Stripping ammonia-removing method based on flash evaporation and heat pump technologies

A flash steam and deamination technology, which is applied in the field of high-efficiency and energy-saving deamination technology, can solve the problems of high unit consumption of wastewater treatment and large steam consumption, and can solve scaling and blockage, reduce consumption, and ensure saturation. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

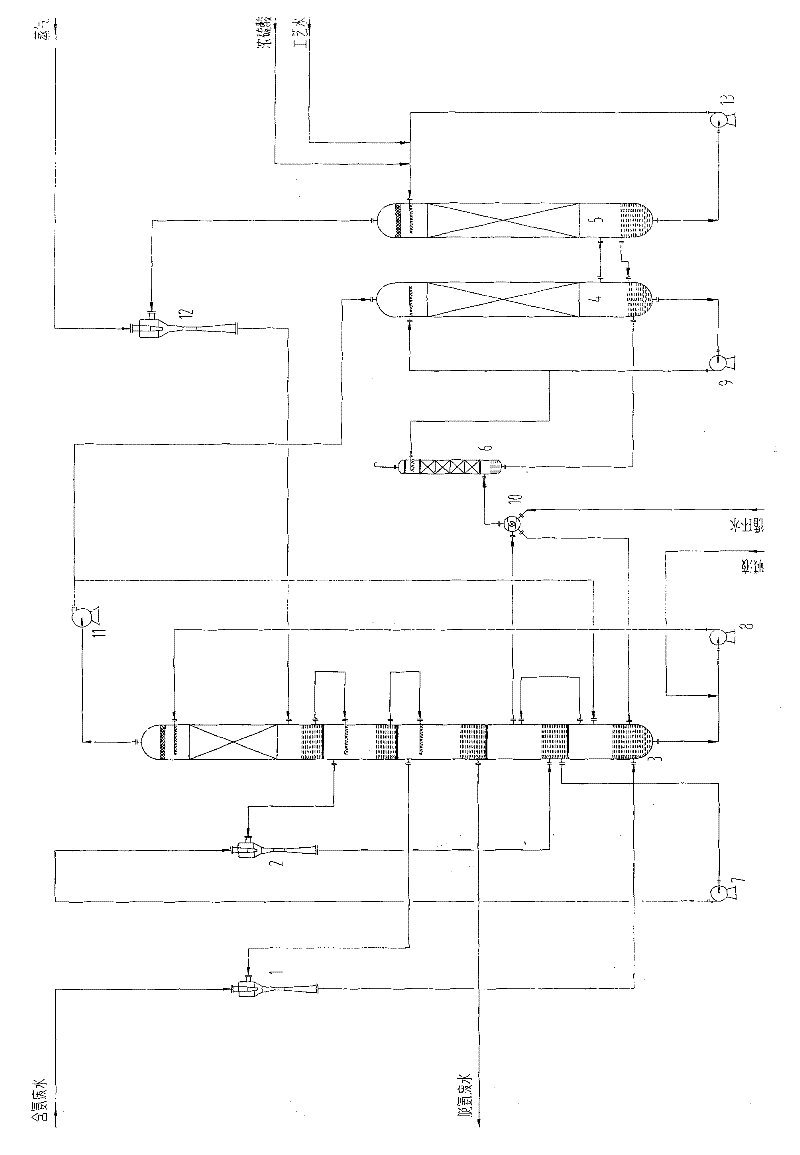

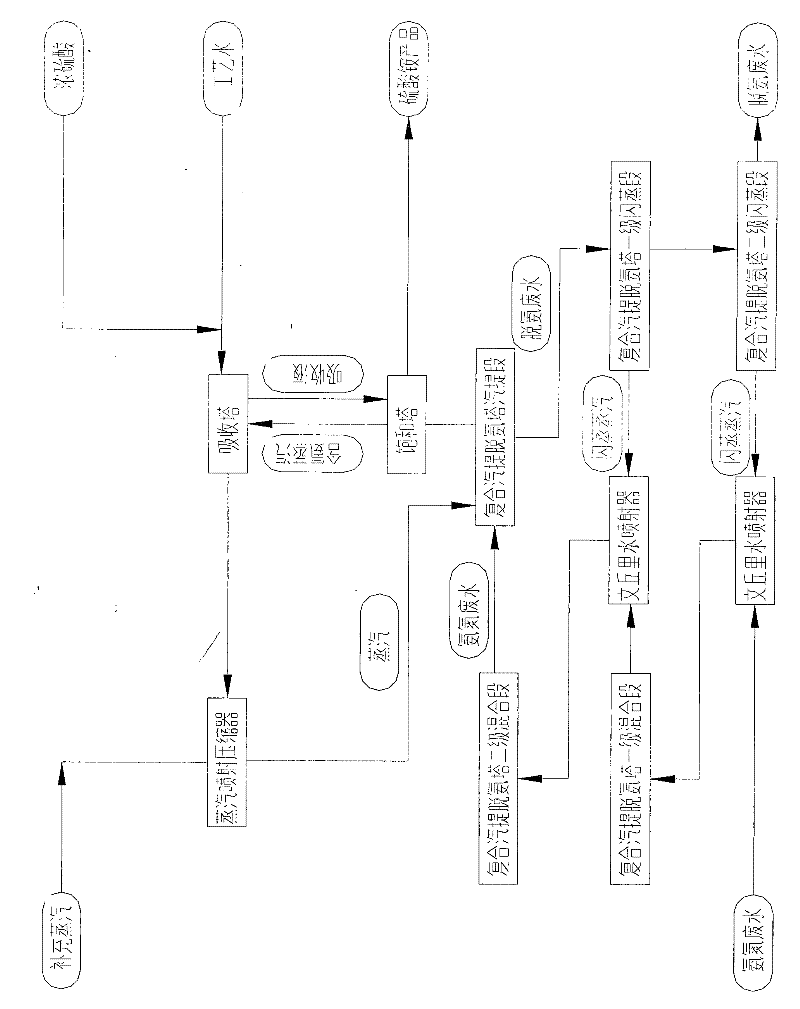

[0033] combine figure 1 The process flow of the ammonia-containing wastewater deamination system is described as follows:

[0034] The high-ammonia nitrogen wastewater is pumped into the Venturi water injector 1, and the steam injected from the secondary flash section of the compound stripping deamination tower 3 is subjected to vapor-liquid rapid cooling and heat exchange, and then enters the compound stripping deamination tower 3 Vapor-liquid separation in the primary mixing section; the non-condensable gas in the secondary flash section of the composite stripping deamination tower 3 is pumped out by the liquid ring vacuum pump 10, and the ammonia gas brought out by the non-condensable gas is absorbed by the tail gas absorption tower 6 and then discharged;

[0035] The ammonia nitrogen wastewater in the primary mixing section of the composite stripping deamination tower 3 enters the Venturi waste water ejector 2 through the flash feed pump 7 and is steamed again by the steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com