Patents

Literature

14248results about How to "Increased sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

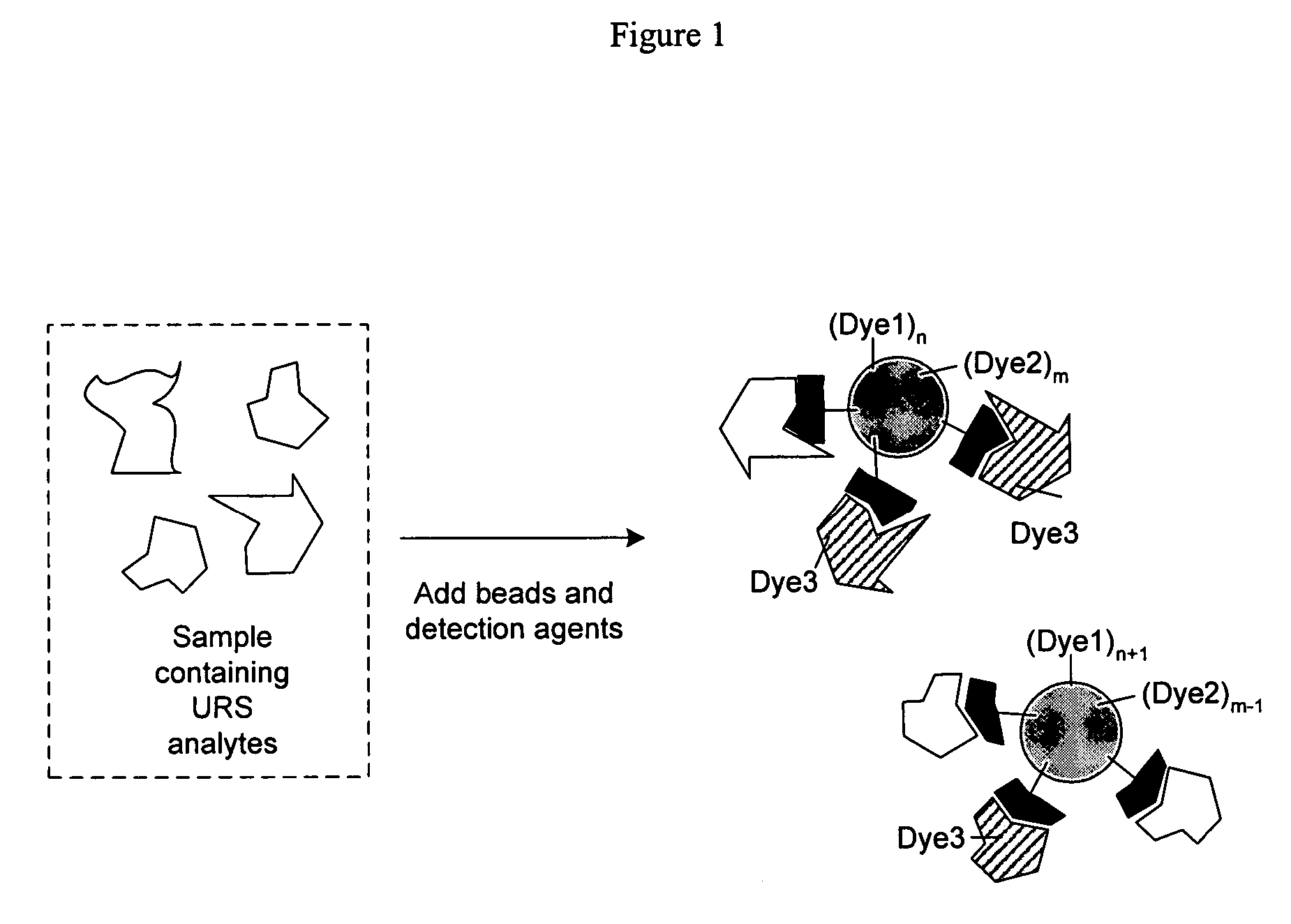

Coded Molecules for Detecting Target Analytes

InactiveUS20070190543A1Easy to detectHigh sensitivityBioreactor/fermenter combinationsBiological substance pretreatmentsAnalytePhysics

Owner:APPL BIOSYSTEMS INC

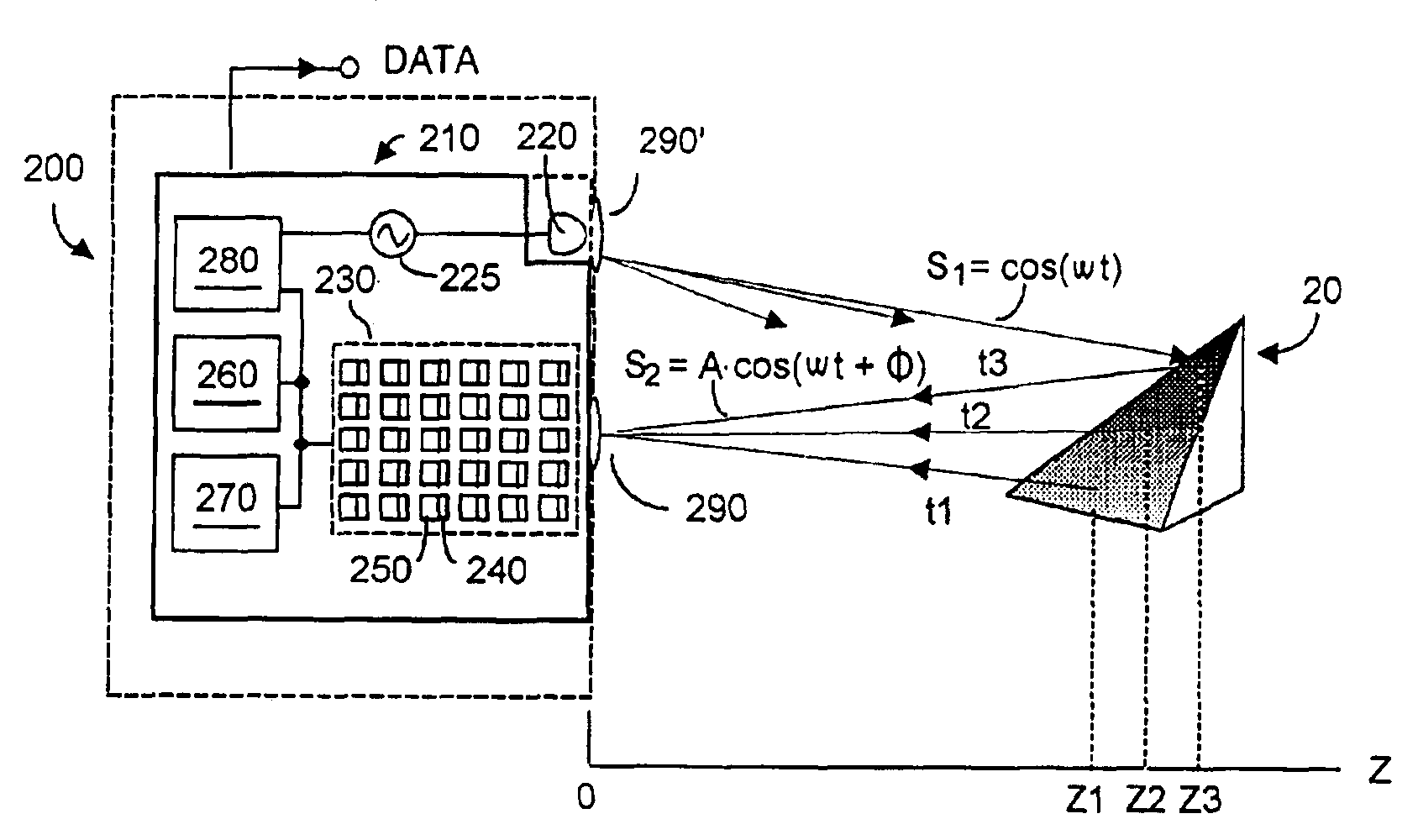

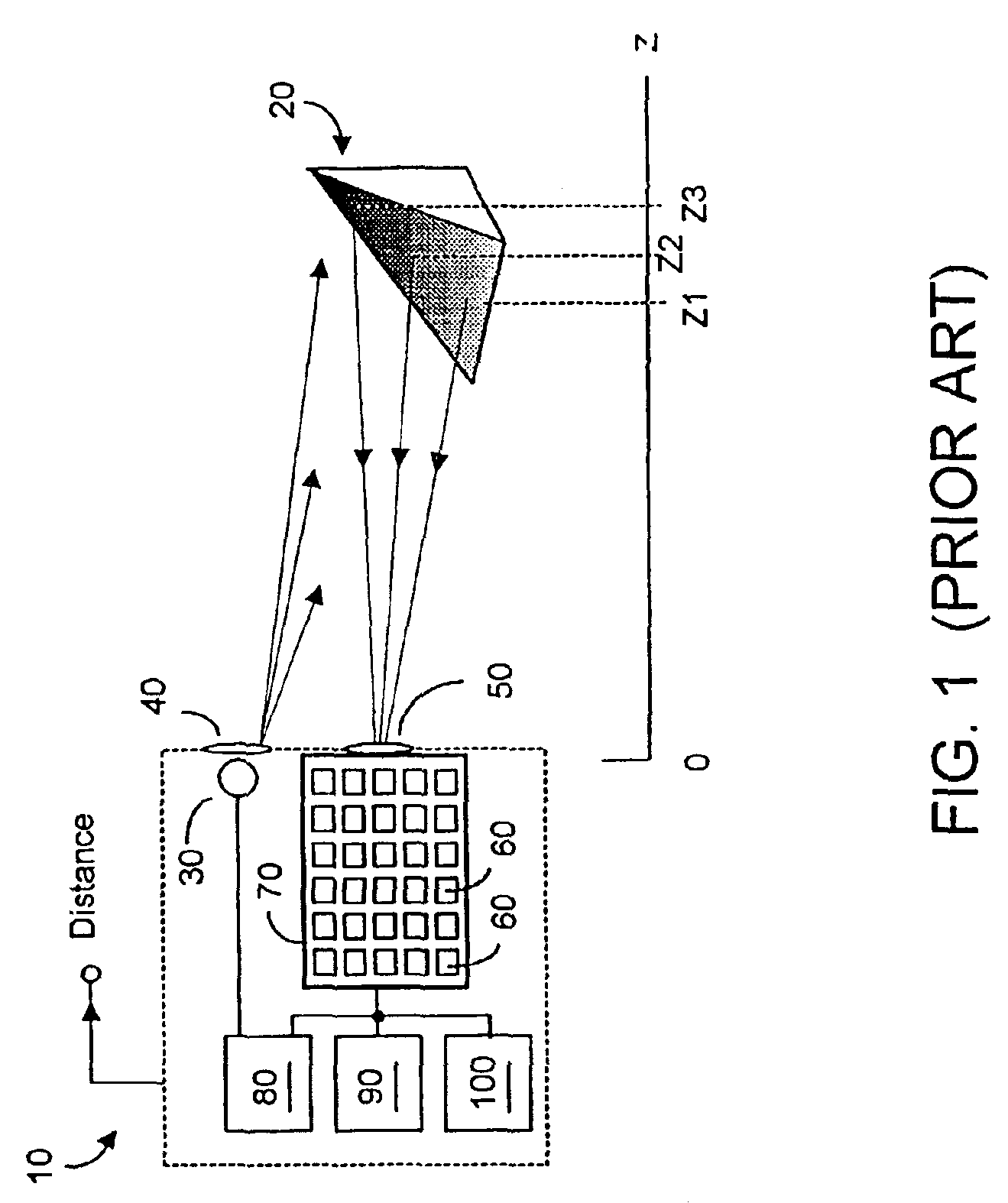

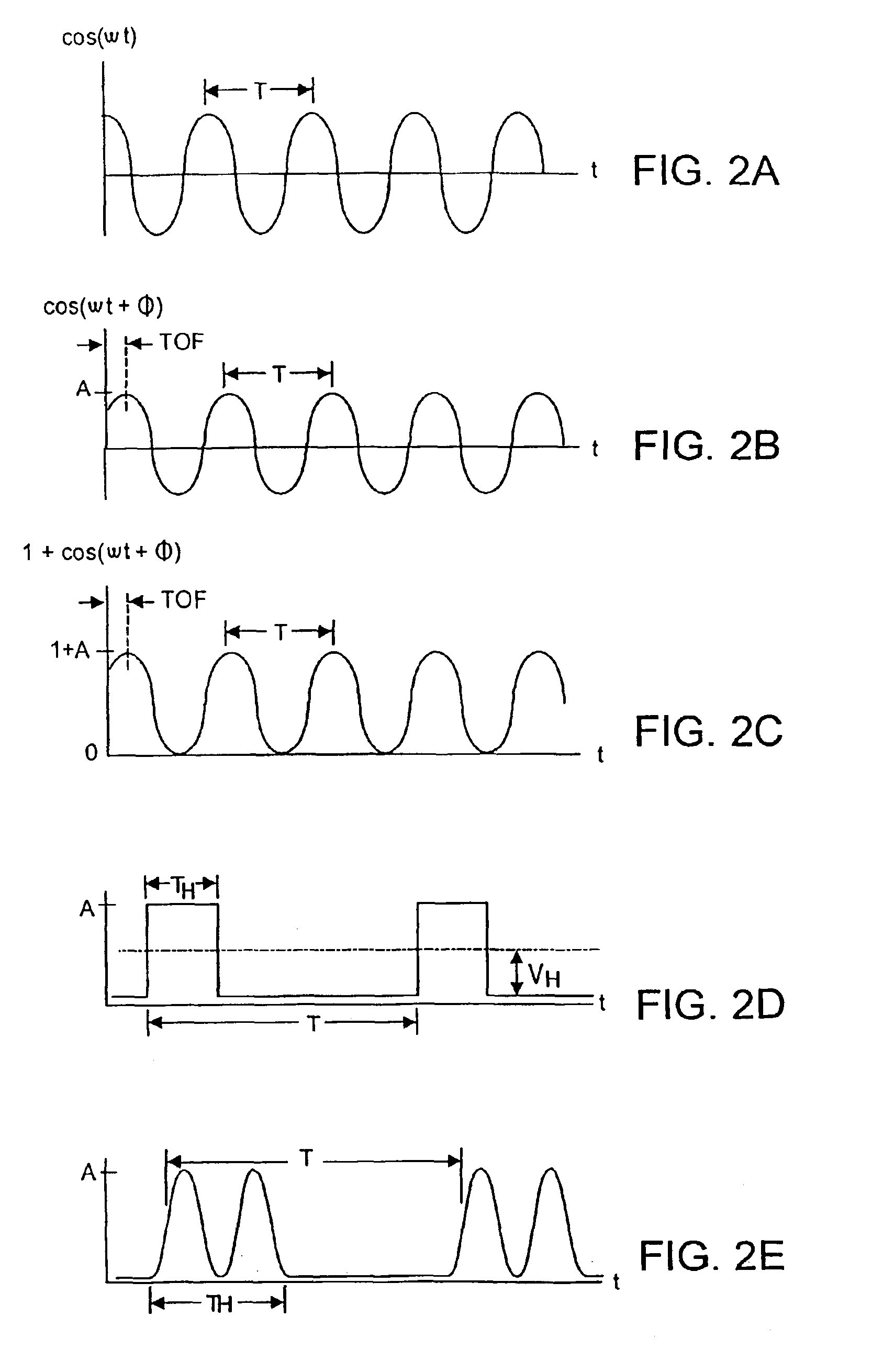

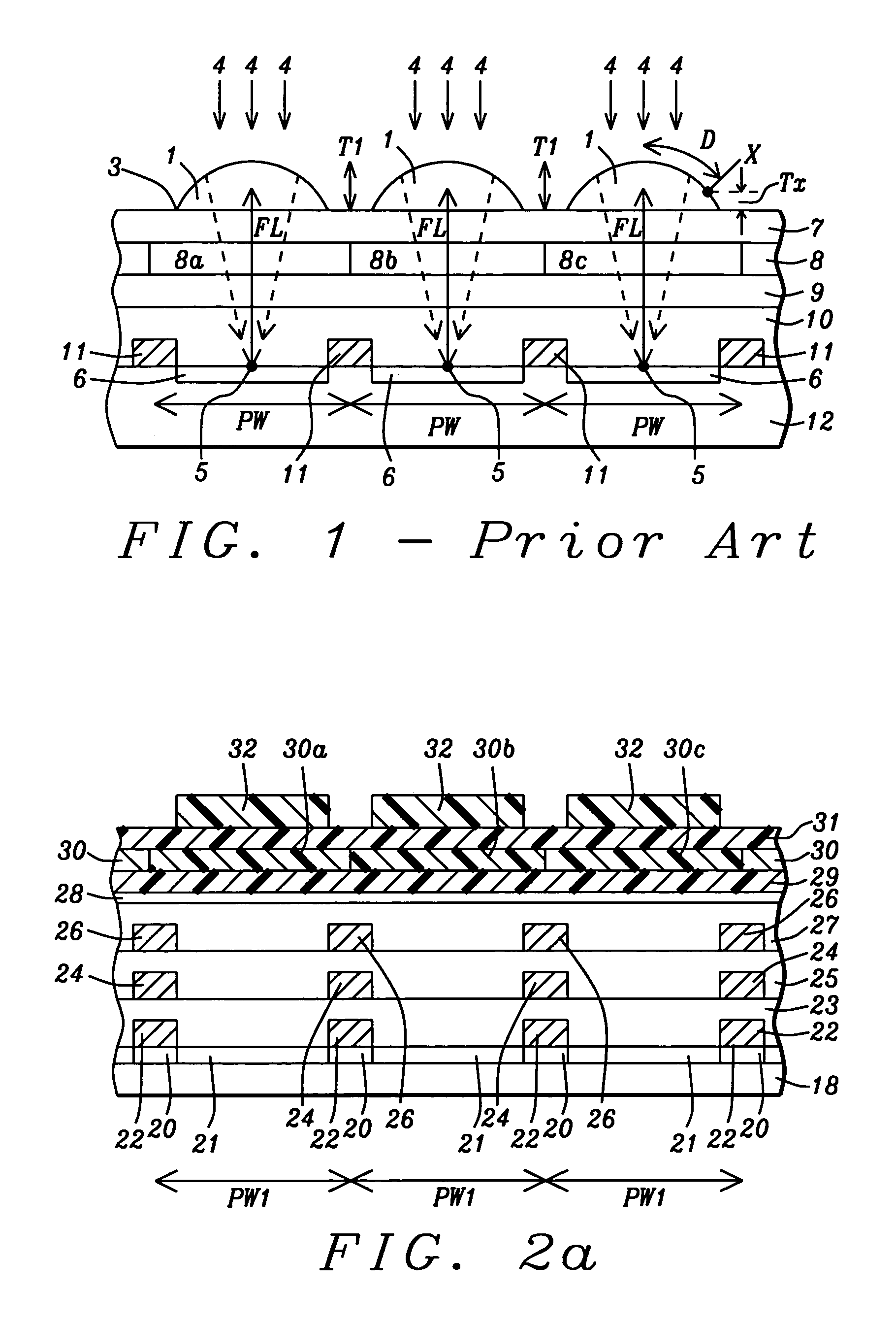

Methods and devices for charge management for three-dimensional sensing

InactiveUS6906793B2Minimal overheadEffective coloringTelevision system detailsOptical rangefindersCMOSHigh frequency modulation

Structures and methods for three-dimensional image sensing using high frequency modulation includes CMOS-implementable sensor structures using differential charge transfer, including such sensors enabling rapid horizontal and slower vertical dimension local charge collection. Wavelength response of such sensors can be altered dynamically by varying gate potentials. Methods for producing such sensor structures on conventional CMOS fabrication facilities include use of “rich” instructions to command the fabrication process to optimize image sensor rather than digital or analog ICs. One detector structure has closely spaced-apart, elongated finger-like structures that rapidly collect charge in the spaced-apart direction and then move collected charge less rapidly in the elongated direction. Detector response is substantially independent of the collection rate in the elongated direction.

Owner:MICROSOFT TECH LICENSING LLC

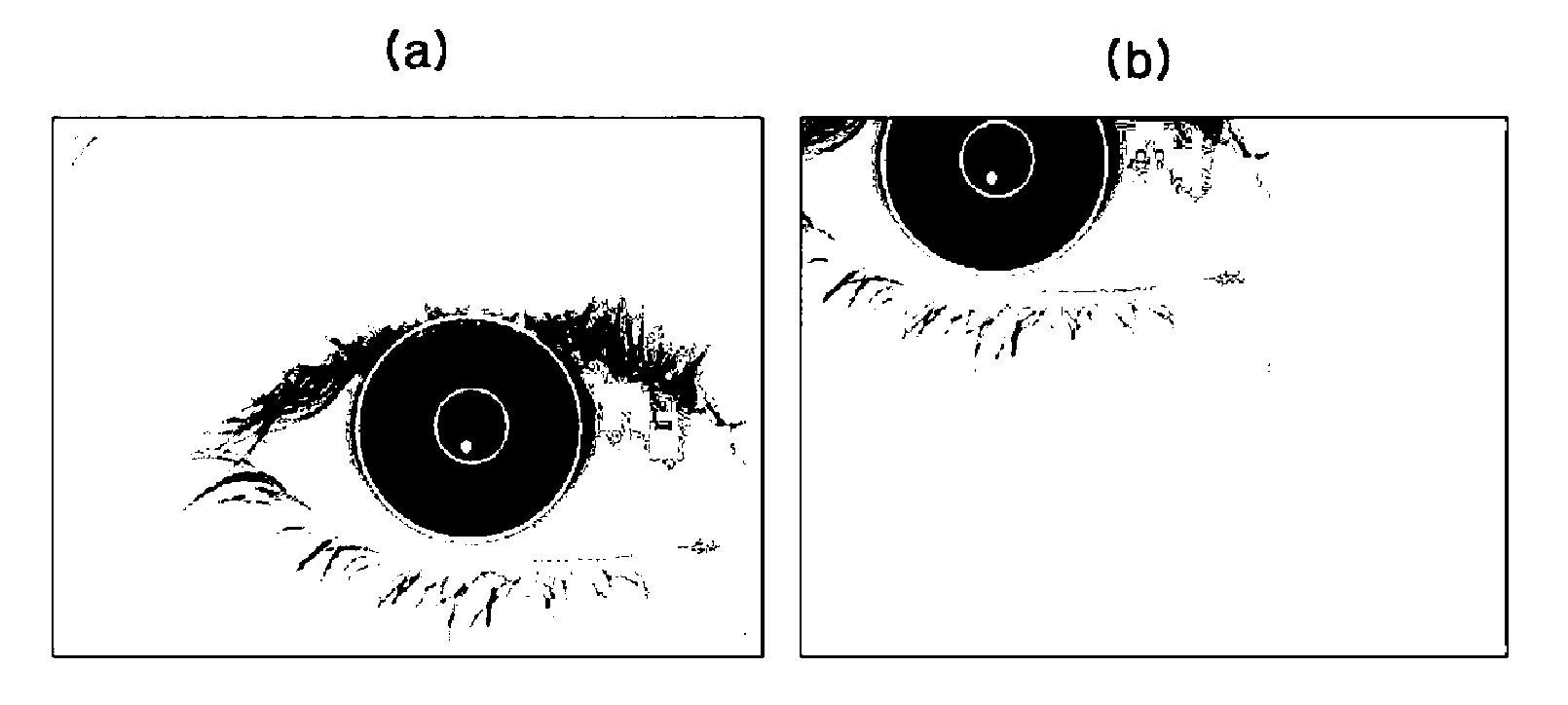

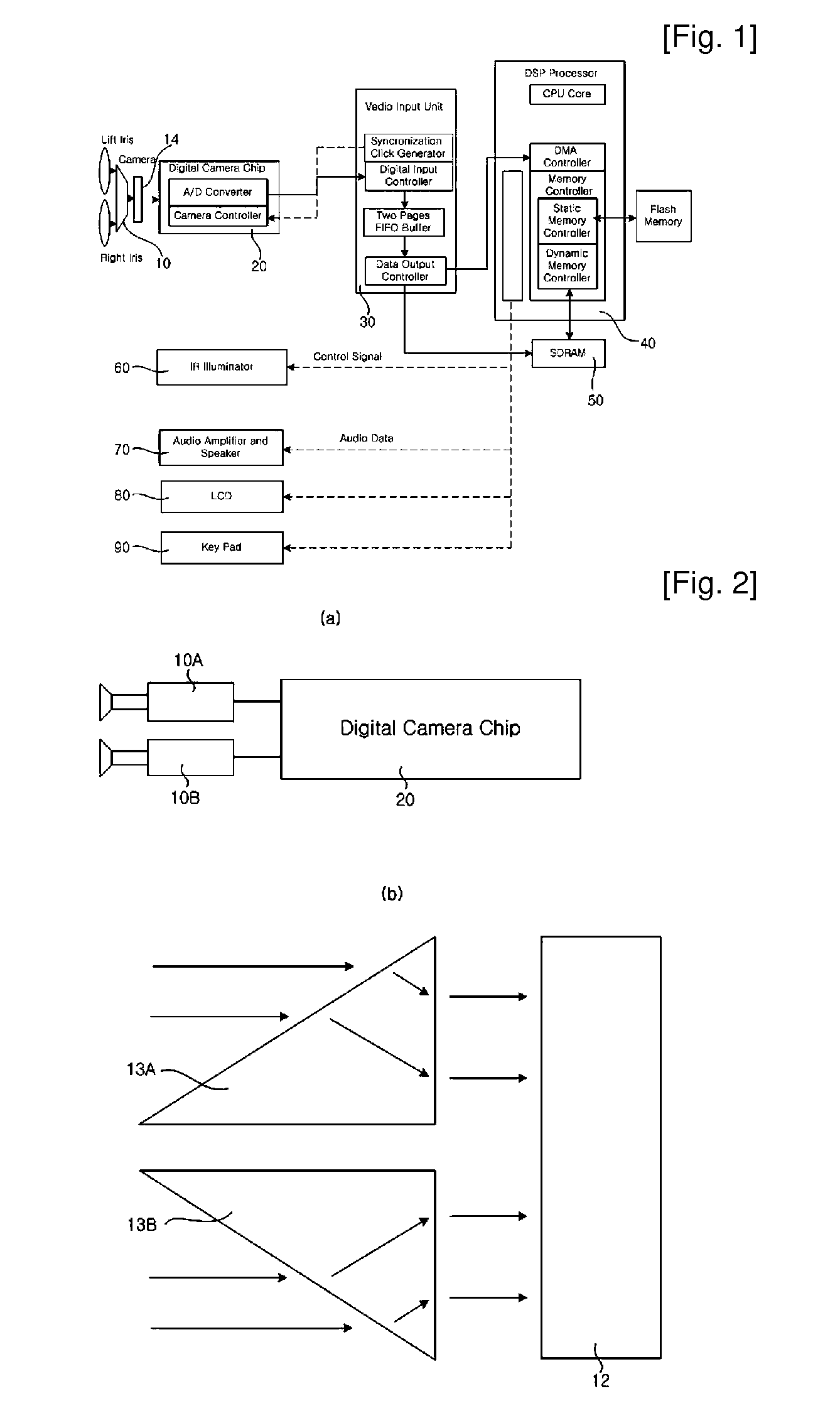

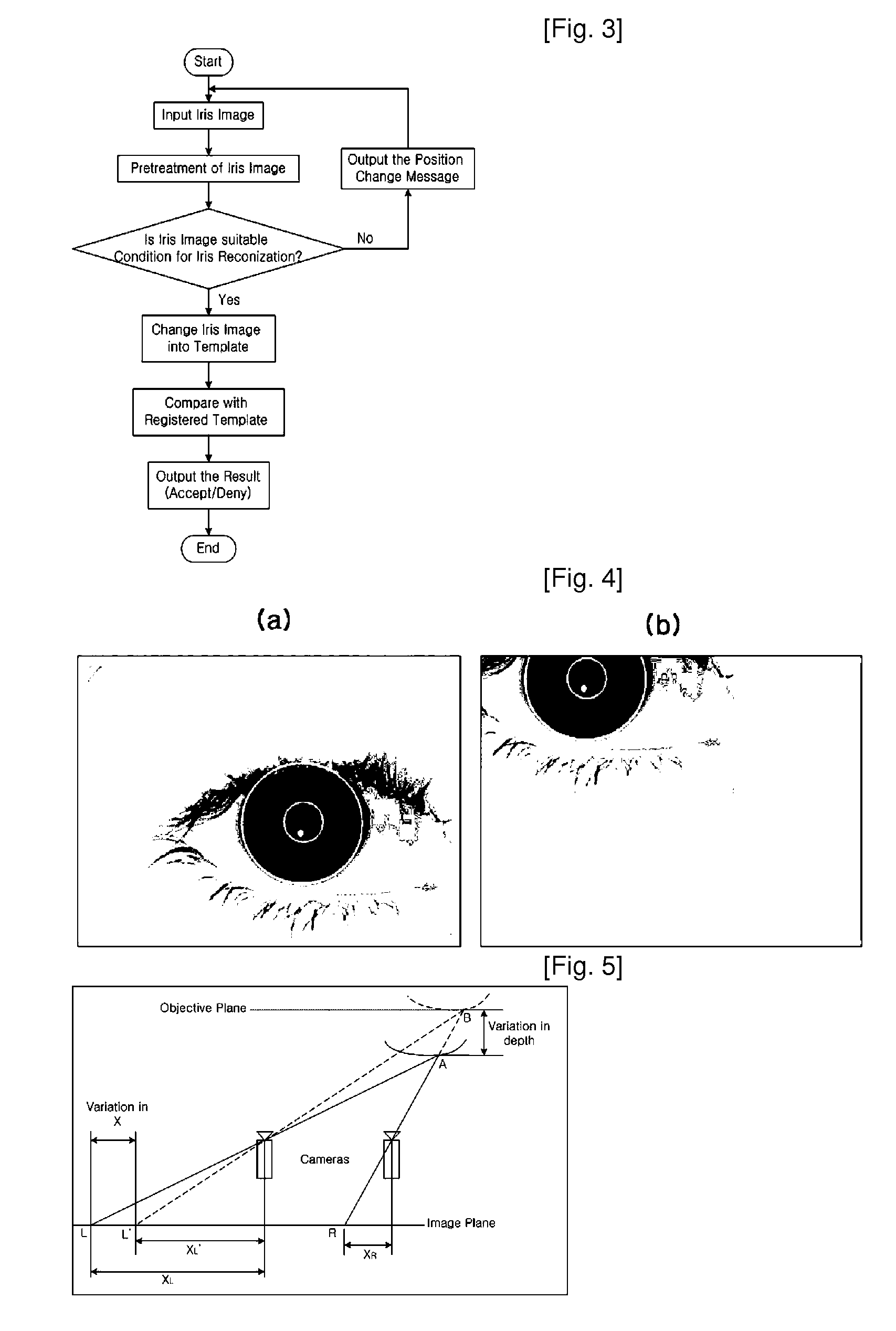

Iris Identification System and Method Using Mobile Device with Stereo Camera

InactiveUS20080292144A1Easy to getImprove recognition rateLighting and heating apparatusAcquiring/recognising eyesCamera lensStereo cameras

The present invention relates to a face recognition and / or iris recognition system and method using a mobile device equipped with a stereo camera, which acquire a stereo image of a user's face using at least two cameras or a method corresponding thereto and, even when the size of the stereo image is varied according to distance, correct the size of the stereo image. The stereo camera uses a single-focus lens with a long depth of focus to acquire a focused iris image over a wider range. When the user is not located at a position suitable for iris recognition, a message is sent to the user such that an iris image suitable for recognition is acquired. Furthermore, an iris image correction process according to distance is performed to prevent recognition rate from decreasing even when the size of the iris image is changed.

Owner:IRITECH

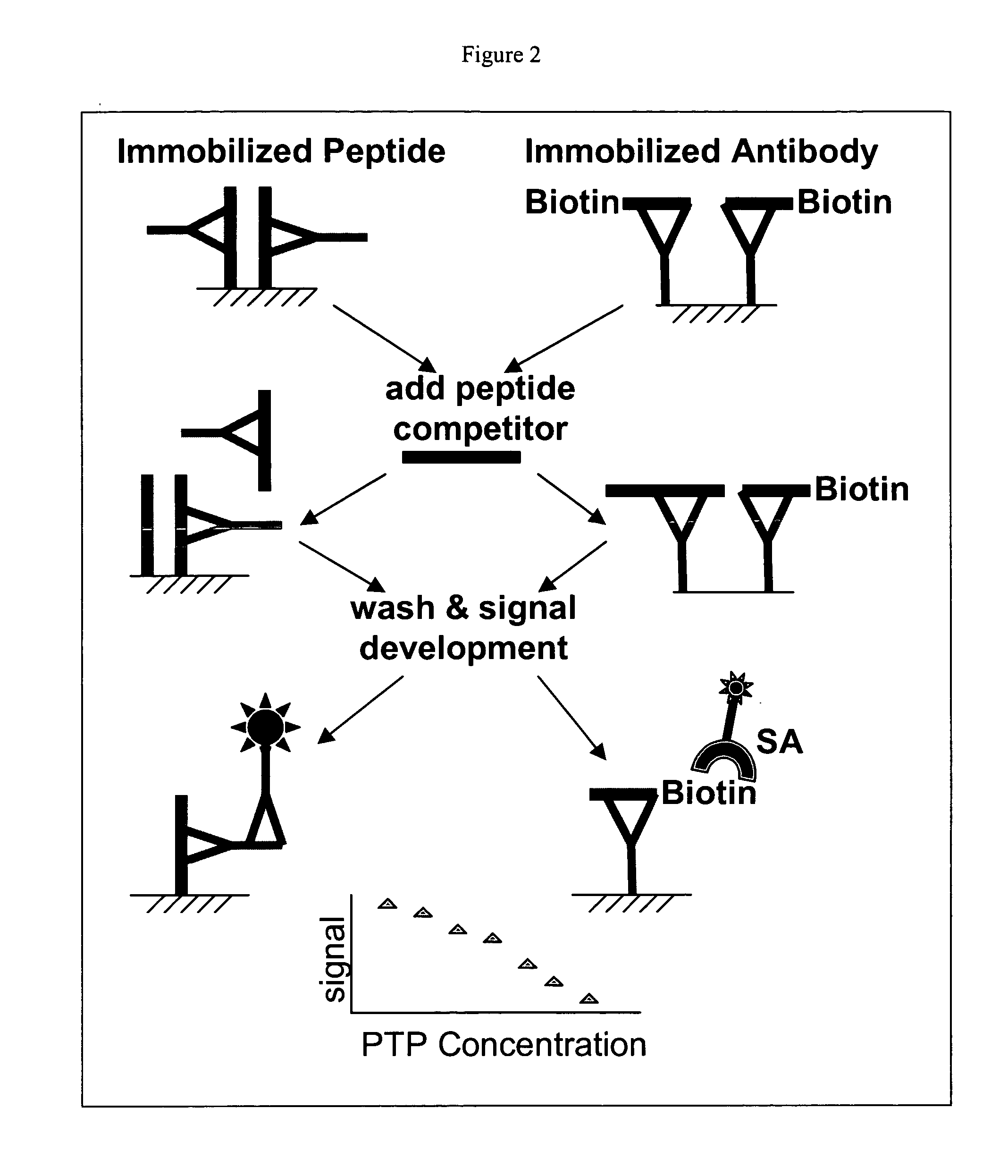

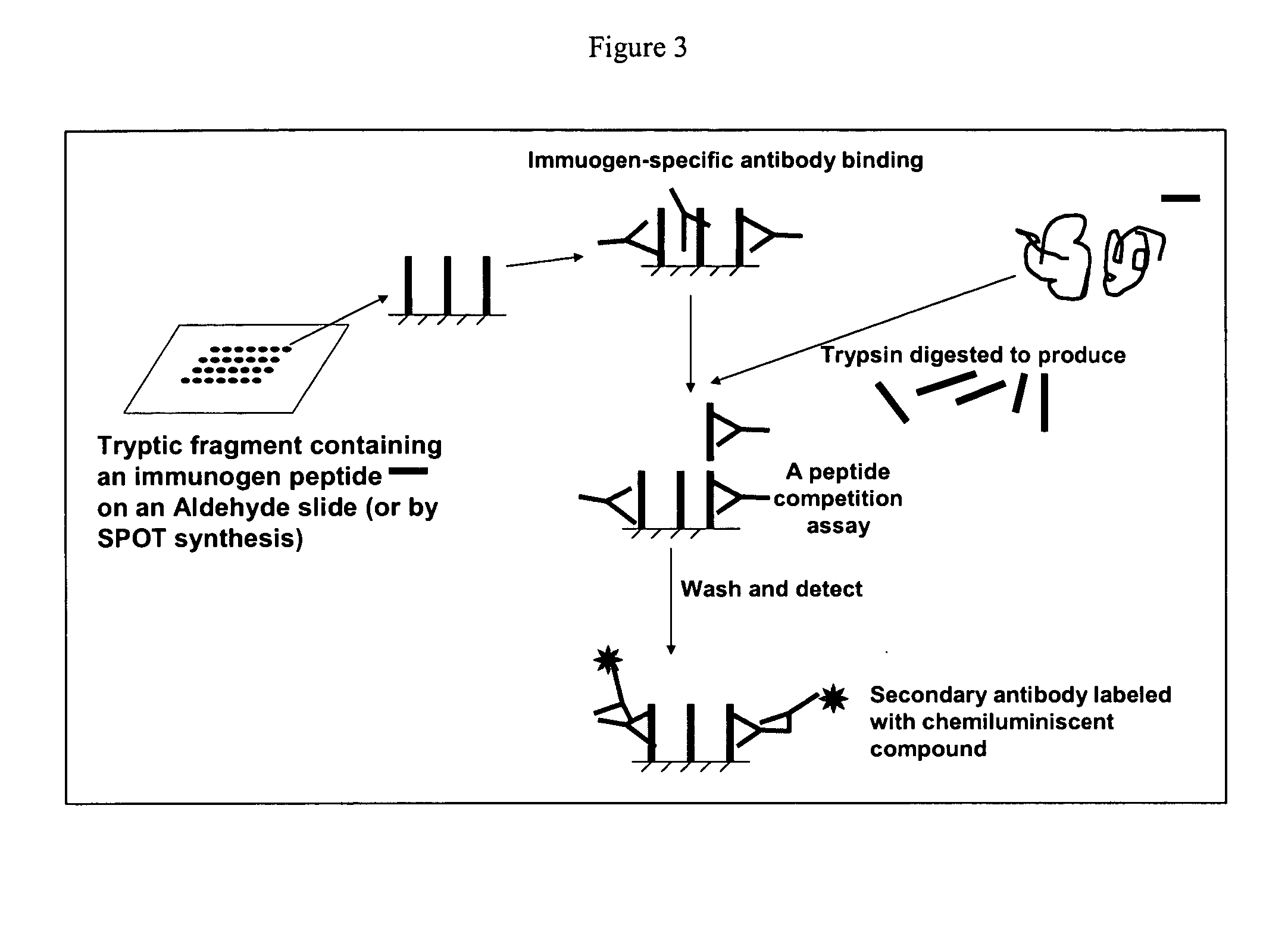

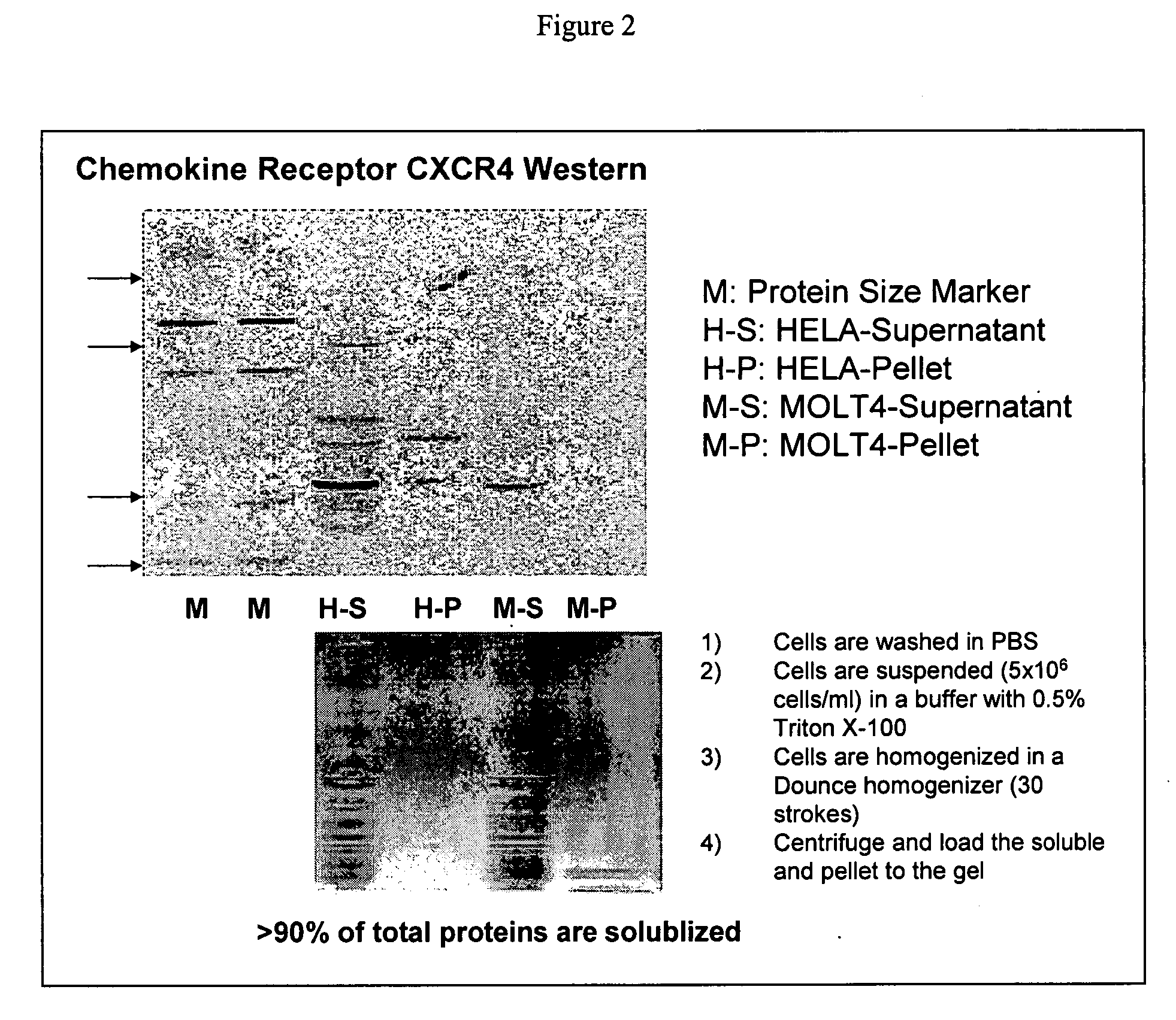

Small molecule and peptide arrays and uses thereof

InactiveUS20050255491A1Improve clinical valueHigh avidityPeptide librariesSugar derivativesChemistryPeptide array

Disclosed are competition assay methods for reliably detecting the presence and / or quantitation of small molecules (e.g., metabolites) and peptides / proteins in a sample by the use of capture agents specific for immobilized small molecules and / or peptides / proteins. Arrays comprising these small molecules and / or peptides / proteins are also provided.

Owner:EPITOME BIOSYST

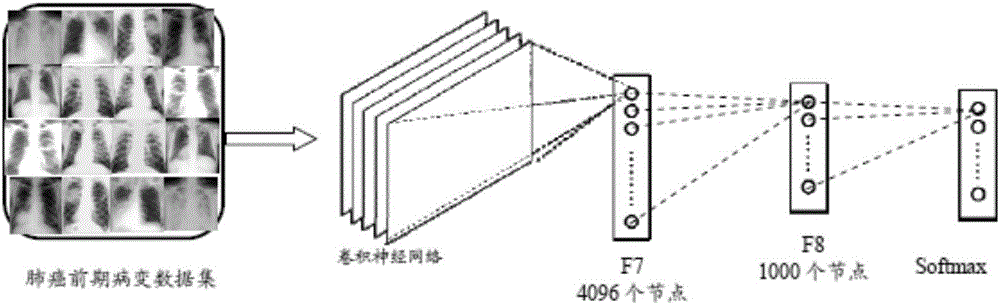

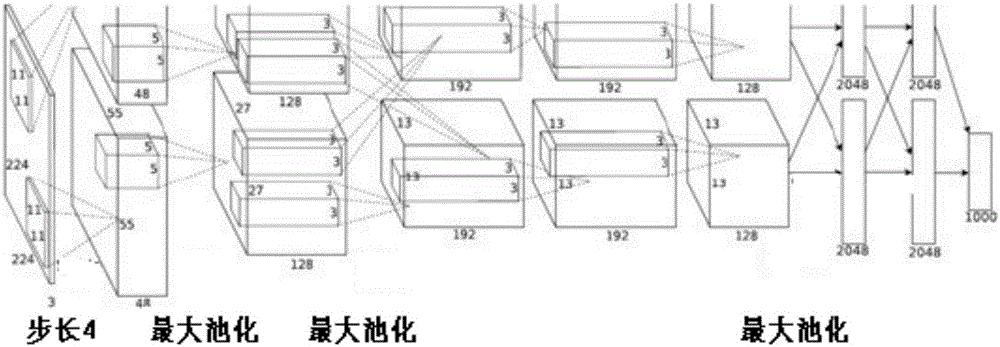

Deep convolutional neural network-based lung cancer preventing self-service health cloud service system

ActiveCN106372390AImprove informatizationIncrease health awarenessSpecial data processing applicationsNerve networkSuspected lung cancer

Owner:汤一平

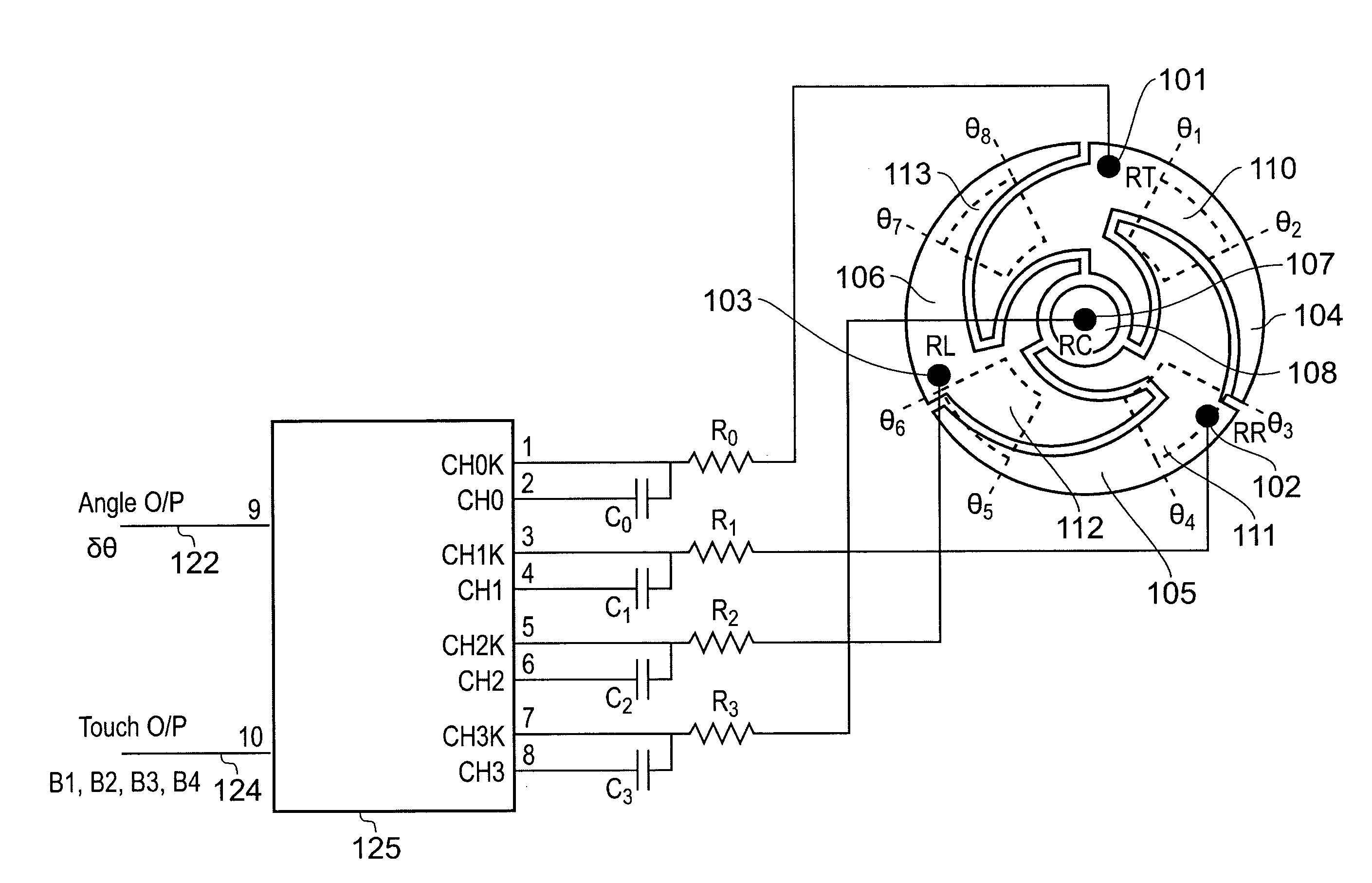

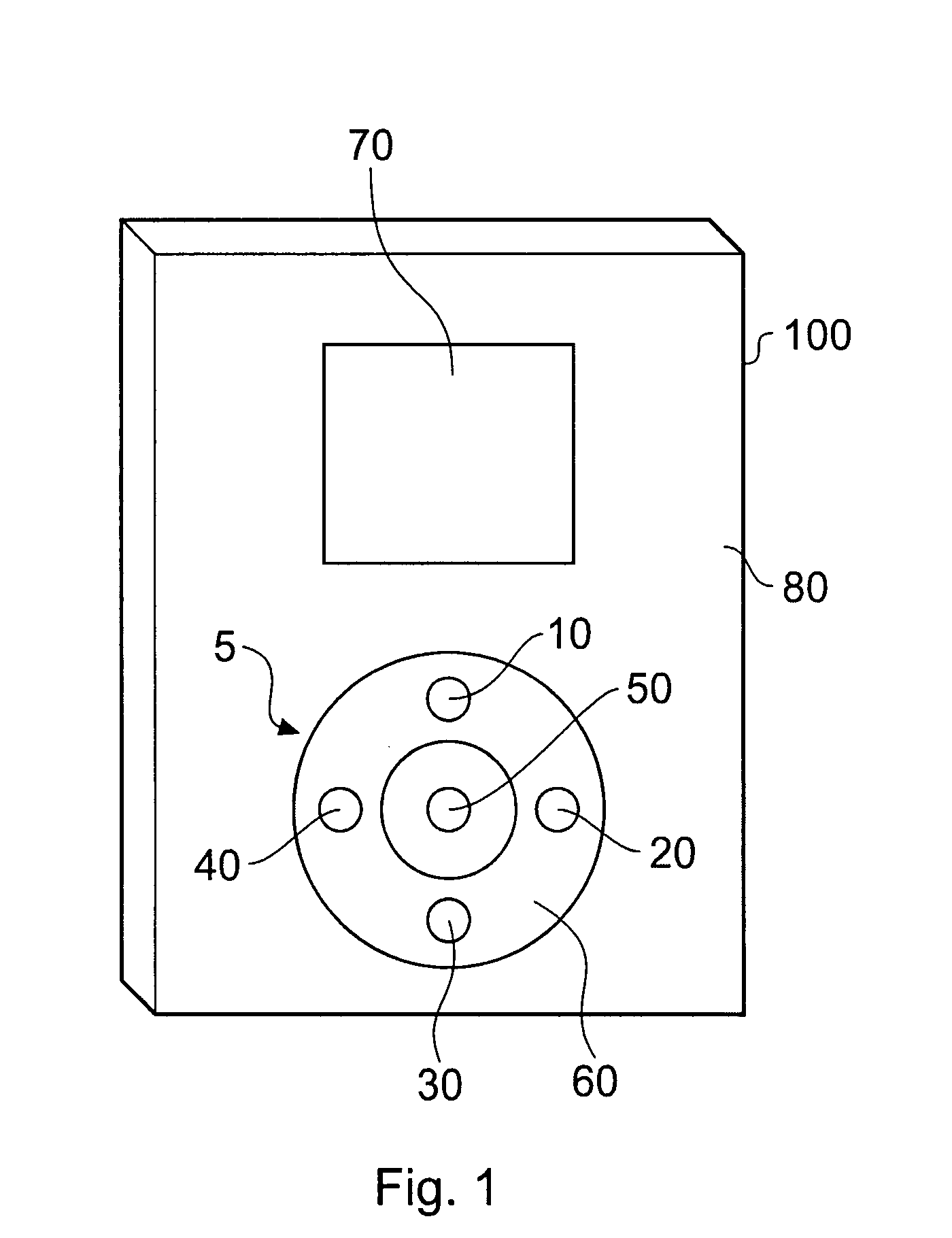

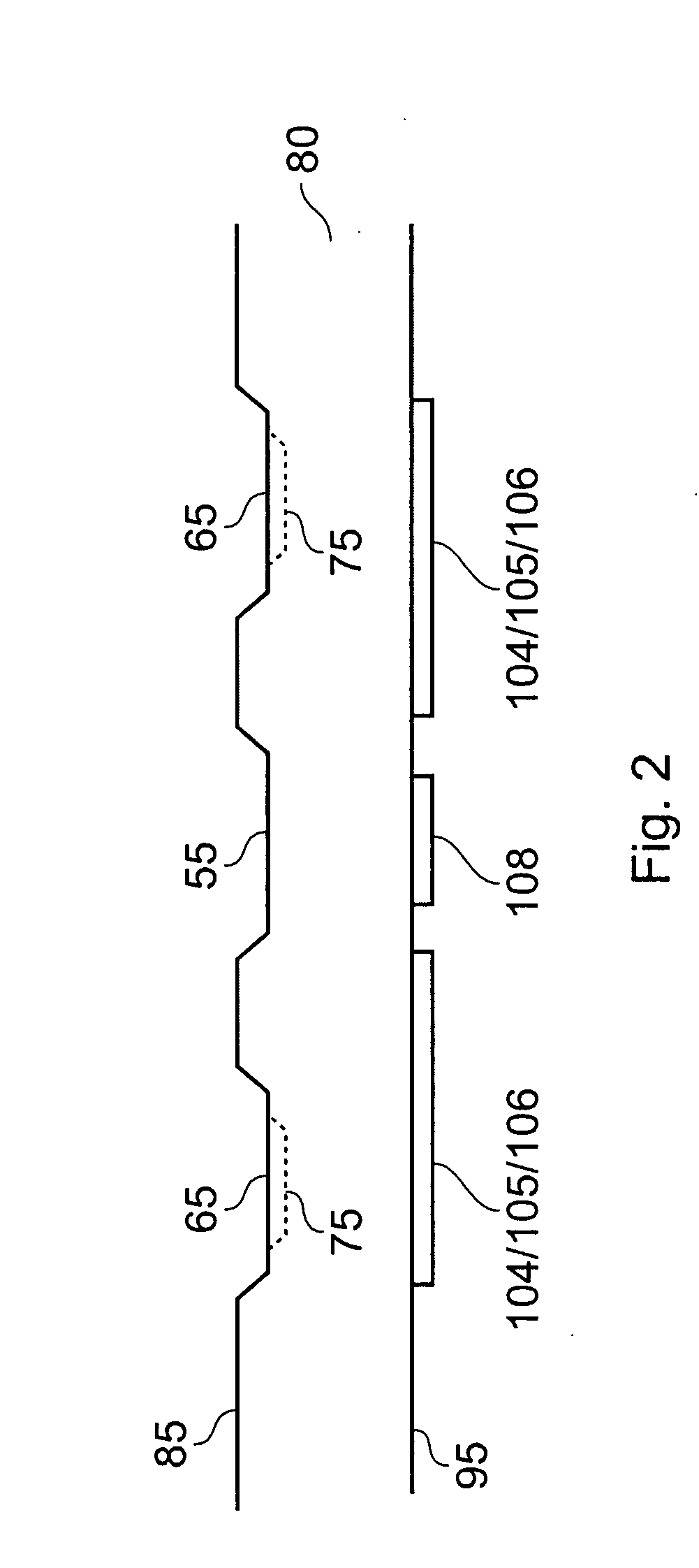

Capacitive Position Sensor

InactiveUS20070291016A1Improve reliabilityReduce power consumptionConverting sensor outputInput/output processes for data processingMicrocontrollerCapacitance

A capacitive position sensor comprising a preferably annular sensing path, the sensing path having one or more virtual buttons designated along its length. The sensing path has a plurality of terminals connected to it to subdivide it into a plurality of sections, each terminal providing a sensing channel for a signal indicative of capacitance. The sensing channels provide the signals to a processor, preferably a microcontroller, that is operable to distinguish between a user making a touch to actuate one of the virtual buttons, and a touch to perform a scrolling function. To be determined as a scroll, it is required that there is a succession of detects which span over at least a threshold distance, for example an angular or linear distance. To be determined as a touch, it is required that there is a succession of detects that all lie within one of the pre-assigned virtual button positions.

Owner:ATMEL CORP

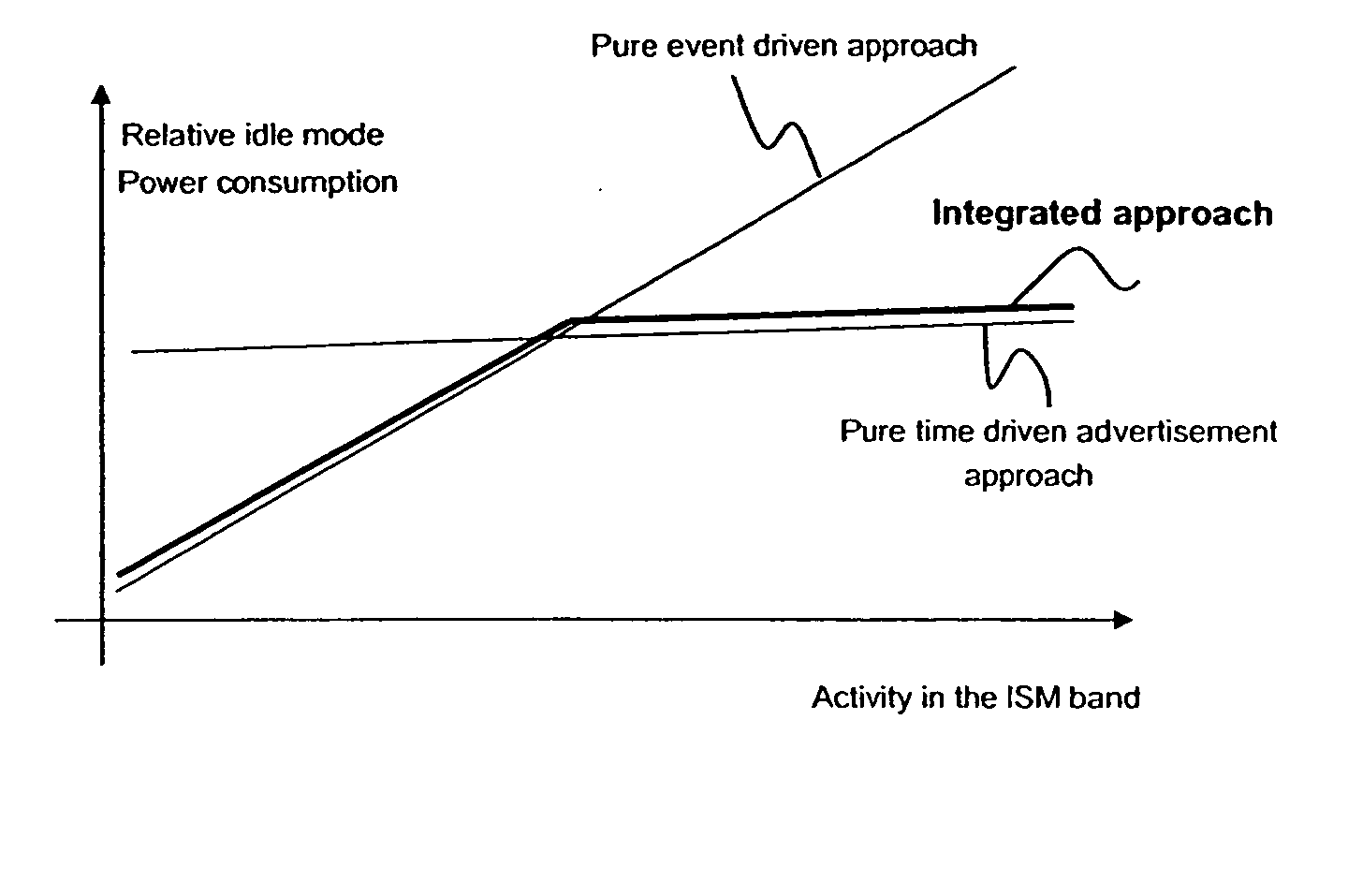

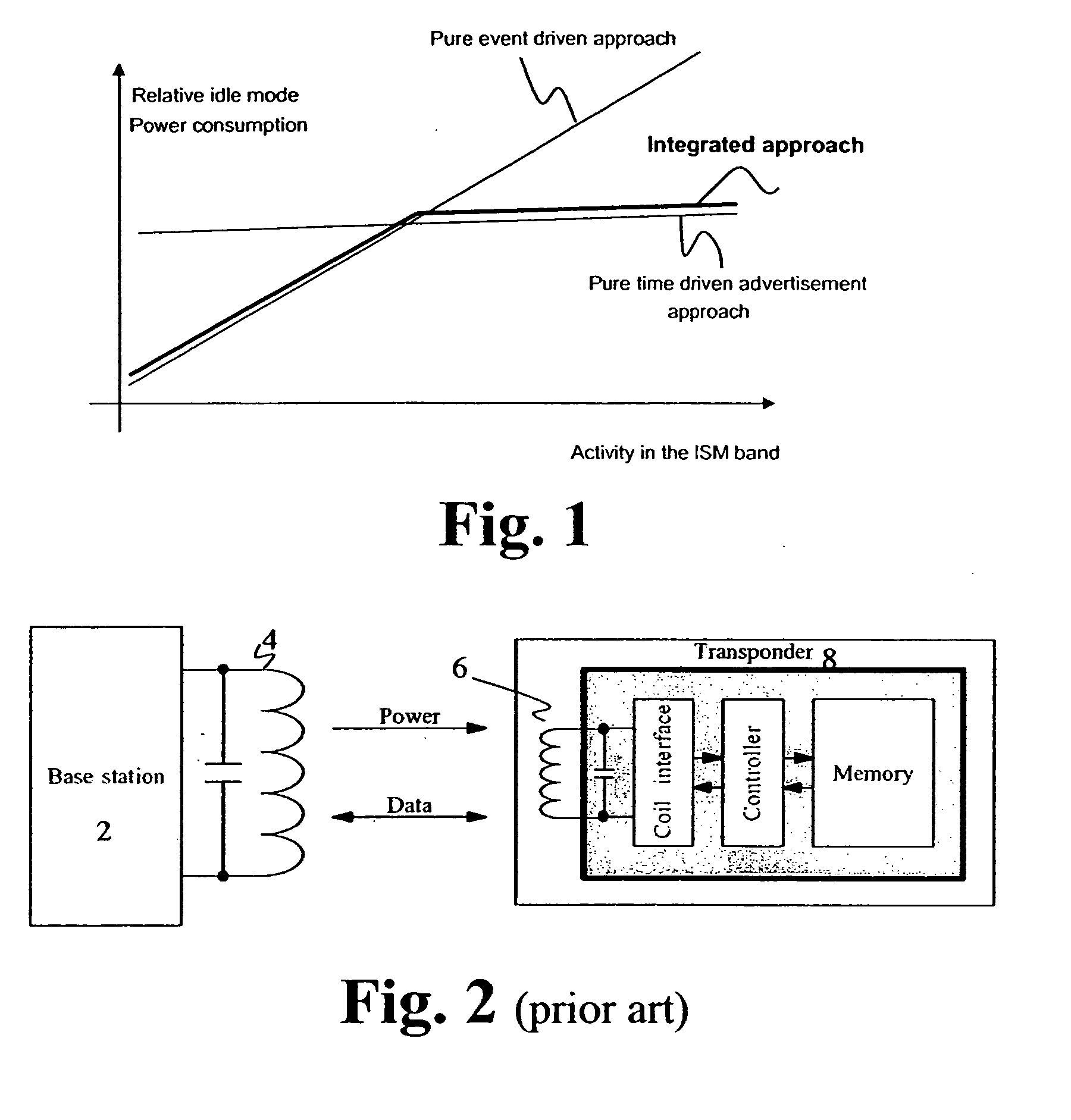

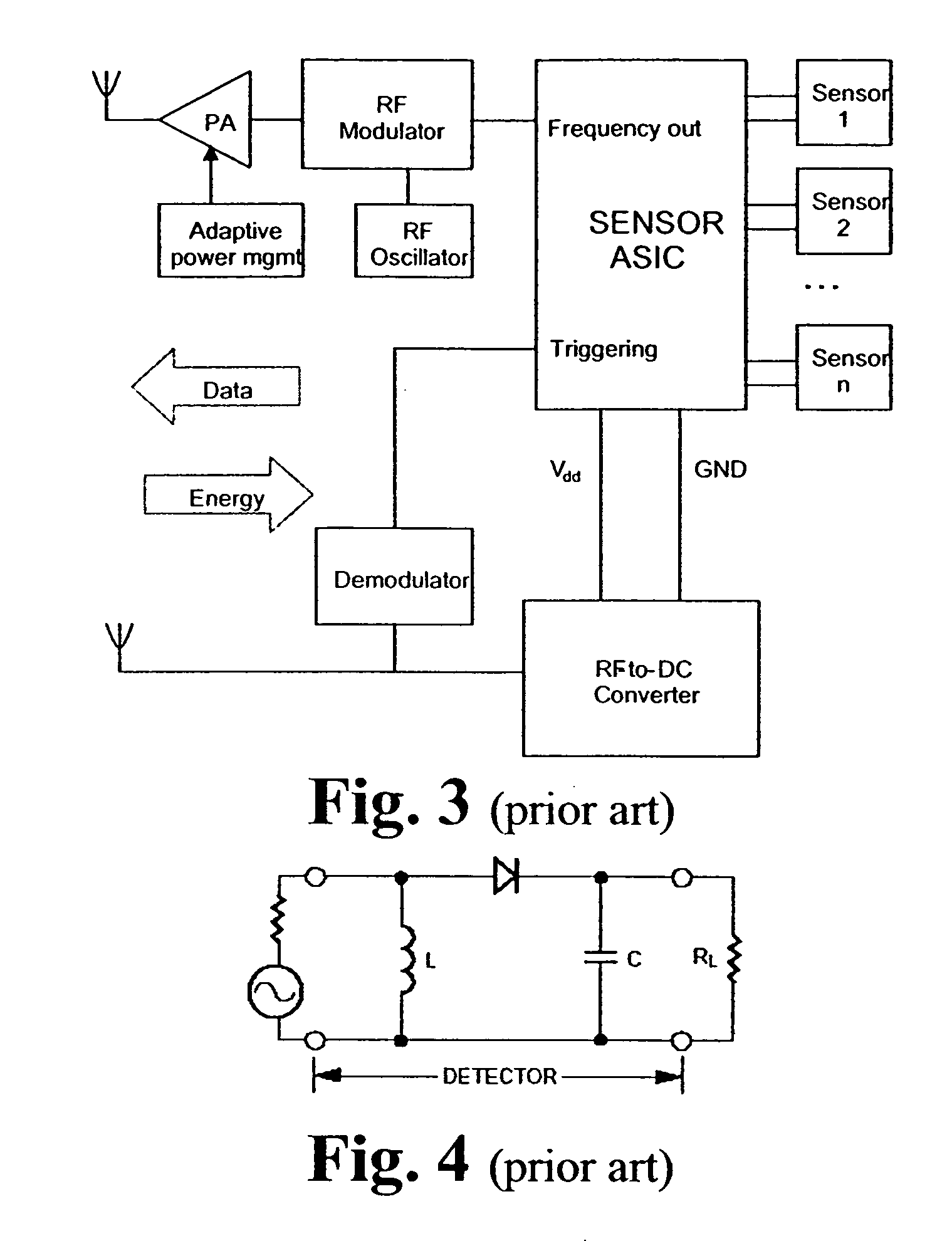

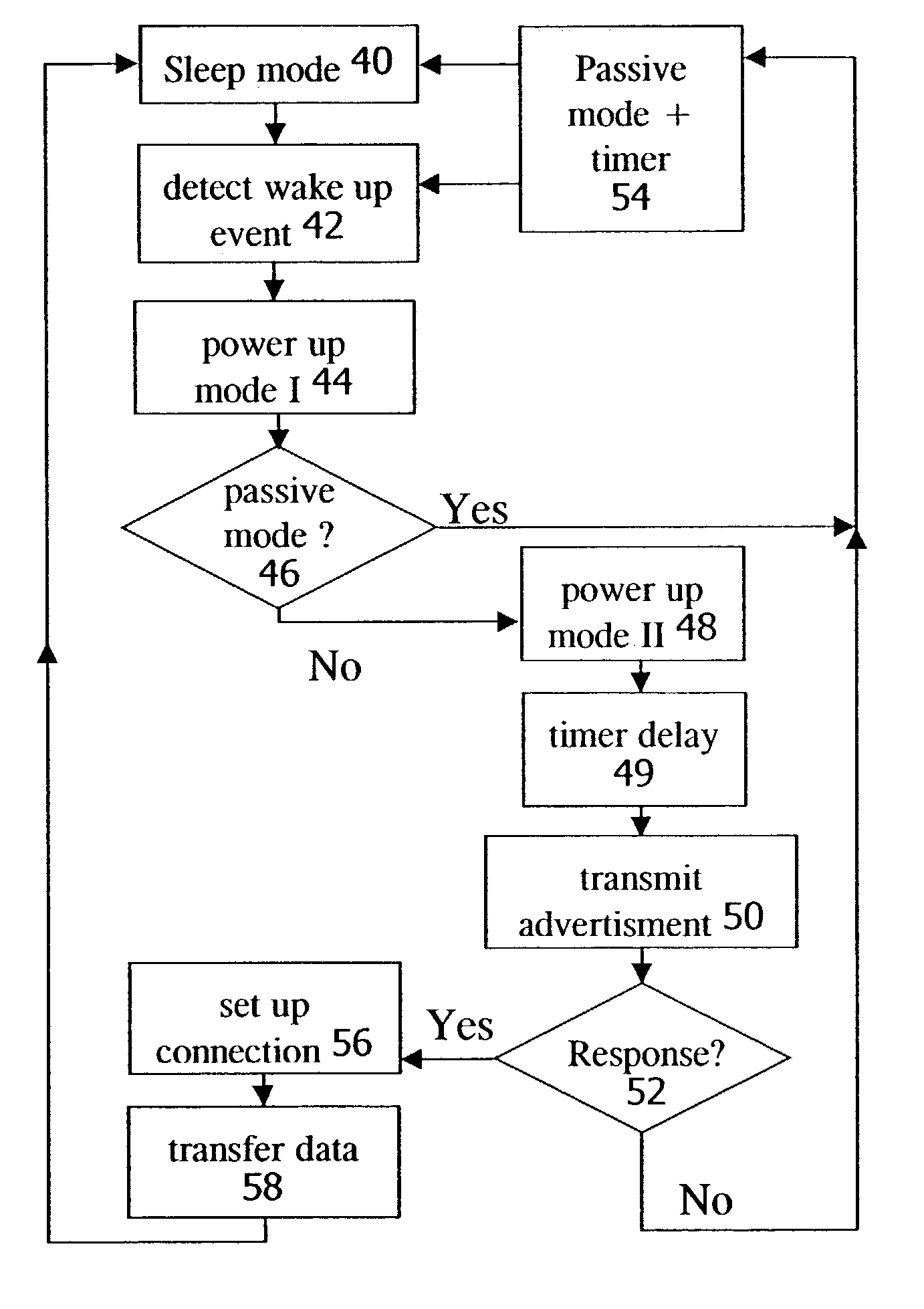

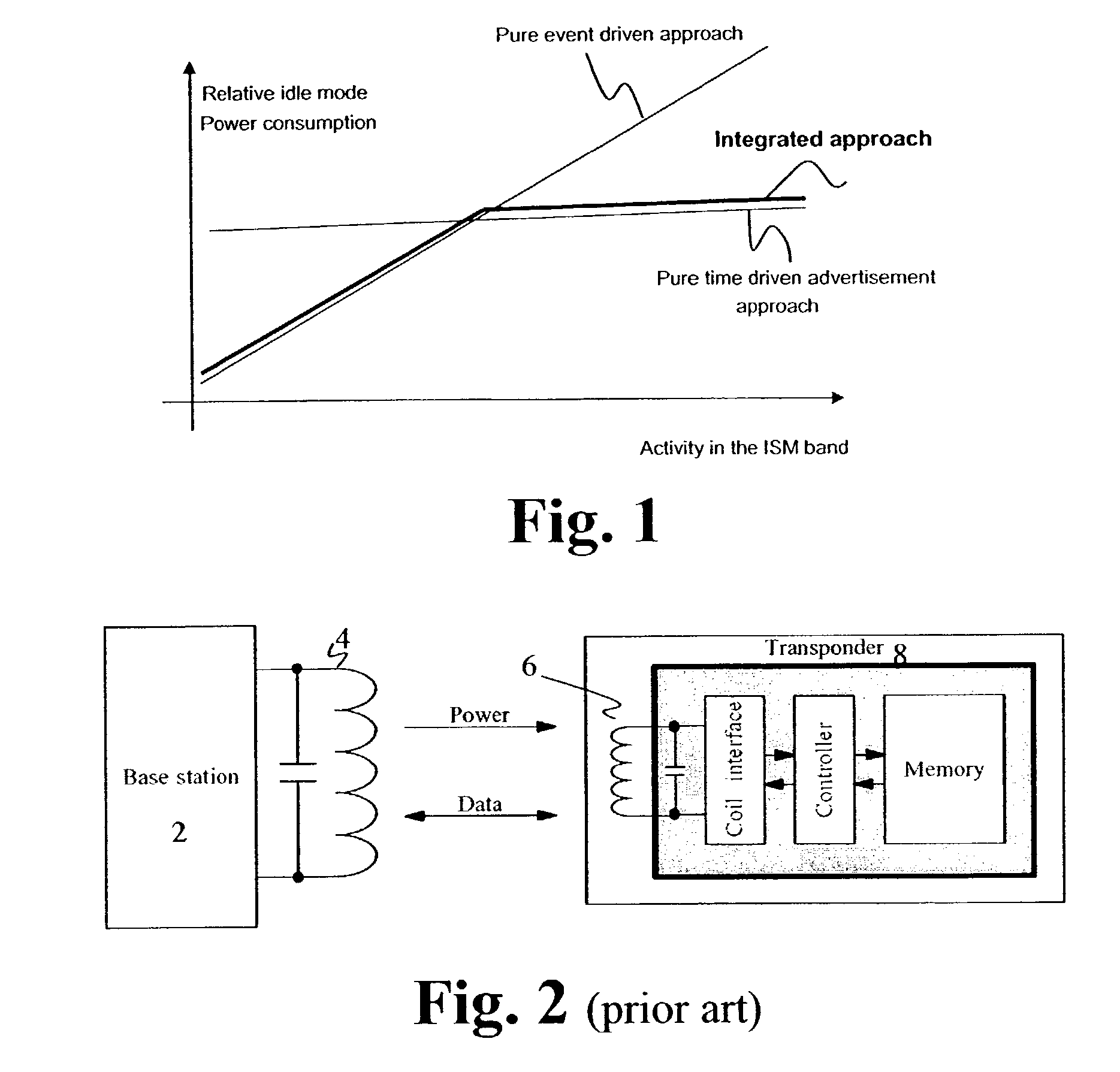

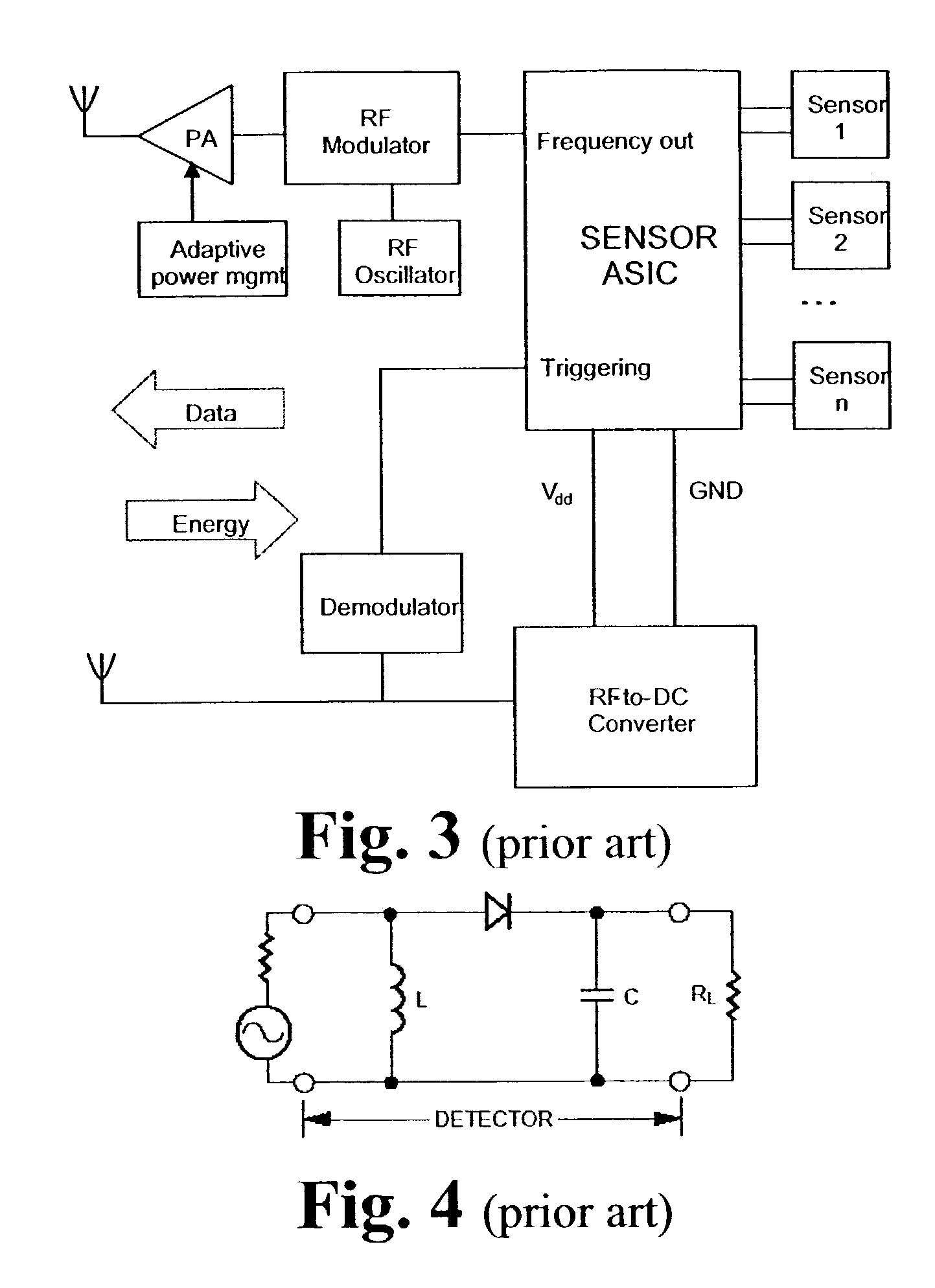

Method and device for transponder aided wake-up of a low power radio device

InactiveUS20060270382A1Reduce in quantityIncreased sensitivityPower managementEnergy efficient ICTRadio equipmentTime segment

Owner:NOKIA CORP

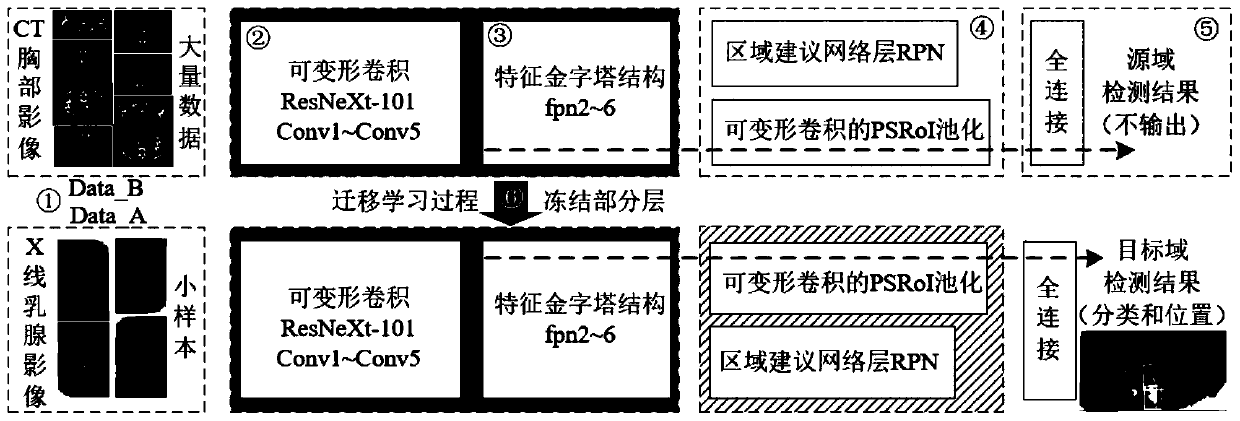

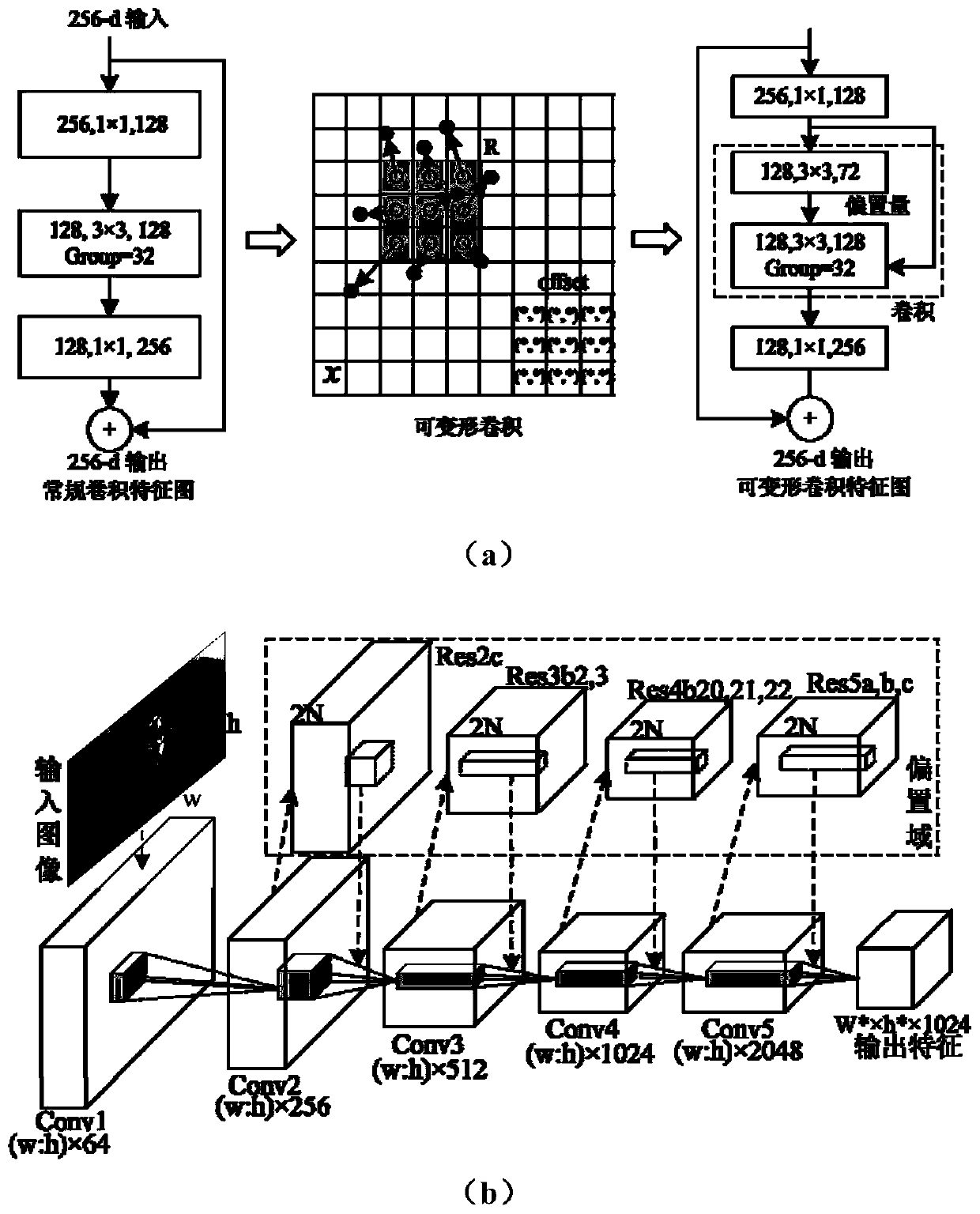

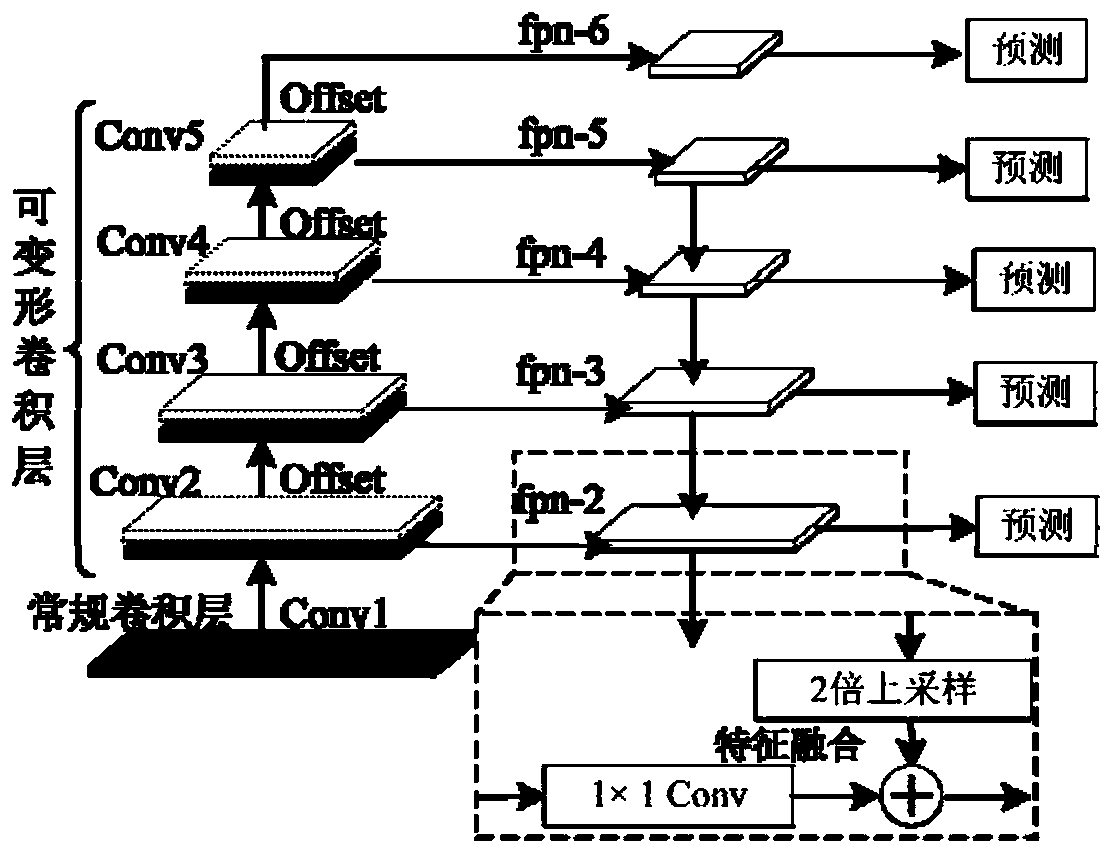

Method for detecting X-ray mammary gland lesion image based on feature pyramid network under transfer learning

ActiveCN110674866AImprove robustnessImprove the extraction effectImage enhancementImage analysisData setImage detection

The invention provides a method for detecting an X-ray mammary gland lesion image based on feature pyramid network under transfer learning. The method comprises the steps: 1, establishing a source domain data set and a target domain data set; 2, establishing a deformable convolution residual network layer by a deformable convolution and extended residual network module; 3, establishing a multi-scale feature extraction sub-network based on a feature pyramid structure through a feature map up-sampling and feature fusion method in combination with a deformable convolution residual network layer;4, establishing a deformable pooling sub-network sensitive to the focus position; 5, establishing a post-processing network layer to optimize a prediction result and a loss function; and 6, migratingthe training model to a small sample molybdenum target X-ray mammary gland focus detection task so as to improve the detection precision of the network model on the focus in the small sample image. According to the method, a transfer learning strategy is combined to realize focus image processing in a small sample medical image.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

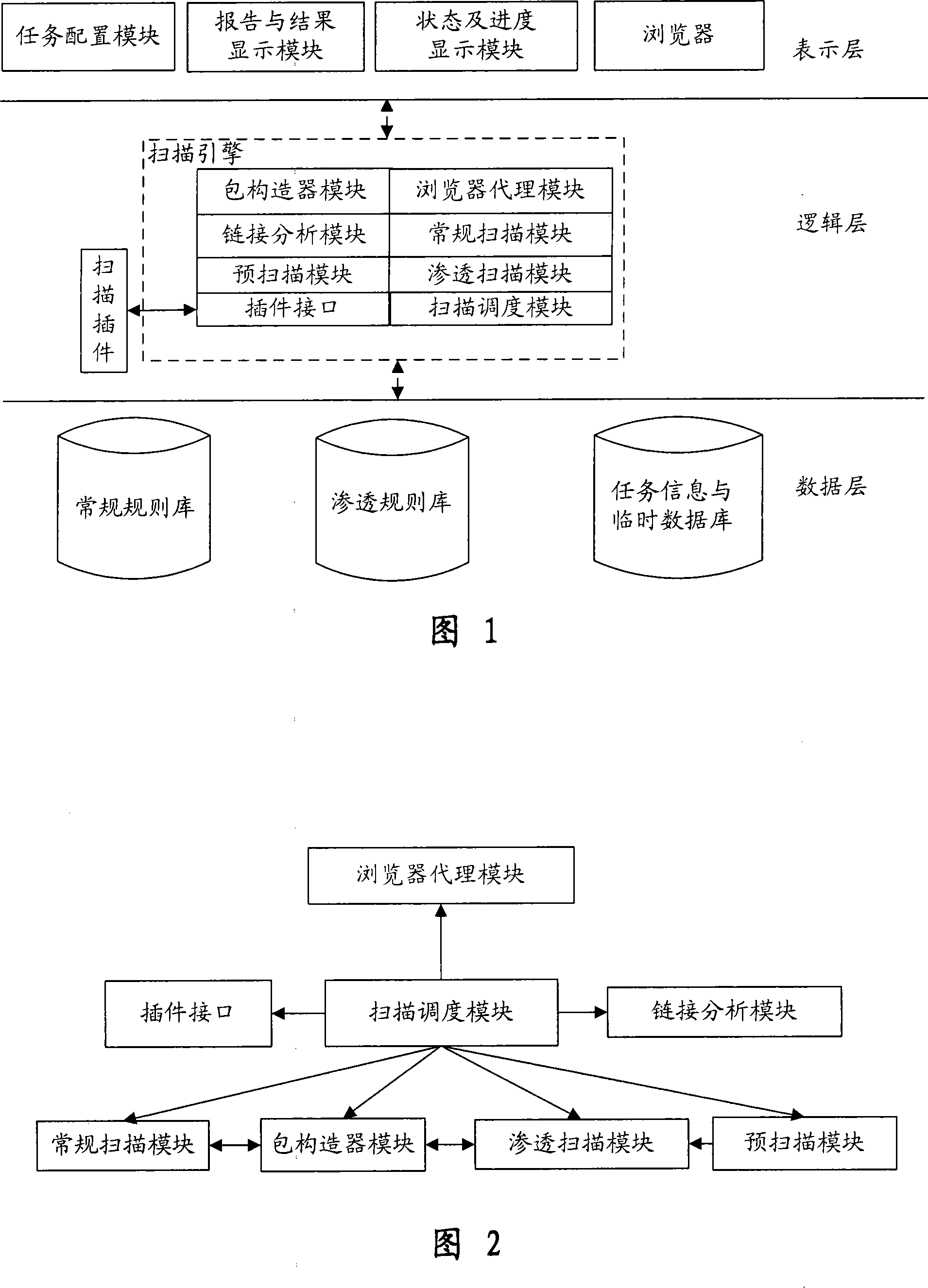

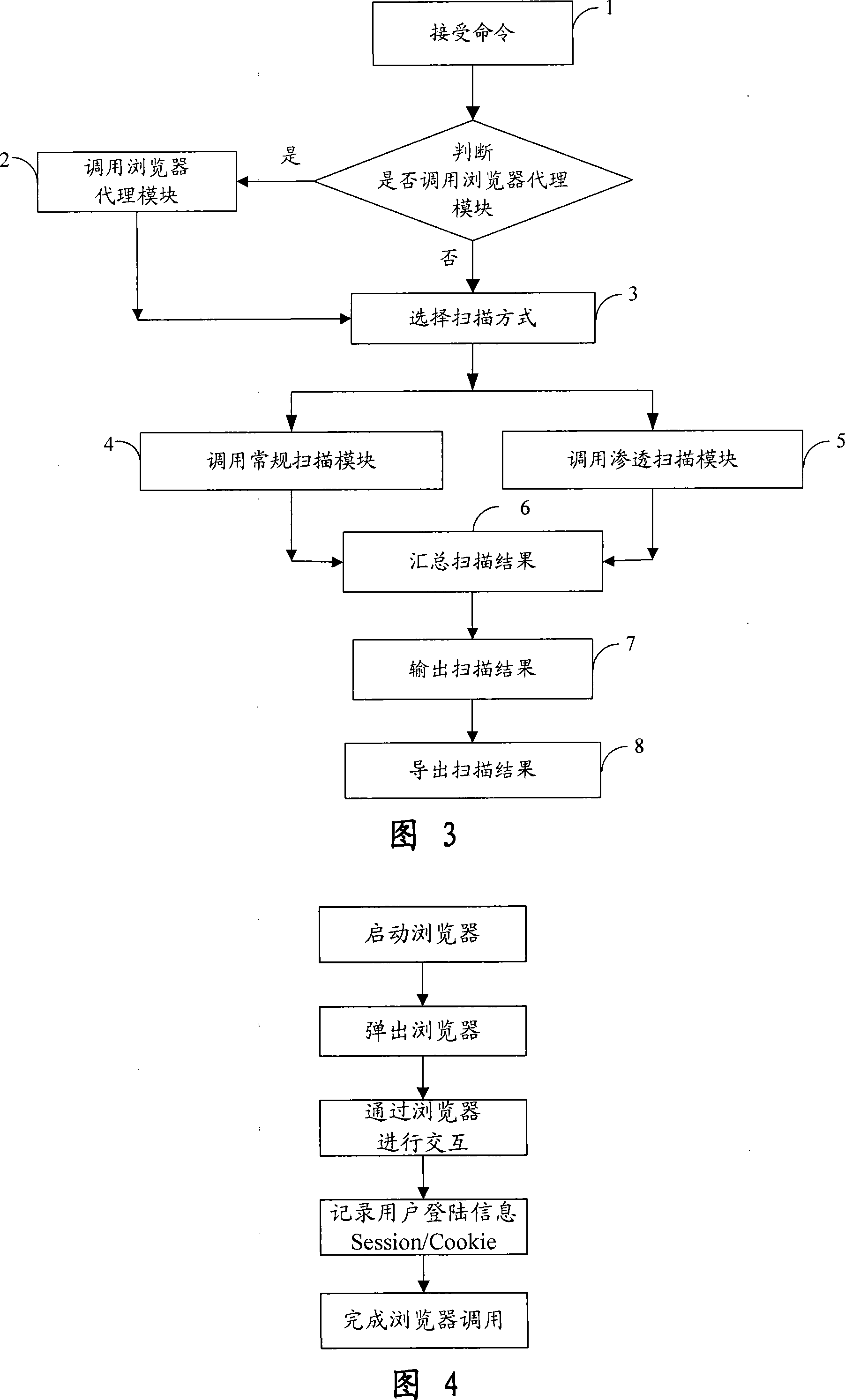

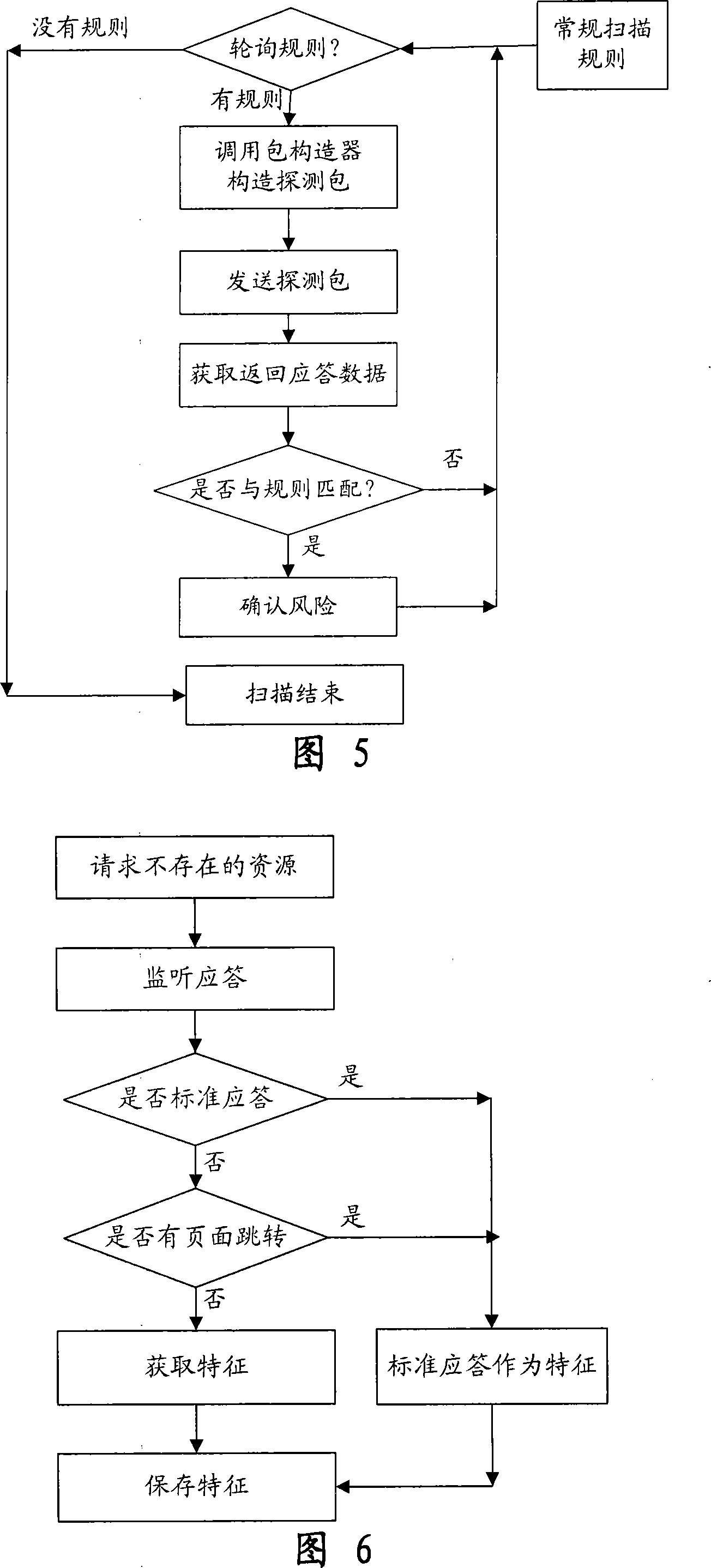

Automatic penetration testing system and method for WEB system

InactiveCN101242279AImprove functional efficiencyImprove work efficiencySpecial data processing applicationsSecuring communicationComputer hardwareSecurity testing

The invention provides an automatic permeability test system for a WEB system, comprising three layers: a GUI presentation layer for alternating interface with a user, a logical layer as runs of control core, executing scanning and confidence program of the system and associative functions, and a data layer for storing and maintaining kinds of scan rules and configuration information in a task execution process. The system can automatically carry out a penetrating scan or a conventional scan to a WEB station based on a WEB scan task in the GUI layer, analyzing the scan result combined with the relative inserters, finds the possible security problems of the WEB station, and then generates a detecting report for reporting a formed aggregate risk list. The invention is used to perform an automatic security test, is capable of replacing the present manual security test and permeability test, greatly reduces the cost of software security test in software develop at present, and also greatly increases accuracy of security test.

Owner:BEIJING UNIV OF POSTS & TELECOMM

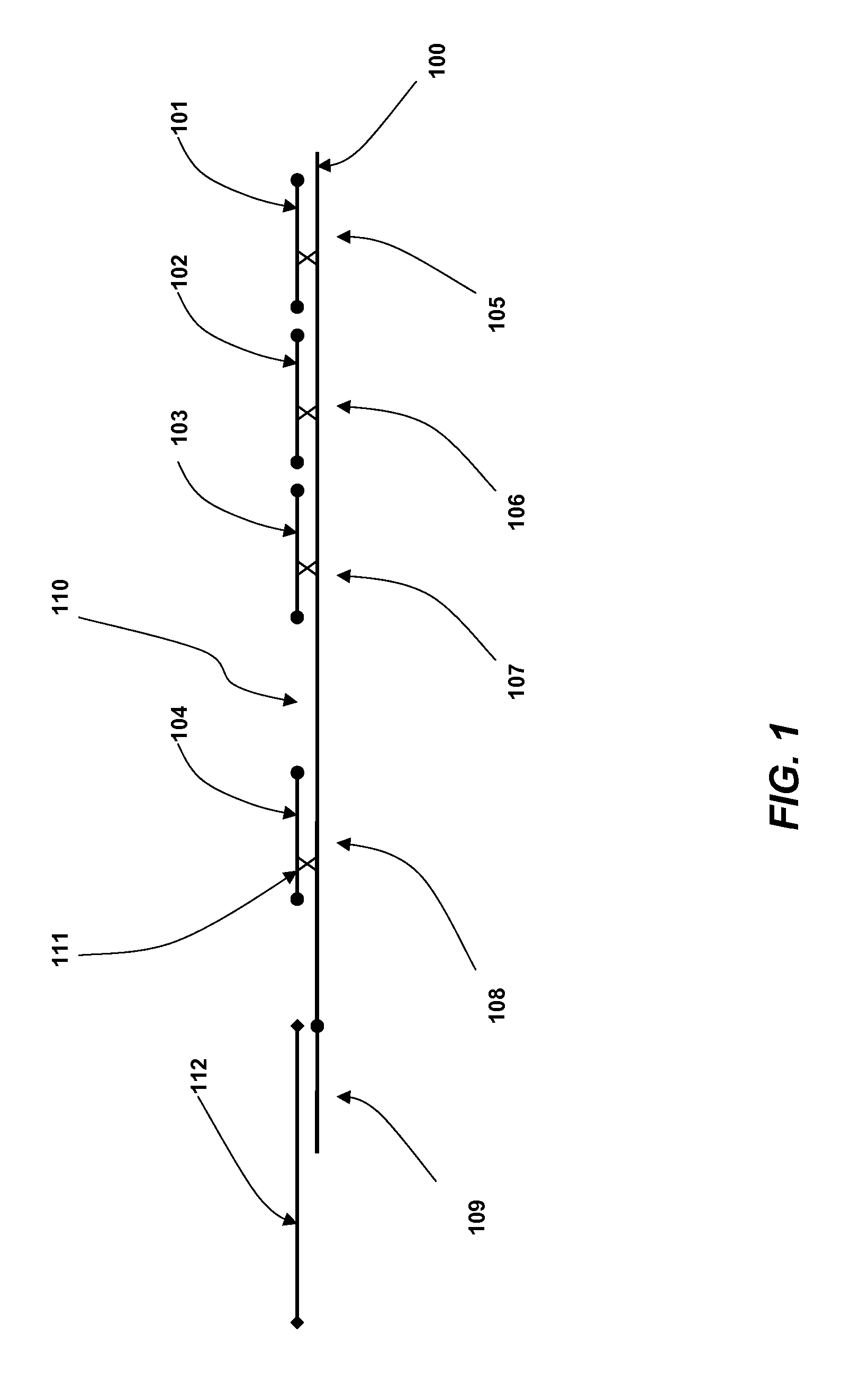

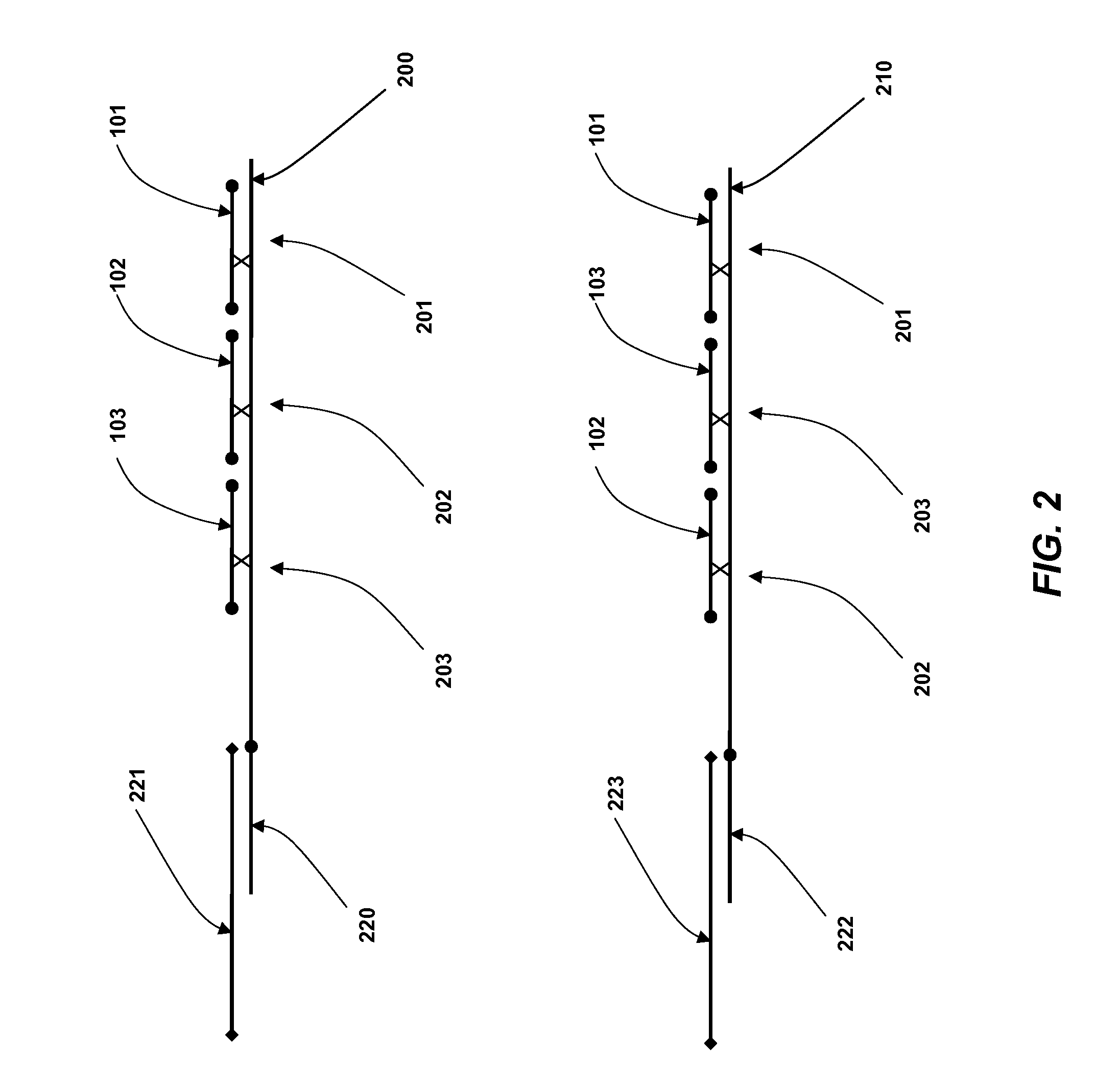

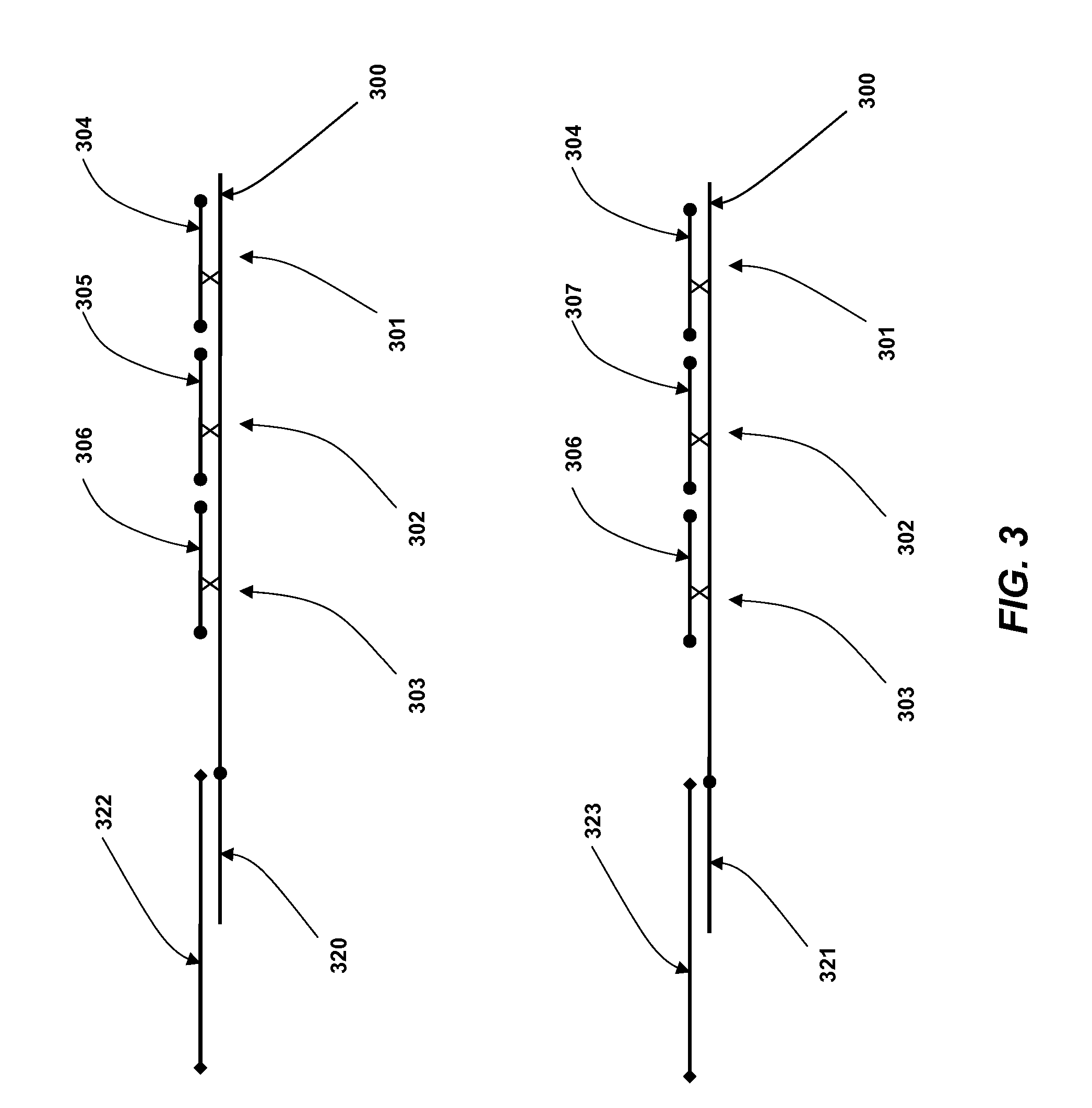

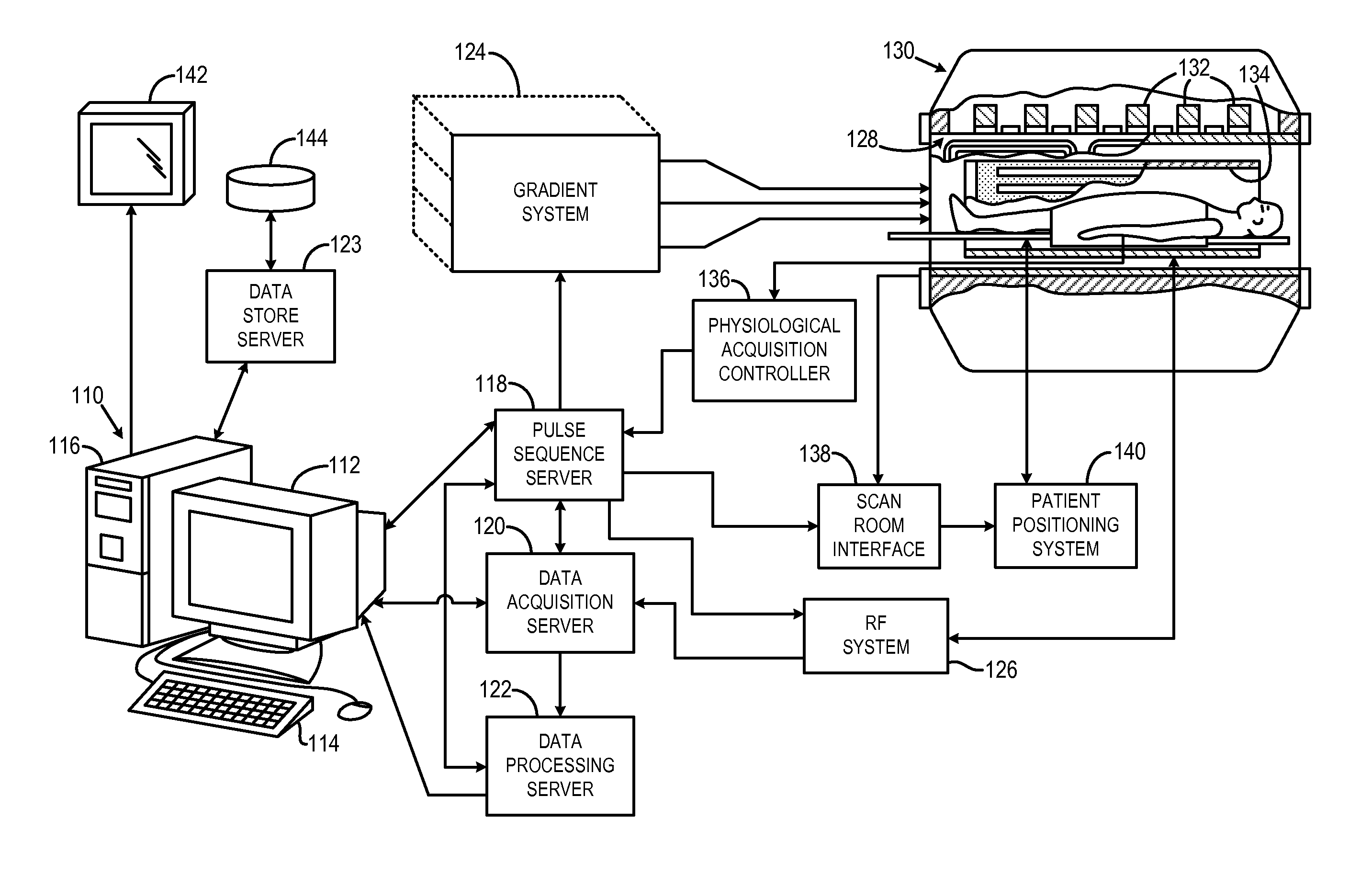

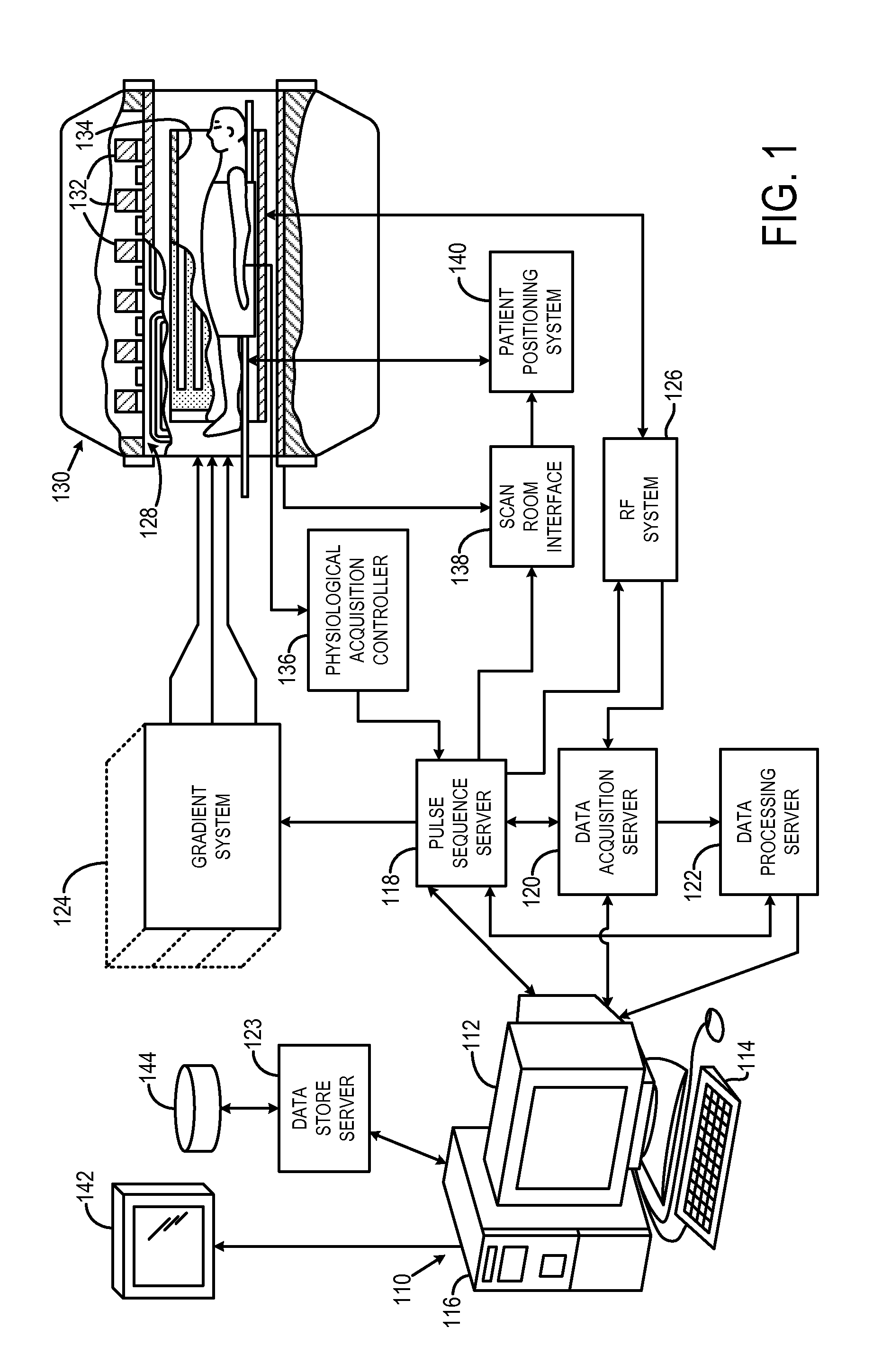

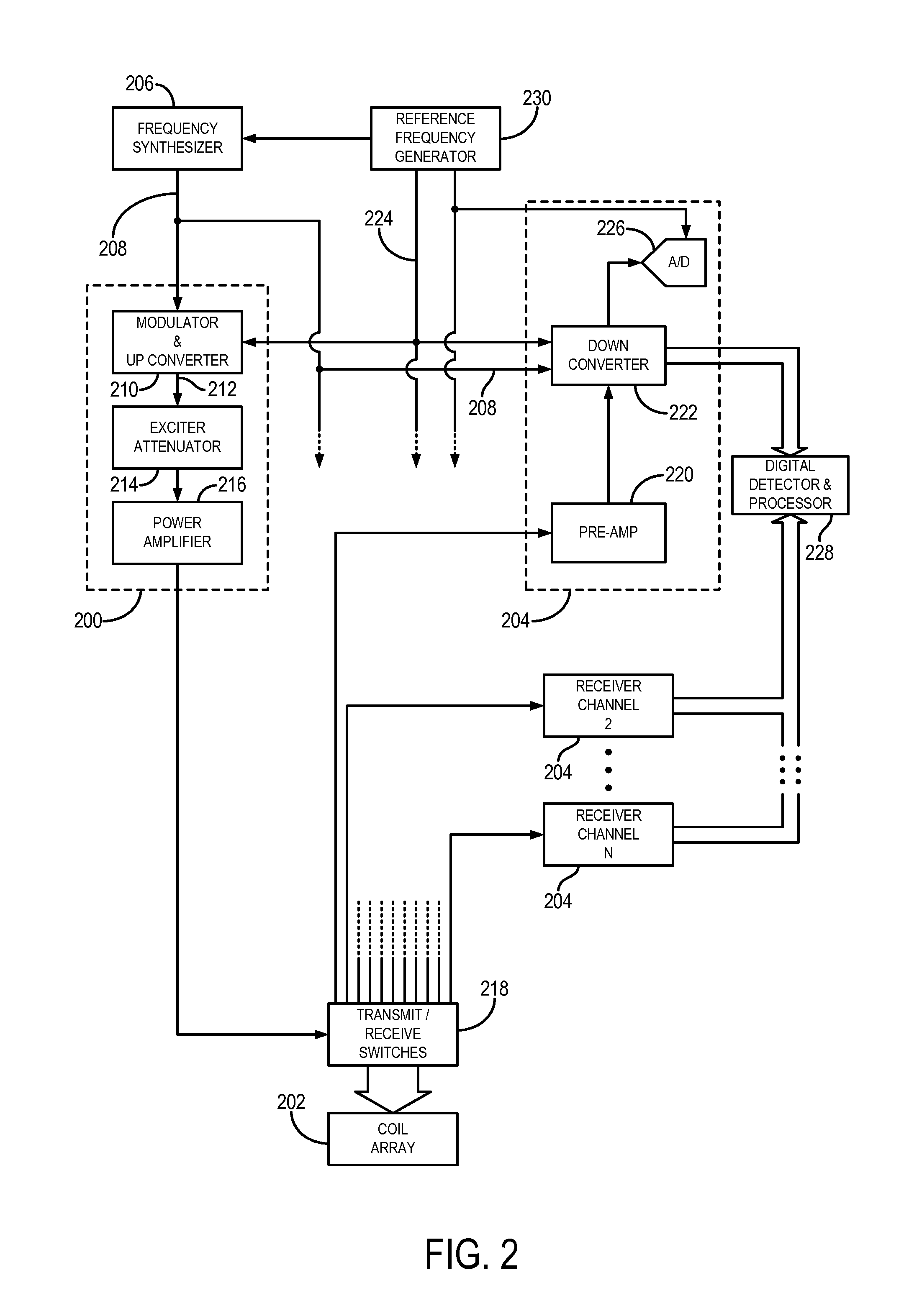

Method for simultaneous multi-slice magnetic resonance imaging

ActiveUS20110254548A1Reliable separationLarge possible separationMeasurements using NMR imaging systemsElectric/magnetic detectionMagnetic gradientMulti slice

A method for multi-slice magnetic resonance imaging, in which image data is acquired simultaneously from multiple slice locations using a radio frequency coil array, is provided. By way of example, a modified EPI pulse sequence is provided, and includes a series of magnetic gradient field “blips” that are applied along a slice-encoding direction contemporaneously with phase-encoding blips common to EPI sequences. The slice-encoding blips are designed such that phase accruals along the phase-encoding direction are substantially mitigated, while providing that signal information for each sequentially adjacent slice location is cumulatively shifted by a percentage of the imaging FOV. This percentage FOV shift in the image domain provides for more reliable separation of the aliased signal information using parallel image reconstruction methods such as SENSE. In addition, the mitigation of phase accruals in the phase-encoding direction provides for the substantial suppression of pixel tilt and blurring in the reconstructed images.

Owner:THE GENERAL HOSPITAL CORP

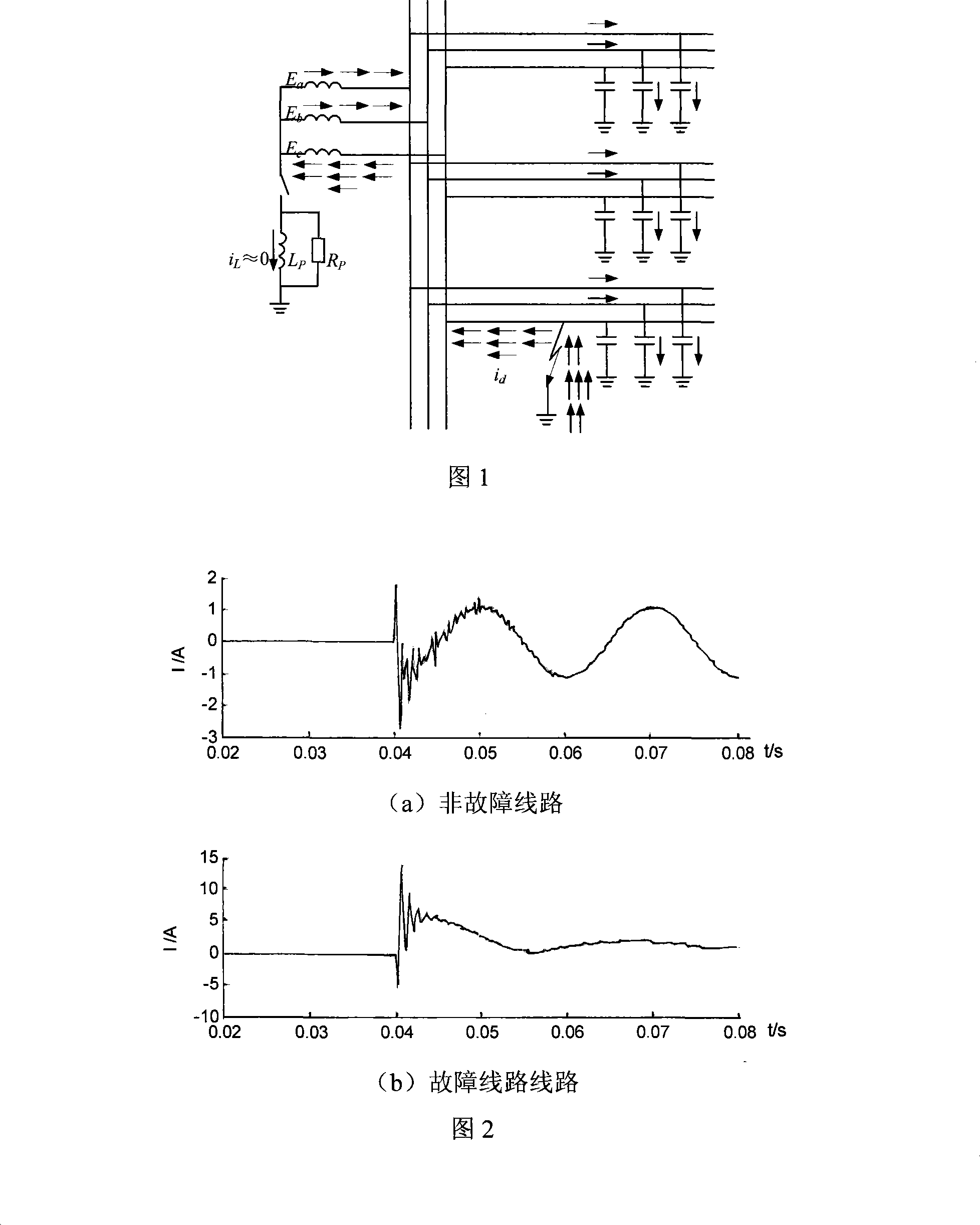

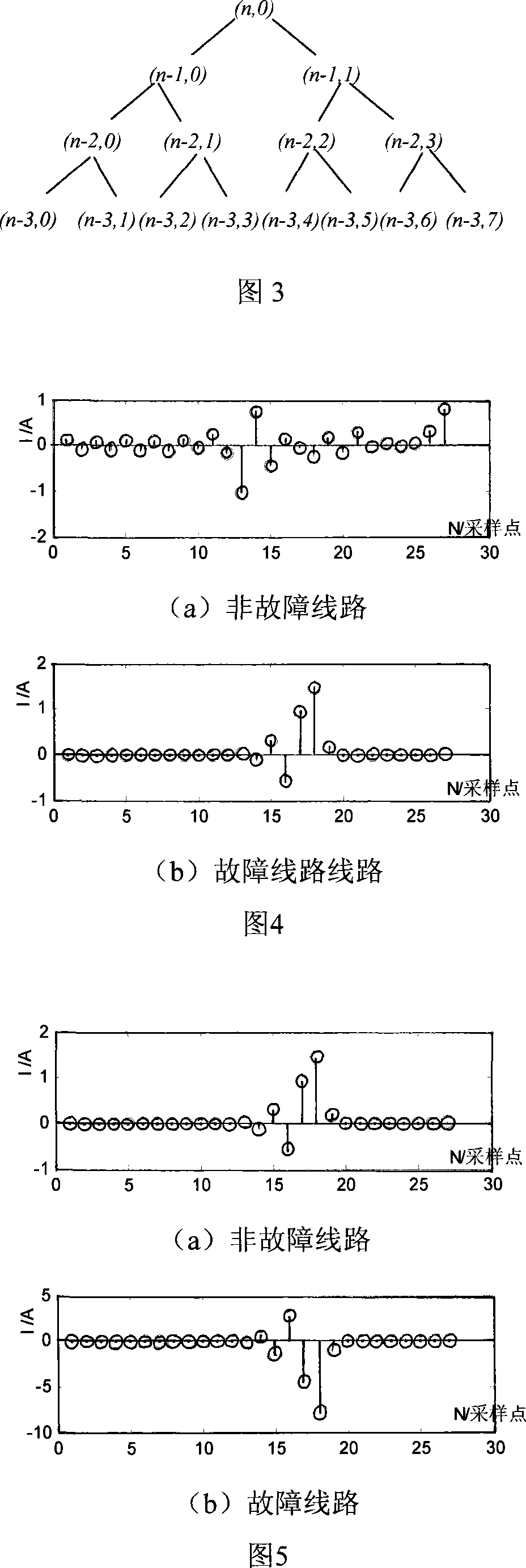

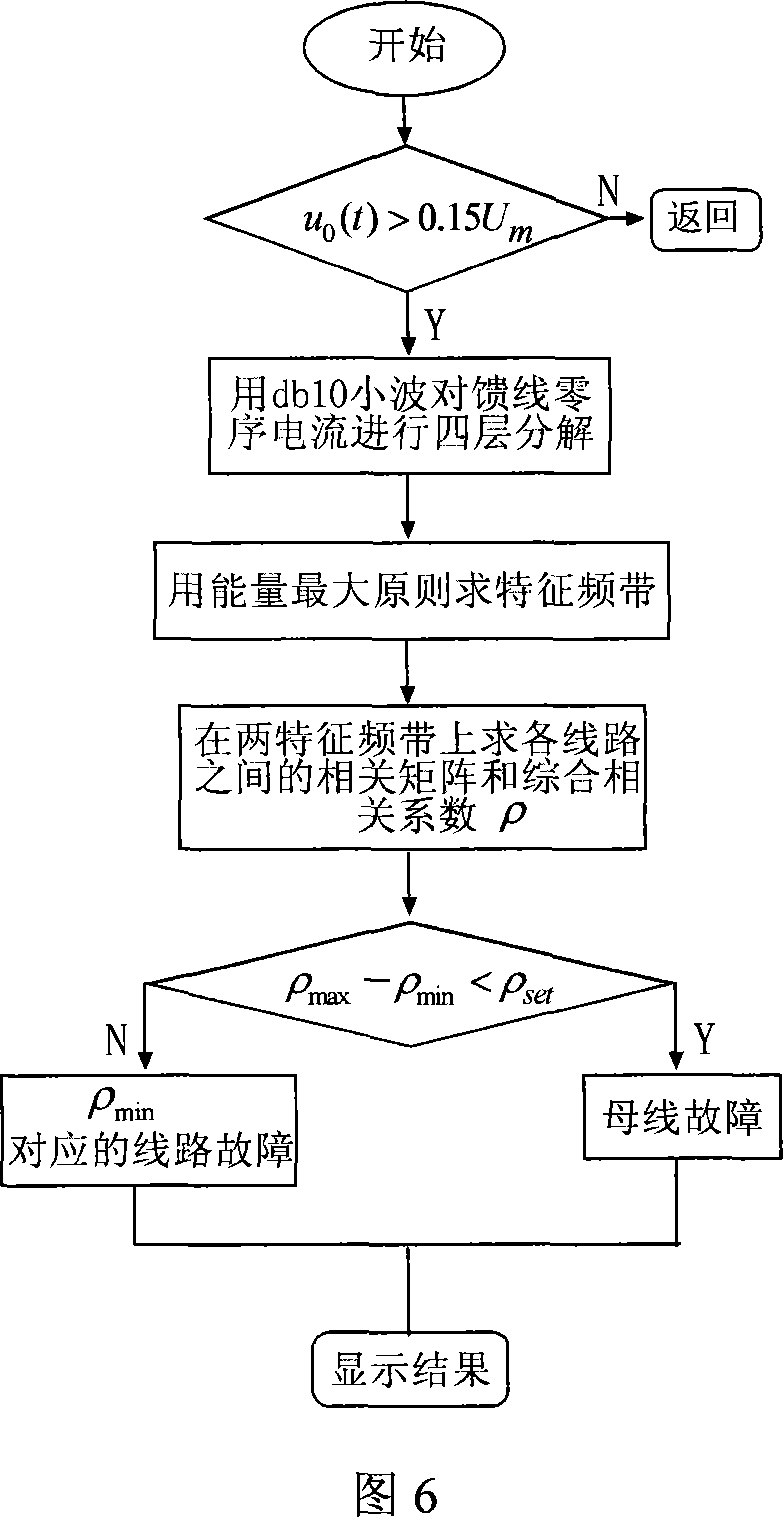

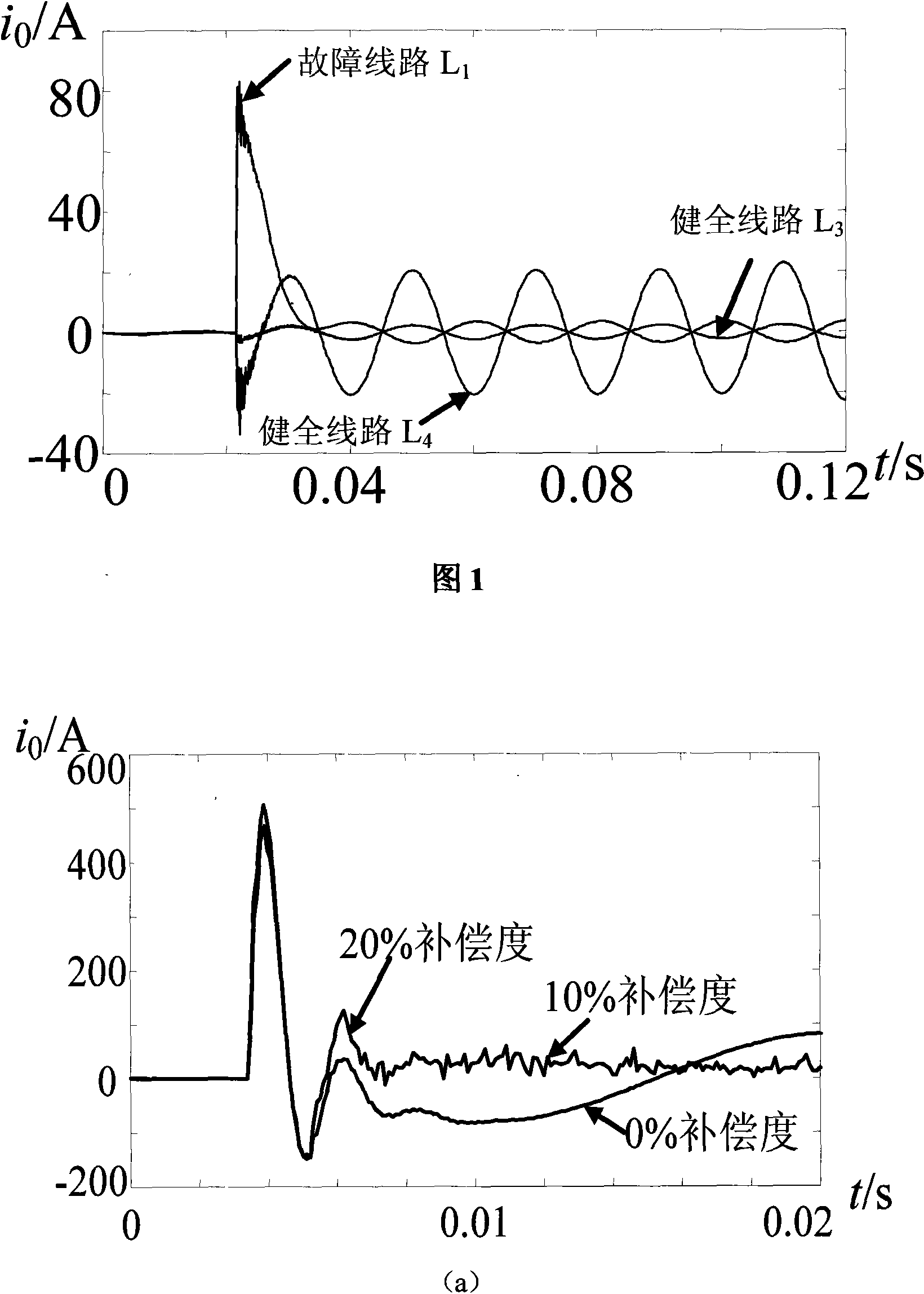

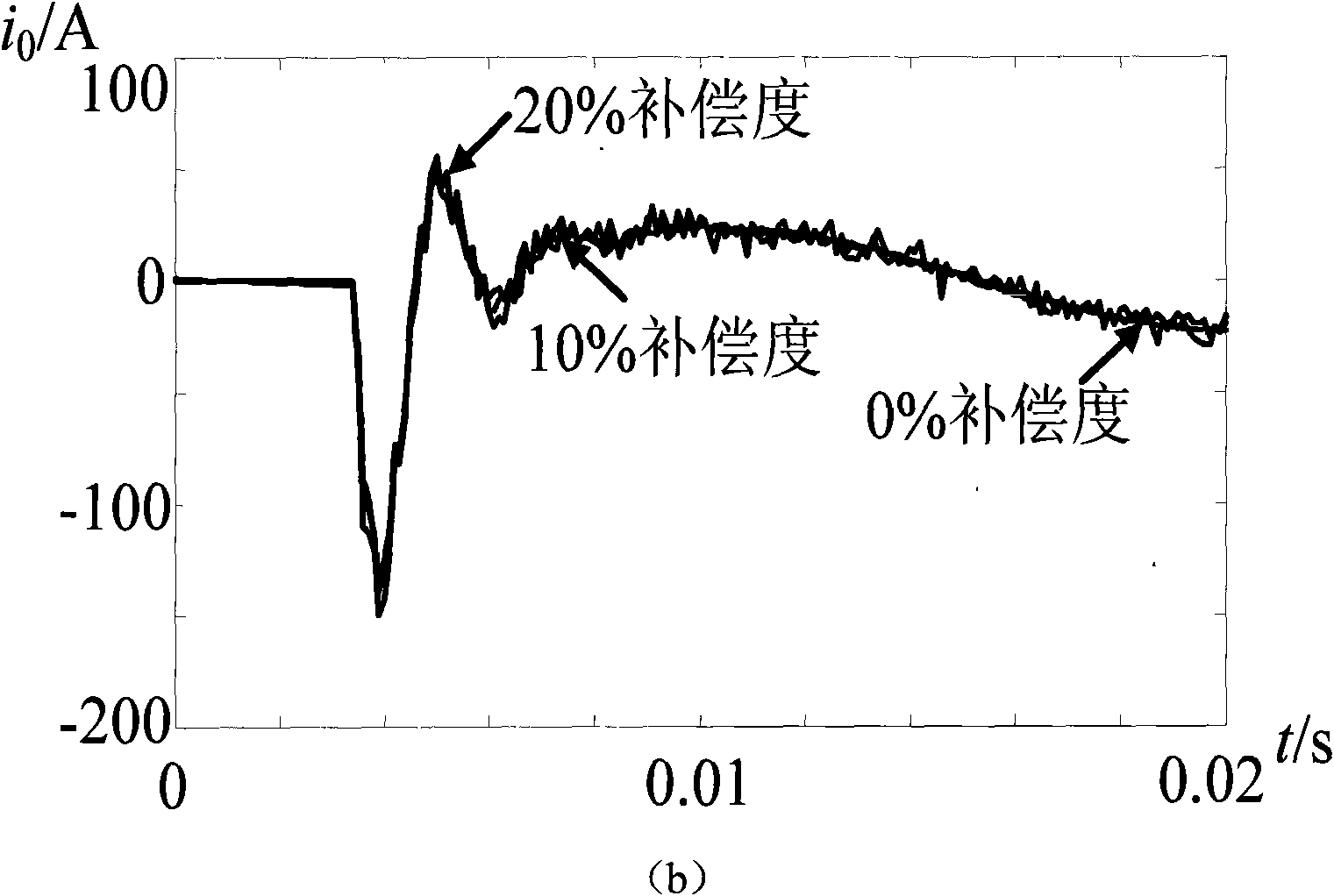

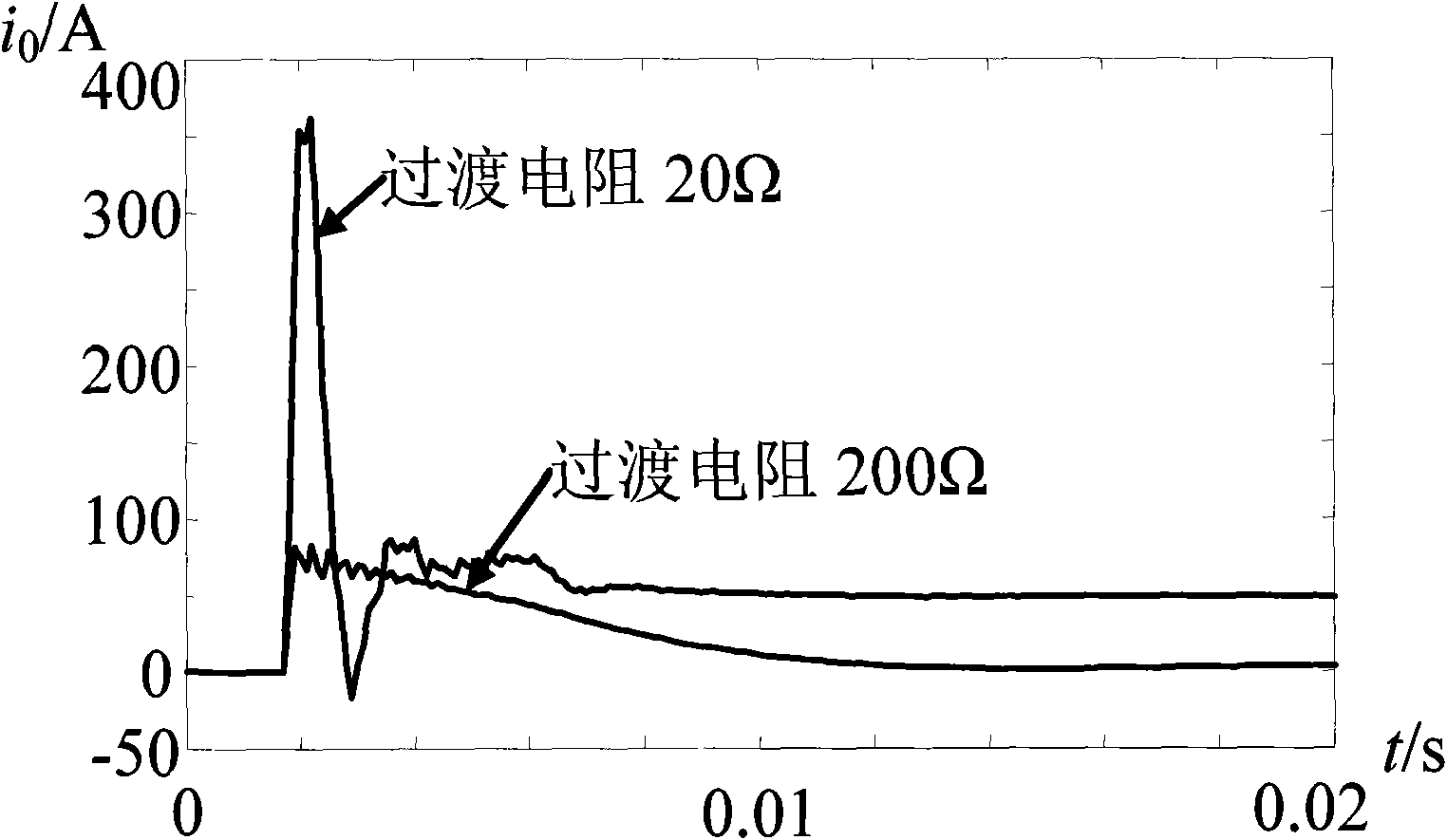

Low current neutral grounding system fault route selecting method by wavelet package decompose and correlation analysis

InactiveCN101162838ARealize correct line selectionStrong anti-arc grounding abilityEmergency protective circuit arrangementsFault locationElectric power systemDecomposition

The present invention relates to a small current grounding system fault line selecting method by wavelet package decomposition and relevant analysis, belonging to the power system relay protection technical field. The method comprises: starting the fault line selecting device and recording wave to acquire transient zero-order current on each of the feeder lines when bus zero-order voltage transient value exceeds limit; calculating energy on each of frequency bands of the transient zero-order current after wavelet package decomposition, summing the energy of transient zero-order current on all the lines according to frequency bands and selecting the frequency bands with the maximum and secondary value of energy and values as the characteristic frequency bands, applying relevant analysis method to line transient zero-order current on the selected characteristic frequency bands in order; and finally determining fault point integrating the relevant analysis results of two frequency bands. The method uses wavelet package decomposition and relevant analysis, thereby effectively using information (amplitude and phase) contained in fault transient process and reflecting differences between fault line and non-fault line to maximum degree. Principle analysis and simulations demonstrate that the method has precise and reliable line selection.

Owner:KUNMING UNIV OF SCI & TECH

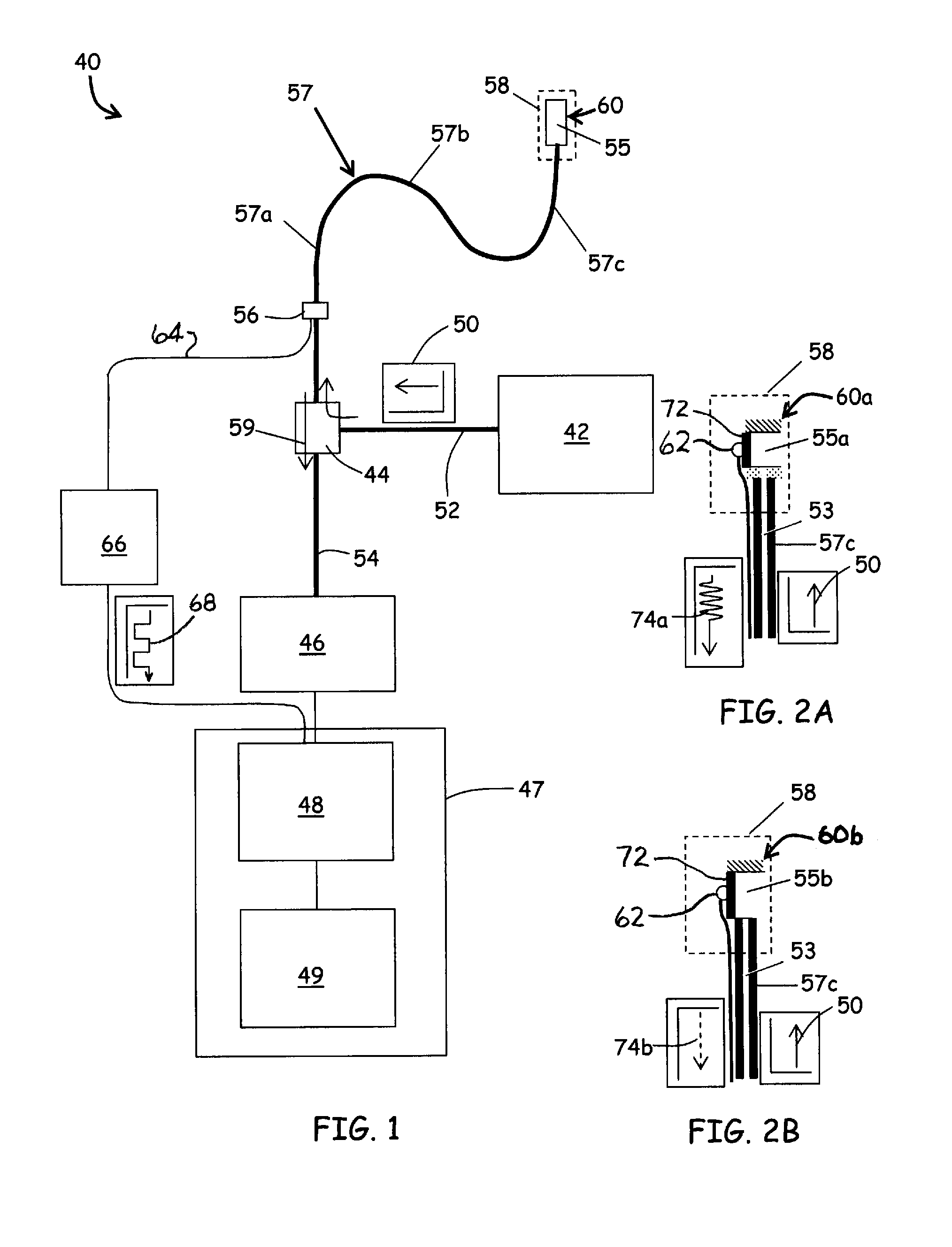

Method and device for transponder aided wake-up of a low power radio device by a wake-up event

ActiveUS7072697B2Reduce in quantityIncreased sensitivityEnergy efficient ICTPower managementRadio equipmentEngineering

A method, software tool, computer program product and low power radio device are provided for transponder aided wake-up and connection set-up by detecting a wake up event in a sleep mode of the low power radio device, putting the radio device into an operative state, transmitting at least one advert message by radio transmission, wherein the low power radio devices put into a passive mode for a predetermined period of time in case no answer is received in response to the at least one transmitted advert message.

Owner:NOKIA TECHNOLOGLES OY

Catalyst for olefine polymerizing reaction and its components

The present invention provides one kind catalyst component for CH2=CHR olifine polymerization, where R is H or alkyl radical or aryl radical of C1-C6. The catalyst component contains Mg, Ti, halogen and electron donor.

Owner:CHINA PETROLEUM & CHEM CORP +1

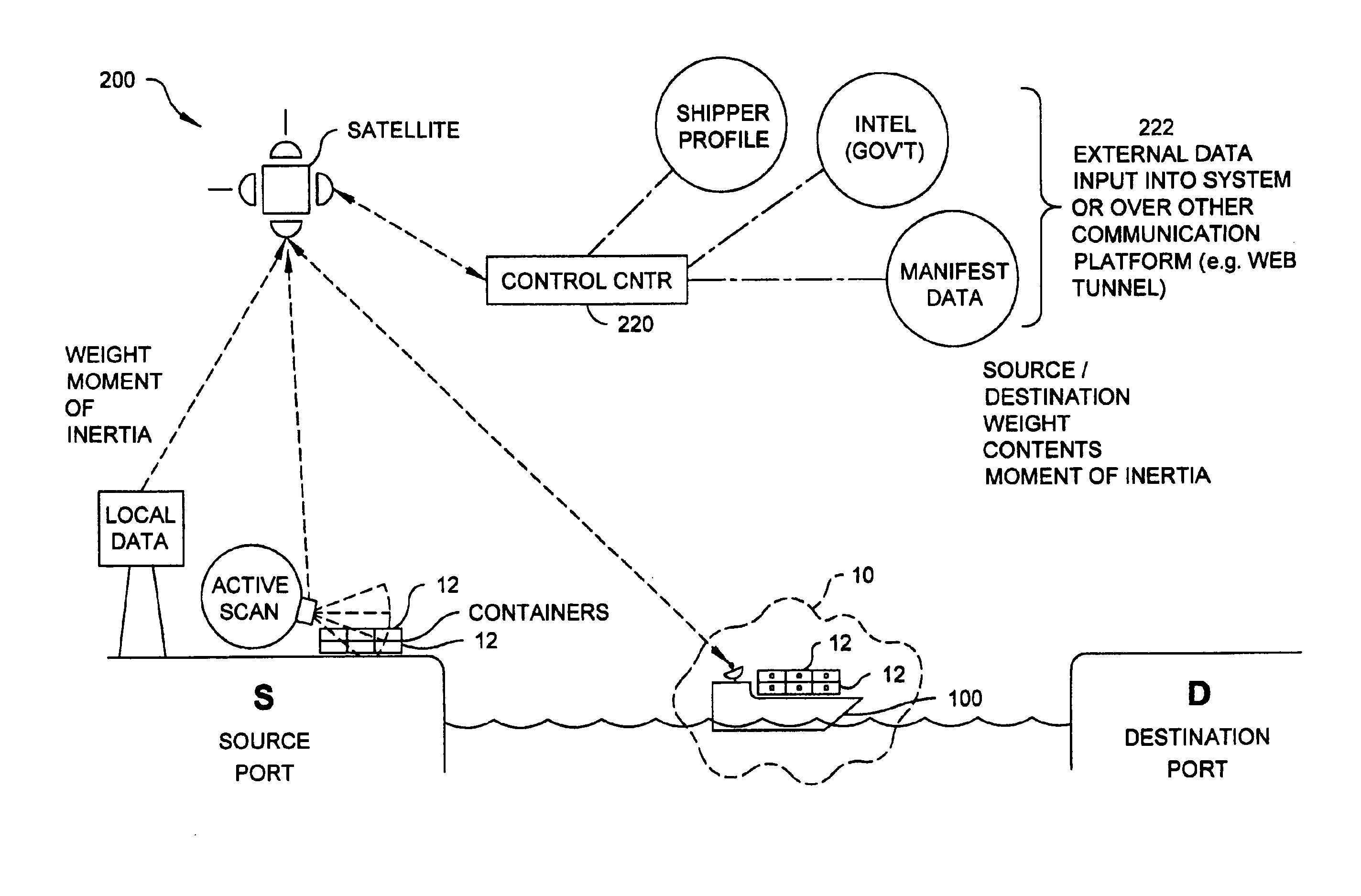

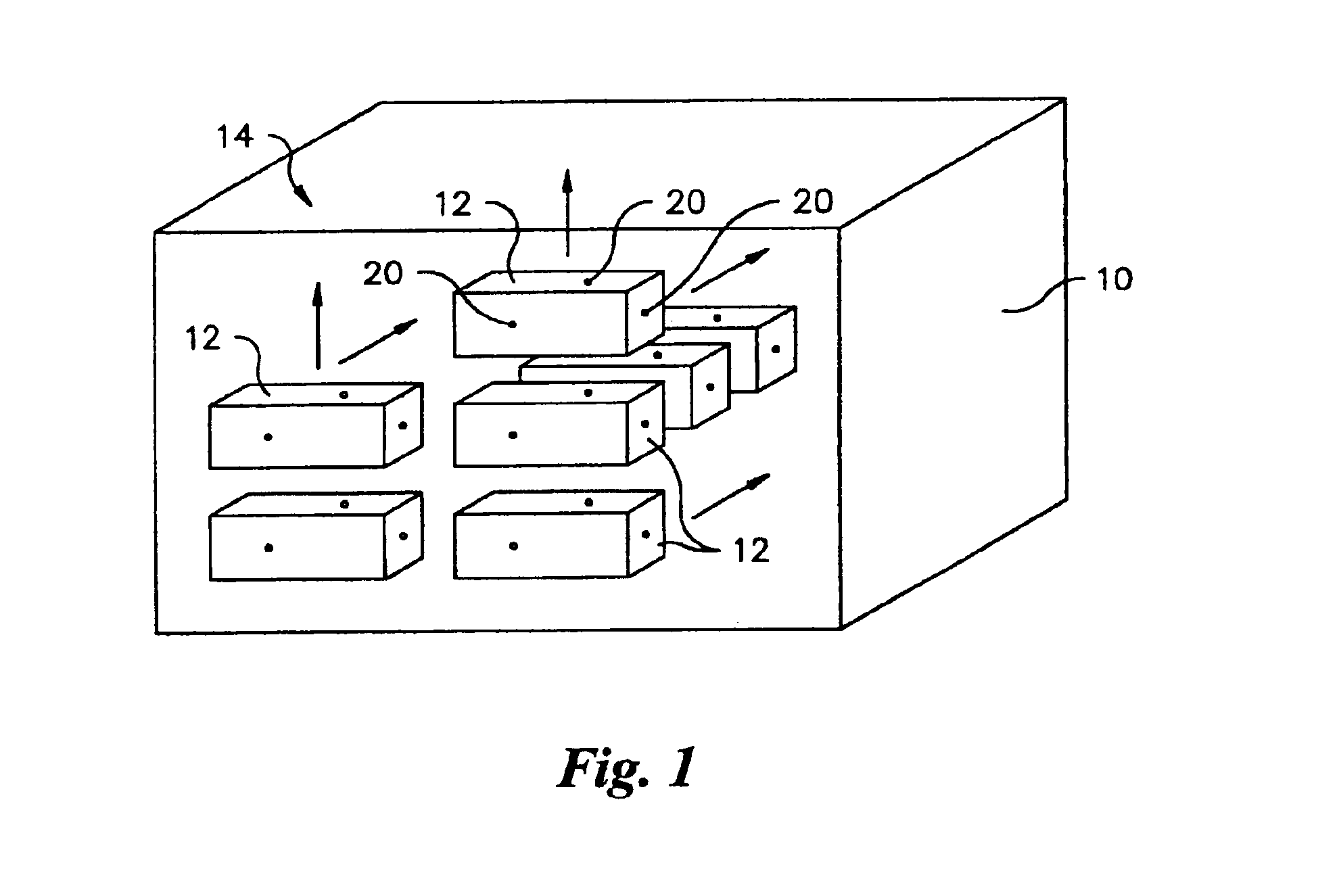

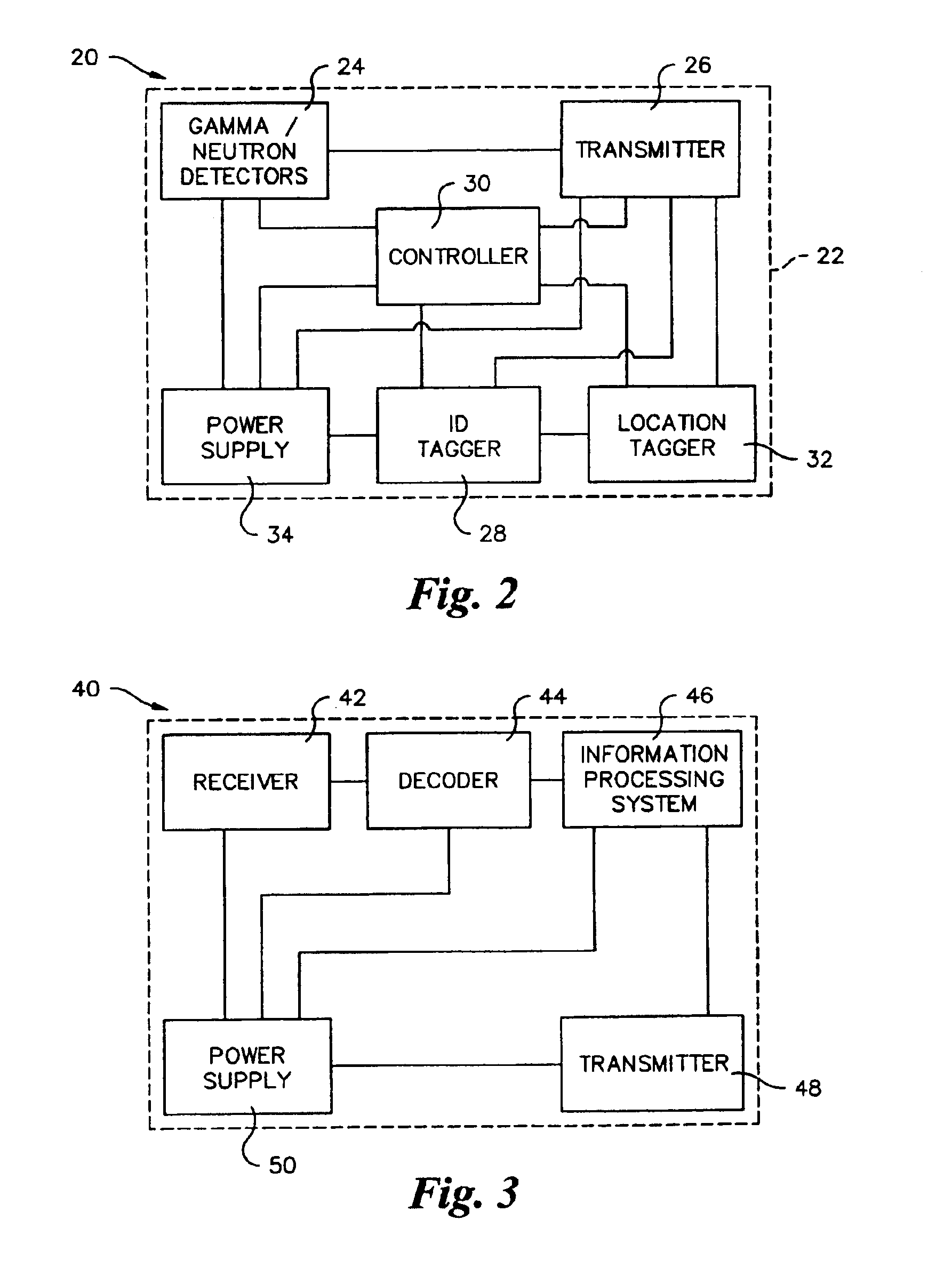

Apparatus and method for asynchronously analyzing data to detect radioactive material

InactiveUS6965314B2High sensitivityEasy to identifyElectric testing/monitoringRadio/inductive link selection arrangementsTransceiverRadioactive agent

A radioactive material detection system includes a cargo container monitoring system and a control center. The cargo container monitoring system has a radiation sensor configured to detect radiation over a predetermined or commanded period of time and a transceiver configured to send the information received from the radiation sensor. The control center is in communication with the transceiver of the cargo container monitoring system. The control center is configured to receive data from at least one additional source other than the cargo container monitoring system and to asynchronously analyze the data from the at least one additional source and the information from the radiation sensor, during transit, so as to detect radioactive material in a cargo container.

Owner:QUINTELL OF OHIO

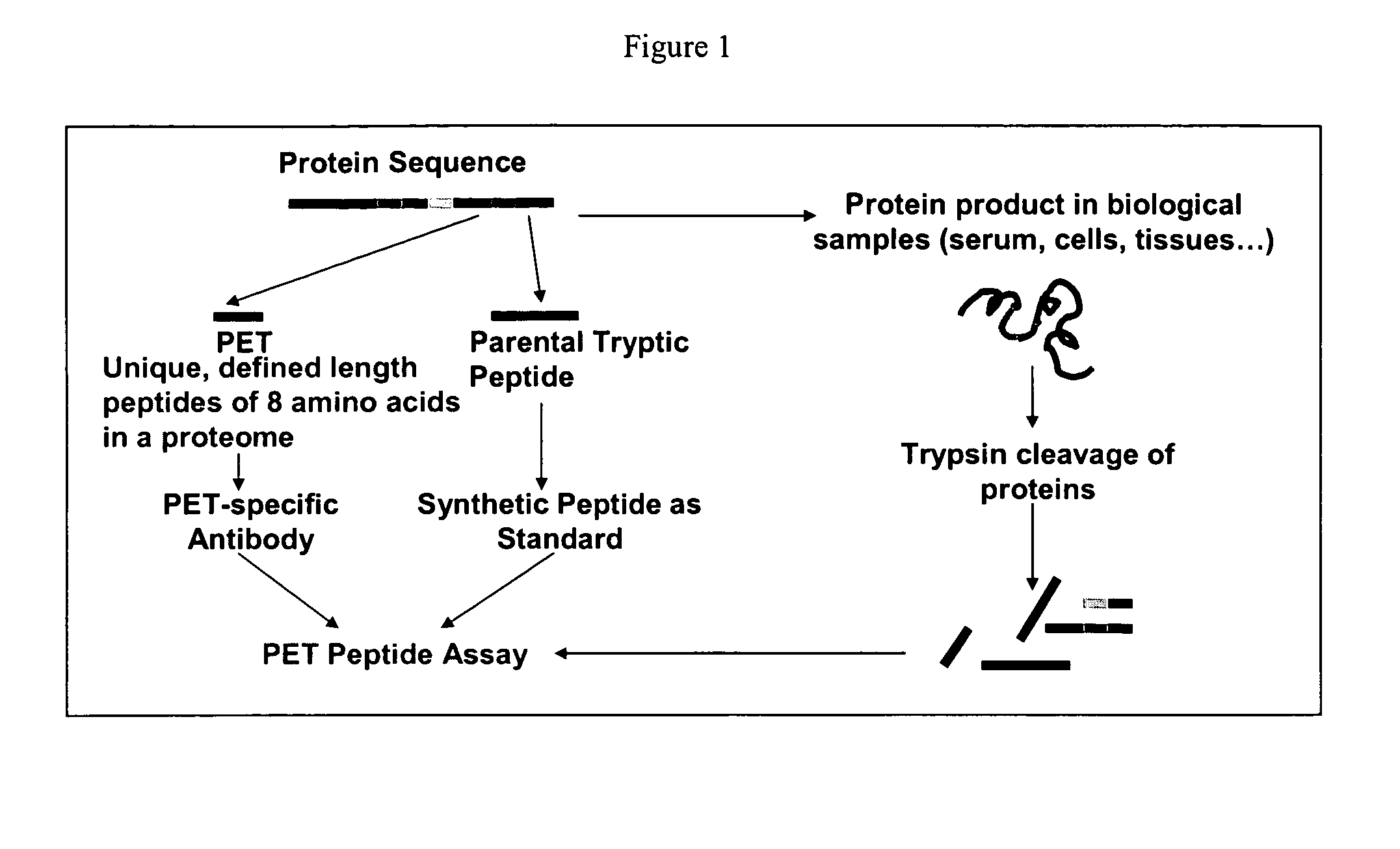

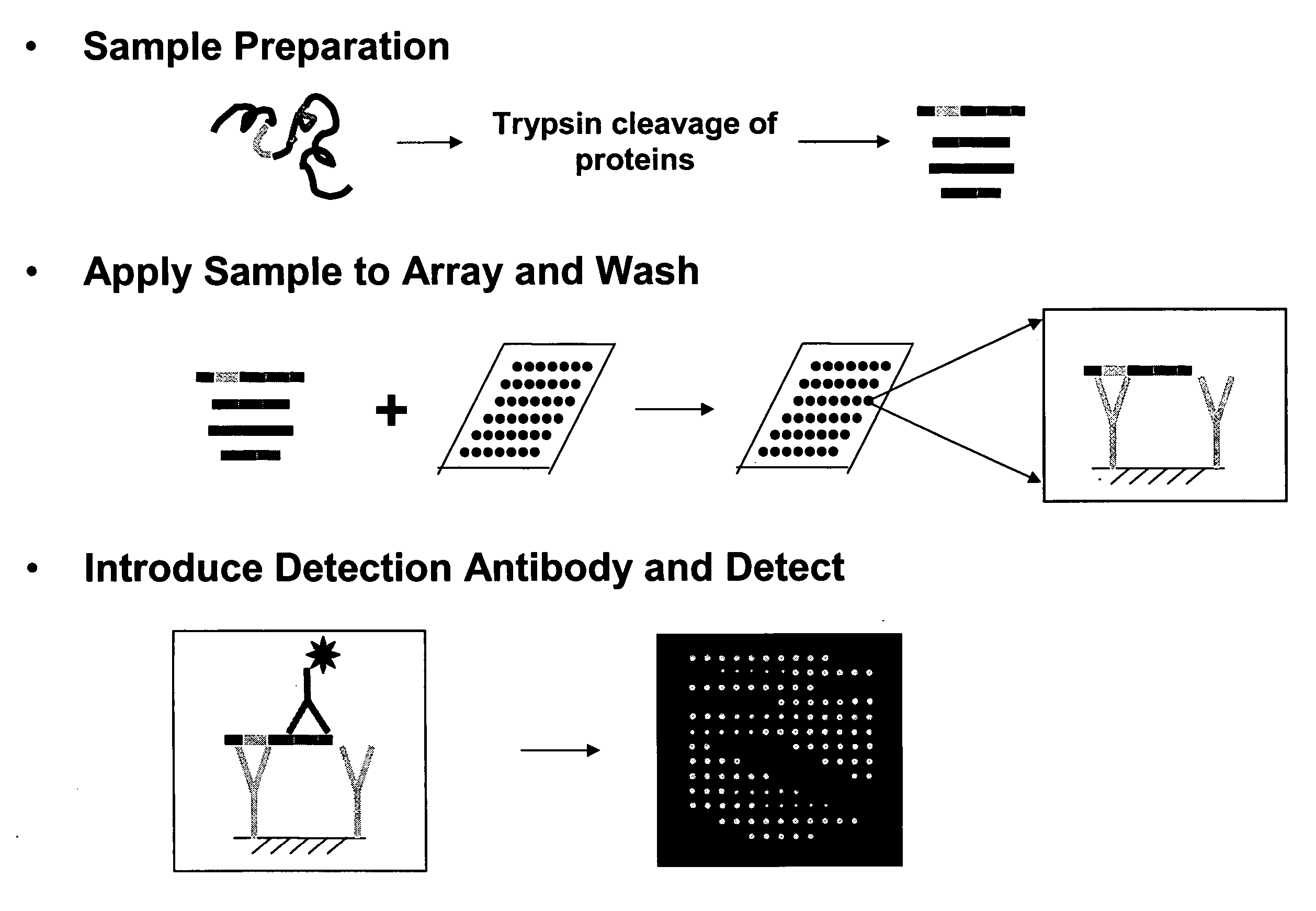

Proteome epitope tags and methods of use thereof in protein modification analysis

InactiveUS20060014212A1High clinical application valueReliable detectionLibrary screeningNanoinformaticsEpitopePost translational

Disclosed are reagents and methods for reliably detecting the presence and measuring the amount of proteins, including proteins with various post-translational modifications (phosphorylation, glycosylation, methylation, acetylation, etc.) in a sample by the use of one or more capture agents that recognize and interact with recognition sequences uniquely characteristic of a protein or a set of proteins (Proteome Epitope Tags, or PETs) in the sample. Arrays comprising these capture agents or PETs are also provided.

Owner:EPITOME BIOSYST

Bulk metallic glass medical instruments, implants, and methods of using same

InactiveUS20020162605A1Good mri signatureHigh susceptibilityIncision instrumentsSurgical needlesMri guidedMetal

MRI-compatible medical instruments and appliances are made using bulk metallic glass alloys. MRI-guided methods include the use of articles that include bulk metallic glass alloys.

Owner:UT BATTELLE LLC

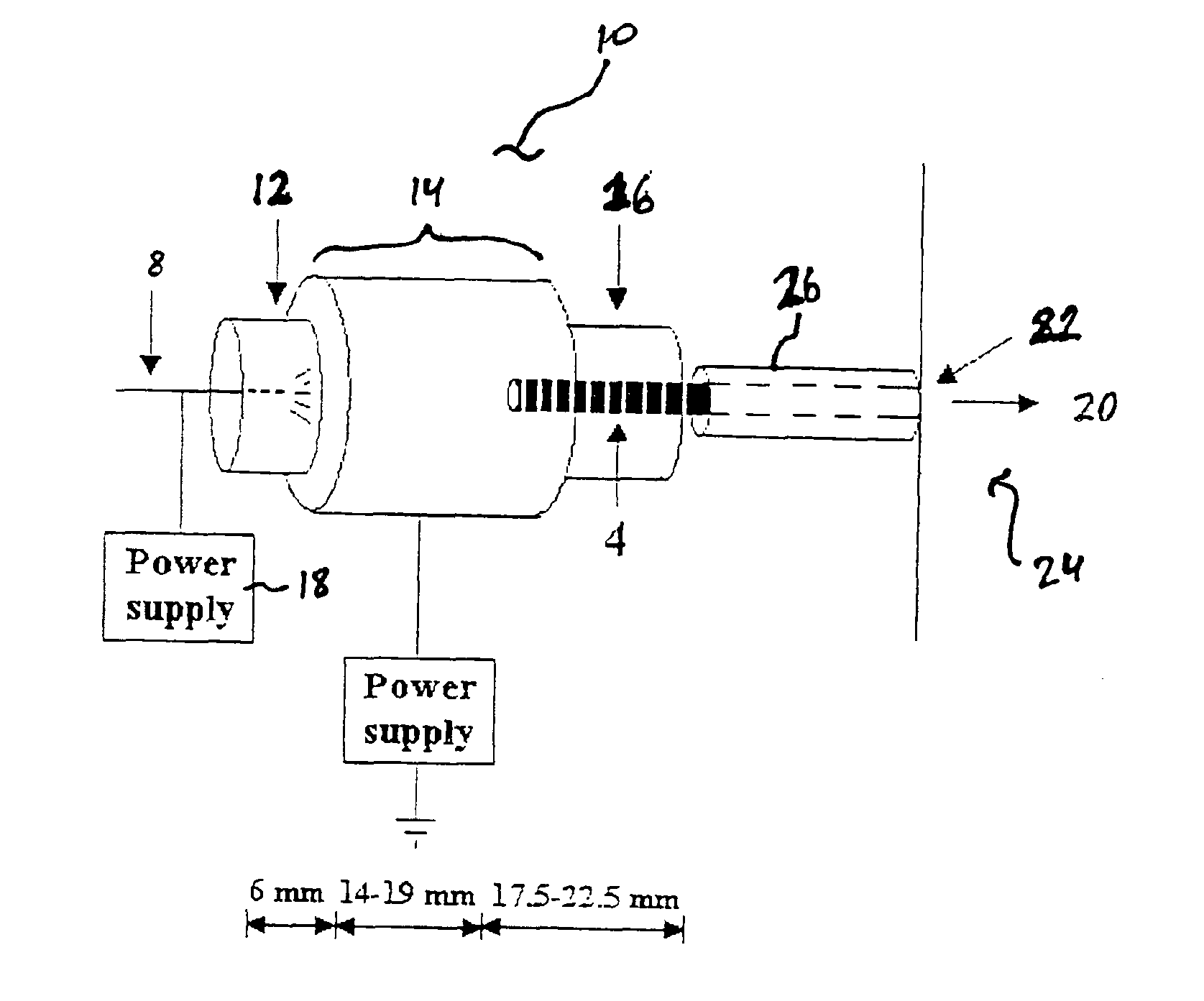

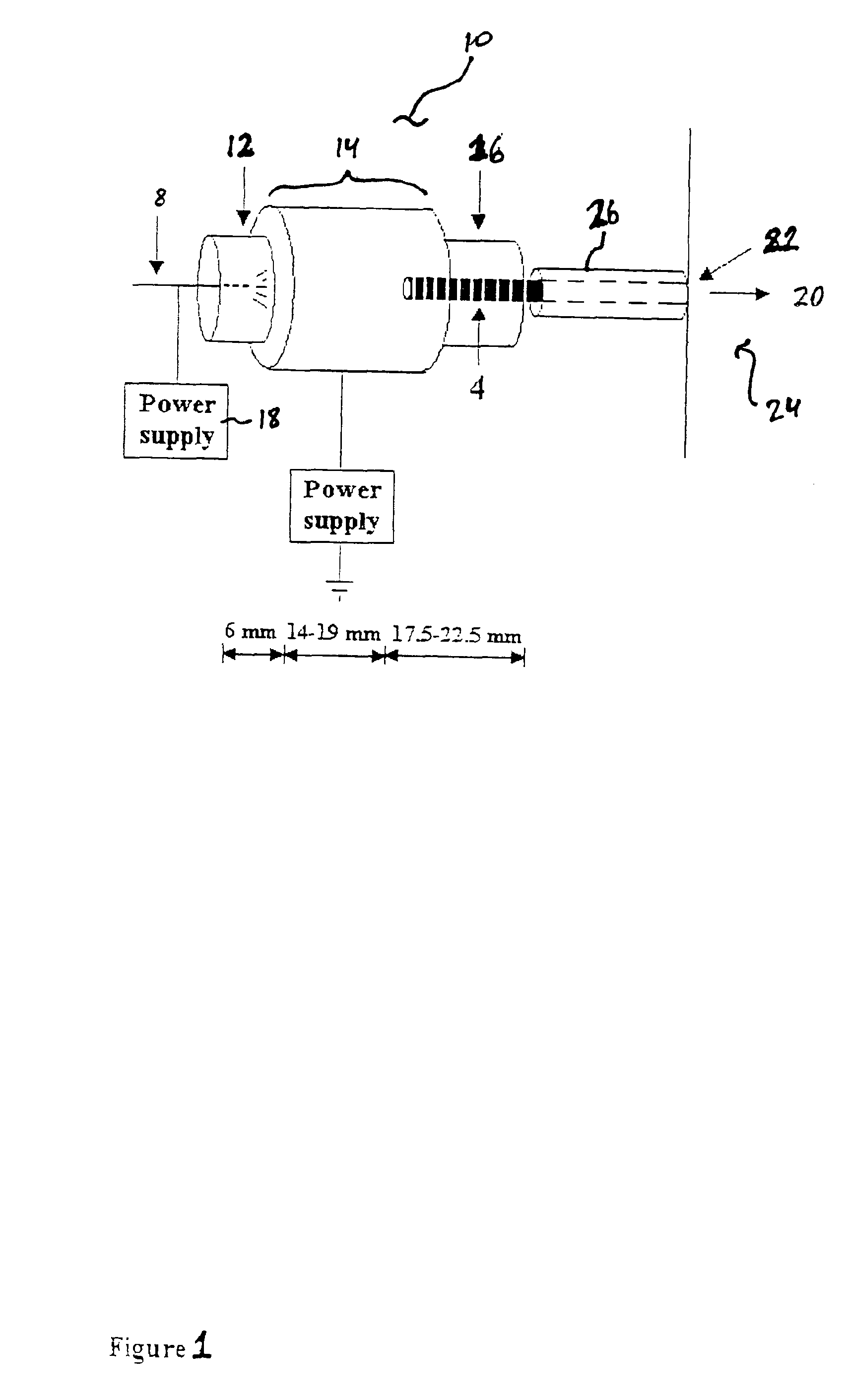

Method and apparatus for aerodynamic ion focusing

InactiveUS6992299B2High sensitivityIncrease the number ofThermometer detailsStability-of-path spectrometersDesolvationHigh velocity

A method and apparatus for focusing ions for delivery to an ion detection device using an aerodynamic ion focusing system that uses a high-velocity converging gas flow at an entrance aperture to focus an ion plume by reducing spreading and increasing desolvation of ions, and wherein a voltage is applied to at least a portion of the aerodynamic ion focusing system to assist in the focusing and delivery of ions to the ion detection device.

Owner:BRIGHAM YOUNG UNIV

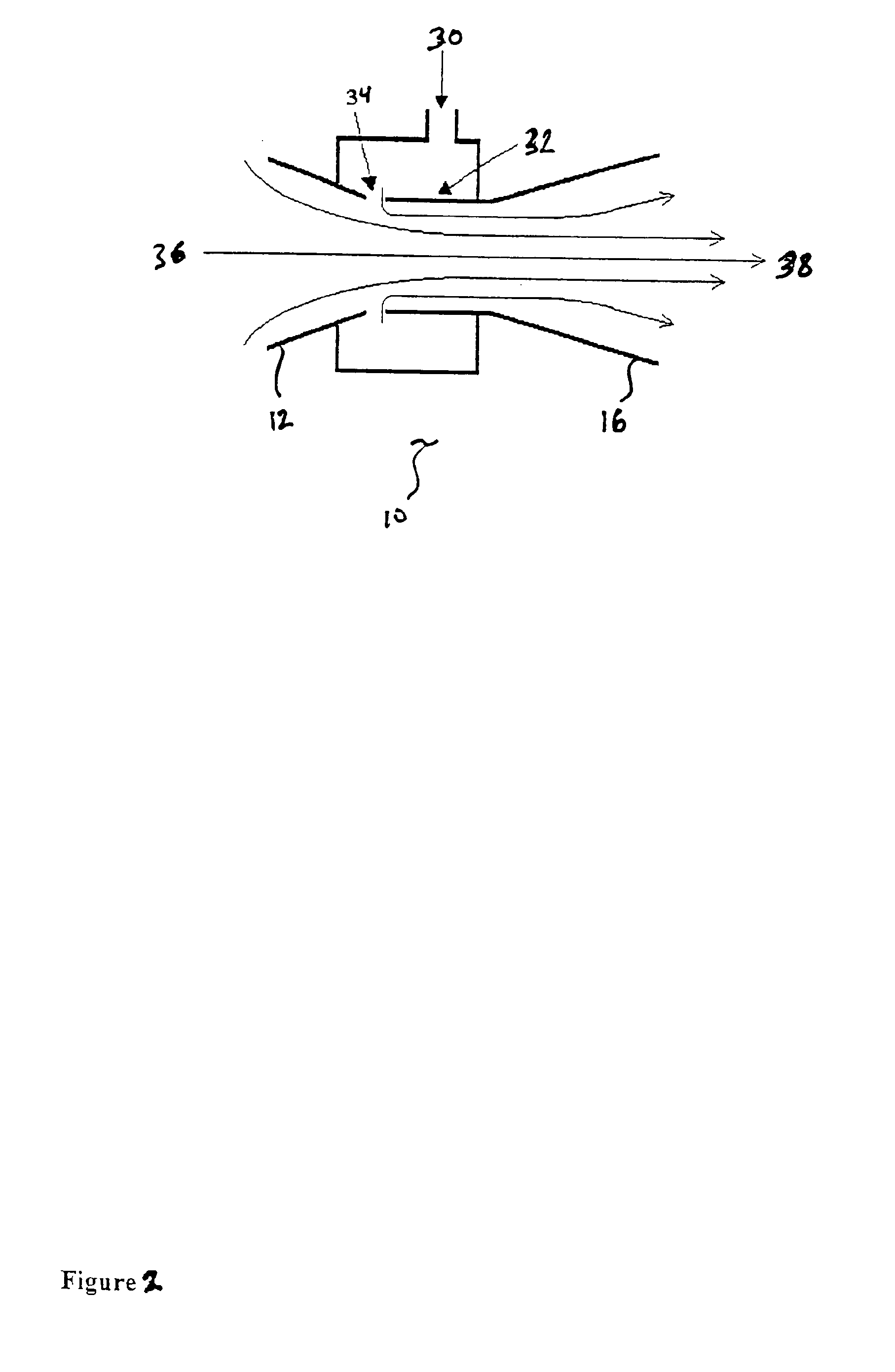

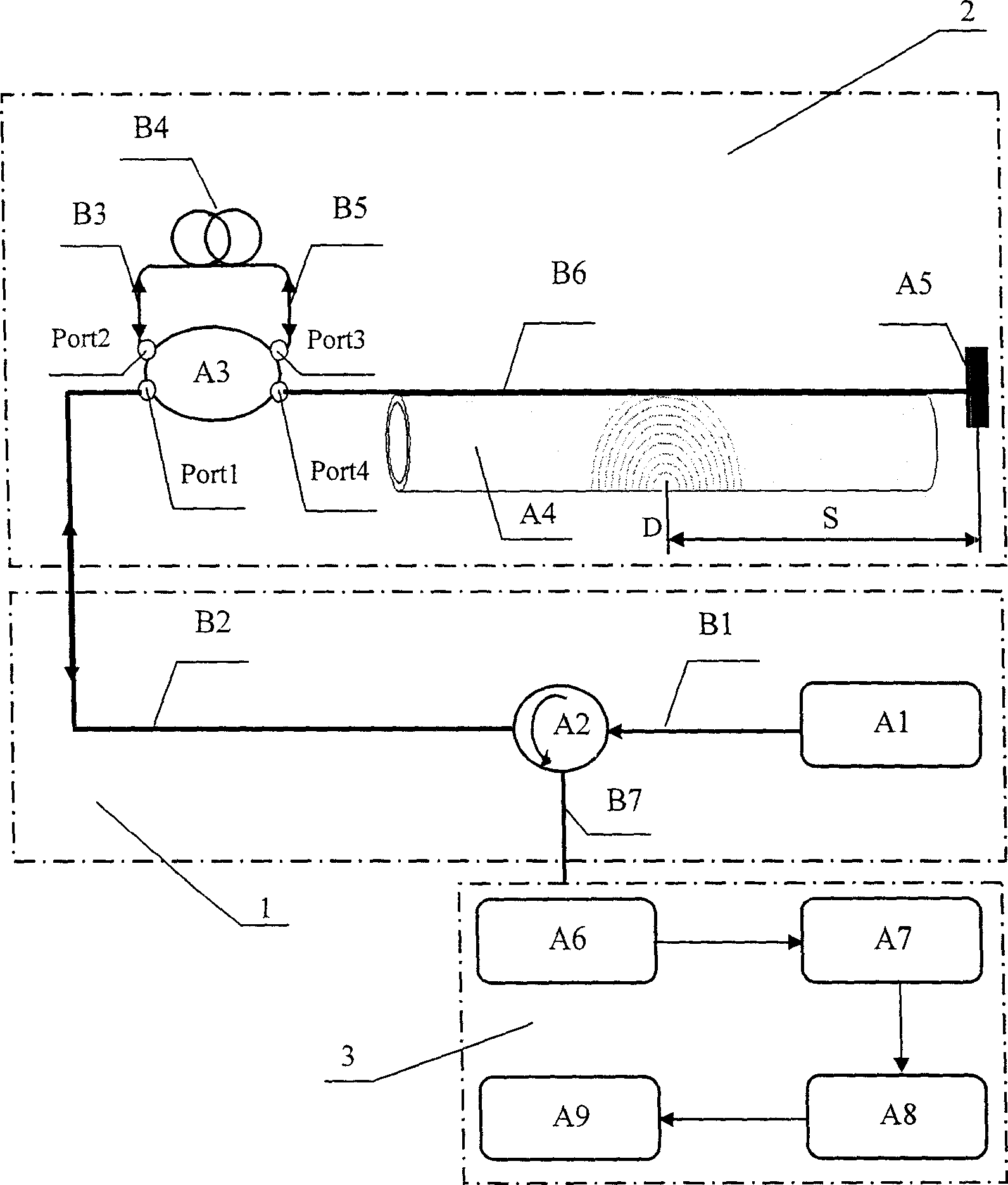

Apparatus and method for monitoring pipeline leakage based on distributed optical fiber acoustic sensing technology

InactiveCN1837674AReduce lossIncreased sensitivityPipeline systemsContinuous lightOptical circulator

The invention relates to a channel leakage detector and method based on distributed optical fiber acoustic sensing technique, which comprises an optical system (1), a distributed optical fiber sensing system (2), and a detecting system (3). Wherein, the optical system comprises a board band continuous light resource A1, and an optical circulator A2; the distributed optical sensing system comprises the first coupler A3, the delay coil B4, and a reflective mirror A5l; the detecting system comprises an optical-electric converter A6, a demodulate system A7, a A / D converter A8, and a computer A9; the board band continuous light resource via the optical circulator is connected to the Port1 interface of the first coupler A3, whose Port2 and Port3 are connected with delay coil; the Port4 of first coupler via sensing optical fiber is connected to the reflective mirror; and the optical circulator is connected to the optical-electric converter of detecting system, while said system can detect any leakage signal at any time.

Owner:BEIJING UNIV OF TECH

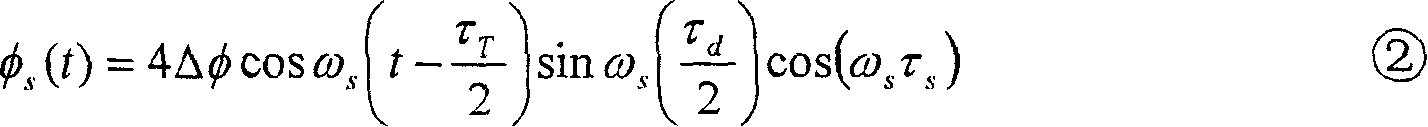

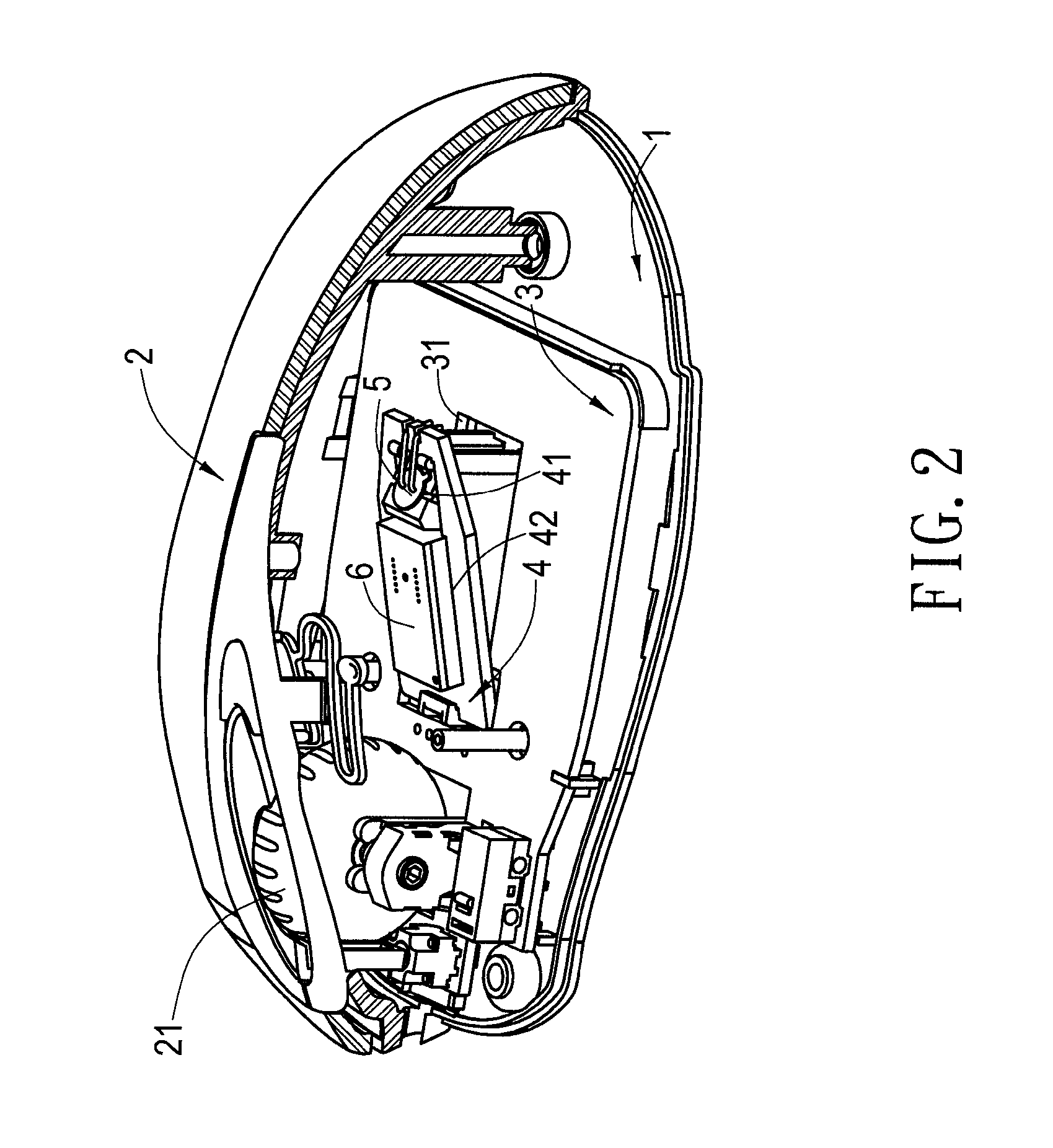

Optical mouse having an optical structure capable of high sensibility

InactiveUS20070222756A1Increased sensitivityConsiderable precisionCathode-ray tube indicatorsInput/output processes for data processingTarget surfaceLight beam

An optical structure of the optical mouse is disclosed, which comprises a light source providing an incident light beam transmitted onto a target surface at a specific incident angle and a photosensor pre-disposed at an angle of between 1 and 179 degrees or between 181 and 359 degrees so as to be aligned to stand at a right angle with respect to a path of the reflected version and thus achieve a proper acquirement of luminance and image of the reflected version of the incident light from the target surface.

Owner:CHIC TECH CORP

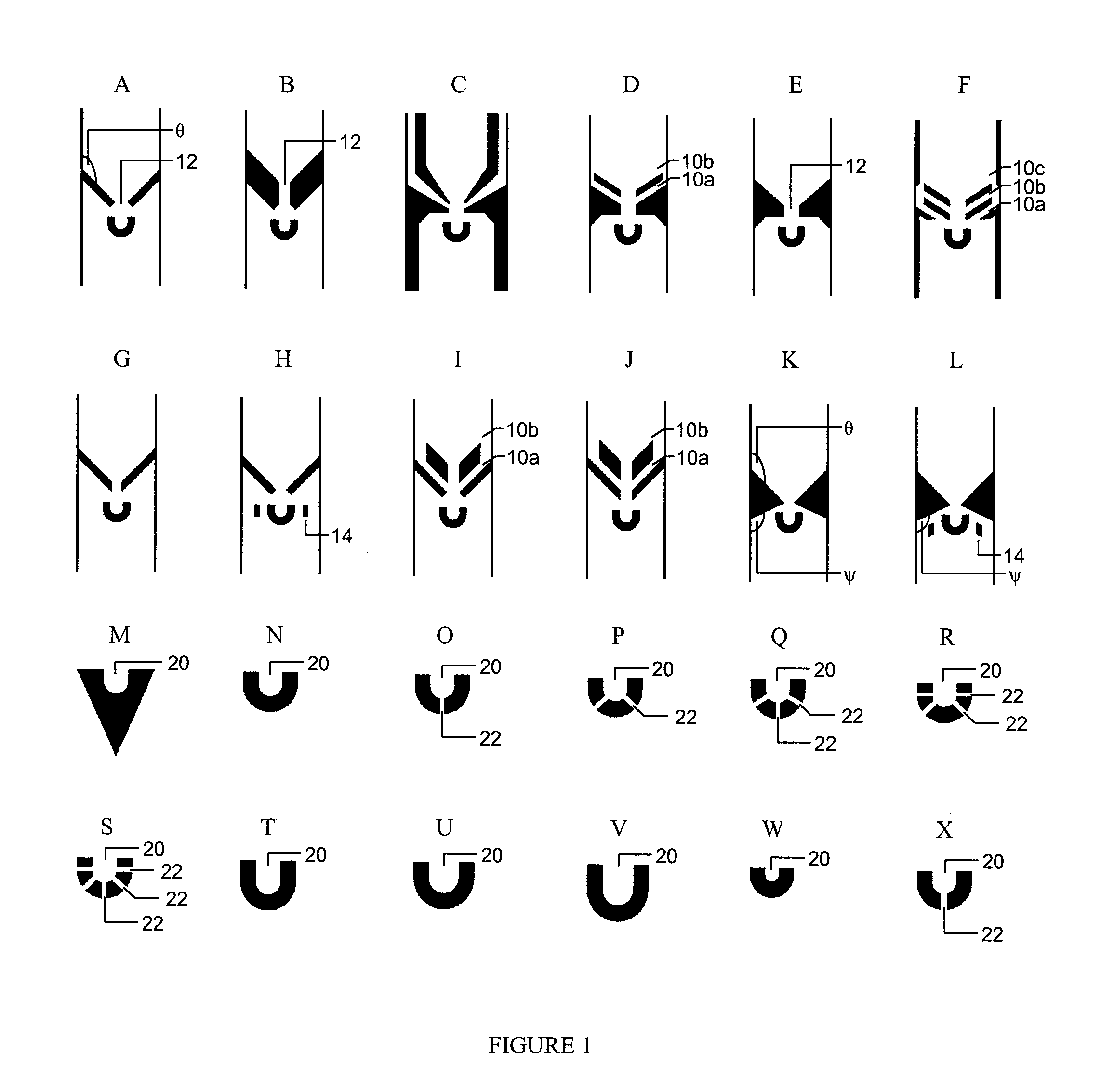

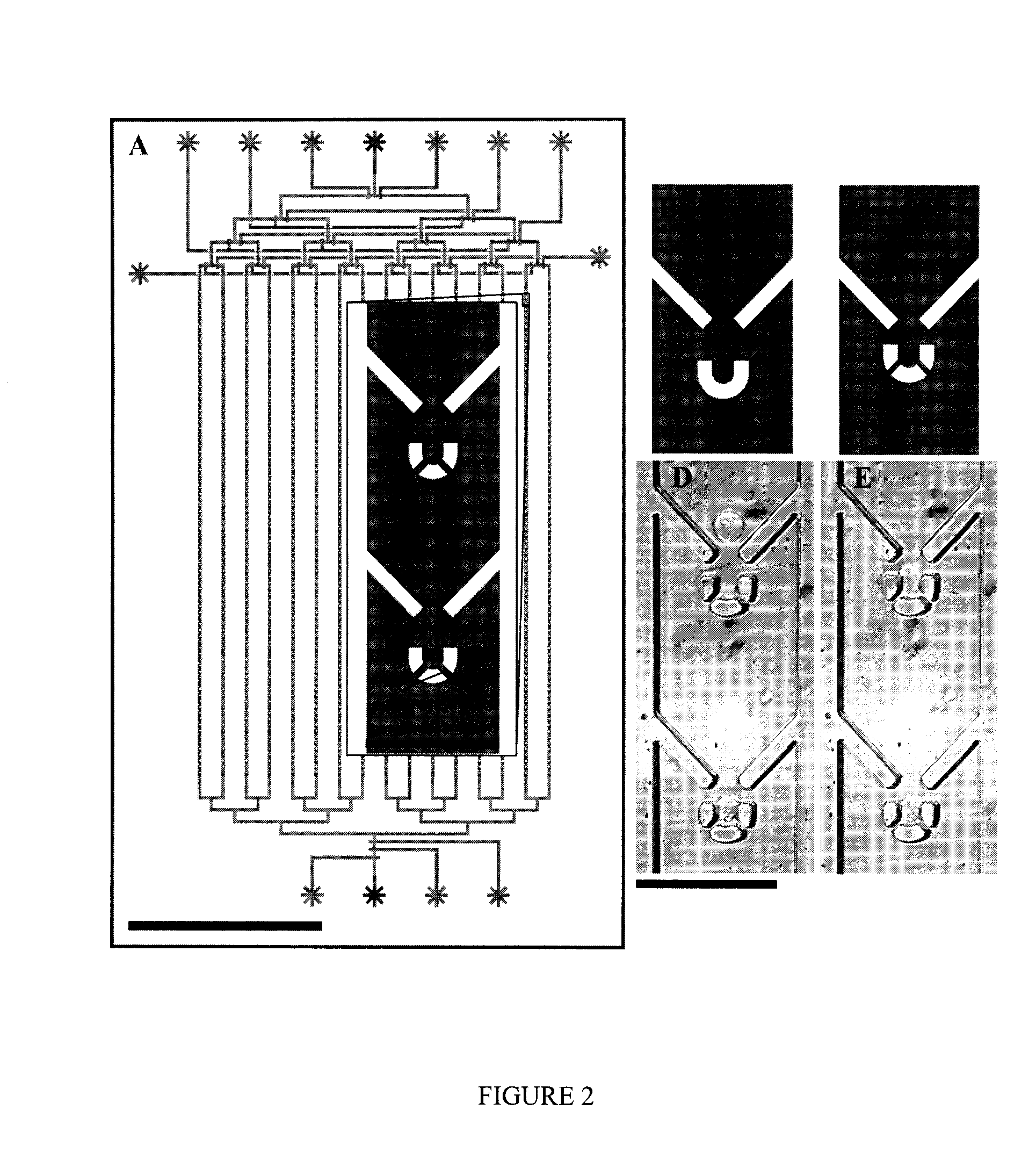

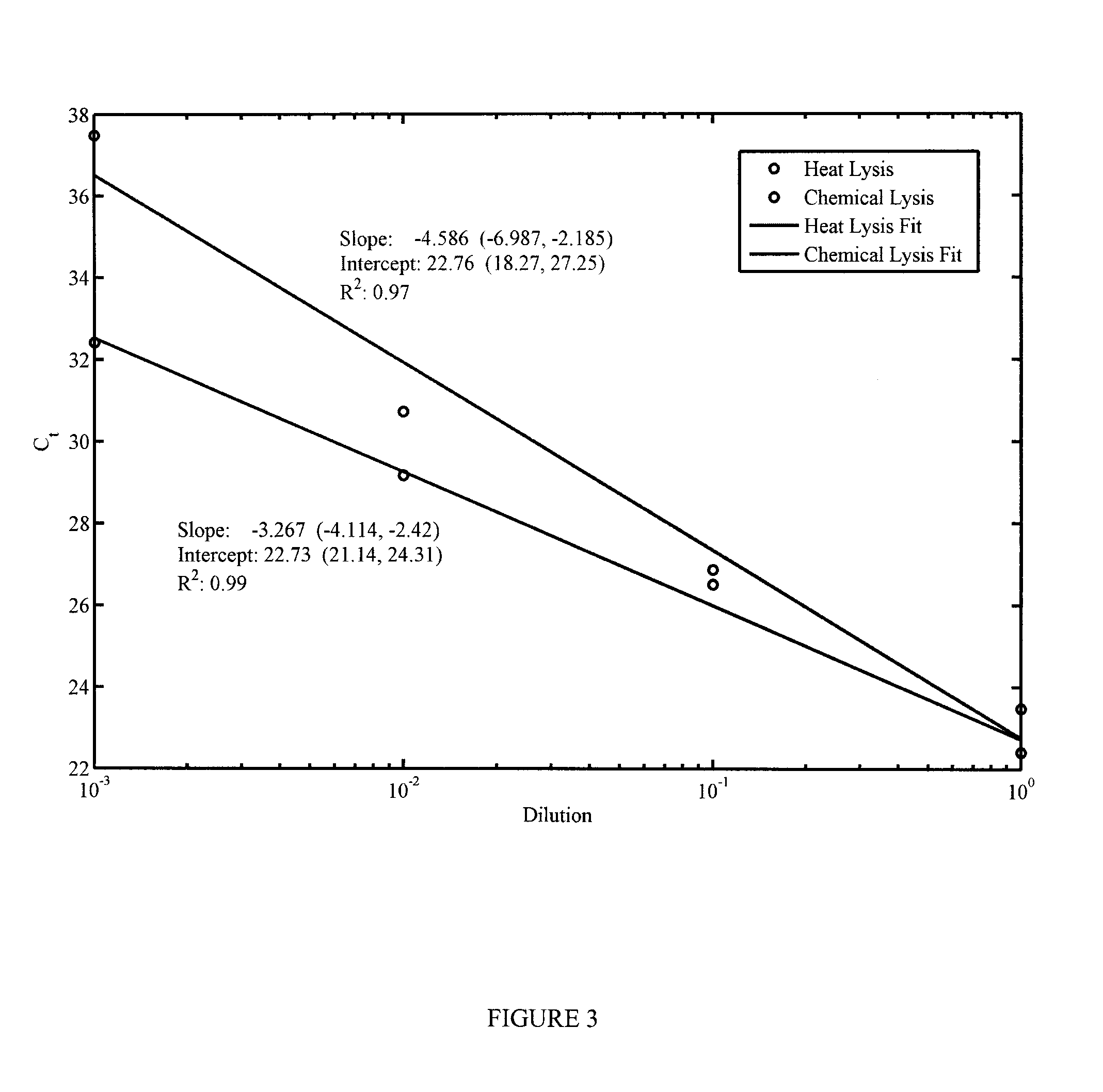

Microfluidic Cell Trap and Assay Apparatus for High-Throughput Analysis

ActiveUS20150018226A1Easy to washImprove performanceHeating or cooling apparatusMicrobiological testing/measurementFlow cellTrapping

Microfluidic devices are provided for trapping, isolating, and processing single cells. The microfluidic devices include a cell capture chamber having a cell funnel positioned within the cell capture chamber to direct a cell passing through the cell capture chamber towards one or more a cell traps positioned downstream of the funnel to receive a cell flowing. The devices may further include auxiliary chambers integrated with the cell capture chamber for subsequent processing and assaying of the contents of a captured cell. Methods for cell capture and preparation are also provided that include flowing cells through a chamber, funneling the cells towards a cell trap, capturing a predefined number of the cells within the trap, interrupting the flow of cells, flowing a wash solution through the chamber to remove contaminants from the chamber, and sealing the predefined number of cells in the chamber.

Owner:THE UNIV OF BRITISH COLUMBIA

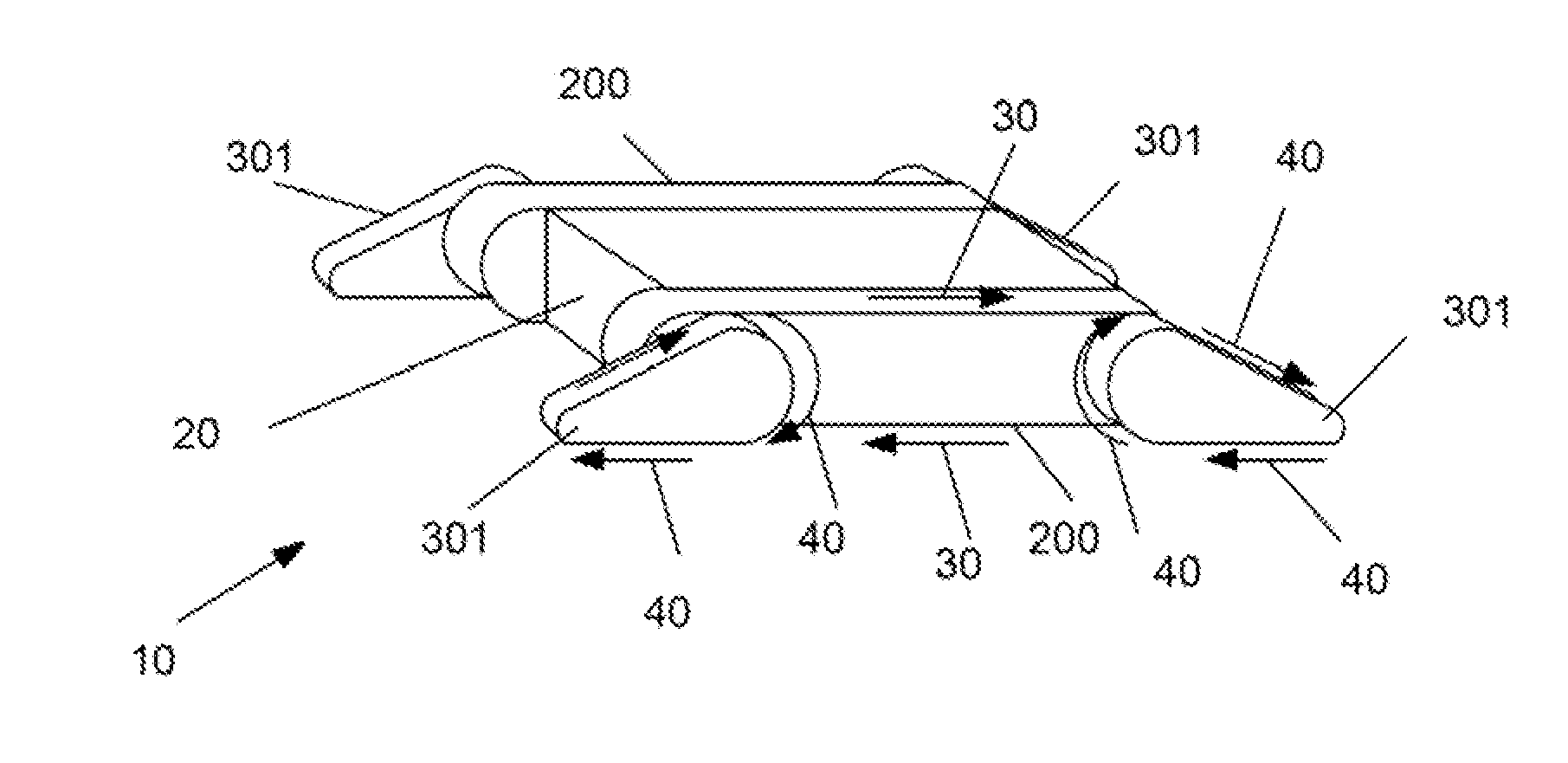

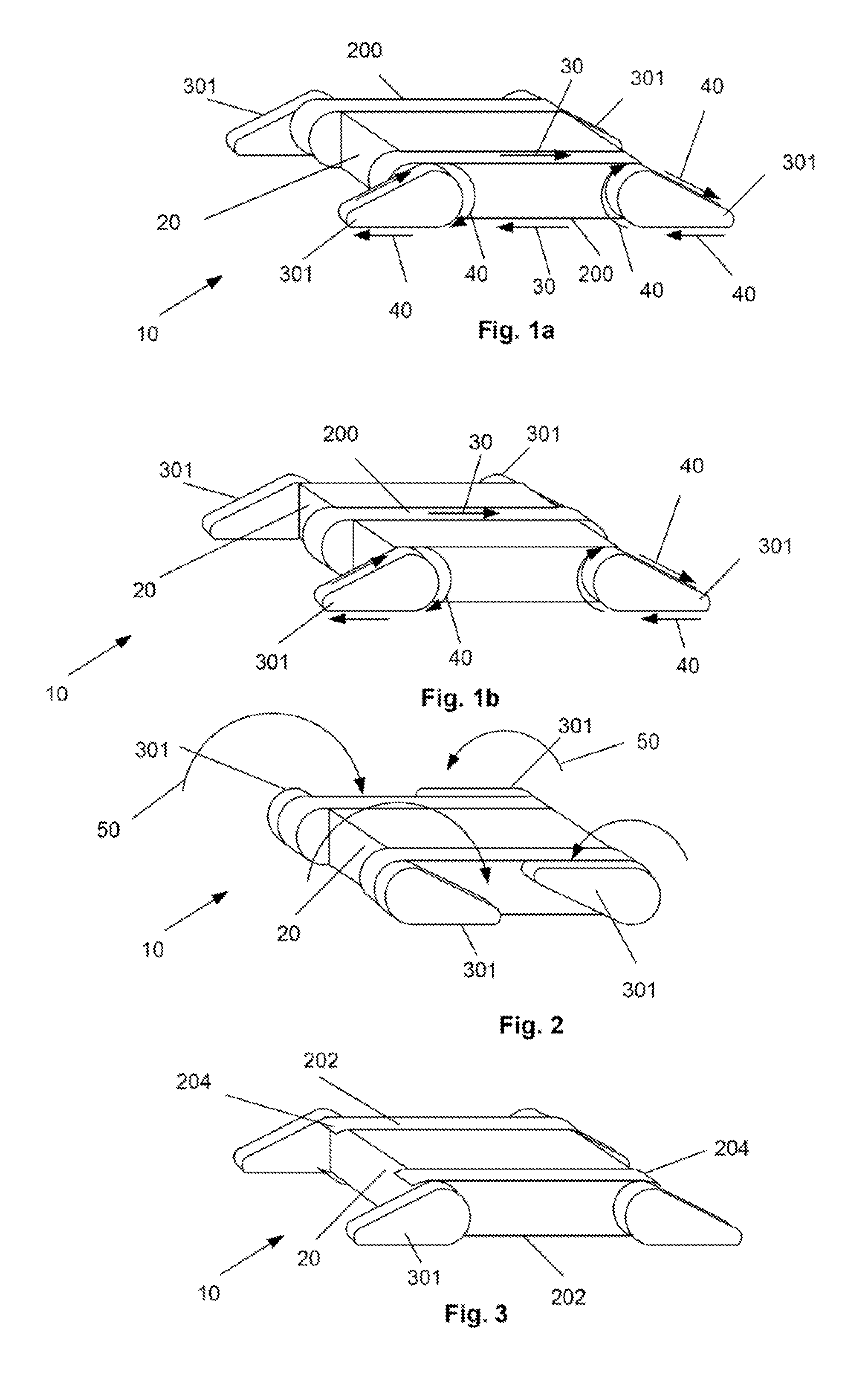

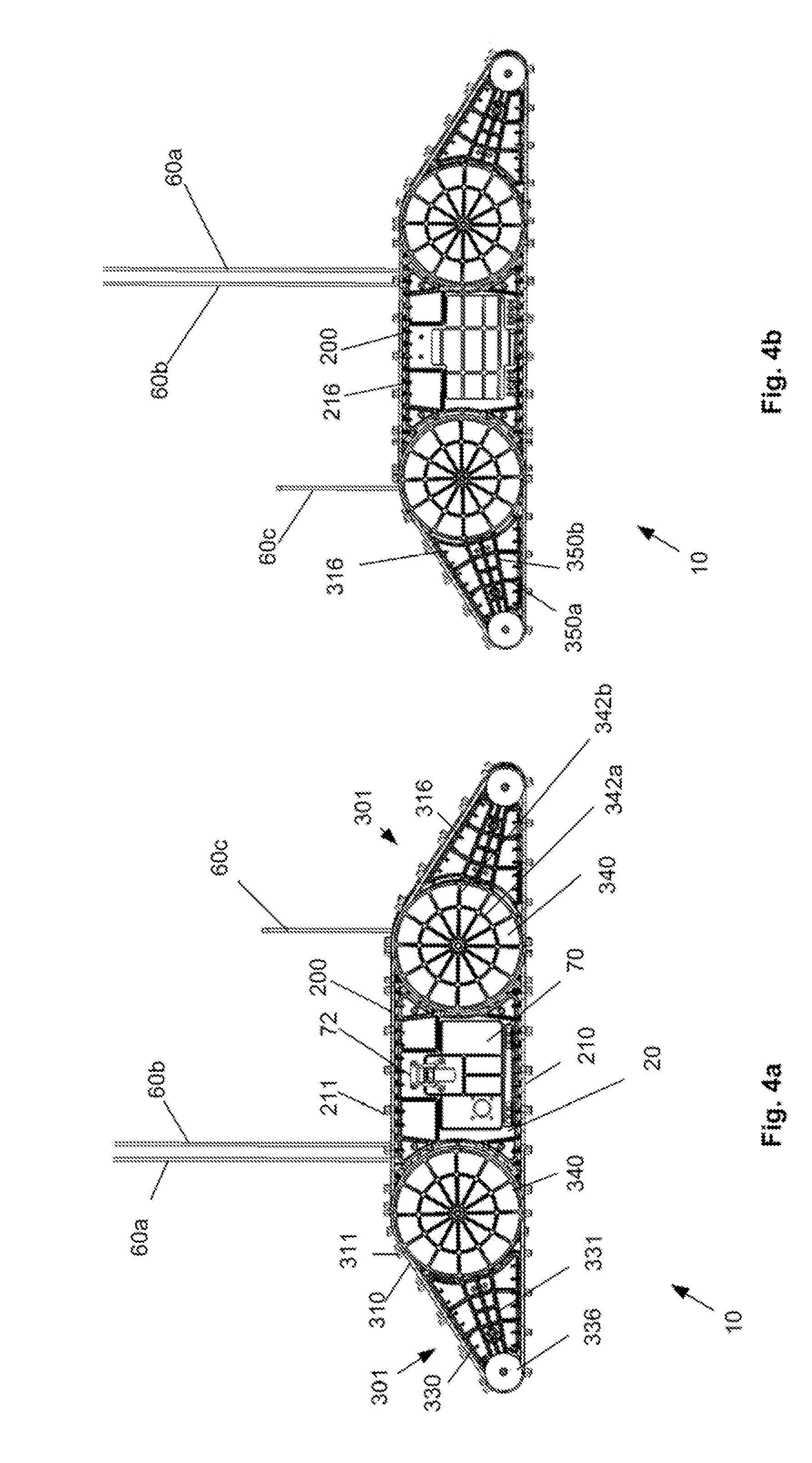

Robotic system and method of use

ActiveUS20110240382A1Enhanced straight line stabilityIncreased sensitivitySuperstructure subunitsVehicle cleaningRobotic systemsEngineering

A robotic system that can have a body and four flippers is described. Any or all of the flippers can be rotated. The flippers can have self-cleaning tracks. The tracks can be driven or passive. The robotic system can be controlled by, and send audio and / or video to and / or from, a remote operator control module. The methods of using and making the robotic system are also described.

Owner:ROBOTEX

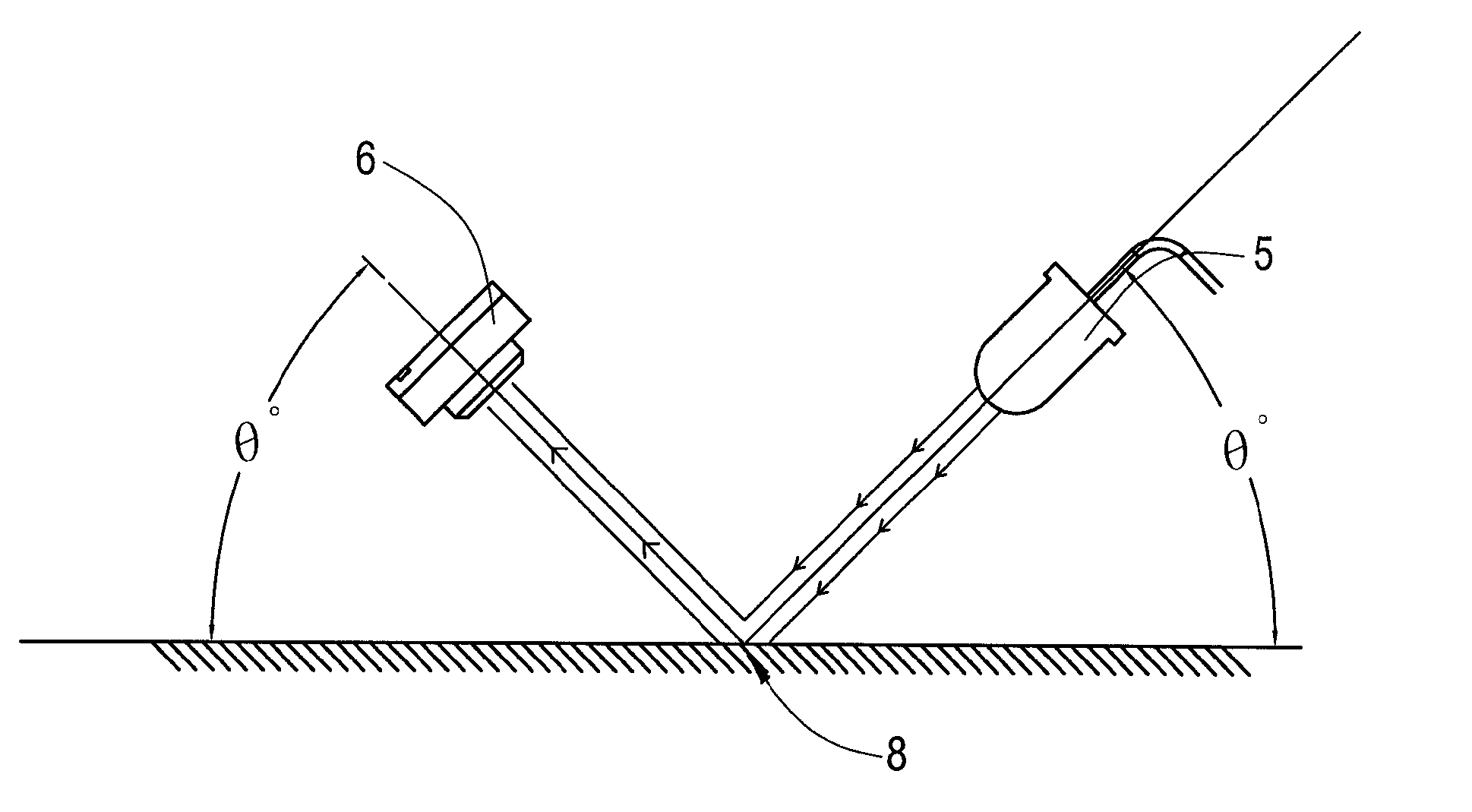

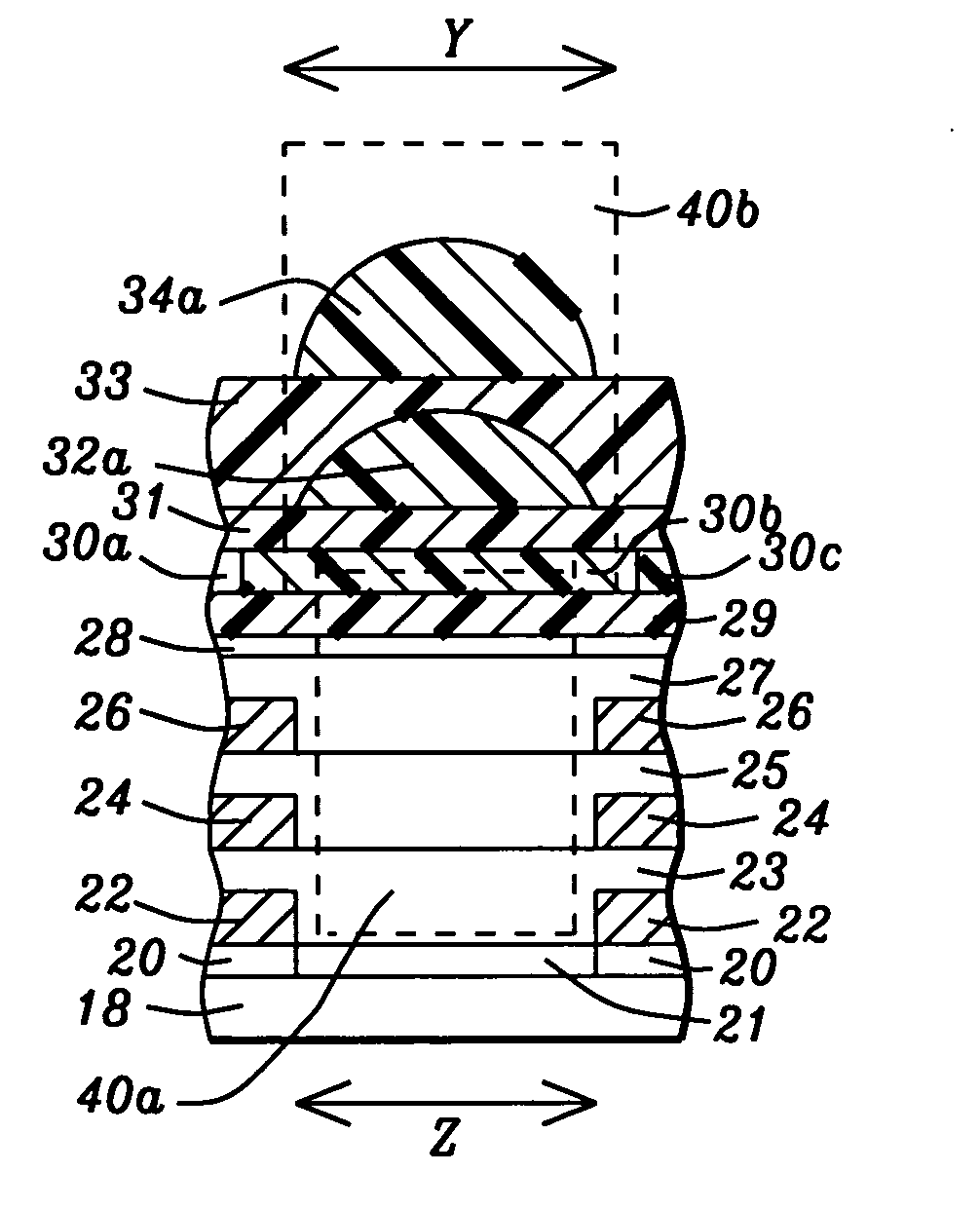

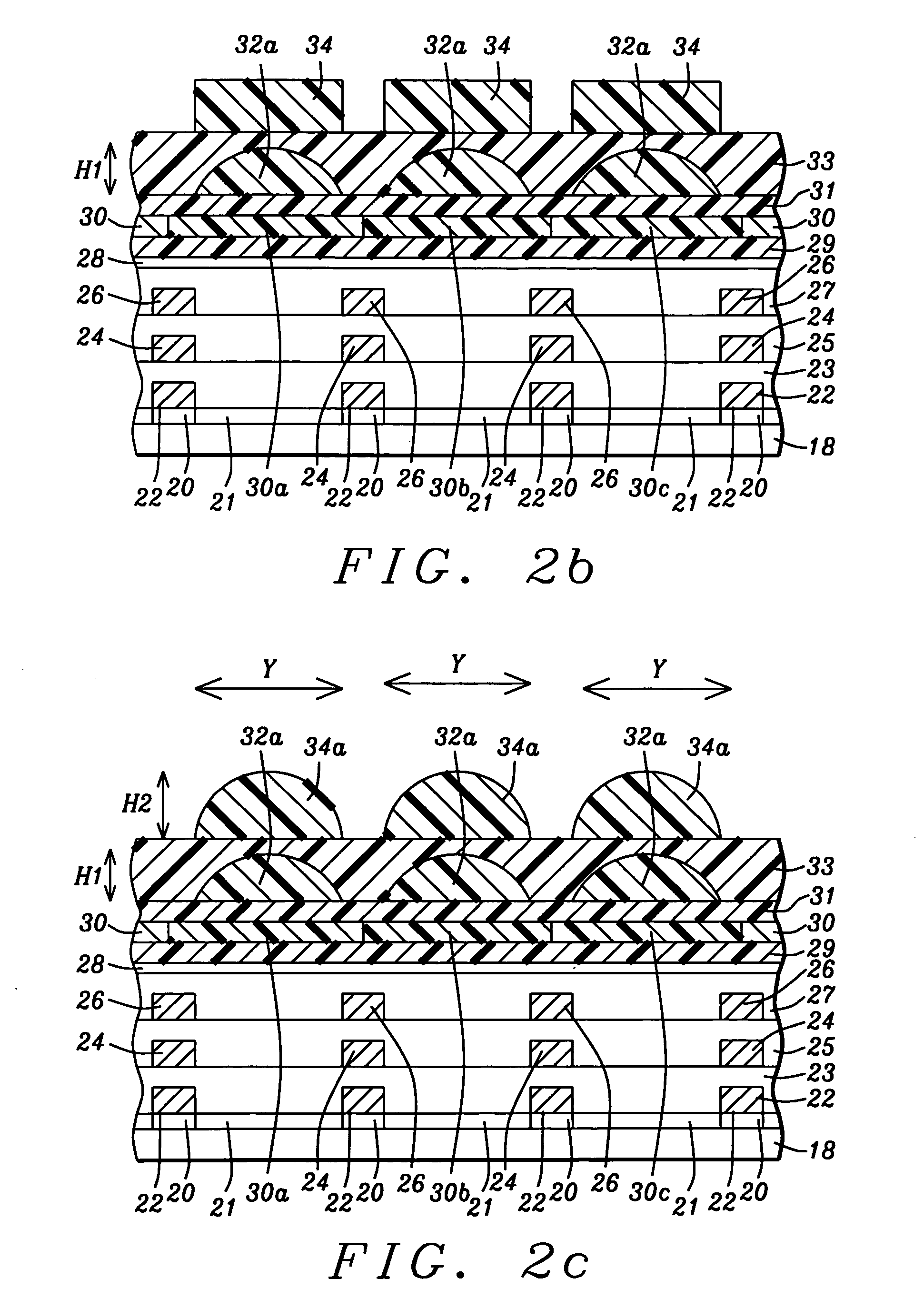

Effective method to improve sub-micron color filter sensitivity

ActiveUS20050242271A1High sensitivityLong focal lengthTelevision system detailsSolid-state devicesColor gelPhotodiode

An image sensor device and method for forming said device are described. The image sensor structure comprises a substrate with photodiodes, an interconnect structure formed on the substrate, a color filter layer above the interconnect structure, a first microlens array, an overcoat layer, and a second microlens array. A key feature is that a second microlens has a larger radius of curvature than a first microlens. Additionally, each first microlens and second microlens is a flat convex lens. Thus, a thicker second microlens with a short focal length is aligned above a thinner first microlens having a long focal length. A light column that includes a first microlens, a second microlens and a color filter region is formed above each photodiode. A second embodiment involves replacing a second microlens in each light column with a plurality of smaller second microlenses that focus light onto a first microlens.

Owner:TAIWAN SEMICON MFG CO LTD

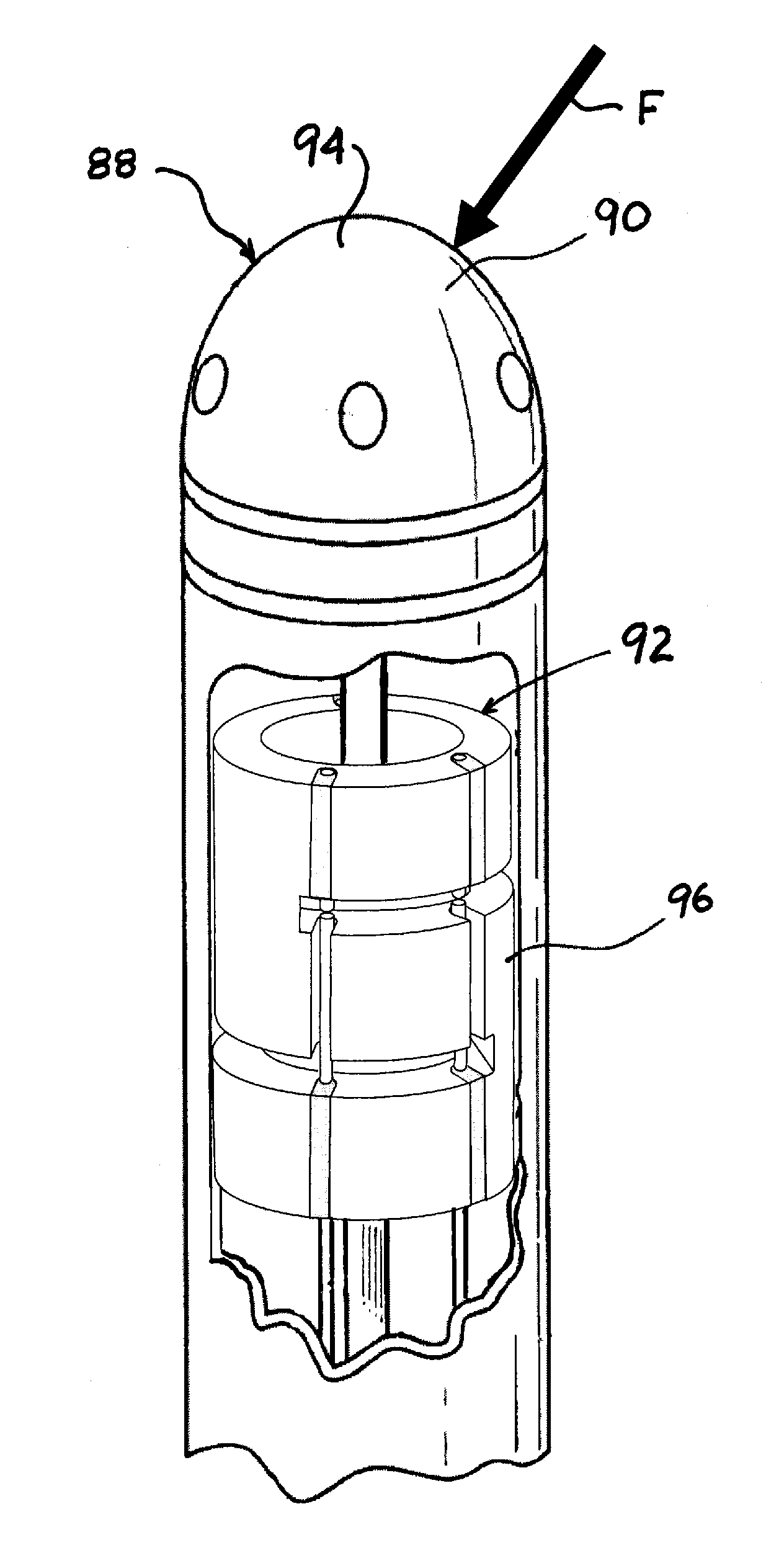

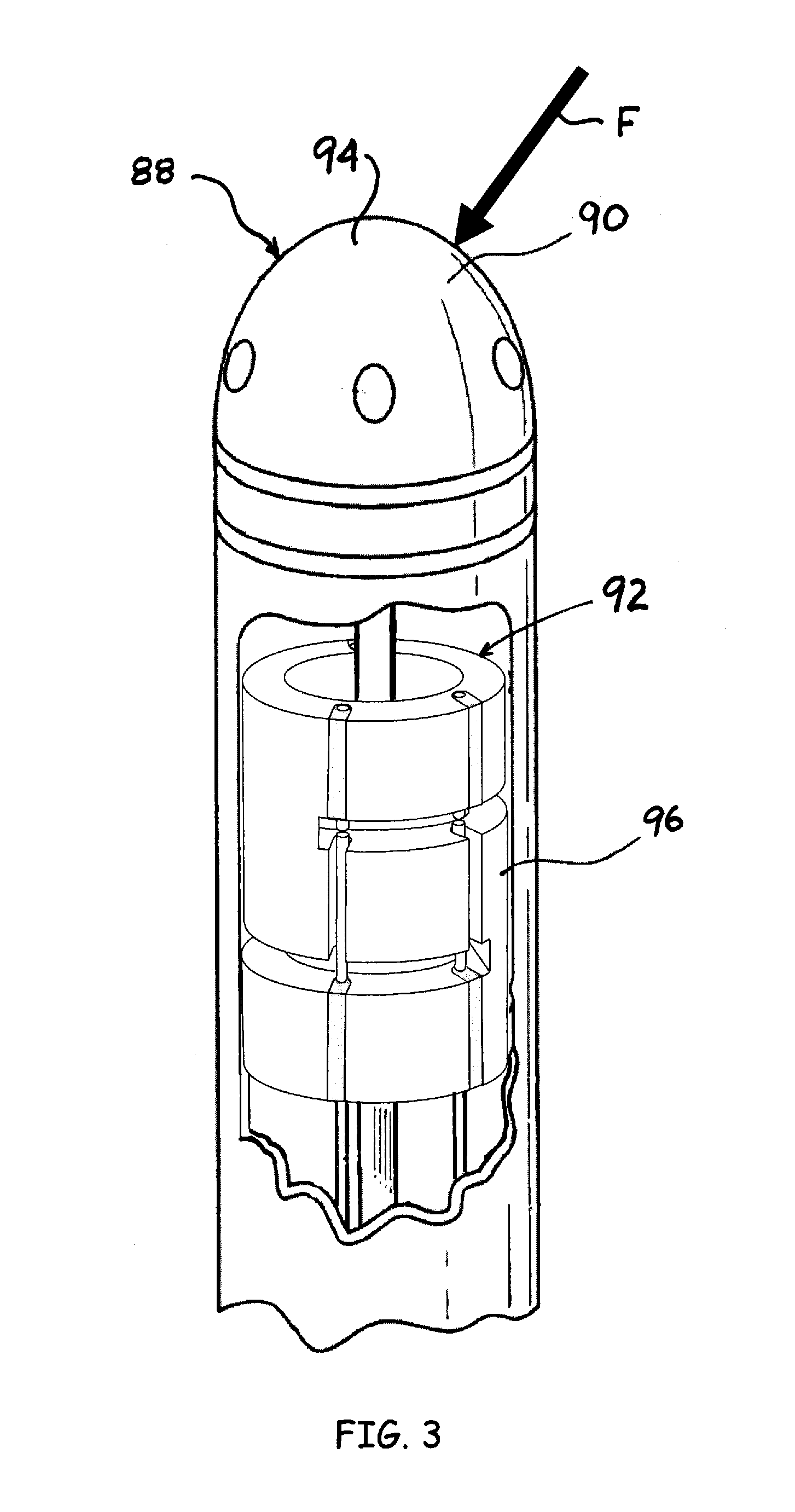

Compact force sensor for catheters

ActiveUS20120265102A1High sensitivityInsensitive to temperature changesStrain gaugeSurgeryFiberContact force

An ablation catheter system configured with a compact force sensor at a distal end for detection of contact forces exerted on an end effector. The force sensor includes fiber optics operatively coupled with reflecting members on a structural member. In one embodiment, the optical fibers and reflecting members cooperate with the deformable structure to provide a variable gap interferometer for sensing deformation of the structural member due to contact force. In another embodiment, a change in the intensity of the reflected light is detected to measure the deformation. The measured deformations are then used to compute a contact force vector. In some embodiments, the force sensor is configured to passively compensate for temperature changes that otherwise lead to erroneous force indications. In other embodiments, the system actively compensates for errant force indications caused by temperature changes by measuring certain local temperatures of the structural member.

Owner:ST JUDE MEDICAL INT HLDG SARL

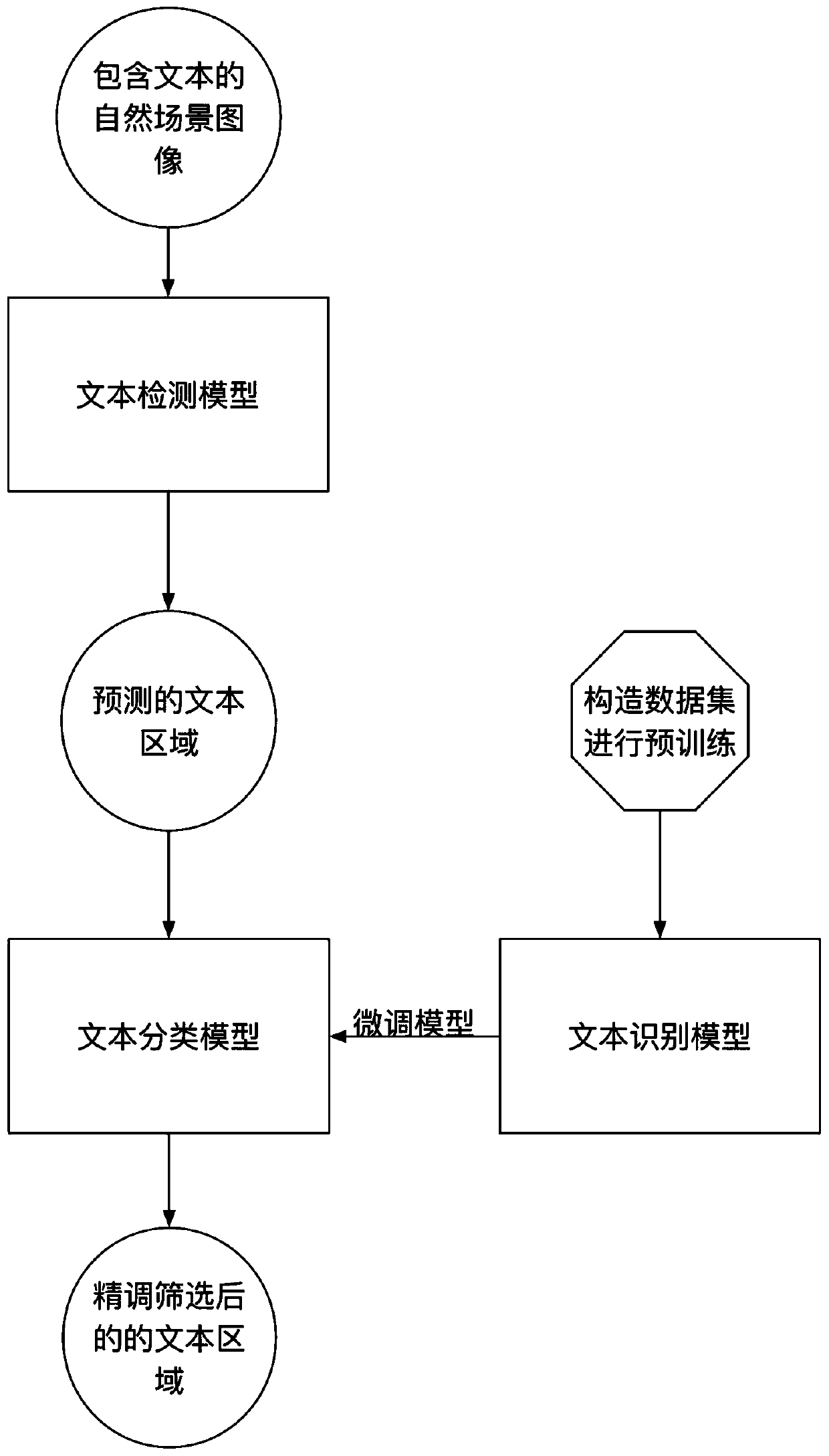

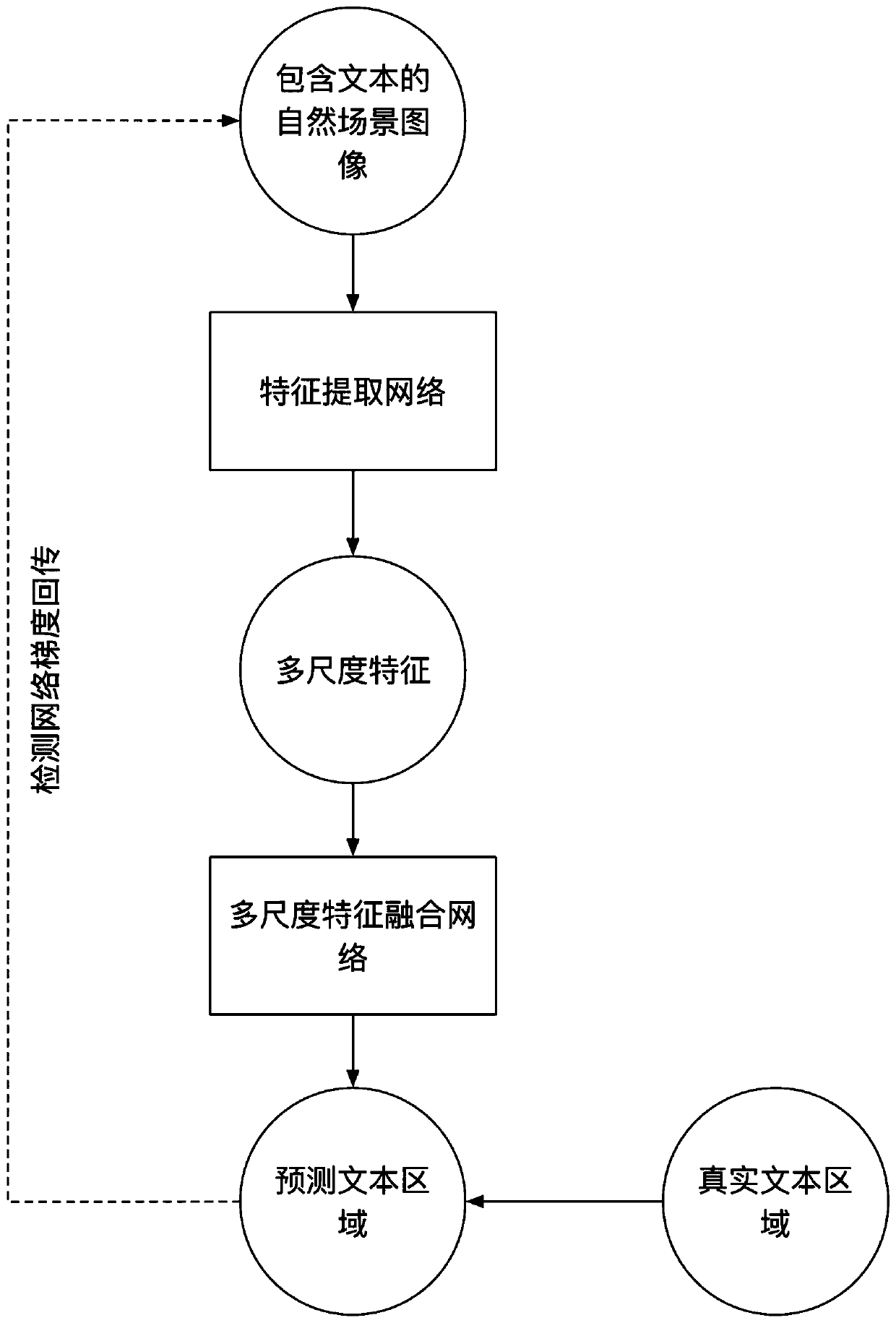

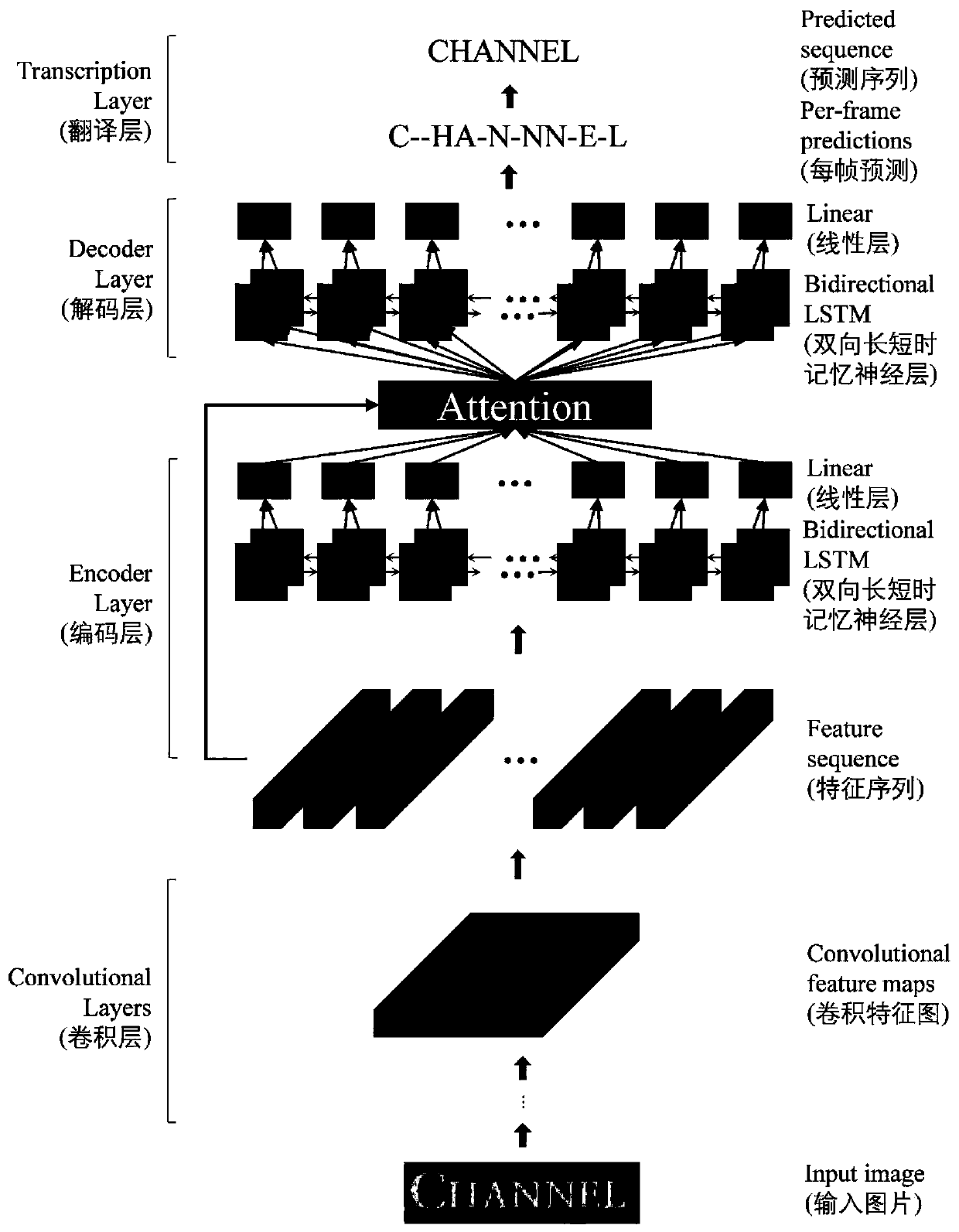

Natural scene text detection method and system

InactiveCN110097049ANo need to manually design featuresSimple methodCharacter and pattern recognitionNeural architecturesText recognitionFeature extraction

The invention provides a natural scene text detection method and system. The system comprises two neural network models: a text detection network based on multi-level semantic feature fusion and a detection screening network based on an attention mechanism, wherein the text detection network is an FCN-based image feature extraction fusion network, and is used for extracting multi-semantic level information of input data, carrying out full fusion of multi-scale features, and finally predicting the position and confidence degree of text information in a natural scene by carrying out convolutionoperation on the fused multi-scale information. According to the detection screening network, the trained convolutional recurrent neural network is used for discriminating and scoring an initial detection result output by the convolutional neural network of the first part, so that a background which is easy to confuse with foreground characters is filtered out, and the accuracy of natural scene text recognition is further improved.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI +1

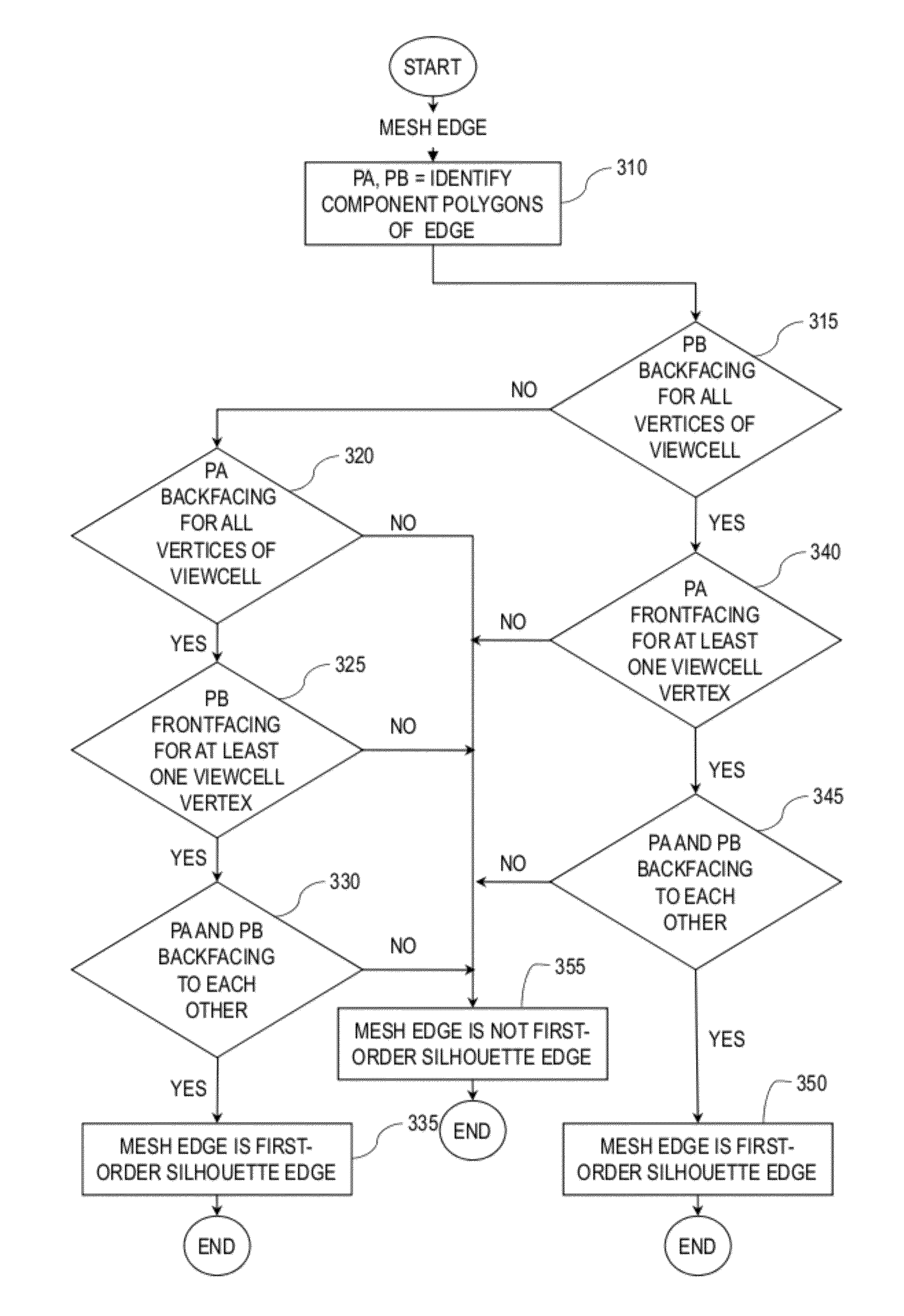

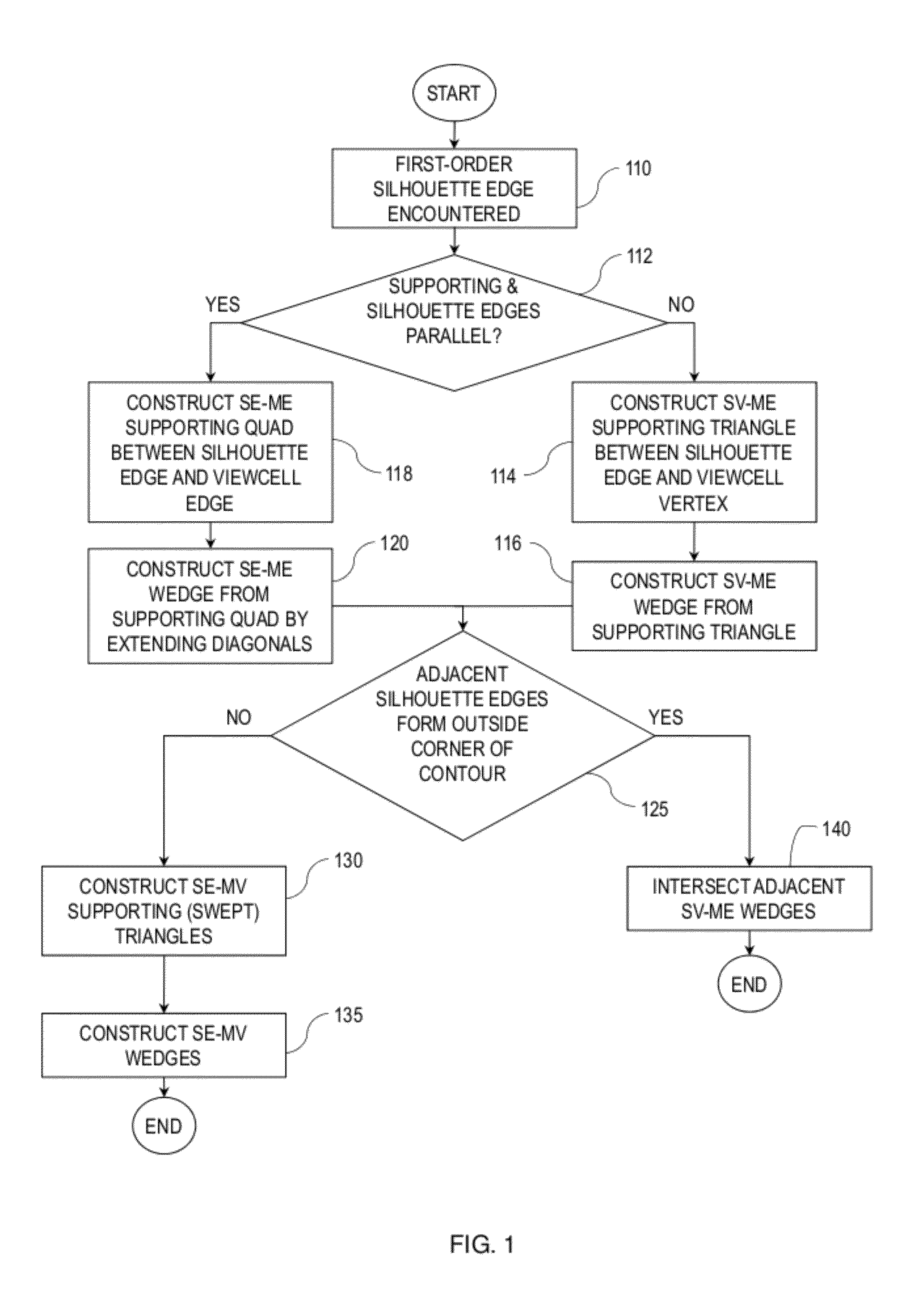

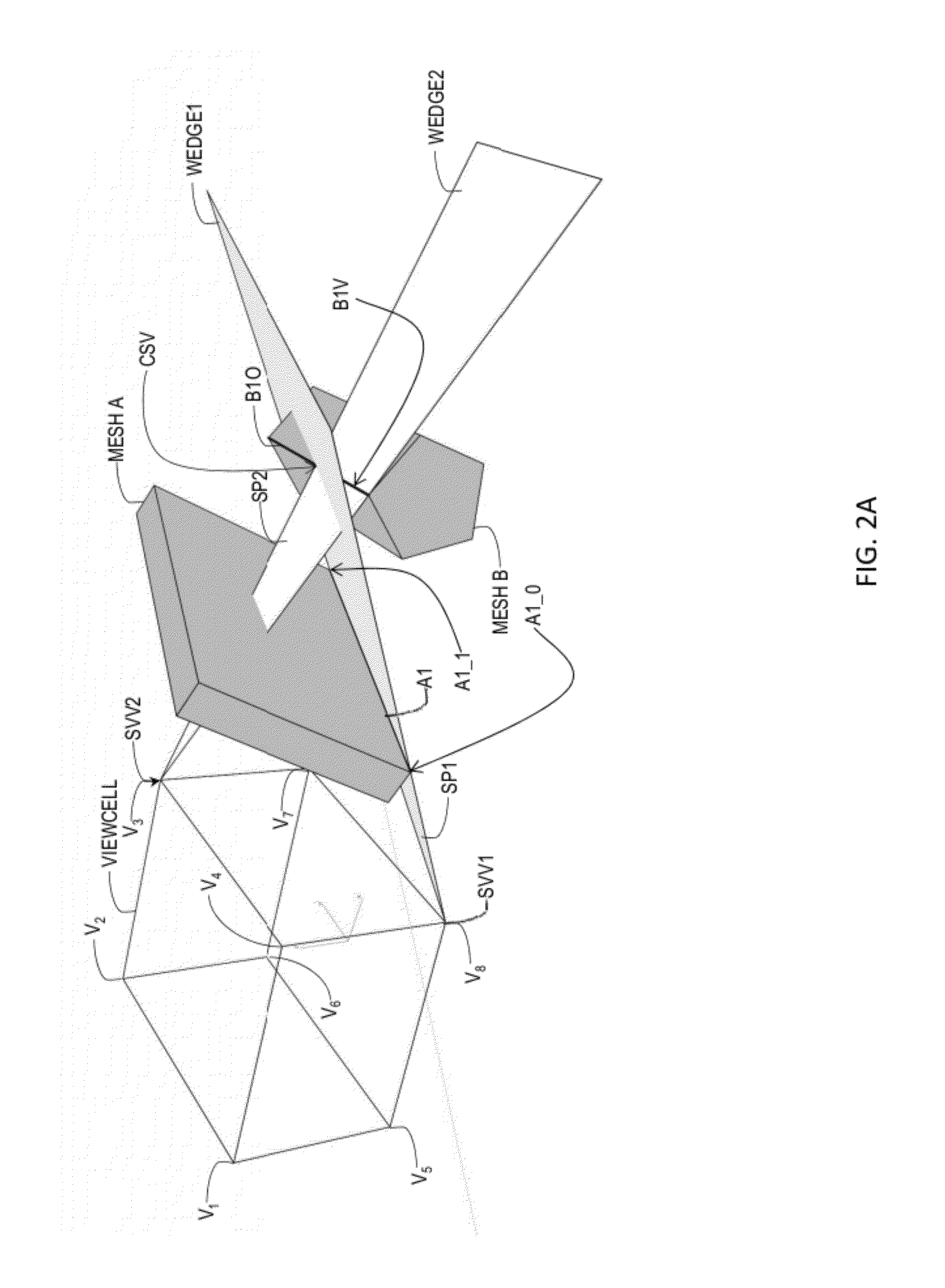

System and method of reducing transmission bandwidth required for visibility-event streaming of interactive and non-interactive content

InactiveUS20120229445A1High precisionReduce computing costSpecial data processing applicationsDetails involving image processing hardwareVisibilityInteractive content

In an exemplary embodiment, a computer-implemented method determines a set of mesh polygons or fragments of the mesh polygons visible from a navigation cell. The method includes determining a composite view frustum containing predetermined view frusta and determining mesh polygons contained in the composite view frustum. The method includes determining at least one supporting polygon between the navigation cell and the contained mesh polygons. The method further includes constructing at least one wedge from the at least one supporting polygon, the at least one wedge extending away from the navigation cell beyond at least the contained mesh polygons. The method includes determining one or more intersections of the at least one wedge with the contained mesh polygons. The method also includes determining the set of the contained mesh polygons or fragments of the contained mesh polygons visible from the navigation cell using the determined one or more intersections.

Owner:JENKINS BARRY L

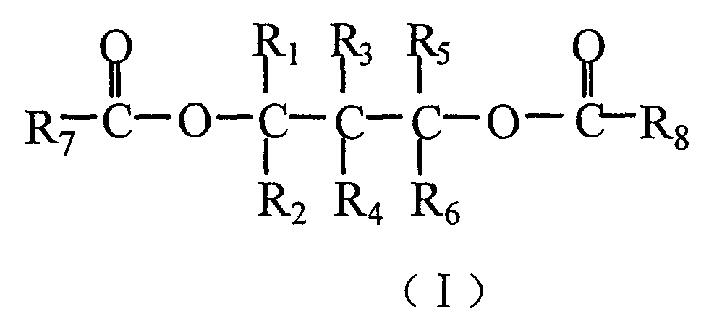

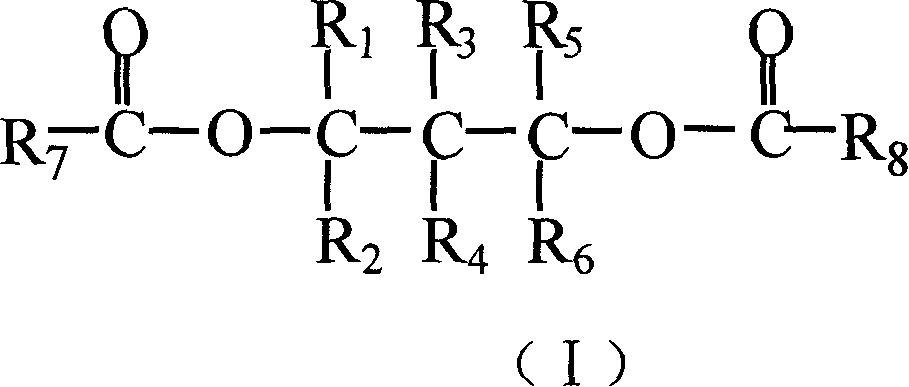

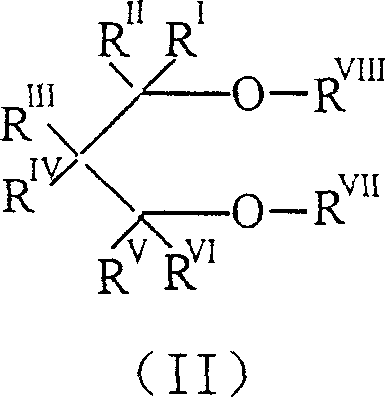

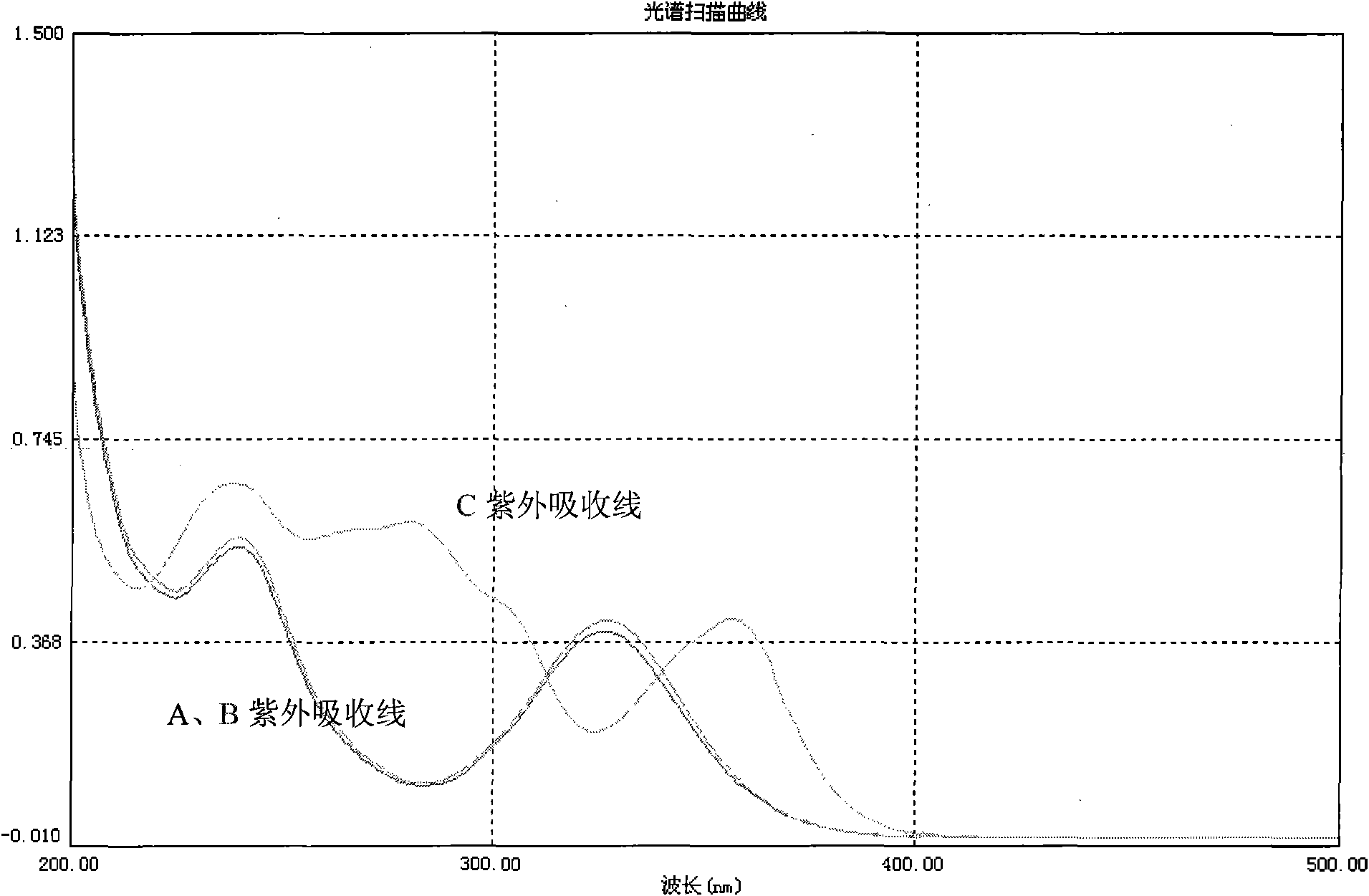

Ketoxime ester photoinitiator

ActiveCN101565472AImprove applicabilityApplication performance (good sensitivityOrganic compound preparationPhotomechanical apparatusCarbazoleMethyl benzene

The invention relates to a ketoxime ester photoinitiator, in particular to a ketoxime ester photoinitiator for a photo-curing material. The ketoxime ester photoinitiator has a chemical structural formula as the right, wherein in a R1 structure, n is an integer of between 0 and 5; m is an integer of between 1 and 6; R2 is methyl, phenyl, substituted phenyl, benzyl or substituted benzyl; and R3 is diphenyl sulfide group, substituted diphenyl sulfide group, carbazole group or substituted carbazole group. The ketoxime ester photoinitiator solves the problems of poor application performance and poor thermal stability of the prior OXE-1 ketoxime ester photoinitiator.

Owner:CHANGZHOU TRONLY NEW ELECTRONICS MATERIALS

Distribution network feed out circuit fault circuit selection method by using HHT detection technology

The present invention is a distribution network cable-line mixed fault circuit selection method by using HHT detection technology. The invention uses HHT singularity detection technology to calibrate fault occurring time accurately, and implements circuit selection according to a principle that, when a fault occurs transient fault zero-sequence current component of the fault circuit and the regular circuit is opposite in direction. The specific method is using HHT to proceed EMD decomposition to the sampling signal of before and after 1 / 4 period each circuit fault zero-sequence current that is morphological filter pretreated, obtaining highest frequency IMF component of each circuit fault zero-sequence current and proceeding a first-order backward difference treatment to the IMF component, comparing the polar mutation of the fault zero-sequence current IMF component at fault moment, and then forming a circuit selection criterion. Analysis and simulation of the principle shows that, using fault information of 1 / 4 period after the fault to select circuit can provide an accurate and reliable circuit selection result and avoid effects of paraphrase and CT saturation on circuit selection accrracy.

Owner:KUNMING UNIV OF SCI & TECH

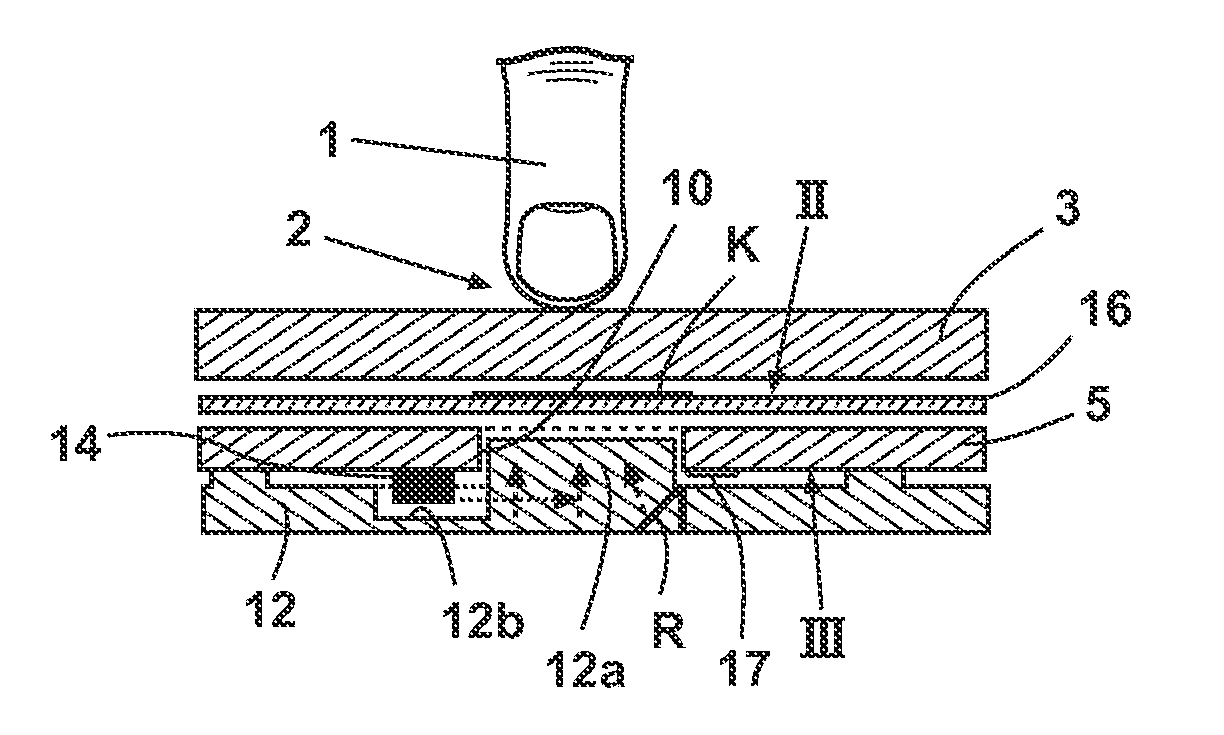

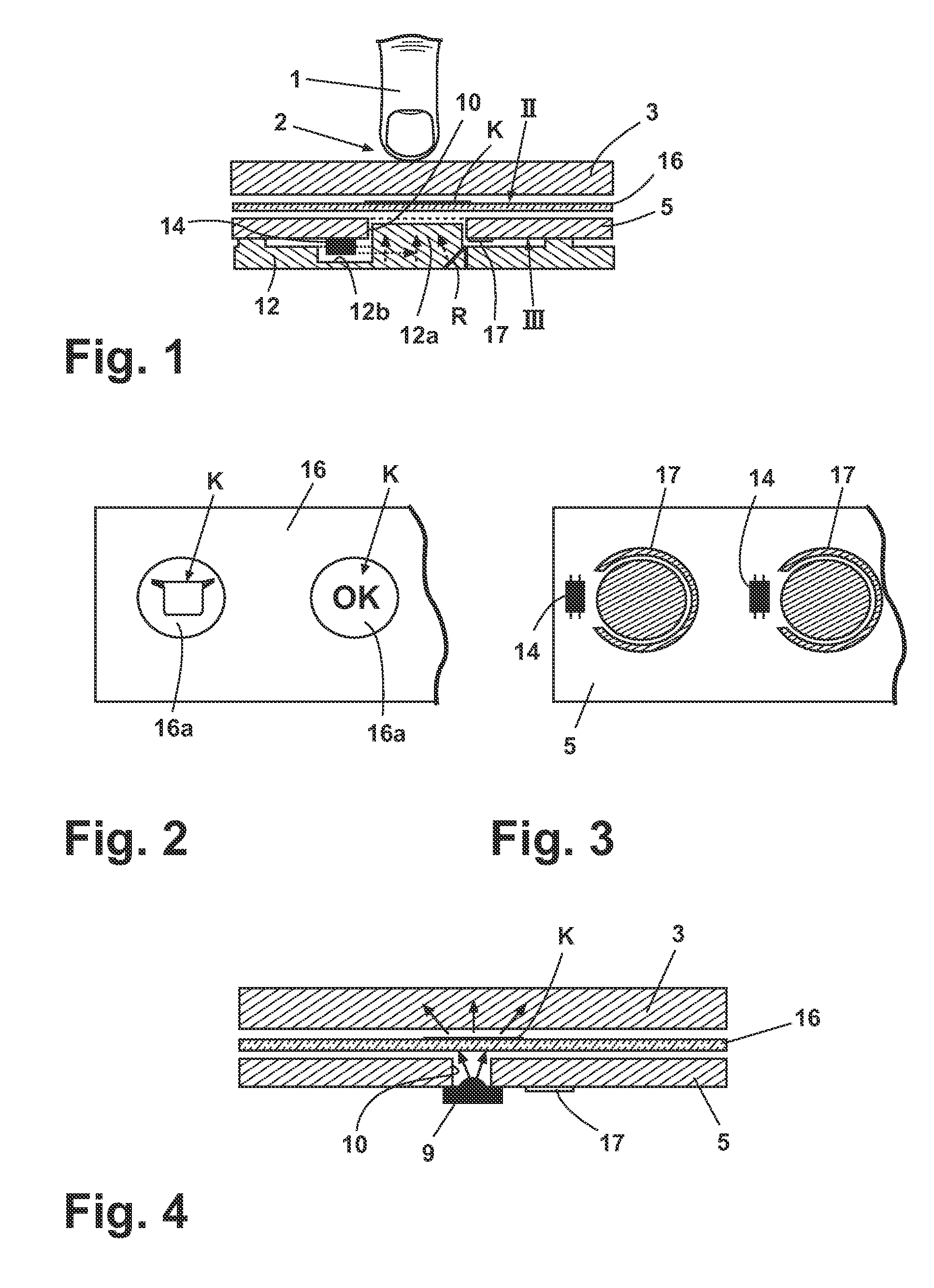

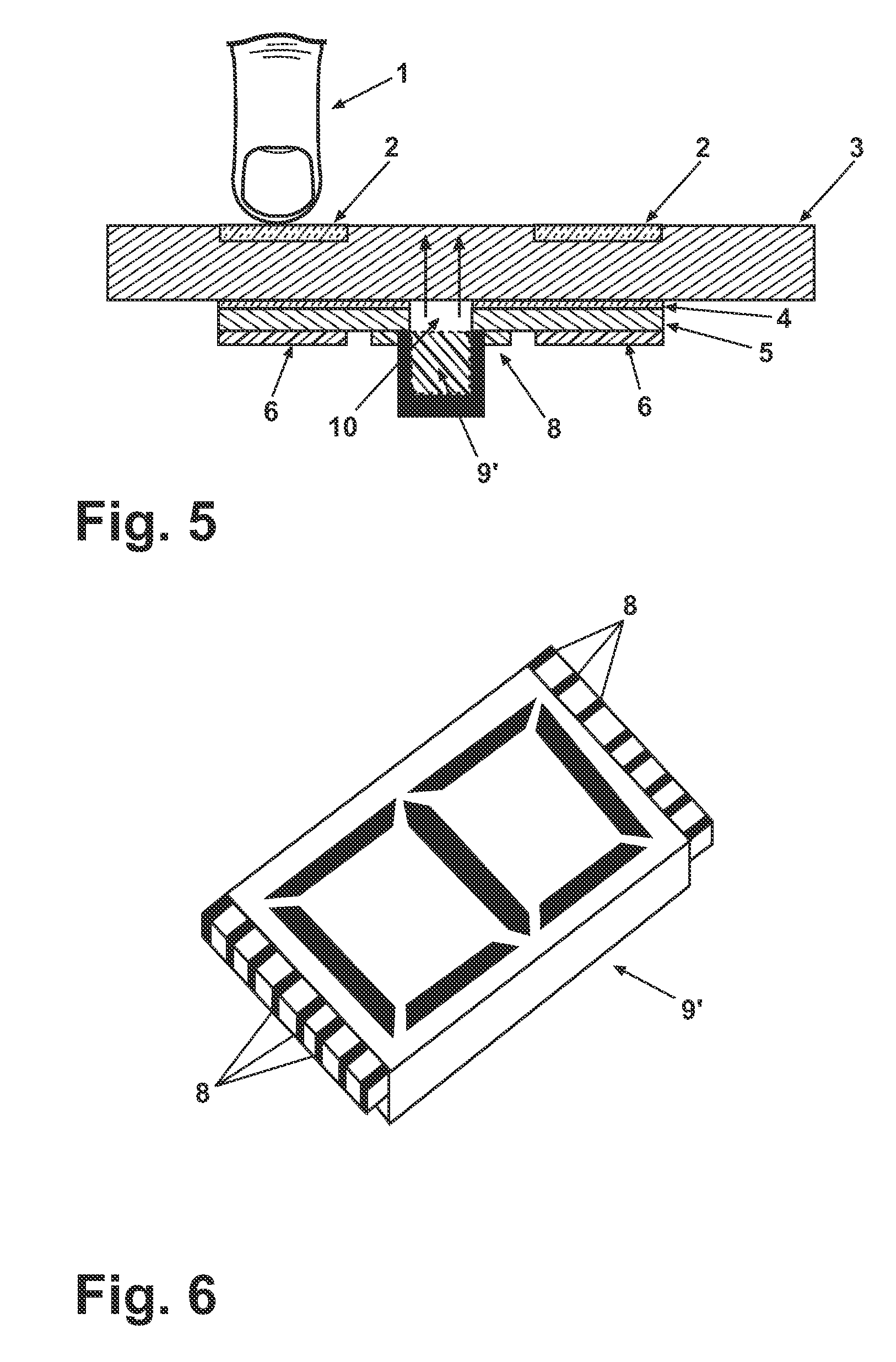

Touch switch for electrical appliances and electrical appliance provided with such switch

InactiveUS20090090605A1Big thicknessReduce physical sizeElectronic switchingElectric switchesPrinted circuit boardLight transmission

A touch switch for an electrical appliance having a capacitive flat electrode, a light source, a transparent cover and a printed circuit board connected to the electrode is disclosed. The light source is mounted on a face of the printed circuit board opposite the transparent cover and the printed circuit board presents a cut-out for allowing light transmission from the light source towards the transparent cover.

Owner:WHIRLPOOL CORP

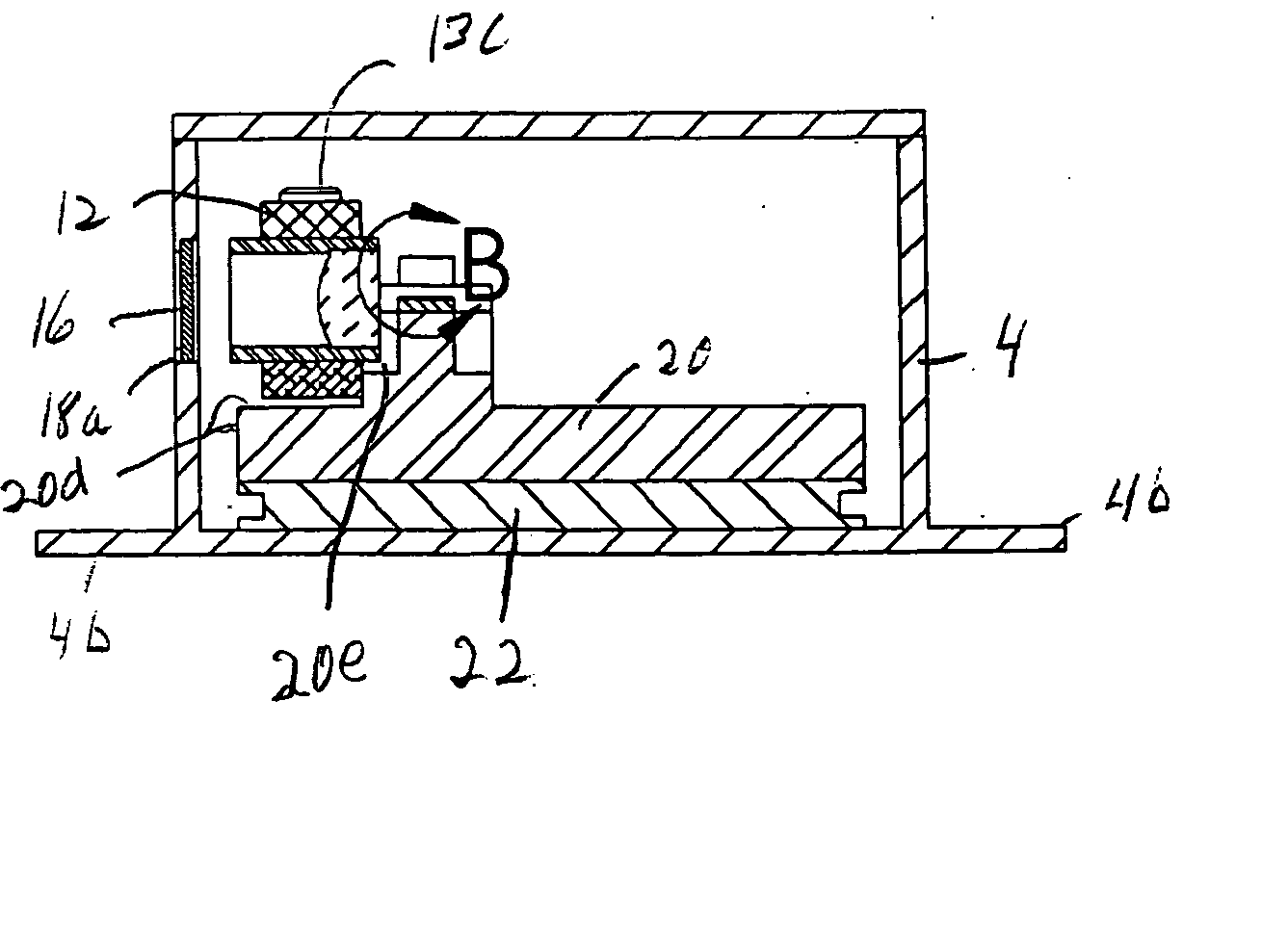

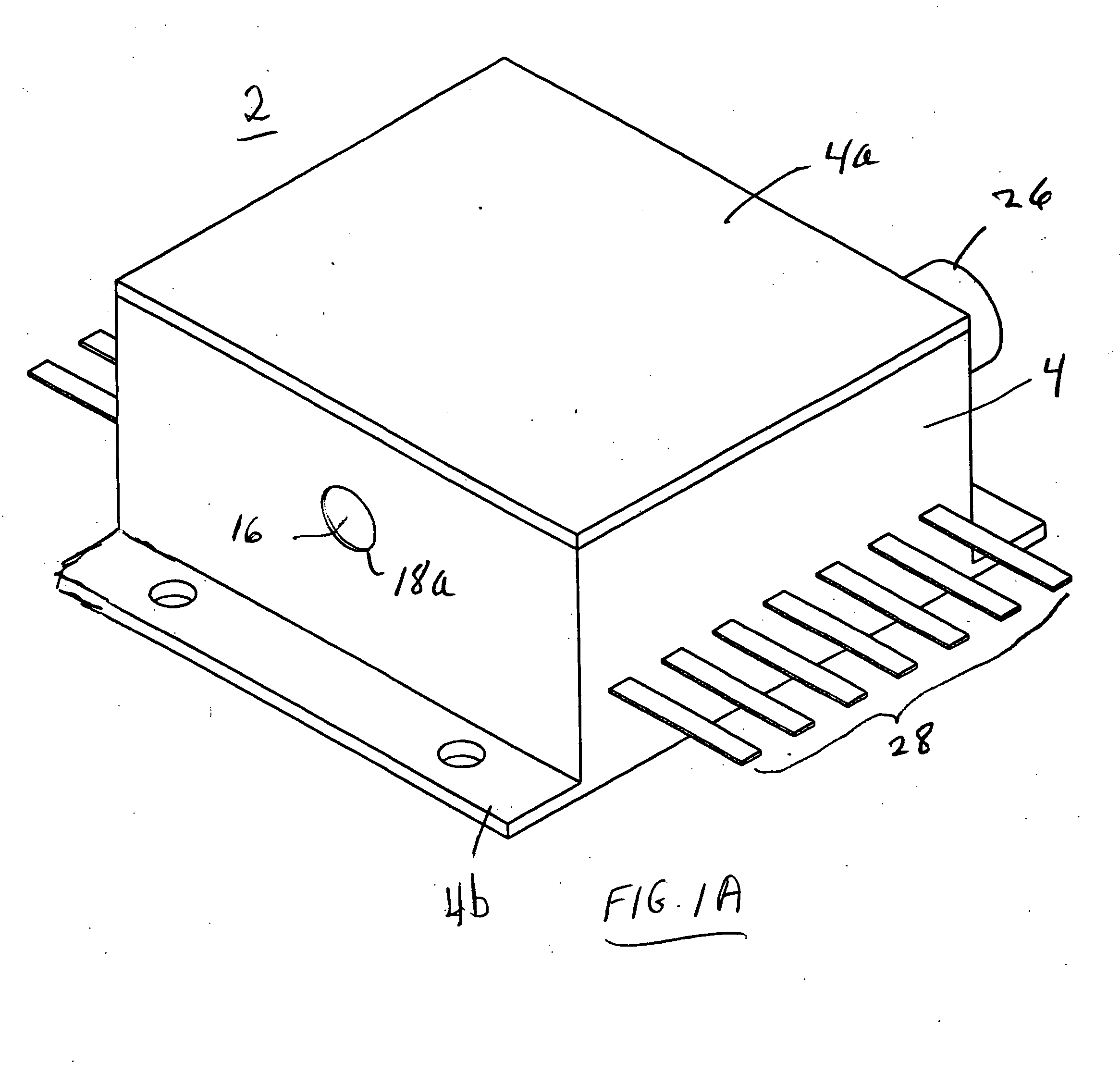

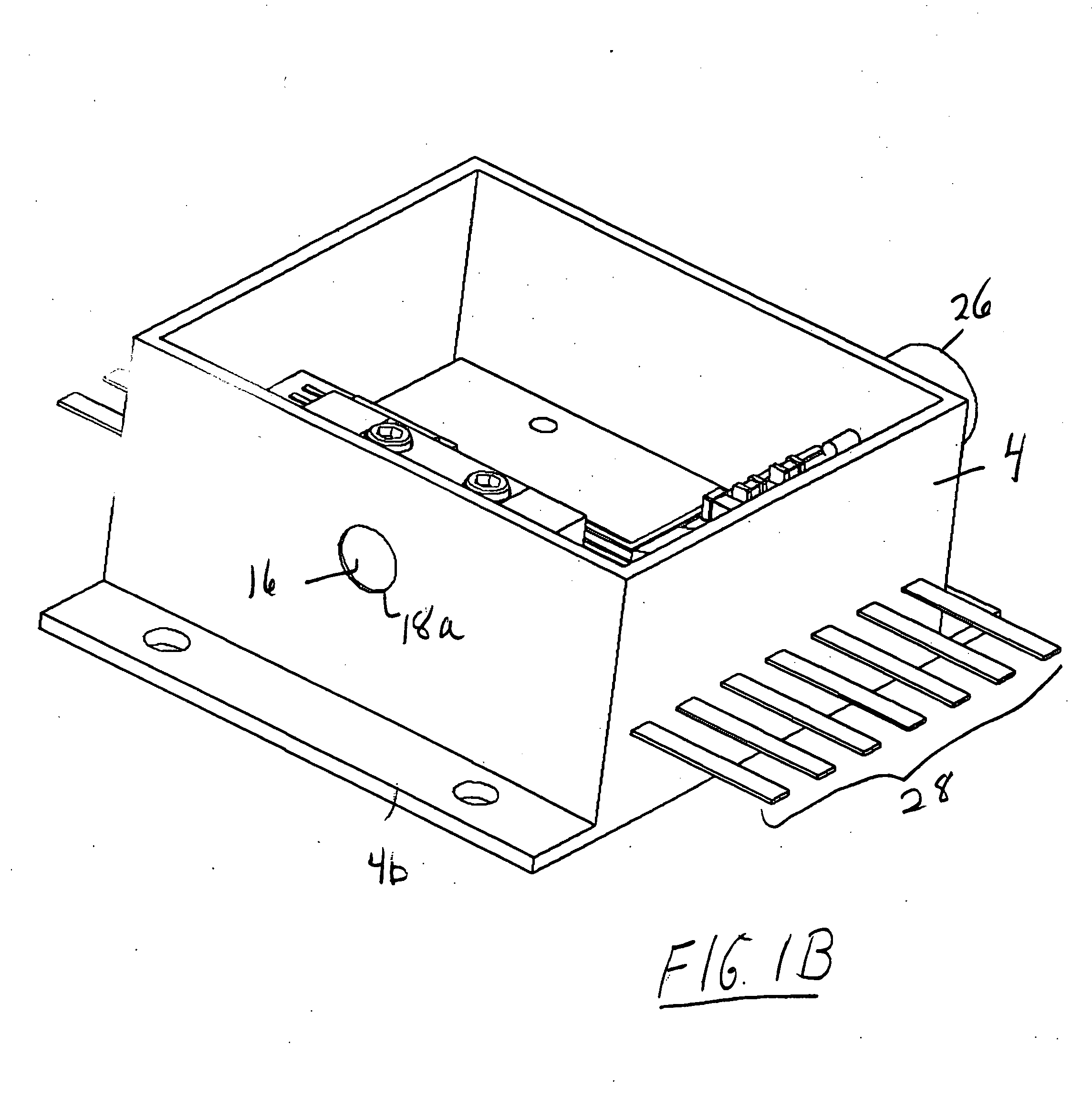

Compact mid-IR laser

ActiveUS20070291804A1Enhanced cooling techniqueLight weightLaser using scattering effectsSemiconductor laser optical deviceThermoelectric coolingAspheric lens

A compact mid-IR laser device utilizes a quantum cascade laser to provide mid-IR frequencies suitable for use in molecular detection by signature absorption spectra. The compact nature of the device is obtained owing to an efficient heat transfer structure, the use of a small diameter aspheric lens and a monolithic assembly structure to hold the optical elements in a fixed position relative to one another. The compact housing size may be approximately 20 cm×20 cm×20 cm or less. Efficient heat transfer is achieved using a thermoelectric cooler TEC combined with a high thermal conductivity heat spreader onto which the quantum cascade laser is thermally coupled.

Owner:DAYLIGHT SOLUTIONS

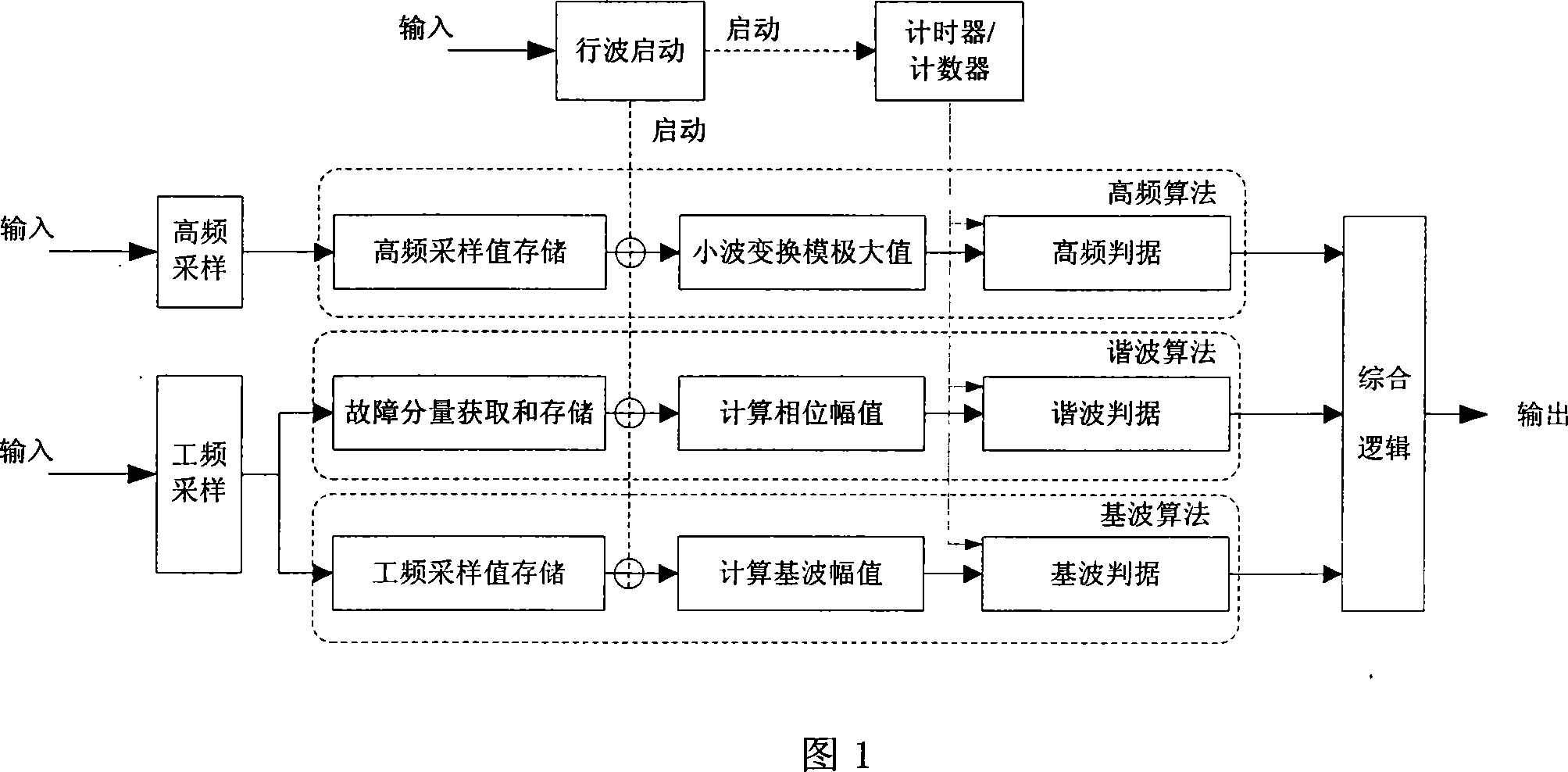

High resistance earthing fault detection method based on transient traveling wave

ActiveCN101187687AIncreased sensitivityEliminate distractionsEmergency protective arrangements for automatic disconnectionFault locationTransient stateFault detection algorithm

The invention relates to a method for testing high impedance faults, which is based on transient traveling waves and belongs to the electric system protecting and controlling technique field. The method comprises faults actuating and faults testing, wherein the faults actuating adopts transient traveling waves electric quantity to judge actuating, The faults testing is actuated through comparing the transient traveling waves electric quantity and a threshold value. The fault testing adopts fault components to judge, faults testing results are output through an algorithm of fault detection. Three algorithms are adopted in high-resistance fault judgments, which include a high frequency algorithm, a harmonic algorithm, and a fundamental wave algorithm. The three algorithms can be used in either a single end form or in combination to judge high-resistance actuating. The method can test thoroughly each main frequency band information which may be produced when high resistance faults occur.

Owner:北京清源继保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com