Patents

Literature

597 results about "Relative refractive index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Relative index of refraction specifically refers to comparing one optically dense media to another background media. It is actually a ratio of refractive indices of two differview the full answer.

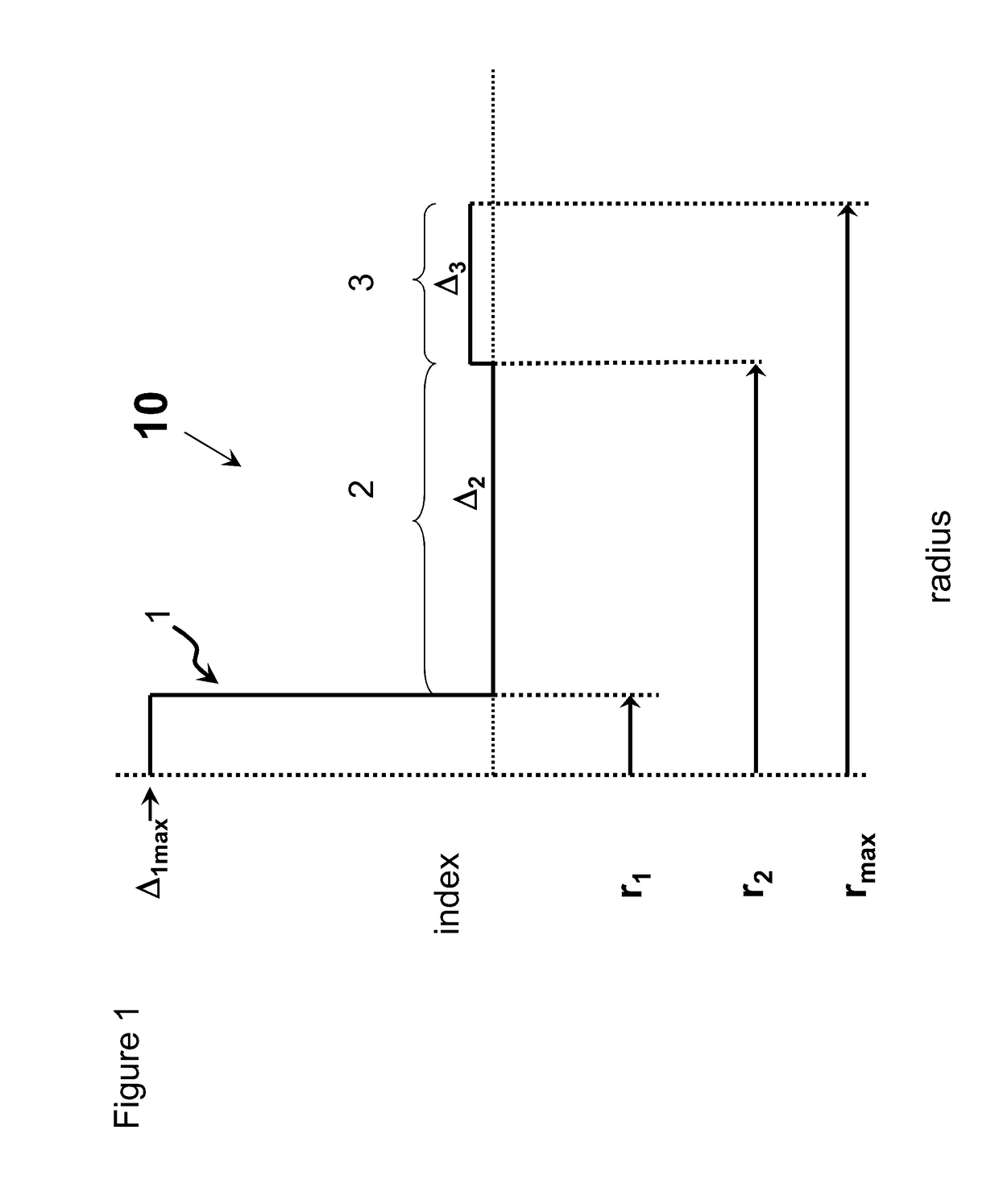

Large effective area fiber

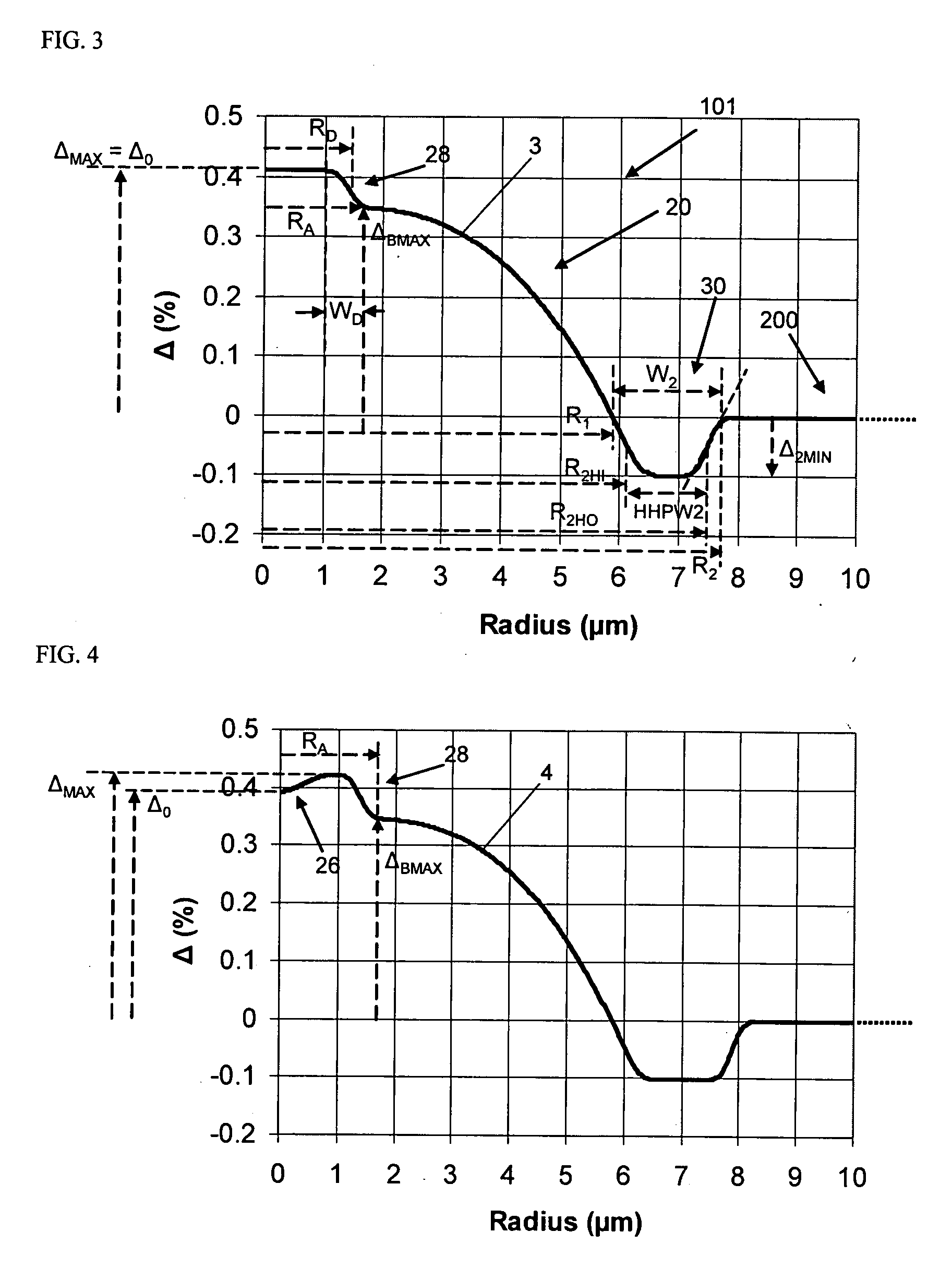

ActiveUS7555187B2Optical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingRelative refractive indexEngineering

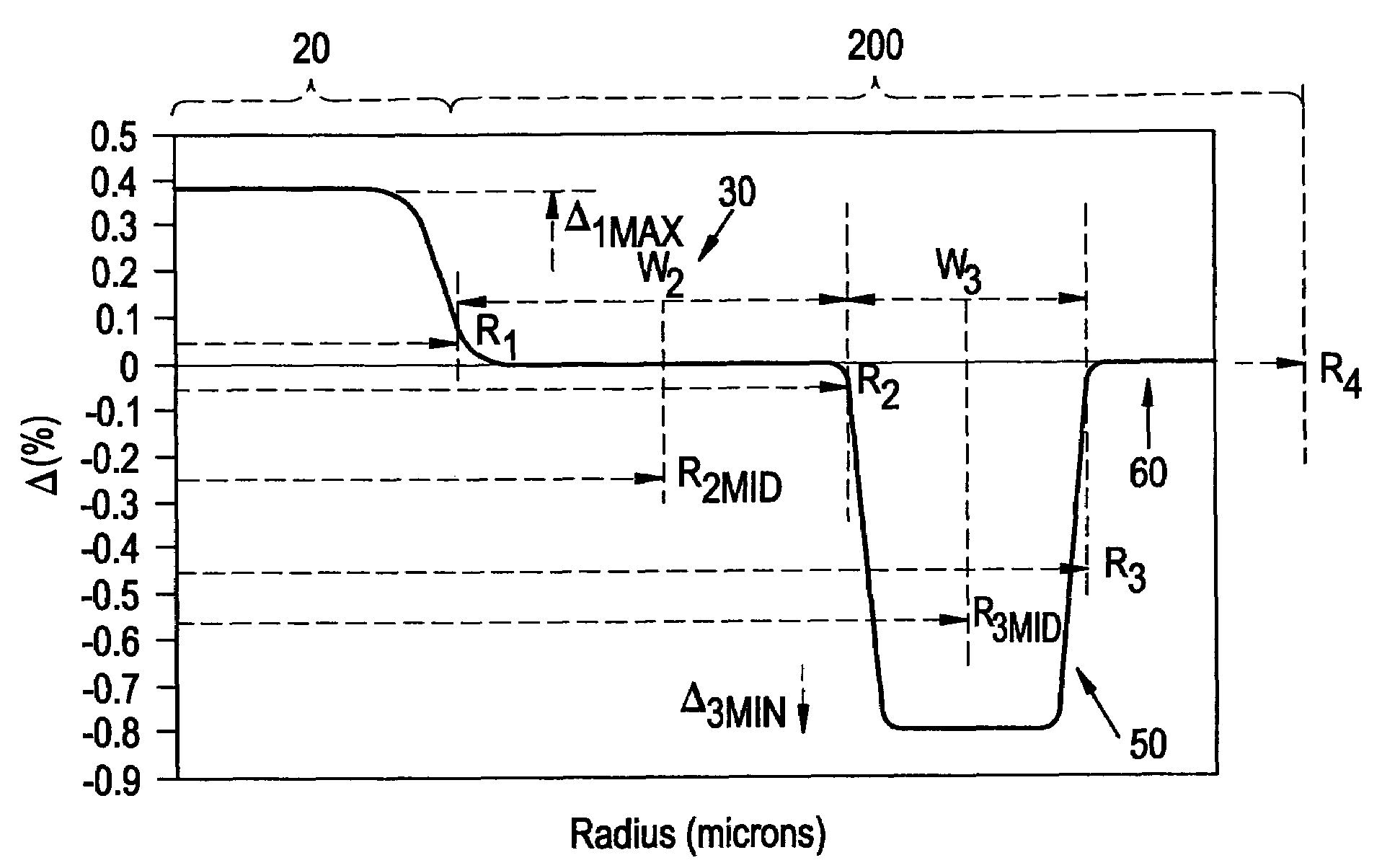

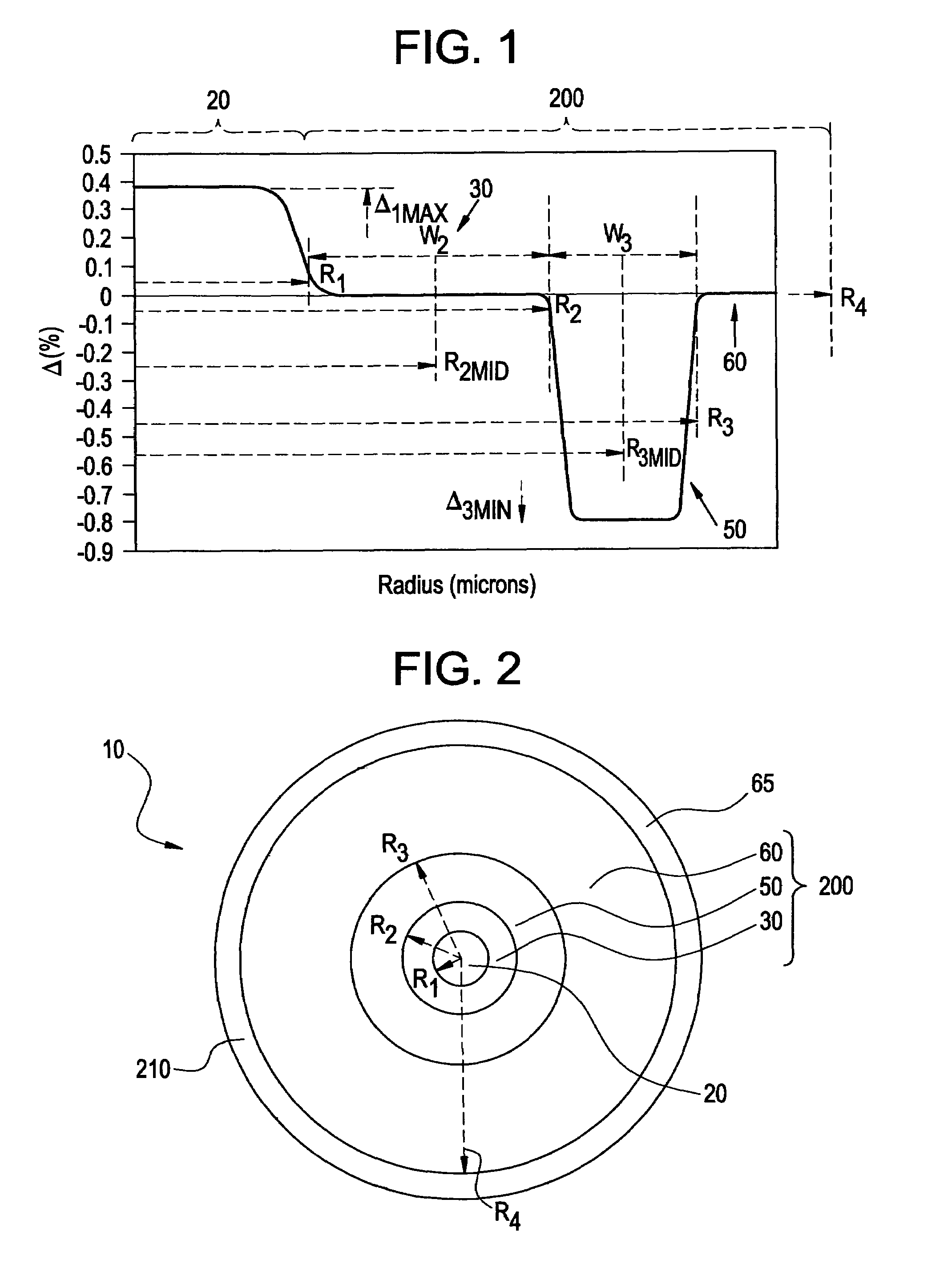

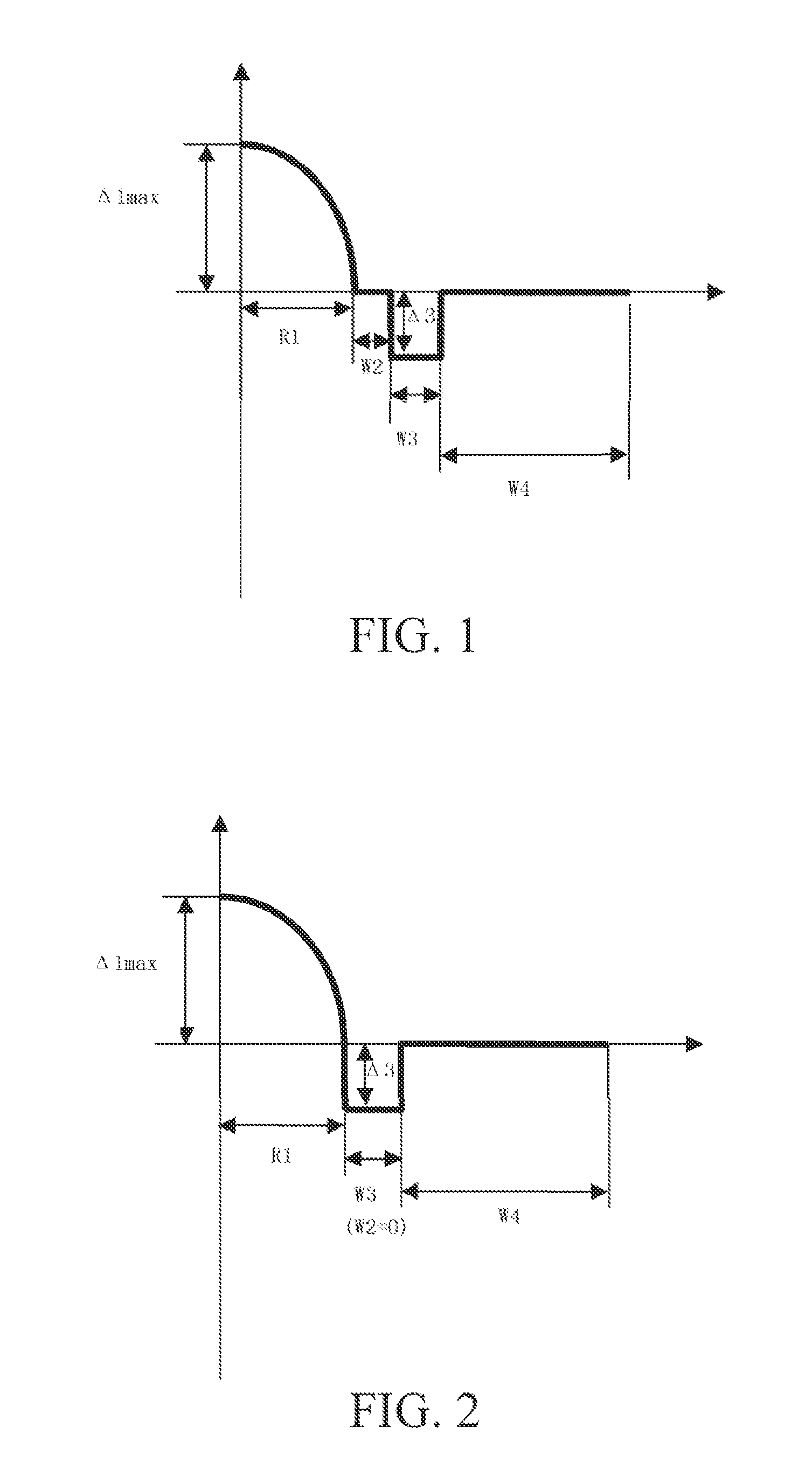

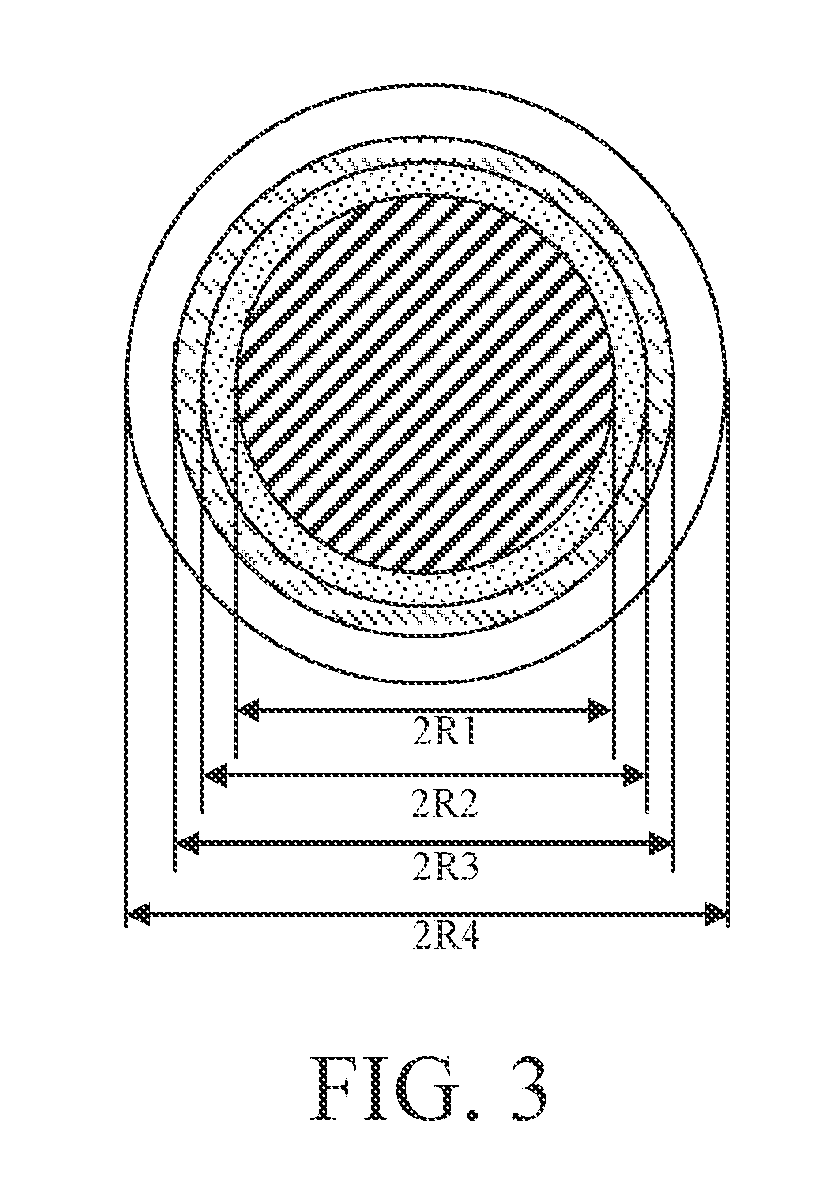

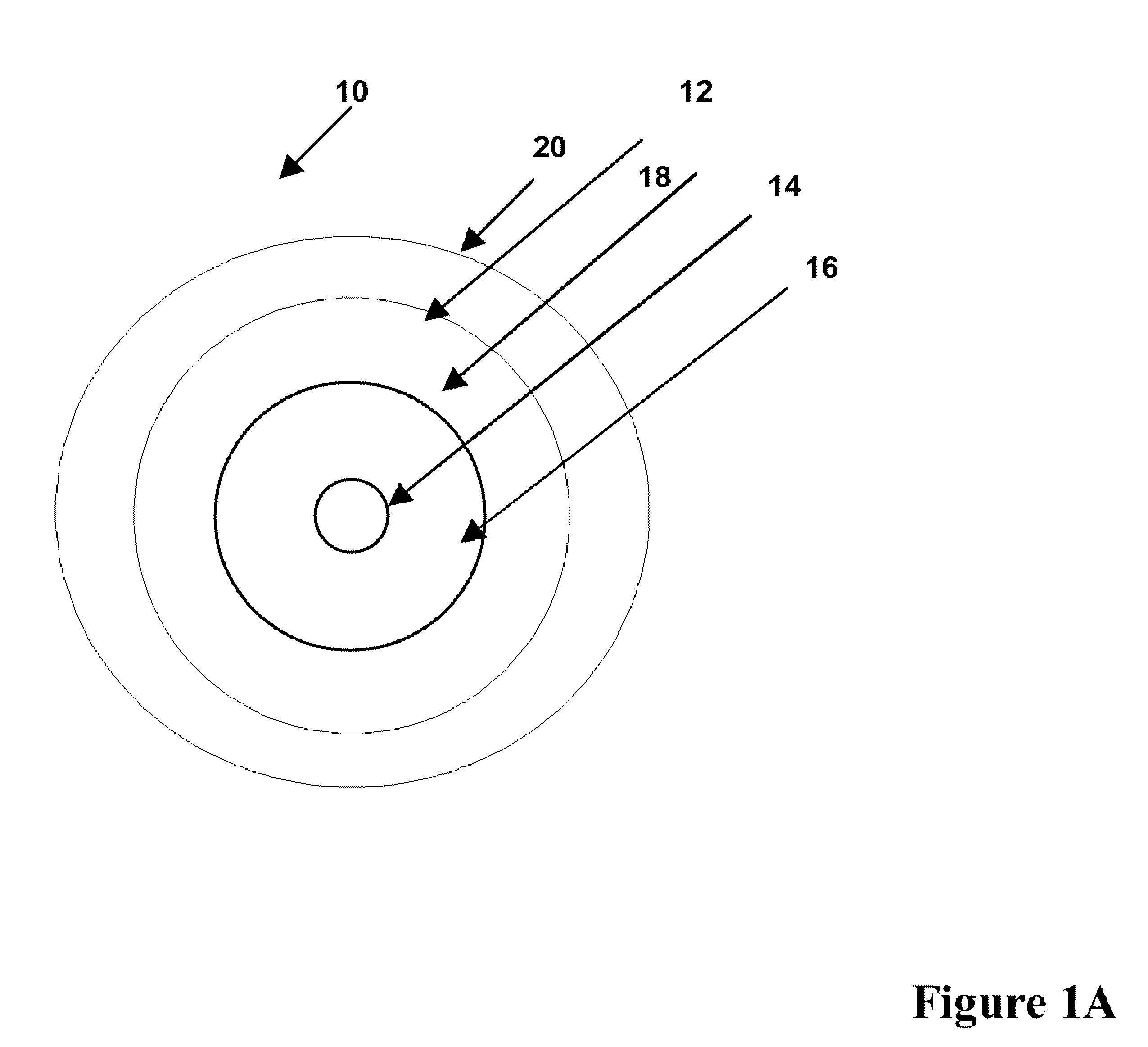

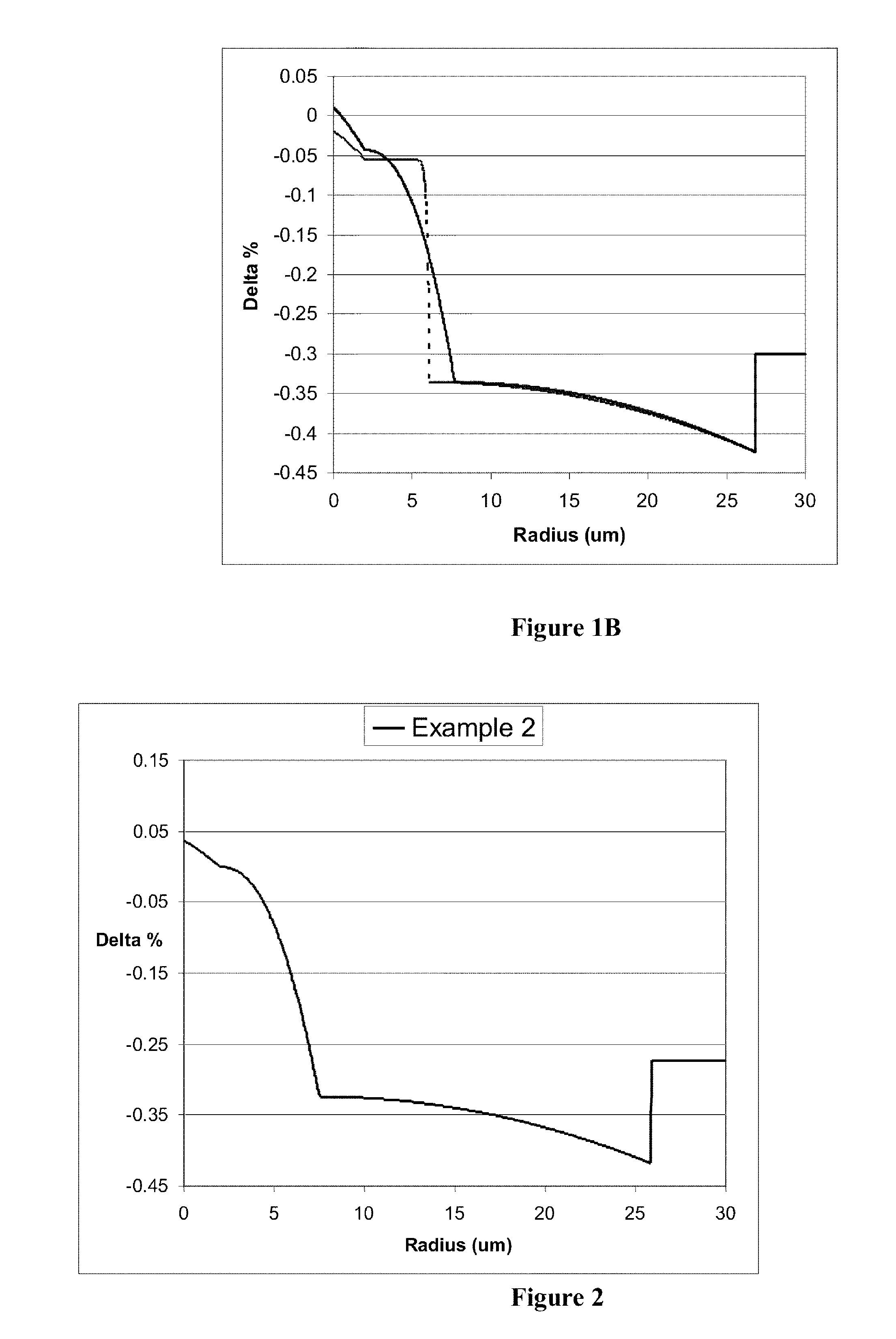

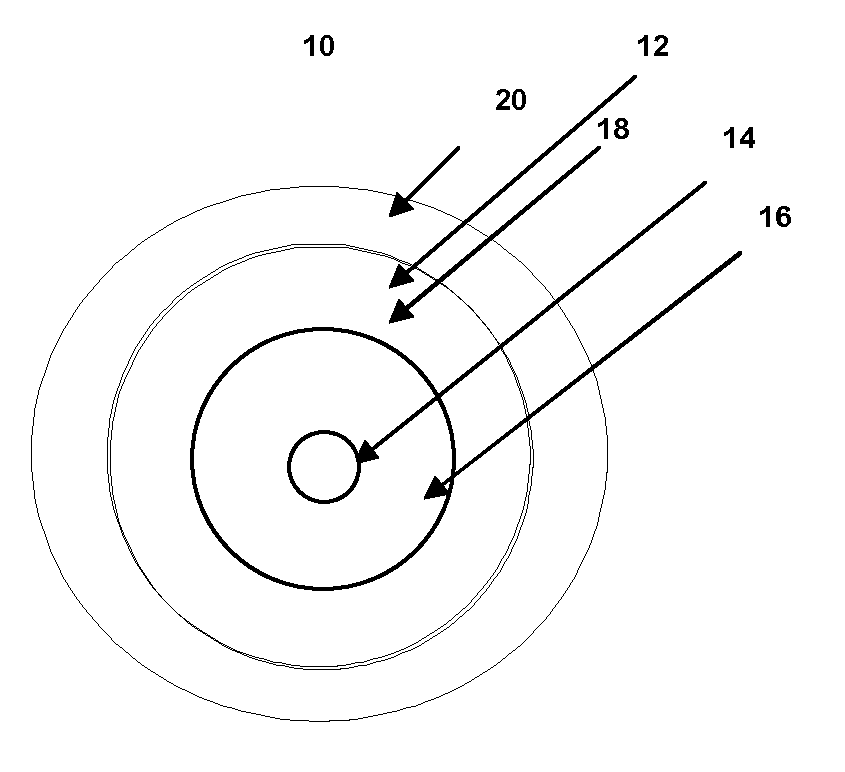

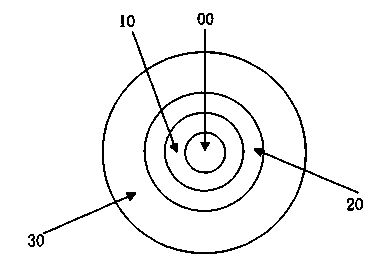

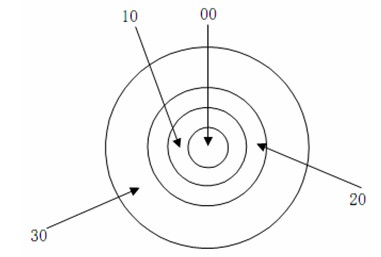

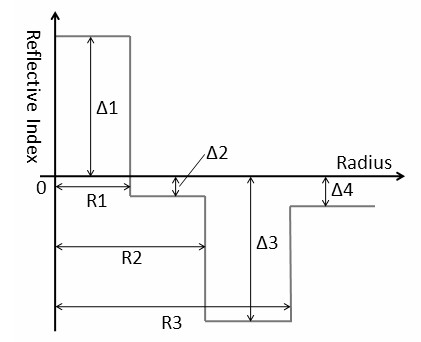

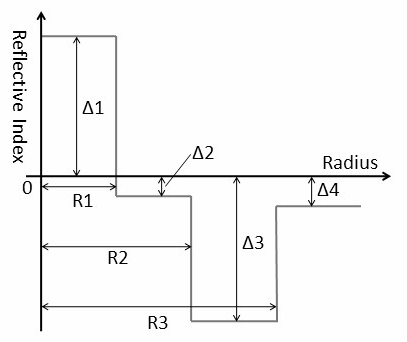

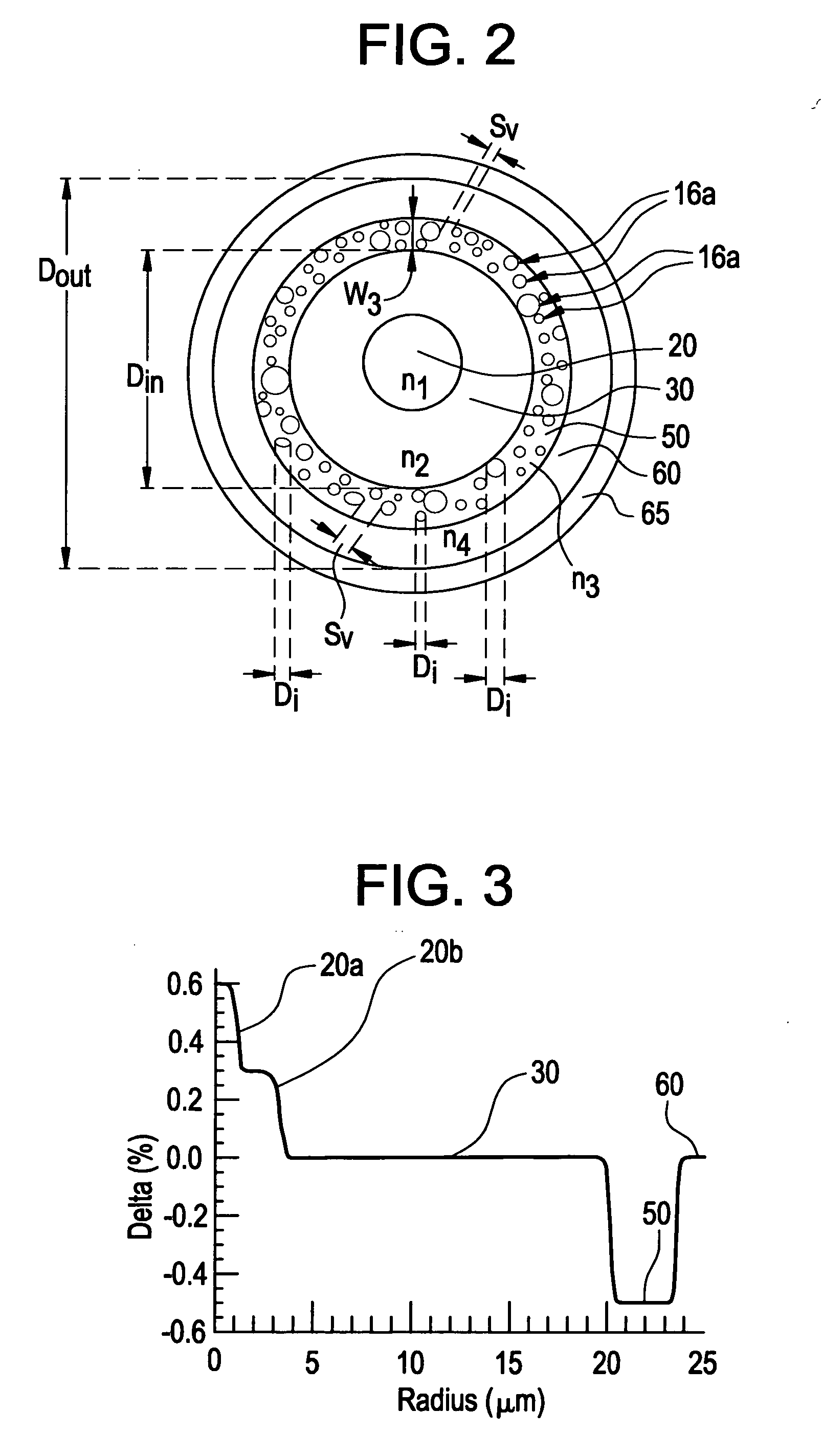

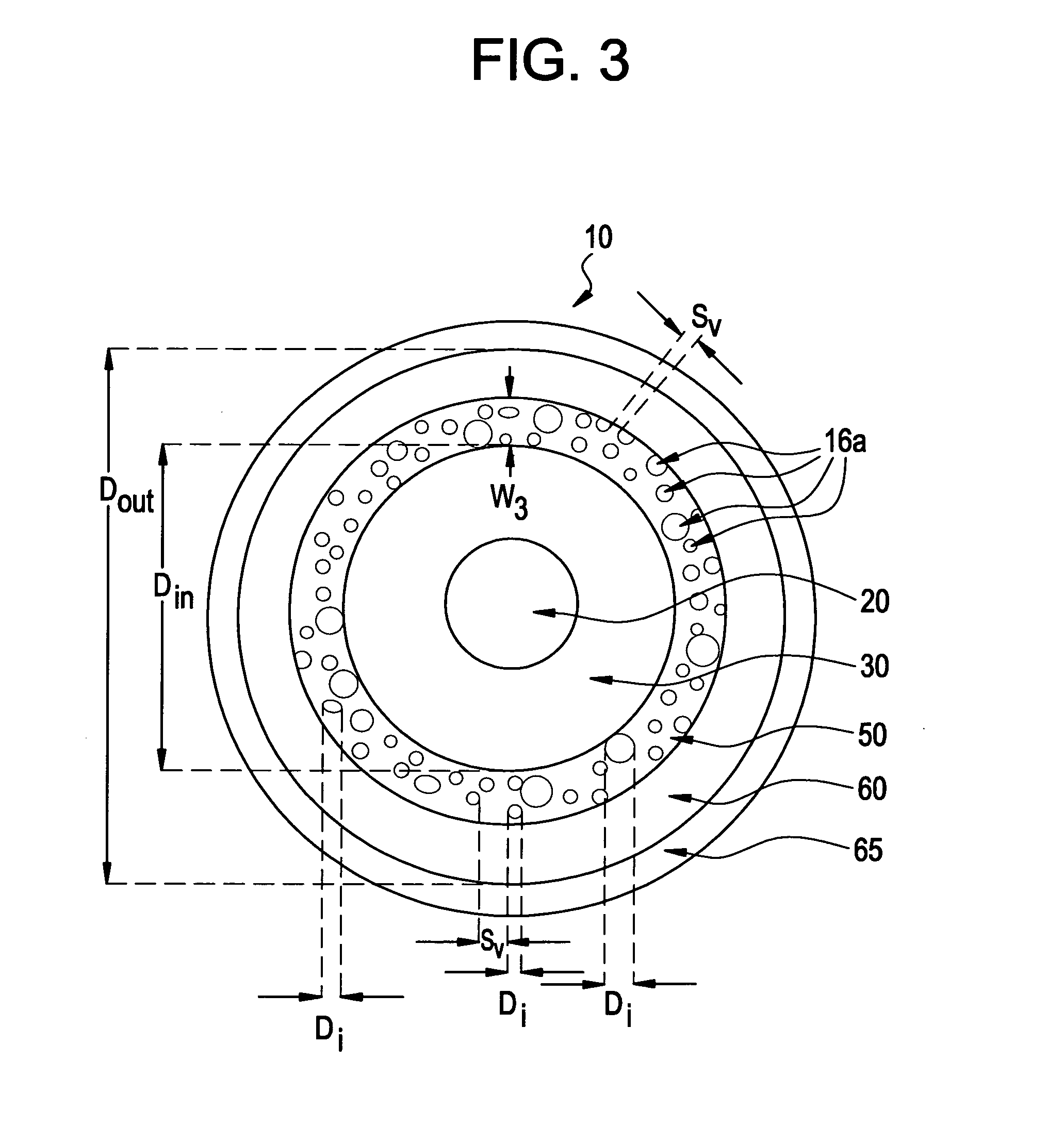

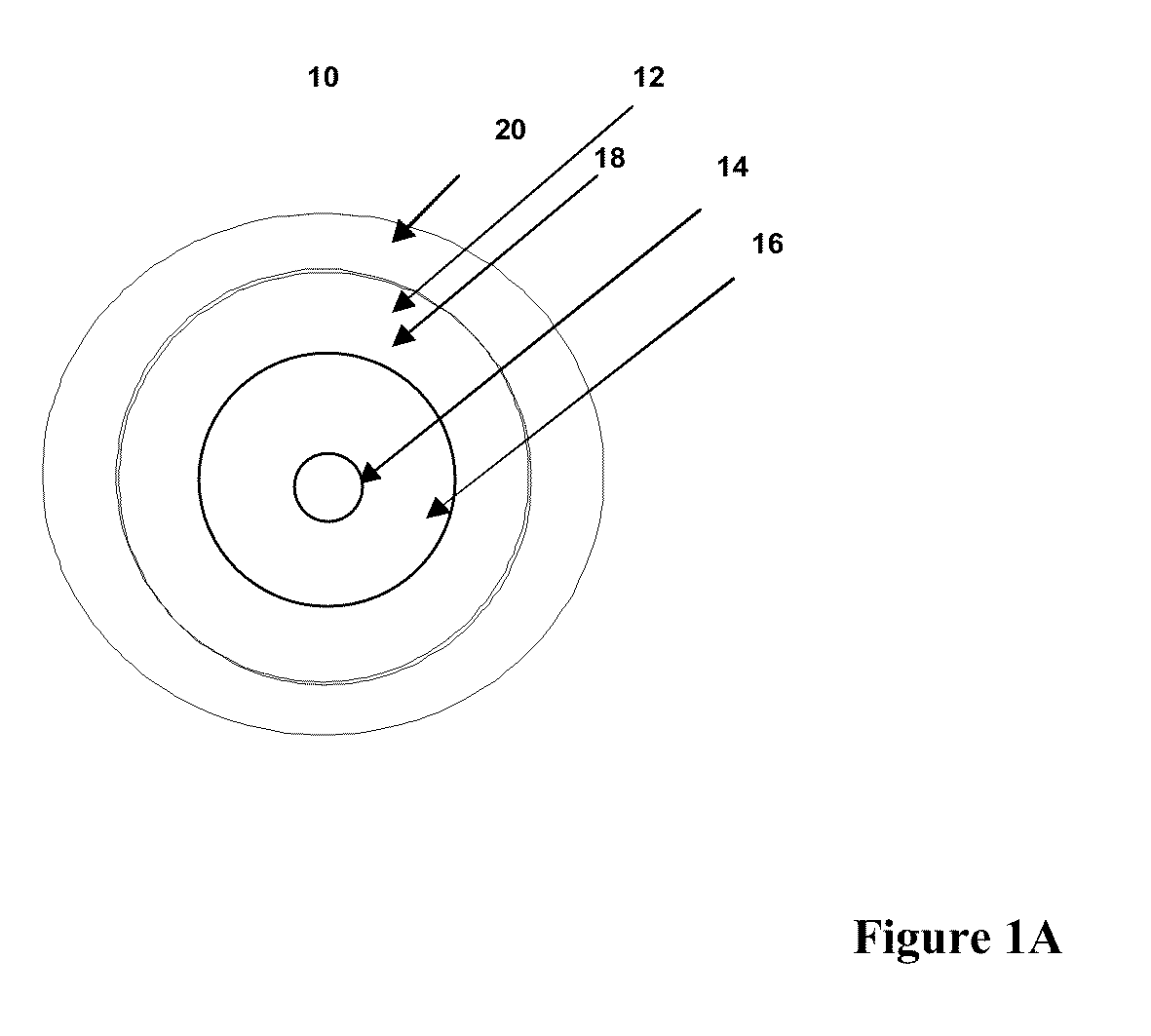

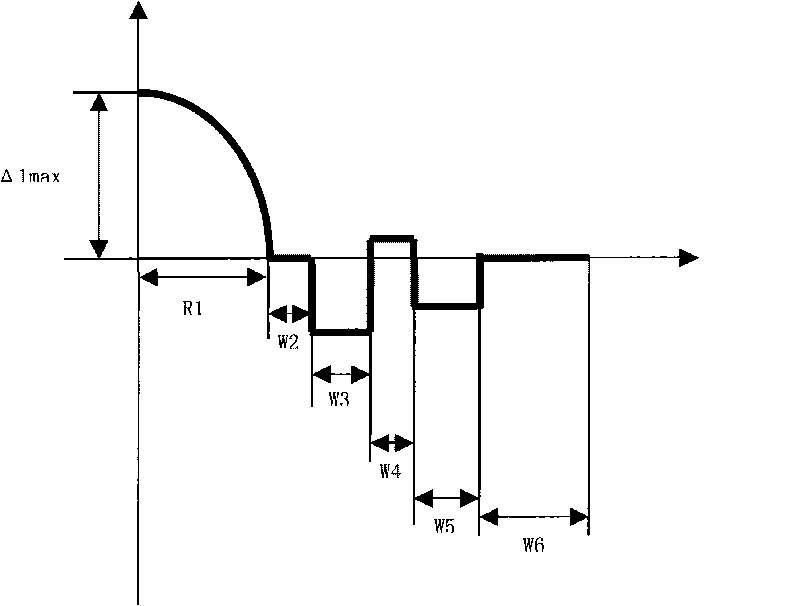

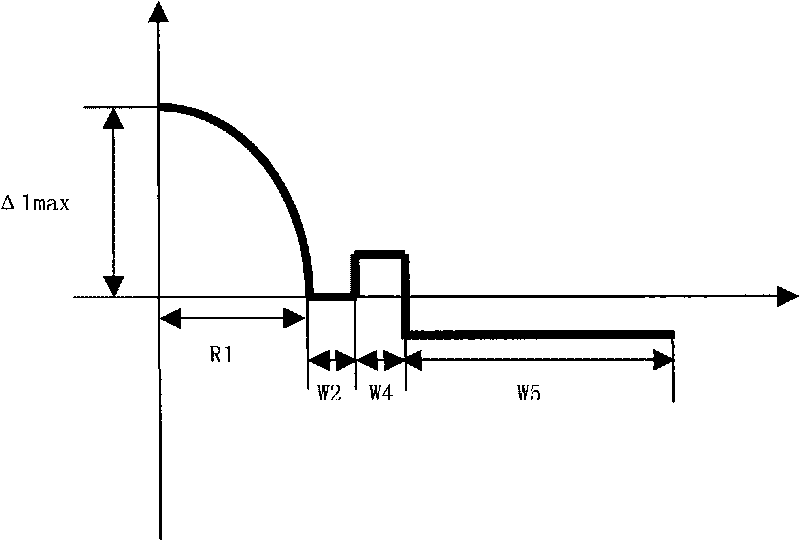

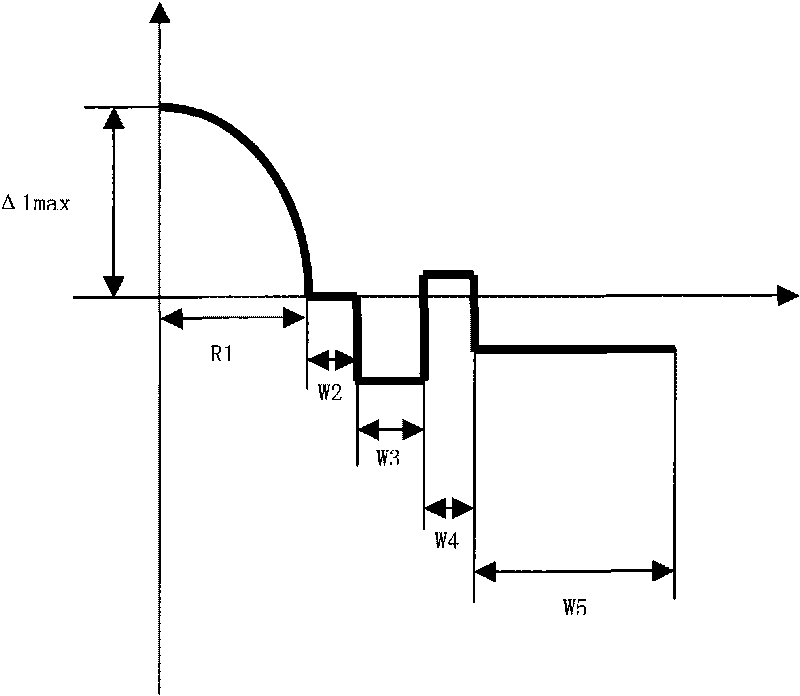

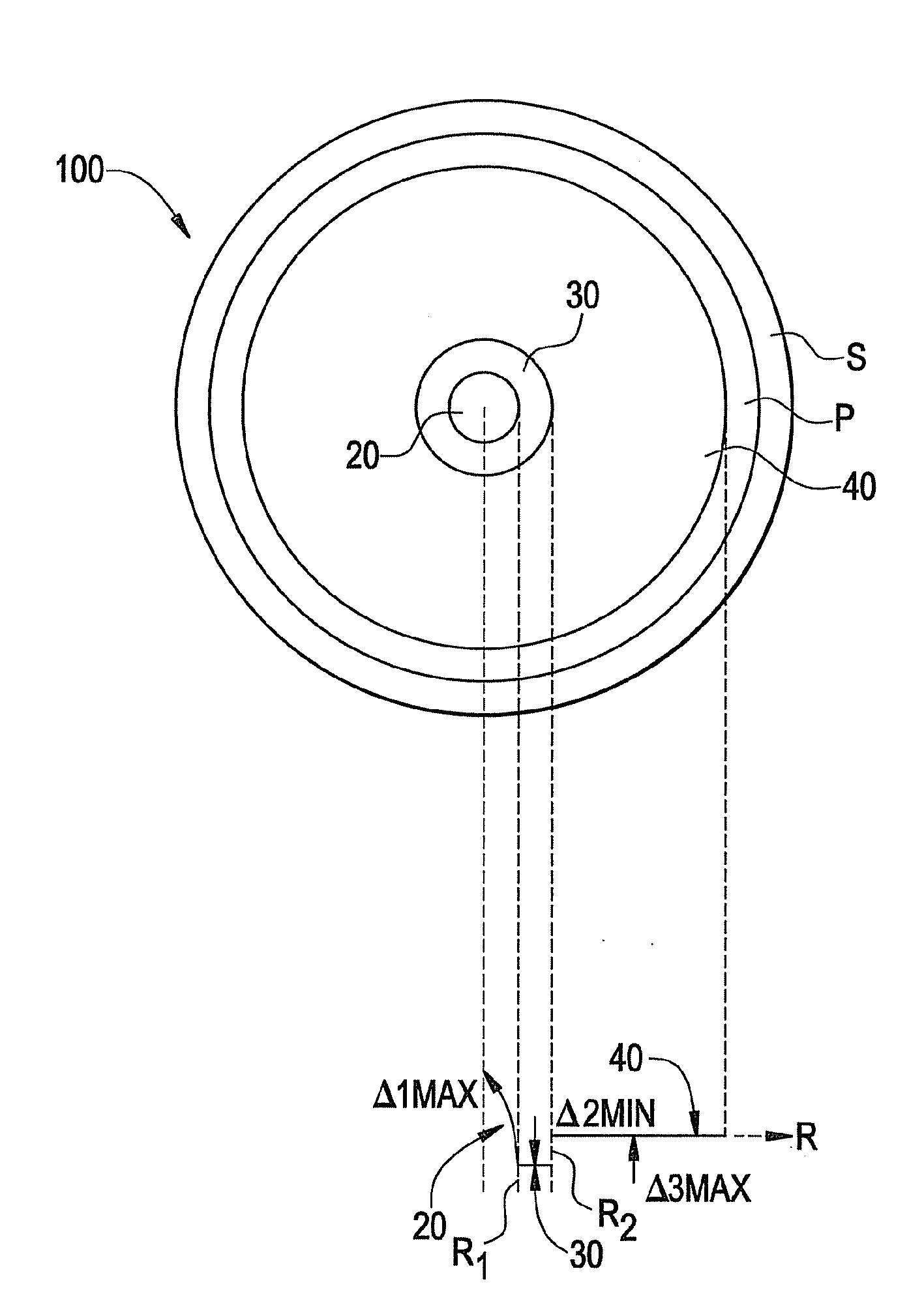

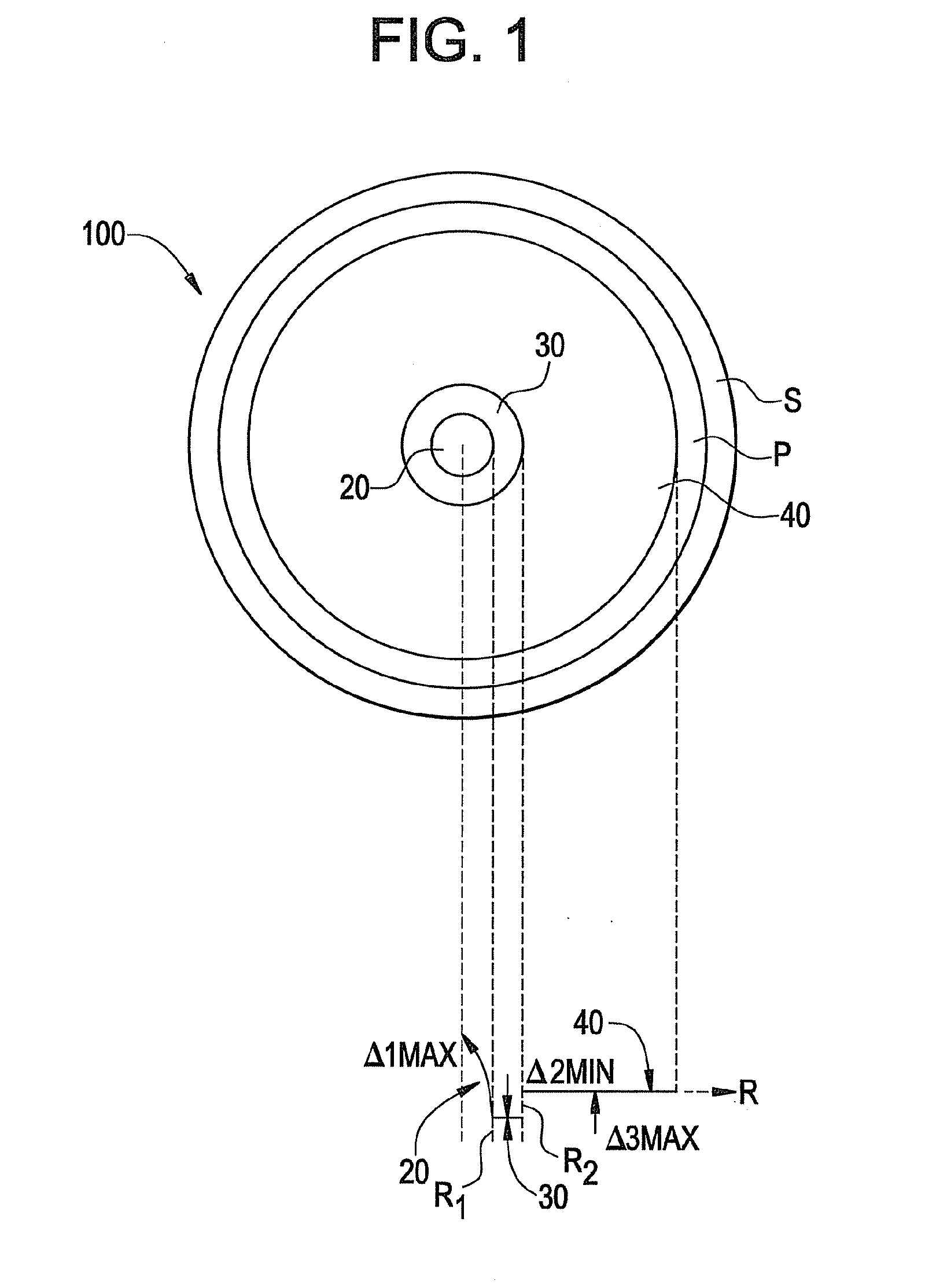

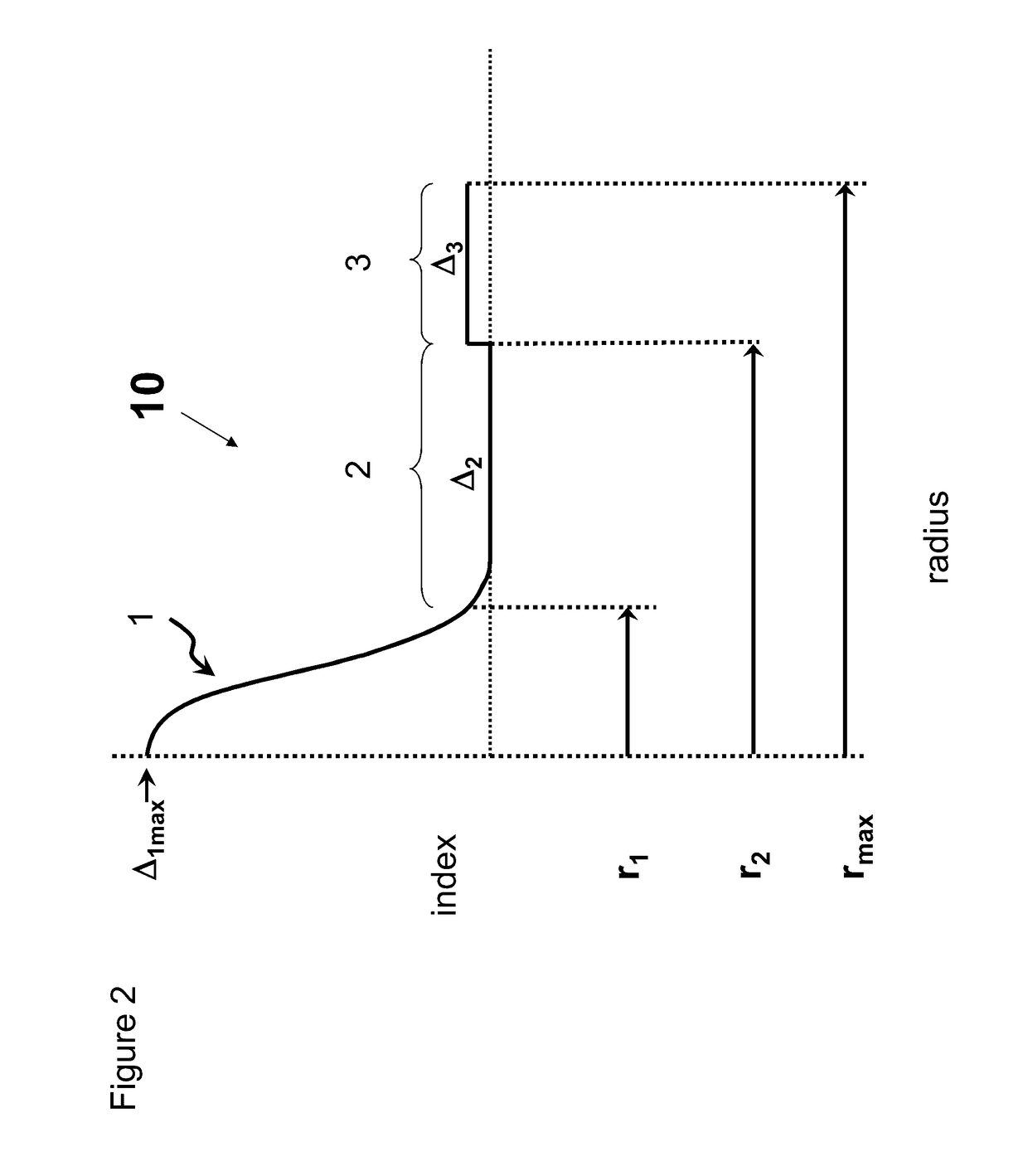

An optical fiber according to an embodiment of the present invention comprises: a glass core extending from a centerline to a radius R1 wherein R1 is greater than about 5 μm; a glass cladding surrounding and in contact with the core, the cladding comprising: (i) a first annular region extending from the radius R1 to a radius R2, the first annular region comprising a radial width, W2=R2−R1, (ii) a second annular region extending from the radius R2 to a radius R3, and comprising a radial width, W3=R3−R2, and (iii) a third annular region surrounding the second annular region and extending from the radius R3 to an outermost glass radius R4; wherein the core comprises a maximum relative refractive index, Δ1MAX, relative to the third annular region, and wherein Δ1MAX is greater than about 0.1% and less than about 0.3%; the first annular region has a refractive index delta Δ2(r) is less than about 0.025%; wherein the second annular region comprises a minimum relative refractive index, Δ3MIN, relative to the third annular region;wherein Δ1MAX>Δ2MAX>Δ3MIN, and Δ2MIN>Δ3MIN<0; andwherein the core and the cladding provide a fiber with cable cutoff less than 1500 nm, and an effective area at 1550 nm greater than 95 μm2 and bend loss of ≦0.5 dB / turn on a 20 mm diameter mandrel.

Owner:CORNING INC

Bending-resistant large core diameter high numerical aperture multimode fiber

ActiveUS20130279868A1Convenient lightingReduce configuration costsOptical fibre with multilayer core/claddingOptical waveguide light guideHigh numerical apertureRelative refractive index

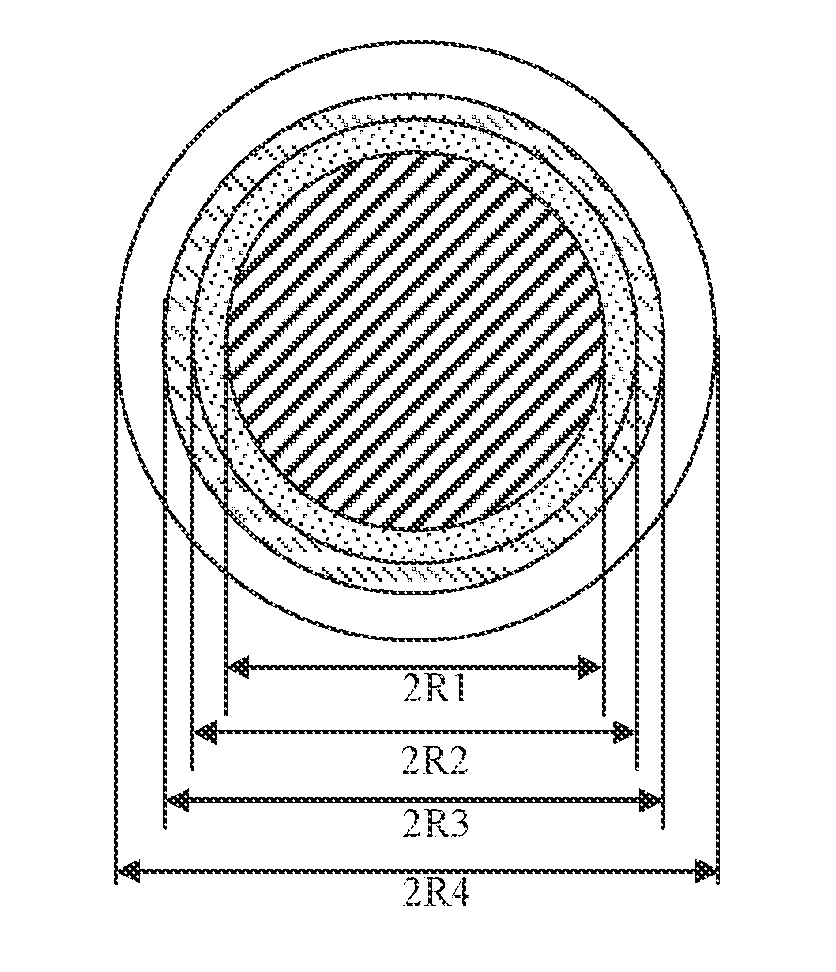

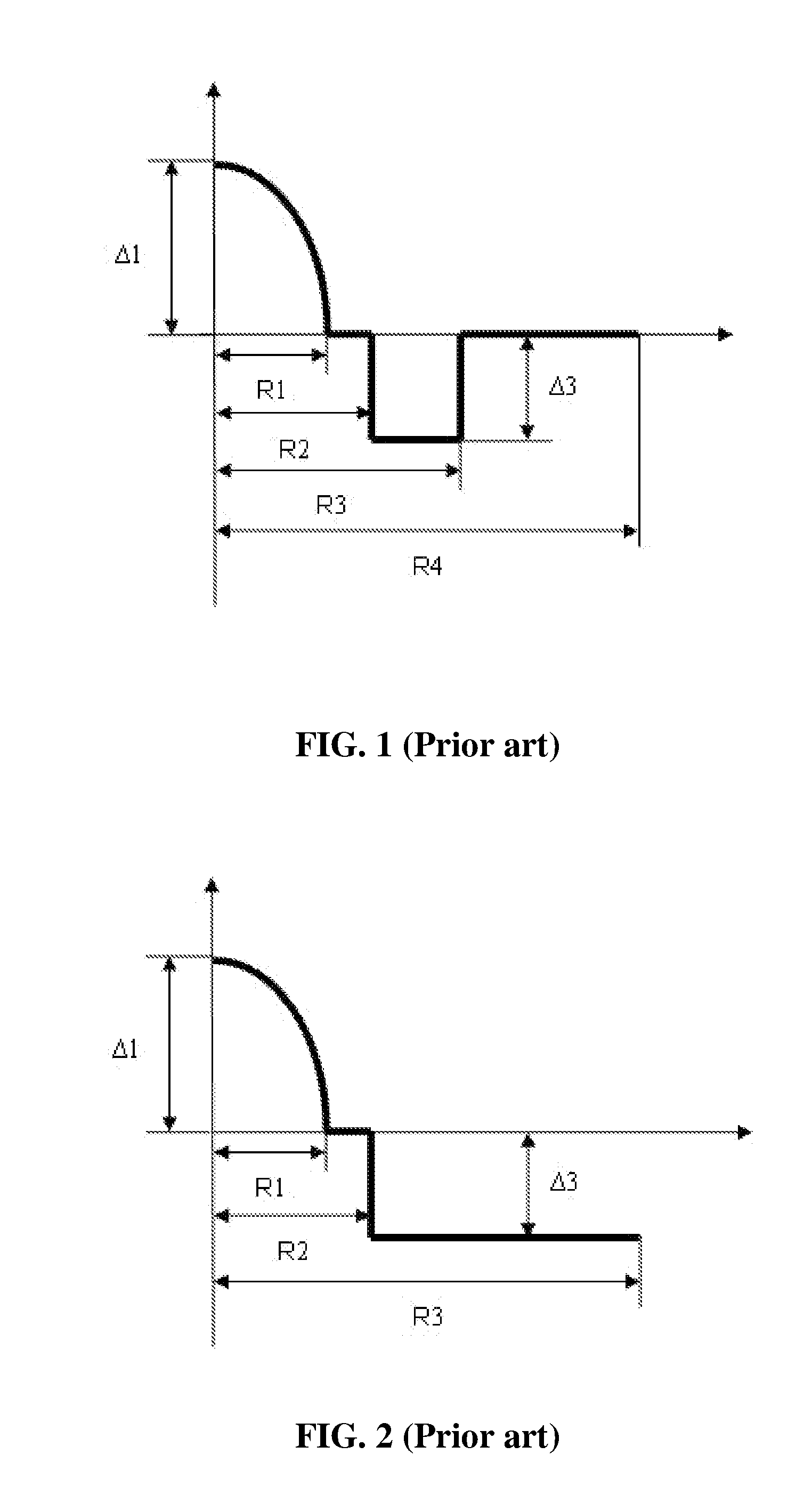

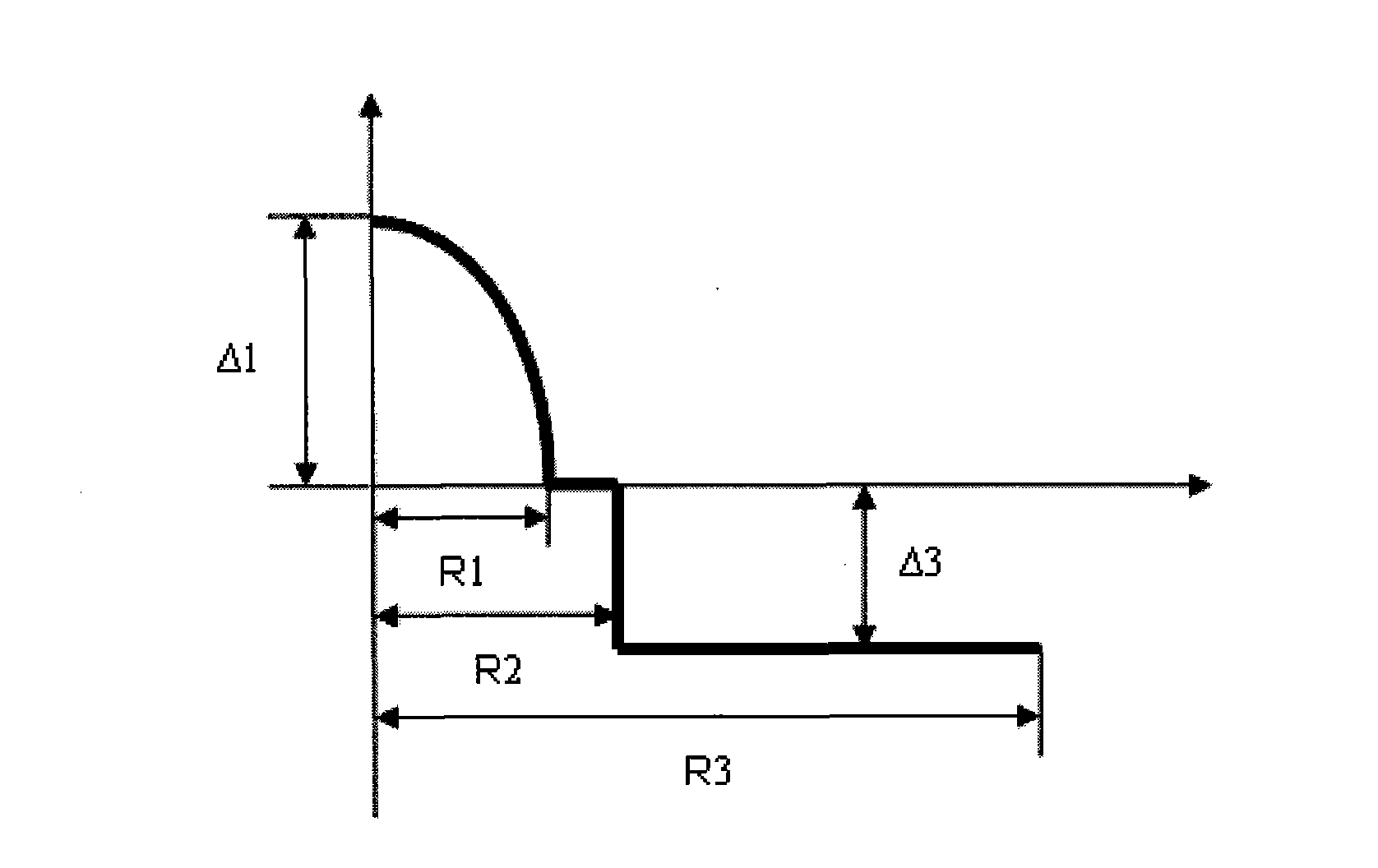

A bending-resistant large core diameter high numerical aperture multimode fiber includes a core and a cladding surrounding the core. The core has a radius R1 in a range of 28 to 50 microns, a refractive index profile of a parabola shape with α being in a range of 1.9 to 2.2, and a maximum relative refractive index difference Δ1% max being in a range of 1.9% to 2.5%. The cladding includes an inner cladding and / or a trench cladding, and an outer cladding disposed from the inner to the outer in sequence. The radius R2 of the inner cladding is in a range of 28 to 55 microns, and the relative refractive index difference Δ2% is −0.1% to 0.1%. The radius R3 of the trench cladding is in a range of 28 to 60 microns, and the relative refractive index difference Δ3% is in a range of −0.15% to −0.8%.

Owner:EVERPRO TECH COMPANY

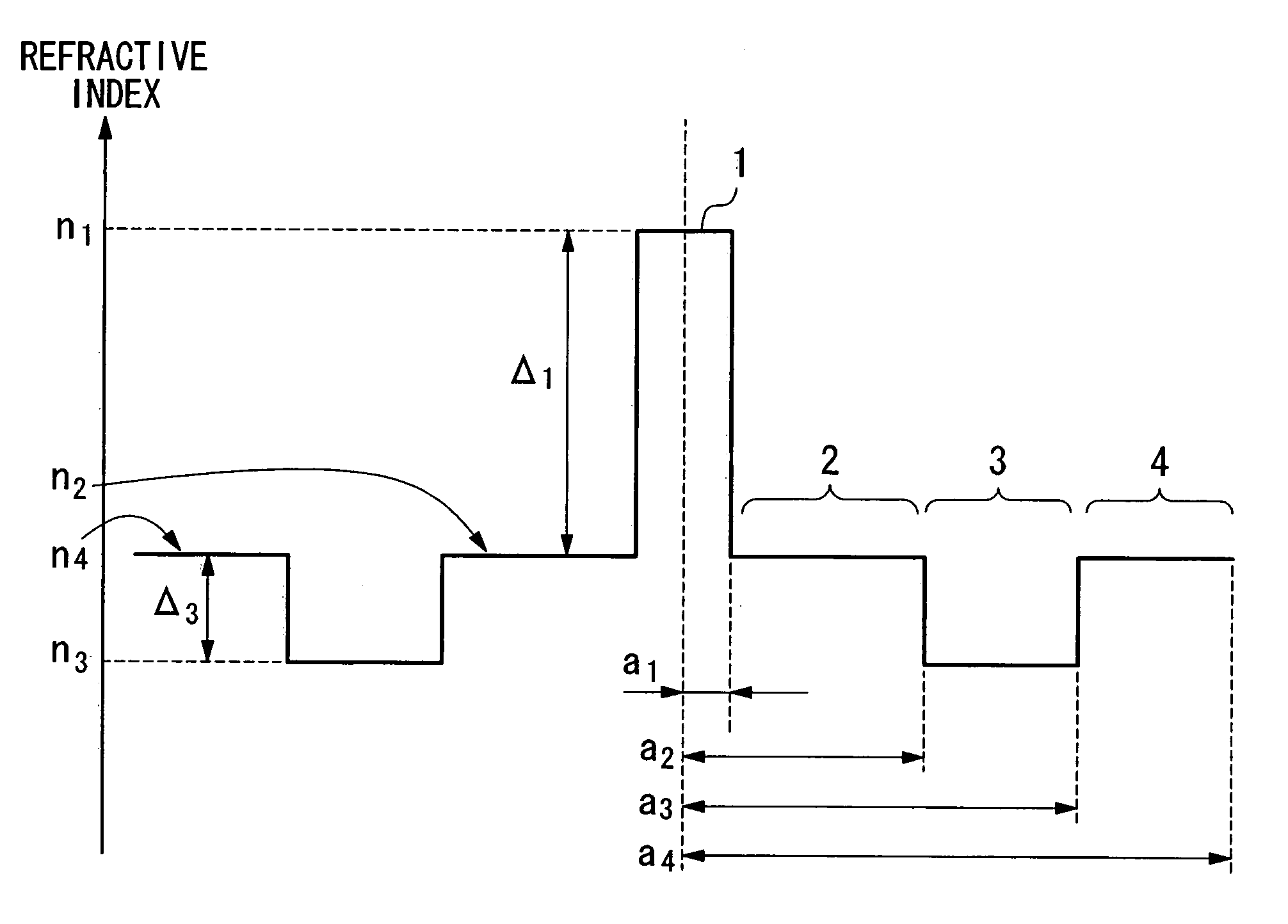

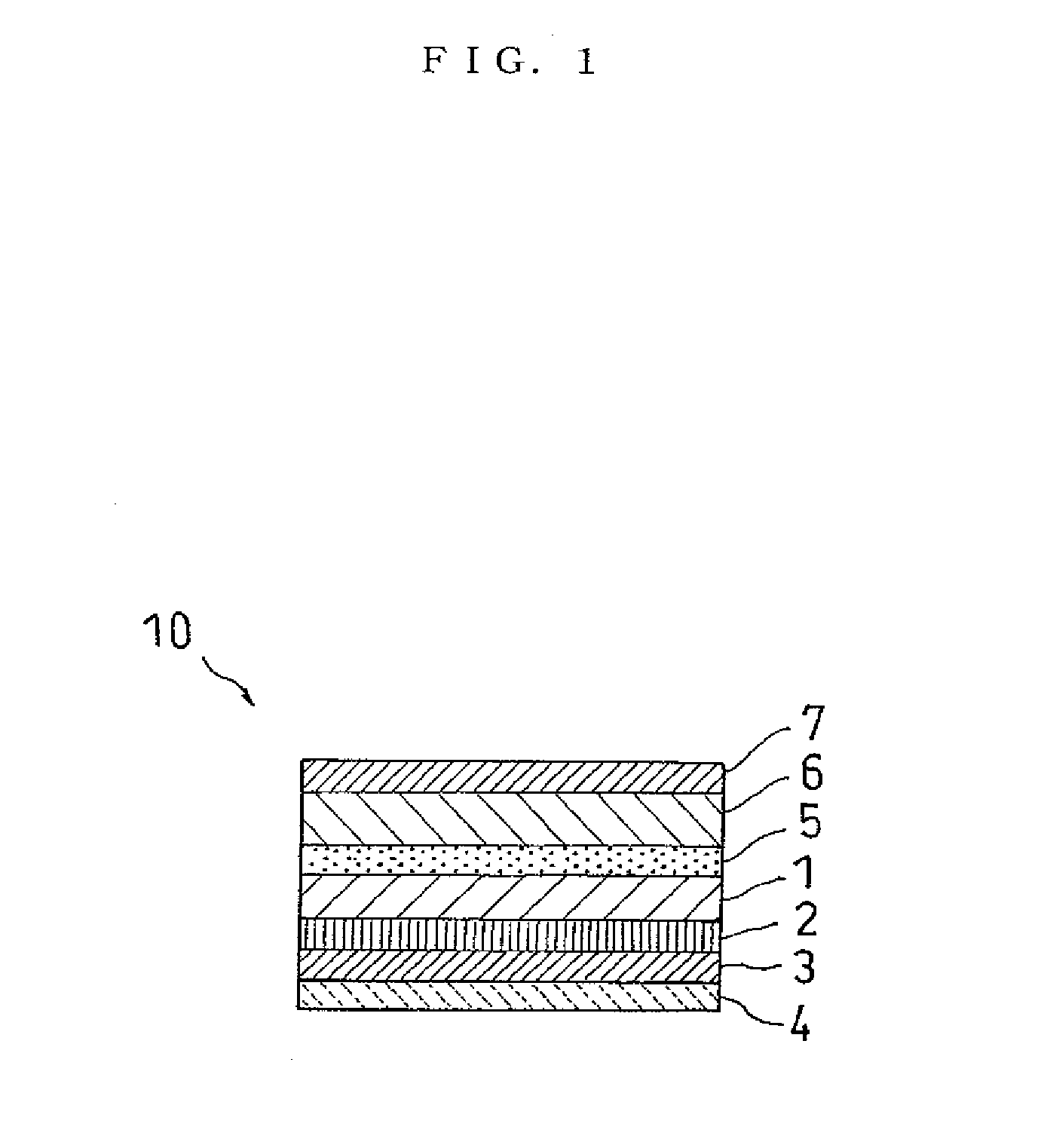

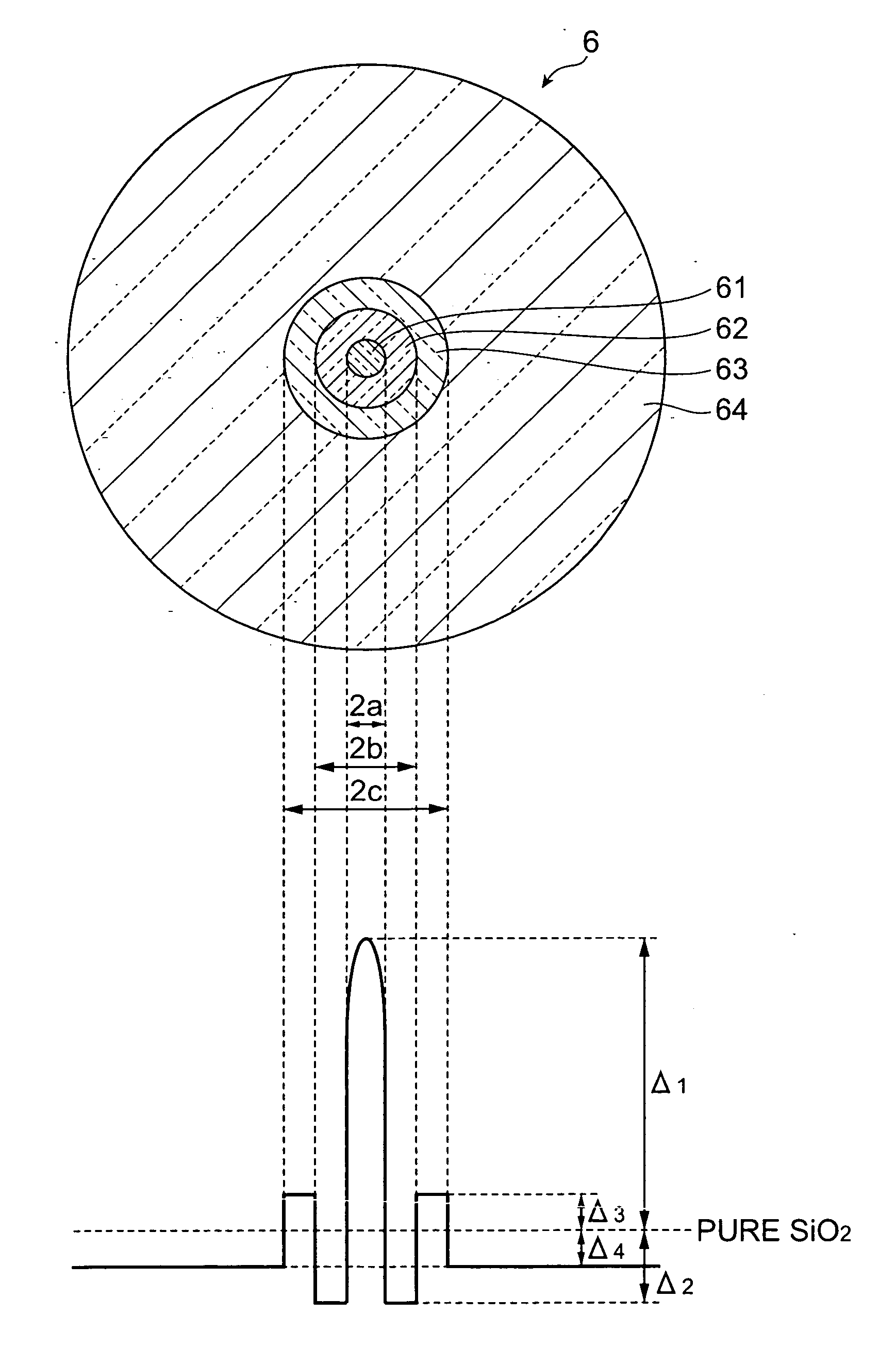

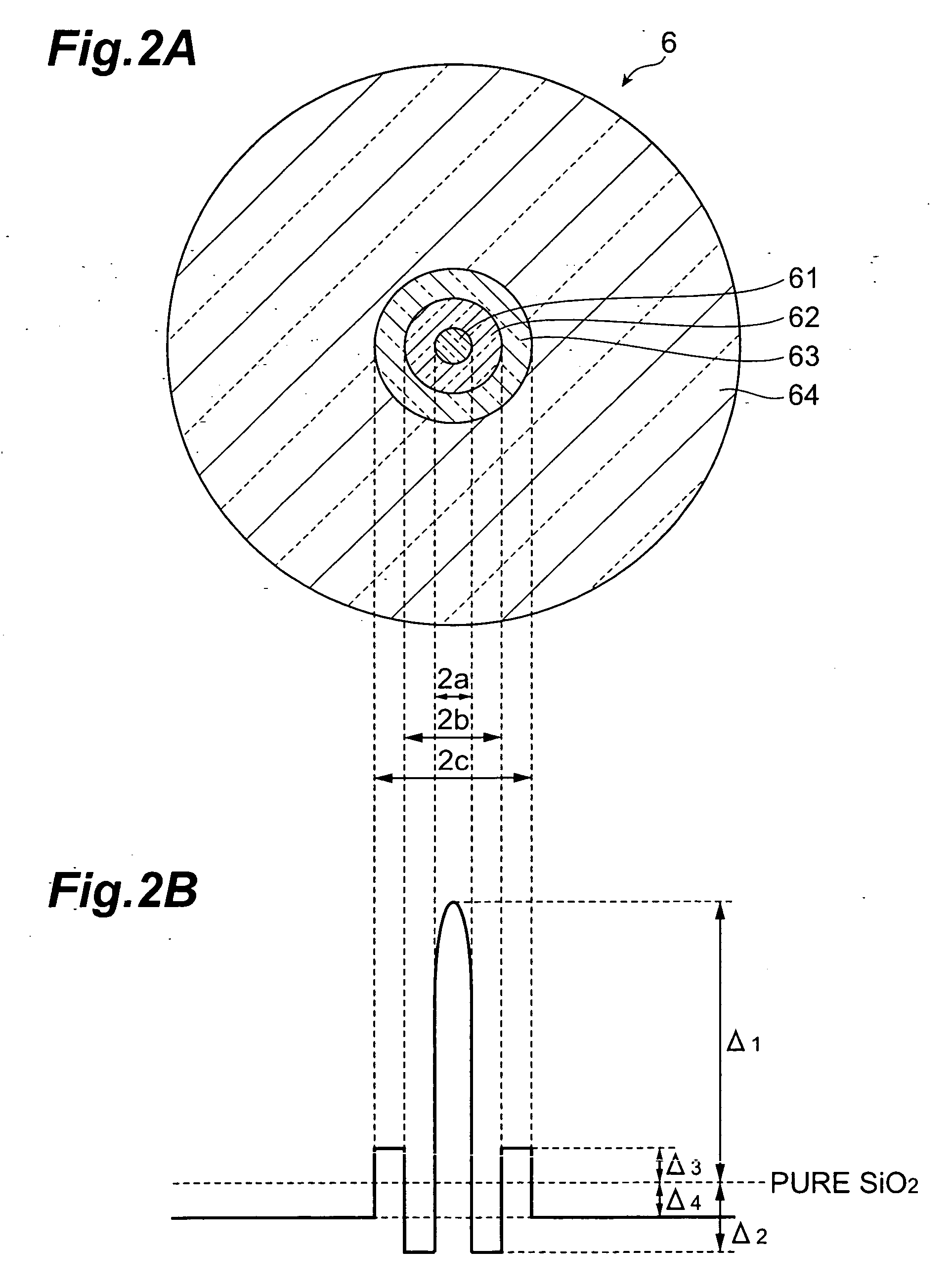

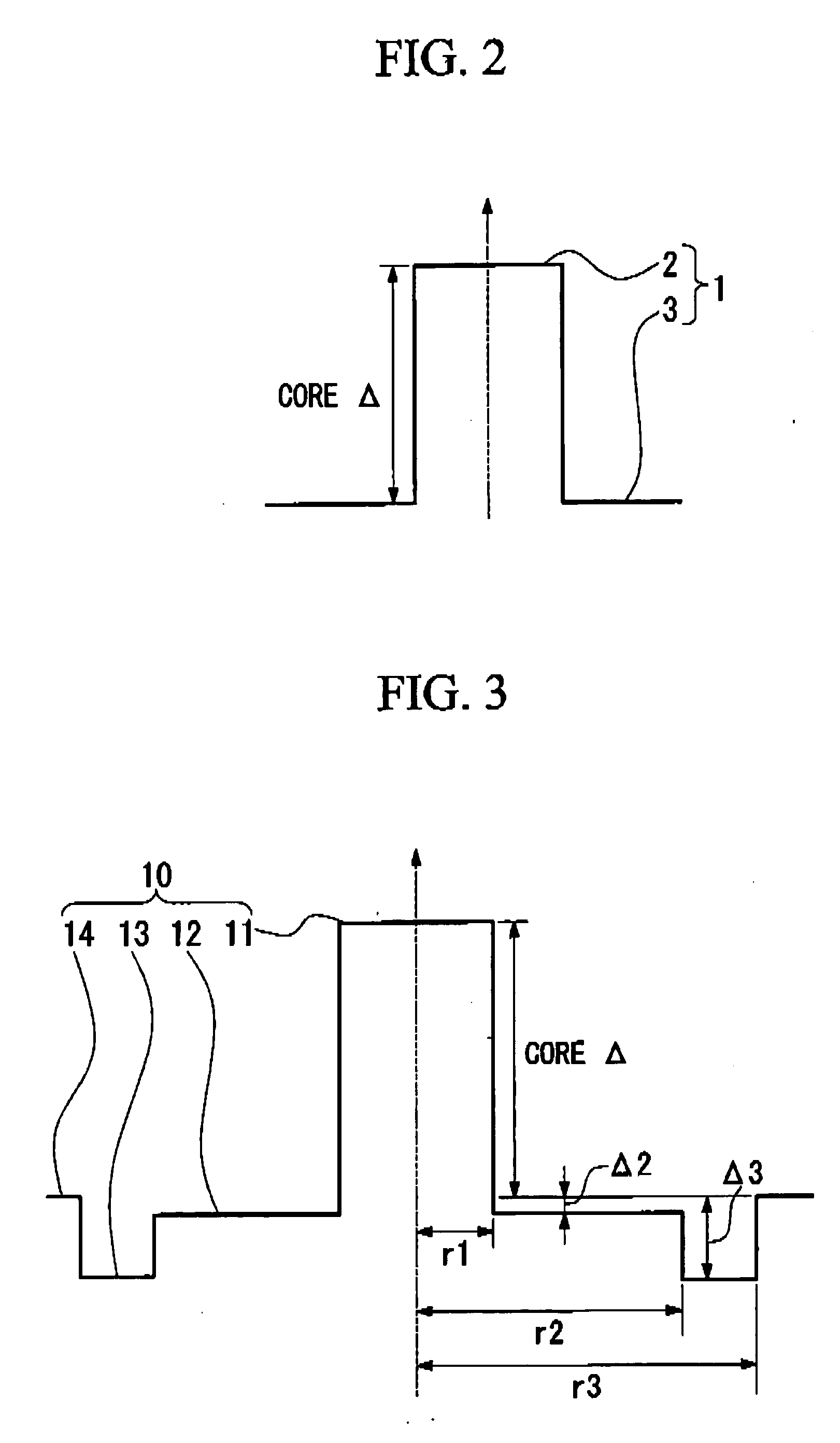

Optical fiber

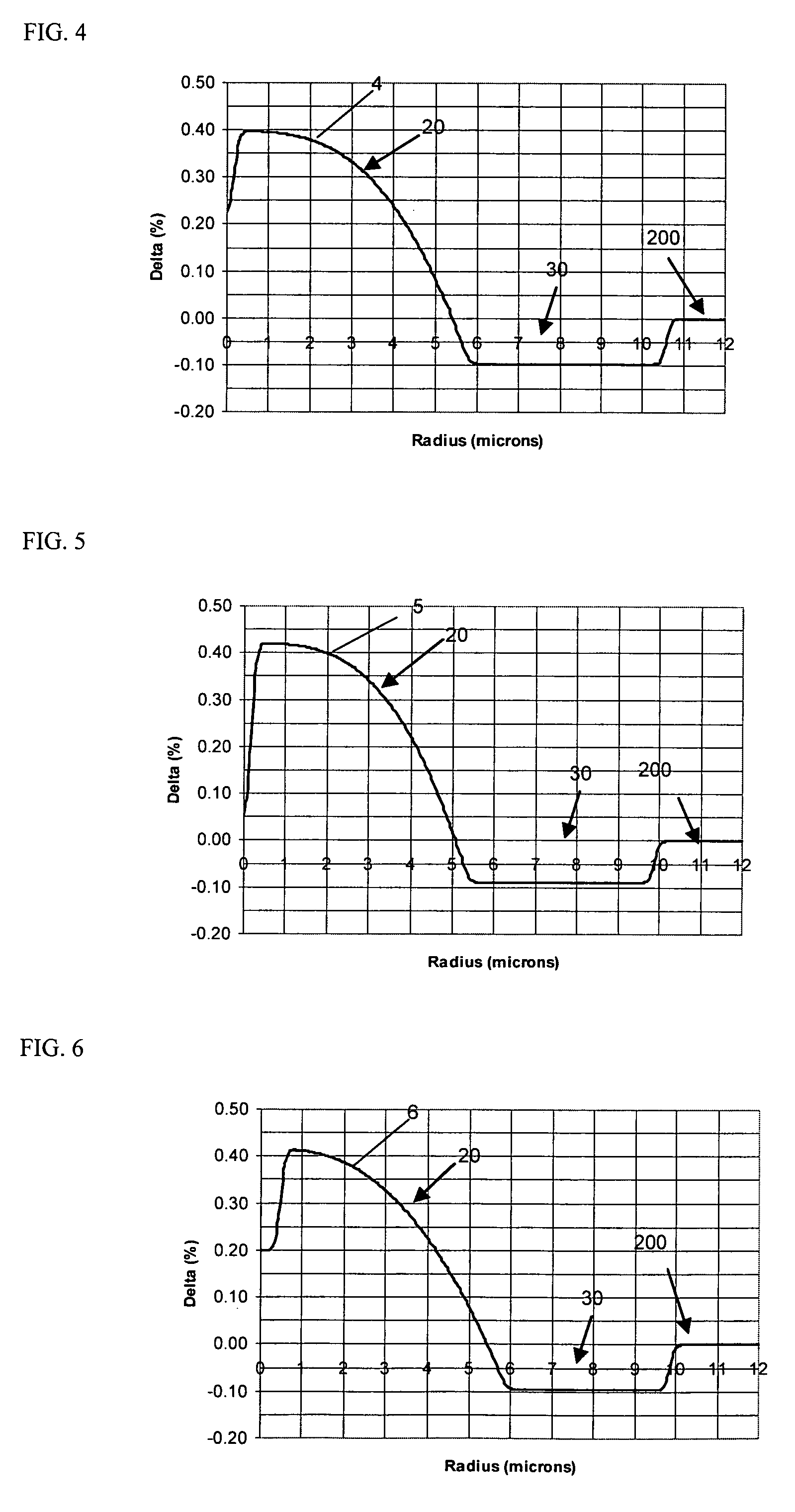

ActiveUS7164835B2Lower refractive indexReduce dispersionOptical fibre with multilayer core/claddingOptical waveguide light guideRelative refractive indexMaterials science

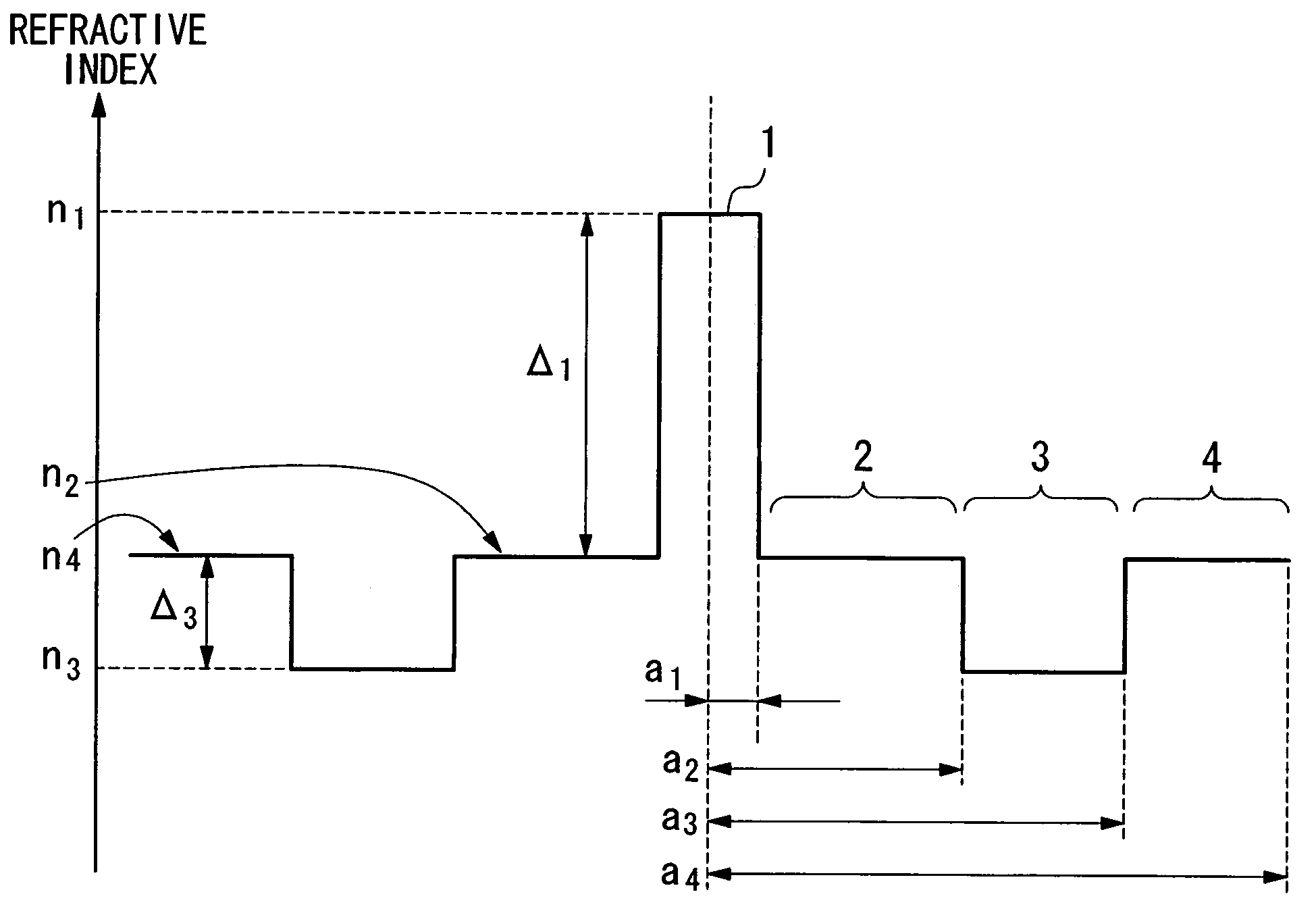

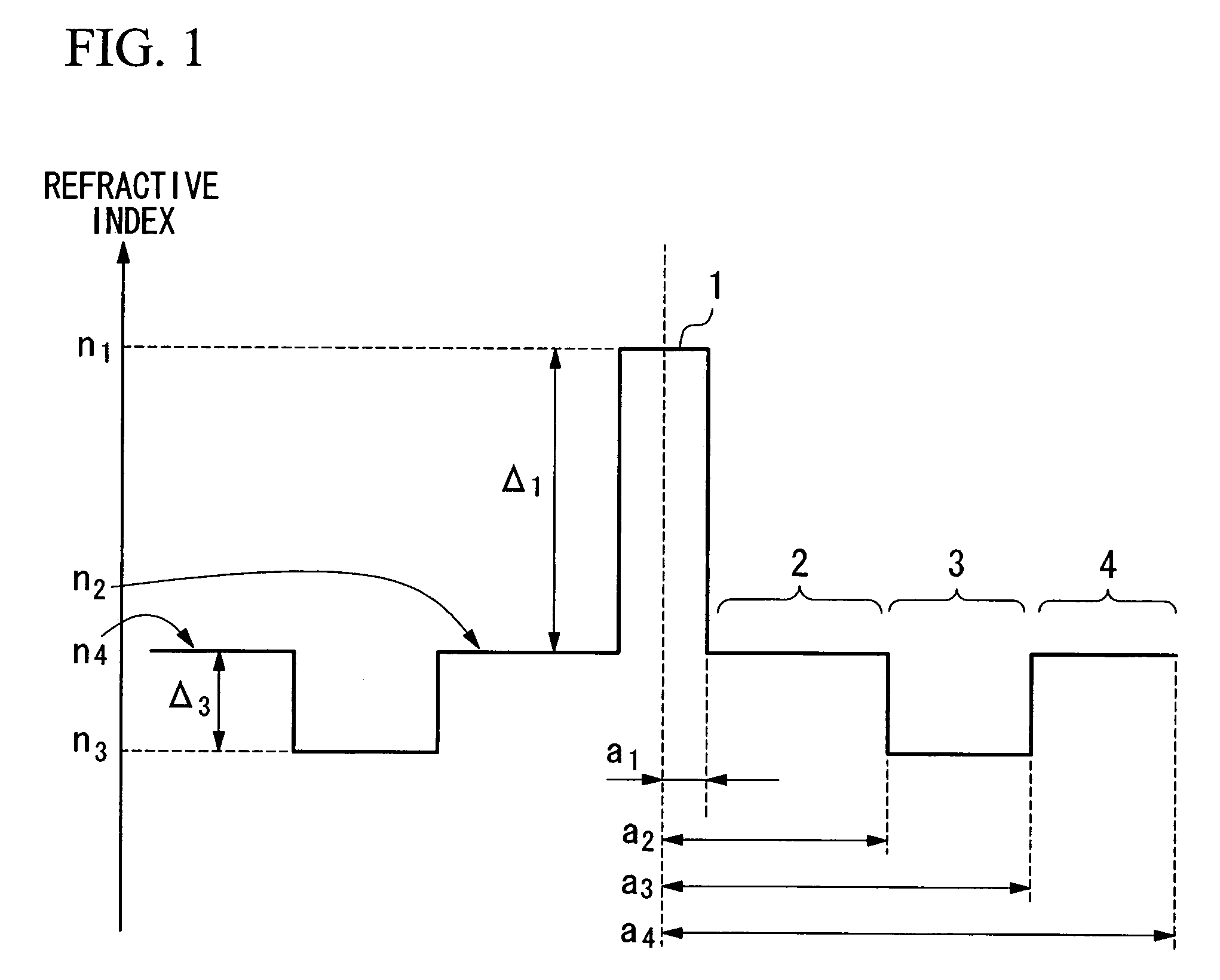

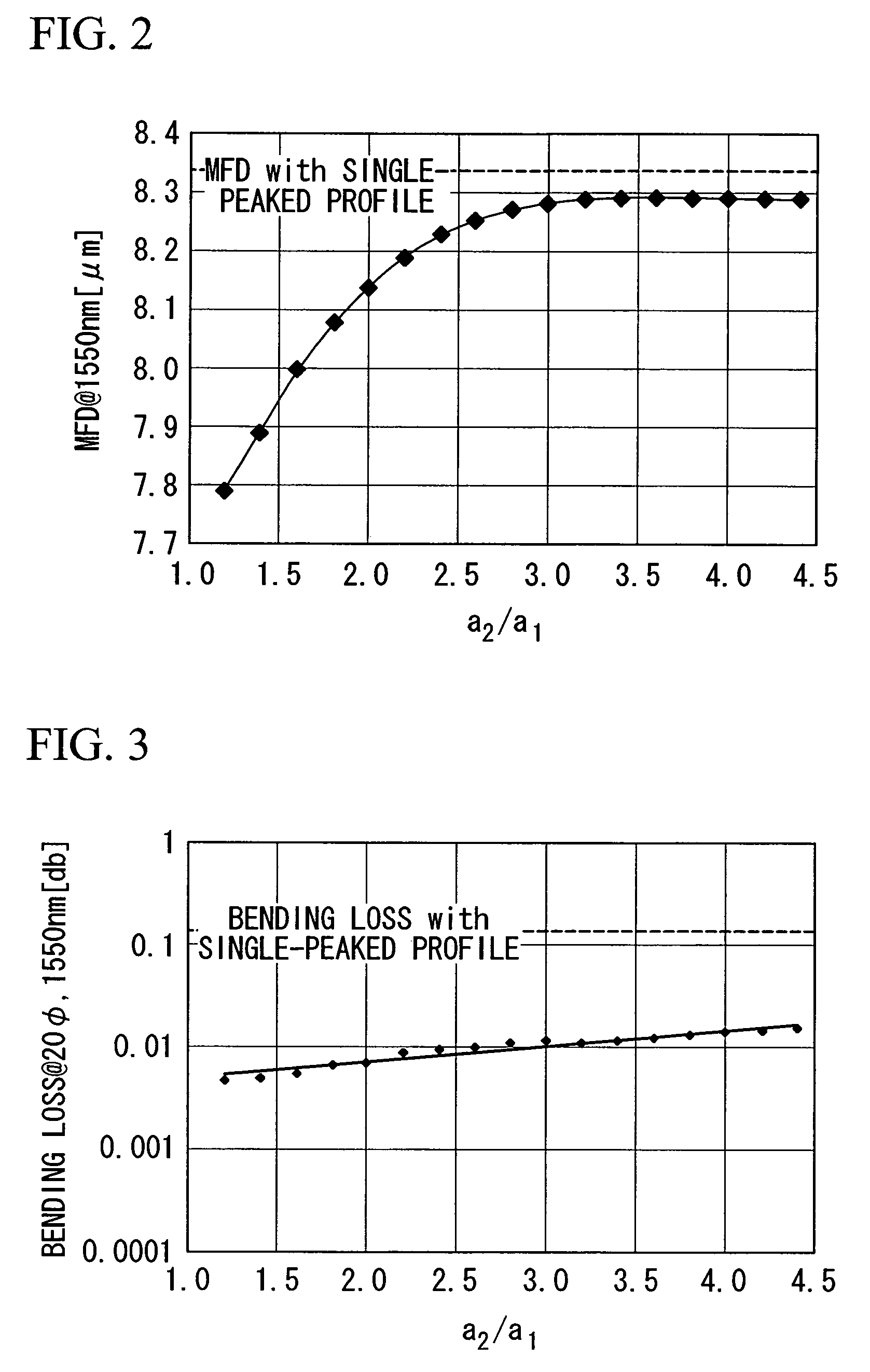

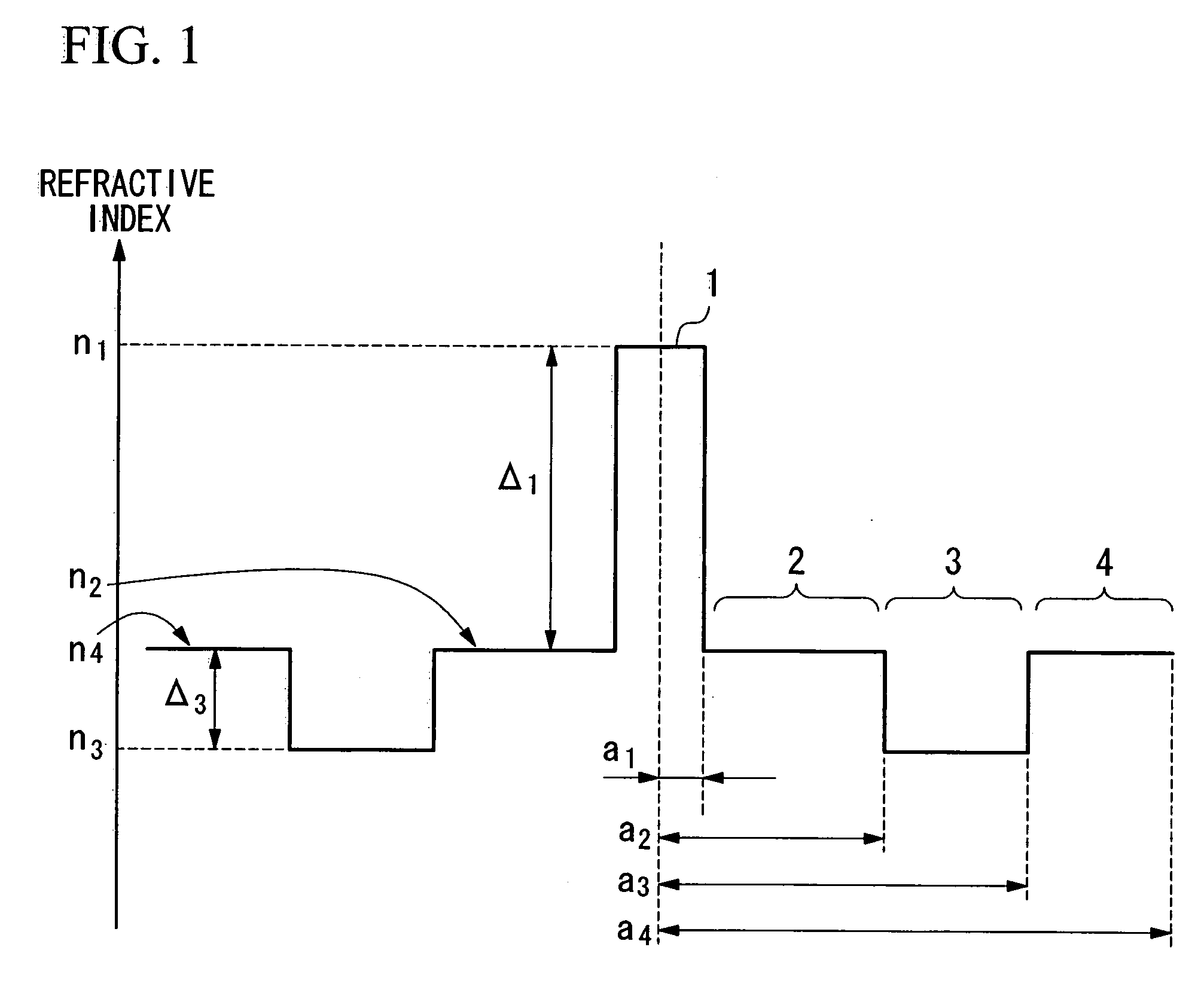

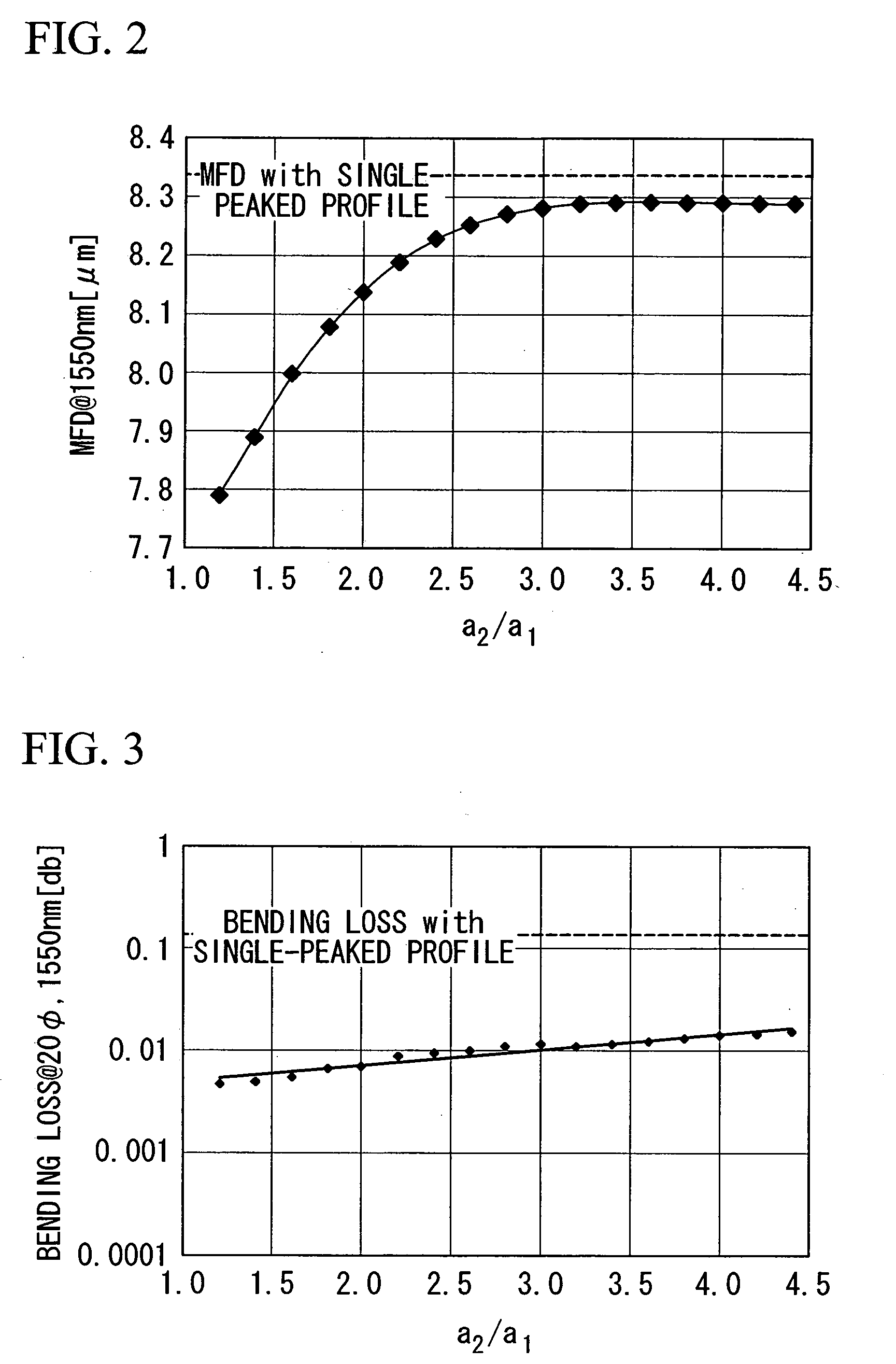

An optical fiber includes: a core at a center; a first cladding layer; a second cladding layer; and a third cladding layer. A maximum refractive index of the core is greater than any of maximum refractive indices of the first cladding layer, the second cladding layer, and the third cladding layer, and the maximum refractive index of the second cladding layer is smaller than any of the maximum refractive indices of the first and the third cladding layer. Additionally, a ratio of a2 / a1 is not less than about 2.5 and not more than about 4.5, where a1 represents the radius of the core, and a2 represents the radius of an outer periphery of the first cladding layer, and a relative refractive index difference of the core with respect to a maximum refractive index of the third cladding layer is not less than 0.20% and not more than 0.70%.

Owner:FUJIKURA LTD

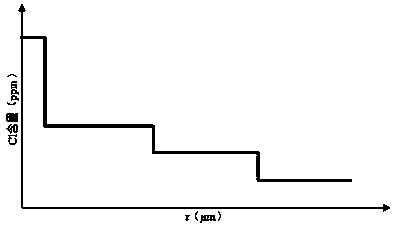

Alkali and fluorine doped optical fiber

ActiveUS7088900B1Reduce decreaseOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingDopantSilica measurement

Disclosed is an optical fiber having a core of SiO2 doped with fluorine and an alkali metal oxide dopant. The alkali metal oxide is selected from the group consisting of K, Na, Li, Cs and Rb and is provided in amount of at least 20 ppm wt. %. The fiber has an inner cladding surrounding the core, which also includes fluorine. A relative refractive index of the inner cladding (Δ2%), measured relative to pure silica, is preferably between −0.39% and −0.7%. The fiber preferably exhibits attenuation at 1550 nm of less than or equal to 0.178 dB / km.

Owner:CORNING INC

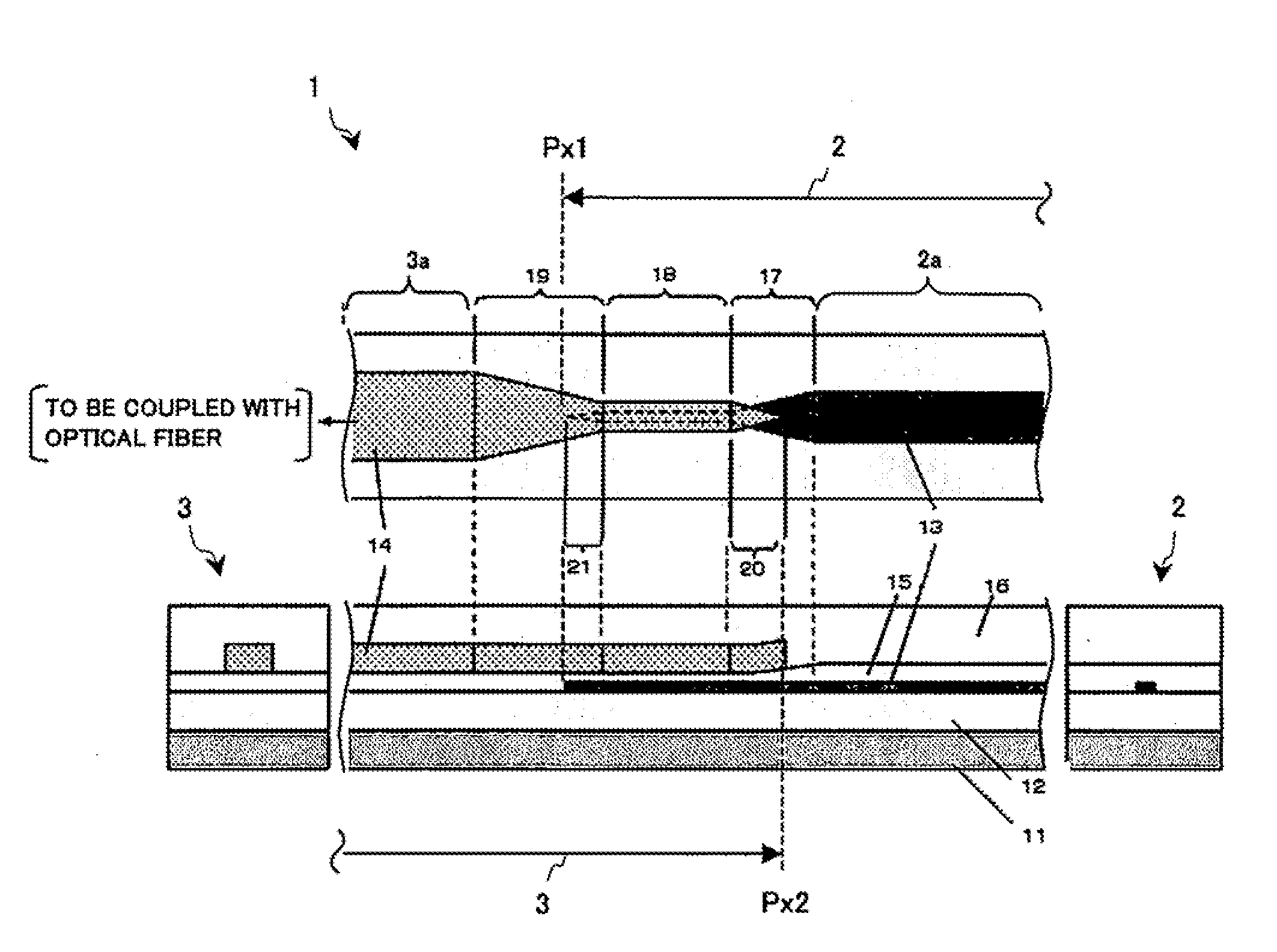

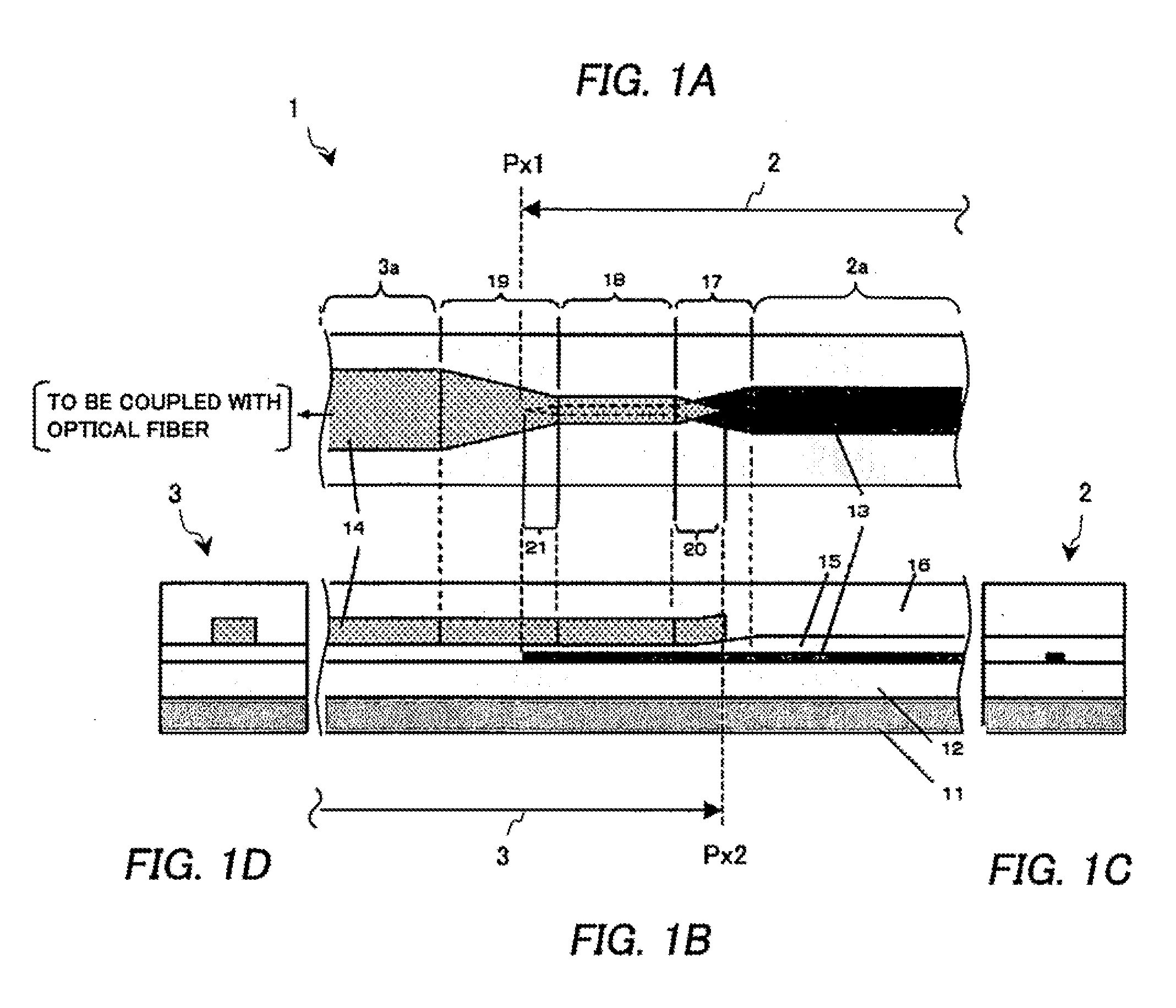

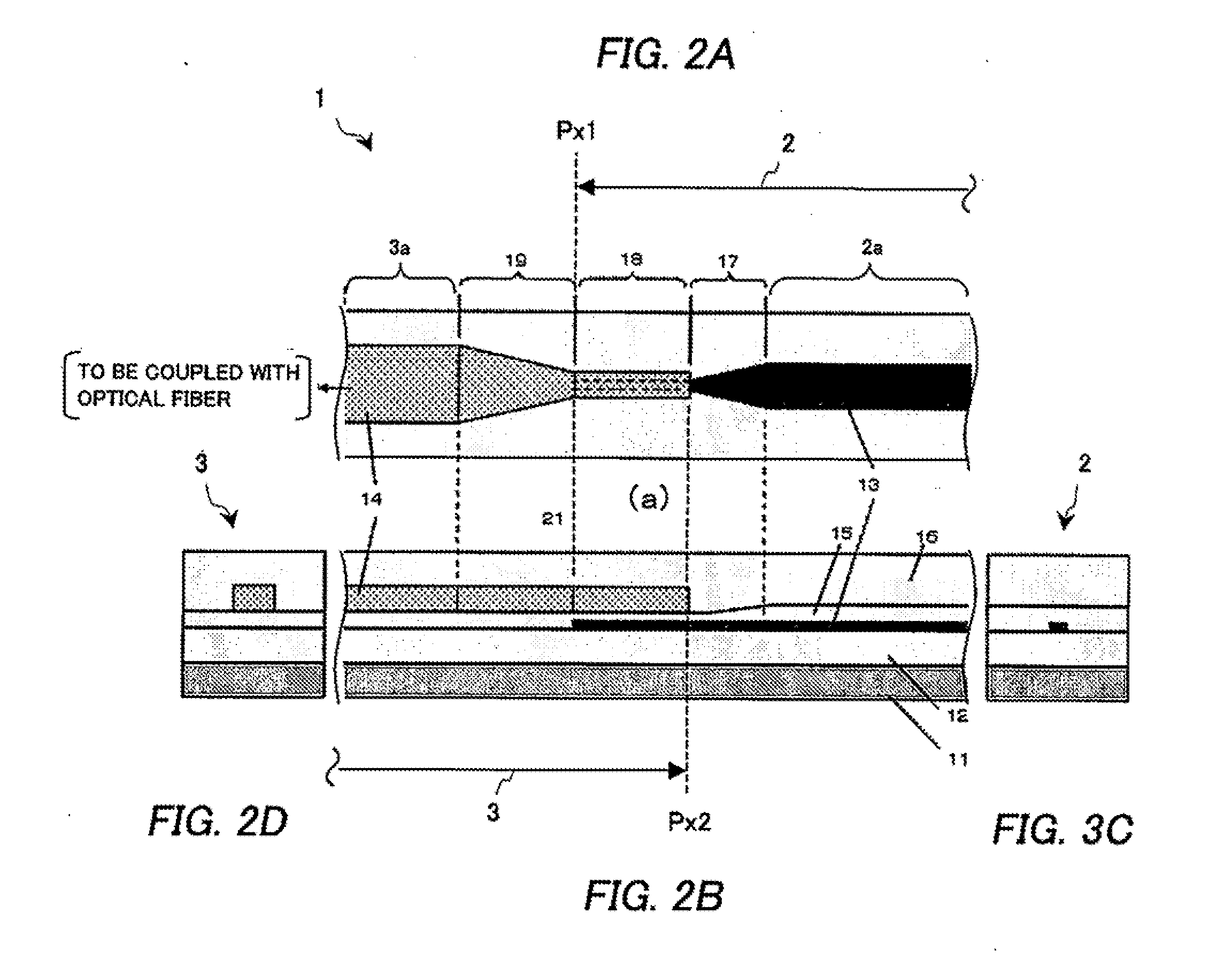

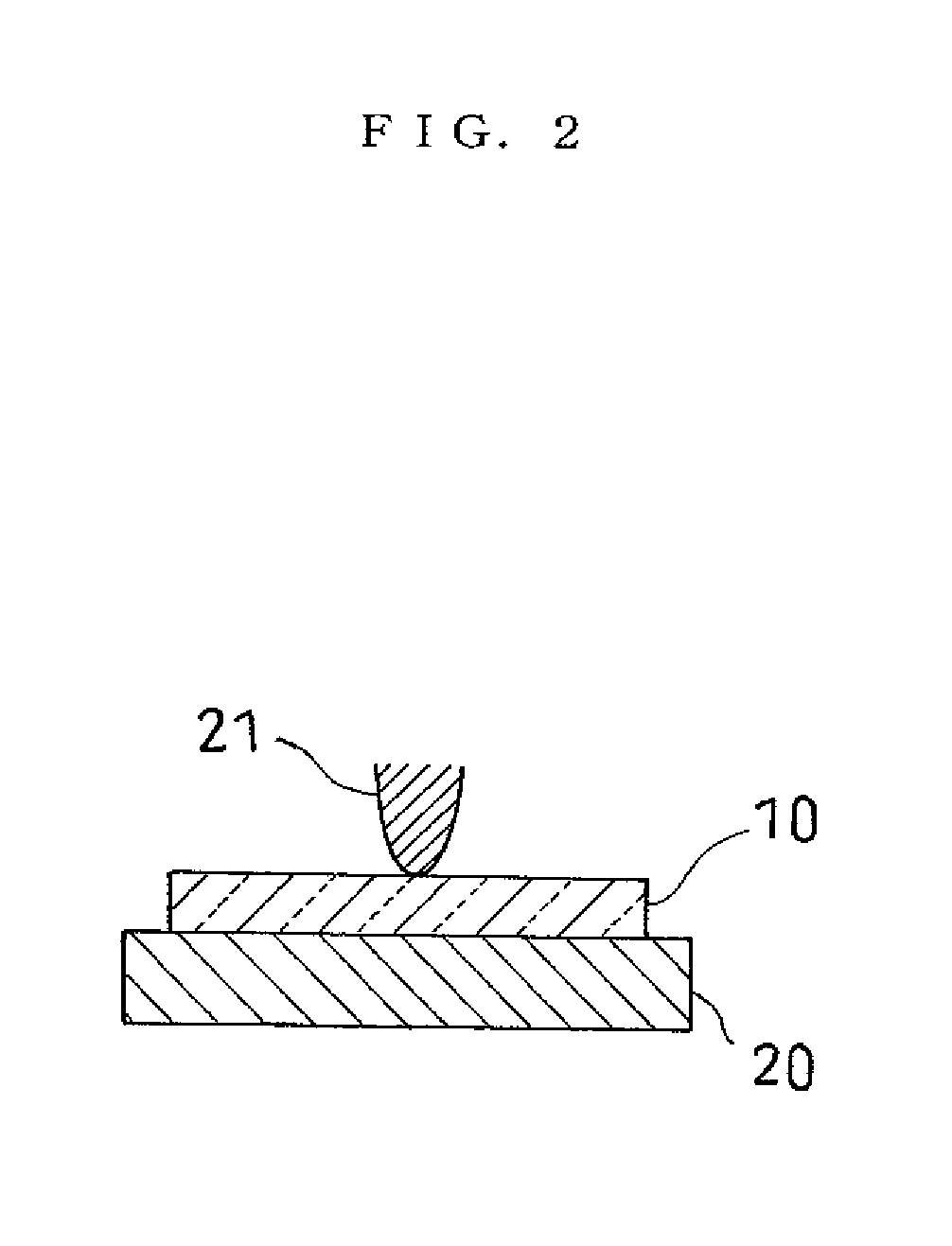

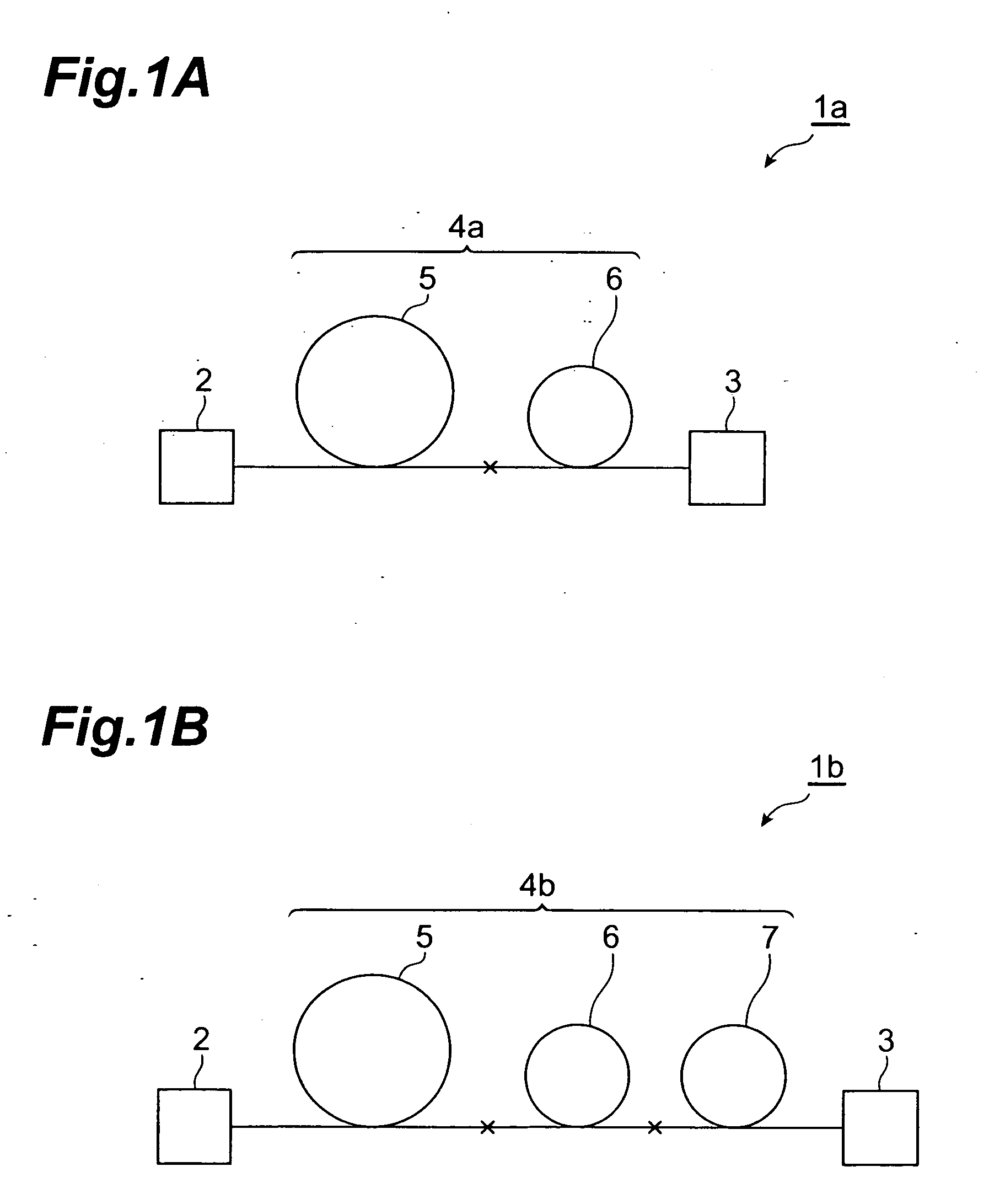

Optical waveguide and spot size converter using the same

ActiveUS20100040327A1Improve efficiencyEfficient couplingCoupling light guidesOptical waveguide light guideRelative refractive indexWaveguide

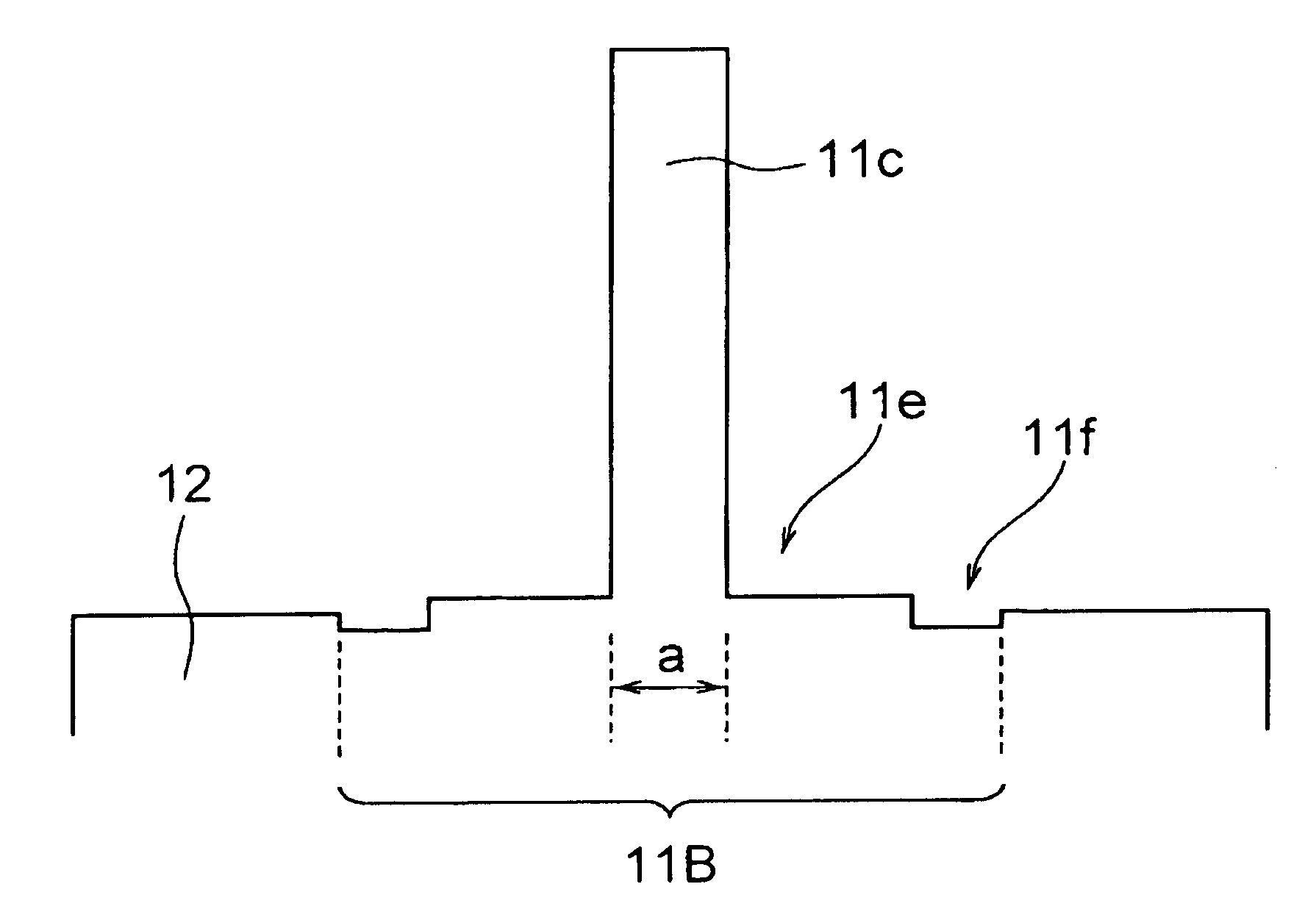

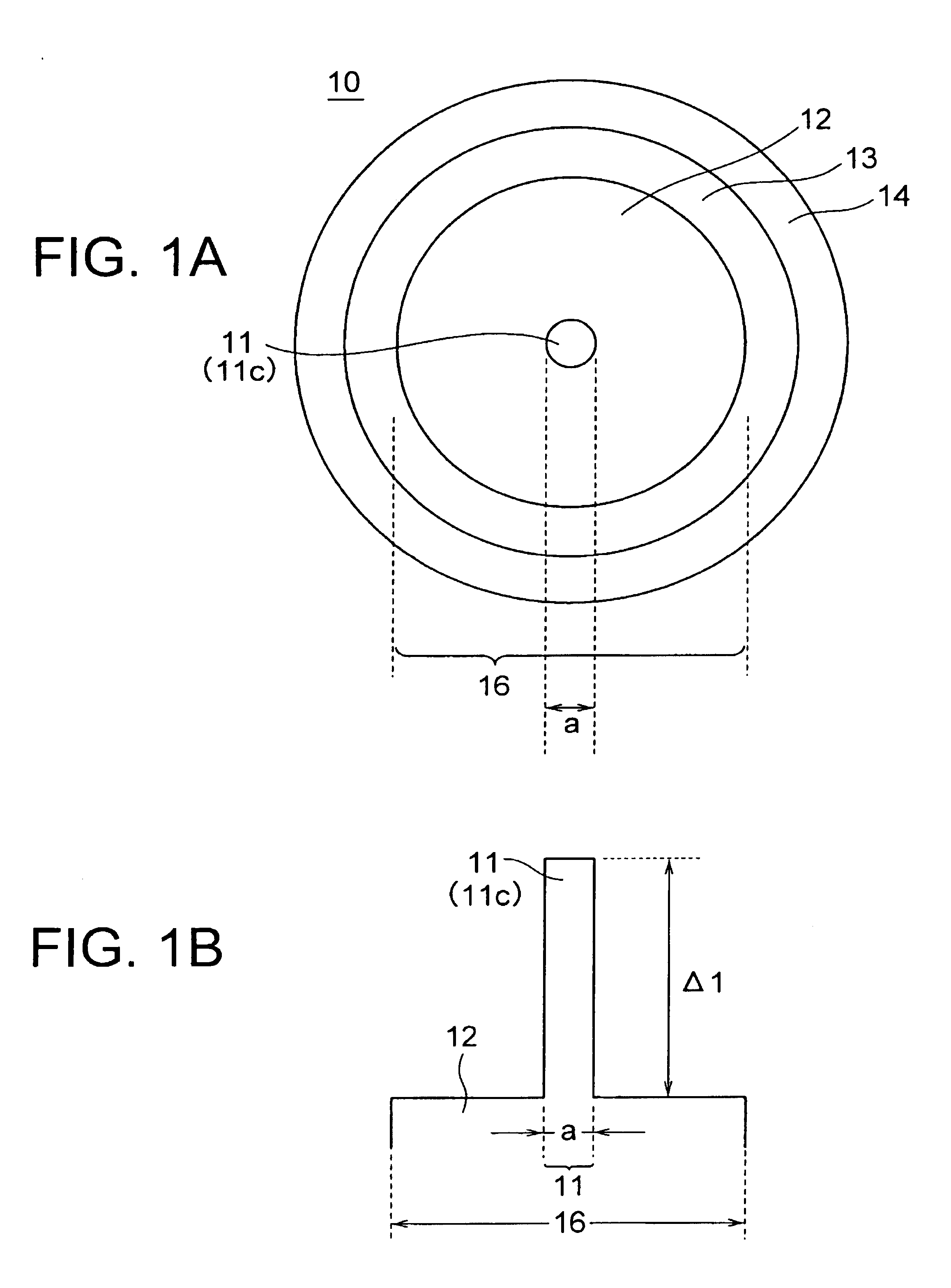

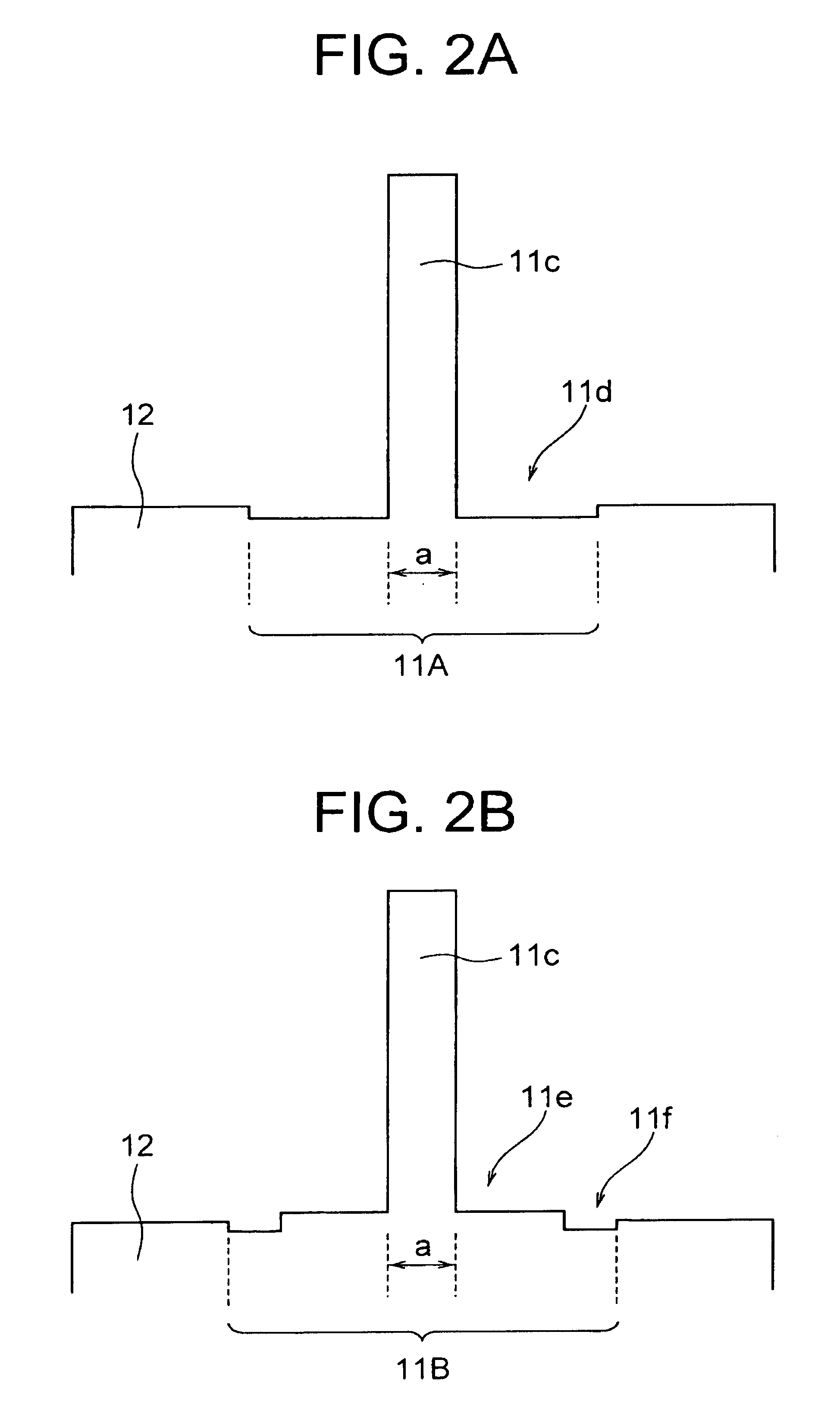

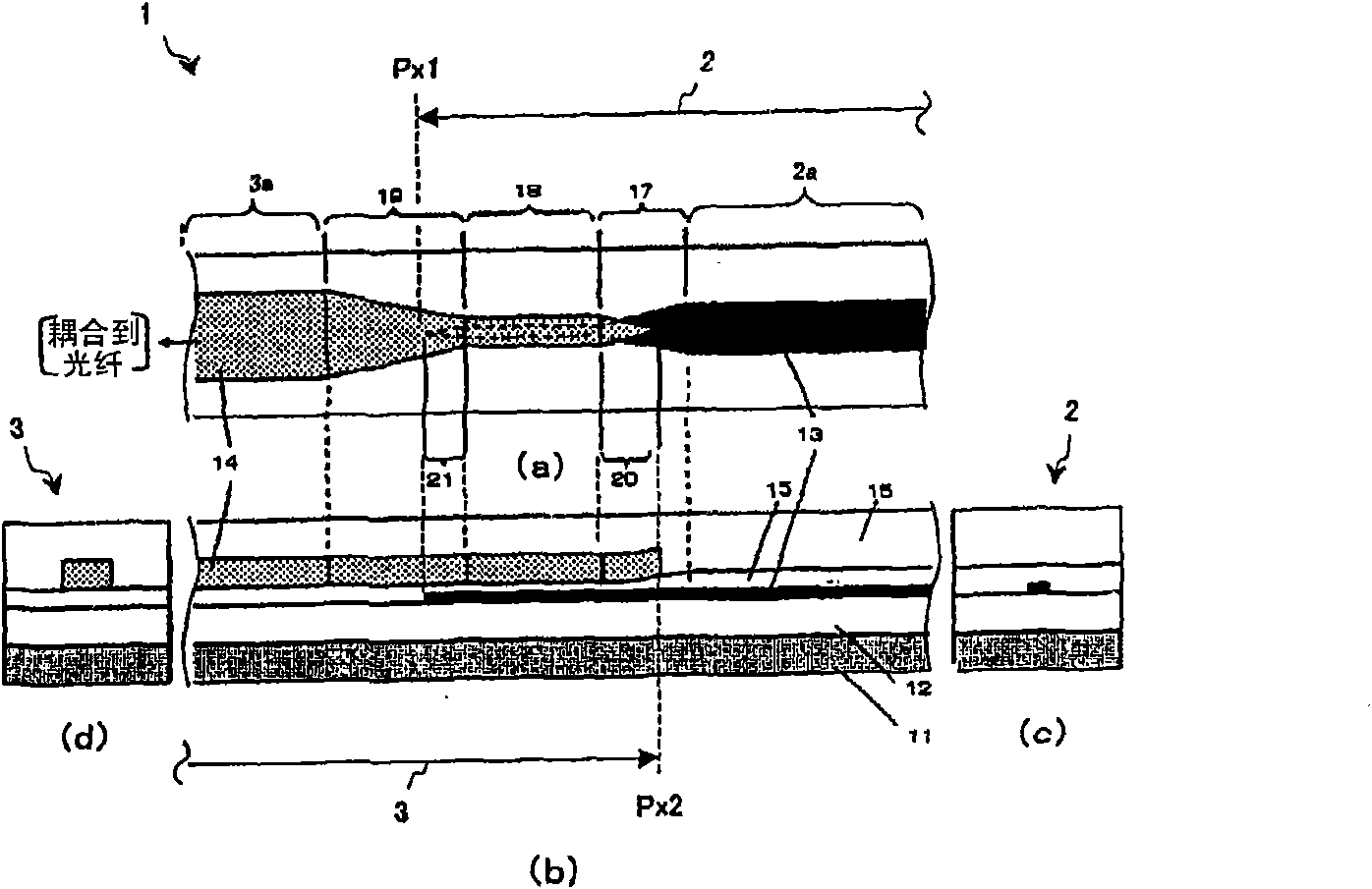

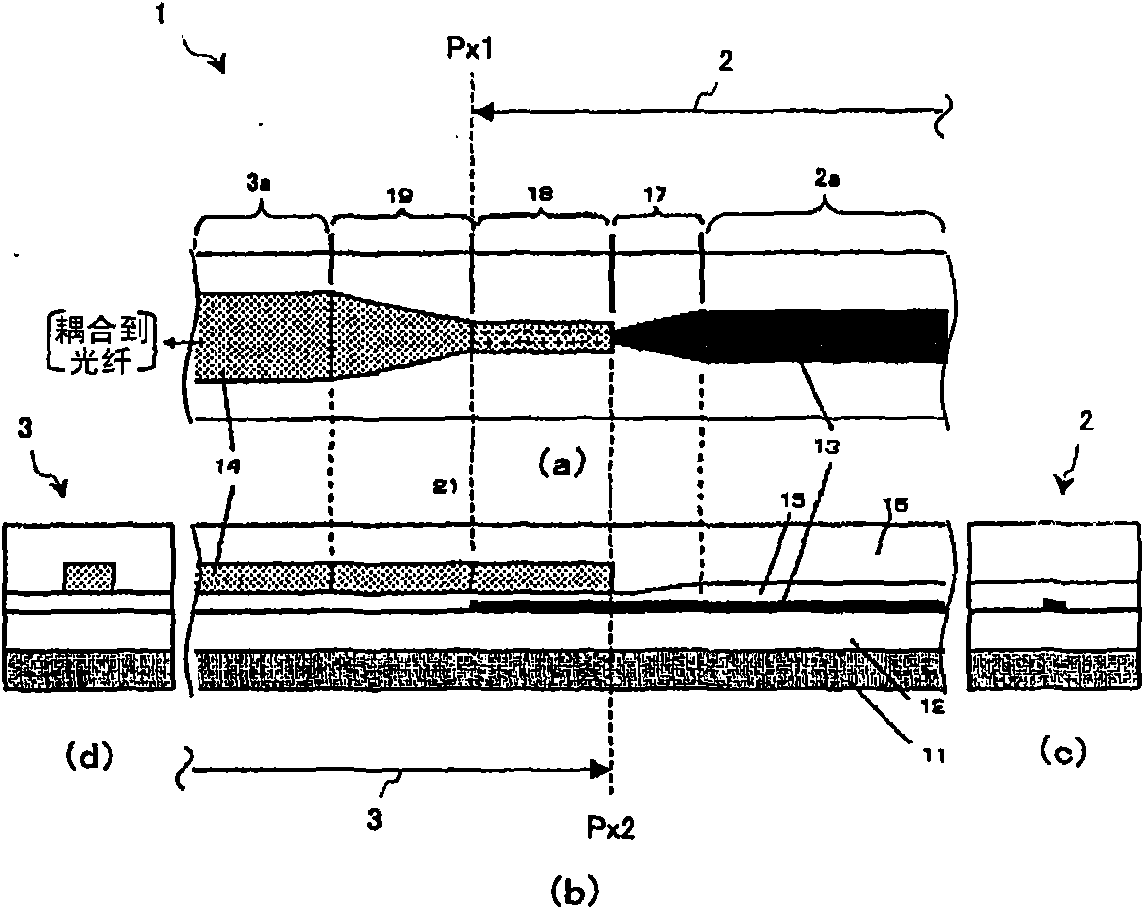

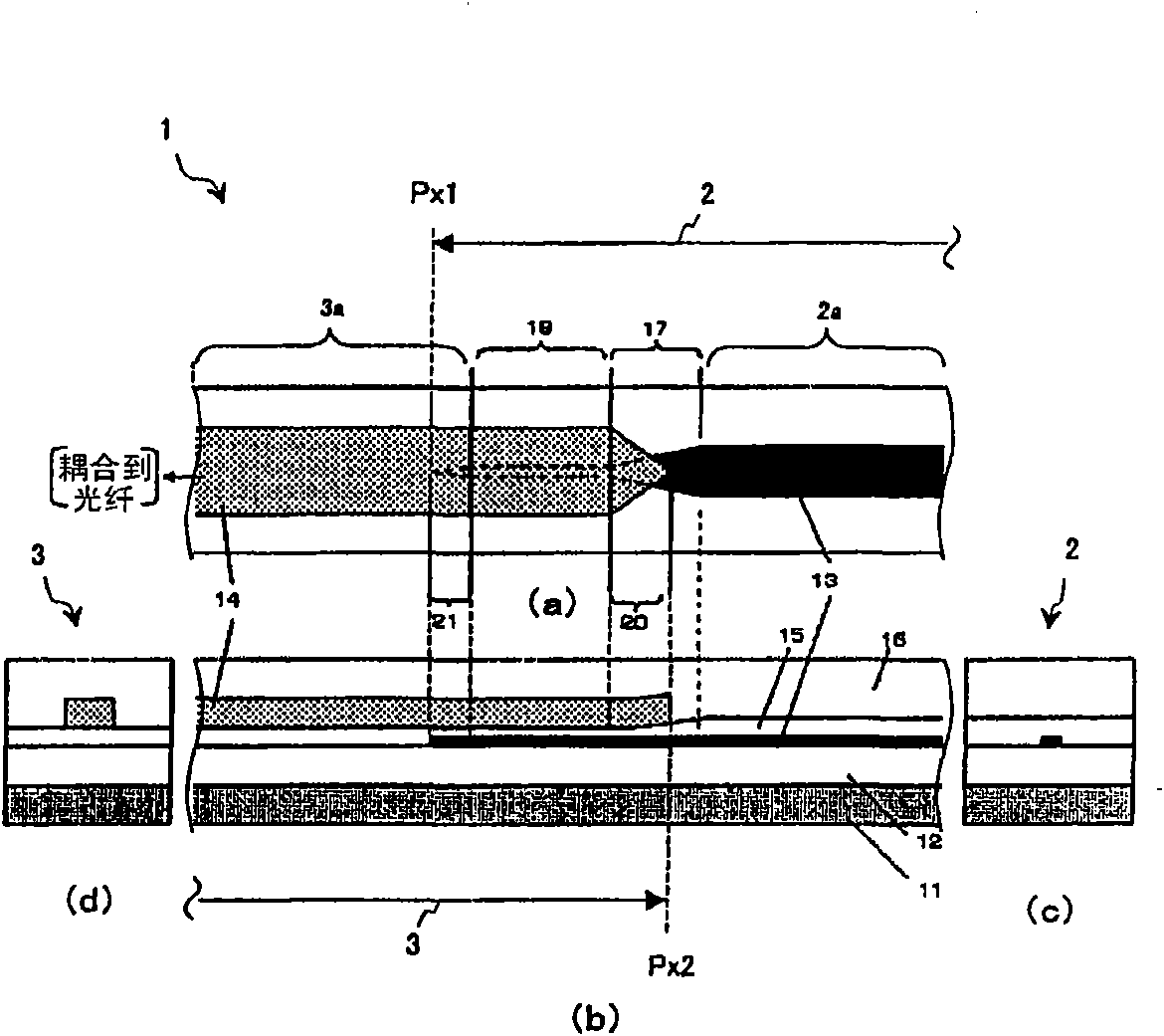

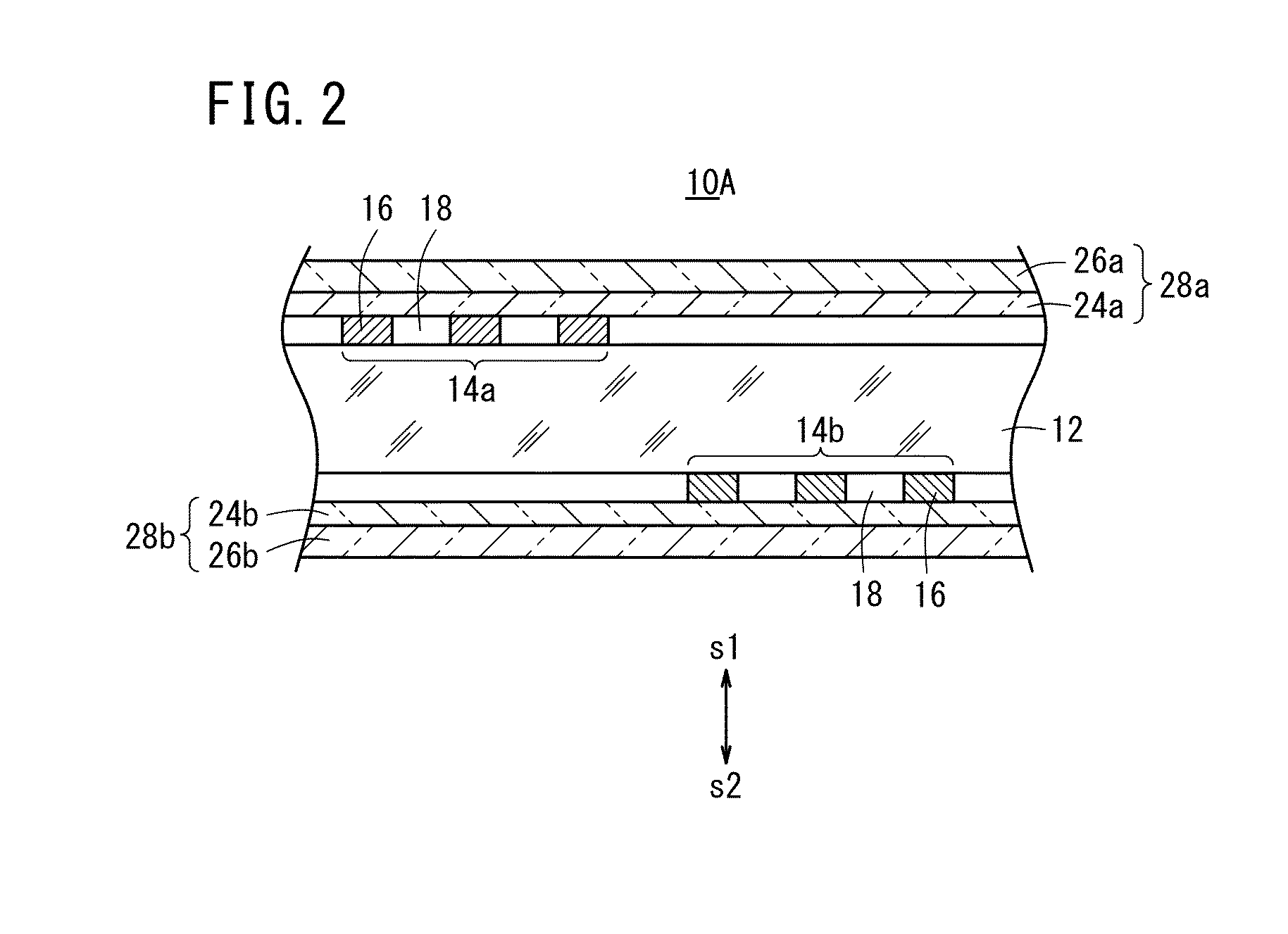

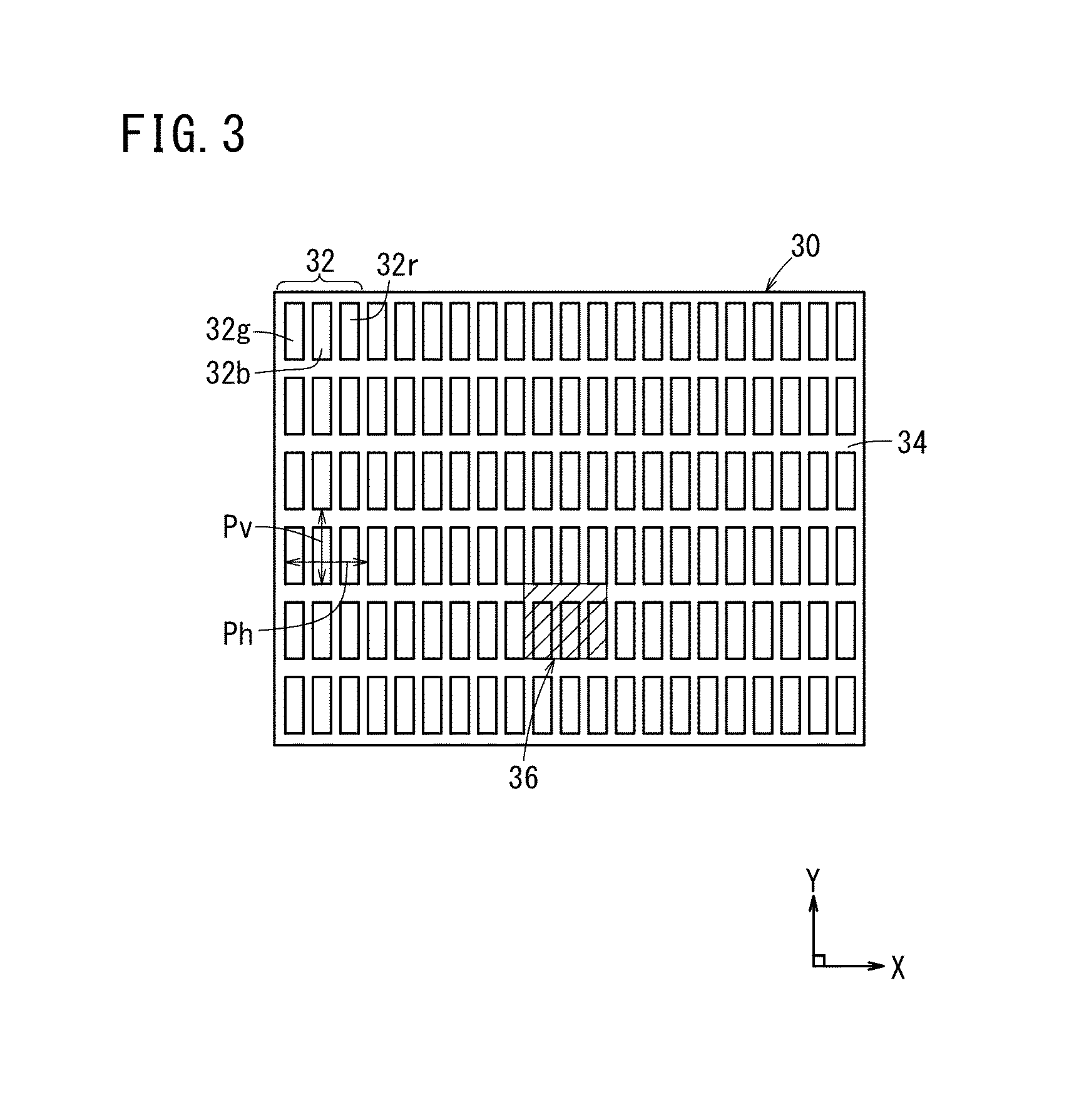

An optical waveguide includes a substrate in the shape of a flat plate; lower clad that is disposed on the substrate; and a core that is disposed on the lower clad and transmits light. The optical waveguide includes a first optical waveguide and a second optical waveguide. The first optical waveguide includes a first core on the lower clad, and is disposed so as to extend along a direction in which the light travels to a first position. The second optical waveguide includes a second core on the lower clad, is disposed so as to extend along a direction in which the light travels to a second position, and has a lower relative refractive index difference than the first optical waveguide. The first optical waveguide and the second optical waveguide form, between the first position and the second position, a layer structure where the first core and the second core are disposed such that the first core is positioned a predetermined distance away from the second core in a direction perpendicular to the substrate. At least either the first optical waveguide or the second optical waveguide includes a mode coupling section and a mode conversion section. The mode coupling section includes a directional coupler to conduct the mode coupling of the first core and the second core between the first position and the second position. The mode conversion section is connected to the mode coupling section, and has a tapered core structure to adjust the mode diameter of the first core to the mode diameter of the second core.

Owner:NEC CORP

Optical fiber

ActiveUS20060039665A1Improve transmission performanceReduce nonlinear effectsOptical fibre with multilayer core/claddingOptical waveguide light guideOptoelectronicsRelative refractive index

An optical fiber includes: a core at a center; a first cladding layer; a second cladding layer; and a third cladding layer. A maximum refractive index of the core is greater than any of maximum refractive indices of the first cladding layer, the second cladding layer, and the third cladding layer, and the maximum refractive index of the second cladding layer is smaller than any of the maximum refractive indices of the first and the third cladding layer. Additionally, a ratio of a2 / a1 is not less than about 2.5 and not more than about 4.5, where a1 represents the radius of the core, and a2 represents the radius of an outer periphery of the first cladding layer, and a relative refractive index difference of the core with respect to a maximum refractive index of the third cladding layer is not less than 0.20% and not more than 0.70%.

Owner:THE FUJIKURA CABLE WORKS LTD

Multi-mode bending-resistant fiber and production method thereof

ActiveUS20110044596A1High mechanical reliabilityEasy to useOptical fibre with graded refractive index core/claddingOptical articlesMedicineRelative refractive index

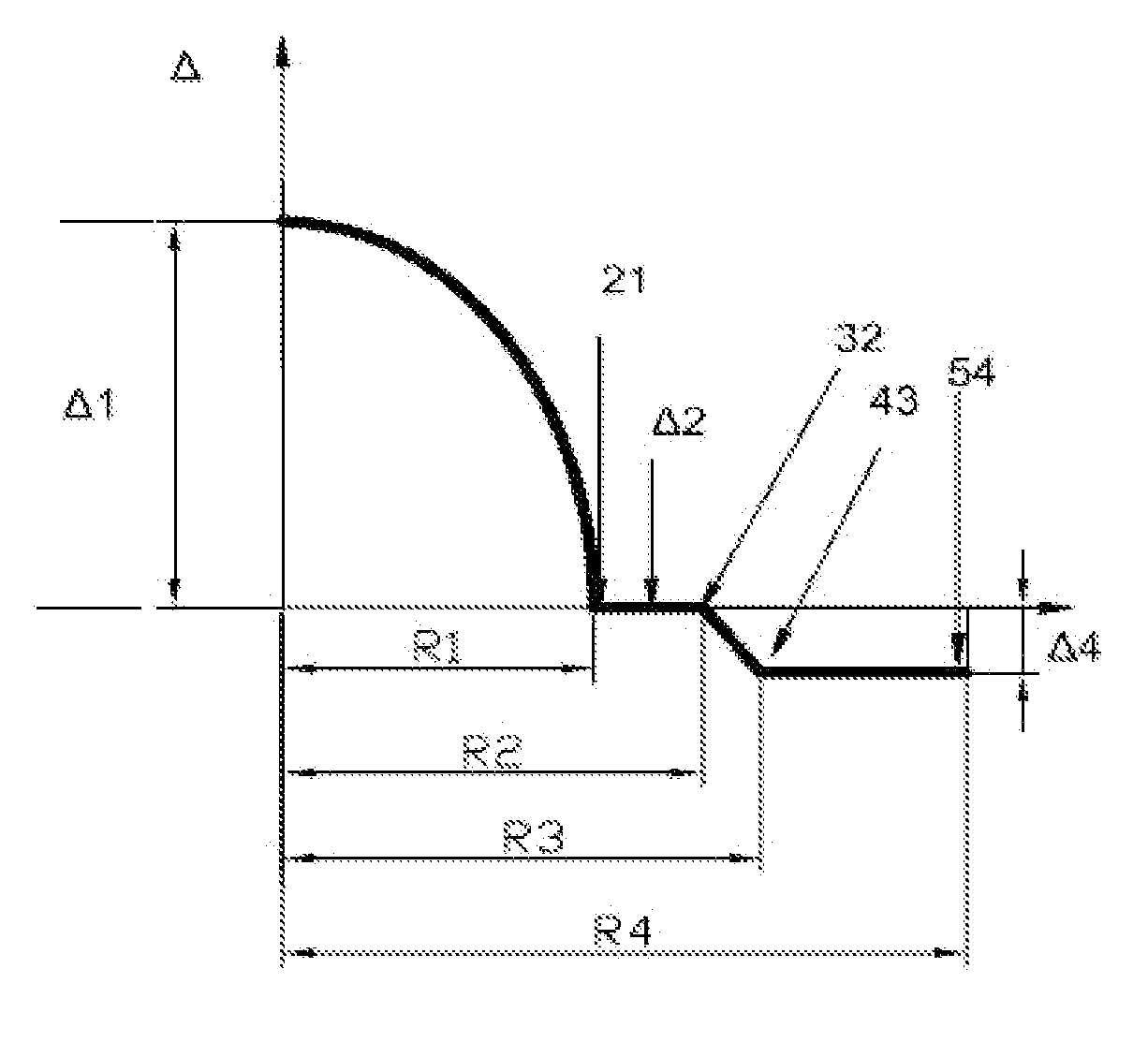

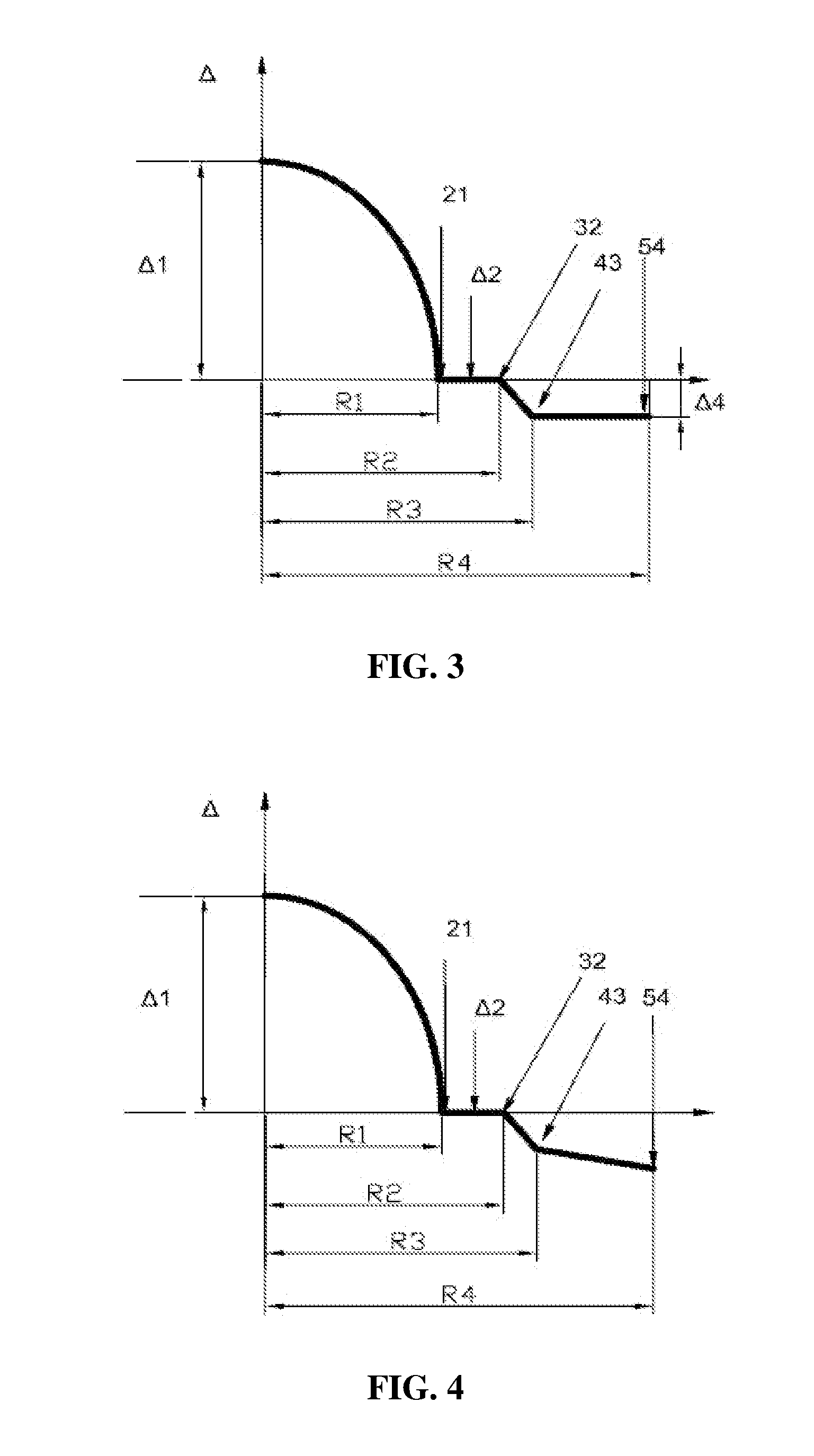

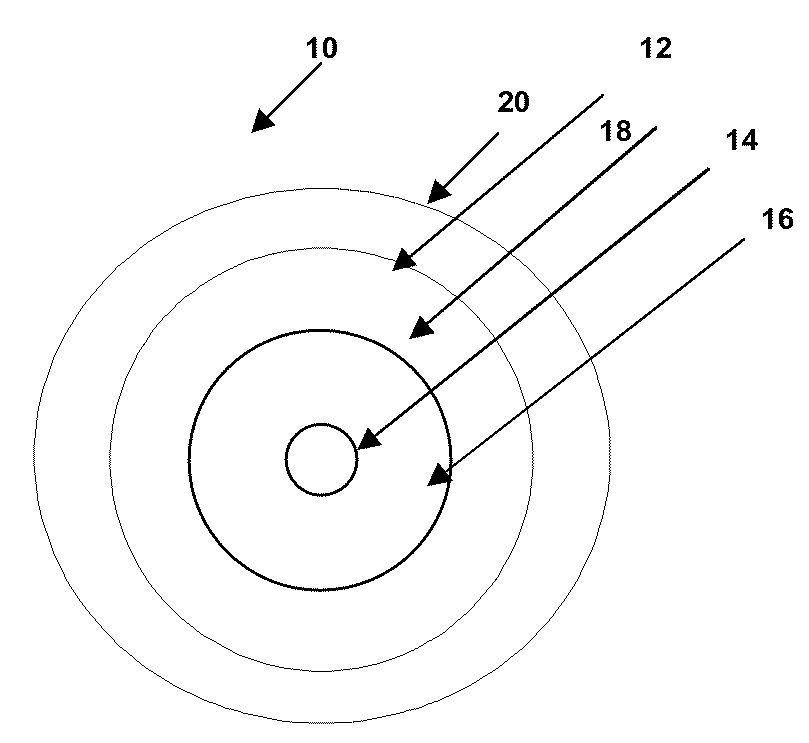

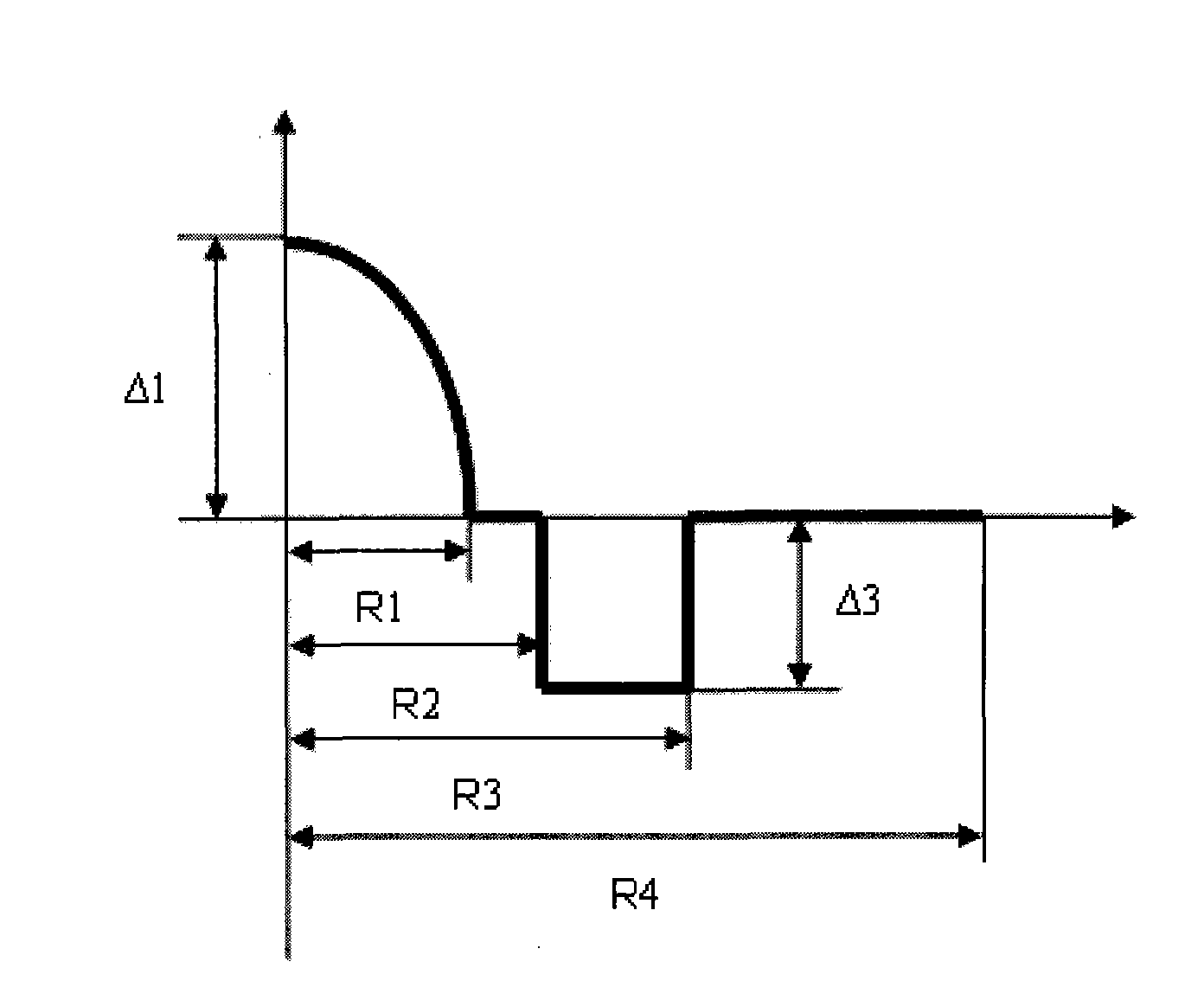

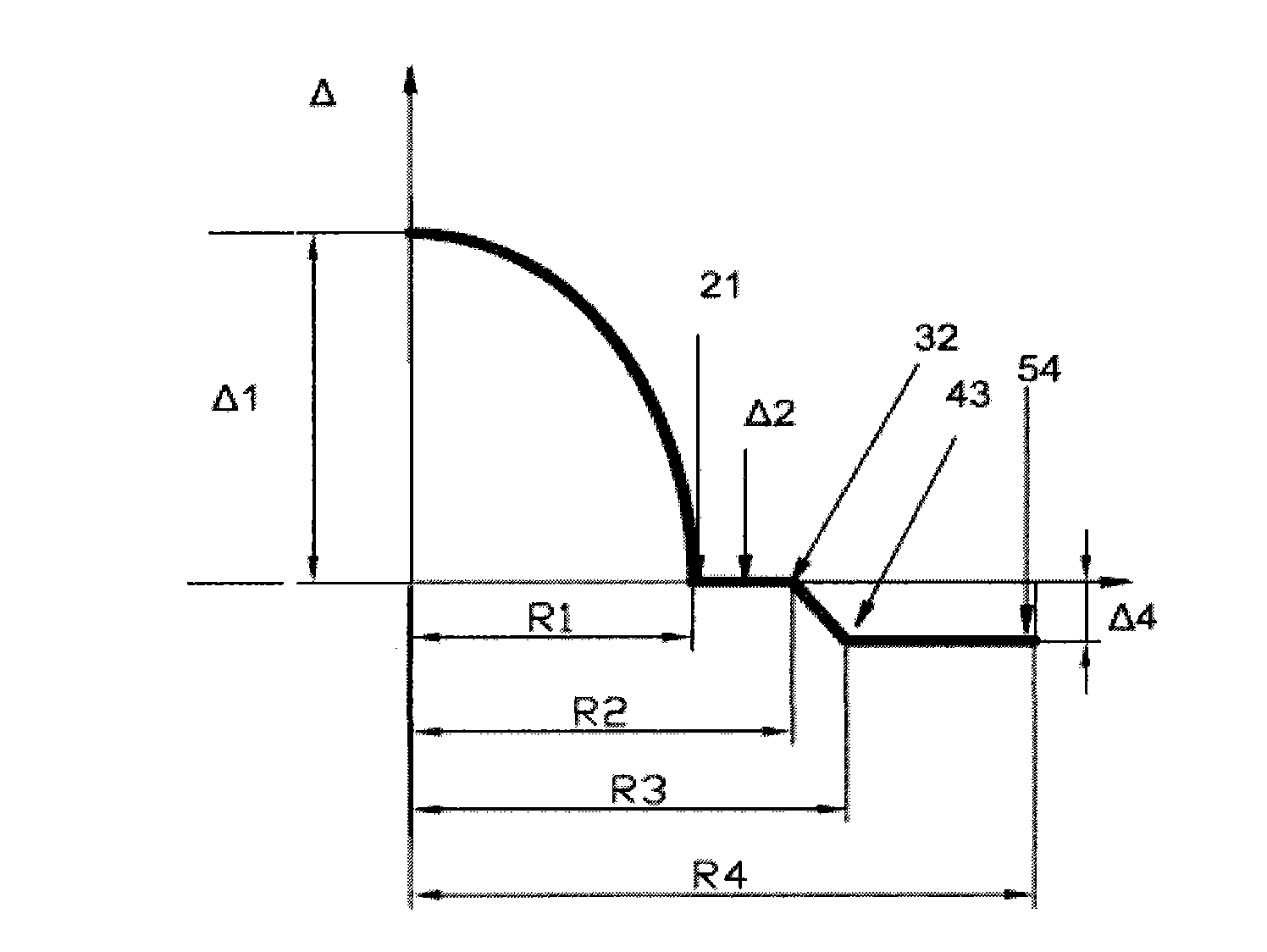

A multimode fiber including a core and a cladding. The core has a radius (R1) of 24-26 μm, the refractive index profile thereof is a parabola, and the maximum relative refractive index difference (Δ1) is 0.9-1.1%. The cladding surrounds the core and includes from inside to outside an inner cladding, a middle cladding, and an outer cladding; a radius (R2) of the inner cladding is 1.04-1.6 times that of the core, and a relative refractive index difference (Δ2) thereof is −0.01-0.01%; the middle cladding is a graded refractive index cladding whose radius (R3) is 1.06-1.8 times that of the core, and a relative refractive index difference thereof is decreased from Δ2 to Δ4; and a radius (R4) of the outer cladding is 2.38-2.63 times that of the core, and a relative refractive index difference (Δ4) thereof is between −0.20 and −0.40%. The invention reduces the additional bending loss of the fiber, improves the bending resistance and mechanical properties, basically eliminates the internal stress, and ensures the service life even working for a long term under the condition of low radius. The method for producing the fiber is simple, effective, and suitable for mass production.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

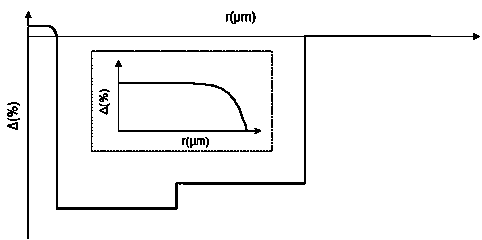

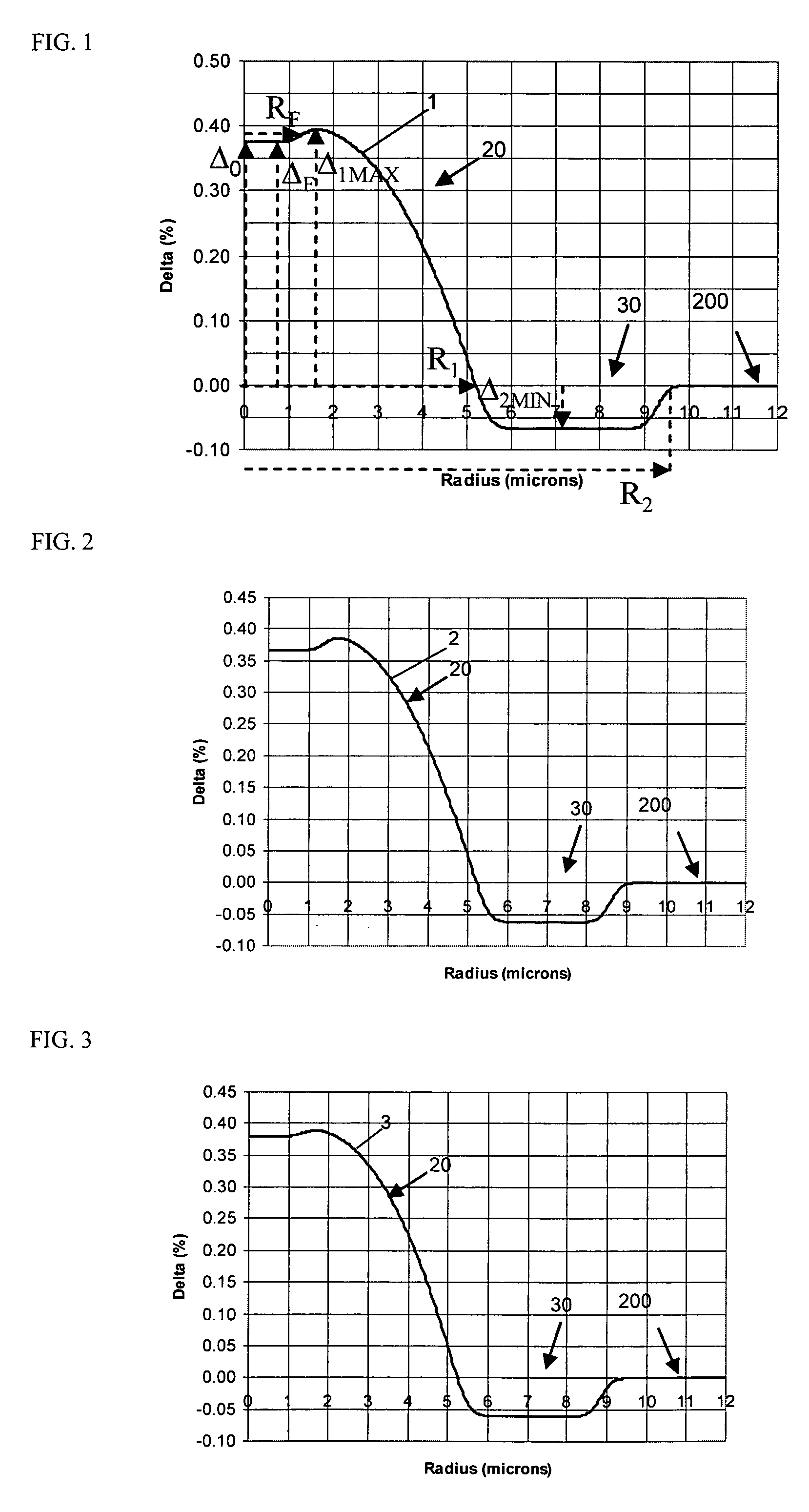

Large effective area fiber with graded index GE-free core

ActiveUS7929818B1Glass optical fibreOptical fibre with graded refractive index core/claddingUltrasound attenuationSilica measurement

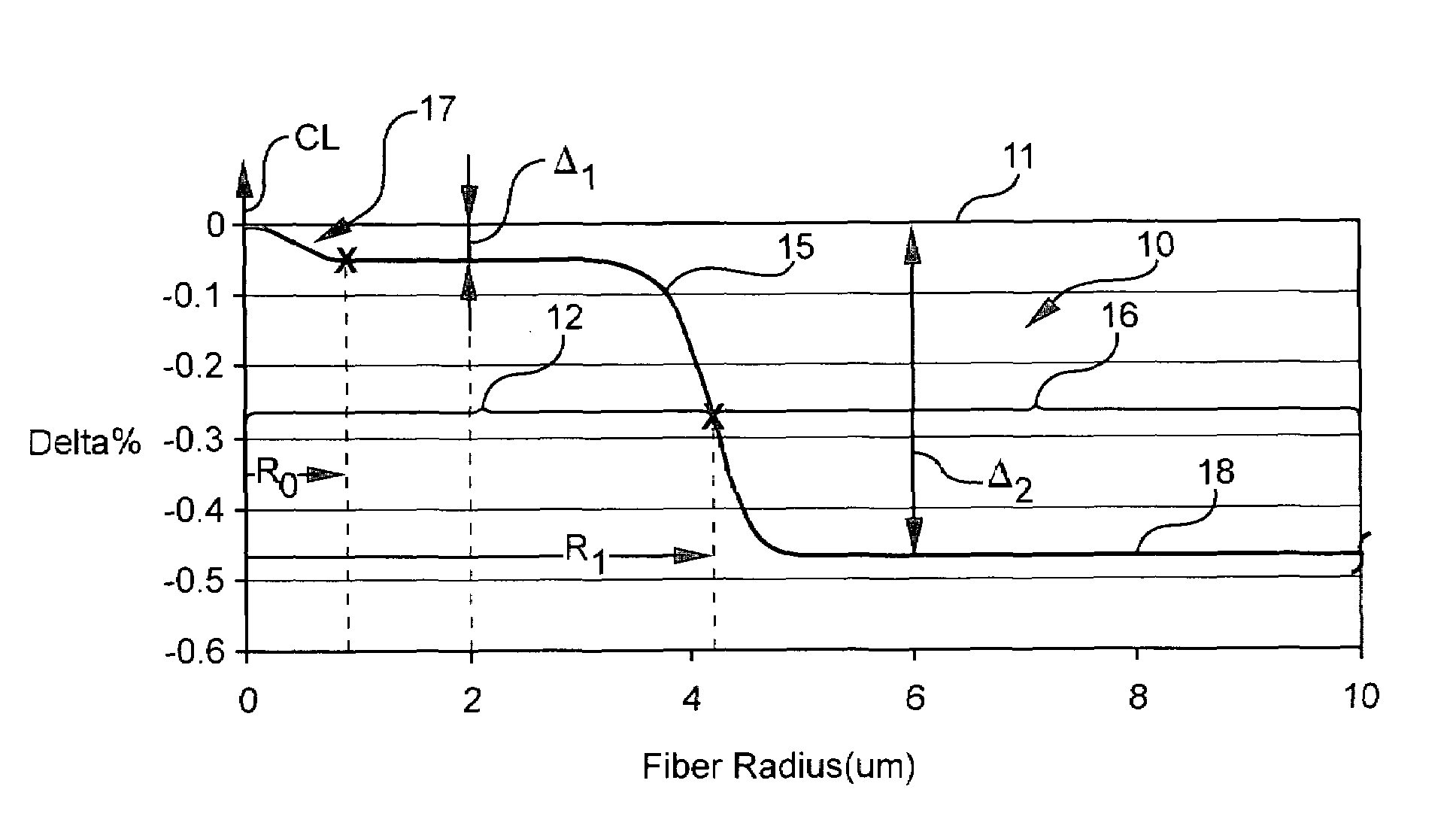

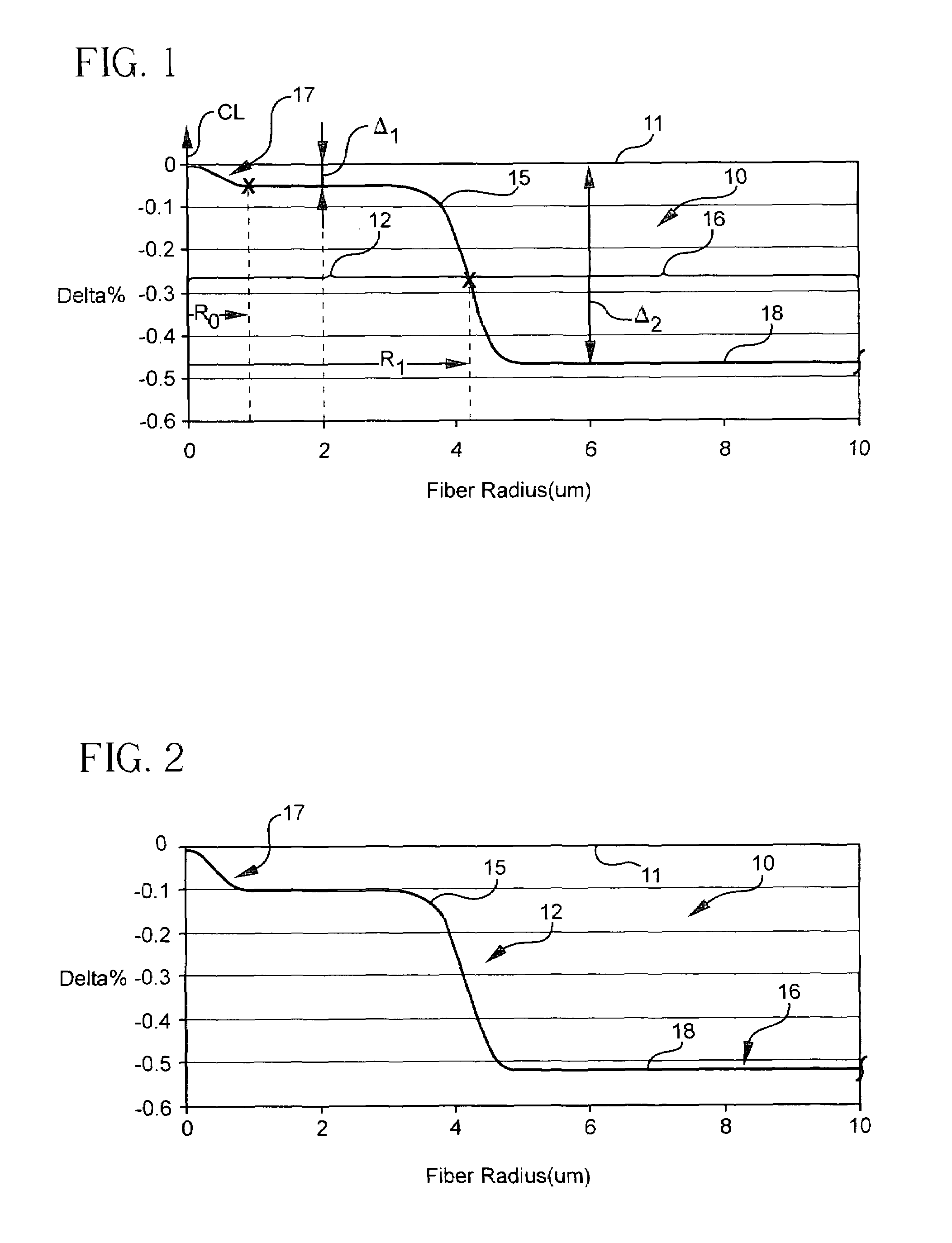

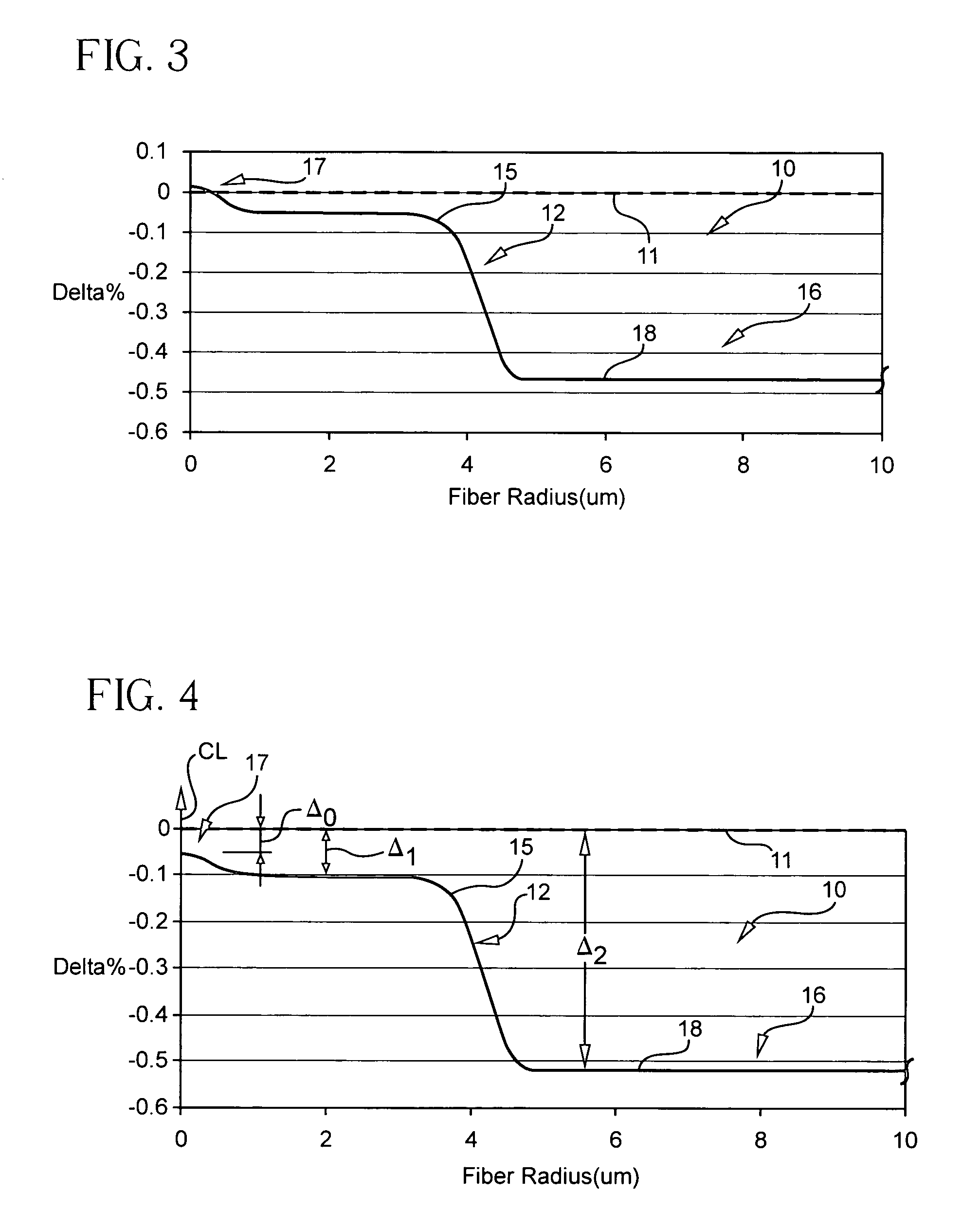

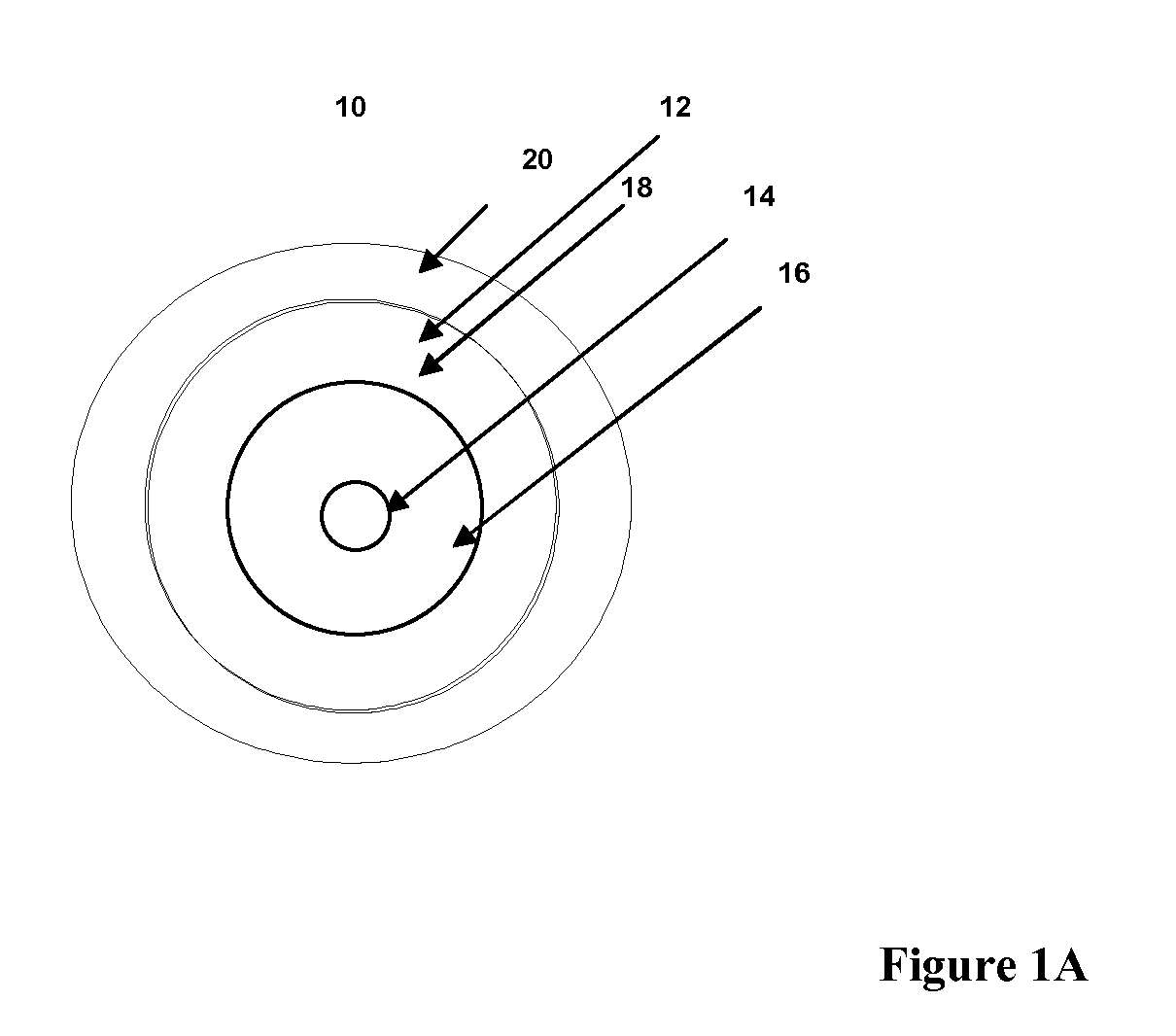

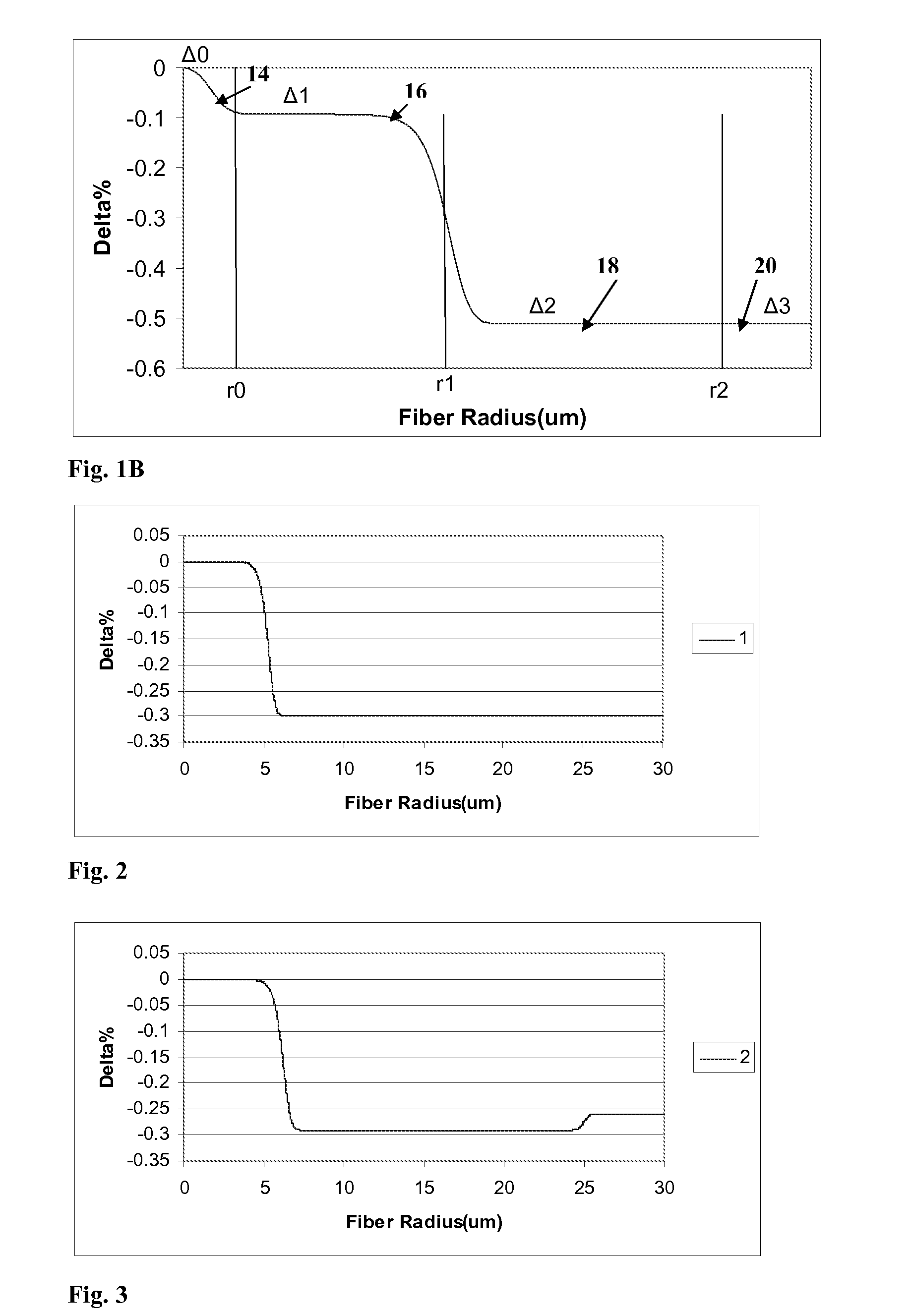

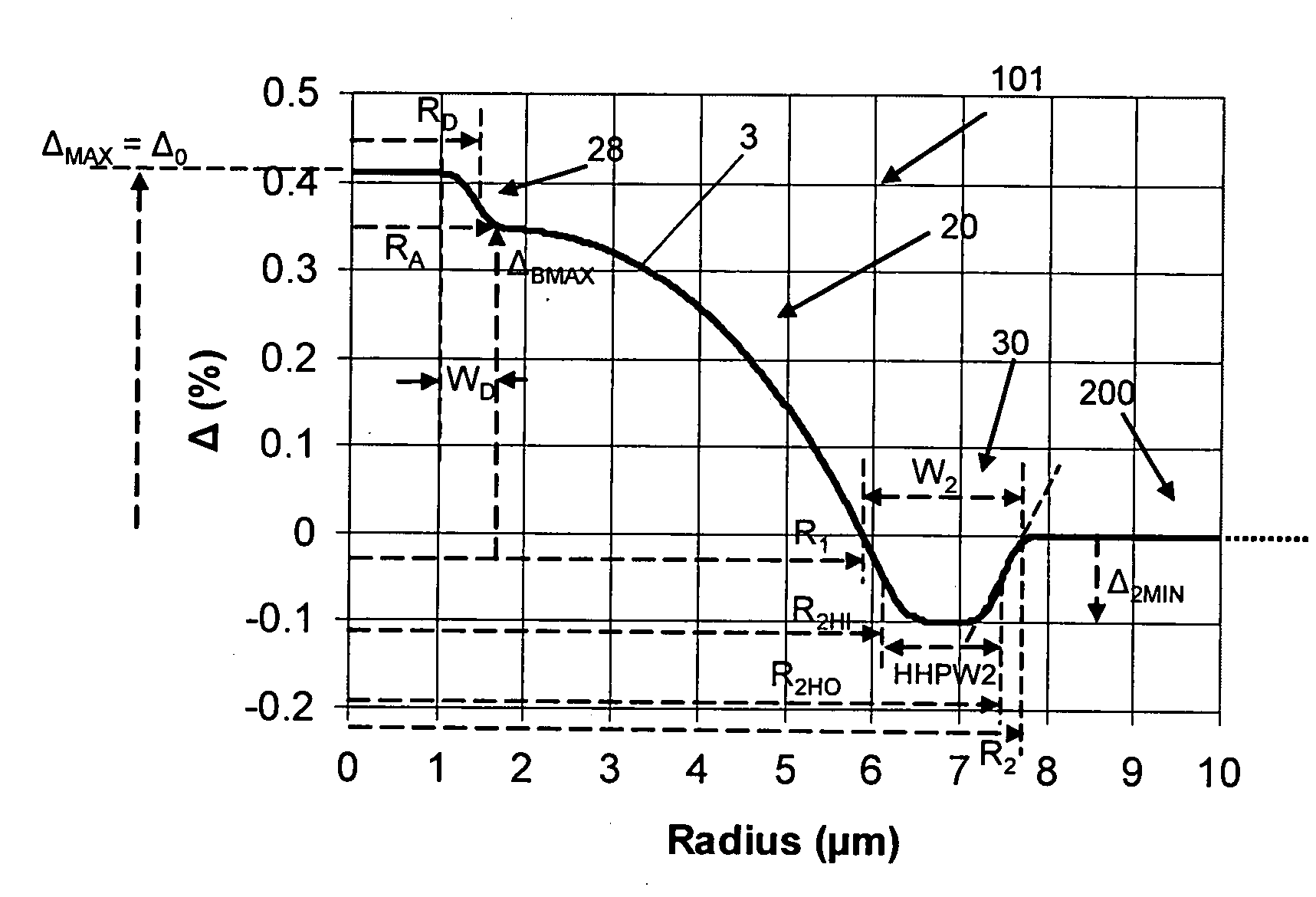

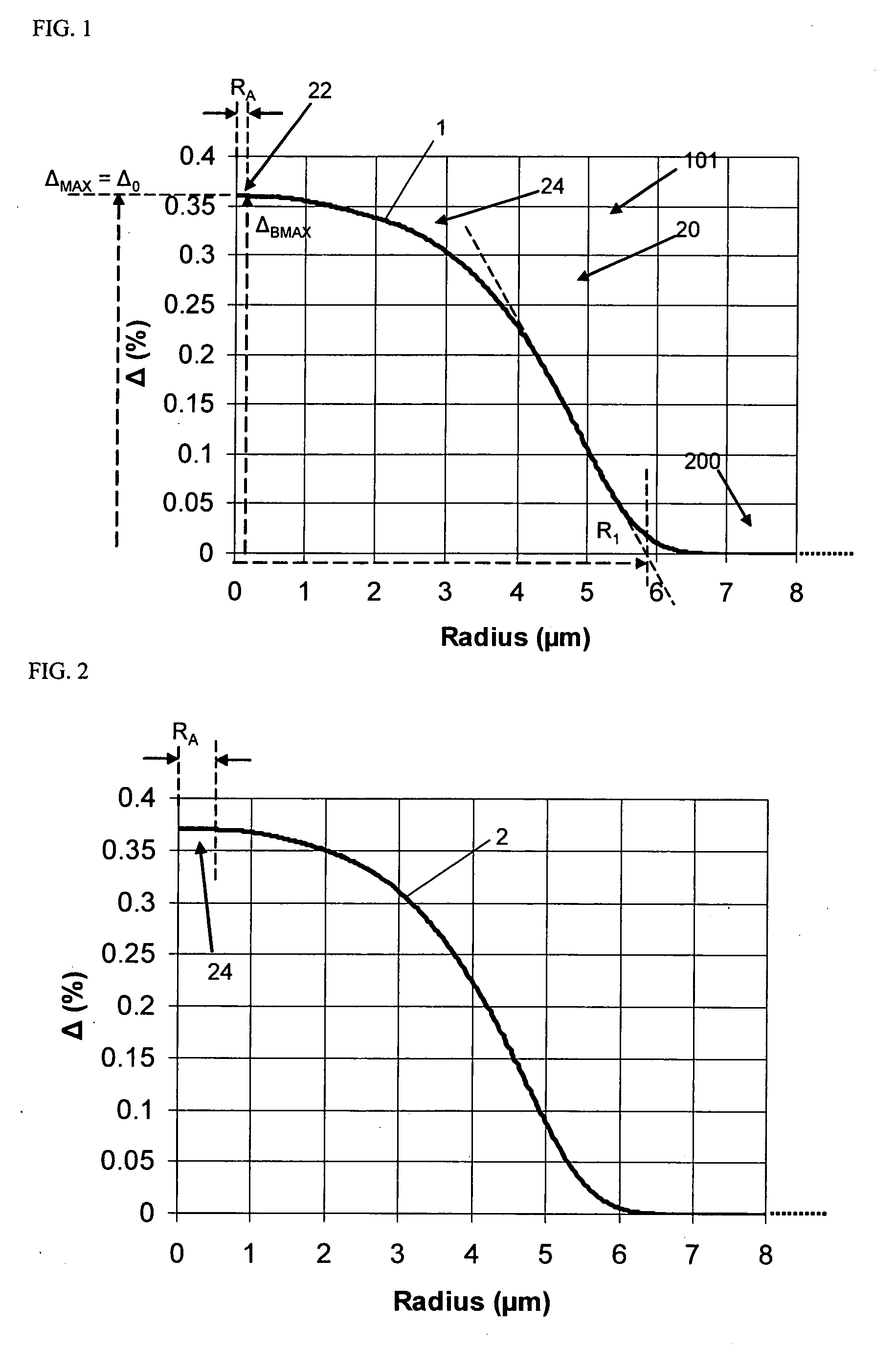

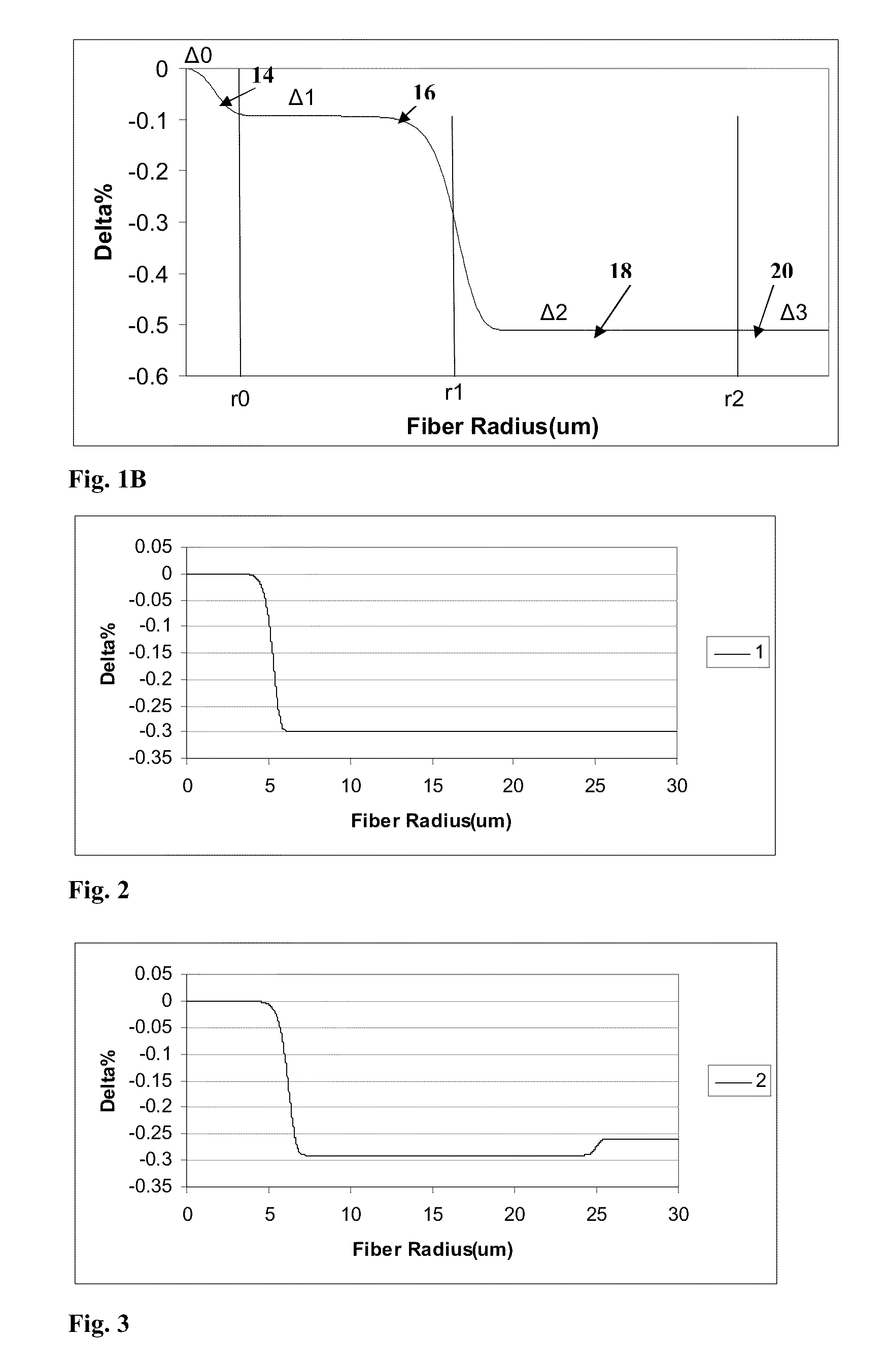

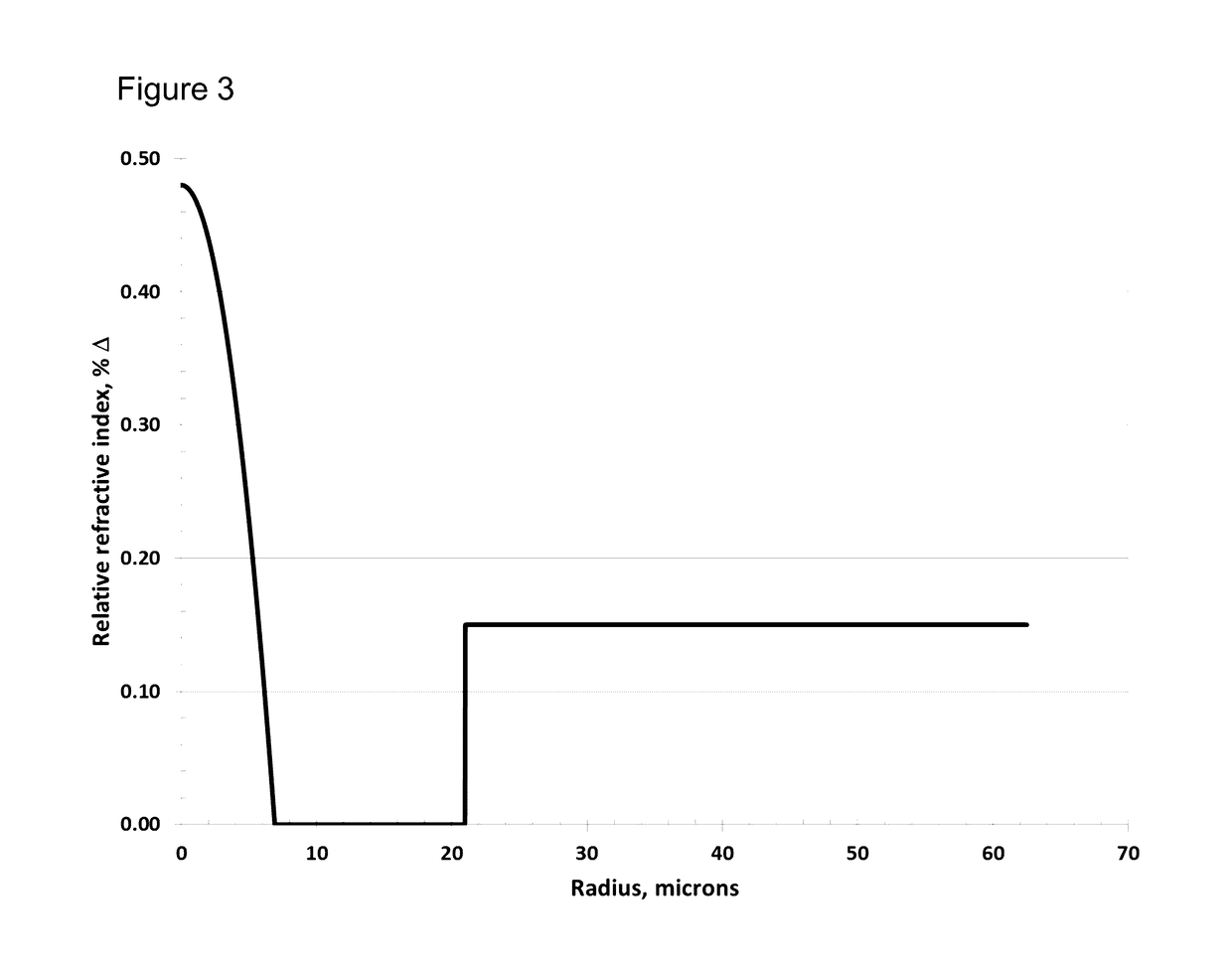

According to some embodiments an optical waveguide fiber comprises (i) a Ge free core having an effective area of 100 μm2to 150 μm2, at 1550 nm wavelength, said core comprising: a) a central core region extending radially outwardly from a centerline to a radius r1, and having a relative refractive index percent profile Δ1(r) in % measured relative to pure silica, wherein −0.1%≦Δ1(r)≦0.12%, wherein the central core region has a maximum relative refractive index percent, Δ1MAX; (b) a first annular core region surrounding and directly adjacent to the central core region, having an α value 1.5≦α≦10, and extending to an outer radius r2, wherein 6 μm≦r2≦10 μm, and having a relative refractive index percent profile, Δ2(r) in % measured relative to pure silica, a minimum relative refractive index Δ2MIN, a maximum relative refractive index Δ2MAX and the relative refractive index measured at a radius r=2 μm, wherein 0.45≦Δ2≦0; −0.25≧Δ2MIN≧−0.45 and Δ1MAX≧Δ2(r=2 μm); (c) a fluorine doped second annular region surrounding and directly adjacent to the first annular core region and extending to a radius 20 μm≦r3≦30 μm and having a negative relative refractive index percent profile, Δ3(r) in %, measured relative to pure silica, with a minimum relative refractive index percent Δ3MIN and −0.5%<Δ3MIN<−0.25%; and Δ3MIN≦Δ2MIN; (ii) a cladding surrounding the core and having a relative refractive index percent Δ4(r) in % measured relative to pure silica and a minimum refractive index delta Δ4MIN, and −0.4%<Δ4<−0.2%; wherein the relative refractive index profile of the optical fiber is selected to provide attenuation of no more than 0.17 dB / km at the 1550 nm wavelength.

Owner:CORNING INC

Large Effective Area Fiber With GE-Free Core

ActiveUS20100195966A1Glass optical fibreOptical fibre with graded refractive index core/claddingUltrasound attenuationSilica measurement

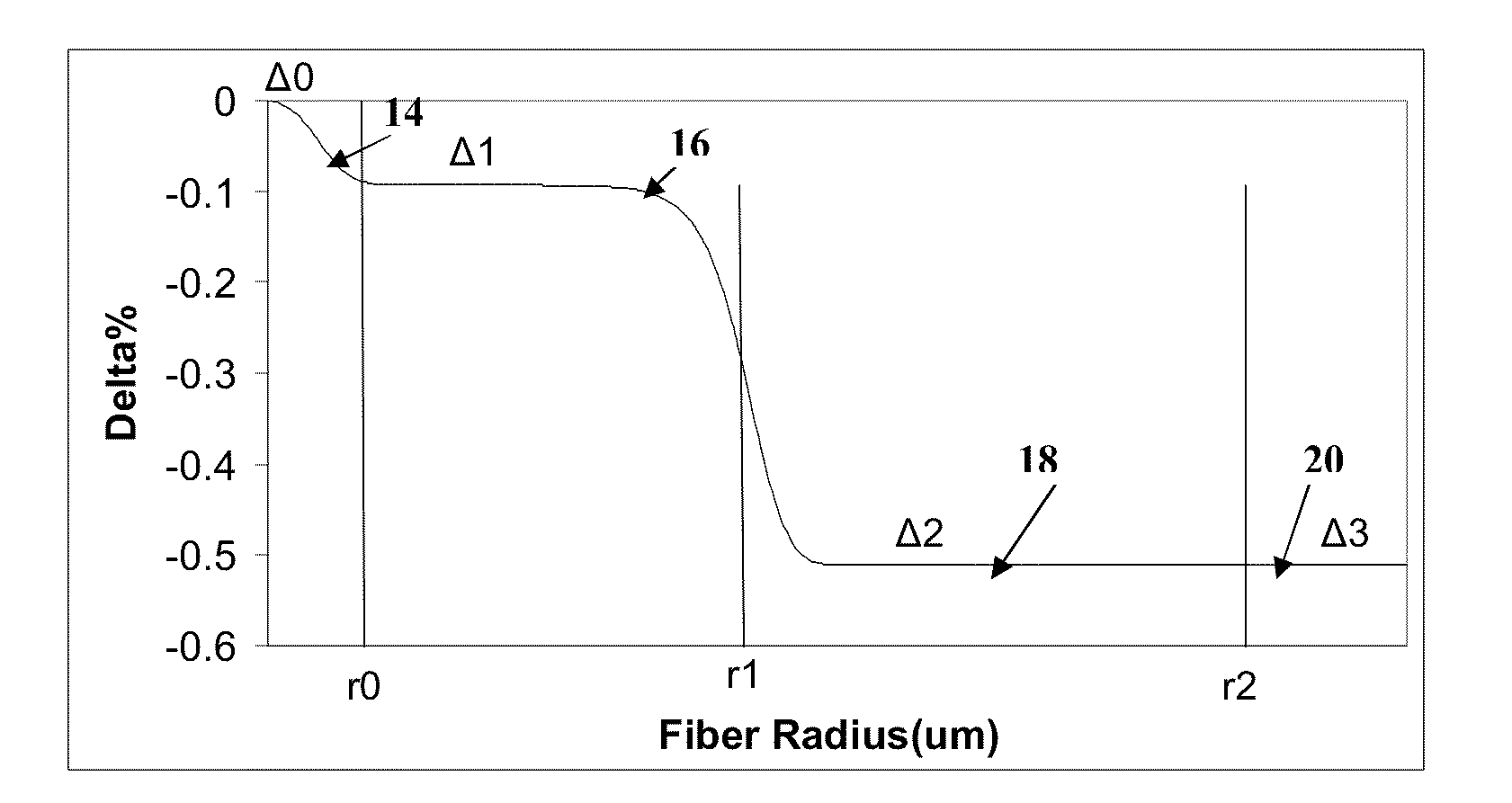

According to some embodiments an optical waveguide fiber comprises:(i) a Ge free core having an effective area of 90 μm2 to 160 μm2, at a 1550 nm wavelength, and α value 12≦α≦25, said core comprising:(a) a central core region extending radially outwardly from a centerline to a radius 0 μm≦r0≦2 μm, and having a relative refractive index percent profile Δ0(r) in % measured relative to pure silica, wherein −0.1%≦Δ0(r)≦0.1%, wherein the central core region has a maximum relative refractive index percent, Δ0MAX,(b) a first annular core region surrounding and directly adjacent to the central core region and extending to an outer radius r1, wherein 4.8 μm≦r1≦10 μm, and having a relative refractive index percent profile, Δ1(r) in % measured relative to pure silica, and a minimum relative refractive index, Δ2MIN, and the relative refractive index measured at a radius r=2.5 μm being:−0.15≦Δ1(r=2.5 μm)≦0, and Δ0MAX≧Δ1(r=2.5 μm);(c) a fluorine doped second annular region surrounding and directly adjacent to the first annular core region and extending to a radius 13 μm≦r2≦30 μm and having a negative relative refractive index percent profile, Δ2(r) in %, measured relative to pure silica,with a minimum relative refractive index percent Δ2MIN being:Δ2MIN≦Δ1(r=2.5 μm), and −0.7%≦Δ2MIN≦−0.28%;(ii) a cladding surrounding the core and having a relative refractive index percent Δc(r) in % measured relative to pure silica, and Δc(r)=Δ2MIN±0.3%;wherein the relative refractive index profile of the optical fiber is selected to provide attenuation of no more than 0.175 dB / km at the wavelength of 1550 nm.

Owner:CORNING INC

Anti-bending multimode fiber and manufacturing method thereof

ActiveCN101634728AReduce bend add-on attenuationImprove bending resistanceGlass making apparatusOptical fibre with multilayer core/claddingUltrasound attenuationRelative refractive index

The invention relates to an anti-bending multimode fiber and manufacturing method thereof. The fiber comprises a core and a cladding and is characterized in that the radius of core R1 is 24-26 microns, refractive index section of the core is like a parabola, refractivity maximum delta1 is 0.9-1.1%, the cladding outside the core is composed of three parts, the radius of inner cladding R2 is 1.04-1.6 times of the radius of core R1, delta2 is minus 0.01-0.01%, intermediate cladding is gradually changed in refractive index, the radius of intermediate cladding R3 is 1.06-1.8 times of R1, refractivity is gradually changed into delta4 from delta2, the radius of outer cladding R4 is 2.38-2.63 times of R1, and delta4 is minus 0.20% to minus 0.40%. The invention reduces fiber bending additional attenuation and improves anti-bending performance of fiber but also basically eliminates inner stress of fiber, greatly improves mechanical properties of fiber, and service life of fiber operating in minor radius for a long time also can be guaranteed. The manufacturing method of the invention is simple, convenient and effective and is applicable to mass production.

Owner:EVERPRO TECH COMPANY

Multiband optical fiber

InactiveUS20070196061A1Suitable performanceOptical fibre with multilayer core/claddingOptical waveguide light guideRelative refractive indexLight wave

An optical waveguide fiber having a core surrounded by a cladding. The core may have only a central segment, or a central segment and an annular segment surrounding the central segment. The central segment has a positive relative refractive index profile. The annular segment has a negative relative refractive index profile. The relative refractive index of the optical fiber provides an LP02 cable cutoff less than 850 nm and an LP21 cable cutoff less than 850 nm.

Owner:CORNING INC

Single mode optical fiber

ActiveCN103454719AGood for drawing processReduce additional lossOptical fibre with multilayer core/claddingOptical waveguide light guideUltrasound attenuationAttenuation coefficient

The invention relates to a low-attenuation single mode optical fiber used in an optical fiber communication system. The single mode optical fiber comprises a core layer and a wrapping layer. The single mode optical fiber is characterized in that the refractive index distribution n (r) of the core layer and the g-type refractive index distribution of the core layer meet the formula: n (r)=n0*[1-2*delta 1*(r / R1)*g]*1 / 2 (r<=R1), the delta 1 of the core layer ranges from -0.05% to +0.05%, g ranges from 10 to 30, and the radius R1 of the core layer ranges from 4.0 microns to 5.0 microns; the wrapping layer sequentially comprises an inner wrapping layer, a middle wrapping layer and an outer wrapping layer from inner to outer, the delta 2 of the inner wrapping layer ranges from -0.3% to -0.45%, the radius R2 ranges from 20 microns to 30 microns, and the delta 3 of the middle wrapping layer is larger than delta 2, the numerical relationship between the relative refraction difference and the radius of the middle wrapping layer and the relative refraction difference and the radius of the inner wrapping layer is V=(R3-R2)*(delta 3-delta 2), and V ranges from 0.5*10-2-micron% to 7*10-2-micron%. The attenuation coefficient, at the 1550-nanometer position, of the optical fiber is smaller than or equal to 0.180dB / km. The low-attenuation single mode optical fiber is low in optical fiber loss, good in manufacturing technology, low in cost and suitable for scale production.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Low-attenuation bend-insensitive single-mode fiber

ActiveCN102645699AImprove the attenuation effectWarranty against bendingOptical fibre with multilayer core/claddingRelative refractive indexOptoelectronics

The invention relates to a low-attenuation bend-insensitive single-mode fiber, which is used in a fiber communication system and comprises a core layer and three claddings. The low-attenuation bend-insensitive single-mode fiber is characterized in that the relative refractive index difference delta1 of the core layer ranges from 0.1% to 0.30%, the radius R1 of the core layer ranges from 3.5 micrometers to 4.5 micrometers, the three claddings are arranged on the outside of the core layer, the first cladding is an inner cladding tightly encircling the core layer, the relative refractive index difference delta2 of the inner cladding ranges from -0.1% to 0.1%, the radius R2 of the inner cladding ranges from 8 micrometers to 10 micrometers, the second cladding is a depressed cladding tightly encircling the inner cladding, the relative refractive index difference delta3 of the depressed cladding ranges from -0.4% to -0.1%, the delta3 is smaller than the delta2, the radius R3 of the depressed cladding ranges from 12 micrometers to 20 micrometers, the third cladding is an outer cladding tightly encircling all sub-claddings of the depressed cladding, and the relative refractive index difference delta4 of the outer cladding ranges from -0.2% to 0.1%. On the basis of comprehensive compatibility to existing G.652 standards, the low-attenuation bend-insensitive single-mode fiber has an attenuation performance far superior to that of a conventional G.652.D fiber, the microscopic bending requirement of G.657.A1 standards can be met, and application of a dense wavelength division multiplexing system is facilitated.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

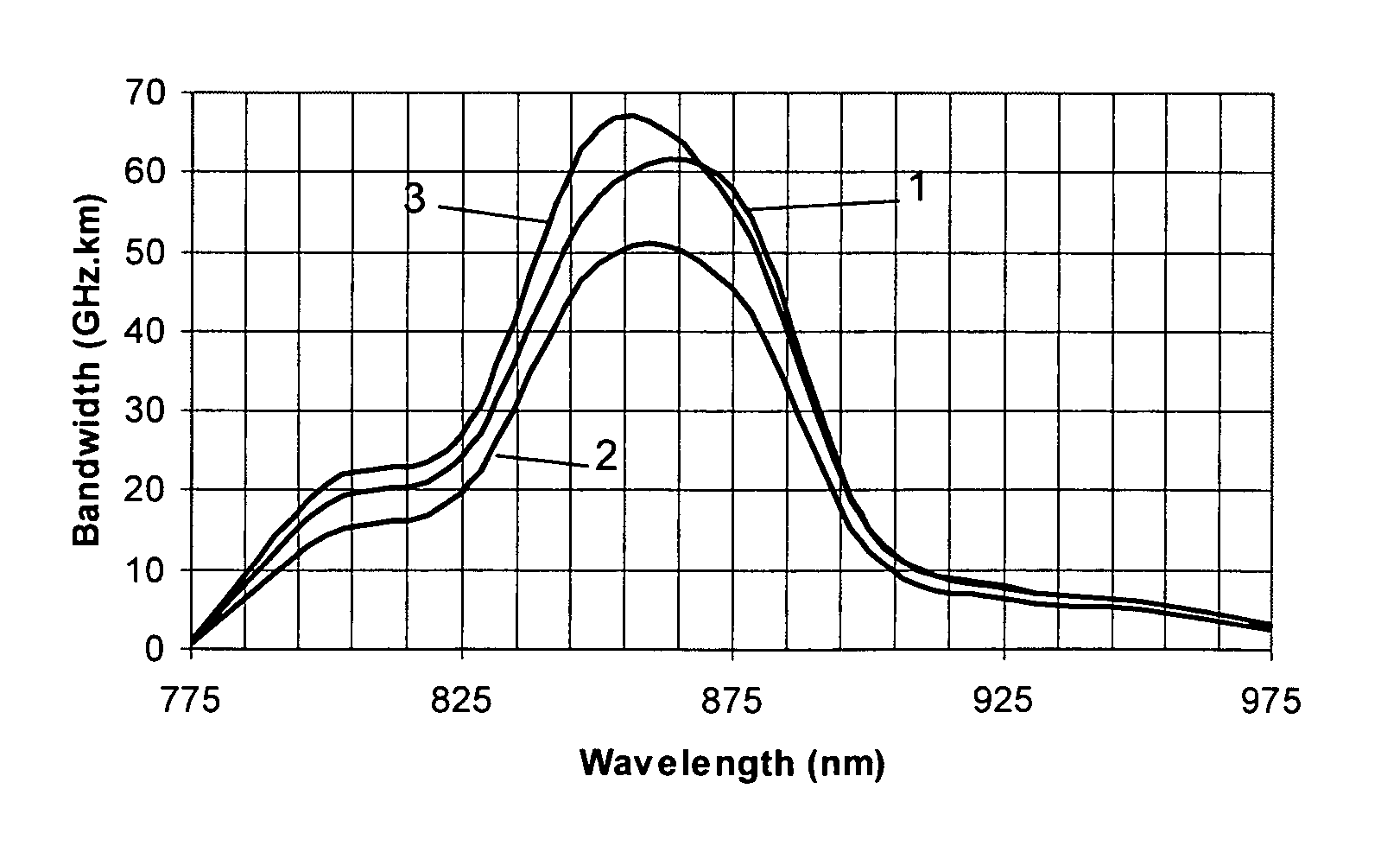

Graded-index multimode fiber and manufacturing method therefor

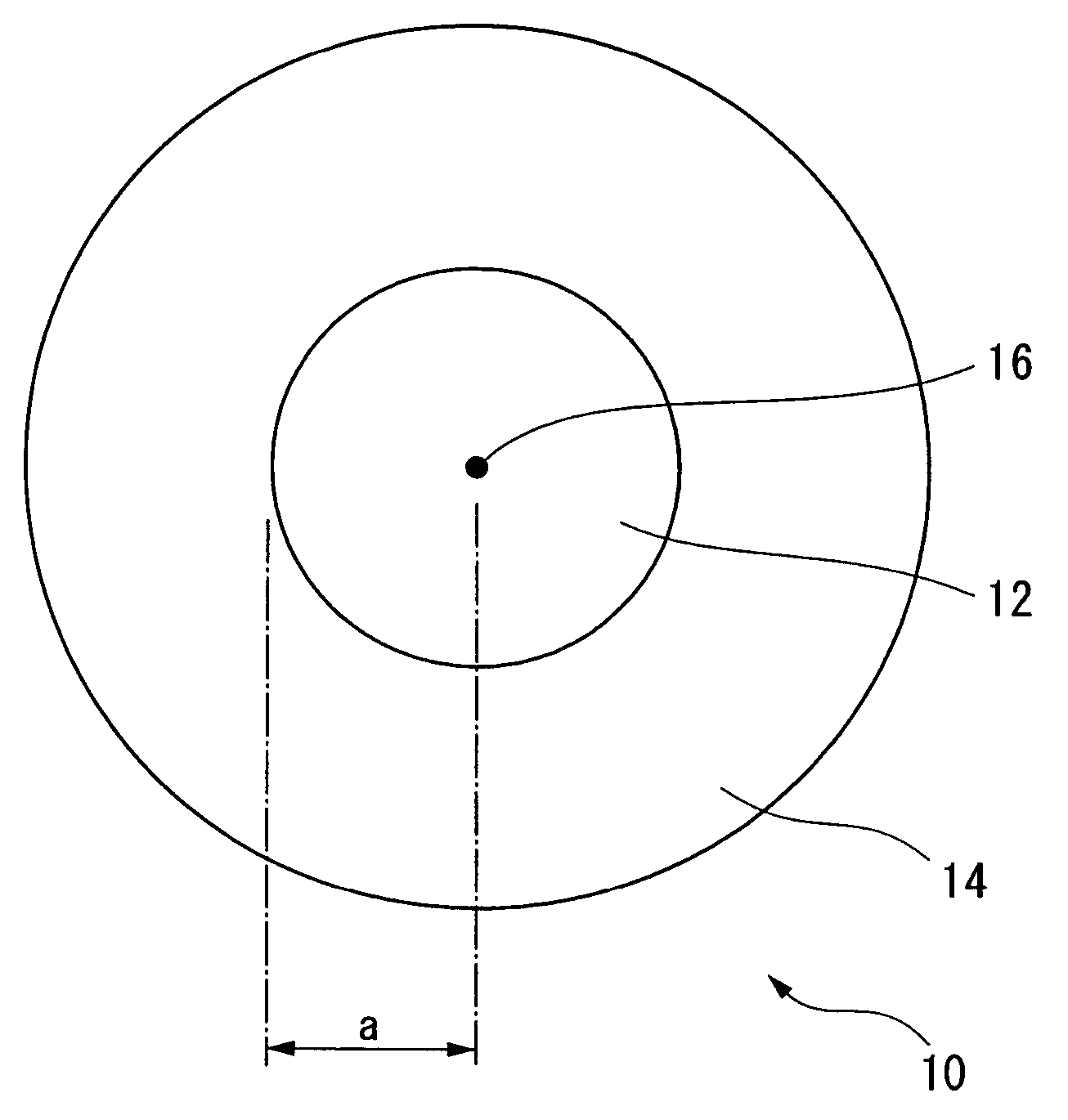

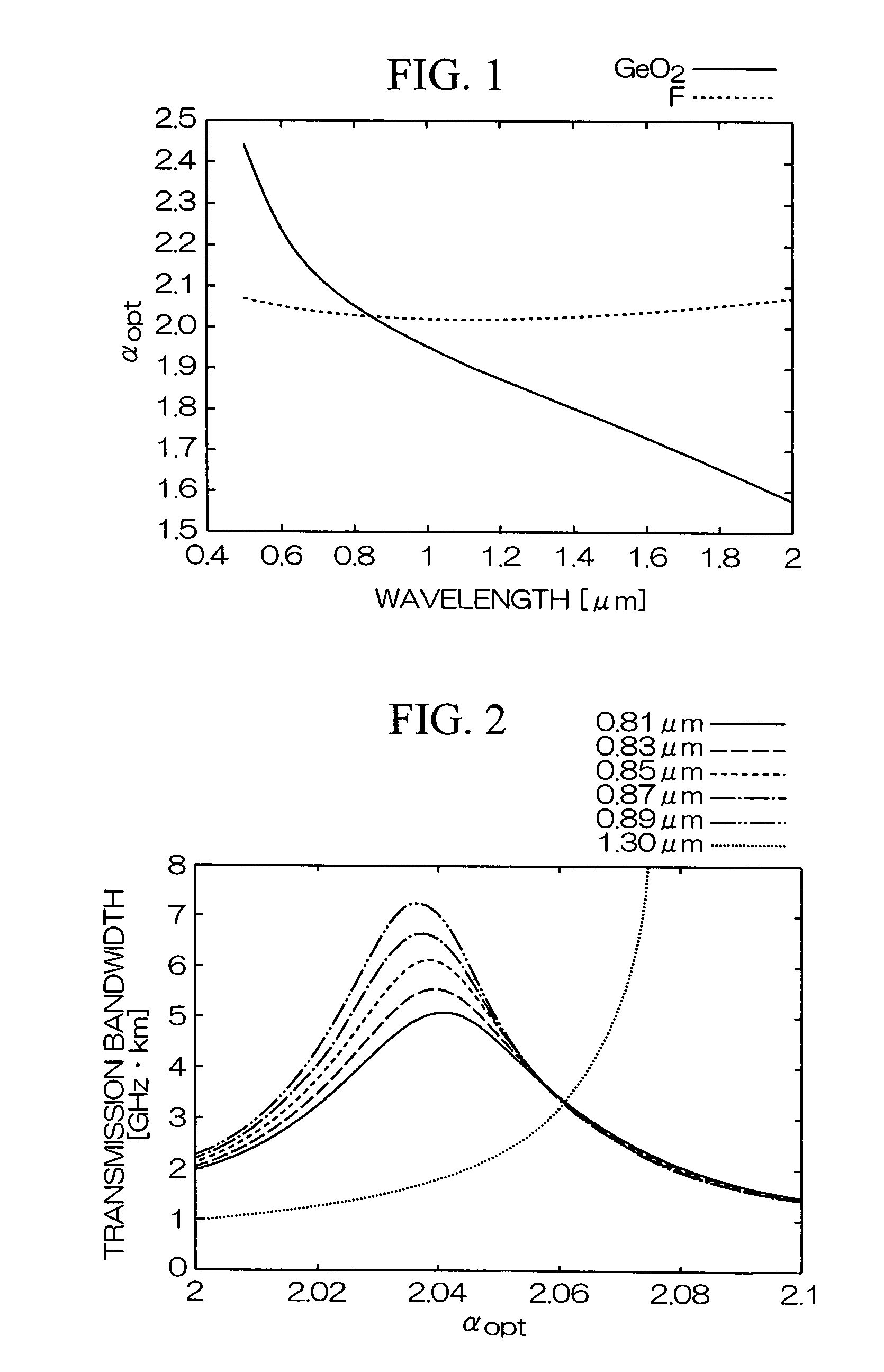

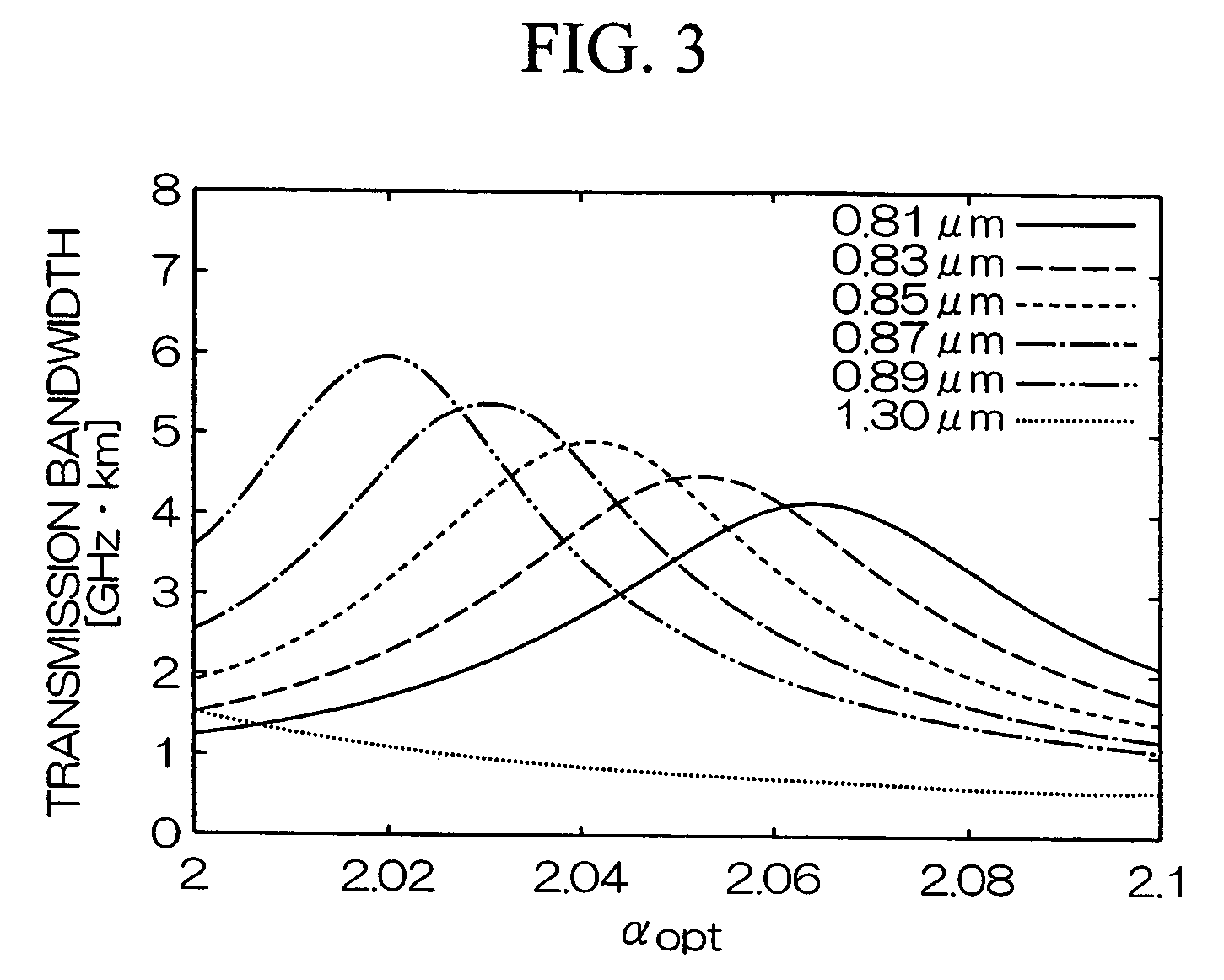

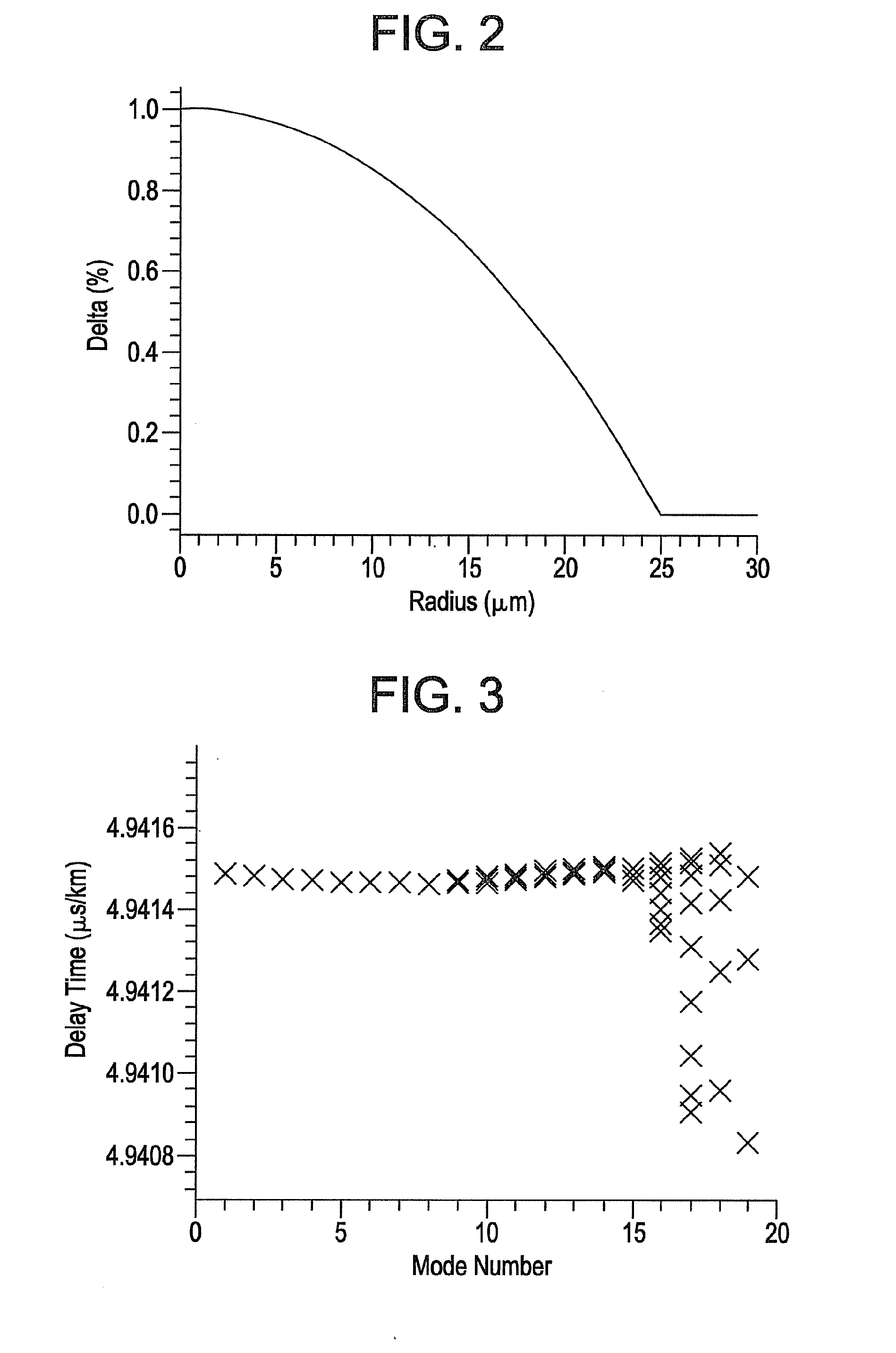

ActiveUS7043126B2Large transmission bandwidthWide wavelength rangeGlass making apparatusOptical fibre with graded refractive index core/claddingRelative refractive indexRefractive index profile

A graded-index multimode fiber includes a core containing fluorine and a cladding which is provided at an outer periphery of the core, and the fiber has a refractive index profile which satisfies the following Formula (1):n(r)={n1[1-2Δ(ra)α]1 / 2(O≤r≤a)n1(1-2Δ)1 / 2(r>a)(1)where n(r) is a refractive index of the optical fiber at a distance “r” from the center of the core, n1 is a refractive index at the center of the core, Δ is a relative refractive index difference of the center of the core with respect to the cladding, “a” is a core radius, and α is a refractive index profile exponential parameter.

Owner:THE FUJIKURA CABLE WORKS LTD

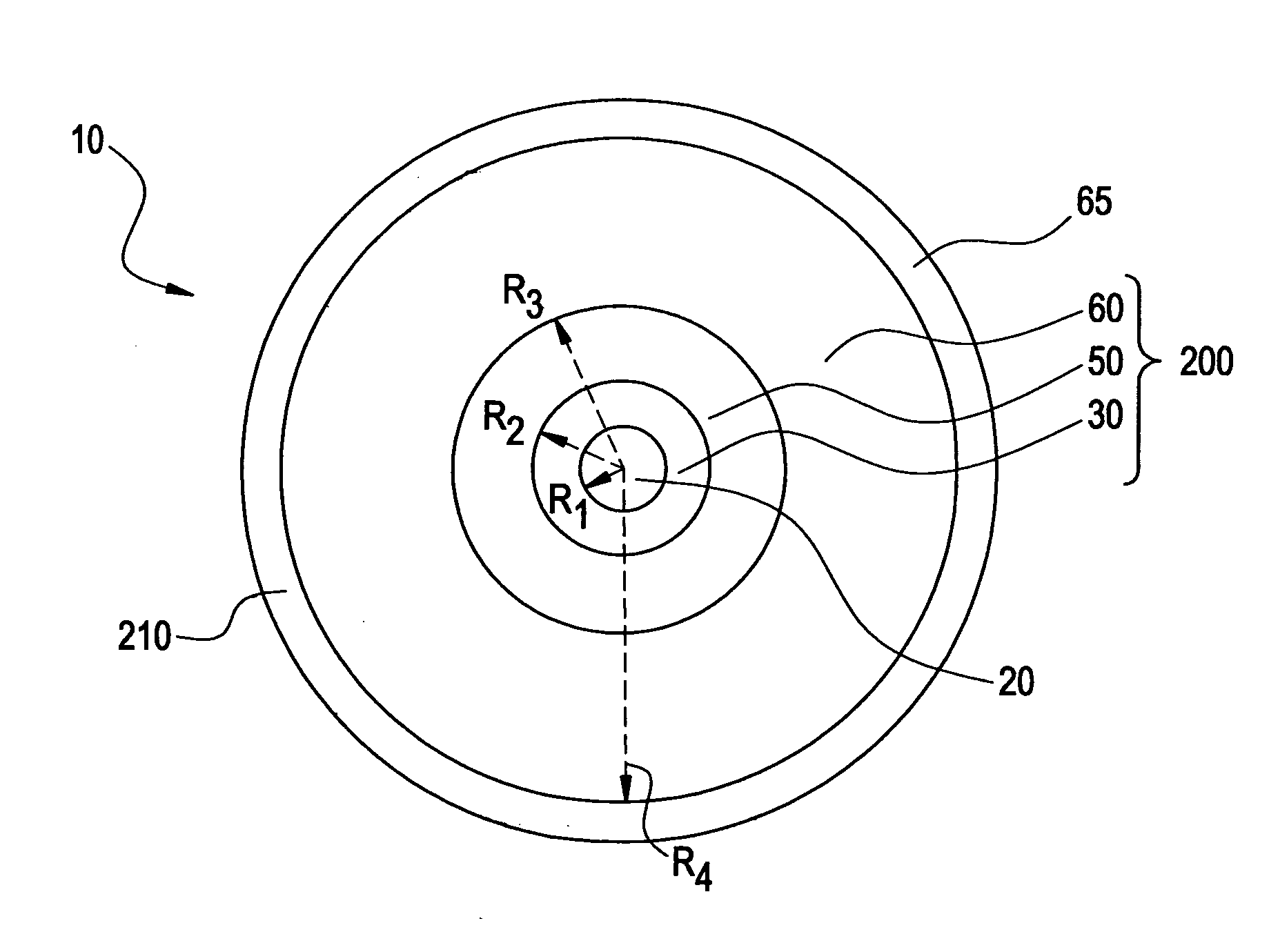

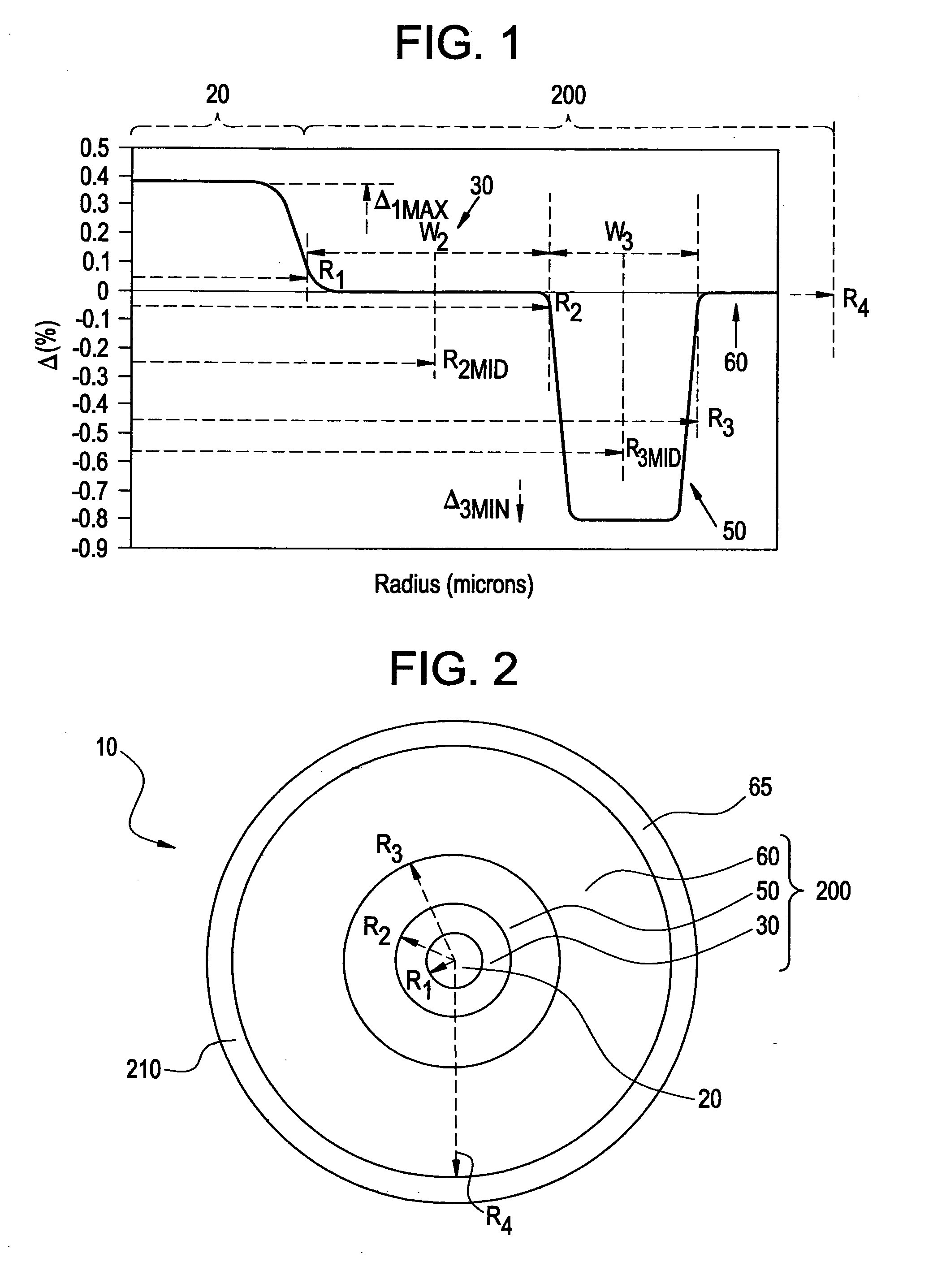

Optical fiber with large effective area

InactiveUS20080304800A1Optical fibre with multilayer core/claddingOptical waveguide light guideRelative refractive indexMaterials science

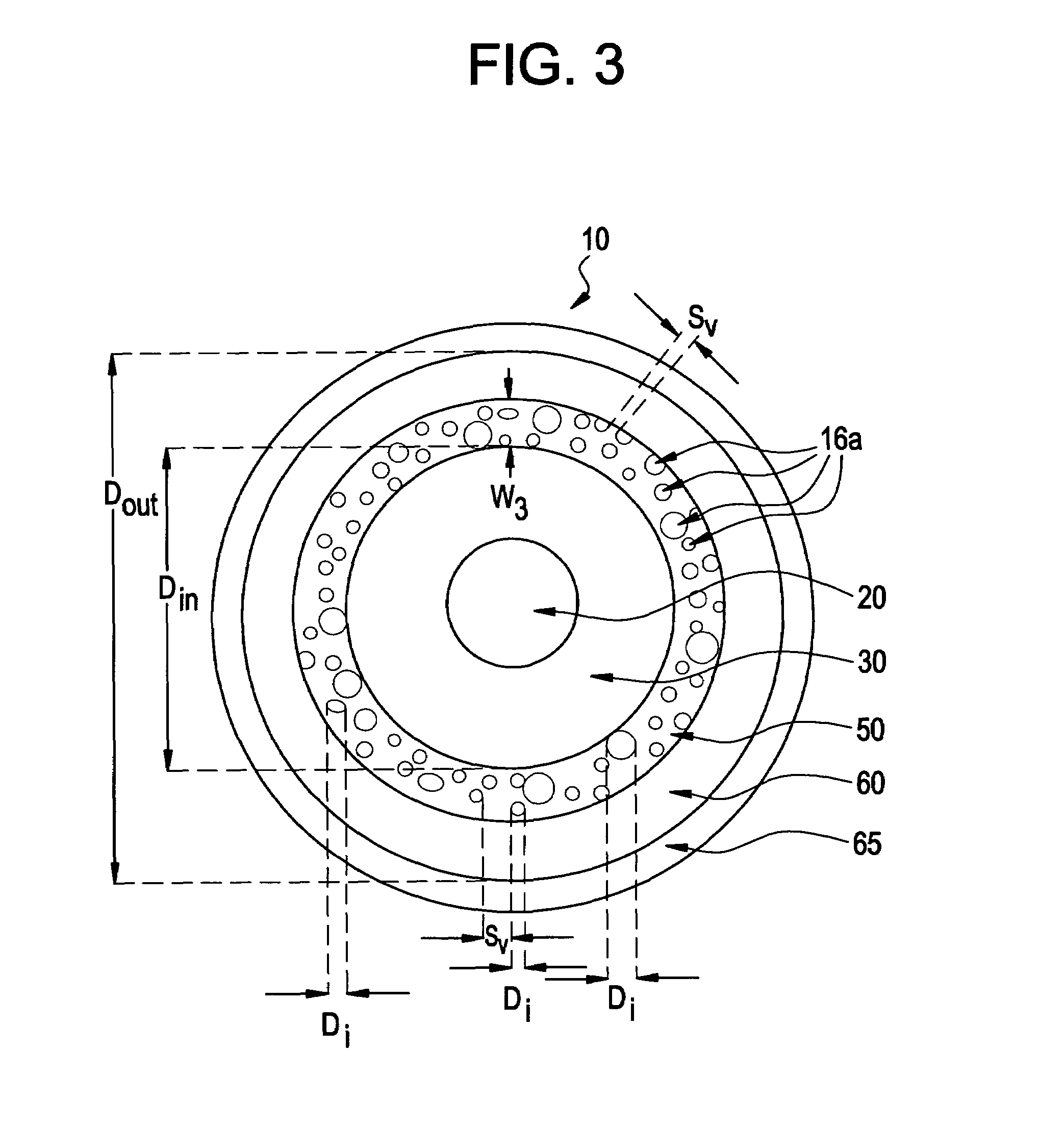

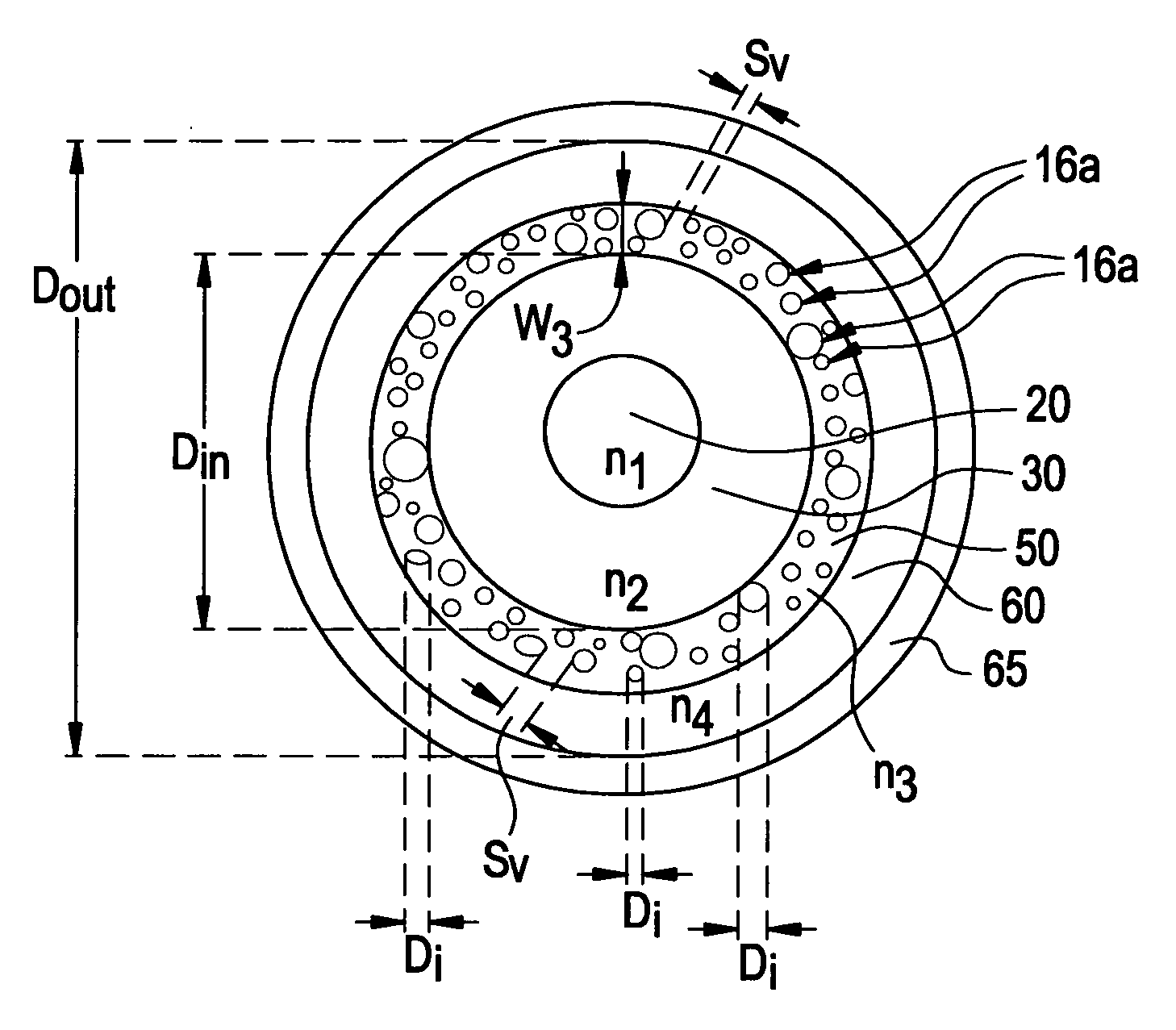

An optical fiber comprising: a glass core extending from a centerline to a radius R1; a glass cladding surrounding and in contact with the core, the cladding comprising:a first annular region extending from R1 to a radius R2, the first annular region comprising a radial width, W2=R2−R1, a second annular region extending from R2 to a radius R3, the second annular region comprising a radial width, W3=R3−R2, and a third annular region extending from R3 to an outermost glass radius R4; wherein (i) the core comprises a maximum relative refractive index, Δ1MAX, relative to the third annular region; (ii) wherein the first annular region comprises a radial width W2; and (iii) the second annular region comprises a minimum relative refractive index, Δ3MIN, relative to the third annular region wherein Δ1MAX>Δ2MAX>Δ3MIN, and Δ2MIN>Δ3MIN; and the core and the cladding provide a fiber with cable cutoff less than 1500 nm, dispersion at 1550 nm less than 12 ps / nm / km, effective area at 1550 nm greater than 60 μm2, and preferably greater than 70 μm2. The second annular cladding region may contain a plurality of randomly dispersed holes.

Owner:CORNING INC

Optical fiber having a lower bending loss

ActiveUS6901196B2Bending lossSuppressing transmission loss increaseGlass optical fibreGlass making apparatusHydrogenRelative refractive index

An optical fiber includes a first core having a relative refractive index difference of larger than 0.36%, and a cladding. The optical fiber has fiber cut-off wavelength λc of more than 1350 nm, cable cut-off wavelength λcc of less than 1285 nm, bending loss at a wavelength of 1625 nm of not more than 10 dB / km when wound at a diameter of 20 mm, transmission loss at a wavelength range of 1285 to 1625 nm of not more than 0.40 dB / km, transmission loss at a wavelength of 1383 nm less than transmission loss at a wavelength of 1310 nm, and difference in transmission loss at a wavelength of 1383 nm of not more than 0.04 dB / km before and after exposure to hydrogen. The lower bending loss of the optical fiber provides an optical fiber cable for use in a WDM transmission in wavelength range of 1285 to 1625 nm.

Owner:FURUKAWA ELECTRIC CO LTD

Optical waveguide and spot size converter using this

An optical waveguide includes a substrate in the shape of a flat plate; lower clad that is disposed on the substrate; and a core that is disposed on the lower clad and transmits light. The optical waveguide includes a first optical waveguide and a second optical waveguide. The first optical waveguide includes a first core on the lower clad, and is disposed so as to extend along a direction in which the light travels to a first position. The second optical waveguide includes a second core on the lower clad, is disposed so as to extend along a direction in which the light travels to a second position, and has a lower relative refractive index difference than the first optical waveguide. The first optical waveguide and the second optical waveguide form, between the first position and the second position, a layer structure where the first core and the second core are disposed such that the first core is positioned a predetermined distance away from the second core in a direction perpendicular to the substrate. At least either the first optical waveguide or the second optical waveguide includes a mode coupling section and a mode conversion section. The mode coupling section includes a directional coupler to conduct the mode coupling of the first core and the second core between the first position and the second position. The mode conversion section is connected to the mode couplingsection, and has a tapered core structure to adjust the mode diameter of the first core to the mode diameter of the second core.

Owner:NEC CORP

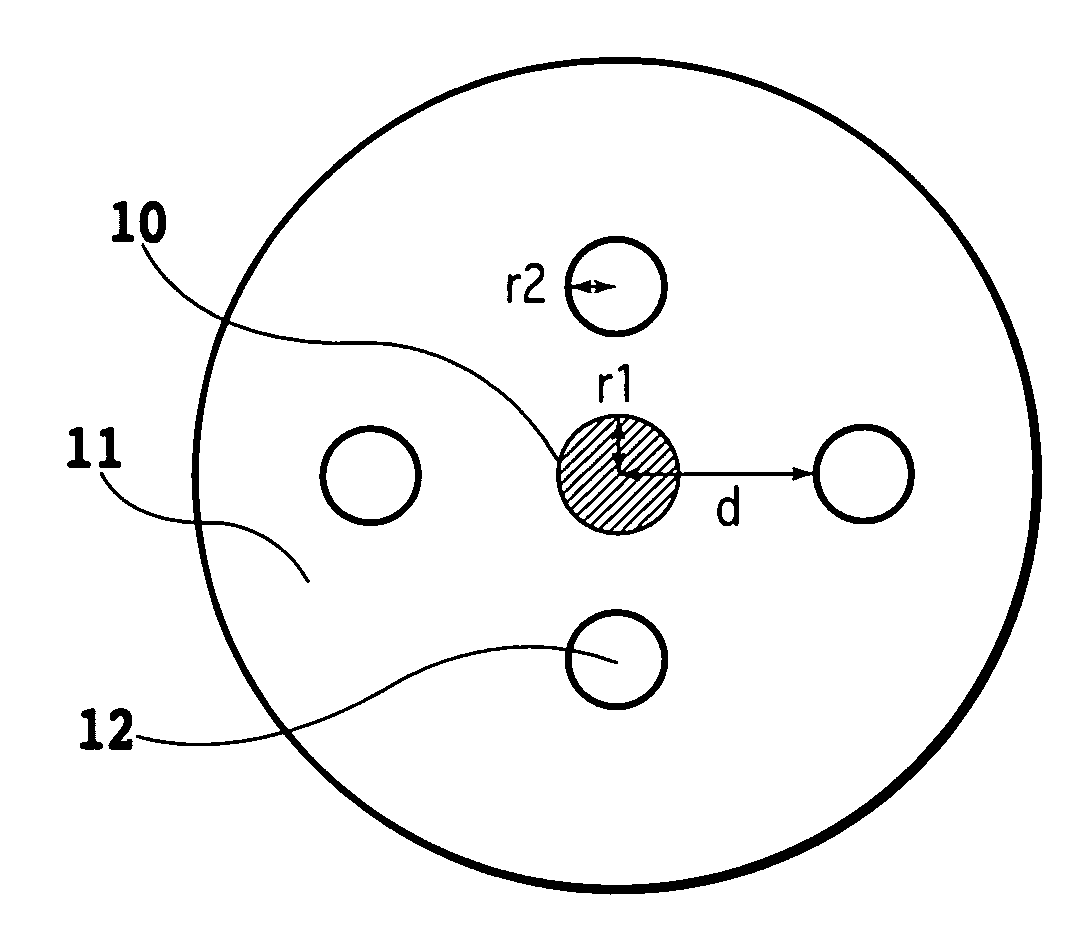

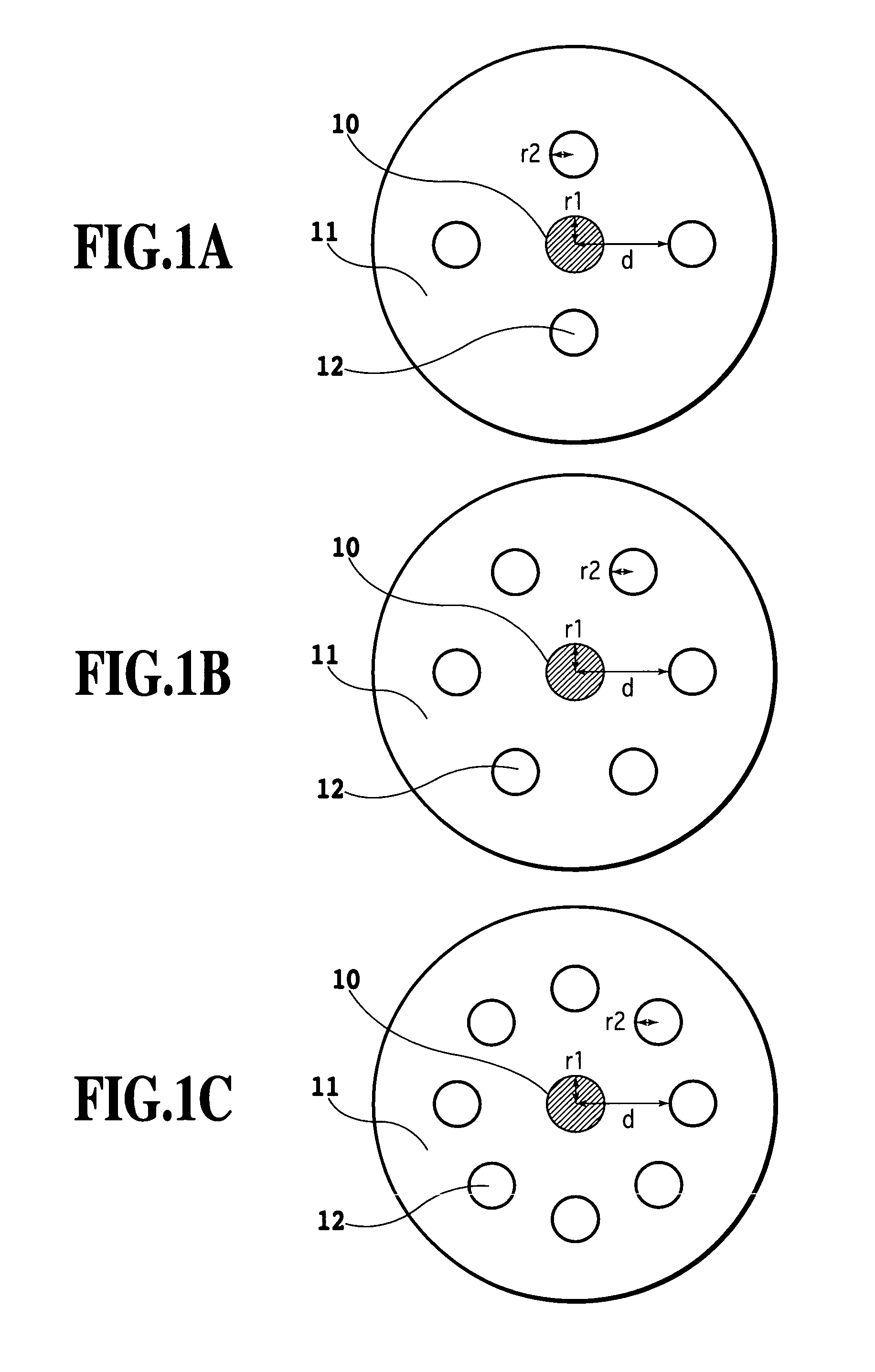

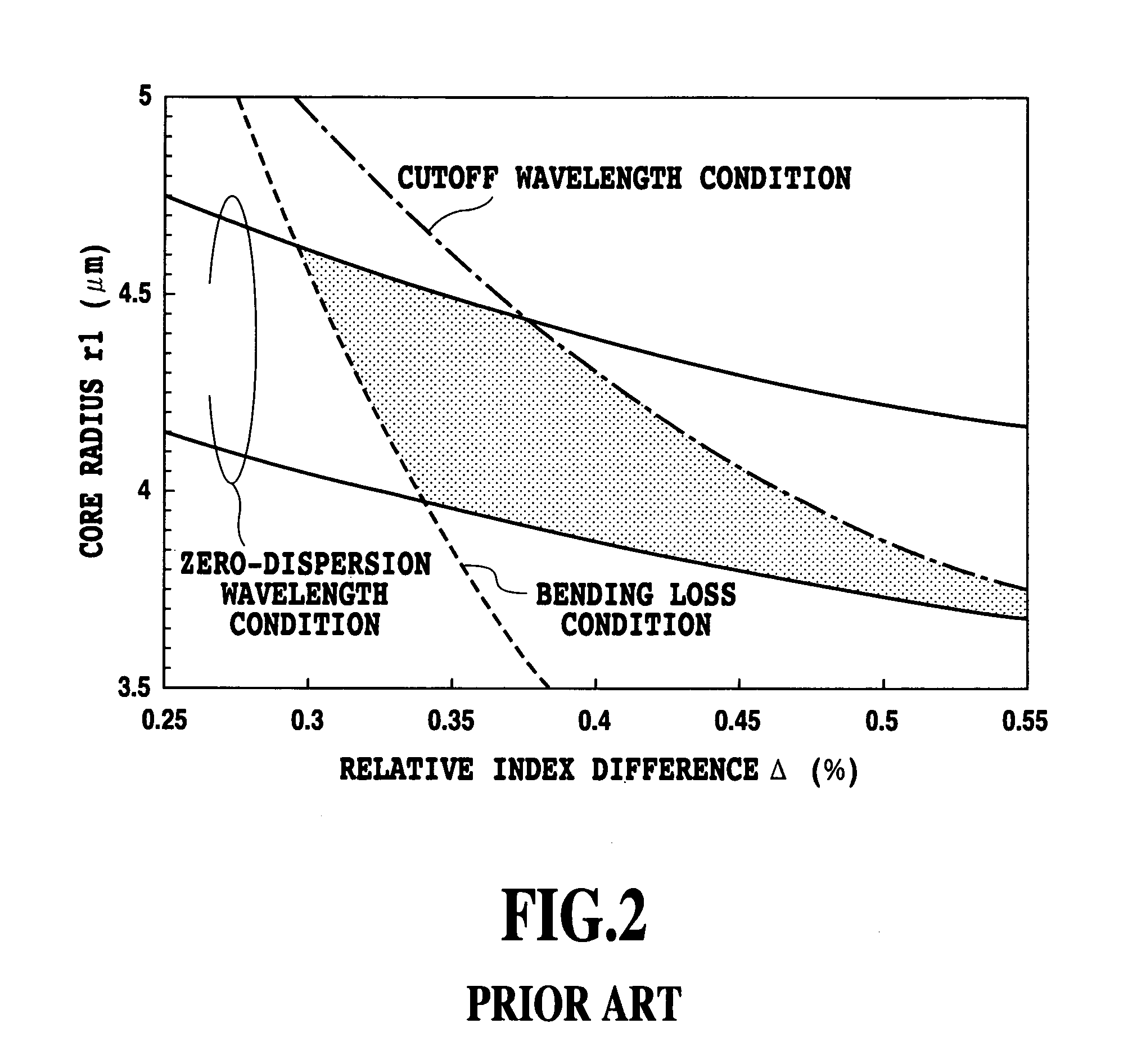

Hole-assisted single mode optical fiber

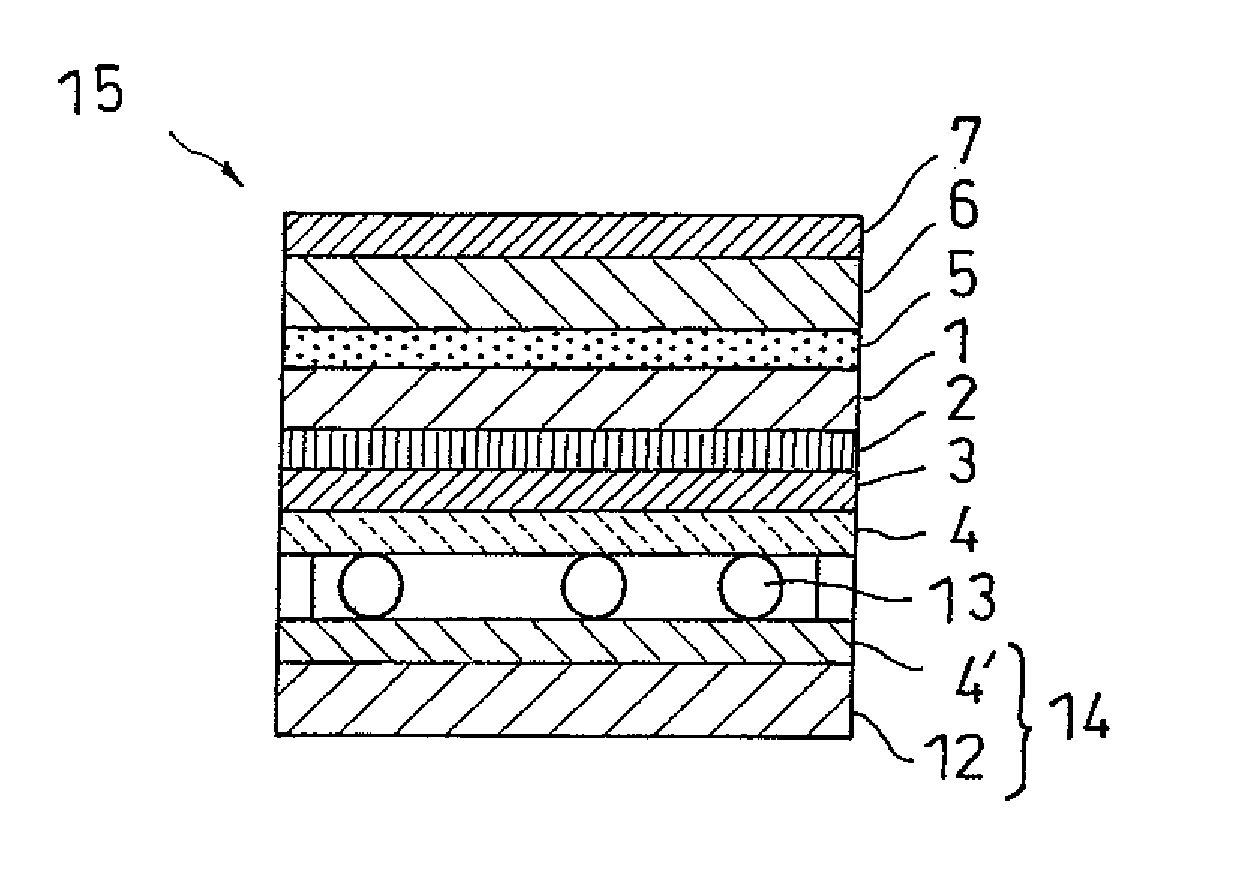

ActiveUS7228040B2Increase resistanceImprove connection characteristicsCladded optical fibreOptical waveguide light guideRelative refractive indexOptical communication

A single mode fiber is provided which is suitable for high-speed, large-capacity optical communication and for optical wiring. The single mode fiber has a first cladding region with a uniform refractive index, a core region with a refractive index higher than that of the first cladding region, and a second cladding region including at least four air hole regions placed in the first cladding region. Optimization can be achieved by making the distance from the center of the core region to the air hole regions equal to 2–4.5 times the core radius, and the air hole radius equal to or greater than 0.2 times the core radius. It is preferable the core radius be 3.7–4.8 μm, the relative index difference of the core region from the first cladding region be 0.3–0.55 %.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

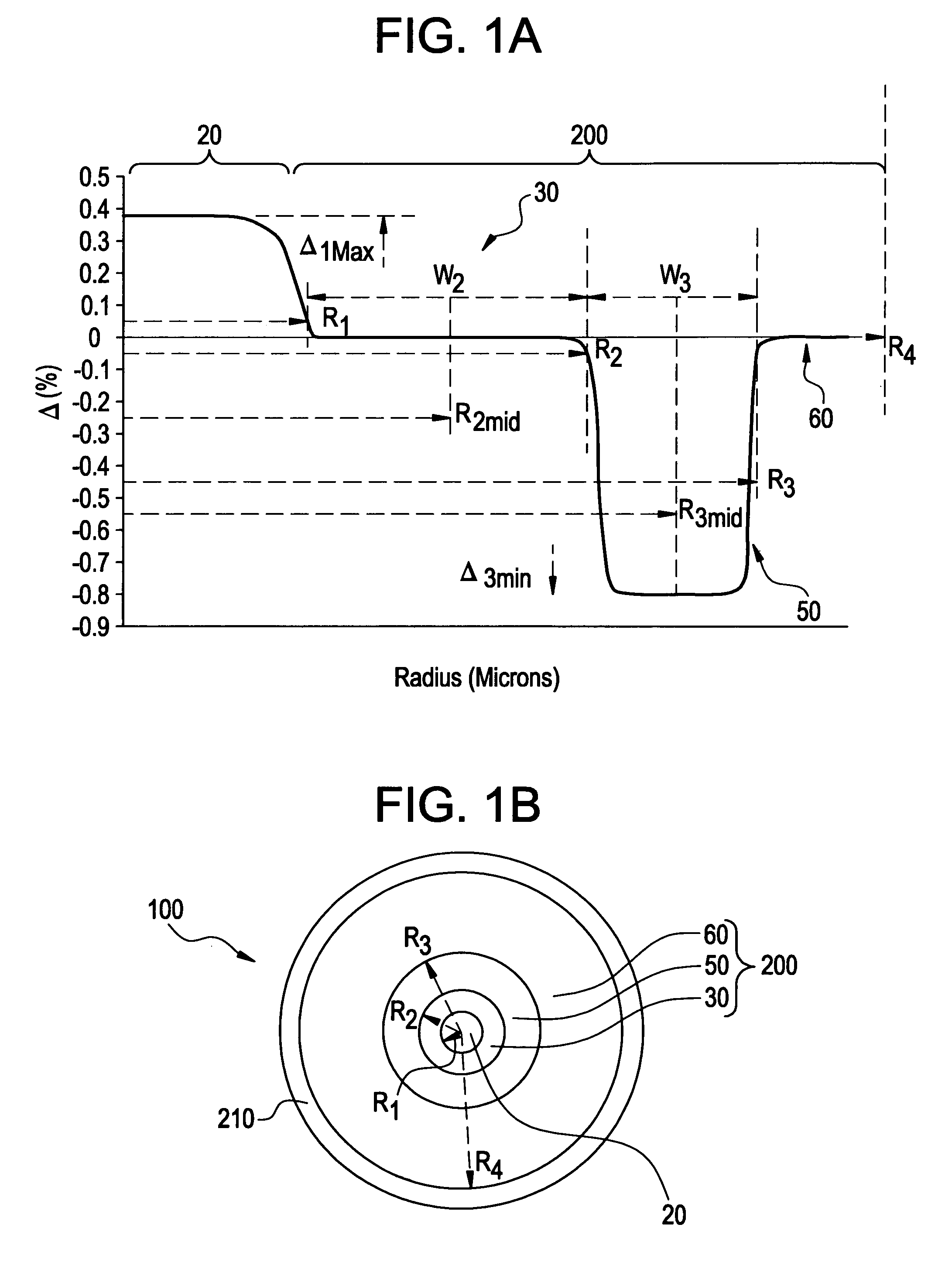

Large effective area fiber

ActiveUS20080279517A1Optical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingRelative refractive indexEngineering

An optical fiber according to an embodiment of the present invention comprises: a glass core extending from a centerline to a radius R1 wherein R1 is greater than about 5 μm; a glass cladding surrounding and in contact with the core, the cladding comprising: (i) a first annular region extending from the radius R1 to a radius R2, the first annular region comprising a radial width, W2=R2−R1, (ii) a second annular region extending from the radius R2 to a radius R3, and comprising a radial width, W3=R3−R2, and (iii) a third annular region surrounding the second annular region and extending from the radius R3 to an outermost glass radius R4; wherein the core comprises a maximum relative refractive index, Δ1MAX, relative to the third annular region, and wherein Δ1MAX is greater than about 0.1% and less than about 0.3%; the first annular region has a refractive index delta Δ2(r) is less than about 0.025%; wherein the second annular region comprises a minimum relative refractive index, Δ3MIN, relative to the third annular region;wherein Δ1MAX>Δ2MAX>Δ3MIN, and Δ2MIN>Δ3MIN<0; andwherein the core and the cladding provide a fiber with cable cutoff less than 1500 nm, and an effective area at 1550 nm greater than 95 μm2 and bend loss of ≦0.5 dB / turn on a 20 mm diameter mandrel.

Owner:CORNING INC

Large effective area fiber with GE-free core

ActiveUS7689085B1Optical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingMedicineRelative refractive index

An optical waveguide fiber comprising:(i) a Ge free core having an effective area of 90 μm2 to 160 μm2, at a 1550 nm wavelength, and α value 12≦α≦25, said core comprising:(a) a central core region extending radially outwardly from a centerline to a radius r0≦2 μm, and having a relative refractive index percent profile Δ0(r) wherein −0.1% ≦Δ0(r) ≦0.1%, and wherein the central core region has a maximum relative refractive index, Δ0MAX,(b) a first annular core region surrounding and directly adjacent to the central core region and extending to an outer radius r1, wherein 4.8 μm ≦r1≦10 μm, and having a relative refractive index percent profile, Δ1(r), and a minimum relative refractive index, Δ2MIN, and the relative refractive index measured at a radius r=2.5 μm being −0.15≦Δ1(r=2.5 μm) ≦0, and Δ0MAX ≧Δ1(r=2.5 μm);(c) a fluorine doped second annular region surrounding and directly adjacent to the first annular core region and extending to a radius 13 μm ≦r2≦30 μm and having a negative relative refractive index percent profile, Δ2(r), with a minimum relative refractive index Δ2MIN being:Δ2MIN<Δ1(r=2.5 μm), and −0.7% ≦Δ2MIN≦−0.28%; and(ii) a cladding surrounding the core and having a relative refractive index percent Δc (r) in % measured relative to pure silica, and Δc (r)=Δ2MIN±0.3%;wherein the relative refractive index profile of the optical fiber is selected to provide attenuation of no more than 0.175 dB / km at the wavelength of 1550 nm.

Owner:CORNING INC

Transparent conductive multilayer body and touch panel having same

InactiveUS20070091074A1Solid-state devicesRecord information storageRelative refractive indexFilm base

A transparent conductive multilayer body of the present invention is characterized by having: a transparent film base; an SiOx film (x is no less than 1.5 and less than 2) which is provided on one surface of the above described film base in accordance with a dry process, and has a thickness of 1 nm to 30 nm and a relative index of refraction of 1.6 to 1.9; an SiO2 film which is provided on the above described SiOx film and has a thickness of 10 nm to 50 nm; and a transparent conductive thin film which is provided on the above described SiO2 film and has a thickness of 20 nm to 35 nm.

Owner:NITTO DENKO CORP

Conductive sheet, touch panel, display device, method for producing said conductive sheet, and non-transitory recording medium

ActiveUS20140111711A1Easy to seeIncrease the differenceConductive layers on insulating-supportsDigital data processing detailsRelative refractive indexDisplay device

The present invention pertains to: a conductive sheet, a touch panel, a display device, a method for producing the conductive sheet, and a recording medium. In the present invention, the relative refractive index of a substrate with respect to a first protective layer, and / or the relative refractive index of the substrate with respect to a second protective layer is 0.86-1.15. The relative refractive index of a first substrate with respect to the first protective layer, and / or the relative refractive index of a second substrate with respect to the second protective layer is 0.86-1.15.

Owner:FUJIFILM CORP

High bandwidth multimode fiber

ActiveCN101738681AImprove bending resistanceHigh bandwidthOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingAccess networkUltrasound attenuation

The invention relates to a high bandwidth multimode fiber used in an access network and a miniaturized optical device, which comprises a core layer and clad layers. The high bandwidth multimode fiber is characterized in that the radius of the core layer is 15 to 35 microns, the refractive index profile of the core layer is parabolic, and the maximum relative refractive index difference delta 1 percent max is over 0.8 percent; and the clad layers outside the core layer comprise an inner clad layer and / or a sunken inner clad layer, a rising ring and a sunken outer clad layer from the inside to the outside, and the relative refractive index difference of each layer satisfies the following relationships at the same time: delta 1 percent max is more than delta 2 percent which is more than delta 3 percent, delta 4 percent is more than delta 3 percent, the delta 4 percent is more than delta 5 percent, and the delta 4 percent is more than or equal to delta 2 percent. The macro-bending additional attenuation of the fiber is remarkably reduced, and the anti-bending performance of the fiber is improved; the fiber is provided with the rising ring so that the energy of some high-order mode of the core layer of the fiber is transferred or coupled to some mode of the rising ring from the core layer to effectively improve the bandwidth of the bending-insensitive multimode fiber; and the manufacturing method of the invention is simple, convenient and effective, and is suitable for mass production.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

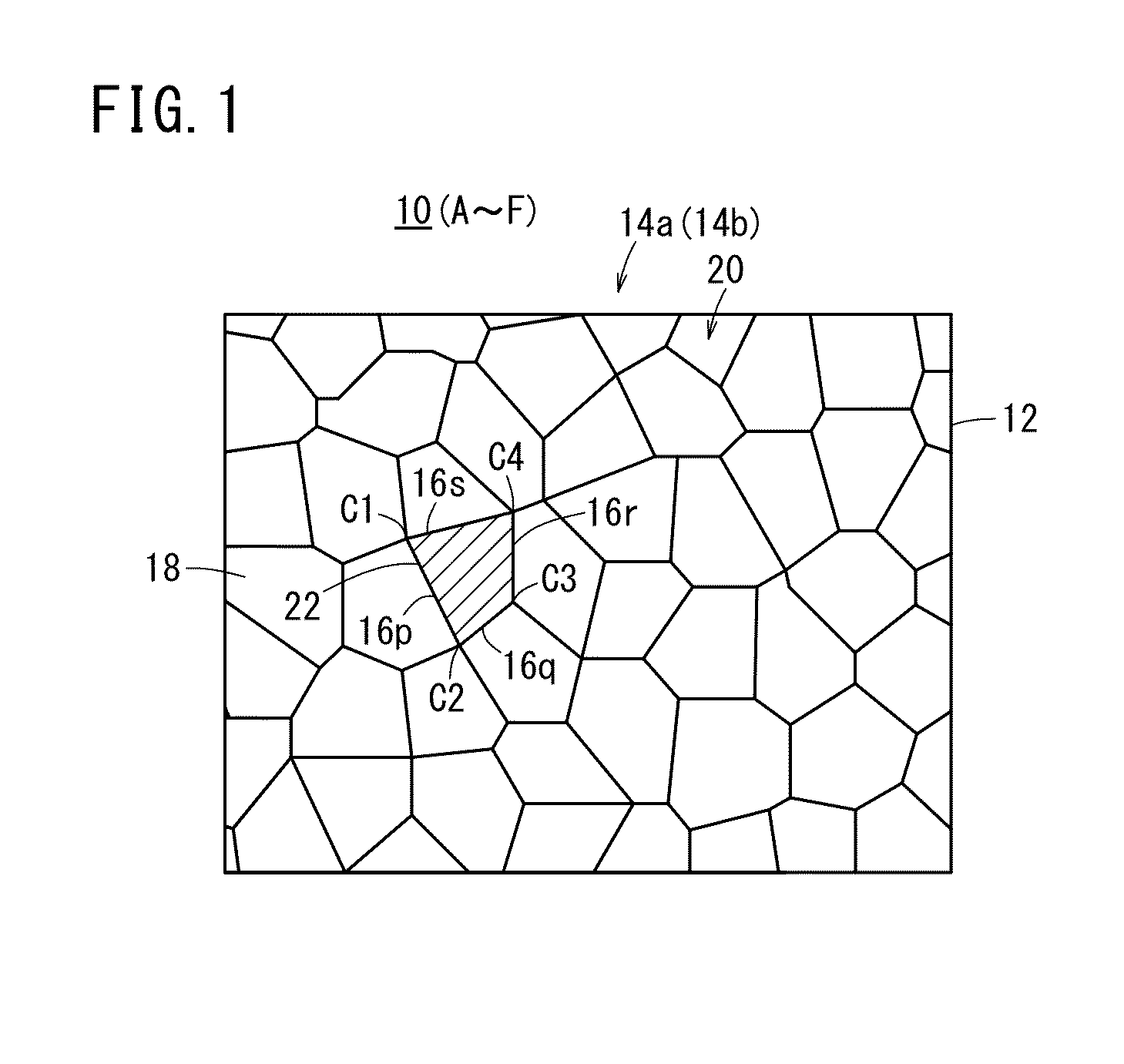

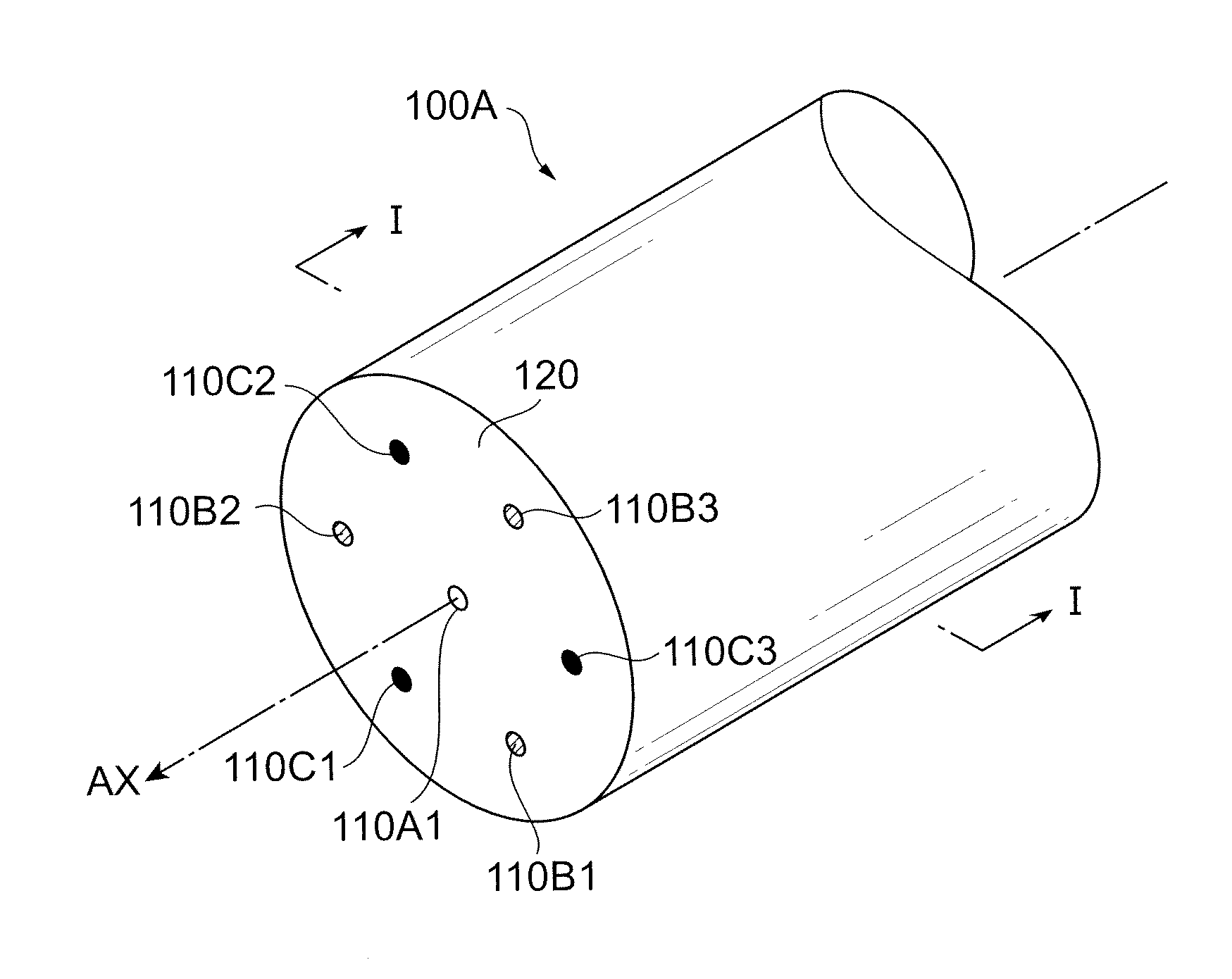

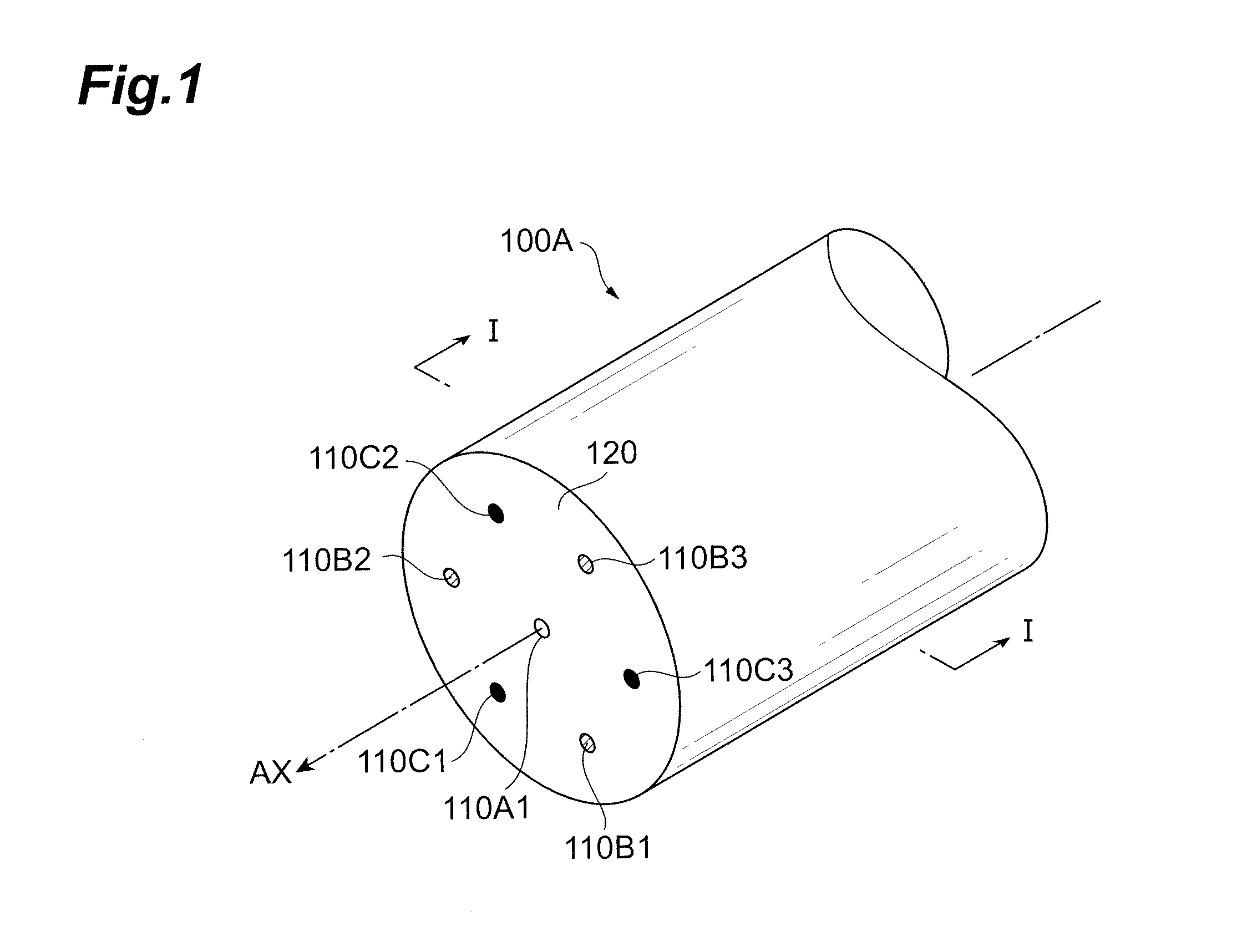

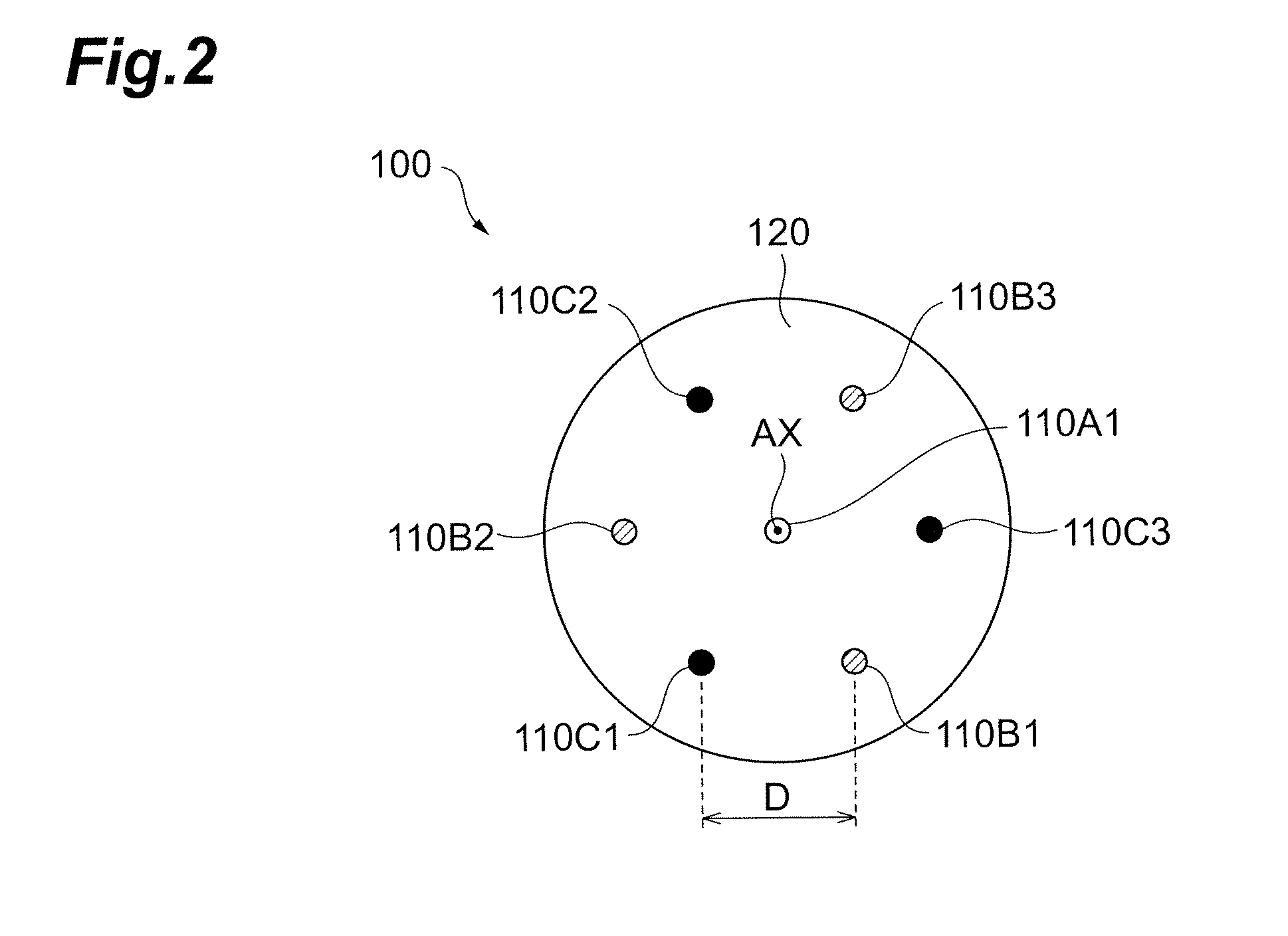

Multi-core fiber

ActiveUS20110182557A1Ensure qualityEasy to spreadOptical fibre with multilayer core/claddingMulticore optical fibreRelative refractive indexOptical axis

The present invention relates to a multi-core fiber having a structure for effectively suppressing crosstalk increase between cores caused by bending within an allowable range. The multi-core fiber comprises a plurality of types of cores respectively extending along an optical axis and a cladding region, and the effective refractive index of each core is set so that, in all pairs of cores of different types, a relative refractive index difference between an effective refractive index of a core of a certain type and an effective refractive index of a core of another type satisfies a condition regulated according to a core spacing between cores and a bending radius.

Owner:SUMITOMO ELECTRIC IND LTD

Optical fiber, optical transmission line, optical module and optical transmission system

ActiveUS20070217754A1Decrease residual dispersionReduce dispersionOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingOptical ModuleRelative refractive index

The present invention relates to an optical fiber which has a structure for further increasing an FOM (=|dispersion| / loss) and which can be applied to a dispersion compensation module. The optical fiber is mainly composed of silica glass and has a core region including a center of an optical axis, a depressed region surrounding the core region, a ring region surrounding the depressed region, and a cladding region surrounding the ring region and doped with F. As compared with the refractive index of pure silica glass, a relative refractive index difference of the core region is 3% or more but 4% or less, a relative refractive index difference of the depressed region is −1% or more but −0.5% or less, a relative refractive index difference of the ring region is 0.01% or more but 0.24% or less, and a relative refractive index difference of the cladding region is −0.3% or more but −0.1% or less. The FOM at the wavelength of 1550 nm is 250 ps / nm / dB or more.

Owner:SUMITOMO ELECTRIC IND LTD

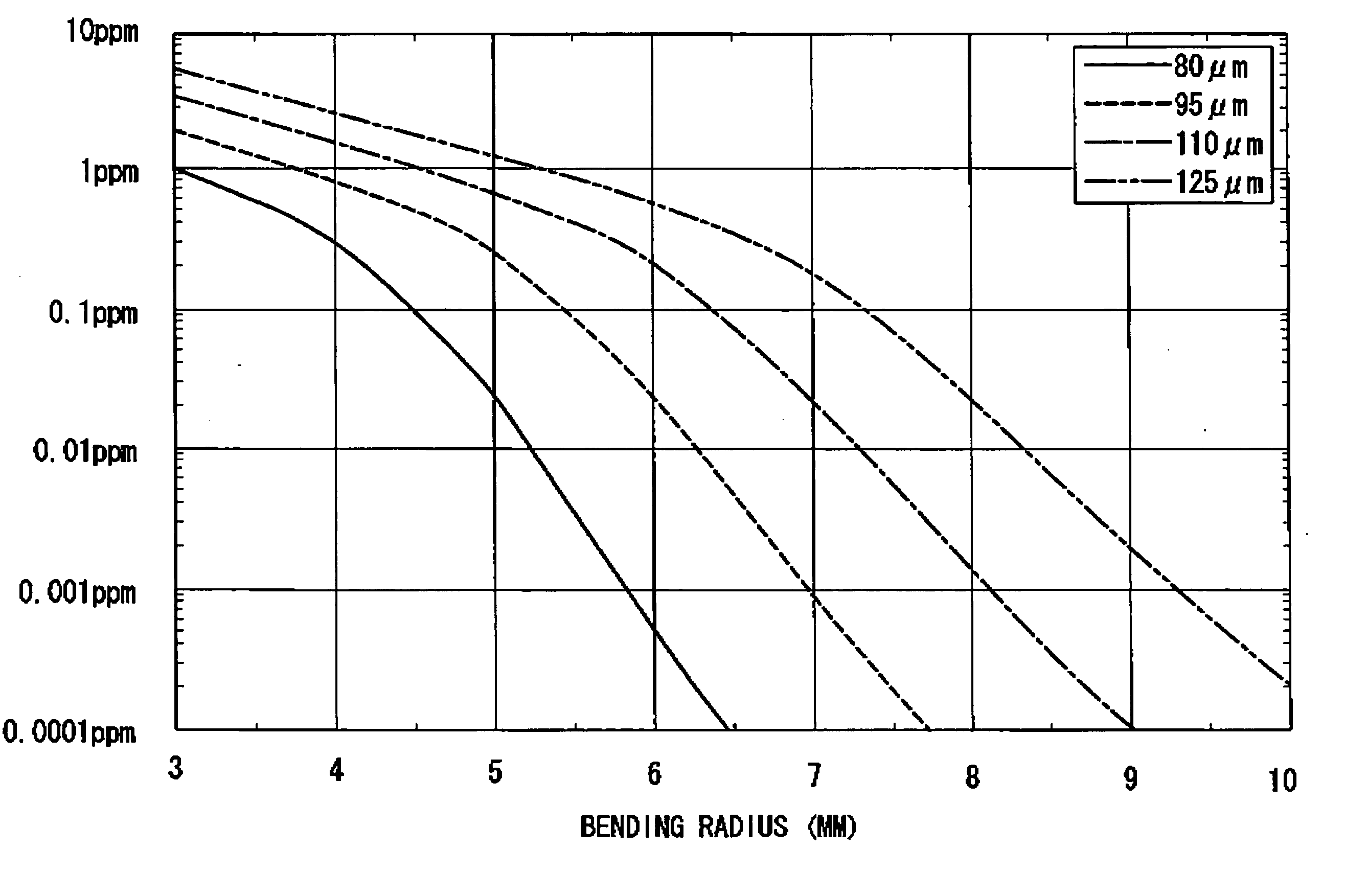

Single-mode optical fiber, optical fiber cable, optical fiber cord, and method for ensuring service life of optical fiber

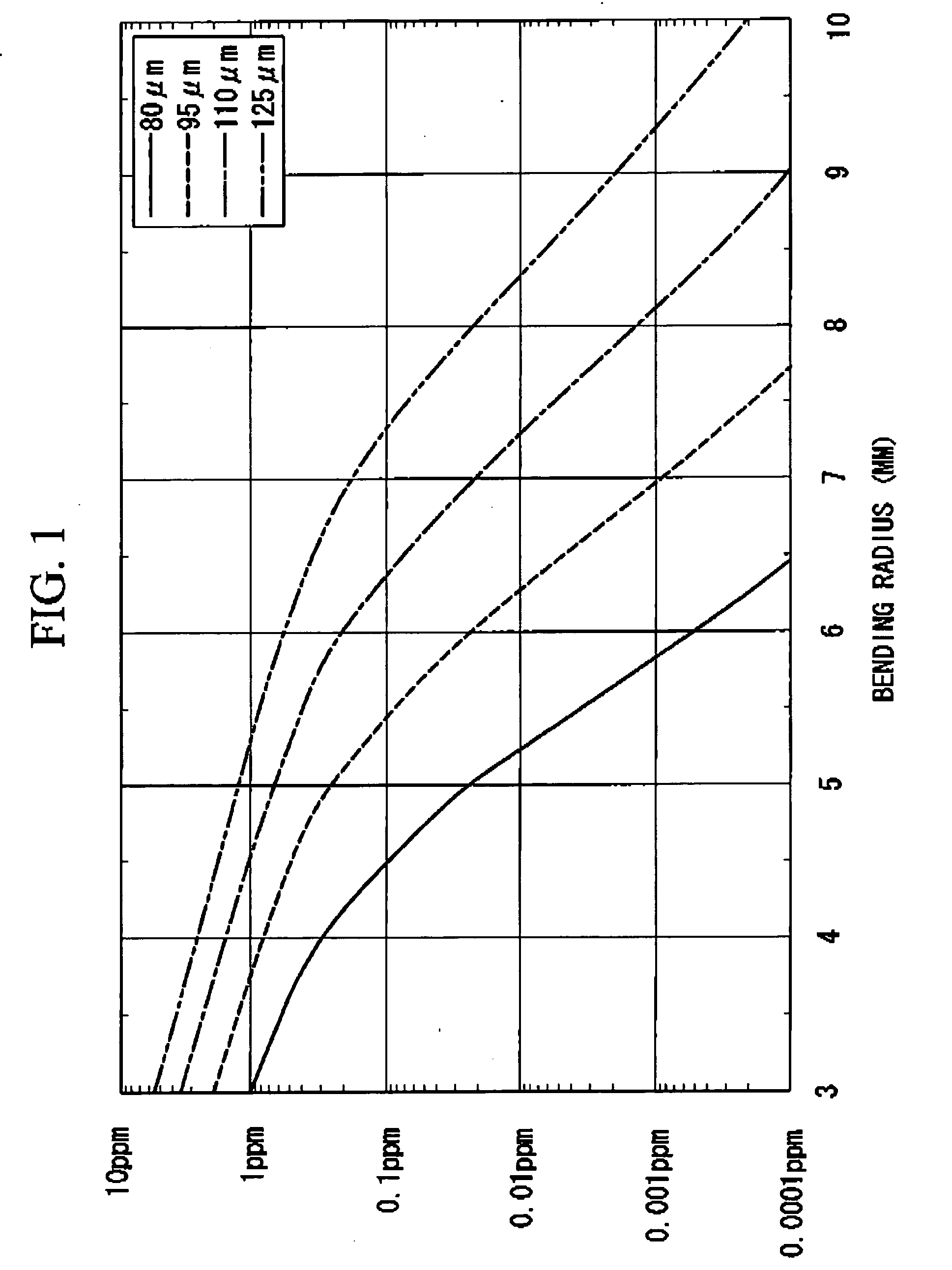

InactiveUS20060115224A1Failure probabilityCladded optical fibreOptical waveguide light guideRelative refractive indexEngineering

A single-mode optical fiber, cable, cord, and a method for ensuring a service life of the fiber are provided. The fiber has a core and a cladding, the fiber having a cut-off wavelength that exhibits a single-mode transmission in a 1.31 μm wavelength band. A relative refractive index difference of the core with respect to the cladding is adjusted such that a bending loss, when a bend is applied in a radius smaller than a limit bending radius of the fiber, becomes greater than a detection limit value. The limit bending radius is calculated from a relationship between a bending radius applied to the optical fiber and a failure probability which occurs after a time period. The method includes measuring a loss and ensuring that a failure probability of the fiber during a service life falls within a failure probability used for setting the limit bending radius.

Owner:THE FUJIKURA CABLE WORKS LTD

Broadband optical fiber

InactiveUS20060045450A1Suitable performanceOptical fibre with multilayer core/claddingElectromagnetic transmissionRelative refractive indexBroadband

An optical waveguide fiber having a multi-segmented core surrounded by a cladding, the core having a central segment and an annular segment surrounding the central segment. The central segment has a positive relative refractive index profile, and the annular segment has a negative relative refractive index profile. The broadband optical fiber has a bandwidth of at least 2 GHz-km for one or more wavelengths between 775 and 1100 nm.

Owner:CORNING INC

Multimode Fiber With At Least Dual Cladding

InactiveUS20100040336A1Optical fibre with graded refractive index core/claddingOptical waveguide light guideRelative refractive indexMulti-mode optical fiber

Multimode optical fiber is disclosed herein having a core surrounded by first and second annular cladding regions. The second annular cladding region has a maximum relative refractive index that is at least 0.05% higher than the minimum relative refractive index of the first annular cladding region.

Owner:CORNING INC

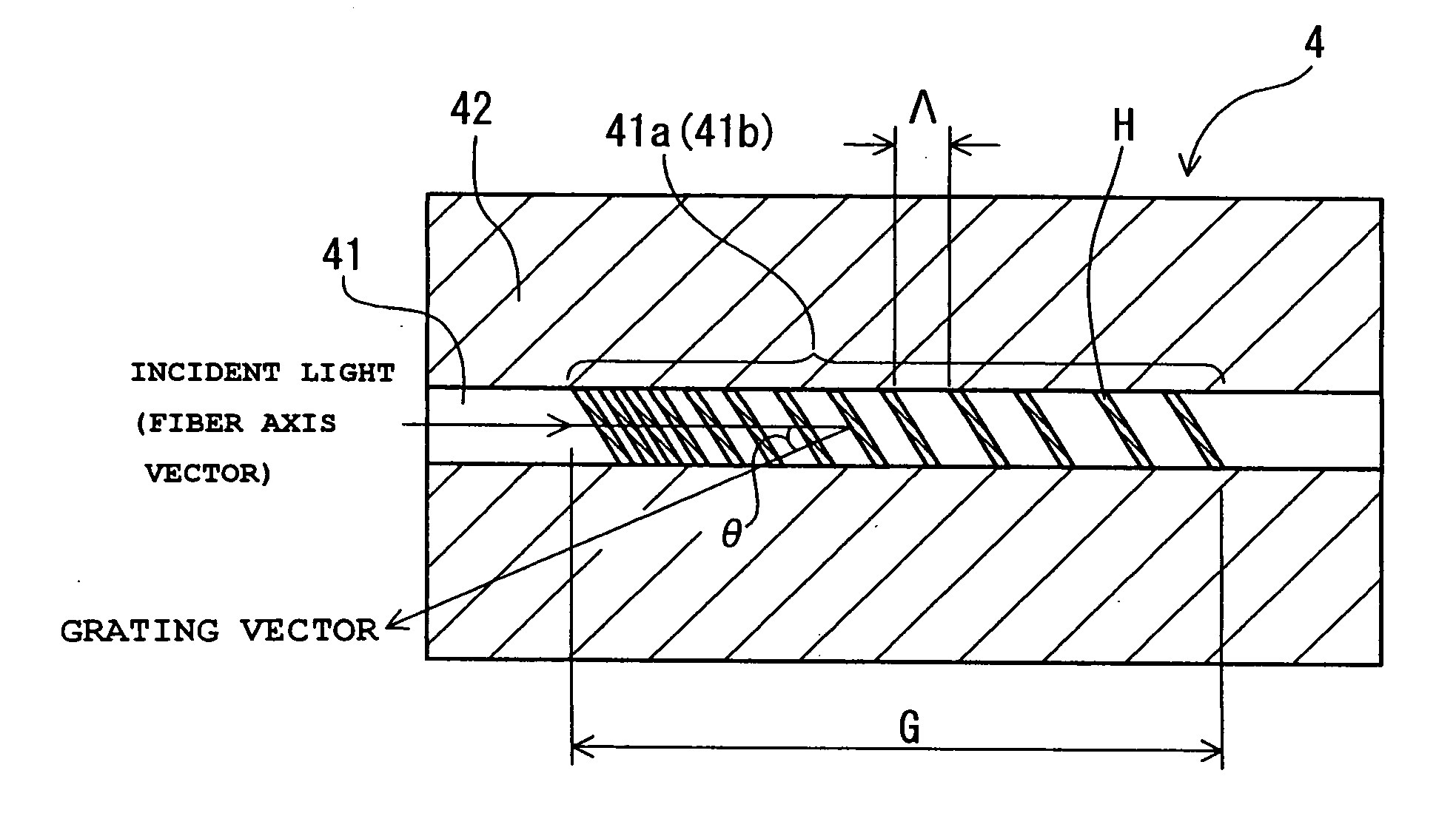

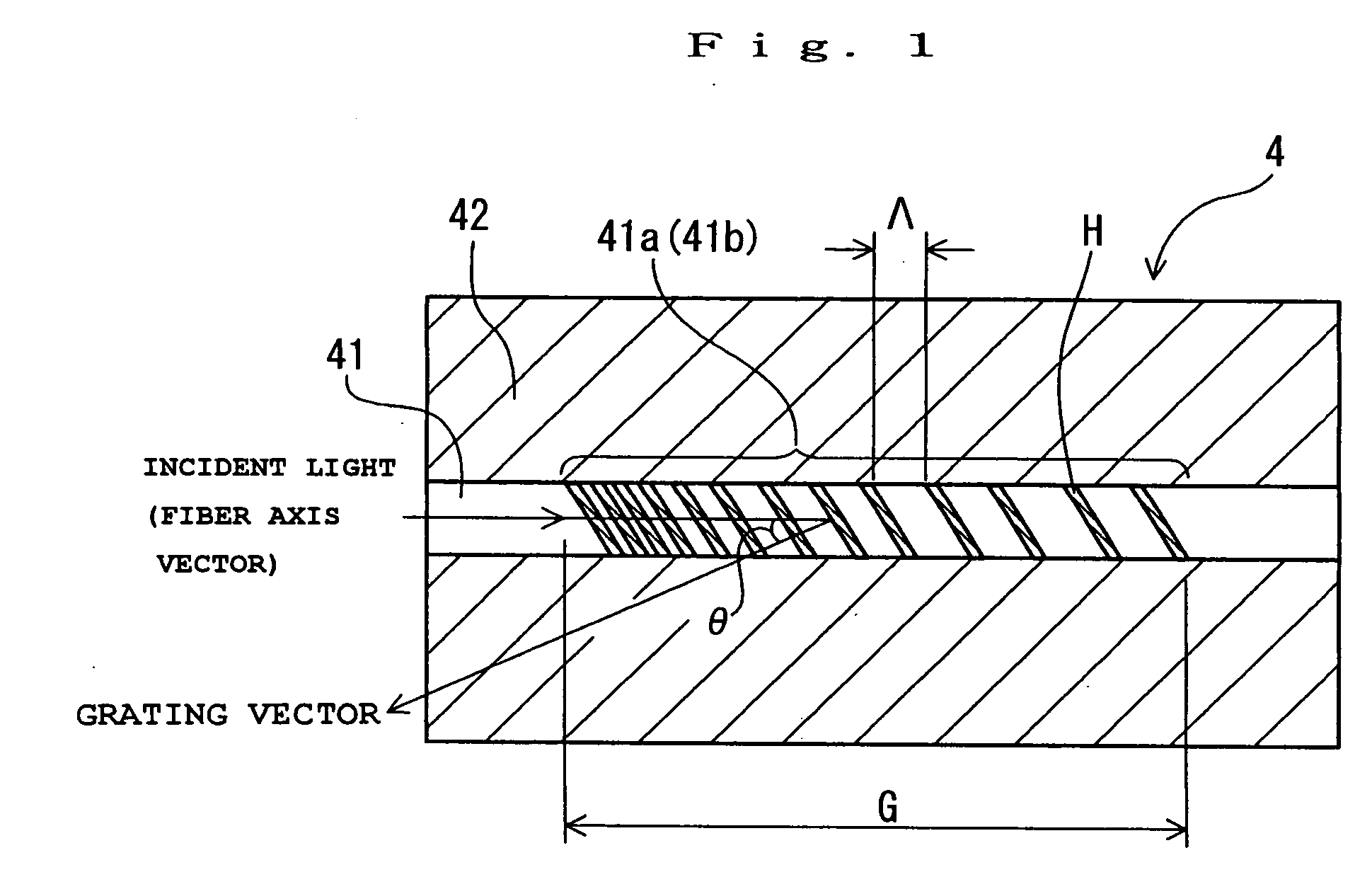

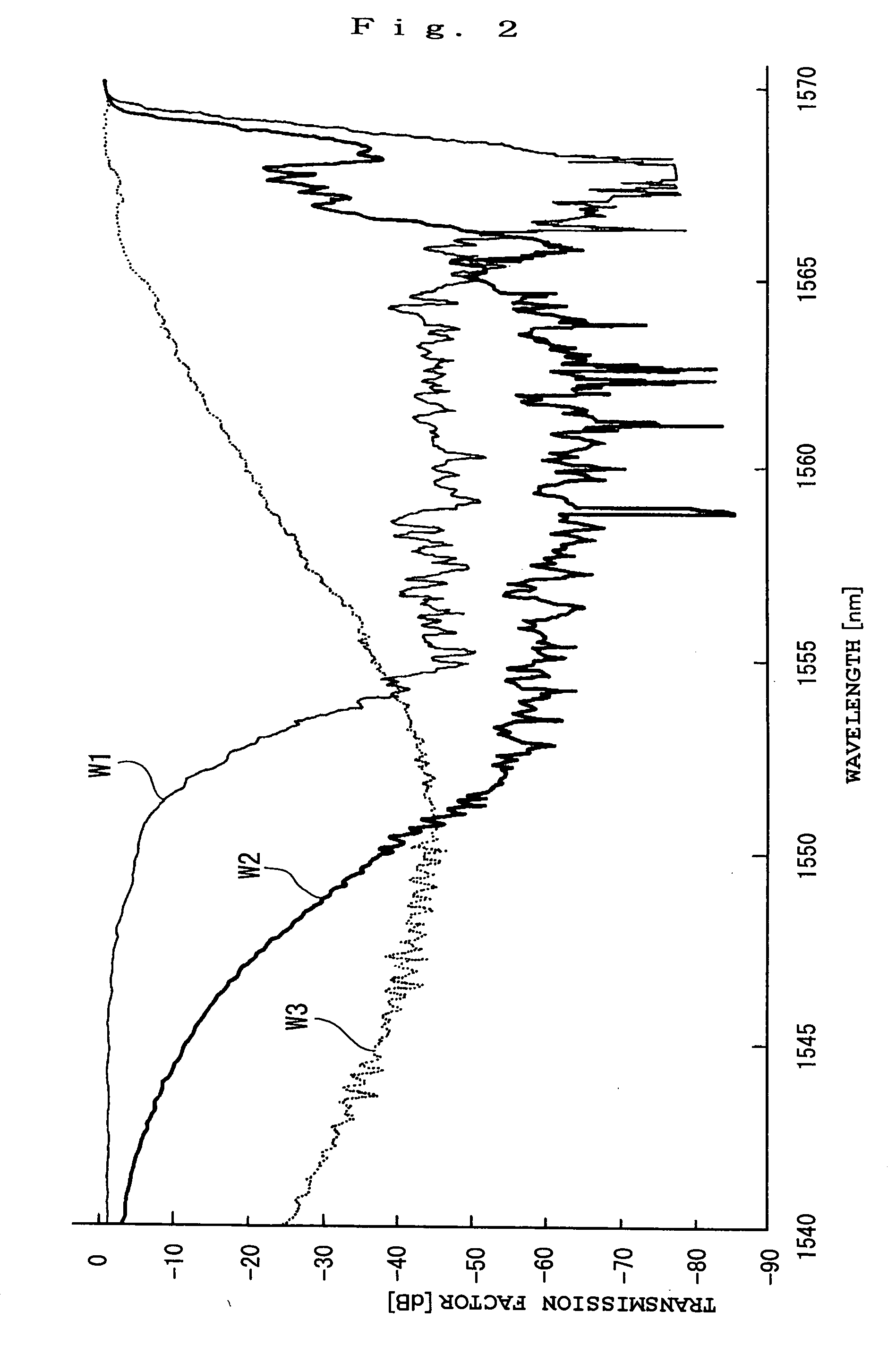

Pseudo slant fiber bragg grating, multiple series fiber bragg grating, optical fiber type coupler and optical connector

InactiveUS20060067616A1Improve featuresEnhanced couplingCoupling light guidesOptical multiplexRelative refractive indexSlant angle

An optical fiber 4 having a clad diameter of 125 μm is made by adding Ge to a core 41 having a core diameter of 8 μm and a relative refractive index difference of 0.3 %, and two refractive index grating portions 41a and 41b having a slant angle of 2° are formed in series in the optical fiber 4 by a phase mask method using KrF excimer laser (λ=248 nm). The central period (2Λ) of the phase mask of a chirped grating is 1,140 nm, the chip rate (C) of the period is 1.2 nm / mm, the length (G) of the first and second index grating portions 41a and 41b is 8 mm, the effective refractive index of the first and second index grating portions 41a and 41b is 1.447, the refractive index modulation is 3×10−3, and the gap between the first and second index grating portions 41a and 41b is 1 mm.

Owner:SHOWA ELECTRIC WIRE & CABLE CO LTD

Low bend loss single mode optical fiber with chlorine updoped cladding

ActiveUS20170075061A1High indexReduced microbending lossesGlass optical fibreOptical fibre with graded refractive index core/claddingRelative refractive indexBend loss

An optical fiber having both low macrobend loss and low microbend loss. The fiber has a central core region, a first (inner) cladding region surrounding the central core region and having an outer radius r2>16 microns and relative refractive index Δ2, and a second (outer) cladding region surrounding the first cladding region having relative refractive index, 43, wherein Δ1>Δ3>Δ2 . The difference between Δ3 and Δ2 is greater than 0.12 percent. The fiber exhibits a 22m cable cutoff less than or equal to 1260 nm, and r1 / r2 is greater or equal to 0.24 and bend loss at 1550 nm for a 15 mm diameter mandrel of less than 0.5 dB / turn.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com