Patents

Literature

22699results about "Physical/chemical process catalysts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for improving viscosity of attapulgite clay

InactiveCN1317067CImprove processing technologyPhysical/chemical process catalystsOther chemical processesPolymer scienceMachining process

The invention discloses a jprocess for improving viscosity of attapulgite clay which comprises the steps of modification treatment, batching, agitating, milling and detect. The process can be applied into the real processing procedure of Attapulgite clay, and can increase the viscosity of the end product by over 35%.

Owner:许庆华

Production of synthetic lubricant and lubricant base stock without dewaxing

InactiveUS6103099AThermal non-catalytic crackingRefining to change hydrocarbon structural skeletonAutomatic transmissionBoiling point

A lubricating base stock useful for forming lubricants such as a multigrade automotive oils, automatic transmission oils, greases and the like is prepared by hydroisomerizing a waxy hydrocarbon feed fraction having an initial boiling point in the 650-750 DEG F. range and an end point of at least 1050 DEG F., synthesized by a slurry Fischer-Tropsch hydrocarbon synthesis process. The hydroisomerization forms a hydroisomerate containing the desired base stock which is recovered, without dewaxing the hydroisomerate. The hydroisomerization is conducted at conditions effective to convert at least 67 wt. % of the 650-750 DEG F.+ waxy feed hydrocarbons to lower boiling hydrocarbons. When combined with a standard lubricant additive package, these base stocks have been formed into multigrade automotive crankcase oils, transmission oils and hydraulic oils meeting the specifications for these oils.

Owner:EXXON RES & ENG CO

Pre-passivation process for a continuous reforming apparatus, and passivation process for a continuous reforming apparatus during the initial reacation

ActiveUS20100282645A1Reduce operational riskReduce contentThermal non-catalytic crackingPhysical/chemical process catalystsLiquid productReaction temperature

The present invention relates to a pre-passivation process for a continuous reforming apparatus prior to the reaction, or a passivation process for a continuous reforming apparatus during the initial reaction, comprising loading a reforming catalyst into the continuous reforming apparatus, starting the gas circulation and raising the temperature of a reactor, injecting sulfide into the gas at a reactor temperature ranging from 100-650° C., controlling the sulfur amount in the recycle gas within a range of 0.5-100×10−6 L / L so as to passivate the apparatus.The process of the present invention may also comprise the following steps:(1) loading a reforming catalyst into the continuous reforming apparatus, starting the gas circulation and raising the temperature of a reactor, feeding the reforming feedstock into the reaction system when the temperature of the reactor is increased to 300-460° C., introducing sulfide into the reaction system while or after the reforming feedstock is fed, controlling the ratio of the total sulfur amount introduced into the system to the reforming feedstock within the range of 0.5 μg / g-50 μg / g, reducing the content of sulfide introduced into the system when hydrogen sulfide concentration in the recycle gas reaches to 2.0 μL / L˜30 μL / L; and(2) maintaining the reforming reactor at a temperature of 460-490° C., controlling the ratio of the total sulfur amount introduced into the system to the reforming feedstock within the range of 0.2 μg / g-0.5 μg / g, adjusting the amount of the reforming feedstock to the design value of the apparatus, increasing the reforming reaction temperature to 490-545° C. according to the requirements on the octane number of the liquid product, and letting the reforming apparatus run under normal operating conditions.

Owner:CHINA PETROCHEMICAL CORP +1

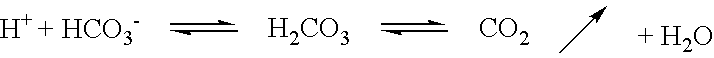

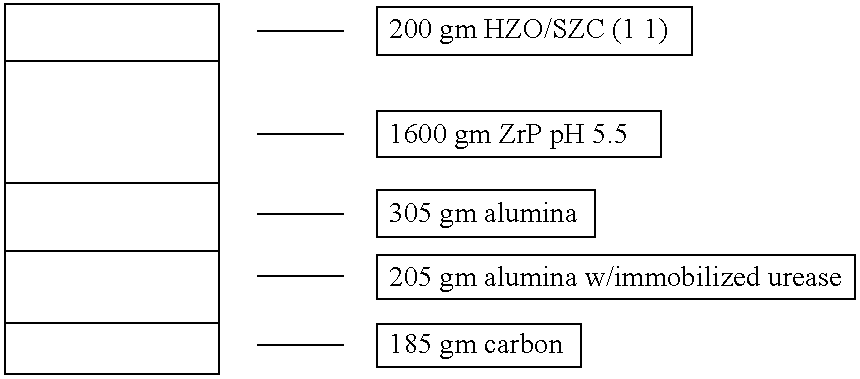

Cartridges useful in cleaning dialysis solutions

InactiveUS20020112609A1Avoid a lotSolve the blockageIsotope separationLoose filtering material filtersHemodialysis membraneChemistry

Owner:RENAL SOLUTIONS

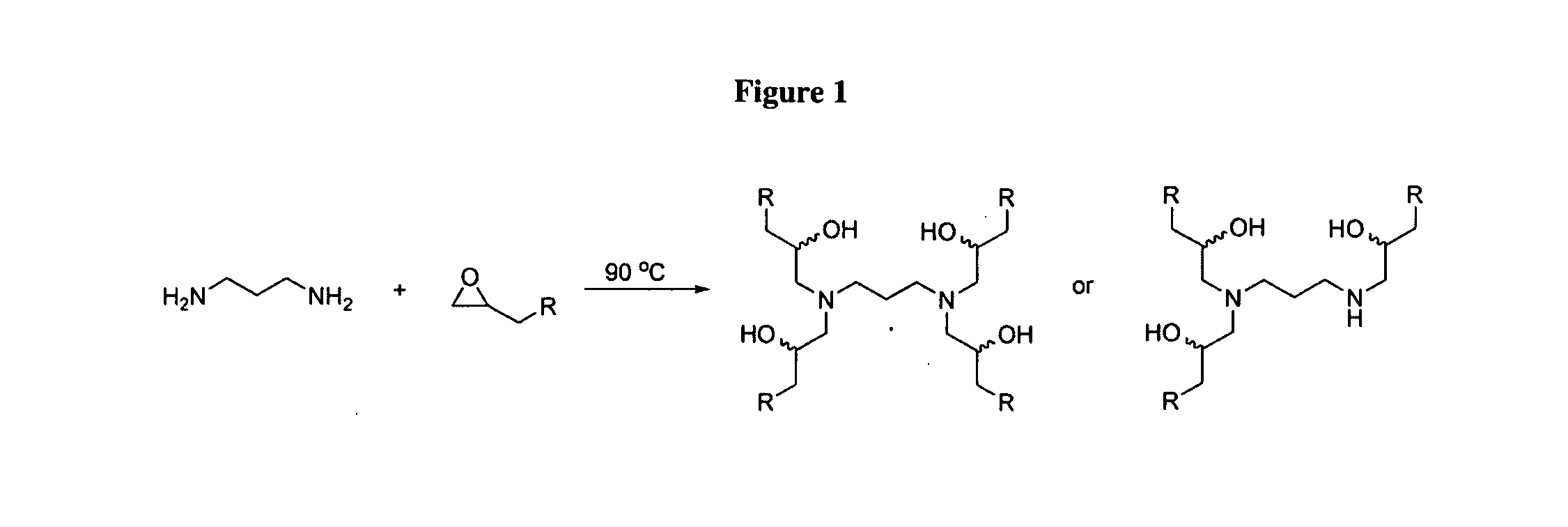

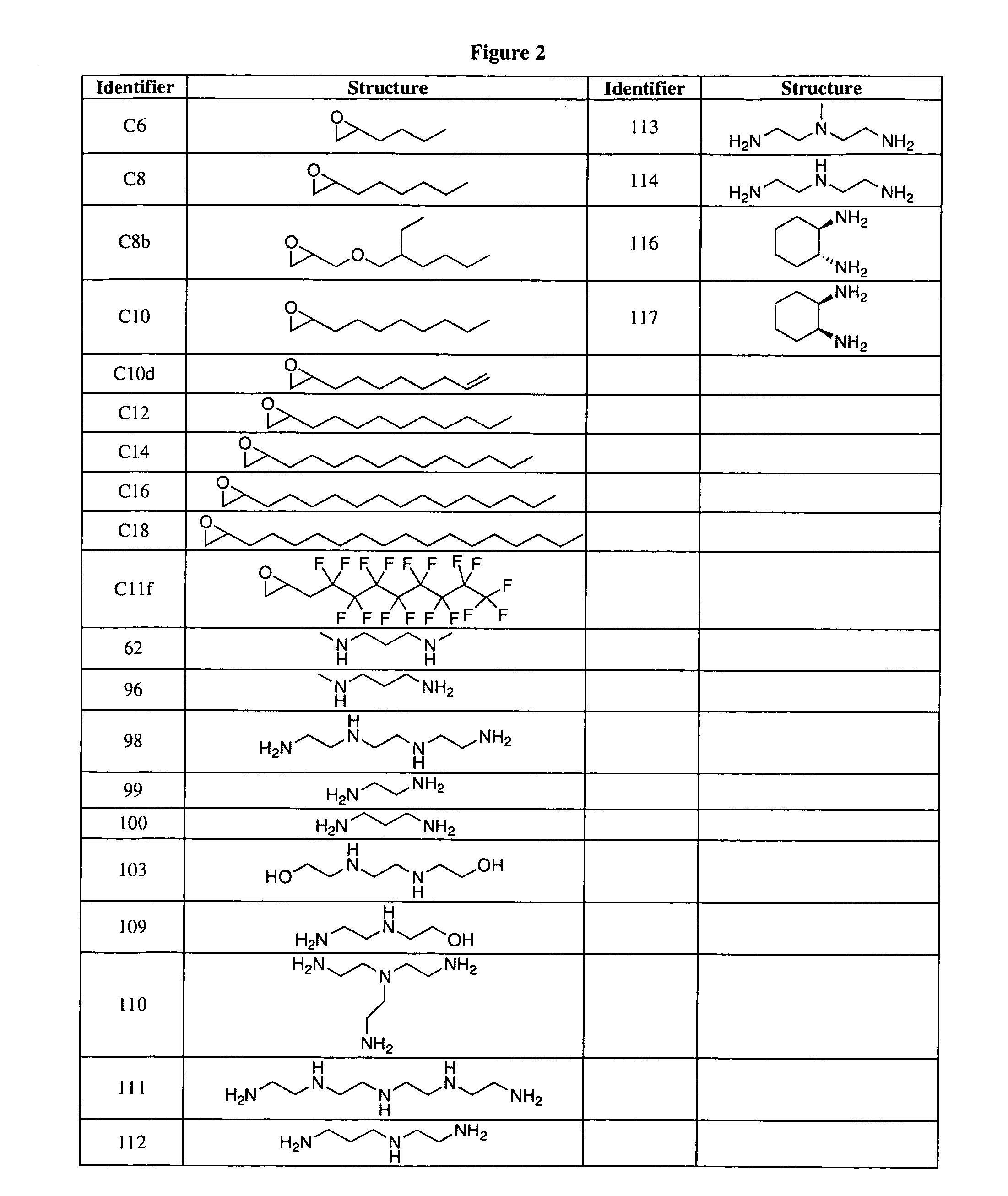

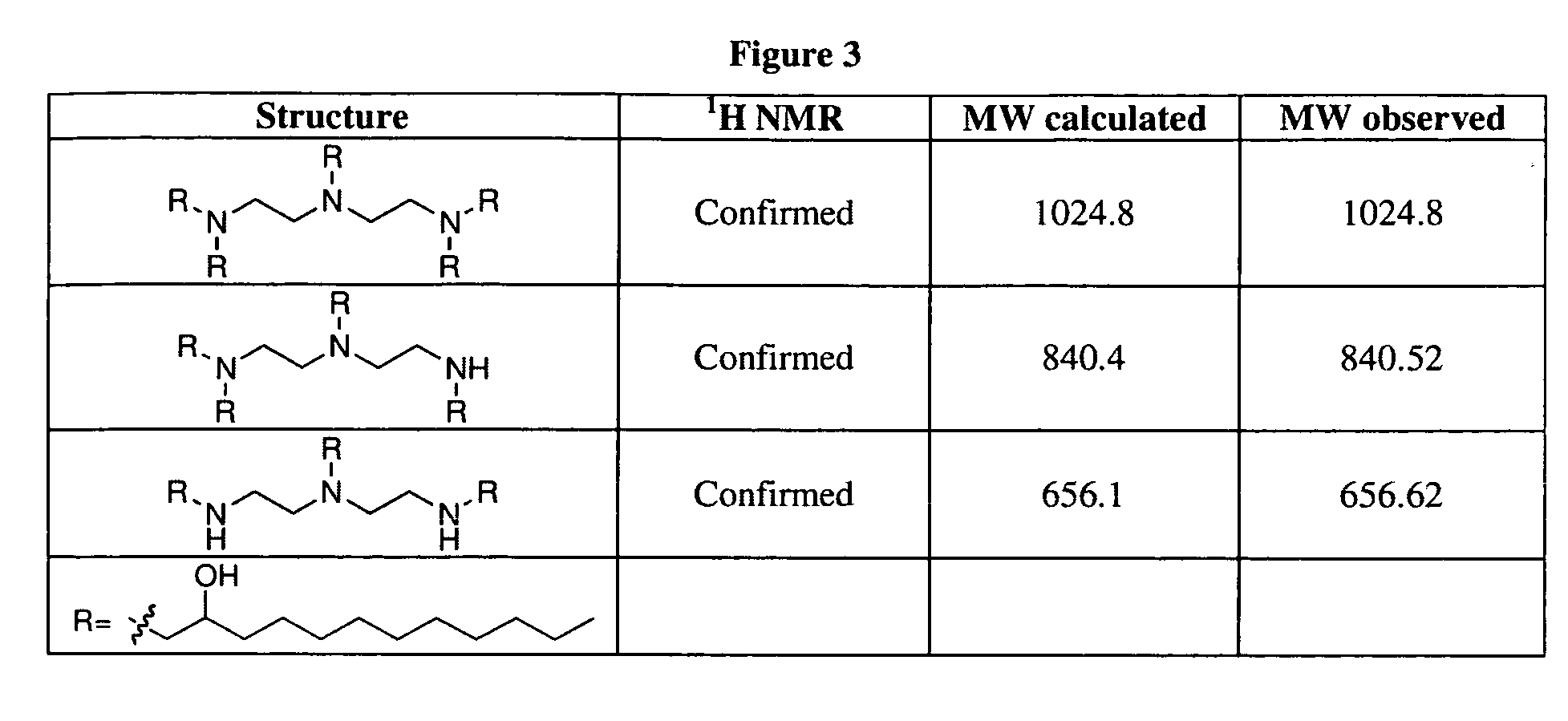

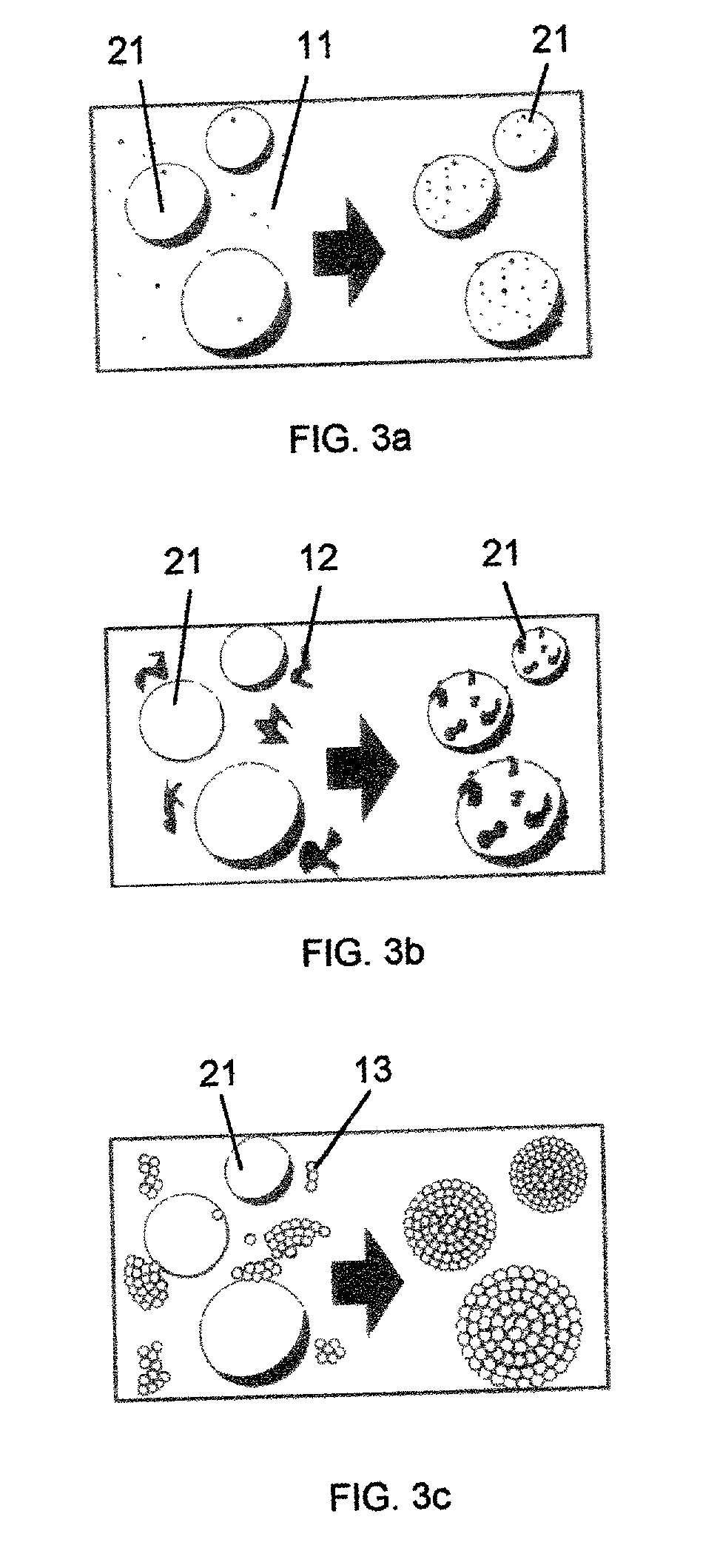

Aminoalcohol lipidoids and uses thereof

Aminoalcohol lipidoids are prepared by reacting an amine with an epoxide-terminated compound are described. Methods of preparing aminoalcohol lipidoids from commercially available starting materials are also provided. Aminoalcohol lipidoids may be prepared from racemic or stereochemically pure epoxides. Aminoalcohol lipidoids or salts forms thereof are preferably biodegradable and biocompatible and may be used in a variety of drug delivery systems. Given the amino moiety of these aminoalcohol lipidoid compounds, they are particularly suited for the delivery of polynucleotides. Complexes, micelles, liposomes or particles containing the inventive lipidoids and polynucleotide have been prepared. The inventive lipidoids may also be used in preparing microparticles for drug delivery. They are particularly useful in delivering labile agents given their ability to buffer the pH of their surroundings.

Owner:MASSACHUSETTS INST OF TECH

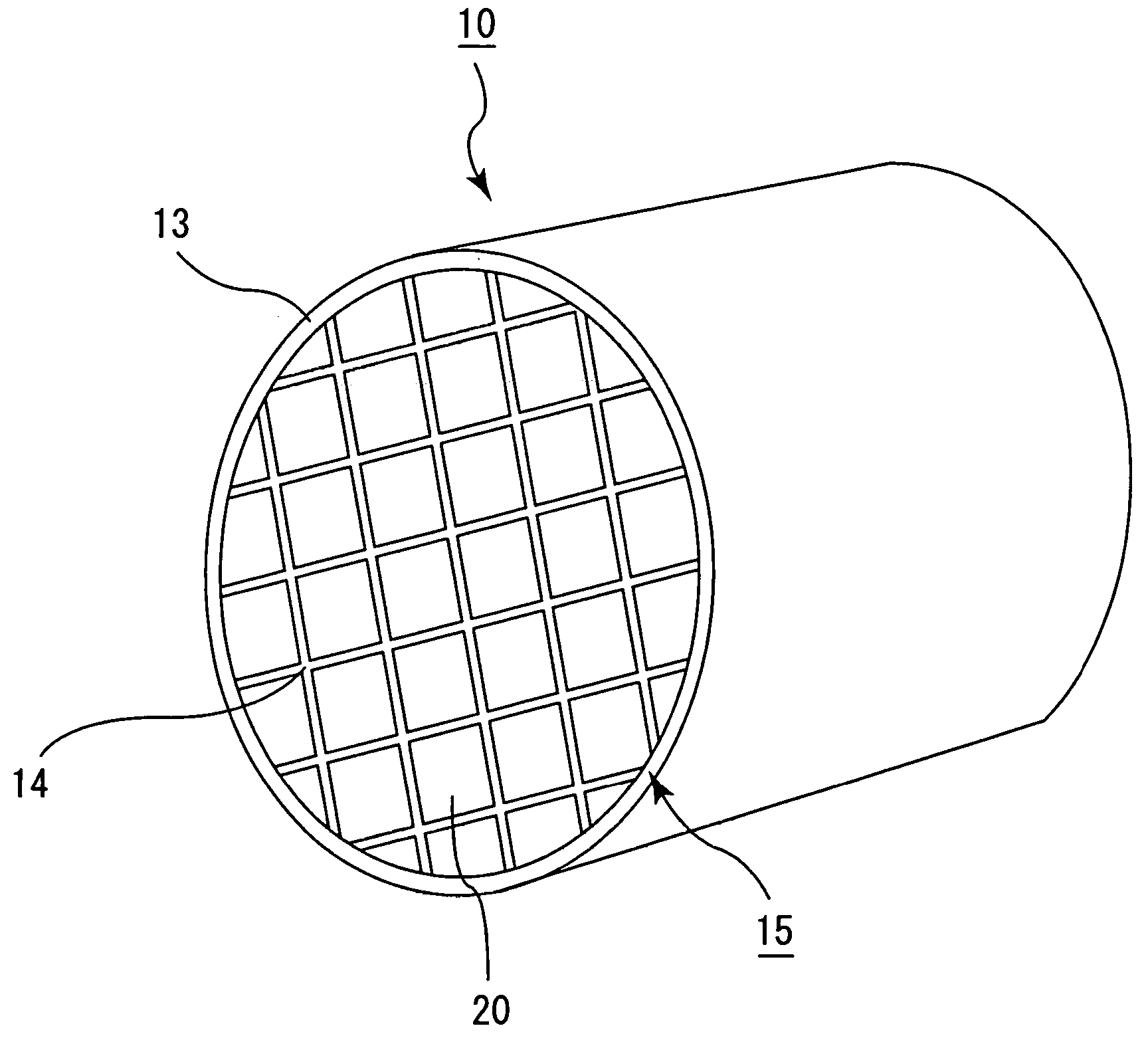

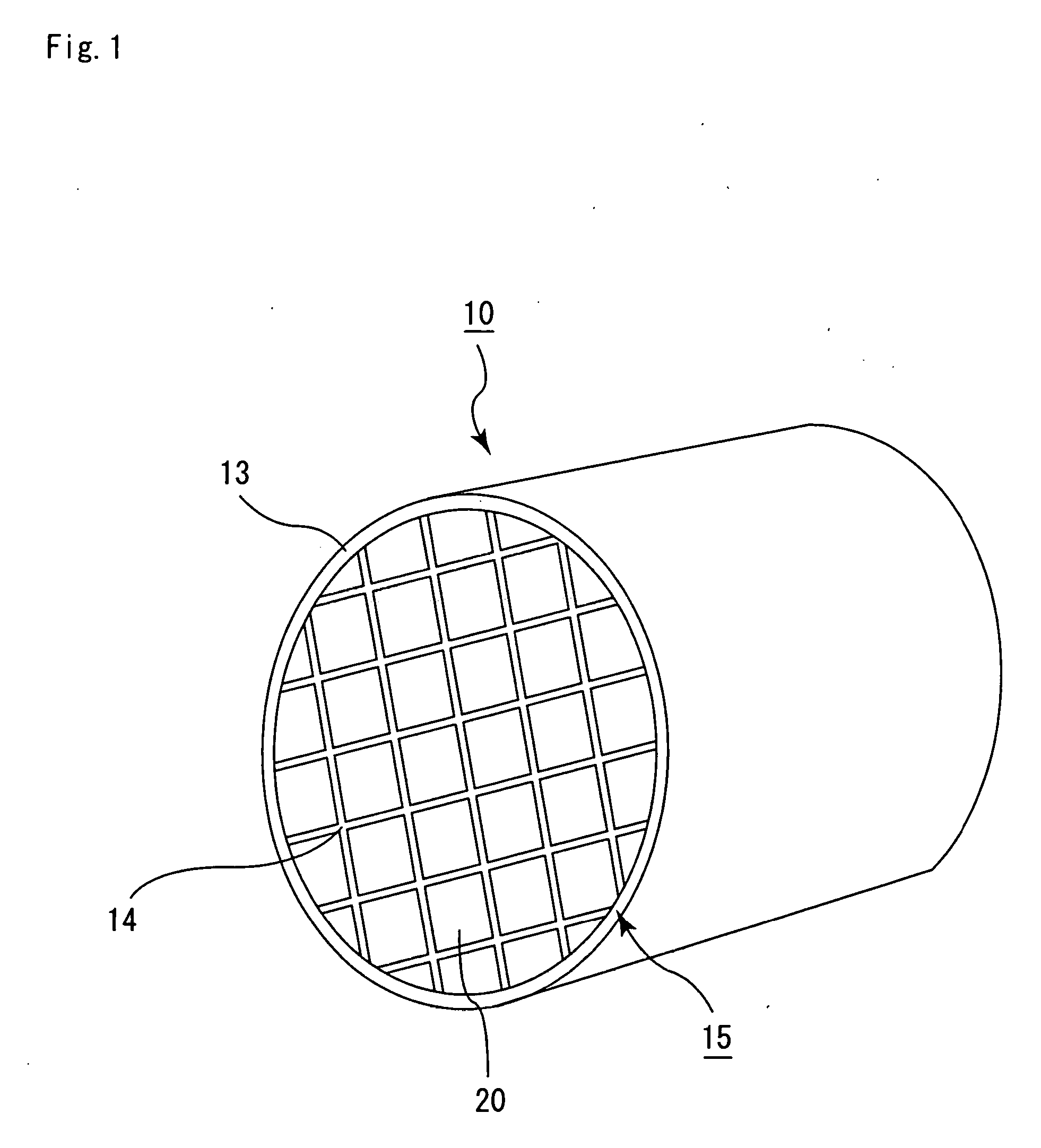

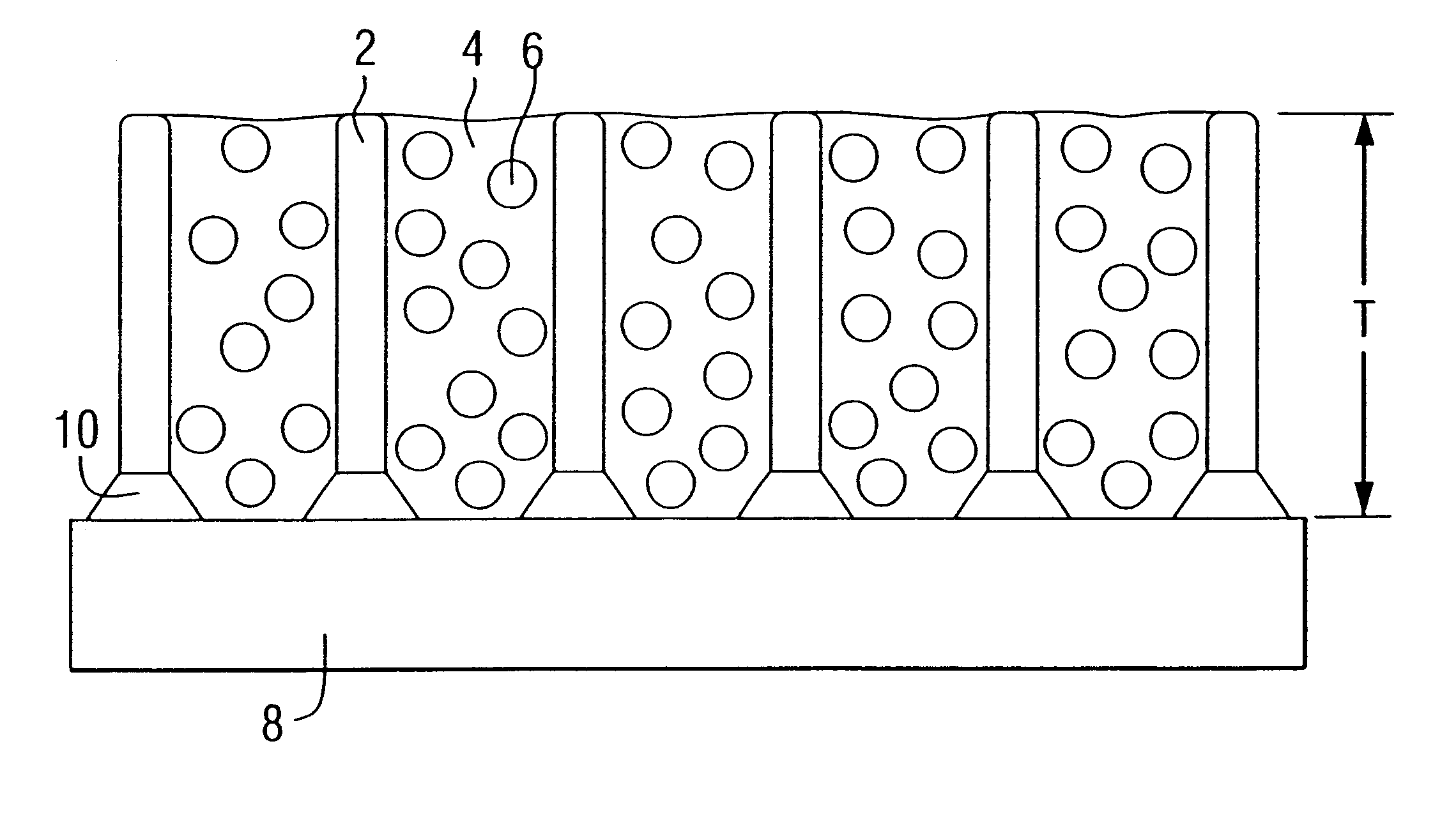

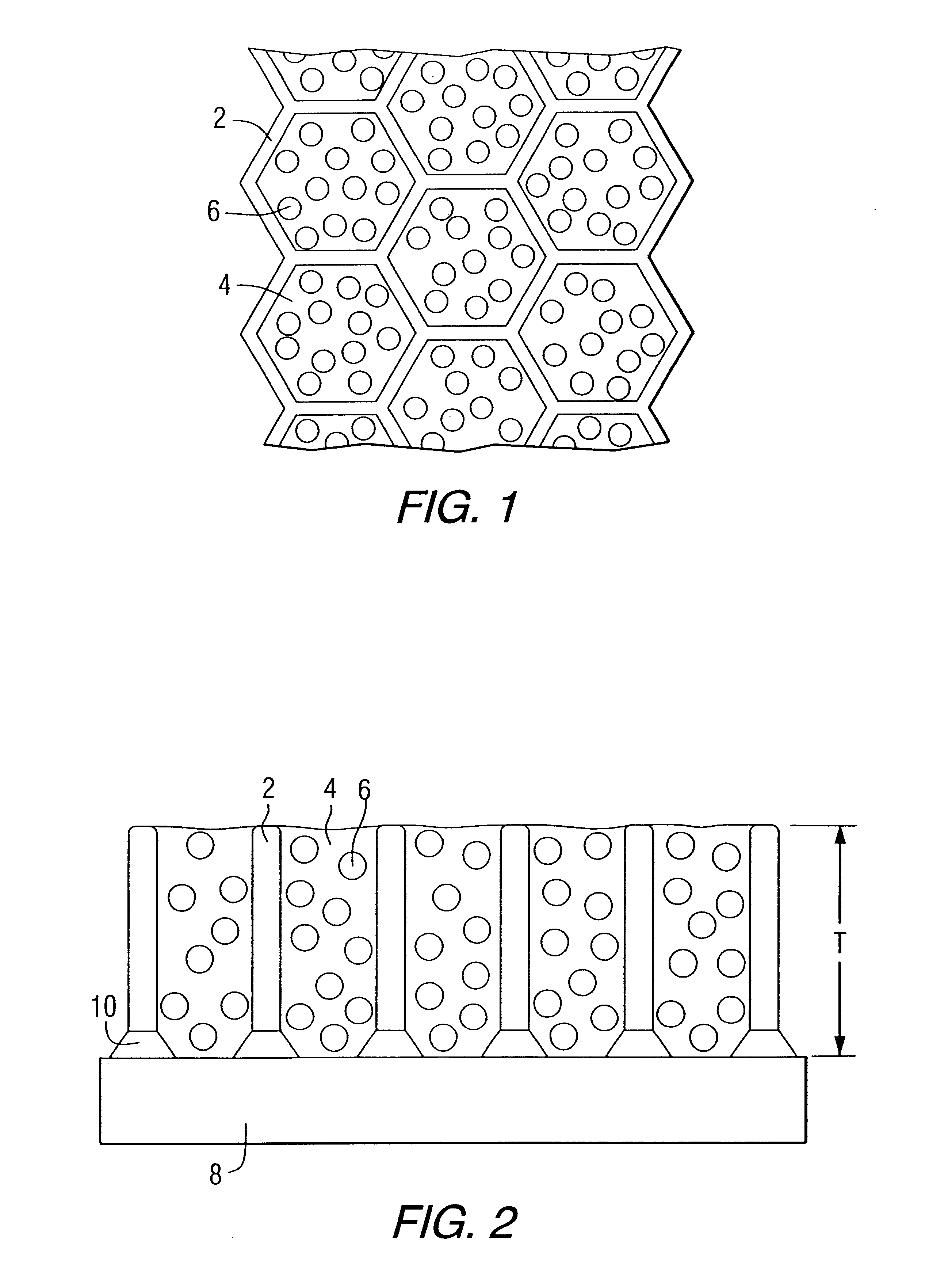

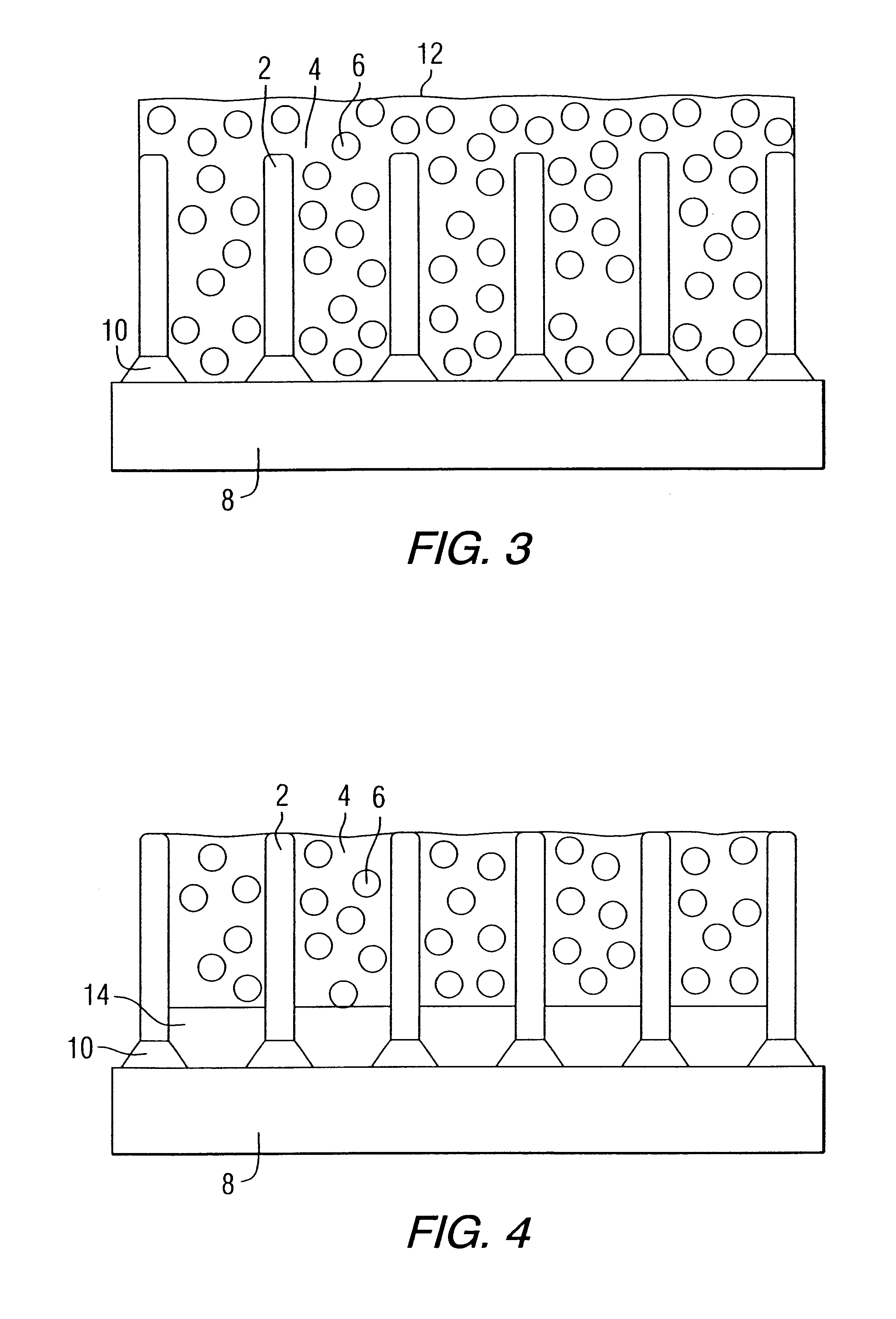

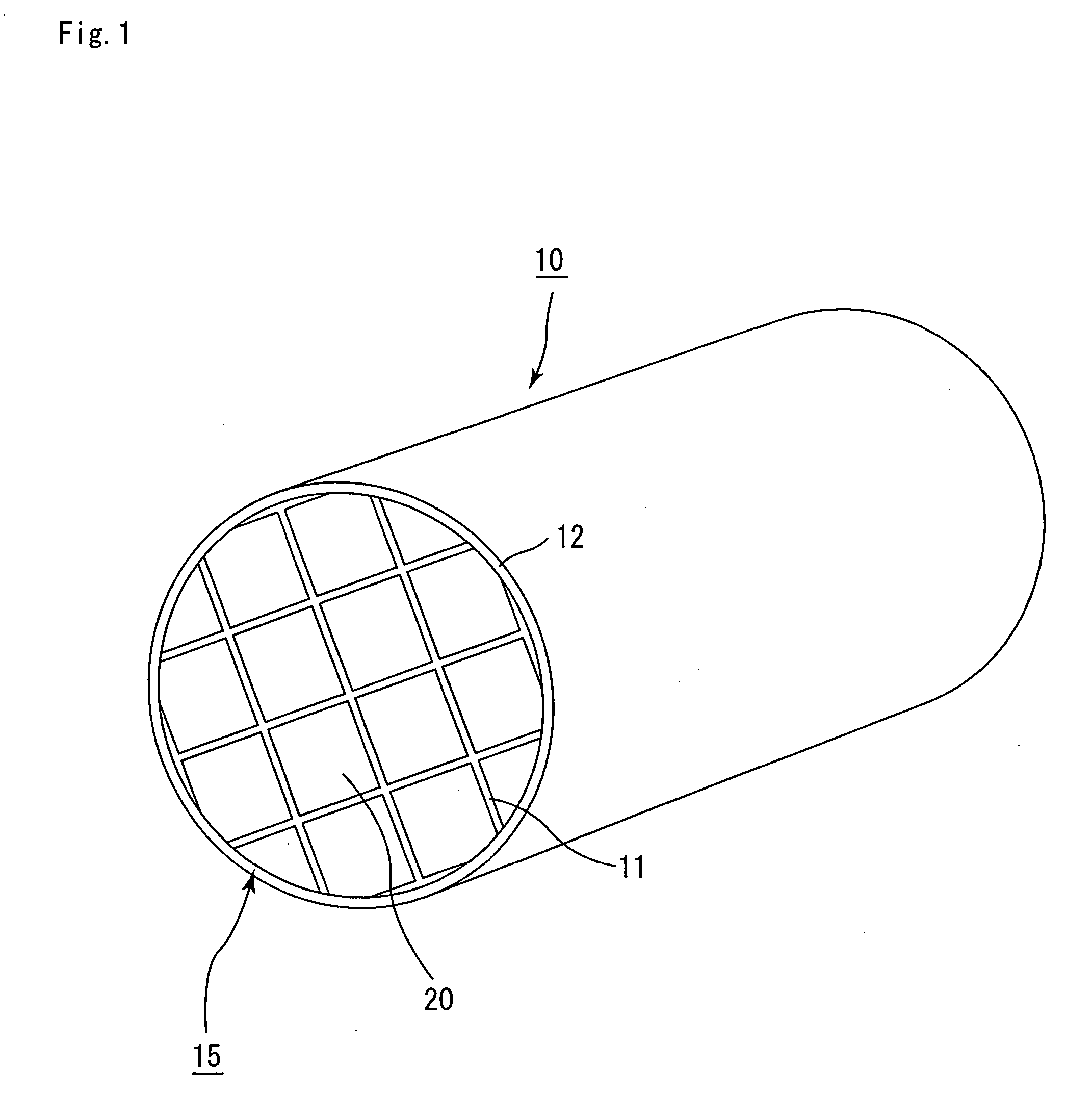

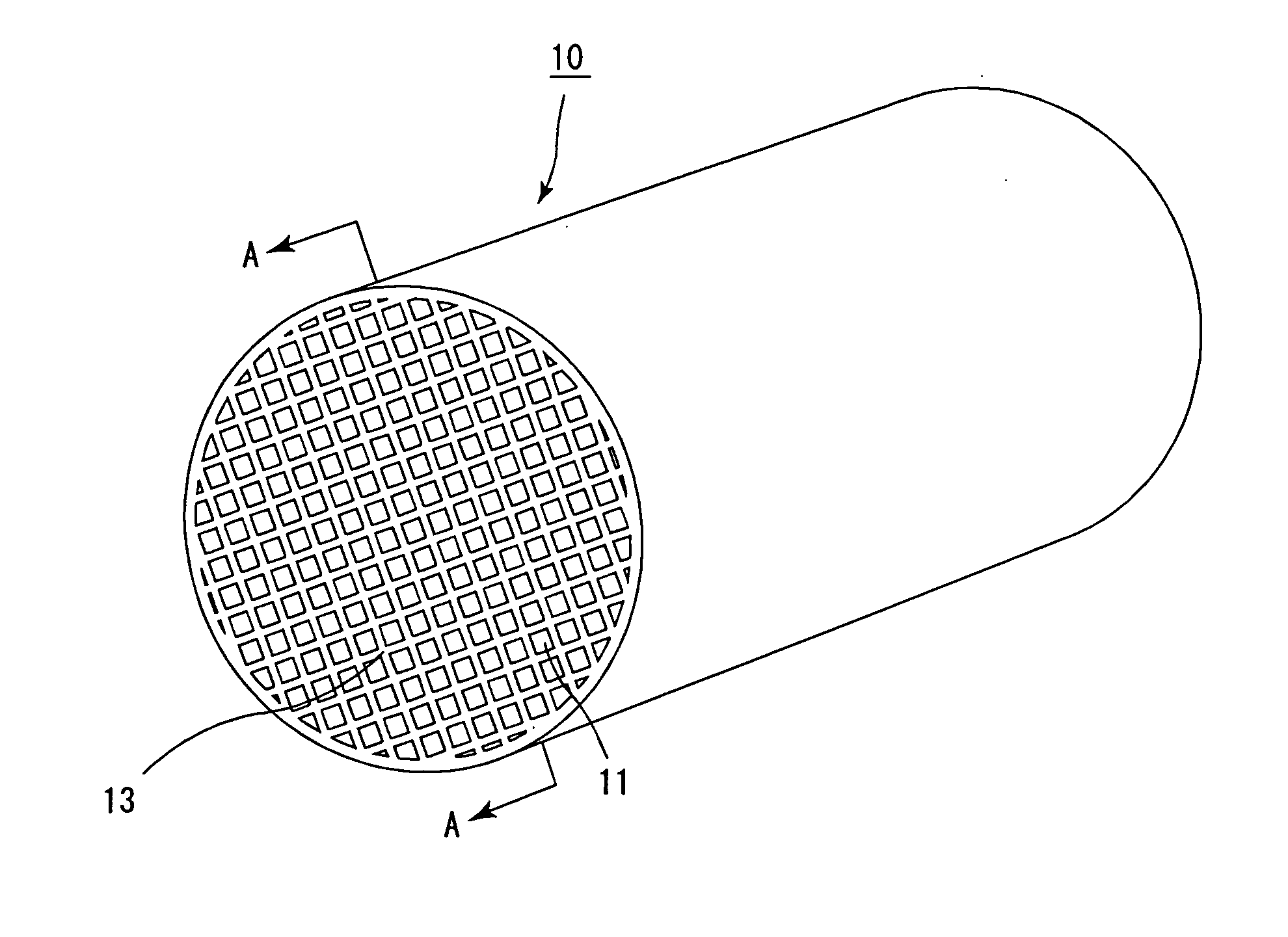

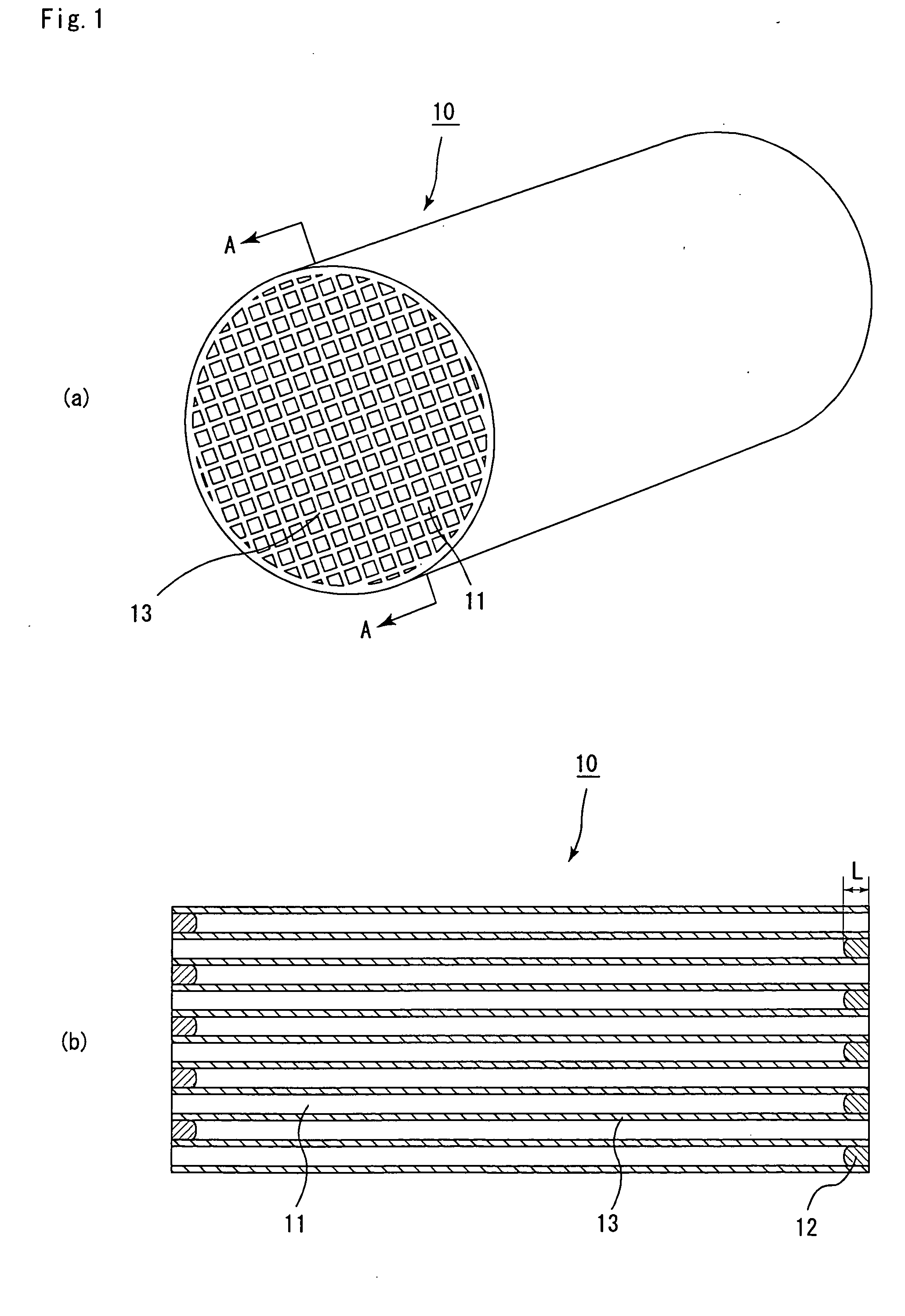

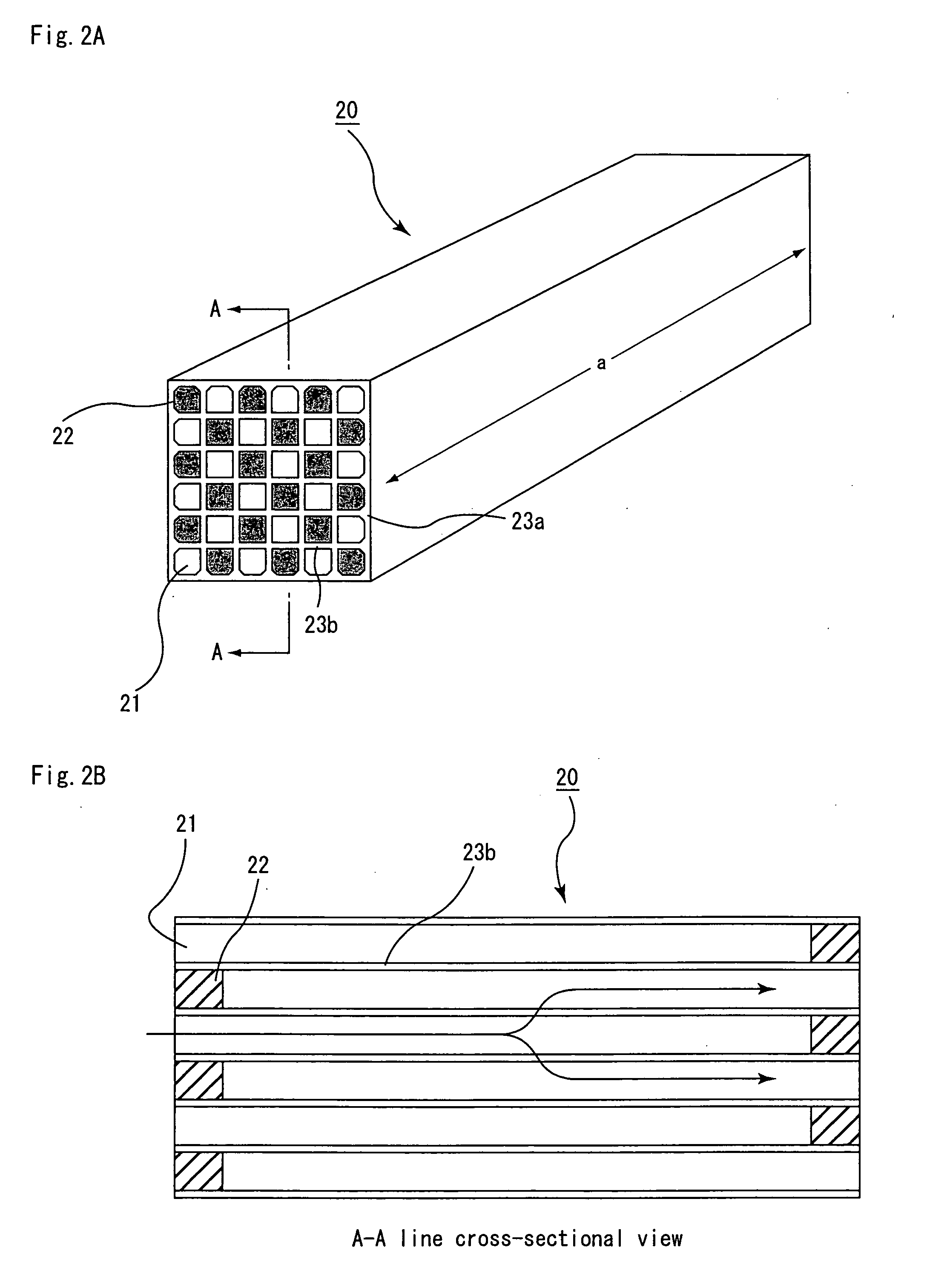

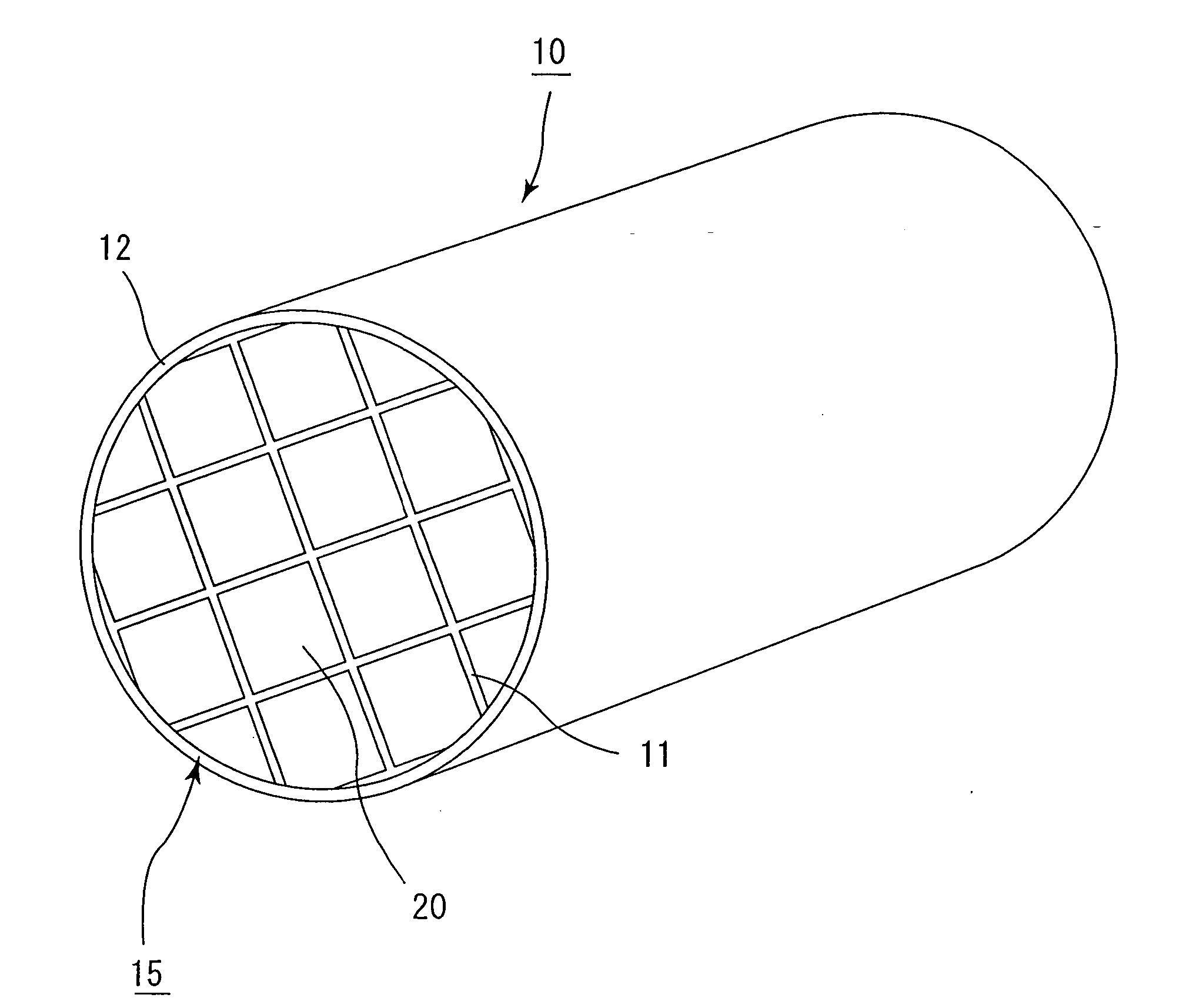

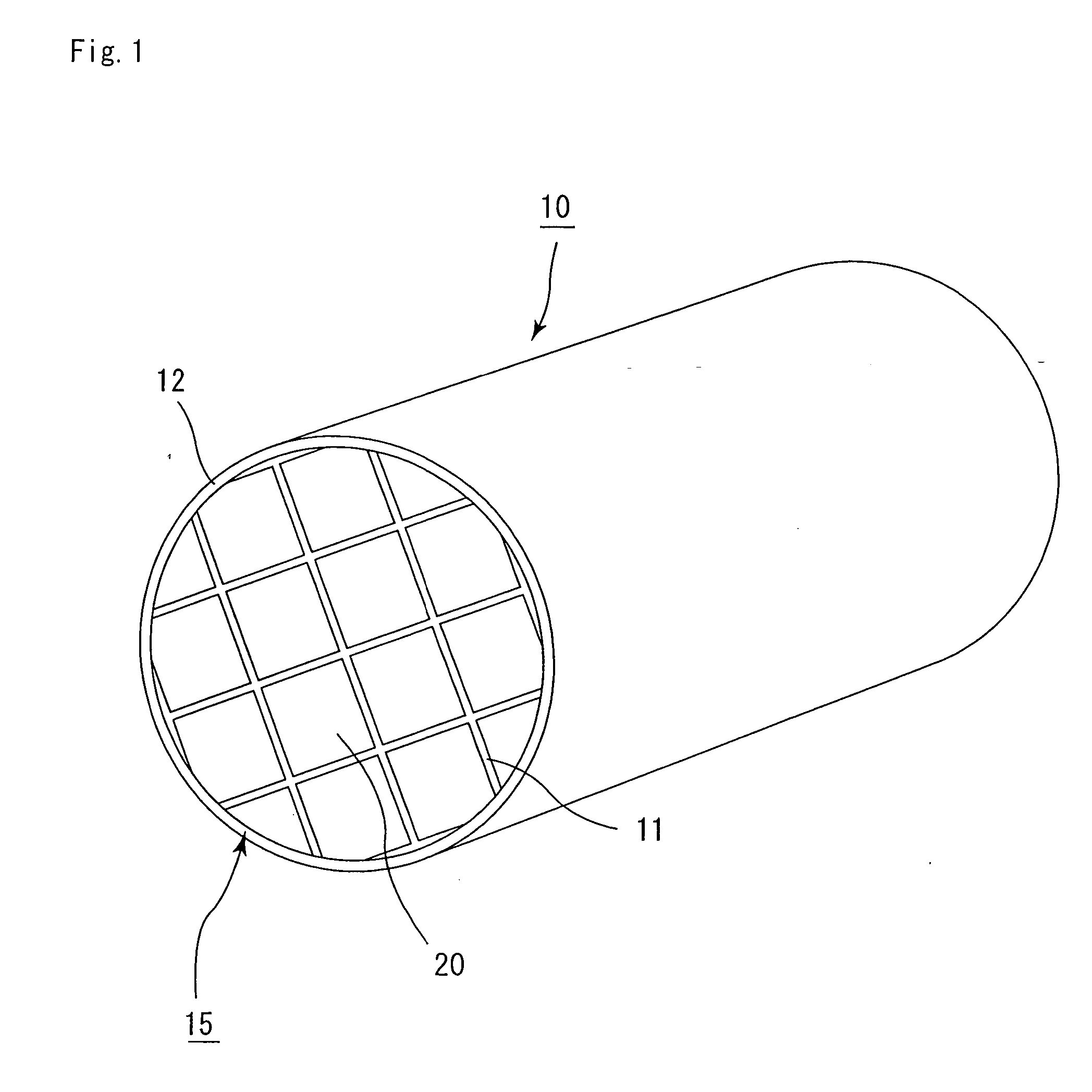

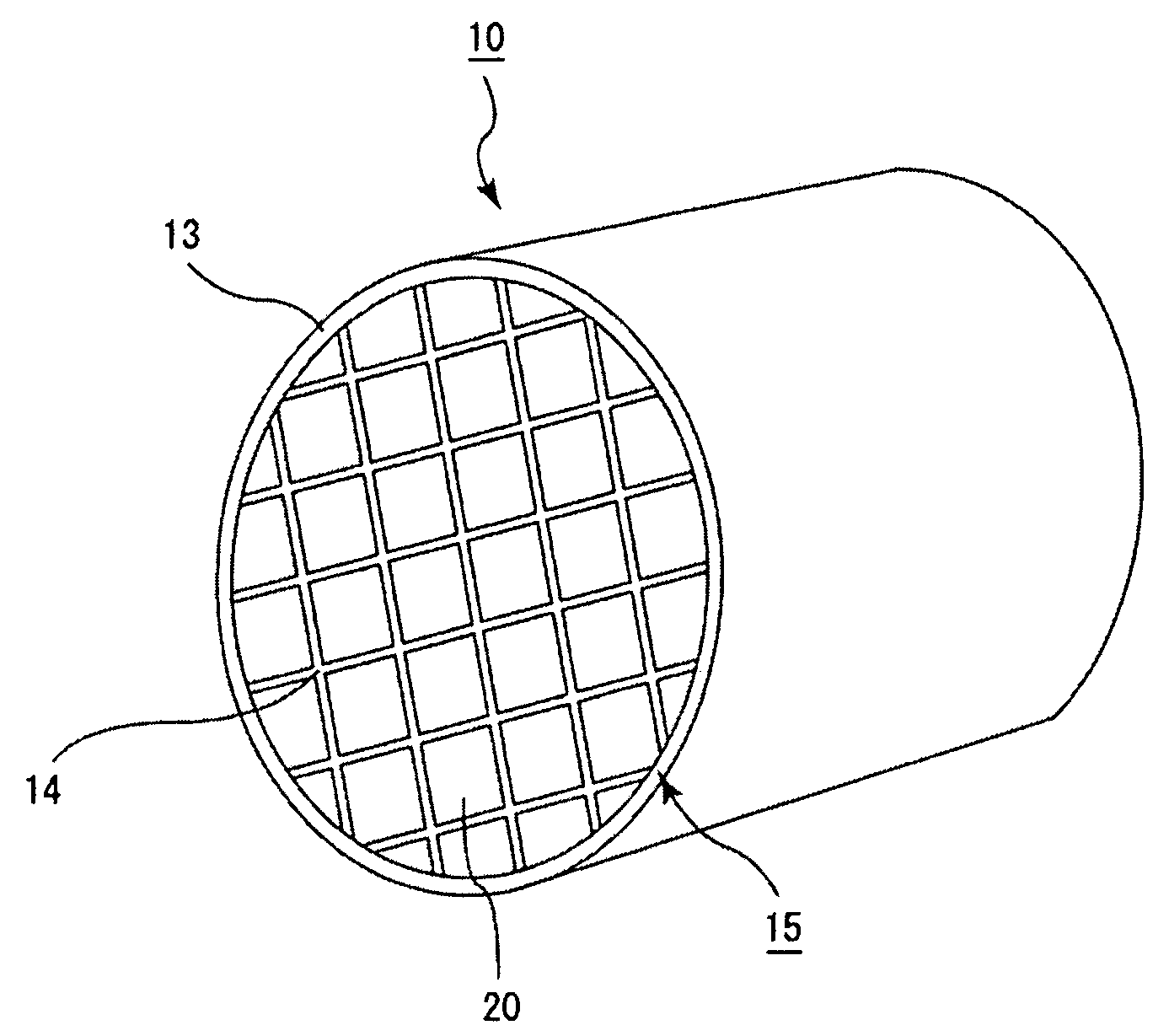

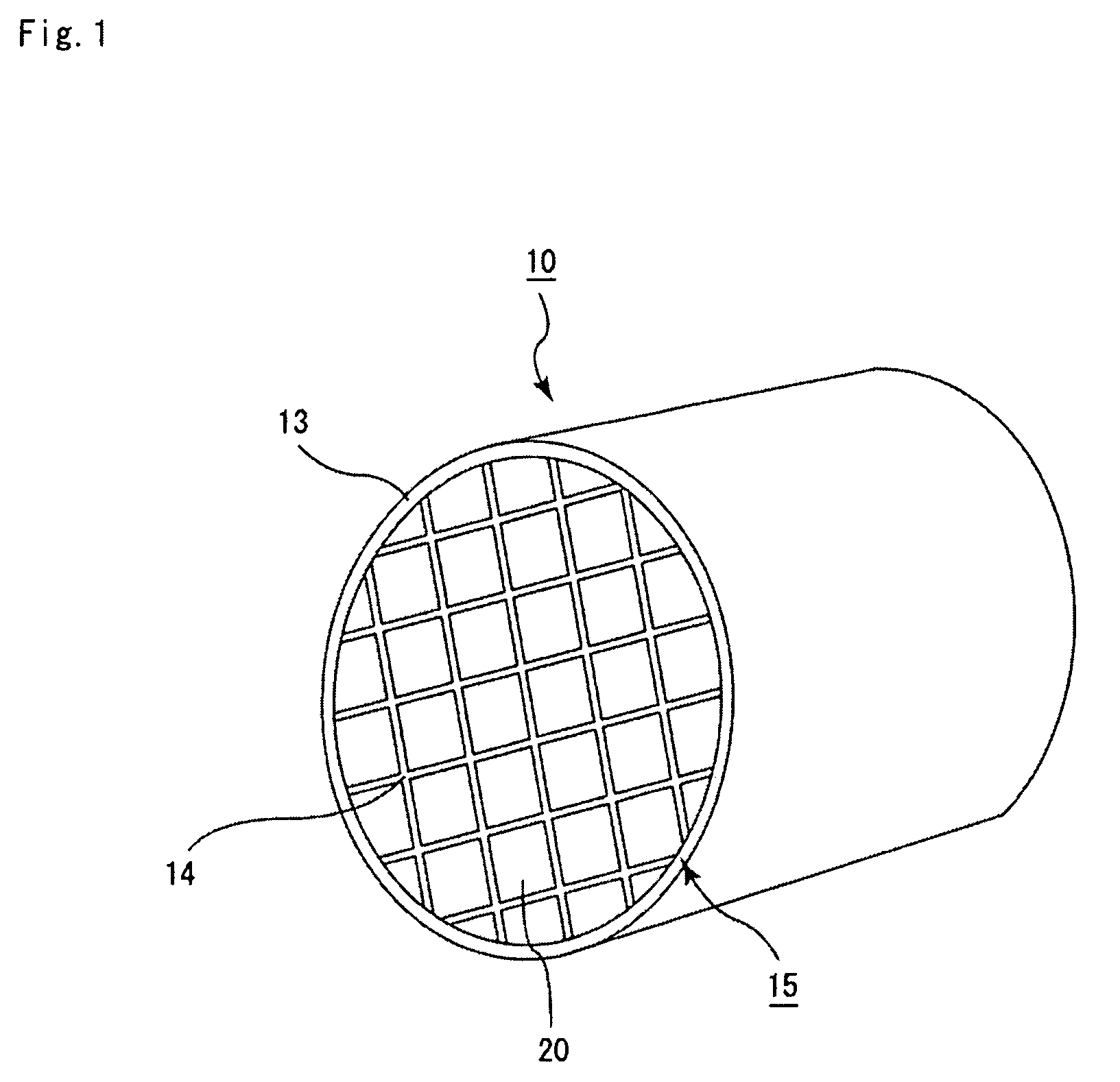

Honeycomb filter for exhaust gas decontamination, adhesive, coating material and process for producing honeycomb filter for exhaust gas decontamination

ActiveUS20050109023A1Reduce thermal stressAlleviating generated thermal stressCombination devicesDispersed particle filtrationParticulatesAdhesive

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases which makes it possible to alleviate a thermal stress generated due to occurrence of a local temperature change and which is less likely to generate cracks and superior in strength and durability, an adhesive that has a low thermal capacity and is capable of alleviating the thermal stress, a coating material that has a low thermal capacity with a superior heat insulating property and is capable of alleviating the thermal stress, and a manufacturing method of the honeycomb filter for purifying exhaust gases that can improve precision in the outside dimension, and reduce damages in the manufacturing processes. The present invention relates to a honeycomb filter for purifying exhaust gases, having a structure in that a plurality of column-shaped porous ceramic members, each having a number of through holes that are placed side by side in the length direction with partition wall interposed therebetween, are combined with one another through adhesive layers so that the partition wall that separate the through holes are allowed to function as a filter for collecting particulates, and in this structure, the thermal expansion coefficient αL of the adhesive layer and the thermal expansion coefficient αF of the porous ceramic member are designed to have the following relationship: 0.01<|αL−αF| / αF<1.0.

Owner:IBIDEN CO LTD

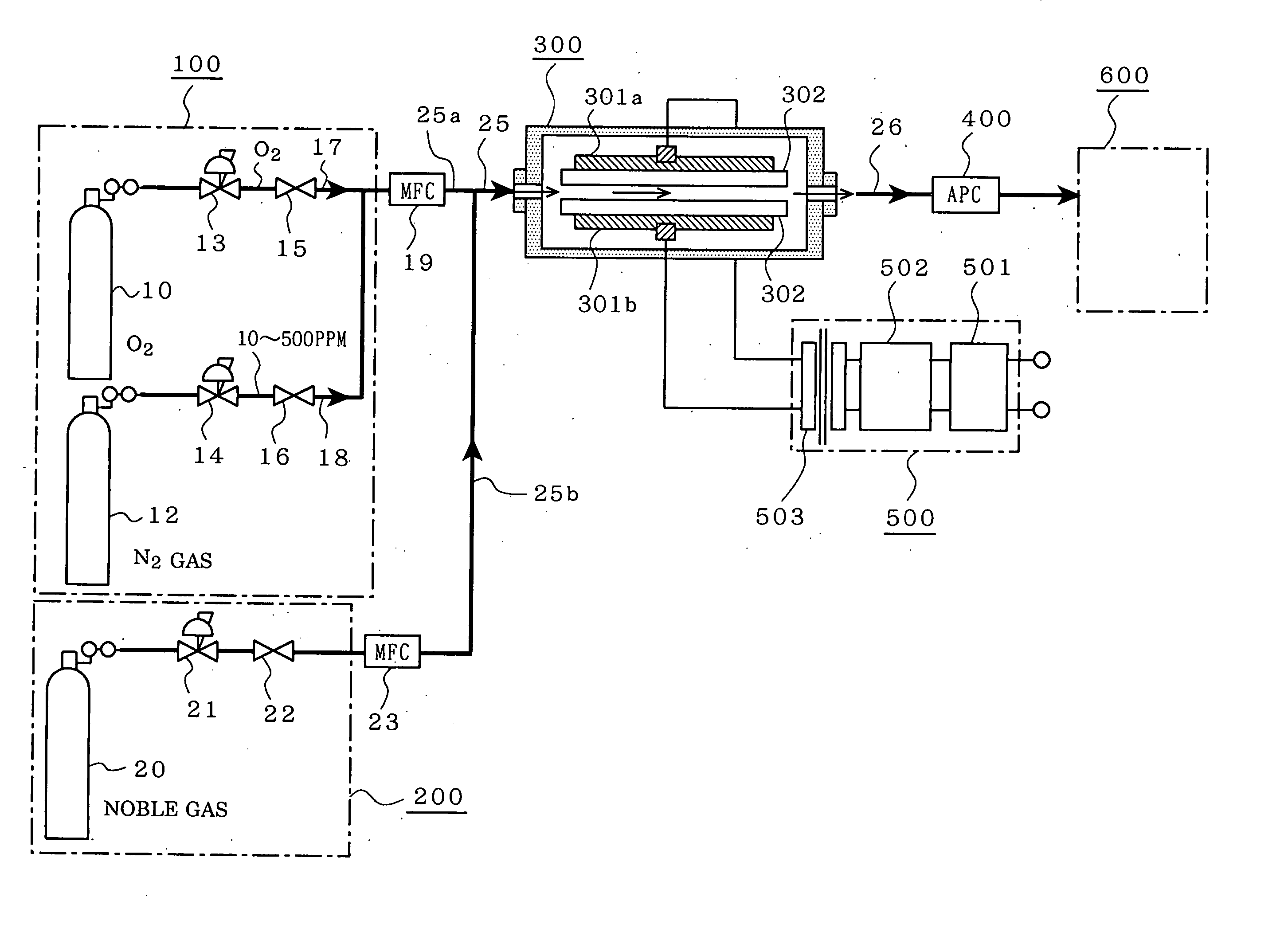

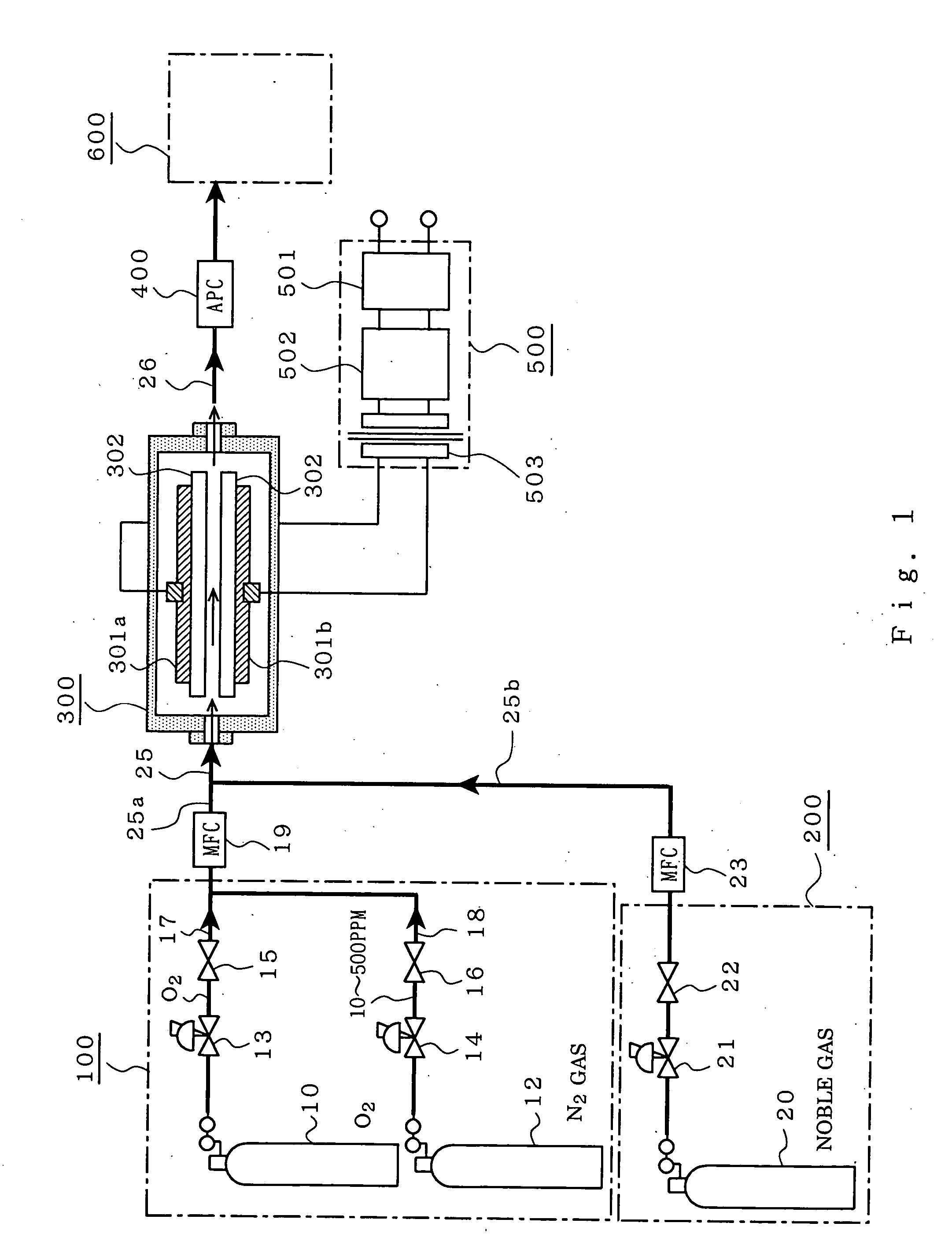

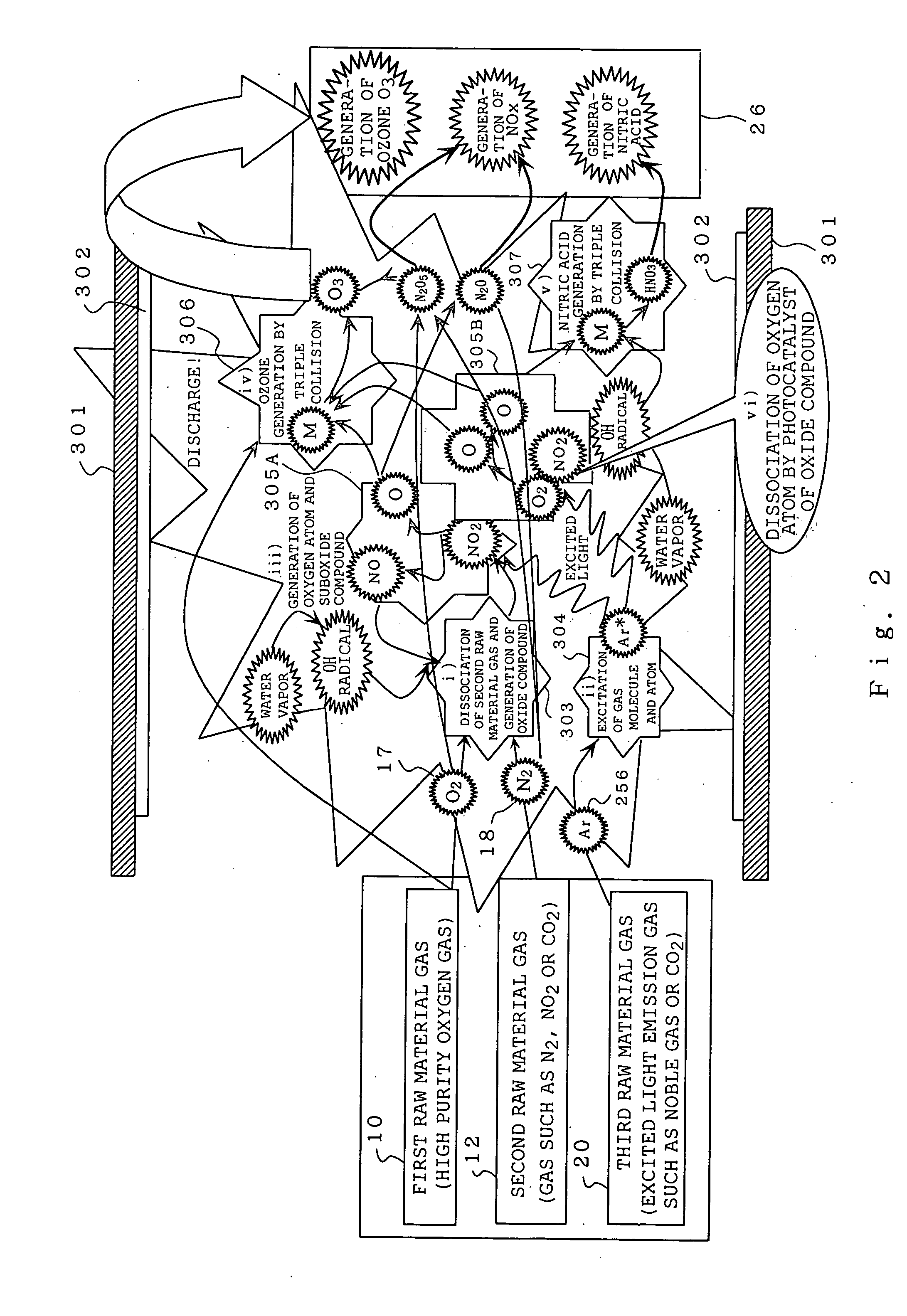

Ozone generator

ActiveUS20040223893A1Physical/chemical process catalystsElectrical discharge ozone preparationAtmospheric sciencesGas supply

An ozone generator for generating ozone by applying a specified process to oxygen by discharge includes a first raw material gas supply unit for supplying the oxygen as a first raw material gas, and a second raw material gas supply unit for supplying an oxide compound gas as a second raw material gas, in which, by excited light, excited and generated by a discharge in the oxygen and the oxide compound gas, the oxide compound gas is dissociated, or the oxide compound gas is excited accelerating dissociation of the oxygen, and ozone is generated. In this way, ozone generation efficiency is raised.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

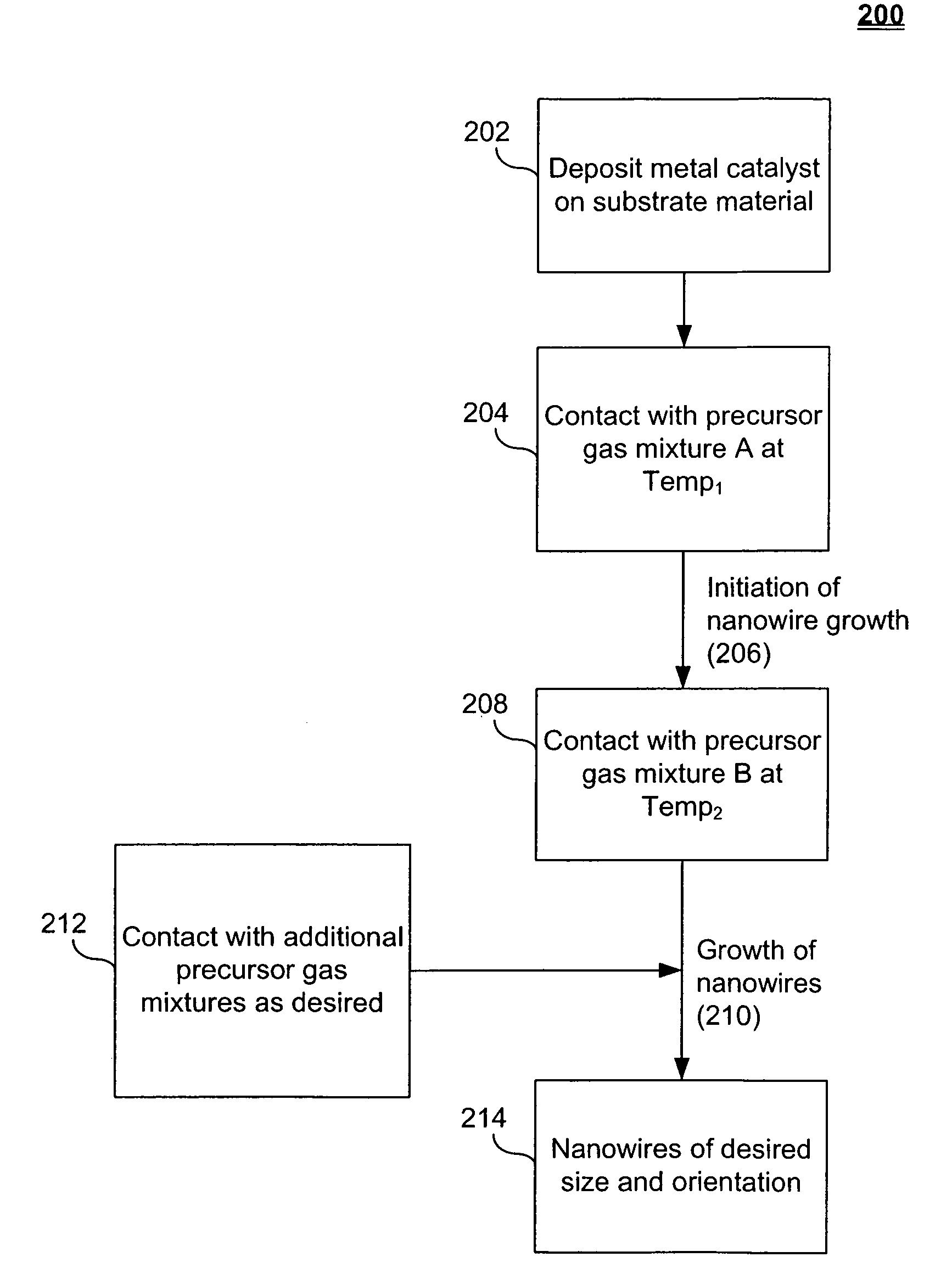

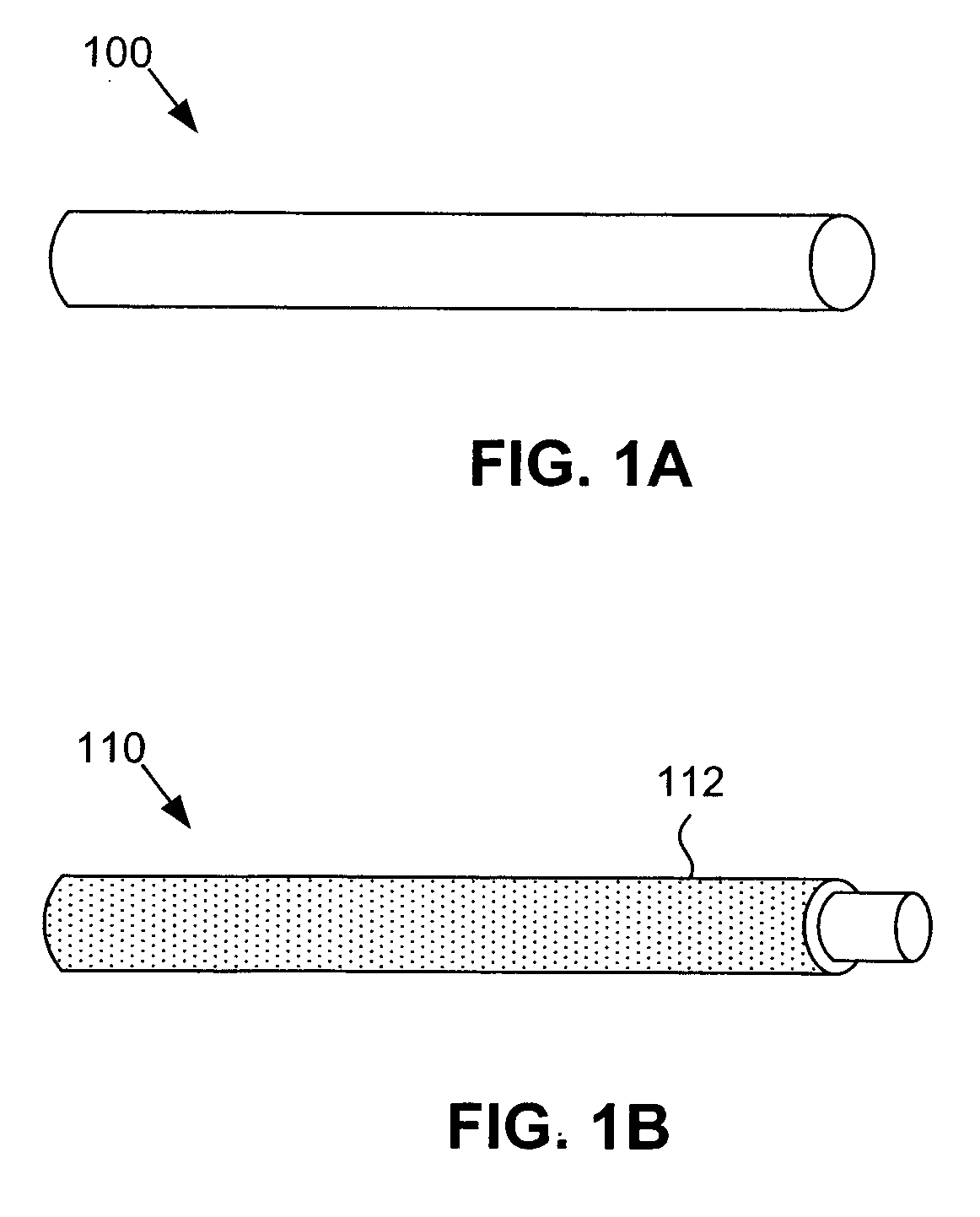

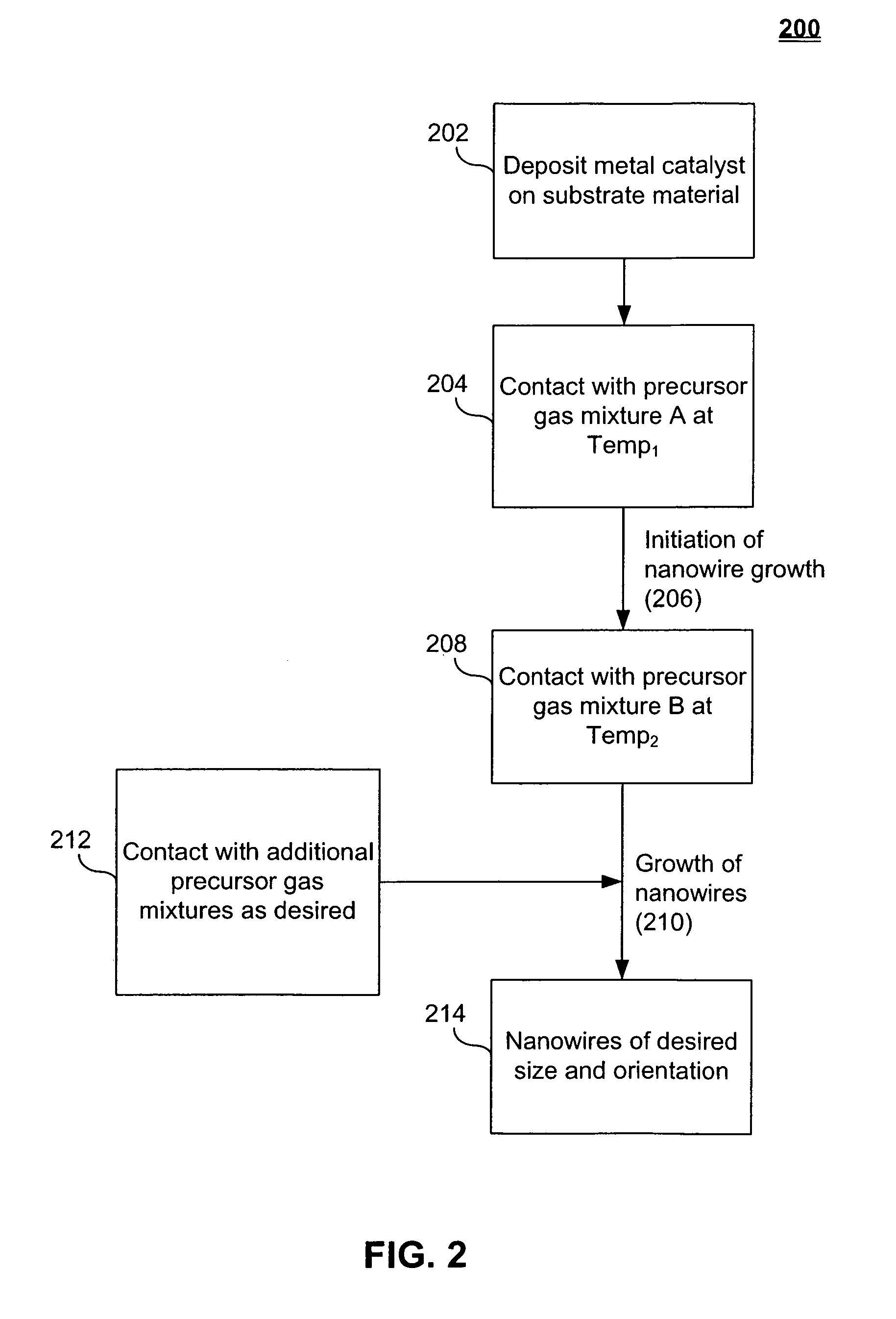

Systems and methods for nanowire growth and harvesting

ActiveUS7105428B2Minimize diffusionIncrease depositionMaterial nanotechnologyNanostructure manufactureNanowireSilicon

Owner:ONED MATERIAL INC

High temperature erosion resistant, abradable thermal barrier composite coating

InactiveUS6235370B1Improve wear resistanceImprove adhesionMolten spray coatingPump componentsCombustorHoneycomb

A composite thermal barrier coating system includes a honeycomb metallic structure filled with high thermal expansion ceramic hollow spheres in a phosphate bonded matrix. The composite thermal barrier coating system may be manufactured to thicknesses in excess of current thermal barrier coating systems, thereby imparting greater thermal protection. Superior erosion resistance and abrasion properties are also achieved. The composite thermal barrier coating is useful on combustion turbine components such as ring seal segments, vane segment shrouds, transitions and combustors.

Owner:SIEMENS ENERGY INC

Honeycomb filter for clarifying exhaust gases

InactiveUS20050153099A1Increased durabilityPhysical/chemical process catalystsInternal combustion piston enginesParticulatesHoneycomb

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases that is free from a gap formed between a plug and a partition wall and cracks generated in the plug and a portion of the partition wall contacting the plug, and is superior in durability. The present invention provides a honeycomb filter for purifying exhaust gases which has a structure in which: a columnar body made of porous ceramic comprises a number of through holes, said through holes being placed in parallel with one another in the length direction with a wall portion interposed therebetween; predetermined through holes of said through holes are filled with plugs at one end of said columnar body, while the through holes that have not been filled with said plugs at said one end are filled with plugs at the other end of said columnar body; and a part or all of said wall portion functions as a filter for collecting particulates, wherein the porosity of the columnar body is in a range from 20 to 80%, and the porosity of the plug is 90% or less and is also set to 0.15 to 4.0 times as much as the porosity of the columnar body.

Owner:IBIDEN CO LTD

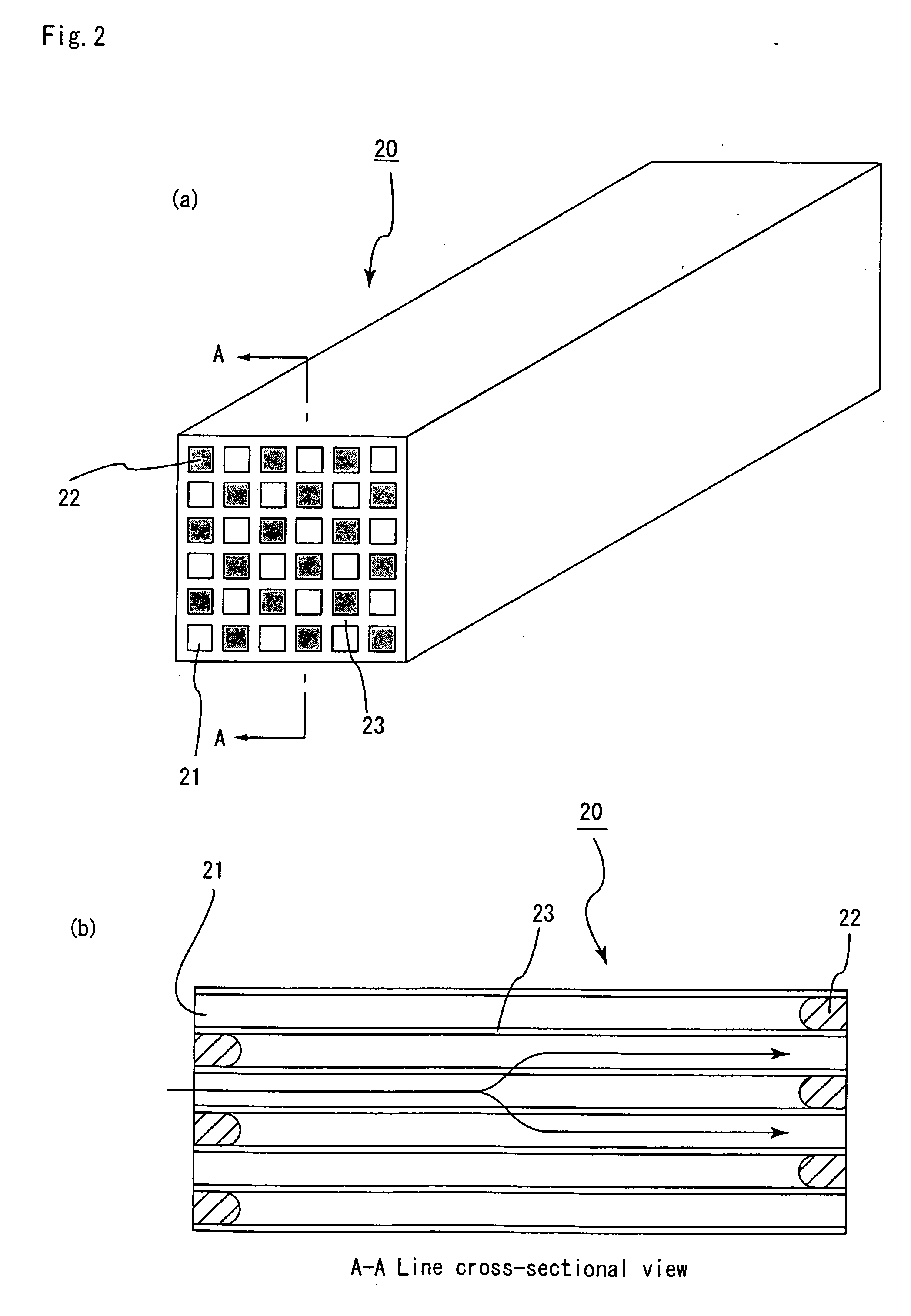

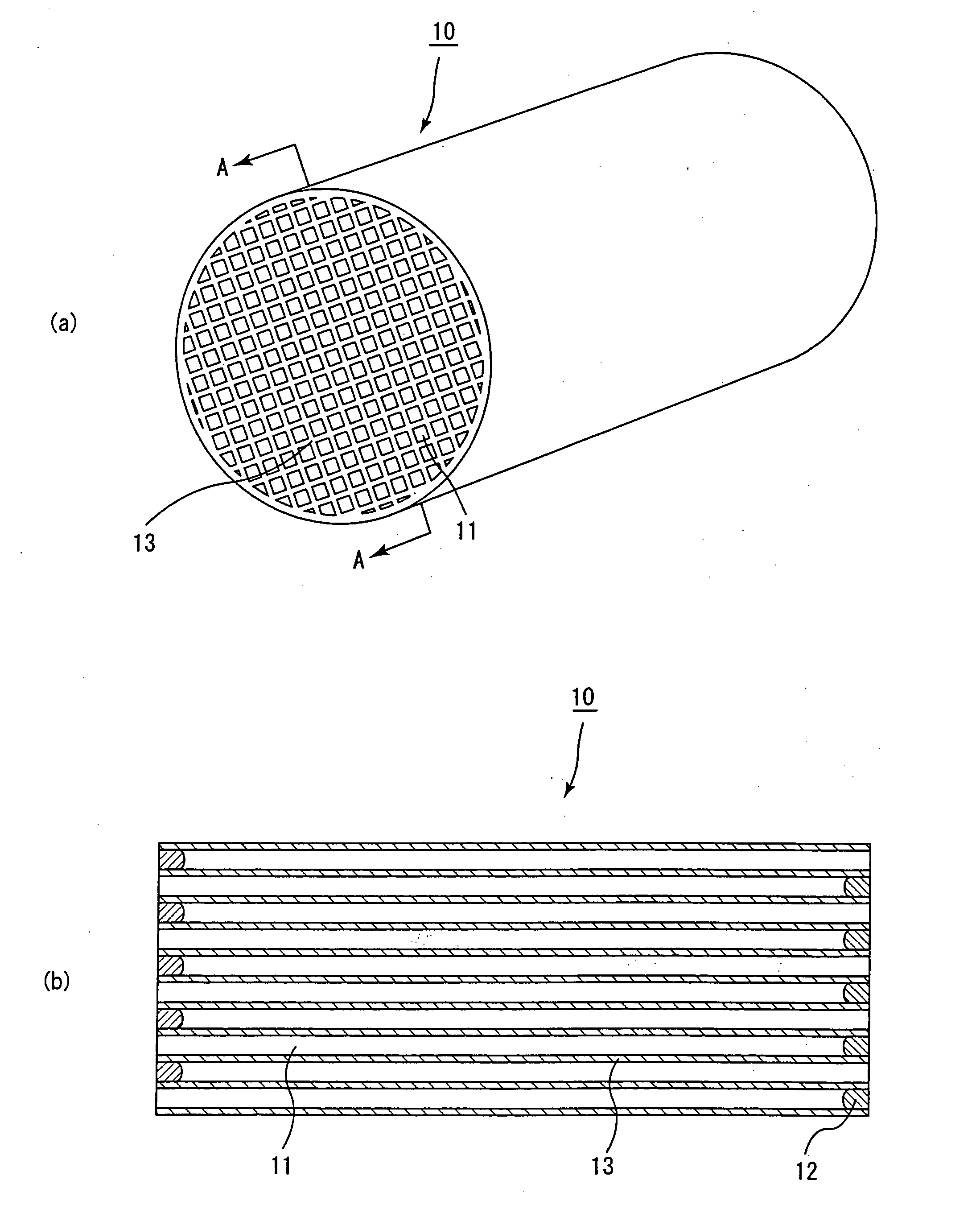

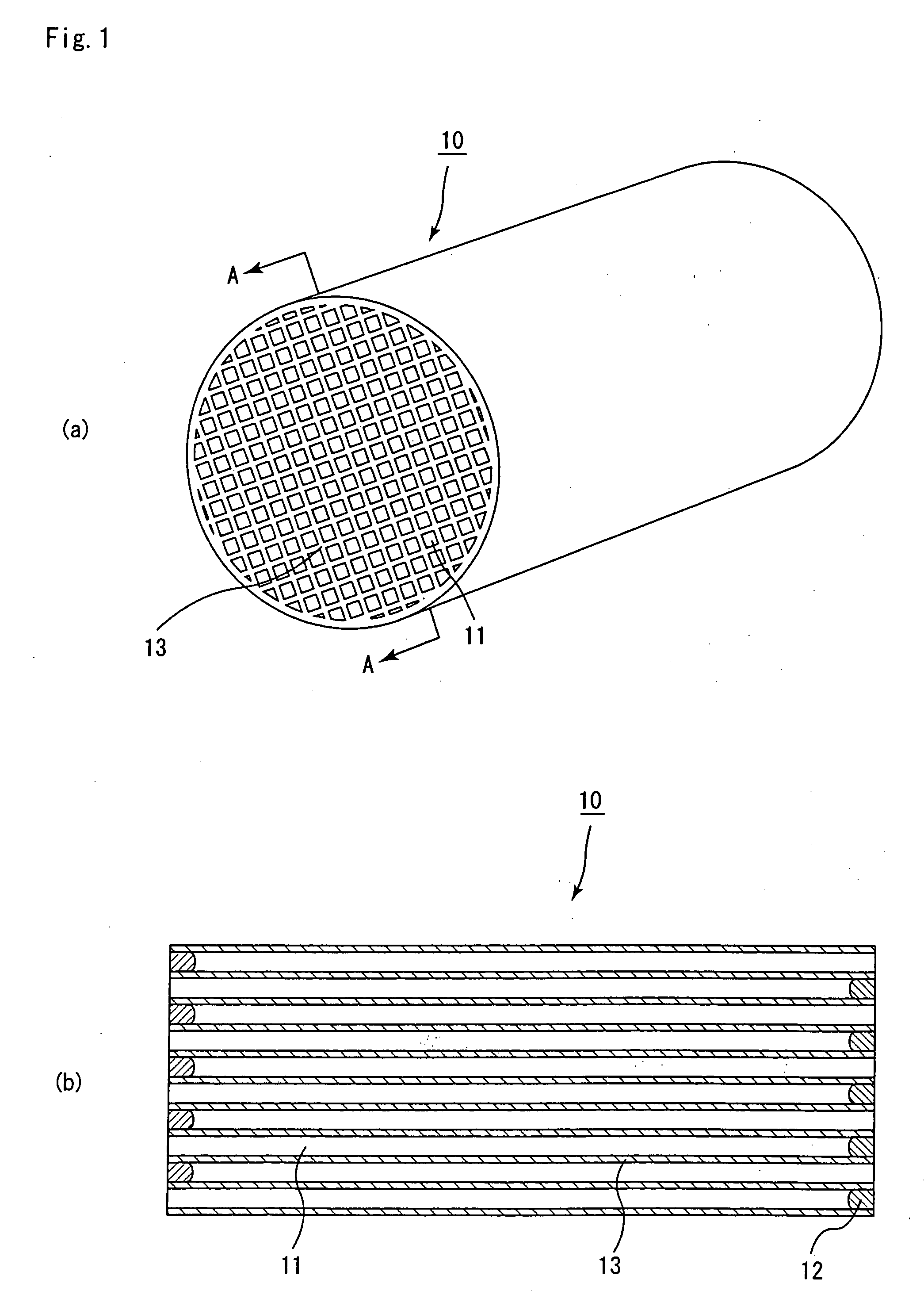

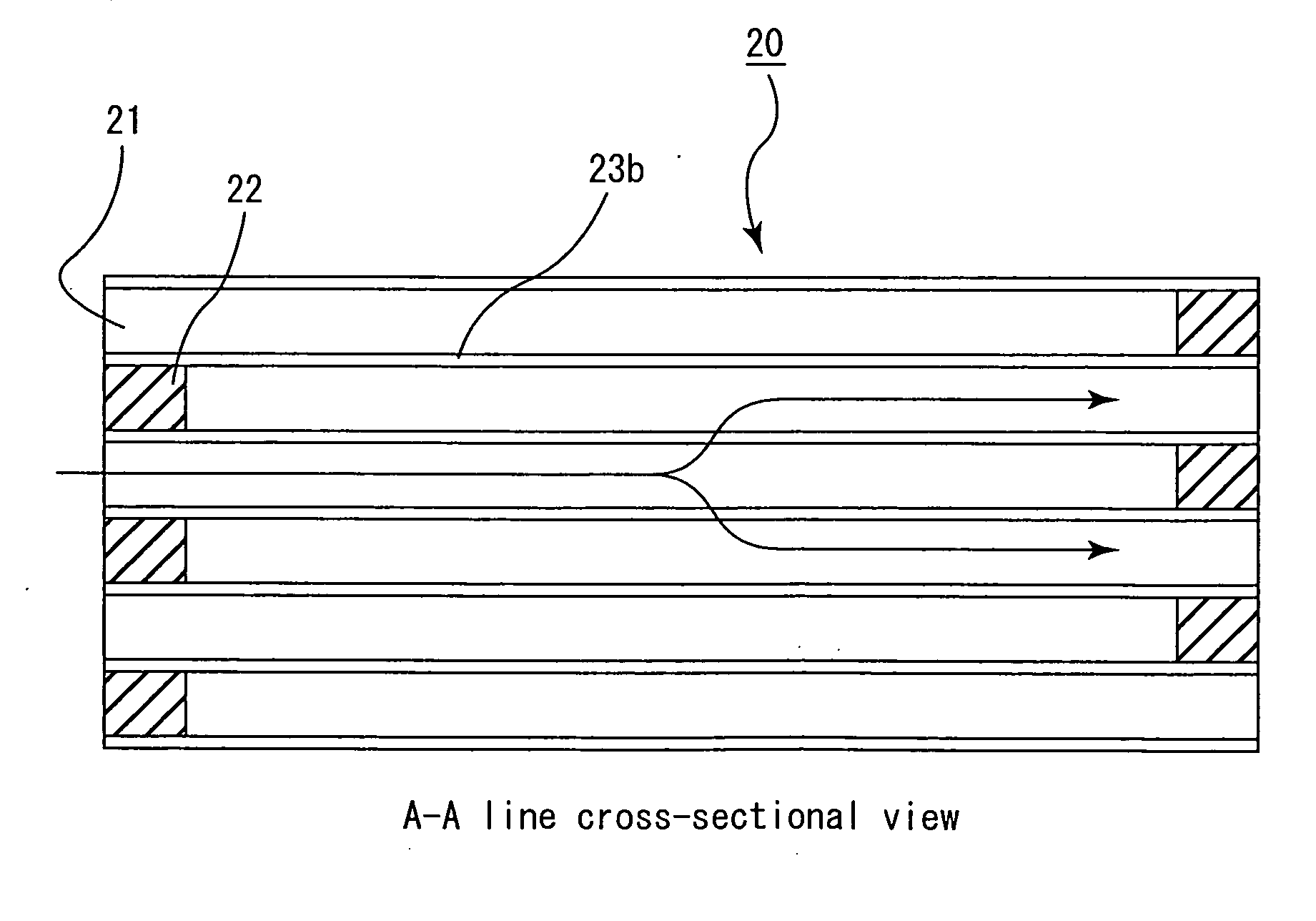

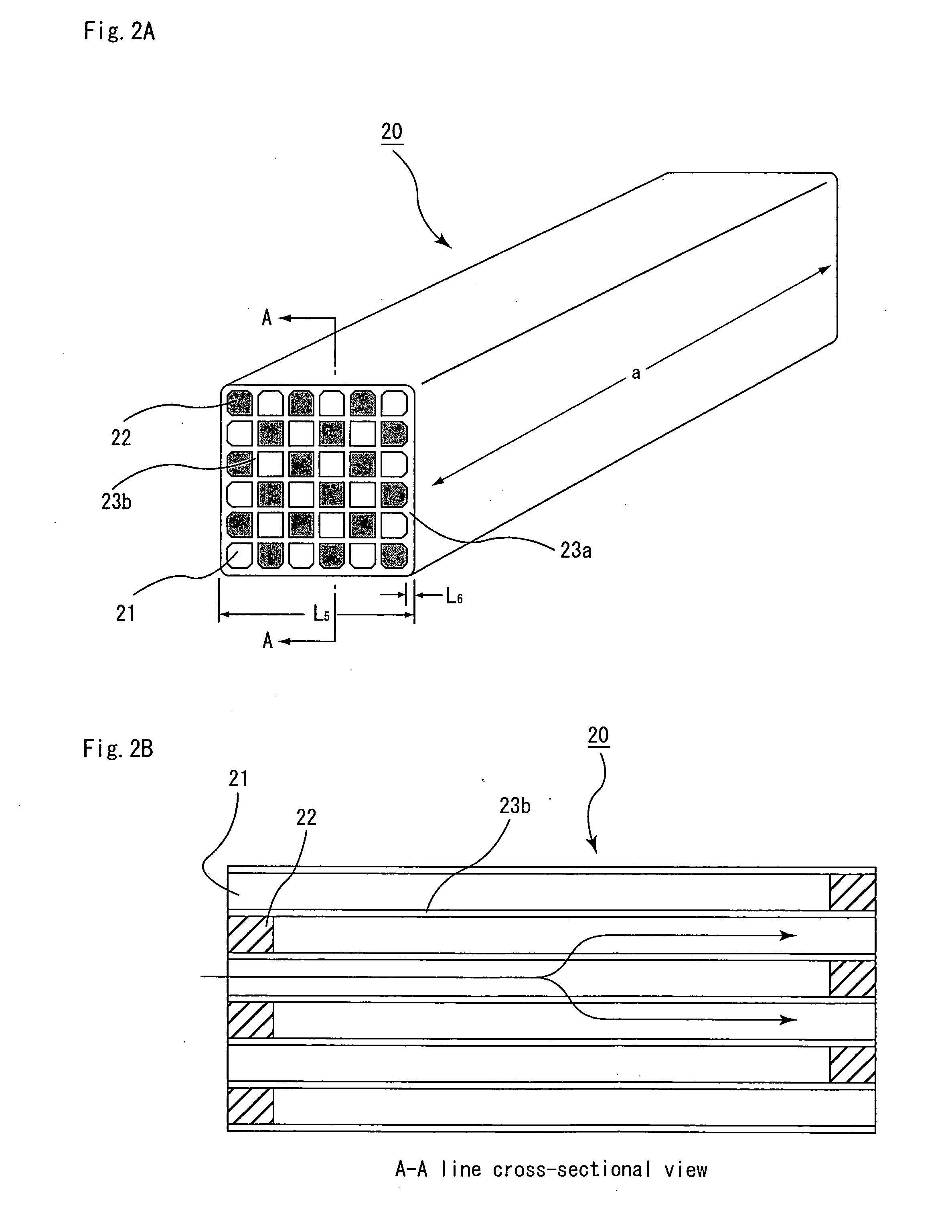

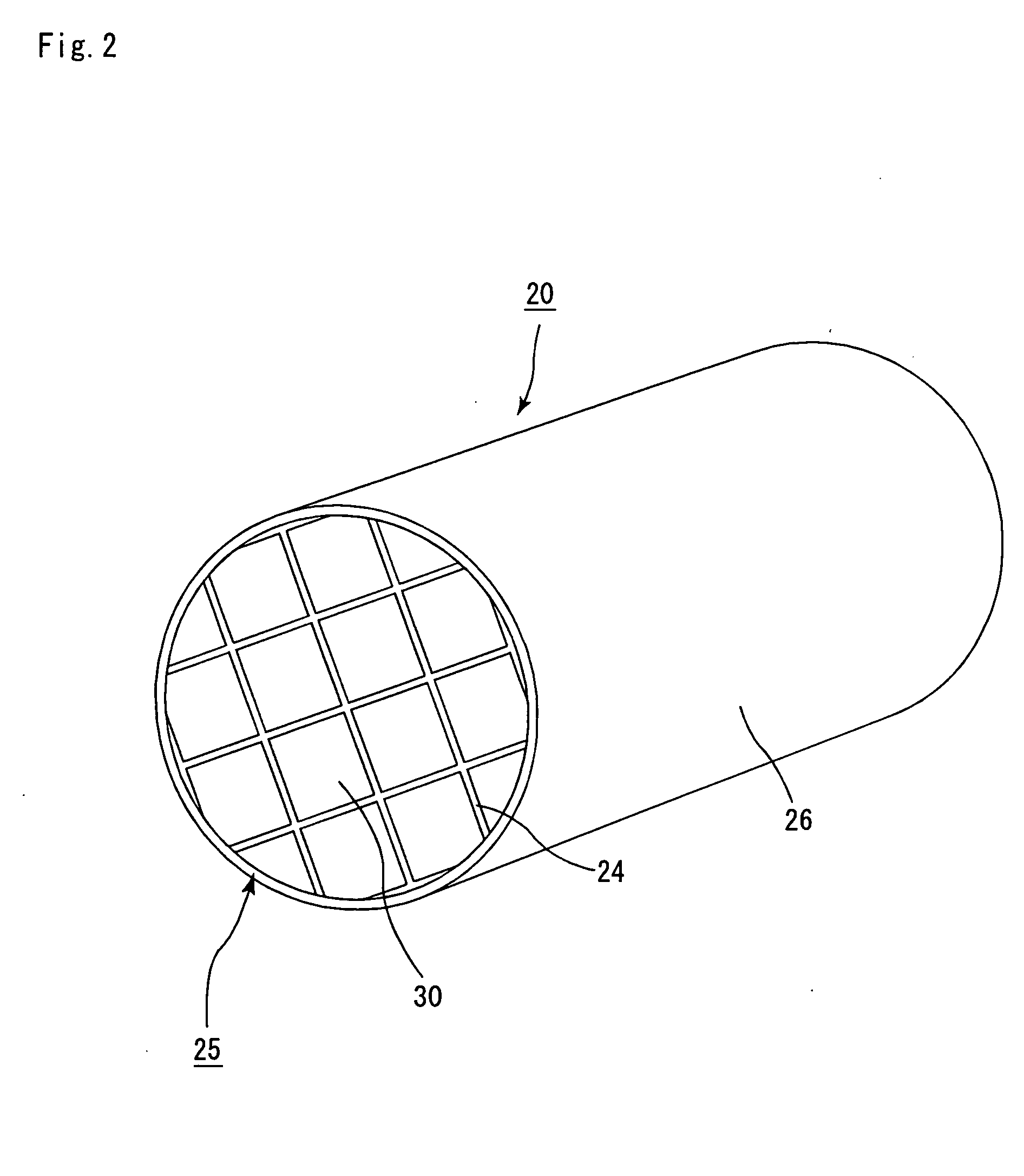

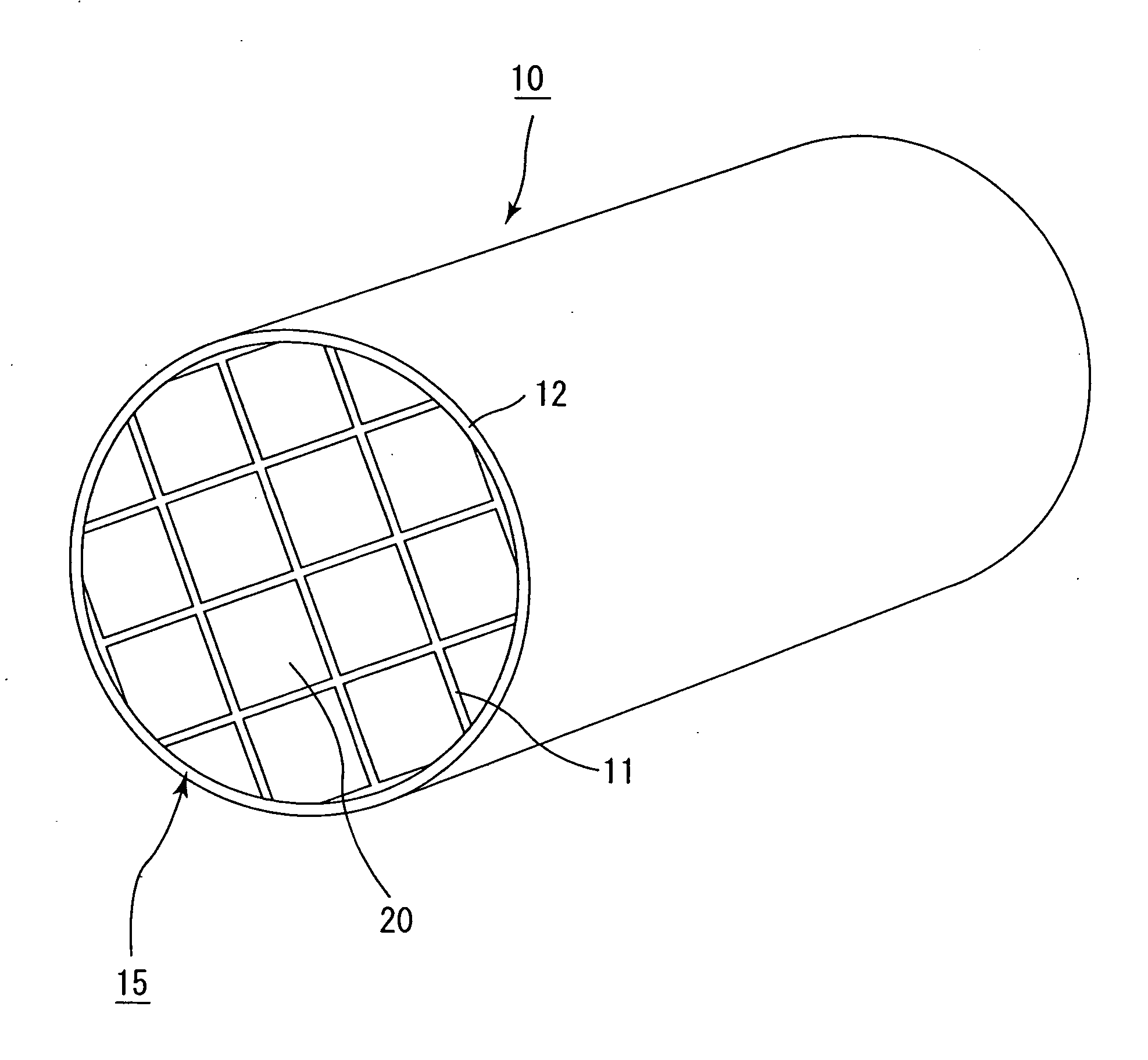

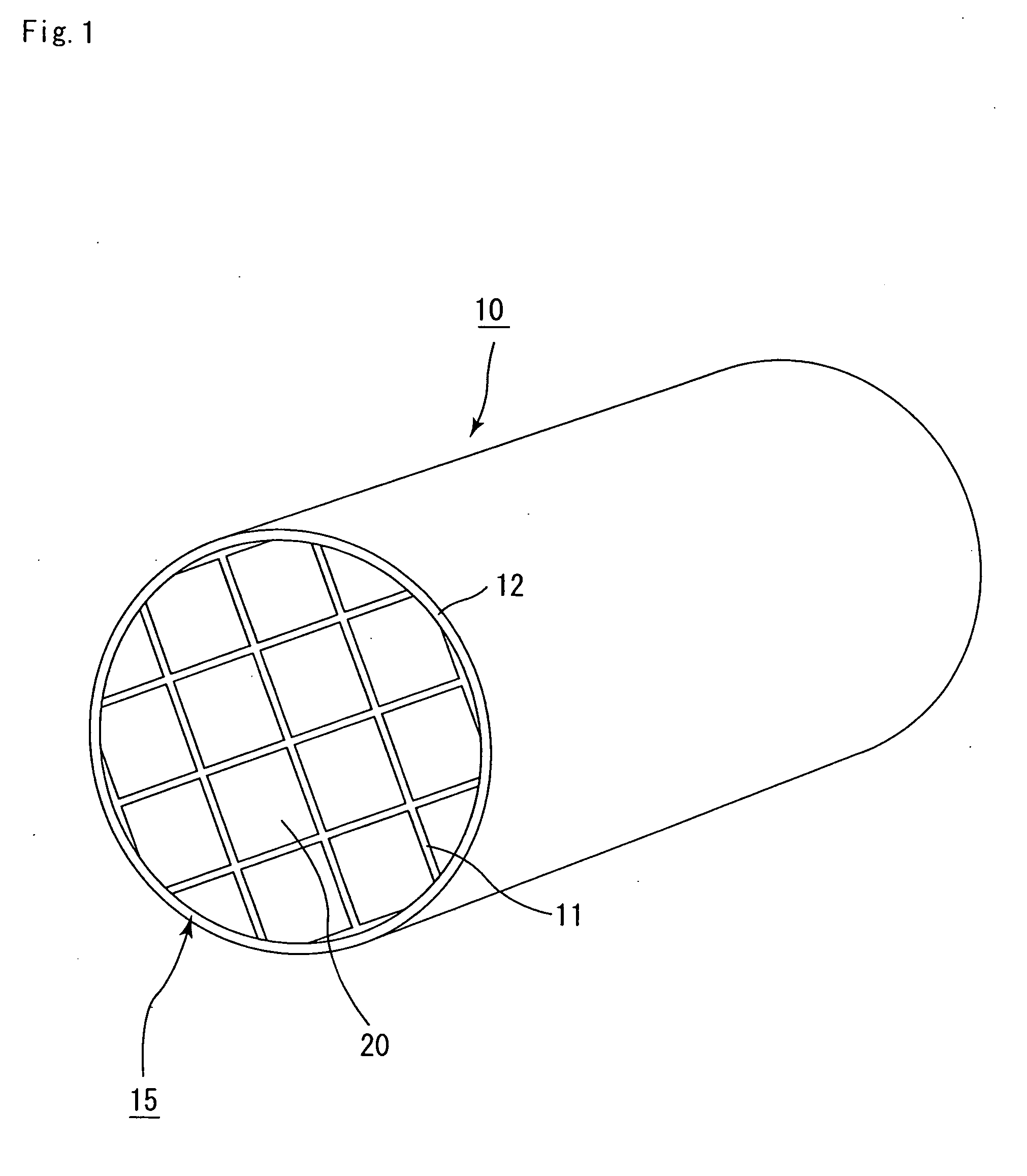

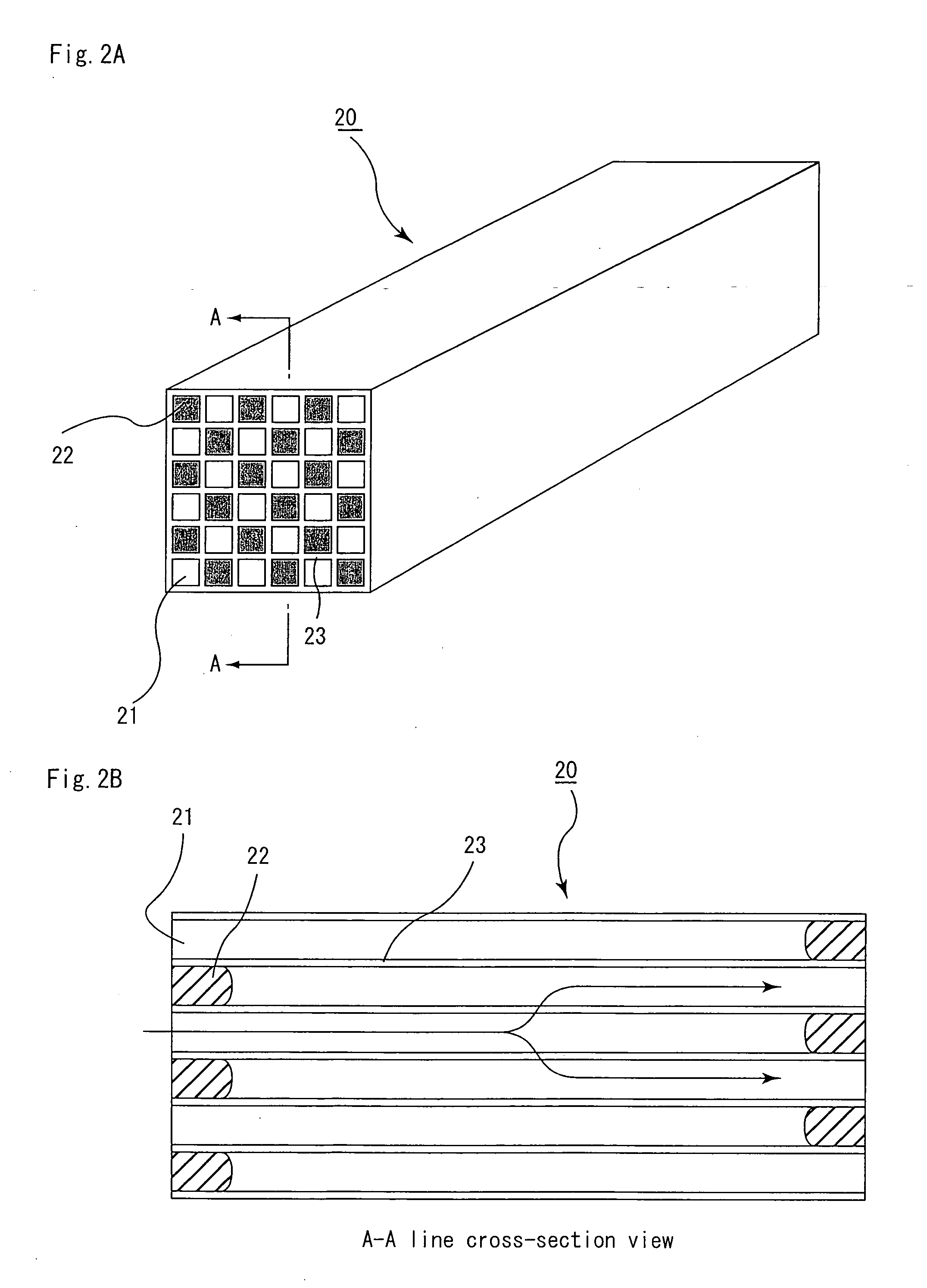

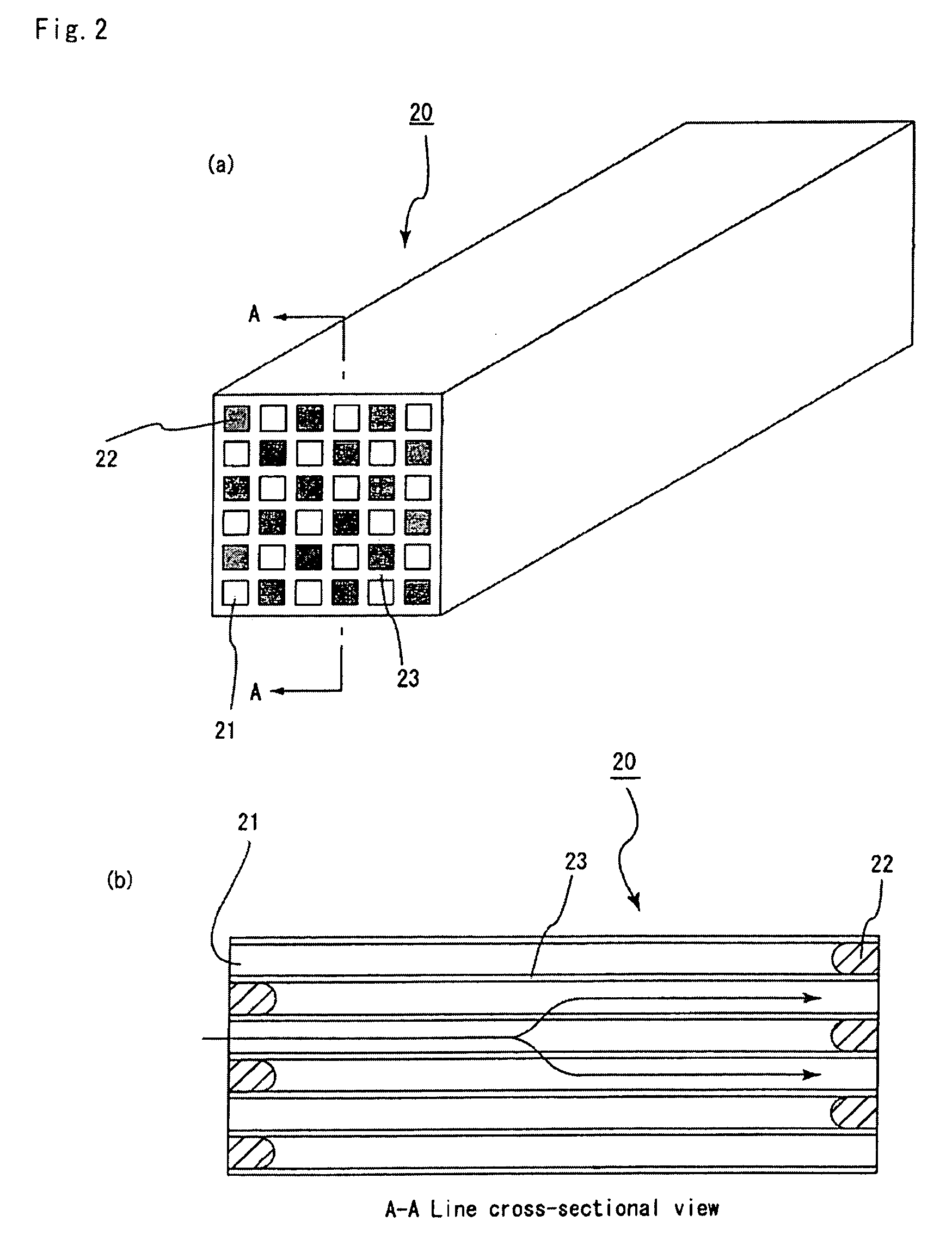

Honeycomb structured body, method for manufacturing honeycomb structured body and exhaust gas purifying device

ActiveUS20070128405A1Secure strengthLoss levelingPhysical/chemical process catalystsInternal combustion piston enginesRight triangleEdge surface

A honeycomb structured body in which a plurality of porous ceramic members are combined with one another by interposing an adhesive layer, each of the porous ceramic members having a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween and having an outer edge wall on the outer edge surface thereof, wherein each of the porous ceramic members has a filling body which is provided so as to fill in at least one corner portion of at least one outermost cell of the porous ceramic members, a cross-sectional shape of the outermost cell at the face orthogonal to the longitudinal direction of the cells is an almost tetragon, and a cross-sectional shape of the filling body at the face orthogonal to the longitudinal direction of the cells is an almost right triangle.

Owner:IBIDEN CO LTD

Honeycomb filter for clarifying exhaust gas

ActiveUS20050175514A1Increased durabilityCombination devicesPhysical/chemical process catalystsHoneycombFlexural strength

A honeycomb filter for purifying exhaust gases that is free from occurrence of cracks and coming-off of plugs and is superior in durability upon its use. The honeycomb filter includes a columnar body made of porous ceramics, which has a number of through holes placed in parallel with one another in the length direction with wall portion interposed therebetween, designed so that predetermined of the through holes are filled with plugs at one end of the columnar body, while the through holes not filled with the plugs at the one end are filled with plugs at the other end of the columnar body, and part of or the entire wall portion functions as a plug for collecting particles. A bending strength Fα (MPa) of the honeycomb filter and a length L (mm) of the plug in the length direction of the through hole satisfy the relationship of Fα×L≧30.

Owner:IBIDEN CO LTD

Biomass Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a biomass, such as switchgrass or hybrid poplar, a non-biomass carbonaceous material, such as petroleum coke or coal, and a gasification catalyst, where the gasification catalyst is loaded onto at least one of the biomass or non-biomass for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

Honeycomb structured body, method for manufacturing honeycomb structured body, and exhaust gas purifying device

InactiveUS20070130897A1Avoid deformationReduce generationPhysical/chemical process catalystsInternal combustion piston enginesEdge surfaceCell wall

A honeycomb structured body in which a plurality of porous ceramic members are combined with one another by interposing an adhesive layer, each of the porous ceramic members having a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween and an outer edgewall on the outer edge surface thereof, wherein the thickness of the outer edge wall of the porous ceramic member is greater than the thickness of the cell wall, and each of the porous ceramic members has a filling body which is provided so as to fill in at least one corner portion of at least one outermost cell of the porous ceramic members.

Owner:IBIDEN CO LTD

Process for producing 1,1,1,3,3-pentafluoro-propane and/or 1-chloro-3,3,3-trifluoropropene

InactiveUS6403847B1Point becomes highManufactured continuously and efficientlyPreparation by dehalogenationPreparation by hydrogen halide split-offBoiling pointPropane

One or more materials selected from 1,1,1,3,3-pentachloropropane, 1,1,3,3-tetrachloropropene and 1,3,3,3-tetrachloropropene are used as the specific materials described above. Before submitting the materials and HF to a fluorination reaction, almost all water is removed from them.To continuously manufacture useful intended products efficiently as well as to prevent deactivation of the catalyst and the accumulation of organic substances with high boiling points when manufacturing said useful 1,1,1,3,3-pentafluoropropane and / or 1-chloro-3,3,3-trifluoropropene, by fluorinating the specific materials with HF in the presence of a catalyst.

Owner:DAIKIN IND LTD

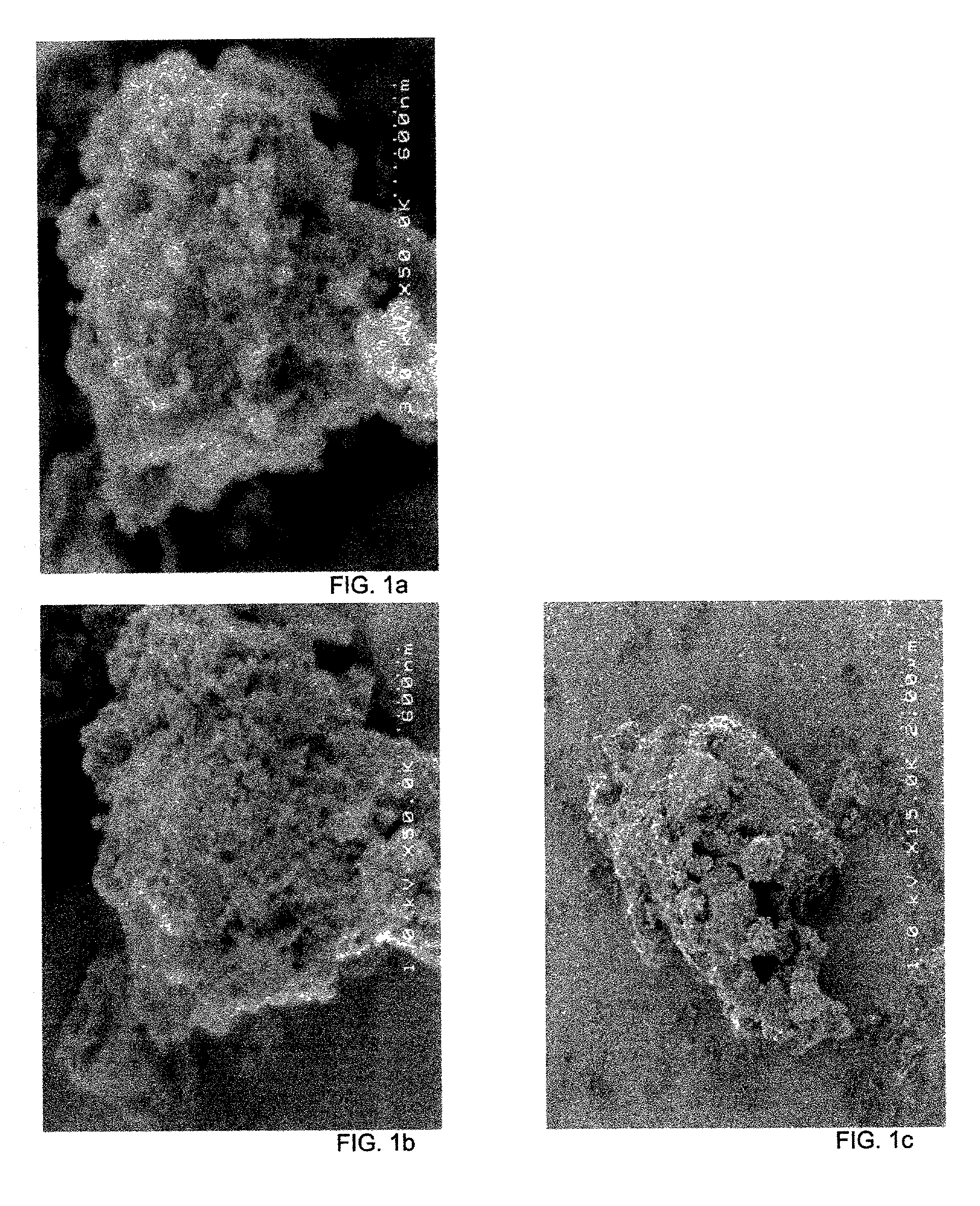

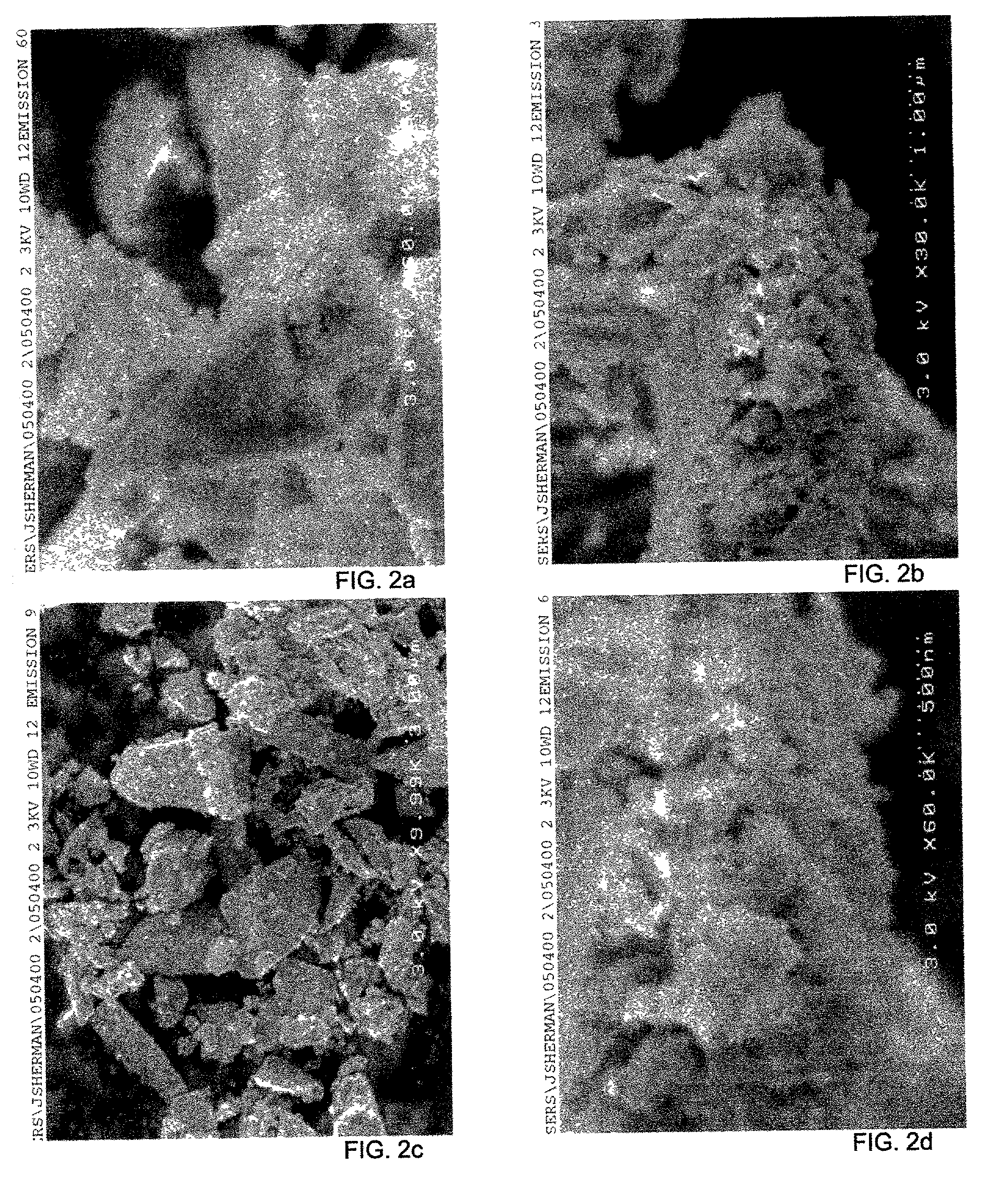

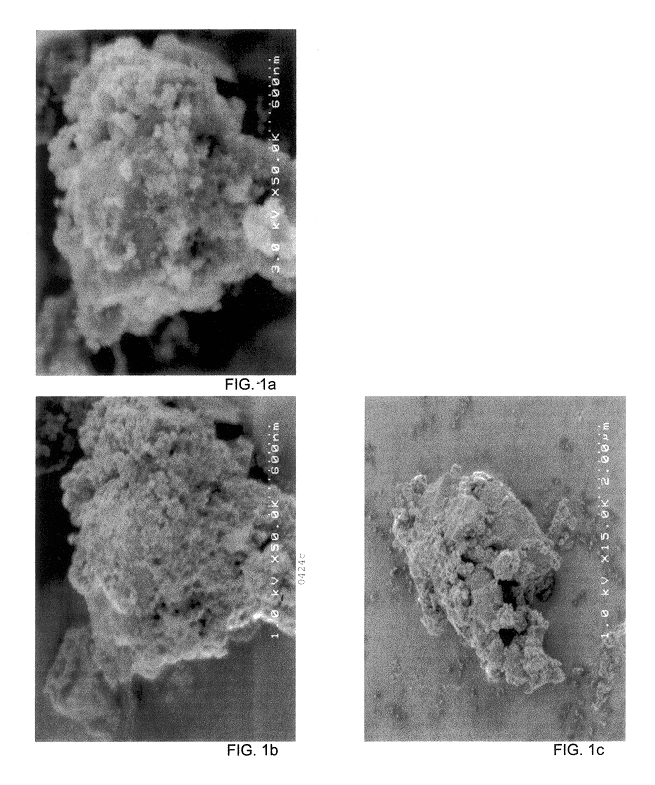

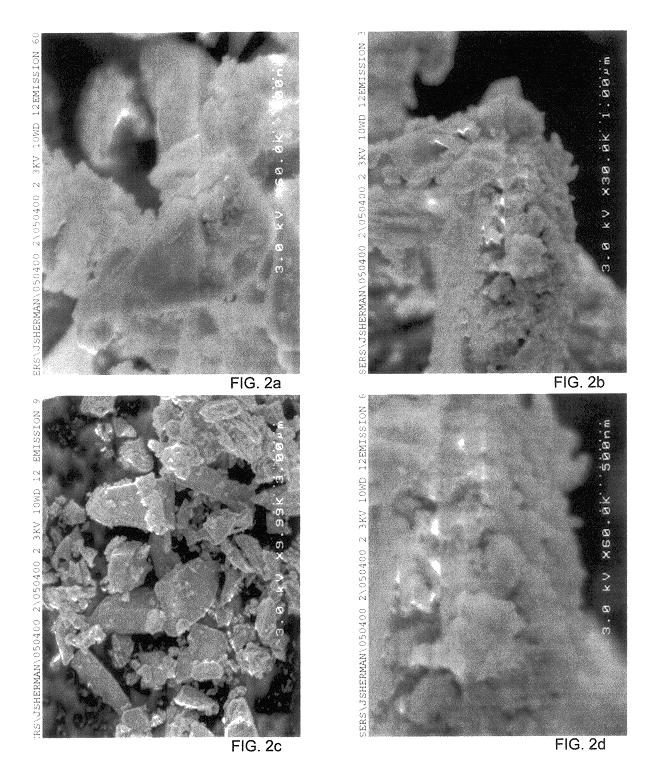

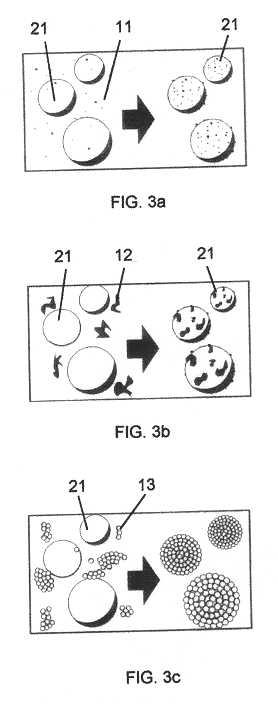

Nanoparticulate titanium dioxide coatings, and processes for the production and use thereof

Nanoparticulate titanium dioxide coating produced by educing flocculates of titanium dioxide nanoparticles from a titanyl sulfate solution and dispersing the nanoparticles in a polar sol-forming medium to make a sol suitable as a coating usable to impart photocatalytic activity, U.V. screening properties, and fire retardency to particles and to surfaces. The photocatalytic material and activity is preferably localized in dispersed concentrated nanoparticles, spots or islands both to save costs and leverage anti-microbial effects.

Owner:SHERMAN JONATHAN

Nanoparticulate titanium dioxide coatings, and processes for the production and use thereof

Nanoparticulate titanium dioxide coating produced by educing flocculates of titanium dioxide nanoparticles from a titanyl sulfate solution and dispersing the nanoparticles in a polar sol-forming medium to make a sol suitable as a coating usable to impart photocatalytic activity, U.V. screening properties, and fire retardency to particles and to surfaces. The photocatalytic material and activity is preferably localized in dispersed concentrated nanoparticles, spots or islands both to save costs and leverage anti-microbial effects.

Owner:SHERMAN JONATHAN

Carbonaceous Fines Recycle

ActiveUS20090217589A1Sufficient amountHydrogen productionCarbon monoxideParticulatesParticle composition

Owner:SURE CHAMPION INVESTMENT LTD

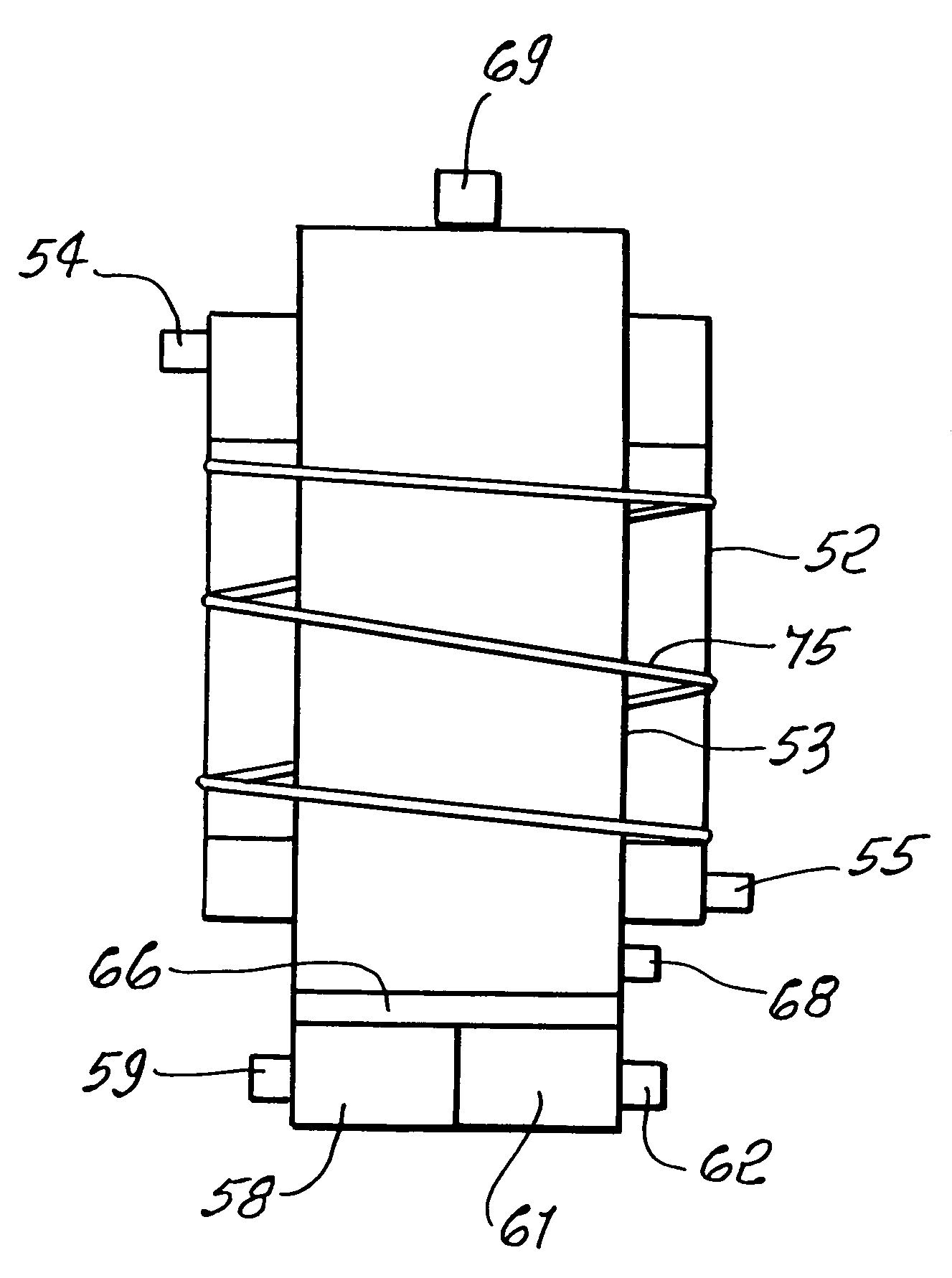

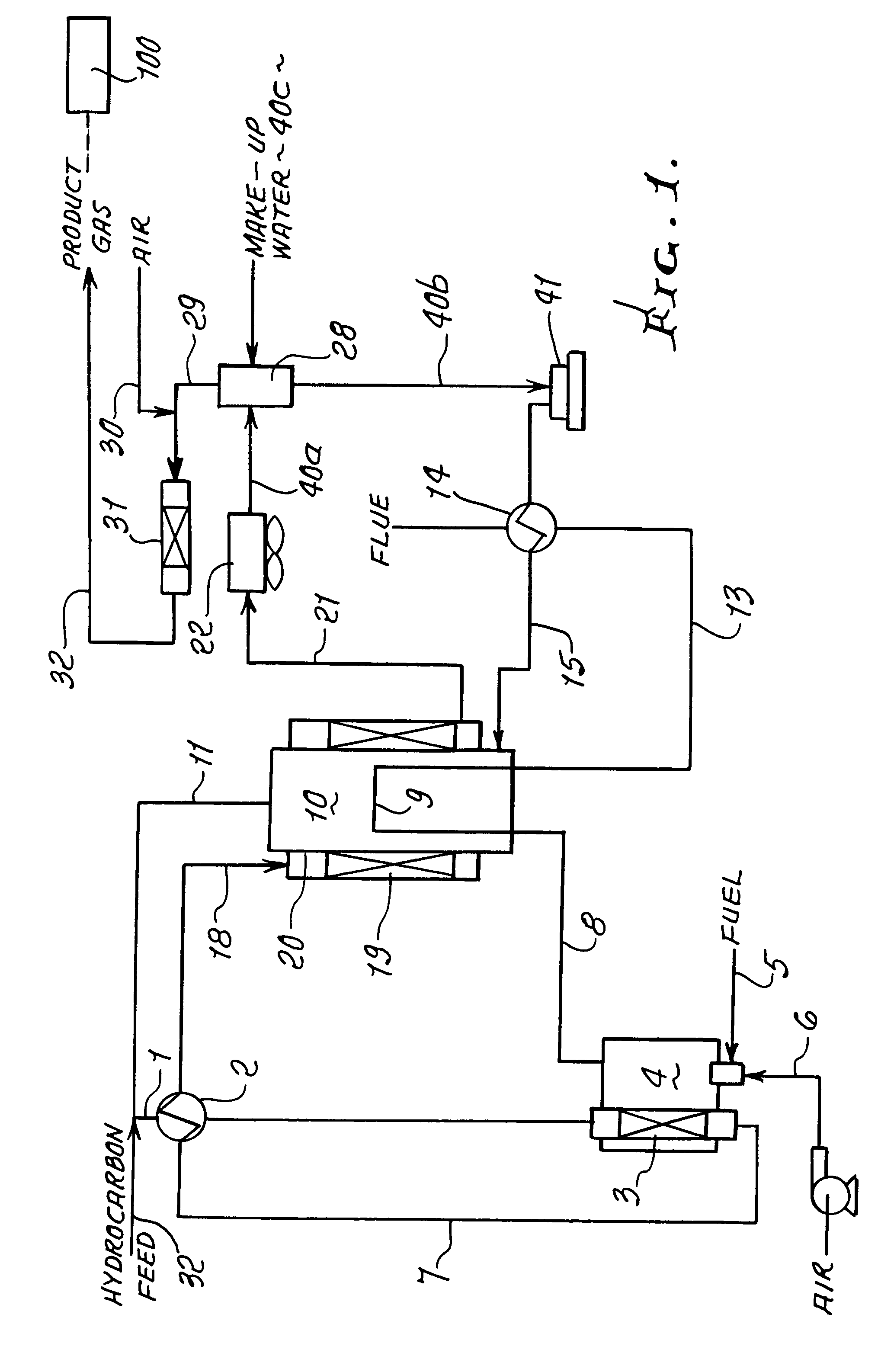

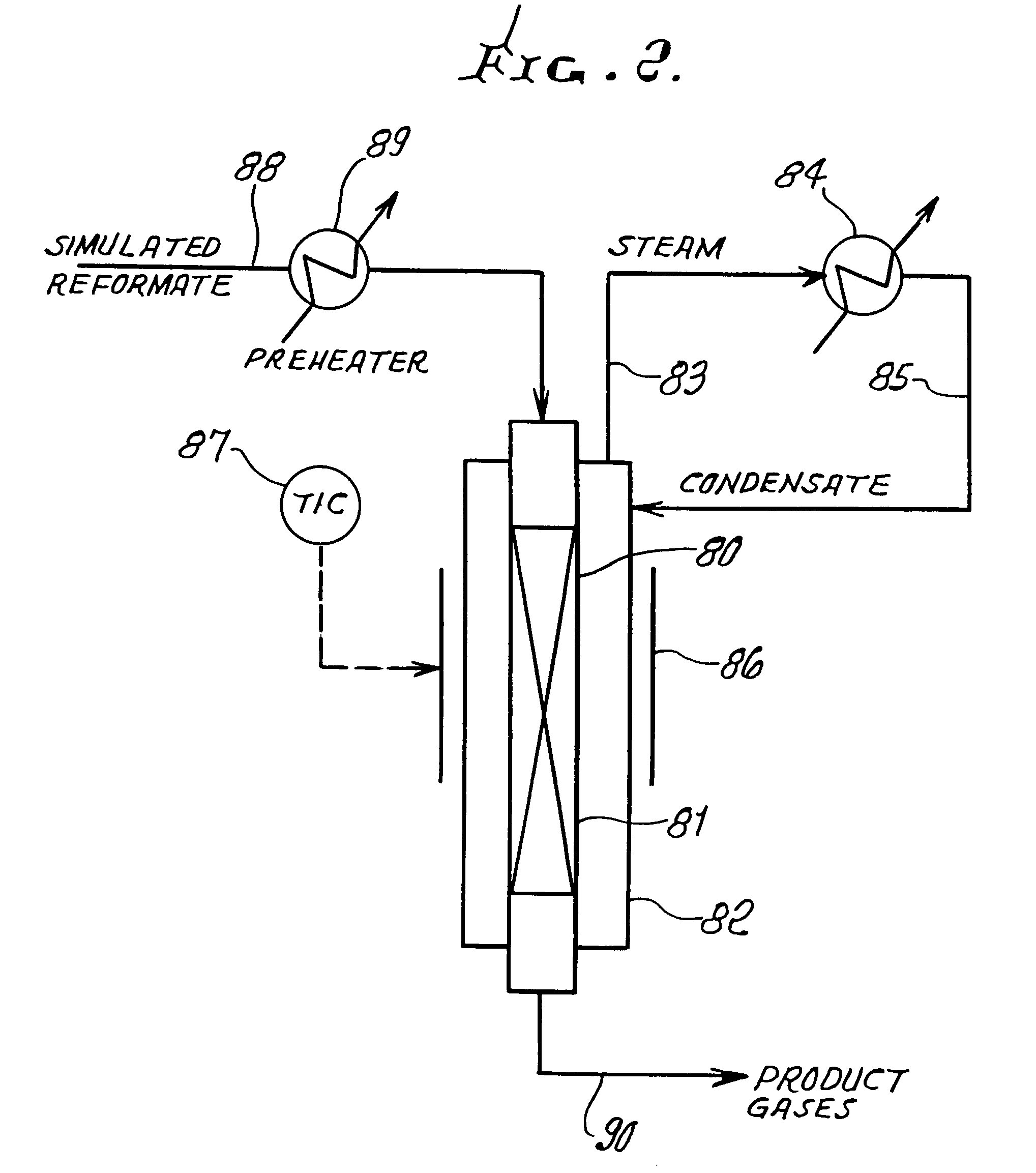

Thermally-integrated low temperature water-gas shift reactor apparatus and process

InactiveUS7074373B1Reduced toleranceExtended temperature rangeHydrogenPhysical/chemical process catalystsWater-gas shift reactionProduct gas

A thermally-integrated lower temperature water-gas shift reactor apparatus for converting carbon monoxide in the presence steam comprises a catalyst bed that is disposed within an outer region surrounding a waste heat recovery steam generator operating at a selected pressure corresponding to the optimum temperature for conducting the catalytic water-gas shift reaction and a process for useful recovery of the exothermic heat of reaction to generate steam that is used in a process for the conversion of hydrocarbon feedstock into useful gases such as hydrogen.

Owner:HARVEST ENERGY TECH

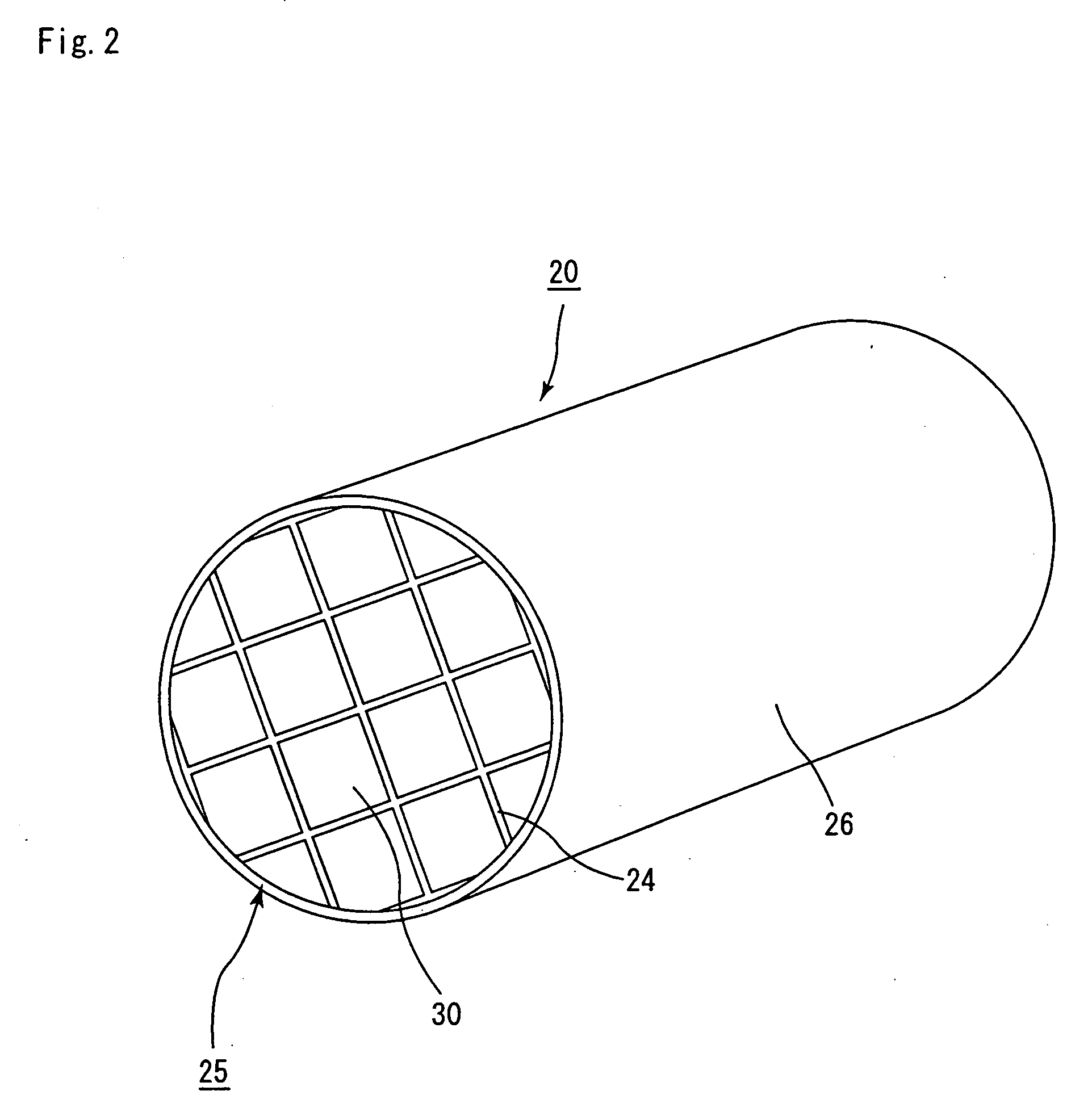

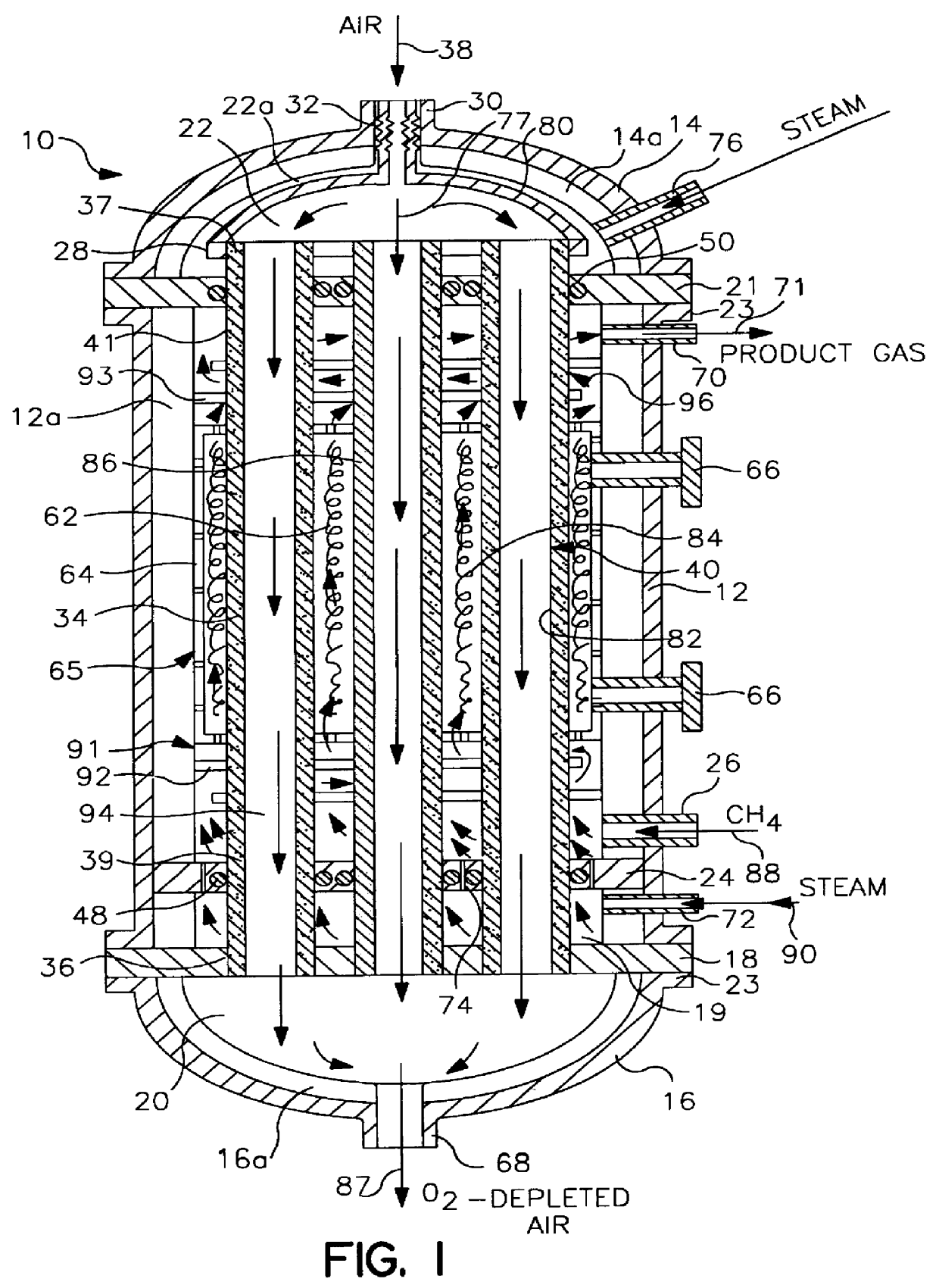

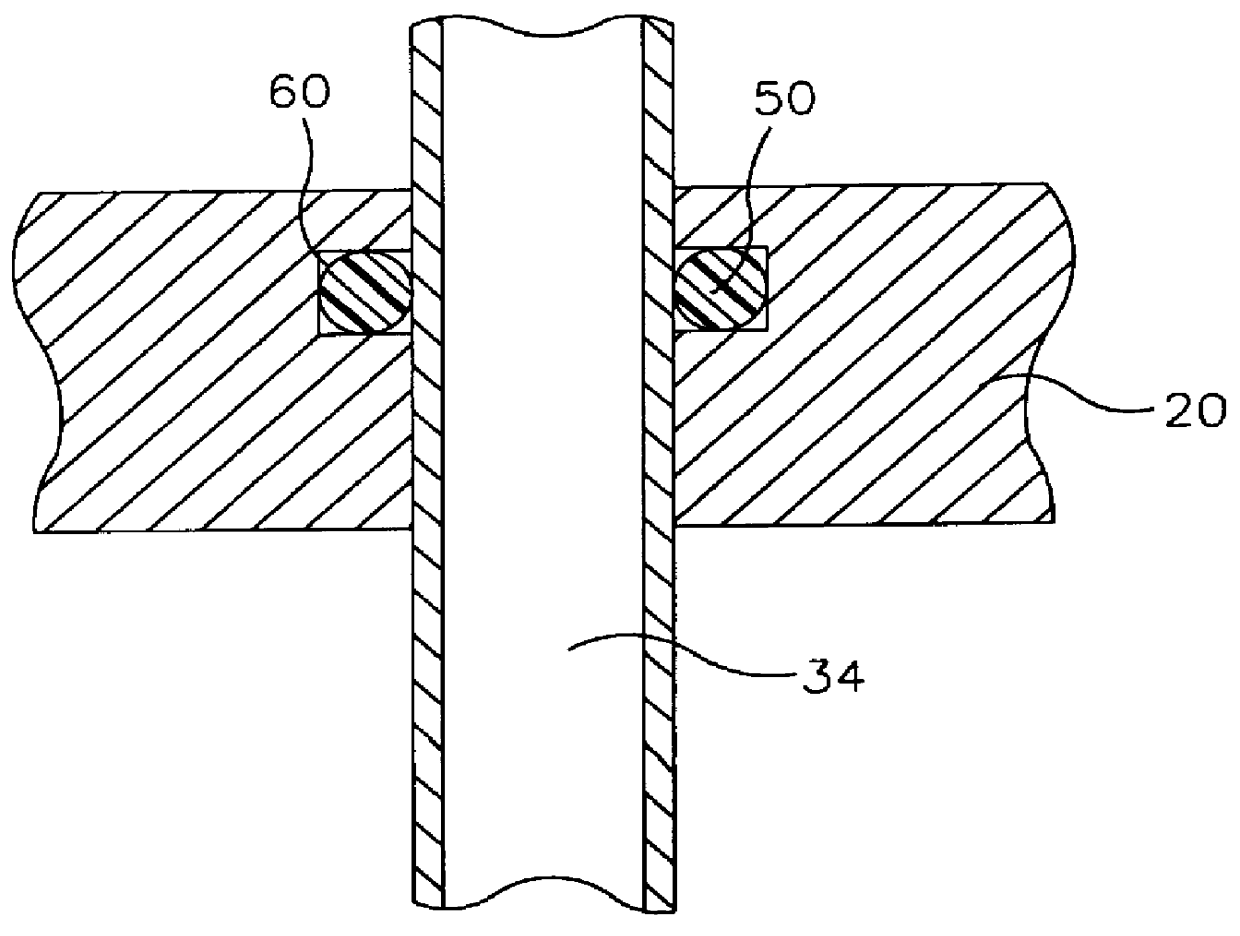

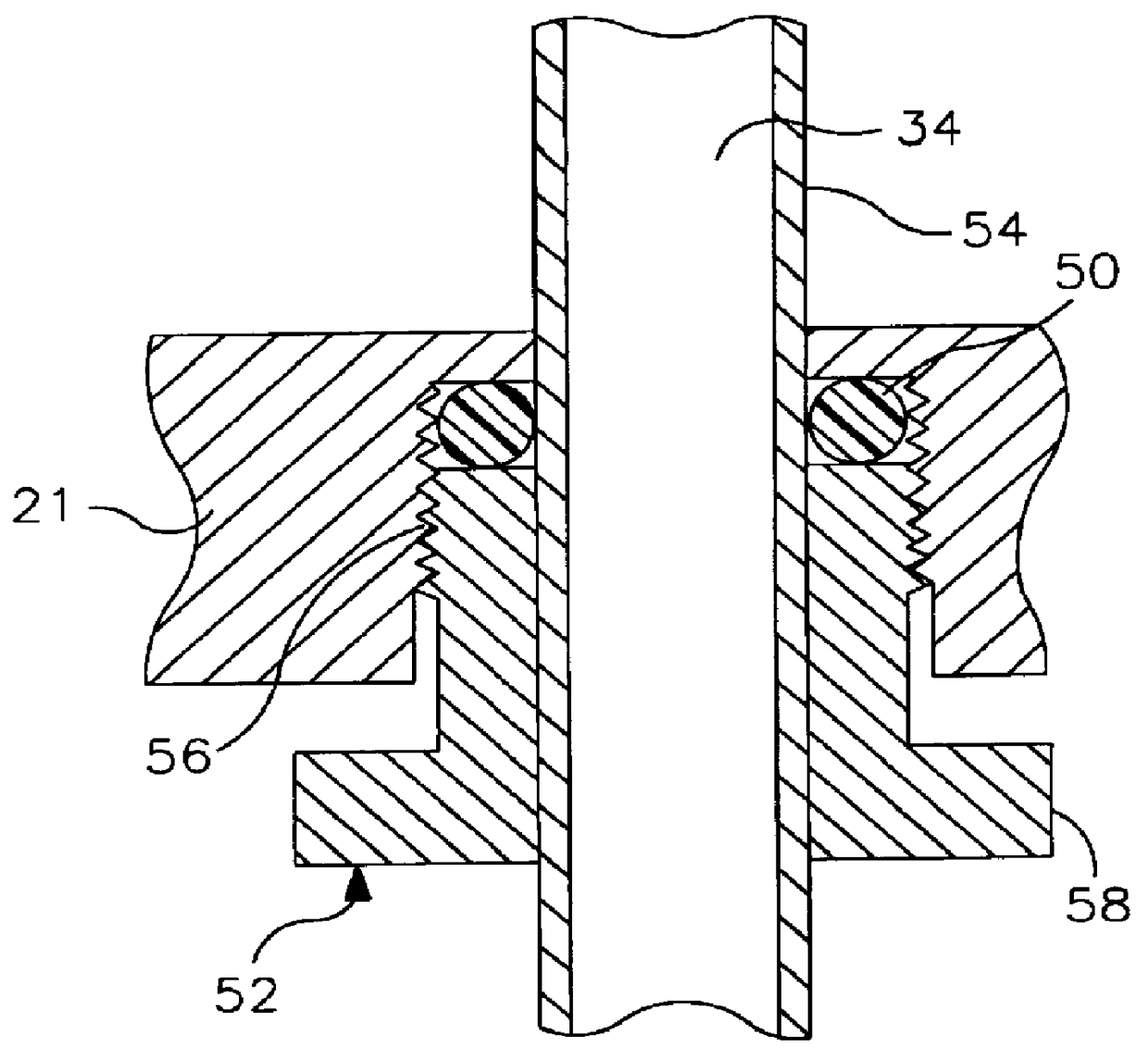

Tube and shell reactor with oxygen selective ion transport ceramic reaction tubes

InactiveUS6139810AIncrease oxygen fluxDecreasing anode side partial oxygen pressureIsotope separationHydrogen/synthetic gas productionPtru catalystElectrical conductor

A reactor comprising: a hollow shell defining a hermetic enclosure; a plurality of tube sheets disposed within said hermetic enclosure, a first one of said plurality of tube sheets defining a first chamber; at least one reaction tube each having a first end and an opposing second end, said first end being fixedly attached and substantially hermetically sealed to one end of said plurality of tube sheets and opening into said first chamber, the second end being axially unrestrained; each of said reaction tubes is comprised of an oxygen selective ion transport membrane with an anode side wherein said oxygen selective ion transport membrane is formed from a mixed conductor metal oxide that is effective for the transport of elemental oxygen at elevated temperatures and at least a portion of said first and second heat transfer sections are formed of metal; each of said reaction tubes includes first and second heat transfer sections and a reaction section, said reaction section disposed between said first and second heat transfer sections; a reforming catalyst disposed about said anode side of said oxygen selective ion transport membrane; a first process gas inlet; a second process gas inlet; and, a plurality of outlets.

Owner:STANDARD OIL CO +1

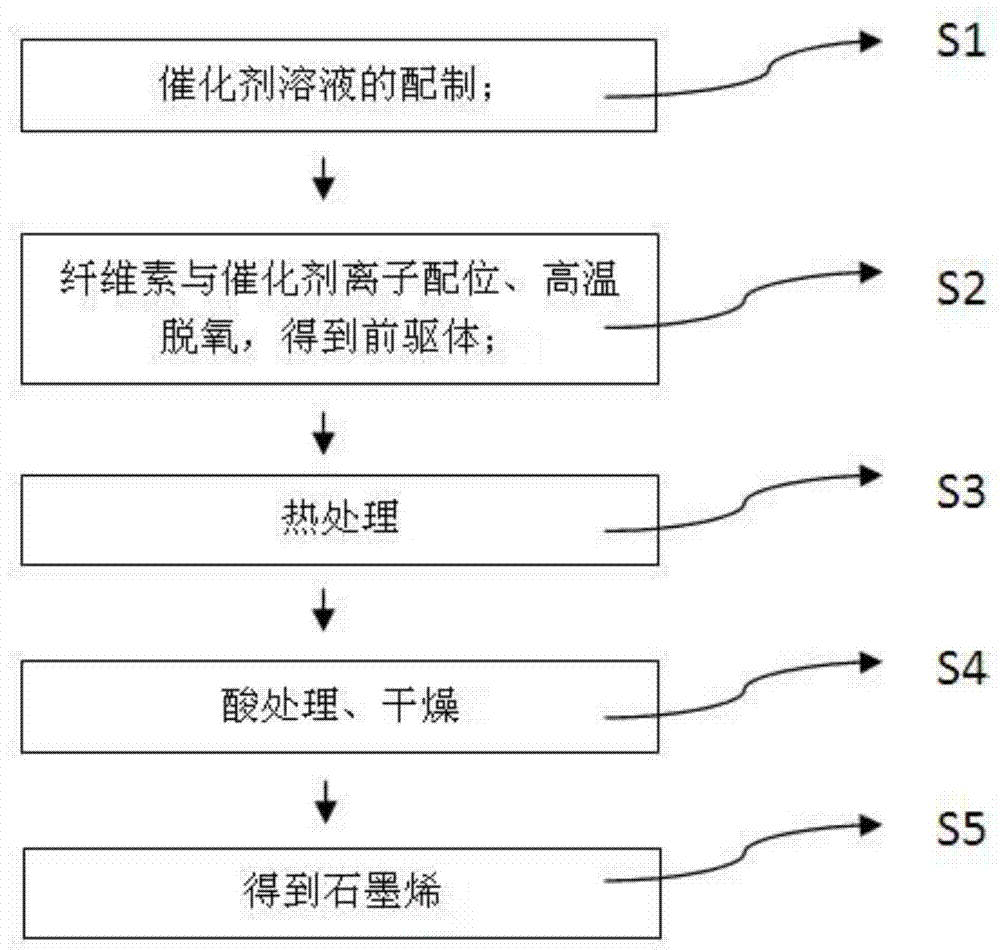

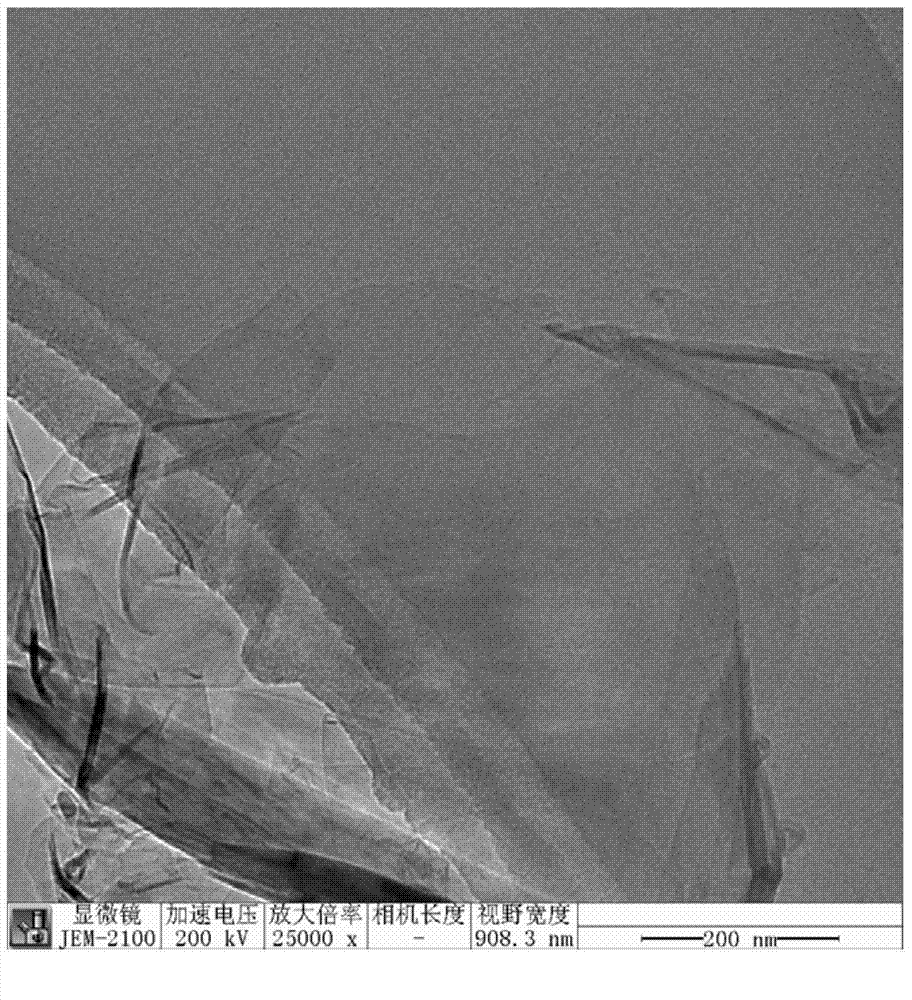

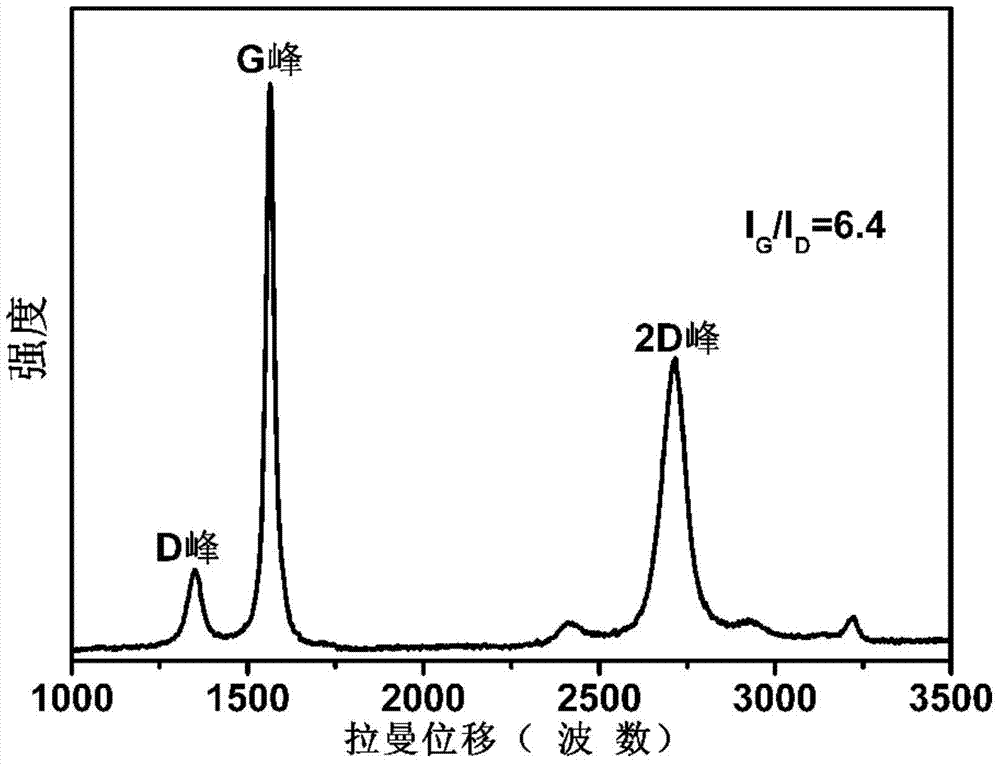

Method for preparing biomass graphene employing cellulose as raw material

ActiveCN104724699AUniform sizeIncrease productionPhysical/chemical process catalystsGrapheneCellulosePolymer science

The invention provides a preparation method of graphene, and particularly relates to a method for preparing biomass graphene employing cellulose as a raw material. The specific preparation method comprises the following steps: 1, preparing a catalyst solution; 2, carrying out ionic coordination and high-temperature deoxidization on cellulose and a catalyst, so as to obtain a precursor; 3, carrying out thermal treatment; 4, carrying out acid treatment, and drying to obtain the graphene, wherein the prepared graphene is uniform in morphology, has a single-layer or multi-layer two-dimensional layered structure; the dimension is 0.5-2 microns; and the electrical conductivity is 25,000-45,000S / m. The preparation method is simple in preparation technology, low in cost, high in yield, high in production safety, and controllable in product dimension and physical property; industrialized production can be realized; the graphene prepared by the method can be applied to electrode materials of super capacitors and lithium ion batteries, and can also be added to resin and rubber as an additive; and the physical property of the material can be improved.

Owner:HEILONGJIANG UNIV +1

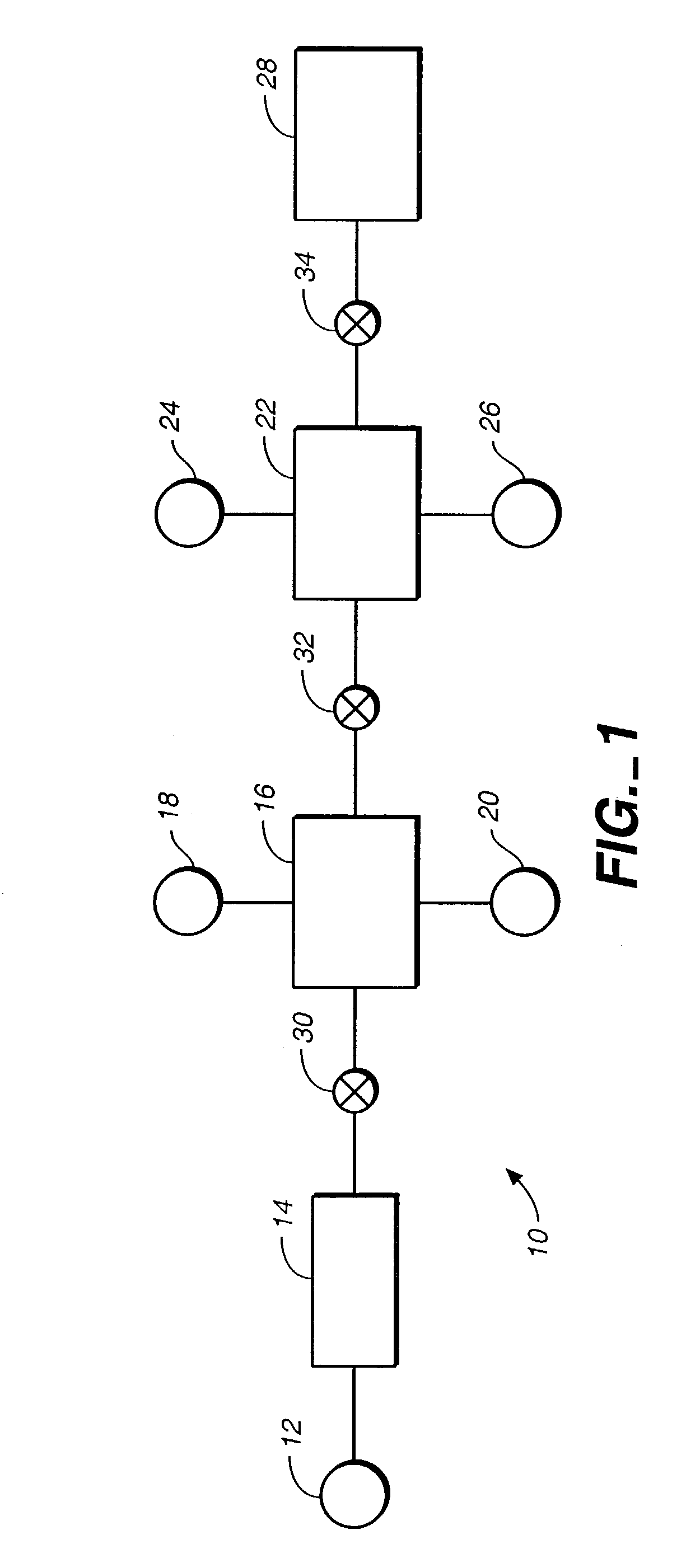

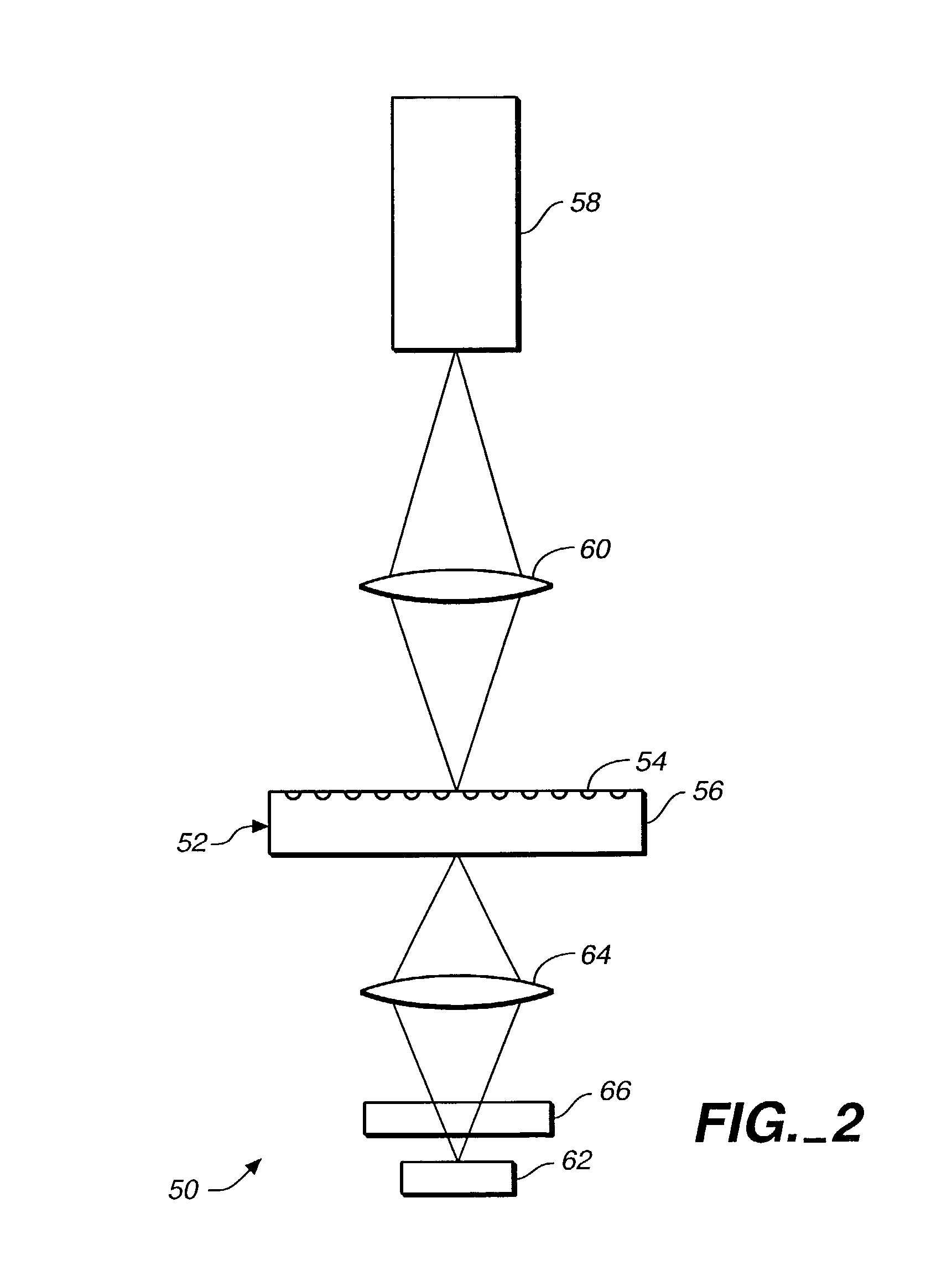

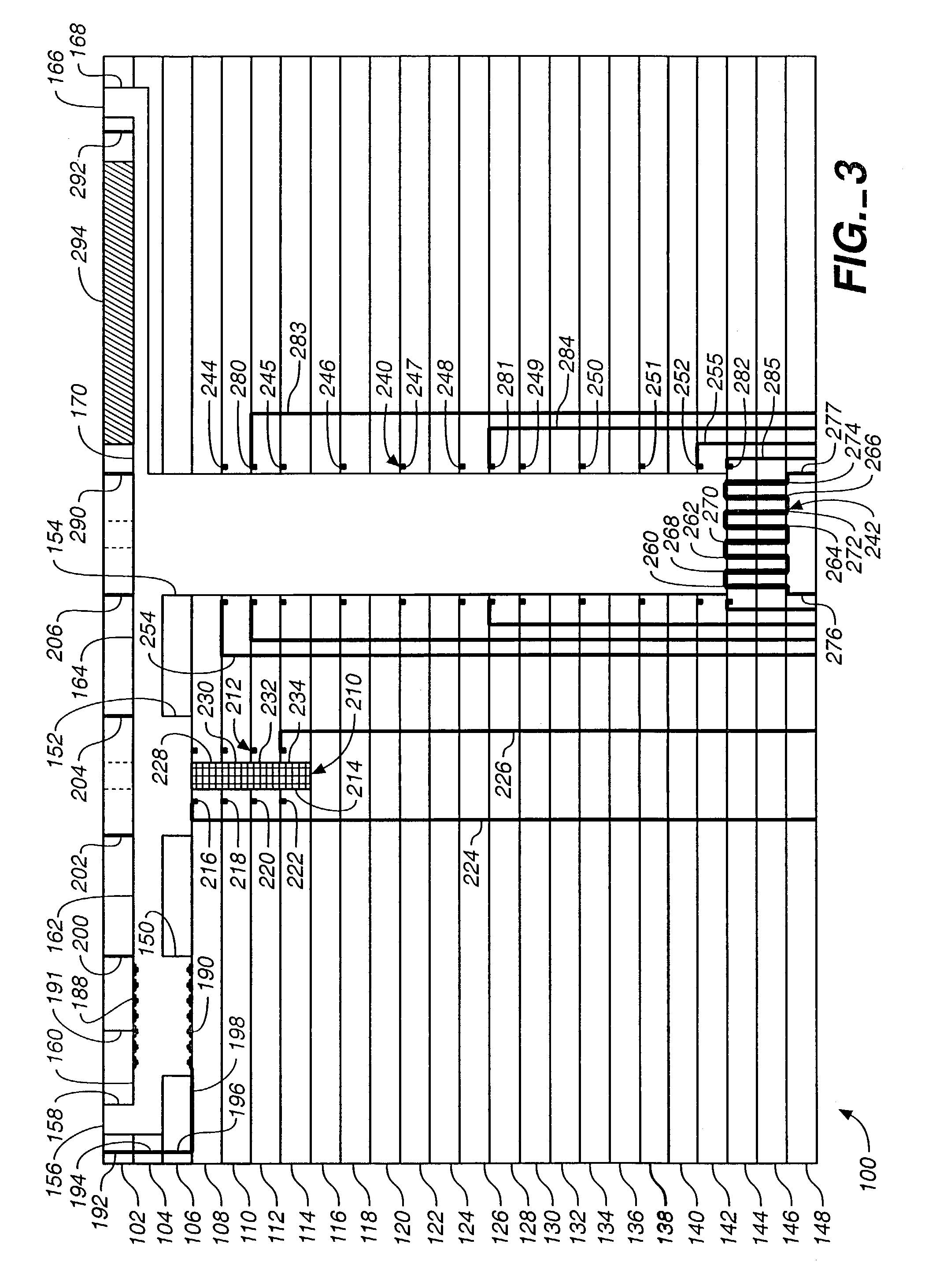

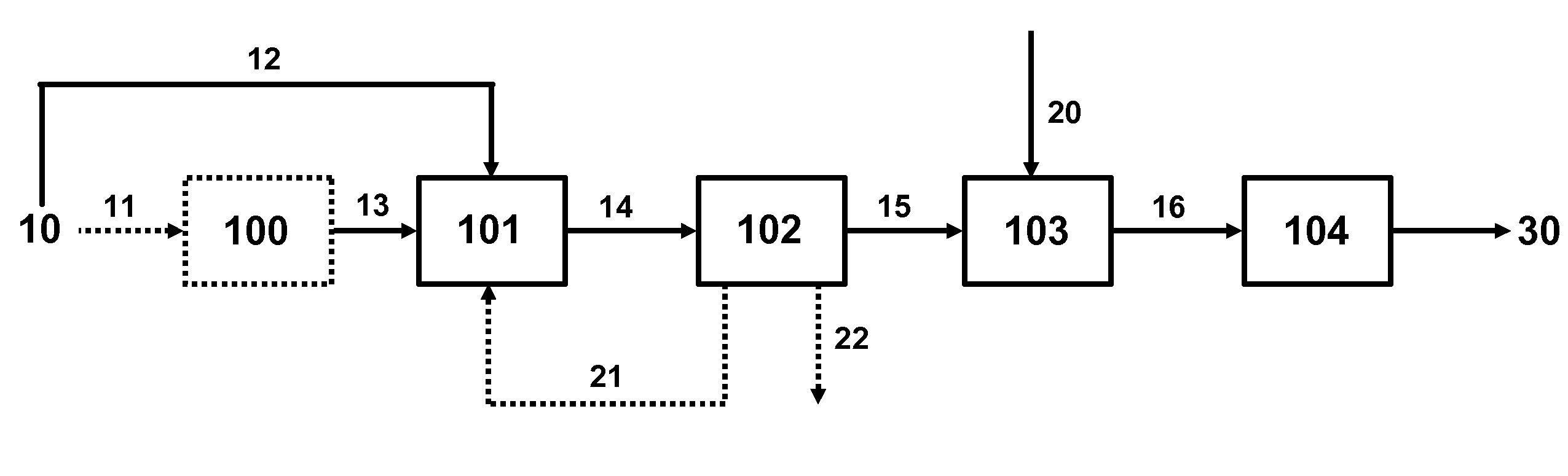

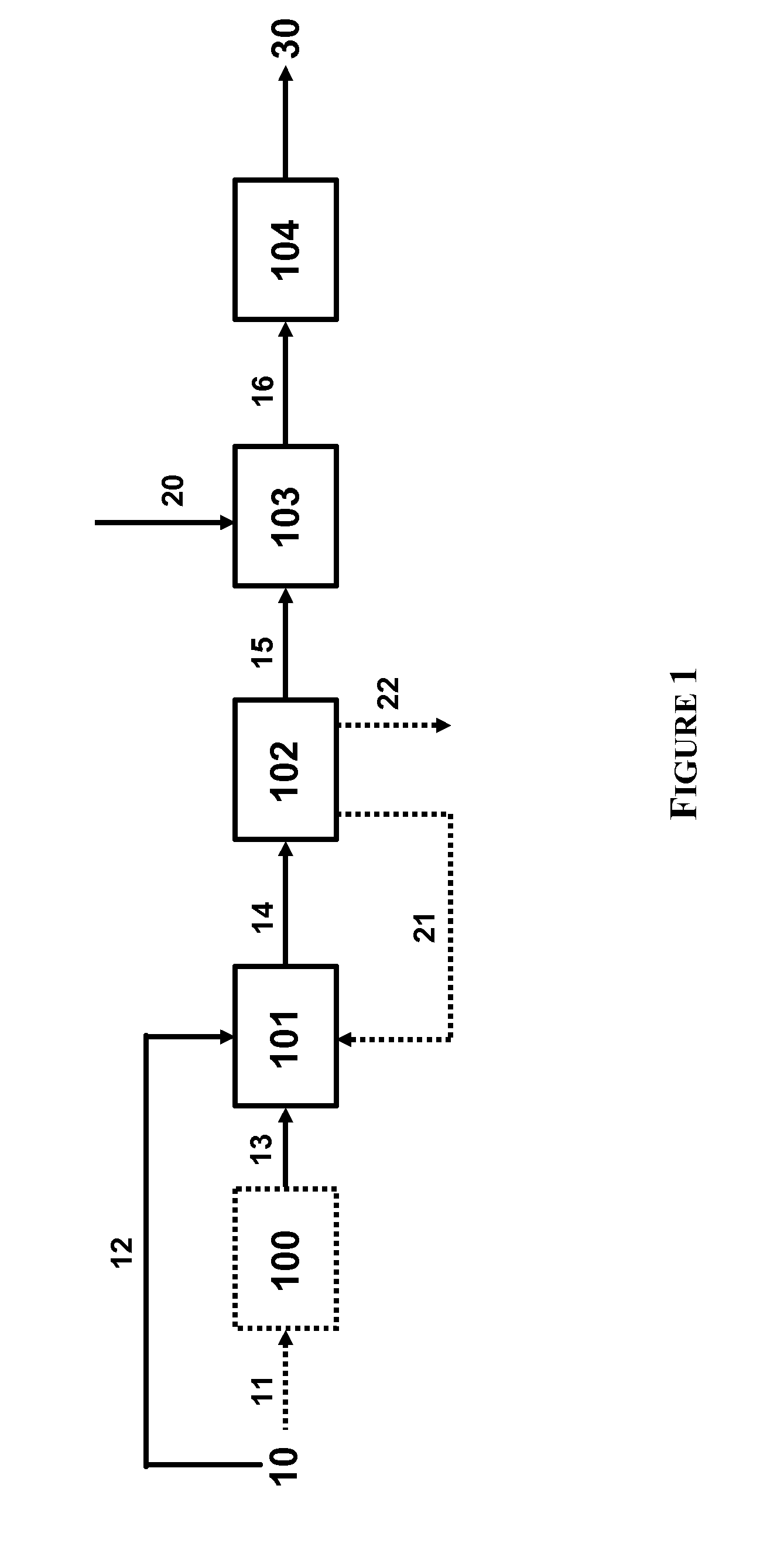

Multilayered microfluidic DNA analysis system and method

A multilayered microfluidic DNA analysis system includes a cell lysis chamber, a DNA separation chamber, a DNA amplification chamber, and a DNA detection system. The multilayered microfluidic DNA analysis system is provided as a substantially monolithic structure formed from a plurality of green-sheet layers sintered together. The substantially monolithic structure has defined therein a means for heating the DNA amplification chamber and a means for cooling the DNA amplification chamber. The means for heating and means for cooling operate to cycle the temperature of the DNA amplification chamber as required for performing a DNA amplification process, such as PCR.

Owner:GOOGLE TECH HLDG LLC

Honeycomb structured body

A honeycomb structured body of the present invention is a honeycomb structured body in which a plurality of porous ceramic members are combined with one another through an adhesive layer, each of the porous ceramic members having a plurality of cells which are allowed to penetrate in a longitudinal direction with a wall portion therebetween and either one end of which is sealed, with a catalyst supporting layer being adhered to the wall portion, wherein, supposing that the rate of the pore volume of pores having a pore diameter of 10 μm or less to the entire pore volume of the porous ceramic member is X1 (%), the porosity is Y1 (%) and the weight of the catalyst supporting layer is Z1 (g / l), these X1, Y1 and Z1 are allowed to satisfy the following expressions (1) and (2): X1≦20−Z1 / 10 (1), and Y1≧35+7Z1 / 40 (2) (where about 20≦Z1≦about 150).

Owner:IBIDEN CO LTD

Processes for Preparing a Catalyzed Coal Particulate

Processes are provided for preparing a substantially free-flowing alkali metal gasification catalyst-loaded coal particulate suitable for use as a feedstock for the production of gaseous products, and in particular methane, via the catalytic gasification of the catalyst-loaded coal particulate in the presence of steam.

Owner:SURE CHAMPION INVESTMENT LTD

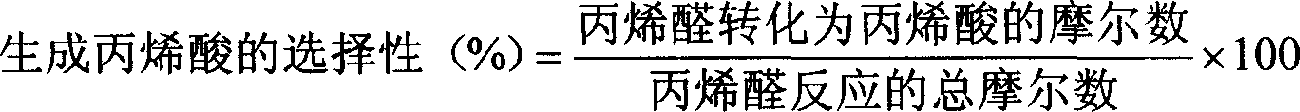

Composite metal oxide for unsaturated aldehyde selective oxidation and preparing method thereof

A composite metallic oxide as catalyst for selective oxidization of unsaturated aldehyde, especially the acrylaldehyde or methyl acrylaldehyde to obtain acrylic acid or methyl acrylic acid, is composed of active components (Mo, V and Cu), stabilizer (at least Sb and Ti) and the composite oxide of Ni, Fe, Si, Al, alkali metal and alkali-earth metal. Its preparing process is also disclosed.

Owner:兰州金润宏成新材料科技有限公司

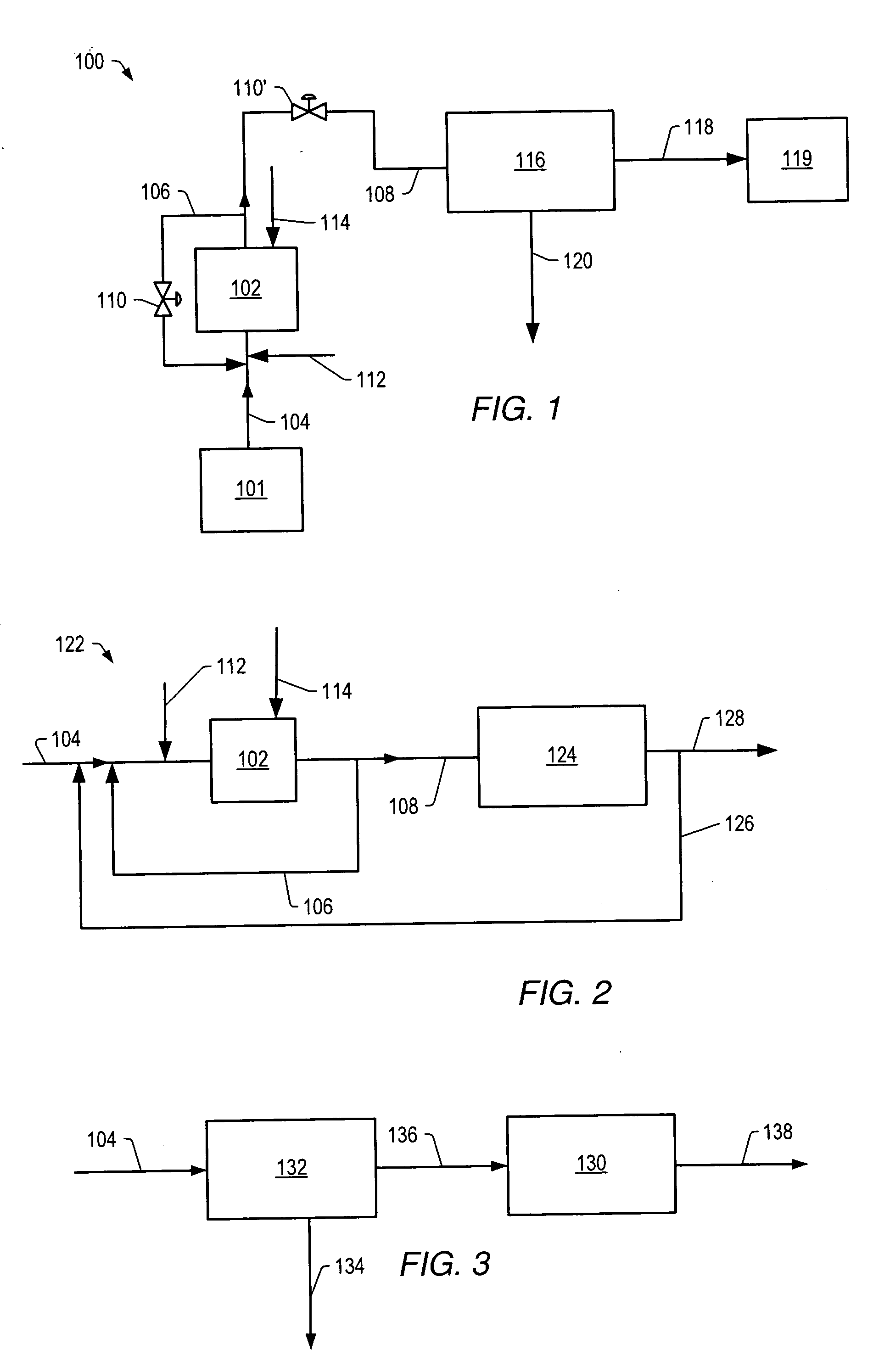

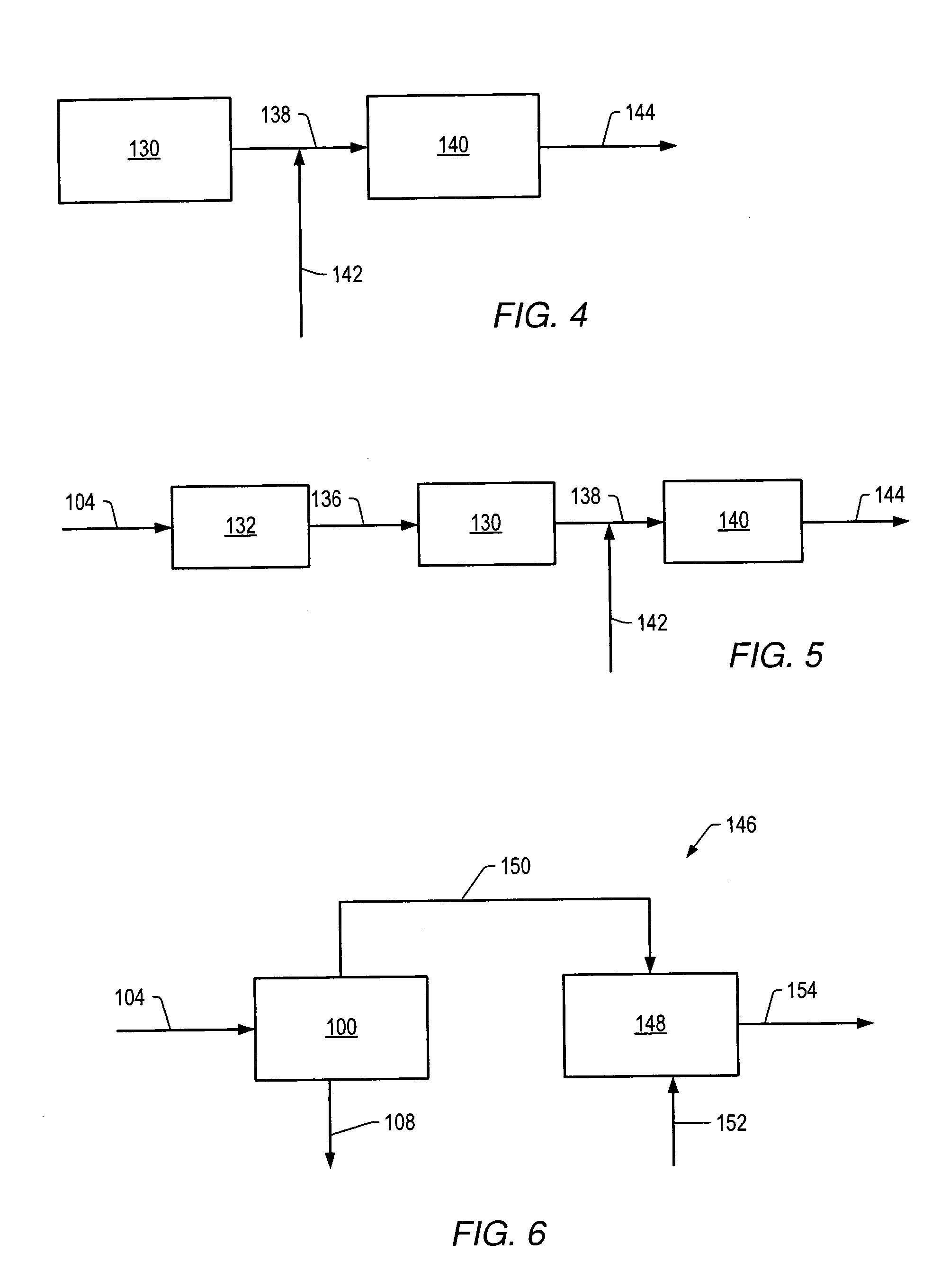

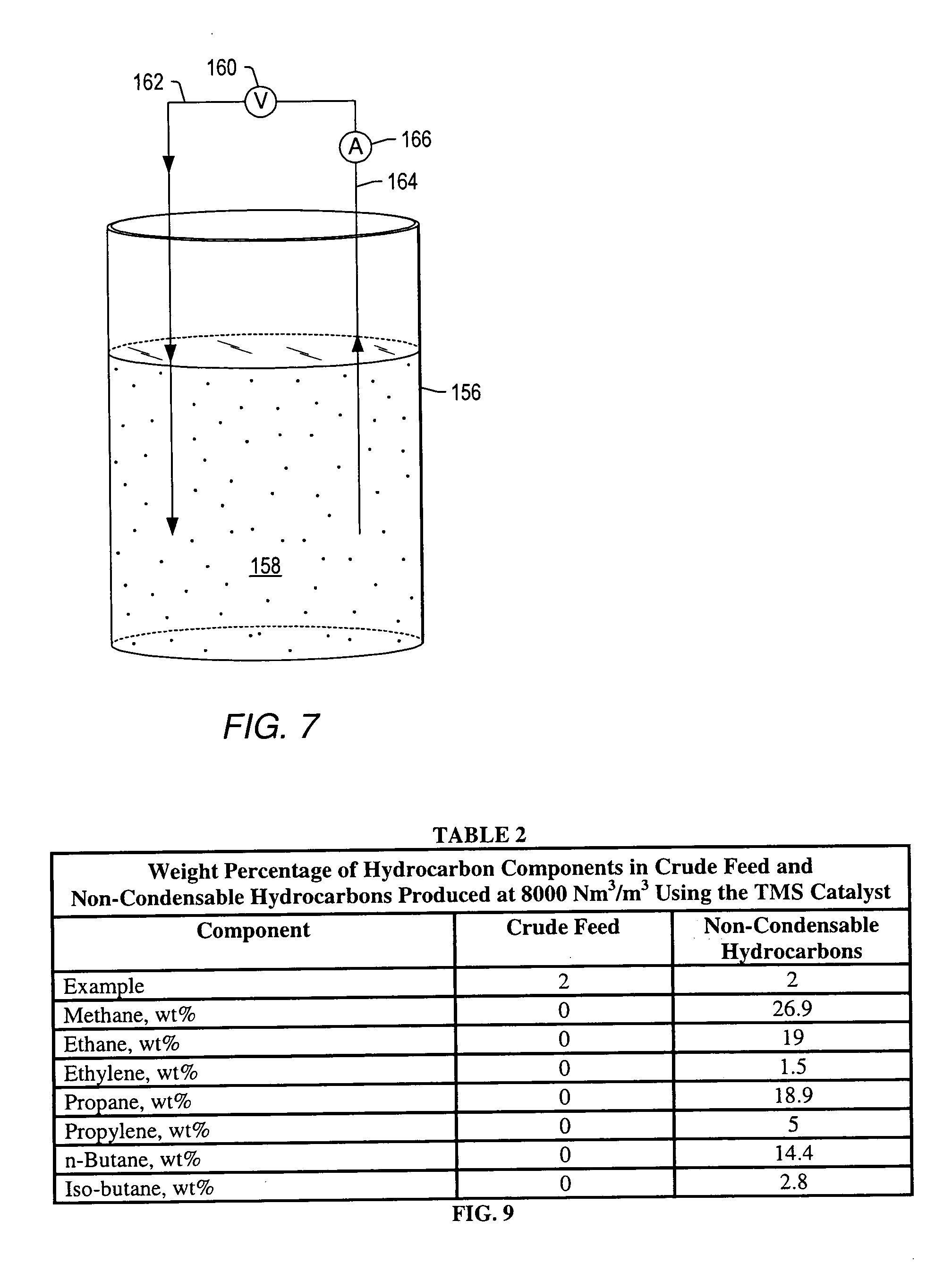

Systems and methods of producing a crude product

Contact of a crude feed with one or more catalysts produces a total product that includes a crude product. The crude feed has a residue content of at least 0.2 grams of residue per gram of crude feed. At least a portion of the crude product may be produced as a vapor. The crude product is a liquid mixture at 25° C. and 0.101 MPa. One or more properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed.

Owner:SHELL OIL CO

Honeycomb filter for purifying exhaust gases, adhesive, coating material, and manufacturing method of honeycomb filter for purifying exhaust gases

InactiveUS20080241015A1Increased durabilityHigh strengthCombination devicesPhysical/chemical process catalystsParticulatesAdhesive

Owner:IBIDEN CO LTD

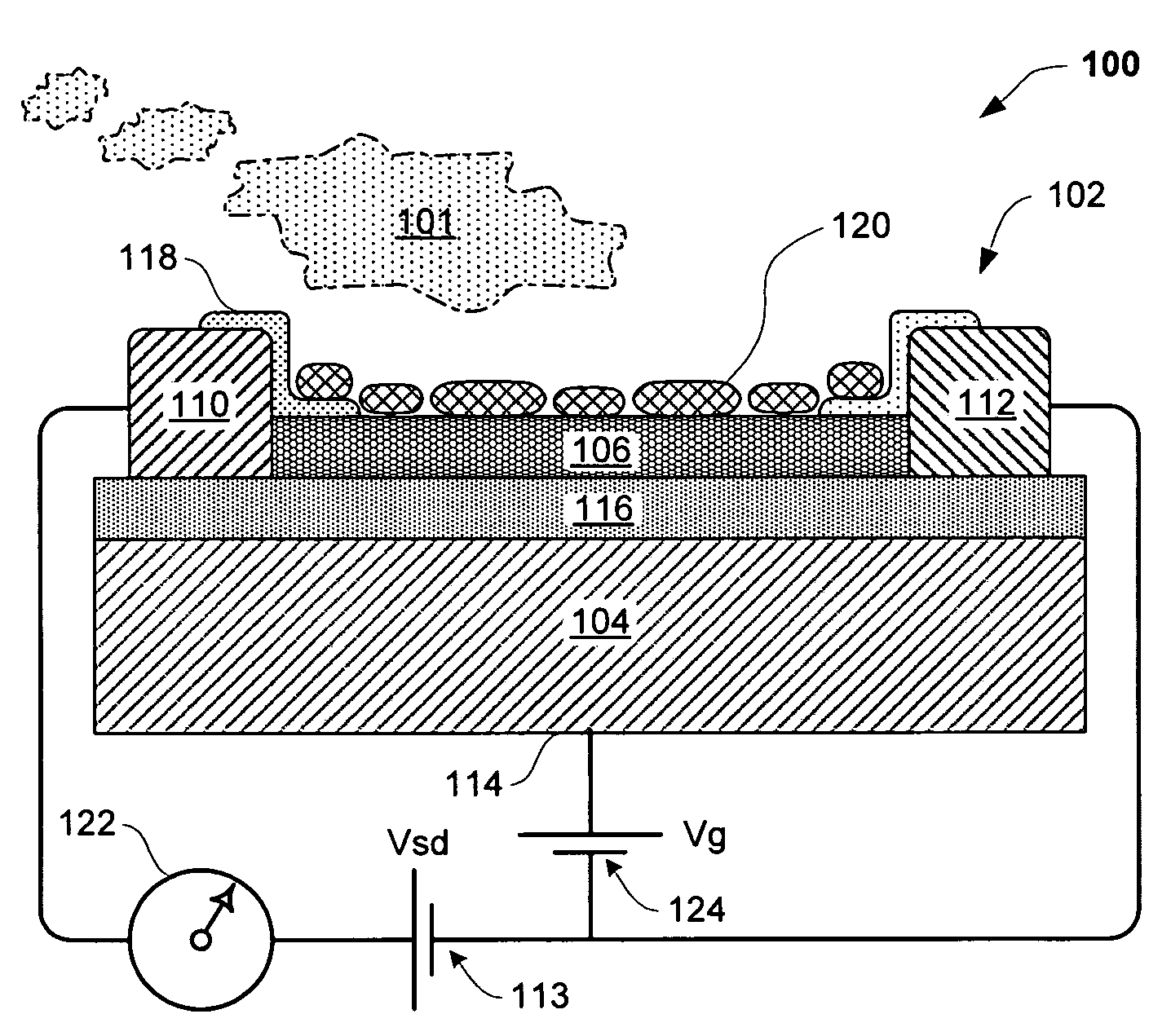

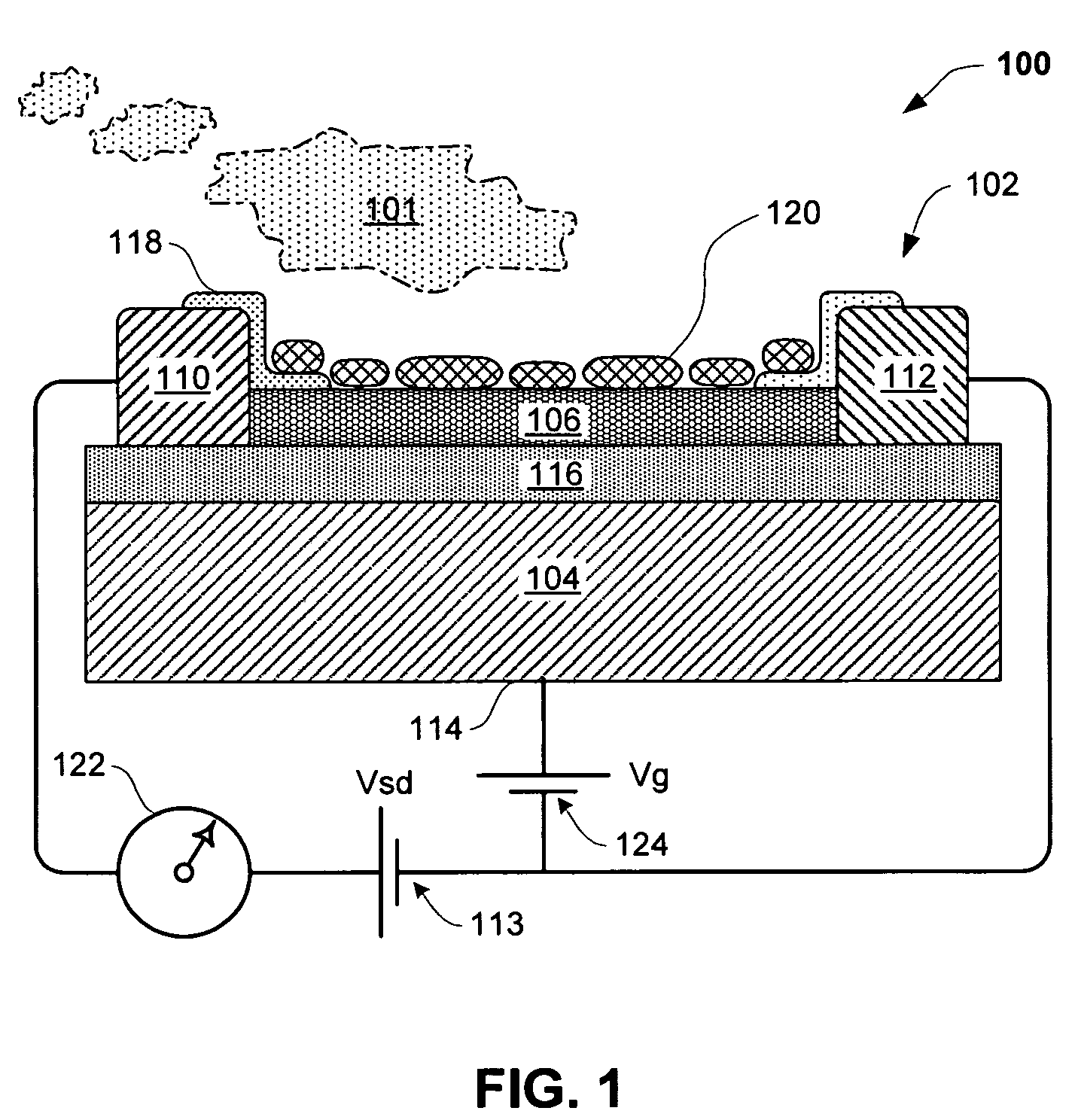

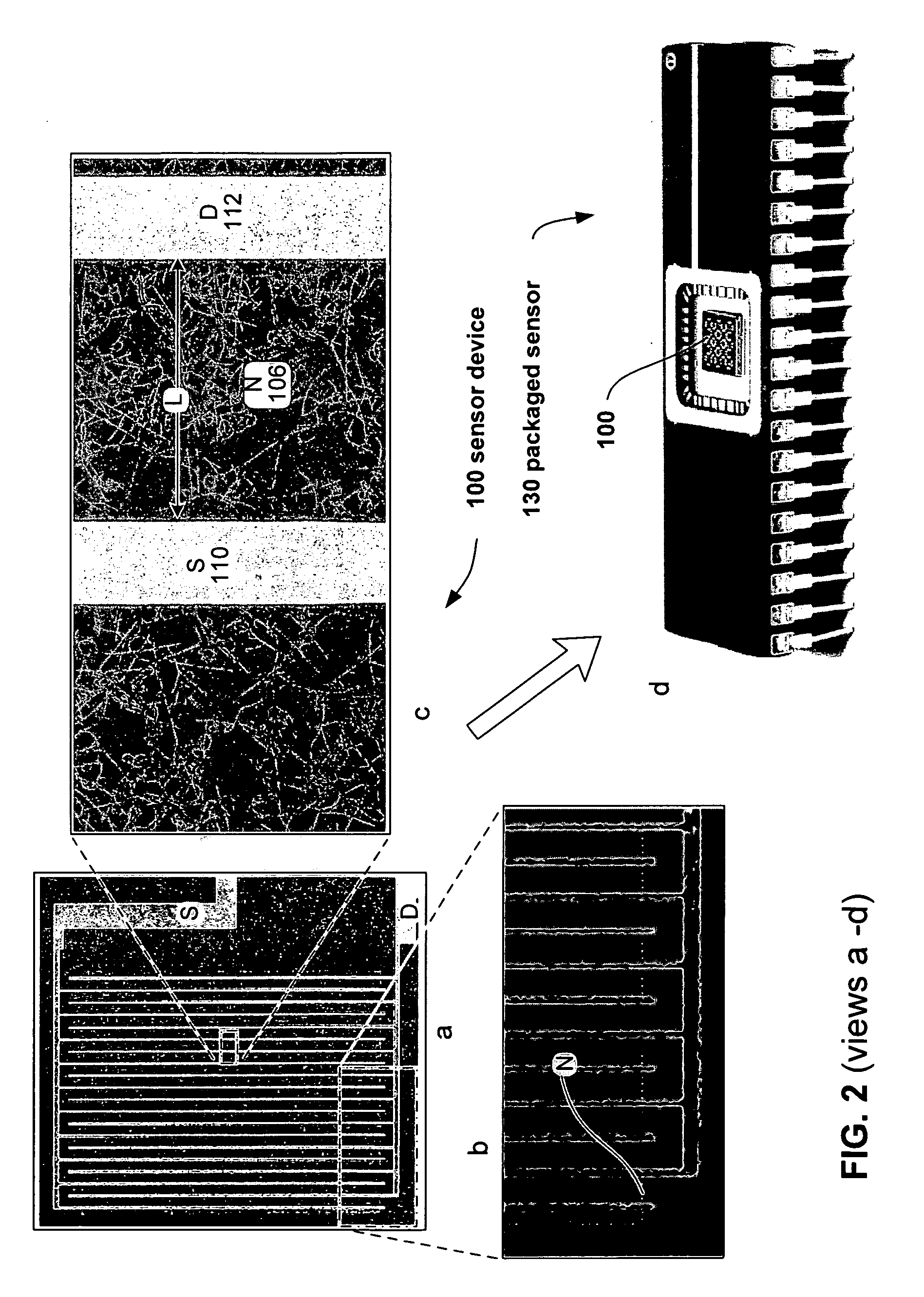

Sensor having a thin-film inhibition layer, nitric oxide converter and monitor

ActiveUS20080221806A1High sensitivityLarge dynamic rangeMaterial nanotechnologyTemperatue controlDiseaseVolatiles

Sensors and detection systems suitable for measuring analytes, such as biomolecule, organic and inorganic species, including environmentally and medically relevant volatiles and gases, such as NO, NO2, CO2, NH3, H2, CO and the like, are provided. Certain embodiments of nanostructured sensor systems are configured for measurement of medically important gases in breath. Applications include the measurement of endogenous nitric oxide (NO) in breath, such as for the monitoring or diagnosis of asthma and other pulmonary conditions.

Owner:NANOMIX

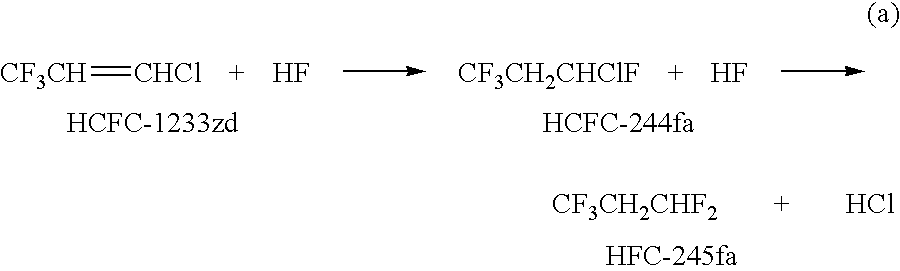

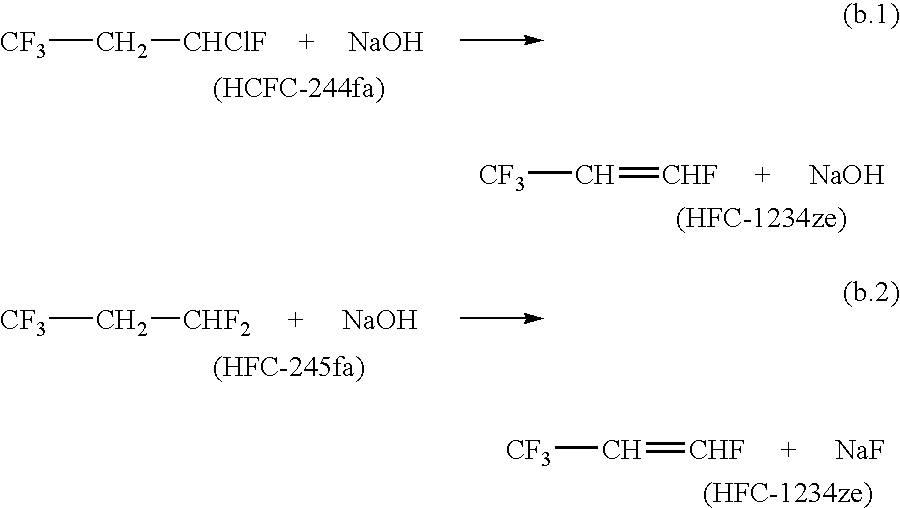

Process for the manufacture of 1,3,3,3-tetrafluoropropene

ActiveUS20050020862A1Physical/chemical process catalystsPreparation by hydrogen halide split-offPentafluoropropaneChemistry

The invention provides an economic process for the manufacture of 1,3,3,3-tetrafluoropropene (HFC-1234ze) by a two stage process. A hydrofluorination of 1-chloro-3,3,3-trifluoropropene (HCFC-1233zd) into 1-chloro-1,3,3,3-tetrafluoropropane (HCFC-244fa) and 1,1,1,3,3-pentafluoropropane (HFC-245fa) is conducted, followed by the dehydrochlorination of HCFC-244fa and dehydrofluorination of HFC-245fa into HFC-1234ze.

Owner:HONEYWELL INT INC

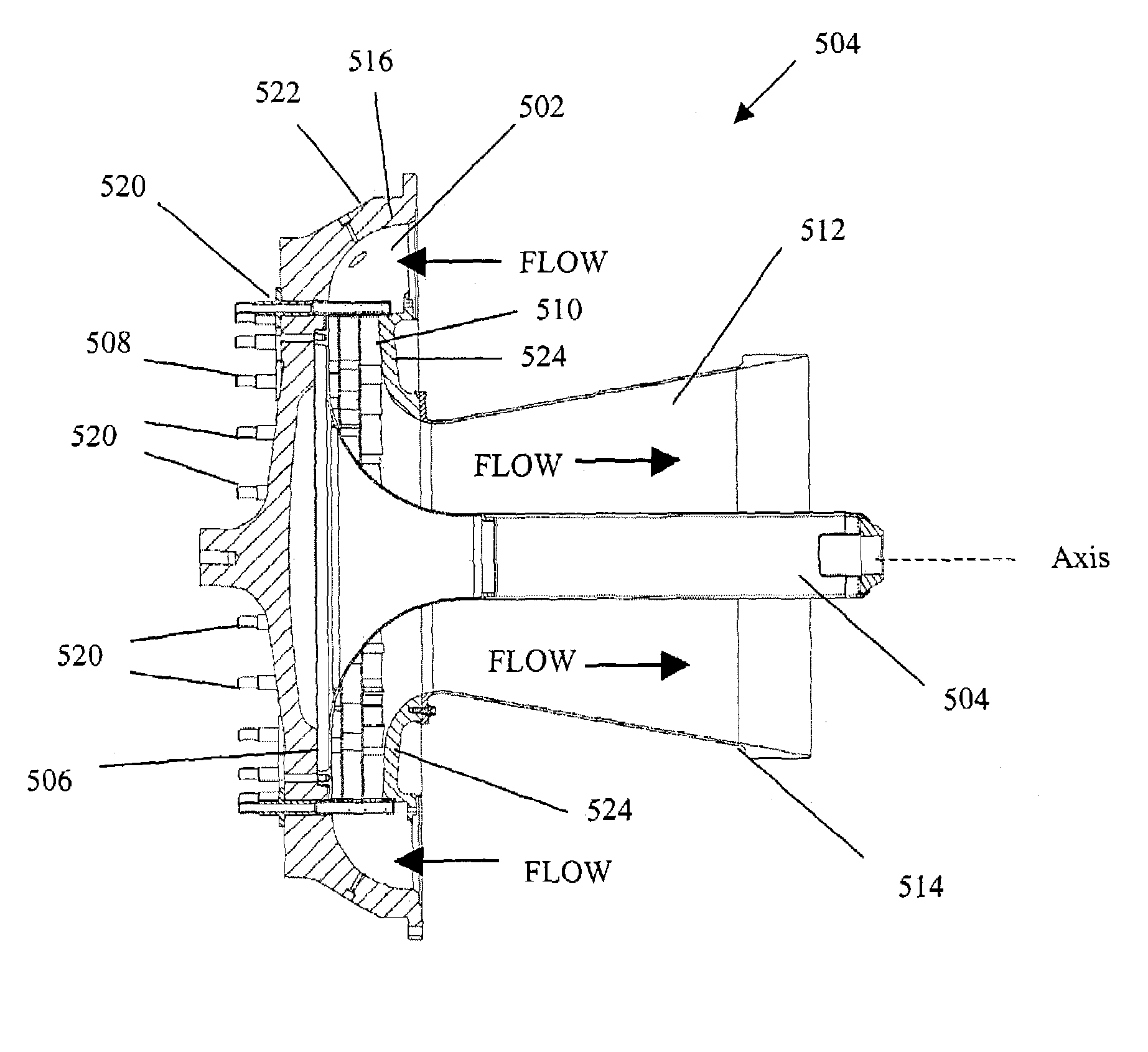

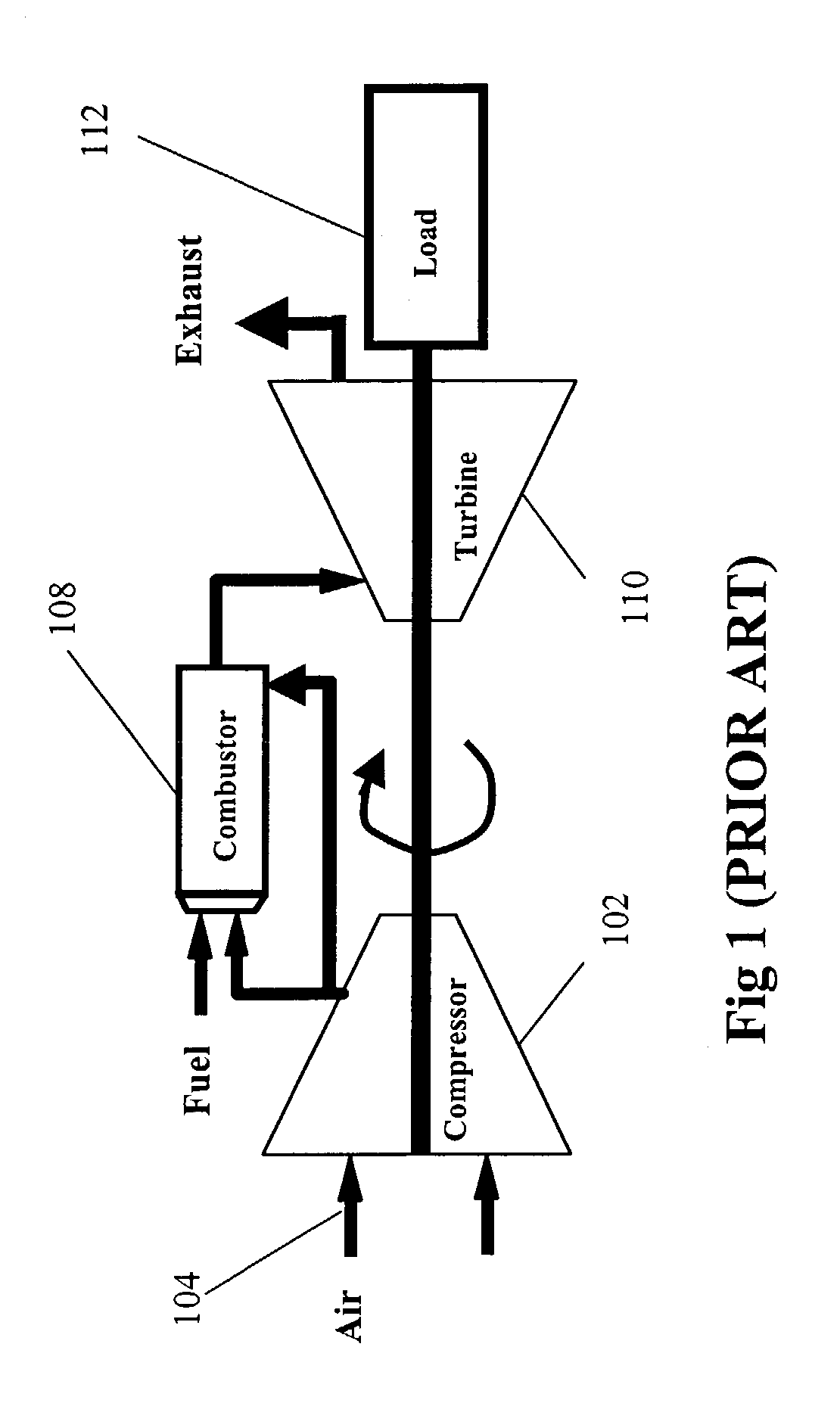

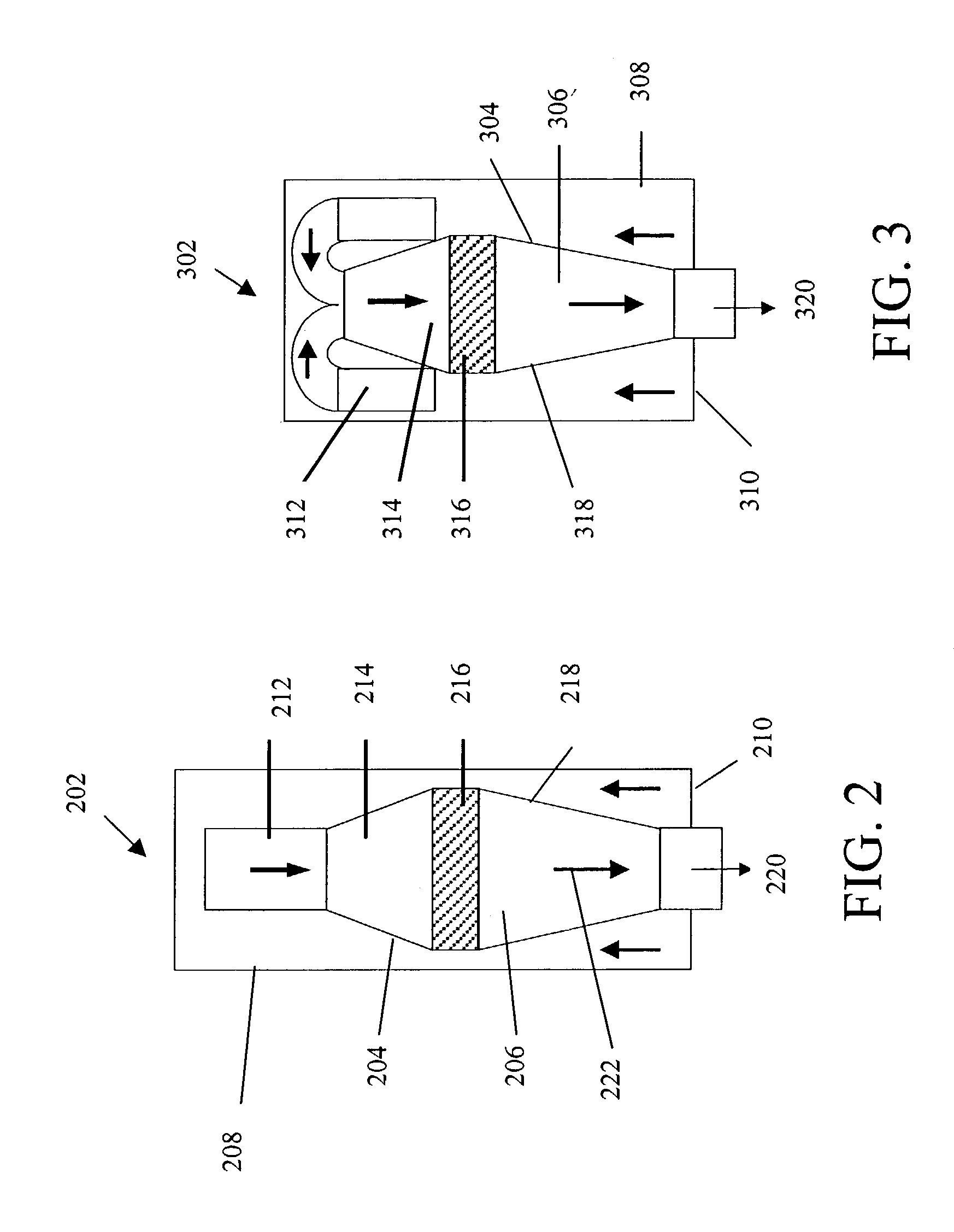

Fuel-air premixing system for a catalytic combustor

InactiveUS7093445B2Continuous combustion chamberTurbine/propulsion fuel supply systemsCombustion systemHybrid system

Disclosed is a unique fuel and air premixing system for a gas turbine catalytic combustion system. The mixer utilizes a multi-channel counter-rotating swirler with aerodynamically shaped fuel pegs located upstream of the swirler. The premixing system provides the downstream catalyst with a fuel-air mixture sufficiently uniform for proper catalyst operation and wide operating limits. Features have been incorporated in the system to make it resistant to flameholding.

Owner:KAWASAKI HEAVY IND LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com