Patents

Literature

85results about How to "Suitable for high-volume industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organosilicon concrete protective agent and preparation method

The invention discloses an organosilicon concrete protective agent and a preparation method. The organosilicon concrete protective agent comprises the main compositions in percent by volume: 50-60% of an alkyl alkoxy silane, 5-10% of terminal-substituted polydimethylsiloxane, 3-5% of an emulsifier, 0.05-1% of a catalyst, 5-10% of a solvent and 20-30% of water. The protective agent is prepared by uniformly mixing the alkyl alkoxy silane, terminal-substituted polydimethylsiloxane and the emulsifier in the organic solvent at room temperature, then adding the catalyst to perform a uniform reaction, then dropwise adding the completely-reacted oil phase system into deionized water, and performing high-speed shearing for obtaining a paste. The preparation method is simple, the coating operation is simple, the cost is low, when the concrete surface is coated with the organosilicon concrete protective agent, a layer of a hydrophobic film is formed along the aperture inner walls of concrete, so that freeze-thaw cycle, chloride ion erosion and the like can be prevented, and the organosilicon concrete protective agent is applicable to facilities such as highways, bridges, tunnels, seaport wharfs, airports and the like, and is applicable to industrialized production.

Owner:XIAMEN NORNS TECH

Cold rolled coil strapping steel having tensile strength of 940MPa or more, and production method thereof

InactiveCN103352165ALow costReduce energy consumption and pollutionFlexible elementsProcess efficiency improvementAlloy elementStrapping

Cold rolled coil strapping steel having a tensile strength of 940MPa or more comprises 0.10-0.22wt% of C, 0.8-1.5wt% of Mn, 0.01-0.03wt% of Si, 0.020wt% or less of P, 0.020wt% or less of S, 0.020-0.070wt% of Als, and the balance Fe and residual elements. The cold rolled coil strapping steel has the advantages of no containment of alloy elements comprising Nb, Ti or V, low cost, small energy consumption and pollution, simple operation, and suitableness for the large-batch industrial production, and follows low carbon and environmental protection ideas. The strapping steel has a tensile strength of 940MPa or more, an elongation rate of 9% or more, and an alternating bending frequency of 4 or more (R=2.5mm), has no brittle fracture layering phenomenon, and has a flexibility of 25.4mm / 2.4m or less and a camber of 2.0mm / m or less.

Owner:武汉钢铁有限公司

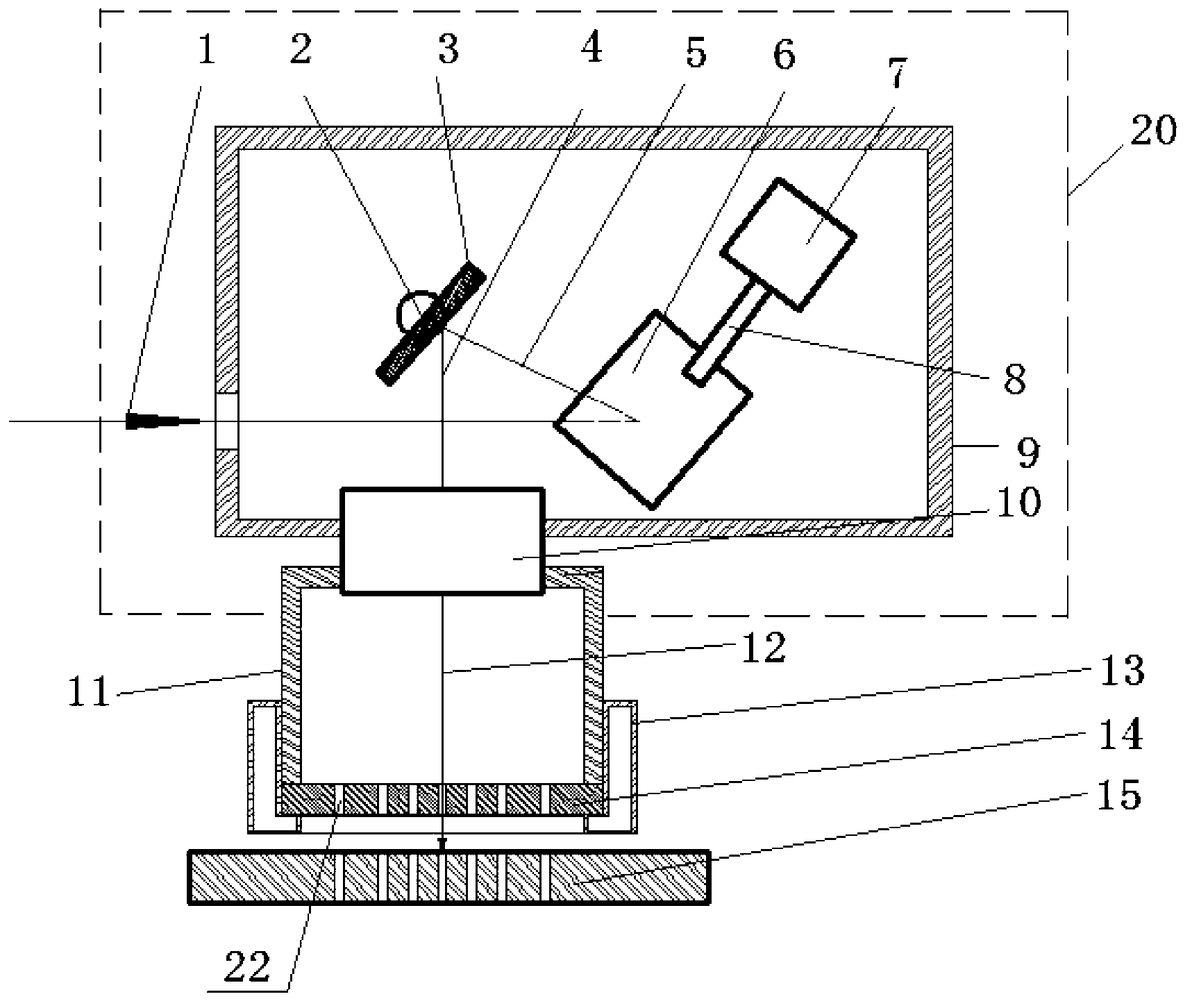

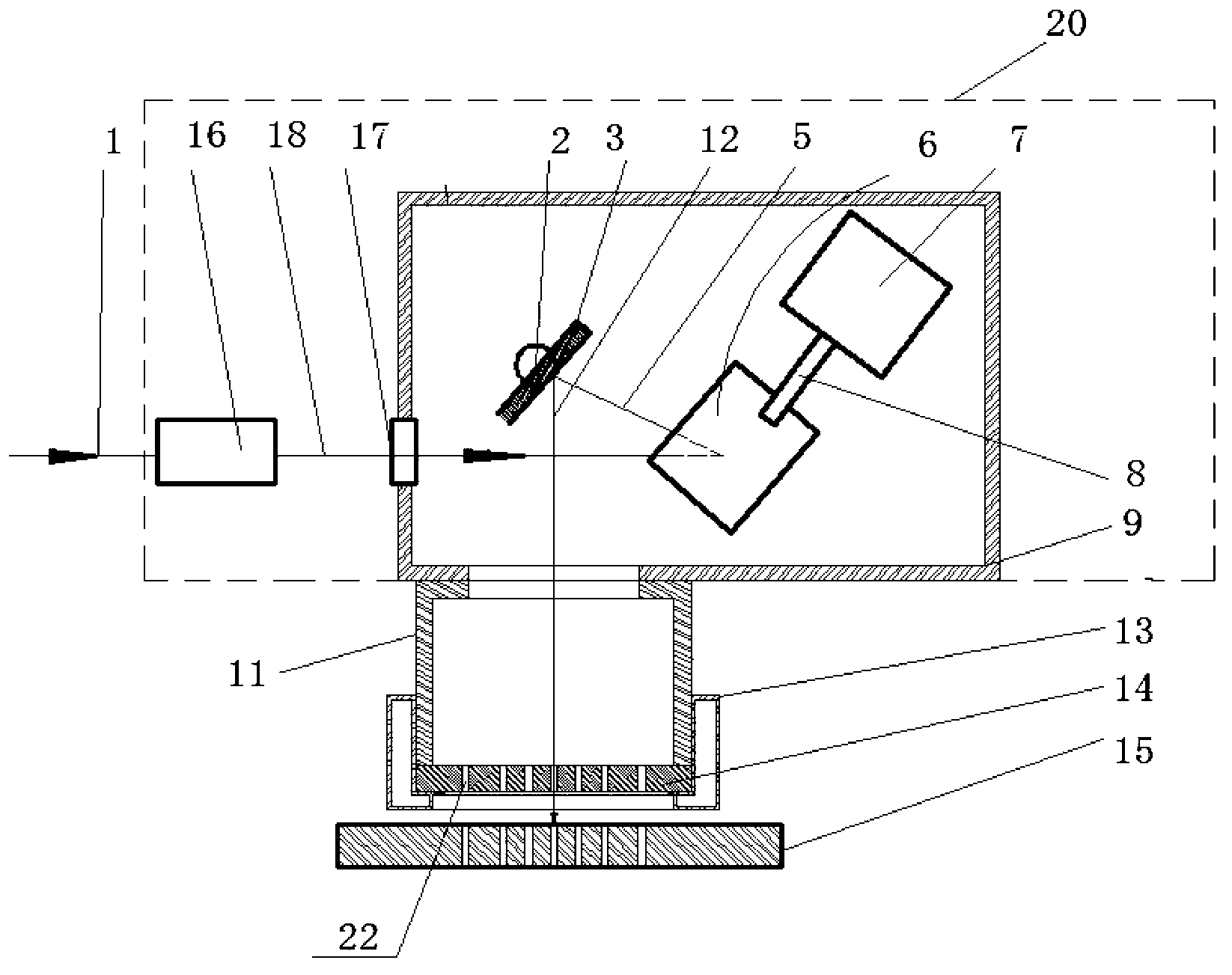

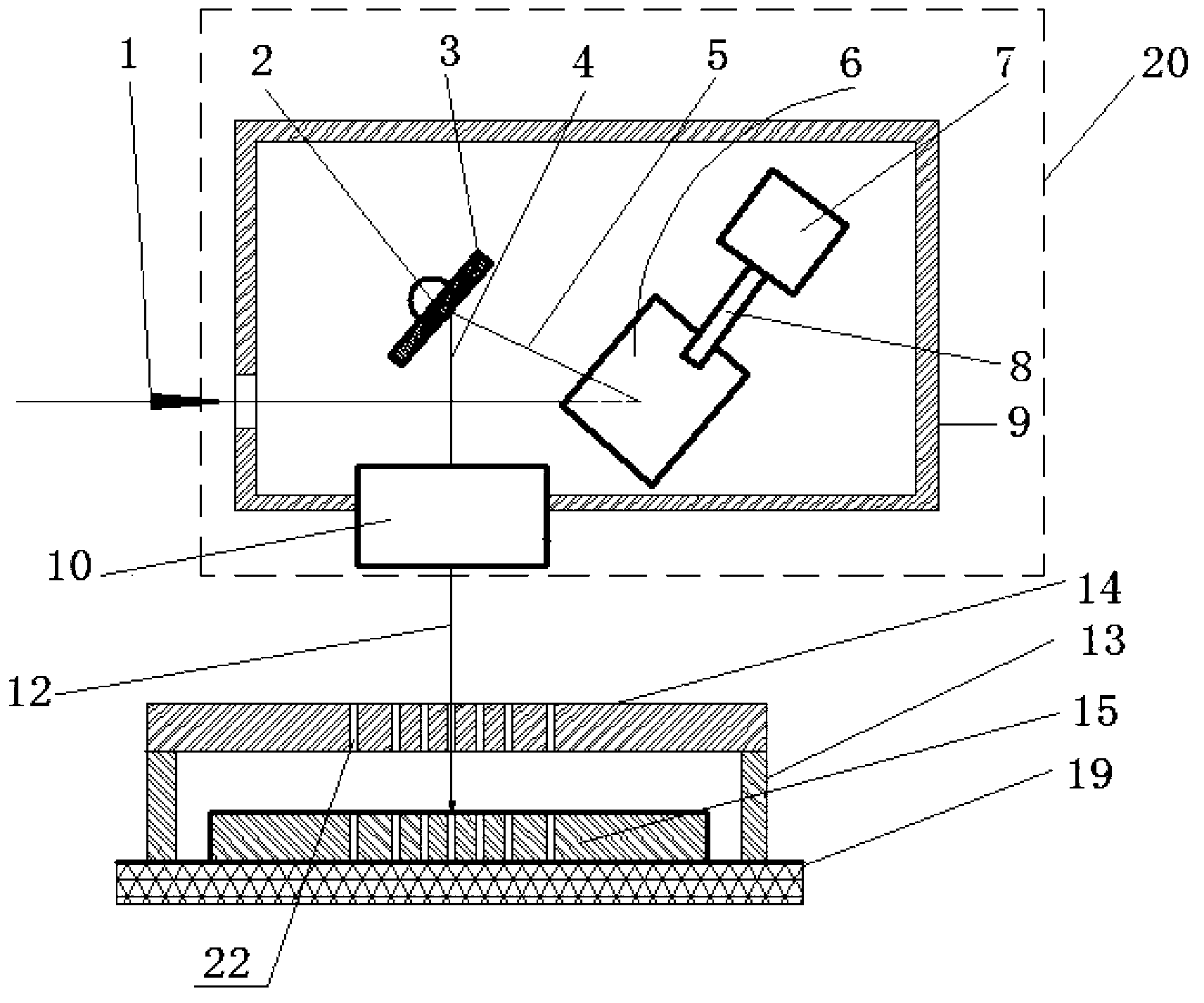

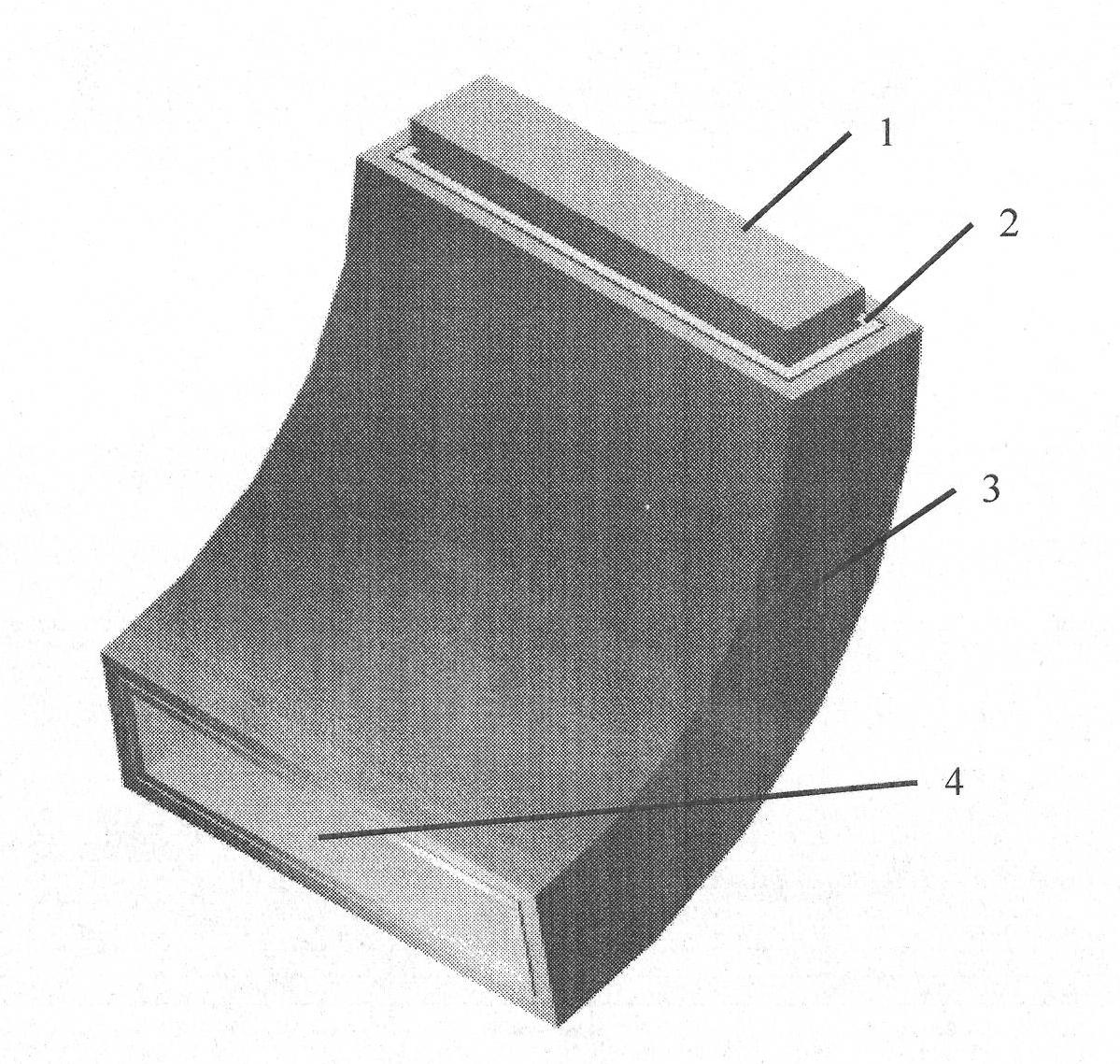

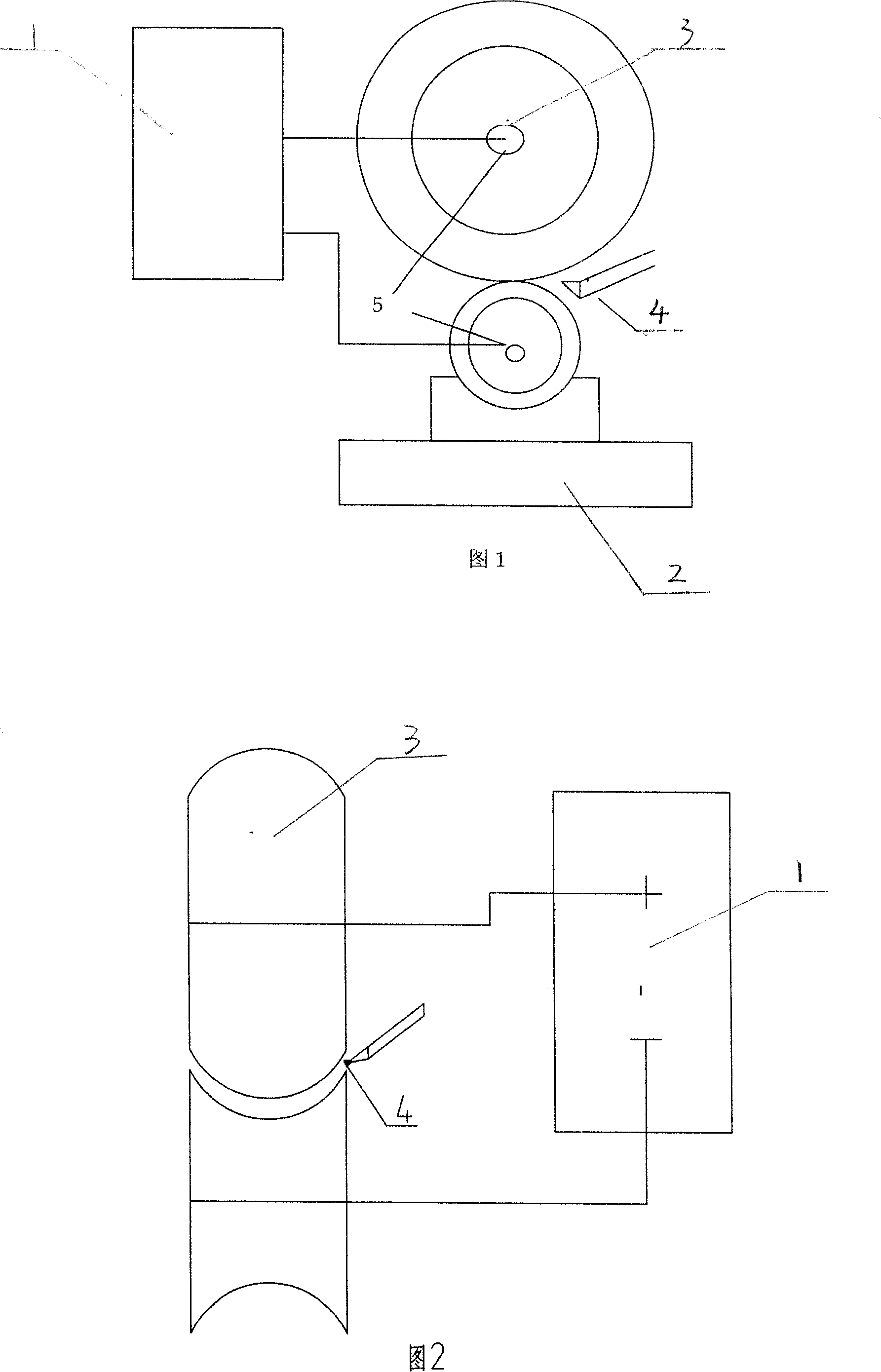

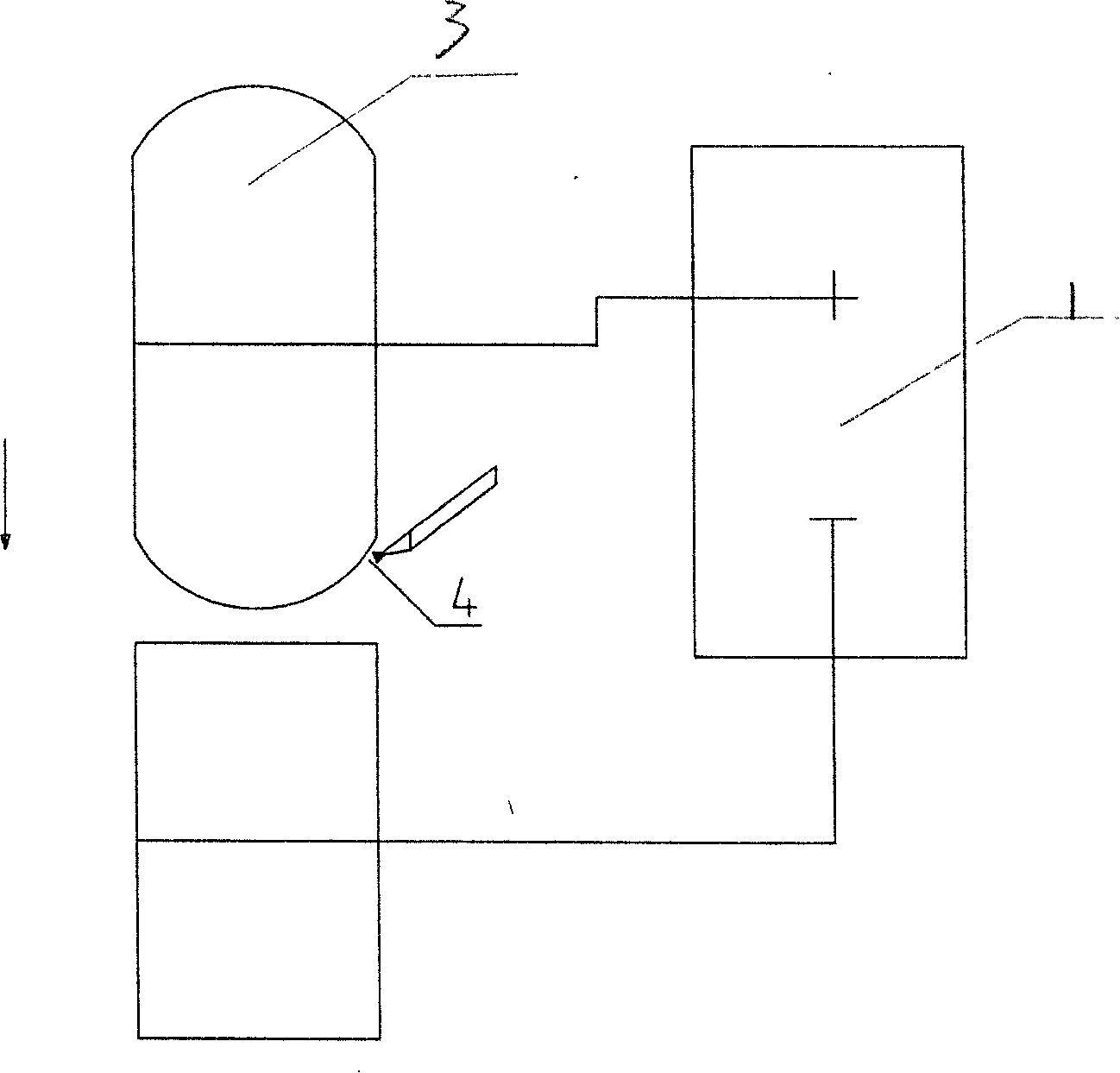

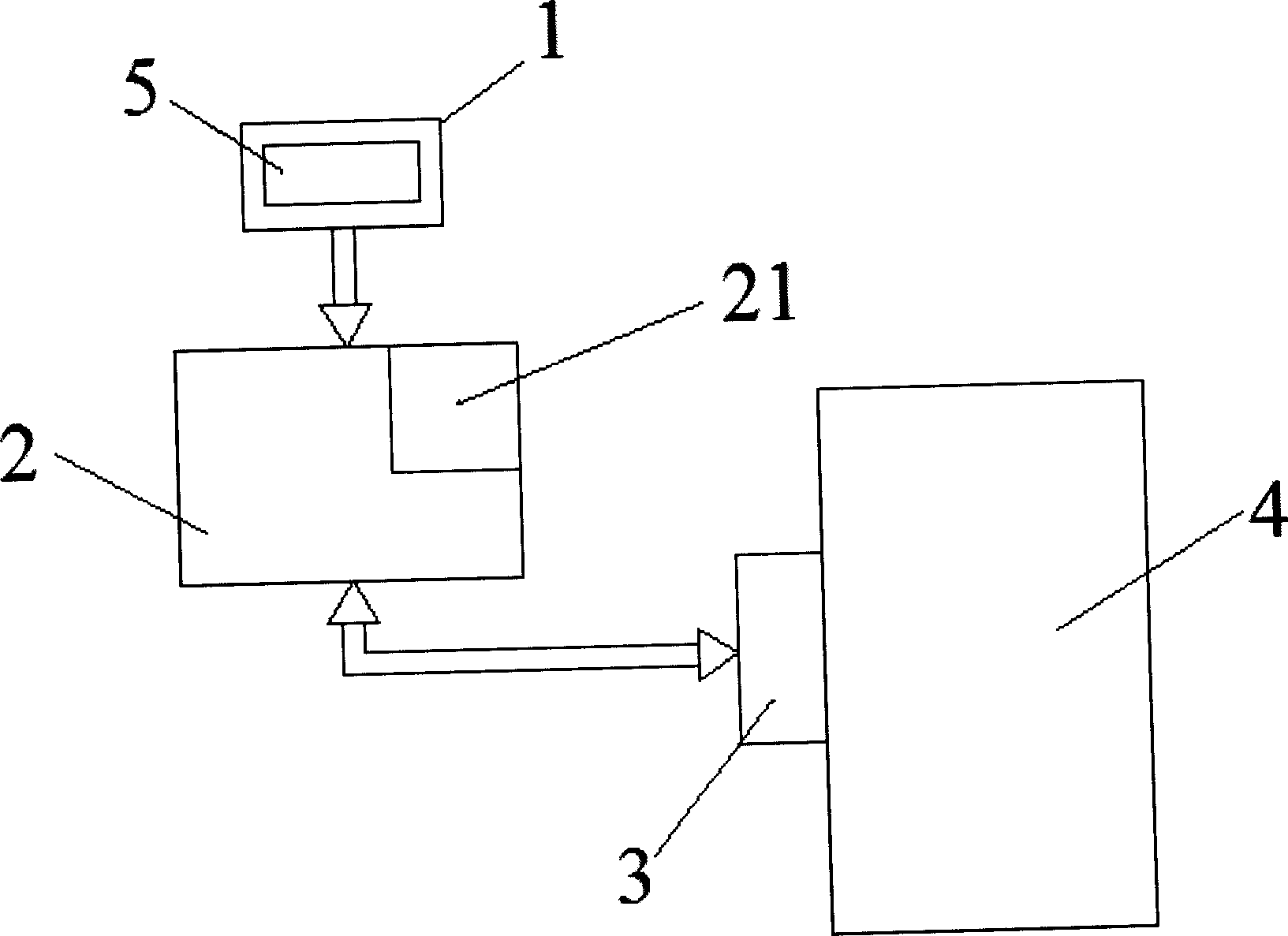

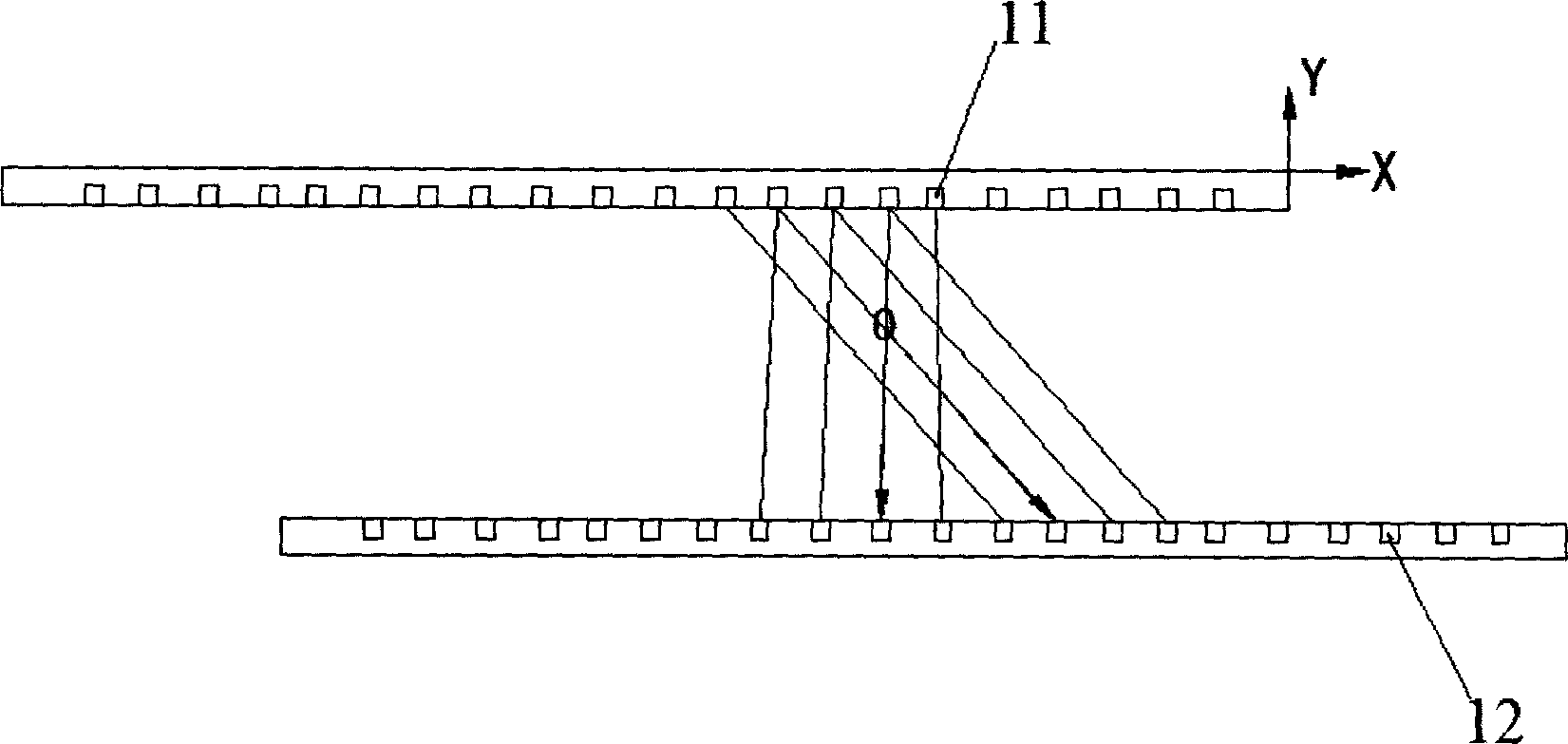

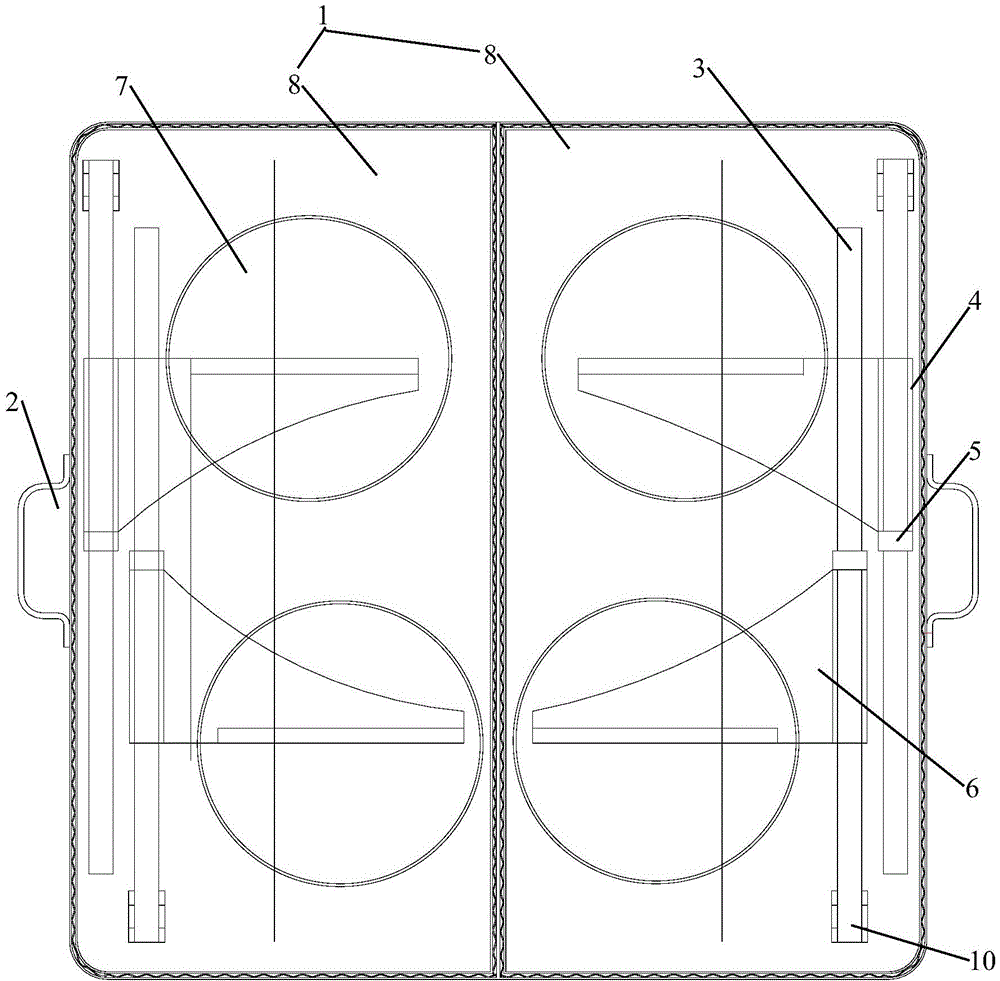

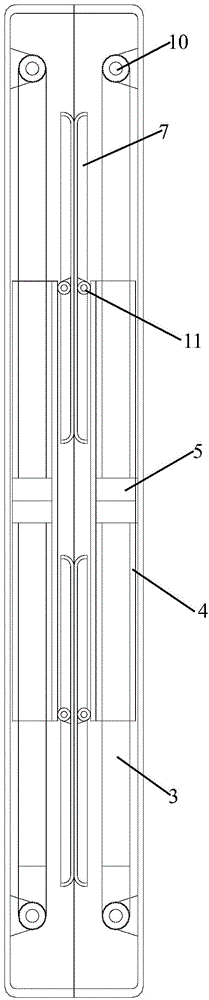

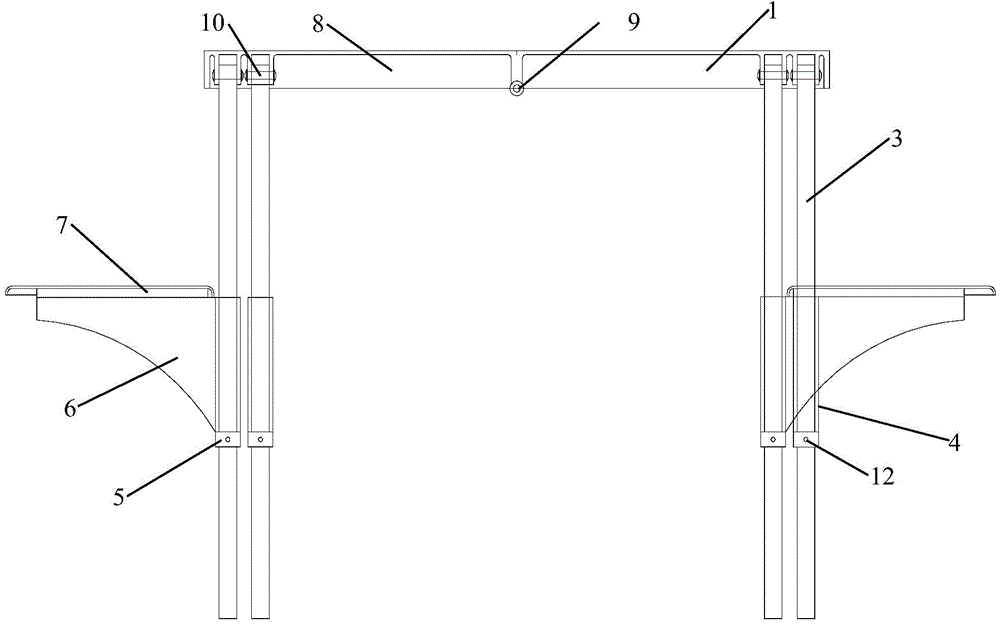

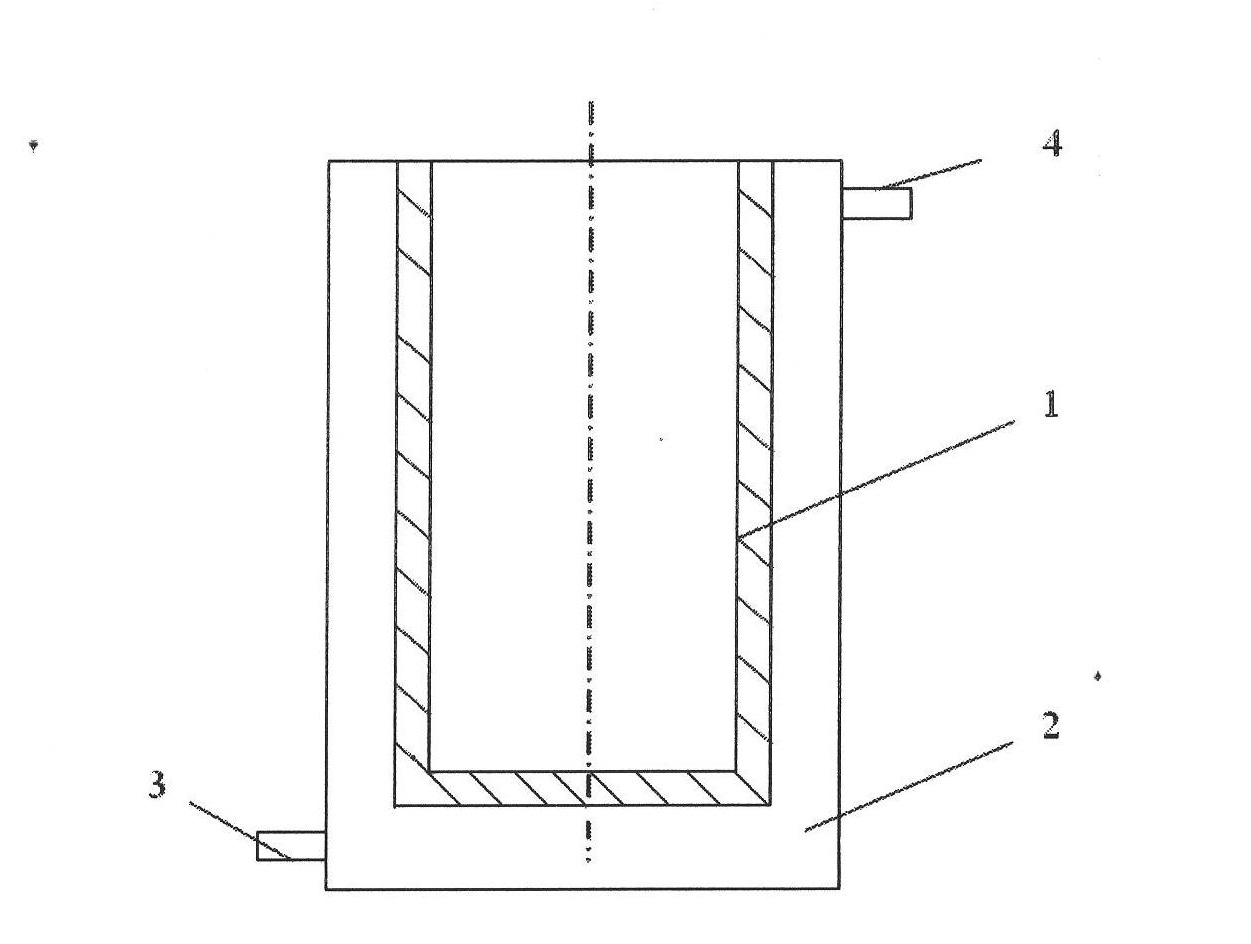

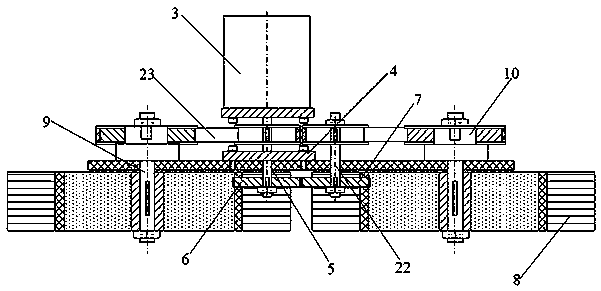

Laser scanning processing device

ActiveCN103182603ASuitable for high-volume industrial productionPromote oxidationLaser beam welding apparatusGalvanometerLaser scanning

The invention relates to a laser scanning processing device which comprises a galvanometer scanning focusing module, a positive pressure gas chamber and / or a negative pressure gas chamber, and an air-blowing mask template, wherein a distributed air-blowing ports are formed by presetting the thickness of the air-blowing mask template, the shapes of air flow windows and the like; and gas, of which the flowing direction is the same as or basically consistent with the transmission directions of lasers transmitting each of air flow windows, is formed by presetting gas pressure difference between a laser incidence surface and a laser emergent surface of the air-blowing mask template. The laser scanning processing device solves a difficult problem in distributed auxiliary air blowing of a galvanometer scanning focusing processing module during large-format laser processing, is a perfect solution of distributed auxiliary air blowing of a laser galvanometer scanning focusing processing method, and is particularly suitable for industrial mass production.

Owner:张立国

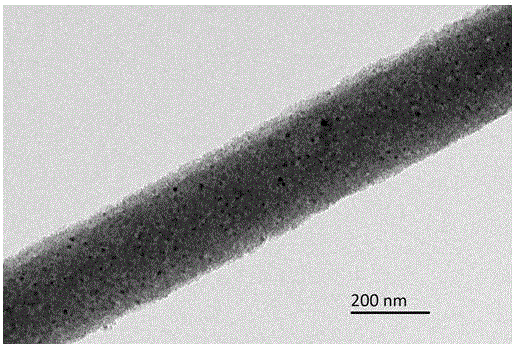

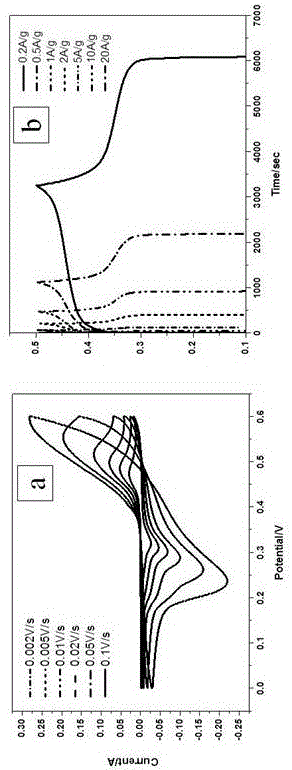

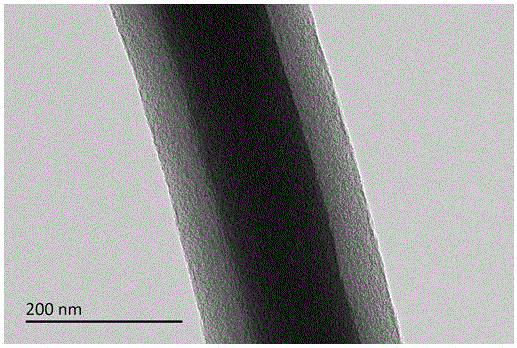

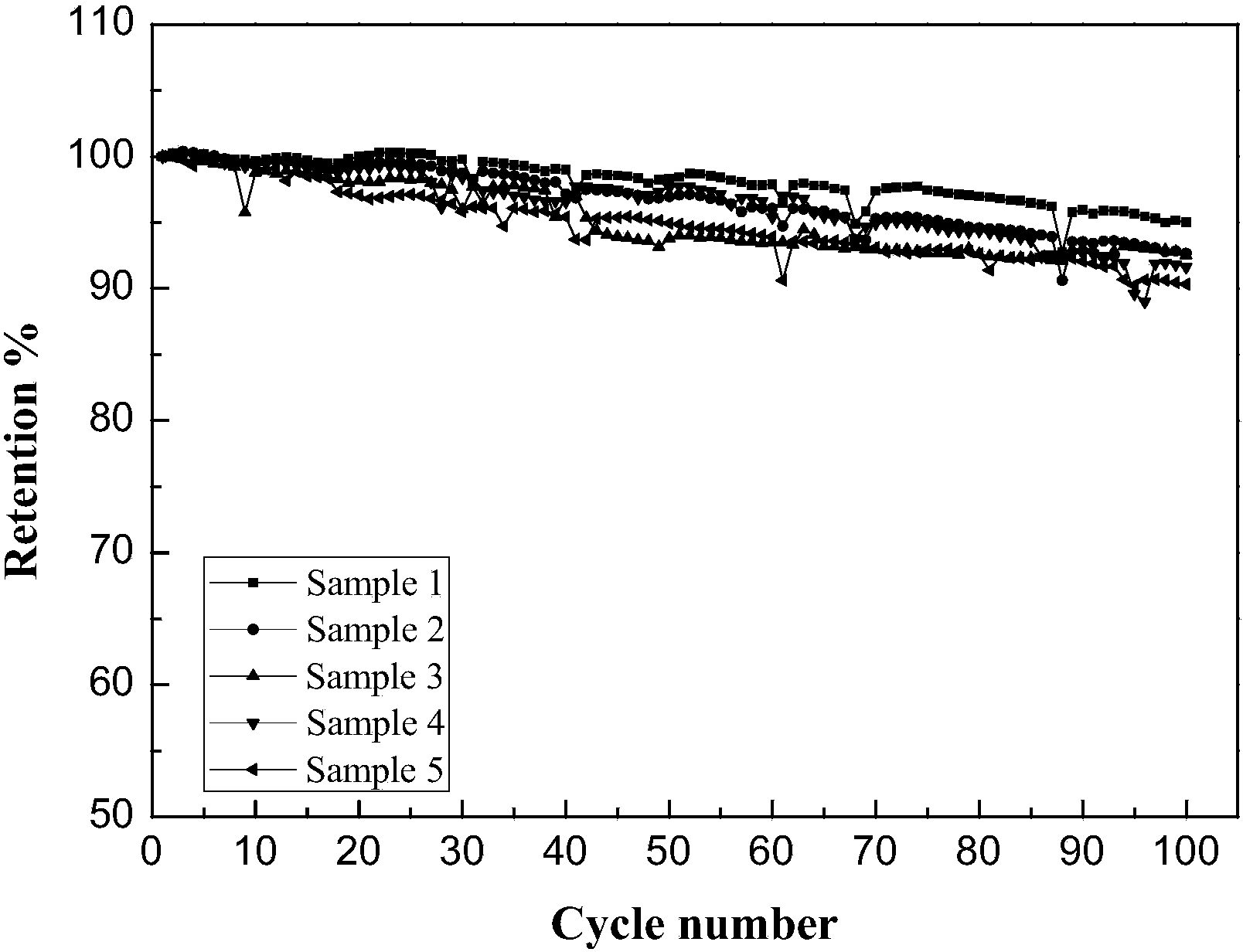

Flexible electrode with carbon fiber wrapped metal oxide for capacitor and preparation method

InactiveCN106449159AGood flexibilitySmall volume effectHybrid capacitor electrodesHybrid/EDL manufactureElectrospinningCapacitance

The invention discloses a flexible electrode with carbon fiber wrapped metal oxide for a capacitor and a preparation method. Through surface modification of metal oxide nanoparticles and the like, a flexible membrane that metal oxide nanoparticles are wrapped with a carbon nano fiber (a one-dimensional carbon material) is prepared by using an electrospinning technique, and the flexible membrane can be used in a flexible super-capacitor electrode. Not only is good flexibility achieved, a sufficient buffer space can be provided for volume variation of the metal oxide nanoparticles in operation through the carbon nano fiber, the volume effect of the metal oxide can be reduced, advantages of high specific capacitance, good stability and the like can be achieved, and the properties of a flexible capacitor can be further improved. In addition, methods such as surface chemical deposition or electric deposition are not needed in the production process, and the flexible electrode is simple to operate, controllable in material structure, low in cost and applicable to large-scale industrial production.

Owner:DALIAN OCEAN UNIV

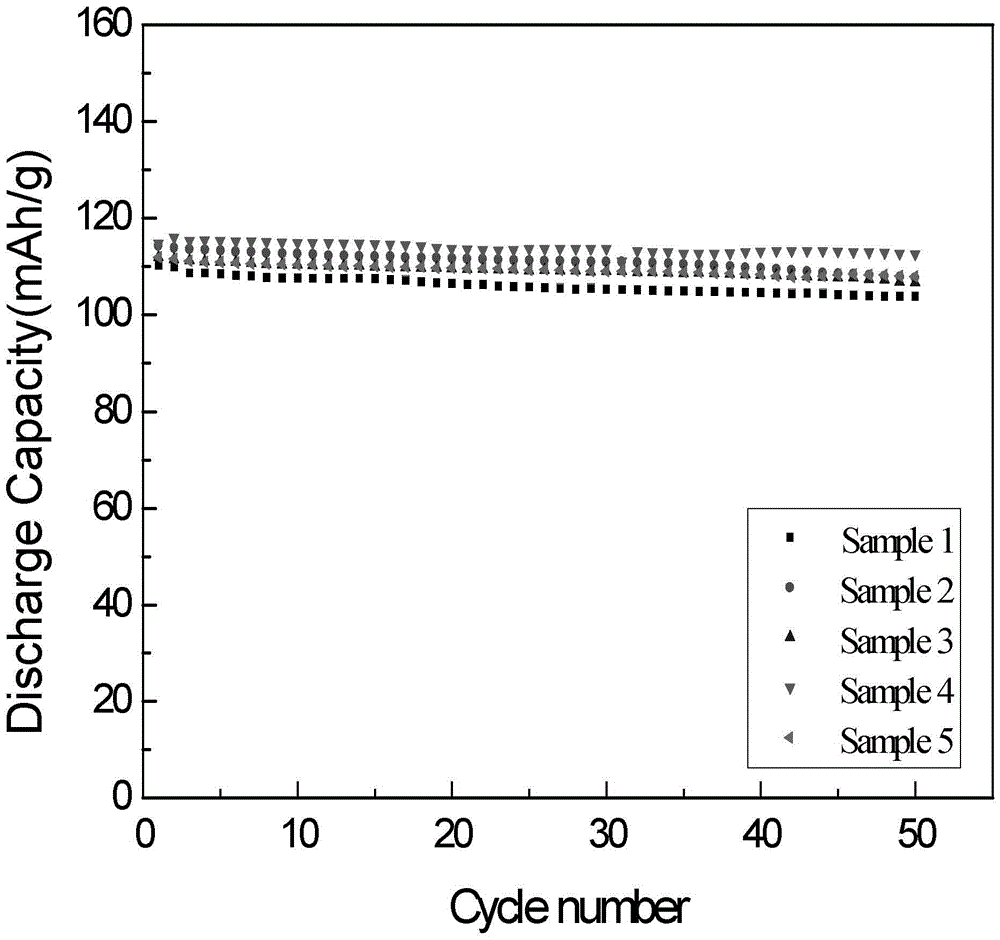

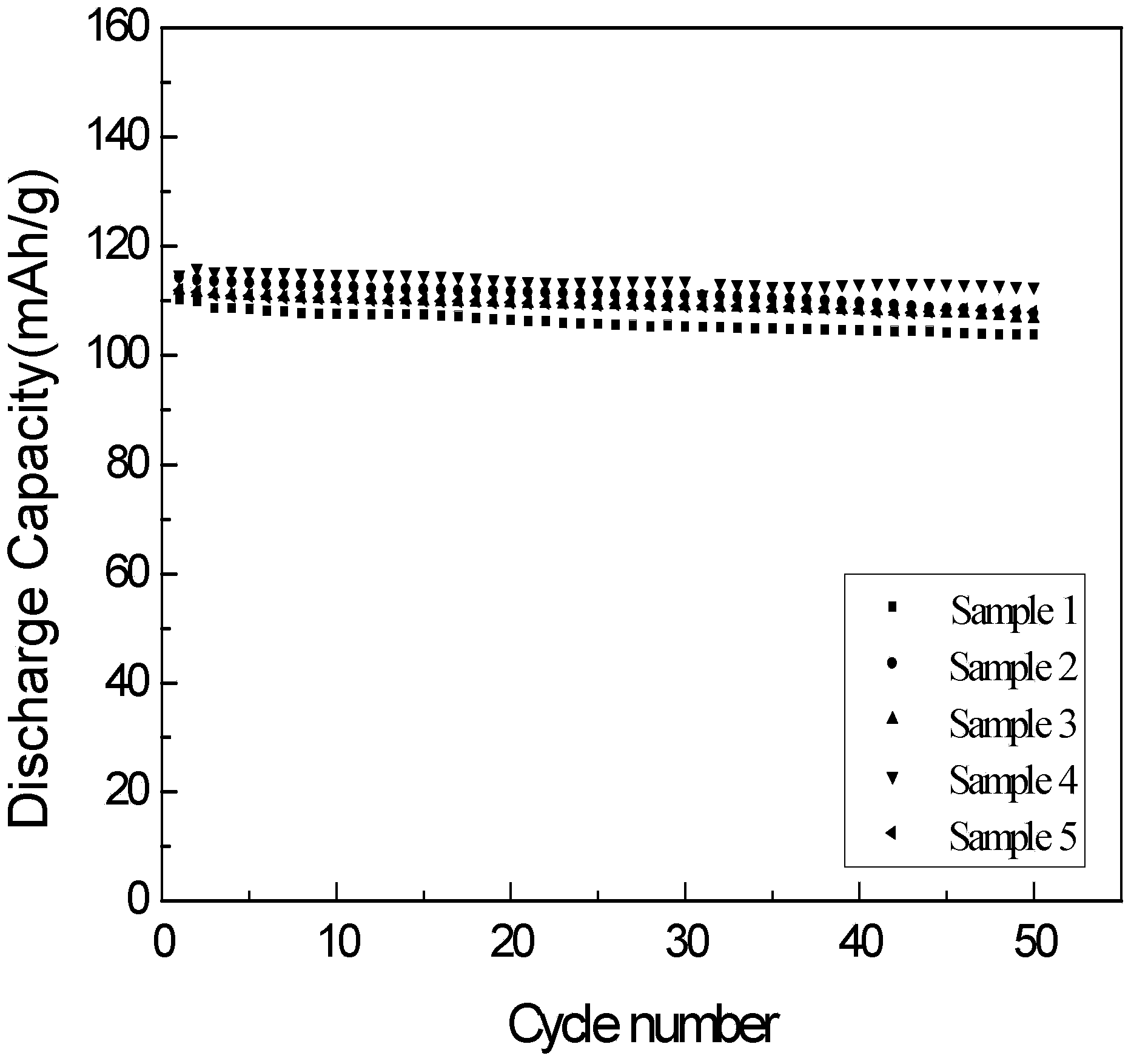

Lithium nickel cobalt aluminum oxide and lithium manganese oxide composite material used for lithium ion battery and preparation method thereof

ActiveCN104037404AReduce solubilityComplete structureCell electrodesSecondary cellsCobaltLithium-ion battery

The invention discloses a lithium nickel cobalt aluminum oxide and lithium manganese oxide composite material used for a lithium ion battery and a preparation method of the lithium nickel cobalt aluminum oxide and lithium manganese oxide composite material. According to the method, suspension liquid is prepared through mixing lithium nickel cobalt aluminum oxide with water, doped type lithium manganese oxide precursors are prepared by the utilization of a co-precipitation method, so that the prepared precursors are evenly precipitated on the surface of lithium nickel cobalt aluminum oxide, and through calcination, crushing and screening, the composite material which is doped with lithium manganese oxide and coated with the lithium nickel cobalt aluminum oxide is obtained. According to the material, the lithium nickel cobalt aluminum oxide (the structural formula is LiNi0.8Co0.15Al0.05O2) serves as a core, and the doped lithium manganese oxide < the structural formula is LiMn2-xMxO4 (0.1<=x<=0.5), and M is one or two of Mg, Co, Al, Cr, Zn and Ti> serves as a shell. The doped lithium manganese oxide serves as a coating layer, through a combination of a control crystallization method and a liquid-phase ball milling method, the doped type lithium manganese oxide precursors are prepared, the defects that a traditional lithium manganese oxide material is low in energy density, and cycling performance of the lithium nickel cobalt aluminum oxide is poor are overcome, the capacity of the material is high, and the cycling performance is excellent. The preparation method is simple, and industrial production is easy.

Owner:TIANJIN B&M SCI & TECH

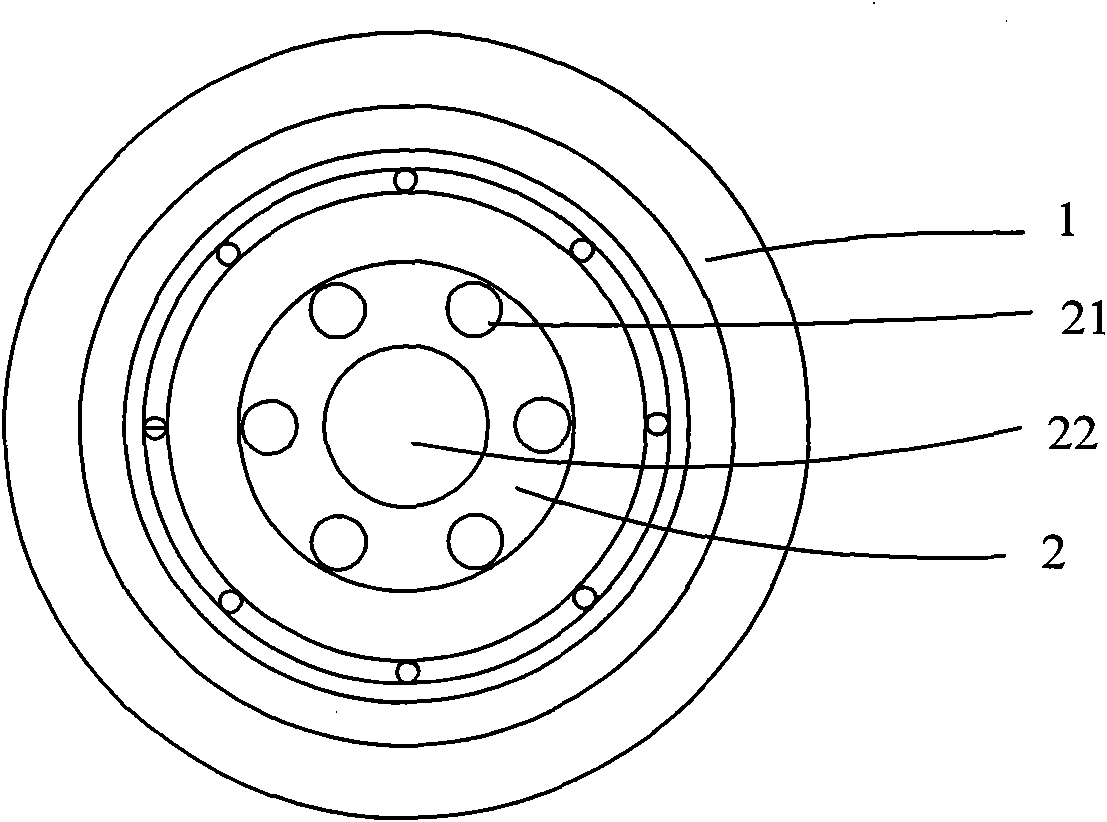

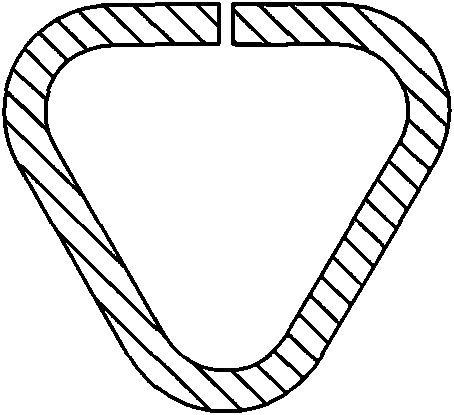

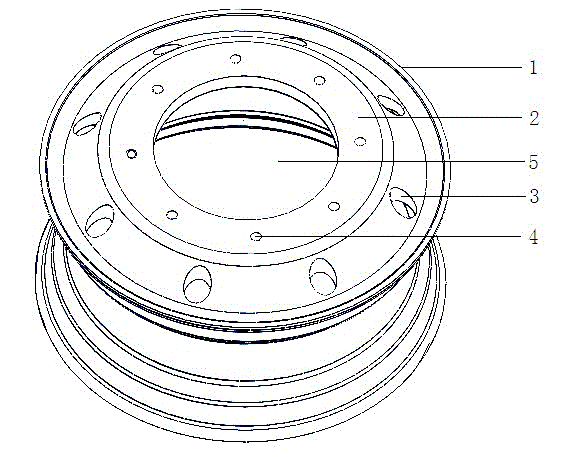

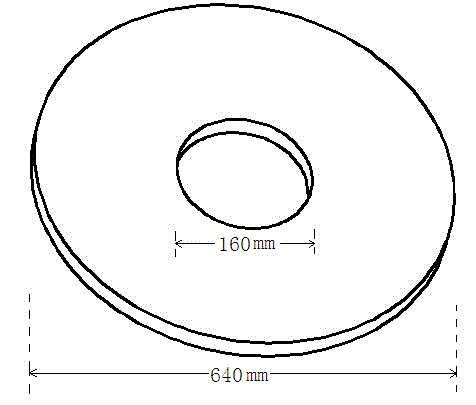

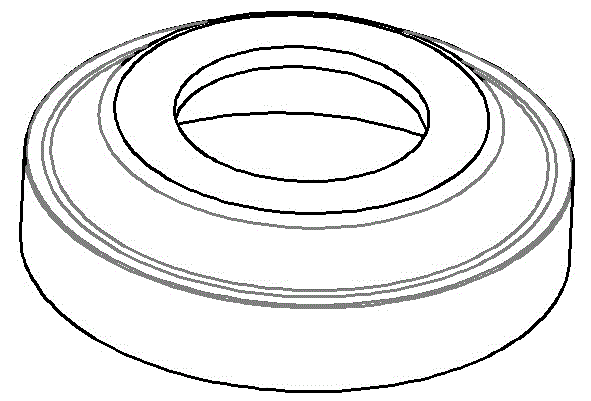

Aluminum alloy hub for super lightweight truck or passenger car and manufacturing method thereof

The invention discloses an aluminum alloy hub for a super lightweight truck or passenger car, which comprises a rim and a spoke arranged on the rim, wherein the rim is a hollow structure made of an aluminum alloy plate through integral spin forming; the spoke is a hollow part made of an aluminum alloy plate through integral spin forming, and the spoke is connected in the hollow cavity of the rim and is isolated from the rim. The invention also discloses a manufacturing method of the super lightweight aluminum alloy hub for the truck or passenger car. The aluminum alloy hub can be applied to super lightweight trucks and passenger cars.

Owner:东莞市汇鑫华翼汽车配件科技有限公司

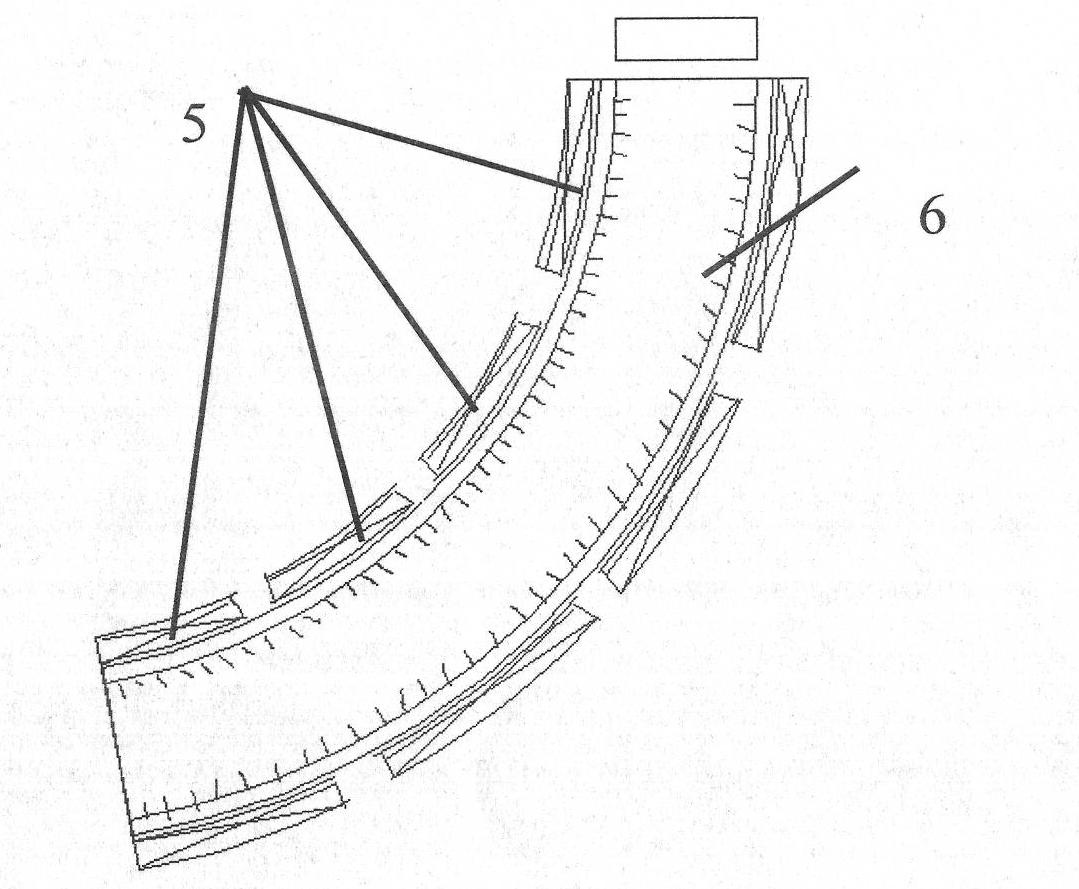

Method for magnetic filtration of strip-sectional vacuum cathodic arc plasma

InactiveCN102634761ASimple methodSuitable for high-volume industrial productionElectric discharge tubesVacuum evaporation coatingBand patternPlasma channel

The invention provides a method for removing electrically neutral drops and macroscopic particles in strip-sectional vacuum cathodic arc plasma, which belongs to the field of vacuum surface modification for materials, and particularly provides a method for magnetic filtration of electrically neutral drops and macroscopic particles by bending strip vacuum cathodic arc plasma by applying a magnetic field to a strip-sectional vacuum cathodic arc plasma channel. By the method, the defects that deposition area is small, deposition film is uneven, and scanning system equipment is complex and expensive and unsuitable for large-scale industrial coating application and the like in existing vacuum cathodic arc magnetic filtration methods for bends are overcome. By the method, coating plasma can be provided within a long strip range. By means of a rotating workpiece target table, application field of filtering arc can be widened greatly. Deposition efficiency is improved, large-space coating is achieved, coating efficiency is improved, and cost is reduced.

Owner:李刘合

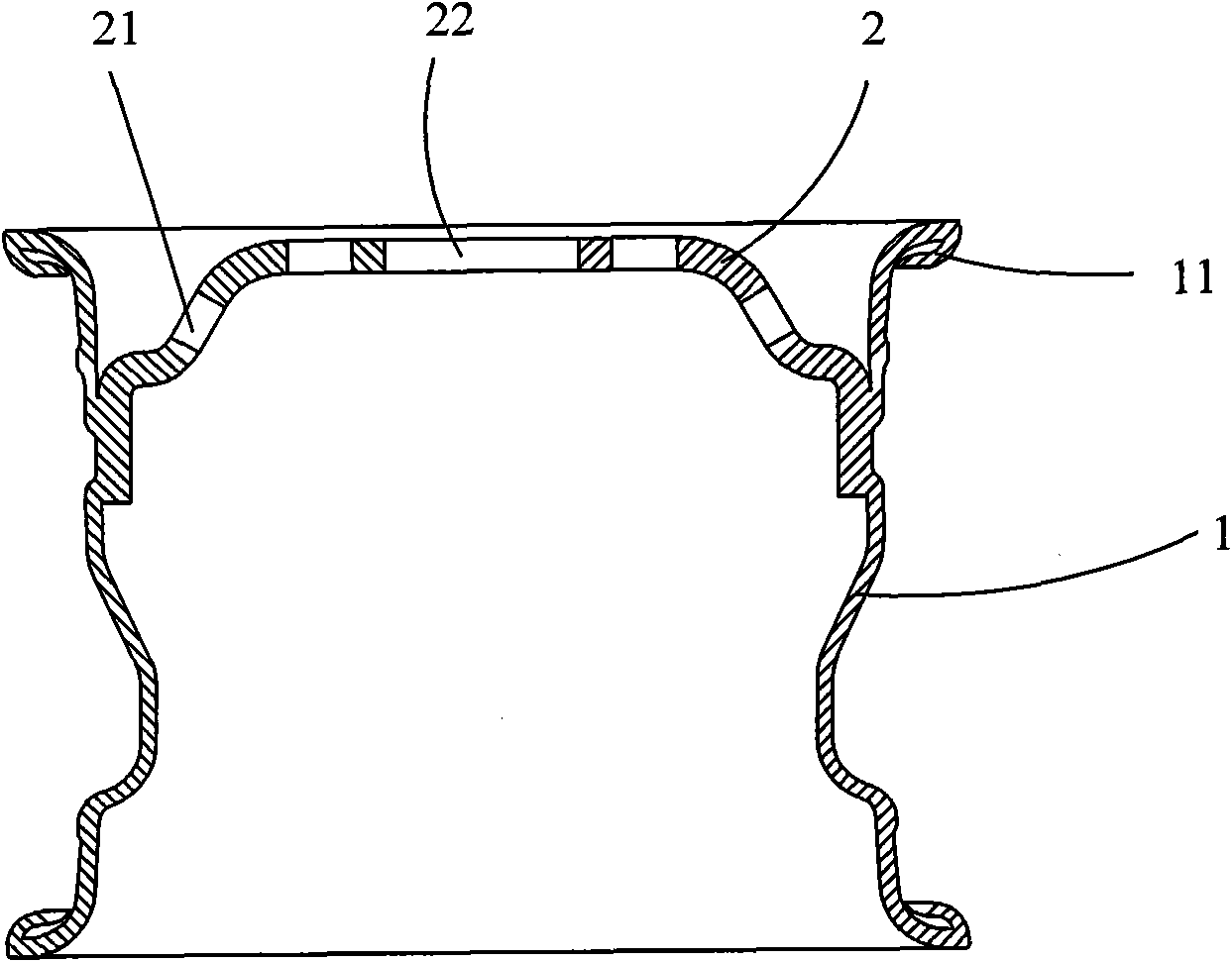

Integral aluminum alloy spinning hub and manufacturing method thereof

The invention discloses an integral aluminum alloy spinning hub and a manufacturing method thereof. The method mainly comprises the steps of (1) selecting an aluminum alloy medium-thickness panel as an initial blank; (2), forming the middle material of the aluminum alloy panel to be a hub and pre-forming the edge material of the aluminum alloy panel to be a rim by adopting strong bending spinning; (3) splitting the preformed rim to be a rim front piece blank and a rim rear piece blank by adopting splitting spinning; (4) respectively forming the front piece blank and the rear piece blank to a rim front piece and a rim rear piece by adopting strong thinning spinning. The spinning hub produced by the process is high in material use rate, and the material is subjected to plastic deformation for multiple times and is high in strength; a workblank does not need to be precast, forged or cast, the process is simple, the machining cost is low and the production efficiency is high. The front piece and the rear piece do not need welding and screw connection and have stable mechanical performance and high safety performance.

Owner:SHANGHAI HUIRU MACHINERY MFG

Preparation method for microporous light-weight corundum fireproof aggregate

The invention relates to a microporous light-weight corundum fireproof aggregate and a preparation method thereof. According to a technical scheme in the invention, 55 to 100 wt% of industrial alumina fine powder and 0 to 45 wt% of industrial aluminum hydroxide fine powder or alpha-Al2O3 micro powder are used as raw materials, and the raw materials undergo dry grinding on a ball mill for 0.5 to 3 h at first, then balling in a ball forming mill to obtain a ball blank with a size of 20 to 30 mm and finally rapid sintering in a shaft kiln at a temperature of 1700 to 1950 DEG C so as to obtain the microporous light-weight corundum fireproof aggregate. The preparation method for the microporous light-weight corundum fireproof aggregate is simple and easy and is applicable to volume industrial production; the microporous light-weight corundum fireproof aggregate has the advantages of a small bore diameter, high strength, low thermal conductivity, anti-scouring performance, erosion resistance and the like, can be used in a part where the wall of a steel ladle directly contacts with molten steel, is also applicable to production of iron runners, slide plates, ventilating bricks and the like and to other industrial kilns used in petrochemistry, ceramics and the like and can obviously reduce energy consumption.

Owner:JIANGSU JINGXIN NEW MATERIAL

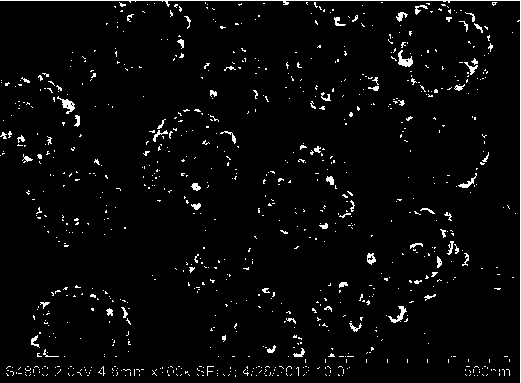

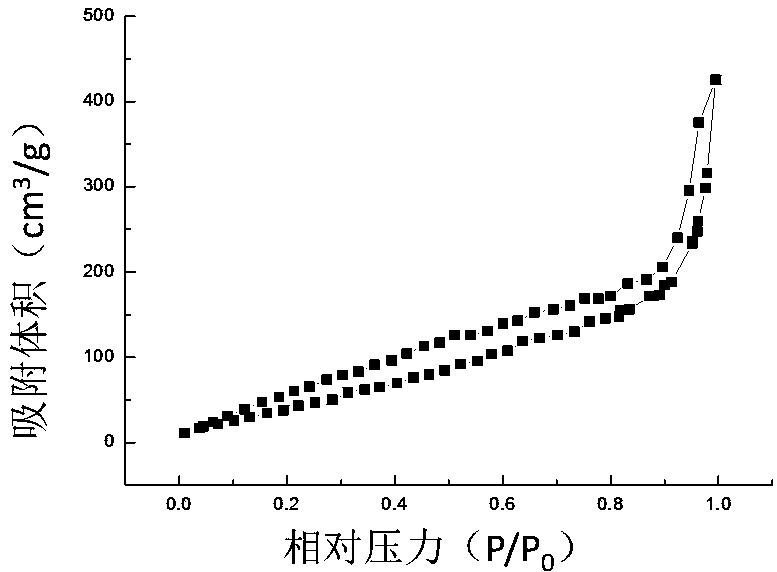

Method for preparing porous magnetic nanoclusters through etching

InactiveCN103803658ASave raw materialsLarge control spaceMaterial nanotechnologyFerric oxidesHydrazine compoundMagnetic colloid

The invention belongs to the technical field of inorganic materials and in particular relates to a method for preparing porous magnetic nanoclusters through etching. According to the method, magnetic colloid nanoclusters subjected to surface glycosylation are taken as a precursor, and porous magnetic nanoclusters with high specific surface area are prepared through a one-step etching method. The method comprises the following steps: by taking agarose as a stabilizer, preparing to obtain the magnetic colloid nanoclusters (called magnetic clusters for short) through a solvothermal method; reacting the prepared magnetic clusters, hydrazine, mercaptoacetate molecules and radical initiators, uniformly etching the original magnetic clusters, and obtaining the porous magnetic nanoclusters with high specific surface area. According to the method, the specific surface area of the porous magnetic nanoclusters can be controlled by controlling the reaction conditions. The method is simple in operation and mild in reaction conditions and has high application prospects, and the porous magnetic nanoclusters which are regular in structures and are acid biodegradable can be prepared.

Owner:FUDAN UNIV

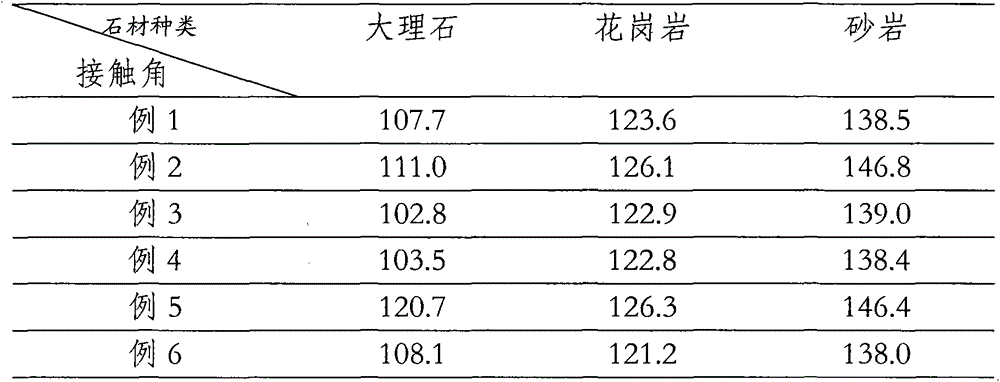

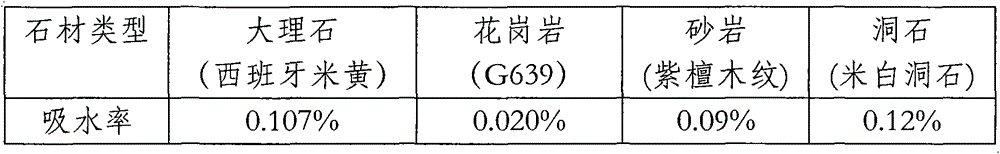

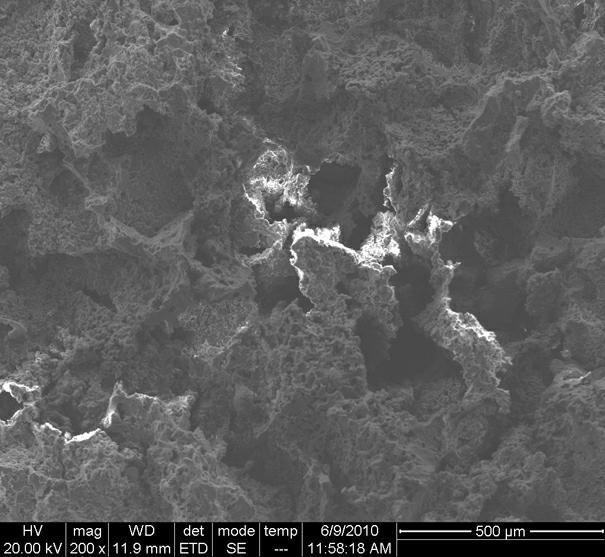

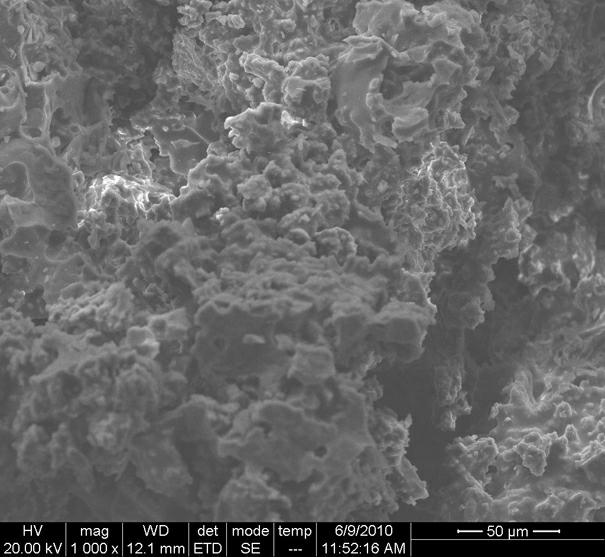

Solvent-type organic silicon stone protectant and preparation method thereof

The invention discloses a solvent-type organic silicon stone protectant and a preparation method thereof. The protectant is characterized by comprising the following polymer monomers by volume percent: at least one alkyl alkoxy silane of which the adding volume accounts for 1% to 10% of the total volume of the polymers, at least one polymethylhydrosiloxane of which the adding volume accounts for 1% to 10% of the total volume of the polymers, at least one titanate catalyst of which the adding volume accounts for 0.05% to 1% of the total volume of the polymers, and at least one solvent oil-type organic solvent of which the adding volume accounts for 79% to 97.95% of the total volume of the polymers. The preparation method comprises the following steps: evenly mixing the alkyl alkoxy silane and the polymethylhydrosiloxane in proportion in partial organic solvents at a room temperature; then carrying out a catalytic reaction by adding the catalyst; and finally, adding the organic solvent and diluting to reach a certain concentration. The protectant which has good permeability can be used for deeply protecting stone and is good in air permeability and recoatability. The protectant is simple in preparation method, simple and convenient to coat as well as relatively low in cost, thereby being suitable for industrial mass production.

Owner:XIAMEN NORNS TECH

Preparation method of high-temperature smoke filter ceramic material with high thermal shock resistance

InactiveCN102442831AGood effectSuitable for high-volume industrial productionCeramicwarePorositySlag

The invention discloses a preparation method of a high-temperature smoke filter ceramic material with high thermal shock resistance, wherein the method takes beta-cordierite, potash feldspar, spodumene and kaolin as raw materials, takes mullite as additive and takes carbon powder, starch, silicon carbide powder, limestone, sawdust, coal slag and ceramic waste as hole-forming agent; the high-temperature smoke filter ceramic material with high porosity, high thermal shock resistance, high compression strength, excellent filter performance and controllable aperture can be prepared by ball grinding, molding and sintering processes. The source of the pore-forming agent is wide; the die pressing, cold isostatic pressing and casting molding can be adopted, so that the operation is convenient andthe production cost is low; the filter ceramic material has controllable aperture and porosity, and excellent high temperature resistance and thermal shock resistance. The technology provided by the invention solves dust filter problem of high-temperature and wet gas well and also is applied in kinds of fields such as separation and purification, sound absorption, catalyst carrier and the like.

Owner:SOUTH CHINA UNIV OF TECH

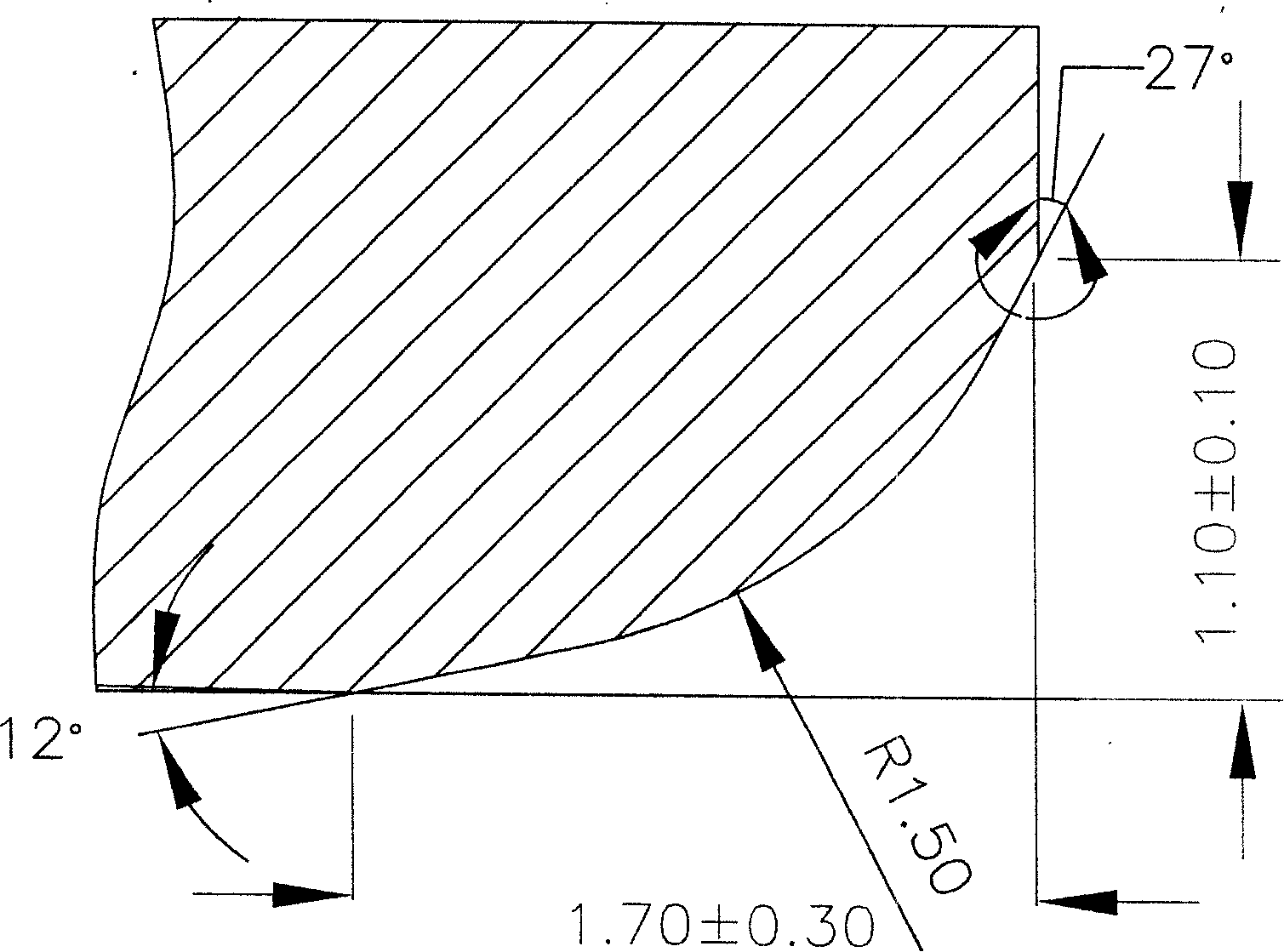

Method for using forming rollers high-efficiency process bearing channel cutting tool

InactiveCN101209531AAchieve ultra-preciseRealize the processing effectOther manufacturing equipments/toolsElectrolysisWear particle

The invention provides a method which processes a bearing channelling cutter with high efficiency by adopting forming grinding, comprising (1) the cutter is designed according to the requirement of a bearing channel and structure and dimension of an electrode used for trimming a grinding wheel is also designed; (2) after the electrode is designed and manufactured, the electrode which is taken as a cathode and the grinding wheel which is taken as an anode are respectively arranged on an ELID trimming system; grinding liquid with electrolysis capability passes through the clearance between the external spherical surface of the grinding wheel and the electrode; under the action of a power supply and the anode solution effect of the electrolysis process, a metal basic body on the surface of the grinding wheel is removed by electrolysis; a metal binder of the grinding wheel which is taken as the anode generates the anode solution effect and is gradually removed and grinding grains which are not affected by the electrolysis are exposed on the surface of the grinding wheel, thus implementing online trimming of the grinding wheel; (3) the profile of the grinding wheel which is trimmed is taken as the anode which is trimmed by the ELID and a corresponding cutter is grinded on the ELID trimming system by taking the hard alloy as the cathode.

Owner:ZHEJIANG UNIV OF TECH

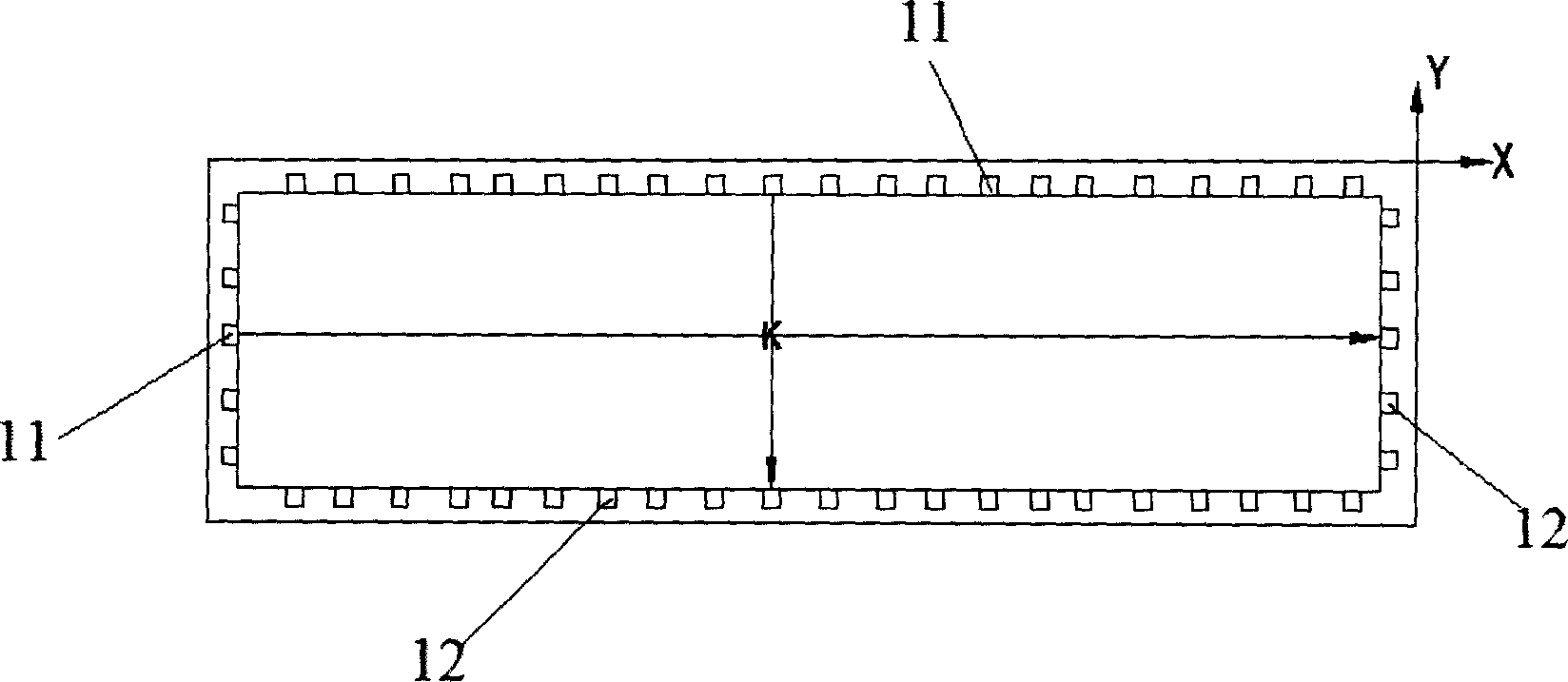

Photoelectric keyboard

InactiveCN1858677ASimple structureReduce manufacturing costInput/output for user-computer interactionSensor arrayCommunication interface

This invention relates to a photoelectric keyboard including a key symbol body, a keyboard encoder and a sensor array arranged on the outer edge of the symbol body and composed of an emitting head of the sensor and a corresponding receiving head at the relative edge of the sensor, in which, the emitting head and the receiving head form an optical path between them when working, fingers click the symbol labels on the keys to result in shading of the optical path and generate shelter signals, the keyboard encoder also includes a scan controller for controlling the scanning mode of the sensor array and converts the shading signals detected by the sensor to a serial keyboard encoding to store it and adjusts the parameters of the keyboard to transmit them to the CPU via the communication interface.

Owner:郭超逸

Method for preparing carbon aerogel by using waste seaweed residues as raw material

InactiveCN110980685ASolve high value-added developmentSolve the use problemCarbon preparation/purificationAerogel preparationCelluloseFreeze-drying

The invention discloses a method for preparing carbon aerogel by using waste seaweed residues as a raw material, which comprises the following steps: separating and purifying industrial waste seaweedresidues to obtain seaweed cellulose, and carrying out sol-gel, vacuum freeze drying and high-temperature carbonization processes to finally obtain the carbon aerogel with a controllable structure. The carbon aerogel does not contain substances harmful to organisms or polluting the environment, so that the problems of high raw material cost and limited application range of the existing carbon aerogel are solved, and the problem of high-added-value development and utilization of the waste seaweed residues is also solved. The method is simple to operate and short in preparation period, the material structure is controllable, the production process is environment-friendly and safe, and the method is suitable for large-scale industrial production.

Owner:DALIAN OCEAN UNIV

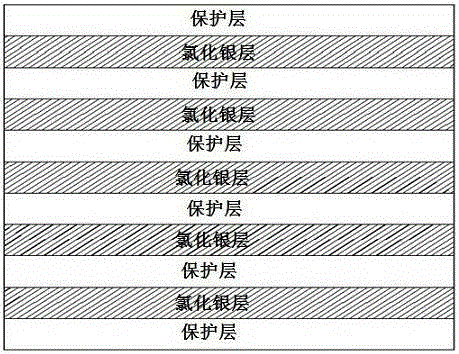

Preparation method of chick embryo extract

ActiveCN106138101AKeep active ingredientsSimple production processCosmetic preparationsToilet preparationsAlcoholChick embryos

The invention belongs to the technical field of medicines and in particular relates to a preparation method of chick embryo extract. Chick embryos are percolated and extracted by utilizing alcohol liquid; a production process is relatively simple; the disadvantage that effective components are damaged by high-temperature extraction is overcome and the disadvantages that a previous process is complicated, low-temperature operation is not easy to control and requirements on equipment are high are also overcome. The chick embryo extract can be used for a traditional Chinese medicine prescription or is singly used; the extract provided by the invention is used for resisting fatigue and improving the immunity and has the advantages that the bioavailability is high and the extract is suitable for large-scale mass production.

Owner:山东宏济堂制药集团股份有限公司

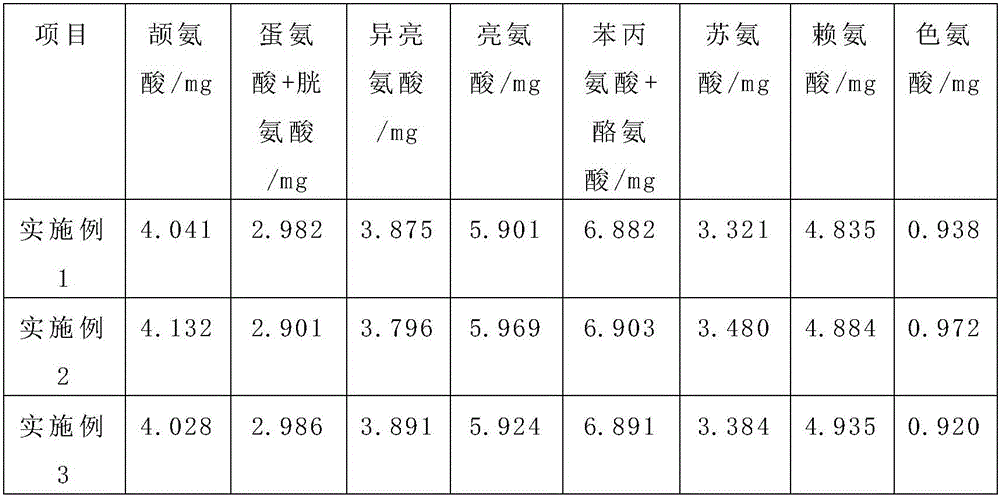

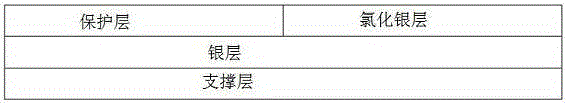

Silver/silver chloride electrode slice and preparation technology thereof

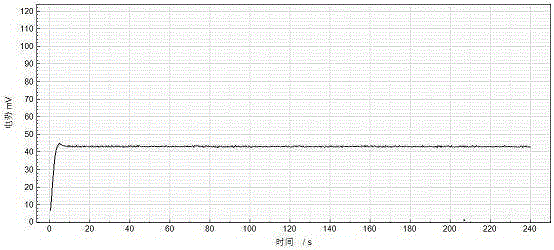

InactiveCN105334250AHigh precisionShort response timeMaterial electrochemical variablesSilver chlorideProtection layer

The invention discloses a silver / silver chloride electrode slice and a preparation technology thereof, and belongs to the field of electrochemical sensors. The silver / silver chloride electrode slice comprises a supporting layer, a silver layer, a protection layer and a silver chloride layer. The preparation method for the silver / silver chloride electrode slice comprises plating the silver layer on the supporting layer through a vacuum silver-plating manner, then covering the protection layer on a part of the silver layer, and finally preparing the silver chloride layer through a chemical oxidation process, so as to prepare the silver / silver chloride electrode slice. The prepared silver / silver chloride electrode slice overcomes the disadvantages that a conventional silver / silver chloride electrode slice is low in precision, short in response time, bad in signal stability among batches, not suitable for organic environment and tedious in preparation technology, and the like. The silver / silver chloride electrode slice is stable in electric potential performance, high in precision, low in signal to noise ratio, low in impedance, short in response time, low in production cost, high in production efficiency and suitable for large-scale industrial production.

Owner:吴国清

Preparation method of lithium manganate cathode material

ActiveCN103715415BComplete structureReduce solubilityCell electrodesSecondary cellsLiquid productPhysical chemistry

The invention discloses a preparation method of a lithium manganate anode material. The preparation method comprises the following steps: (1) preparing a salt-mixture solution; (2) preparing a precipitant solution; (3) slowly pumping the salt-mixture solution and the precipitant solution into a reaction kettle at a pH value of 7-13; (4) weighing manganese dioxide in proportion, adding the manganese dioxide to a mixed solution obtained in the step (3), continuously stirring, ageing for 5-20 hours, then separating solid-liquid products, and washing an obtained precursor with deionized water to alkalescence; (5) adding a lithium source and the washed precursor to a ball-milling tank, carrying out ball-milling for 2-5 hours, and then drying at the temperature of 80-120 DEG C, thus obtaining a precursor material; and (6) respectively roasting the obtained precursor material two times, breaking the material obtained by sintering, and sieving, thus obtaining the lithium manganate anode material. The preparation method is simple; the prepared lithium manganate anode material has high capacity and excellent high-temperature cycle performance.

Owner:TIANJIN B&M SCI & TECH

Handheld combined table and stool

The invention belongs to the field of tables and chairs, and particularly relates to a handheld combined table and stool. The handheld combined table and stool is characterized in that a tabletop is unfolded as a suitcase and composed of two half tabletop bodies; the two half tabletop bodies are hinged together, and two sides of the tabletop are fixedly connected with carrying handles respectively; the four corners of the back of the tabletop are movably connected with foldable table legs, the table legs are fixedly provided with sliding rails through adjustable locating hoops, a supporting frame is fixedly connected with the table legs through the sliding rails, and a stool surface is arranged on the supporting frame and connected with the supporting frame in a rotating mode. The handheld combined table and stool has the advantages that the structure is simple, folding is convenient, the height of the stool surface is adjustable, carrying is convenient after the handheld combined table and stool is folded, and the handheld combined table and stool is small in size, light in weight, low in cost, convenient to carry and store after being folded in a suitcase mode, and capable of being placed in a sedan trunk and bringing convenience to floating personnel to enable the floating personnel to go out, travel and take vehicles conveniently.

Owner:TIANJIN RUOWANG TECH CO LTD

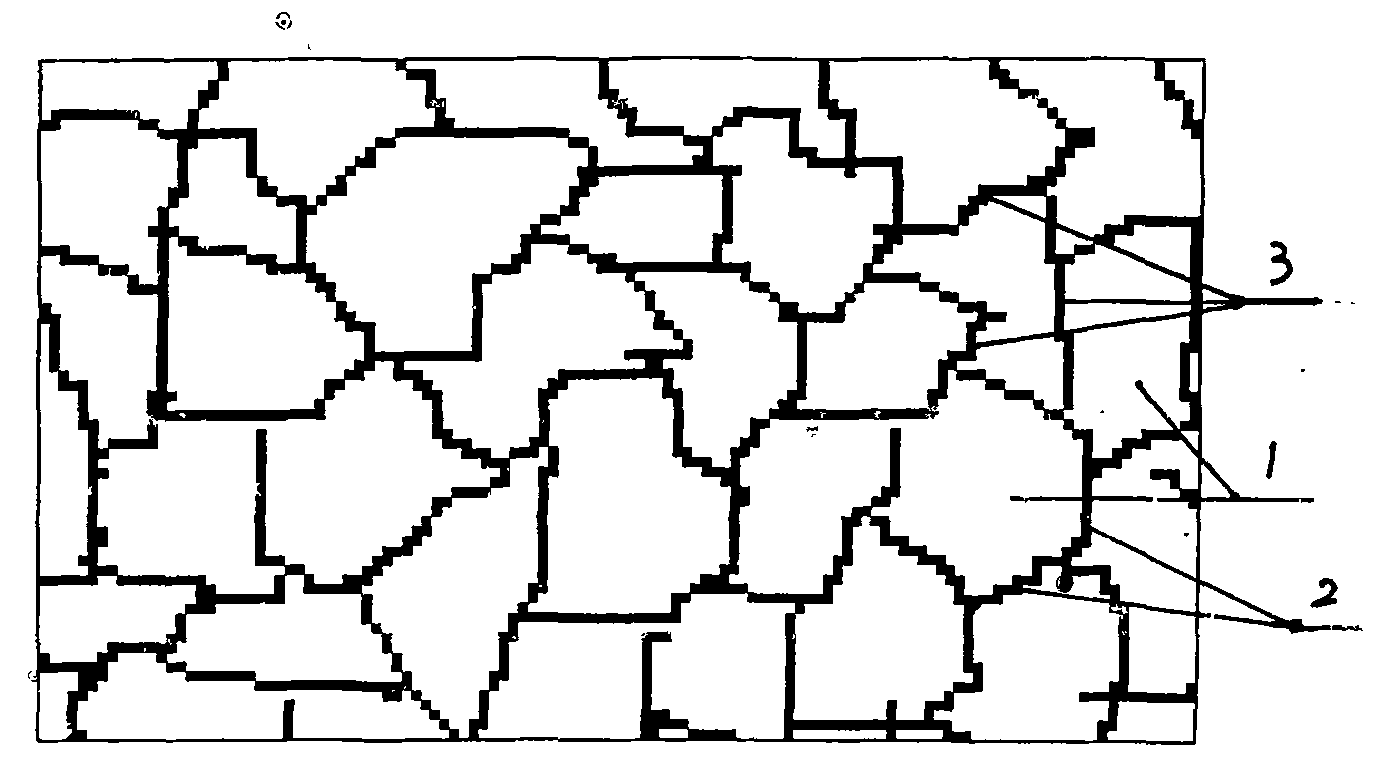

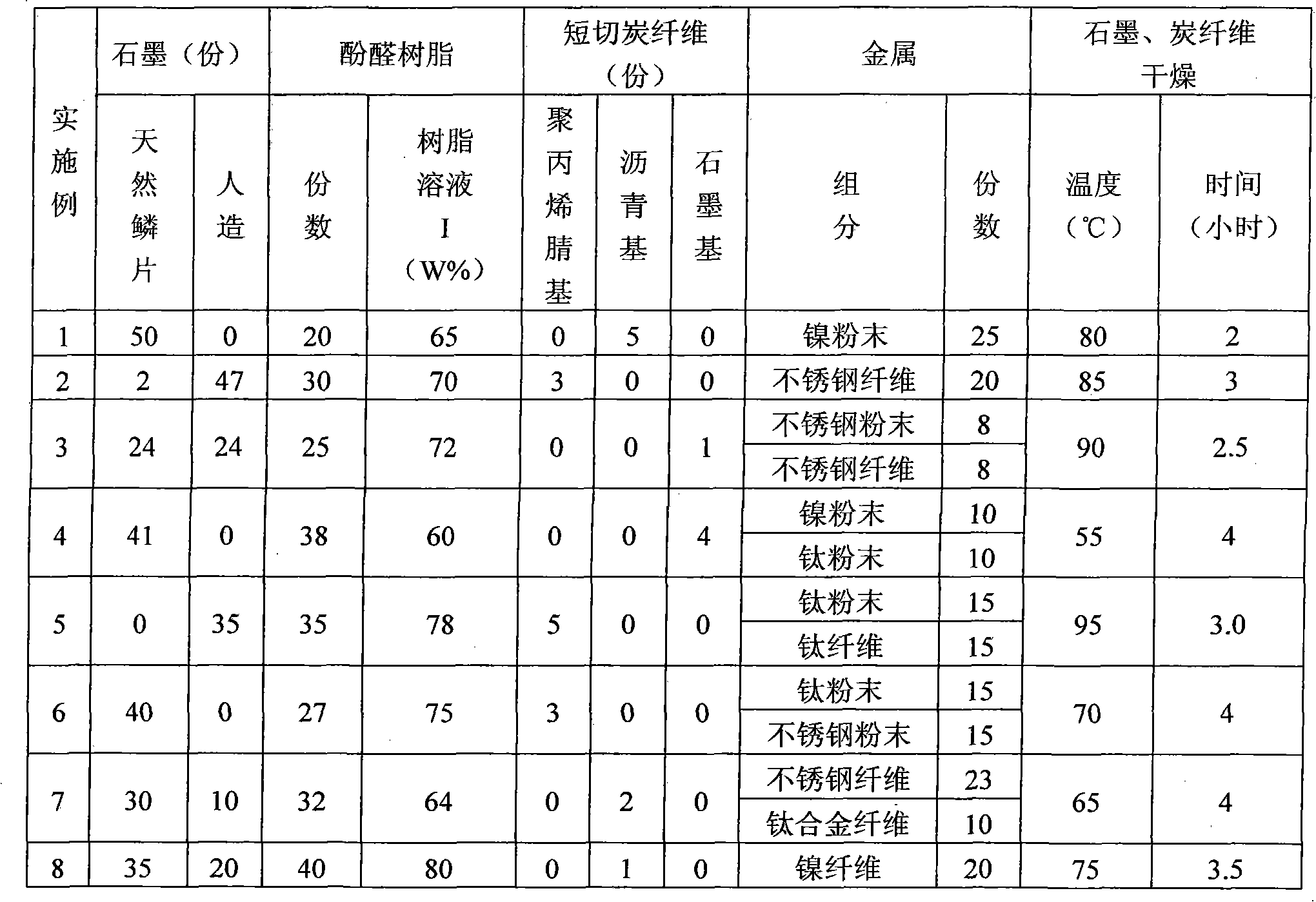

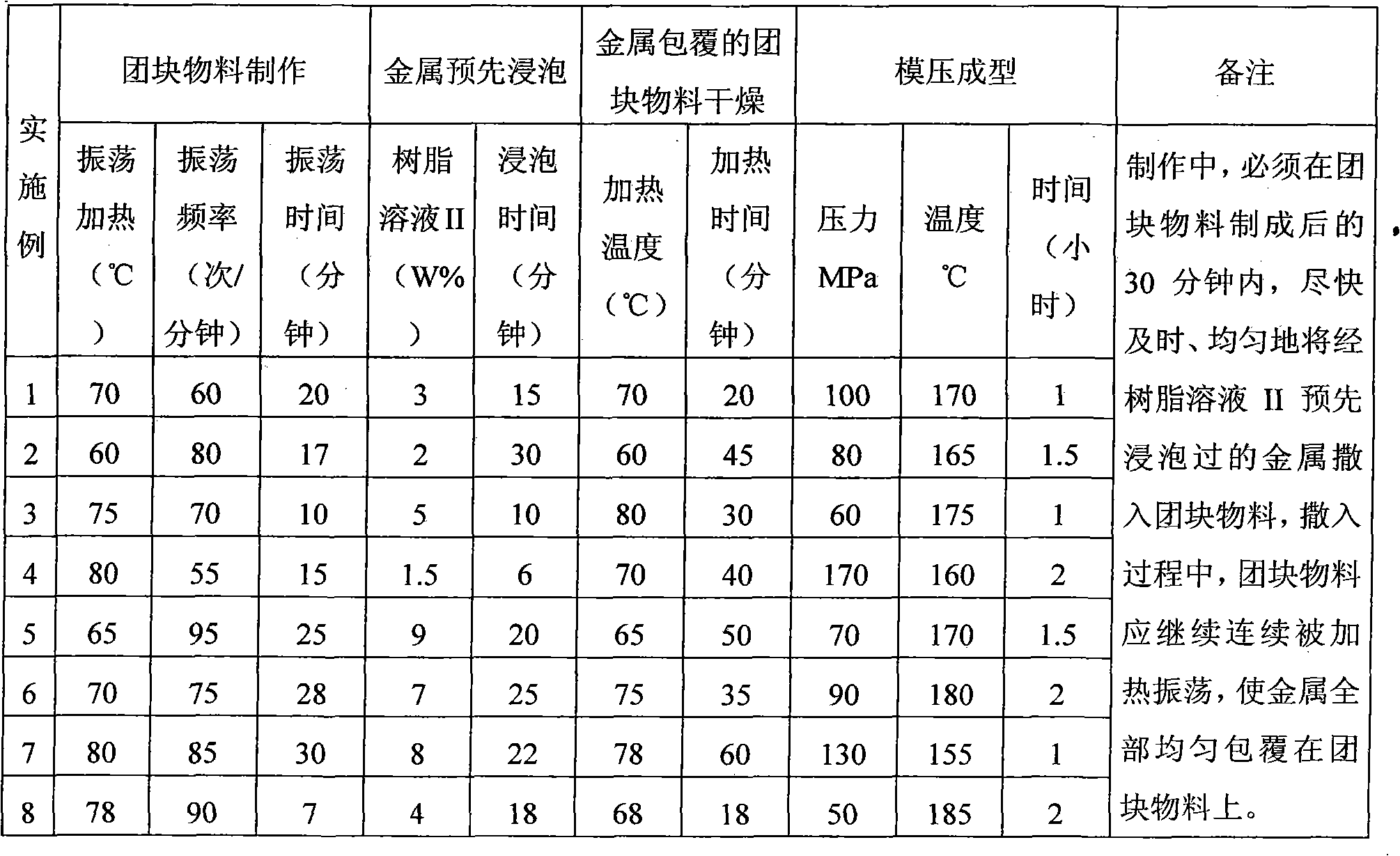

Composite material bipolar plate for proton exchange membrane fuel cell and manufacturing method thereof

The invention discloses a composite material bipolar plate for a proton exchange membrane fuel cell and a manufacturing method thereof, and belongs to the field of fuel cells. The composite material comprises the following components in part by mass: 60 to 80 parts of conductive filler, 20 to 40 parts of phenolic resin, and 1 to 5 parts of fiber reinforcing agent; the conductive filler is graphite and / or metal; the mass ratio of the graphite to the metal is 1:1-3:1; the manufacturing method comprises the following steps of: preparing 60 to 80 mass percent absolute ethanol solution from a phenolic resin; mixing the absolute ethanol solution, the graphite and the fiber reinforcing agent and preparing a block material; scattering the metal which is presoaked in 1 to 10 mass percent phenolic resin absolute ethanol solution, and coating on the block material uniformly; and then heating and performing pressure forming, wherein volume density is 1.90 to 2.50g / cm<3>; bending strength is 60 to100MPa; and conductivity is 5.0*10<4> to 3.0*10<5>S / m. The raw materials are easily obtained, the manufacturing process is simple, and the bipolar plate is low in cost and is suitable to be industrially produced on a large scale.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Embedded cladding-type nickel cobalt aluminium lithium material for lithium ion battery and preparation method thereof

InactiveCN106571447AIncrease capacityPromote circulationCell electrodesSecondary cellsNickel saltMixed materials

The invention relates to an embedded cladding-type nickel cobalt aluminium lithium material for a lithium ion battery and a preparation method thereof. The material is composed of a body material and a clad material. The body material is nickel cobalt aluminium lithium, and the clad material is nickel cobalt manganese lithium. The preparation method comprises the following steps: preparing a nickel cobalt aluminium lithium suspension; preparing a mixed salt solution of nickel salt, cobalt salt, manganese salt and M metal salt; adding the mixed salt solution and the suspension into a reaction vessel, heating and stirring, standing, filtering, washing until washing liquor is neutral, and drying; ball-milling a lithium source and the obtained dry sample and mixing by a mixer so as to obtain a mixed material of nickel cobalt aluminium lithium coated with a lithium nickel cobalt manganese oxide precursor and the lithium source; and calcining, crushing, and screening so as to obtain the embedded cladding-type nickel cobalt aluminium lithium material for a lithium ion battery. The invention has the following advantages: the material has high capacity, excellent cycle performance, low pH value and good processing property and safety performance; and the preparation method is simple, safe and easy to operate, and is suitable for large-scale industrial production.

Owner:HENAN KELONG NEW ENERGY CO LTD

Vacuum circuit-breaking switch contact material preparation method

InactiveCN101787453AImprove electrical conductivitySpeed up coolingMetal/alloy conductorsChromiumCopper

The invention discloses a vacuum circuit-breaking switch contact material preparation method and water-cooled mould equipment used by the method. The preparation method includes that copper and chromium are melt in a vacuum induction furnace to form alloy liquid, and then the melt alloy is cast into casting blanks. The concrete process parameters include: the vacuum degree is less than 1*10<-1>Pa, the heating temperature range is 1600-1950 DEG C according to the proportion of chromium content, when chromium is melted completely, the stirring refinement process lasts for 20 min, and then the alloy melt is injected into a water-cooled mould equipment with cooling water on periphery, and the casting temperature is maintained at 1600-1800 DEG C. The contact material prepared by the method has compact structure and fine crystalline grains, improves the electrical conductivity, reduces gas content, realizes large-size ingot blank and has high qualified rate; besides, the production equipment is general, the production cost is low and the mass production can be realized more easily.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

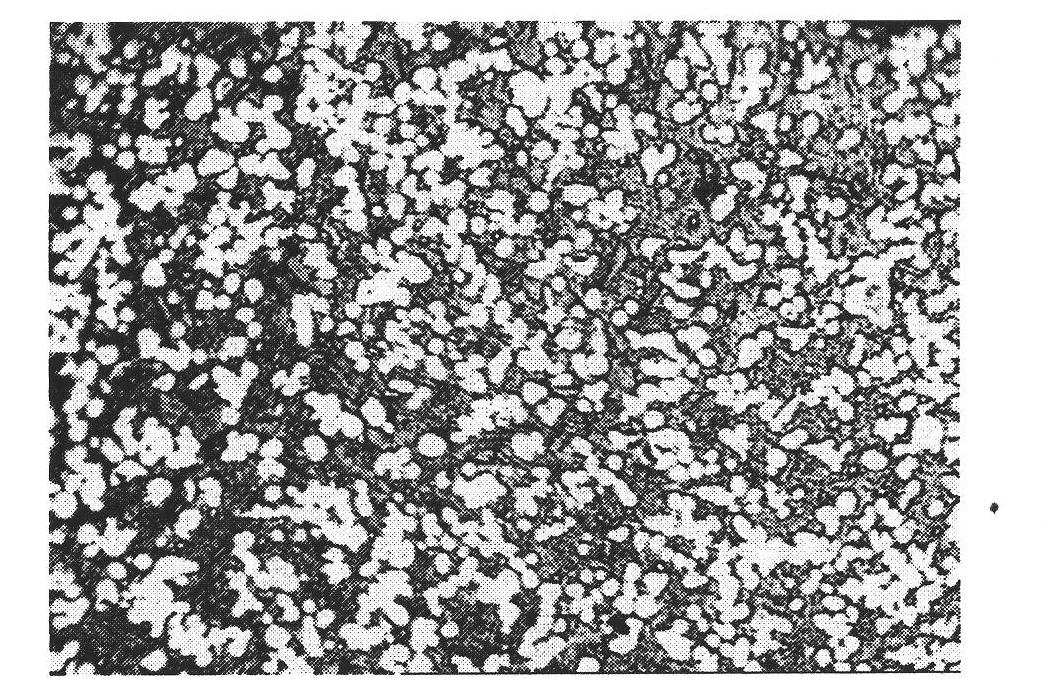

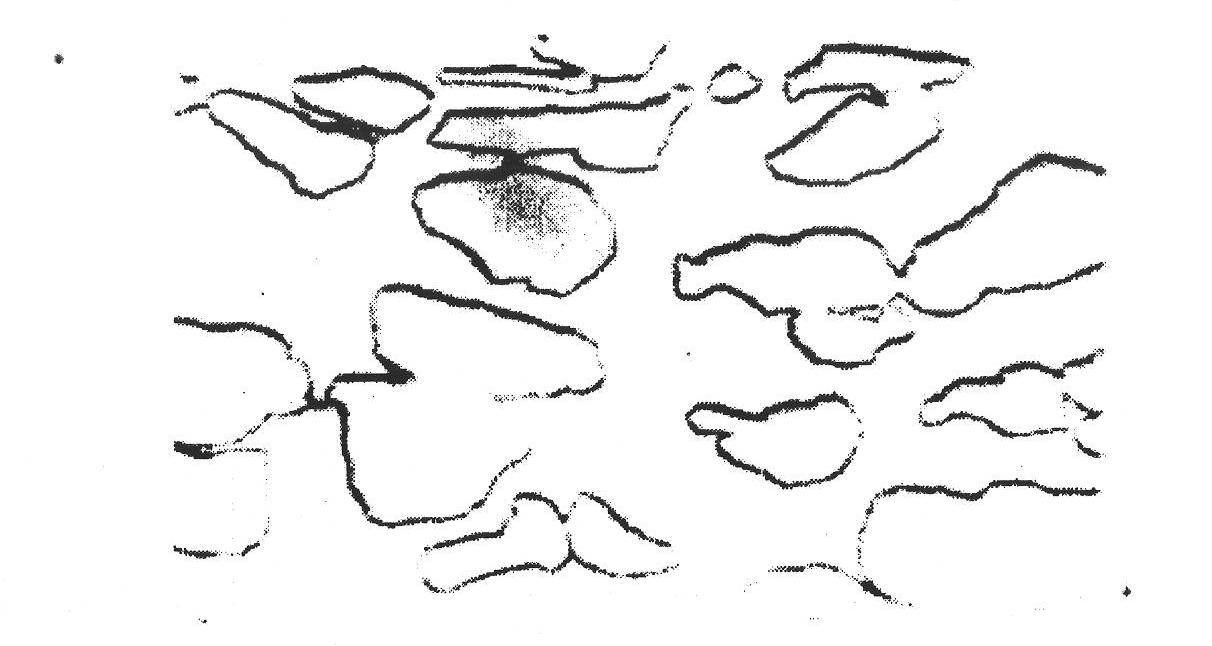

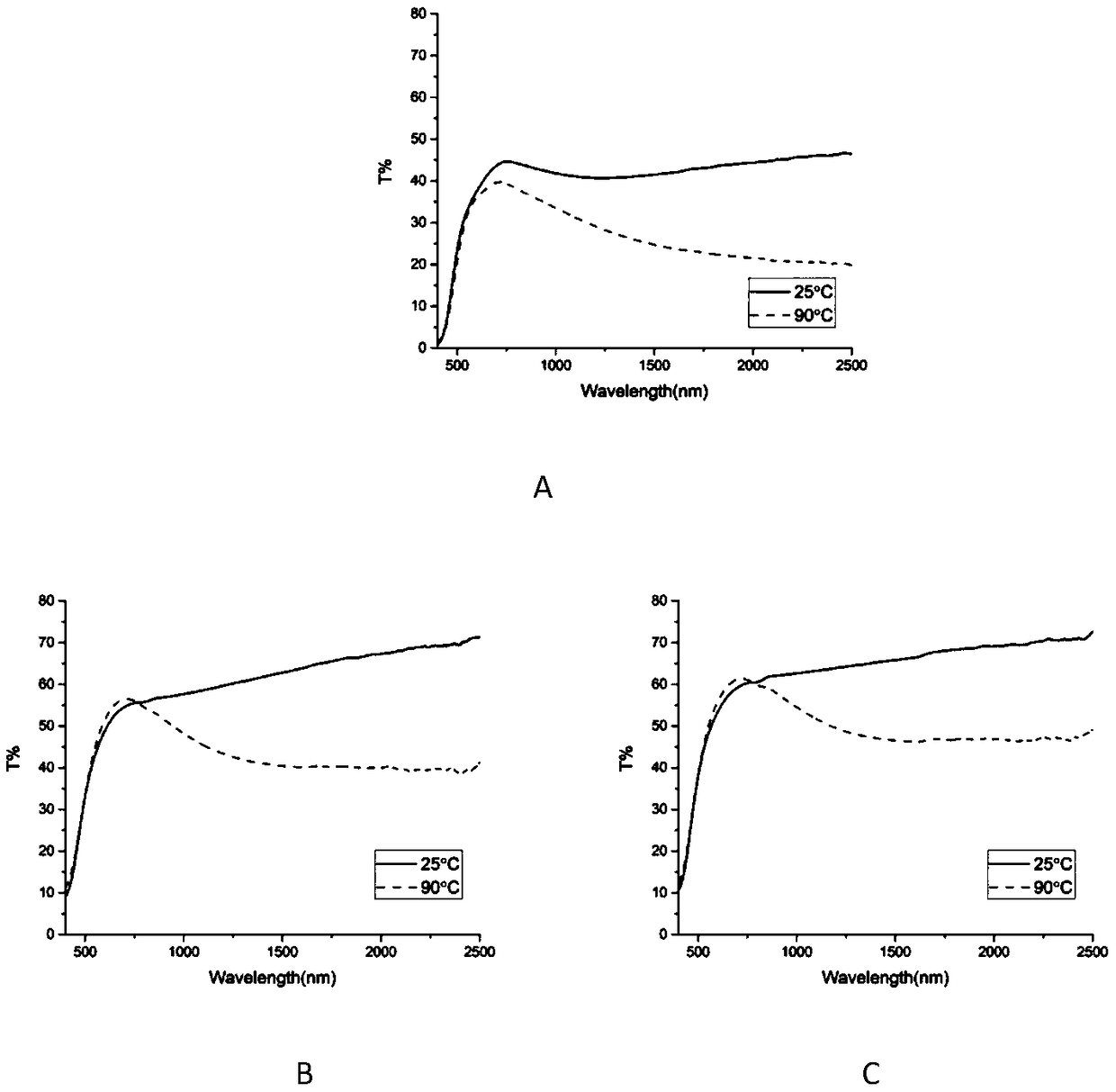

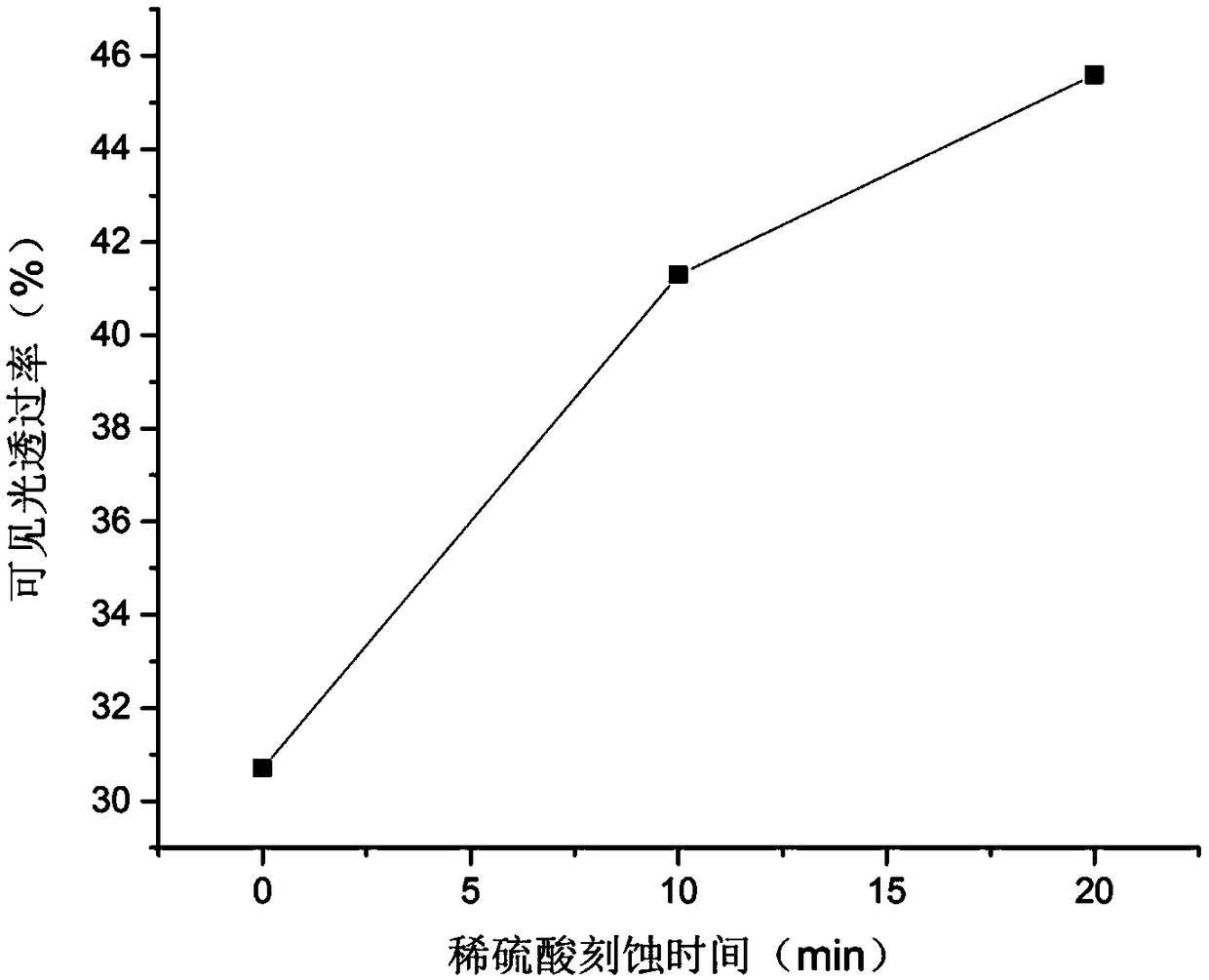

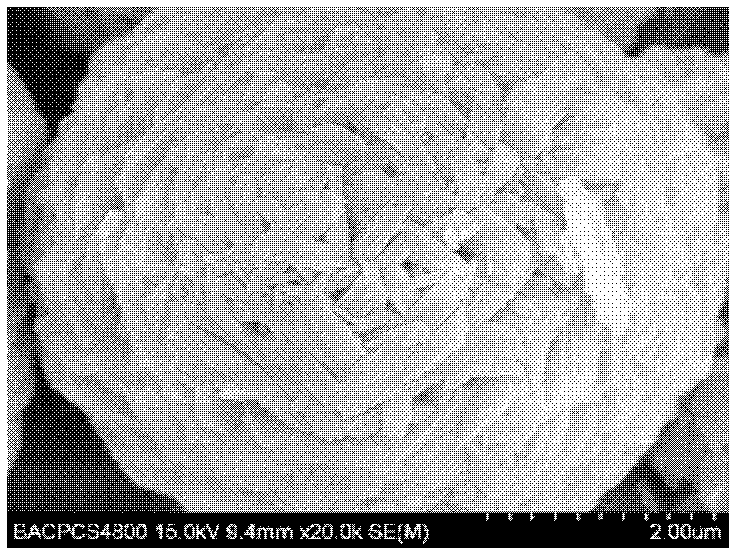

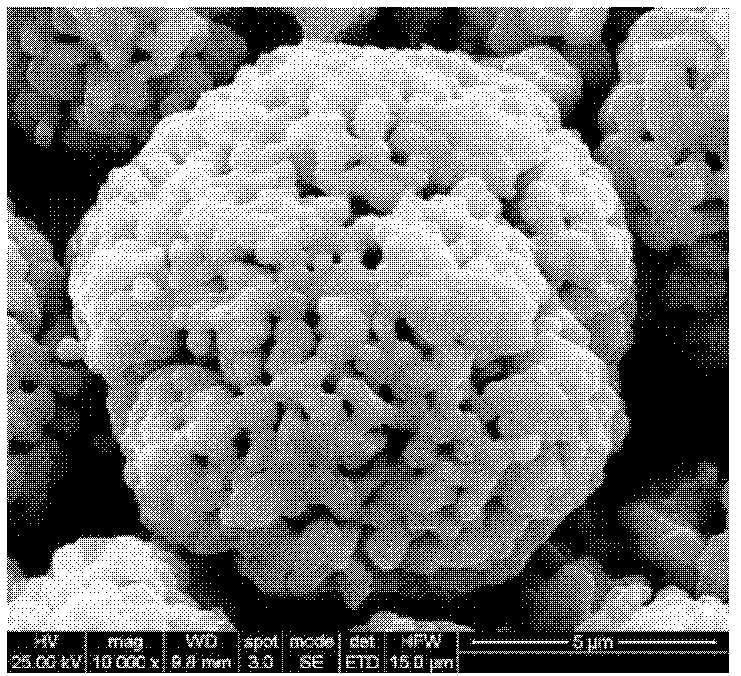

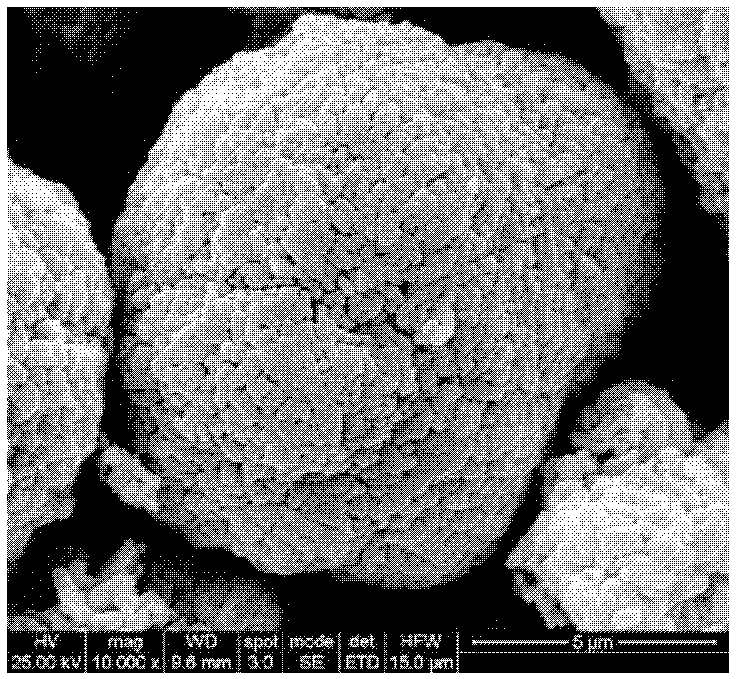

Method for improving visible light transmittance of vanadium dioxide film by using dilute sulfuric acid etching

InactiveCN109402581AHigh porosityLow process conditionsVacuum evaporation coatingSputtering coatingTransmittanceVanadium dioxide

The invention discloses a method for improving visible light transmittance of a vanadium dioxide film by using dilute sulfuric acid etching. A vanadium dioxide film, prepared through combining magnetron sputtering and rapid annealing, is etched by adopting a dilute sulfuric acid treatment mode, and the continuous planar vanadium dioxide film is etched into separate particles in an acid treatment manner in a whole preparation process, so that the porosity of the film is improved. According to the method disclosed by the invention, required process conditions are low and are easily controlled, and the visible light transmittance of VO2 can be effectively improved. A vanadium metal film is sputtered firstly, then, thermal annealing oxidation is carried out, and finally, soaking etching is carried out by using dilute sulfuric acid, so that the manufacturing cost is low, and the method is applicable to large-batch industrial production.

Owner:TIANJIN UNIV

Lithium battery metal oxide precursor, cathode material, and preparation method thereof

ActiveCN103187561APrimary particle gap increasesAdequate responseCell electrodesImpurityEnergy consumption

The invention relates to a lithium battery metal oxide precursor, a cathode material, and a preparation method thereof, and particularly relates to a lithium battery metal oxide precursor with large primary particle gaps, a cathode material with low impurity content, and a preparation method thereof. The precursor has a molecular formula of (Ni1-x-yCoxMy)2O3, wherein 0<=x<1, 0<=y<1, M is Mn, Al, Fe, Ti, or the like, and the gas between primary particles is 0.05-2 microns; the cathode material prepared by the precursor has a molecular formula of Li1+thetaNi1-x-yCoxMyO2, wherein 0<=theta<=0.15, the residual alkali content is not more than 1200 ppm, and the sulfur content is not more than 1200 ppm. The precursor has large primary particle gaps; the lithium battery cathode material prepared by the precursor has low residual alkali content and low sulfur content; the preparation method is simple; problems of no effective removal of residual alkali and sulfur impurities, great lithium loss caused by multielement material washing, energy consumption increase during high temperature processing of multielement materials, and the like are overcome; and the preparation method is suitable for large scale industrial production.

Owner:当升科技(常州)新材料有限公司

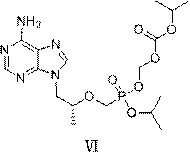

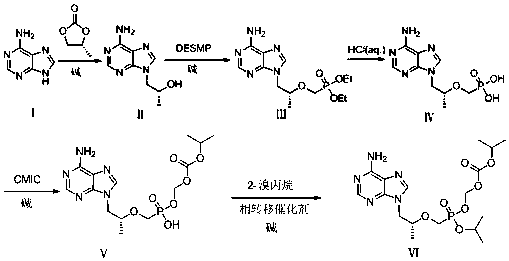

Tenofovir disoproxil fumarate analog preparation method

ActiveCN109384813AHigh purityThe synthesis process is simpleGroup 5/15 element organic compoundsPropylene carbonateSubstitution reaction

The present invention discloses a tenofovir disoproxil fumarate analog preparation method, which comprises: carrying out a substitution reaction on adenine as a raw material and (R)-propylene carbonate in the presence of an alkali, carrying out a substitution reaction with (diethoxyphosphoryl)methyl-4-methylbenzenesulfonate, hydrolyzing with a concentrated hydrochloric acid solution, crystallizingto obtain anhydrous tenofovir, carrying out a reaction on the anhydrous tenofovir and chloromethyl isopropyl carbonate to obtain tenofovir monoester, and carrying out a reaction with 2-bromopropane to obtain the target compound. According to the present invention, the selected starting raw materials are inexpensive and easy to obtain, the process is simple, and the material utilization rate and total yield are improved; and the intermediate of the method is purified by re-crystallization, such that the yield is high, and the purity is high.

Owner:GUANGZHOU BAIYUNSHAN PHARMA HLDG CO LTD BAIYUNSHAN PHARMA GENERAL FACTORY

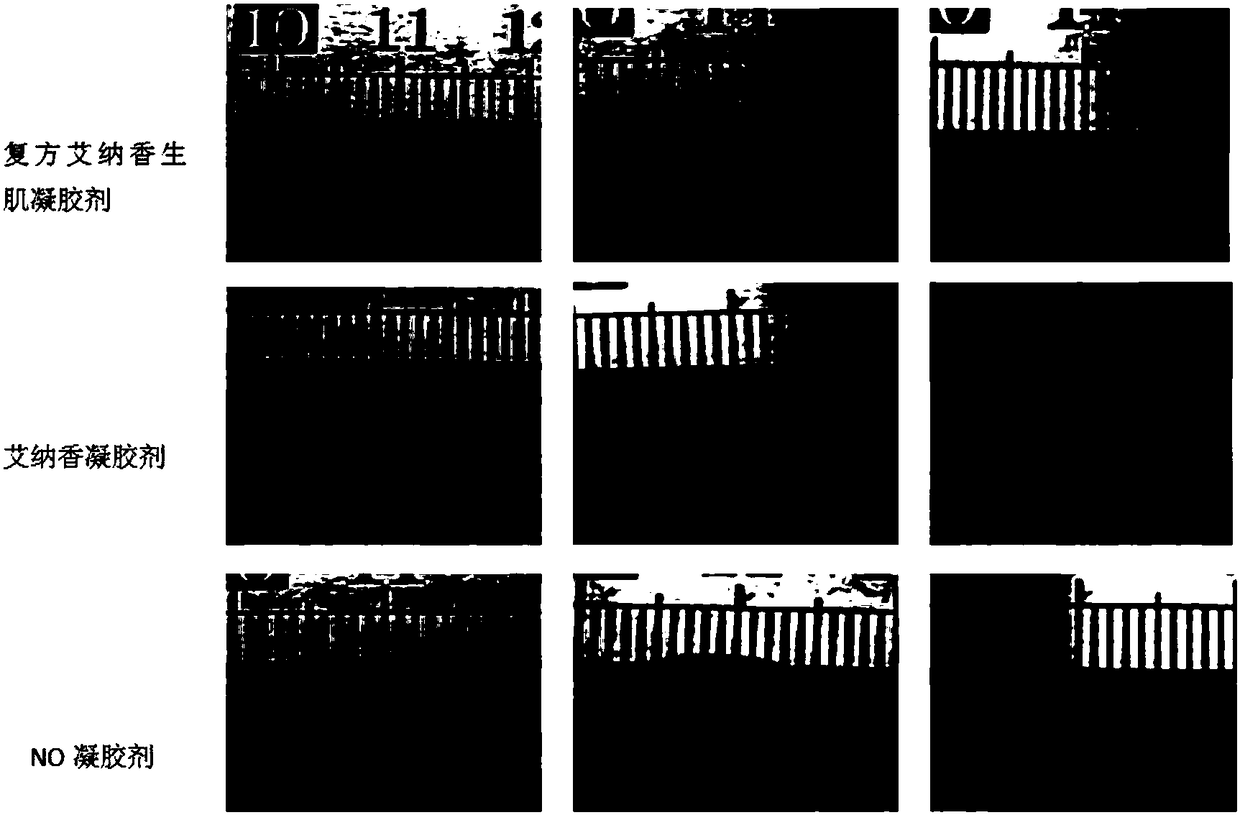

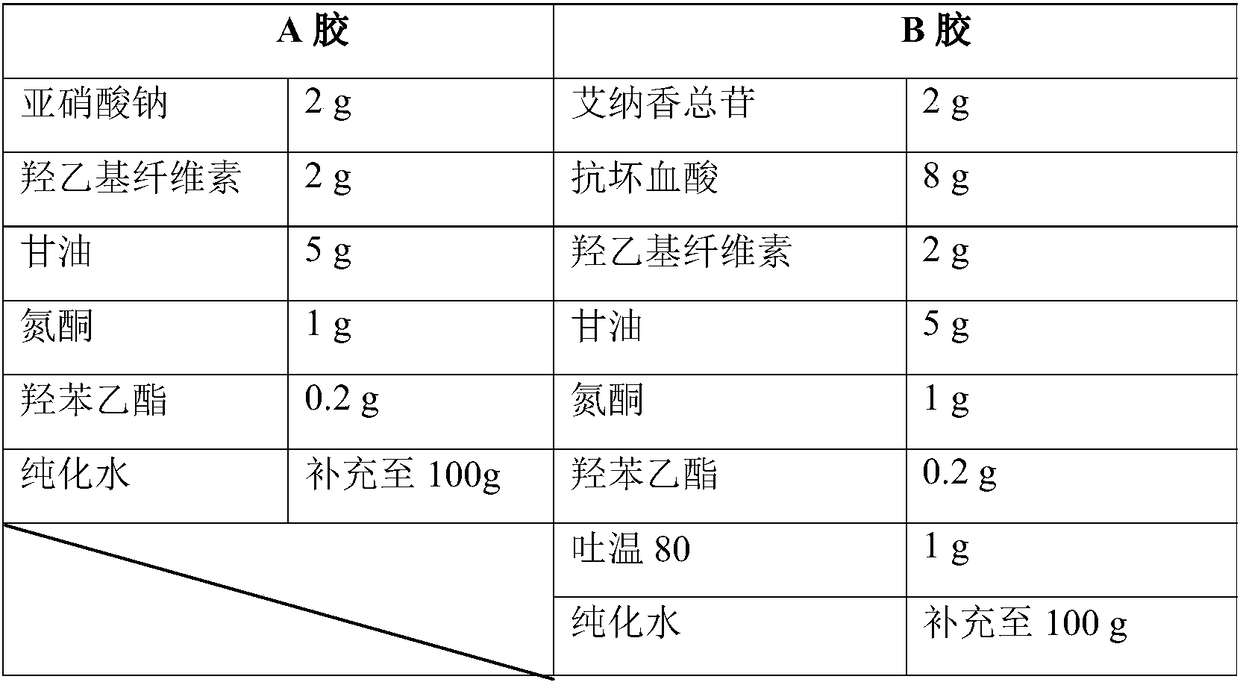

Compound blumea balsamifera tissue-regeneration gel capable of promoting repair of skin ulcer wounds and preparation method thereof

InactiveCN108524570APromote wound healingHas anti-infective effectMetabolism disorderInorganic active ingredientsMedicineNitric oxide

The invention discloses compound blumea balsamifera tissue-regeneration gel capable of promoting repair of skin ulcer wounds and a preparation method thereof in the technical field of medical health and belongs to the field of medicine. The compound is prepared by blumea balsamifera (L-borneol), nitric oxide (NO) and suitable excipients, and the gel is composed of A glue and B glue. The gel is mainly used for treatment of diabetic skin ulcers and can also be used for treatment of burns, wound repair, scleroderma, other types of skin ulcers and other symptoms. The gel is easy to clean, high inhydration degree, appropriate in consistency and viscosity, easy to apply and use and good in stability, does not contaminate clothes, facilitates drug absorption and has the functions of moisturizingand protecting wounds.

Owner:ZUNYI MEDICAL UNIVERSITY

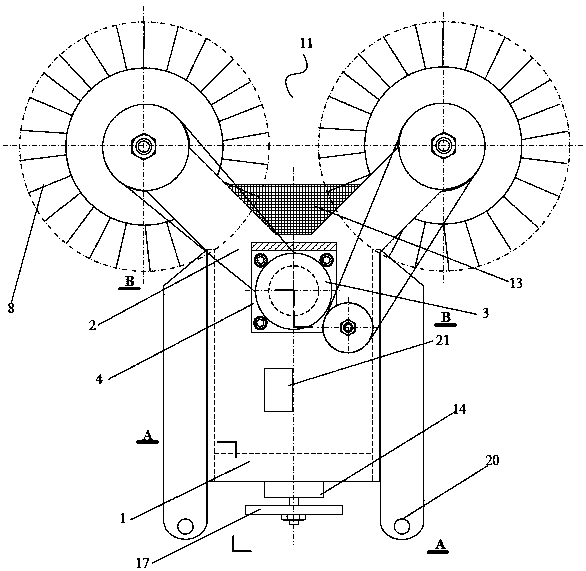

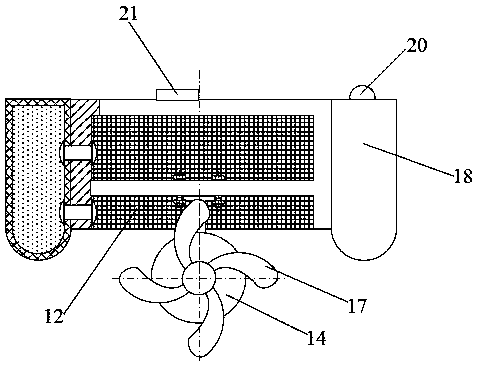

Water surface fishing robot

InactiveCN109837876AImprove cleaning efficiencyImprove collection efficiencyWater cleaningMotor driveElectromagnetic clutch

The invention discloses a water surface cleaning device, and particularly relates to a water surface fishing robot. In a structure of the water surface fishing robot, a first ranging sensor monitors an offshore distance in the forward direction of the water surface fishing robot, and a second ranging sensor monitors an offshore distance in the left and right direction; a first motor drives a pairof brush wheels to rotate in different directions, and any one of the brush wheels can be independently rotated by controlling a pair of electromagnetic clutches; a second motor drives the water surface fishing robot to operate back and forth; and a controller judges and determines the respective offshore distances in the forward direction and the left and right direction of the water surface fishing robot according to electrical signals of the first ranging sensor and the second ranging sensor, switches the working states of the first motor, the second motor and the electromagnetic clutches,and can automatically adjust the operating state and path of the water surface fishing robot. The water surface fishing robot is capable of automatically controlling the operating state and path, andhas the advantages of being intelligent and multifunctional.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Surface smoking and rapid coloring method for sausage type products

InactiveCN105105097AUniform colorSolid colorFood ingredient as colourFood preparationManufacturing cost reductionPhosphate

The invention relates to a surface smoking and rapid coloring method for sausage type products. The method is characterized by comprising the following steps: (1) immersing edible animal sausage casings for filling for 2-12 hours, wherein an immersing solution is prepared from the following components in percentage by mass: 1%-50% of a glucose solution, 0.01%-0.1% of D-sodium isoascorbate, 0.1%-0.5% of phosphate, 0.01%-0.1% of smoking liquid and the balance of water; (2) filling seasoned meat stuffing with the immersed edible animal sausage casings; (3) drying filled sausages; and (4) finally, conveying the dried sausages into a smoking furnace to be smoked. The surface smoking and rapid coloring method for the sausage type products, provided by the invention, has the advantages that the products are colored uniformly, rapidly and stably; the coloring of the products is accelerated and the production cost is reduced; the appearance of the products is greatly improved; the flavor of the products is relatively rich and the color and luster are relatively lasting; and the operation process is simple and convenient so that the method is suitable for large-batch industrial production.

Owner:HENAN ZHONGPIN FOOD IND

Lithium manganate anode material and preparation method thereof

ActiveCN103715415AComplete structureReduce solubilityCell electrodesSecondary cellsManganateBall mill

The invention discloses a preparation method of a lithium manganate anode material. The preparation method comprises the following steps: (1) preparing a salt-mixture solution; (2) preparing a precipitant solution; (3) slowly pumping the salt-mixture solution and the precipitant solution into a reaction kettle at a pH value of 7-13; (4) weighing manganese dioxide in proportion, adding the manganese dioxide to a mixed solution obtained in the step (3), continuously stirring, ageing for 5-20 hours, then separating solid-liquid products, and washing an obtained precursor with deionized water to alkalescence; (5) adding a lithium source and the washed precursor to a ball-milling tank, carrying out ball-milling for 2-5 hours, and then drying at the temperature of 80-120 DEG C, thus obtaining a precursor material; and (6) respectively roasting the obtained precursor material two times, breaking the material obtained by sintering, and sieving, thus obtaining the lithium manganate anode material. The preparation method is simple; the prepared lithium manganate anode material has high capacity and excellent high-temperature cycle performance.

Owner:TIANJIN B&M SCI & TECH

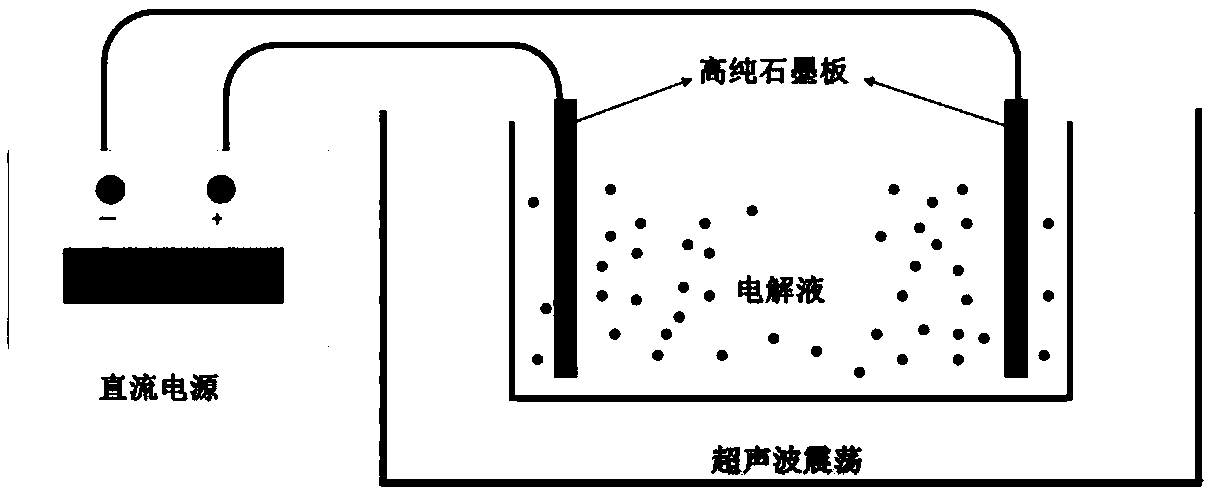

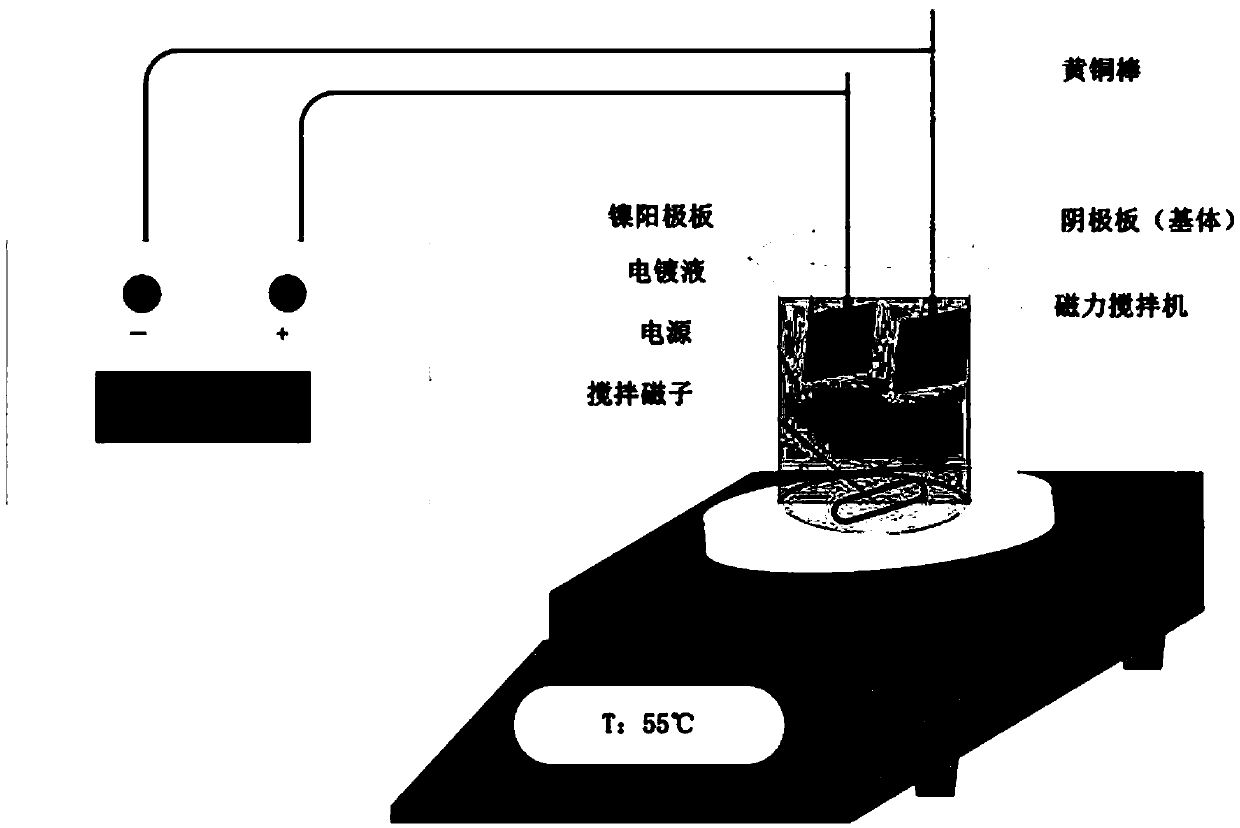

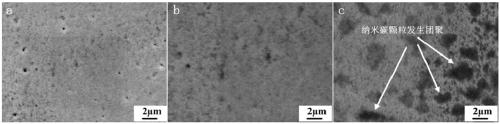

Preparation method of carbon nanoparticle solution and application of carbon nanoparticle solution in nickel coating

ActiveCN109537030AImprove performanceHigh hardnessElectrolytic coatingsEnvironmental resistanceHardness

The invention discloses a preparation method of a carbon nanoparticle solution and application of the carbon nanoparticle solution in a nickel coating. The preparation method of a nickel-carbon nano composite coating comprises the following steps that an electrolyte is prepared, wherein the solute of the electrolyte comprises 0.15-0.25 mol / L of HNO3, 0.08-0.12 mol / L of (CH2OH)2 and 0.15-0.25 g / L of C12H25NaSO4, and the solvent is deionized water; the carbon nanoparticle solution is obtained through electrolyzing; and the carbon nanoparticle solution is added into a nickel plating solution, andthe nickel-carbon nano composite coating can be obtained through deposition. The preparation method of the nickel-carbon nano composite coating is harmless, non-toxic, environment-friendly, convenient and fast, moreover, the hardness and the wear resistance of the composite coating are quite obviously improved, moreover, the corrosion resistance is obviously improved, the comprehensive performance of the nickel coating is greatly improved, the application of the nickel coating in industry is expanded, and the preparation method has good development prospects.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com