Patents

Literature

4185results about How to "Solve the blockage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

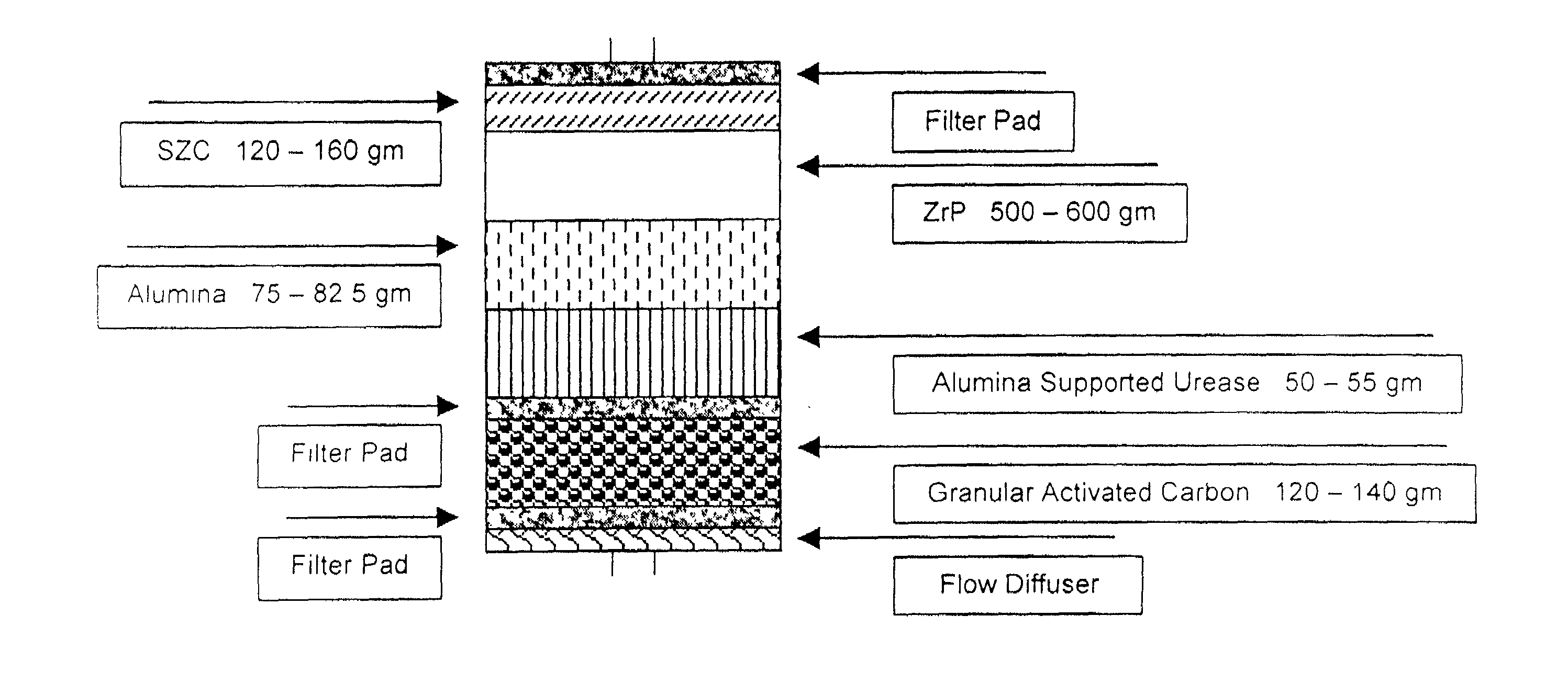

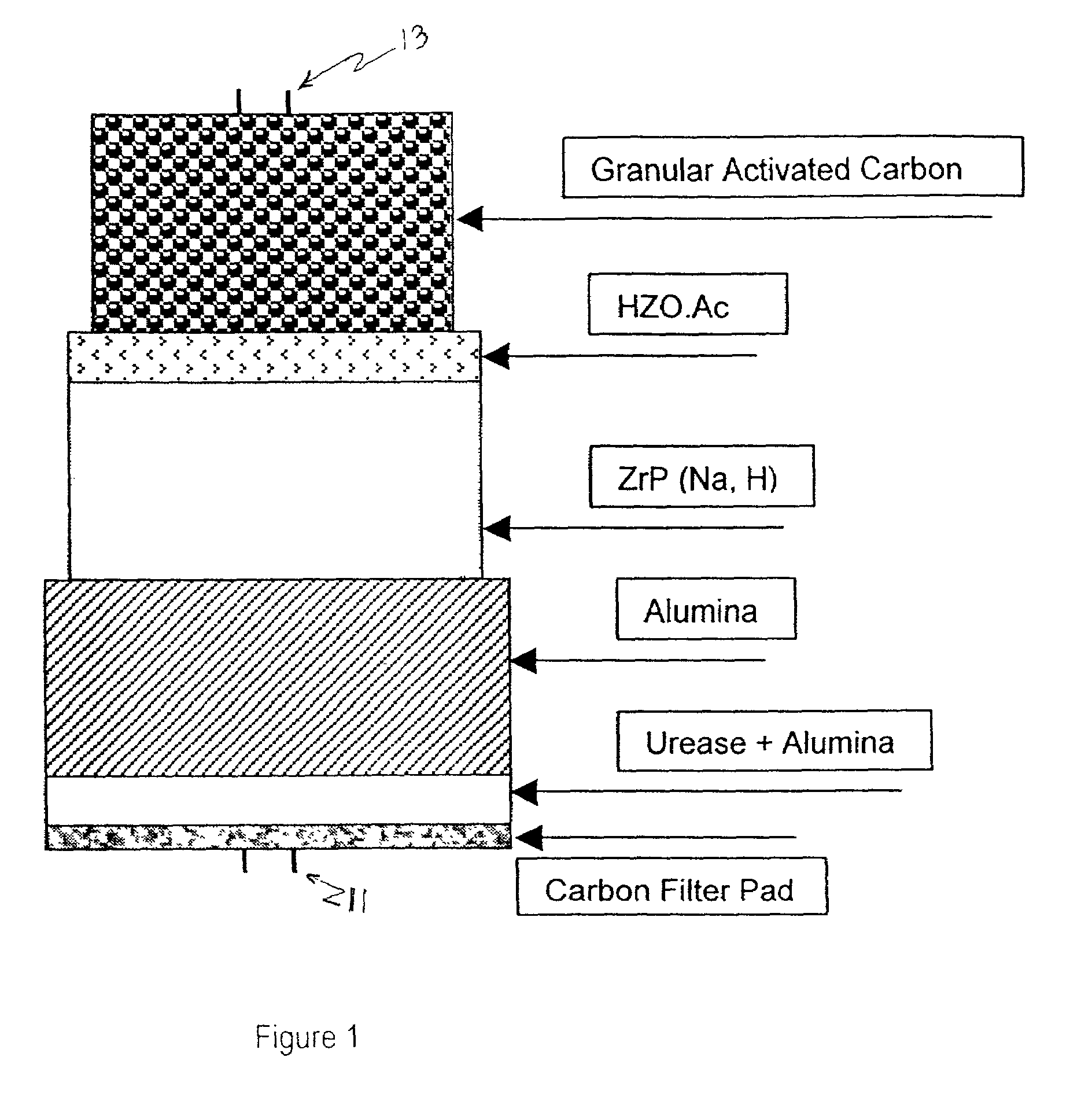

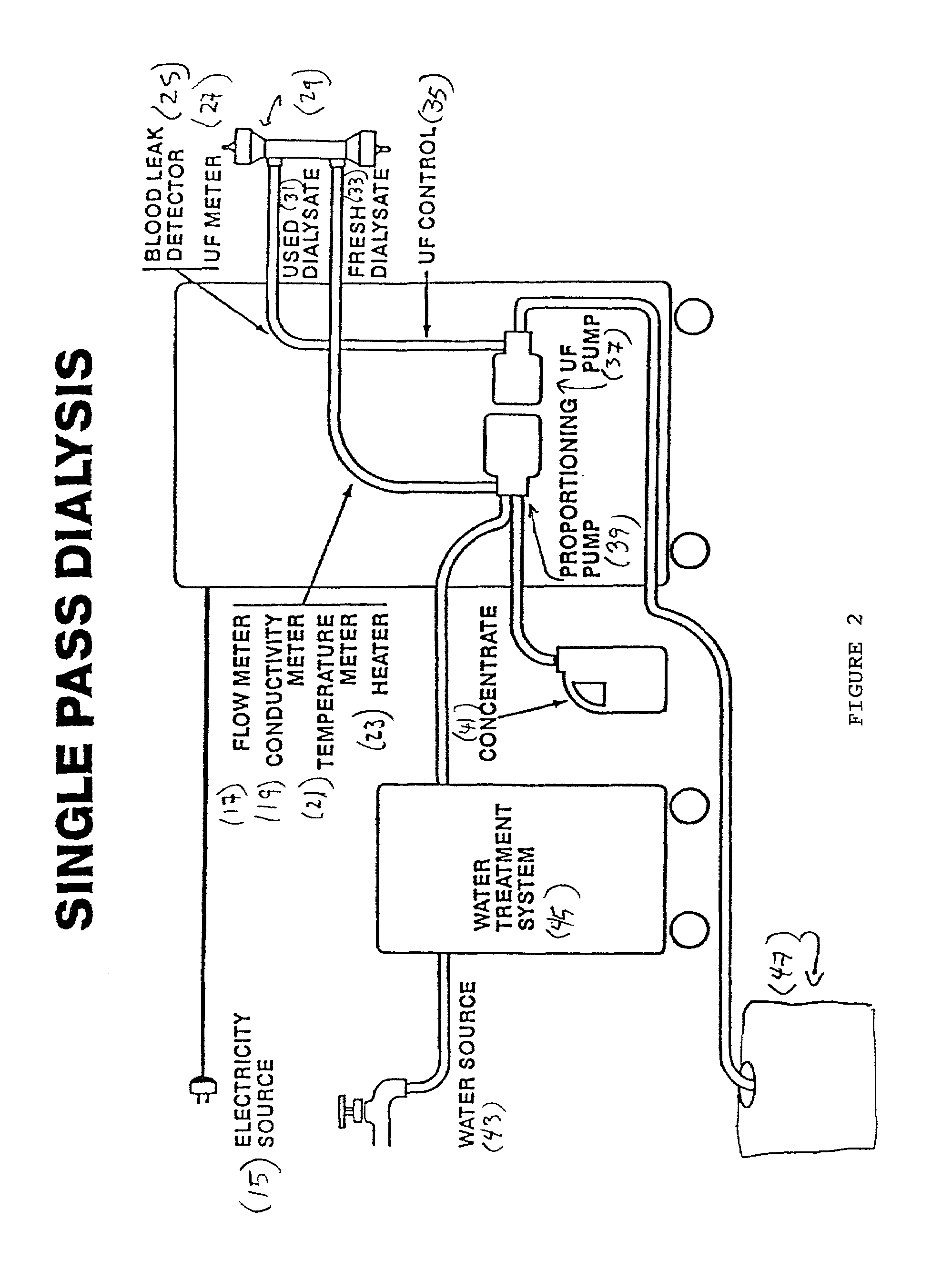

Cartridges useful in cleaning dialysis solutions

InactiveUS7033498B2Avoid a lotSolve the blockageZirconium compoundsLoose filtering material filtersMedicineHemodialysis membrane

Owner:RENAL SOLUTIONS

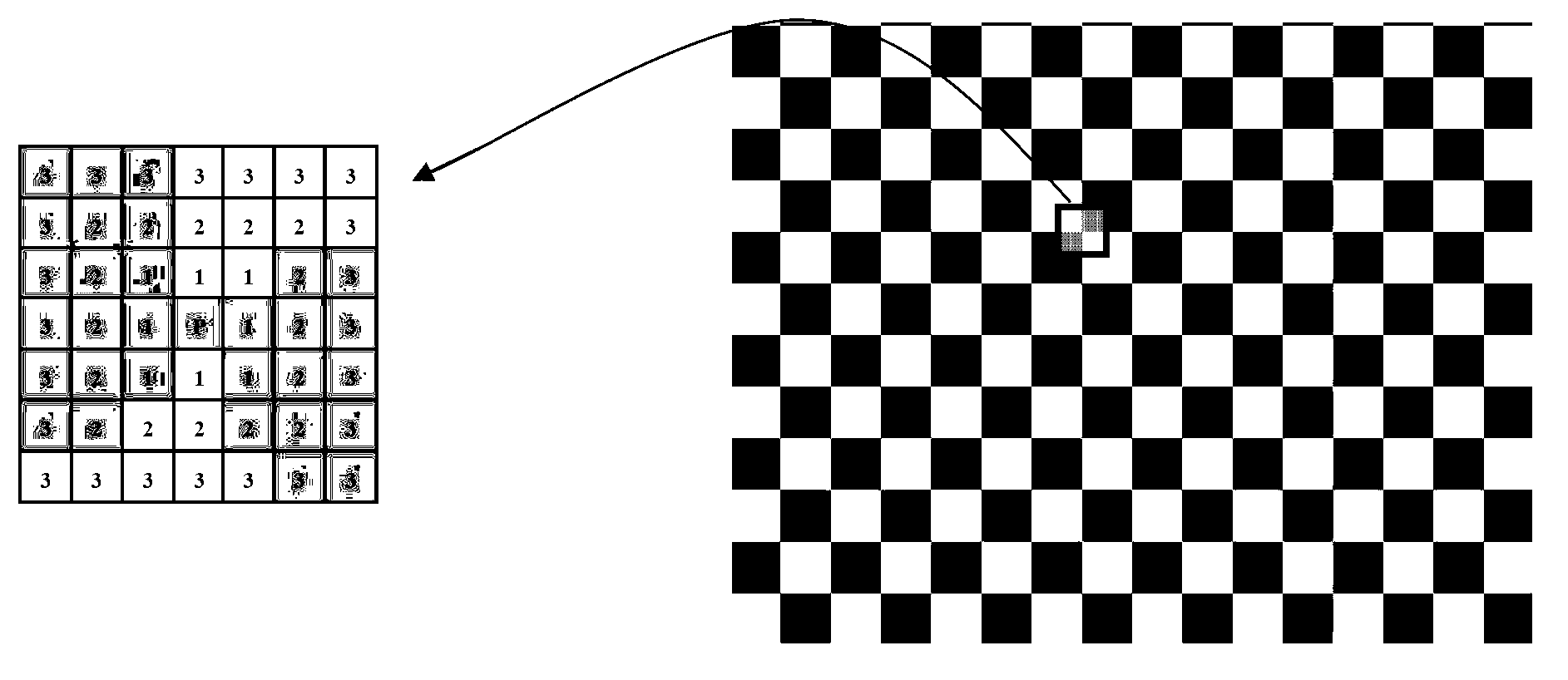

Method for automatic correction and tiled display of plug-and-play large screen projections

ActiveCN103019643ASmart and Simple PreprocessingEasy to detectTelevision system detailsProjectorsLarge screenFeature detection

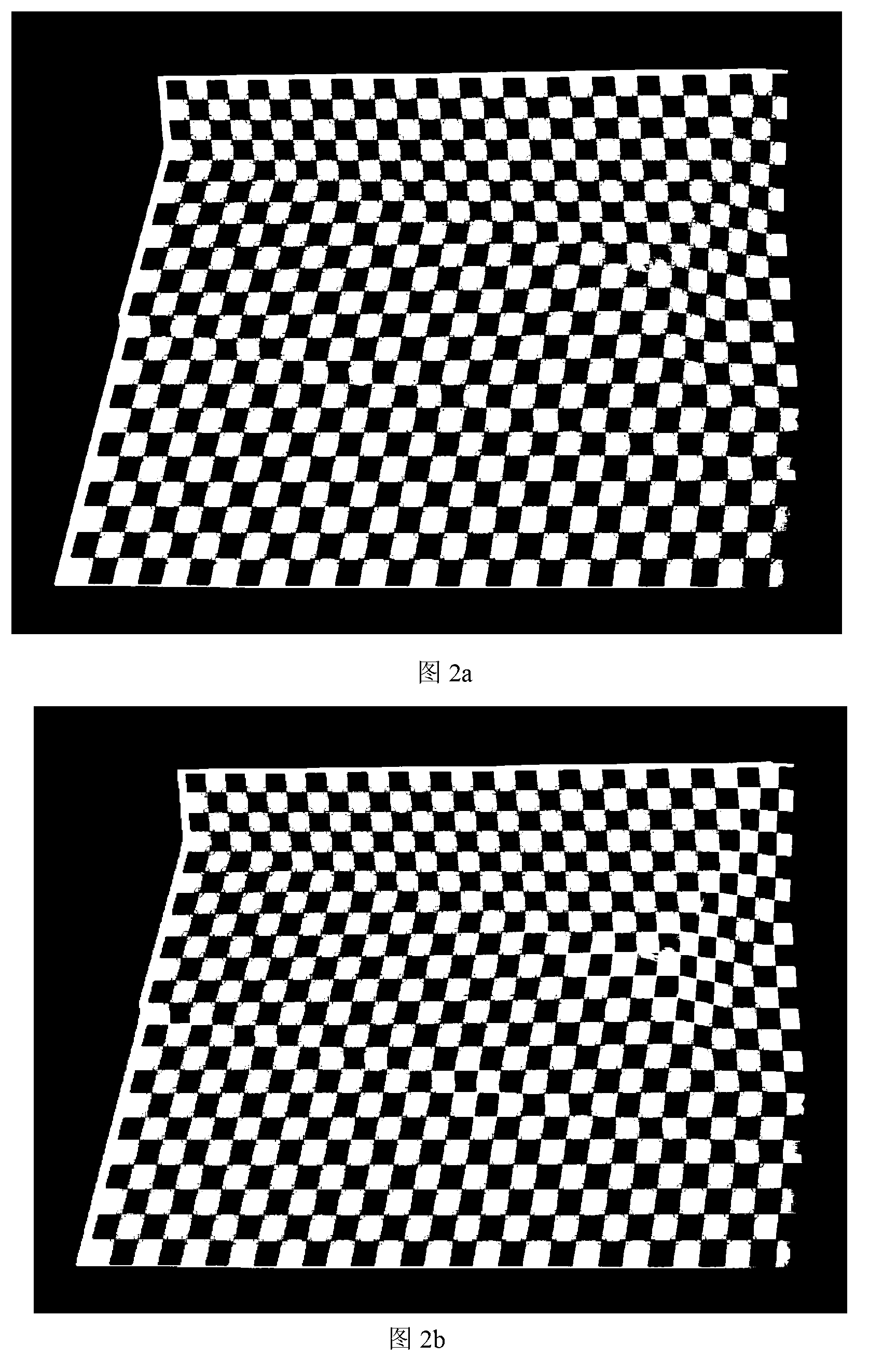

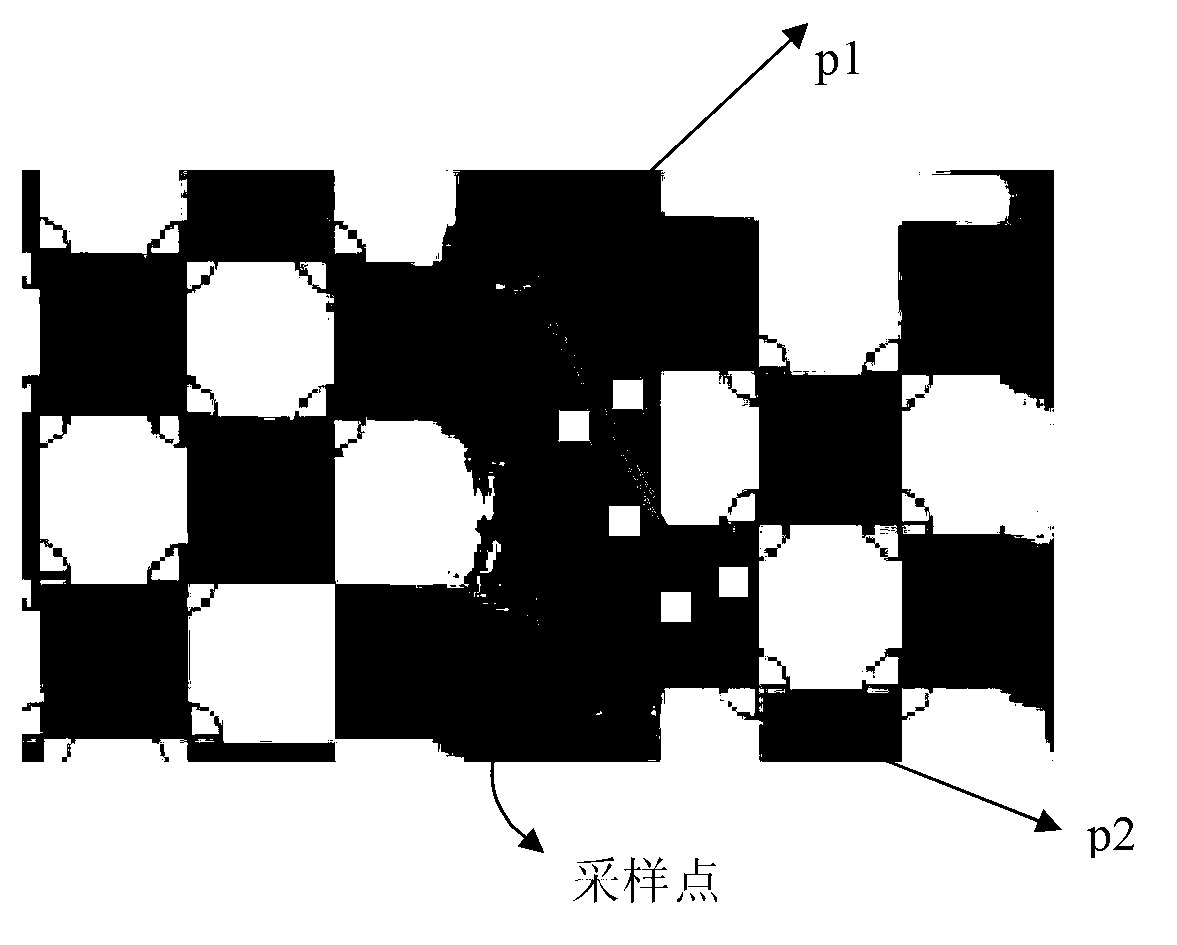

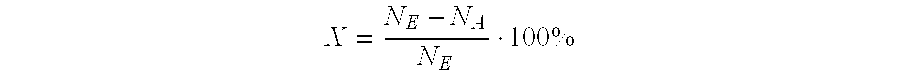

The invention discloses a method for automatic correction and tiled display of plug-and-play large screen projections. The method comprises the steps as follows: adaptively generating a checker pattern with a certain resolution ratio, projecting by projectors in sequence, capturing by cameras, carrying out feature detection and identification on complicated projection surfaces or checkers under the illumination condition with a multi-feature detection method based on color and geometry, and creating a Bezier curve function to represent a corresponding relation of points between projector images and camera images; and obtaining effective display areas for screen projection with a quick approach method, determining a corresponding relation of the projection contents of the projectors and the display areas, carrying out geometrical distortion on the images to be projected for geometrical correction, and calculating weight values of pixels in projection overlapping areas with a distance-based nonlinear weight value distribution method for fusion of edge brightness. According to the invention, a plurality of projection images of irregular surfaces can be aligned and seamlessly spliced, and the whole method is simple and easy to use, higher in autonomy and better in seamless splicing performance.

Owner:OCEAN UNIV OF CHINA

Process for preparing a catalyst

InactiveUS6342465B1Uniform penetrationConsiderable energy savingOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPowder mixtureActive component

A process for preparing a catalyst which has a catalytically active coating of high surface area finely divided materials and catalytically active components on an inert carrier structure. A powder mixture of the finely divided materials used is impregnated with a solution of precursor compounds of the catalytically active components. By suitable combination of the finely divided materials and the precursor compounds and appropriate management of the impregnation process, a highly dispersed deposition and adsorption of the catalytically active components is ensured on the finely divided materials. Then ai aqueous coating dispersion is produced using the impregnated powder mixture and the carrier structure is coated therewith. The coating is then dried and calcined.

Owner:UMICORE AG & CO KG +1

Accompanying robot path planning method and system based on obstacle virtual expansion

InactiveCN108775902AChange pass valueSolve the blockageNavigational calculation instrumentsTarget-seeking controlSlide windowShortest distance

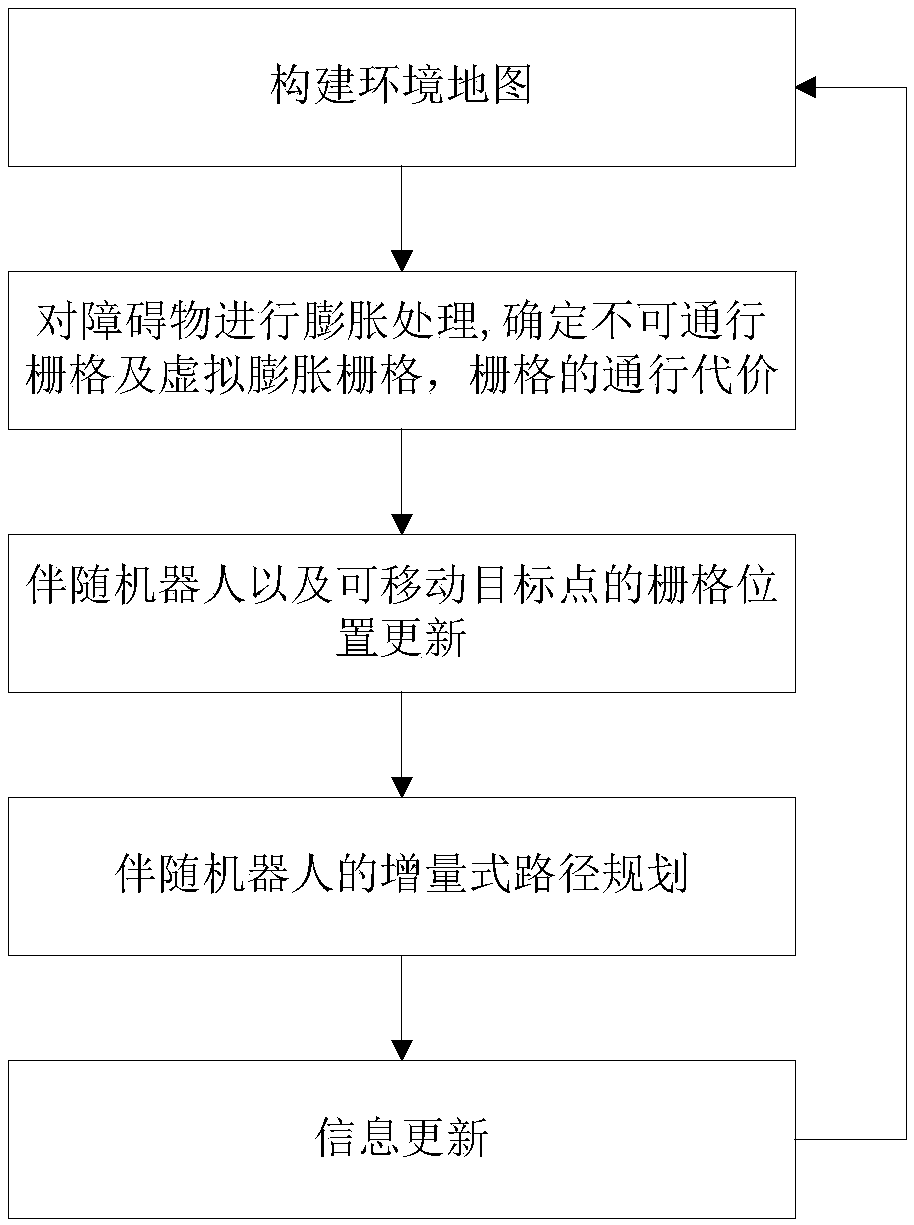

The invention discloses an accompanying robot path planning method and system based on obstacle virtual expansion. The method includes a step of constructing an environment map, namely a step of constructing a two-dimensional occupancy grid map according to an actual scene, with each grid being labeled as an obstacle zone or a walkable zone; a step of setting initial coordinate positions of an accompanying robot and a movable target in the grid map; a step of constructing a sliding window for the robot; a step of subjecting the obstacle zones to expansion processing, namely a step of performing initial expansion on grids where an obstacle is according to a shortest distance between the center of the robot and a body edge, determining the number of grid layers expanded on the basis of the minimum impassable zone, adopting the grids in the expanded zones as obstacle virtual expansion grids, and labeling the grade of danger of obstacle influences on the obstacle virtual expansion grids; and a step of planning a path for the accompanying robot based on an A* algorithm and an incremental path planning process. Incremental path updating is performed by adopting a path of the last moment,thus saving path planning time and increasing the response speed of the accompanying robot.

Owner:QILU UNIV OF TECH

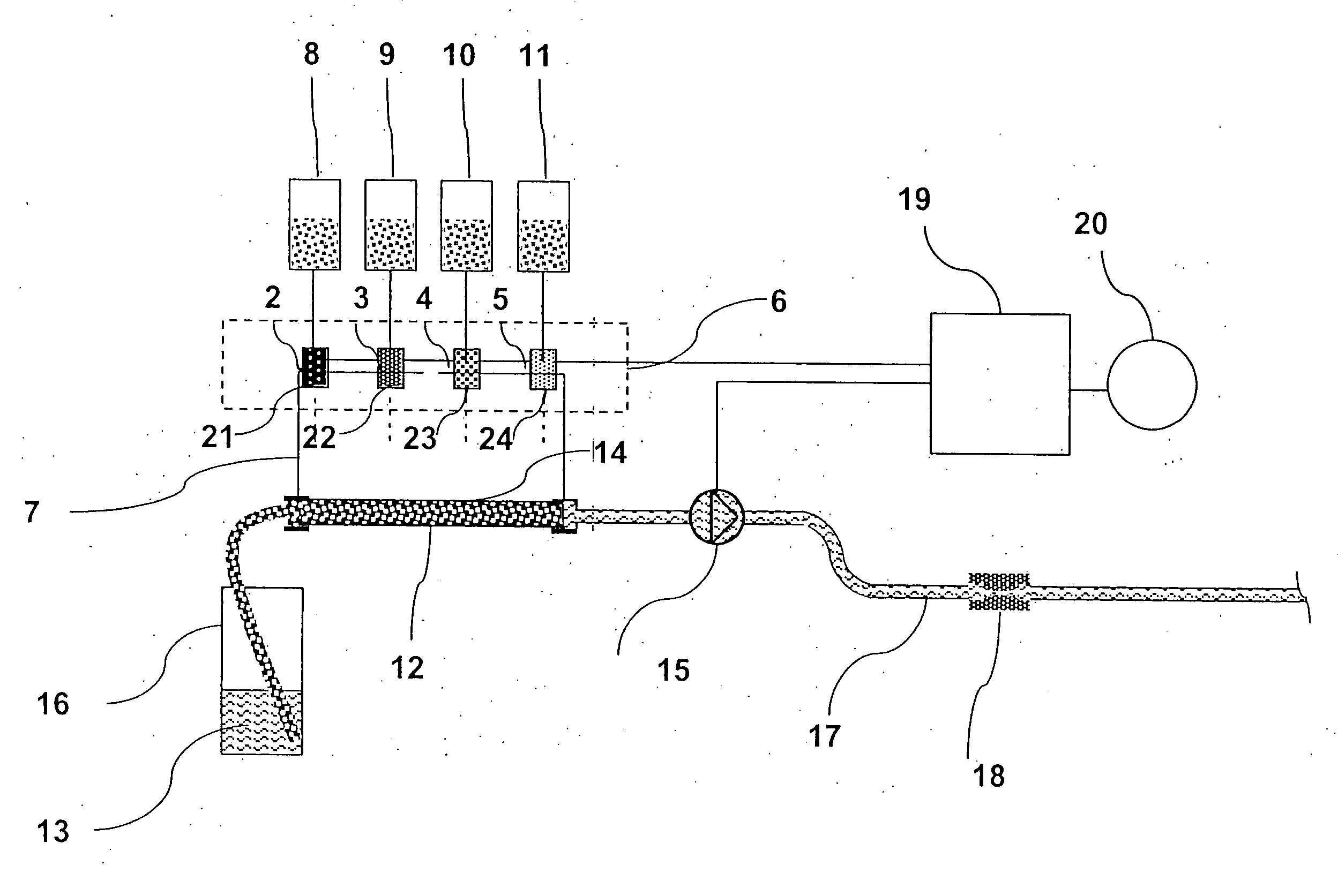

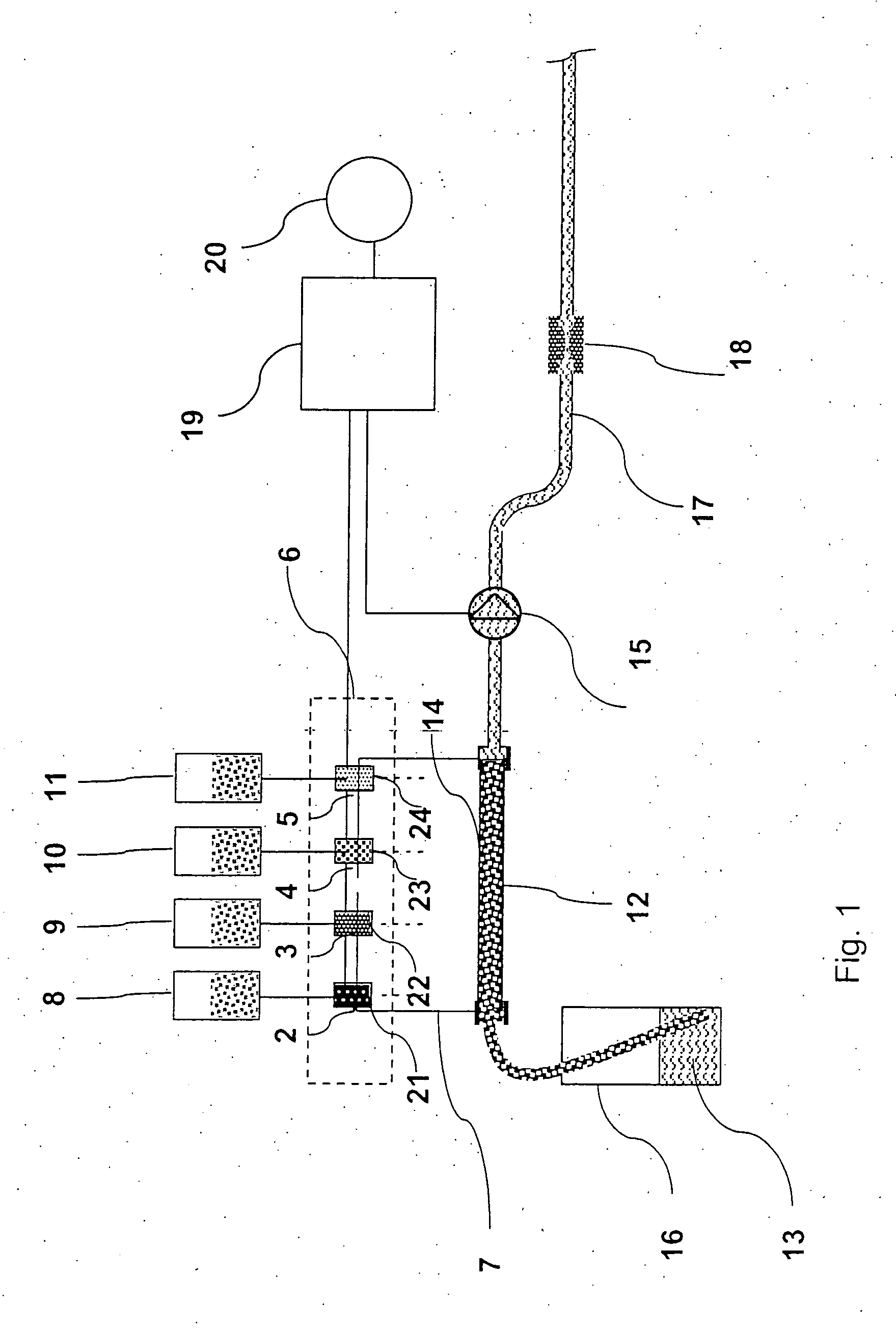

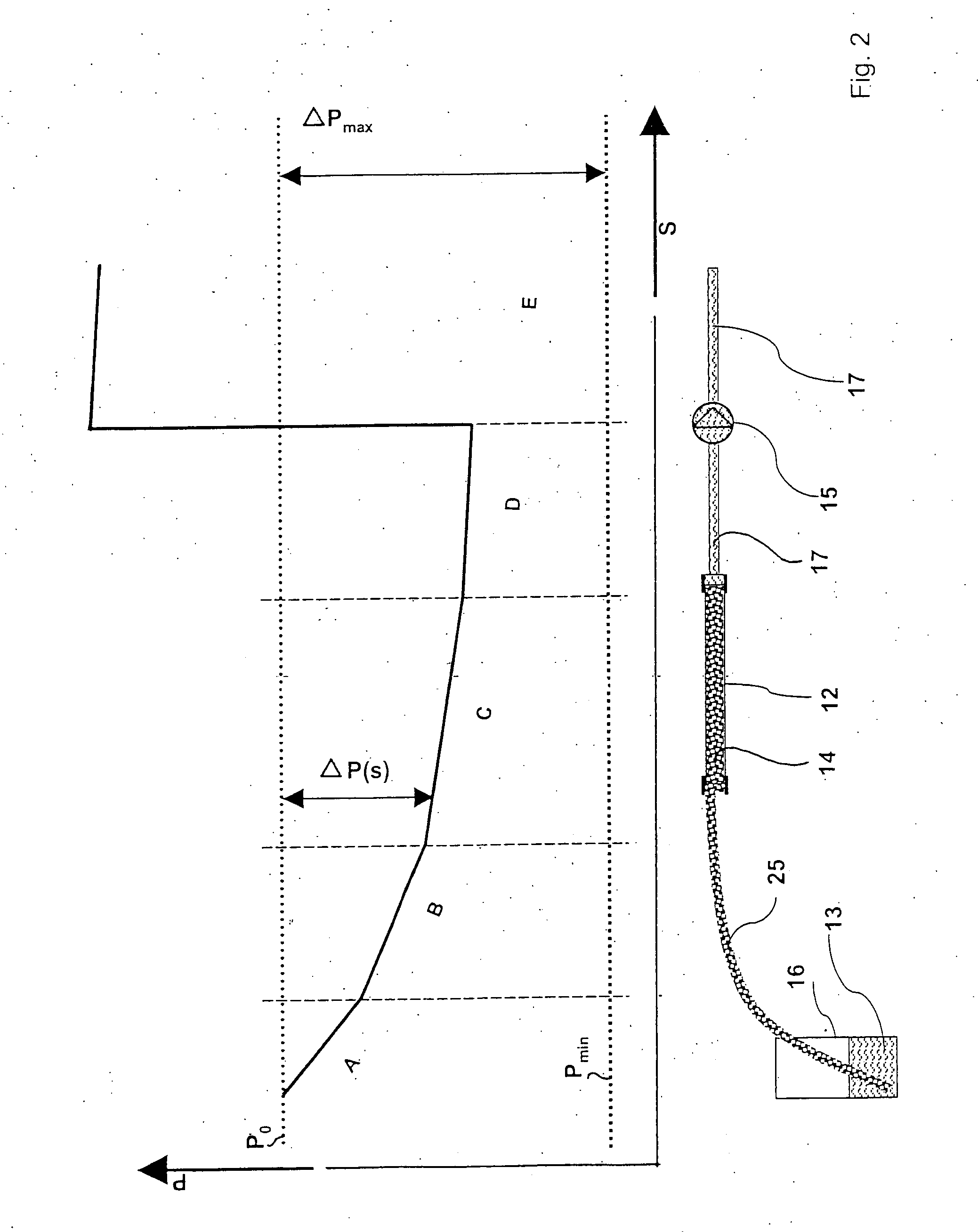

Device for dispensing substances

InactiveUS20050197622A1Solve the blockagePrevent wettingMedical devicesMixer accessoriesBiomedical engineeringMedical treatment

A drug dispensing system is provided that may be used universally and in which medical substances can be mixed with a carrier solution (13) in a simple manner. The device and system have a dispensing module (6) for medical substances and a hydrophilic nonwoven (14) with a carrier solution (13). The emission area of substance discharge openings (21, 22, 23, 24) of the dispensing module (6) are directed toward the nonwoven (14).

Owner:DRAGERWERK AG

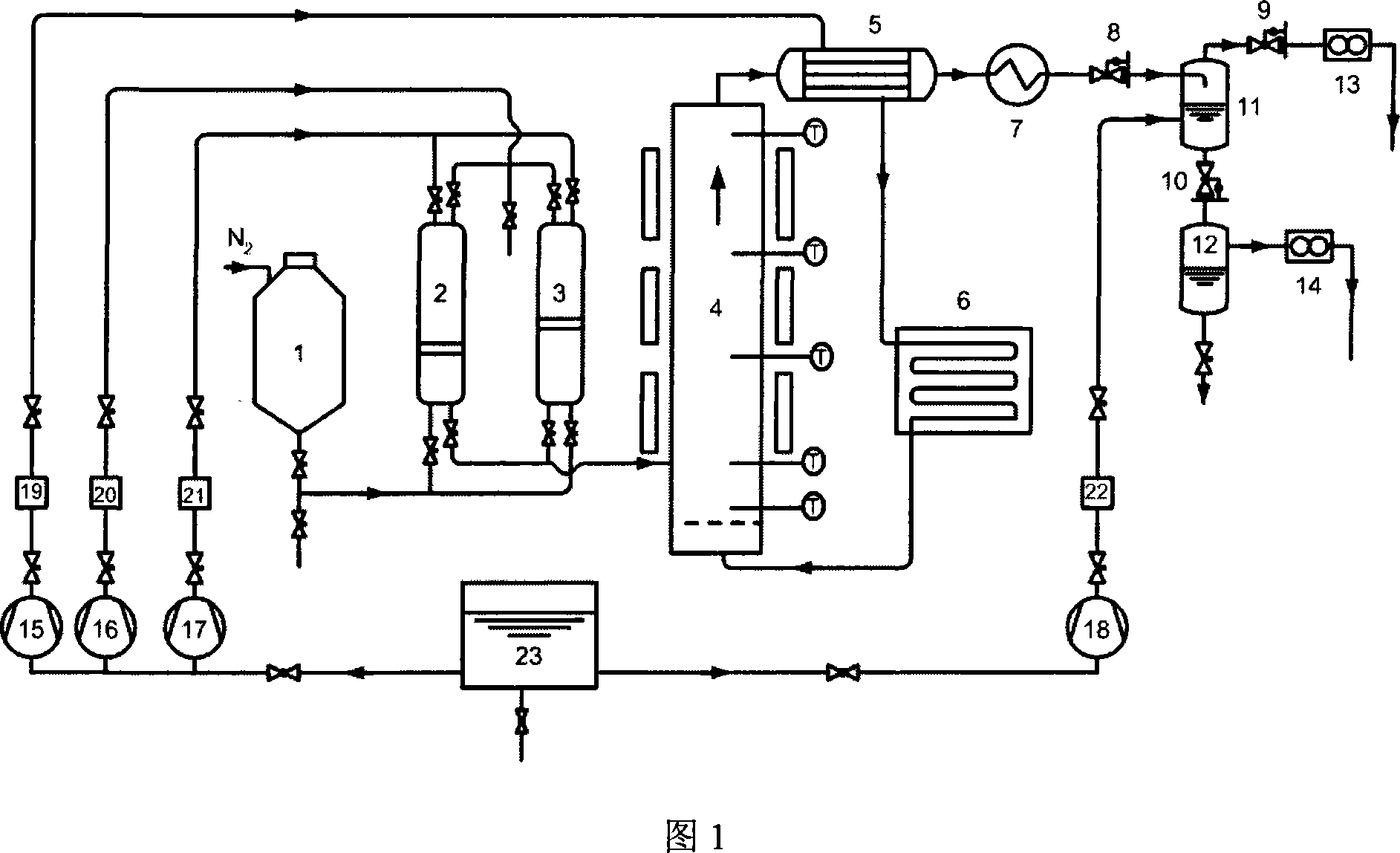

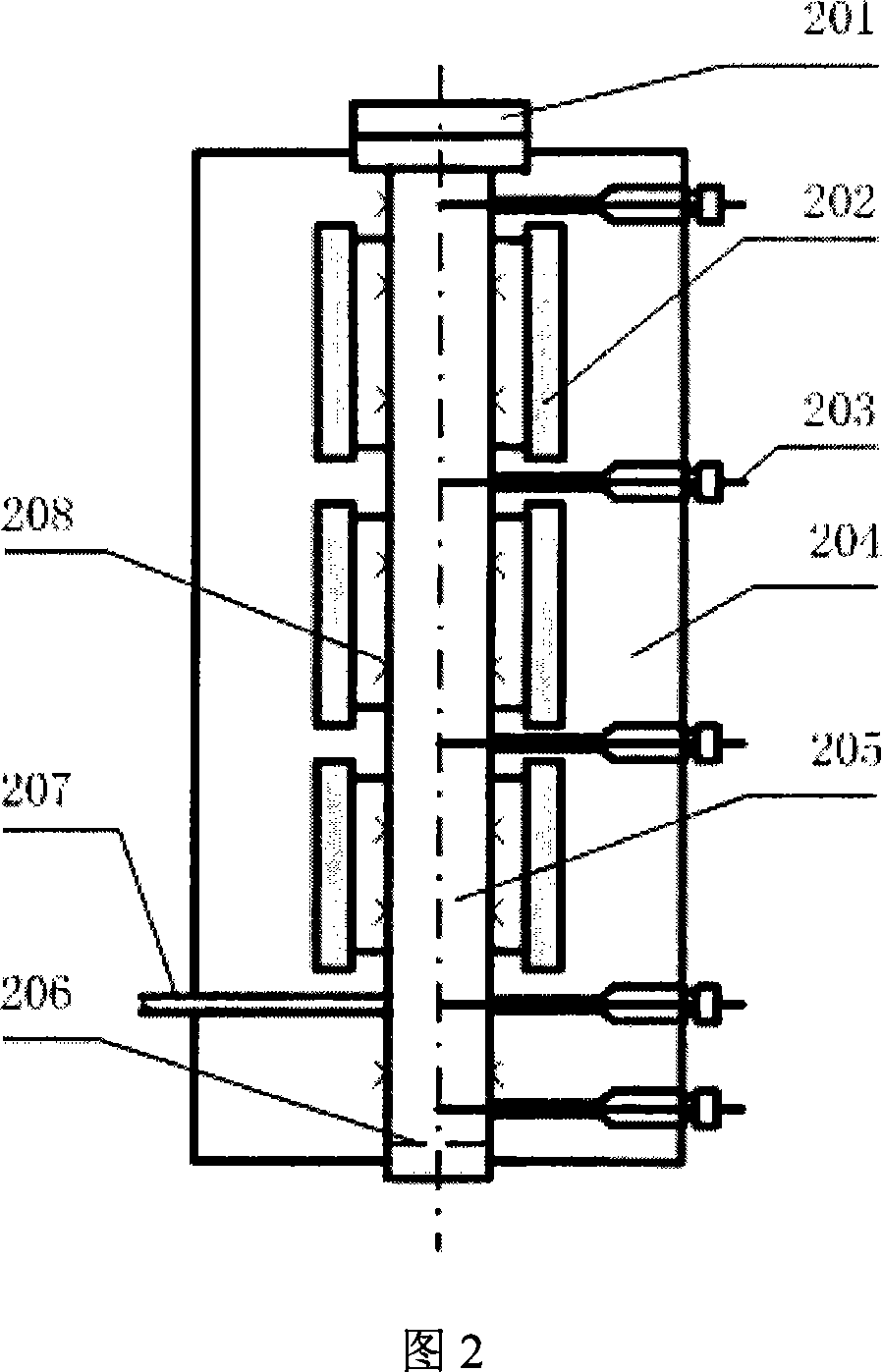

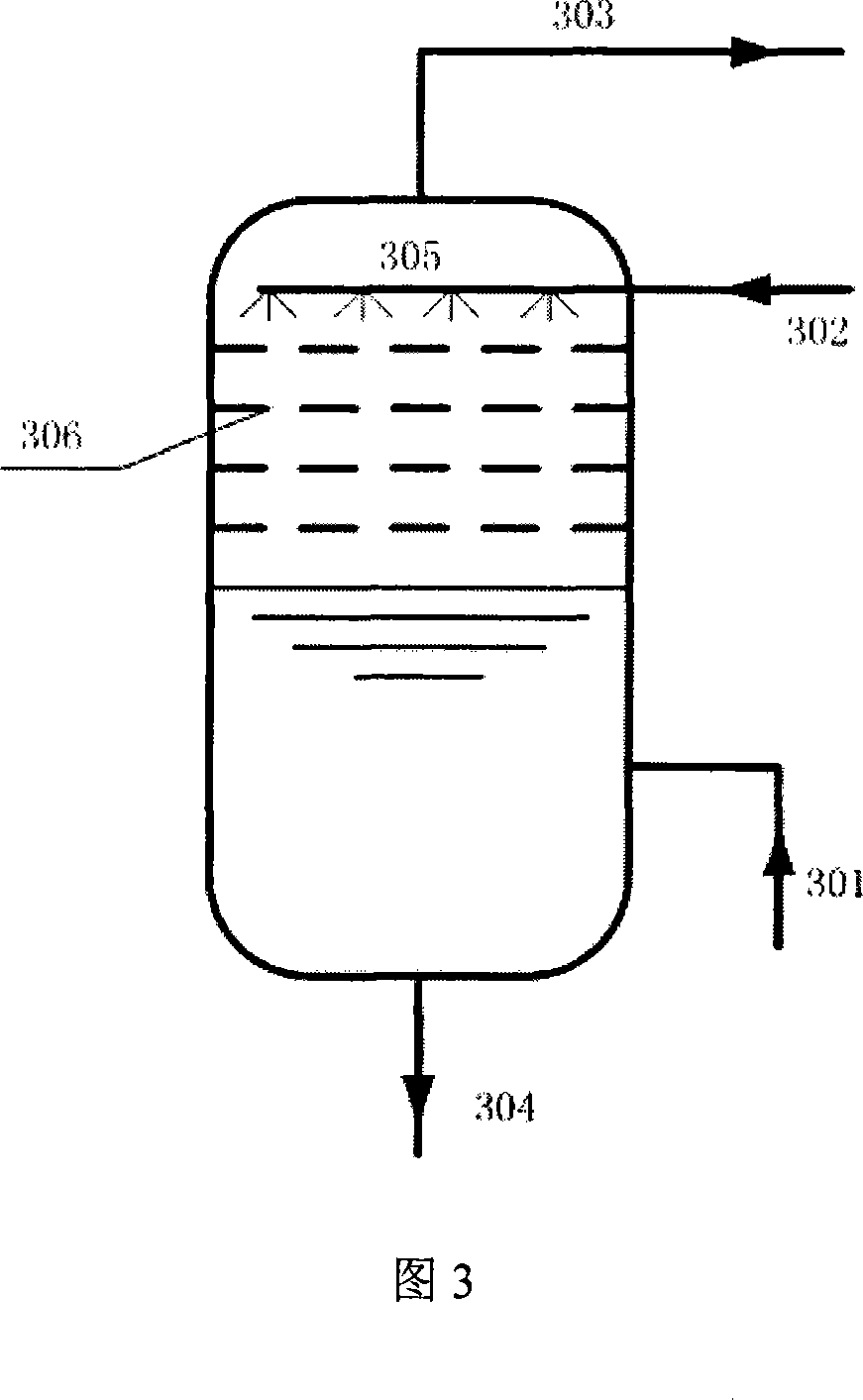

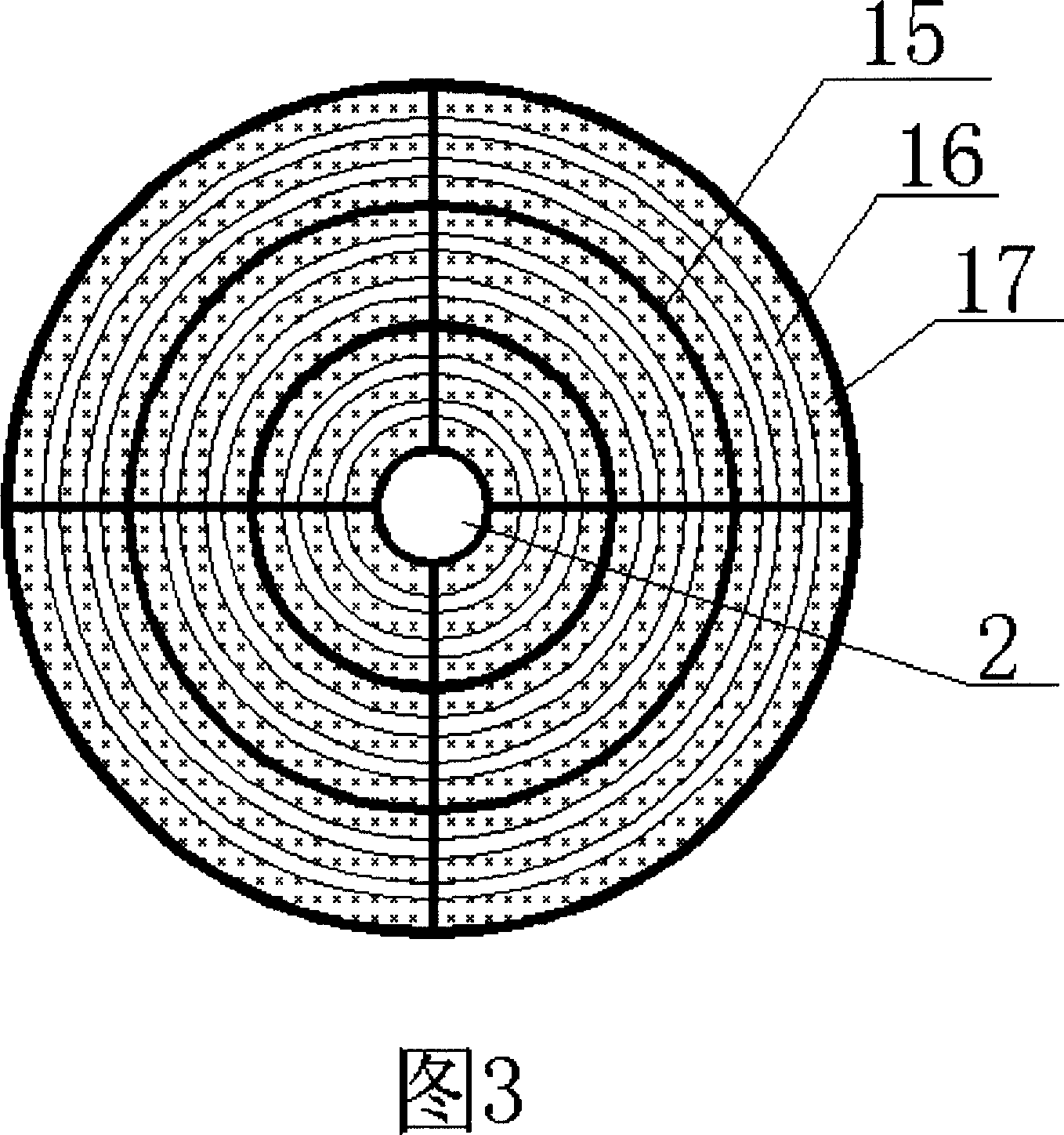

Biomass castoff supercritical water fluid bed partial oxidation hydrogen-preparation device and method

ActiveCN101058404AImprove heat transfer efficiencyConducive to centralized processing and resource utilizationSolid waste disposalHydrogen productionBiomassChemistry

The invention discloses an oxidizing and gasifying hydrogen-making device and method of hypercritical water fluid-bed part of the biological waste, which is characterized by the following: adopting hypercritical water fluid-bed reactor to prevent slagging and blocking problem in the pipe flow reactor; using high-pressure separator to generate high-pressure water to adsorb carbon dioxide in the gas product; realizing the separation of the hydrogen from the carbon dioxide; making the separated high-density carbon dioxide concentrate to be disposed and do resoursing usage conveniently; compacting the device structure; simplifying and conveniencing the operation; improving the gasifying rate of the biological waste with less pollution in the liquid product; realizing the oxidizing and gasifying fusion in the reactor; improving the biological mass transmitting rate and system energy transmitting efficiency; transmitting the biological waste into high-quality hydrogen through the method; reducing the environmental pollution; realizing the dual goals to harness pollution and make hydrogen.

Owner:陕西中核交大超洁能源技术有限公司

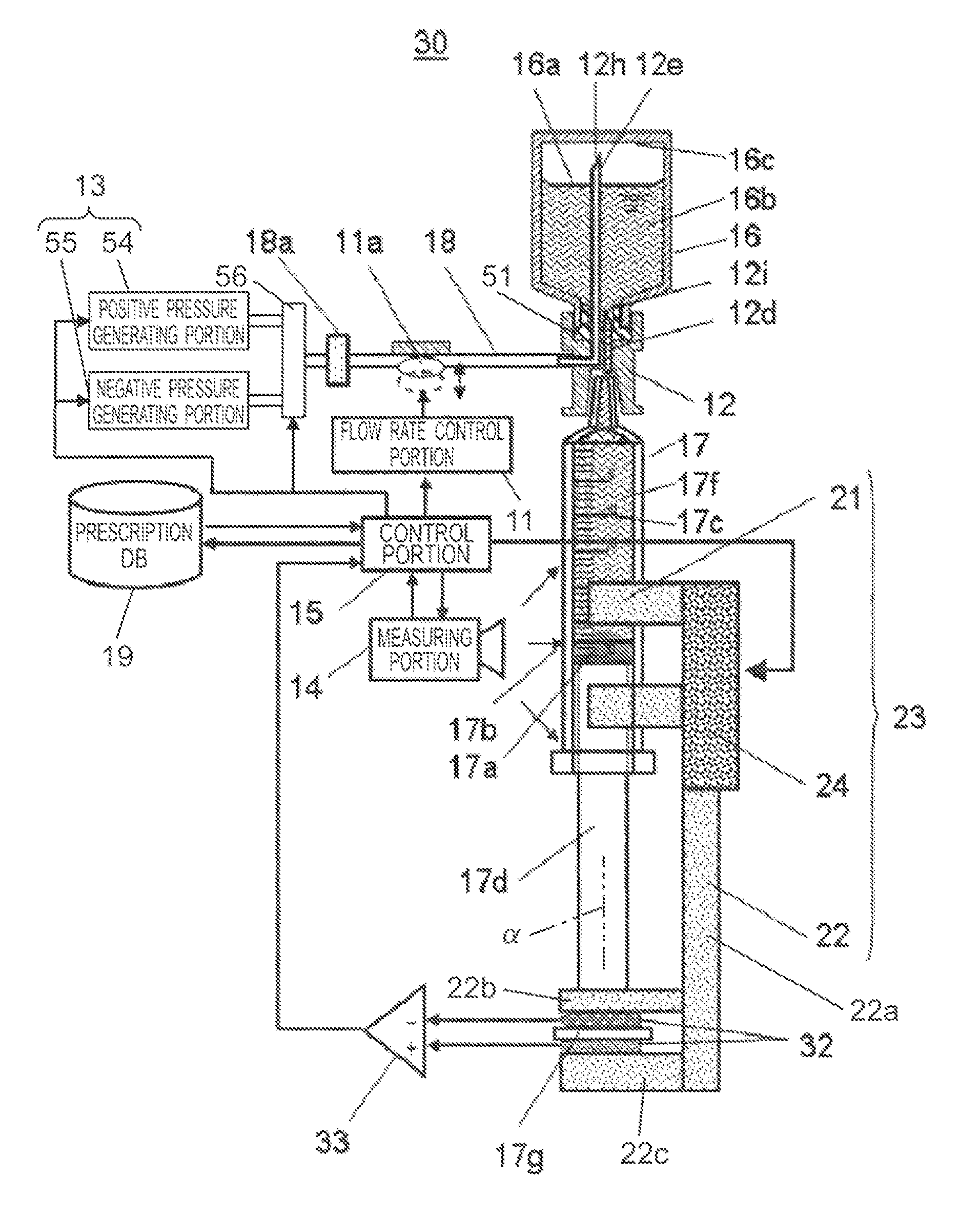

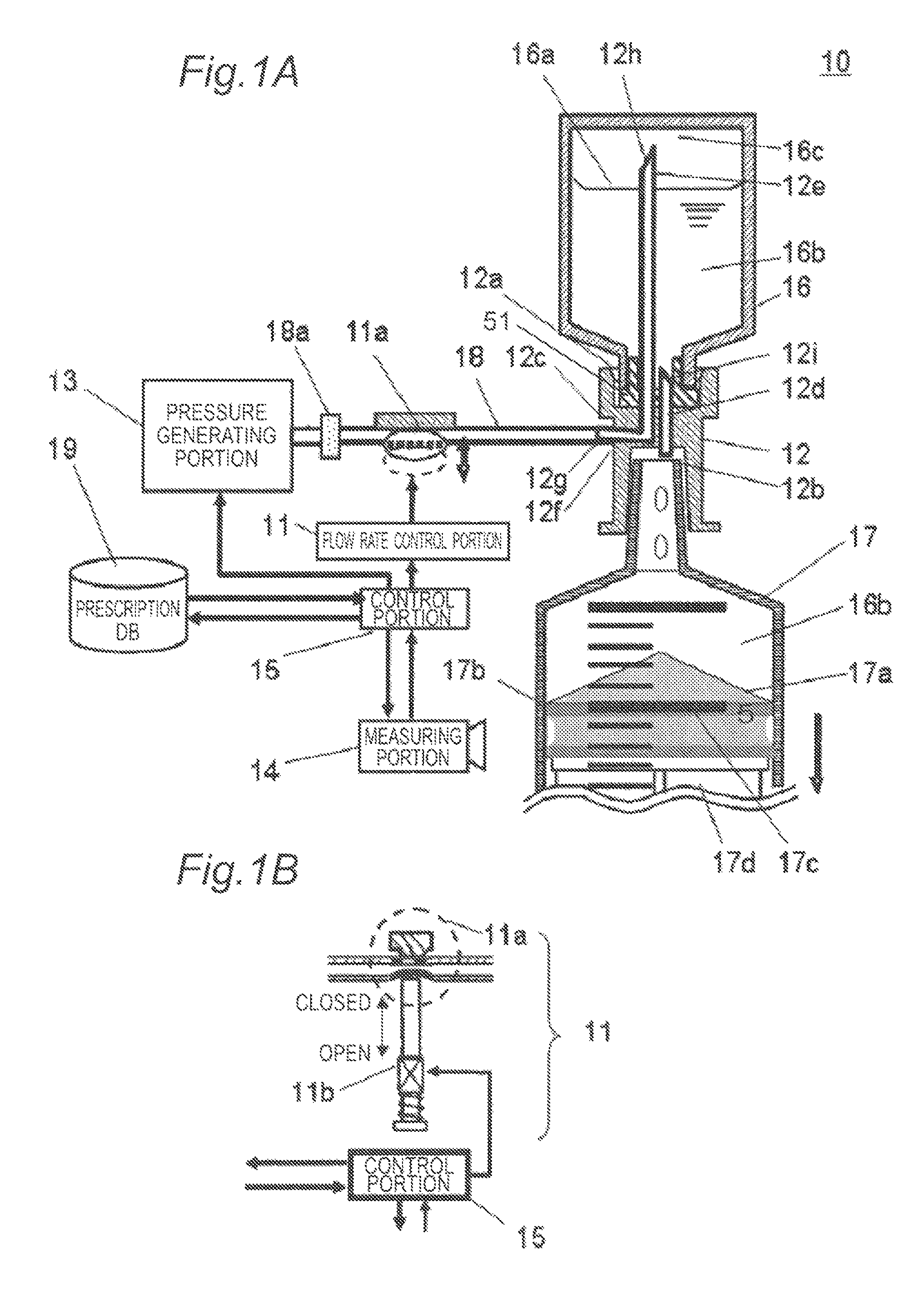

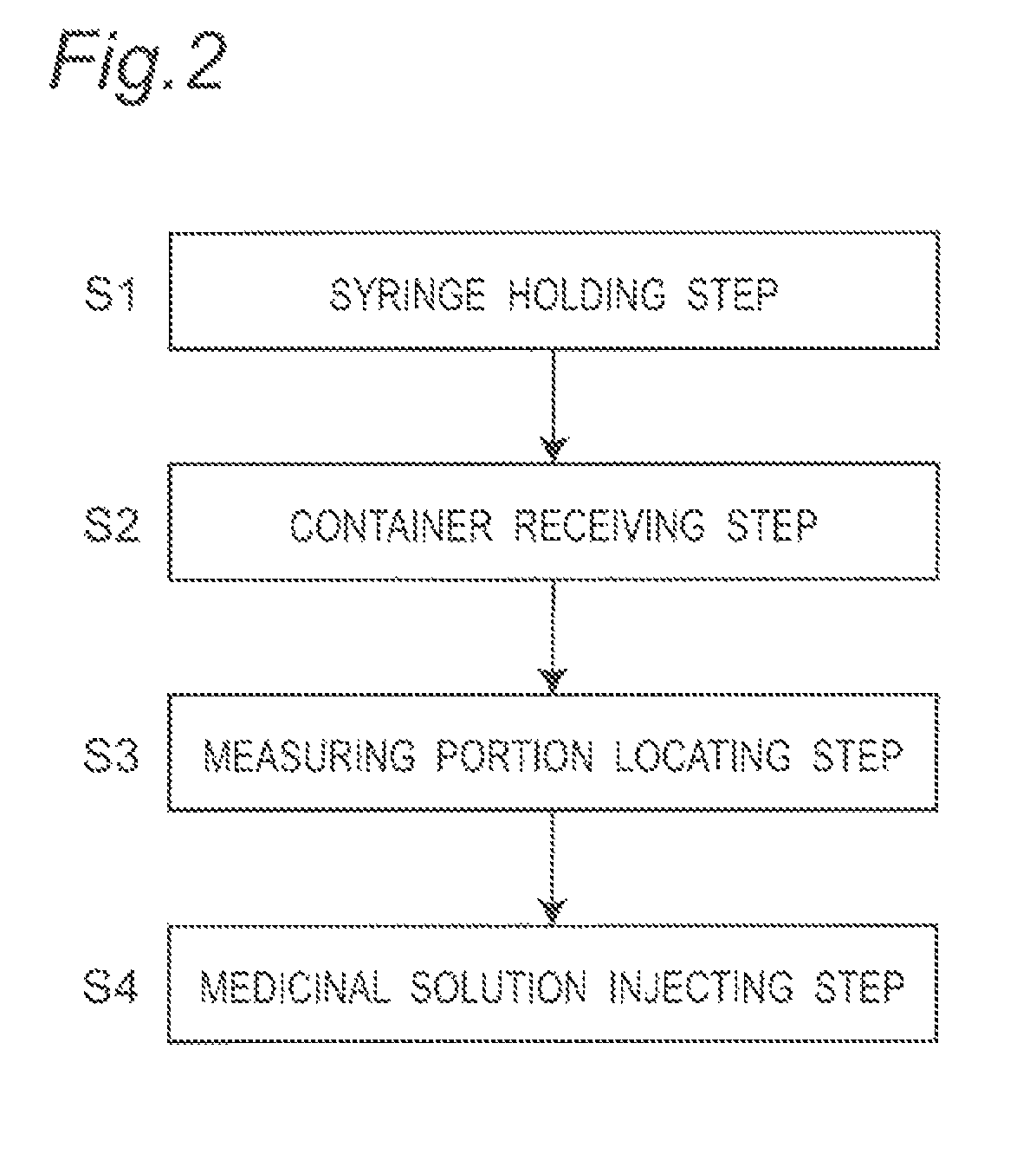

Medicinal solution injection device and medicinal solution injection method

InactiveUS8926554B2Efficient and accurate solutionSolve the blockagePharmaceutical containersMedical devicesInjection deviceLiquid surfaces

A medicinal solution injection apparatus 10 includes a composite needle 12 including a needle base portion 12c, an injection needle 12d, and an adjustment needle 12e, a pressure generating portion 13 configured to discharge a compressed air, a measuring portion 14 configured to measure a filling amount and a filling speed of a medicinal solution by measuring a position of a gasket 17a of a syringe 17, and a control portion 15 configured to control the pressure generating portion 13 and the measuring portion 14. The compressed air is introduced into a vial container 16 through an edge 12h of the adjustment needle 12e located above a liquid surface 16a of the medicinal solution in the vial container 16 (outside the liquid surface) to press the liquid surface 16a of the medicinal solution downward, so that a medicinal solution 16b is injected into the syringe 17 through an edge 12i of the injection needle 12d in the medicinal solution 16b. The medicinal solution injection apparatus 10 can accurately and efficiently inject the medicinal solution 16b of the vial container 16 into the syringe 17 while suppressing the medicinal solution 16b from foaming.

Owner:PANASONIC CORP

Production method of ultra low carbon steel

InactiveCN102719600AReduce the rate of oxygen blowing heating upReduce temperature dropManufacturing convertersSlagNitrogen

The invention provides a production method of an ultra low carbon steel. The method comprises the steps of: employing a blowing process for desulfurization and slag removal of molten iron, with control of oxygen blowing time and smelting cycle of a converter, argon bottom-blowing in the whole course, and control of S content in slag lime, [C] content at converter end point, and temperature and oxygen activity at the endpoint, adding lime in a tapping process, and modifying ladle top slag after tapping; employing natural decarburization to control carbon content in an RH, wherein Als in molten steel is less than 0.03% after deoxidation, carrying out vacuum-breaking, adding aluminum powder and top slag modifier into the top slag, blowing argon with stirring, vacuumizing again, and carrying out clean circulation for 2-10 min; and carrying out continuous casting with protective casting in the whole course, wherein a nitrogen increase amount in the molten steel is controlled at less than 2 ppm. The invention can effectively reduce temperature drop in a transmission process, reduce oxygen blowing heating rate in a subsequent RH refining treatment, save energy and shorten the time of refining. Besides, the method can effectively guarantee modification effect of the top slag, prevent nozzle clogging and realize sequence casting. Therefore, the method is particularly applicable to the production of high purity ultra low carbon steel.

Owner:ANGANG STEEL CO LTD

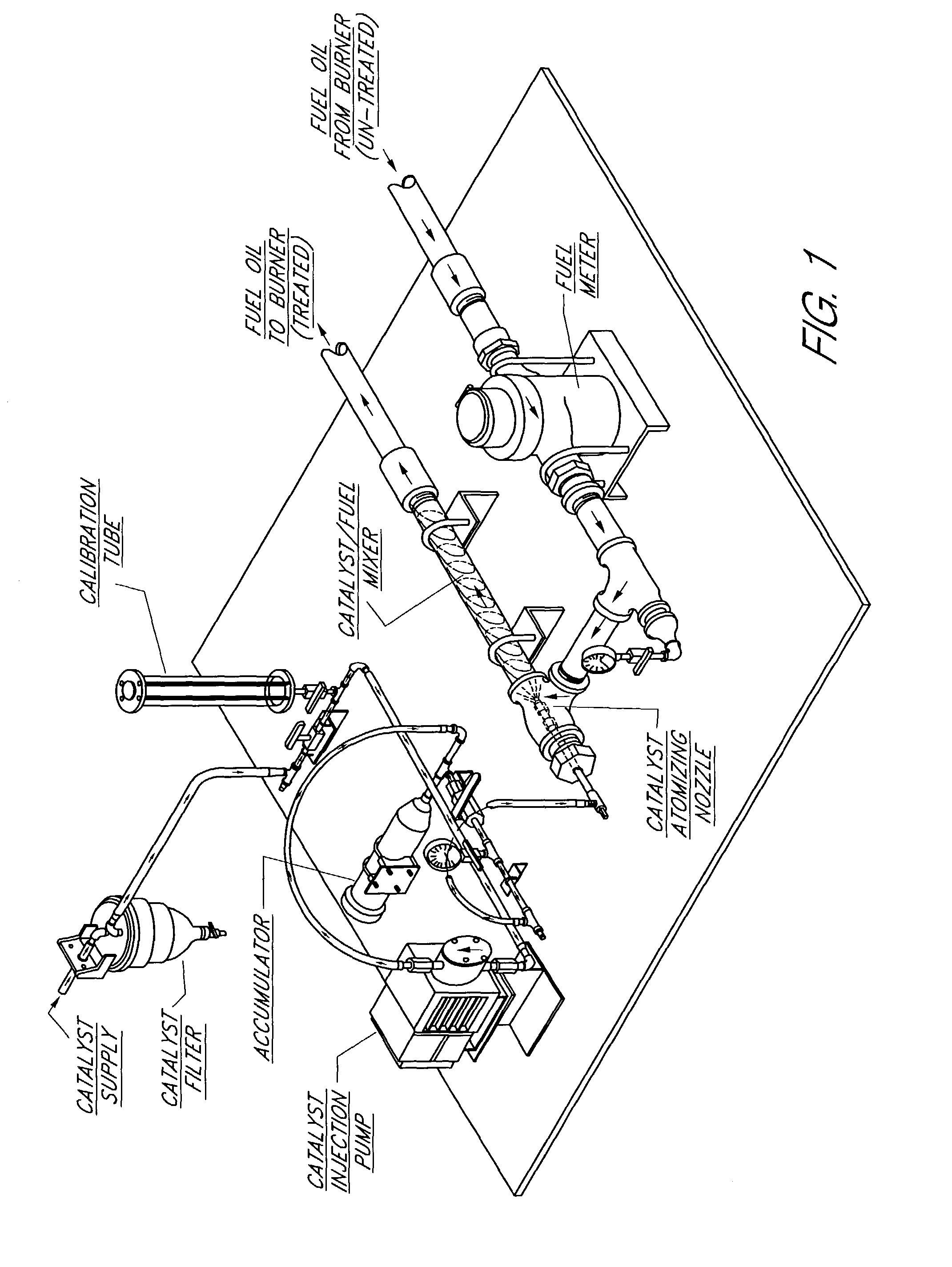

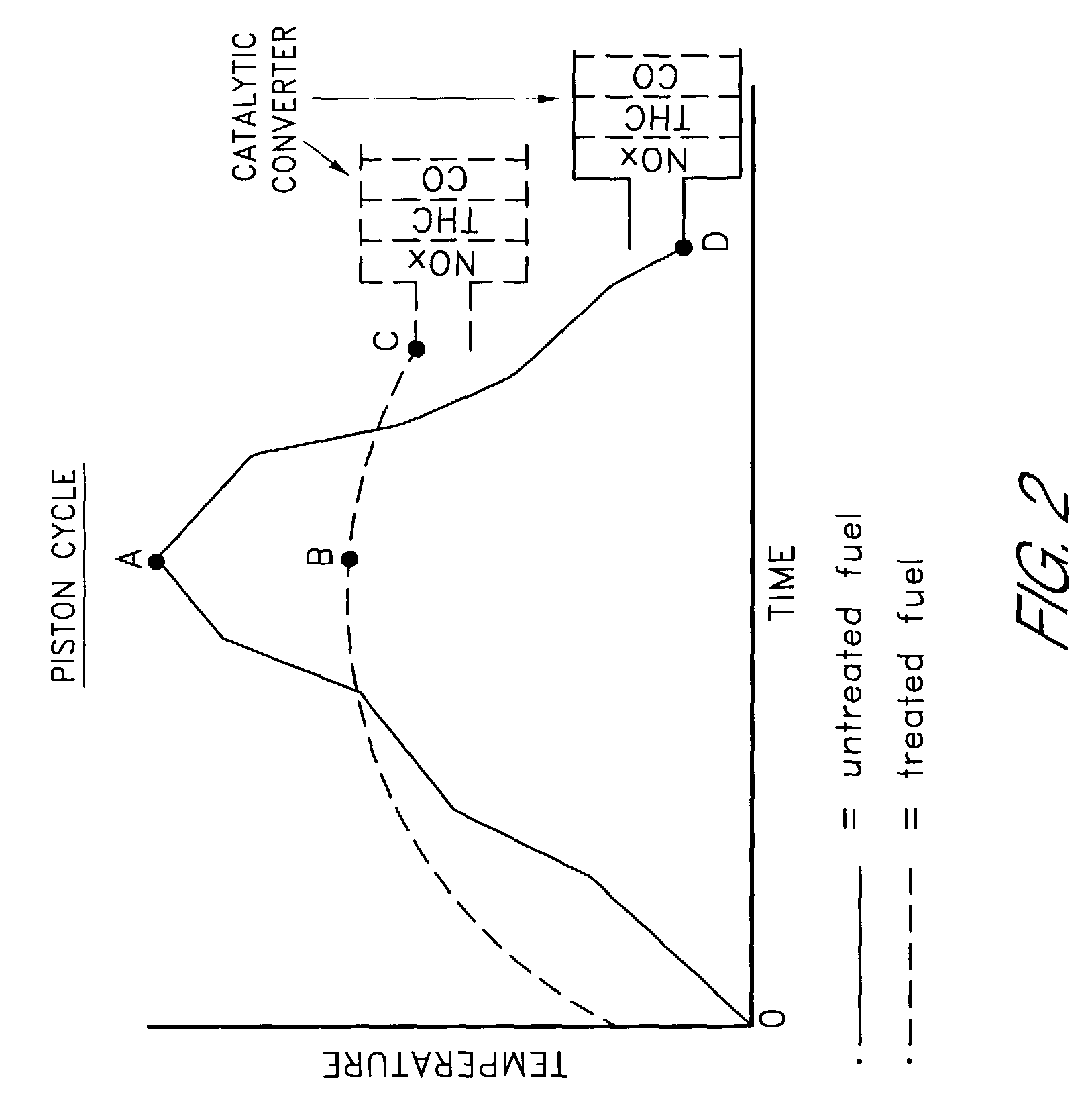

Method and composition for using organic, plant-derived, oil-extracted materials in resid fuel additives for reduced emissions

InactiveUS7141083B2Reduce pollutant emissionsAvoid equipmentSolid fuelsLiquid carbonaceous fuelsCombustionEngineering

A resid fuel additive is provided that includes a plant oil extract, β-carotene, and jojoba oil. The additive may be added to any resid fuel to reduce emissions of undesired components during combustion of the fuel. A method for preparing the additive is also provided.

Owner:AQ

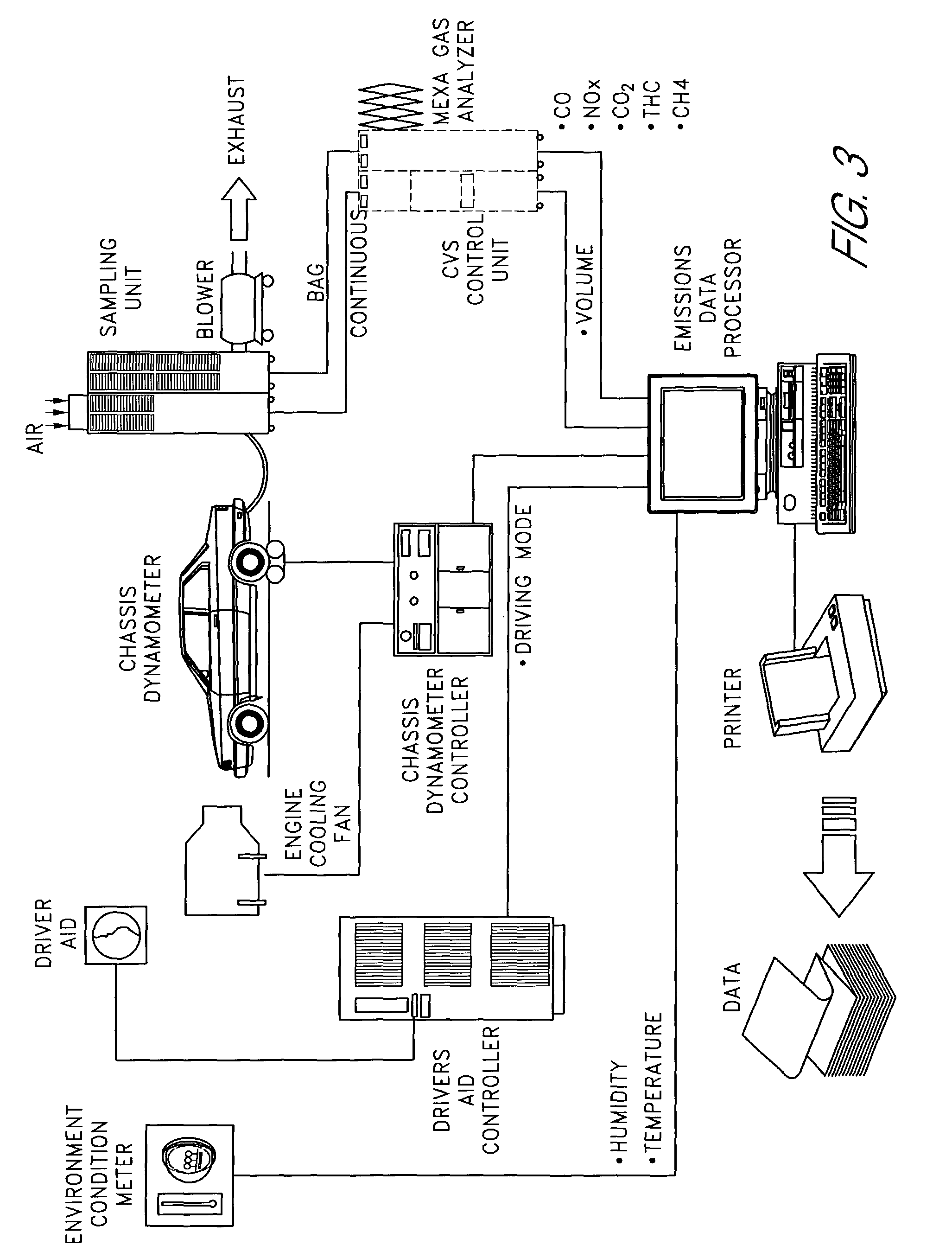

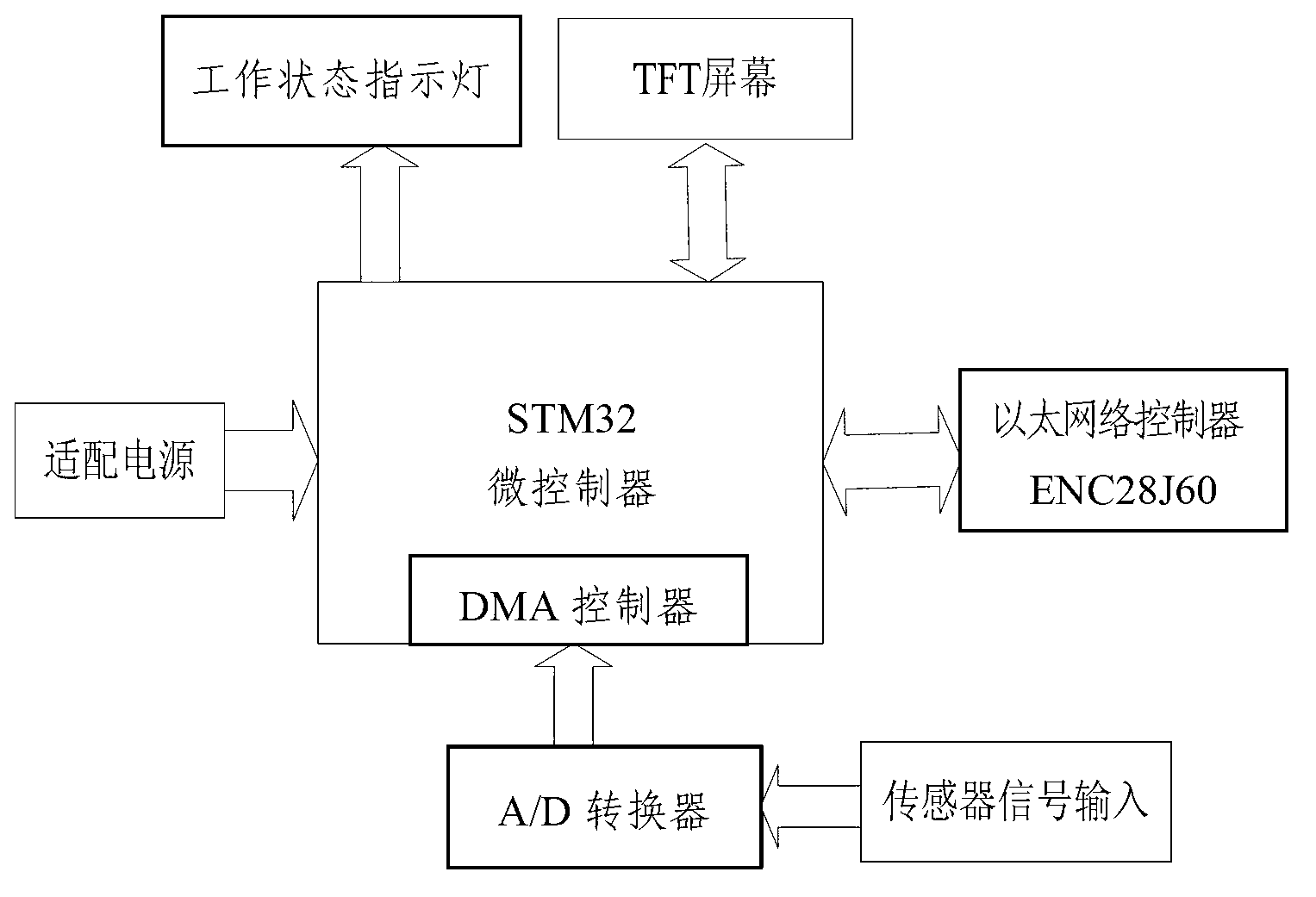

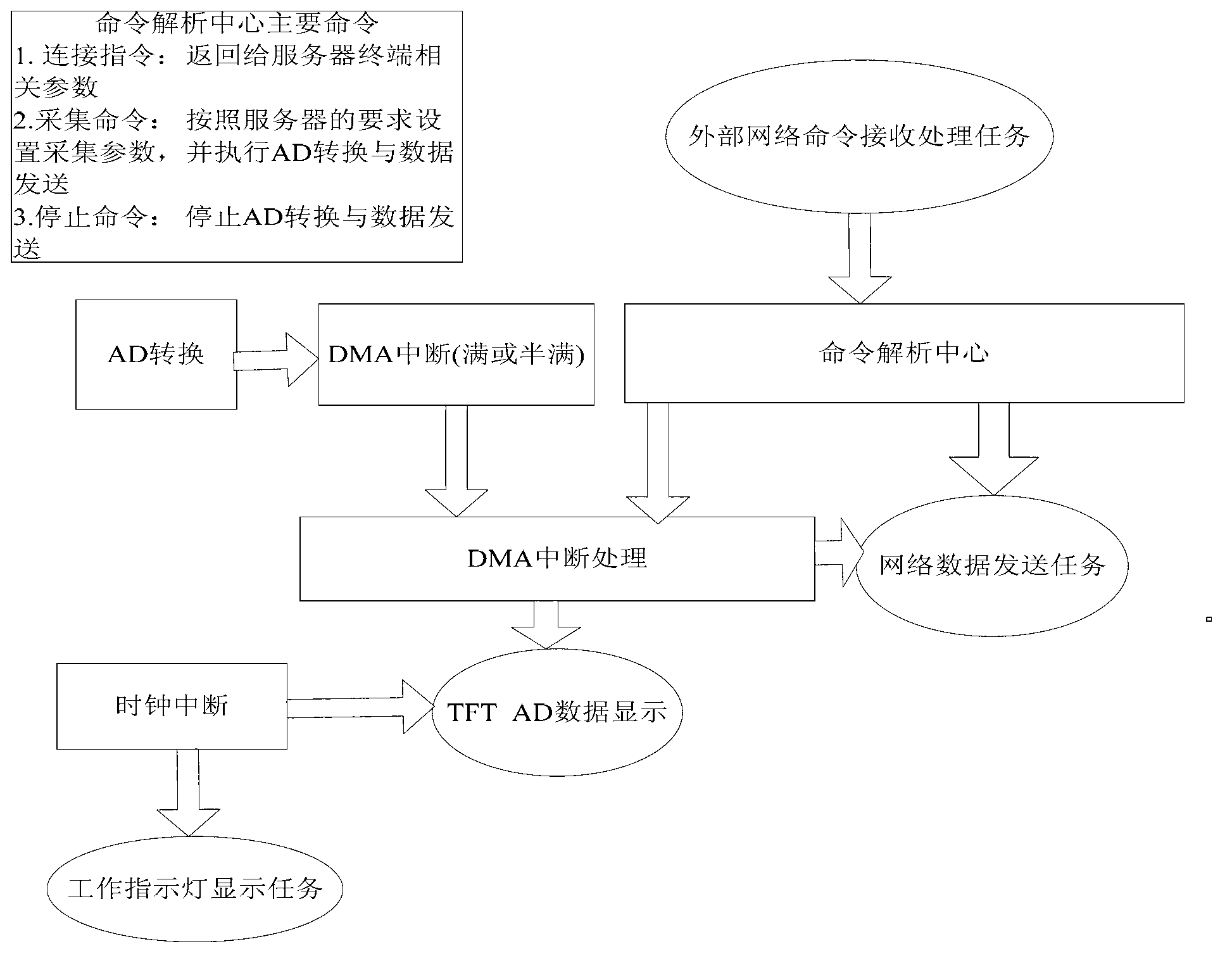

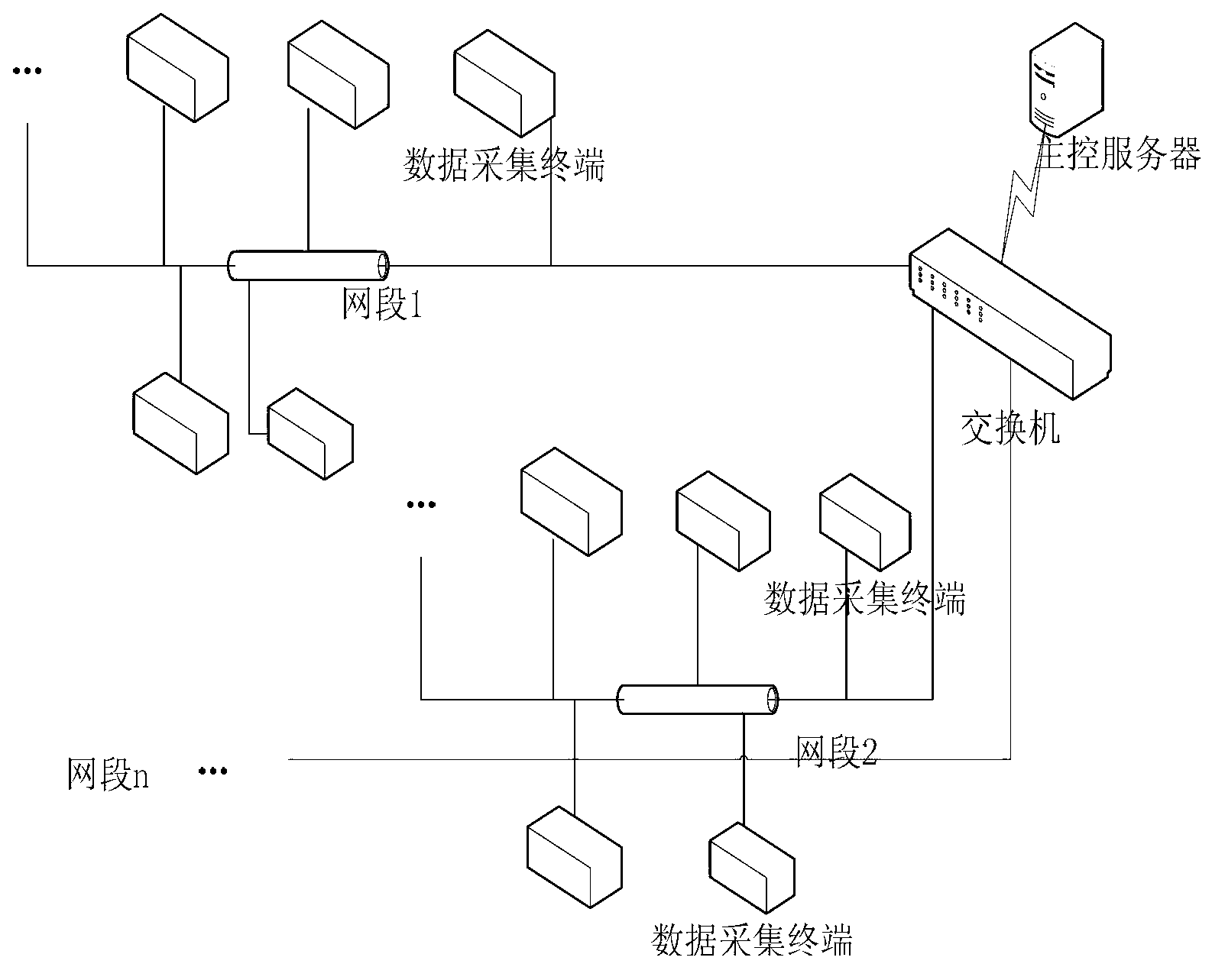

Welding process information acquisition and quality monitoring device and method based on Ethernet

ActiveCN102922089ASolve the blockageRealize online monitoringArc welding apparatusTotal factory controlData acquisitionComputer terminal

The invention discloses a welding process information acquisition and quality monitoring system based on an Ethernet. STM32 is used as a remote data acquisition terminal main control unit for receiving welding parameters acquired by a sensing device in real time and implement analog / digital (A / D) conversion; and the STM32 sends A / D conversion data to a main control server by using an ENC28J60 and using a user datagram protocol (UDP) through a switch, receives control commands, and returns response information to the main control server. If the main control server sends an acquisition instruction, the STM32 executes A / D conversion and sends the result to the main control server, the main control server converts the result into current and voltage parameters, and the parameters are displayed and stored in a waveform mode; and by adopting command interaction in the main control server, all terminals connected with the main control server execute the acquisition command according to the specified requirement, acquire running state information of welding equipment and display states in real time to finish remote online monitoring operation of the welding equipment.

Owner:TIANJIN UNIV

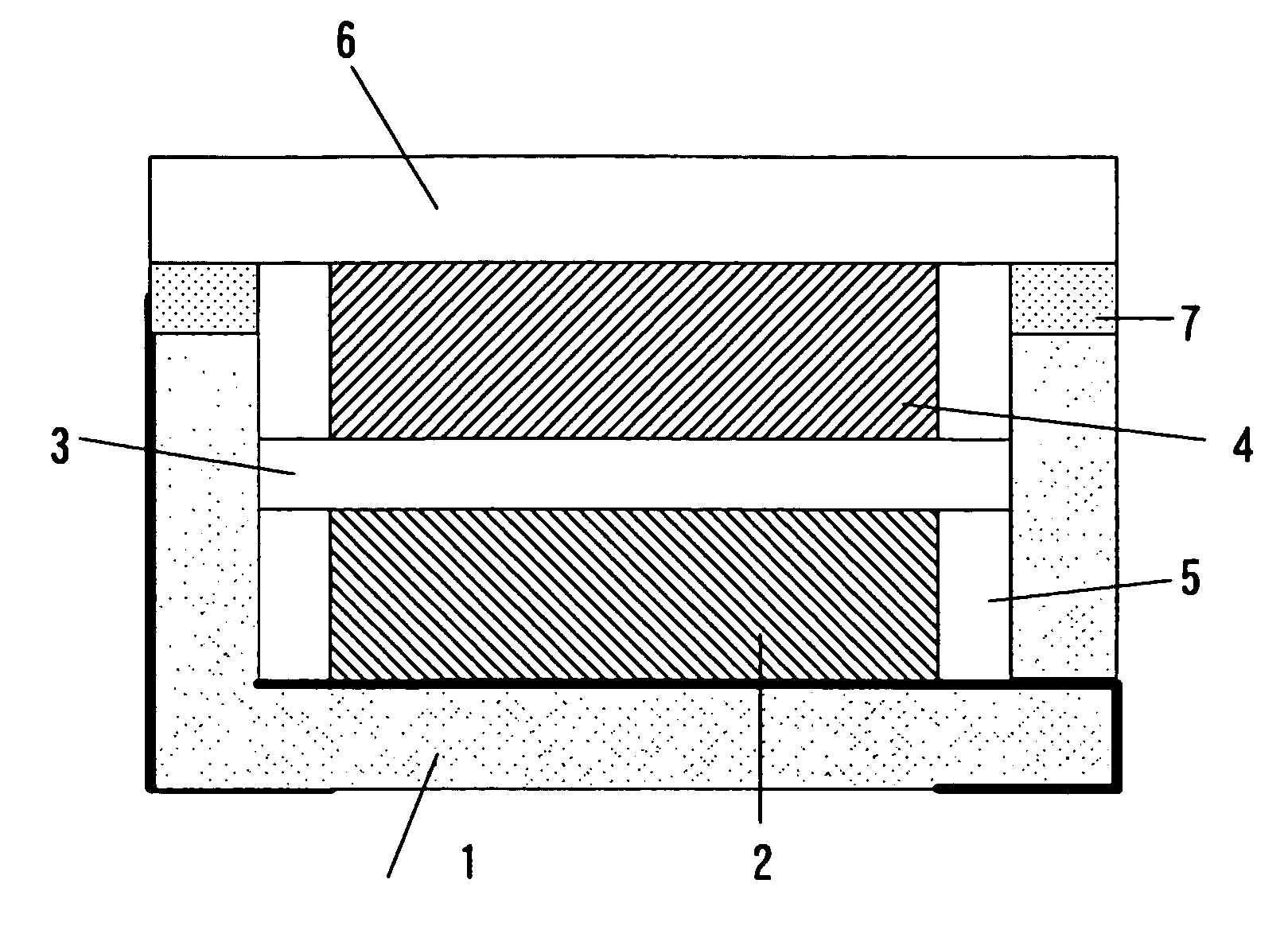

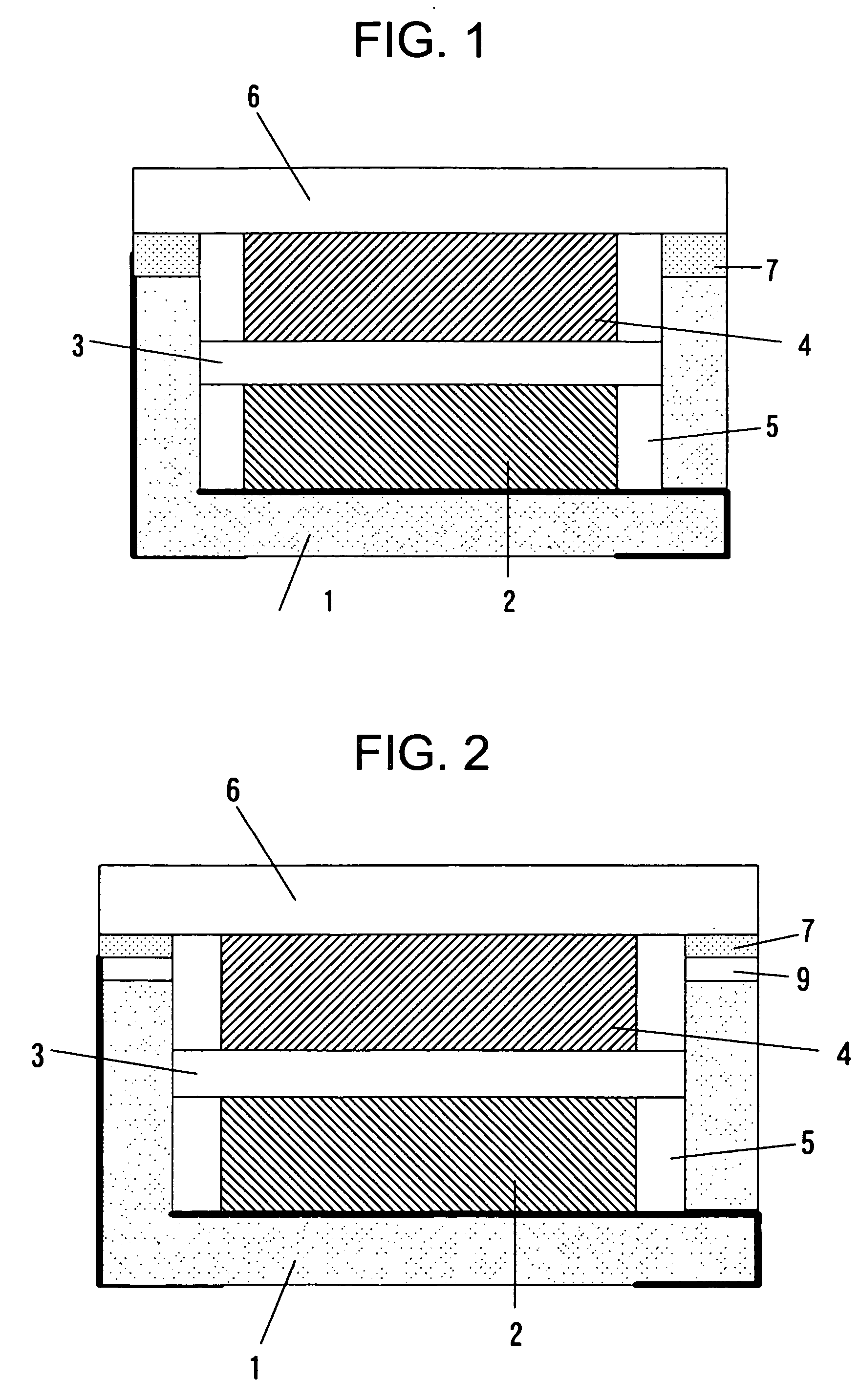

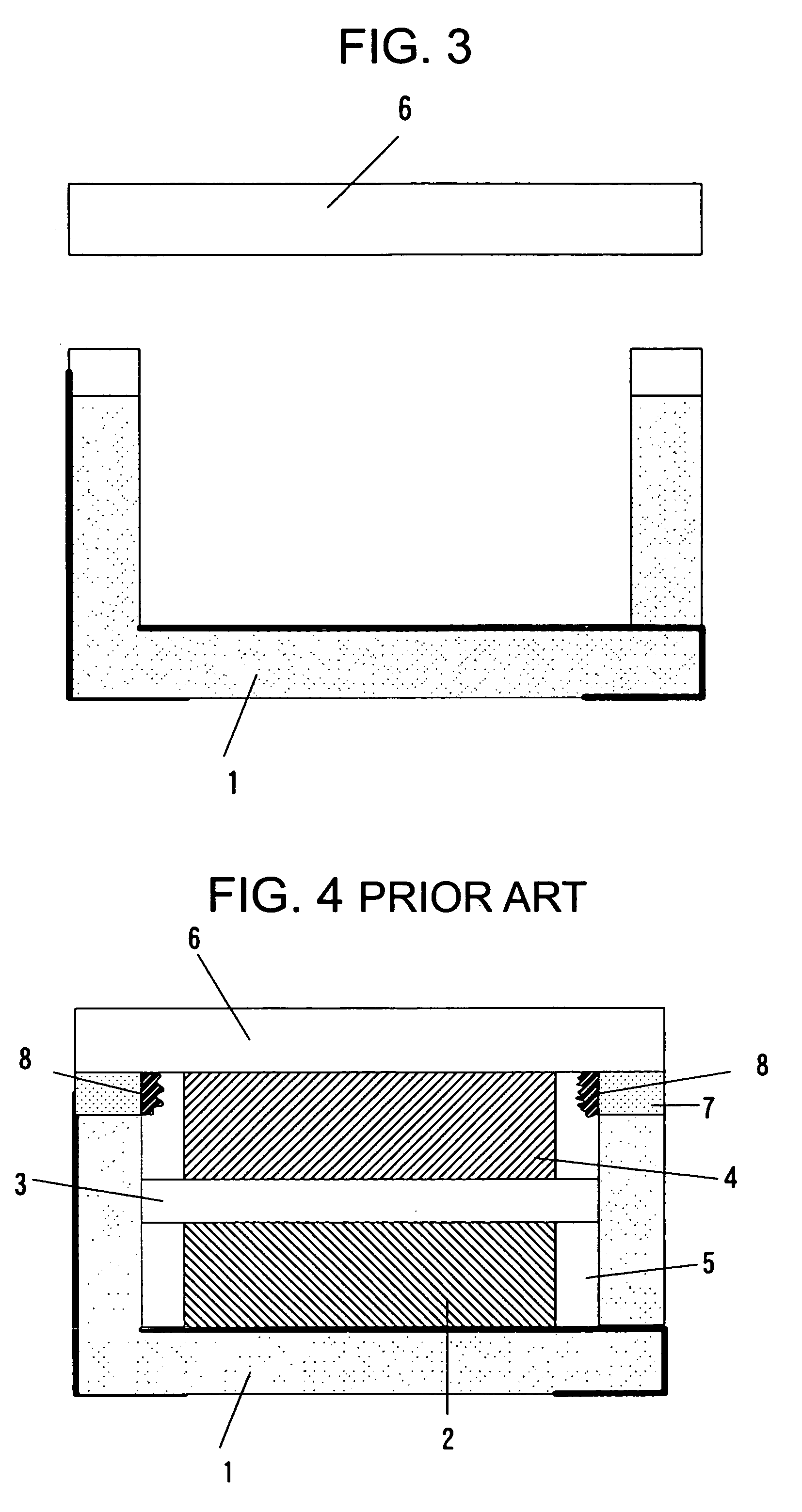

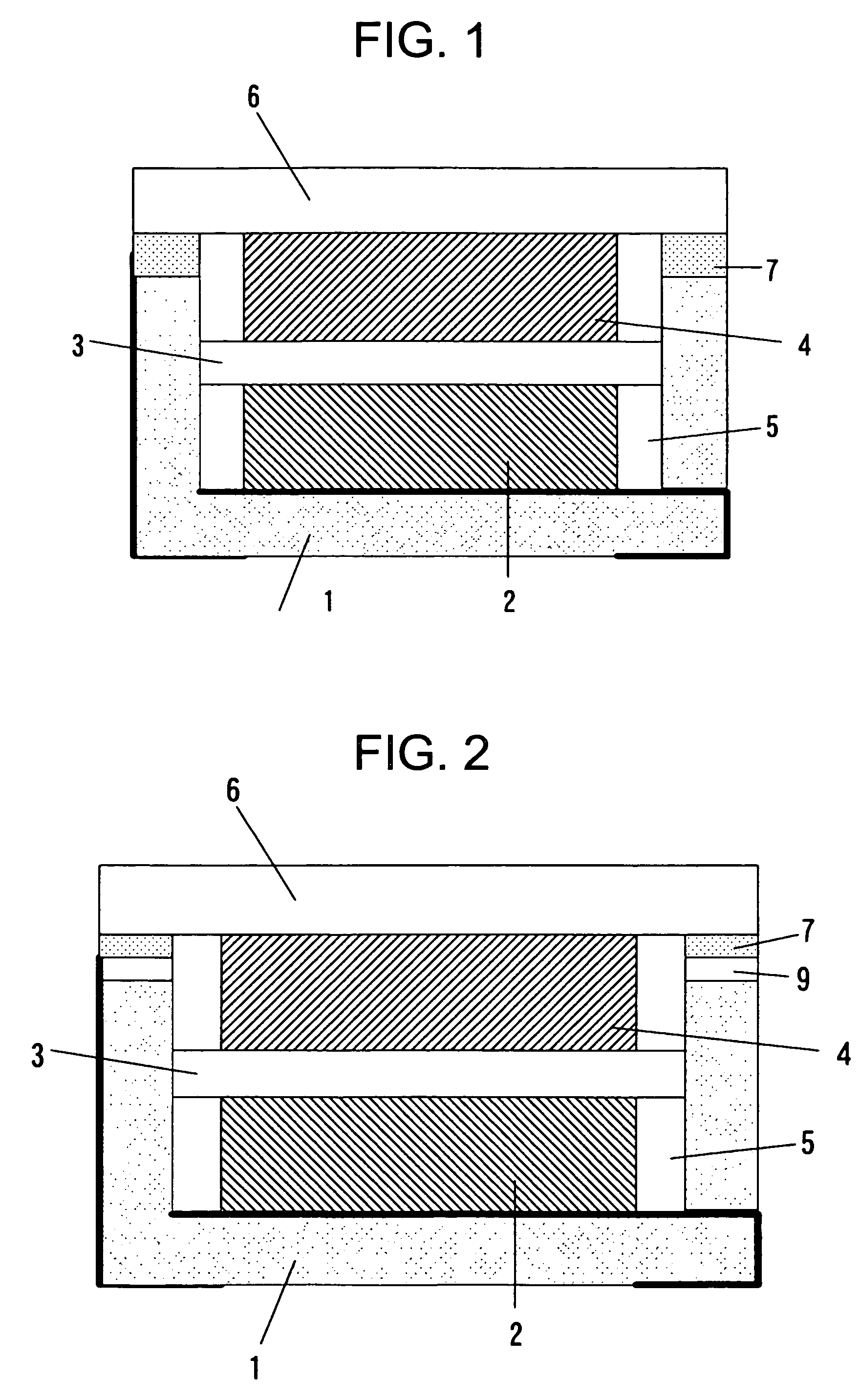

Electrochemical cell

InactiveUS20060035143A1Prevent oxidationInhibition capacityHybrid capacitor electrodesFinal product manufactureOrganic solventInternal resistance

In a conventional electrochemical cell, since a welding between a container and a sealing plate is performed in the atmospheric air, a weld zone is oxidized and a corrosion resistance decreases. For this reason, impurities are eluted from the weld zone into an electrolyte, and this causes an internal resistance increase and a capacity decrease of the electrochemical cell. Further, there is a possibility that an organic solvent in the electrolyte is oxidized by the welding. According to the invention, in order to solve the above problems, the seal welding between the container and the sealing plate of the electrochemical cell is performed under an inert atmosphere.

Owner:SEIKO INSTR INC

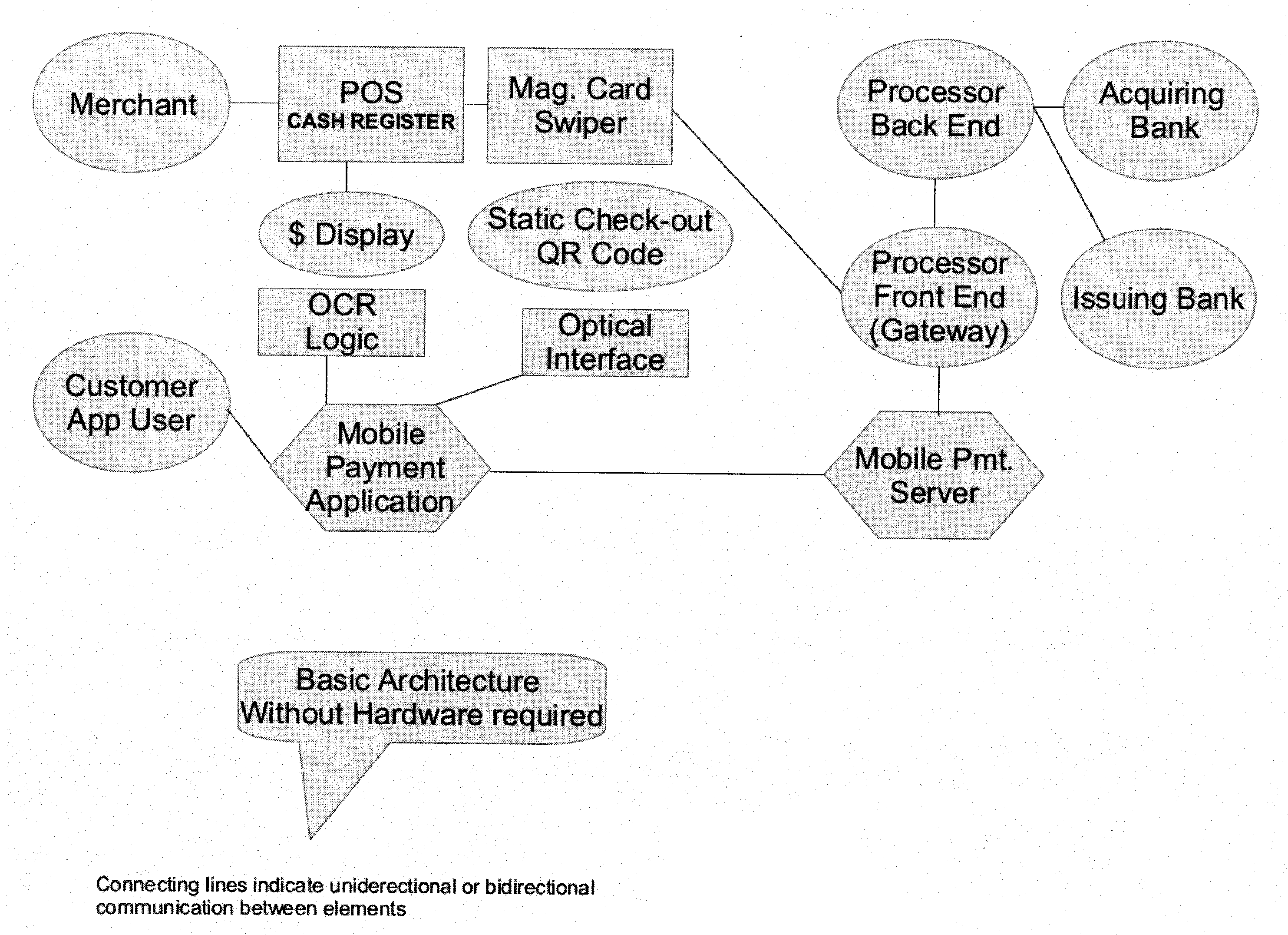

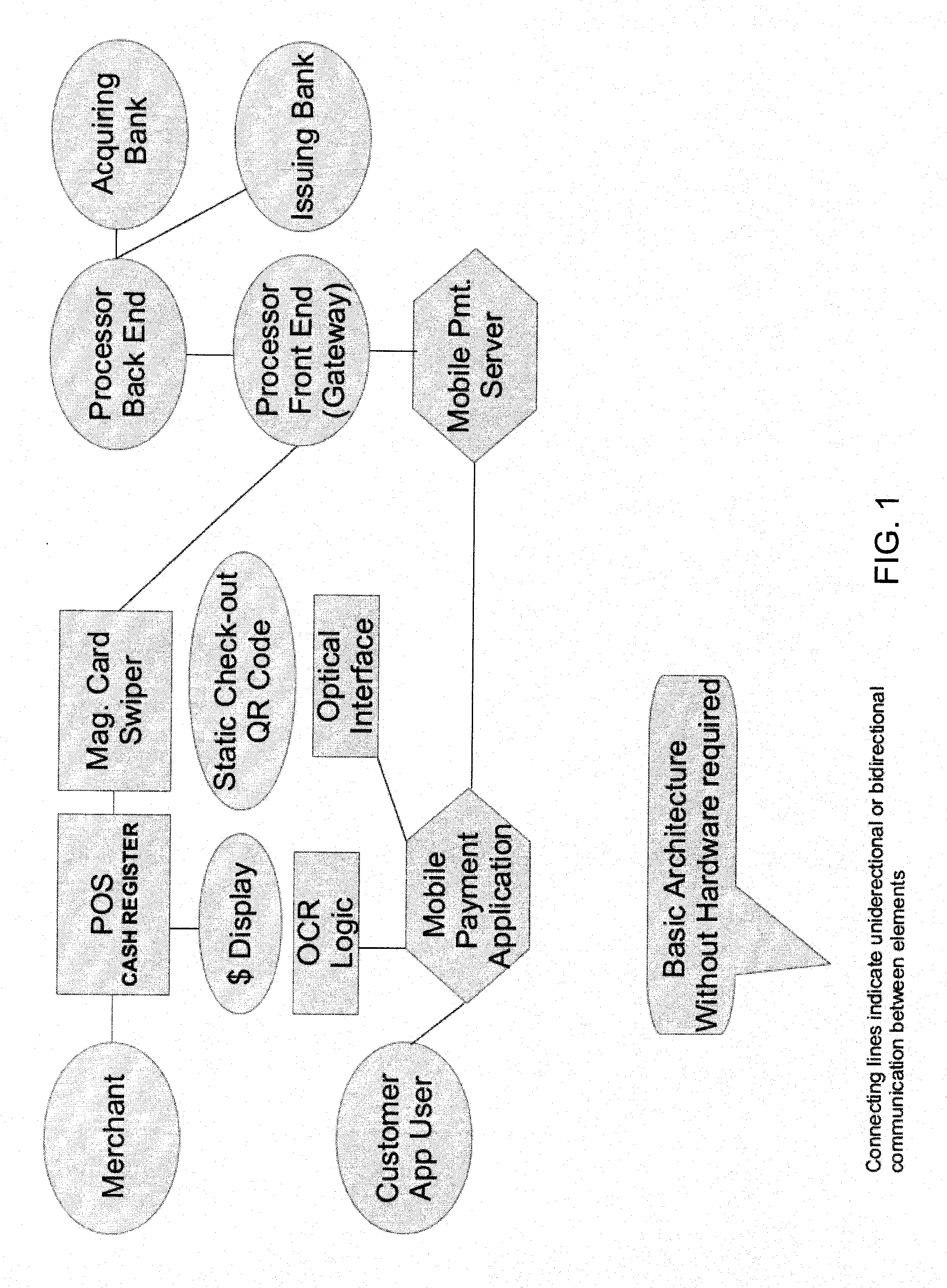

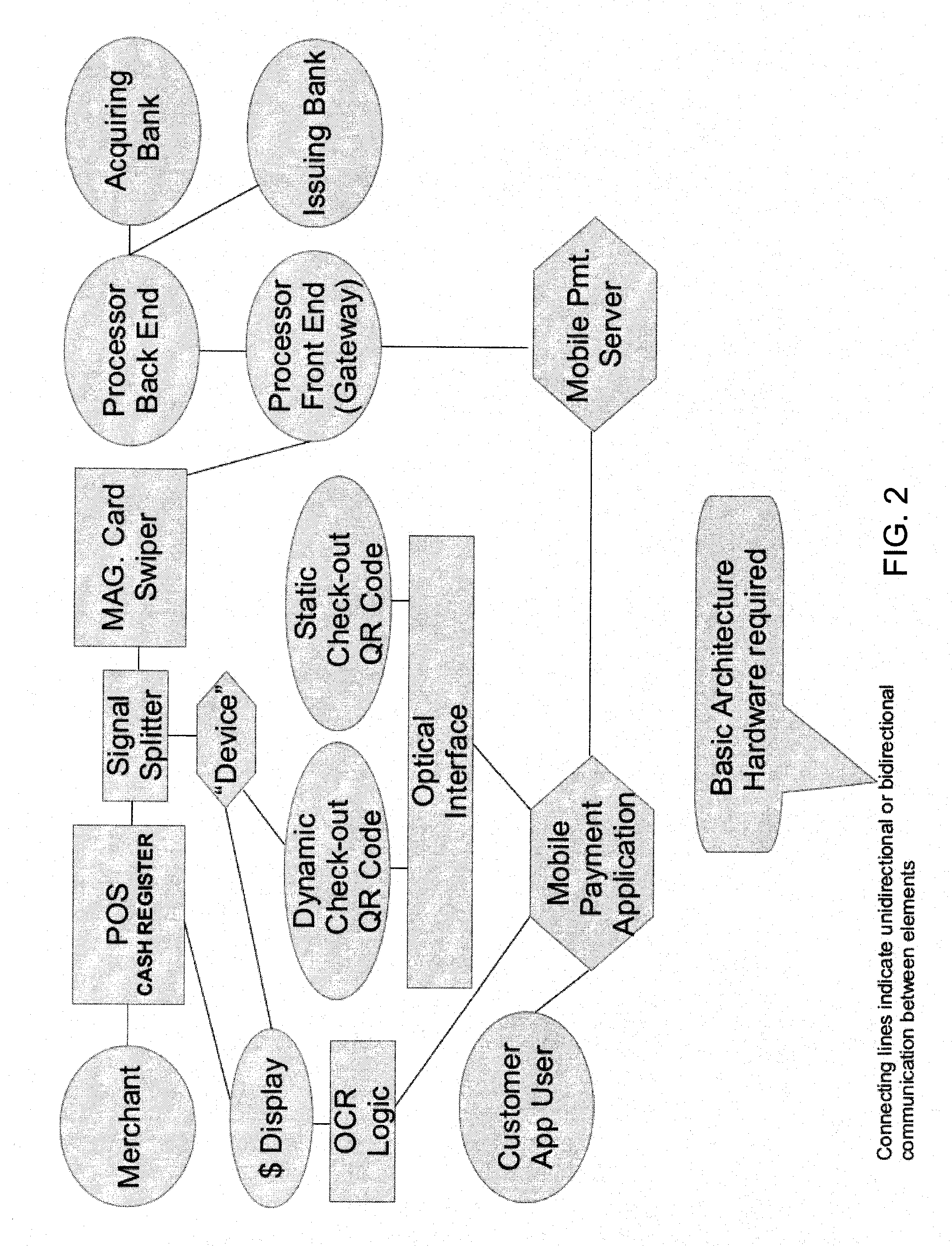

Universal check-out system for Mobile Payment Applications/Platforms

InactiveUS20150058145A1Solve the blockageIncrease the number ofPoint-of-sale network systemsCOLA (software architecture)Computer architecture

A hardware / software architecture and process methodology are disclosed by which mobile payment platforms are enabled in an existing payment processor's merchant base at their point of sale system (“POS”) without the necessity of implementing new hardware or software at the merchant level and for each of said merchant's POS system.

Owner:MOBILE PAYMENTS INTERCHANGE LLC

Method for producing ultra-low-carbon steel

A method for producing ultra-low-carbon steel belongs to steel-making technology field. The process route is: molten iron desulfuration preprocess -converter smelting -RH vacuum process -slab continuous casting. The iron desulfuration preprocess applies blowing magnesium granules for desulfuration; the converter smelting terminal carbon content and oxygen activity of molten steel; applying slag dam operation when tapping without deoxidation; the ladle furnace proceeds operation of top slag modification and temperature controlling; RH vacuum processing to control the maximum vacuum; applying Al for deoxidation when the decarburization is finished, and alloying if the deoxidation is finished and assuring the deep vacuum processing time after the deoxidation; calming the molten steel when the vacuum is finished; applying non-carbon covering agent and non-carbon protection slag in the slab casting process; the continuous casting process uses full protection casting, and the casting process controls a reasonable pulling speed according to slab section. The advantages are: the invention resolves problem of nozzle clogging and improves castability of the ultra-low-carbon steel and implements multi-furnace continuous casting, and the components of carbon, phosphorus, sulphur and nitrogen of the completed product conforms smelting request of the ultra-low-carbon steel.

Owner:SHOUGANG CORPORATION

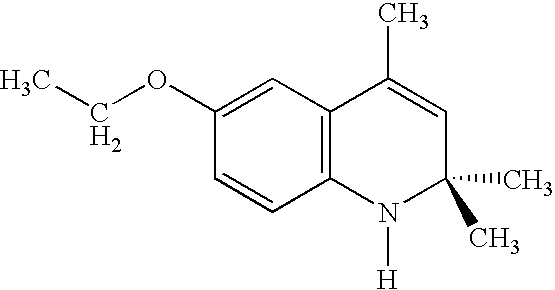

Method and composition for using stabilized beta-carotene as cetane improver in hydrocarbonaceous diesel fuels

InactiveUS20050160662A1Increase cetane numberReduce pollutant emissionsLiquid carbonaceous fuelsFuel additivesCombustionBeta-Carotene

A diesel fuel additive is provided that includes beta-carotene stabilized with 2,2,4-trimethyl-6-ethoxy-1,2-dihydro-quinoline. The additive may be added to any liquid hydrocarbon fuel, solid hydrocarbon fuel, or other hydrocarbonaceous combustible fuel to reduce emissions of undesired components during combustion of the fuel, provide improved fuel economy, engine cleanliness, and / or performance. A method for preparing the additive is also provided.

Owner:AQ

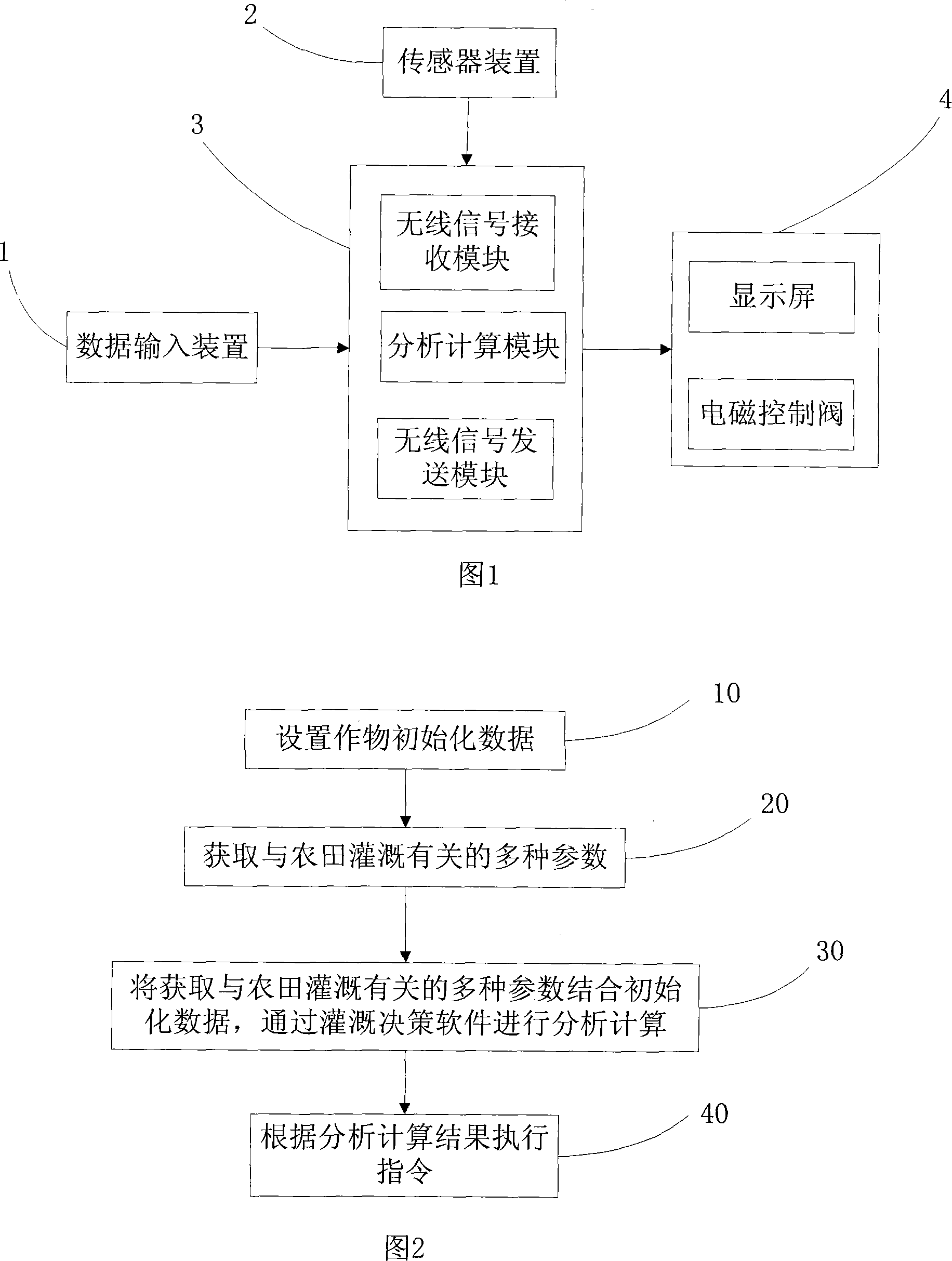

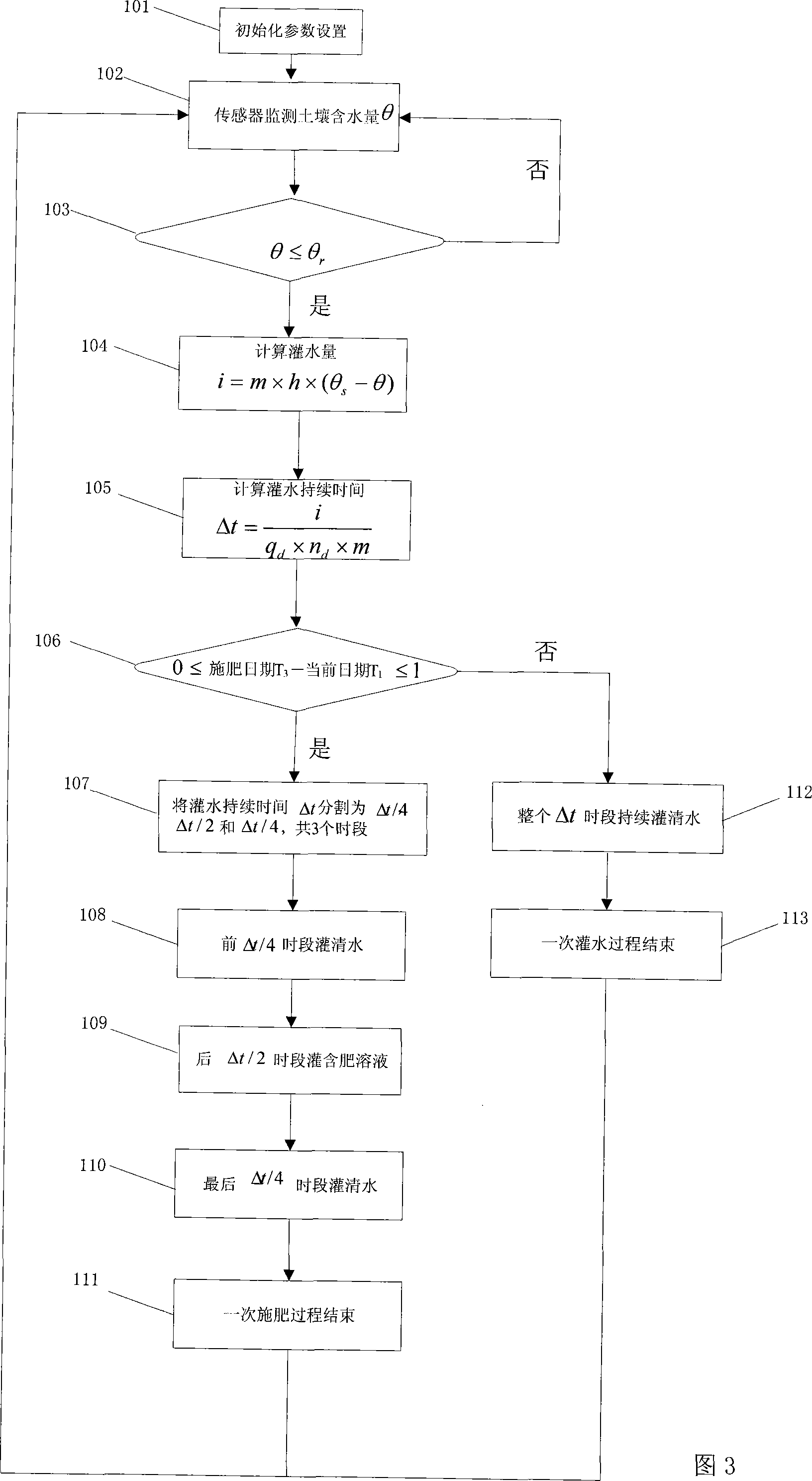

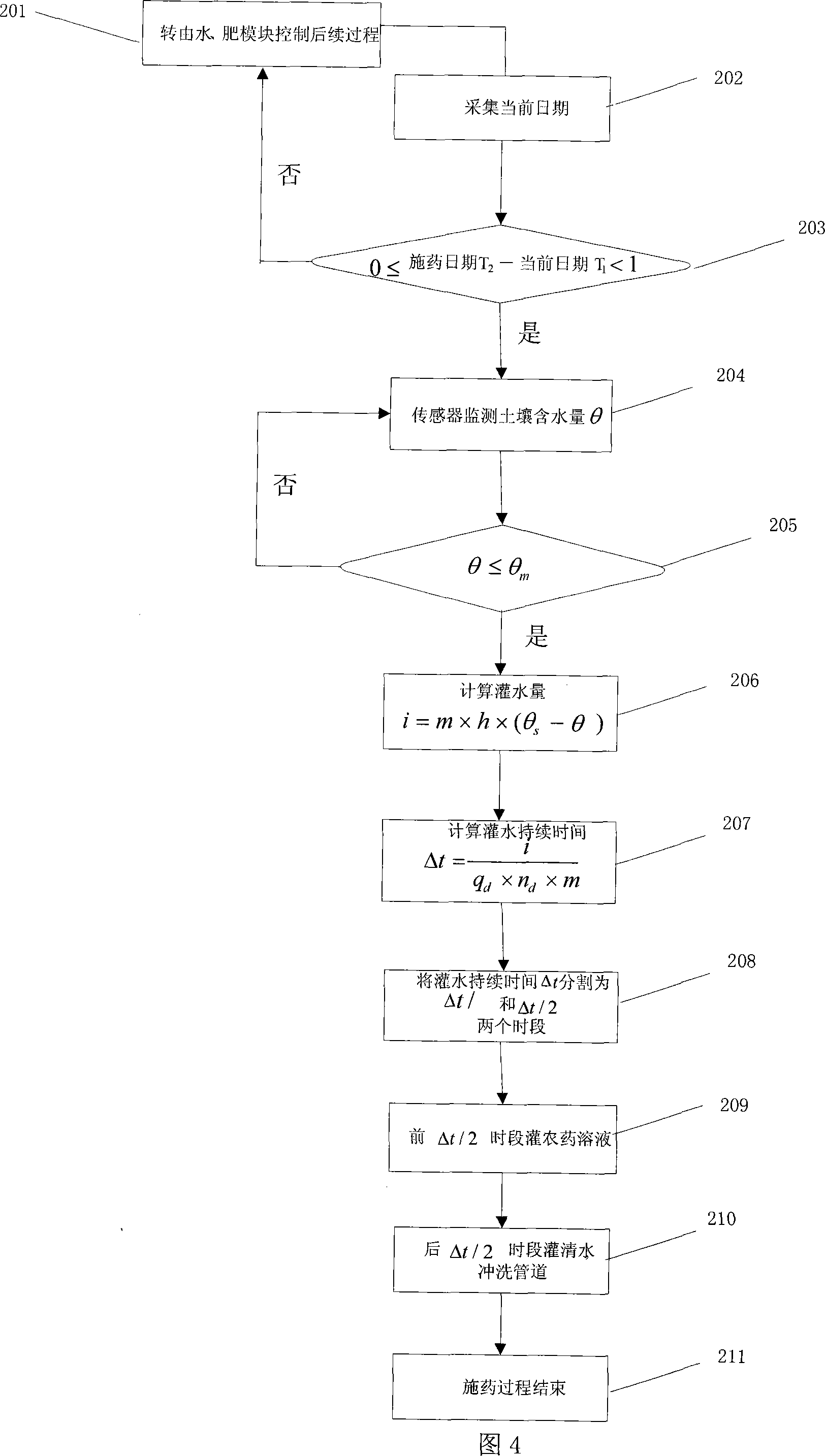

Automatic control system and method for trickle irrigation of water, fertilizer and drug underground

InactiveCN101206459AImprove utilization efficiencySolve the blockageClimate change adaptationWatering devicesFertilizerInformation technology

The invention provides an integrated automatic control system for underground dripping irrigation water, fertilizer and medicine and a method thereof, which belongs to the water saving irrigation field, wherein, the system comprises a data input system, a sensor device, a master control device and an output device; the method comprises the following steps: A. initialization data of crops is set; B. a plurality of parameters related to cropland irrigation are acquired; C. a plurality of acquired parameters related to cropland irrigation are combined with the initialization data, and irrigation decision-making software is used for analysis and calculation; D. instructions are executed according to analysis and calculation results. The invention utilizes modern information technologies to grasp mutation of cropland environmental parameters, and has the advantages of high automatic control degree of scientific irrigation and drip irrigation and effective lightening of labor intensity.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

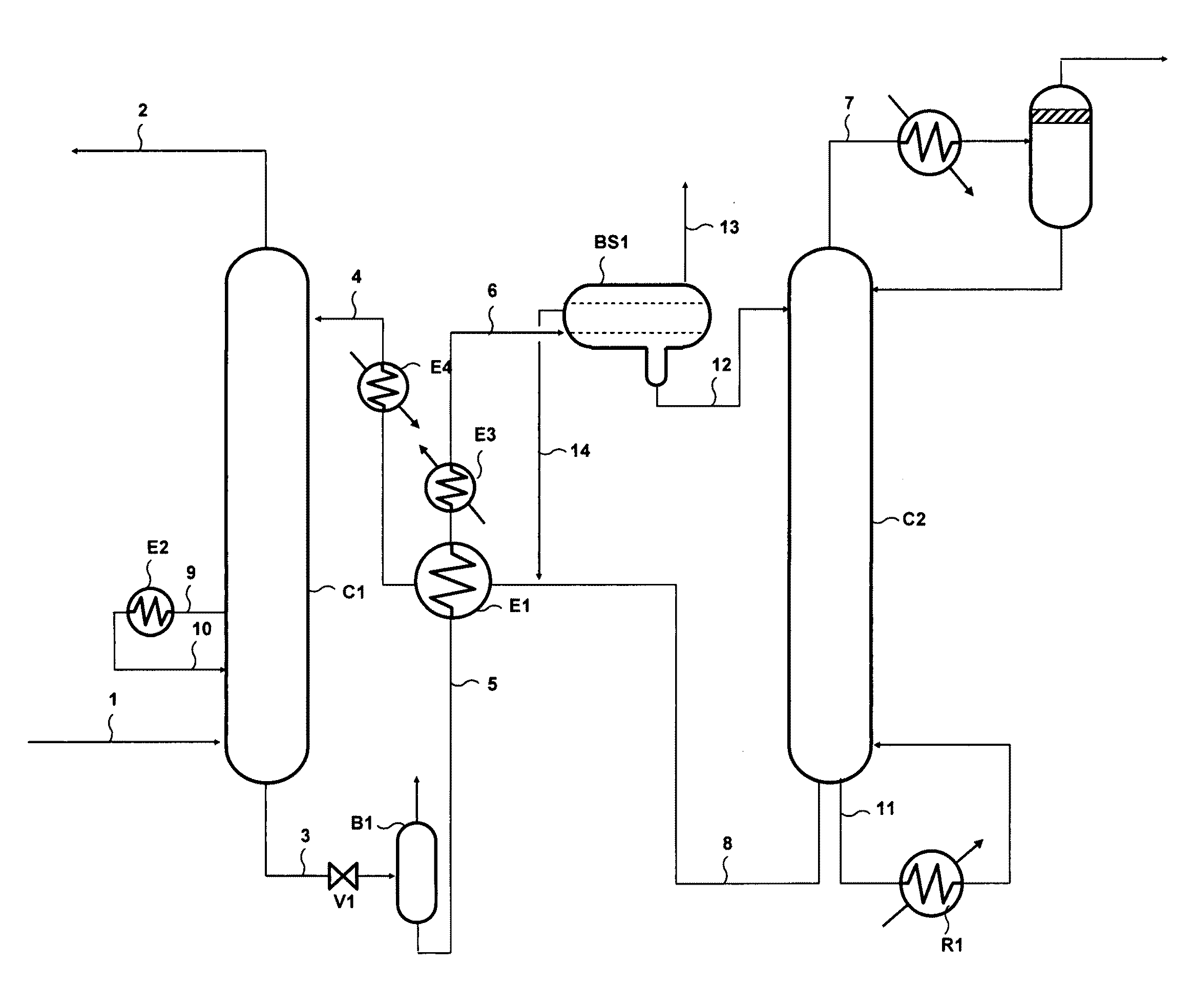

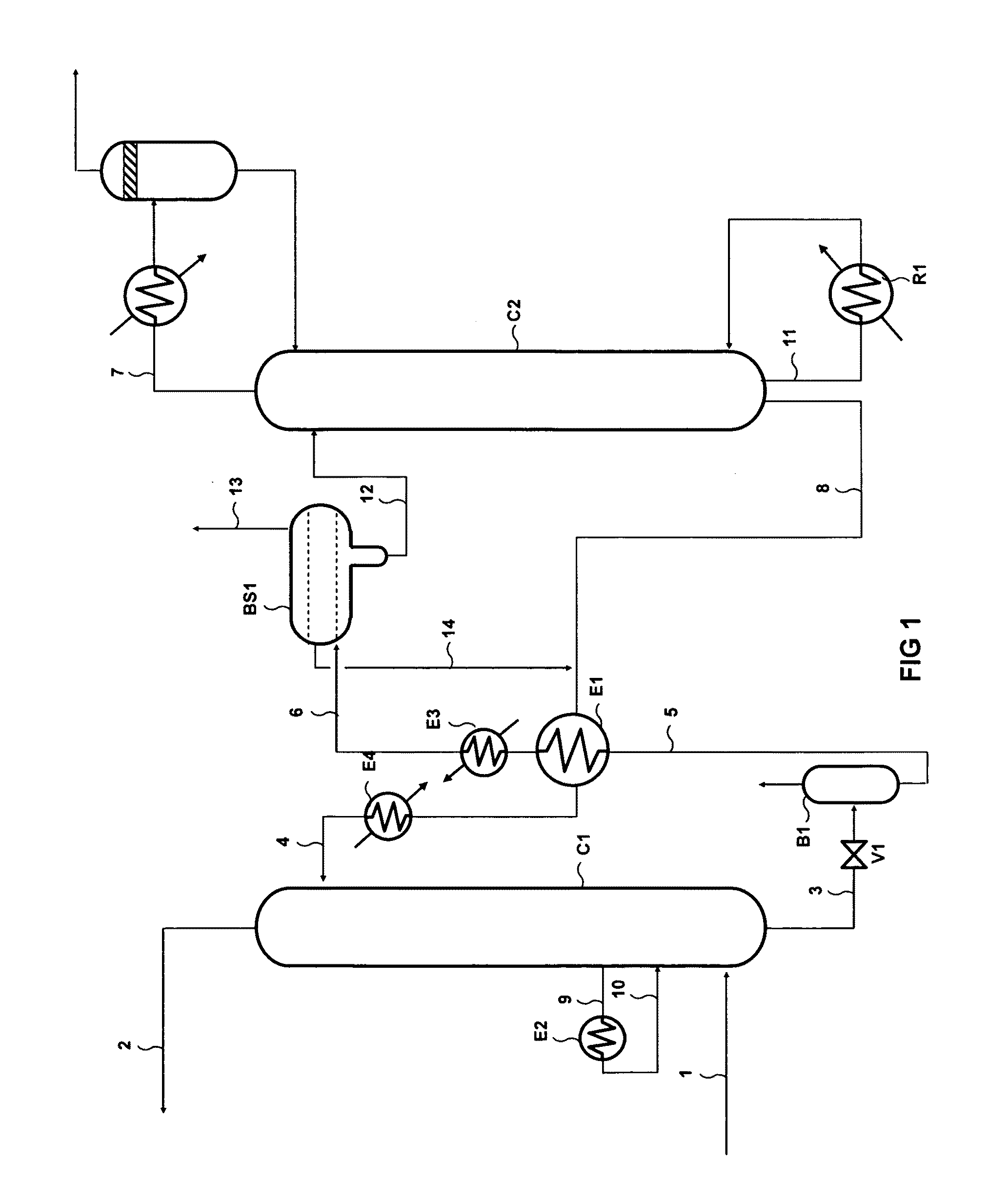

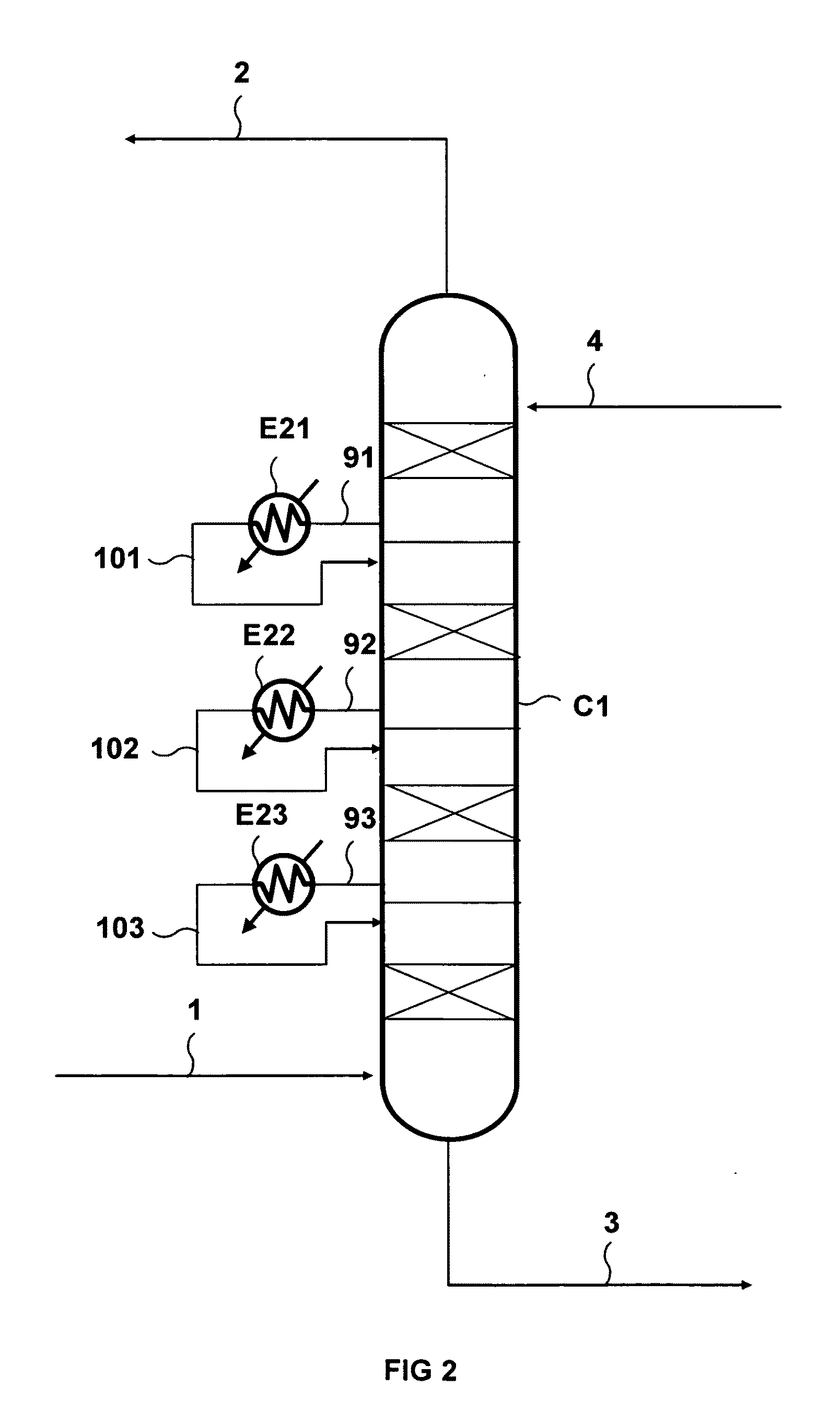

Gas deacidizing method using an absorbent solution with demixing control

ActiveUS20100104490A1Keep absorbingSolve the blockageGas treatmentLiquid degasificationProduct gasCOMPONENT II

The gaseous effluent to be treated is contacted in C1 with an absorbent solution selected for its property of forming two separable phases when it has absorbed an amount of acid compounds and when it is heated. The absorbent solution laden with acid compounds is then heated in E1 and E3 so as to separate two fractions in BS1: a first absorbent solution fraction depleted in acid compounds and a second absorbent solution fraction enriched in acid compounds. The second fraction is regenerated in C2 so as to release part of the acid compounds, and the first absorbent solution fraction and the regenerated absorbent solution are recycled as absorbent solution.According to the invention, an absorbent solution portion circulating in C1 is cooled in E2 in order to prevent demixing of the solution in column C1.

Owner:INST FR DU PETROLE

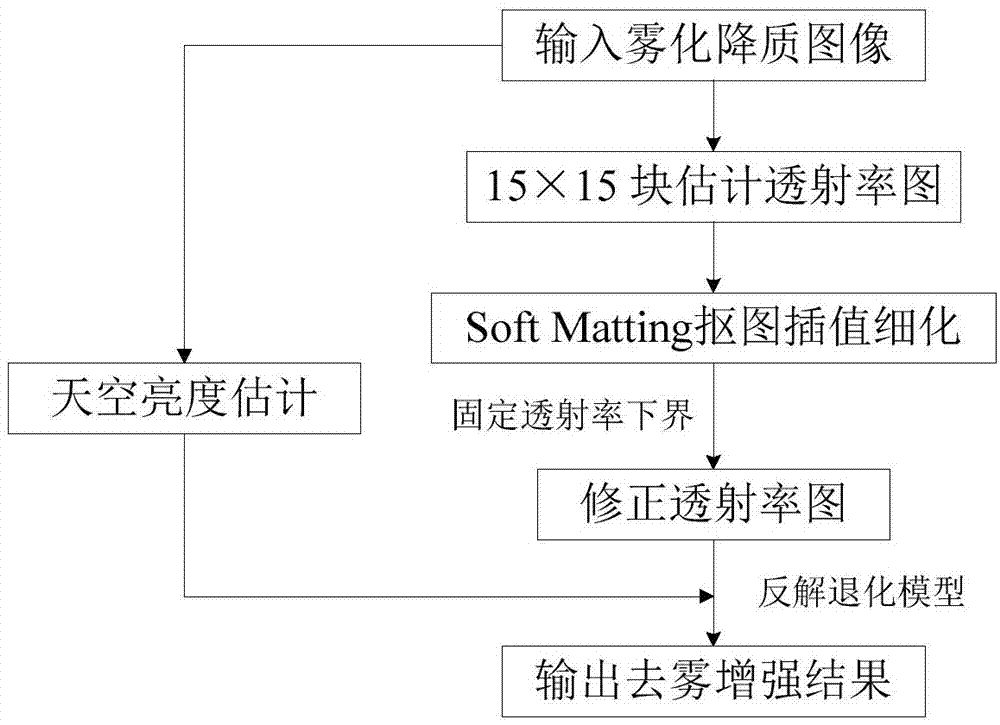

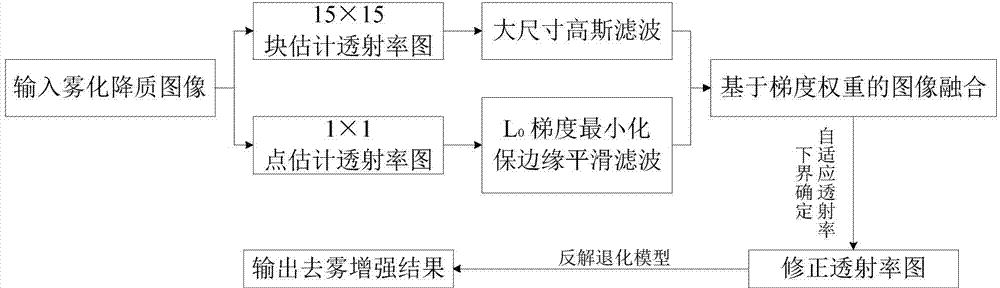

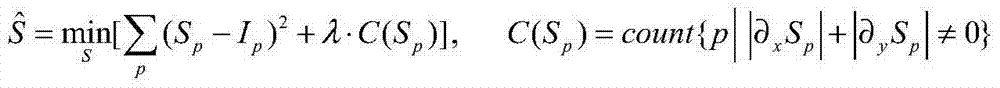

Dark channel prior image dehazing method based on multiscale fusion

ActiveCN103942758ASuppress false edgesTransmittance images are accurateImage enhancementTransmittanceSky brightness

The invention discloses a dark channel prior image dehazing method based on multiscale fusion. The dark channel prior image dehazing method based on multiscale fusion comprises the steps that (1) minimum value filter is conducted on a fog-degraded image through a color channel with a neighborhood size of 1*1 and a color channel with a neighborhood size of 15*15, so that corresponding dark channel images are obtained, and an estimated point transmissivity graph and an estimated block transmissivity graph are calculated based on the dark channel images; (2) edge image smoothness protection based on L0 gradient minimization is conducted on the estimated point transmissivity graph; (3) large-size Gaussian filter is conducted on the estimated block transmissivity graph; (4) with a normalized gradient magnitude as the weight, the estimated point transmissivity graph and the estimated block transmissivity graph are fused to enable a corrected transmissivity graph to be obtained; (5) the lower bound of the transmissivity is estimated based on median filtering; (6) the sky brightness is estimated by means of a 15*15 dark channel image; (7) inverse solution is conducted on a fog-degraded model, and a dehazing result is output. The dark channel prior image dehazing method based on multiscale fusion has the advantages that the dehazing capacity is high, the complexity is low, the image dehazing quality and the image dehazing efficiency can be improved.

Owner:NAT UNIV OF DEFENSE TECH

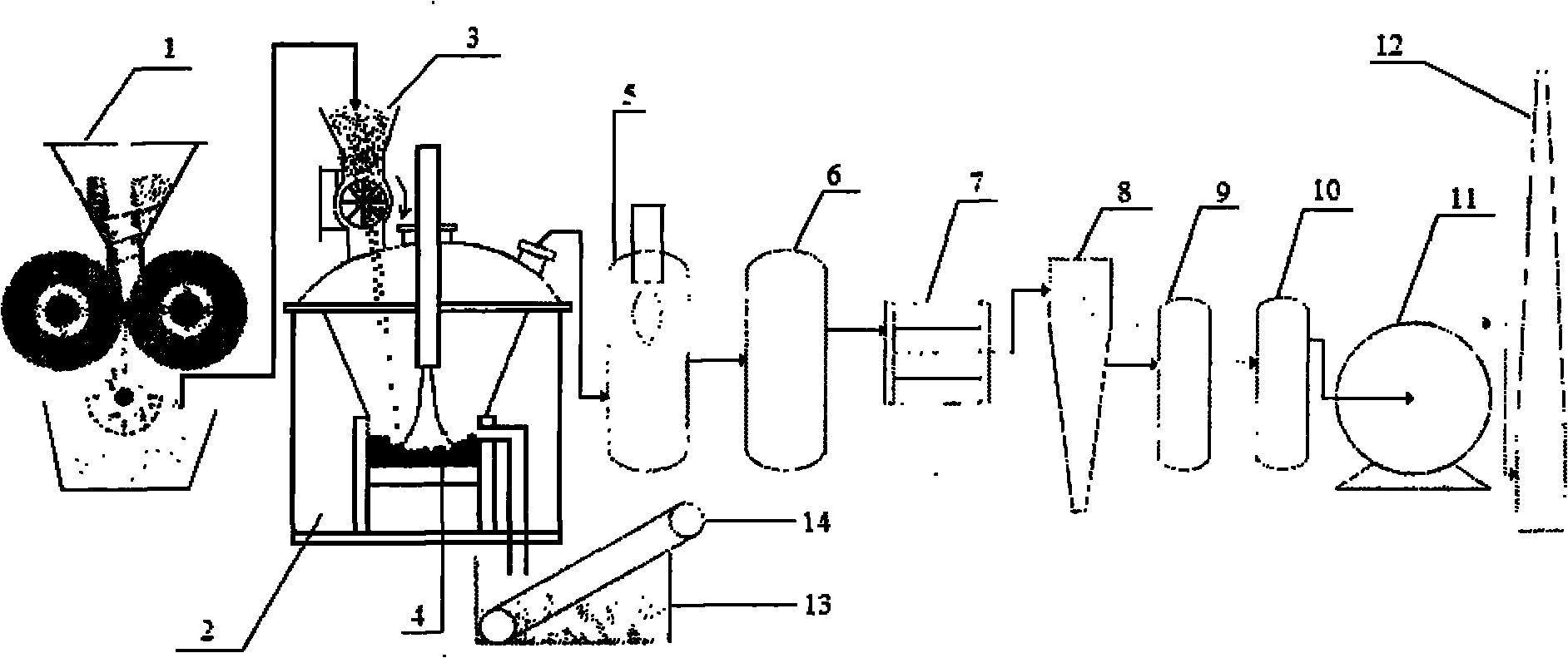

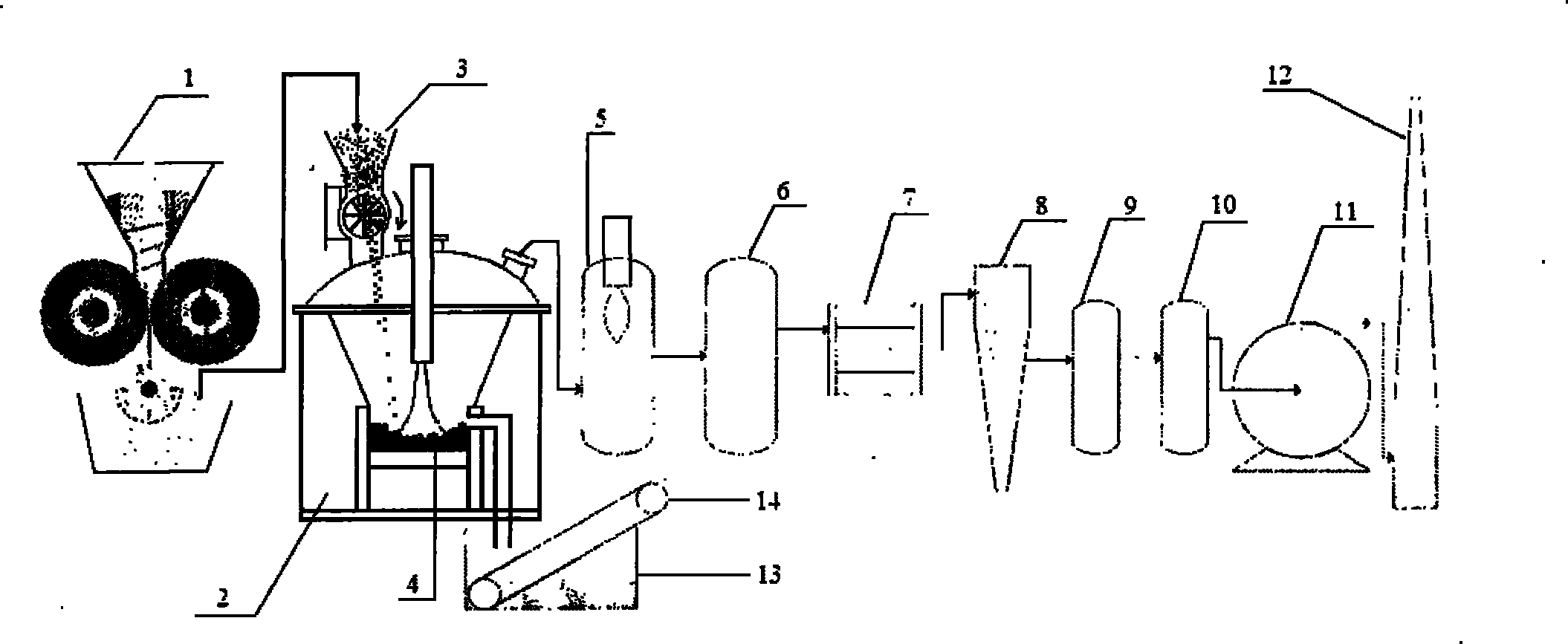

Method for treating waste incineration fly ash by using plasmas

InactiveCN101797572APromote vitrificationSolve the "bridge" problemSolid waste disposalMelting tankVitrification

Owner:安徽中科华炬环保科技有限公司

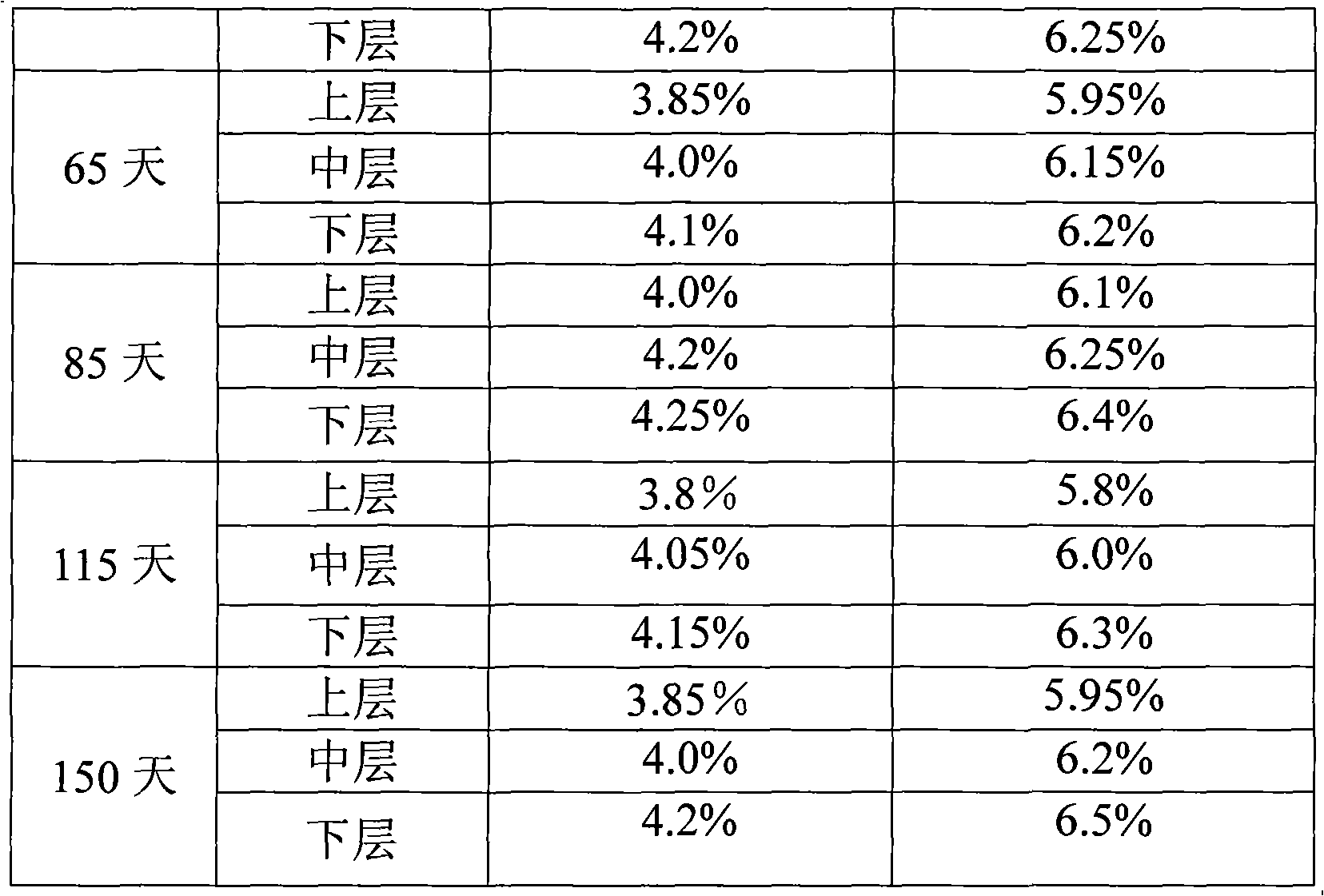

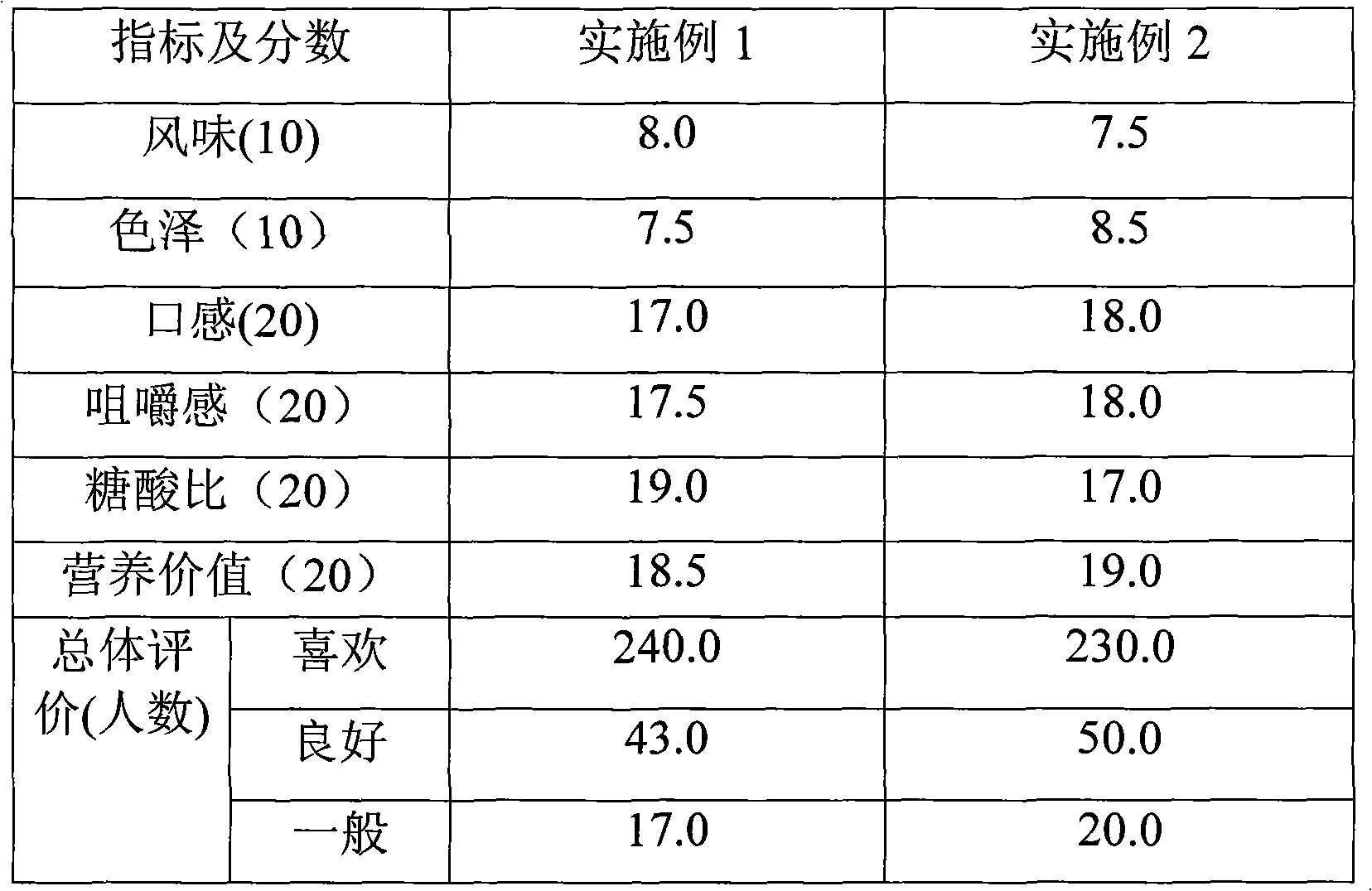

Milk and dairy food containing fruit granules and method for producing the same

The present invention relates to a diary product containing fruit granules. Every 100 weight parts of the diary product of the present invention contains 30 to 80 parts of milk and milk product, 1 to 15 parts of fruit granules, 0.2 to 1.0 part of stabilizer compound and 0.25 to 0.6 part of acidity regulator; wherein, the stabilizer compound contains modified bio-fermentation polysaccharide and thickener; the fruit granule contains coconut juice fermented polysaccharide granule and fruit vegetable granule. A production method of the diary product containing fruit granules is also related by the present invention.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

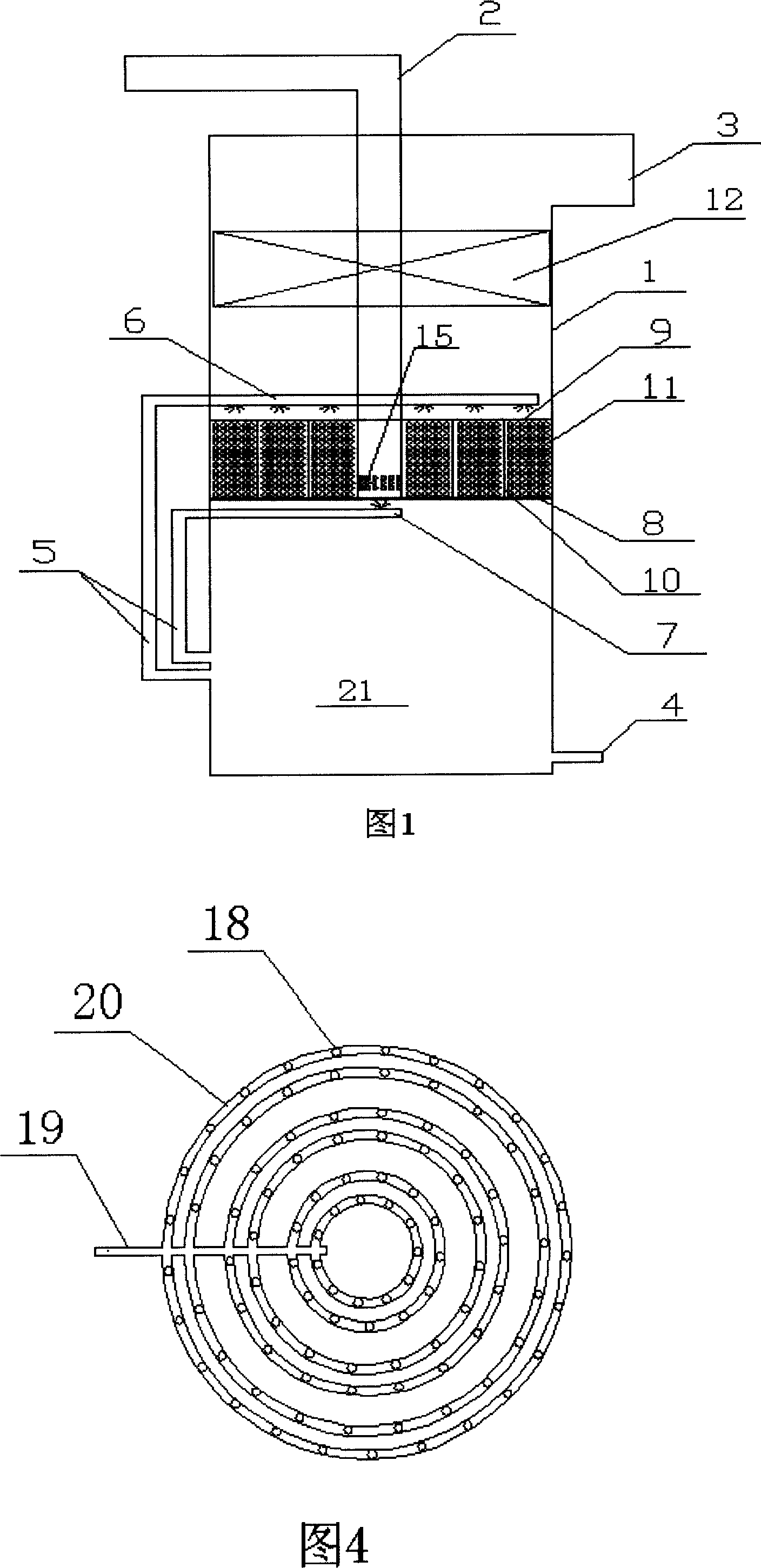

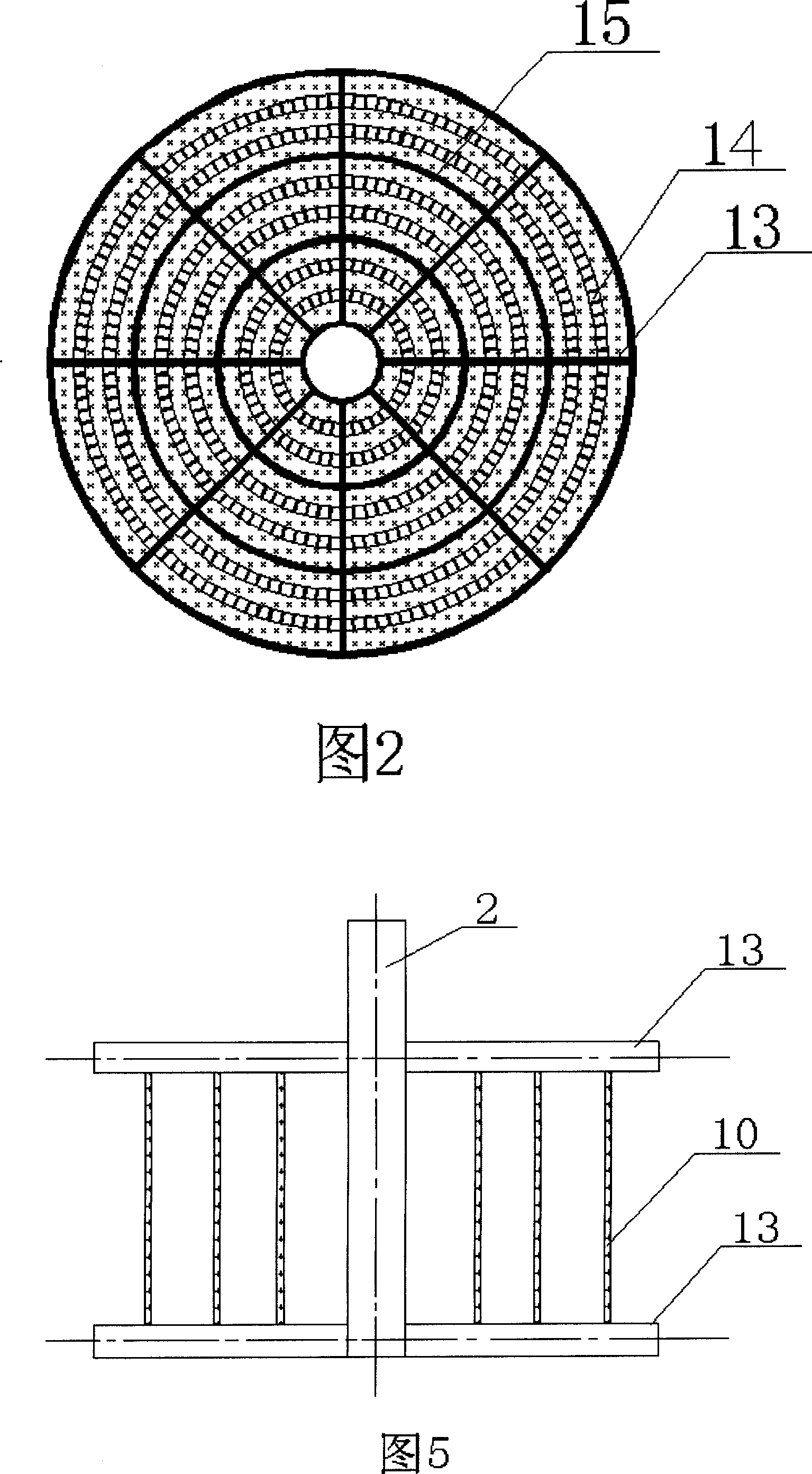

Novel barrier type air-actuated three-phase fluidization synthetized absorbing tower

InactiveCN101081348ANot easy to cause blockageTo achieve the purpose of purification and absorptionDispersed particle separationInlet channelGrating

The grating type pneumatic triphase fluidizing comprehensive absorption tower includes one housing, one gas inlet channel and gas outlet channel in the top of the tower, one rotary defogging and dewatering unit, one stuffing assembly comprising support boards, hold-down boards and stuffing, one coaxial tubular grating member, one liquid distributor with ring sprinkler pipe, one large caliber reverse sprayer inside the gas inlet channel, and one absorbing slurry pond in the bottom of the tower. It features the special grating structure, the regularly arranged stuffing for cyclic fluidizing, the combined foam absorption and stuffing absorption, etc, and has high absorption efficiency, great gas treating amount and other advantages.

Owner:BEIJING HUAYU RONGTONG POWER TECH DEV

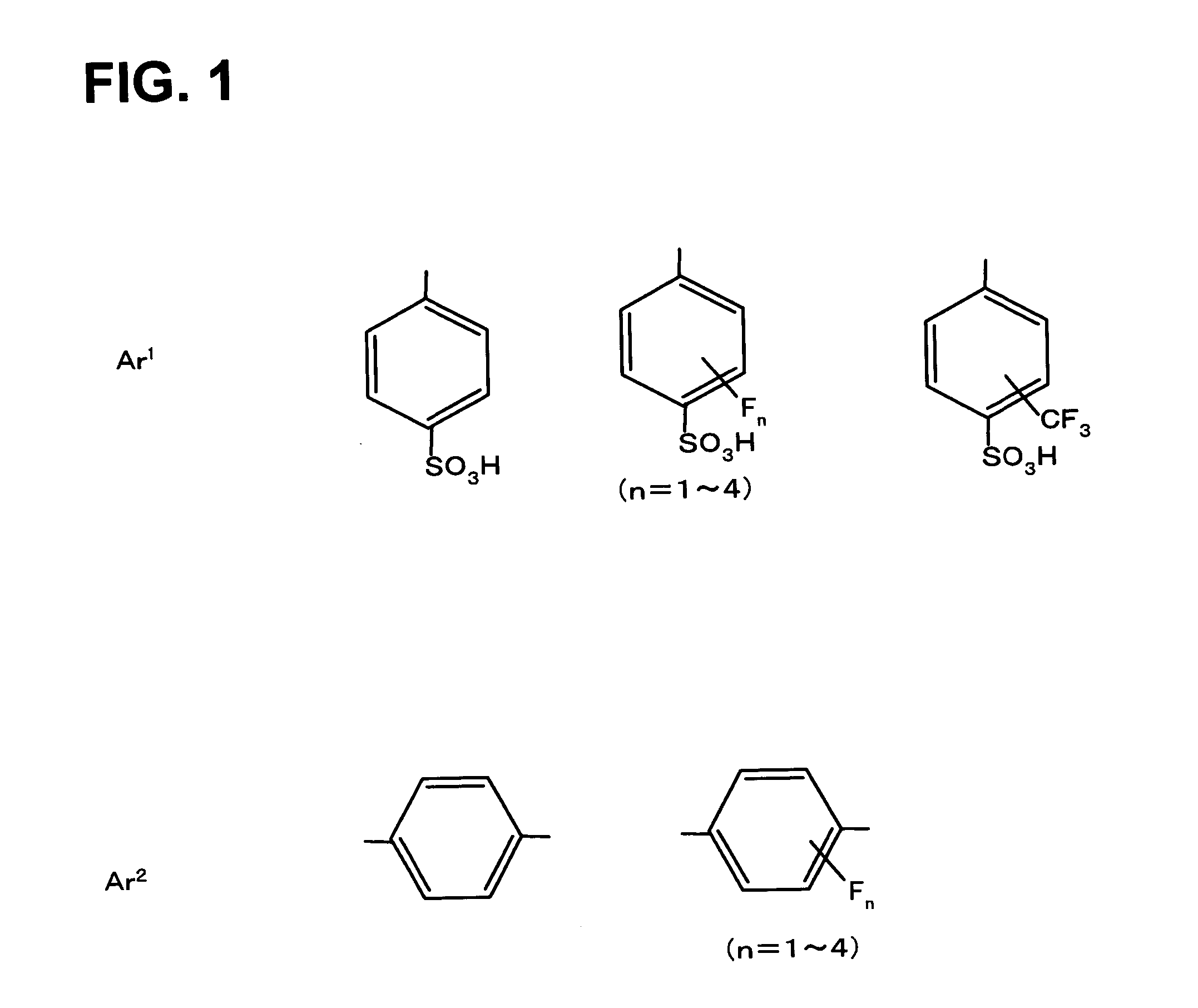

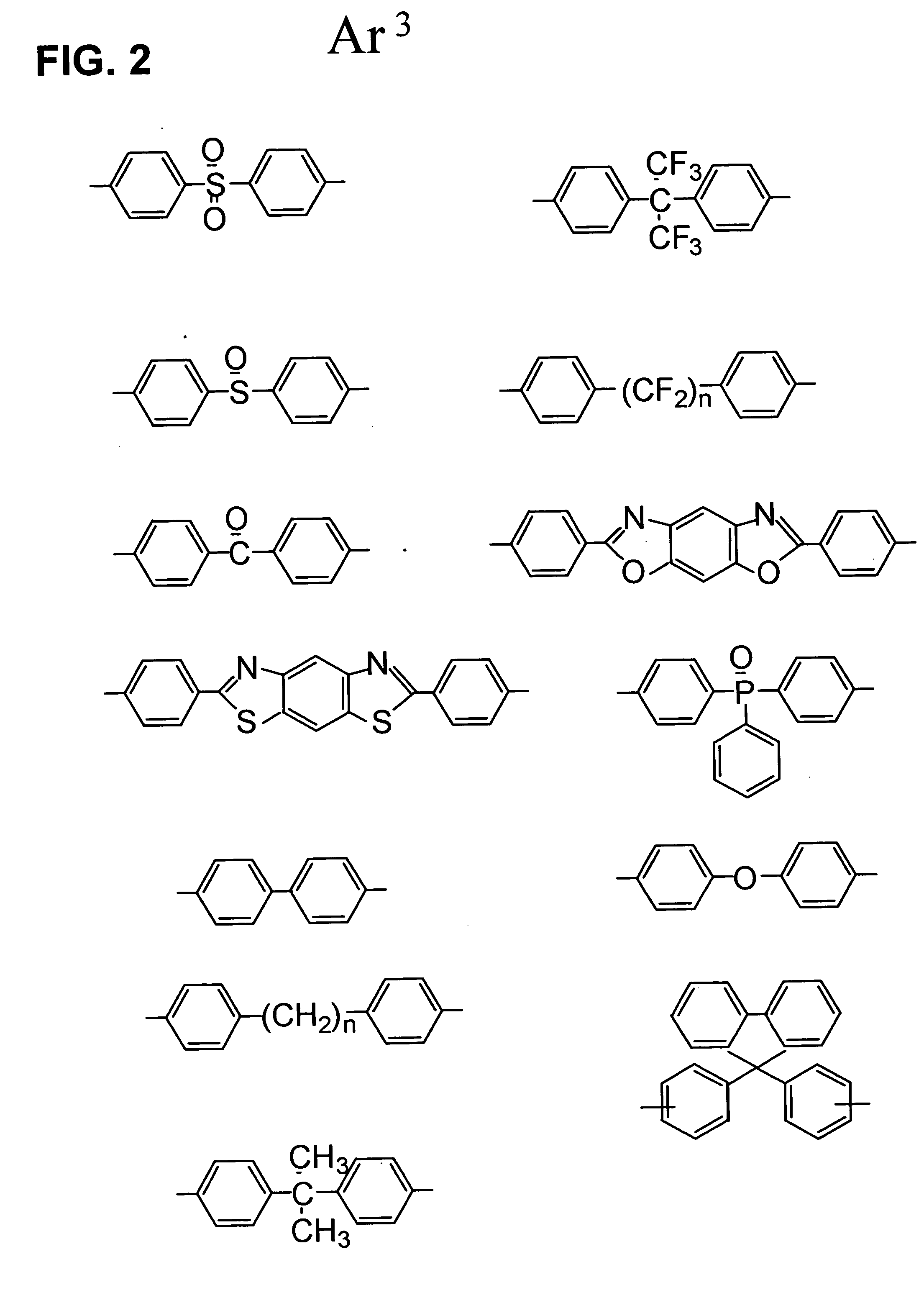

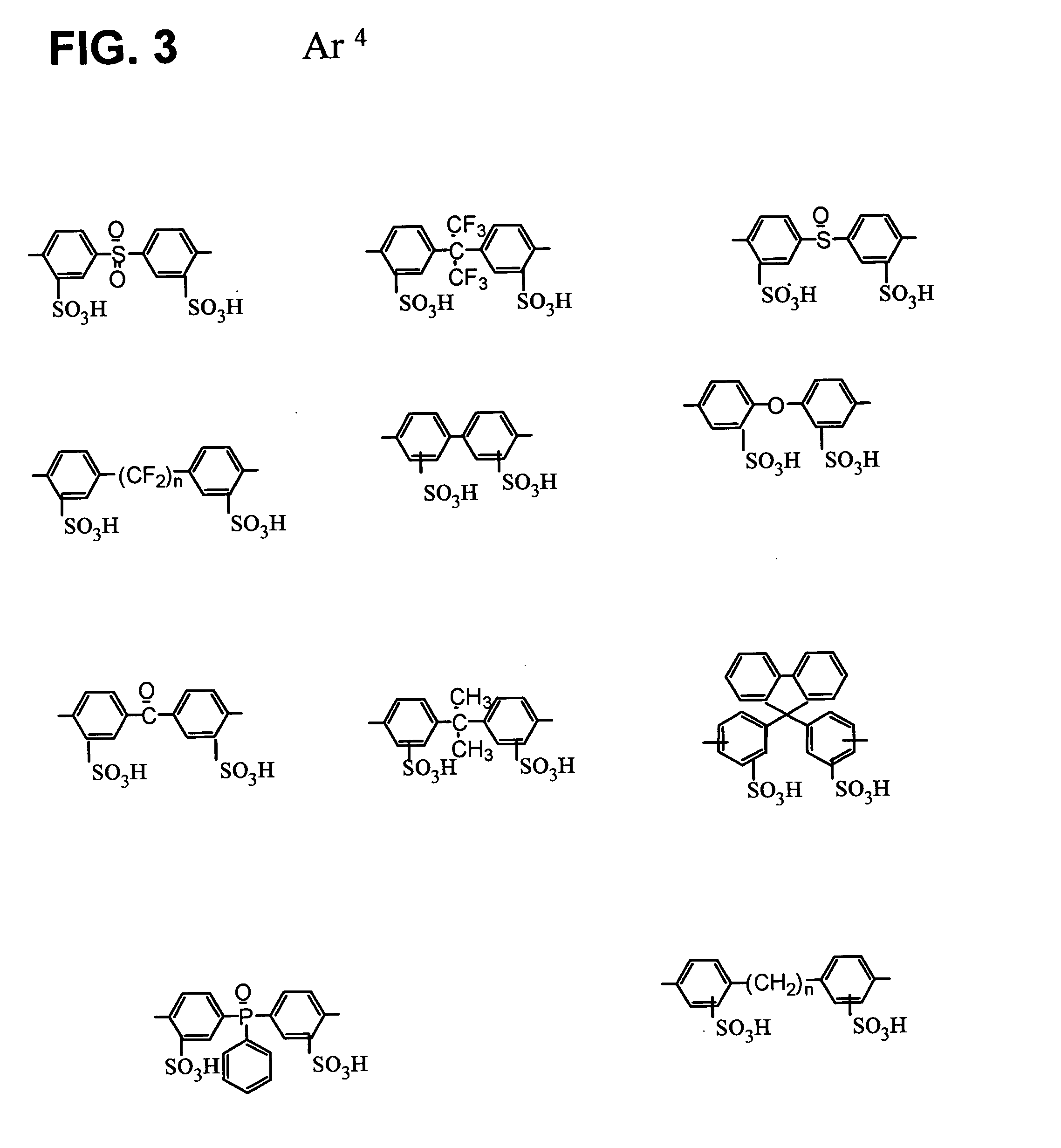

Sulfonic acid group-containing, proton-conducting polymer composition, a solid electrolyte membrane and a solid polymer fuel cell

InactiveUS20050221135A1Low methanol cross-overImprove proton conductivityOrganic chemistryIon-exchanger regenerationFuel cellsTriazine

A solid electrolyte membrane for solid polymer fuel cells, or the like is provided that is chemically stable in a strong acid atmosphere, and has low methanol cross-over as well as high proton conductivity. The solid electrolyte membrane is manufactured, using an electrolyte composition comprising a sulfonic acid group-containing polymer having a specific triazine structure. This polymer can be synthesized, for example, from a sulfonic acid group-containing dihydroxy compound having a triazine structure, and a difluoride.

Owner:FUJITSU LTD

Preparation method of hollow fiber in coaxial electrostatic spinning

InactiveCN103088442ASolve the blockageIncrease viscosityHollow filament manufactureFilament/thread formingElectrospinningEngineering

The invention discloses a preparation method of hollow fiber in coaxial electrostatic spinning. The method includes a first step of selecting synthetic macromolecule and enabling the synthetic macromolecule to be solved in solution and stirred until the synthetic macromolecule is completely solved according to prepared final fiber, and a second step of using the solution obtained in the first step as outer pipe spinning liquid which is injected into an outer pipe of a coaxial spinning nozzle, ventilating air into an inner pipe and conducting the coaxial electrostatic spinning under the condition of room temperature. The prepared fiber is in an obvious hollow structure and can be applied to the medical field of drug carriers, artificial dialysis and the like. The preparation method of the hollow fiber in the coaxial electrostatic spinning has the advantages of being simple and convenient to operate, temperate in reaction condition, low in cost, and capable of being completed just by one step without need of using inner layer materials and subsequent processing, greatly saving time and material cost, meanwhile avoiding influences of the remained inner layer materials on the hollow fiber and having good application prospect.

Owner:SHANGHAI JIAO TONG UNIV +1

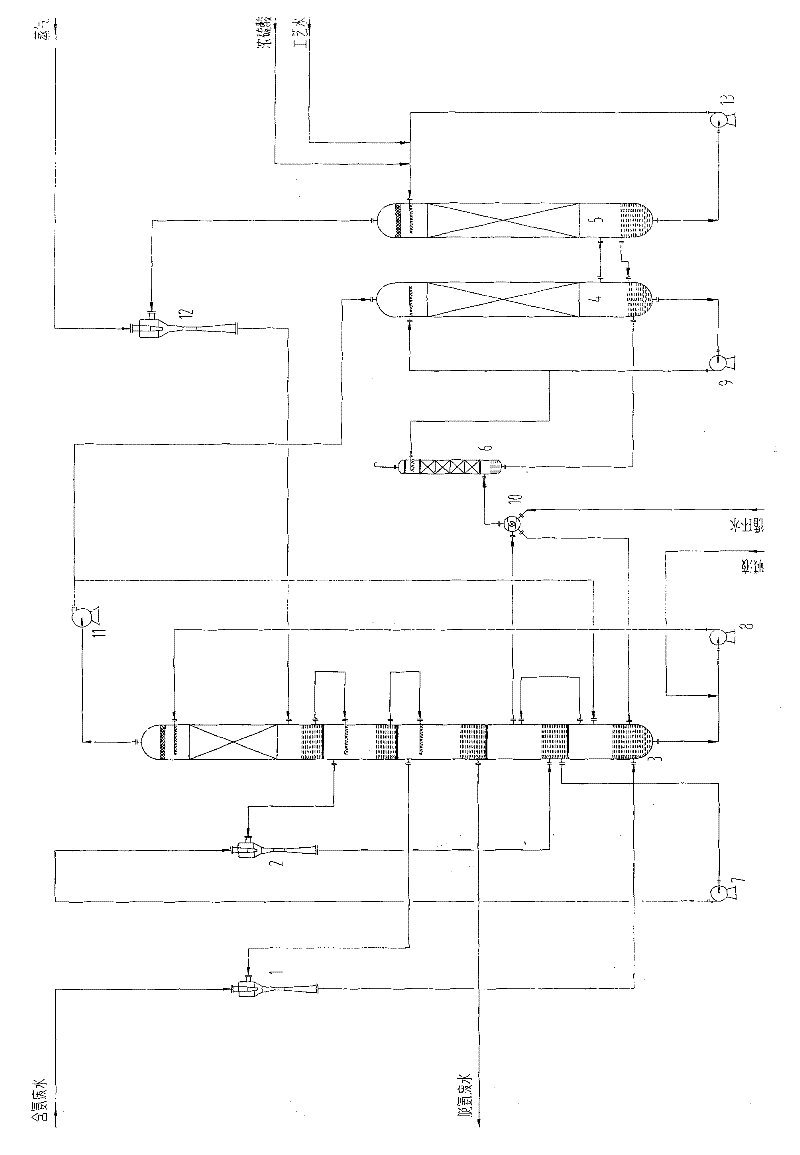

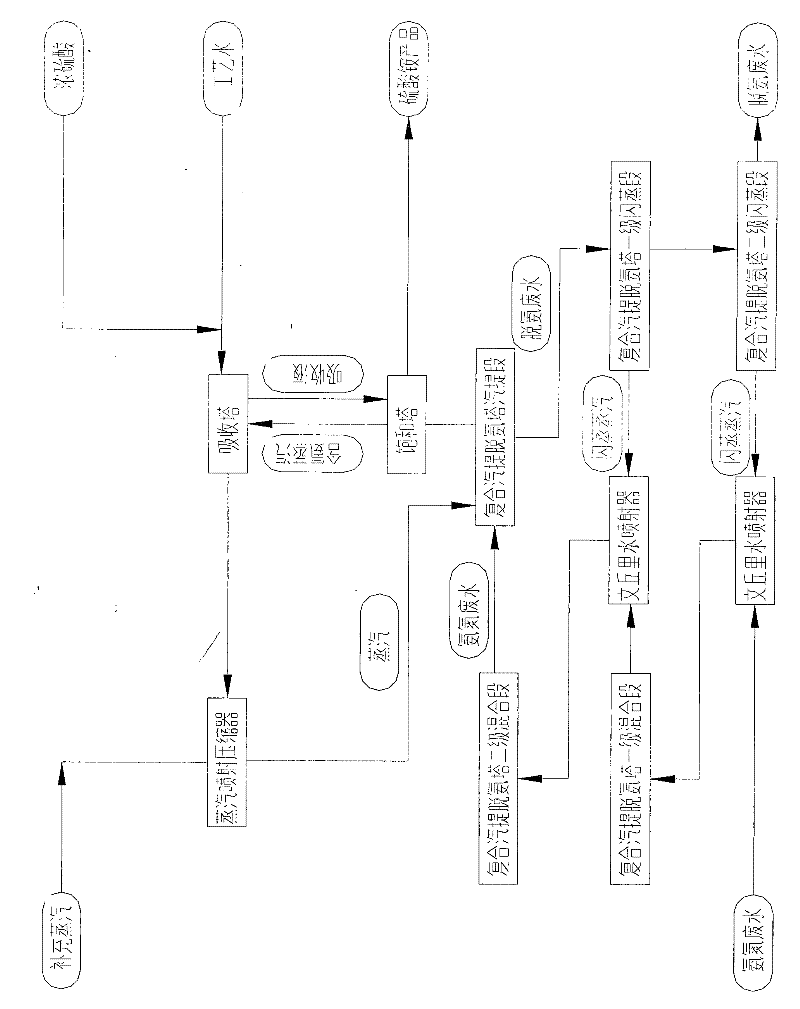

Stripping ammonia-removing method based on flash evaporation and heat pump technologies

ActiveCN102190341ARealize heat exchangeAvoid badWater contaminantsWater/sewage treatment by degassingAbsorption columnDirect heating

The invention relates to a stripping ammonia-removing method based on flash evaporation and heat pump technologies. The method comprises the following steps of: absorbing steam which is obtained after stripping ammonia removal and rich in ammonia nitrogen with an absorption column, pressurizing the purified steam with a heat pump set for recycling, carrying out flash evaporation on wastewater subjected to ammonia-removing process with a vacuum flash evaporation set composed of a Venturi and a liquid ring vacuum pump, and directly heating for pretreating wastewater with high ammonia nitrogen content. Compared with the traditional process with high ammonia-removing steam consumption and high operation cost, the method disclosed by the invention has prominent effects in energy saving and consumption reducing, and has broad market application prospect and high application potential in the treatment of wastewater containing ammonia nitrogen.

Owner:CHINA PETROLEUM & CHEM CORP +3

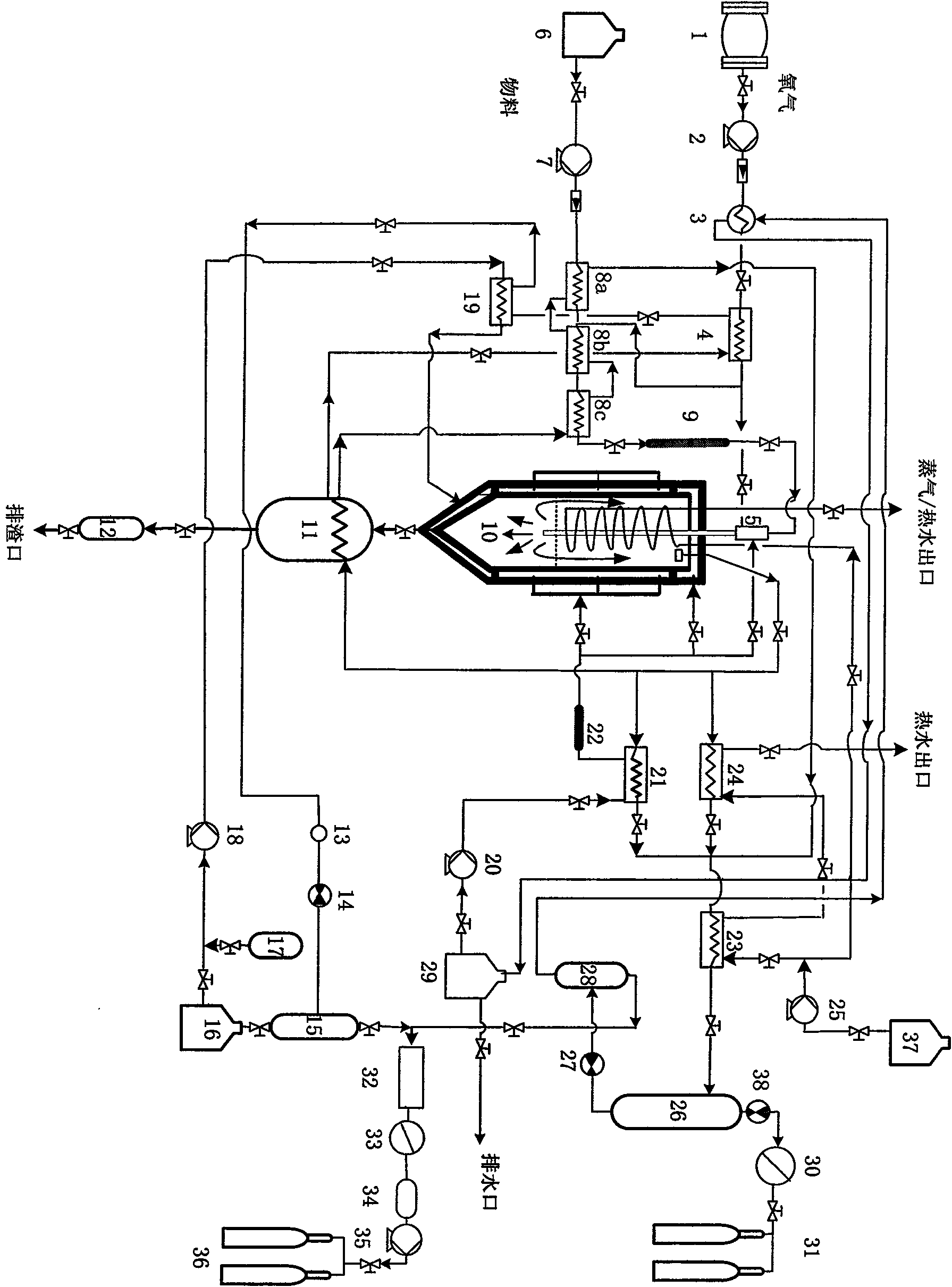

Supercritical water treatment and resource utilization system for waste organic matter

InactiveCN101607772AIncrease flow rateAvoid cloggingGeneral water supply conservationSolid waste disposalSlagPre treatment

The invention belongs to the field of environmental protection, relating to a technology for carrying out harmless treatment and resource utilization on waste organic liquid such as organic waste water / municipal sludge, and the like which has high concentration and is difficult for biochemical degradation, taking supercritical water as a reaction medium. The invention also discloses a supercritical water treatment and resource utilization system for waste organic matters. The system has the versatility, can flexibly select an optimal supercritical water treatment method in SCWO, SCWPO and SCWG according to the characteristics of different materials, integrates pretreatment, mixing, reaction, as well as product separation and collection of the materials, integrates COD emission reduction, desalination, slag removal and hydrogen production, and integrates the harmless treatment and the resource utilization of the waste organic matters.

Owner:XI AN JIAOTONG UNIV

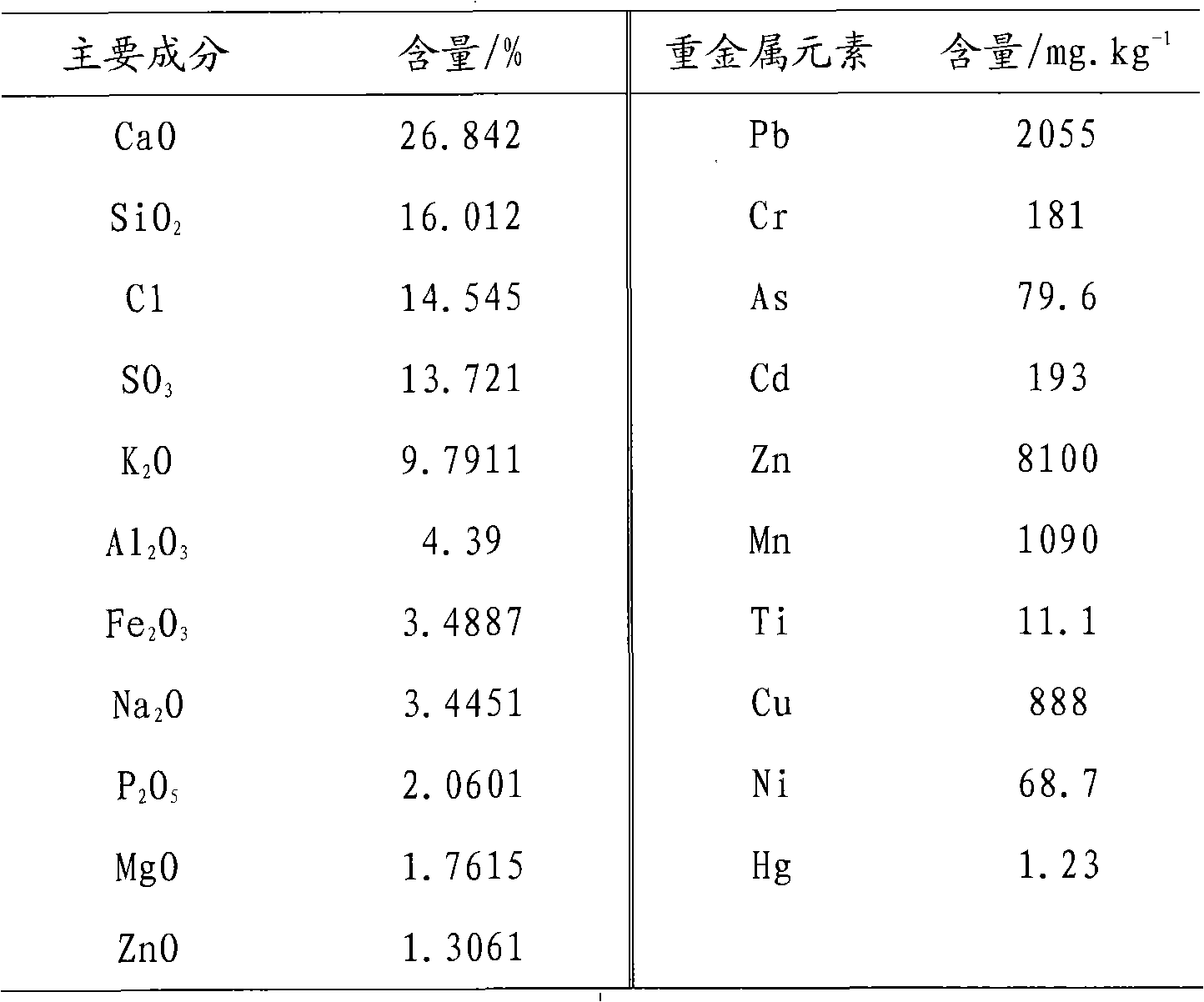

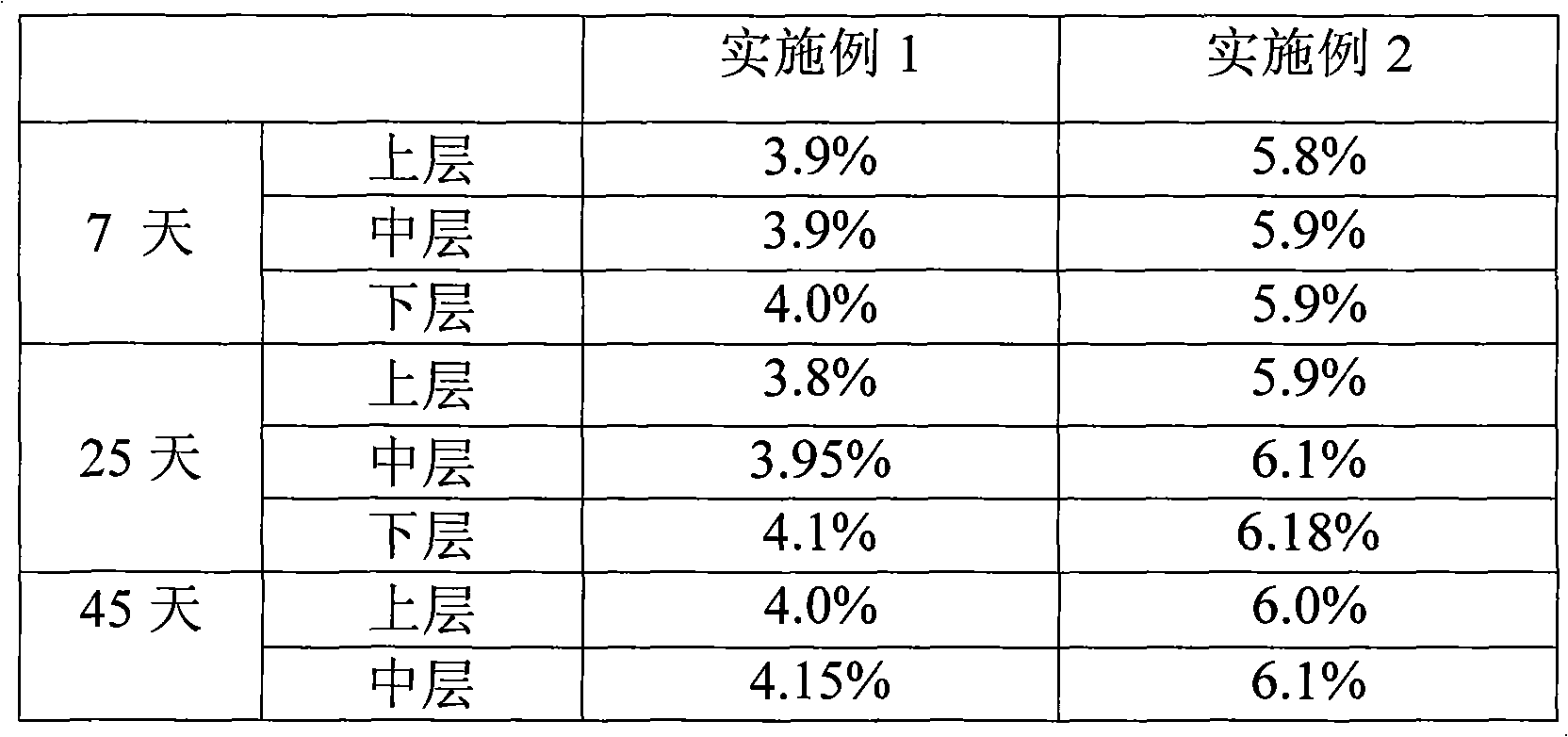

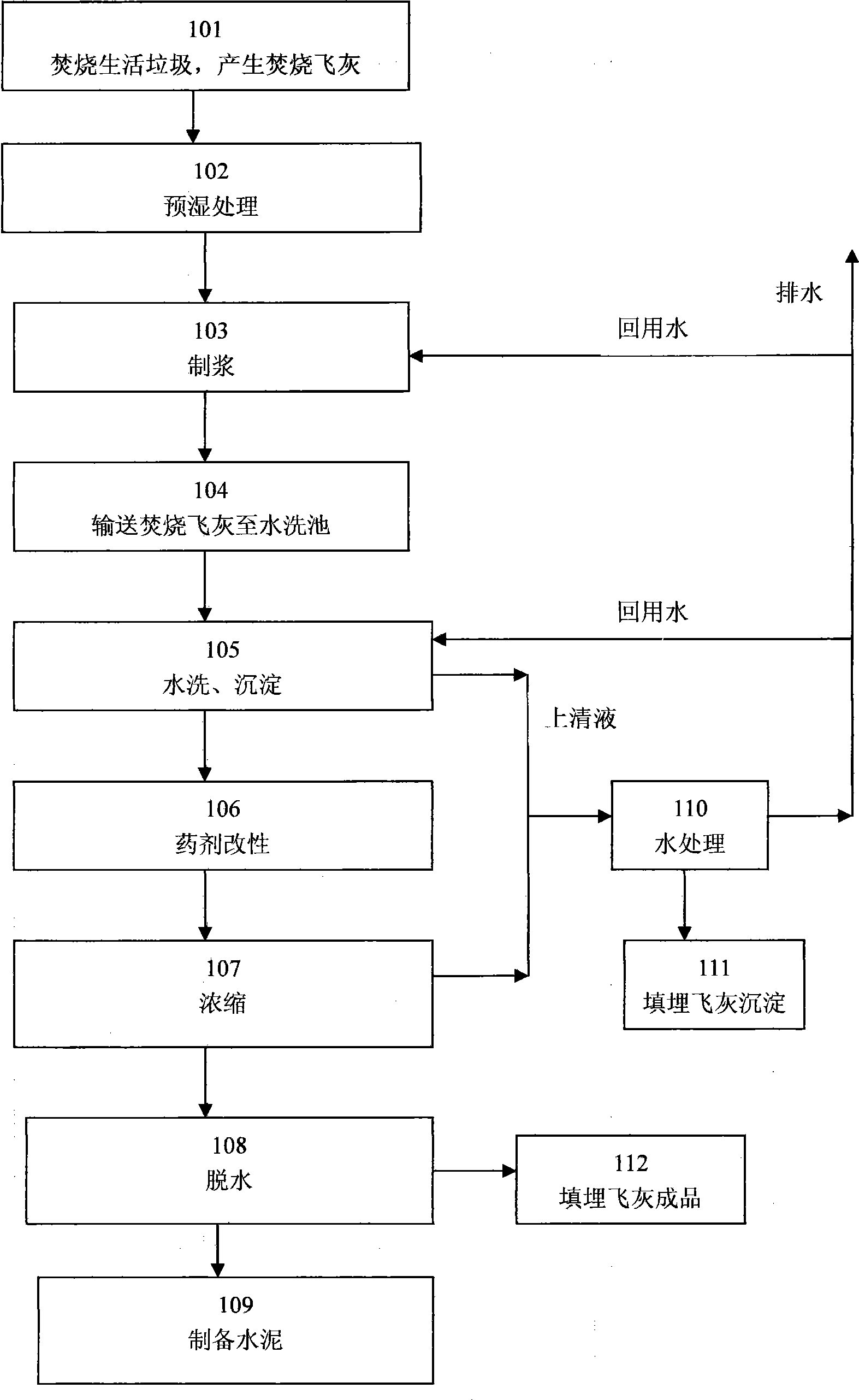

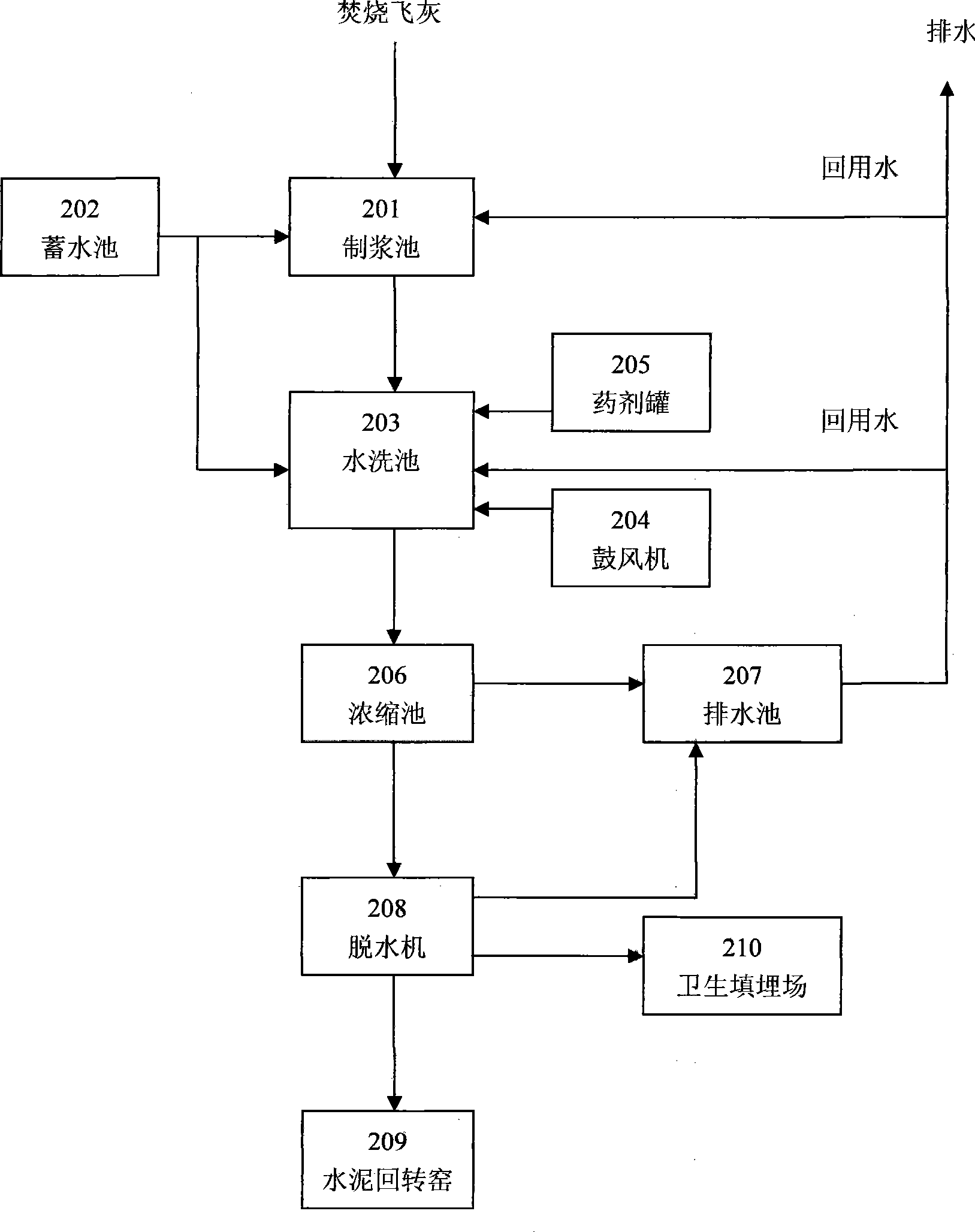

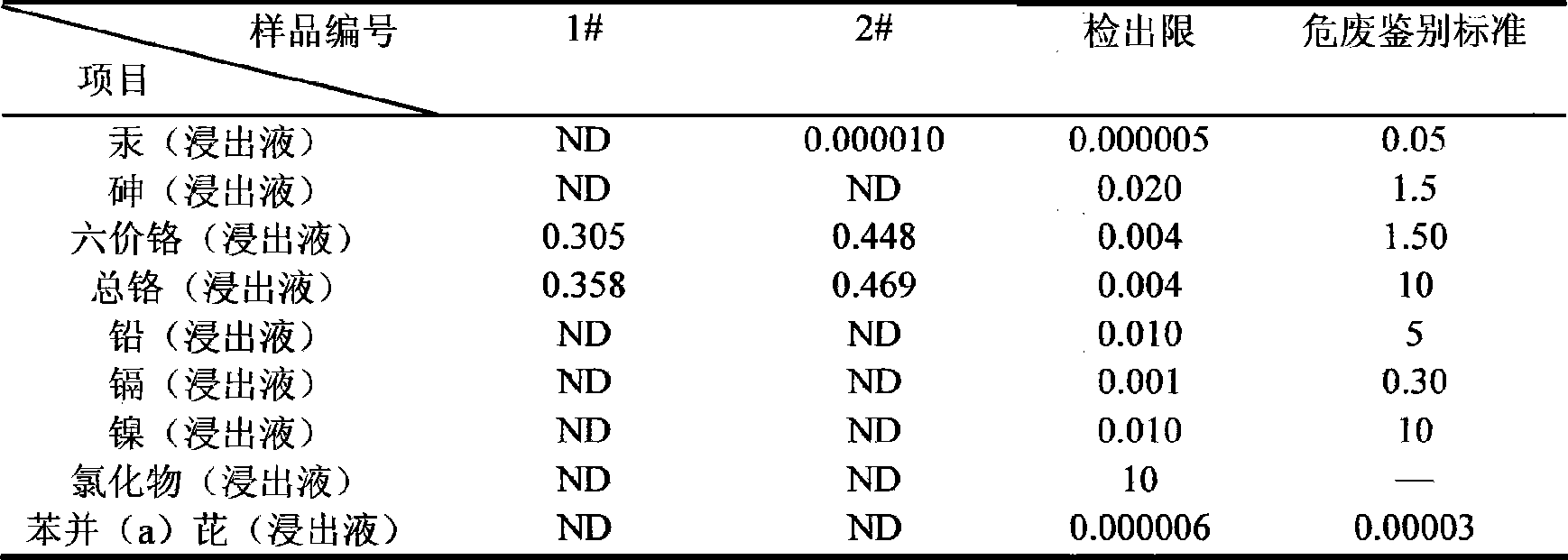

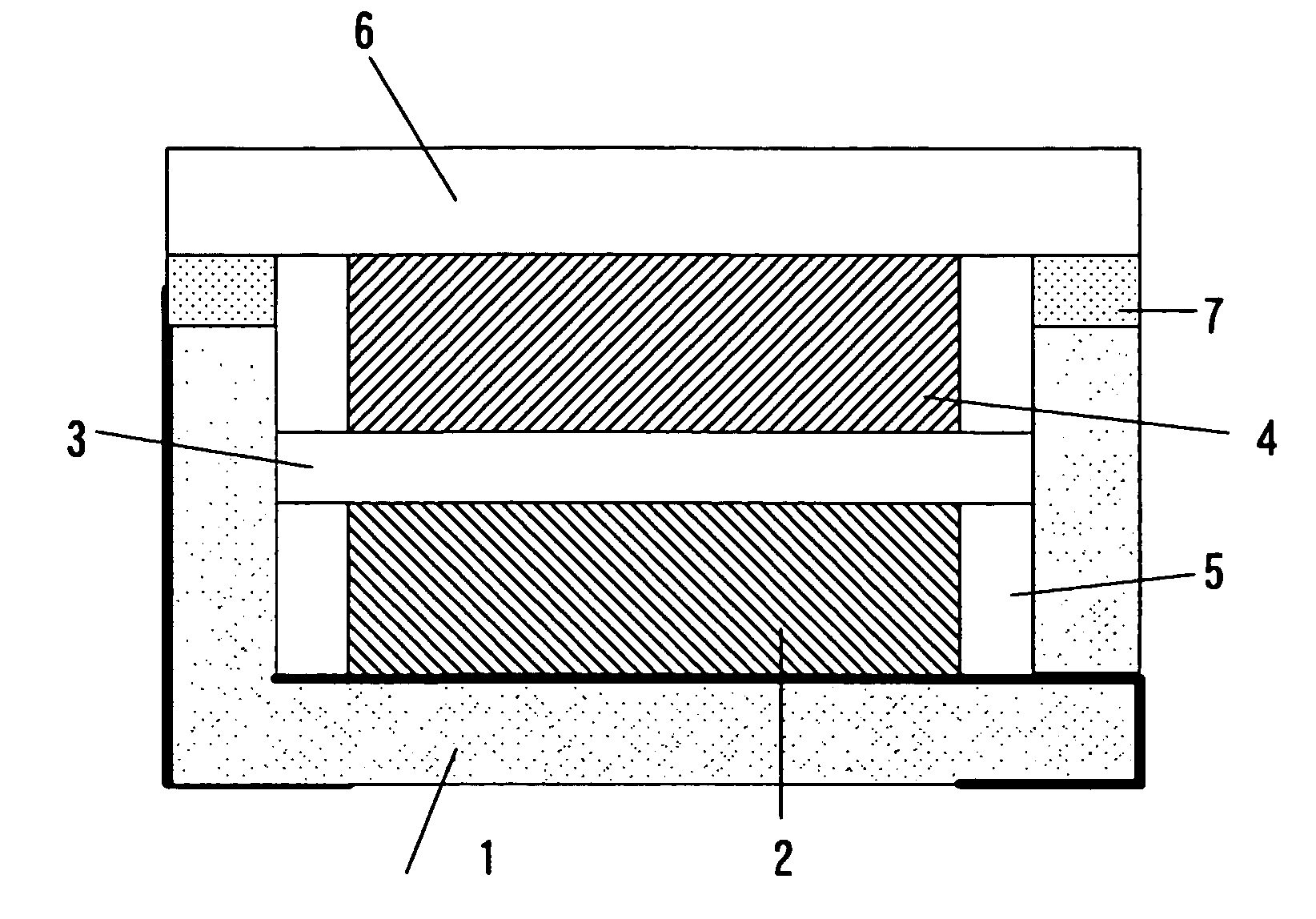

Innocent treatment method and apparatus for refuse burning flyash

ActiveCN101462835AReduce chlorine contentSolve the blockageSolid waste disposalCement productionWater qualitySlurry

The invention proposes a method for the innocent treatment of refuse burning fly ash. The method comprises the following steps: prewetting; pulping: mixing and stirring the fly ash and water in the proportion of 1:2 to 1: 20 to form ash slurry; water washing and precipitation: dissolving the soluble salts in the fly ash; modification through a reagent; concentration for reducing the water content of the ash slurry to 70 to 90 percent; dehydration for reducing the water content of the ash slurry to below 35 percent; water treatment: charging CO2 or acid to make the strongly basic supernatant with the pH value as high as 11 to 12 become the neutral water quality with the pH value of 6.0 to 8.5; flocculant addition for catching tiny particles and speeding up the precipitation process; cement preparation: heating up the fly ash end product in a cement rotary kiln to 1,000 to 1,450 DEG C, and decomposing dioxin and inhibiting the regeneration of the dioxin at the low temperature; and increase of the boiling point of heavy metals for passivating the volatility.

Owner:SHANGHAI SOLID WASTE DISPOSAL CENT +2

Electrochemical cell

InactiveUS7883796B2Inhibition capacityInternal resistanceHybrid capacitor electrodesFinal product manufactureEngineeringElectrochemical cell

An electrochemical cell has a container having a main surface and a cavity containing therein a positive electrode, a negative electrode, a separator separating the positive and negative electrodes from one another, and an electrolyte. A sealing plate that seals the cavity of the container is bonded to the main surface of the container with an unoxidized weld.

Owner:SEIKO INSTR INC

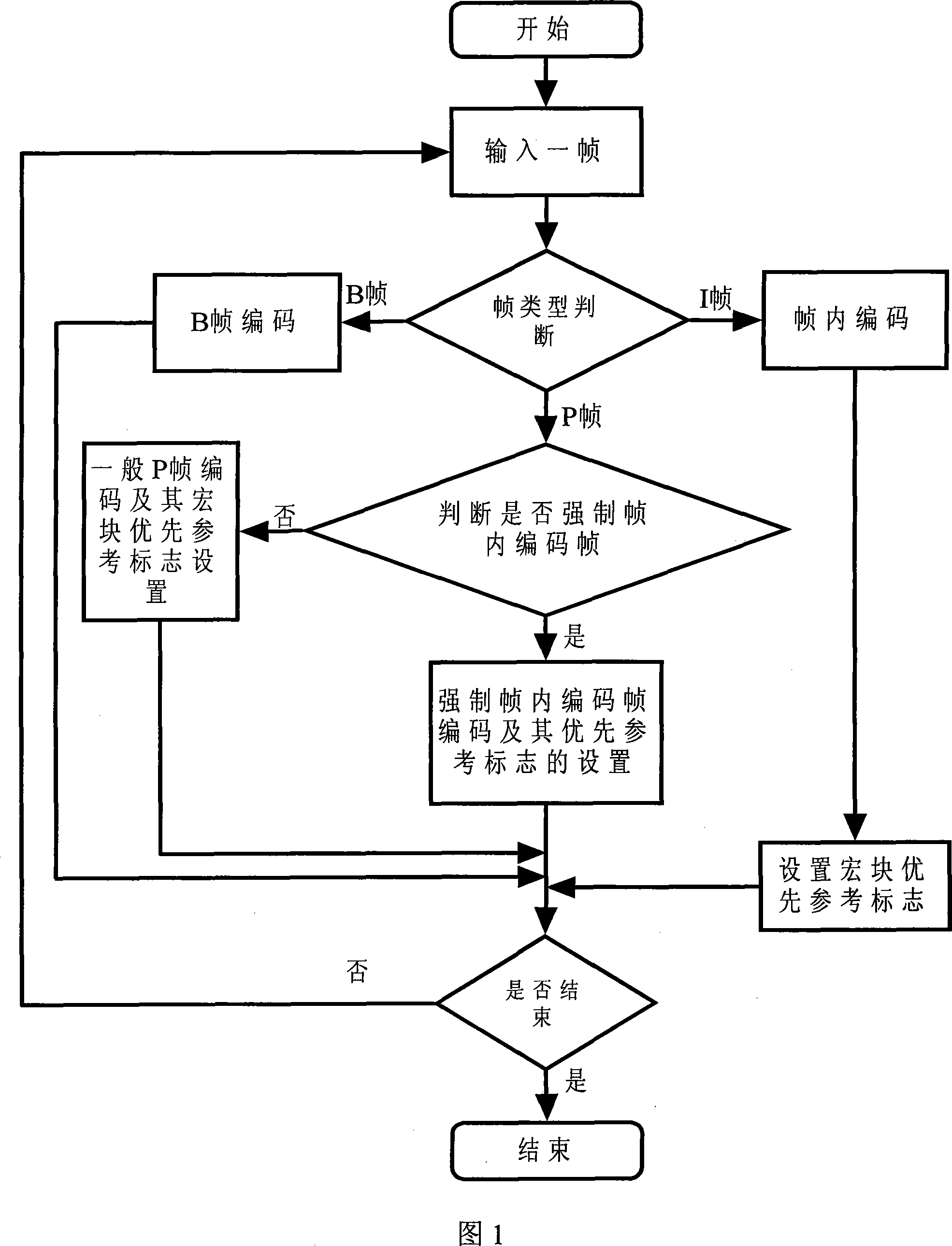

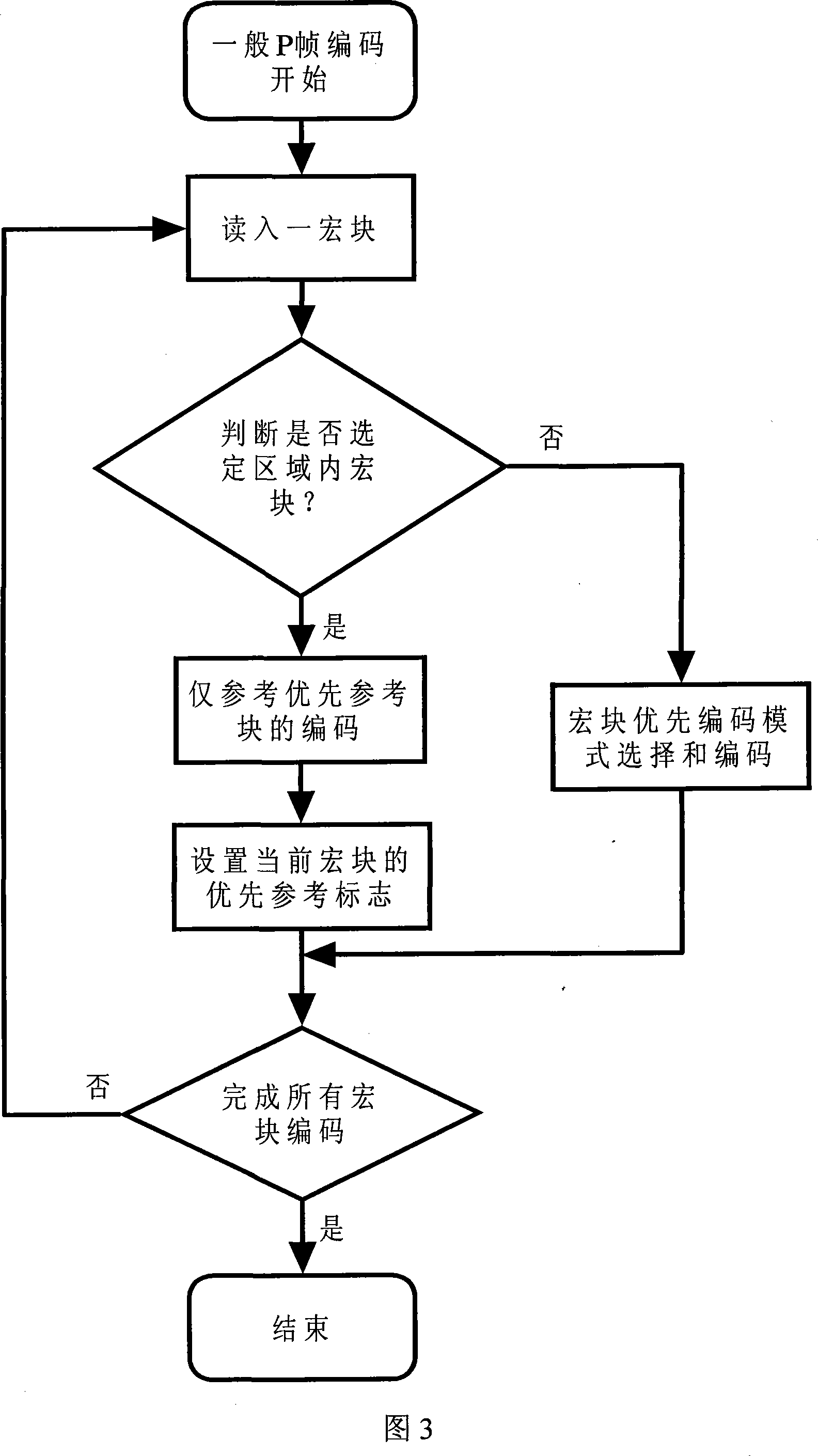

Video encoding method of embedding intraframe coding block

ActiveCN101232619ASolve the blockageIncrease intervalTelevision conference systemsClosed circuit television systemsComputer hardwareCoding block

The invention discloses a video coding method for coding blocks inside the embedded frame; in every fixed frame interval, the invention can perform forcible frame internal coding in a specified region for a preceding estimated frame (P frame); the macro block reconstructed in predication for coding blocks in reference of the forcible frame can be deemed as a preferential reference block; if the reference block pixels in the macro block coding are inside the coding block or preferential reference block in the frame, the reconstructed macro block is still a preferential reference block. The preferential reference block can be reconstructed from the coding block frame inside the embedded frame. The invention is applicable to video monitoring and video conferences and able to increase I frame interval on the premise of guaranteeing random access points; therefore, the invention can lower bit spending.

Owner:华雁智能科技(集团)股份有限公司

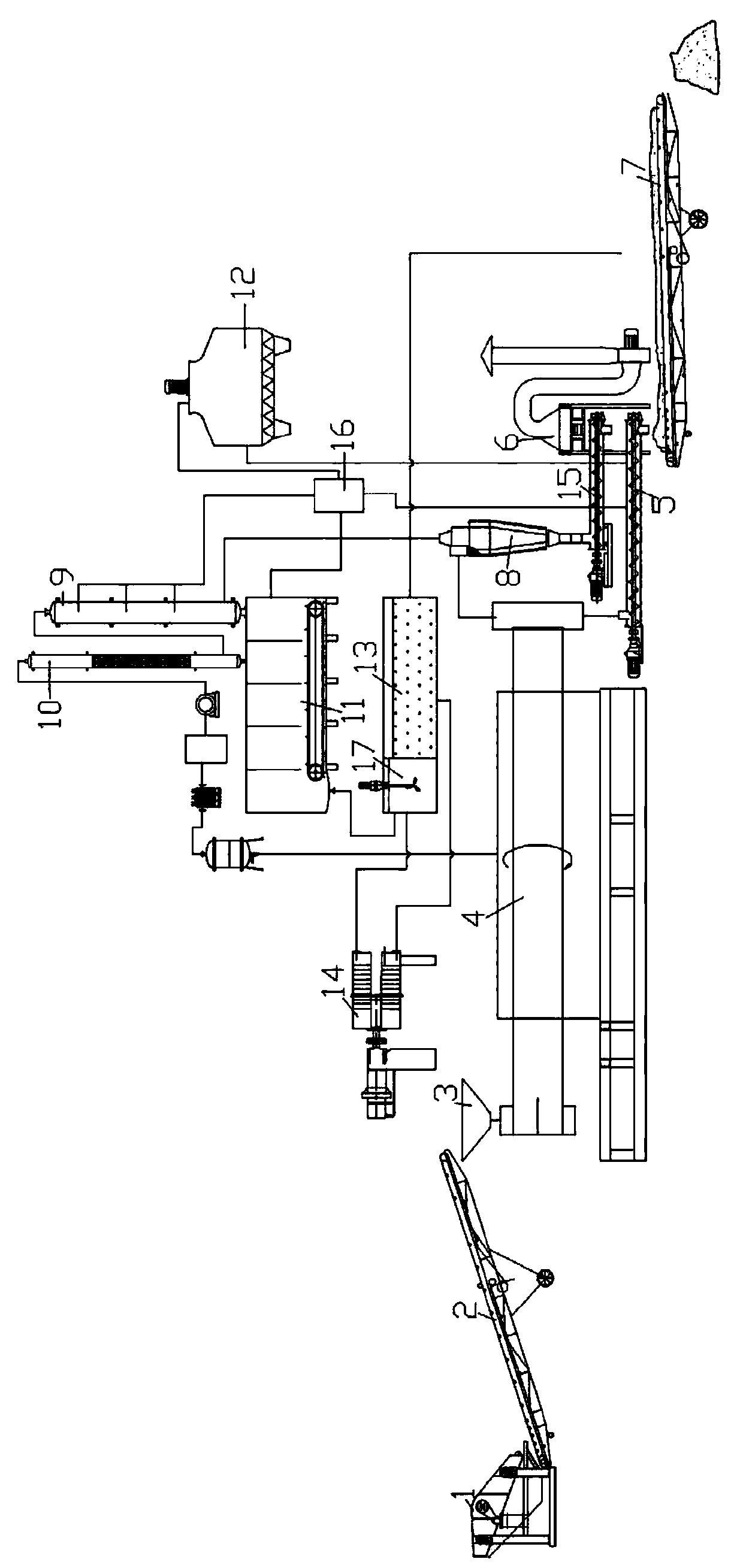

Device and method for indirect thermal desorption disposal of persistent organic pollutant contaminated soil

ActiveCN104226681ASimple ingredientsReduce the risk of secondary pollutionCombination devicesContaminated soil reclamationAutomatic controlCvd risk

The invention discloses a device and a method for indirect thermal desorption disposal of persistent organic pollutant contaminated soil. The device comprises a contaminated soil pretreatment system, a feeding system, a thermal desorption system, a discharging system, a tail gas purification system and an automatic control system, wherein the contaminated soil pretreatment system is connected with a feed opening of the thermal desorption system through the feeding system, a solid discharge opening of the thermal desorption system is connected with the discharging system, and a gas discharge opening of the thermal desorption system is connected with an inlet of the tail gas purification system. According to the method, after pretreatment, contaminated soil is conveyed to the thermal desorption system for desorption for 10-40 min at the temperature of 400-600 DEG C, and desorption exhaust gas adopts a technology including procedures of cyclone dust removal, two stages of spraying, drying and activated carbon adsorption / gliding arc degradation. The device and the method adopt indirect heating, so that risks of generation of poisonous materials such as dioxine and the like are avoided effectively; and a double-layer cylinder rotary kiln type furnace body, the furnace body axis and the ground form a 0-degree angle, and accordingly, the operation and maintenance costs are reduced.

Owner:中节能大地(杭州)环境修复有限公司

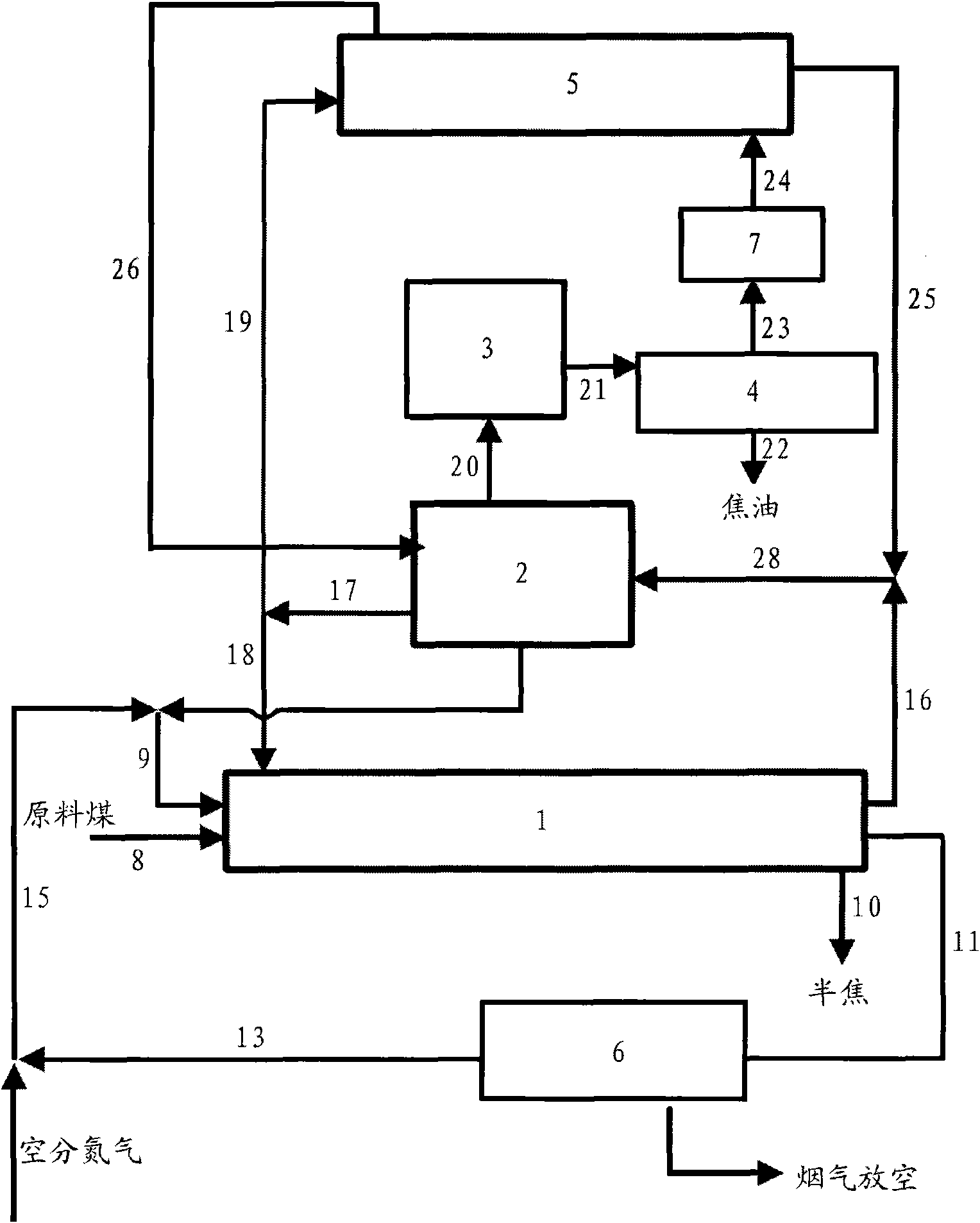

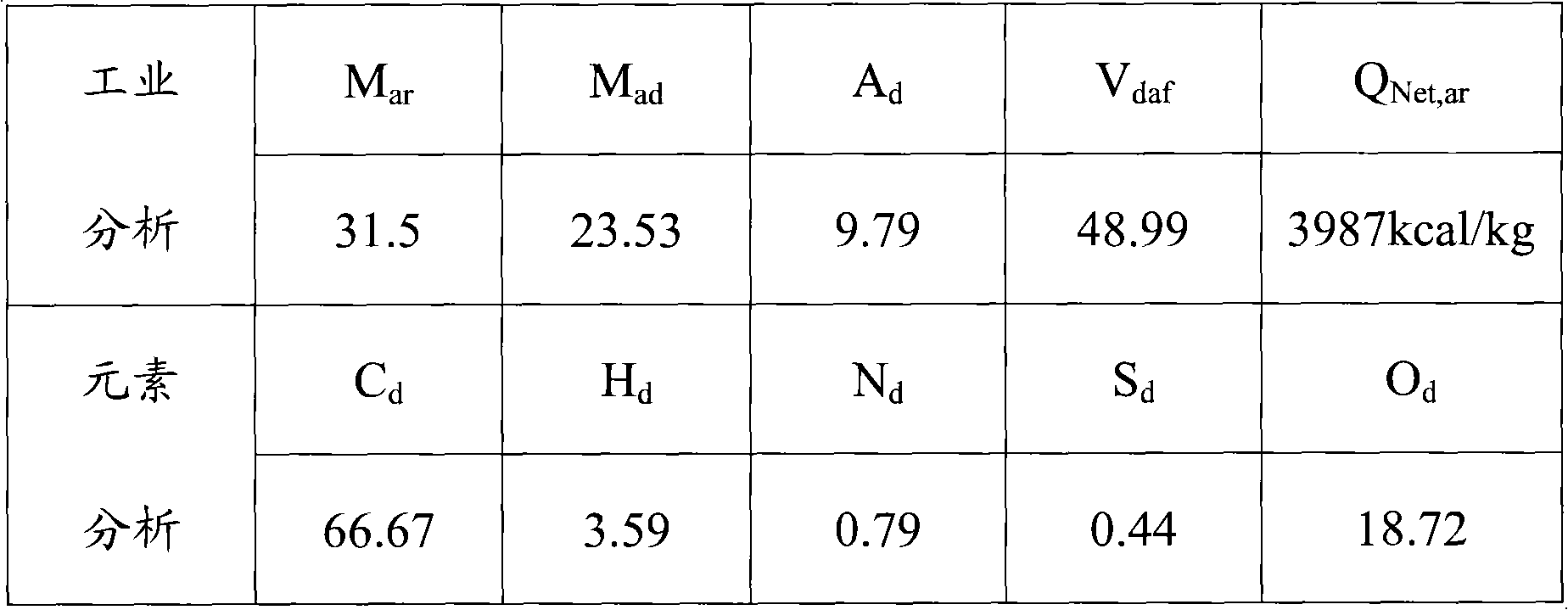

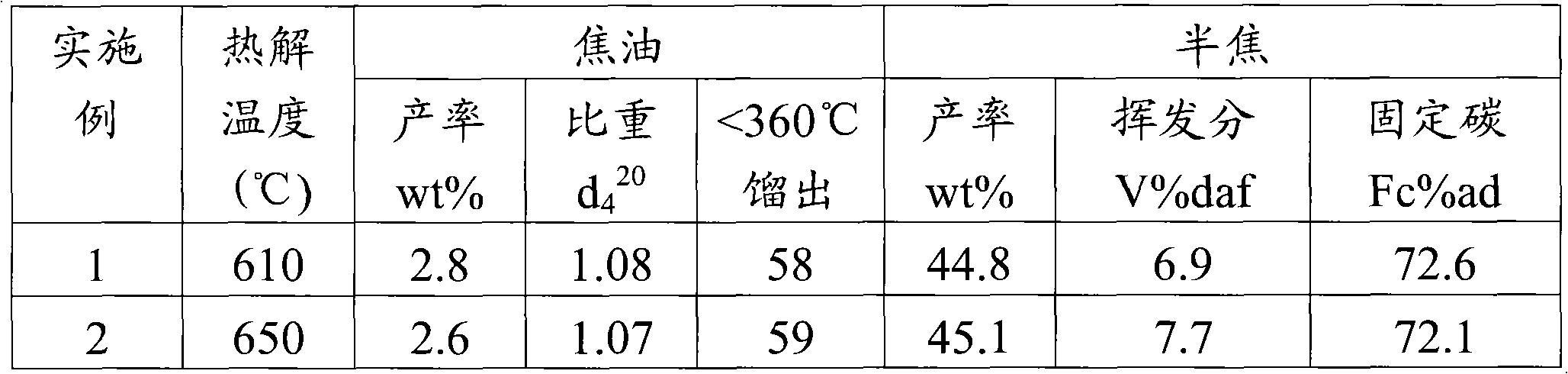

Method for upgrading coal pyrolysis

ActiveCN101608125AAvoid enteringReduce separation loadDirect heating destructive distillationOven incrustations prevention/removalGranularityFlue gas

The invention provides a method for upgrading coal pyrolysis, comprising the following steps: (a) sending raw coal with granularity being less than and equal to 30mm into a rotary drier, so that the raw coal and hot flue gas are connected with each other by the means of parallel flow and directly change heat, and the raw coal exchanges heat indirectly with hot semicoke from a pyrolyzer in the rotary drier, to dry the raw coal; (b) mixing the dried raw coal with the high-temperature semicoke from a heating rotary kiln and sending the mixture into the pyrolyzer, wherein the coal material directly changes heat with the high-temperature semicoke and pyrolyzes to generate hot semicoke, tar steam and coal gas, wherein final pyrolyzing temperature is 500 DEG C-700 DEG C; and (c) sending a part of the hot semicoke generated into the heating rotary kiln for processing by means of heating, and sending the rest part of the hot semicoke into the rotary drier for exchanging heat directly with the raw coal. The method for upgrading coal pyrolysis has flexible operation, wide granularity range of the coal material, good quality of the generated semicoke and the generated tar, high cascade utilization of energy and high system thermal efficiency, properly solving the technical problems such as dust and tar blocking, high dust content in the tar, etc.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

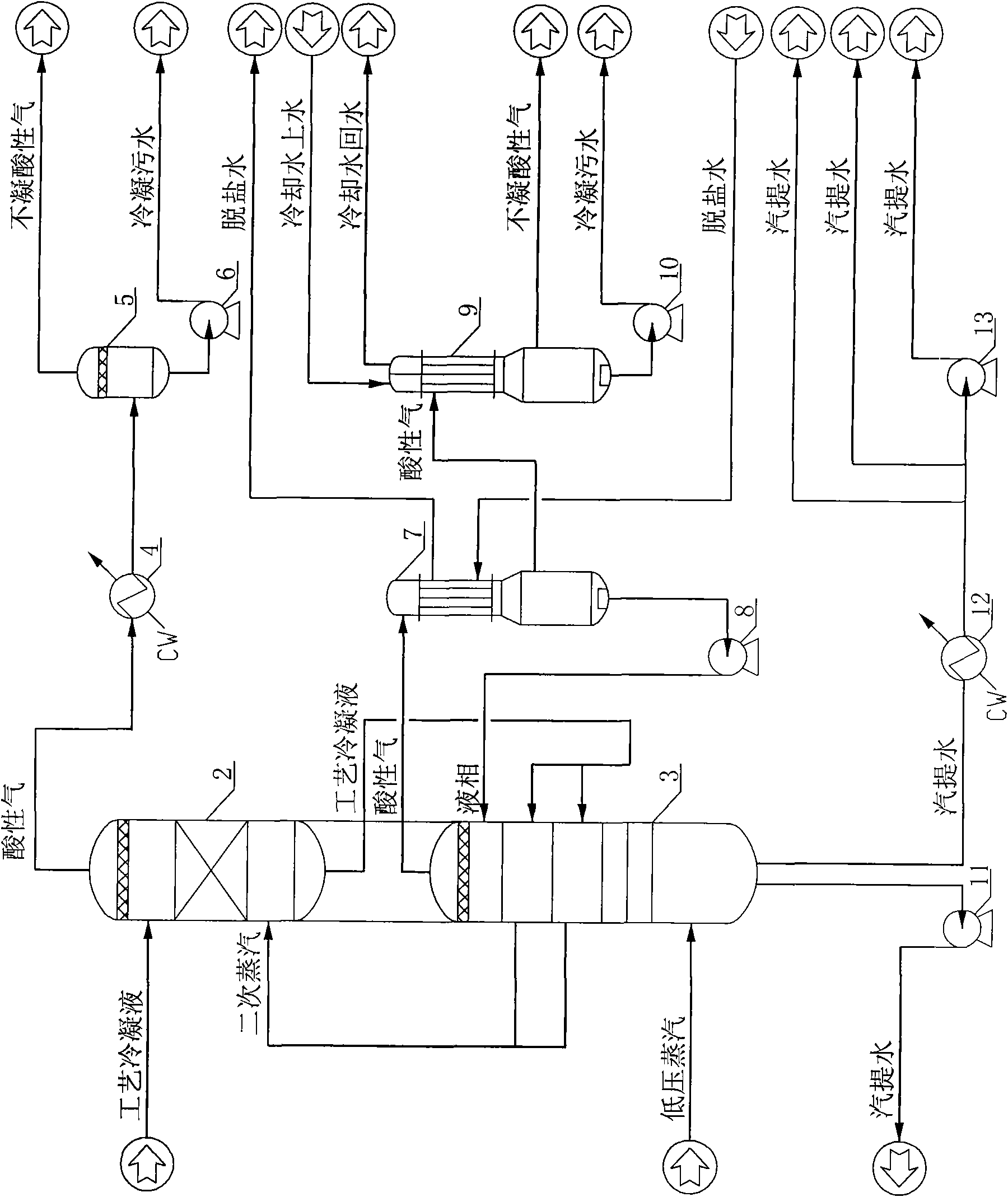

Steam stripping method of process condensate in CO conversion

ActiveCN101570350AAvoid the possibility of simultaneousSolve the blockageWater/sewage treatment by heatingWater/sewage treatment by degassingGas phaseEvaporation

The invention relates to a steam stripping method of process condensate in CO conversion. The invention is characterized in that the process condensate firstly enters the upper part of a carbon dioxide steam stripping tower for flashing evaporation; secondary steam from the upper part of an ammonia-evaporated steam stripper tower enters the bottom part of the carbon dioxide steam stripping tower and steam strips carbon dioxide by countercurrent contacting with the process condensate after flashing evaporation; the process condensate after flash evaporation and the steam stripped carbon dioxide carry out countercurrent contact; the process condensate after flash evaporation and steam stripping enters the upper part of the ammonia-evaporated steam stripper tower from the bottom part of the carbon dioxide steam stripping tower and is steam-stripped by low-pressure steam entering from a kettle of the ammonia-evaporated steam stripper tower; gas phase is treated by secondary condensation to obtain non-acid-coagulated gas and condensate sewage; and steam stripping water is obtained from the bottom part of the ammonia-evaporated steam stripper tower. The invention carries out steam stripping on the upper and lower towers to carbon dioxide and ammonia in the process condensate respectively, thus avoiding the possibility of coexistence of carbon dioxide and ammonia in a condensing system, effectively solving the problem that the steam stripping system of the process condensate in the conversion procedure occurs ammonium salt crystallization blockage and prolonging the period of stable operation of a conversion device.

Owner:CHINA PETROCHEMICAL CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com