Patents

Literature

342results about How to "Short structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellular plastic material

An improved cellular plastic material comprises a urethane foam that is the reaction product of soy oil, an isocyanate, and a cross linker. The soy oil replaces the polyol typically generally required in the production of urethanes. Because the replaced polyol is a petrochemical, use of a renewable and environmentally friendly material such as soy oil is most advantageous. Further, plastic materials of many final qualities may be formed using a single vegetable oil. In addition to cellular foams, solid plastic elastomers may be formed.

Owner:URETHANE SOY SYST +1

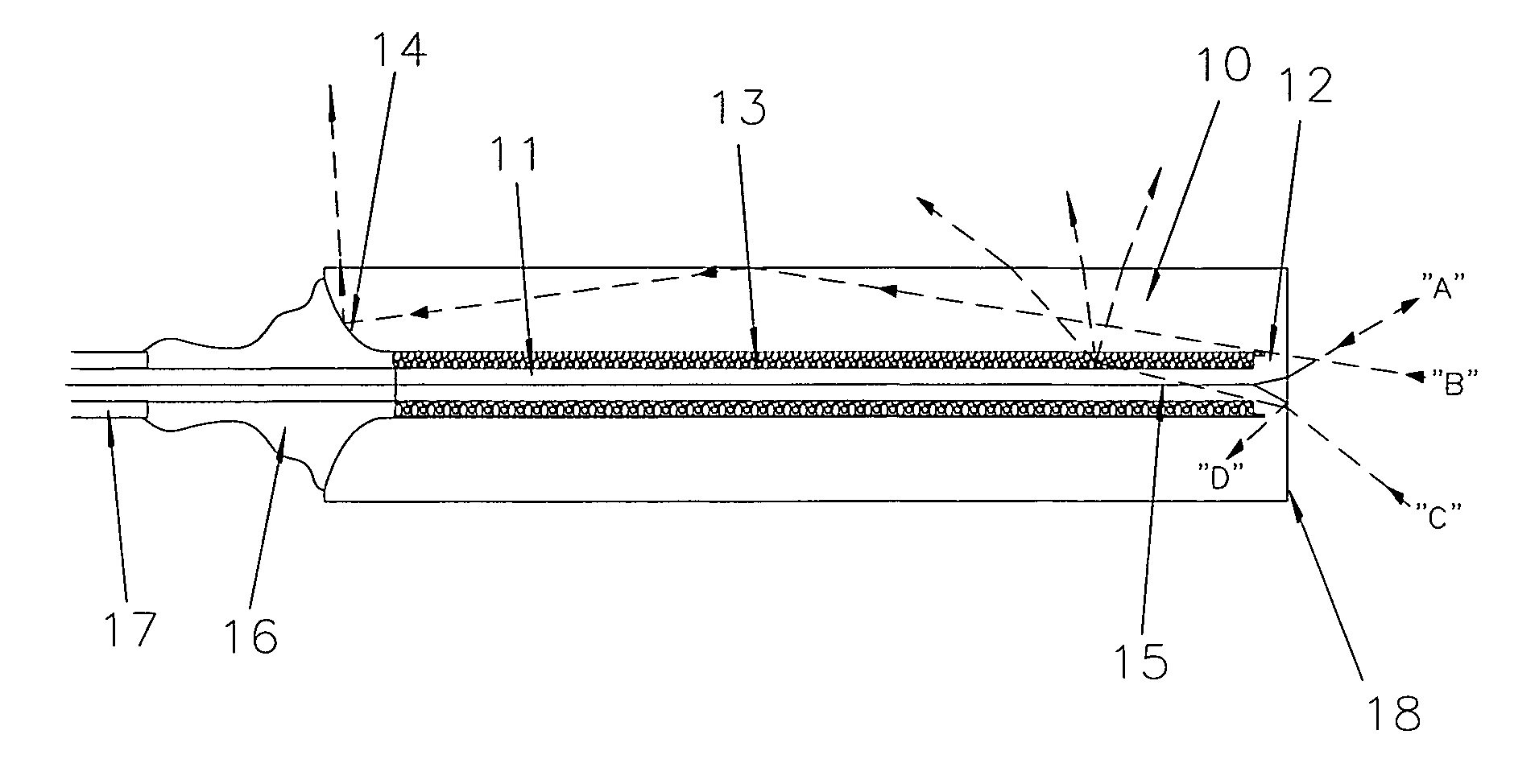

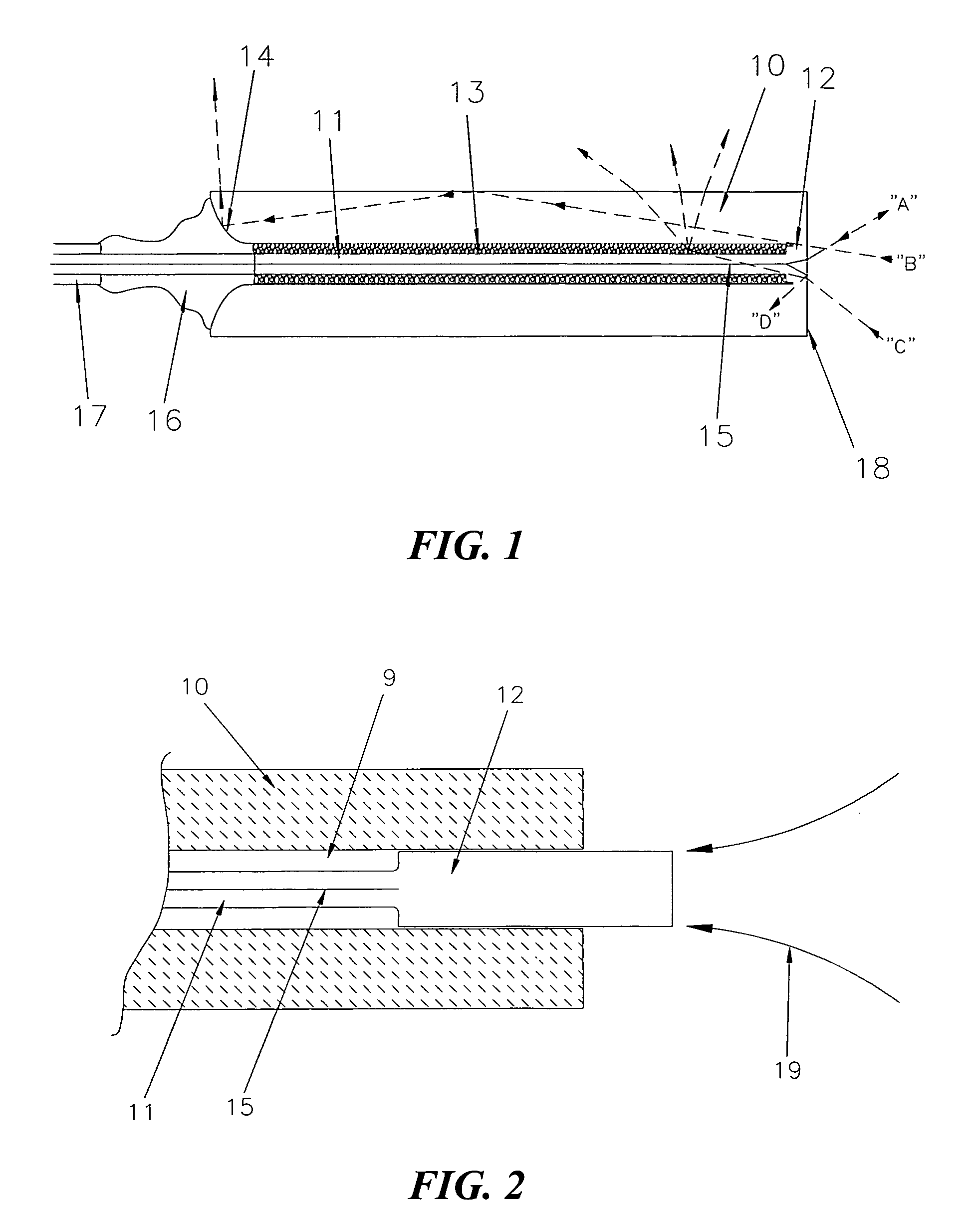

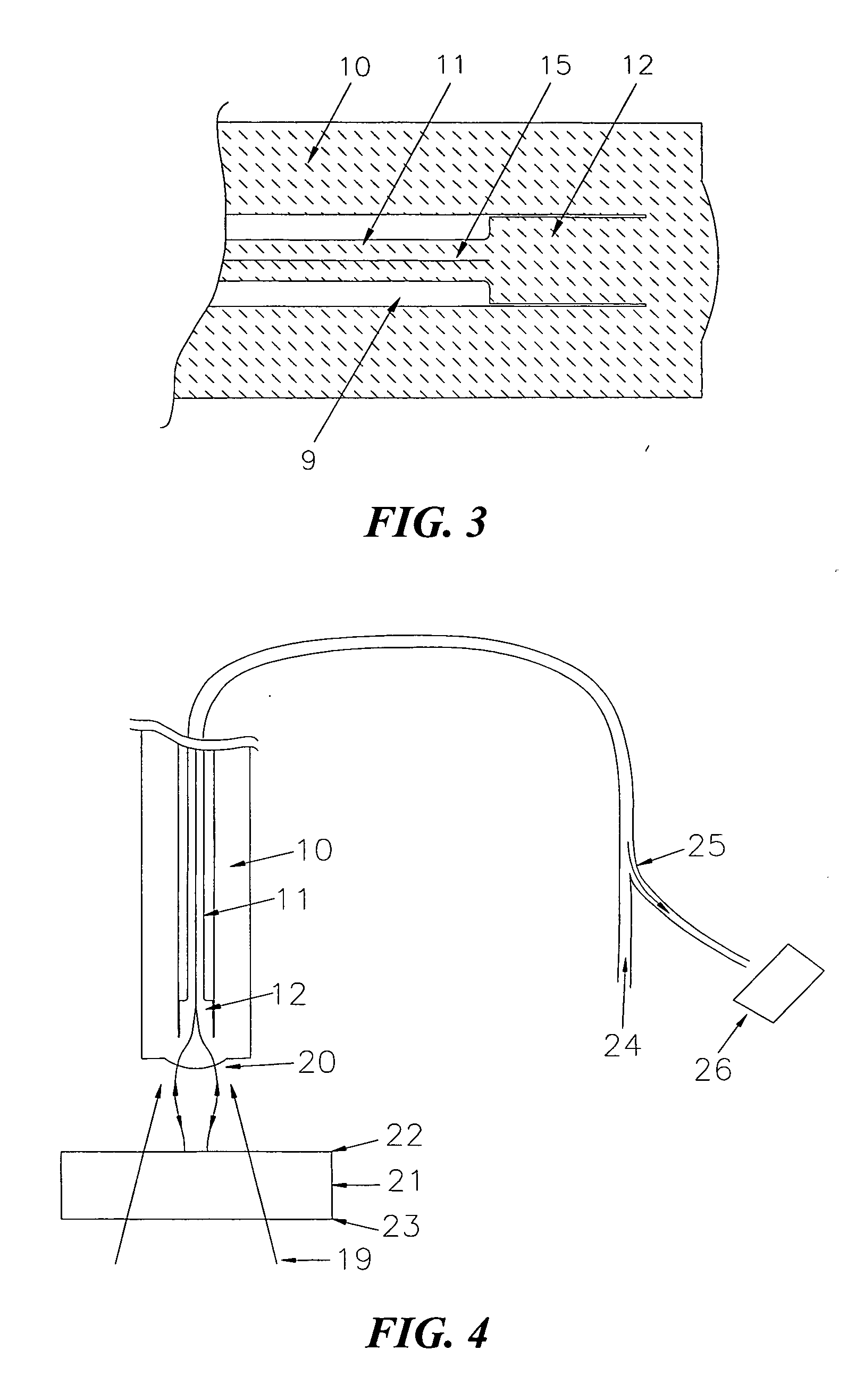

Monolithic mode stripping fiber ferrule/collimator and method of making same

A monolithic ferrule / endcap / optical fiber structure is provided wherein an optical fiber is terminated in a ferrule and bonded by fusion to form a monolithic unit which minimizes optical loss and is typically capable of transmitting high power laser radiation, preferably on the order of 500 W and higher, without damage to the optical fiber and ferrule. Ferrule, endcap, optical fiber and fusible powder are composed of material of substantially the same physical characteristics such that, when all are fused together, the structure so formed is monolithic and the optical path is transparent.

Owner:ELECTRO OPTICS TEVCHNOLOGY

Method for preparing super-hydrophobic fabric through polyphenol modification

ActiveCN106087404AIncrease productivityGood soaping resistanceFibre treatmentTextile technologyIron(III) chloride

The invention discloses a method for preparing super-hydrophobic fabric through polyphenol modification, and belongs to the technical field of weaving. The method comprises dipping fabric successively in a ferric chloride solution and a polyphenol compound solution, so as to obtain fabric of which the surface is modified by a metal-polyphenol layer; then dipping the fabric of which the surface is modified by the metal-polyphenol layer into an ethanol-water mixed solution containing a low-surface-energy substance, reacting for 6-24 h, washing successively by deionized water and absolute ethyl alcohol, and drying the fabric at 40 DEG C in vacuum for 5-10 h, so as to obtain phenol-modified super-hydrophobic fabric. The super-hydrophobic fabric possesses extremely good soaping resistance and efficient endurable hydrophobicity, the static contact angle is still larger than 150 DEG after the fabric is washing for 20 times, the fabric variety is diversified, application is wide, and the preparation technology is simple, green, friendly to environment, low in cost and suitable for large-scale production.

Owner:DONGGUAN YIMAO FILTER MEDIA

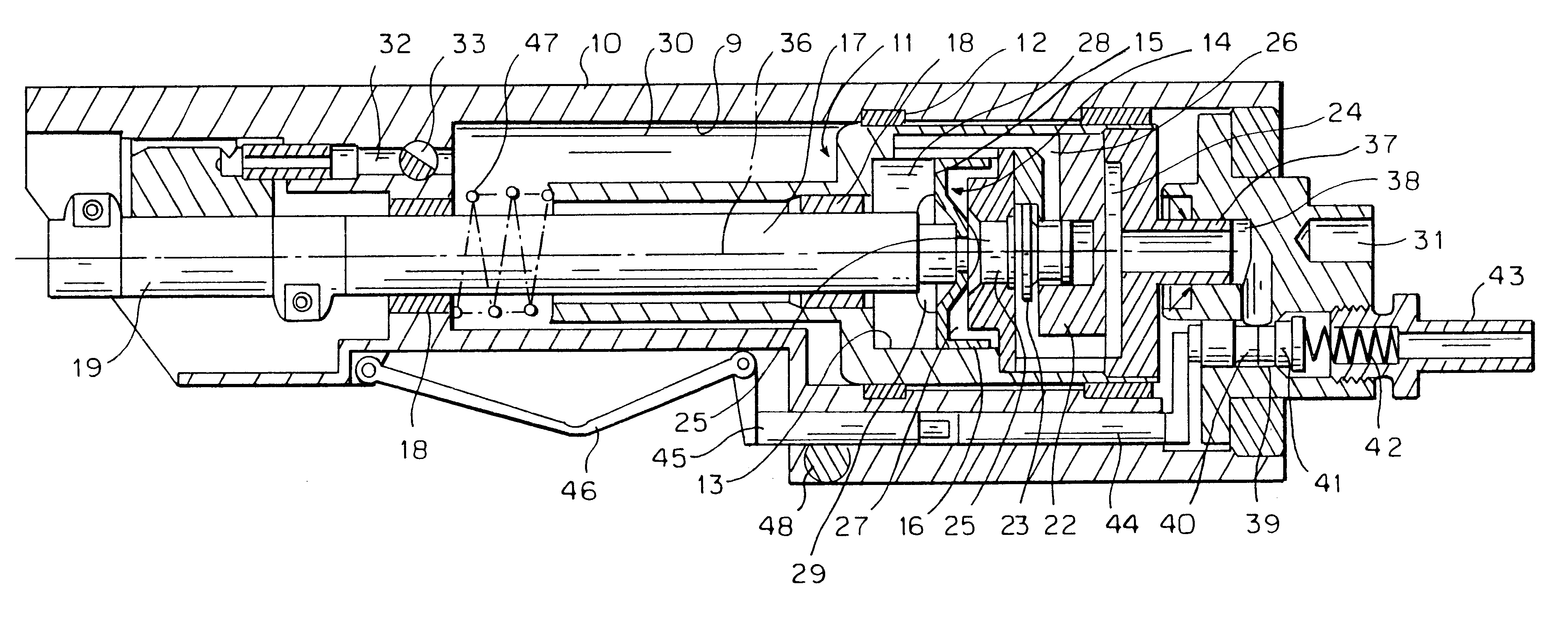

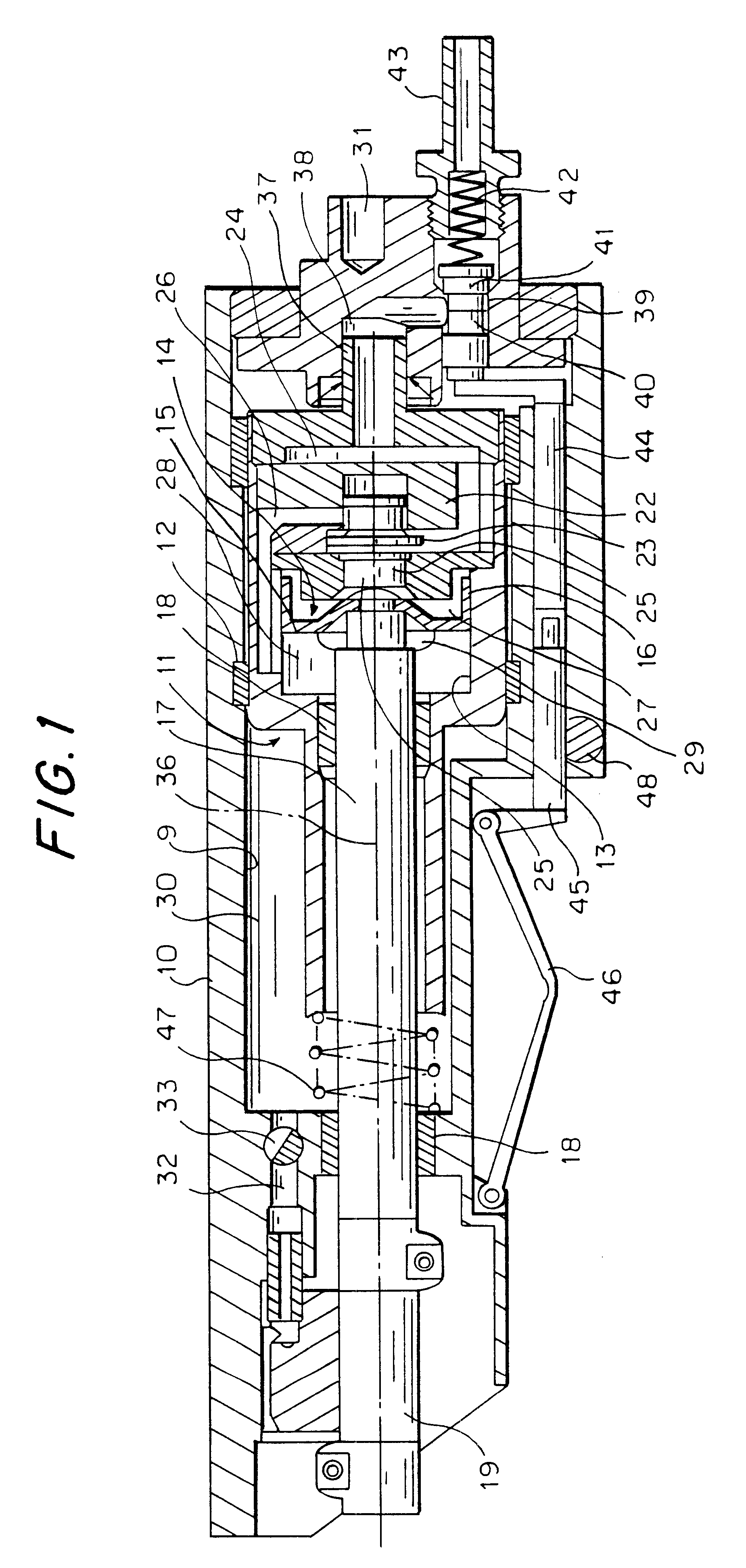

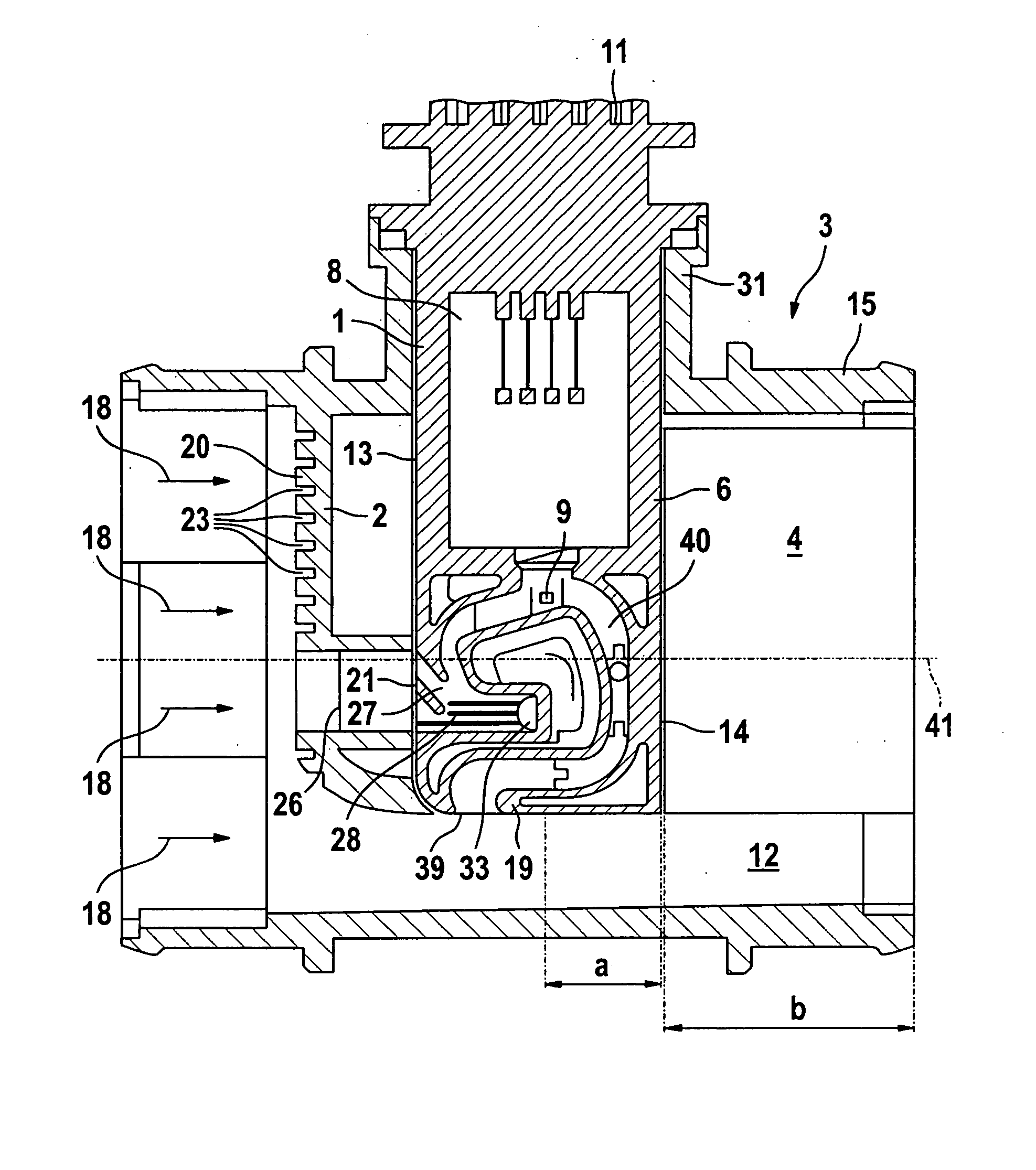

Hand-held tool with a linear oscillating drive

InactiveUS6415876B1Small outer diameterEffective vibrationMetal sawing devicesReciprocating drilling machinesHand heldEngineering

A motor housing (11) is mounted in a handle body (10) so as to slide in the longitudinal direction. A tubular pipe (37) that can slide in a bore (38) of the body (10) projects from the back of the housing (11). Compressed air can be applied to the bore (38) through a switching valve (40). A piston (14) with a piston rod (17) can slide in the housing and a tool can be secured to its front end. A flutter valve (23) which alternatingly connects the bore (38) to the two cylinder chambers (27, 28) is built into the valve housing (22). The piston (14) alternatingly opens the connection to an outgoing air conduit (29-31). A pre-stressed spring (47) is set between the body (10) and the housing (11). In operation, the housing (11) oscillates out of step with the piston (14), so that their initial forces are largely compensated and no vibrations are transmitted to the handle body (10).

Owner:BIAX MASCHEN

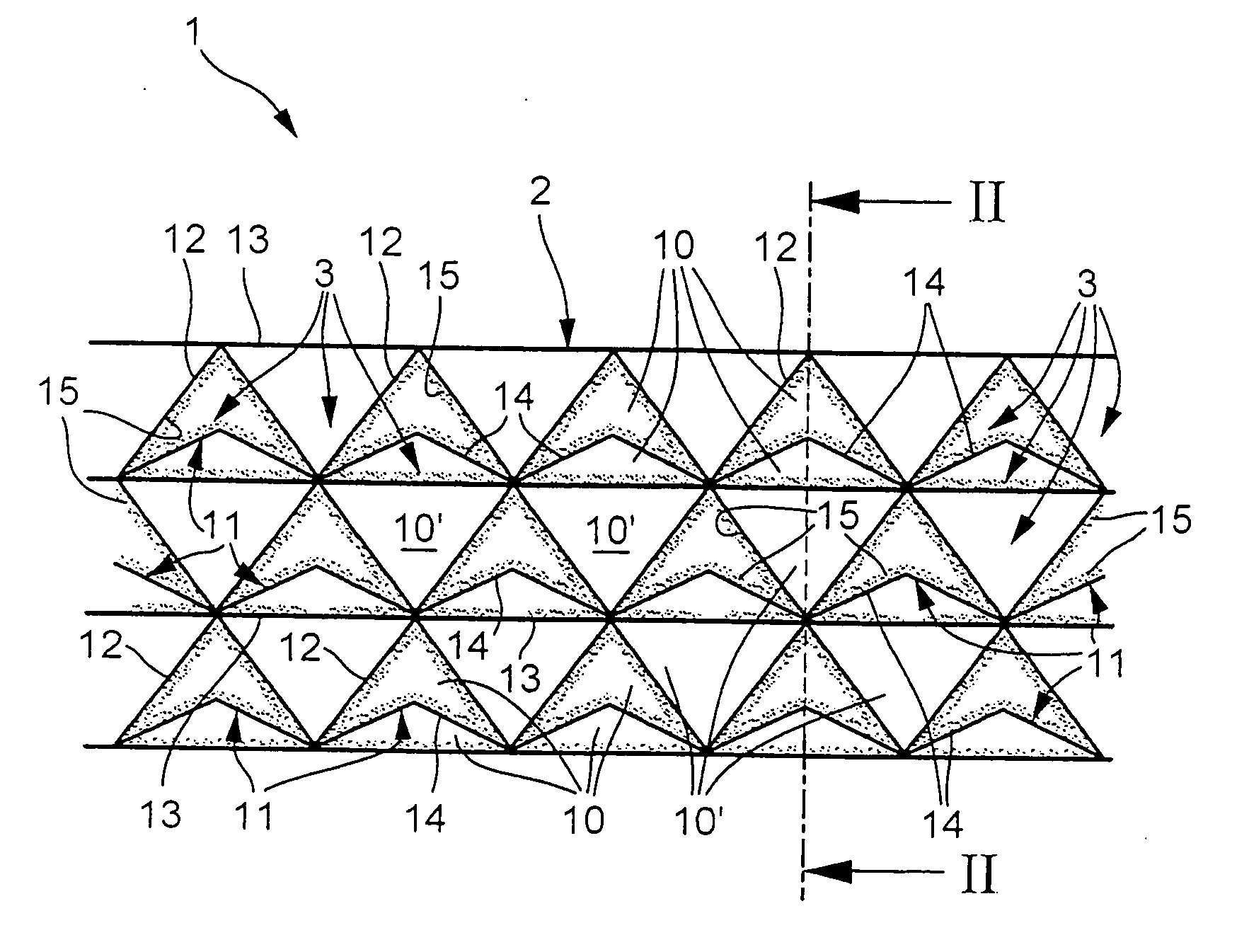

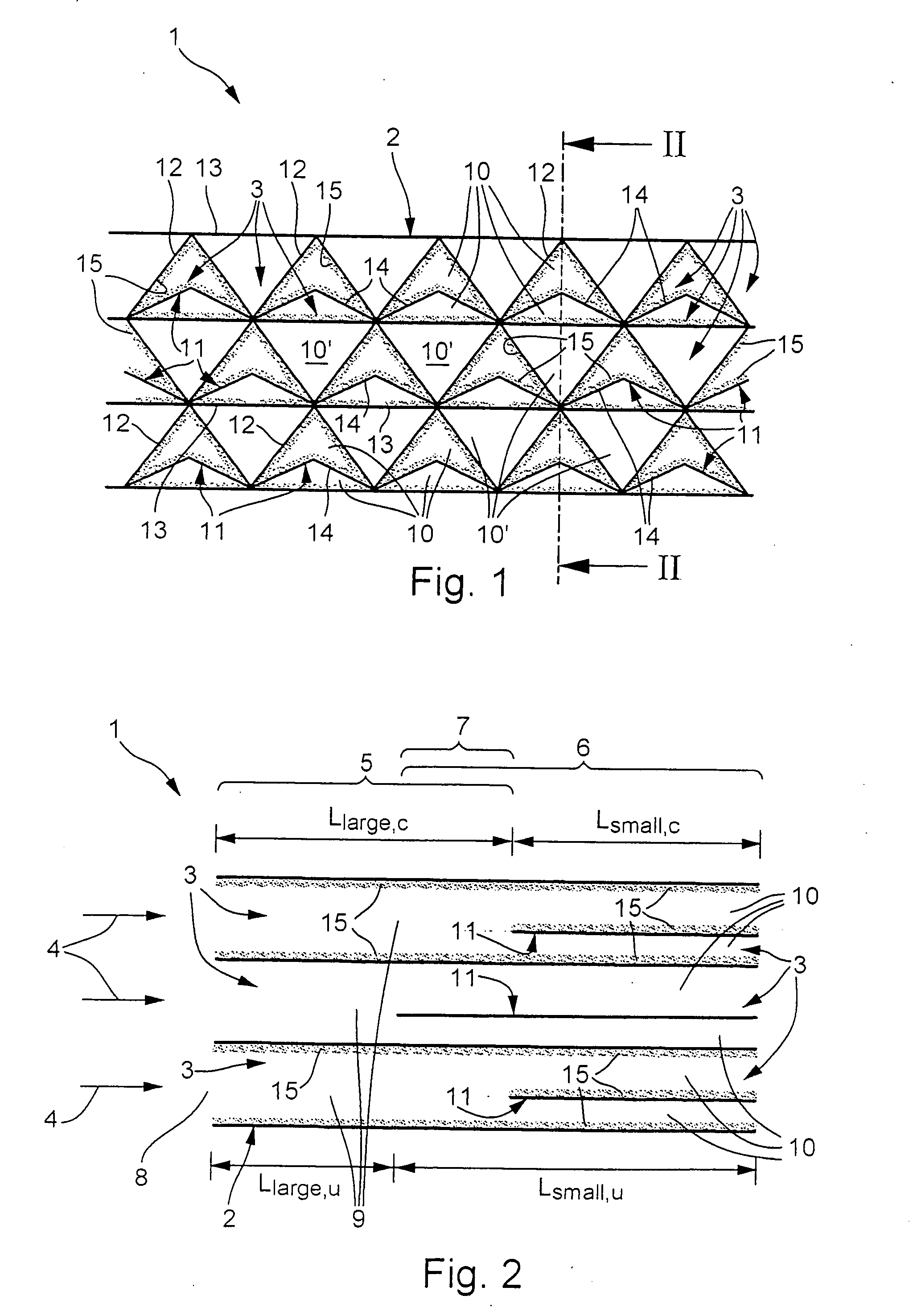

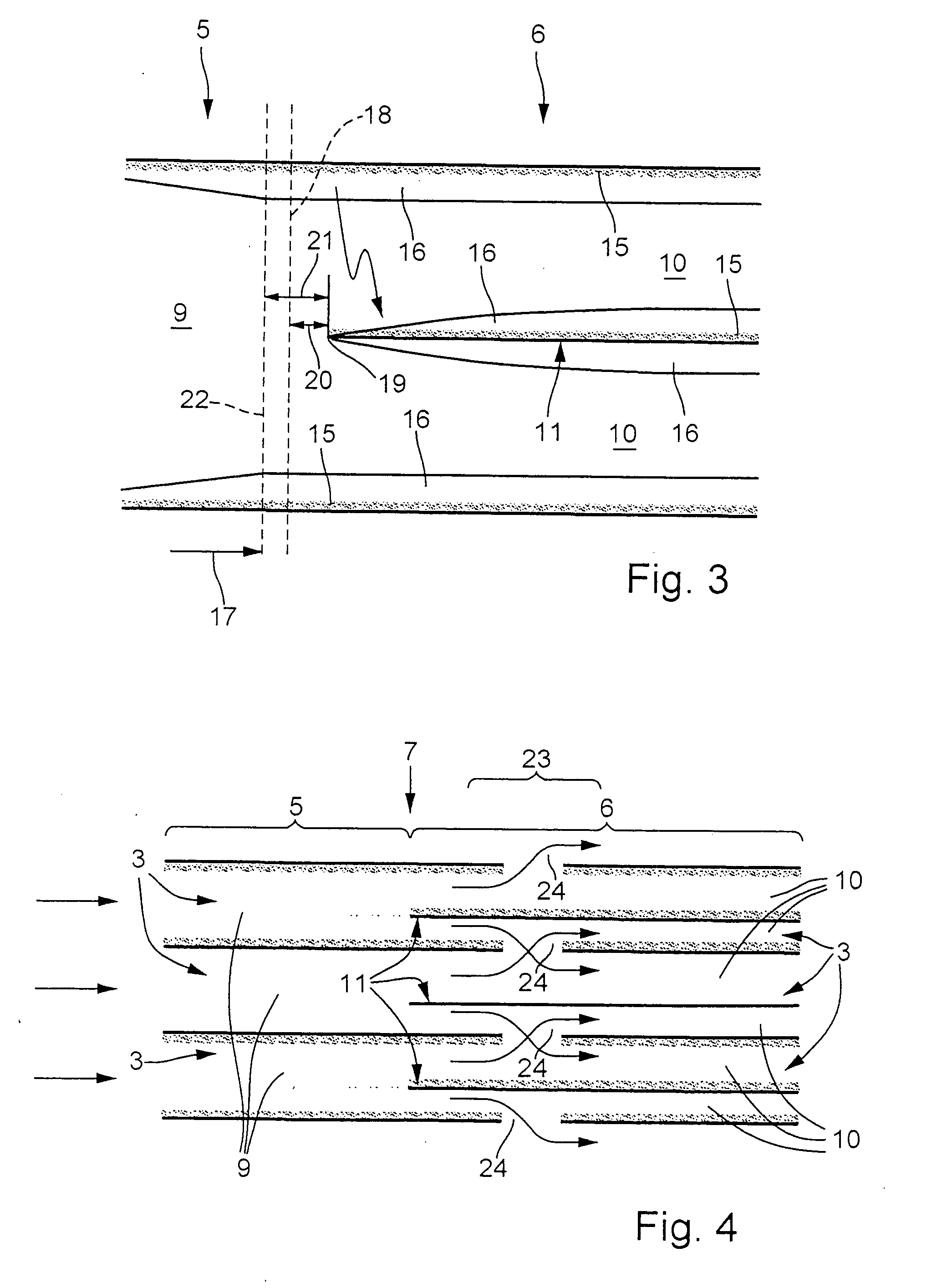

Catalyst

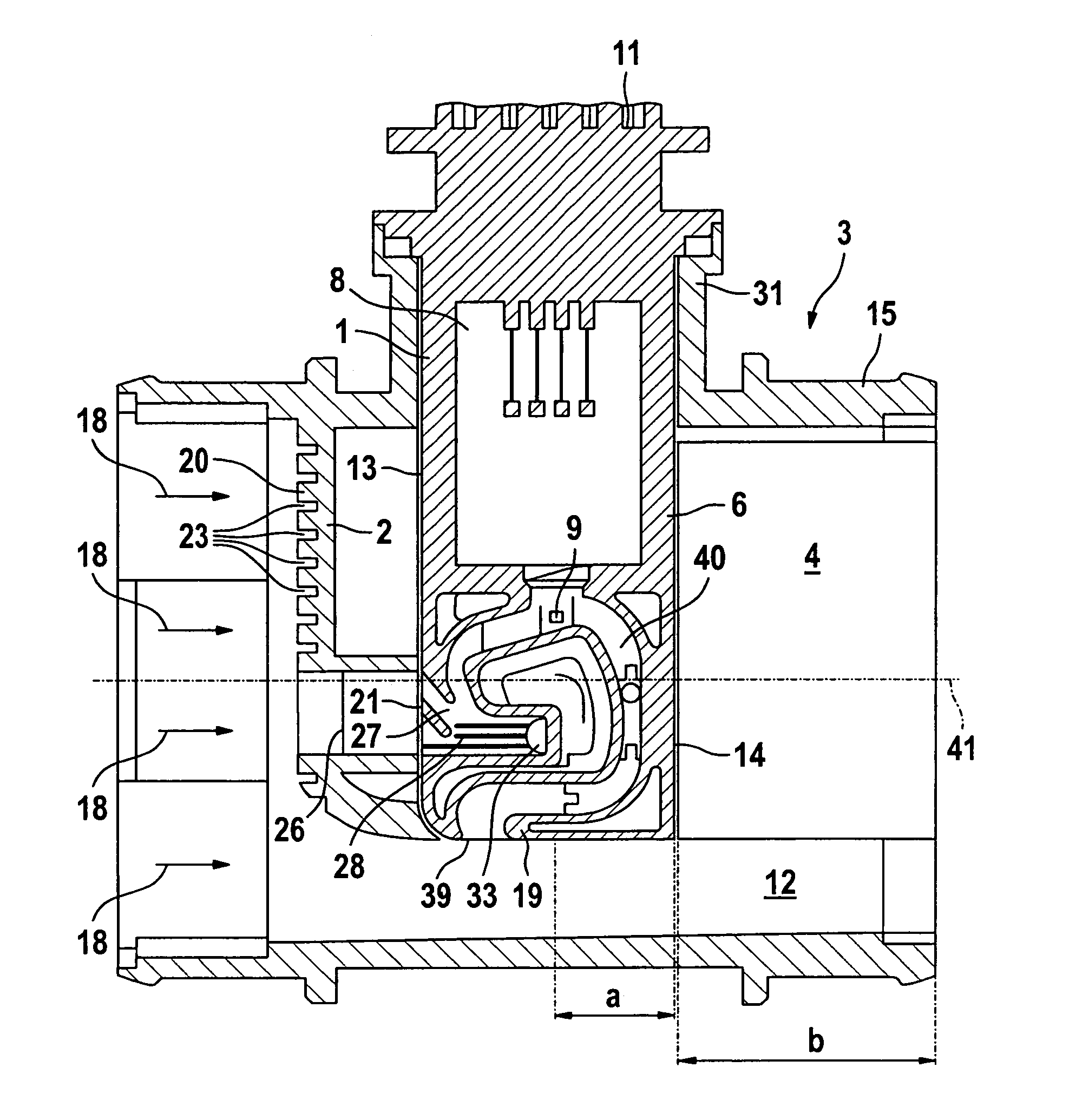

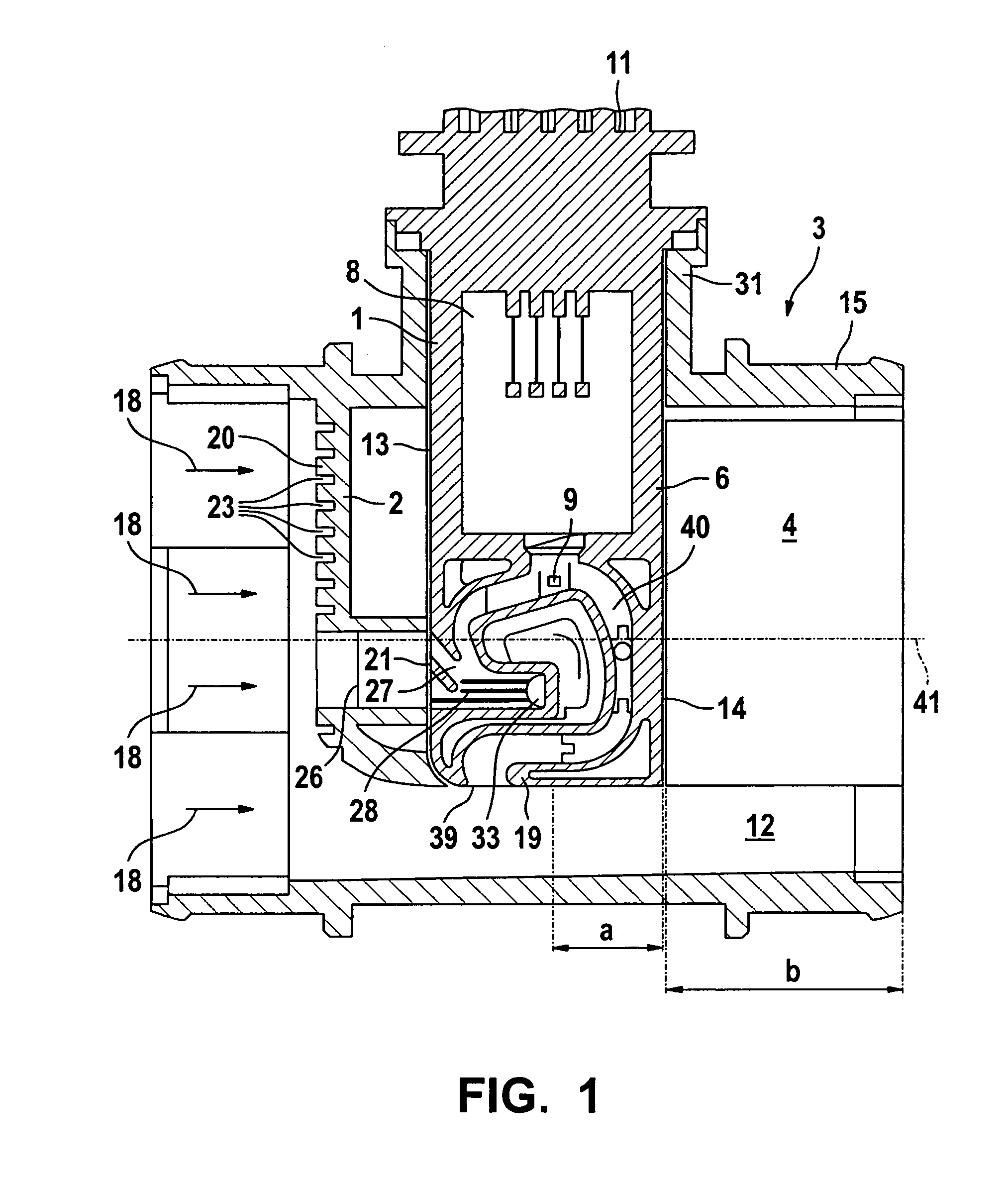

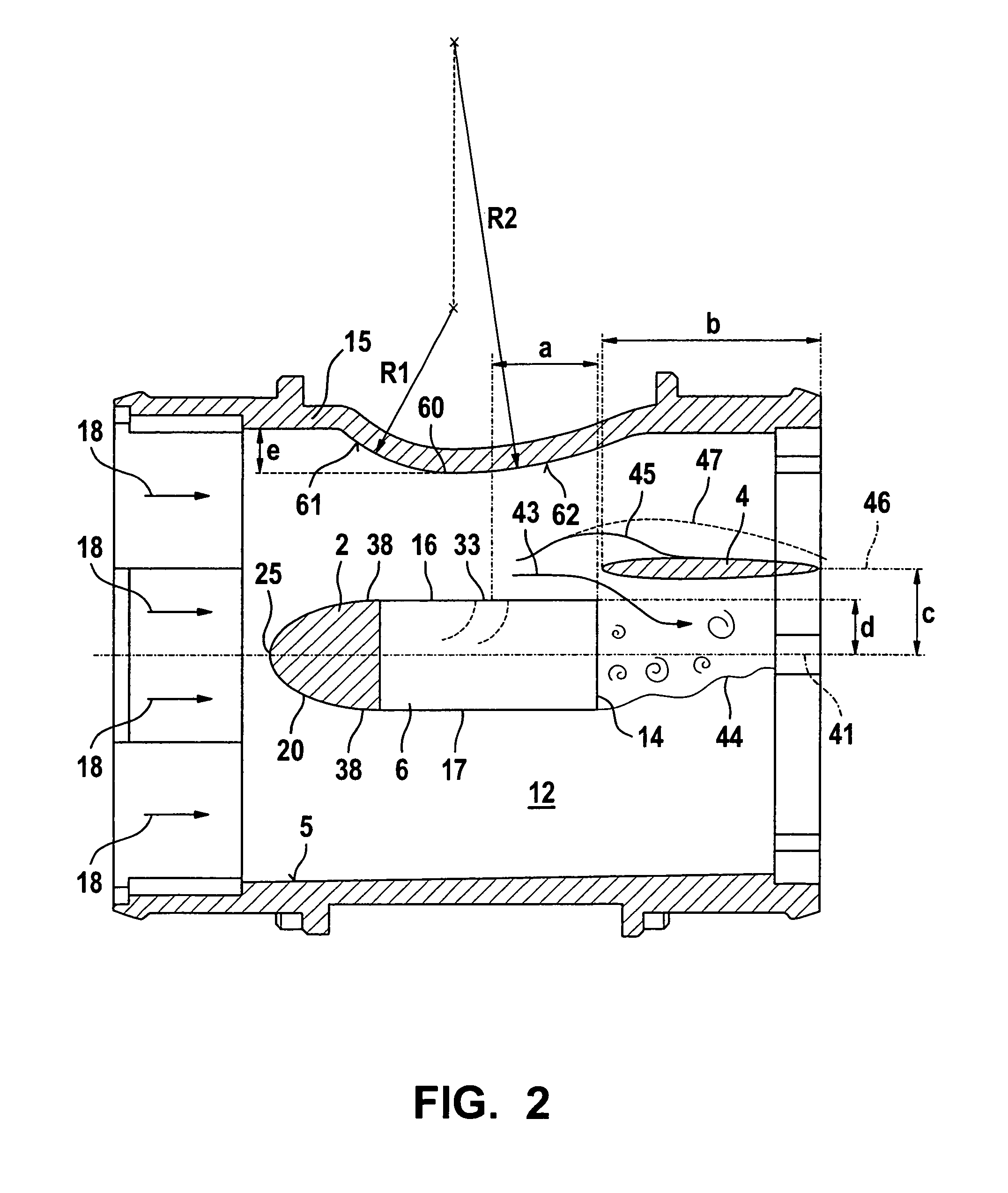

InactiveUS20050201909A1Reduced dimensionIncrease cell densityPhysical/chemical process catalystsCombustion using catalytic materialCombustionInlet channel

The present invention relates to a catalyst (1) for combustion of at least a portion of a gaseous fuel-oxidant mixture flowing through the catalyst (1), in particular for a burner of a power plant. An inlet sector (5) comprises inlet channels (9). A succeeding sector (6) comprises succeeding channels (10). The succeeding channels (10) have smaller internal cross-sectional areas than the inlet channels (9). To improve the production of the catalyst (1), the invention proposes channels (3) which extend through the inlet sector (5) and through the succeeding sector (6) and have the internal cross-sectional area of the inlet channels (9). The inlet channels (9) are formed by portions of the channels (3) lying in the inlet sector (5). The succeeding channels (10) are provided by arranging separation walls (11) within portions of the channels (3) lying in the succeeding sector (6), the separation walls (11) dividing each of the respective channel portions in the succeeding sector (6) into two succeeding channels (10).

Owner:ALSTOM TECH LTD

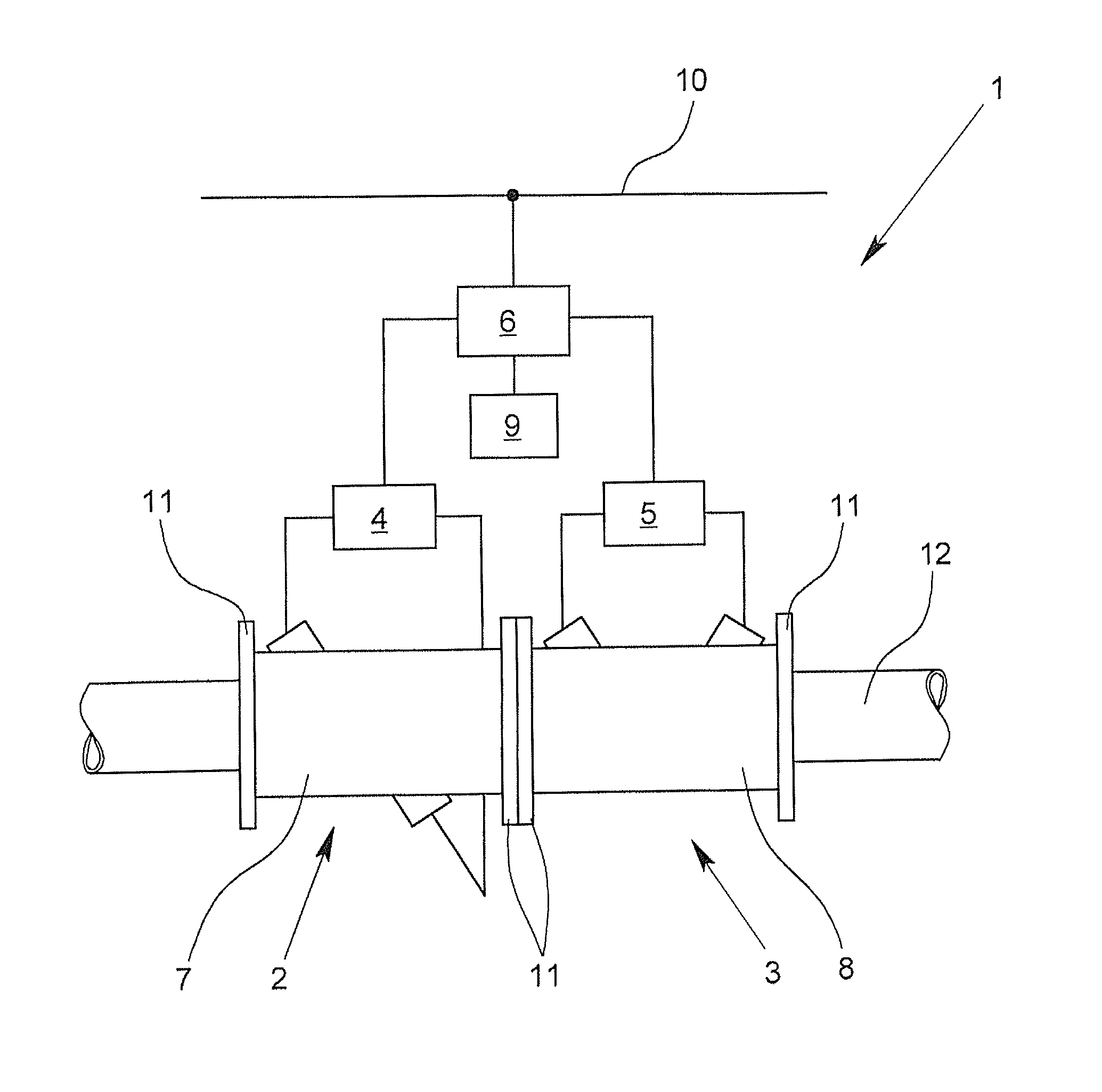

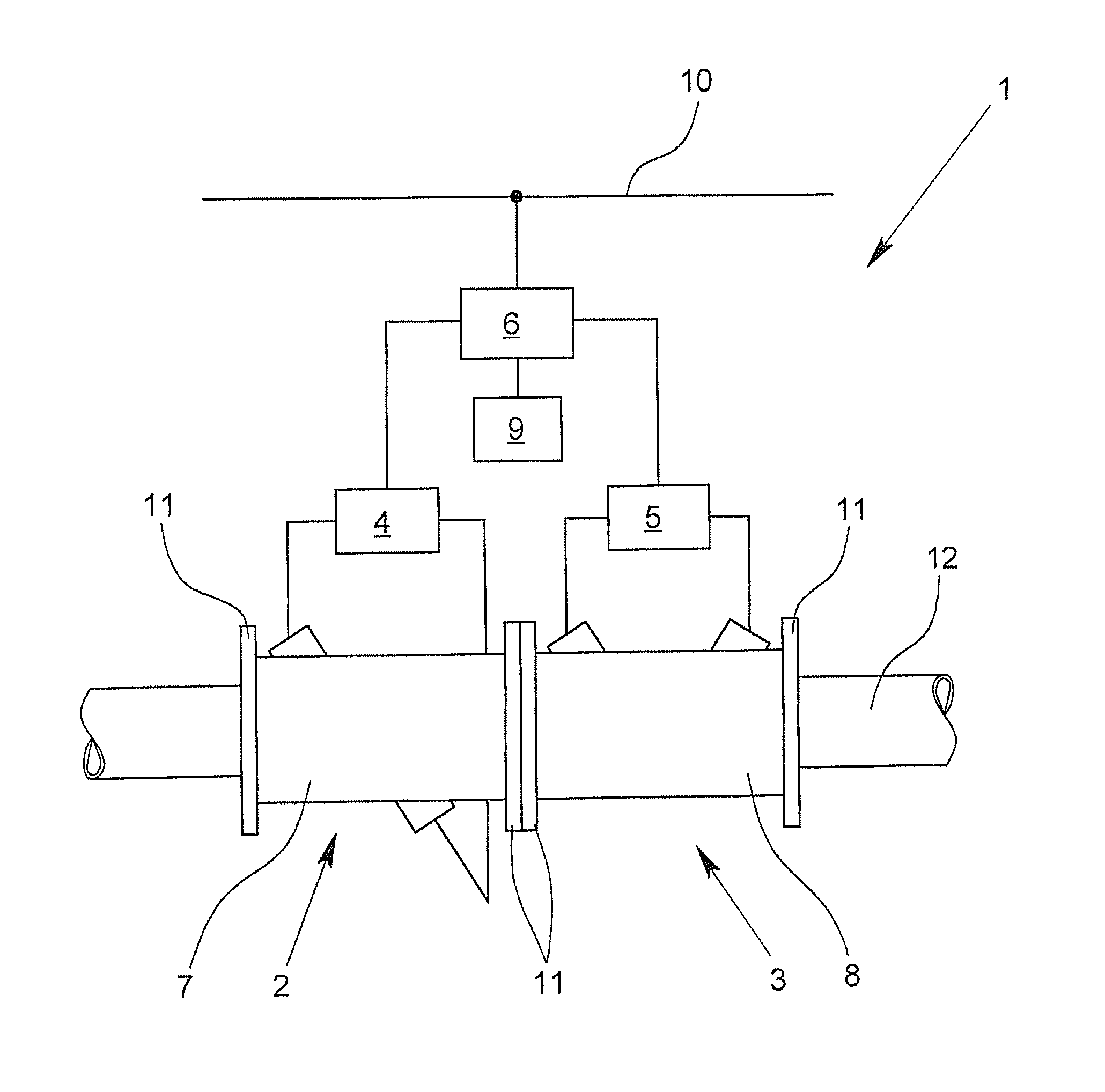

Flow-rate measurement system

ActiveUS20130340519A1Easily allows self-monitoringShort structureVolume/mass flow measurementTesting/calibration for volume flowTraffic volumeRate measurement

A system for measuring flow rate with at least a first and a second flow meter provides a flow-rate measurement system which easily allows self-monitoring. This result is achieved by the system in that the first flow meter and the second flow meter differ from one another and / or have different orientations for the flow rate measurement, and each have an evaluation unit which produces data from the flow rate measurement. Furthermore, there is a monitoring device which is connected to the evaluation units such that the monitoring device acquires data produced by the evaluation units, and which is made such that it produces at least one comparison result from a comparison of the data produced by the evaluation units and signals at least the occurrence of a fault state which is associated with at least one comparison result.

Owner:KRONE GMBH

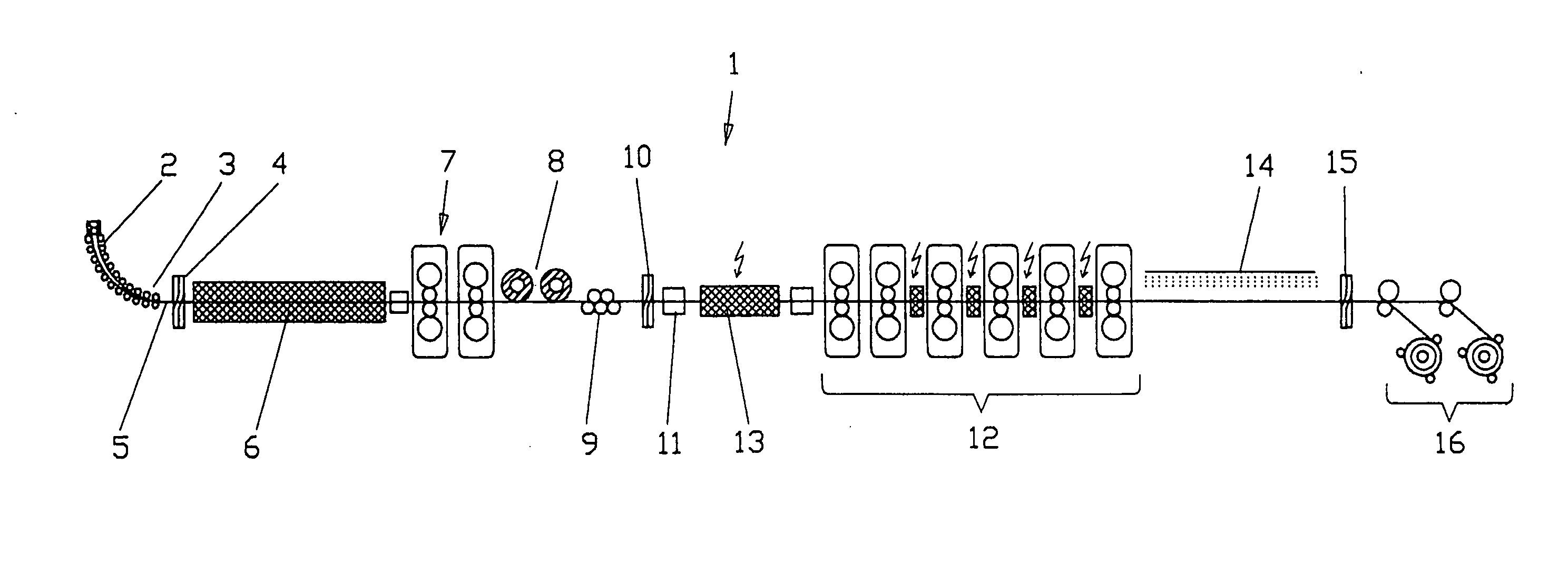

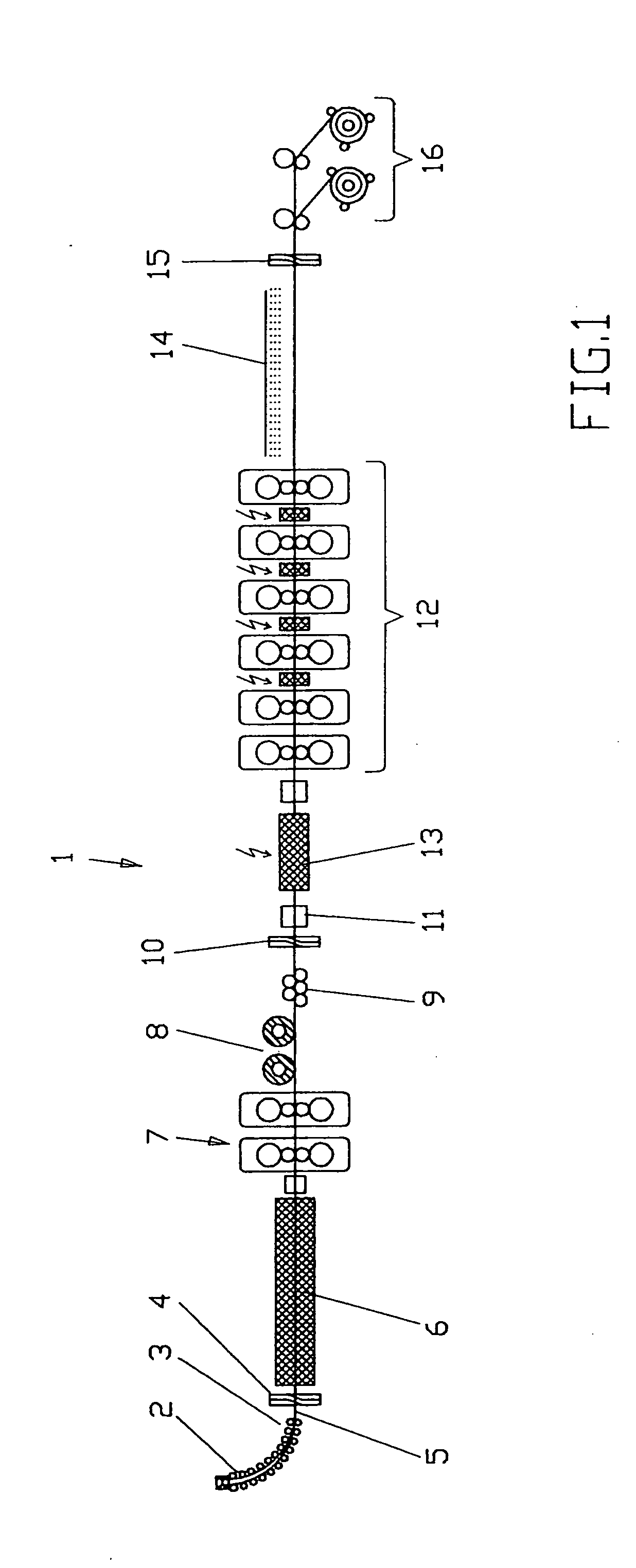

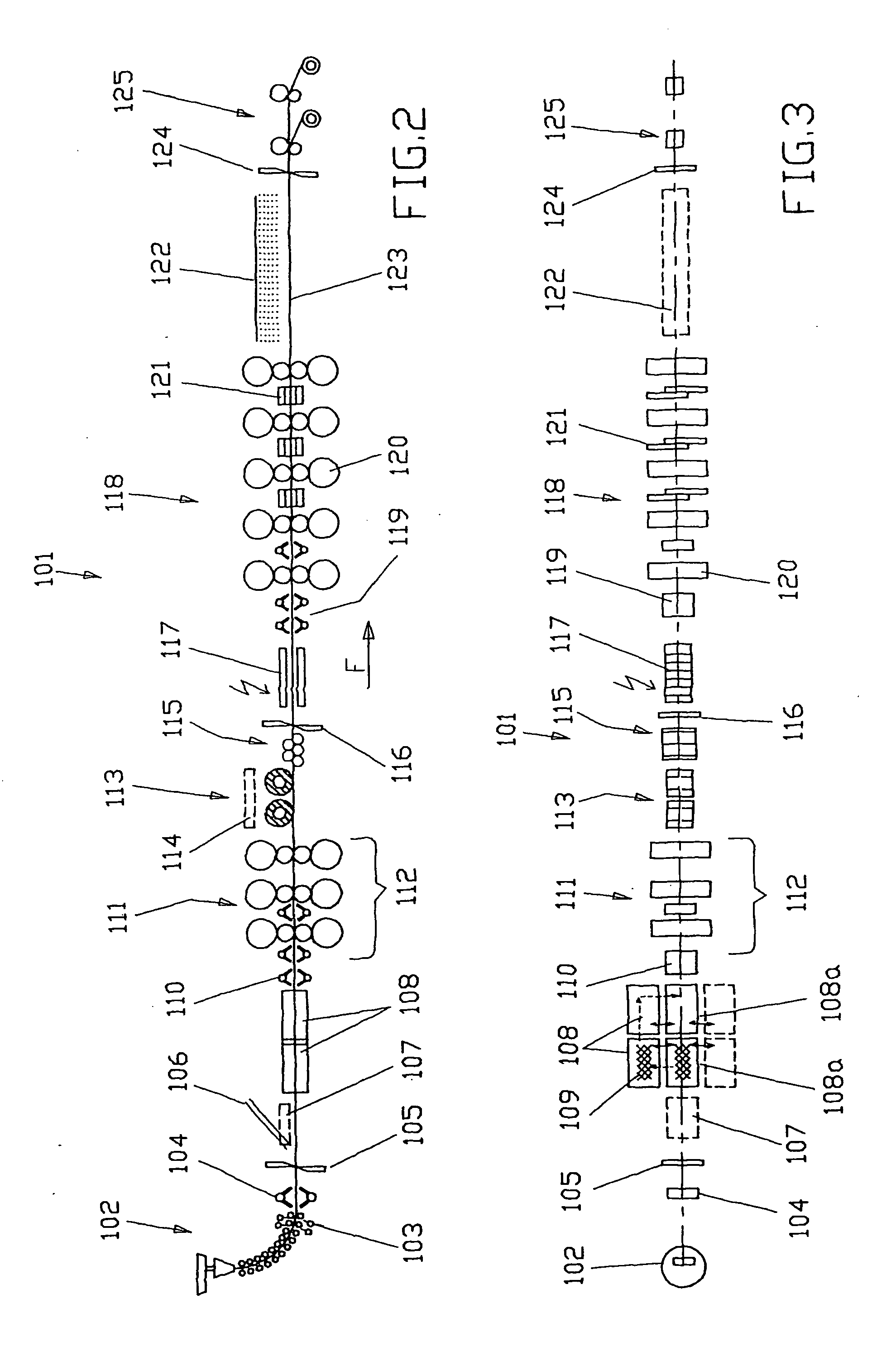

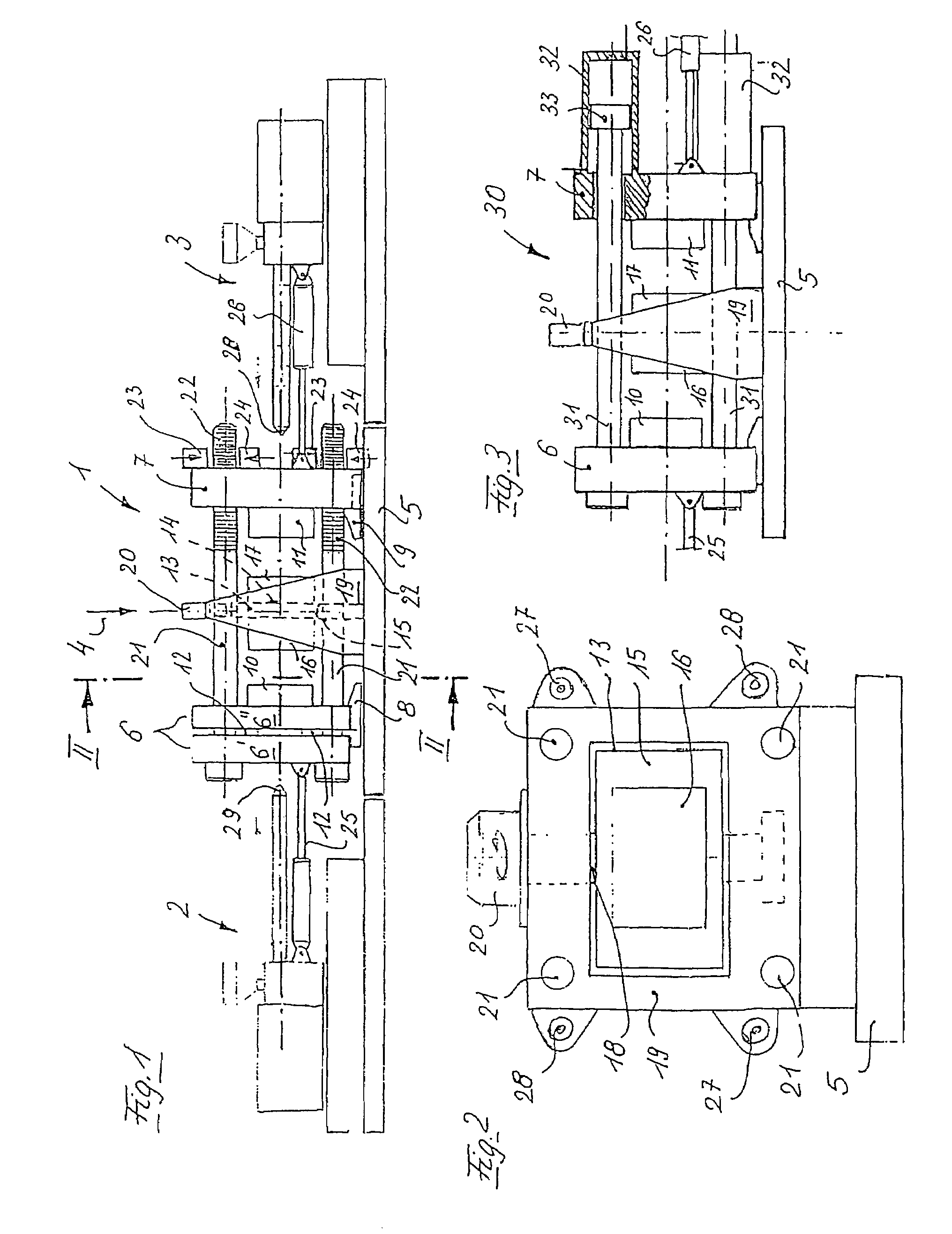

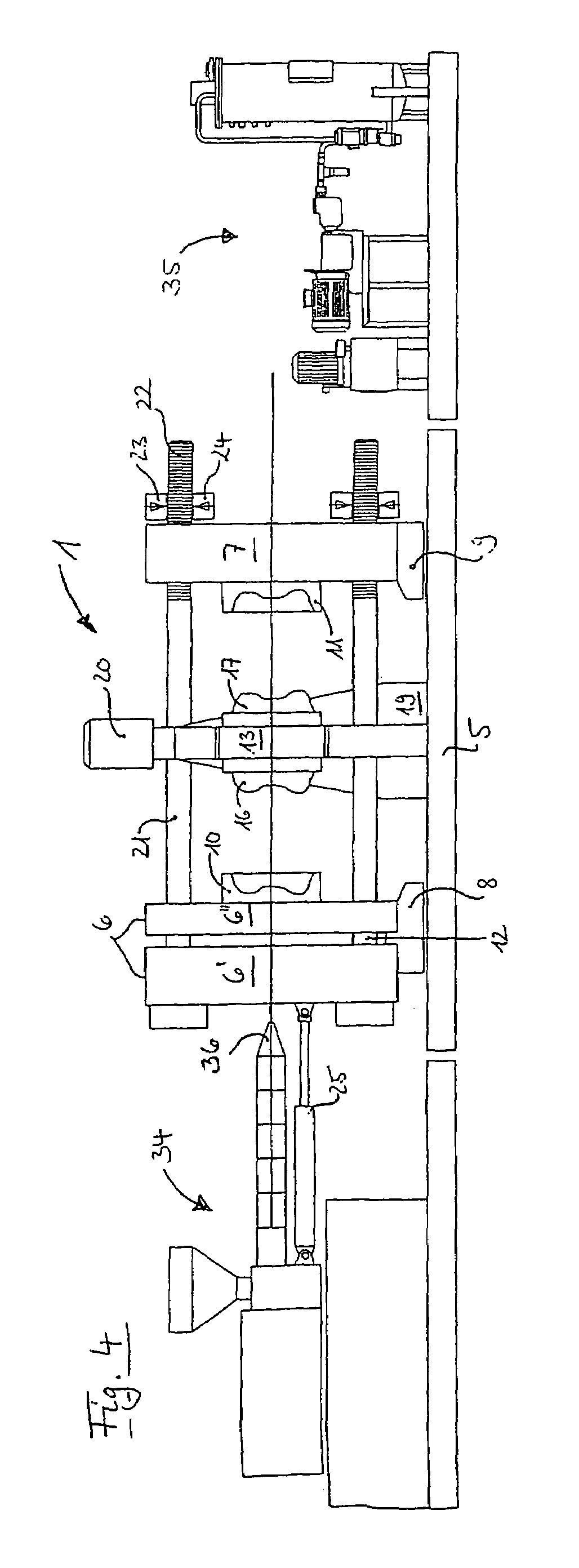

Compact, flexible csp installation for continuous, semi-continuous and batch operation

InactiveUS20100275667A1Increase holding capacityShorter lengthMetal rolling stand detailsTensioning/braking arrangementsEngineeringBatch operation

The invention relates to a compact, flexible CSP installation (1,101,201,301,401) for endless, semi-endless and batch operation with a casting machine, a roughing stand group (7,111,211) and a finishing stand group (12,118,218), wherein for the batch operation or the semi-endless operation, a coil store (8,113,213,501) is integrated into the roll table, which stores the pre-strip or slab coming from the roughing stand, with the coil store being deactivated in the case of endless operation. The coil store (8,113,213,501) is designed for an increased holding quantity of pre-strips or slabs such that two, three or more pre-strips or slabs can be wound to jumbo coils on a coil.

Owner:SMS DEMAG AG

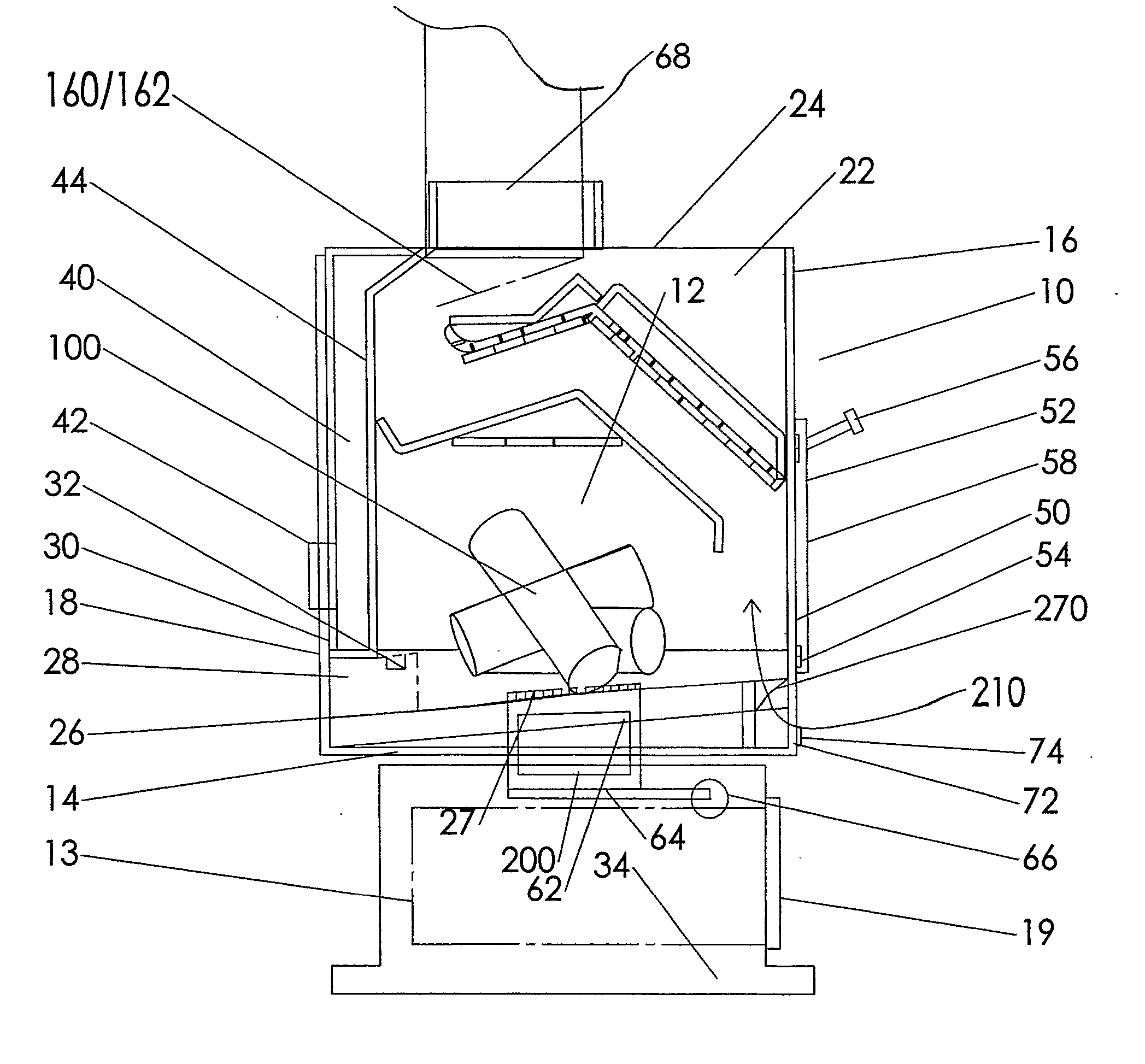

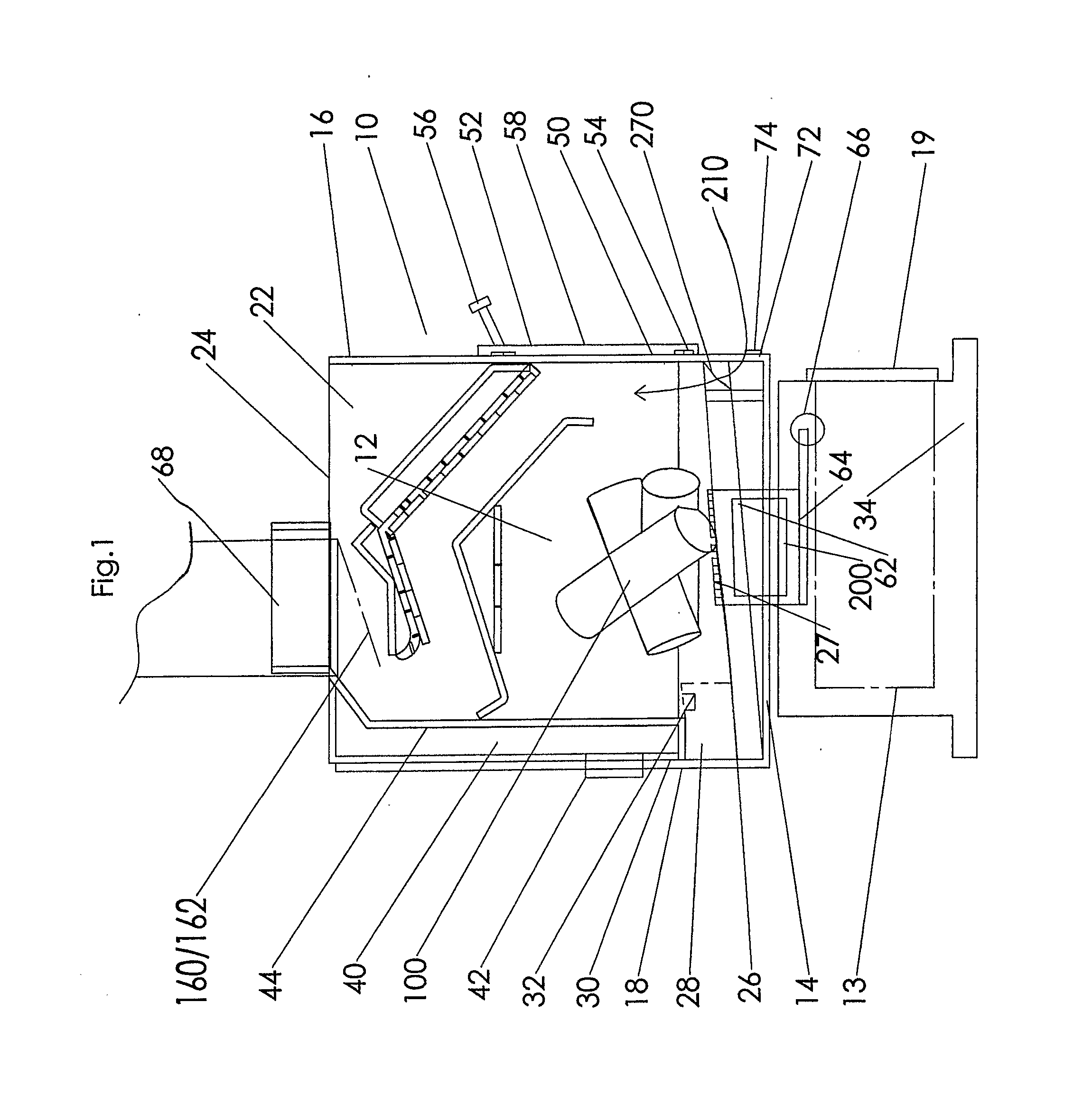

Combustion Apparatus for Solid Fuel

InactiveUS20080041357A1Emission reductionShort structureCombustion-air/flue-gas circulation for stovesIndirect carbon-dioxide mitigationSolid fuelHearth

A combustion apparatus for the burning of solid fuel using a plurality of secondary combustion zones is disclosed. The combustion apparatus includes primary and secondary air inlets, an inclined hearth and a unique second air source which washes up a window in the combustion apparatus creating a floating flame effect and rendering the window self-cleaning. A series of baffles define a secondary combustion pathway which optimizes secondary combustion of exhaust gasses and particulate matter. Coaxial rear and top direct venting apparatus are also disclosed. The combustion apparatus provided combusts a wide range of solid fuel at a high level of efficiency.

Owner:BROWN STEPHEN CHARLES

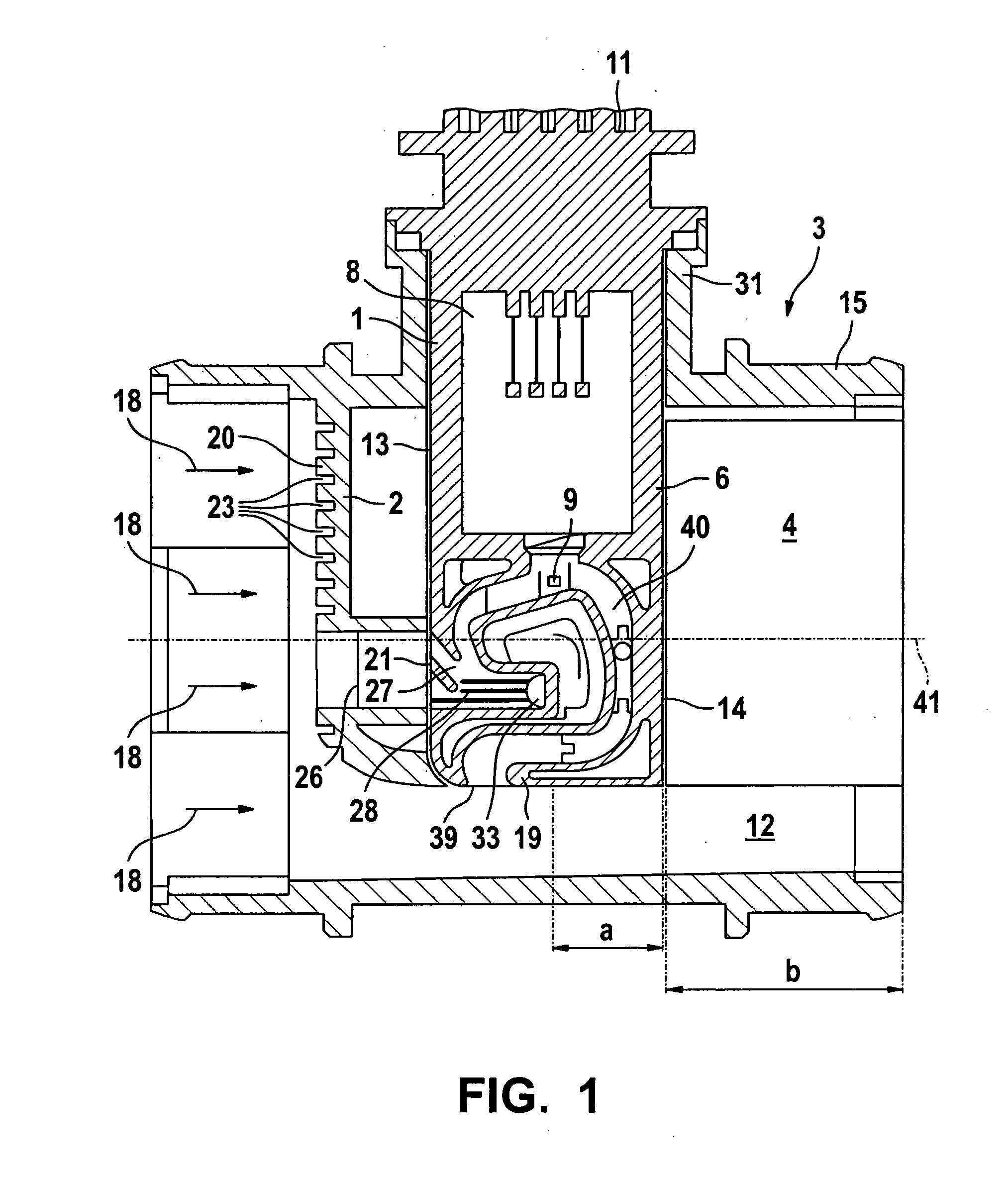

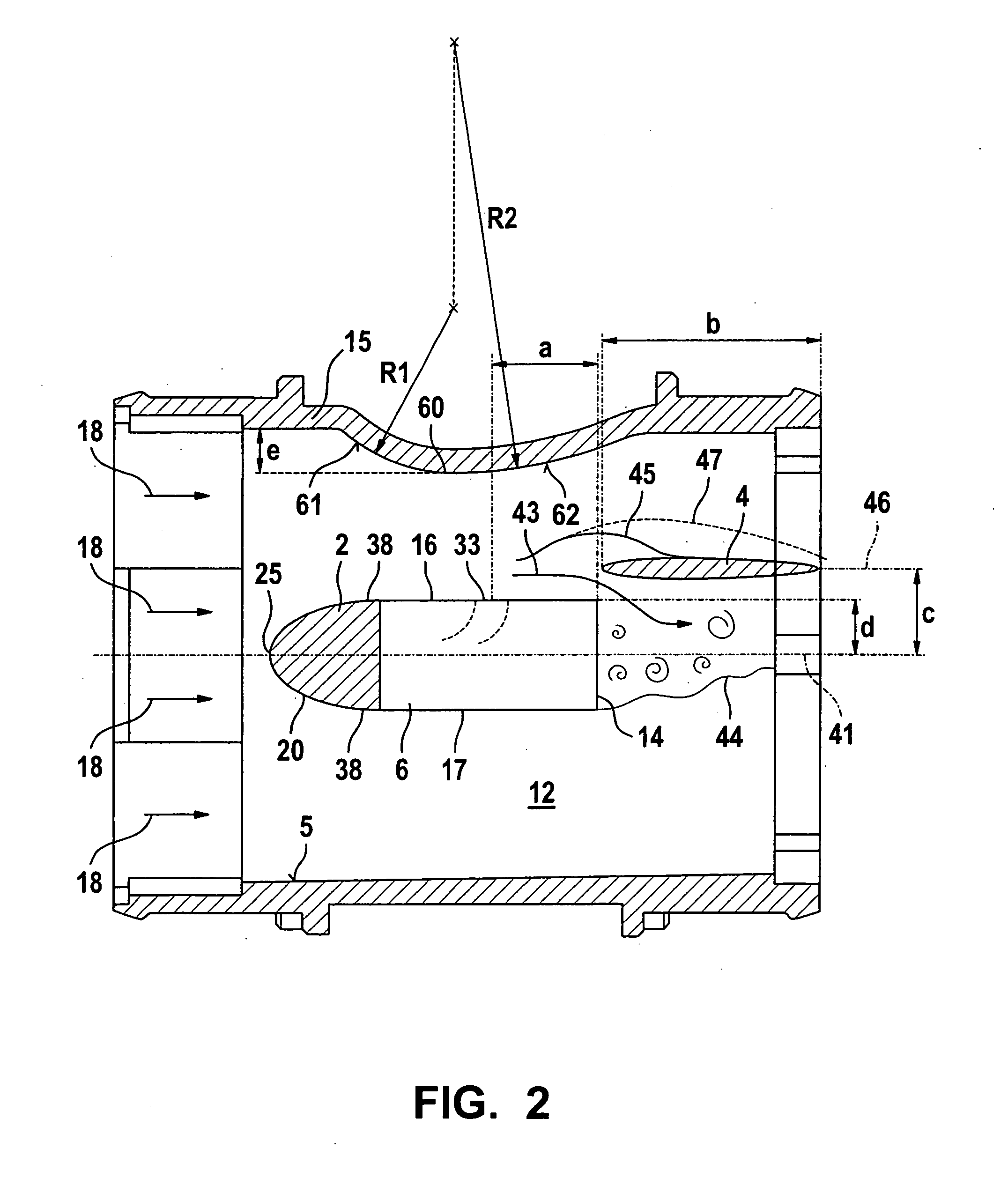

Device for determining at least one parameter of a medium flowing in a conduit

ActiveUS7162920B2Reduce total pressure lossAvoiding undesirable pulsation in flowElectrical controlVolume/mass flow by thermal effectsInternal combustion engineMechanics

Devices are previously known for determining at least one parameter of a medium flowing in a conduit, in particular for determining the air mass flow in the intake section of an internal combustion engine, having a conduit part and a sensor device that has a bypass part. In order to avoid a flow detachment at the side walls of the bypass part, it is provided that a flow vane, running at least approximately parallel to a side wall, provided with a separation opening, of the bypass part, be provided in a conduit part behind a separation opening, seen in the main flow direction, and that the conduit part be provided, in the area of the bypass part, with at least one projection that protrudes from an inner wall of the conduit part towards the bypass part.

Owner:ROBERT BOSCH GMBH

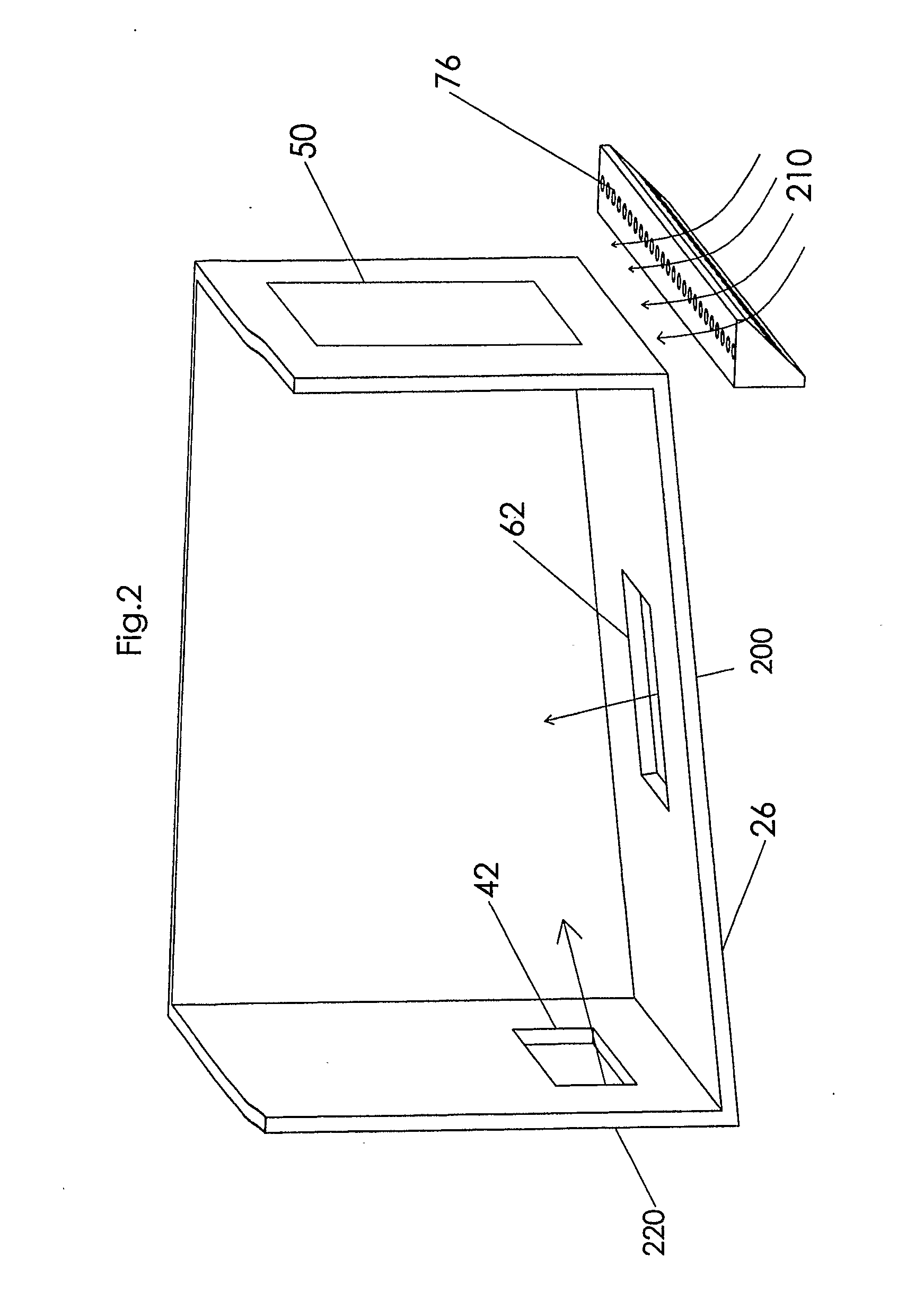

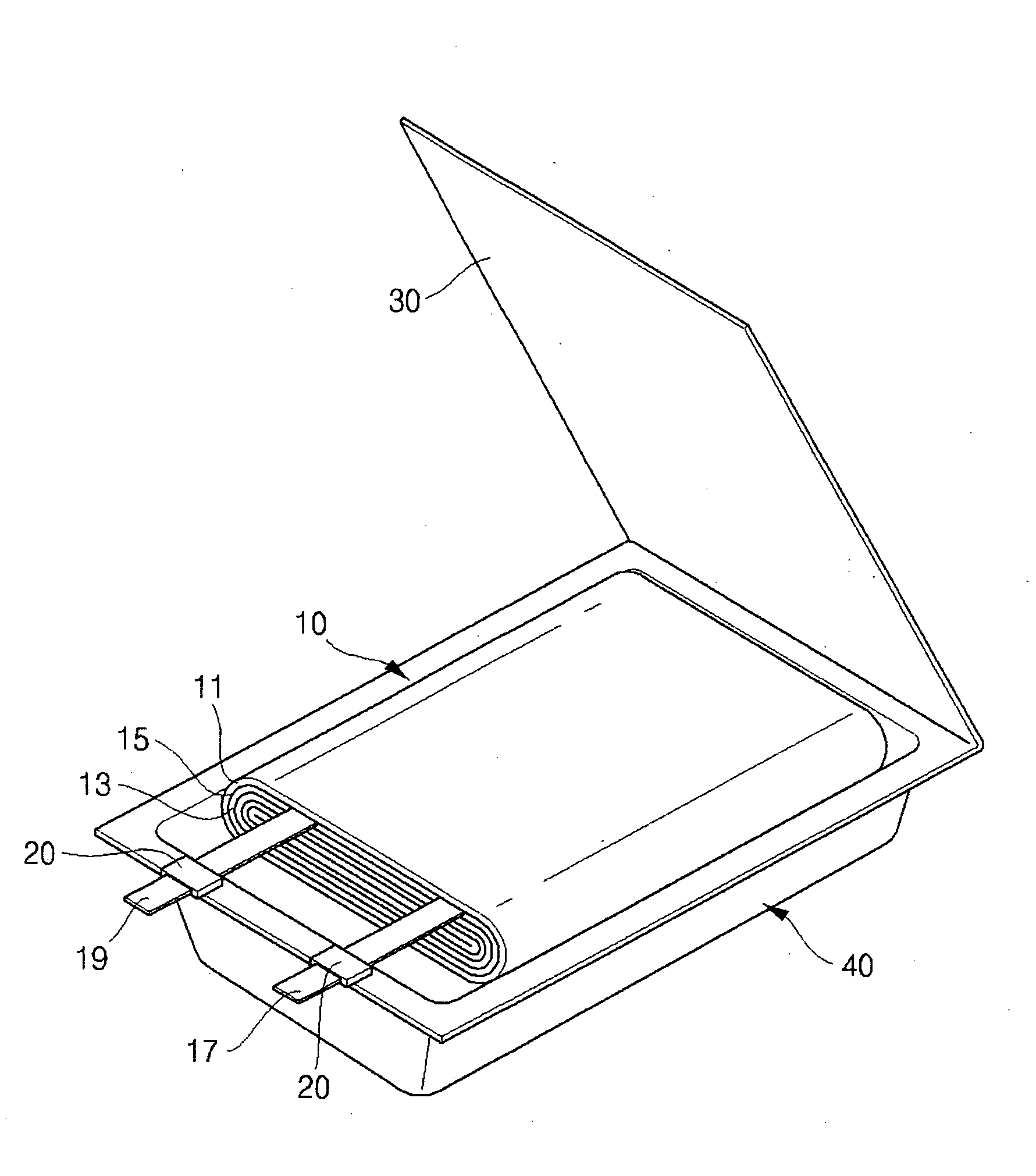

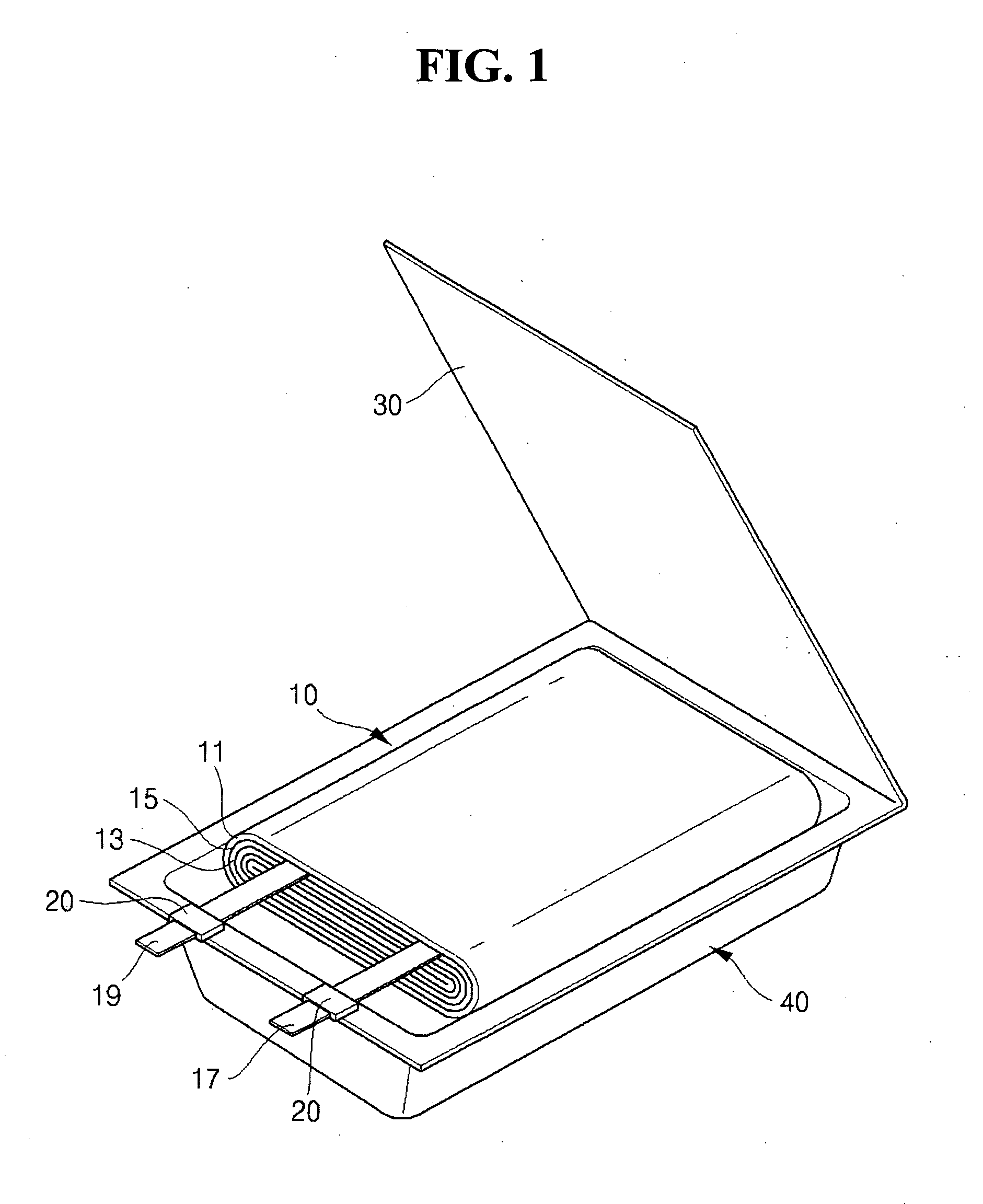

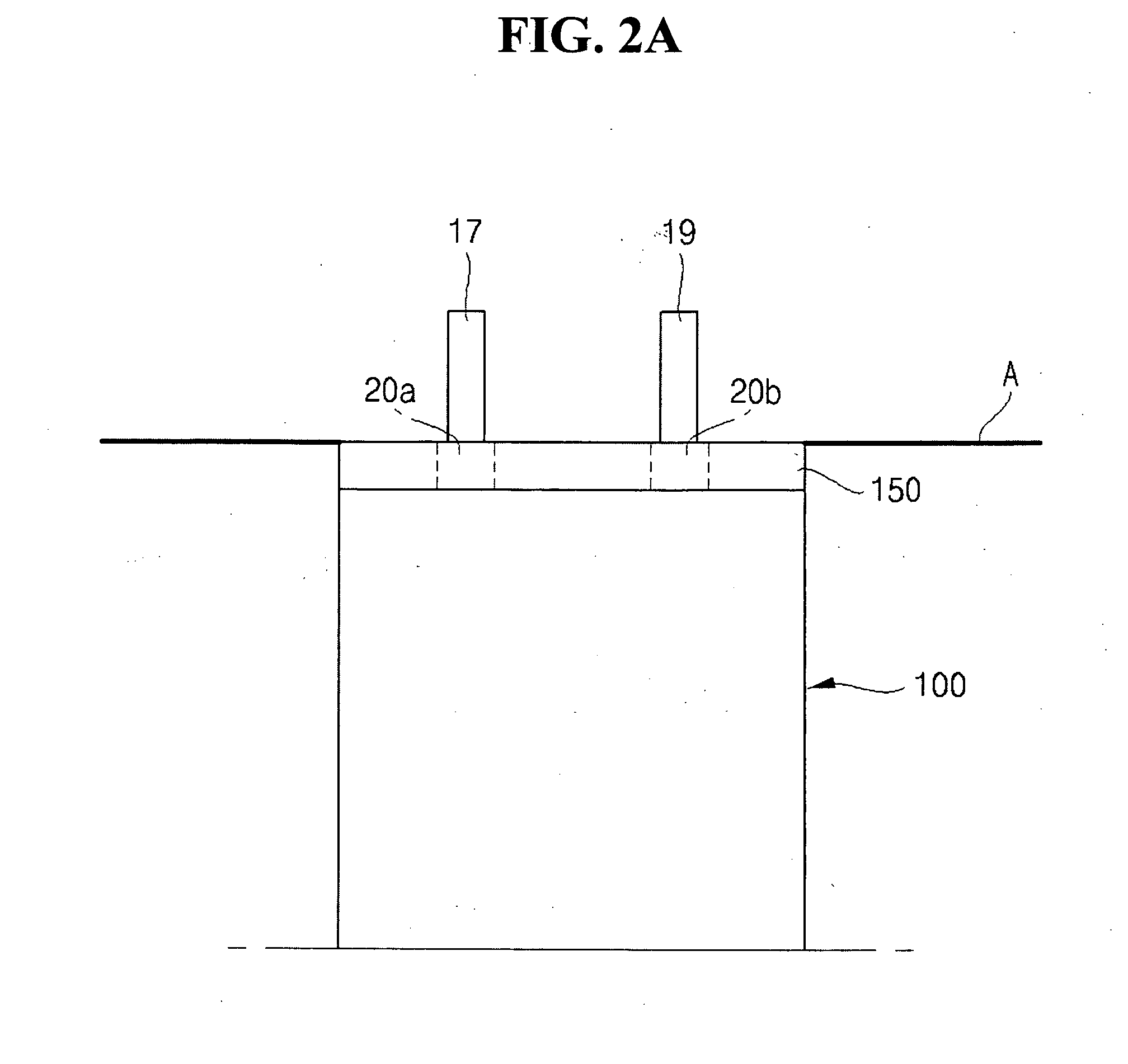

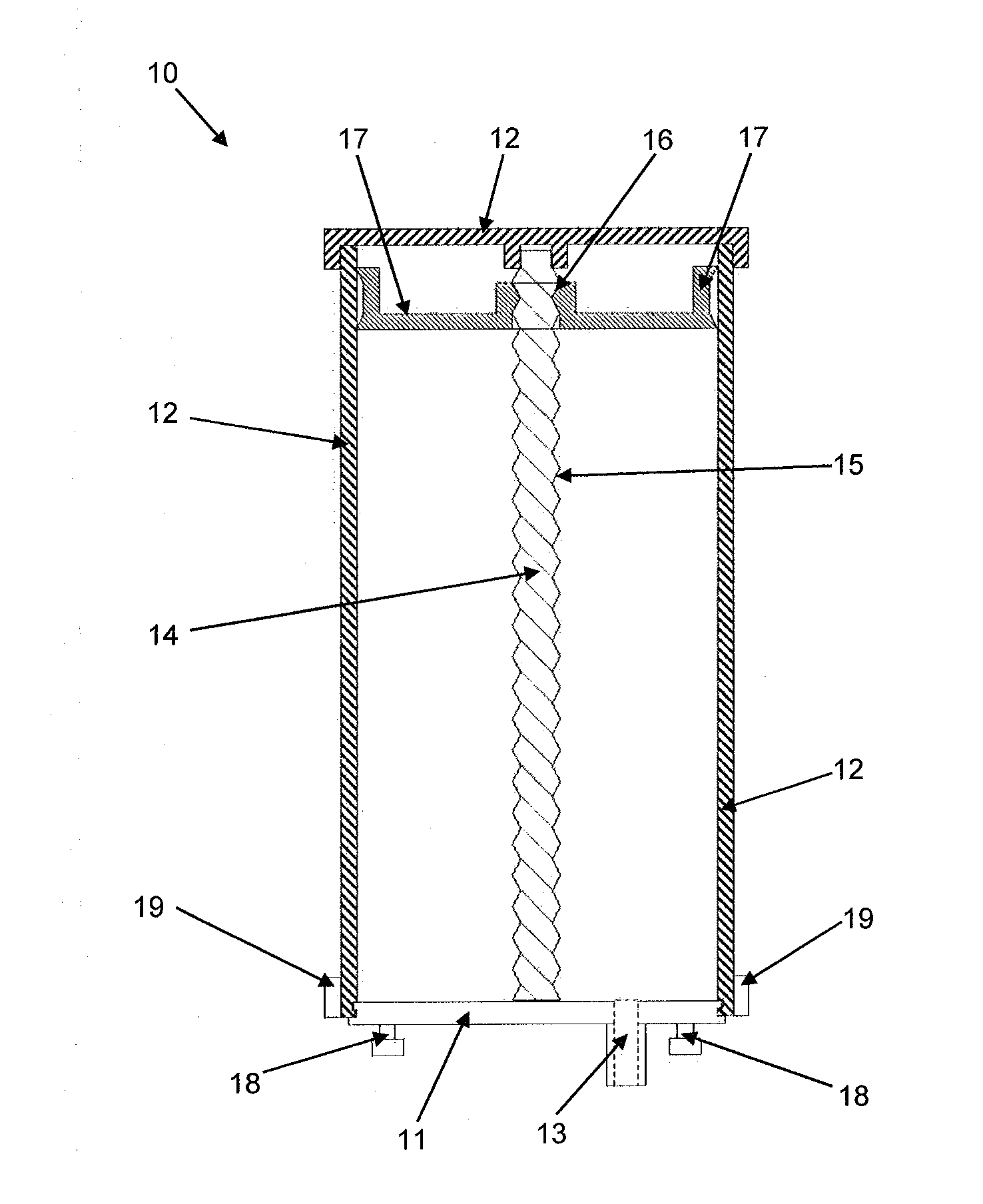

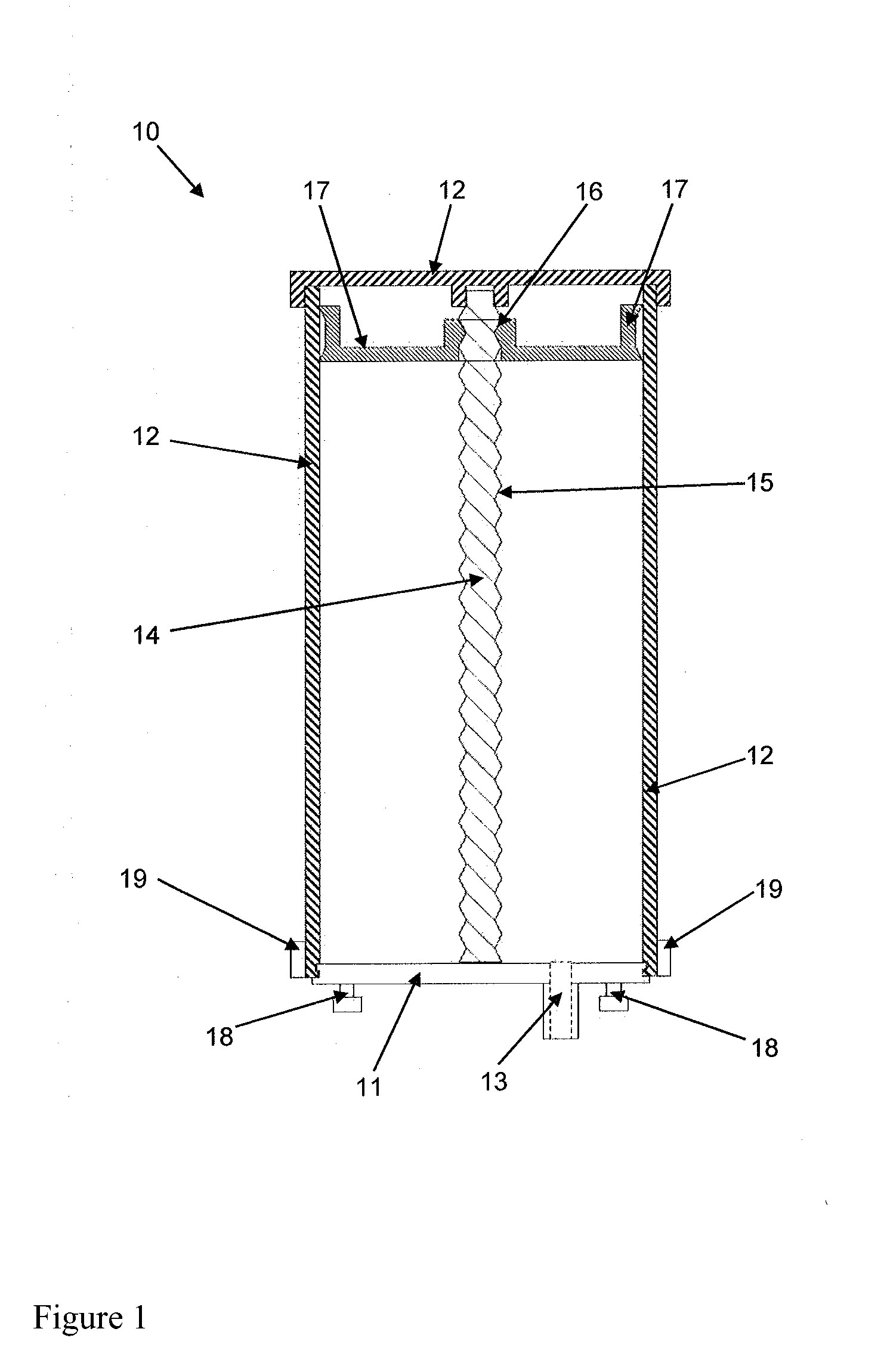

Pouch-type rechargeable battery and its method of manufacture

InactiveUS20080311469A1Improve capacity-to-volume and width ratioShort structureSmall-sized cells cases/jacketsPrimary cellsElectrical and Electronics engineeringRechargeable cell

A pouch-type rechargeable battery and its method of manufacture includes: an electrode assembly having a resin layer attached to the outer surface of an electrode tap, and a pouch having a sealing part formed on the ends of the top and bottom thereof, housing the electrode assembly. The resin layer is positioned inside the sealing part and sealed by heat and pressure for preventing it from being exposed outside the sealing part. Thus, the pouch-type rechargeable battery is adapted to seal the resin layer in the sealing part, instead of exposing it outside the sealing part so as to reduce the longitudinal length of the battery, thereby improving the capacity of the battery.

Owner:SAMSUNG SDI CO LTD

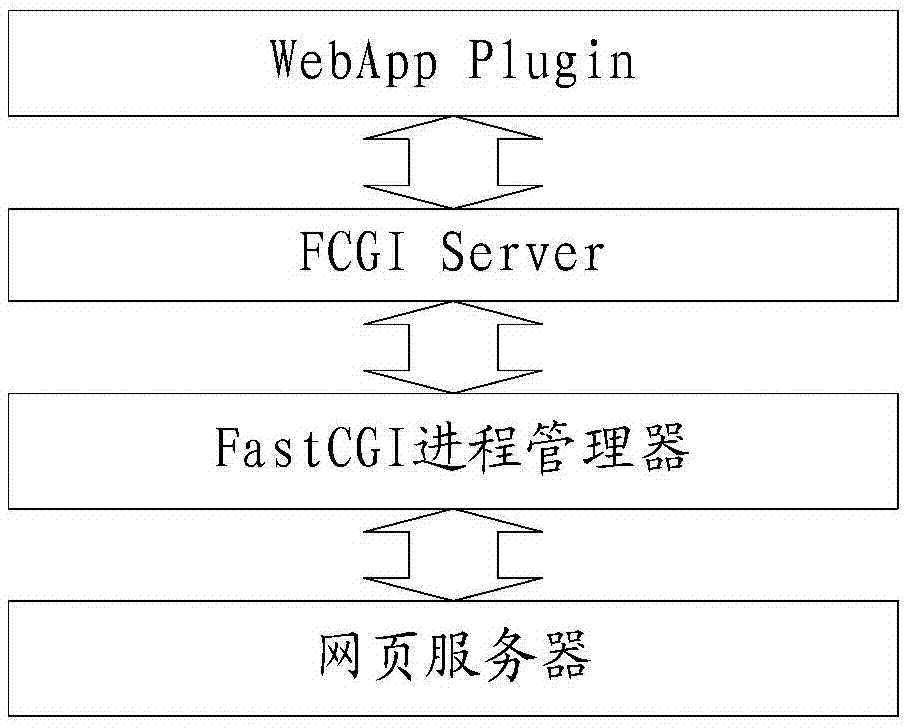

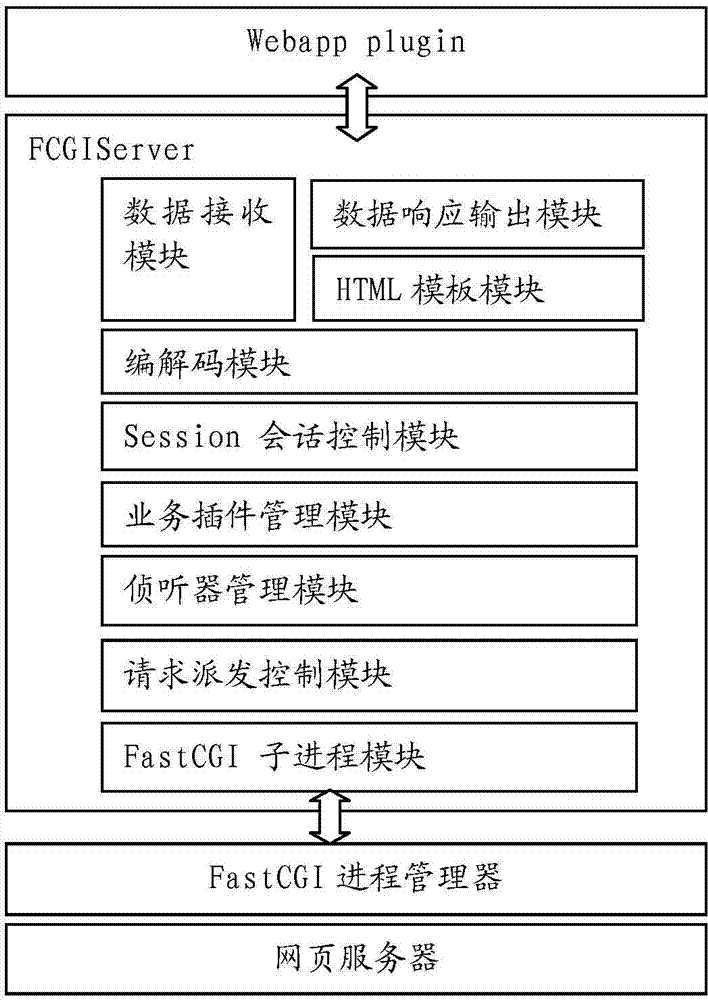

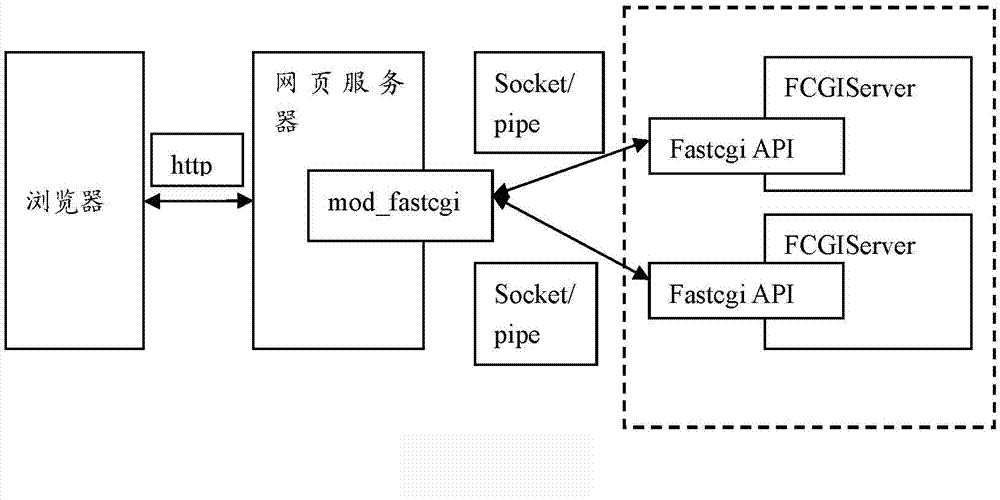

Embedded WEB model view controller (MVC) development framework based on Fast common gateway interface (CGI) and hypertext markup language (HTML) template

ActiveCN102902537ASolve the problem of slow responseCompact structureSpecific program execution arrangementsSession controlProcess module

Disclosed is an embedded WEB MVC development framework based on a Fast CGI and an HTML template. The operation of the framework depends on a Fast CGI process manager and a web page server downward and provides service for a Web App Plug in business logic processing module upward. The framework comprises a Fast CGI sub-process module, a request distribution control module, a listener management module, a business plug-in management module, a Session control module, an encoding and decoding module, a data receiving module, a data response output module and an HTML template module. The embedded WEB MVC development framework based on the Fast CGI and an HTML template is applicable to small embedded devices, small and exquisite, efficient and good in structure, and the framework is small and exquisite in volume and accounts for about 100K of flash space.

Owner:XIAMEN YEALINK NETWORK TECH

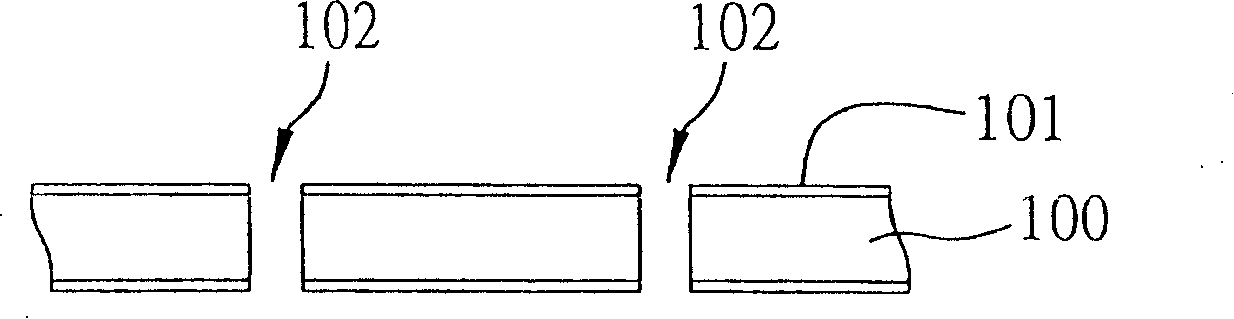

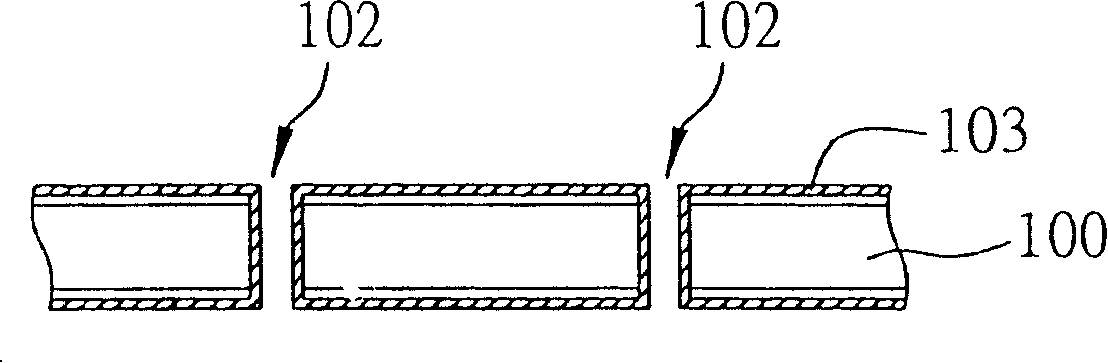

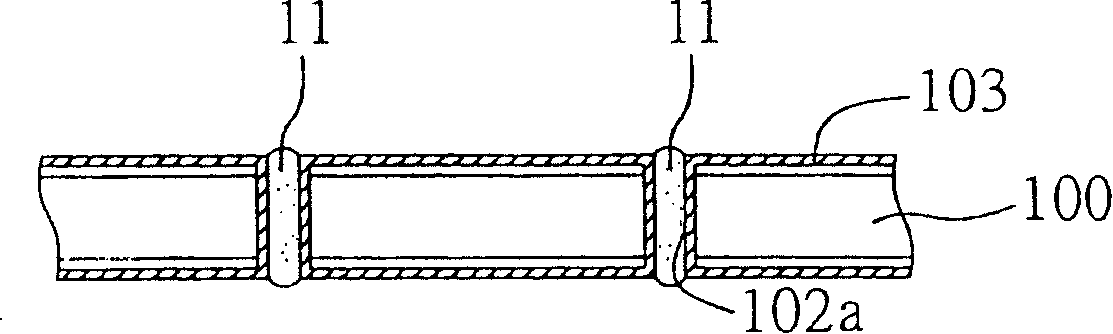

Circuit board structure and its manufacture method

InactiveCN101192542AReduce thicknessSmall sizePrinted circuit detailsSemiconductor/solid-state device detailsMiniaturizationEngineering

The invention relates to a circuit board structure and a manufacturing method thereof, which comprises the following steps: a bearing device is provided as an insulation plate which has a metal layer on a surface; an insulation protection layer is formed on the bearing device and a plurality of openings are formed in the insulation protection layer for discovering the metal layer; a circuit structure is formed in the surface of the insulation protection layer and in the openings to electrical connect the circuit structure with the metal layer; a dielectric layer is formed on the insulation protection layer and on the circuit structure and a plurality of openings are formed on the dielectric layer, thus exposing part of the circuit structure. The bearing device can be removed then for forming a circuit plate without a chip layer, thus reducing the circuit plate thickness and being conducive to decreasing the size of the sealed products and enhancing the performance so as to go in line with the development trend of miniaturization of electrical products.

Owner:PHOENIX PRECISION TECH CORP

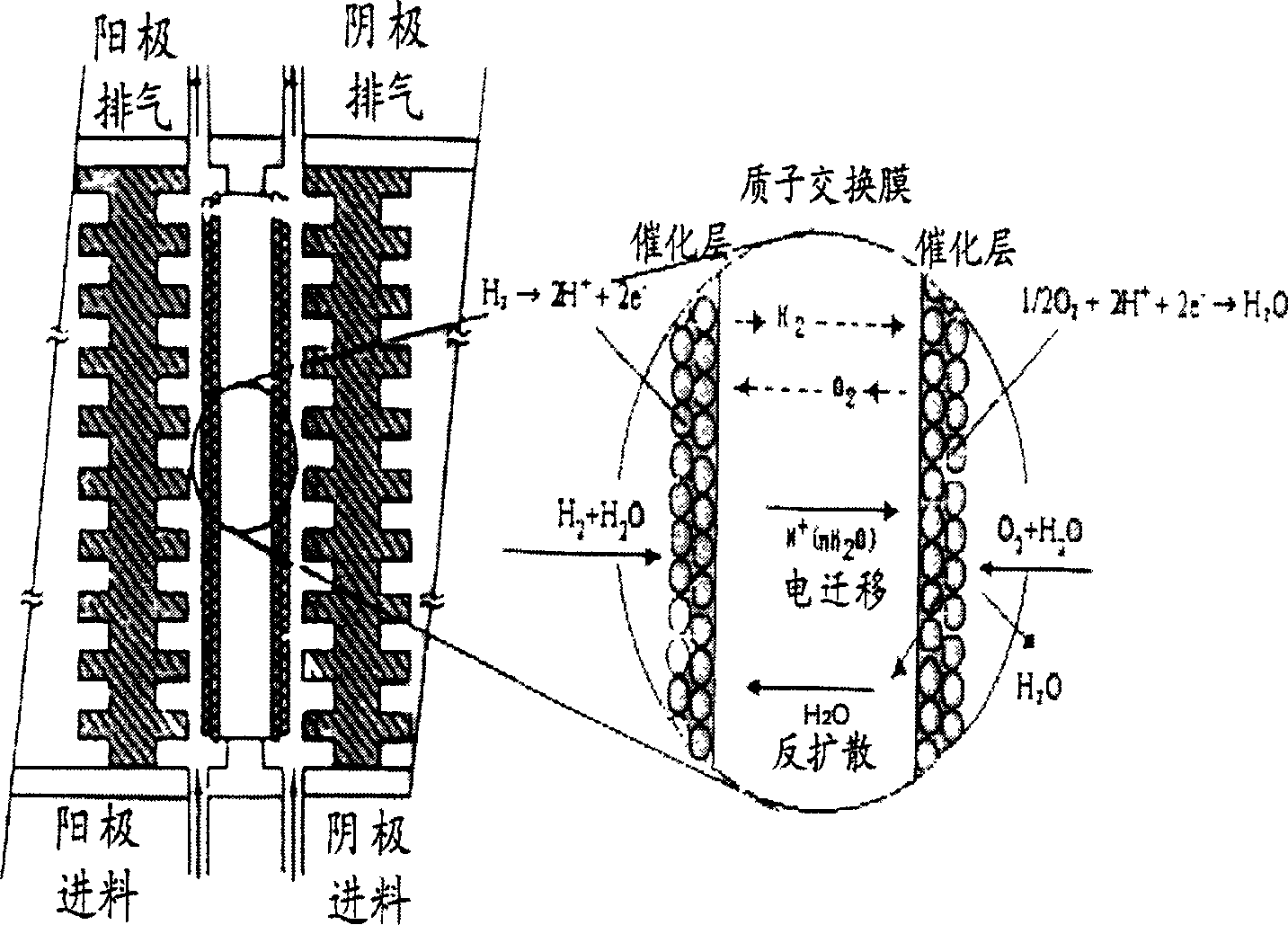

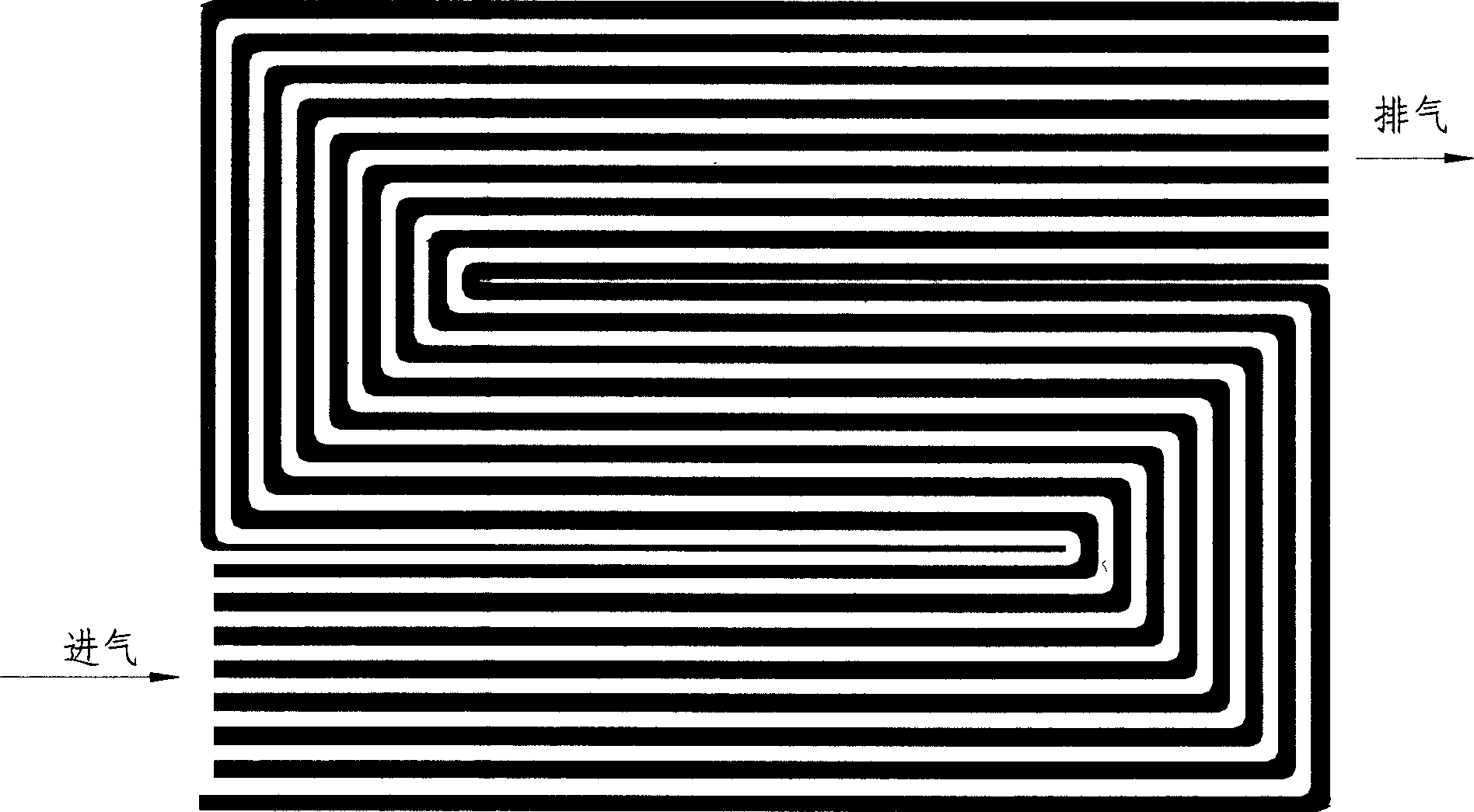

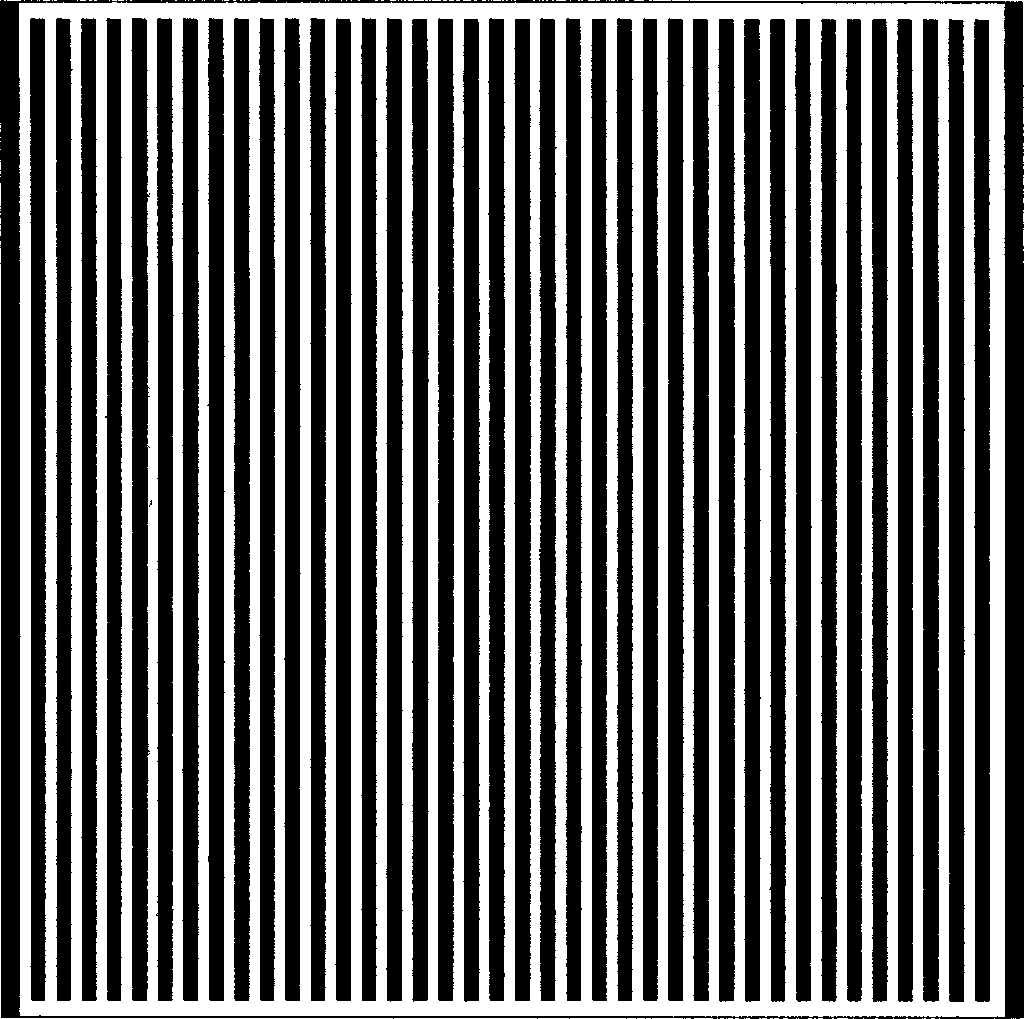

Proton exchange film fuel cell flow field structure

ActiveCN1622377AEasy to excludePromote accumulationCell electrodesSolid electrolyte fuel cellsProtonEngineering

The present invention relates to proton exchange membrane fuel cell. The flow field structure of proton exchange membrane fuel cell consists of netted flow field and deflecting stripes. The deflecting stripes are set inside the netted flow field and parallel to one group of sealing side walls, and have width equal to the height of the netted flow field. Each of the deflecting stripes has one end connected perpendicularly to the side wall and the other end constituting the gas channel. The gas channel has width not smaller than that of the gas inlet. The present invention has the advantages of high pole area utilization, being favorable to the exhaust of water produced in the electrochemical reaction and the elimination of inertial component, no dead arean of gas flow, and stable operation of the cell under low pressure and normal pressure.

Owner:SUNRISE POWER CO LTD

Instant dried white fungus and production method thereof

InactiveCN103610030AAvoid churnTo achieve the effect of natural ripeningFood dryingFood preparationMicrowaveTremella

The invention relates to a production method of instant dried white fungus. The production method comprises the following steps: (1) material selection, namely removing impurities from fresh white fungus, and cleaning; (2) slicing; (3) pre-freezing, namely carrying out pre-freezing for 12-14 hours at temperature from -10 DEG C to -25 DEG C; (4) drying, namely carrying out microwave vacuum freeze drying, wherein the microwave vacuum freeze drying comprises a low-temperature sublimation stage and a normal-temperature vacuum microwave drying stage; (5) vacuum encapsulation. According to the process, a curing process before drying is omitted, so that the loss of the tremella polysaccharide is avoided, and processing cost is saved by 15%. According to the instant dried white fungus processed by utilizing the production method, the product is pure in appearance and color and plump in form; after being rehydrated, the product is nature in form and pure in taste and flavor, the product quality is greatly improved, and the product is obviously superior to similar products processed by utilizing traditional methods.

Owner:GUANGYUAN YUER FOOD CO LTD

Device for determining at least one parameter of a medium flowing in a conduit

ActiveUS20060021429A1Inhibition of flow separationReduce total pressure lossElectrical controlVolume/mass flow by thermal effectsEngineeringInternal combustion engine

Devices are previously known for determining at least one parameter of a medium flowing in a conduit, in particular for determining the air mass flow in the intake section of an internal combustion engine, having a conduit part and a sensor device that has a bypass part. In order to avoid a flow detachment at the side walls of the bypass part, it is provided that a flow vane, running at least approximately parallel to a side wall, provided with a separation opening, of the bypass part, be provided in a conduit part behind a separation opening, seen in the main flow direction, and that the conduit part be provided, in the area of the bypass part, with at least one projection that protrudes from an inner wall of the conduit part towards the bypass part.

Owner:ROBERT BOSCH GMBH

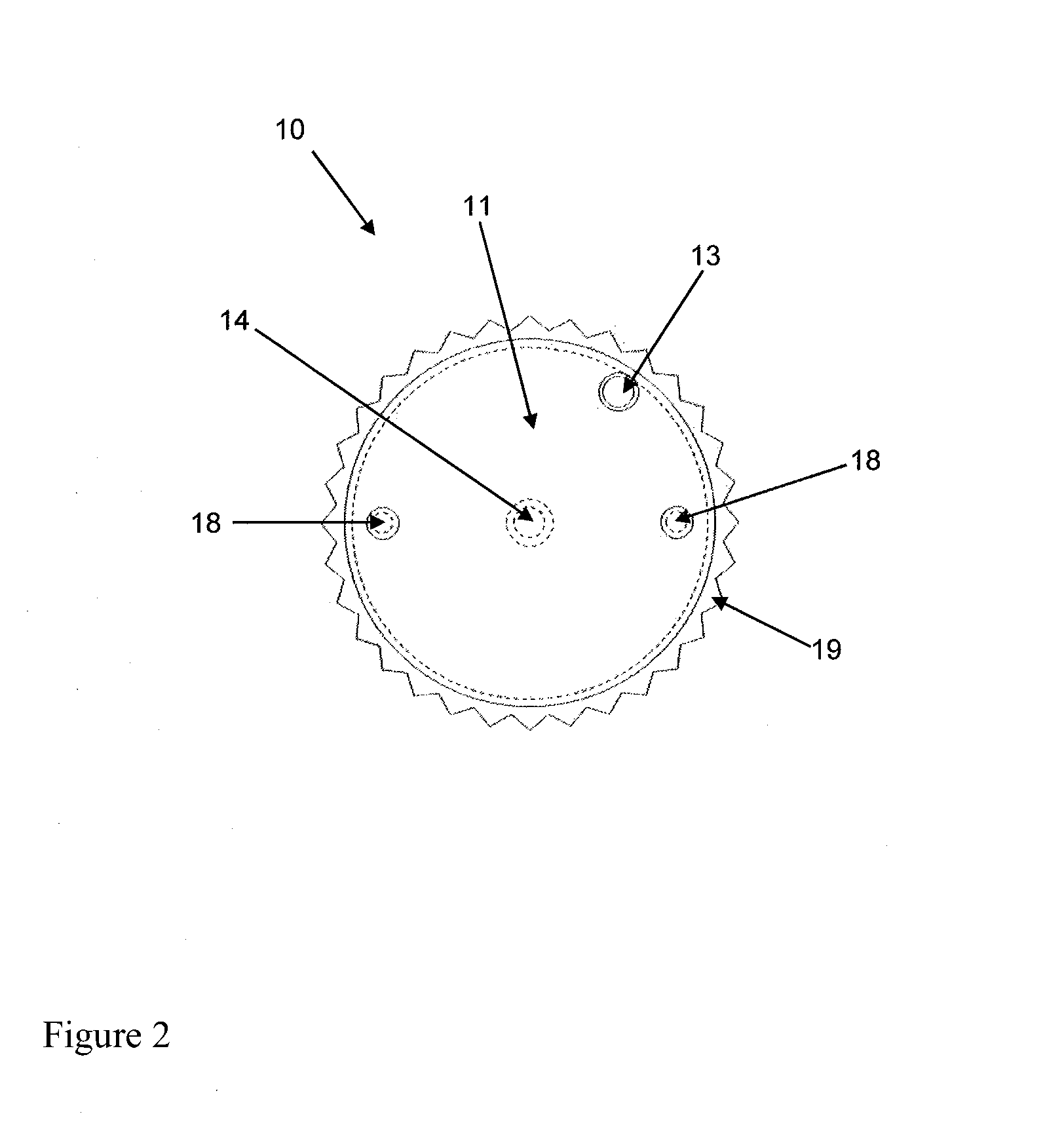

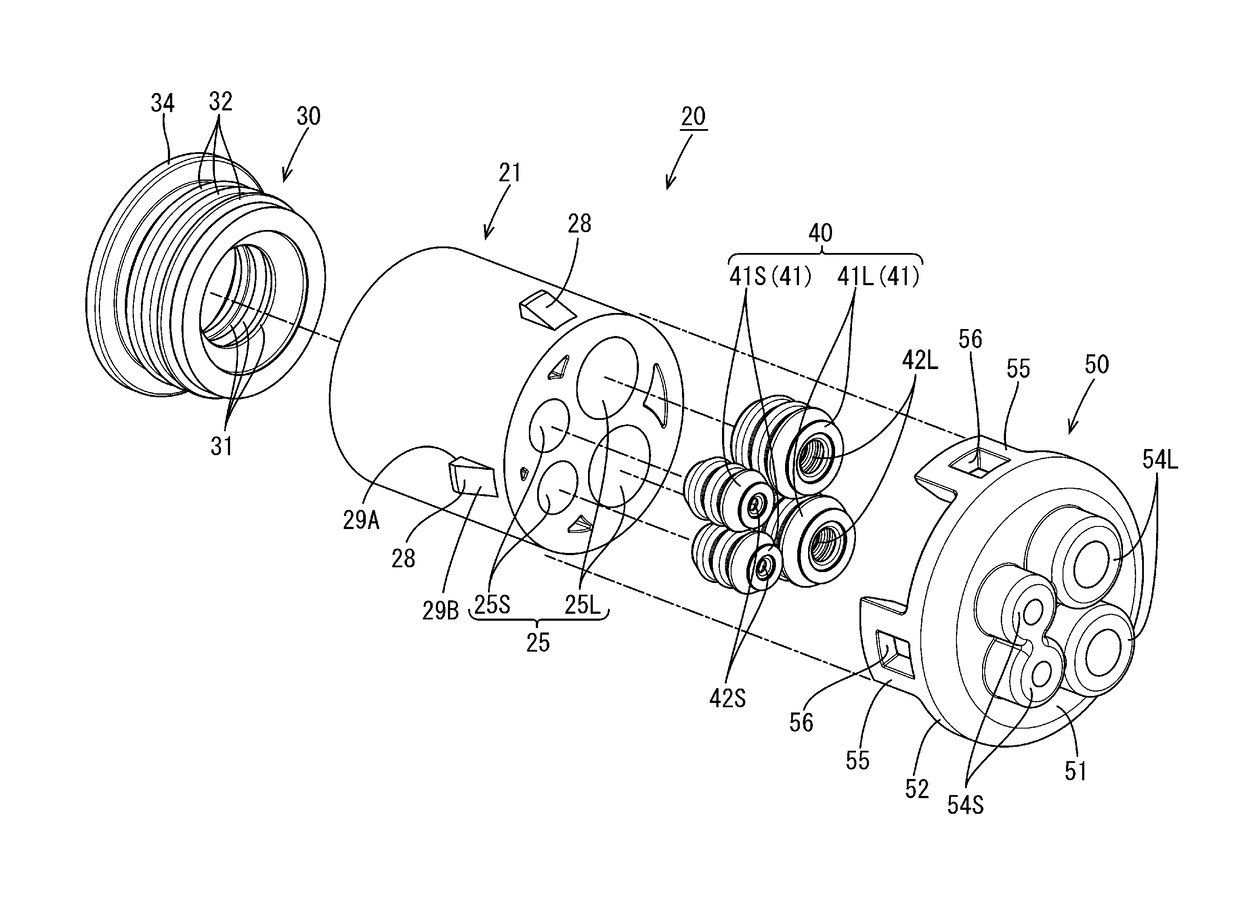

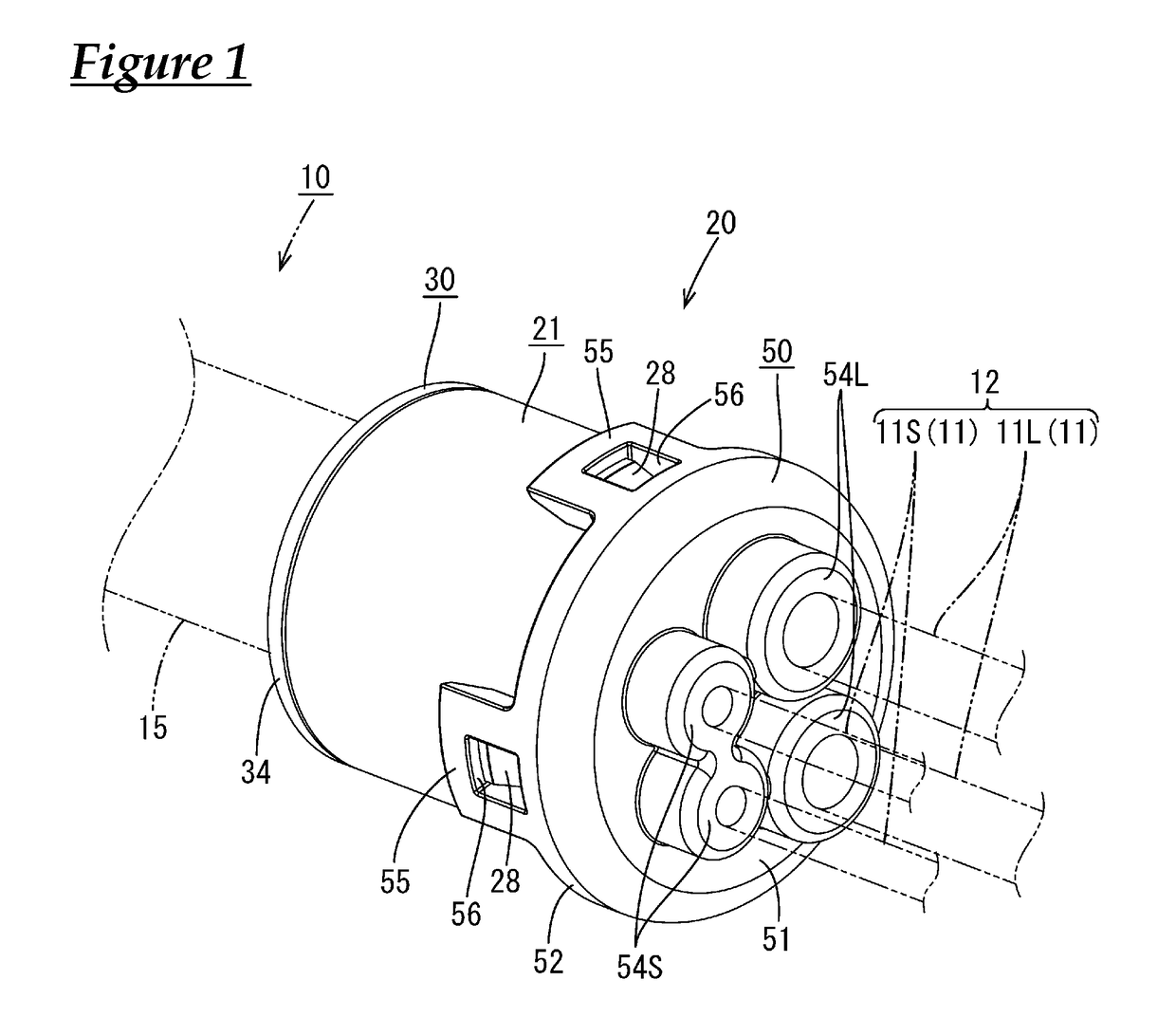

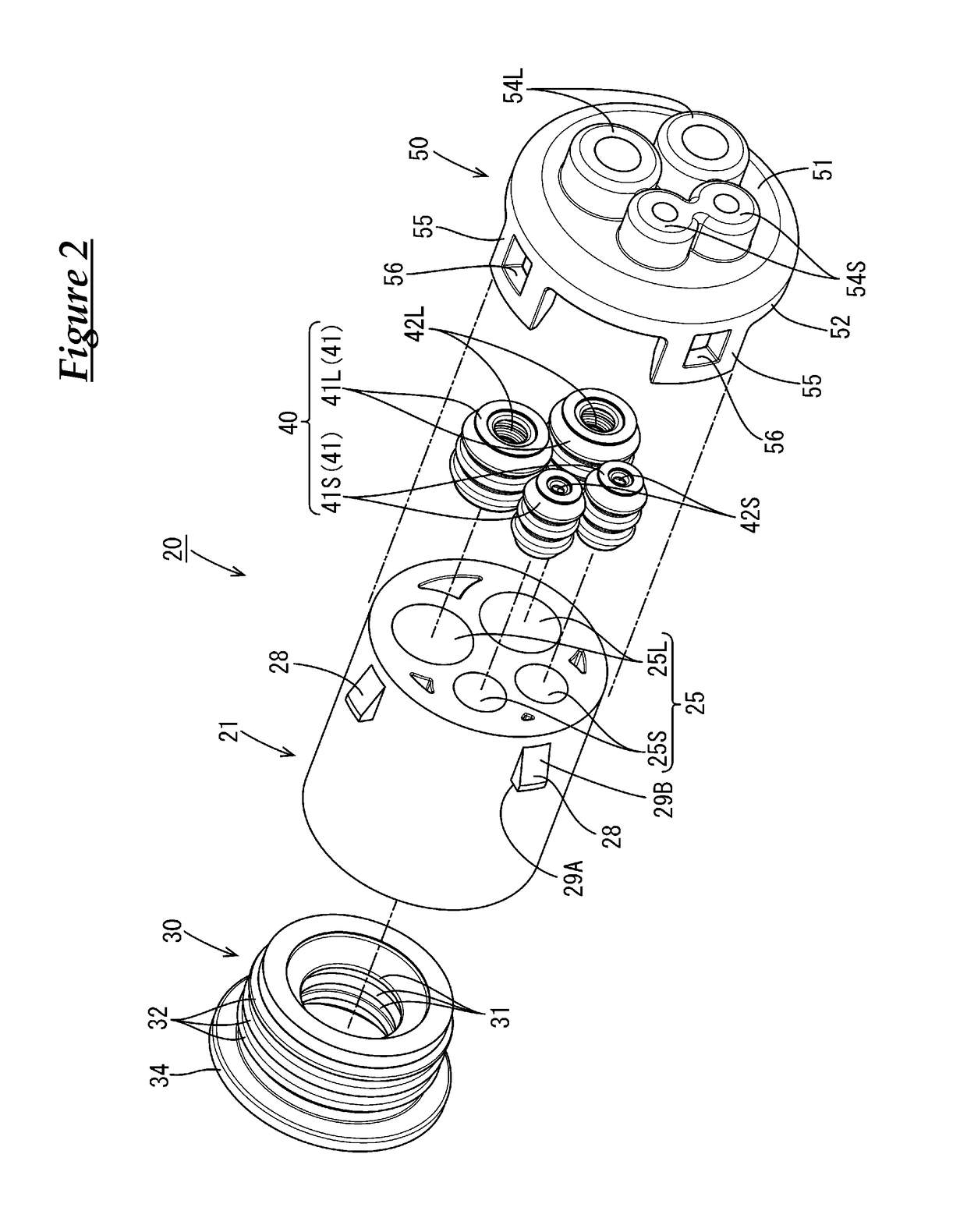

Multi-component mixing system having a rotatable container and container therefor

ActiveUS20130181012A1Easy to replaceIncrease distanceRotating receptacle mixersImpression capsEngineeringPiston

A container (10, 30, 50) is provided for single- or multi-component molding materials. The container has a container body (12, 32, 52) having a constant outer contour in a longitudinal extent of the container (10, 30, 50), a piston (17, 37) movable in the longitudinal direction, and a cover (11, 31) having an outlet opening (13, 33, 53). A volume for a molding material is defined between the piston (17, 37) and the cover (11, 31), the volume being variable in the direction of the longitudinal extent of the container (10, 30, 50). The container distinguishes itself in that the container body (12, 32, 52) is rotatable relative to the outlet opening (13, 33, 53), and the piston (17, 37) thereby pushes out the content of the container (10, 30, 50).

Owner:HERAEUS KULZER

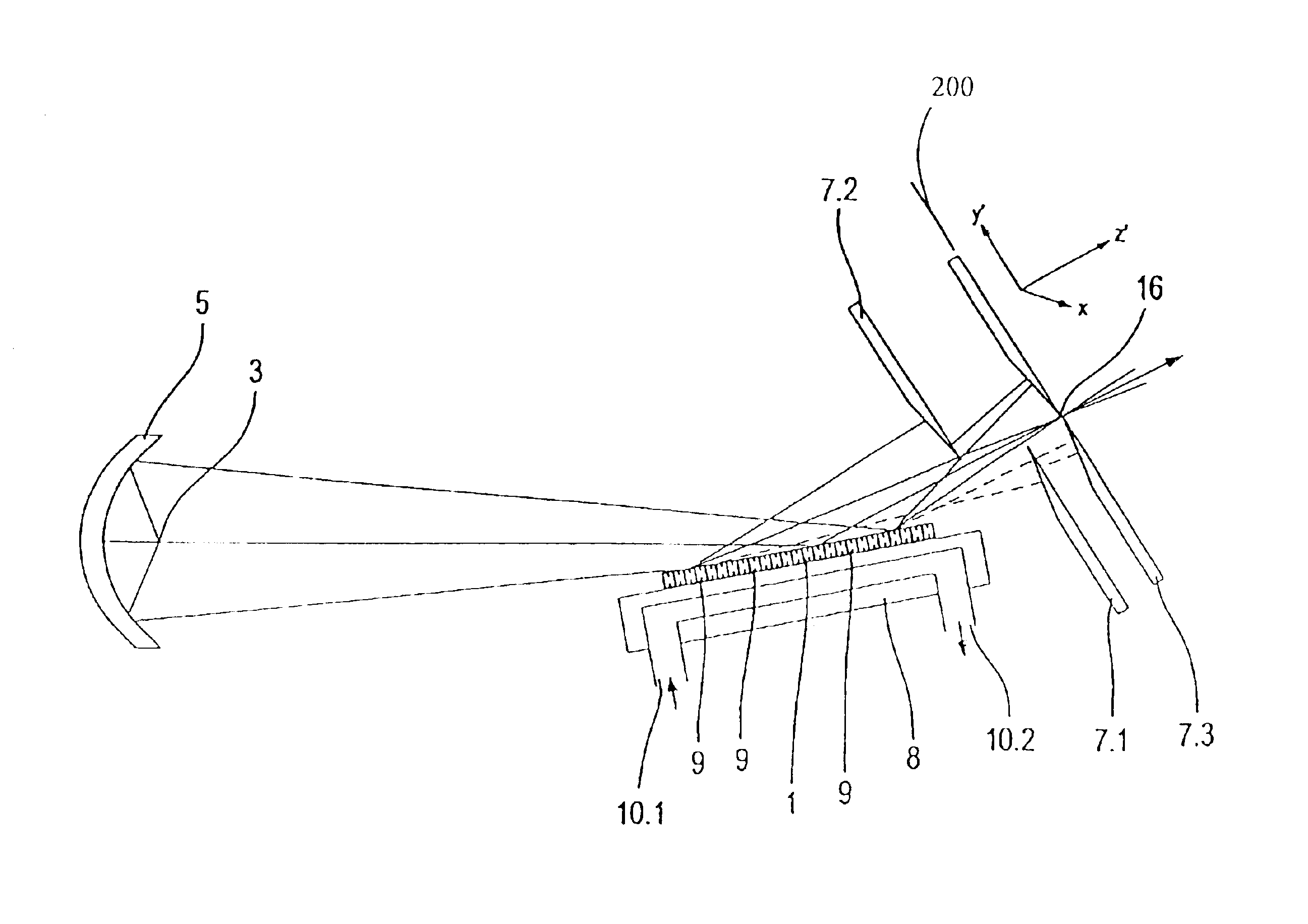

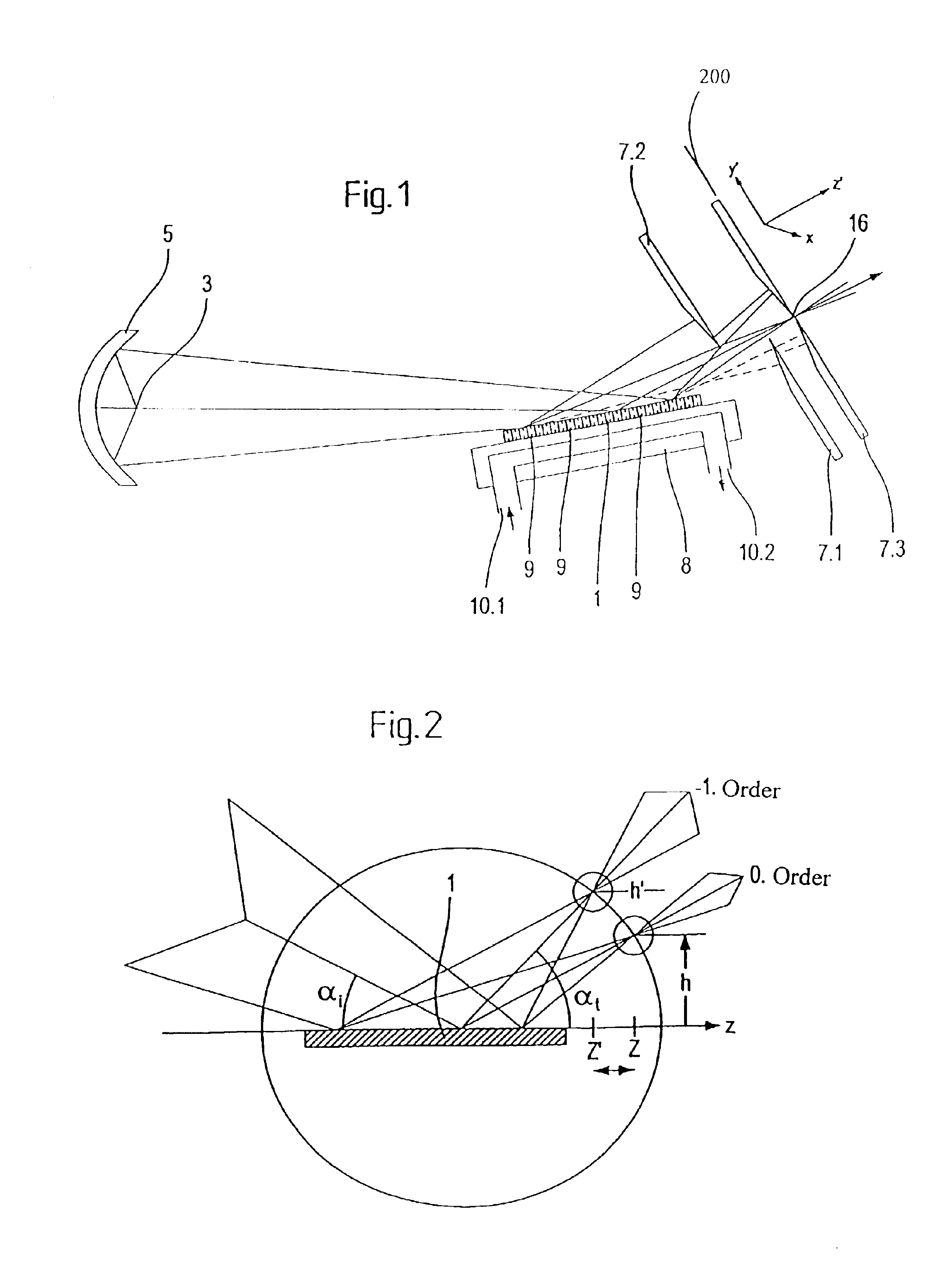

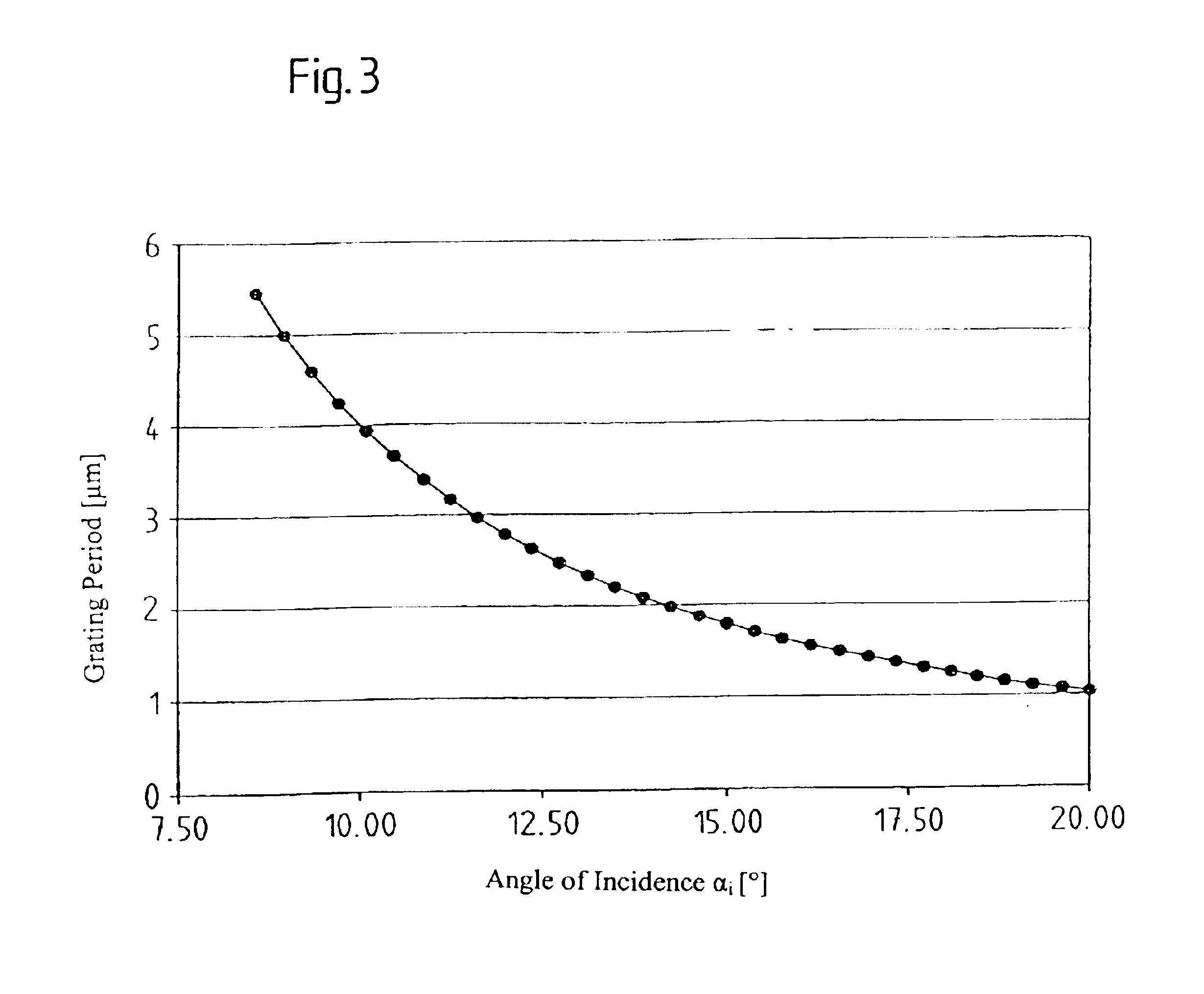

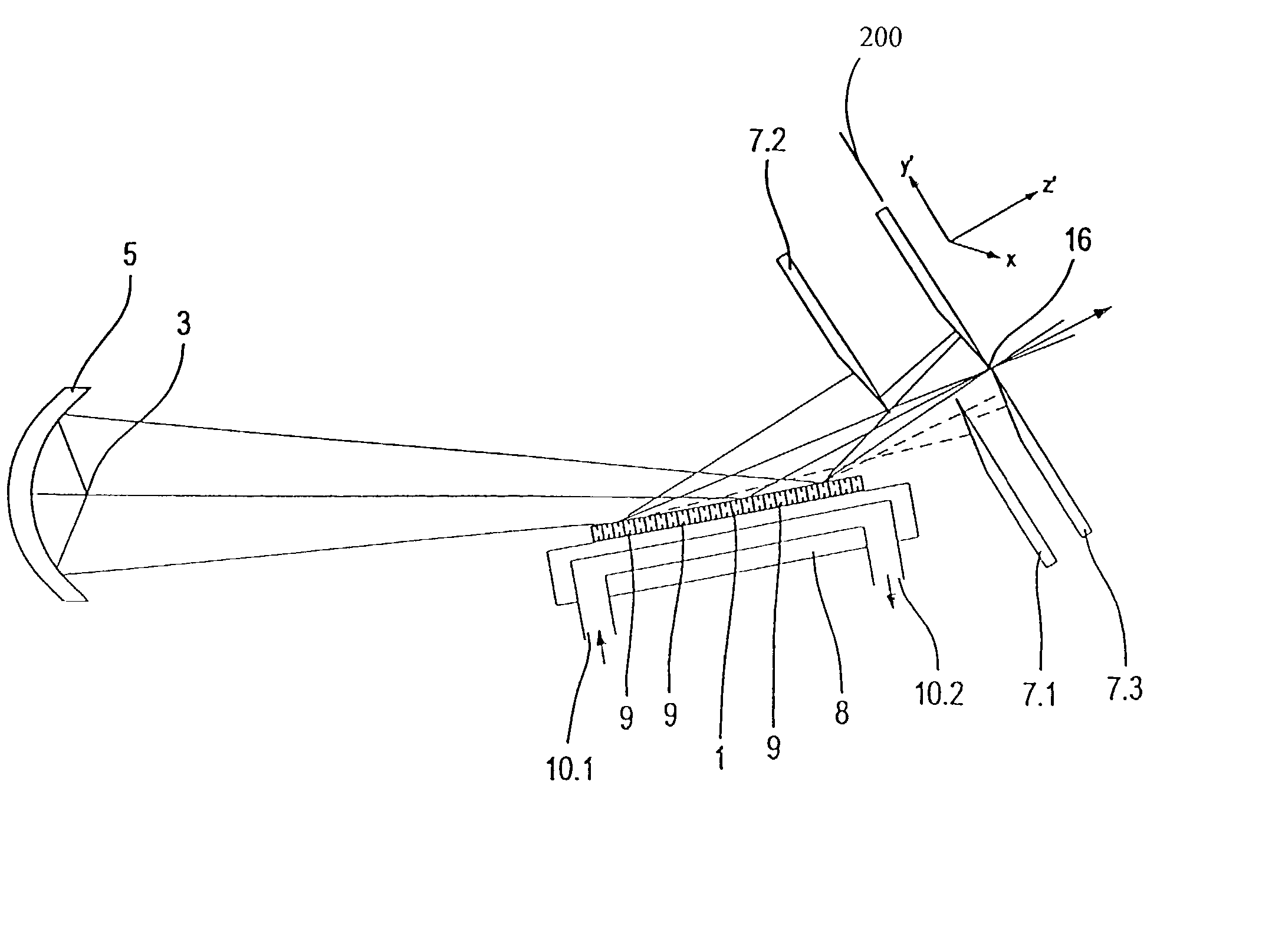

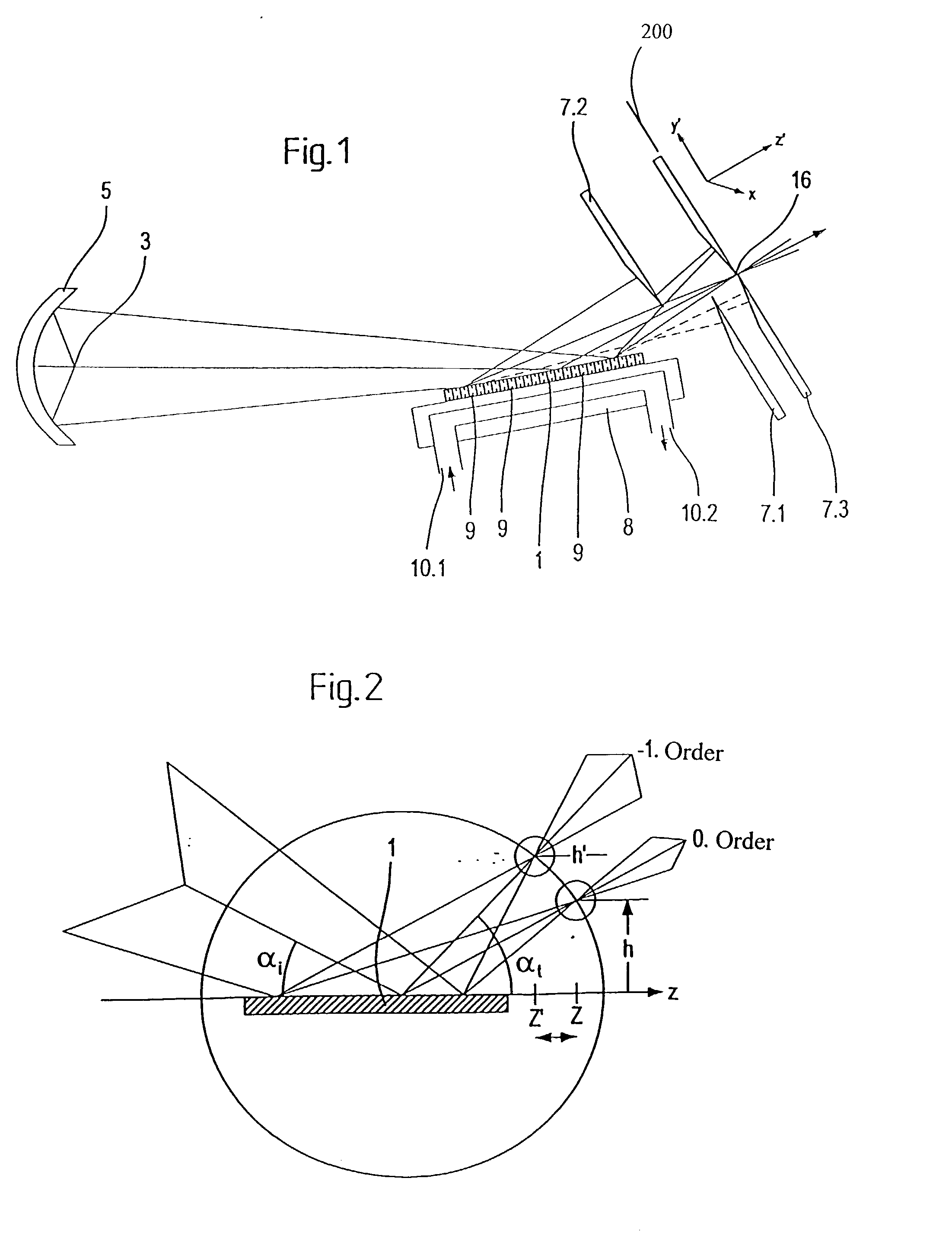

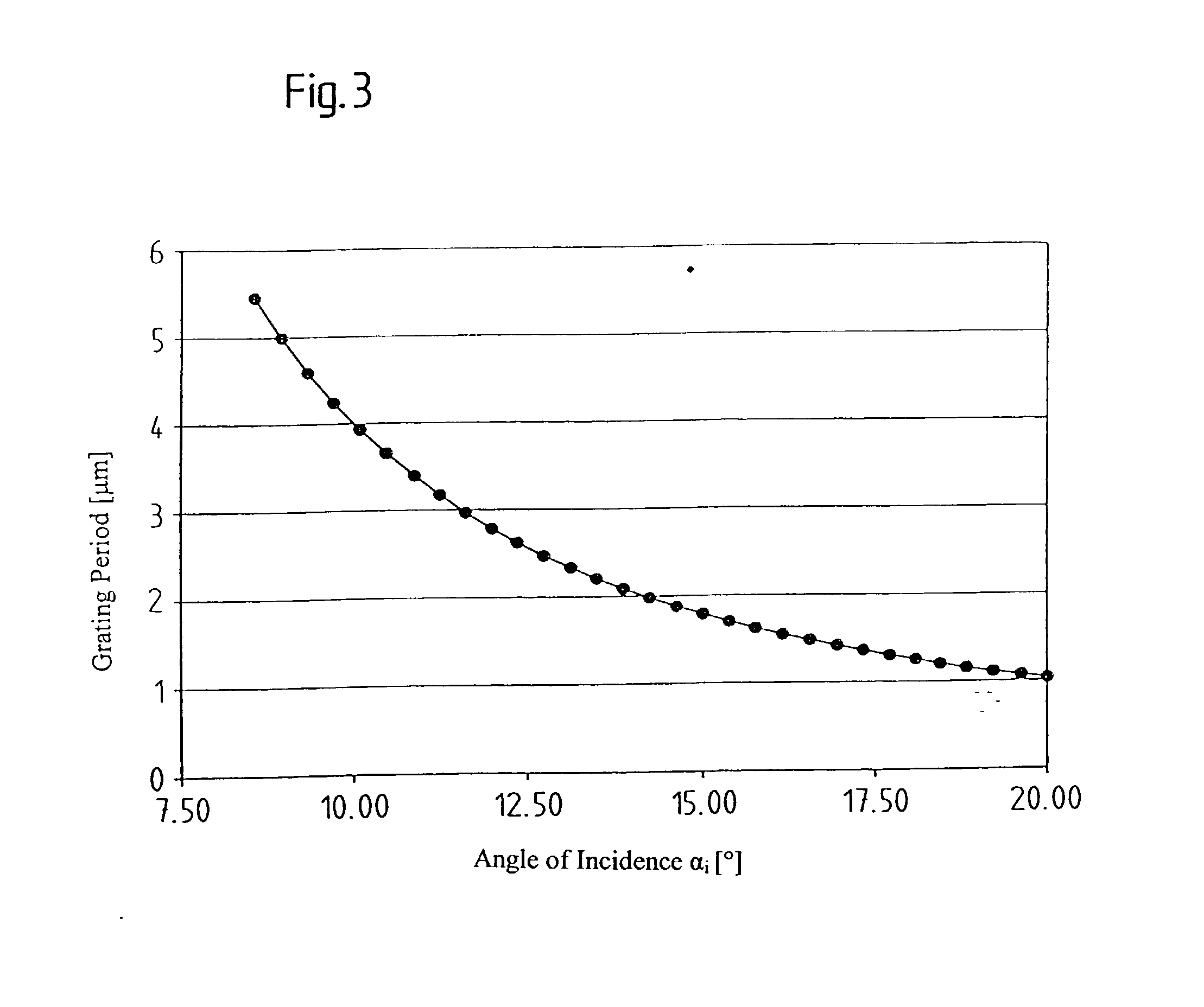

Illumination system with a plurality of individual gratings

InactiveUS6836530B2Easy to separateShort structureRadiation pyrometrySpectrum investigationGratingLight beam

There is provided an illumination system for wavelengths of <=100 nm, having an object plane and a field plane. The illumination system includes a grating element having a plurality of gratings, and a diaphragm. The diaphragm is arranged after the grating element in a beam path from the object plane to the field plane.

Owner:CARL ZEISS SMT GMBH +1

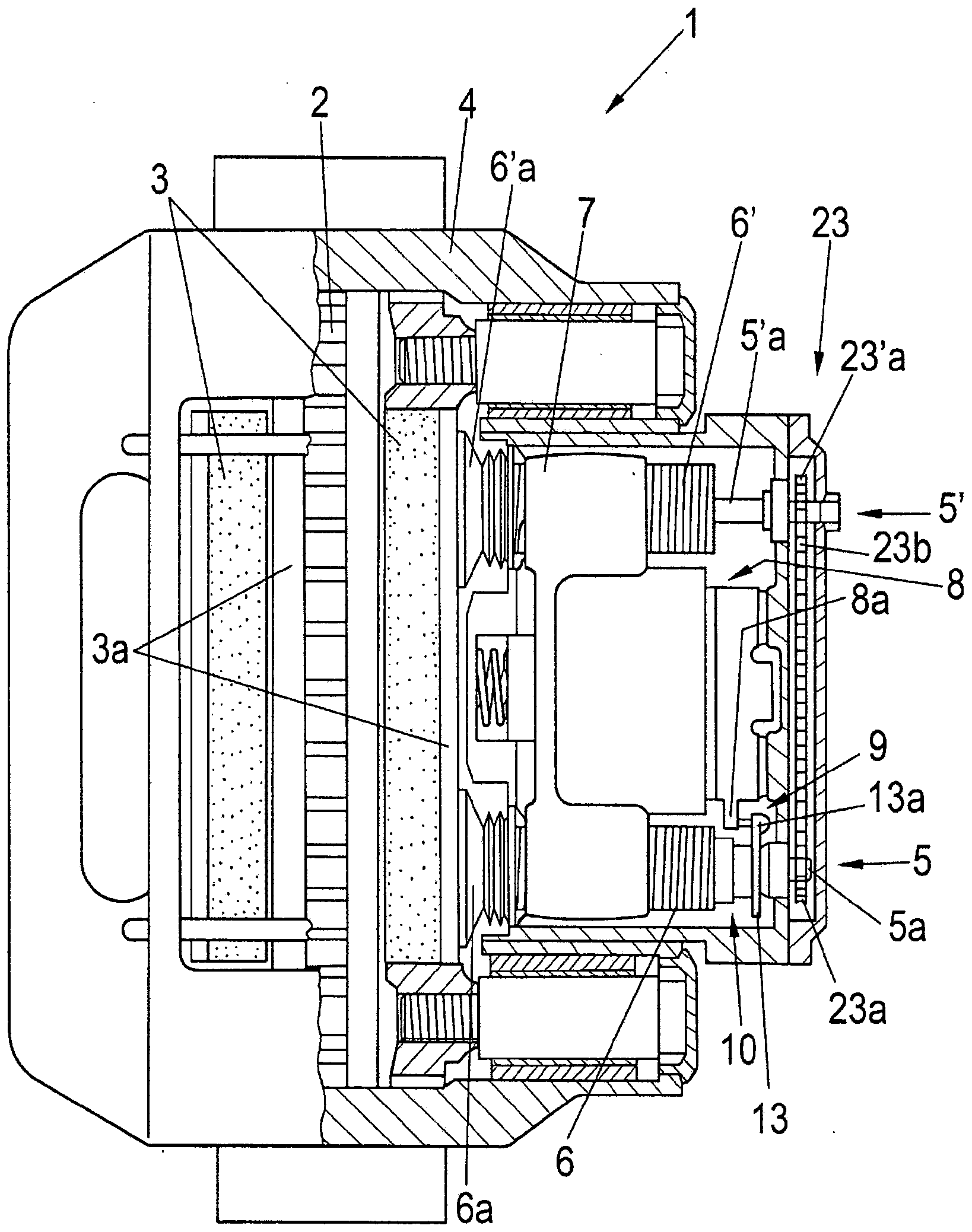

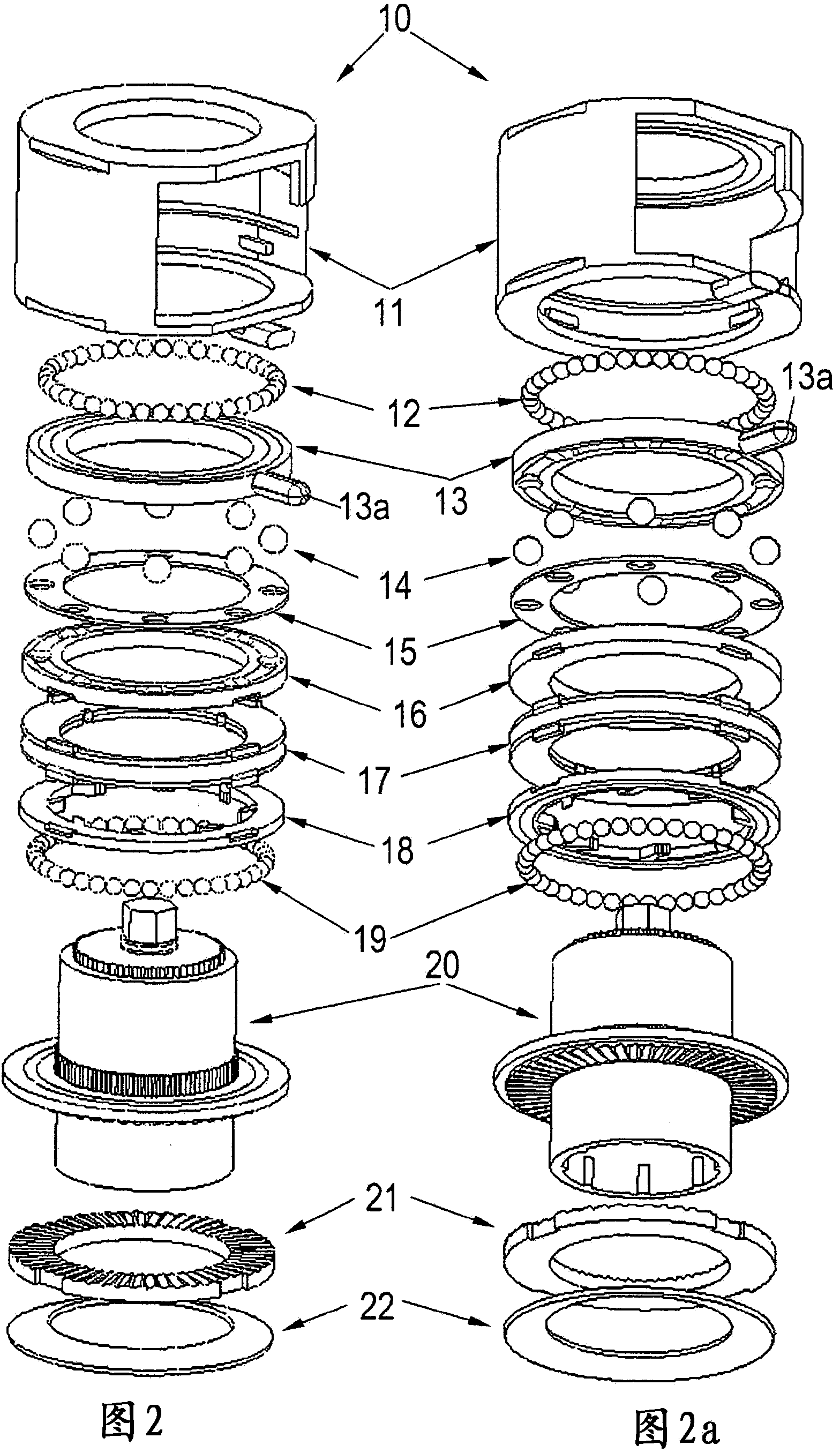

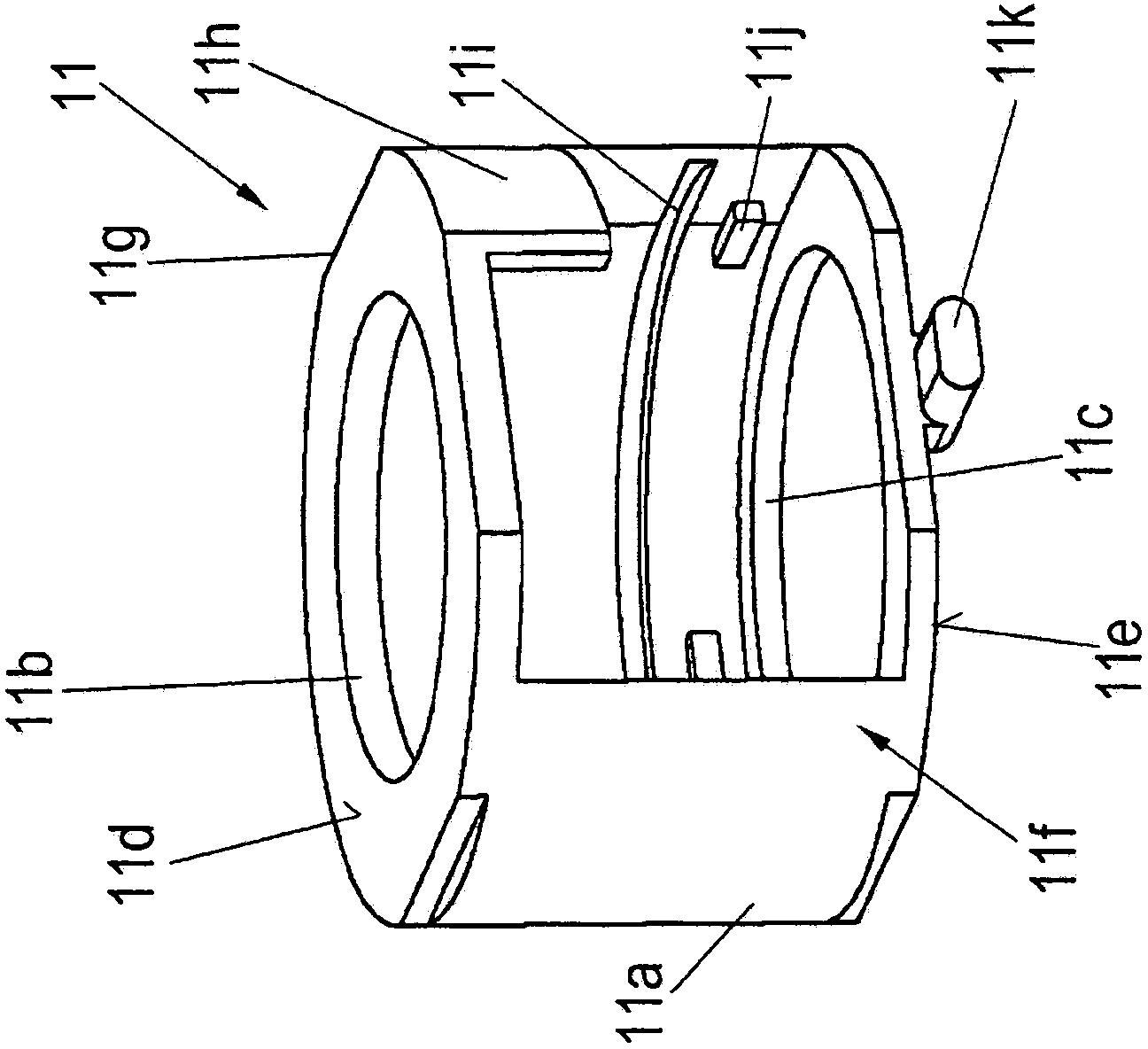

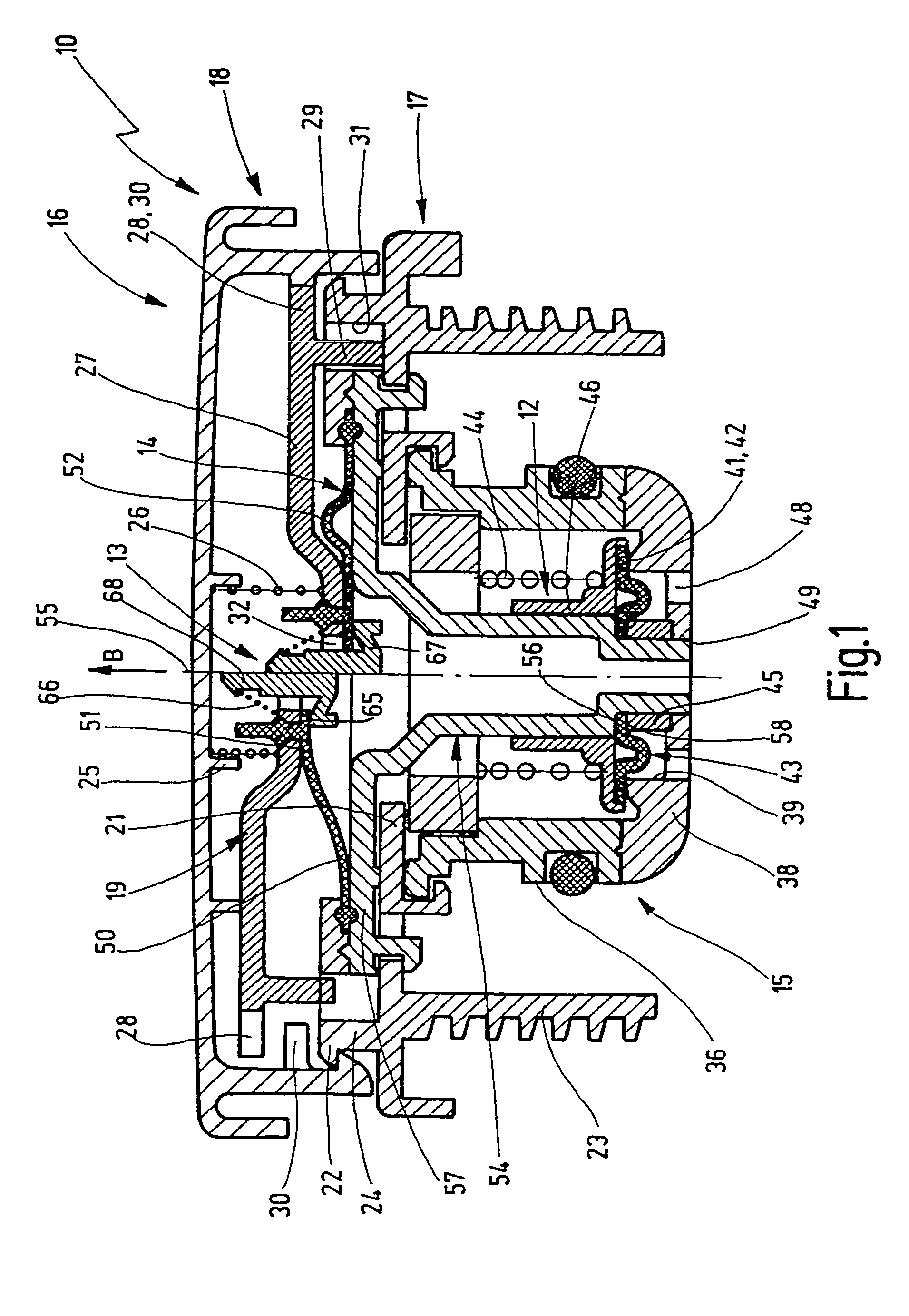

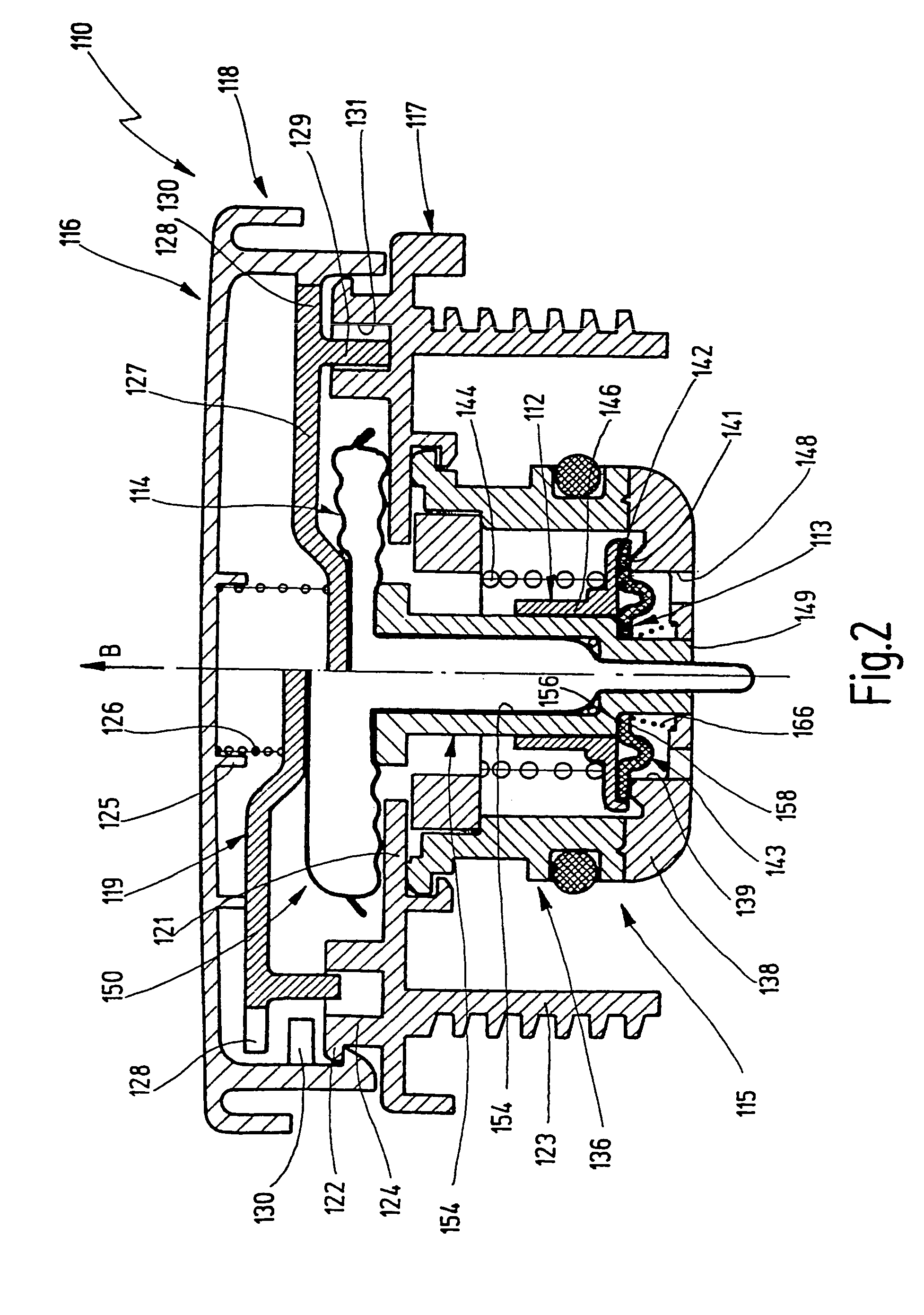

Wear adjustment device of a disc brake and corresponding disc brake

InactiveCN104395633AIntermittent feedFunction torque adjustableBraking element arrangementsSlack adjustersFreewheelCoupling

A wear adjustment device is provided for the adjusting friction surface wear on a brake pad and a brake disc of a disc brake having a brake application device, preferably with a rotary lever. The wear adjustment device can be coupled on the drive side to the brake application device, and on the output side to a spindle unit. A respective rolling body arrangement is axially arranged on both sides of a drive element, one of which is designed as a roller bearing and one is designed as a ball ramp coupling. A central shaft is coupled to the ball ramp coupling and has an output interface for coupling to the spindle unit. A radial freewheel is coupled to the ball ramp coupling by an overload spring unit and to the central shaft. A directionally-dependent torque device is provided, along with a housing in which the drive element, the rolling body arrangements, the overload spring unit, the radial freewheel, the central shaft and the directionally-dependent torque unit are arranged.

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

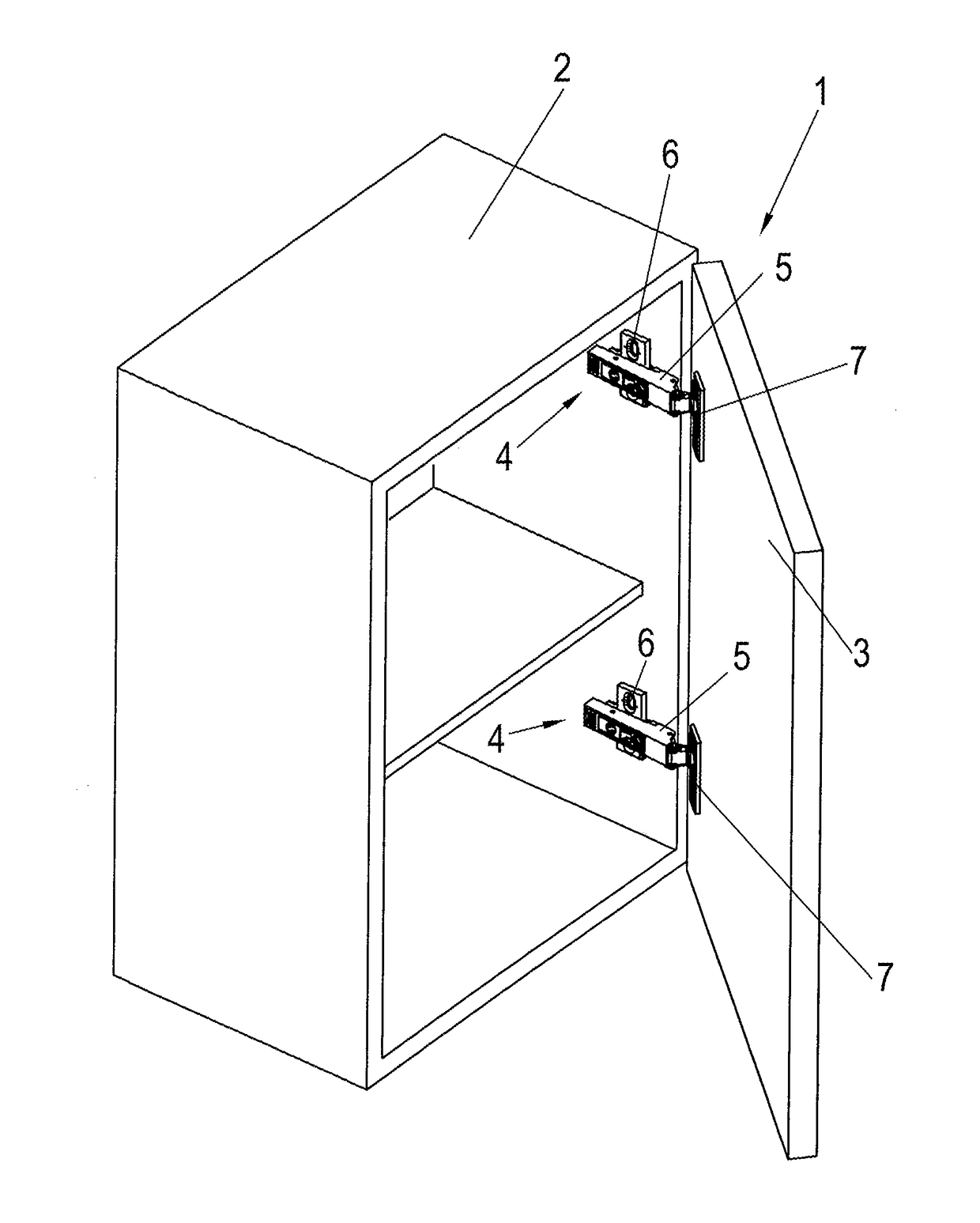

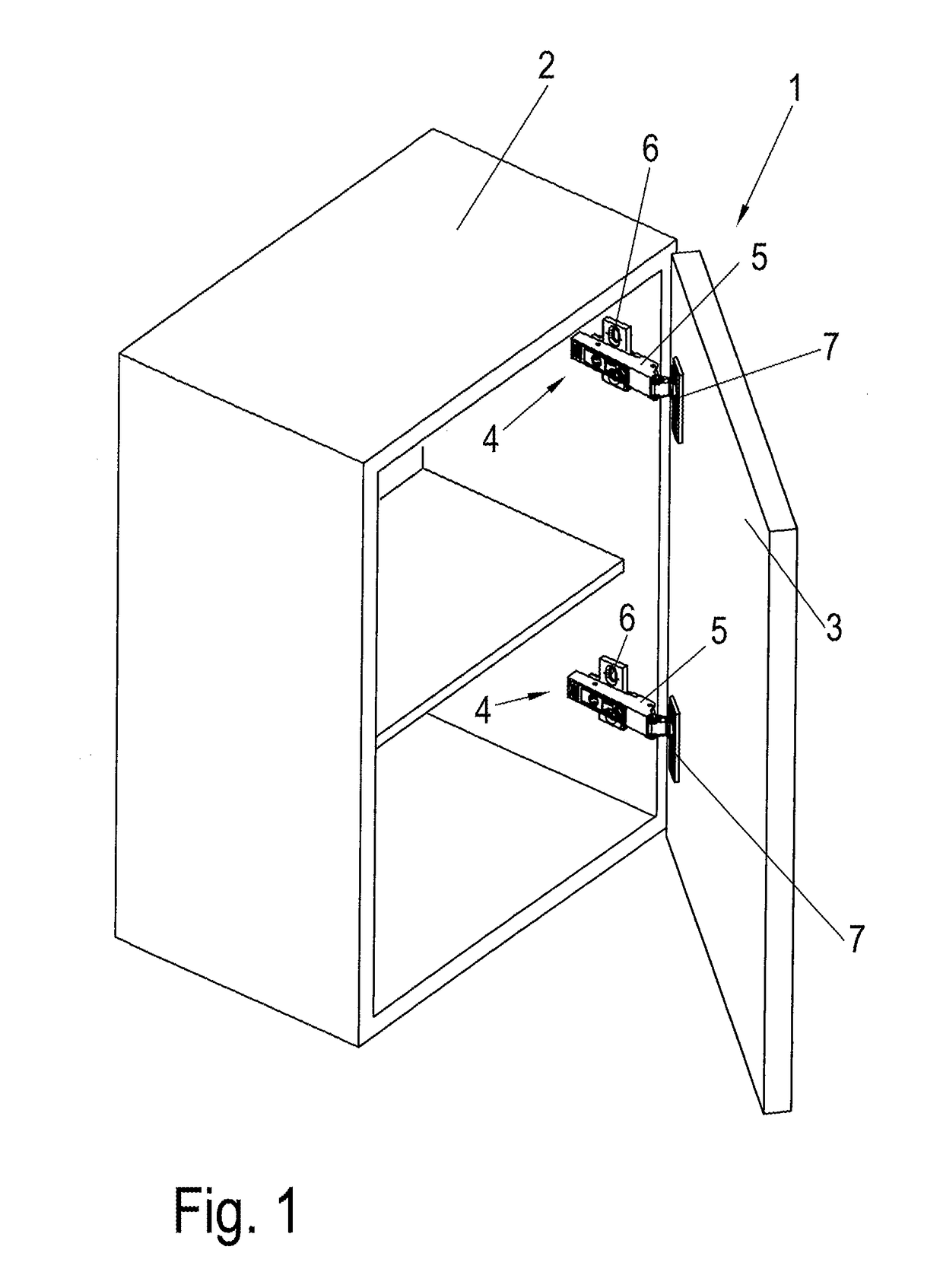

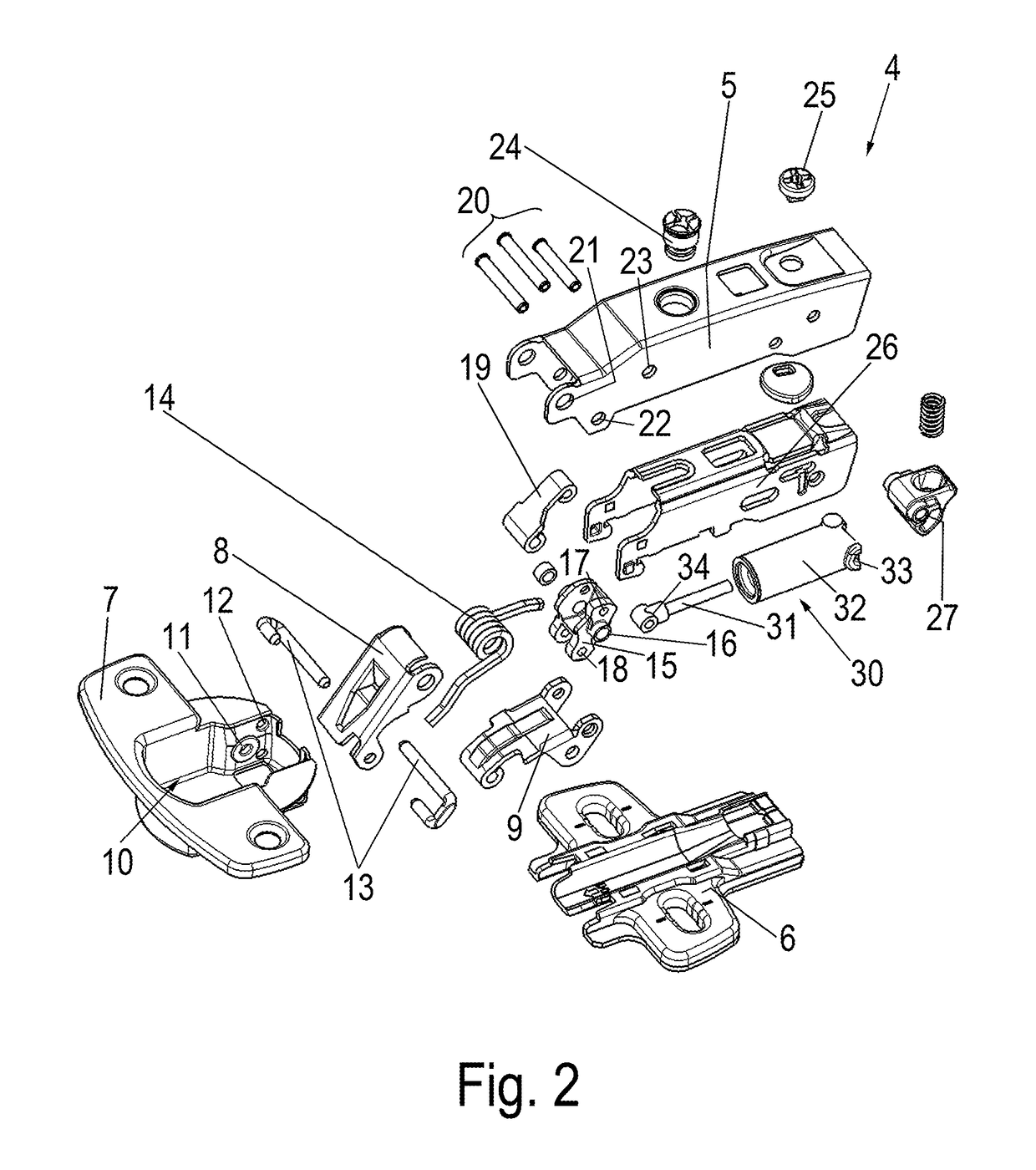

Hinge

ActiveUS20170138106A1Great damp forceLow damping forceBuilding braking devicesHingesHinge angleEngineering

Owner:HETTICH ONI

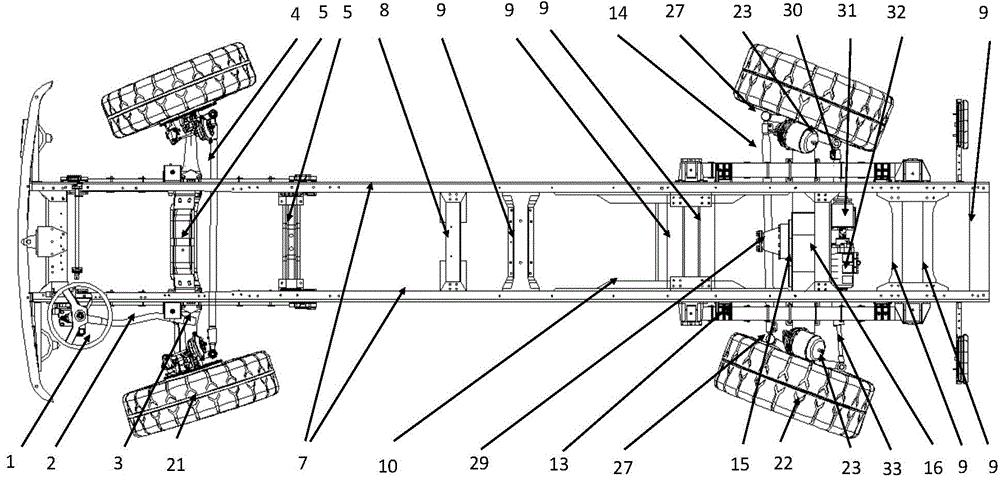

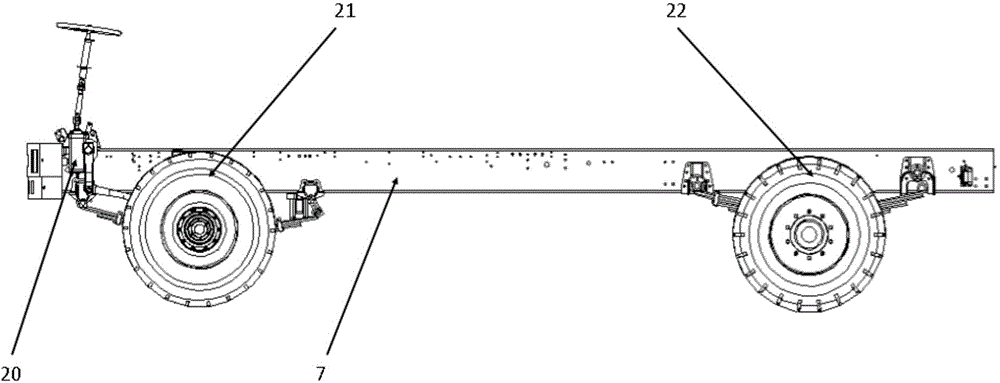

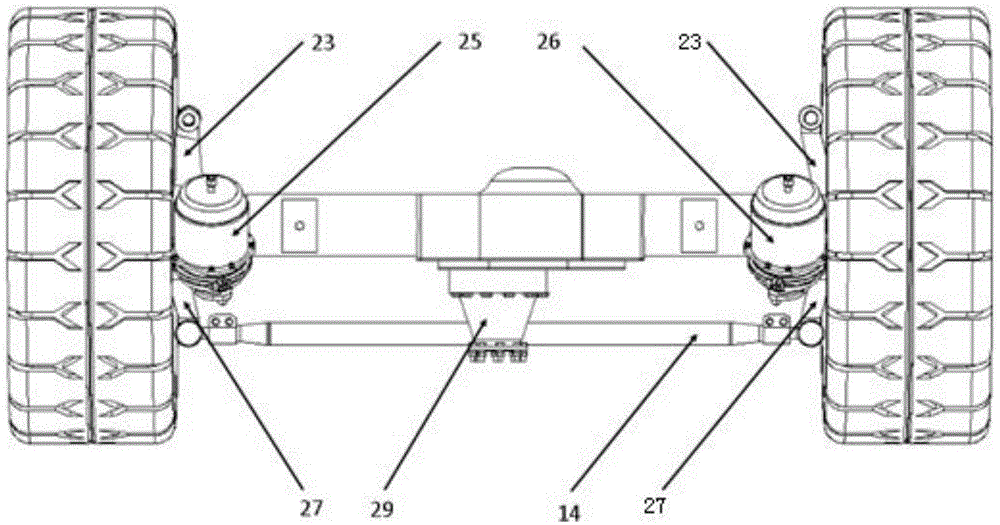

Chassis with four-wheel steering function

InactiveCN104925132AEnsure driving stability and handling stabilitySimple structureSteering linkagesTransaxleRocker arm

The invention discloses a chassis with a four-wheel steering function. The chassis comprises a rear steering axle. The rear steering axle comprises a rear wheel steering drive axle and a rear wheel steering reversal mechanism. The rear wheel steering drive axle comprises an axle body, a left steering knuckle, a right steering knuckle, two steering knuckle arms, two trapezoid arms and a rear steering tie rod. The left steering knuckle and the right steering knuckle are arranged at the two ends of the axle body respectively. The two steering knuckle arms are fixed to the left steering knuckle and the right steering knuckle respectively. The two trapezoid arms are fixed to the left steering knuckle and the right steering knuckle respectively. The rear steering tie rod is connected with the two trapezoid arms. The left steering knuckle and the right steering knuckle are fixedly connected with hubs of two rear wheels respectively. The rear wheel steering reversal mechanism comprises a hydraulic reversal cylinder, a motor, a rear wheel steering machine, a steering rocker arm and a rear wheel steering pull rod. The motor, the rear wheel steering machine, the steering rocker arm and the rear wheel steering pull rod are sequentially connected. The steering knuckle arm connected with the rear wheel steering pull rod moves to drive the rear wheels to steer, and the other steering knuckle arm is connected with a piston rod of the hydraulic reversal cylinder. The chassis achieves the four-wheel steering function of a commercial vehicle and meanwhile is simple in structure and small in control difficulty.

Owner:WUHAN UNIV OF TECH

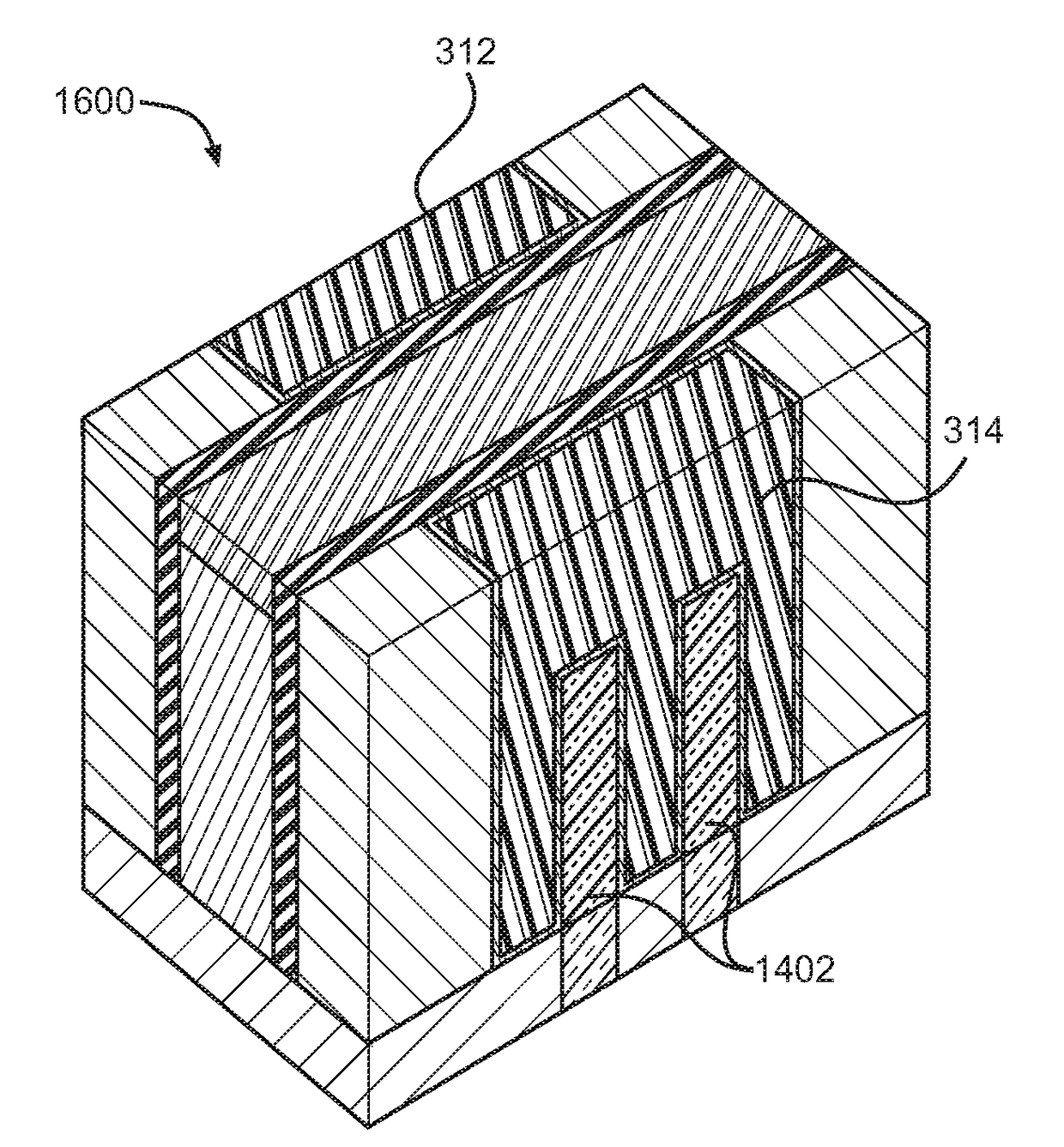

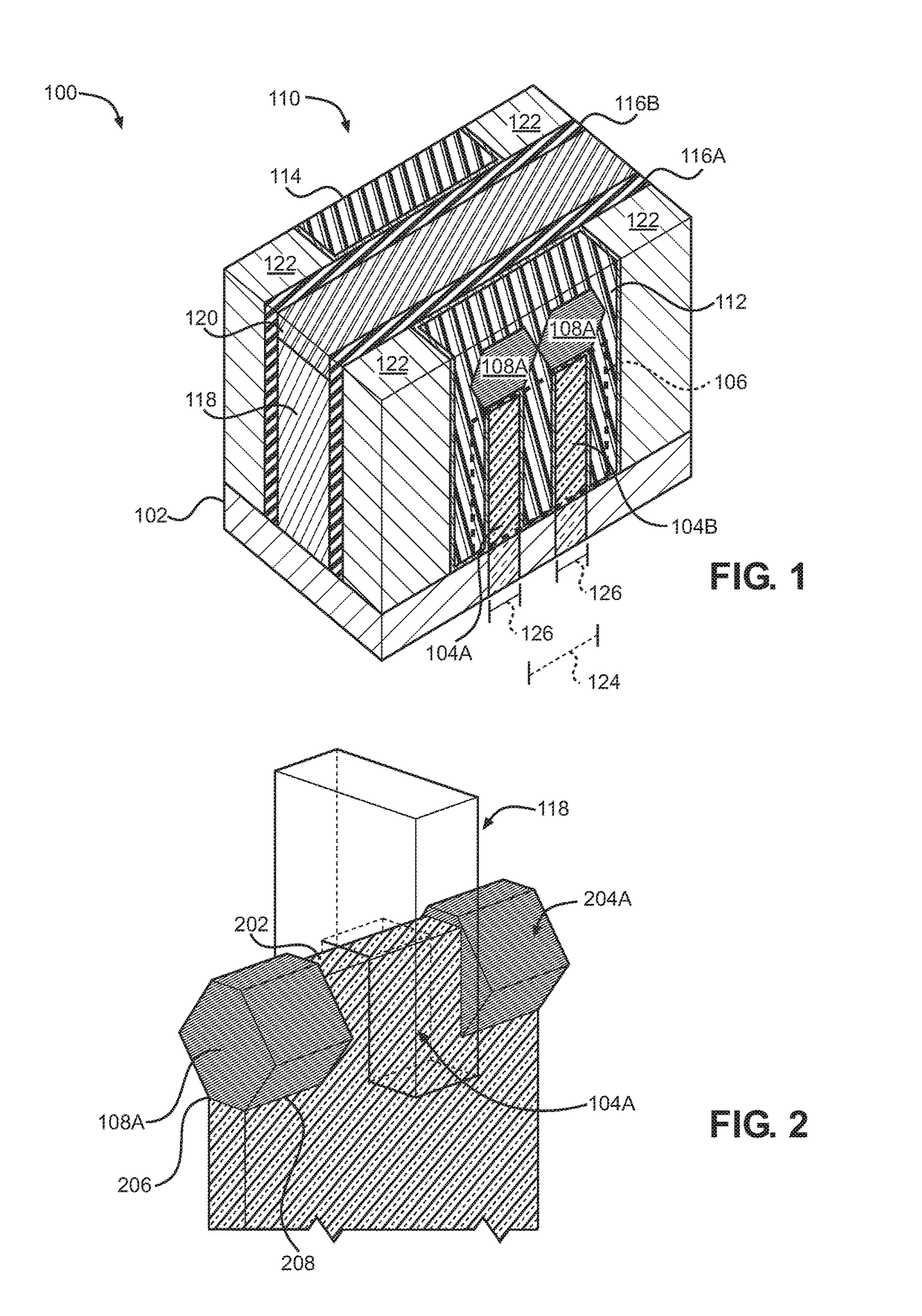

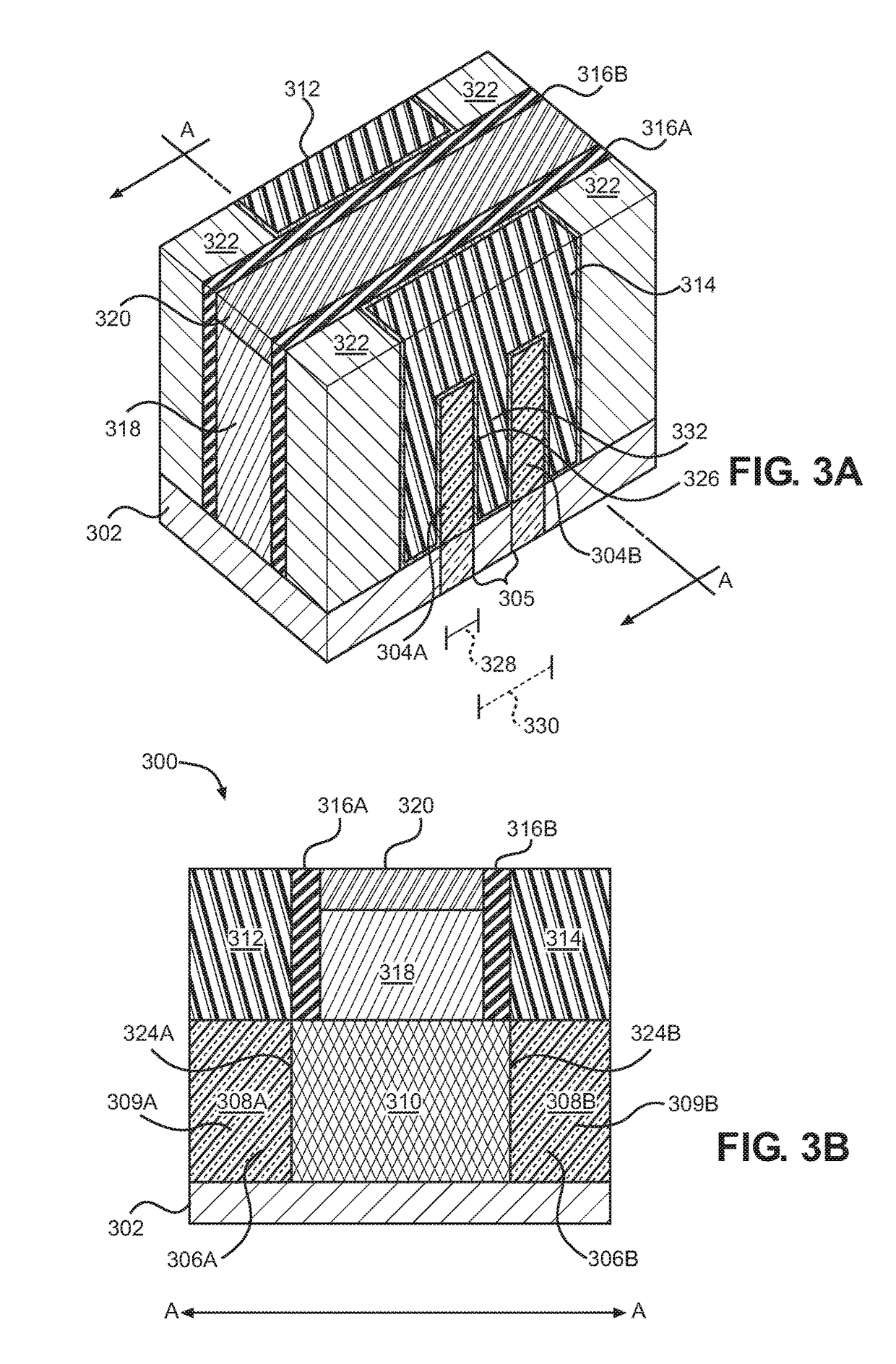

Complementary metal oxide semiconductor (CMOS) devices employing plasma-doped source/drain structures and related methods

InactiveUS20170352662A1Channel contact resistanceReduced channel structure widthTransistorSolid-state devicesSolubilityEngineering

Complementary metal oxide semiconductor (CMOS) devices employing plasma-doped source / drain structures and related methods are disclosed. In certain aspects, a source and drain of a CMOS device are formed at end portions of a channel structure by plasma doping end portions of the channel structure above solid state solubility of the channel structure, and annealing the end portions for liquid phase epitaxy and activation (e.g., superactivation). In this manner, the source and drain can be integrally formed in the end portions of the channel structure to provide coextensive surface area contact between the source and drain and the channel structure for lower channel contact resistance. This is opposed to forming the source / drain using epitaxial growth that provides an overgrowth beyond the end portion surface area of the channel structure to reduce channel contact resistance, which may short adjacent channels structures.

Owner:QUALCOMM INC

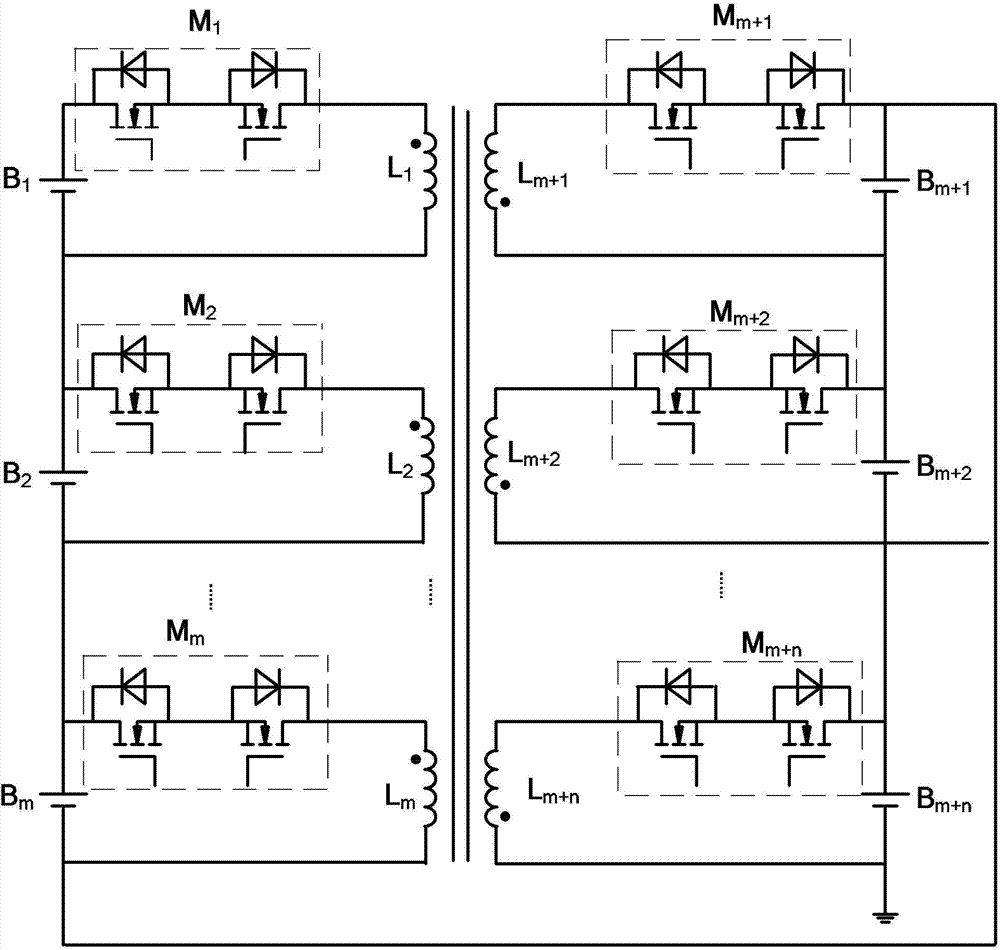

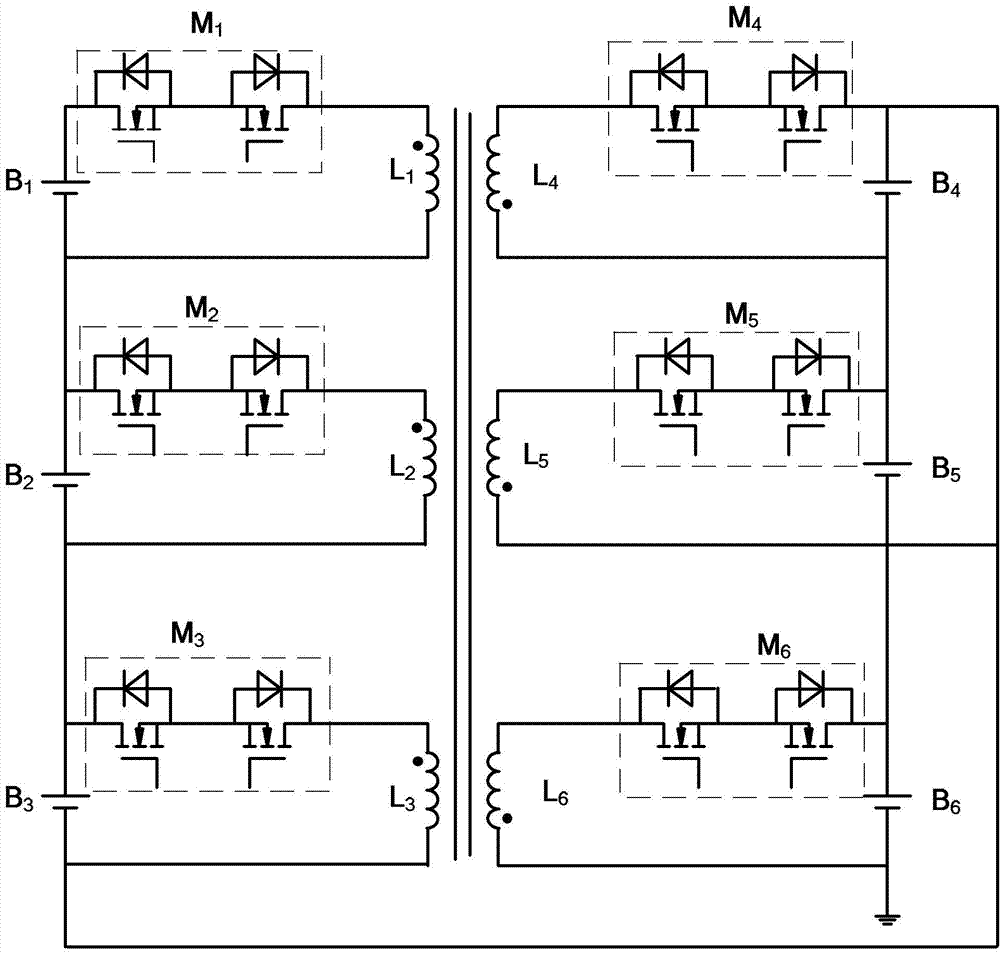

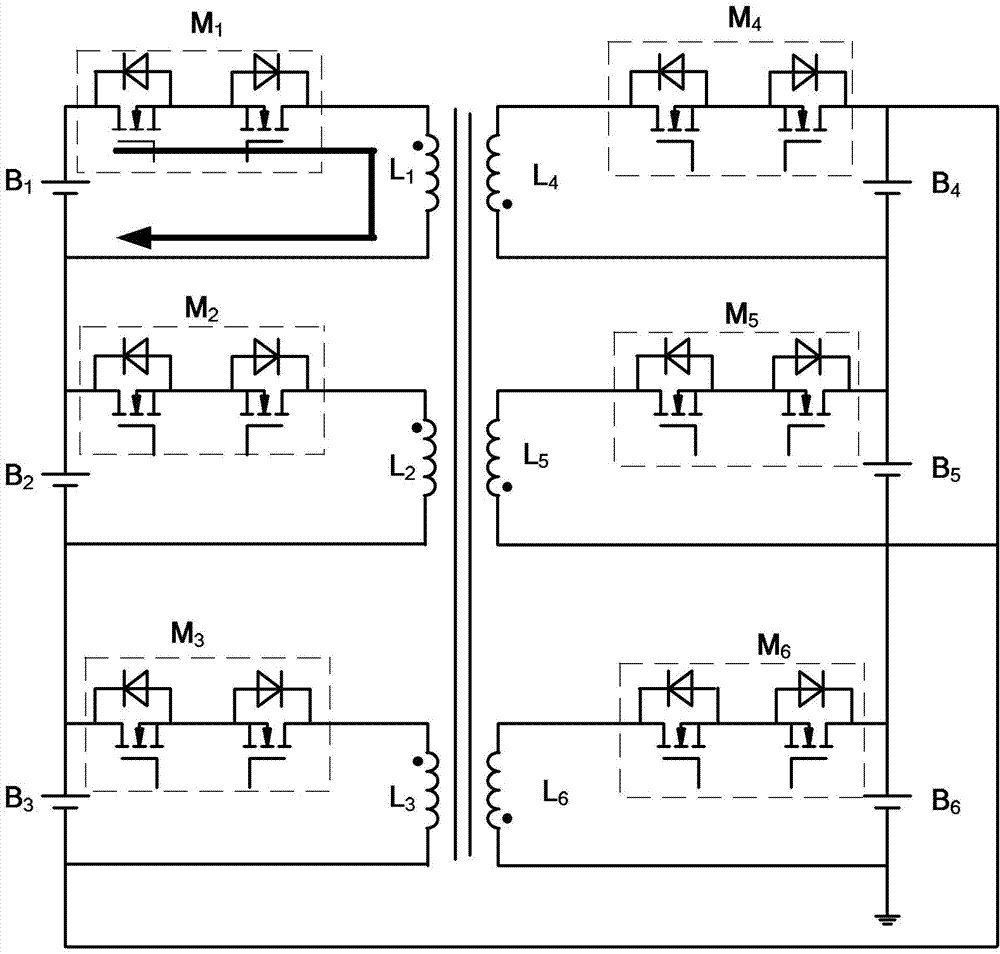

Multi-monomer directly equalizing device and method of series battery pack

ActiveCN103618360ASimple circuit structureShort energy transfer pathBatteries circuit arrangementsElectric powerMagnetic coreEngineering

The invention provides a multi-monomer directly equalizing device and method of a series battery pack, and relates to a monometer equalizing circuit of the series battery pack. The multi-monomer directly equalizing device and method of the series battery pack solve the problems that direct energy transfer between any two energy storage monomers can not be achieved, the energy equalizing path is long and the energy equalizing efficiency is low according to an existing energy equalizing device between the energy storage monomers. The series battery pack is formed by series connection of m+n monomer batteries. The multi-monomer directly equalizing device comprises a transformer and m+n bilateral switches, wherein the transformer is provided with m+n windings, the first m energy storage monomers in the series battery pack are used as the first group, and the last n energy storage monomers in the series battery pack are used as the second group; m coils in the m+n windings of the transformer are in one-to-one correspondence with the m energy storage monomers in the first group respectively, and the rest of the n coils are in one-to-one correspondence with the n energy storage monomers in the second group respectively; the m+n windings share one magnetic core, and the number of turns of the m+n windings is equal, so the energy direct transfer between any two energy storage monomers can be achieved. The multi-monomer directly equalizing device and method can be applied to the field of energy equilibrium of the series energy storage monomers.

Owner:HARBIN INST OF TECH

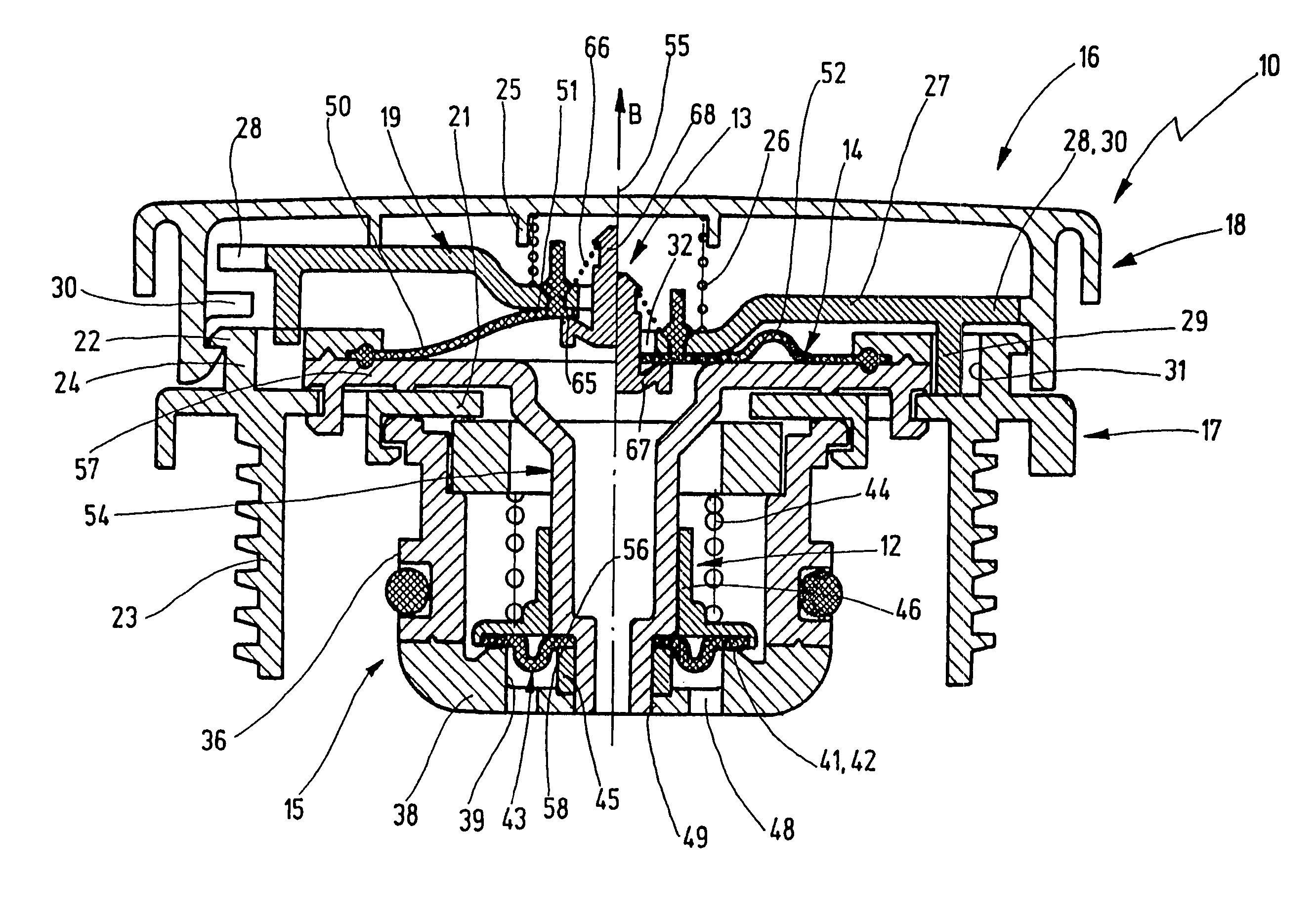

Sealing lid for motor vehicle radiator

InactiveUS7380681B2Without impermissibly high lossShort structureClosuresRefuse receptaclesMobile vehiclePressure transmission

A sealing lid for the fixed nozzle of a container, particularly a motor vehicle radiator, comprising an outer part and an inner part. The outer part of the lid is provided with a sealing element for the container nozzle and a grip element which is rotatable in relation thereto. A torsional stop acts between the grip element and the sealing element of the outer part of the lid. The inner part of the lid is provided with a flow connection between the inside and outside of the container and a valve system opening and closing the flow connection. The torsional stop which can be disengaged by applying prestress to a spring or is disengaged, can be engaged by a pressure-controlled drive in the form of a membrane. The drive is positioned in the outer part of the lid and is provided with an elongate pressure-transmitting element which penetrates the pressure relief valve body in the lid axis and extends into the area of the inner part of the lid, which is connected to the container nozzle so as to interact therewith. The suction relief valve body is arranged concentrically to the lid axis.

Owner:REUTTER HEINRICH

Seal structure for multi-core cable

ActiveUS20180048081A1Increase contact pressureReduce manufacturing costCoupling device detailsConnection insulationEngineeringElectric wire

Owner:AUTONETWORKS TECH LTD +2

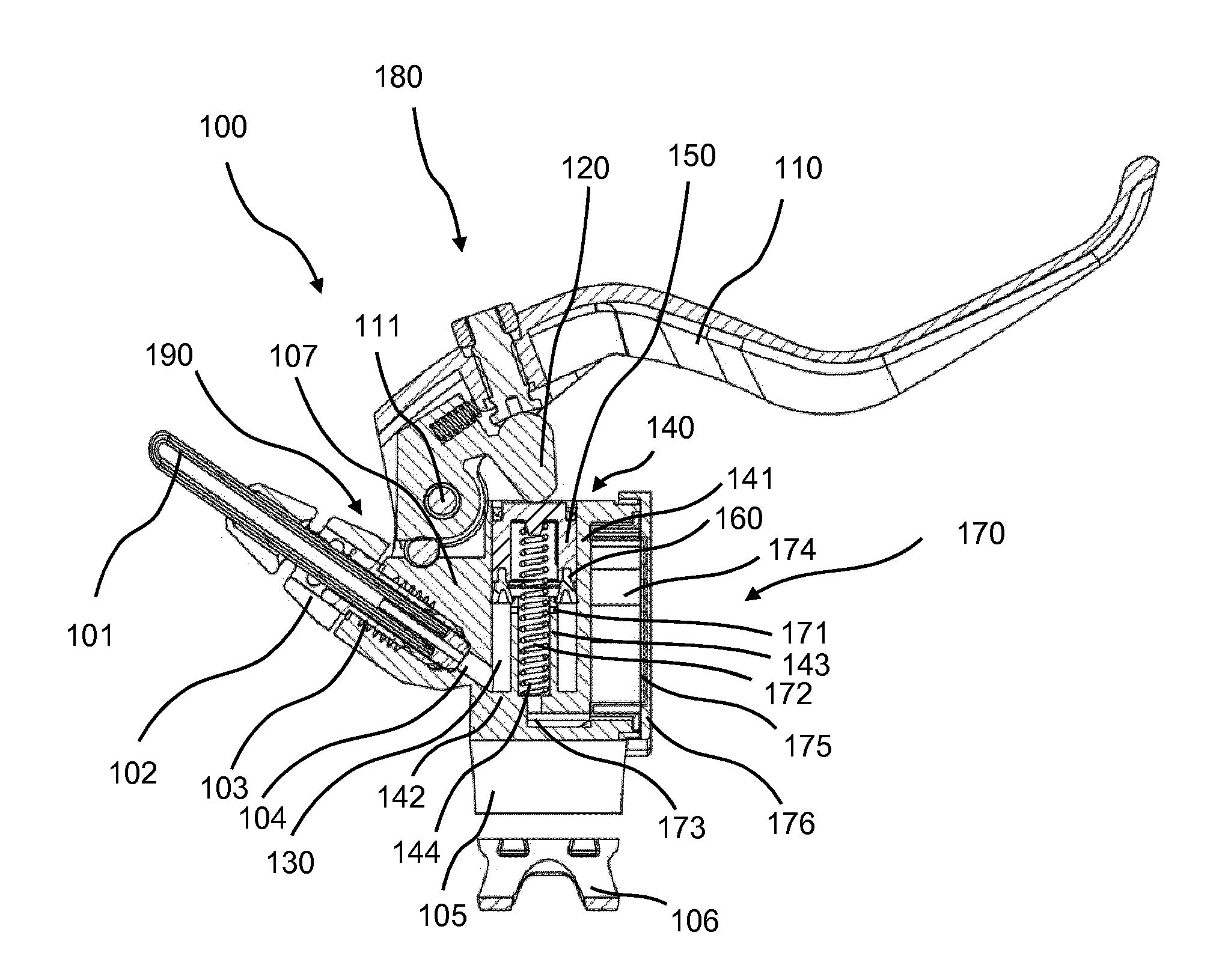

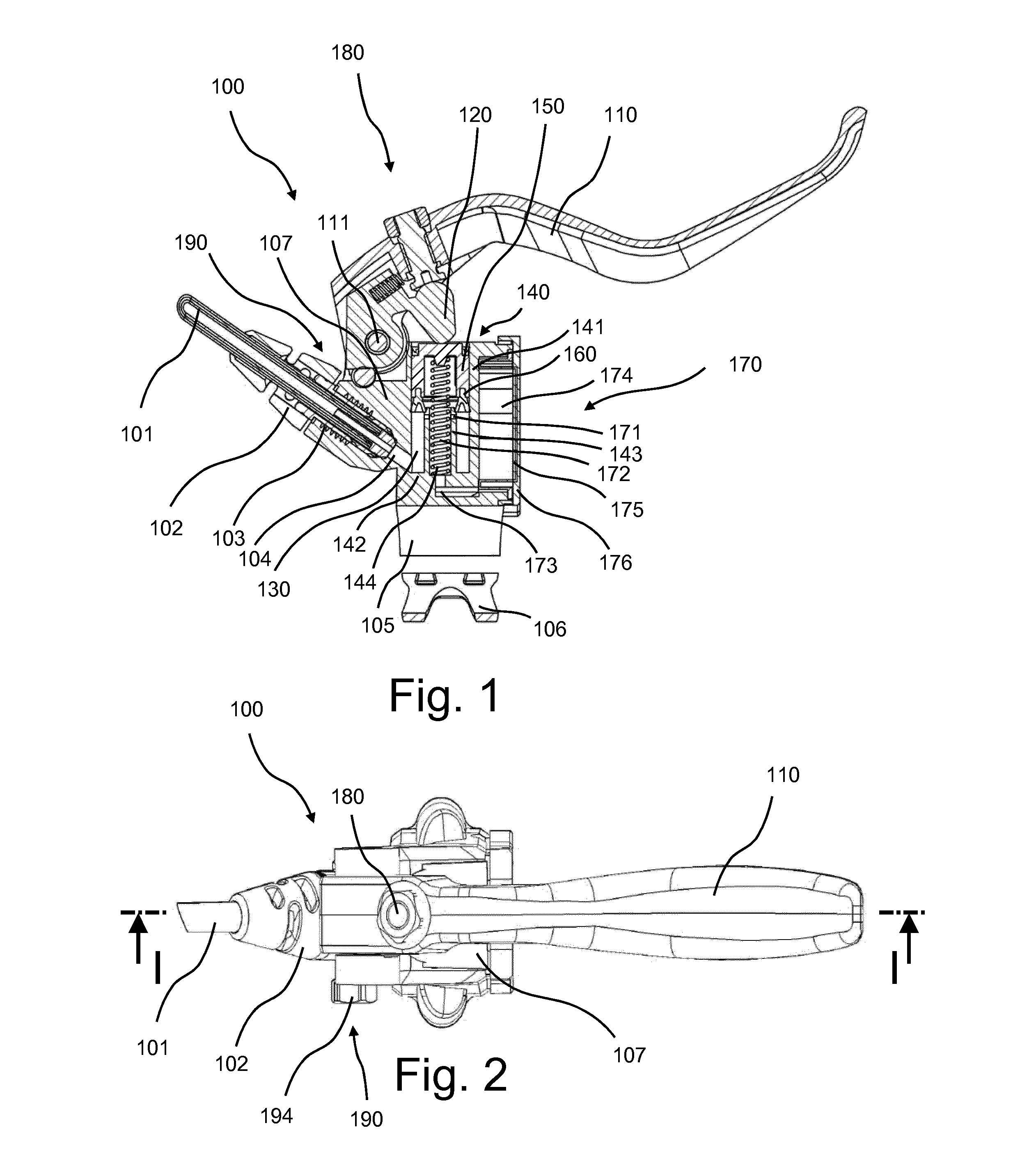

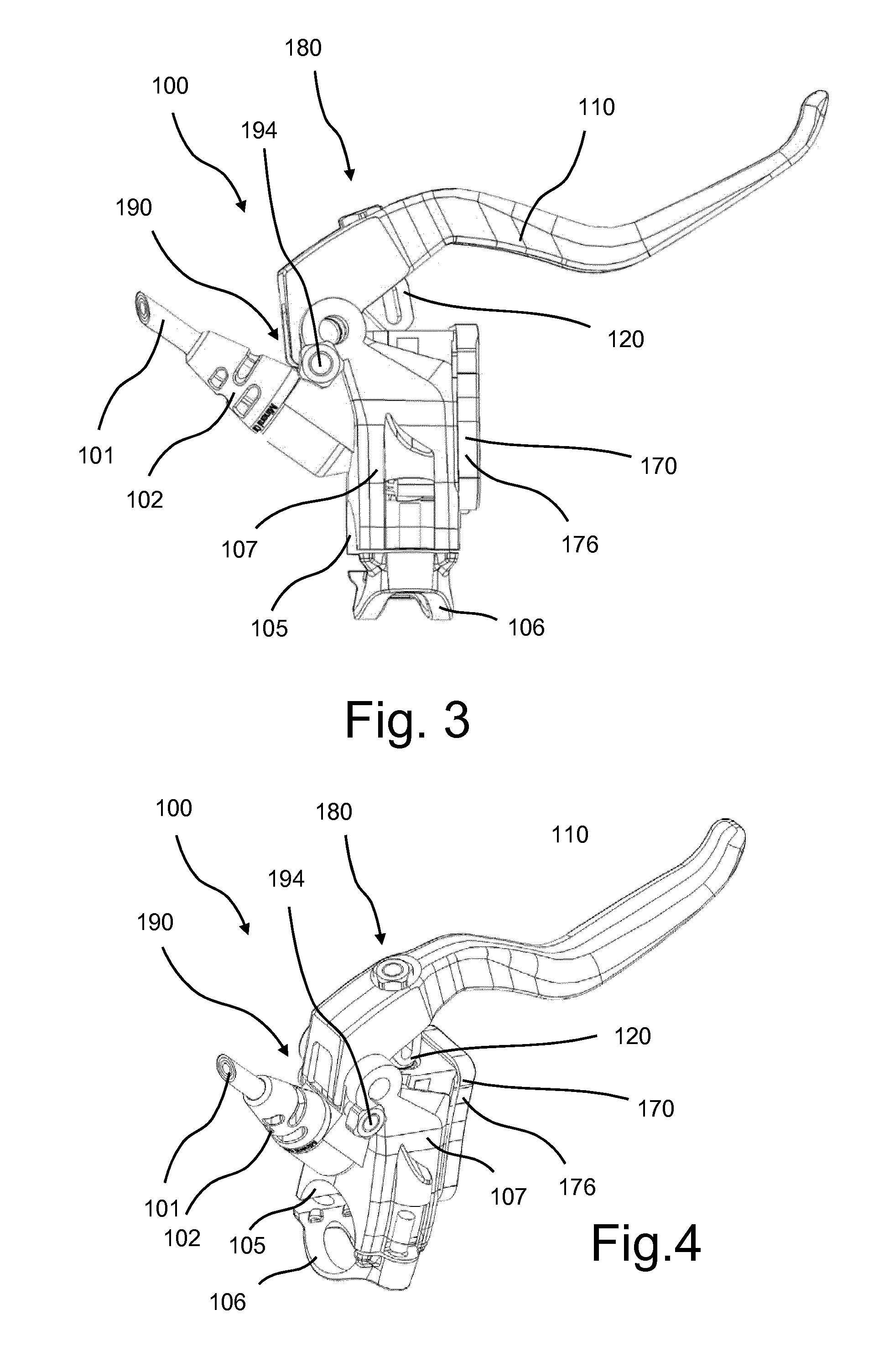

Master Cylinder Device for a Hydraulic Disk Brake

A master cylinder for a hydraulic brake comprises a compensating chamber, a cylinder in which a piston is movably disposed, a pressure chamber disposed in the cylinder and connected to the compensating chamber through at least one connecting opening, and a gasket for interrupting the connection between the pressure chamber and the compensating chamber. The gasket seals the compensating chamber and the pressure chamber against the environment.

Owner:GUSTAV MAGENWIRTH GMBH & CO KG

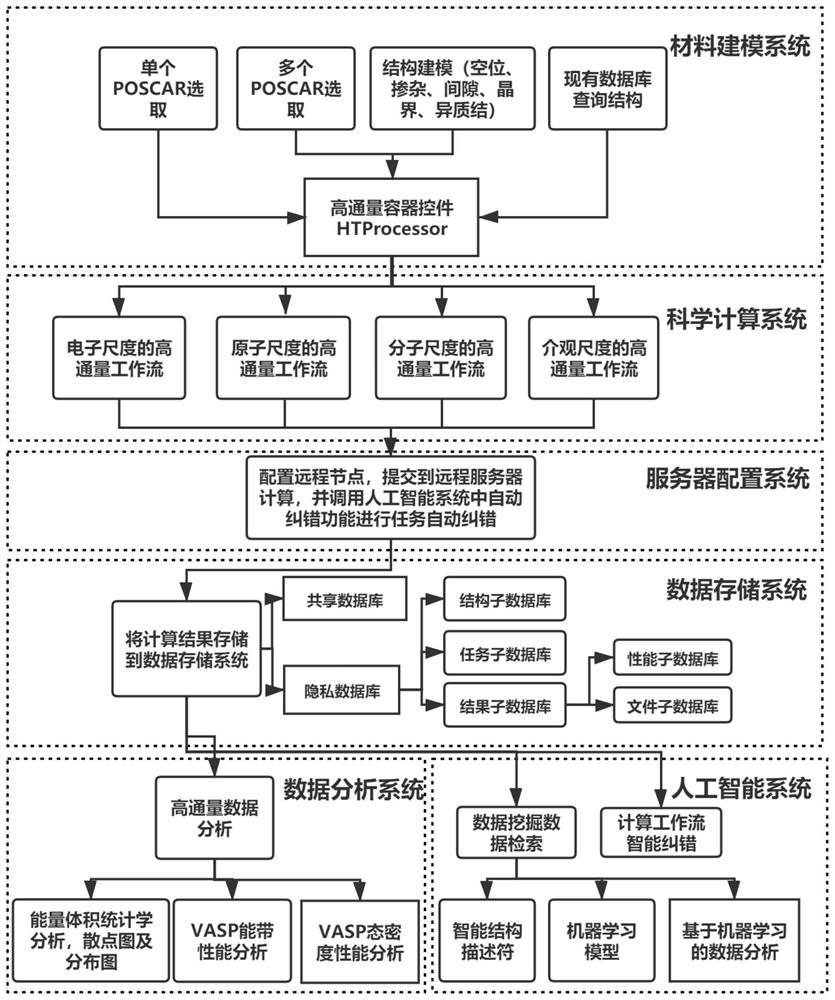

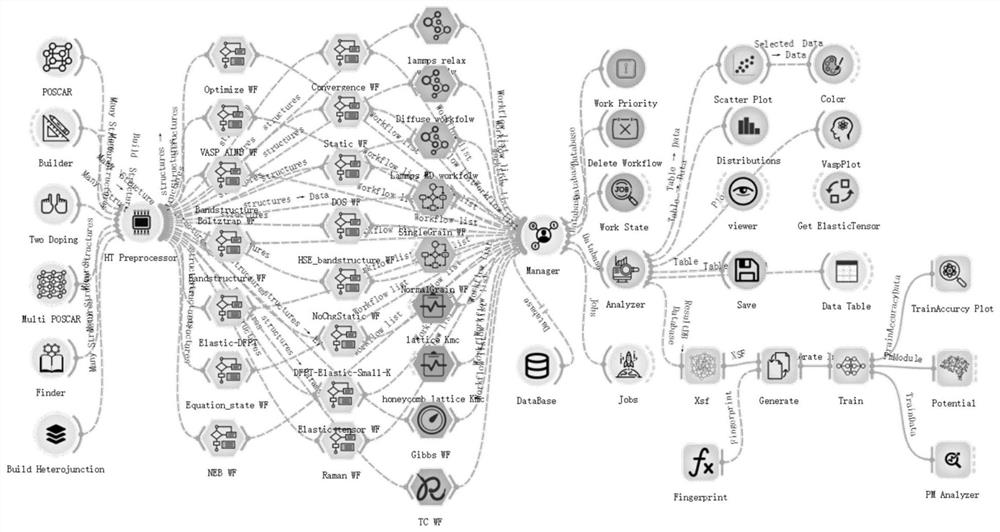

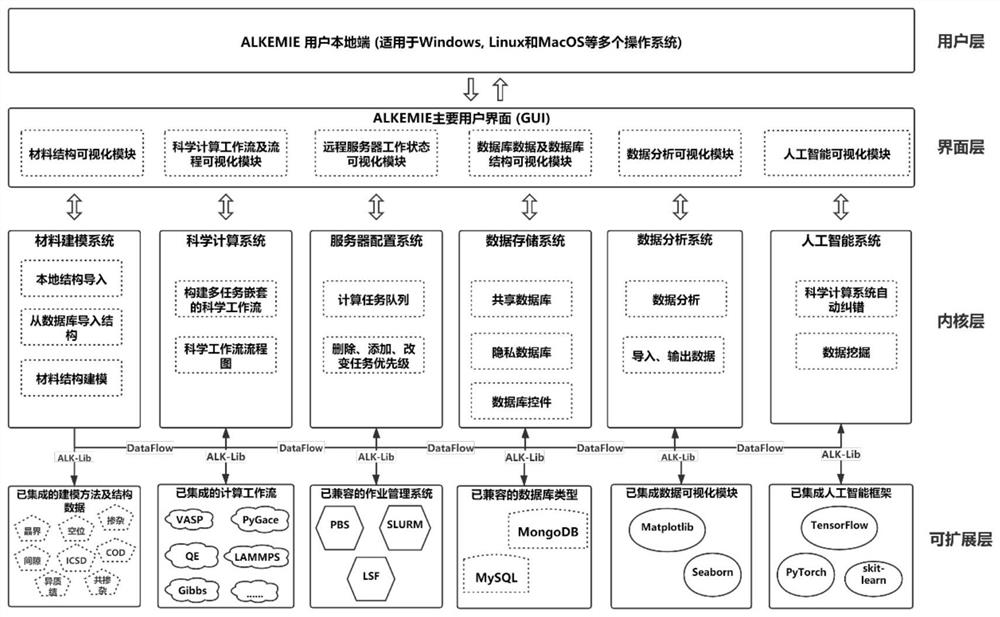

Multi-scale integrated visual high-flux automatic calculation process and data intelligent system

ActiveCN112102887AFacilitate communicationSimple structureChemical property predictionChemical data visualisationData analysis systemGenetic engineering

The invention belongs to the field of material genetic engineering, multi-scale simulation and material big data, and relates to a multi-scale integrated visual high-flux automatic calculation processand data intelligent system, which comprises a material modeling system, a scientific calculation system, a server configuration system, a data storage system, a data analysis system and an artificial intelligence system. According to the method, an automatic construction method of a material complex model, various material calculation simulation methods with different scales, various types of material databases, a material performance analysis technology and a data mining technology based on artificial intelligence are combined, and 1000-magnitude material high-flux calculation simulation can be automatically carried out; material calculation simulation of multiple scales such as an electronic scale, an atomic scale, a molecular scale and a mesoscopic scale can be carried out, and errorspossibly occurring in the calculation process can be automatically corrected; all calculated structural data, intermediate metadata and result data can be stored in various types of material databases, so that a user can conveniently inquire and carry out data mining analysis.

Owner:BEIHANG UNIV

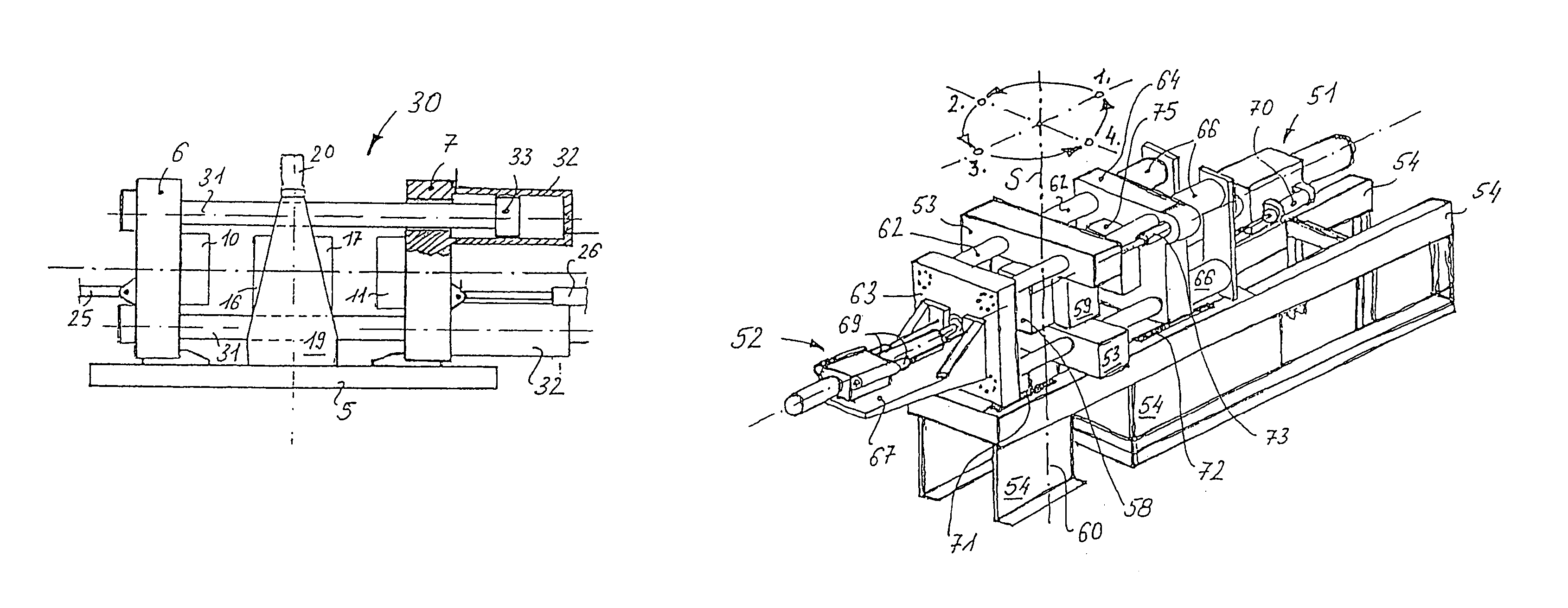

Mold closing device for an injection molding machine

InactiveUS7018189B2Improve adhesionShorten cycle timeTailstocks/centresConfectioneryBraced frameEngineering

A mold closing device of an injection molding machine for producing plastic parts made of two or more plastic components includes a central mold carrier element which is arranged between two outer mold mounting plates and has two or four opposing mold mounting areas arranged in pairs for affixing two or four mold halves and which is fitted with a turning device supported in a supporting frame. Each of the mold halves of the mold carrier element can be closed against the mold halves of the outer mold mounting plates by a drive mechanism and a mold pressure unit. The outer mold mounting plates are interconnected by columns which extend through the supporting frame for the central mold carrier element. The supporting frame is fixedly connected to the machine frame while the outer mold mounting plate is displaceably supported on the machine frame.

Owner:KRAUSS MAFFEI KUMSTSTOFFTECHNIK GMBH

Illumination system with a plurality of individual gratings

InactiveUS20030099040A1Easy to separateShort structureRadiation pyrometrySpectrum investigationGratingLight beam

There is provided an illumination system for wavelengths of <=100 nm, having an object plane and a field plane. The illumination system includes a grating element having a plurality of gratings, and a diaphragm. The diaphragm is arranged after the grating element in a beam path from the object plane to the field plane.

Owner:CARL ZEISS SMT GMBH +1

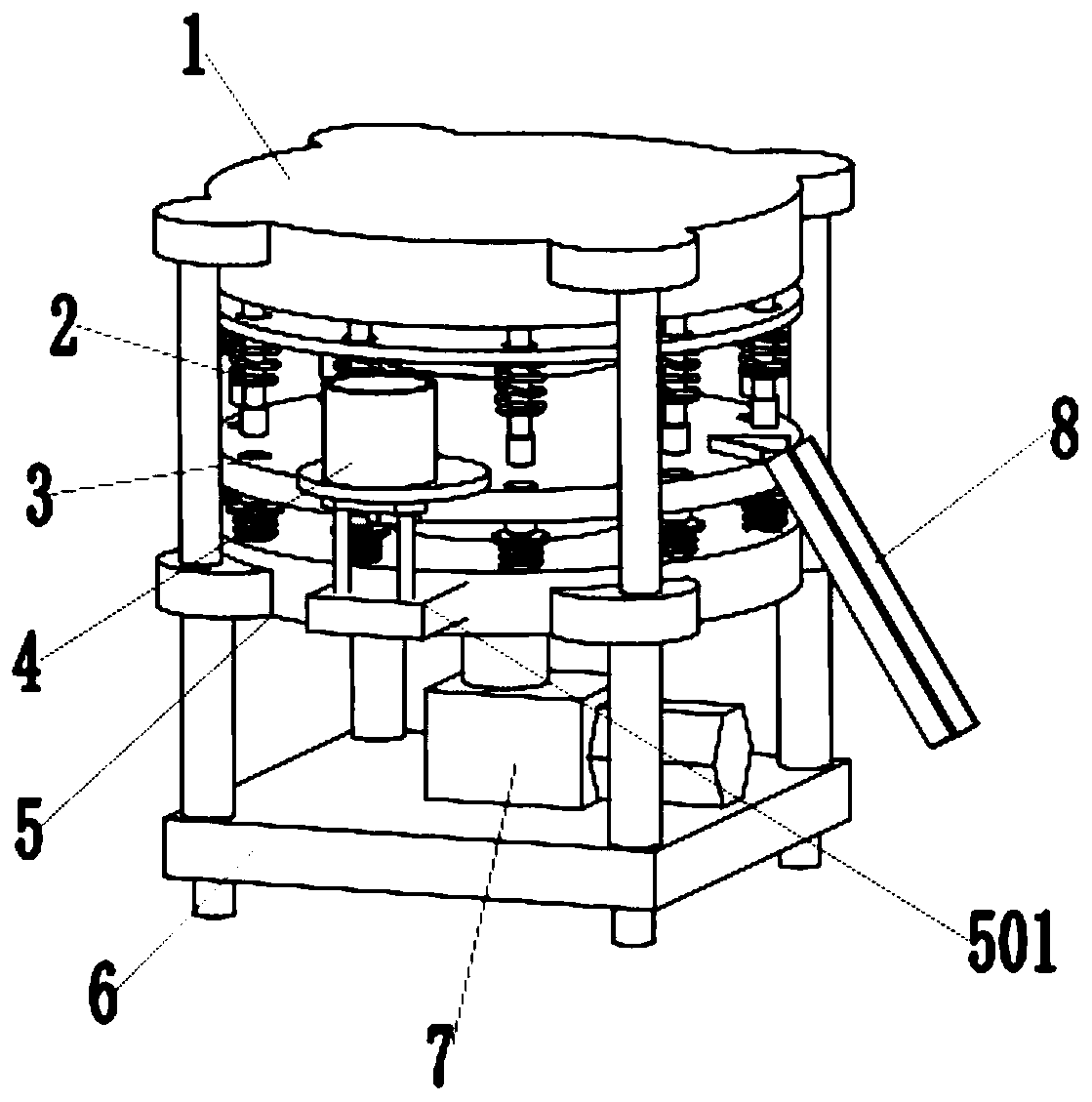

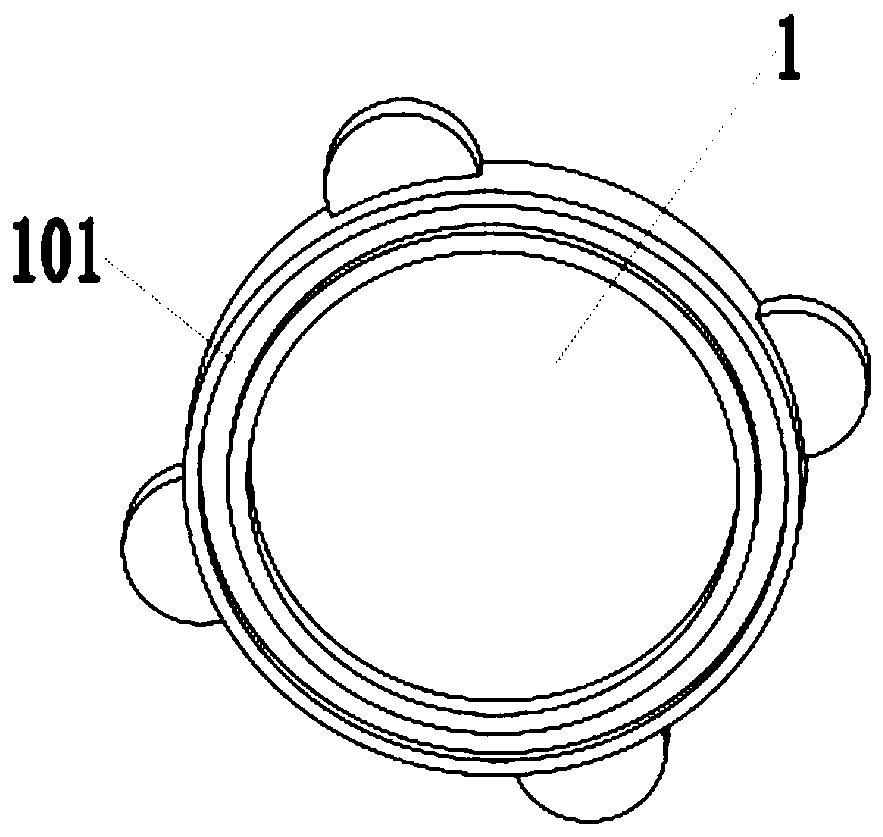

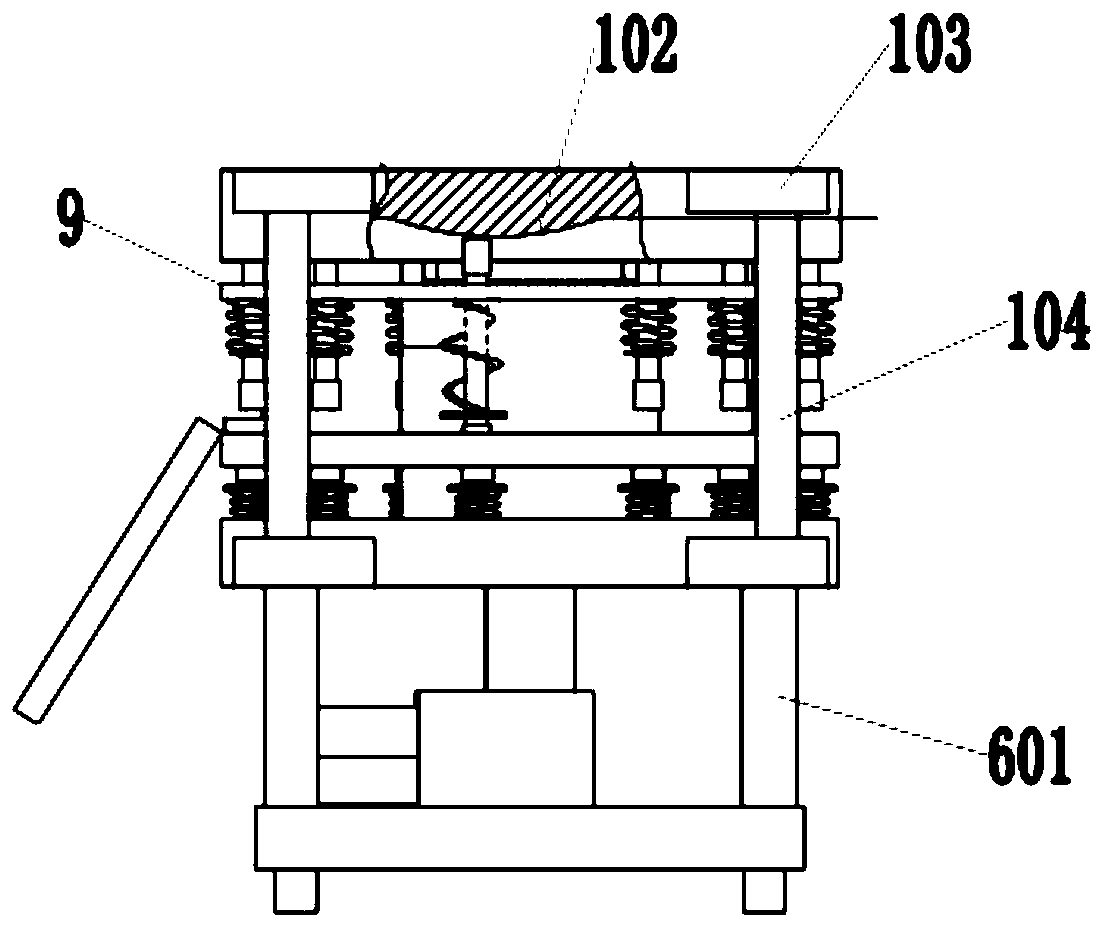

Tablet press for producing tablets

The invention discloses a tablet press for producing tablets. The tablet press comprises a pressure disc, the die punching rods, a die pressing rod, a feeder, a tray, a base and a motor. The upper endof the base is connected with the tray, the upper end of the tray is connected with the pressure disc, and a pressing mold disc is arranged between the pressing disc and the tray; the motor is arranged at the upper end of the base and is connected with the die pressing disc through a rotating shaft, an upper rotating disc is arranged between the pressing die disc and the pressing disc and is connected with the rotating shaft, and a lower rotating disc is arranged between the pressing die disc and the tray and is connected with the rotating shaft; the punching die rods are arranged on the upper side and the lower side of the pressing die disc; the punching die rods are arranged at the two sides of the pressing die disc, the punching die rod arranged above the pressing die disc penetrates through the upper rotating disc to be connected with the pressing disc in a sliding manner, and the punching die rod arranged below the pressing die disc penetrates through the lower rotating disc to be connected with the tray in the rotating manner; a pressing die hole is formed on the pressing die disc, the feeder matched with the pressing die hole is arranged at one side of the tray, and a discharging sliding way is arranged at one side of the pressing die disc.

Owner:SHANDONG KANGFUSEN BIOTECH CO LTD

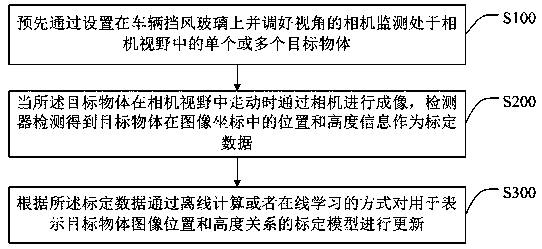

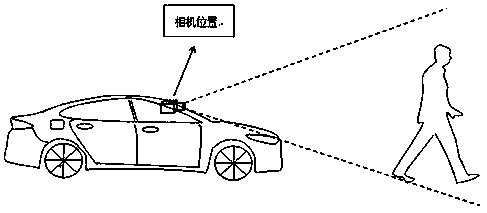

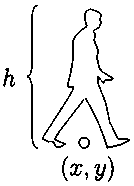

Calibration method and system applying camera and scene association of intelligent driving

PendingCN107316332AShort structurePrecise structureImage enhancementImage analysisOnline learningMultiple target

The invention discloses a calibration method and system applying a camera and scene association of intelligent driving. The method comprises steps of monitoring a single or multiple target objects in the camera view field in advance through a camera which is arranged on an automobile windshield and has an adjusted view angle; when each target object walks in the camera view field, carrying out imaging through the camera, and using the position and height information, detected by a detector, of each target object in an image coordinate as calibration data; and according to the calibration data, through offline calculation or online learning, updating a calibration model used for representing the position and height relations of the target objects. According to the invention, by calibrating the target objects appearing in the camera view field through the camera installed on the automobile, structure distribution properness of pictures and targets in the imaging pictures are mainly calibrated; and the calibration method is advantageous in that the calibration method is simple, rapid, accurate and free of environment limitations.

Owner:SHENZHEN PROTRULY ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com