High-refraction and high- dispersion optical glass and method of manufacture

A technology of optical glass and manufacturing method, which is applied in the direction of glass manufacturing equipment, manufacturing tools, glass furnace equipment, etc., can solve the problems of high price, reduce glass coloring, low economy, etc., and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

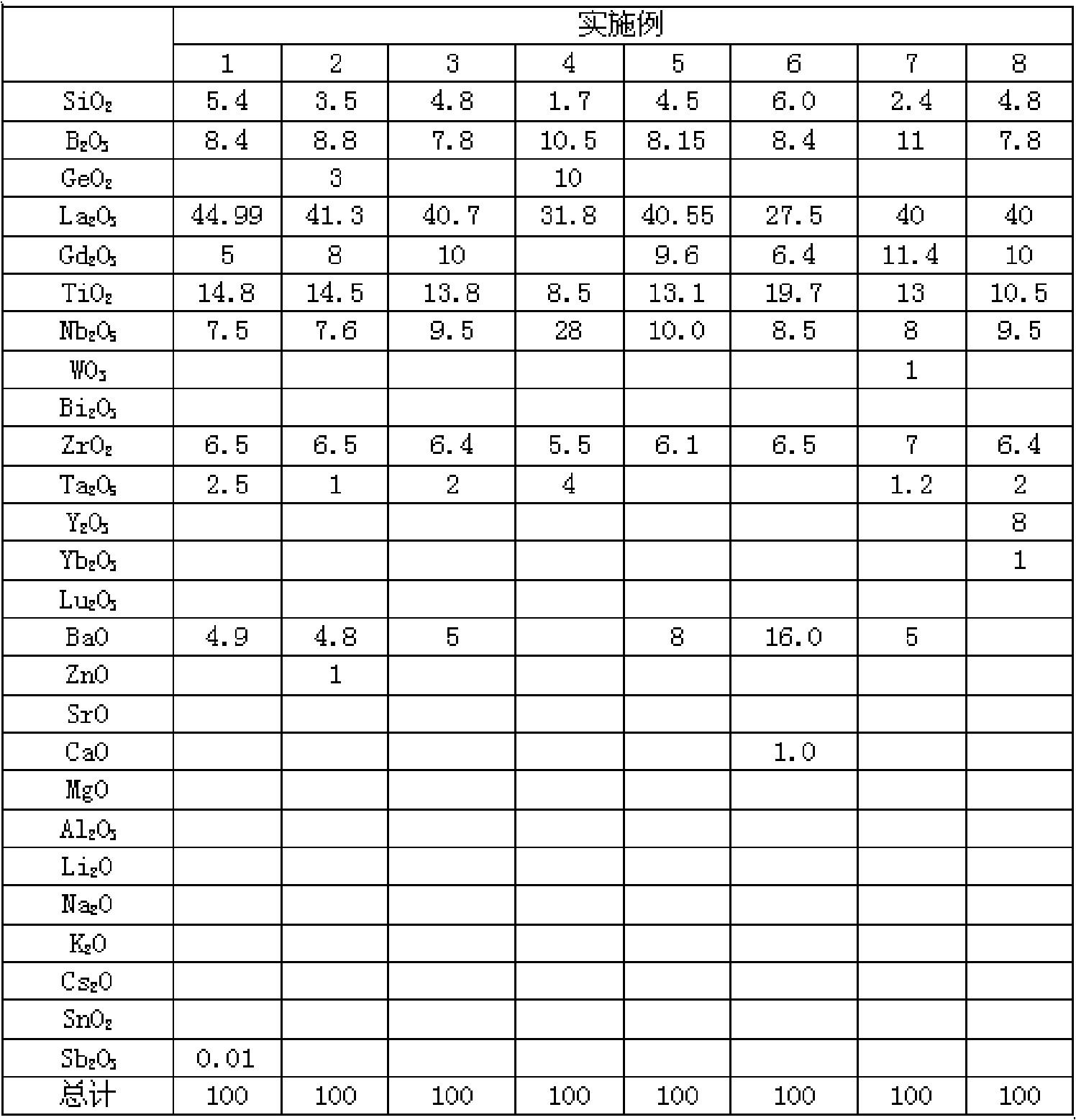

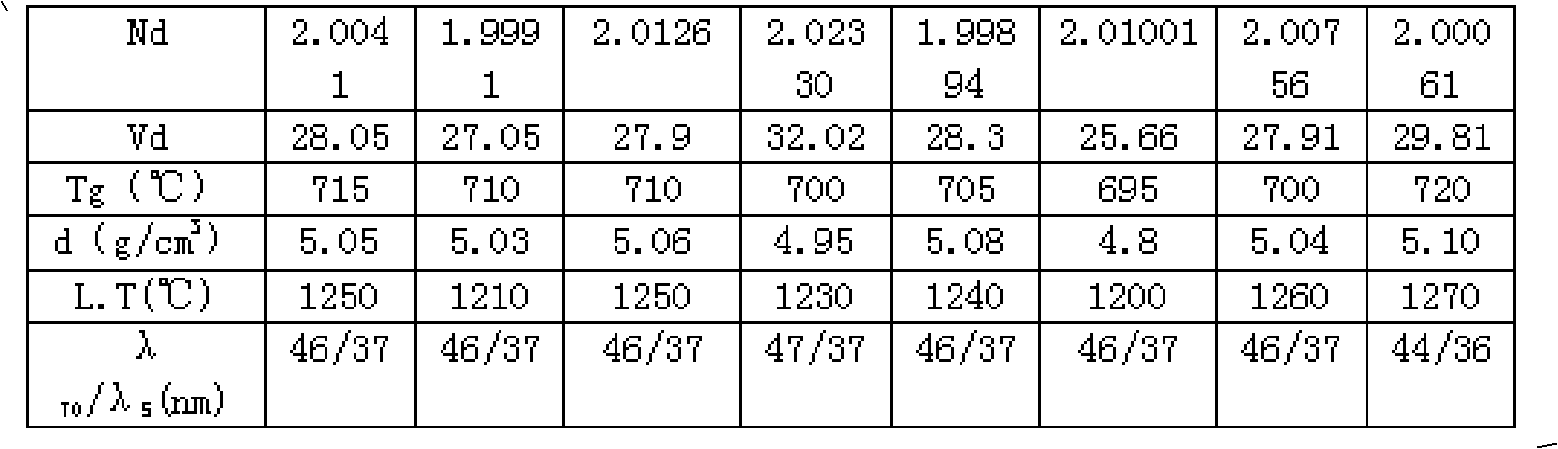

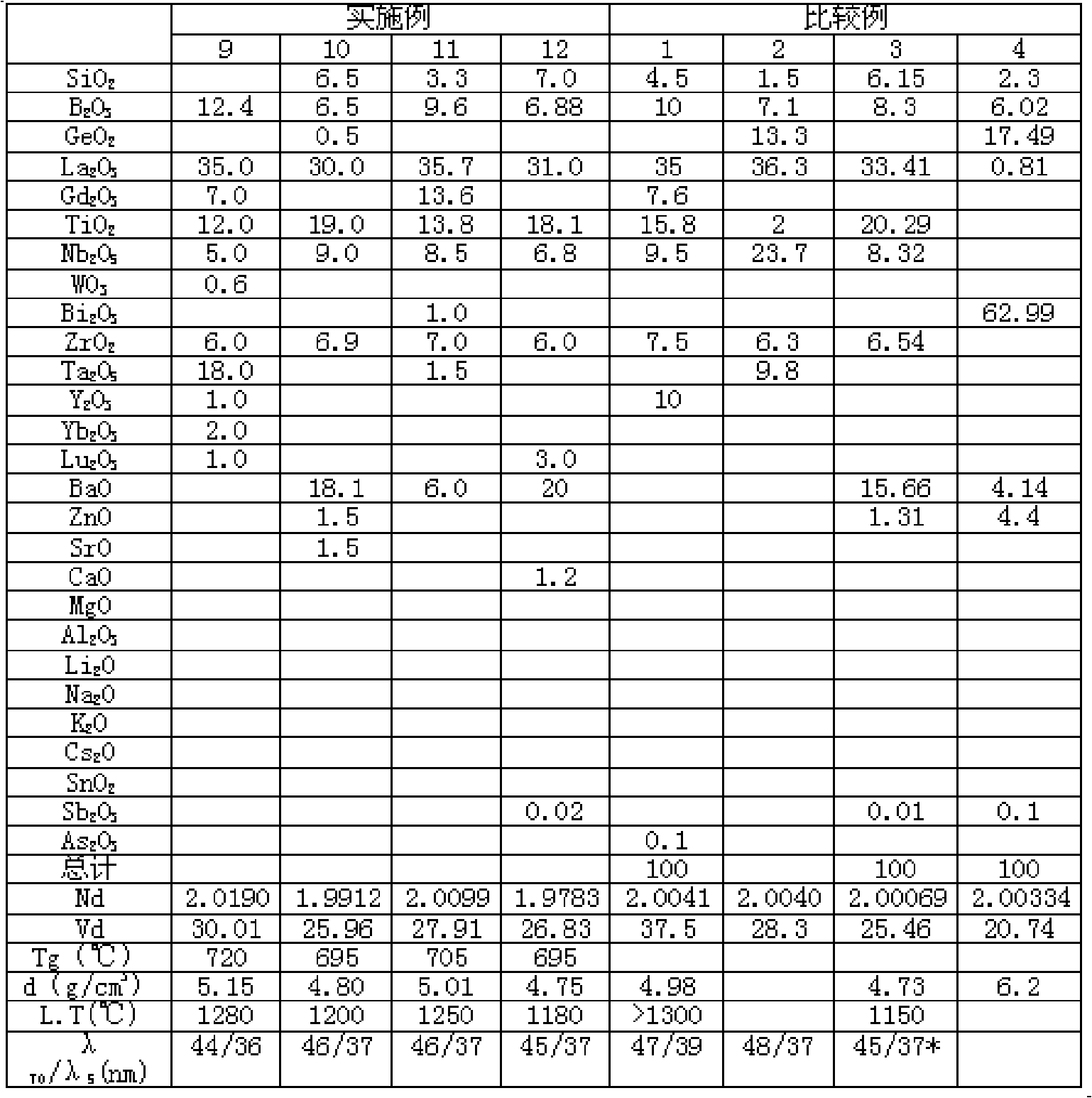

Examples

Embodiment Construction

[0012] The present invention studies through repeated experiments, adopts B 2 o 3 (SiO 2 )-La 2 o 3 (Gd 2 o 3 )-TiO 2 (Nb 2 o 5 )-ZrO 2 system.

[0013] B 2 o 3 It is a glass network generator oxide, which is an essential component of the glass network, especially in the high refractive index lanthanide glass, B 2 o 3 It is the main ingredient to obtain stable glass. When B 2 o 3 When content is lower than 4% (weight percent content, hereinafter the same), the fusing performance of glass becomes bad, and devitrification resistance performance is unsatisfactory; When B 2 o 3 If the content is higher than 16%, the refractive index of the glass cannot reach the design target, so the B 2 o 3 The content is limited to 4-16%, more preferably 6-12%.

[0014] SiO 2 It is also a network generator oxide that forms glass, adding a certain amount of SiO 2 It can increase the high-temperature viscosity of the glass, improve the devitrification resistance and chemical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com