Patents

Literature

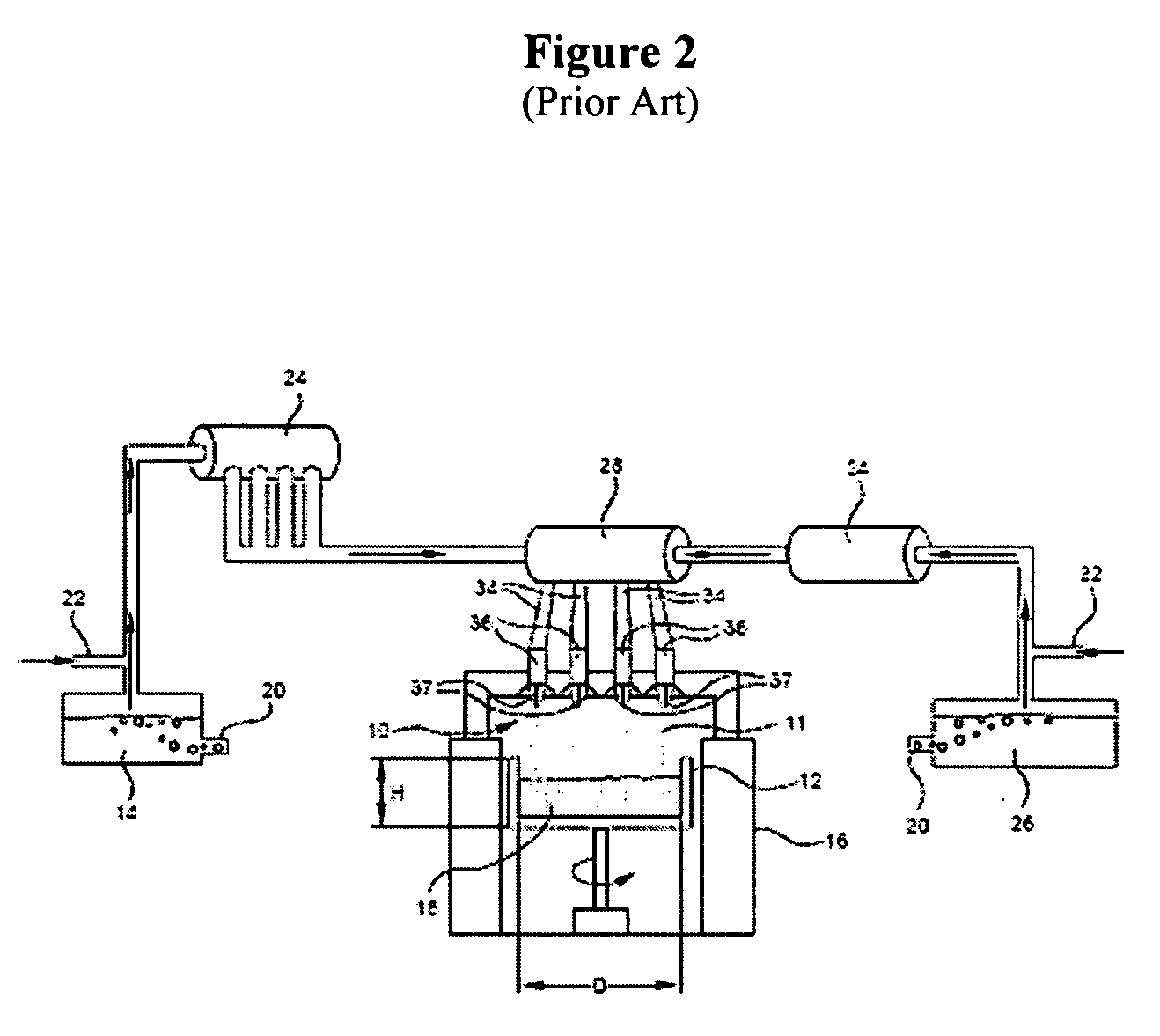

2668 results about "Cooling rates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calculate the cooling rate by dividing each temperature data point by its corresponding time data point then average all of your answers to achieve a cooling rate. In other words, the change in the temperature divided by the change in time will give you an average temperature rate change.

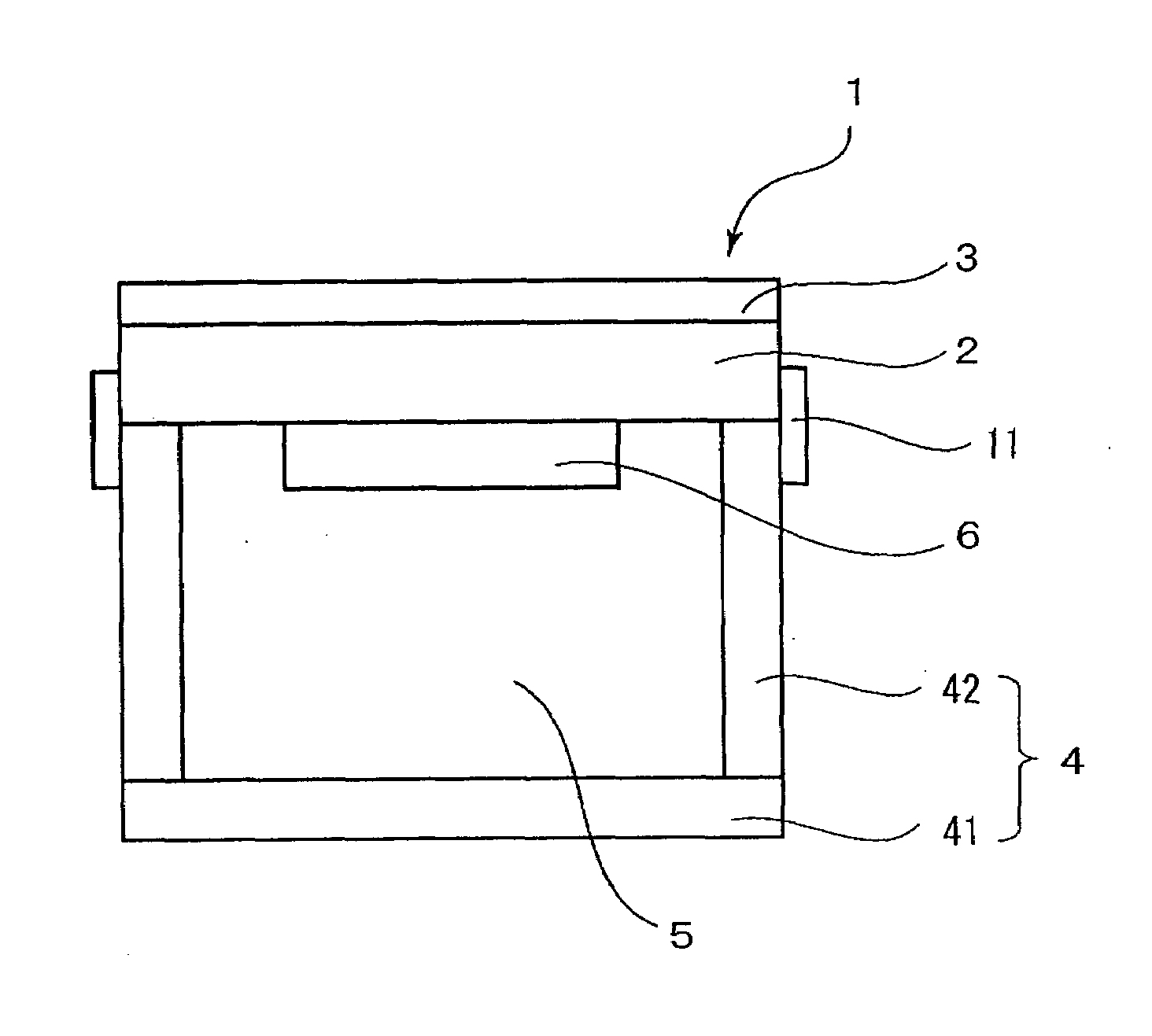

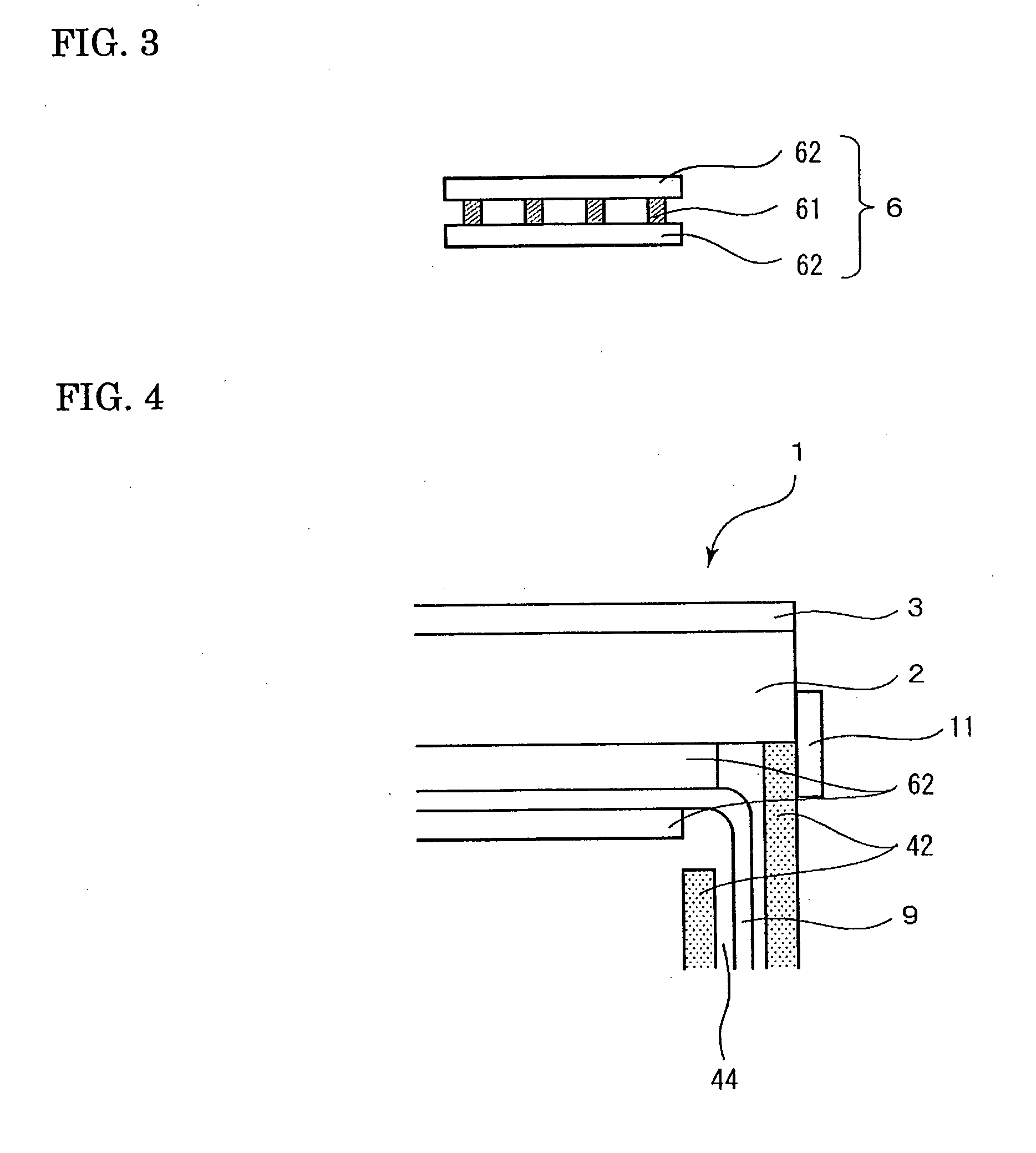

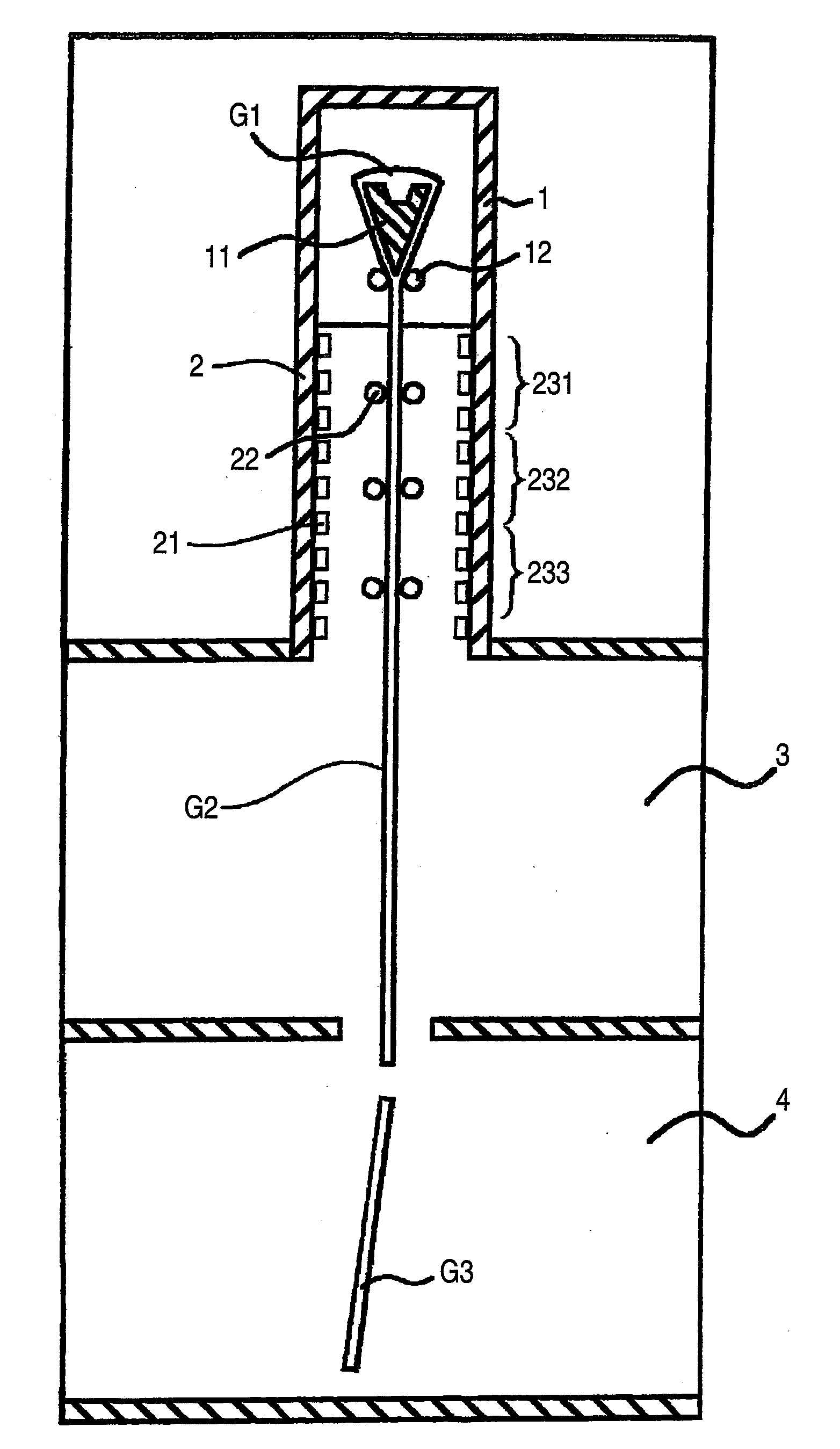

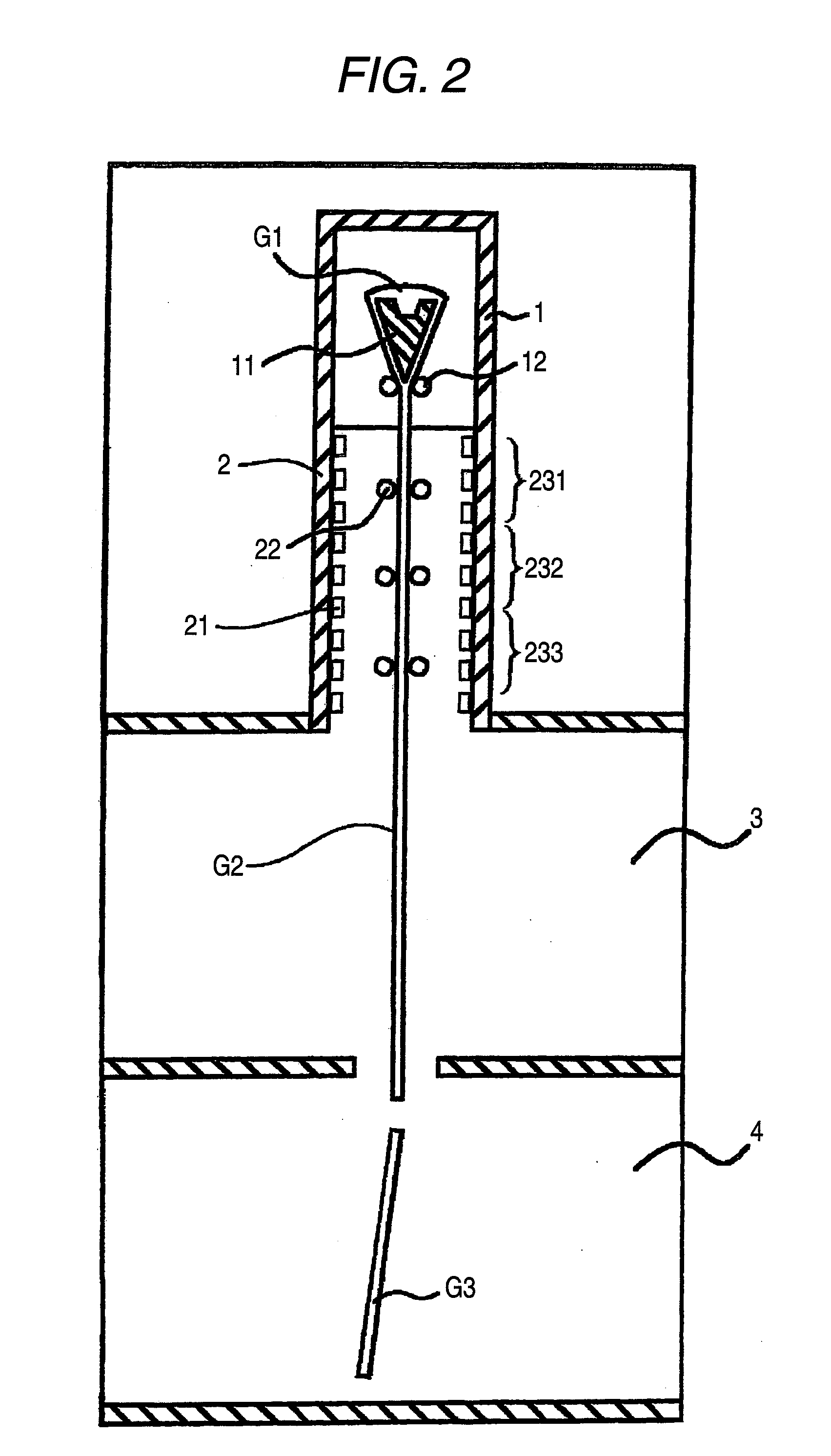

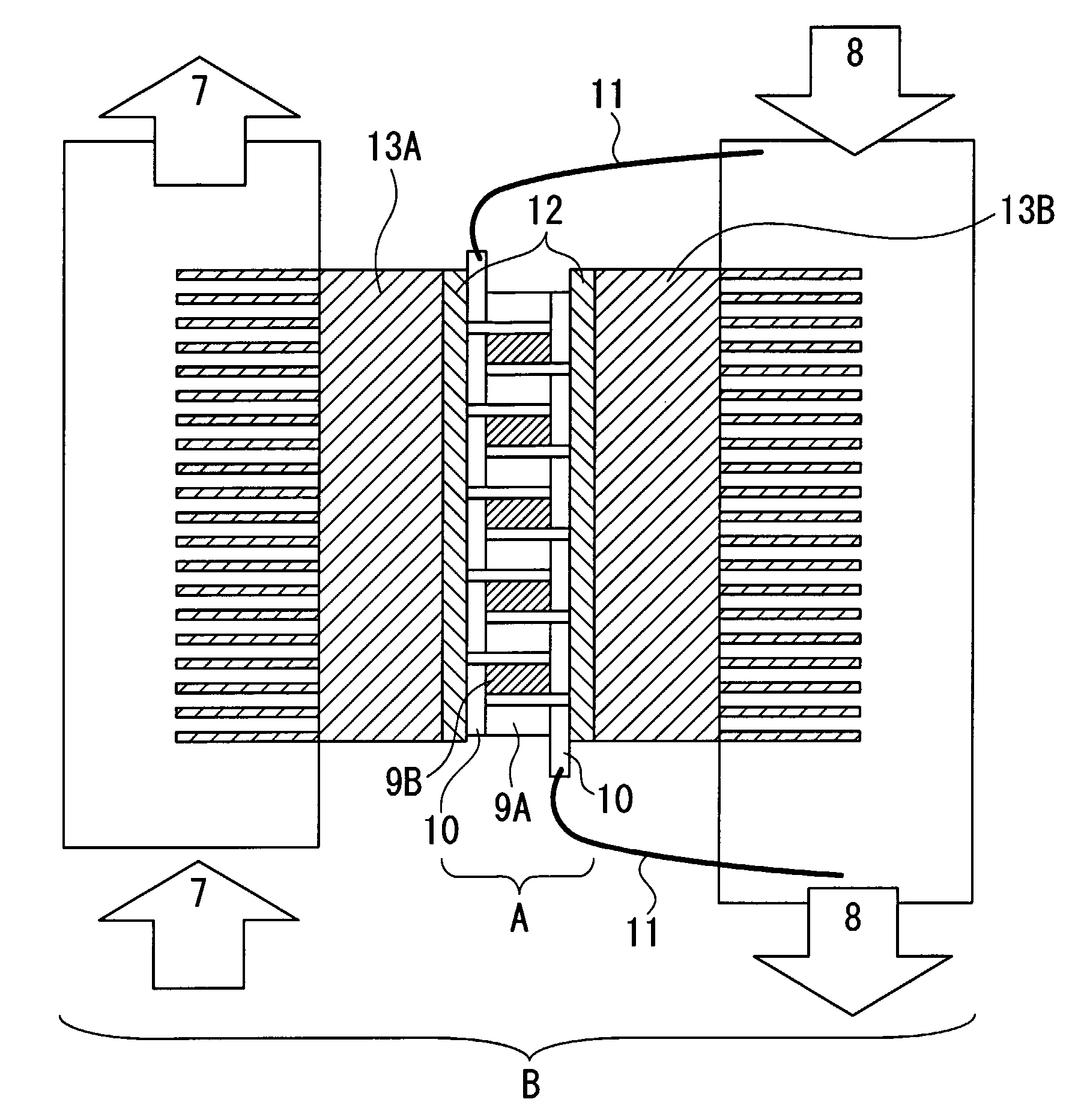

Wafer holder for wafer prober and wafer prober equipped with same

InactiveUS20090045829A1Improve rigidityGood effectHot plates heating arrangementsIndividual semiconductor device testingRoom temperatureEngineering

It is an object of the present invention to provide a wafer prober wafer holder that is highly rigid and increases the heat insulating effect, thereby improving positional accuracy, thermal uniformity, and chip temperature ramp-up and cooling rates, as well as a wafer prober device equipped therewith.A wafer holder of the present invention includes a chuck top that mounts a wafer, and a support member that supports the chuck top, wherein, a restricting member is provided that covers an interface between the chuck top and the support member. By covering the gap between the chuck top and the support member with the restricting member, the heat insulating effect can be increased by preventing the flow of outside air through the gap into the support member, and the cooling rate can be particularly improved if cooling to a temperature below room temperature.

Owner:SUMITOMO ELECTRIC IND LTD

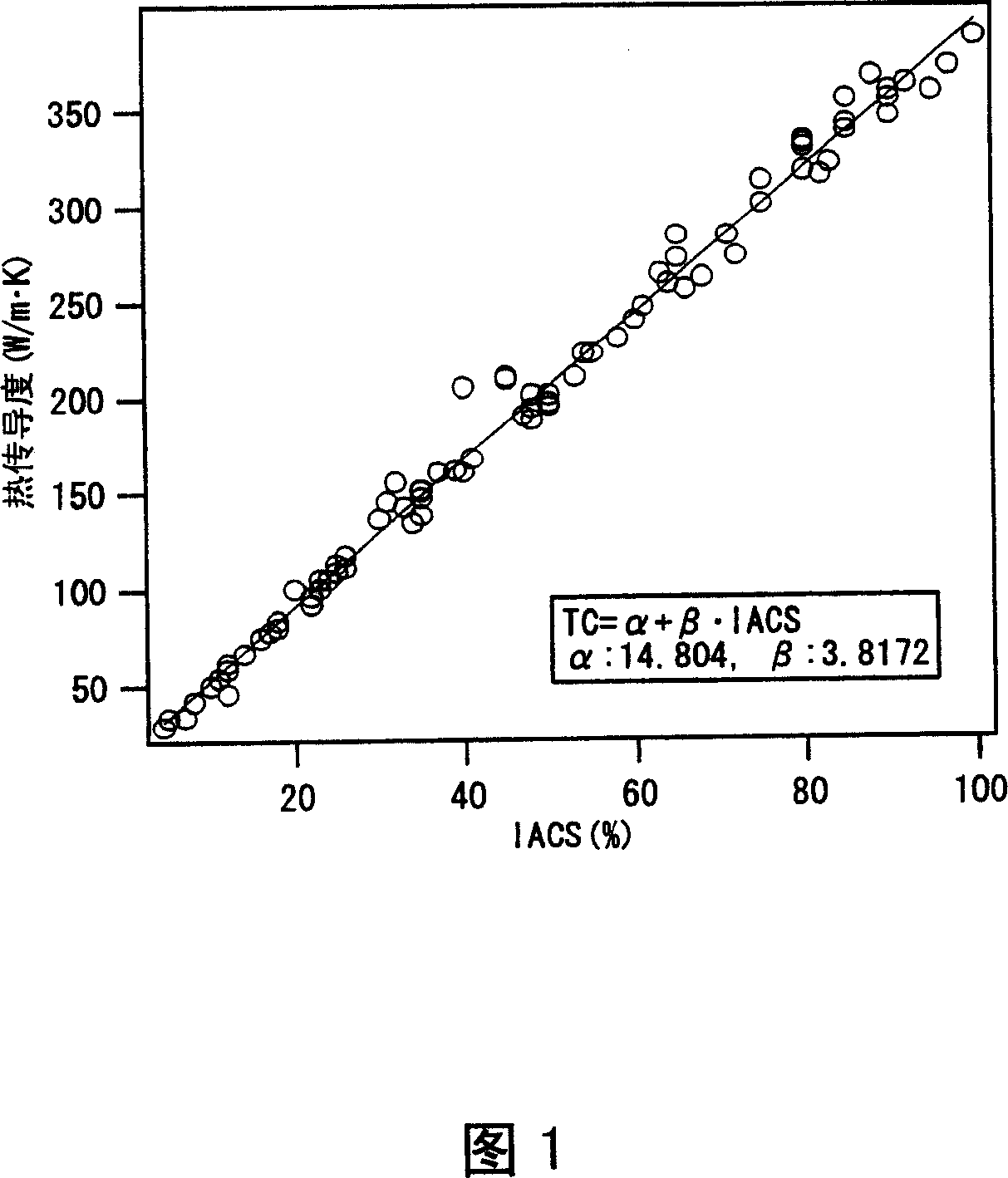

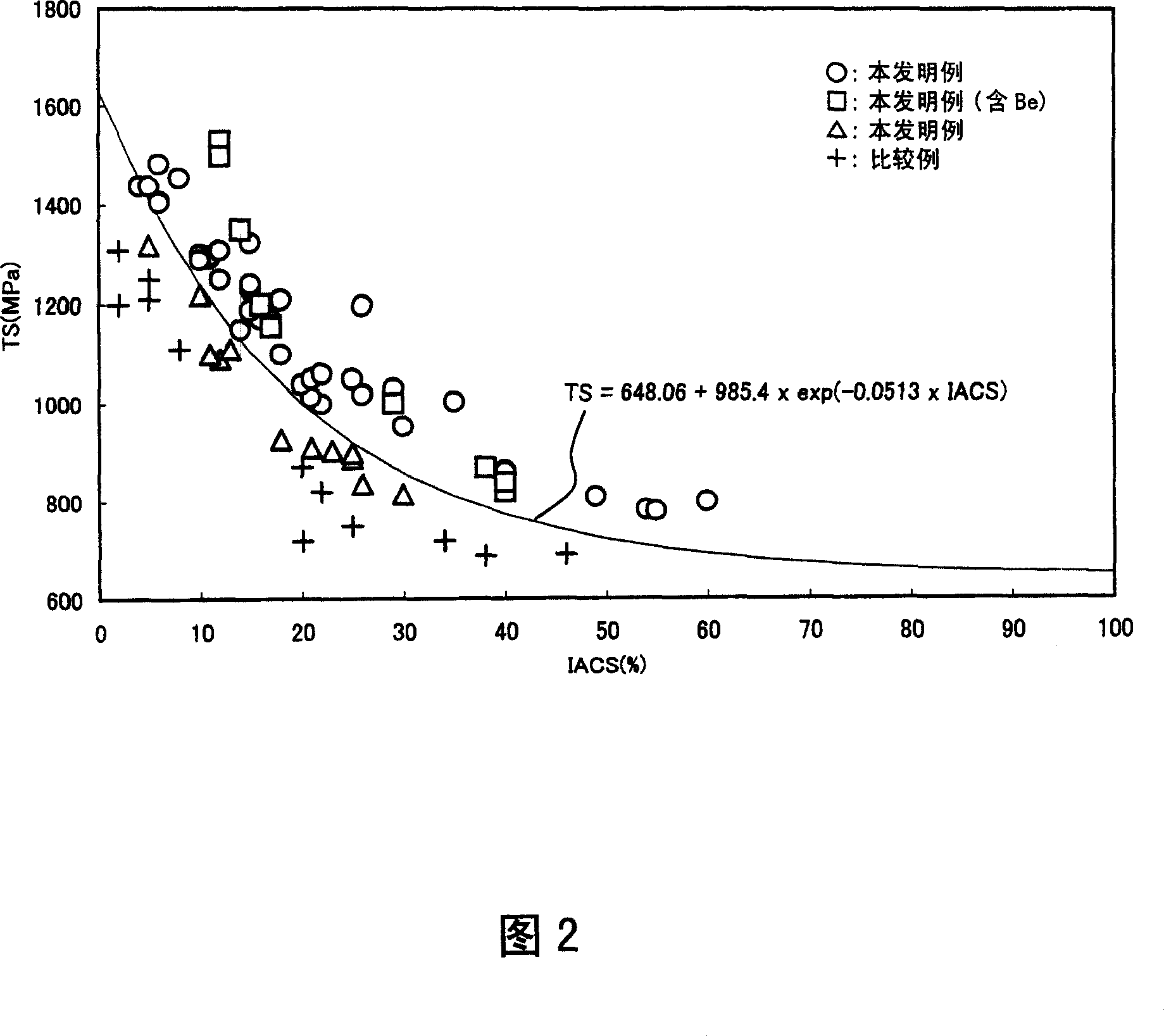

Copper alloy and process for producing the same

A copper alloy that has a specific chemical composition, the balance being Cu and impurities, in which the relationship between the total number N and the diameter X satisfies the following formula (1). This copper alloy is obtained by cooling a bloom, a slab, a billet or an ingot in at least a temperature range from the temperature of the bloom, the slab, the billet or the ingot just after casting to 450 DEG C, at a cooling rate of 0.5 DEG C / s or more. After the cooling, working in a temperature range of 600 DEG C or lower and further heat treatment of holding for 30 seconds or more in a temperature range of 150 to 750 DEG C are desirably performed. The working and the heat treatment are most desirably performed for a plurality of times. logN 0.4742 + 17.629 exp - 0.1133 X wherein N means the total number of precipitates and inclusions, having a diameter of not smaller than 1 [mu]m which are found in 1 mm 2 of the alloy; and X means the diameter in [mu]m of the precipitates and the inclusions having a diameter of not smaller than 1 [mu]m.

Owner:SUMITOMO METAL IND LTD

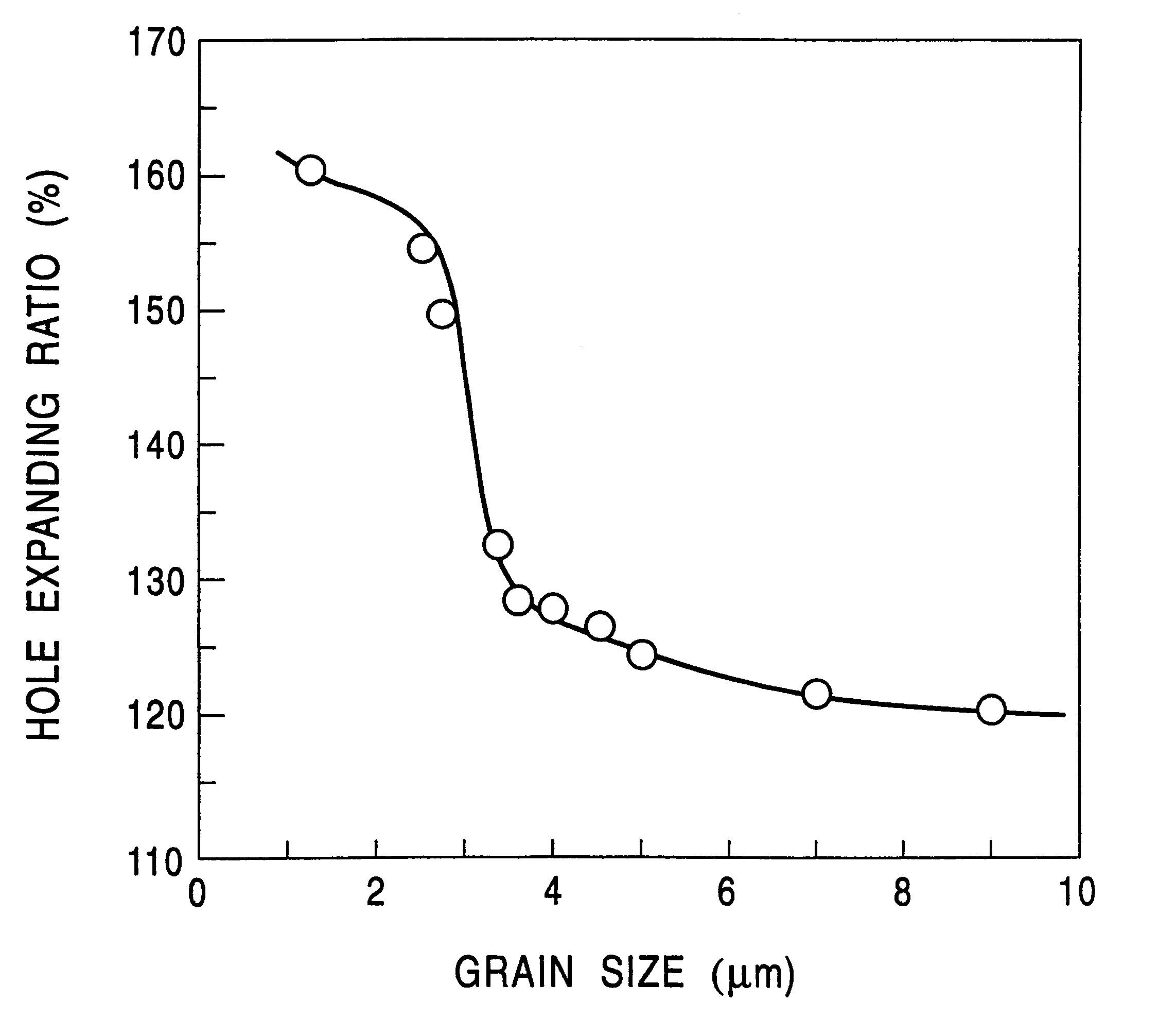

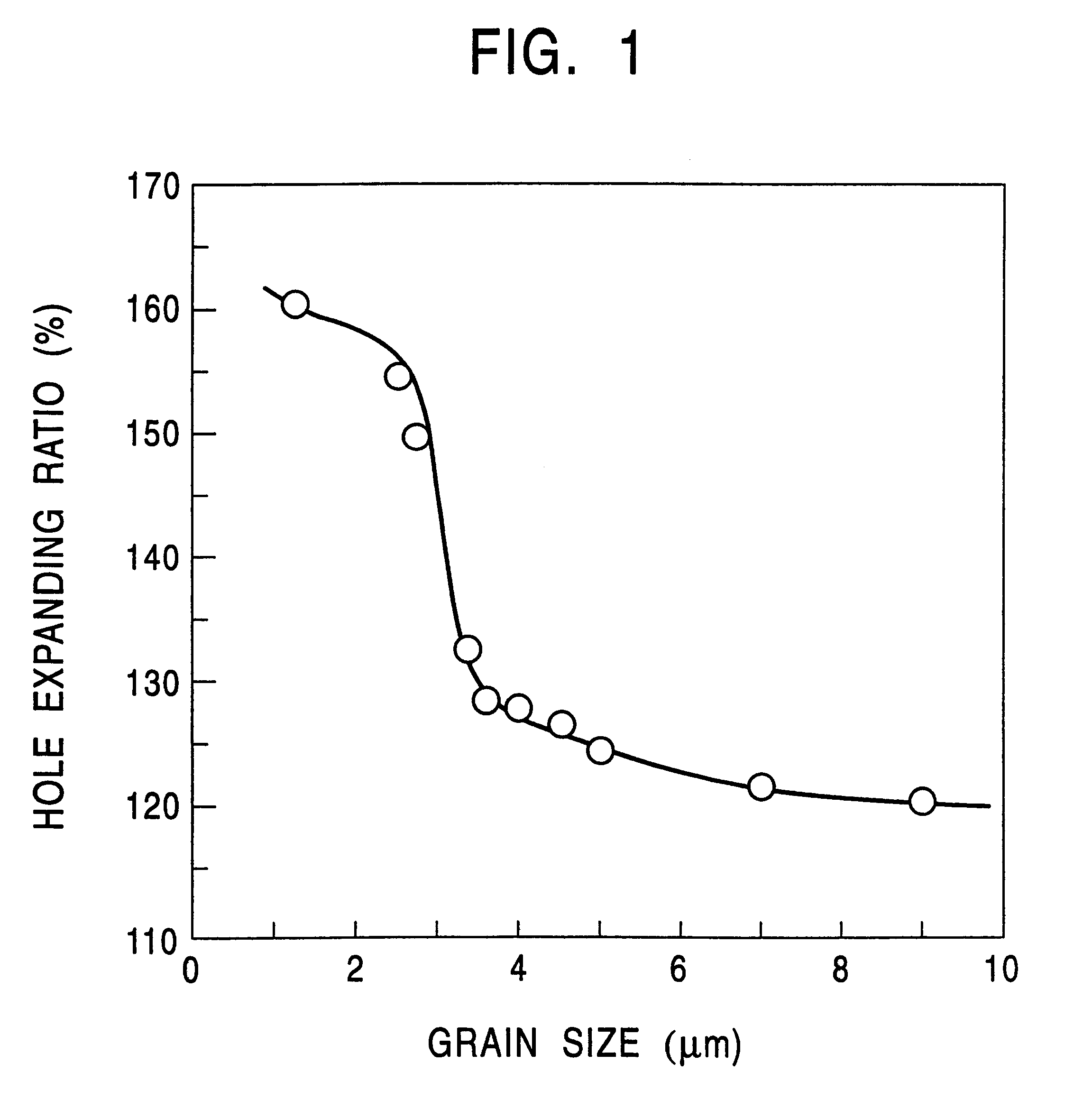

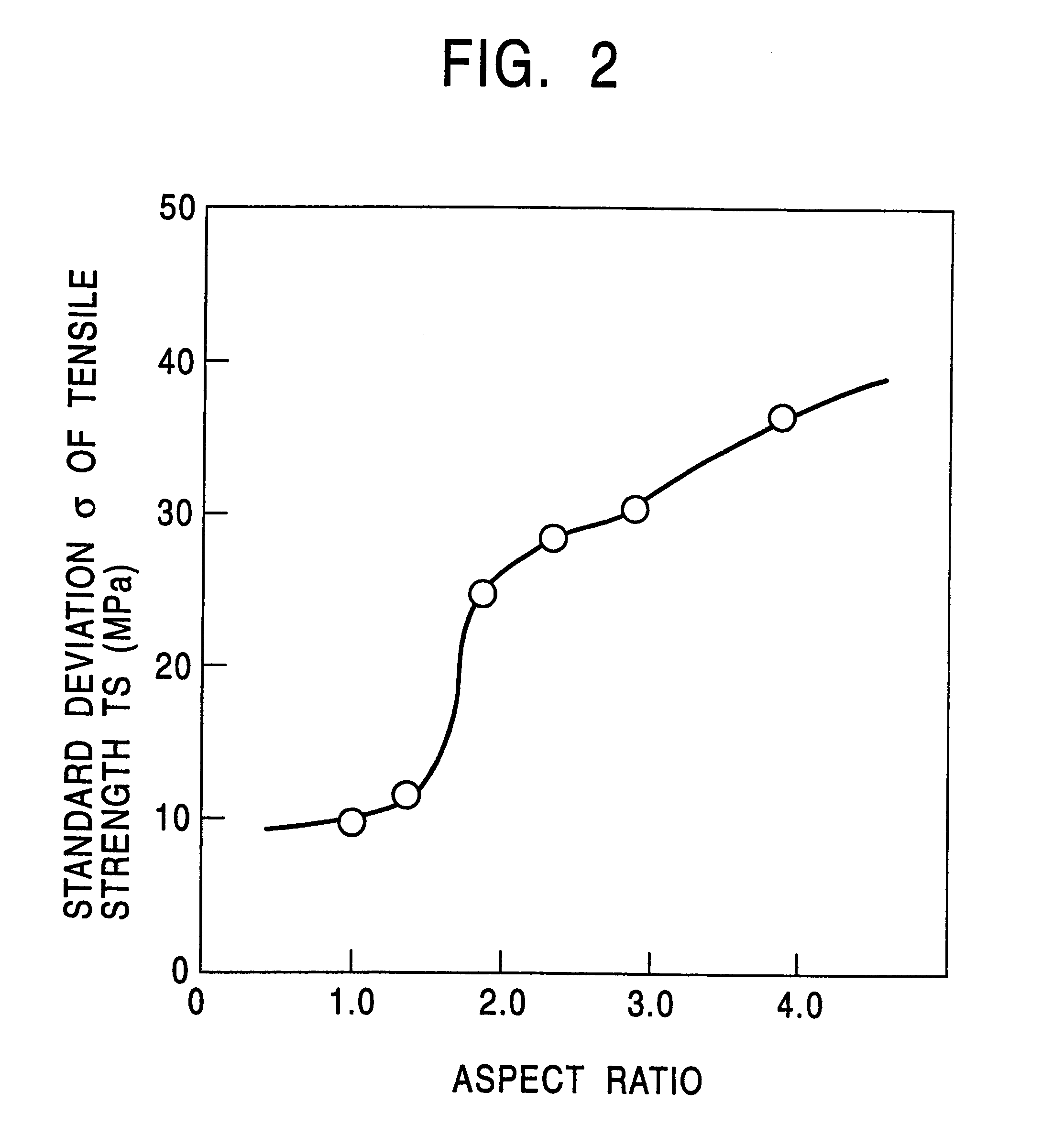

High-strength hot-rolled steel sheet having excellent stretch flangeability, and method of producing the same

InactiveUS6364968B1Easy to stretchImprove uniformityFurnace typesHeat treatment furnacesHigh intensityMechanical property

The invention provides a thin high-strength hot-rolled steel sheet with a thickness of not more than 3.5 mm which has excellent stretch flangeability and high uniformity in both shape and mechanical properties of the steel sheet, as well as a method of producing the hot-rolled steel sheet. A slab containing C: 0.05-0.30 wt %, Si: 0.03-1.0 wt %, Mn: 1.5-3.5 wt %, P: not more than 0.02 wt %, S: not more than 0.005 wt %, Al: not more than 0.150 wt %, N: not more than 0.0200 wt %, and one or two of Nb: 0.003-0.20 wt % and Ti: 0.005-0.20 wt % is heated at a temperature of not higher than 1200° C. The slab is hot-rolled at a finish rolling end temperature of not lower than 800° C., preferably at a finish rolling start temperature of 950-1050° C. A hot-rolled sheet is started to be cooled within two seconds after the end of the rolling, and then continuously cooled down to a coiling temperature at a cooling rate of 20-150° C. / sec. The hot-rolled sheet is coiled at a temperature of 300-550° C., preferably in excess of 400° C. A fine bainite structure is obtained in which the mean grain size is not greater than 3.0 mum, the aspect ratio is not more than 1.5, and preferably the maximum size of the major axis is not greater than 10 mum.

Owner:KAWASAKI STEEL CORP

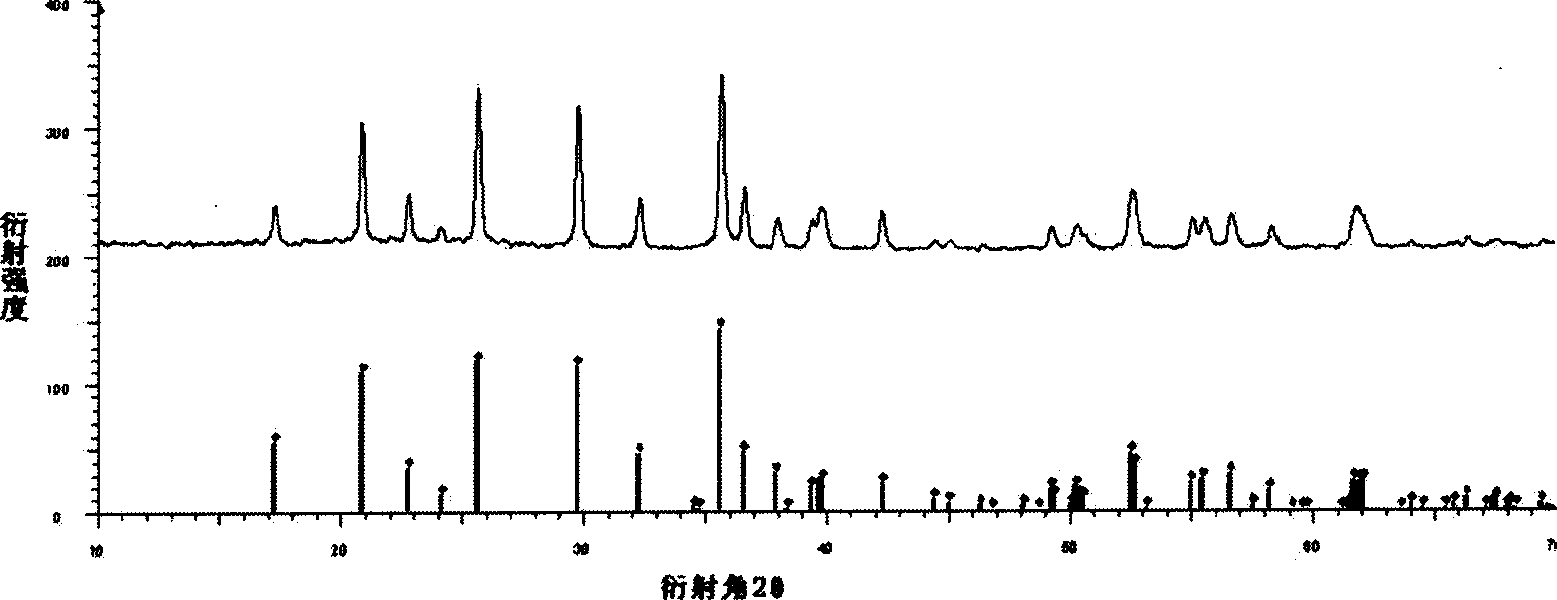

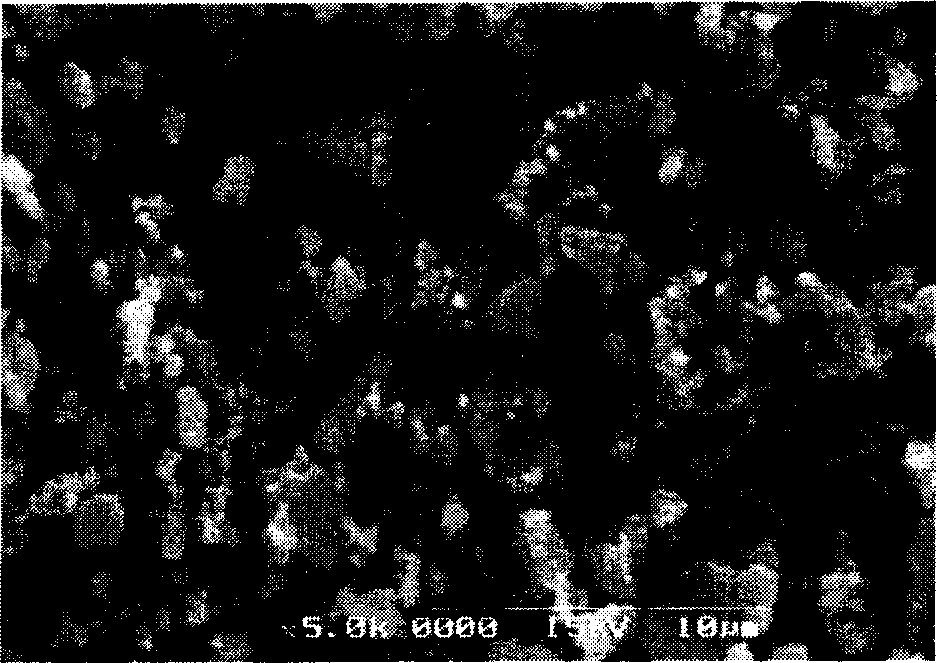

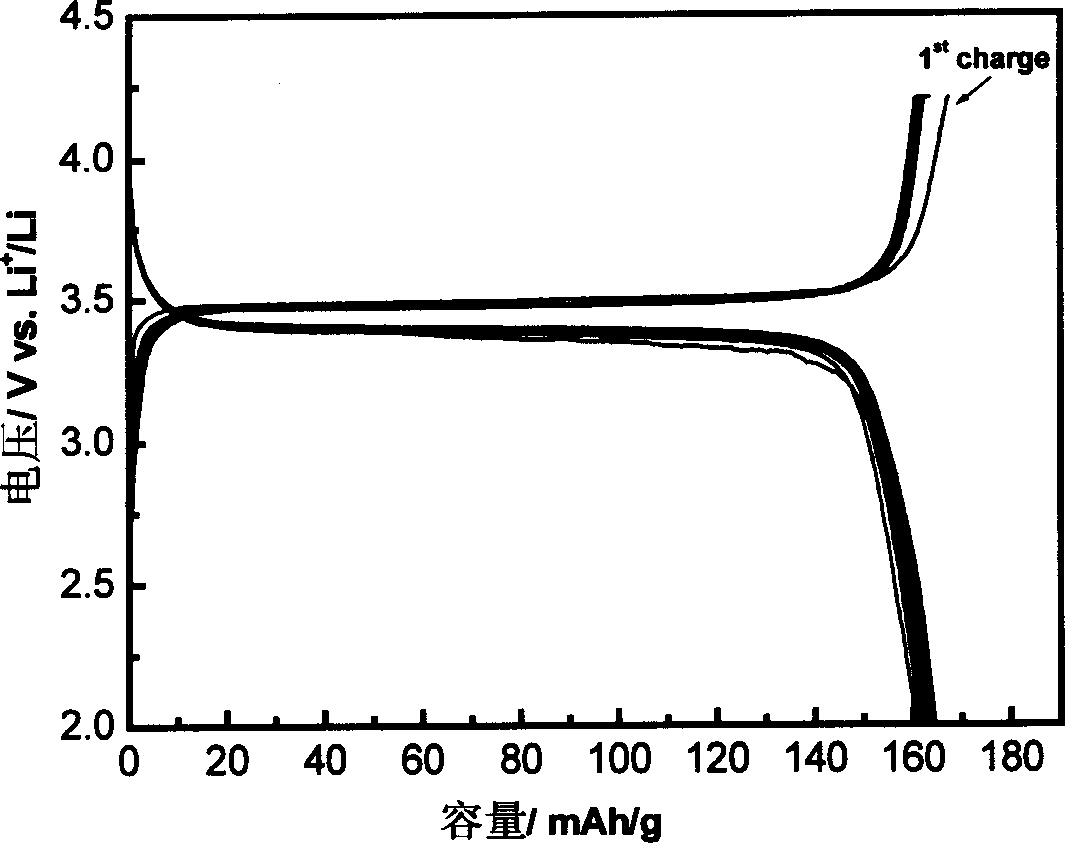

Method for producing carbon coated nano stage lithium iron phosphate by precipitation

InactiveCN101393982AAvoid synthetic stepsEasy to controlElectrode manufacturing processesIron saltsPhosphate

The invention discloses a precipitation method for preparing nanometer level iron phosphate lithium coated with carbon. The method comprises the following steps: firstly, weighing iron salt, deionized water and a compound of metallic elements; after the stirring and the mixing are performed, adding a phosphorous compound and citric acid diluted with water to the mixture; after the stirring is performed again, adding a precipitation agent to the mixture and controlling to the neutrality; stirring to react in a container, and after the static placement, respectively adding the deionized water, a carbon source and lithium salt to mix uniformly after the precipitate is filtered and washed; stirring again to react, and drying the water at 30 to 160 DEG C and warming up at the heating rate under the protection of non-oxidized gas after a product is crashed; baking at a constant temperature of 450 to 850 DEG C, cooling down to a room temperature at a cooling rate or with a stove, and finally obtaining the nanometer level ferric phosphate lithium coated with the carbon after crashing is performed. The precipitation method has the advantage that the raw material cost and the processing cost are low because bivalent iron is taken as the raw material. The iron phosphate lithium prepared by using the process has the characteristics of good physical processing performance and good electrochemistry performance, and is suitable for industrialized production.

Owner:南京海泰纳米材料有限公司

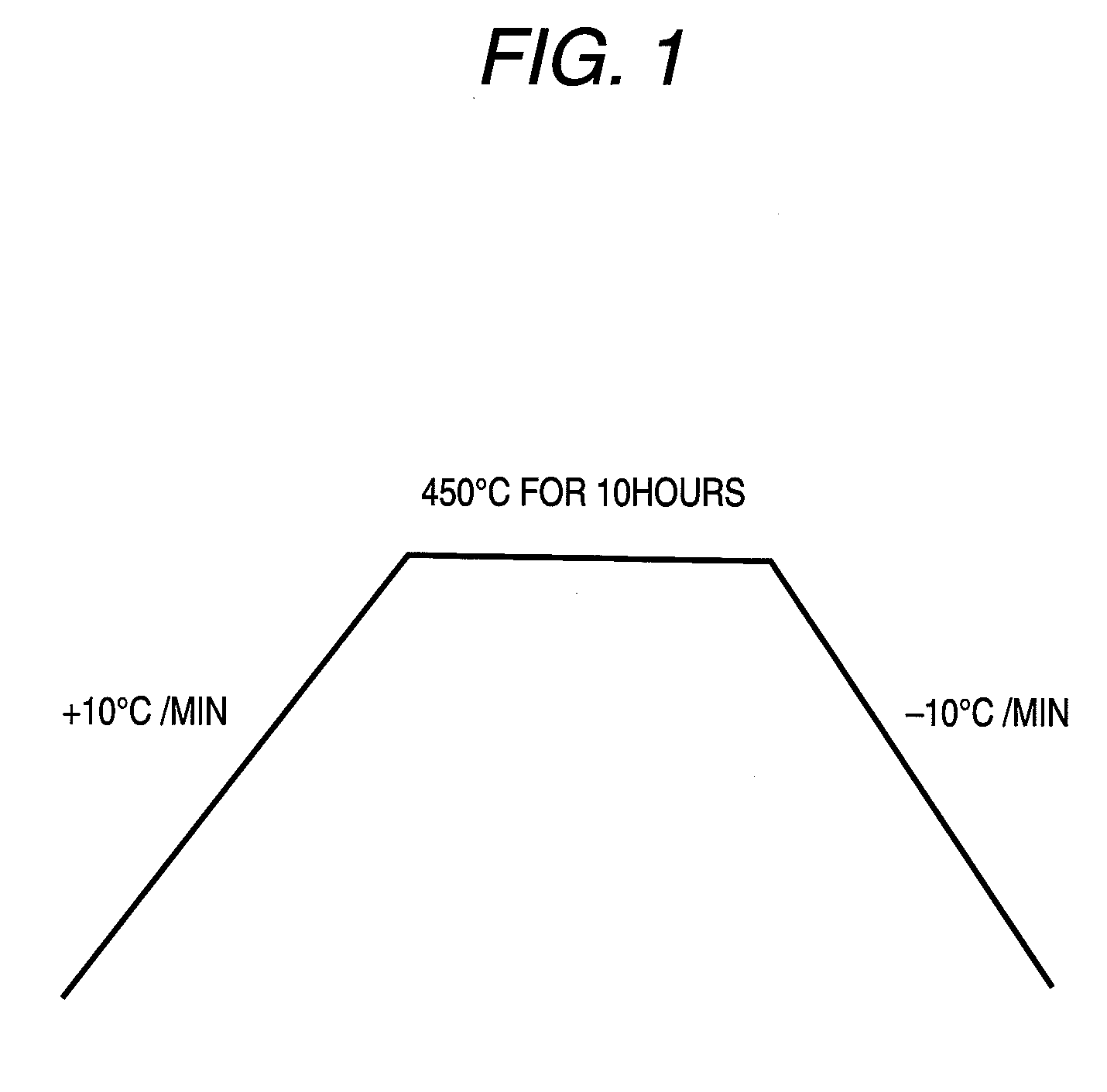

Method for preparing lithiumion cell positive material Iron-lithium phosphate

ActiveCN1581537AAvoid synthetic stepsSolve the problem of impurityElectrode manufacturing processesLithium compoundsPhosphateNitrogen gas

Mechanical solid phase method for synthesizing lithium ferric phosphate includes following steps: mixing iron powder, ferric phosphate, lithium phosphate, doping elements of phosphate, conducting agent or predecessor of conducting agent according to proportion evenly; placing the mixed admixture into ball milling container with inert gases being filled and ball milling for 18-36 hours; then putting the produced result from ball milling into high-temperature furnace with inert gases such as nitrogen gas and argon gas being filled; heating up in 10-30 deg.C / minute heating rate, baking at constant temperature 450-750 deg.C for 10-60 minutes; then cooling at 10-30 deg.C / minutes cooling rate, cooling the admixture to room temperature so as to obtain powder of lithium ferric phosphate or powder of doped powder of lithium ferric phosphate. Advantages are: feasible, no pollution, high specific capacity and good cycle performance.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH

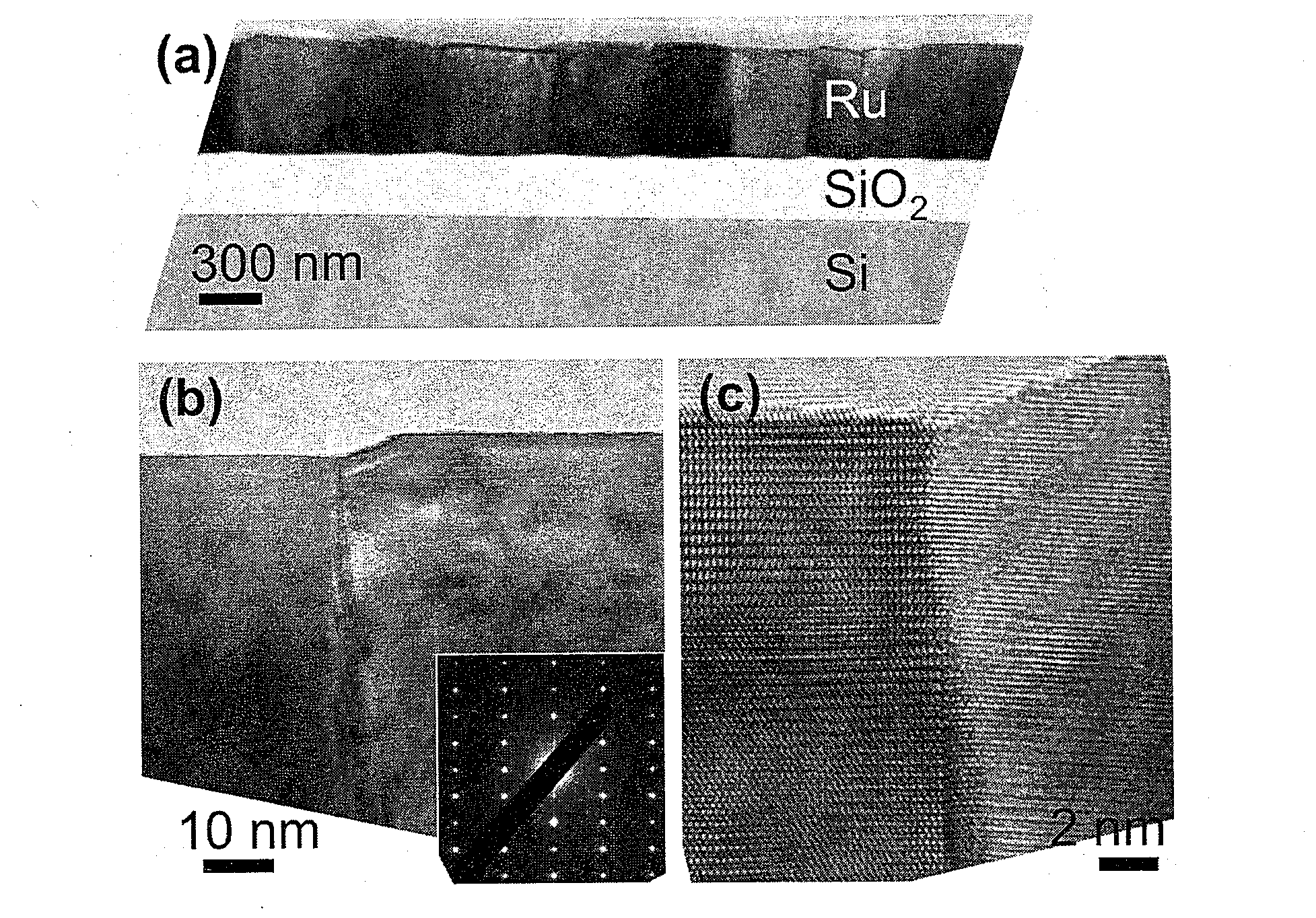

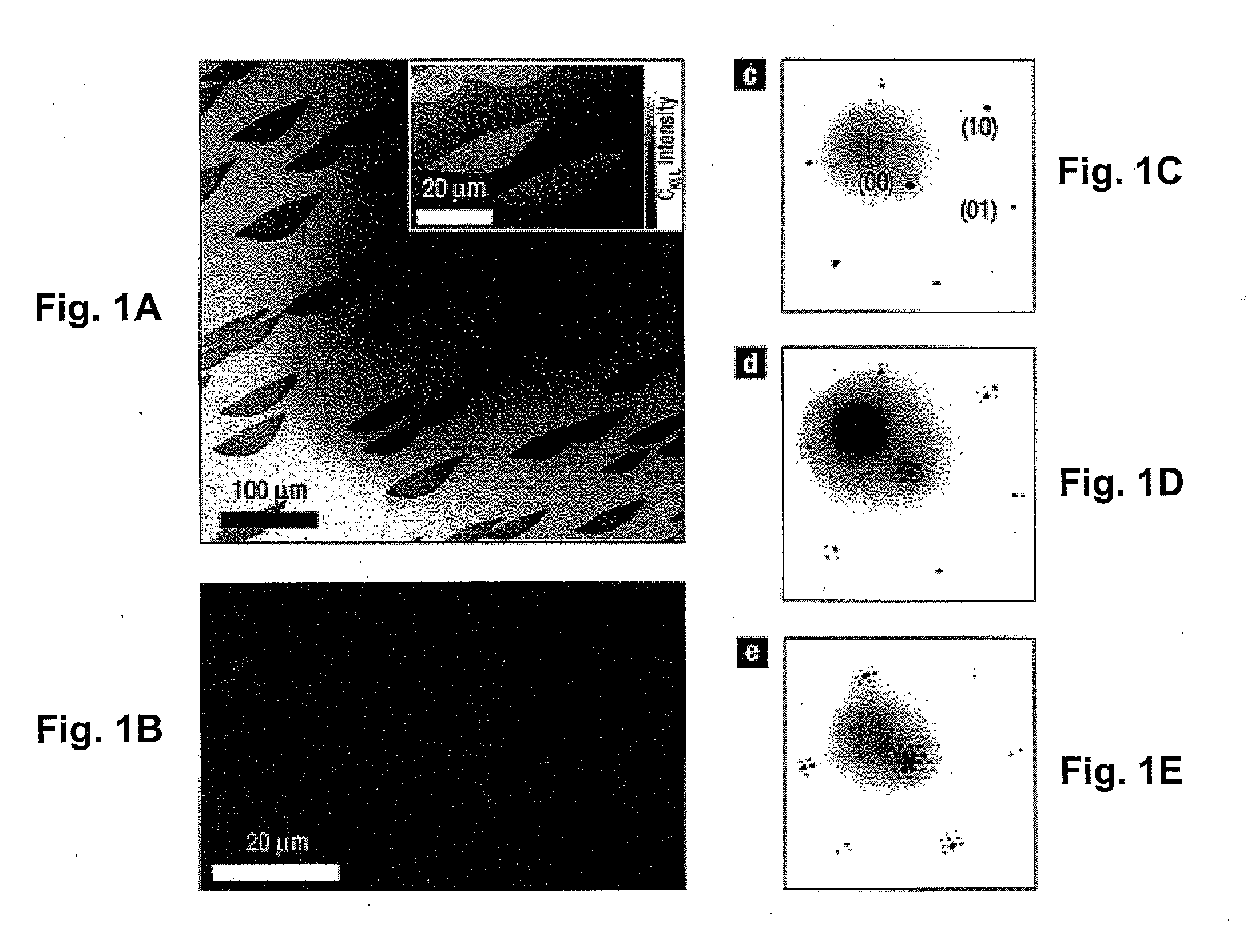

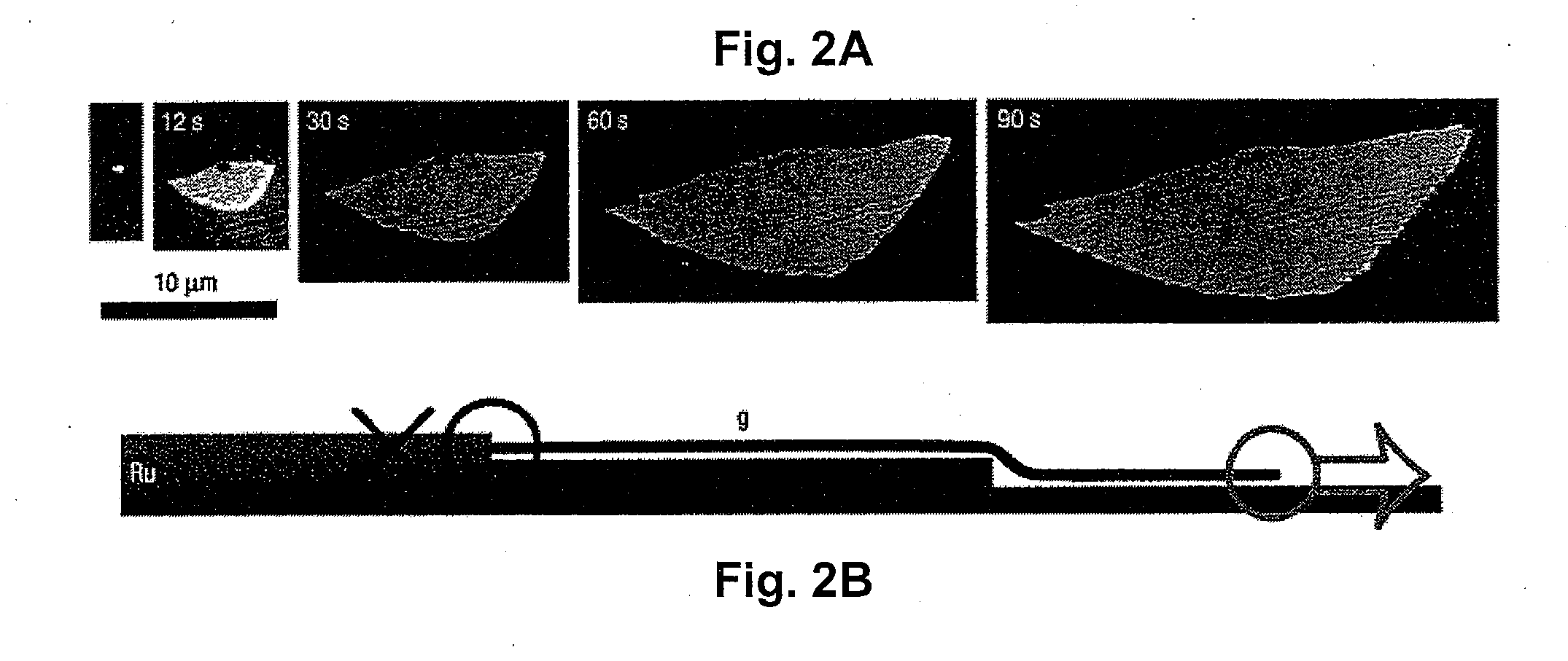

Monolayer and/or Few-Layer Graphene On Metal or Metal-Coated Substrates

InactiveUS20100255984A1Easy to disassembleMaterial nanotechnologyParticle separator tubesHigh concentrationIn plane

Graphene is a single atomic layer of sp2-bonded C atoms densely packed into a two-dimensional honeycomb crystal lattice. A method of forming structurally perfect and defect-free graphene films comprising individual mono crystalline domains with in-plane lateral dimensions of up to 200 μm or more is presented. This is accomplished by controlling the temperature-dependent solubility of interstitial C of a transition metal substrate having a suitable surface structure. At elevated temperatures, C is incorporated into the bulk at higher concentrations. As the substrate is cooled, a lowering of the interstitial C solubility drives a significant amount of C atoms to the surface where graphene islands nucleate and gradually increase in size with continued cooling. Ru(0001) is selected as a model system and electron microscopy is used to observe graphene growth during cooling from elevated temperatures. With controlled cooling, large arrays of macroscopic single-crystalline graphene domains covering the entire transition metal surface are produced. As the graphene domains coalesce to a complete layer, a second graphene layer is formed, etc. By controlling the interstitial C concentration and the cooling rate, graphene layers with thickness up to 10 atomic layers or more are formed in a controlled, layer-by-layer fashion.

Owner:BROOKHAVEN SCI ASSOCS

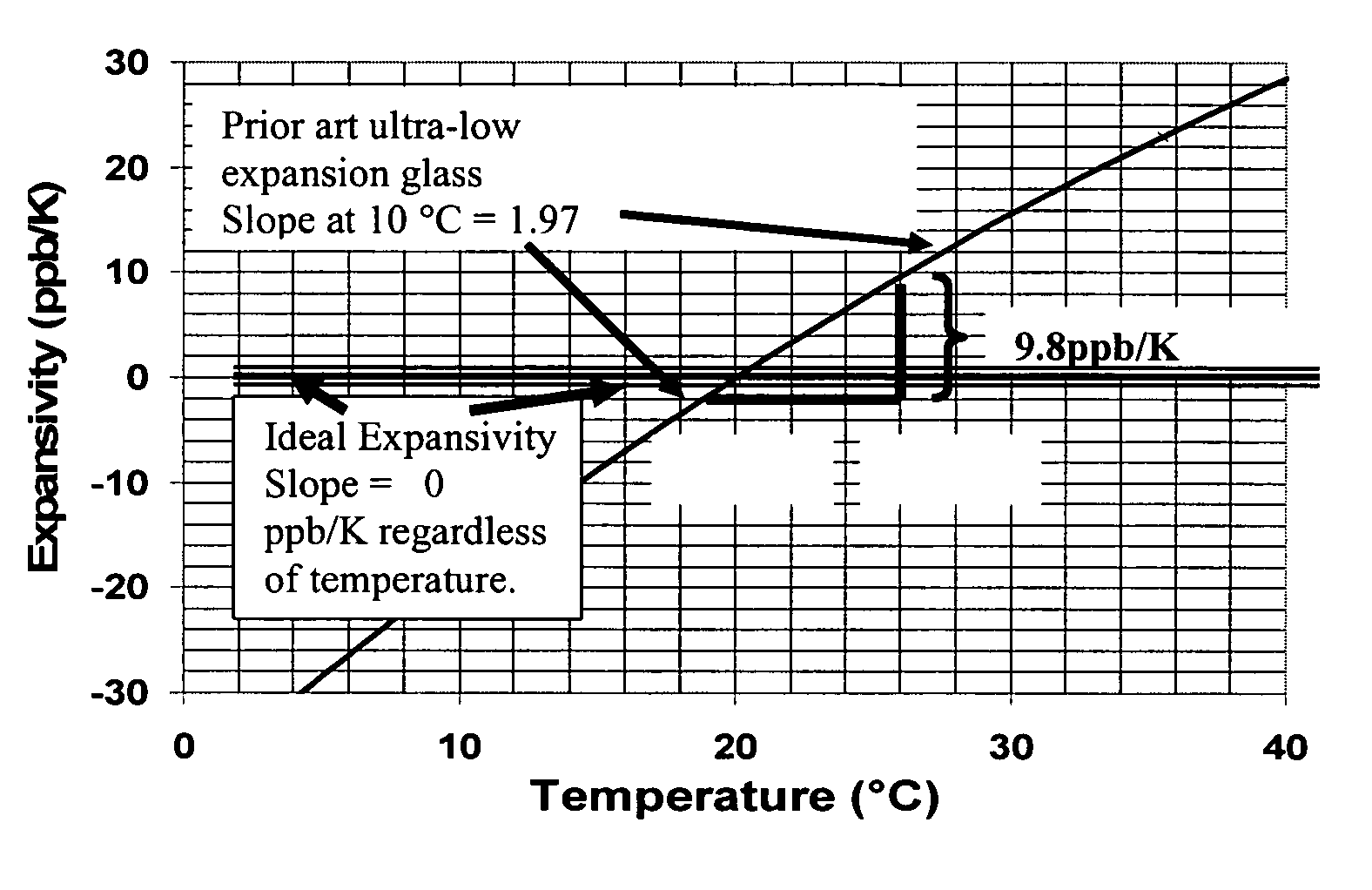

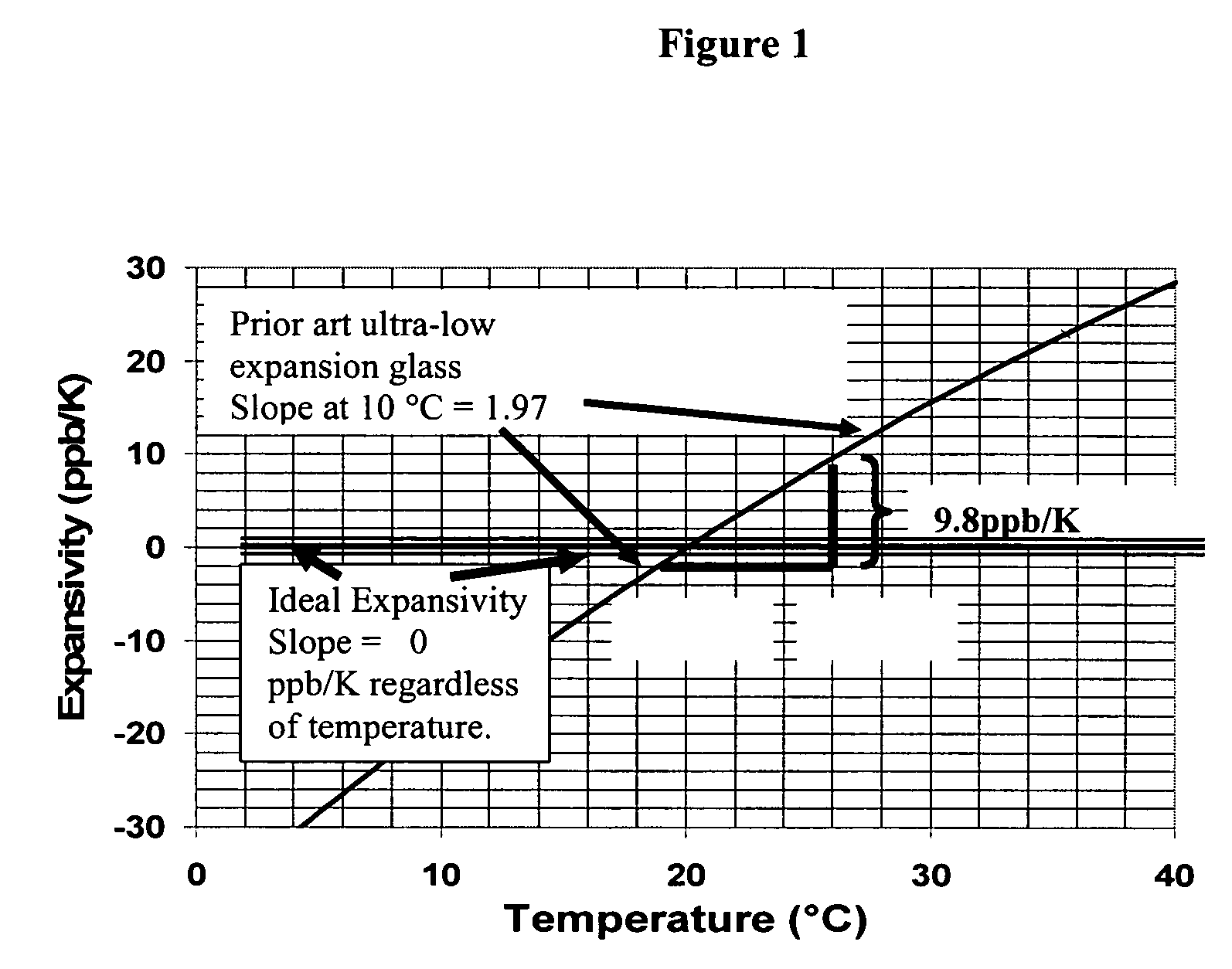

Adjusting expansivity in doped silica glasses

InactiveUS20060179879A1Low viscosityGlass shaping apparatusGlass deposition burnersDopantUltra low expansion glass

The invention is directed to ultra-low expansion glasses to which adjustments have been made to selected variables in order to improve the properties of the glasses, and particularly to lower the expansivity of the glasses. The glasses are titania-doped silica glasses. The variables being adjusted include an adjustment in β-OH level; an adjustment to the cooling rate of the molten glass material through the setting point; and the addition of selected dopants to impact the CTE behavior.

Owner:CORNING INC

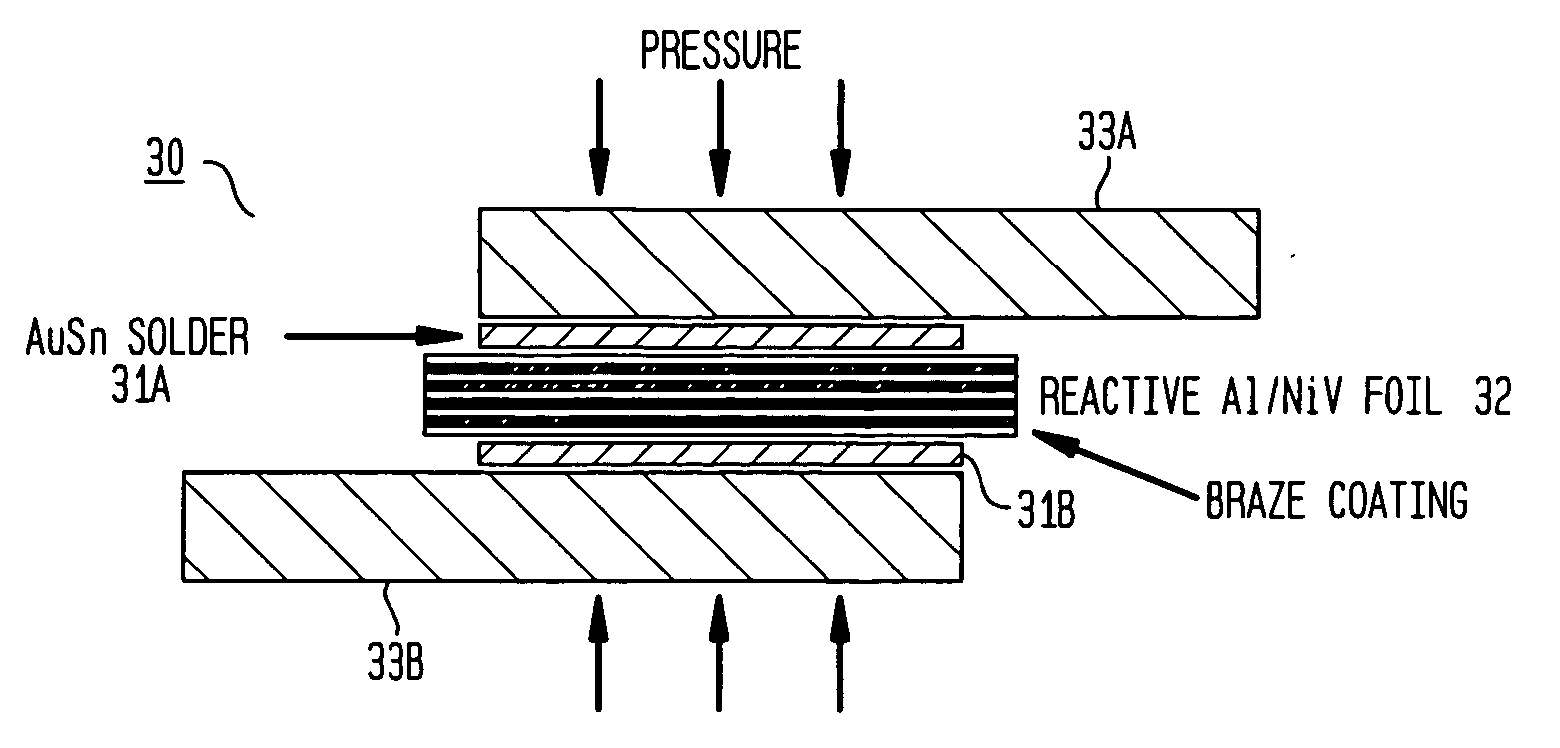

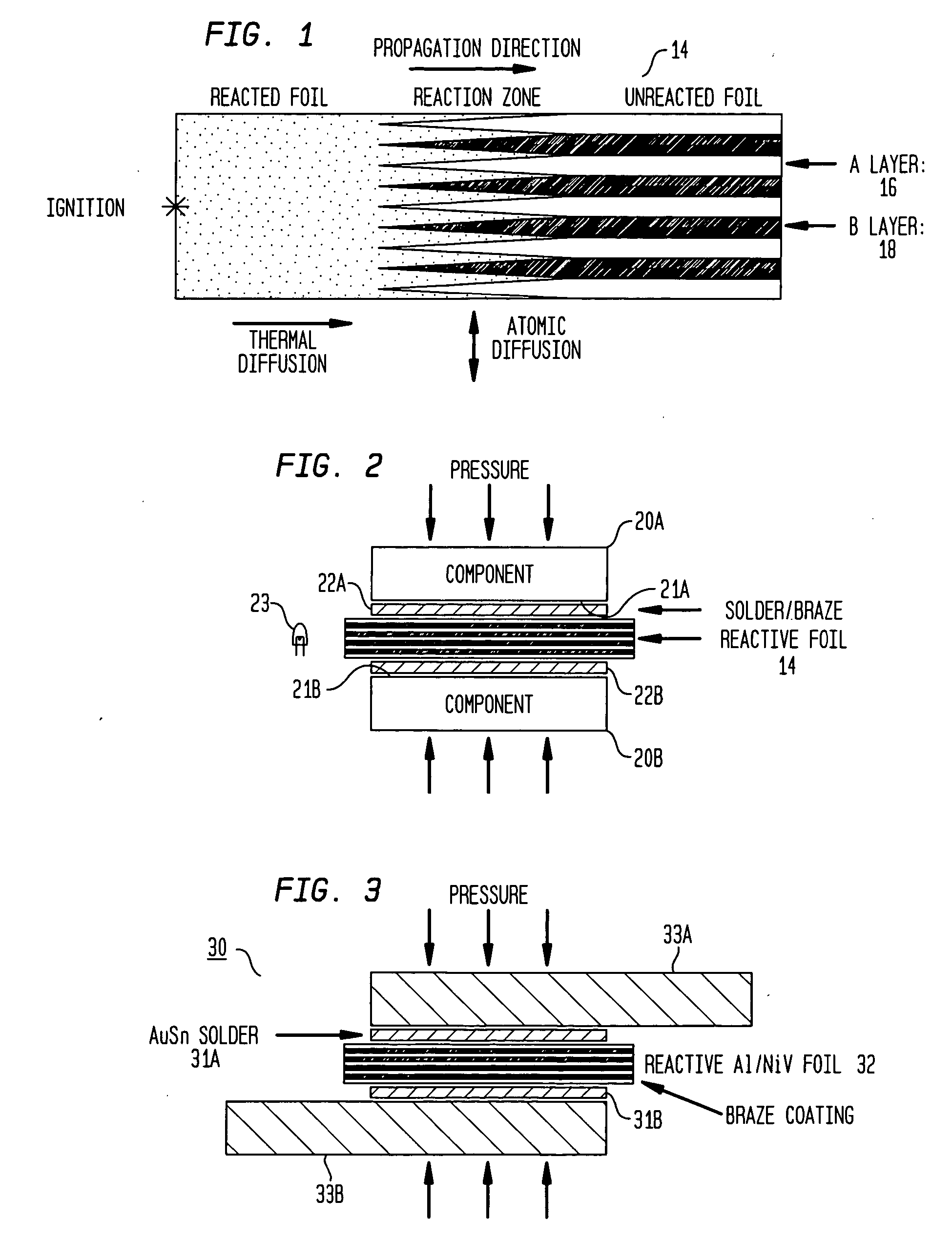

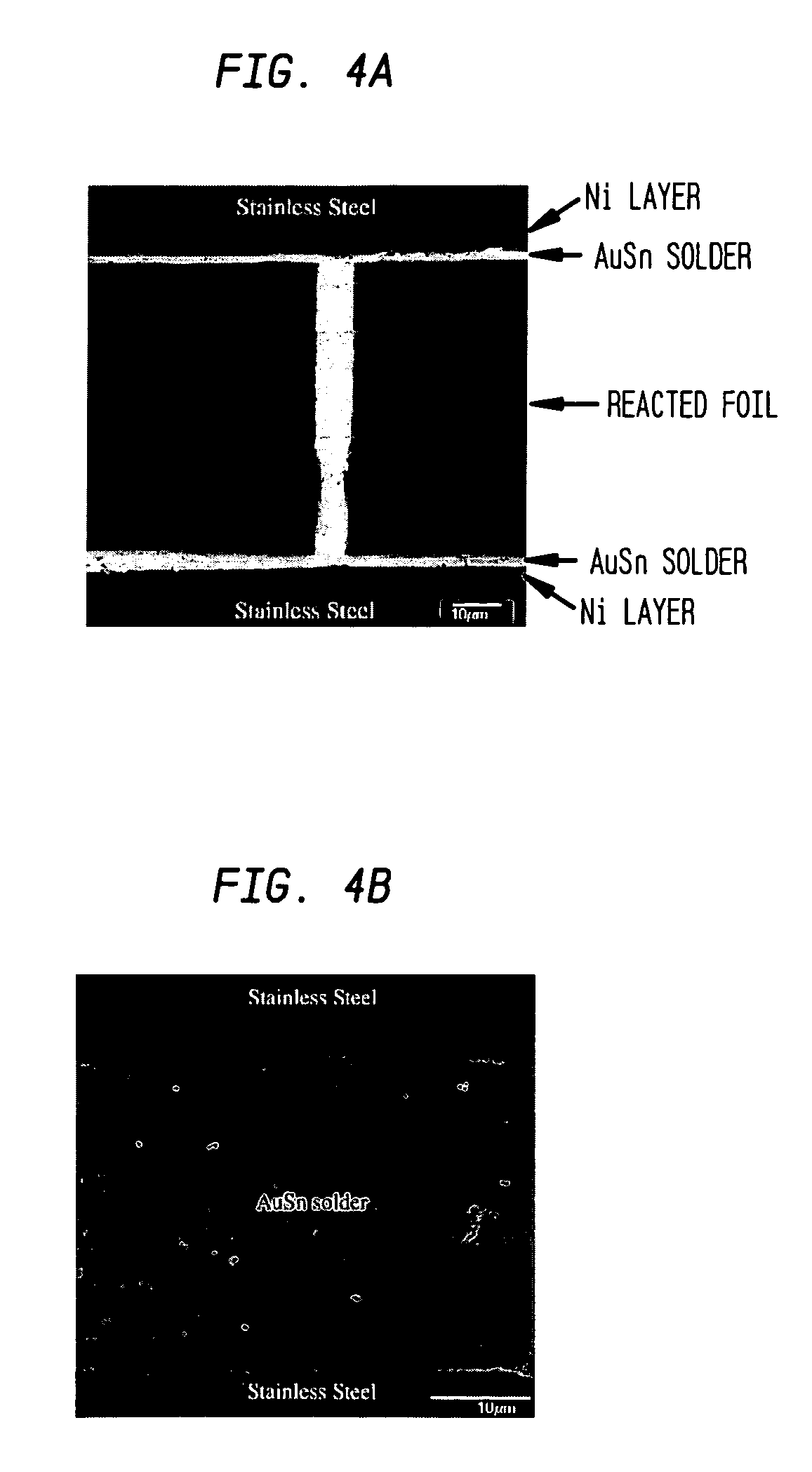

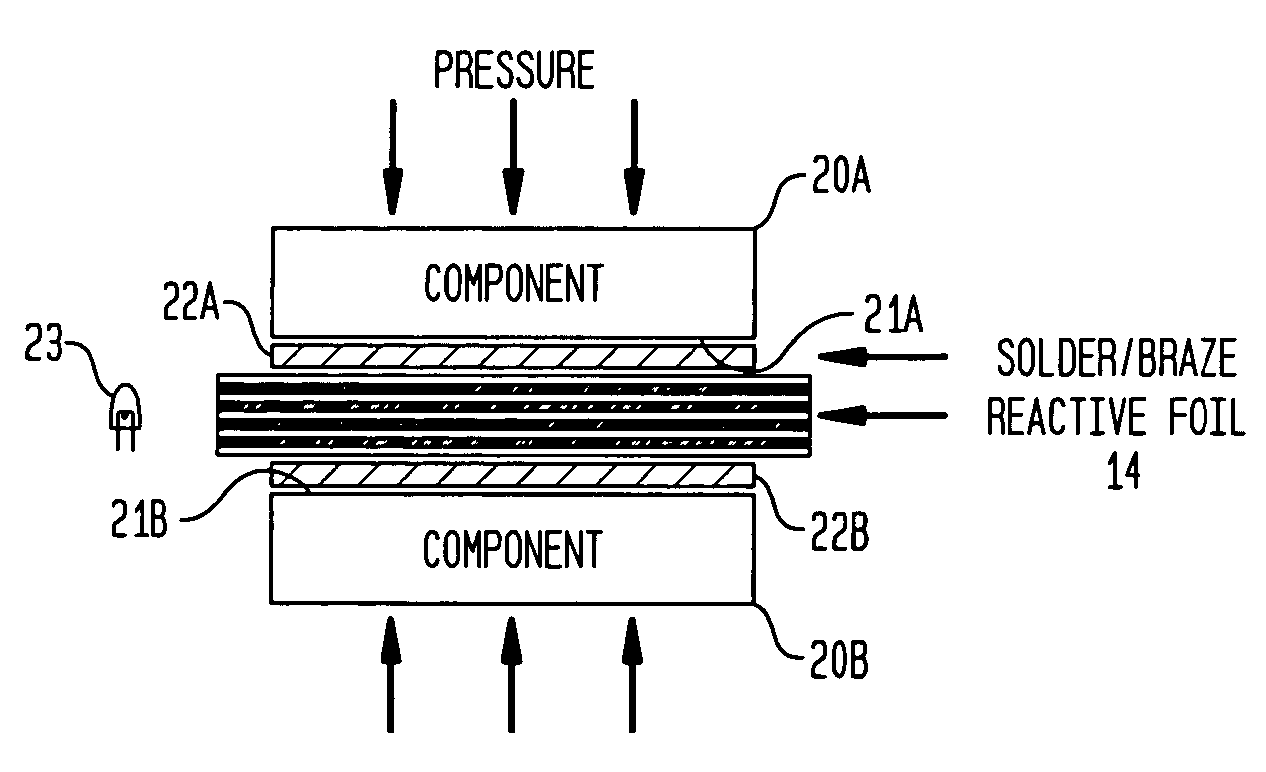

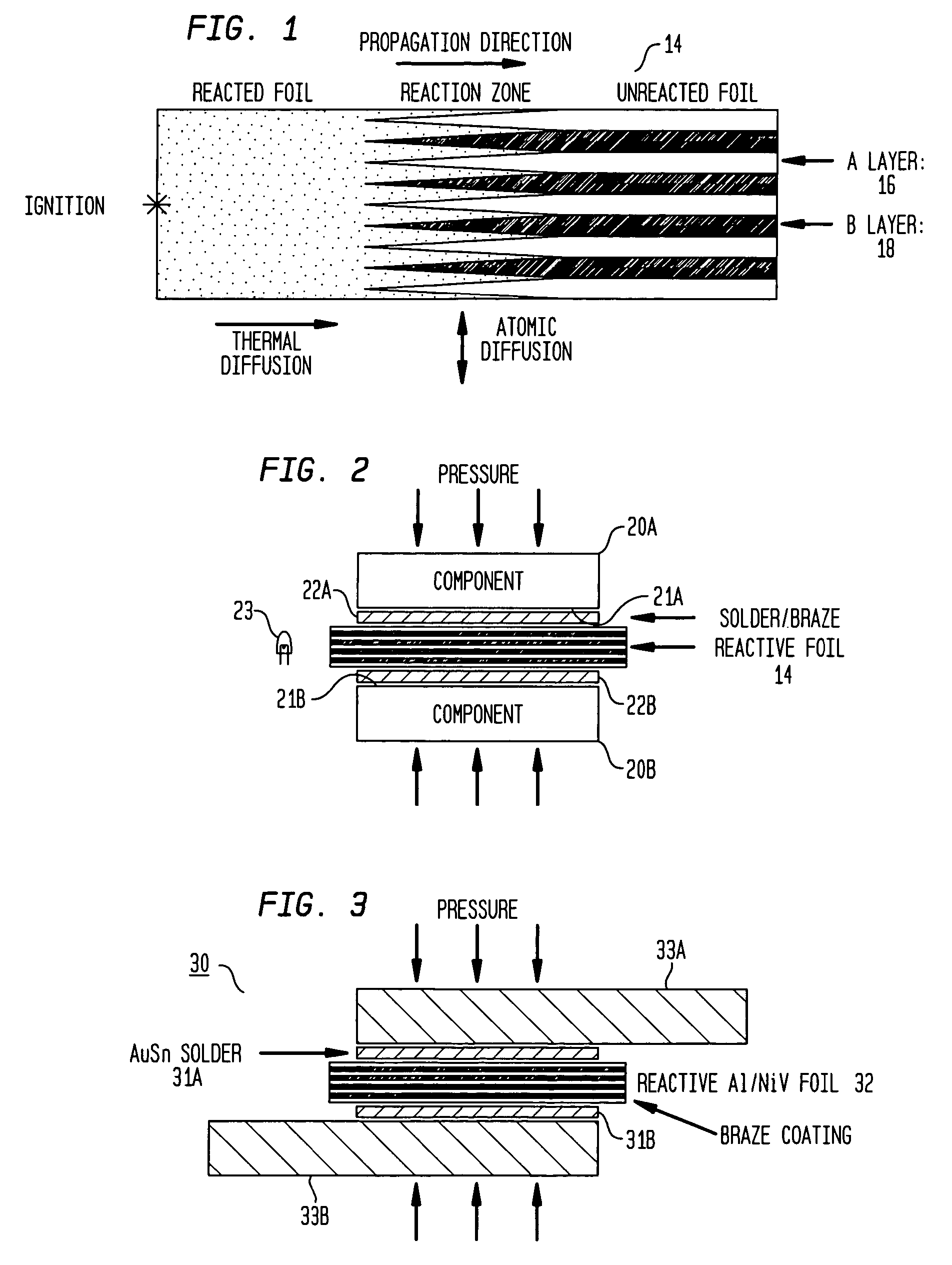

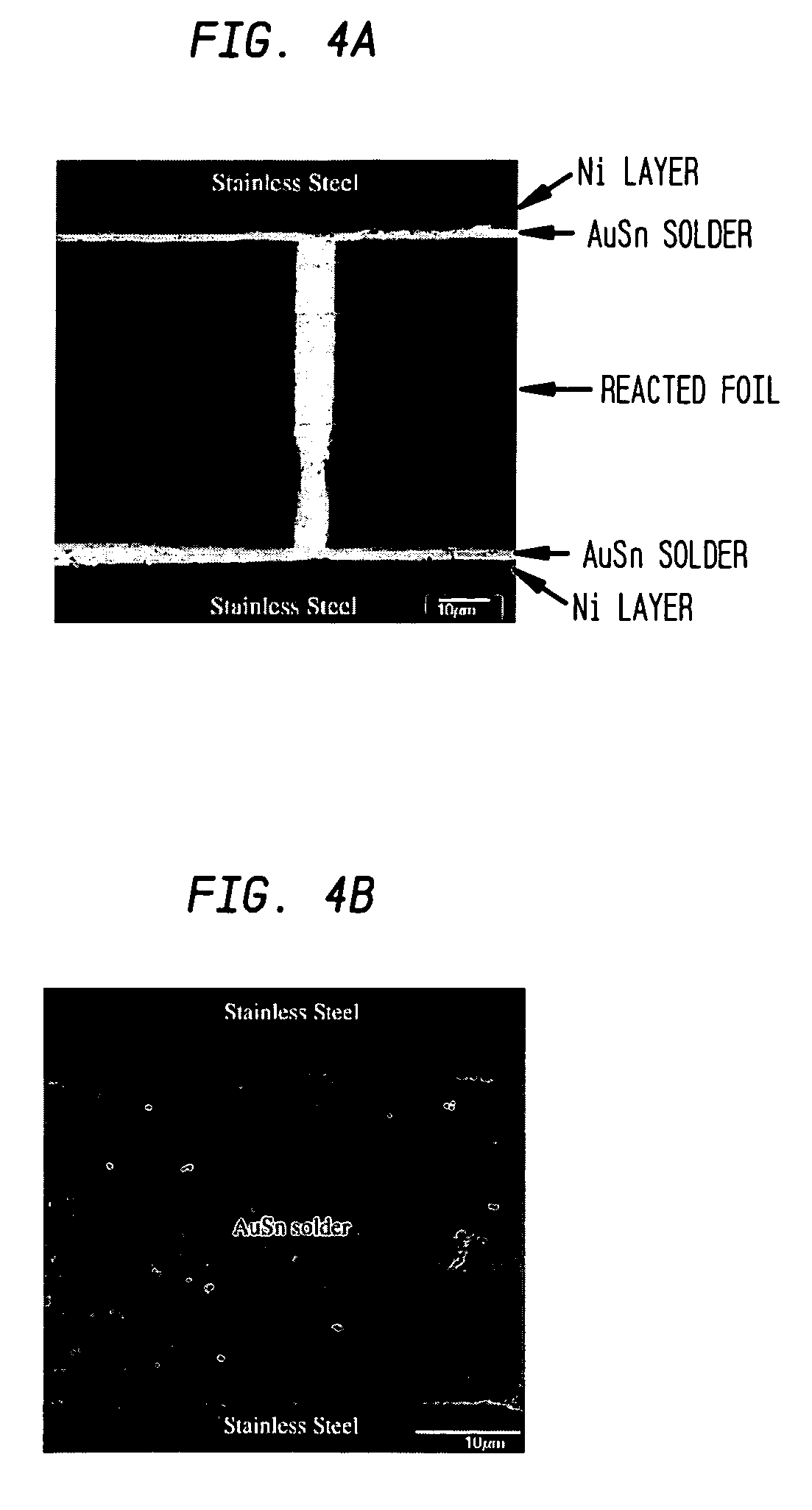

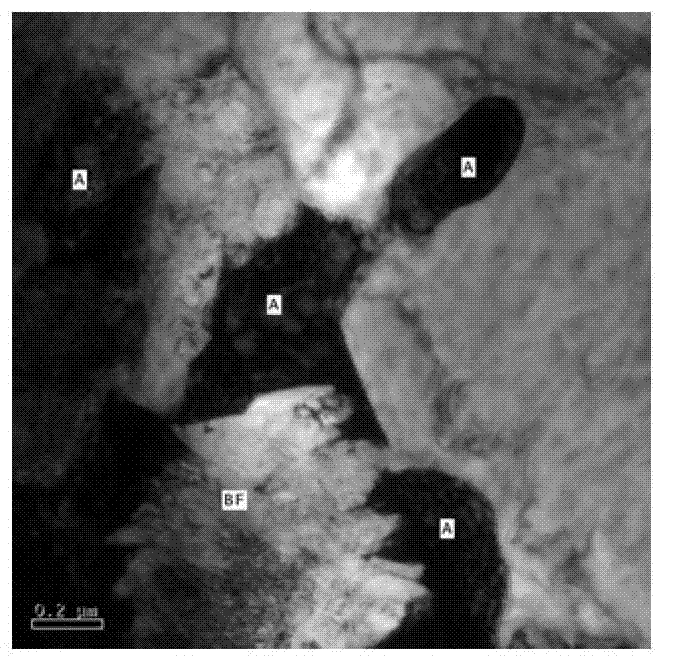

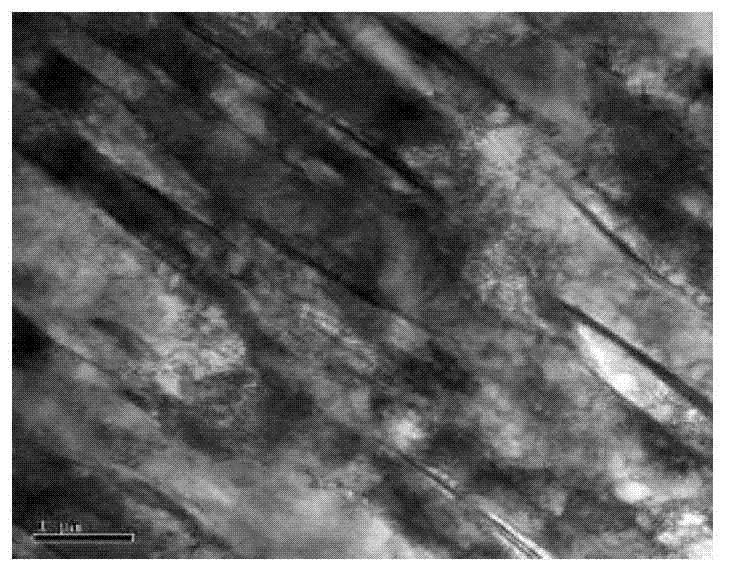

Nanostructured soldered or brazed joints made with reactive multilayer foils

InactiveUS20050051607A1Reduce coolingImprove microstructureExothermal chemical reaction heat productionVacuum evaporation coatingRoom temperatureSlow cooling

Self-propagating formation reactions in nanostructured multilayer foils provide rapid bursts of heat at room temperature and therefore can act as local heat sources to melt solder or braze layers and join materials. This reactive joining method provides very localized heating to the components and rapid cooling across the joint. The rapid cooling results in a very fine microstructure of the solder or braze material. The scale of the fine microstructure of the solder or braze material is dependant on cooling rate of the reactive joints which varies with geometries and properties of the foils and components. The microstructure of the solder or braze layer of the joints formed by melting solder in a furnace is much coarser due to the slow cooling rate. Reactive joints with finer solder or braze microstructure show higher shear strength compared with those made by conventional furnace joining with much coarser solder or braze microstructure. It is expected that the reactive joints may also have better fatigue properties compared with conventional furnace joints.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

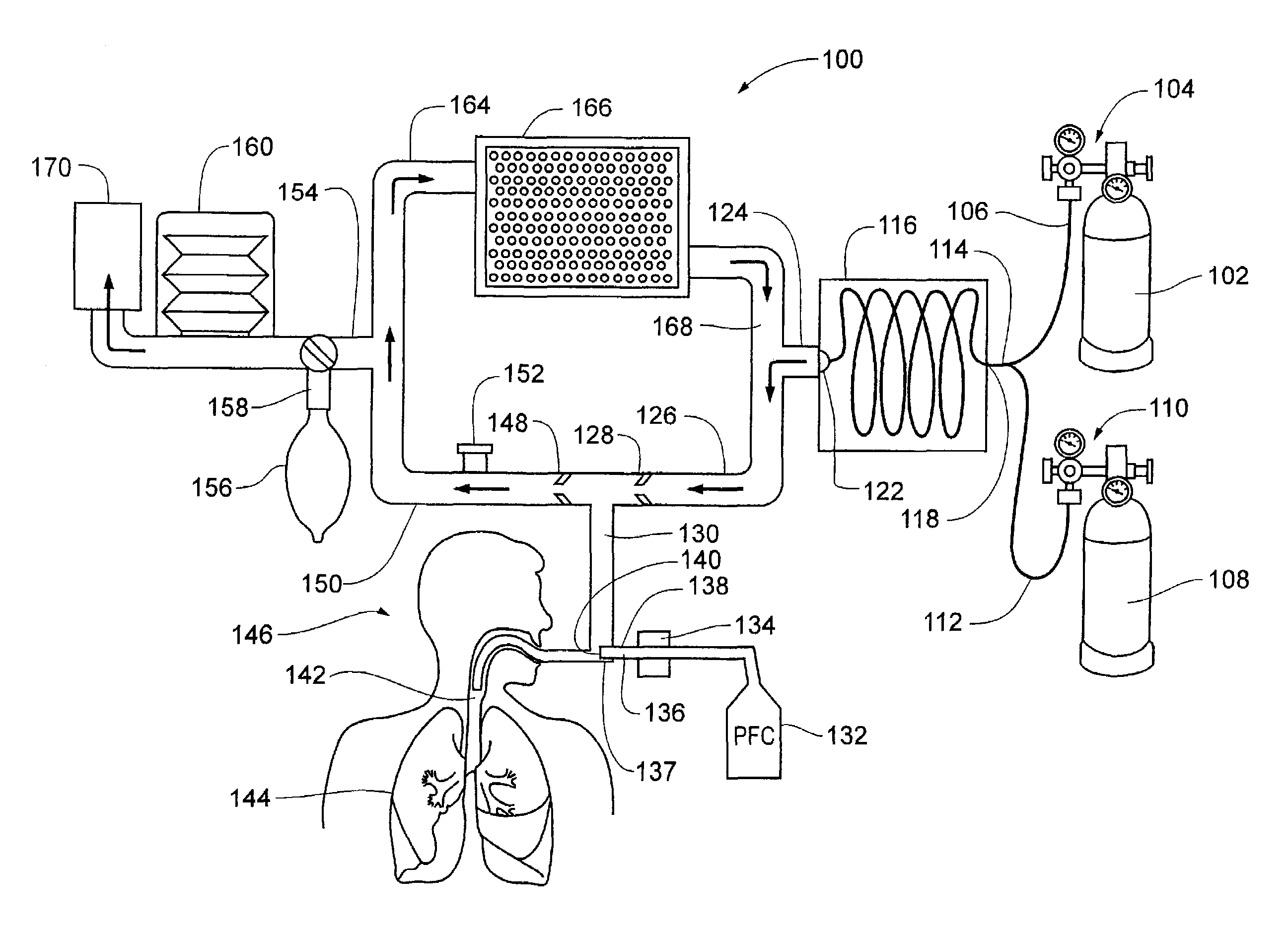

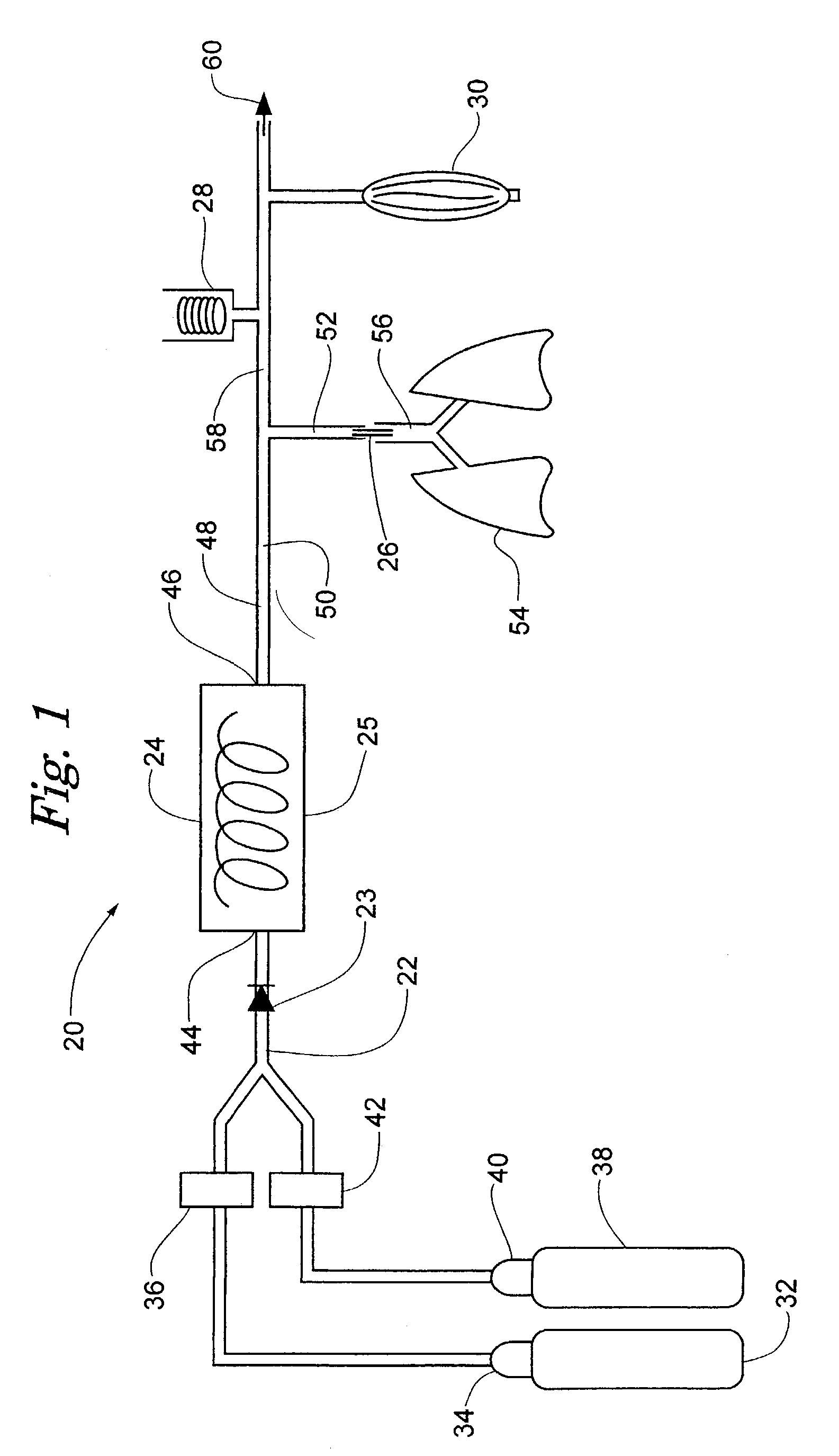

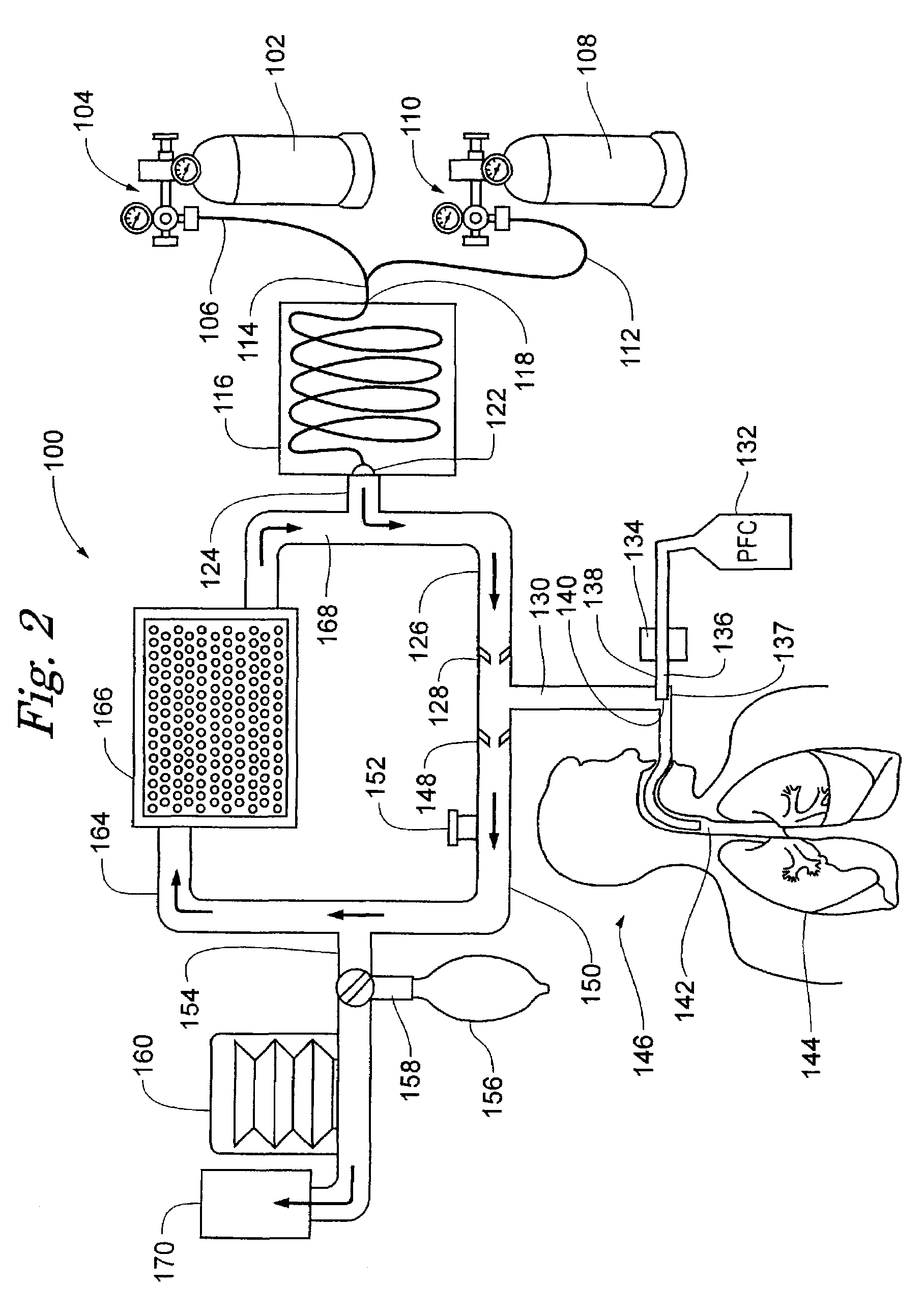

Inducing hypothermia and rewarming using a helium-oxygen mixture

ActiveUS6983749B2Mitigate warmingReduce coolingLighting and heating apparatusInorganic active ingredientsREFLEX DECREASEInspired gas temperature

Devices and methods to heat and cool human beings, including inducing and maintaining hypothermia in human patients. Methods include inducing hypothermia to treat ischemic events, including heart attack and stroke, to limit damage caused by the ischemic event. Methods can include: using the lungs for heat exchange; using cooled gases for ventilation; using helium in the ventilation gas mixture, using medications to control reflex heat production; and injecting a perfluorocarbon mist into the gas stream to increase the cooling rate. The high thermal conductivity and diffusivity of helium results in greater inspired gas temperature equalization toward body temperature. Due to the latent heat of vaporization, addition of even small quantity of phase-change perfluorocarbon dramatically increases the heat carrying capacity of the respiratory gases. Hypothermia may be terminated by discontinuing the medications and warming the patient using a warmed helium-oxygen mixture.

Owner:MINNESOTA HIGH TECH RESOURCES

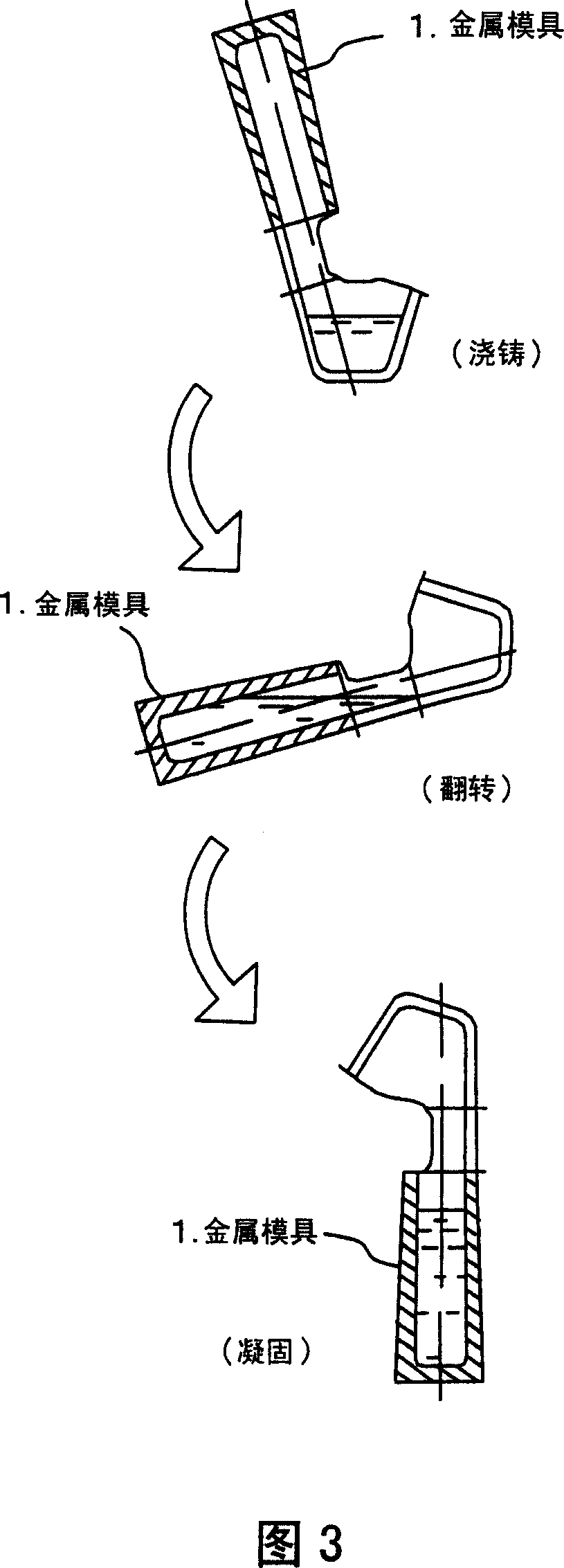

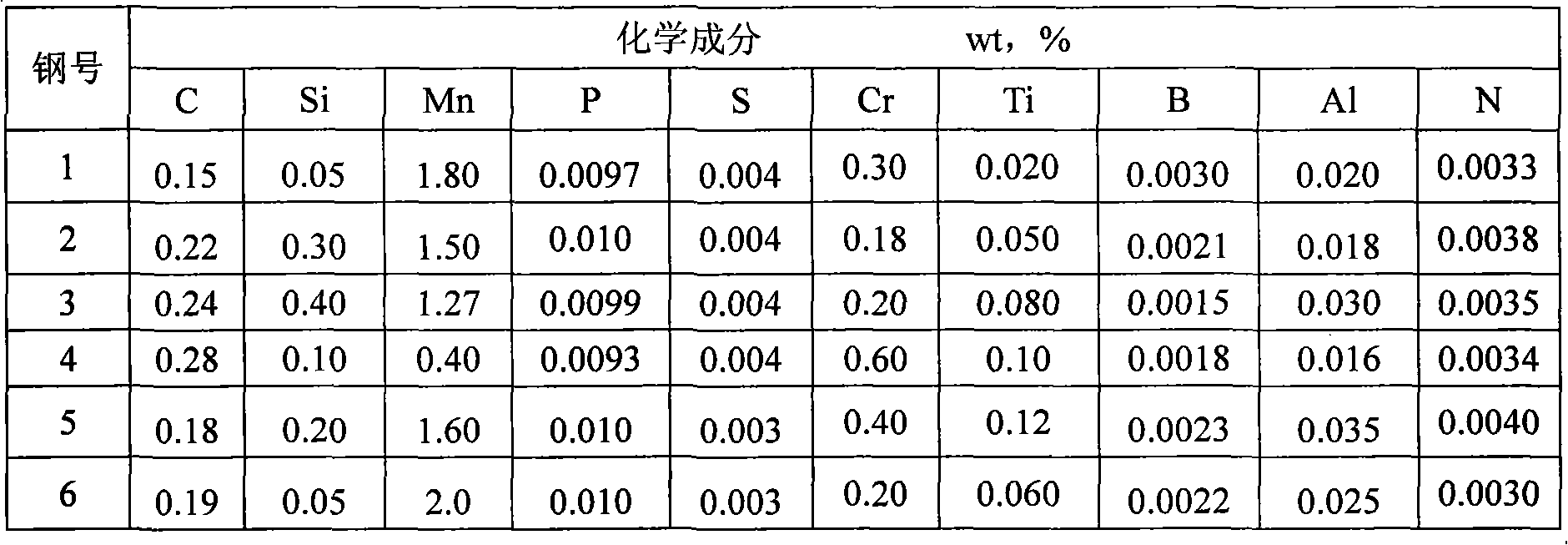

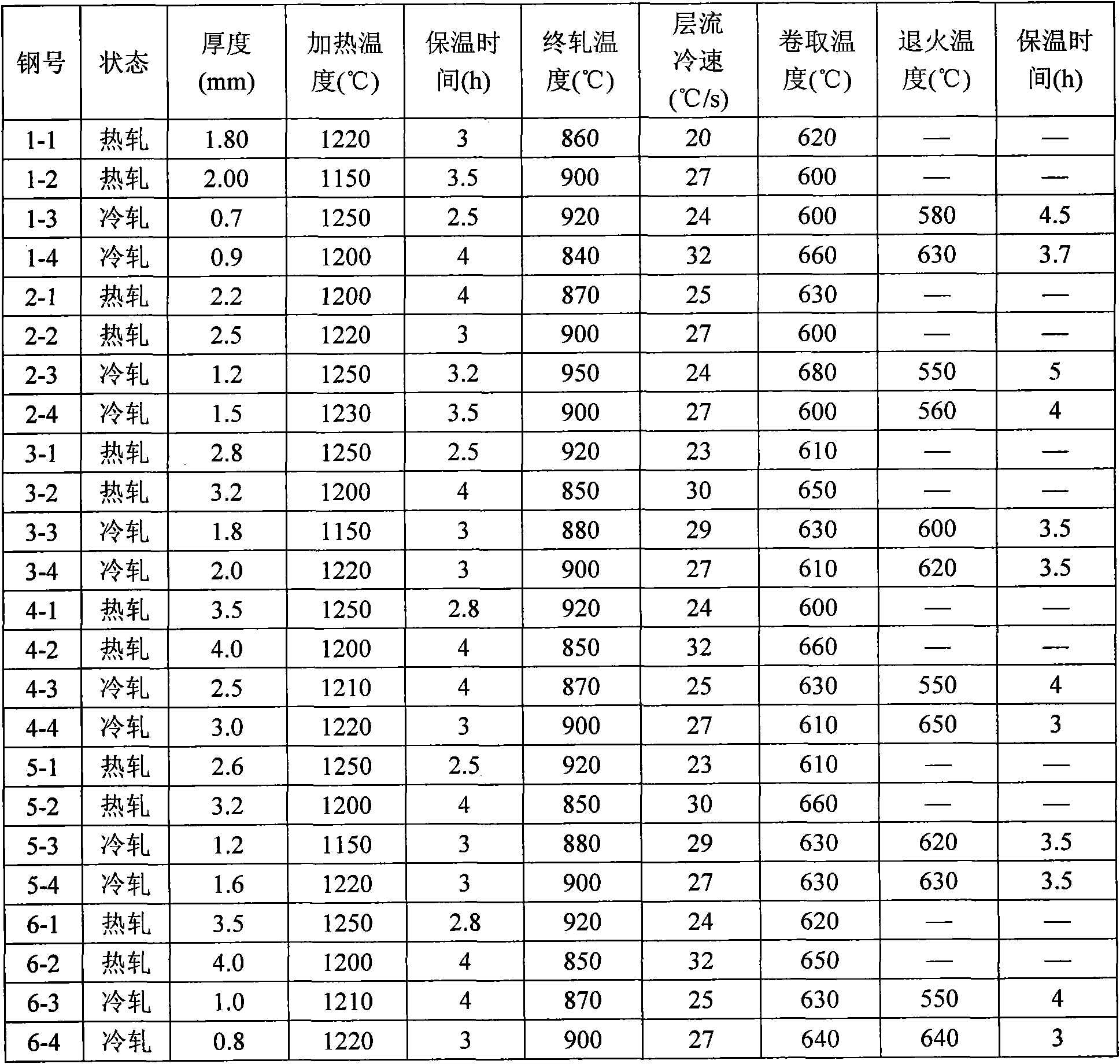

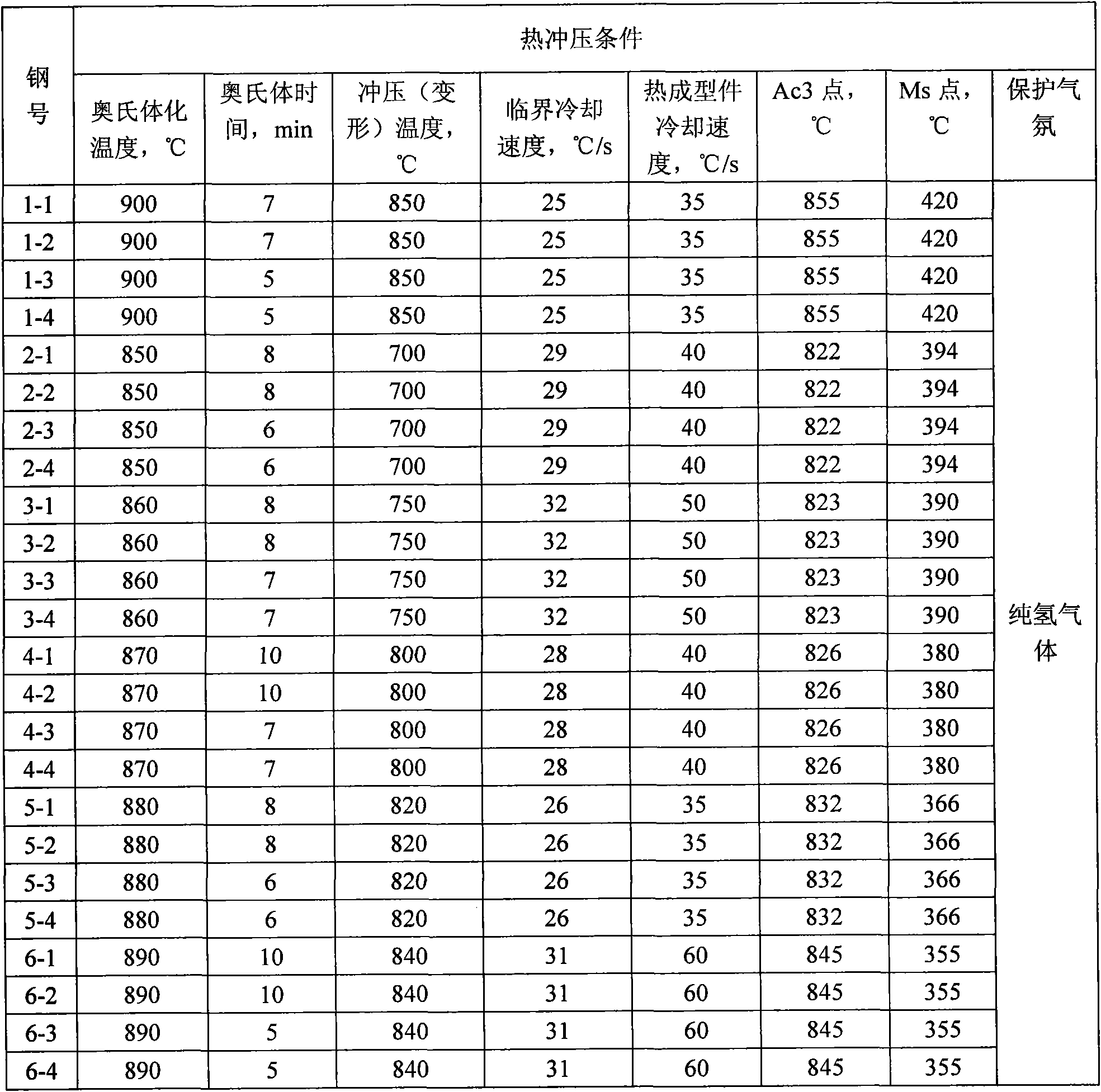

Steel plate for stamping and quenching and thermoforming method of steel plate

ActiveCN102031456ASimple compositionPlay the effect of weight reduction and energy savingHot stampingSimple component

The invention discloses a steel plate for stamping and quenching and a thermoforming method of the steel plate. The steel plate comprises the following chemical components in percentage by weight: 0.14-0.28% of C, less than 0.40% of Si, 0.4-2.0% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.016-0.040% of Al, 0.15-0.8% of Cr, 0.015-0.12% of Ti, 0.0001-0.005% of B, less than or equal to 0.005% of N, and the balance of Fe and inevitable impurities. The thermoforming method comprises the following steps: blanking by shearing the steel plate, and heating at Ac3 to (Ac3+80) DEG C to carry out austenization; after insulating for 5-10 minutes in the heating furnace, immediately transferring the steel plate to a metal mold the inside of which is cooled by introducing water, and stamping at the high temperature of 650-850 DEG C; cooling the formed workpiece in the closed mold, and cooling the mold by water circulation in the mold, wherein the cooling rate is greater than the critical cooling rate when austenite forms martensite, and the temperature of the workpiece leaving the hot stamping production line is below 150 DEG C; and carrying out air-cooling to room temperature. The steel plate has the advantages of simple component system and favorable hardenability; and the substrate tissues, which are ferrite and pearlite, are processed by hot stamping andquenching to obtain the all martensitic structure. The tensile strength of the steel plate can be higher than 1300 N / mm<2>.

Owner:ANGANG STEEL CO LTD

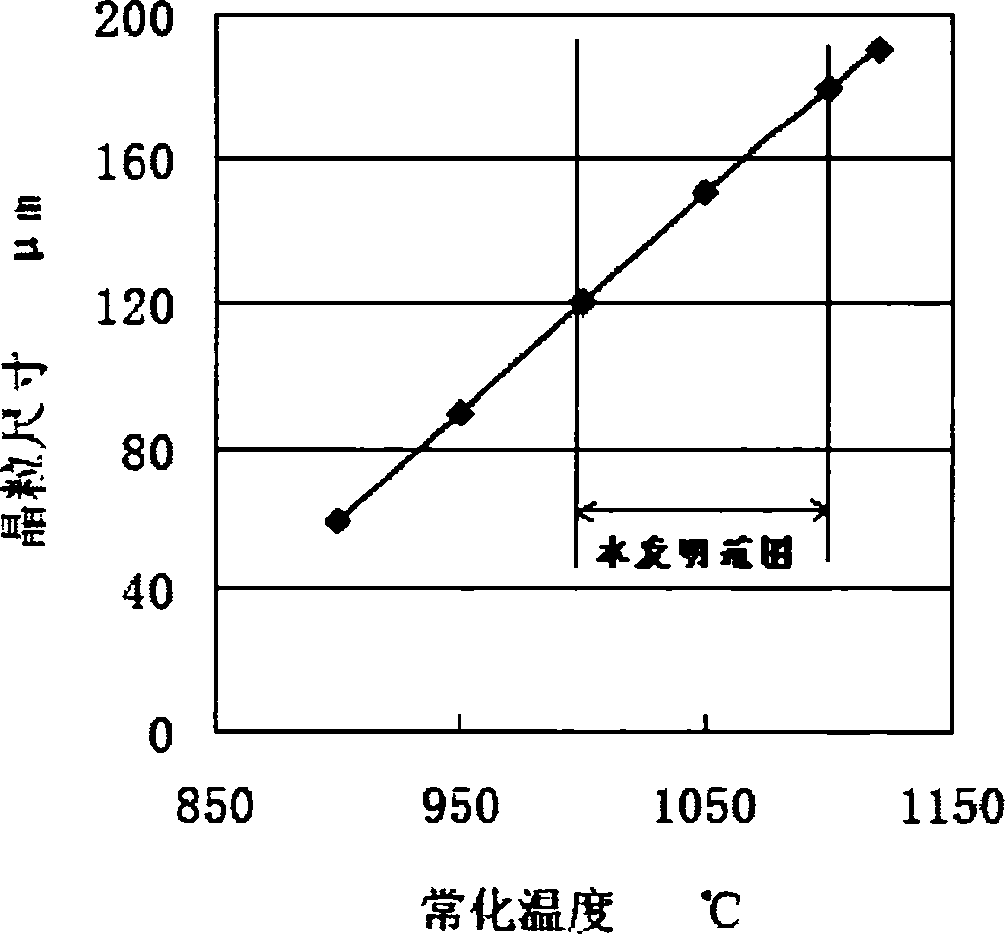

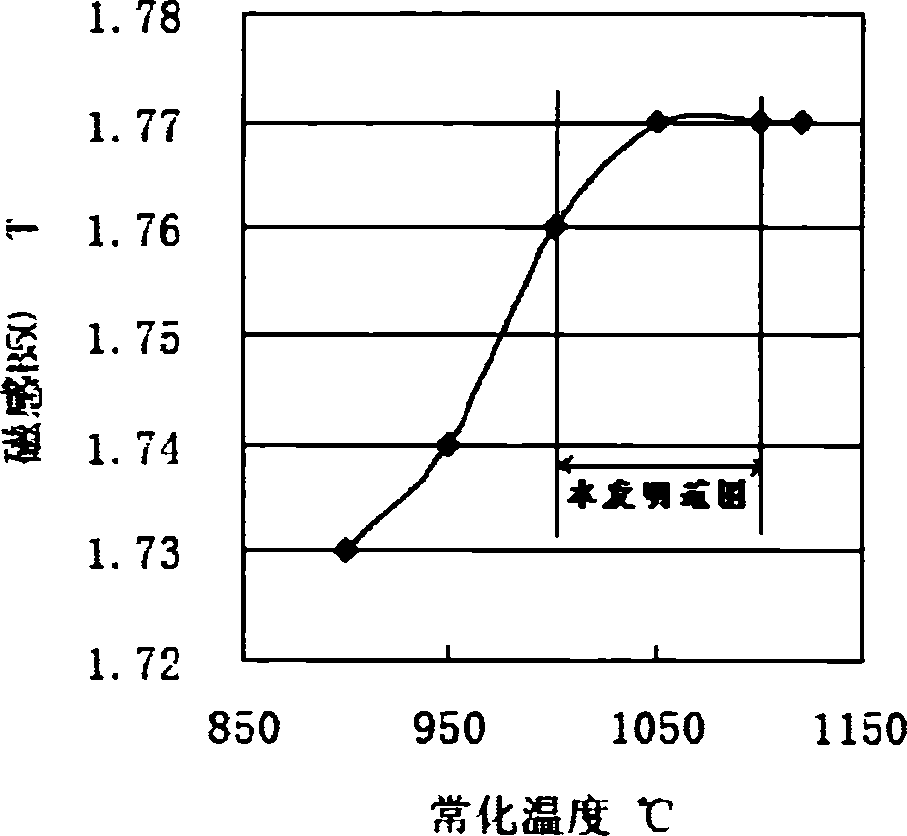

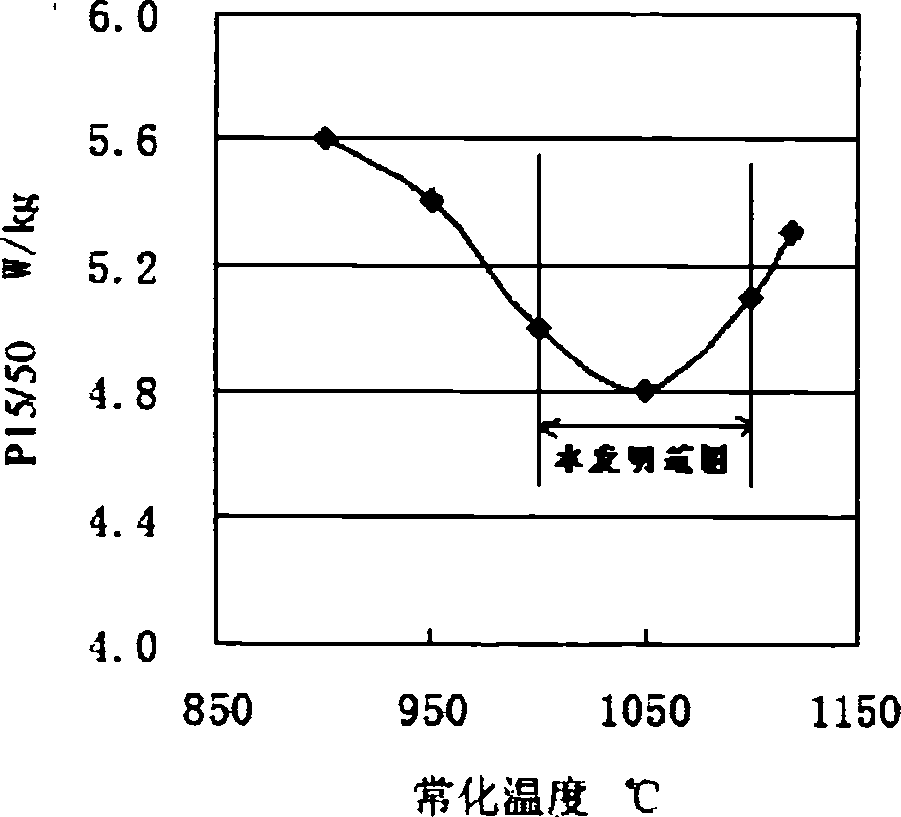

Production process of cold rolled orientation-free electrical steel plate with low iron loss and high magnetic induction

ActiveCN1887512ALow investment costReduce operating costsOther manufacturing equipments/toolsElectrical steelImpurity

The production process of cold rolled non-orientation electric steel plate comprising C not more than 0.0050 wt%, Si not more than 2.50 wt%, Al not more than 1.0 wt%, Si+2Al not more than 2.50 wt%, Mn 0.10-1.50 wt%, P not more than 0.20 wt%, S not more than 0.005 wt%, N not more than 0.0025 wt%, Sn+Sb not more than 0.2 wt%, and Fe and inevitable impurities for the rest includes the following steps: 1. smelting, continuous casting and rolling; 2. normalizing treatment of the hot rolled plate through heating at heating rate of 5-15 deg.c / s to over Ac1, heat soaking at 1100 deg.c below for 10-90 s, cooling in two stages including cooling at the cooling rate belw 15 deg.c / s to below 650 deg.c and cooling at the cooling rate capable of ensuring the plate form to below 80 deg.c; 3. cold rolling; and 4. final annealing to form the cold rolled non-orientation electric steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

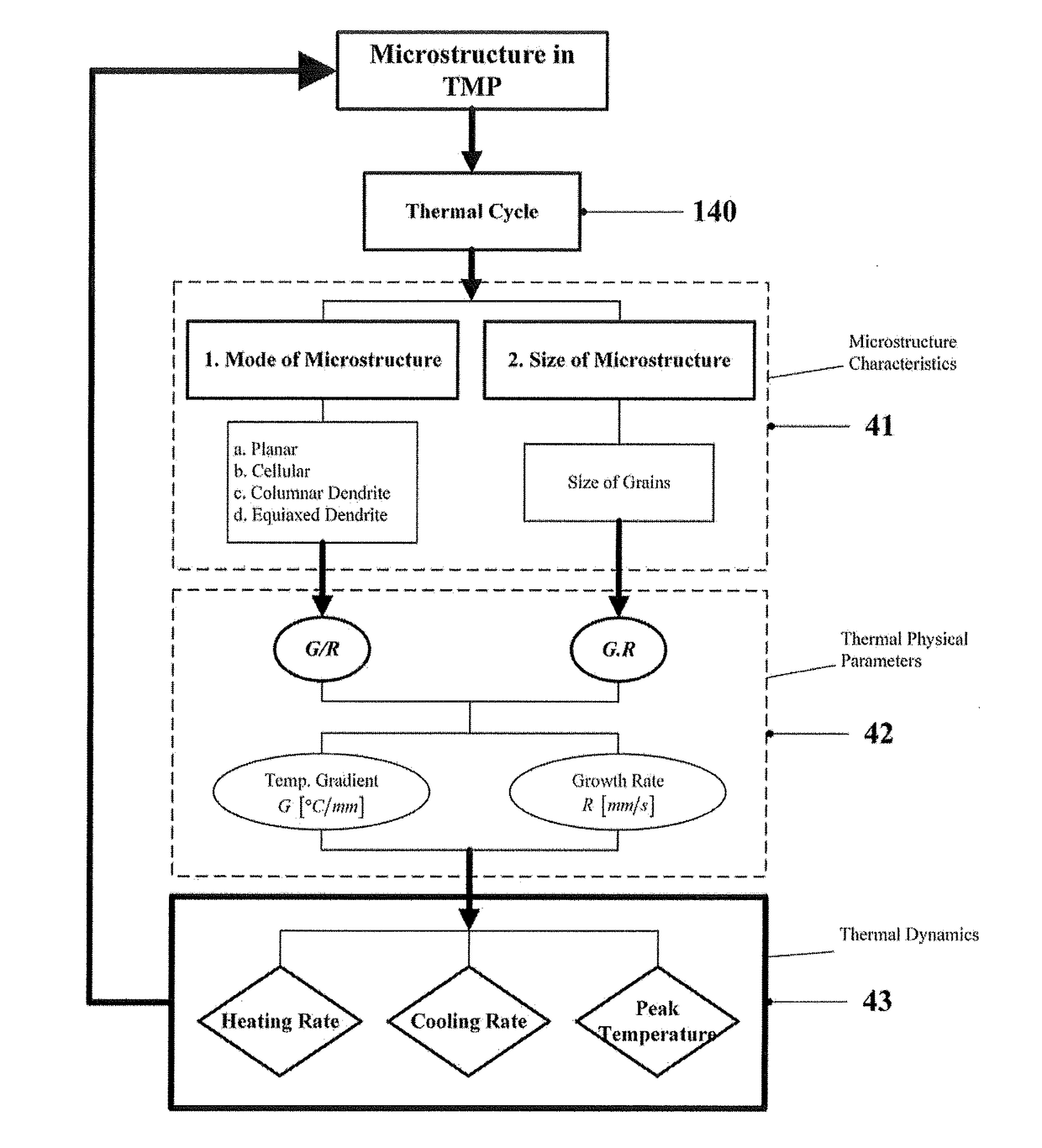

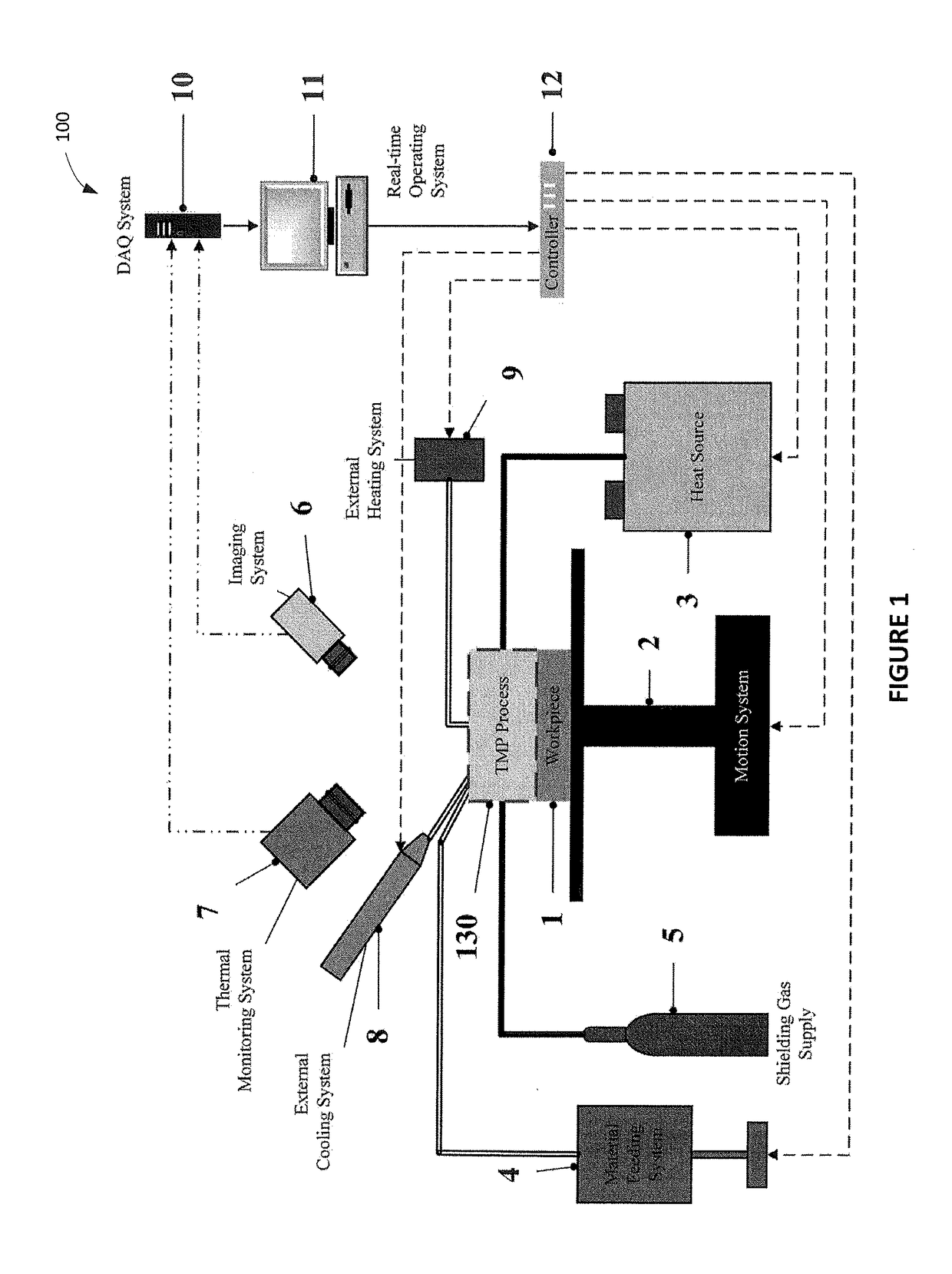

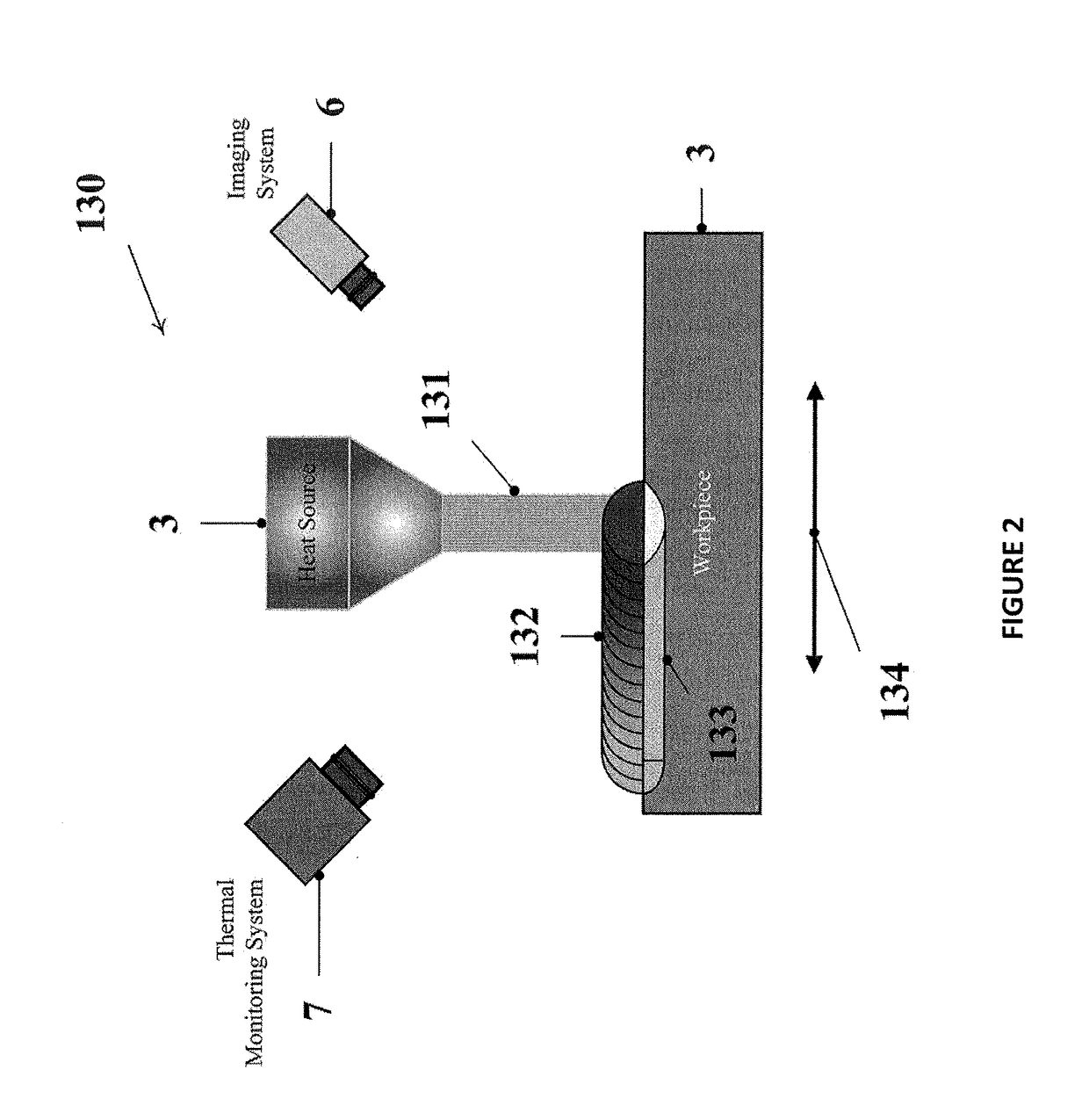

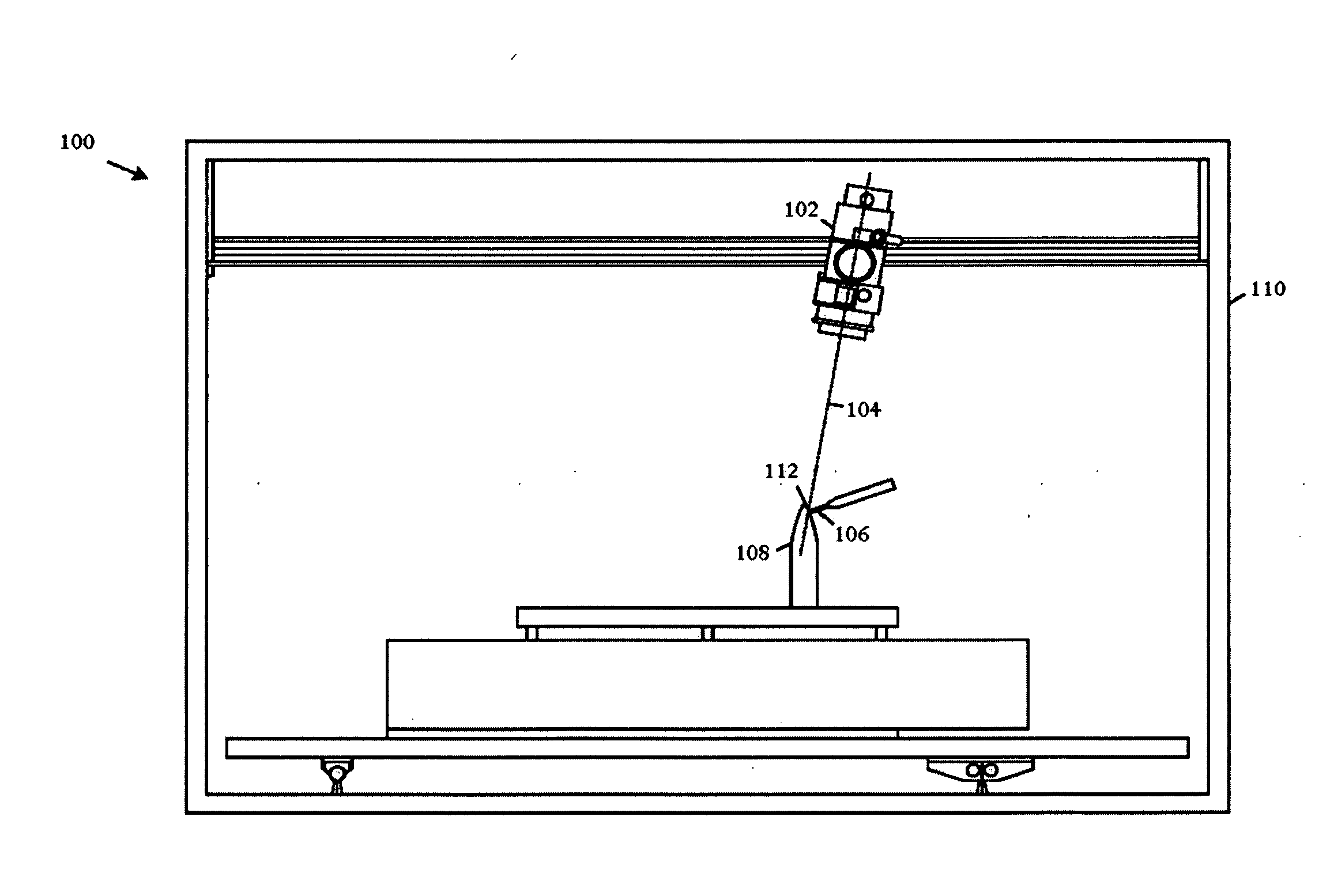

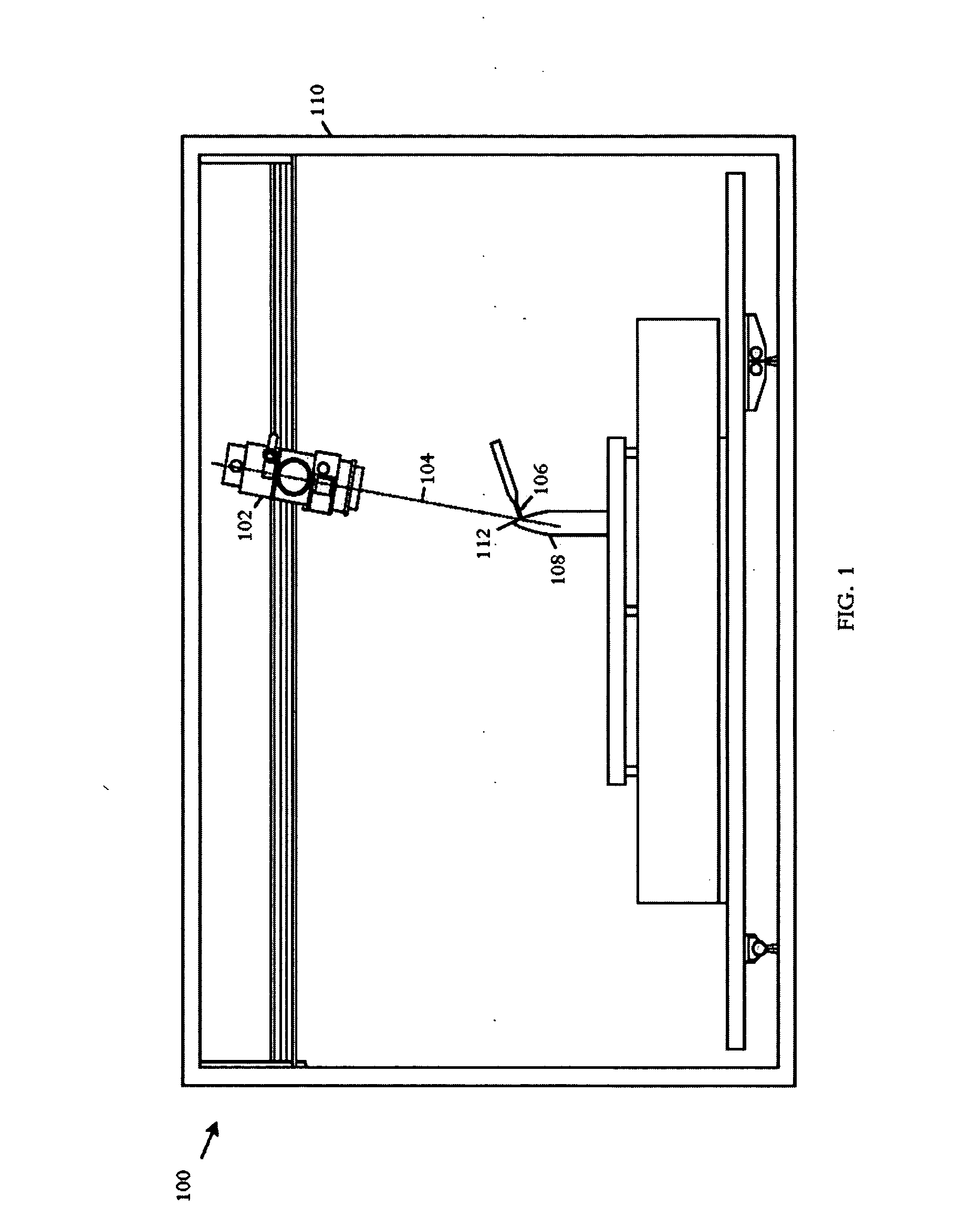

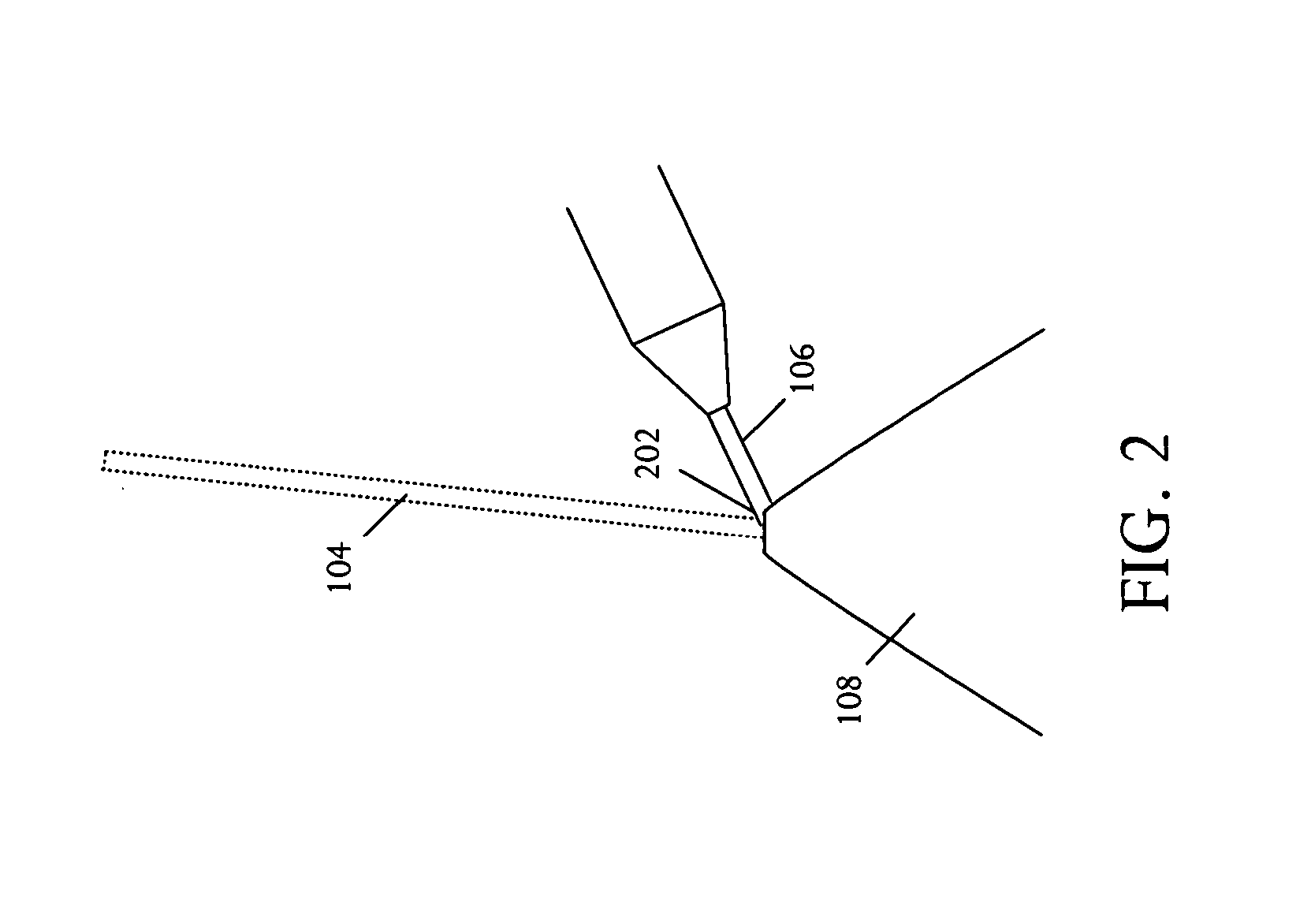

System and method for real time closed-loop monitoring and control of material properties in thermal material processing

ActiveUS20170102689A1Programme controlAdditive manufacturing apparatusProcess engineeringMonitoring and control

The disclosure is directed at a method and apparatus for integrated real-time monitoring and control of microstructure and / or geometry in thermal material processing (TMP) technologies. The method includes obtaining real-time thermal dynamic variables, such as, but not limited to the cooling rate, peak temperature and heating rate, and geometry of the thermal material process. These real-time thermal variables are then analyzed along with a thermal model to determine a microstructure / geometry model. This microstructure / geometry model can then be used to provide the real-time monitoring and control of a finished state for the material being processed by the thermal material processing procedure.

Owner:KHAJEPOUR AMIR +2

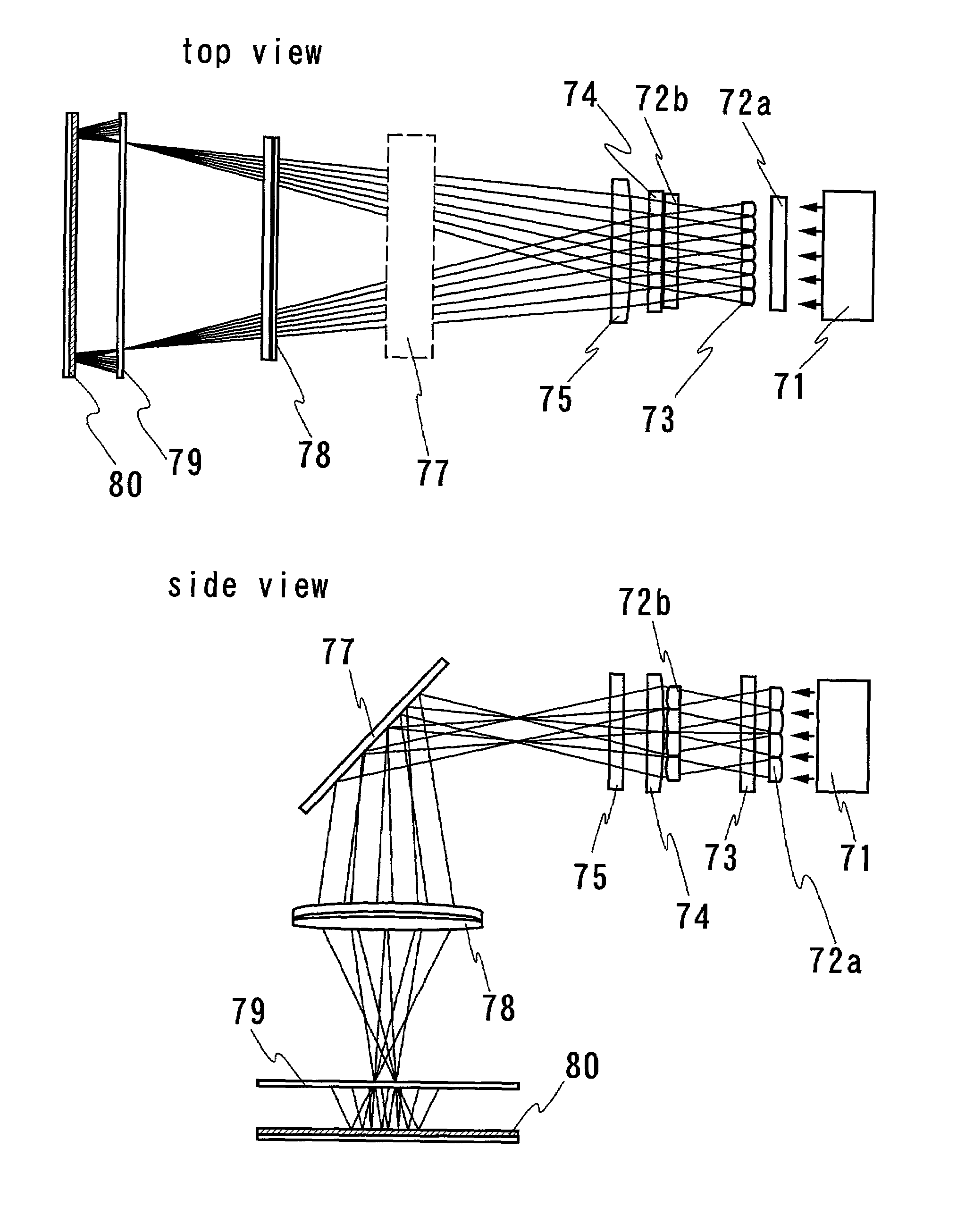

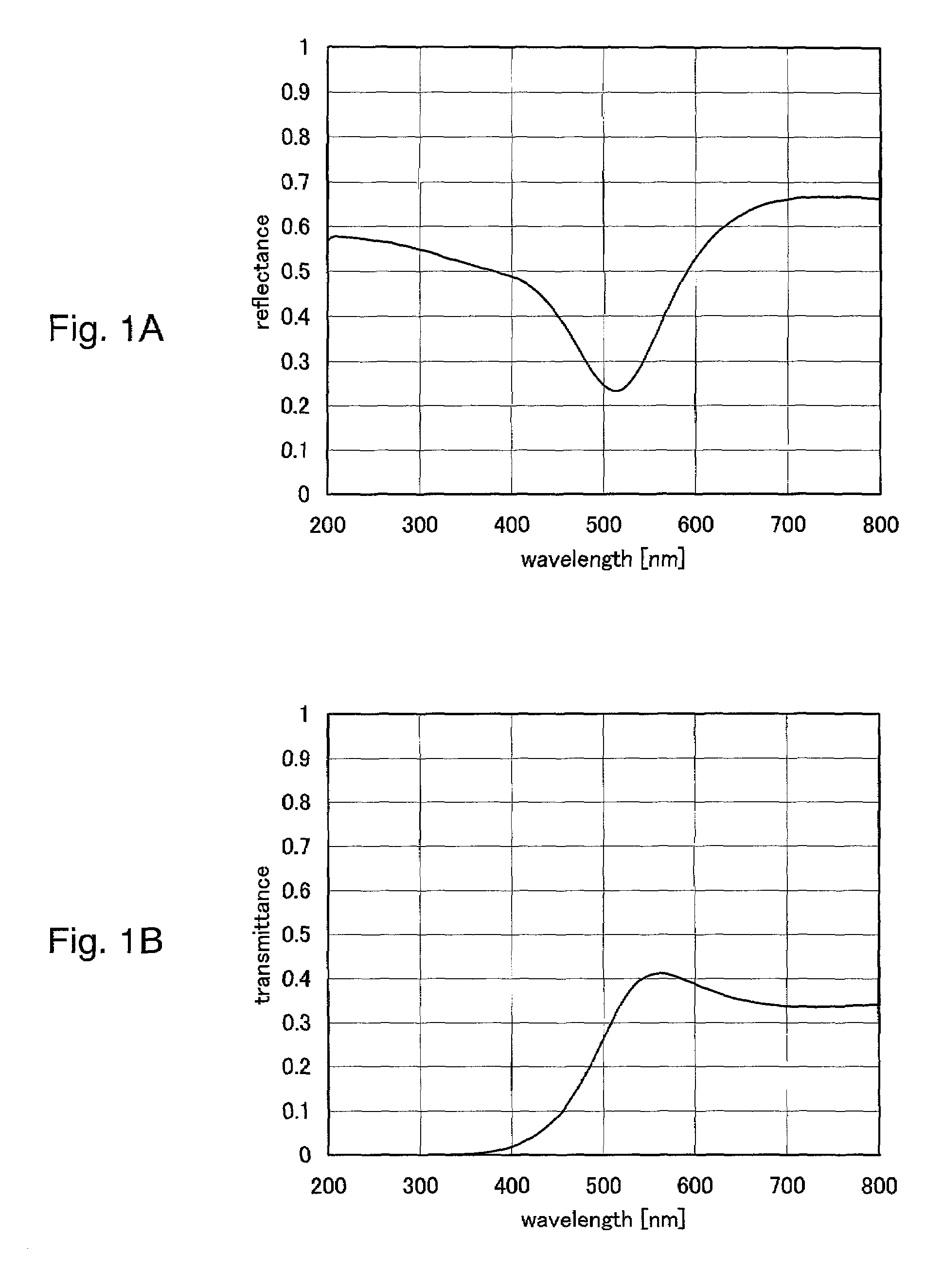

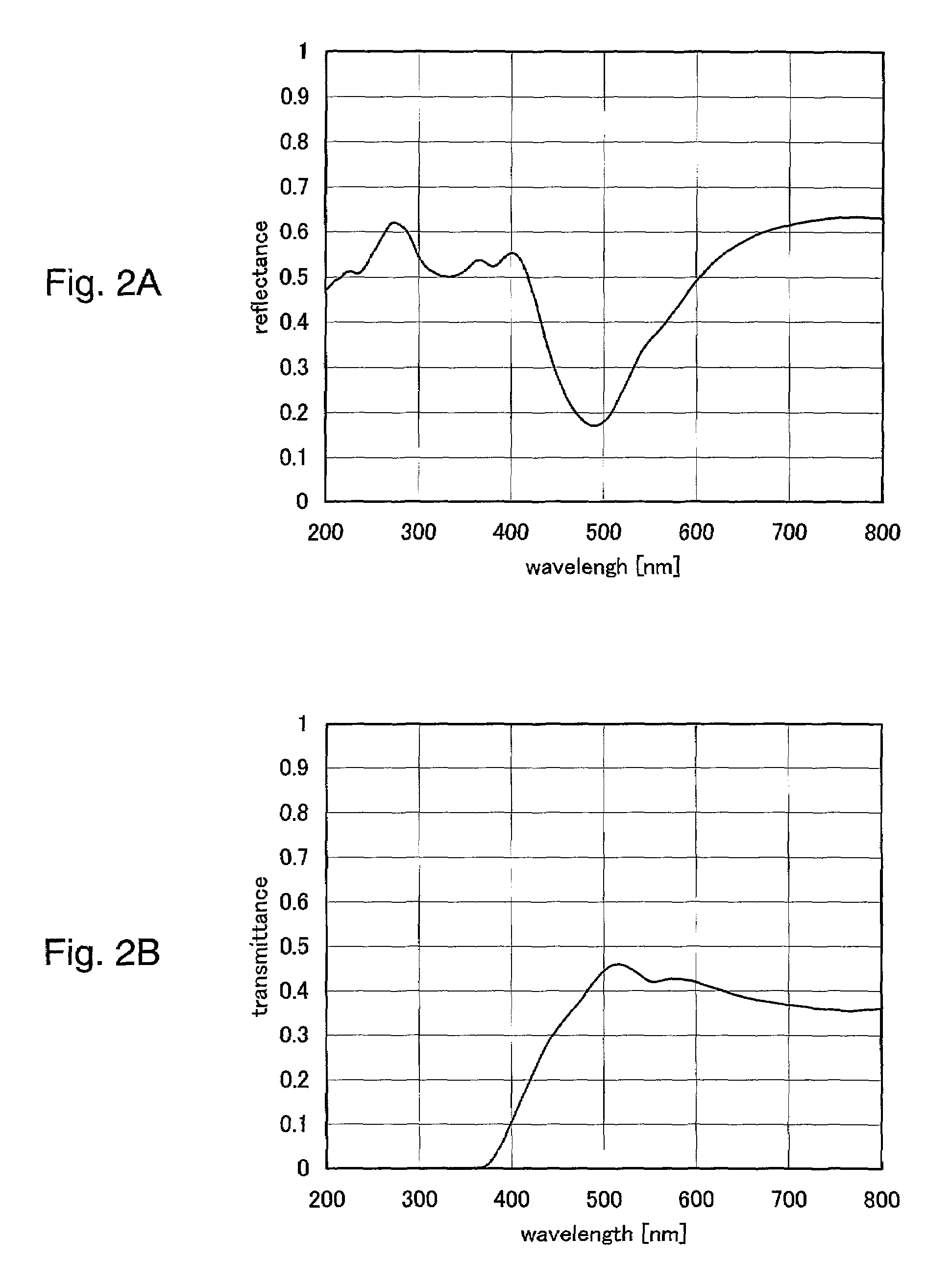

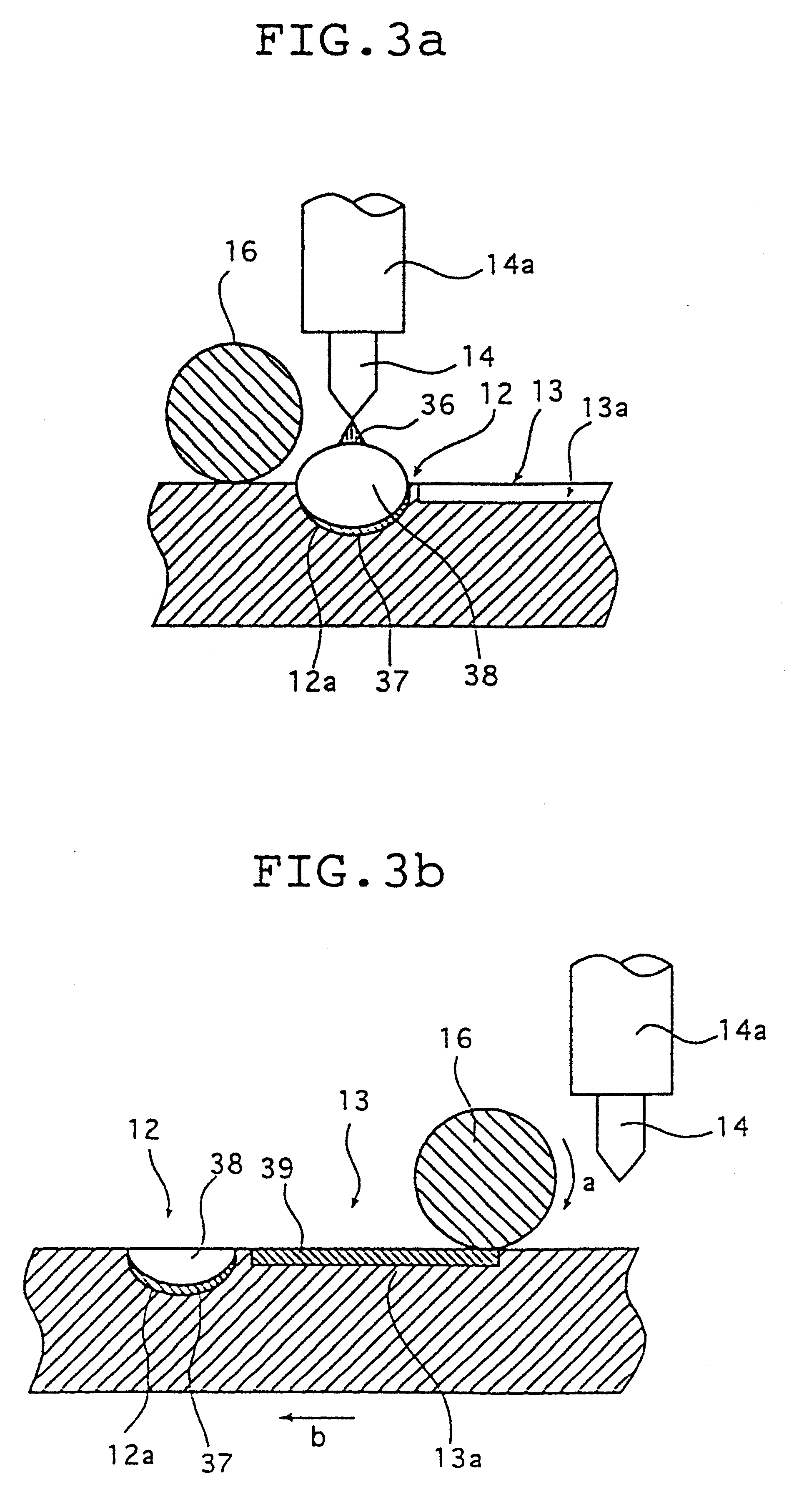

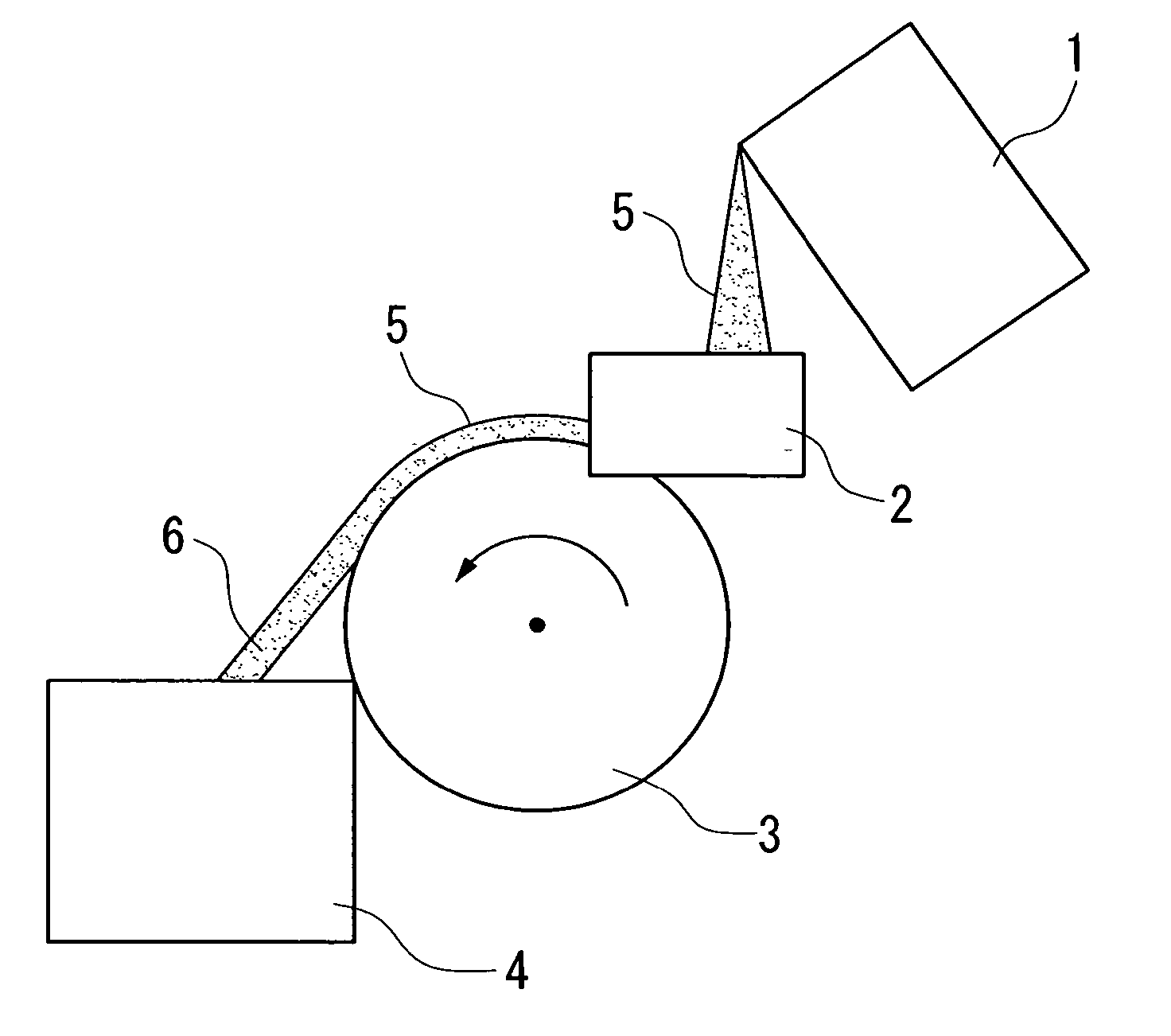

Laser irradiation method and method of manufacturing a semiconductor device

InactiveUS7217605B2Improve mobilityImprove semiconductor device performanceFrom solid stateSolid-state devicesLight beamReflective layer

A crystalline semiconductor film having crystal grains of large grain size or crystal grains in which the position and the size are controlled is formed to manufacture a TFT, whereby a semiconductor device that enables a high-speed operation is realized. First, a reflecting member is provided on a rear surface side of a substrate on which a semiconductor film is formed (semiconductor film substrate). When a front surface side of the semiconductor film substrate is irradiated with a laser beam that penetrates the semiconductor film substrate, the laser beam is reflected by the reflecting member to irradiate the semiconductor film from the rear surface side. With this method, an effective energy density is raised in the semiconductor film, and an output time is made long. Thus, the cooling rate of the semiconductor film is made gentle and crystal grains of large grain size are formed. Further, the front surface side of the semiconductor film substrate is irradiated with the laser beam by using a substrate on which a reflecting layer is partially formed as the reflecting member, whereby the semiconductor film is partially irradiated with the laser beam from the rear surface side. Thus, a temperature distribution is generated in the semiconductor film, and the location where a lateral growth is generated and the lateral direction can be controlled. Therefore, the crystal grains of large grain size can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

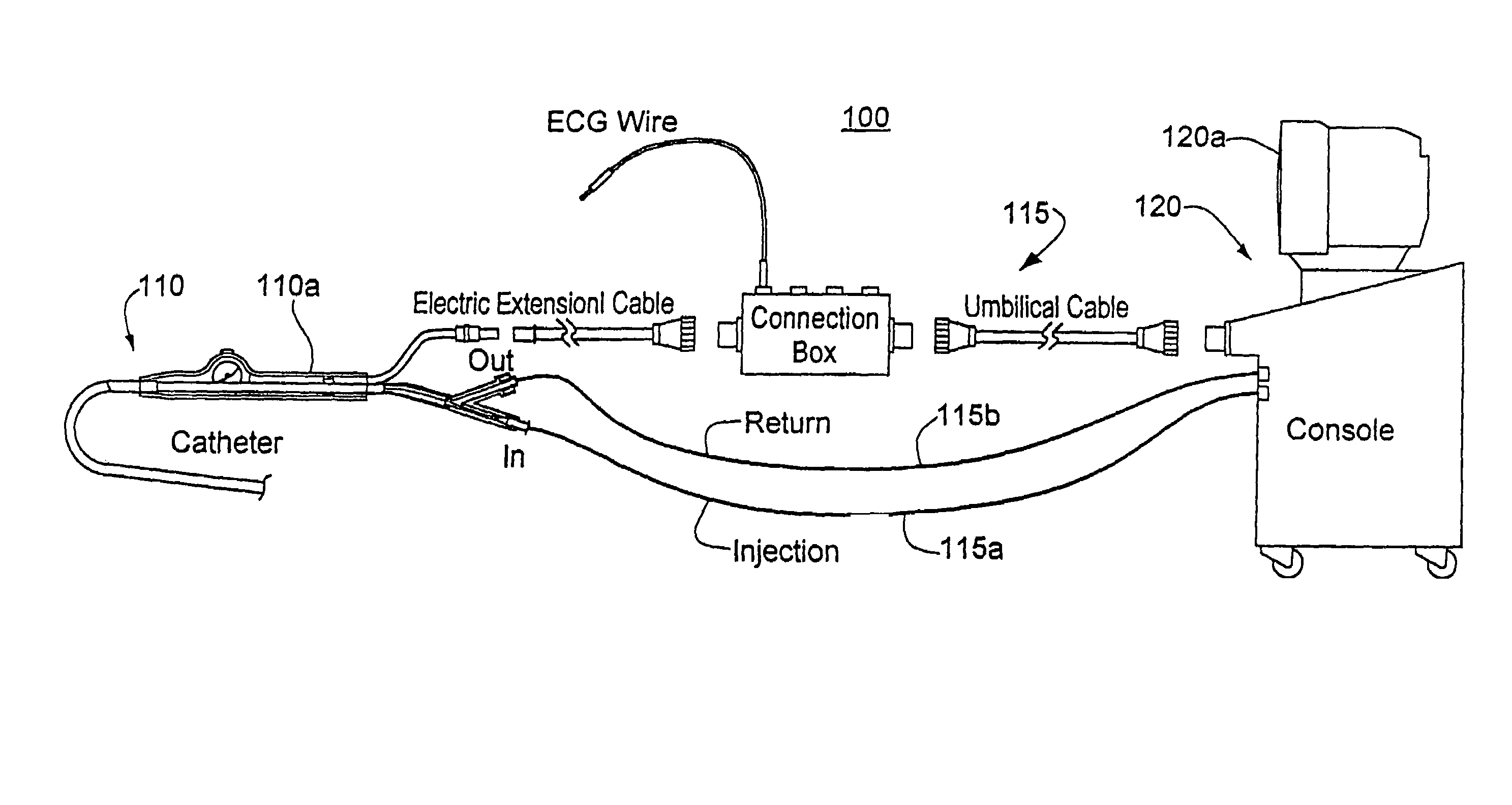

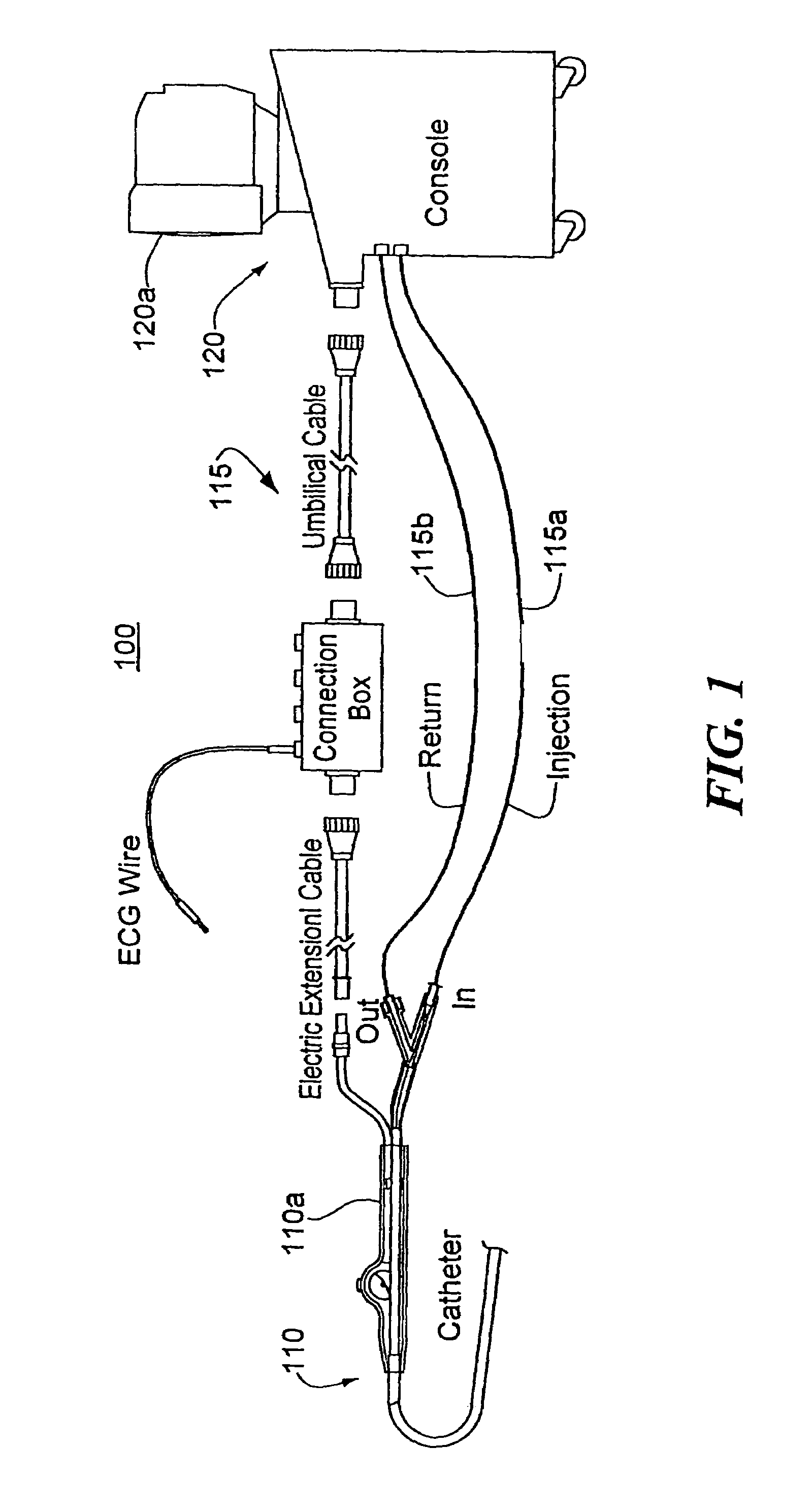

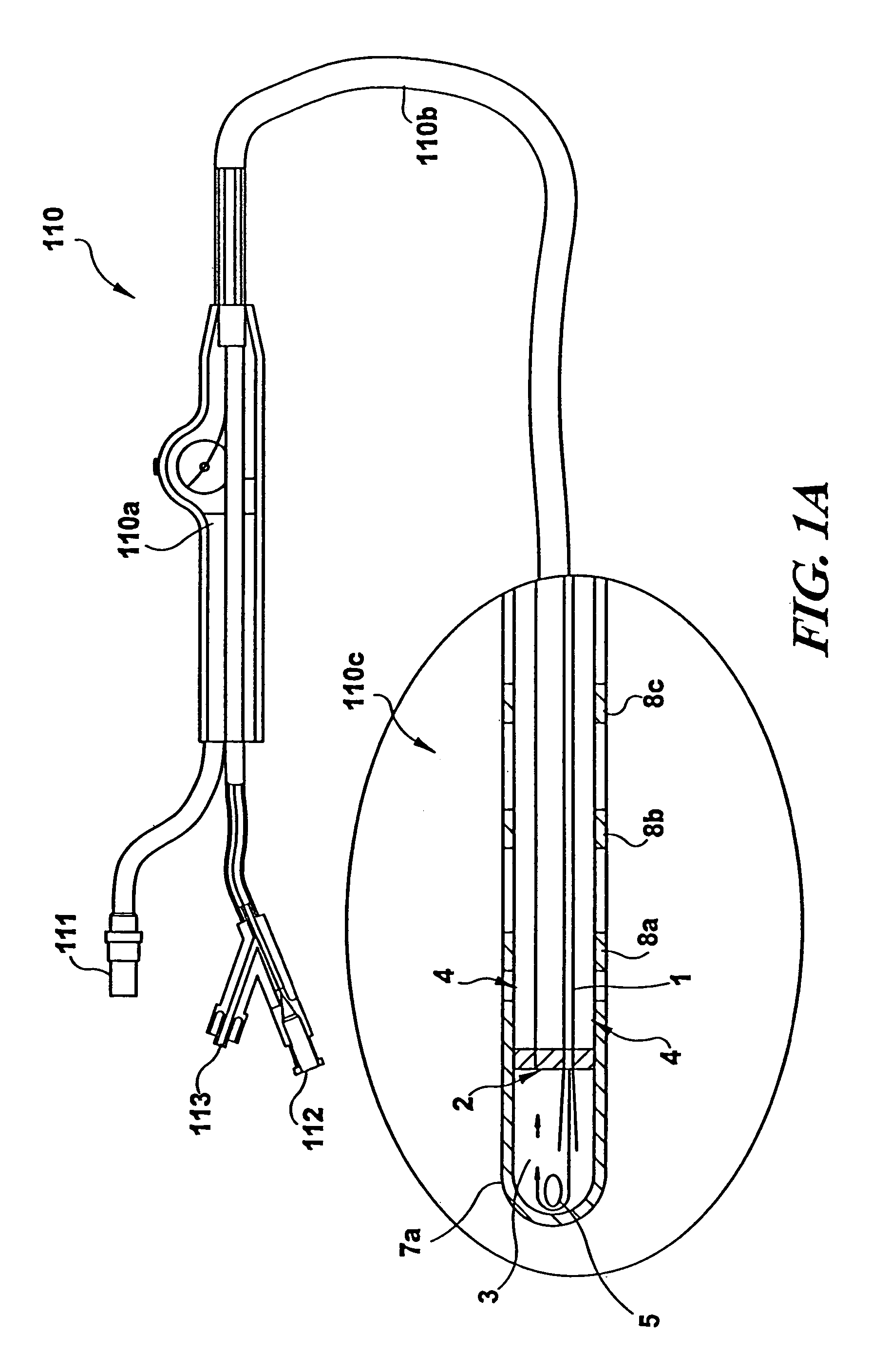

Closed loop catheter coolant system

A coolant system for a cryoablation or treatment probe such as a mapping or ablation catheter, or a treatment wand, includes a compressor and condenser having a low pressure inlet side and a high pressure outlet side, wherein the outlet side passes through a heat exchanger and is cooled by the inlet side and conditioned for injection to a catheter inlet. A vacuum return system connectable to the catheter outlet draws thermally expended coolant from the catheter and returns it to the low pressure inlet side. A motorized pressure regulator between the heat exchanger and the catheter inlet determines the pressure of coolant passing into the catheter and thus regulates the cooling rate for a selected mapping or ablation regimen. The low pressure compressor inlet supply preferentially conditions the pressurized coolant to ambient temperature or lower before injection into the catheter, allowing the coolant to travel through the body at ambient before expansion in the tip.

Owner:MEDTRONIC CRYOCATH LP

Process for producing glass substrate and glass substrate

ActiveUS20090226733A1Easy to distortReadily warpedGlass drawing apparatusGlass forming apparatusBand shapeMolten glass

Provided are a process for producing a glass substrate usable for low-temperature p-SiTFT substrates directly in accordance with a down draw method, and the glass substrate obtained by the process. The process for producing a glass substrate includes a forming step of forming a molten glass into a ribbon shape in accordance with a down draw method, an annealing step of annealing the glass ribbon, and a cutting step of cutting the glass ribbon to give a glass substrate, in which, in the annealing step, an average cooling rate from the annealing point to the (annealing point −50° C.) is lower than an average cooling rate from the (annealing point +100° C.) to the annealing point.

Owner:NIPPON ELECTRIC GLASS CO LTD

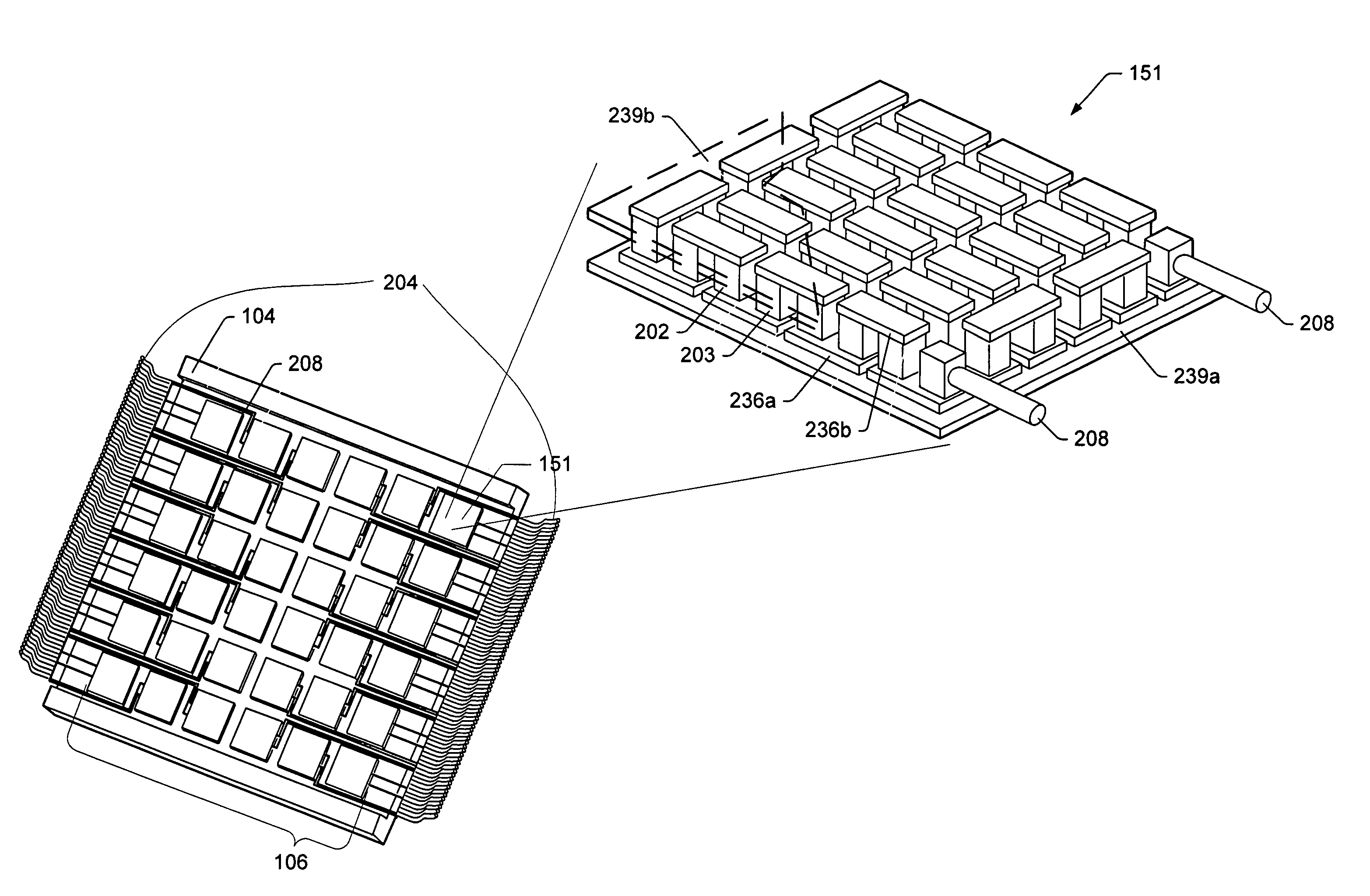

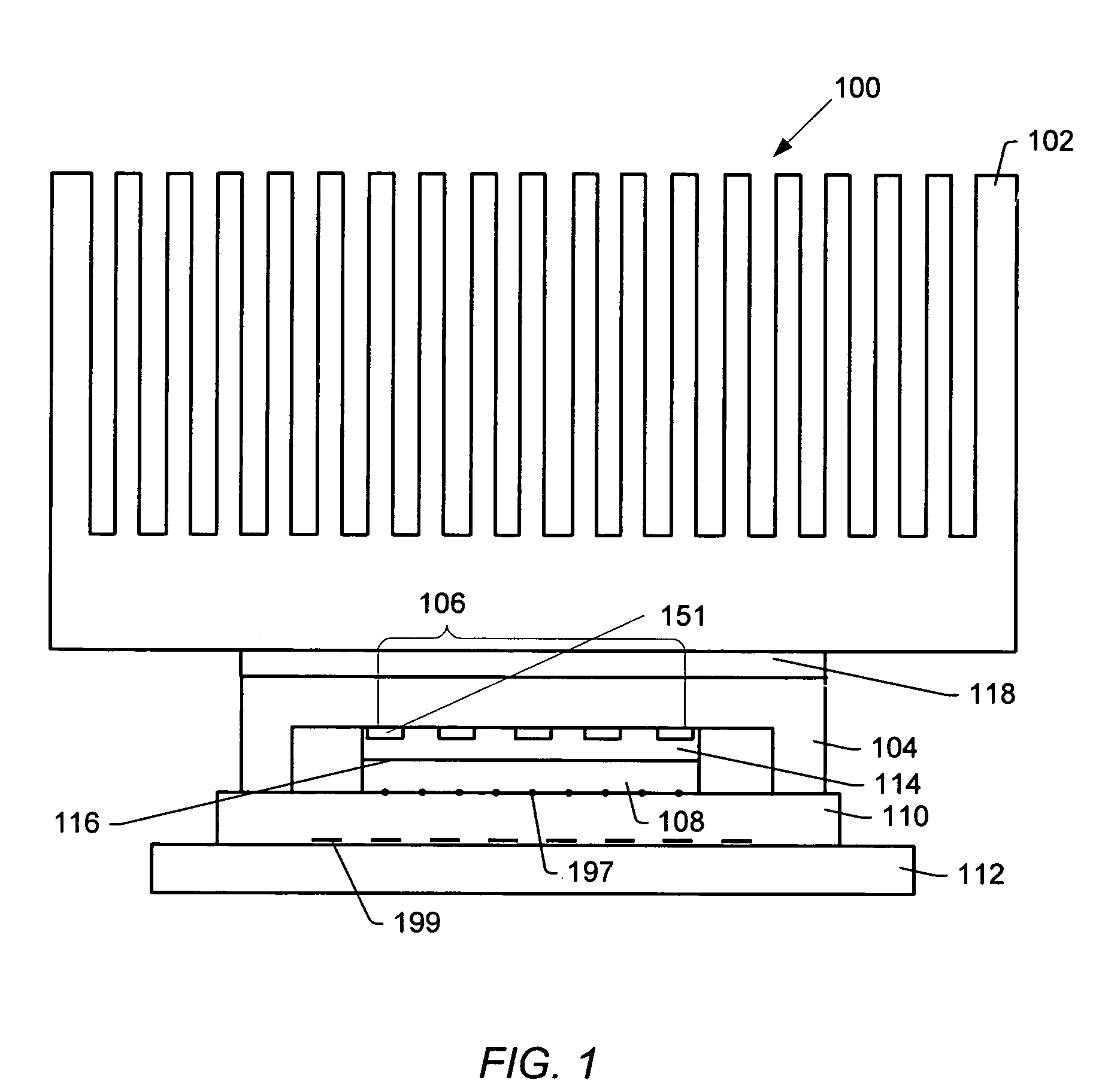

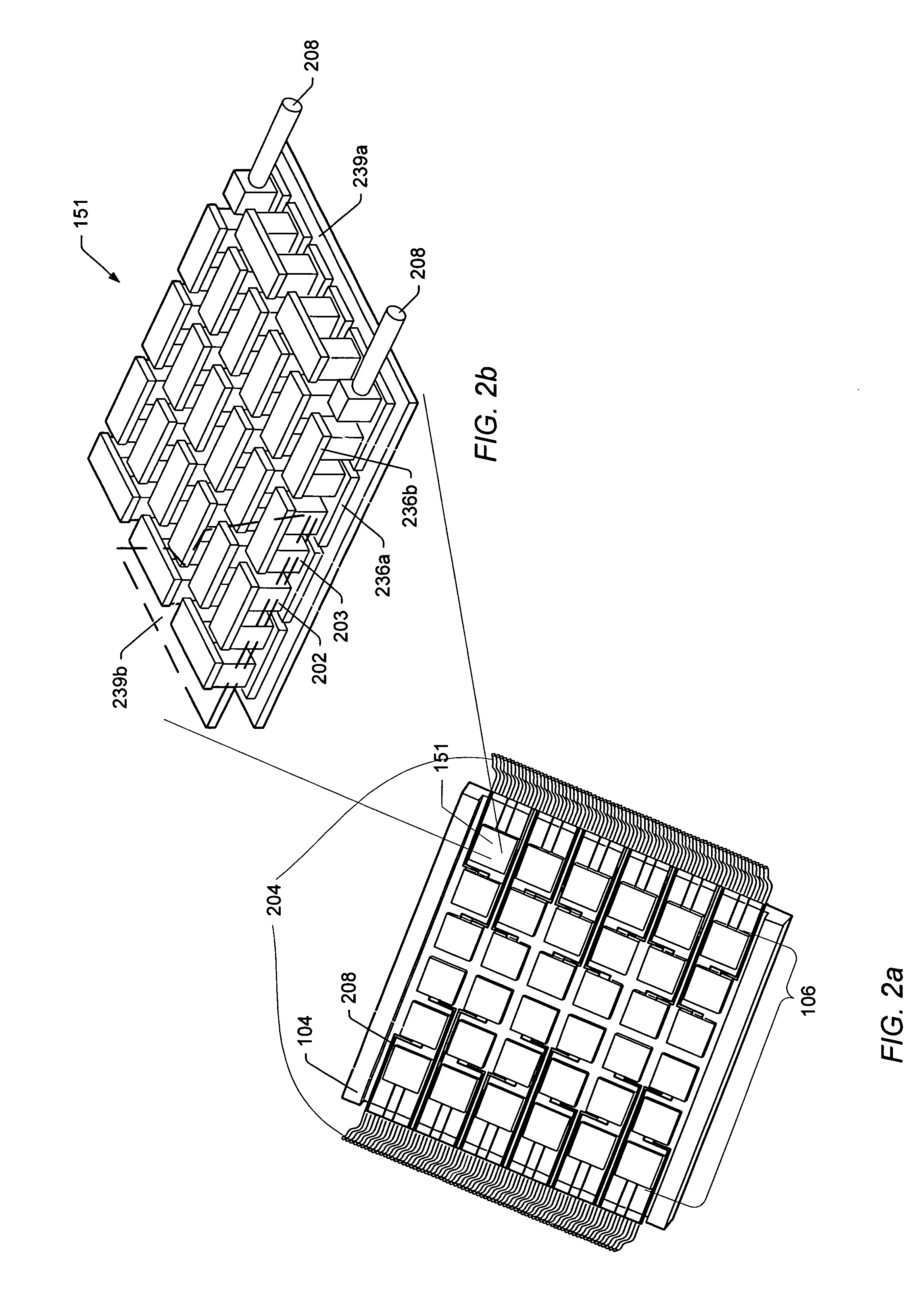

Thermoelectric cooling device arrays

ActiveUS7436059B1Speed up coolingReduce cooling rateThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsThermoelectric coolingEngineering

In various embodiments, a TEC device array may be coupled to a chip and a heat sink to cool the chip. The TEC device array may include multiple TEC devices separately controlled to provide different cooling rates at different points in the TEC device array coupled to the chip. In some embodiments, temperature data for areas on the chip or for separate electronic components may be determined using one or more thermal sensors and then sent to a controller. The controller may then determine an appropriate response for the TEC devices in the TEC device array near the area of the thermal sensor(s). The controller may thus control the cooling rates (which may be different) of several TEC devices in the TEC device array.

Owner:ORACLE INT CORP

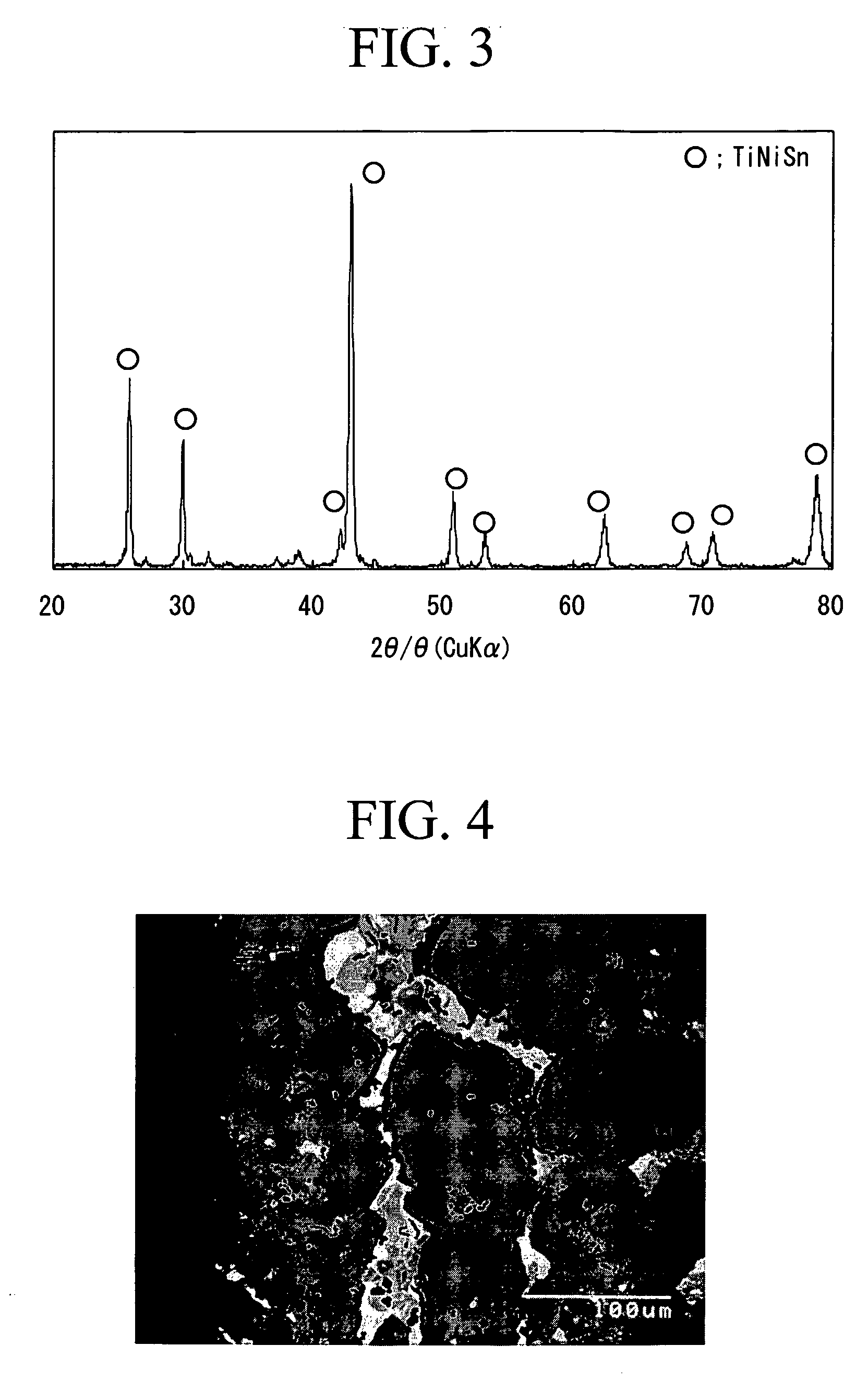

Production Method of Thermoelectric Semiconductor Alloy, Thermoelectric Conversion Module and Thermoelectric Power Generating Device

InactiveUS20080092940A1Improve performanceLow costThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentSemiconductor alloysThermoelectric conversion

The present invention provides a method for producing a half Heuslar alloy including quench-solidifying a molten alloy at a cooling rate of 1×102 to 1×103° C. / sec to produce a Heuslar alloy represented by the formula: ABC (wherein A and B each is at least one member selected from transition metals such as Fe, Co, Ni, Ti, V, Cr, Zr, Hf, Nb, Mo, Ta and W, and C is at least one member selected from Group 13 or 14 element such as Al, Ga, In, Si, Ge and Sn), and a high-performance thermoelectric power generating device using the thermoelectric semiconductor alloy.

Owner:SHOWA DENKO KK

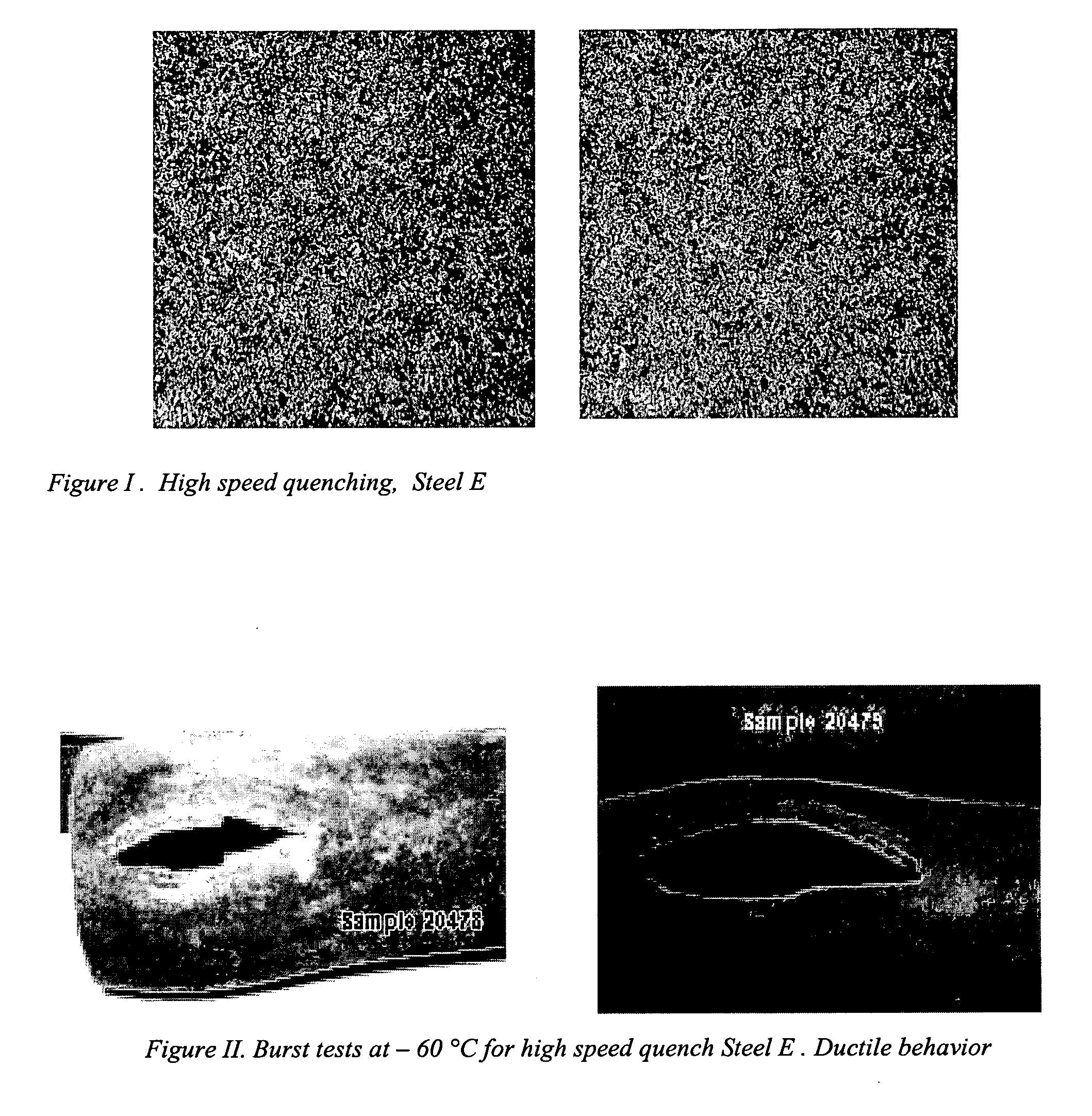

Low carbon alloy steel tube having ultra high strength and excellent toughness at low temperature and method of manufacturing the same

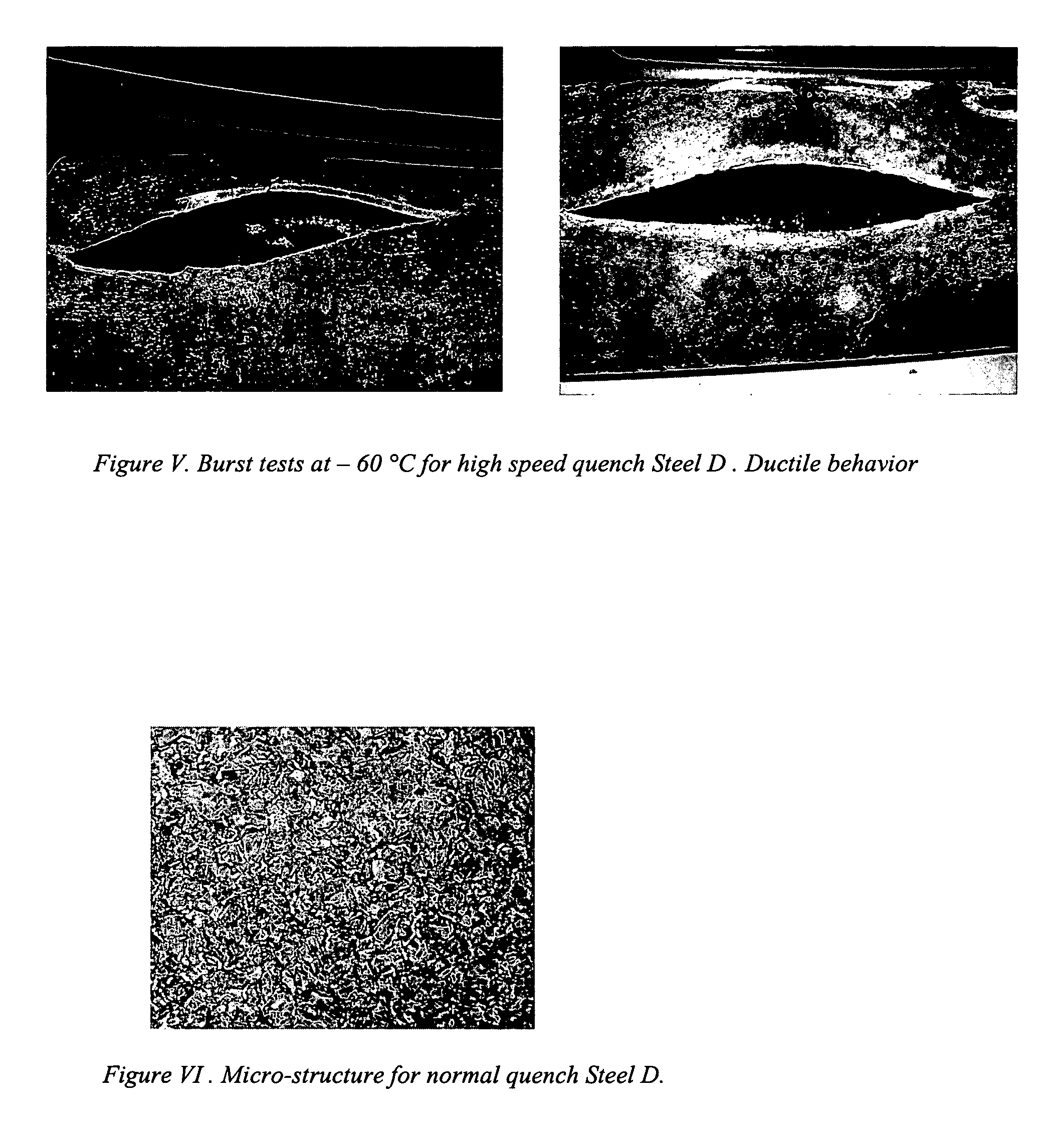

InactiveUS20060169368A1Increase burst pressureImprove toughnessFurnace typesHeat treatment furnacesWater basedNiobium

A low carbon alloy steel tube and a method of manufacturing the same, especially for a stored gas inflator pressure vessel, in which the steel tube consists essentially of, by weight: about 0.06% to about 0.18% carbon, about 0.3% to about 1.5% manganese, about 0.05% to about 0.5% silicon, up to about 0.015% sulfur, up to about 0.025% phosphorous, and at least one of the following elements: up to about 0.30% vanadium, upto t about 0.10% aluminum, up to about 0.06% niobium, up to about 1% chromium, up to about 0.70% nickel, up to about 0.70% molybdenum, up to about 0.35% copper, up to about 0.15% residual elements, and the balance iron and incidental impurities. After a high heating rate of about 100° C. per second; rapidly and fully quenching the steel tubing in a water-based quenching solution at a cooling rate of about 100° C. per second. The steel has a tensile strength of at least about 145 ksi and as high as 220 ksi and exhibits ductile behavior at temperatures as low as -100° C.

Owner:TENARIS CONNECTIONS LIECHTENSTEIN CORP

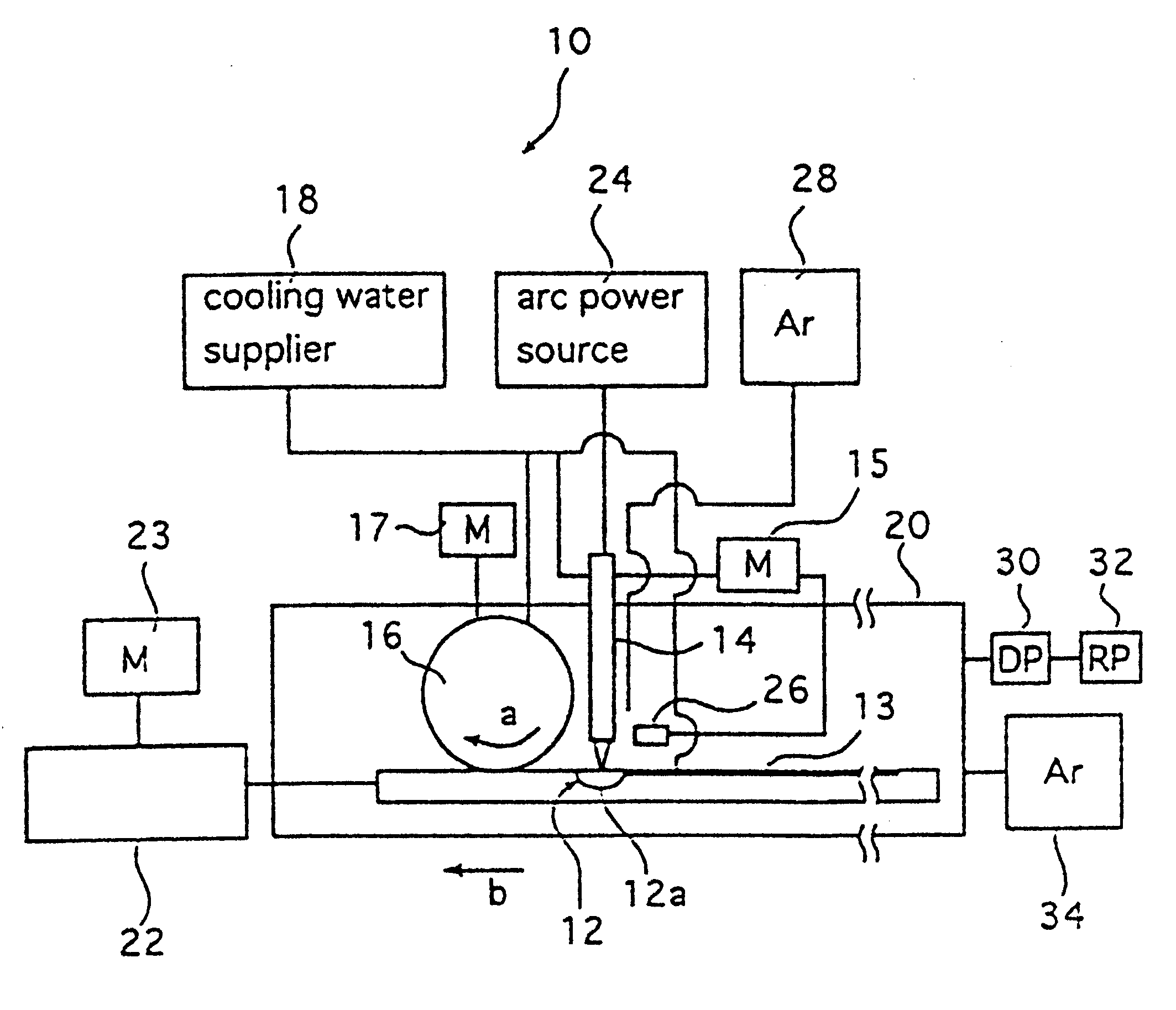

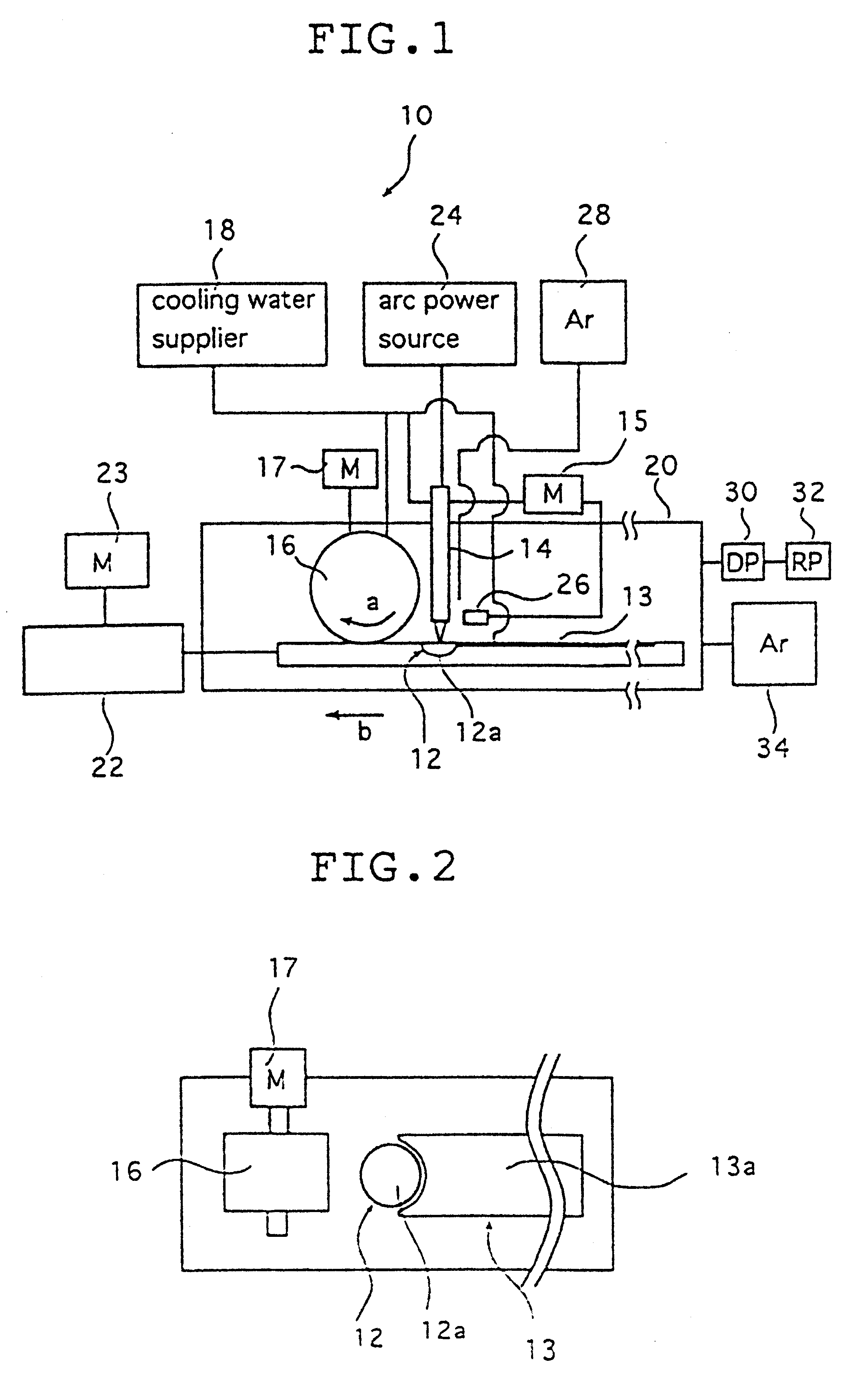

Process and apparatus for producing metallic glass

InactiveUS6427753B1Simple processGood strength performanceFoundry mouldsFoundry coresHigh energyHearth

A process and an apparatus for producing metallic glass which are capable of producing a bulk amorphous alloy of desired shape, in particular, a bulk amorphous alloy of desired final shape are provided. In the present invention, the molten metal at a temperature above the melting point is selectively cooled at a rate higher than the critical cooling rate, and the product comprises single amorphous phase which is free from the crystalline phase formed by the development of crystal nuclei through nonuniform nucleation. The present invention is capable of producing the bulk amorphous alloy which is free from casting defects such as cold shuts and which has excellent strength properties in a simple process at a high reproducibility. Accordingly, a bulk metallic glass of desired shape is produced by filling a metal material in a hearth; melting the metal material by using a high-energy heat source which is capable of melting the metal material; pressing the molten metal at a temperature above the melting point of the metal material to deform the molten metal into the desired shape by at least one of compressive stress and shear stress at a temperature above the melting point, while avoiding the surfaces of the molten metal cooled to a temperature below the melting point of the metal material from meeting with each other during the pressing; and cooling the molten metal at a cooling rate higher than the critical cooling rate of the metal material simultaneously with or after the deformation to produce the bulk metallic glass of desired form.

Owner:MAKABE GIKEN

Nanostructured soldered or brazed joints made with reactive multilayer foils

InactiveUS7361412B2Reduce coolingImprove microstructureExothermal chemical reaction heat productionVacuum evaporation coatingRoom temperatureSlow cooling

Self-propagating formation reactions in nanostructured multilayer foils provide rapid bursts of heat at room temperature and therefore can act as local heat sources to melt solder or braze layers and join materials. This reactive joining method provides very localized heating to the components and rapid cooling across the joint. The rapid cooling results in a very fine microstructure of the solder or braze material. The scale of the fine microstructure of the solder or braze material is dependant on cooling rate of the reactive joints which varies with geometries and properties of the foils and components. The microstructure of the solder or braze layer of the joints formed by melting solder in a furnace is much coarser due to the slow cooling rate. Reactive joints with finer solder or braze microstructure show higher shear strength compared with those made by conventional furnace joining with much coarser solder or braze microstructure. It is expected that the reactive joints may also have better fatigue properties compared with conventional furnace joints.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Warhead with integral, direct-manufactured features

InactiveUS20050235862A1Improve functionalityImprove permeabilityAmmunition projectilesAdditive manufacturing apparatusManufacturing technologyHigh energy

Owner:LOCKHEED MARTIN CORP

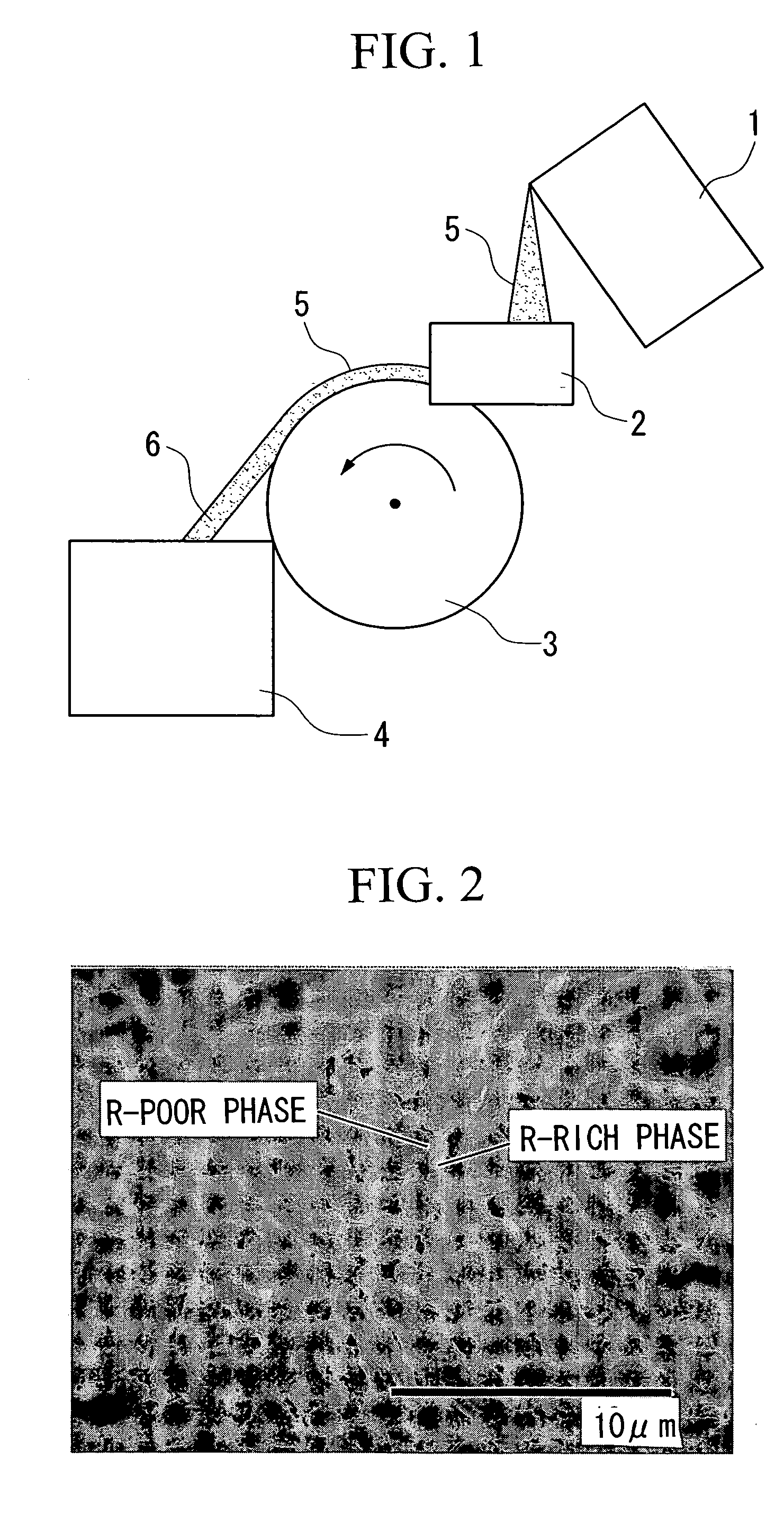

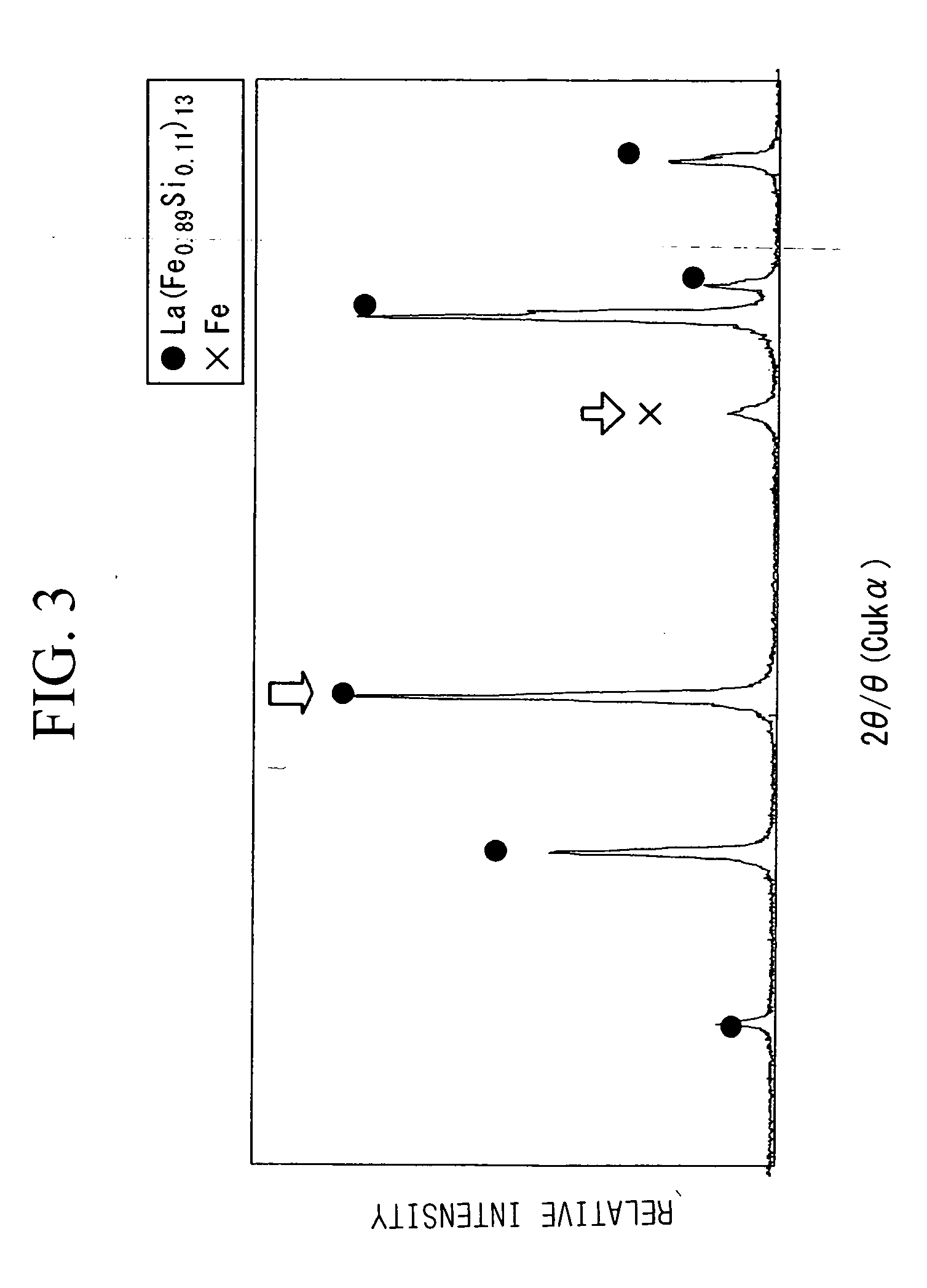

Alloy containing rare earth element, production method thereof, magnetostrictive device, and magnetic refrigerant material

InactiveUS20060076084A1Improve efficiencyReliably producedEnergy efficient heating/coolingInorganic material magnetismRare-earth elementCrystal structure

A method for producing an RE-containing alloy represented by formula R(T1−xAx)13−y (wherein R represents Ce, etc.; T represents Fe, etc.; and A represents Al, etc; 0.05≦x≦0.2; and −1≦y≦1) including a melting step of melting alloy raw materials at 1,200 to 1,800° C.; and a solidification step of rapidly quenching the molten metal produced through the above step, to thereby form the first RE-containing alloy, wherein the solidification step is performed at a cooling rate of 102 to 104° C. / second, as measured at least within a range of the temperature of the molten metal to 900° C.; and an RE-containing alloy, which is represented by a compositional formula of RrTtAa(wherein R and A represent the same meaning as above, T represents Fe, etc.; 5.0 at. %≦r≦6.8 at. %, 73.8 at. %≦t≦88.7 at. %, and 4.6 at. %≦a≦19.4 at. %) and has an alloy microstructure containing an NaZn13-type crystal structure in an amount of at least 85 mass % and α-Fe in an amount of 5-15 mass % inclusive.

Owner:ERASTEEL

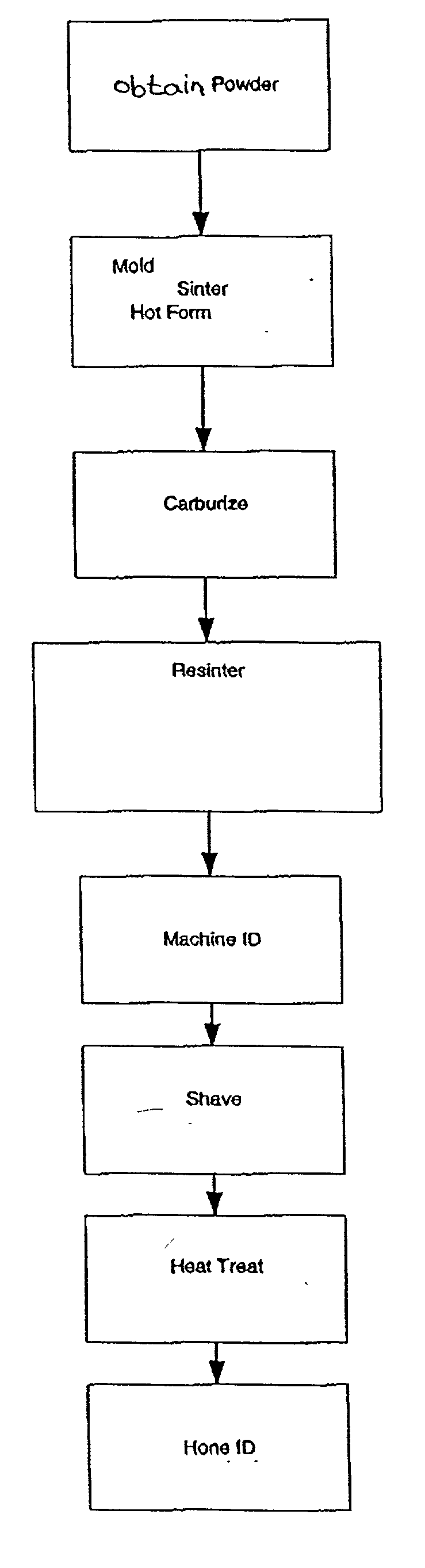

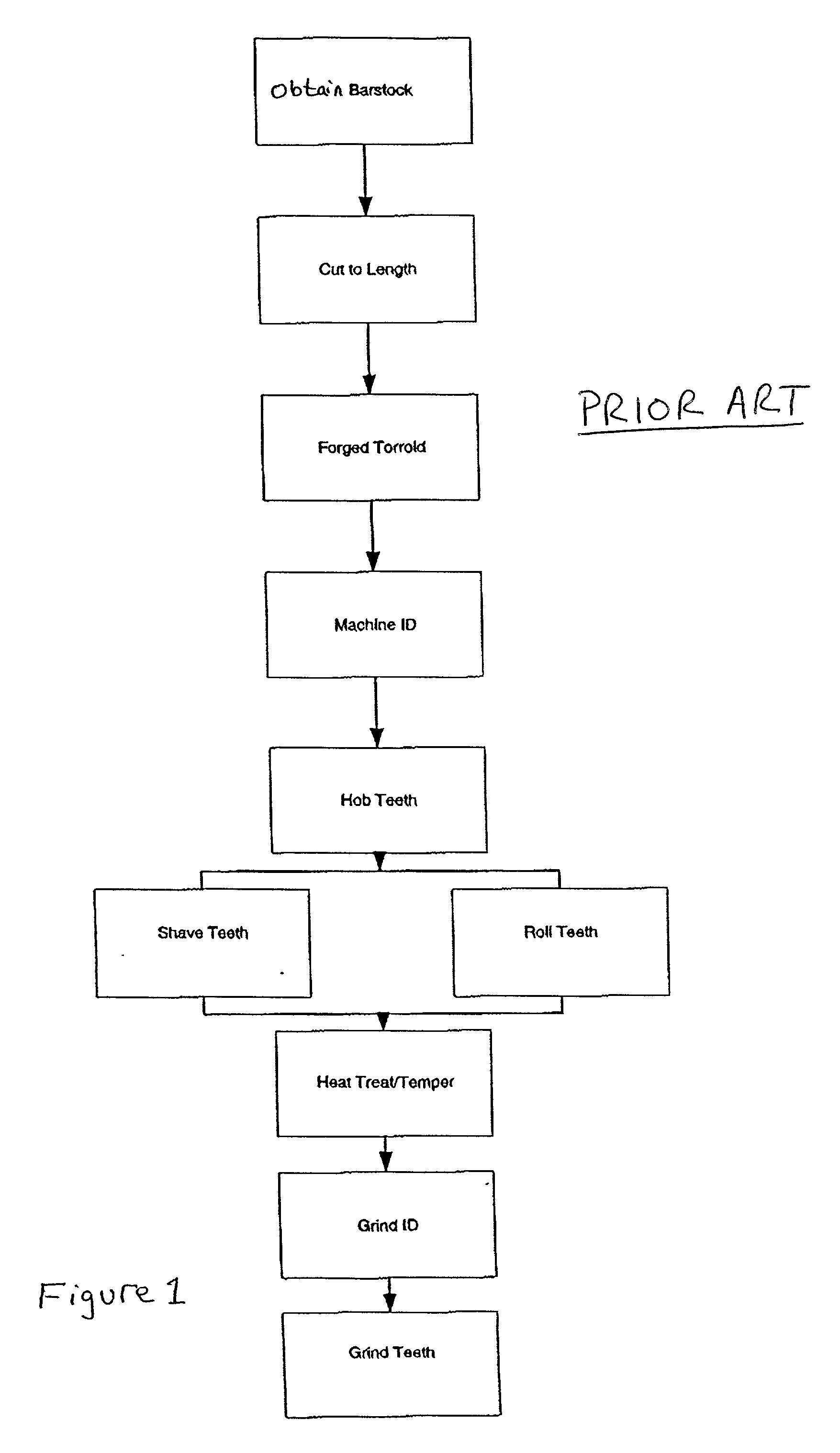

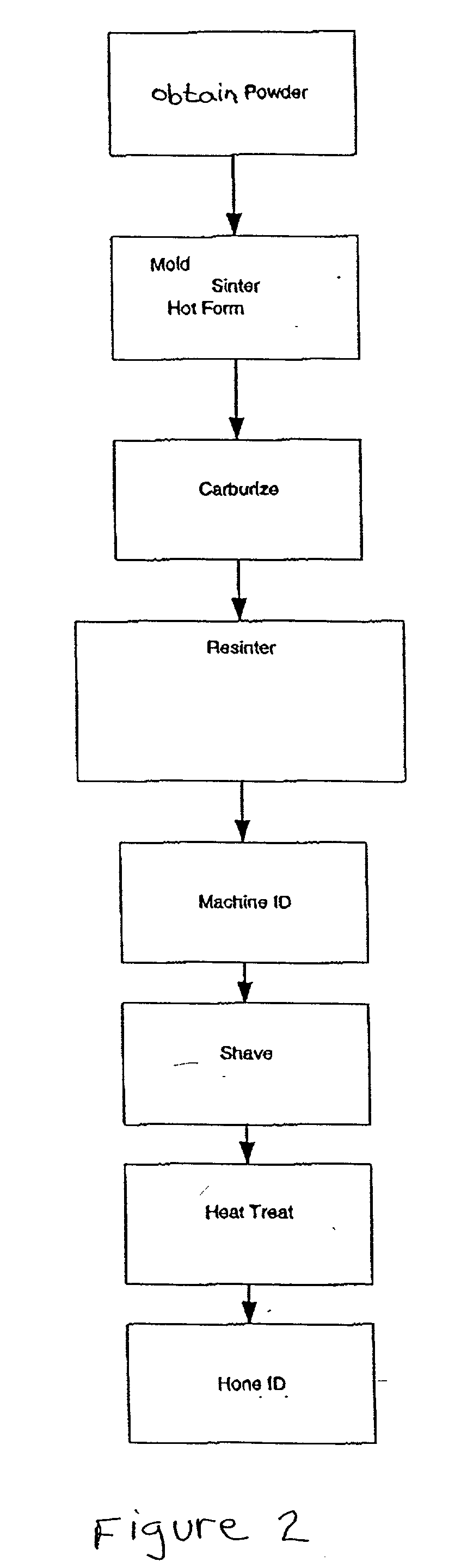

Method for producing powder metal gears

InactiveUS20030035747A1Improve uniformityHigh hardnessFurnace typesHeat treatment furnacesGear toothMetal

A method of producing a gear from a metallurgical powder includes molding at least a portion of the powder to provide a gear preform. The gear preform is sintered and hot formed, and subsequently may be carburized. The gear preform is resintered and cooled at a cooling rate suitable to provide a bainitic microstructure in at least a surface region of the preform. The gear teeth of the preform may be shaved to, for example, adjust dimensions, and enhance dimensional uniformity.

Owner:KEYSTONE INVESTMENT CORP

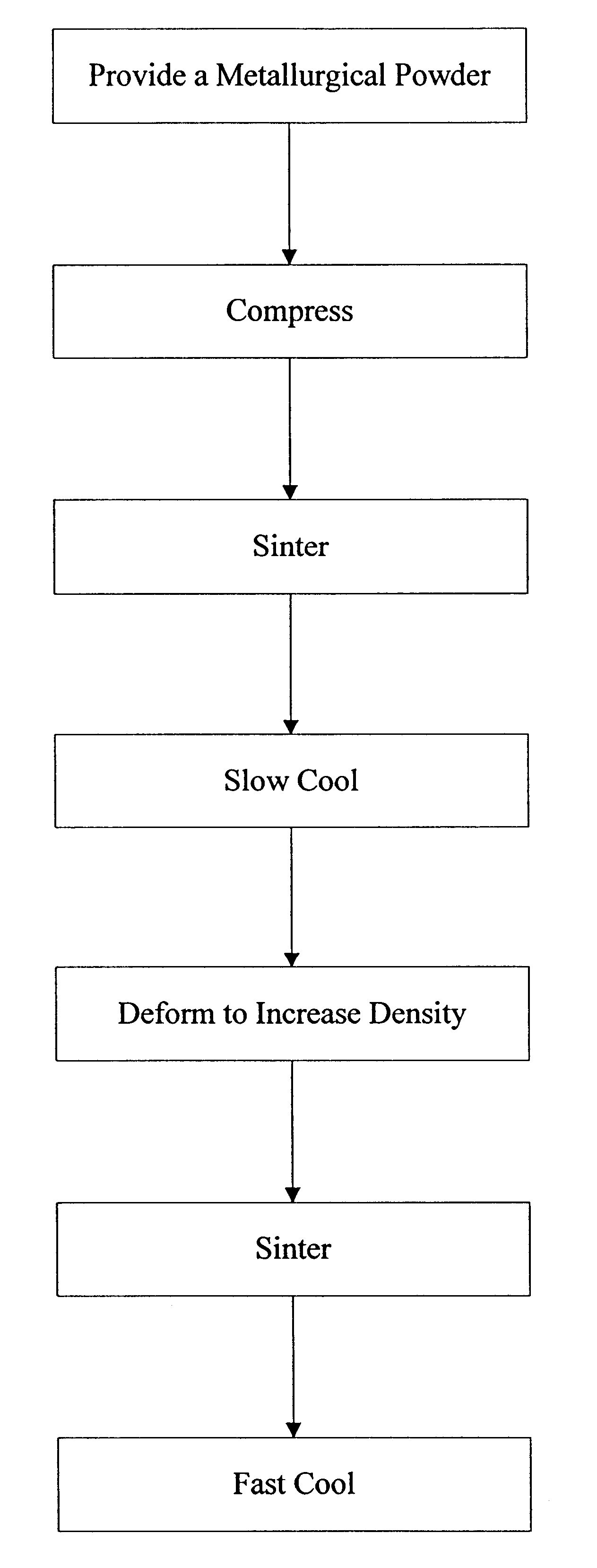

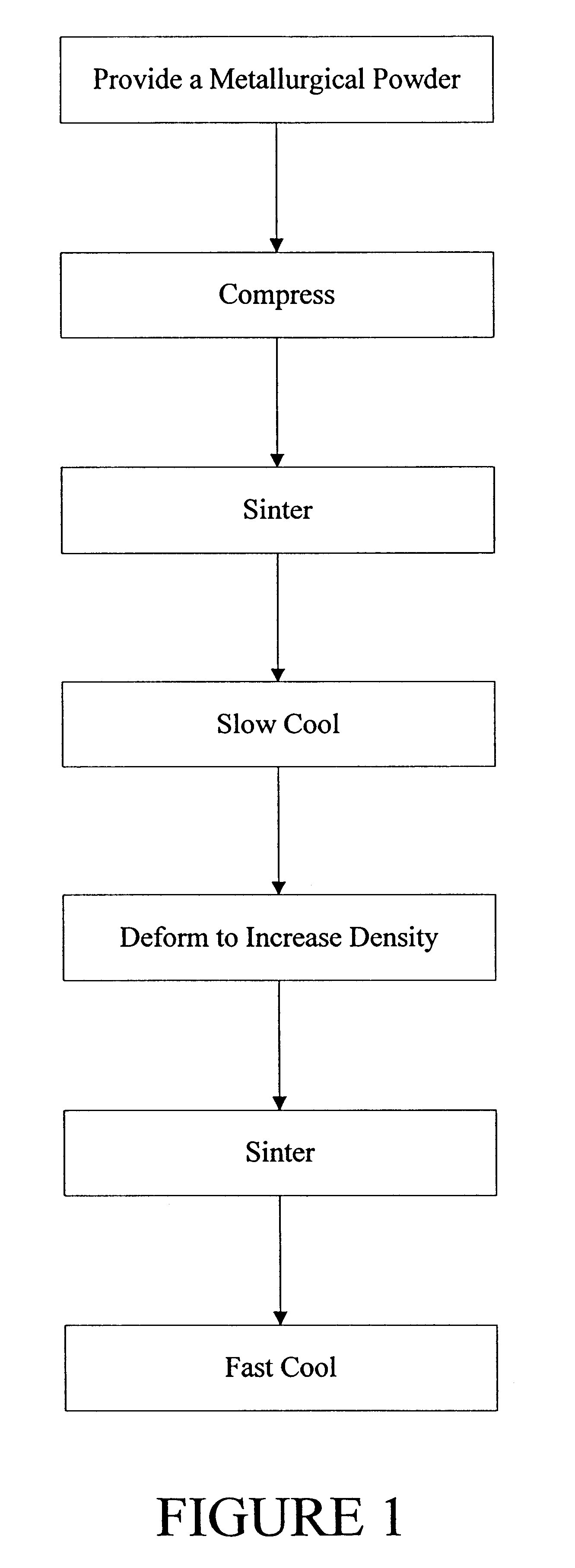

Method for producing powder metal materials

A method for producing a material includes providing a metallurgical powder including iron, 1.0 to 3.5 weight percent copper, and 0.3 to 0.8 weight percent carbon. At least a portion of the powder is compressed at 20 tsi to 70 tsi to provide a compact, and subsequently the compact is heated at high temperature and then cooled at a cooling rate no greater than 60° F. per minute to increase the surface hardness of the compact to no greater than RC 25. The density of at least a region of the sintered compact is increased, by a mechanical working step or otherwise, to at least 7.6 grams / cc. The sintered compact is then re-heated to high temperature and cooled at a cooling rate of at least 120° F. / min. so as to increase the surface hardness of the compact to greater than RC 25, and preferably at least RC 30. Material made by the method of the invention also is disclosed.

Owner:KEYSTONE INVESTMENT CORP

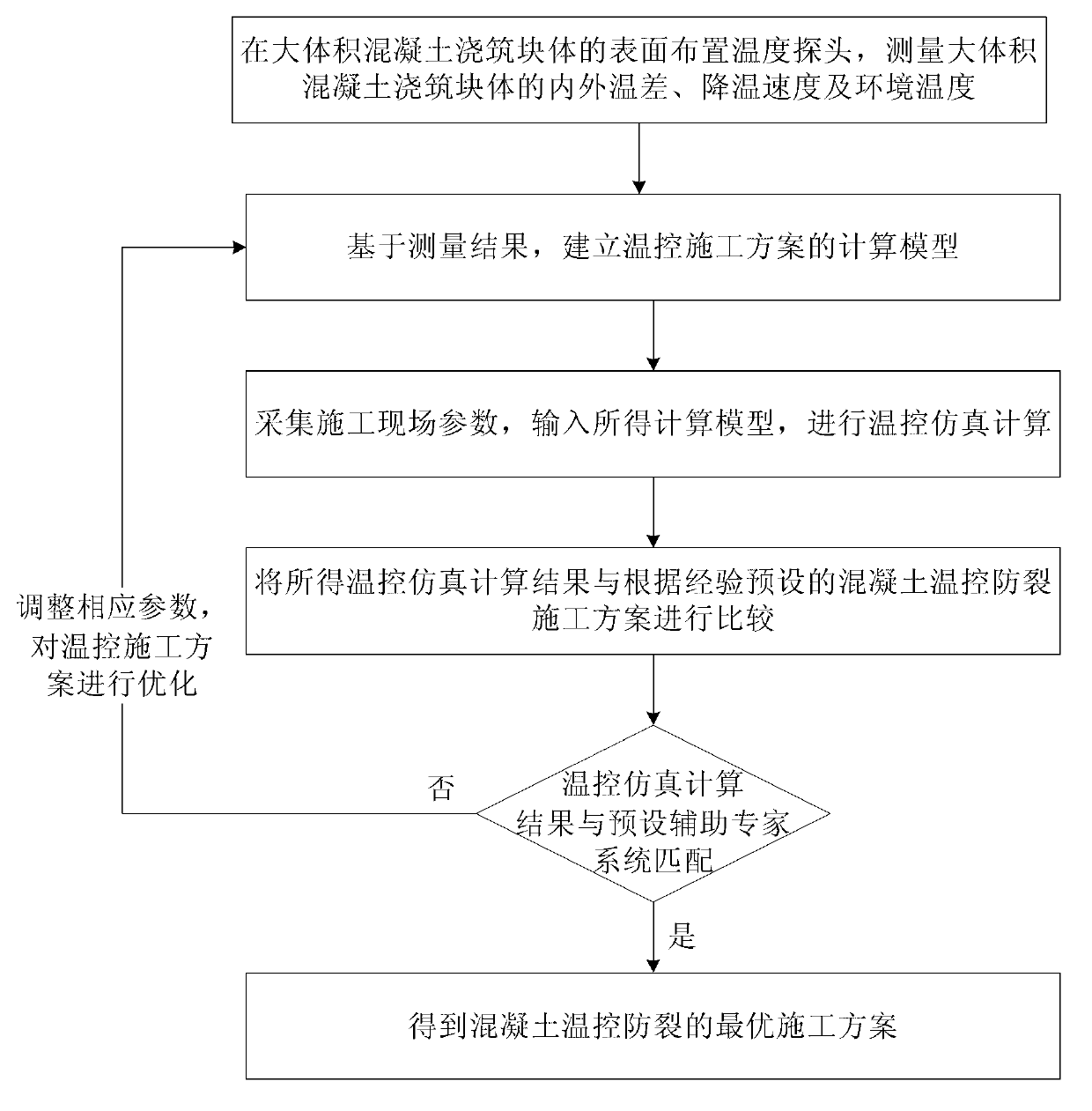

Temperature-controlled crack prevention construction method for concrete structure

ActiveCN102979307AOvercoming easy cracksOvercoming reliabilityFoundation engineeringBuilding material handlingTemperature controlTemperature difference

The invention discloses a temperature-controlled crack prevention construction method for a concrete structure. The method comprises the steps of (1) arranging temperature probes on the surface of a large-size concrete pouring block to measure the temperature difference between inside and outside, the cooling rate of the large-size concrete pouring block and the environment temperature; (2) establishing a calculation model for the temperature-controlled construction scheme based on the obtained measuring result; (3) collecting the construction site parameters, and inputting the parameters into the obtained calculation model for temperature-controlled simulation calculation; and (4) comparing the temperature-controlled simulation calculation result obtained in the step (3) with the preset auxiliary expert system, repeating the step (2) to adjust the corresponding parameters when the temperature-controlled simulation calculation result obtained in the step (3) and the preset auxiliary expert system mismatch, and optimizing the temperature-controlled crack prevention construction scheme for concrete preset based on experience until the optimal temperature-controlled crack prevention construction scheme for the concrete is obtained. The temperature-controlled crack prevention construction method for the concrete structure disclosed by the invention has the advantages that the concrete is not prone to crack, the crack prevention reliability is high, and the crack prevention commonality is good.

Owner:JINLAI CONSTR ENG TECH RES & DEV CO LTD OF THE XINJIANG PRODION & CONSTR CORPS

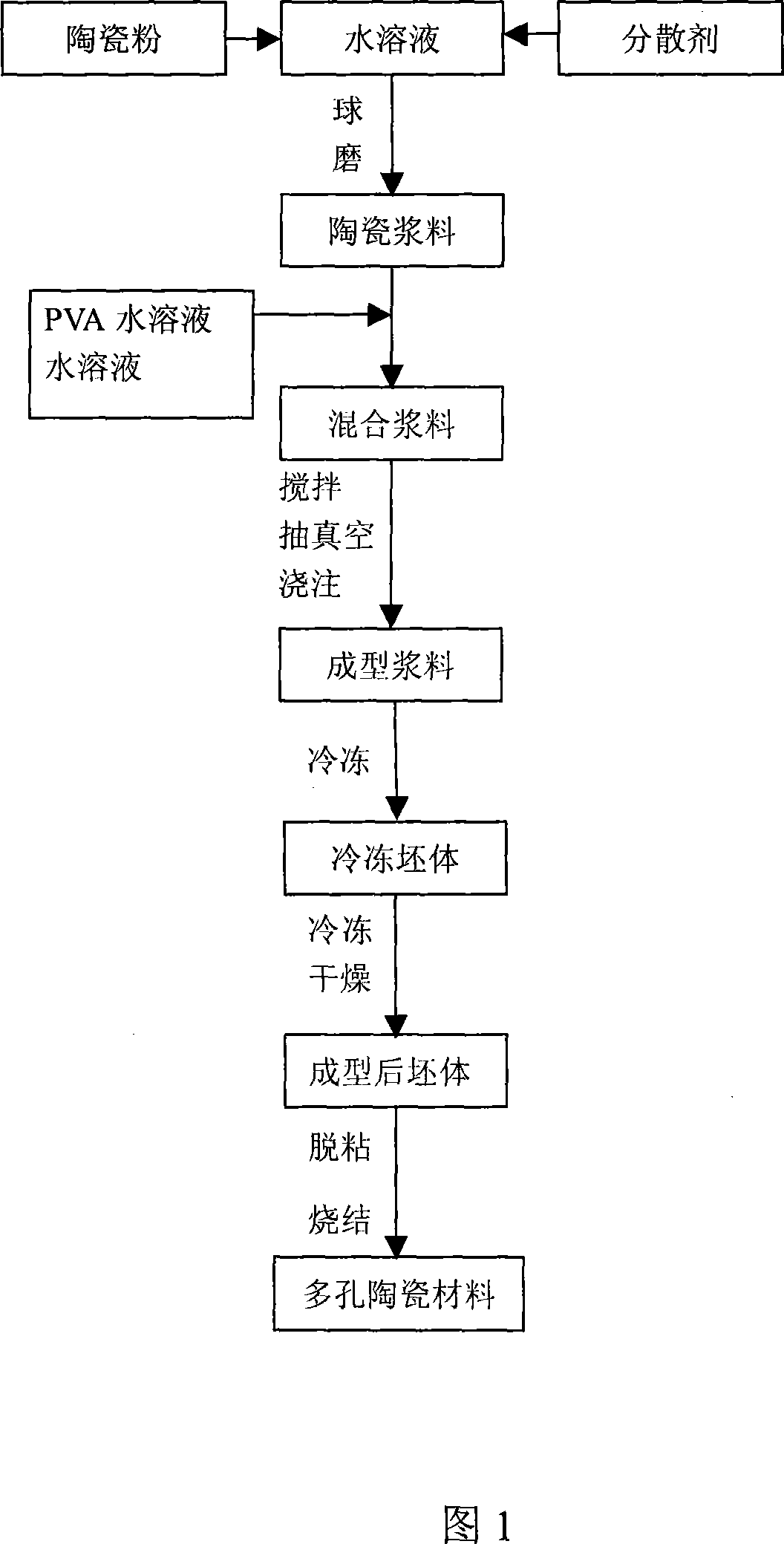

Modified freeze dehydration method for preparing porous material

InactiveCN101050128AEasy to adjust performanceHigh porosityDrying solid materials without heatCeramicwarePorosityFreeze-drying

This invention relates to an improved method for preparing porous material by freeze-drying. The method comprises: selecting organic additive, mixing the additive with the matrix powder, molding, and sintering. The method can prepare porous green body by controlling the solid content of the slurry, as well as the cooling rate, and then prepare porous material by sintering. The obtained porous material has a porosity of 10-90%, and an average particle size of 0.2-300 mu.m.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

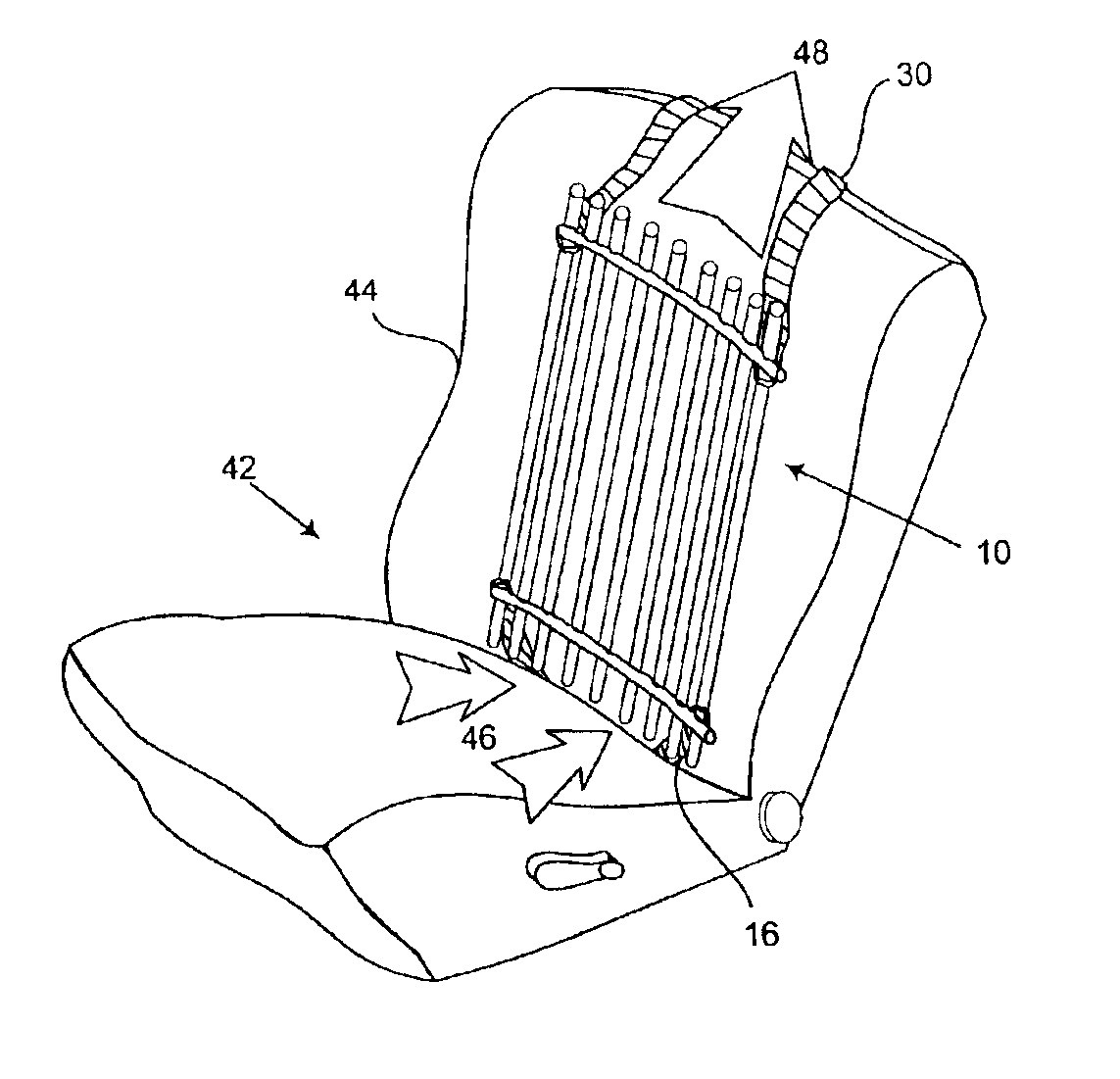

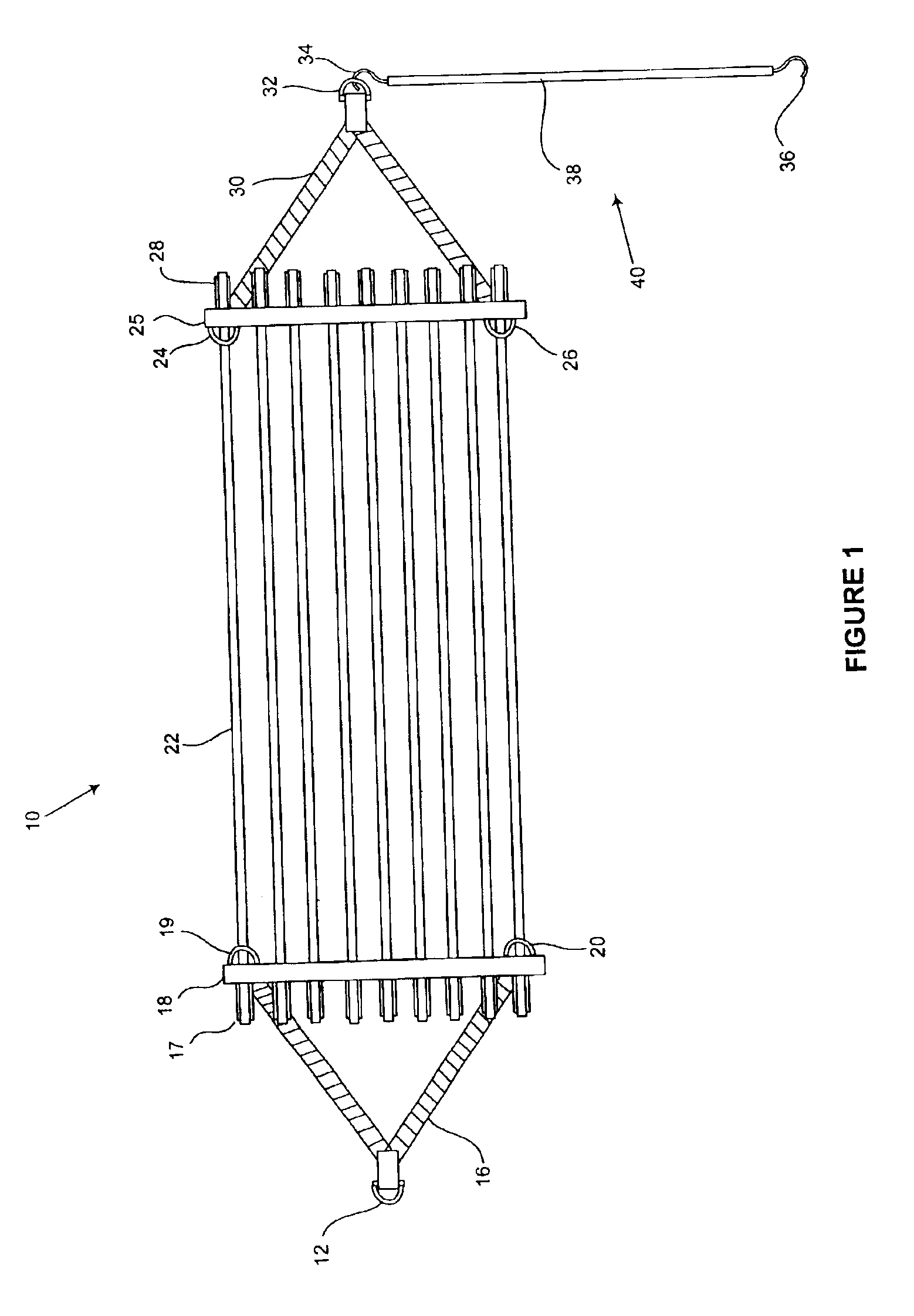

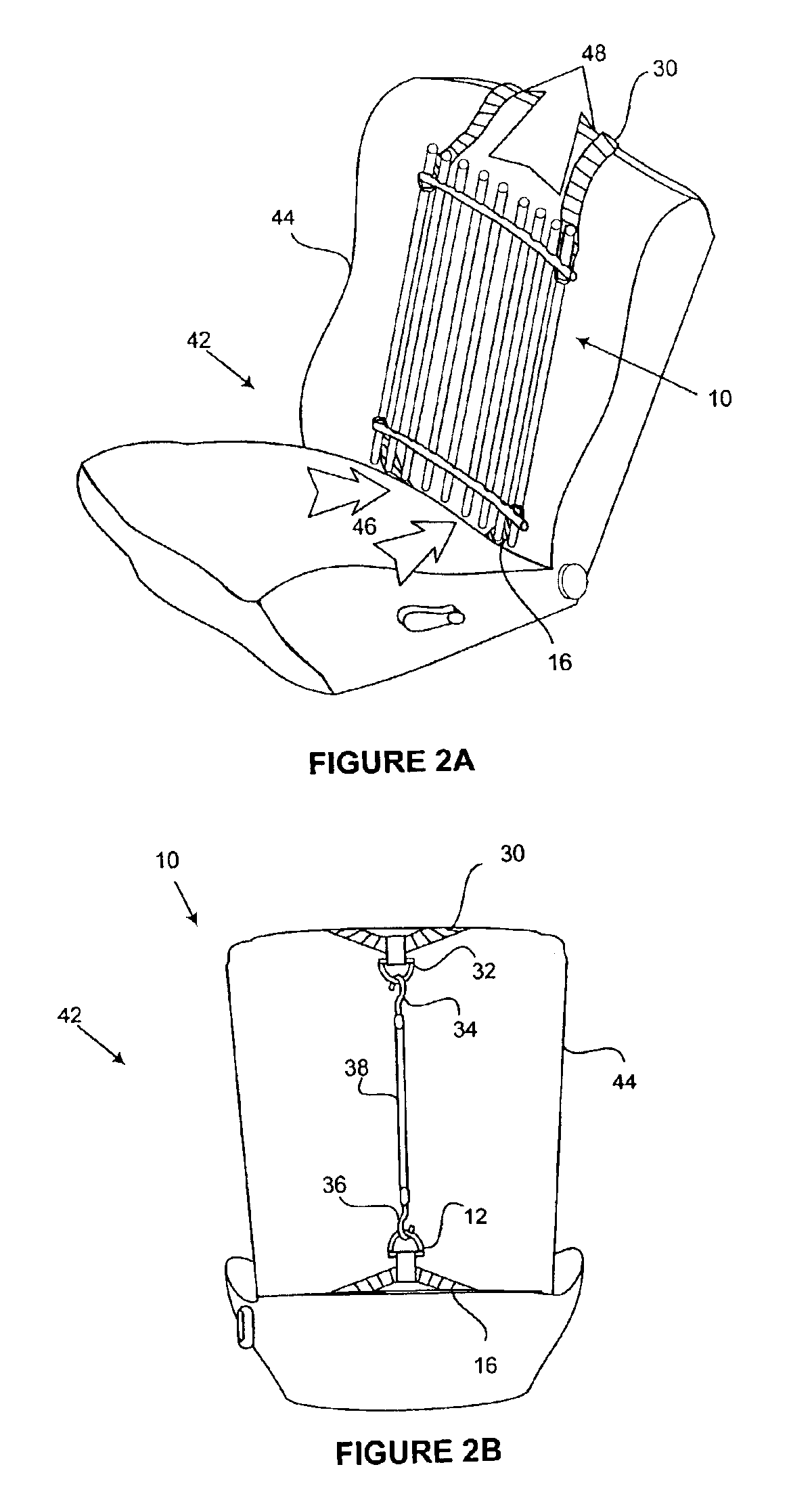

Portable seat cooling apparatus

InactiveUS6857954B2Light weightEasy to disassembleSeat coveringsAir-treating devicesAir movementForced-air

The present invention relates to a seat or chair cooling apparatus. In an embodiment the seat cooling apparatus cools the back of a user without the need of forced air. The seat cooling apparatus includes an array of conduits held in place by a set of supports to form a heat exchanger. Heat from the contact surfaces is removed by free convection, an upward air movement due to density difference. When the seat cooling apparatus is in the preferred substantially vertical arrangement, the warm air exiting the conduits is replaced by cooler air entering the conduits. A seat securing attachment secures the heat exchanger components to a seat. The seat cooling apparatus shapes into the back of the user to provide comfort that is effective in cooling. The seat cooling apparatus can be light weight, portable, and occupies little space, can be quickly installed and removed, easily cleaned and is very low cost to manufacture. In another embodiment, the seat cooling apparatus is easily connected to a forced air cooling source to increase the cooling rate if desired by the user.

Owner:FRONT END SOLUTIONS

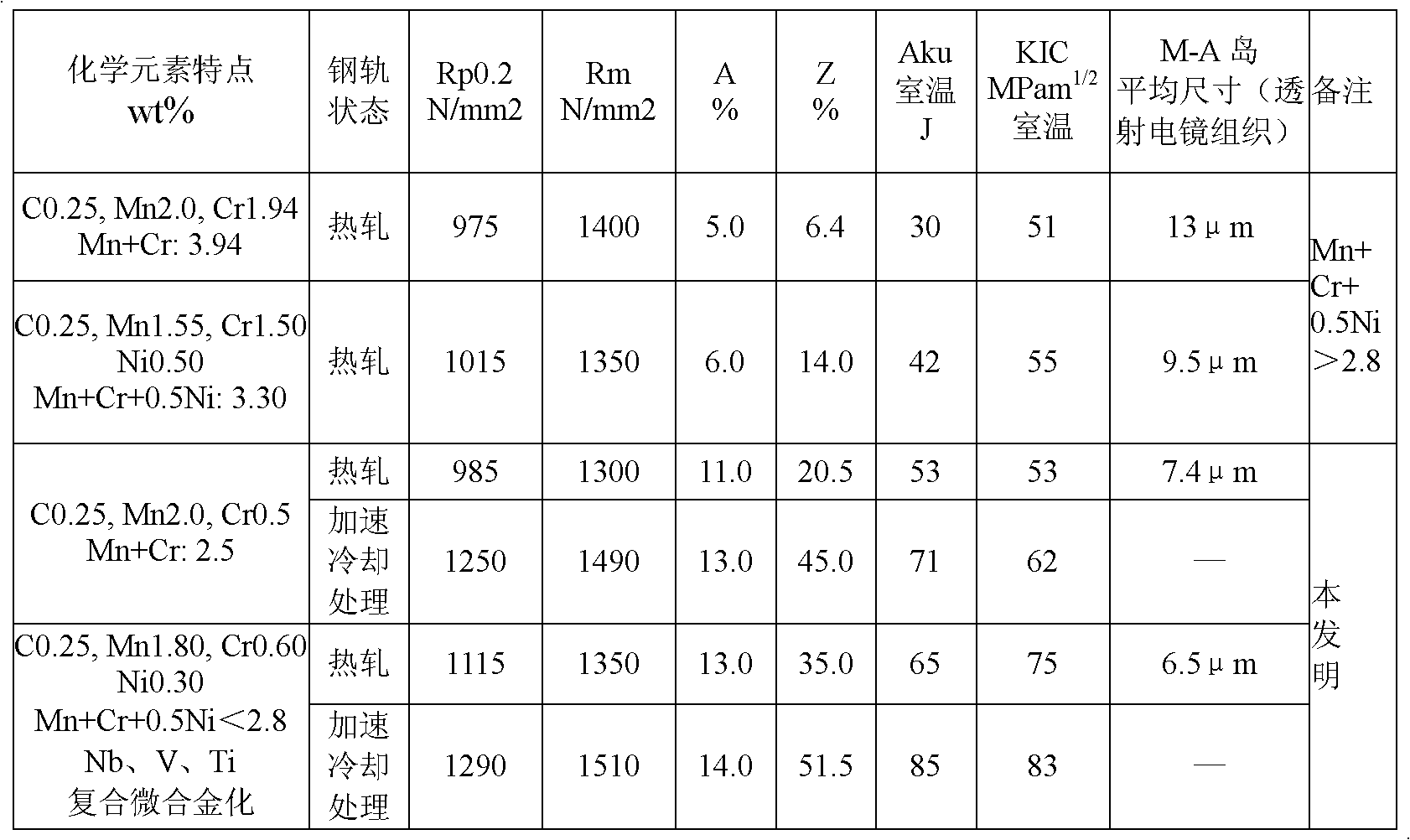

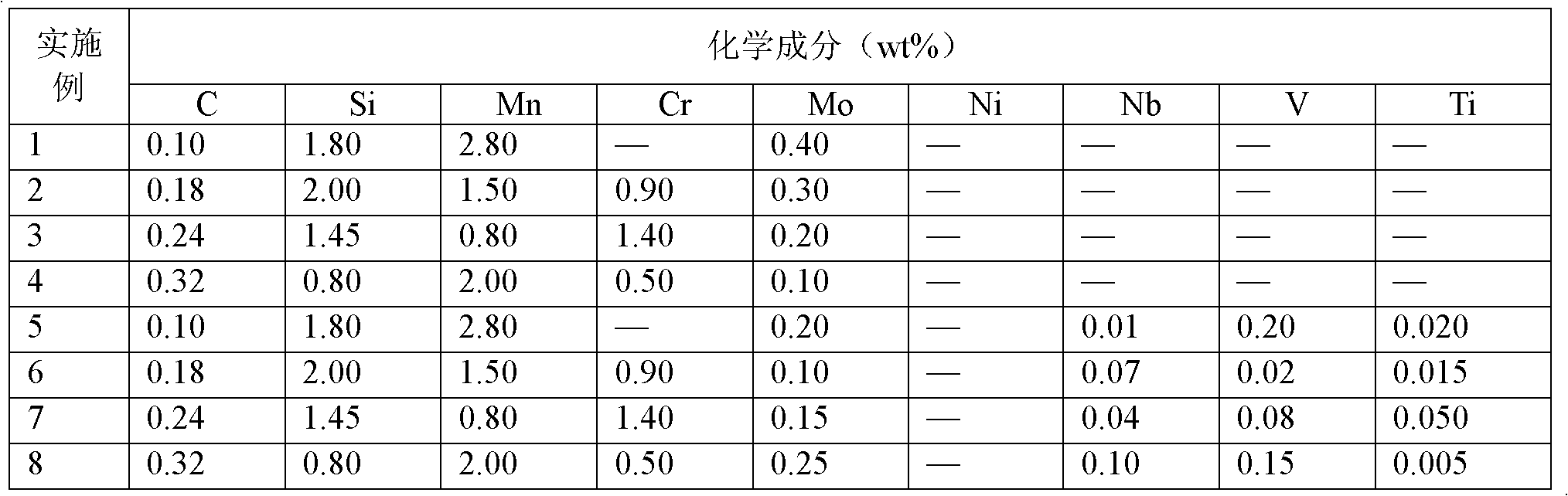

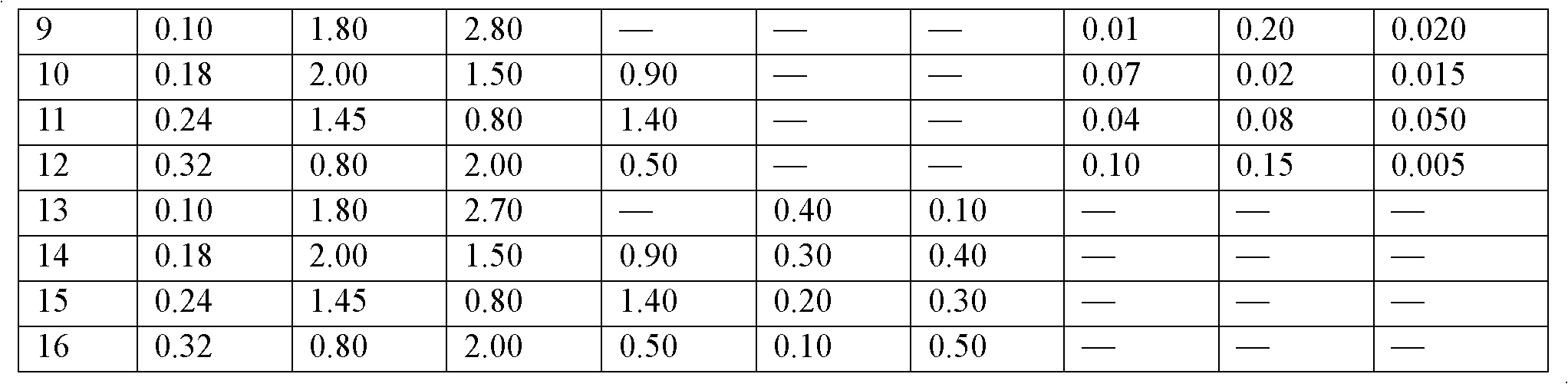

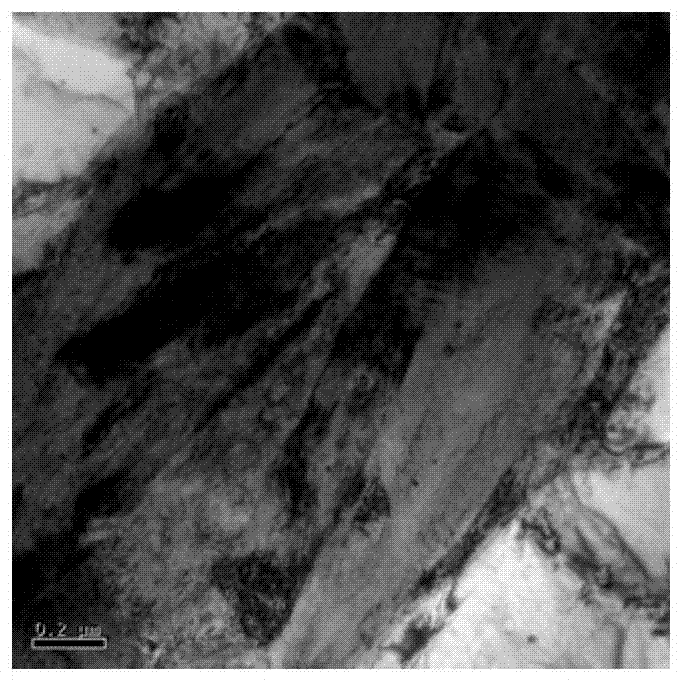

High strength bainitic steel rail and heat treatment process thereof

ActiveCN103160736AImprove wear resistanceImprove impact toughnessFurnace typesHeat treatment furnacesImpurityHeat treated

The invention provides a high strength bainitic steel rail and a heat treatment process thereof. The steel rail comprises the following chemical compositions by weight percentage: 0.10%-0.32% of C, 0.80%-2.00% of Si, 0.80%-2.80% of Mn, Cr less than 1.50%, 0.10%-0.40% of Mo, 0-0.5% of Ni, wherein Mn, Cr and Ni satisfy the relation of: Mn+Cr+0.5Ni<=2.8%, and the balance of Fe and unavoidable impurities. The process is as below: conducting hot rolling on the steel rail or air cooling on the steel rail to room temperature, then reheating to 850-1000 DEG C for austenization; cooling the steel rail head to 620-570 DEG C with a cooling rate of 0.3-15 DEG C / s; when the temperature is lower than 620-570 DEG C, cooling to 350-200 DEG C with a cooling rate of 0.5-5 DEG C / s; and then conducting air cooling to room temperature. The invention avoids generation of excessive unstable thick M-A islands in granular bainite during air cooling to room temperature in hot rolling, reduces the risk of straightening fracture (or delayed fracture)of hot-rolled steel rail, and improves the adaptability of steel production process. The steel rail has tensile strength higher than 1400MPa, and realizes optimum matching of strength, toughness and ductility, and excellent rolling contact fatigue resistance and wear resistance.

Owner:ANGANG STEEL CO LTD

High-elongation cold-rolled TRIP (Transformation-Induced Plasticity) steel plate and preparation method thereof

InactiveCN102952996AHigh elongationLow costProcess efficiency improvementRoom temperatureHeating temperature

The invention discloses a high-elongation cold-rolled TRIP (Transformation-Induced Plasticity) steel plate, comprising 0.15-0.25% of C, 0.4-1.5% of Si, 0.5-2.5% of Mn, 0.04-0.10% of P, less than or equal to 0.02% of S, 0.02-0.5% of Al, less than or equal to 0.01% of N, 0-0.5% of Nb, 0-0.5% of V, 0-0.5% of Ti, 0-2% of Cr, 0-1% of Mo, and the balance of Fe and inevitable impurities, wherein in the microscopic structure, the area ratio of ferrite is 10-80%, while the area ratio of residual austenite is 3-20% and the area ratio of martensite is 0-20%, and the rest part is bainite; the hot rolling heating temperature is 1100-1250 DEG C, the heat preservation time is greater than or equal to 2 h, the rolling starting temperature is equal to or higher than 1100 DEG C, the final rolling temperature ranges from 850 to 950 DEG C, and the coiling temperature is lower than 720 DEG C; the hot-rolled plate is 2-4 mm thick; accumulated compression quantity of cold rolling is 40-80%; the annealing temperature is 700-(Ac3+50) DEG C, the heat preservation time is 30-360 s, the cooling rate is 10-150 DEG C / s, the aging temperature is 300-600 DEG C, the aging time is 30-1200 s and the cooling rate is 5-100 DEG C / s; and finally, cooling is performed until the temperature reaches the room temperature.

Owner:ANGANG STEEL CO LTD

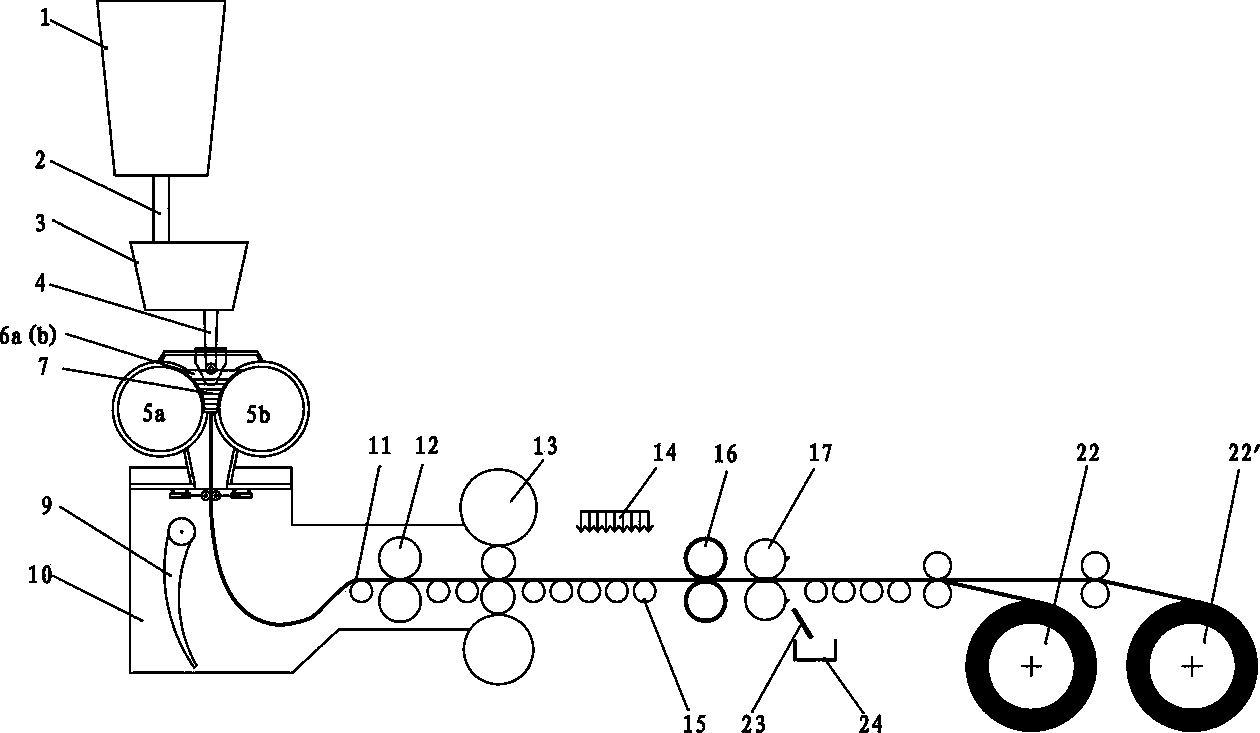

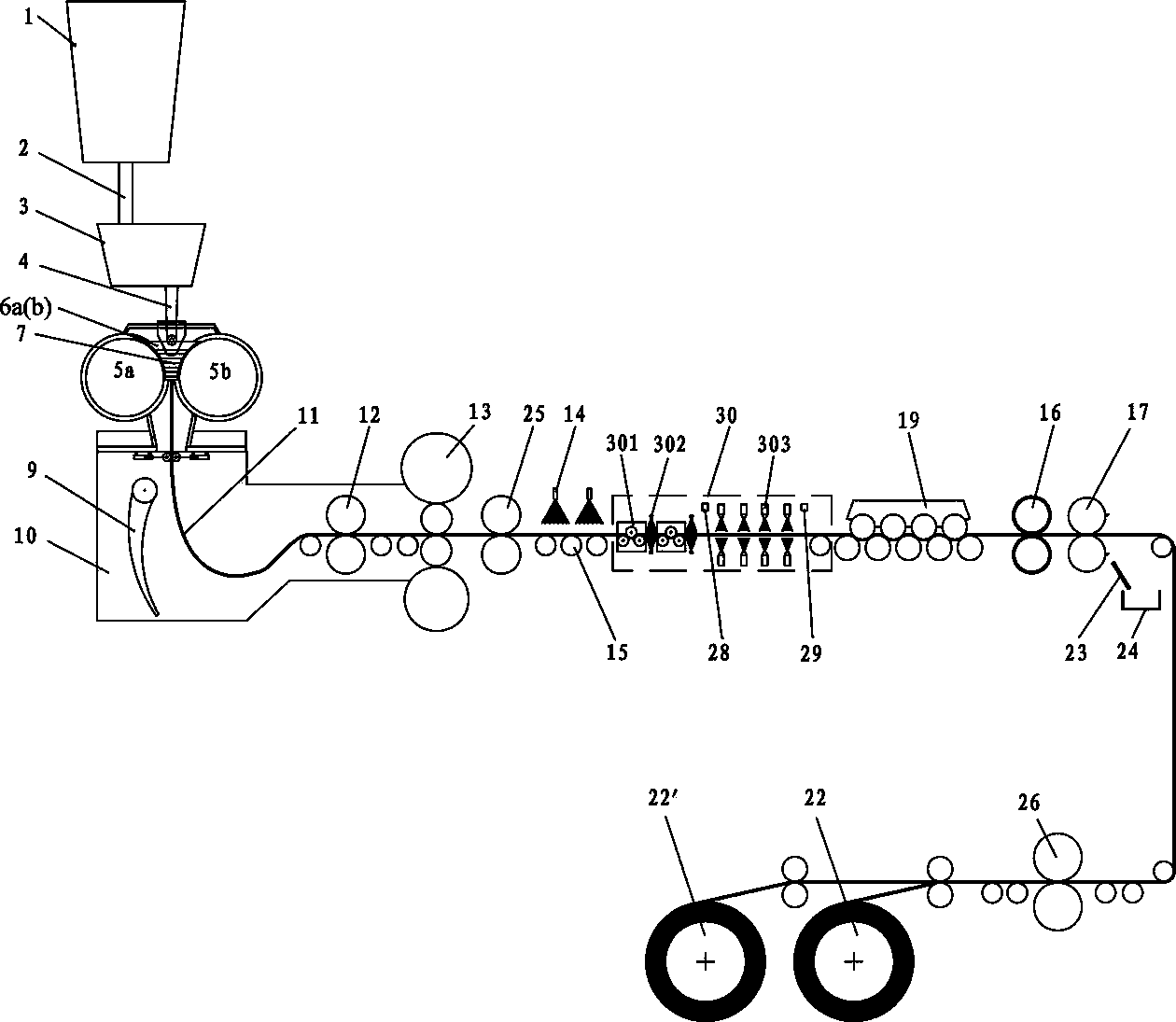

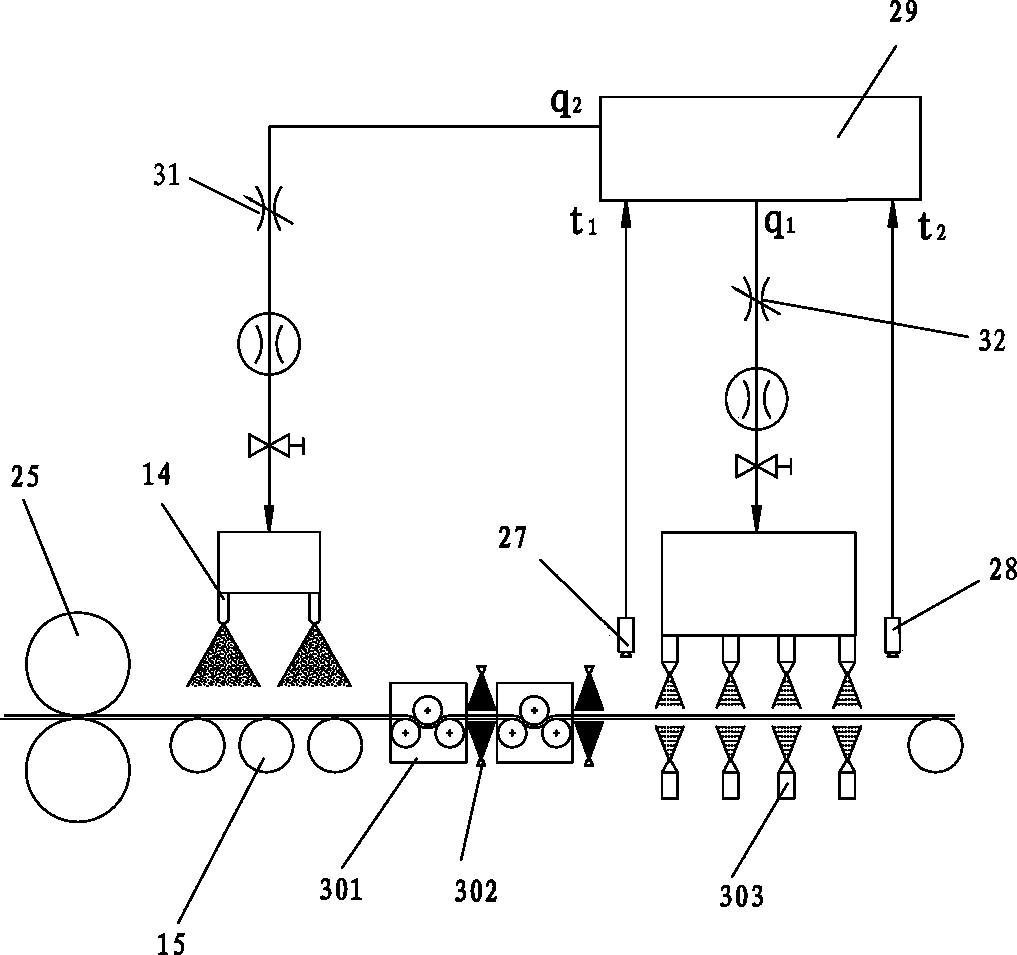

Method for producing high-strength thin strip steel in short process

ActiveCN103658178ACost-effectiveShorten the lengthWork treatment devicesMetal rolling arrangementsRare-earth elementMicroscopic scale

The invention relates to a method for producing high-strength thin strip steel in a short process. Twin roll strip casting is adopted for producing an atmospheric-corrosion-resistant steel casting belt containing a rare earth element Re, hot rolling, cooling and anti-oxidation intensive cooling scale removing are performed on the steel casting belt, and then the steel casting belt is reeled up after being straightened, wherein in the hot rolling process of the strip steel, rolling reduction is not smaller than 20%, and finishing rolling temperature is 850-1000 DEG C; then, a staged cooling mode of atomization cooling plus anti-oxidation intensive cooling ( spraying dry ice) is adopted, and intensive cooling is carried out on the high-temperature strip steel, wherein the cooling rate in the atomization cooling process is 50-100 DEG C / s, and the cooling rate in the anti-oxidation intensive cooling process is 100-200 DEG C / s. In this way, through the combined type staged cooling, the uniform steel of a bainite microscopic structure can be obtained, and the bainite structure can remarkably improve the toughness of the steel. The method is especially applicable to atmospheric-corrosion-resistant high-strength thin strip steel with the surface roughness Ra smaller than 2 microns, the thickness of typical strip steel is 0.8-1.6mm, and the strip steel can be supplied in a hot mode instead of a cool mode.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com