Apparatus and method for monitoring pipeline leakage based on distributed optical fiber acoustic sensing technology

A distributed optical fiber and acoustic sensing technology, used in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as leak location capability and difficulty in detecting leaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

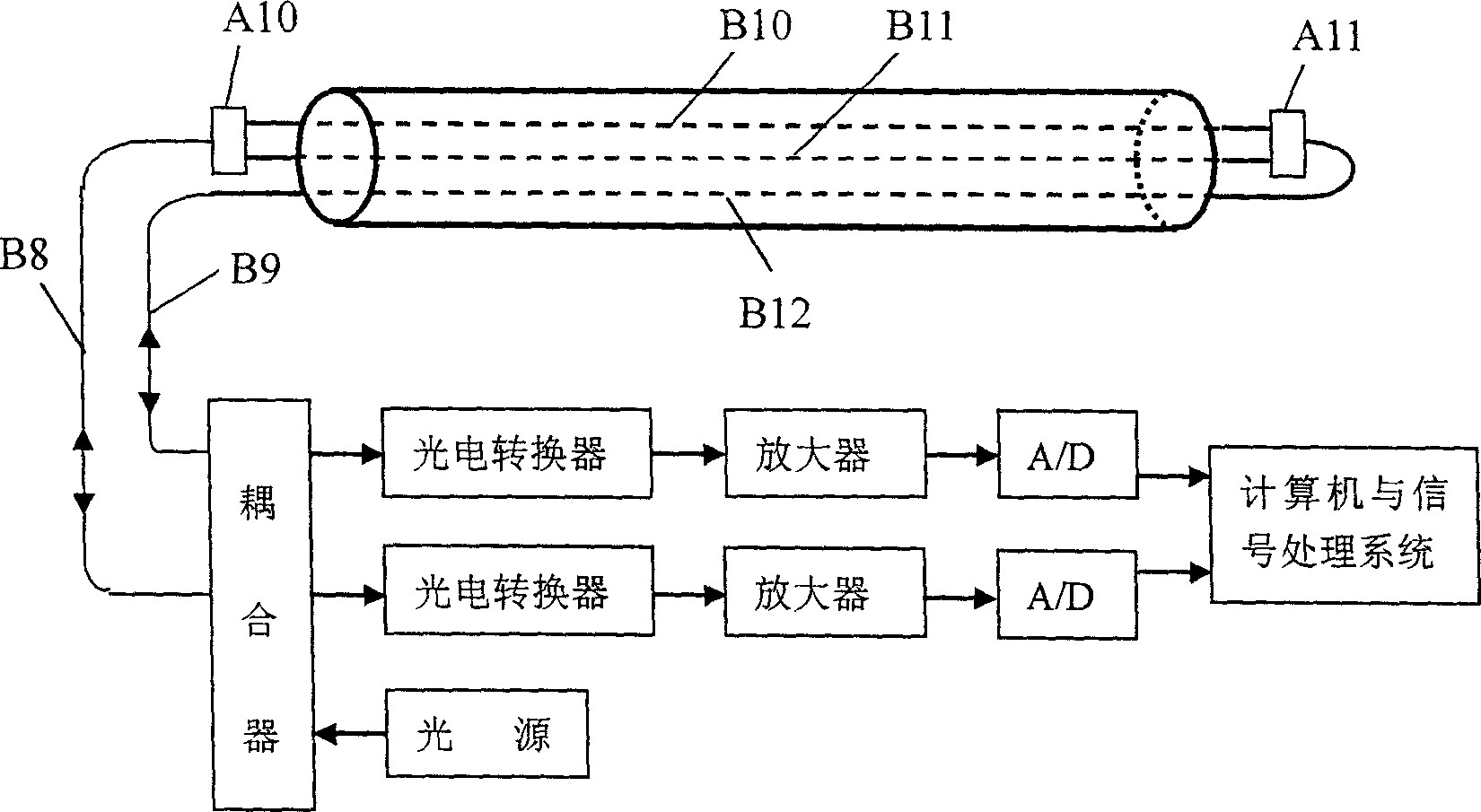

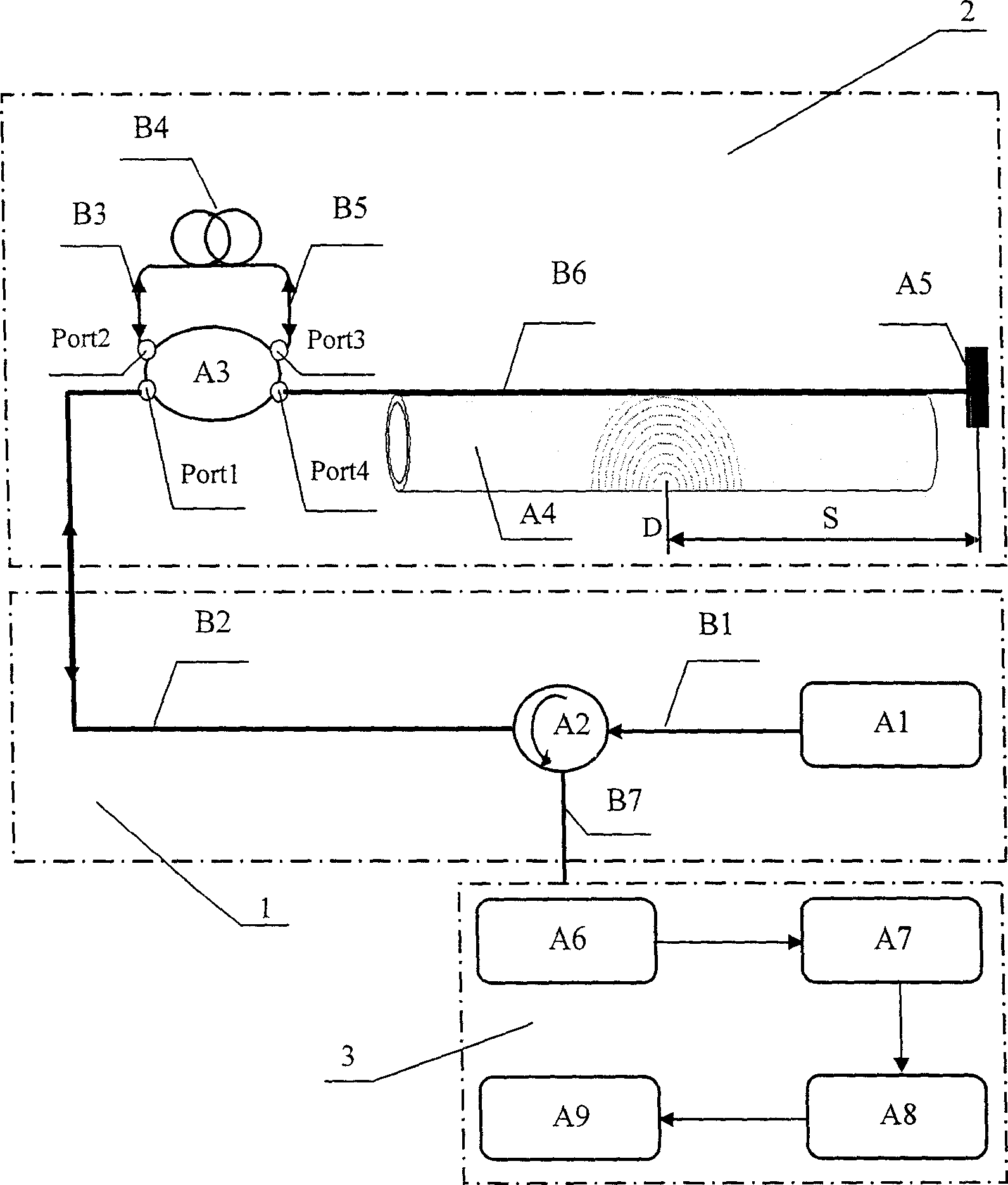

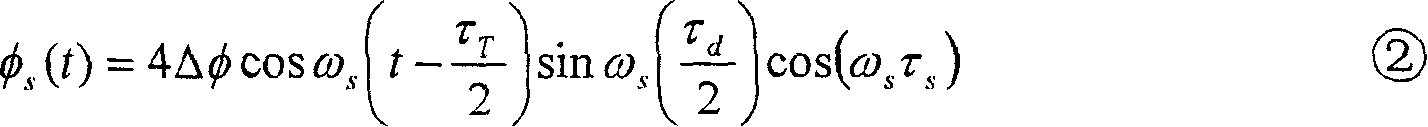

[0029] For the specific structure of this embodiment, see figure 2 , the device is mainly composed of an optical path system 1, a distributed optical fiber sensing system 2, and a detection system 3. Optical path system 1 is composed of JW-3107 ASE broadband continuous light source A1, optical circulator A2, and first guiding fiber B2; distributed optical fiber sensing system 2 is composed of first coupler A3, delay coil B4, and reflector A5; Detection system 3 is composed of 1811 photoelectric converter A6, demodulation system A7, A / D converter A8 and computer A9. Wherein, the ASE broadband continuous light source A1 of the optical path system 1 is connected to the optical circulator A2 through the first single-mode optical fiber B1, and the optical circulator A2 is connected to the Port1 port of the first coupler A3 through the first guiding optical fiber B2, and the first coupling The Port2 port of the coupler A3 is connected to the delay coil B4 through the second single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com