Patents

Literature

348results about How to "Lower refractive index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanocomposites

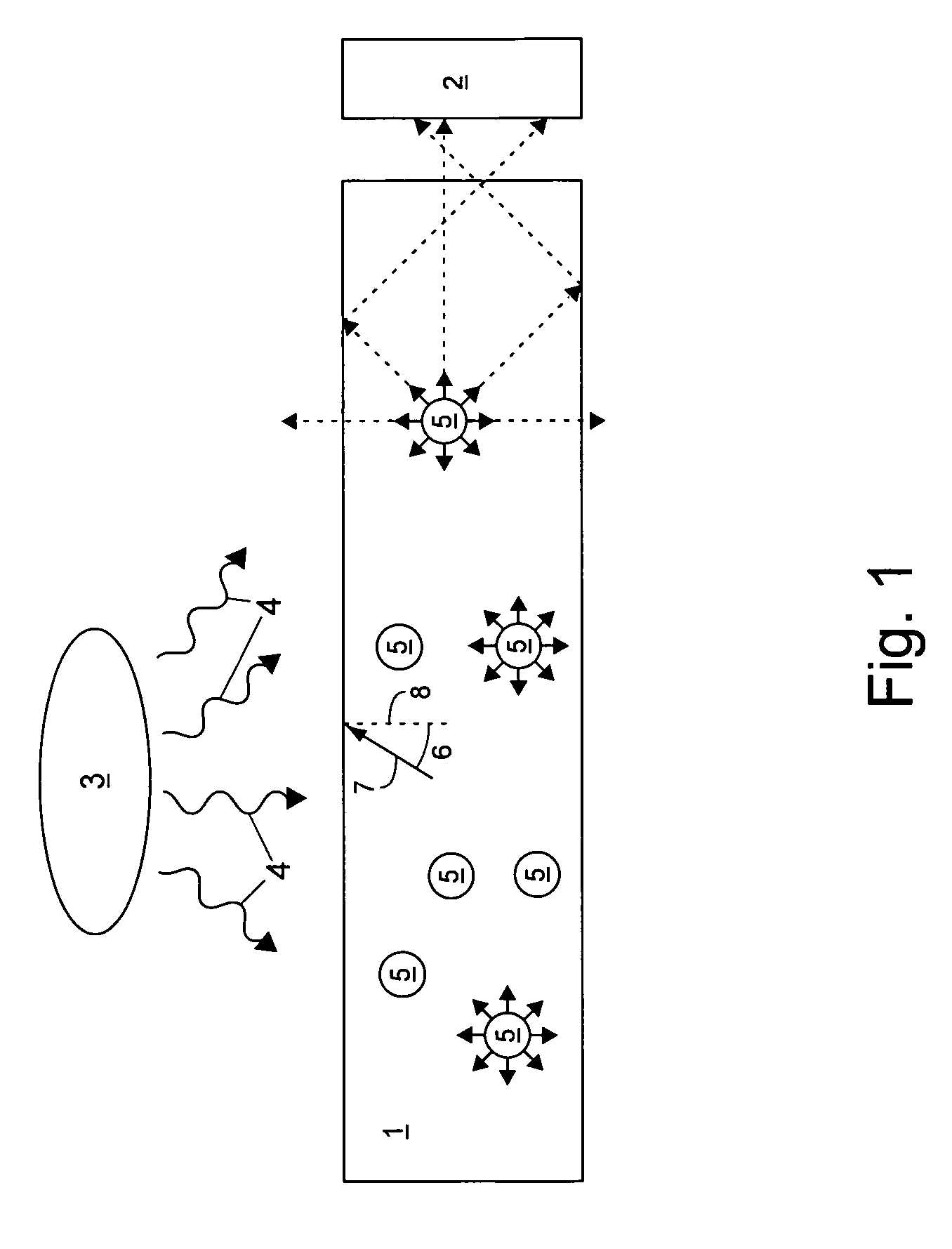

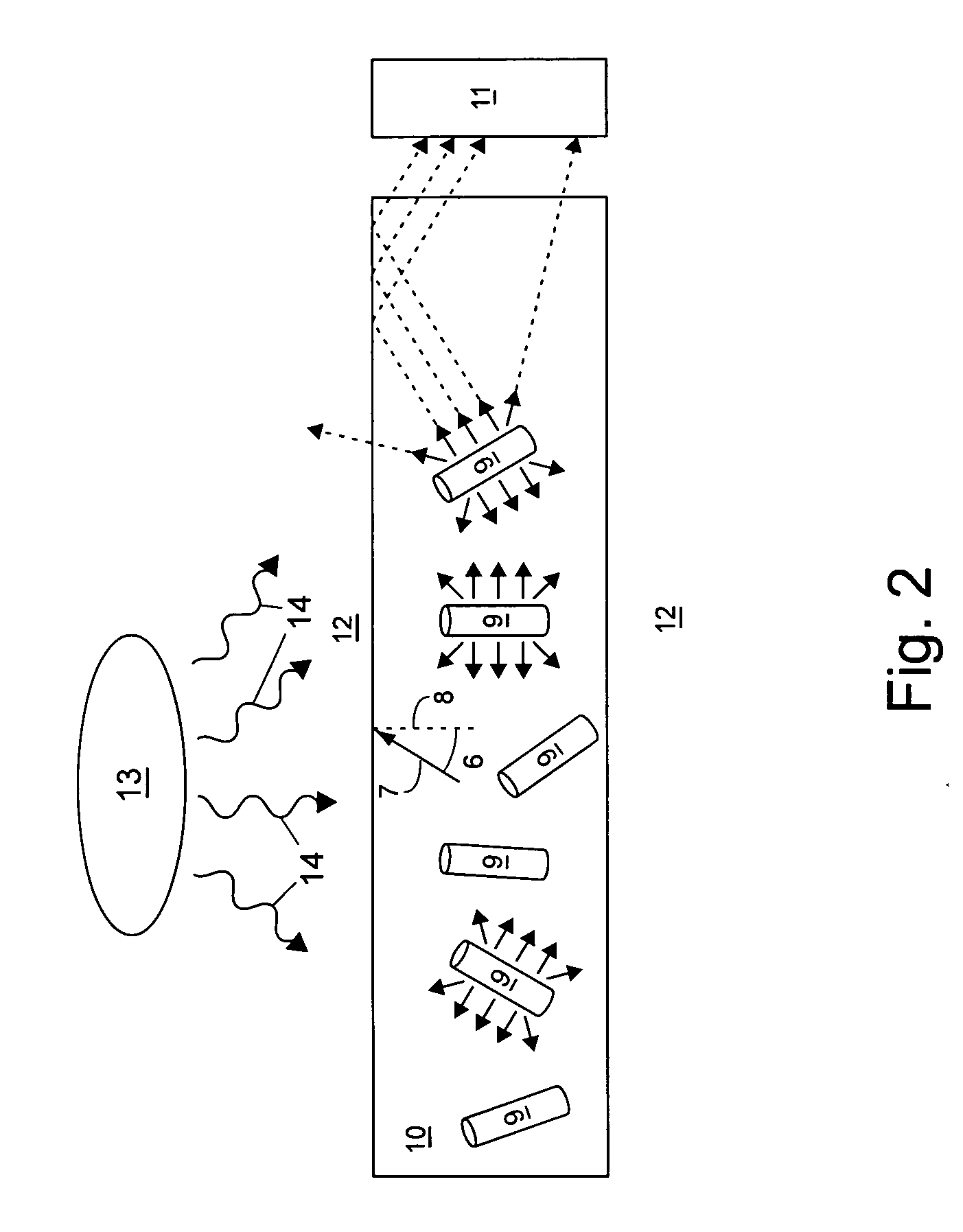

ActiveUS7068898B2Increase percentageEfficiently waveguidedSolar heating energyMaterial nanotechnologyNanowireNanoparticle

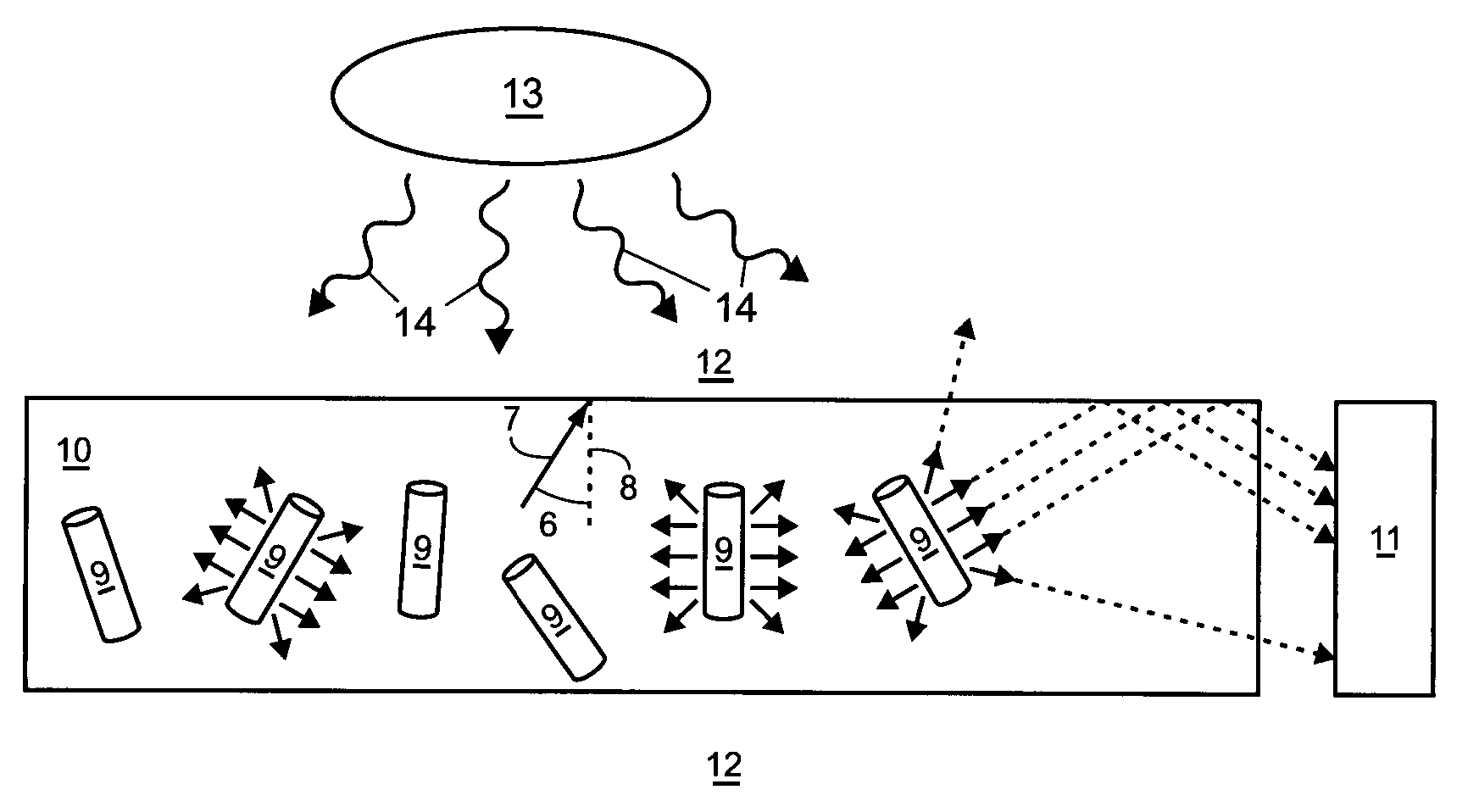

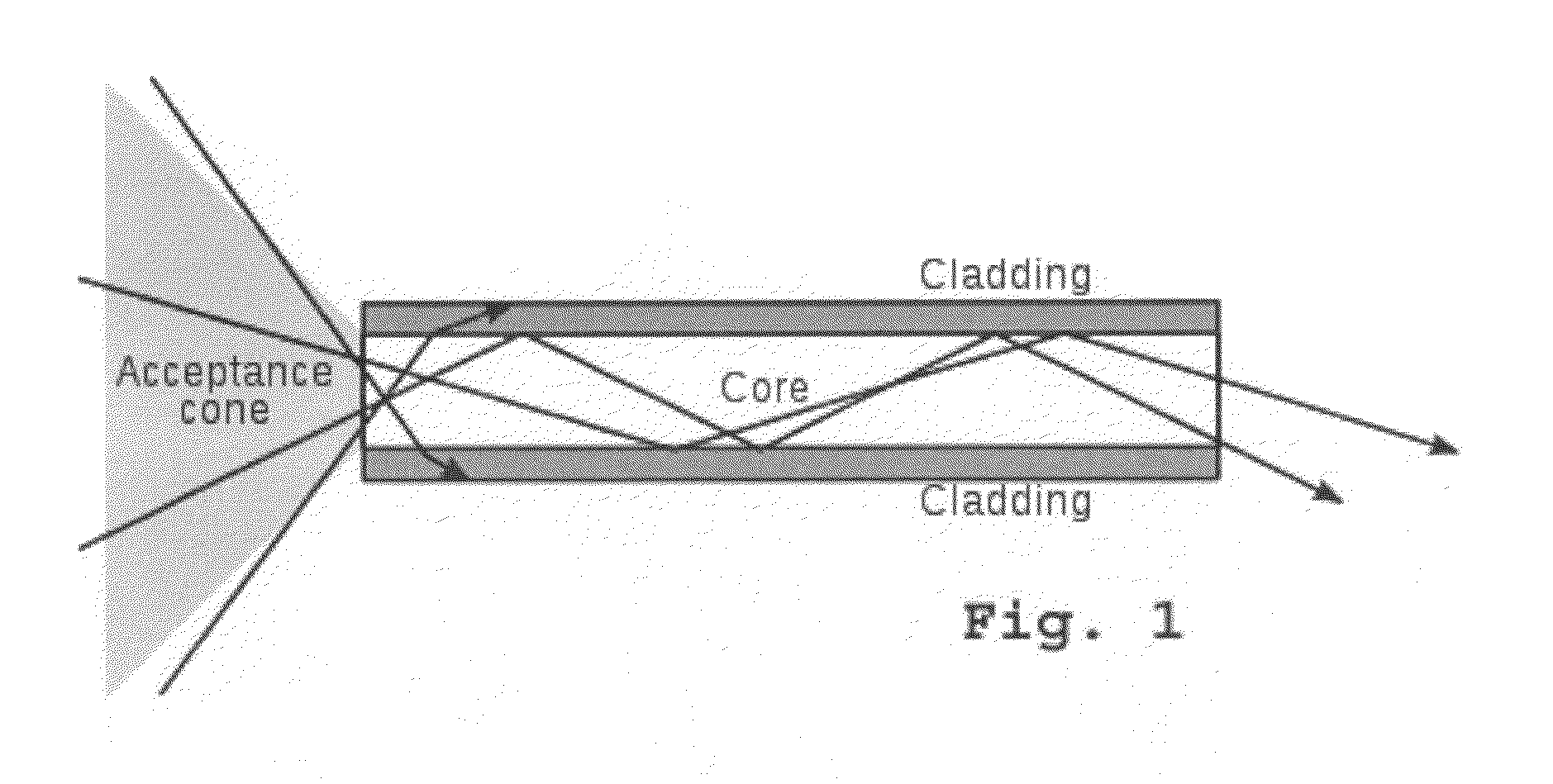

This invention provides composite materials comprising nanostructures (e.g., nanowires, branched nanowires, nanotetrapods, nanocrystals, and nanoparticles). Methods and compositions for making such nanocomposites are also provided, as are articles comprising such composites. Waveguides and light concentrators comprising nanostructures (not necessarily as part of a nanocomposite) are additional features of the invention.

Owner:ONED MATERIAL INC

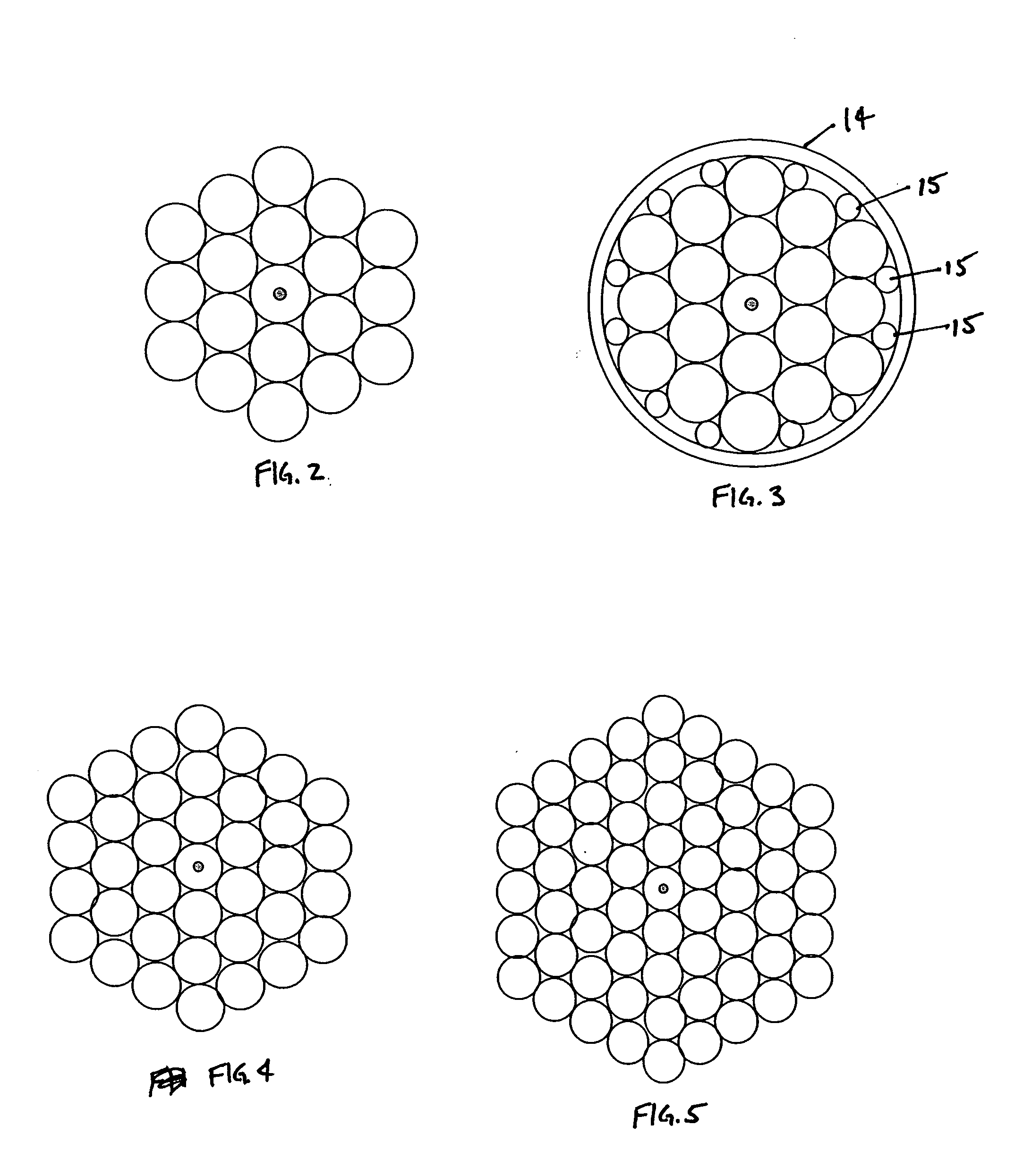

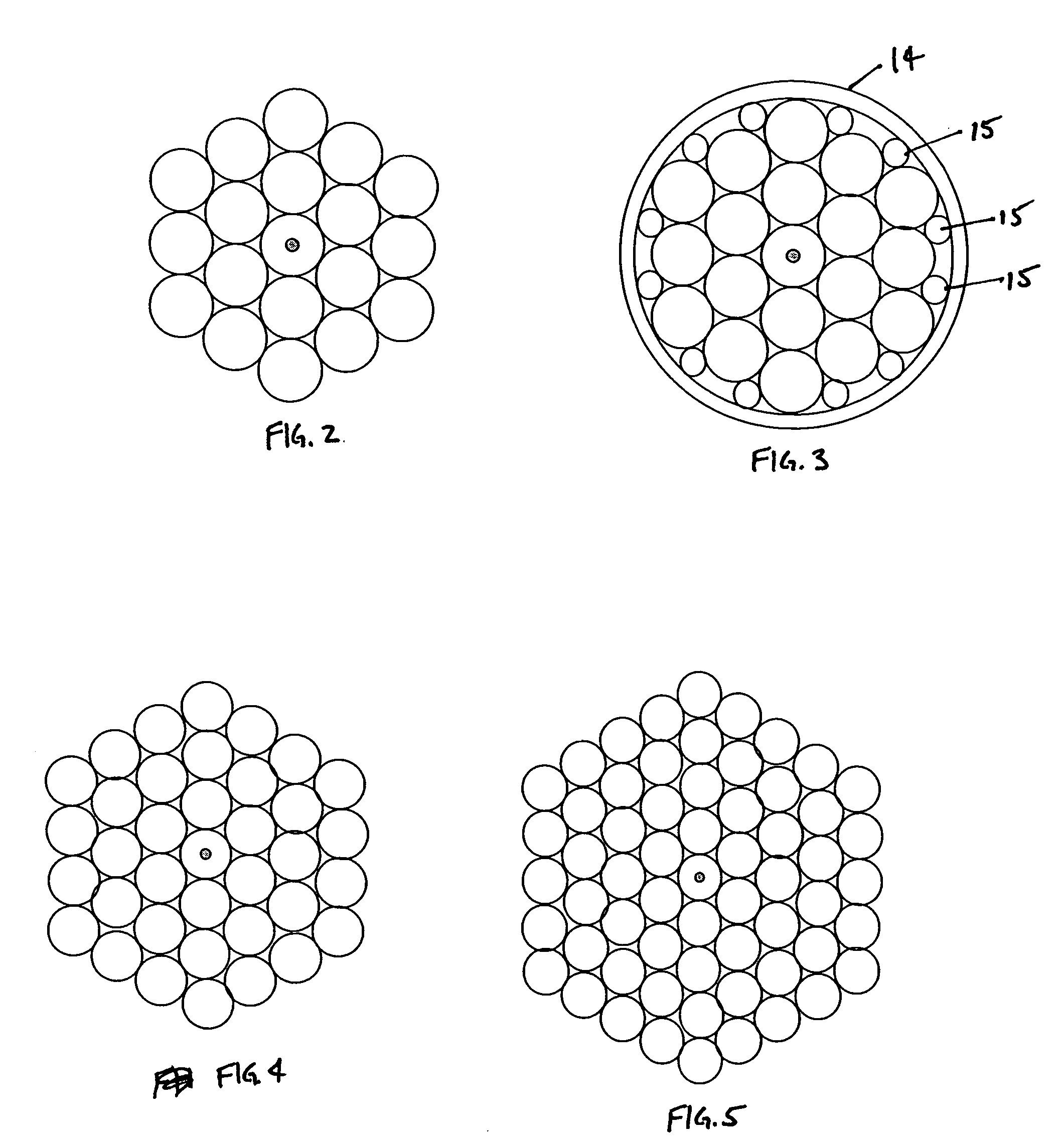

Microstructured optical fibers and methods

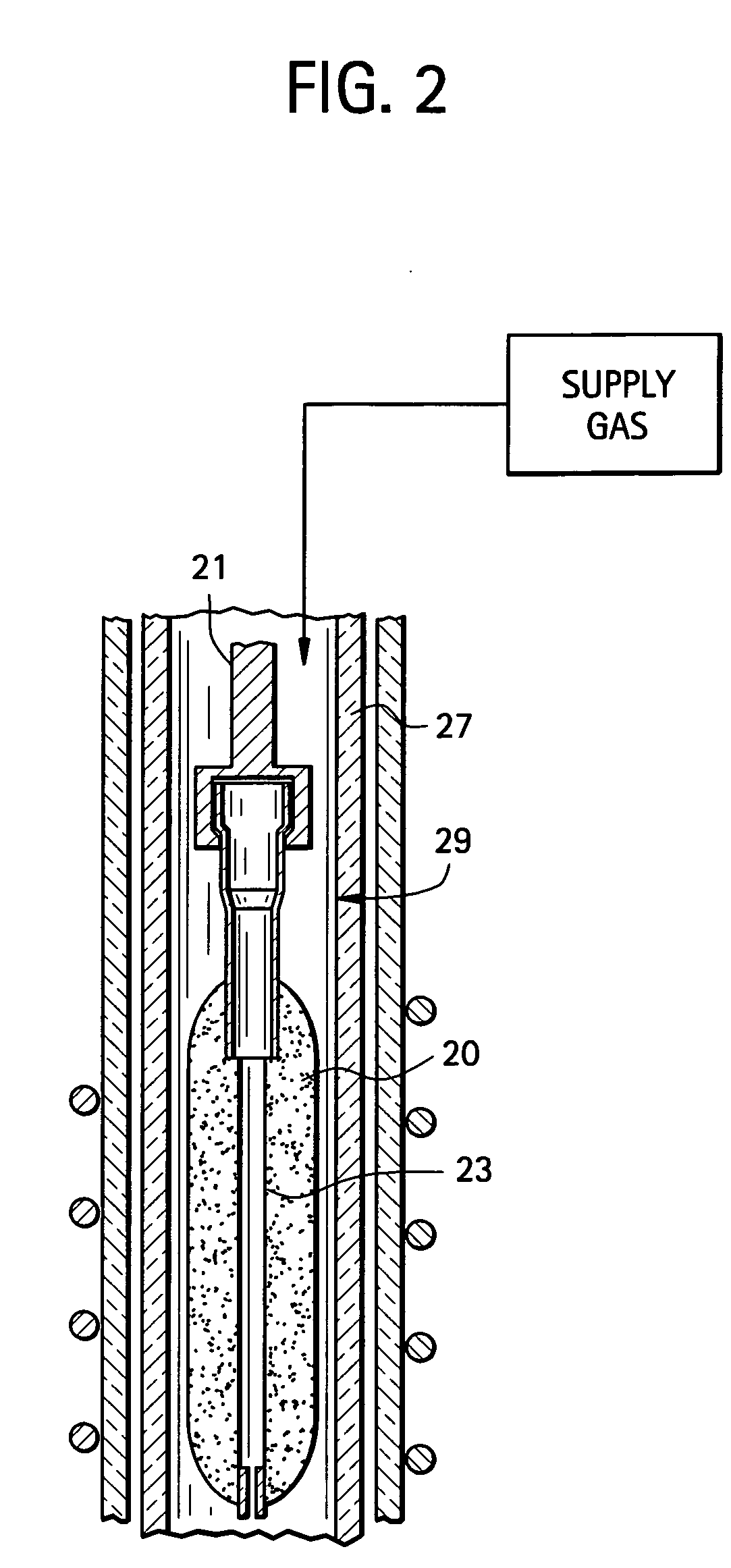

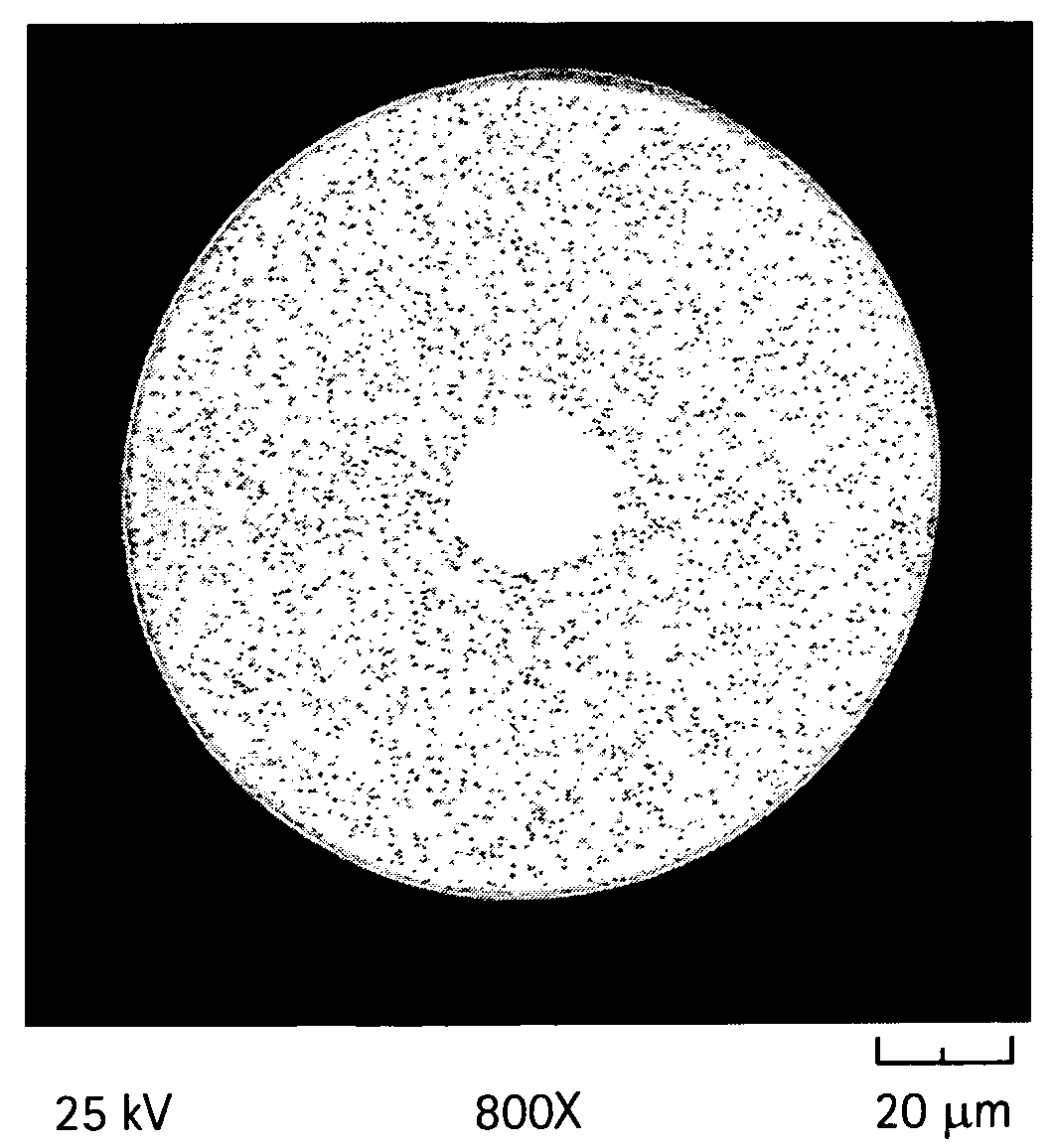

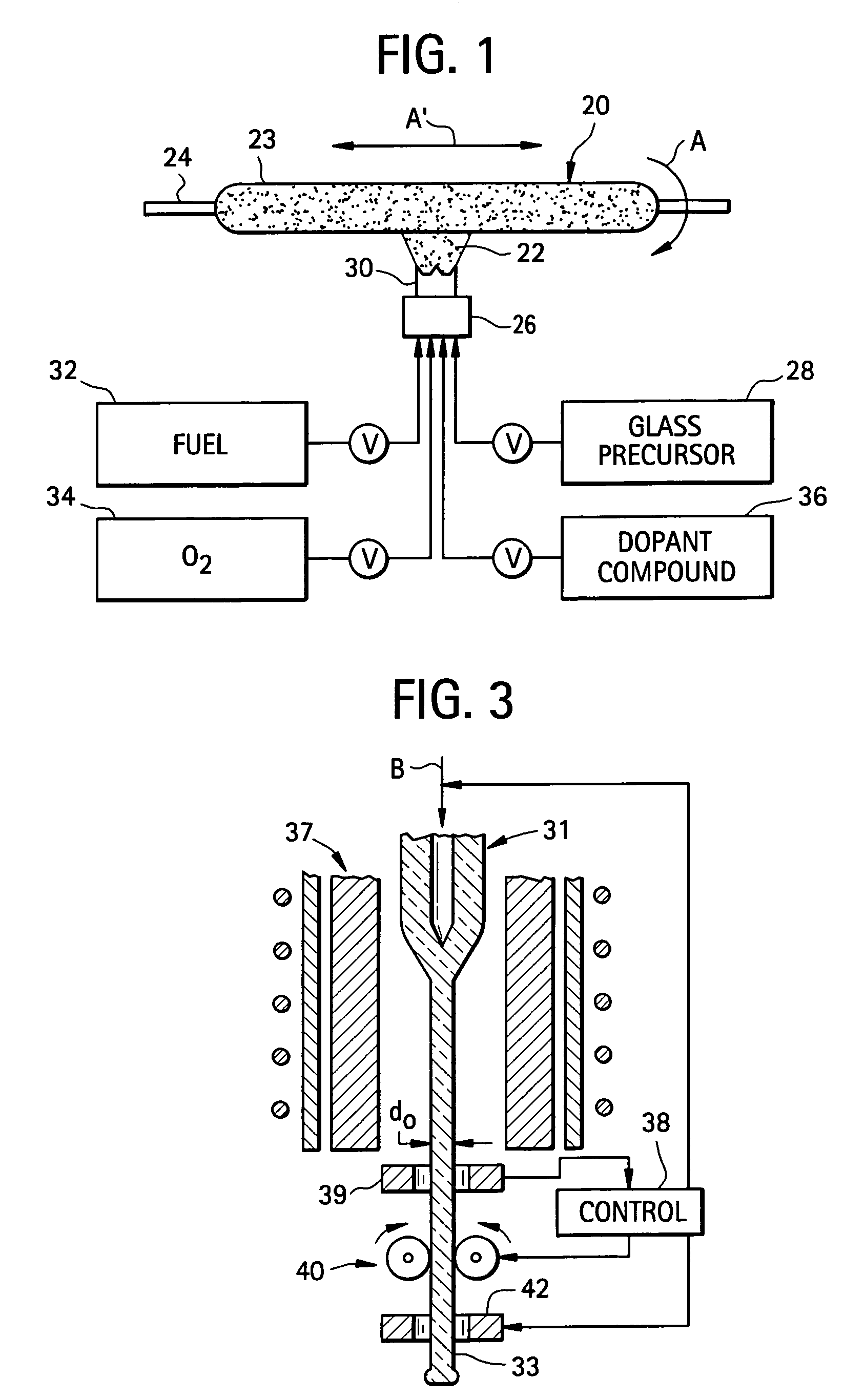

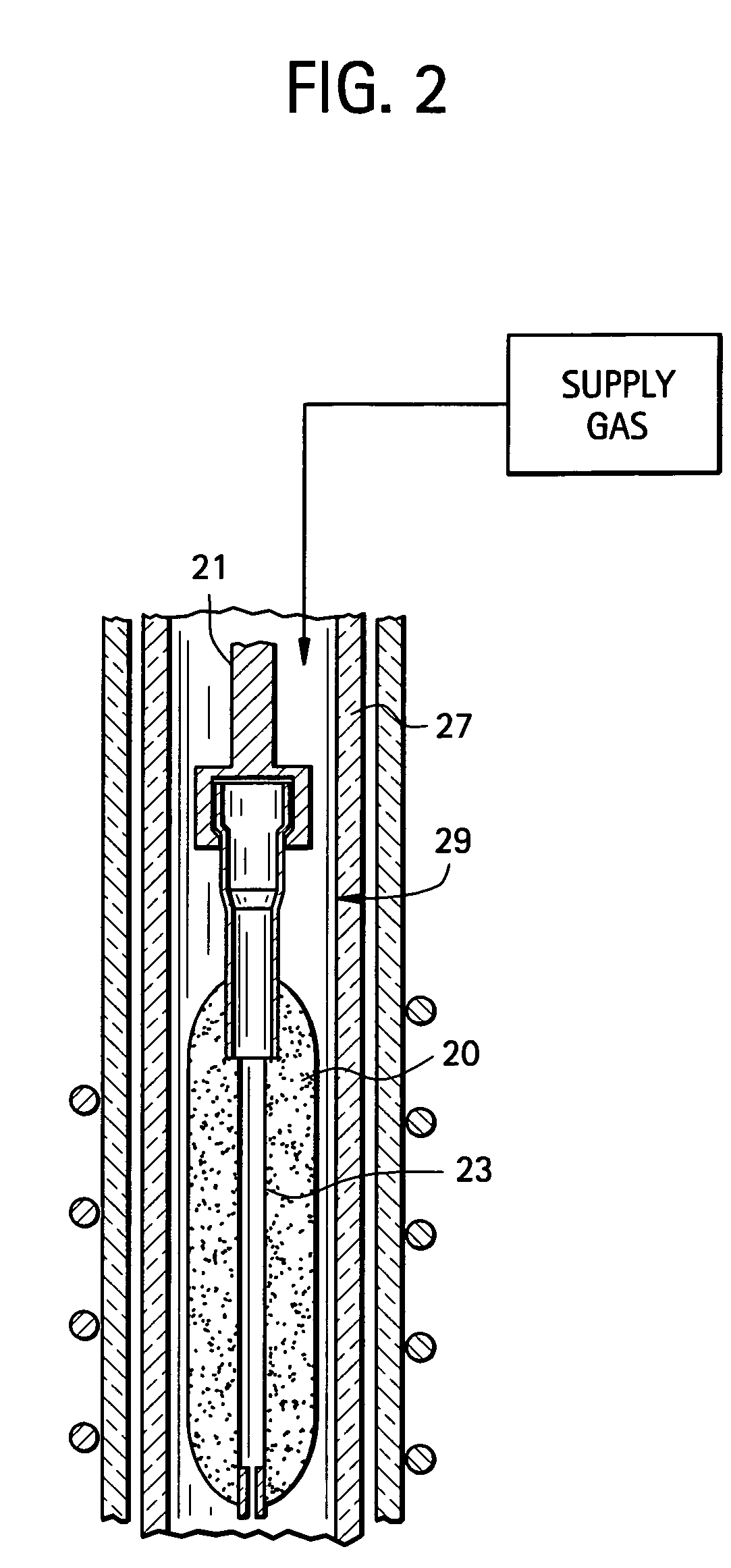

InactiveUS20070104437A1Improve bending performancePromote lowerGlass making apparatusOptical fibre with graded refractive index core/claddingNitrogen gasNitrogen

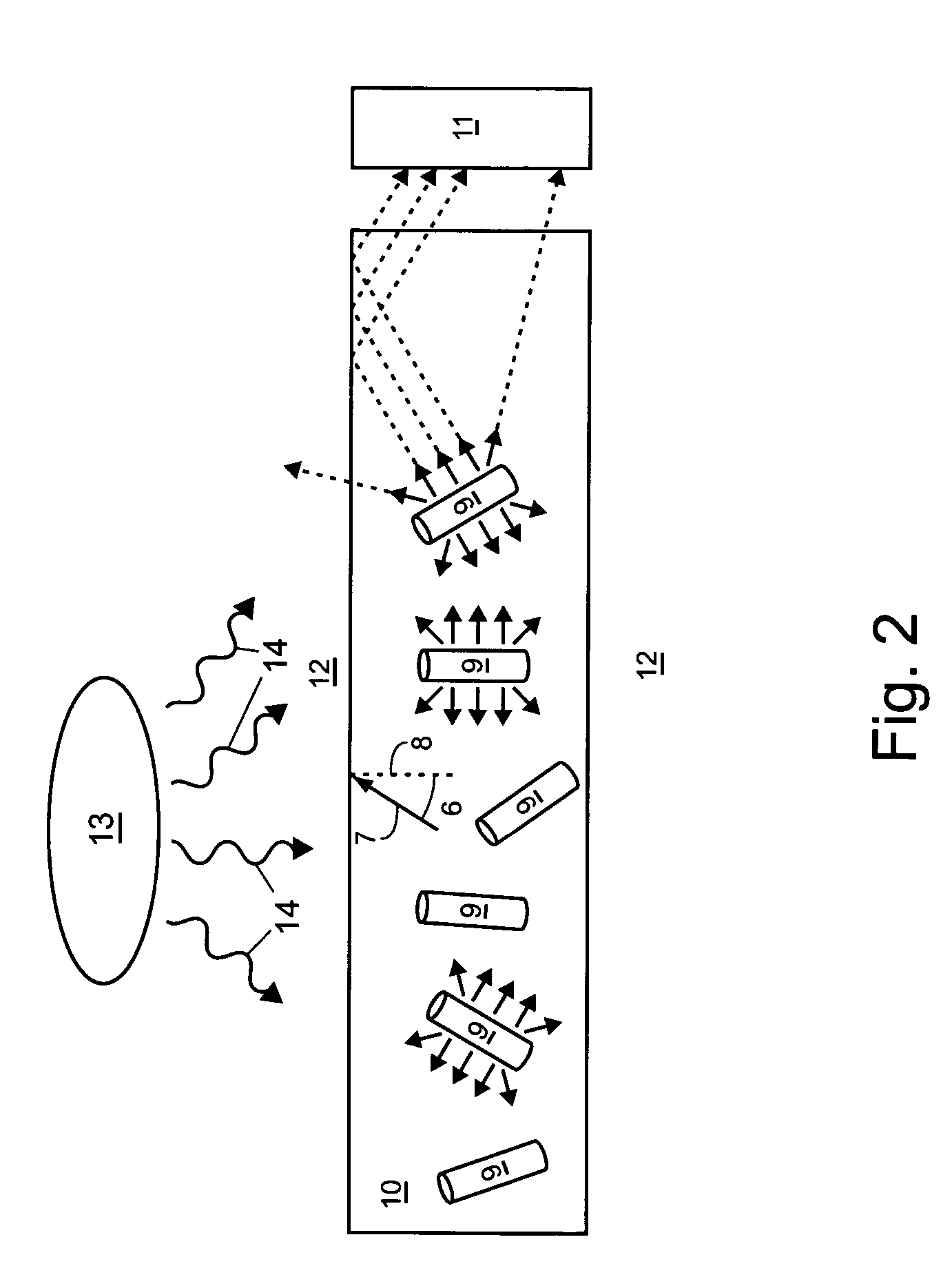

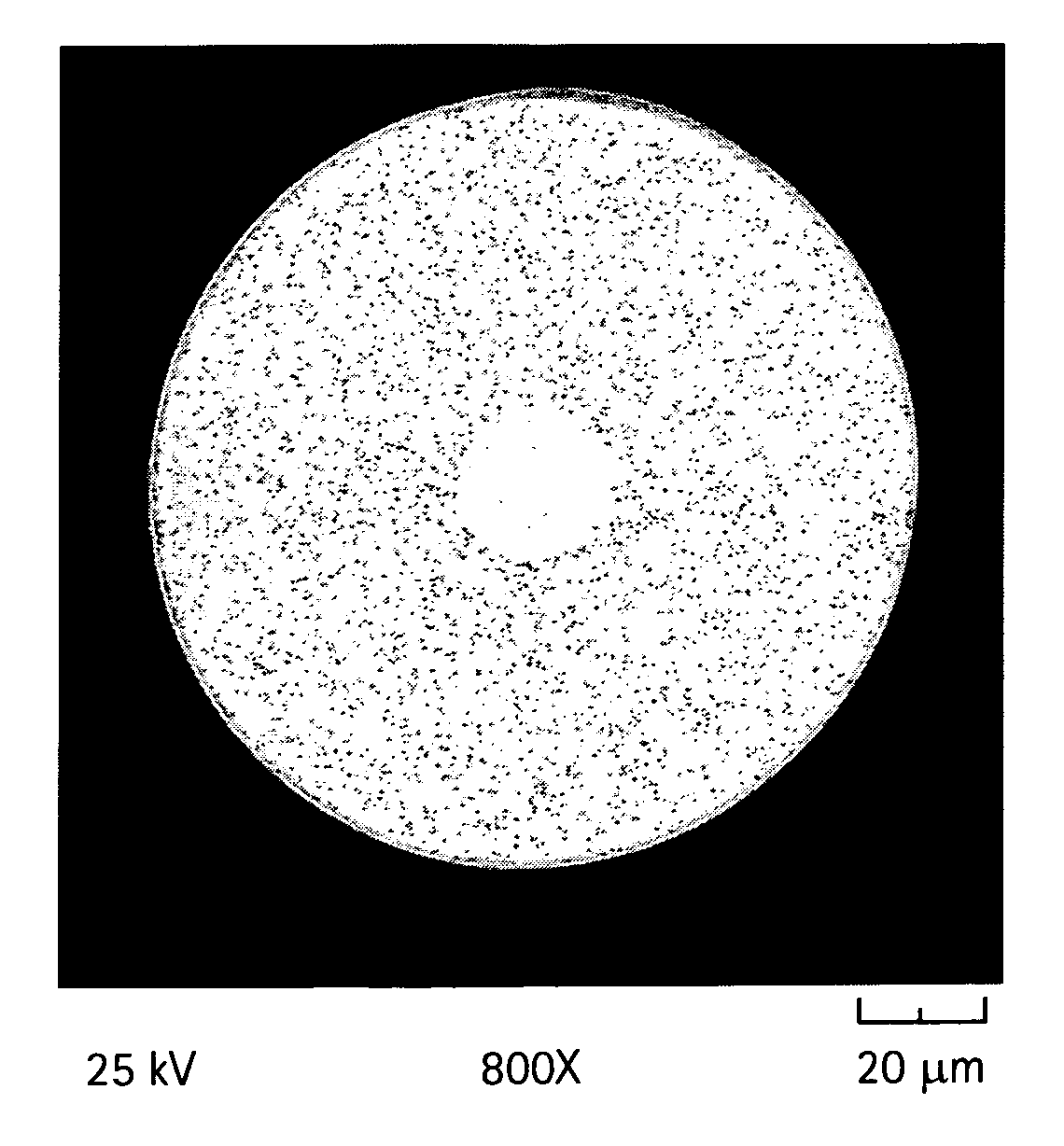

Microstructured optical fiber and method of making. Glass soot is deposited and then consolidated under conditions which are effective to trap a portion of the consolidation gases in the glass to thereby produce a non-periodic array of voids which may then be used to form a void containing cladding region in an optical fiber. Preferred void producing consolidation gases include nitrogen, argon, CO2, oxygen, chlorine, CF4, CO, SO2 and mixtures thereof.

Owner:CORNING INC

Microstructured optical fibers and methods

InactiveUS7450806B2Improve bending performanceLower refractive indexGlass making apparatusOptical fibre with graded refractive index core/claddingNitrogenNitrogen gas

Microstructured optical fiber and method of making. Glass soot is deposited and then consolidated under conditions which are effective to trap a portion of the consolidation gases in the glass to thereby produce a non-periodic array of voids which may then be used to form a void containing cladding region in an optical fiber. Preferred void producing consolidation gases include nitrogen, argon, CO2, oxygen, chlorine, CF4, CO, SO2 and mixtures thereof.

Owner:CORNING INC

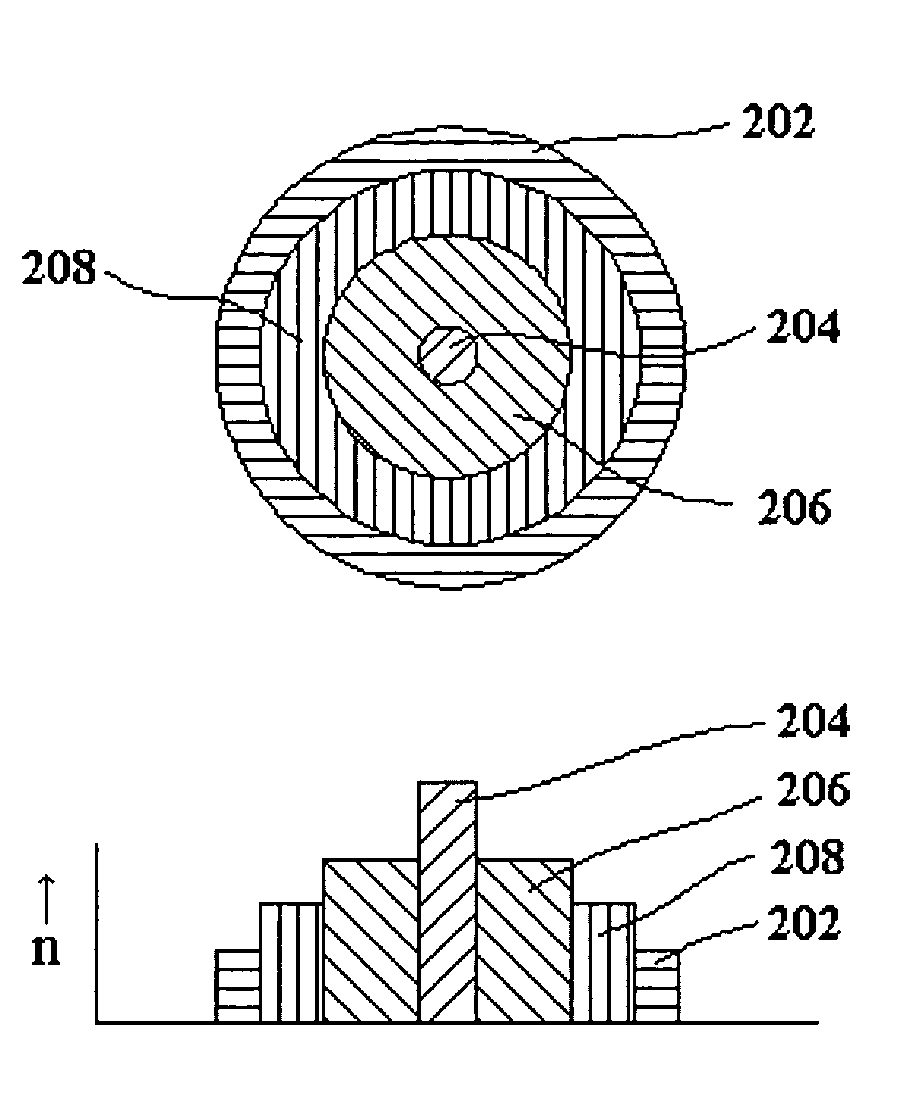

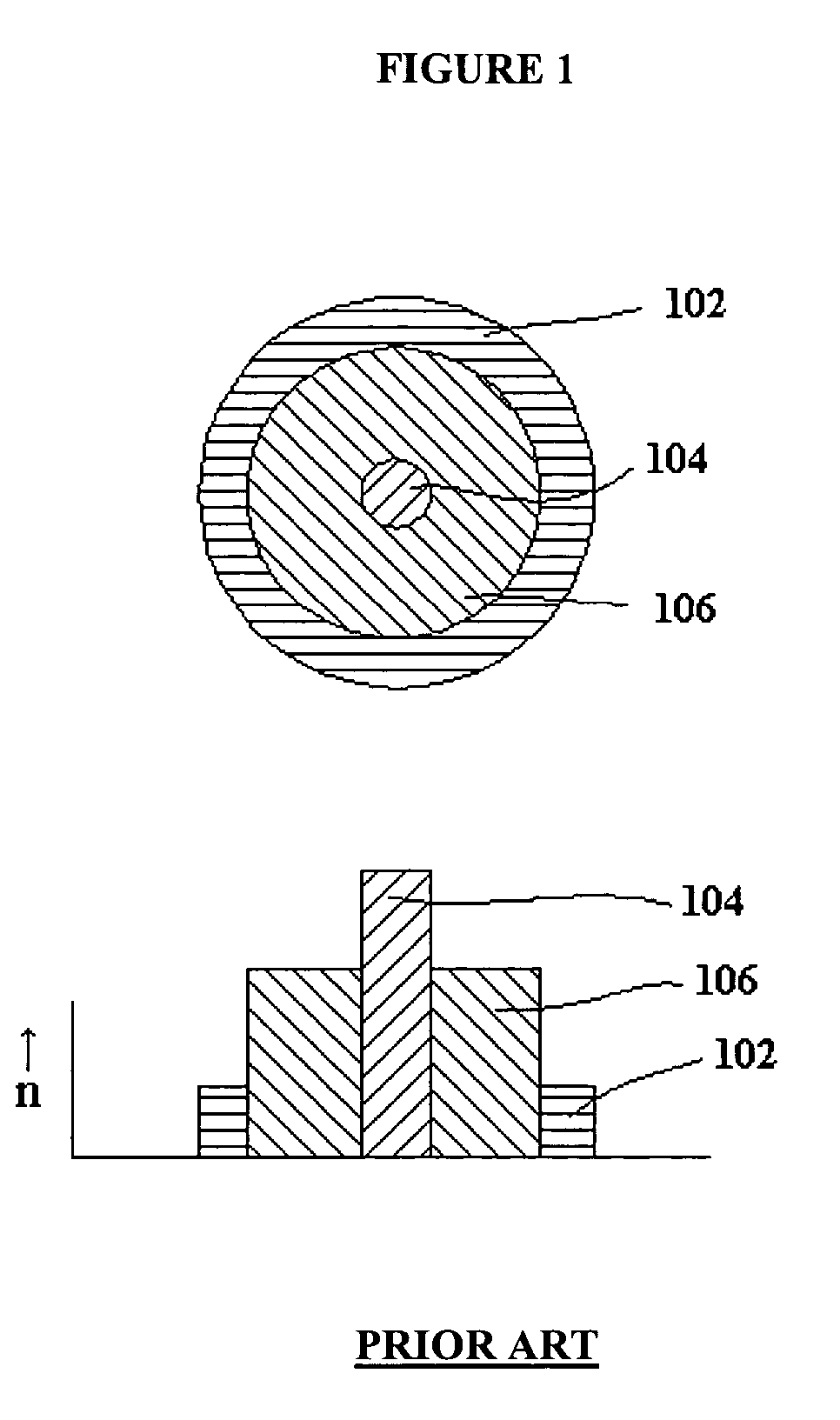

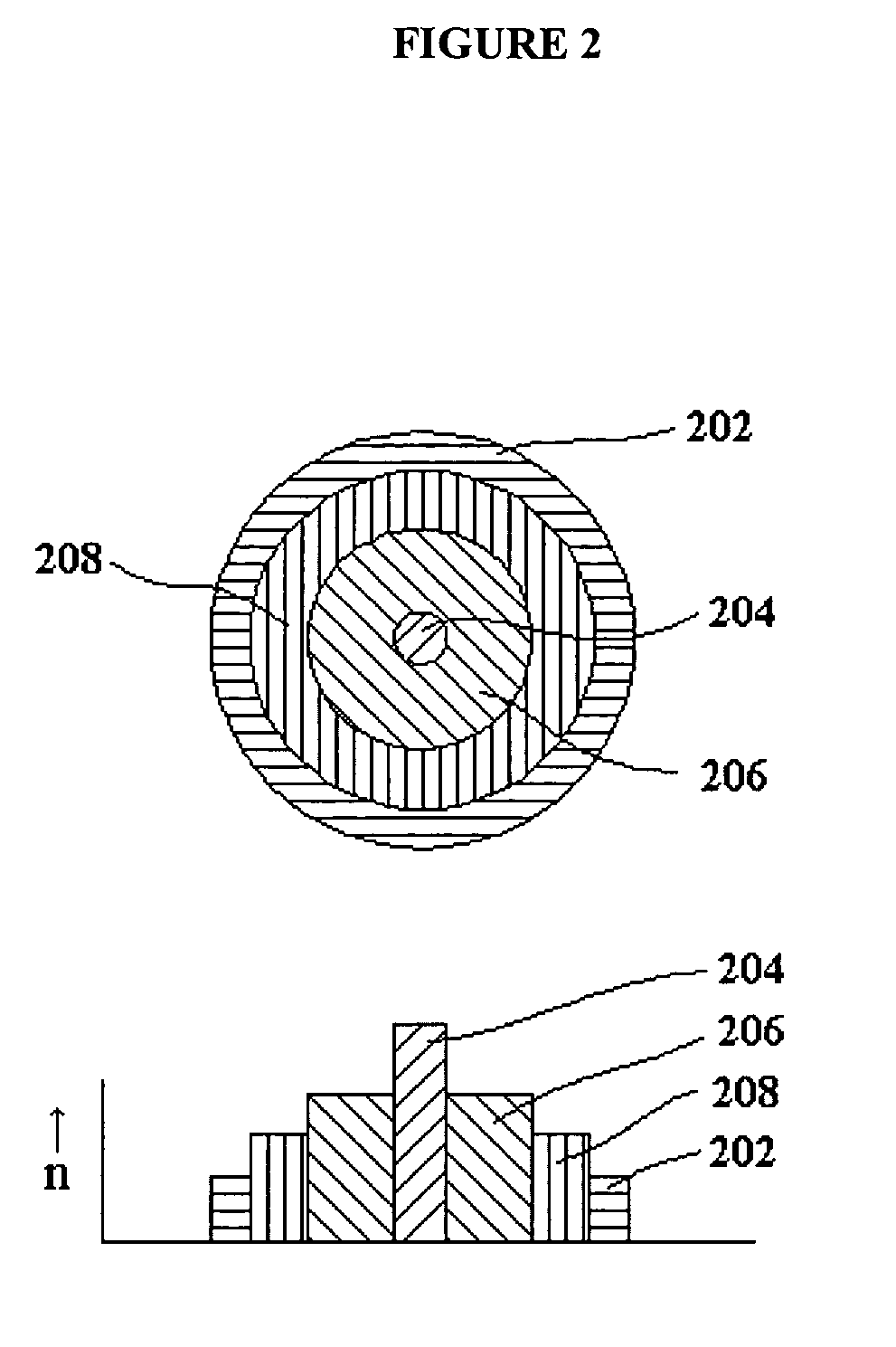

Optical fiber

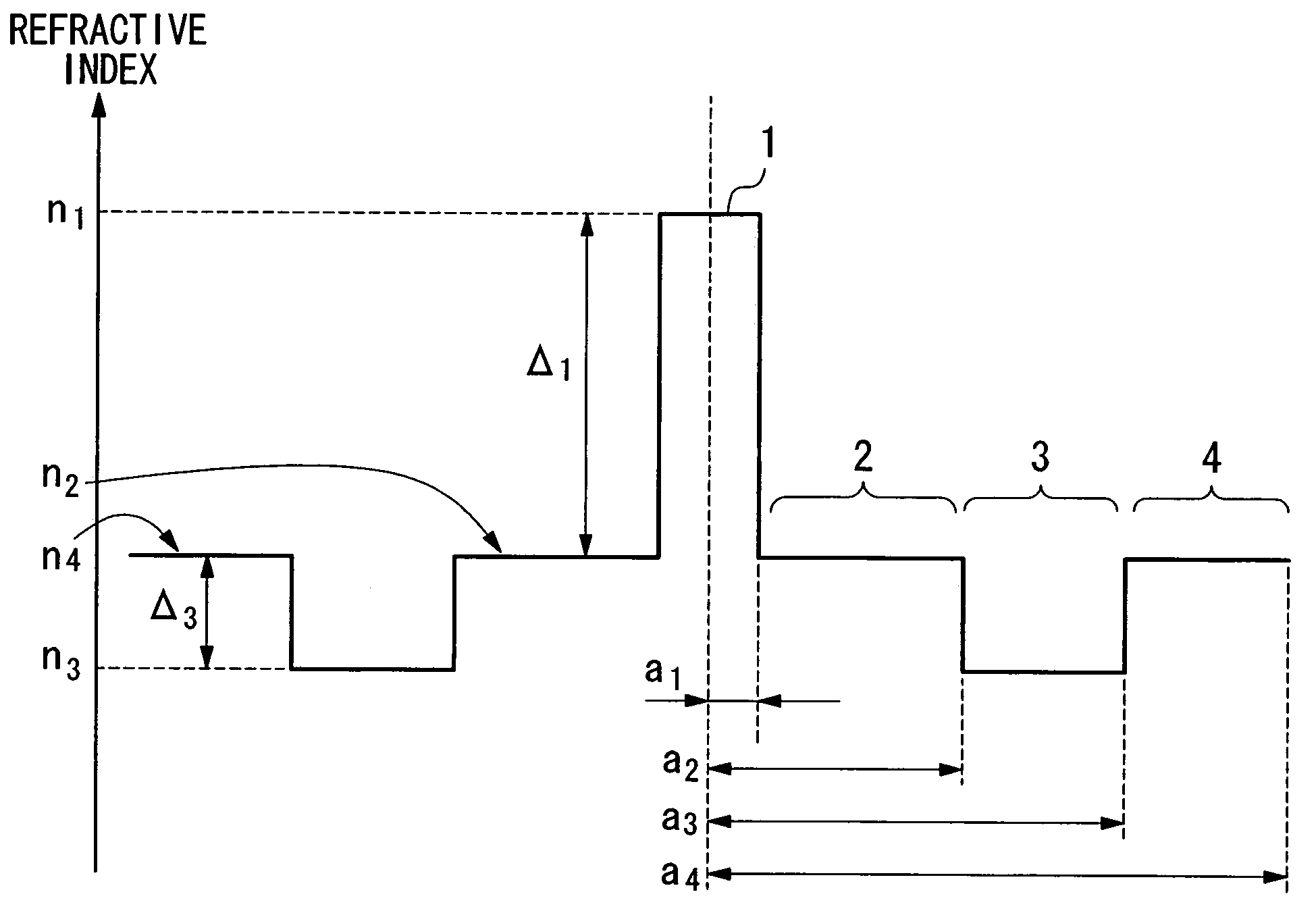

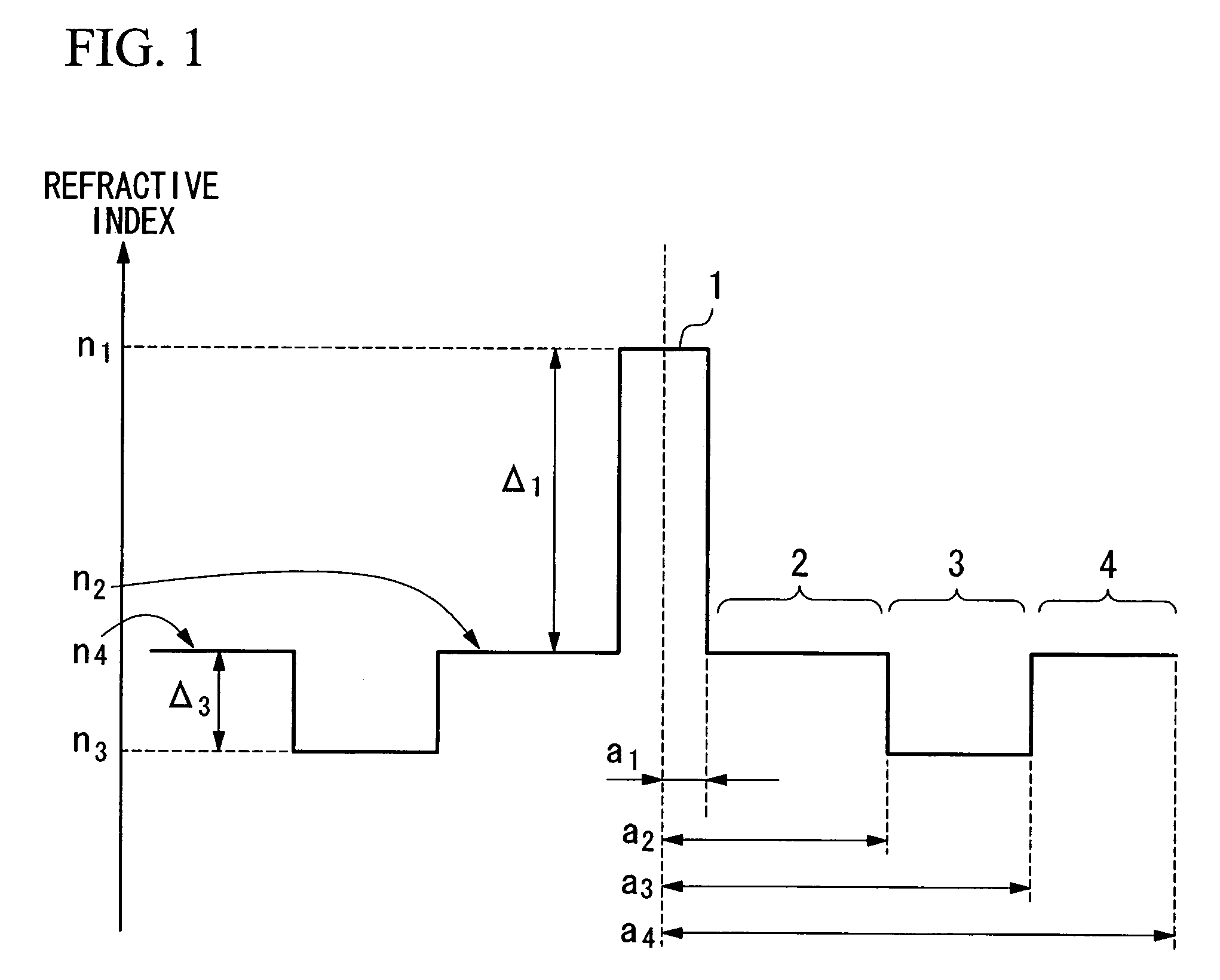

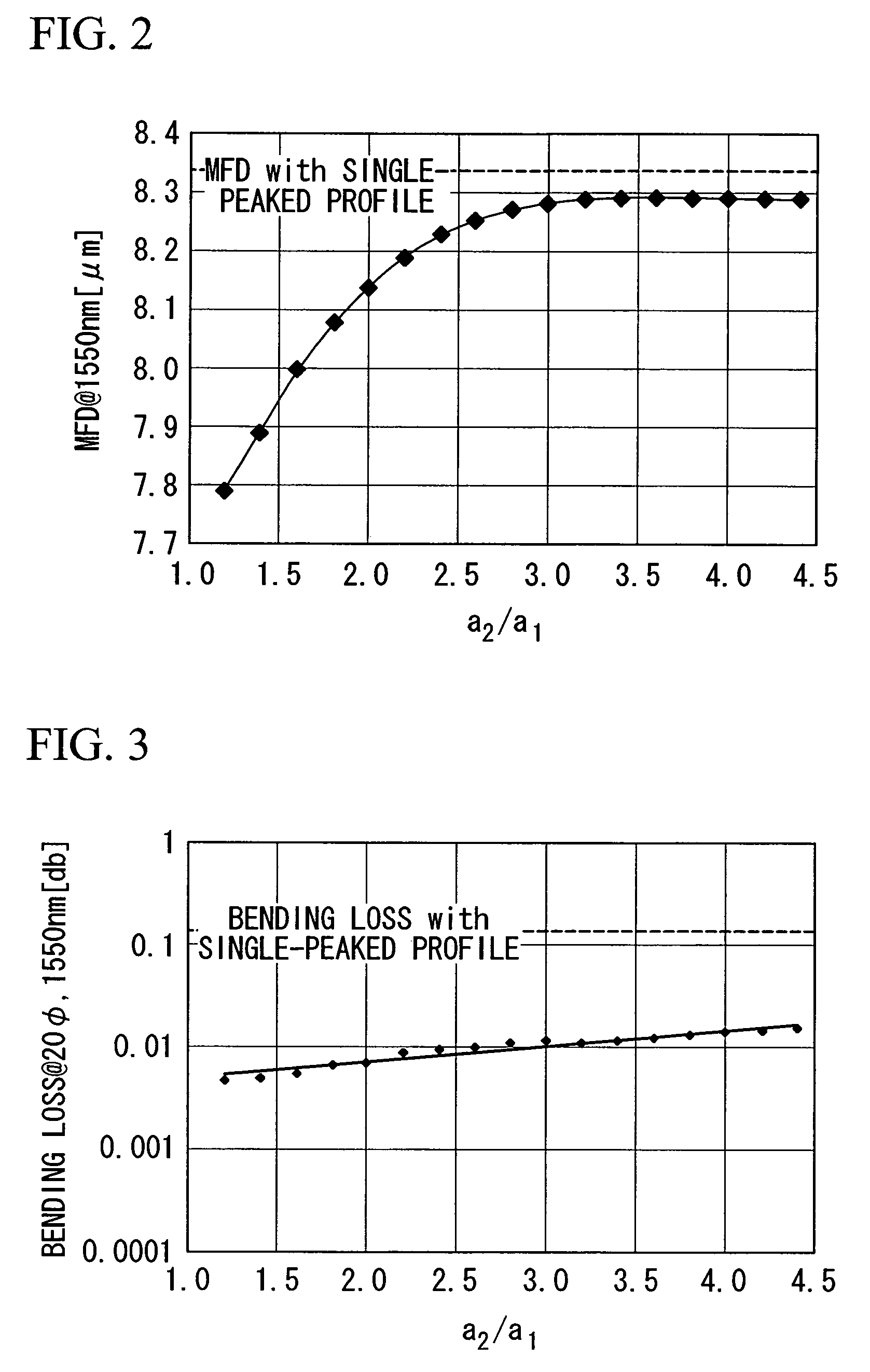

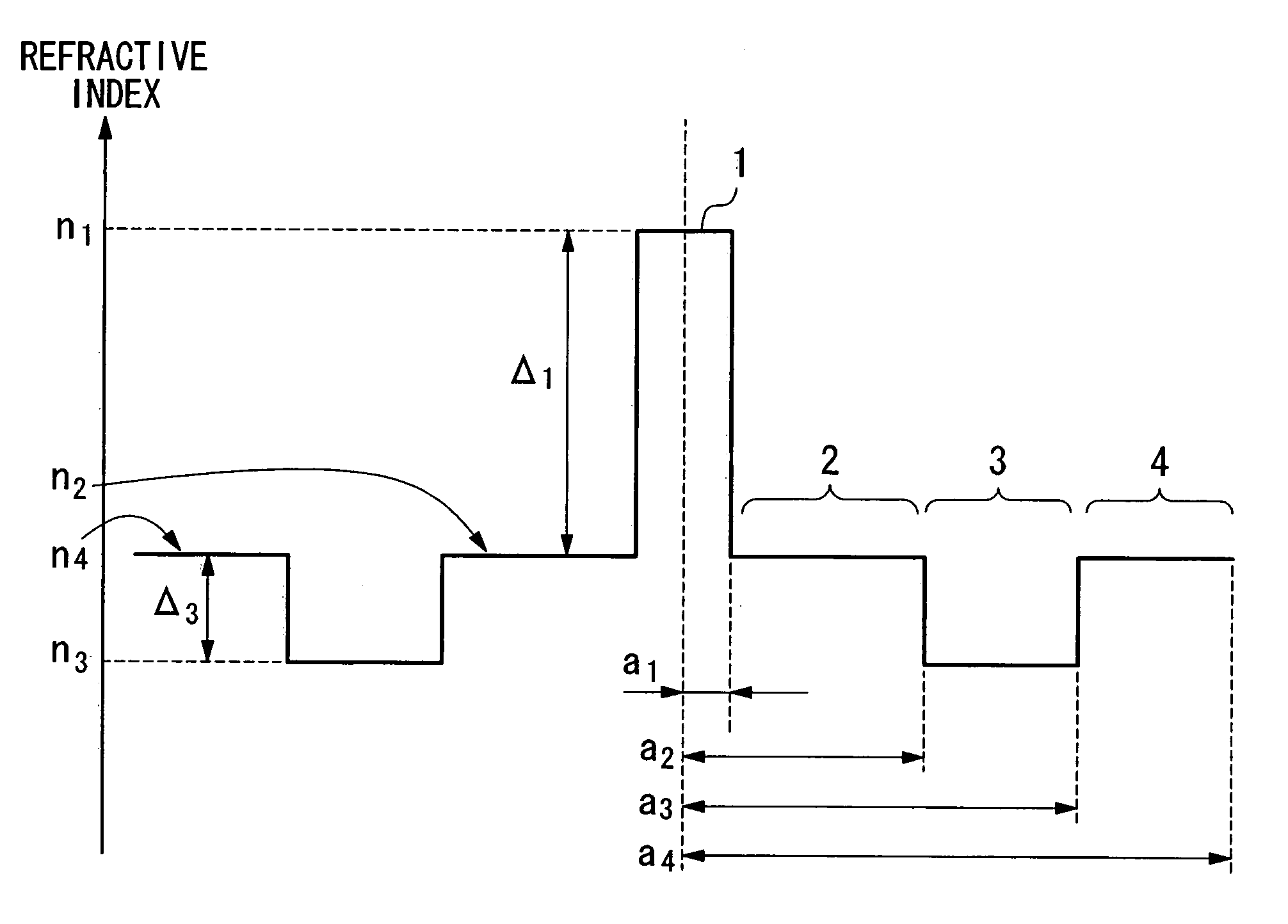

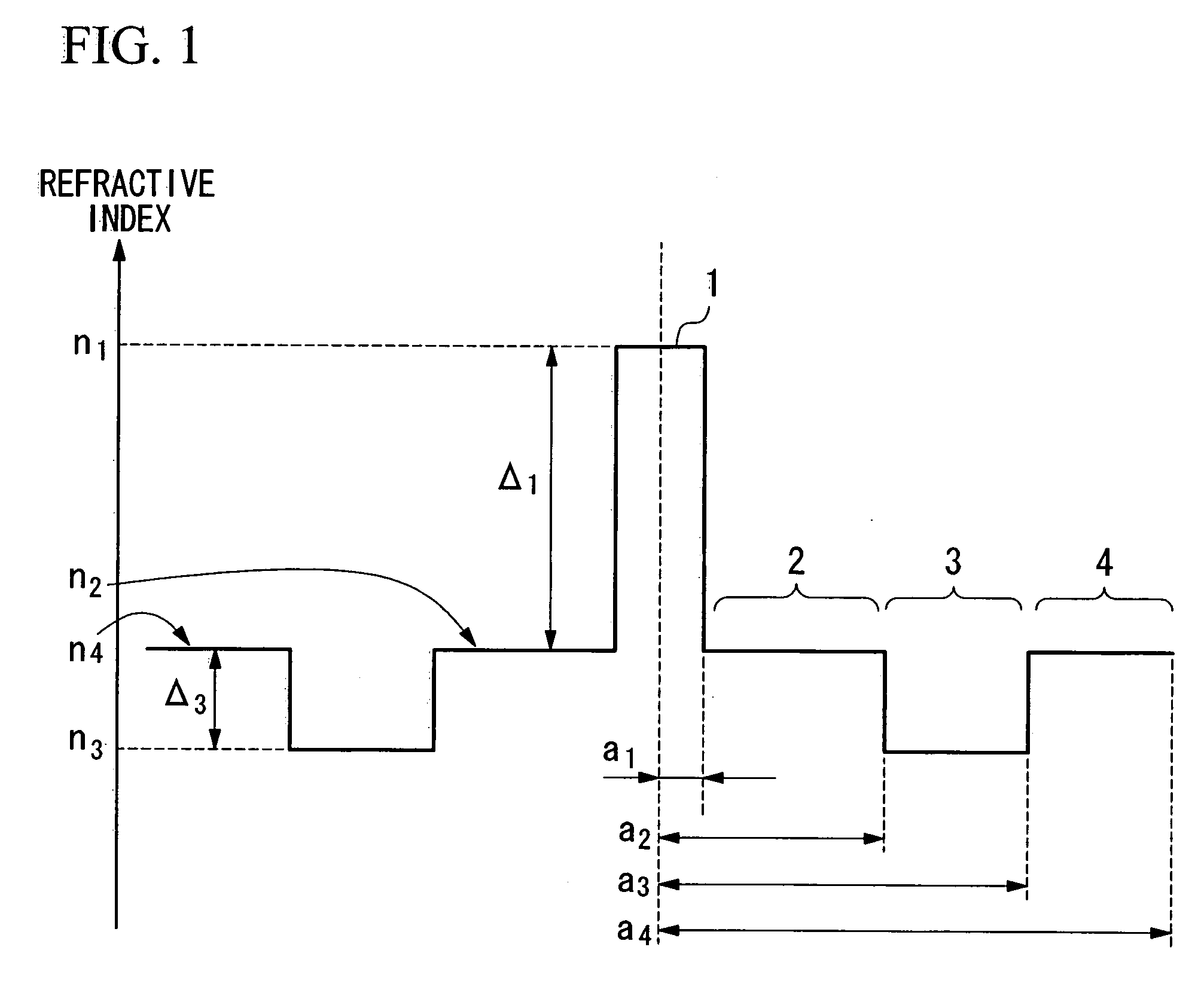

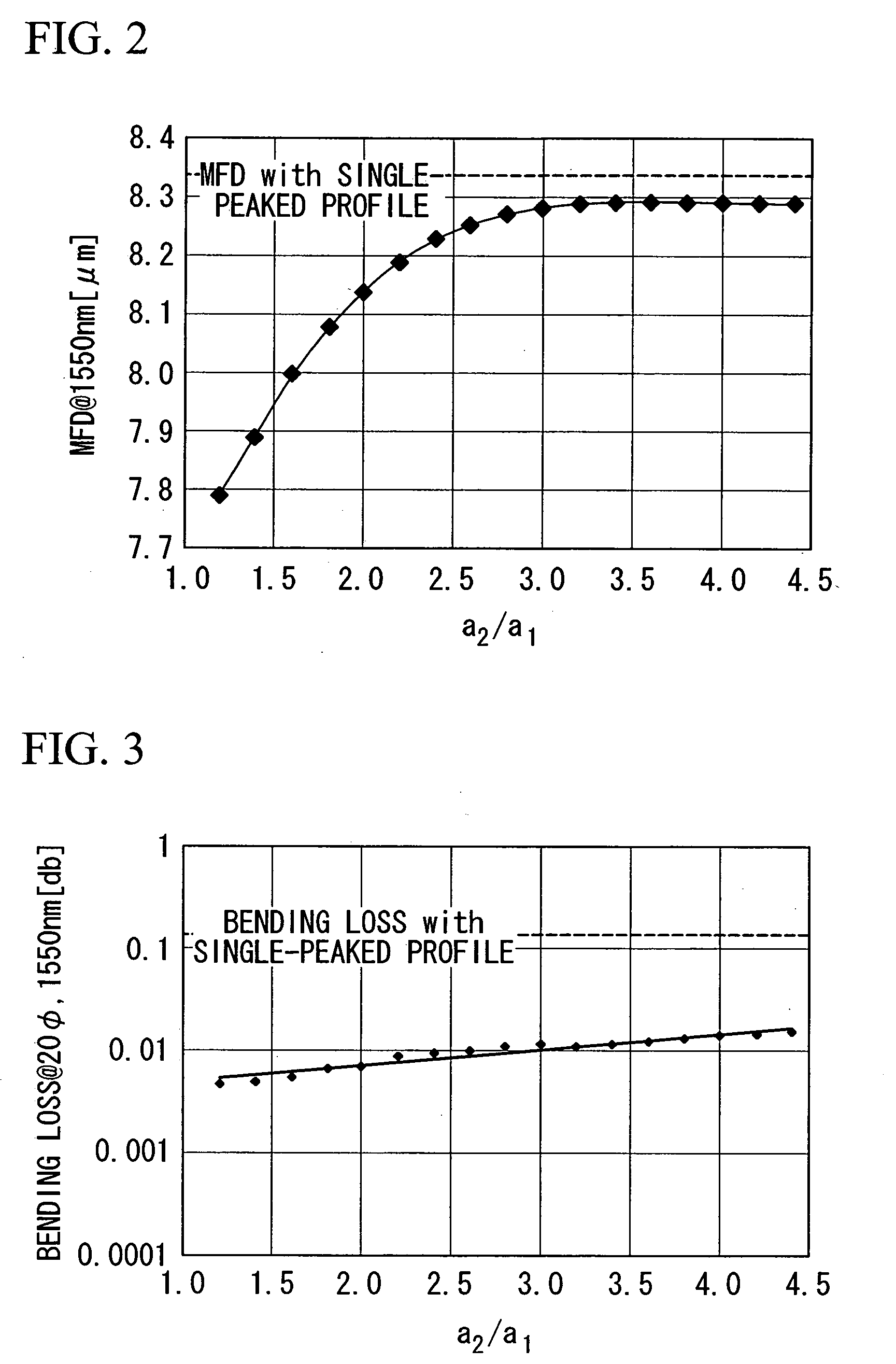

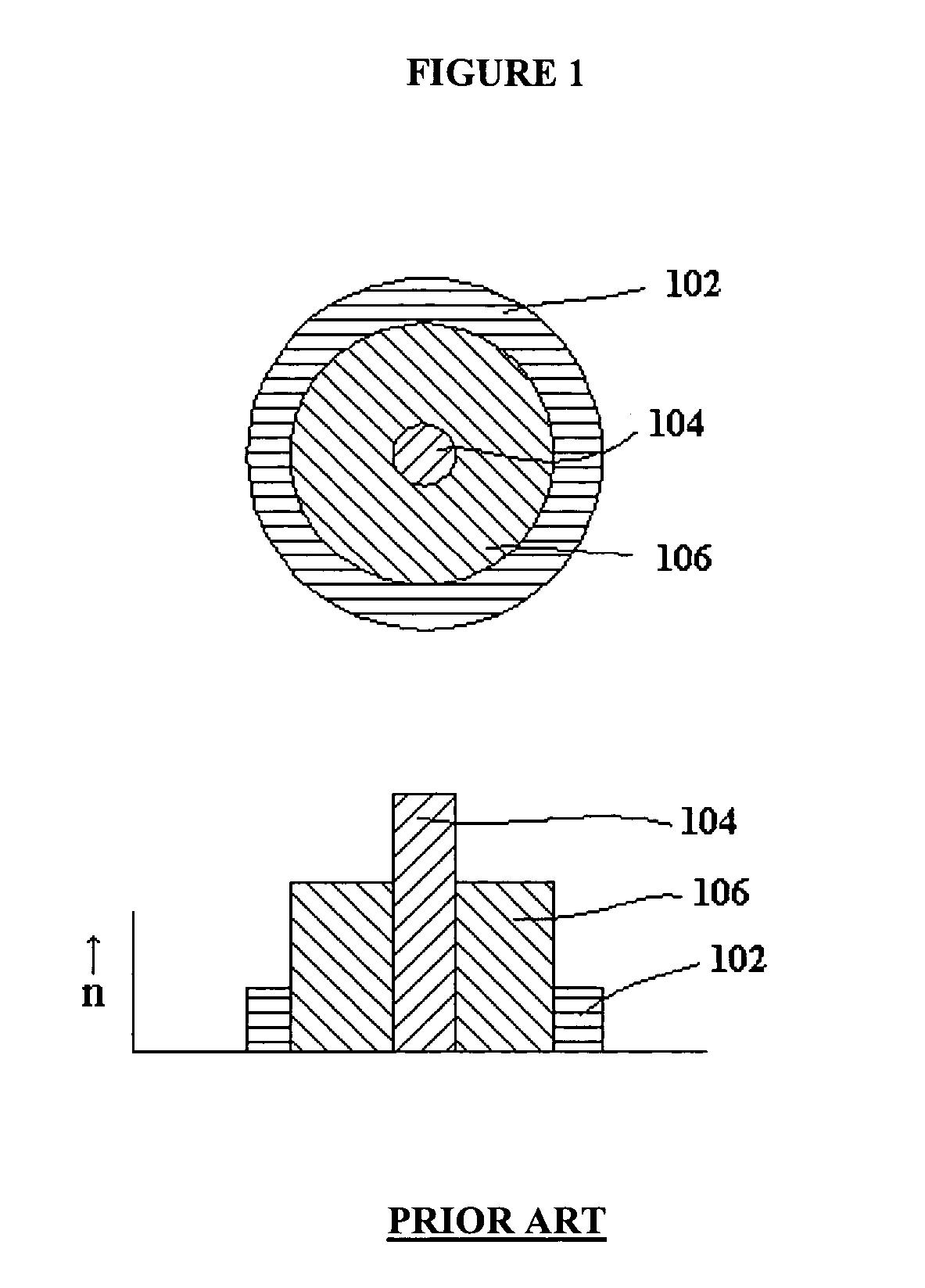

ActiveUS7164835B2Lower refractive indexReduce dispersionOptical fibre with multilayer core/claddingOptical waveguide light guideRelative refractive indexMaterials science

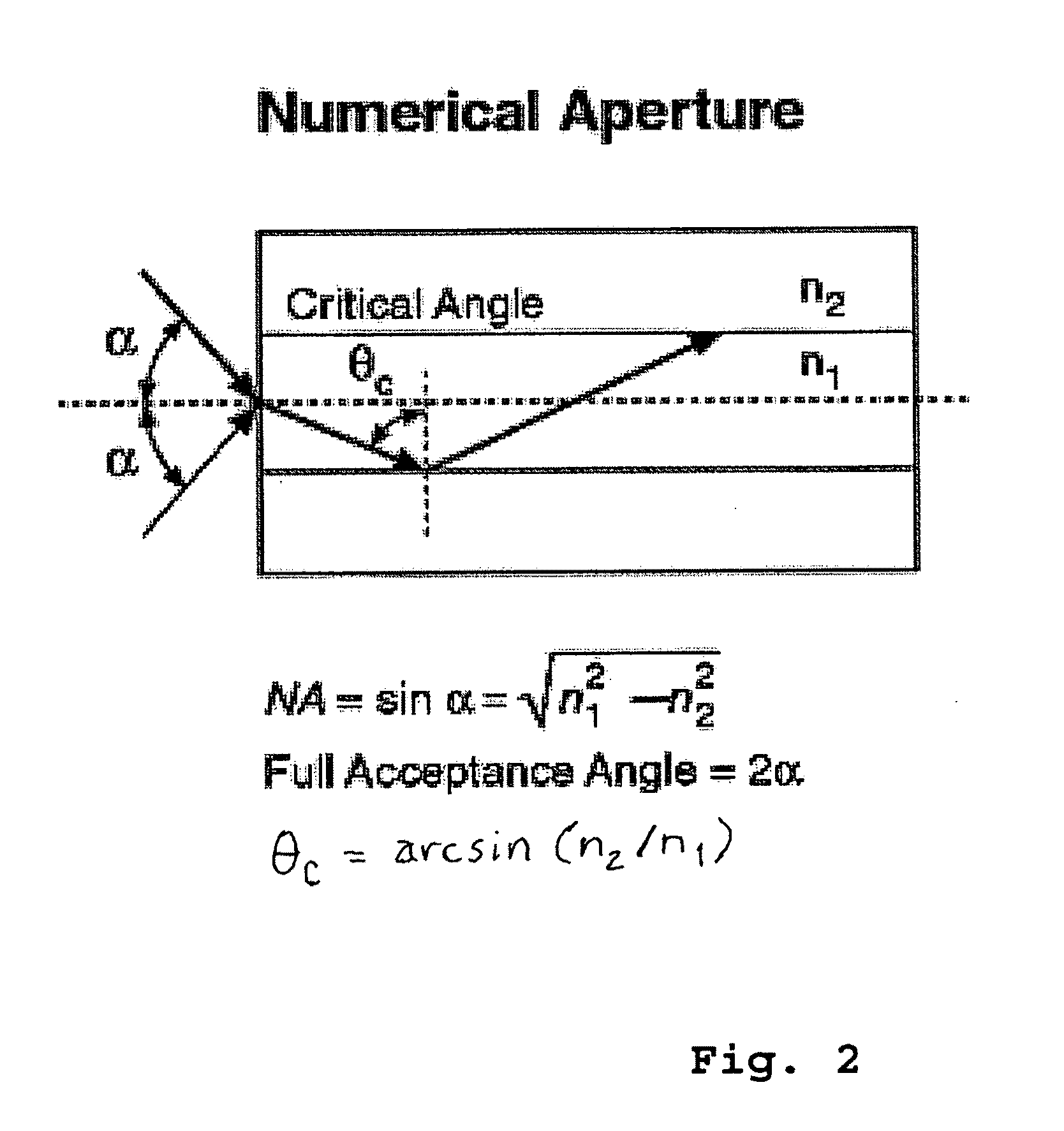

An optical fiber includes: a core at a center; a first cladding layer; a second cladding layer; and a third cladding layer. A maximum refractive index of the core is greater than any of maximum refractive indices of the first cladding layer, the second cladding layer, and the third cladding layer, and the maximum refractive index of the second cladding layer is smaller than any of the maximum refractive indices of the first and the third cladding layer. Additionally, a ratio of a2 / a1 is not less than about 2.5 and not more than about 4.5, where a1 represents the radius of the core, and a2 represents the radius of an outer periphery of the first cladding layer, and a relative refractive index difference of the core with respect to a maximum refractive index of the third cladding layer is not less than 0.20% and not more than 0.70%.

Owner:FUJIKURA LTD

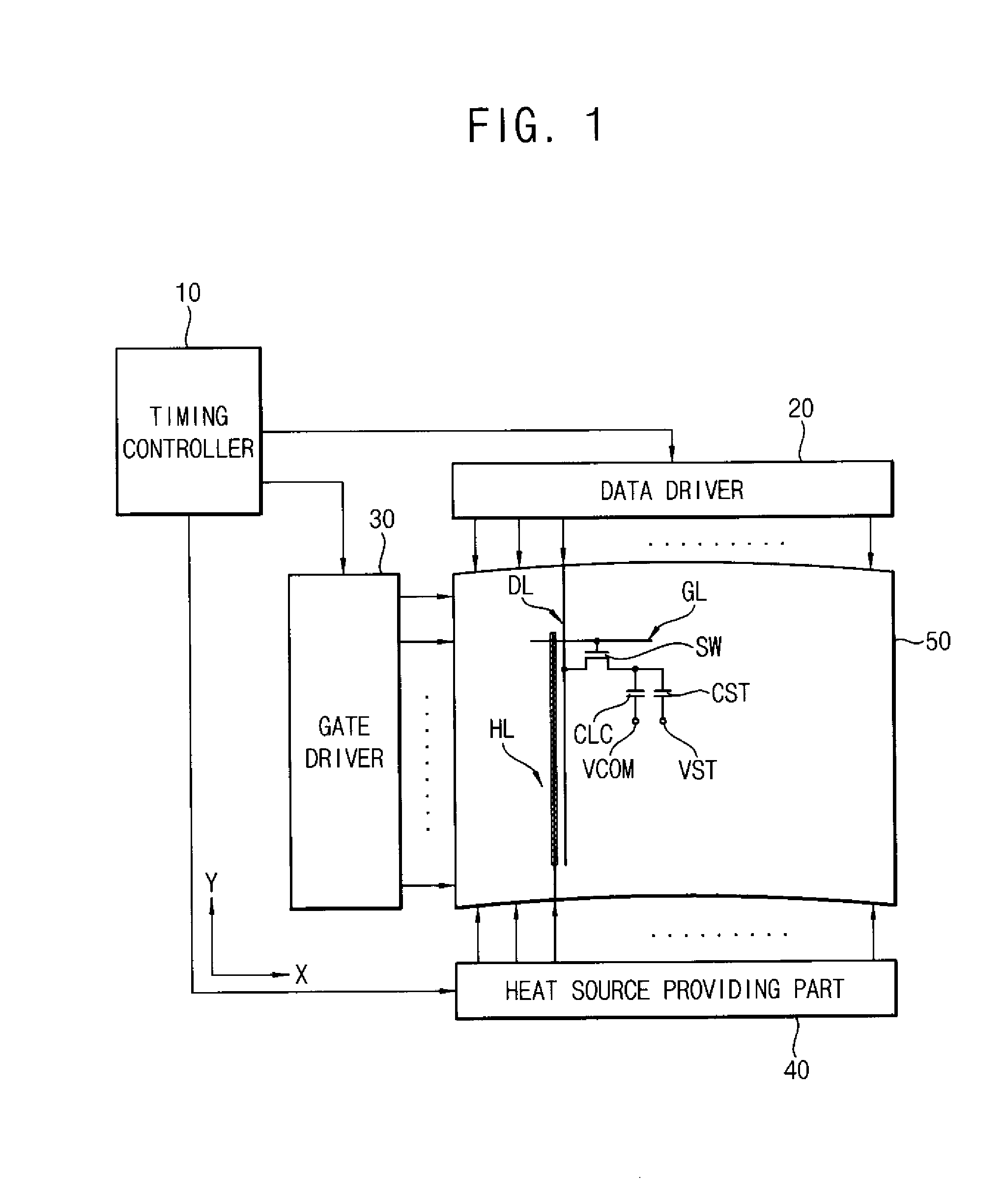

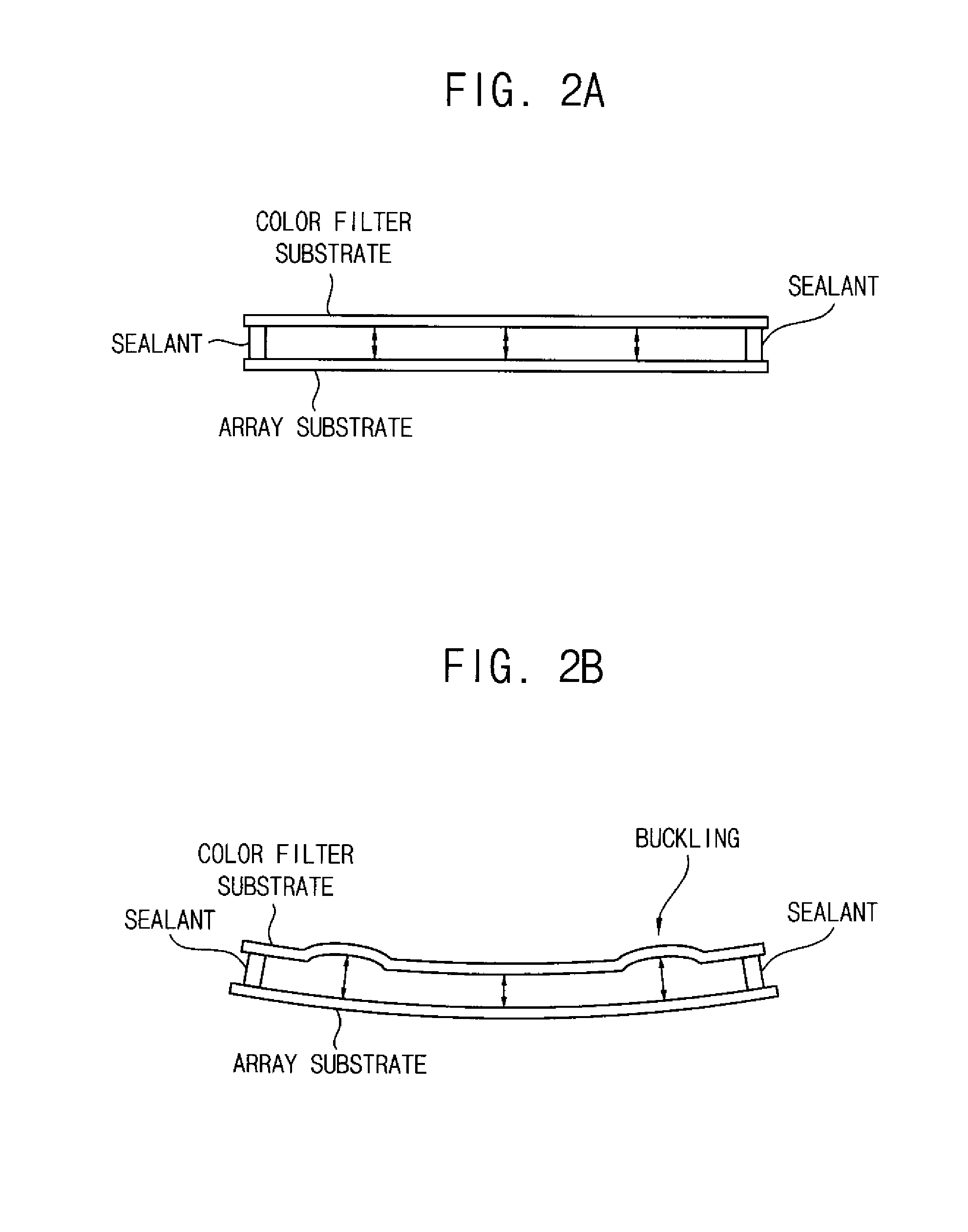

Curved liquid crystal display panel and curved display device having the same

ActiveUS20140055696A1Refractive index difference be decreaseResponse speed be increaseStatic indicating devicesNon-linear opticsCurve shapeLiquid-crystal display

A curved liquid crystal display panel includes an upper substrate having a curved shape, a liquid crystal layer, a lower substrate having a curved shape, where the lower substrate is combined with the upper substrate and the liquid crystal layer is disposed between the upper substrate and the lower substrate, and a heating line disposed on at least one of the upper substrate and the lower substrate and which provides heat to the liquid crystal layer such that a temperature of the liquid crystal layer increases.

Owner:SAMSUNG DISPLAY CO LTD

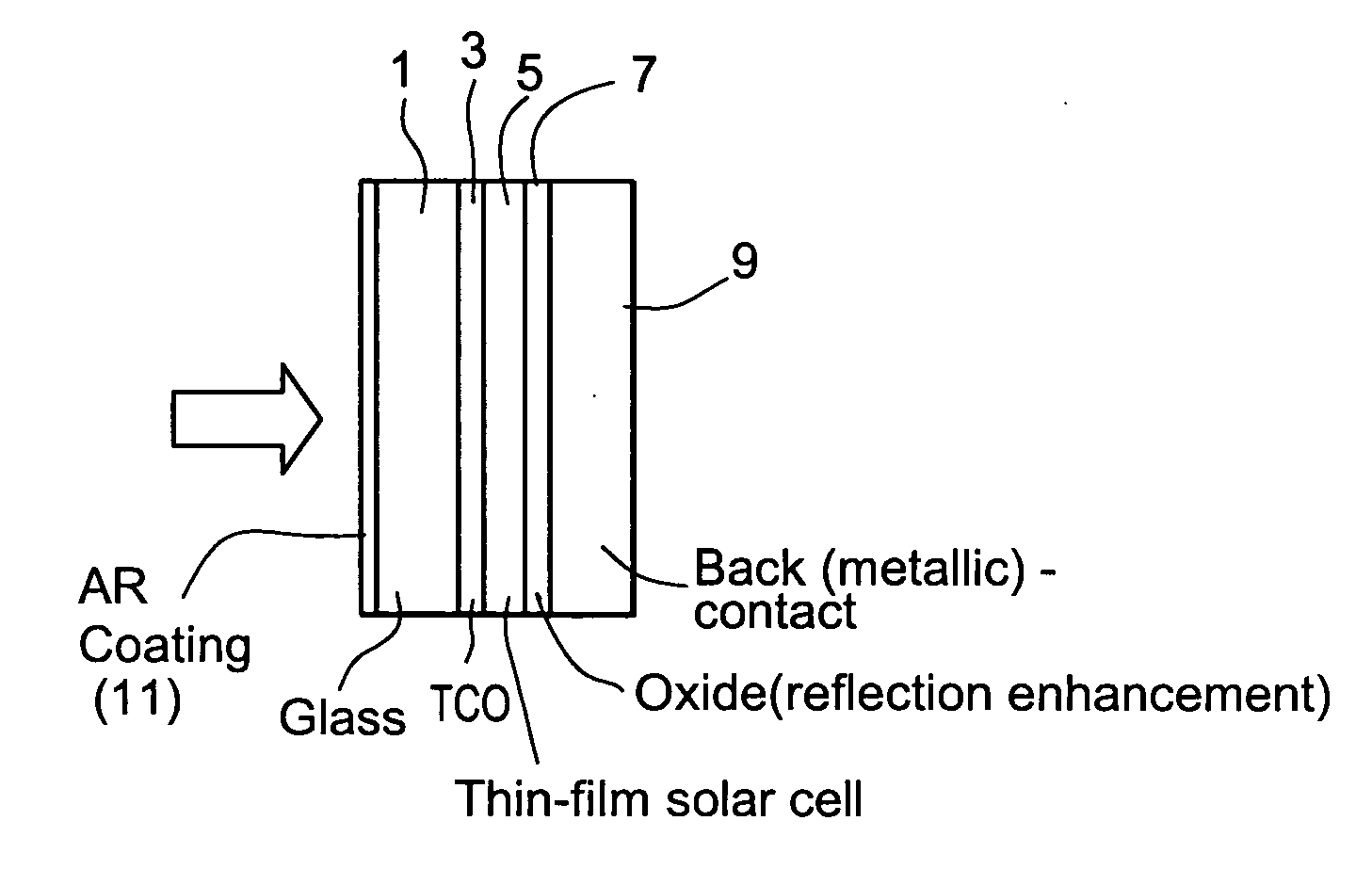

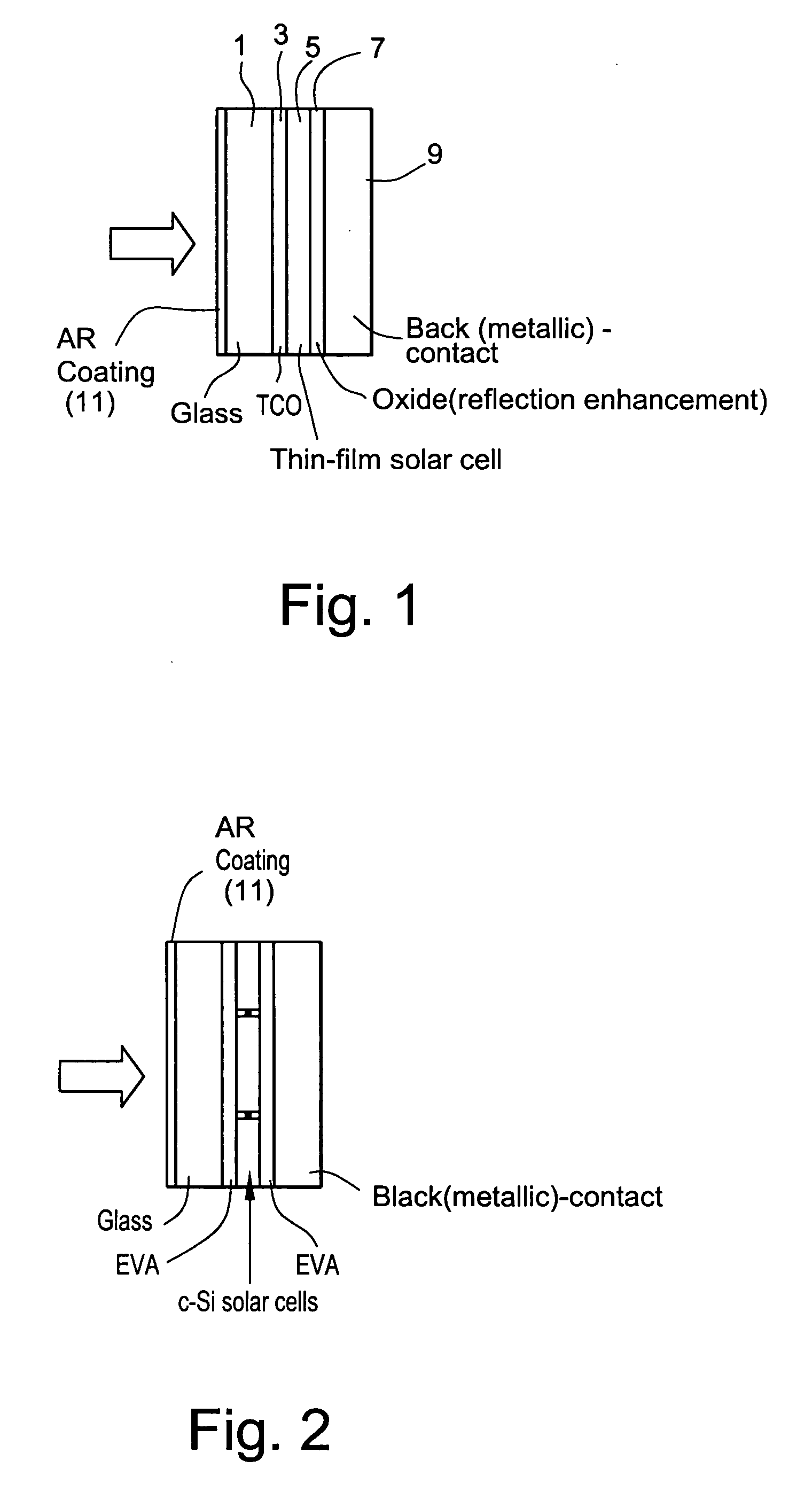

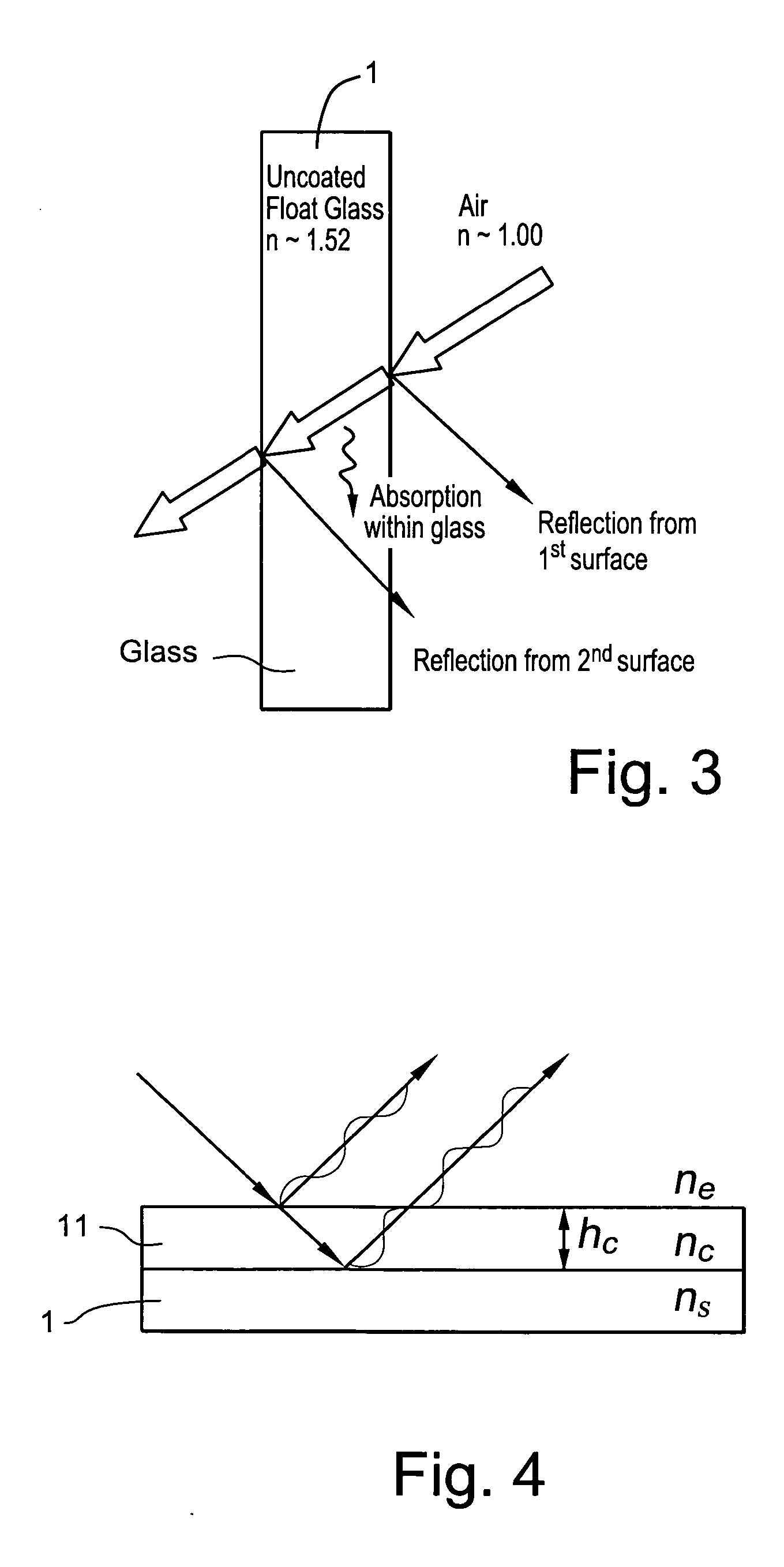

Method of making solar cell/module with porous silica antireflective coating

InactiveUS20070074757A1Improved anti-reflection (AR) coatingReduce reflectionCoatingsPhotovoltaic energy generationColloidal silicaAnti-reflective coating

A solar cell includes an improved anti-reflection (AR) coating provided on an incident glass substrate. In certain example embodiments, the AR coating includes a layer comprising porous silica. The porous nature of the silica inclusive layer permits the refractive index (n) of the silica inclusive layer to be reduced, thereby decreasing reflection and permitting more radiation to make its way to the active layer(s) of the solar cell. In certain example embodiments, a coating solution may be formed by mixing a colloidal silica solution and a polymeric silica solution, then applying the coating solution to a substrate and curing the same in order to form an AR coating.

Owner:GUARDIAN GLASS LLC

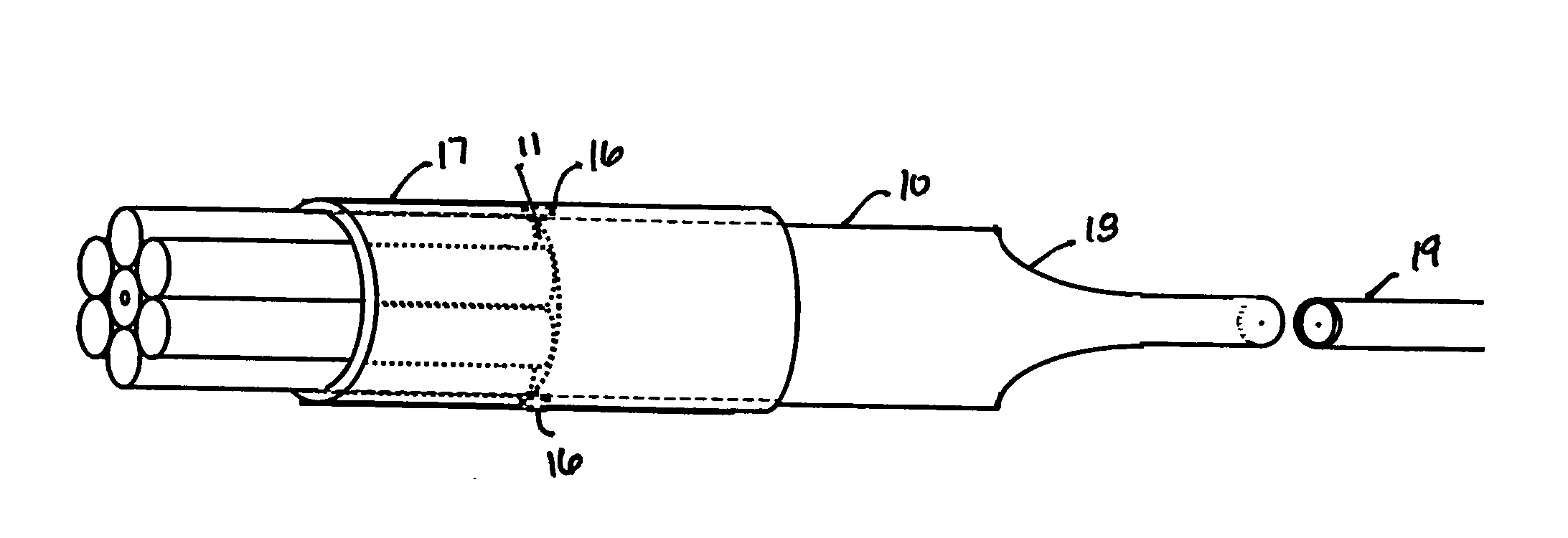

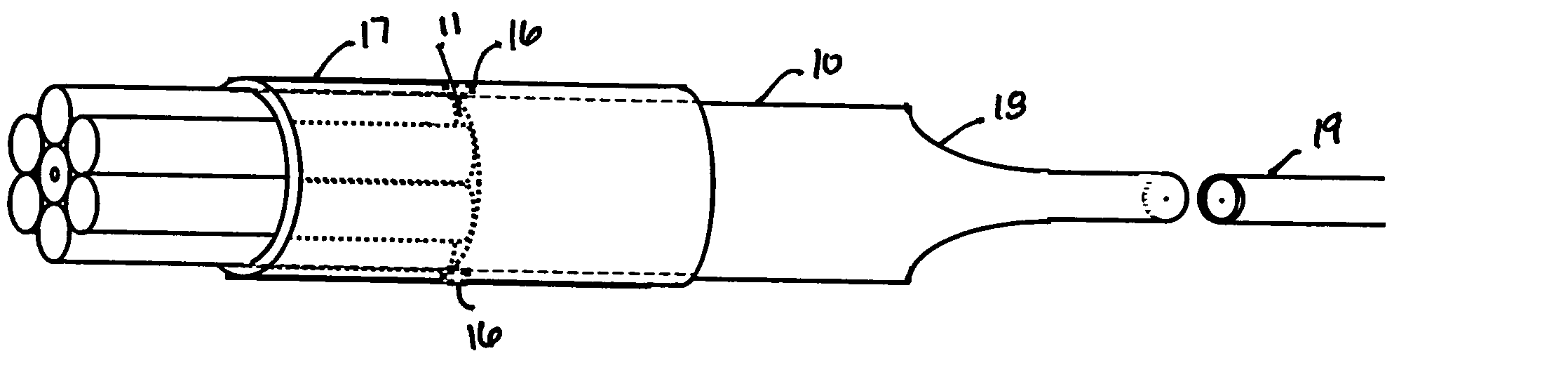

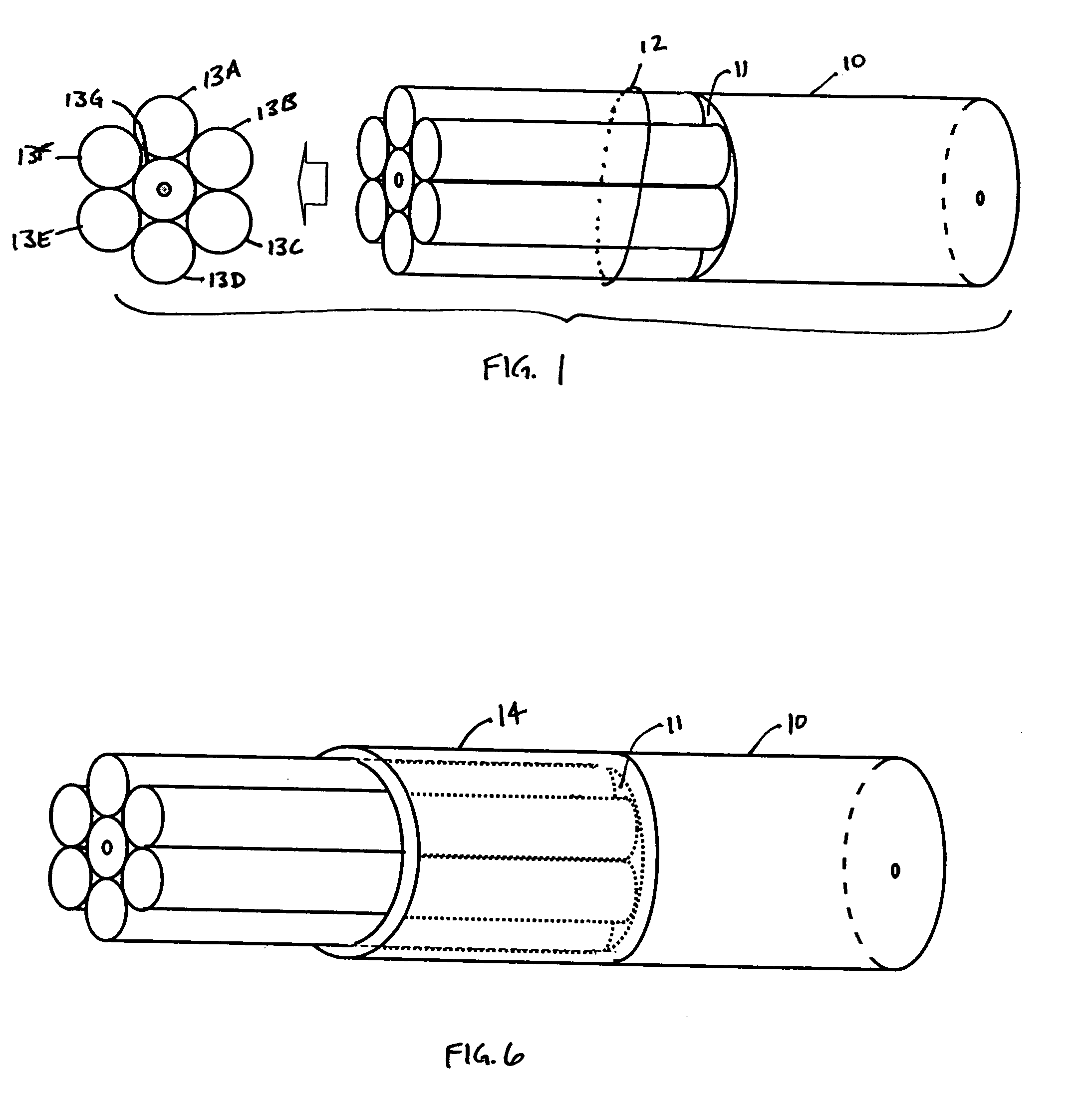

Optical fiber pump multiplexer

InactiveUS20050105854A1Lower refractive indexLaser detailsCoupling light guidesSignal waveDouble-clad fiber

One or more single mode few-moded or multimode fibers are incorporated into a bundle to carry input to a fiber amplifier or output from a fiber amplifier or a fiber laser. The input is at the signal wavelength, which is the wavelength where amplification or lasing occurs. Each of the fibers in the bundle is cleaved individually or as a group and fiber ends are aligned in the same plane. The fiber amplifier or fiber laser may include a double clad fiber and the other fibers of the bundle couple light for cladding pumping. The device may also include a mode filter for controlling the output mode.

Owner:IMRA AMERICA

Optical fiber

ActiveUS20060039665A1Improve transmission performanceReduce nonlinear effectsOptical fibre with multilayer core/claddingOptical waveguide light guideOptoelectronicsRelative refractive index

An optical fiber includes: a core at a center; a first cladding layer; a second cladding layer; and a third cladding layer. A maximum refractive index of the core is greater than any of maximum refractive indices of the first cladding layer, the second cladding layer, and the third cladding layer, and the maximum refractive index of the second cladding layer is smaller than any of the maximum refractive indices of the first and the third cladding layer. Additionally, a ratio of a2 / a1 is not less than about 2.5 and not more than about 4.5, where a1 represents the radius of the core, and a2 represents the radius of an outer periphery of the first cladding layer, and a relative refractive index difference of the core with respect to a maximum refractive index of the third cladding layer is not less than 0.20% and not more than 0.70%.

Owner:THE FUJIKURA CABLE WORKS LTD

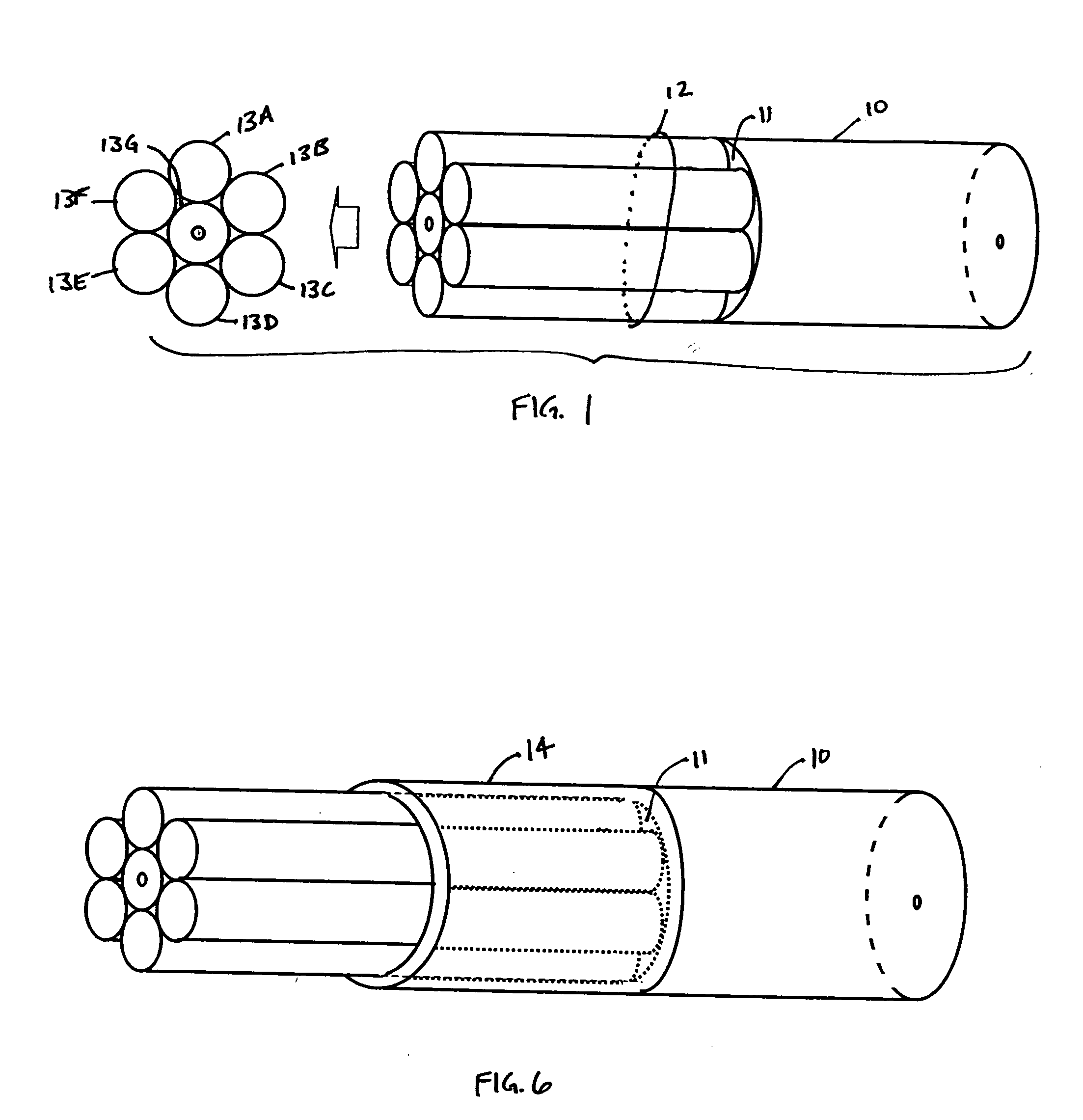

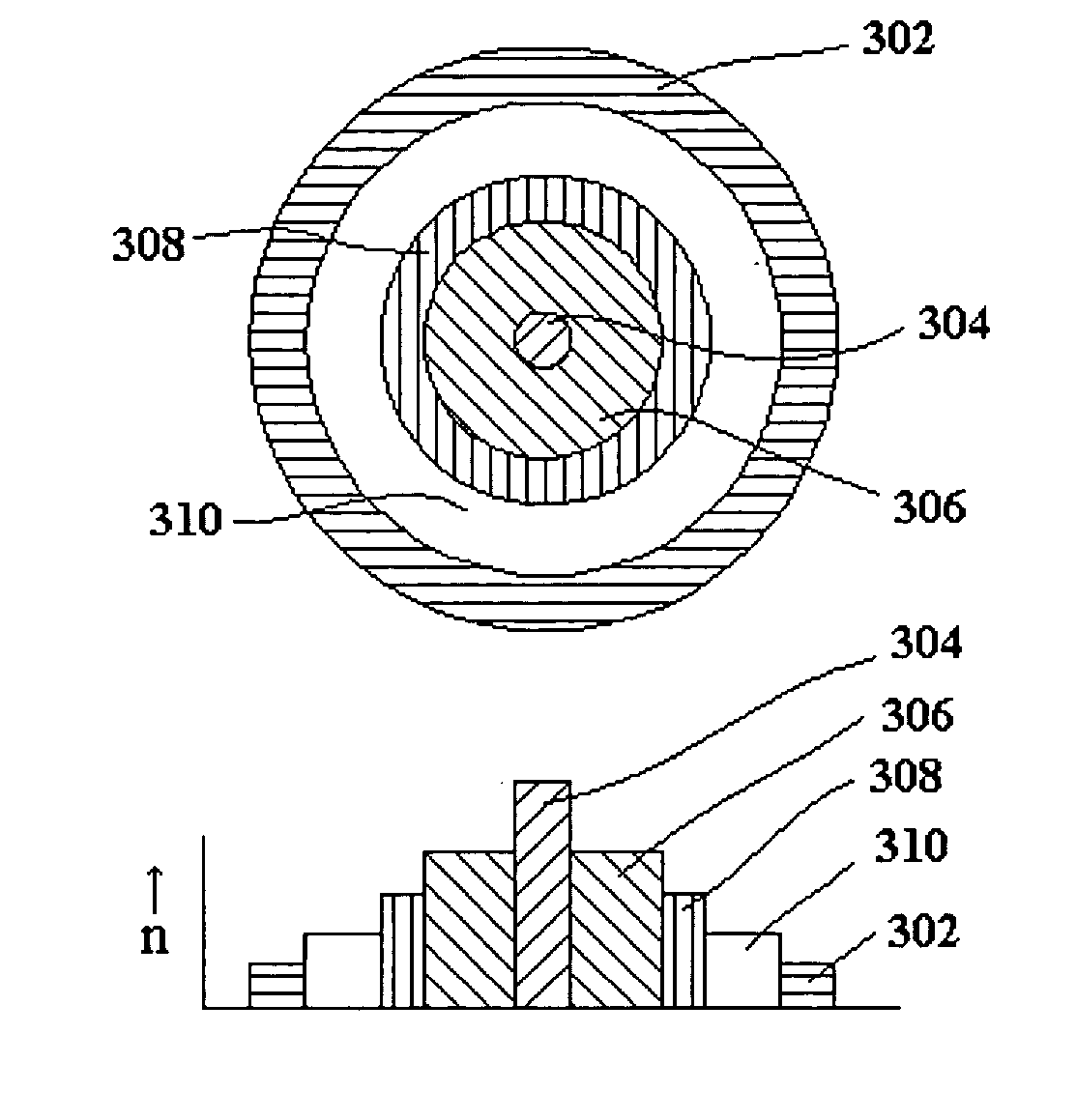

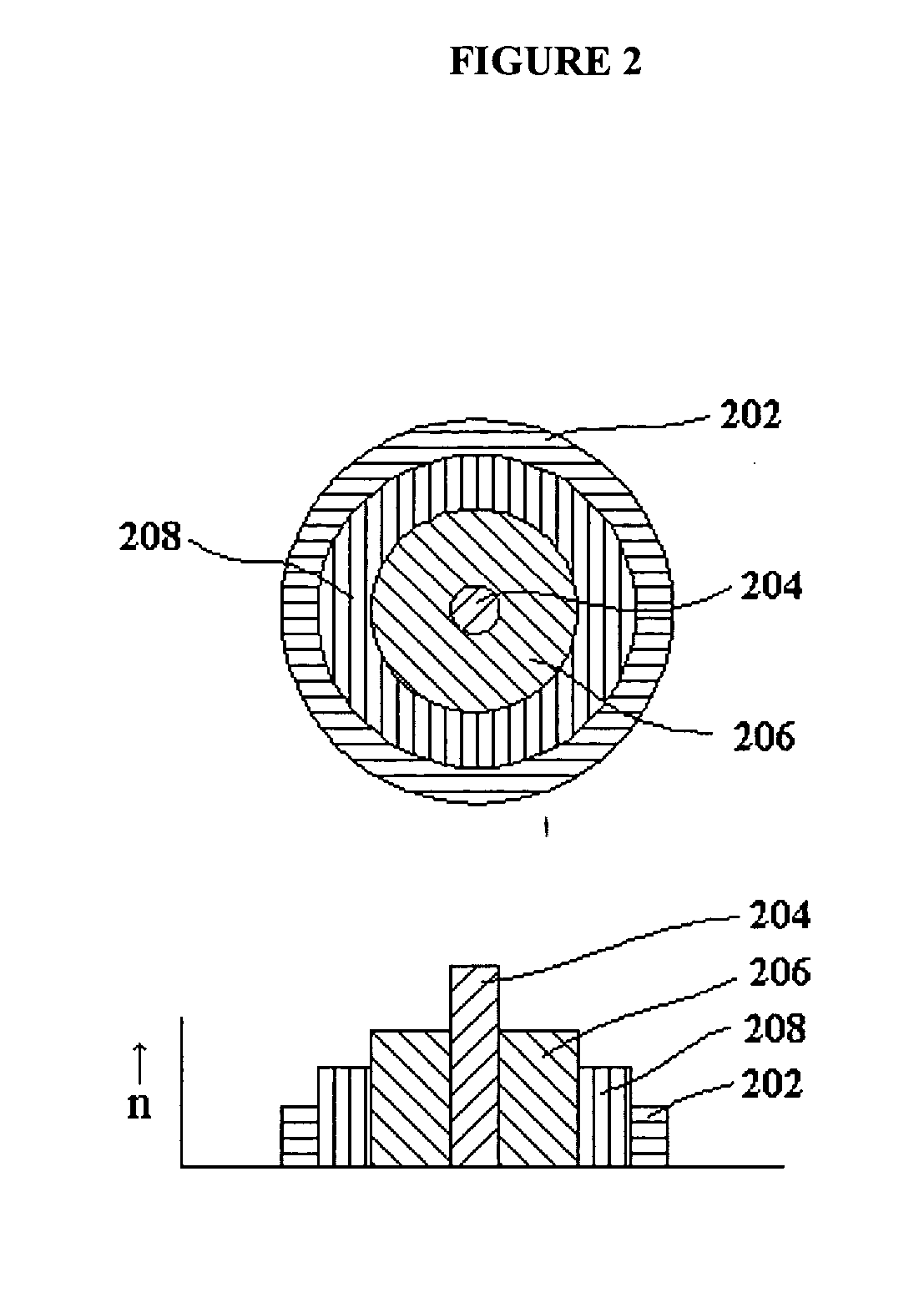

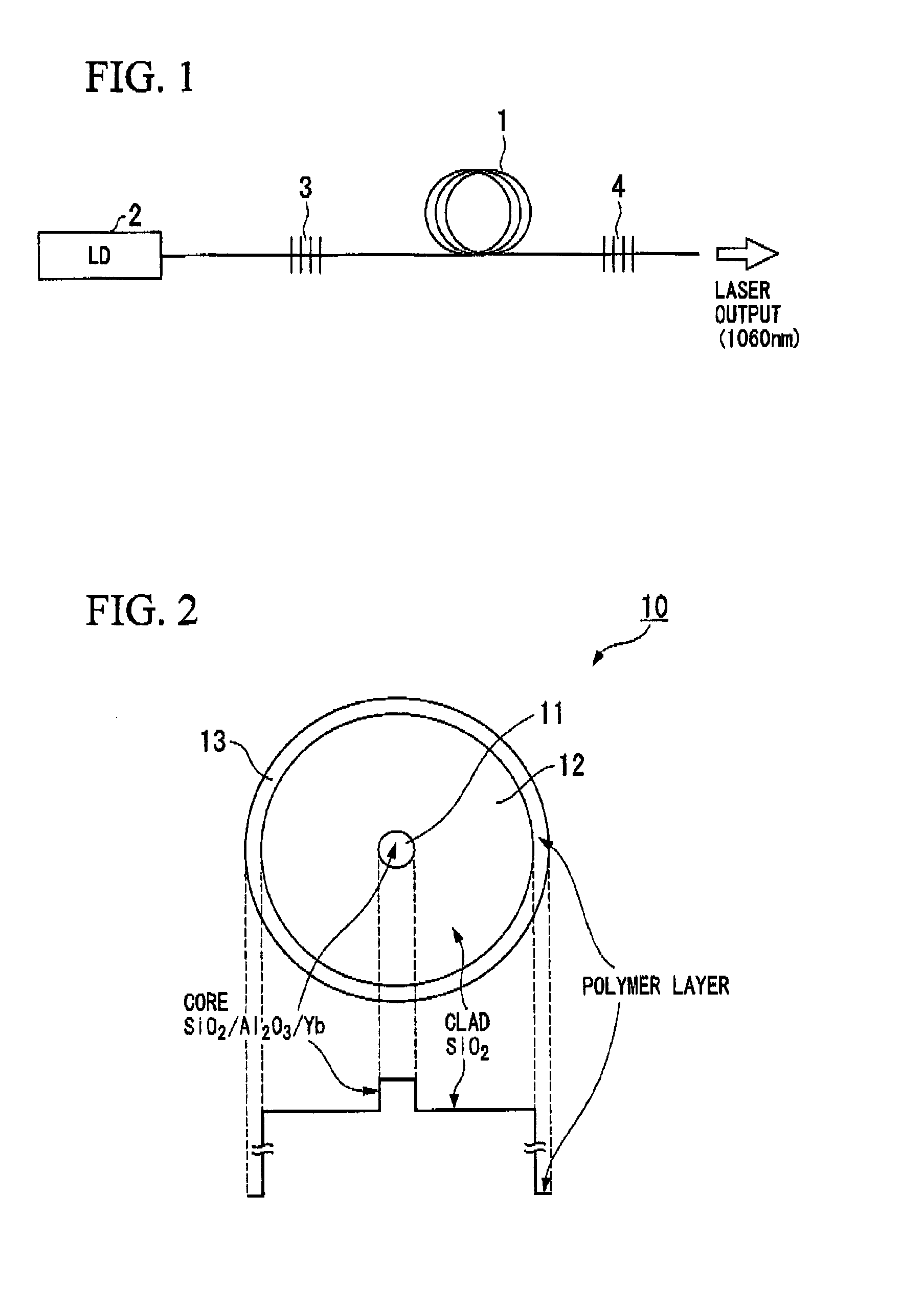

Multi-clad optical fiber lasers and their manufacture

ActiveUS20040156401A1Low refractive indexProtection from damageGlass making apparatusCladded optical fibreRare earthRefractive index

An optical fiber is disclosed that can be used as an active medium in fiber lasers and / or fiber amplifiers, featuring a preferably rare-earth-doped silica active core surrounded by a pure or doped silica cladding layer ("pump core"). The pump core is surrounded by a doped or pure silica inner cladding for guiding pumping radiation within the pump core. Thus, the refractive index of the inner cladding is lower than that of the pump core. The fiber is surrounded by a protective coating made of polymeric material. One or more additional outer cladding layers, having refractive indexes lower than said inner cladding, may optionally be placed between the inner cladding and the protective coating to further protect the polymer coating from damage. Unlike the prior art, the protective coating does not serve as the only cladding, but is assisted by the inner cladding and optional outer cladding(s). The resultant fiber restricts radiation mainly to silica layers, thereby increasing the damage threshold and the applicable maximum pump power of the fiber.

Owner:BIOLITEC UNTERNEHMENSBETEILLIGUNGS II AG +1

Optical fiber pump multiplexer

InactiveUS7016573B2Lower refractive indexLaser detailsCoupling light guidesDouble-clad fiberMultiplexer

Owner:IMRA AMERICA

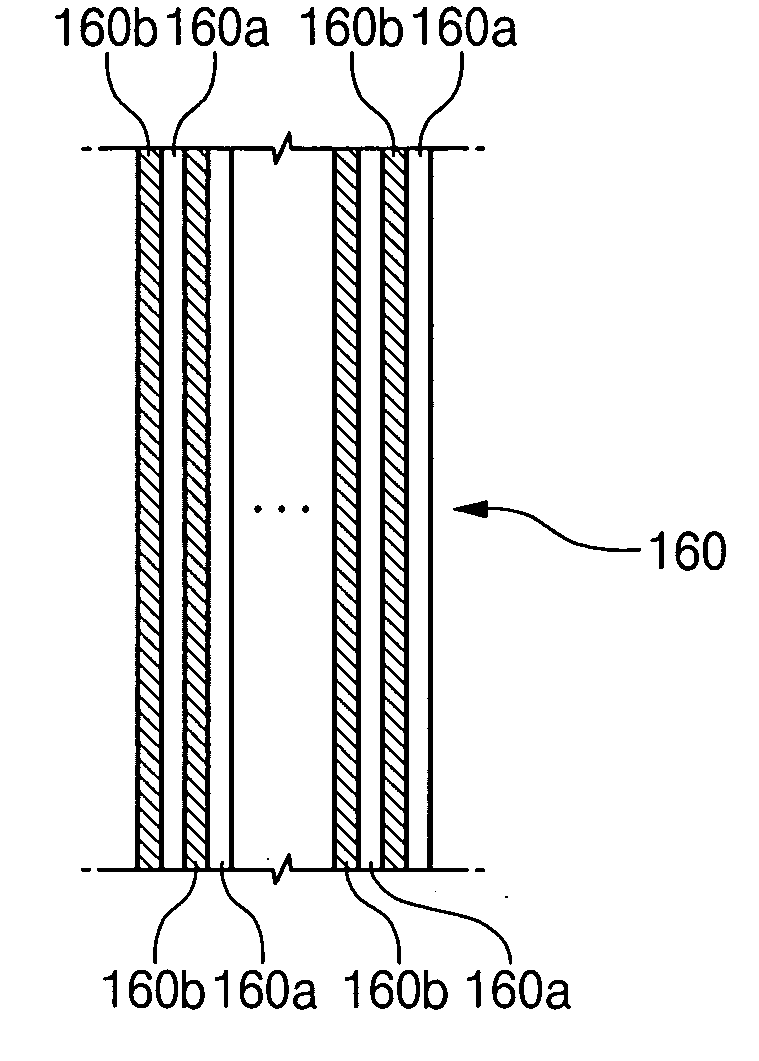

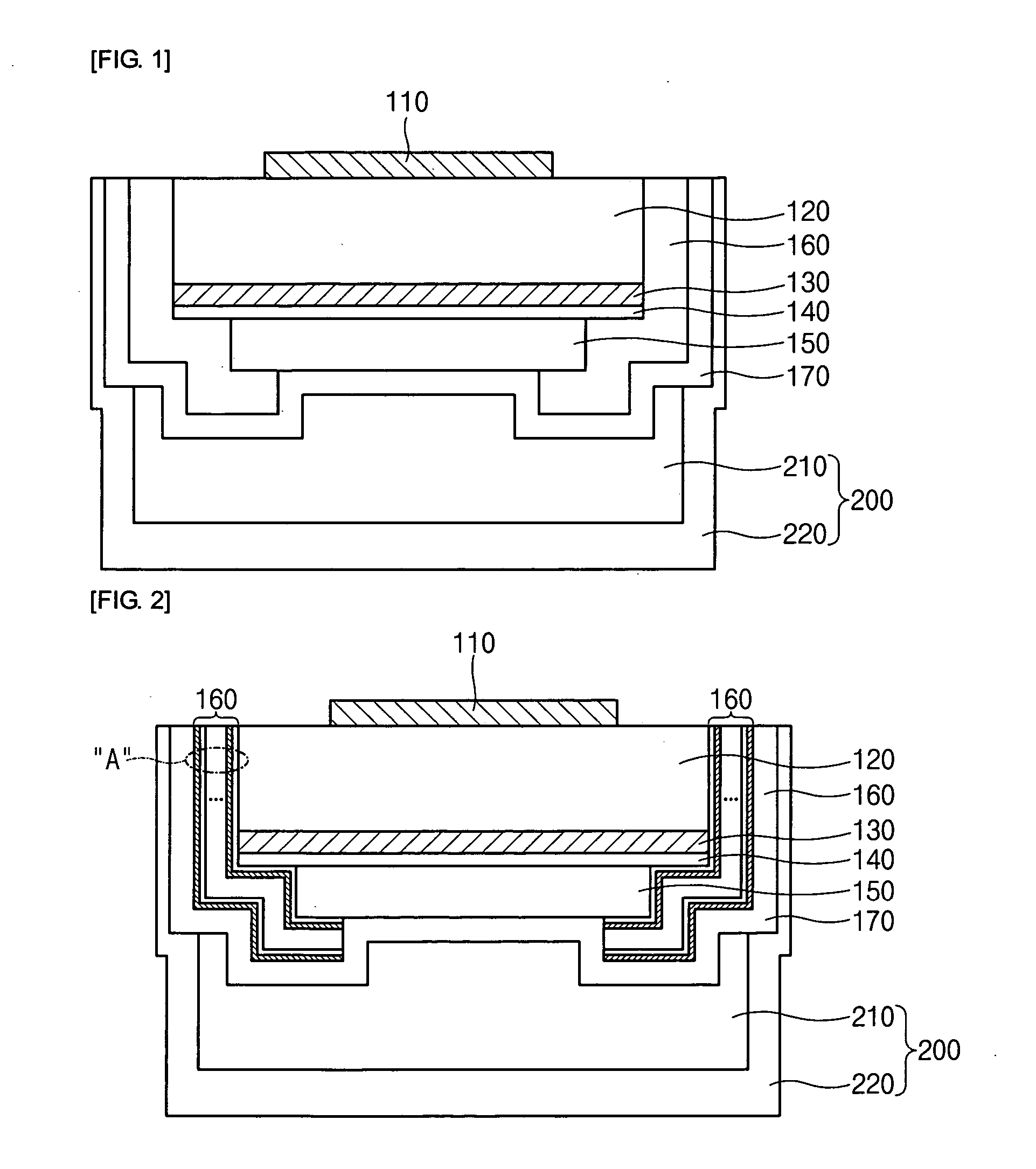

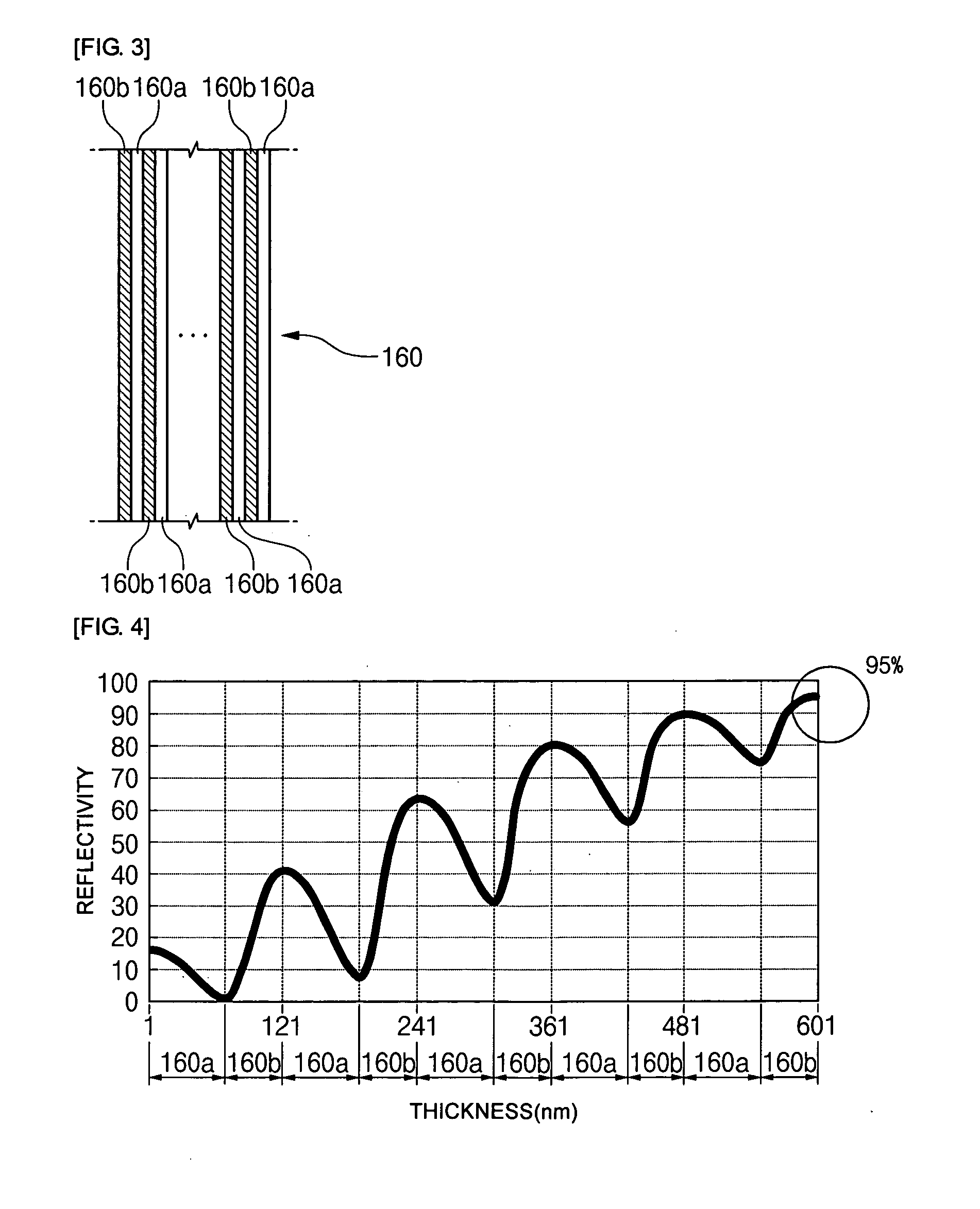

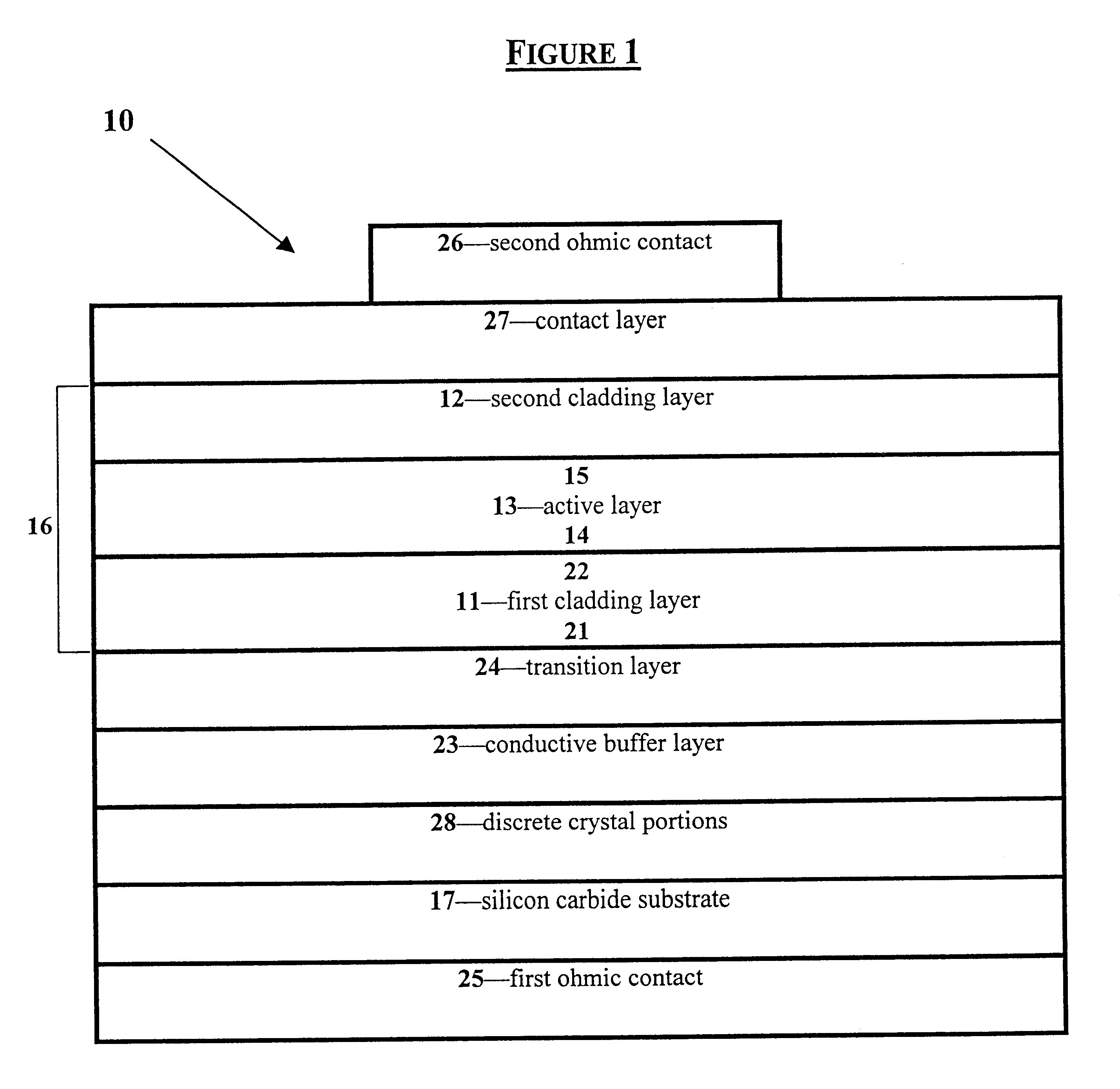

Vertical gallium-nitride based light emitting diode

ActiveUS20070114552A1Light extraction efficiency can be improvedImprove reflectivitySemiconductor devicesDistributed Bragg reflectorGallium nitride

A vertical GaN-based LED includes: an n-electrode; a light-emitting structure in which an n-type GaN layer, an active layer, and a p-type GaN layer are sequentially formed under the n-electrode; a p-electrode formed under the light-emitting structure; a passivation layer formed to cover the side and bottom surfaces of the light-emitting structure and expose a predetermined portion of the p-electrode, the passivation layer being formed of a distributed Bragg reflector (DBR); a plating seed layer formed under the passivation layer and the p-electrode; and a support layer formed under the plating seed layer.

Owner:SAMSUNG ELECTRONICS CO LTD

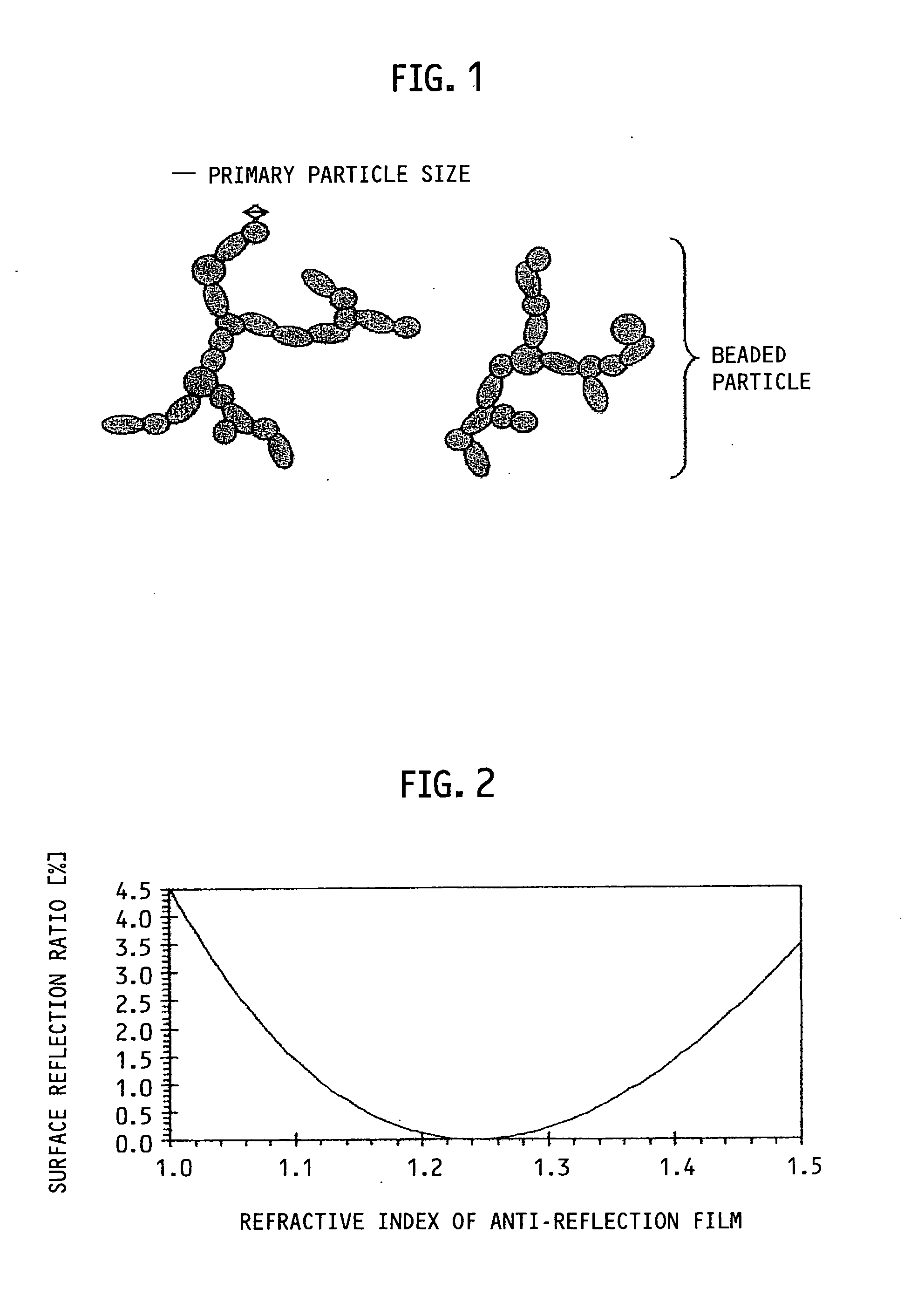

Nano-structured thin film with reduced light reflection

InactiveUS20070065638A1Improve performance and durabilityImprove the immunityMaterial nanotechnologyRecord information storageNanometreDisplay device

The present invention is directed to a multilayer optical film, for use in a display or component thereof, comprising a substrate having a topmost layer that is an anti-reflective layer having a nano-structured surface, the layer comprising elongated-shaped silica particles. Another aspect of the present invention relates to a method of forming the single anti-reflective layer and its use in various applications including displays and components thereof.

Owner:EASTMAN KODAK CO

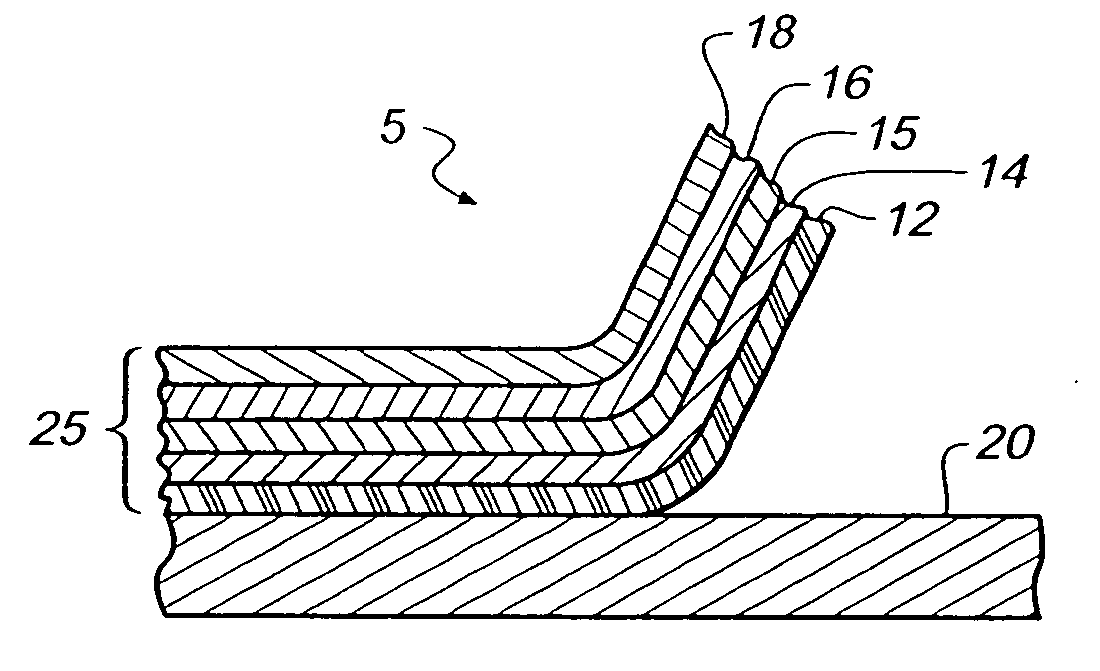

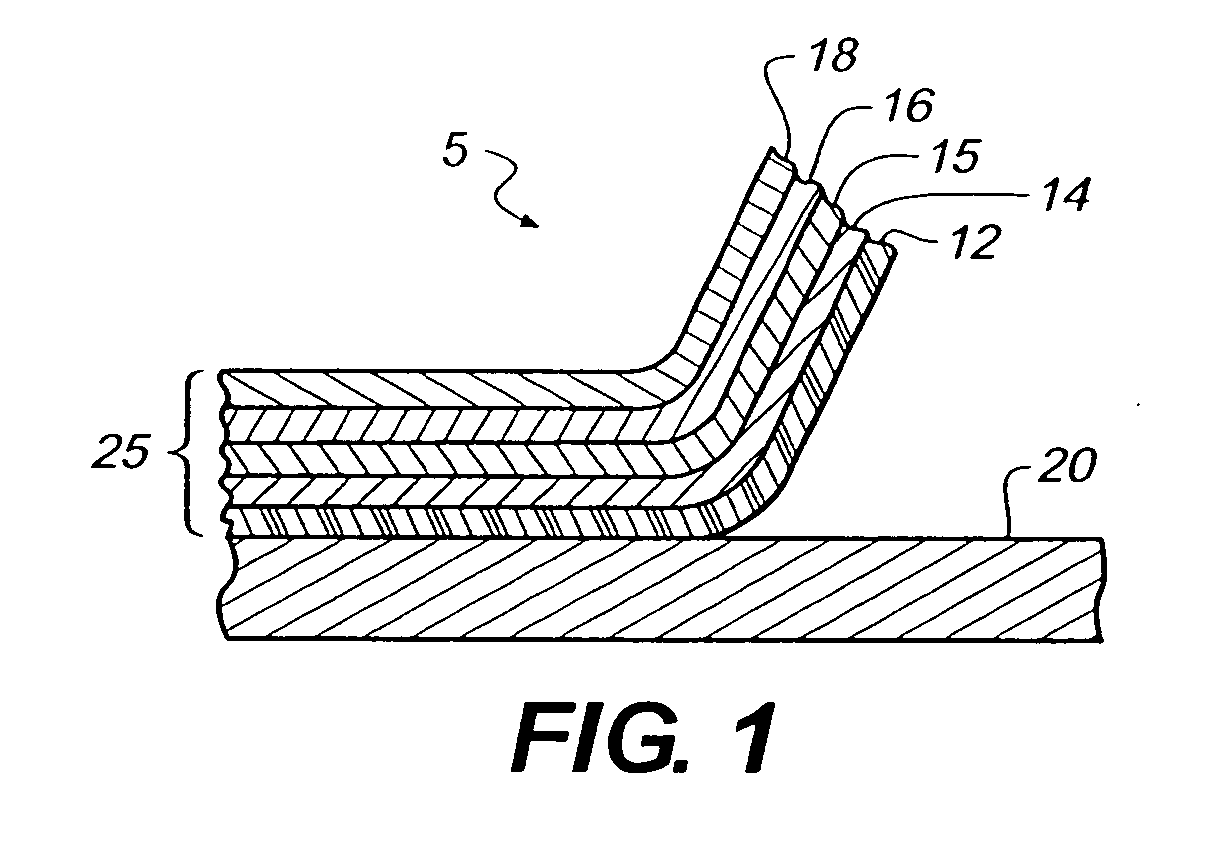

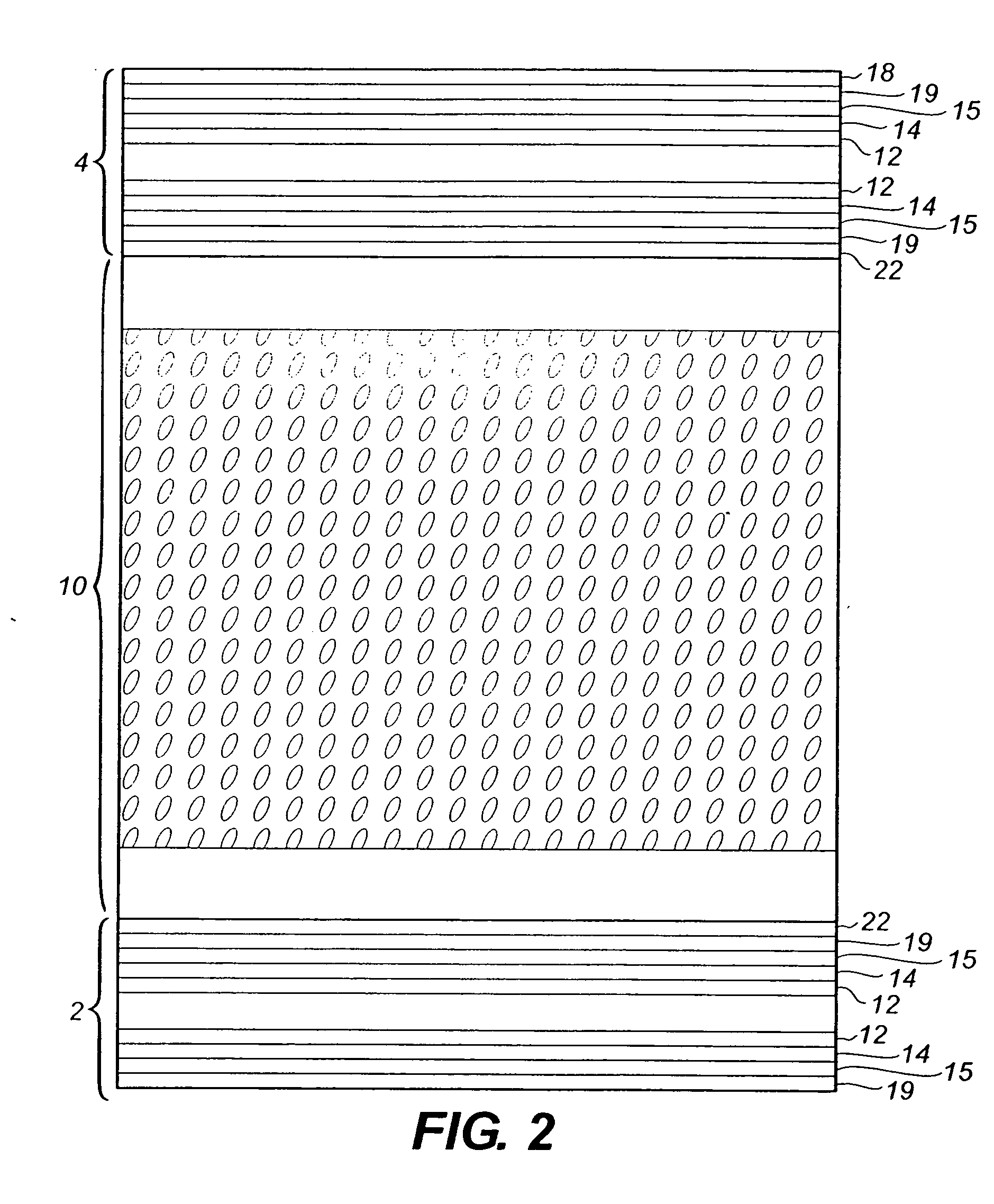

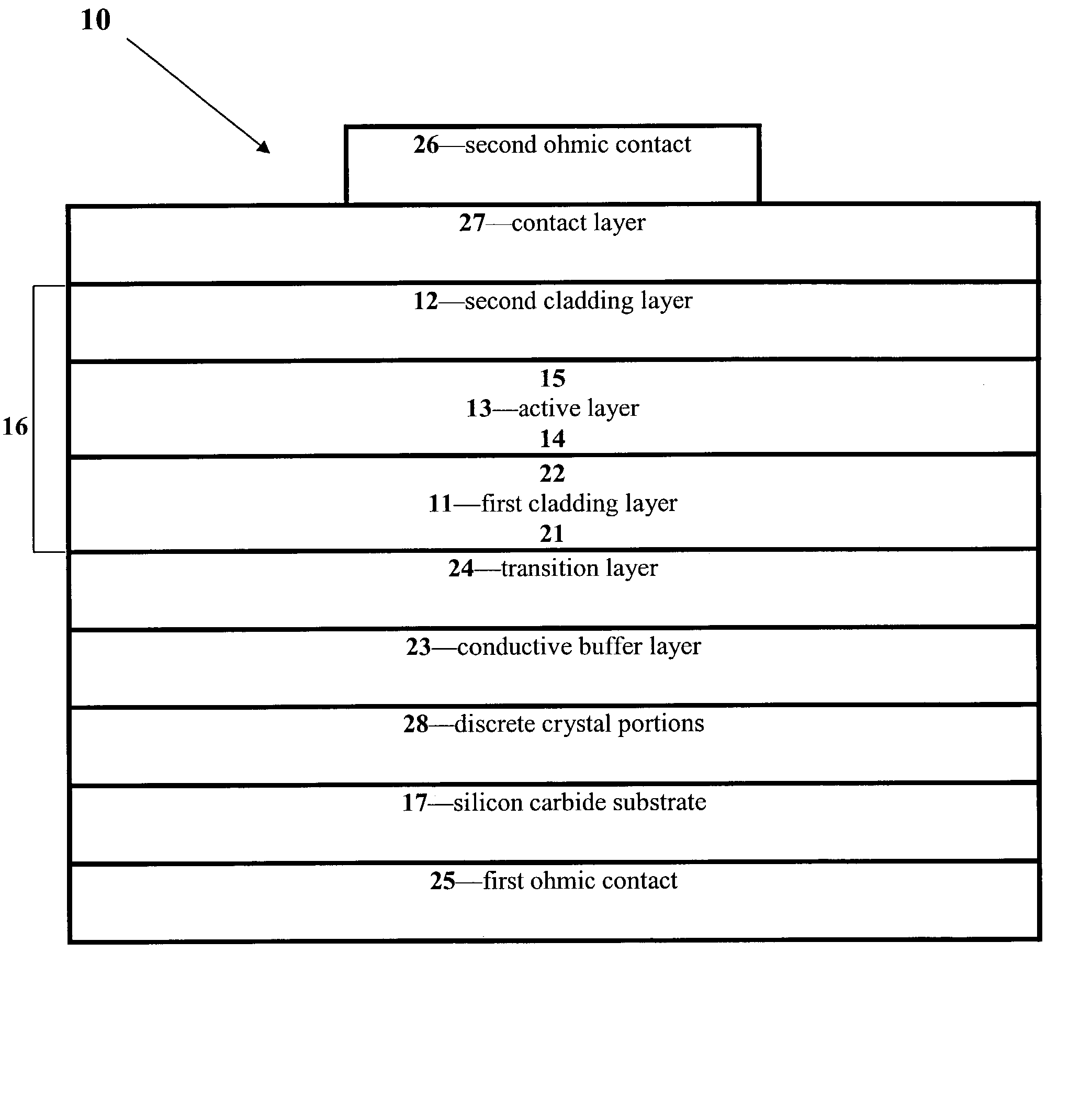

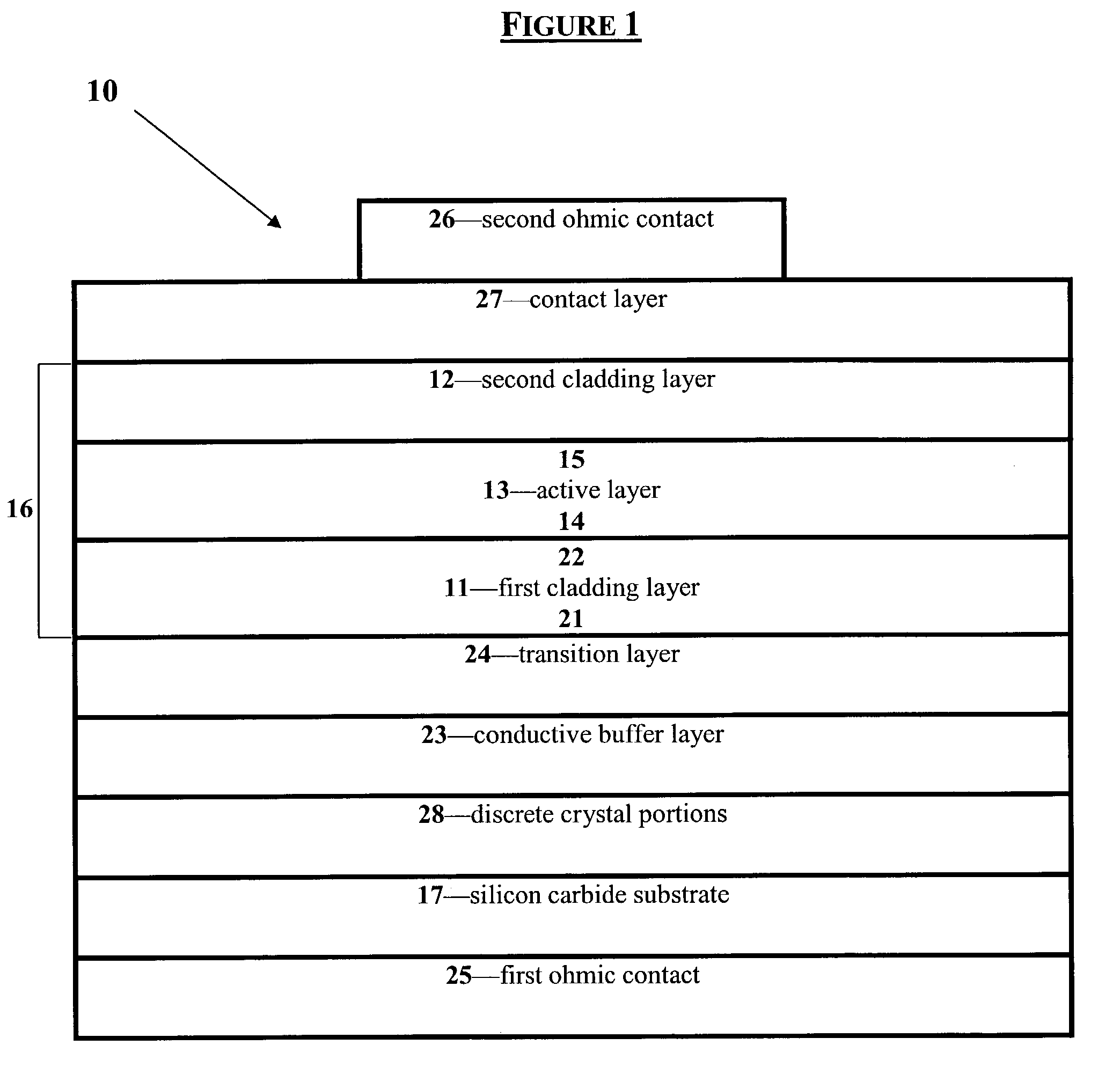

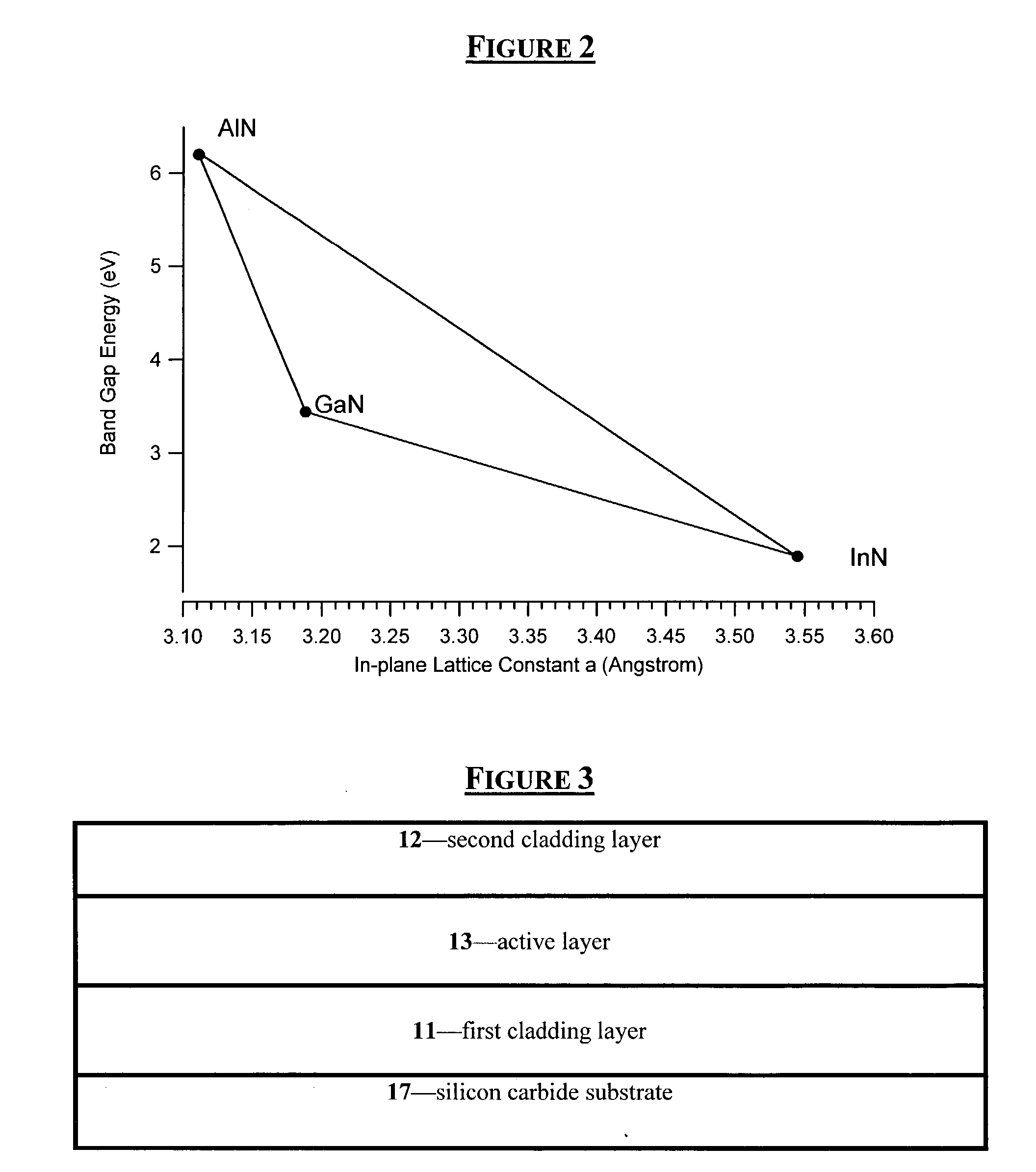

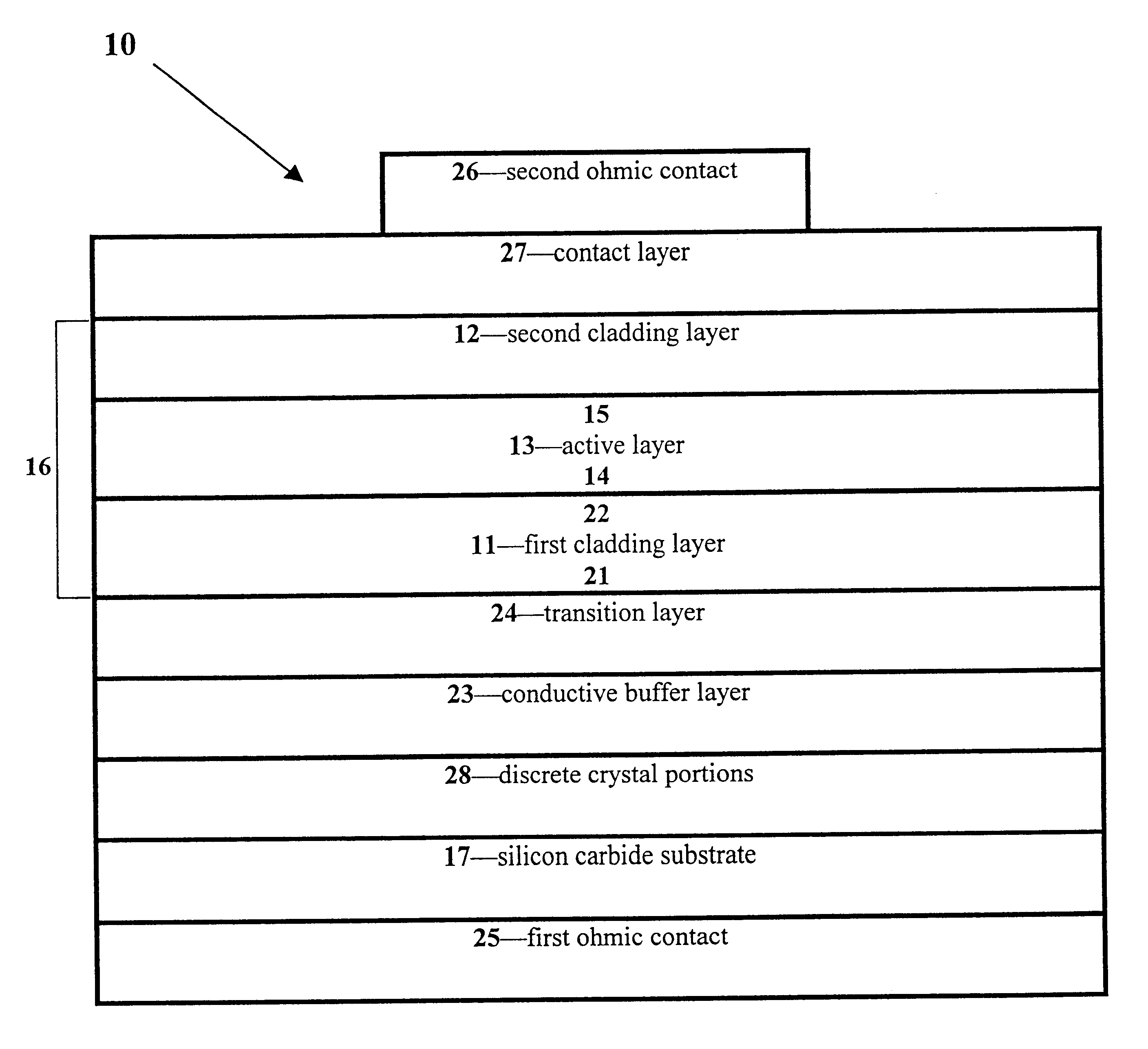

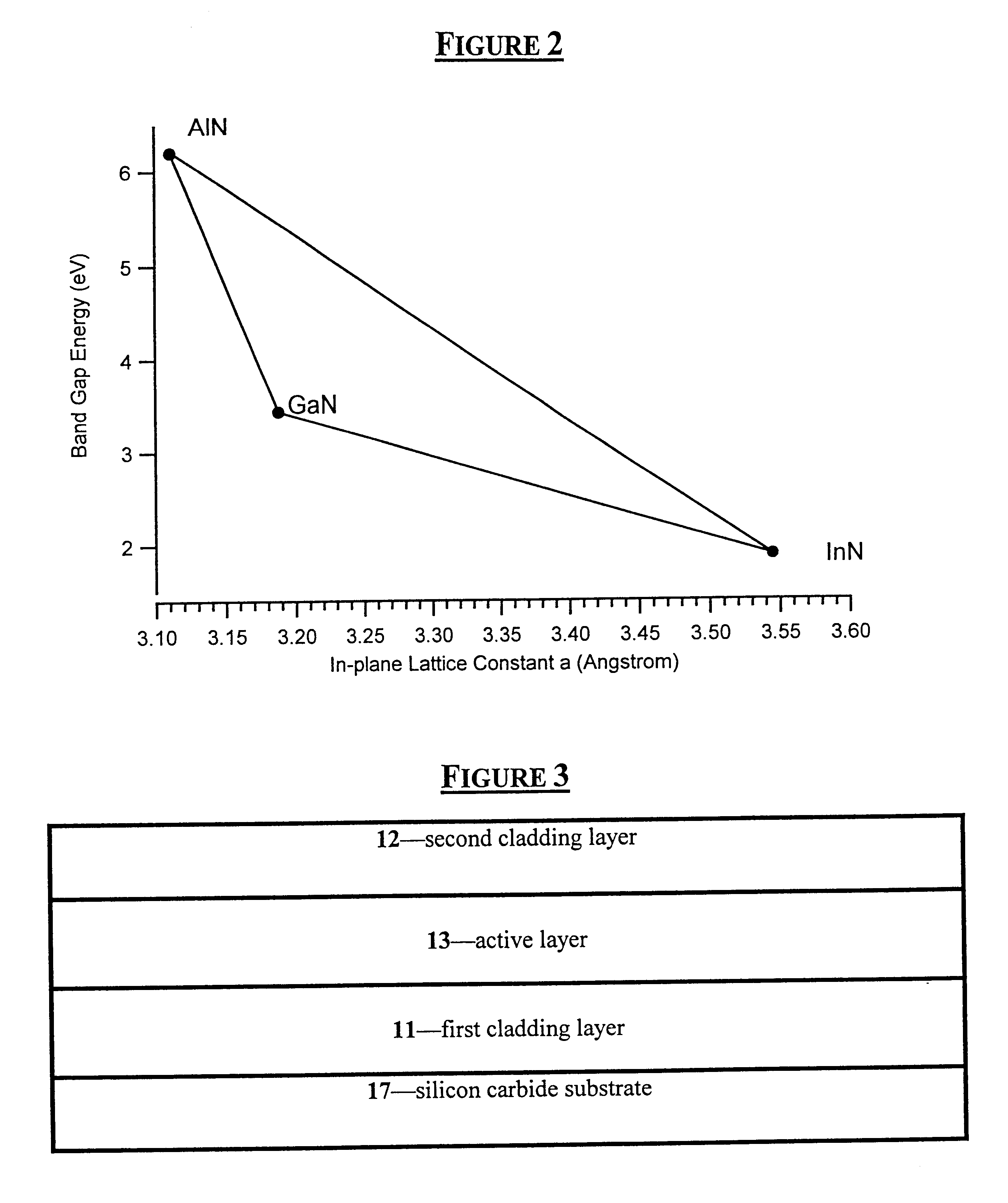

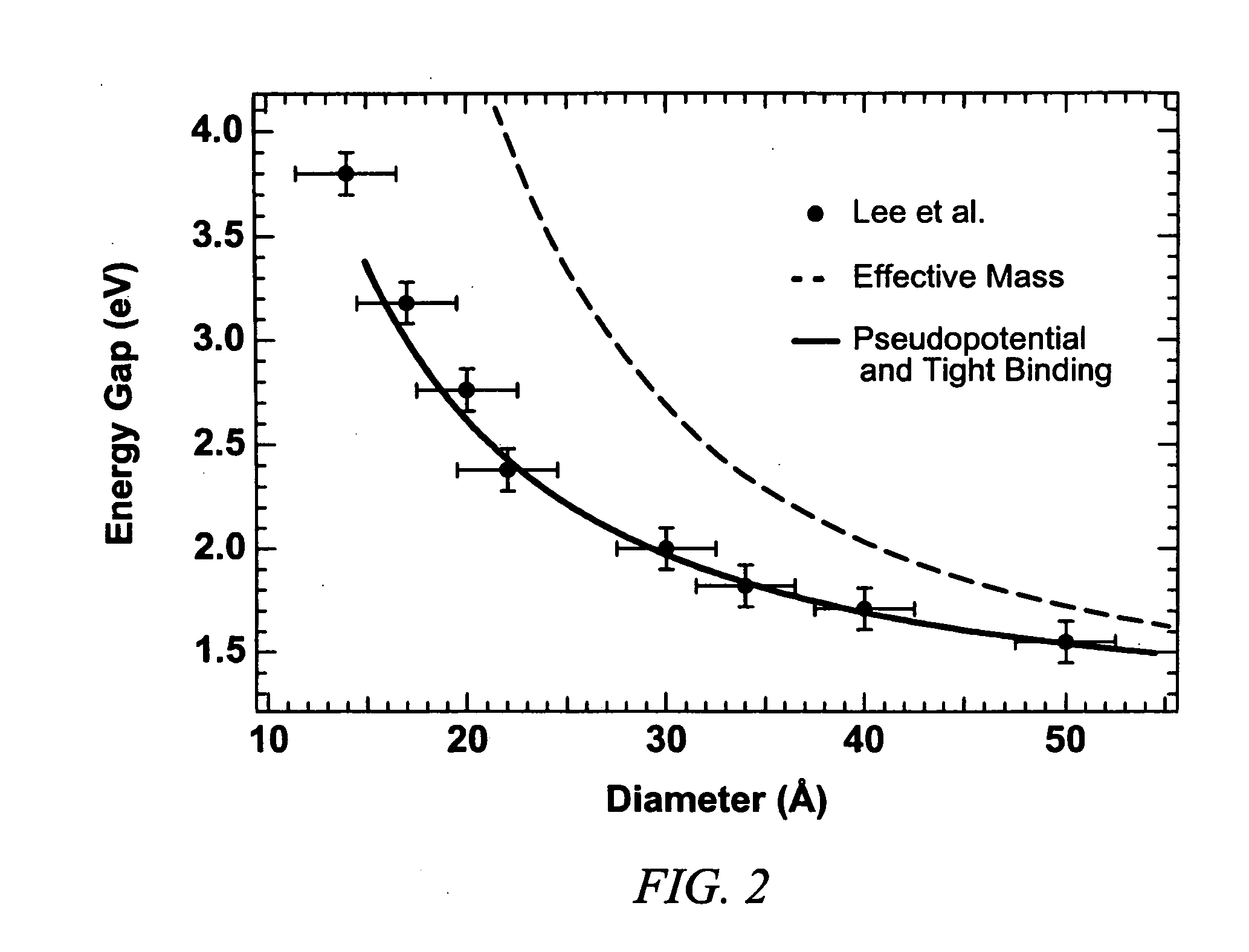

Group III nitride light emitting devices with progressively graded layers

InactiveUS20030164507A1Improve emission efficiencyReduce non-radiative recombinationLaser detailsSolid-state devicesSemiconductor structureElectromagnetic spectrum

The present invention is a semiconductor structure for light emitting devices that can emit in the red to ultraviolet portion of the electromagnetic spectrum. The semiconductor structure includes a first cladding layer of a Group III nitride, a second cladding layer of a Group III nitride, and an active layer of a Group III nitride that is positioned between the first and second cladding layers, and whose bandgap is smaller than the respective bandgaps of the first and second cladding layers. The semiconductor structure is characterized by the absence of gallium in one or more of these structural layers.

Owner:CREE INC

Multi-clad optical fiber lasers and their manufacture

ActiveUS6959022B2Easily damagedIncrease powerGlass making apparatusLaser using scattering effectsRare earthRefractive index

An optical fiber is disclosed that can be used as an active medium in fiber lasers and / or fiber amplifiers, featuring a preferably rare-earth-doped silica active core surrounded by a pure or doped silica cladding layer (“pump core”). The pump core is surrounded by a doped or pure silica inner cladding for guiding pumping radiation within the pump core. Thus, the refractive index of the inner cladding is lower than that of the pump core. The fiber is surrounded by a protective coating made of polymeric material. One or more additional outer cladding layers, having refractive indexes lower than said inner cladding, may optionally be placed between the inner cladding and the protective coating to further protect the polymer coating from damage. Unlike the prior art, the protective coating does not serve as the only cladding, but is assisted by the inner cladding and optional outer cladding(s). The resultant fiber restricts radiation mainly to silica layers, thereby increasing the damage threshold and the applicable maximum pump power of the fiber.

Owner:BIOLITEC UNTERNEHMENSBETEILLIGUNGS II AG +1

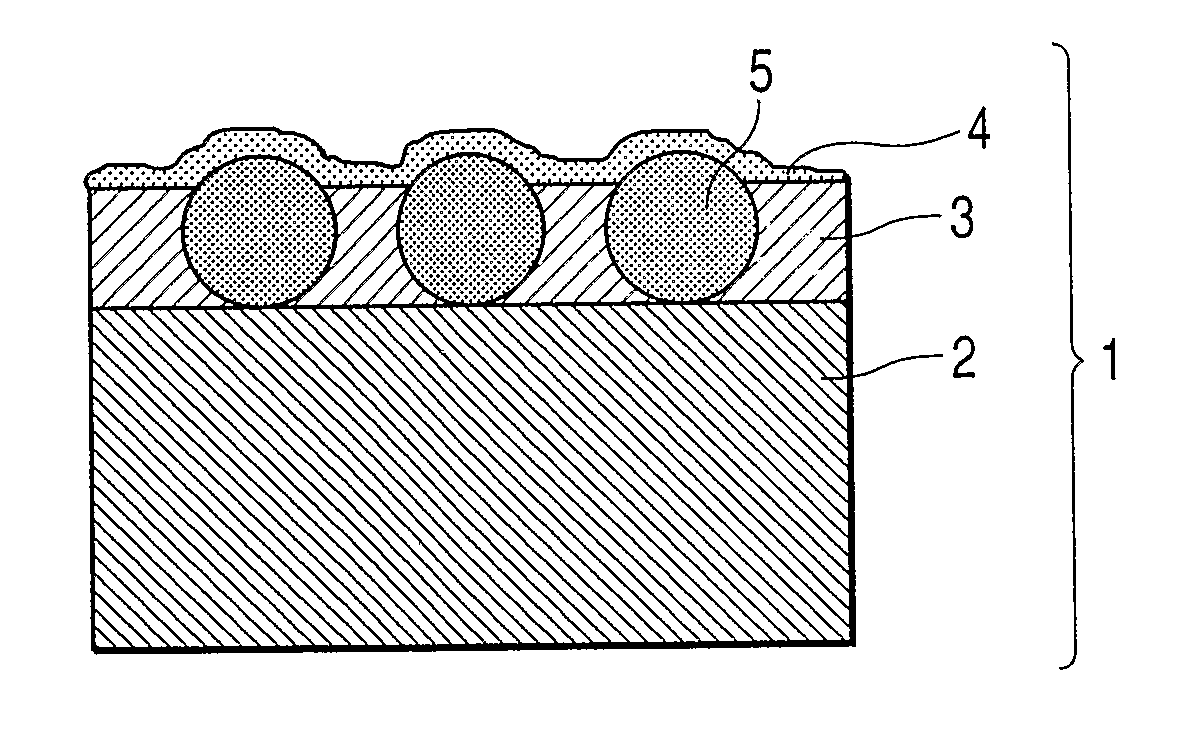

Coating material composition and article having coating film formed therewith

InactiveUS20050109238A1Low refractive indexEnsure mechanical strengthGroup 4/14 element organic compoundsElectric discharge tubesRefractive indexPolymer chemistry

The present invention provide a coating material composition comprising at least fine hollow particles and a matrix-forming material, wherein when the coating material composition is applied and dried to form a coating film having a low refractive index, the matrix-forming material forms a porous matrix.

Owner:MATSUSHITA ELECTRIC WORKS LTD

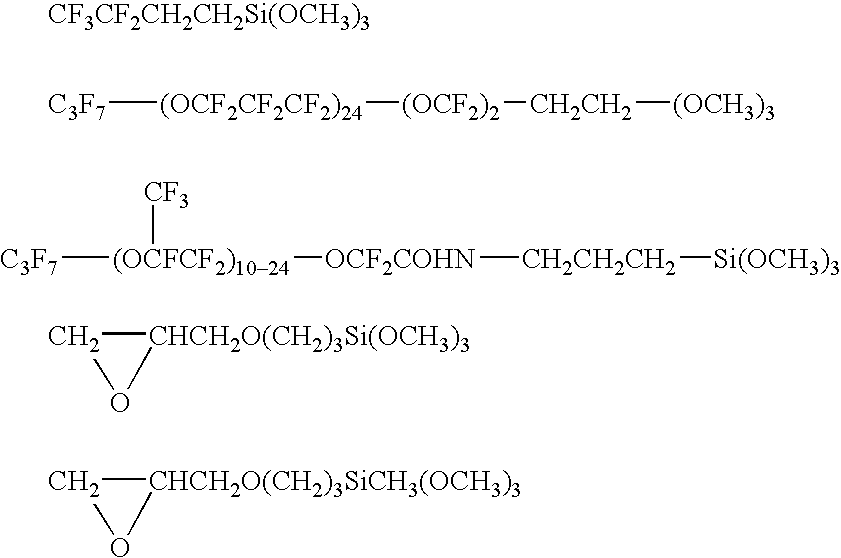

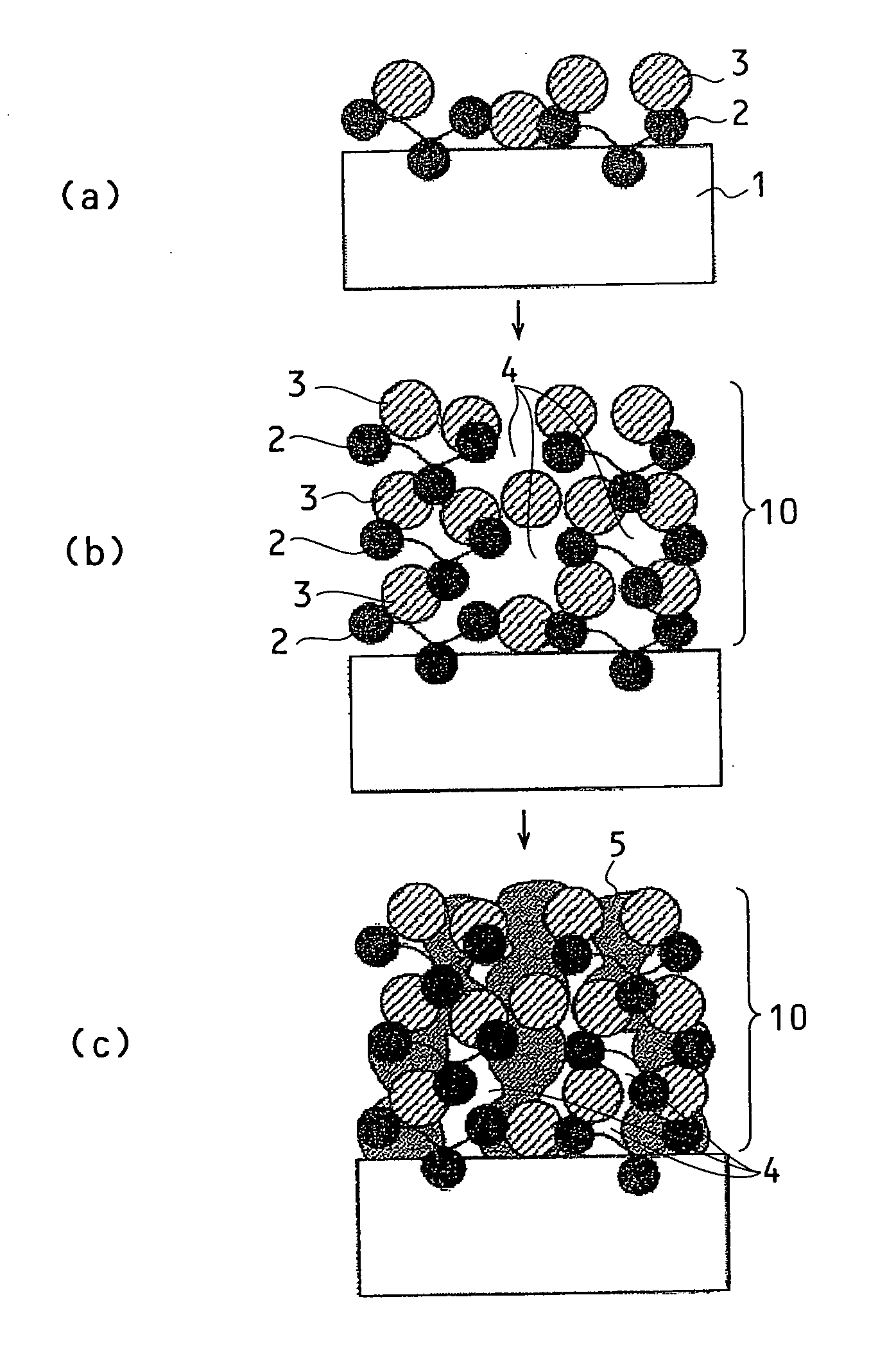

Film having low refractive index film and method for producing the same, Anti-relection film and method for producing the same, coating liquid set for low refractive index film, substrate having microparticle-laminated thin film and method for producing the same, and optical member

ActiveUS20110195239A1Low refractive indexImprove adhesionMaterial nanotechnologyCladded optical fibrePolymer scienceSilanes

Provided is a film having a low refractive index, which can be formed under normal temperature and pressure while obtaining a lower refractive index, has excellent adhesion with a solid substrate, and does not lose geometric optical properties, such as the diffusibility or light-harvesting capability attributed to the microstructure. Also disclosed is a method for producing the same. The film having a low refractive index is obtained by causing an electrolyte polymer and microparticles to be alternately adsorbed on the surface of a solid substrate and bringing the resulting microparticle-laminated film into contact with a silicon compound solution in order to bond the solid substrate with microparticles and microparticles with microparticles. The silicon compound solution is selected from (1) the hydrolysis product of alkoxysilane (I) wherein the functional groups are formed from hydrolyzable groups and non-hydrolyzable organic groups, and the condensation reaction product thereof, (2) the hydrolysis product of a mixture of alkoxysilane (I) and alkoxysilane (II) wherein the functional groups are formed from hydrolyzable groups alone, and the condensation reaction product thereof; and (3) a mixture of hydrolysis product and condensation product thereof according to (1) and alkoxysilane (II).

Owner:RESONAC CORP

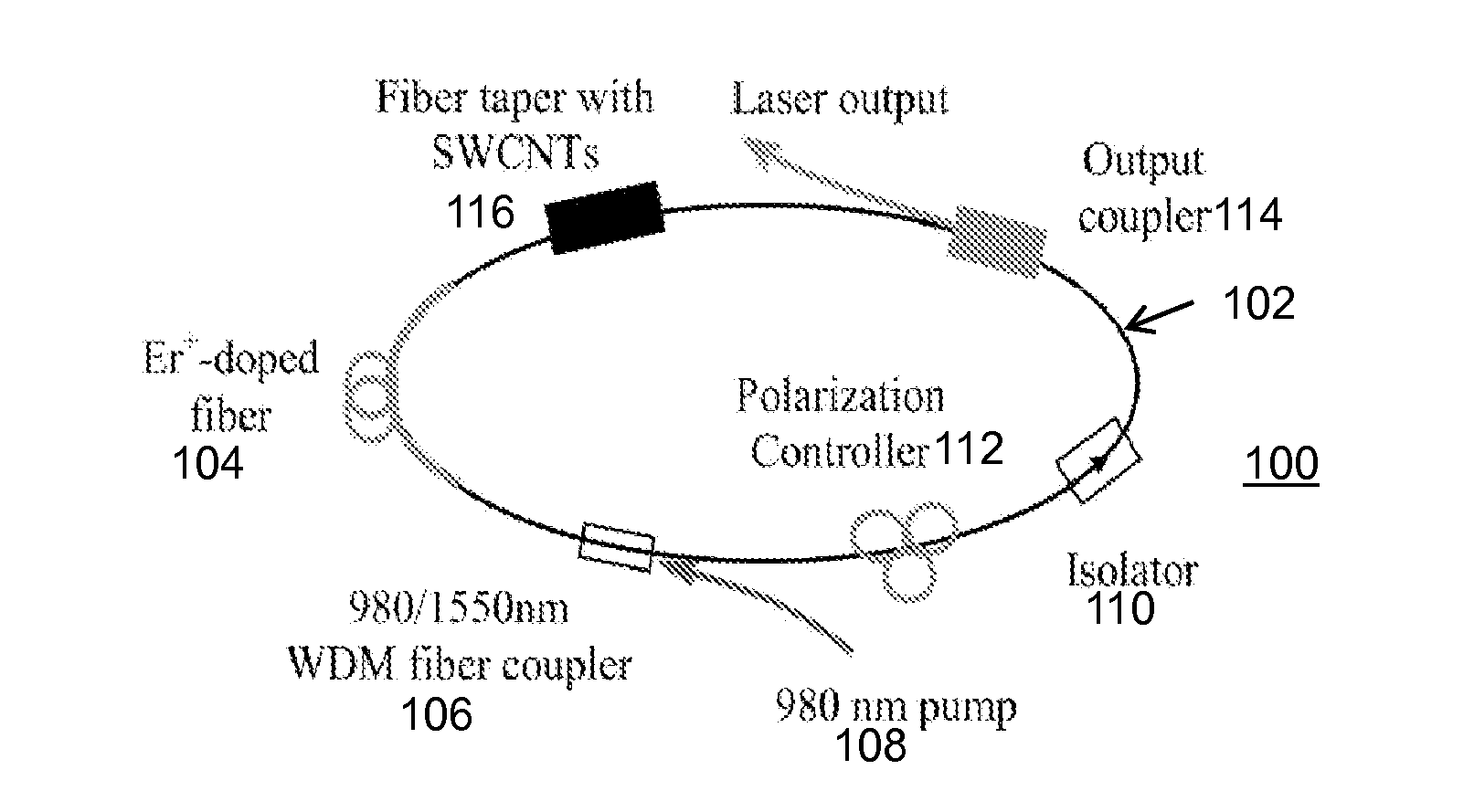

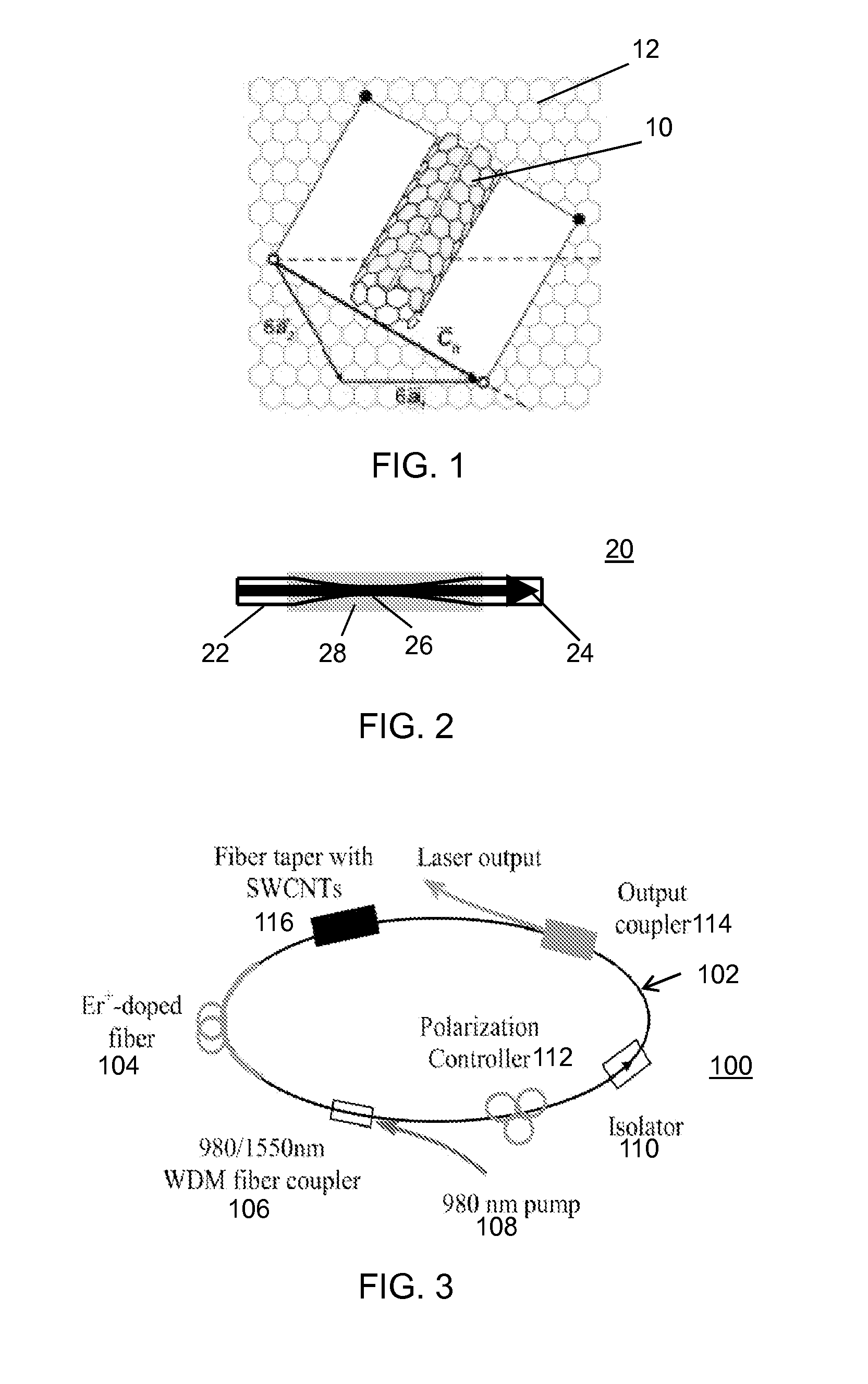

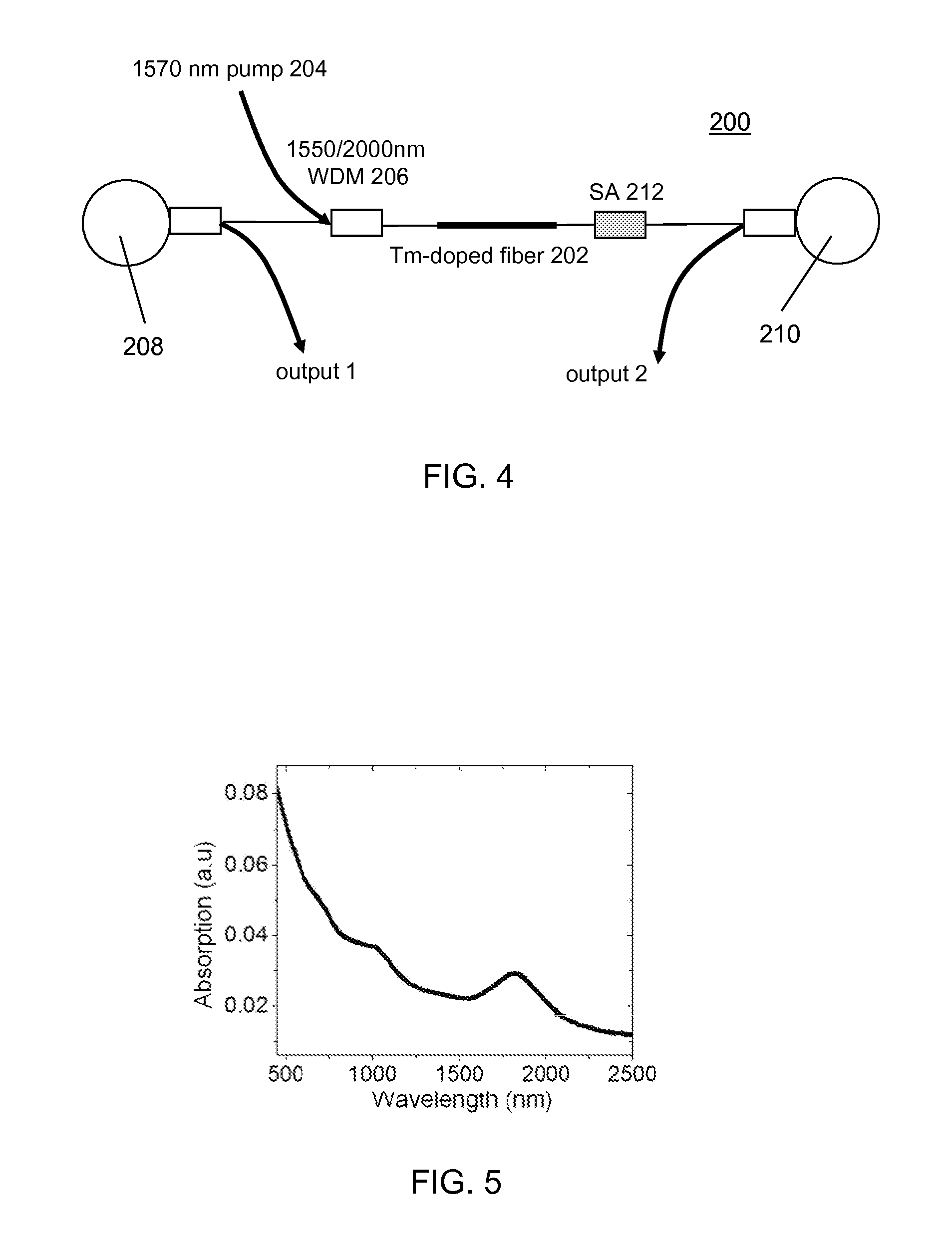

Saturable absorber using a fiber taper embedded in a nanostructure/polymer composite and lasers using the same

ActiveUS20110280263A1Wide working wavelength rangeSimplify the manufacturing processLaser using scattering effectsOptical articlesFiberAir interface

A saturable absorber (SA) is constructed using a fiber taper embedded in a carbon nanotube / polymer composite. A fiber taper is made by heating and pulling a small part of standard optical fiber. At the taper's waist light is guided by the glass-air interface, with an evanescent field protruding out of the taper. Carbon nanotubes mixed with an appropriate polymer host material are then wrapped around the fiber taper to interact with the evanescent field. Saturable absorption is possible due to the unique optical properties of the carbon nanotubes. The device can be used in mode-locked lasers where it initiates and stabilizes the pulses circulating around the laser cavity. The SA can be used in various laser cavities, and can enable different pulse evolutions such as solitons, self-similar pulses and dissipative solitons. Other applications include but are not limited to optical switching, pulse cleanup and pulse compression.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

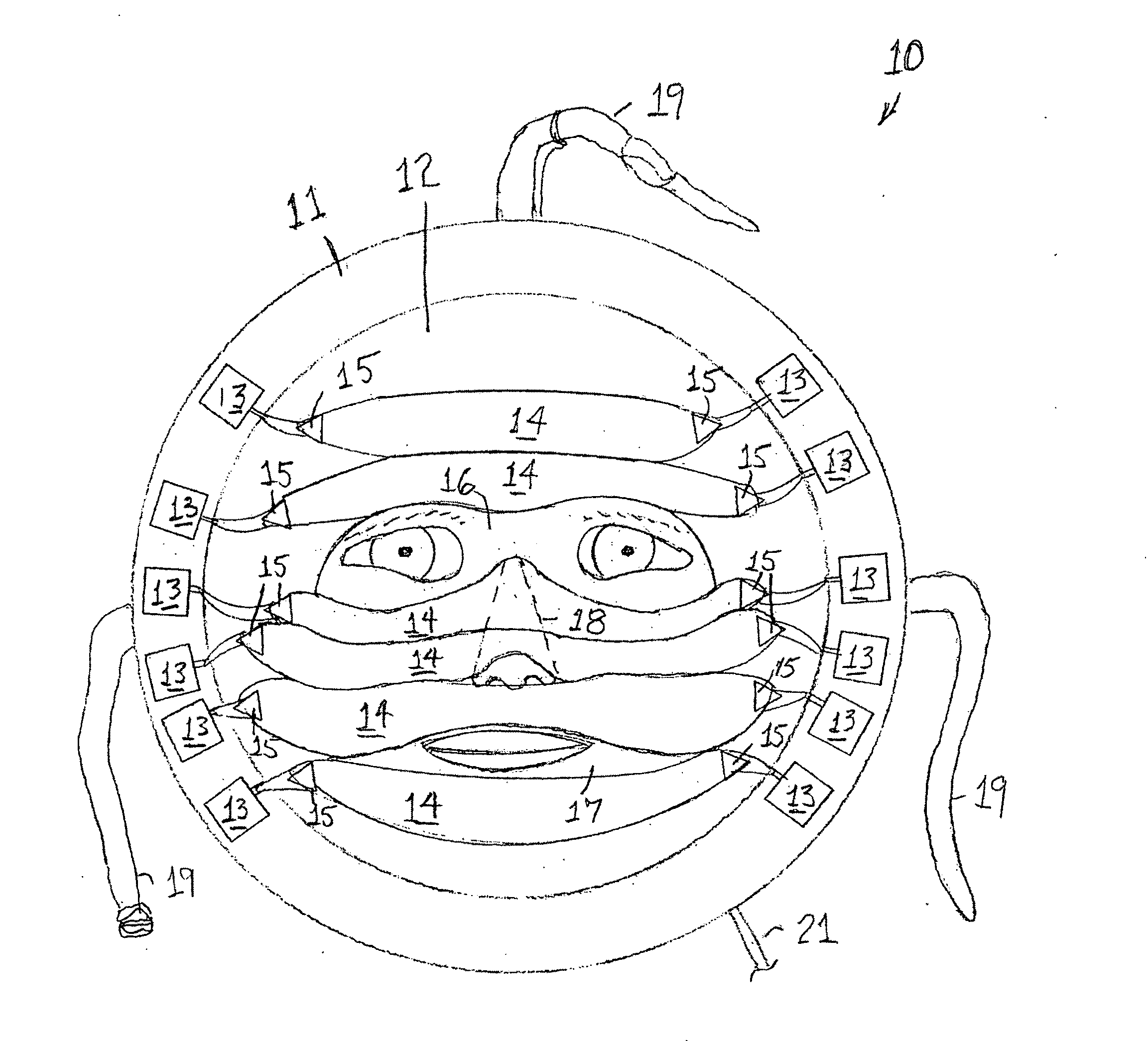

Phototherapy mask

InactiveUS20110040355A1Low refractive indexReduce diffuseLight therapySingle-mode optical fiberMulti-mode optical fiber

A phototherapy mask uses optical fibers coupled to LEDs to irradiate a treated epidermal skin area on or around a person's face with specific wavelengths of light in selected dosages (J / cm2). Peripheral configuration of LEDs on the mask eliminates problems of heat dissipation, and multi-mode optical fiber is employed for diffusion of light uniformly over the treated epidermal skin area.

Owner:FRANCIS STACY

Group III nitride light emitting devices with gallium-free layers

InactiveUS6534797B1Maintain good propertiesImprove emission efficiencyLaser detailsSemiconductor lasersSemiconductor structureElectromagnetic spectrum

The present invention is a semiconductor structure for light emitting devices that can emit in the red to ultraviolet portion of the electromagnetic spectrum. The semiconductor structure includes a first cladding layer of a Group III nitride, a second cladding layer of a Group III nitride, and an active layer of a Group III nitride that is positioned between the first and second cladding layers, and whose bandgap is smaller than the respective bandgaps of the first and second cladding layers. The semiconductor structure is characterized by the absence of gallium in one or more of these structural layers.

Owner:CREE INC

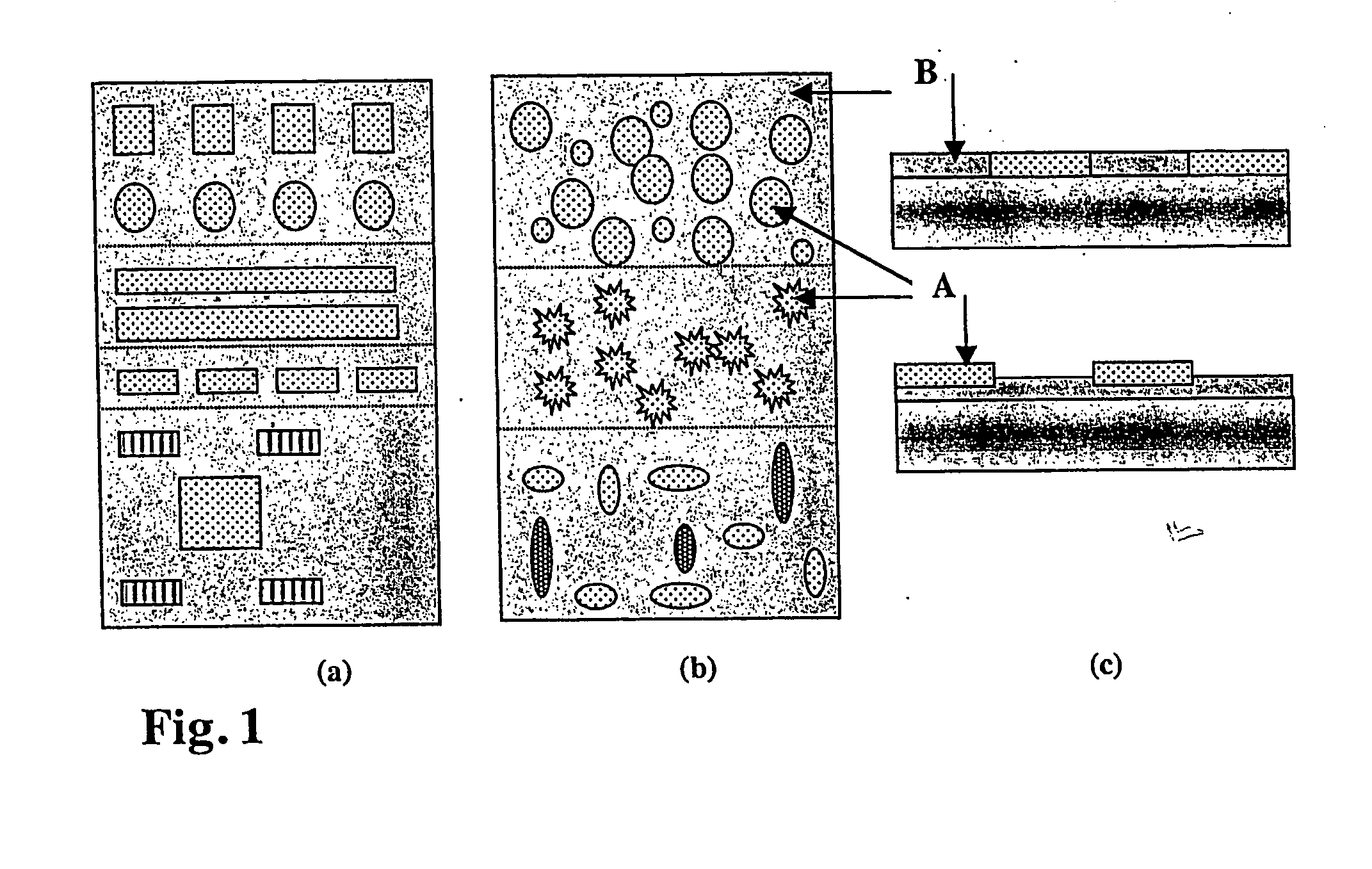

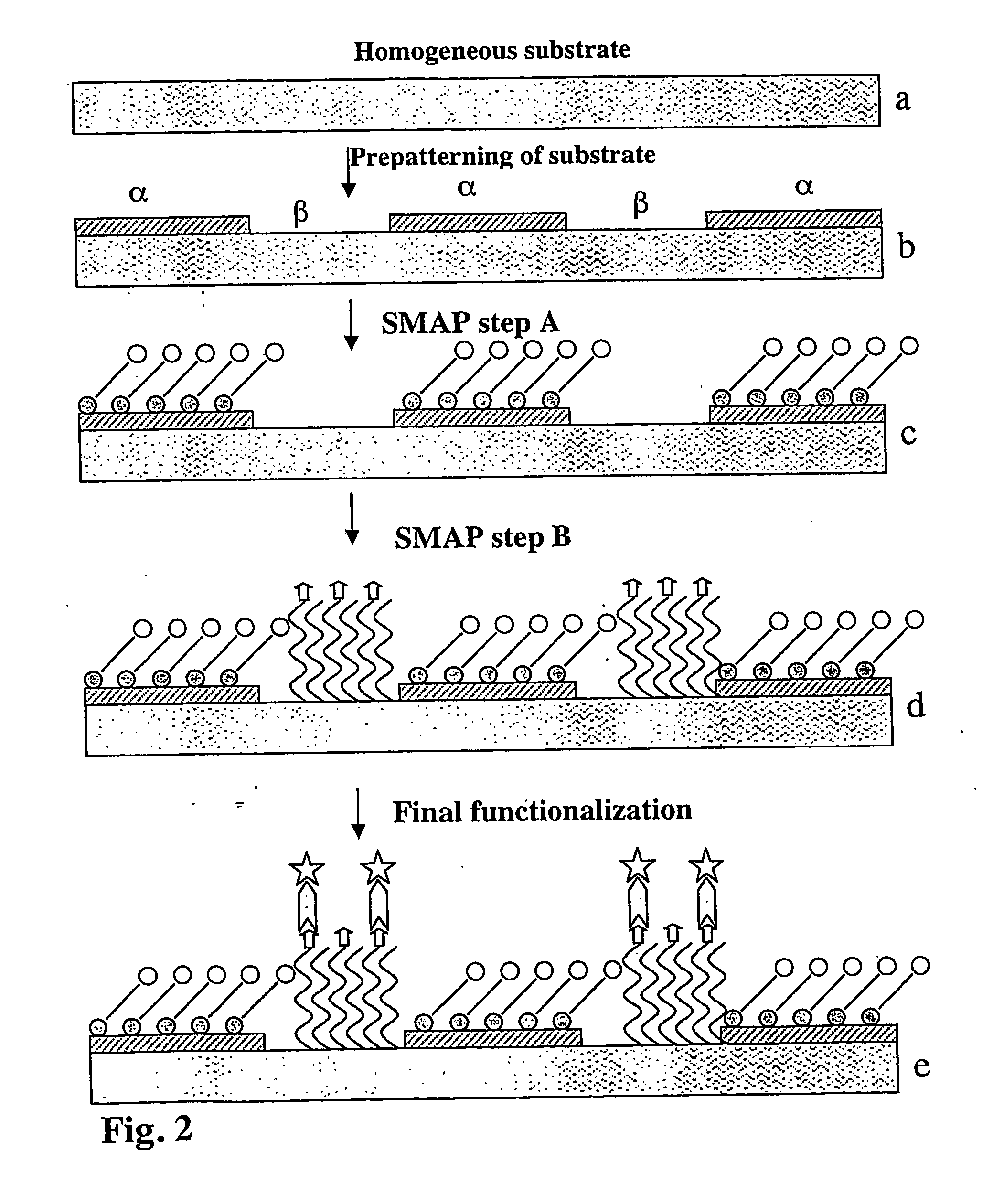

Device with chemical surface patterns

InactiveUS20050014151A1Retarded and prevented reactionSustained inflammationMaterial nanotechnologyBioreactor/fermenter combinationsSurface patternChemical composition

A device with chemical surface patterns (defined surface areas of at least two different chemical compositions) with biochemical or biological relevance on substrates with prefabricated patterns of at least two different types of regions (α, β, . . . ), whereas at least two different, consecutively applied molecular self-assembly systems (A, B, . . . ) are used in a way that at least one of the applied assembly systems (A or B or . . . ) is specific to one type of the prefabricated patterns (α or β or . . . ).

Owner:ETH ZZURICH

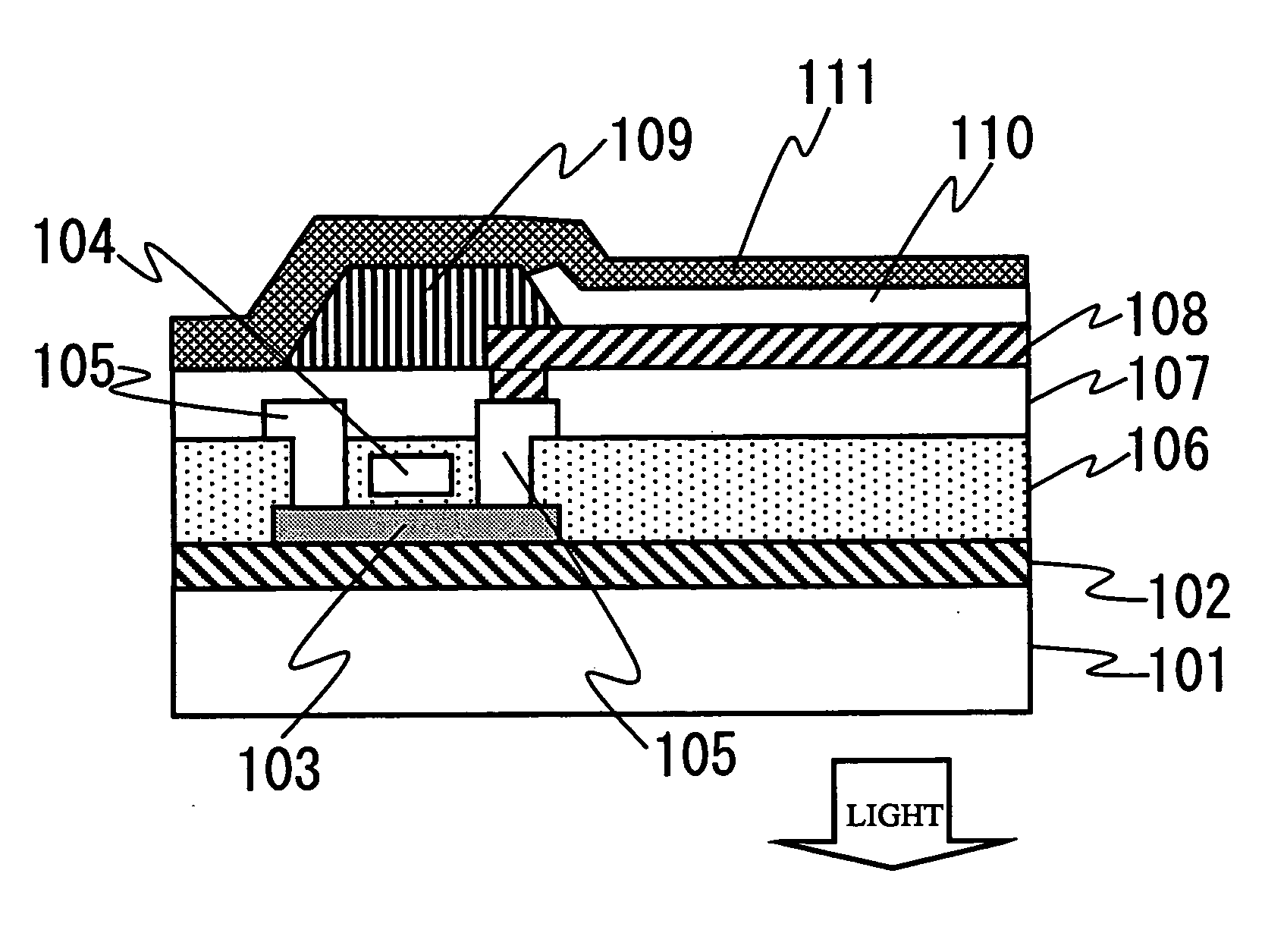

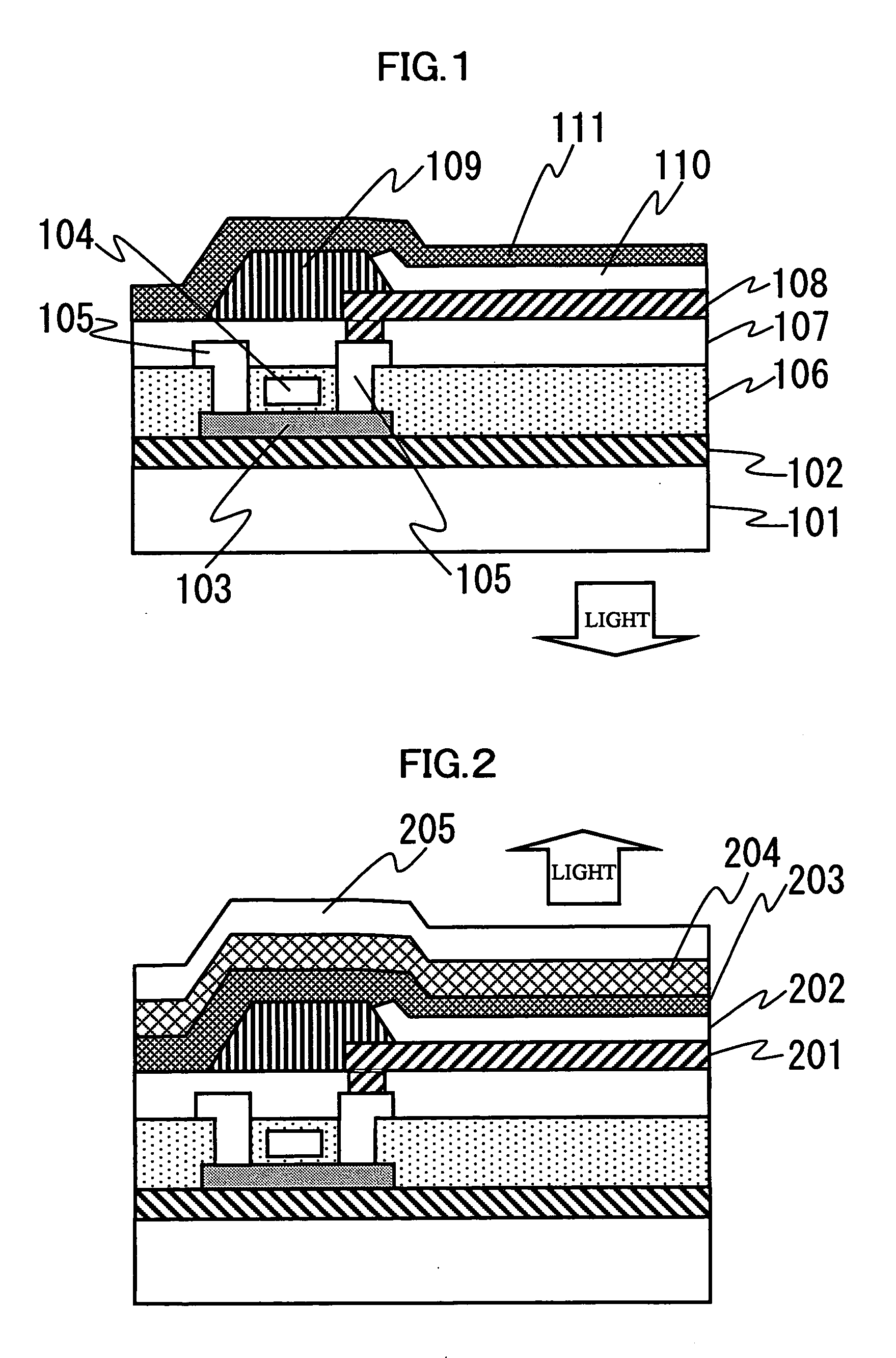

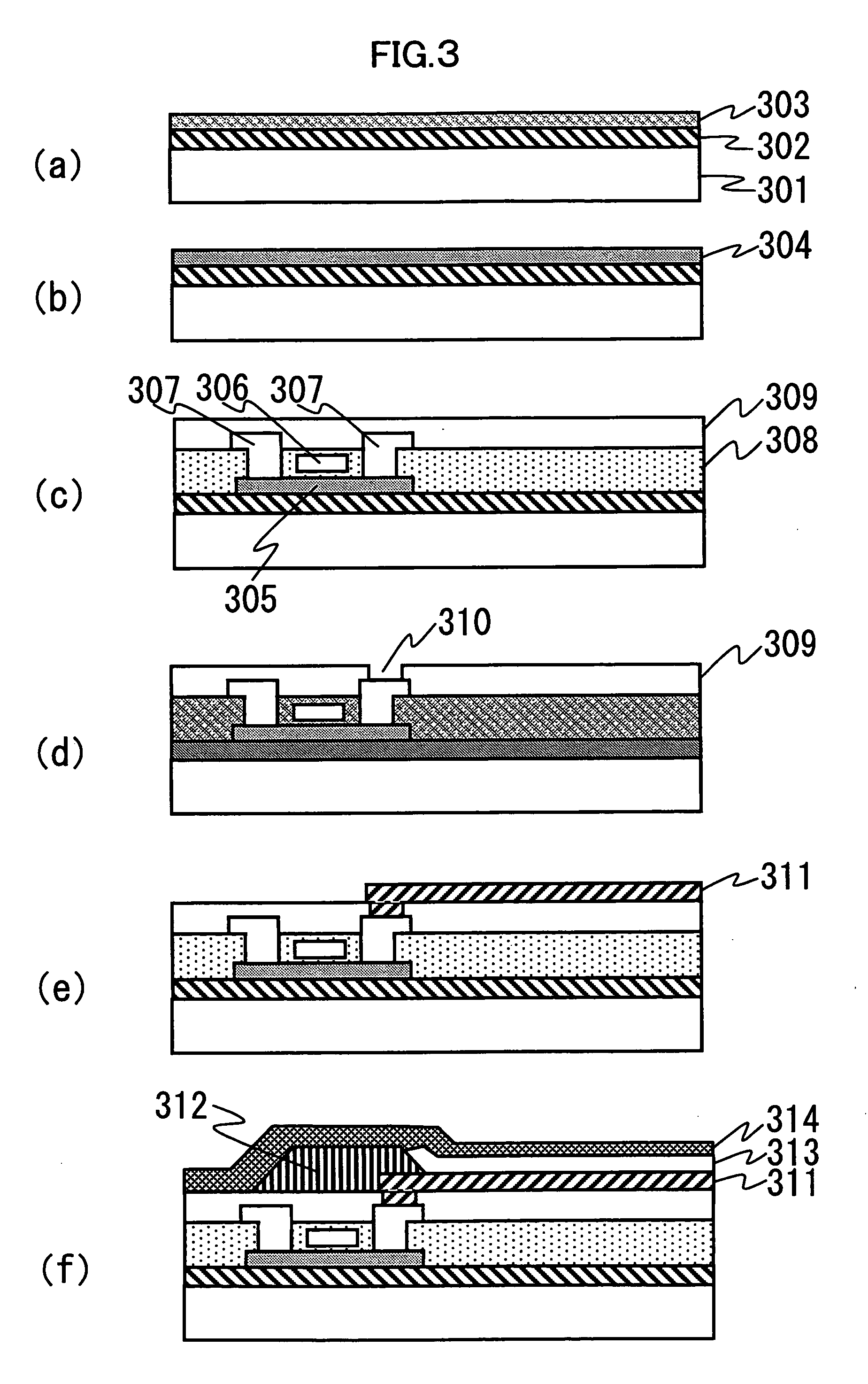

Organic light emitting diode display and method for manufacturing the same

ActiveUS20050156520A1Decreasing density of filmCoefficient loweredDischarge tube luminescnet screensElectroluminescent light sourcesActive matrixRefractive index

An active matrix type organic light emitting diode display serving as a bottom emission type device coupling out emission of an organic electroluminescence layer from a substrate where thin film transistors are formed or as a top emission type device coupling out the emission on the opposite side to the substrate. In a suitable layer (102, 106, 107) in each device, an insulating film containing SiO is formed. The insulating film is porous with nano pores in the film. The porous insulating film is controlled as to film density, film refractive index, nano pore diameter in film, average nano pore diameter in film and maximum nano pore diameter in film so that the refractive index is lower than that of a transparent electrode or a transparent substrate of the display holding the organic electroluminescence layer therebetween, and nano pores are present in the film. Light scattering effect can be obtained so that emission from the organic electroluminescence layer (110) can be coupled out to the outside efficiently.

Owner:SAMSUNG DISPLAY CO LTD +1

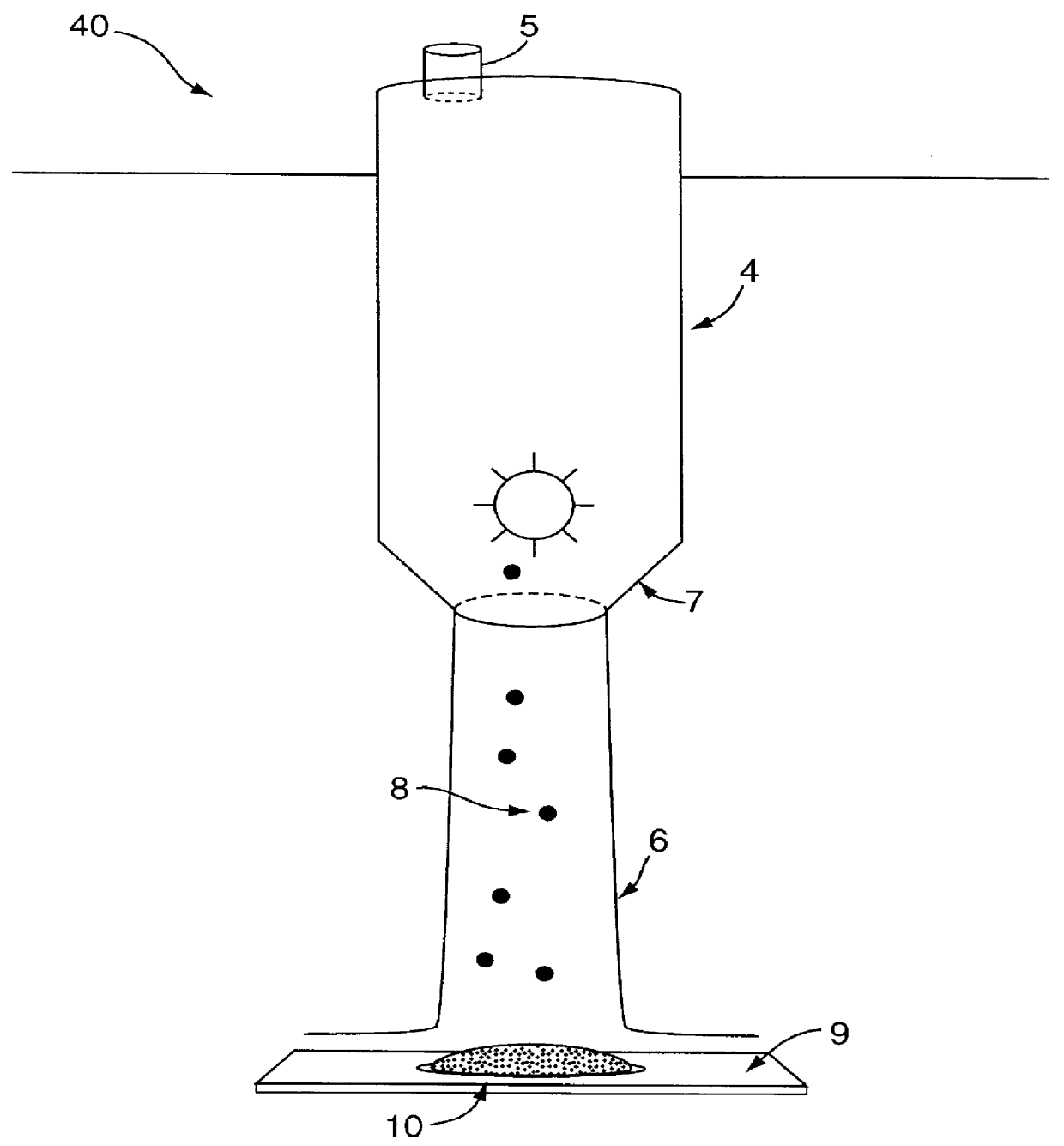

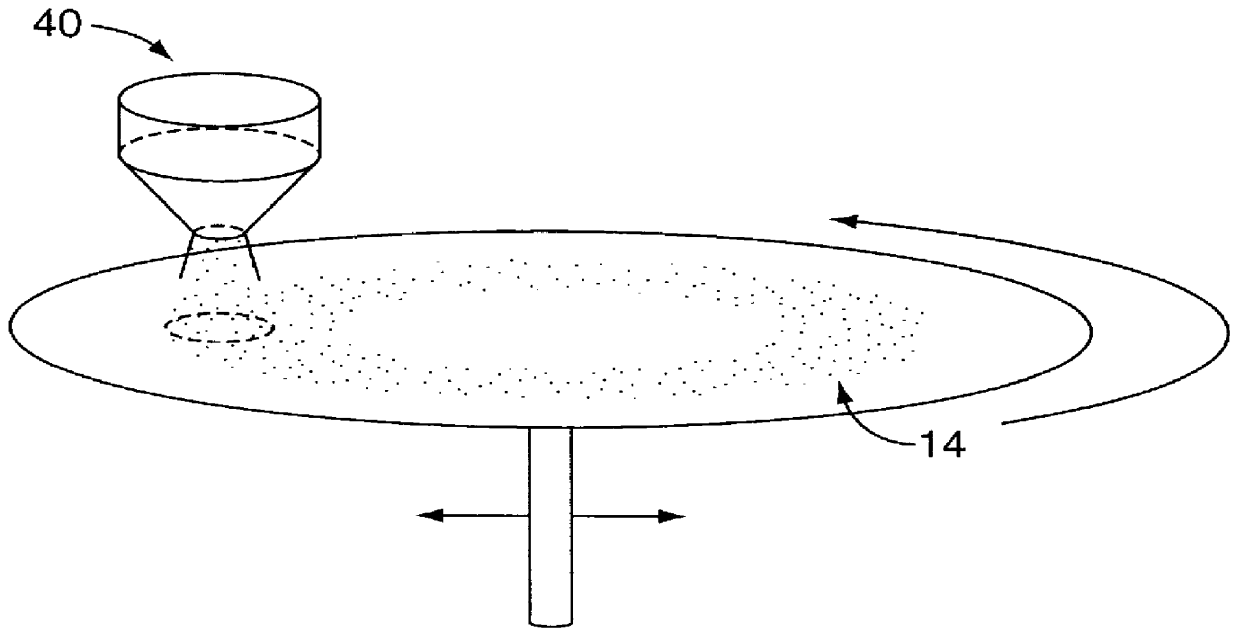

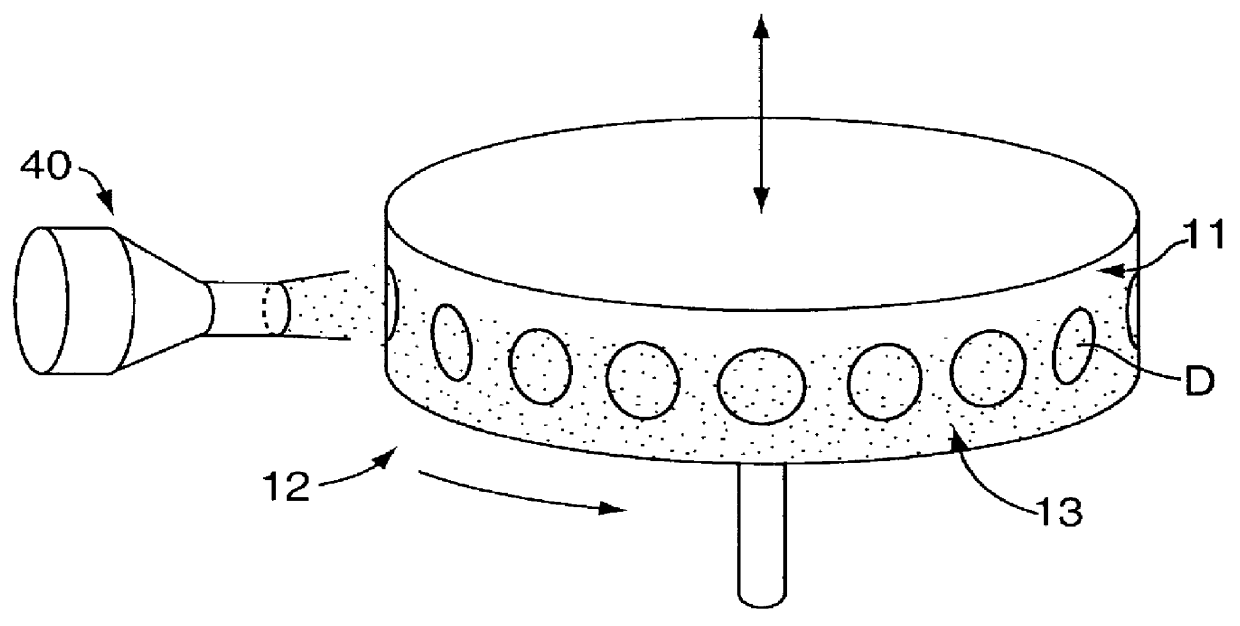

Method for hydrogen atom assisted jet vapor deposition for parylene N and other polymeric thin films

InactiveUS6165554AImprove adhesionIncrease deposition rateLiquid surface applicatorsMolten spray coatingHydrogen atomParylene

A method is presented for the vapor deposition of a material film upon a substrate. The method comprises the use of a Jet Vapor Deposition process with a vaporized polymer gas flowing at supersonic velocity. The vaporized polymer gas consists of a carrier gas and a vaporized polymer, such as Parylene. The vaporized polymer gas impinges upon the substrate through a port and forms the material film.

Owner:JET PROCESS

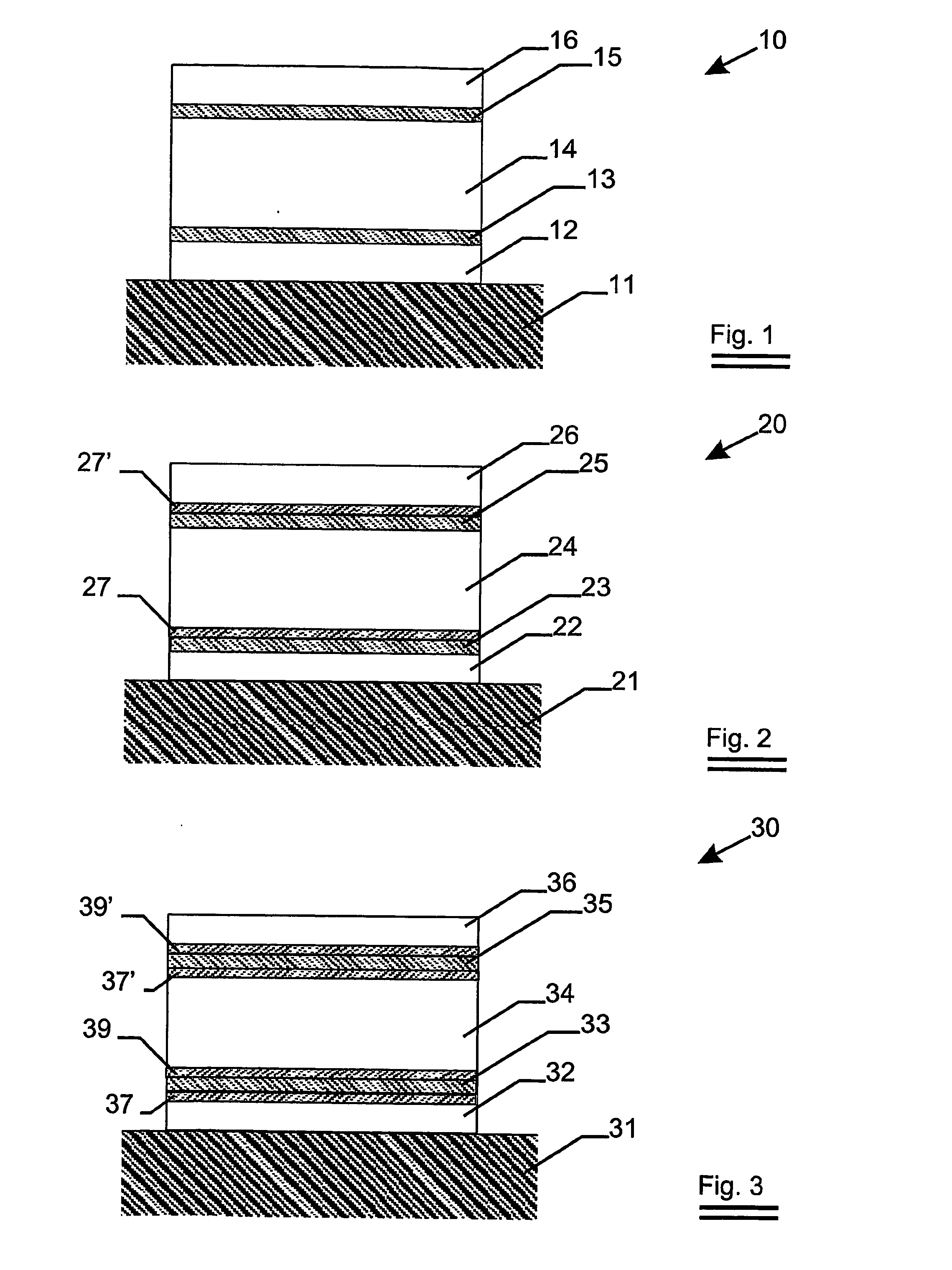

Infra-red reflecting layered structure

ActiveUS20060057399A1Good visible light transmittanceLow solar heat gain coefficientElectric discharge tubesMagnetic/electric field screeningInfraredRefractive index

The invention relates to an infra-red reflecting layered structure comprising a transparent substrate layer; a first metal oxide layer; a first silver containing layer, a second metal oxide layer; a second silver containing layer and a third metal oxide layer. The first, second and third metal oxide layer have a refractive index of at least 2.40 at a wavelength of 500 nm. The layered structure according to the present invention laminated on glass has a visual light transmittance (VLT) higher than 70% and a solar heat gain coefficient (SHGC) lower than 0.44. The invention further relates to the use of a layered structure as a transparent heat-mirror.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CHAINEUX

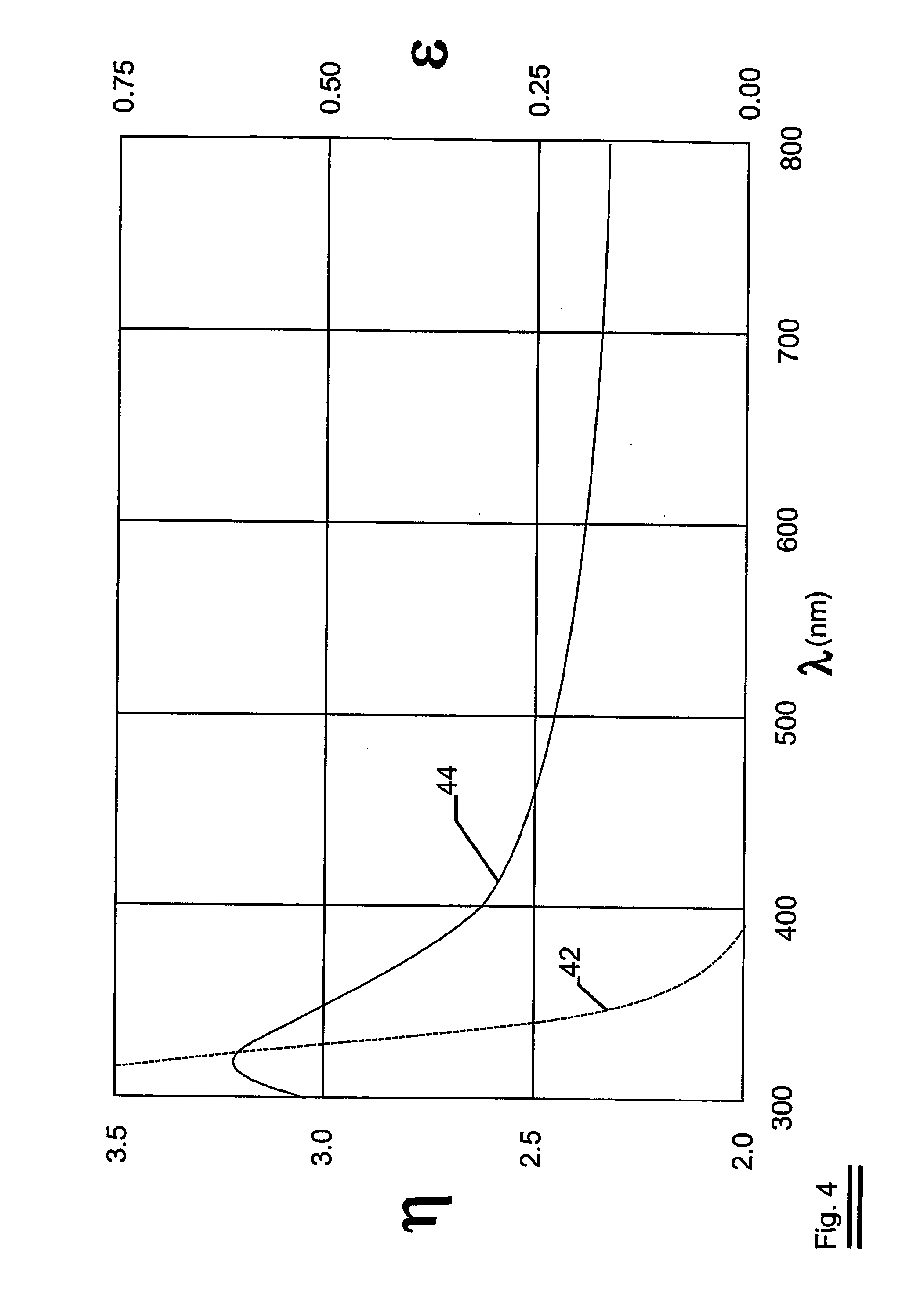

Optical devices with engineered nonlinear nanocomposite materials

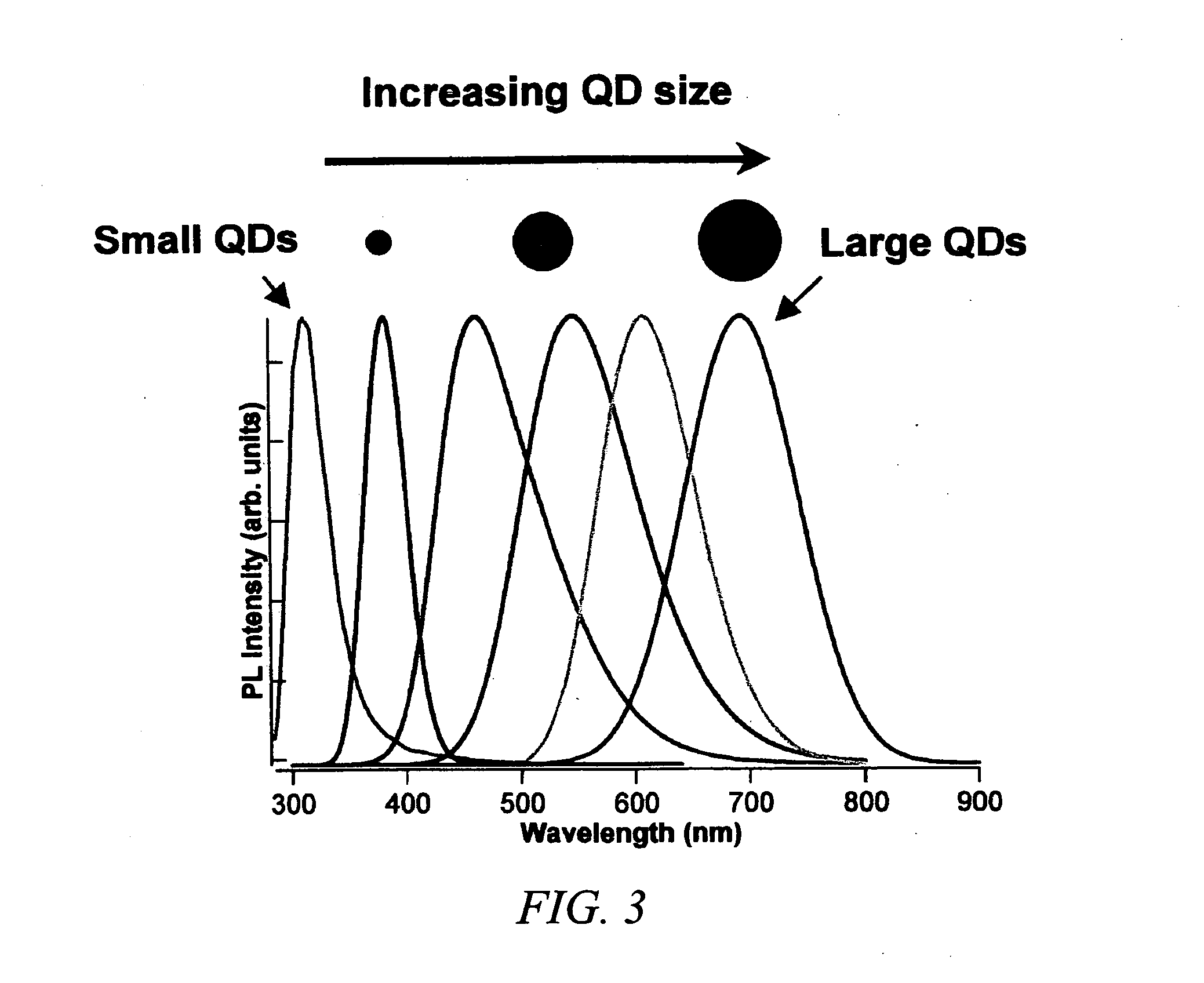

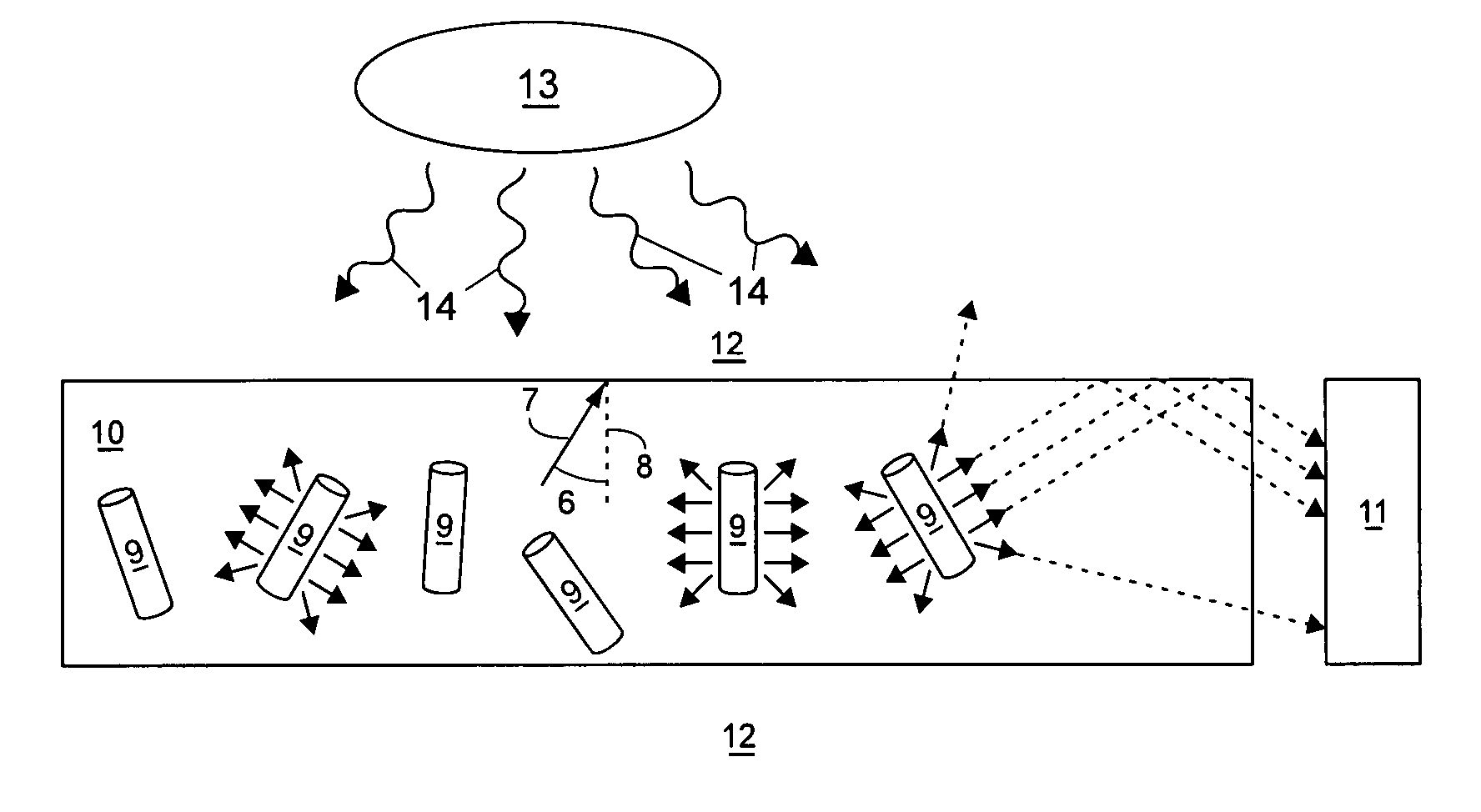

InactiveUS20050058415A1Lower refractive indexReduce absorptionNanoinformaticsSemiconductor/solid-state device manufacturingNanometreQuantum dot

The invention relates to an optical device. The optical device comprises a waveguide core and a nanocomposite material optically coupled to the waveguide core. The nanocomposite material includes a plurality of quantum dots. The nanocomposite material has a nonlinear index of refraction γ that is at least 10−9 cm2 / W when irradiated with an activation light having a wavelength λ between approximately 3×10−5 cm and 2×10−4 cm.

Owner:SAMSUNG ELECTRONICS CO LTD

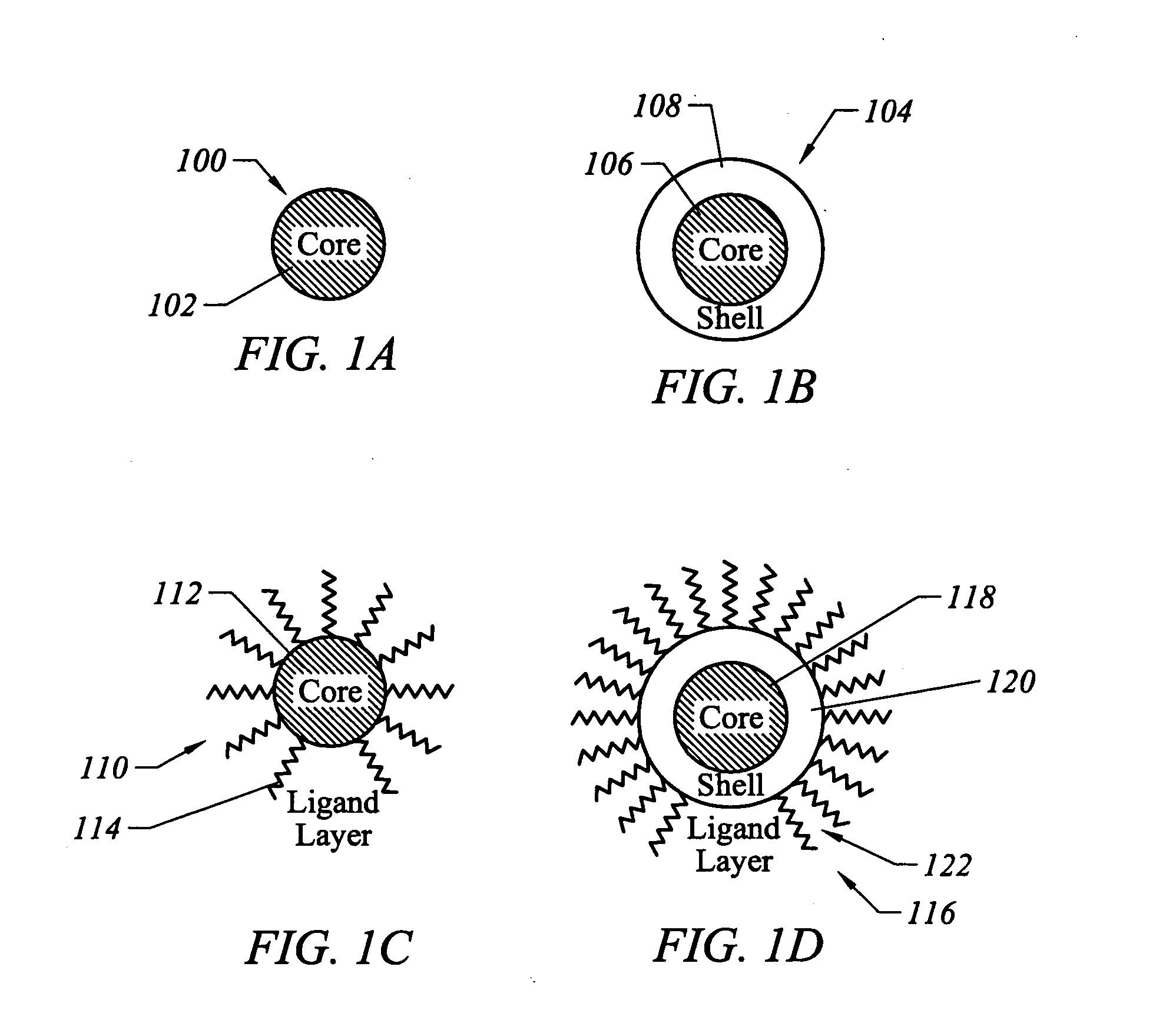

Nanocomposites

InactiveUS20070122101A1Increase percentageEfficiently waveguidedSolar heating energyMaterial nanotechnologyNanowireNanocrystal

This invention provides composite materials comprising nanostructures (e.g., nanowires, branched nanowires, nanotetrapods, nanocrystals, and nanoparticles). Methods and compositions for making such nanocomposites are also provided, as are articles comprising such composites. Waveguides and light concentrators comprising nanostructures (not necessarily as part of a nanocomposite) are additional features of the invention.

Owner:ONED MATERIAL INC

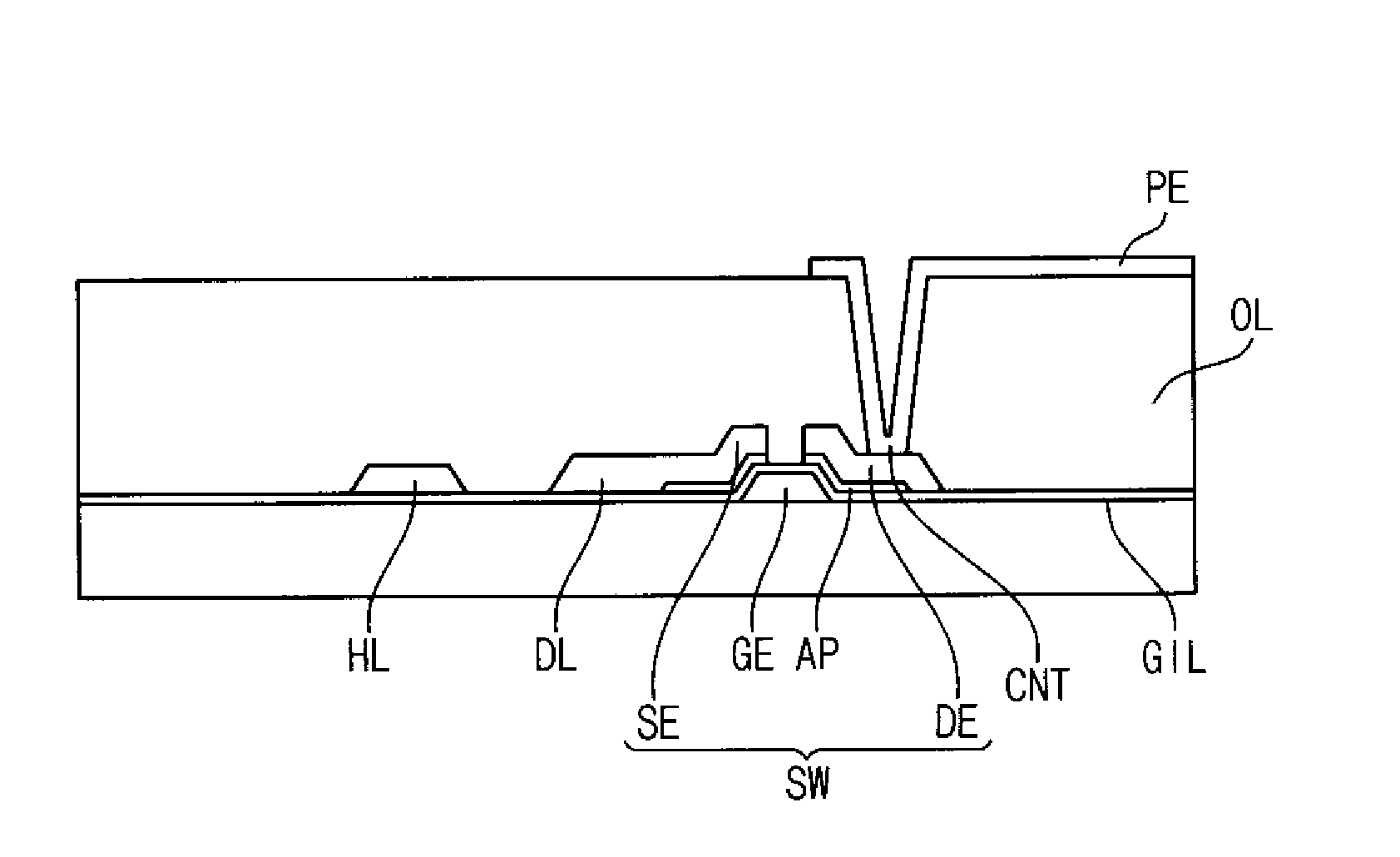

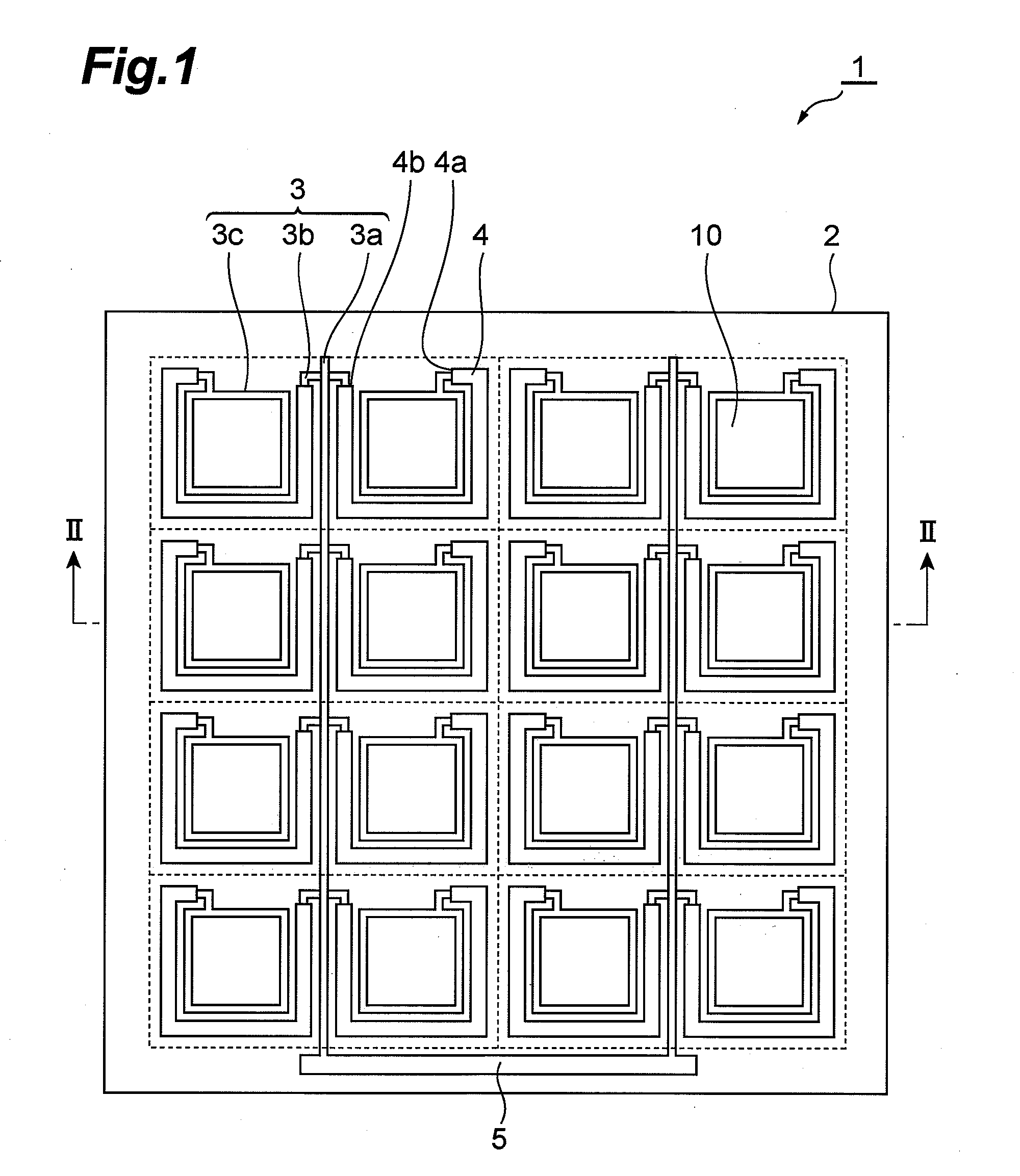

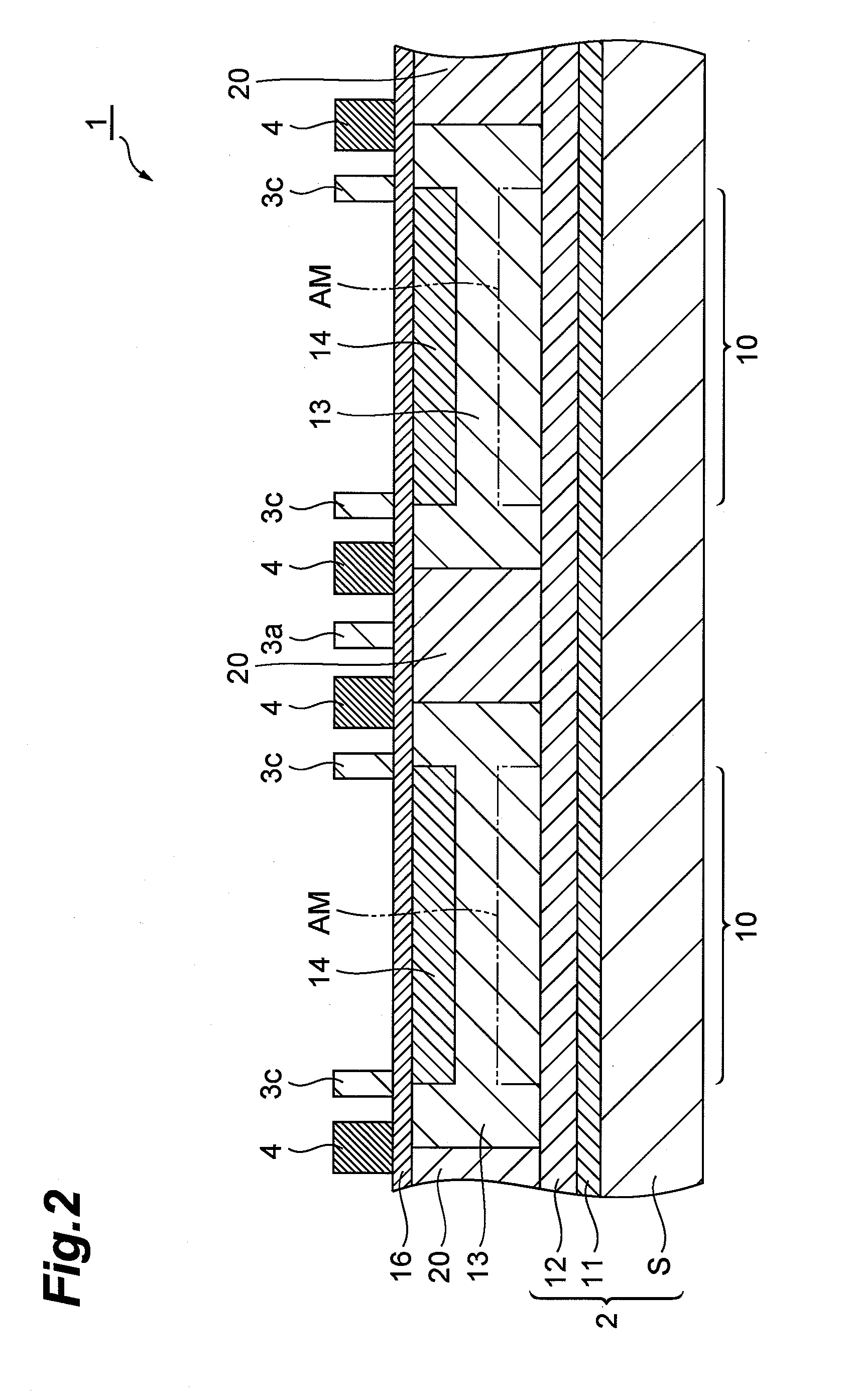

Solid-state imaging device, method for manufacturing solid-state imaging device, and electronic apparatus

InactiveUS20100078745A1Increased sensitivityImprove efficiencyTelevision system detailsSolid-state devicesRefractive index profileSolid-state

A solid-state imaging device includes a light-receiving portion, which serves as a pixel, and a waveguide, which is disposed at a location in accordance with the light-receiving portion and which includes a clad layer and a core layer embedded having a refractive index distribution in the wave-guiding direction.

Owner:SONY CORP

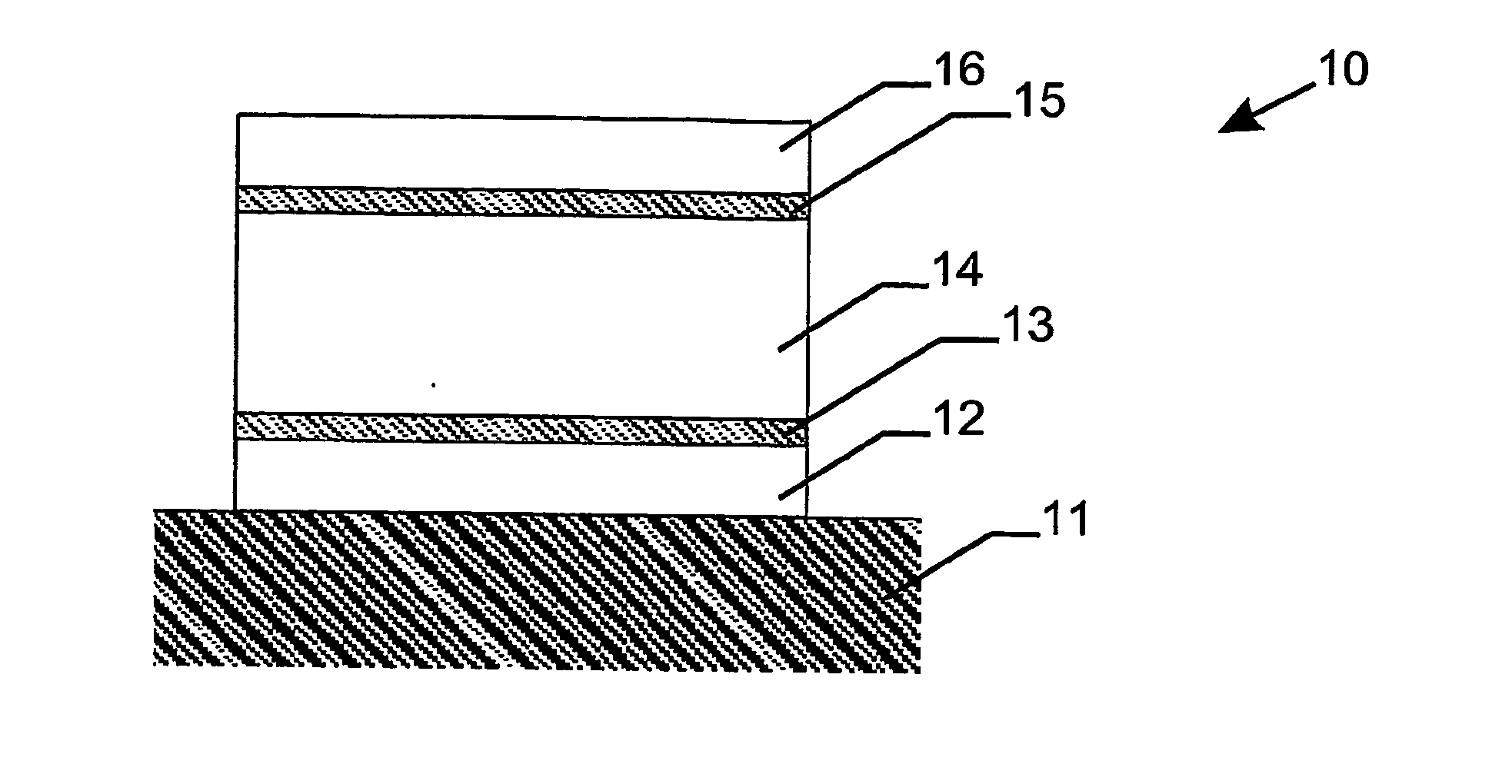

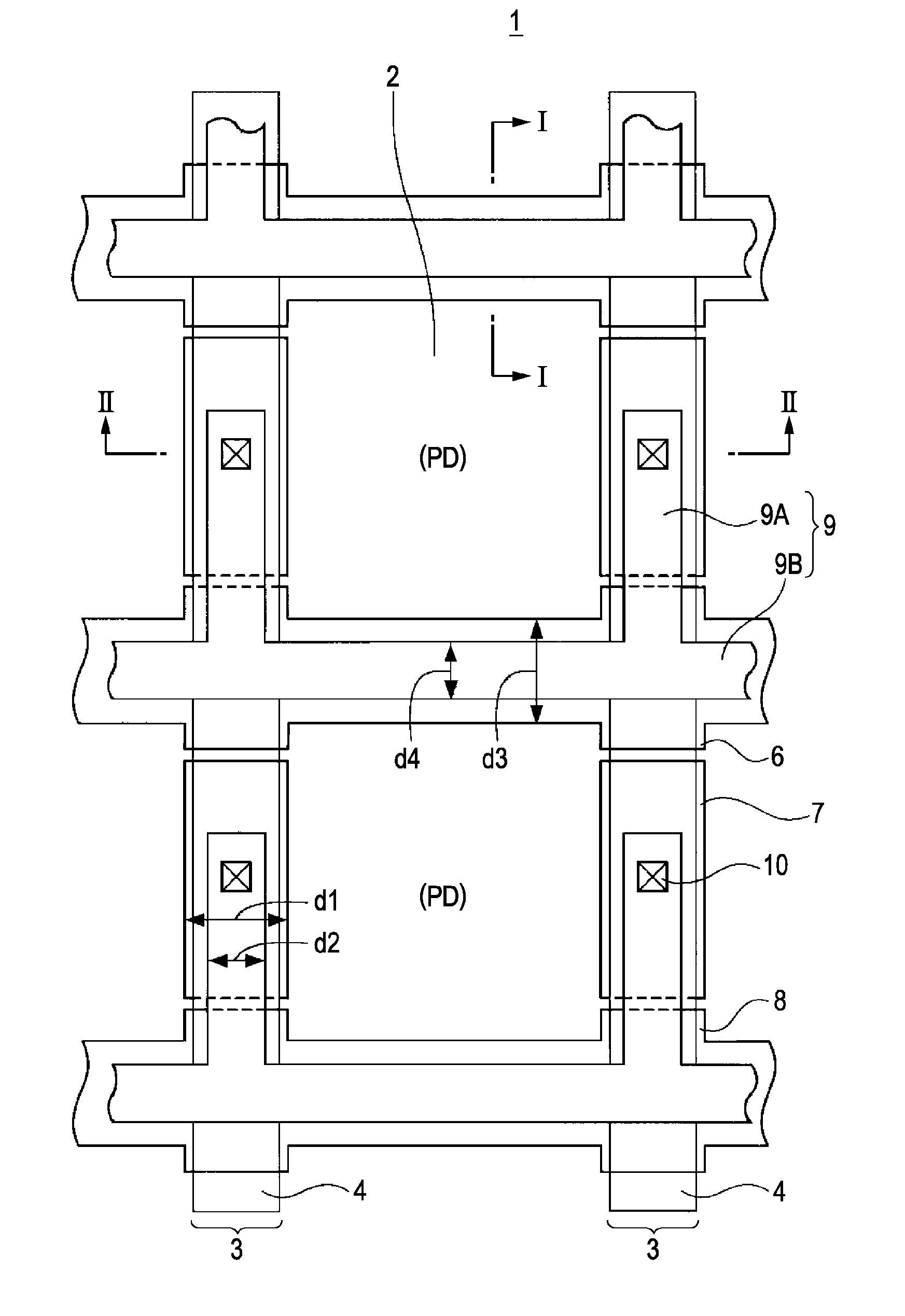

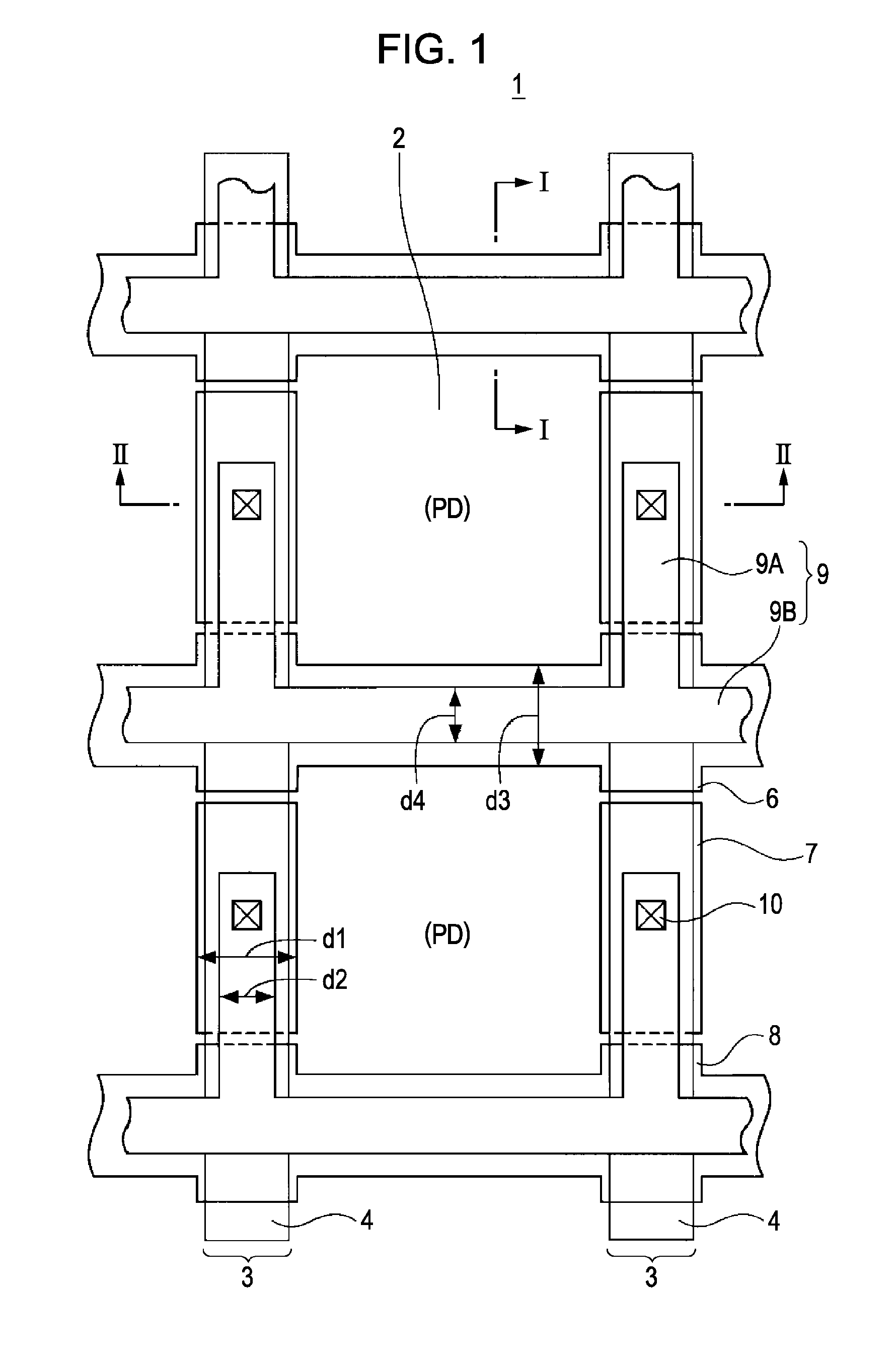

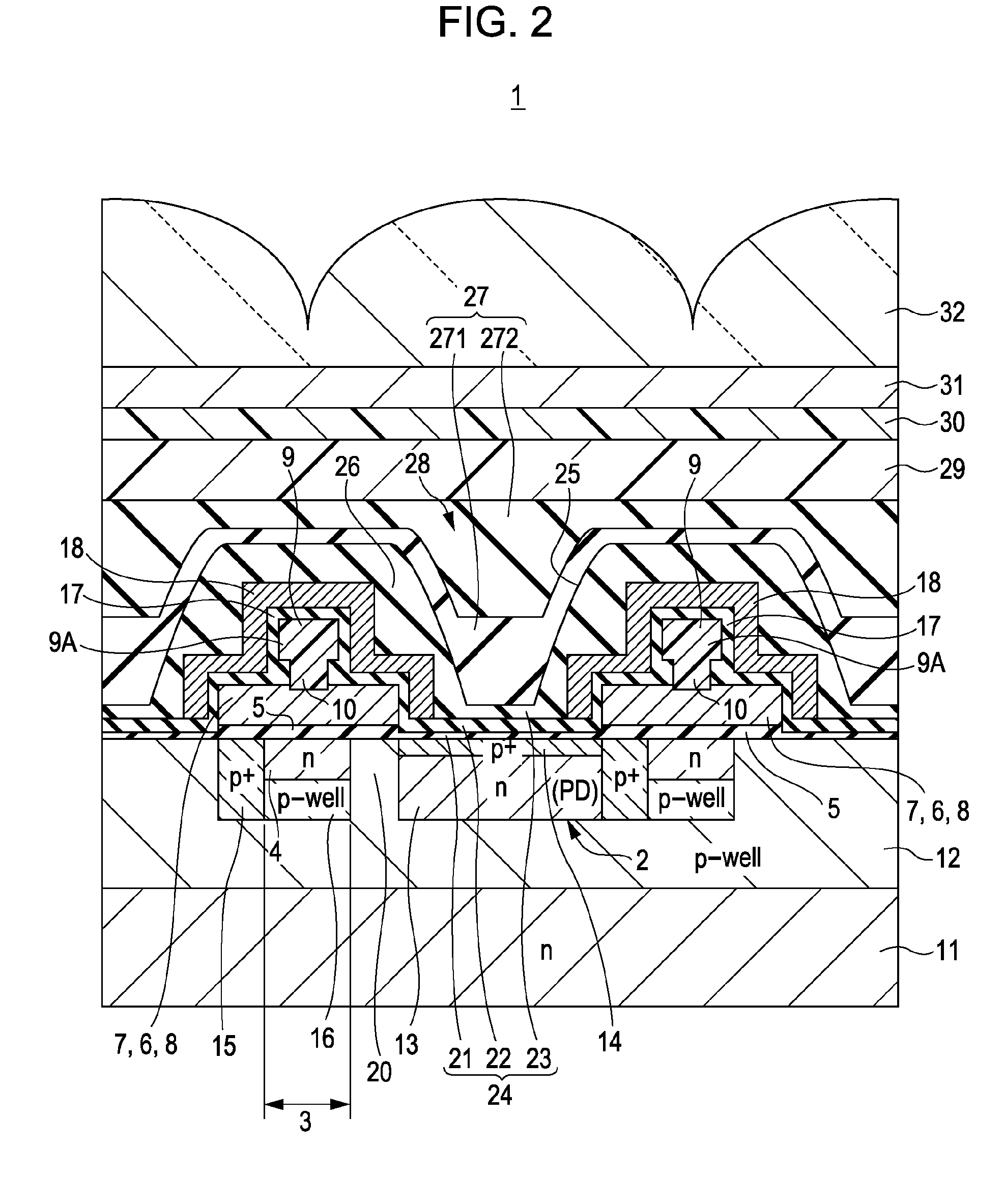

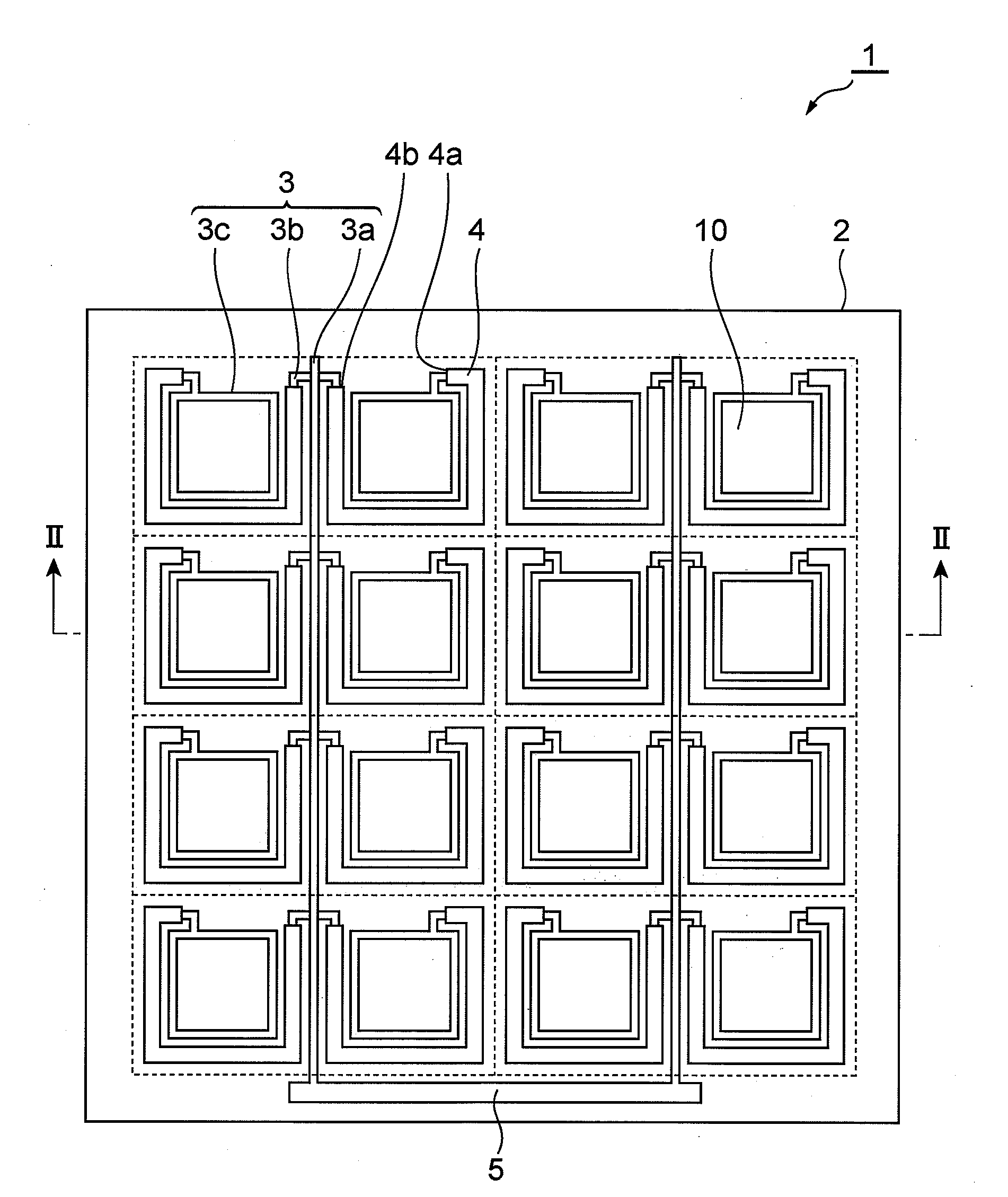

Photodiode array

ActiveUS20090256223A1High ratioImprove detection efficiencySolid-state devicesRadiation controlled devicesPhotodetectorPhotovoltaic detectors

A photodiode array 1 has a plurality of photodetector channels 10 which are formed on an n-type substrate 2 having an n-type semiconductor layer 12, with a light to be detected being incident to the plurality of photodetector channels 10. The photodiode array 1 comprises: a p−-type semiconductor layer 13 formed on the n-type semiconductor layer 12 of the substrate 2; resistors 4 each of which is provided to each of the photodetector channels 10 and is connected to a signal conductor 3 at one end thereof; and an n-type separating part 20 formed between the plurality of photodetector channels 10. The p−-type semiconductor layer 13 forms a pn junction at the interface between the substrate 2, and comprises a plurality of multiplication regions AM for avalanche multiplication of carriers produced by the incidence of the light to be detected so that each of the multiplication regions corresponds to each of the photodetector channels. The separating part 20 is formed so that each of the multiplication regions AM of the p−-type semiconductor layer 13 corresponds to each of the photodetector channels 10.

Owner:HAMAMATSU PHOTONICS KK

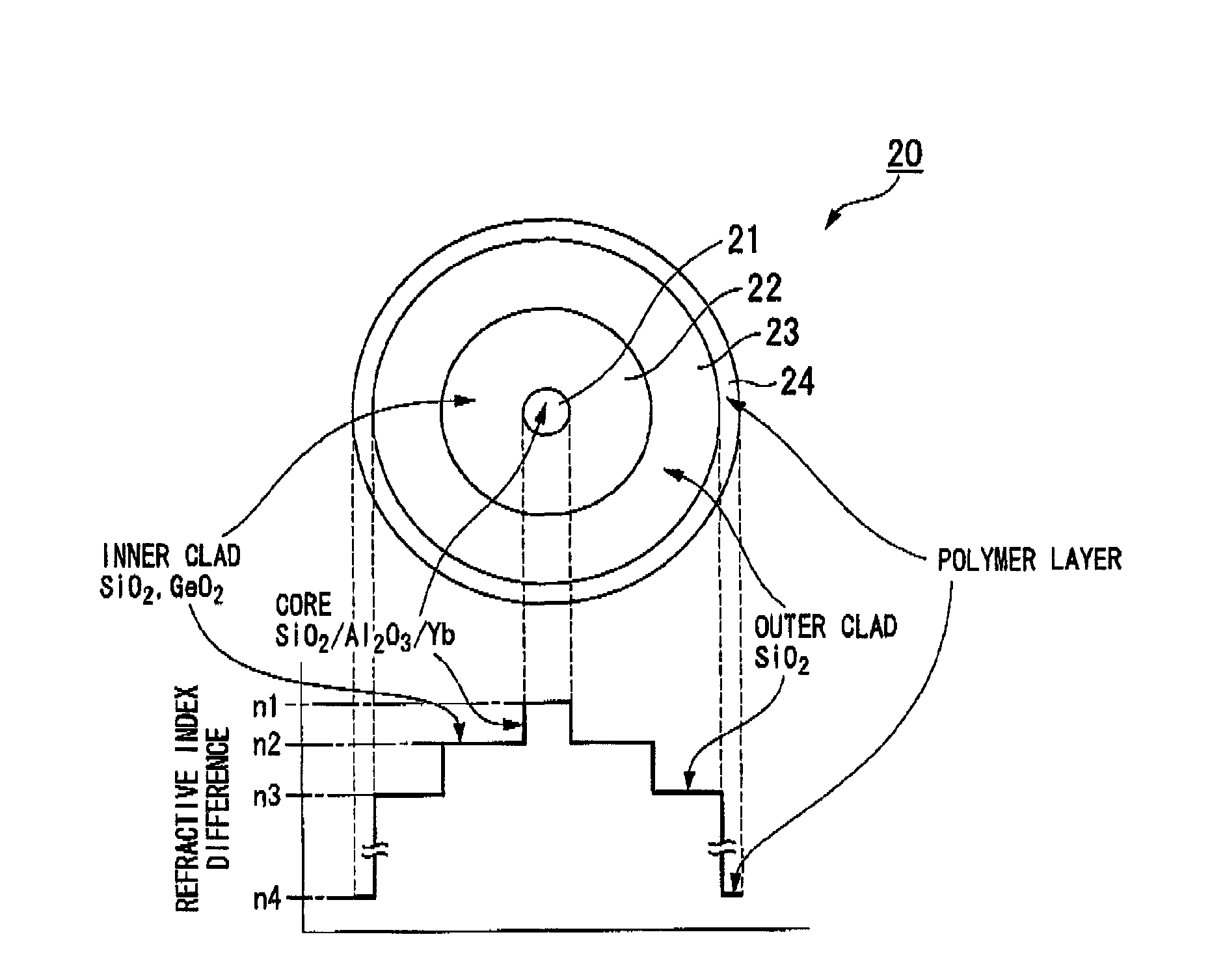

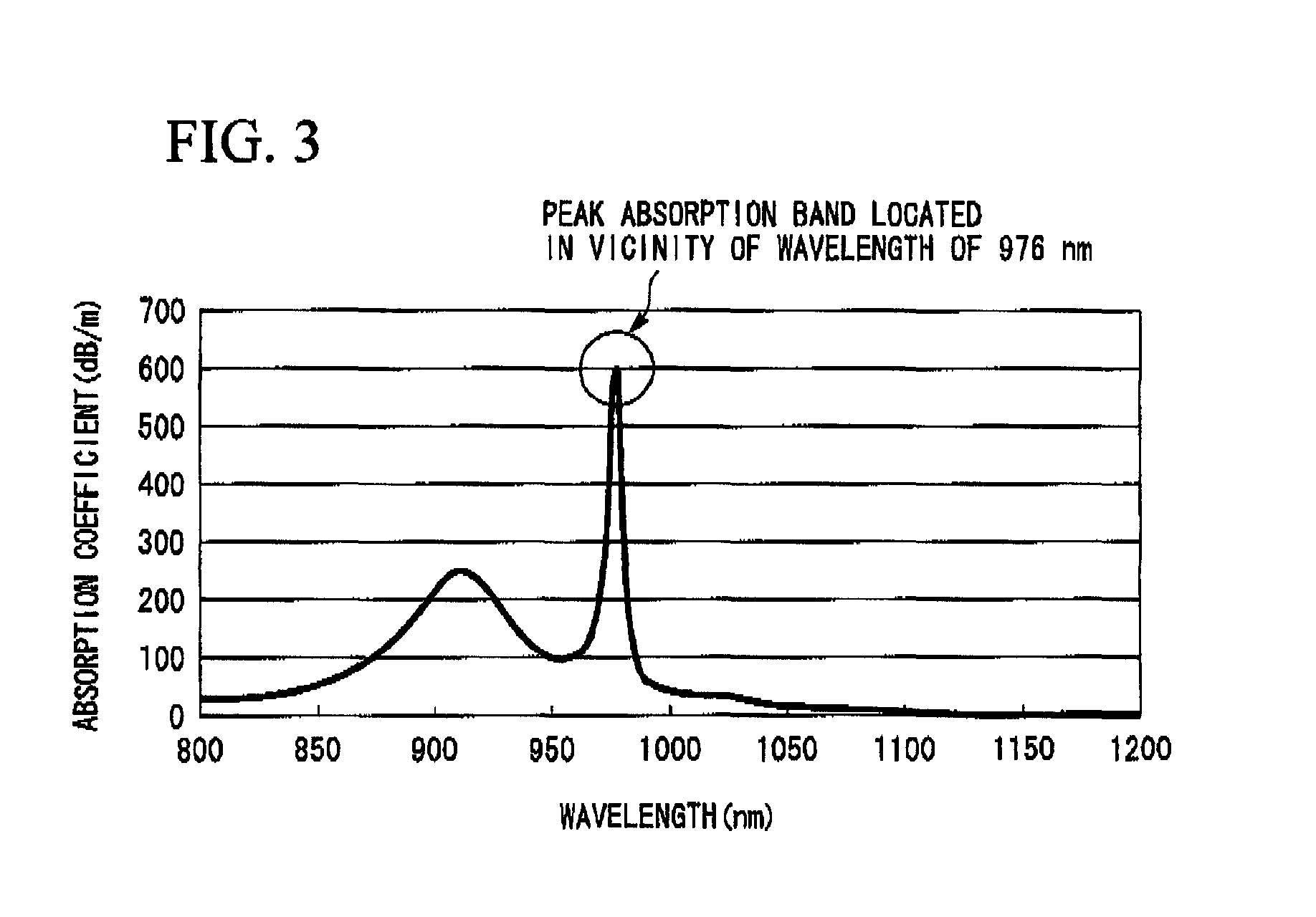

Rare earth-doped core optical fiber

InactiveUS20100067860A1Lower refractive indexSufficient powerLaser detailsOptical fibre with multilayer core/claddingRefractive indexRare earth

A rare earth-doped core optical fiber includes a core comprising a silica glass containing at least aluminum and ytterbium, a clad provided around the core and comprising a silica glass having a lower refraction index than that of the core, and a polymer layer provided on the outer circumference of the clad and having a lower refractive index than that of the clad, wherein aluminum and ytterbium are doped into the core such that a loss increase by photodarkening, TPD, satisfies the following inequality (A). By this rare earth-doped core optical fiber, it is possible to manufacture an optical fiber laser capable of maintaining a sufficient laser oscillation output even when used for a long period of time.TPD≧10{−0.655*(D<sub2>Al< / sub2>)−4.304*exp{−0.00343*(A<sub2>Yb< / sub2>)}+1.274} (A)

Owner:THE FUJIKURA CABLE WORKS LTD

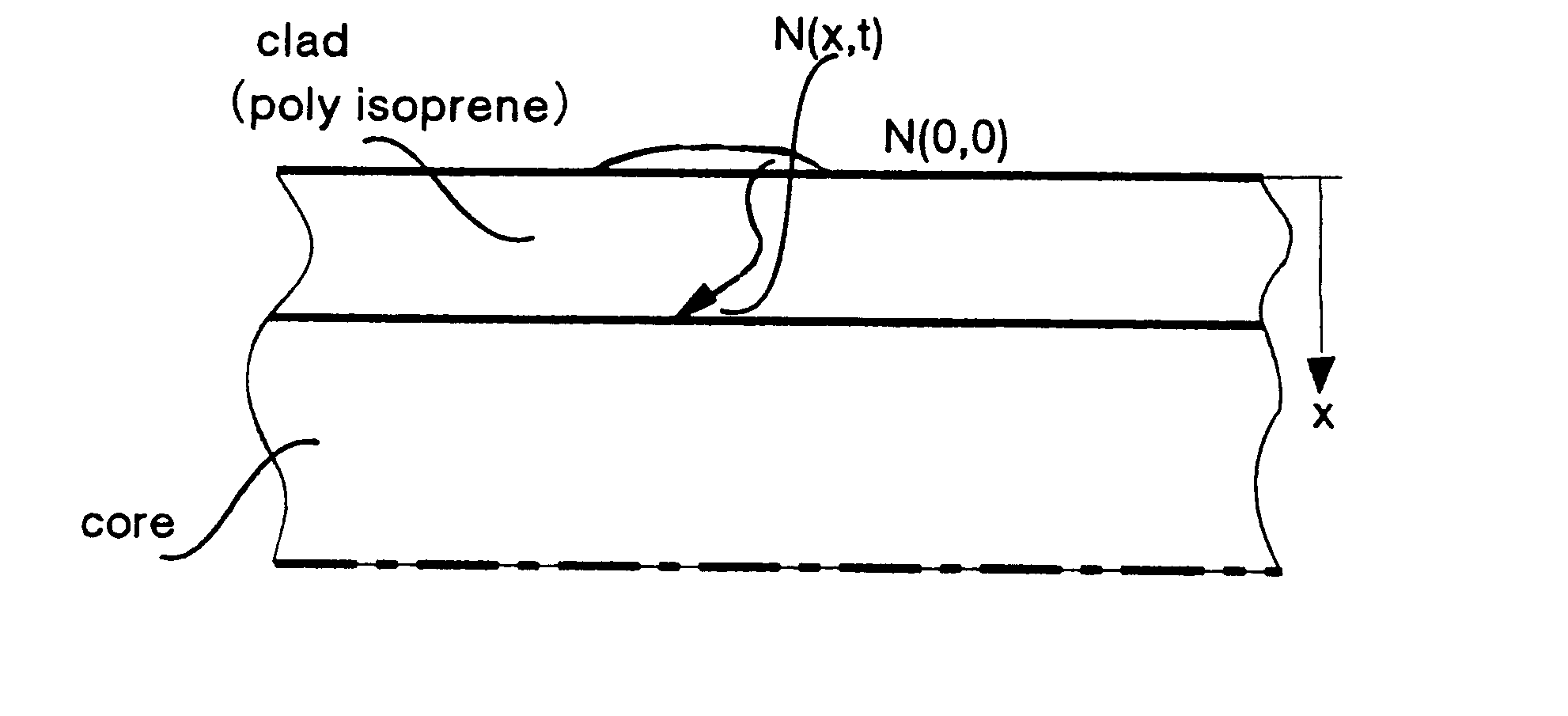

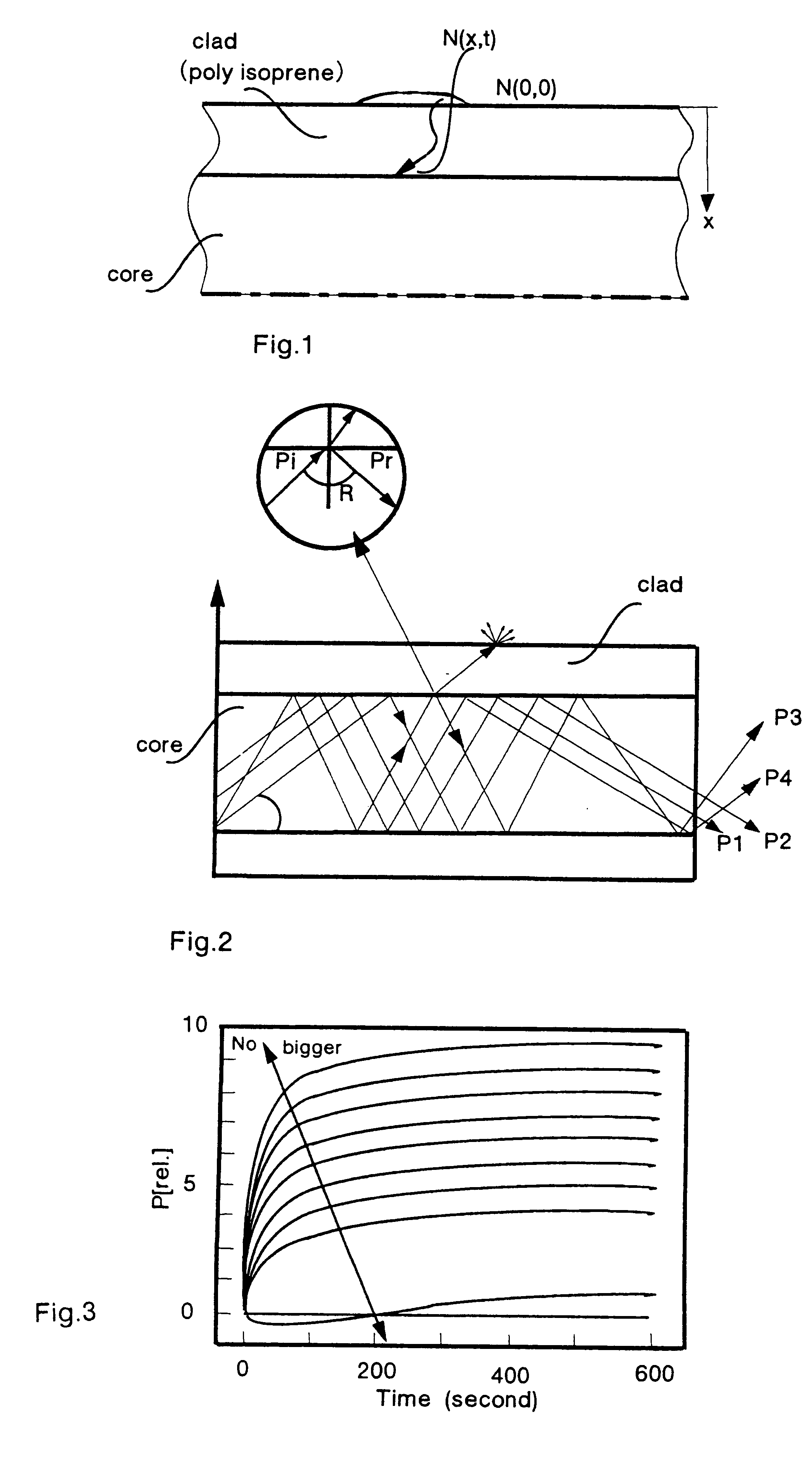

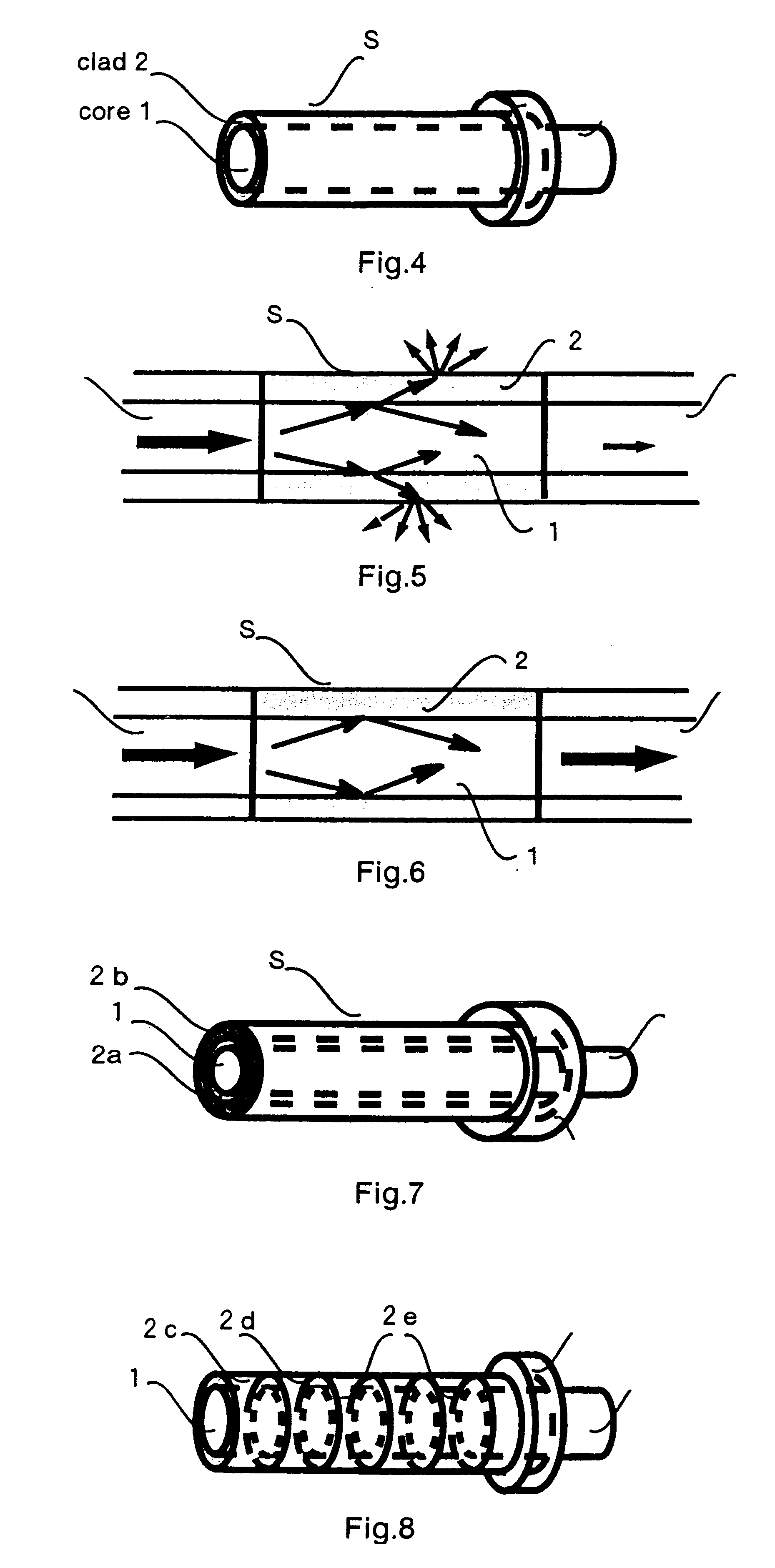

Optical sensor and sensing method

InactiveUS6278106B1High sensitivityLower refractive indexRadiation pyrometryMaterial analysis by observing effect on chemical indicatorRefractive indexLeaky mode

The optical sensor of the present invention detects both the existence and concentration of substances by changing from light leakage mode to wave guide mode when the sensor is exposed to the substances to be detected. The changes in the mode results in a large change in optical output. This change is measured and the substance is identified and / or measured with high sensitivity.The change in light leakage mode to wave guide mode of the sensor is possible by having a clad material around the core material, with the clad material decreasing in the index of refraction when exposed to the substance to be detected. When the index of refraction of the clad becomes less than that of the core material, the sensor changes from the light leakage mode and operates in the wave guide mode. Changes in light intensity output from the sensor is measured over time, and correlated to the substance to be detected.

Owner:MUTO SHINZO

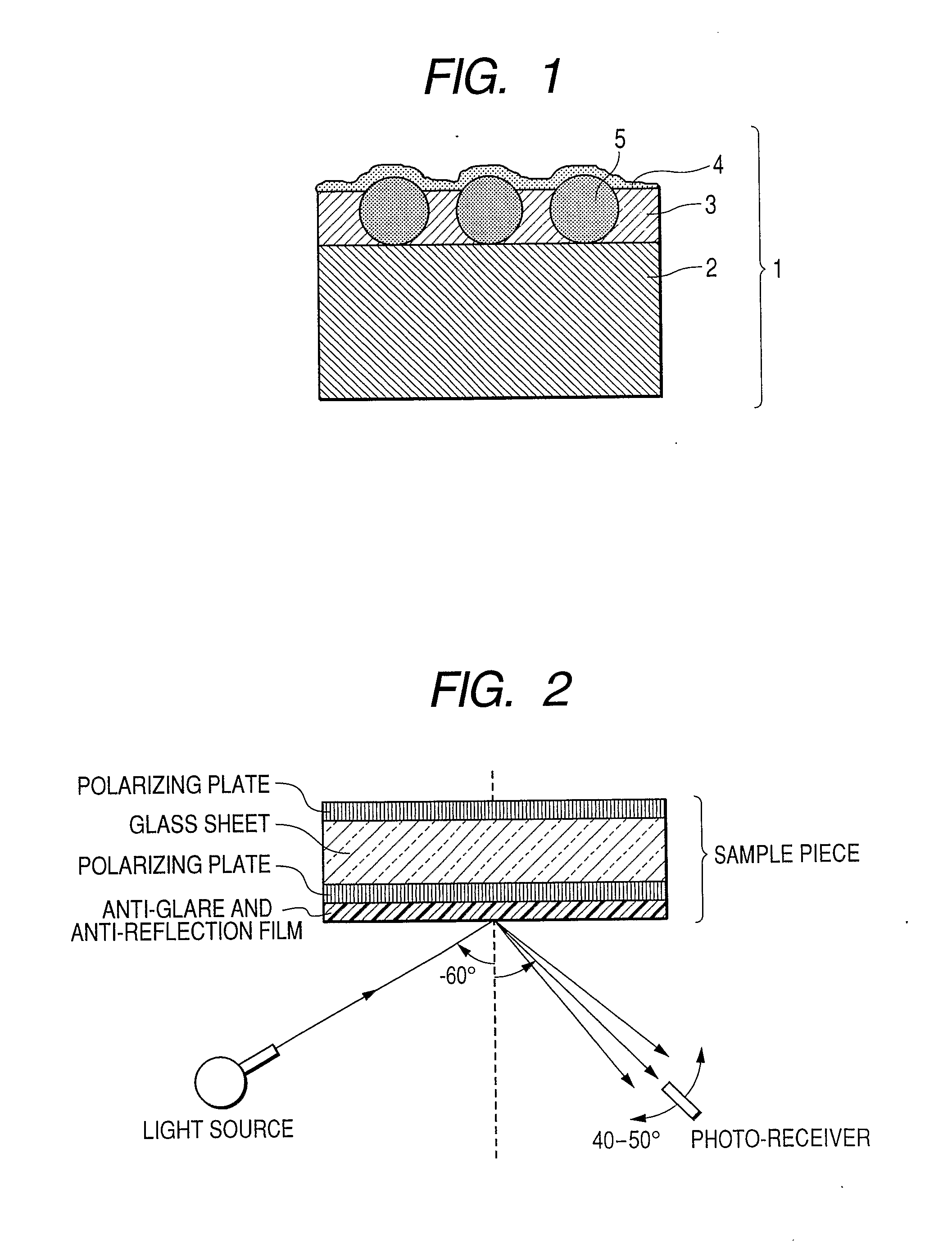

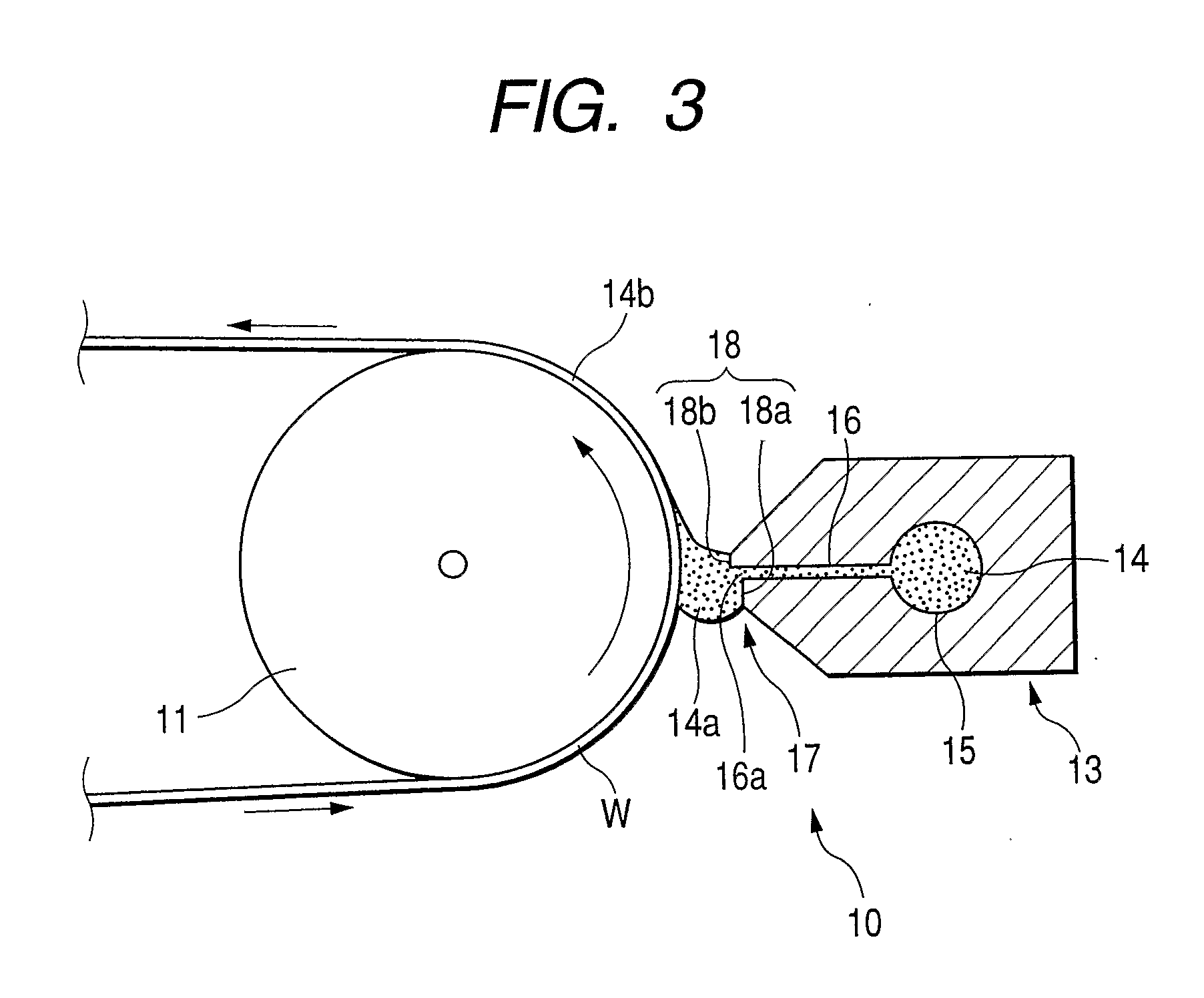

Film, Manufacturing Method Thereof, Polarization Plate Using the Film, and Liquid Crystal, and Display Device Using the Polarizing Plate

InactiveUS20080137206A1Improving dazzlingSuppressing whiteningPolarising elementsCoatingsDisplay devicePolarizer

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com