Patents

Literature

3646 results about "Optical glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optical glass is a specialty glass product which is designed for use in optical devices such as telescopes, binoculars, eyeglasses, and so forth. This glass is formulated very precisely so that its properties are known, and it must be handled with care to ensure that it is free of impurities and produced in...

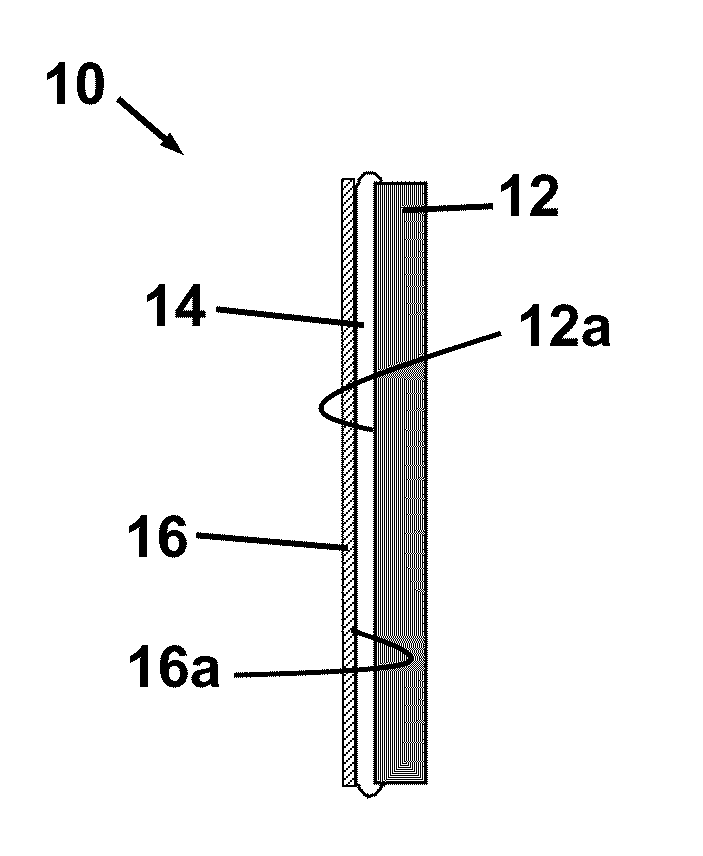

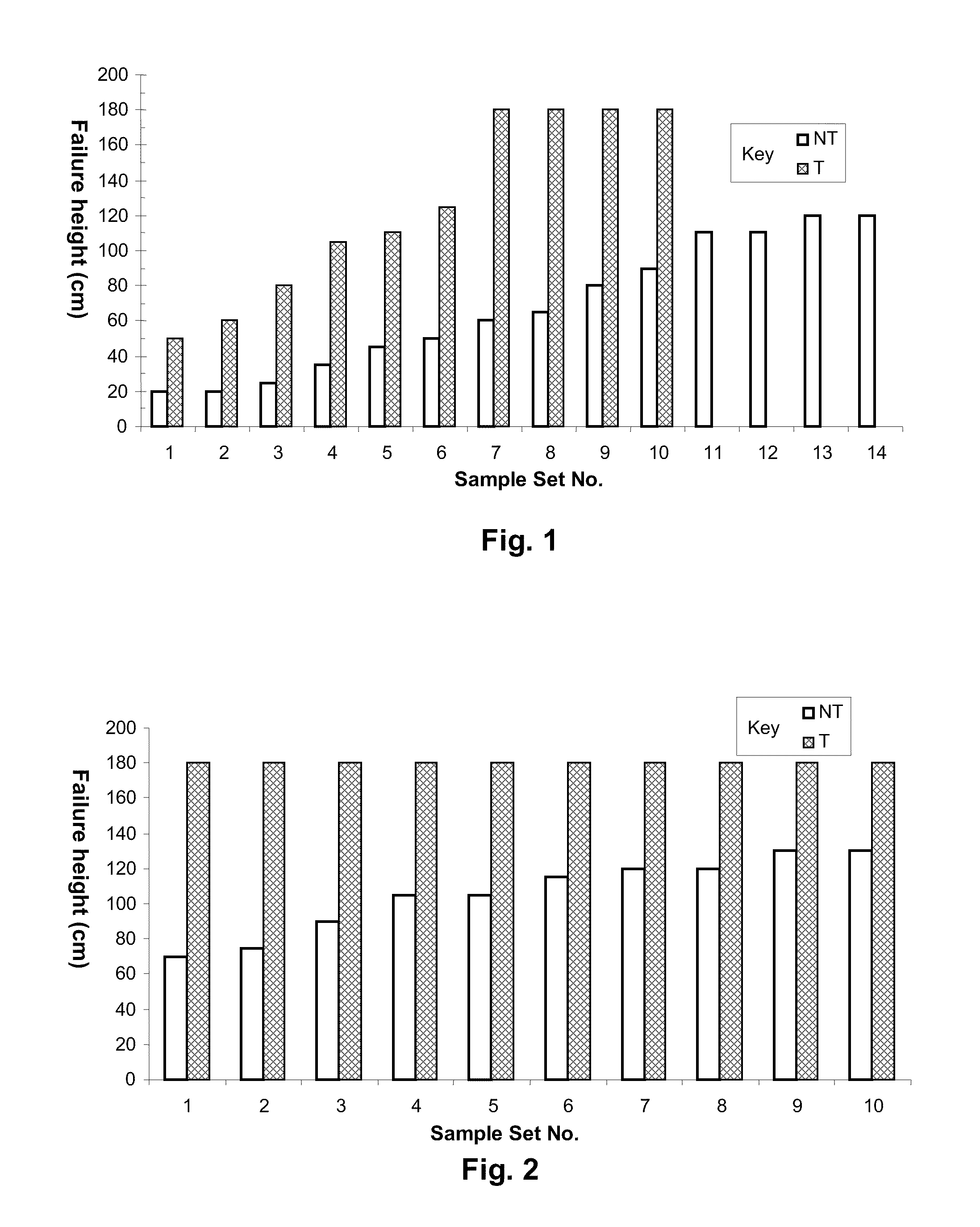

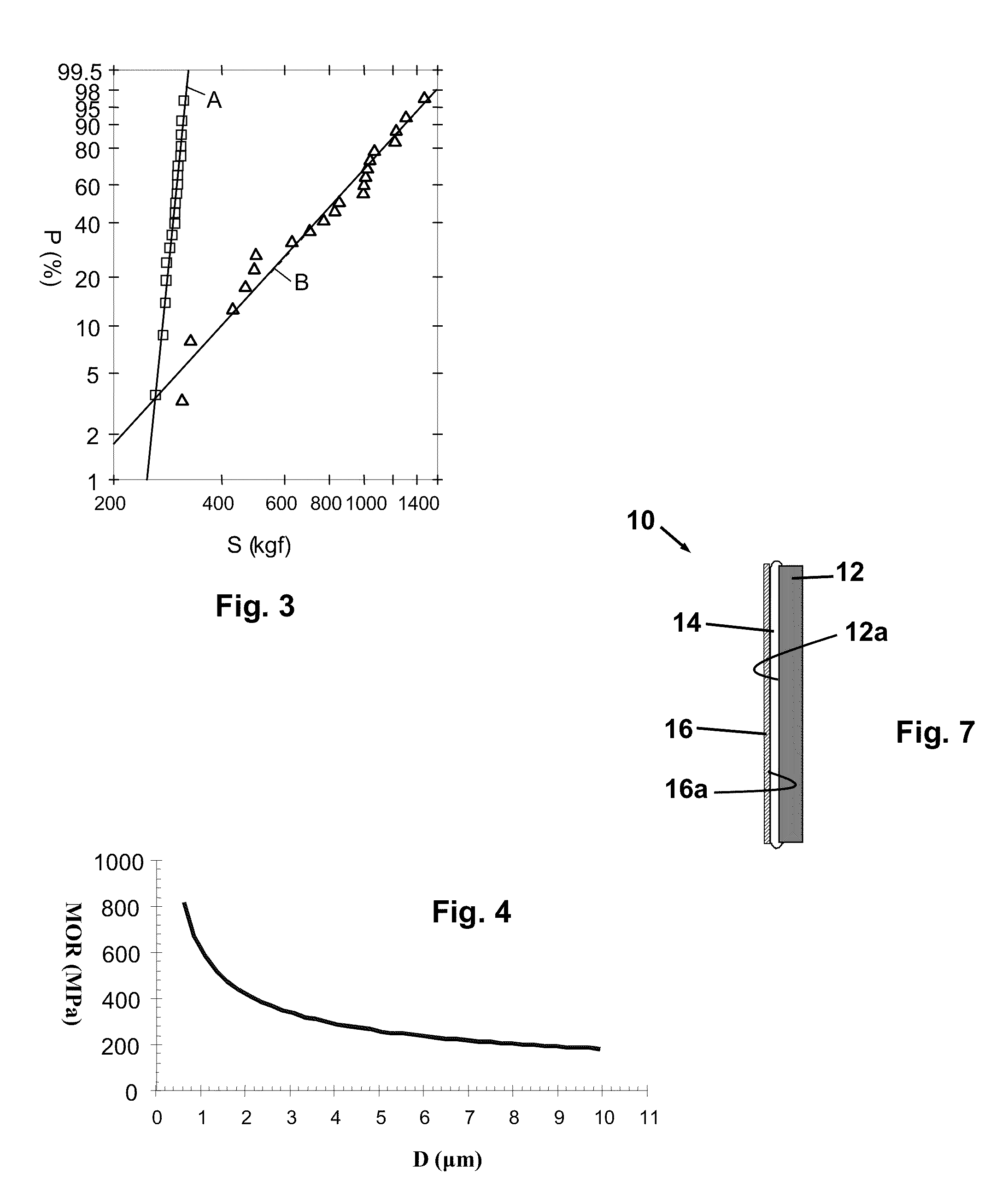

Impact-damage-resistant glass sheet

ActiveUS20110165393A1Increased and more consistent resistanceImprove flexural strengthSynthetic resin layered productsRecord information storageGlass coverDisplay device

Impact-damage-resistant glass sheet comprising at least one chemically etched surface in combination with a tempering surface compression layer, the glass sheet exhibiting a high standardized ball drop failure height and a high flexural modulus of rupture strength, useful to provide damage-resistant glass cover sheets for consumer electronic video display devices, is provided by subjecting thin glass sheet to a combination of a surface tempering treatment and a surface etching treatment that improves strength while maintaining the optical glass sheet properties required for video display applications.

Owner:CORNING INC

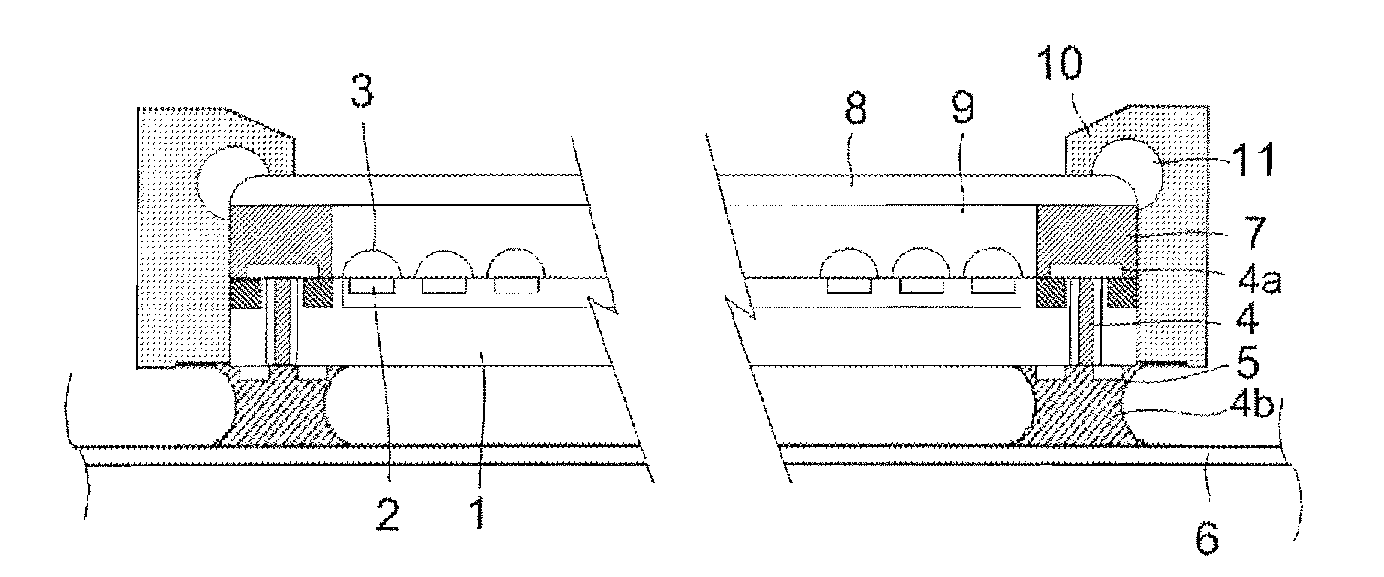

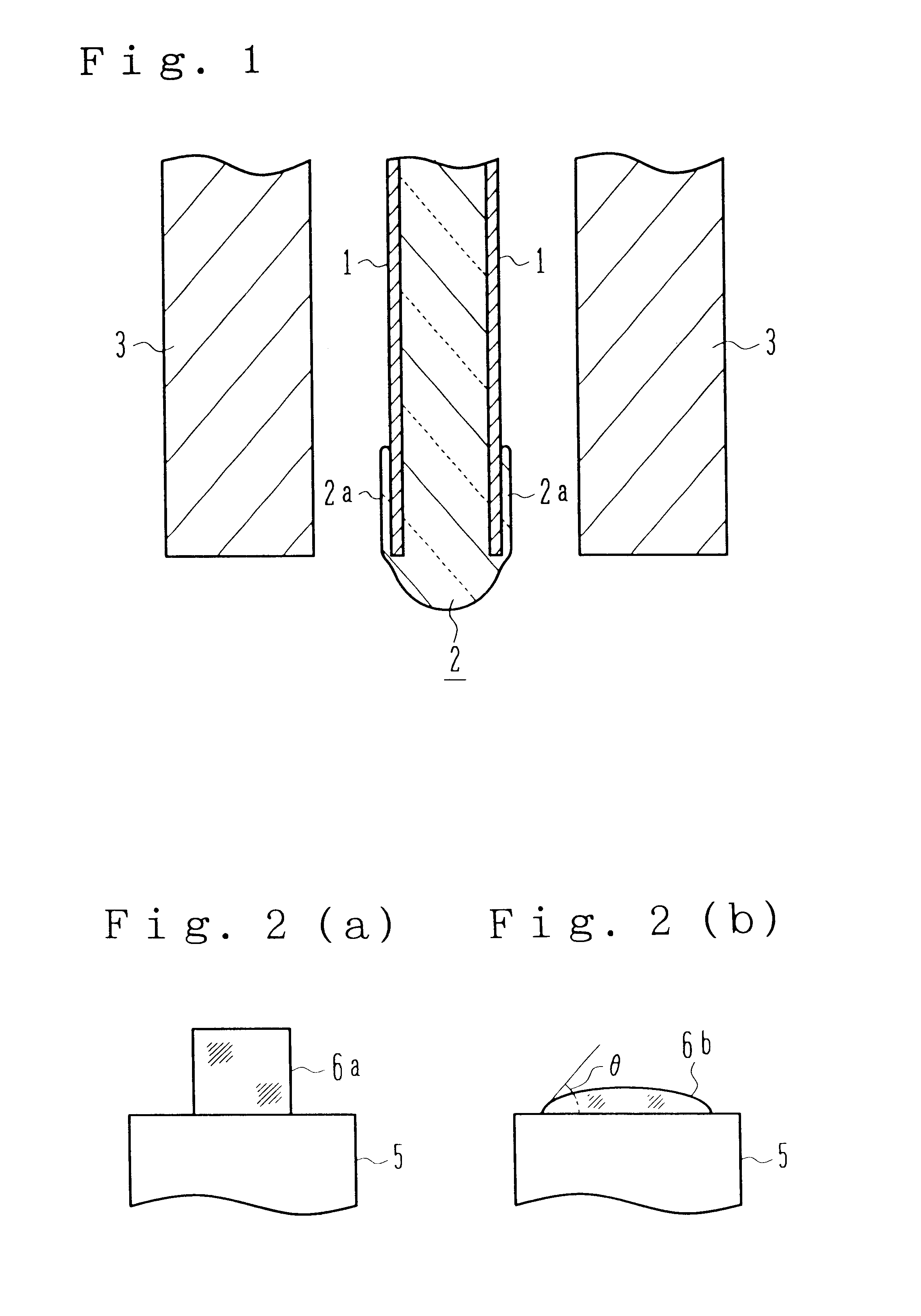

Solid-Stated Image Pickup Device And Method For Manufacturing Same

ActiveUS20080042227A1Reliability of device can be ensuredImprove production yieldTelevision system detailsSolid-state devicesEngineeringOptical glass

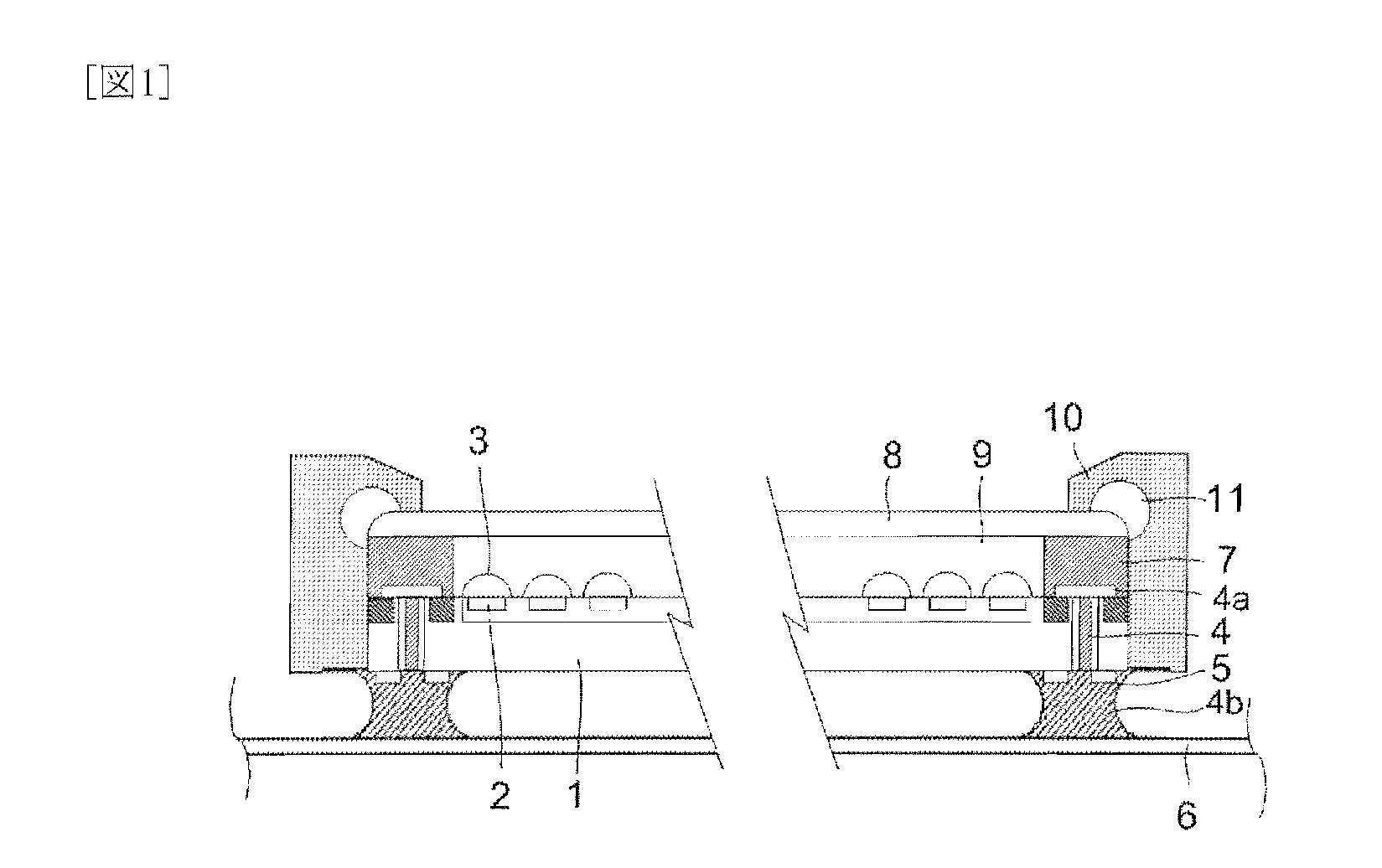

There are provided image pickup devices capable of significantly increasing production yield and ensuring long-term reliability and a method for manufacturing the image pickup devices. This invention is characterized in that it has a large number of light-receiving portions 2 formed at a surface portion of a wafer 1 and a microlens 3 formed for each of the light-receiving portions, through electrodes 4 for performing supply of power to the light-receiving portions 2 and passing and reception of an electrical signal are provided all over the periphery of the wafer 1, one end of each through electrode 4 is connected to an electrode pad 4a which is connected to a wire leading to a light-receiving element at the surface portion of the wafer 1, the other end is connected to a wire through a back electrode 5, a rib 7 which serves as a partition portion arranged to surround the microlenses 3 on four sides is provided on the surface of the wafer 1, a transparent plate 8 of optical glass or the like is bonded to an upper surface of the rib 7 with adhesive, and a protective frame 10 is provided at a junction between the rib 7 and the transparent plate 8.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD +1

Optical glass for precision press molding, preform for precision press molding, and process for the production thereof

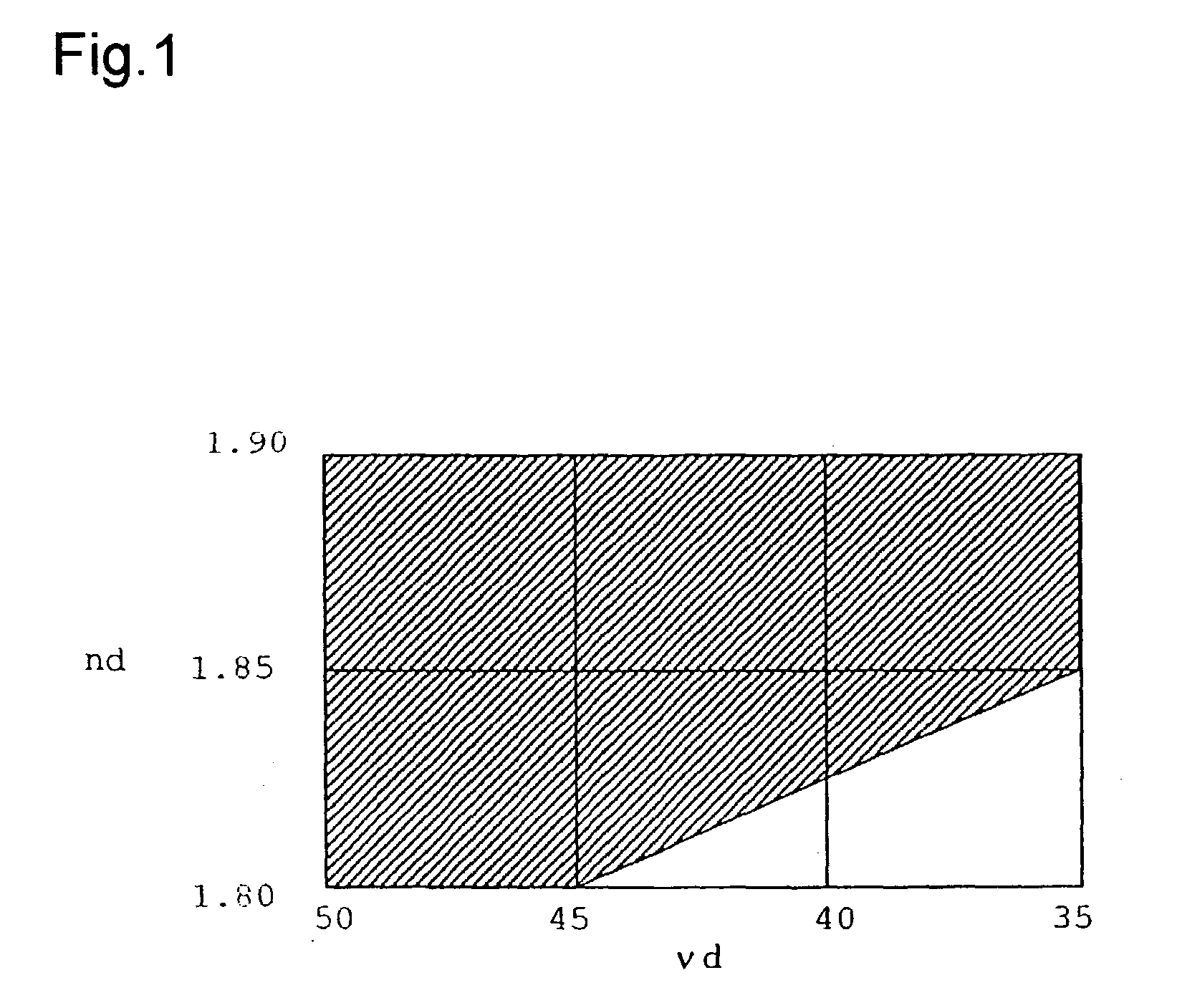

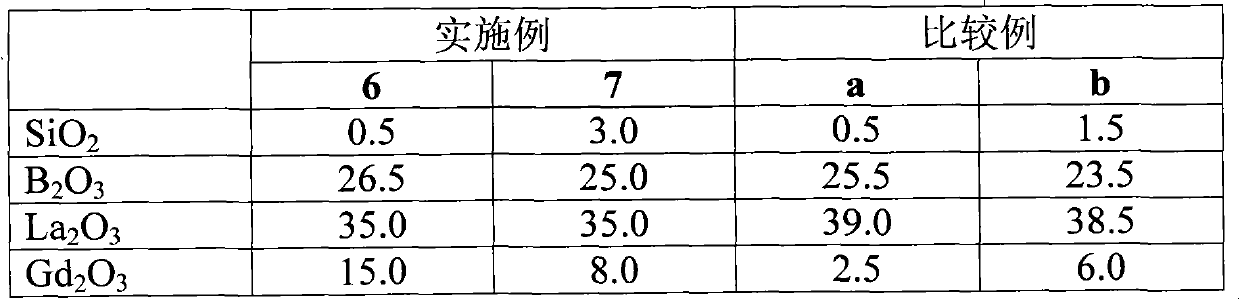

A high-refractivity high-dispersion optical glass for producing an optical element, which requires no machining, such as polishing or lapping, of an optical-function surface after precision press molding, containing B2O3, SiO2, La2O3, Gd2O3, ZnO, Li2O, ZrO2 and Ta2O5 as essential components, containing 0 to 1 mol % of Sb2O3 as an optional component, substantially containing none of PbO and Lu2O3, having a glass transition temperature of 630° C. or lower, and (1) having a refractive index nd and an Abbe's number nud which satisfy all of the following relational expressions, 1.80<nd<=1.90, 35<nud<=50, and nd>=2.025-(0.005xnud) or (2) having an nd of greater than 1.85 and a nud of greater than 35.

Owner:HOYA CORP

Optical glass, press-molding preform and optical part

InactiveUS6844279B2Improve plasticityGlass pressing apparatusGlass reforming apparatusRefractive indexGlass transition

A high-refractivity low-dispersion optical glass that gives press-molding preforms excellent in high-temperature shapability and suitable for precision press-molding, including an optical glass comprising B2O3, La2O3, Gd2O3 and ZnO as essential components, substantially containing none of lead and fluorine, having a refractive index (nd) of 1.72 to 1.83, an Abbe's number (νd) of 45 to 55 and a glass transition temperature (Tg) of 630° C. or lower and having a viscosity of at least 0.6 Pa·s at its liquidus temperature, and an optical glass comprising, by mol %, 45 to 65% of B2O3, 5 to 22% of La2O3, 1 to 20% of Gd2O3, provided that the total content of La2O3 and Gd2O3 is 14 to 30%, 5 to 30% of ZnO, 0 to 10% of SiO2, 0 to 6.5% of ZrO2 and 0 to 1% of Sb2O3, substantially containing none of lead and fluorine, and having a refractive index (nd) of 1.72 to 1.83 and an Abbe's number (νd) of 45 to 55.

Owner:HOYA CORP

Optical glass composition, preform and optical element

InactiveUS20080287280A1Excellent heating characteristicImprove the heating effectOptical glassMaterials science

An optical glass composition contains, in % by weight, 1.0% or more and 12.0% or less of SiO2, 8.0% or more and 18.0% or less of B2O3, 0% or more and 6.0% or less of ZnO, 1.0% or more and 10.0% or less of ZrO2, 25.0% or more and 47.0% or less of La2O3, 0% or more and 5.0% or less of R2O (here, R is at least one of Li, Na and K), 0% or more and 15.0% or less of Nb2O5, 0% or more and 7.0% or less of TiO2, 0% or more and 15.0% or less of Ta2O5, 1.0% or more of Nb2O5+TiO2+Ta2O5, 0% or more and 25.5% or less of Gd2O3, 0.5% or more and 15.0% or less of WO3 and 0.5% or more and 26.0% or less of Gd2O3+WO3, and has nd of 1.88 or higher and 1.92 or lower and νd of 33 or higher and 37 or lower, and a preform and an optical element are formed from the optical glass composition.

Owner:PANASONIC CORP

Method for manufacturing auxiliary gas-adding polyurethae/polyurethane-urea polishing pad

InactiveUS20040021243A1Improve accuracyImprove flatnessFlexible-parts wheelsLapping toolsHydrogenPolythiol resin

A method for manufacturing a PU (polyurethane) polishing pad is provided. Resins containing active hydrogen functional groups such as polyol resins, polyamine resins, and polythiol resins, and polyisocyanate resins containing -NCO functional groups are mixed to form a foamed PU polishing pad with excellent polishing properties by reaction injection-molding under high pressure, low temperature and auxiliary gas-adding. The PU polishing pad in accompany with an abrasive slurry can be widely used to polish high-level products such as wafers and optical glass.

Owner:IV TECH CO LTD

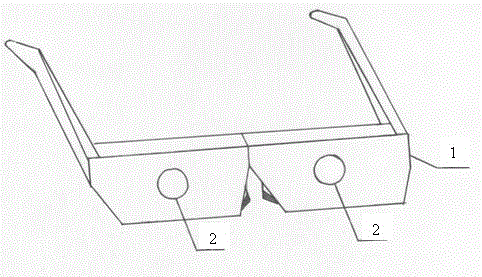

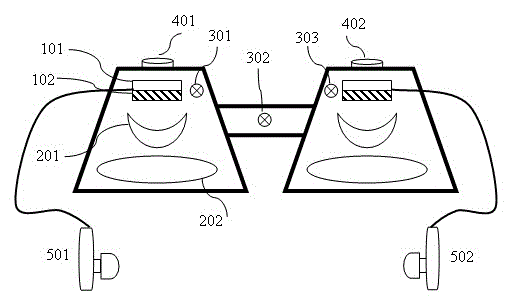

Three-dimensional (3D) head-mounted display

InactiveCN103149690AReduce volumeImprove performanceTelevision system detailsColor television detailsStereoscopic videoDisplay device

The invention provides a three-dimensional (3D) head-mounted display. The 3D head-mounted display comprises an image displaying component, an optical imaging system, an optical adjustment component, an audio transmission component, a camera module, a control module and an eyeglass type casing. The 3D head-mounted display is characterized in that the control module is respectively connected with the image displaying system, the audio transmission component and the camera module; the optical adjustment component is connected with the optical imaging system; the relative position of optical glasses of the optical imaging system can be adjusted through the optical adjustment component; and the camera module is connected with the image displaying component through wired connection. The 3D head-mounted display can be suitable for human engineering to a maximum measure, can protect the eyes from being fatigued, and can be used for displaying 3D stereoscopic video and common 2D video and be suitable for more people; and through the switchable performance of the camera module, the 3D head-mounted display is more humanized, and can prevent users from feeling panic caused by confining for a long time.

Owner:NANJING UNIV OF SCI & TECH +1

Optical glass, press-molding glass gob and optical element

InactiveUS6912093B2Reduce colorHigh refractive indexGlass transportation apparatusMountingsRefractive indexOptical glass

An optical glass whose refractive index is high and whose coloring is decreased comprising, by weight %, 2 to 45% of B2O3, 0 to 30% of SiO2 provided that the content of B2O3>the content of SiO2, 10 to 50% of La2O3, 0 to 30% of TiO2, 0 to 15% of ZnO, 0 to 15% of ZrO2, 0 to 35% of Nb2O5, 0 to 35% of BaO, 0 to 5% of SrO, 0% or more but less than 8% of CaO, 0% or more but less than 13% of MgO, provided that the total content of BaO, SrO, CaO and MgO is 0 to 40%, 0 to 20% of Gd2O3, 0 to 15% of Y2O3, 0 to 18% of Ta2O5, 0% or more but less than 0.5% of WO3, 0% or more but less than 1.5% of a total of Na2O, K2O and Li2O, 0 to 10% of GeO2, 0 to 20% of Bi2O3, 0 to 10% of Yb2O3, 0 to 10% of Al2O3, 0% or more but less than 2% of Sb2O3 and 0 to 1% of SnO2.

Owner:HOYA CORP

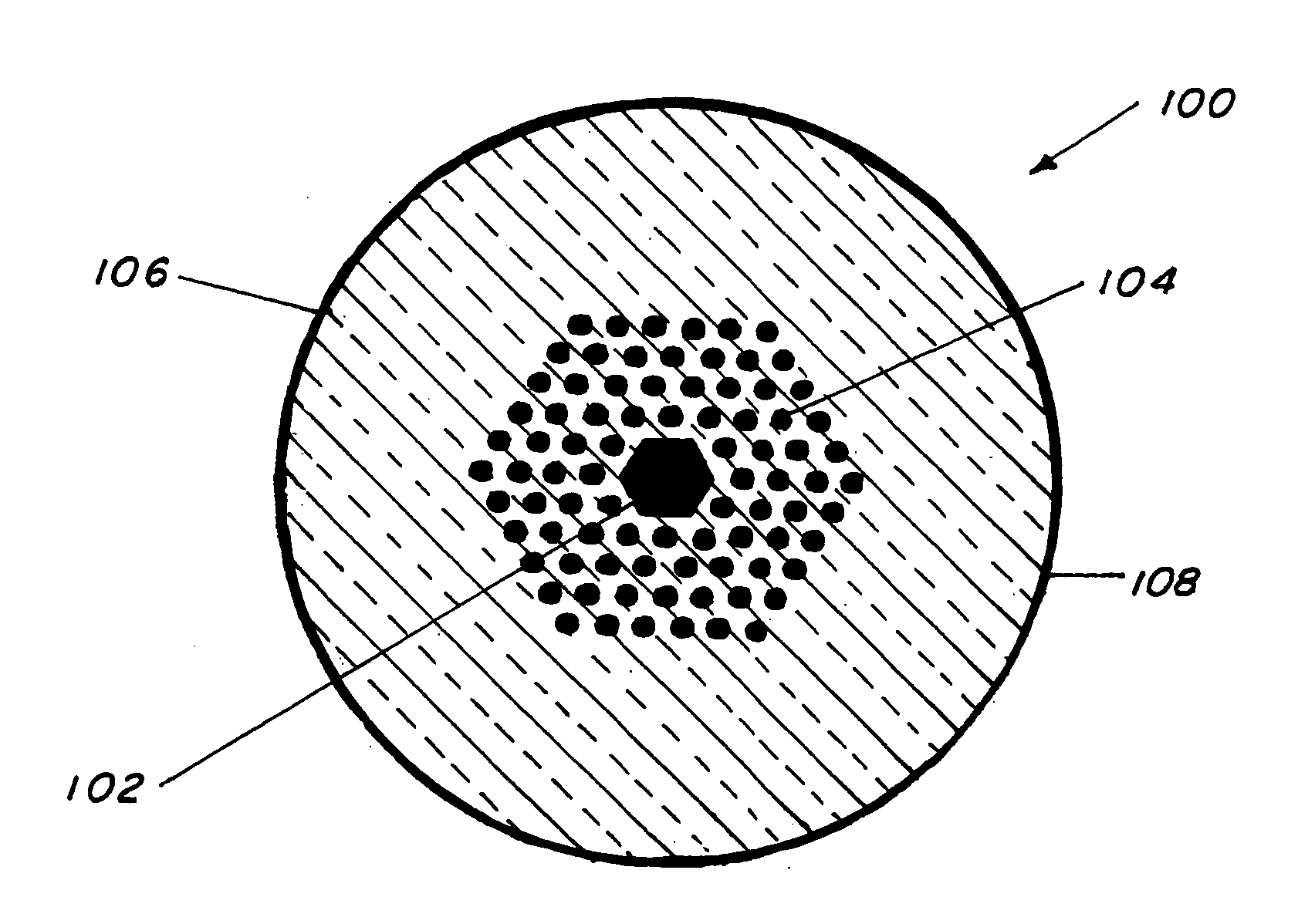

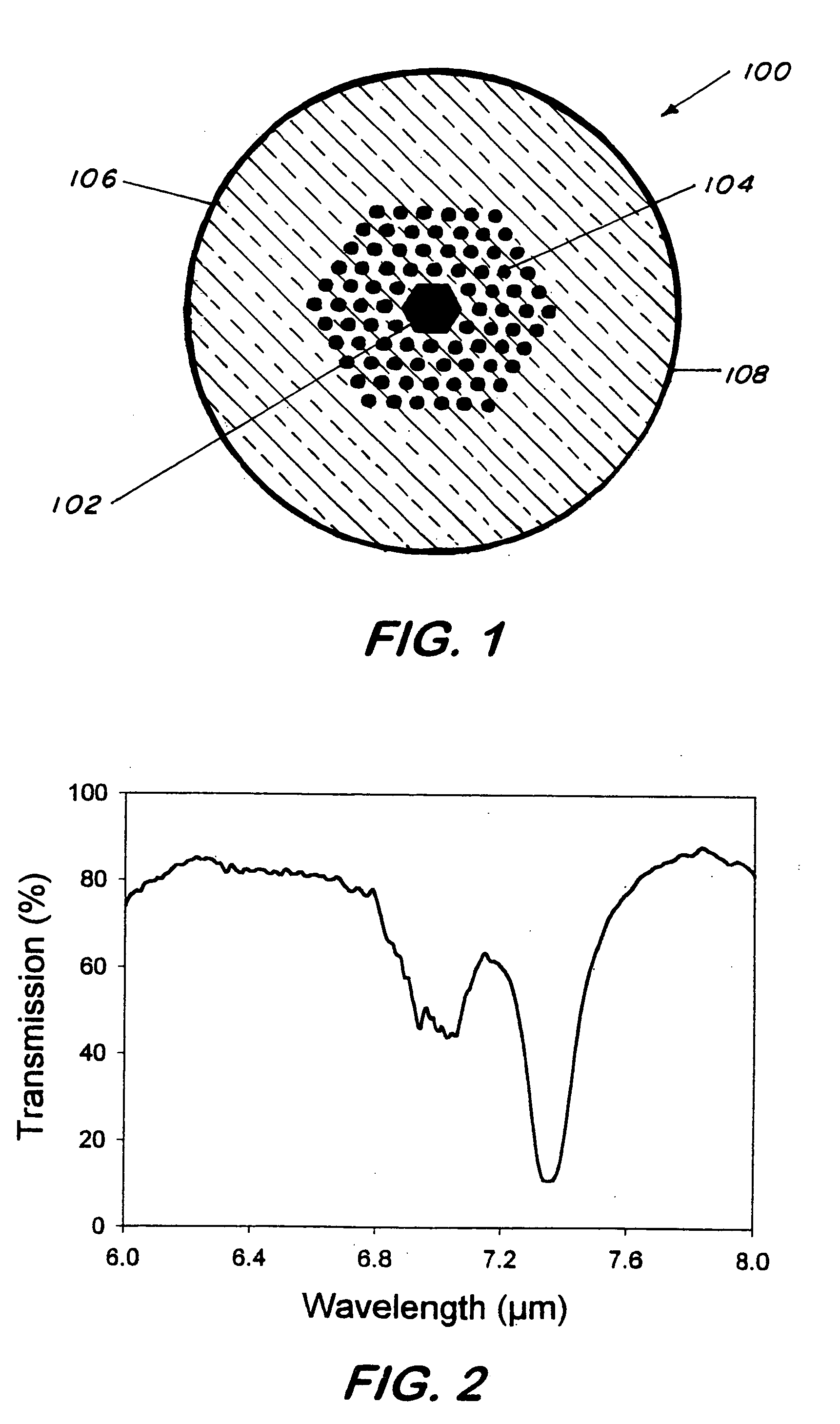

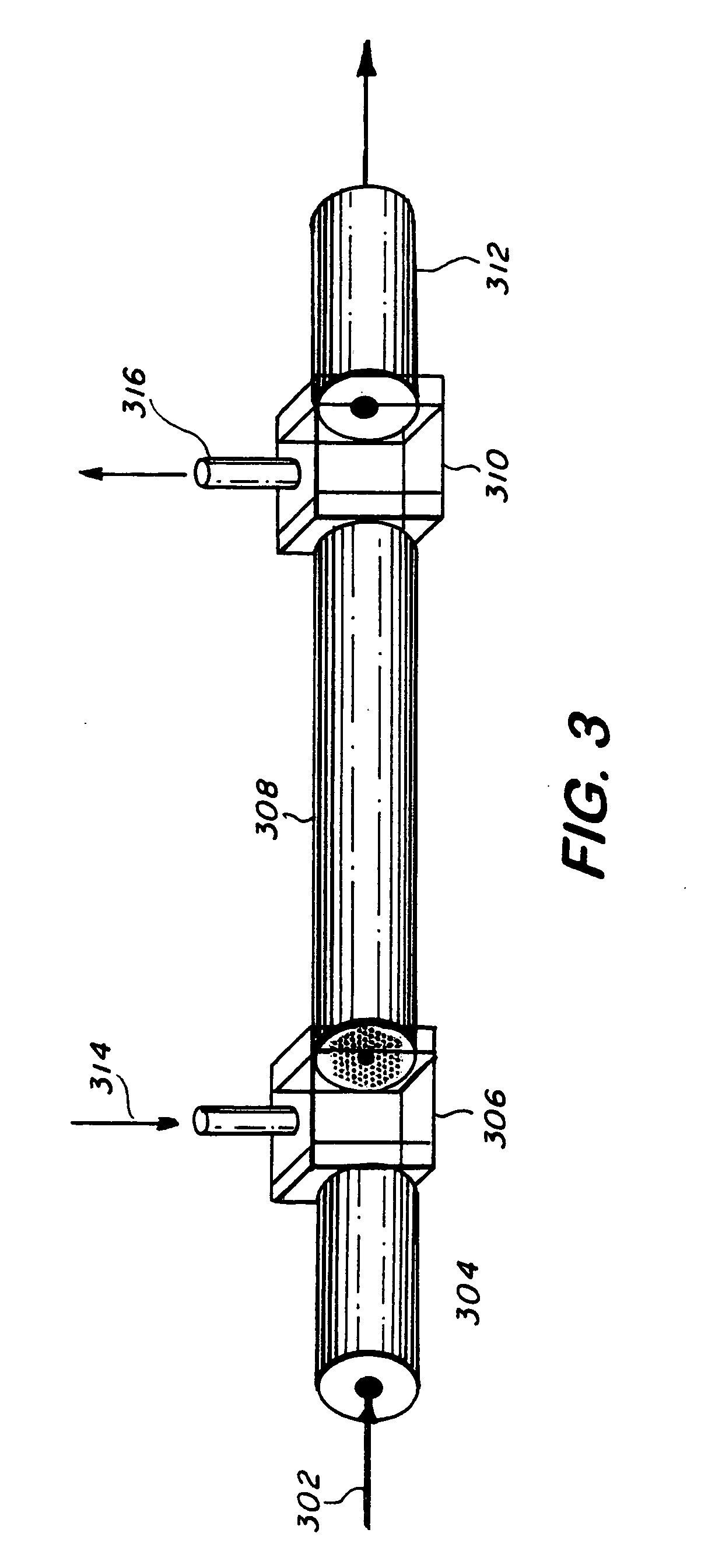

Hollow core photonic band gap infrared fibers

This invention pertains to a hollow core photonic band gap chalcogenide optical glass fiber and to a fabrication method for making the fiber. The fiber, which is 80-1000 microns in outside diameter, is characterized by a solid glass circumferential region and a structured region disposed centrally within the solid region, the structured region includes a hollow core of 1 micron to several hundreds of microns in diameter surrounded by a plurality of parallel hollow capillaries extending parallel to the core, the core being centrally and longitudinally located within the fiber. Ratio of open space to glass in the structured region is 30-99%. The fabrication method includes the steps of providing a mold, placing chalcogenide micro-tubes around the mold, stacking chalcogenide micro-canes around the stacked micro-tubes, fusing the micro-tubes and the micro-canes to form a preform, removing the mold and drawing the preform to obtain the fiber. In an alternative fabrication method, the fiber is made by extruding flowing chalcogenide glass through suitably made plate to form a preform and then drawing the preform to form the fiber.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Mineral glass beads for road markings

InactiveCN101857368AHigh reflective brightnessStrong retro-reflective effectSmithsoniteRefractive index

The invention relates to mineral glass beads for road markings, which relates to optical glass beads and solves the problems of low refractive index and poor reflective brightness of the current glass beads for the road markings. The mineral glass beads for the road markings are the optical glass beads, wherein the glass beads are prepared from the following components in part by weight: 40 parts of sandstone, 28 to 32 parts of barite, 1835 to 22.5 parts of diamond, 2.5 parts of datolite, 2 parts of feldspar, 4 parts of mirabilite and 2 parts of smithsonite. The mineral glass beads can be widely used in road markings of airfield runways and high-level roads.

Owner:大庆路通科技有限公司

Optical glass, glass gob for press-molding, optical part, process for producing glass shaped material and process for producing optical part

An optical glass having a high light transmittance, a high refractive index and excellent production stability, which contains at least one of CaO and SrO together with SiO2, B2O3, La2O3, Nb2O5, TiO2 and BaO, having a composition that substantially contains, by weight %, 1 to 18% of SiO2, 3 to 24% of B2O3, provided that the ratio of content of B2O3 to the content of SiO2 (B2O3 / SiO2) is over 1, 10 to 50% of La2O3, 1 to 30% of Nb2O5, 1 to 30% of TiO2, over 6% but not more than 25% of BaO, less than 7% of CaO, 6% or less of SrO, 0 to 13% of MgO, provided that the total content of BaO, CaO, SrO and MgO is 40% or less, 0 to 15% of ZnO, 0 to 15% of ZrO2, 0 to 10% of Al2O3, 0 to 20% of Gd2O3, 0% or more but less than 2% of Y2O3, 0 to 5% of Yb2O3, 0 to 18% of Ta2O5, 0 to 20% of Bi2O3, 0 to 10% of GeO2, 0% or more but less than 2% of Sb2O3, and 0% or more but less than 2% of SnO2, and having a refractive index (nd) of over 1.8, Abbe's number (νd) of 28 to 40 and a density of 4.2 g / cm3 or more.

Owner:HOYA CORP

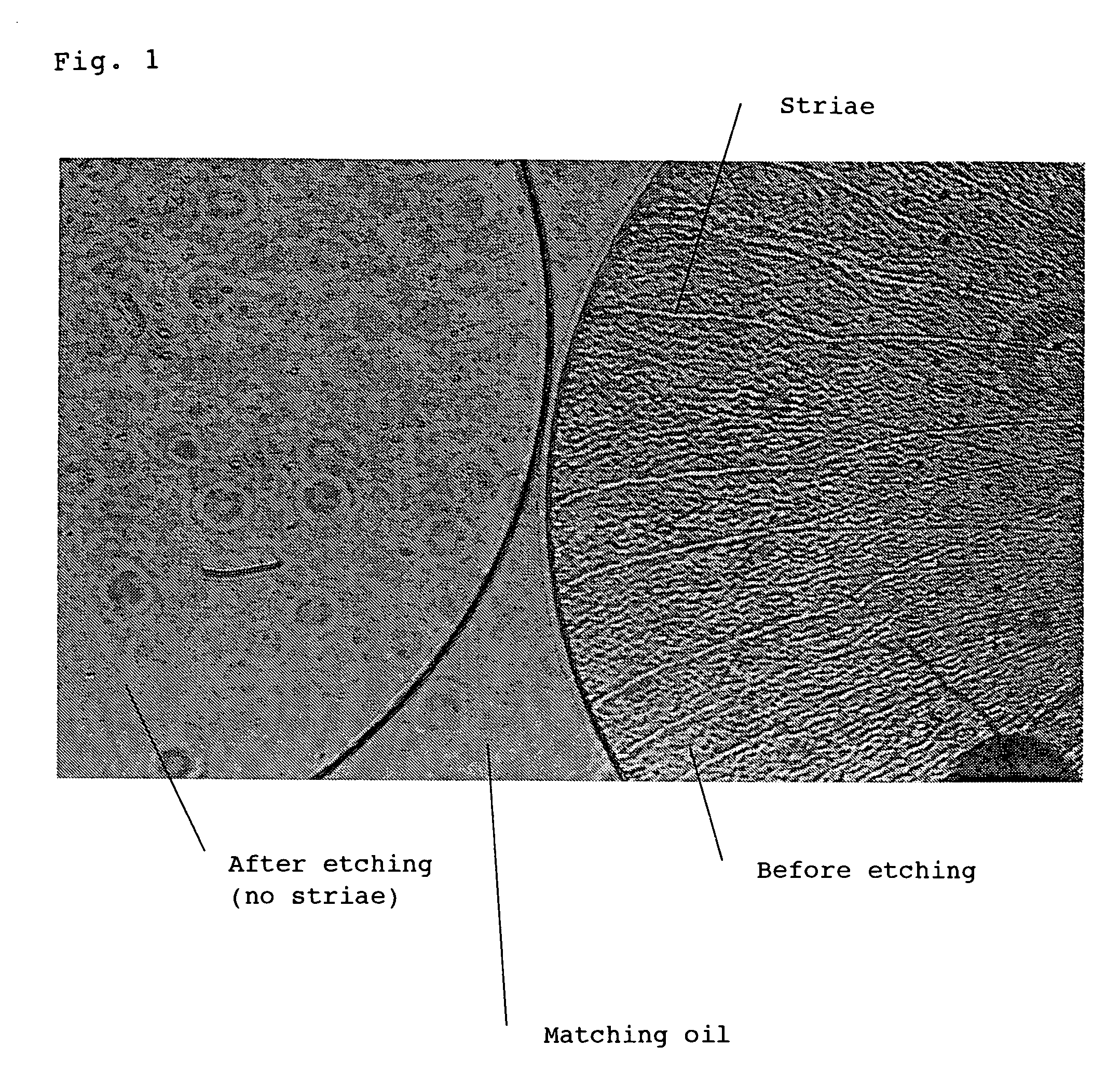

Optical glass and optical product

When a glass melt of an optical glass having a refractive index (nd) of at least 1.7 and an Abbe number (νd) of 28 to 41 is flowed down from a flow pipe made of Pt or a Pt alloy to form glass gobs continuously, there is caused a problem that the glass gobs have striae or that the weight variability among the glass gobs is large, and the problem can be overcome by the use of an optical glass comprising silicon oxide and boron oxide, the ratio of a content of the silicon oxide to a content of the boron oxide being greater than 0.78, the optical glass having a contact angle of at least 40° to Pt or a Pt alloy at a predetermined temperature equivalent to, or higher than, its liquidus temperature or in a predetermined temperature range whose lower limit is equivalent to, or higher than, the liquidus temperature and having a sag temperature Ts of 580° C. or lower.

Owner:HOYA CORP

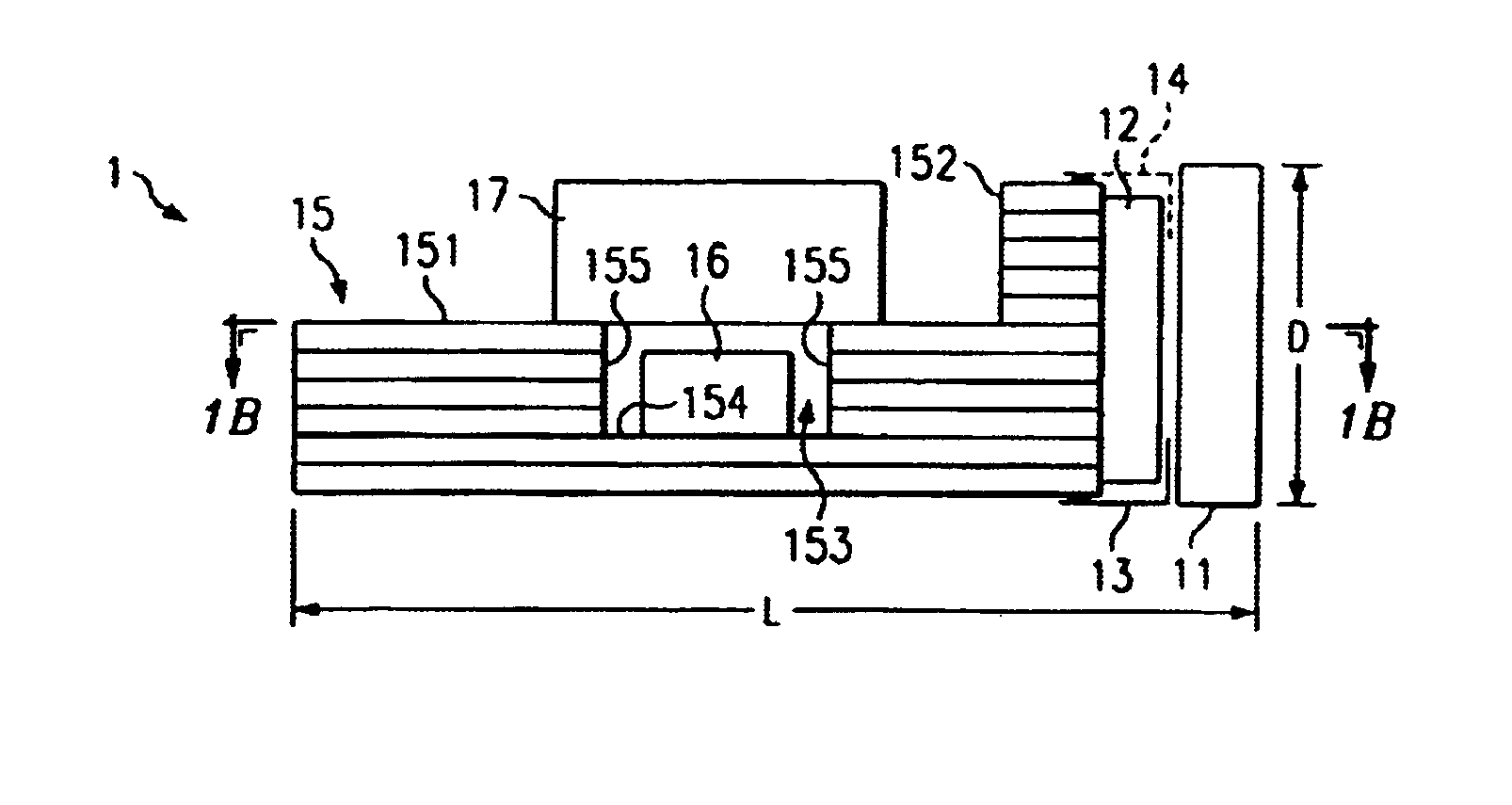

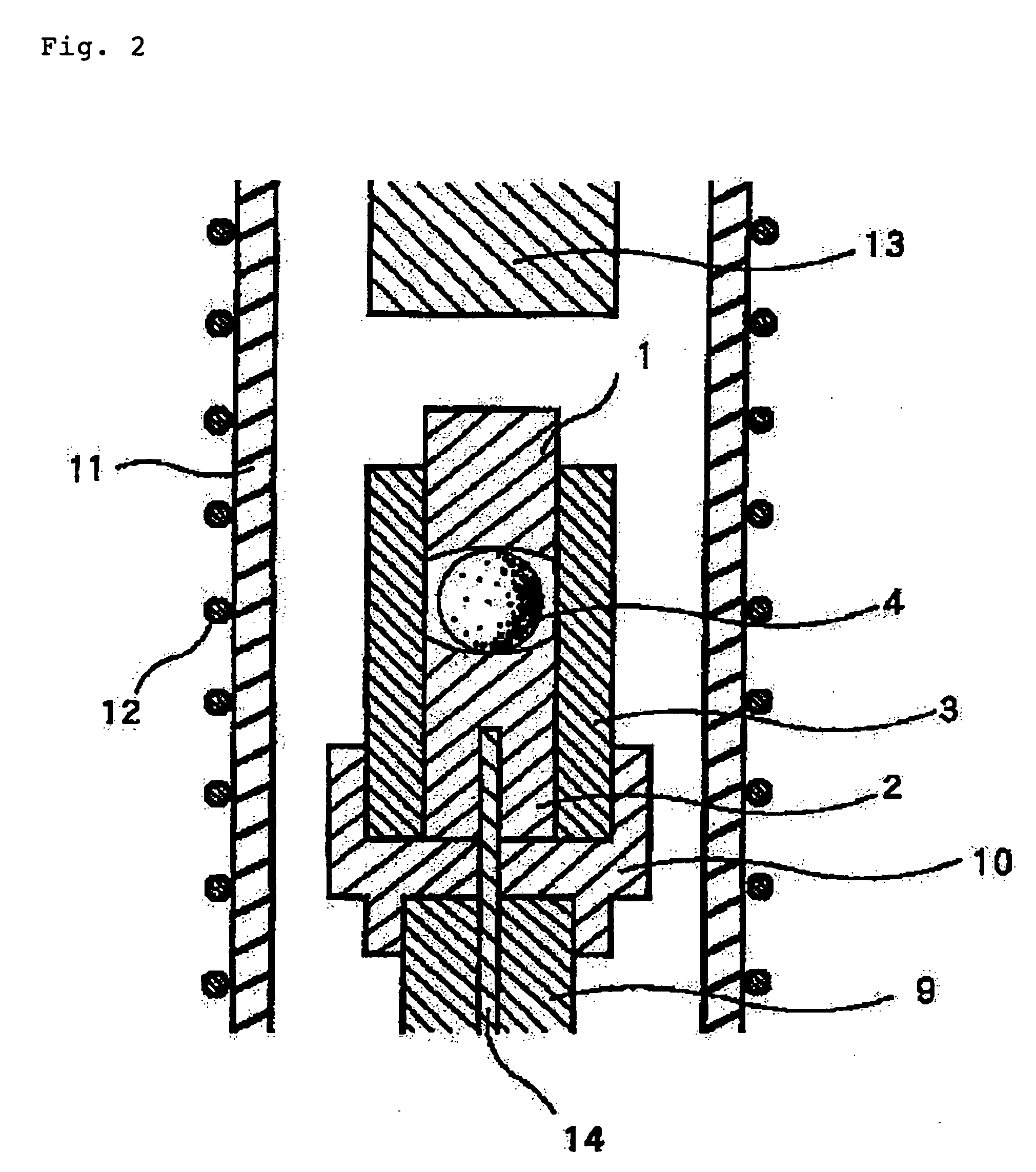

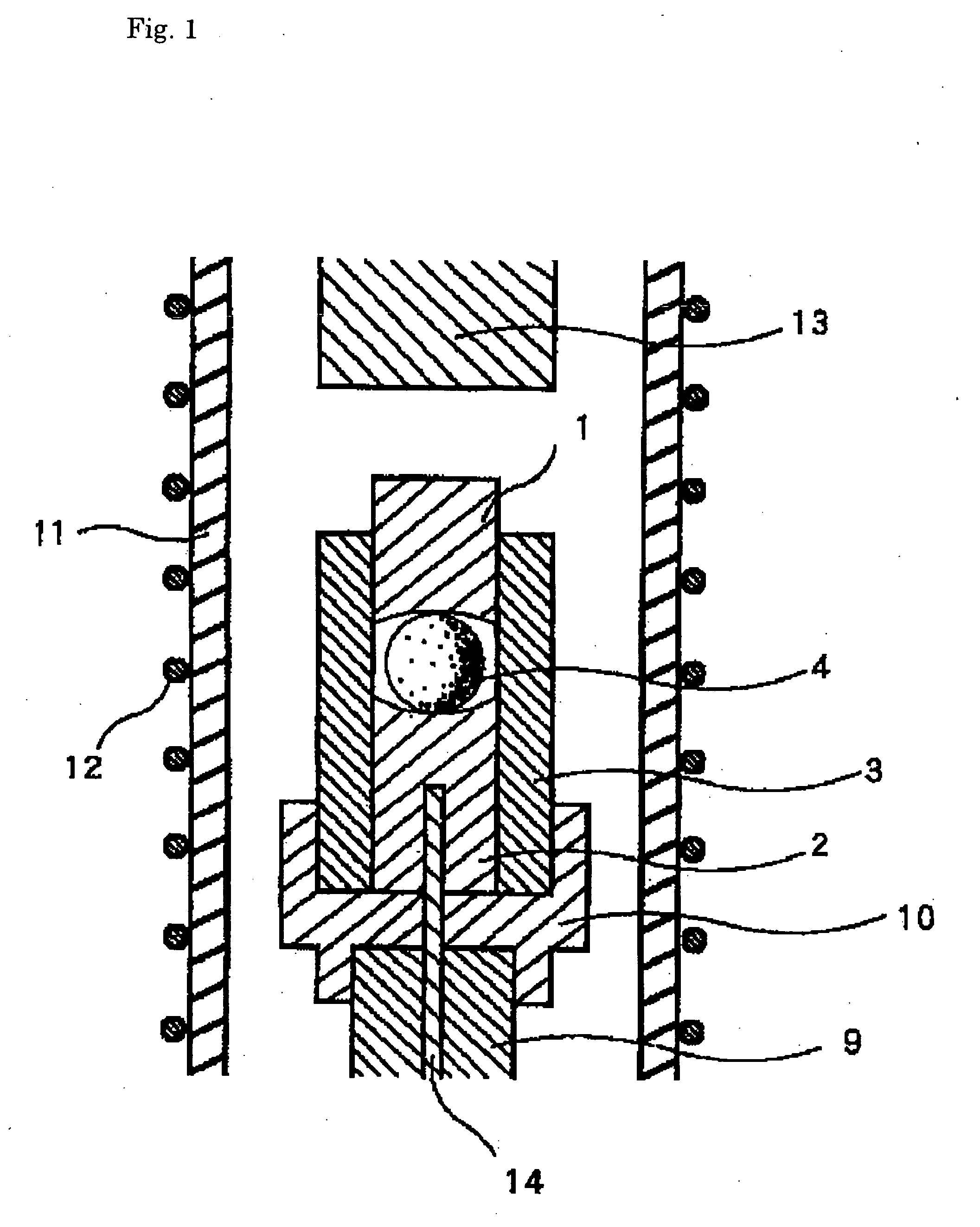

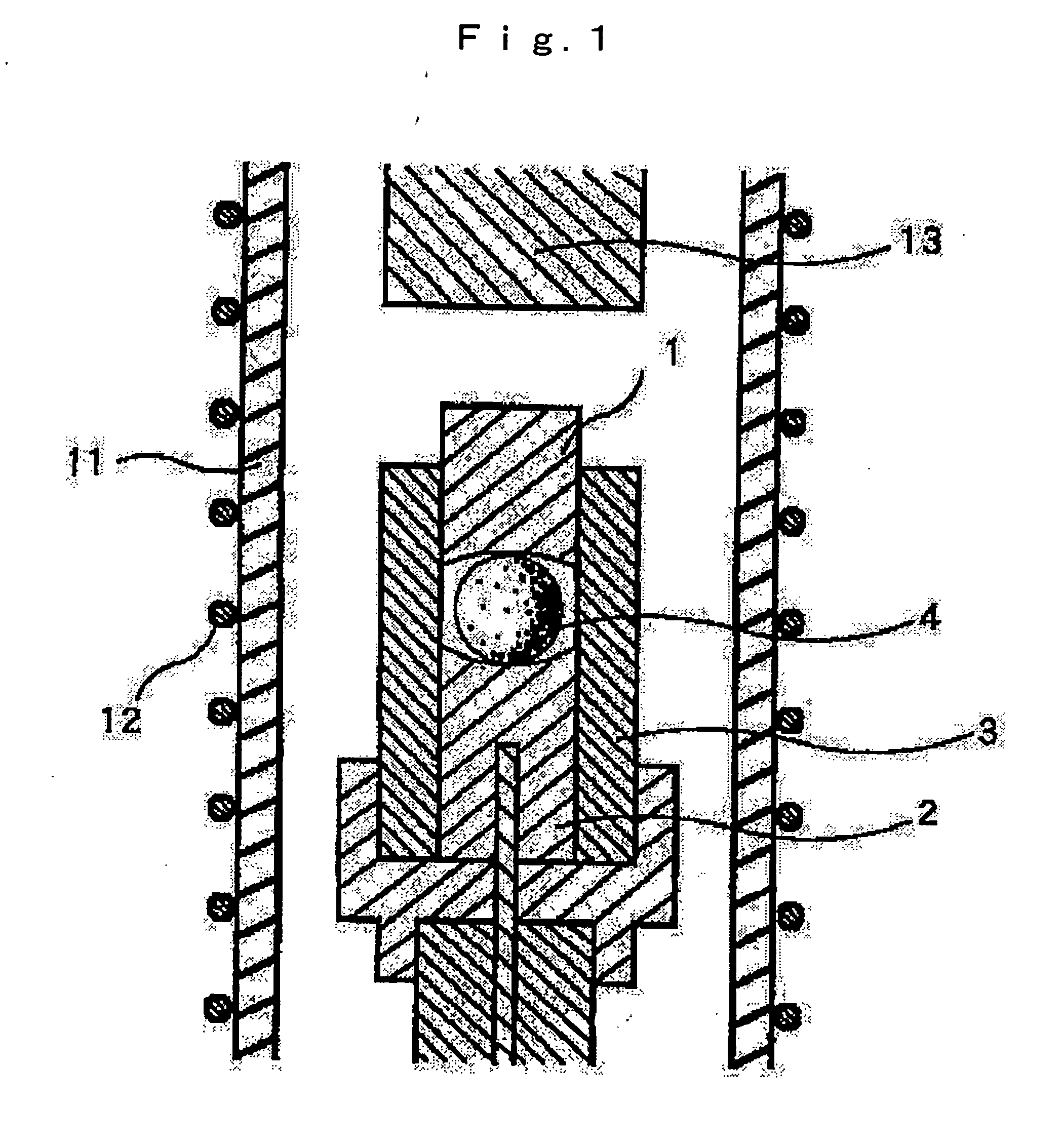

Microminiature image pickup device

InactiveUS6947090B2Simple processReduce processing timeTelevision system detailsSolid-state devicesEngineeringOptical glass

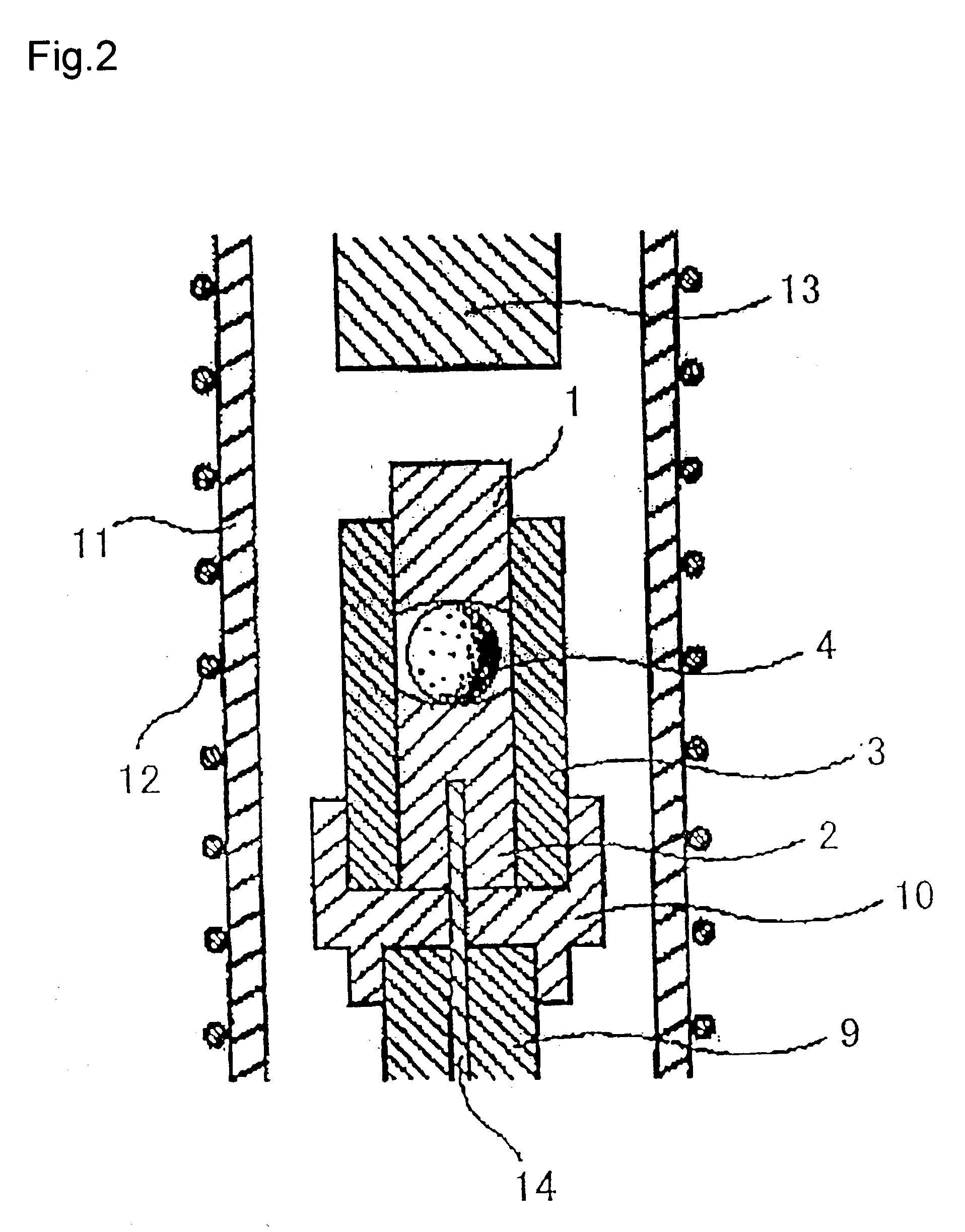

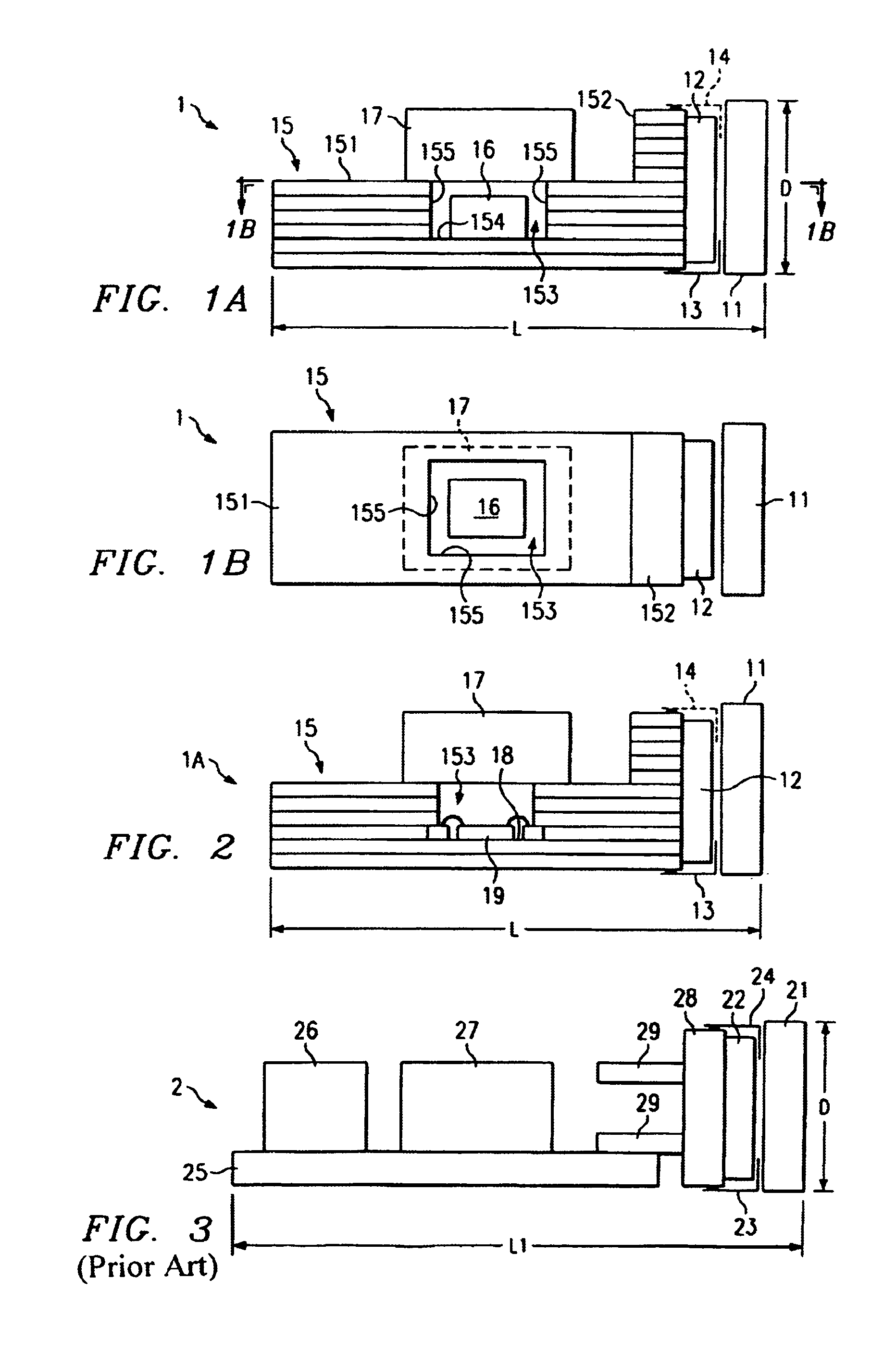

A microminiature CCD image pickup device with a shortened length that can be applied to an electronic medical endoscope or the like. Microminiature CCD image pickup device (1) has optical glass (11), CCD chip (12), and stacked circuit board (15) that are disposed in that order along its length orientation. It further has TAB tape (13) that connects CCD chip (12) and the electronic circuits mounted on stacked circuit board (15). Stacked circuit board (15) is formed with insulated circuit board in which are packaged electronic circuits, including their wiring pattern, stacked in stacked layers in the diametral direction perpendicular to said length orientation, and has at least one cavity (153) formed as an indention in the diametral direction. At least one miniature chip component (16) is mounted in cavity (153), and at least one chip component (17) is mounted on the surface of stacked circuit board (15) over cavity (153). The electronic circuits are stacked in stacked circuit board (15) and chip components (16) and (17) are disposed in the diametral direction, so that the length of microminiature CCD image pickup device (1) is shortened.

Owner:TEXAS INSTR INC

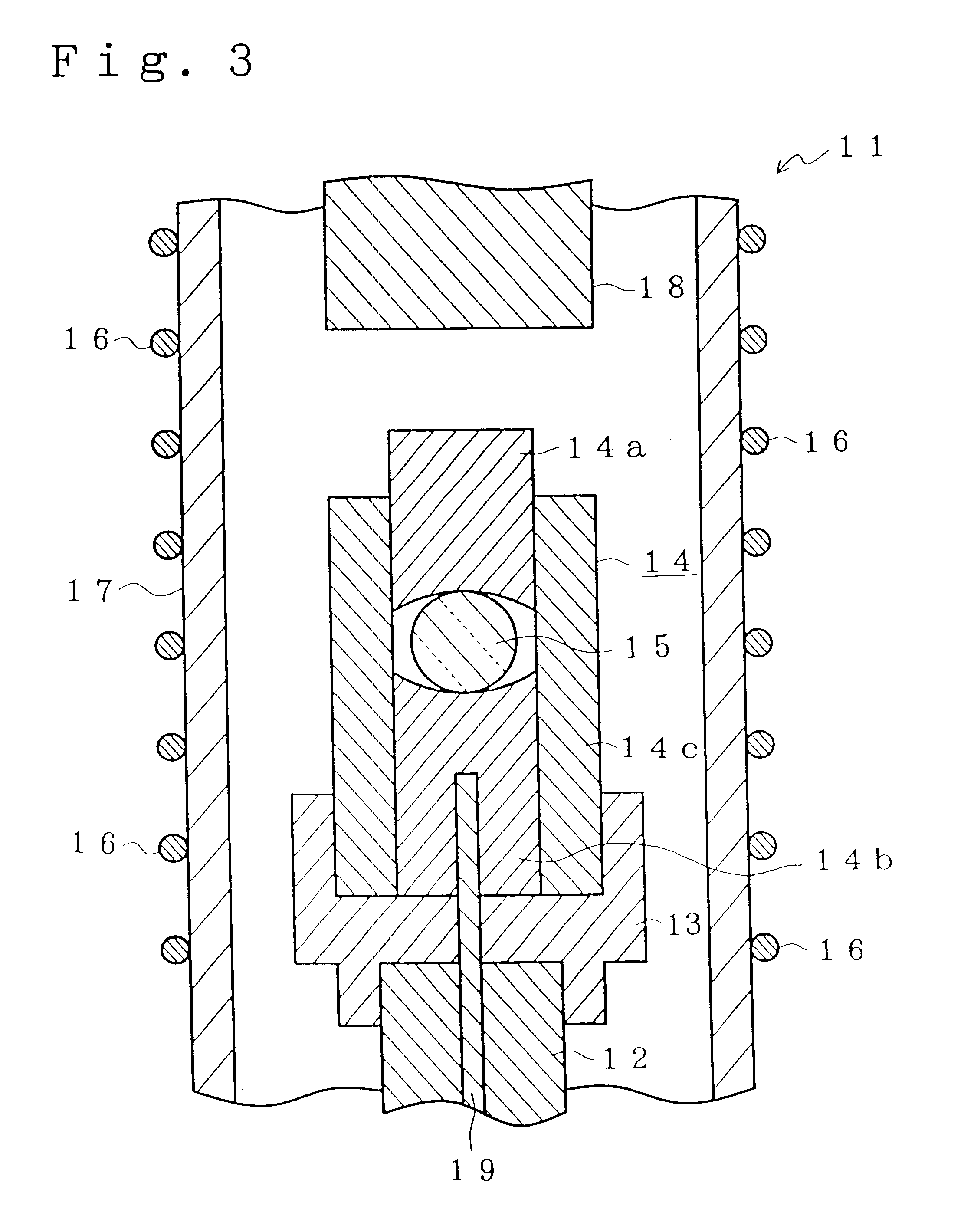

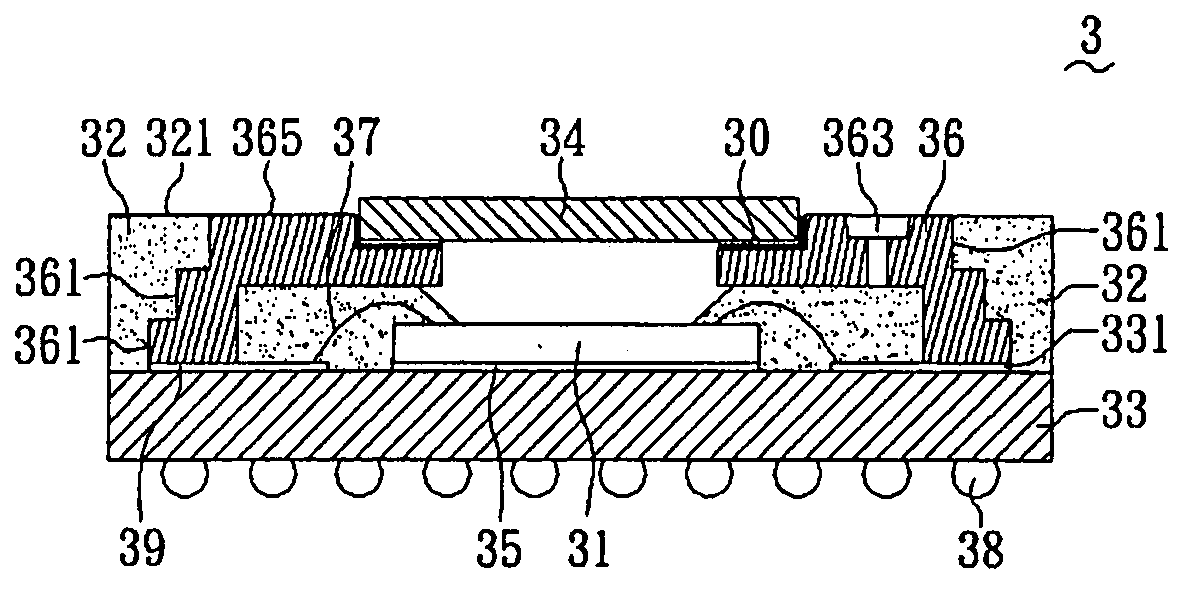

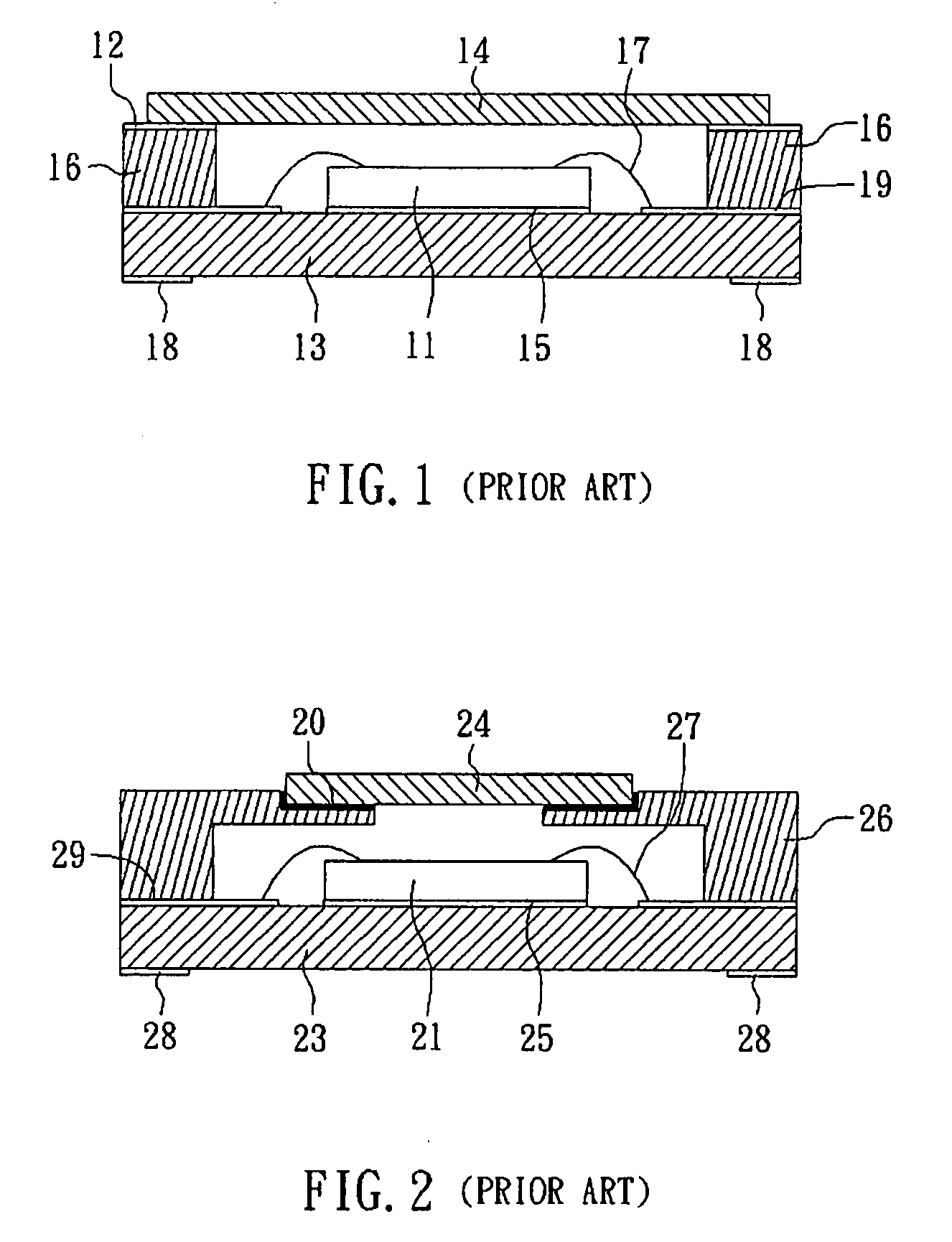

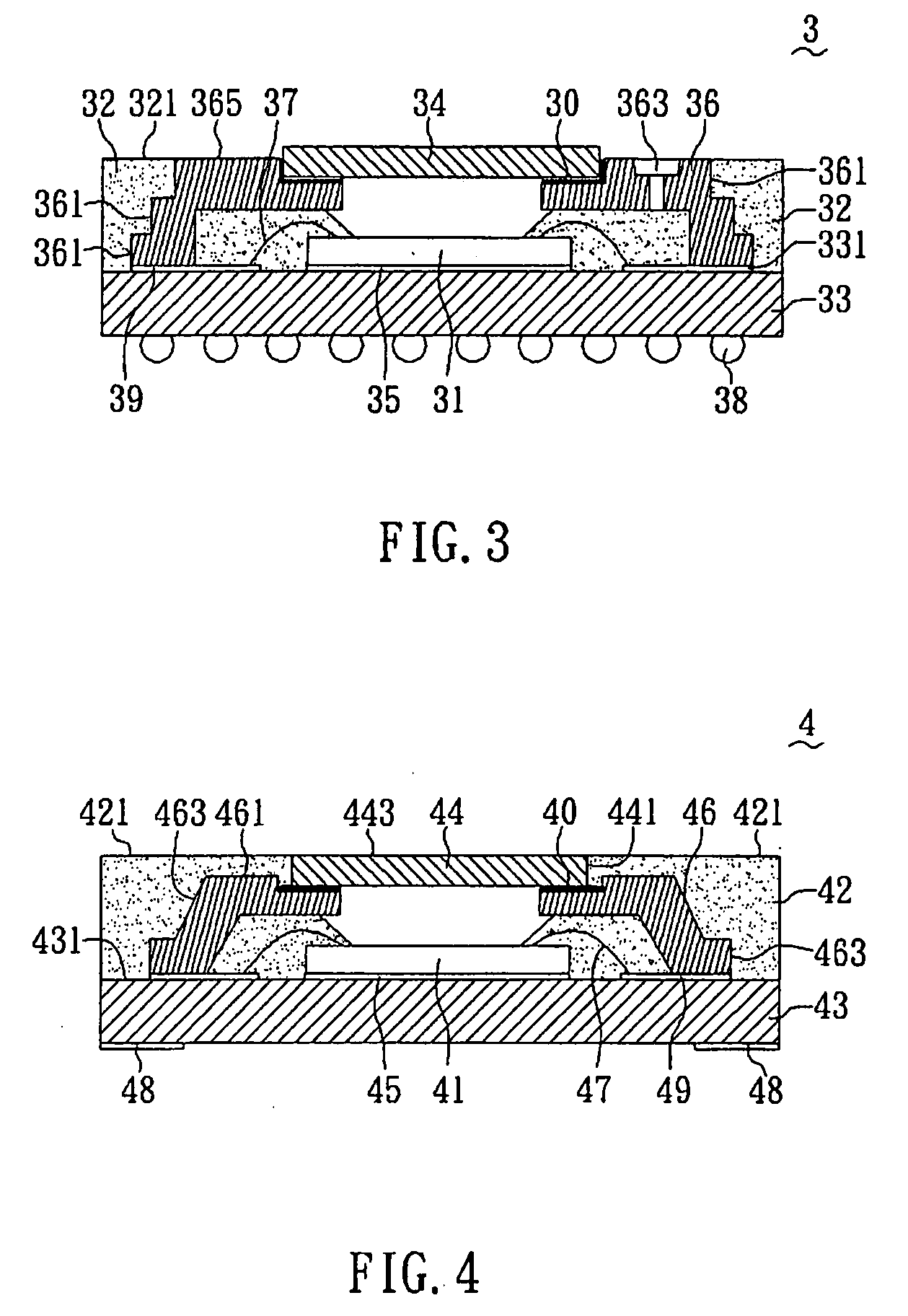

Image sensor package and method for forming the same

InactiveUS20090045476A1Improving structure robustImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesEdge surfaceAdhesive

An image sensor package is provided including a substrate; a sensor chip; a plurality of bond wires for connecting the sensor chip to the substrate at predetermined locations; a sensor housing on the substrate for substantially encompassing the sensor chip, the sensor housing having a through-hole cavity defining an optical glass (IR filter) seat, the sensor housing defining an upper surface and an edge surface thereof; an optical glass (IR filter) on the optical glass (IR filter) seat; an encapsulation material for substantially encapsulating the upper surface and edge surface of the sensor housing, a corresponding surface of the substrate adjacent the edge surface of the sensor housing, and the side edge of the optical glass (IR filter); wherein the sensor housing is provided with a gas-exit allowing possible high temperature gas to exit; the encapsulation material forms an upper surface which is substantially aligned with a top surface of the optical glass (IR filter); the encapsulation material forms an upper surface which is lower than a top surface of the optical glass (IR filter); the sensor housing defines a profile shape, the profile shape has at least a step-wise configuration for facilitating and accommodating flowing of the encapsulation material; the sensor housing has a bottom surface adhered to the substrate by an adhesive; and a slot is provided on the bottom surface of the sensor housing for accommodating the adhesive.

Owner:KINGPAK TECH INC

Process for the production of precision press-molding preform and process for the production of optical element

InactiveUS20050188724A1Highly producedReliably producedGlass drawing apparatusGlass pressing apparatusSurface layerOptical glass

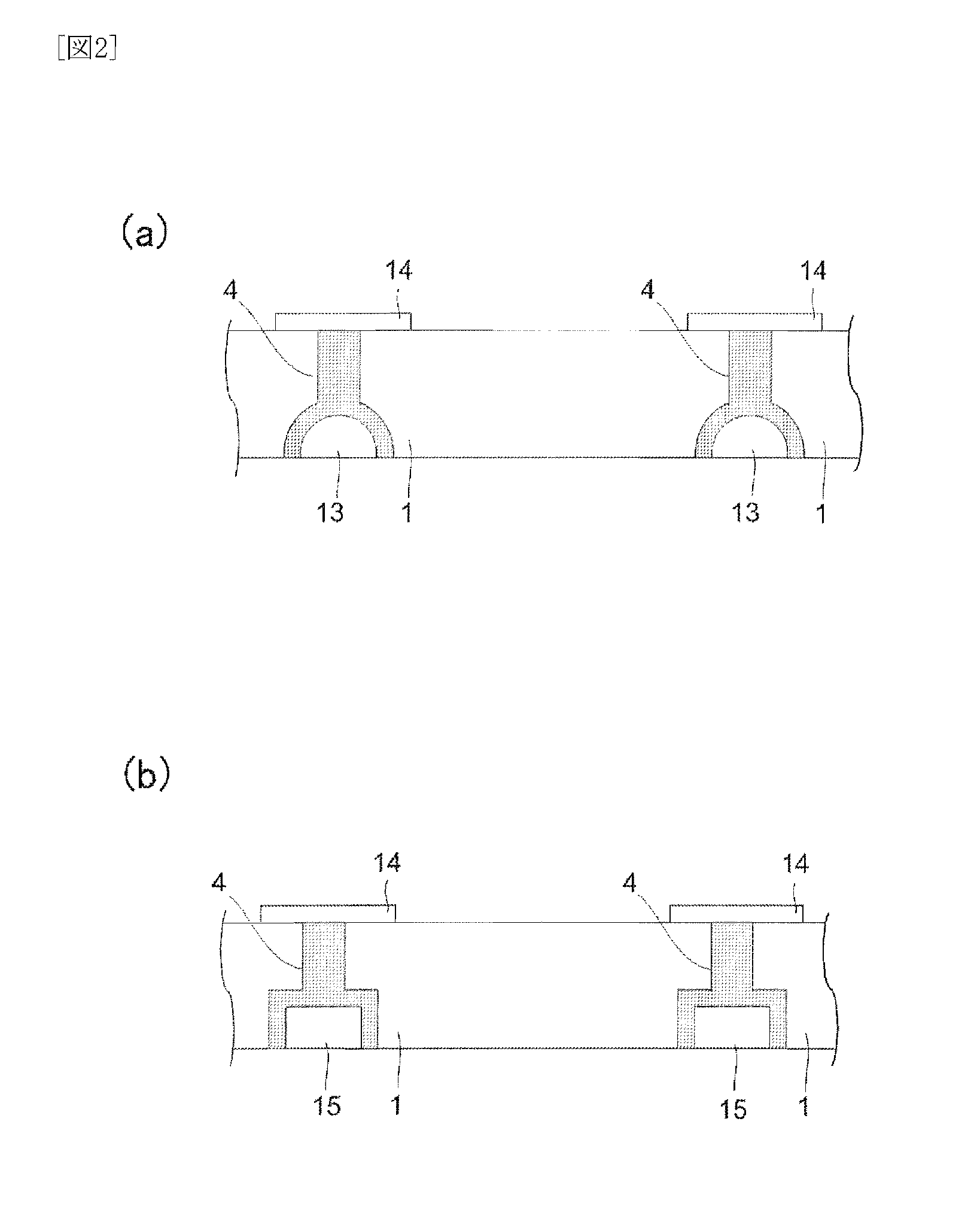

A process for producing a precision press-molding preform having a predetermined weight from a molten glass, wherein the molten glass is shaped into a glass gob and the above glass gob is etched to remove a surface layer of the glass gob to produce the precision press-molding preform formed of an optical glass having said weight, and further wherein said surface layer has a thickness of 0.5 μm or more.

Owner:HOYA CORP

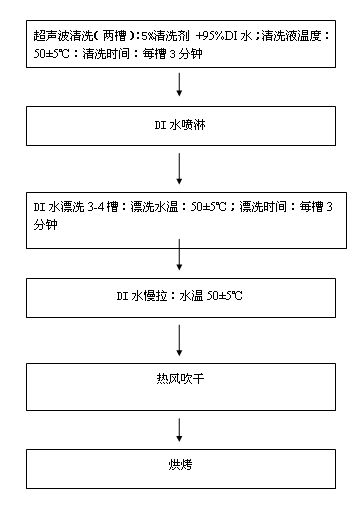

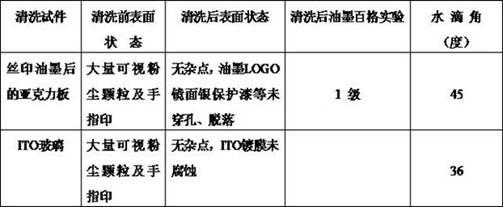

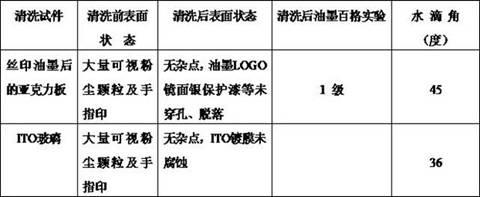

Cleaning agent for optical glass

ActiveCN102604751AEasy to cleanPromote wettingOrganic detergent compounding agentsNon-ionic surface-active compoundsOrganic baseCarbon chain

The invention discloses a cleaning agent for optical glass, which comprises the following components in weight percentage: 2-4% of long carbon chain dibasic acid; 6-10% of an anionic surfactant; 2-4% of an inorganic base; 2-6% of a nonionic surfactant; 2-4% of a special surfactant; 6-12% of a chelator; 10-20% of an organic base; and 40-70% of deionized water, wherein the long carbon chain dibasic acid is dicarboxylic acid with 21 carbon atoms, the anionic surfactant is dodecylbenzene sulfonic acid, the inorganic base is industrial NaOH, the nonionic surfactant is primary alcobol ethoxylate AEO9, the special surfactant is sodium POE nonylphenol ether sodiosulfosuccinate, the chelator is a mixture of Tetrasodium Ethylenediamine Tetraacetate and sodium gluconate, and the organic base is diethanol amine. The cleaning agent for optical glass provided by the invention has low corrosivity and good cleaning effect.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

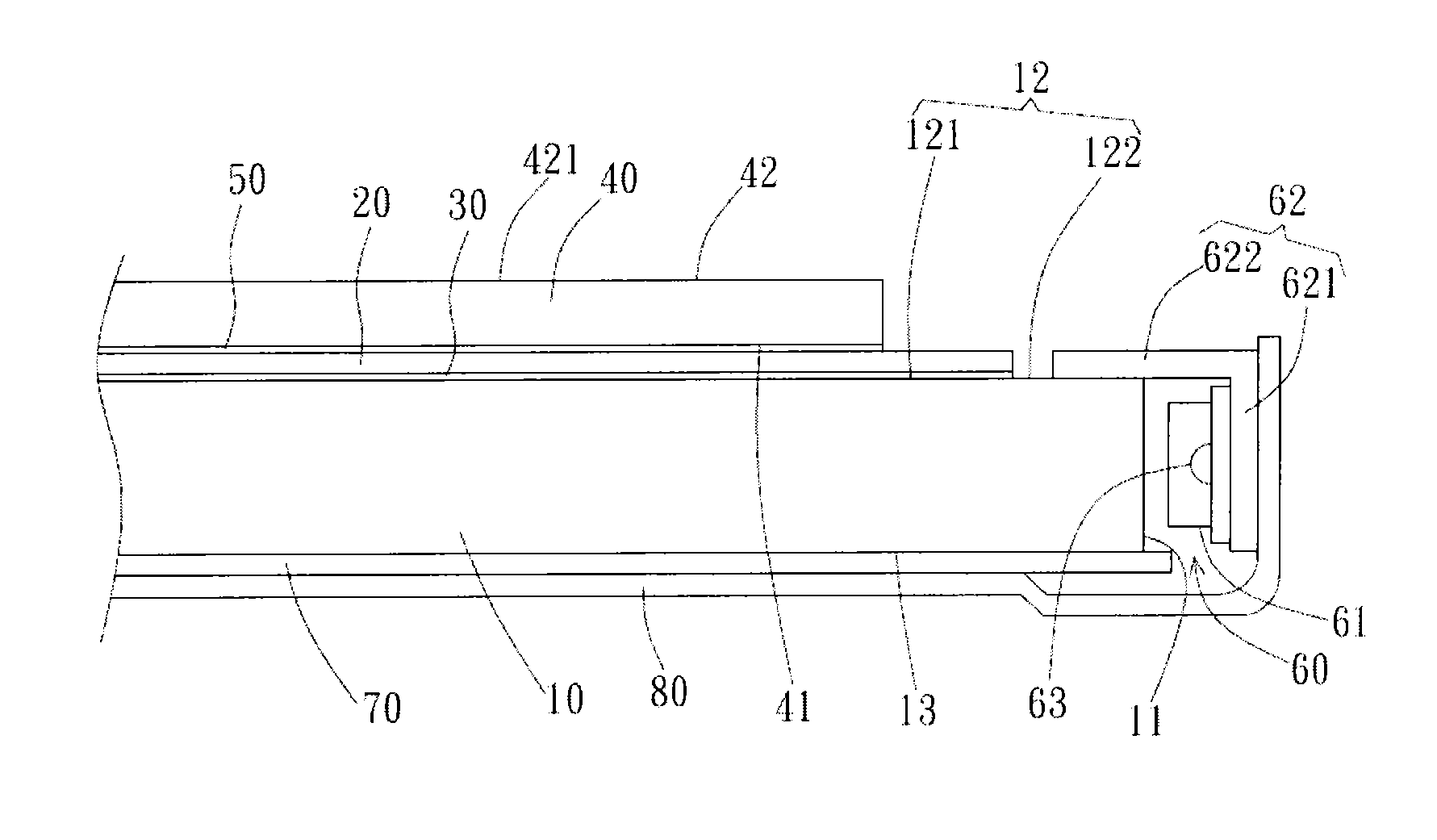

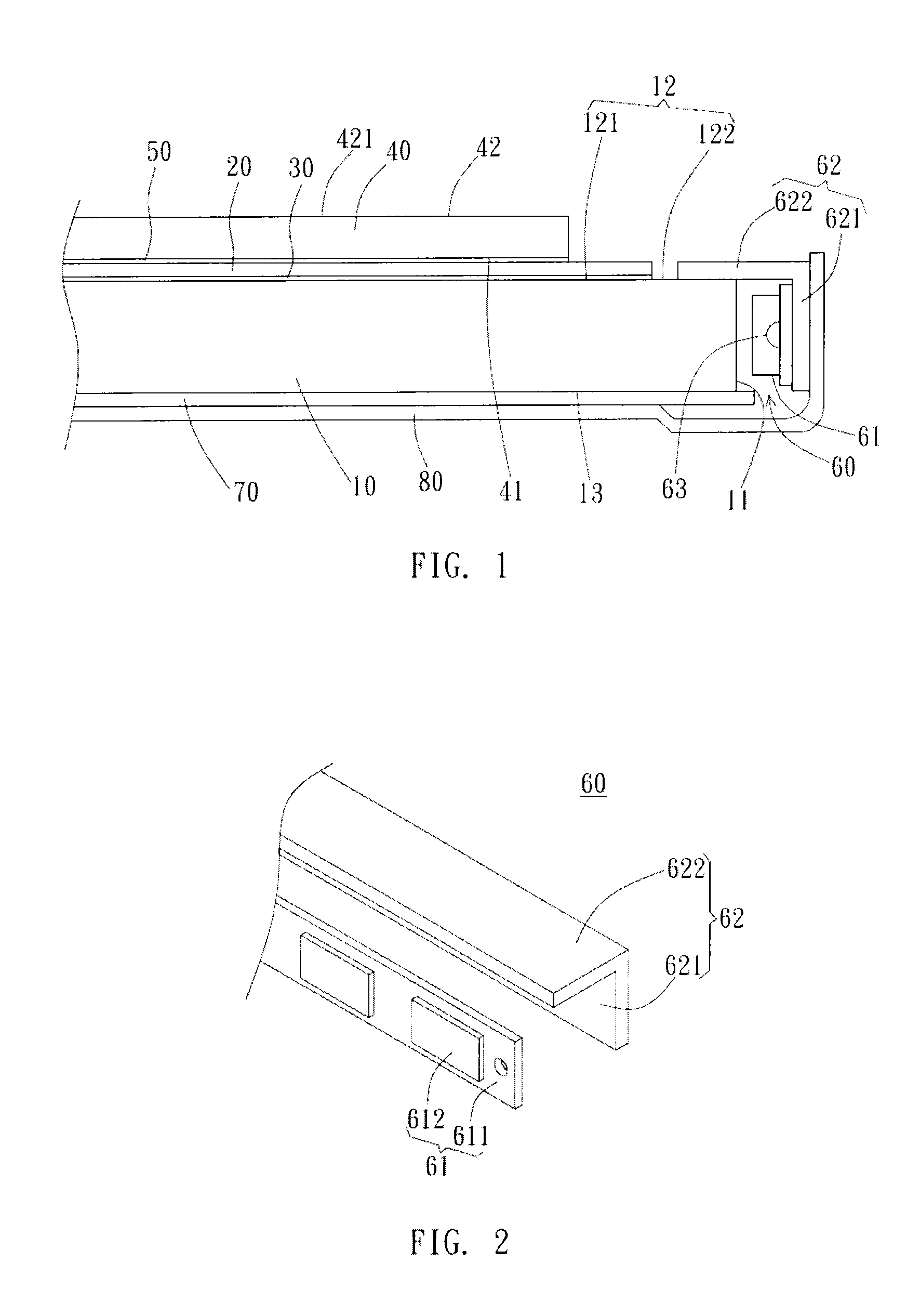

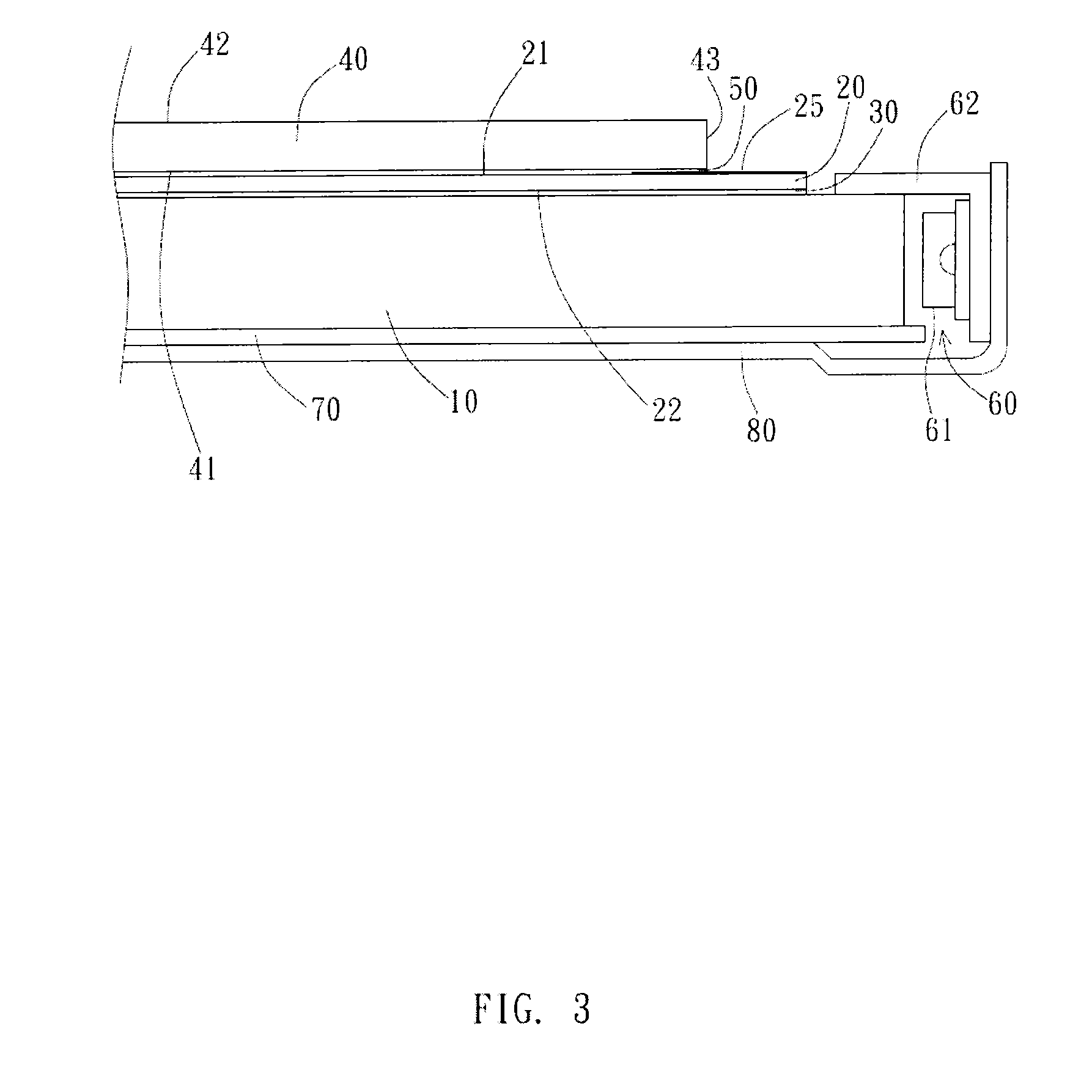

Flat Panel Display Structure and Manufacturing Method Thereof

InactiveUS20120106197A1Avoid deformationHigh strengthAdhesive processesMechanical apparatusLight guideRefractive index

A flat panel display structure and a manufacturing method thereof are provided. The flat panel display structure includes a light guide plate made of optical glass, an optical film disposed on the light guide plate and glued thereon through a first glue layer, a display panel having a light incident surface facing the optical film and a display surface with an active area located at the central portion thereof, a second glue layer gluing the optical film and the display panel so as to cover the light incident surface including the projection of the display area thereon, and a light module emitting lights toward the light guide plate. The refractive indices of the first glue layer and the second glue layer are smaller than or equal to that of the light guide plate and the optical film.

Owner:AU OPTRONICS CORP

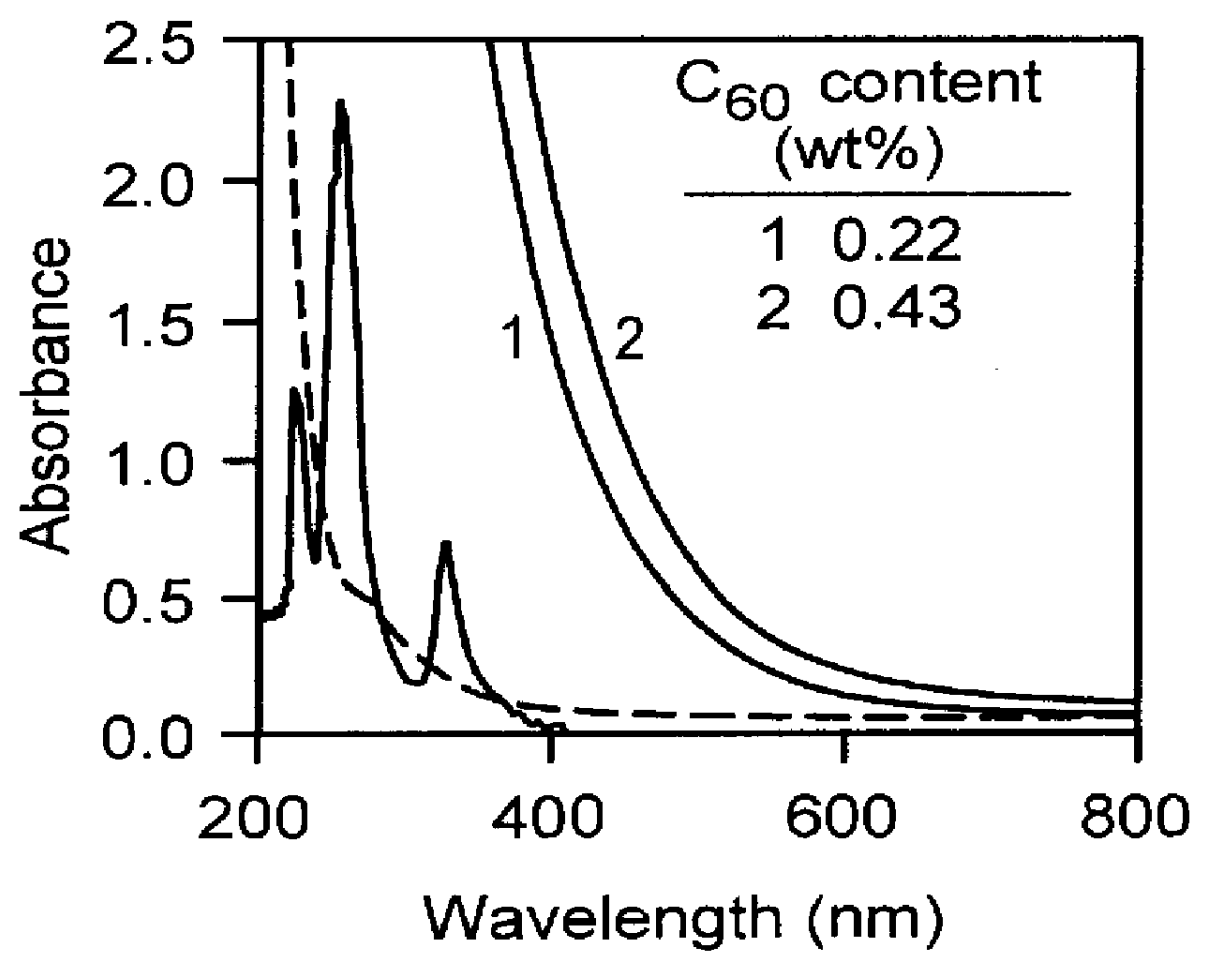

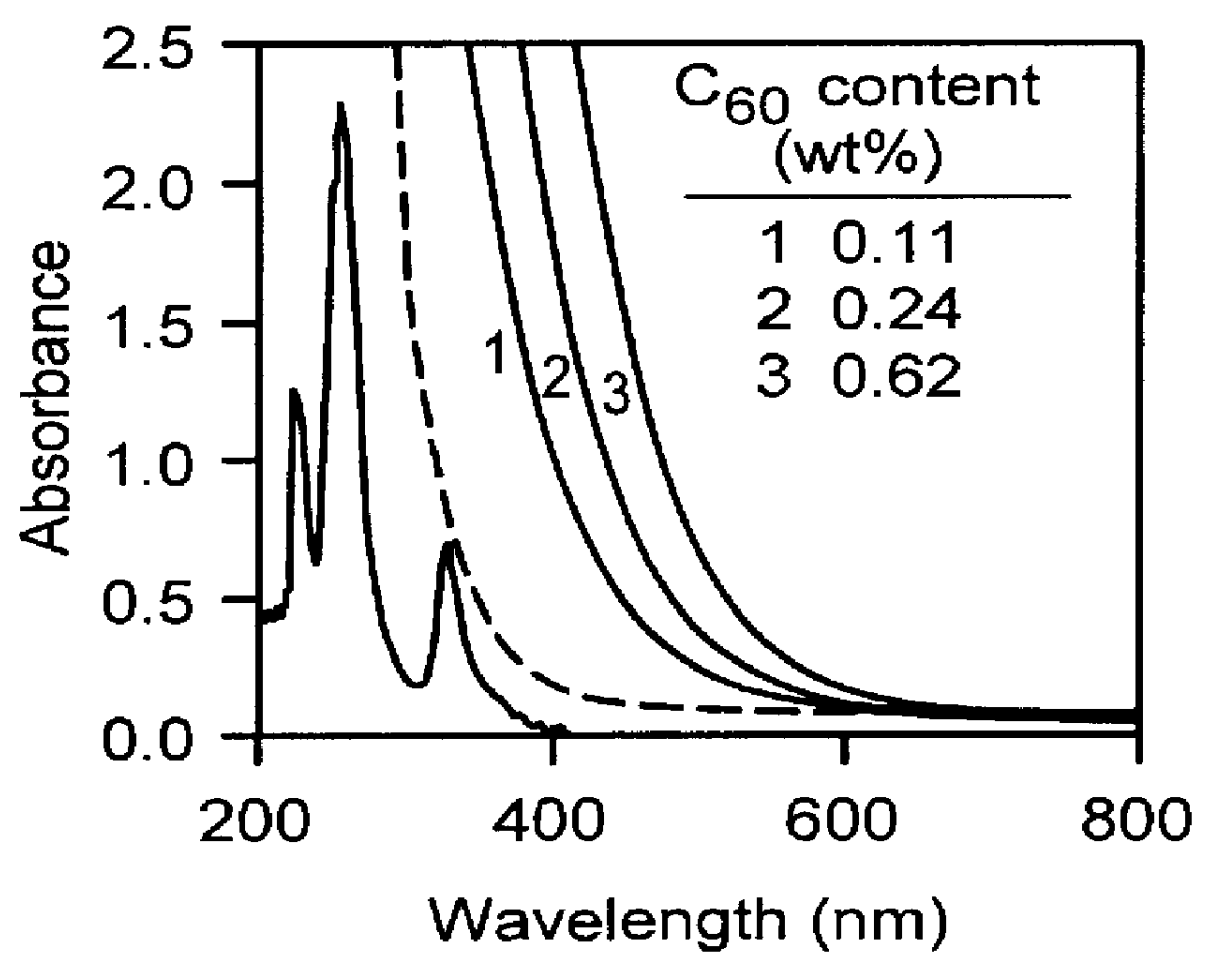

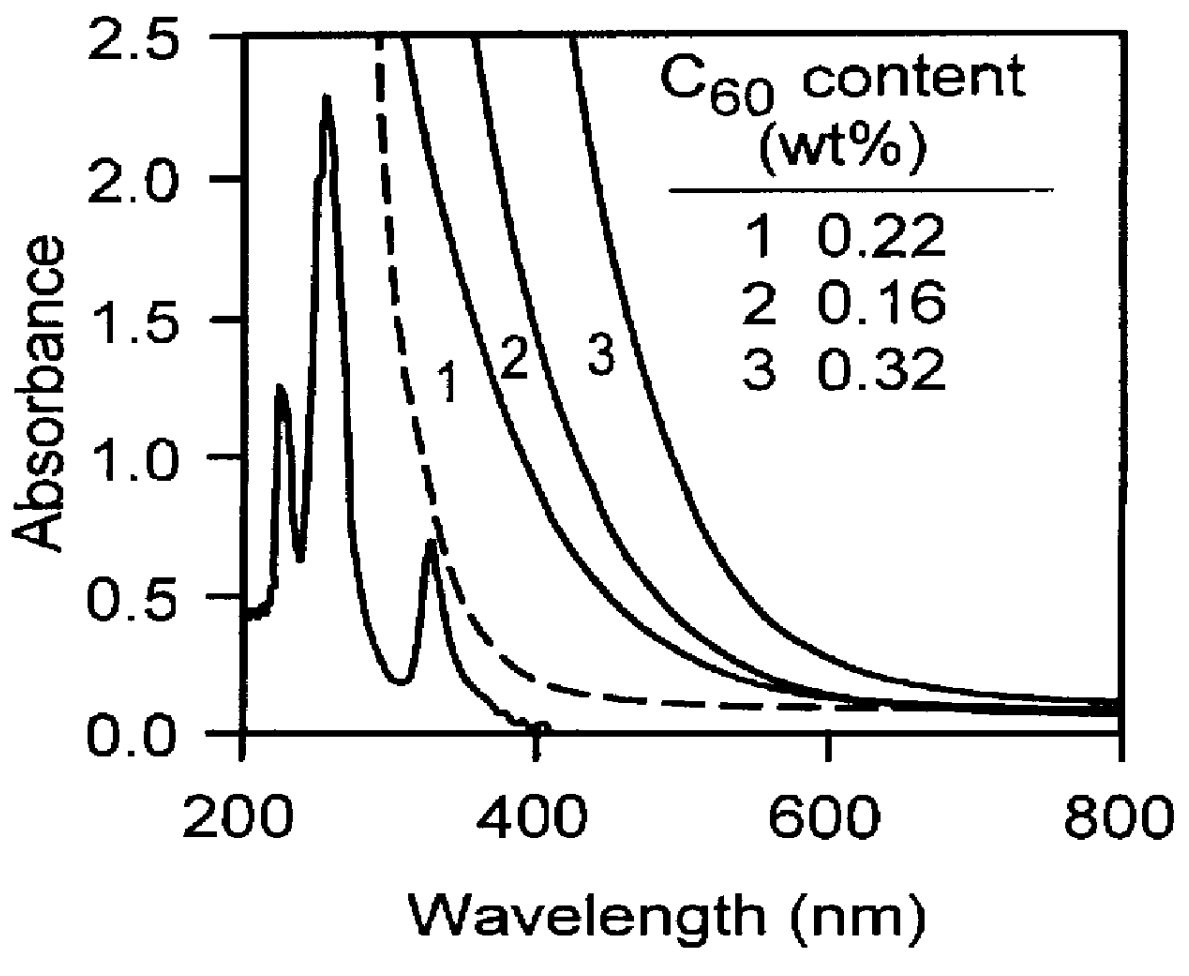

Fullerene-containing optical materials with novel light transmission characteristics

Optical glasses and polymers are described that incorporate homogeneously dispersed fullerene molecules. The resultant materials may be used as optical filters, the cut-off frequency being easily adjustable by changing the fullerene content. To prepare glasses fullerene molecules are firstly functionalized by amination prior to being incorporated into a sol-gel process to prepare the glass. To prepare polymers a pre-existing polymer may be subject to fullerenation, or fullerene may be copolymerized with a selected monomer.

Owner:THE HONG KONG UNIV OF SCI & TECH

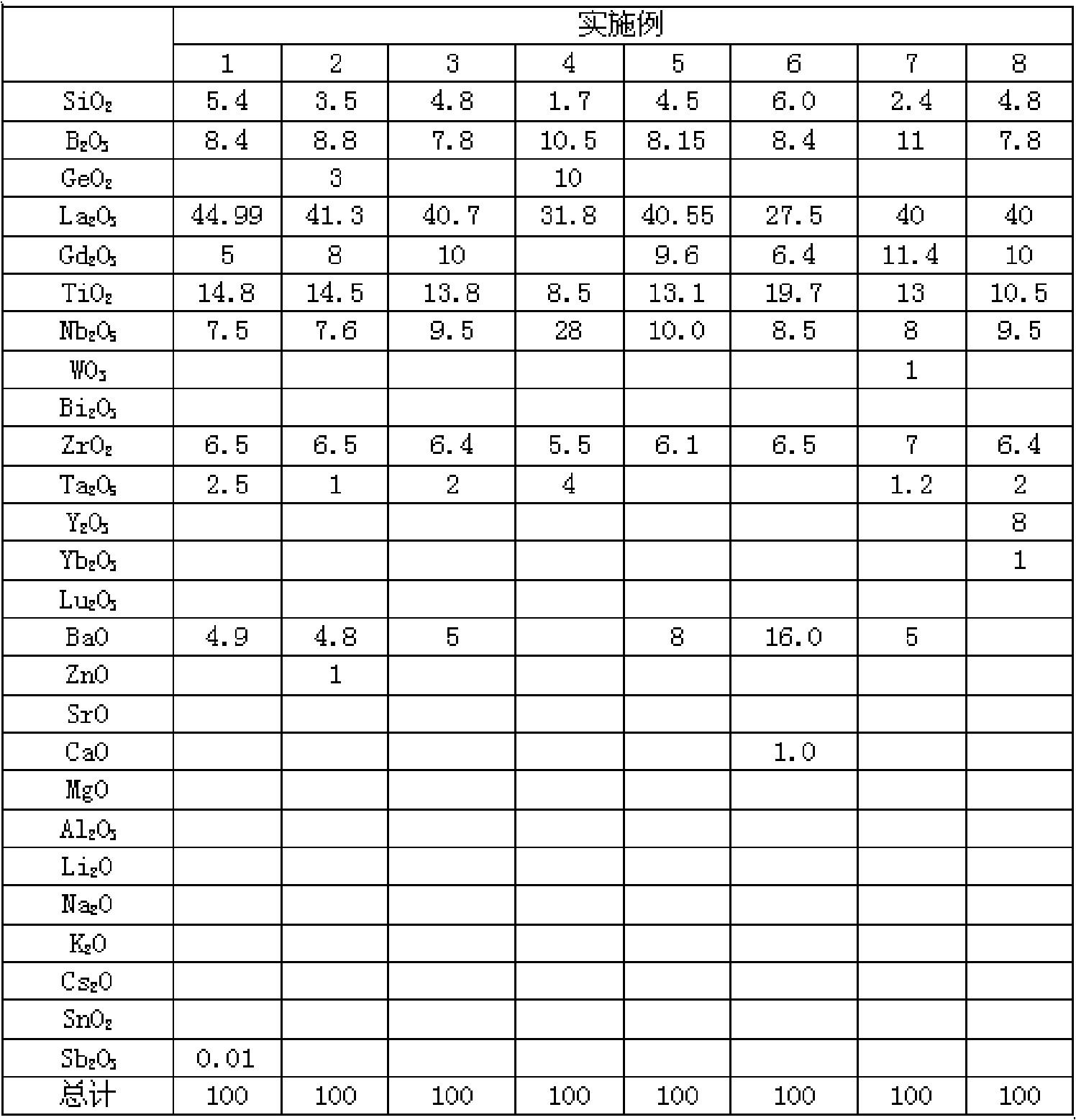

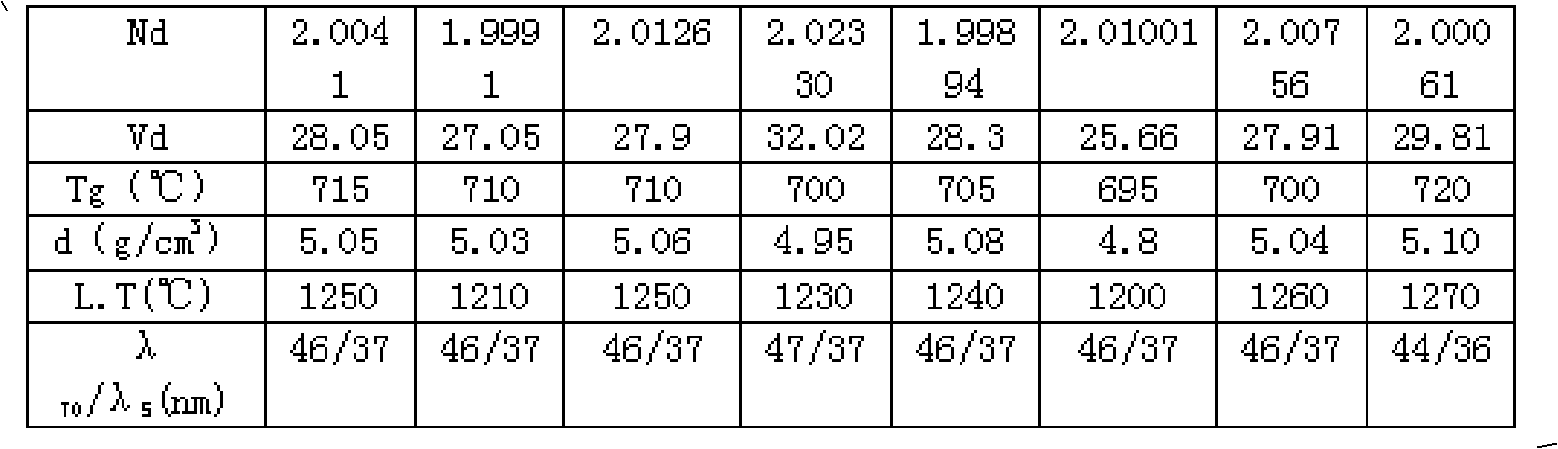

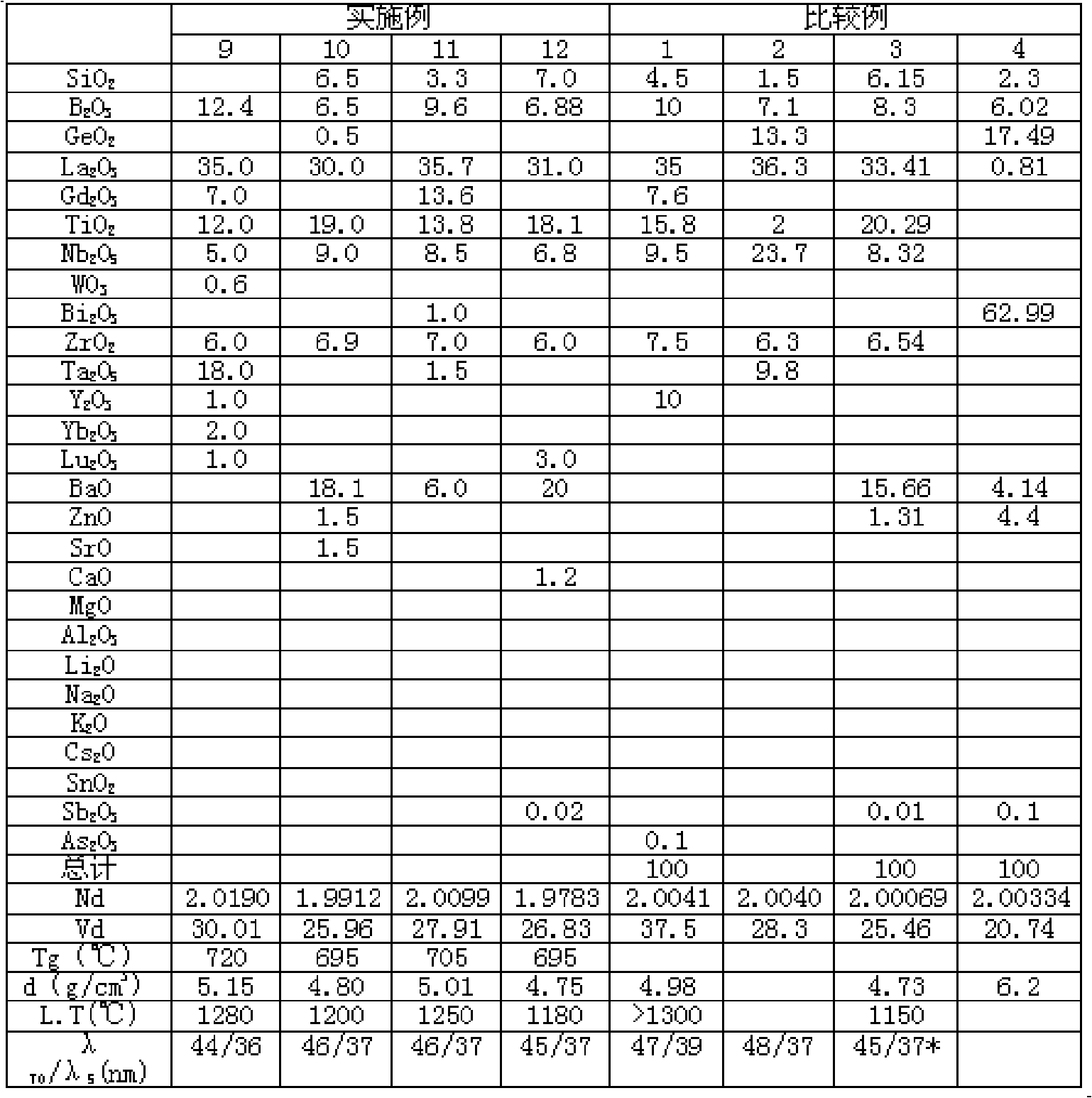

High-refraction and high- dispersion optical glass and method of manufacture

The invention provides a high-refraction and high-dispersion optical glass which comprises 4 percent to 16 percent of B2O3, 0 percent to 15 percent of SiO2, 0 percent to 10 percent of GeO2, 20 percent to 55 percent of La2O3, 0 percent to 20 percent of Gd2 O3, 8 percent to 20 percent of TiO2, 0 percent to 30 percent of Nb2O5, 0 percent to 8 percent of WO3, 0 percent to 20 percent of BaO, 1 percent to 10 percent of ZrO2, 0 percent to 18 percent of Ta2O5, 0 percent to 8 percent of Y2O3, 0 percent to 10 percent of Yb2O3, 0 percent to 15 percent of Lu2O3, 0 percent to 20 percent of Bi2O3, 0 percent to 1 percent of Li2O, etc. The optical glass of the invention contains no environmentally-harmful substances such as lead, arsenic, cadmium, etc., and Nd is more than or equal to 1.95 while Vd is less than or equal to 35; in addition, the L.T of the optical glass is lower than 1300 DEG C and the optical glass is applicable to the industrial mass production.

Owner:CDGM OPTICAL GLASS

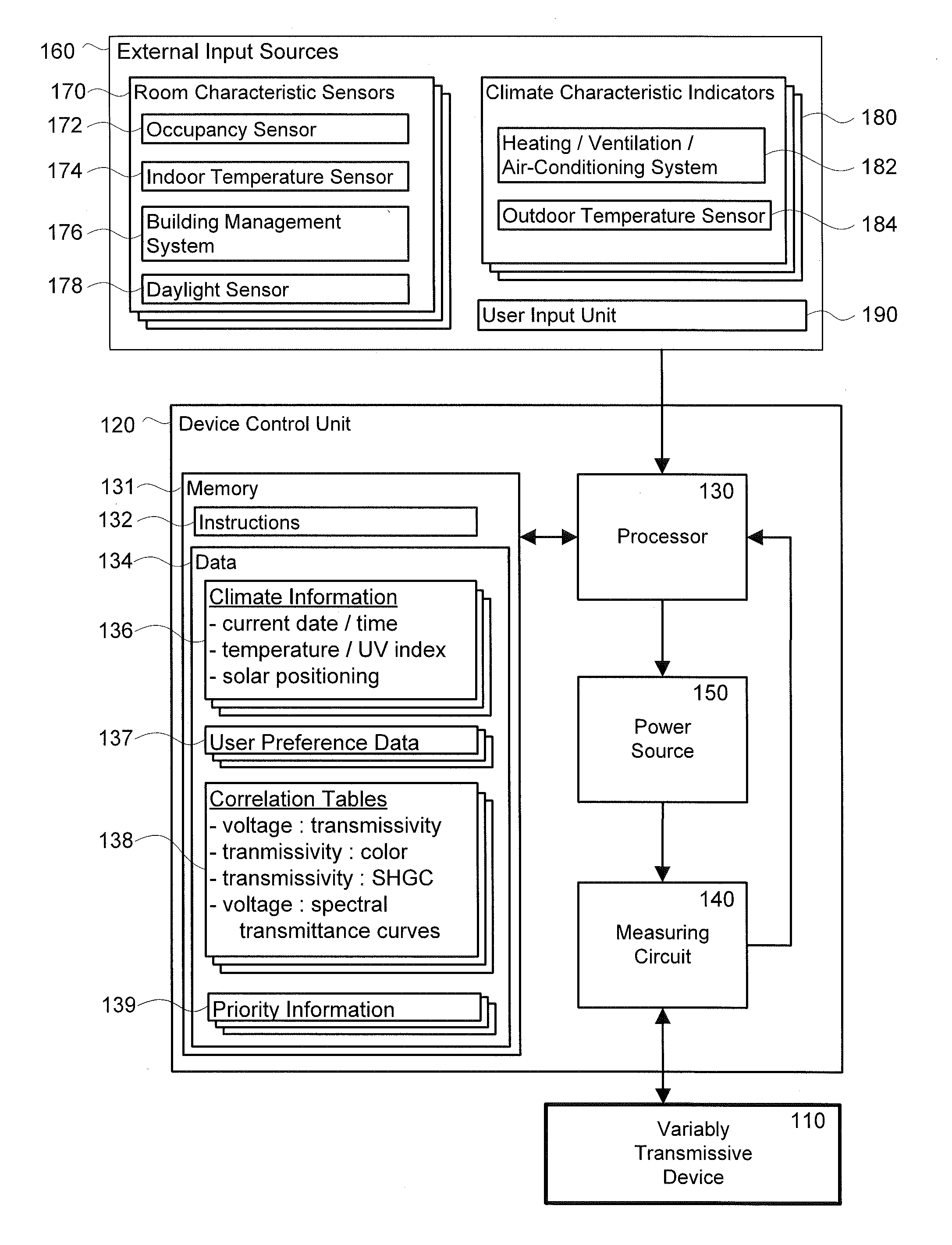

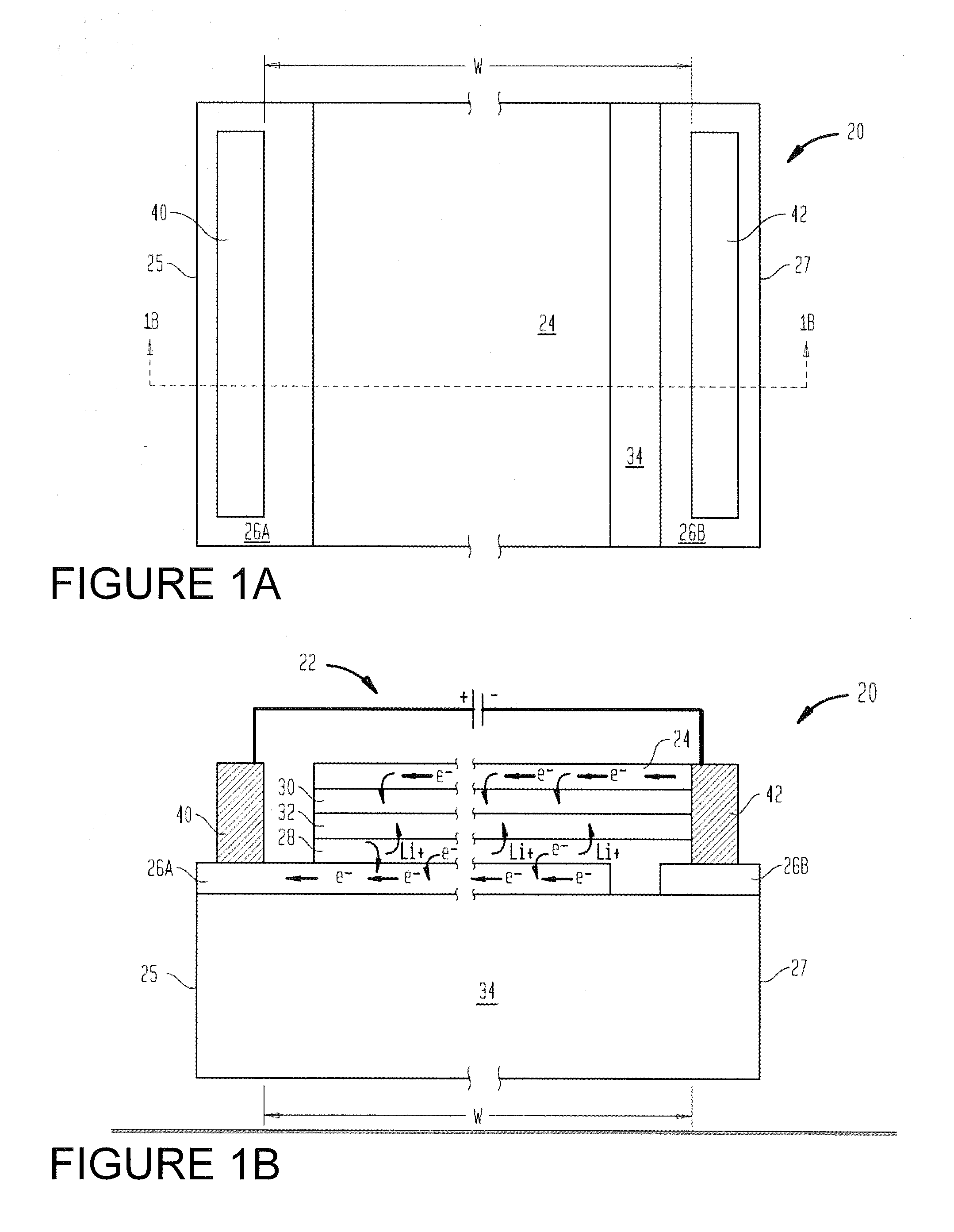

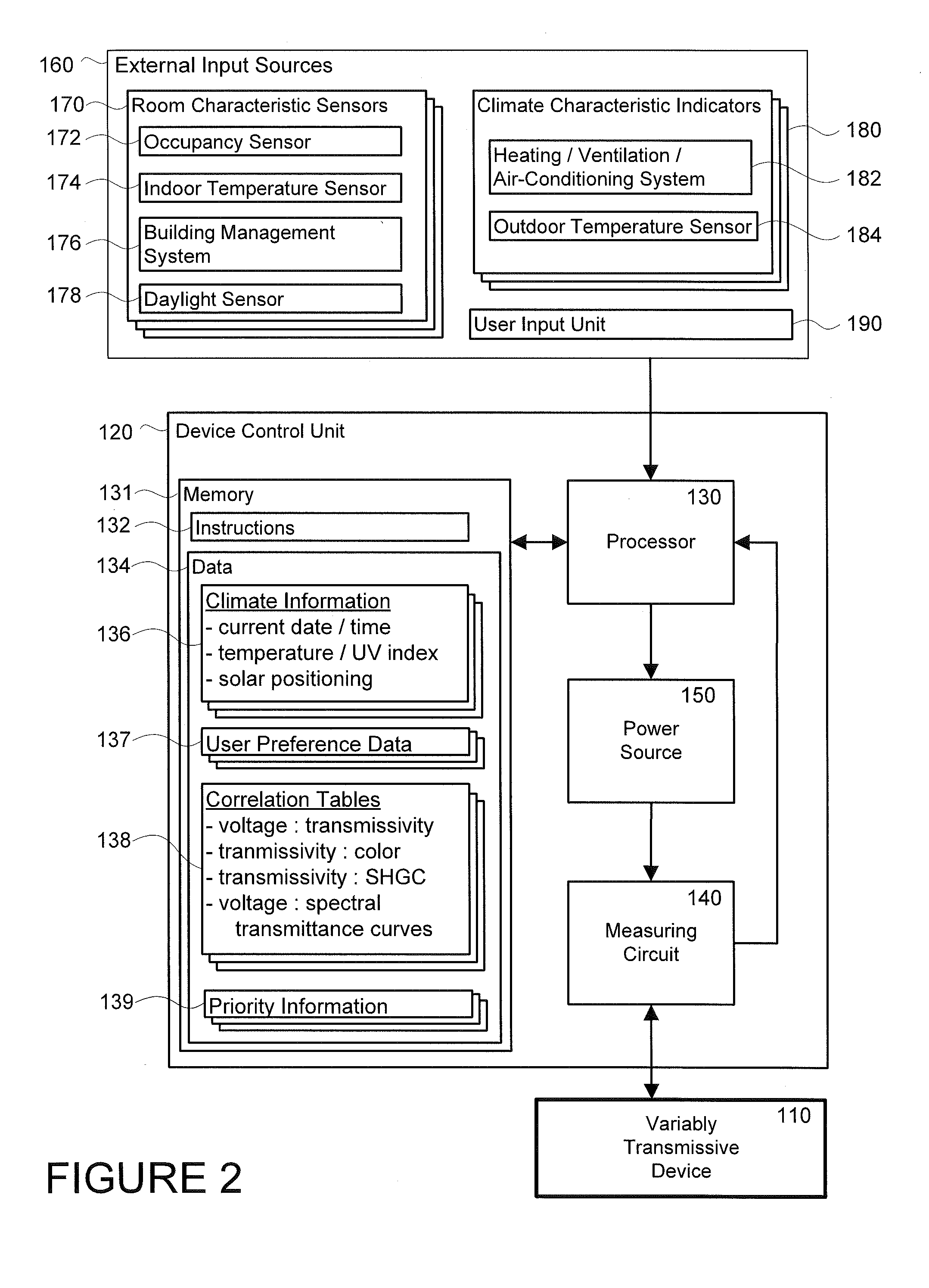

Control System For Color Rendering Of Optical Glazings

The present disclosure provides for a method of controlling a plurality of independently controllable sections of one or more electrochromic devices belonging to a common interior space to provide lighting having a substantially color neutral or aesthetically pleasing spectrum to the interior space. The method comprises receiving a desired illuminance input indicating an amount of lighting desired in the interior space, and a neutral lighting input indicating a quantifiable amount of the sections of the electrochromic devices to be set to a high transmittance state. One or more sections of the electrochromic devices are selected in accordance with the neutral lighting input. The selected sections of the electrochromic device are set to the high transmittance state. The one or more electrochromic devices collectively transmit an amount of light into the interior space in accordance with the desired illuminance input.

Owner:SAGE ELECTROCHROMICS

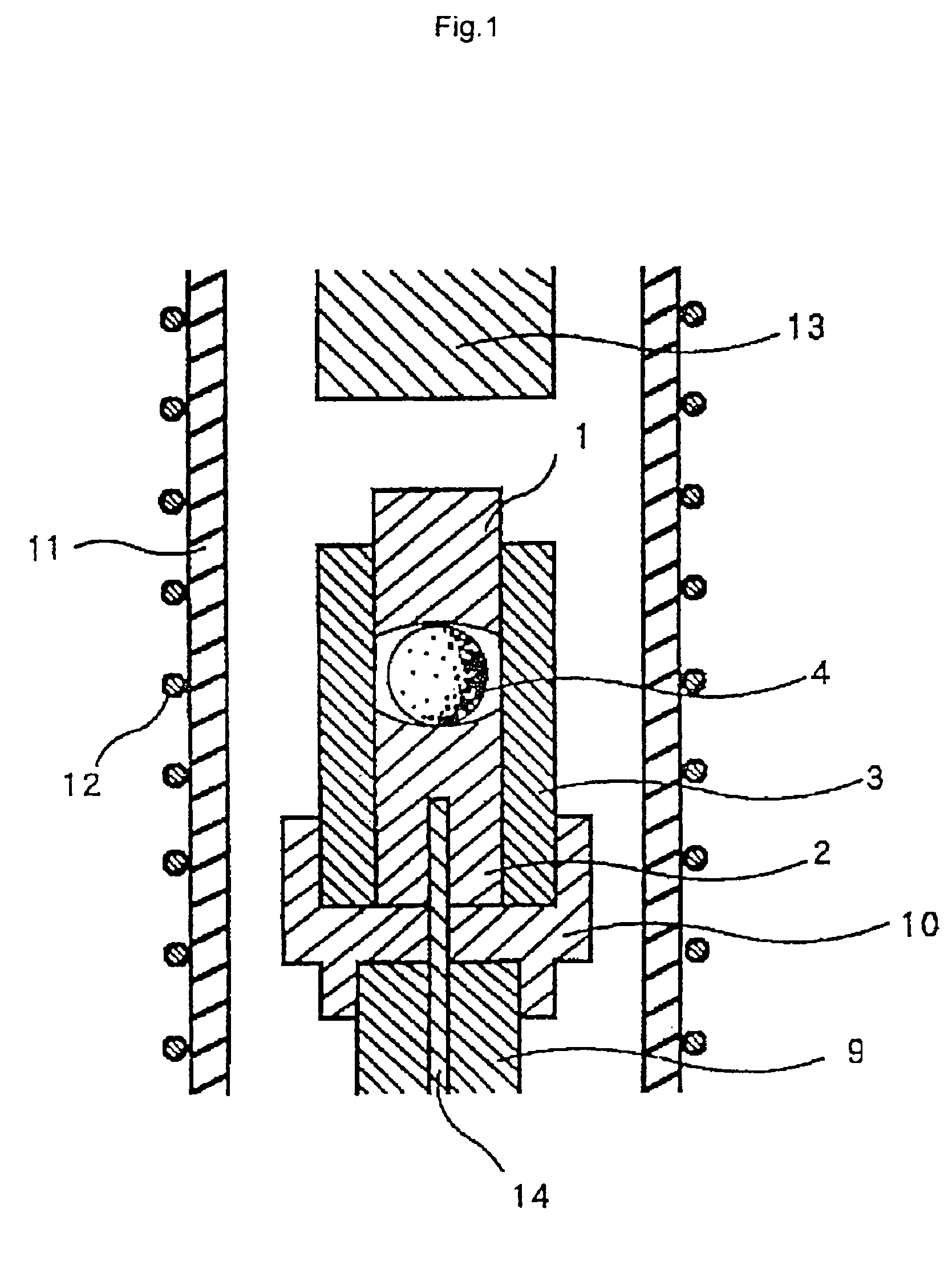

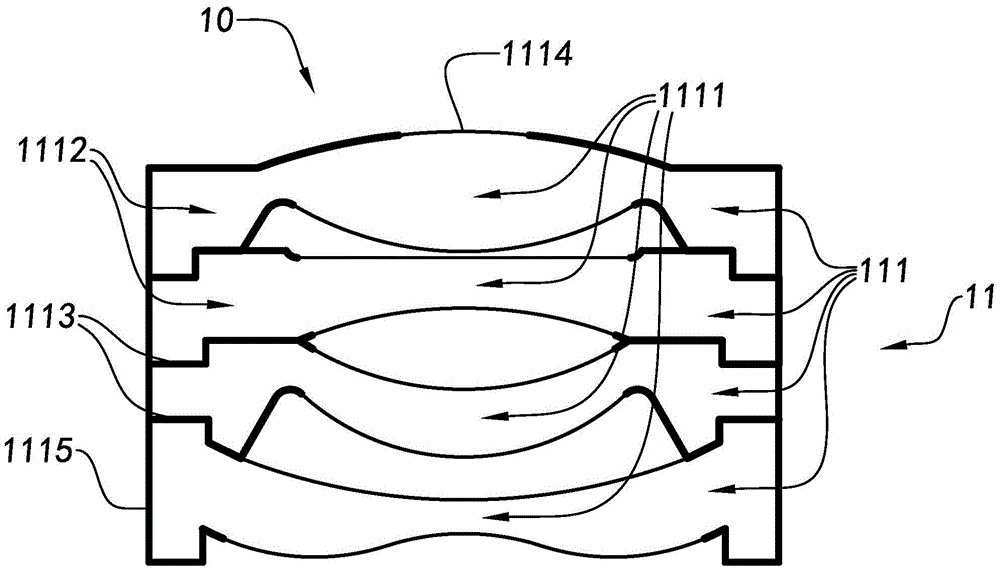

Dynamic pressure cavitation jet polishing device of colloidal flow and method

InactiveCN101670556AImprove quality and efficiencyImprove processing efficiencyBlast gunsAbrasive feedersCavitationSemiconductor materials

The invention discloses a dynamic pressure cavitation jet polishing device of colloidal flow and a method, relating to a polishing device and a method and aiming at solving the problems that the existing polishing method of the ultrasmooth surface has low processing efficiency and high cost, the adaptability of the work piece material is limited and the existing polishing device of the ultrasmoothsurface has complex equipment and high maintenance cost. The device is characterized in that a cavitation jet device is fixed on a bracket; the input end of the cavitation jet device is connected with an outlet of a first flow reversing valve by a pipeline. The method comprises the following steps: (1) the polished work piece is immersed with 10 to 200mm by the colloidal polished liquid level; (2) the oil pressure of the cavitation jet device is 0.5 to 15MPa; (3) the cavitation jet pressure is 0.5 to 15MPa; and (4) the cavitation jet device is arranged in colloidal polishing liquid, the cavitation jet device sprays to the work piece at the speed of 15 to 250m / s, and after polishing, the work piece is taken out, namely the polished work piece. The invention is used for ultraprecise and ultrasmooth polishing of optical glass, microcrystal glass, semiconductor materials and monocrystal materials.

Owner:HARBIN INST OF TECH

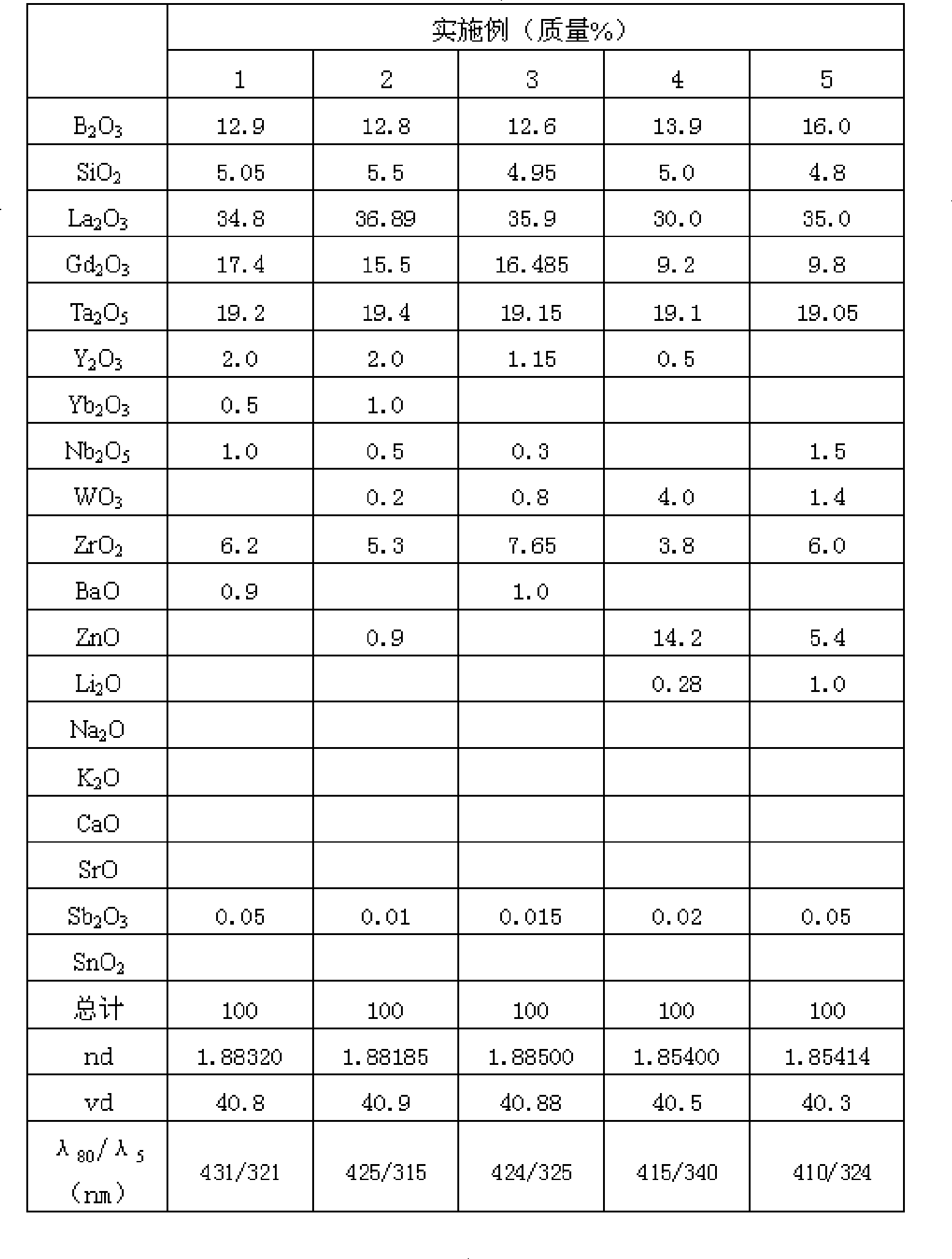

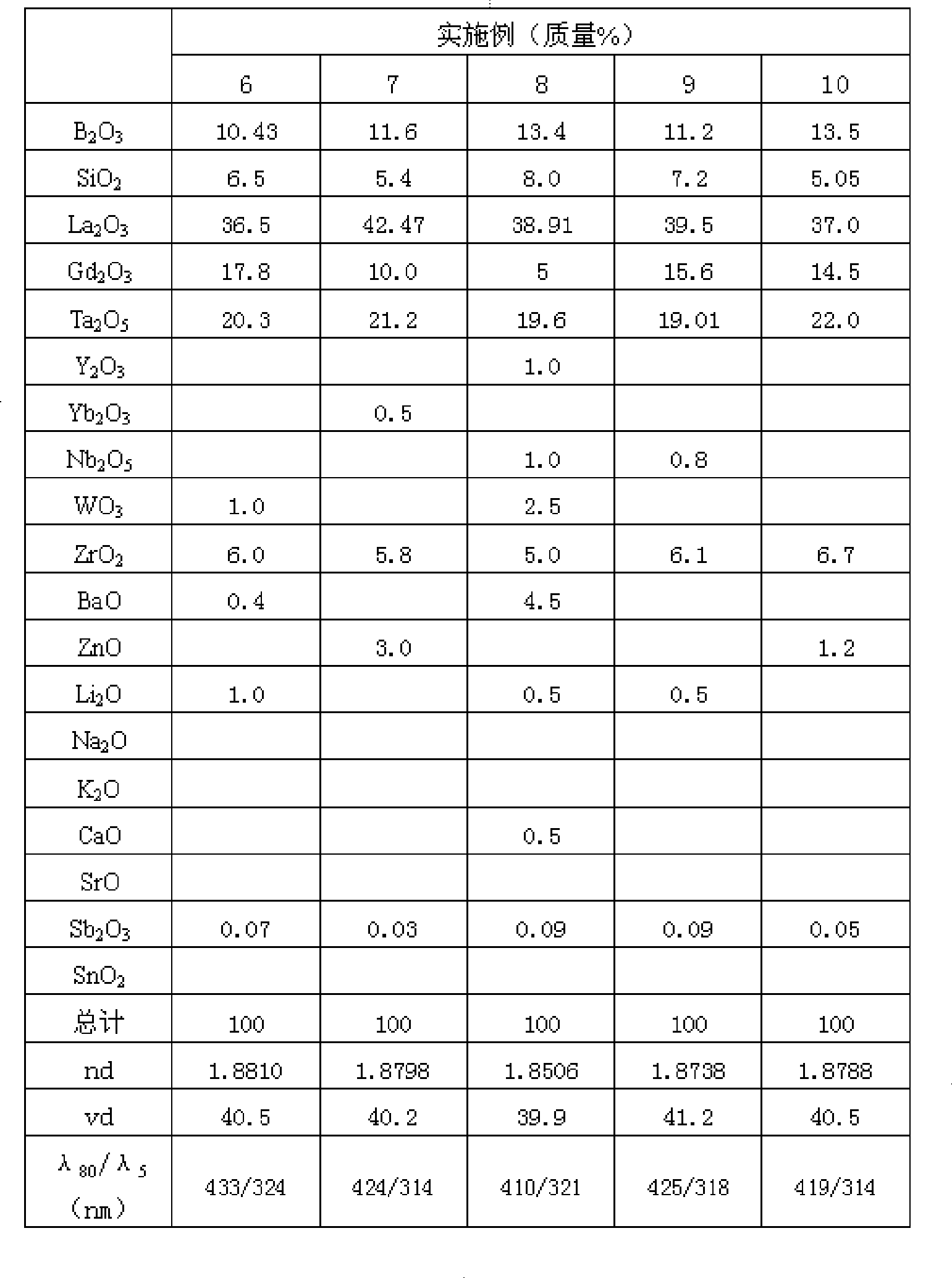

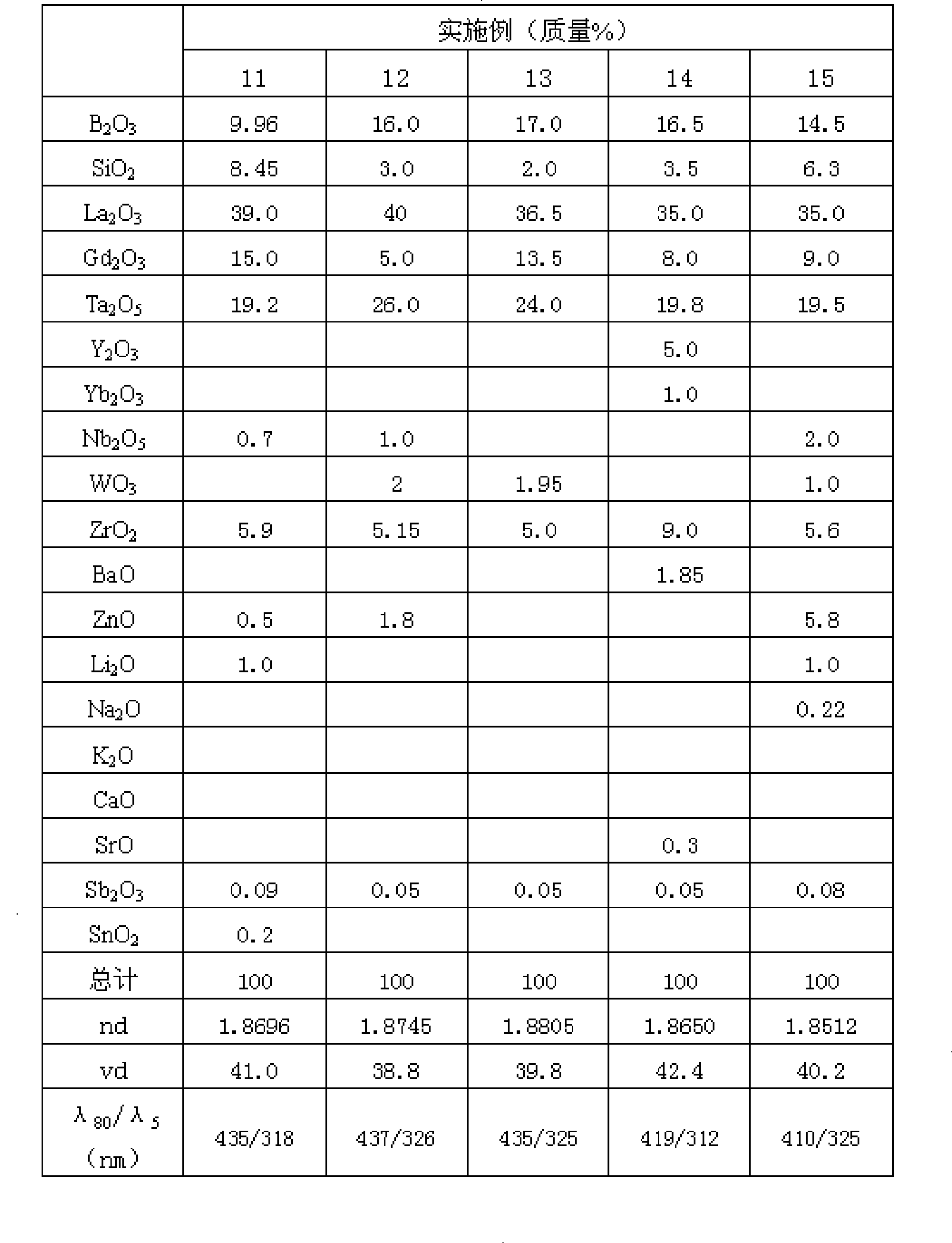

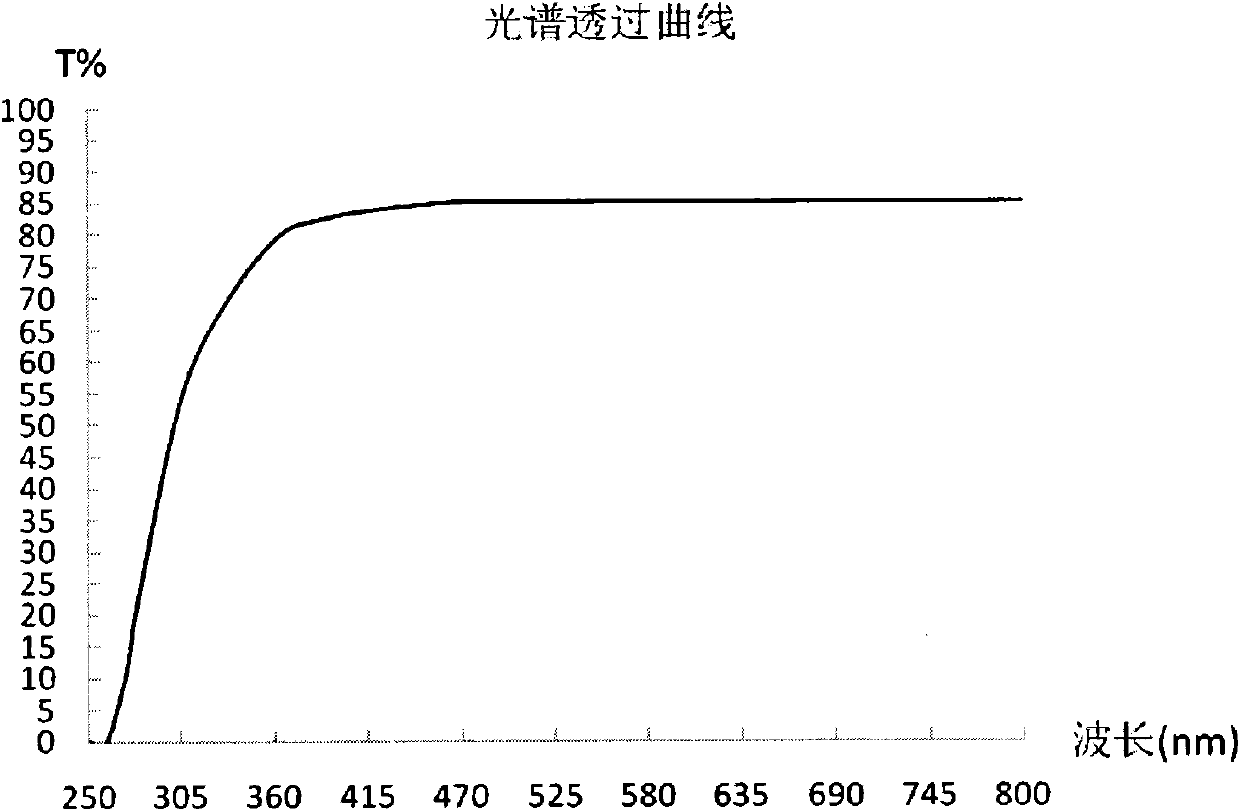

High refraction and low dispersion optical glass

The invention provides an environment-friendly optical glass with high refractive index, low dispersion and high light transmittance, which has components according to weight percentage: B2O3: 6 percent to 17 percent, SiO2: 2 percent to 10 percent, La2O3: more than 25 percent but less than 45 percent, Gd2O3: 5 percent to 25 percent, Nb2O5: 0 to 3 percent, Ta2O5: more than 19 percent but less than 27 percent, ZnO: 0 percent to 16 percent, BaO: 0 percent to 5 percent, CaO: 0 percent to 5 percent, SrO: 0 percent to 5 percent, ZrO2: 0 percent to 9 percent, Y2O3: 0 percent to 8 percent, Yb2O3: 0 percent to 8 percent, WO3: 0 percent to 5 percent, Li2O, Na2O and K2O: the total content of 0 percent to 2 percent, Sb2O: equal to 0.01 percent or less than 0.1 percent, SnO2: 0 percent to 1 percent. GeO2 is not included in the components of the environment-friendly optical glass and the refractive index is 1.85 to 1.90, while the Abbe number is 35 to 45. Meanwhile, the corresponding wavelength is below 440nm when the transmittance thereof is up to 80 percent, and the environment-friendly optical glass has high light transmittance.

Owner:CDGM OPTICAL GLASS

Optical glass, optical element and process for the production thereof

InactiveUS20070027017A1Easy to processSuppress chromatic aberrationGlass drawing apparatusGlass forming apparatusAlkaline earth metalRefractive index

Provided are an optical glass having high-refractivity, low-dispersion and anomalous partial dispersion properties, having excellent processability, being excellent as an anomalous partial dispersion glass for suppressing chromatic aberration, containing P5+, Al3+ and alkaline earth metal ions selected from the group consisting of Mg2+, Ca2+, Sr2+ and Ba2+ as essential cationic components and F− and O2− as essential anionic components, wherein the ratio of content of Ba2+ to the total content R2+ of Mg2+, Ca2+, Sr2+ and Ba2+, Ba2+ / R2+, is 0.01 or more but less than 0.5 on the basis of cationic %, and having an Abbe's number (νd) of 68 or more, optical glass having an Abbe's number (νd) of 68 or more, a partial dispersion ratio of 0.535 or more and a frictional abrasion of 500 or less and an optical glass which is to be polished in a polishing step for producing an optical element and which is a fluorophosphate glass having a frictional abrasion of 500 or less.

Owner:HOYA CORP

Optical glass

InactiveCN1450010AHigh coefficient of thermal expansionPrecise without migrationOptical elementsLithium oxideSilicic acid

The present invention relates to an optical glass using silicic acid group as main body, said optic glass has high expansion coefficient, high Young modulus, excellent weatherability and high transmissivity in the infrared wave zone. Said glass composition contains (mole%) 36-66% of silicon dioxide, 0-12% of aluminium oxide, 0-6% of boric oxide, 0-10% of magnesium oxide, 0-16% of calcium oxide, 0-16% of strontium oxide, 0-16% of baria, 0-8% of zinc oxide, 0-32% of lithium oxide, 0-25% of sodium oxide, 0-25% of potassium oxide, 0-20% of cesium oxide, 0-6% of phosphorus pentoxide, 0-8% of scandium oxide and others.

Owner:PICVUE OPTOELECTRONICS INT

Optical glass, precision press-molding preform, process for producing the preform, optical element and process for producing the element

InactiveUS20060105900A1Low-temperature softeningHigh refractive indexGlass pressing apparatusRefractive indexOptical glass

An optical glass having high refractivity and a low sag temperature and having a low-temperature softening property that enables precision press-molding is provided, and the optical glass contains, by mol %, 5 to 50% of B2O3, 3 to 50% of SiO2, 5 to 40% of TiO2, 1 to 40% of ZnO, 5 to 20% of La2O3, 0 to 10% of Gd2O3, 0 to 15% of Nb2O5, 0 to 10% of ZrO2, 0 to 5% of Ta2O5, 0 to 10% of Bi2O3, 0 to 10% of MgO, 0 to 8% of CaO, 0 to 10% of SrO, 0 to 10% of BaO, provided that the total content of MgO, CaO, SrO and BaO is 15% or less, 0 to 20% of Li2O, and 0 to 5% of Na2O, optionally containing Sb2O3 as a refining agent, and having a refractive index (nd) of 1.8 or more and an Abbe's number (vd) of 35 or less.

Owner:HOYA CORP

Optical glass, optical element and process for the production thereof

InactiveCN1903765AIncrease refractionImprove machinabilityGlass pressing apparatusAlkaline earth metalRefractive index

Provided are an optical glass having high-refractivity, low-dispersion and anomalous partial dispersion properties, having excellent processability, being excellent as an anomalous partial dispersion glass for suppressing chromatic aberration, containing P5+, Al3+ and alkaline earth metal ions selected from the group consisting of Mg2+, Ca2+, Sr2+ and Ba2+ as essential cationic components and F- and O2- as essential anionic components, wherein the ratio of content of Ba2+ to the total content R2+ of Mg2+, Ca2+, Sr2+ and Ba2+, Ba2+ / R2+, is 0.01 or more but less than 0.5 on the basis of cationic %, and having an Abbe's number (nud) of 68 or more, optical glass having an Abbe's number (nud) of 68 or more, a partial dispersion ratio of 0.535 or more and a frictional abrasion of 500 or less and an optical glass which is to be polished in a polishing step for producing an optical element and which is a fluorophosphate glass having a frictional abrasion of 500 or less.

Owner:HOYA CORP

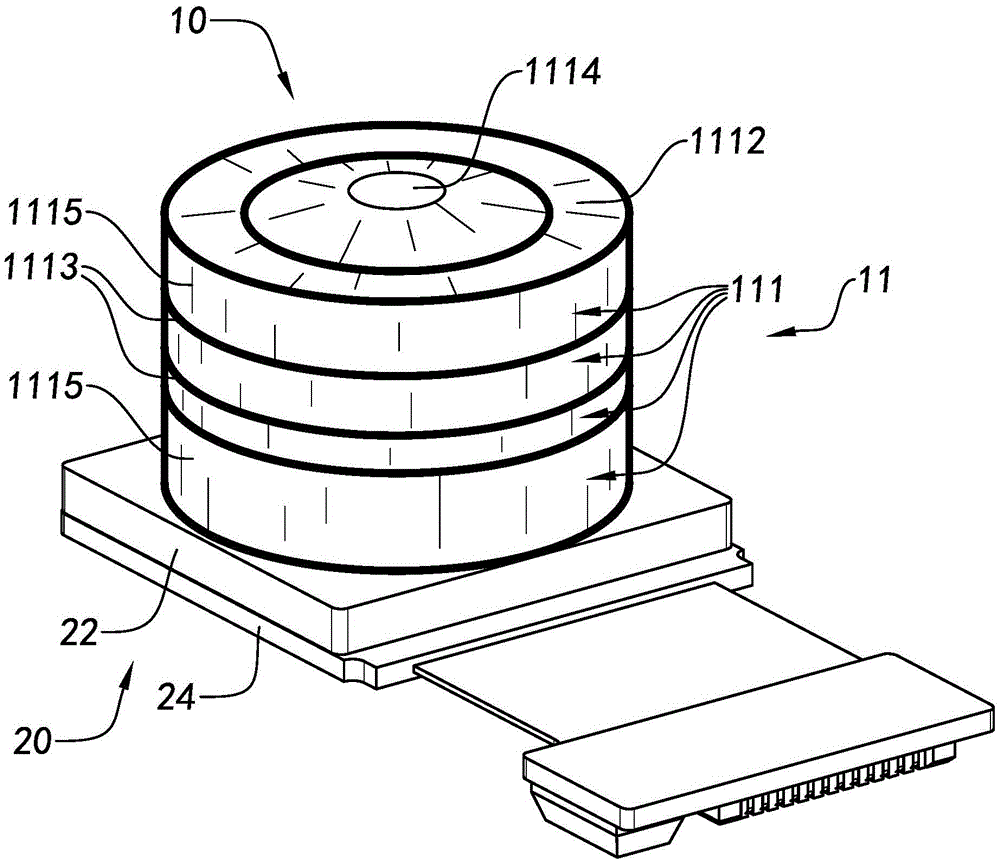

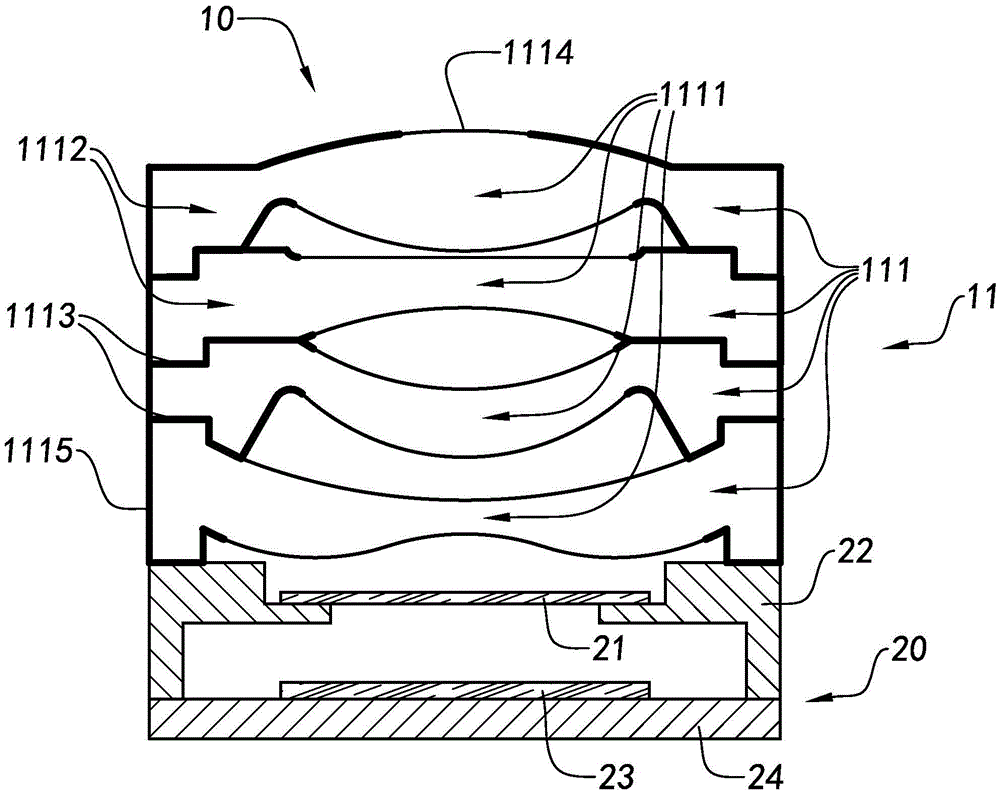

Optical lens, camera module group and assembly method thereof

The present invention discloses an optical lens, a camera module group and an assembly method thereof. The camera module group comprises a sensitization chip and an optical lens; the optical lens includes a plurality of optical glasses, wherein the assembly position one optical glass is adjustable, and the blacking extinction processing of each optical glass is performed; and a connection part, a light beam incidence aperture and a shielding part are formed on corresponding optical glasses so as to embed and assemble each optical glass together in order, therefore parts such as a spacing ring, a diaphragm, a lens barrel structure piece and the like used in a traditional camera module group are omitted, and the manufacture precision, the yield rate and the imaging quality of the camera module group are improved.

Owner:NINGBO SUNNY OPOTECH CO LTD

Optical glass, precision press-molding preform, process for production thereof, optical element and process for the production thereof

InactiveUS20050197243A1High refractive indexLow dispersionGlass pressing apparatusGlass reforming apparatusRefractive indexOptical glass

Provided is an optical glass having high-refractivity low-dispersion properties, having a low glass transition temperature and having the property of being softened at a low temperature so that a preform therefrom is precision press-moldable, and the optical glass comprises, as essential components, B2O3, La2O3, Gd2O3 and ZnO and has a refractive index (nd) of over 1.86, an Abbe's number (νd) of less than 35 and a glass transition temperature (Tg) of 630° C. or lower.

Owner:HOYA CORP

Optical glass for high-refractivity low dispersion precision die mould

ActiveCN1935717AExcellent physical and chemical propertiesGood chemical stabilityRefractive indexOptical glass

The invention provides a high-refractivity, low-dispersivity, fine moulding optical glass, comprising SiO2:1-8wt%, B2O3:16-30wt%, La2O3:15-40wt%, Gd2O3:0-20wt%, ZnO:8-30wt%, Nb2O5:0.5-14.5wt%, WO3:0-12.5wt%, TiO2:0-9wt%, Li2O:0.5-4wt%, ZrO2:1-10 wt%, Y2O3:0-5 wt%, Yb2O3:0-5 wt%, Lu2O3:0-5 wt%, Na2O: 0-3 wt%, K2O:0-2 wt%, Al2O3:0-2 wt%, BaO:0-3 wt%, CaO:0-3 wt%, SrO:0- 3 wt%, MgO:0-3 wt%, Sb2O3:0-0.5 wt%, and SnO2:0-0.5 wt%. And the invention adopts a B2O3-SiO2-La2O3(Gd2O3)-ZnO system, and uses Nb2O5, WO3 and TiO2 in the reasonable proportion to make glass have the required optical constants and good physicochemical properties of fine moulding. And its transformation temperature (Tg) is lower than 560 deg.C. And it has no high-price Ta2O5 but has good chemical stability, able to be produced in batches and stably by single pot or continous smelting furnace, or other equipment, and suitable for low-cost and fine moulding nonspherical lenses and other optical components.

Owner:CDGM OPTICAL GLASS

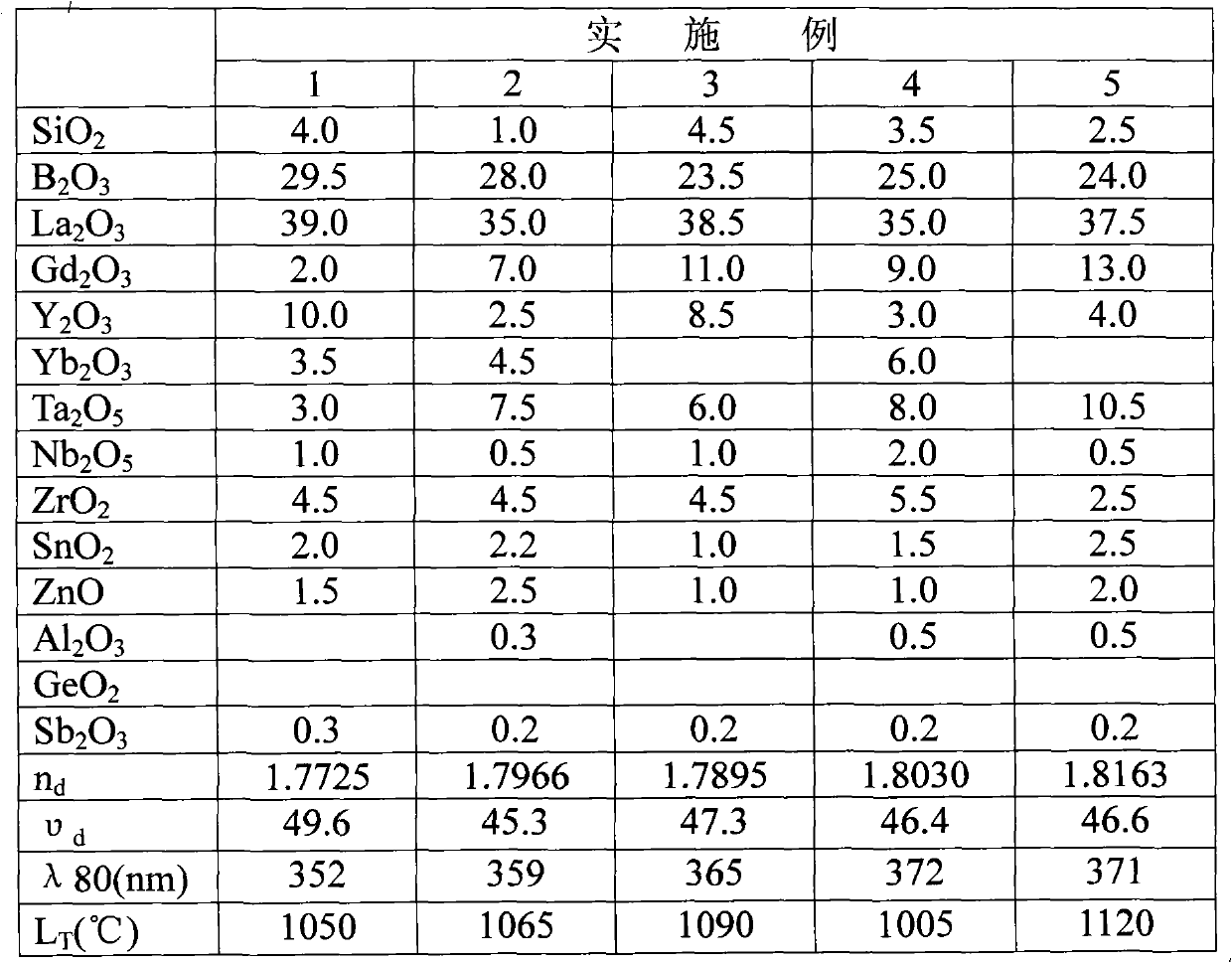

Optical glass with high index of refraction

The invention discloses optical glass with high index of refraction, and belongs to the technical field of optical glass. The invention mainly provides the optical glass with high index of refraction, wherein the index of refraction (nd) of the optical glass is 1.77 to 1.82, the Abbe number (nu d) of the optical glass is in a range of 45 to 50, and the optical glass has low devitrification tendency and high transmittance in the absence of ThO2, harmful components and expensive GeO2 component and is suitable for secondary die pressing. The optical glass is mainly characterized by comprising the following components: 0.5 to 7 percent of SiO2, 20 to 40 percent of B2O3, 25 to 45 percent of La2O3, 1 to 20 percent of Gd2O3, 0 to 15 percent of Y2O3, 0 to 15 percent of Yb2O3, 1 to 20 percent of Ta2O5, 0 to 5 percent of Nb2O5, 0.5 to 8 percent of ZrO2, 0.5 to 5 percent of SnO2, 0.5 to 7 percent of ZnO, and 0 to 5 percent of Al2O3, wherein sigma (La2O3 + Gd2O3 + Y2O3 + Yb2O3) is more than or equal to 35 and less than or equal to 60, and sigma (ZrO2 + SnO2 + ZnO) is more than or equal to 5 and less than or equal to 15. The optical glass is mainly used for small, ultrathin and wide-angle optical elements matched with the optical glass with high index of refraction and low Abbe number.

Owner:北方光电股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com