Patents

Literature

2298results about How to "Speed up cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

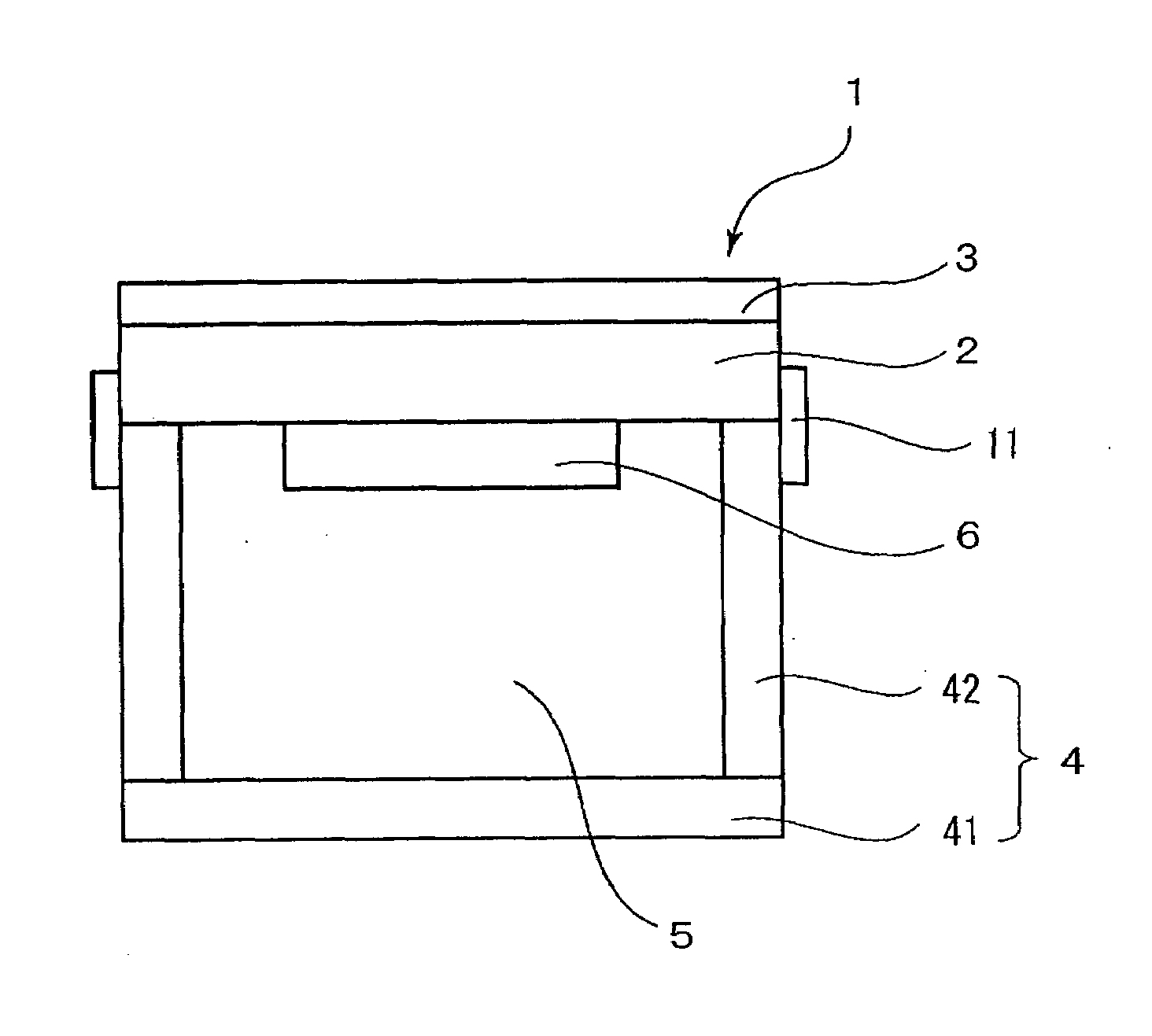

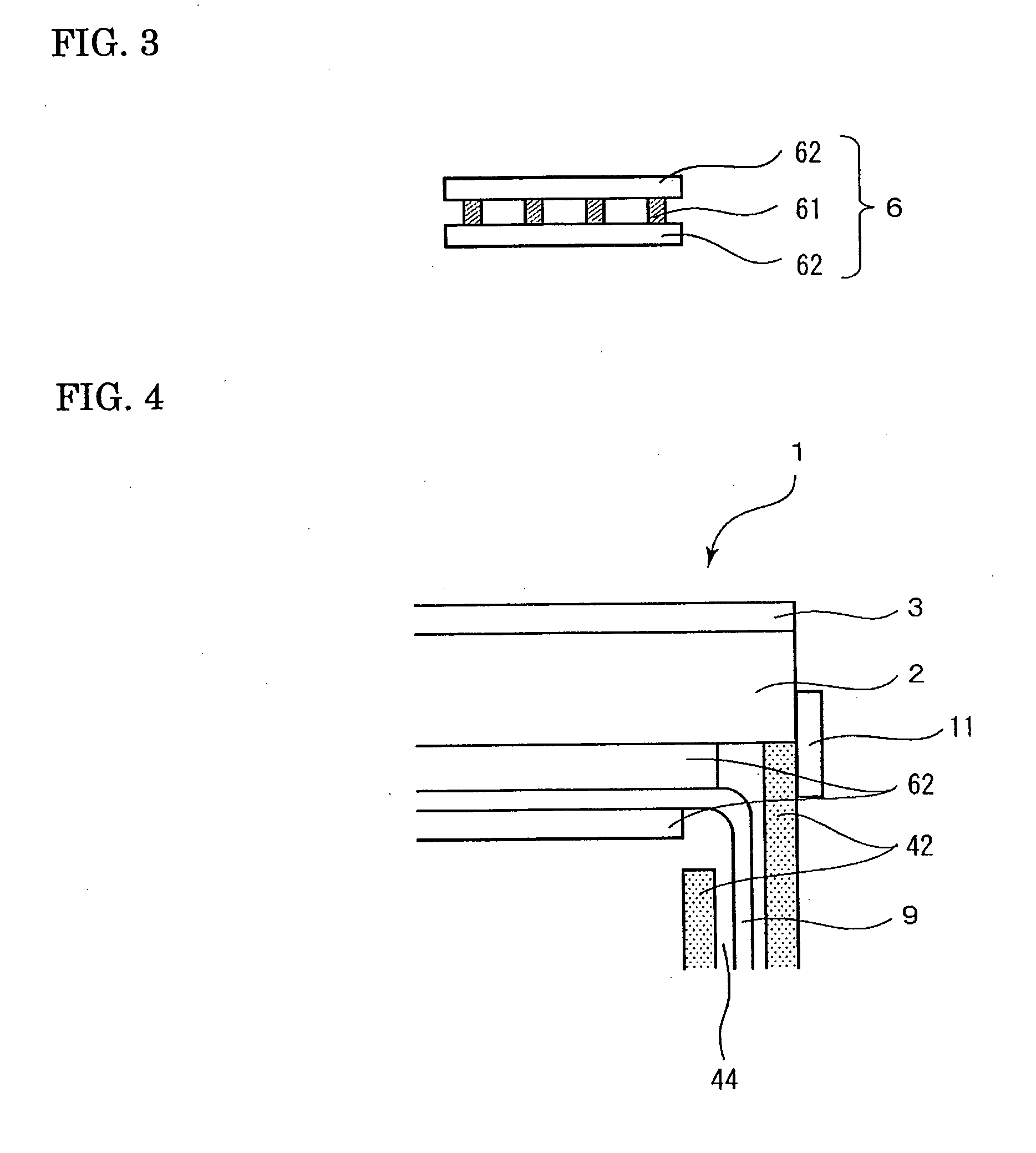

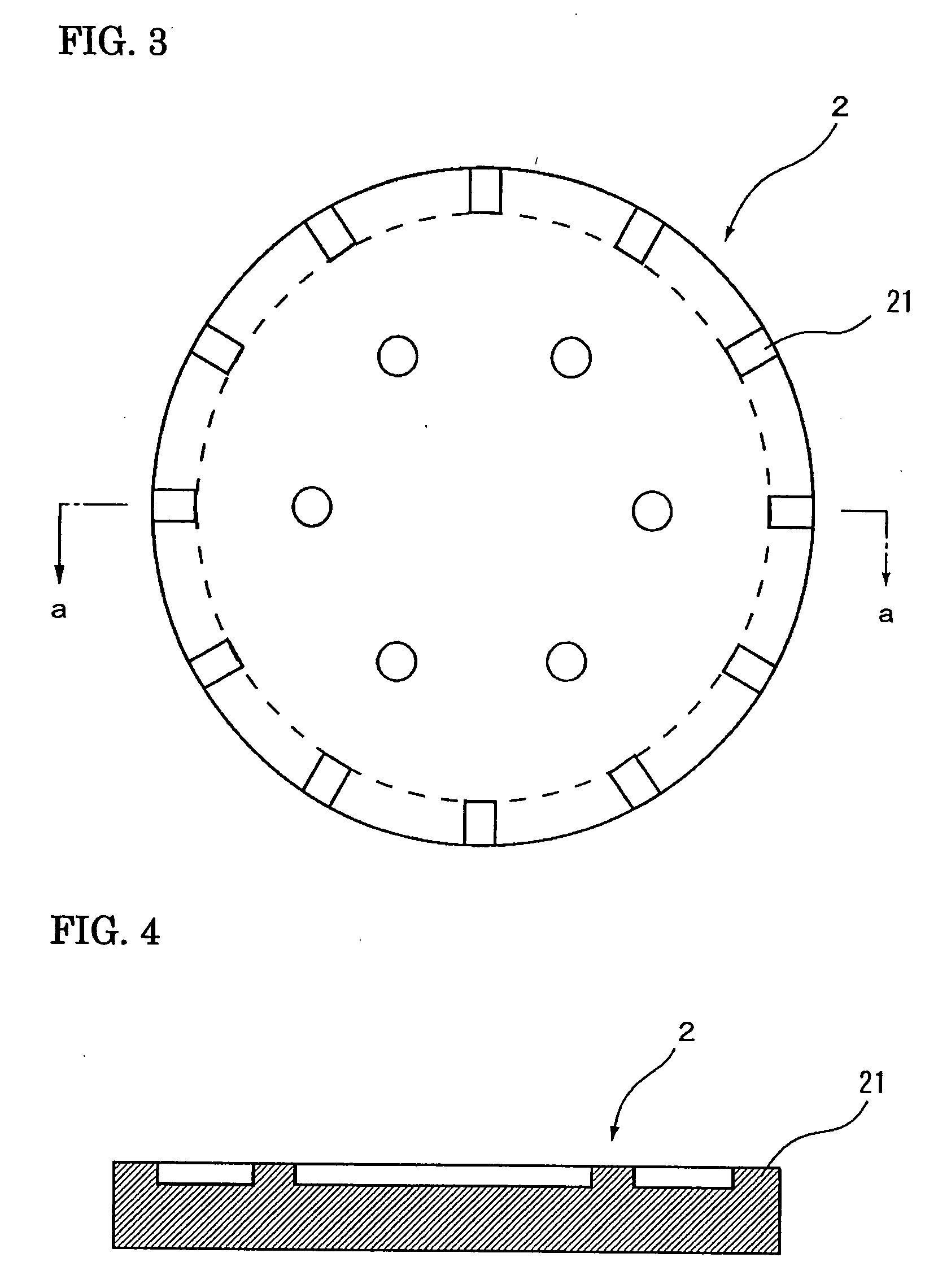

Wafer holder for wafer prober and wafer prober equipped with same

InactiveUS20090045829A1Improve rigidityGood effectHot plates heating arrangementsIndividual semiconductor device testingRoom temperatureEngineering

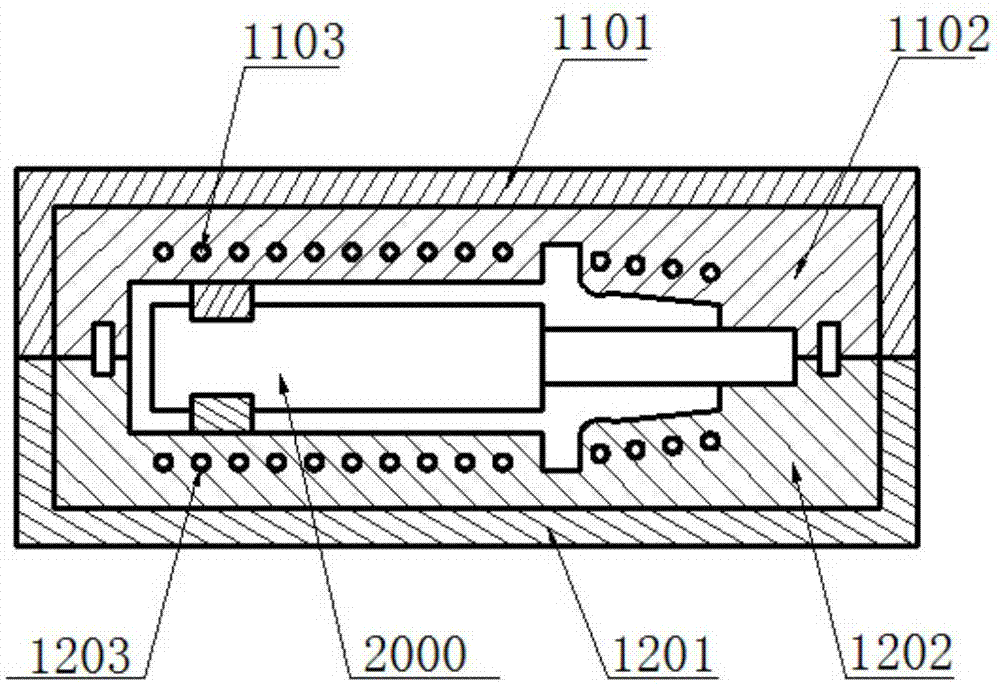

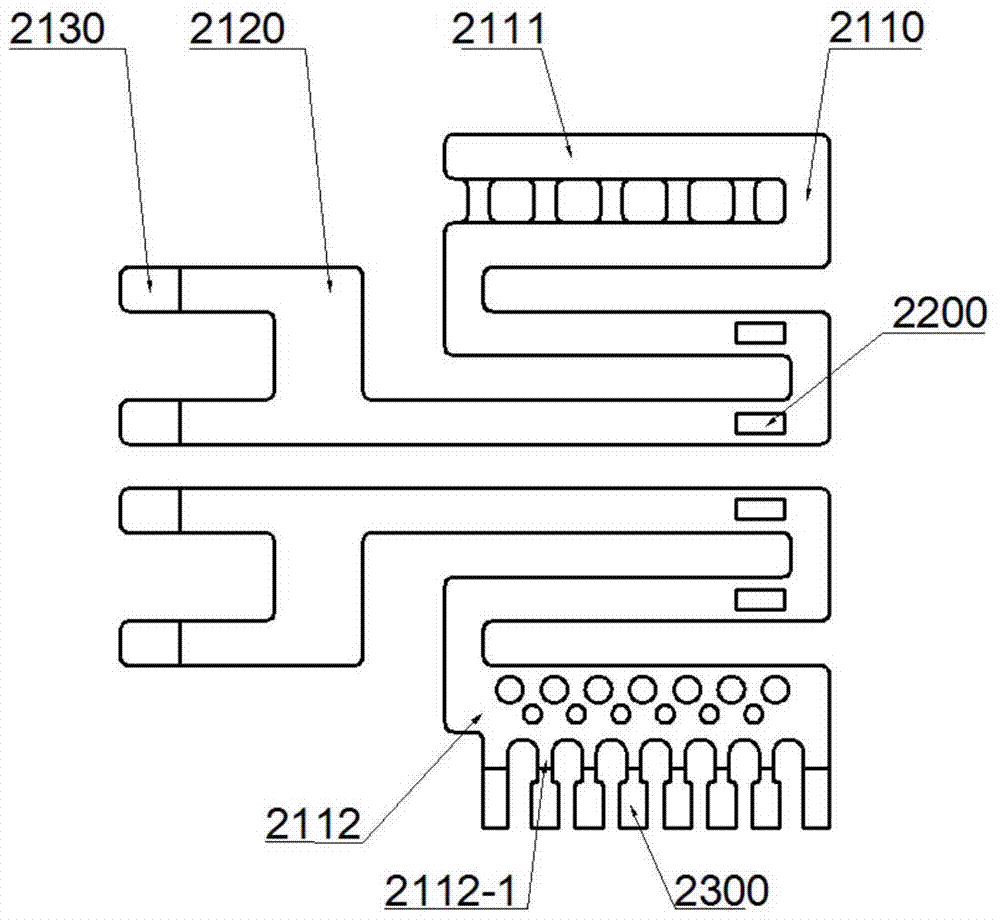

It is an object of the present invention to provide a wafer prober wafer holder that is highly rigid and increases the heat insulating effect, thereby improving positional accuracy, thermal uniformity, and chip temperature ramp-up and cooling rates, as well as a wafer prober device equipped therewith.A wafer holder of the present invention includes a chuck top that mounts a wafer, and a support member that supports the chuck top, wherein, a restricting member is provided that covers an interface between the chuck top and the support member. By covering the gap between the chuck top and the support member with the restricting member, the heat insulating effect can be increased by preventing the flow of outside air through the gap into the support member, and the cooling rate can be particularly improved if cooling to a temperature below room temperature.

Owner:SUMITOMO ELECTRIC IND LTD

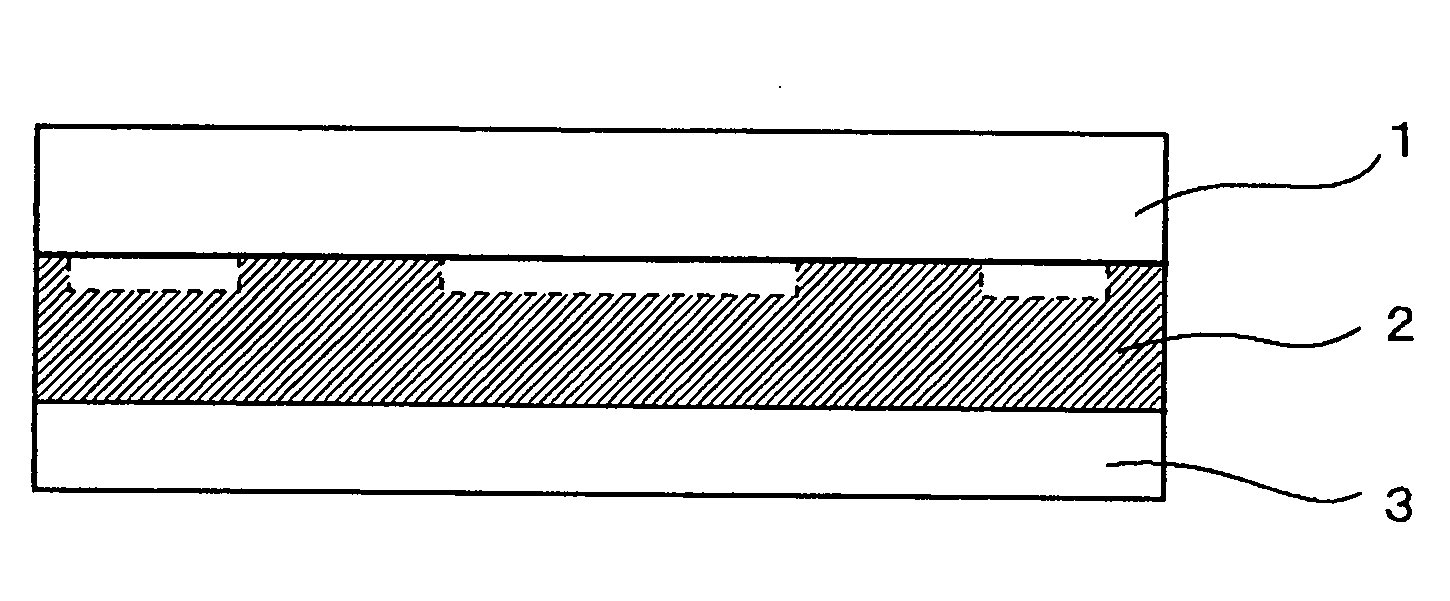

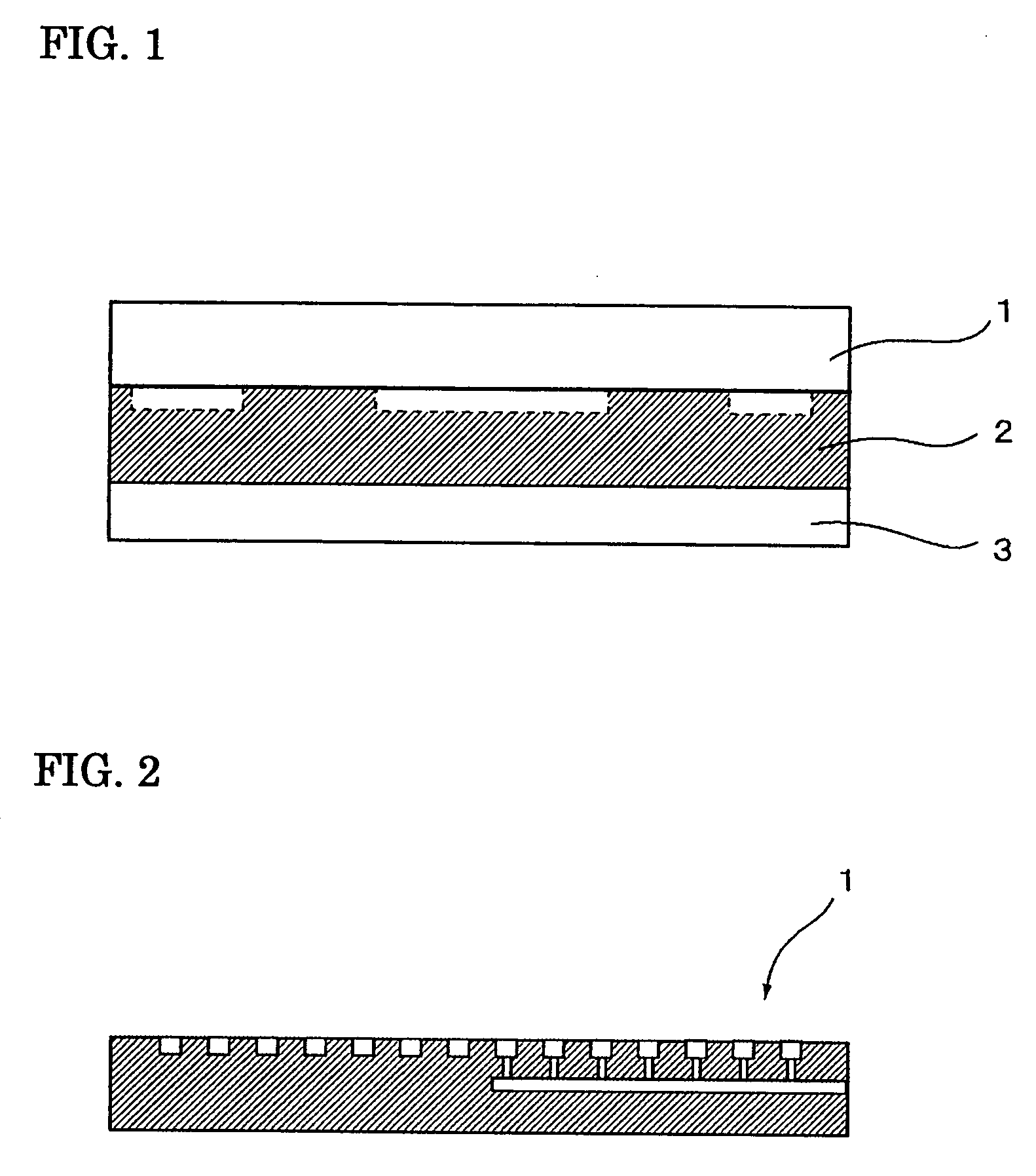

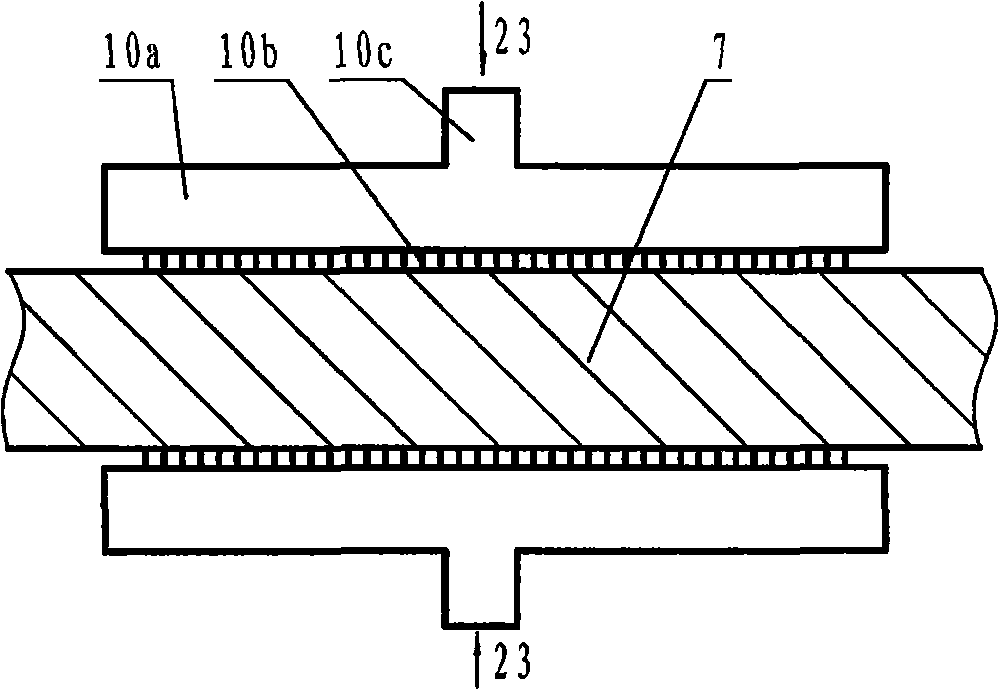

Wafer holder, and wafer prober provided therewith

InactiveUS20070205788A1Good effectIncrease speedSemiconductor/solid-state device manufacturingHot plates heating arrangementsYoung's modulusEngineering

A wafer holder is provided having high rigidity and an enhanced heat-insulating effect that allow positional accuracy and heating uniformity to be improved, a chip to be rapidly heated and cooled, and the manufacturing cost to be reduced, and a wafer prober apparatus on which the wafer holder is mounted. The wafer holder of the present invention includes a chuck top for mounting a wafer, a support member for supporting the chuck top, and a stand for supporting the support member. The chuck top has a thermal conductivity K1 and a Young's modulus Y1; the support member has a thermal conductivity K2 and a Young's modulus Y2; and the stand has a thermal conductivity K3 and a Young's modulus Y3. K1>K2 and K1>K3; and Y3>Y1 and Y3>Y2.

Owner:SUMITOMO ELECTRIC IND LTD

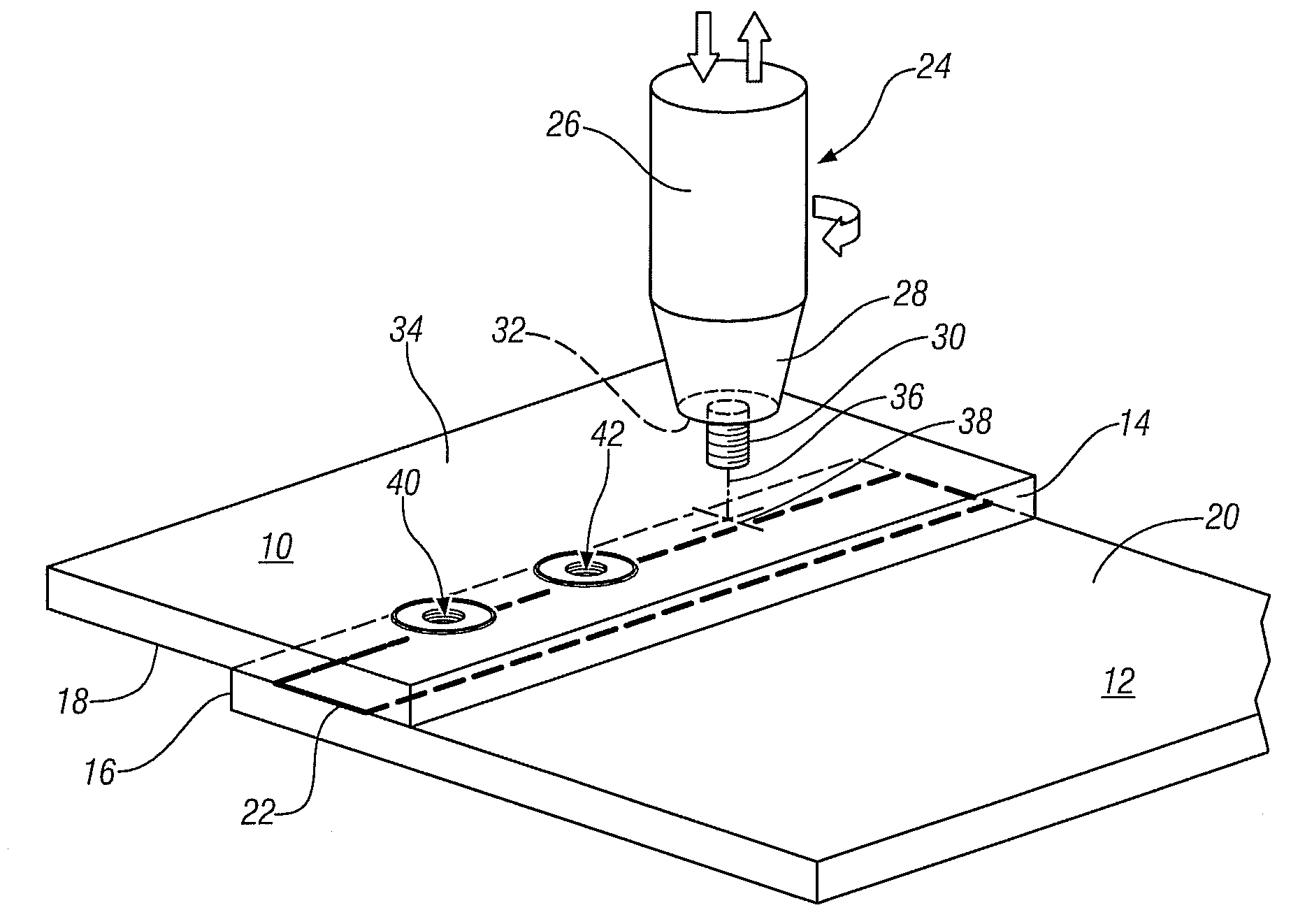

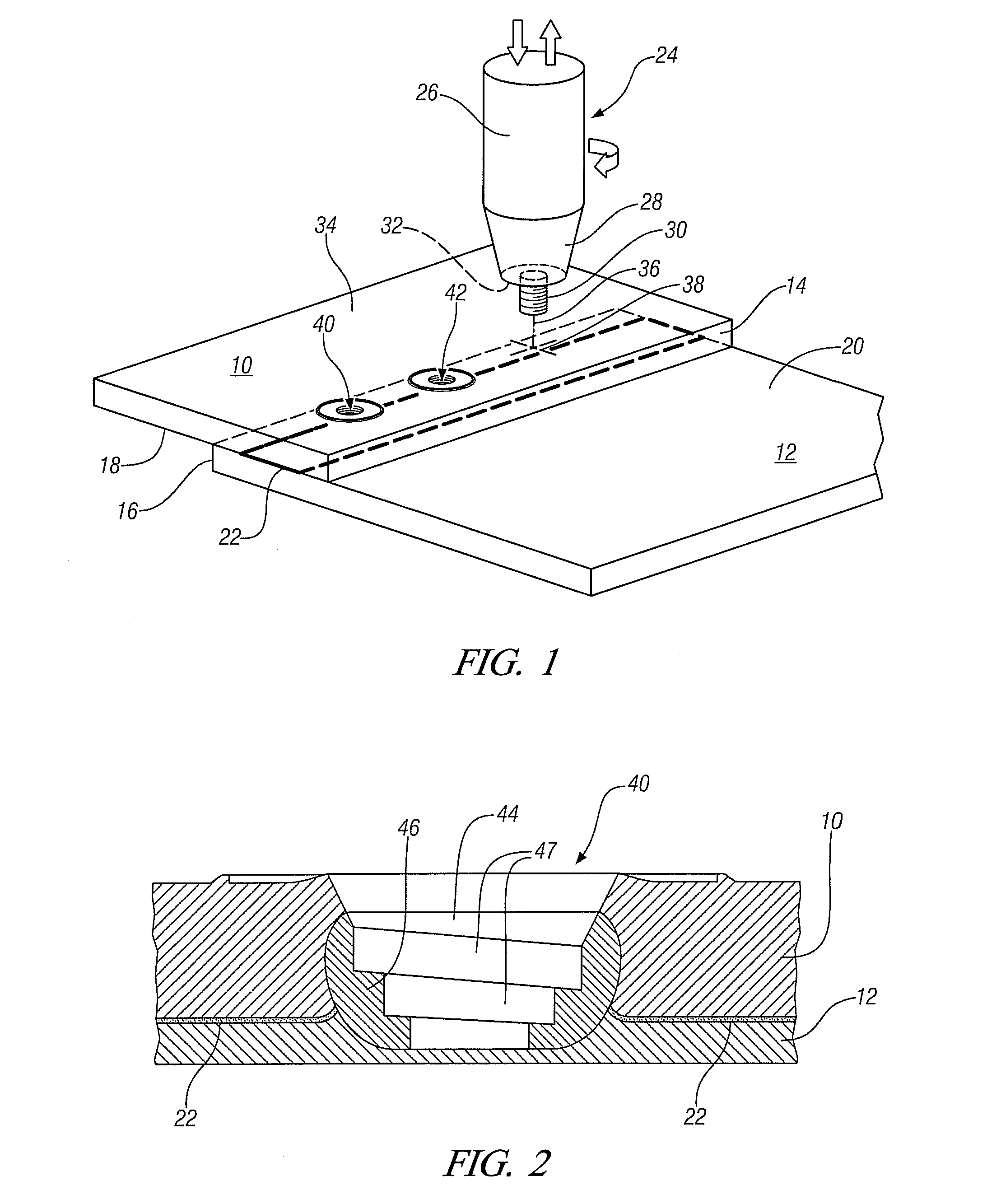

Friction stir welding of dissimilar metals

InactiveUS20100089977A1Improve mechanical propertiesHigh viscosityWelding/soldering/cutting articlesNon-electric welding apparatusFriction stir weldingTin

When a friction stir weld tool penetrates the interface of two workpieces of dissimilar metal alloy materials, the resultant weld of the different alloy materials may produce a weak weld joint. Such weak joints are often experienced, for example, when attempting to form spot welds or other friction stir welds between a magnesium alloy sheet or strip and an aluminum alloy sheet or strip. It is discovered that suitable coating compositions placed at the interface of assembled workpieces can alter the composition of the friction stir weld material and strengthen the resulting bond. In the example of friction stir welds between magnesium alloy and aluminum alloy workpieces, it is found that combinations of copper, tin, and zinc, and other powders can strengthen the magnesium-containing and aluminum-containing friction stir weld material.

Owner:GM GLOBAL TECH OPERATIONS LLC

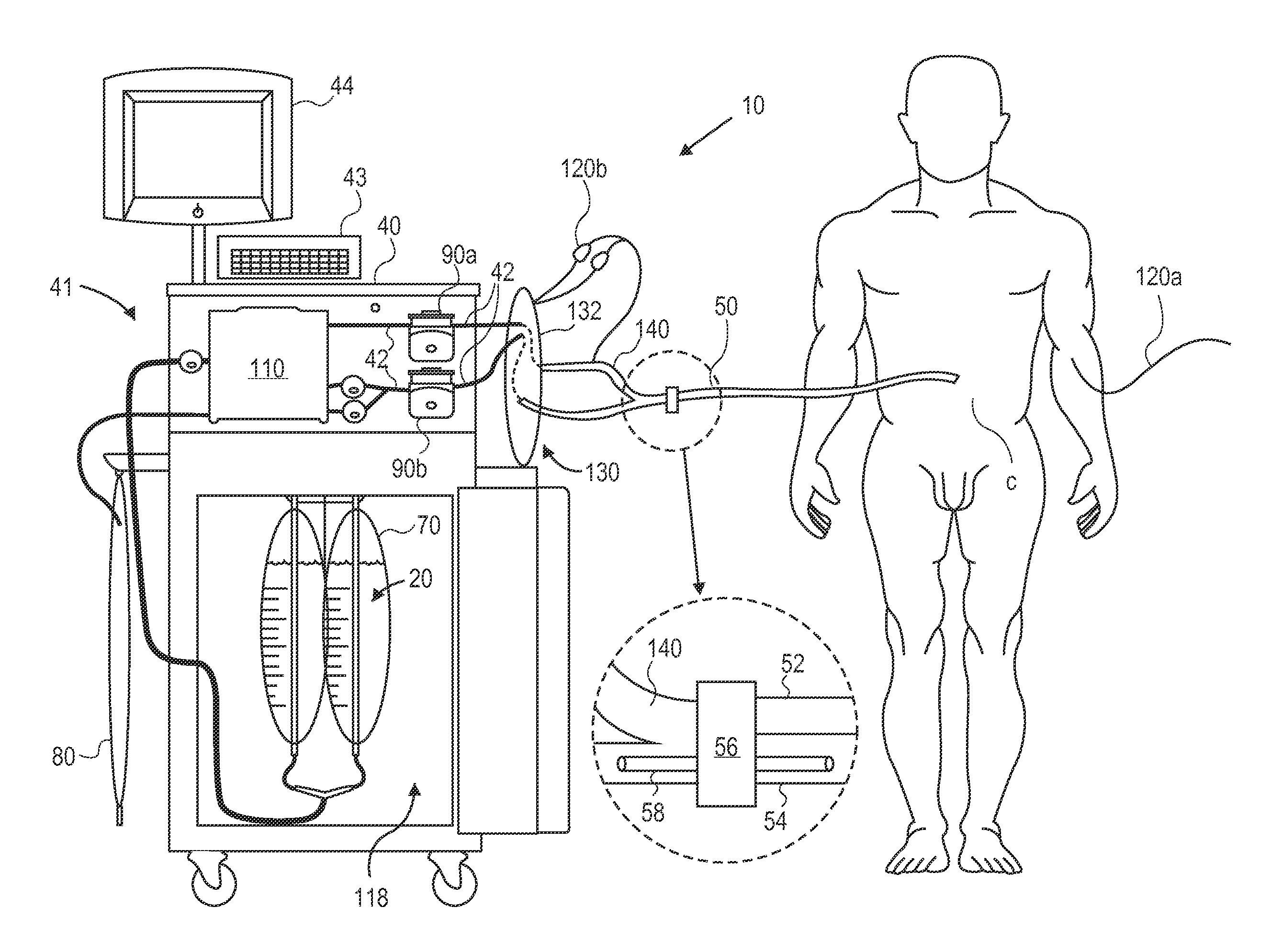

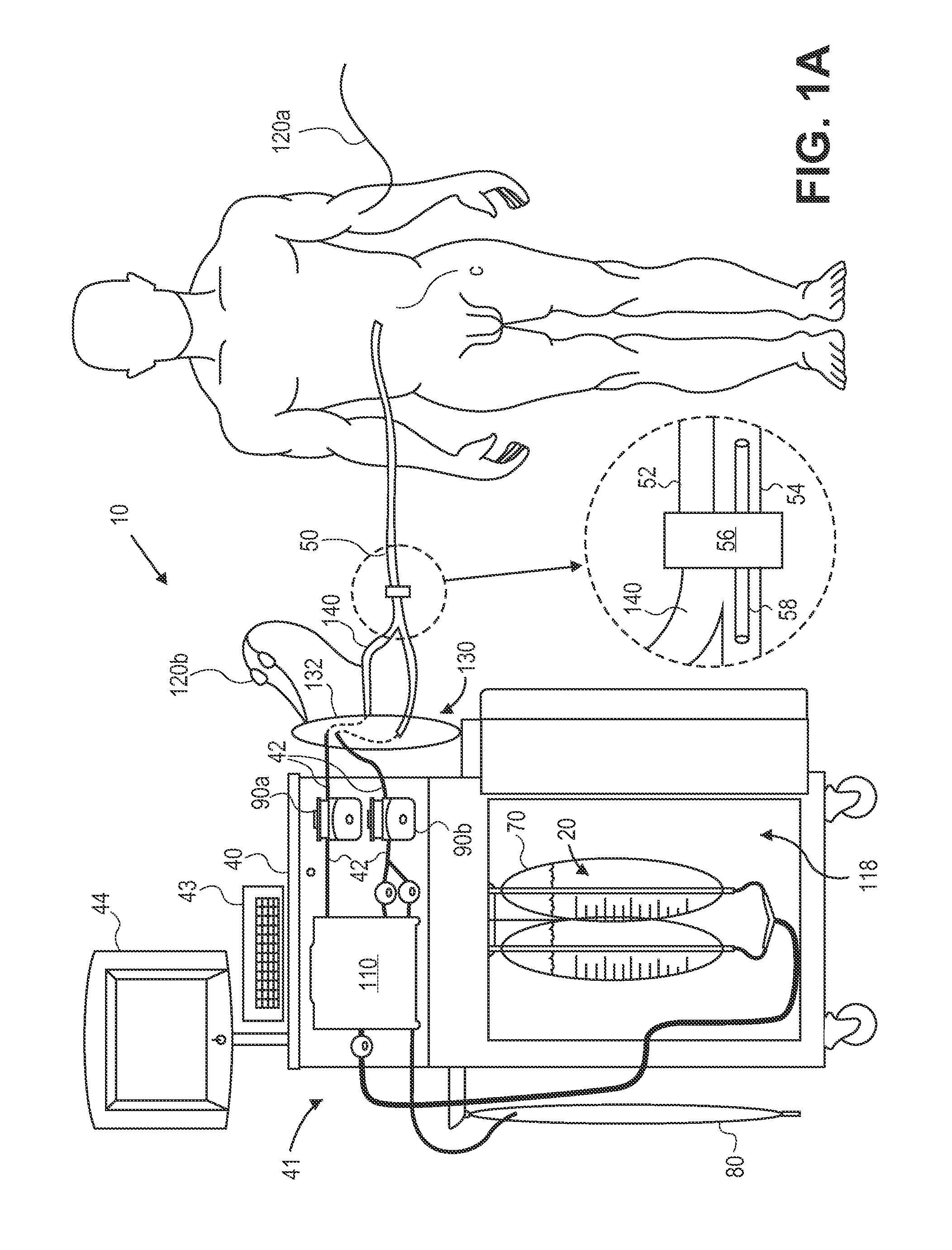

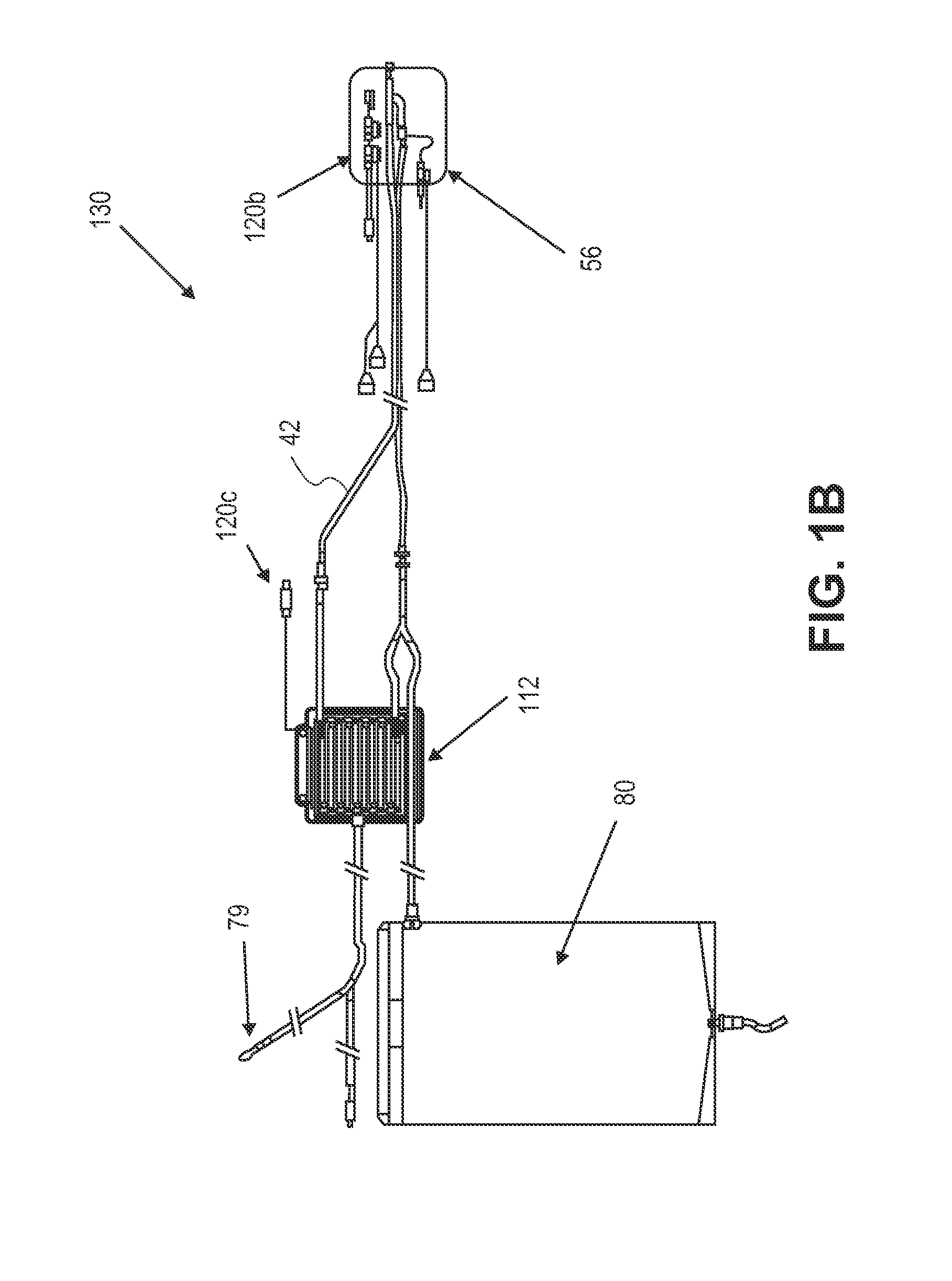

Method and Apparatus for Inducing Therapeutic Hypothermia

InactiveUS20120095537A1Increase warm rateIncrease rateMedical devicesCatheterHypothermia inducedHeat exchanger

Methods and apparatus for delivering therapeutic hypothermia to a patient are provided which may include any number of features. One feature is a hypothermia system comprising a fluid source, a heat exchanger assembly, a catheter in fluid communication with the fluid source, and a pump system configured to infuse hypothermic fluid into a patient cavity and extract hypothermic fluid from the patient cavity. The hypothermia system can infuse and extract fluid automatically from the patient cavity. In one embodiment, the patient cavity is a peritoneal cavity. A safe access device to gain access to the patient cavity is also provided.

Owner:VELOMEDIX

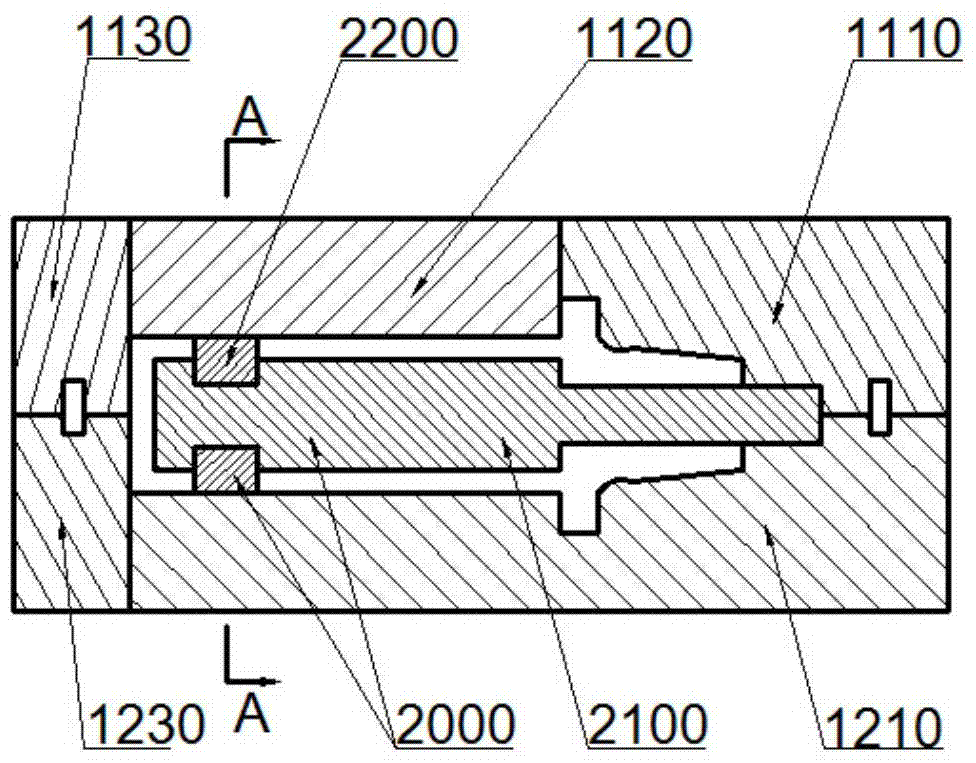

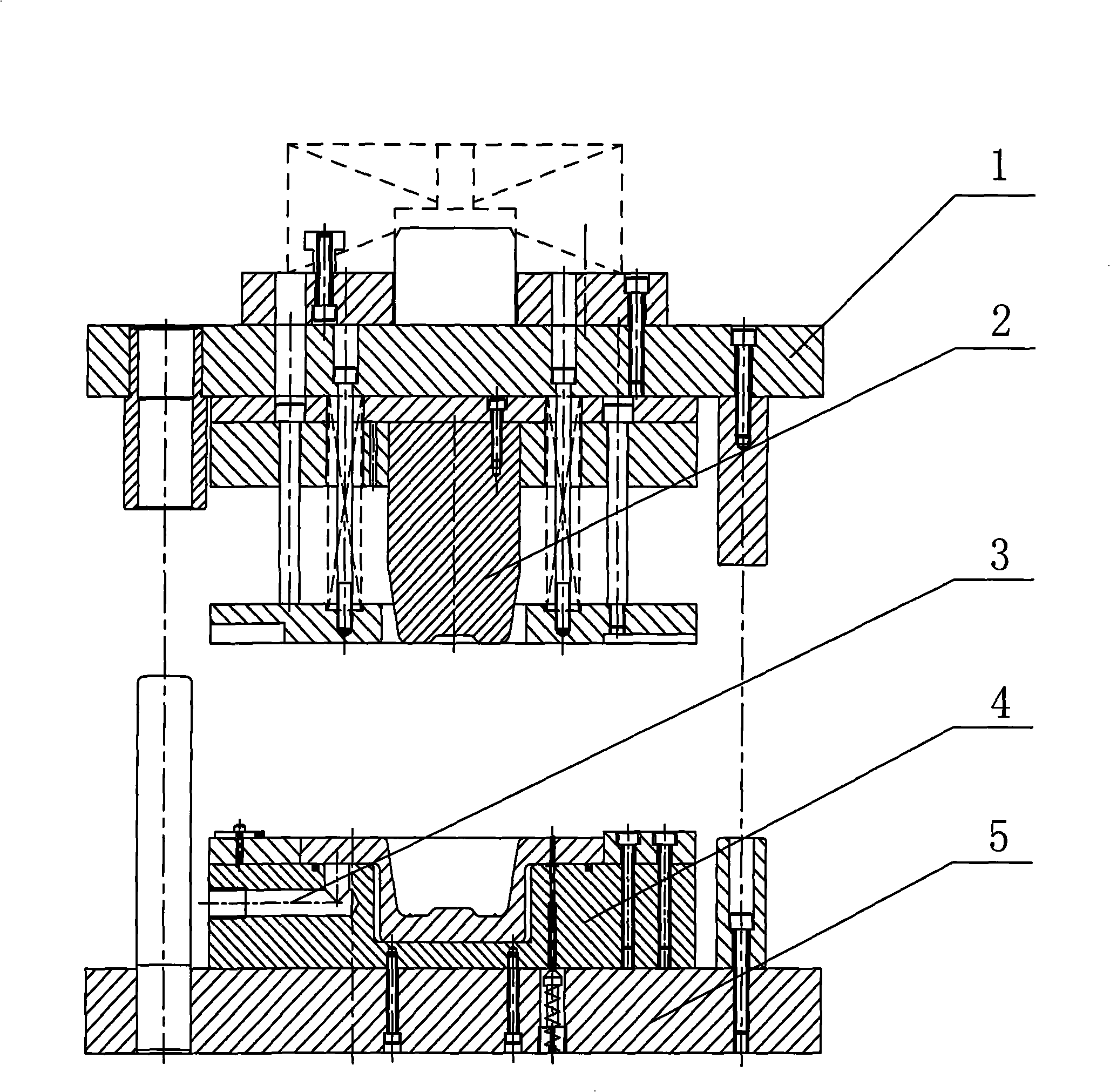

Wax injection mold for investment casting of hollow turbine blades and method for rapidly manufacturing wax injection mold

The invention discloses a wax injection mold for investment casting of hollow turbine blades and a method for rapidly and accurately manufacturing the wax injection mold. The mold consists of a cavity mold, a mold core and an accessory structure, wherein the cavity mold comprises an upper mold and a lower mold of a combined structure; each mold block forming the cavity mold consists of an external aluminum mold frame, an internal cast zinc alloy inlay and a conformal cooling copper pipe embedded into the inlay; a mold core positioning piece which can be decomposed at a high temperature is arranged on a longitudinal rib of the mold core; and water-soluble core blocks used for forming exhaust openings in the rear edges of the turbine blades are arranged on rear edge ribs of the mold core. The matching precision of the mold core positioning piece and the cavity mold is guaranteed by adopting a cavity mold interior running-in method, and the matching precision of the water-soluble core blocks and the cavity mold is guaranteed by adopting a cavity mold interior adhesion method. The wax injection mold disclosed by the invention is low in manufacturing cost and short in period, and the high wax pattern precision and core positioning precision can be obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

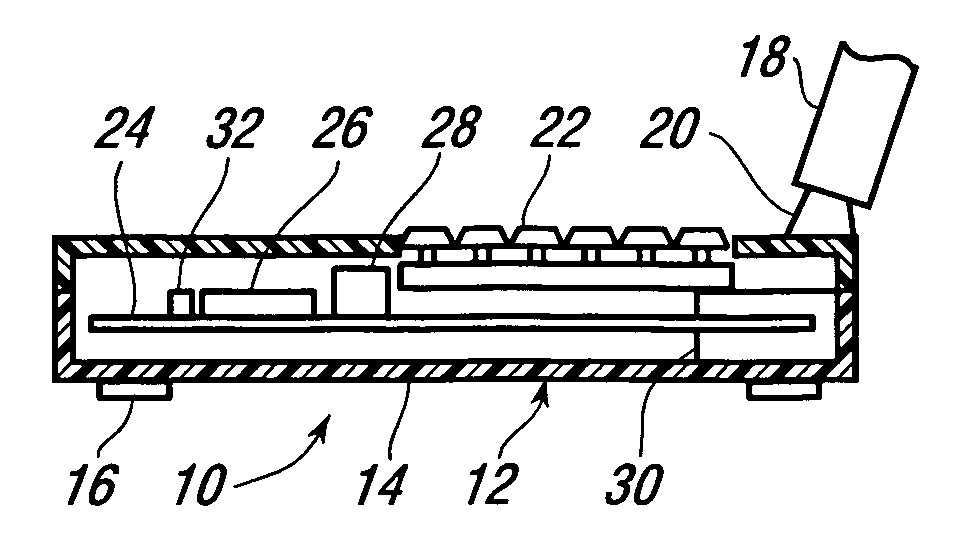

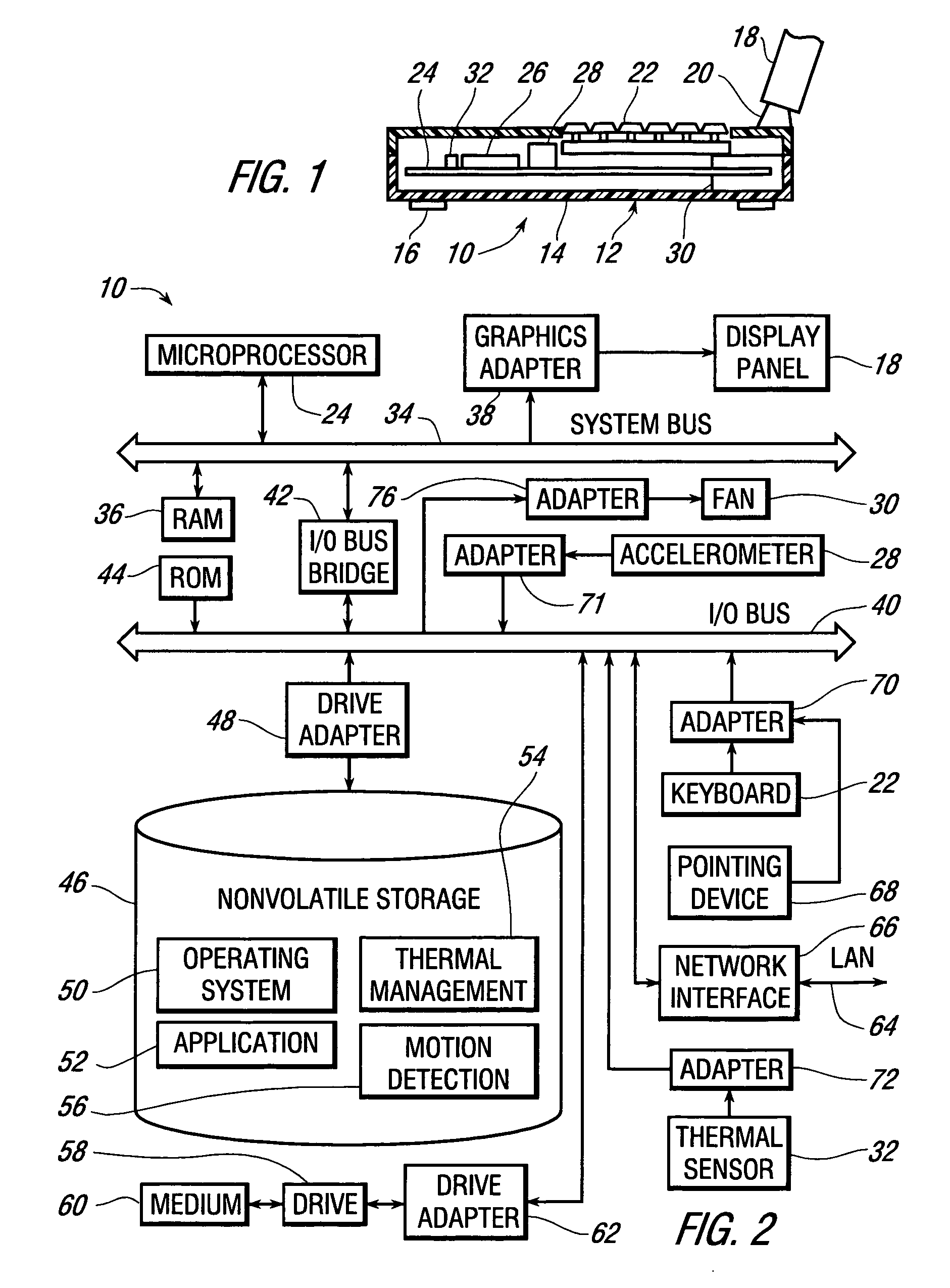

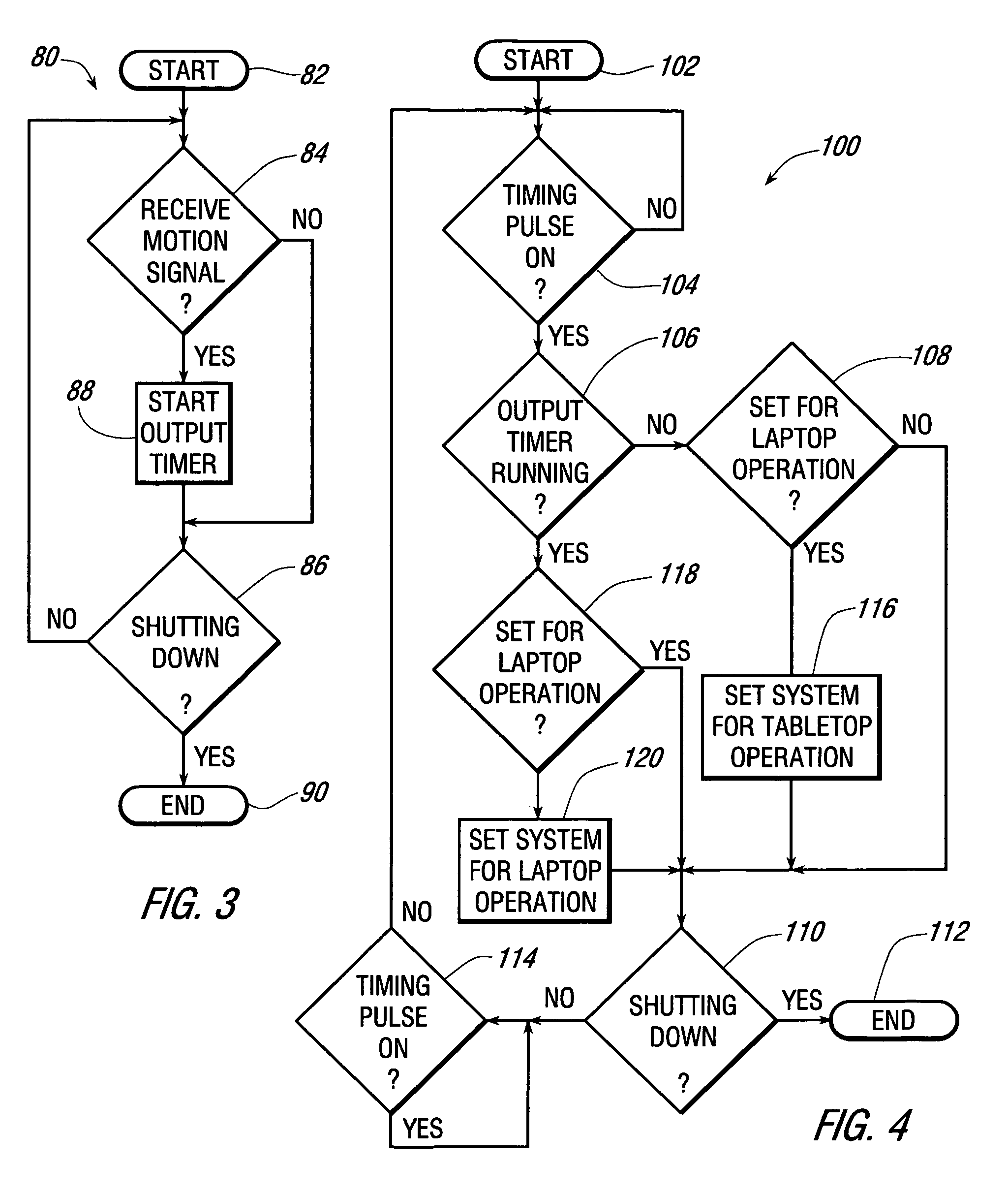

Controlling a surface temperature of a portable computer for user comfort in response to motion detection

InactiveUS20060193113A1High level of performanceDissipate heat generatedDigital data processing detailsCooling/ventilation/heating modificationsMotion detectorEngineering

A portable computer includes a motion detector providing input signals used for detecting movements indicating that the computer is held on the users lap or in his hands instead of on a desktop. When such movements are detected, the computer is operated in a first mode, with temperatures within the computer being controlled to maintain a surface of the housing at a temperature that is comfortable for the user. Otherwise, temperatures within the computer are allowed to rise to provide for faster processing or less fan noise.

Owner:LENOVO (SINGAPORE) PTE LTD

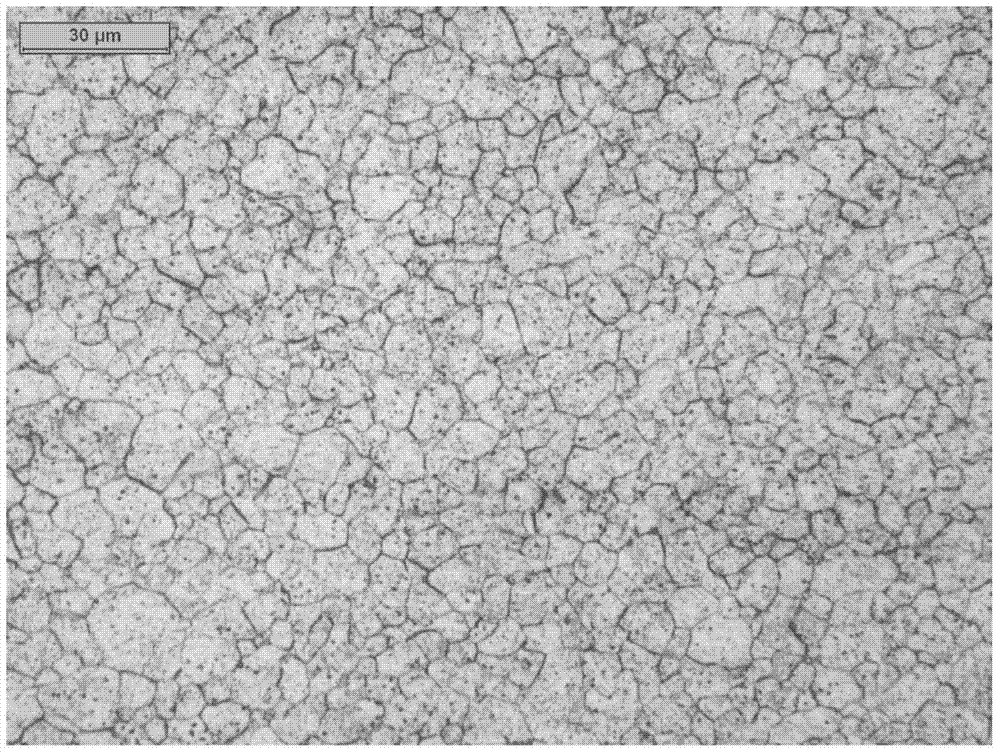

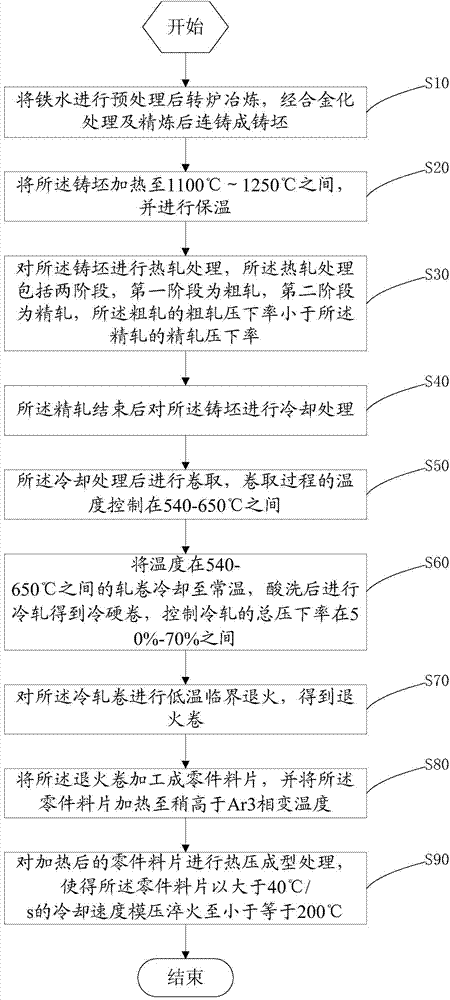

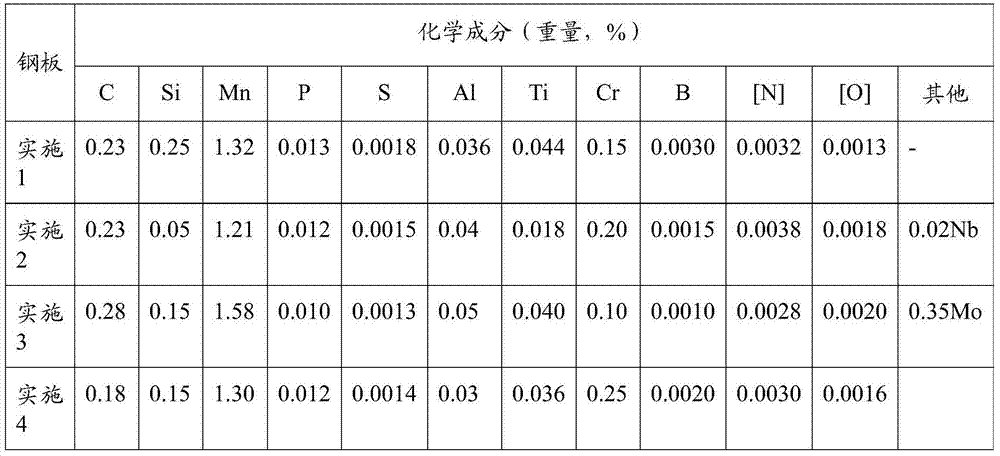

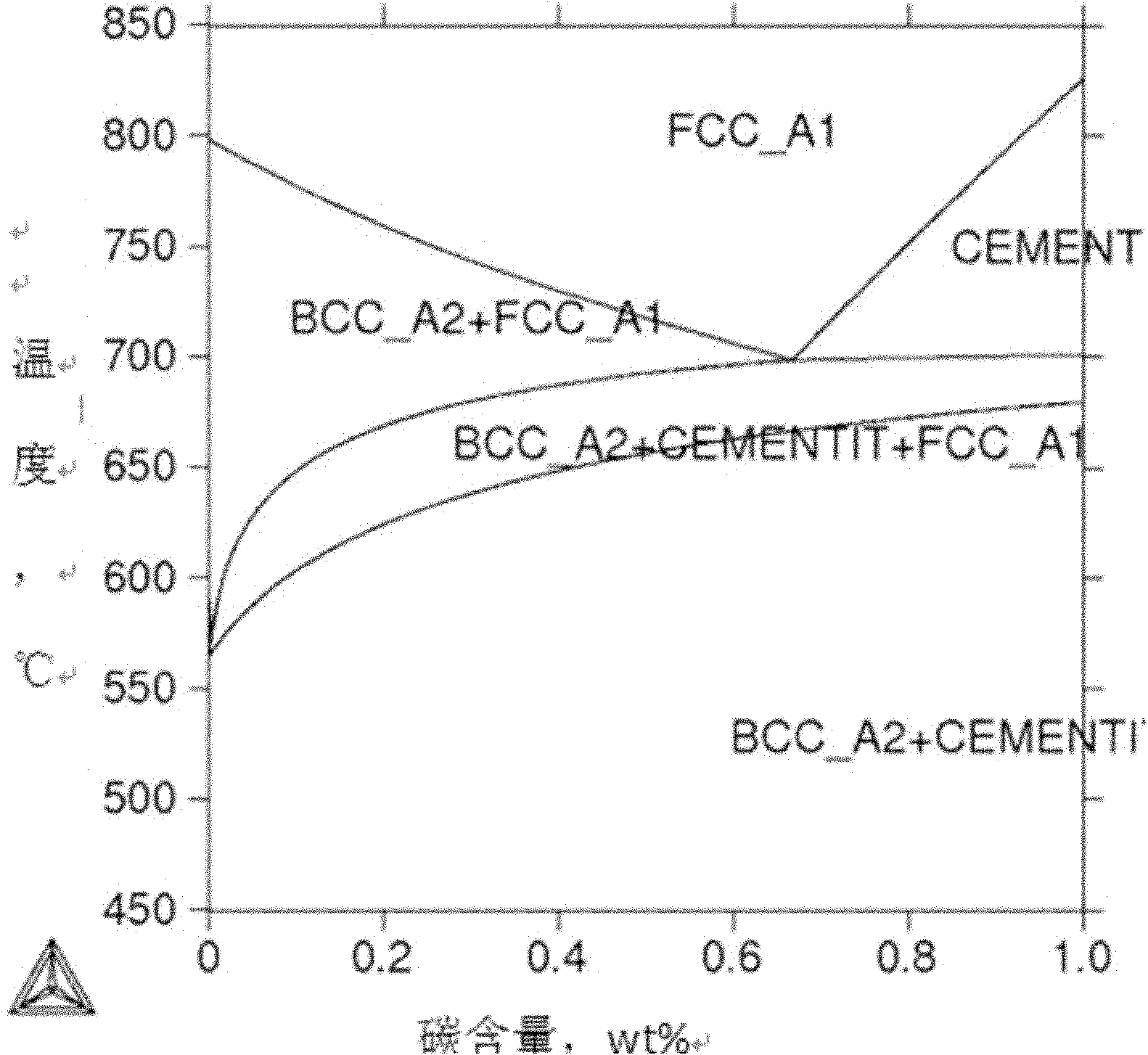

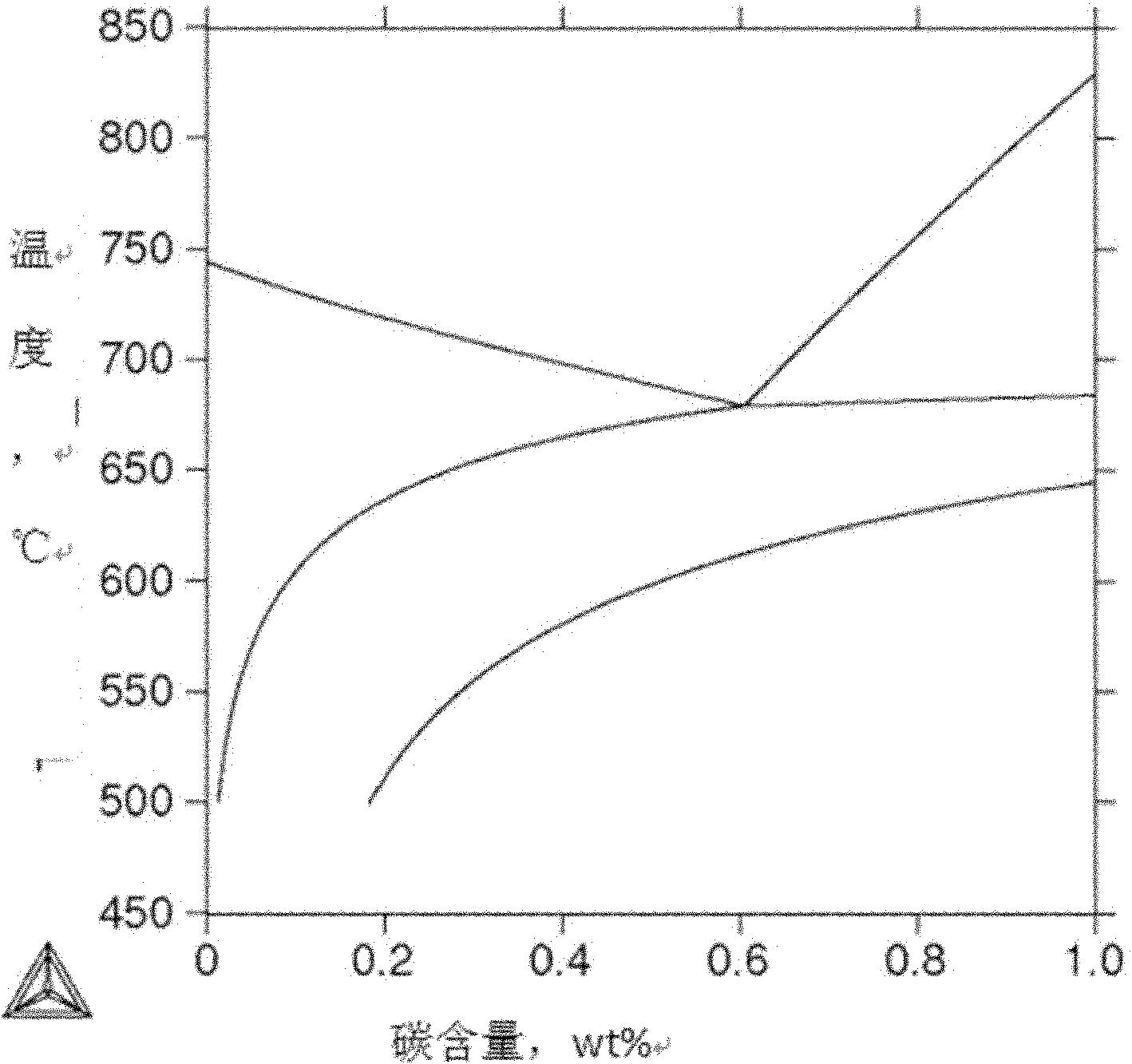

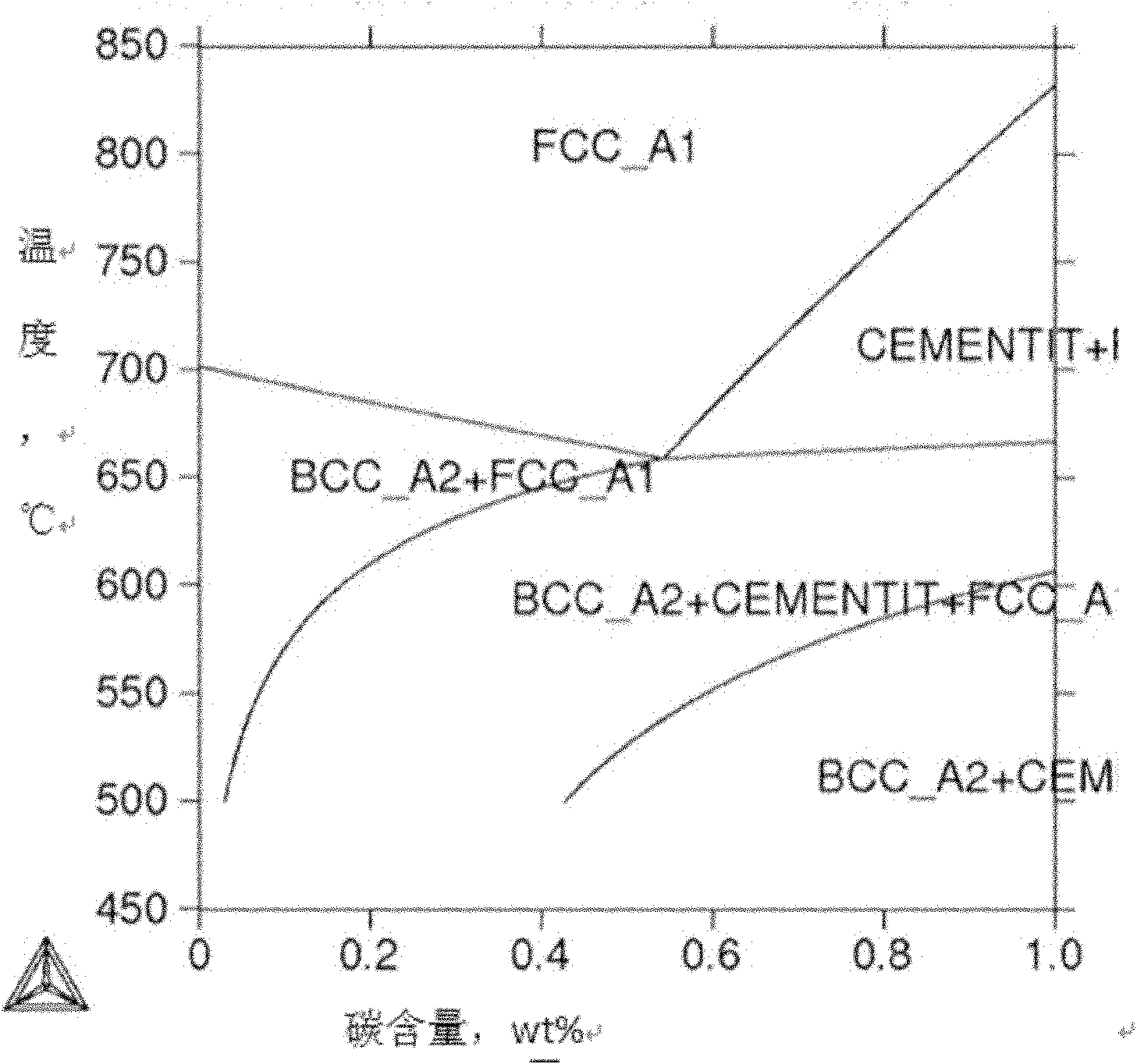

High-flexural-behavior hot-formed steel used for automobiles and manufacturing method thereof

The invention belongs to the technical field of steel rolling, and particularly relates to high-flexural-behavior hot-formed steel used for automobiles and a manufacturing method thereof. The steel comprises following trace elements by mass: 0.18-0.3% of C, not more than 0.3% of Si, 1-1.6% of Mn, not more than 0.015% of P, not more than 0.002% of S, 0.1-0.3% of Cr, 0.02-0.06% of Ti, 0.02-0.06% of Al, 0.0005-0.004% of B, not more than 0.004% of [N] and not more than 0.003% of [O]. The manufacturing method includes: heating a casting blank at a low temperature, performing controlled rolling in two stages, rapidly cooling, reeling up at a low temperature, preparing a steel coil by cold rolling and low-temperature critical annealing, shearing to prepare component tablets and performing hot press molding. By the manufacturing method, steel crystal grains are refined and ductility and toughness of the steel are enhanced, so that more energy is absorbed during deformation of the steel and automobile safety performance is enhanced.

Owner:SHOUGANG CORPORATION

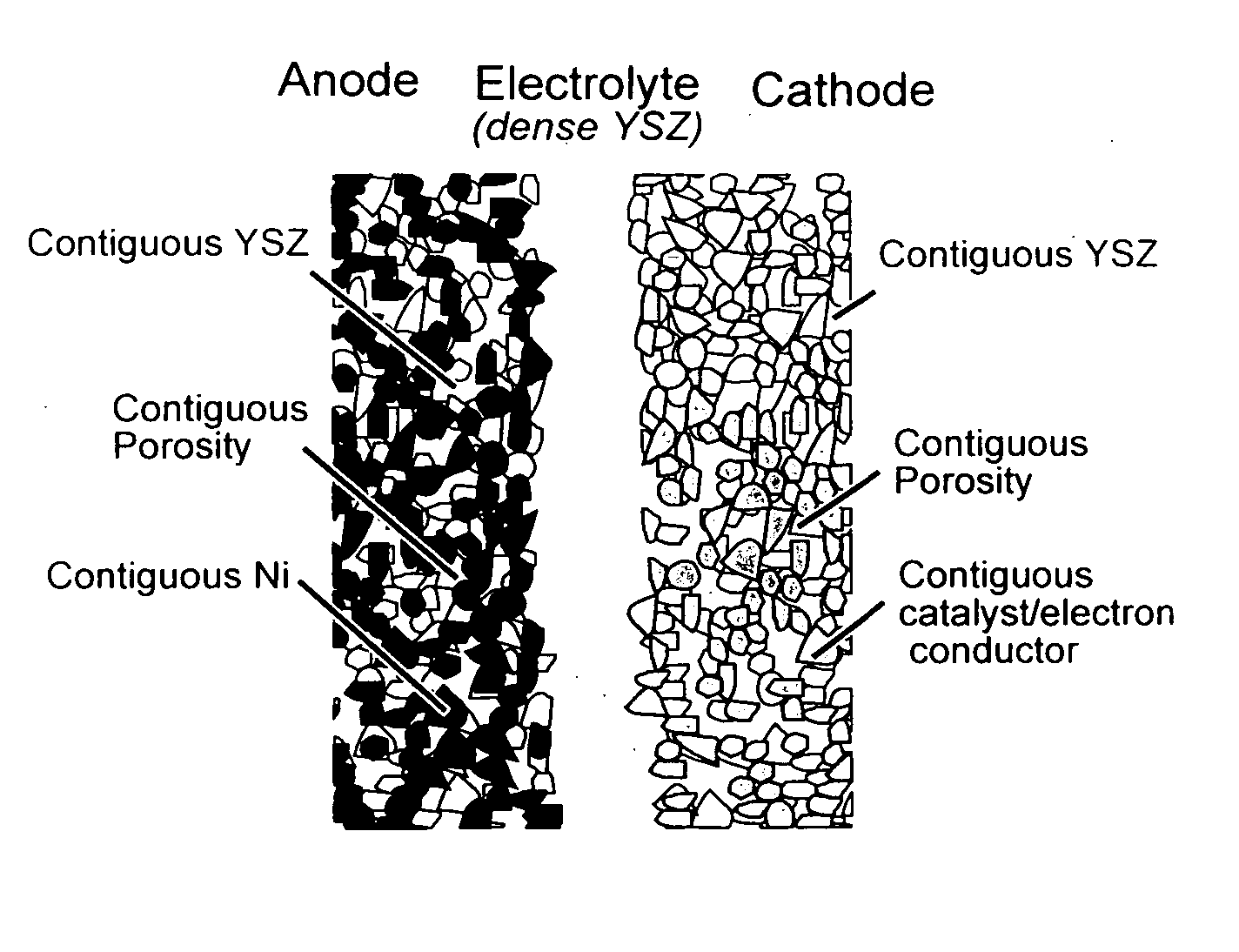

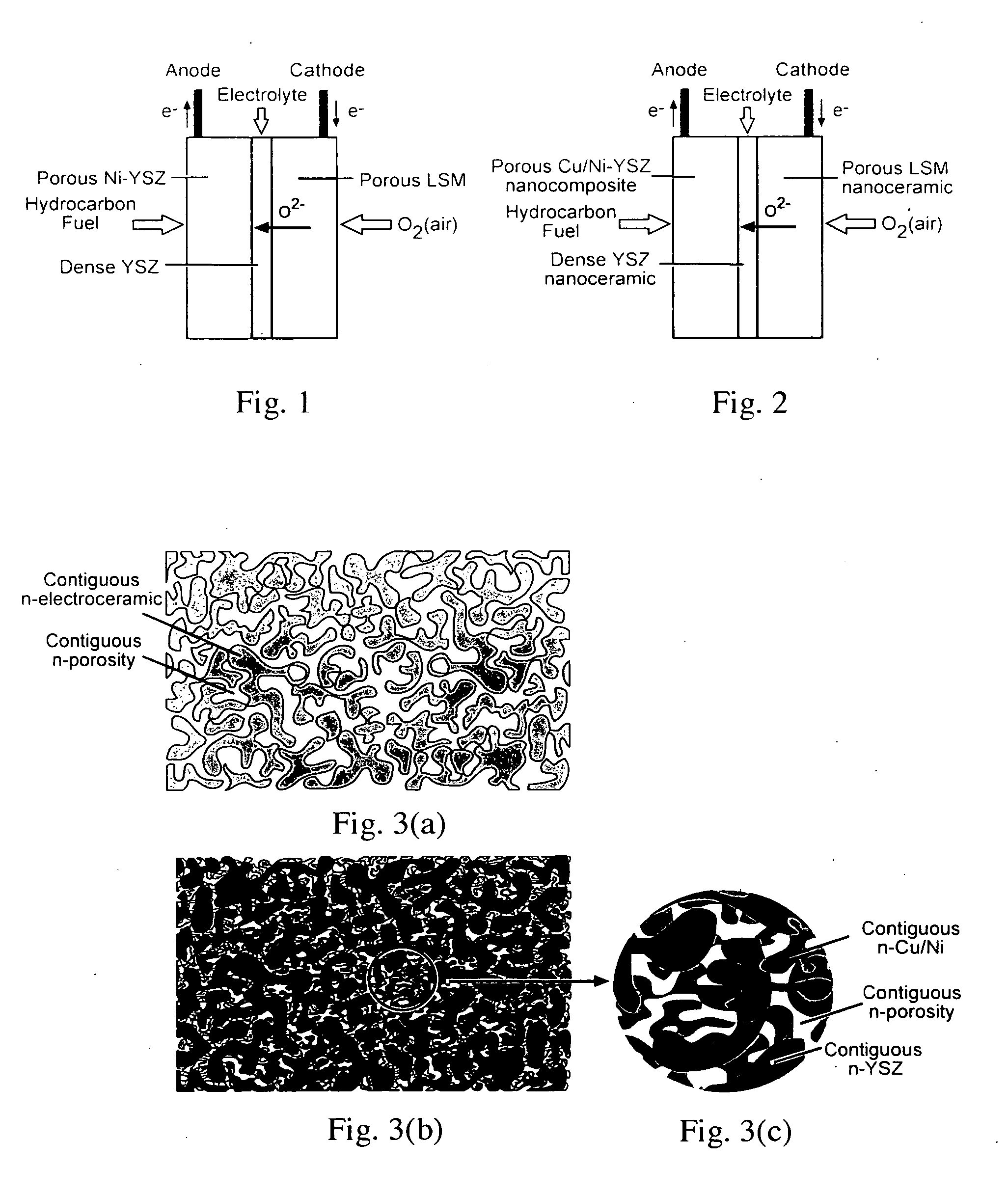

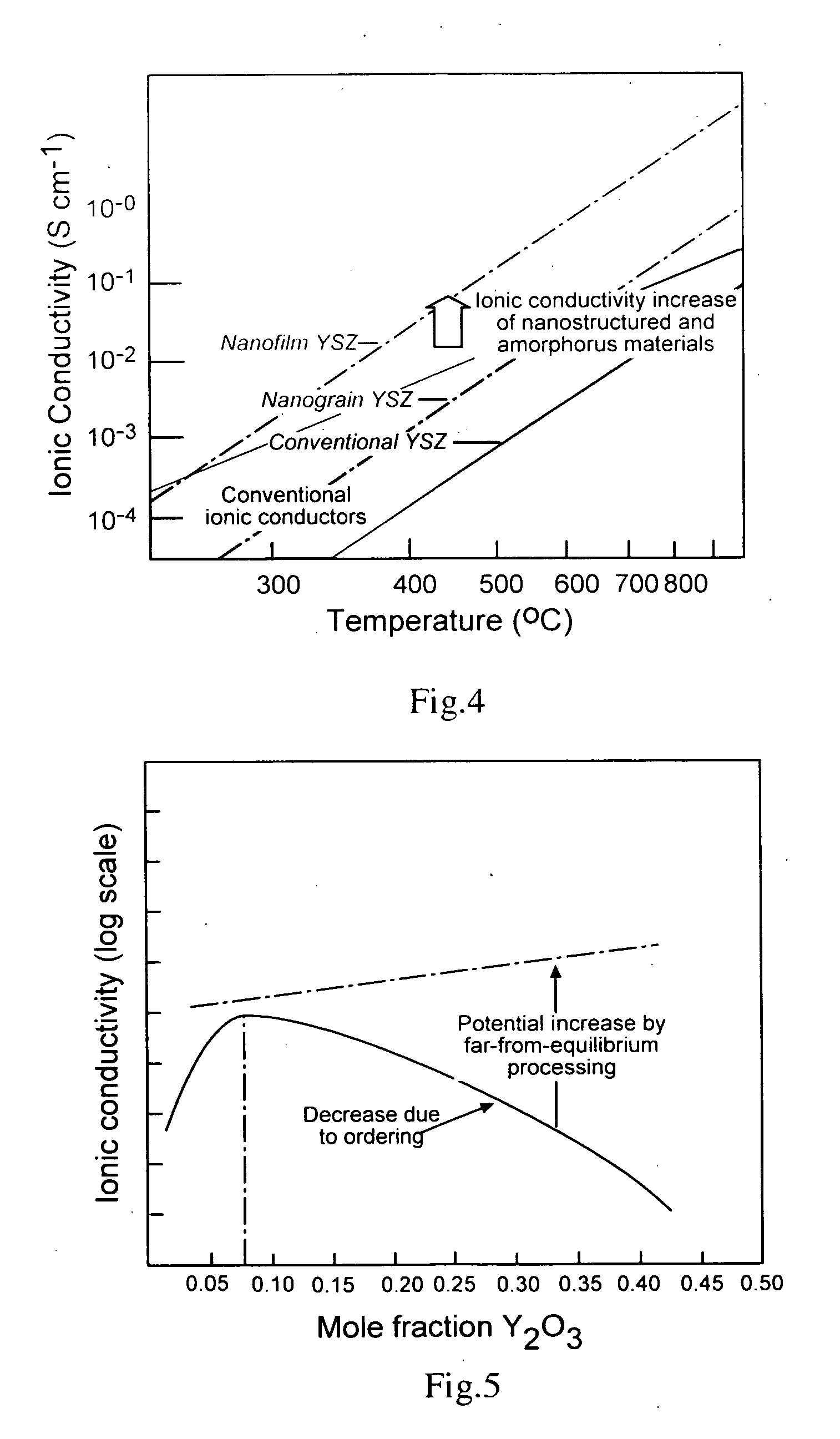

Mestastable ceramic fuel cell and method of making same

InactiveUS20050244693A1Little attentionSpeed up coolingFinal product manufactureCell electrodesSolubilityOxide ceramic

A solid oxide fuel cell has anode, cathode and electrolyte layers each formed essentially of a multi-oxide ceramic material and having a far-from-equilibrium, metastable structure selected from the group consisting of nanocrystalline, nanocomposite and amorphous. The electrolyte layer has a matrix of the ceramic material, and is impervious and serves as a fast oxygen ion conductor. The electrolyte layer has a matrix of the ceramic material and a dopant dispersed therein in an amount substantially greater than its equilibrium solubility in the ceramic matrix. The anode layer includes a continuous surface area metallic phase in which electron conduction is provided by the metallic phase and the multi-oxide ceramic matrix provides ionic conduction.

Owner:NANOCELL SYST

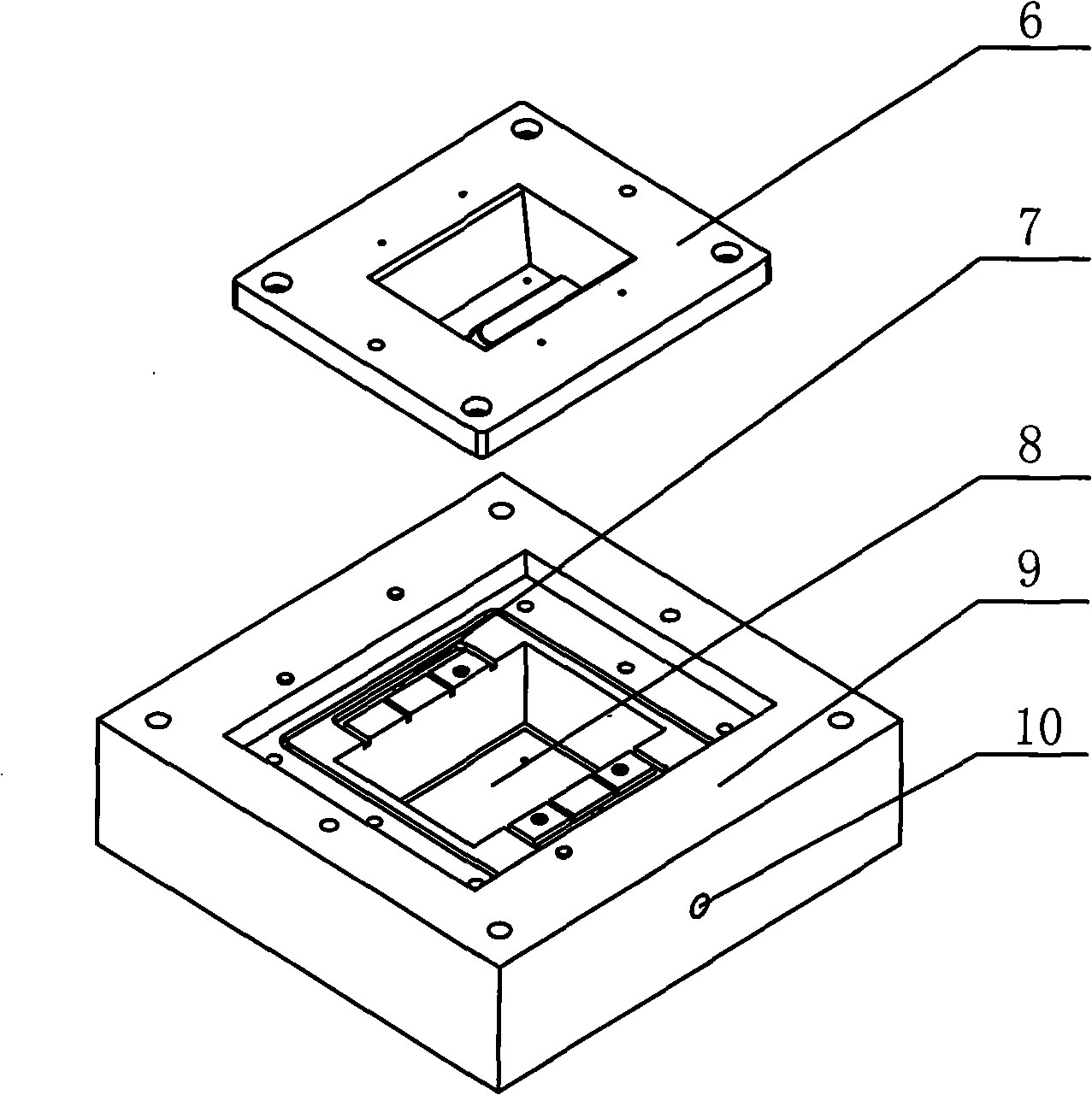

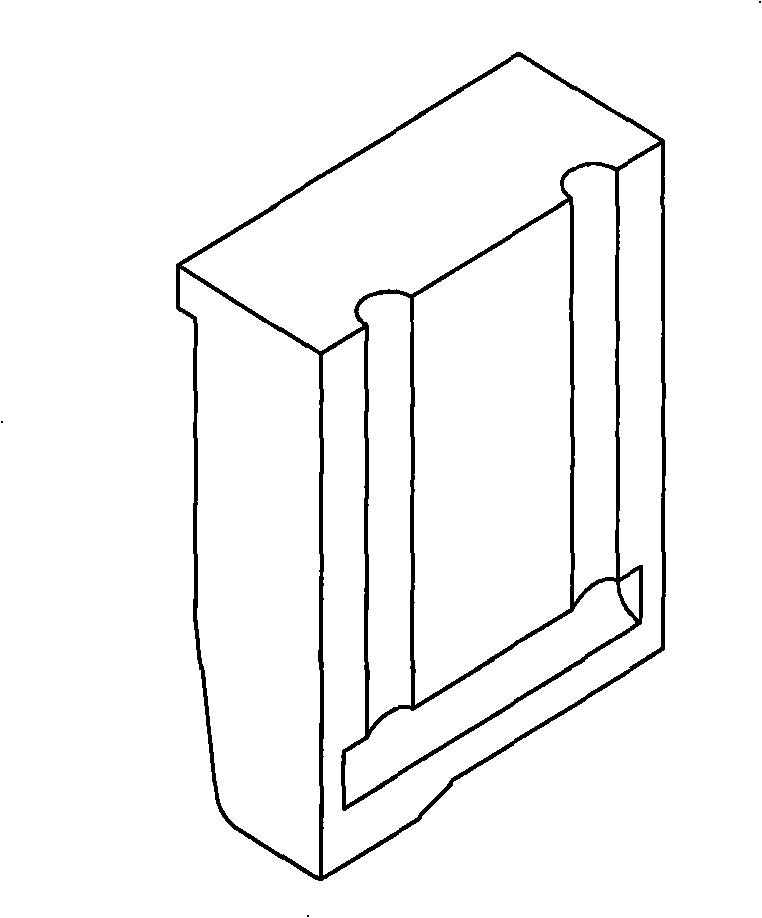

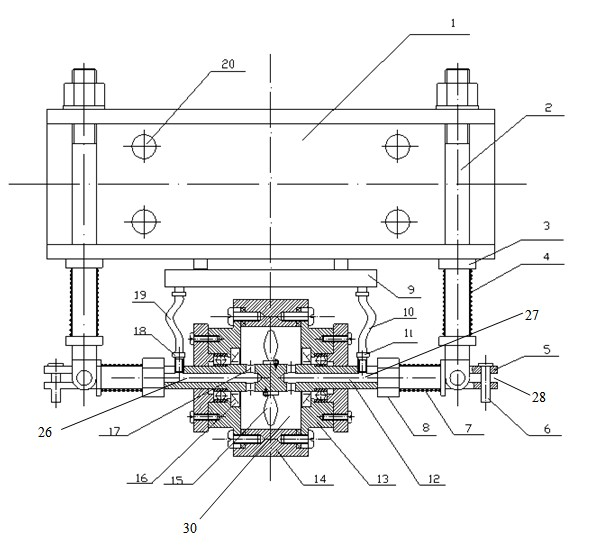

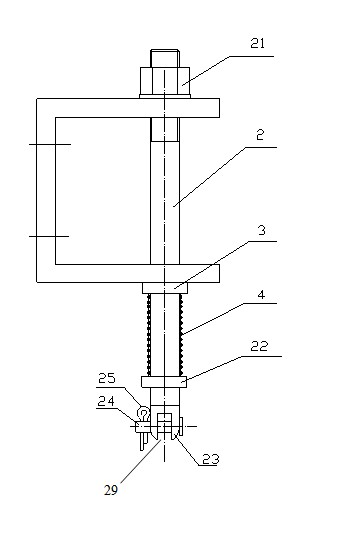

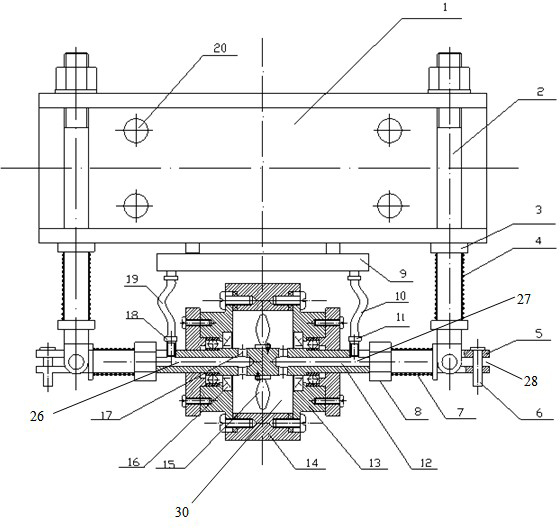

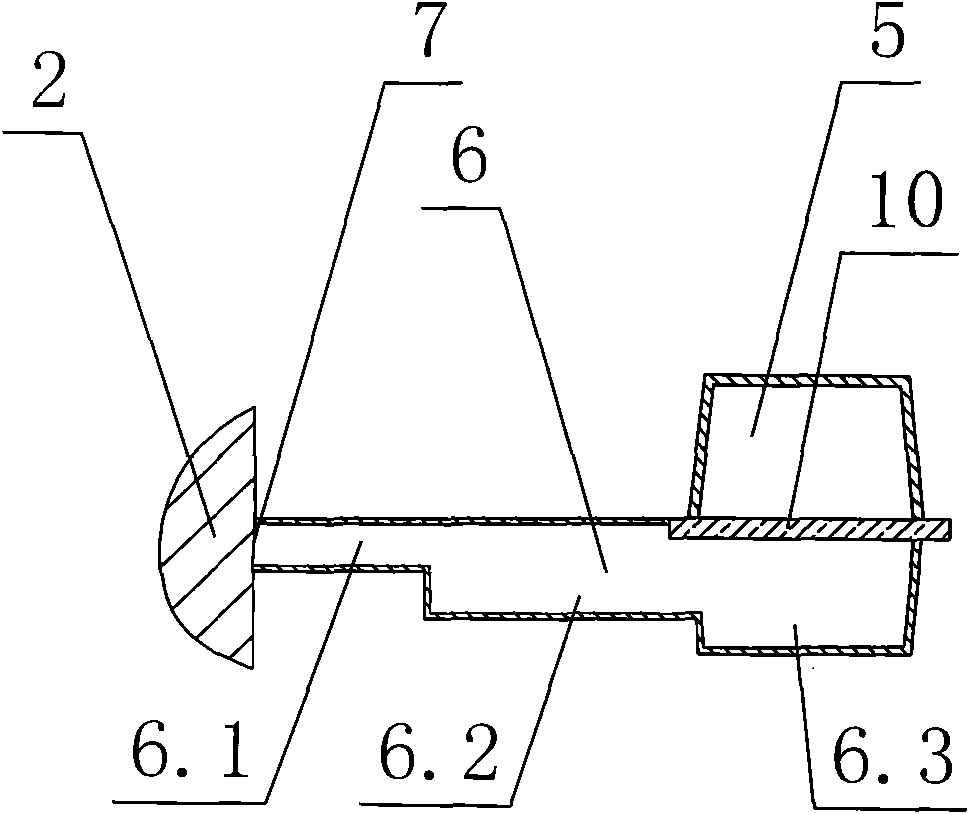

Ultra-high strength steel hot stamping forming die

The invention discloses an ultra-high strength steel plate thermal die cutting and forming die, comprising an upper die seat and a convex die which is fixed on the upper die seat, a lower die seat and a concave die that is fixed on the lower die seat; the concave die is internally provided with a cooling water passage which is connected with a cooling water circulation system. More particularly, the concave die is compose of a trough-shaped concave die seat and a cavity body; the concave die seat is provided with a water inlet and a water outlet; the cavity body is arranged in the concave trough of the concave die seat; a gap is arranged between the cavity body and the concave die seat; the gap is communicated with the water inlet and the water outlet. The die improves cooling speed, ensures the uniformity of cooling, has simple and practical structure, and fast cools the die and the punching parts in the die by the water cooling system of the die, so as to achieve the effect of quenching. As the process is completed under the pressure preservation process of the die, the workpiece has extremely small deformation and the dimension precision of the punching part can be excellently ensured.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD +1

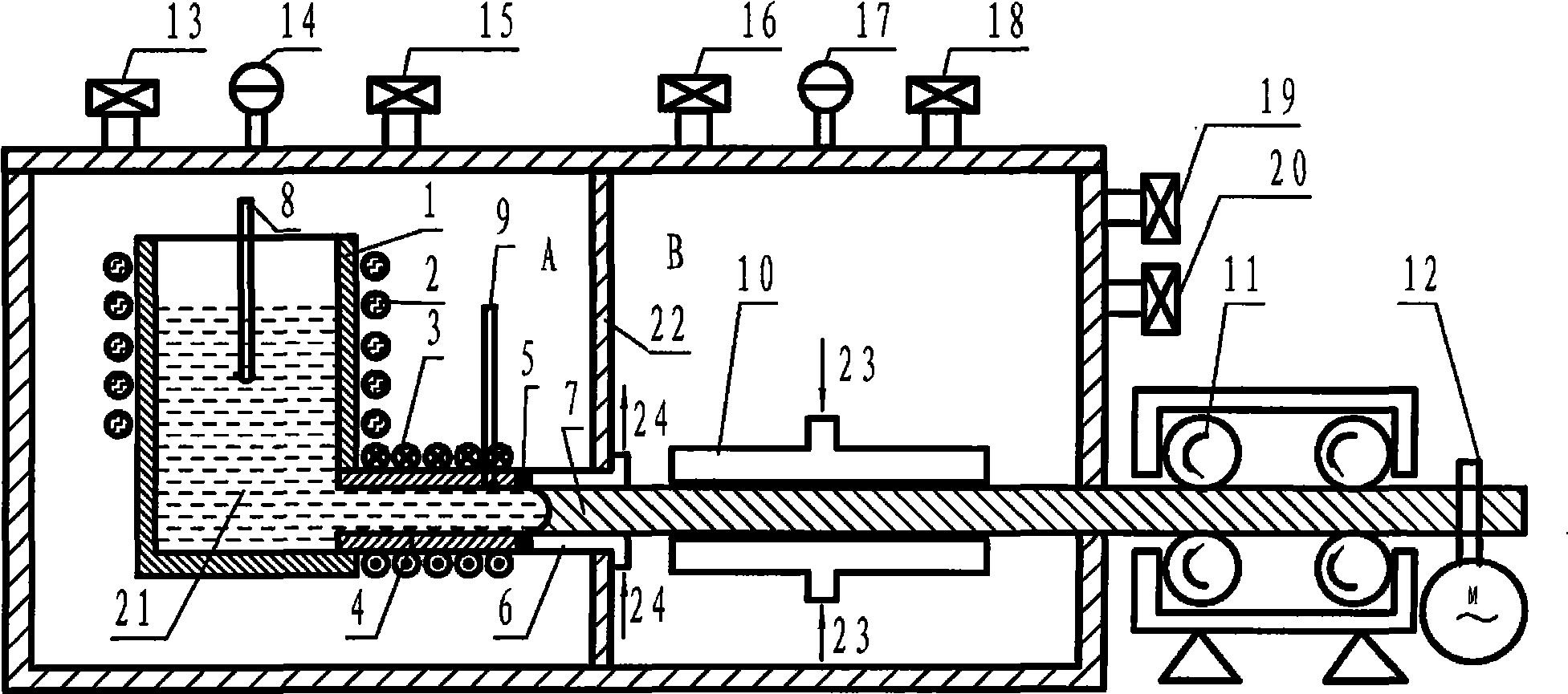

Device and method for continuous block metal glass shaping

InactiveCN101543885ASolve the vacuum problemIncrease cooling intensityMetallic materialsPressure difference

The invention relates to a device and method for continuous block metal glass shaping, belonging to the technical field of metal material preparation. A heat insulating ring is arranged between a graphite casting mould and a water cooling copper mould which are arranged in a first vacuum chamber, an air cooler is arranged in a second vacuum chamber, and a traction rod enters the graphite casting mould and horizontally moves by a traction device. The method uses the graphite casting mould and the water cooling copper mould for primary main cooling and the air cooling mode for secondary auxiliary cooling, and the two vacuum chambers have a certain air-pressure difference. The device and the method have a high cooling speed, satisfy the requirements of the amorphous phase change of the block metal glass material. The shaping pressure of a metal melting body can be easily controlled, and the good shaping performance of the metal melting body is ensured by adjusting the pressure in the vacuum chambers. The metal passes through the graphite casting mould in a liquid state and is solidified in the water cooling copper mould, and the casting graphite casting mould has long service. The composite casting mould and the traction device have exchangeability to be convenient for realizing the continuous shaping of rod wires, boards, pipes and abnormal-shaped materials of different section sizes.

Owner:江苏苏州洲盛非晶科技有限公司

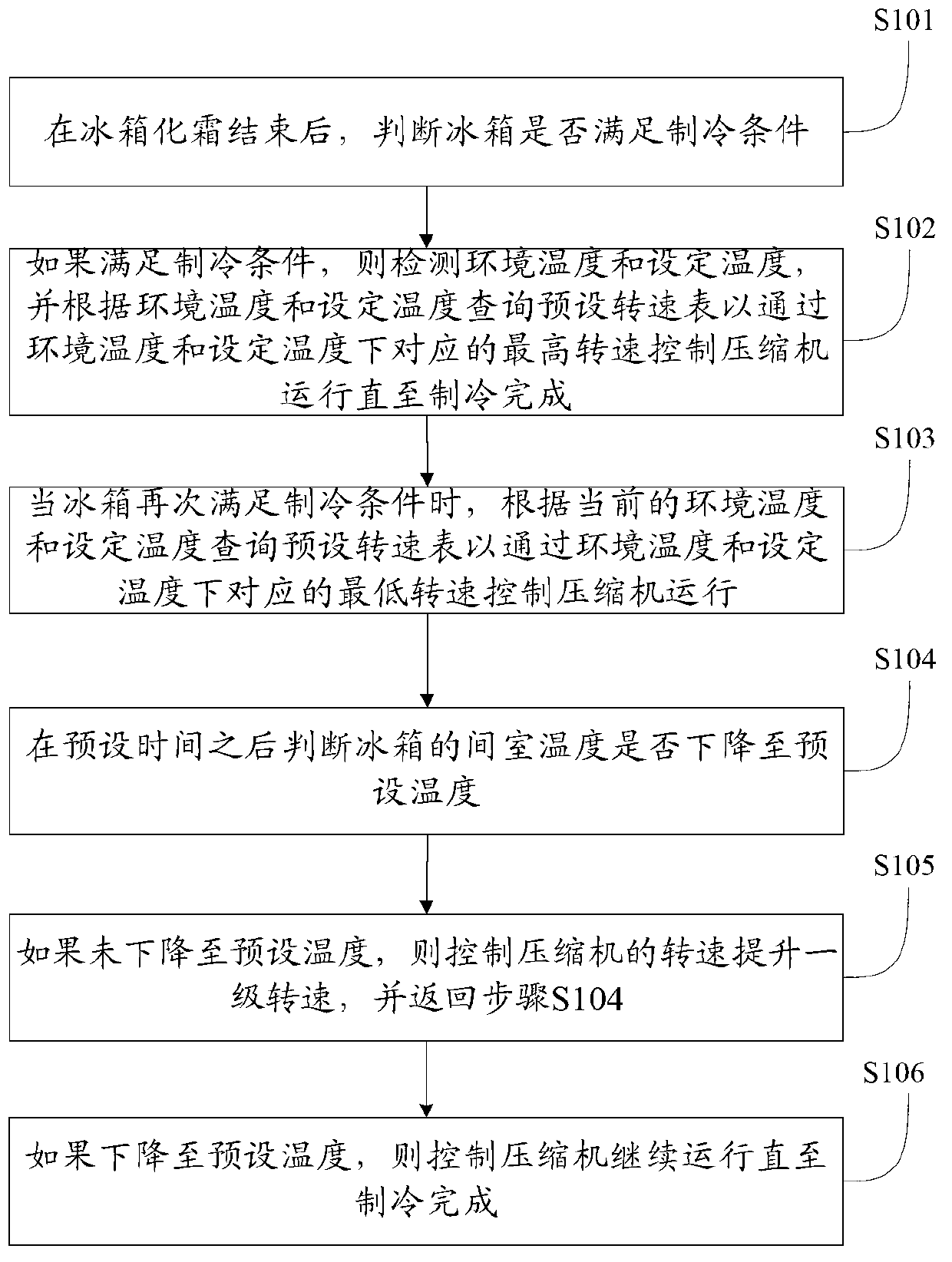

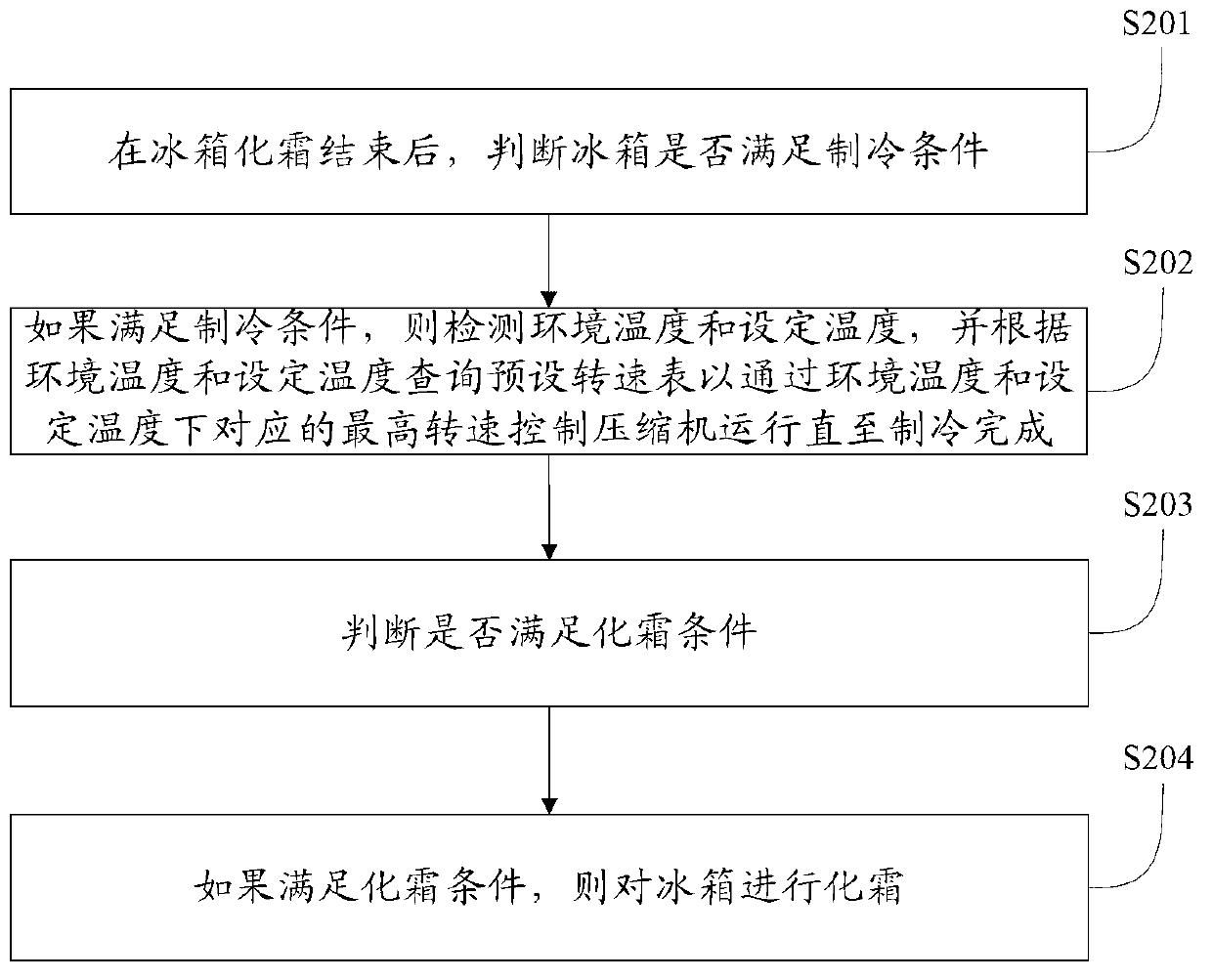

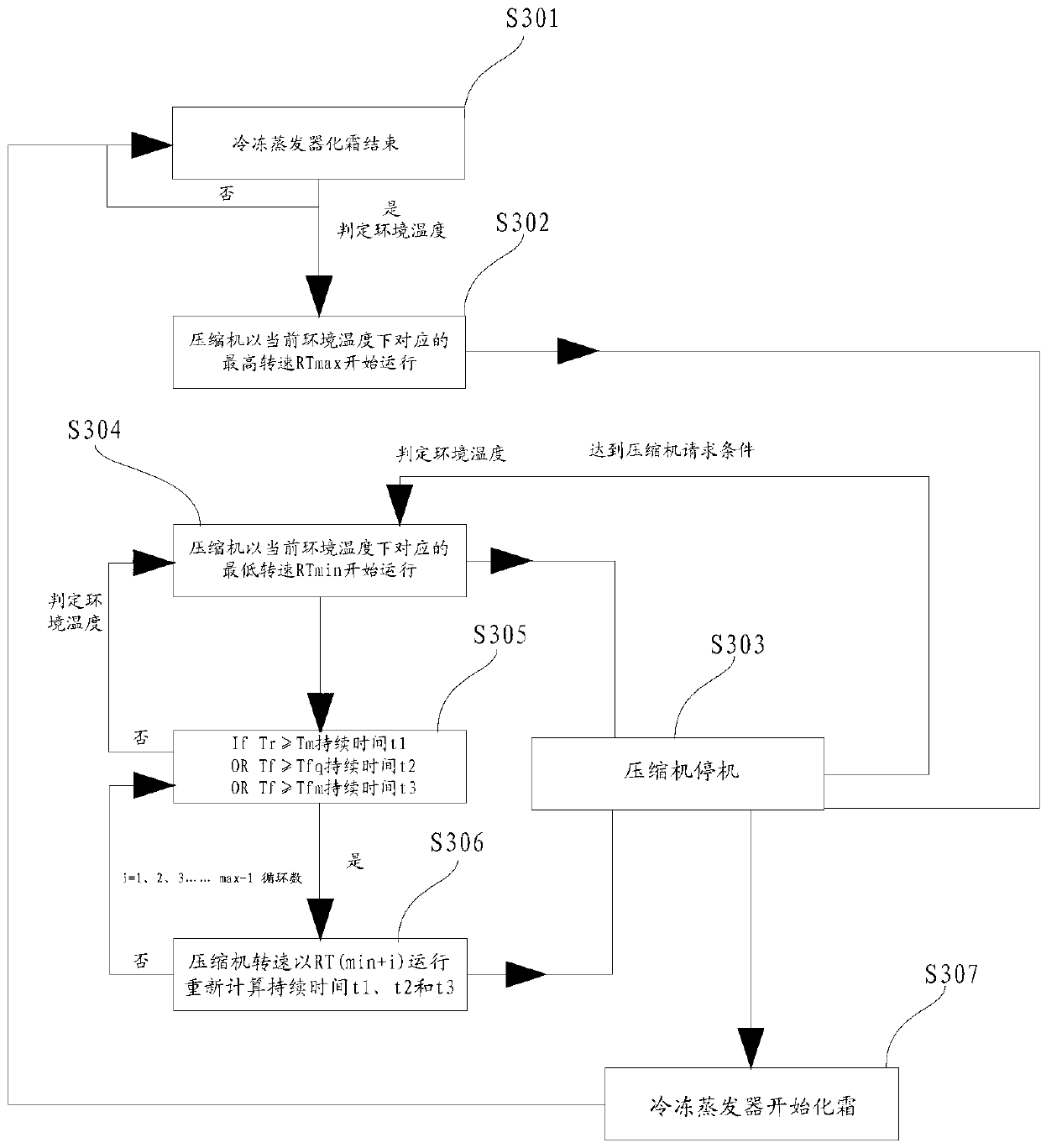

Frequency converting control method for refrigerator

ActiveCN102997609ASpeed up coolingReduce wasteDomestic cooling apparatusLighting and heating apparatusFrequency conversionEngineering

The invention provides a frequency converting control method for a refrigerator. The method includes that (1) whether the refrigerator meets a refrigeration condition or not is determined after defrosting of the refrigerator is finished; (2) if the refrigerator meets the refrigeration condition, an environment temperature and a setting temperature are detected, and a preset revolution meter is inquired so as to control the operation of a compressor at a corresponding maximum revolution speed until the refrigeration is completed; (3) when the refrigerator meets the refrigeration condition again, the operation of the compressor is controlled at a corresponding minimum revolution speed; (4) whether the compartment temperature of the refrigerator decreases to a preset temperature or not after preset time is determined; (5) if the compartment temperature of the refrigerator does not decrease to the preset temperature, the revolving speed of the compressor is increased by one level, and the step (4) is returned; and (6) if the compartment temperature of the refrigerator decreases to the preset temperature, the compressor is controlled to continue operating until the refrigeration is finished. According to the frequency converting control method for the refrigerator, the revolving speed of the compressor is continuously adjusted according to the environment temperature, interior temperatures of compartments and the like, so that the frequency conversion is achieved, the cooling speed of the refrigerator is improved, waste of cooling capacity of the compressor is reduced, and the energy consumption is lowered.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

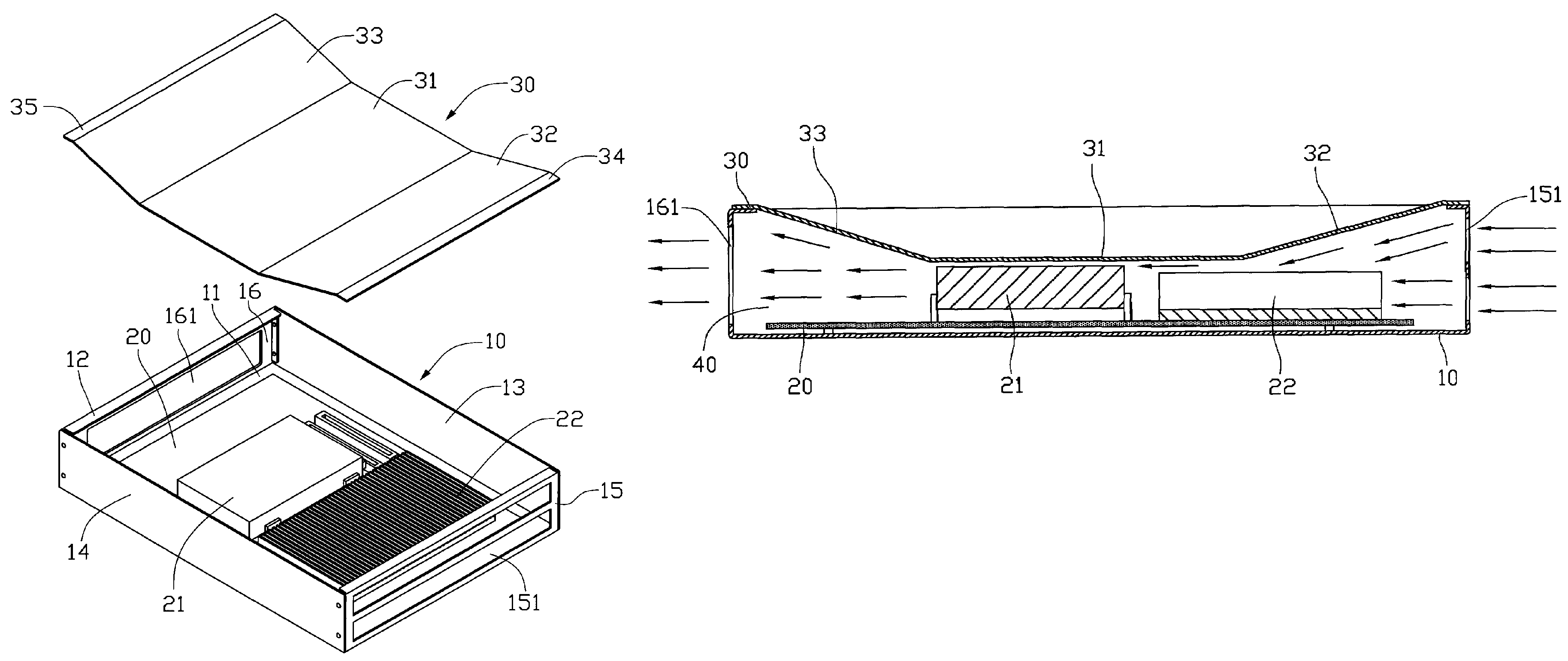

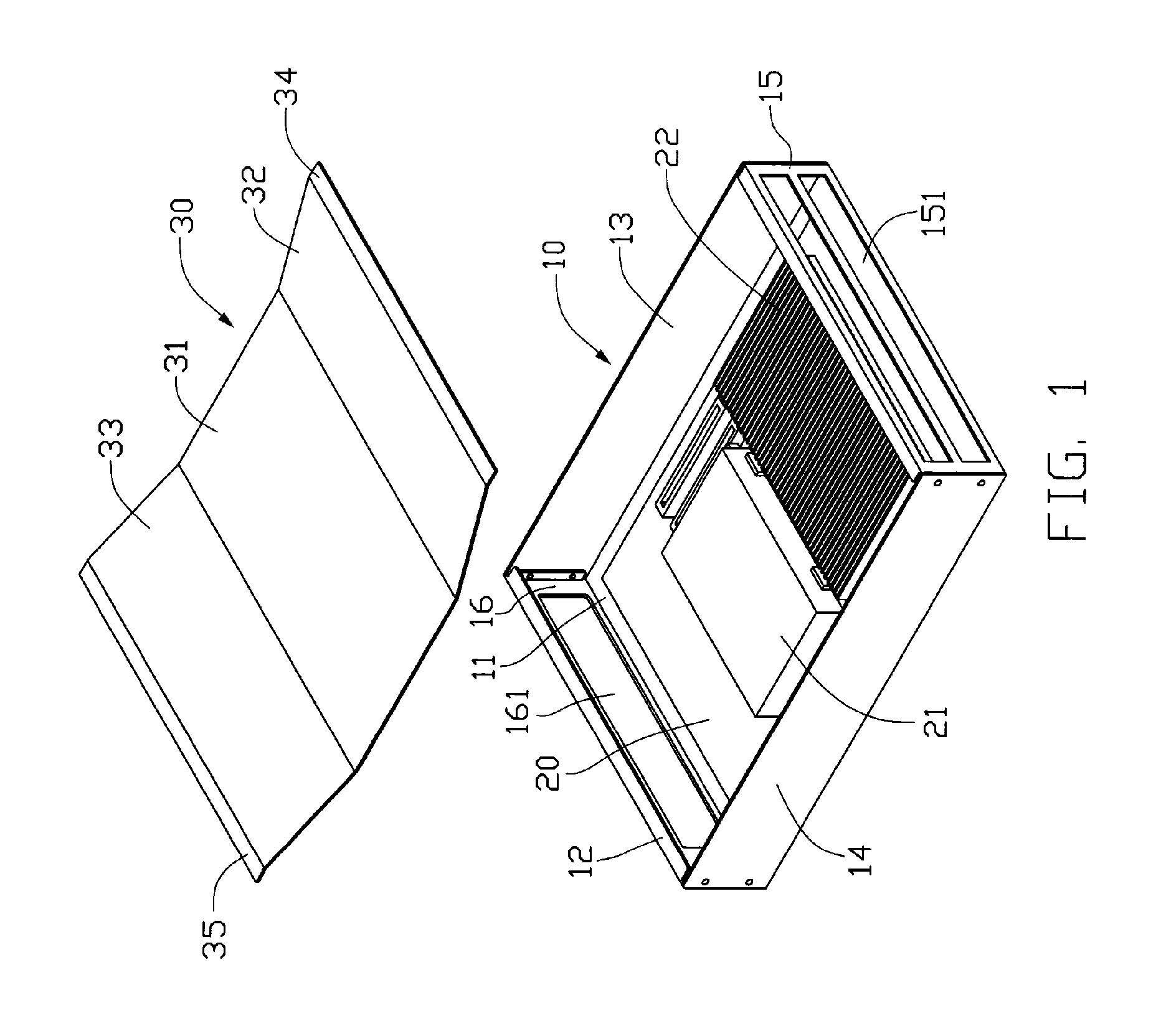

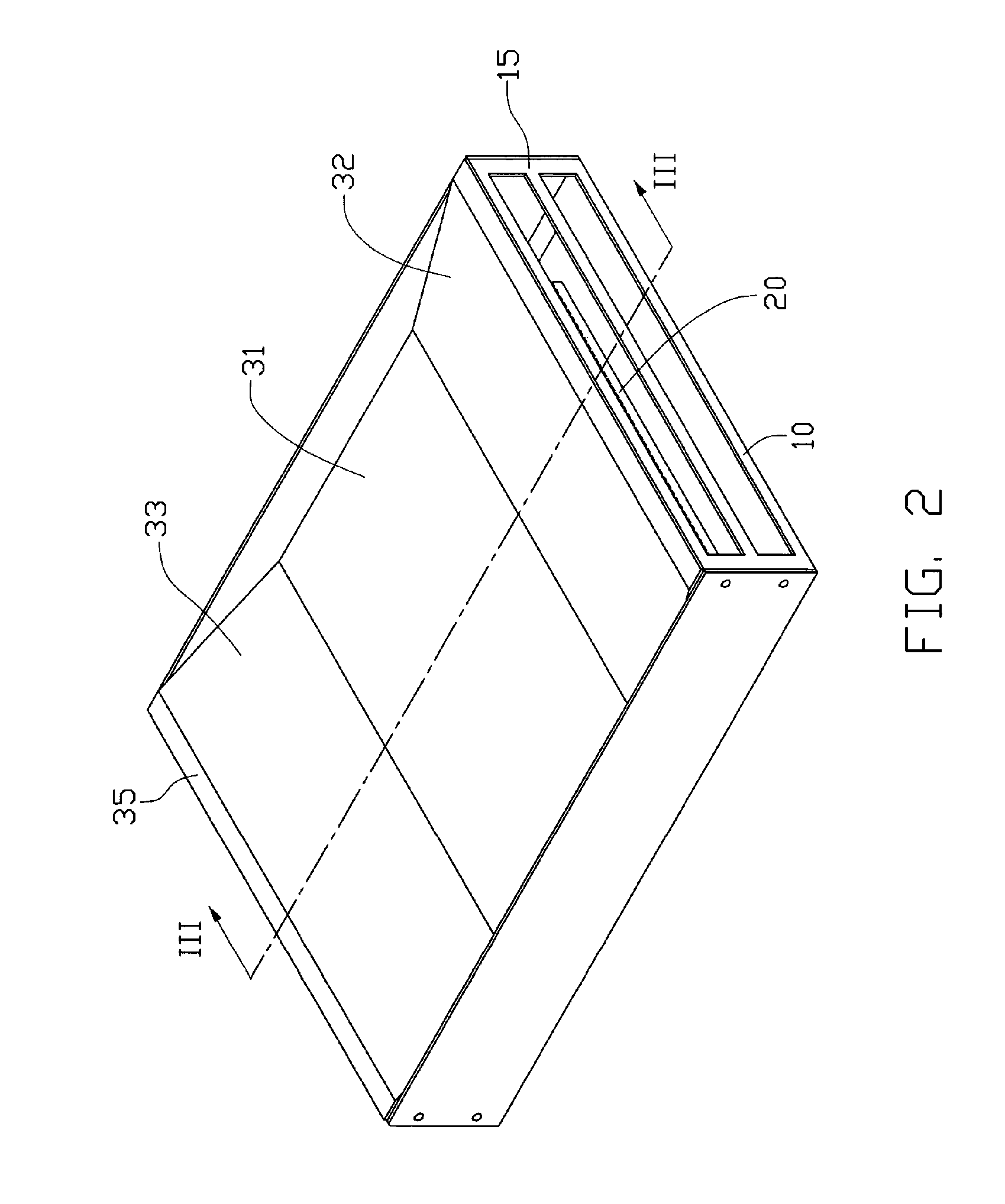

Air guiding cover

InactiveUS7447021B2Improve cooling efficiencySpeed up coolingLighting and heating apparatusDigital data processing detailsEngineeringMotherboard

Owner:HON HAI PRECISION IND CO LTD

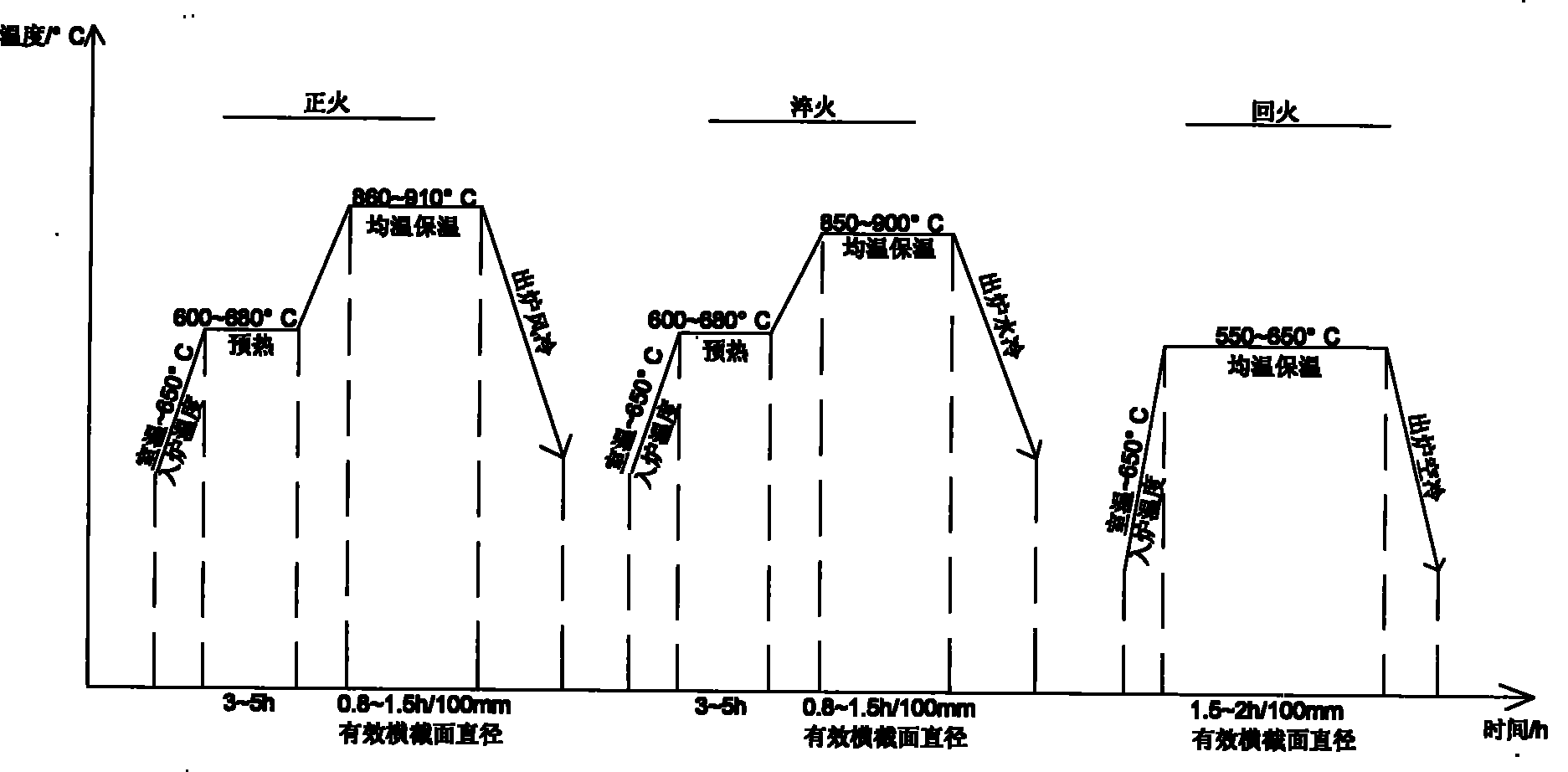

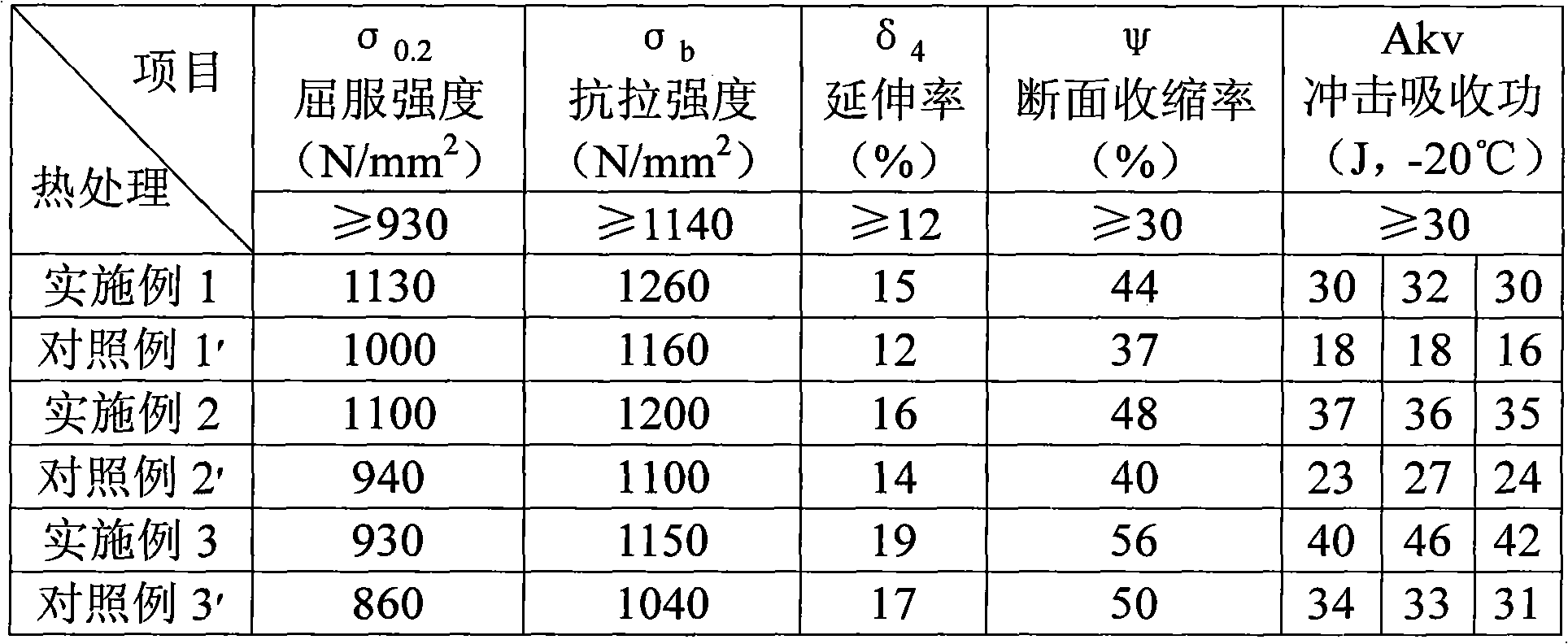

Heat treatment process of AISI4340 steel forgings

The invention belongs to the technical field of the production technology of steel forging products used in low temperature and discloses a heat treatment process of AISI4340 steel forgings. In the heat treatment process, air cooling is performed after normalization; the temperature of water-cooling after quenching is 10-20 DEG C, the dimension unit of the effective cross-section is millimeter, the unit of cooling time is second, and the cooling time is 2-3 times of the effective cross-section dimension of AISI4340 steel forgings. By using the heat treatment process of the invention, the strength of the AISI4340 steel forgings can be enabled and the low-temperature impact toughness is effectively improved, thus the service life of forgings is prolonged.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

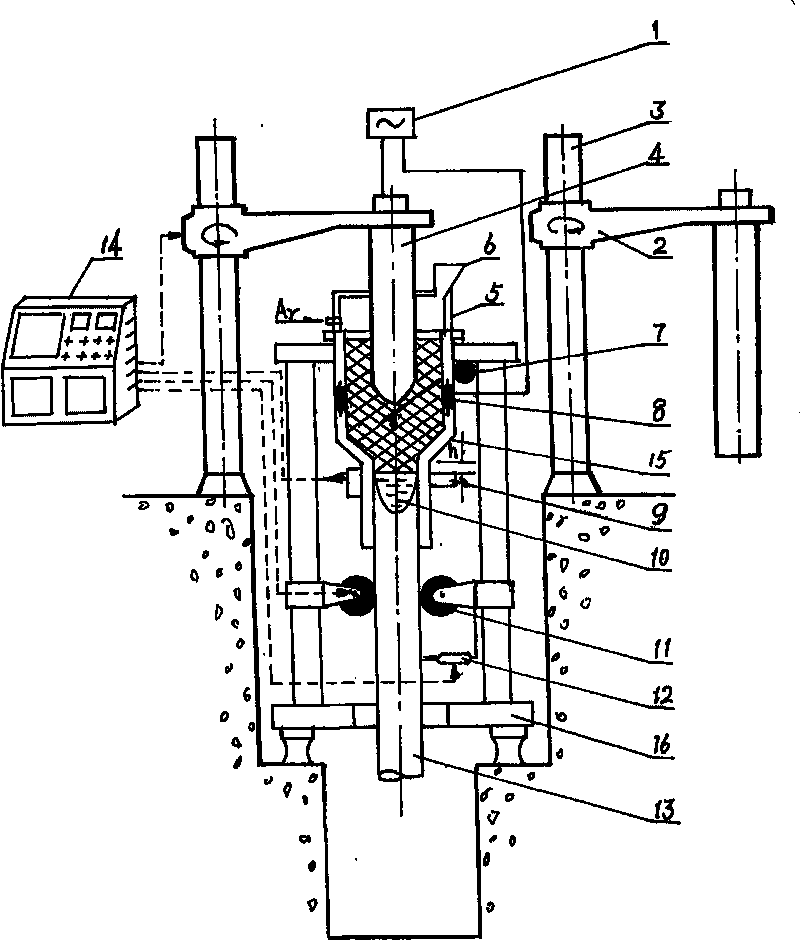

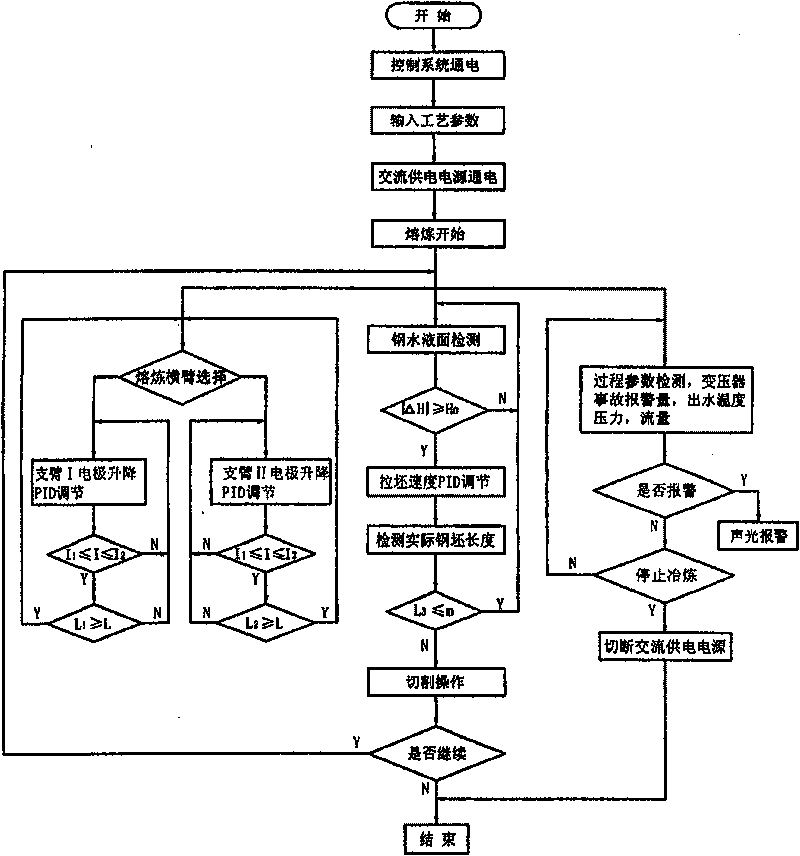

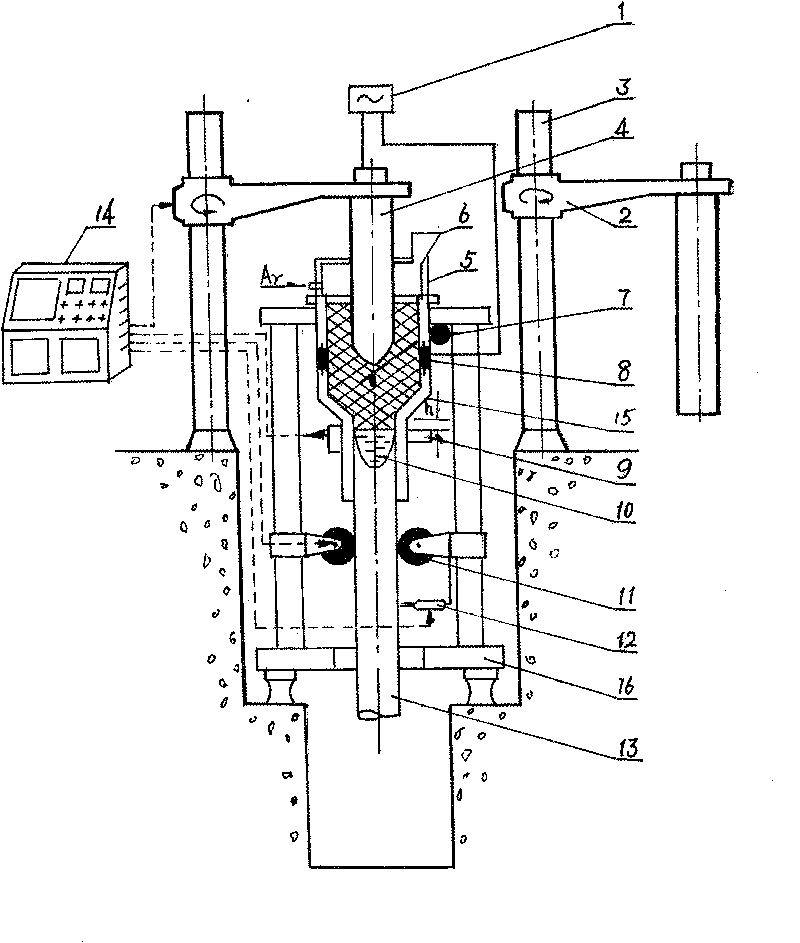

Protective atmosphere electro-slag continuous casting furnace

The invention discloses a protective atmosphere electro-slag continuous casting furnace, which belongs to metal electro-slag re-melting equipment. The furnace comprises an alternating current power supply, electrode lifting mechanisms, a consumable electrode, a conductive crystallizer, a supporting mechanism, a molten steel liquid level detection device, an argon protective cover, a vibration mechanism, a throwing mechanism, a cutting device and a control system. The electrode lifting mechanisms are fixed on two sides of the conductive crystallizer; one end of the consumable electrode is fixed on a cross arm of the electrode lifting mechanism and is connected with the alternating current power supply, while the other end passes through the argon protective cover and is placed inside the conductive crystallizer; the conductive crystallizer is a jacket type water-cooled crystallizer with combined upper and lower parts, a conductive ring is embedded at the upper wall, and the conductive ring is connected with the alternating current power supply through a cable so that a loop is formed from the alternating current power supply, the consumable electrode, furnace slag, the conductive ring to the alternating current power supply; the vibration mechanism is fixed on the supporting mechanism, and a cam of the vibration mechanism is tightly contacted with a shell of the conductive crystallizer; the joint of upper and lower cavities of the conductive crystallizer is provided with the molten steel liquid level detection device; the throwing mechanism and the cutting device are fixed under an ejection port of the conductive crystallizer in turn; and the control system is electrically connected with the cross arm of the electrode lifting mechanism, the molten steel liquid level detection device, the drawing mechanism and the cutting device respectively. The protective atmosphere electro-slag continuous casting furnace can realize electro-slag continuous casting.

Owner:SHENYANG HUASHENG METALLURGICAL TECH & INSTALLATION

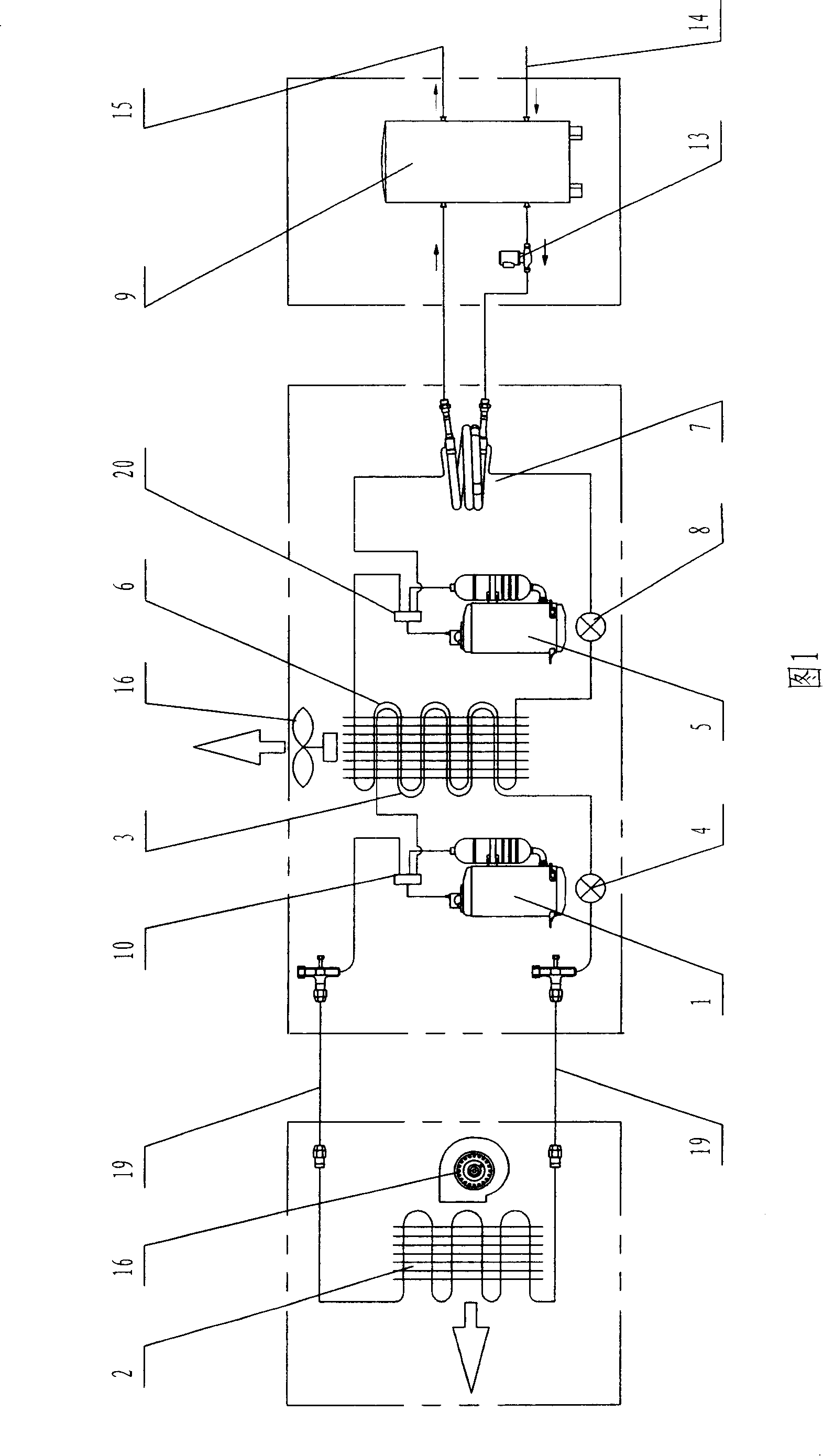

Air-conditioner hot-water composite machine

InactiveCN101210748AEnergy savingSimple structureCompression machines with cascade operationHeating and refrigeration combinationsProcess engineeringThrottle

The invention discloses an air-conditioning / water-heating compound machine which comrprises (1) a circulation loop for an air-conditioning system, consisting of a first compressor, a first heat exchanger, a second heat exchanger and a first throttle mechanism; and (2) a circulation loop for a water-heating system, consisting of a second compressor, a third heat exchanger, a fourth heat exchanger and a second throttle mechanism. The second heat exchanger and the third heat exchanger form a heat-transfer connection. The fourth heat exchanger and a hot-water pipeline form a water-passage connection. The hot-water pipeline is provided thereon with a water inlet and a water outlet. The invention can reduce energy consumption and has simple structure.

Owner:苏宇贵

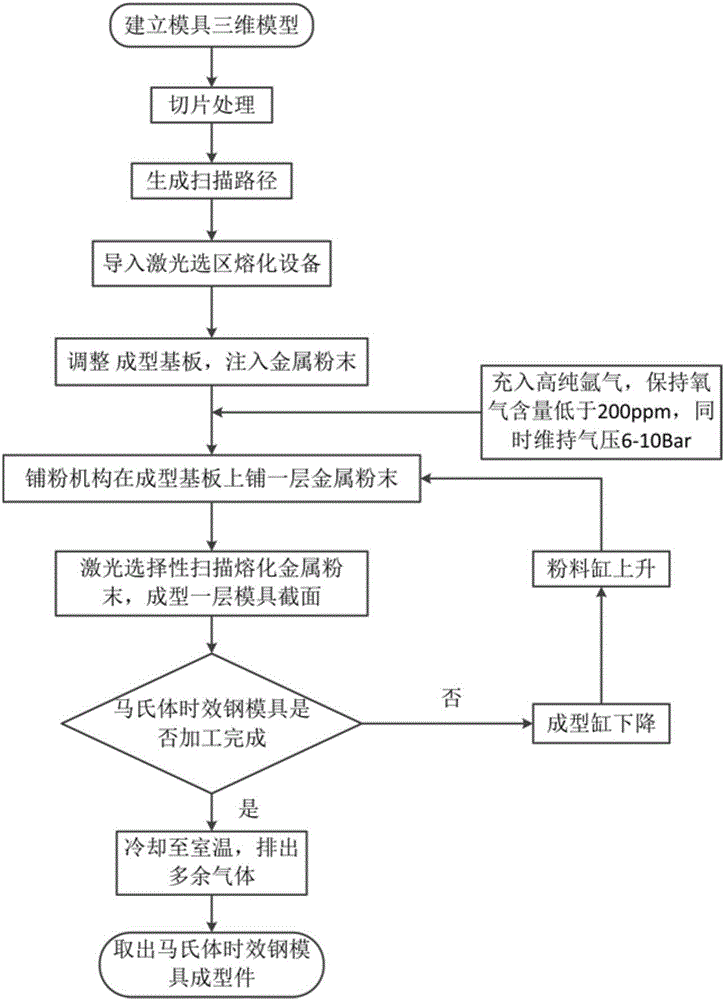

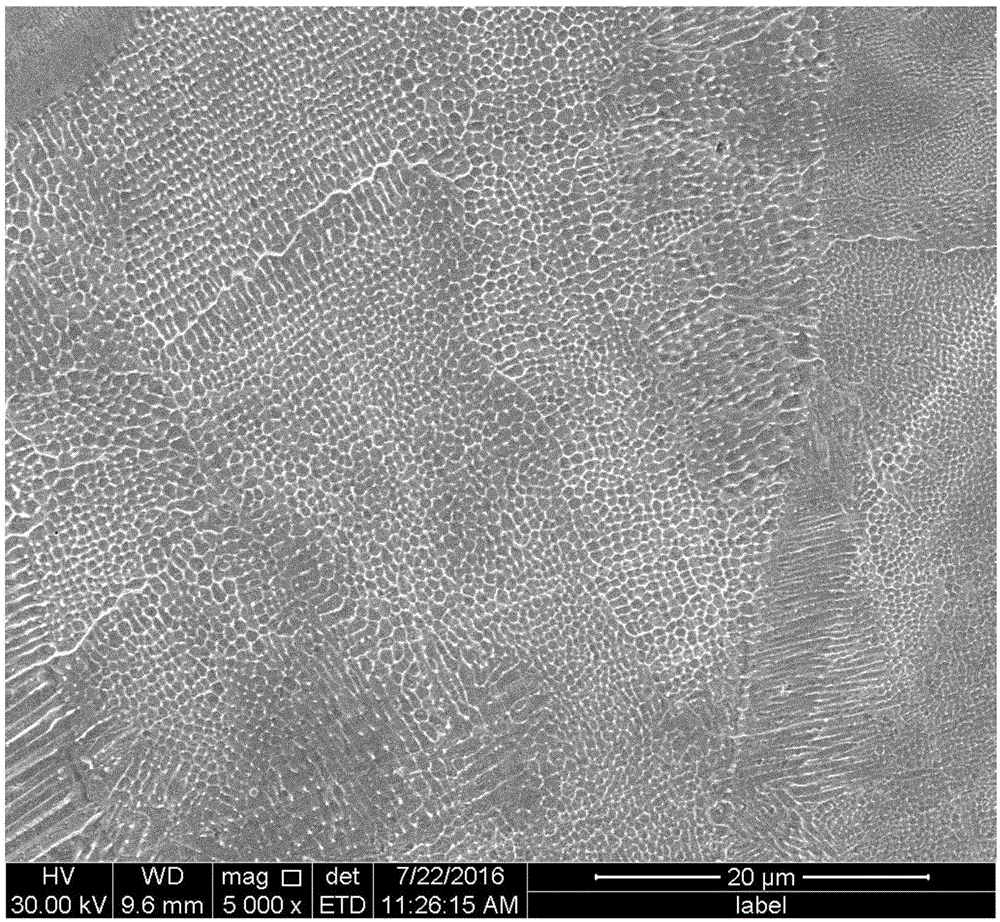

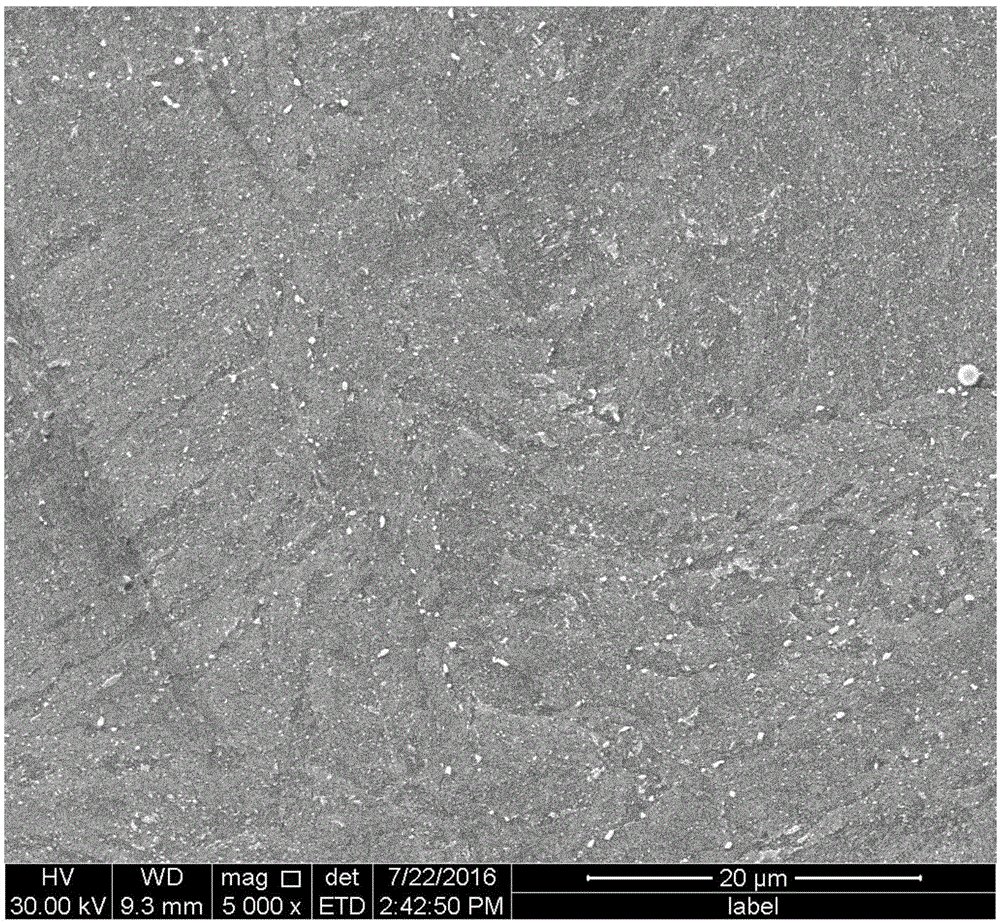

Forming method of maraging steel mold adopting selective laser melting

InactiveCN106825566AEasy to manufactureReduce pollutionAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingManufacturing cost reduction

The invention discloses a forming method of a maraging steel mold adopting selective laser melting. A three-dimensional structure of the mold is designed firstly by using three-dimensional design software such as Solidworks, ProE and Ug; and then the three-dimensional mold is subjected to slicing layering and route planning treatment, data are guided into a selective laser melting device, reasonable technical parameters are set, and the mold with a complex cooling channel is formed at a time. The mold formed by the method has the advantages of being high in compactness, few in internal defect, high in forming efficiency and high in free degree on the follow-up forming cooling channel. According to the forming method of the maraging steel mold adopting selective laser melting, the production period of the mold is effectively shortened, forming efficiency is high, external disturbance is small, the compressive property and production efficiency of the mold are remarkably improved, and meanwhile manufacturing cost is greatly reduced. After the directly-formed mold is subjected to solution and aging treatment, hardness and strength of the mold are remarkably improved, and the using requirements of the mold are met.

Owner:SOUTH CHINA UNIV OF TECH

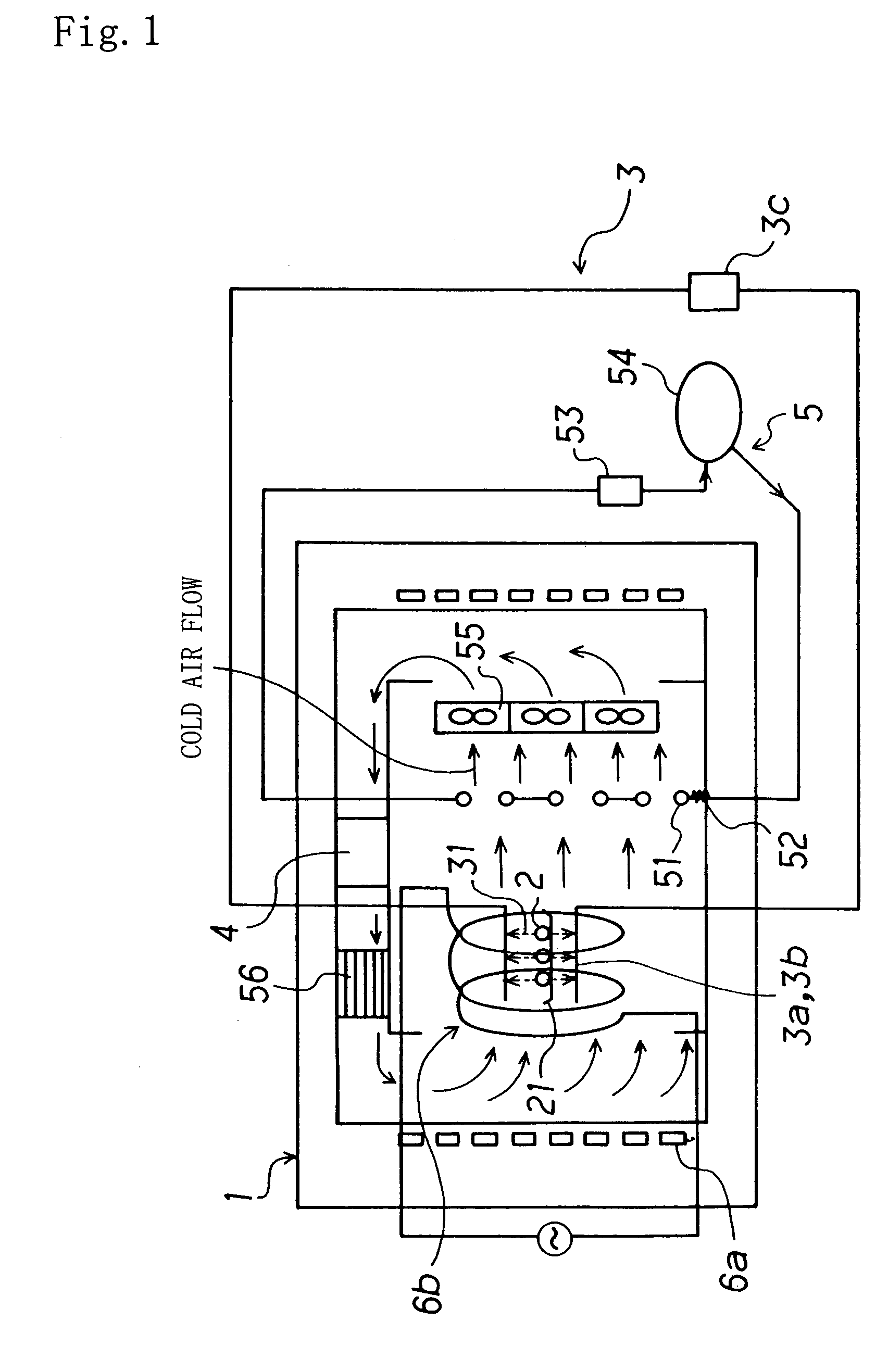

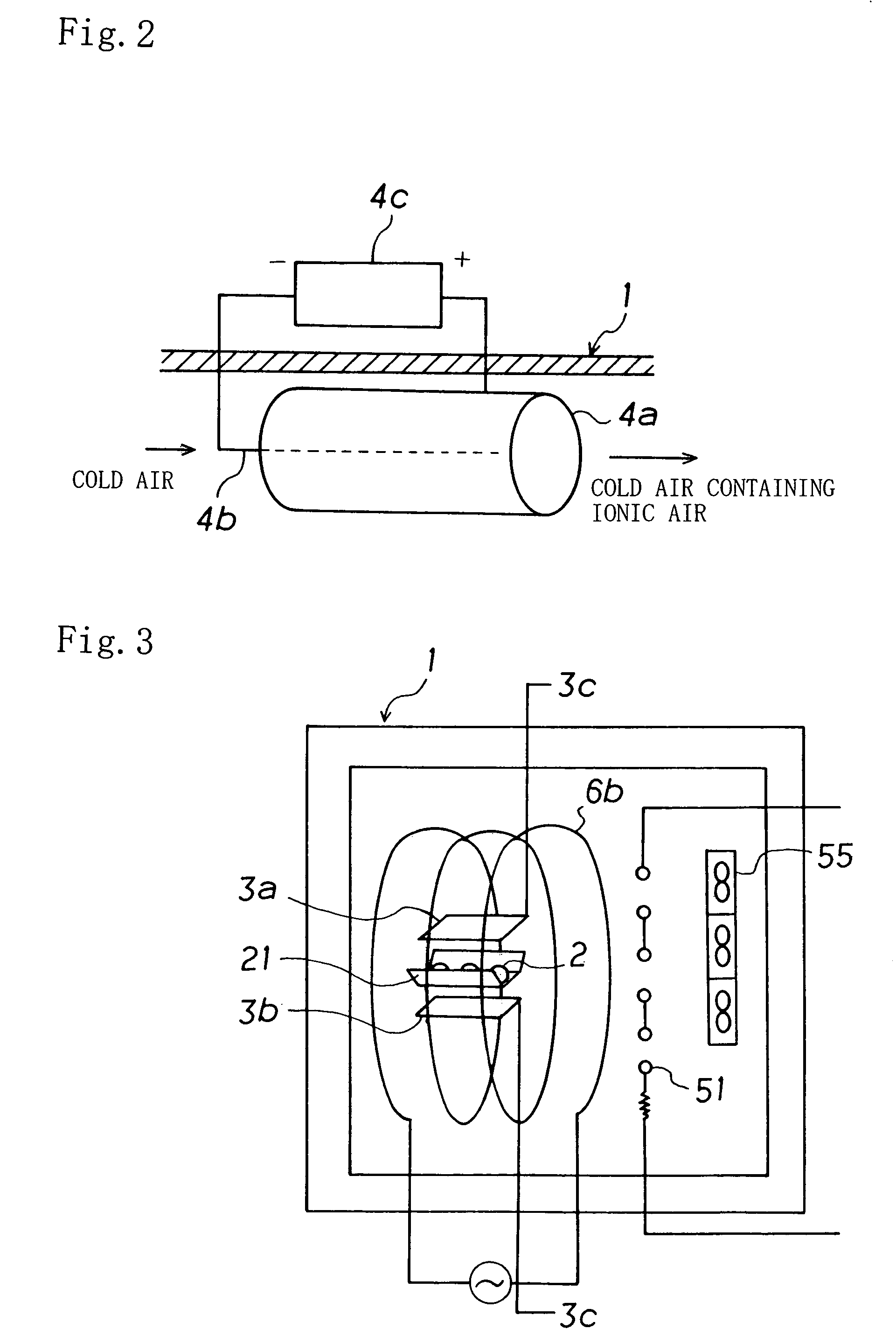

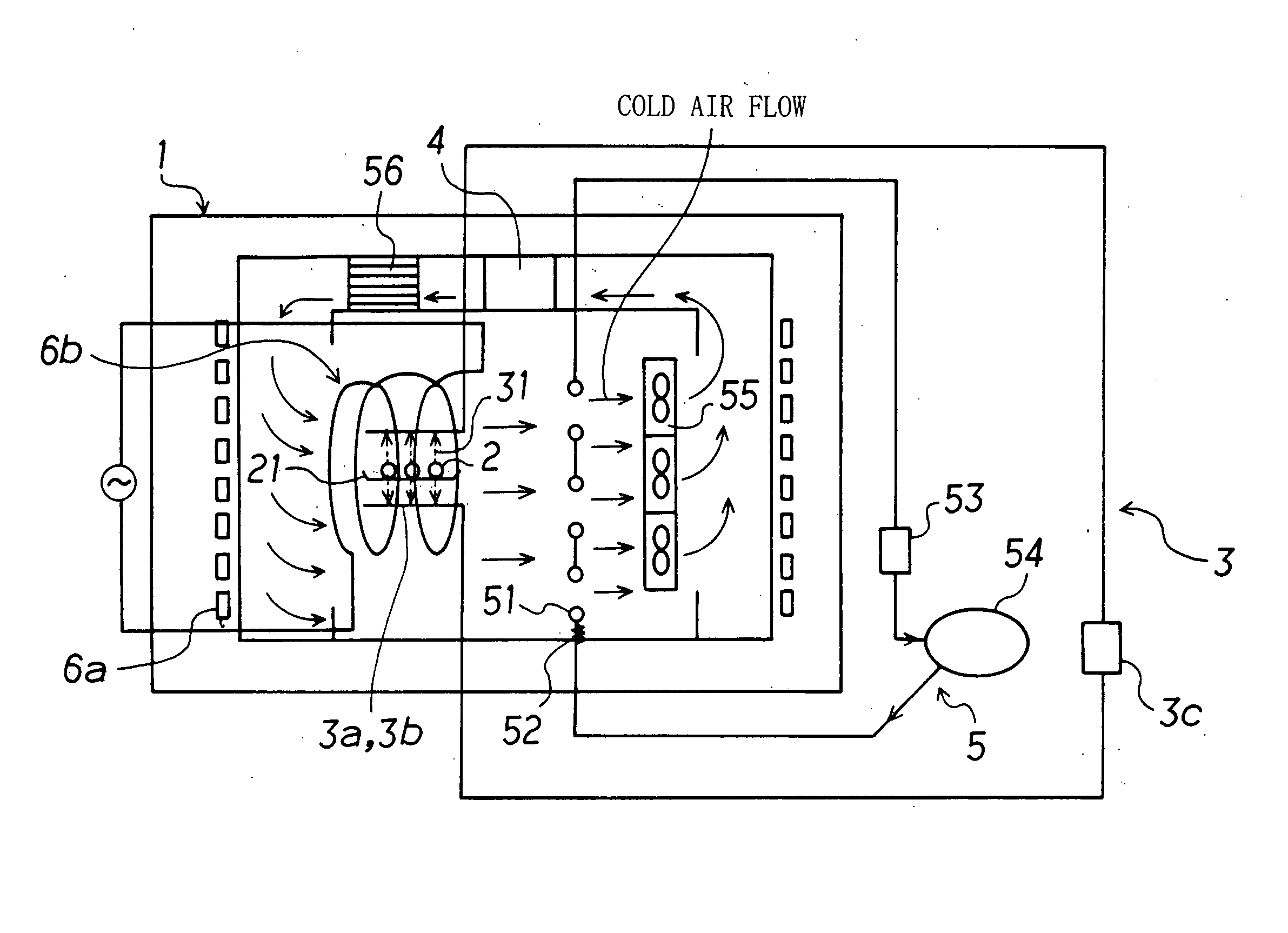

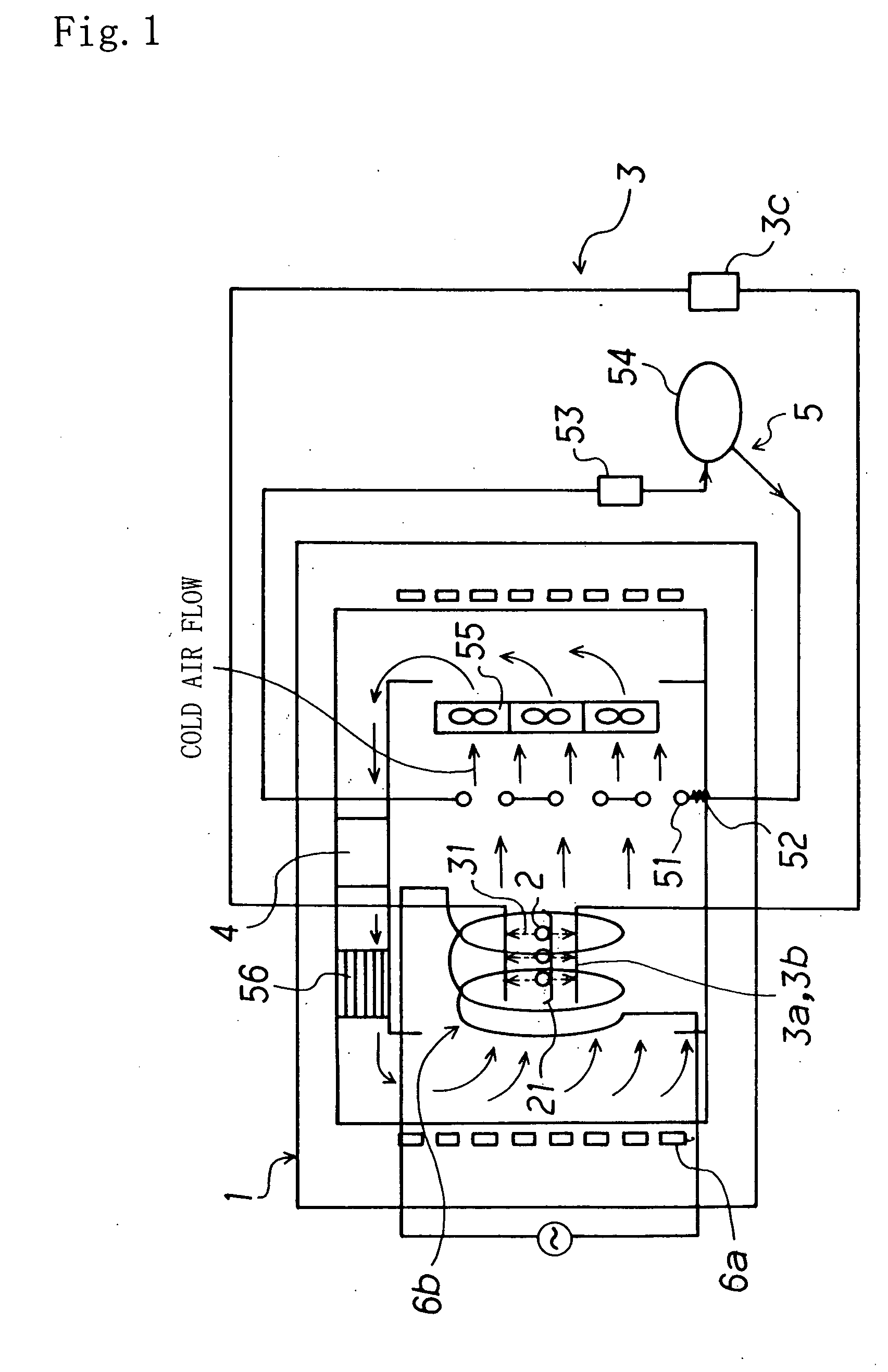

Highly-efficient freezing apparatus and highly-efficient freezing method

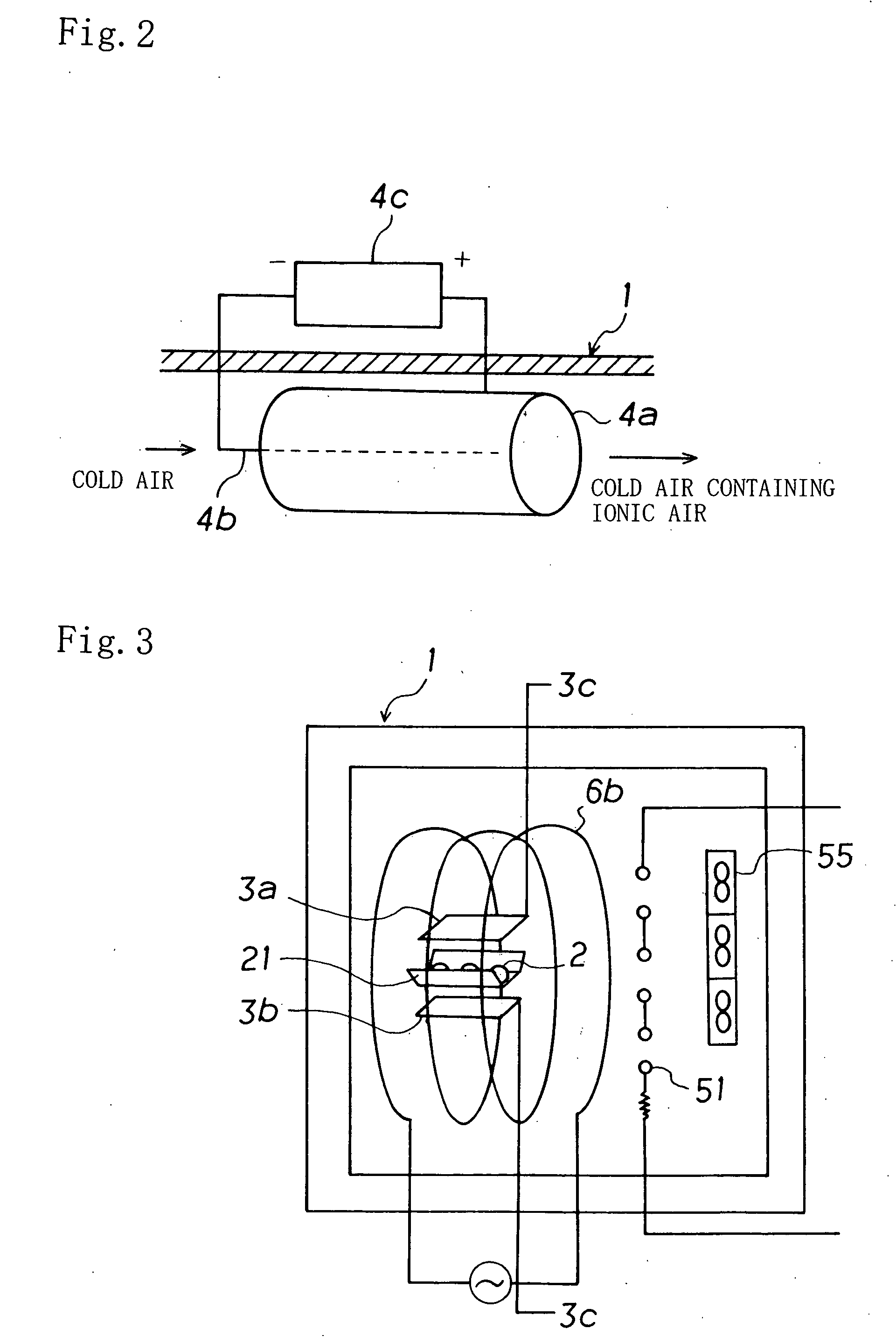

InactiveUS7237400B2Avoid destructionRapid coolingDomestic refrigeratorsFood preservationOscillating electric fieldMagnetic field

An object accommodated in an internal space of a freezer is quickly cooled to a predetermined temperature with preventing water from freezing while an oscillating electric field of, preferably, a variable frequency in the range of 50 Hz to 5 MHz and / or a magnetic field are applied to the object, or further ionic air is added to clod air, and subsequently the object is instantaneously frozen at the predetermined temperature. Preferably, the magnetic field is a static magnetic field and / or a variable magnetic field.

Owner:ABI

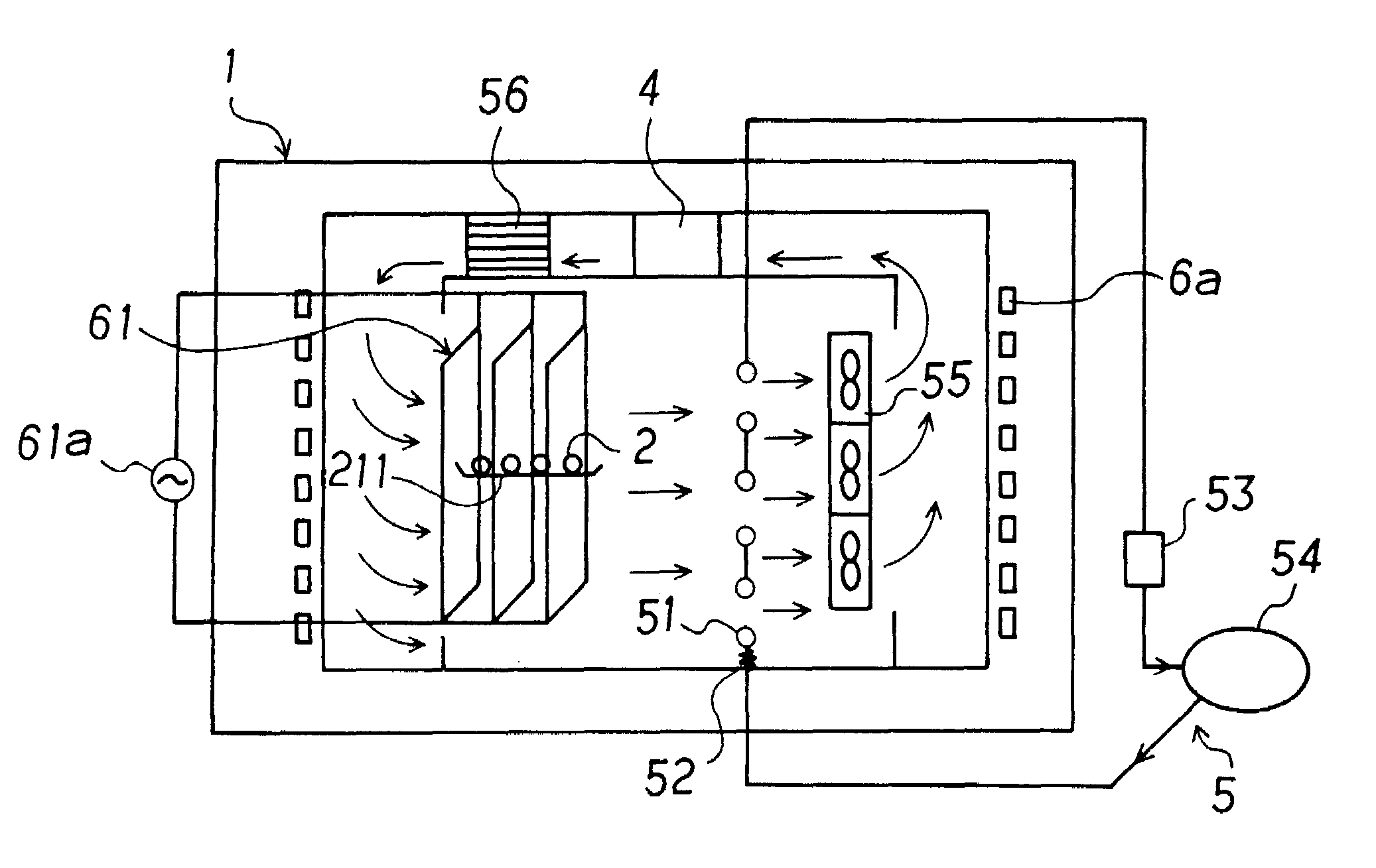

Highly-efficient freezing apparatus and highly-efficient freezing method

InactiveUS20050005611A1Avoid destructionRapid coolingDomestic refrigeratorsFood preservationOscillating electric fieldMagnetic field

An object accommodated in an internal space of a freezer is quickly cooled to a predetermined temperature with preventing water from freezing while an oscillating electric field of, preferably, a variable frequency in the range of 50 Hz to 5 MHz and / or a magnetic field are applied to the object, or further ionic air is added to clod air, and subsequently the object is instantaneously frozen at the predetermined temperature. Preferably, the magnetic field is a static magnetic field and / or a variable magnetic field.

Owner:ABI

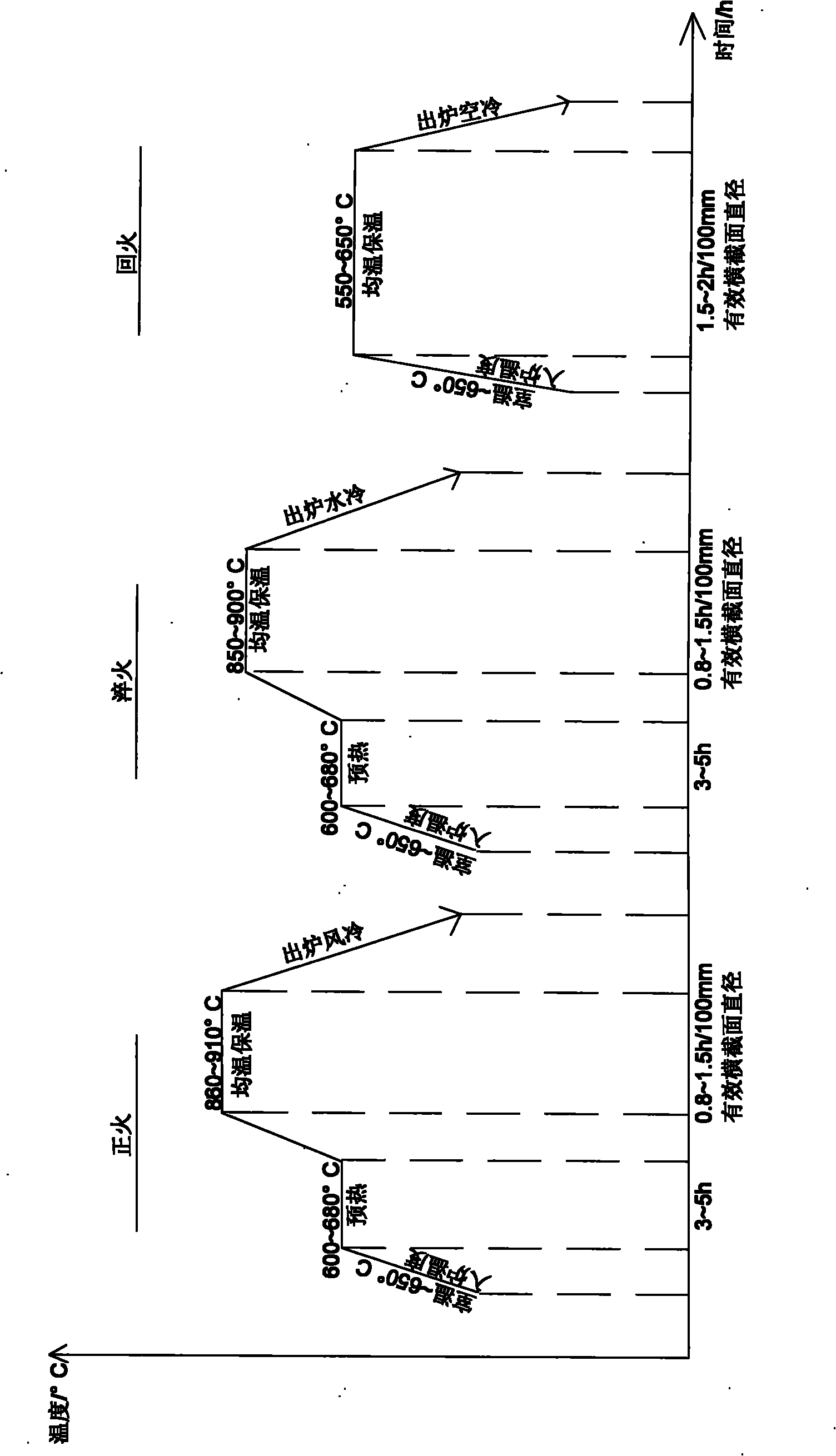

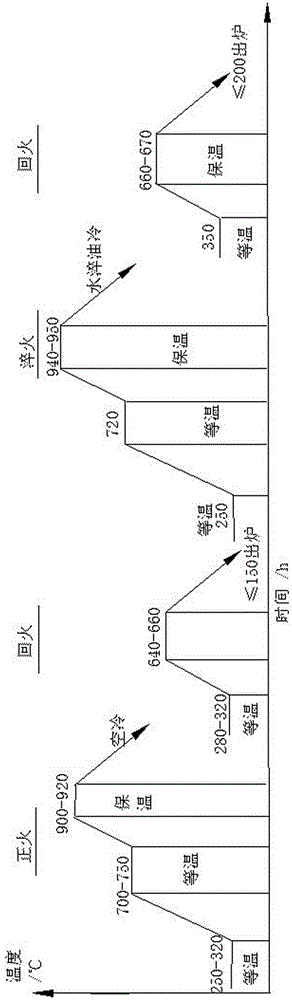

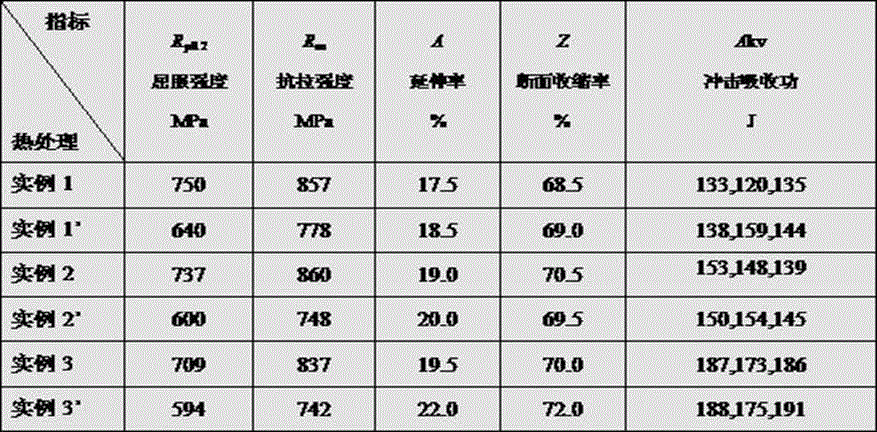

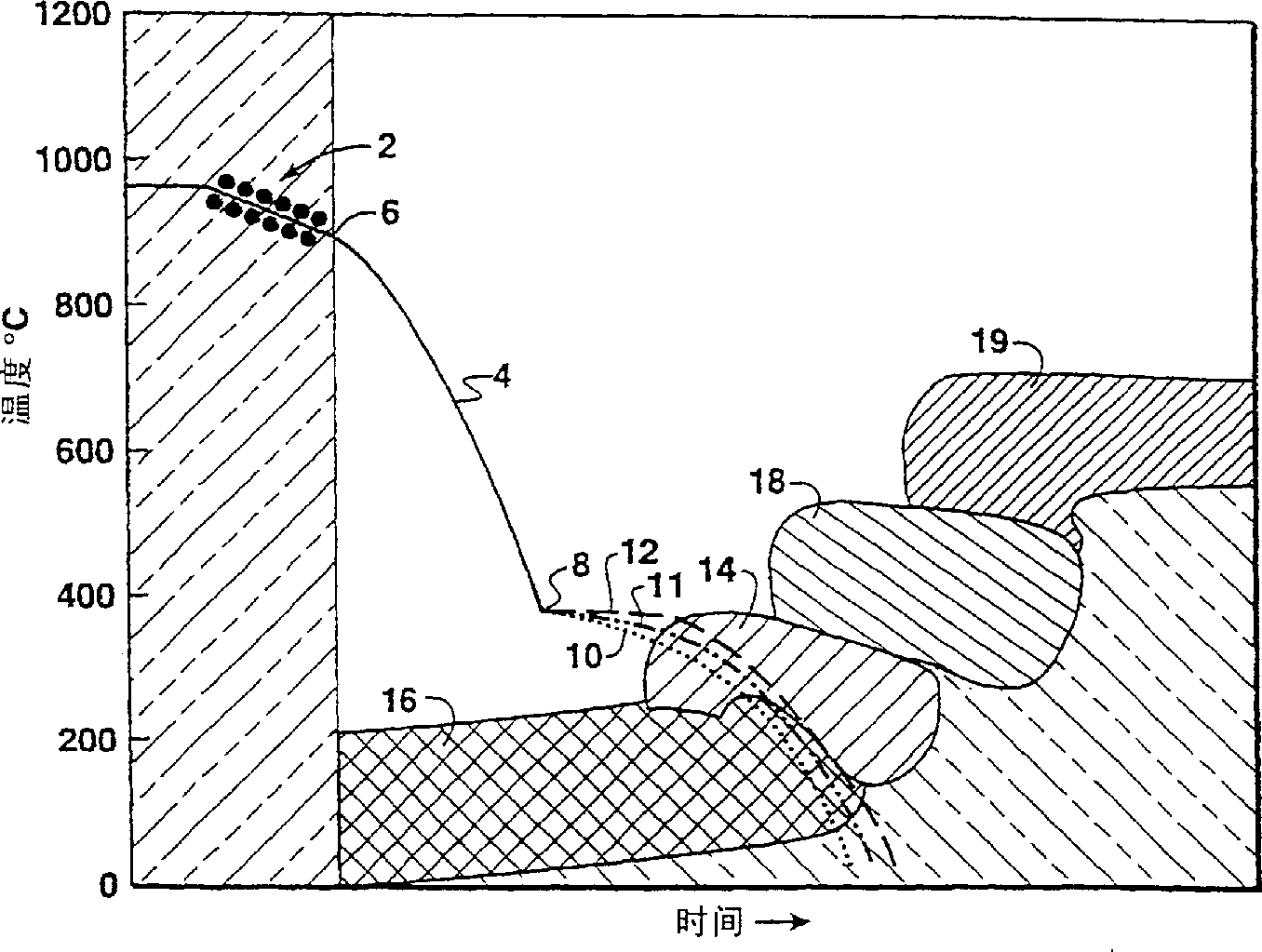

Heat treatment method for strength of 28CrMoNiV steel capable of improving industrial steam turbine rotor forge piece

A heat treatment method for strength of 28CrMoNiV steel capable of improving an industrial steam turbine rotor forge piece. The technology comprises the steps that (1), a normalizing and tempering manner is adopted in a preparation heat treatment technology and is used for refining crystalline grains and improving a material internal tissue, residual stress is reduced, and the good foundation is laid for conditioning heat treatment; a ladder heating manner is adopted in heating of normalizing and quenching, and fast heating is avoided; in the rising process, if the heating speed is too high, residual stress obtained after quenching is overlapped, and the problems that the defect of the forge piece is expanded, and even, the forge piece is cracked are possibly caused; in a quenching cooling process, a water quenching oil cooling manner is adopted, the cooling speed of a workpiece in the high-temperature stage is improved, and meanwhile, the cooling speed of a Martensite transition zone is reduced; in the water cooling initial stage, the workpiece vertically moves in a front-and-back manner in water, the quenching effect of the workpiece is fully ensured, and meanwhile, the structural stress and heat stress are reduced; in the medium heat treatment, the tempering temperature is properly reduced, impact toughness is ensured, and meanwhile, the strength of the force piece is improved.

Owner:HANGZHOU TURBINE POWER GRP +1

Dry cooling device and cooling method for friction stir welding seam

InactiveCN102615419ASpeed up coolingAchieve dry coolingNon-electric welding apparatusEngineeringWeld seam

The invention discloses a dry cooling device for a friction stir welding seam. Cooling medium is in a close circular flow with a radiator by the aid of a left tube outside a trolley and a right tube outside the trolley, so that cooling process of the welding seam is continuous, dry cooling without direct contact of the cooling medium and the welding seam is realized, and cooling speed of the welding seam is increased by the aid of the cooling medium. In the mean time, the cooling medium is in a close circular passage, pollution of the cooling medium to the field is avoided, and cleaning and recycling of the cooling medium after welding are not needed.

Owner:JIANGSU UNIV OF SCI & TECH

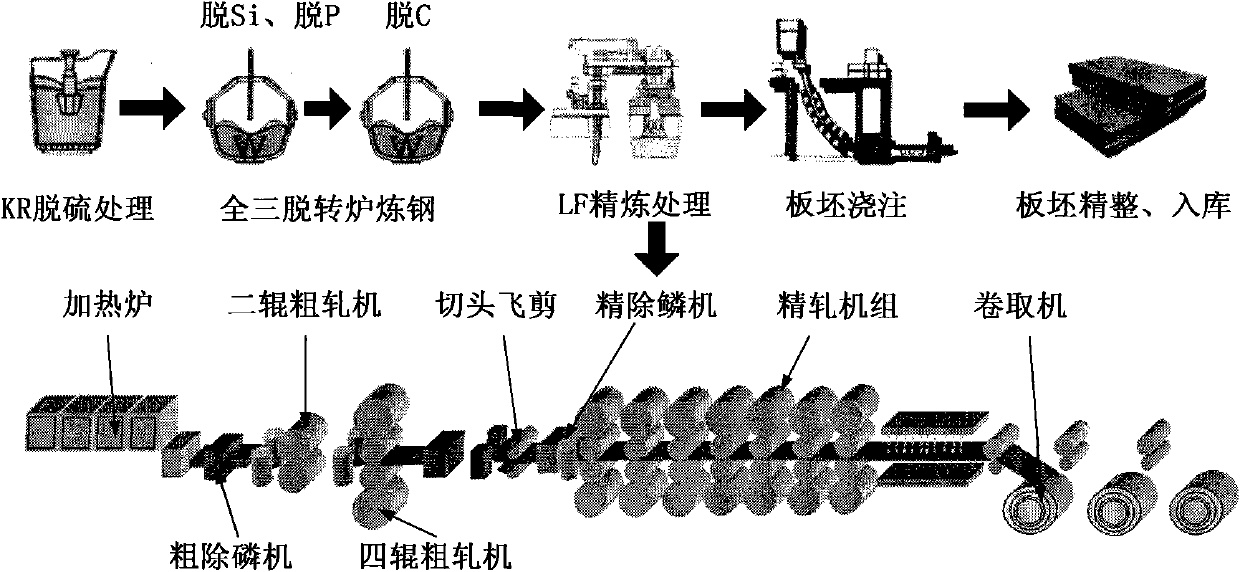

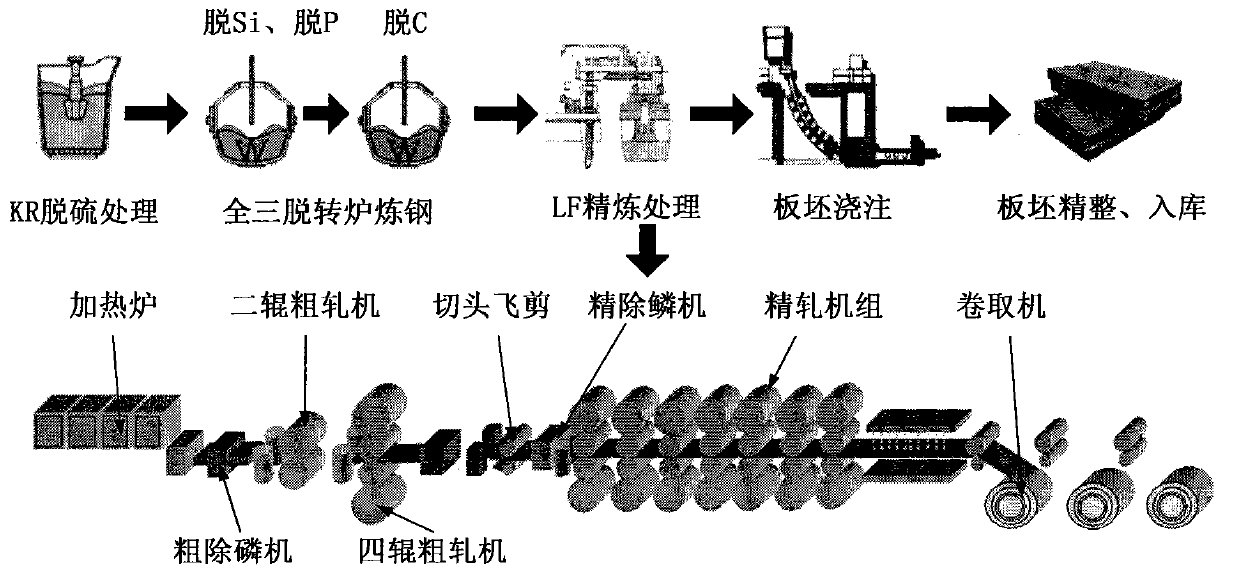

Production method of environment-friendly high-surface quality and pickling-free beamsteel

ActiveCN101906584AAvoid breakingSpeed up coolingTemperature control deviceMetal rolling arrangementsSteelmakingChemical composition

The invention provides a production method of environment-friendly high-surface quality and pickling-free beamsteel, belonging to the technical field of steel rolling and comprising the following steps: continuously casting molten iron after KR desulfuration treatment, complete pretreatment convertor steelmaking and LF furnace refining treatment; crimping a plate blank after reheating, roughing, finish rolling and laminar cooling; and finally obtaining the beamsteel satisfying the production requirement. Therefore, on the basis of meeting the beamsteel performance, by optimizing the chemical components of the beamsteel, heating cycle, rolling technology and the like and controlling the structure of surface scale of the beamsteel, the high-surface quality and pickling-free beamsteel can be produced. A 2250mm hot continuous rolling broad strip mill is used to produce pickling-free 510L and 610L steel plates for automobile beams, wherein the width of the steel plate is 1100-2100mm and the thickness thereof is 1.6-14.0mm. By controlling the chemical components and melting and rolling key process parameters, the high-surface quality and pickling-free steel plate for the automobile beam can be produced, which meets the production requirement.

Owner:SHOUGANG CORPORATION +1

Direct quenching technology suitable for steel plates with different thicknesses and high durability

InactiveCN101633976ATo achieve the cooling water requirementSimple production processSheet steelHigh density

The invention provides an online direct quenching technology for producing steel plates with different thicknesses and high durability, which adopts the technical scheme that billets are heated to 1150-1280DEG C; the billets are rolled into steel plates at two stages in an austenitic recrystallization zone and an austenitic non-recrystallization zone, and the finishing temperature is 800-880DEG C; and high-density laminar flow cooling is adopted for realizing the online quenching of the steel plates, the laminar flow cooling is formed by a cooling zone consisting of an upper flow collecting pipe and a lower injection collecting pipe, the cooling zone comprises an intensive cooling section, a rough cooling section and a precise cooling section, the water flow ratio of upper collecting pipes and lower collecting pipes of the rough cooling section and the precise cooling section is fixed to be 1:1.5, and the water flow of the upper collecting pipe and the lower collecting pipe of the intensive cooling section can be freely adjusted within a range of 1:3.0-1:1.4. The invention solves the technical bottleneck of large investment and high cost brought by a traditional quenching and tempering technology of reheating quenching and tempering for producing high-strength steel, and the direct quenching technology has the remarkable efficacy of saving energy sources, shortening a process flow and improving the production efficiency, and is suitable for being popularized and produced in steel industry.

Owner:UNIV OF SCI & TECH BEIJING

Thermally-conductive, metal-based bandages with hydrogel substrate

InactiveUS20150290042A1Less discomfortRelief the painSynthetic resin layered productsAdhesive dressingsThin metalSun exposure

The invention is a class of medical bandages that are effective for use in the treatment of various types of tissue burns, such as burns due to heat, chemicals, or sun exposure. The inventive bandages are comprised of a thin metal substrate in combination with a heat-sink. The inventive bandages incorporate a metal substrate (such as aluminum) having a burn-facing side for direct contact with the burn to draw heat away from the burn by conduction, and a heat-sink facing side opposite the burn-facing side for contact with a hydrogel to draw heat away from the metal layer by conduction. The thin aluminum layer and associated hydrogel heat-sink ensures flexibility and effective heat-transfer characteristics to rapidly cool a burn wound.

Owner:ADVANCED FIRST AID RES

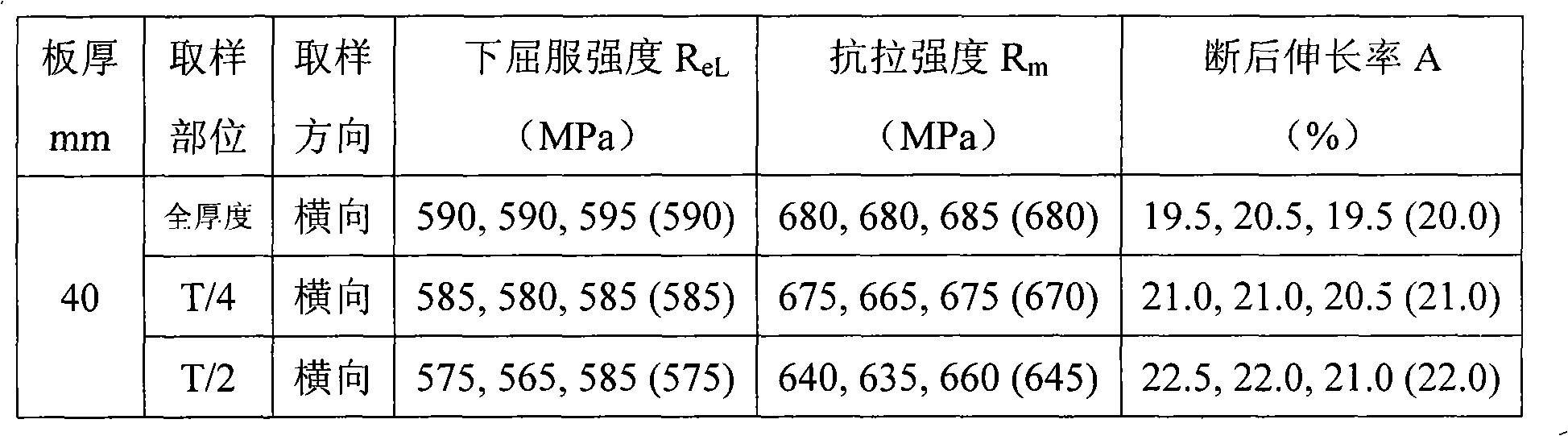

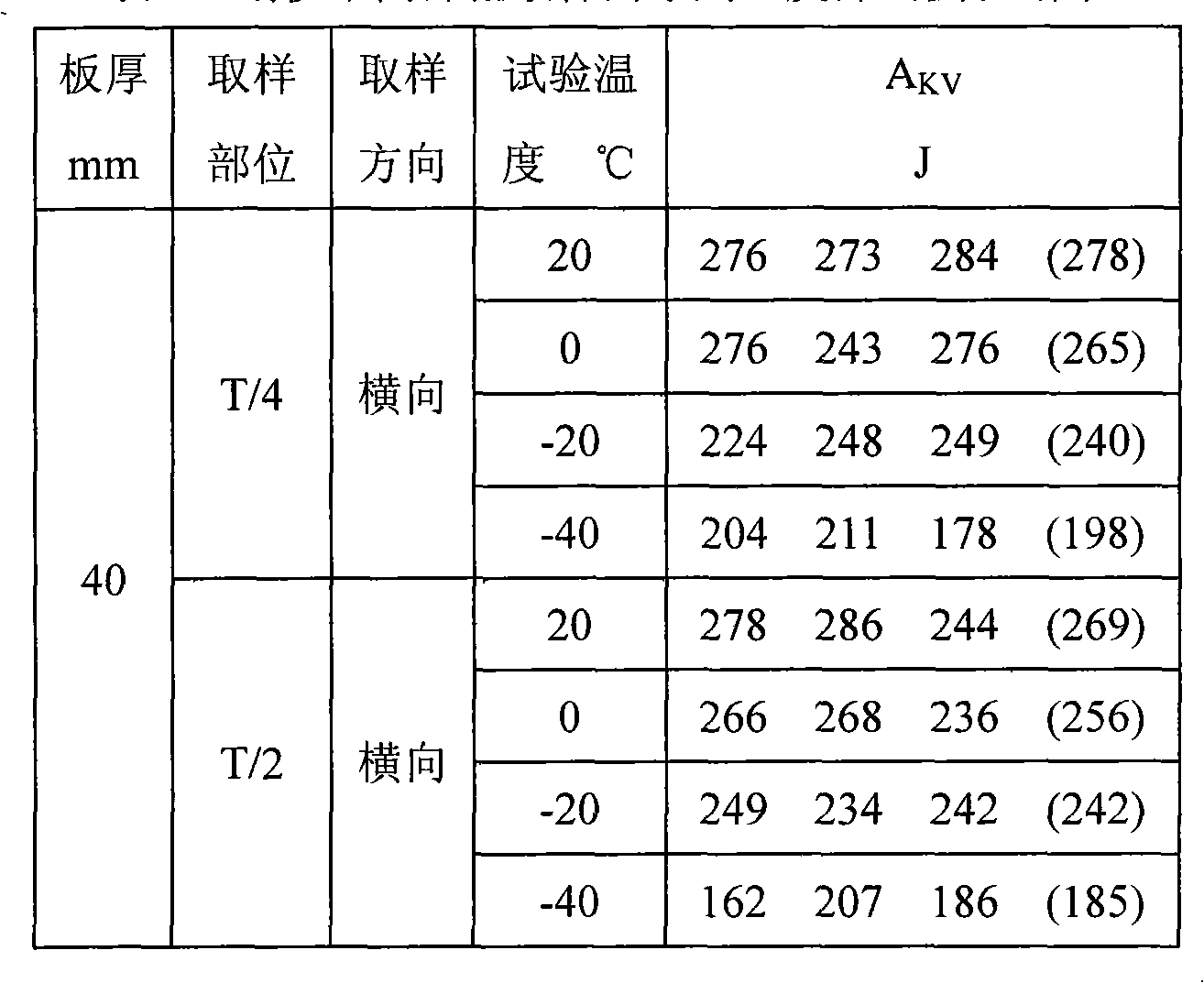

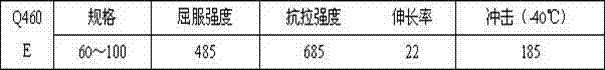

High strength and toughness Q460E structural steel thick plate and production method thereof

The invention discloses a high strength and toughness Q460E structural steel thick plate. The thick plate comprises the following chemical components by weight percent: 0.10-0.17% of C, 0.20-0.45% of Si, 1.30-1.65% of Mn, 0.018% or less of P, 0.007% or less of S, 0.015-0.050% of Als, 0.025-0.060% of Nb, 0.055-0.070% of V, 0.015-0.025% of Ti and the balance Fe and residual elements. The carbon equivalent [Ceq = C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15] is no more than 0.48. The production method comprises the following technologies: KR molten iron pretreatment, converter smelting, argon-blowing treatment, ladle furnace (LF) refining, vapor deposition (VD) refining, die casting, heating, controlled rolling and controlled cooling and stack cooling. On the basis of ensuring the original components of the high strength and toughness Q460E structural steel, the contents and ratio of the alloy elements in the Q460E steel, namely C, Mn and Nb are adjusted properly; the content of harmful elements in thesteel such as P and S which can influence the plasticity and toughness of the steel plate can be strictly controlled; the heating cycle of steel rolling is strictly controlled; and the rolling process adopts the ways of reducing the finish rolling temperature, increasing the cooling rate after rolling and perform stacking and slow cooling to the steel plate after rolling, thus each performance index of the steel plate meet the standard requirement.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

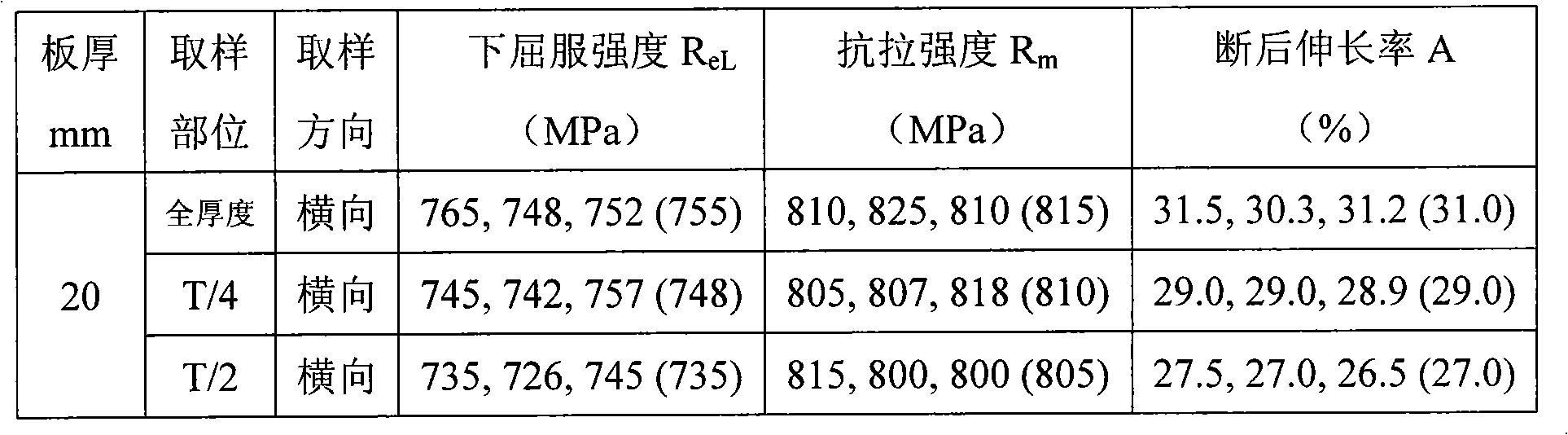

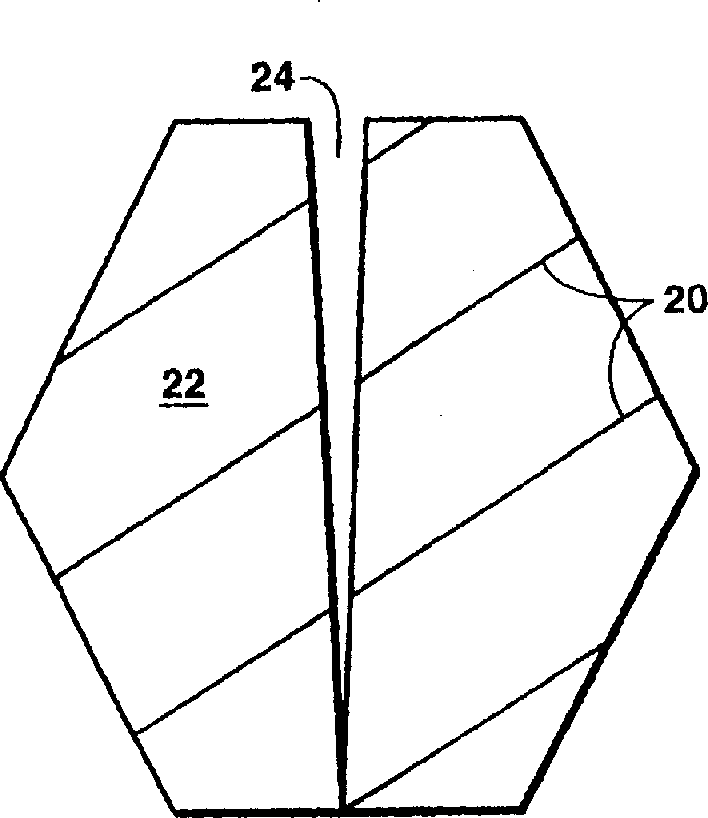

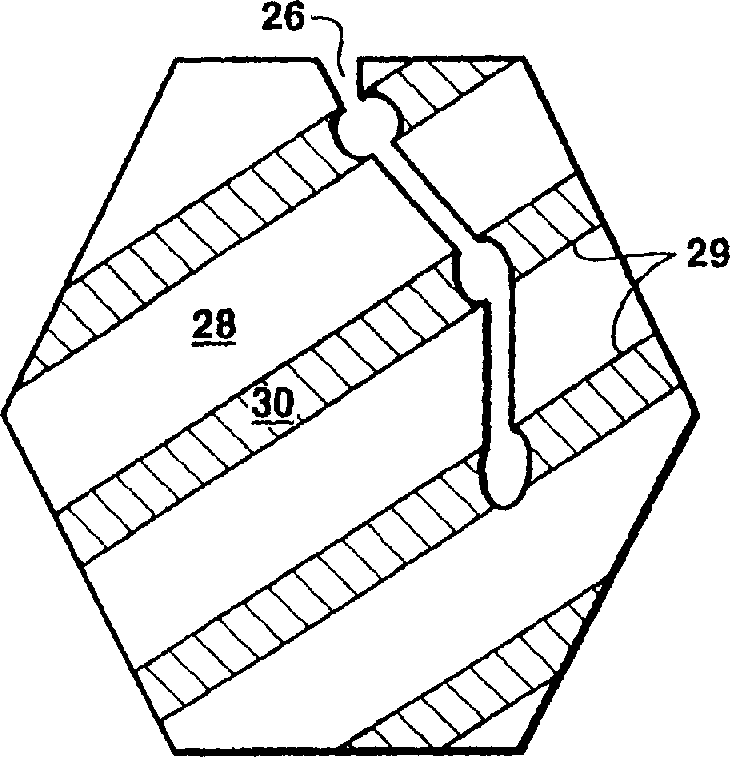

Ultra-high strength Ausaged steels with excellent cryogenic temp. toughness

An ultra-high strength, weldable, low alloy steel with excellent cryogenic temperature toughness in the base plate and in the heat affected zone (HAZE) when welded, having a tensile strength greater than 830 MAP (120 KS) and a micro-laminate microstructure comprising austenite film layers and fine-grained marten site / lower bainite laths, is prepared by heating a steel slab comprising iron and specified weight percentages of some or all of the additives carbon, manganese, nickel, nitrogen, copper, chromium, molybdenum, silicon, niobium, vanadium, titanium, aluminum, and boron; reducing the slab to form plate in one or more passes in a temperature range in which austenite recrystallizes; finish rolling the plate in one or more passes in a temperature range below the austenite recrystallization temperature and above the Ar3 transformation temperature; quenching the finish rolled plate to a suitable Quench Stop Temperature (QST); stopping the quenching; and either, for a period of time, holding the plate substantially isothermally at the QST or slow-cooling the plate before air cooling, or simply air cooling the plate to ambient temperature.

Owner:EXXONMOBIL UPSTREAM RES CO

Steel plate warm formed parts with high efficiency, low energy consumption and high quality and production method thereof

The invention relates to steel plate warm formed parts with high efficiency, low energy consumption and high quality and a production method thereof, belonging to the technical field of part forming. The steel plate for producing parts comprises the following components in percent by weight: 0.02-0.45% of C, 3.50-9.0% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, and the balance of Fe and unavoidable impurities. On the basis of these components, one or more of the following components (in percent by weight) are additionally added: 0.1-3.0% of Ni, 0.2-3.0% of Cr, 0.1-0.8% of Mo, 0.3-2.3% of Si, 0.5-2.0% of Cu, 0.0005-0.0050 of B, 0.02-0.30% of Nb, 0.002-0.250% of [N], 0.05-0.25% of Ti, 0.02-0.25% of V, 0.015-3.0% of Al, 0.002-0.005% of RE, and 0.005-0.03% of Ca. The production method comprises the following steps: steel plate heating, steel plate transferring, steel plate precooling, part forming, part cooling, and part temperature control treatment. The production method provided by the invention has the advantages of low cost and high efficiency, and improves the forming rate and final mechanical properties of workpieces.

Owner:CENT IRON & STEEL RES INST

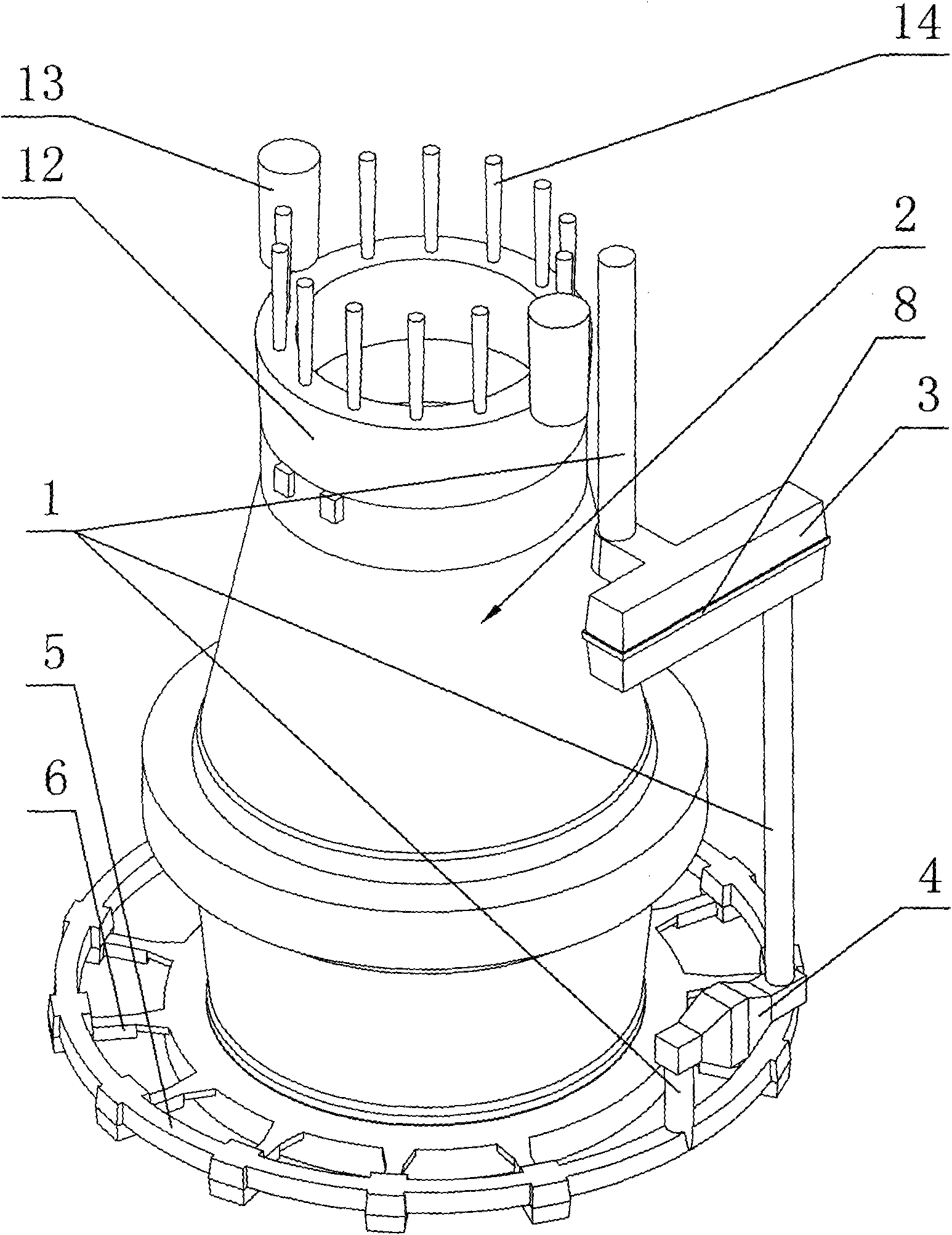

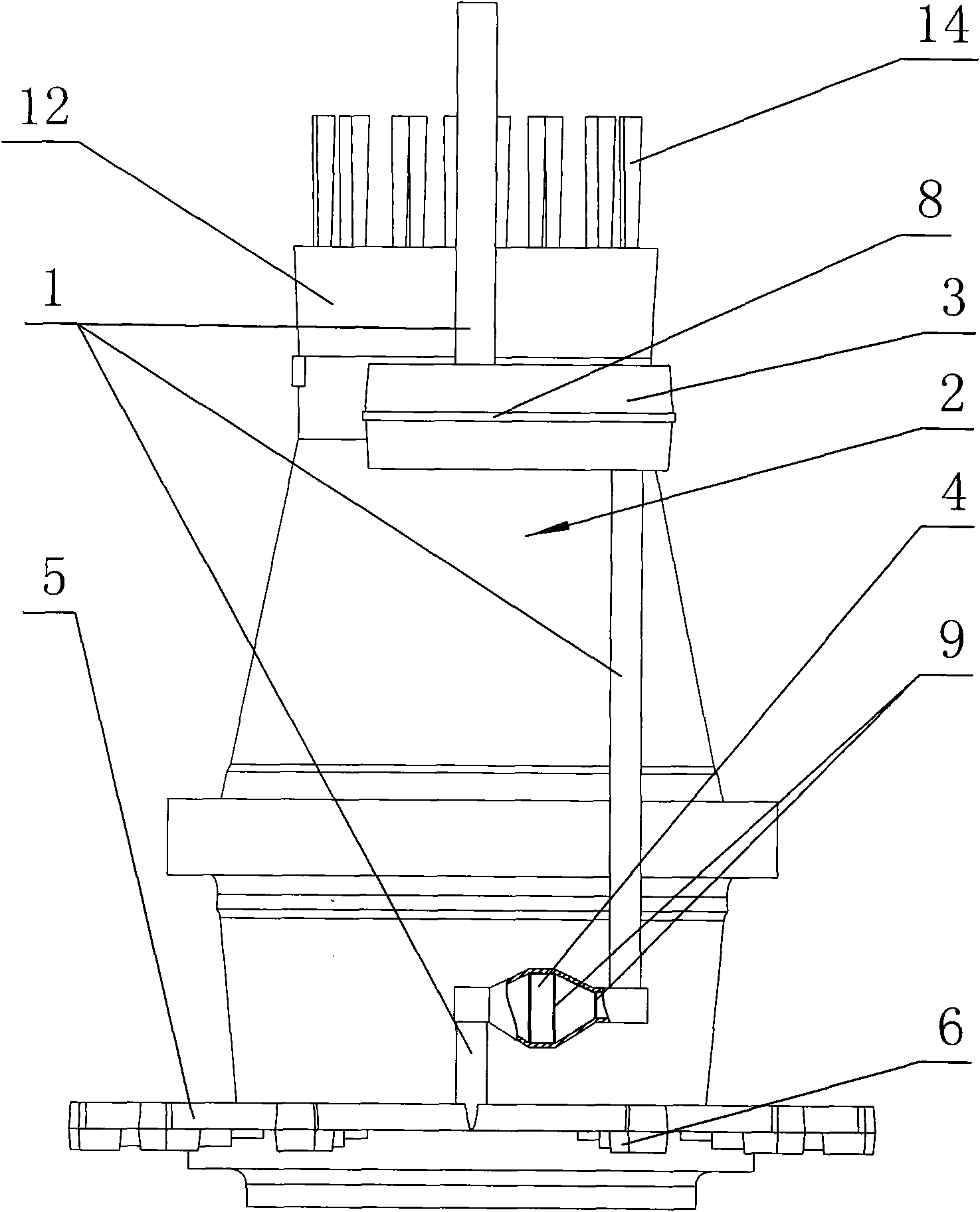

Method for casting rotary axis casts of aerogenerators

The invention discloses a method for casting rotary axis casts of aerogenerators, which comprises the steps of mould manufacture, the manufacture of sand moulds and moulding by casting. In the step b of the manufacture of sand moulds, a top sprue (1) is used as an inlet of iron liquor, and is alternately communicated with runners; a bottom runner is communicated with an ingate communicated with a cast mould cavity; the runners are designed into a first runner (3), a second runner (4) and a circular runner (5); the ingate is designed into a plurality of radial runners (6) for communicating the circular runner (5) and the cast mould cavity; filtering apparatuses are arranged on the first runner (3) and the second runner (4), and are also arranged between each radial runner (6) and the circular runner (5); and in the step c of moulding by casting, the casting temperature is controlled from 1310 DEG C to 1350DEG C; and finally, a cast (2) is obtained. The method for casting rotary axis cast of aerogenerator has the advantages of good residue blocking effect and low production cost.

Owner:RIYUE HEAVY IND

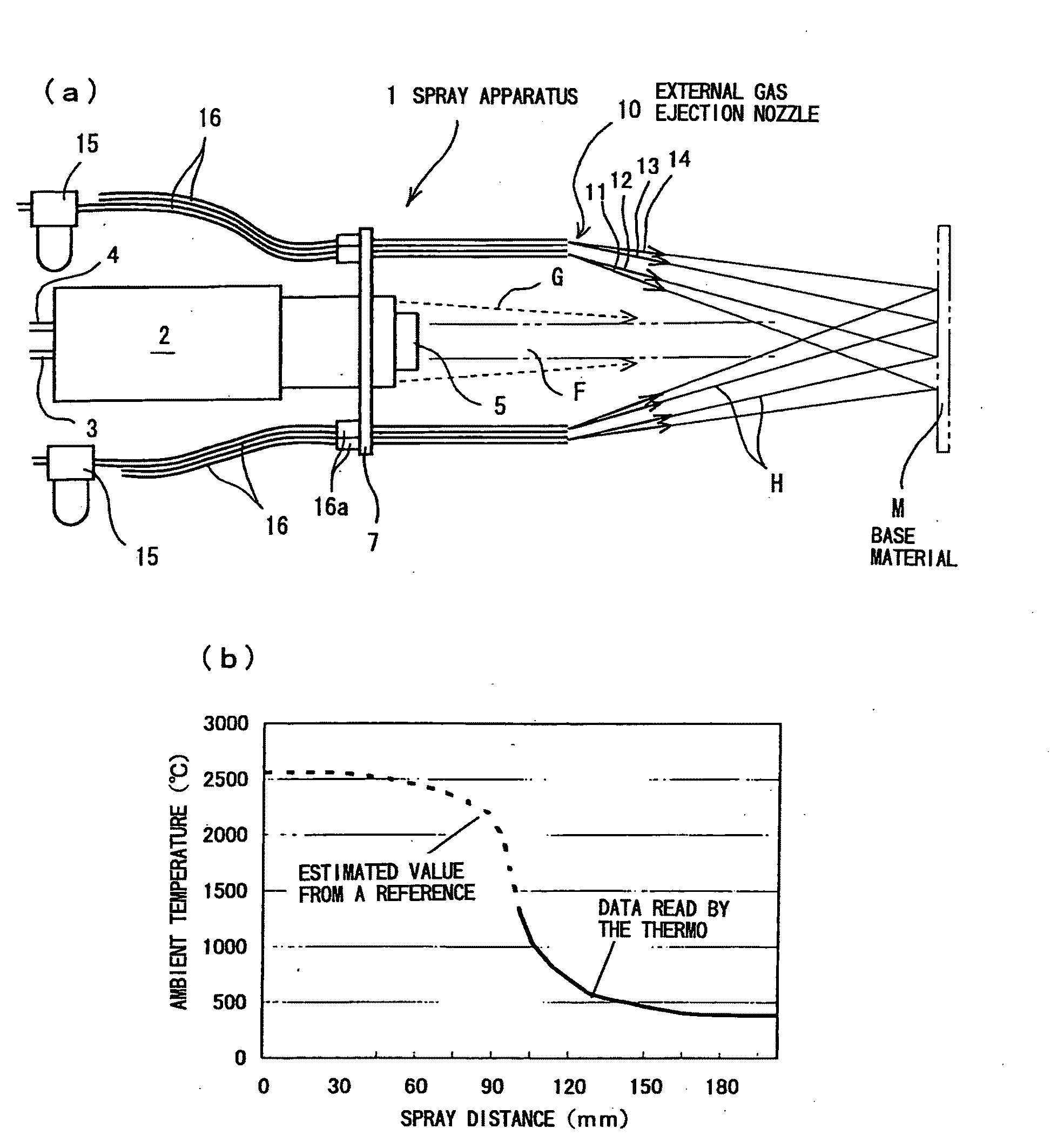

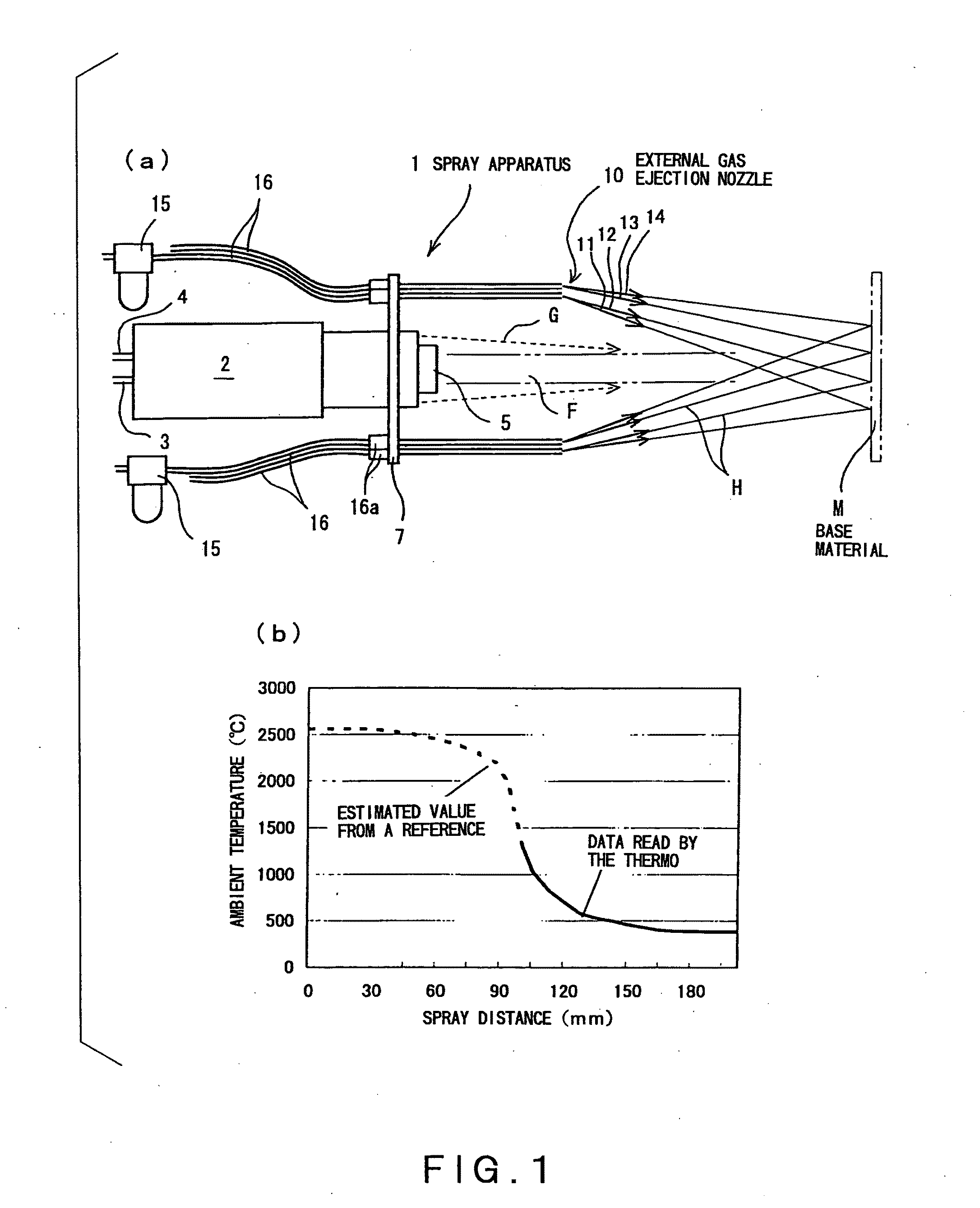

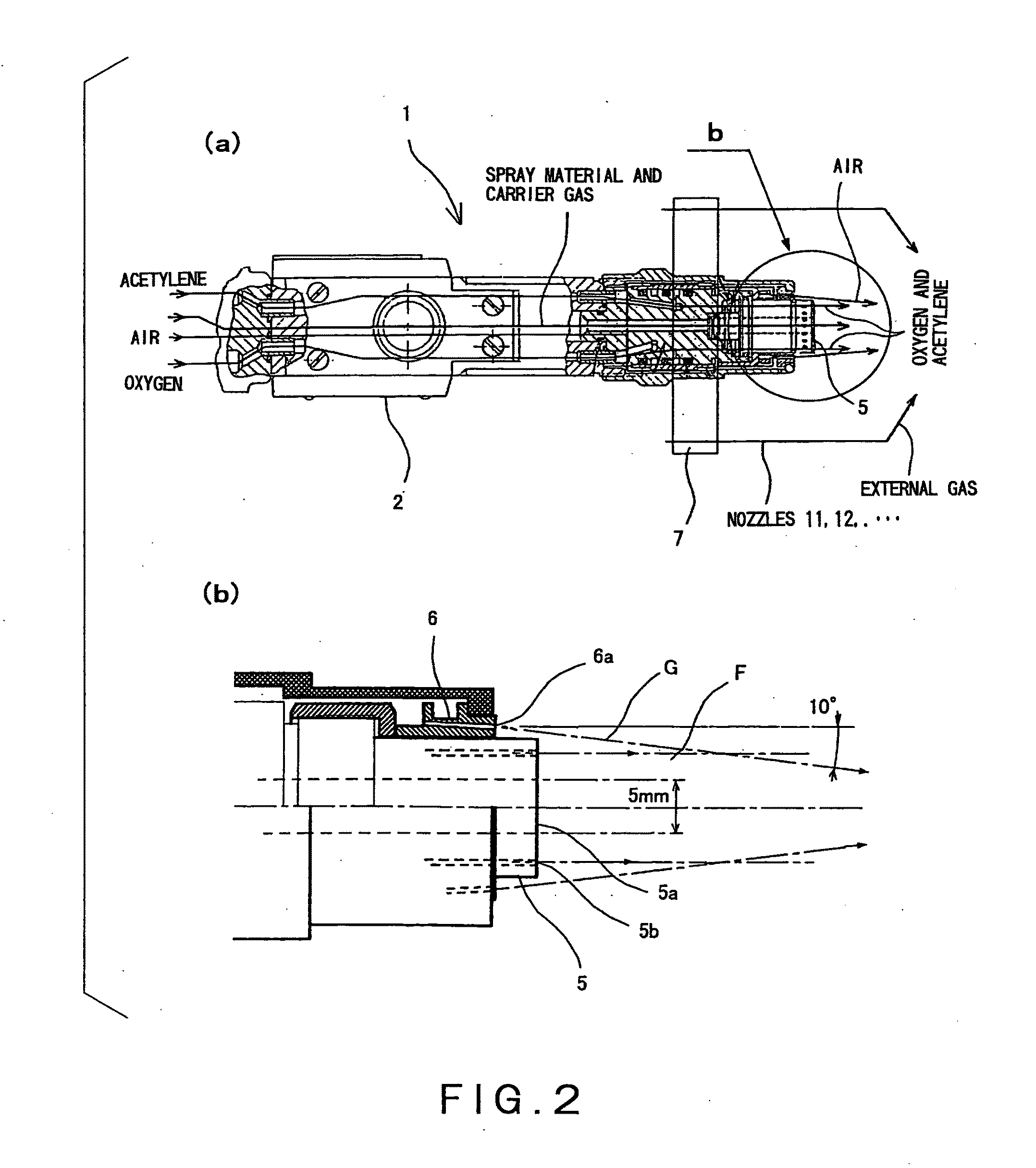

Method and apparatus for forming amorphous coating film

InactiveUS20090246398A1Cost reductionSimplify workLiquid surface applicatorsMolten spray coatingNozzleCoating

The present invention provides a method and an apparatus for forming, by spraying, a commonly known amorphous coating film, which is not limited to a metallic glass or the like. According to this invention, a flame containing metal particles is ejected toward a base material from a nozzle, such that the material particles are melted with the flame. Thereafter, the melted material particles and flame are cooled before they reach the base material. For this cooling process, a gas is externally ejected toward the flame, such that the gas can gradually approach the central line of the flame. Preferably, the particle size of the material particles in the flame is within a range of 10 to 100 μm.

Owner:NAKAYAMA AMORPHOUS CO LTD

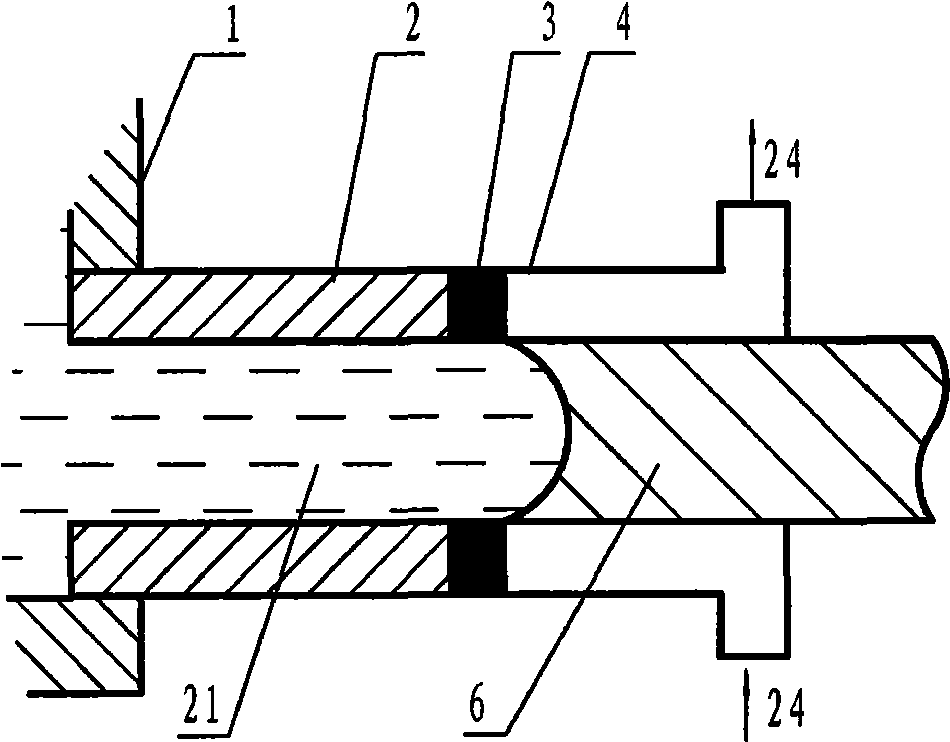

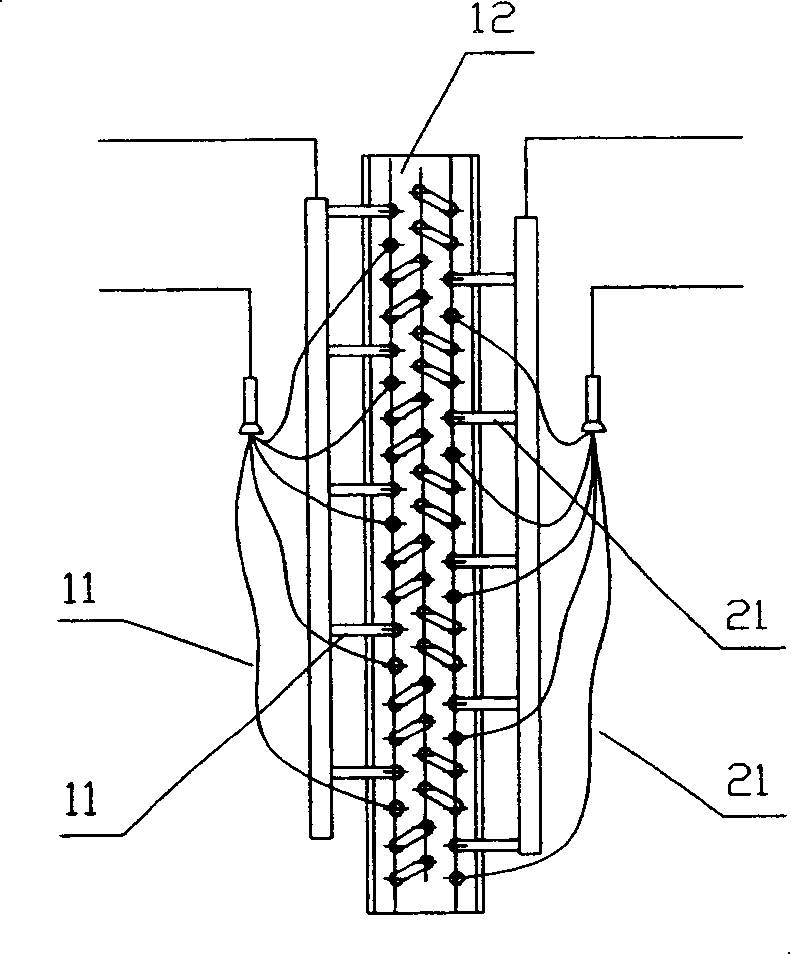

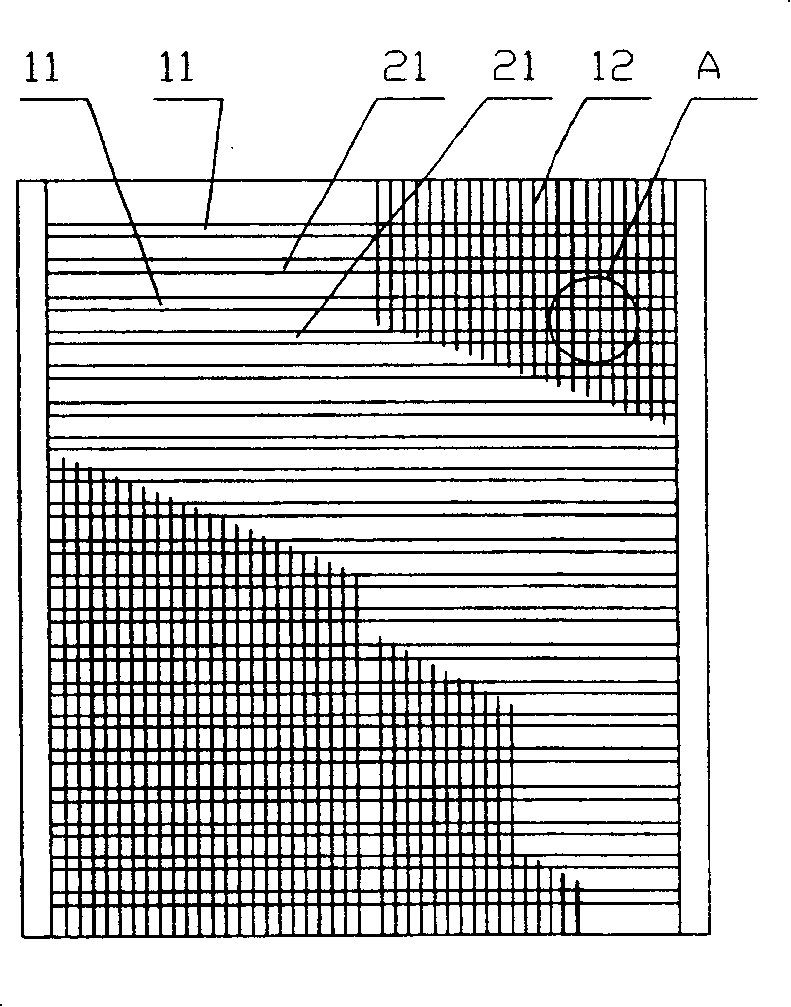

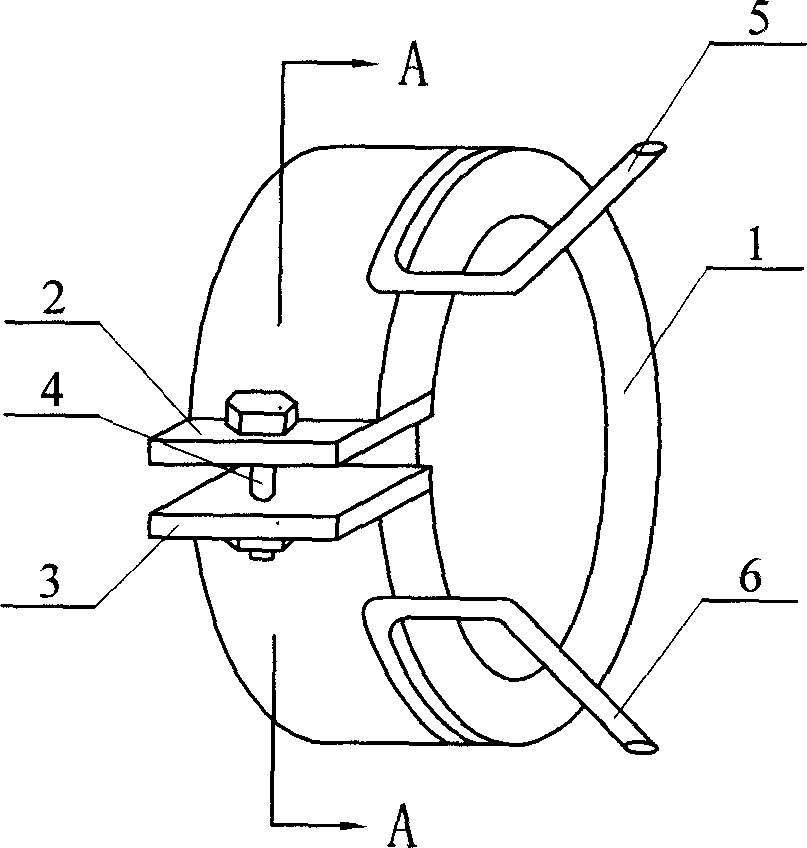

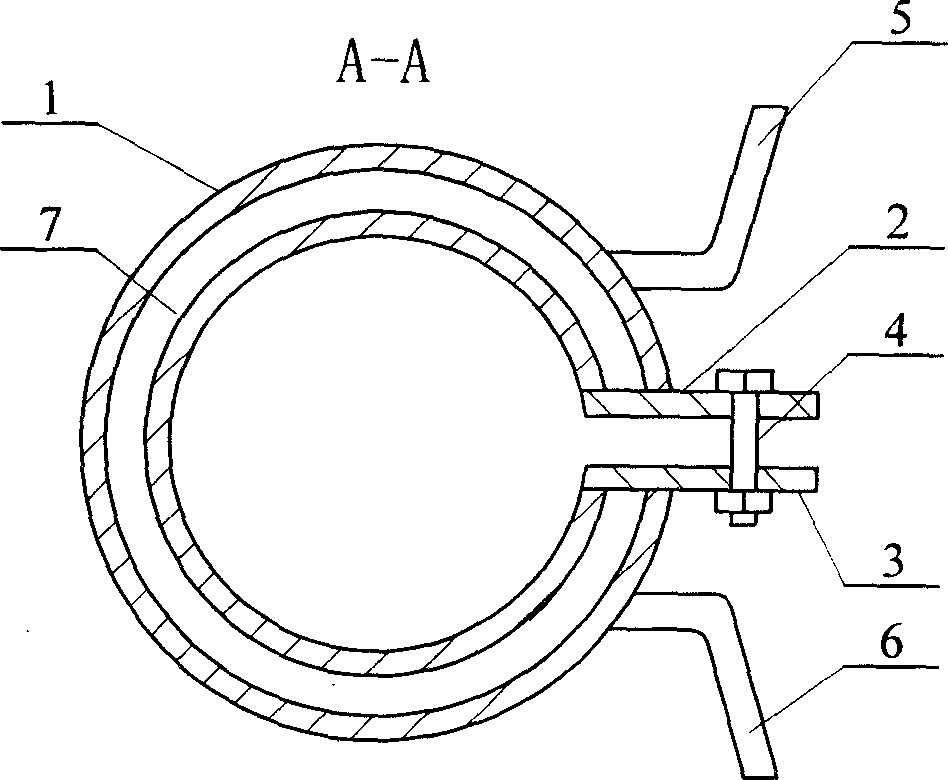

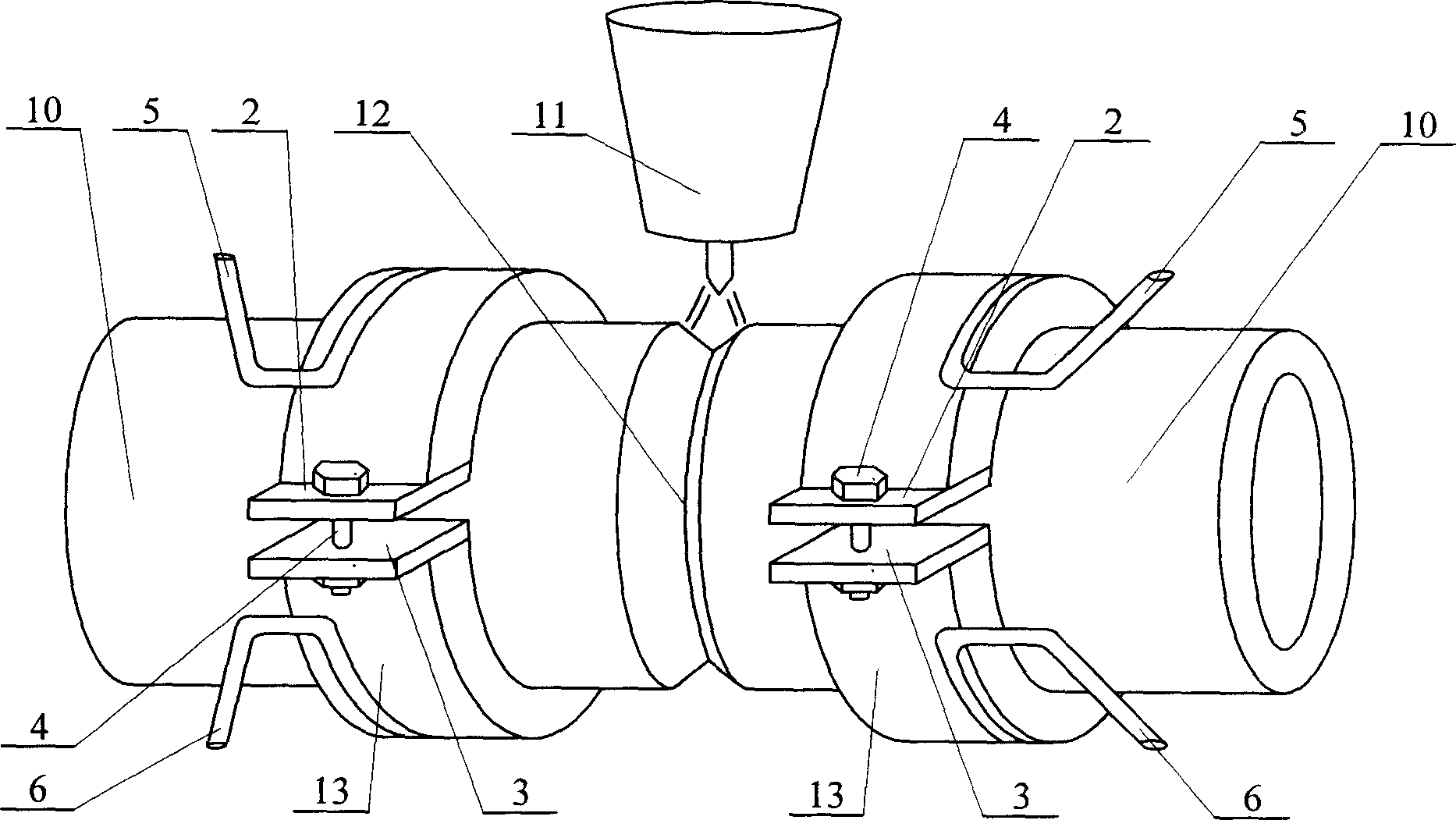

Water cooling jacket for titanium alloy tube ring seam by tungsten argon arc welding and seam following cooling welding method

The present invention relates to water cooling jacket for welding and corresponding welding method by means of using the water cooling jacket. The water cooling jacket has upper connecting plate with one side plane connected hermetically with the upper end of the C-shaped sleeve, and lower connecting plate with one side plane connected hermetically with its lower end. The welding method includes screwing the water cooling jacket tightly to the titanium alloy tube. The water cooling jacket of the present invention has simple structure and high cooling effect, and the welding and cooling method is simple, high in weld seam cooling speed, high welding quality, high welding efficiency, less argon consumption and low welding cost.

Owner:HARBIN INST OF TECH

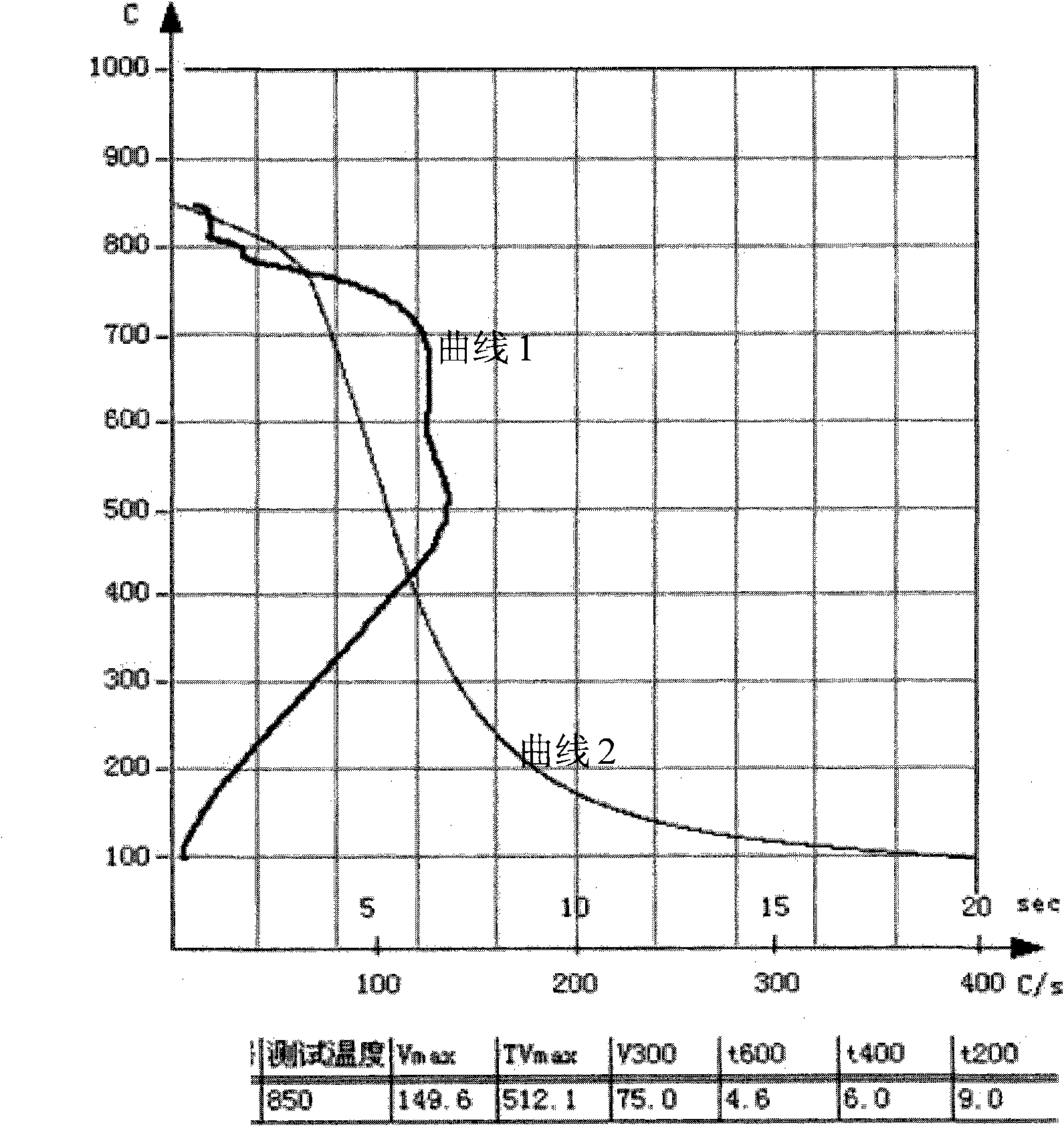

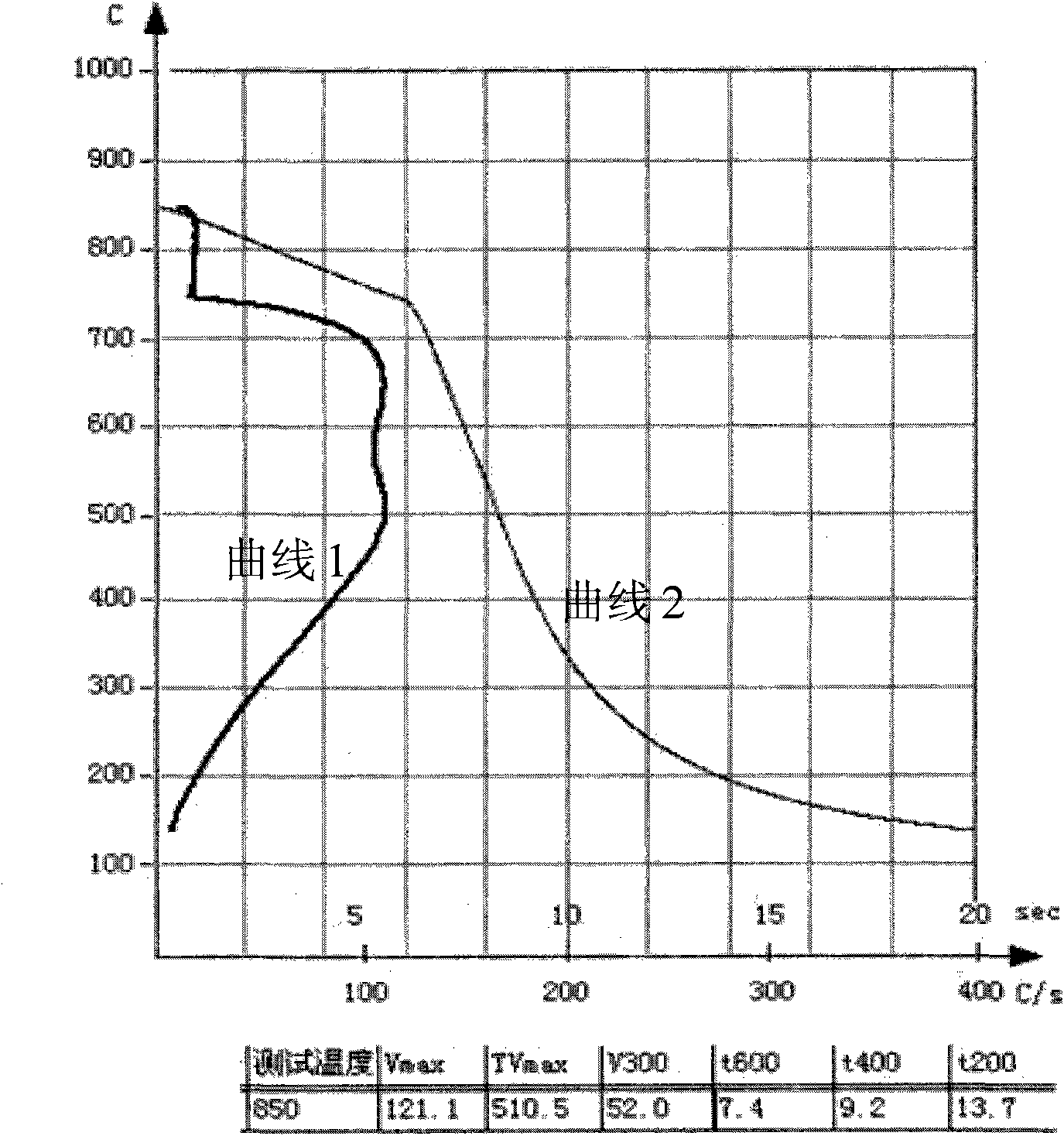

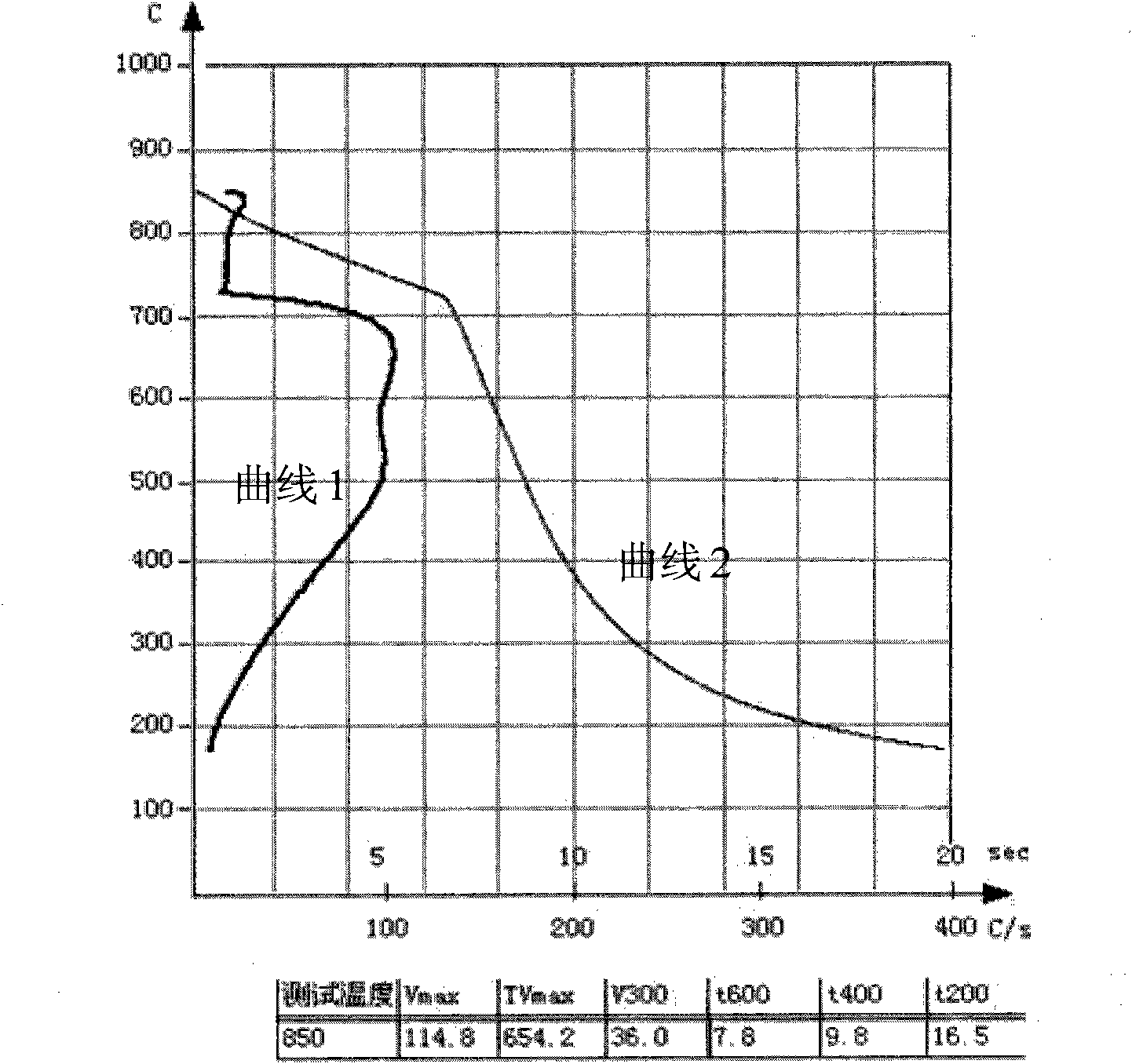

Quenching agent

The invention provides a quenching agent which is characterized by comprising the following components in percentage by weight: 13%-40% of polyether, 1%-5% of triethanolamine, 0.2%-1% of sodium benzoate, 0.05%-0.5% of defoaming agent and the balance of water. By preparing the quenching agent provided by the invention into different concentration for carrying out cooling experiment, the experiment result shows that the quenching agent provided by the invention has high cooling speed at the temperature higher than 400 DEG C, thereby obtaining fine workpiece grains and improving the performance of workpieces; and the quenching agent provided by the invention has lower cooling speed at the temperature lower than 400 DEG C, thereby preventing larger internal stress from forming in the workpieces to achieve the purpose of preventing the workpieces from cracking.

Owner:KASONG SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com