Patents

Literature

807 results about "Radiant heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radiant heating is a technology for heating indoor and outdoor areas. Heating by radiant energy is observed every day, the warmth of the sunshine being the most commonly observed example. Radiant heating as a technology is more narrowly defined. It is the method of intentionally using the principles of radiant heat to transfer radiant energy from an emitting heat source to an object. Designs with radiant heating are seen as replacements for conventional convection heating as well as a way of supplying confined outdoor heating.

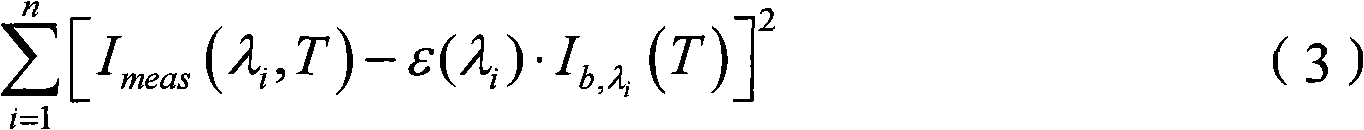

Film formation apparatus and methods including temperature and emissivity/pattern compensation

InactiveUS20070077355A1Good effectImprove absorption rateLiquid surface applicatorsSemiconductor/solid-state device manufacturingEmissivityRadiant heating

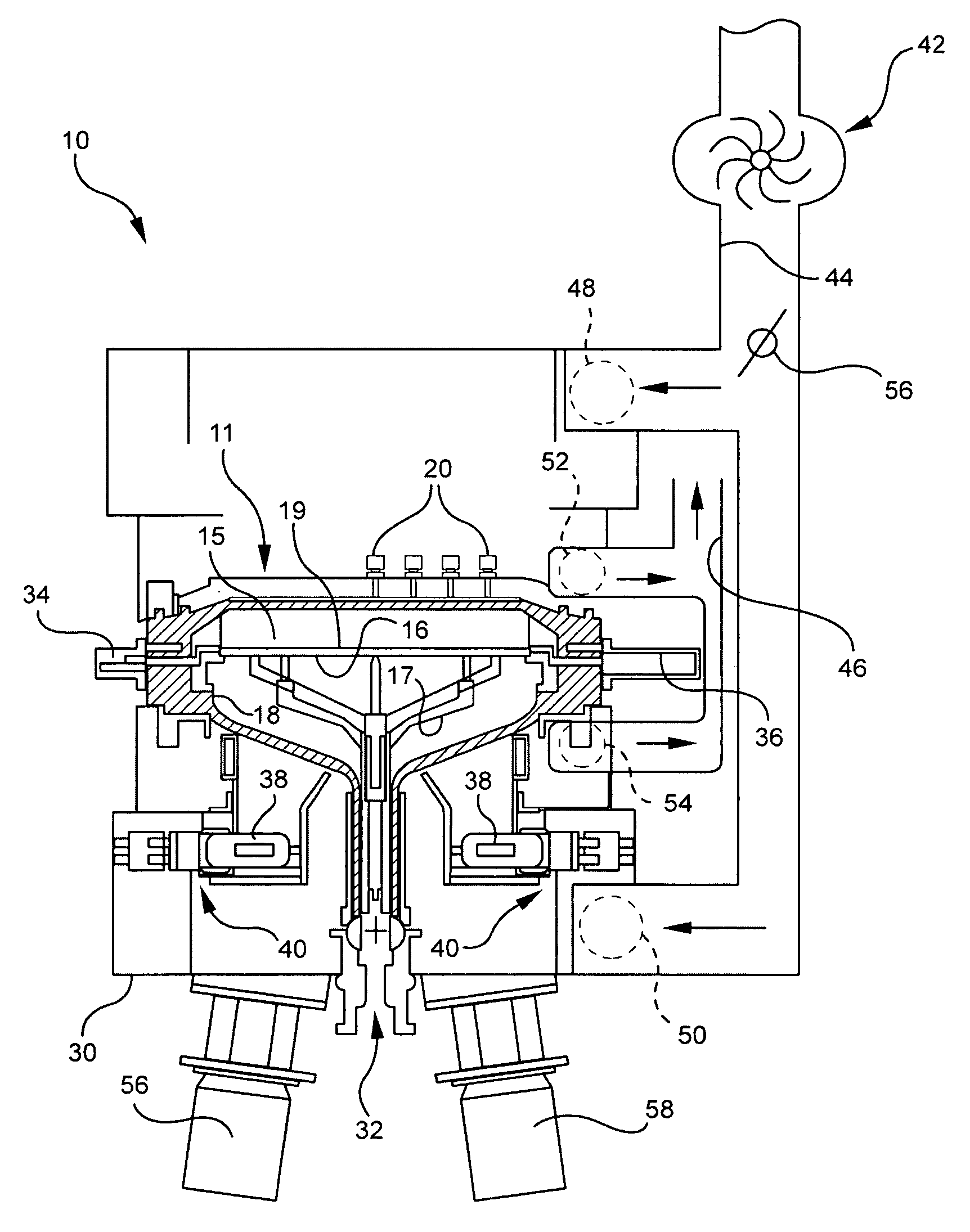

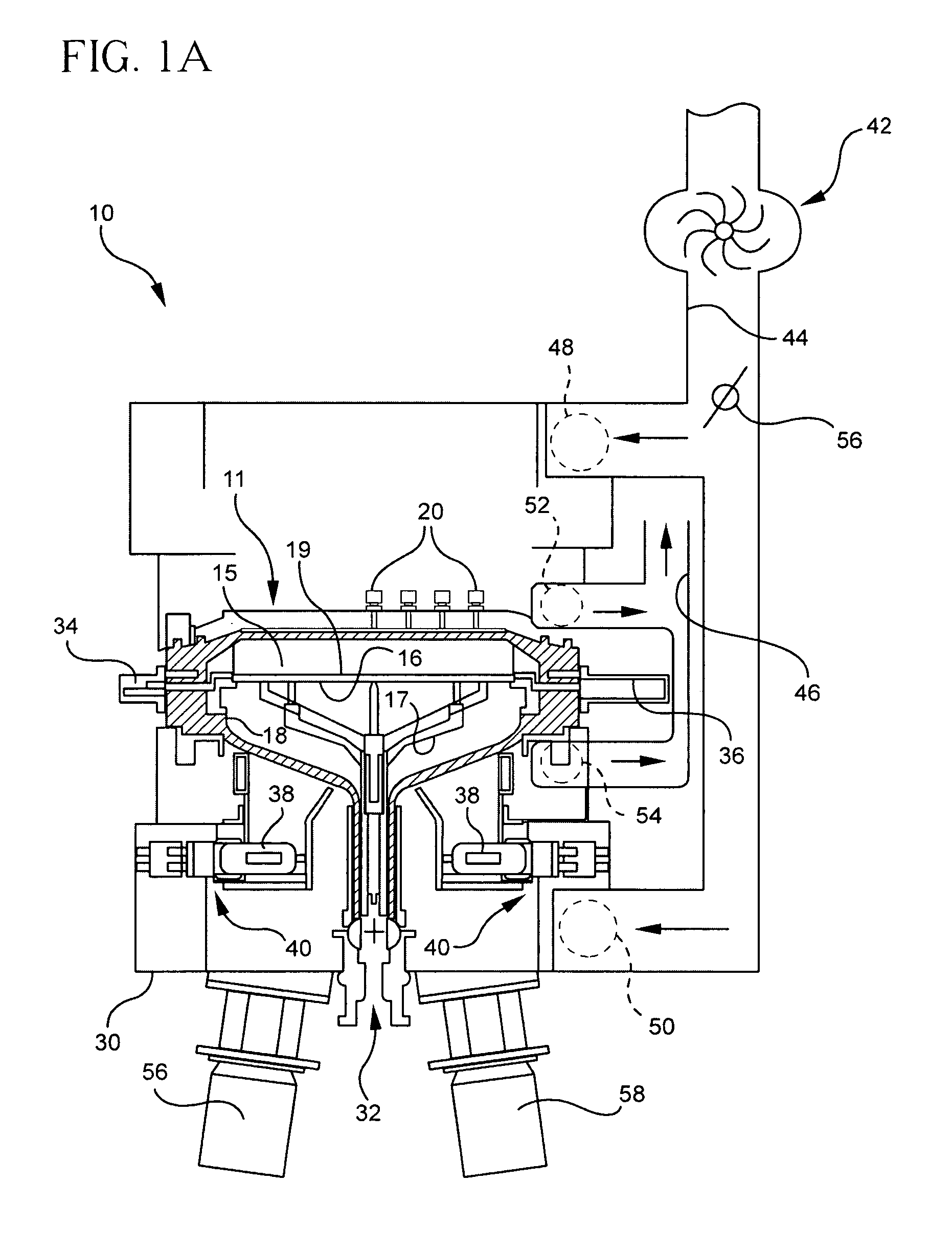

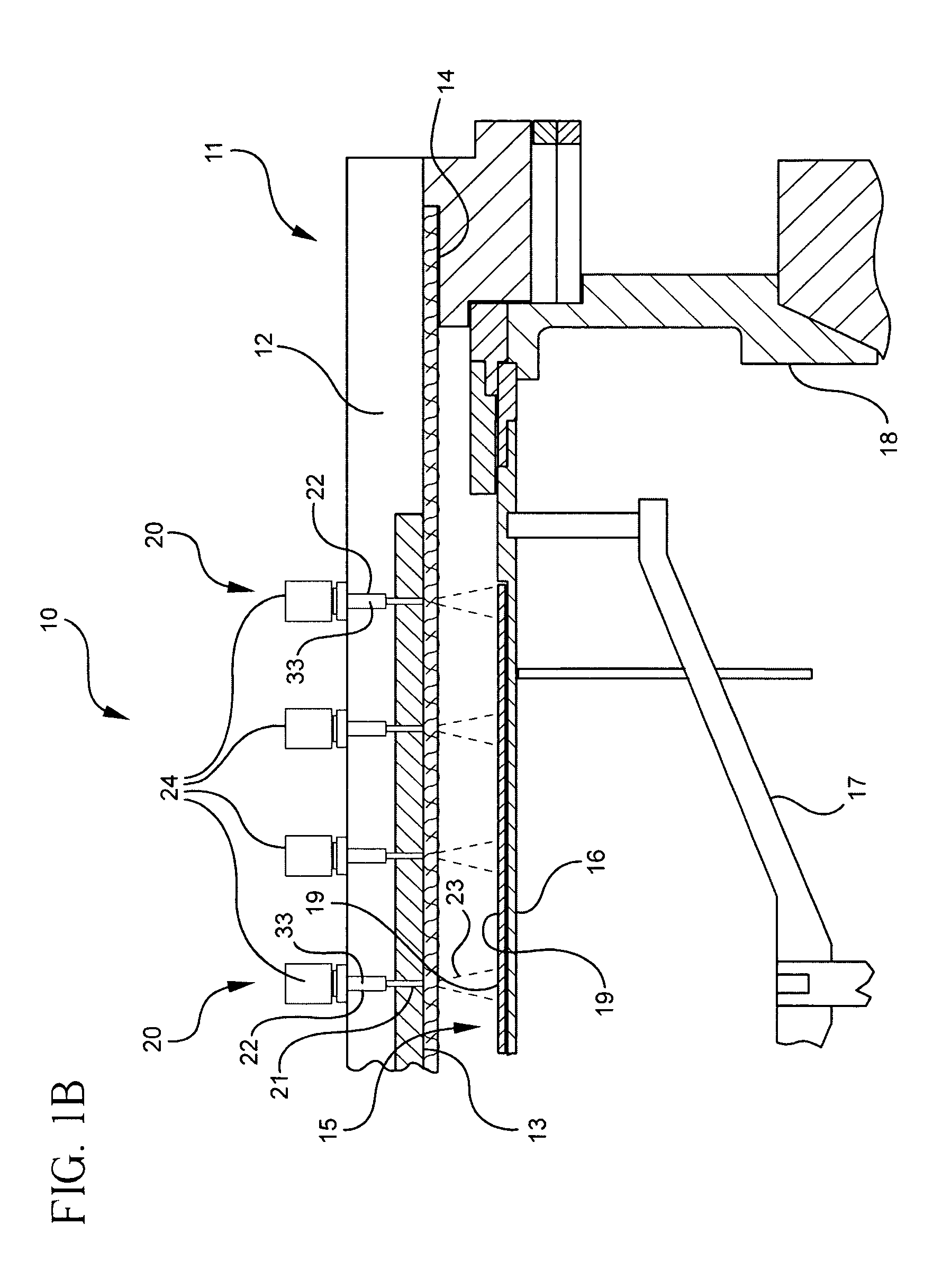

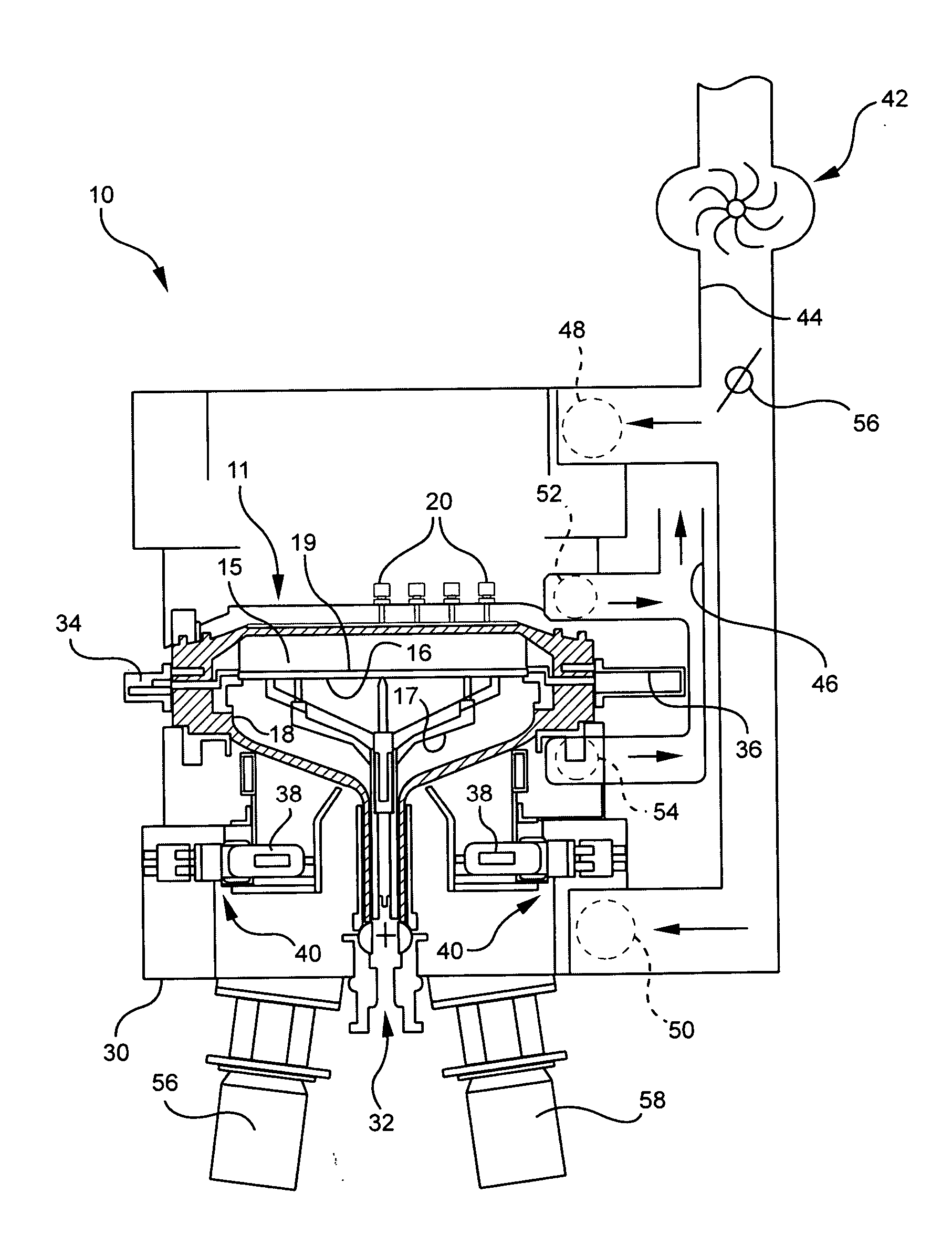

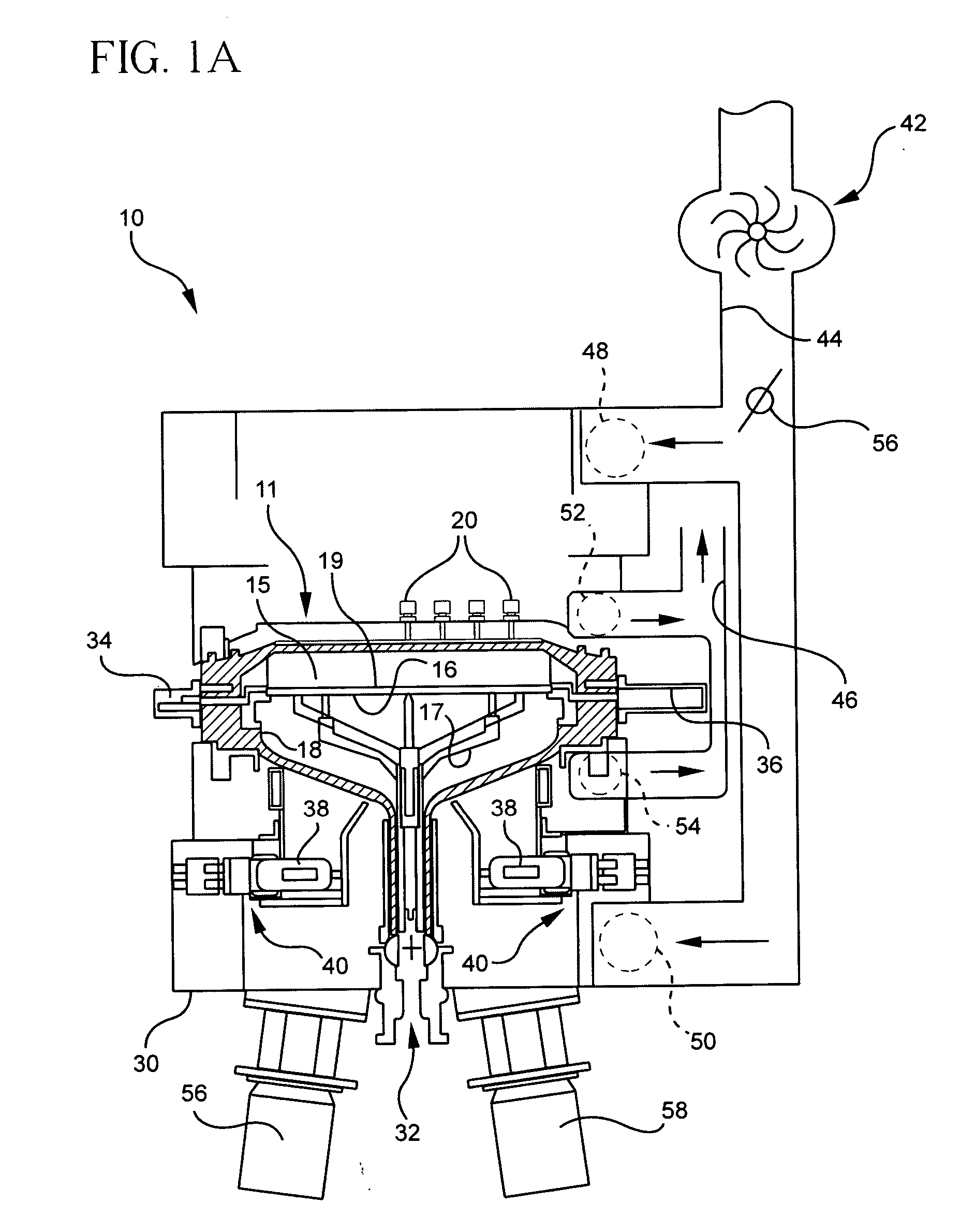

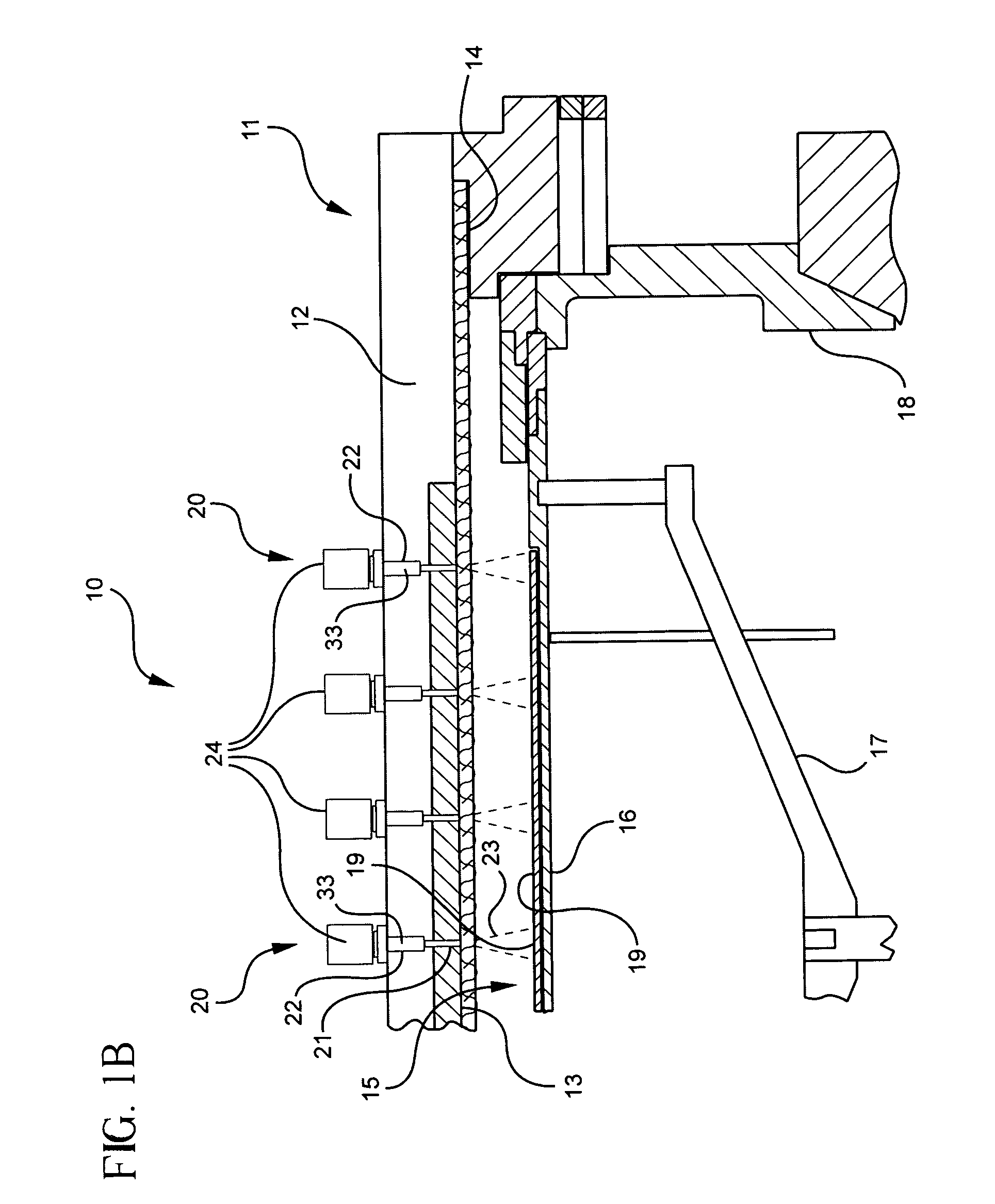

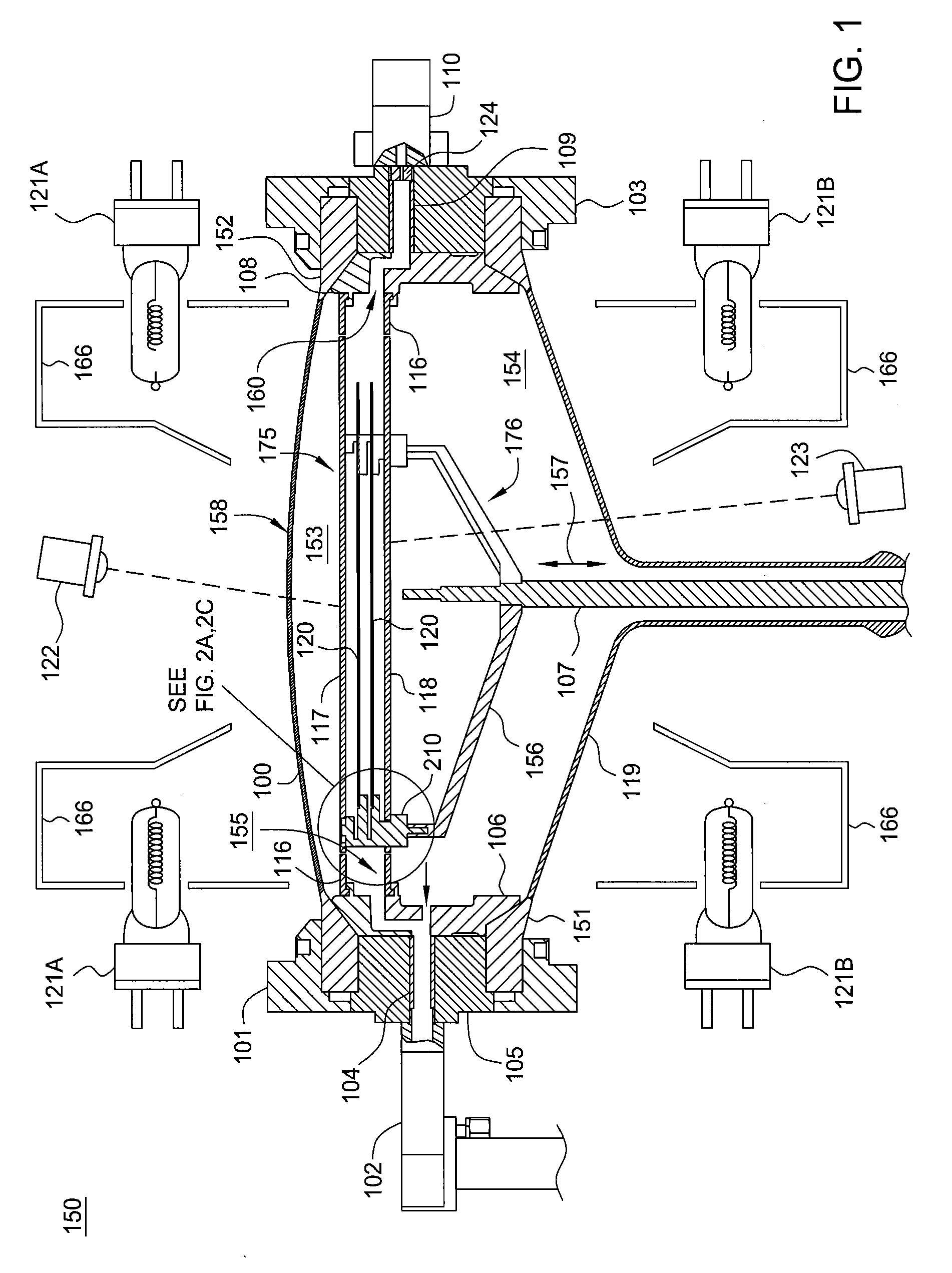

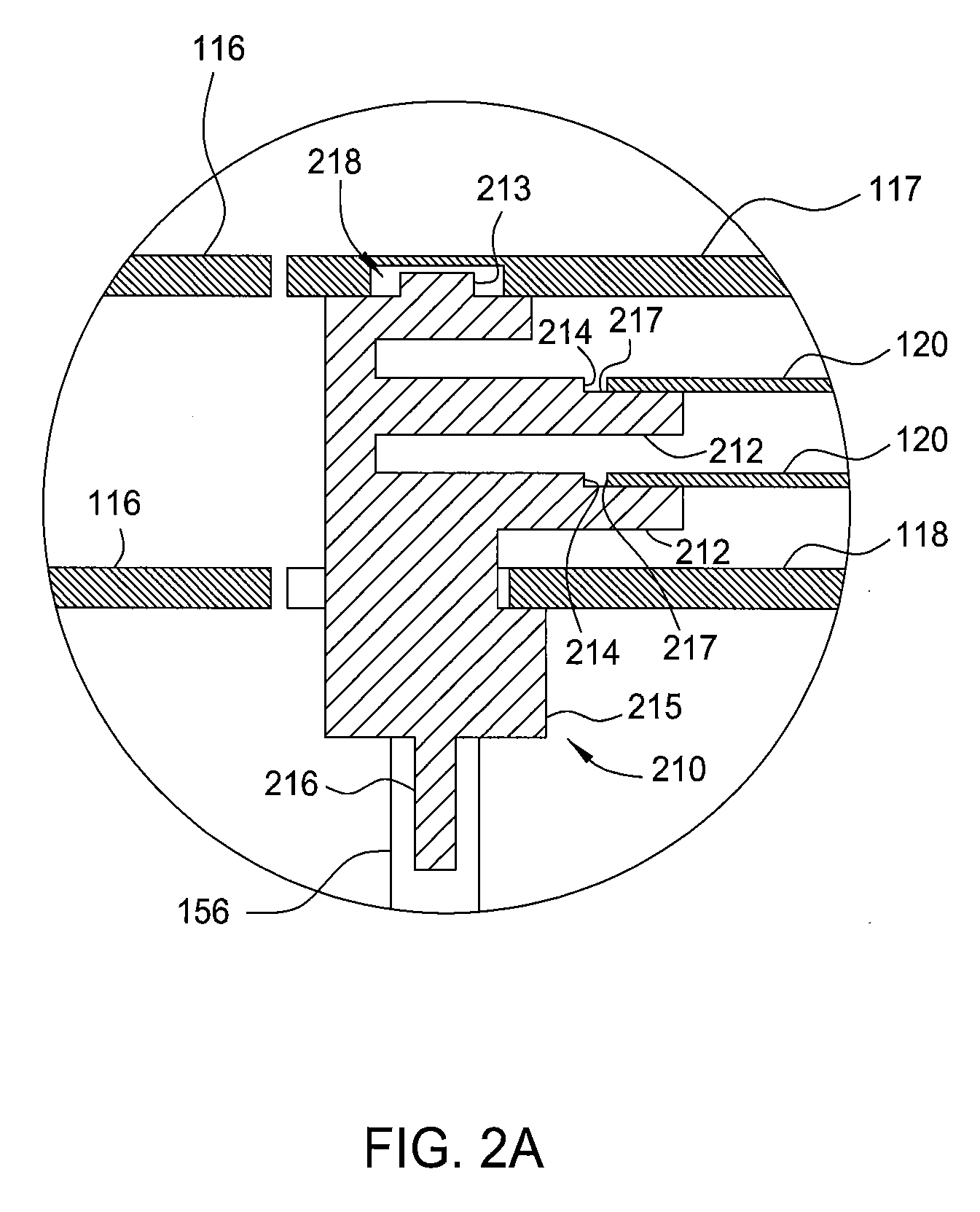

A film formation system 10 has a processing chamber 15 bounded by sidewalls 18 and a top cover 11. In one embodiment, the top cover 11 has a reflective surface 13 for reflecting radiant energy back onto a substrate 19, pyrometers 405 for measuring the temperature of the substrate 19 across a number of zones, and at least one emissometer 410 for measuring the actual emissivity of the substrate 19. In another embodiment, a radiant heating system 313 is disposed under the substrate support 16. The temperature of the substrate 19 is obtained from pyrometric data from the pyrometers 405, and the emissometer 410.

Owner:APPLIED MATERIALS INC

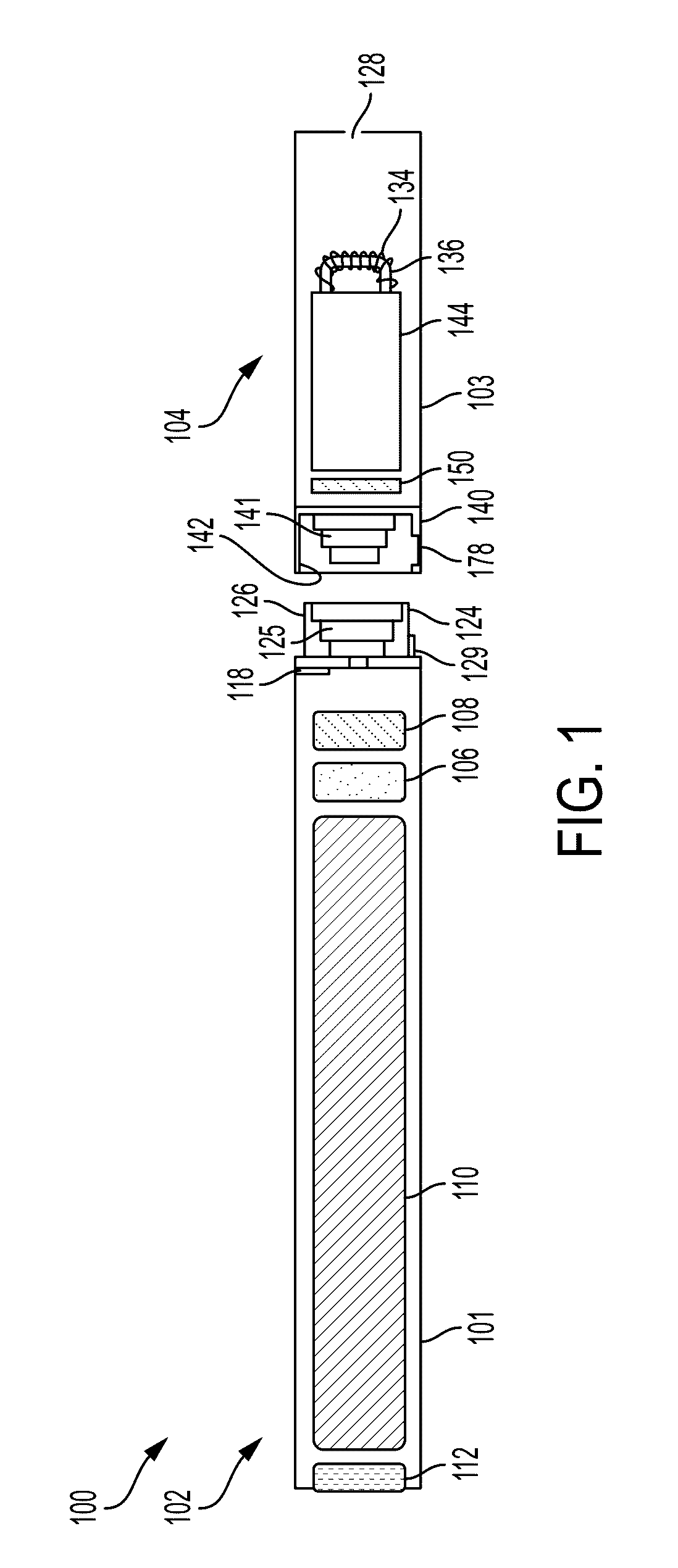

Apparatus temperature control and pattern compensation

ActiveUS20070074665A1Accurate monitoringEasy to controlSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTemperature controlEngineering

A film formation system 10 includes a processing chamber 15 bounded by sidewalls 18 and a top cover 11. In one embodiment, a susceptor 16 is rotatably disposed in the system 10, and overlaps with a first peripheral member205 disposed around the sidewalls 18. A radiant heating system 313 is disposed under the susceptor 305 to heat the substrate 19. In another embodiment, the top cover 11 has equally spaced pyrometers 58 for measuring the temperature of the substrate 19 across a number of zones. The temperature of the substrate 19 is obtained from pyrometric data from the pyrometers 58.

Owner:APPLIED MATERIALS INC

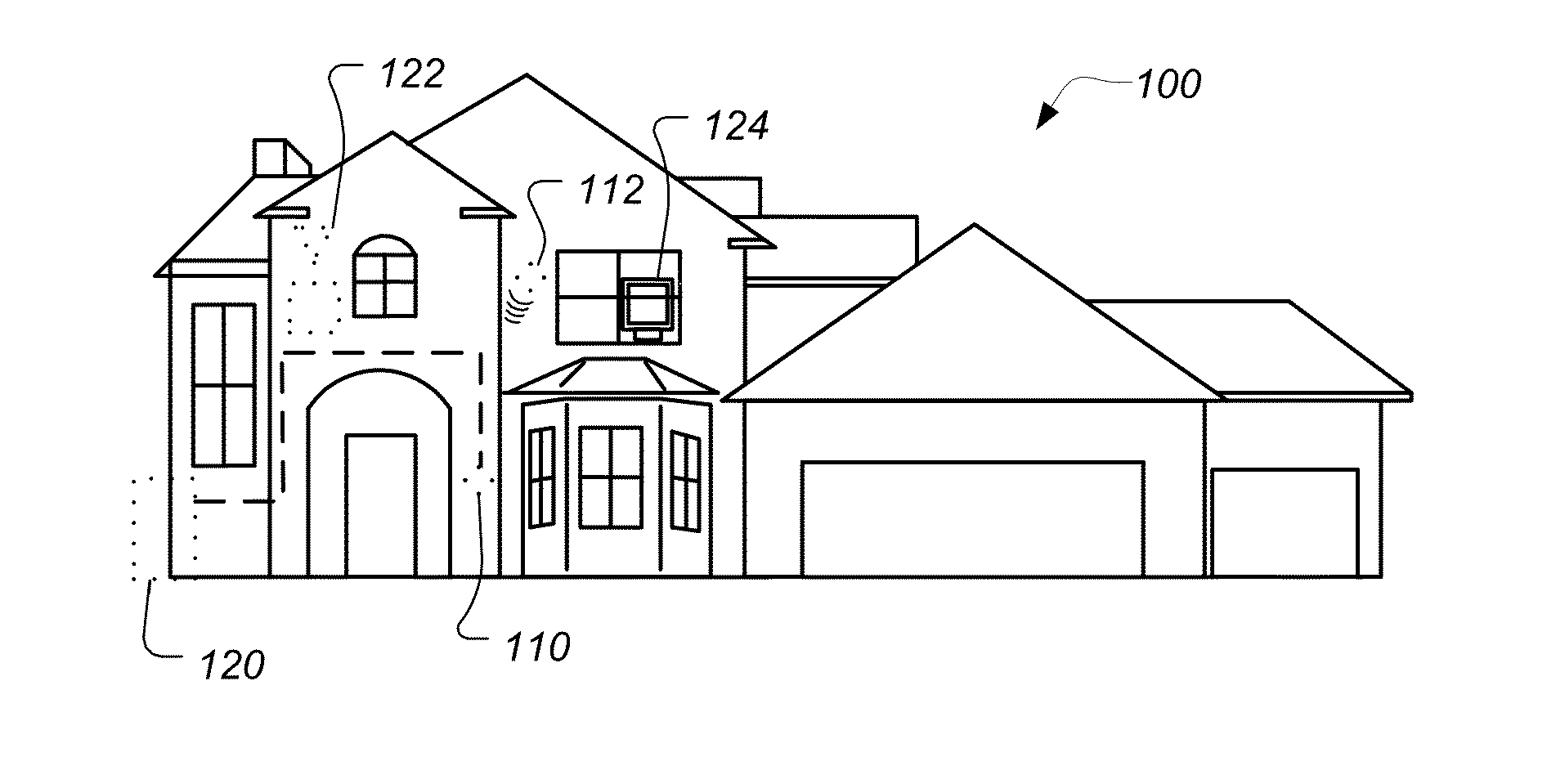

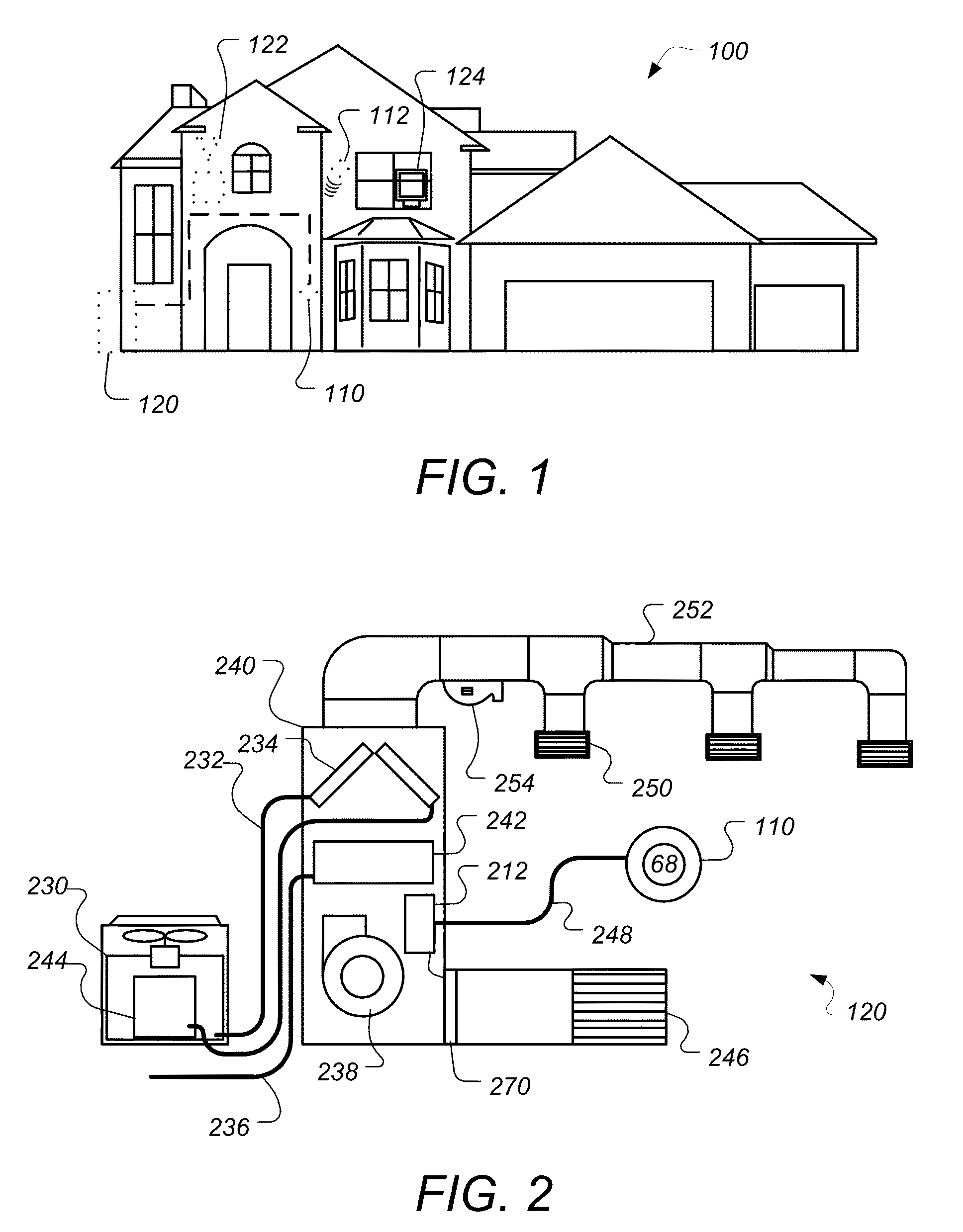

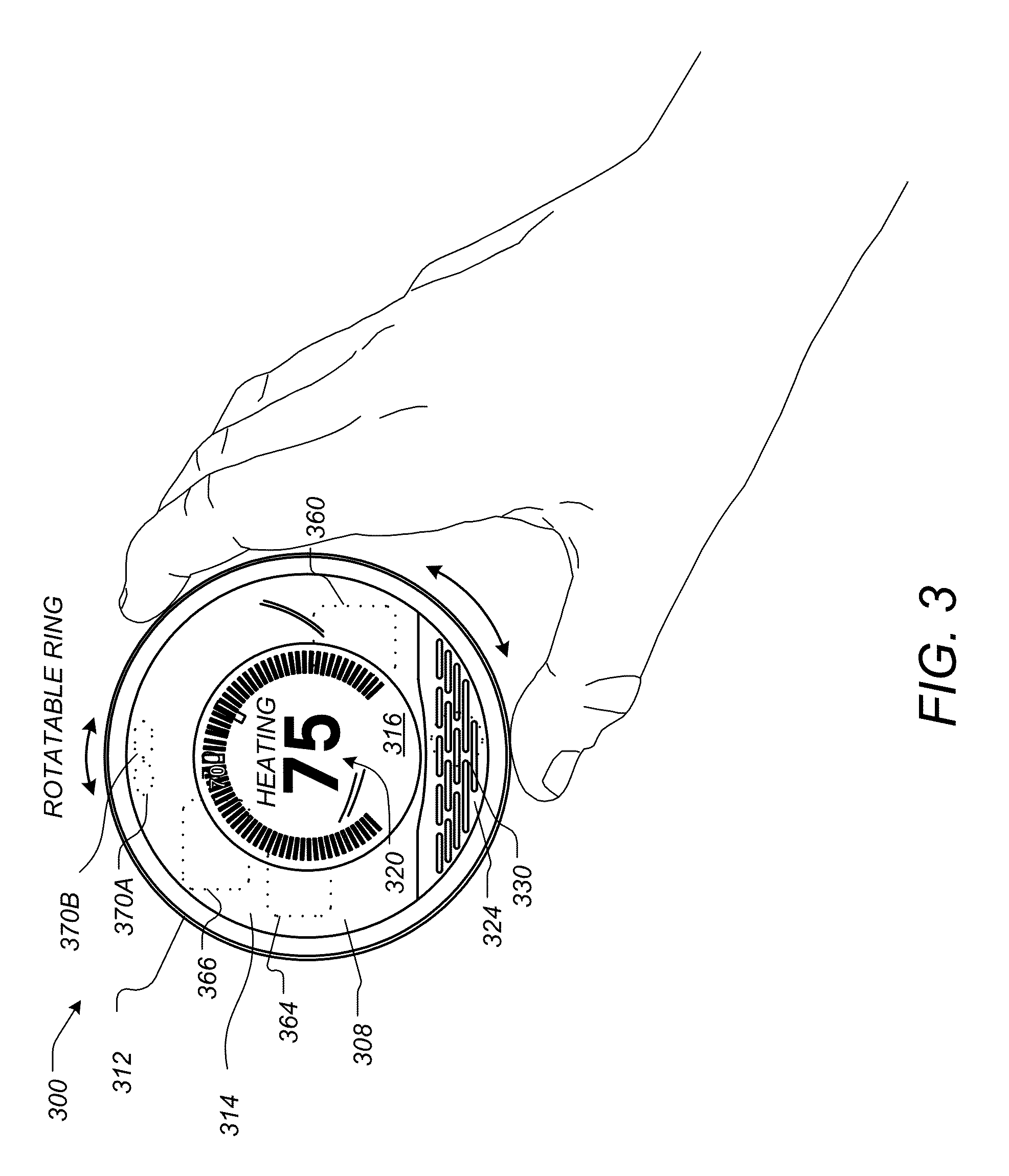

Radiant heating controls and methods for an environmental control system

ActiveUS8600561B1Function increaseIncrease valueMechanical apparatusStatic/dynamic balance measurementPrediction algorithmsOptimal control

Embodiments of the invention describe thermostats that use model predictive controls and related methods. A method of controlling a thermostat using a model predictive control may involve determining a parameterized model. The parameterized model may be used to predicted ambient temperature values for an enclosure. A set of radiant heating system control strategies may be selected for evaluation to determine an optimal control strategy from the set of control strategies. To determine the optimal control strategy, a predictive algorithm may be executed, in which each control strategy is applied to the parameterized model to predict an ambient temperature trajectory and each ambient temperature trajectory is processed in view of a predetermined assessment function. Processing the ambient temperature trajectory in this manner may involve minimizing a cost value associated with the ambient temperature trajectory. The radiant heating system may subsequently be controlled according to the selected optimal control strategy.

Owner:GOOGLE LLC

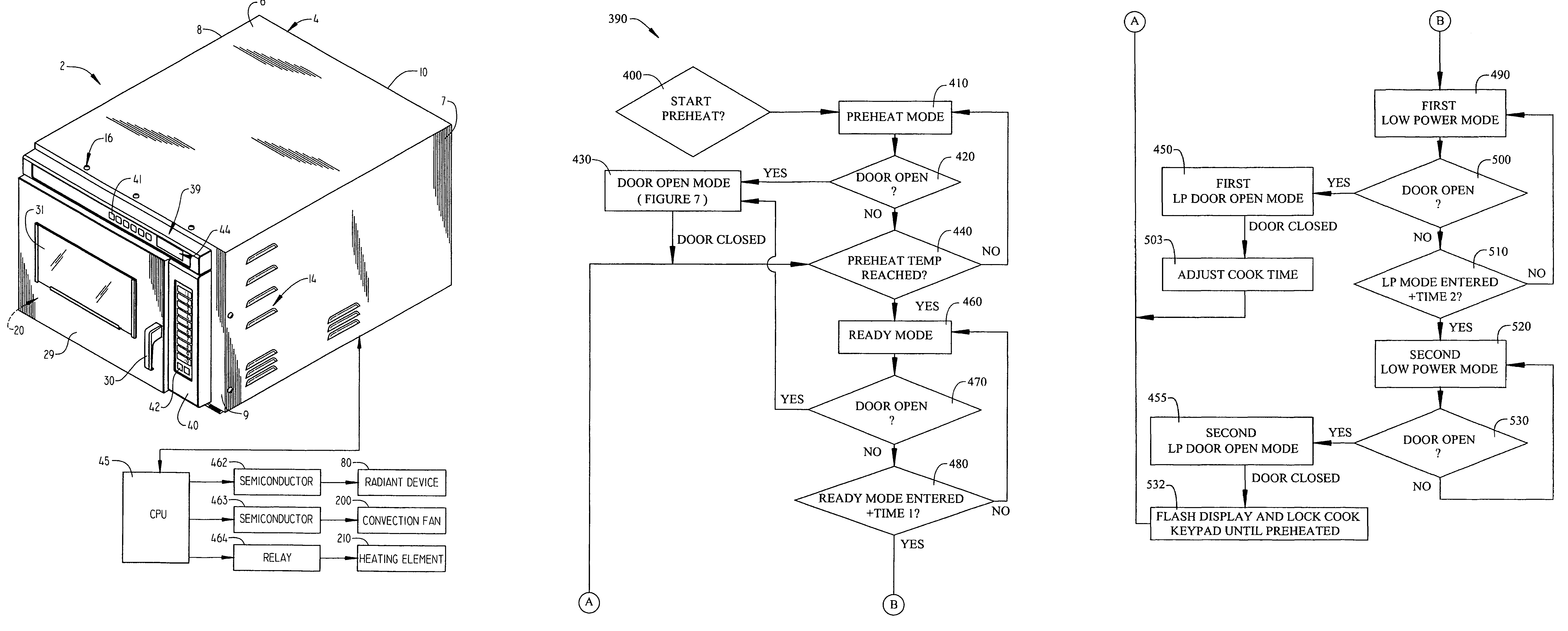

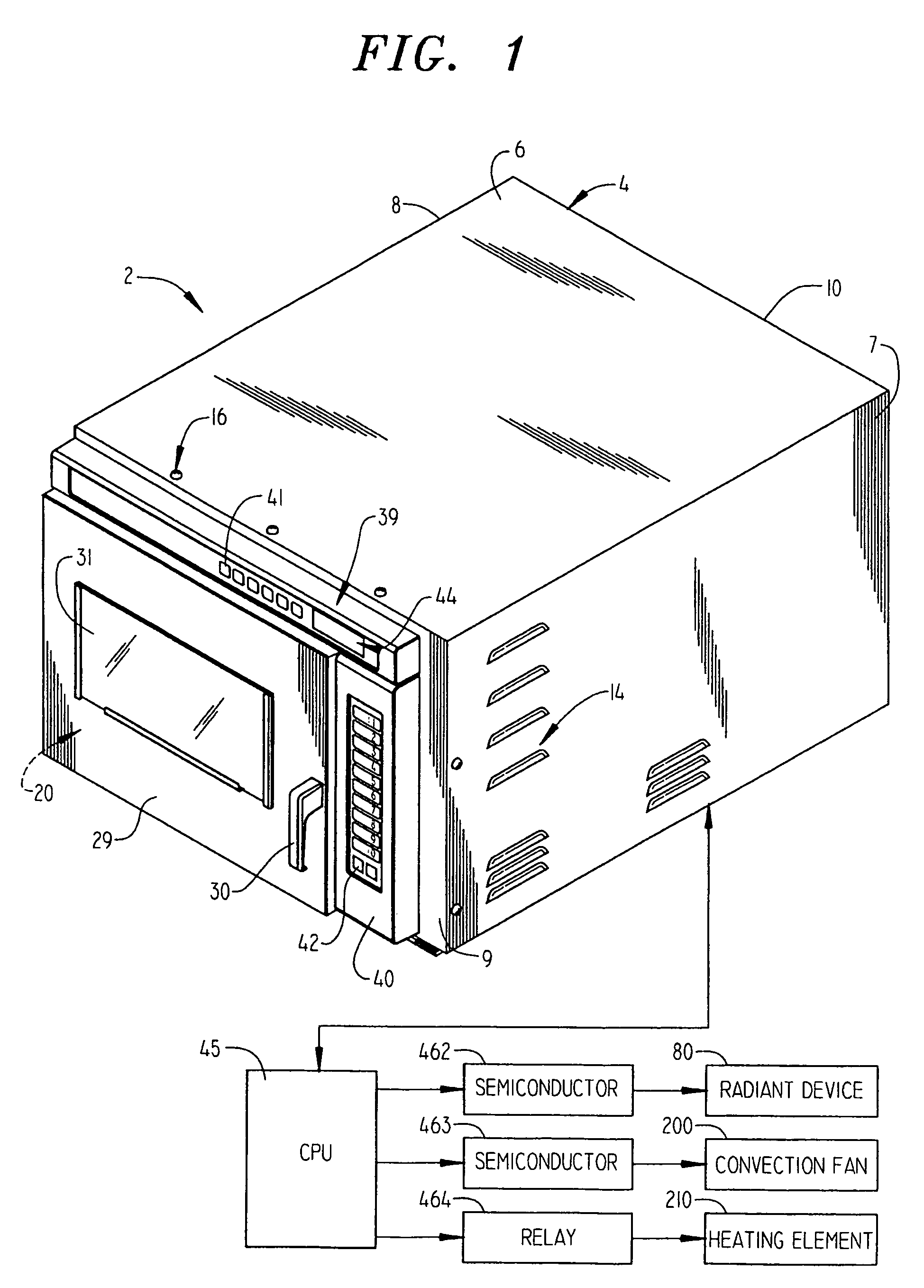

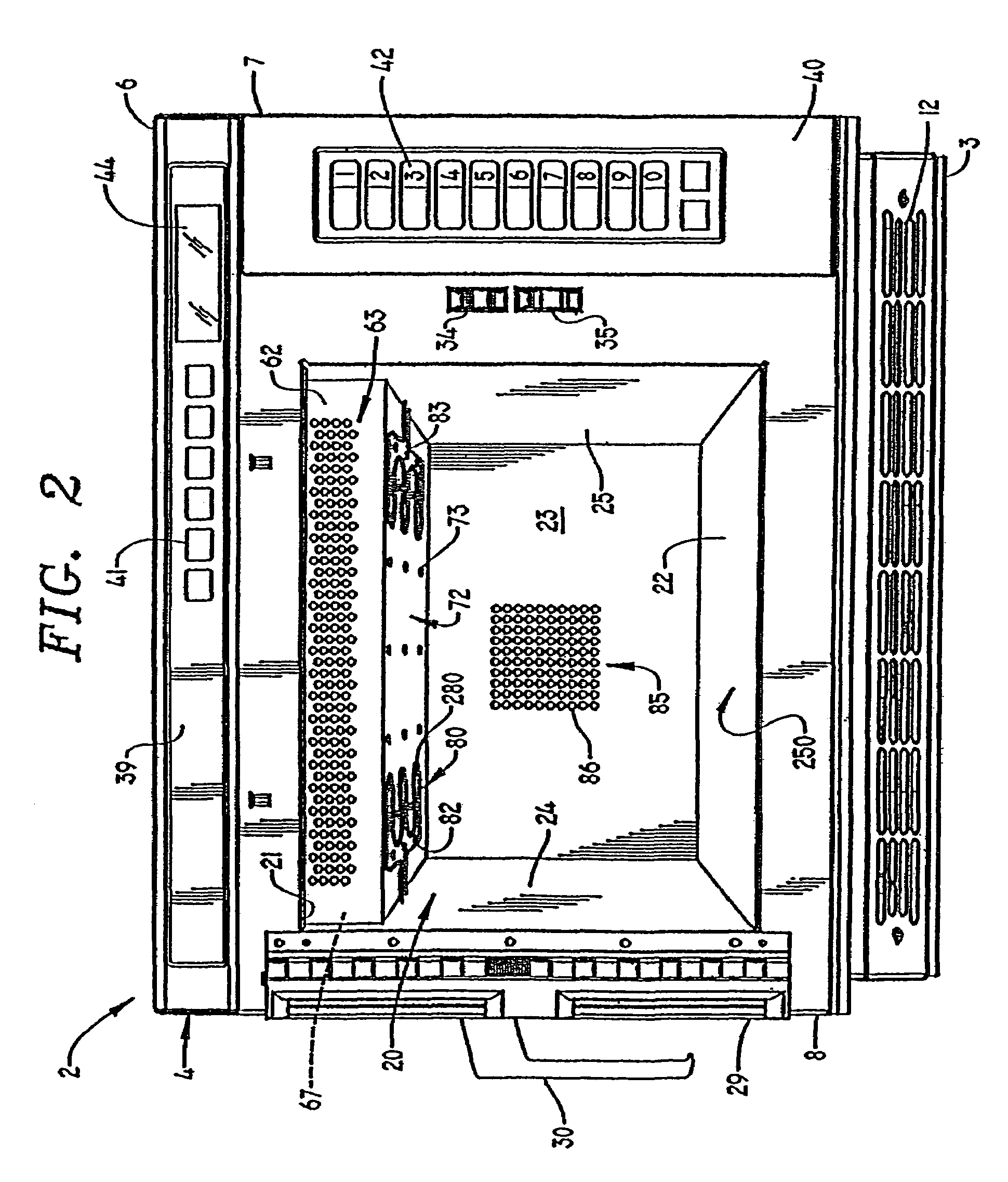

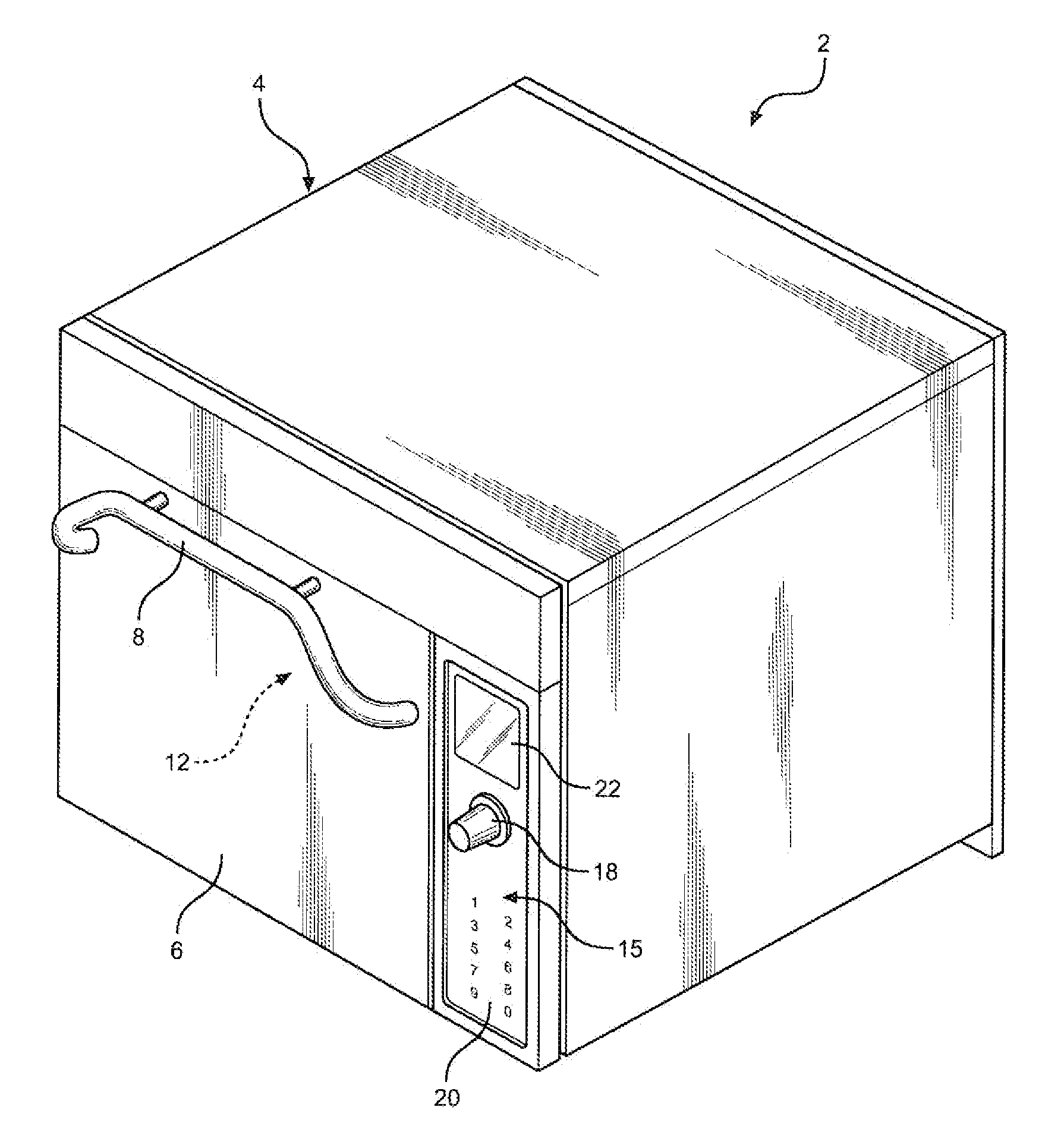

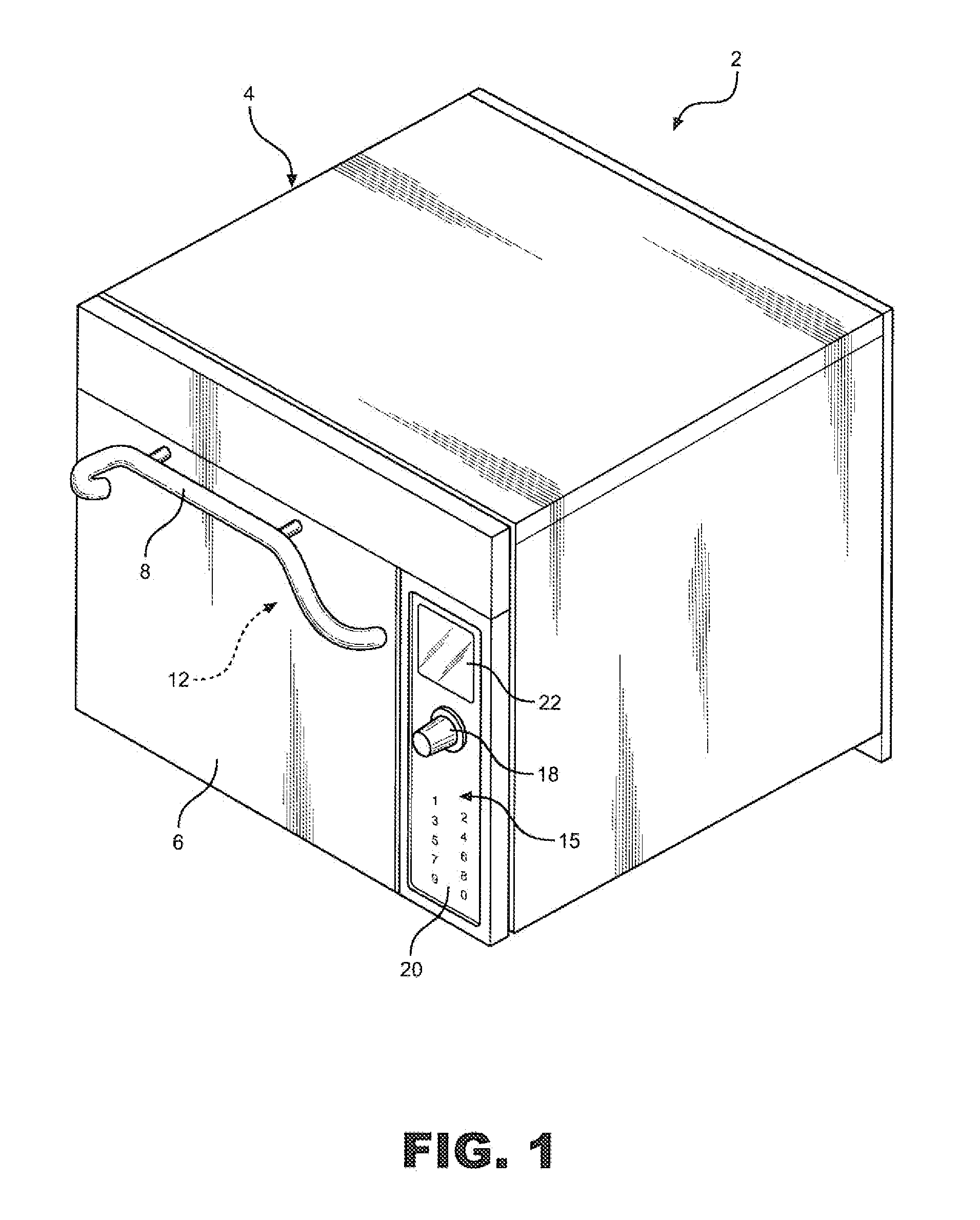

Operational modes for a cooking appliance employing combination cooking technology

A cooking appliance includes a controller for establishing a plurality of operating modes for heating an oven cavity. Specifically, the controller establishes one of a pre-heat mode, a ready mode, a first low power mode and a second low power mode for controlling a temperature of the oven cavity. Upon selecting a temperature for the oven cavity, the controller operates a radiant heating device, a convection fan and a convection heating device at full power to establish the selected temperature. After the selected temperature is achieved, the controller switches to a ready mode and reduces heat output of both the radiant heating device and the convection heating device, while also reducing fan speed. After respective periods of time in which a door of the appliance is not opened, the controller switches to first and second low power modes to conserve energy.

Owner:ACP OF DELAWARE

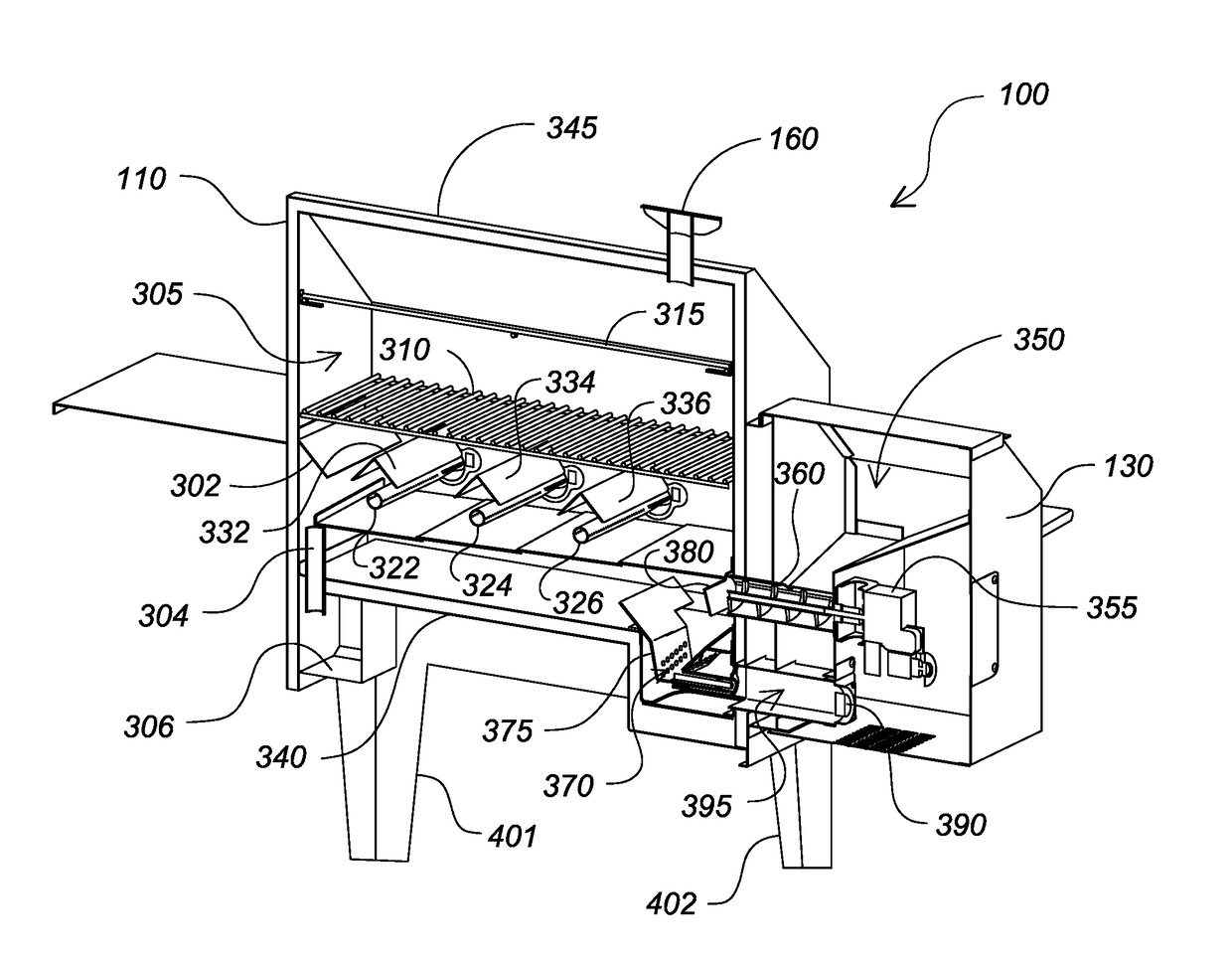

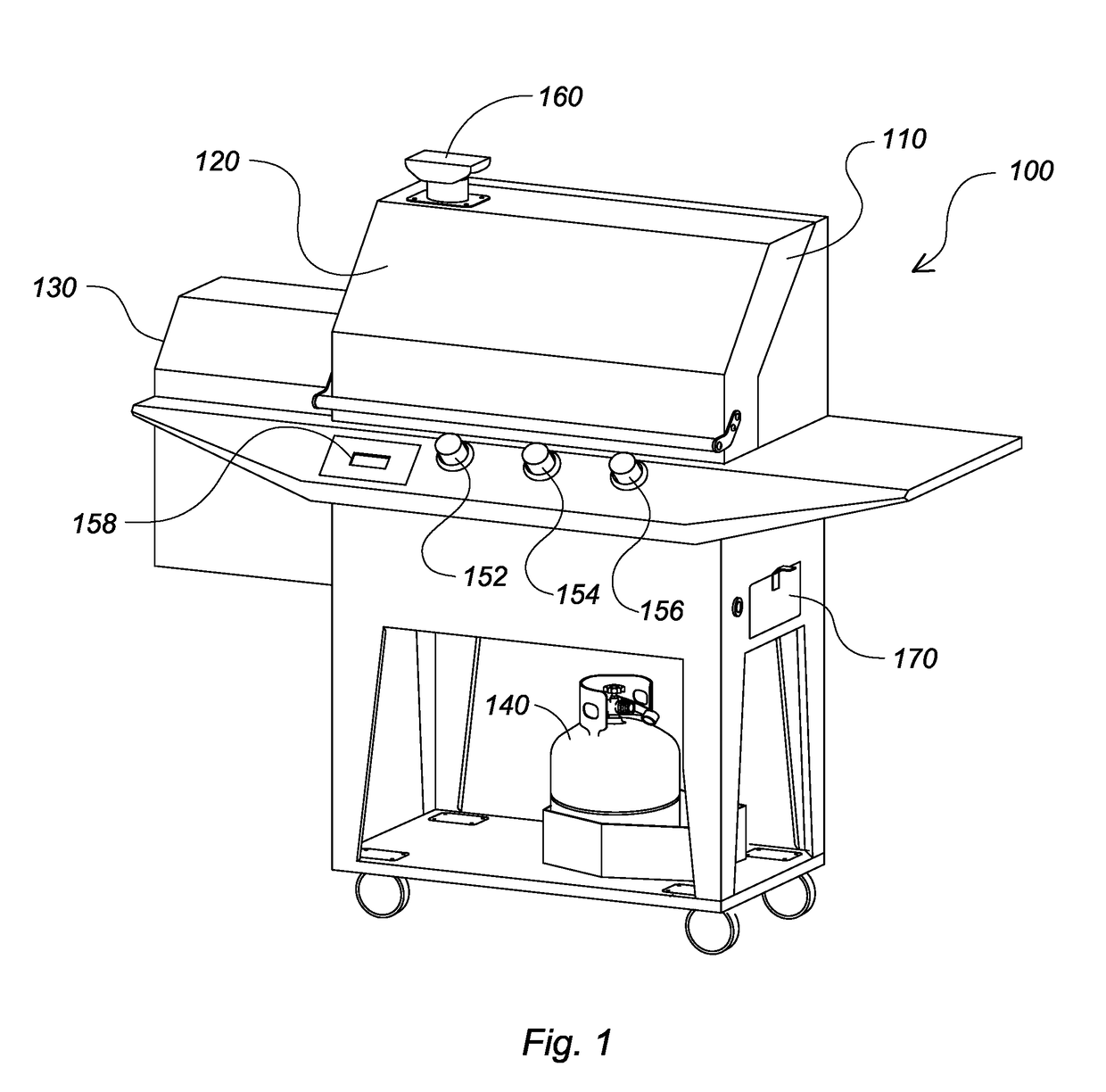

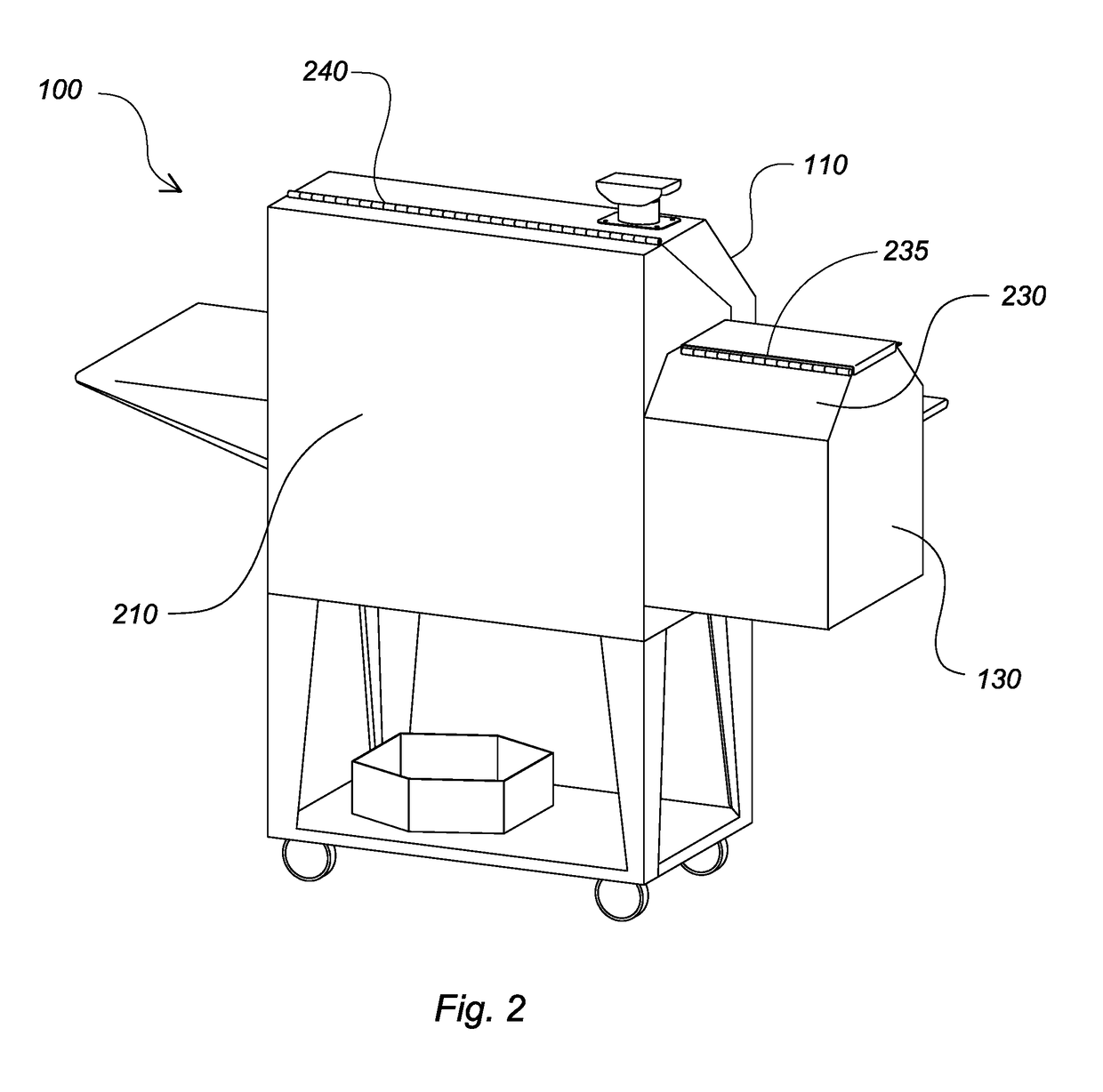

Multiple fuel cooking unit

InactiveUS20170164783A1Maintain sufficiencyWide rangeDomestic stoves or rangesLiquid heating fuelElectrical resistance and conductanceAutomatic control

A cooking unit may operate using multiple types of fuel to cook food. One or more first heat source, such as gas burners, electrical resistive heaters, and / or other heating technology, may provide radiant heat to a cooking chamber. One or more second heat source, such as a firebox, may provide indirect heat to the cooking chamber, for example by producing smoke. User operable controls and / or an automated control unit may alter the rate at which a fuel and / or air is supplied to one or more heat source.

Owner:SMOKESTEAK LLC

Temperature Control for Cooking Appliance Including Combination Heating System

A combination cooking appliance controls a radiant heating element provided in an oven cavity and a convection heating element provided in an air plenum with a regulating system which receives signals from multiple temperature sensors. More specifically, the appliance includes a first temperature sensor provided in an air return plenum portion for controlling the radiant heating element and a second temperature sensor arranged in a discharge air plenum portion, preferably downstream of a catalyst, for controlling the convection heating element. The heating elements are independently controlled based on the sensed temperatures to establish a desired oven cavity temperature, while accommodating for temperature fluctuations due to the incoming fresh air stream.

Owner:ACP

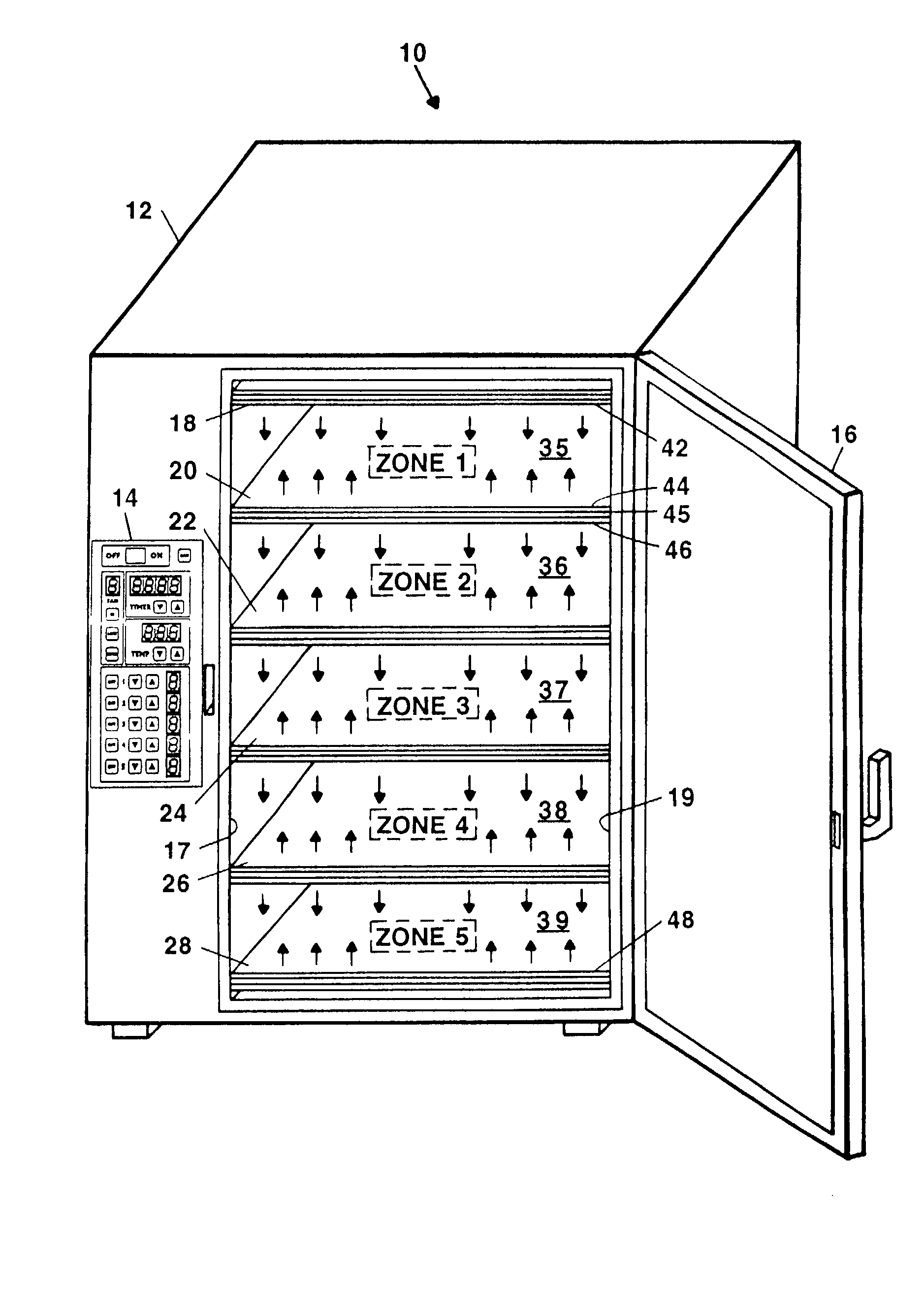

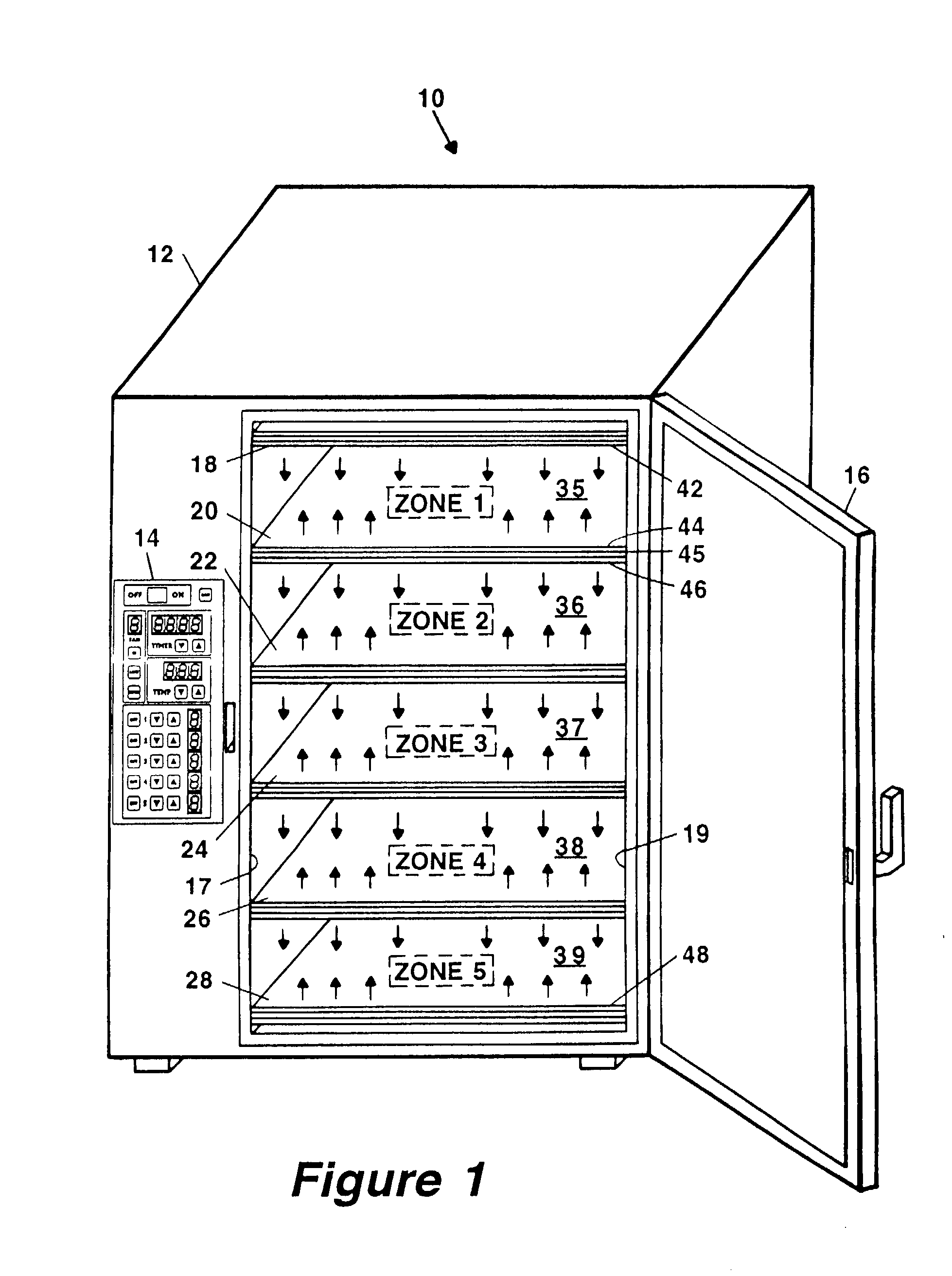

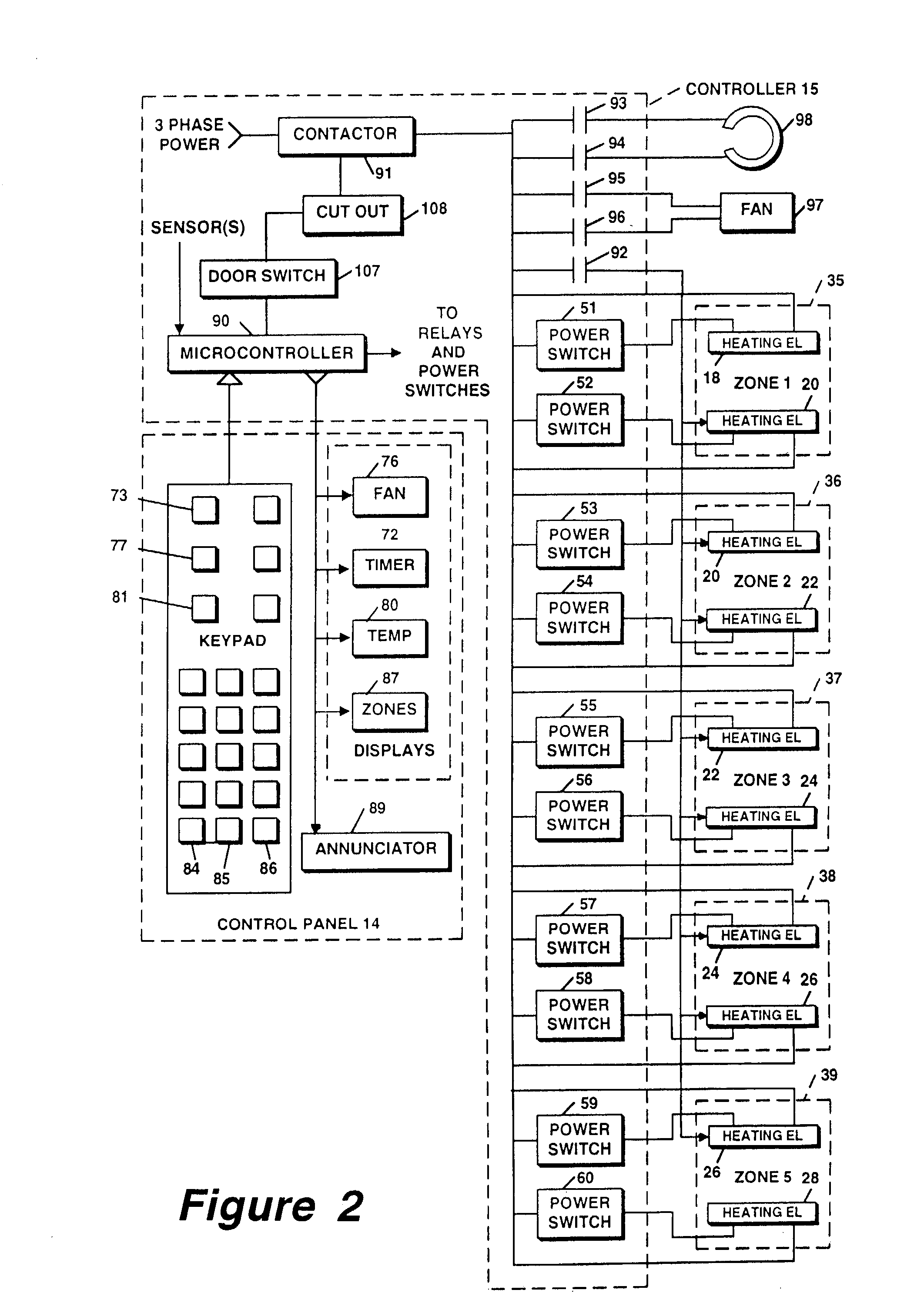

Multiple panel oven having individual controls for combined conductive and radiant heating panels

A multiple panel cooking oven having individual controls for combined conductive and radiant heating. Each panel comprises an upper heating element for conductive heating and a lower heating element for radiant heating to obtain uniform baking within a zone between panels in the oven. A control panel having displays and keypads interfaces with a processor which provides control signals for adjusting the temperature of the heating elements of the panels. Cooking energy efficiency is increased through the use of radiative and conductive heat transfer, to reduce bake times by significantly increasing heat transfer to the food products. Independent cook zones allow preparation of multiple products simultaneously under different cooking conditions. The oven, in one embodiment may include a convection heating mode of operation. In an alternative embodiment no convection mode is provided and the sole source of heat is provided by the conductive / radiant panels.

Owner:TIAX LLC

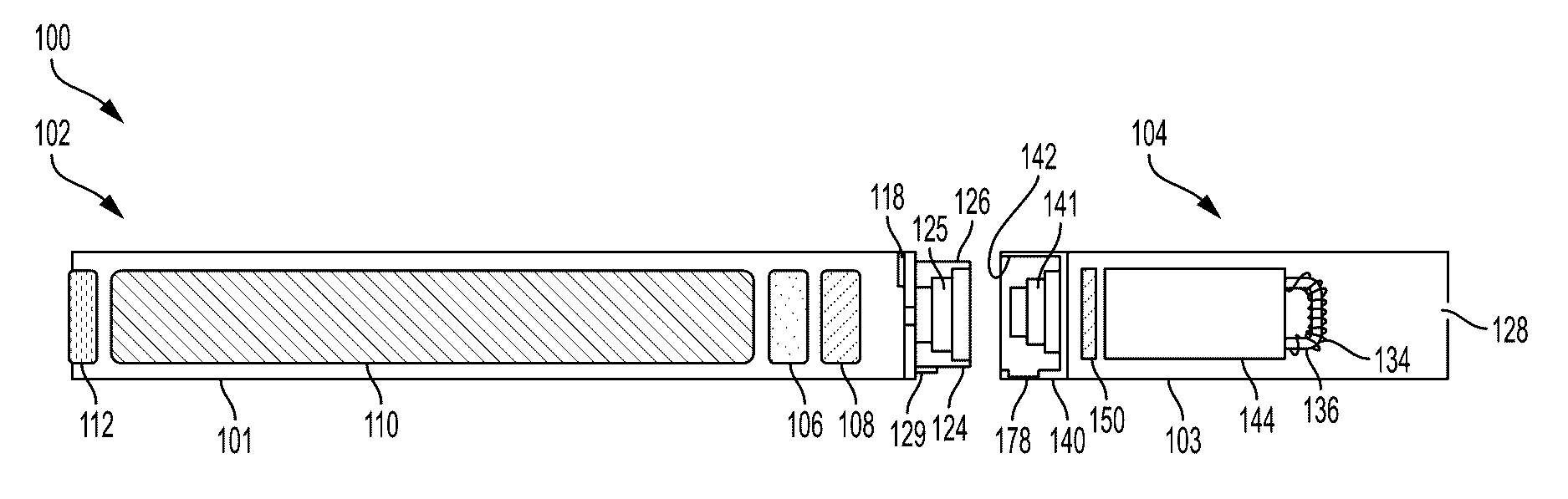

Aerosol delivery device with radiant heating

ActiveUS20170020193A1Increase heatExtended service lifeRespiratorsOhmic-resistance waterproof/air-tight sealsBlack bodyVaporization

The present disclosure relates to aerosol delivery devices, methods of forming such devices, and elements of such devices. In some embodiments, the present disclosure provides devices configured for vaporization of an aerosol precursor composition through radiant heating. The radiant heat source may be a laser diode or further element suitable for providing electromagnetic radiation, and heating may be carried out within an optional chamber, which can be a radiation-trapping chamber. In some embodiments, an interior of such chamber may be configured as a black body or as a white body.

Owner:RAI STRATEGIC HLDG INC

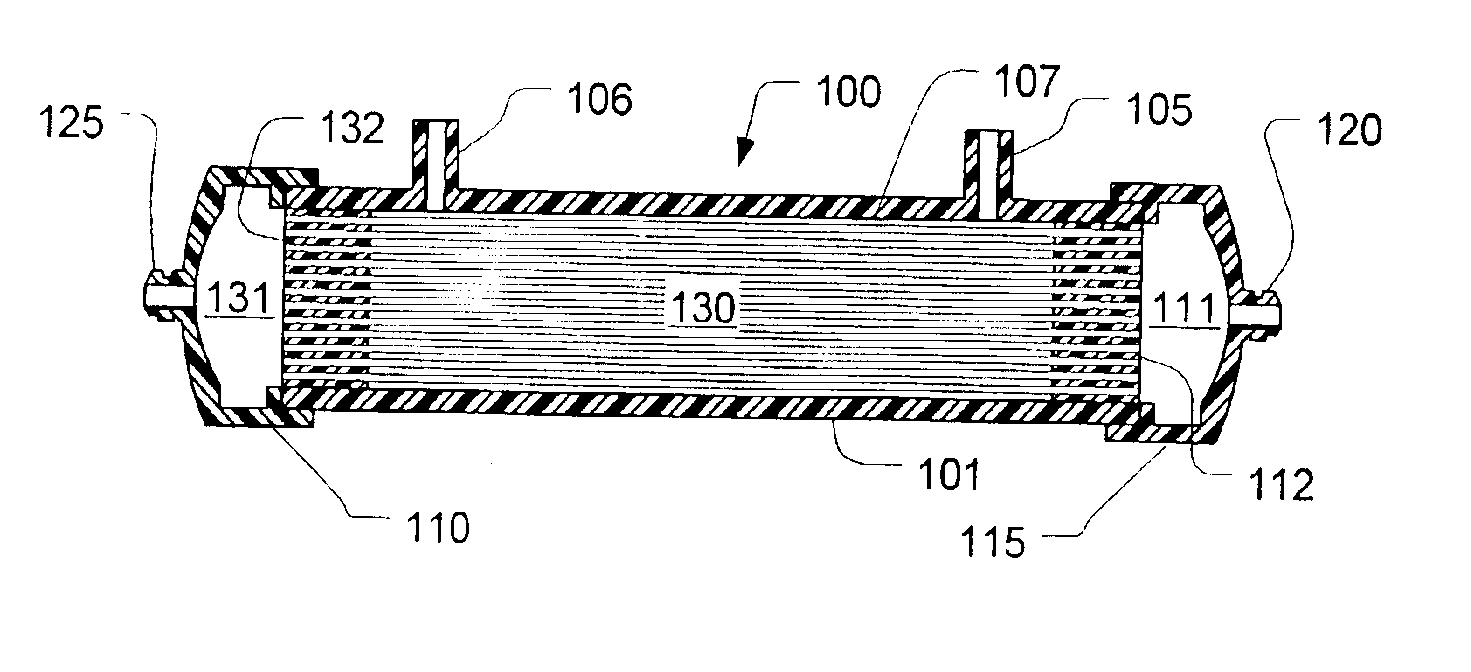

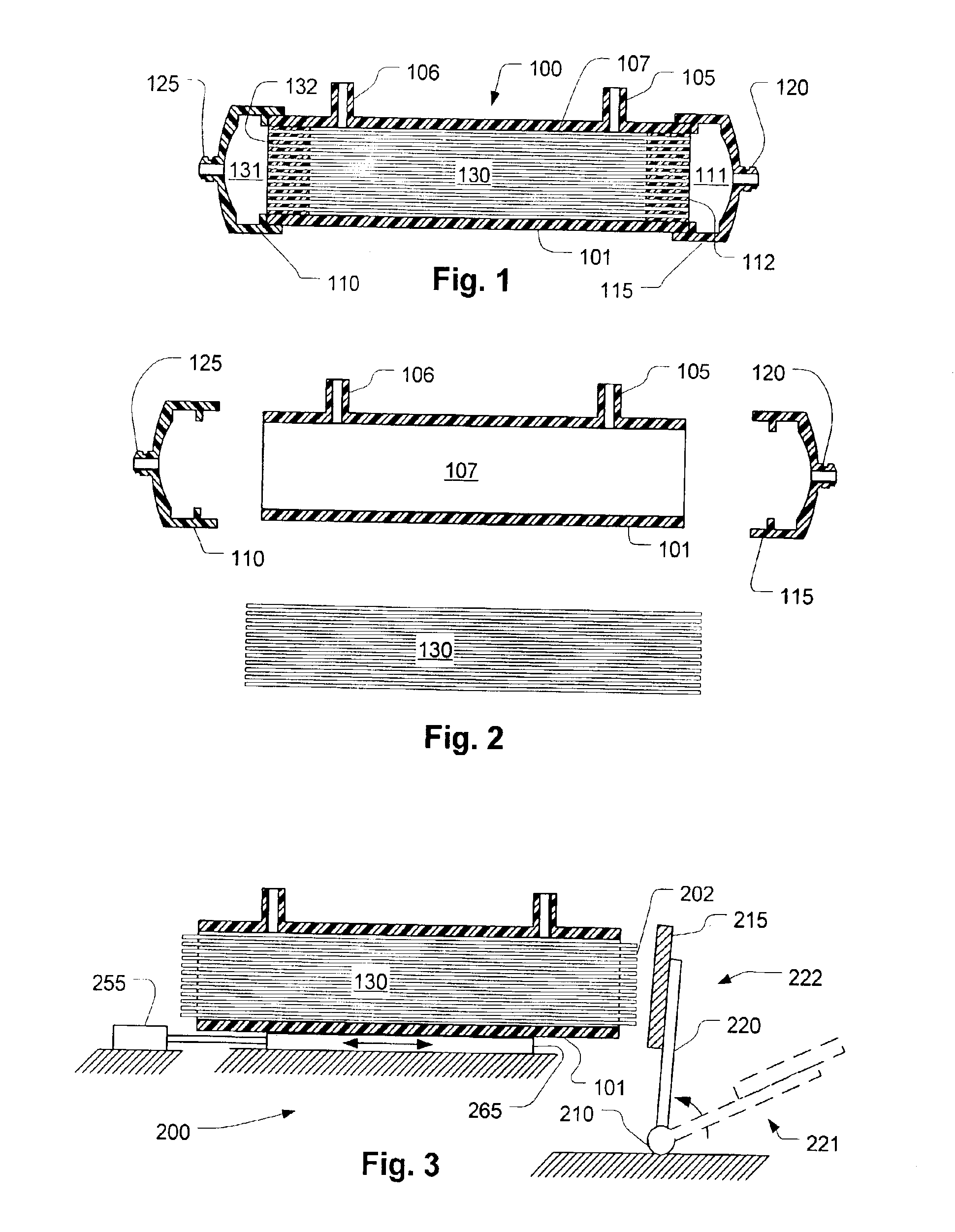

Method and apparatus for manufacturing filters

InactiveUS6872346B2Speed productionShort amount of timeSemi-permeable membranesTailstocks/centresEngineeringMechanical engineering

A problem in the manufacture of filters using tubular membrane bundles is keeping potting material from flowing into the openings at the ends of the tubes. A preferred embodiment of a method for manufacturing a tubular membrane filter employs a non-contact heat source such as radiant heating to melt the tips of the tubular membranes. This prevents the migration of potting material into the tubes when the potting material is flowed into the ends of tube bundles during the manufacturing process for a filter.

Owner:NXSTAGE MEDICAL

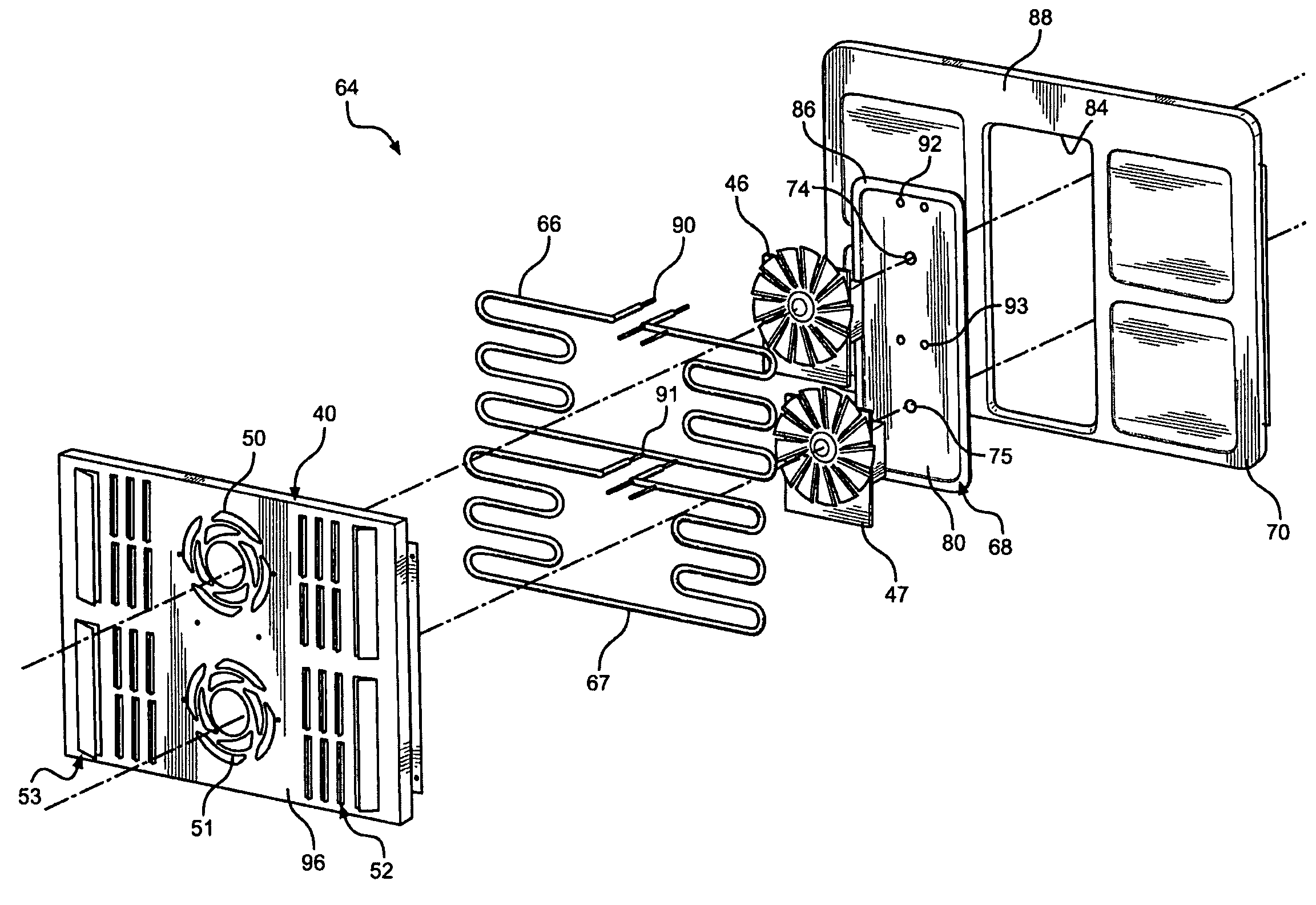

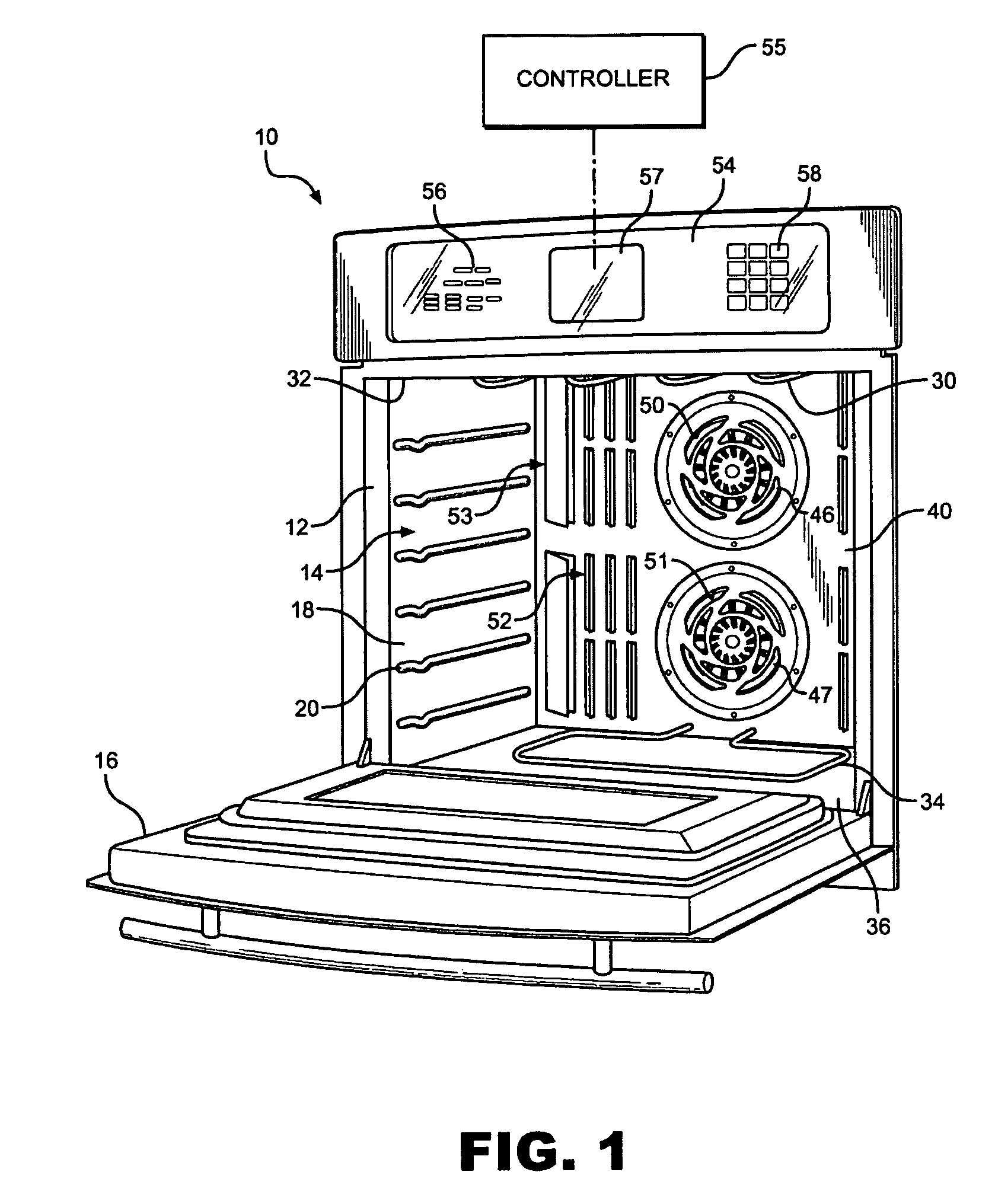

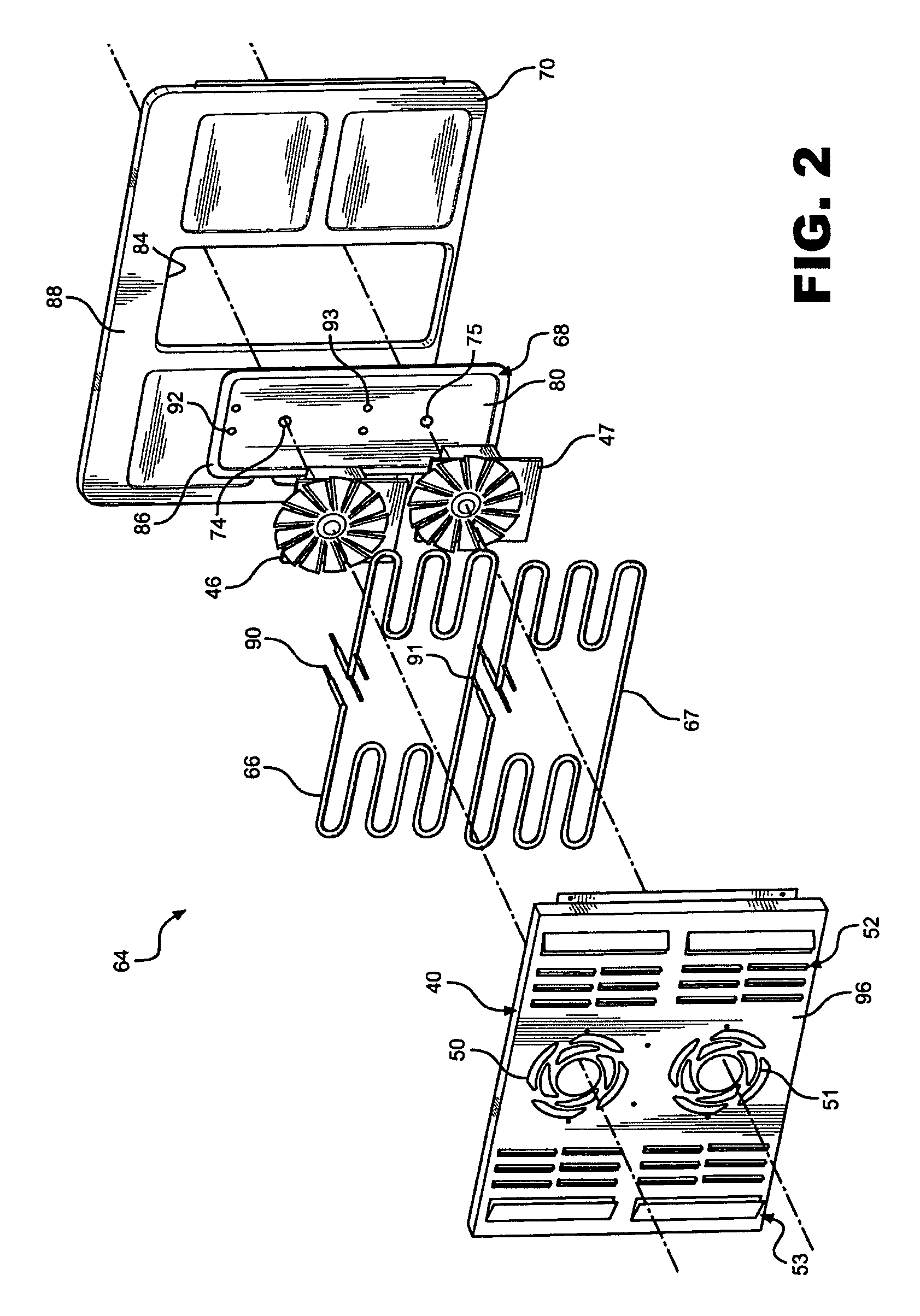

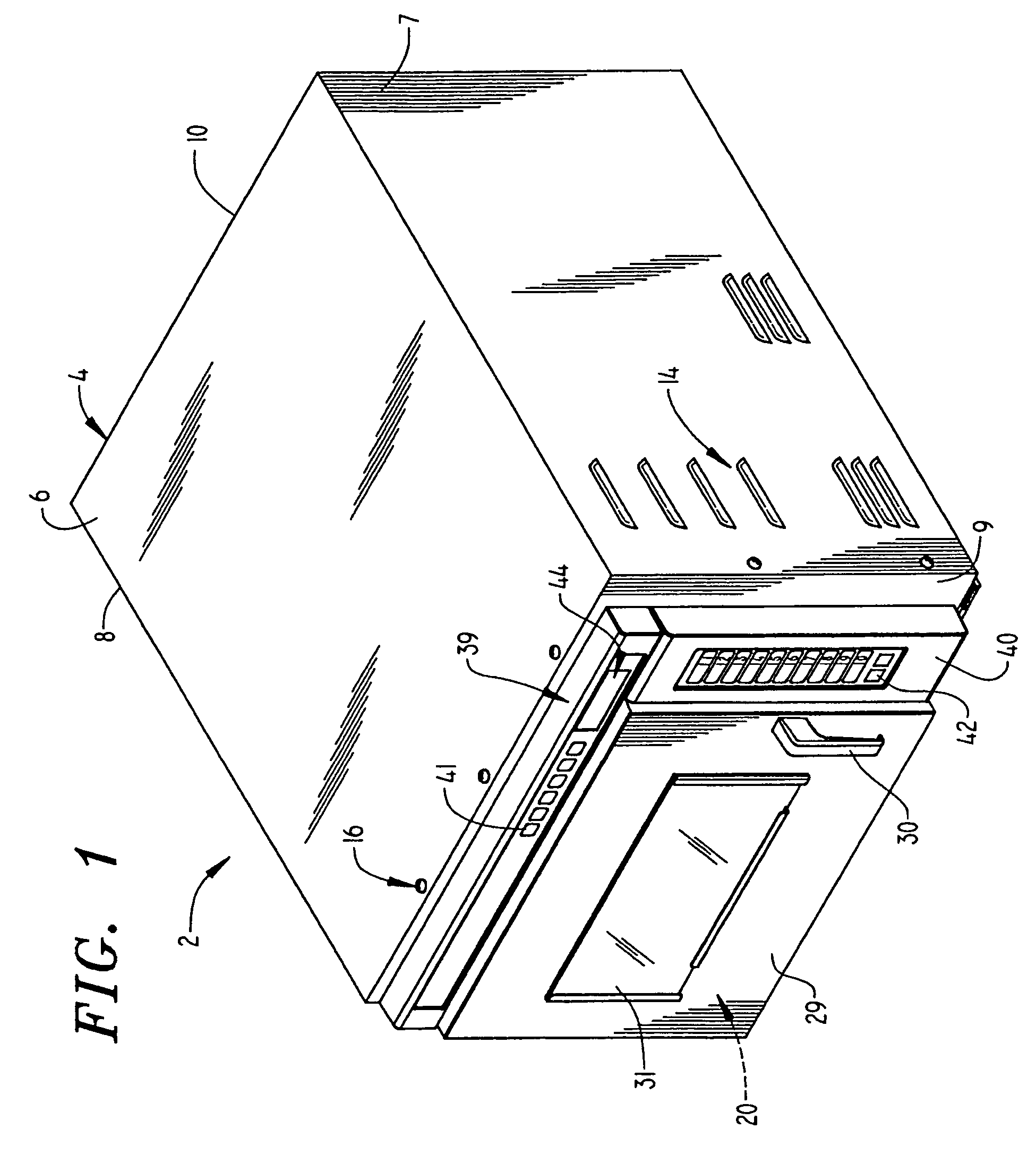

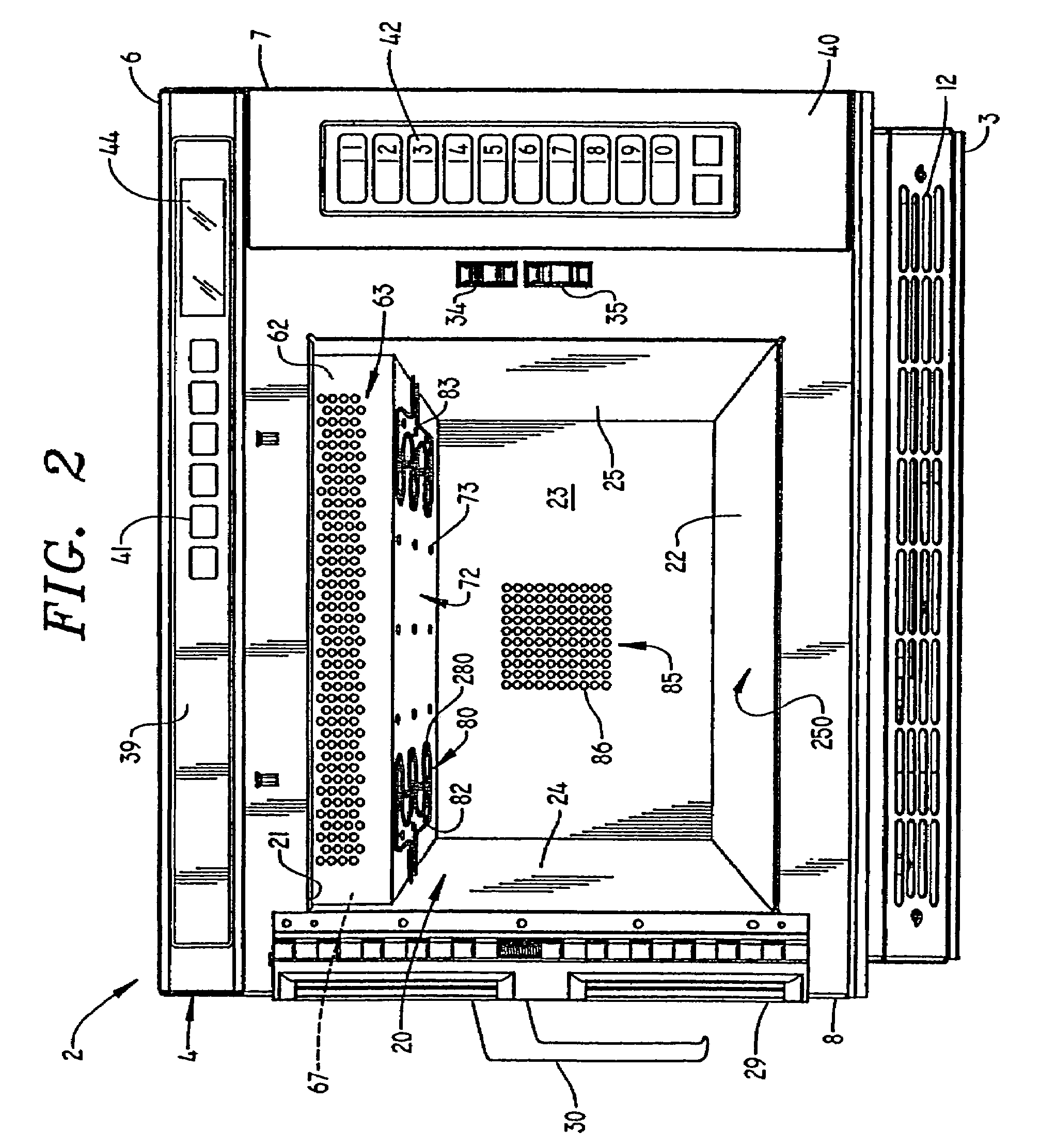

Dual fan convection oven

A combination convection and radiant cooking appliance includes an oven cavity, broil and bake radiant heating elements, a convection cover defining a rear wall of the oven cavity, a back panel, and a dual fan convection heating system mounted between the convection cover and the back panel. Each combination fan / heater of the dual convection heating system includes a multi-speed fan and an associated electric heating element, with the fans being vertically disposed in the oven cavity. Controls are provided to enable a user to select between at least a bake mode, a no preheat convection bake mode, a rapid preheat convection bake mode, a preheat convection bake mode and a convection roast mode.

Owner:WHIRLPOOL CORP

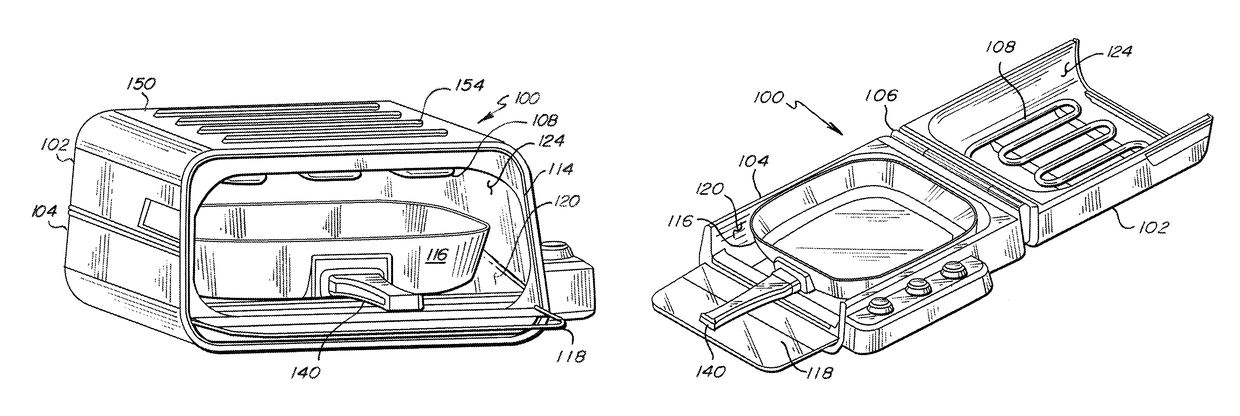

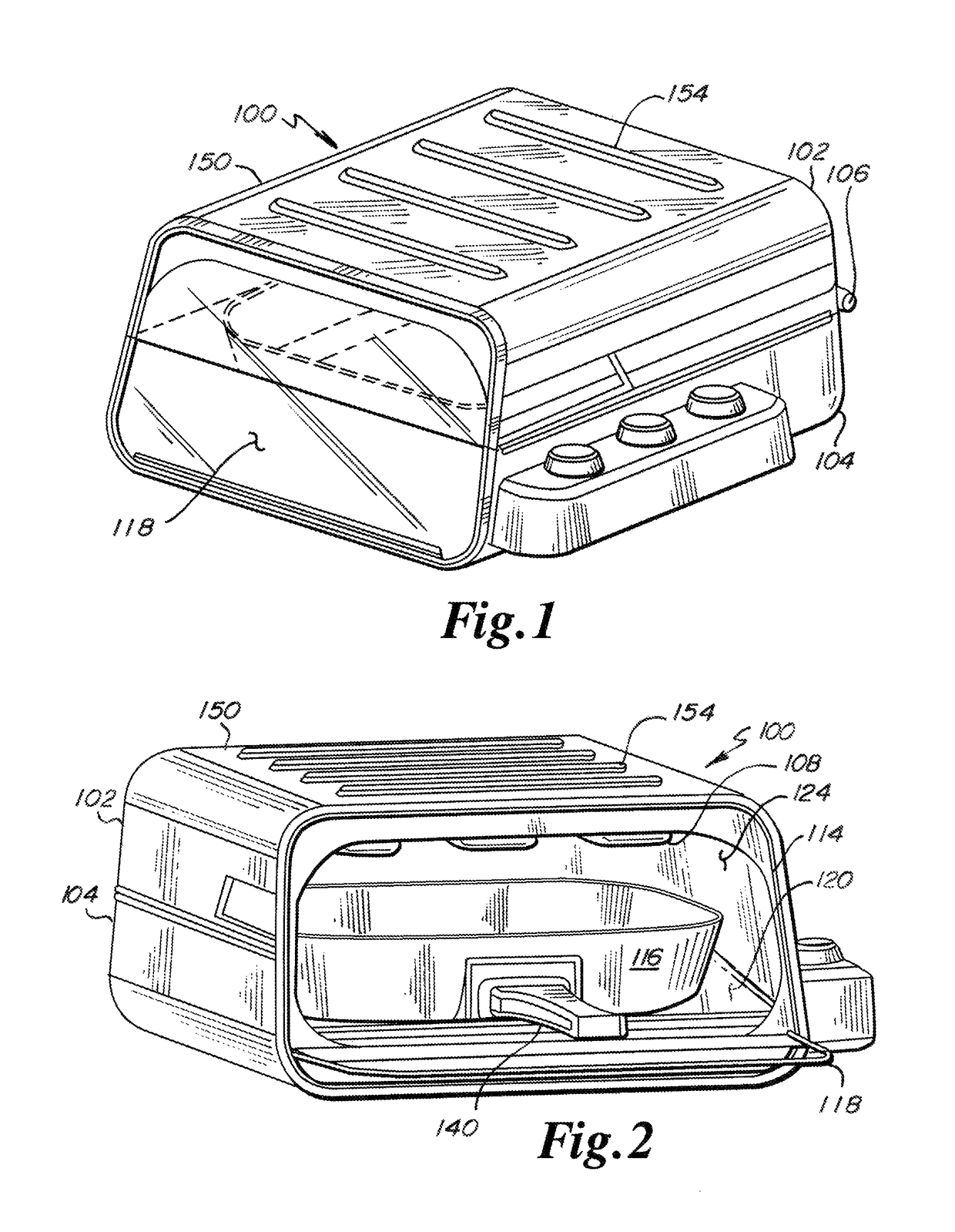

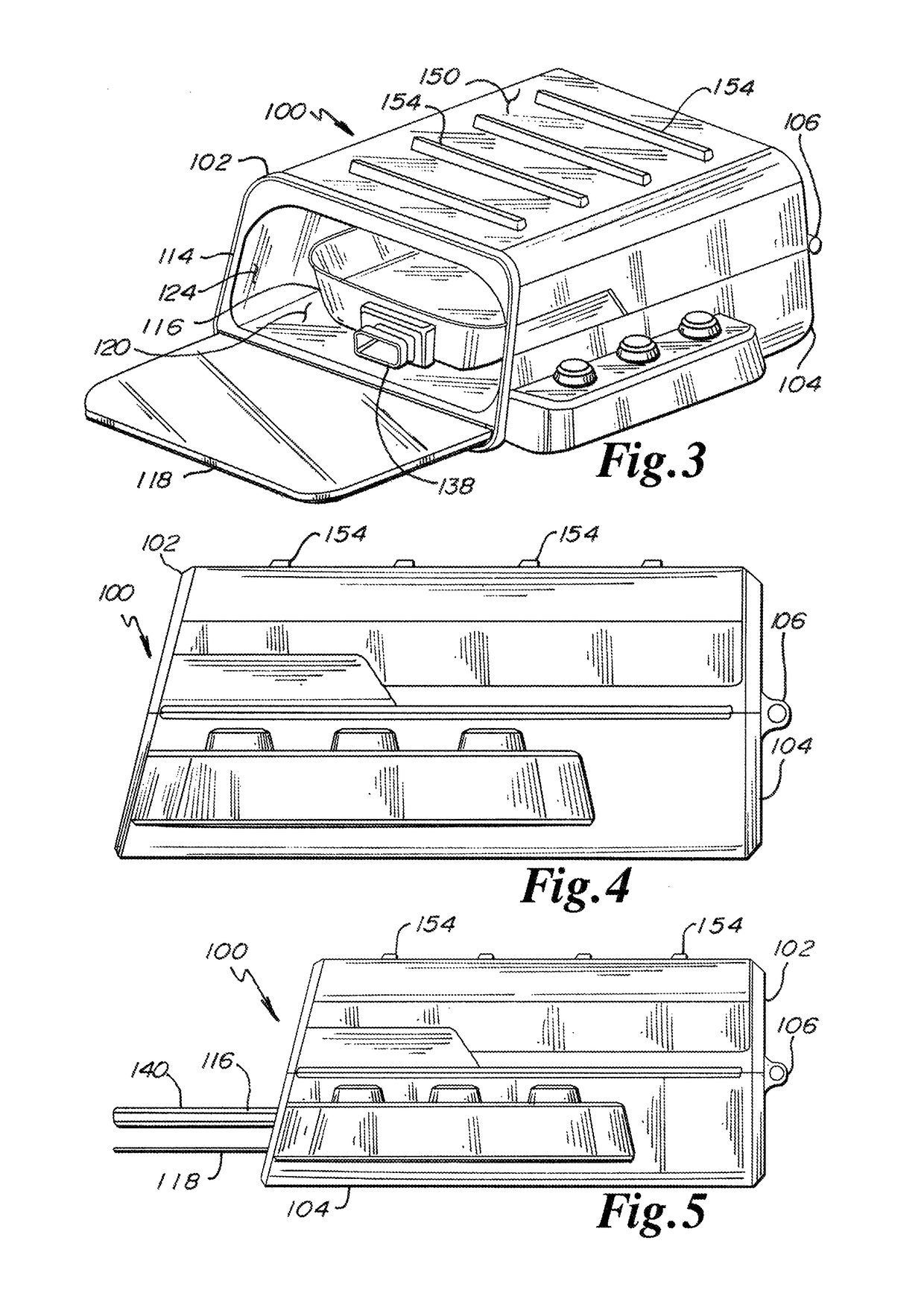

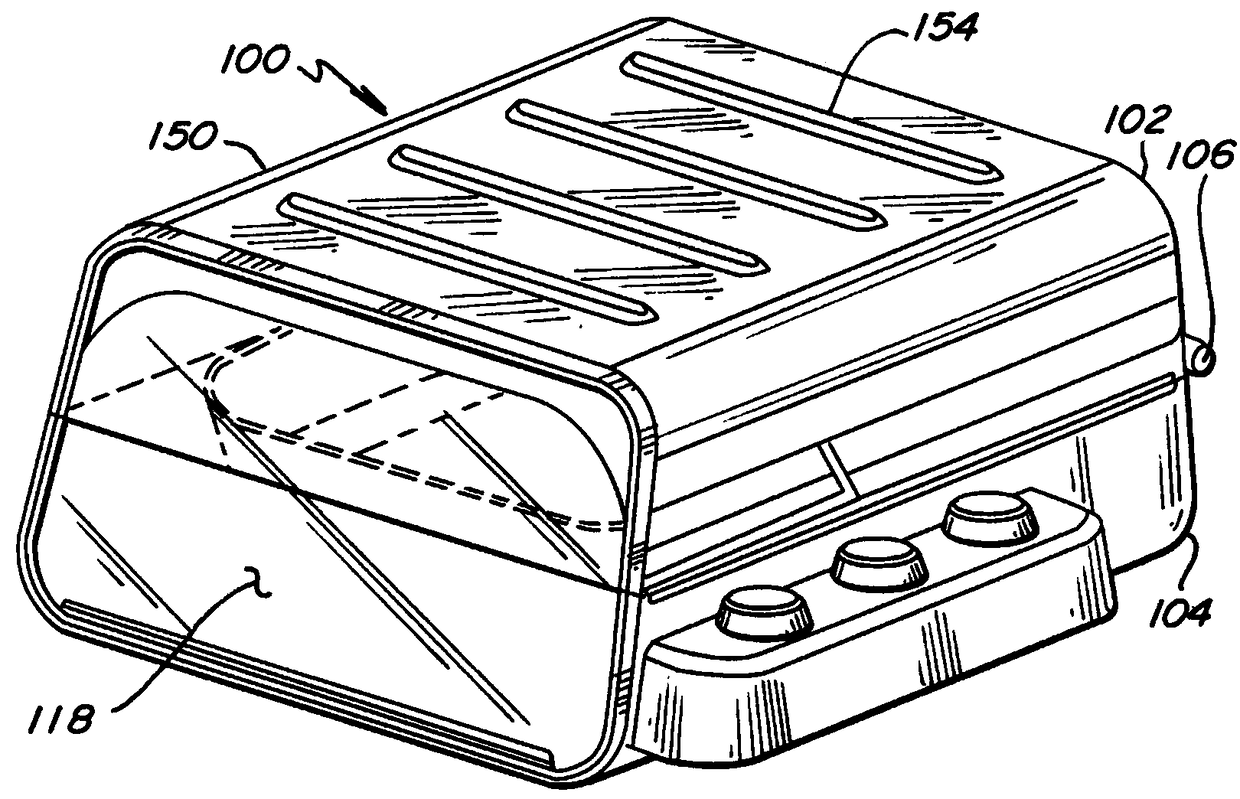

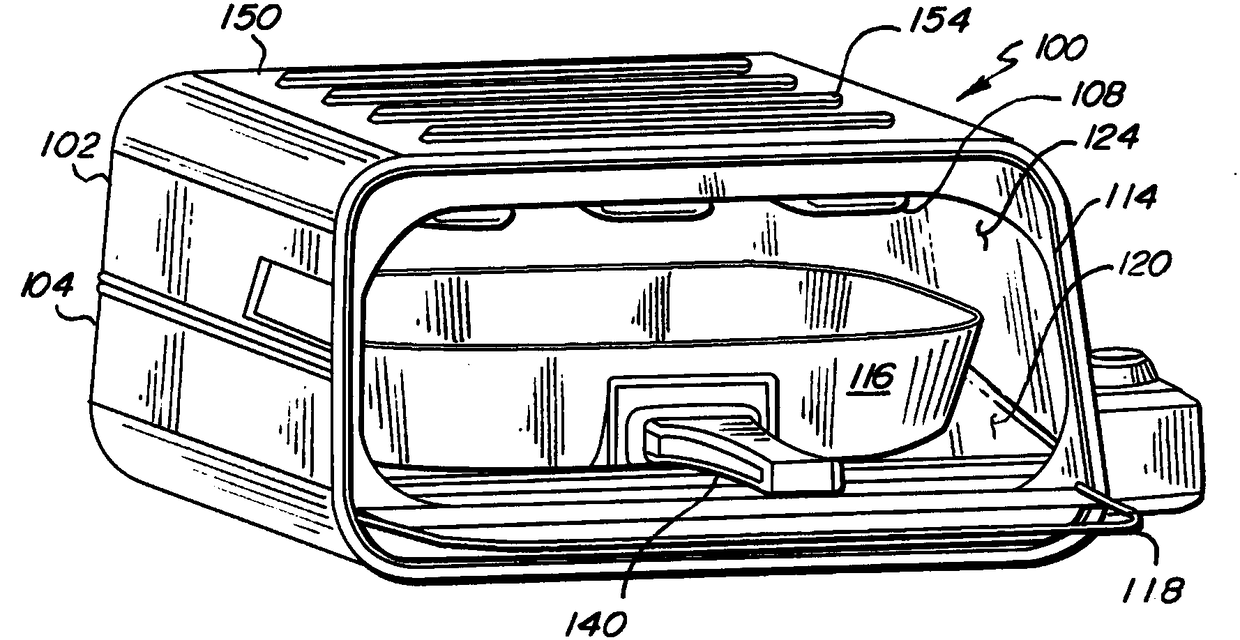

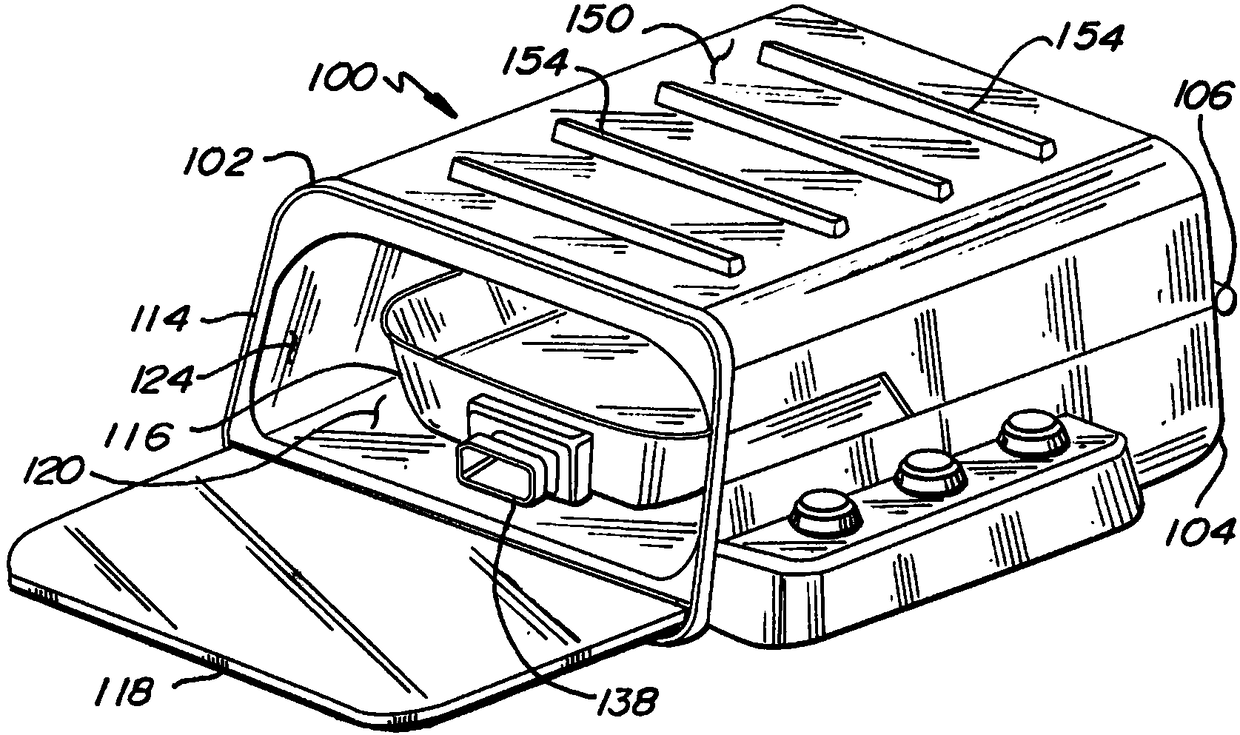

Countertop cooking appliance

InactiveUS9924830B1Domestic stoves or rangesLighting and heating apparatusRadiant heatingIngested food

A counter top cooking appliance has an enclosure defining a cooking chamber arranged to receive a cooking pan. The cooking chamber includes a lower heating element arranged so that the cooking pan may be supported thereon to receive conductive heating there-from, and an upper heating element disposed above and spaced from the cooking pan to provide radiant heating to food there-within. The enclosure includes an upper portion including the upper heating element, and a lower portion including the lower heating element, and a hinge connecting the upper portion to the lower portion. The hinge enables the upper portion to rest atop the lower portion to define the cooking chamber, and alternatively enables the upper portion to be swung relative to the lower portion so that the upper and lower portions are in a parallel side-by-side relationship and both heating elements are arranged so that the cooking pan may be supported on either thereof to receive conductive heating there-from.

Owner:TEAM INT GRP OF AMERICA INC

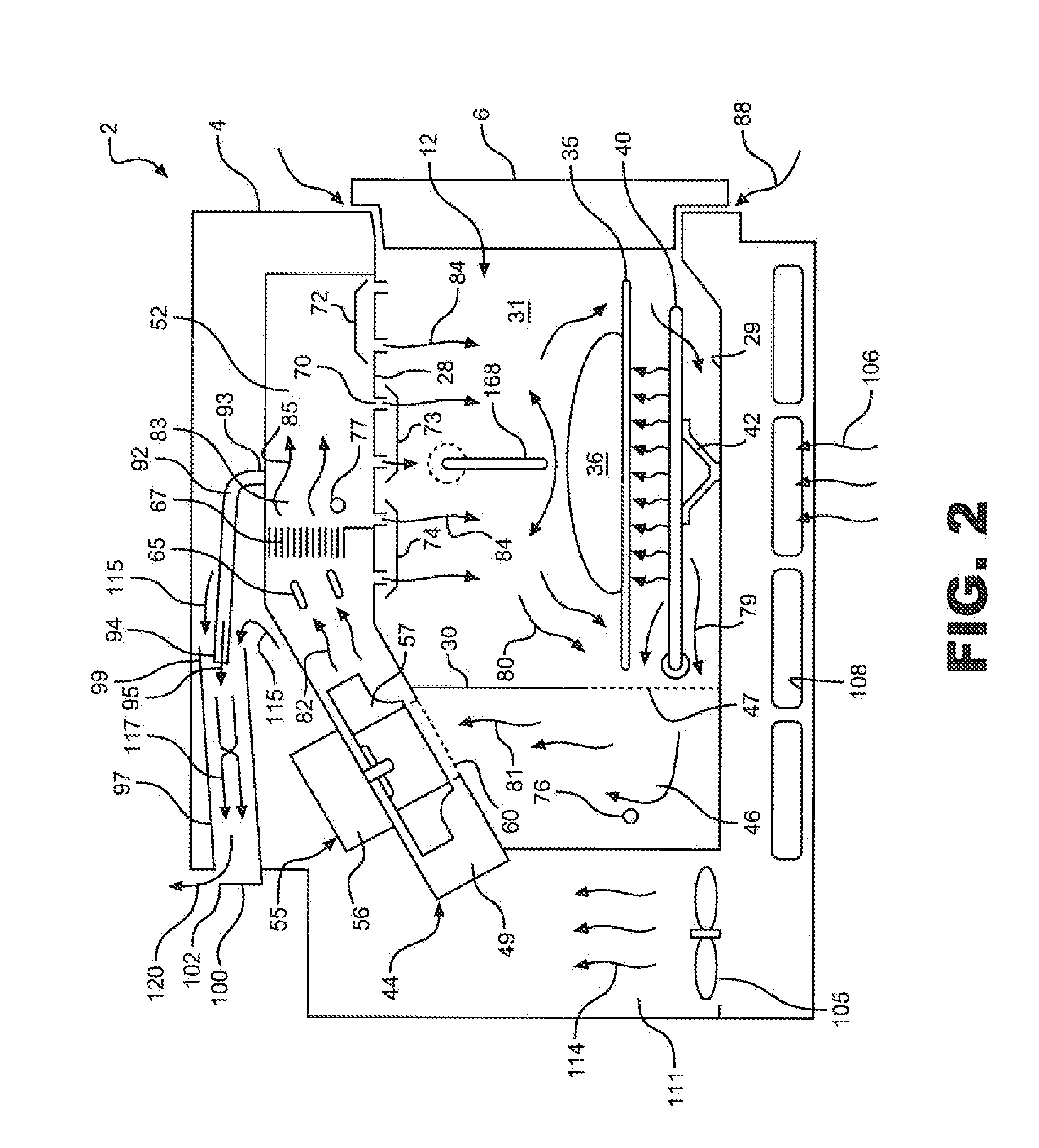

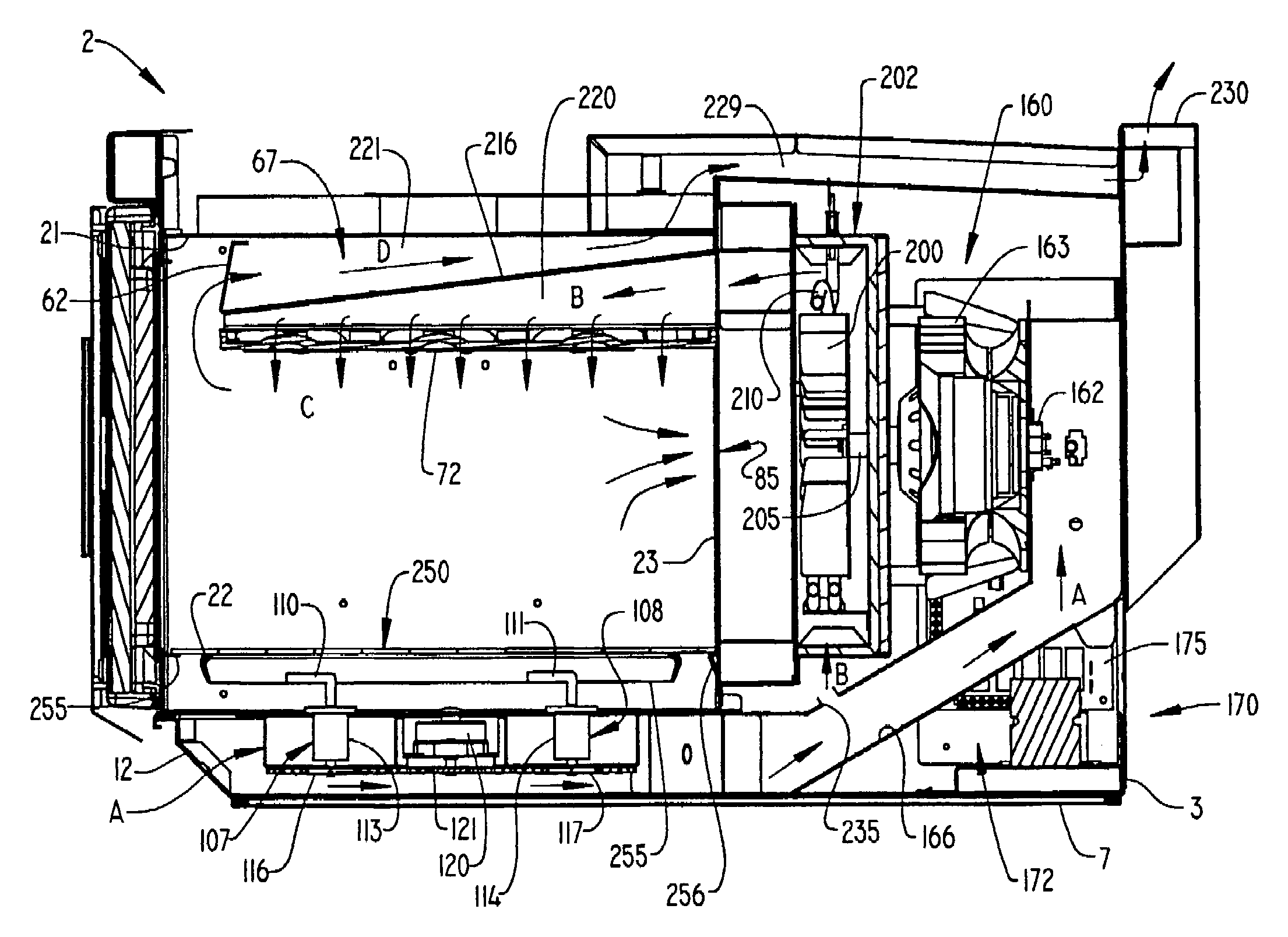

Cooking appliance including combination heating system

A cooking appliance includes a heating system capable of combining radiant, convection, microwave and conduction heating techniques to perform a cooking operation. The cooking appliance includes a cooking chamber and a bifurcated air plenum having an angled divider that defines a tapered air delivery portion and a tapered exhaust portion. The tapered air delivery portion actually guides a convective air flow through an air emitter plate positioned at a top of the cooking chamber. The air emitter plate includes a recessed, serpentine-like channel having a plurality of openings that lead to the air delivery portion. A radiant heating element is nested within the recessed channel. The cooking appliance further includes a convection fan, as well as a magnetron having a rotatable antenna positioned below the cooking chamber and a conductive plate upon which food to be cooked is supported.

Owner:AGA FOODSERVICE GROUP +1

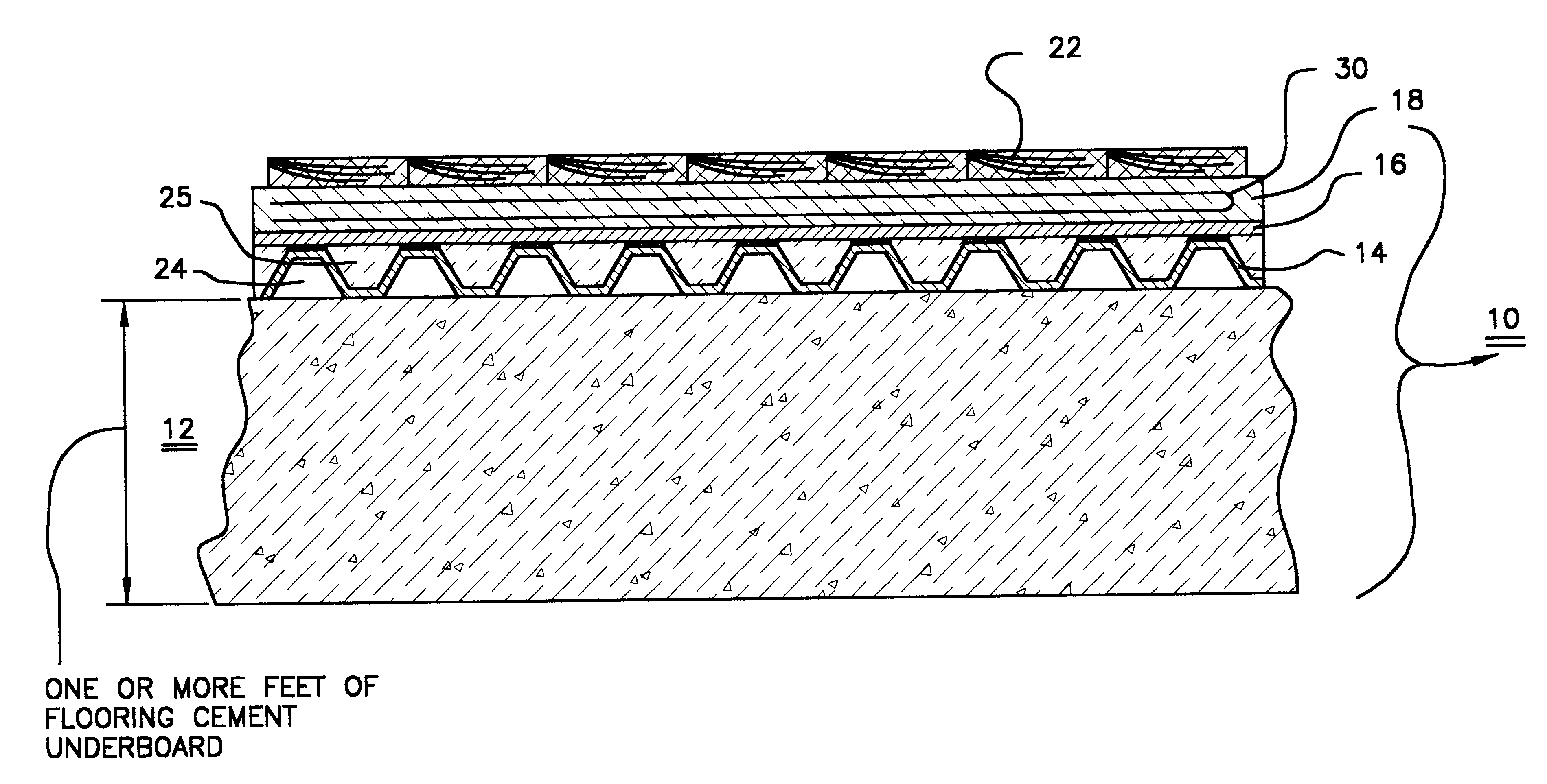

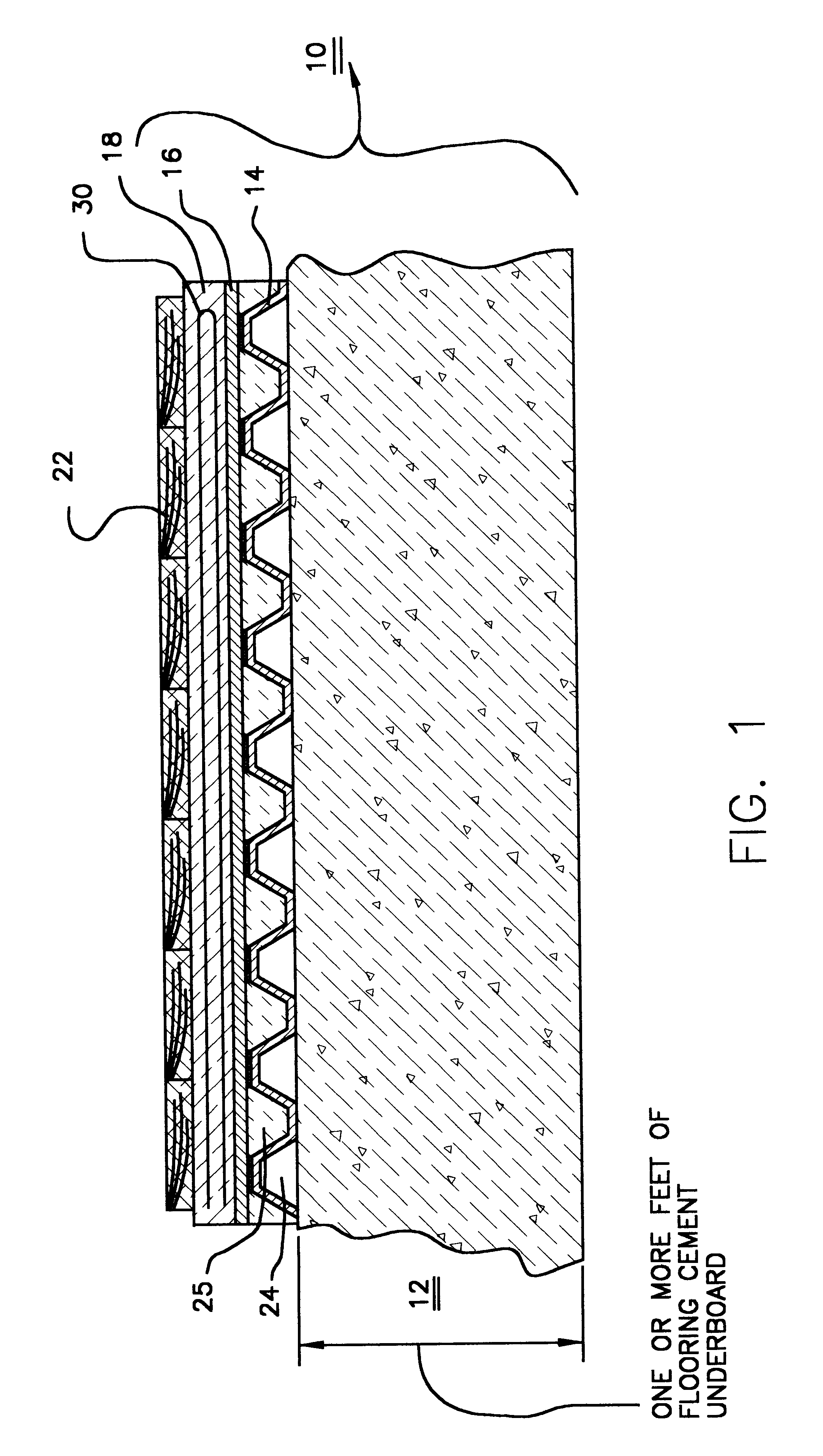

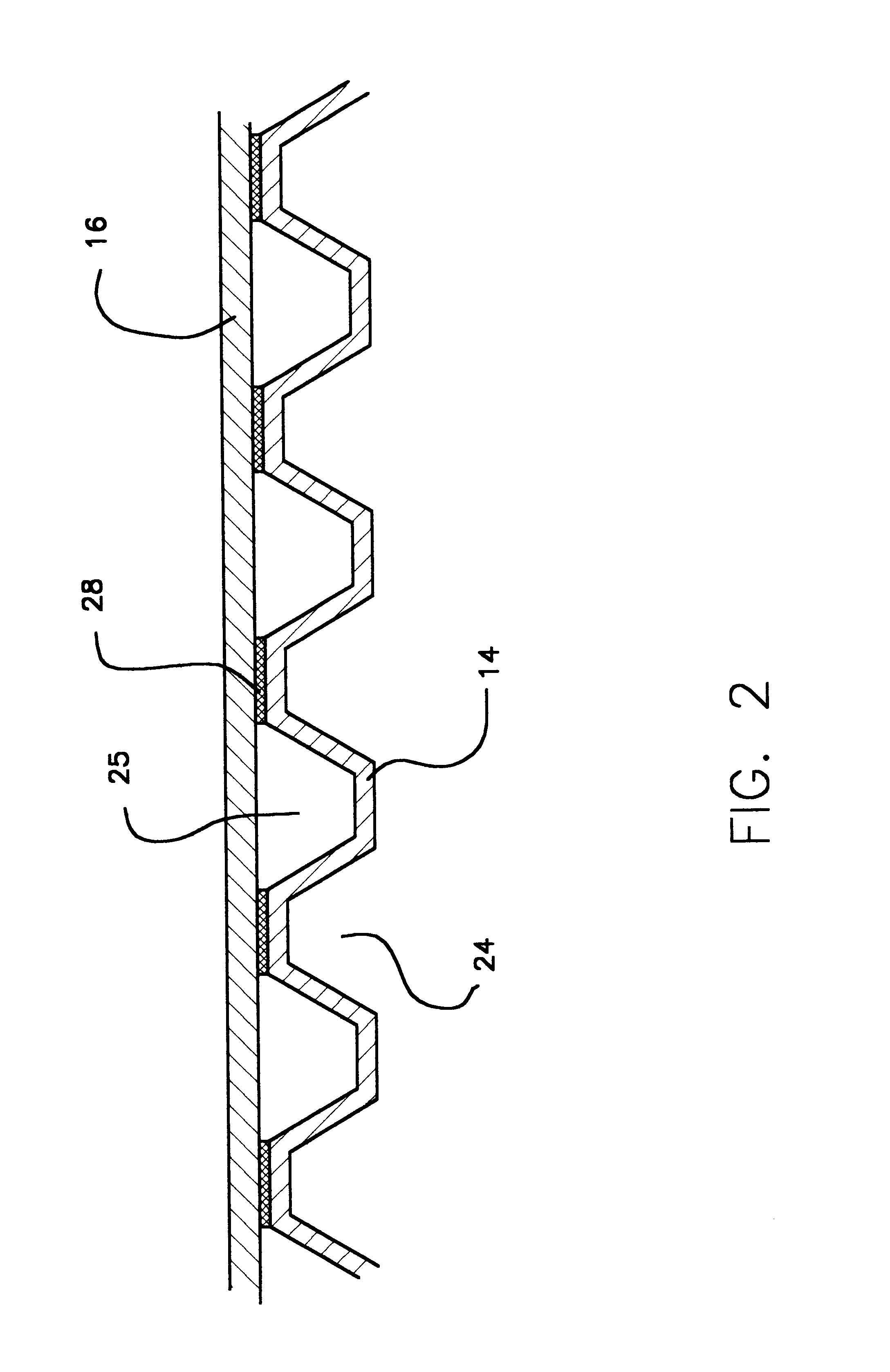

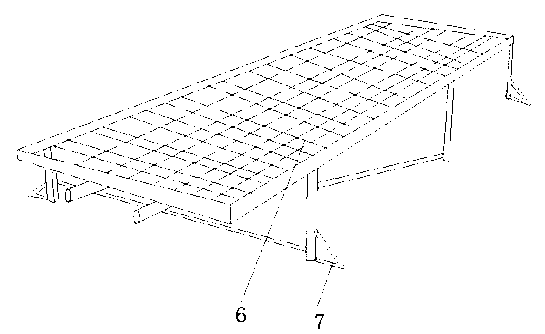

Radiant floor heating system with reflective layer and honeycomb panel

InactiveUS6188839B1Prevent heat lossPrevents dispersal (and hence waste)Fluid heatersLayered productsThermal breakHoneycomb

A radiant floor heating system and method of installation is provided, the system of the present invention being disposed within a solidified cement or under board. A panel member having a laminated reflective material which serves as a thermal break is placed upon the hardened cement or under board. The panel member may be comprised of any substance to which the reflective material may be secured such as a honeycombed plastic panel to which the reflective material layer is laminated. A heating element is disposed on the reflective material. Thereafter, both the heating element and the reflective layer are coated with a layer of thin set or cement. The heating element may include a heated wire element which is unwound off a roll, or the heating element may be meshed within a web of material which is cut to match the dimensions of the floor and then disposed on top of the reflective layer. After the thin set or cement dries with the heating element embedded within, marble or other types of tiles may be laid as flooring.

Owner:PENNELLA RONALD J

Countertop cooking appliance

ActiveCN108113501ADomestic stoves or rangesLighting and heating apparatusProcess engineeringRadiant heating

A countertop cooking appliance has an enclosure defining a cooking chamber arranged to receive a cooking pan. The cooking chamber includes a lower heating element arranged so that the cooking pan maybe supported thereon to receive conductive heating there-from, and an upper heating element disposed above and spaced from the cooking pan to provide radiant heating to food there-within. The enclosure includes an upper portion including the upper heating element, and a lower portion including the lower heating element, and a hinge connecting the upper portion to the lower portion. The hinge enables the upper portion to rest atop the lower portion to define the cooking chamber, and alternatively enables the upper portion to be swung relative to the lower portion so that the upper and lower portions are in a parallel side-by-side relationship and both heating elements are arranged so that the cooking pan may be supported on either thereof to receive conductive heating there-from.

Owner:TEAM INT GRP OF AMERICA INC

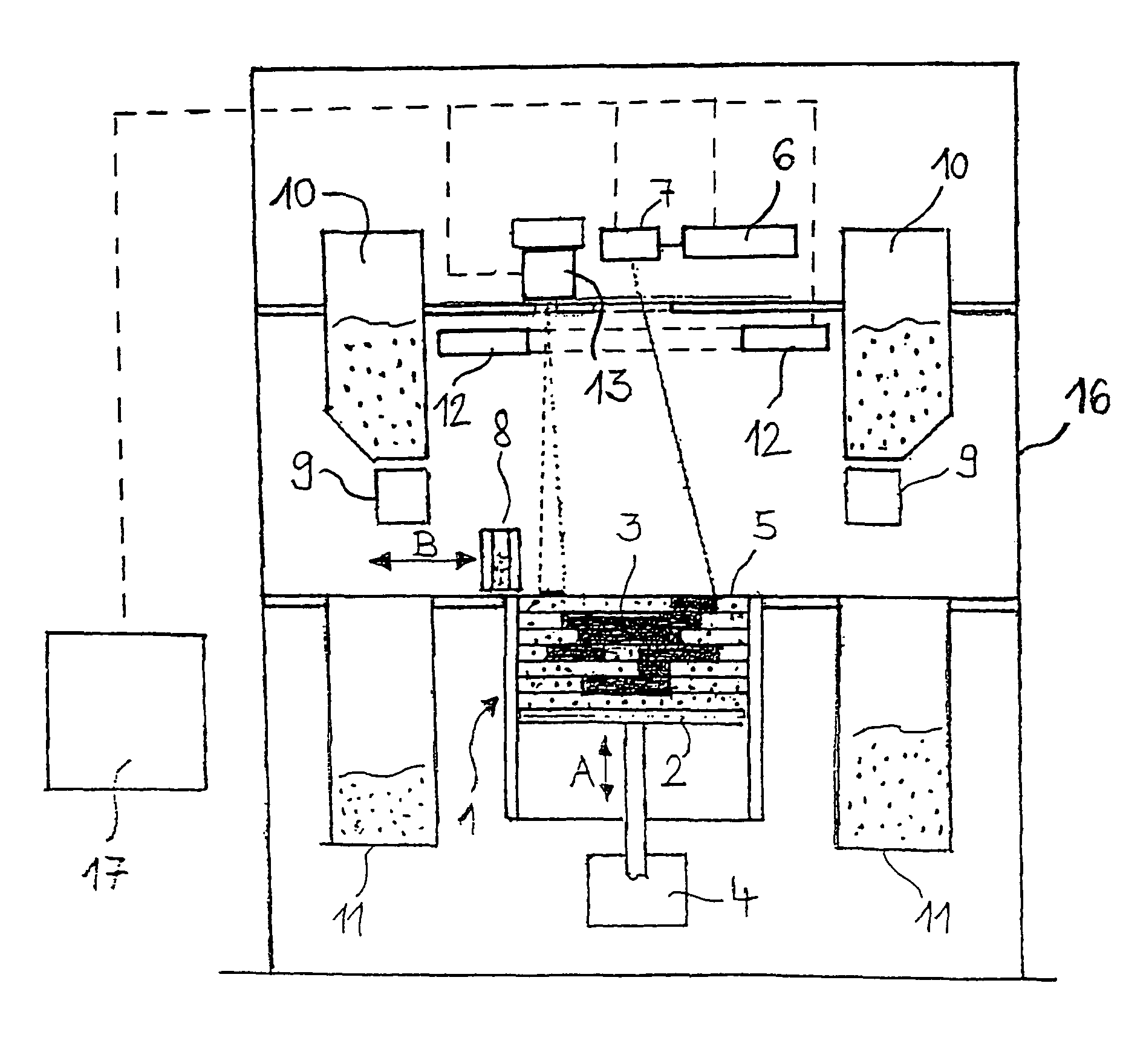

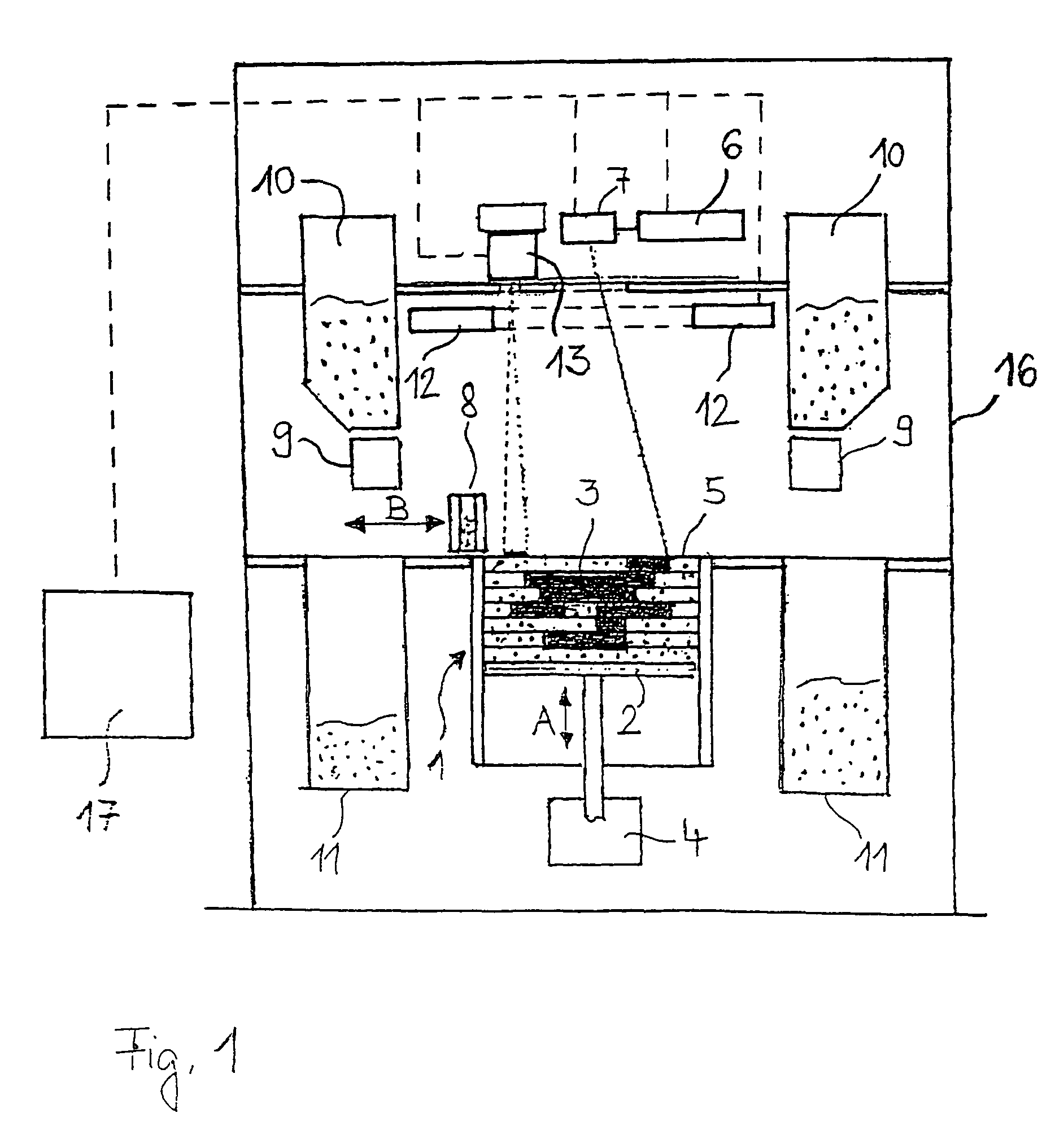

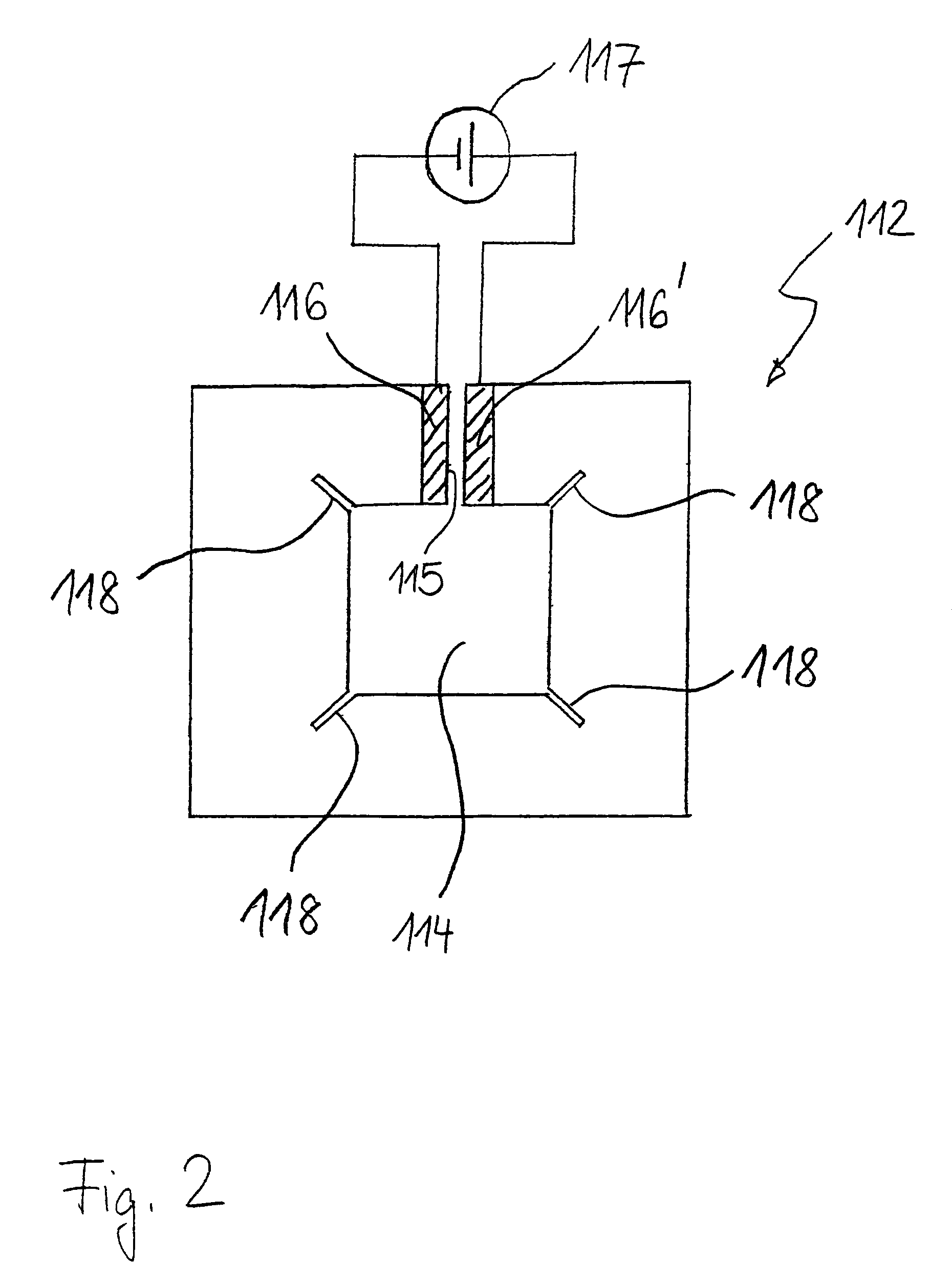

Radiant heater for heating the building material in a laser sintering device

InactiveUS8073315B2Reduce the temperatureThermal inertiaDomestic stoves or rangesDrying solid materials with heatRadiant heaterMetallurgy

A radiant heating for heating the building material in a laser sintering device and a laser sintering device having such a radiant heating are described. The radiant heating has a sheet-like heat radiating element (113, 213, 313), which is characterized in that it is made of a material, that has a low thermal inertia with a thermal diffusivity of preferably more than 1.5·10−4 m2 / s and preferably has a thickness of 2 mm or less.

Owner:EOS ELECTRO OPTICAL SYST

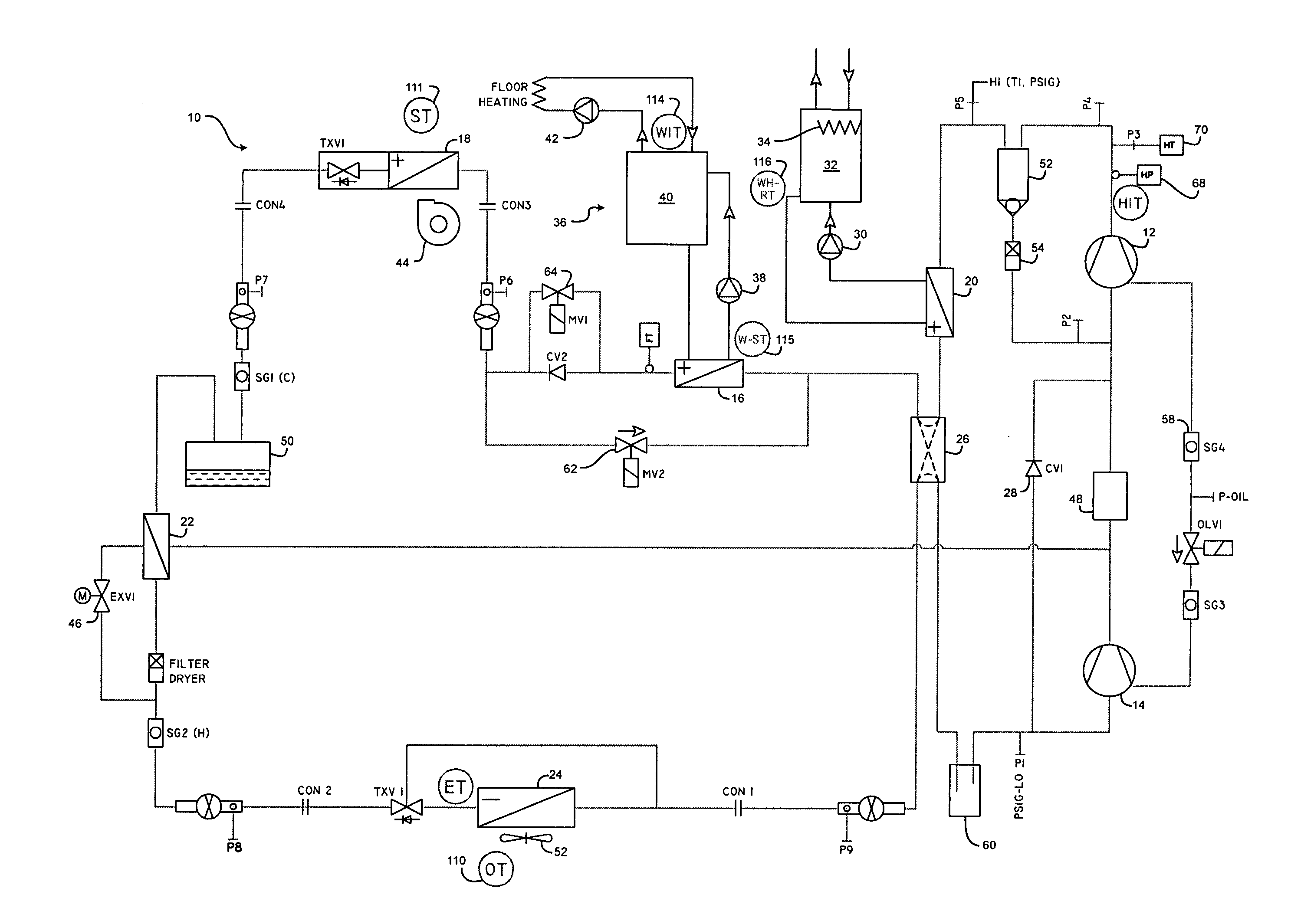

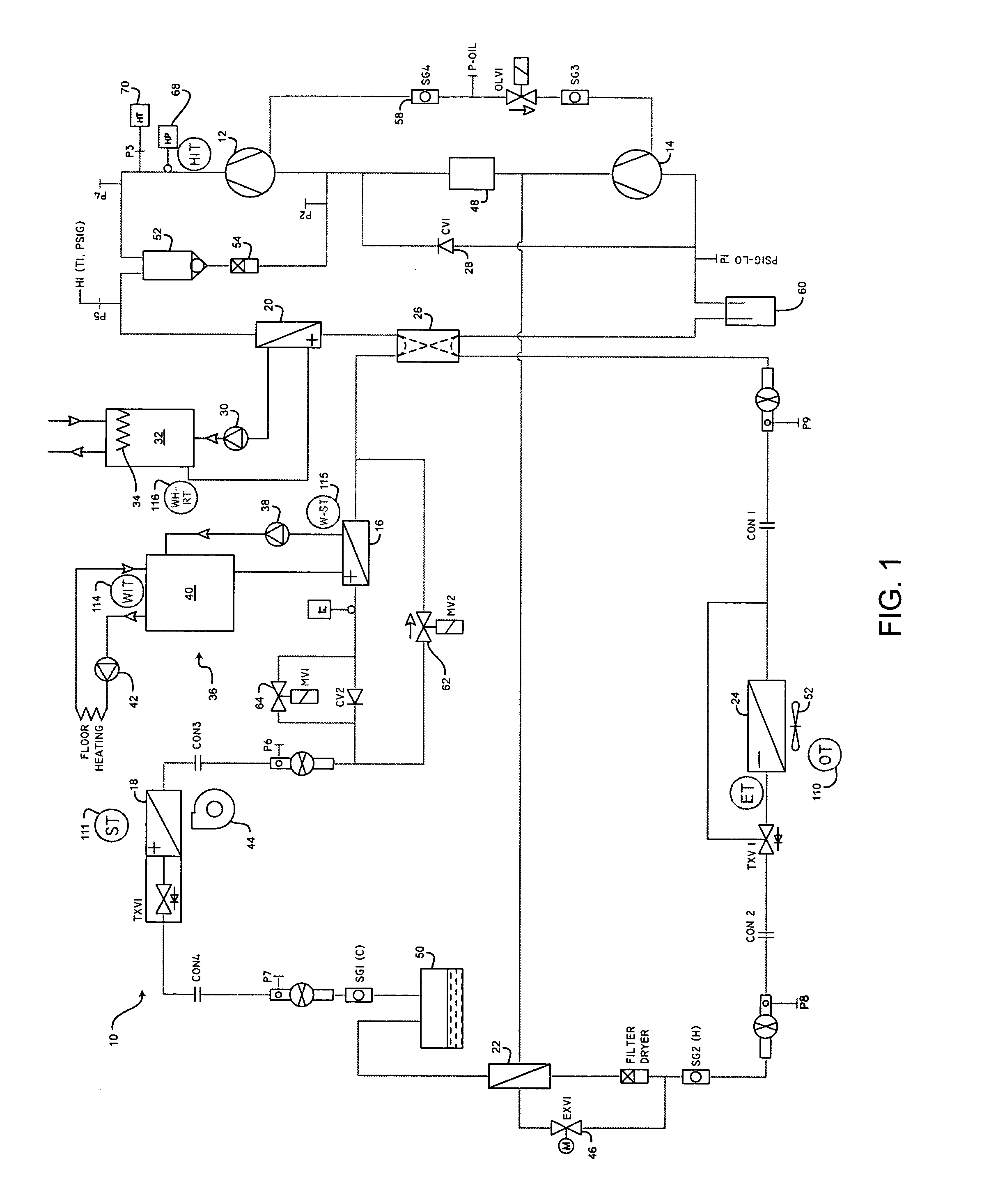

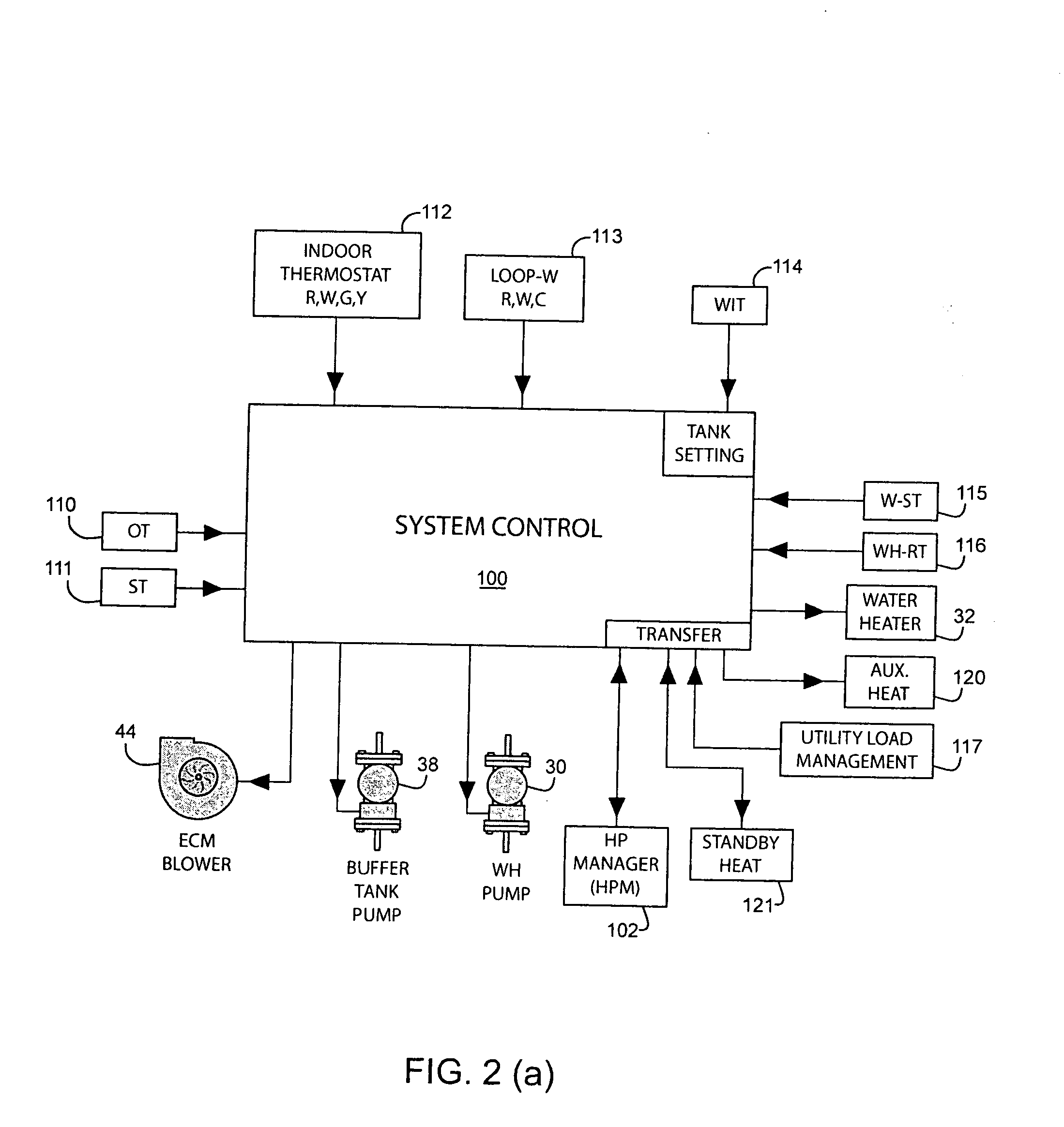

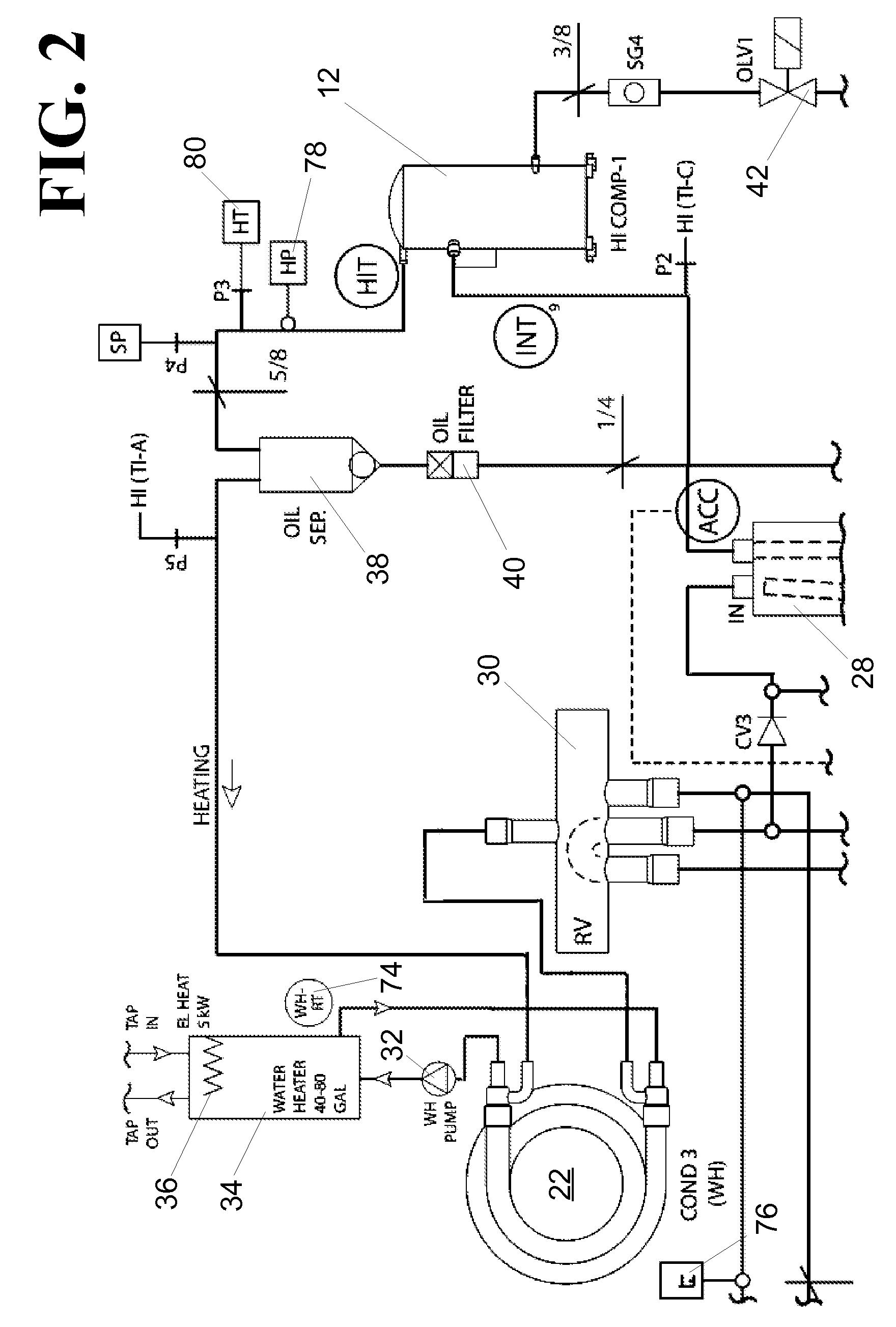

Heat pump system and controls

InactiveUS20080098760A1Improve the heating effectEasy transferCompression machines with non-reversible cycleEvaporators/condensersForced-airEngineering

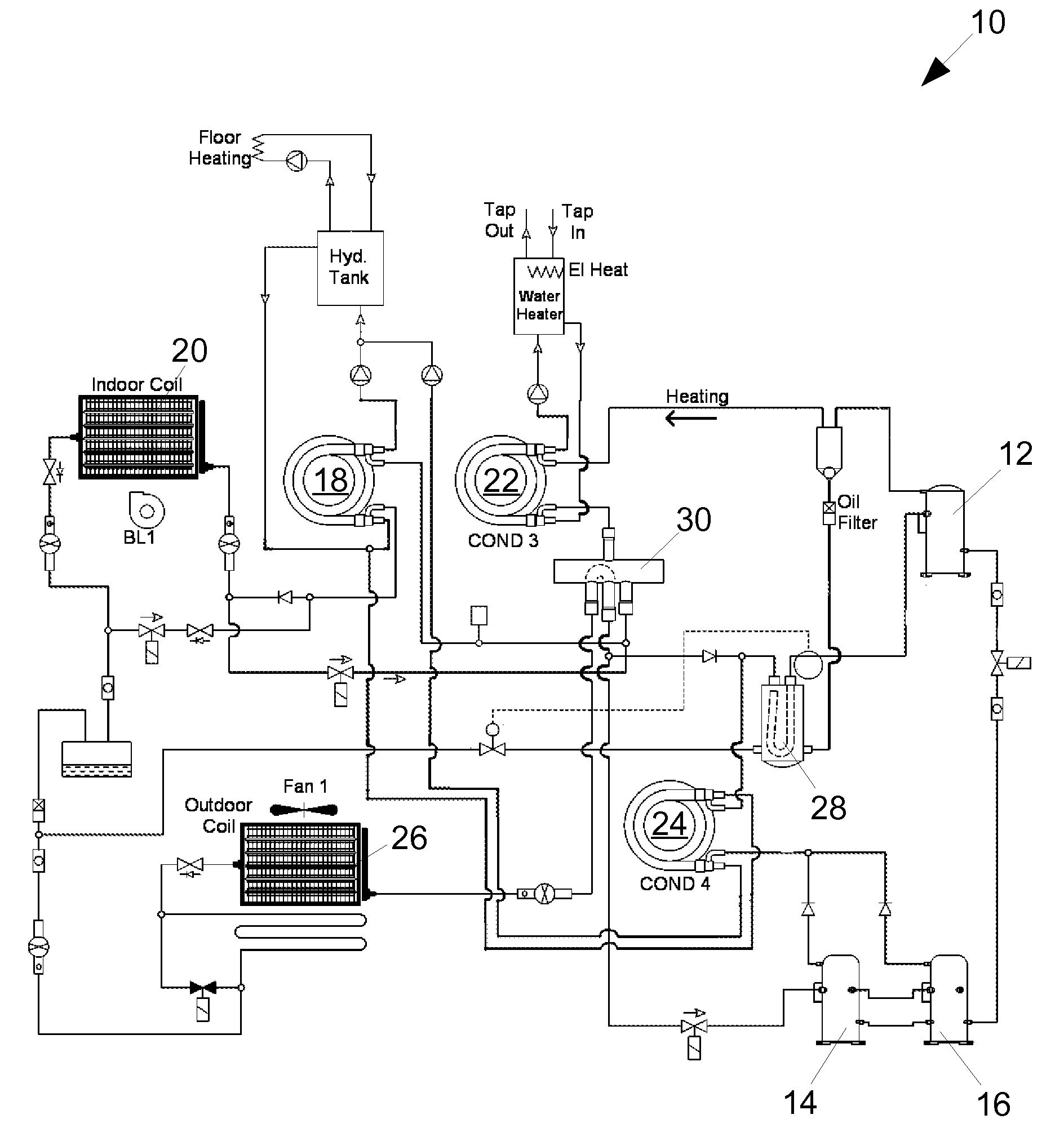

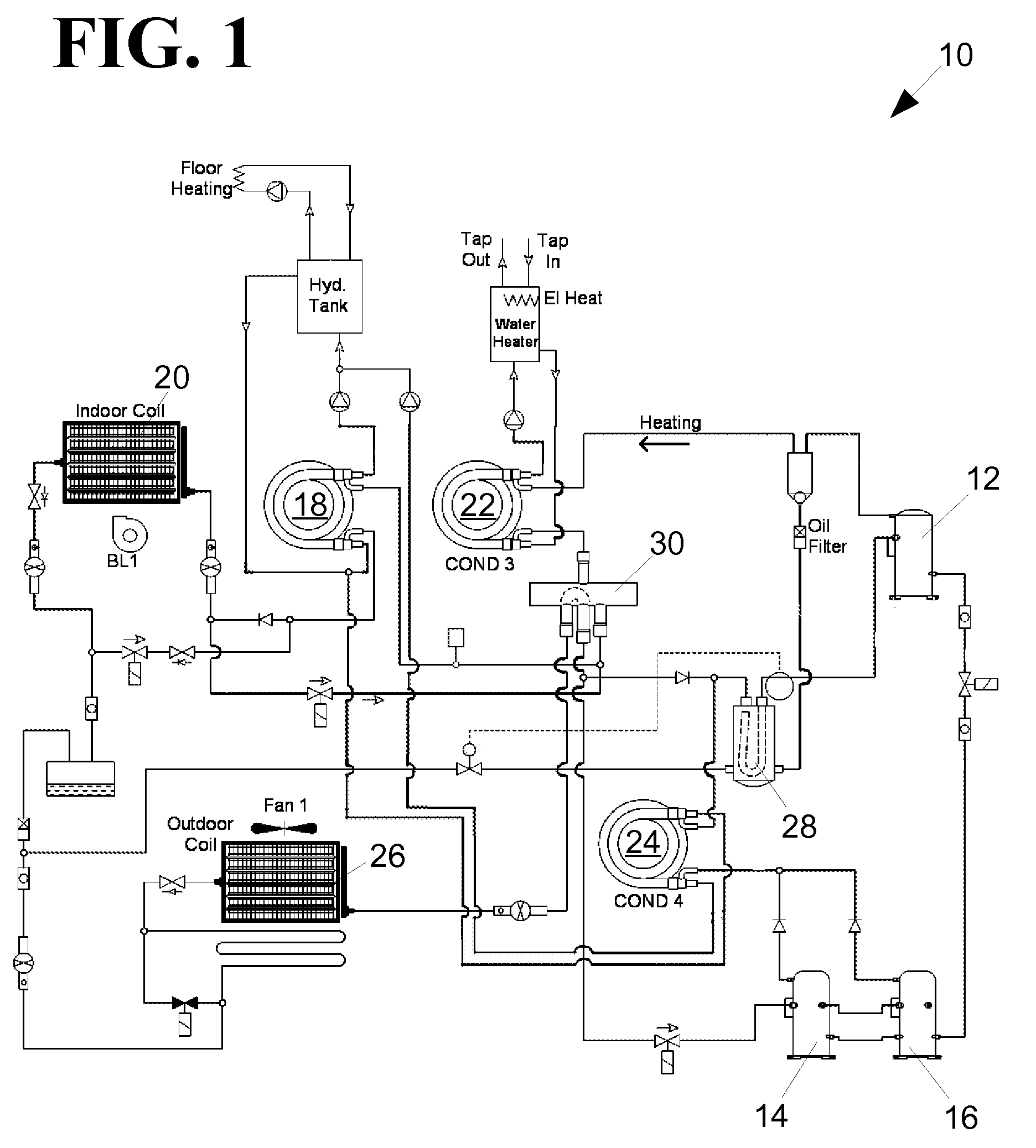

A heat pump system is disclosed that utilizes one or two compressors and multiple heat exchangers to provide forced air heating, radiant heating and / or water heating for an interior space. A controller directs energy to these multiple system outputs to provide maximum comfort, effectively utilize any excess energy, address fluctuations in energy output, prevent unsafe operating conditions and avoid intermittent compressor operation. The system may provide energy for a water heater in both heating and cooling mode, and control operation of the water heater to utilize system energy whenever possible and avoid use of a conventional water heater heating element. Load Management Control is also provided so that the system may be shut down remotely by a utility company.

Owner:ELECTRO IND

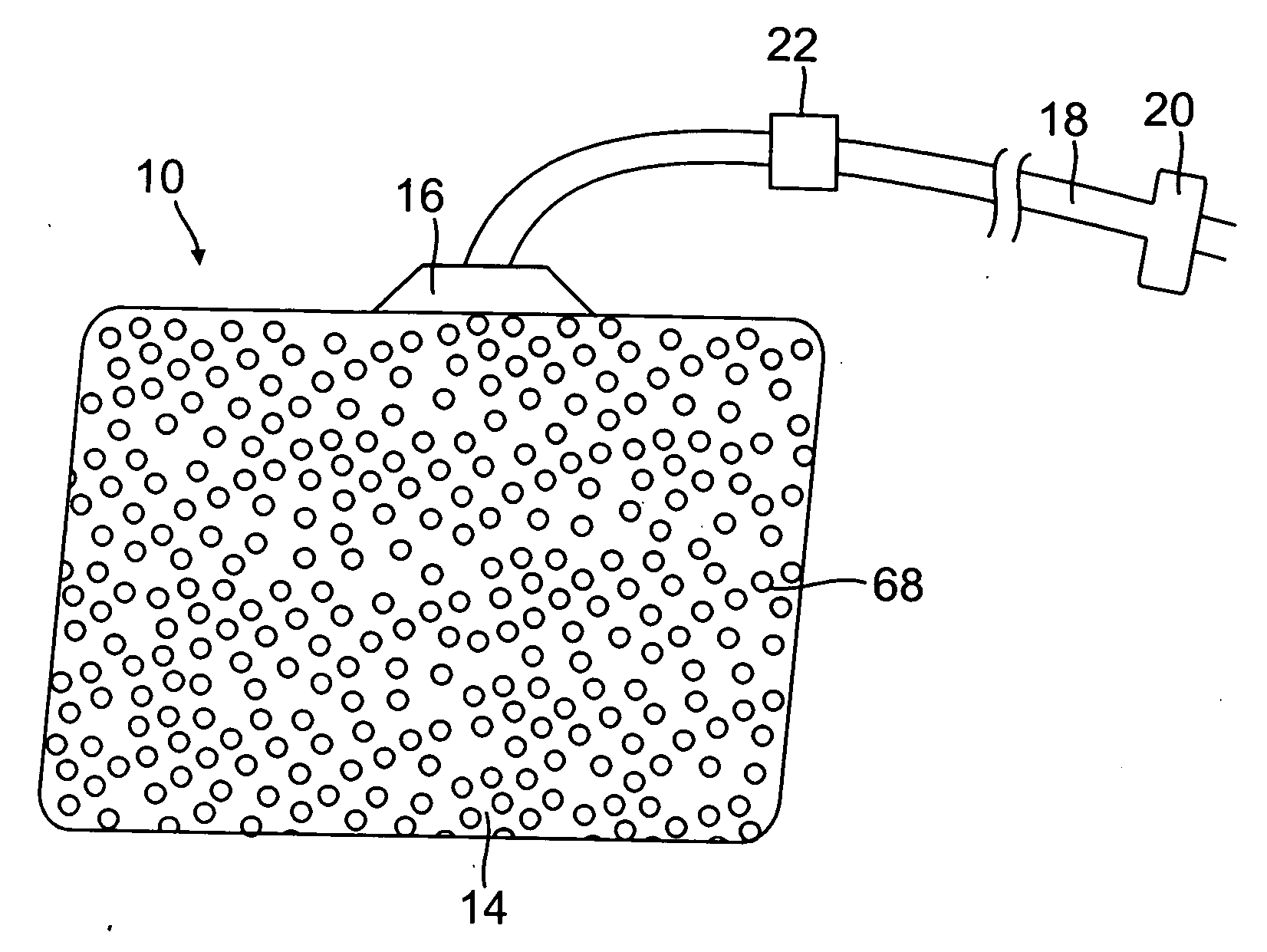

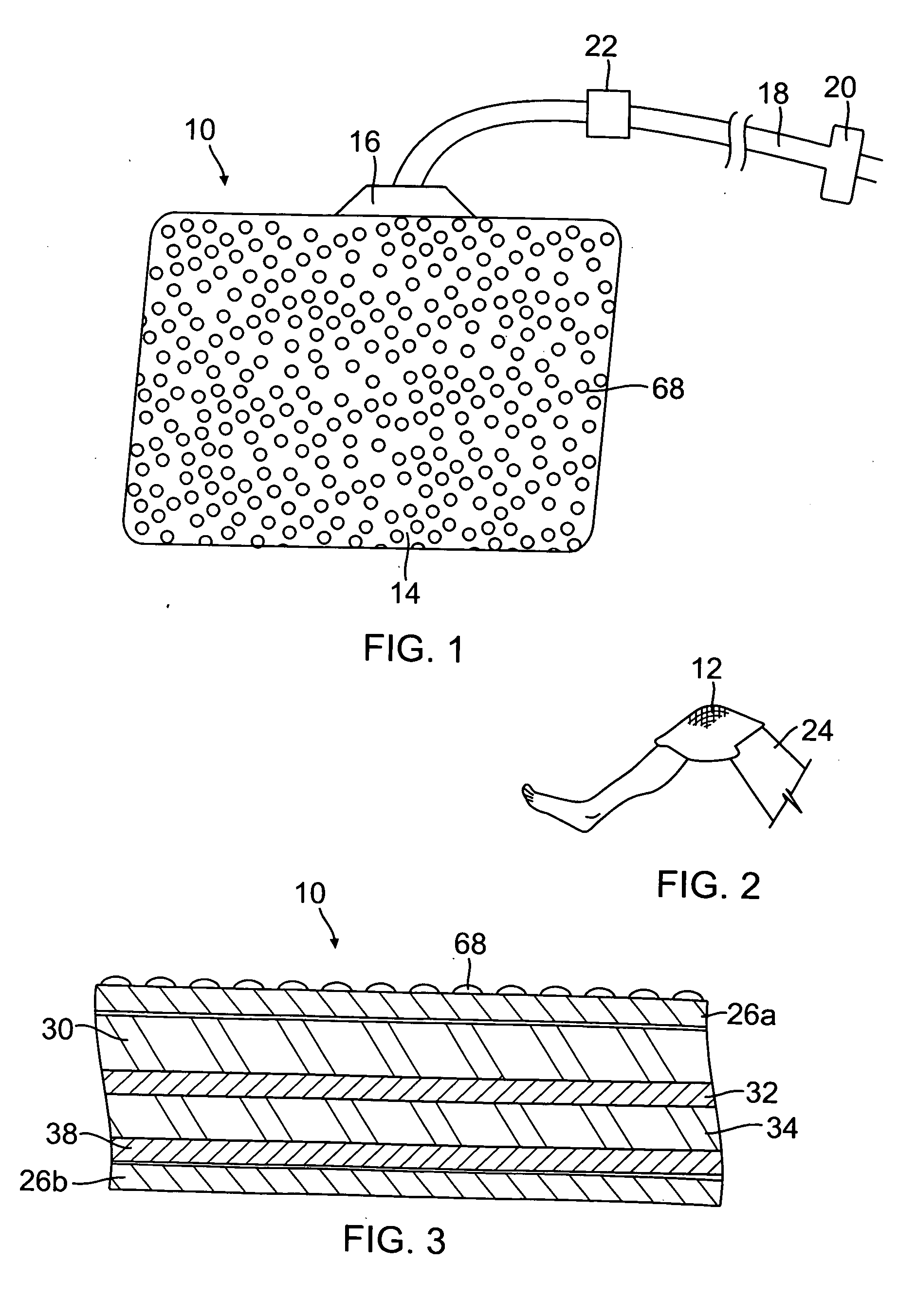

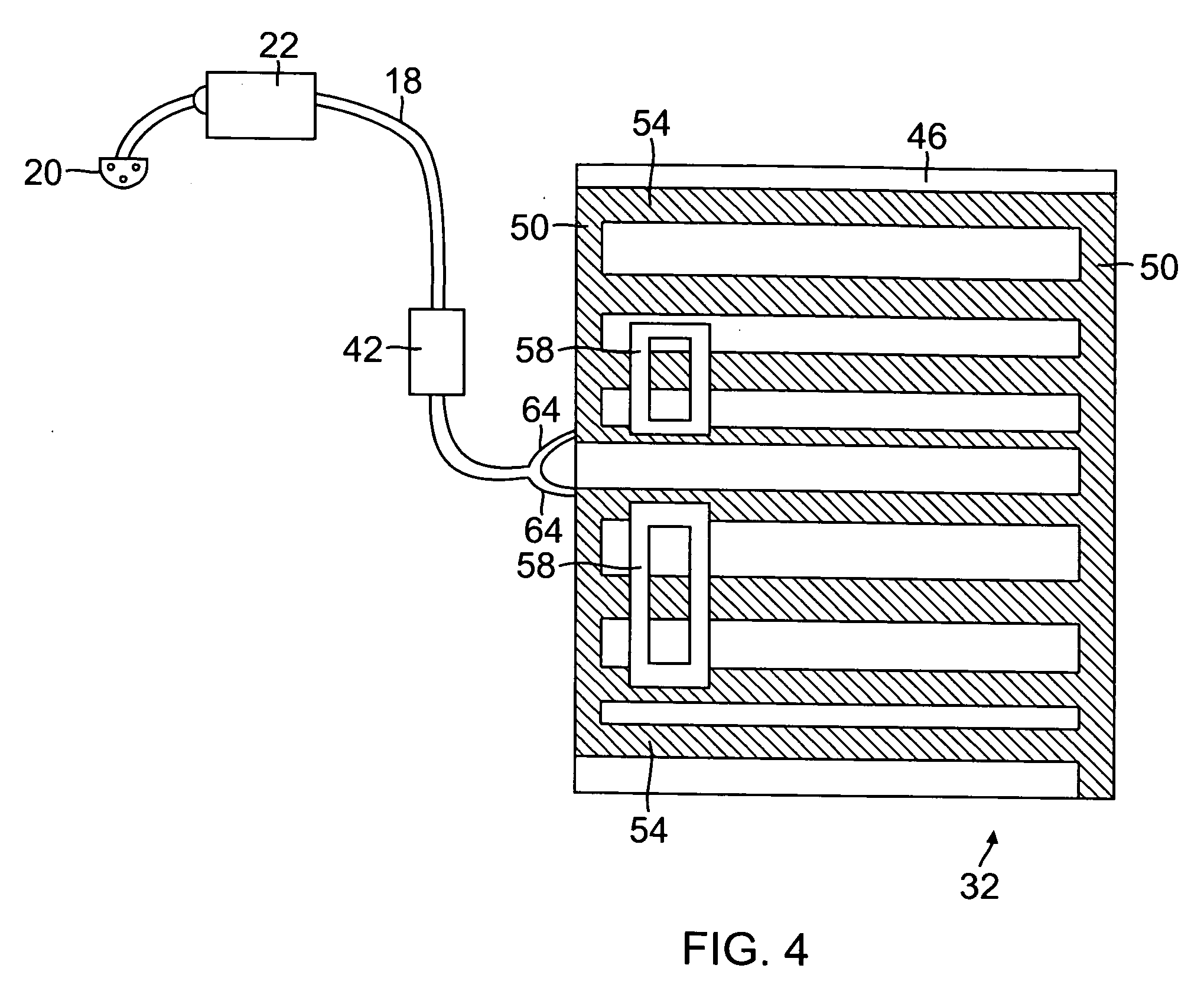

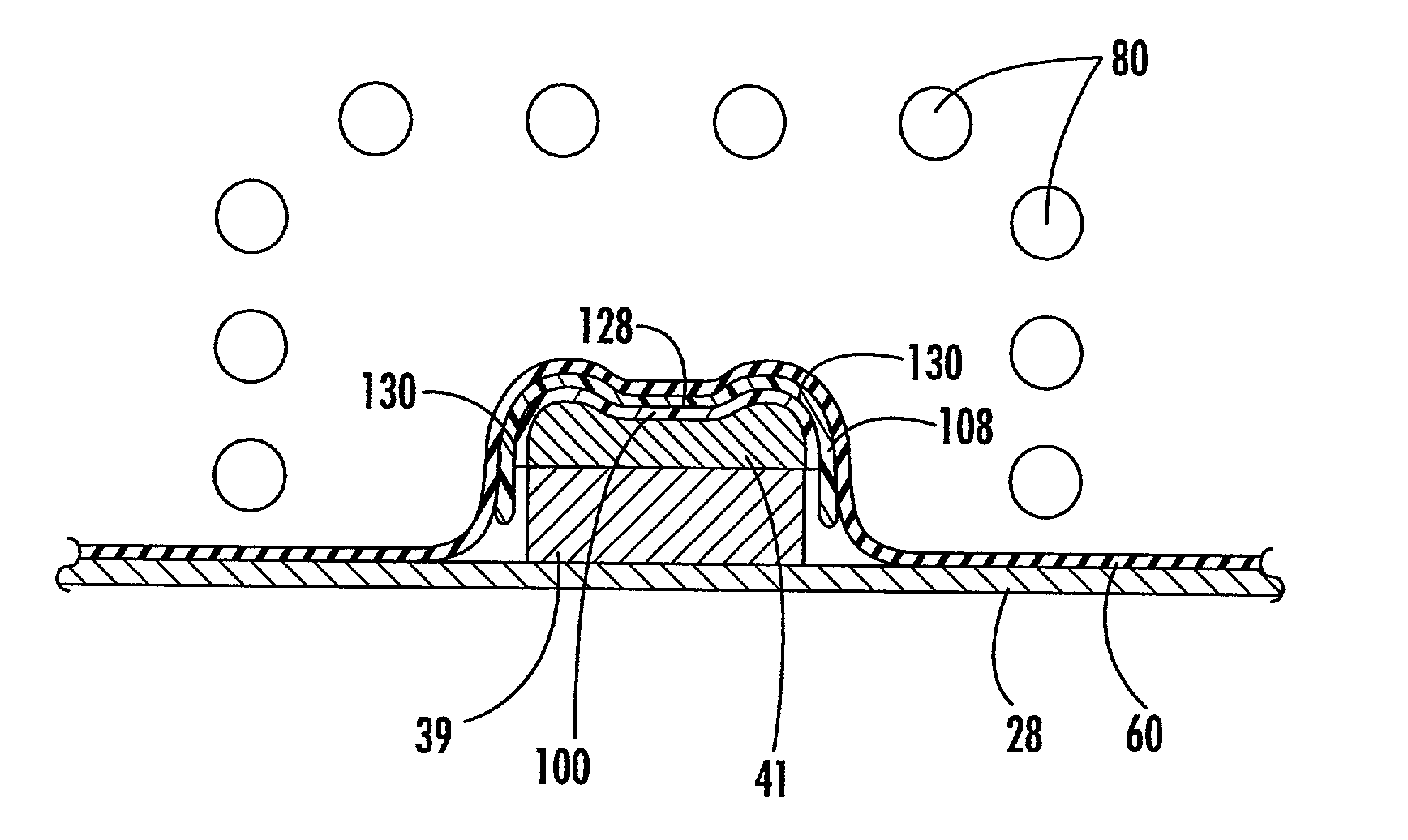

Radiant heating apparatus and method for therapeutic heating

The present invention provides a method and apparatus for heating via infrared radiation. The invention may incorporate a heating pad, safe to the touch, for therapeutic treatment. A heating pad according to the present invention may comprise of layers, such as a heat generation layer, electrically insulating layers, radiation permeable layers, with a sealed cover enclosing the entire pad. This invention is especially useful for heat therapy when a heat pad is applied to the skin of a human or an animal.

Owner:GANDER NICHOLAS M +1

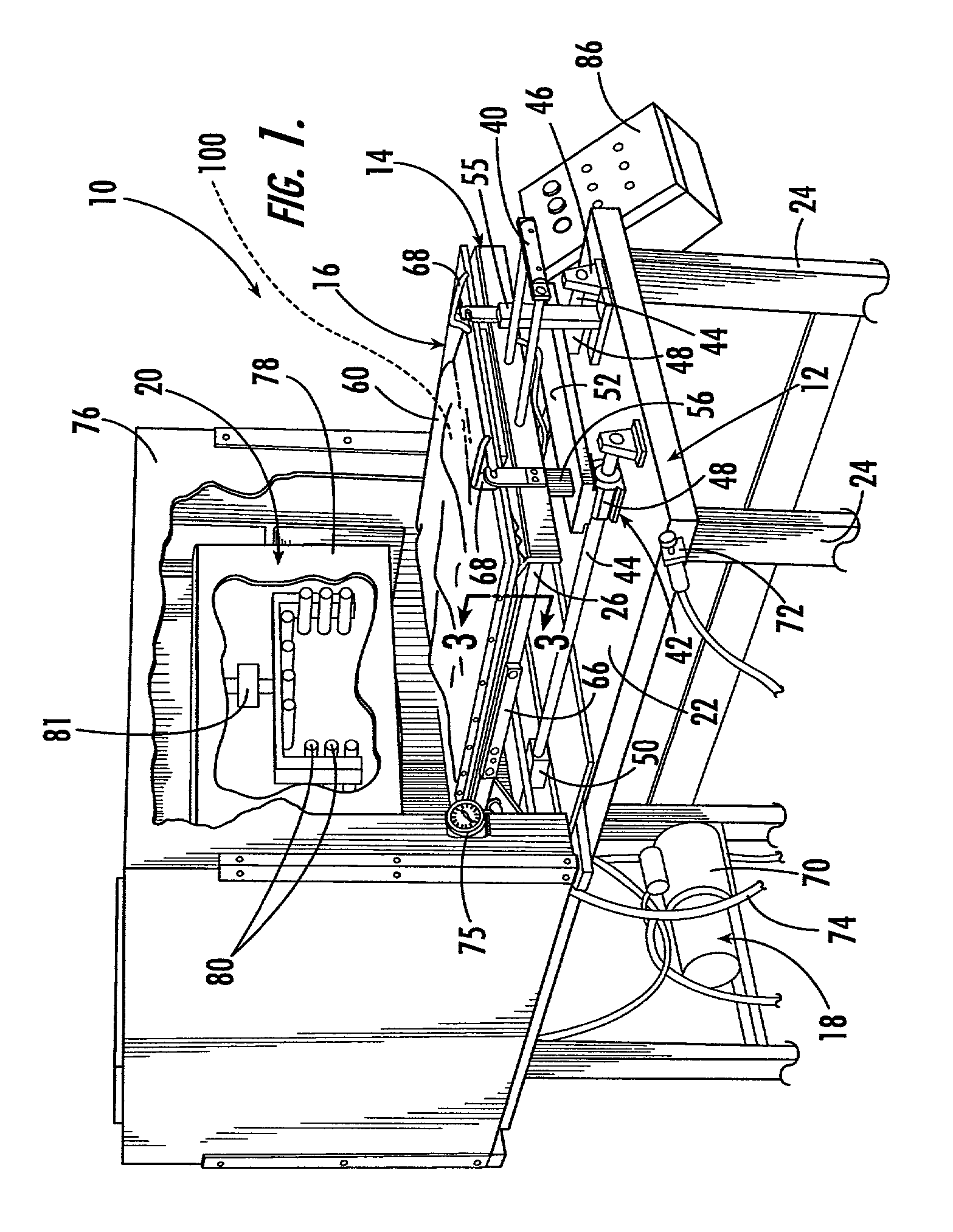

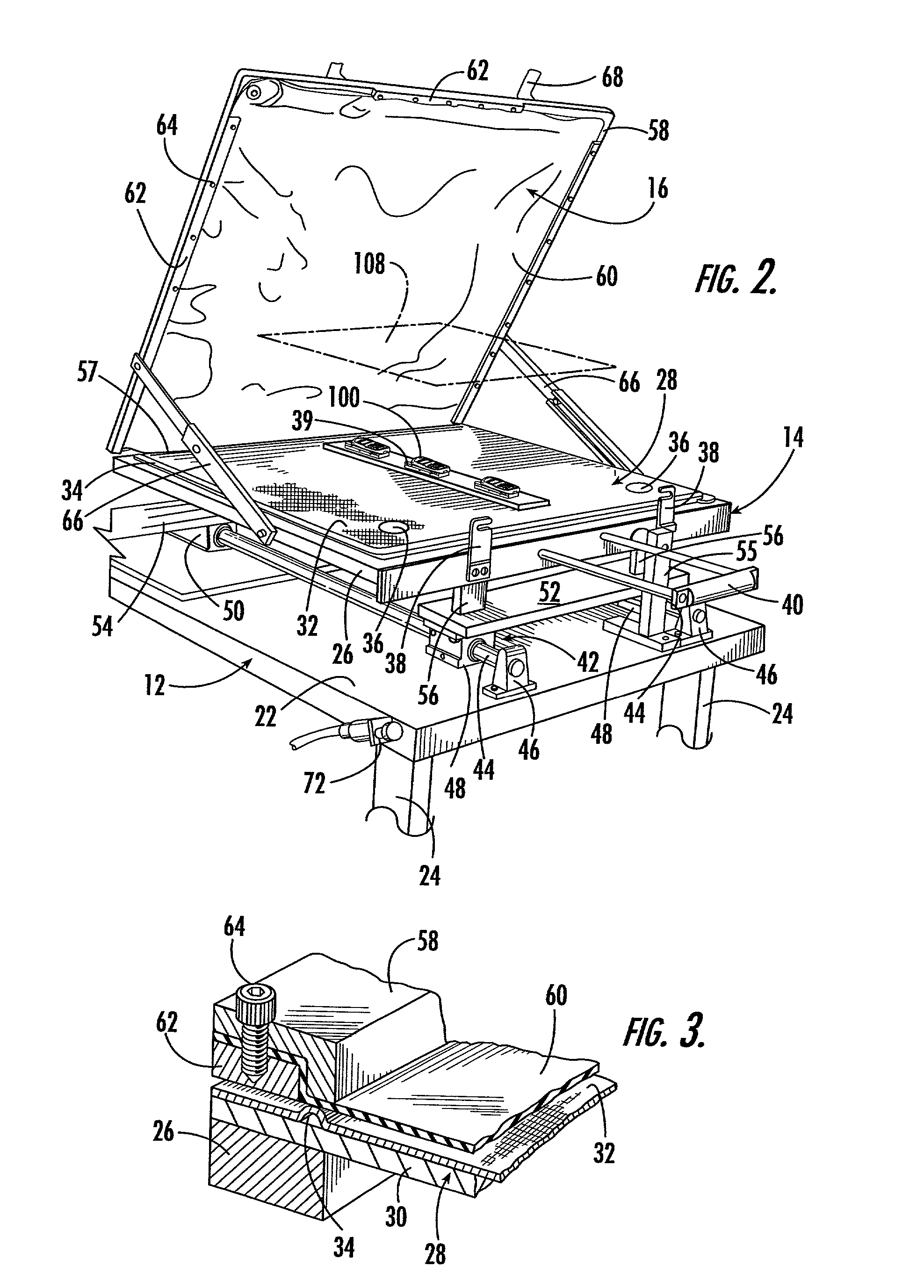

Apparatus with multi-directional radiation emitters for printing a dye image onto a three dimensional object

InactiveUS7137426B2Improve heating efficiencyEfficient transferTransfer printingDigitally marking record carriersEngineeringMirror image

The present invention provides an apparatus and method for applying preselected dye images to three dimensional objects, having plastic outer surfaces, utilizing flexible carrier sheets bearing dyes in the mirror images of the preselected images, where the sheets are overlaid in registration with the objects and maintained in pressurized engagement therewith while the sheets and the objects are heated. The present invention includes a bed for receiving at least one three-dimensional object member thereon with a flexible dye bearing carrier sheet placed in registration on the object and a resiliently flexible membrane, which is positionable over the sheet on the member. A vacuum assembly of the apparatus is operable to evacuate the area between the membrane and the bed in order to draw the membrane into pressurized engagement with the flexible sheet on the member thereby drawing the flexible sheet around the various surfaces of the three dimensional object. Radiant heating elements are operable both to preheat the carrier sheet, improving its flexibility and to heat the membrane after the vacuum assembly has been actuated, whereby the dye on the sheet is applied to the surfaces of the object to produce the preselected image thereon.

Owner:KII TEKU INC

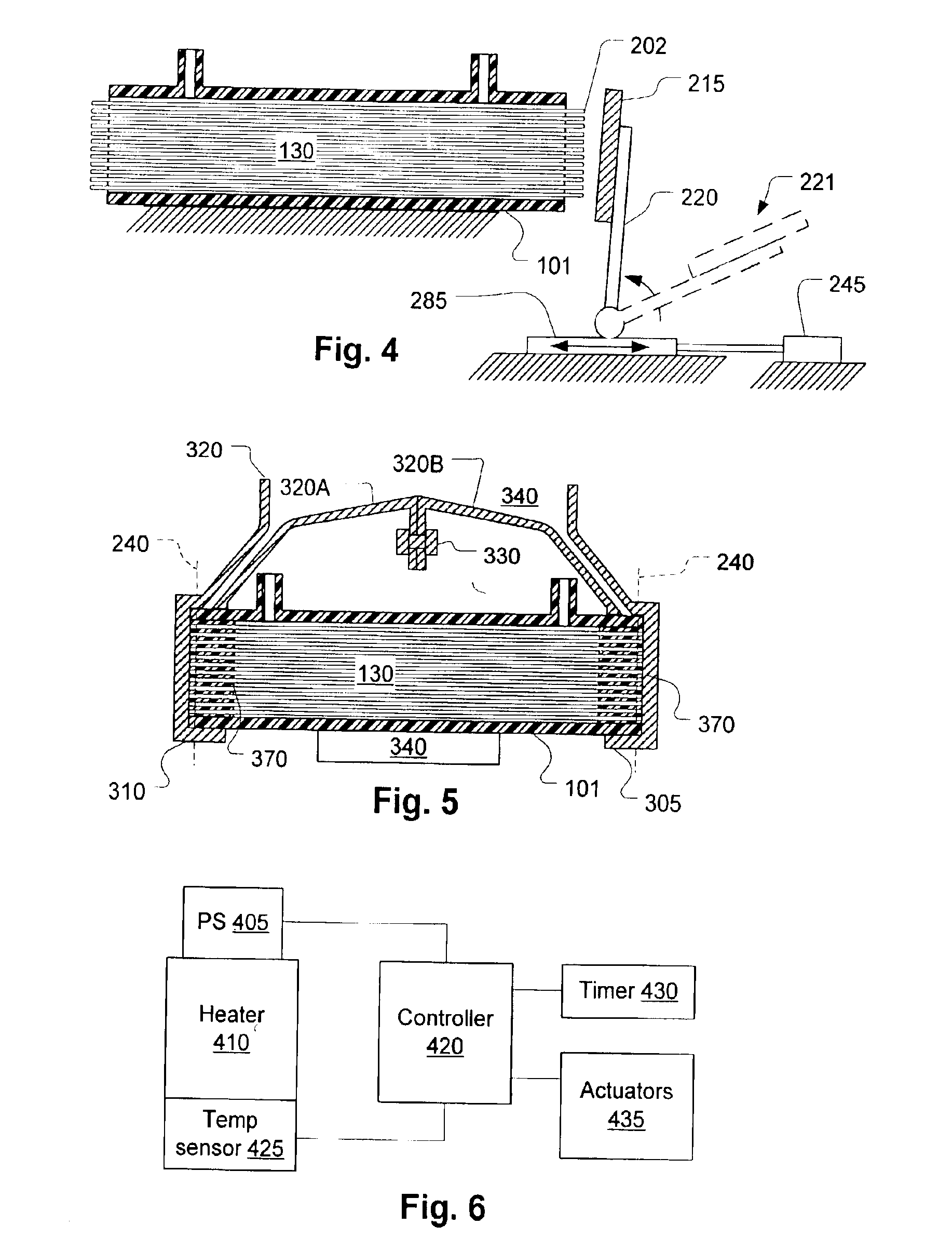

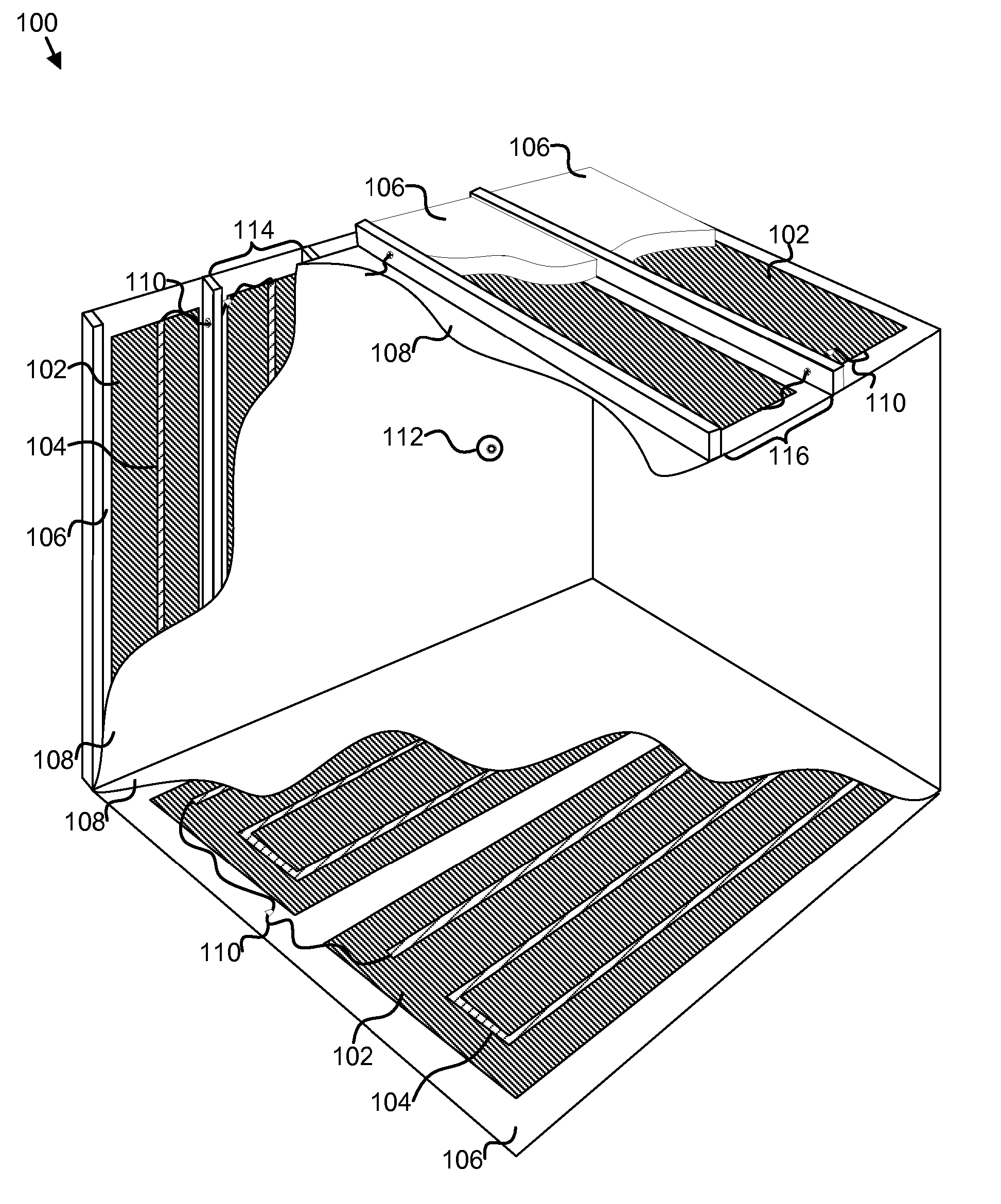

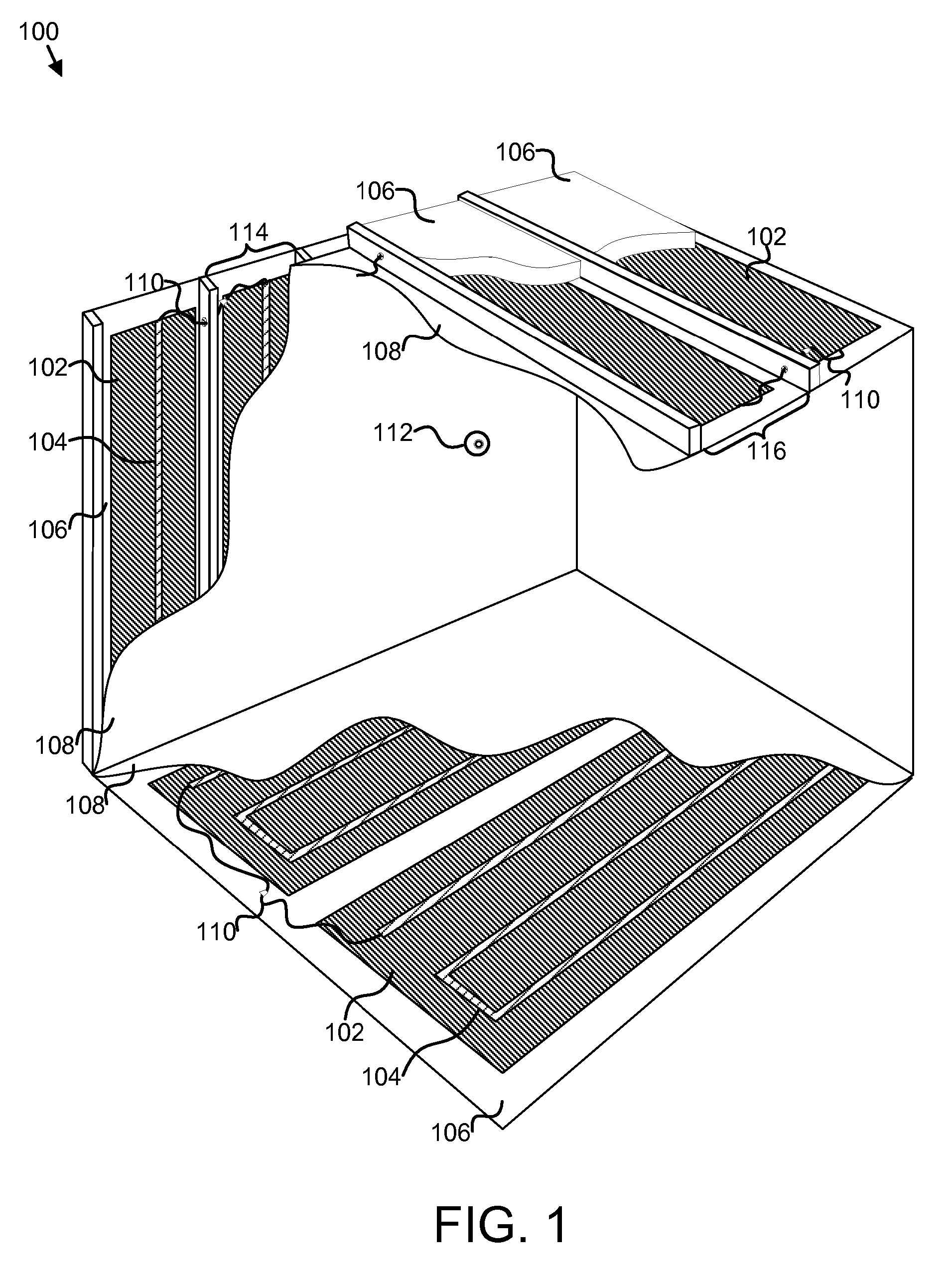

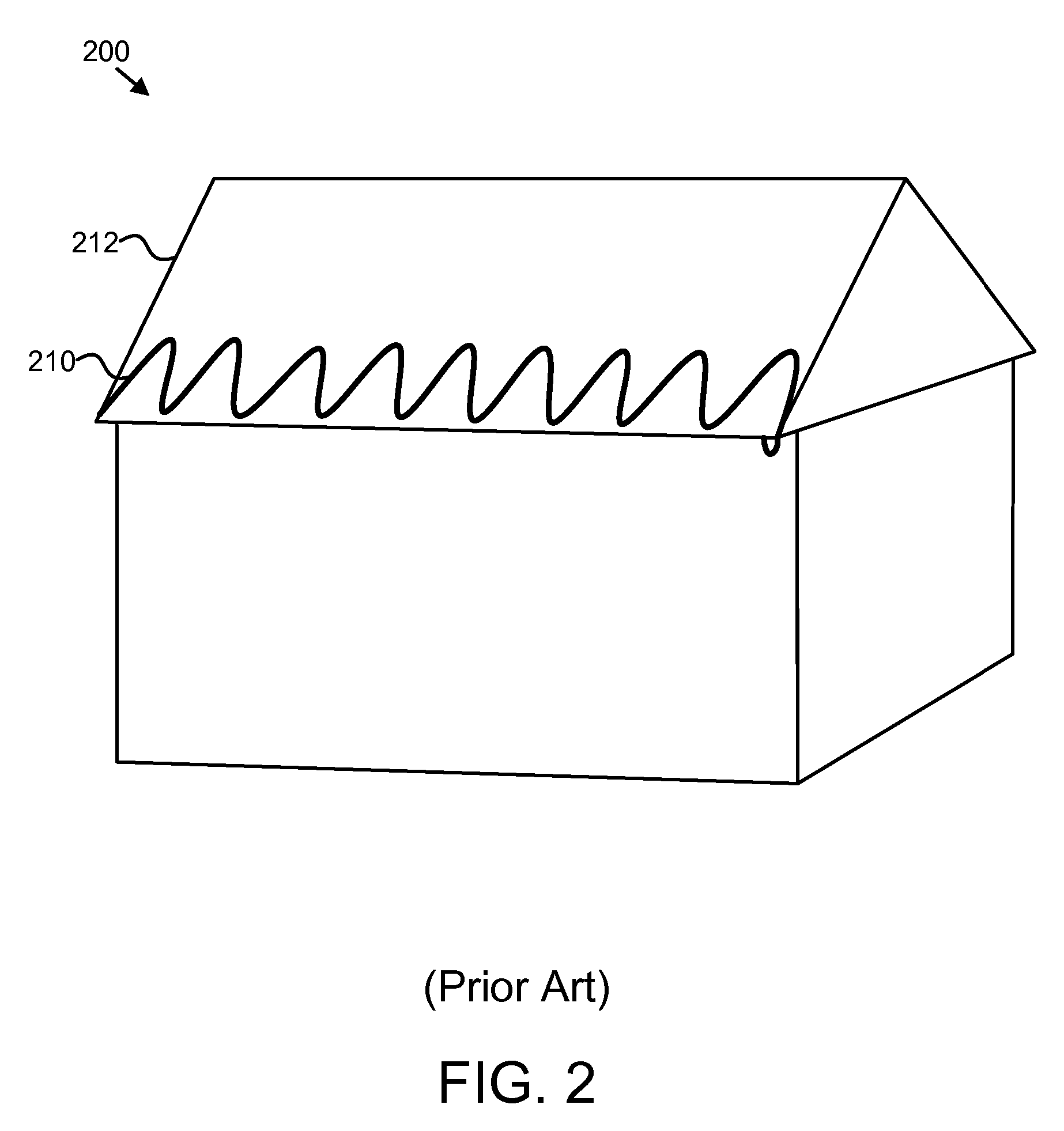

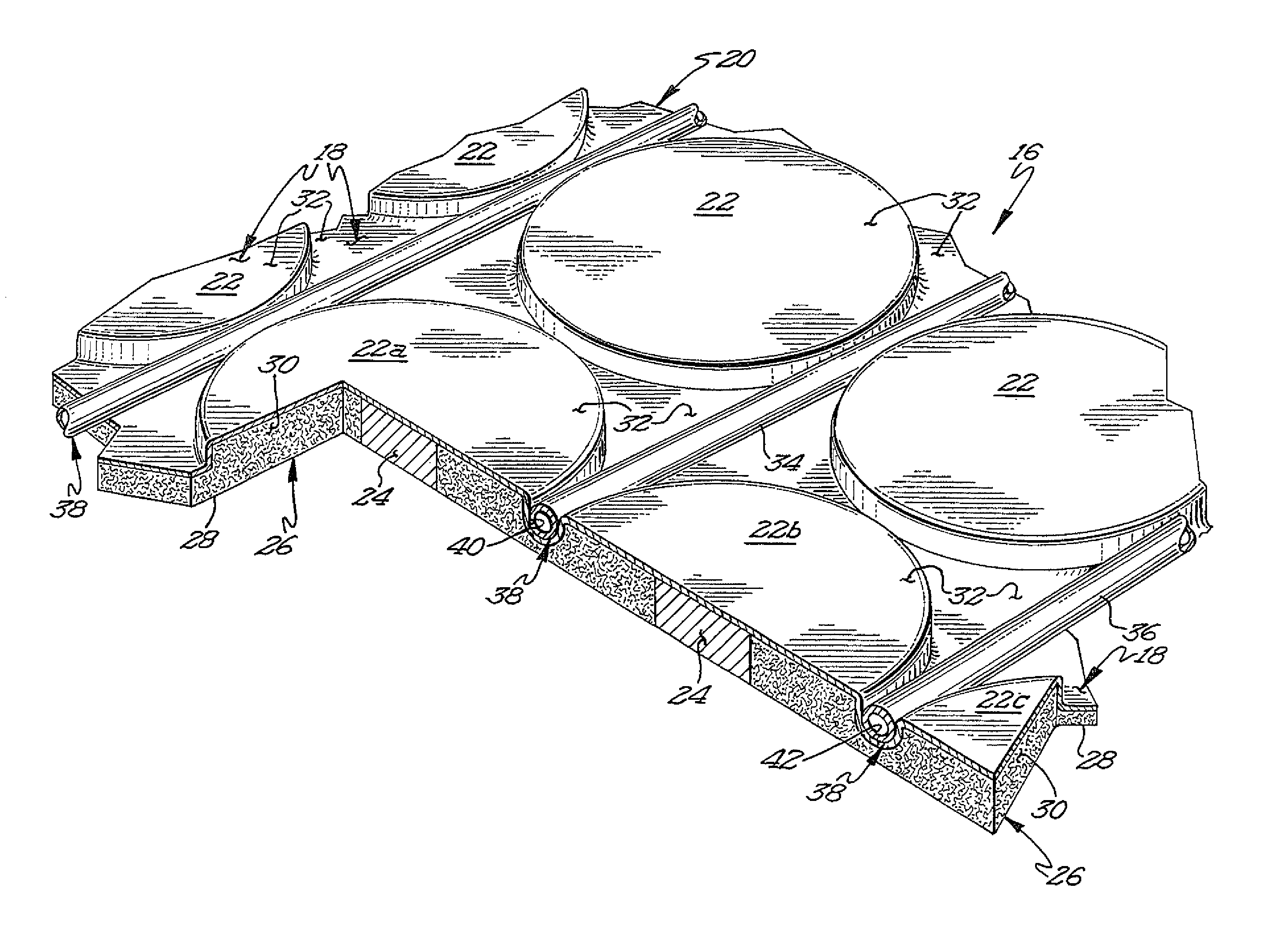

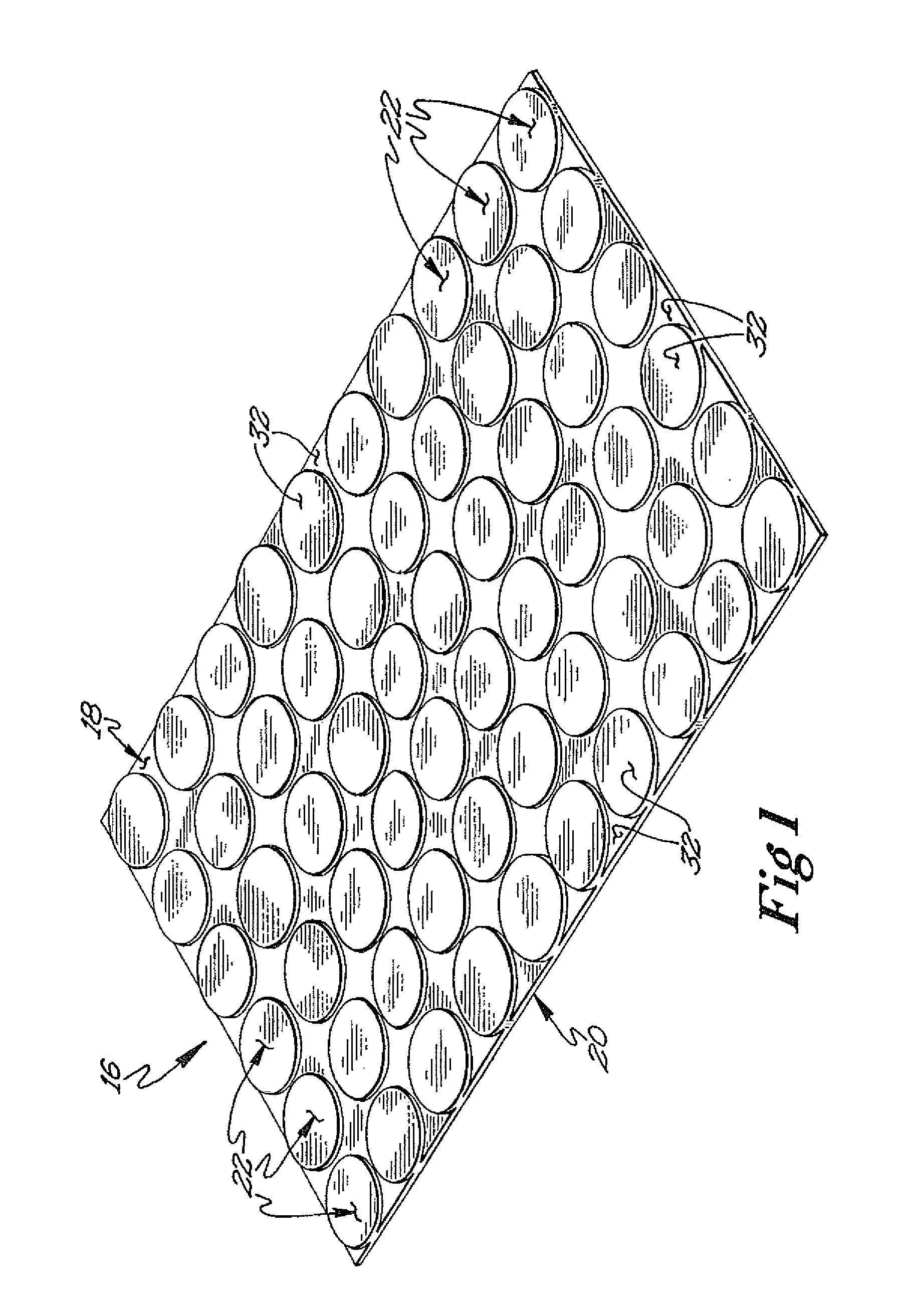

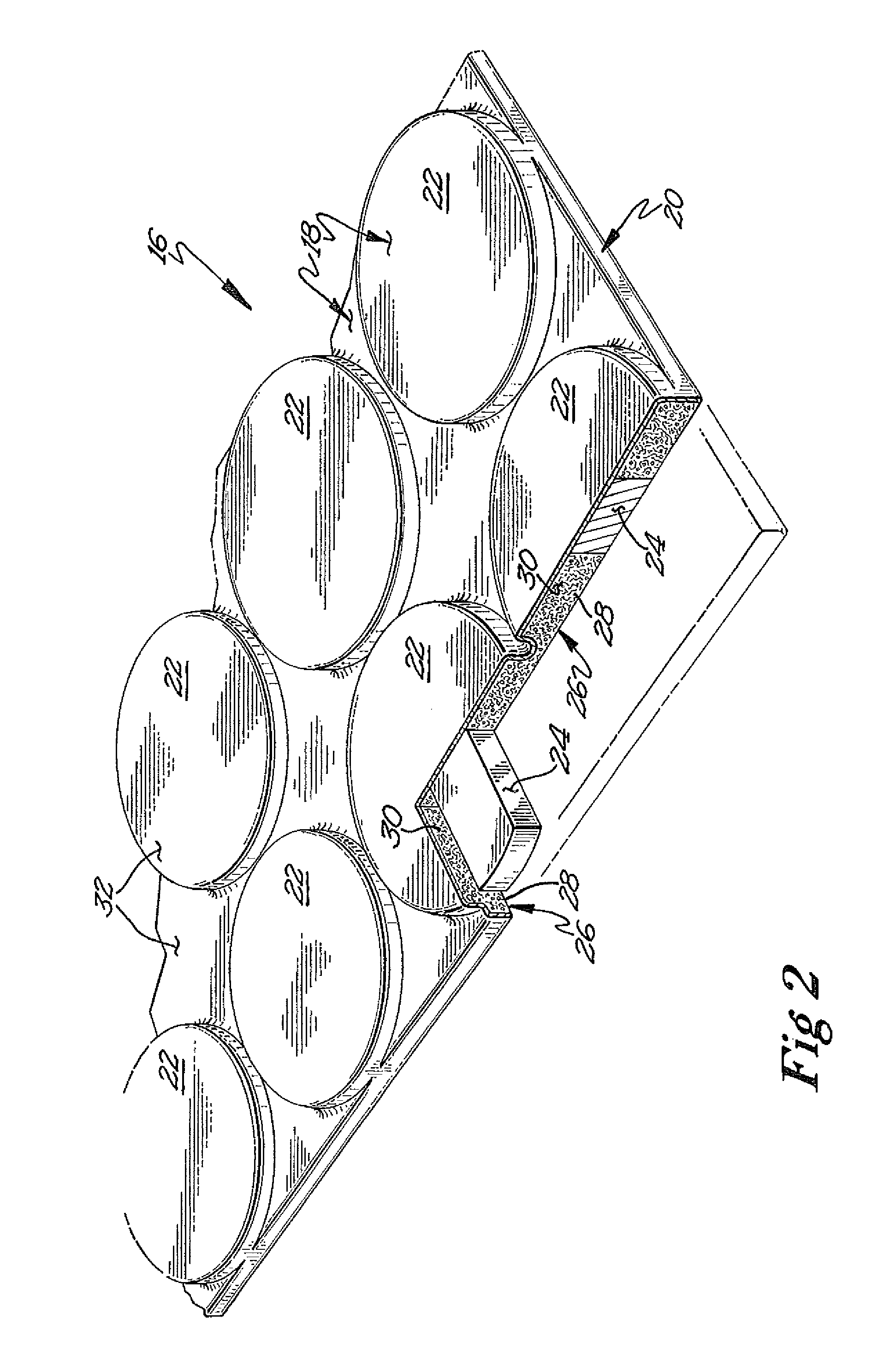

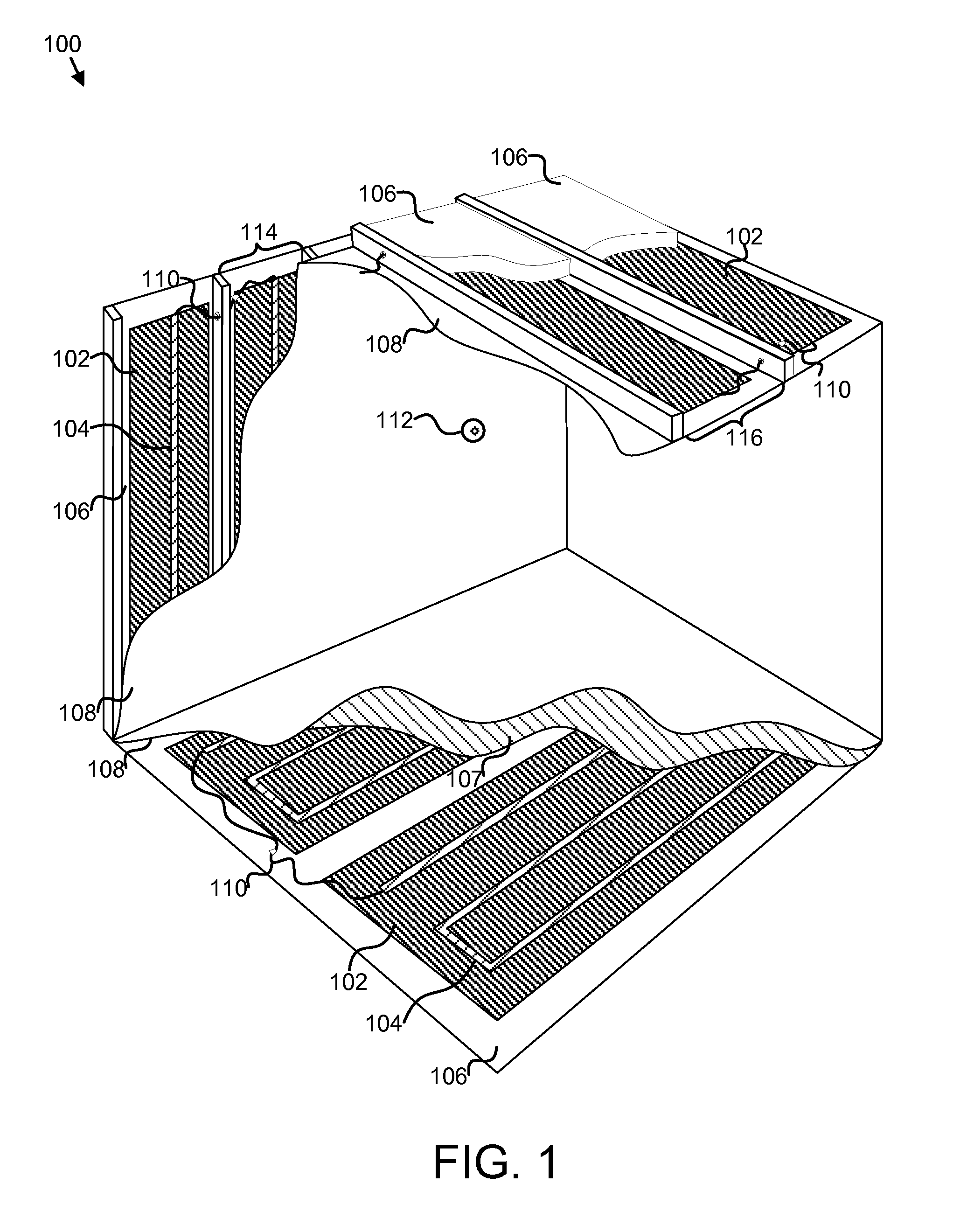

Modular radiant heating apparatus

ActiveUS20060289000A1Improve protectionRoof coveringDomestic stoves or rangesThermal isolationCoupling

The radiant heating apparatus is disclosed, having a planar electrical heating element, a planar heat spreading layer, a finishing layer, a thermal isolation layer, and an electric power coupling. The planar electrical heating element converts electrical energy to heat energy. The planar heat spreading layer is in contact with the planar electrical heating element, and draws the heat energy out of the planar electrical heating element and distributes the heat energy. The finishing layer is disposed to one side of the planar heat spreading layer. The thermal isolation layer is disposed to an opposite side of the planar heat spreading layer as the finishing layer. Heat from the planar heat spreading layer conducts away from the thermal isolation layer and toward the finishing layer. The electric power coupling is connected to the electrical heating element to supply electrical power.

Owner:GREENHEAT IP HLDG LLC

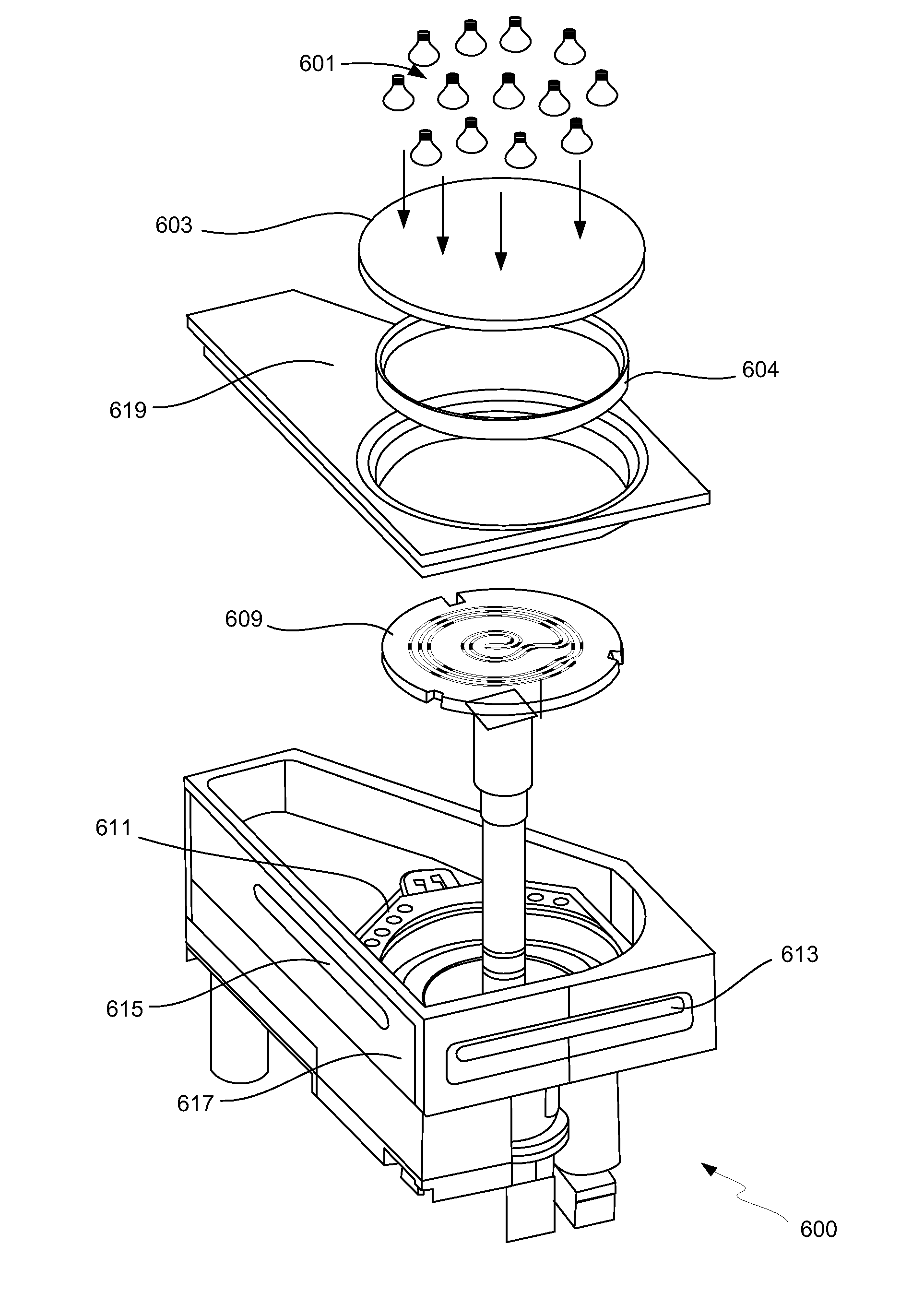

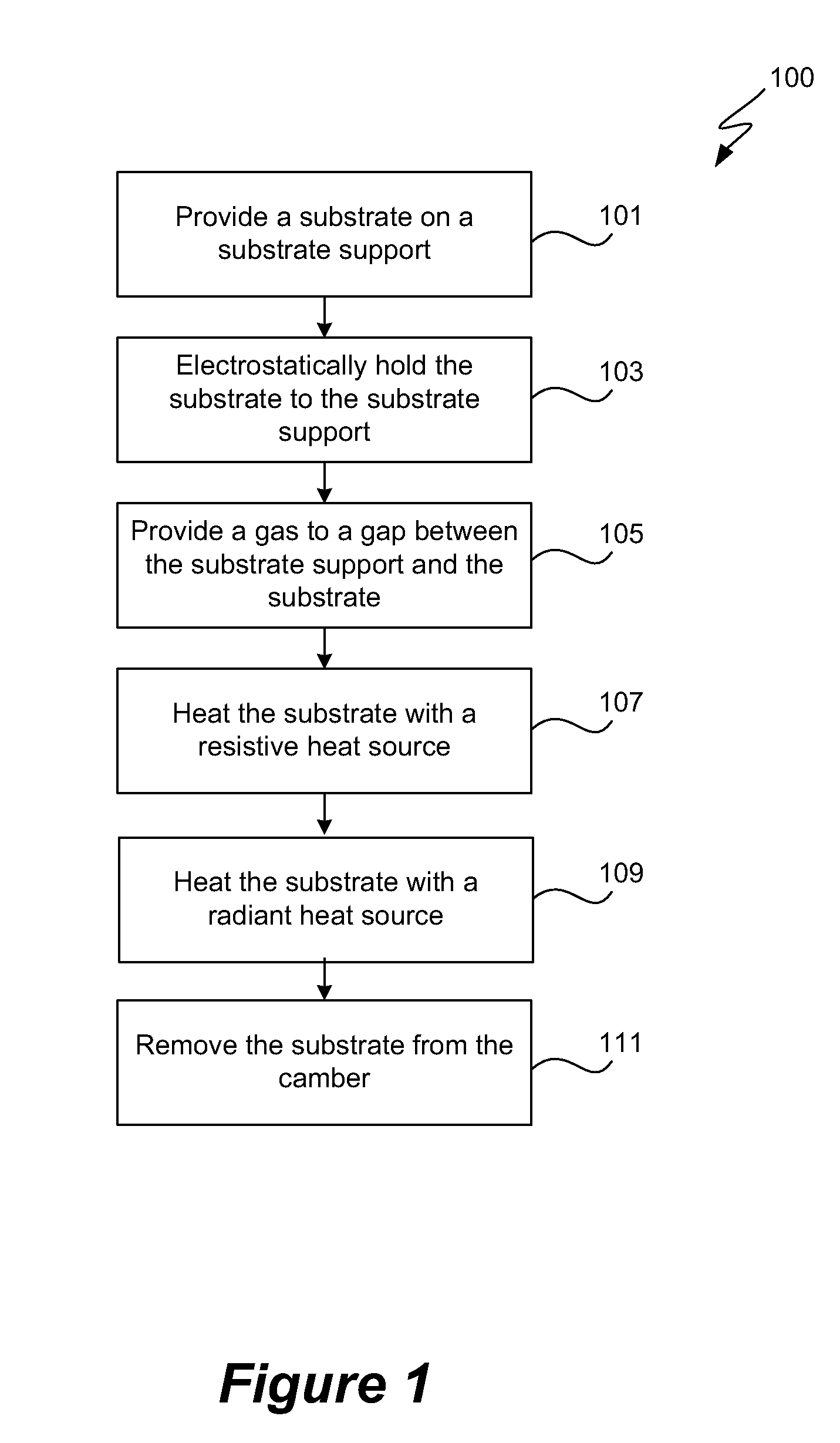

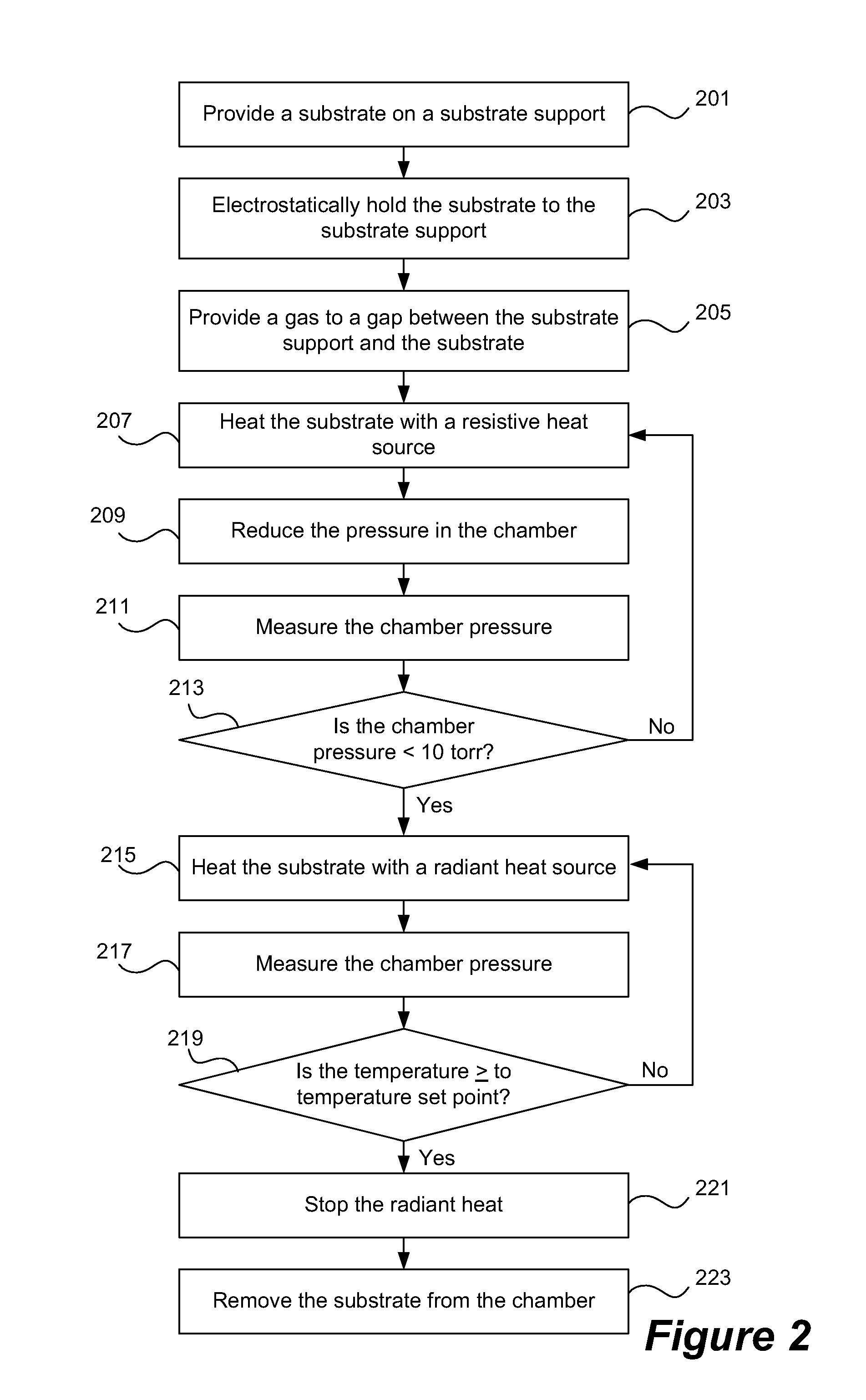

Load lock design for rapid wafer heating

ActiveUS7960297B1Heating evenly and quicklyImprove throughputSemiconductor/solid-state device manufacturingElectrostatic spraying apparatusElectrical resistance and conductanceEngineering

A semiconductor processing tool heats wafers using radiant heat and resistive heat in chamber or in a load lock where pressure changes. The wafers are heated in greater part with a resistive heat source until a transition temperature or pressure is reached, then they are heated in greater part with a radiant heat source. Throughput improves for the tool because of the wafers can reach a high temperature uniformly in seconds.

Owner:NOVELLUS SYSTEMS

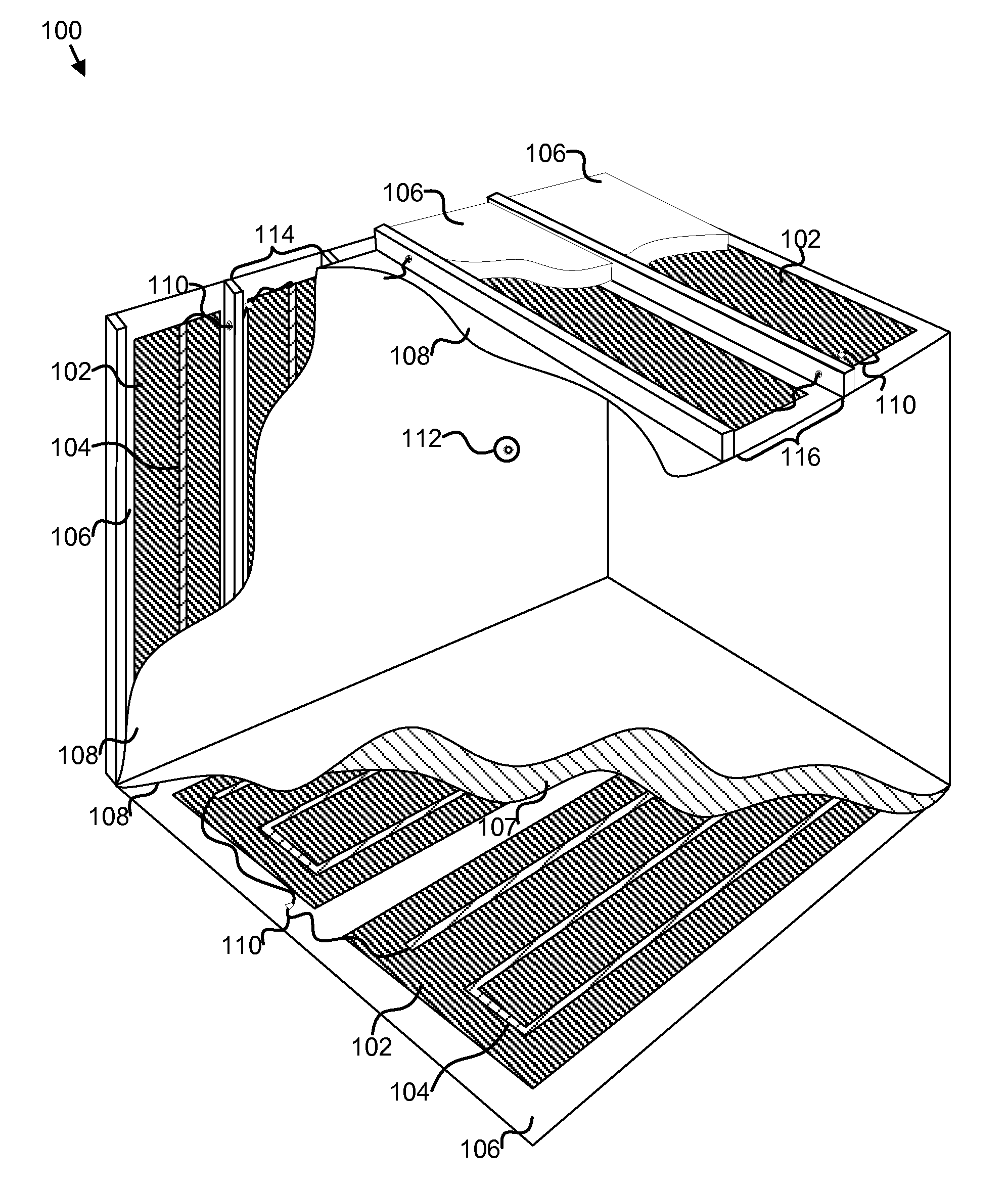

Radiant heating and cooling panel

InactiveUS8288689B1Easy to useFacilitate placement of the thermal control componentIncandescent ignitionBaking ovenAdhesiveEngineering

A panel for radiant heating and cooling includes a moisture impermeable shell with protrusions extended from a base. Channels between adjacent protrusions frictionally retain a thermal control component such as flexible tubing or an electrical heating element. The protrusions define chambers open at the bottom of the shell. An anchor in each chamber is secured to the top wall and extends downwardly beyond the base. A thermally conductive film is applied to the top surface of the shell. An insulative layer extends downwardly from inside the shell and beyond the base, surrounding the anchors while leaving bottom surfaces of the anchors exposed. The anchors are secured to a floor or substrate by an adhesive to integrally mount the panel. The anchors can receive and frictionally retain axially driven fasteners such as nails and staples, facilitating the attachment of a flooring overlayer integrally with respect to the substrate through the panel.

Owner:ADELMAN DEAN W

Modular radiant heating apparatus

An apparatus, system, and method provide radiant heat. A planar electrical heating element converts electrical energy to heat energy. A planar heat spreading layer is in contact with the planar electrical heating element, drawing the heat energy out of the planar electrical heating element and distributing the heat energy. A finishing layer is disposed to one side of the planar heat spreading layer. A thermal isolation layer is disposed to an opposite side of the planar heat spreading layer as the finishing layer. Heat from the planar heat spreading layer conducts away from the thermal isolation layer and toward the finishing layer. An electric power coupling is connected to the electrical heating element to supply electrical power.

Owner:GREENHEAT IP HLDG LLC

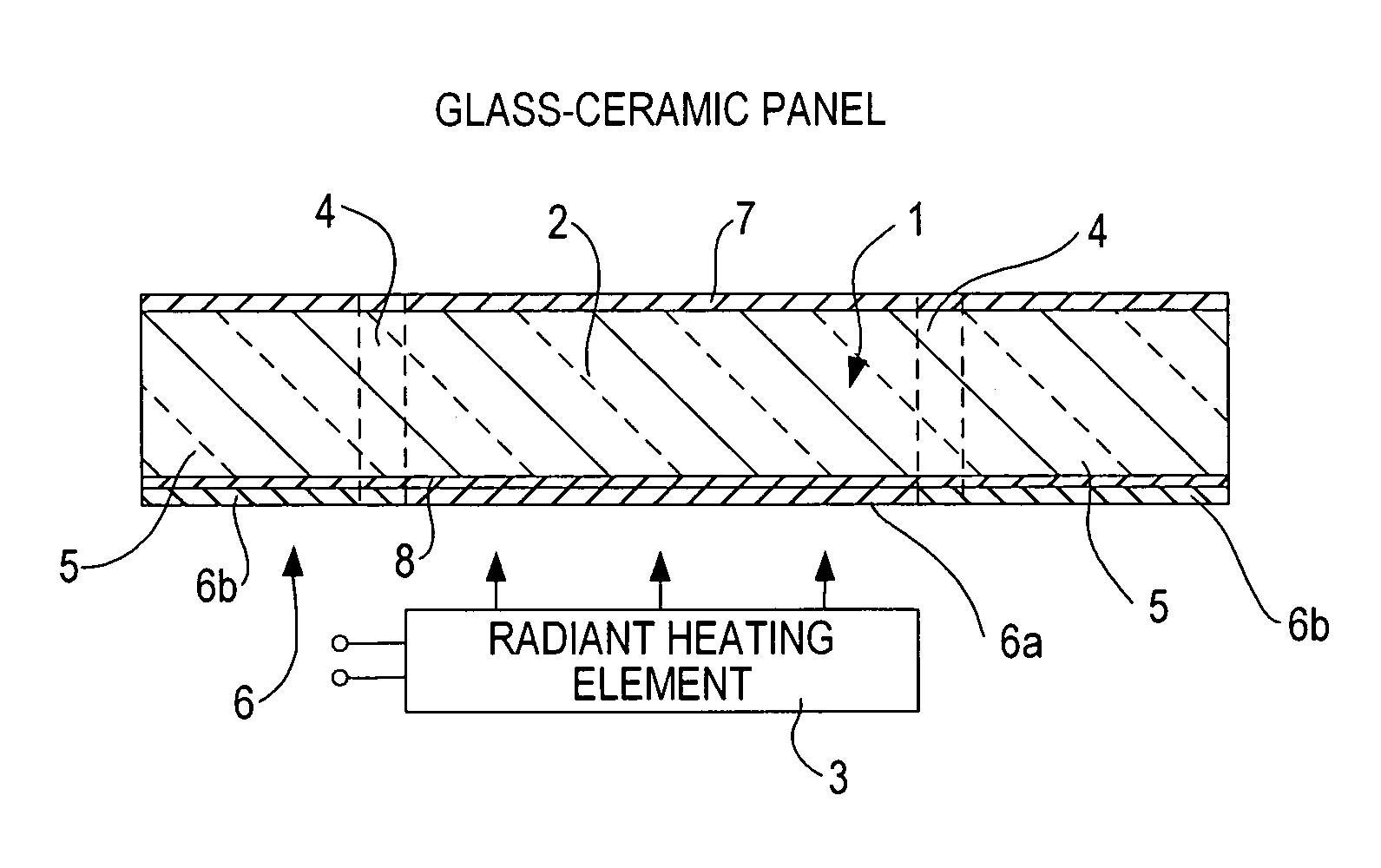

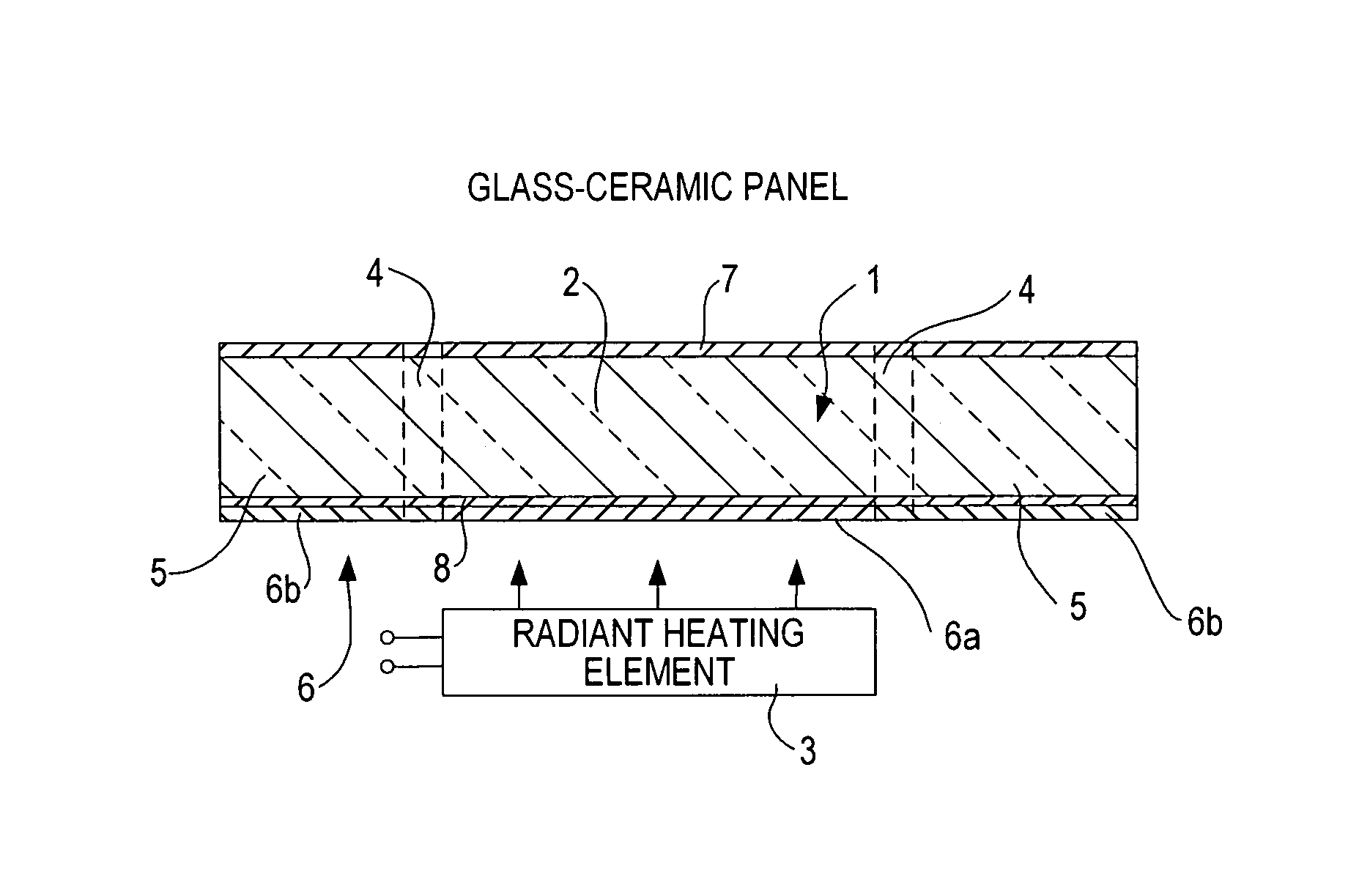

Cooking unit with a glass-ceramic or glass panel made of transparent colorless material and provided with an IR permeable solid colored underside coating

InactiveUS7009150B2Reduce above-described conspicuousnessProvide protectionDomestic stoves or rangesLighting and heating apparatusPre stressPre stressing

The cooking unit has a glass-ceramic panel (1) providing a cooking surface, which is made of transparent colorless glass-ceramic bulk material or a glass panel made of pre-stressed transparent colorless glass material. Radiant heating elements (3) are provided under the glass or glass-ceramic panel, which heat respective cooking zones. The glass or glass-ceramic panel has a full surface decorative coating (7) on its upper side, which makes dirt and usage marks less conspicuous, and an IR permeable coating (6) having a solid or plain color, preferably bisque-like, on its underside. The IR permeable coating having the solid or plain color prevents an observer from viewing the internal components of the cooking unit that are under the cooking panel from above it.

Owner:SCHOTT AG

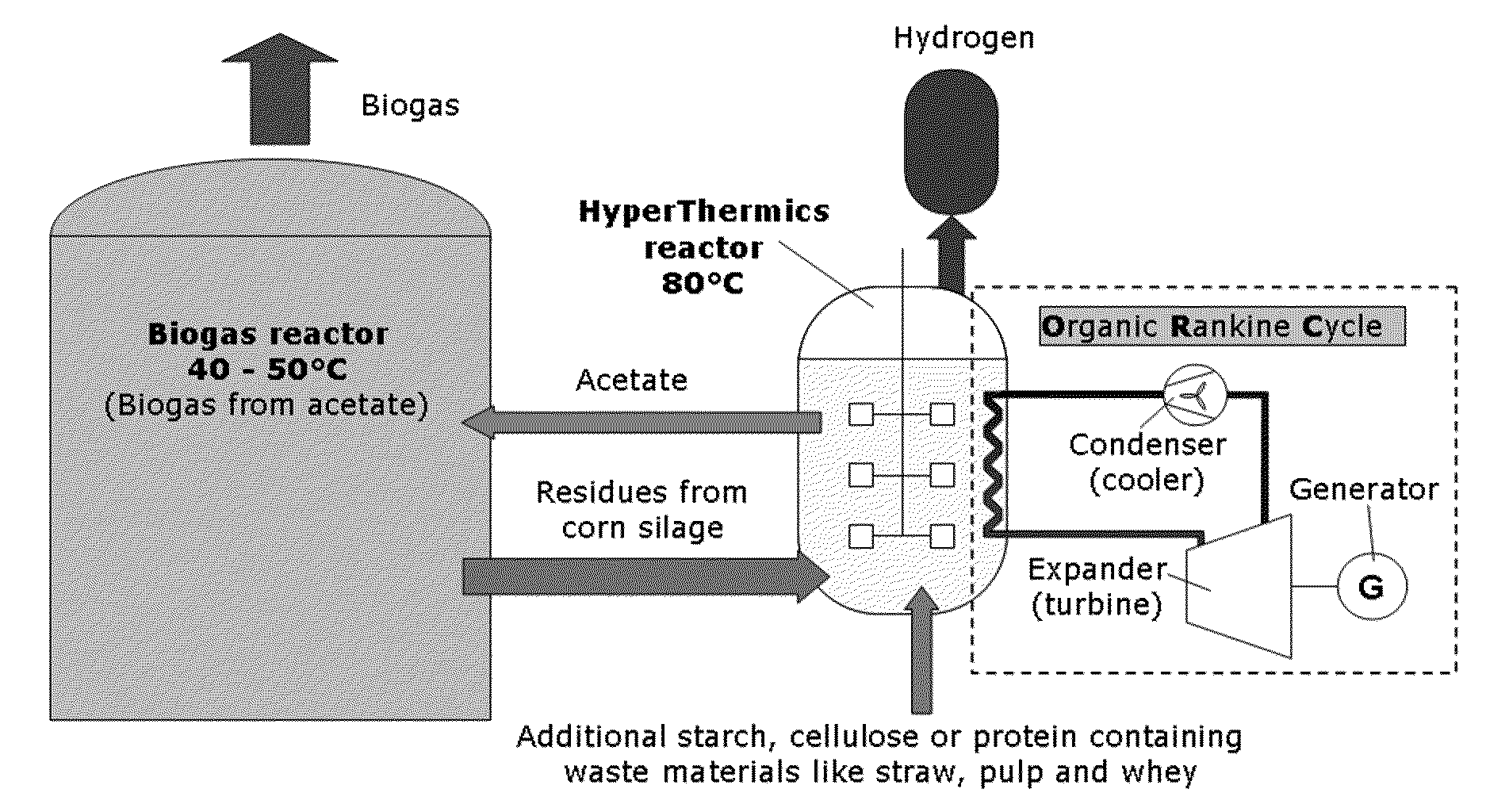

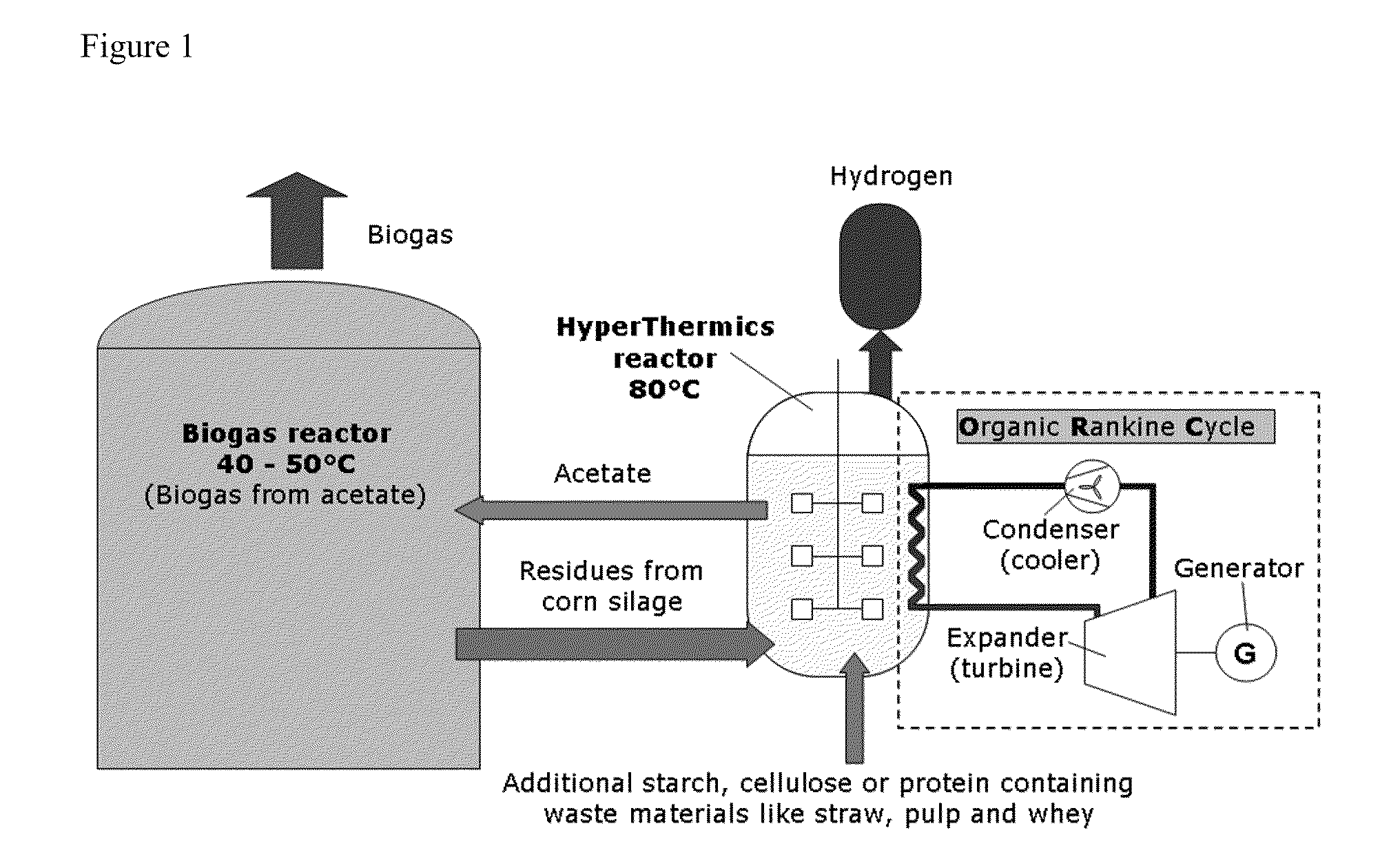

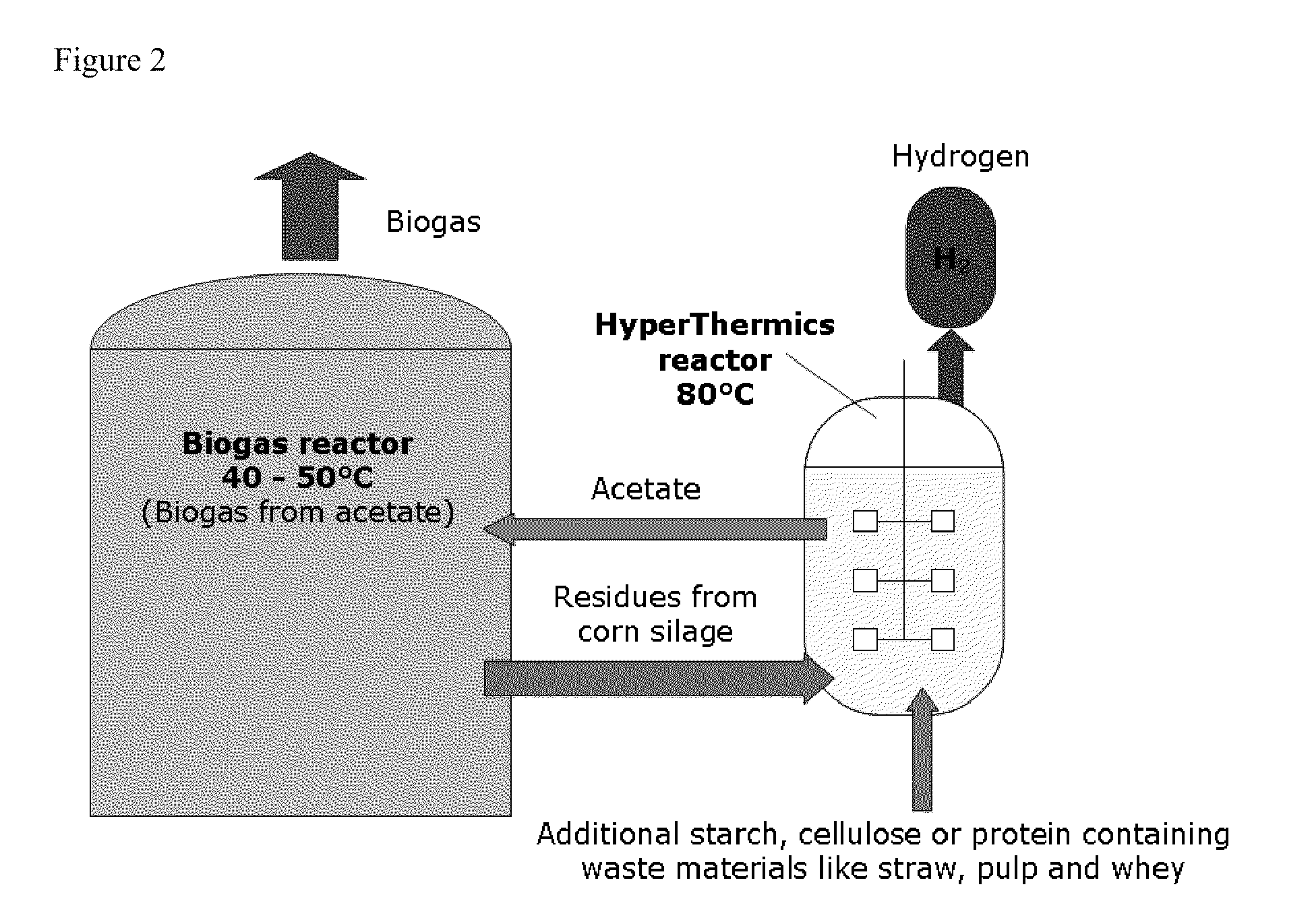

Energy production with hyperthermophilic organisms

ActiveUS20100093046A1Increase methane productionReduce oxygenBioreactor/fermenter combinationsBiological substance pretreatmentsRadiant heatOrganism

The present invention relates to the field of degradation with hyperthermophilic organisms, and in particular to the use of hyperthermophilic degradation to produce heat and energy rich components including hydrogen and ethanol from a biomass. In some embodiments, a biomass is fermented in the presence of hyperthermophilic organisms to produce heat. The heat is used to heat a liquid which is used directly in a heat pump or radiant heat or to produce electricity or drive a steam turbine. In some embodiments, acetate is utilized as a substrate to produce energy by methanogenesis.

Owner:HYPERTHERMICS HLDG

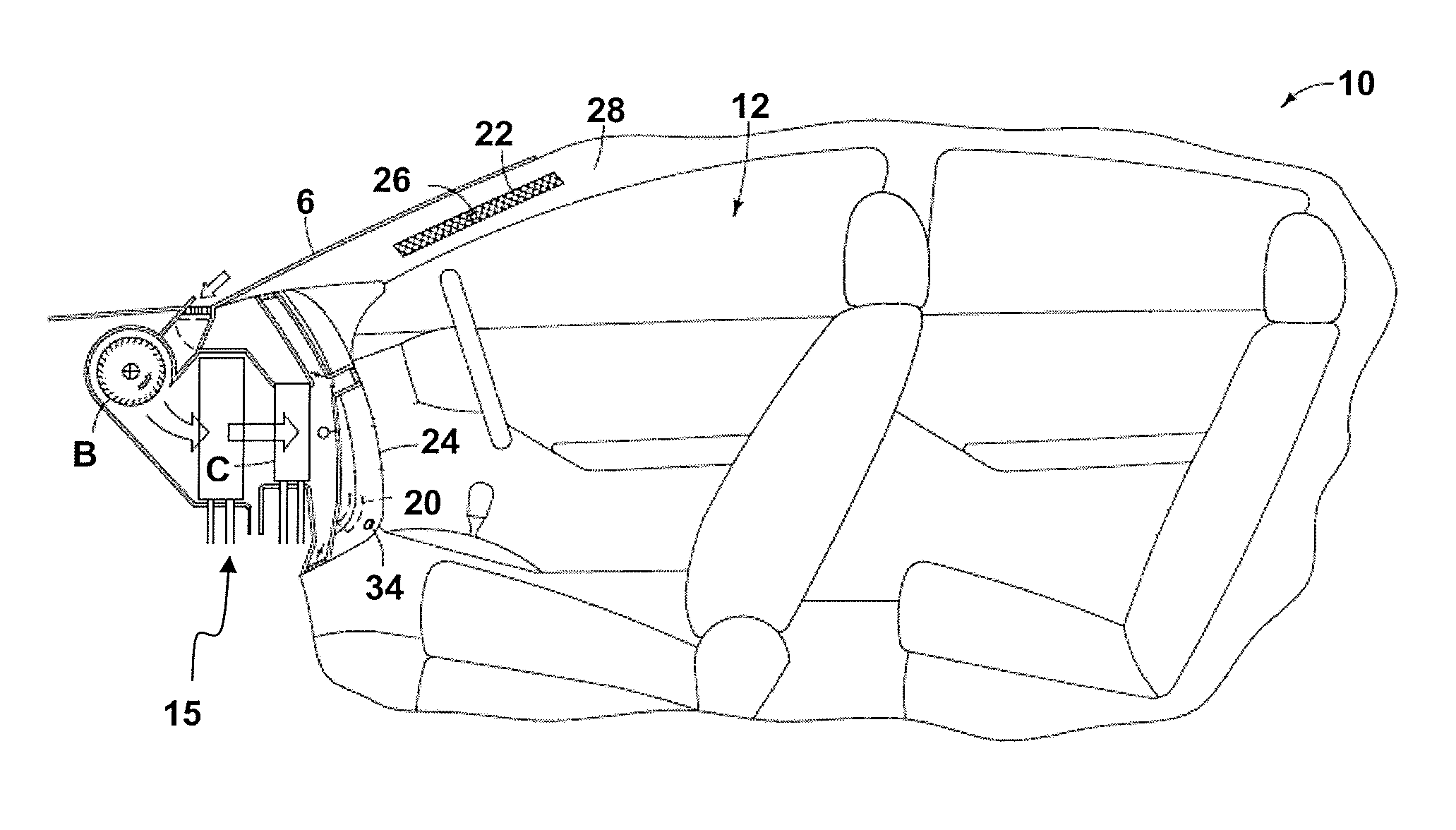

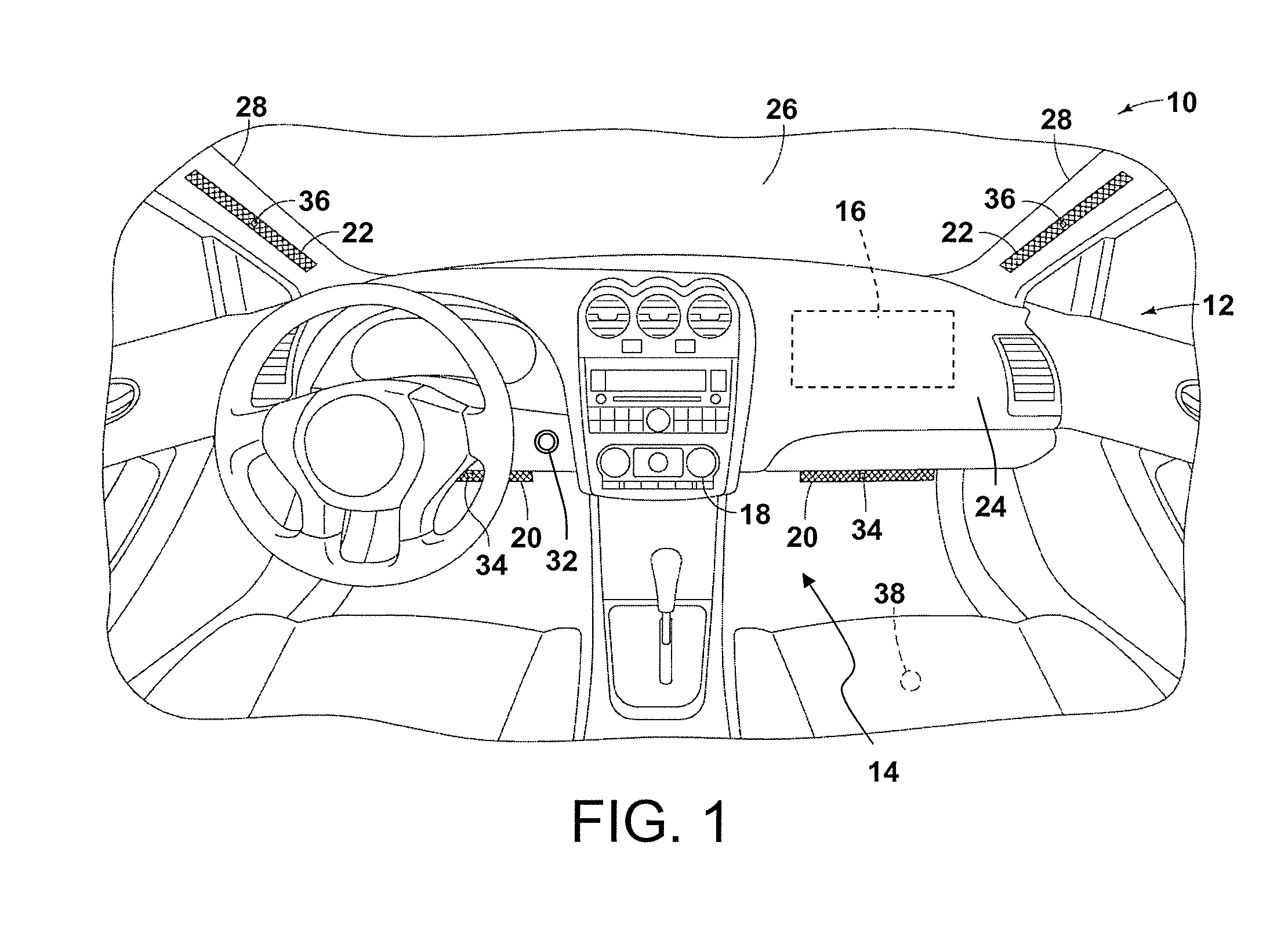

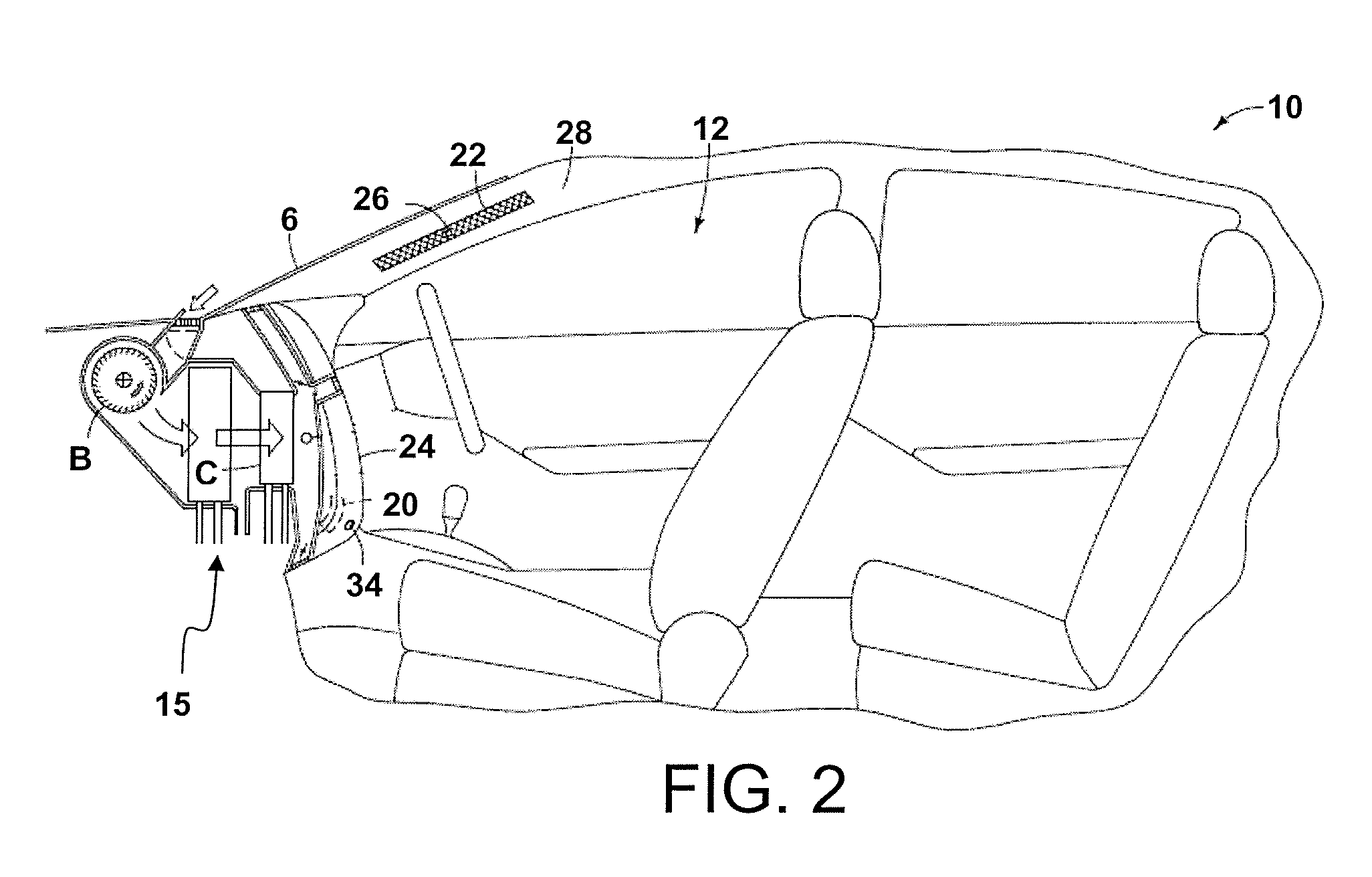

Vehicle radiant heating control system

InactiveUS20110127246A1Good suitVehicle heating/cooling devicesOhmic-resistance heating detailsControl systemRadiative heating

A vehicle radiant heating control system is provided that comprises a radiant heating element, a power source and a controller. The power source is operatively connected to the radiant heating element. The controller operatively controls the radiant heating element and the power source. The controller operates the radiant heating element by intermittently supplying power generated by the power source to the radiant heating element.

Owner:NISSAN MOTOR CO LTD

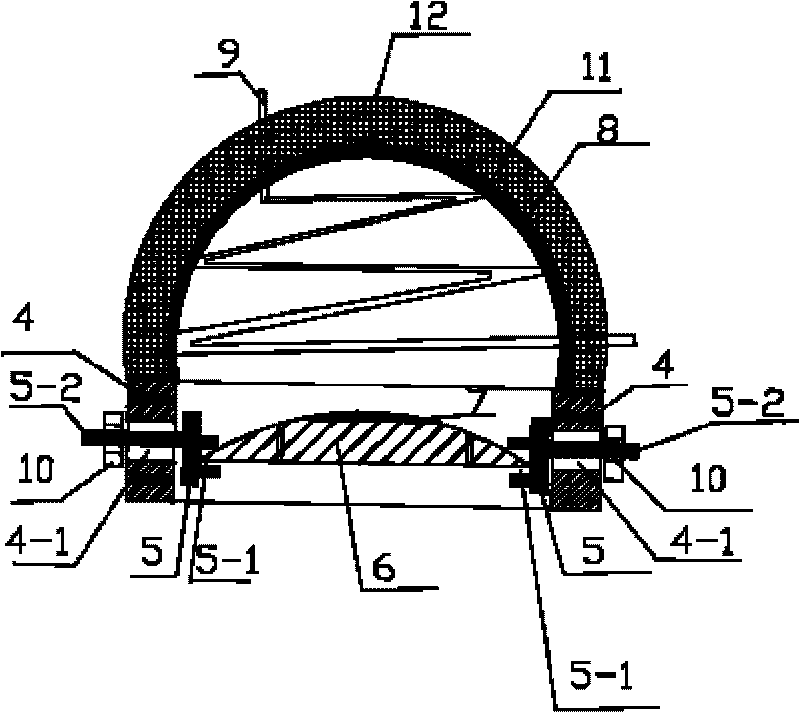

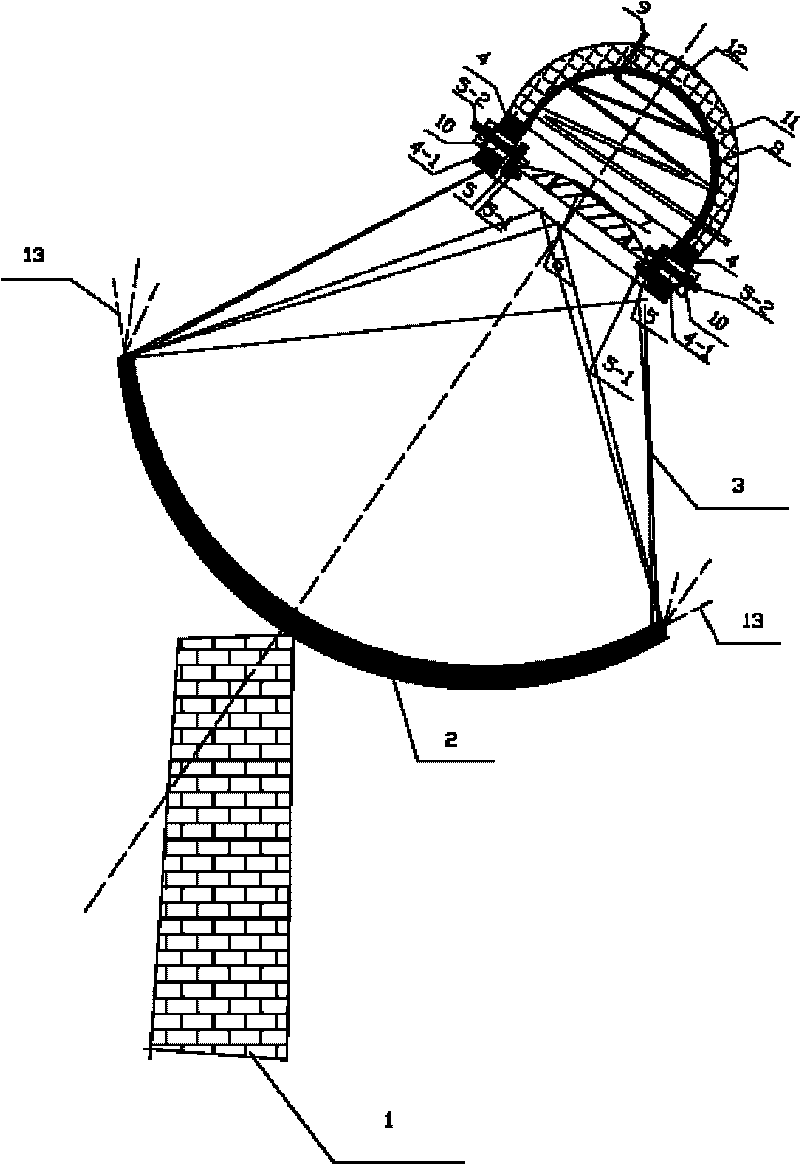

Cavity type solar heat absorber provided with optical window

InactiveCN101706161ANo burn-through phenomenonEvenly distributedSolar heating energySolar heat devicesStress concentrationHeat flow

The invention relates to a cavity type solar heat absorber provided with an optical window, which relates to the technical field of solar energy and aims to solve the problems that the solar energy radiant heat flows absorbed by the conventional solar heat absorber are not distributed evenly so that the heat absorber has an over-high local temperature and is easy to be burnt through. The cavity type solar heat absorber comprises the heat absorber and heat absorbing tubes; the heat absorbing tubes are coiled up on the internal wall of the heat absorber according to the shape of the inner cavity of the heat absorber; and the shape of the inner cavity of the heat absorber is semi-spherical. The cavity type solar heat absorber also comprises an upward convex optical glass body and a protecting sheet; the heat absorber is a hollow cavity body; the protecting sheet is annular and is fixed on an inlet of the heat absorber; the upward convex optical glass body is arranged on the protecting sheet; and an inlet surface of the upward convex optical glass body facing the heat absorber is a convex surface, while an inlet surface backing on to the heat absorber is a flat surface. The cavity type solar heat absorber can efficiently receive radiant heat and transfer heat to working fluids so as to reduce local high temperatures and thermal stress concentrations on the wall surfaces of the heat absorbing tubes. The cavity type solar heat absorber can be widely used in the field of solar heat absorbers.

Owner:HARBIN INST OF TECH

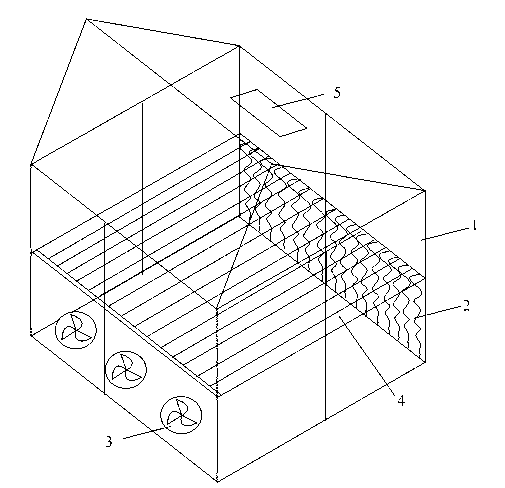

Greenhouse

InactiveCN103299861AWith high temperature resistance and corrosion resistanceImprove sound insulationClimate change adaptationGreenhouse cultivationInfraredDisplay device

A greenhouse comprises a greenhouse body, wherein the greenhouse body is formed by inlaying hollow glass into a stainless steel framework; a skylight is arranged on one side of a ridge of the greenhouse body; a plurality of cultivating beds are arranged inside the greenhouse body; a sunlight-shading system is arranged above the cultivating beds; a wet curtain and fan cooling system and a fuel gas and infrared radiant heating system are arranged inside the greenhouse body; a light-supplementing illumination system is also arranged inside the greenhouse body; the sunlight-shading system, the wet curtain and fan cooling system, the fuel gas and infrared radiant heating system and the light-supplementing illumination system are controlled by a controller; a temperature sensor, a humidity sensor and an illuminance sensor are connected at the input end of the controller; and a display device is connected at the output end of the controller and is used for displaying the temperature, the humidity and the illuminance inside the greenhouse body in real time.

Owner:ANHUI LONGCOM INTERNET OF THINGS

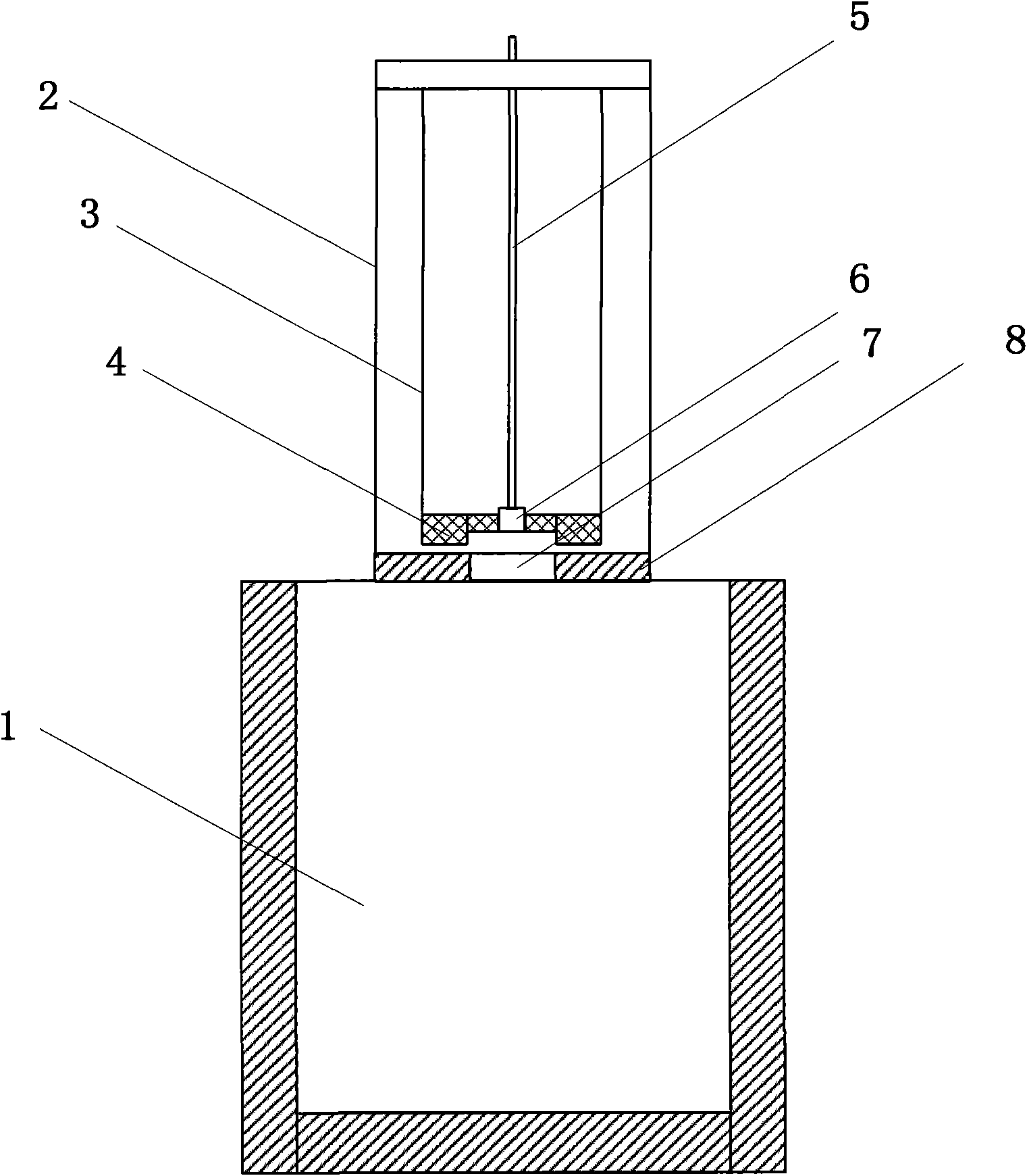

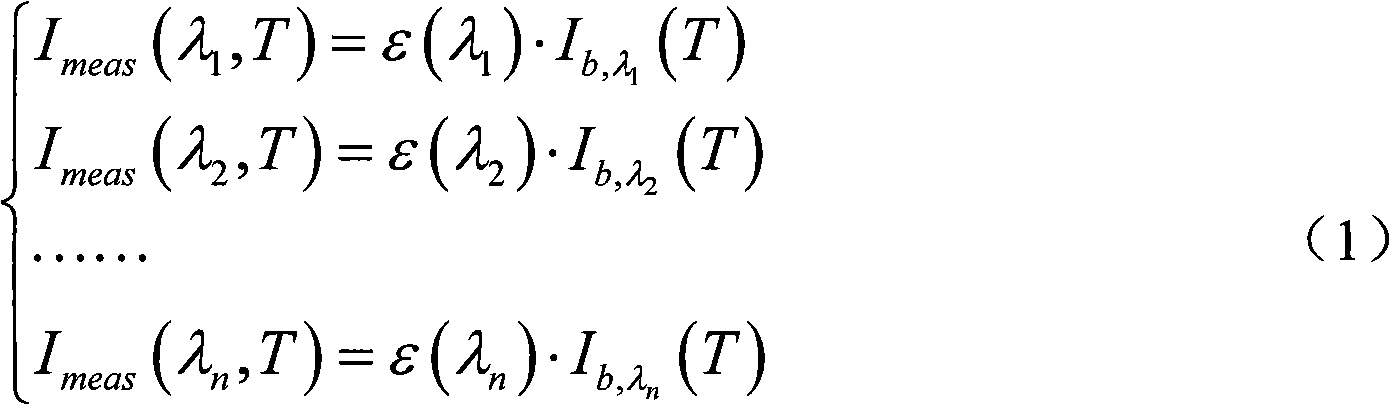

System for measuring normal spectral emissivity of high-temperature material

ActiveCN102042993ASimple designLess interference with radiometric measurementsSpectrum investigationMaterial thermal analysisData acquisitionEngineering

The invention discloses a system for measuring the normal spectral emissivity of a high-temperature material, comprising a vacuum heating unit, a water cooling sleeve unit, an optical fiber sensor measurement unit and a data acquisition and analysis unit, wherein a test sample is arranged on the upper part of the vacuum heating unit, and the vacuum heating unit performs radiant heating on the lower surface of the test sample; the water cooling sleeve unit is sleeved on the upper part of the test sample, and the upper surface of the test sample is placed in a constant-temperature cold environment; the optical fiber sensor measurement unit is arranged above the test sample to measure the normal spectral radiant intensity of the upper surface of the test sample; and the data acquisition and analysis unit is connected with the optical fiber sensor measurement unit and is used for calculating the normal spectral emissivity through a multi-spectrum inversion algorithm according to the measured normal spectral radiant intensity. The invention realizes material normal spectral emissivity measurement in a spectrum range of 0.4-1.7mum and a temperature range of 600-1,500 DEG C without on-line radiometric calibration, is accurate and reliable to realize the technology, and overcomes limitations on high price, complicated structure, high difficulty in technical implementation and other applications of the conventional spectral emissivity device.

Owner:TSINGHUA UNIV +1

Microbatch deposition chamber with radiant heating

InactiveUS20080220150A1Polycrystalline material growthPretreated surfacesEngineeringRadiative heating

The present invention generally provides an apparatus and method for processing and transferring substrates in an epitaxial deposition chamber. Embodiments of the invention described herein are adapted to maximize chamber throughput and improve film deposition uniformity. In one embodiment, two substrates are processed simultaneously using radiant heating of the substrates in a cold wall, low pressure chemical vapor deposition reactor.

Owner:APPLIED MATERIALS INC

Heat pump with forced air heating regulated by withdrawal of heat to a radiant heating system

InactiveUS20080276638A1Easy transferImprove the heating effectSpace heating and ventilation safety systemsSpace heating and ventilation control systemsThermal energyCirculator pump

A heat pump system is disclosed that utilizes a variable speed hydronics pump to selectively divert heat energy from a forced air heating system to a hydronics radiant heating system. By actively controlling the speed of the withdrawal of heat, the temperature of the forced air output may be maintained while maximizing the amount of heat delivered by the efficient hydronics system. The heat pump system also actively controls the blower of the forced air system. To reduce the frequency of the compressors cycling on and off, a tank may be used to store and dispense heat if the hydronics system is not of sufficient size.

Owner:ELECTRO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com