Patents

Literature

566results about "Glass deposition burners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

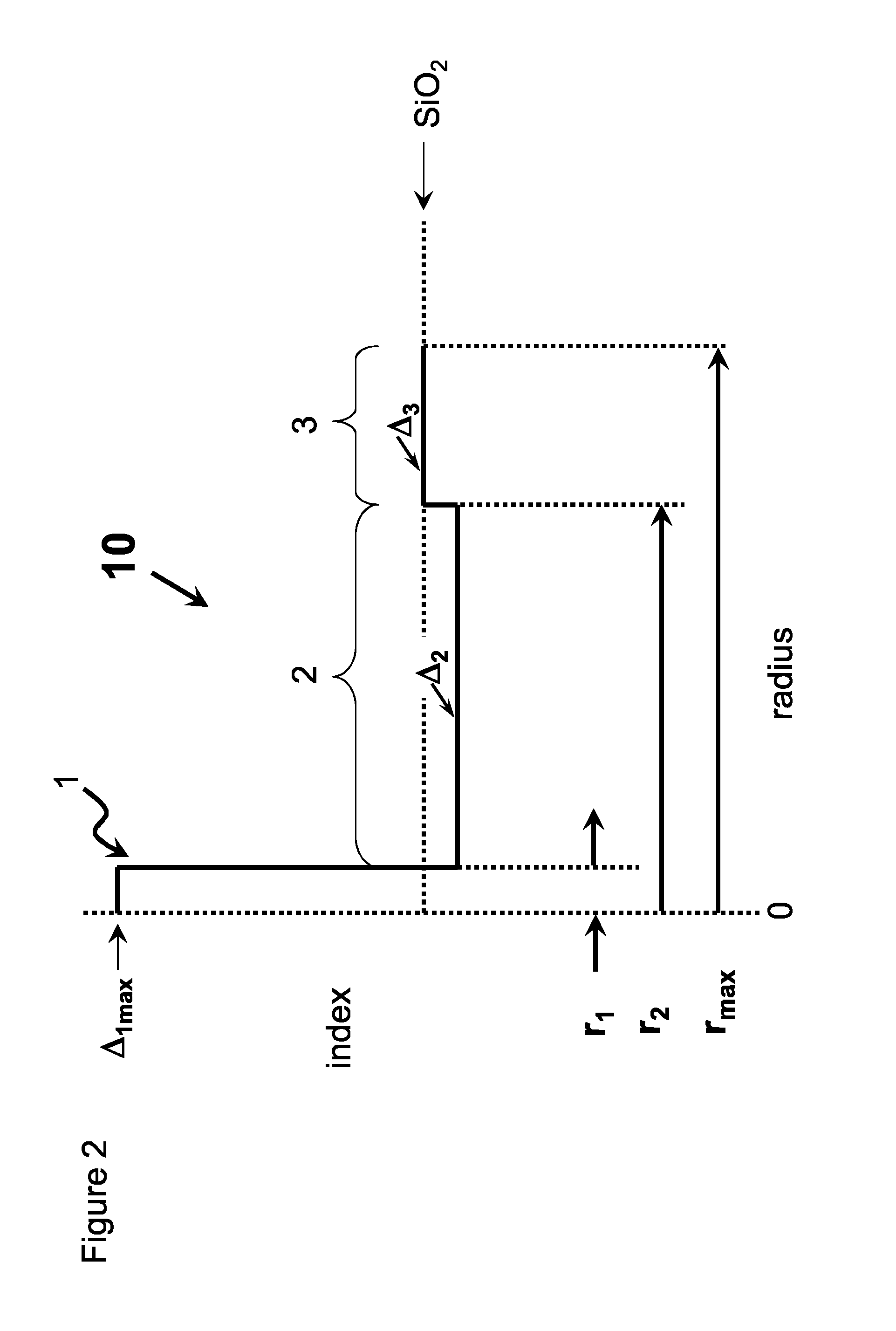

Optical fiber and method for making such fiber

ActiveUS7313312B2Coupling efficiency is highIncrease optical powerOptical fibre with polarisationOptical fibre with multilayer core/claddingFiberRare earth

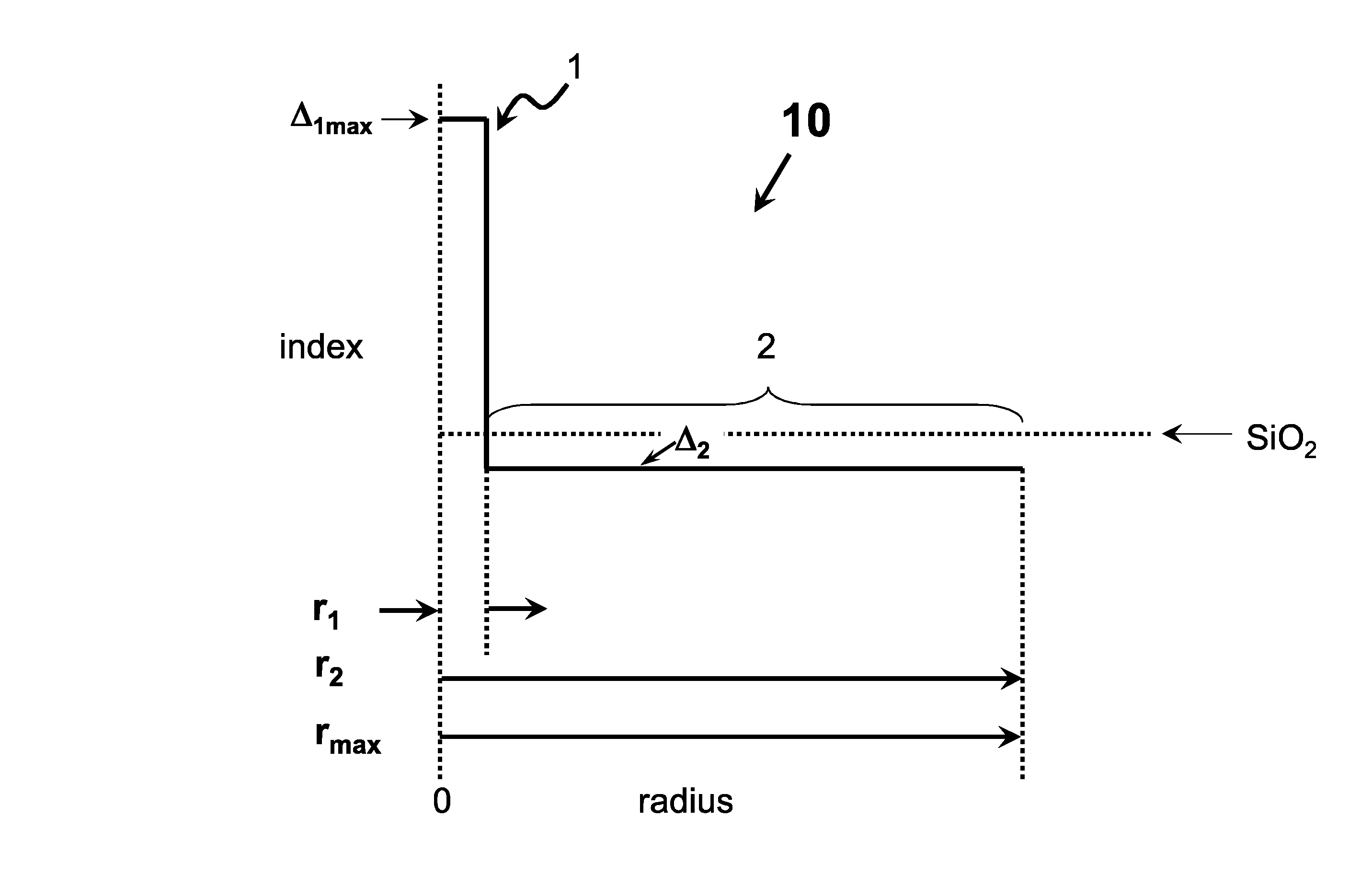

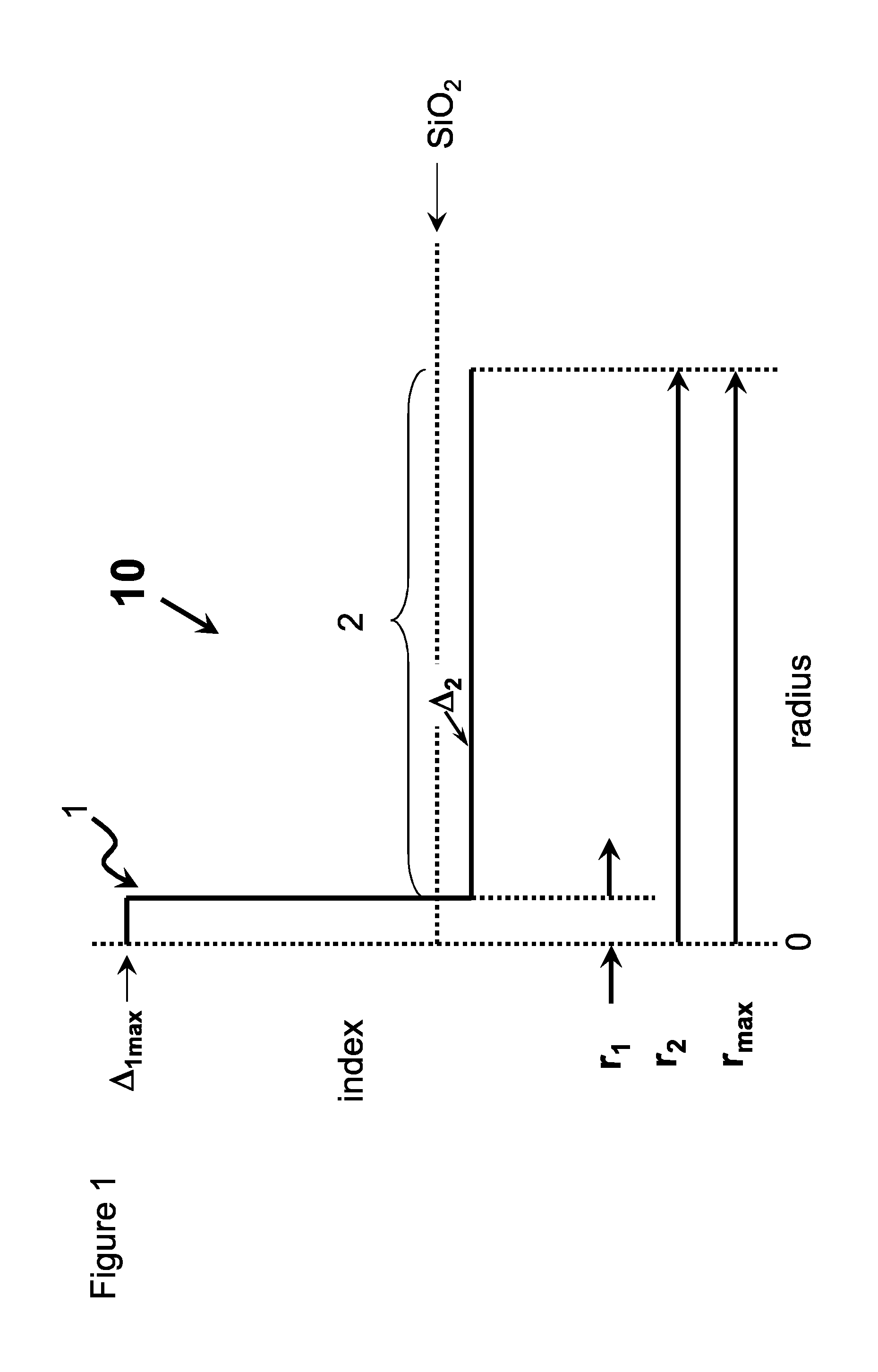

According to one example of the invention an optical fiber comprises: (i) silica based, rare earth doped core having a first index of refraction n1; (ii) at least one silica based cladding surrounding the core and having a second index of refraction n2, such that n1>n2; wherein at least one of the core or cladding is doped with Al2O3, such that the ratio of max wt % to min wt % of Al2O3 concentration is less than 2:1.

Owner:CORNING INC

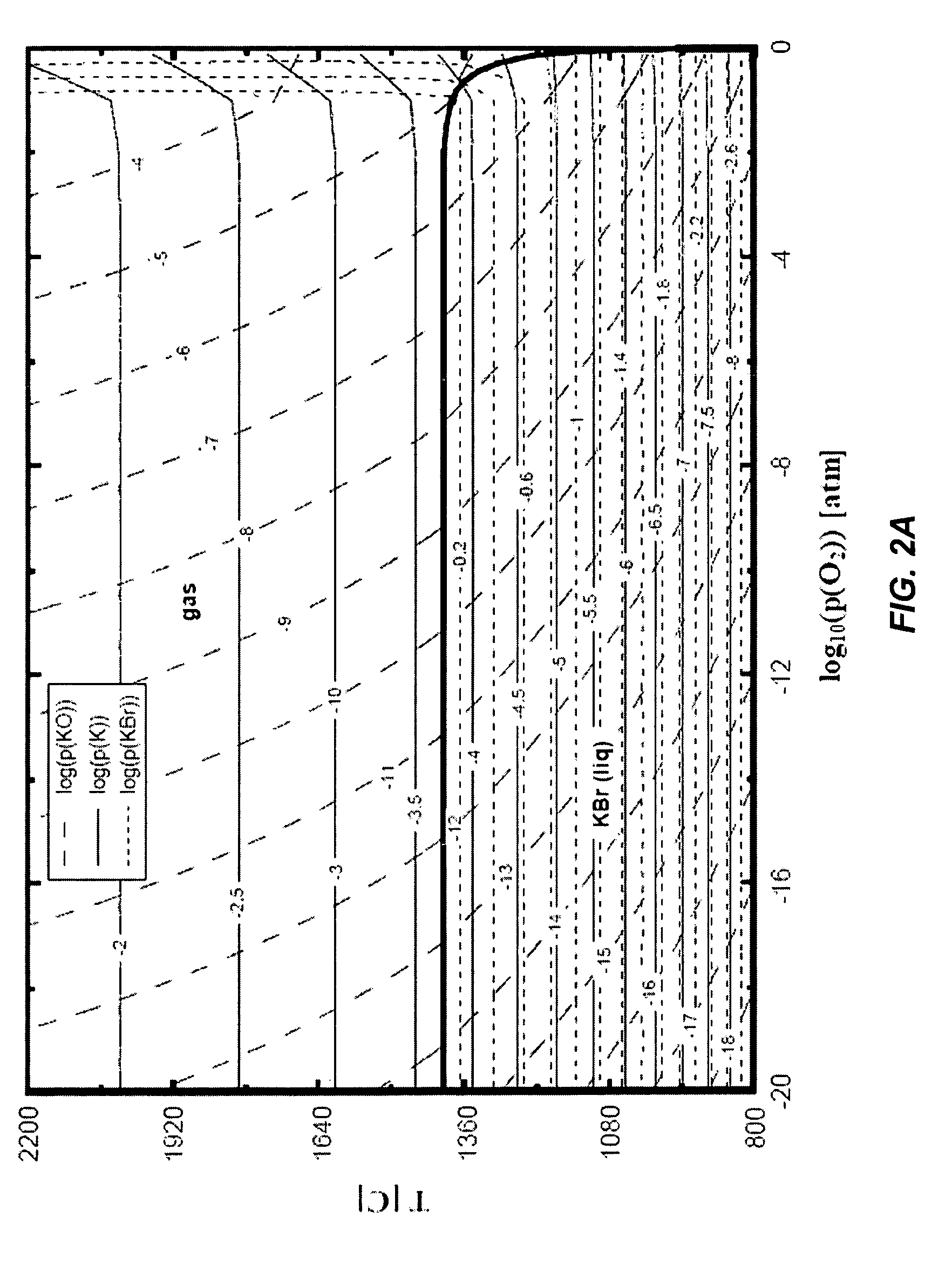

Method of doping silica glass with an alkali metal, and optical fiber precursor formed therefrom

A method of making an optical fiber precursor includes generating vapors from an alkali metal source comprising compound containing oxygen and one or more alkali metals and applying the vapors to a surface of a glass article comprising silica at a temperature that promotes diffusion of the alkali metal into the surface of the glass article. An optical fiber has a core comprising silica and an alkali metal oxide of the form X2O, where X is selected from the group consisting of K, Na, Li, Cs, and Rb, wherein a concentration of the alkali metal oxide along a length of the core is uniform.

Owner:CORNING INC

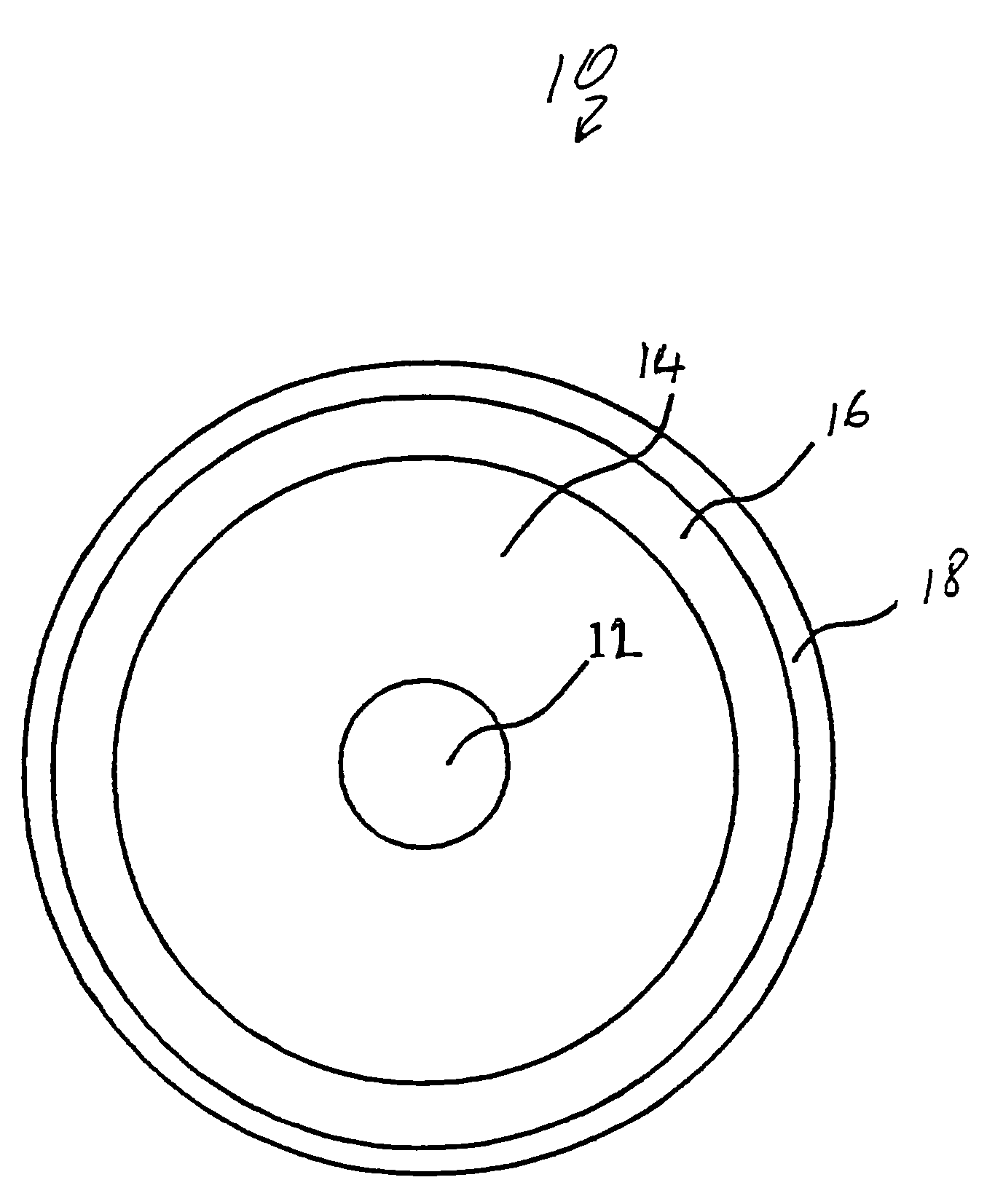

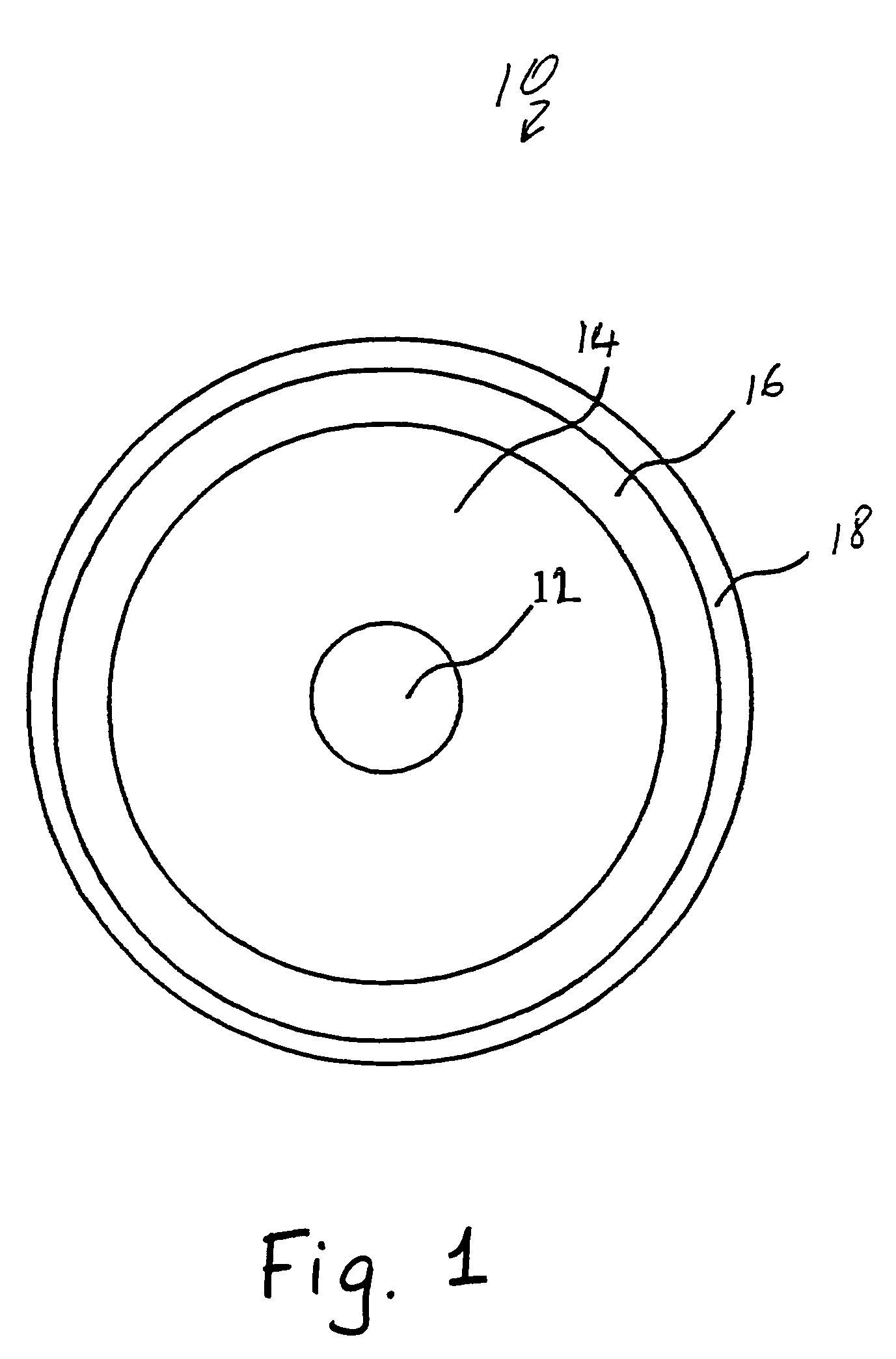

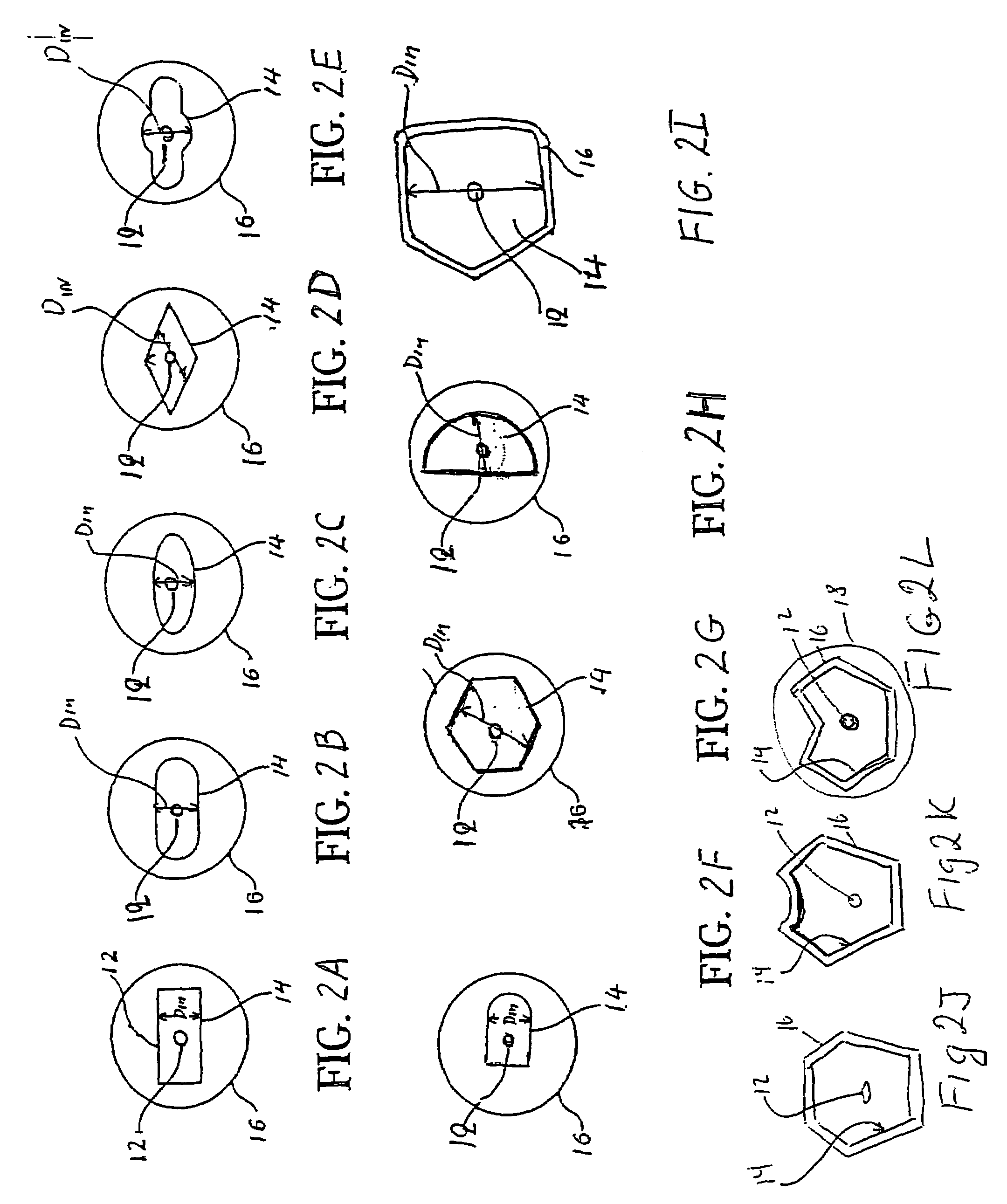

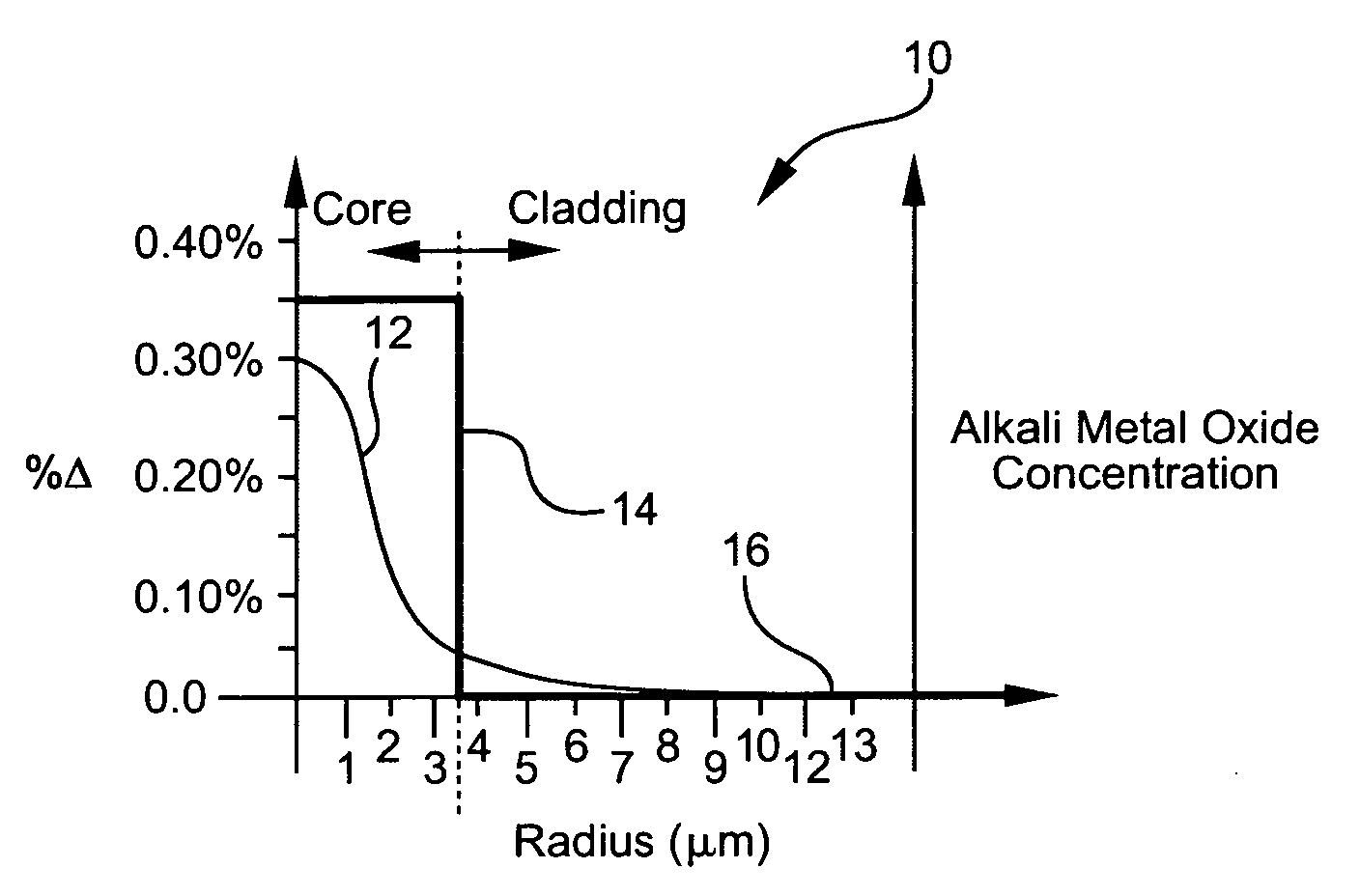

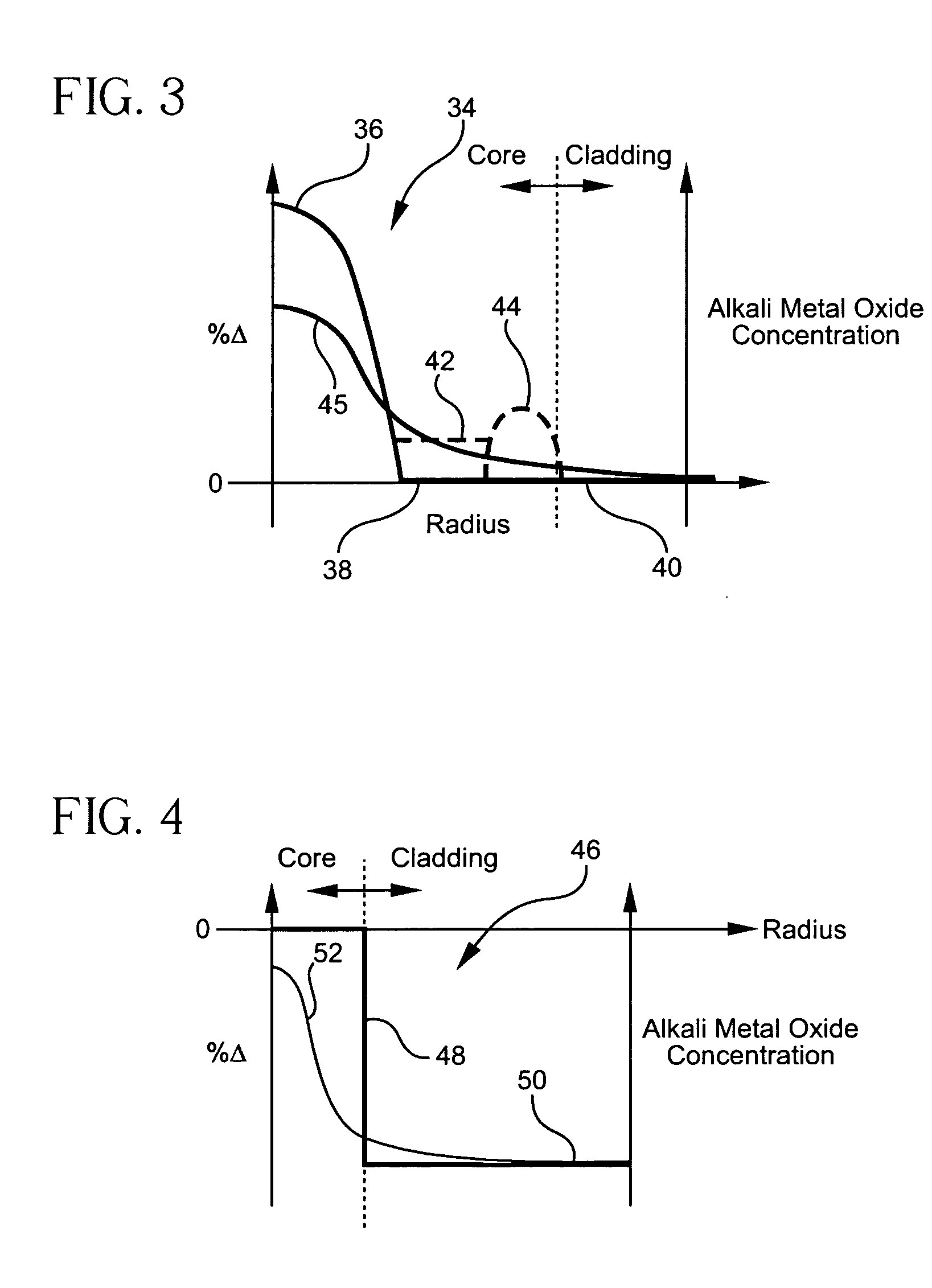

Optical fiber containing an alkali metal oxide and methods and apparatus for manufacturing same

ActiveUS20050063663A1Increase radiusReduce doping concentrationOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingDopantAlkali metal oxide

Disclosed is an optical fiber having a core with an alkali metal oxide dopant in an peak amount greater than about 0.002 wt. % and less than about 0.1 wt. %. The alkali metal oxide concentration varies with a radius of the optical fiber. By appropriately selecting the concentration of alkali metal oxide dopant in the core and the cladding, a low loss optical fiber may be obtained. Also disclosed are several methods of making the optical fiber including the steps of forming an alkali metal oxide-doped rod, and adding additional glass to form a draw perform. Preferably, the draw preform has a final outer dimension (d2), wherein an outer dimension (d1) of the rod is less than or equal to 0.06 times the final outer dimension (d2). In a preferred embodiment, the alkali metal oxide-doped rod is inserted into the centerline hole of a preform to form an assembly.

Owner:CORNING INC

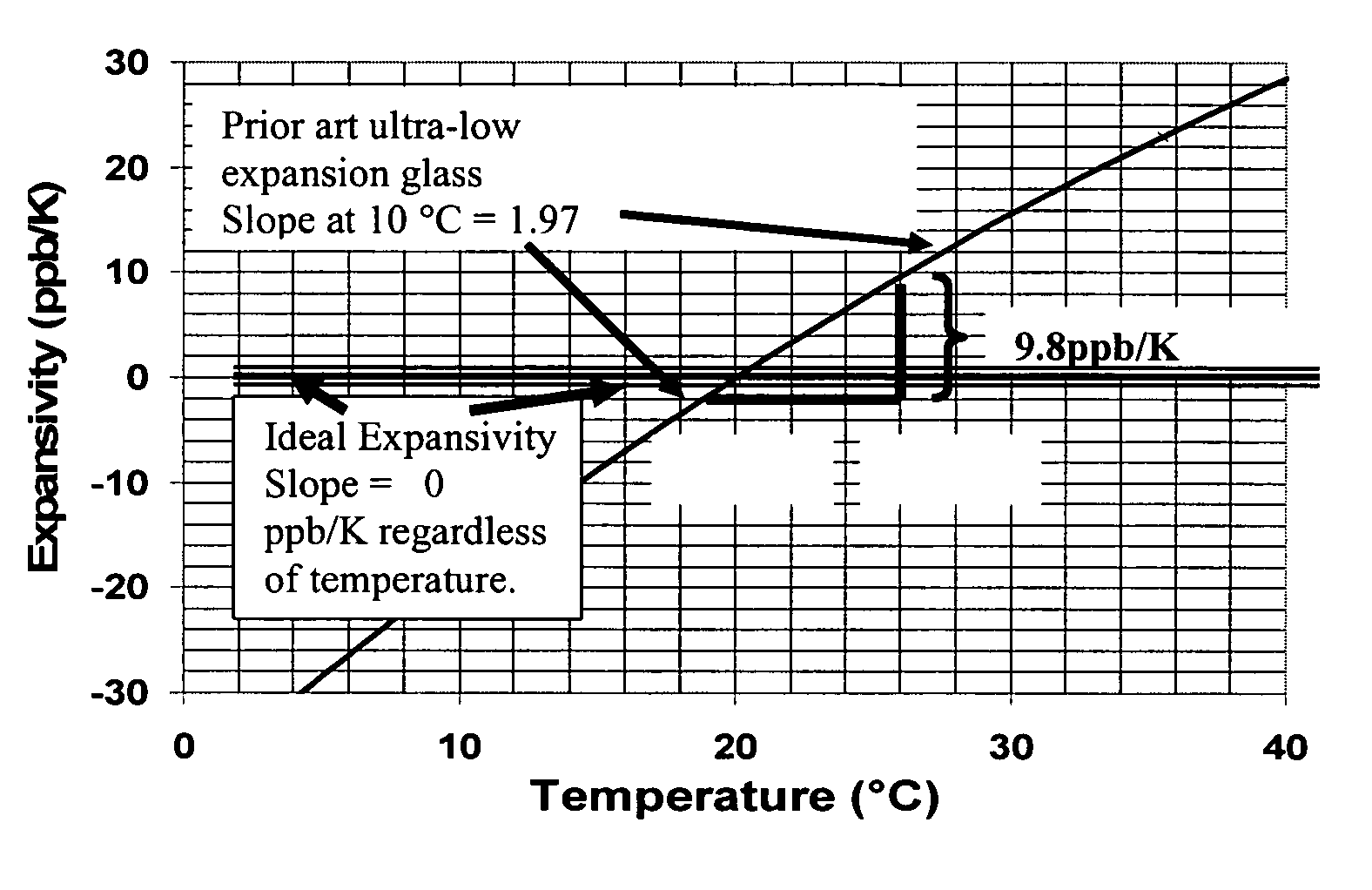

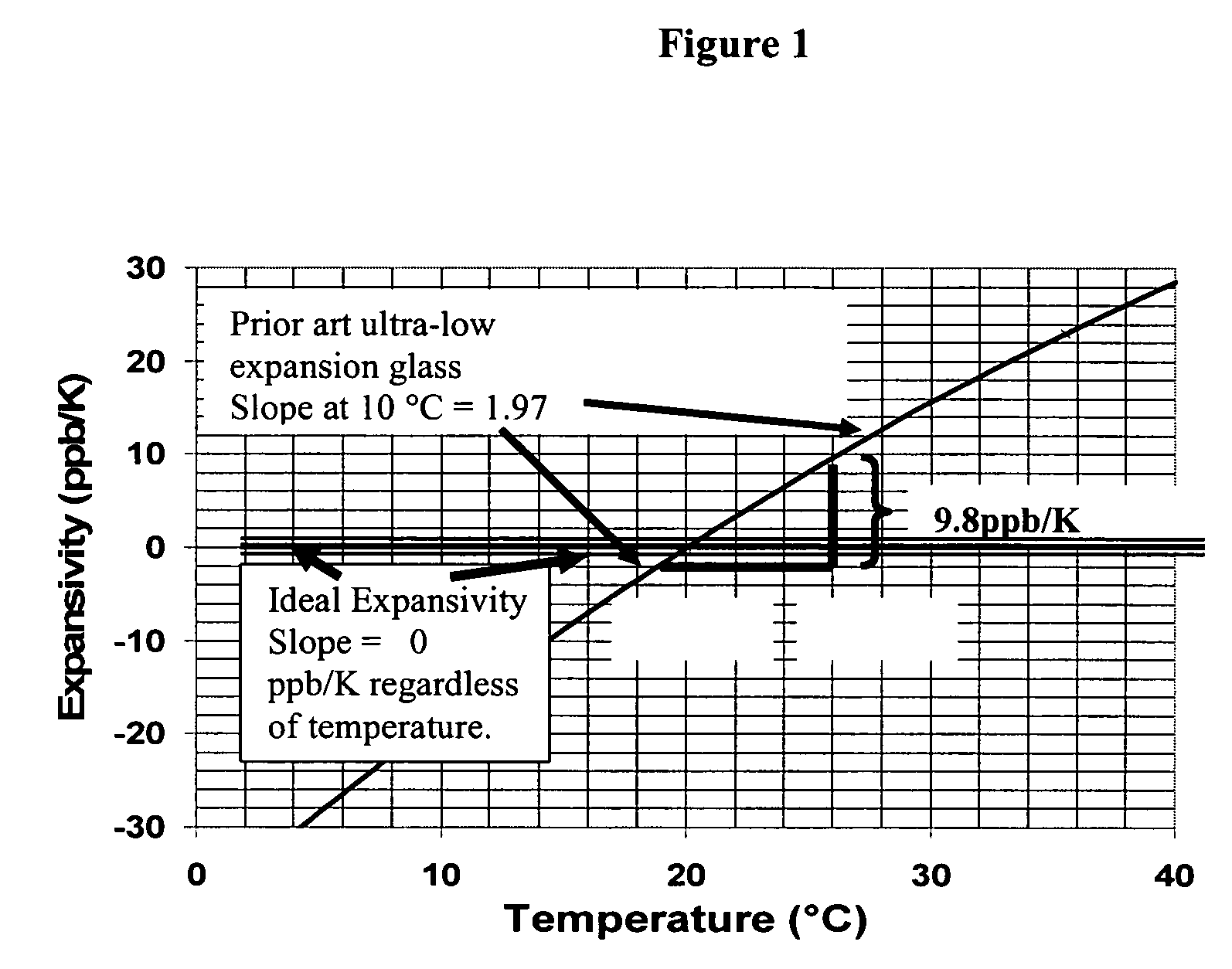

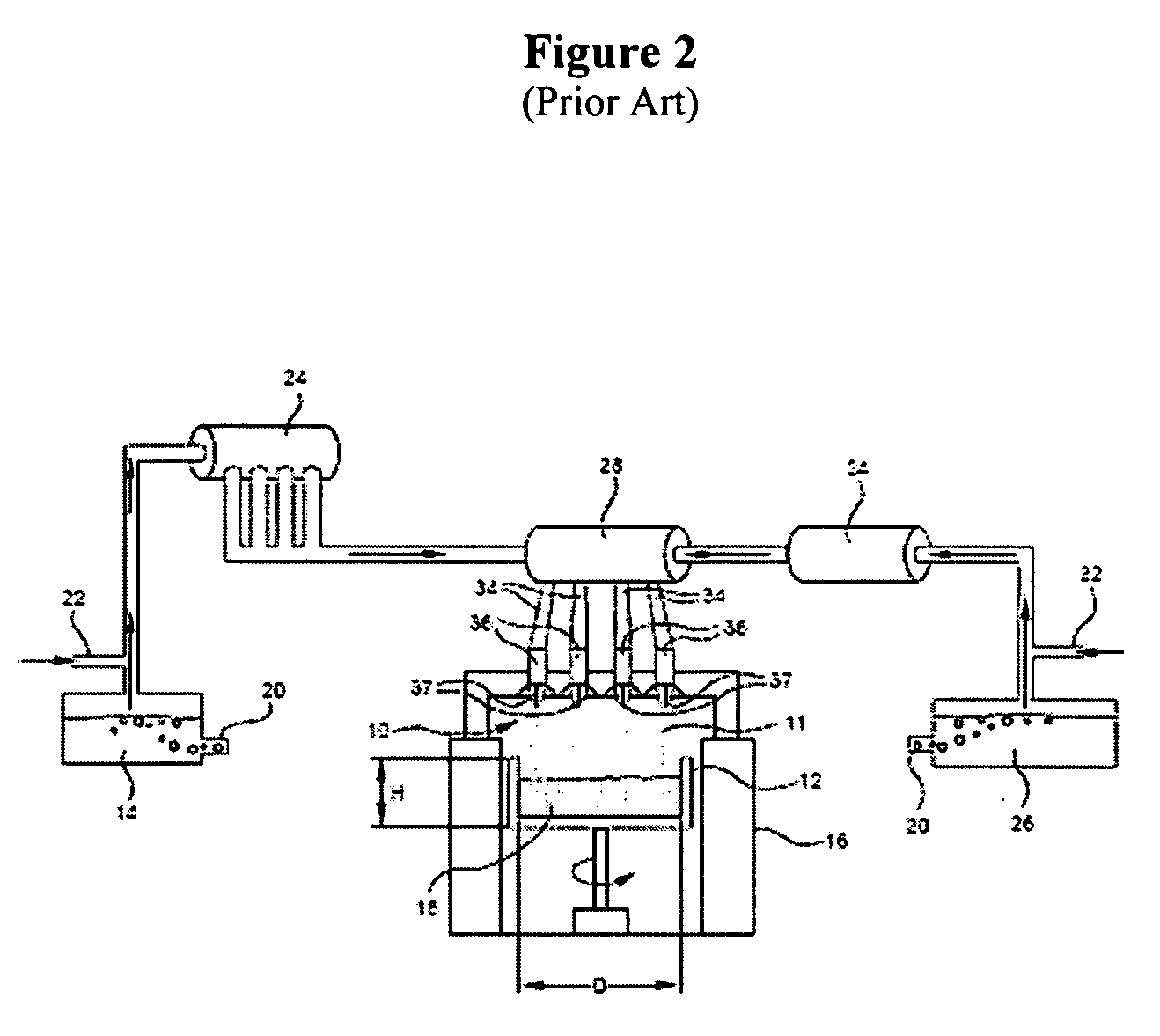

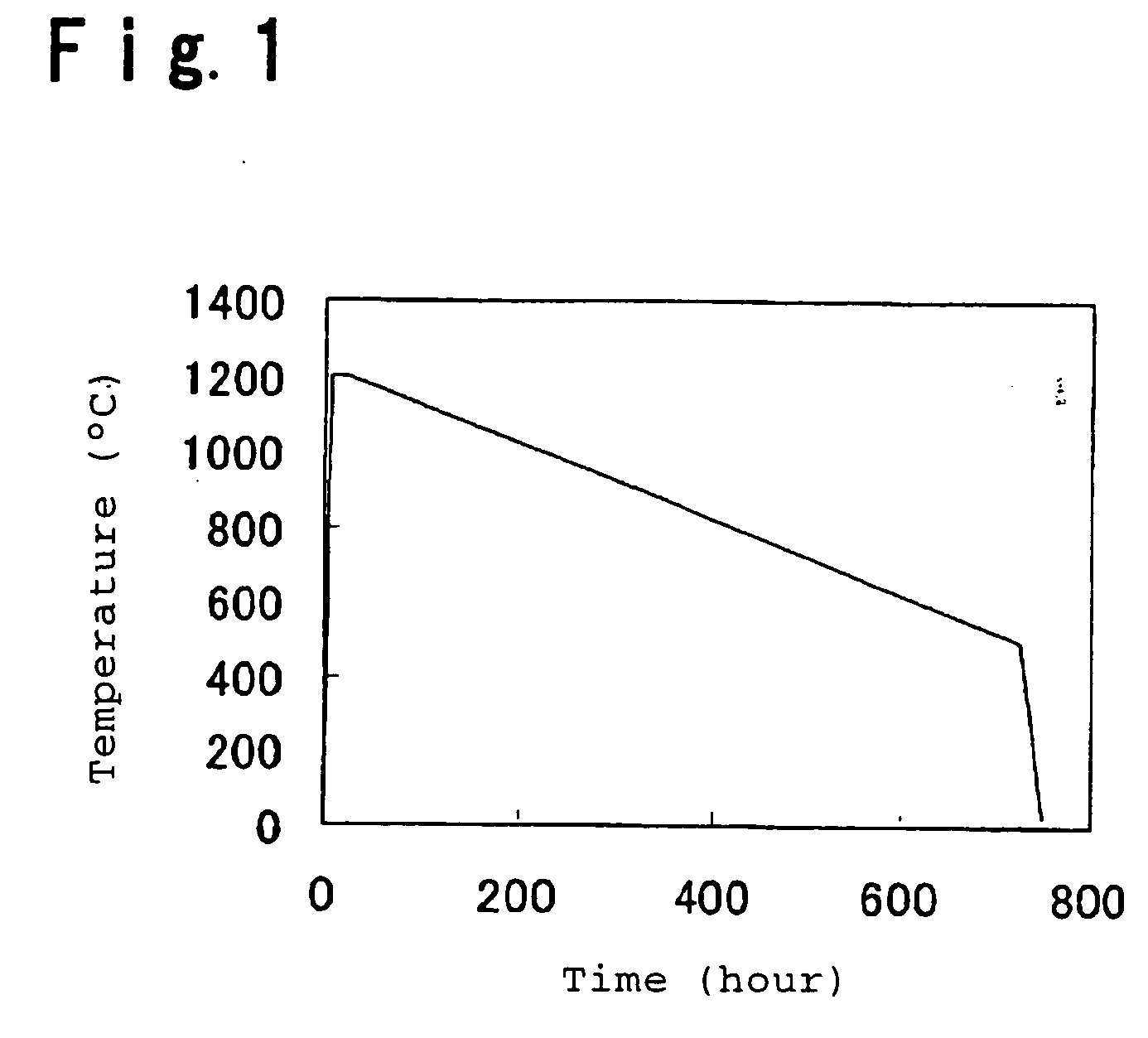

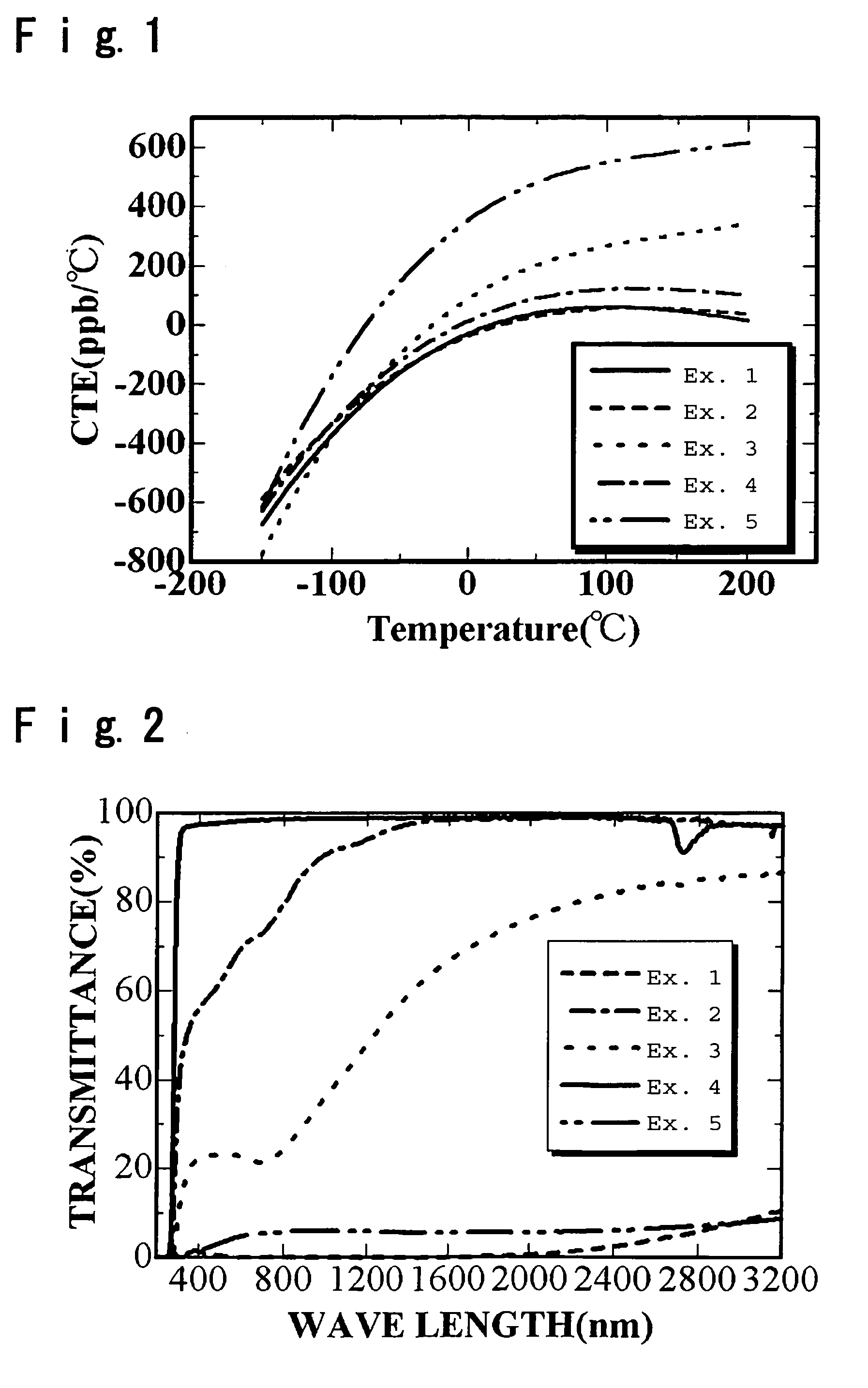

Adjusting expansivity in doped silica glasses

InactiveUS20060179879A1Low viscosityGlass shaping apparatusGlass deposition burnersDopantUltra low expansion glass

The invention is directed to ultra-low expansion glasses to which adjustments have been made to selected variables in order to improve the properties of the glasses, and particularly to lower the expansivity of the glasses. The glasses are titania-doped silica glasses. The variables being adjusted include an adjustment in β-OH level; an adjustment to the cooling rate of the molten glass material through the setting point; and the addition of selected dopants to impact the CTE behavior.

Owner:CORNING INC

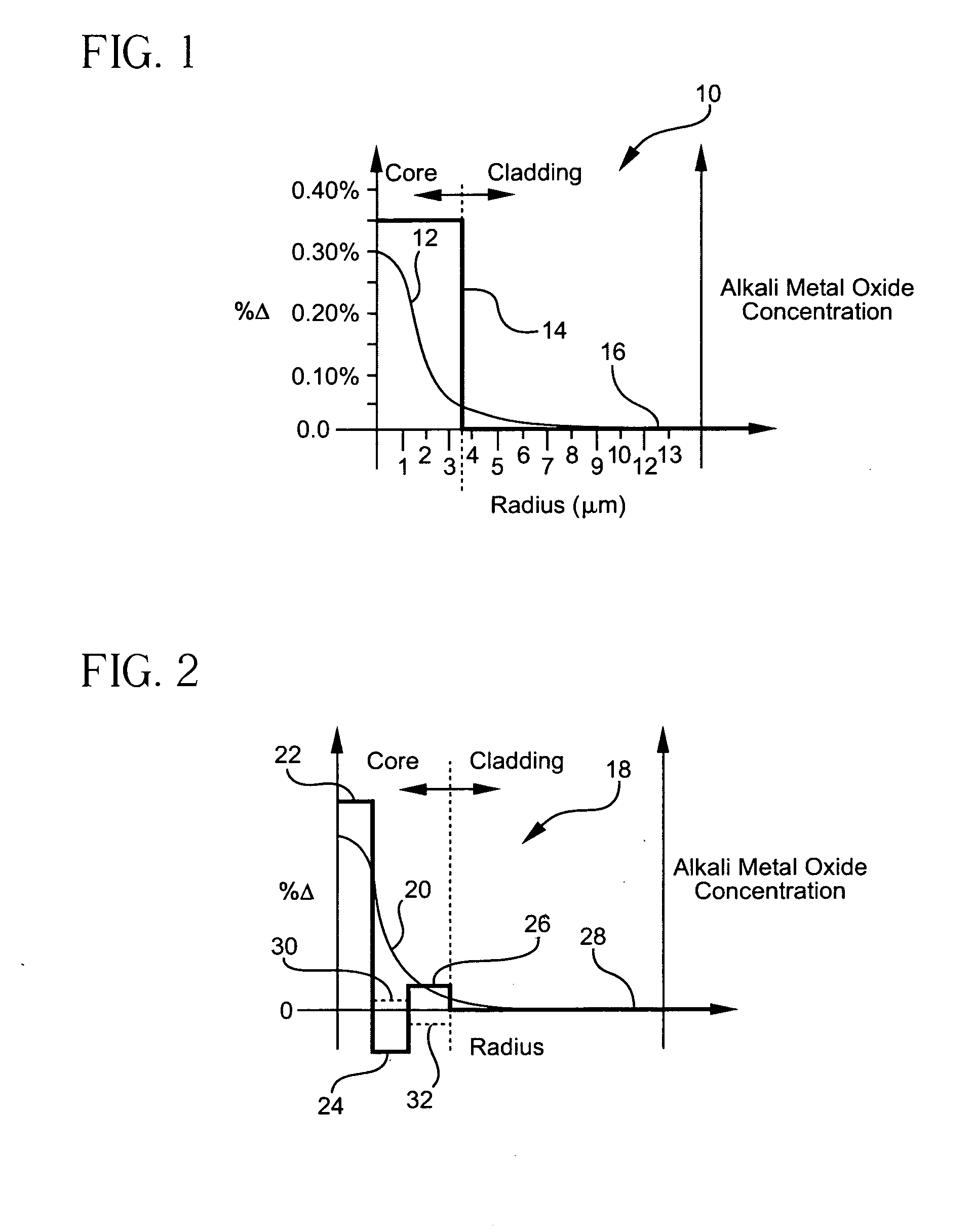

Alkali and fluorine doped optical fiber

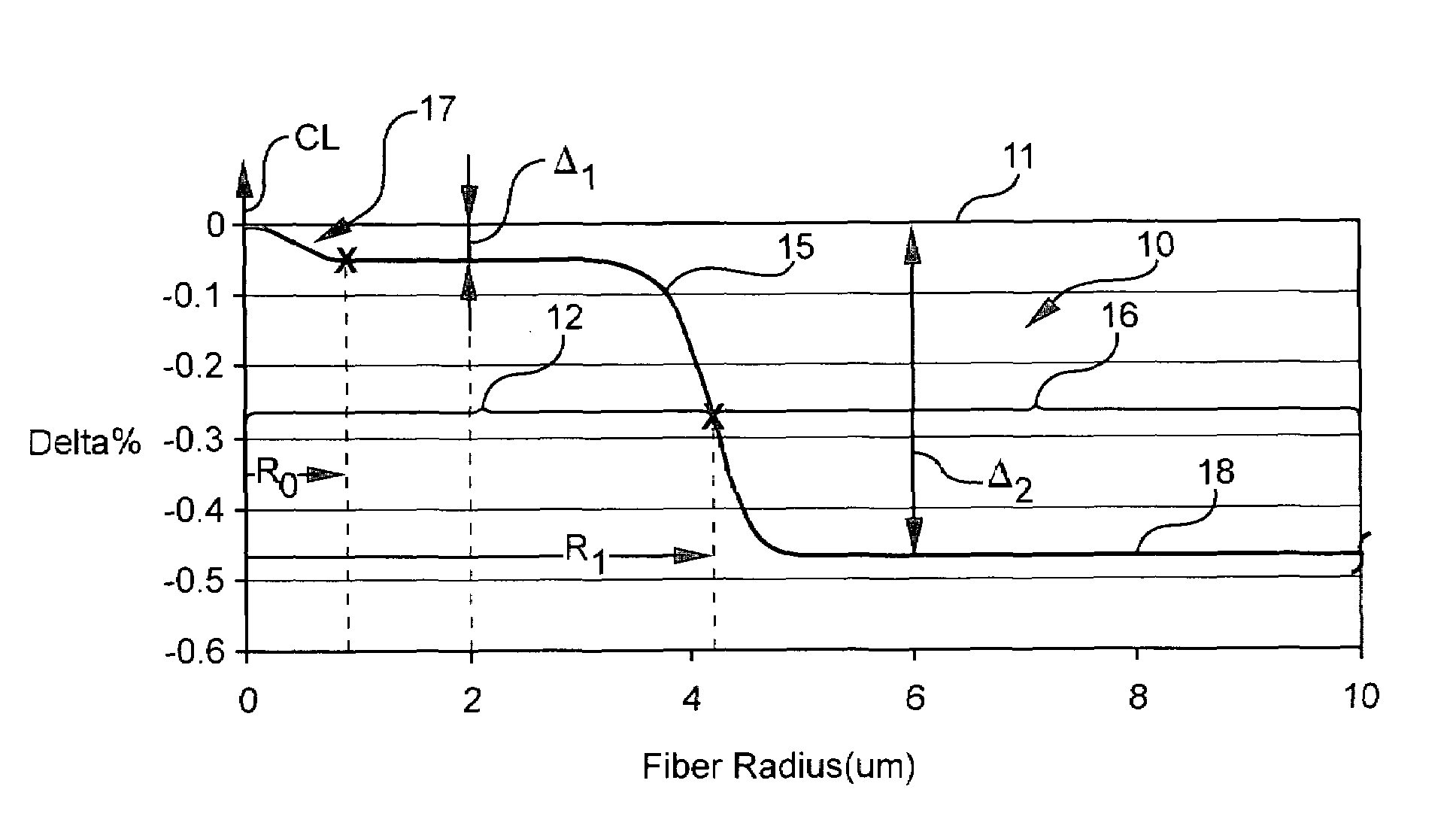

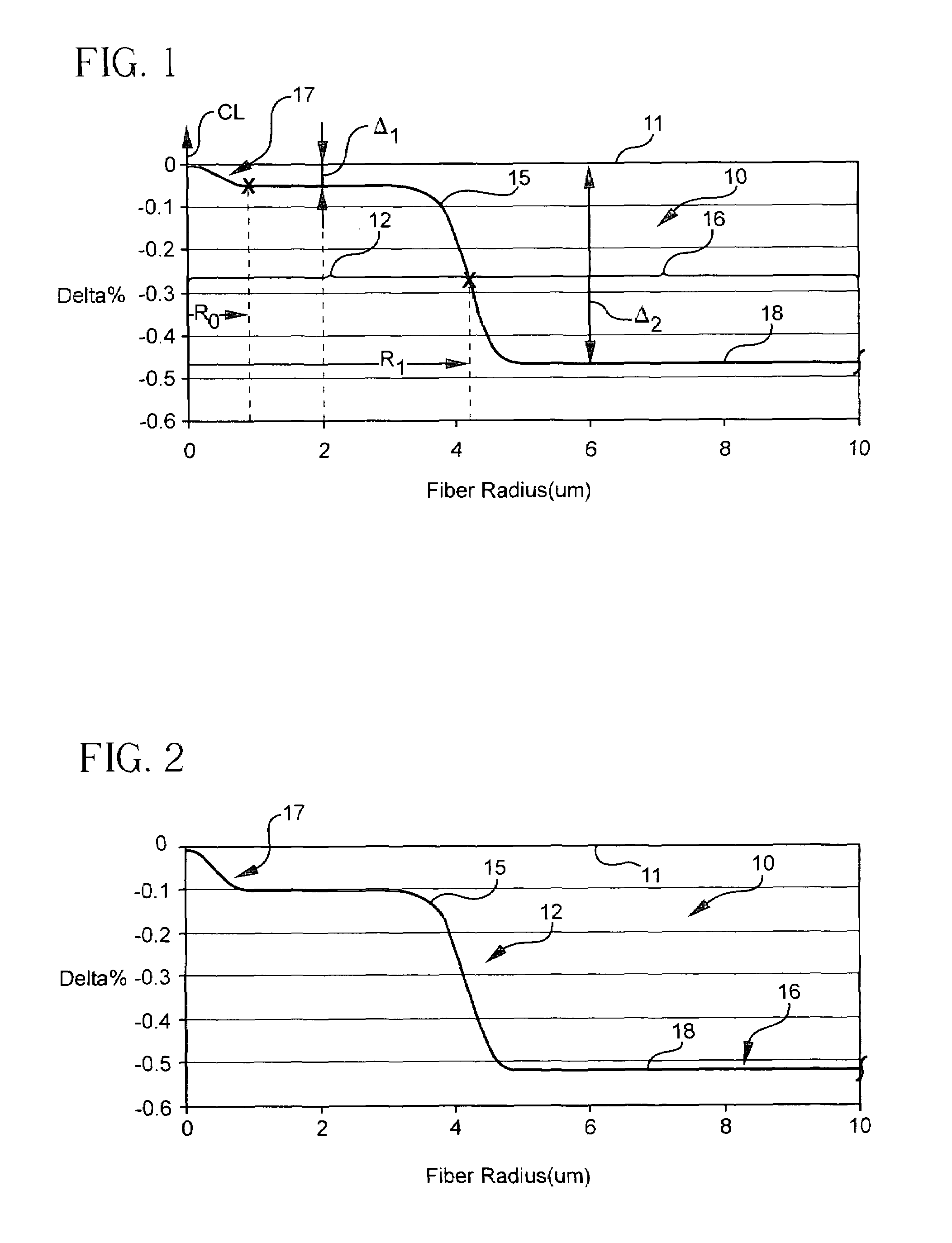

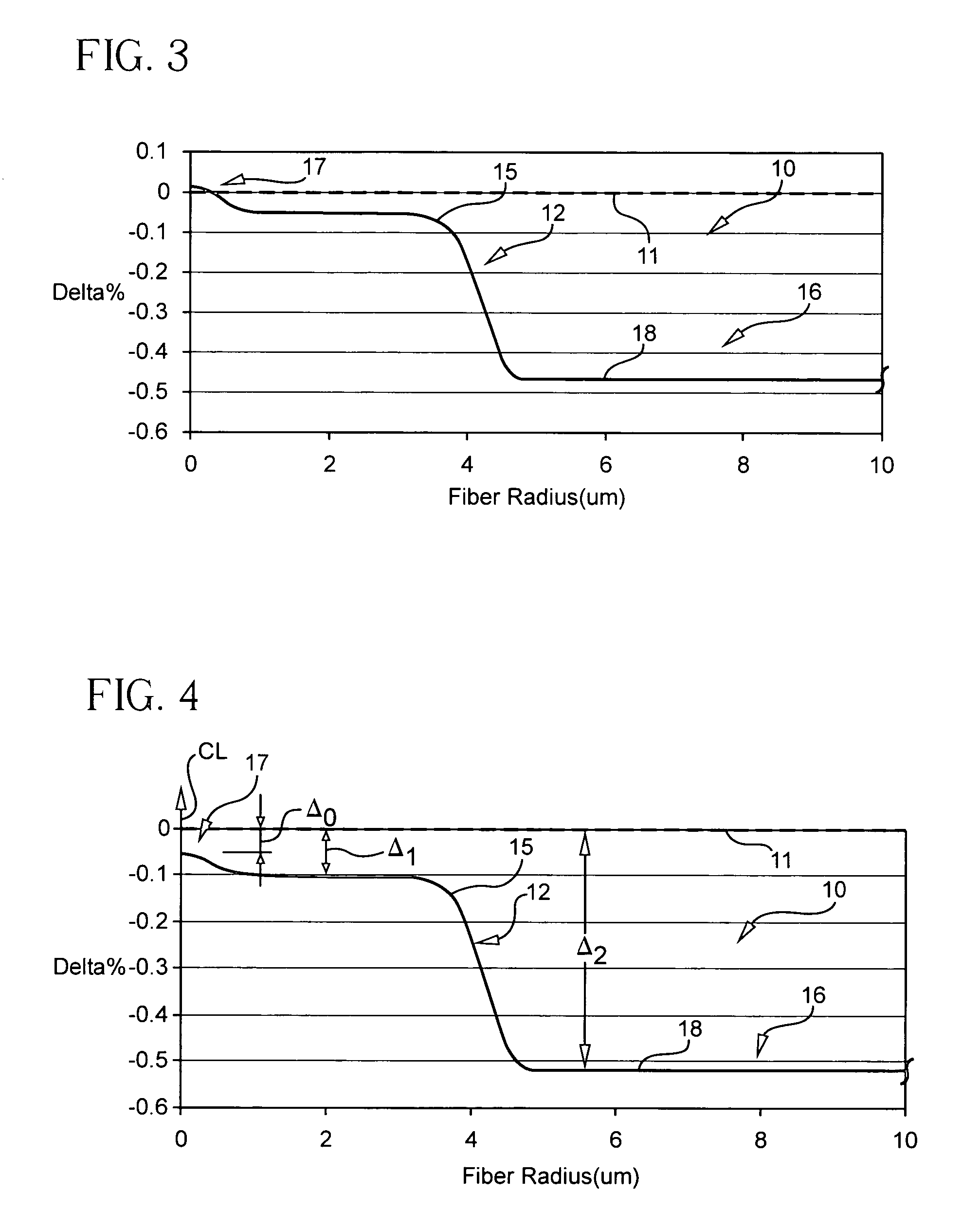

ActiveUS7088900B1Reduce decreaseOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingDopantSilica measurement

Disclosed is an optical fiber having a core of SiO2 doped with fluorine and an alkali metal oxide dopant. The alkali metal oxide is selected from the group consisting of K, Na, Li, Cs and Rb and is provided in amount of at least 20 ppm wt. %. The fiber has an inner cladding surrounding the core, which also includes fluorine. A relative refractive index of the inner cladding (Δ2%), measured relative to pure silica, is preferably between −0.39% and −0.7%. The fiber preferably exhibits attenuation at 1550 nm of less than or equal to 0.178 dB / km.

Owner:CORNING INC

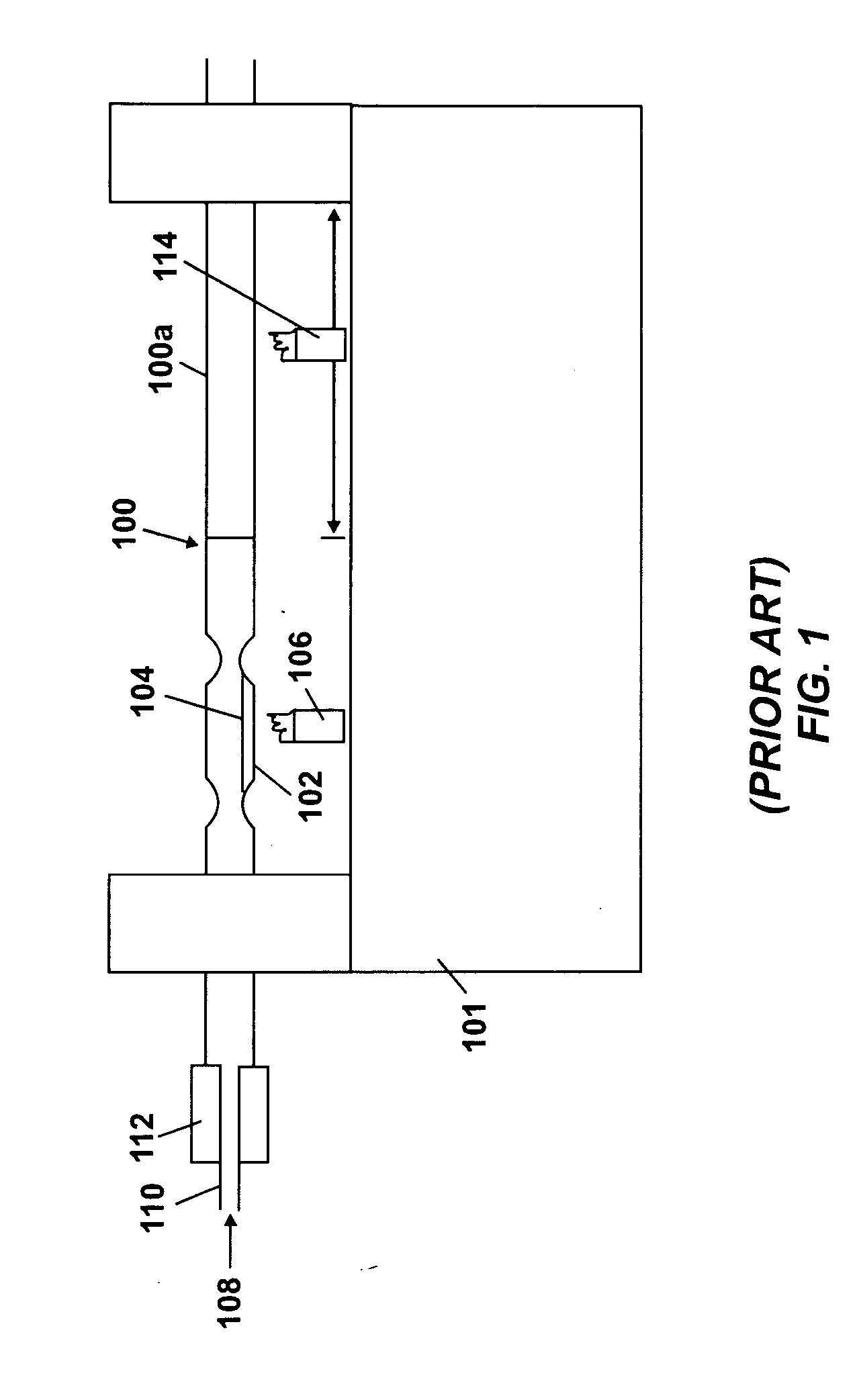

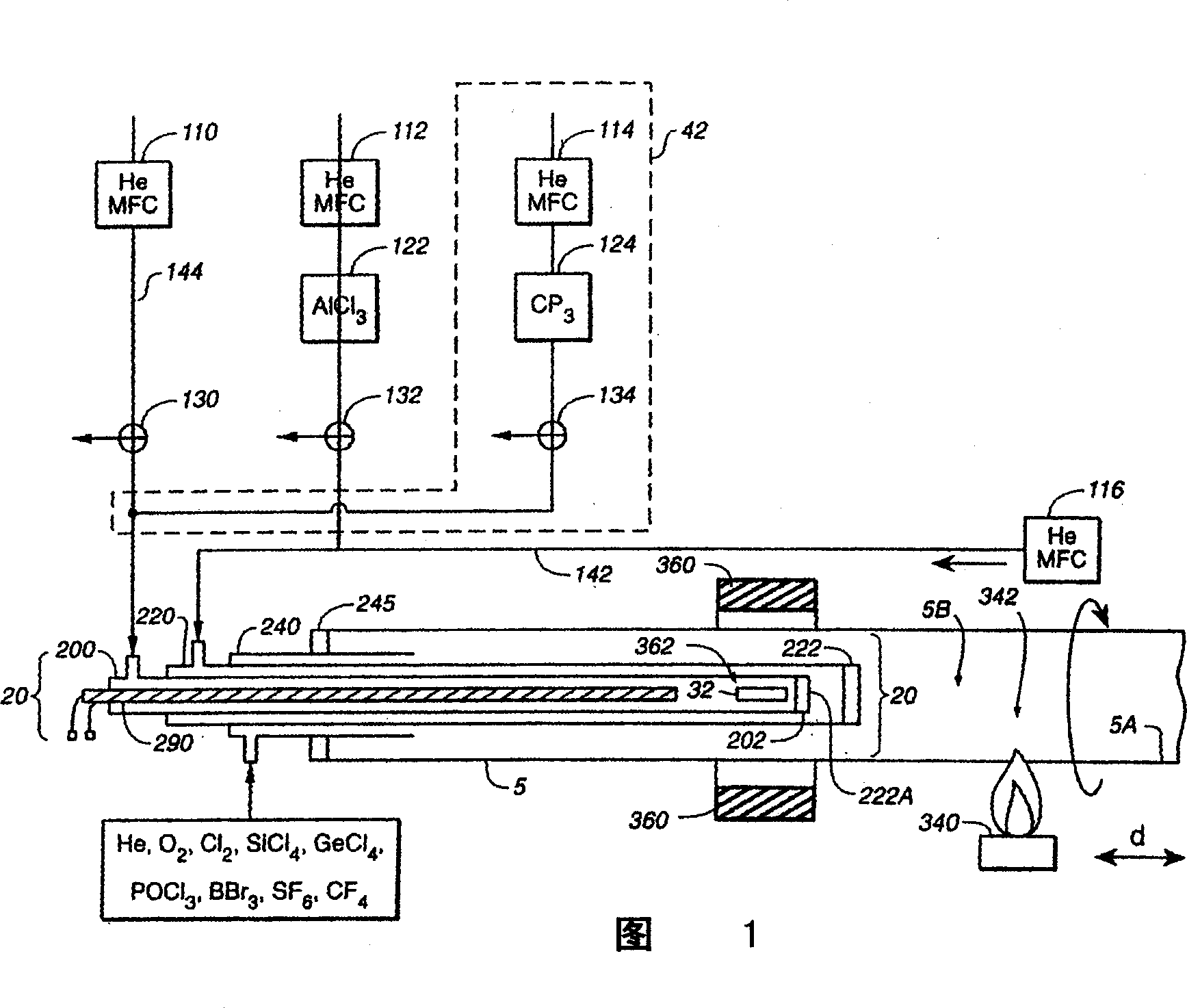

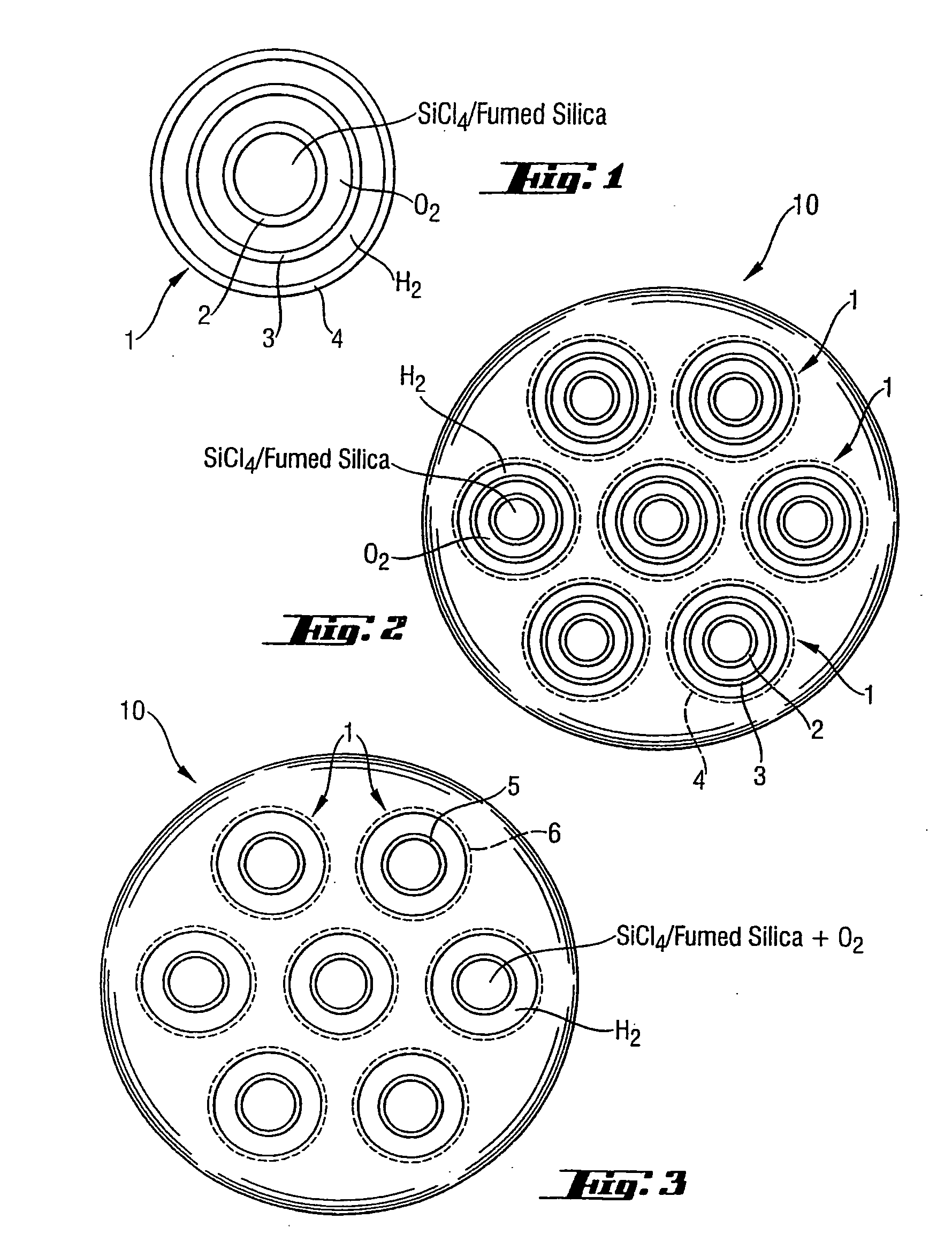

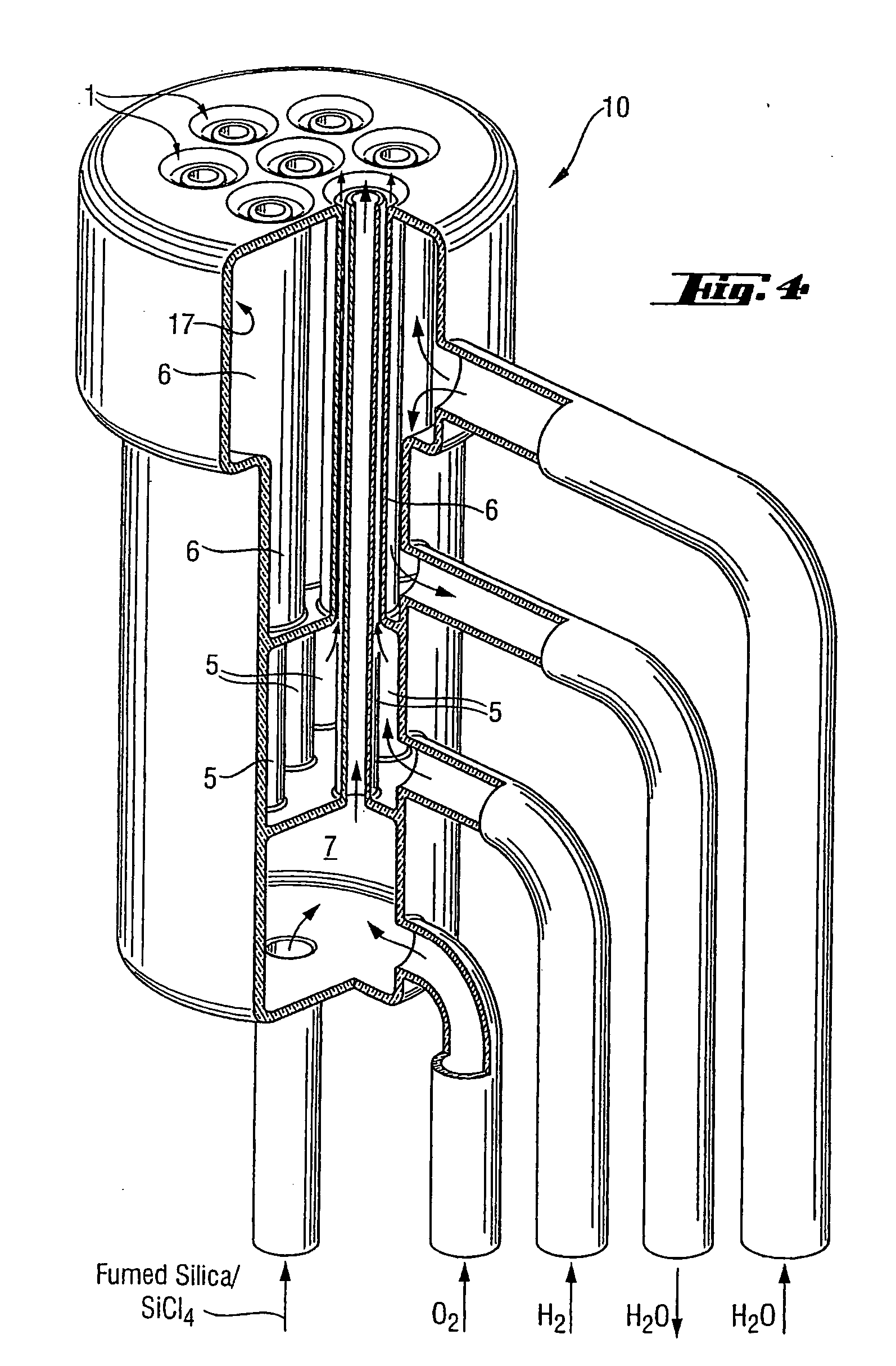

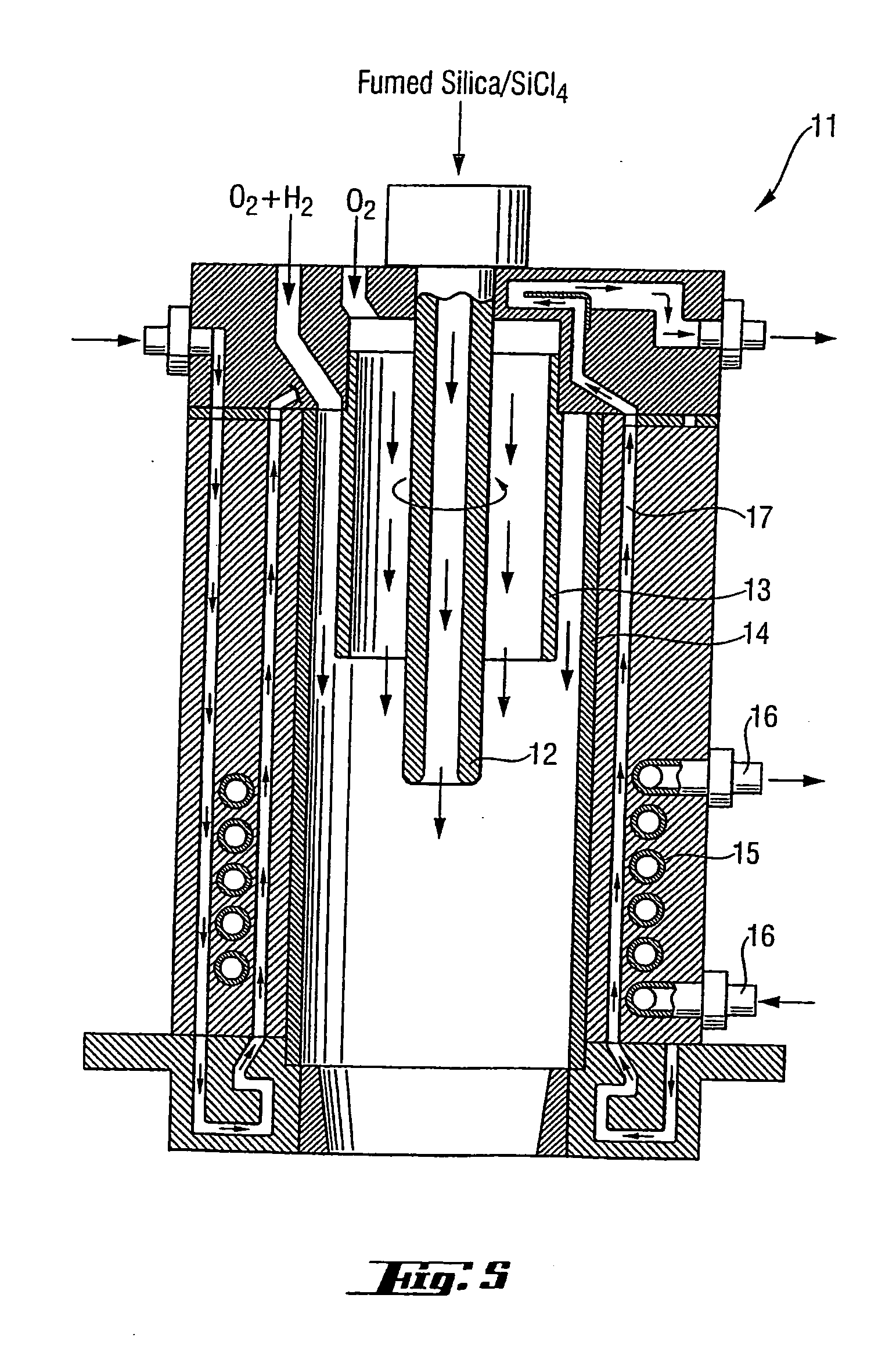

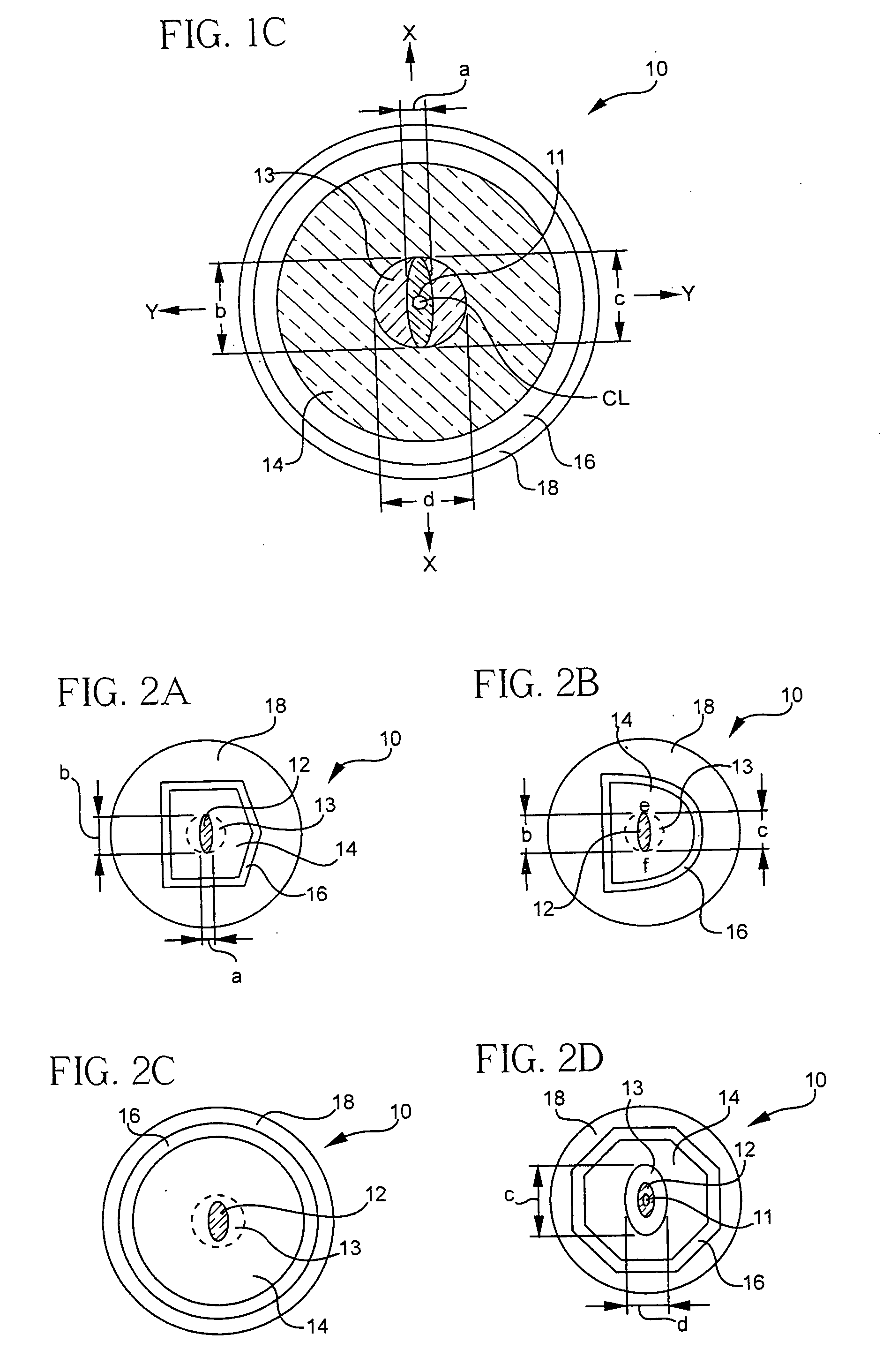

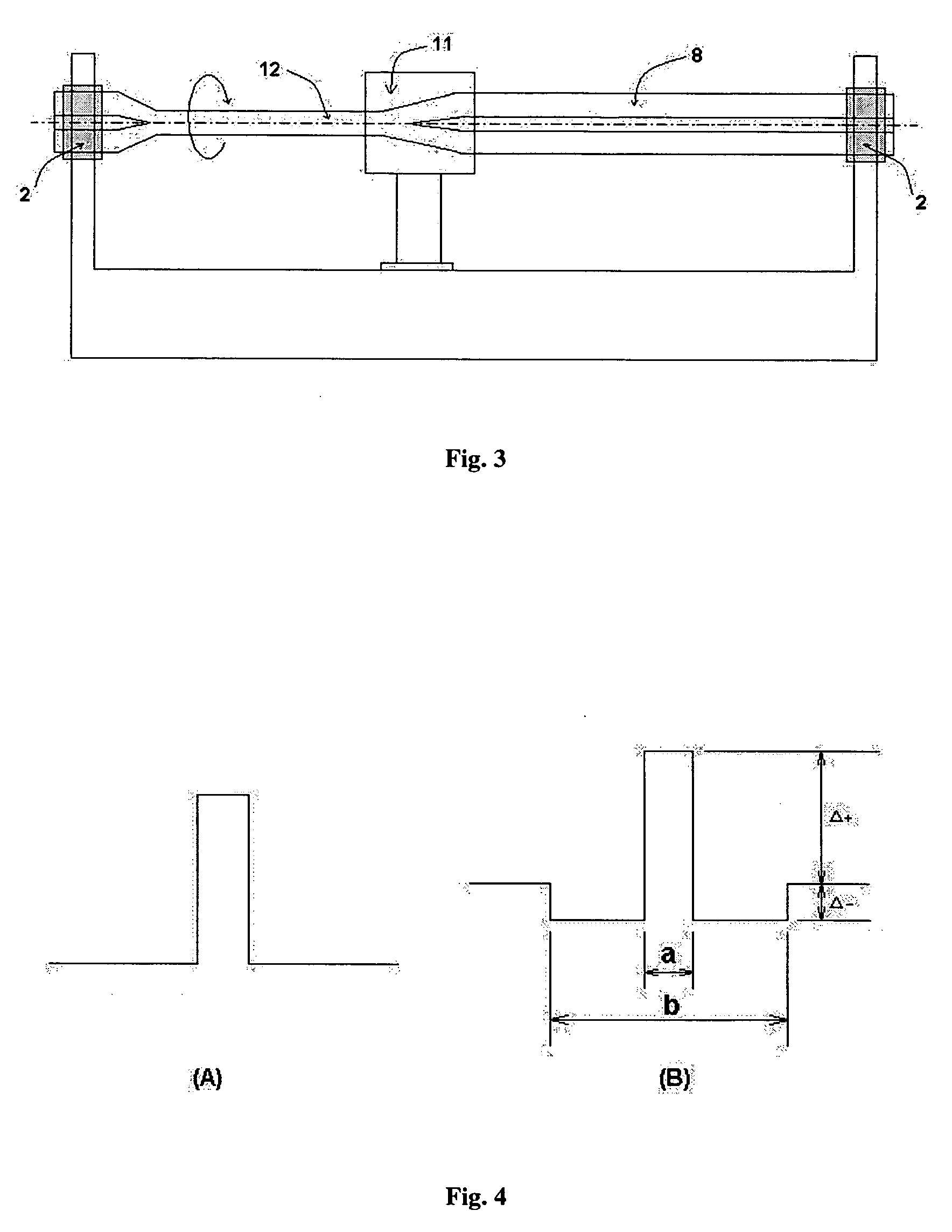

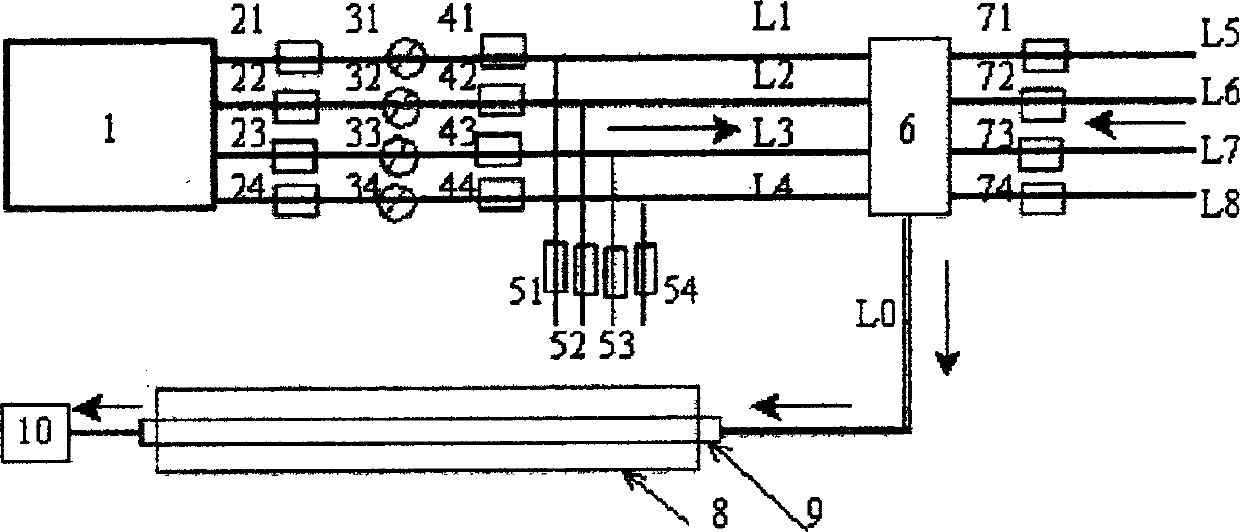

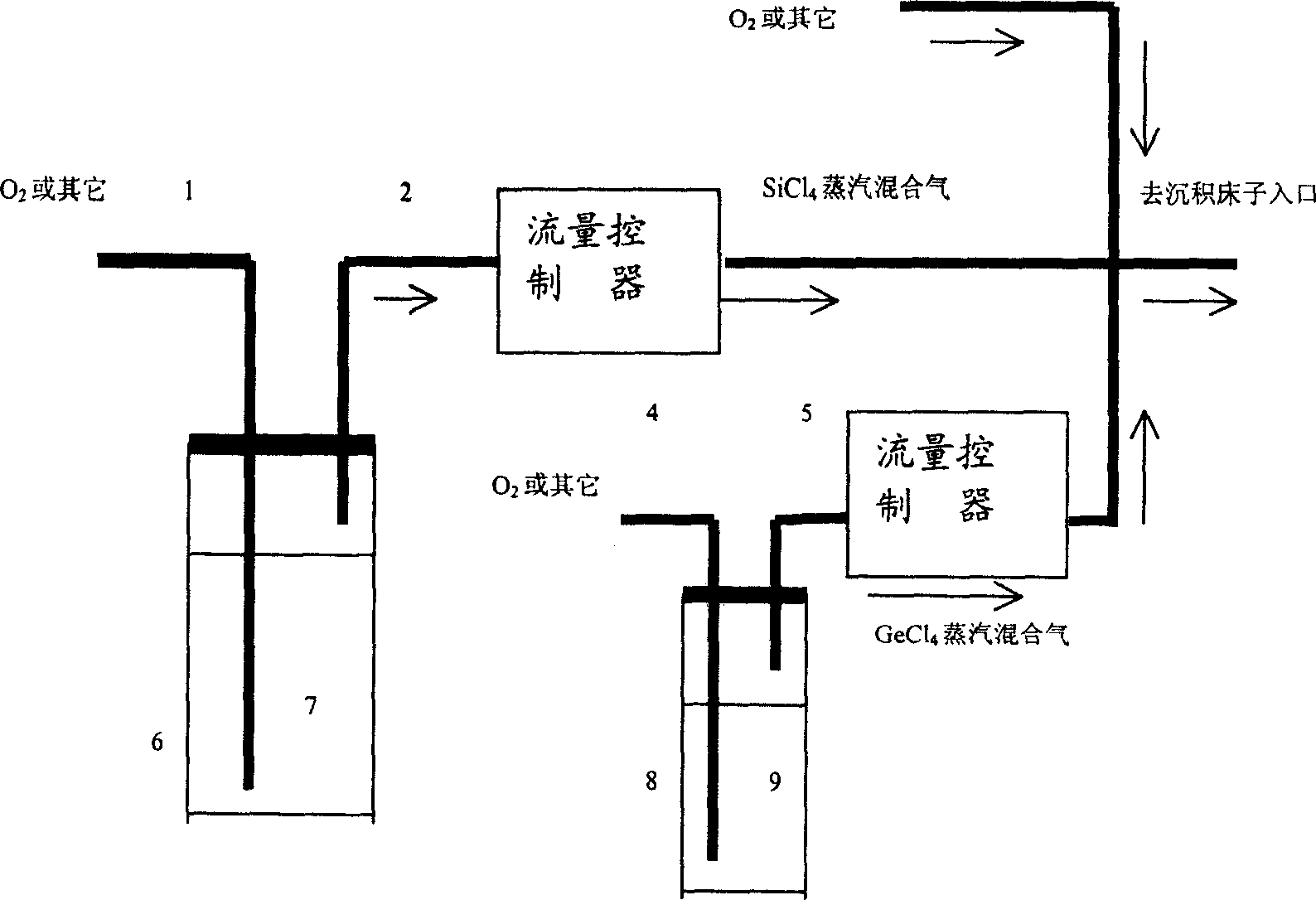

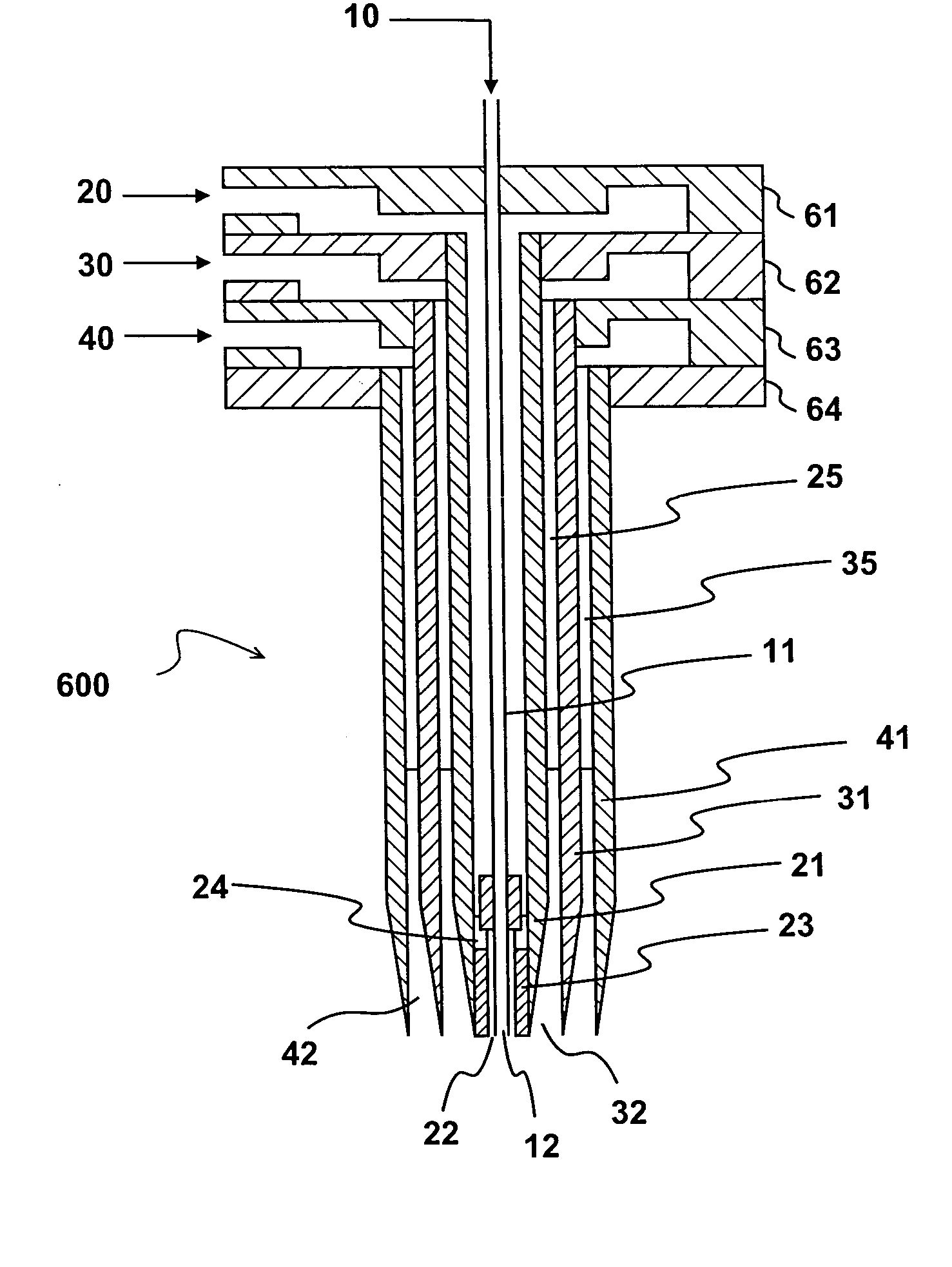

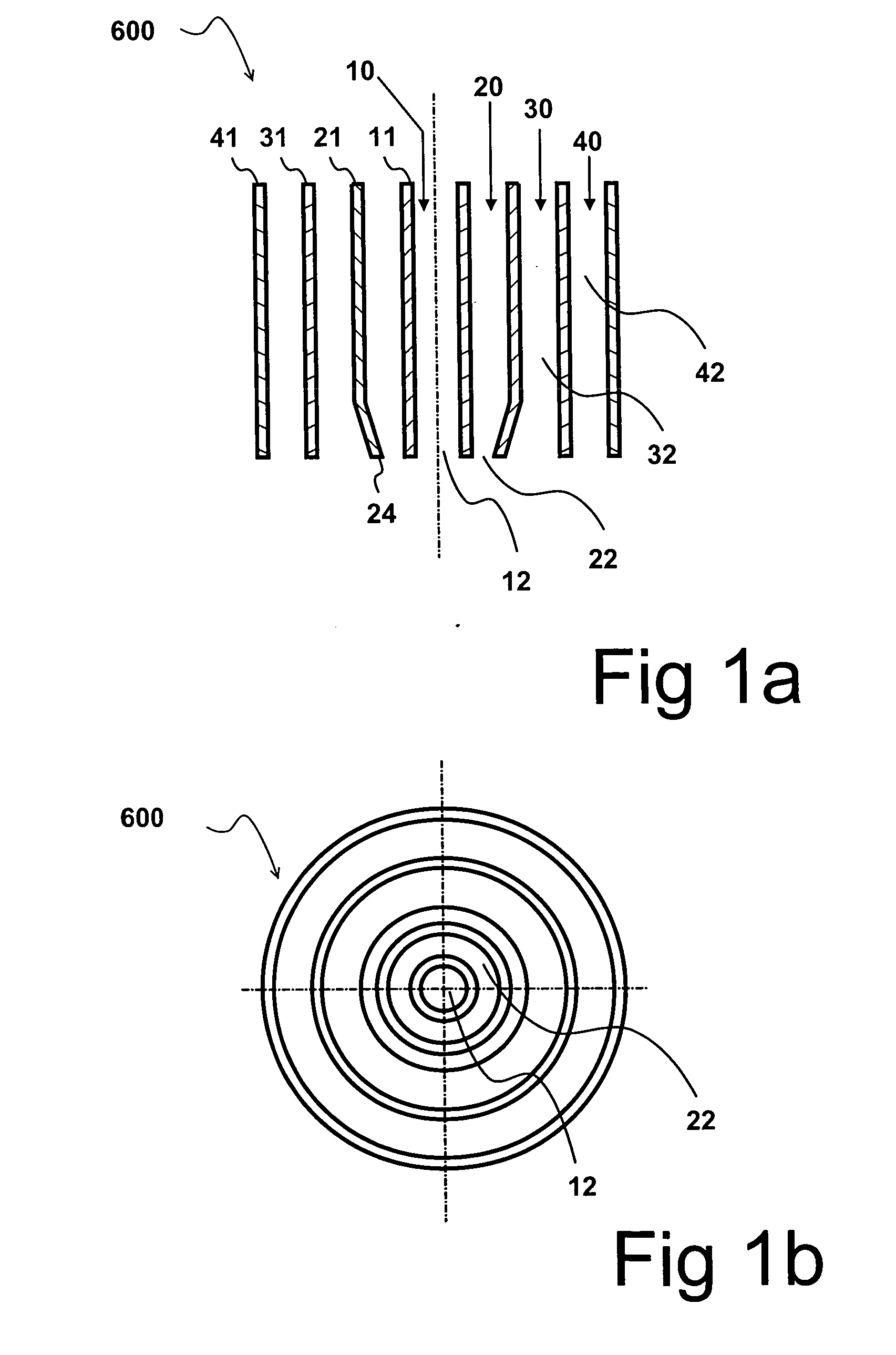

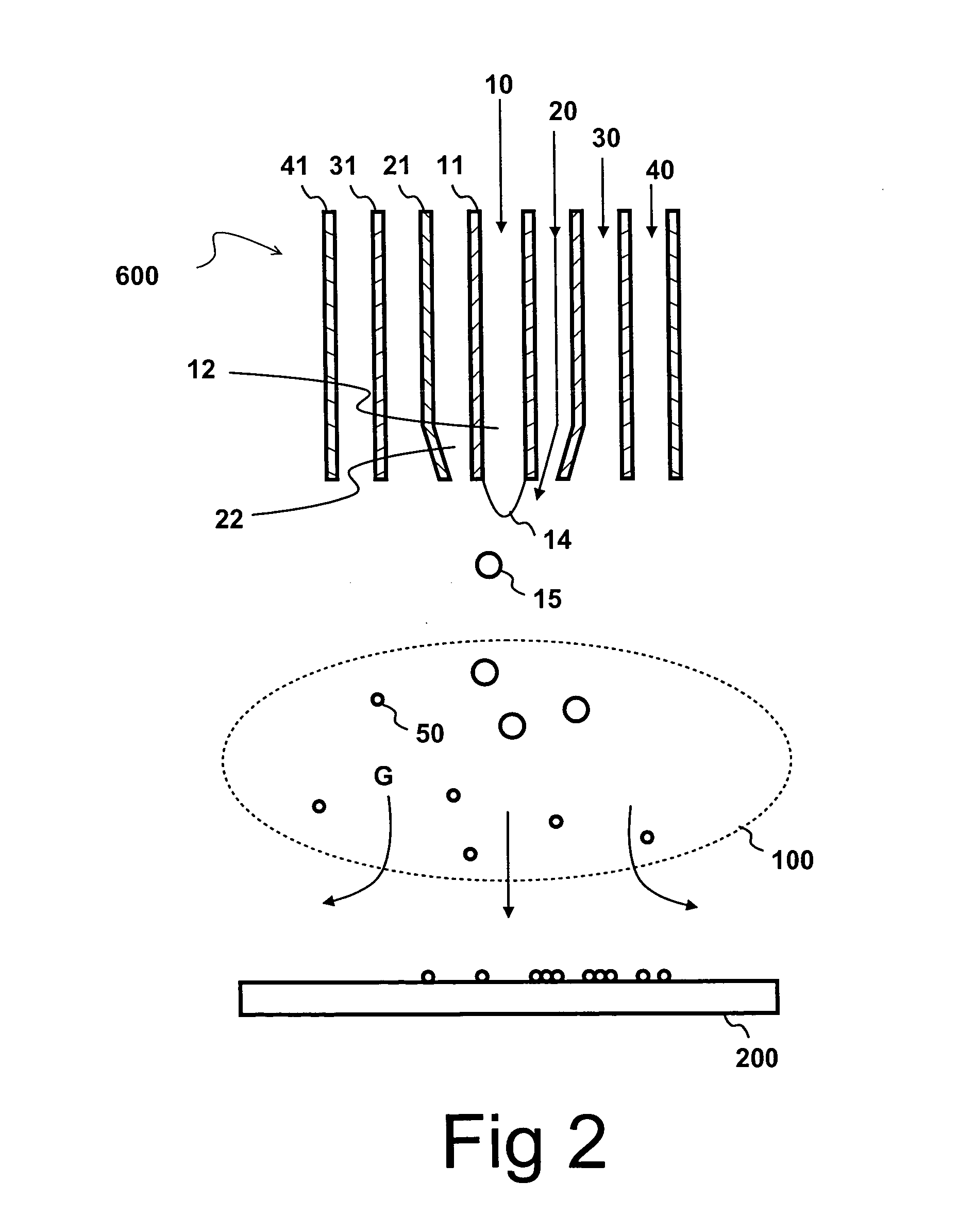

Method and apparatus for manufacturing a rare-earth metal doped optical fiber preform

InactiveCN1307544AHigh pump power absorptionSmall numerical apertureGlass deposition burnersOptical light guidesHigh concentrationGlass forming

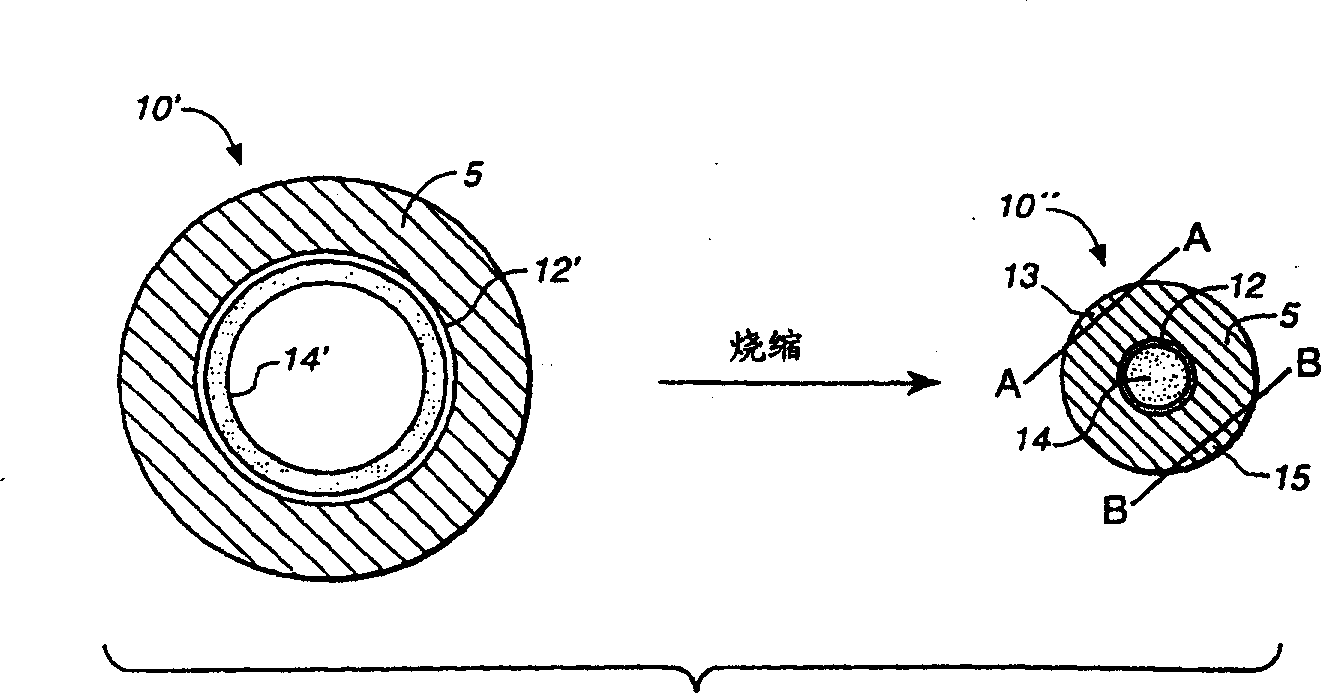

A method and apparatus is disclosed for the manufacture of an optical fiber preform having incorporated therein a comparatively high concentration of rare earth metal dopant material, and which thus can be drawn and processed into an optical fiber having low numerical aperture, low core attenuation, and high pumping power absorption. The high concentrations of rare earth metal dopant material are accomplished through a ''hybrid vapor processing'' (HVP) method or a ''hybrid liquid processing'' (HLP) method, either being practiced in combination or independently of one another. The HVP method involves the vaporization of a rare earth metal halide by the exposure thereof to a sufficiently elevated temperature, independently, or contemporaneously with the transport of the resultant rare earth metal halide laden vapor, into a glass-forming oxidation reaction zone on a flowing stream of essentially an unreactive inert gas, such as helium. According to the HLP method, a first amount of rare earth metal dopant is provided according to the HVP method and / or other vapor source of rare earth metal dopant which is mixed with glass-forming vapors to form a deposited soot layer on the internal surface of a glass tube. The soot-deposited tube is then impregnated with a dopant solution comprising, a second amount of rare earth metal dopant. The tube is then thermally collapsed resulting in an optical preform with an enhanced amount of rare earth metal dopant incorporated at a comparatively high concentration. The apparatus comprises means, such as tubes, for introducing the rare earth metal dopant as a vapor, formed from a solid state form of the dopant, into the main glass deposition tube separately from glass-forming material vapors and oxygen for the reaction within the main tube.

Owner:JDS单相公司

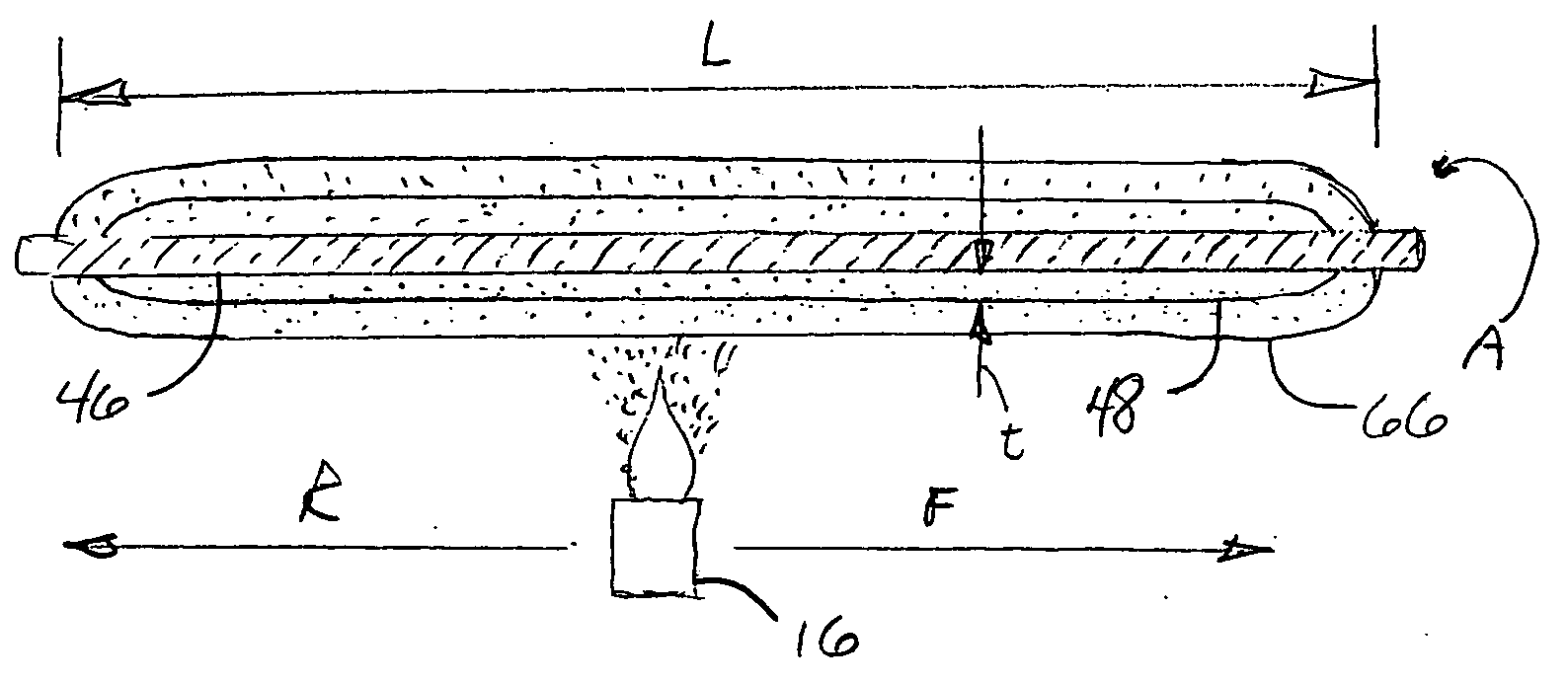

Method of producing quartz glass bodies

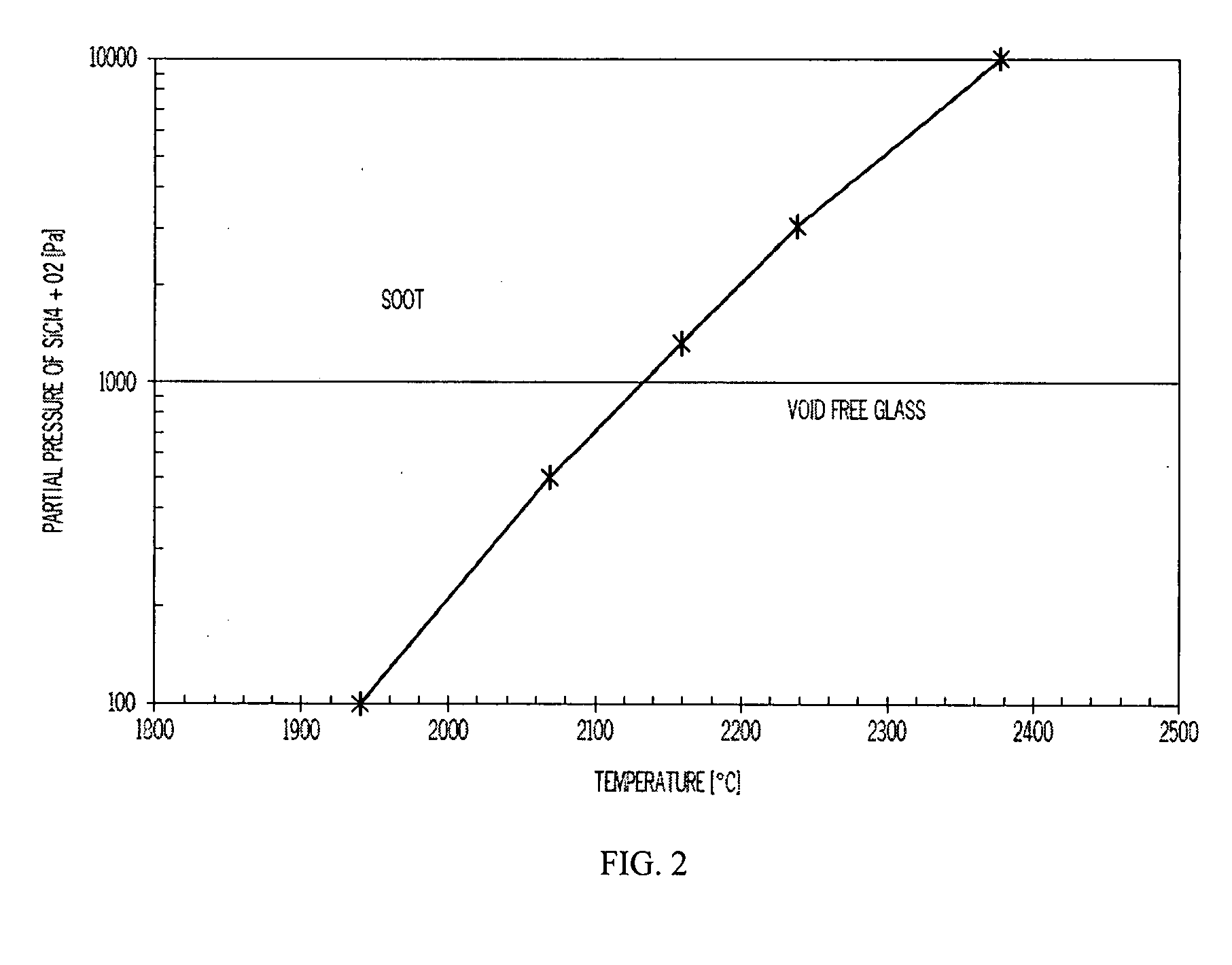

InactiveUS6047564AImprove the usefulnessIncrease surface temperatureBlowing machine gearingsGlass deposition burnersVitreous BodiesEngineering

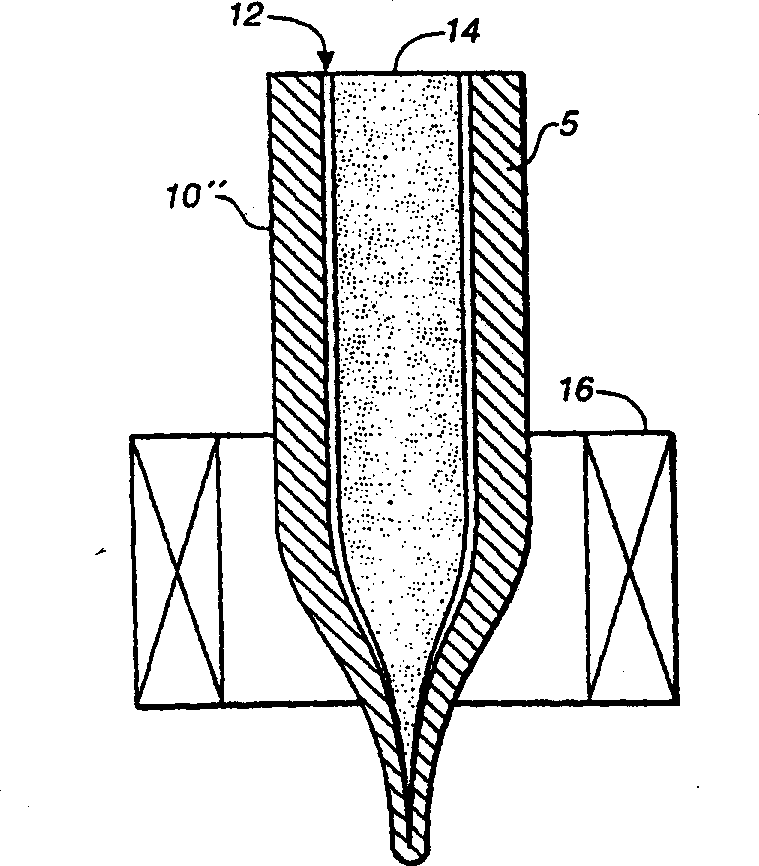

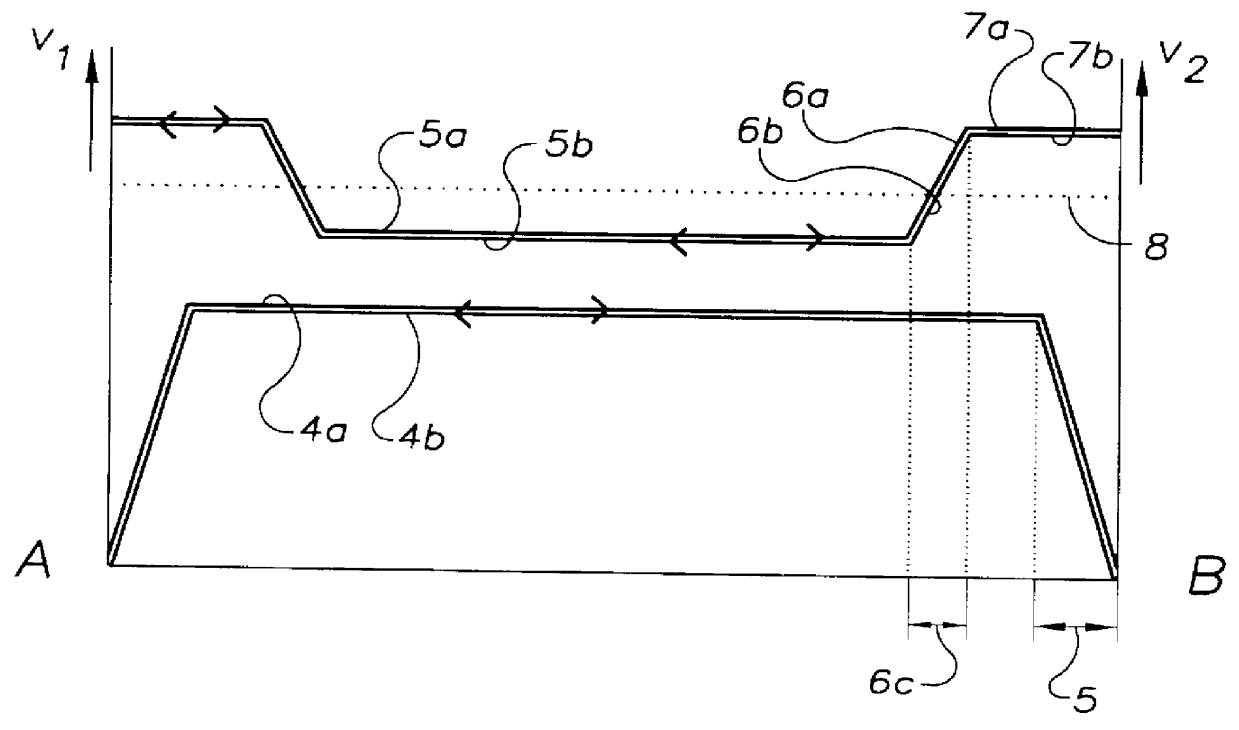

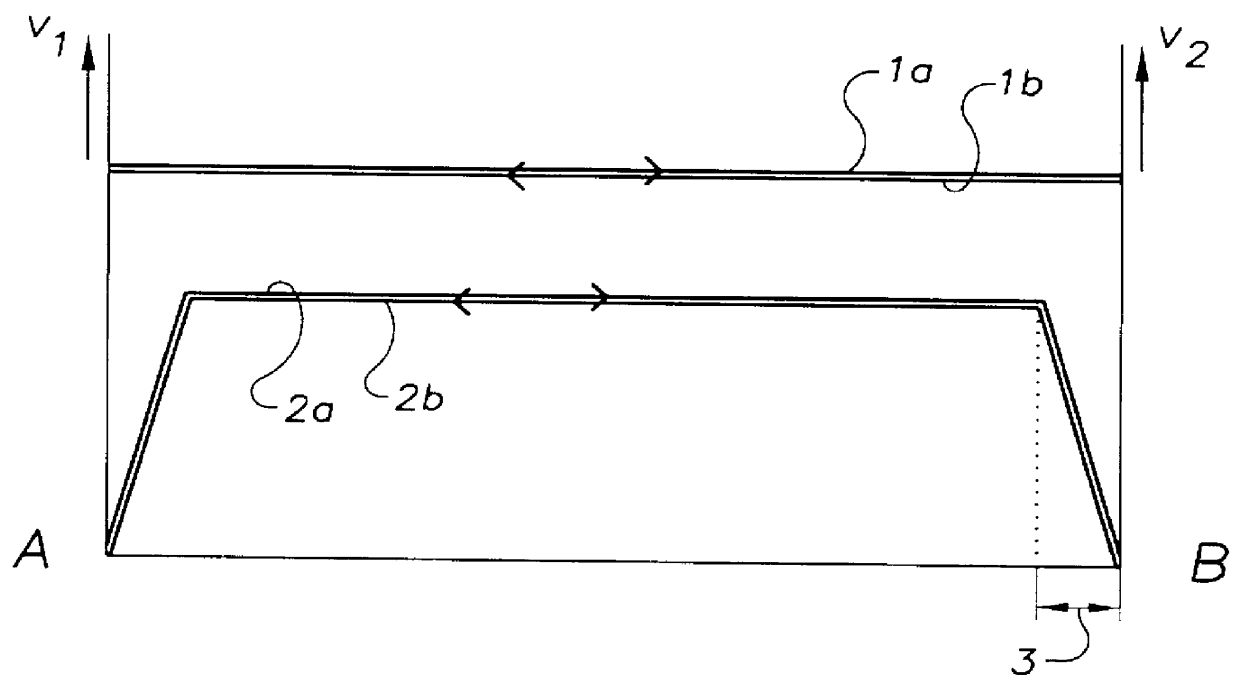

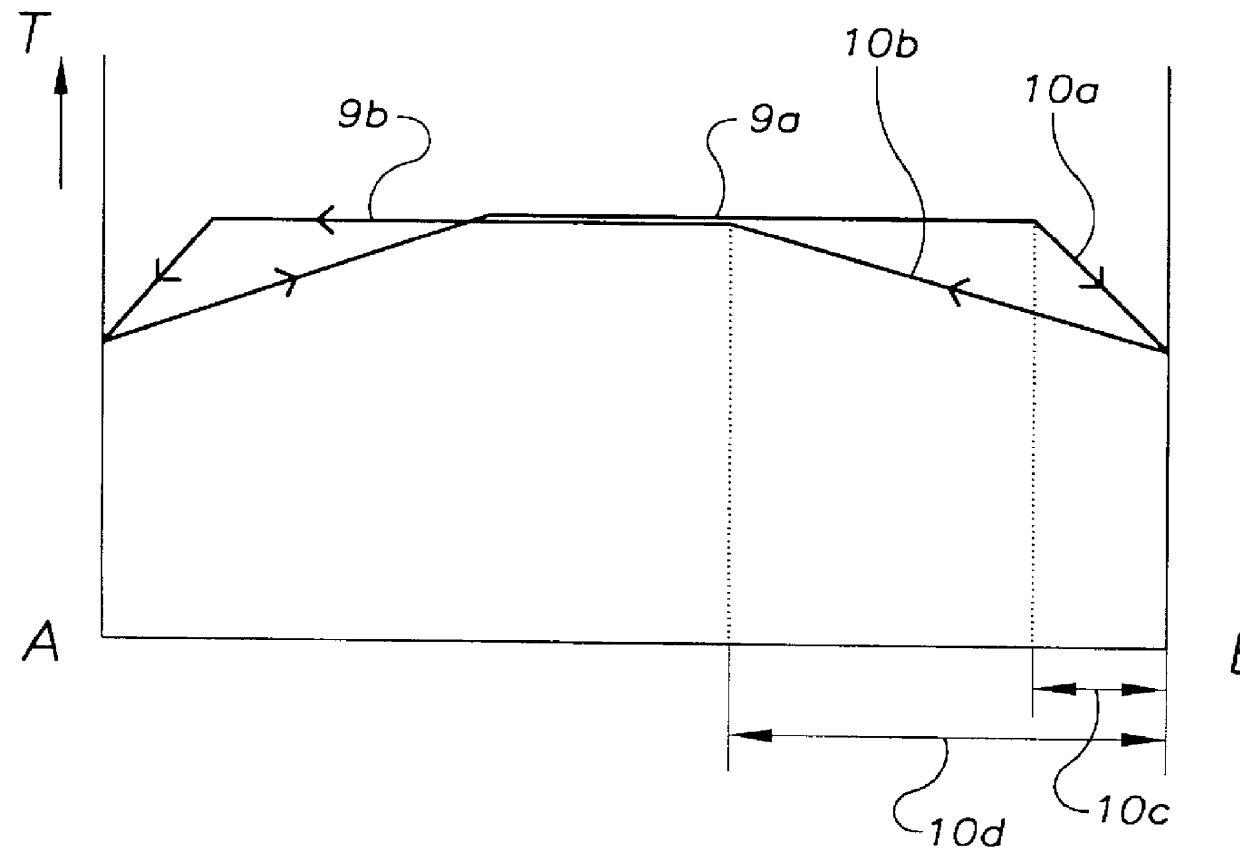

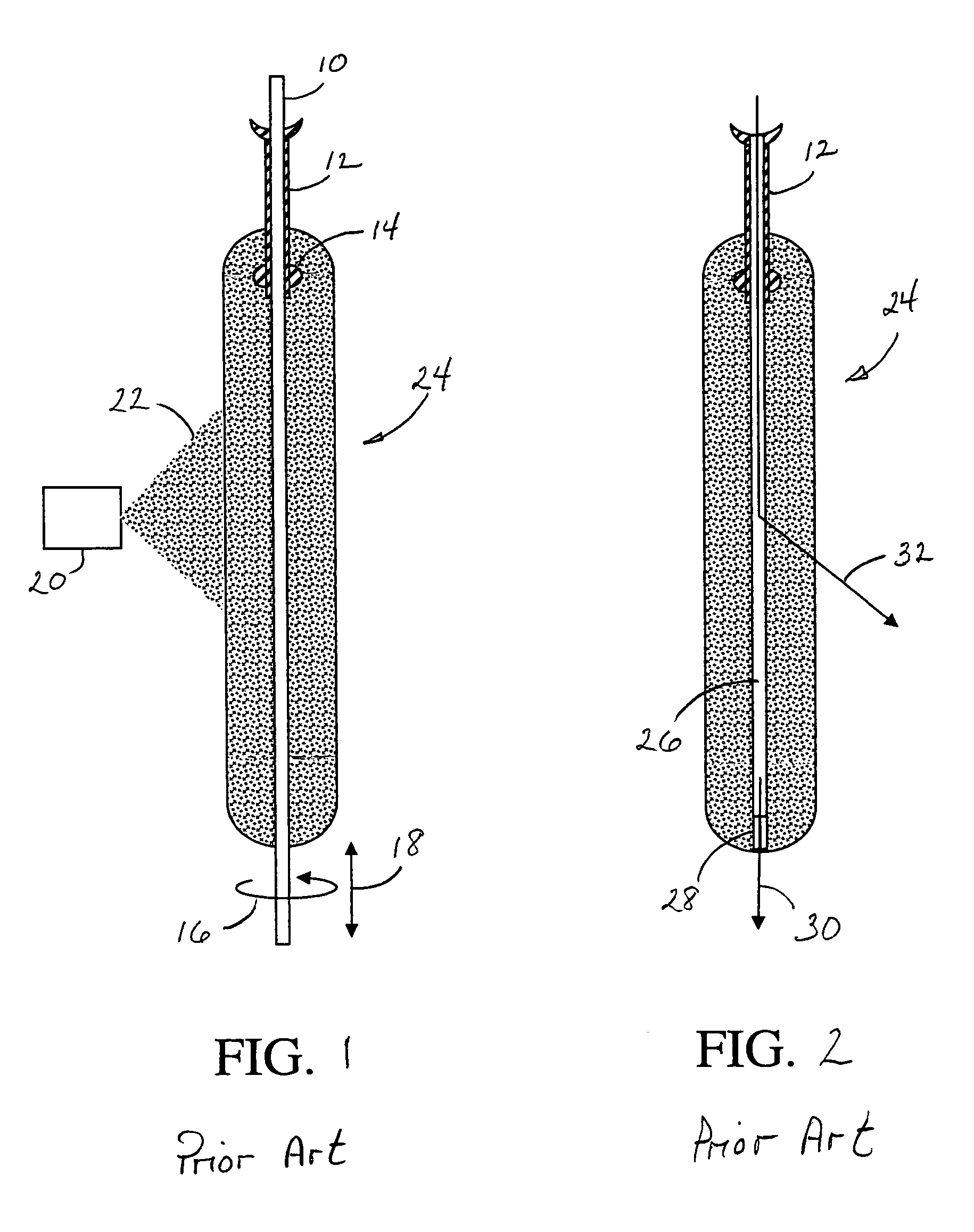

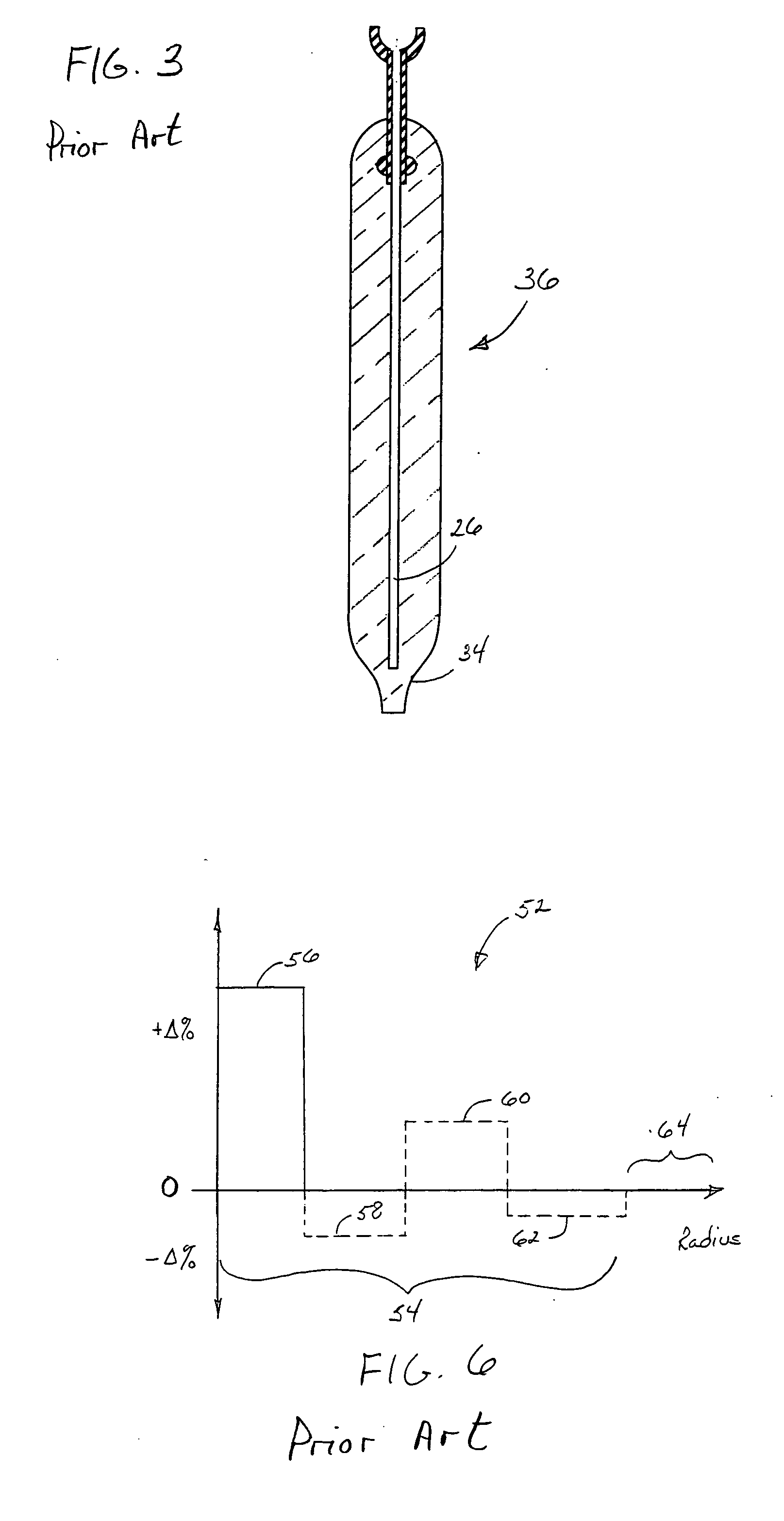

PCT No. PCT / EP97 / 03818 Sec. 371 Date Mar. 3, 1998 Sec. 102(e) Date Mar. 3, 1998 PCT Filed Jul. 17, 1997 PCT Pub. No. WO98 / 03440 PCT Pub. Date Jan. 29, 1998In a known process for the production of quartz glass bodies, SiO2 particles are deposited of the mantle surface of a cylindrical carrier rotating about its longitudinal axis, forming an elongated, porous preform, where the SiO2 particles are formed in a plurality of flame hydrolysis burners which are arranged in at least one burner row parallel to the longitudinal axis of the carrier and are moved at a preset translational speed forward and back between turnaround points at which points their direction of movement is reversed, and in which process the preform is sintered. In order to make available on this basis an easily accomplished process that makes it possible to manufacture a preform which is largely free of localized density variations, the invention proposes on the one hand that the base value of the surface temperature of the preform being formed be kept in a range between 1,050 DEG C. and 1,350 DEG C., that the average peripheral velocity of the preform be kept in the range between 8 m / min and 15 m / min and the average translational velocity of the burner row be kept in a range between 300 mm / min and 800 mm / min. On the other hand, the object is also accomplished according to the invention and on the basis of the known process in that in the area of the turnaround points (A, B) the peripheral velocity of the preform being formed is increased and / or the flame temperature is lowered and / or the distance of the burners from the preform surface is changed.

Owner:HERAEUS QUARZGLAS

High-purity silica powder, and process and apparatus for producing it

Use of a flame hydrolysis apparatus for preparing fumed silica particles or a plasma torch apparatus for sintering fumed silica particles to fused silica particles is capable of producing highly pure silica with non-silicon metal impurities less than 500 pb, when at least an inner nozzle is constructed of a silicon-containing material having a low level of non-silicon metal impurities. Preferably, all surfaces in the respective apparatus which contact silica are of similar construction. The silica contains a low level of impurities as produced, without requiring further purification.

Owner:WACKER CHEM GMBH

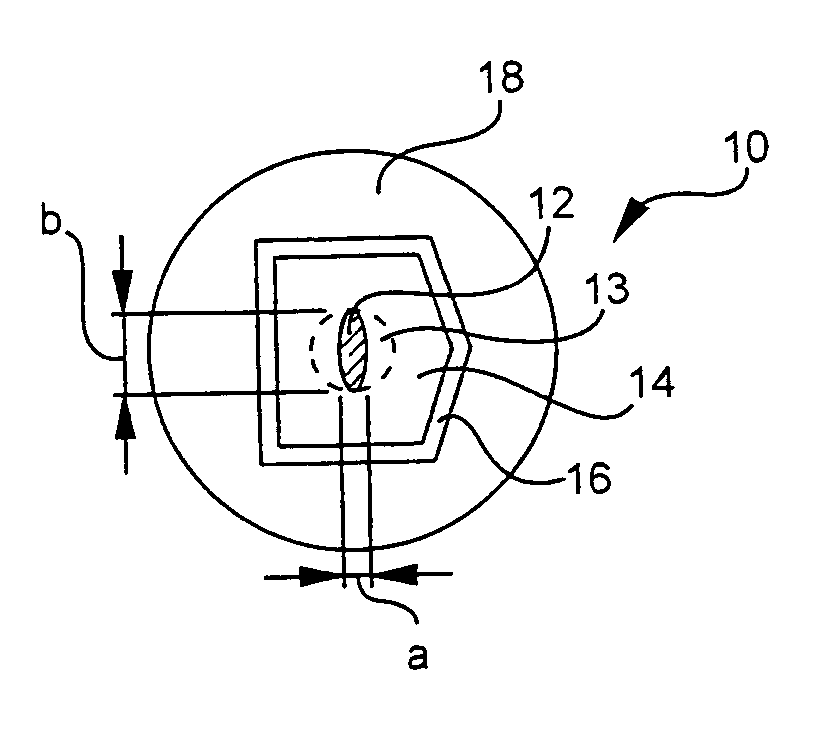

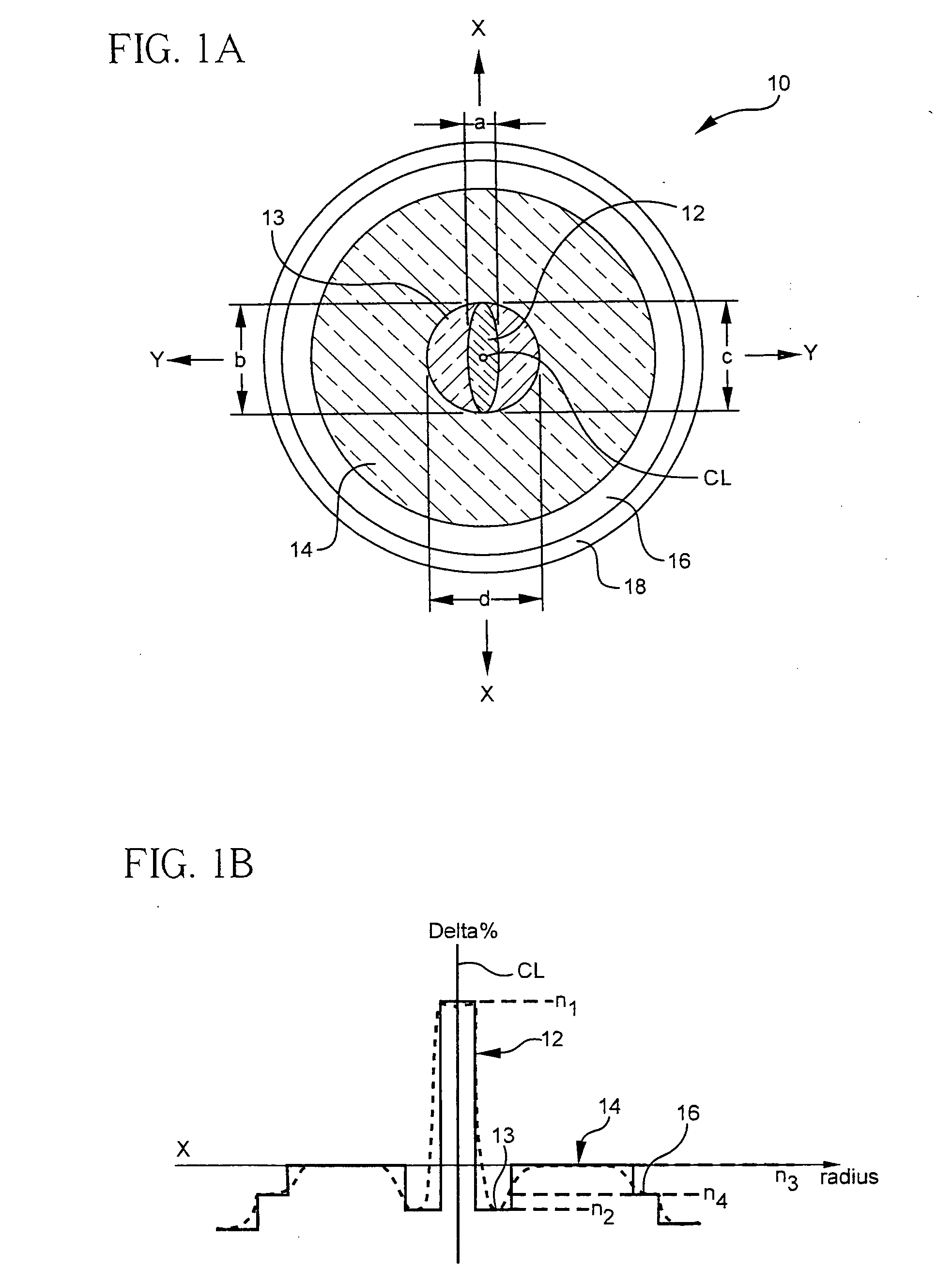

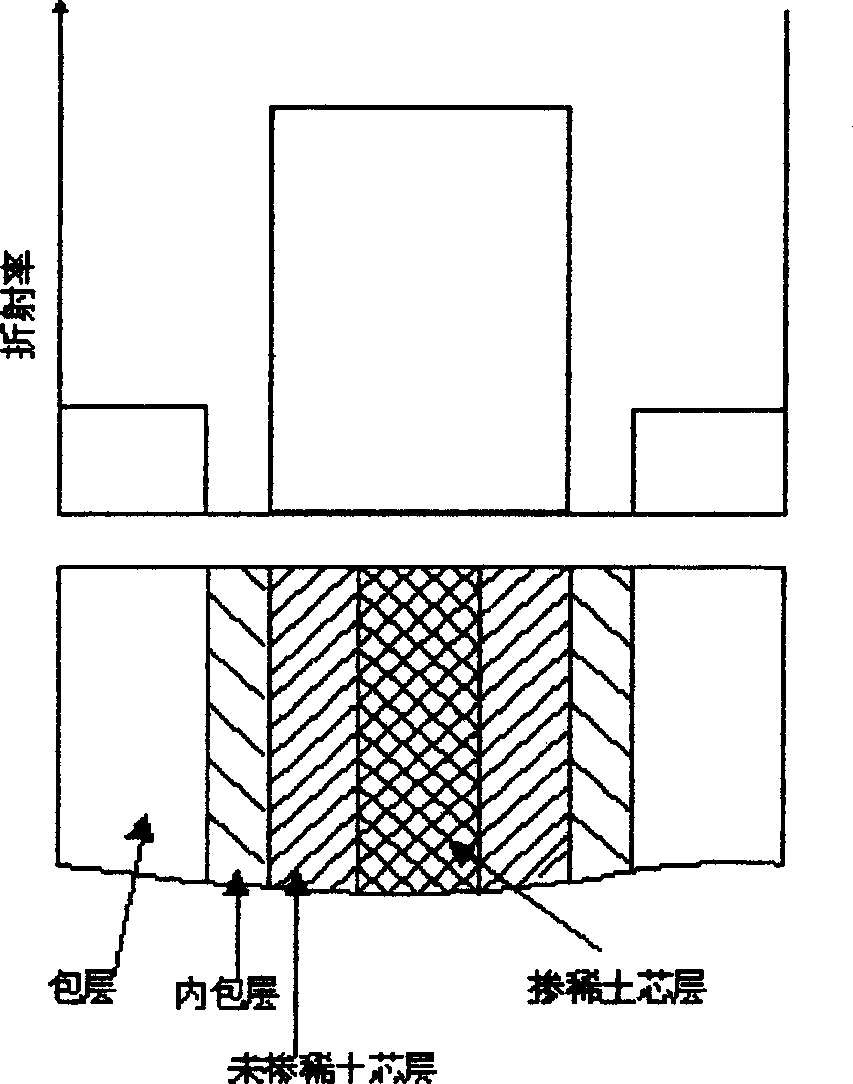

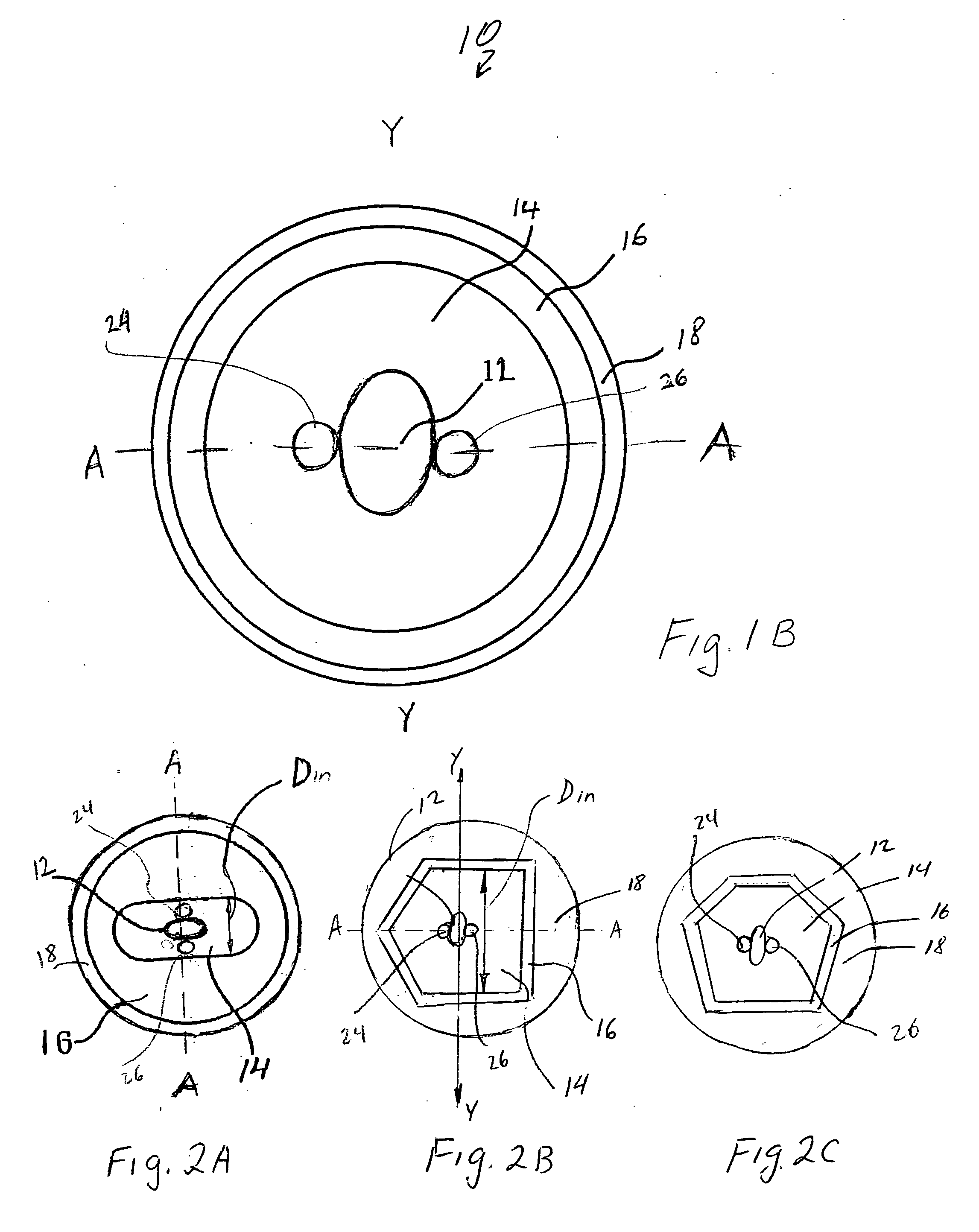

Rare earth doped single polarization double clad optical fiber and a method for making such fiber

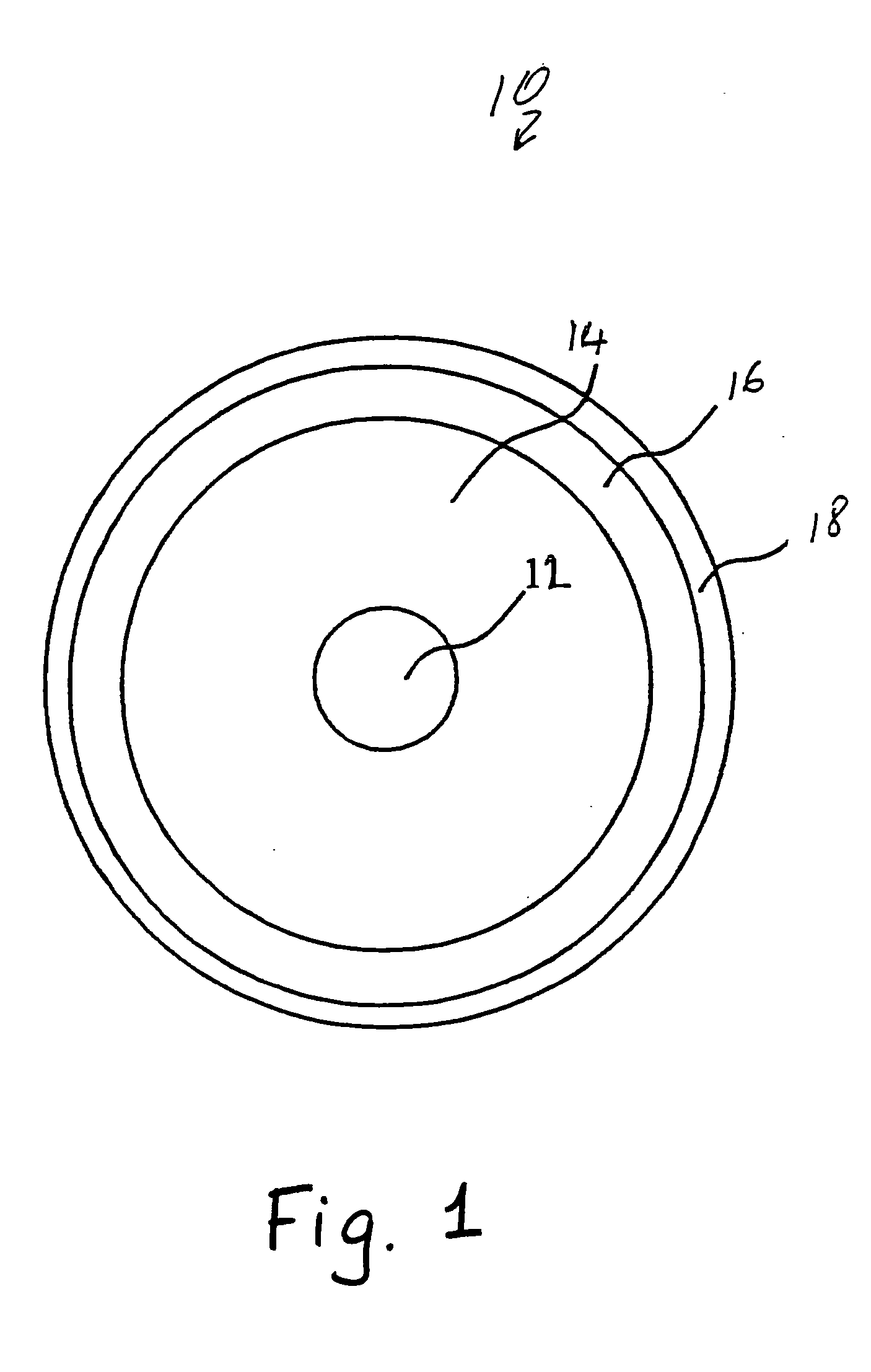

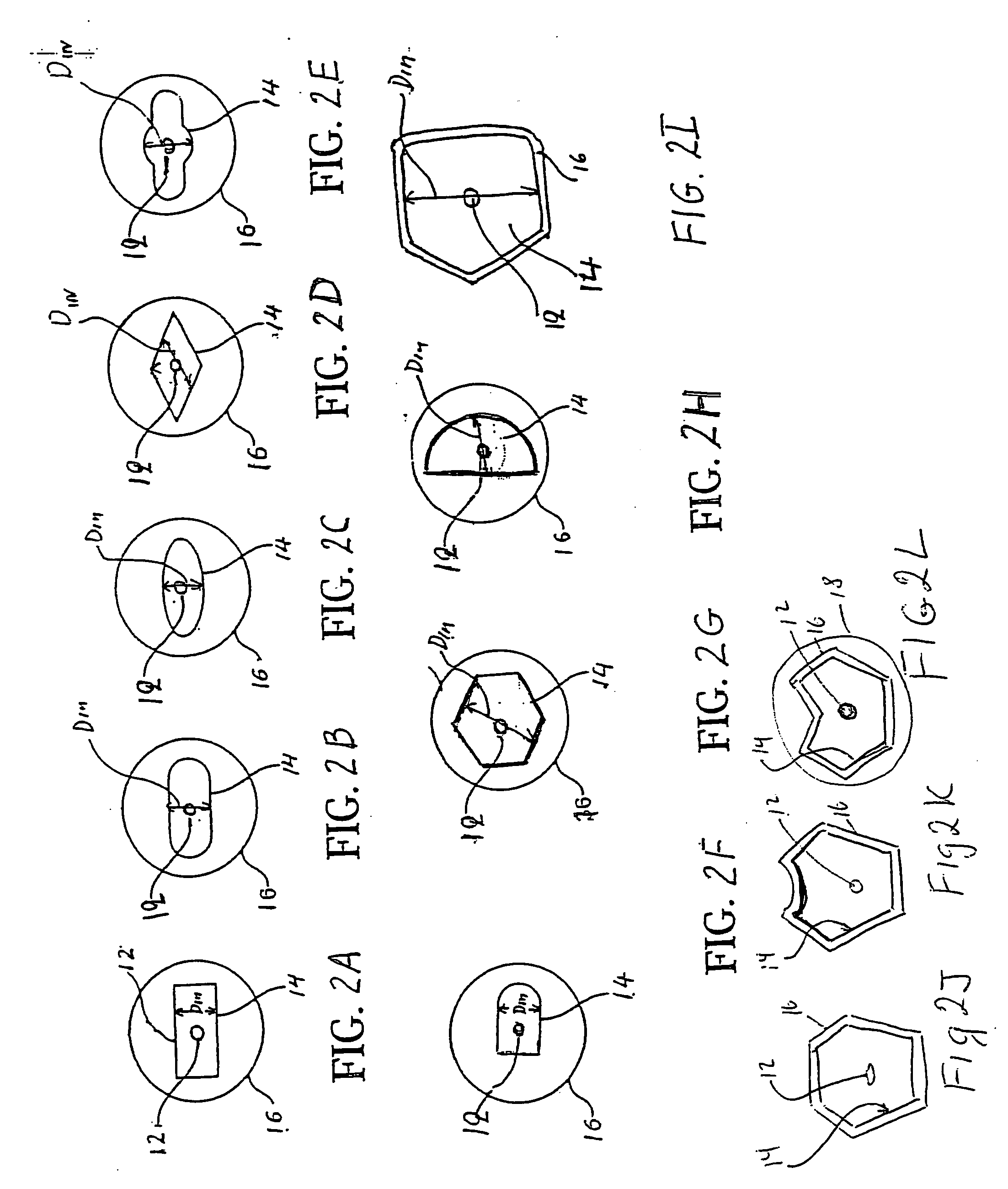

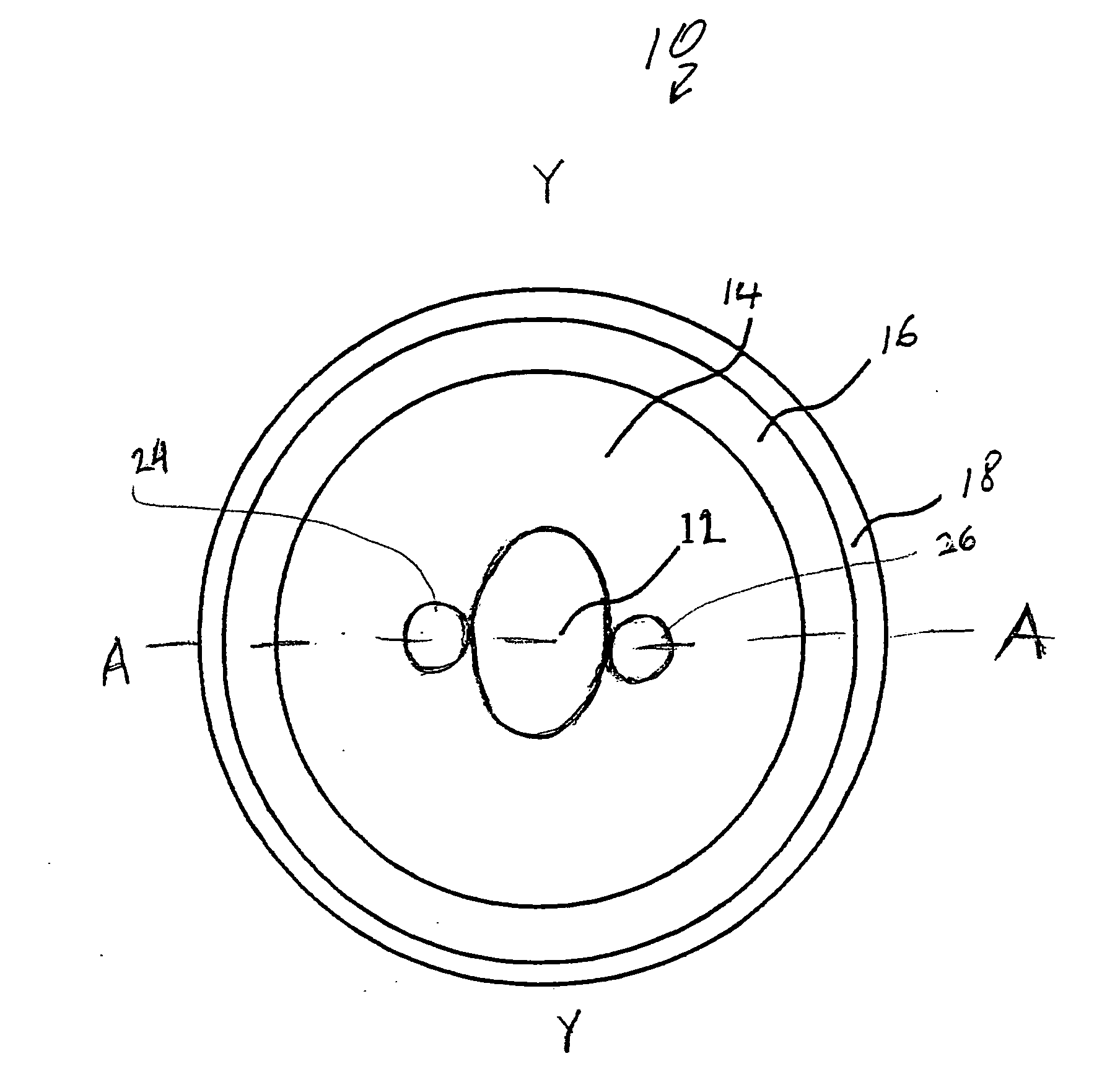

ActiveUS20060088261A1Produced in advanceLarge amount of processingLaser detailsOptical fibre with polarisationFiberRefractive index

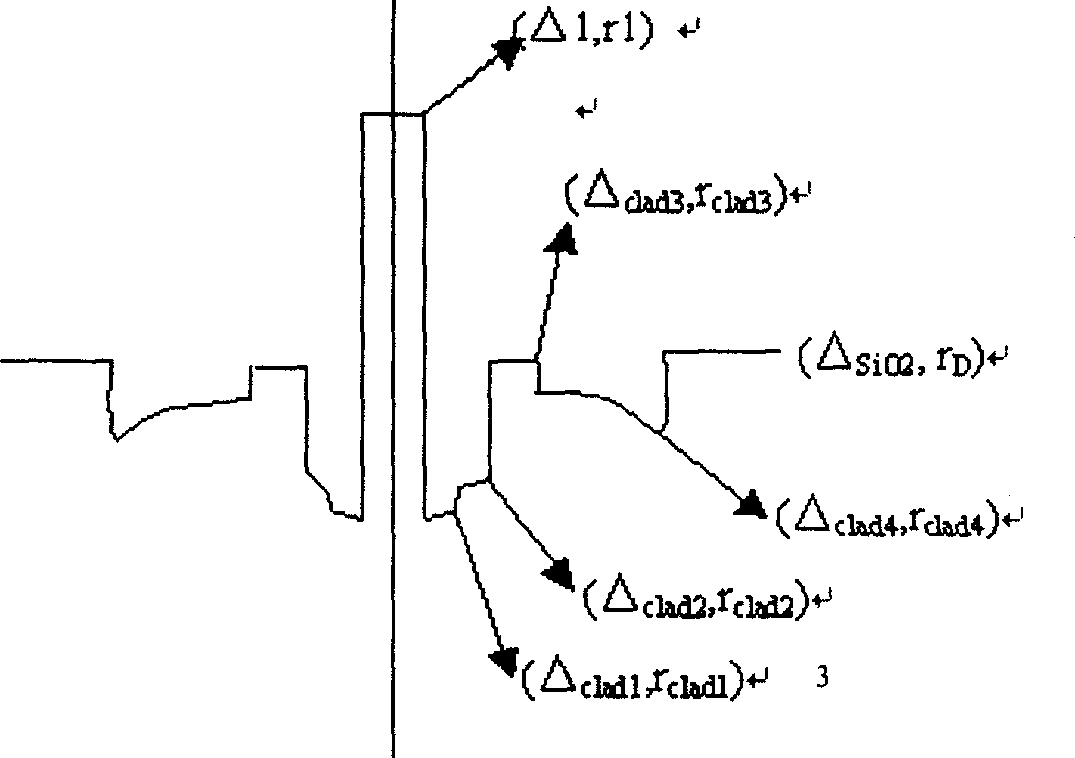

An optical fiber, comprising: (i) a rare earth doped silica based elongated core with a first refractive index (n1) with an aspect ratio of 1:5 to 1; (ii) a silica based moat abutting and at least substantially surrounding the core, the moat having a refractive index n2, wherein n2<n1; (iii) a silica based inner cladding surrounding the moat, the inner cladding having a third refractive index (n3), wherein n1>n3; and n3>n2; (iv) a silica based outer cladding surrounding said inner cladding, the outer cladding having a fourth refractive index (n4), such that n4<n3; the optical fiber exhibits single polarization at the operating wavelength band.

Owner:DARPA

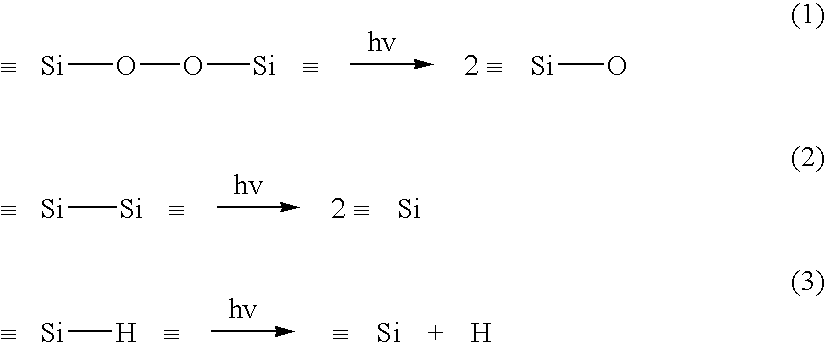

Synthetic quartz glass for optical member and its production method

ActiveUS20060183623A1Suppress compactionSlow changeGlass shaping apparatusGlass deposition burnersOxygen deficientLength wave

A synthetic quartz glass for an optical member which is free from compaction and rarefaction is obtained. A synthetic quartz glass for an optical member to be used for an optical device employing a light having a wavelength of at most 400 nm and at least 170 nm as a light source, which contains substantially no oxygen excess defects, dissolved oxygen molecules nor reduction type defects, which has a chlorine concentration of at most 50 ppm and a OH group concentration of at most 100 ppm, and which contains oxygen deficient defects within a concentration range of at most 5×1014 defects / cm3 and at least 1×1013 defects / cm3. The fluorine concentration is preferably at most 100 ppm.

Owner:ASAHI GLASS CO LTD

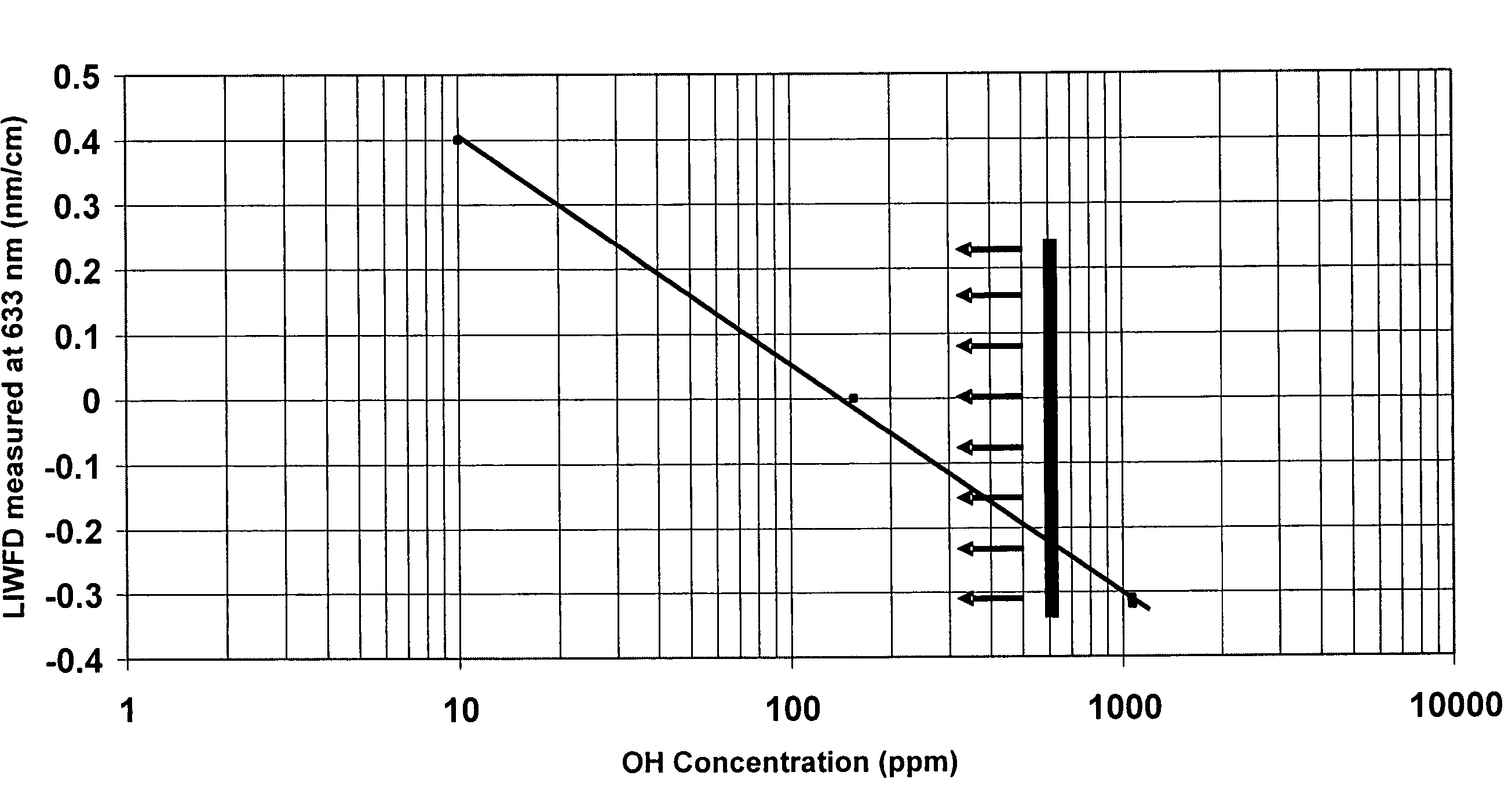

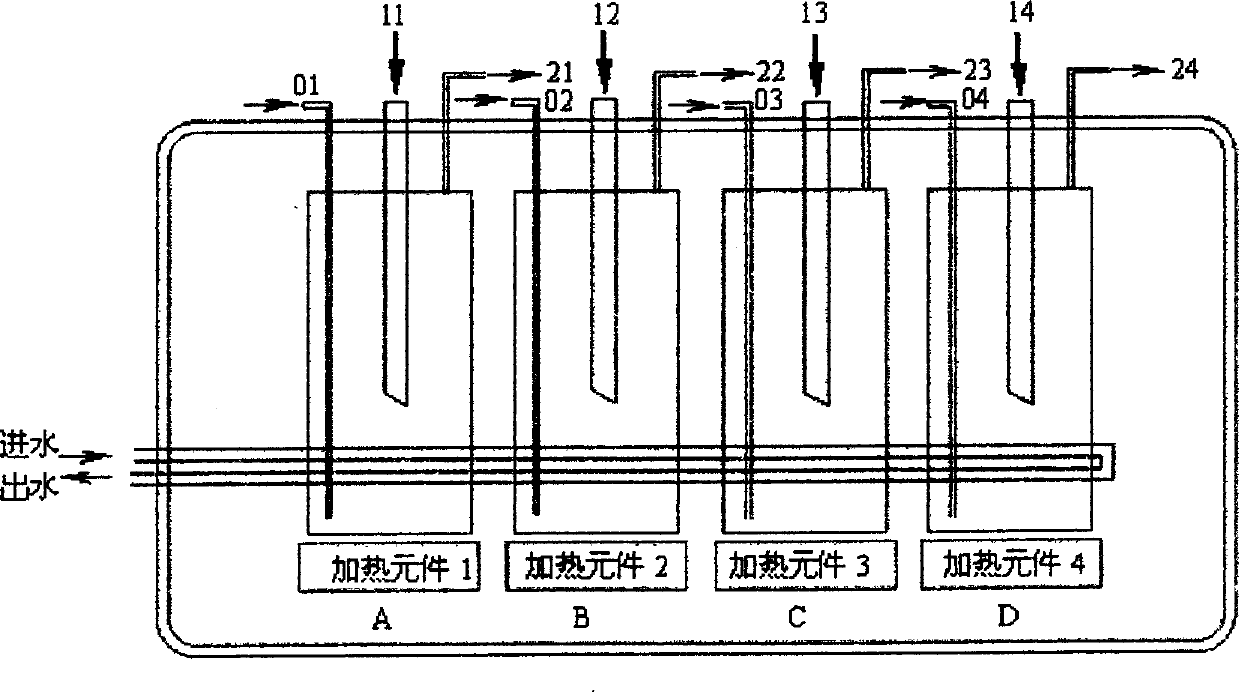

Method of manufacture of low water peak single mode optical fiber

The present invention directs to a method of manufacturing low water peak single mode optical fiber, which comprises performing deposition in a substrate tube using PCVD technology, whereby a deposited layer of a certain construction design is formed on the inner wall of the substrate tube, melt contracting the substrate tube into a solid core rod according to melt contraction technology, producing an optical fiber preform by combining the core rod and a jacket tube of low hydroxyl content by means of RIT technology or by depositing an outer cladding on the outer surface of the core rod using OVD technology, sending the optical fiber preform into a fiber drawing furnace to draw it into an optical fiber, wherein: in the PCVD technology, the content of impurities in a gas mixture of raw materials, which is characterized by the infrared spectrum transmissivity thereof, is required to a transmissivity of 90% or greater, the water content in O2 is 100 ppb or less, the water content in C2F6 is 1000 ppb or less, the hydroxyl content of the substrate tube is 1000 ppb or less, the dynamic leak rate of a deposition machine is 1.0×10−5 mbar·l / s or less; during melt contraction of the substrate tube, the dynamic leak rate of a melt contraction machine is 1.0×10−5 mbar·l / s or less; the hydroxyl content of the jacket tube of low hydroxyl content is required to be 10 ppm or less; the relative humidity of environment during the process of manufacture is 25% or less; the ratio of the cladding diameter to the core layer diameter (b / a value) in the waveguide structure of the optical fiber is from 2.0 to 7.0.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

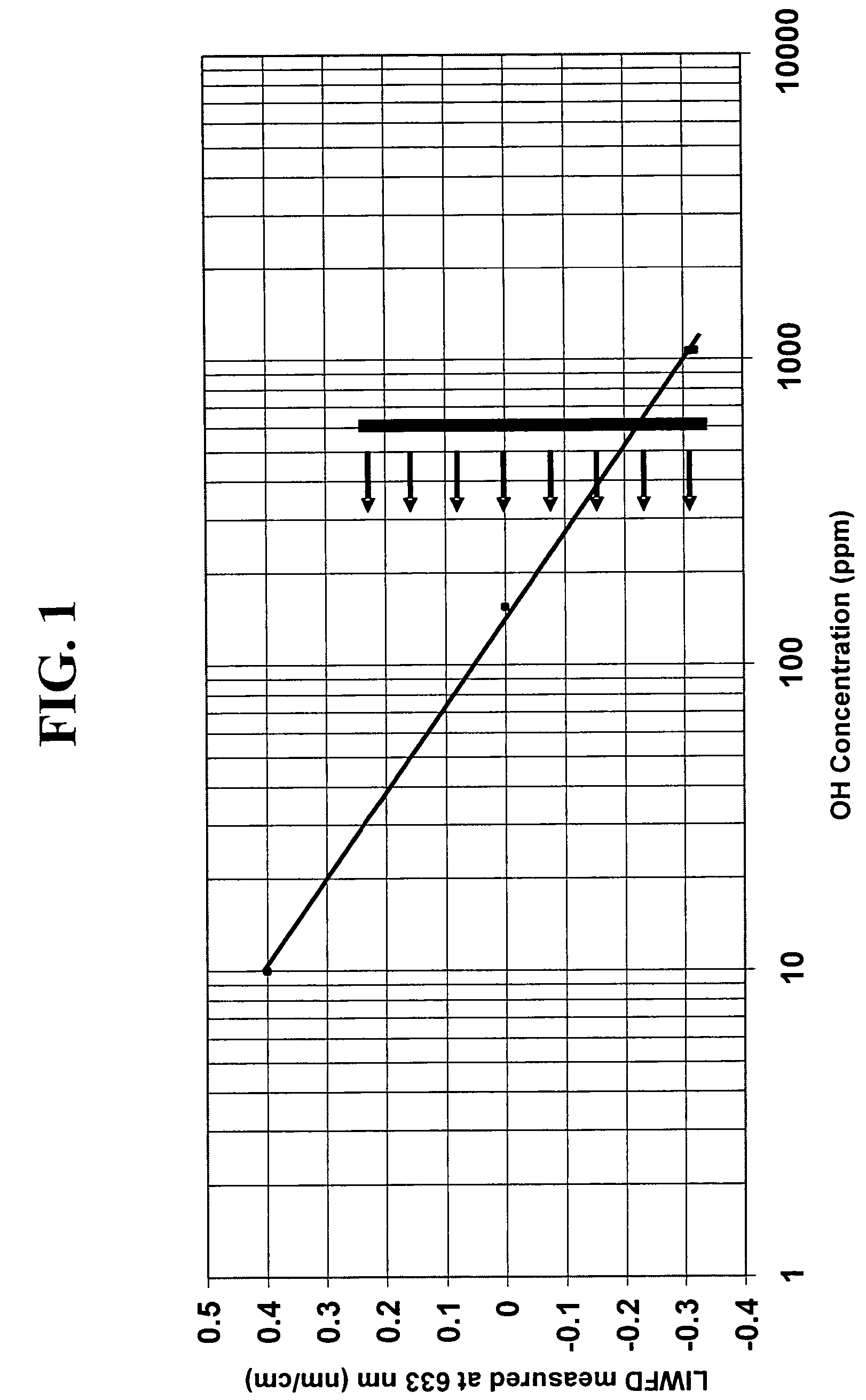

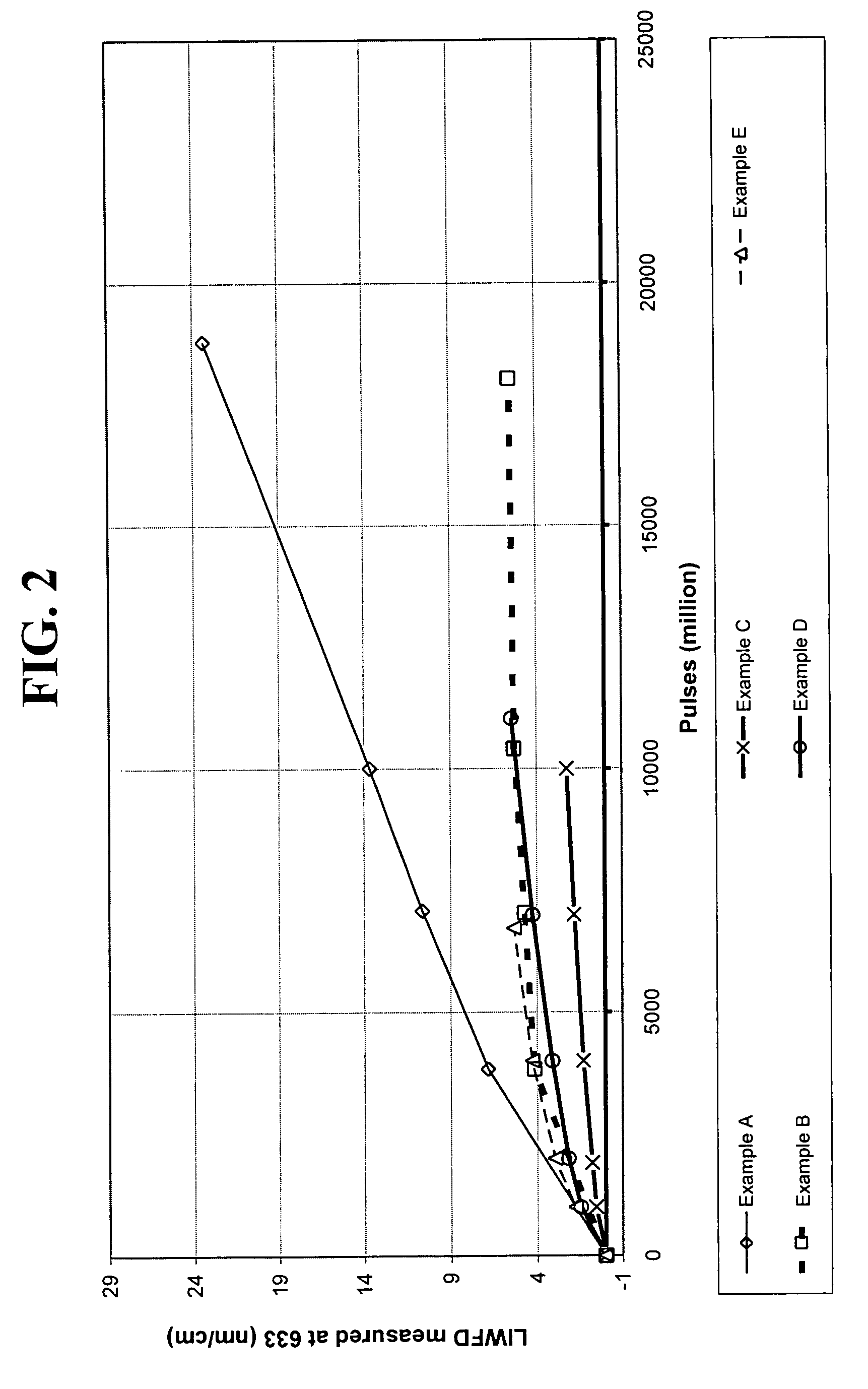

Synthetic silica glass optical material having high resistance to laser induced damage

InactiveUS7534733B2Decrease in levelGlass shaping apparatusGlass deposition burnersHigh resistanceLength wave

Disclosed is a synthetic silica glass optical material having high resistance to optical damage by ultraviolet radiation in the ultraviolet wavelength range, particularly in the wavelength less than about 250 nm and particularly, exhibiting a low laser induced wavefront distortion; specifically a laser induced wavefront distortion, measured at 633 nm, of between about −1.0 and 1.0 nm / cm when subjected to 10 billion pulses of a laser operating at approximately 193 nm and at a fluence of approximately 70 μJ / cm2. The synthetic silica glass optical material of the present invention comprises OH concentration levels of less than about 600 ppm, preferably less than 200 ppm, and H2 concentration levels less than about 5.0×1017 molecules / cm3,and preferably less than about 2.0×1017 molecules / cm3.

Owner:CORNING INC

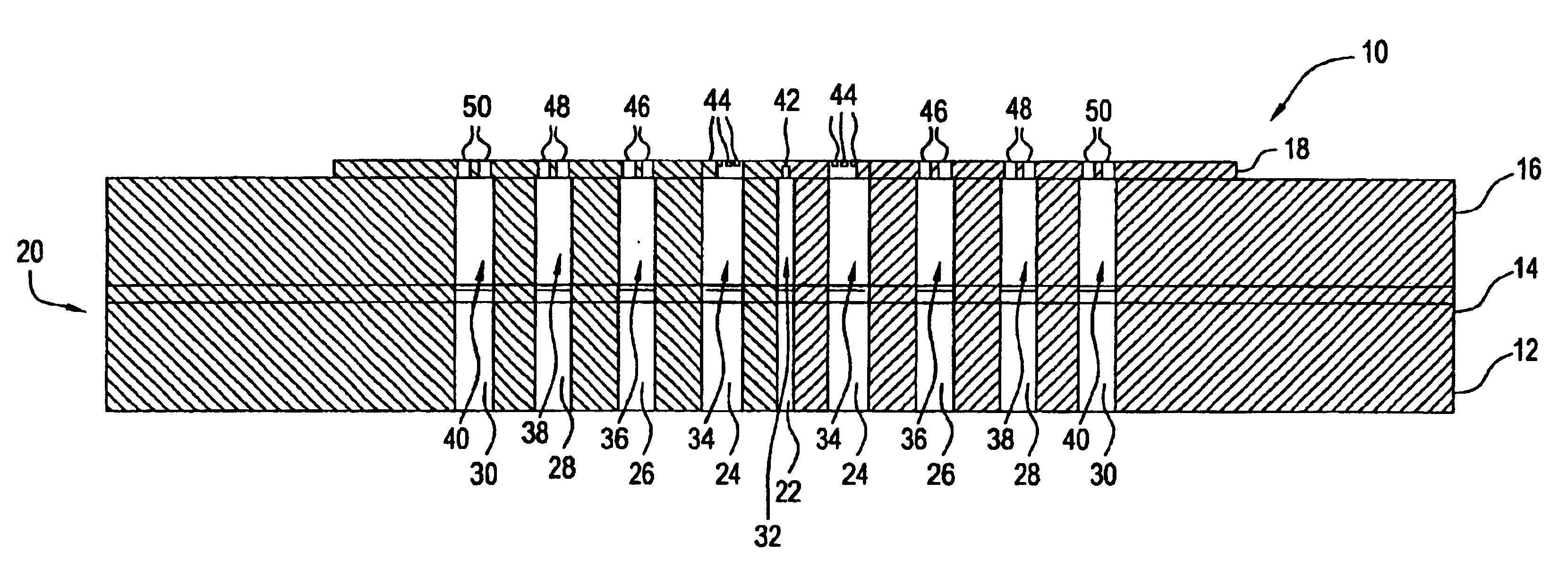

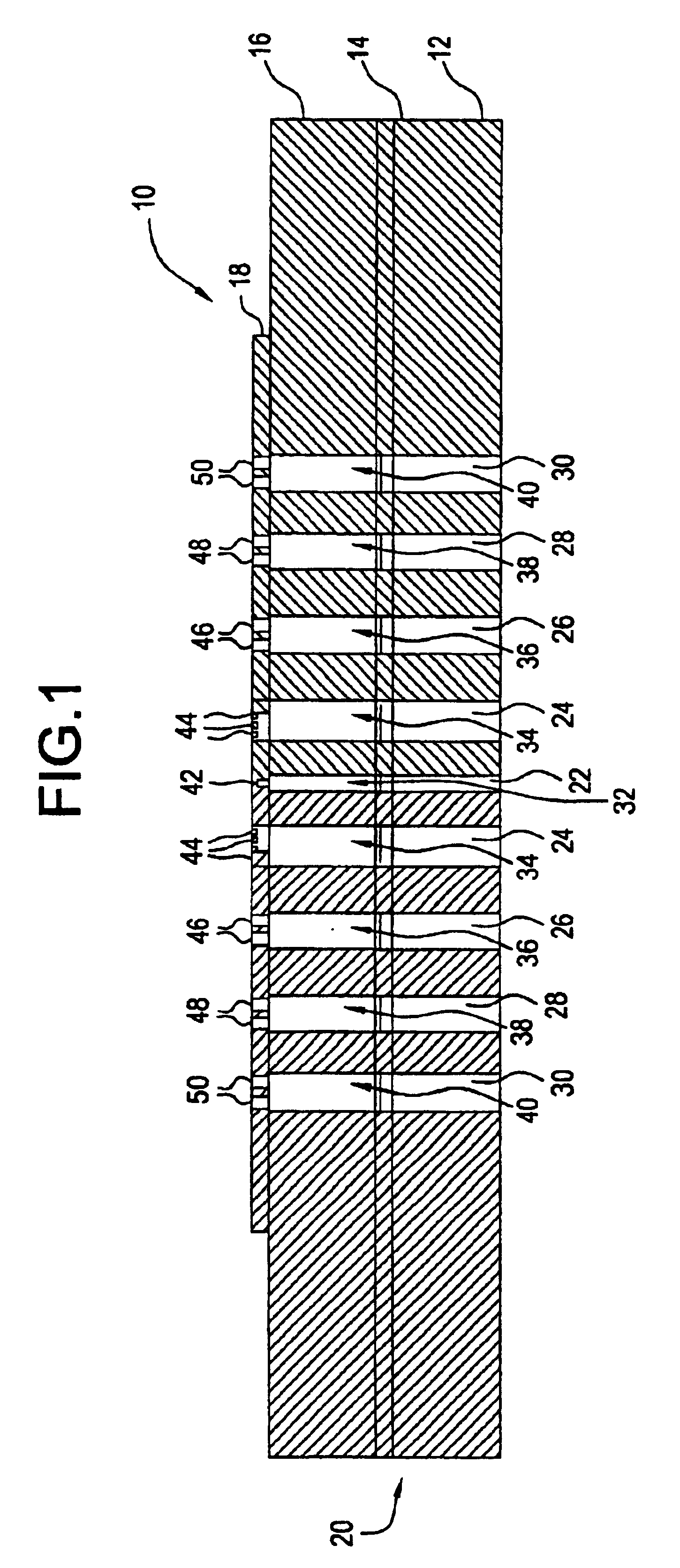

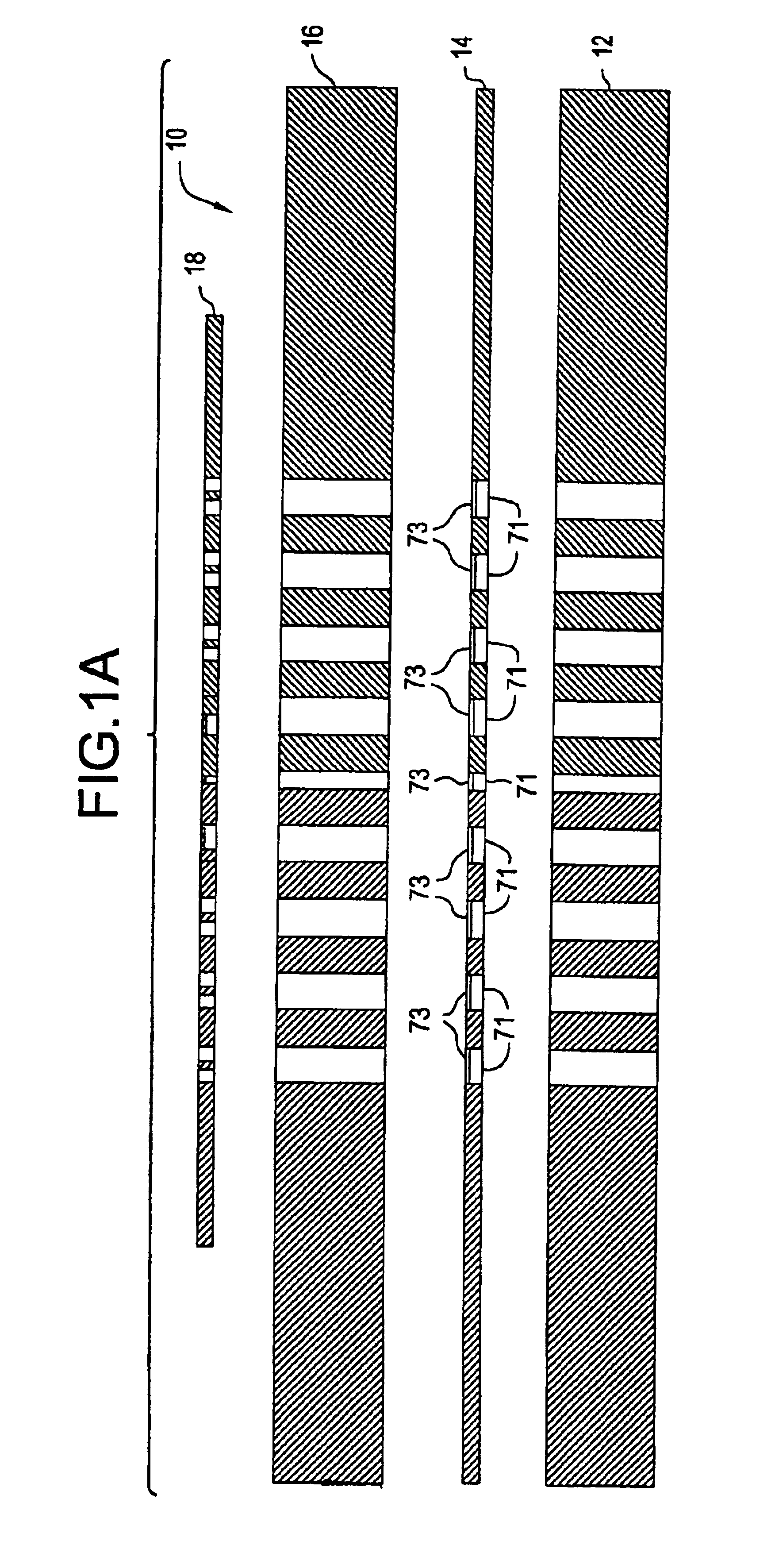

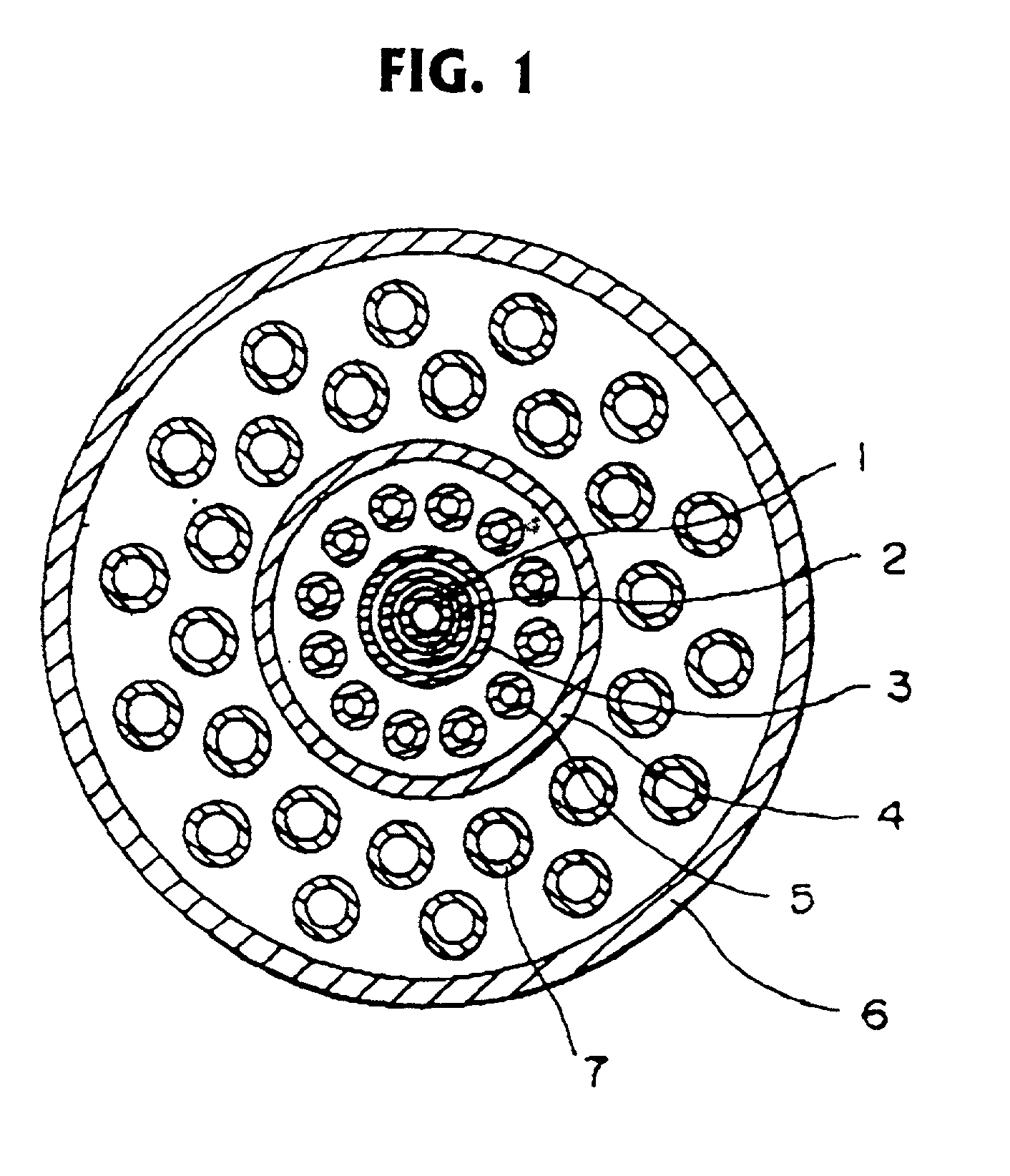

Method of producing oxide soot using a burner with a planar burner face

InactiveUS6837076B2Accurate and efficient depositionIncrease back pressureOxygen/ozone/oxide/hydroxideSilicaChemical reactionCombustor

A burner and a method for producing an inorganic soot such as silica comprising a plurality of substantially planar layers having multiple openings therethrough formed by a micromachining process. The openings are in fluid communication with a precursor inlet and a gas inlet to permit the gas and the precursor to flow through and exit the burner. The burner produces a flame from a combustible gas in which the precursor undergoes a chemical reaction to form the soot.

Owner:CORNING INC

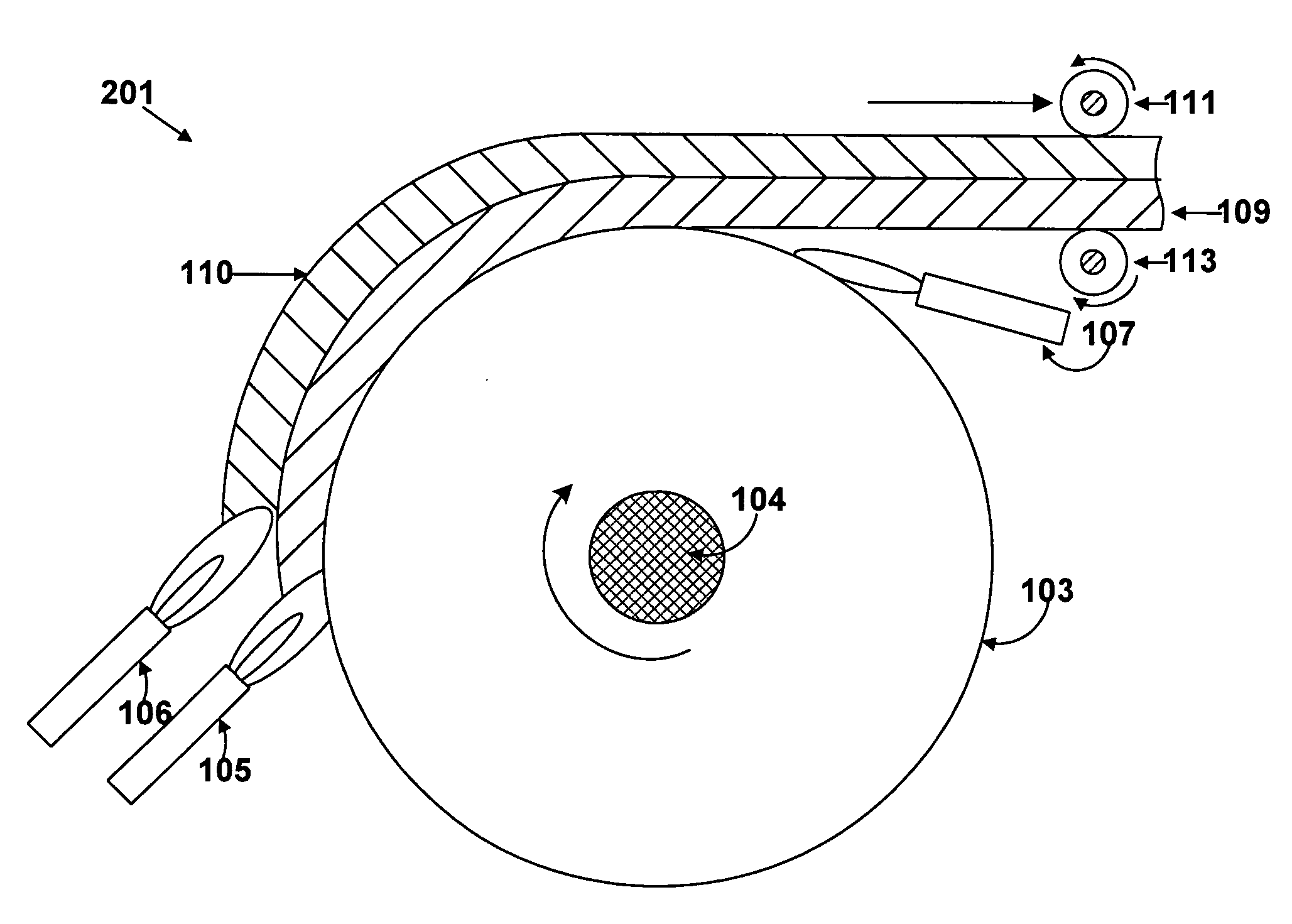

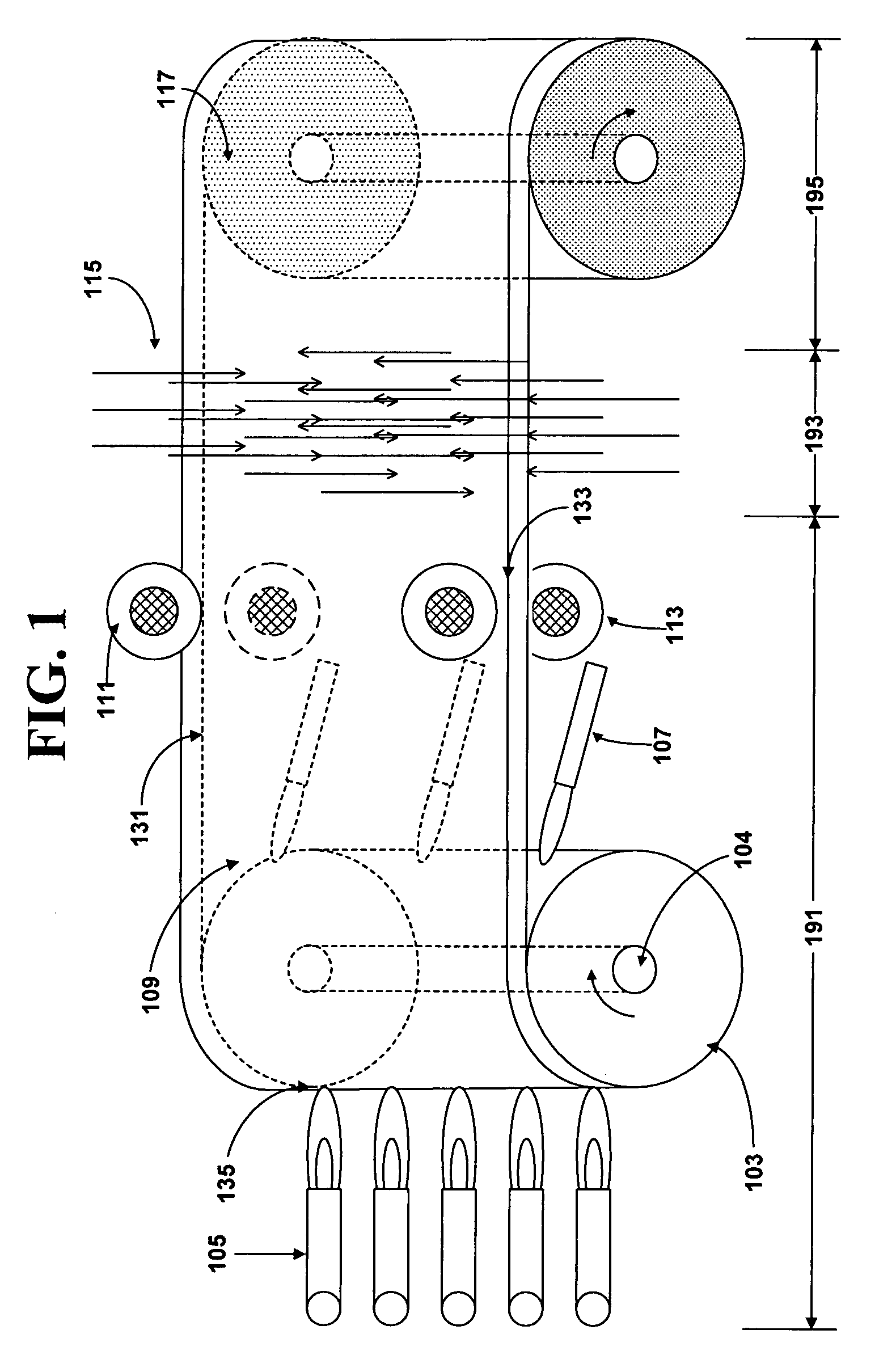

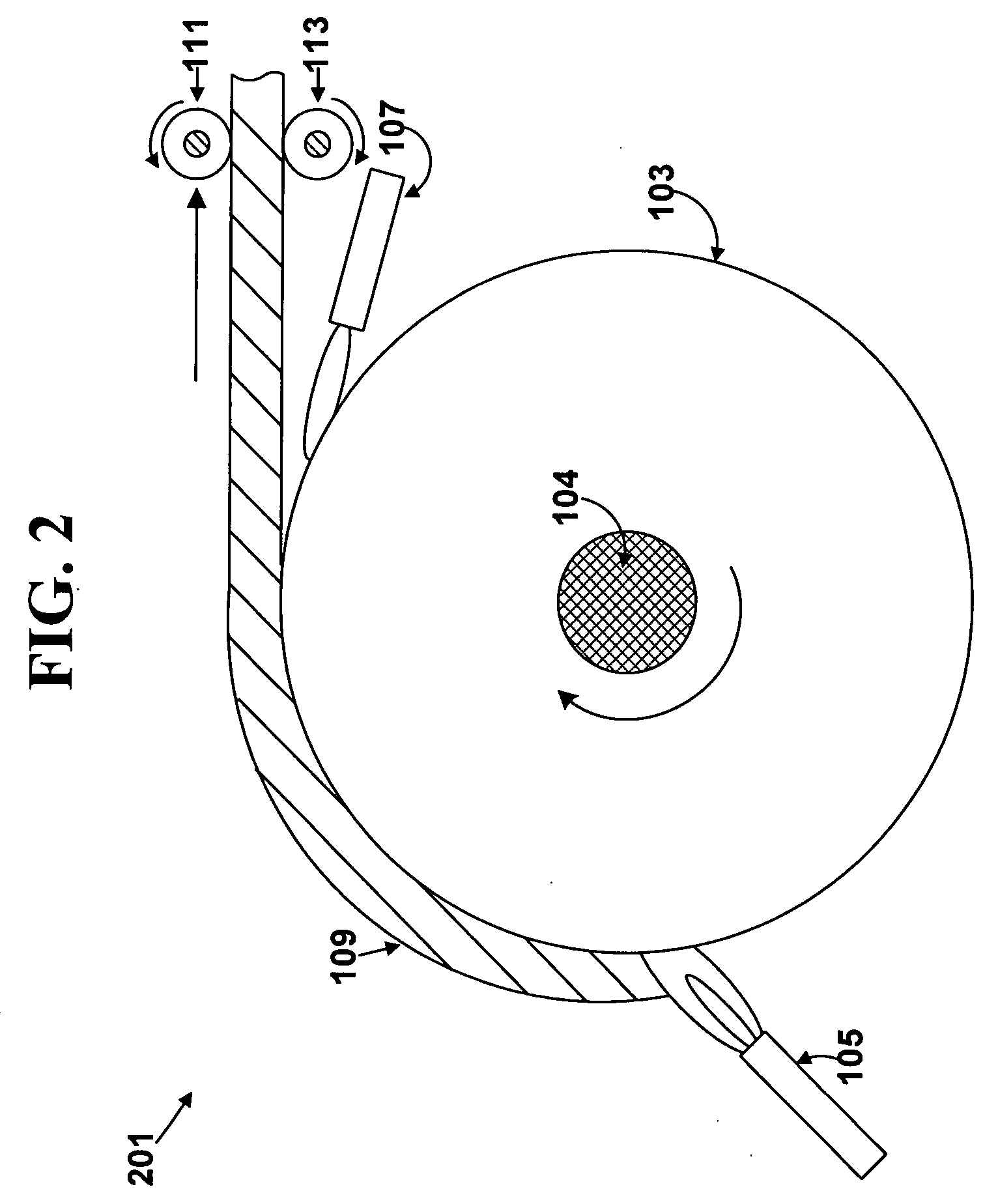

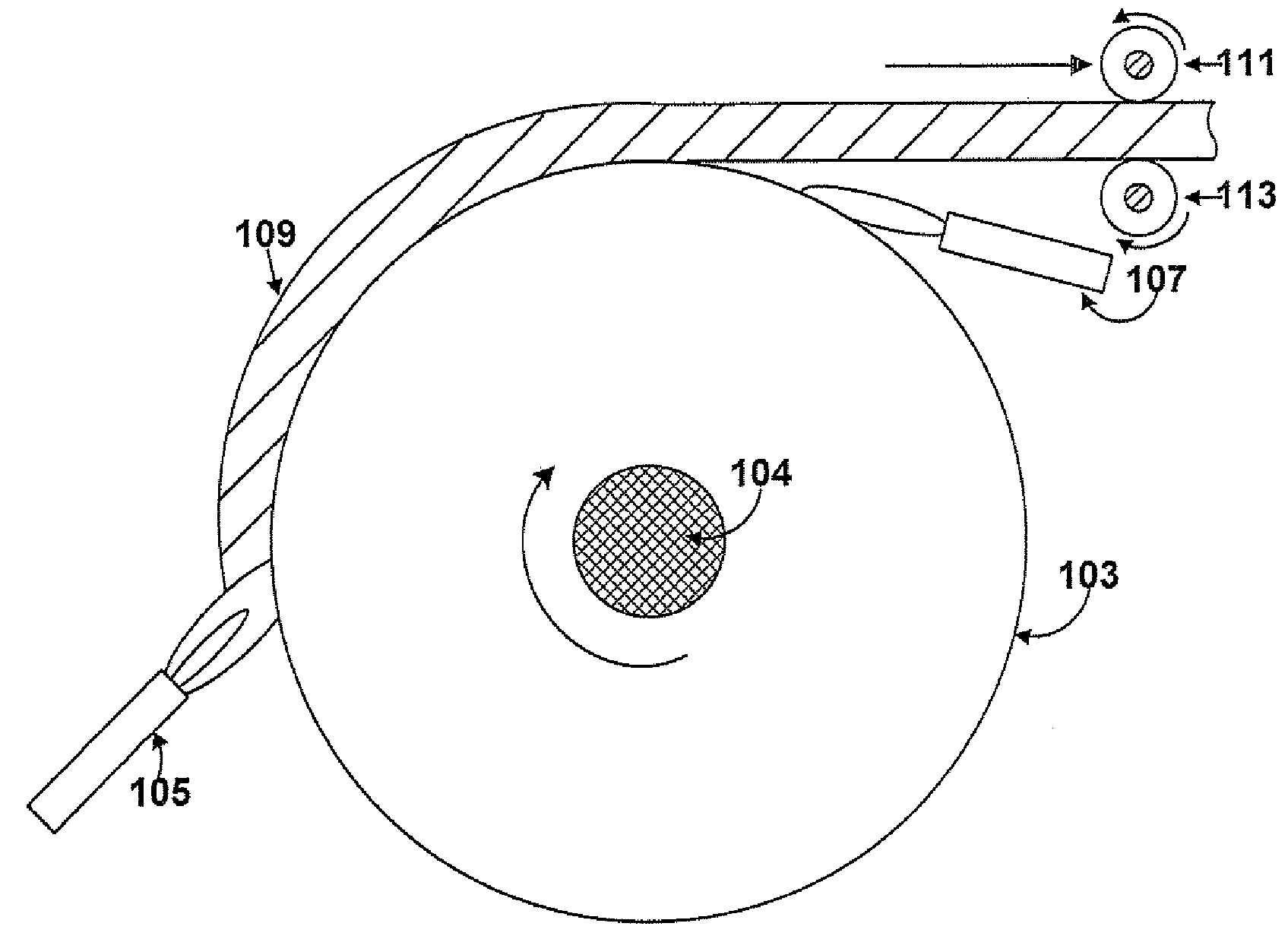

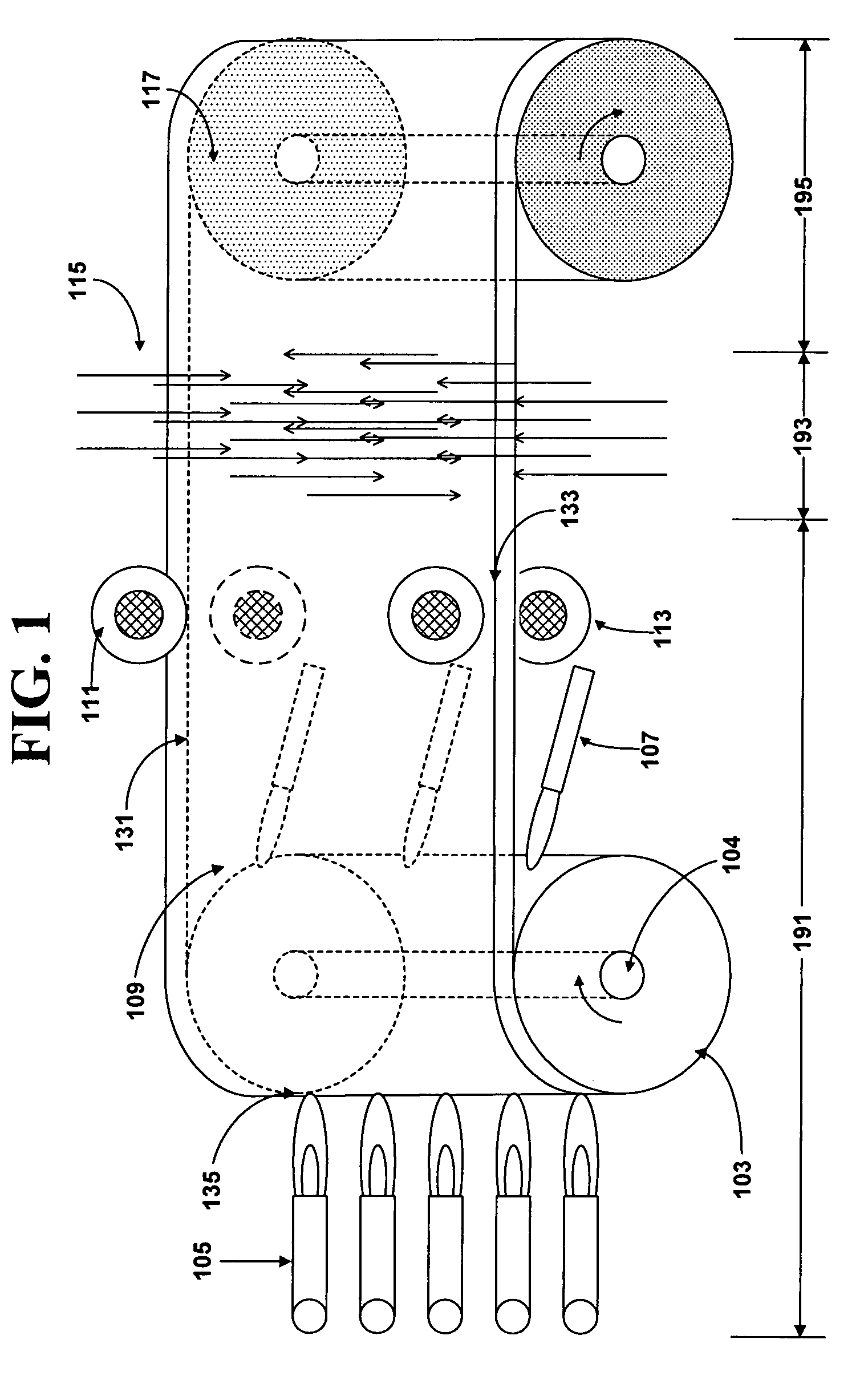

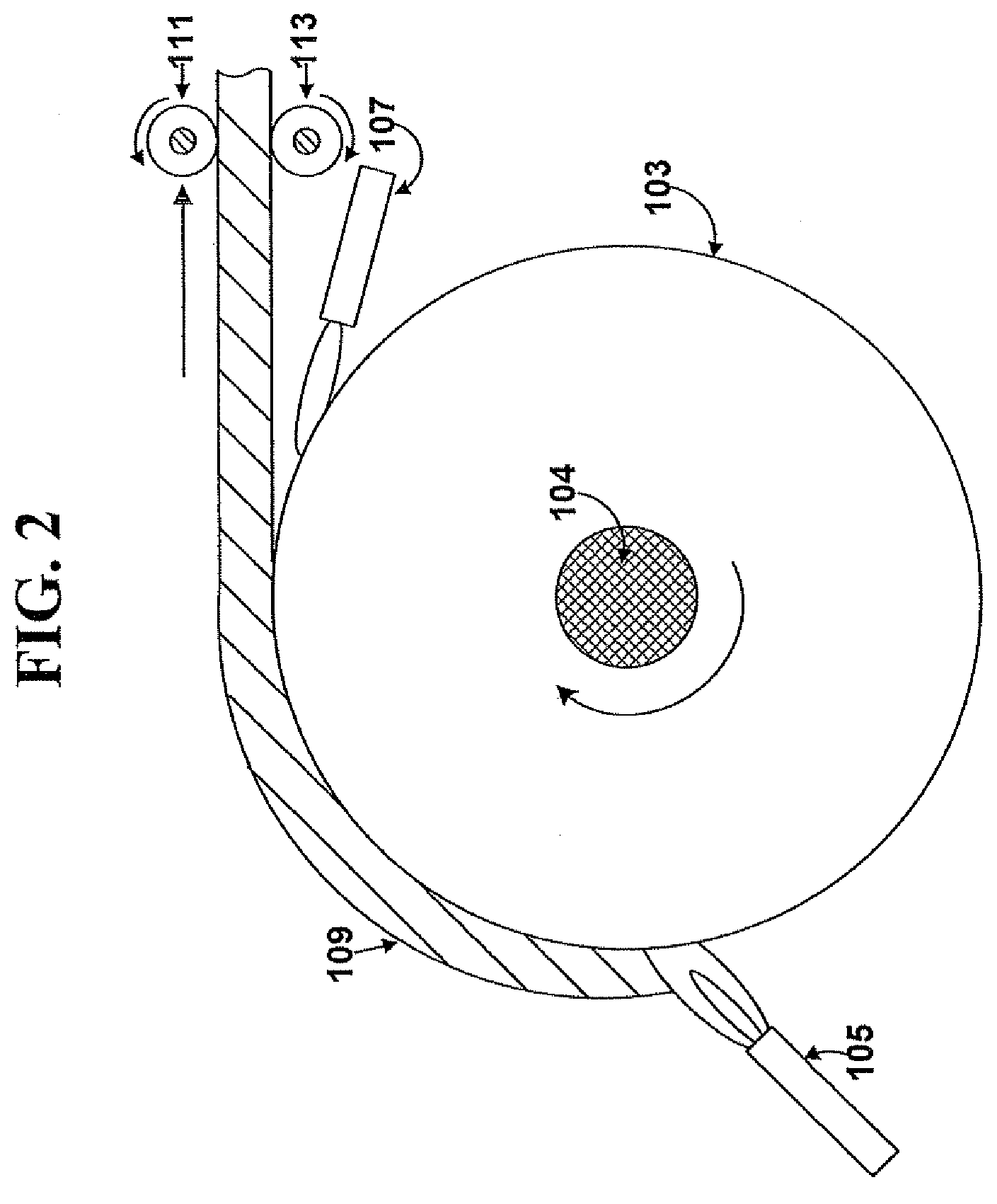

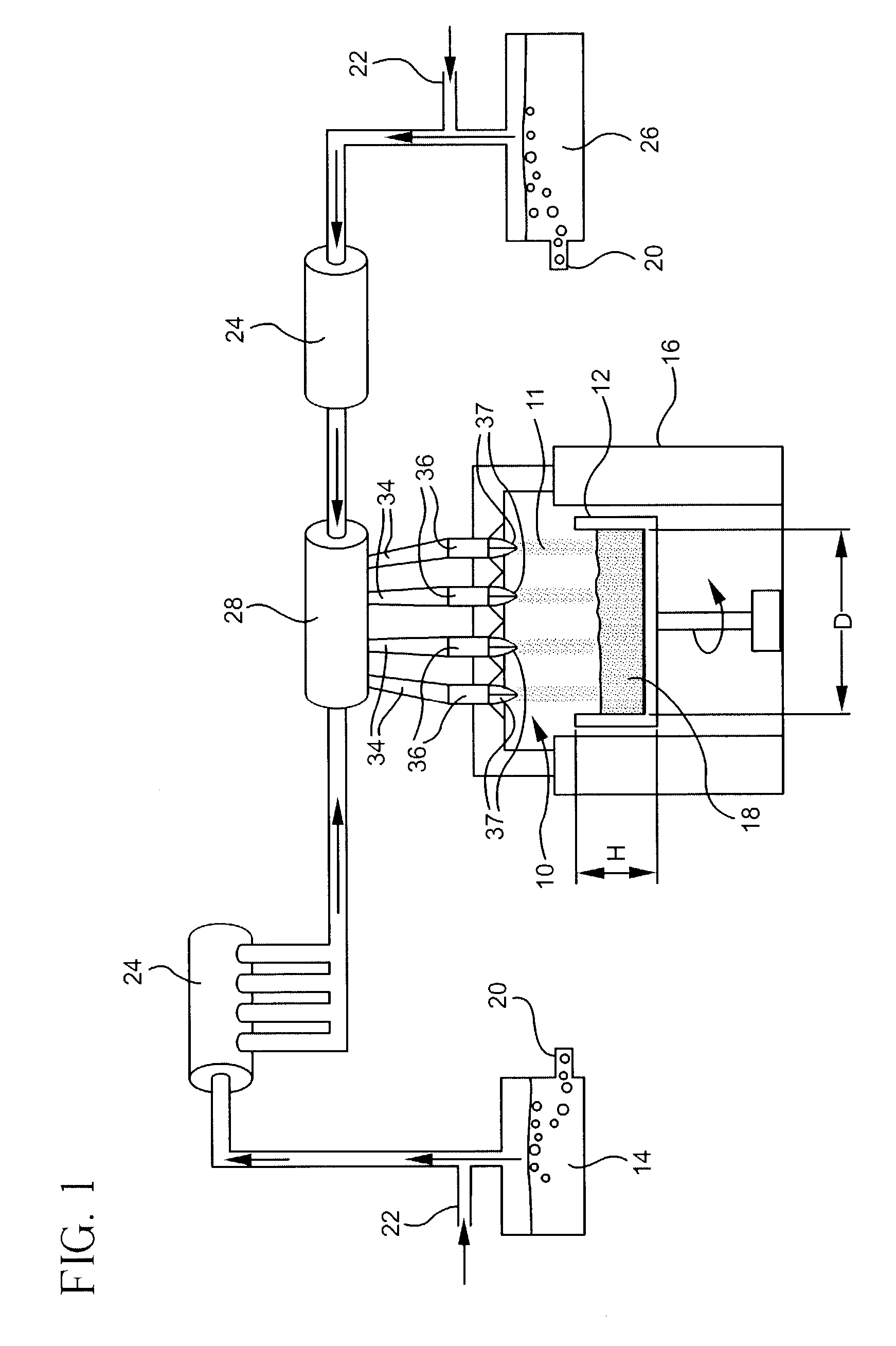

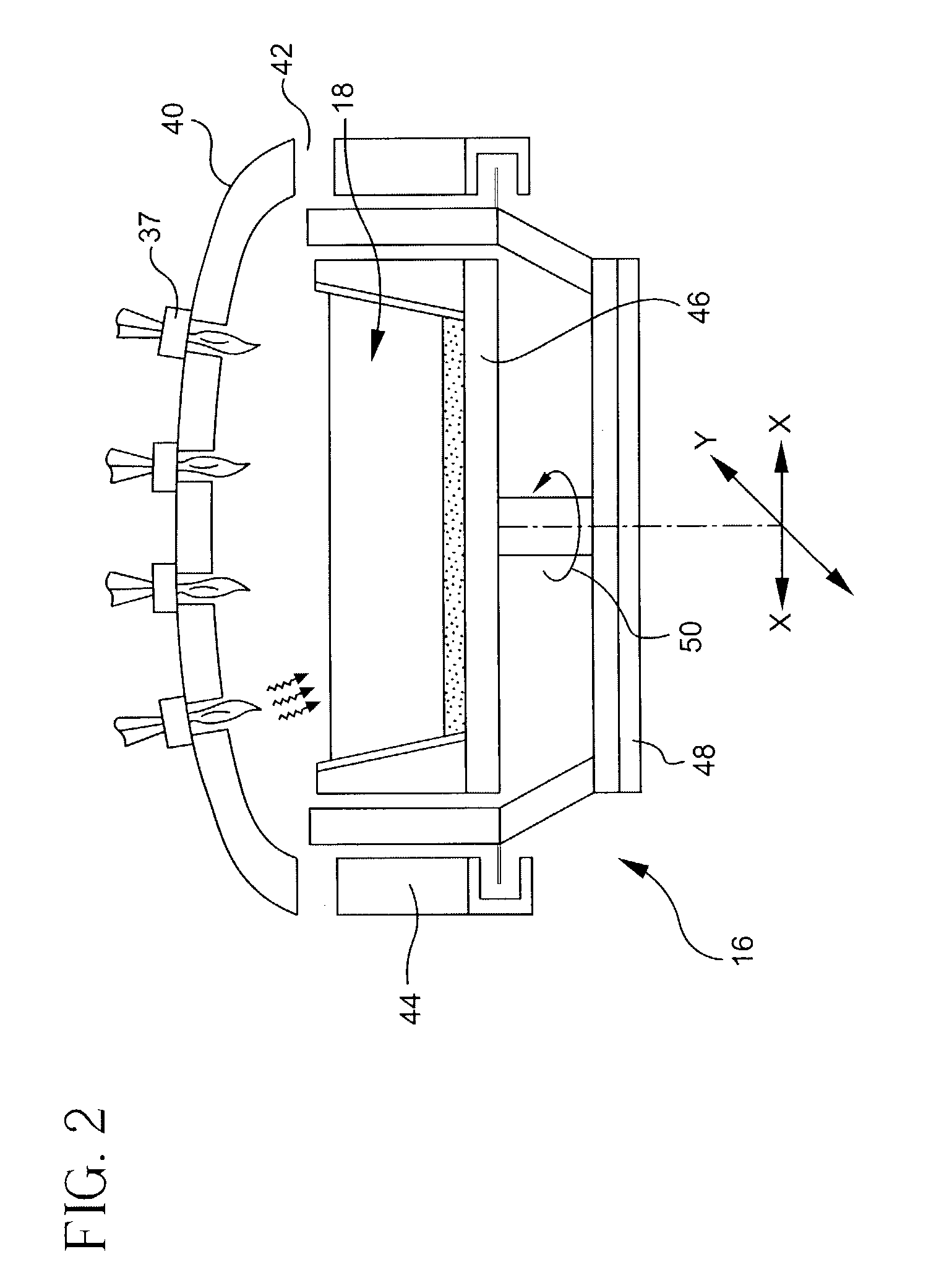

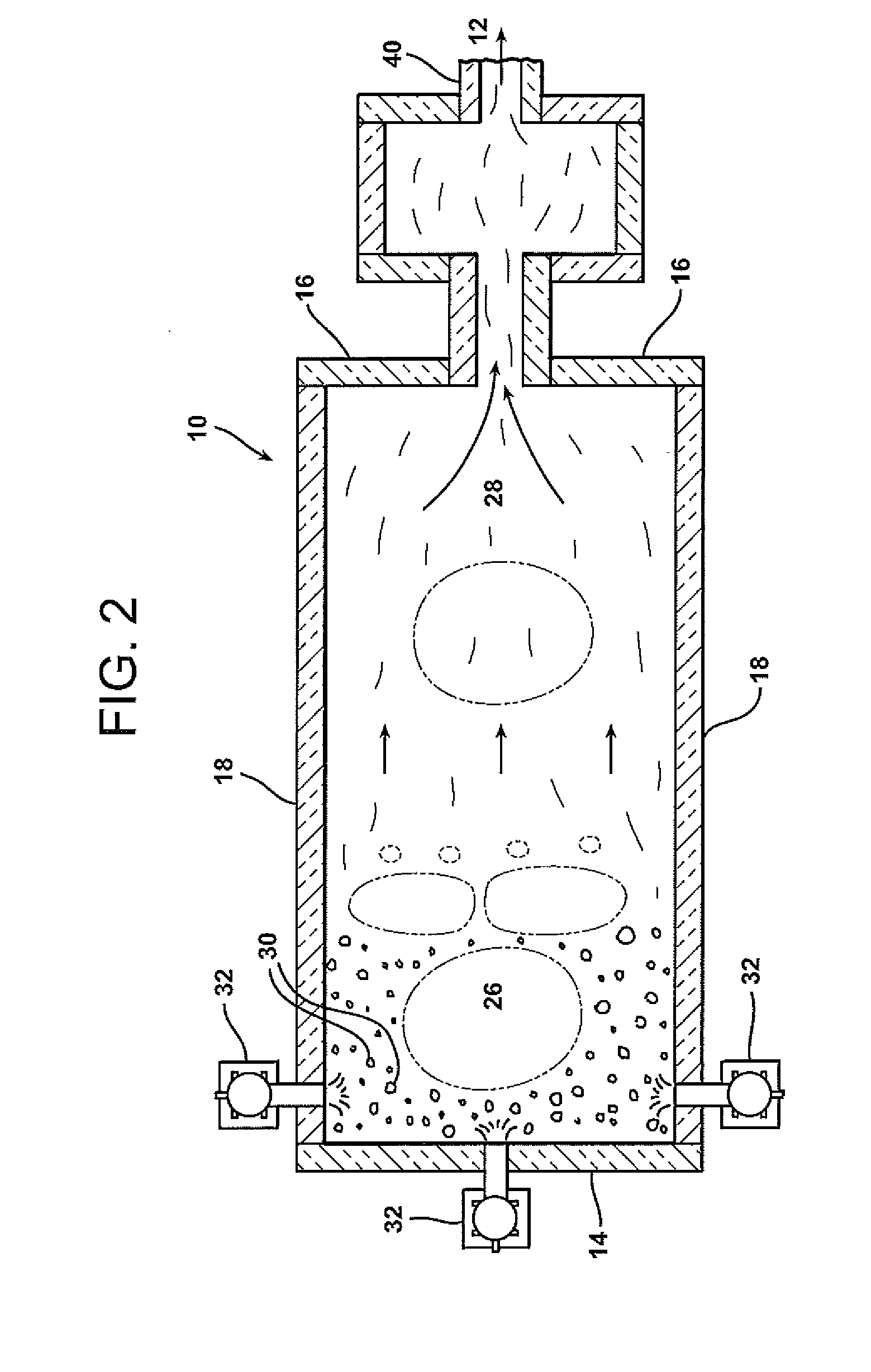

Process and apparatus for making glass sheet

ActiveUS20080280057A1Improve thickness uniformityUniform thicknessMolten spray coatingGlass shaping apparatusMetallurgyFritted glass

An apparatus and process for making glass soot sheet and sintered glass sheet. Glass soot particles are deposited on a curved deposition surface of a rotating drum to form a soot sheet. The soot sheet is then released from the deposition surface. The soot sheet can be sintered into a consolidated glass. The soot sheet and the sintered glass can be sufficiently long and flexible to be reeled into a roll.

Owner:CORNING INC +1

Methods for making optical fiber preforms and microstructured optical fibers

InactiveUS20090126407A1Glass deposition burnersGlass fibre productsRefractive indexChemical vapor deposition

A method of making an optical fiber preform includes depositing silica glass on the inside of a tube substrate via a plasma chemical vapor deposition (PCVD) operation. The parameters of the PCVD operation are controlled such that the silica glass deposited on the interior of the tube substrate contains a non-periodic array of voids in a cladding region of the optical fiber preform. The optical fiber preform may be used to produce an optical fiber having a core and a void containing cladding. The core of the optical fiber has a first index of refraction and the cladding has a second index of refraction less than that of the core.

Owner:CORNING INC

Process and apparatus for making glass sheet

ActiveUS7677058B2Improve uniformityUniform thicknessMolten spray coatingGlass shaping apparatusMetallurgyFritted glass

An apparatus and process for making glass soot sheet and sintered glass sheet. Glass soot particles are deposited on a curved deposition surface of a rotating drum to form a soot sheet. The soot sheet is then released from the deposition surface. The soot sheet can be sintered into a consolidated glass. The soot sheet and the sintered glass can be sufficiently long and flexible to be reeled into a roll.

Owner:CORNING INC +1

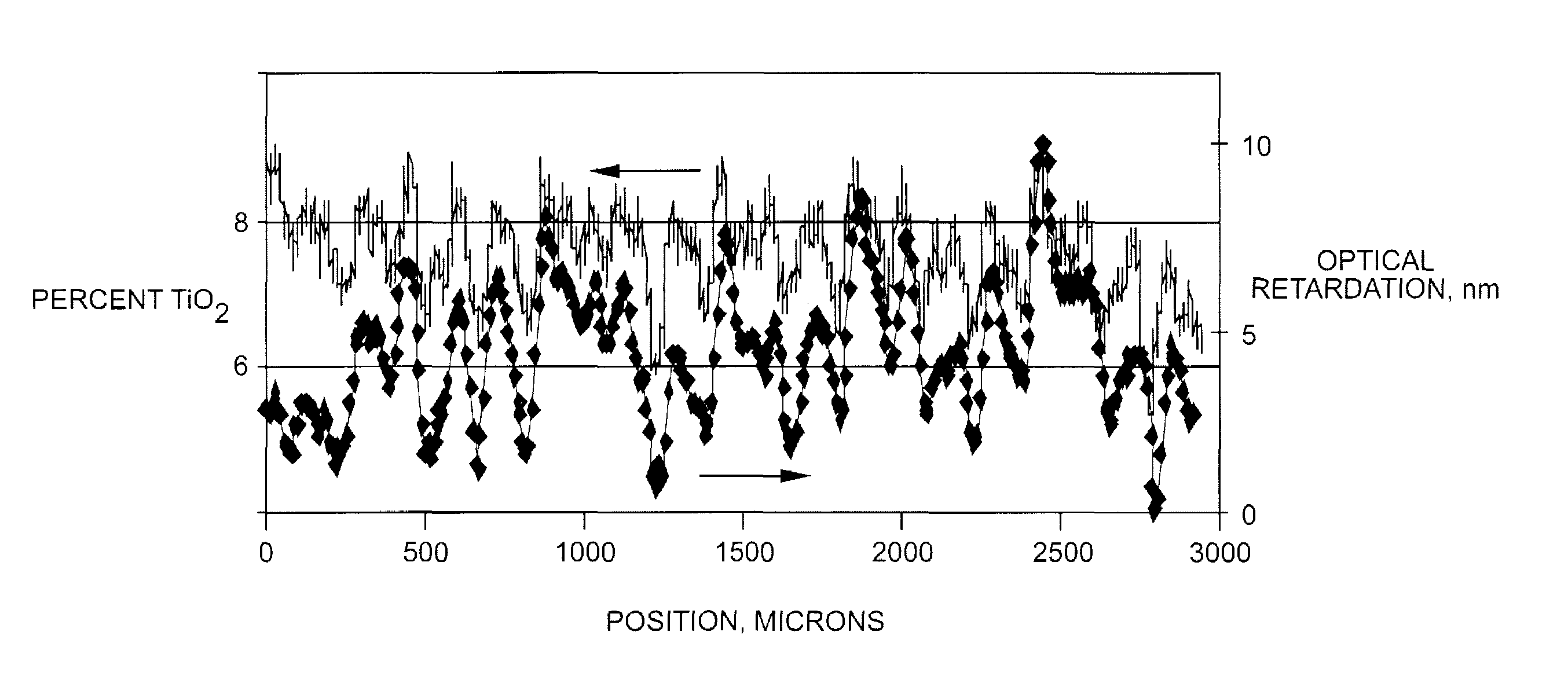

Reduced striae extreme ultraviolet elements

Titania-containing silica glass bodies and extreme ultraviolet elements having low levels of striae are disclosed. Methods and apparatus for manufacturing and measuring striae in glass elements and extreme ultraviolet elements are also disclosed.

Owner:CORNING INC

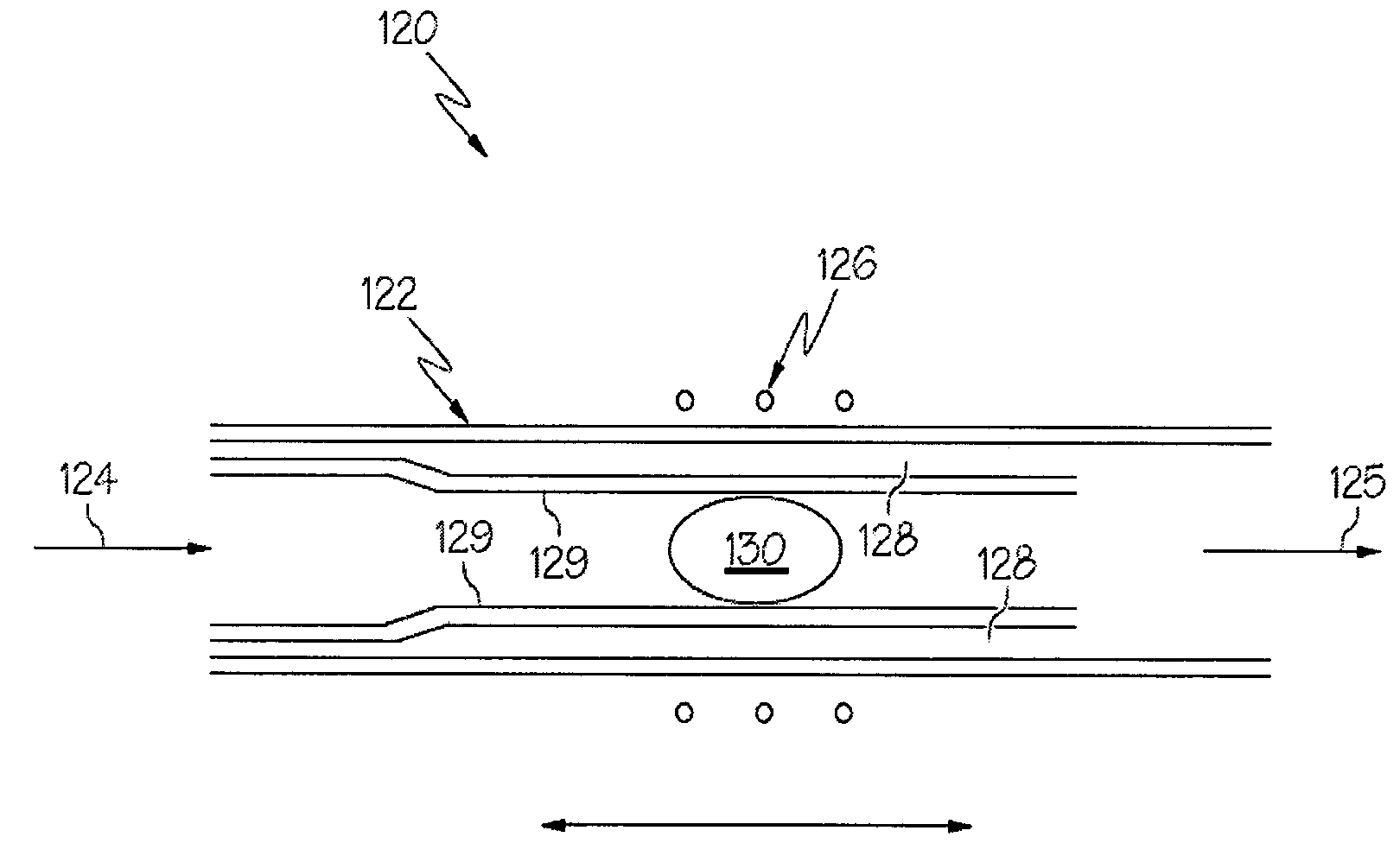

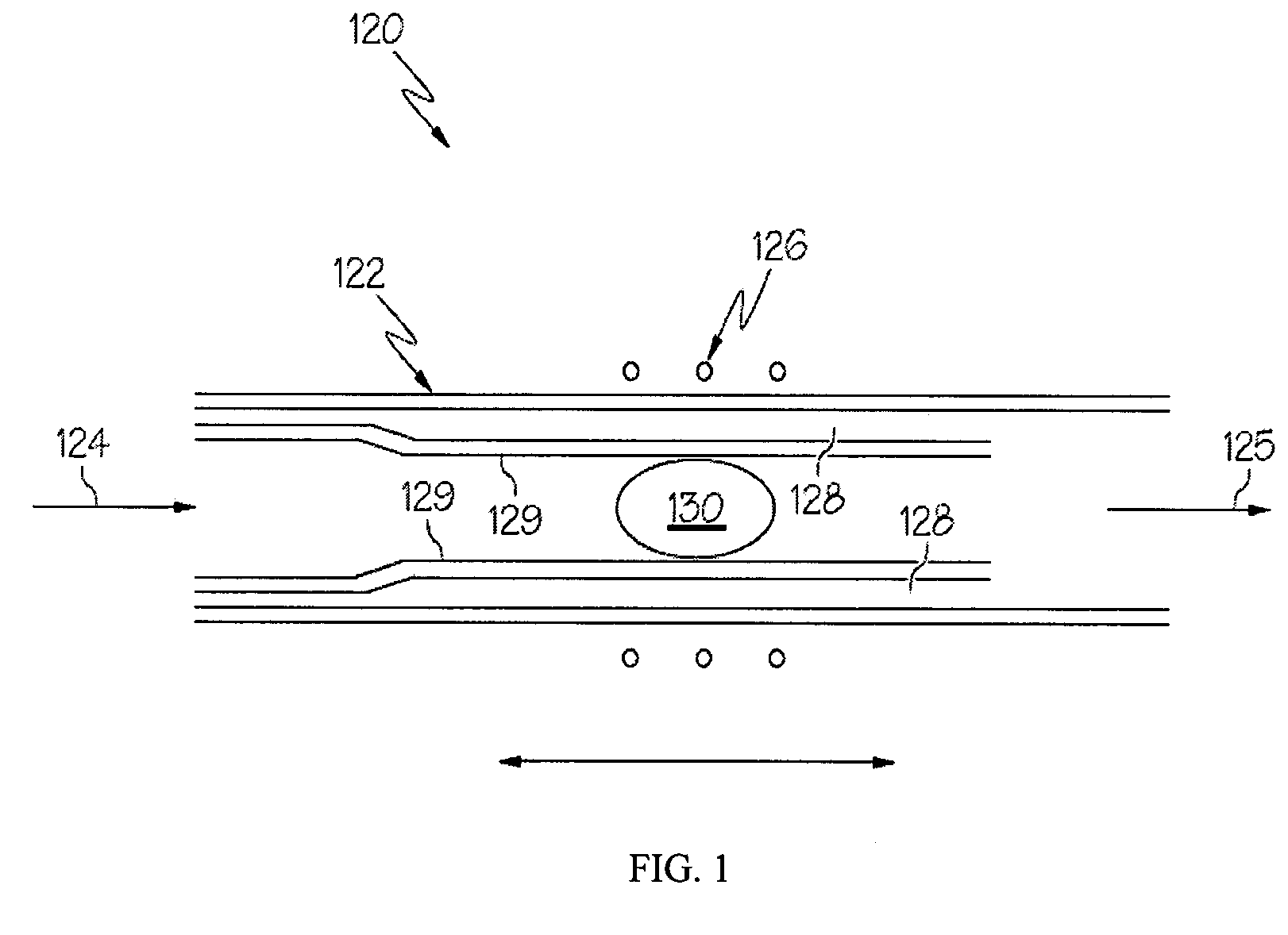

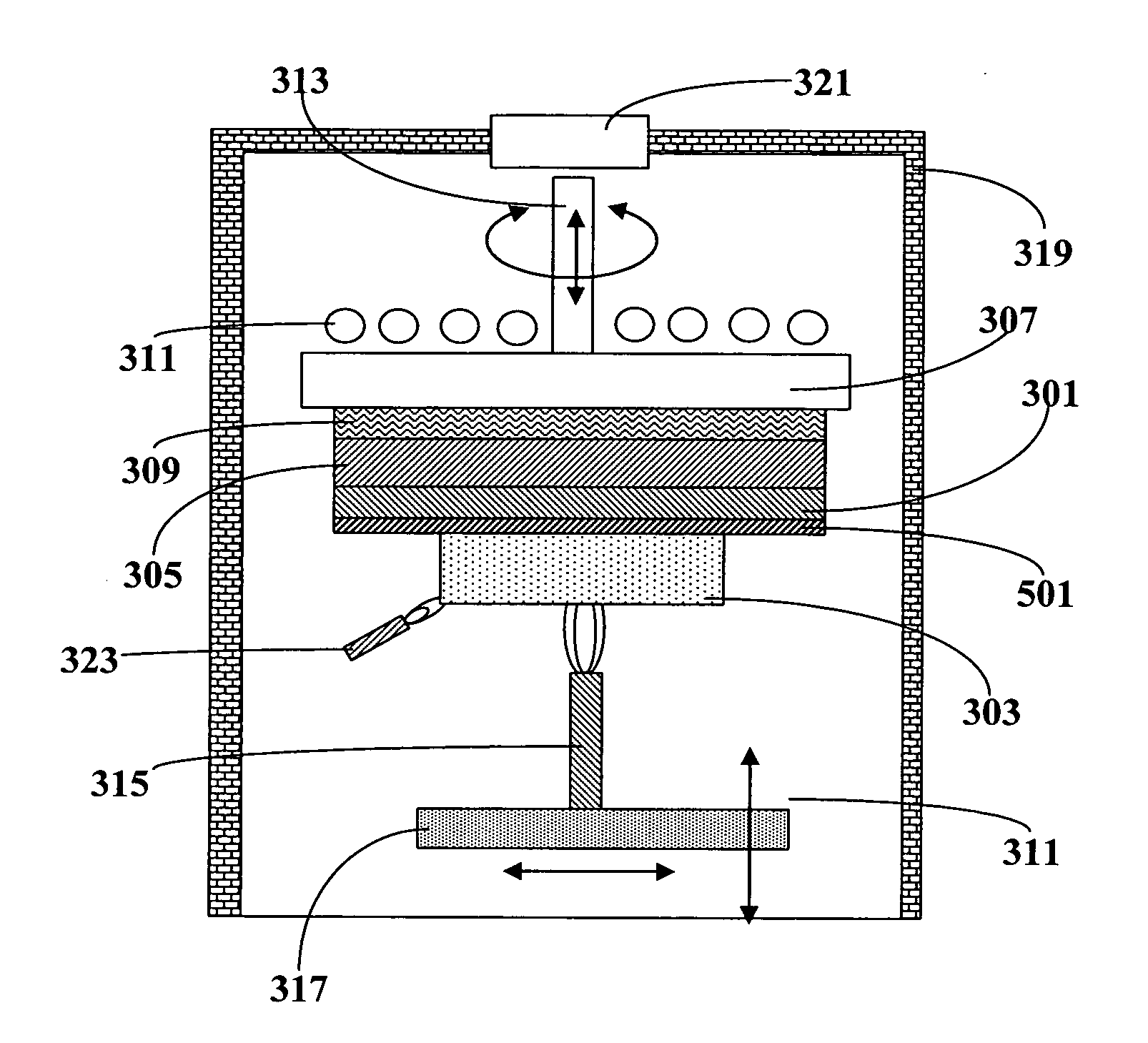

Method and apparatus for making fused silica

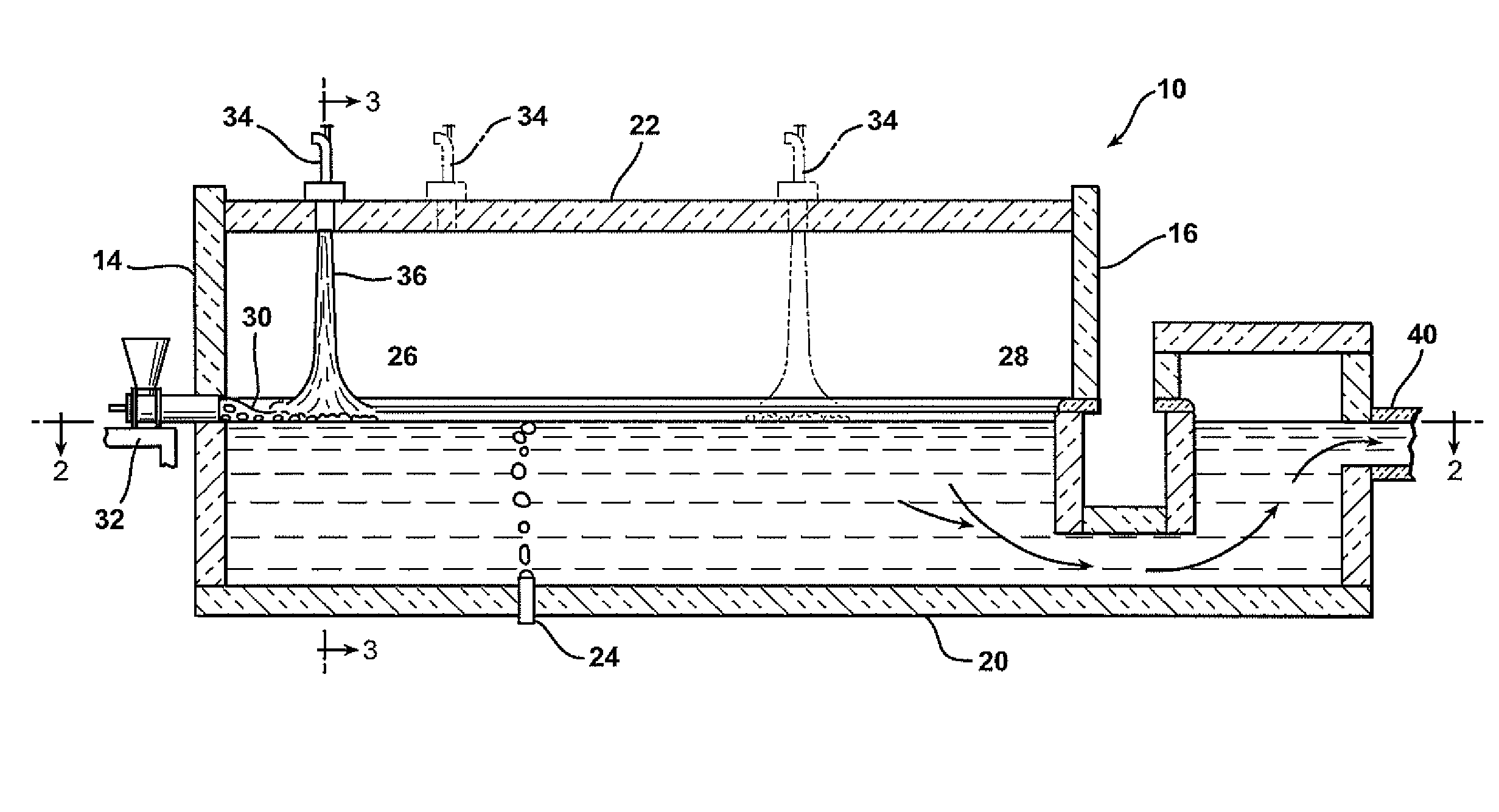

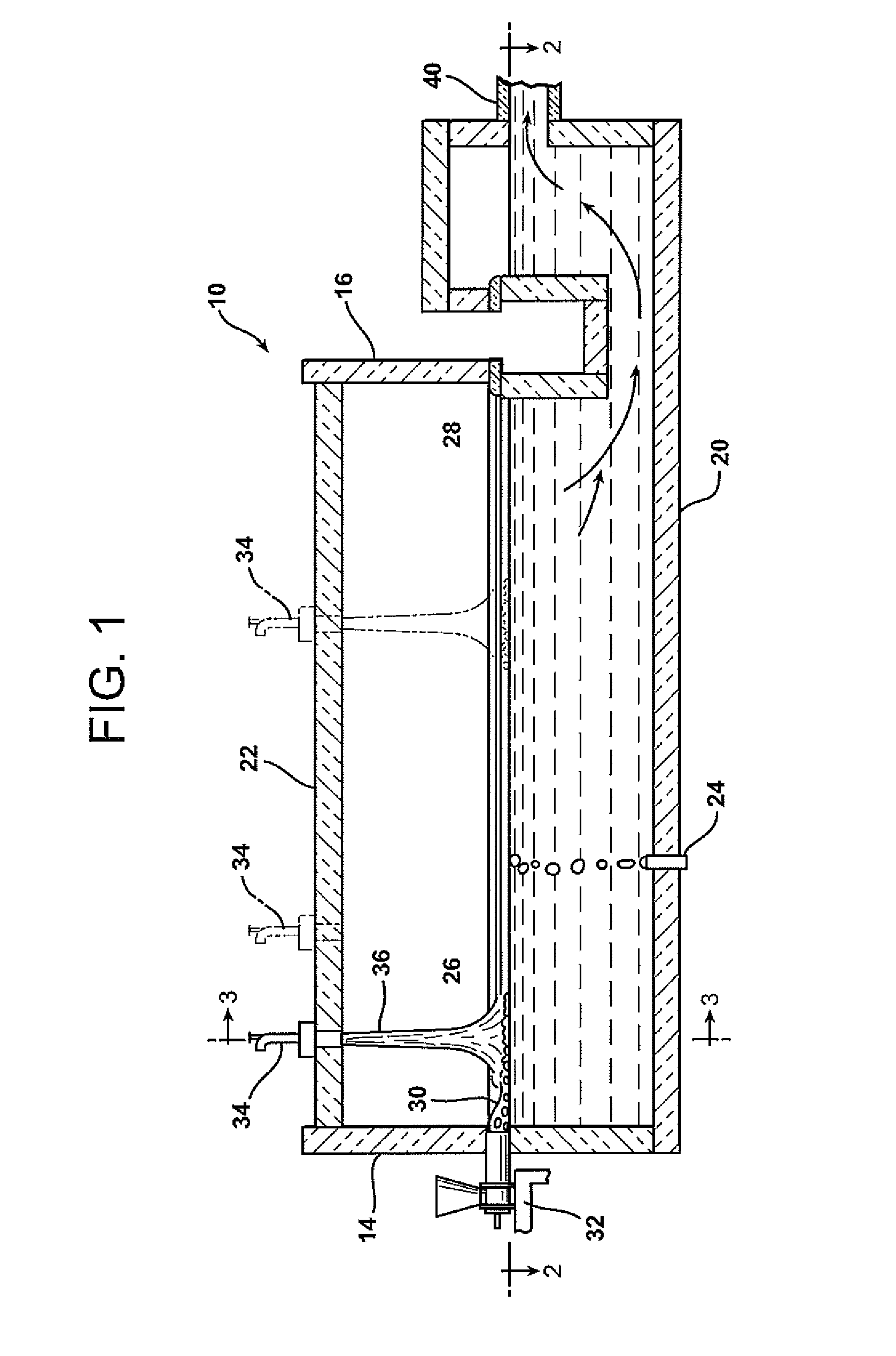

ActiveUS20070130995A1High purityHigh OH concentration uniformityGlass furnace apparatusMaterial analysis by optical meansBrickDeposition process

Disclosed are process and apparatus for making high purity fused silica glass materials. The process involves depositing soot particles onto an essentially planar deposition supporting surface and modulation of motion of the soot-generating device relative to the deposition supporting surface to result in a low local soot density variation. The apparatus is designed to implement the planar deposition process. The invention makes it possible to produce fused silica glass without the use of potentially contaminating refractory bricks.

Owner:CORNING INC

High chlorine content low attenuation optical fiber

ActiveUS20160011365A1Relieve pressureLow viscosityOptical fibre with multilayer core/claddingGlass fibre drawing apparatusRefractive indexMaterials science

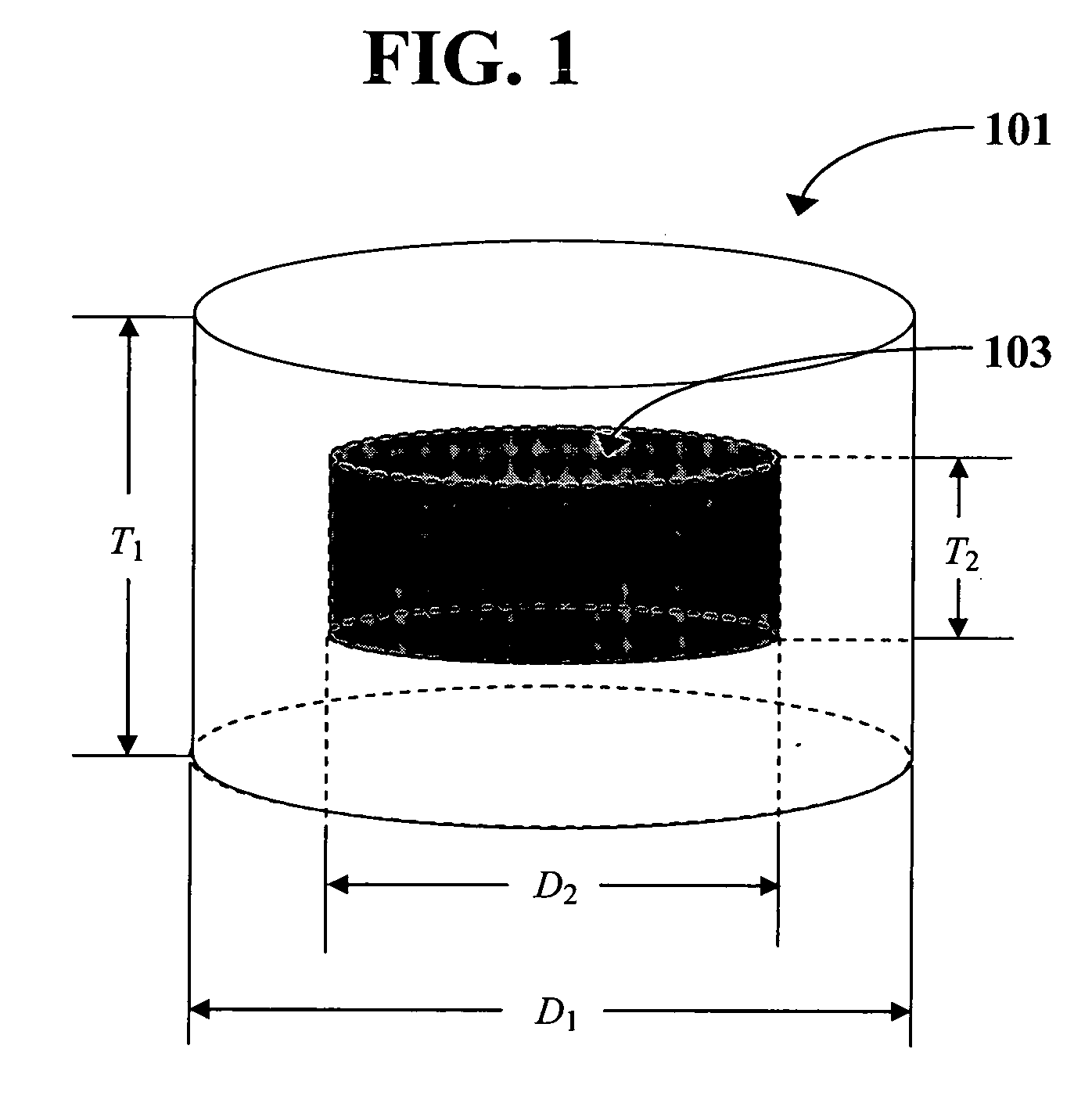

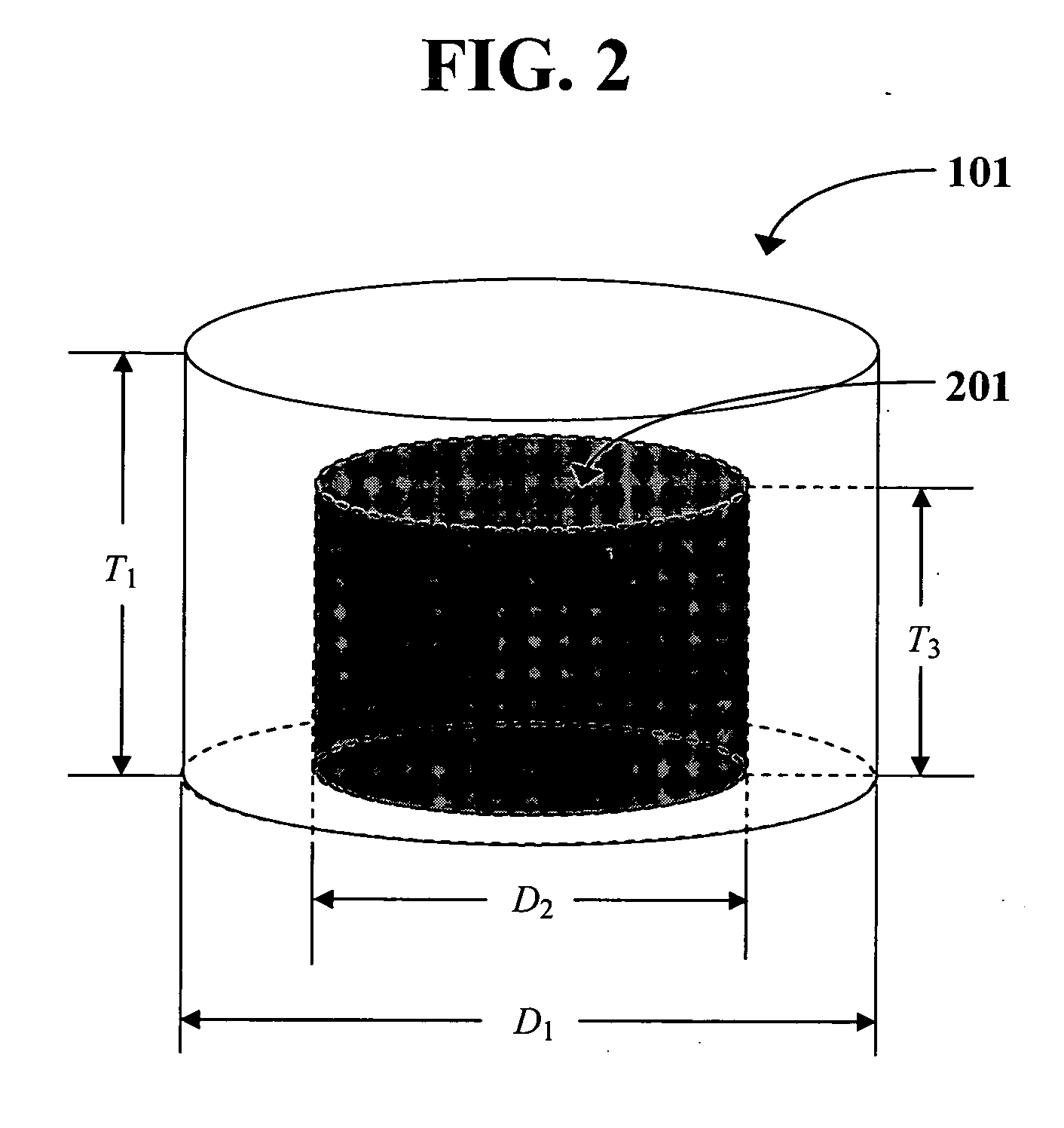

An optical fiber having a core comprising silica and greater than 1.5 wt % chlorine and less than 0.5 wt % F, said core having a refractive index Δ1MAX, and a inner cladding region having refractive index Δ2MIN surrounding the core, where Δ1MAX>Δ2MIN.

Owner:CORNING INC

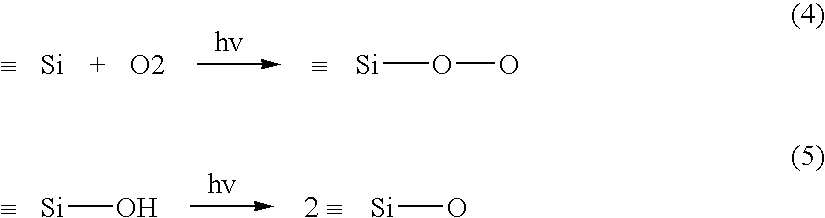

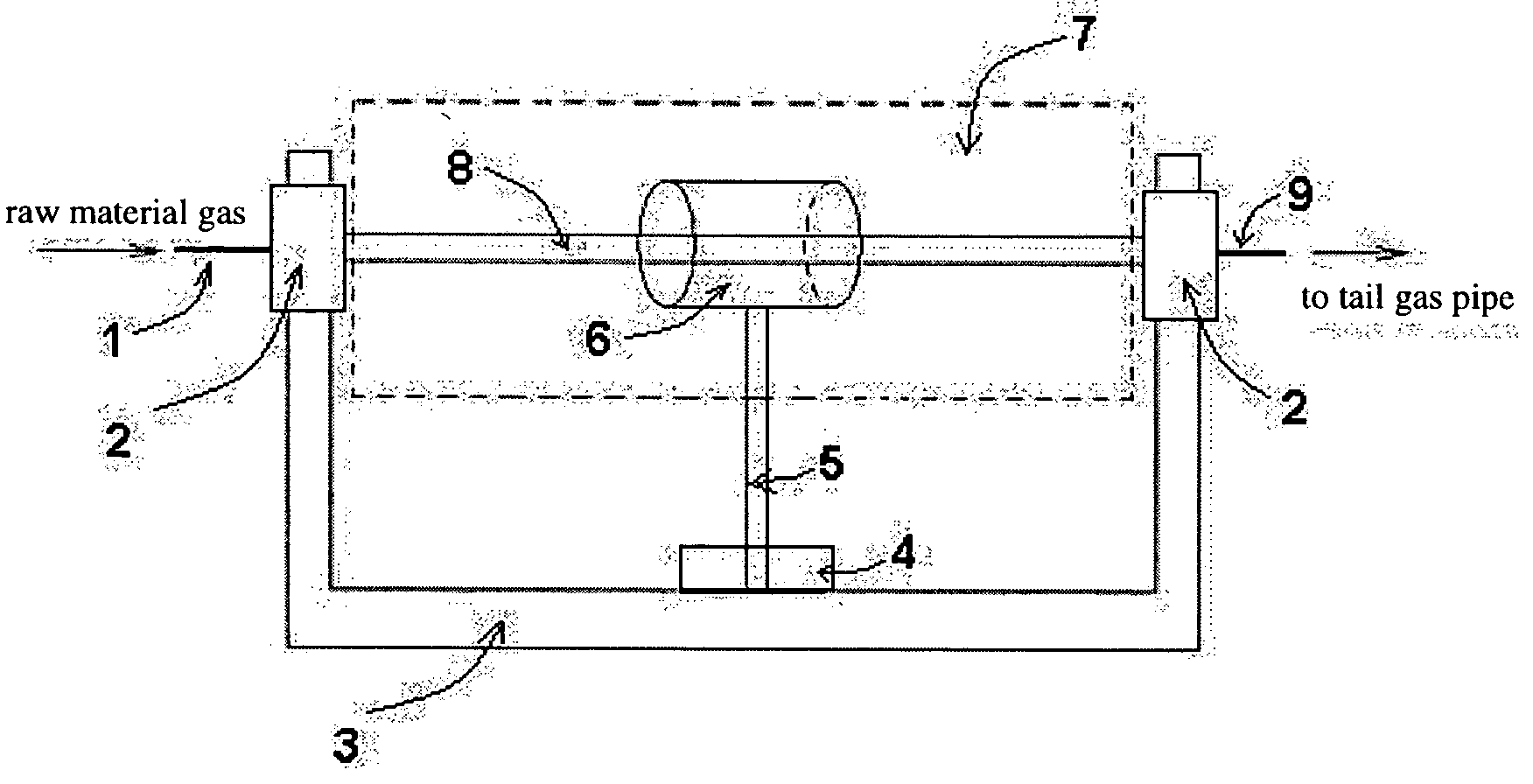

Method for manufacturing rare earth extended fibre-optical prefabricated bar

InactiveCN1490267APrecise control of doping amountImprove performanceGlass shaping apparatusGlass deposition burnersGas phaseRare earth

A process for preparing the prefabricated RE-doped optical-fibre rod features that the chemical gas-phase deposition of plasma is used to deposit the doped SiO2 layer on the inner surface of liner quartz tube and the evaporator is used to directly deliver the RE compound and other codoping agent into reaction tube for direct deposition without pollution.

Owner:FENGHUO COMM SCI & TECH CO LTD

Bending insensitive optical fiber and preparing method thereof

ActiveCN1632628AGlass deposition burnersOptical light guidesZero-dispersion wavelengthRefractive index

This invention relates to a bending-insensitive single module optics fiber and its process method. Its wave-guide structure comprises core layer and cover layer. Its process adopts PCVD work that the materials are burned solid without the oxygen and Freon with different proportions to get the fiber. The fiber bending consumption lies between 1310nm wavelength and 1550nm wavelength relative to regular 0.652 fibers and its fiber module field diameter is 7í‚0.8ª–m and its zero color diffusion wavelength is near 1310nm.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

Silica glass

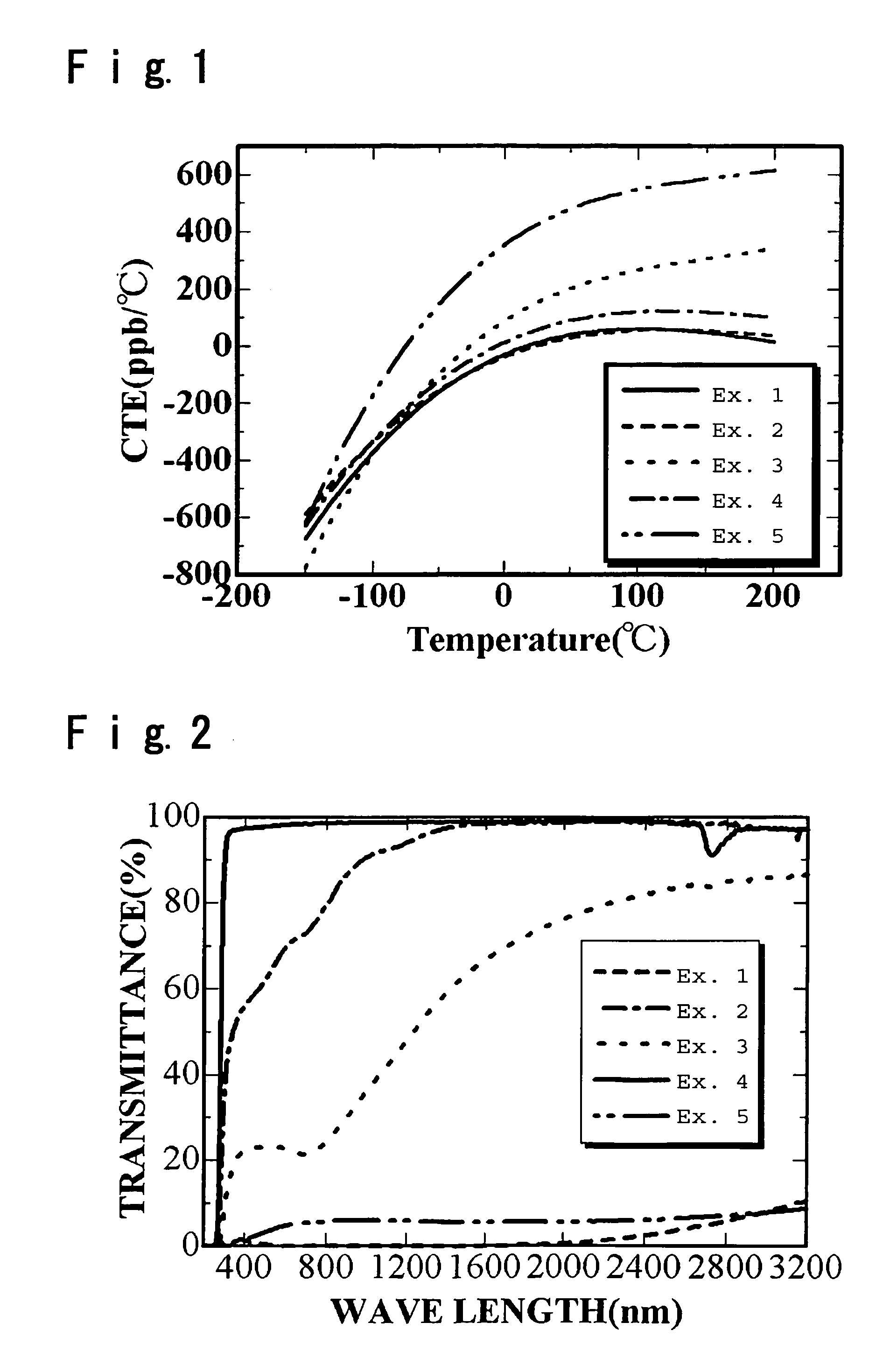

InactiveUS7294595B2Increased durabilityIncrease resistanceRadiation pyrometryMaterial analysis by optical meansTransmittanceThermal expansion

Owner:ASAHI GLASS CO LTD

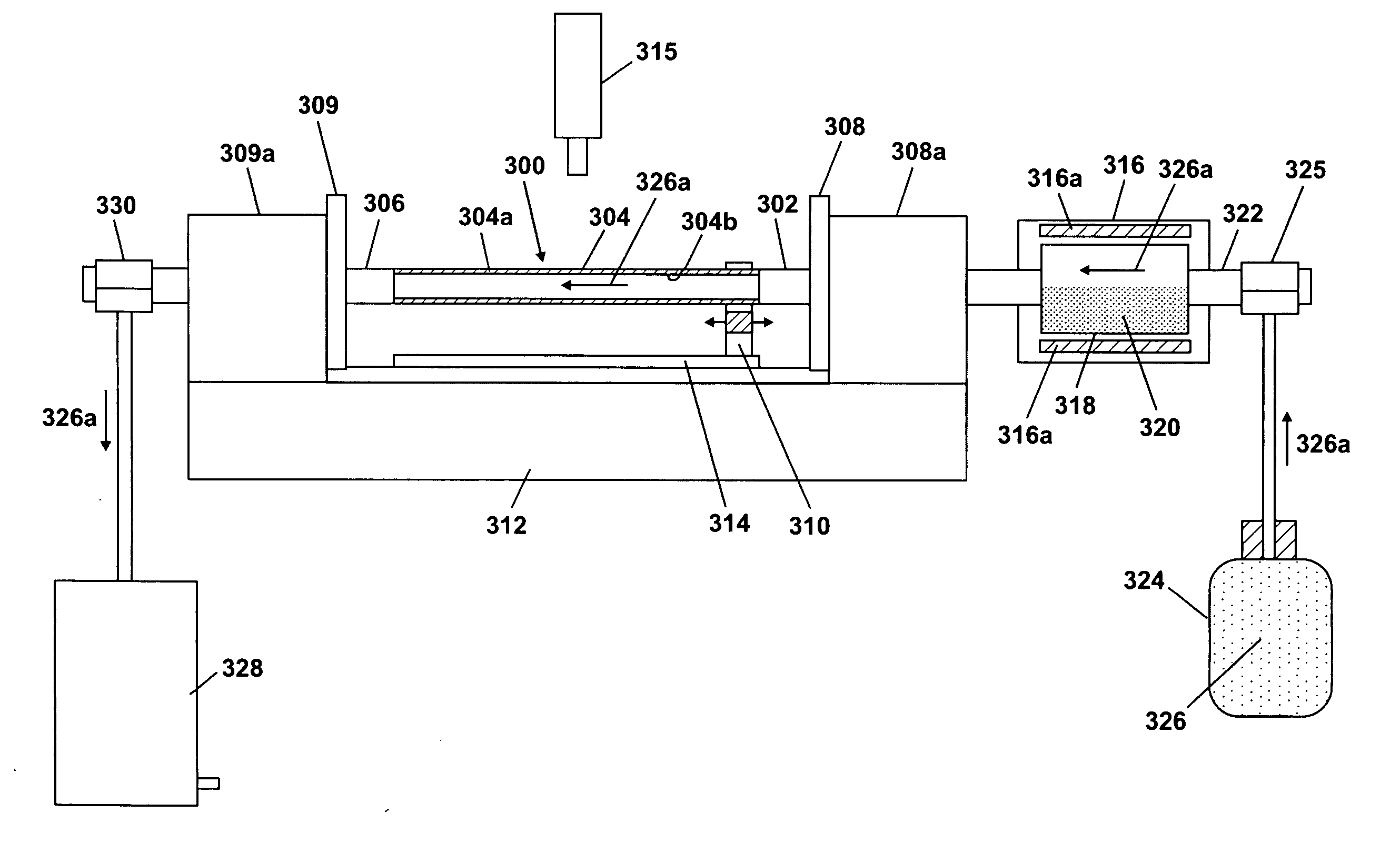

Method and apparatus for depositing glass soot

The invention includes methods and apparatus for depositing soot onto a glass surface to minimize water in the deposited soot and the diffusion of the water into the glass surface. The invention includes depositing a first layer of soot a on the glass surface at a first forward traverse rate and depositing a second layer of soot at a second forward traverse rate.

Owner:CORNING INC

Method Of Manufacturing S-Glass Fibers In A Direct Melt Operation And Products Formed There From

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

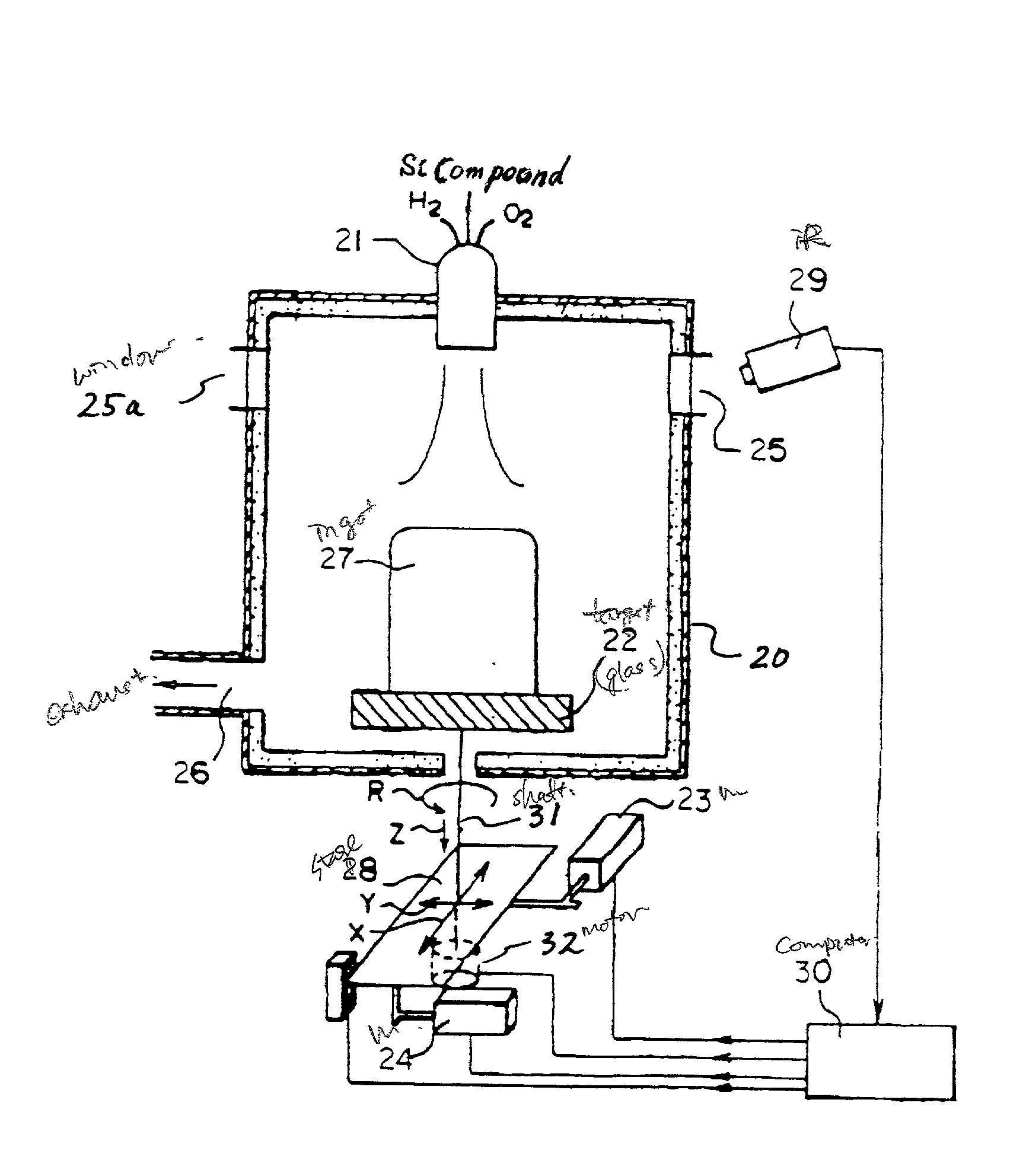

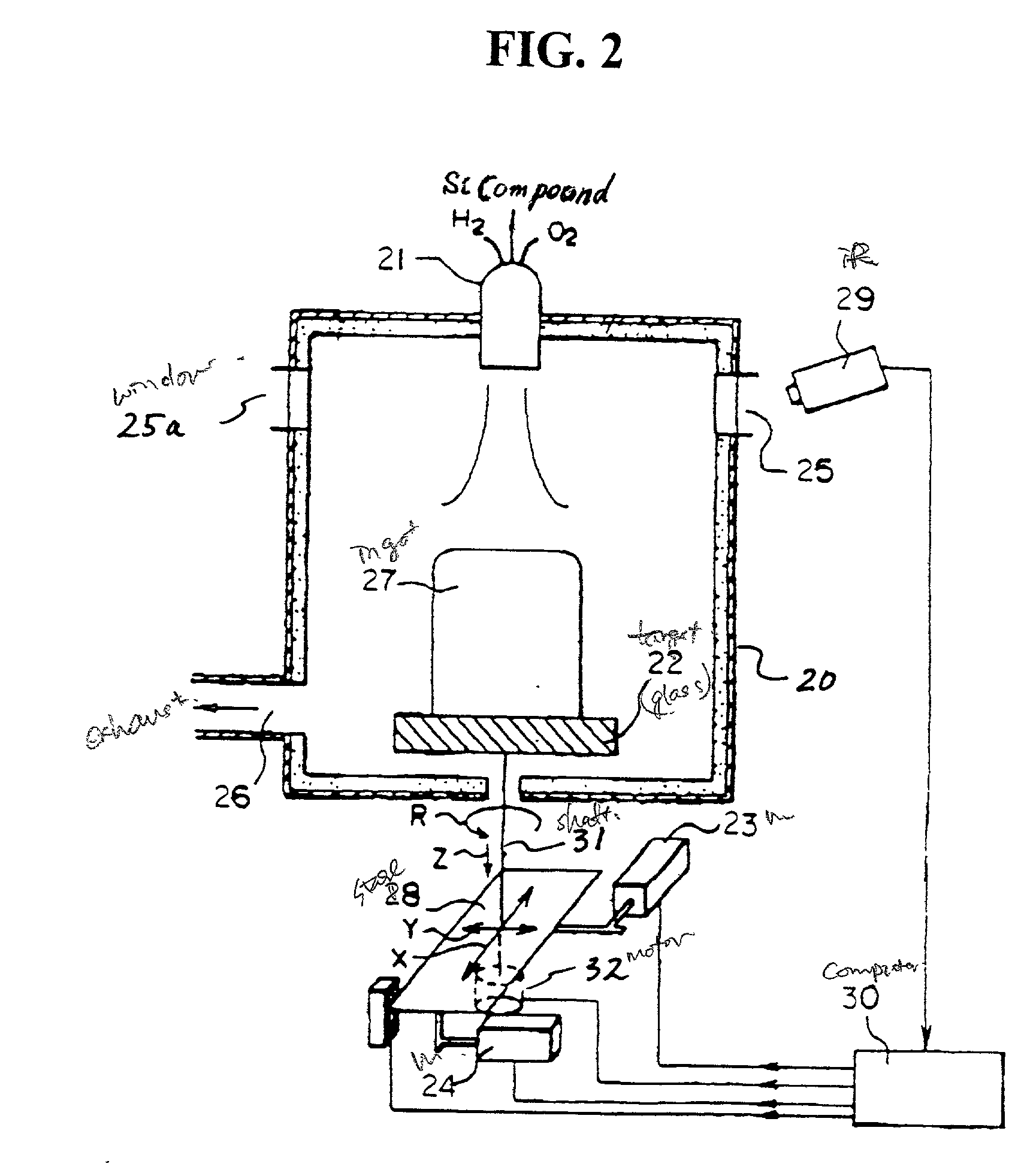

Synthetic silica glass optical member and method of manufacturing the same

A method is provided for manufacturing a synthetic silica glass. The method includes the steps of emitting an oxygen containing gas and a hydrogen containing gas from a burner; emitting a mixture of an organic silicon compound and a halogen compound from the burner; and reacting the mixture with the oxygen containing gas and the hydrogen containing gas to synthesize the silica glass.

Owner:NIKON CORP

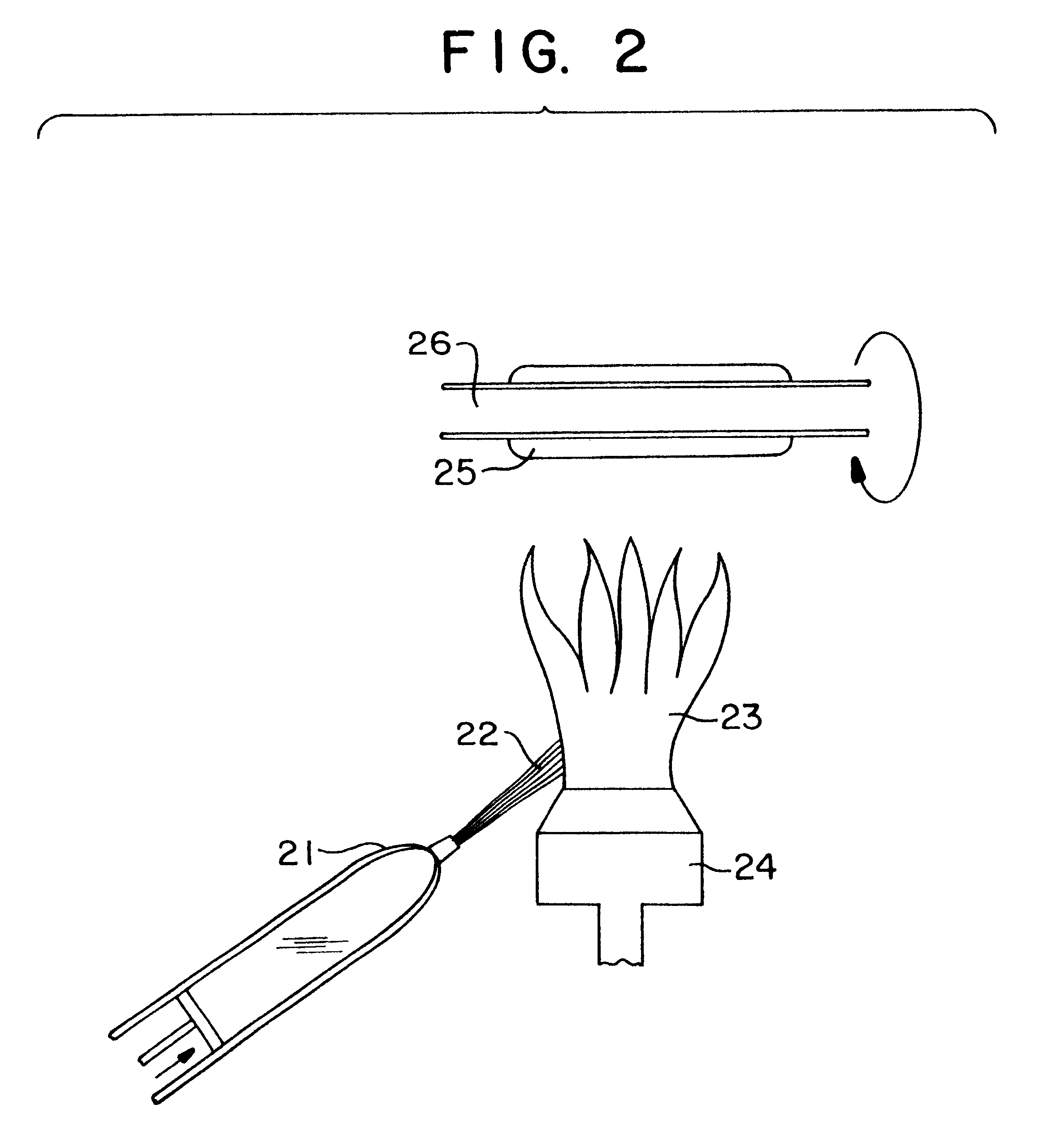

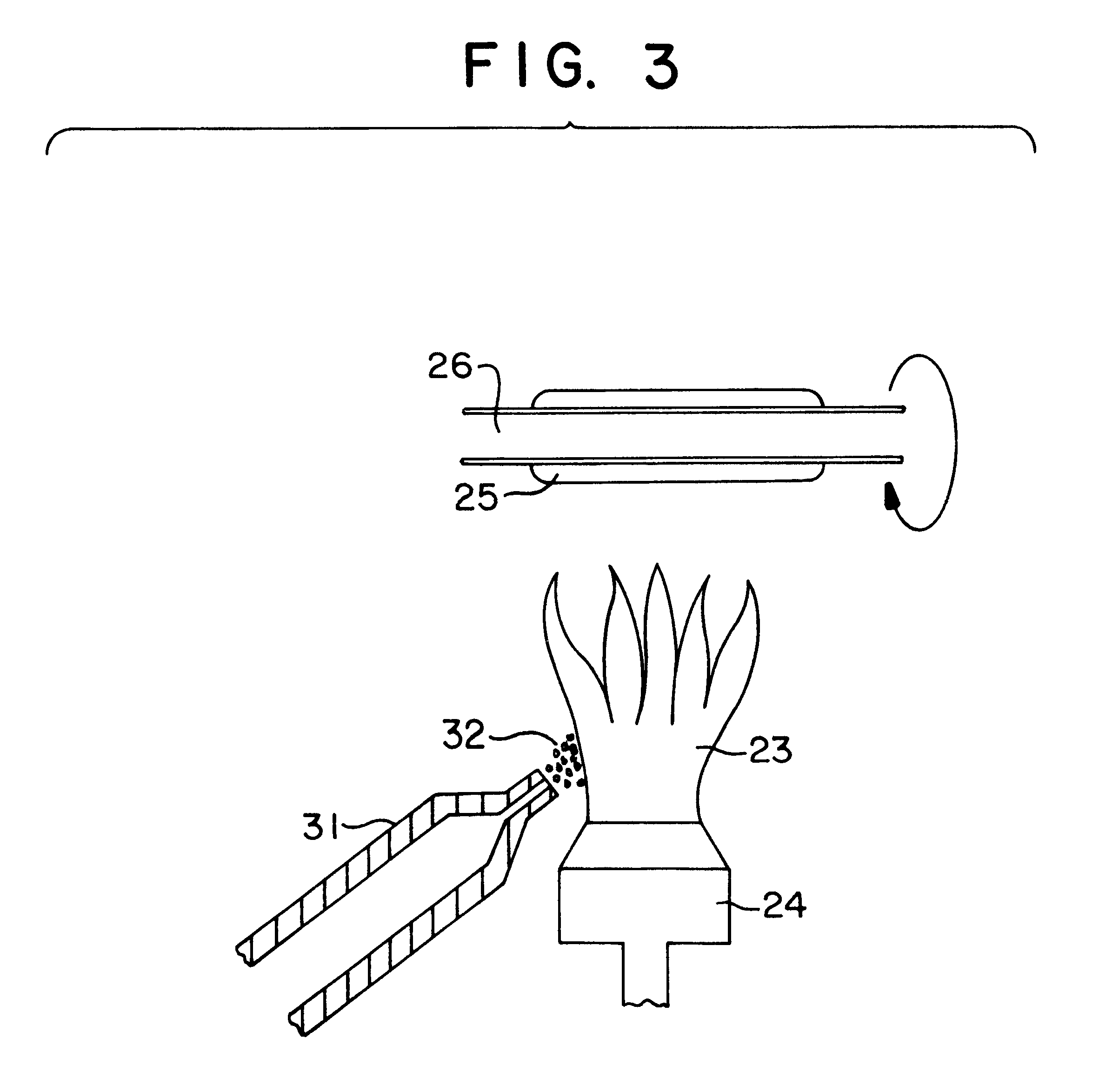

Method and device for producing optical material, and an optical waveguide

InactiveUS20060001952A1Improve abilitiesImprove homogeneityLaser detailsMolten spray coatingReaction rateErbium doping

The invention relates to the production of light-amplifying optical material. Liquid reactant is atomized into droplets using a high velocity gas. The droplets are subsequently introduced into a flame. Reactants are oxidized in the flame and condensed by forming small particles. At least a fraction of said particles is collected and fused to form optical waveguide material, which is subsequently drawn to form an optical waveguide. According to the invention, the velocity of the atomizing gas stream is in the order of the velocity of sound. The high velocity enhances atomization and increases reaction rates in the flame. The residence times are reduced to such a degree that unwanted phase transformations in the produced particles are substantially minimized. Consequently, very homogeneous material is produced. Especially, in the production of erbium-doped silica, low percentage of clustered erbium ions is achieved.

Owner:LIEKKI OY

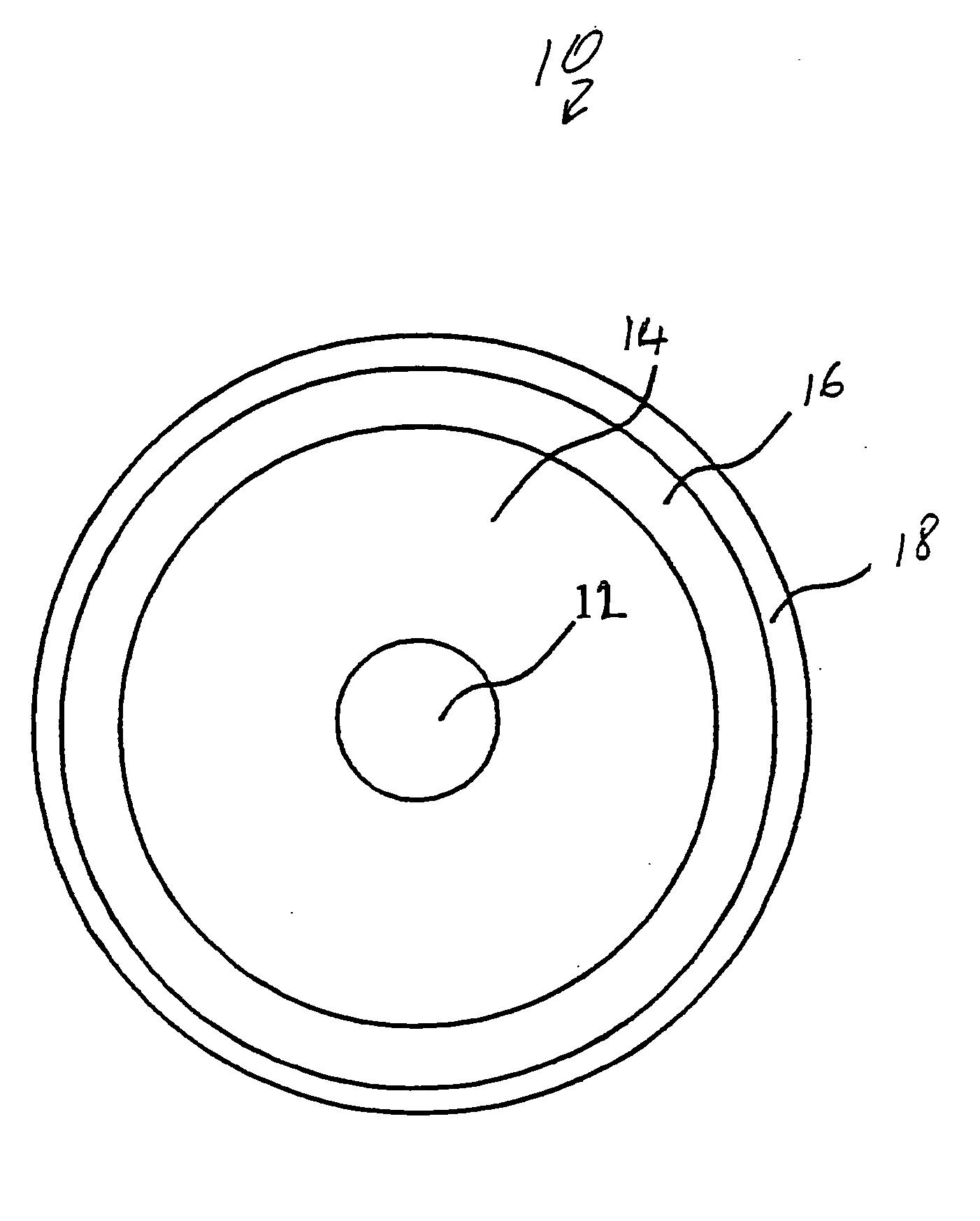

Optical fiber and method for making such fiber

ActiveUS20050271347A1Coupling efficiency is highIncrease optical powerOptical fibre with polarisationOptical fibre with multilayer core/claddingFiberRare earth

According to one example of the invention an optical fiber comprises: (i) silica based, rare earth doped core having a first index of refraction n1; (ii) at least one silica based cladding surrounding the core and having a second index of refraction n2, such that n1>n2; wherein at least one of the core or cladding is doped with Al2O3, such that the ratio of max wt % to min wt % of Al2O3 concentration is less than 2:1

Owner:CORNING INC

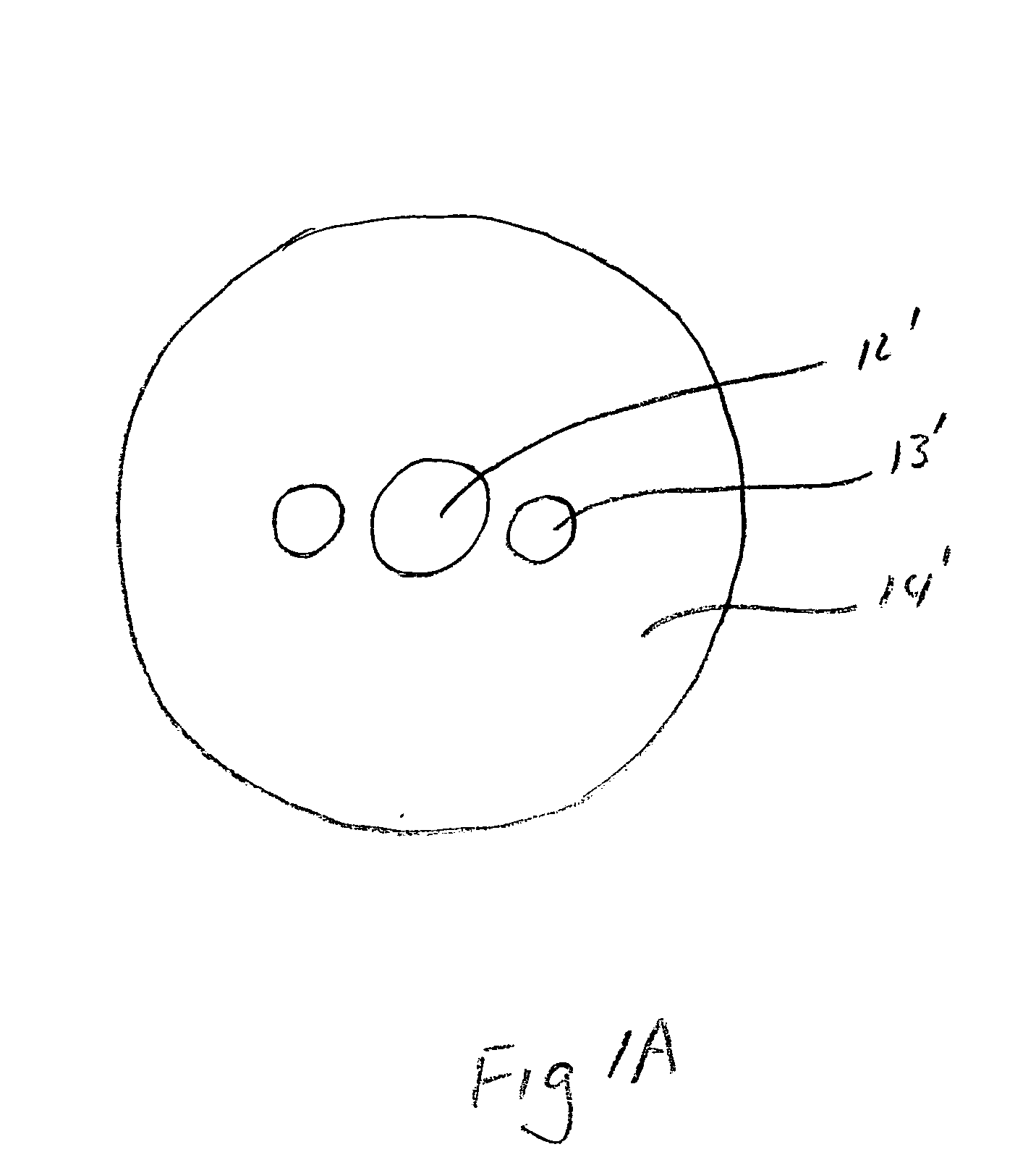

Rare earth doped single polarization double clad optical fiber with plurality of air holes

InactiveUS20060088262A1Large amount of processingRemoval costLaser detailsOptical fibre with polarisationRefractive indexRare earth

An optical fiber including: (i) a silica based, rare earth doped core having a first index of refraction n1; (ii) a silica based inner cladding surrounding the core and having a second index of refraction n2, such that n1>n2, said inner cladding having a plurality of air holes extending longitudinally through the length of said optical fiber; (iii) a silica based outer cladding surrounding said inner cladding and having a third index of refraction n3, such that n2>n3, wherein said optical fiber supports a single polarization mode within the operating wavelength range.

Owner:CORNING INC

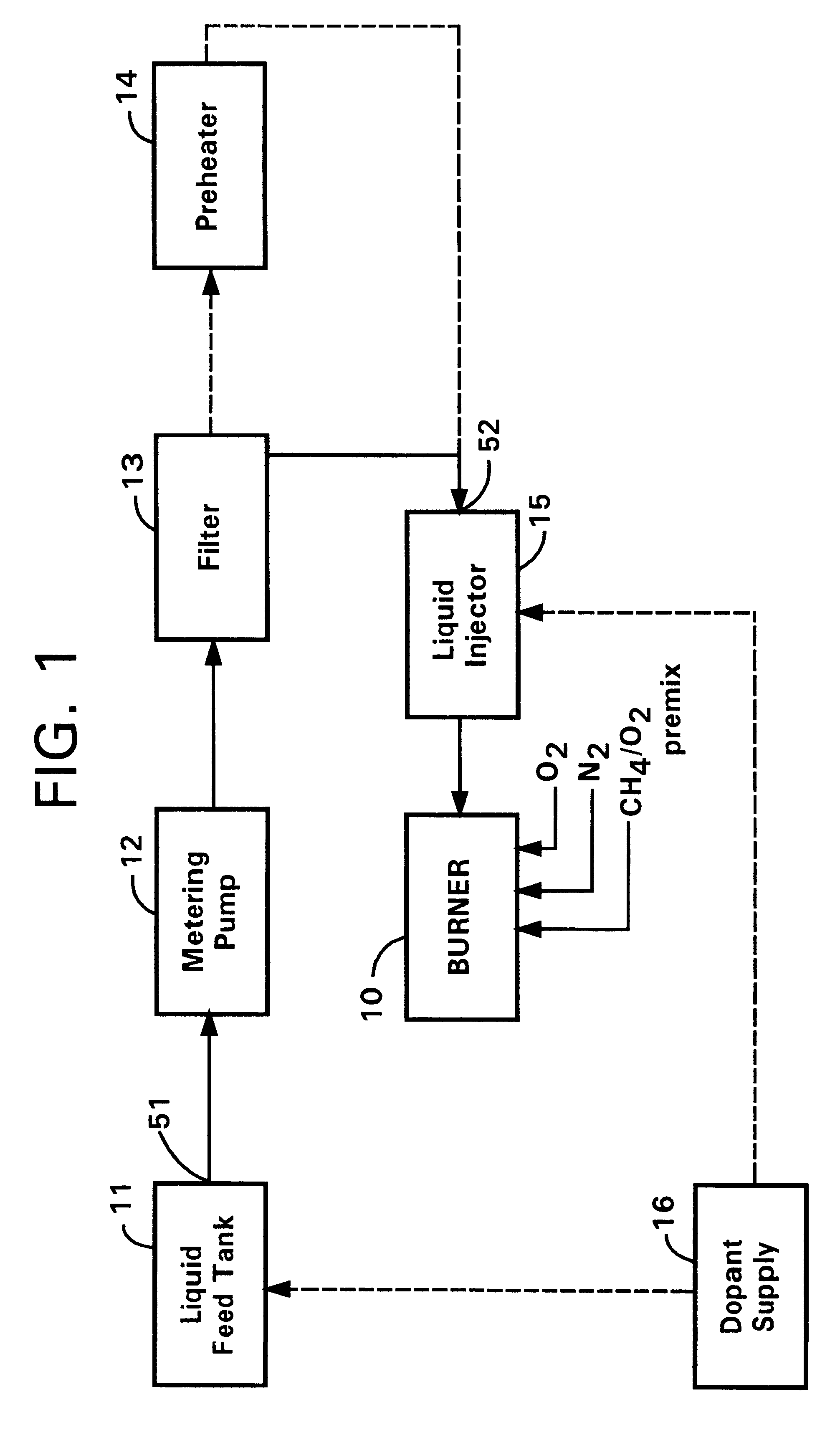

Method and apparatus for forming fused silica by combustion of liquid reactants

InactiveUS6565823B1High concentricityPrevents burner buildupSilicaSpray nozzlesCombustorDecomposition

The present invention is directed to a method for making fused silica glass. A liquid, preferably halide-free, silicon-containing compound capable of being converted by thermal oxidative decomposition to SiO2 is provided and introduced directly into the flame of a combustion burner, thereby forming finely divided amorphous soot. The amorphous soot is deposited on a receptor surface where, either substantially simultaneously with or subsequently to its deposition, the soot is consolidated into a body of fused silica glass. The invention further relates to an apparatus for forming fused silica from liquid, preferably halide-free, silicon-containing reactants which includes: a combustion burner which, in operation, generates a flame; an injector for supplying a liquid silicon-containing compound to the flame to convert the compound by thermal oxidative decomposition to a finely divided amorphous soot; and a receptor surface on which the soot is deposited.

Owner:CORNING INC

Silica glass

InactiveUS20060276323A1Increased durabilityIncrease resistanceGlass shaping apparatusGlass deposition burnersSilica glassQuartz

A silica glass containing from 3 to 10 mass % of TiO2, which has a coefficient of thermal expansion from 0 to 100° C., i.e. CTE0 to 100, of 0±300 ppb / ° C. and an internal transmittance per mm in thickness within a wavelength region of from 200 to 700 nm, i.e. T200 to 700, of at most 80%.

Owner:ASAHI GLASS CO LTD

Popular searches

Active medium material Active medium shape and construction Optical waveguide light guide Thin material handling Optical fibre with desired dispersion Molecular-sieve and base-exchange compounds Chemical/physical/physico-chemical processes Liquid-gas reaction processes Microstructured optical fibre Glass production

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com