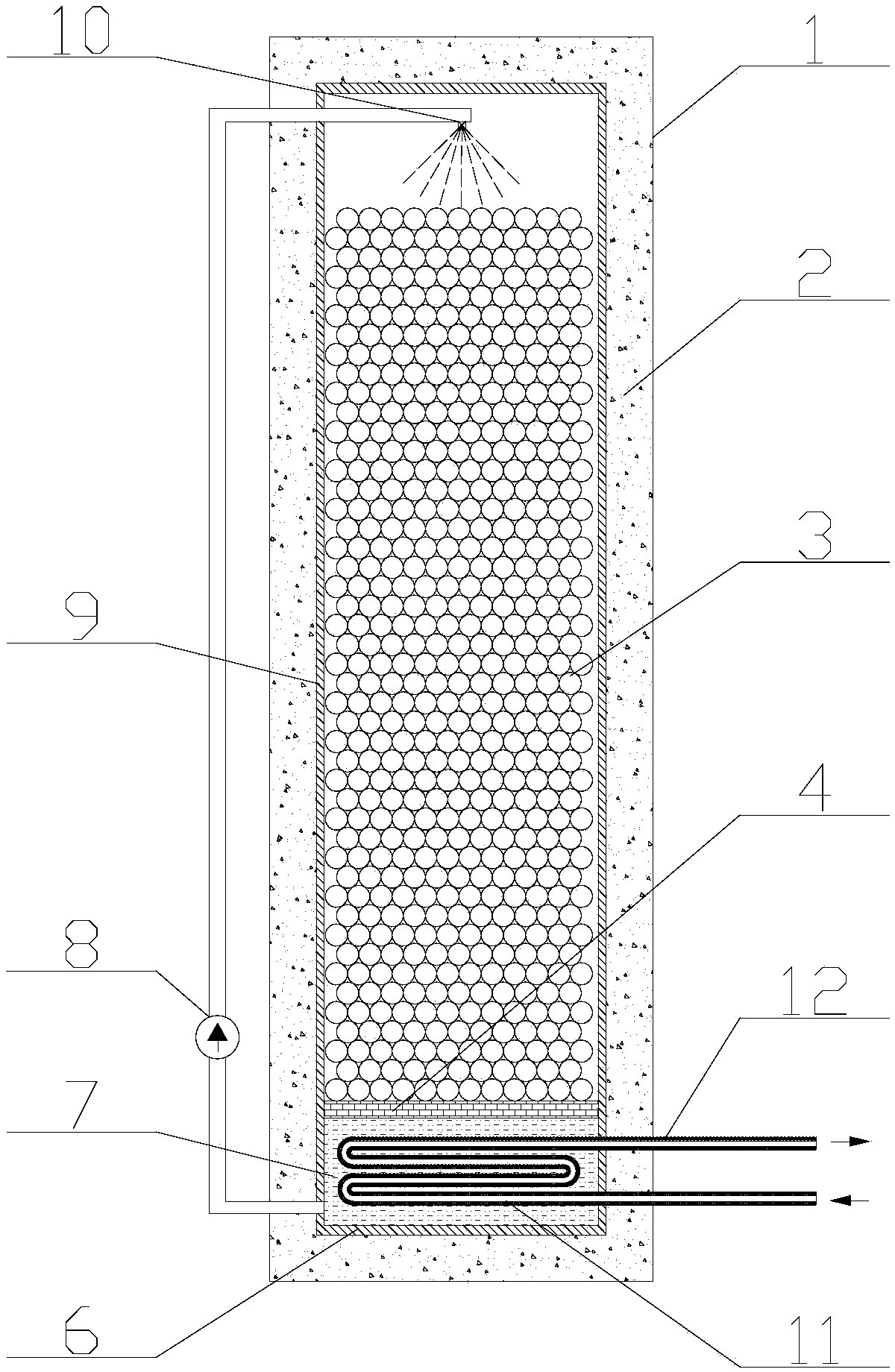

Novel phase change heat storage heat exchanger and working method

InactiveCN109631648AImprove stabilityGood independenceHeat storage plantsTubular elementsOrifice plateEngineering

The invention discloses a novel phase change heat storage heat exchanger and a working method of the novel phase change heat storage heat exchanger. The novel phase change heat storage heat exchangercomprises a heat storage heat exchanger shell, the heat storage heat exchanger shell is internally provided with a heat insulation layer, a cavity inside the heat insulation layer is divided into an upper part and a lower part by an orifice plate, the upper part of the cavity is provided with a heat storage medium, the lower part of the cavity is provided with a heat exchange medium, the lower part of the cavity communicates with the top of the upper part of the cavity through a pipe, the pipe is provided with a circulation pump, and the cavity inside the heat insulation layer is in a vacuum state or a negative pressure state. The novel phase change heat storage heat exchanger has the beneficial effects that heat is transferred to the heat exchange medium through a heat exchange pipe or aheat pipe, the heat exchange medium is transported to the upper part of a tank through the circulation pump for atomization spraying, the medium and the heat storage medium in the tank are subjected to heat exchange, and therefore a good heat storage effect is obtained.

Owner:SHANDONG UNIV

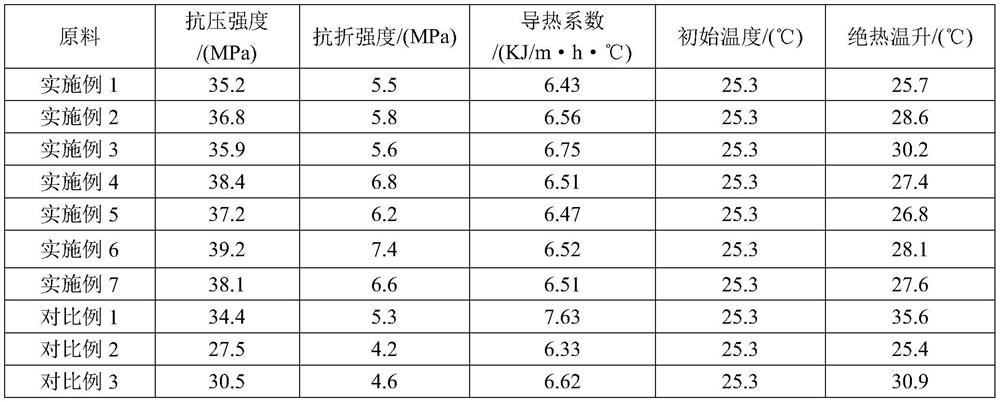

Concrete material with phase change heat storage function and preparation method

The invention relates to the technical field of concrete, and particularly discloses a concrete material with a phase change heat storage function and a preparation method of the concrete material. The concrete material with a phase change heat storage function is prepared from the following raw materials: water, Portland cement, silica fume, fly ash, slag powder, quartz sand, stones, a water reducing agent, polyvinyl alcohol fibers, graphene oxide and solid-phase phase change powder, wherein the solid phase change powder is obtained by wrapping modified silicon dioxide grafted graphene oxidewith n-alkane paraffin, and modified silicon dioxide is obtained by modifying silicon dioxide with ferric nitrate and 3-aminopropyltriethoxysilane. According to the concrete material with the phase change heat storage function, the heat conductivity coefficient and the adiabatic temperature rise of the concrete material are reduced, so that the concrete material has a good heat storage effect, andthe compressive strength and the breaking strength of the concrete material are also improved.

Owner:上海群宝建材有限公司

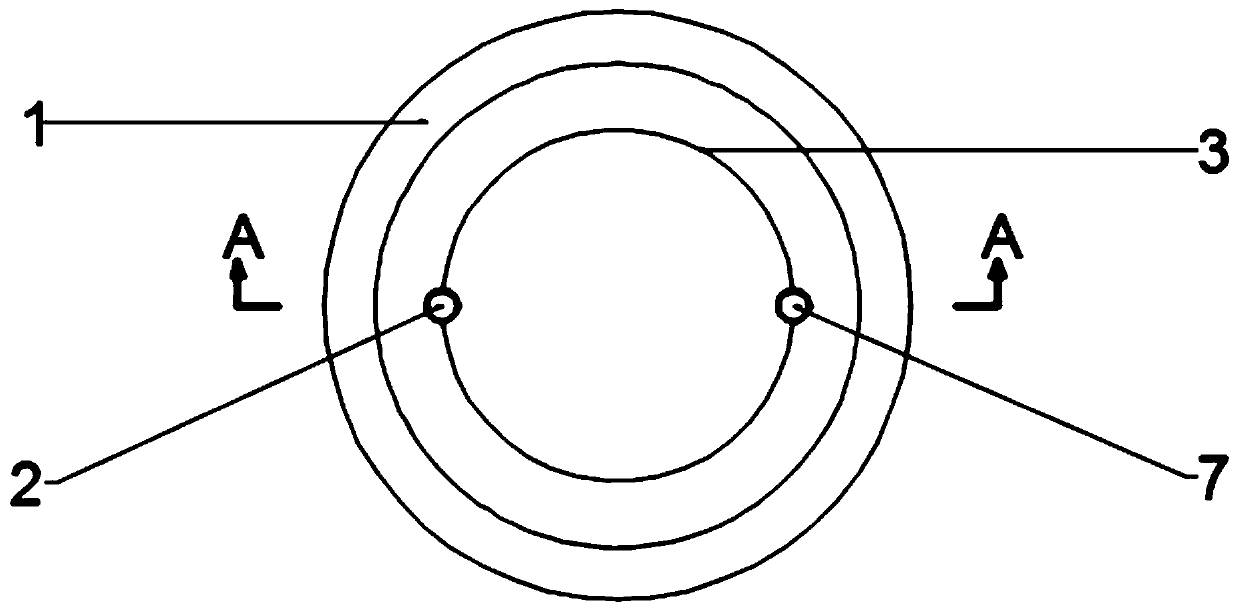

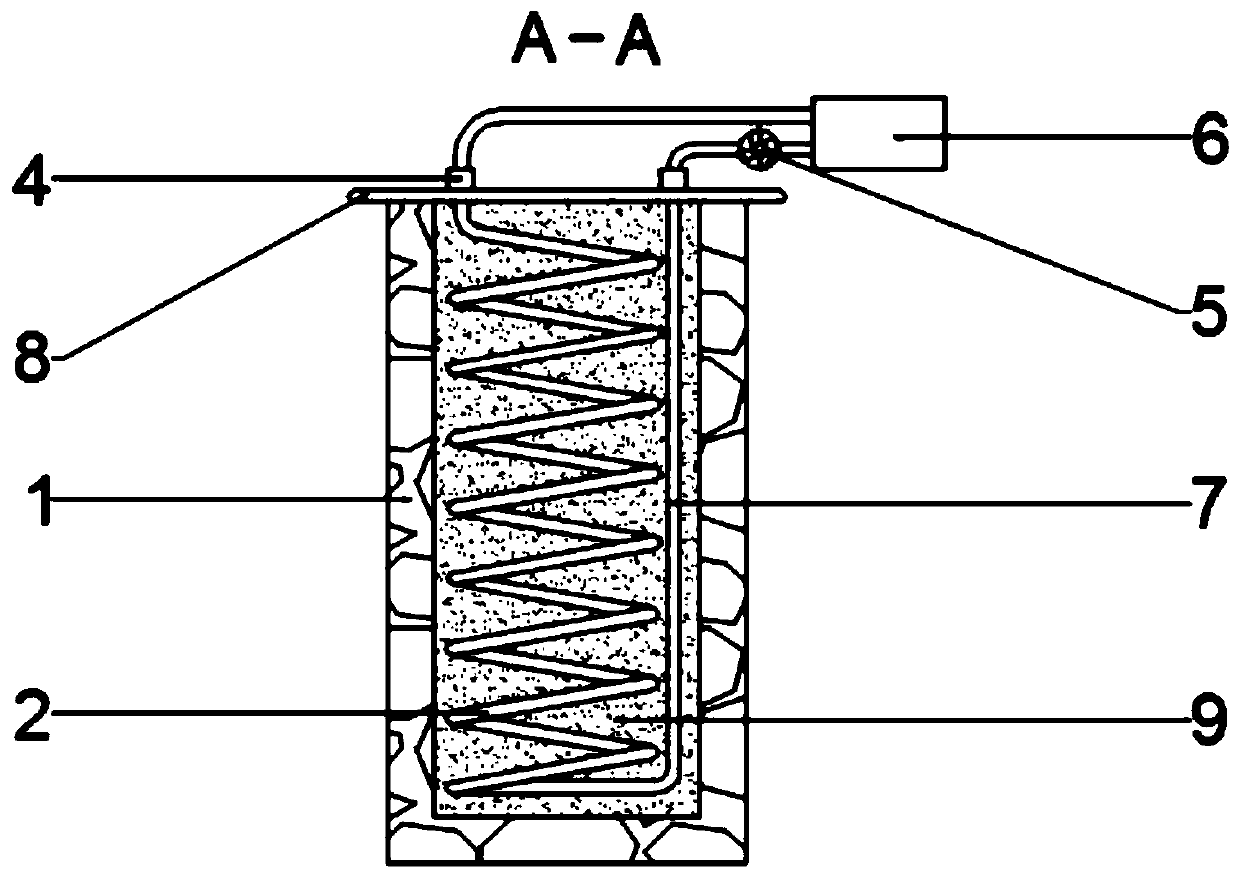

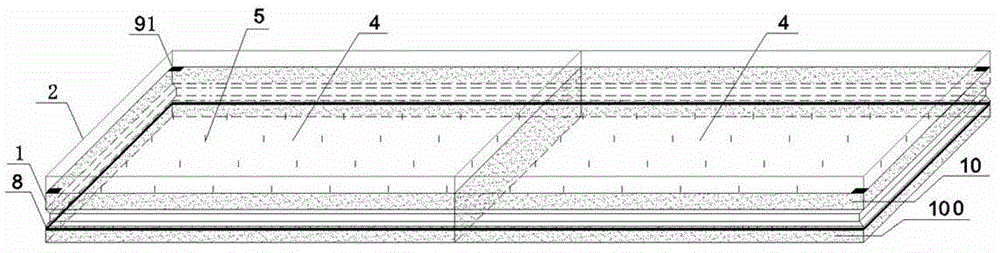

Graphene modified energy pile

PendingCN110067244AHigh strengthSpeed up heat transferGeothermal energy generationHeat storage plantsHeat conductingEngineering

The invention discloses a graphene modified energy pile, and relates to the technical field of ground source heat pumps and pile foundations. The graphene modified energy pile comprises a pile body poured by a graphene and concrete mixture, and a hole is formed in the inner center of the pile body; a spiral pipe-shaped heat transfer pipe is arranged in the hole in the pile body, and the bottom ofthe heat transfer pipe is connected with a return pipe; the positions between the interior of the pile body and the heat transfer pipe as well as between the interior of the pile body and the return pipe are fully filled with filler, and the middle sections of the heat transfer pipe and the return pipe are bound on a reinforcement cage; heat conducting liquid is loaded in the heat transfer pipe and the return pipe, and a pile cap is arranged at the top of the pile body in a sealed mode; the heat transfer pipe and the return pipe vertically extend out of the pile cap, and ports, outside the pile cap, of the heat transfer pipe and the return pipe communicate through a connecting pipe and a heat collector; and the return pipe is connected with a geothermal pump. According to the graphene modified energy pile, the heat transfer pipe is designed into the spiral type to be fixed into the pile body, the return pipe is designed, thus the contact area between the heat transfer pipe and the filler can be effectively increased, and the heat transfer capacity of the pile body is improved.

Owner:ECONOMIC RES INST OF STATE GRID GANSU ELECTRIC POWER +2

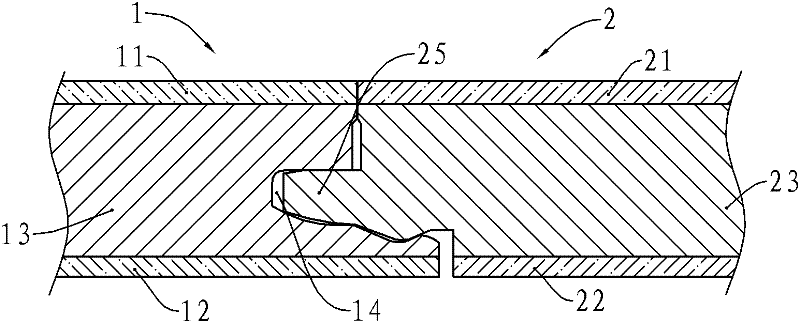

floor heating system

ActiveCN102261692AImprove heat storage effectReduce usageLighting and heating apparatusHot-water central heatingTemperature controlKeel

The invention provides a floor heating system which comprises a floor board and a keel bracket paved on the ground, wherein the floor board is paved on the keel bracket, the middle part of the keel bracket is provided with a mounting groove, a heating device is arranged in the mounting groove and a heating medium is installed in the heating device, an energy supply device is connected with the heating device and is used to heat the heating medium, and at least one of the heating device and the energy supply device is provided with a temperature control mechanism which is used to control the temperature of the heating medium. The floor heating system provided by the invention has an obvious heat storage effect, can generate a lot of heat and store heat for a long time, as well as consume less energy.

Owner:ANHUI YANGZI FLOORING

Three-chamber regenerative thermal oxidizer (RTO) regenerative combustion furnace with purging pipeline

The invention relates to the technical field of waste gas treatment equipment, in particular to a three-chamber regenerative thermal oxidizer (RTO) regenerative combustion furnace with a purging pipeline. The three-chamber RTO regenerative combustion furnace with the purging pipeline comprises a furnace body, a combustion chamber and a first regenerative chamber; the combustion chamber is disposedinside the furnace body; a combustor is disposed at the top of the combustion chamber and is connected with the combustion chamber in an embedded mode; the first regenerative chamber is disposed on the lower portion of one side of the combustion chamber; a second regenerative chamber is disposed in the middle of the lower portion of the combustion chamber; a third regenerative chamber is disposedon the lower portion of the other side of the combustion chamber; supporting legs are disposed at the bottom of the furnace body and connected with the furnace body in a welded mode; and a main fan is disposed on one side of the furnace body. Through the structural improvement, the three-chamber RTO regenerative combustion furnace with the purging pipeline has the advantages that the structural design is reasonable, pipeline layout is in order, an air source is clean, the back blowing effect is good, and the VOC removal rate is high.

Owner:SUZHOU HUAXI ENVIRONMENTAL TECH CO LTD

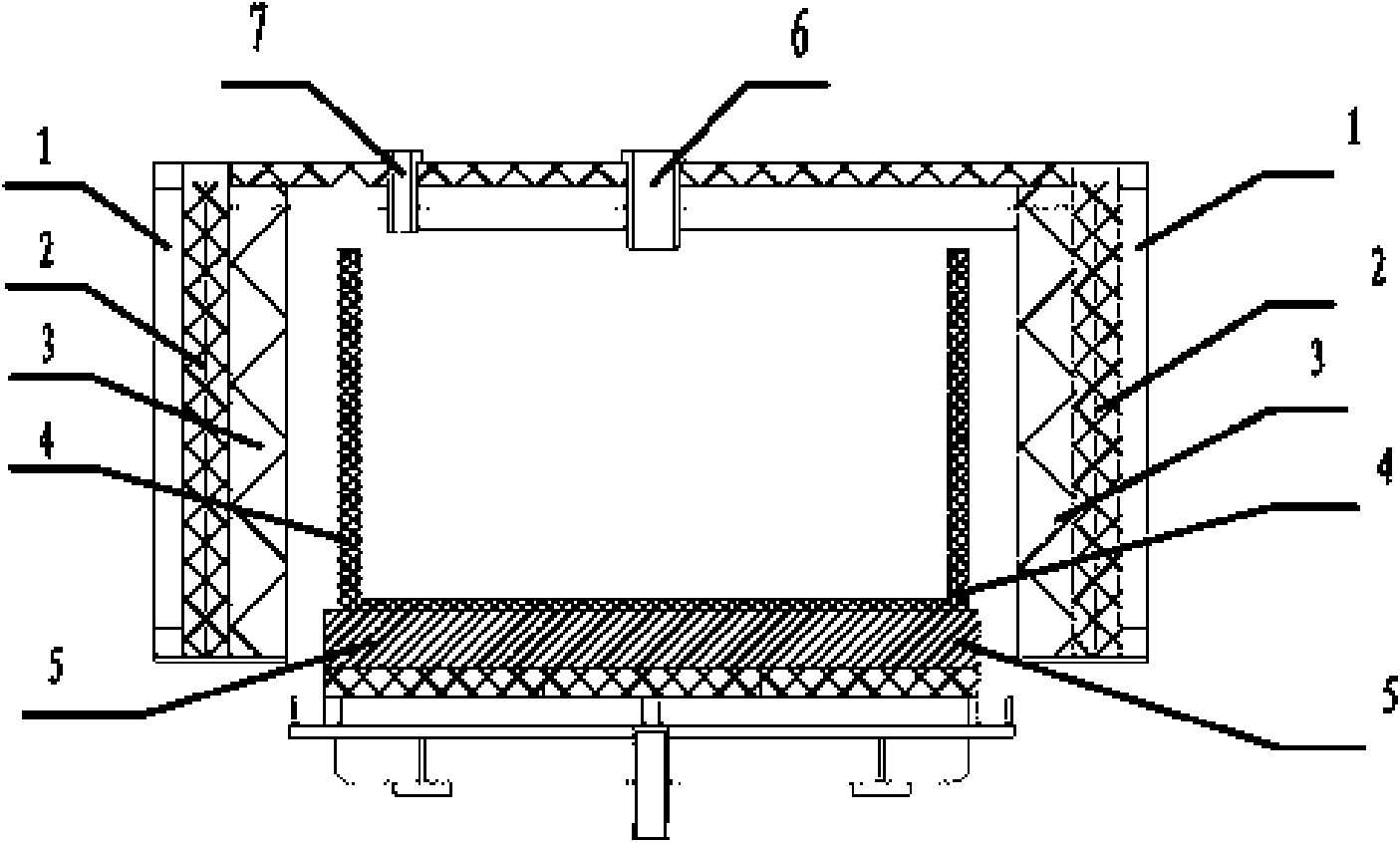

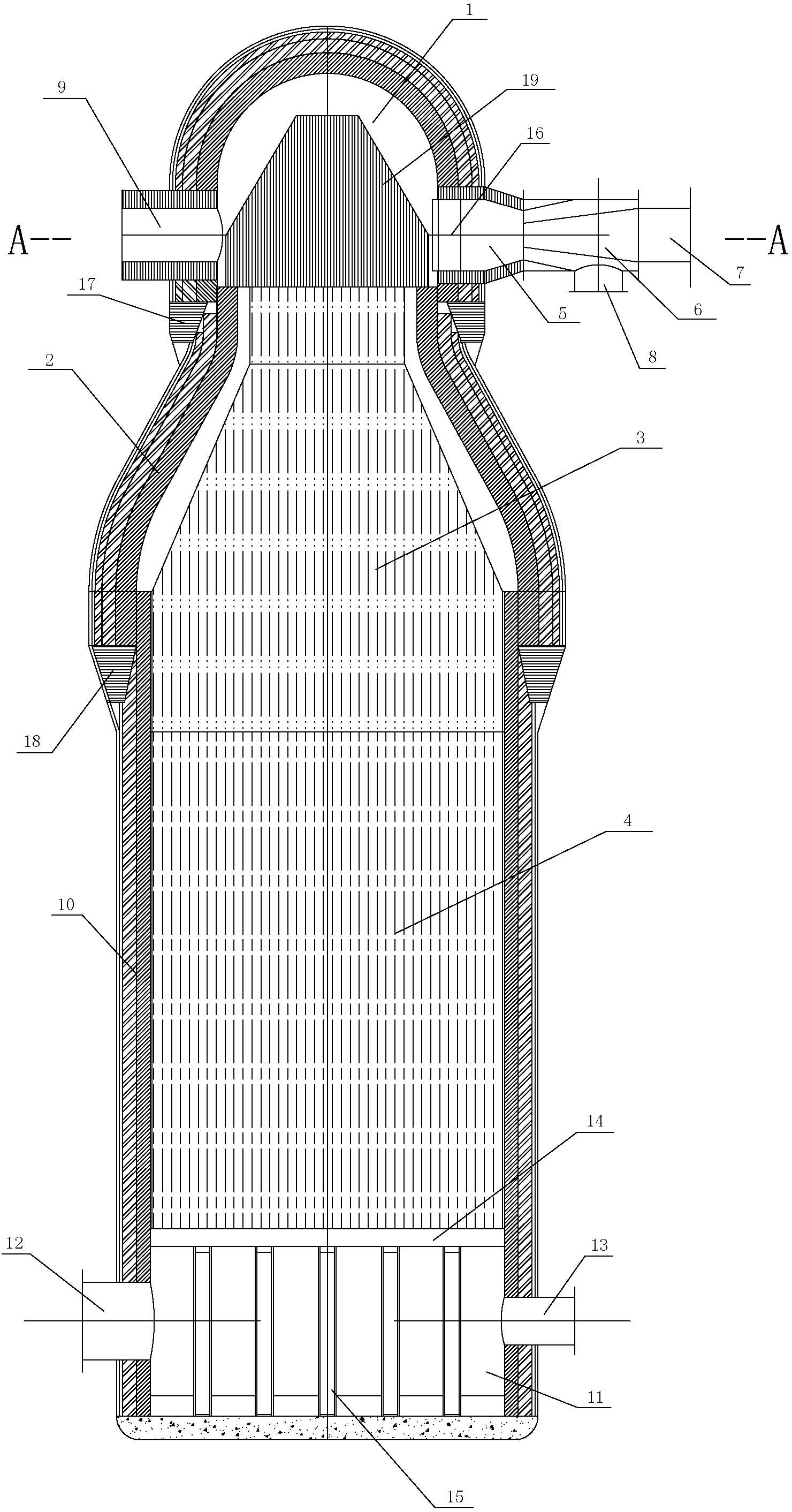

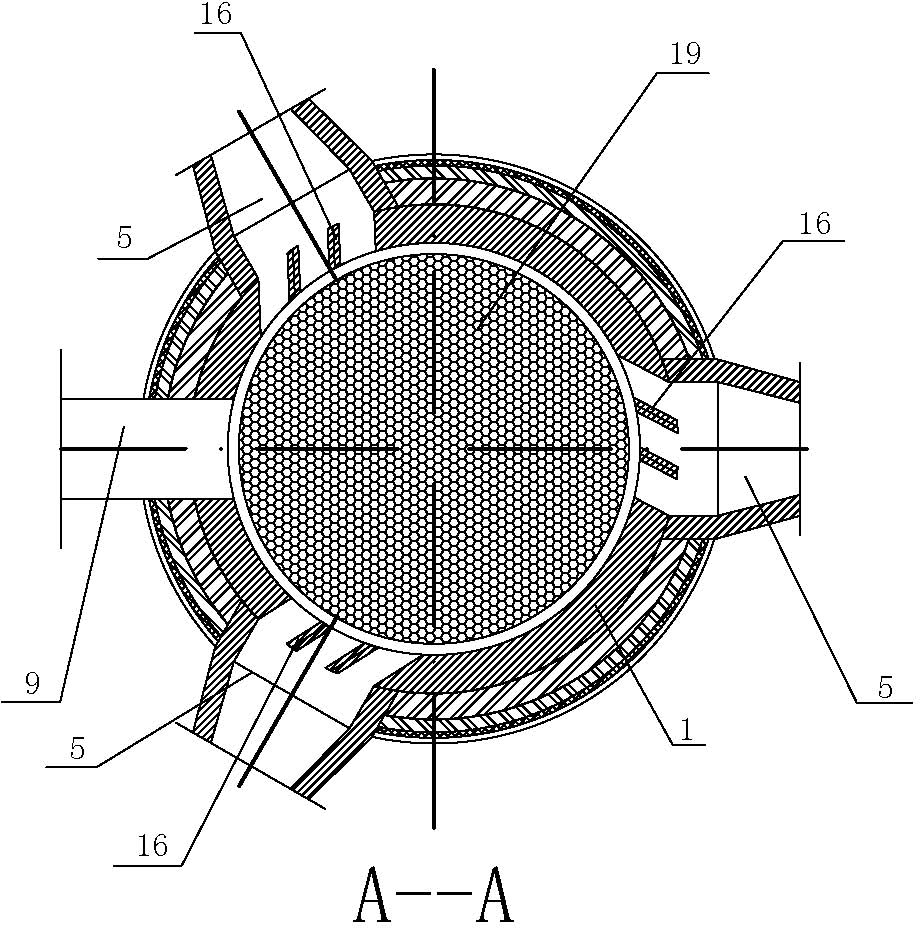

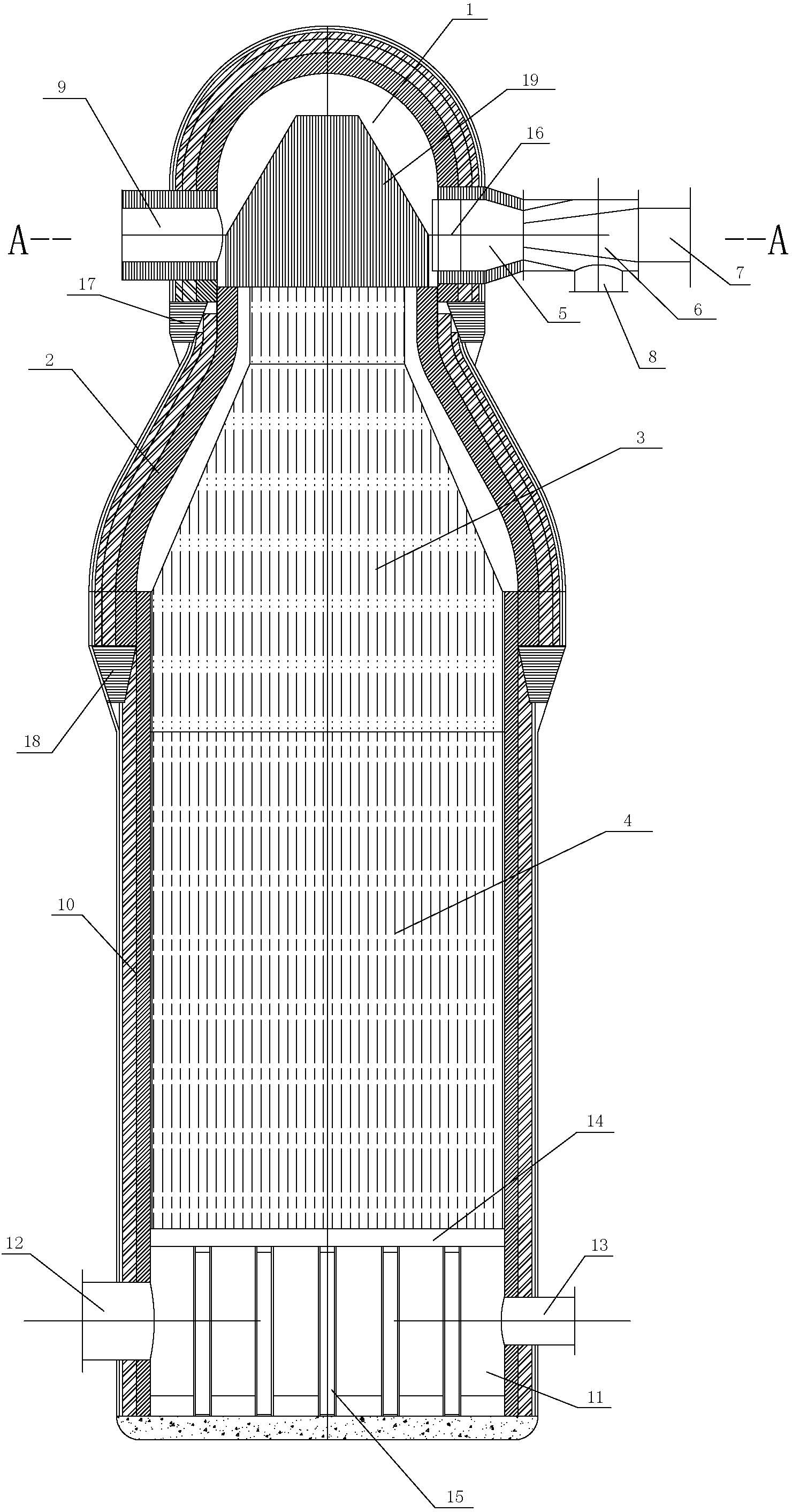

Insulation system for polycrystalline silicon ingot furnace

InactiveCN101660201AImprove heat stabilityHigh thermal efficiencyPolycrystalline material growthSilicon compoundsFiberMetal framework

The invention relates to an insulation system for a polycrystalline silicon ingot, comprising a furnace body. A metal frame is arranged on the periphery inside the furnace body; the lateral wall of the metal frame is provided with a lateral mullite fiber board; the top part of the metal frame is provided with a top mullite fiber board; the bottom of a graphite plate under a crucible is provided with a bottom mullite fiber plate; a closed space is formed by the mullite fiber plates which are positioned on the bottom of the graphite plate, in the lateral wall of the metal frame and on the top ofthe metal frame respectively; a layer of a corundum mullite burning plate is arranged inside of the lateral mullite fiber plate close to the center of the furnace center. The insulation system can reduce electric energy consumption in a process for casting the polycrystalline silicon, reduces thermal stress of the silicon ingot and improves yield of slices when large silicon ingots are cast, andis particularly suitable for producing polycrystalline silicon ingots over 450kgs.

Owner:NAN AN SANJING SOLAR POWER

Efficient PC component hot mold platform integrating dry and wet heat curing

The invention discloses an efficient PC component hot mold platform integrating dry and wet heat curing. The hot mold platform comprises a concrete bottom frame, a mold platform for installing and fixing a PC component mold, and a sliding telescopic type steam curing cover; heat preserving plates are attached to the periphery of the inner side of the concrete bottom frame which comprises two sunken holes; positioning FRP ribs are arranged at the bottoms of the sunken holes; colored steel plates are arranged on the tops of the FRP ribs; meshes are laid on the colored steel plates; by means of casting of foam concrete, the colored steel plates, the meshes and the foam concrete are connected into a whole to form a heat insulating concrete layer; the mold platform is installed on the concrete bottom frame through welding between the mold platform and an embedded part; a heat preserving layer with a cavity is formed between a panel and each sunken hole; and the sliding telescopic type steam curing cover comprises a supporting framework and heat preserving tarpaulin. The efficient PC component hot mold platform integrating dry and wet heat curing can perform full-dry heat curing, full-wet heat curing and dry-wet heat curing on PC components and has the beneficial effects of being high in temperature rise speed, good in heat accumulation, small in energy consumption and high in production efficiency and space utilizing rate.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

Half-heavy refractory brick for dry-quenching furnace annular air duct and production method of half-heavy refractory brick

Disclosed is a half-heavy refractory brick for dry-quenching furnace annular air duct. The half-heavy refractory brick is produced from raw materials including, by weight, 16%-25% of mullite aggregates 5-3mm in particle size, 15%-30% of mullite aggregates smaller than 3-1mm in particle size, 5%-15% of mullite aggregates smaller than 0.074mm in particle size, 5%-15% of andalusite smaller than 1-0.074 in particle size, 10%-30% of fined mullite powder, 3%-10% of fined andalusite powder, 5%-20% of hollow spheres, 1%-8% of kaolin micro powder, 0.01%-2% of an interface treating agent and 2%-5% of a binding agent. The production method includes: firstly, mixing the hollow spheres with the interface treating agent; then adding the fined mullite powder, the fined andalusite powder and the kaolin micro powder; evenly mixing all of the mullite aggregates, the andalusite, the hollow spheres and the binding agent; pressing into a brick; drying; baking for standby use. By the arrangement, problems that the brick for the dry-quenching furnace annular air duct is prone to bloating and cracking are solved, compression strength of the brick can reach more than 60MPa, unit weight of the brick can be lowered more than 10%, and usage period is greatly prolonged.

Owner:武汉钢铁有限公司

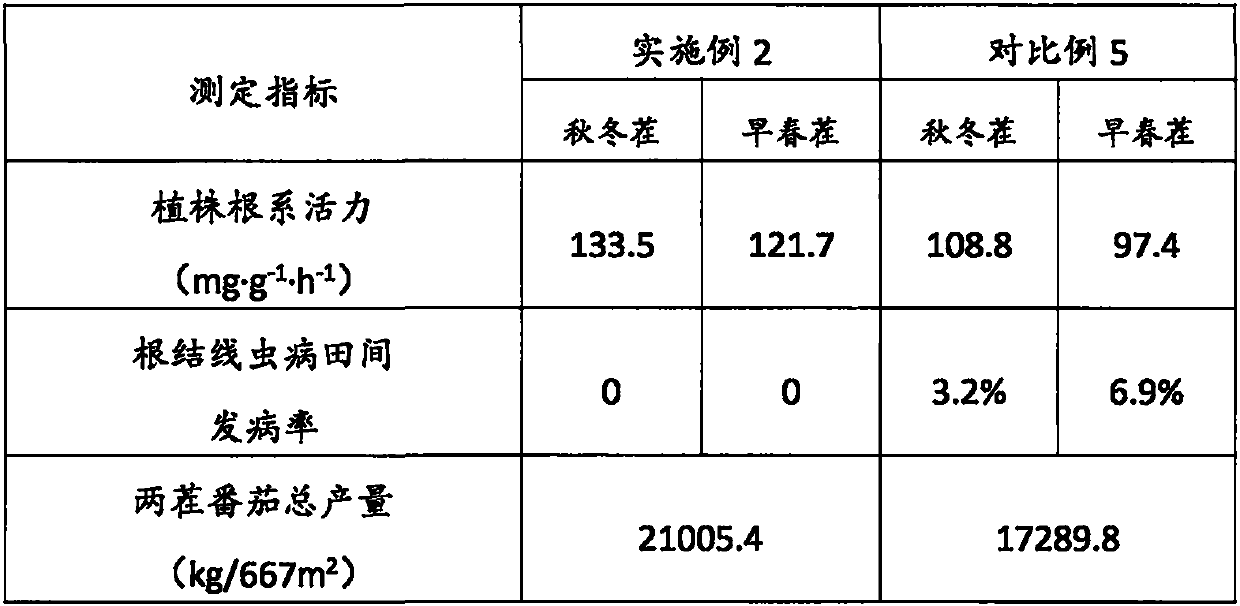

Substrate and method for cultivating tomatoes in solar greenhouse in saline-alkali soil

InactiveCN110150086AStrong water and fertilizer retention capacityReduce the frequency of watering and fertilizingPlant growth regulatorsBiocideAllyl isothiocyanateBacterial agent

The invention provides a substrate and method for cultivating tomatoes in a solar greenhouse in saline-alkali soil, and belongs to the technical field of vegetable cultivation in saline-alkali soil. The substrate disclosed by the invention comprises a filling substrate and a cultivation substrate, and the substrate has strong water and fertilizer holding capacity, good air permeability, good heatstorage property and strong heat exchange capacity with soil. The method provided by the invention comprises the following main steps: arranging a cultivation tank in the solar greenhouse, and sequentially laying an isolation film, the filling substrate, an insect-proof net and a cultivation substrate from bottom to top in the cultivation tank; applying an EM bacterial agent and an amino acid liquid fertilizer in the cultivation substrate of the cultivation tank; planting the tomatoes, and applying an attractant after field planting; and after early spring cultivated tomato seedlings are pulled, applying allyl isothiocyanate, and closing the greenhouse. The method can slow down the salinization of the substrate, control the occurrence of soil-borne diseases, reduce the use of chemical pesticides and improve the yield of tomatoes.

Owner:山东永盛农业发展有限公司 +2

Hot blast stove for preheating combustion in gas and air jet mixed porous body

InactiveCN102277460AFix stability issuesSolve the strength problemBrick-hot blast stovesBlast furnace detailsCombustion chamberBrick

The invention relates to a hot blast furnace for preheating and combusting a gas-air jet mixture in a porous body, which effectively solves the problems of non-uniform gas mixing, insufficient combustion and resource wastage of a hot blast furnace. A porous combination block body is arranged in a flameless combustion chamber in a housing, a premixed gas intake pipe on the flameless combustion chamber is connected with a gas intake pipe and an air intake pipe through a jet premixer, and a flow guide block is partitioned in the premixed gas intake pipe. A hot blast outlet pipe is arranged on the flameless combustion chamber, the lower part is butted with a conical regenerative chamber, a cylindrical heat accumulation chamber is arranged below the conical heat accumulation chamber, and lattice brick heat accumulators are arranged in the conical regenerative chamber and the cylindrical heat accumulation chamber. A smoke exhaust pipe and a cold blast inlet pipe are arranged on a cold blastchamber below the cylindrical heat accumulation chamber, lattice brick heat accumulators are arranged on a furnace grill, and pillars below the furnace grill are fixed on a pedestal. Through the hot blast furnace, gas and air are quickly, stably and intensively combusted through jet mixing, the manufacturing cost is effectively lowered, and the heat transfer and heat accumulation effects of lattice bricks are improved.

Owner:ZHENGZHOU YUXING REFRACTORY MATERIAL

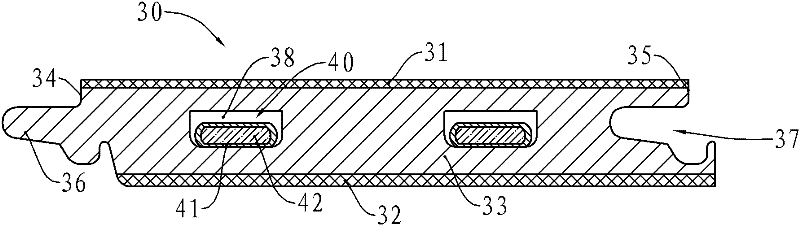

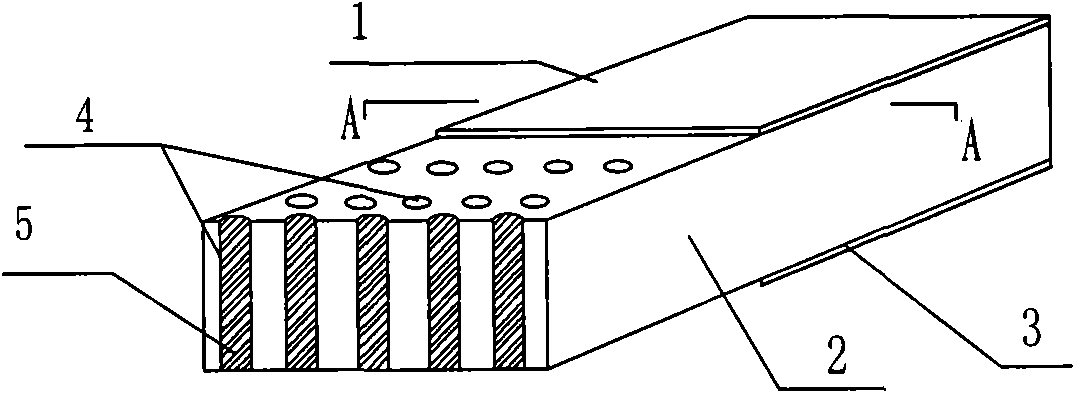

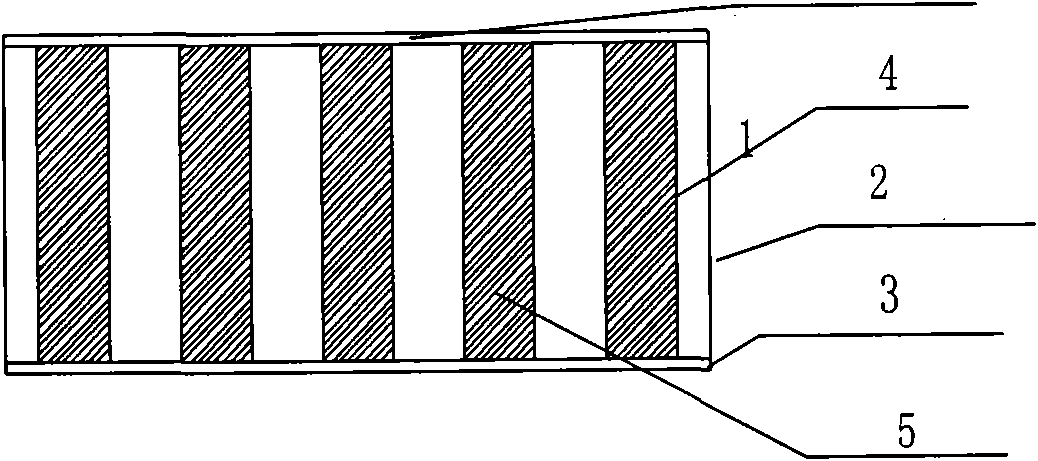

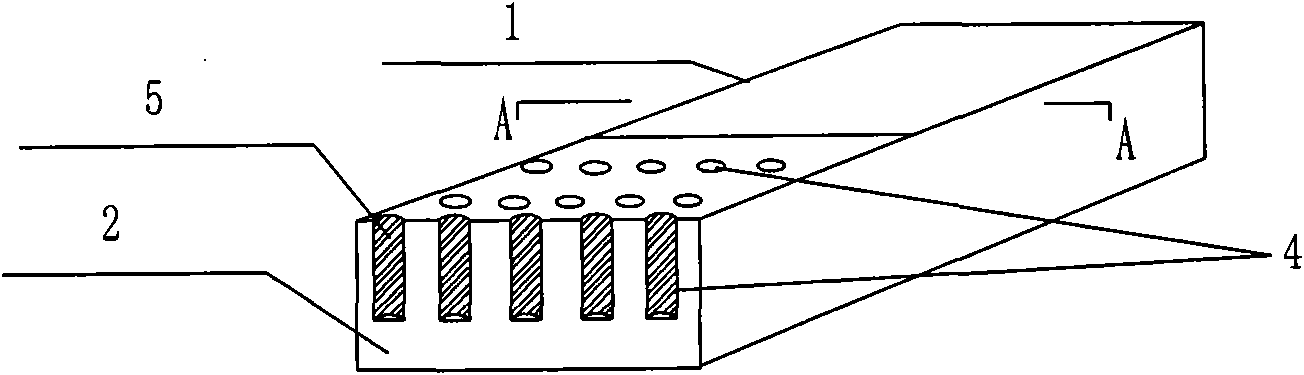

Heat accumulation plate

InactiveCN102061751AReduce manufacturing costGood heat storage effectWallsHeat storage plantsExcess heatPolystyrene

The invention discloses a heat accumulation plate formed by mutually splicing an outer surface layer, an intermediate layer and an inner surface layer, wherein the outer surface layer (1) and the inner surface layer (3) are both metal plates; the intermediate layer (2) is made of material with smaller heat capacity ratio or insulation; holes (4) are formed on the surface of the intermediate layer (2) and are filled with a heat accumulation medium (5) with higher heat capacity ratio; the intermediate layer (2) is one of polyurethane plate, polystyrene plate, wood plate and foam plate; and the heat accumulation medium (5) is water or sodium sulfate decahydrate. The heat accumulation plate can absorb a large amount of excess heat into a heat accumulation medium generated by sufficient sunlight at daytime and avoid the phenomenon that greenhouses and buildings are required to ventilate and discharge when the air temperature is higher at daytime; and the heat accumulation medium releases the heat accumulated at daytime when the air temperature at night is low without supplementing the heat. The heat accumulation plate disclosed by the invention has the advantages of low production cost, favorable heat accumulation effect, energy saving and environmental protection.

Owner:YANGLING ZHENGHE AGRI TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com