Patents

Literature

839 results about "Coal pyrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

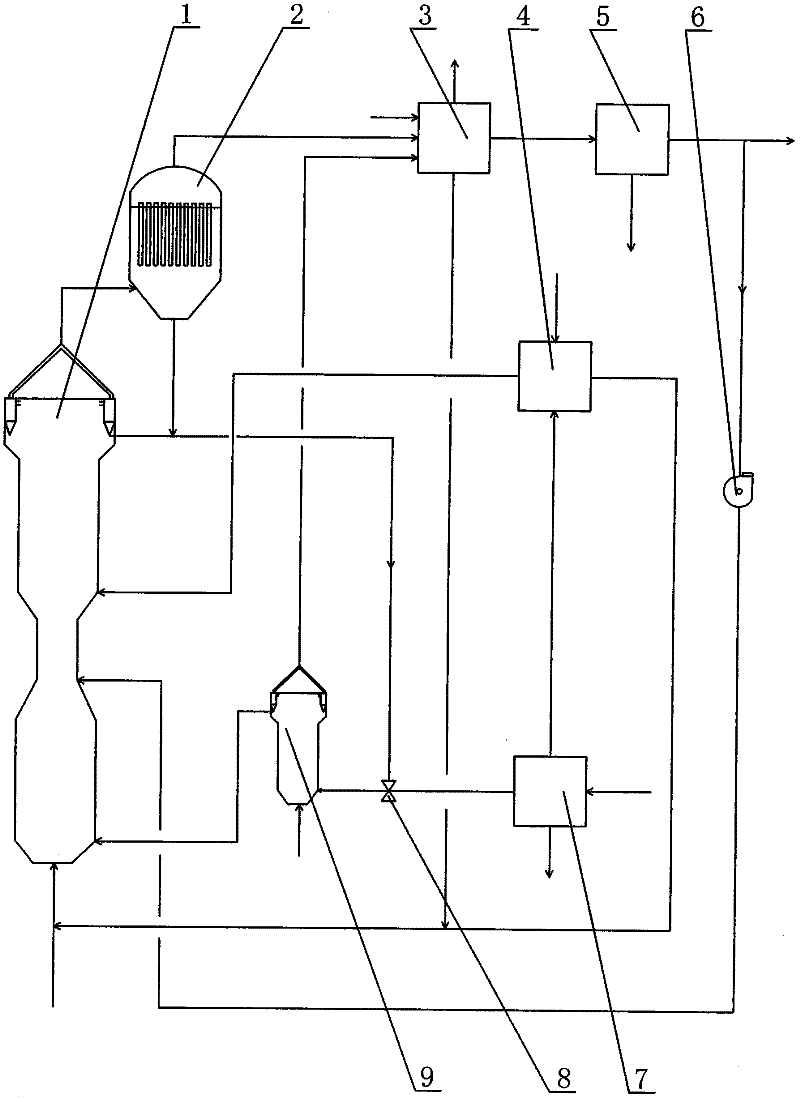

Process for upgrading coal pyrolysis oils

ActiveUS20100147743A1Reduce and eliminate needMinimize feedstock foulingLiquid hydrocarbon mixture productionHydrocarbon oil crackingOxygen contaminationPtru catalyst

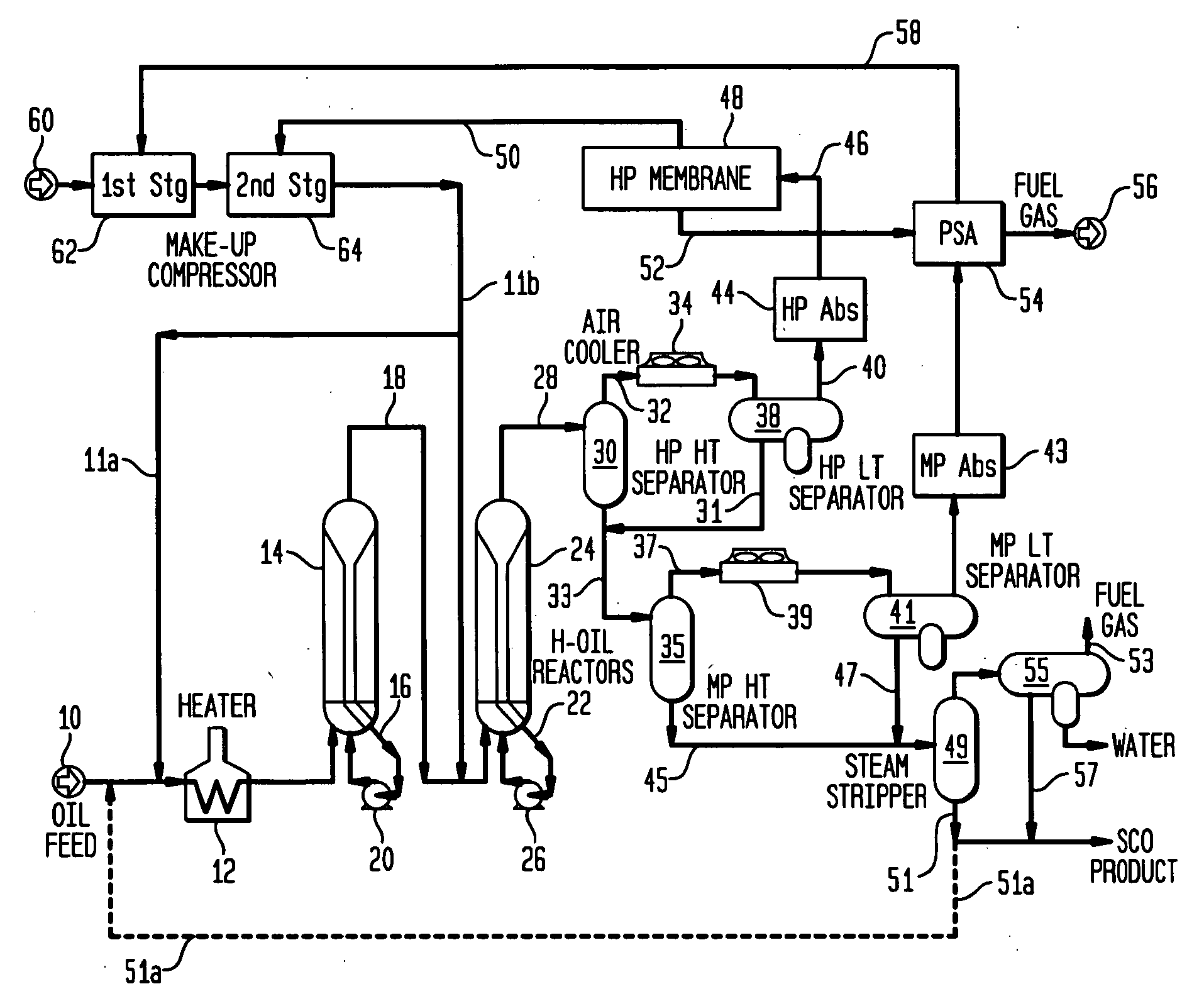

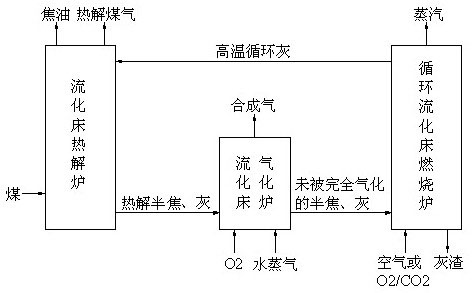

This invention utilizes a novel method and set of operating conditions to efficiently and economically process a potentially very fouling hydrocarbon feedstock. A multi-stage catalytic process for the upgrading of coal pyrolysis oils is developed. Coal Pyrolysis Oils are highly aromatic, olefinic, unstable, contain objectionable sulfur, nitrogen, and oxygen contaminants, and,may contain coal solids which will plug fixed-bed reactors. The pyrolysis oil is fed with hydrogen to a multi-stage ebullated-bed hydrotreater and hydrocracker containing a hydrogenation or hydrocracking catalyst to first stabilize the feed at low temperature and is then fed to downstream reactor(s) at higher temperatures to further treat and hydrocrack the pyrolysis oils to a more valuable syncrude or to finished distillate products. The relatively high heat of reaction is used to provide the energy necessary to increase the temperature of the subsequent stage thus eliminating the need for additional external heat input. A refined heavy oil product stream is recycled to the fresh feed to minimize feedstock fouling of heat exchangers and feed heaters.

Owner:MACARTHUR JAMES B +2

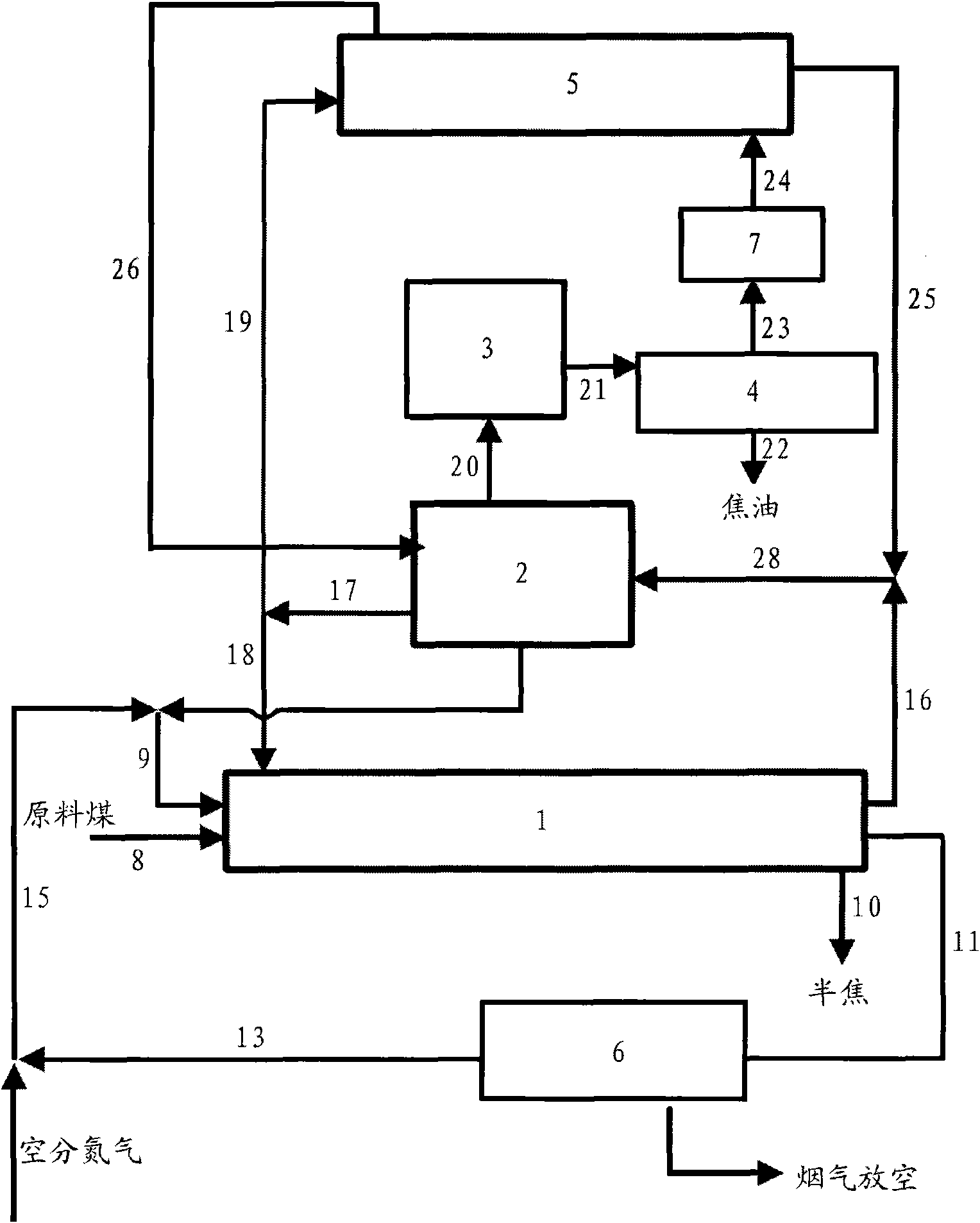

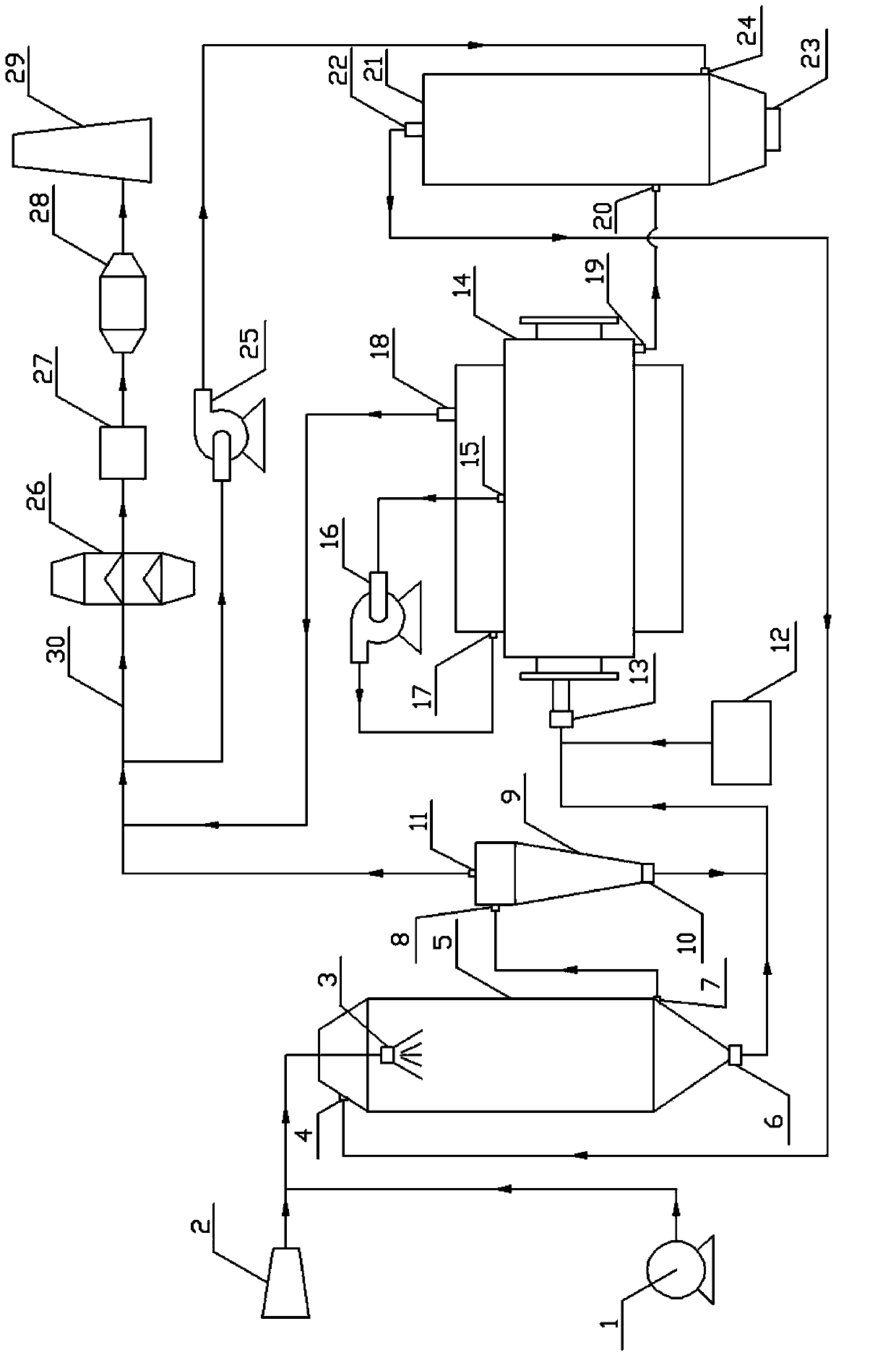

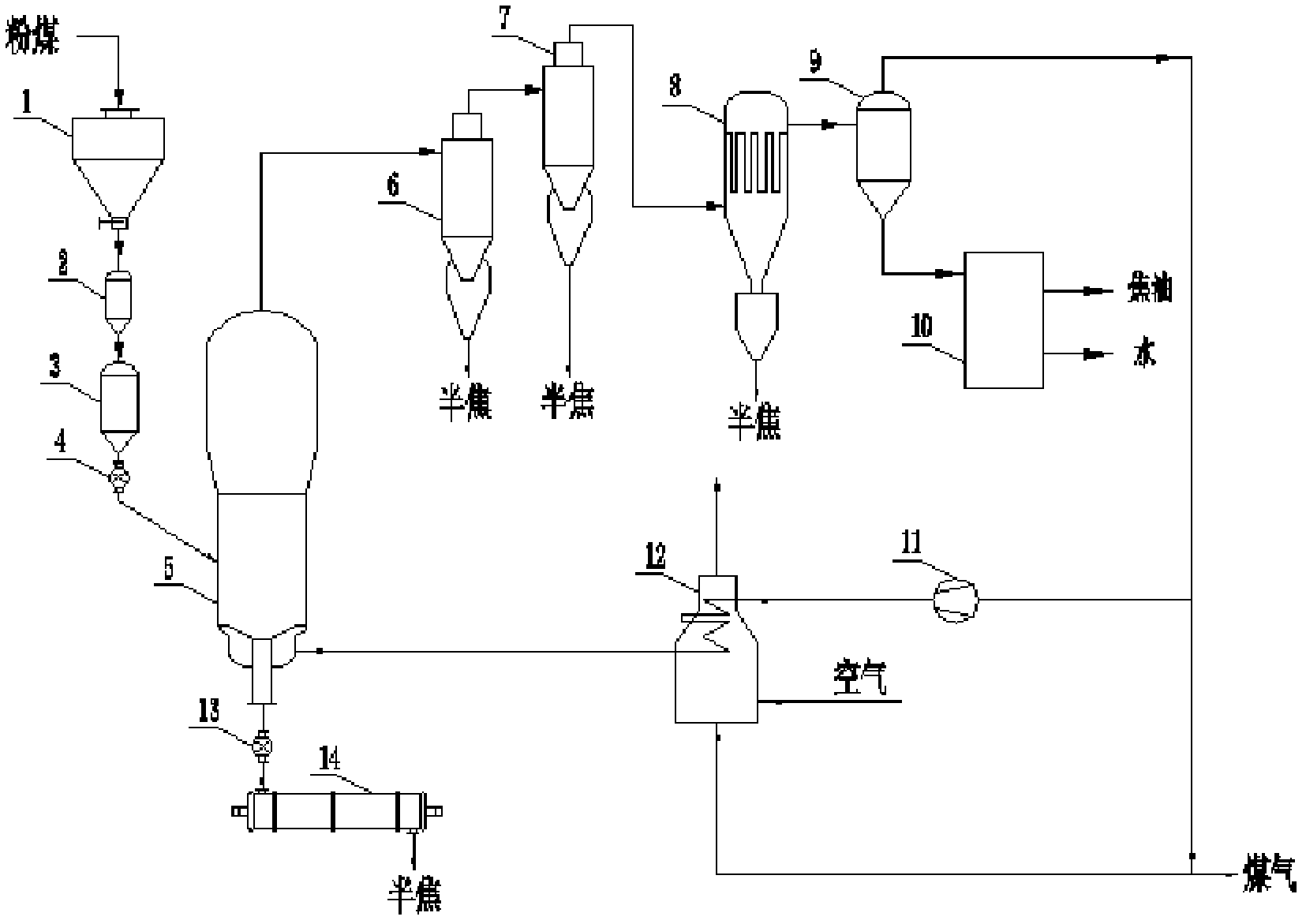

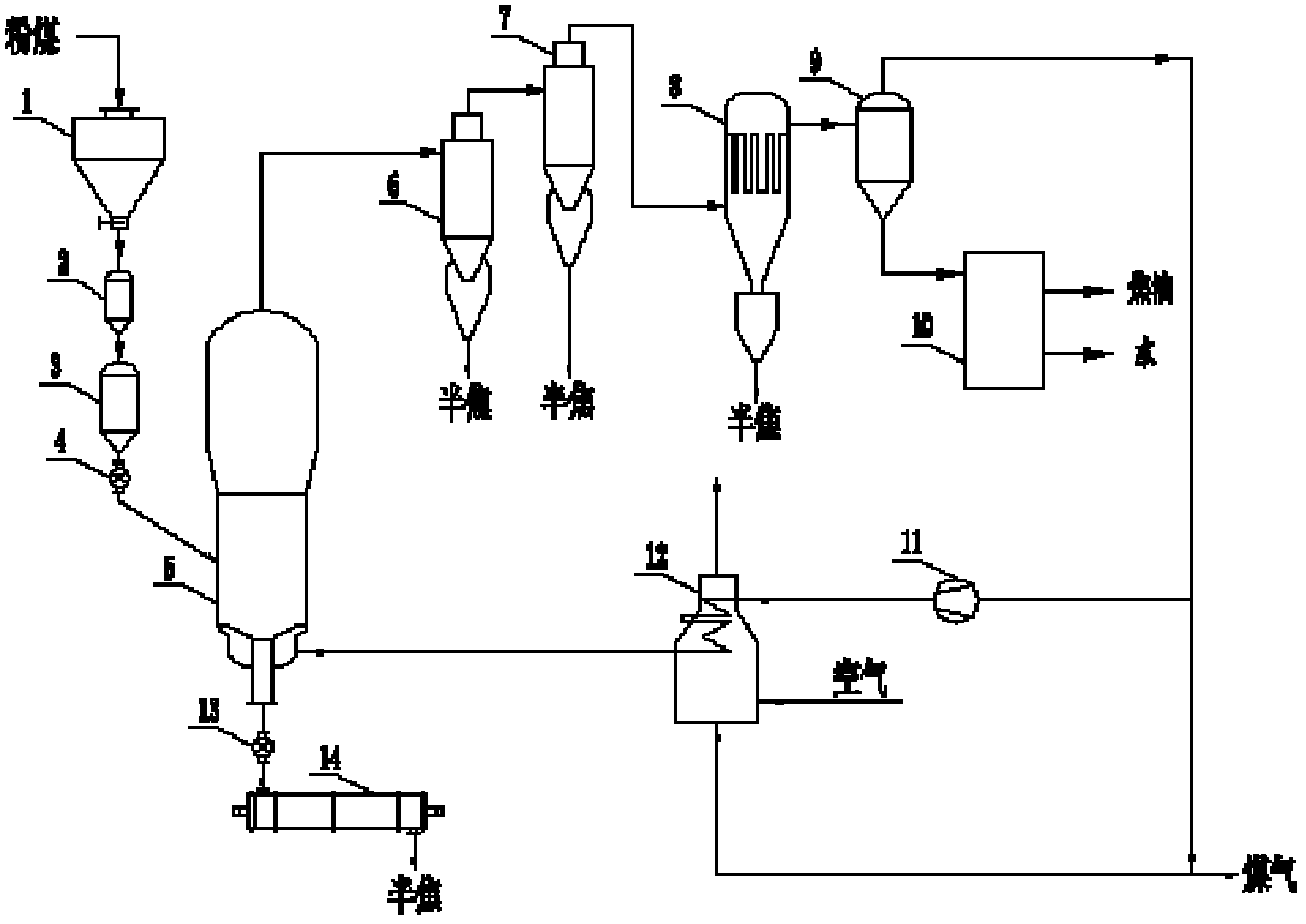

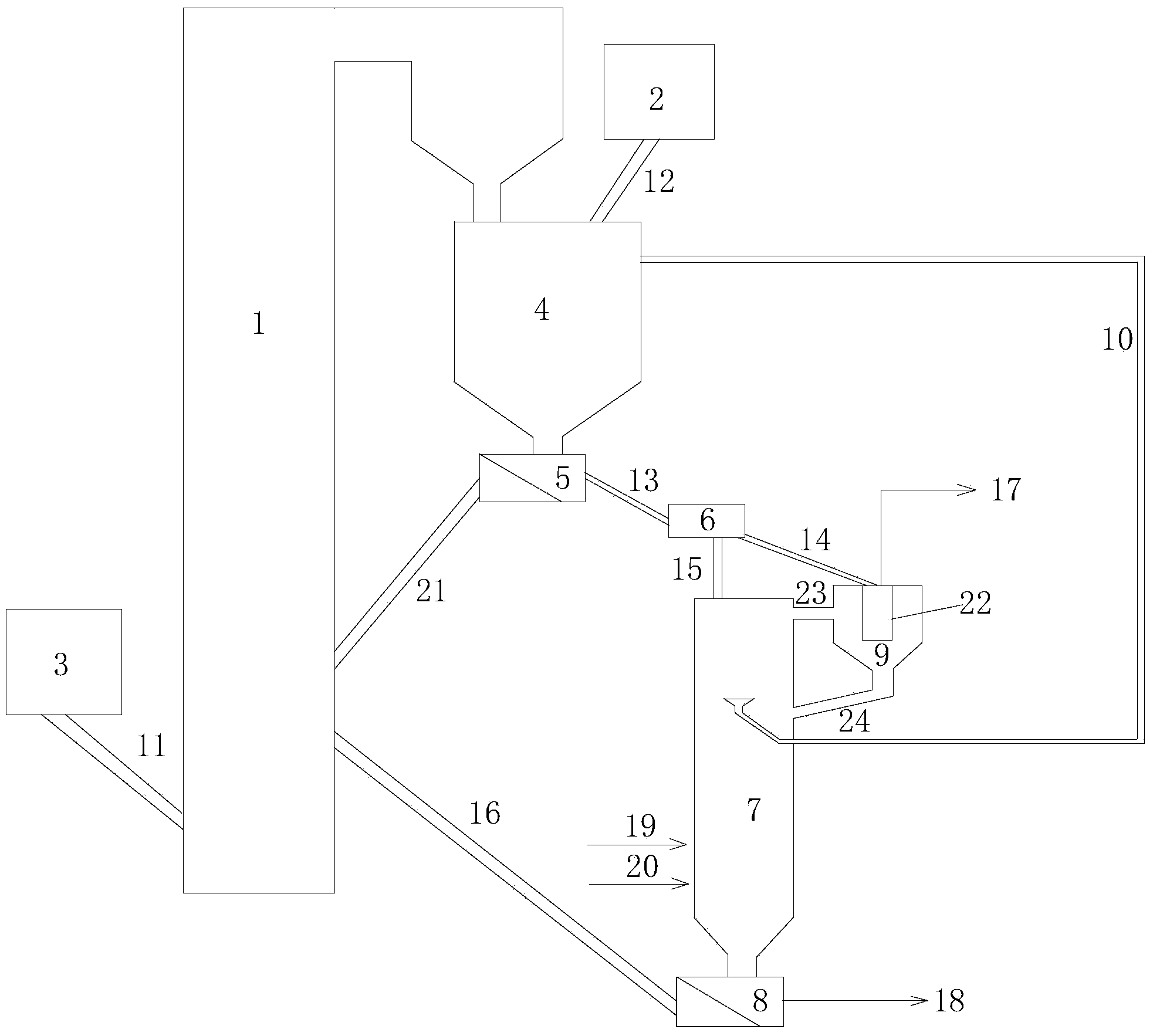

Three-fluidized-bed solid heat carrier coal pyrolysis, gasification and combustion cascade utilization method

InactiveCN102504842AImprove conversion efficiencyImprove utilization efficiencyDirect heating destructive distillationTreatment with hydrotreatment processesFluidized bed gasifierSyngas

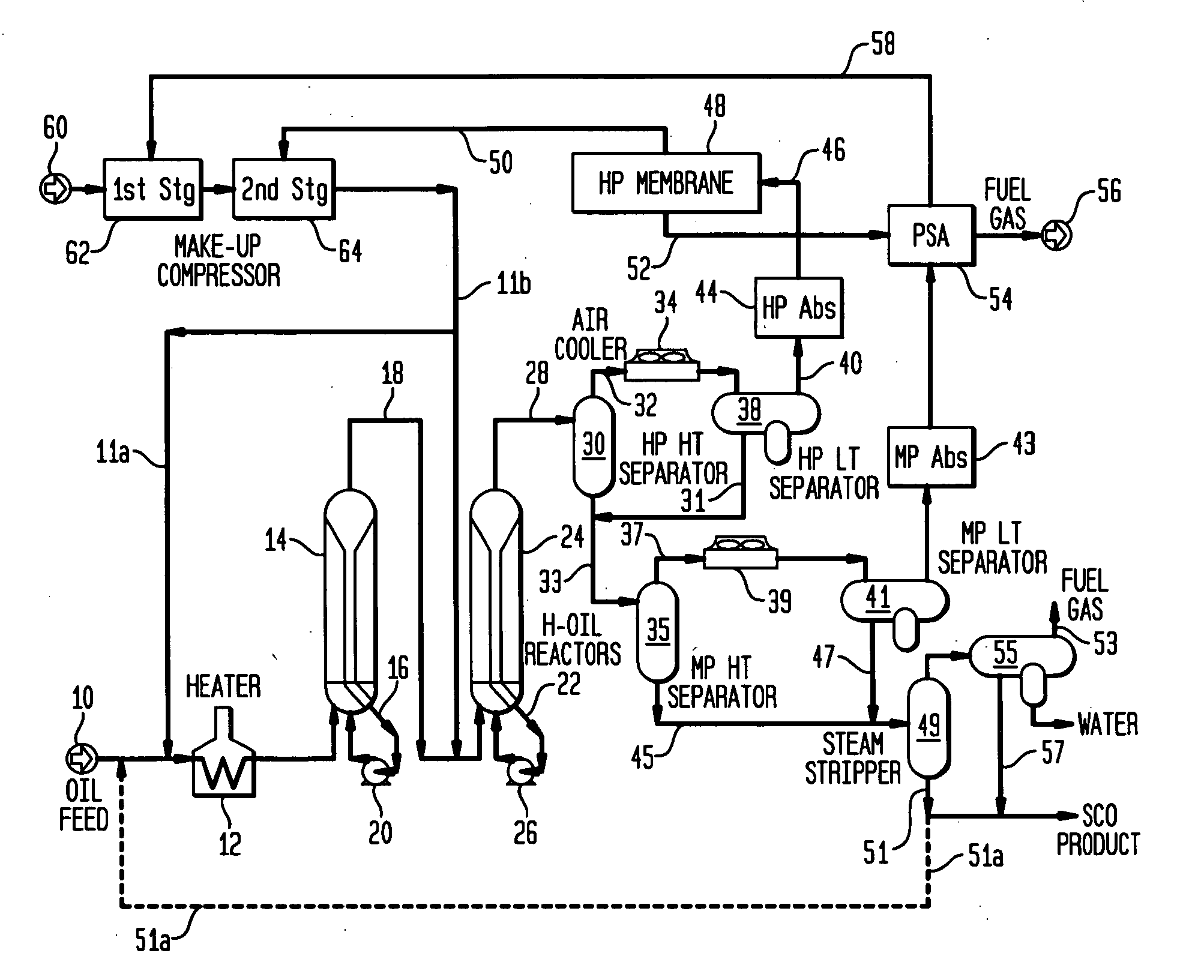

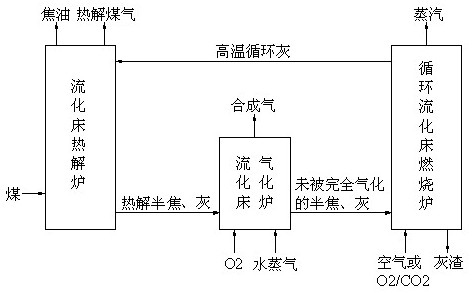

The invention discloses a three-fluidized-bed solid heat carrier coal pyrolysis, gasification and combustion cascade utilization method. The method comprises the following steps of: mixing coal and high temperature circulating ash serving as a solid heat carrier in a fluidized bed pyrolysis furnace, pyrolyzing to separate out volatile, cooling and separating the volatile to obtain tar and pyrolysis gas, conveying pyrolysis semi-coke generated by pyrolyzing the coal to a fluidized bed gasification furnace, performing gasification reaction by using water vapor and O2 as gasification agents to prepare synthesis gas, conveying the semi-coke which is incompletely gasified in the gasification furnace to a circulating fluidized bed combustion furnace, blowing air for the conventional combustion or blowing O2 / CO2 for oxygen-enriched combustion, heating the circulating ash serving as the solid heat carrier, and producing gasification agent vapor required by the gasification furnace by using high temperature flue gas generated by combustion. The method has the advantages that: the tar, the pyrolysis gas and the synthesis gas are co-produced through coal pyrolysis, gasification and combustion cascade utilization, the gasification condition of the semi-coke is reduced, and good economic benefits and social benefits are achieved.

Owner:ZHEJIANG UNIV

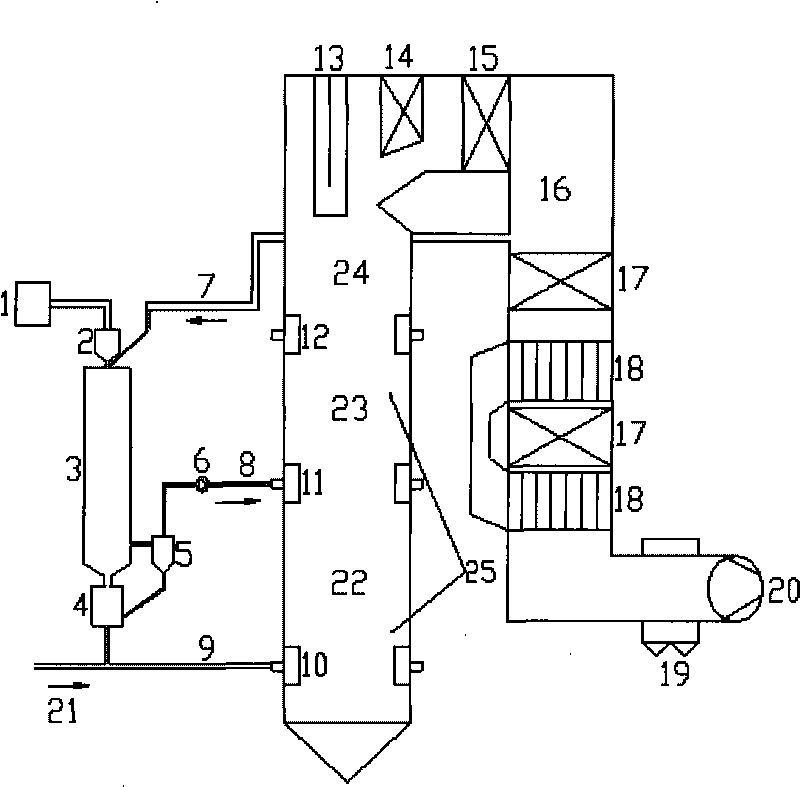

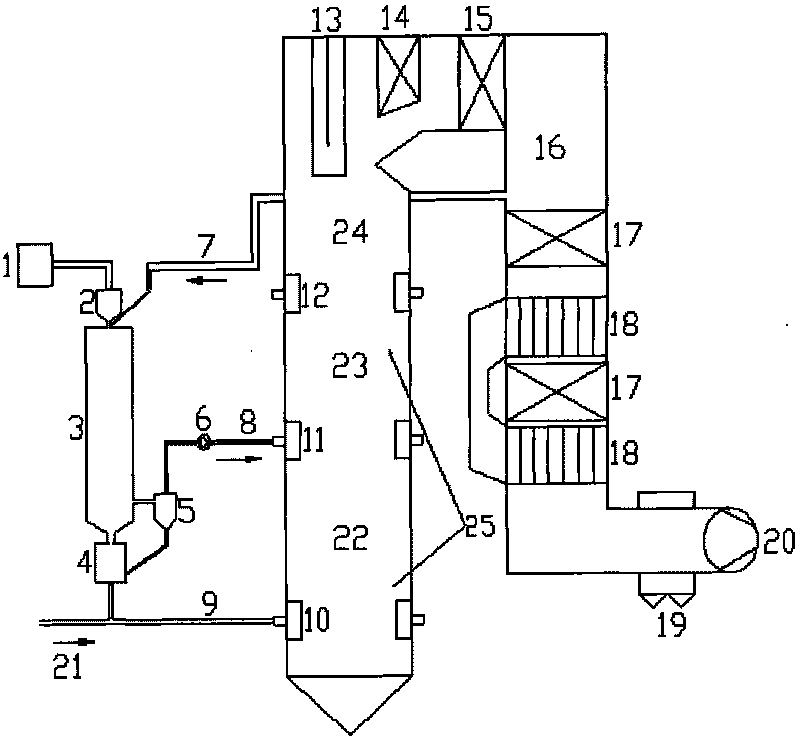

Method and device for burning low NOx by utilizing reburning of pulverized coal pyrolysis gas

InactiveCN101761920AEasy to transformEfficient reductionCombustion apparatusFlue gasProcess engineering

The invention discloses a method and device for burning low NOx by utilizing reburning of pulverized coal pyrolysis gas. The method comprises the following steps: quickly pyrolizing the pulverized coal by utilizing partial hot smoke gas of a tail flue of a pulverized coal boiler entering a pyrolysis reactor; delivering the pulverized coal pyrolysis gas serving as the gas reburning fuel into a reburning area of the pulverized coal boiler to perform high-efficiency NOx reduction, and completely burning the gas reburning fuel subjected to NOx reduction in a burning-out area of the pulverized coal boiler to discharge the low NOx of the pulverized coal boiler; and allowing semicoke which is produced through the pulverized coal pyrolysis to enter a main burning area of the pulverized coal boiler which is carried by primary air to finish burning. The device of the technique mainly comprises a pulverized coal quick pyrolysis device, a pulverized coal flue gas circulating system, a boiler low NOx burning system and a pipeline which is connected with the boiler low NOx burning system. The method and the device have the advantages of simple structure, low investment, high denitration efficiency, and wide application prospect.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

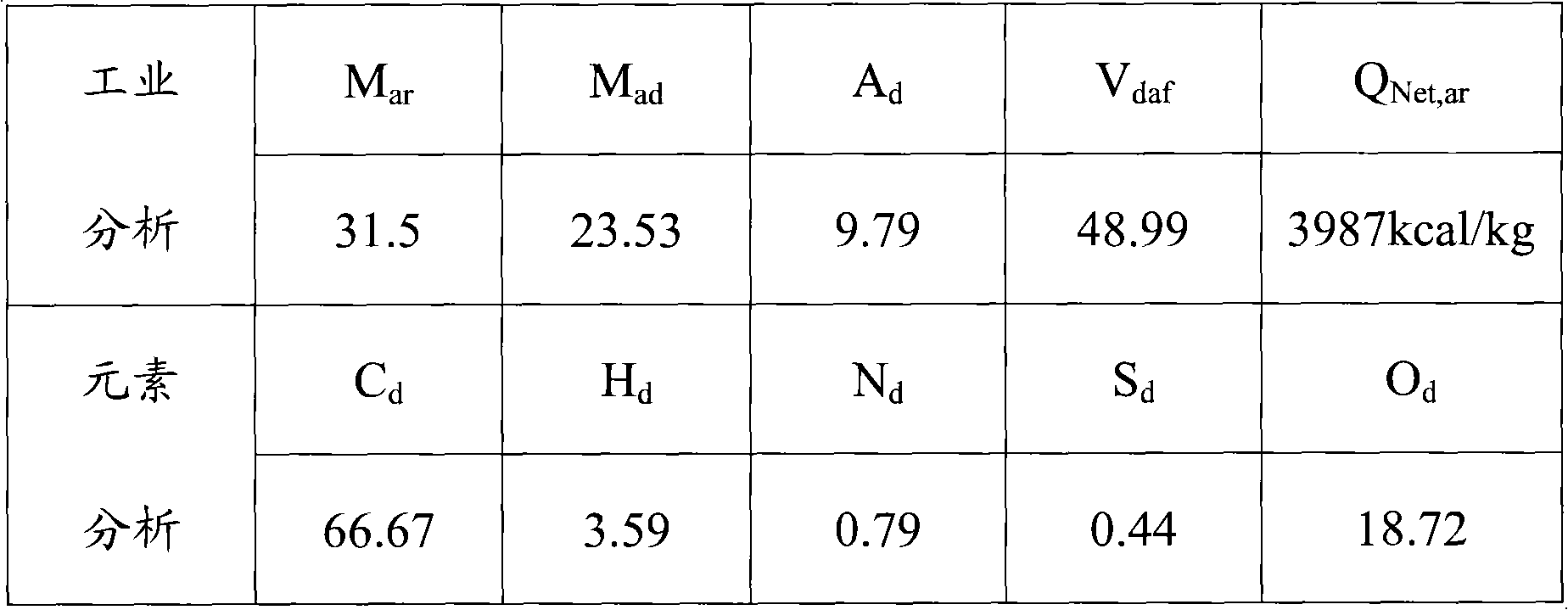

Low-coalification degree pulverized coal pyrolysis method and product prepared through the same

ActiveCN101880540AAlleviate the difficulty of efficient utilizationAlleviate the problem of secondary pyrolysisCoke quenchingSpecial form destructive distillationCoal pyrolysisCoal tar

The invention relates to a low-coalification degree pulverized coal pyrolysis method and a product prepared through the same. The method comprises the following four steps: low-coalification degree pulverized coal pre-drying, low-coalification degree pulverized coal pyrolysis reaction, gas cooling and tar recovery, and hot semi-coke cooling. The method is applicable to heat treatment to low-coalification degree pulverized coal resources so as to obtain high-quality pyrolysis gas and tar products, wherein the gas contains low inert component content, tar contains high light component content and low dust content, and semi-coke products with wide purposes are obtained. The process method is characterized by high comprehensive utilization rate of energy, large amount of treated material, lowdevice investment, easy industrialization realization, environmental friendliness and the like while improving the raw material utilization efficiency.

Owner:XIAN ORIGIN CHEM TECH

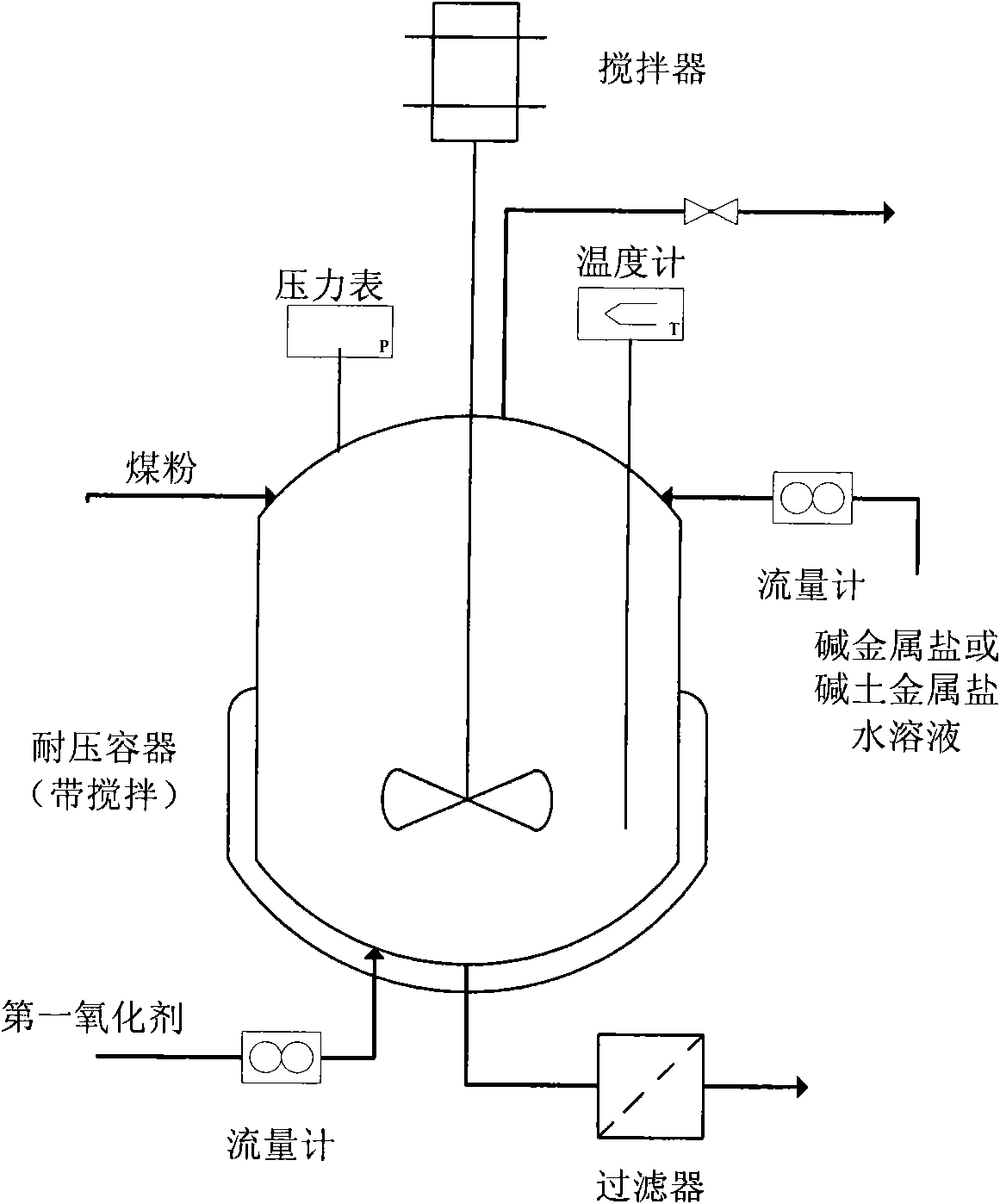

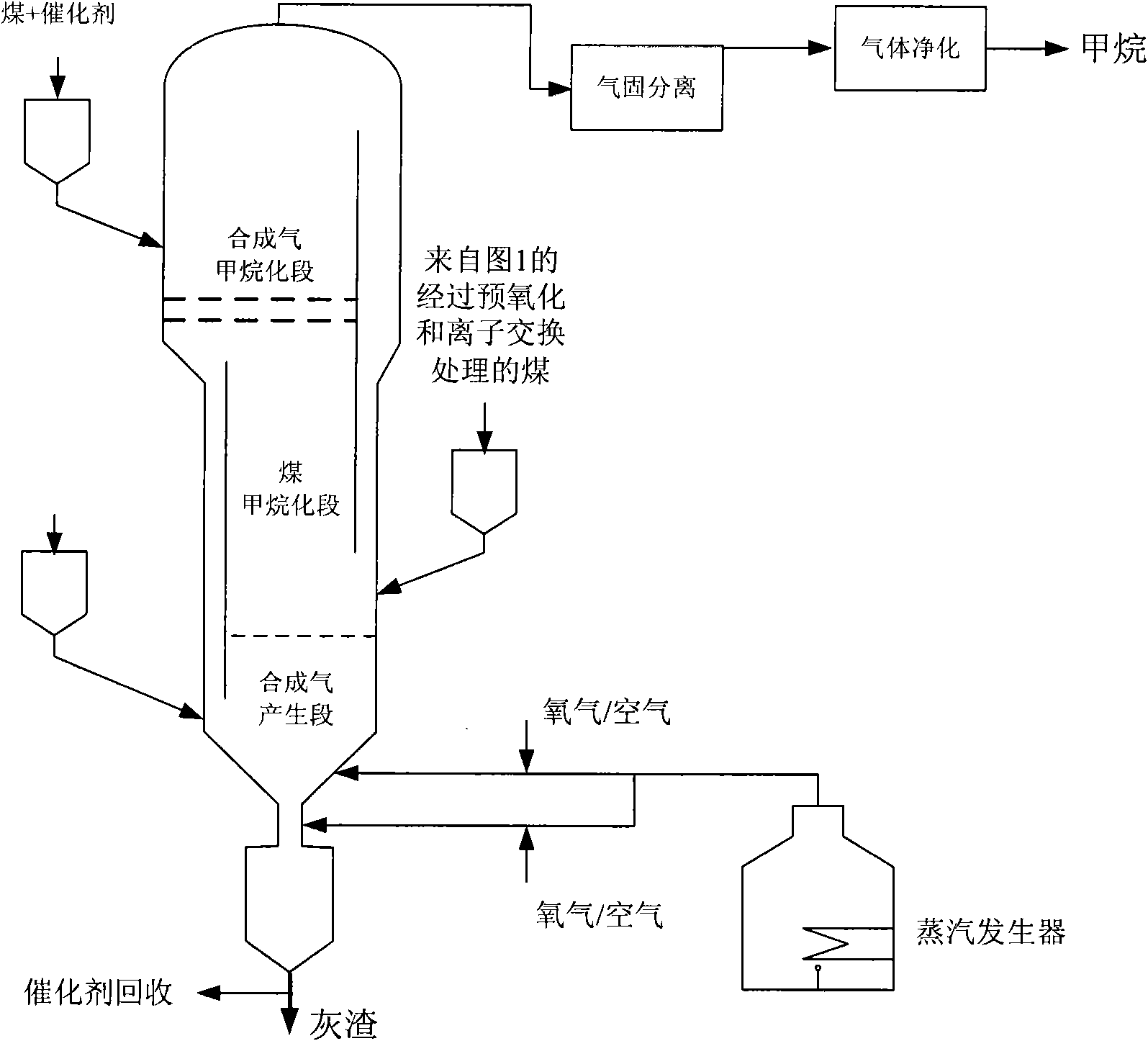

Method for preparing methane by catalyzing and gasifying coal

ActiveCN102465047AIncrease the amount of chemical bindingDoes not affect movement characteristicsHydrocarbon from carbon oxidesGaseous fuelsMethanationIon exchange

The invention relates to a method for preparing methane by catalyzing and gasifying coal. The method sequentially comprises the following two steps: 1, successively or simultaneously carrying out preoxidation and ion exchange treatment on coal in a slurry containing coal and water; and 2, gasifying the product obtained in step 1 by sending it to a gasification furnace which sequentially comprises a gas generation segment, a coal methanation segment, a synthetic gas methanation segment and an optional coal pyrolysis segment from bottom to top to obtain a gas product containing methane.

Owner:ENN SCI & TECH DEV

Method for upgrading coal pyrolysis

ActiveCN101608125AAvoid enteringReduce separation loadDirect heating destructive distillationOven incrustations prevention/removalGranularityFlue gas

The invention provides a method for upgrading coal pyrolysis, comprising the following steps: (a) sending raw coal with granularity being less than and equal to 30mm into a rotary drier, so that the raw coal and hot flue gas are connected with each other by the means of parallel flow and directly change heat, and the raw coal exchanges heat indirectly with hot semicoke from a pyrolyzer in the rotary drier, to dry the raw coal; (b) mixing the dried raw coal with the high-temperature semicoke from a heating rotary kiln and sending the mixture into the pyrolyzer, wherein the coal material directly changes heat with the high-temperature semicoke and pyrolyzes to generate hot semicoke, tar steam and coal gas, wherein final pyrolyzing temperature is 500 DEG C-700 DEG C; and (c) sending a part of the hot semicoke generated into the heating rotary kiln for processing by means of heating, and sending the rest part of the hot semicoke into the rotary drier for exchanging heat directly with the raw coal. The method for upgrading coal pyrolysis has flexible operation, wide granularity range of the coal material, good quality of the generated semicoke and the generated tar, high cascade utilization of energy and high system thermal efficiency, properly solving the technical problems such as dust and tar blocking, high dust content in the tar, etc.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

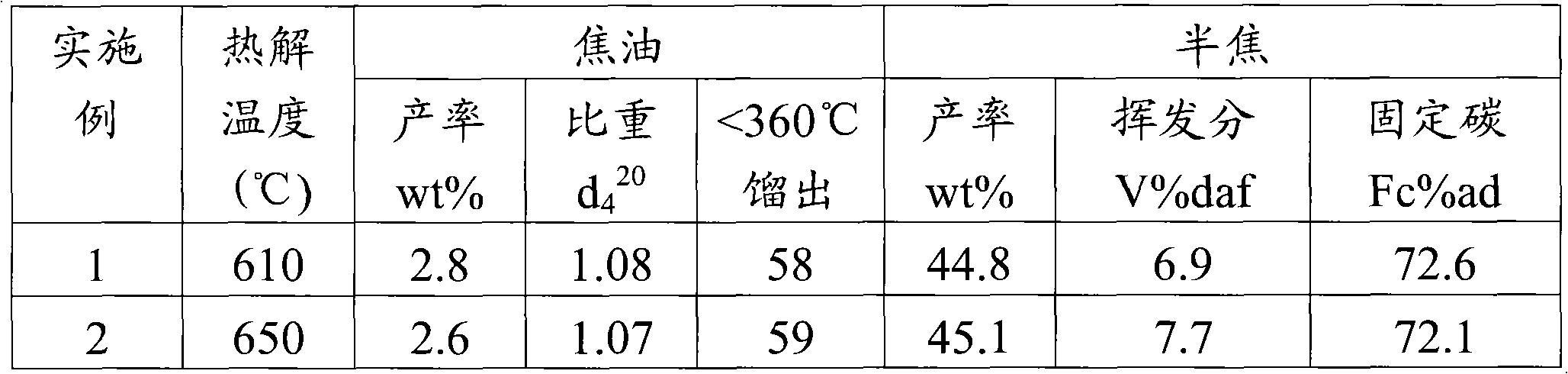

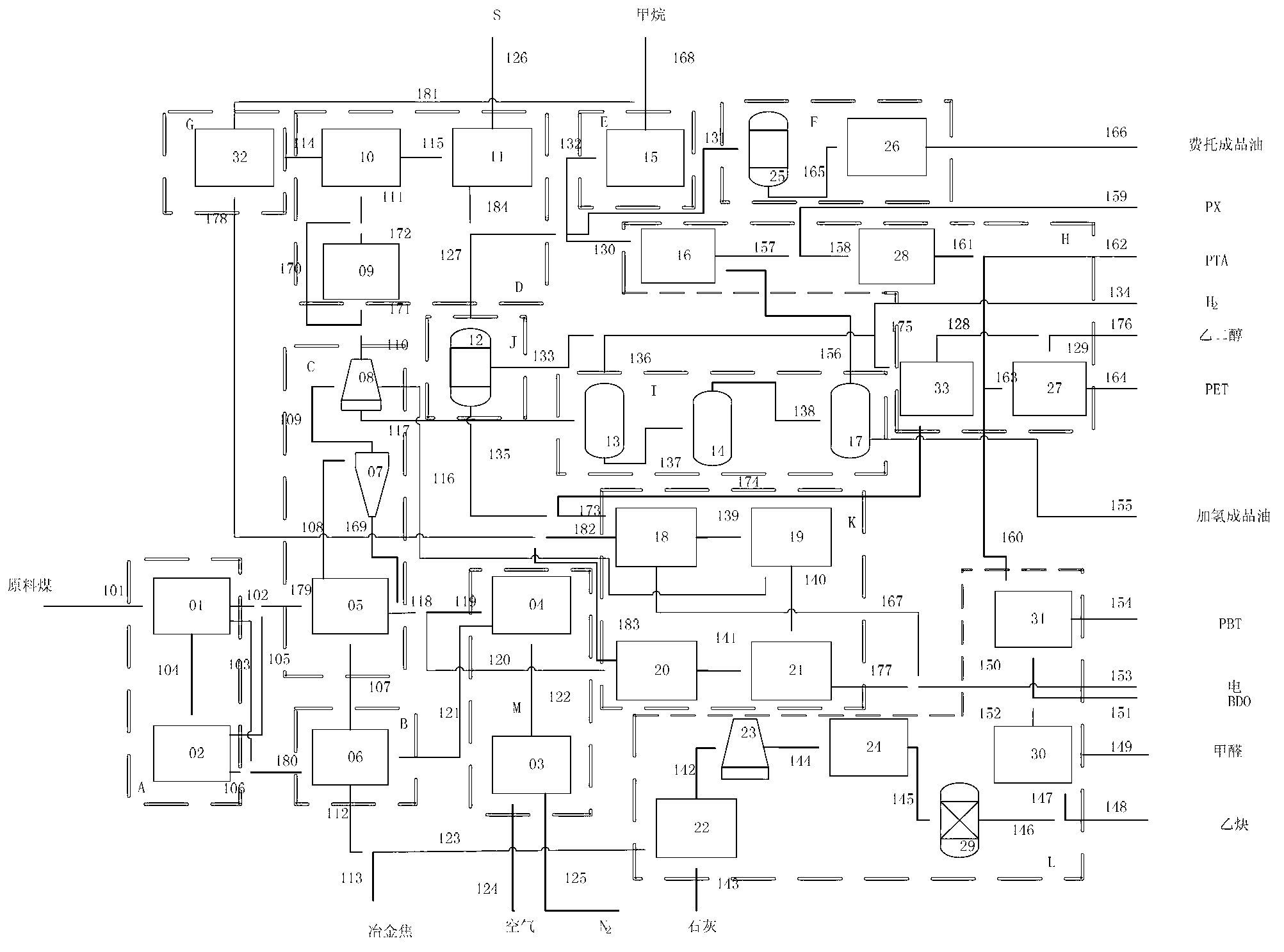

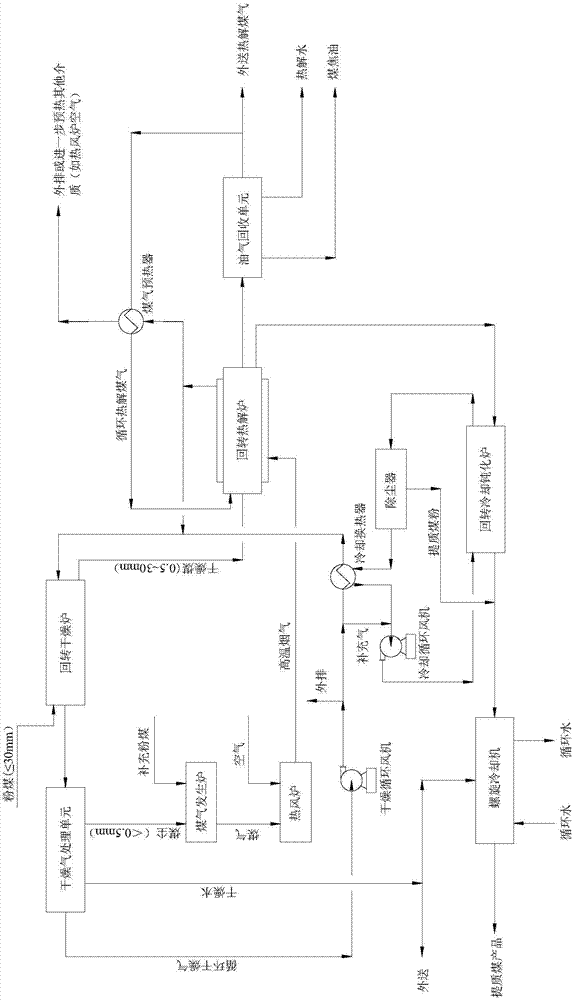

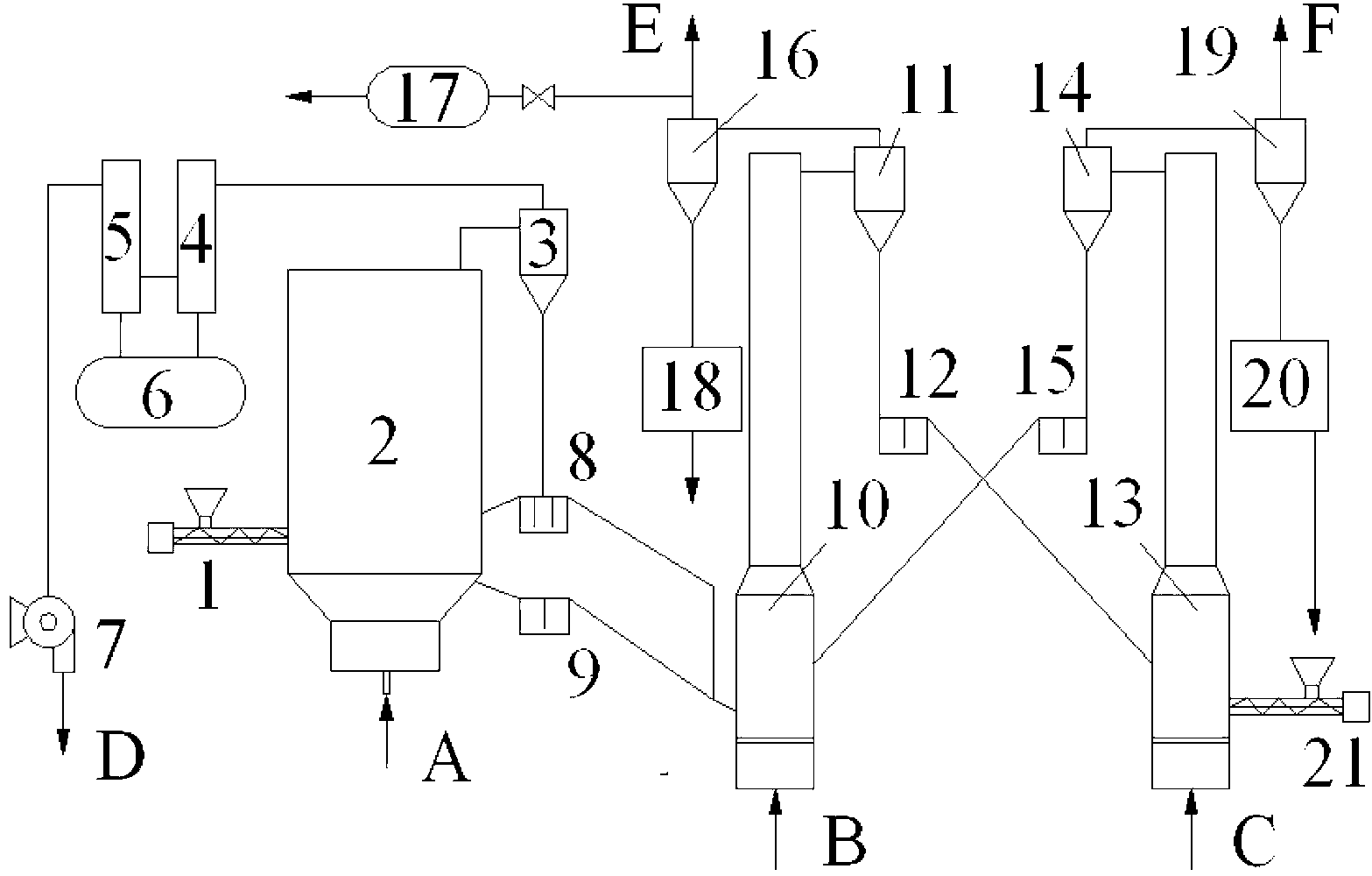

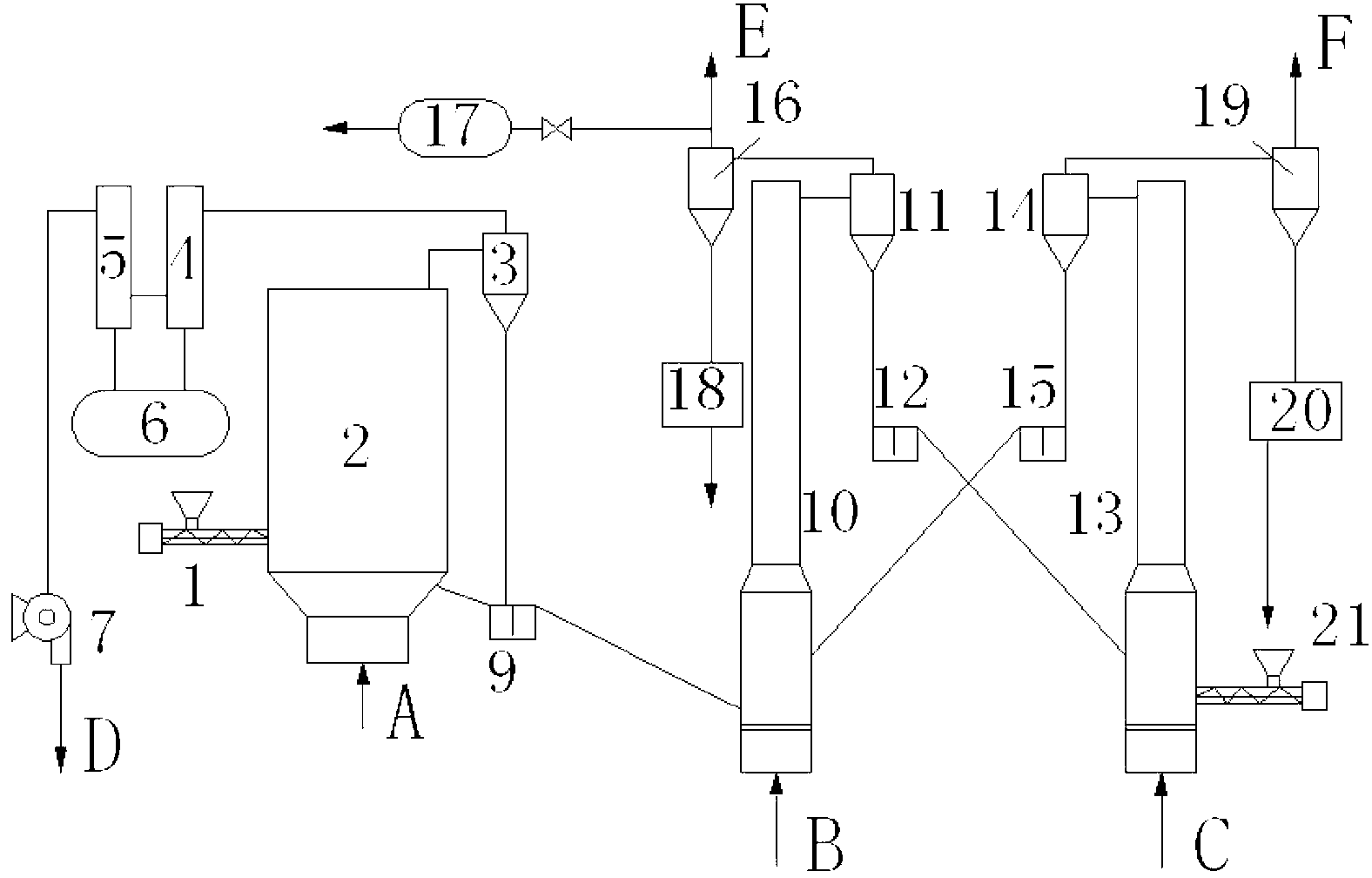

Omnibearing coproduction system and method by utilizing coal grading

ActiveCN103160294AImprove applicabilityAchieve self-balancingDirect heating destructive distillationEnergy inputHeat carrierCarbide

The invention provides an omnibearing coproduction system and method by utilizing coal grading. A standby coal system is respectively connected with a lump coal pyrolysis system and a pea coal pyrolysis system; a gasification system uses air as an input, semicoke generated by the pea coal pyrolysis system as a raw material, and generated gasified coal gas as a heat carrier of the lump coal pyrolysis system; lump coal pyrolysis oil gas generated by the lump coal pyrolysis system is used as a heat carrier of the pea coal pyrolysis system, part of generated lump coke is output as metallurgical coke, and the rest lump coke is used as a raw material for preparing carbide; pyrolysis coal gas generated by the pea coal pyrolysis system enters a crude gas treatment system, generated pyrolysis tar is used for hydrogenation grading, and generated semicoke is respectively used as semicoke for power generation and semicoke for gasification; and the crude gas treatment system uses pyrolysis coal gas generated by the pea coal pyrolysis system as a raw material, generated recovery waste heat is applied to a waste heat boiler of a power generation system, and generated carbon dioxide enters a carbon dioxide displaced coal gas system.

Owner:SHAANXI COAL & CHEM TECH INST

Sludge reduction and recycling treatment device and sludge treatment method

InactiveCN104211274AAchieve recyclingHarmlessSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisOxygenCoal pyrolysis

Provided are a sludge reduction and recycling treatment device and a sludge treatment method. The method includes the steps of performing spray drying on dewatered sludge, mixing coal pyrolysis, using pyrolytic carbon incineration ash as a raw building material, recycling pyrolysis oil and pyrolysis gas as supplement energy, performing up-to-standard discharging on flue gas emitted by a pyrolysis furnace after subjecting the flue gas to treatment in a spray tower, a mist removal device and an activated carbon adsorption bed, and supplying an incinerator with low heat of the pyrolysis furnace. The sludge reduction and recycling treatment device and the sludge treatment method have the advantages of being capable of achieving a sludge recycling recovery rate of 95%, a sludge reduction rate of over 96%, a heavy metal solidification rate of 95% and zero emission of pollutants; the generation of harmful gas such as dioxin is inhibited due to fully-enclosed oxygen-free environment pyrolysis and sulfur in coal; residual dioxin can be decomposed by being burnt at the temperature above 950 DEG C so as to ensure no generation and emission of dioxin in an entire reaction process of a system; a mixture of flue gas, low heat, pyrolysis gas and pyrolysis oil can be recycled, so that energy consumption and treatment costs are reduced.

Owner:天津德人生态环境科技集团有限公司

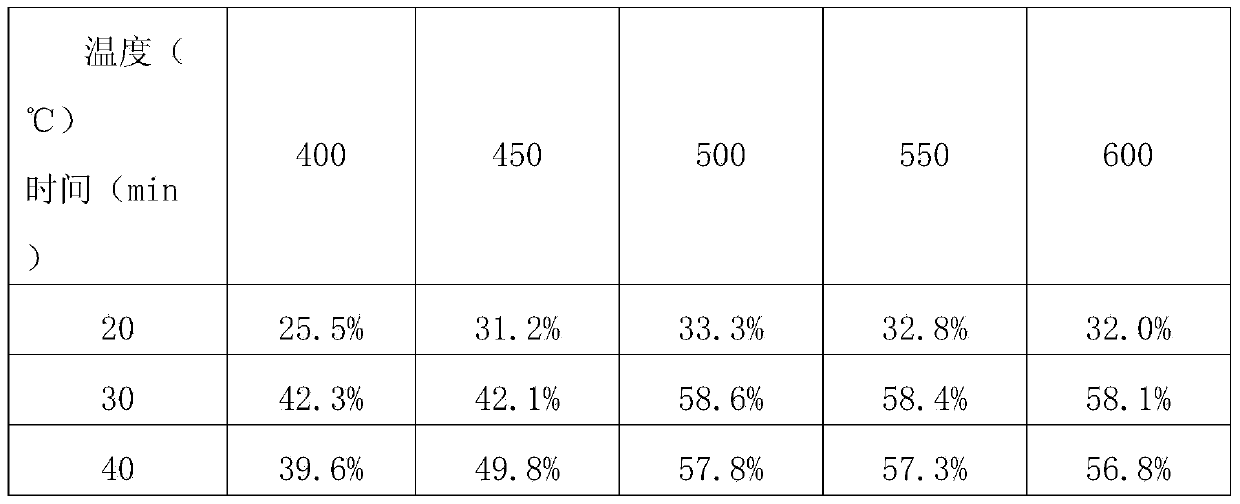

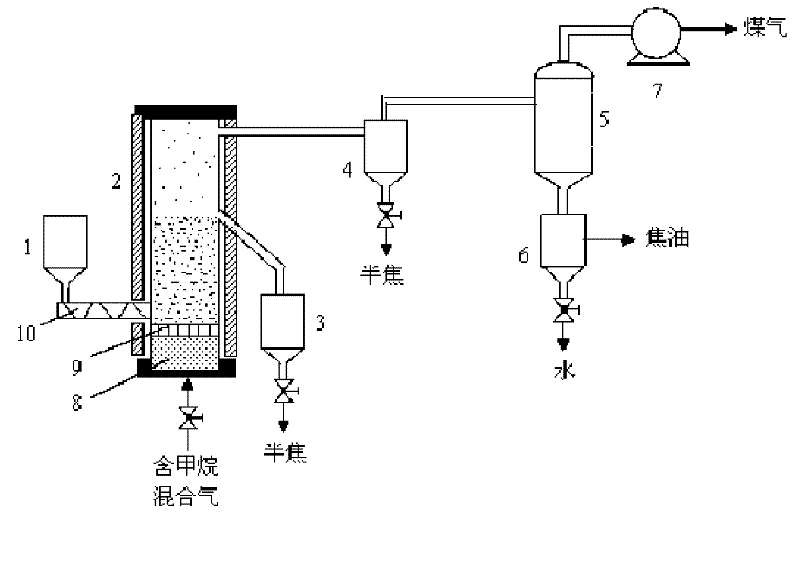

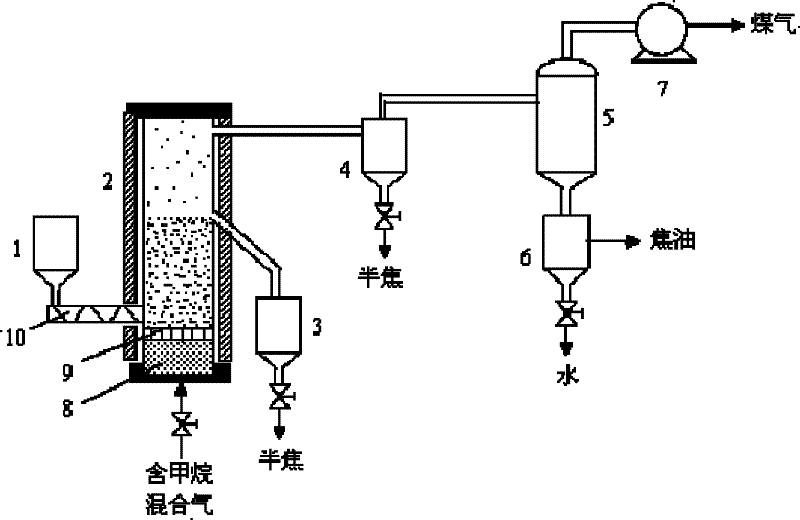

Method for increasing yield of coal-pyrolysis-based tar in reaction atmosphere of methane-rich gas mixture in fluidized bed

InactiveCN101747922AImprove bindingSimple and fast operationLiquid hydrocarbon mixture productionCoal pyrolysisProduct gas

The invention belongs to the technical field of energy and provides a method for increasing the yield of coal-pyrolysis-based tar in the reaction atmosphere of a methane-rich gas mixture in a fluidized bed. The method is characterized by comprising the following steps: feeding the methane-rich gas mixture into the fluidized bed from the bottom of a pyrolysis reactor; conducting reaction firstly on a catalyst layer, so as to activate the gas mixture; adding the activated gas mixture as a fluidized gas to the fluidized coal in the fluidized bed, and subjecting the fluidized gas and the fluidized coal to pyrolysis and coking in a fluidized state; and subjecting the generated pyrolysis products to the treatment in a gas-solid separator, a condenser and an oil-water separator where carbocoal, coal gas and tar are respectively obtained. Accordingly, the activated gas mixture and the coal come into full contact through the coal pyrolysis in the fluidized bed, thereby help combining activated molecules with free radicals generated through the coal pyrolysis; the yield of pyrolysis-based tar is higher than that of the tar based on the pyrolysis conducted in the hydrogen atmosphere or inert atmosphere under the identical conditions; moreover, the catalysts are indirectly mixed with coal, thereby facilitating the cyclic regeneration and repeated use.

Owner:DALIAN UNIV OF TECH

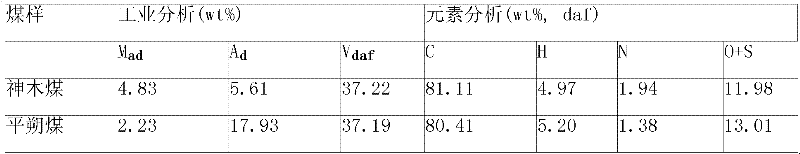

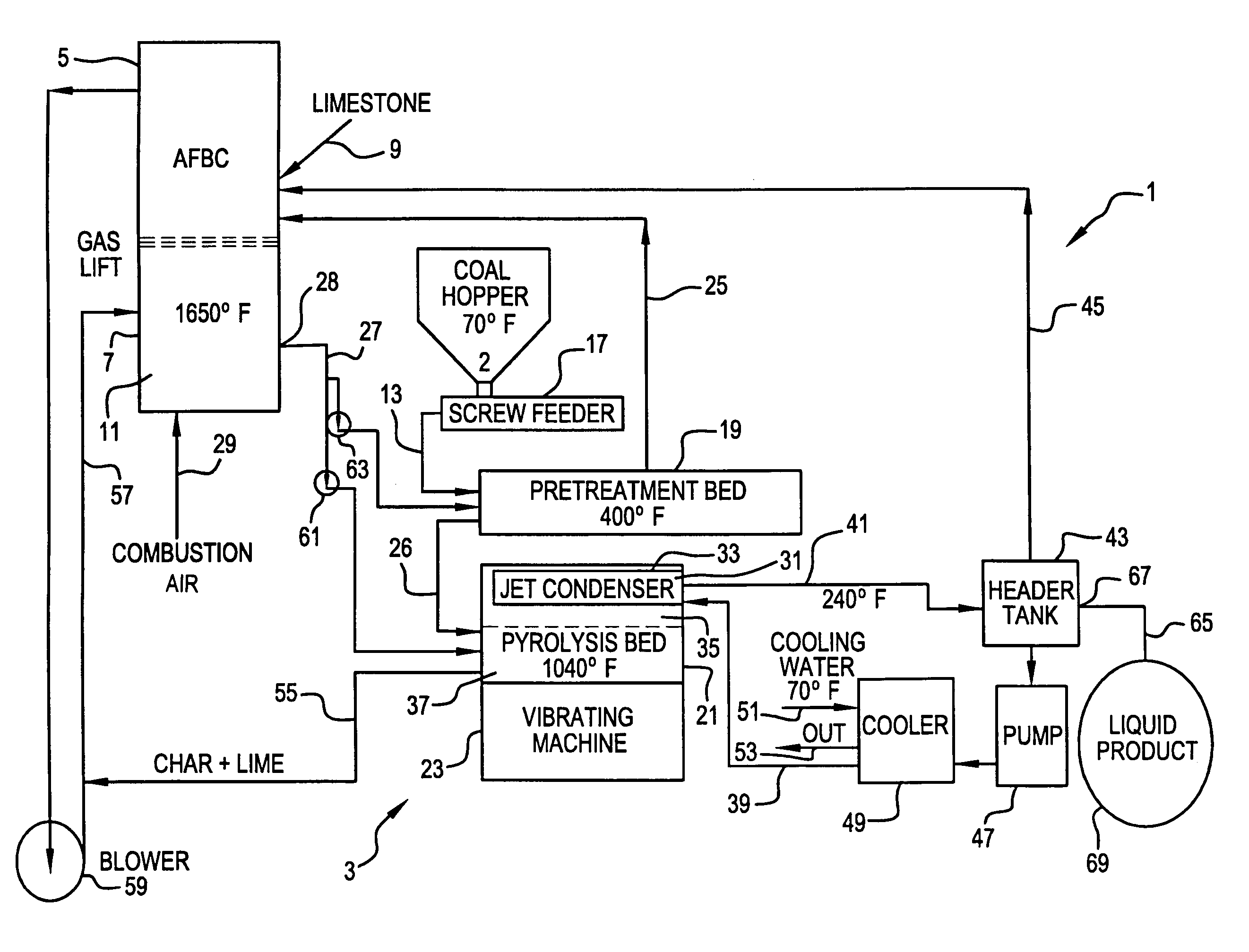

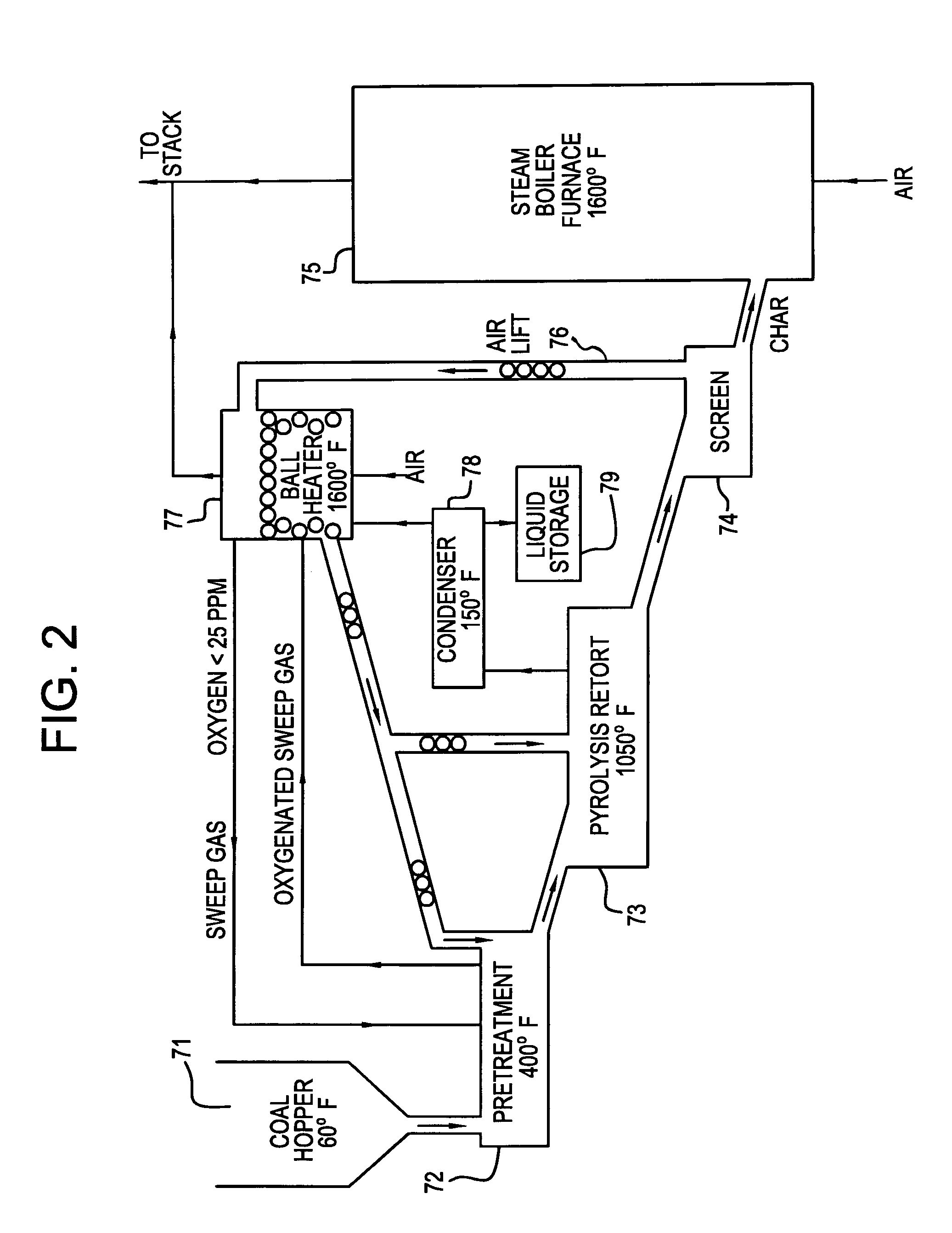

Pretreatment process to remove oxygen from coal en route to a coal pyolysis process as a means of improving the quality of the hydrocarbon liquid product

InactiveUS7008459B1Heat loss minimizationOxygen in-leakage can be kept extremely lowMechanical conveying coke ovensDirect heating destructive distillationLiquid productFlue gas

A process and apparatus for coal pyrolysis pretreatment. The apparatus is made up of a pretreatment vessel for holding a bed of coal particles, a preheater for heating the bed of coal particles to a temperature below the coal pyrolysis temperature range and an oxygen remover for removing oxygen released from the heated coal particles. The apparatus can also have a flue gas source as an oxygen removal sweep gas to the bed of coal, a collector for collecting non-condensable combustible gases, and the preheater having a furnace holding ceramic balls which are circulated from the furnace to the bed of coal particles. The process involves heating the bed of coal particles to a temperature below the coal pyrolysis temperature range and preventing air from contacting the bed of coal particles in addition to collecting non-condensable combustible gases or the preheating step accomplished by having a furnace holding ceramic balls which are circulated from the furnace to the bed of coal particles.

Owner:MACLEAN JOHN DR

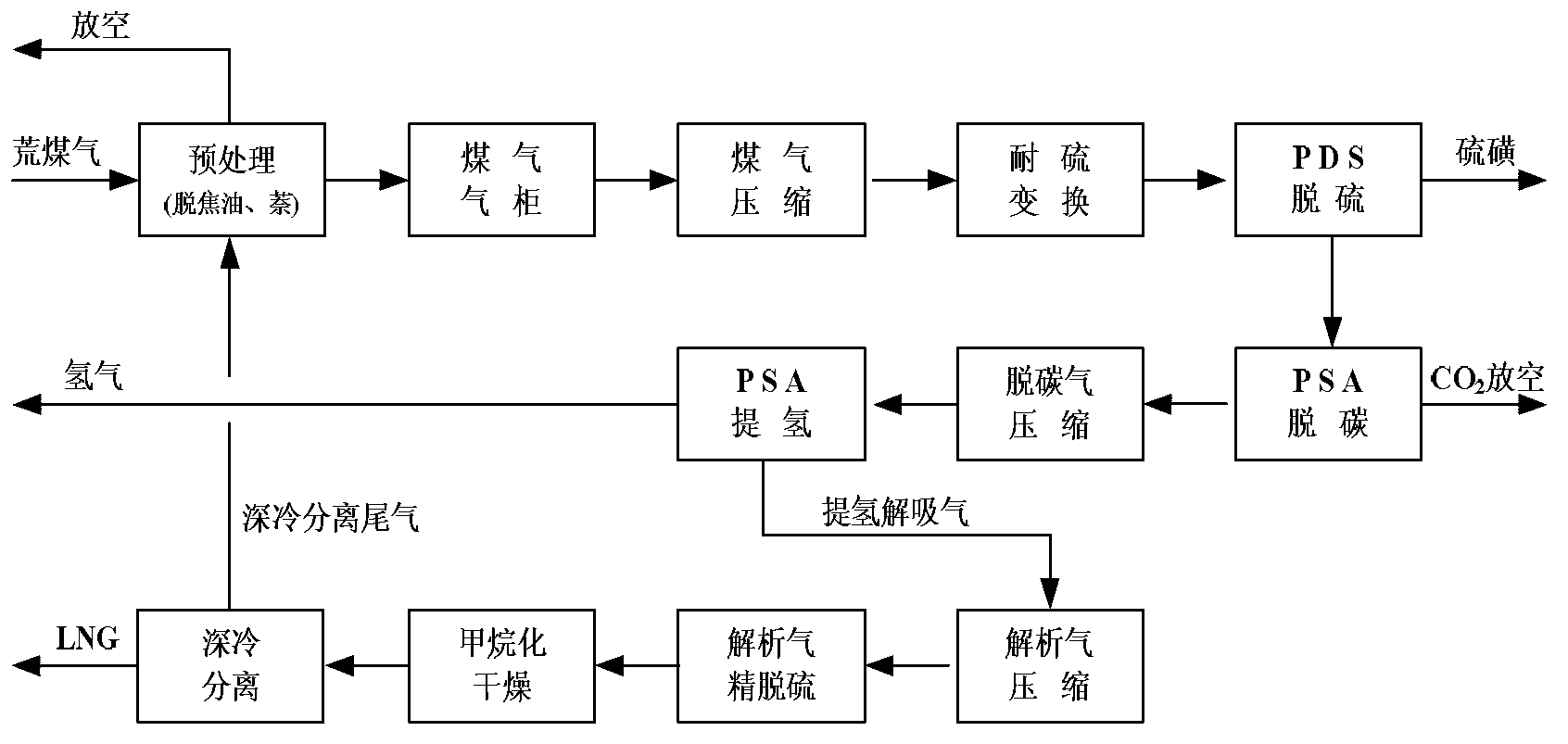

Method for preparing hydrogen and liquefied natural gas through using gas retort raw gas

ActiveCN103275777AImprove recycling efficiencyImprove utilization efficiencyHydrogenGaseous fuelsMethanationCoal pyrolysis

The invention discloses a method for preparing hydrogen and liquefied natural gas through using a gas retort raw gas. The method comprises the following steps: carrying out adsorbing pretreatment of the gas retort raw gas for removing tar and naphthalene in the gas retort raw gas, and allowing the obtained gas retort raw gas to enter a coal gas holder for buffering; pressurizing the buffered raw gas, allowing the pressurized raw gas to enter a sulfur-tolerant shift conversion reactor, and reacting carbon monoxide with steam to generate carbon dioxide and hydrogen; carrying out PDS wet desulphurization of the obtained shift conversion gas to obtain a byproduct sulfur, and regenerating a desulphurization liquid; carrying out a two-stage PSA (pressure swing adsorption) technology of the desulphurized shift conversion gas for carbon removal and hydrogen extraction; sending the obtained hydrogen to a tar hydrogenating apparatus as a raw material; carrying out pressurization and fine desulphurization of the obtained hydrogen extracted and desorbed gas, allowing the obtained gas to enter a methanation reactor, carrying out a methanation reaction of hydrogen in the desorbed gas, carbon monoxide and carbon dioxide to generate methane, drying the obtained generated gas, and allowing the generated gas to enter a cooling box; and liquefying methane through adopting a mixed refrigerating agent liquefying process to prepare the liquefied natural gas. The method increases the recycling efficiency of hydrogen and the comprehensive utilization efficiency of the raw material, and realizes the efficient and comprehensive utilization fo the coal pyrolysis raw gas.

Owner:HUADIAN HEAVY IND CO LTD

Fine coal pyrolysis reaction carbon burning circulation system

InactiveCN105694933AImprove resource utilizationImprove qualityDirect heating destructive distillationLiquid hydrocarbon mixture productionHeat carrierEngineering

The invention provides a novel pulverized coal pyrolysis reaction charcoal burning circulation system, including a charcoal burner, etc., the cyclone separator of the charcoal burner is located in the charcoal burner, the cyclone separator of the settler is located in the settler, and the settler is located in the On one side of the charcoal burner, the external heat extractor and the charcoal burner are connected through an inclined pipe. The heat carrier riser passes through the bottom of the charcoal burner and is connected to the riser reactor. The main air distributor is located at the charcoal burner In the bottom of the device, one end of the U-shaped pipe for heat carrier circulation passes through the bottom of the charcoal burner and is connected to the main air distributor, the other end of the U-shaped pipe for heat carrier circulation is connected to the settler, and the air stripping section is located at the bottom of the settler Inside, one end of the riser reactor is connected to the settler, the other end of the riser reactor is connected to the heat carrier standpipe, and the main air pipe part passes through the bottom of the charcoal burner. The invention improves the utilization rate of pulverized coal resources and does not cause environmental pollution.

Owner:胜帮科技股份有限公司

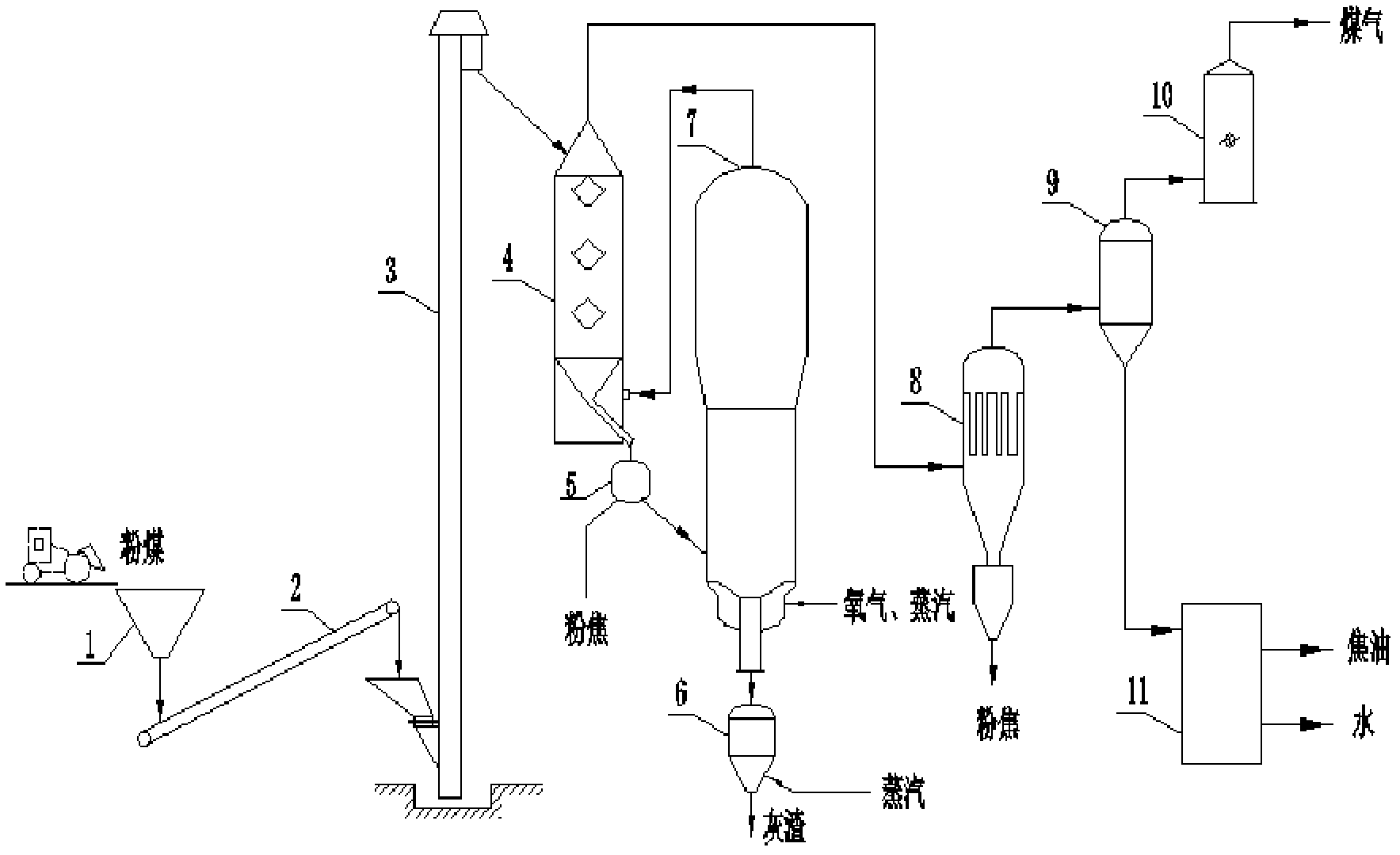

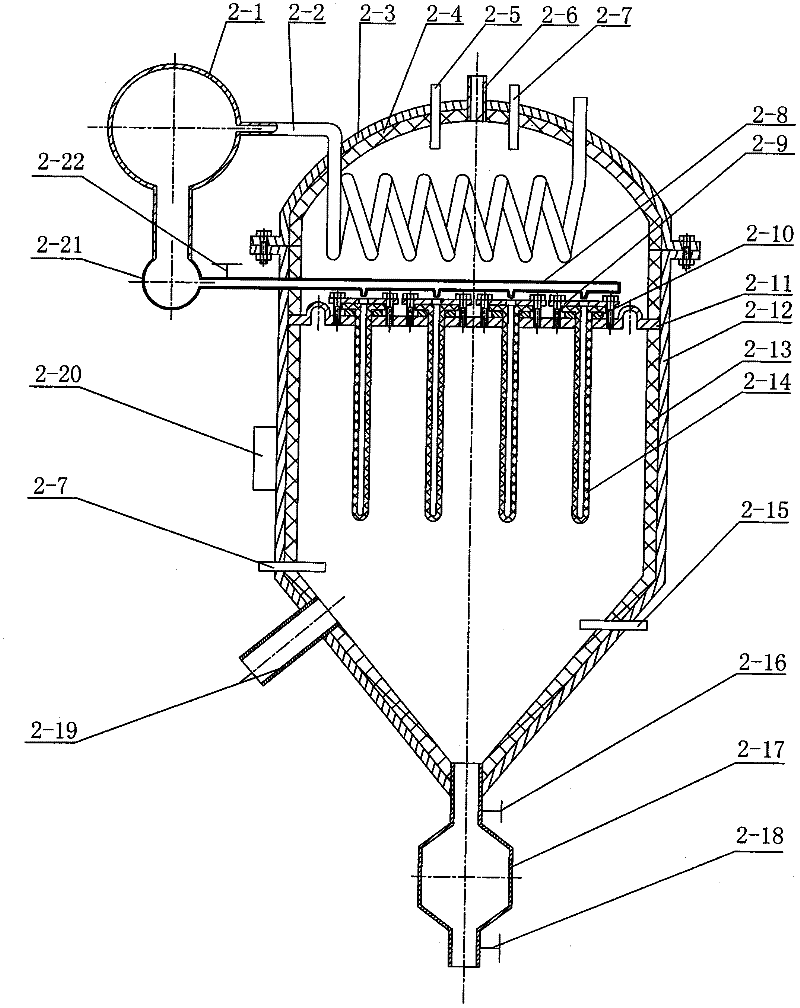

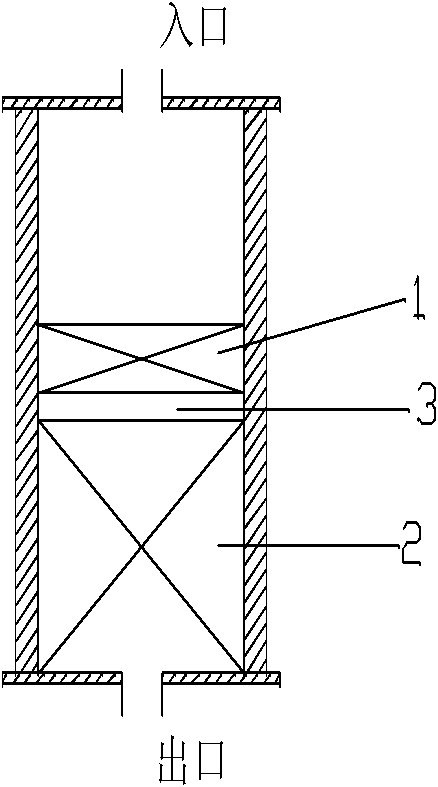

Moving bed pulverized coal pyrolysis and fluidized bed coke powder gasification coupled device and coupling method thereof

InactiveCN102433166APolygenerationSimple processSpecial form destructive distillationGas purification by non-gaseous materials condensationCouplingFluidized bed

The invention discloses a moving bed pulverized coal pyrolysis and fluidized bed coke powder gasification coupled device and a coupling method thereof. The device comprises a moving bed pulverized coal pyrolysis furnace and a fluidized bed coke powder gasification furnace which is connected with the moving bed pulverized coal pyrolysis furnace, wherein the moving bed pulverized coal pyrolysis furnace is communicated with the inlet of the fluidized bed coke powder gasification furnace through a low pipe, and is connected with a high-temperature deep deduster; coke powder dedusted by the high-temperature deep deduster is discharged from the lower end of the high-temperature deep deduster; dedusted pyrolysis coal gas and tar vapor enter a gas cooler to be cooled; and the condensed tar and water enter a separator, tar is separated, the coal gas from the gas cooler passes through a static tar removing device for further removal of tar, and finally the coal gas enters a purification system. In the invention, high-temperature coal gas in the fluidized bed coke powder gasification furnace is used as a carrier, pulverized coal is subjected to low-temperature pyrolysis in the moving bed pulverized coal pyrolysis furnace to release volatile matters for producing coal gas and tar, the coke powder obtained after pyrolysis is returned to the fluidized bed coke powder gasification furnace to be gasified into coal gas, and thus, the combined production of coal gas, semicoke and tar is realized.

Owner:陕西华祥能源科技集团有限公司

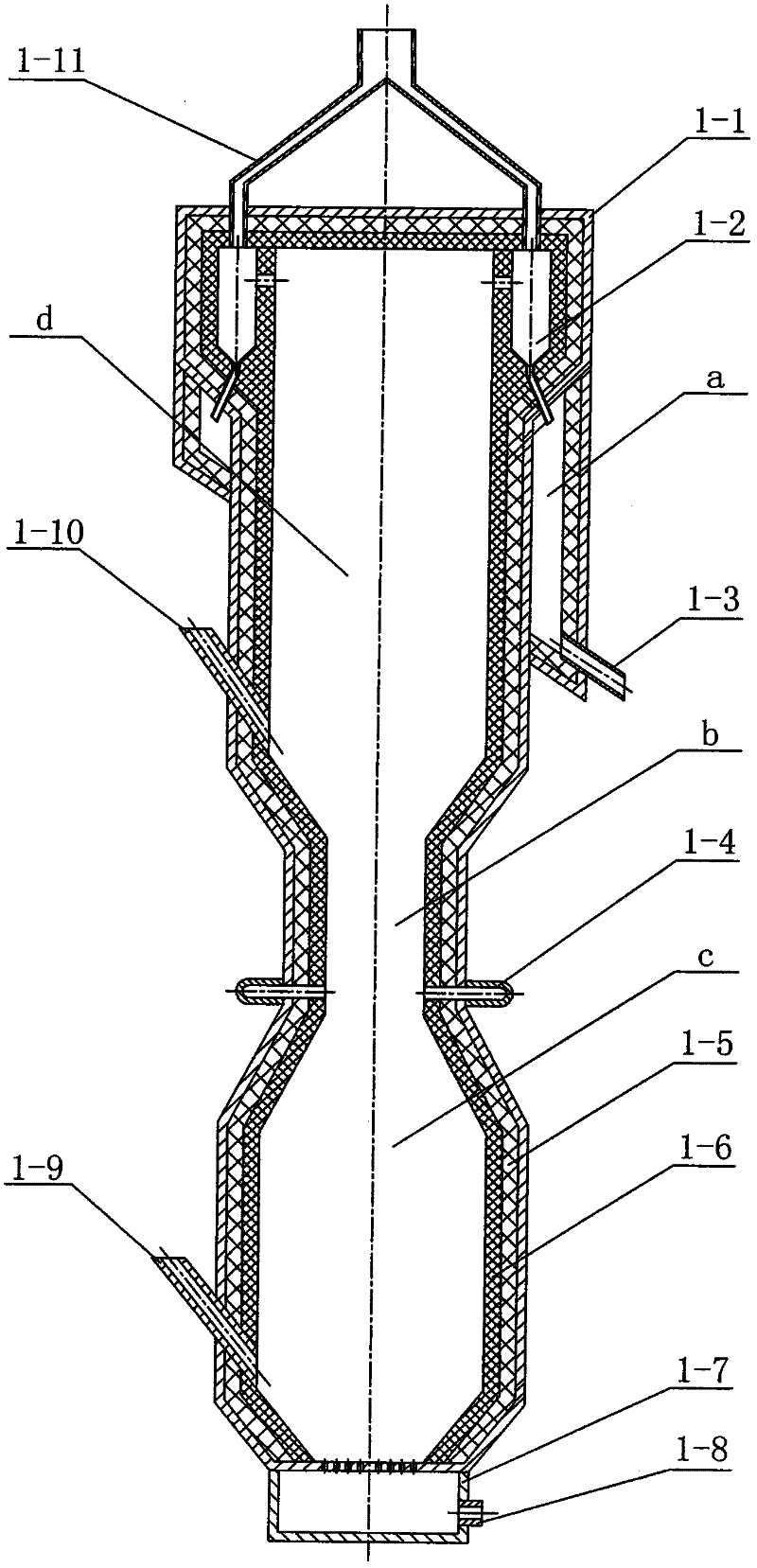

Coal pyrolysis reactor

ActiveCN101818071AIncrease profitReduce contentDirect heating destructive distillationSpecial form destructive distillationGas phaseCombined method

The invention discloses a coal pyrolysis reactor, which comprises a pyrolysis reactor. An upper part of the pyrolysis reactor is provided with a raw material coal pipe for leading a coal raw material in and a leading-out pipeline for leading a coal pyrolysis gas-phase product out; the bottom of the pyrolysis reactor is provided with a discharging opening for leading a semi-coke out; a pipeline structure for leading a high temperature grain medium out is arranged in the pyrolysis reactor; and an outlet of the pipeline structure is extended to the middle part or the middle lower part of the pyrolysis reactor. The pyrolysis reactor is provided with the pipeline structure for shunting the high temperature grain medium, and the pipeline structure is extended to the middle part or the middle lower part of the pyrolysis reactor; and the raw material coal is pyrolyzed by adopting a combined method of indirectly pre-heating or directly heat exchanging, so that the use ratio of the heat energy is increased, the coal raw material on the upper part of the pyrolysis reactor plays a role in filtering dusts, and the structure reduces the content of the dust carried in the product to the largest extent.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD

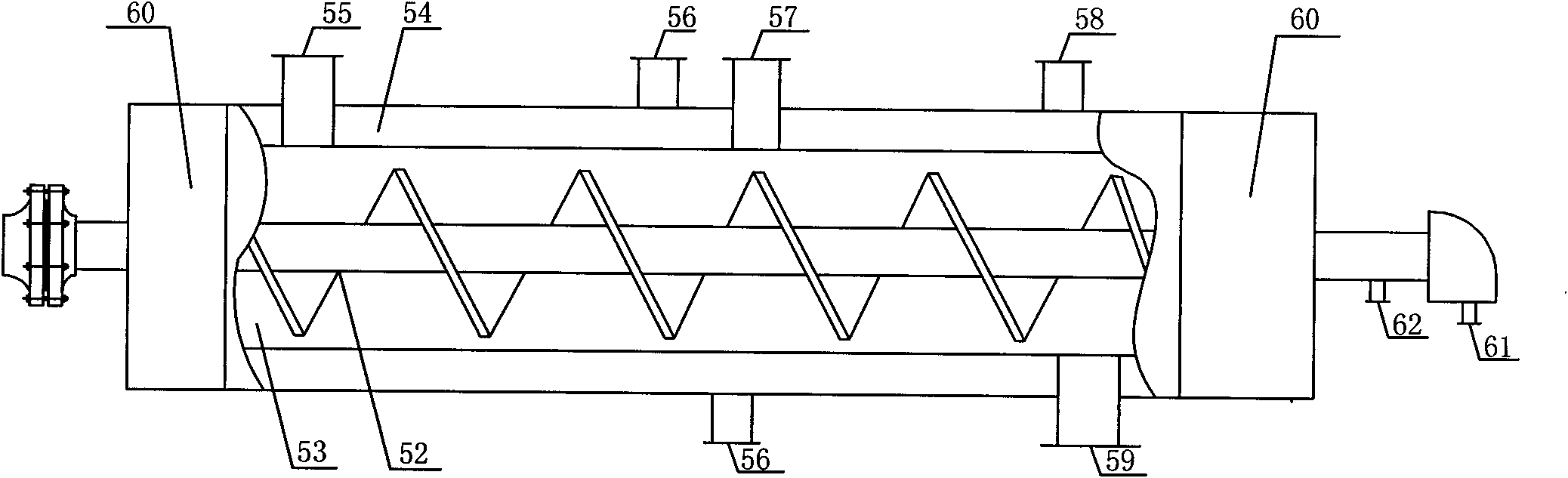

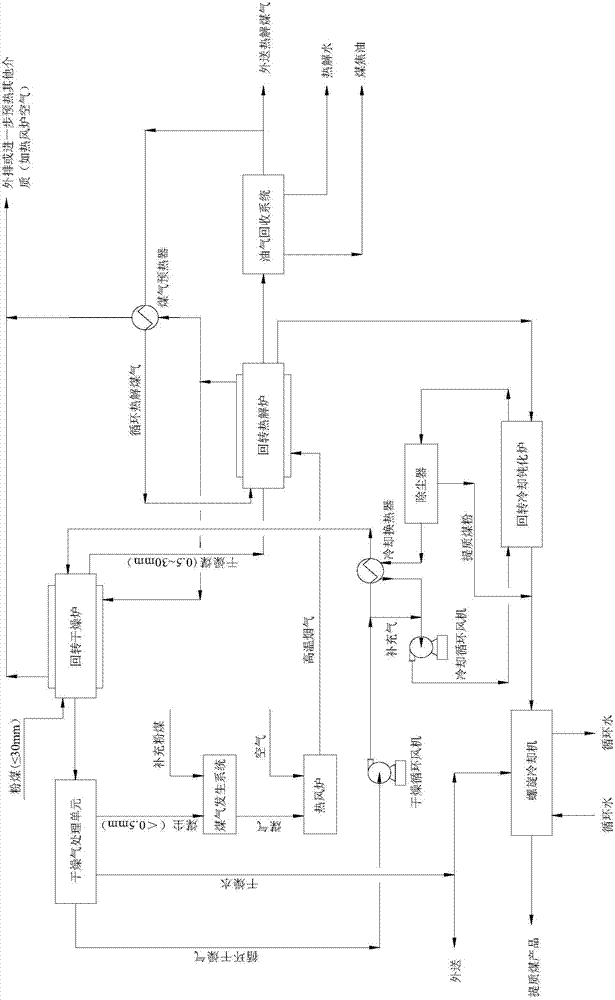

Rotary furnace low-order powdered coal pyrolysis upgrading method with coal gas circulation

ActiveCN104762097AReduce coal dust contentImprove qualitySpecial form destructive distillationGranularityCoal dust

The invention provides a rotary furnace low-order powdered coal pyrolysis upgrading method with coal gas circulation. The rotary furnace low-order powdered coal pyrolysis upgrading method comprises the following steps: heating and drying raw material powdered coal with the granularity less than or equal to 30mm to be 110-280 DEG C in a low-order powdered coal rotary drying system with dust collection, and removing 85% of coal dust with the granularity less than 0.5mm in the powdered coal; feeding the dried coal with the granularity of 0.5-30mm to a downstream rotary pyrolysis system to react at 500-700 DEG C so as to generate upgraded coal and a high-temperature oil gas; feeding the high-temperature upgraded coal to a rotary cooling passivating furnace for primary cooling and medium / low temperature passivation, further cooling by using a spiral cooling machine, spraying water, and discharging out the product; feeding the high-temperature oil gas into an oil gas recycling system, and performing temperature reduction separation, thereby obtaining coal tar, pyrolysis water and pyrolysis coal gas; preheating a part of the pyrolysis coal gas, circulating back to the pyrolysis furnace, and discharging out the rest part of the pyrolysis coal gas.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

Low-rank coal gradation usage poly-generation system and method

InactiveCN105154121AStrong complementarityRich varietyCombustible gas chemical modificationCoke ovensChemical synthesisSyngas

The invention discloses a low-rank coal gradation usage poly-generation system and a method thereof. The low-rank coal gradation usage poly-generation system comprises a feed coal pyrolysis carbonization system and an entrained bed dry powder gasification system, wherein in the pyrolysis carbonization system, high water / high ash low-rank coal is subjected to pyrolysis and carbonization treatment, so as to obtain crude gas, tar and semi-coke; an oil product is obtained through coal tar hydrogenation; crude gas is purified to obtain coal gas; semi-coke is fed into an entrained bed for gasification; dry powder feeding is adopted during entrained bed gasification; semi-coke is grinded and fed in a powder form; after gasification, a synthesis gas is purified and changed to obtain hydrogen needed during coal tar hydrogenation and a synthesis gas needed during chemical synthesis. The low-rank coal gradation usage poly-generation system and the method thereof have the characteristics of stable and reliable operation, easy large-scale amplification, environmental protection, energy conservation, and the like.

Owner:SHANGHAI BOILER WORKS

Purifying and tar recovery system for high temperature gas containing ash and tar and method thereof

InactiveCN103409175ALow ash contentImprove liquidityEnergy inputGas purification by non-gaseous materials condensationThermodynamicsWastewater

The invention discloses a purifying and tar recovery system for high temperature gas containing ash and tar and a method thereof. A high temperature cyclone dust collector, a high temperature electric dust collector, an exhaust-heat boiler, a first level electrical tar precipitator, an intercooler, a second level electrical light oil precipitator and a gas exhauster are connected in order. High-temperature raw gas containing ash and tar from coal pyrolysis technology successively passes through the high temperature cyclone dust collector and the high temperature electric dust collector to be subjected to high temperature dusting; dusted raw gas is subjected to waste heat recovery in the exhaust-heat boiler by cooling water to generate low pressure steam; after the exhaust-heat boiler is cooled, the raw gas is introduced into the first level electrical tar precipitator for tar precipitation; output raw gas is cooled in the intercooler by cooling water; outlet gas enters into the second level electrical light oil precipitator; and purified is sent out by the gas exhauster. The invention can realize cooling, heat recovery and effective tar precipitation of high-temperature pyrolysis gas containing ash and tar, and greatly reduce waste water discharge, so as to save energy and reduce emission.

Owner:ZHEJIANG UNIV

Circulated coal gas heat carrier fluidized bed ash coal pyrolysis device and method

InactiveCN102352262ASimple processAchieving hydropyrolysisDirect heating destructive distillationSpecial form destructive distillationCycloneHeat carrier

The invention discloses a circulated coal gas heat carrier fluidized bed ash coal pyrolysis device and method. The device comprises a coal-adding system and a fluidized bed pyrolyzing furnace which is communicated with the coal-adding system and provided with a coke-discharging hole, wherein the gas distributor of the fluidized bed pyrolyzing furnace is communicated with a high temperature heating furnace, the coal gas outlet of the fluidized bed pyrolyzing furnace is communicated with a first-stage cyclone separator, a second-stage cyclone separator, a high temperature deep dust collector and a gas cooler in turn through a pipeline, the lower outlet of the gas cooler is communicated with a separator, and the gas outlet of the gas cooler is connected with the high temperature heating furnace and a coal gas delivering device respectively. The device has simple flow and does not require an air separation device; as the circulated coal gas contains a lot of hydrogen, the hydropyrolysis of coal is realized to a certain extent, the yield of oil is increased to above 12%; and the operating pressure can be increased to the medium / high level, and industrial clusters and polygeneration are applied on the basis of equipment scale expansion while the products such as coal gas with high calorific value, semicoke, tar and the like are prepared.

Owner:陕西华祥能源科技集团有限公司

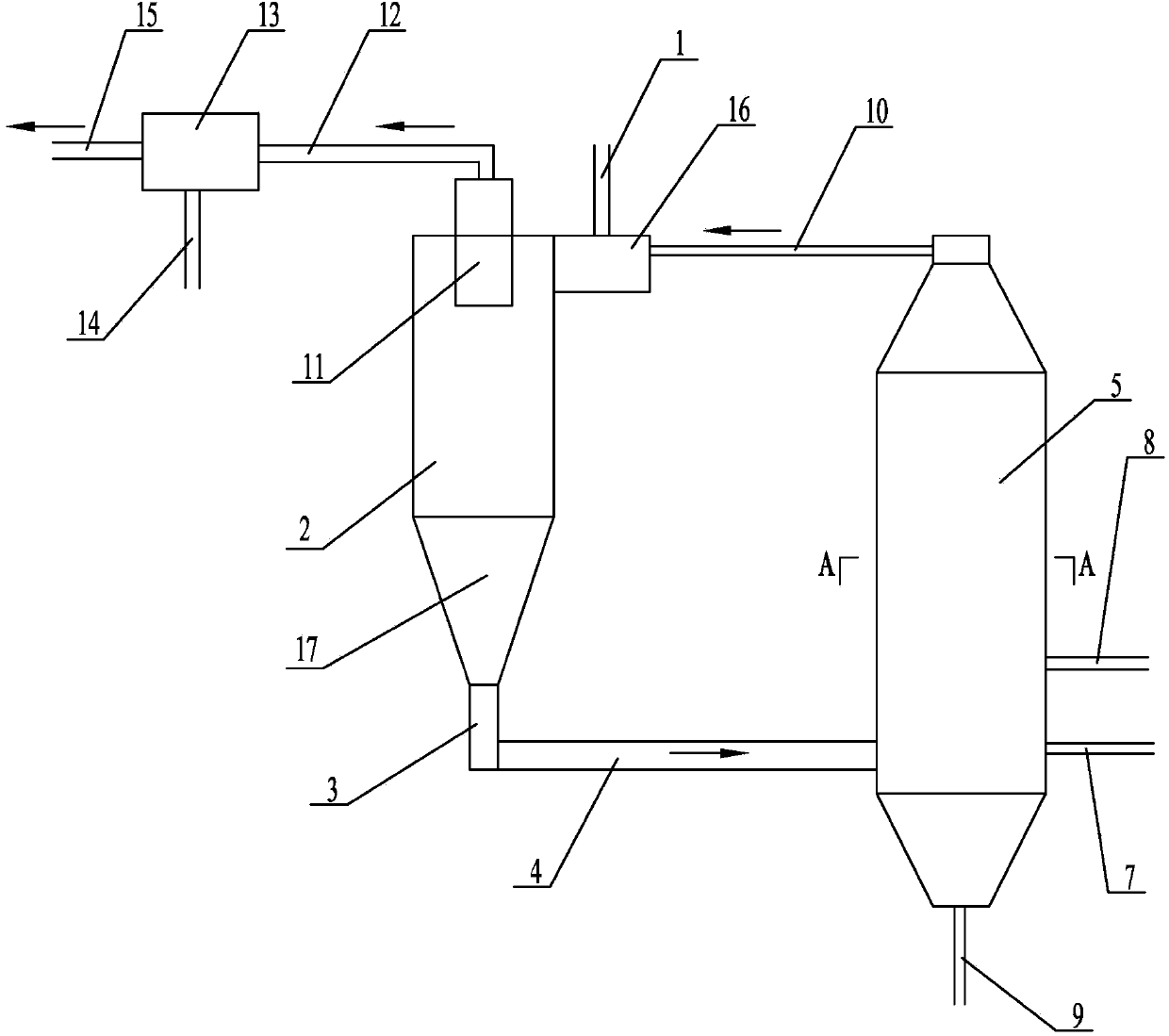

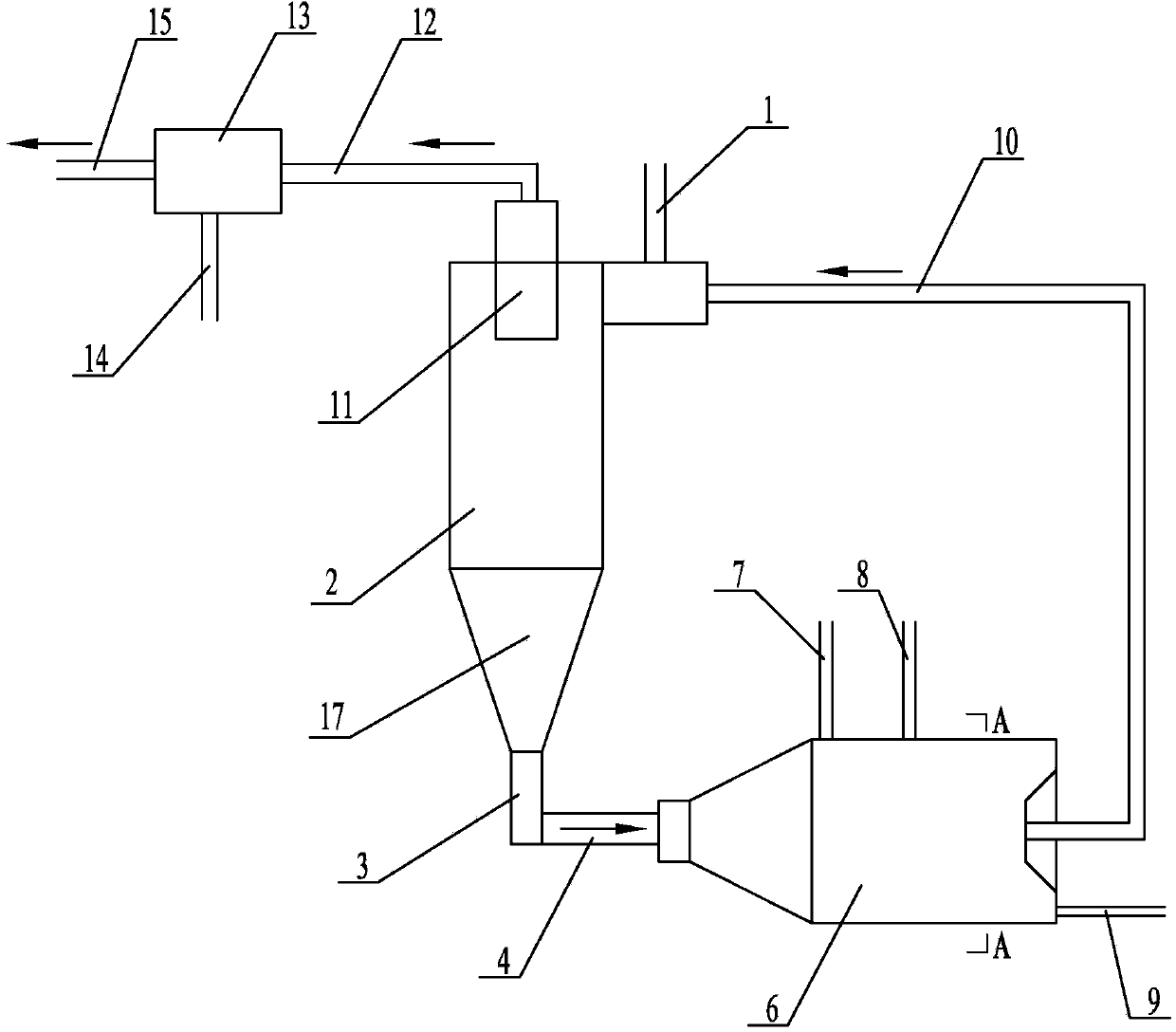

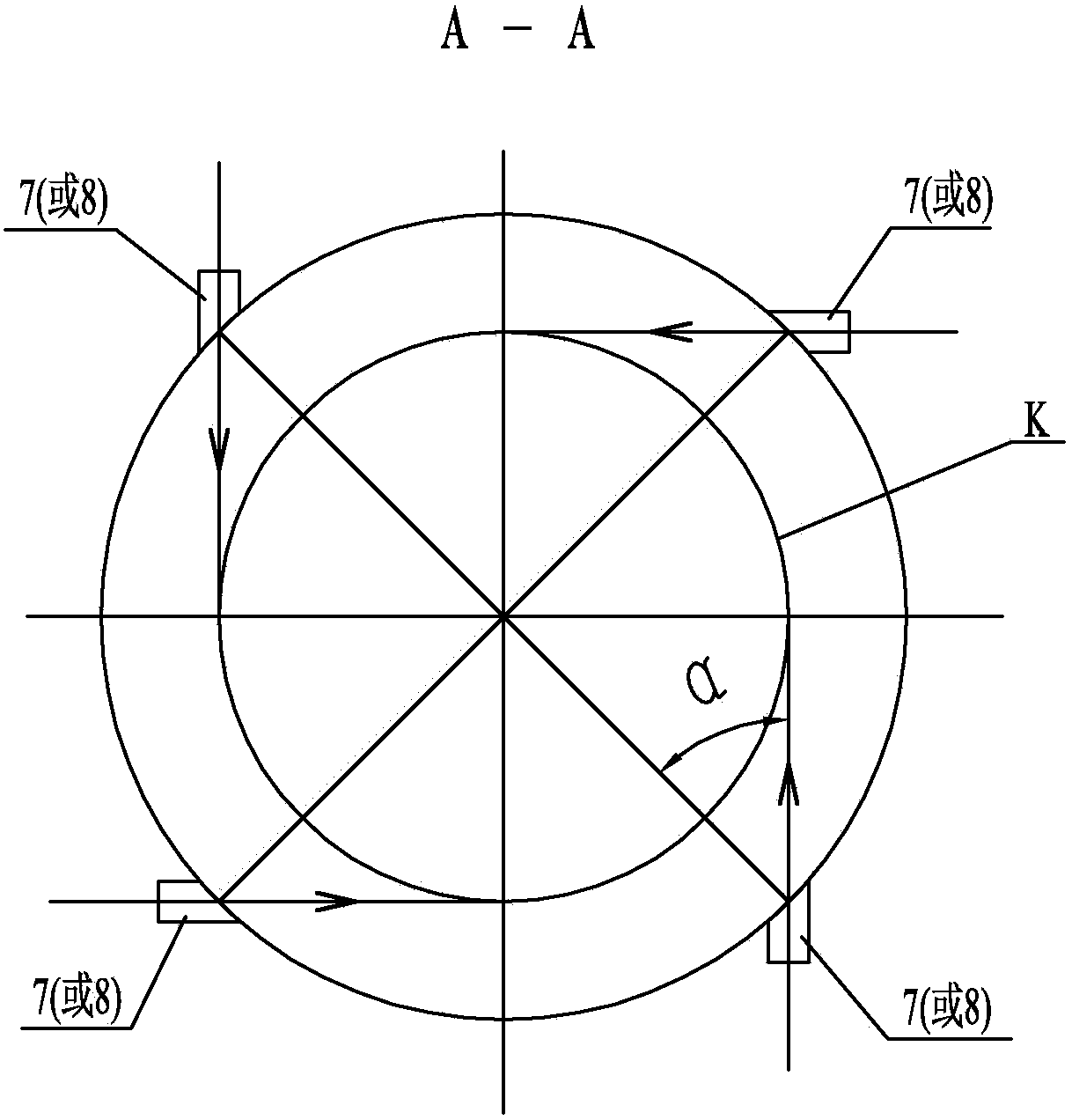

Double-cyclone coal pyrolysis gasification step converting device and double-cyclone coal pyrolysis gasification step converting method

ActiveCN103992824AIncrease profitFully pyrolyzedGranular/pulverulent flues gasificationCycloneWater vapor

The invention discloses a double-cyclone coal pyrolysis gasification step converting device and a double-cyclone coal pyrolysis gasification step converting method, and relates to a combusting device and a combusting method. The device is characterized in that a cyclone pyrolyzing furnace is communicated with a cyclone gasifying furnace by a material backing device and a pyrolyzing semi-coke channel; the cyclone gasifying furnace is communicated with the cyclone pyrolyzing furnace by a high-temperature raw coal gas channel; the cyclone pyrolyzing furnace is communicated with a cooling device by a pyrolyzing gas-mixing channel; an oxidant spray nozzle and a vapor spray nozzle are arranged on the outer wall of the cyclone gasifying furnace. The method is as follows: firstly, feeding coal dust into the cyclone pyrolyzing furnace under blocking and feeding of the high-temperature raw coal gas; secondly, pyrolyzing the coal dust in the cyclone pyrolyzing furnace, exhausting the pyrolyzed gas mixture into the cooling device, cooling, and conveying back the pyrolyzed semi-coke to the cyclone gasifying furnace; thirdly, spraying the oxidant and the vapor into the cyclone pyrolyzing furnace by the oxidant spray nozzle and the vapor spray nozzle at the same time, wherein the produced high-temperature raw coal gas is re-fed into the cyclone pyrolyzing furnace as a coal pyrolyzing gas heater carrier; coal residue in the cyclone gasifying furnace is exhausted through an ash residue discharge hole in the form of solid or liquid. The double-cyclone coal pyrolysis gasification step converting device and the double-cyclone coal pyrolysis gasification step converting method are used for gasifying clean coal gas.

Owner:HARBIN INST OF TECH

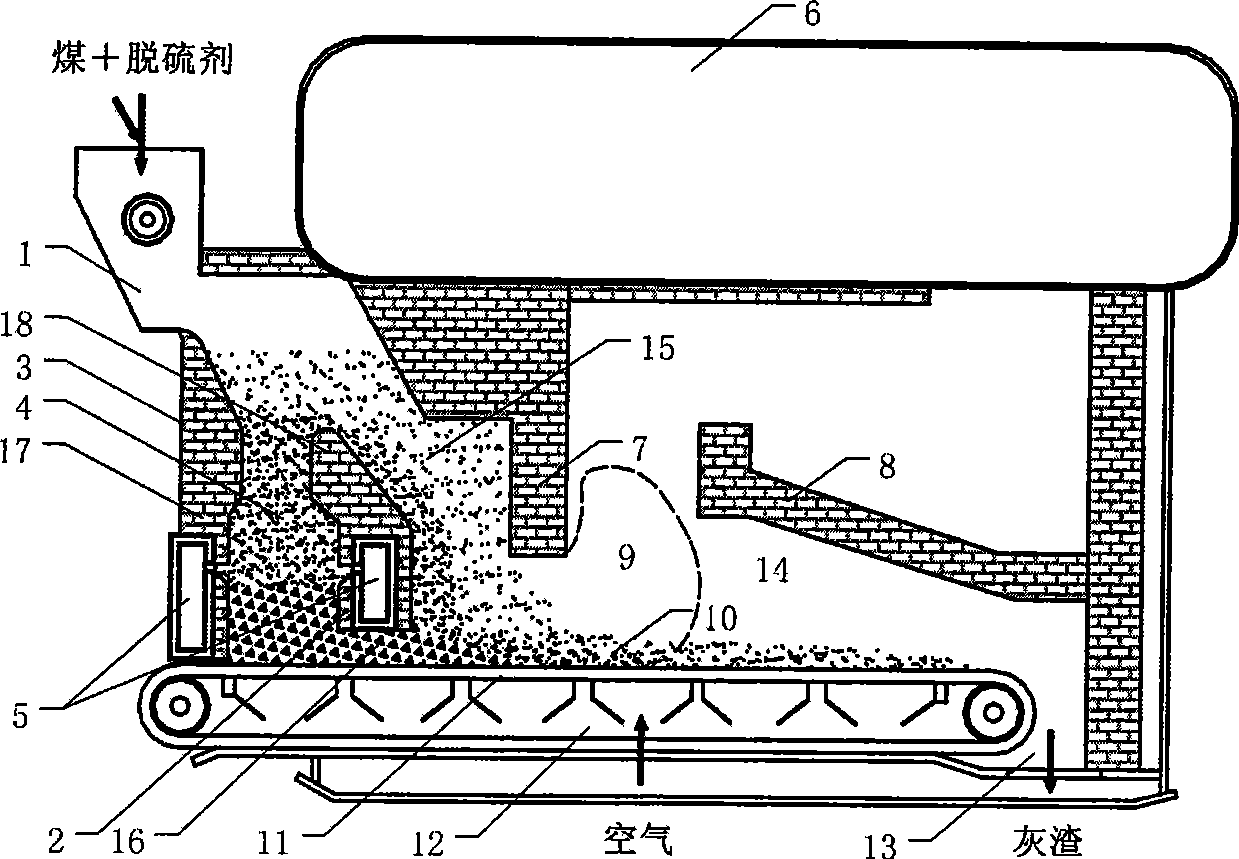

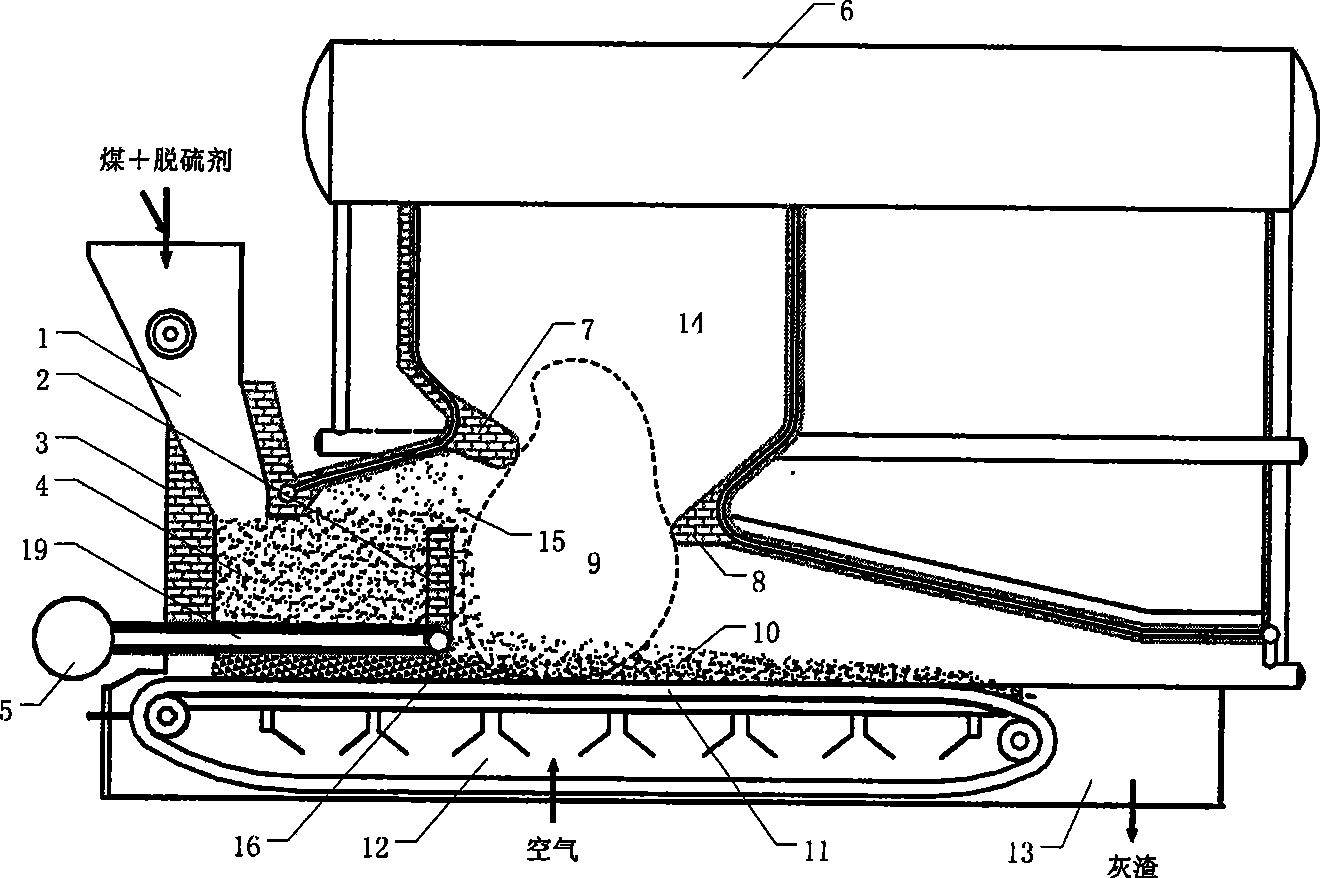

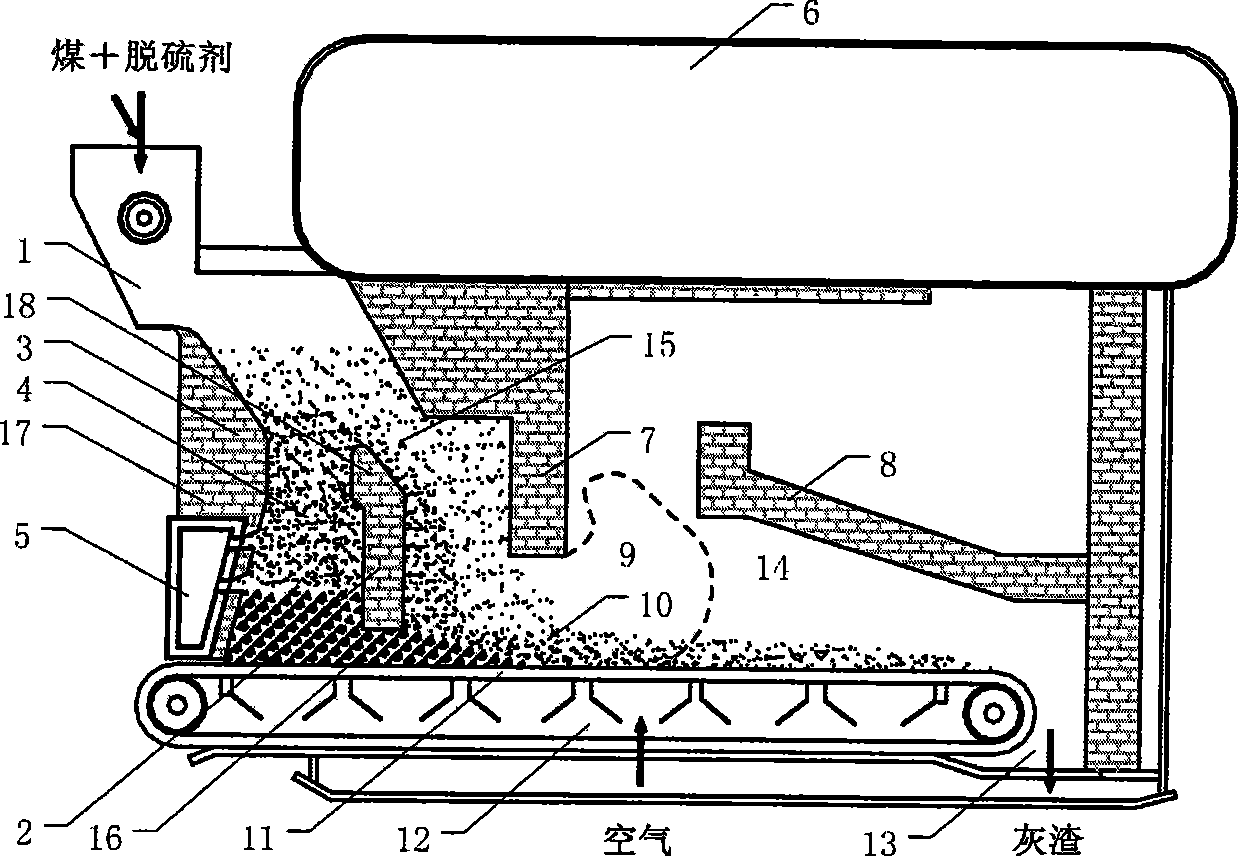

Coal thermal decomposition grate firing apparatus and its combustion method

InactiveCN101368724ASimple structureNo increase in sizeSolid fuel combustionCombustion apparatusCombustion chamberCombustible gas

The invention relates to a coal pyrolysis layer combustion device and the combustion method thereof, including that the furnace body interior of the first layer combustion furnace is divided into an upper oxidation pyrolysis chamber and a lower fire grate layer combustion chamber which is communicated with each other; the coal and desulfurizer are mixed to be fed into the middle part of the oxidation pyrolysis for oxidation pyrolysis through a hopper; the generated combustible gas and the smaller semi-coke particles are overflowed through the upper-connected through port or are carried in the airflow to be fed into the mechanical fire grate layer combustion chamber; the bigger semi-coke particles fall on the mechanical fire grate and are fed into the layer combustion layer for combustion; the mechanical fire grate layer combustion chamber is provided with a front arch and a back arch for organizing the airflow field inside the furnace; the coal pyrolysis layer combustion device and the combustion method thereof adopt the fluidization characteristics of the coal particles with different particle diameters and the high thermal capacity characteristic inside the oxidation pyrolysis chamber to realize the natural separation of the coal particles with different particle diameters and the rapid oxidation pyrolysis of coal, reduce the fire grate coal leakage loss and the incomplete combustion loss caused by the front segment low temperature of the fire grate and reduce the emission of the SOx and NOx pollutant through the combination of the pyrolysis desulfurization and the combustion desulfurization, and the reburning denitration formed by the coal pyrolysis product.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

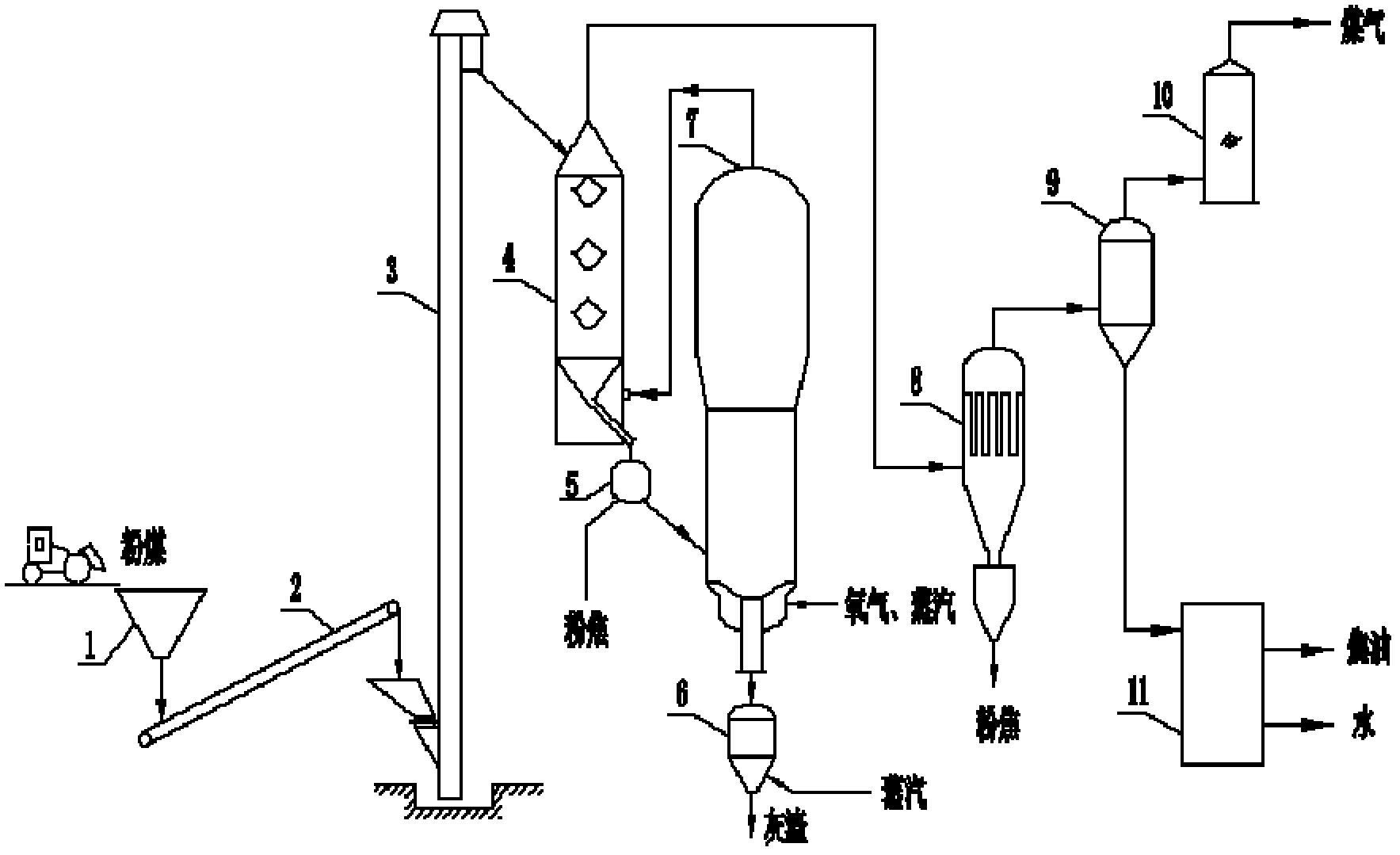

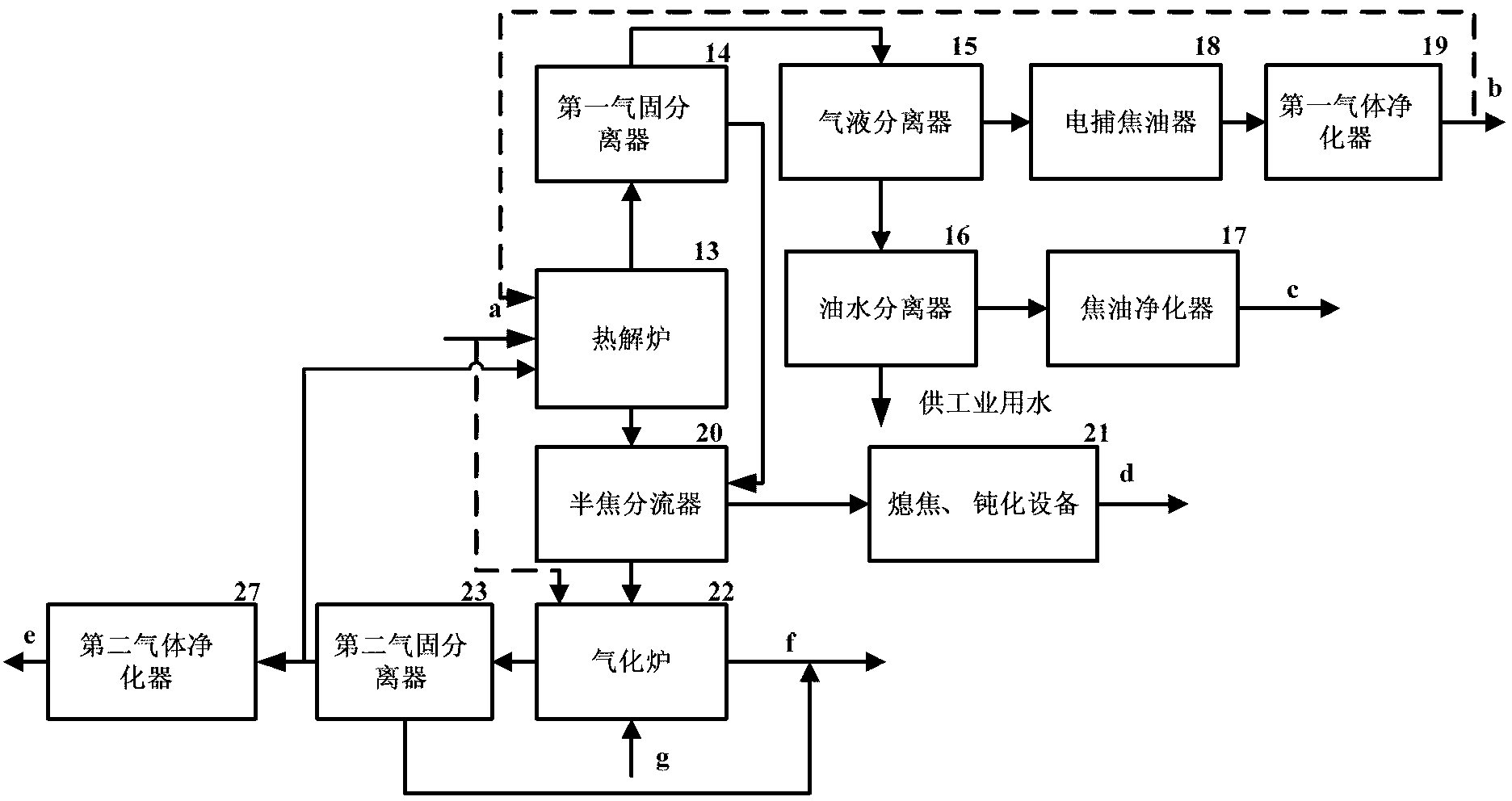

Coal pyrolysis gasification poly-generation device and process based on circulating fluidized bed

InactiveCN103881761ARealize hierarchical optimization utilizationTo solve the purpose of efficient purificationFluidized bed combustionCombustible gas productionElectricityCombustion

The invention discloses a coal pyrolysis gasification poly-generation device and process based on a circulating fluidized bed. A circulating fluidized bed boiler is organically coupled with a moving bed coal pyrolysis reactor and a moving bed gasification furnace, the high temperature circulation ash of the circulating fluidized bed boiler is used as a carrier for pyrolyzing high volatile coal steam coal from a coal funnel in the moving bed coal pyrolysis reactor, the semicoke generated in pyrolysis is separated out from the pyrolysis reactor and is fed into the moving bed gasification furnace for gasification, and at the same time the moving bed gasification furnace is used as a device for purifying a pyrolysis coal gas, thereby achieving the function of on-line dust collection of the pyrolysis coal gas. The gasified activated coke as a byproduct is discharged outside the reaction system. Therefore, through organic combination of three procedures, including pyrolysis, gasification and combustion, graded optimized utilization of the coal resource is achieved, joint production of heat, electricity, tar, coal gas and activated coke is achieved, and meanwhile the purposes of gasifying the coal gas and efficiently purifying the pyrolysis coal gas are achieved.

Owner:SHANXI LUAN MINING GRP +1

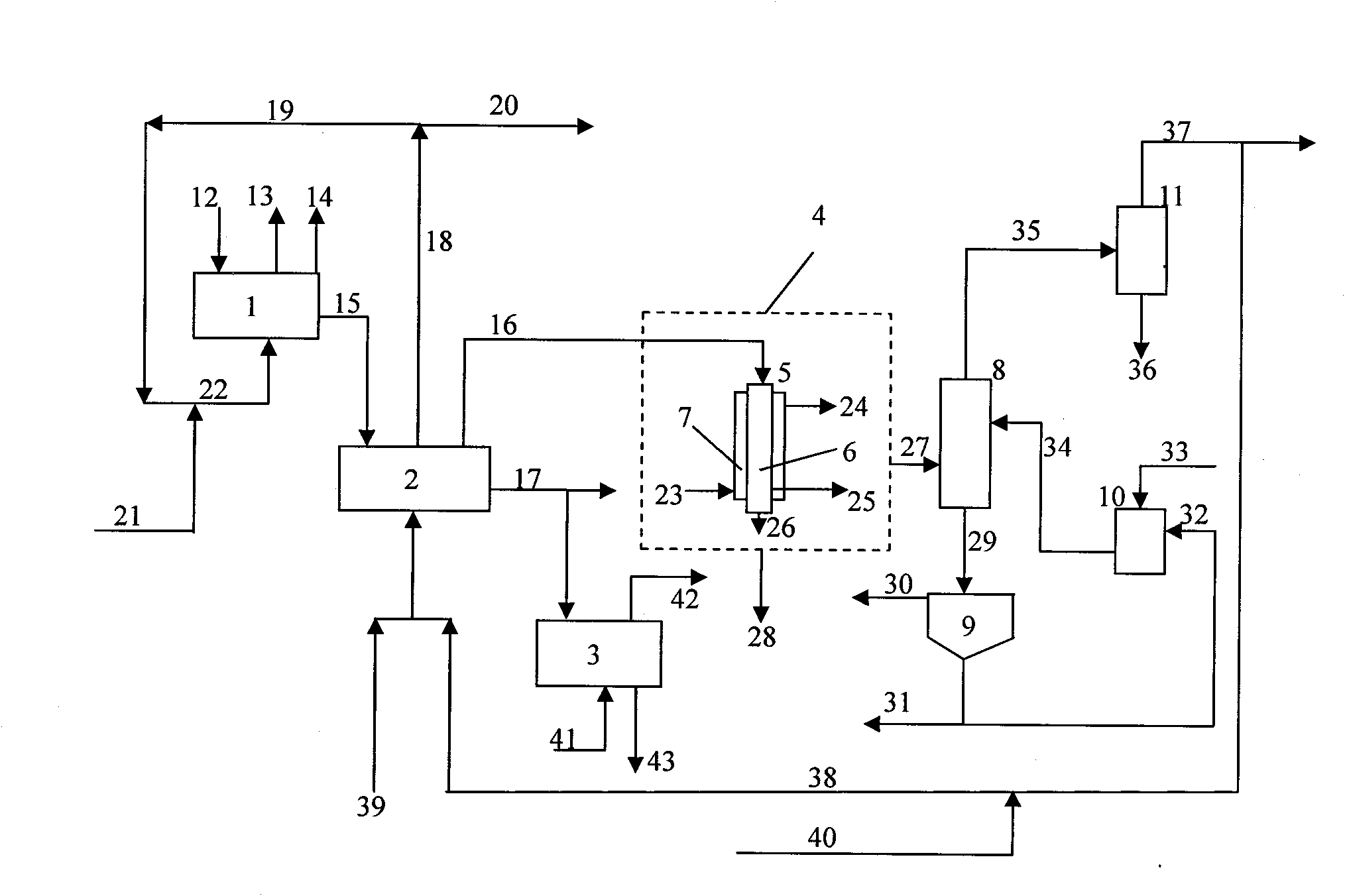

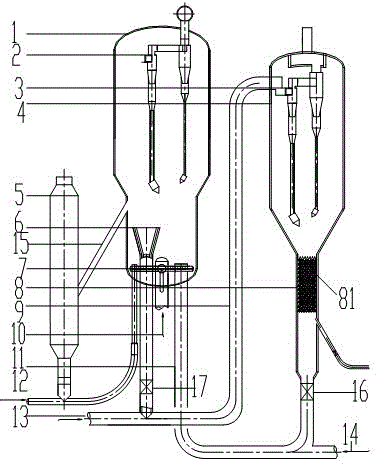

Device for preparing coal tar and coal gas by coupling semi-coke powder gasification and reformed gas pyrolysis and method using same

ActiveCN102250646AHigh yieldReduce pollutionEnergy inputCombustible gas purificationProcess engineeringCrusher

The invention discloses a device for preparing coal tar and coal gas by coupling semi-coke powder gasification and reformed gas pyrolysis. In the device, a semi-coke heating furnace is communicated with the lower part of a gasification and pyrolysis reactor, the top of the semi-coke heating furnace is communicated with an afterheat boiler, and the lower part of the semi-coke heating furnace is communicated with the upper part and a high-temperature semi-coke heat exchanger through valves; the high-temperature semi-coke heat exchanger is communicated with a crusher which is communicated with the lower end and the upper part of the gasification and pyrolysis reactor; the upper end of the gasification and pyrolysis reactor is communicated with a raw coke oven gas filter; the raw coke oven gas filter is communicated with the afterheat boiler, a semi-coke outlet and the upper part of the gasification and pyrolysis reactor; one outlet of the afterheat boiler is communicated with lower end of the gasification and pyrolysis reactor; an oil and gas outlet is communicated with an oil and gas separator; and the oil and gas separator is communicated with the middle part of the gasification and pyrolysis reactor through a circulating fan. A method preparing coal tar and coal gas by using the device comprises the steps of pulverized coal preparation and drying, semi-coke gasification, methane reforming, coal pyrolysis, gas and solid separation and oil and gas separation. The device and the method, which are disclosed by the invention, can be used for preparing coal tar and coal gas.

Owner:王树宽

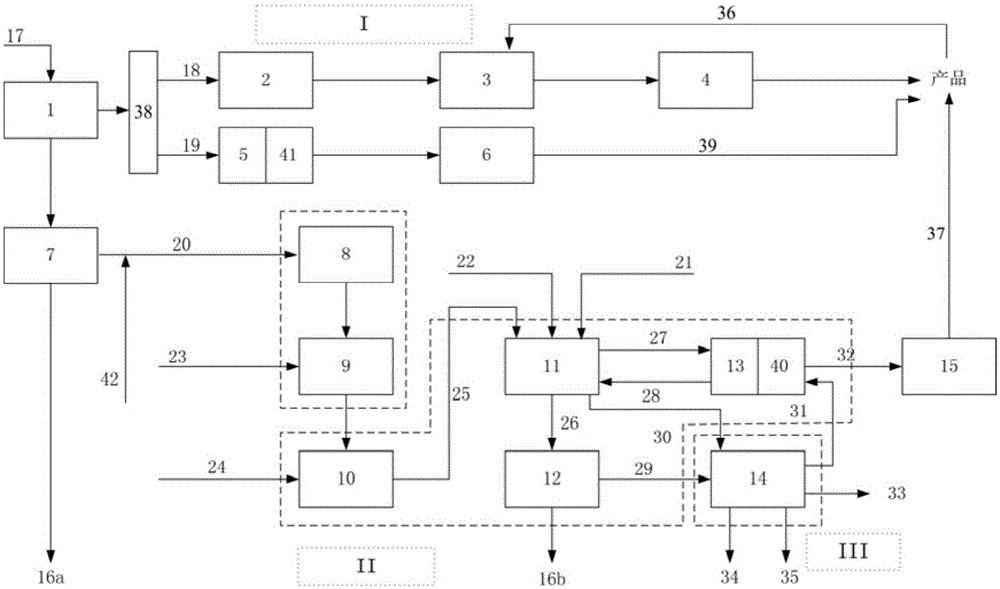

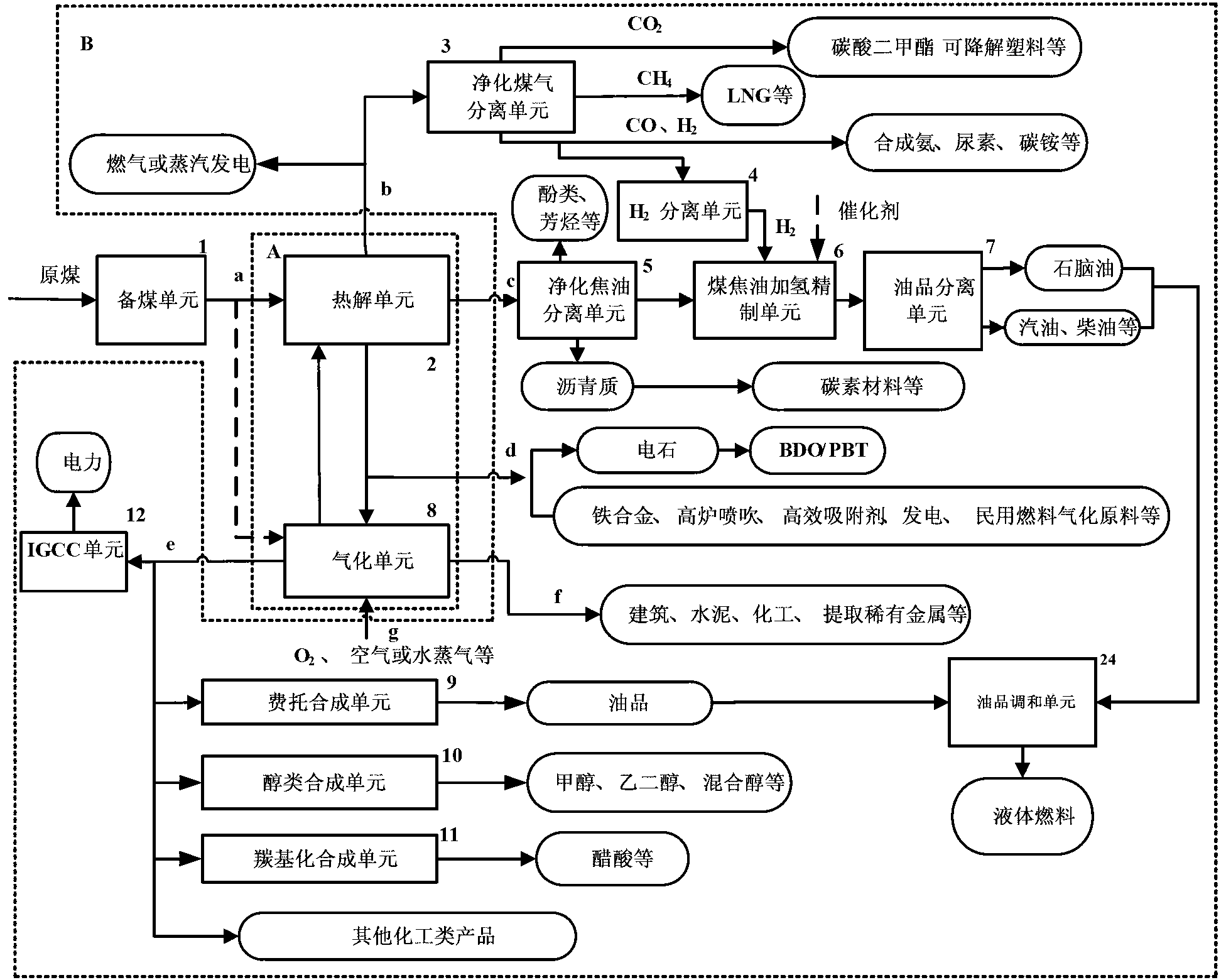

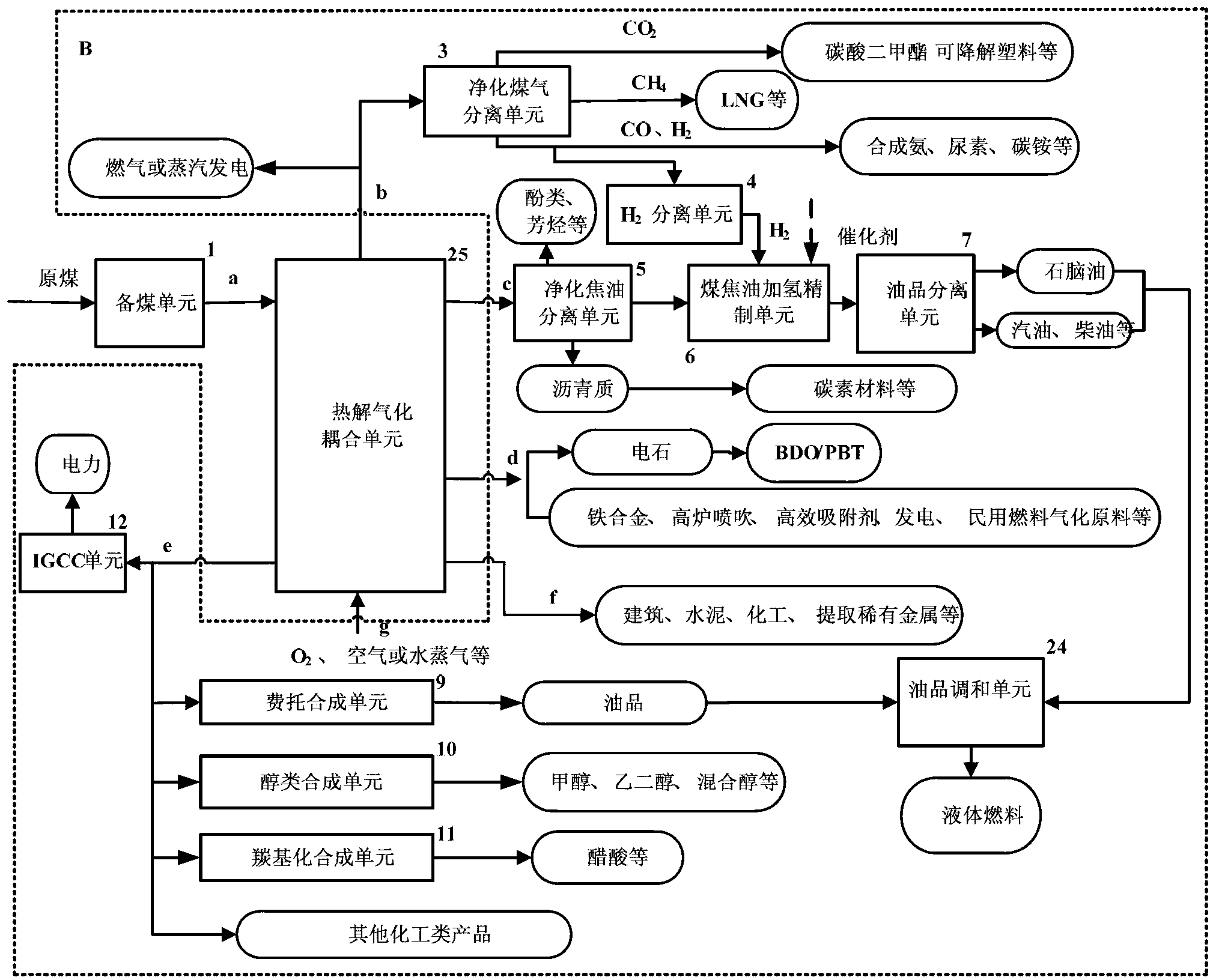

Pyrolysis gasification coupling integrated poly-generation system and process for coal chemical industry

ActiveCN103160296AImprove utilization efficiencyMaximize Utilization EfficiencyUrea derivatives preparationCarbon compoundsElectricityEngineering

The invention provides a pyrolysis gasification coupling integrated poly-generation system and process for the coal chemical industry. The system comprises a coal preparation unit, a pyrolysis-gasification coupling system A and a poly-generation system B, wherein the poly-generation system B comprises a purified gas separation unit connected with the purified gas outlet of the pyrolysis unit, a purified tar separation unit connected with the purified tar outlet of the pyrolysis unit, and a chemical product synthesis unit and an IGCC (Integrated Gasification Combined Cycle) unit which are respectively connected with purified gasification gas outlet of the gasification unit; and the purified tar separation unit is sequentially connected with a coal tar hydrofining unit and an oil product separation unit. The pyrolysis gasification coupling integrated poly-generation system and process can be used for organically combining coal pyrolysis gasification and the production process of oil, gas, chemicals, electricity and heat to realize integration of material conversion and energy conversion, maximize classified utilization, value promotion, utilization efficiency and economical benefit of coal resources, and improve the energy utilization efficiency.

Owner:SHAANXI COAL & CHEM TECH INST

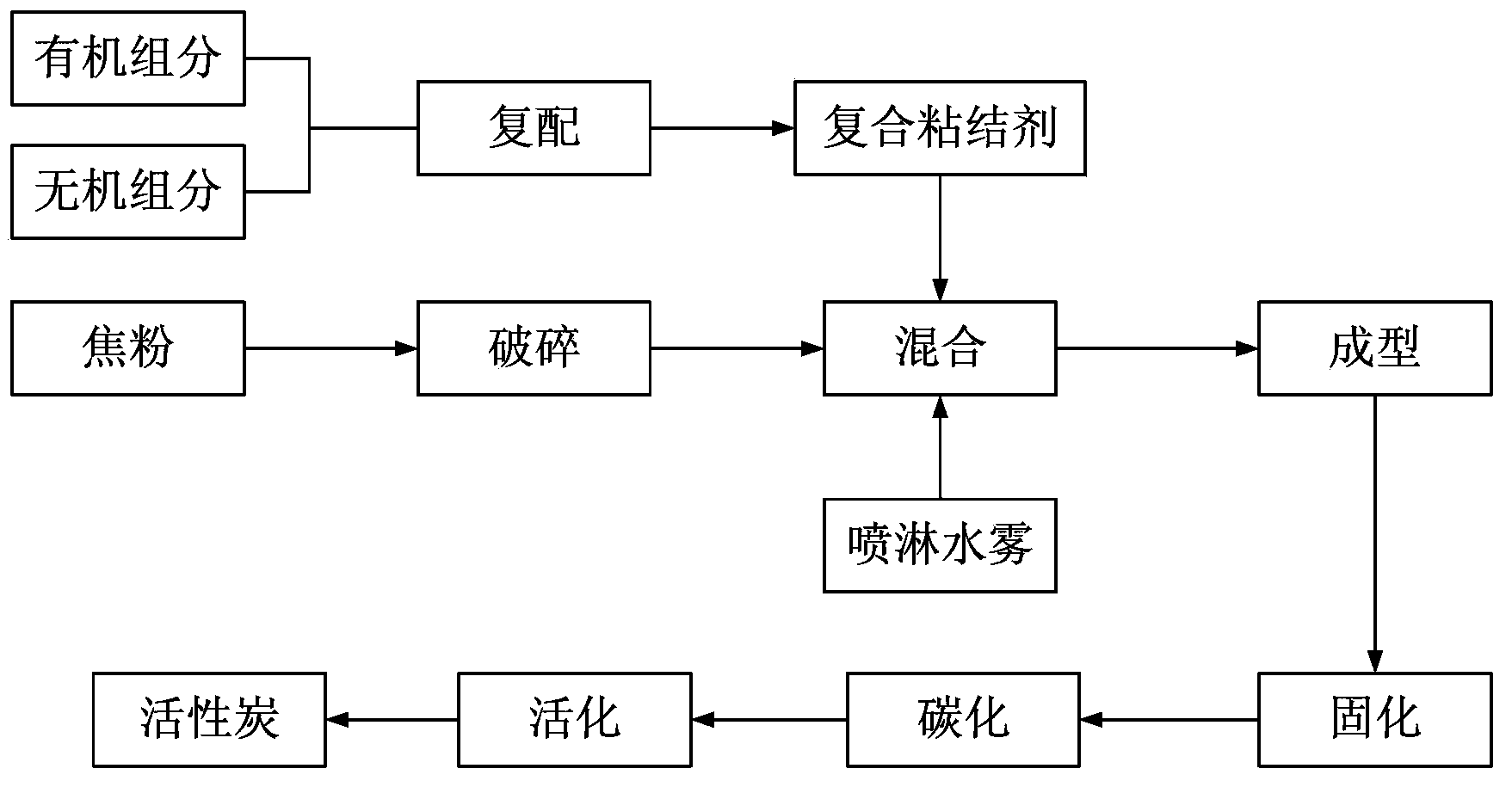

Technique for preparing activated carbon with powdered coal pyrolysis powdered coke

The invention discloses a technique for preparing activated carbon with powdered coal pyrolysis powdered coke. The technique comprises the steps as follows: 1) shattering powdered coke; 2) mixing 90-95 percent of organic components and 5-10 percent of inorganic components and obtaining a compound adhesive; 3) uniformly mixing the 90-95 percent of organic components and 5-10 percent of inorganic components; 4) performing cold pressing or extruding of a mixture of the powdered coke and the compound adhesive to form particles; 5) solidifying the formed particles; 6) carbonizing the solidified and formed particles; 7) performing activation of the carbonized product to obtain a ball-shaped or columnar activated carbon product. The technique improves solidification strength by adopting the novel compound adhesive and effectively solves the breaking problem during carbonization and activation. The technique is simple, the operation is convenient, the comprehensive utilization of the powdered coke is achieved, the added value is increased, and a certain economic benefit is obtained. The activated carbon prepared by the technique can be applied in the fields of gas separation, sewage treatment, flue gas desulfuration and the like.

Owner:SHAANXI COAL & CHEM TECH INST

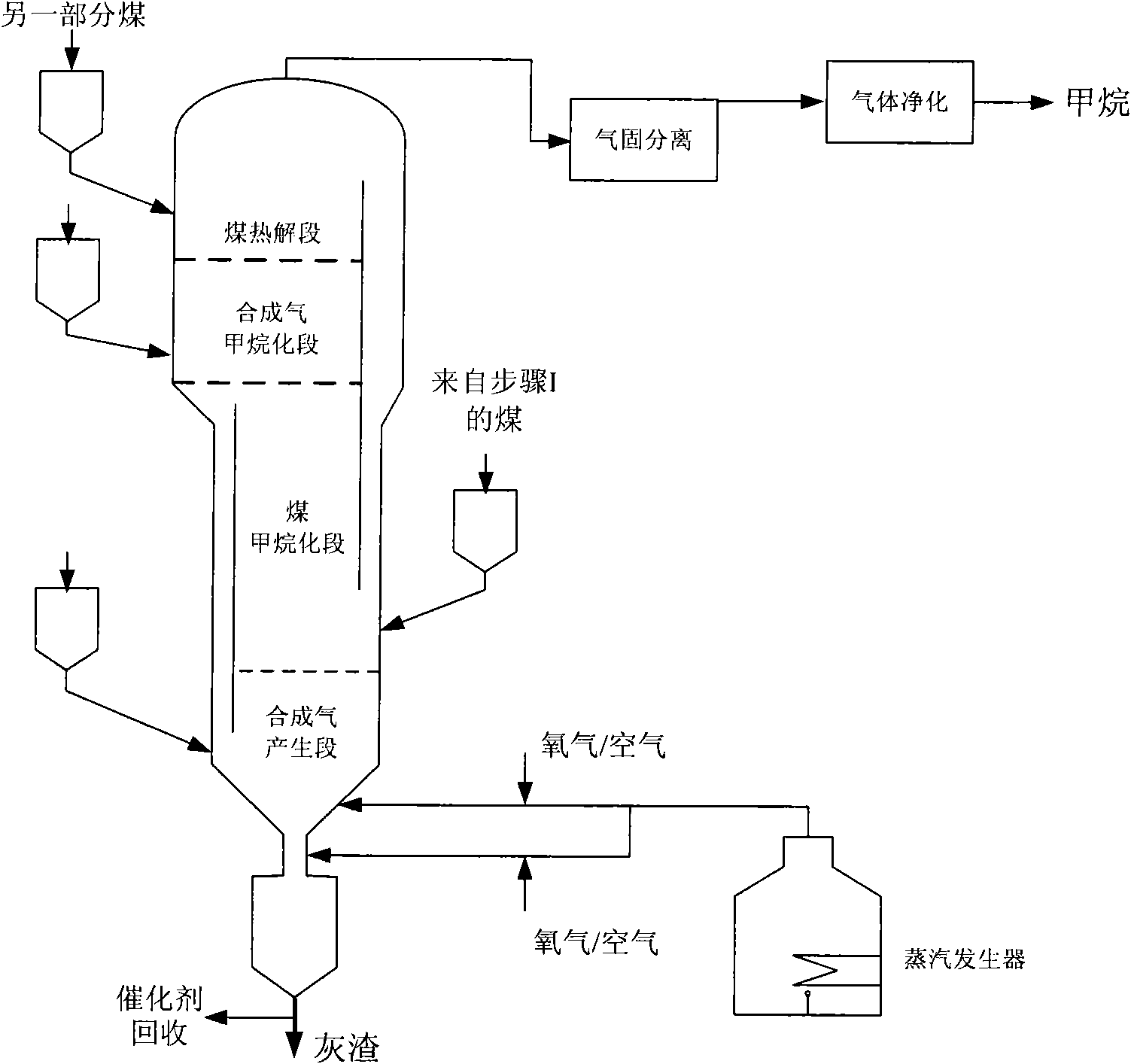

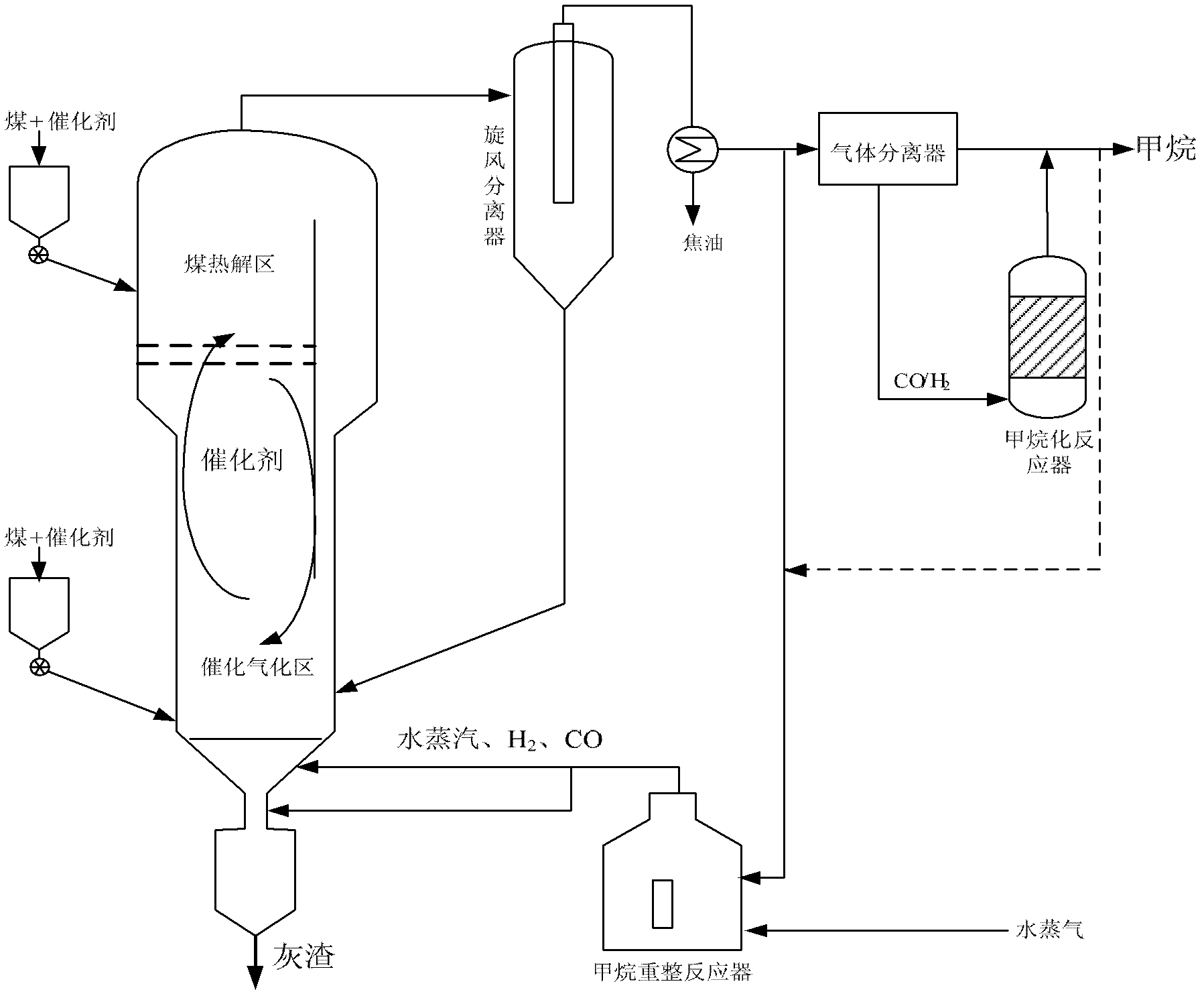

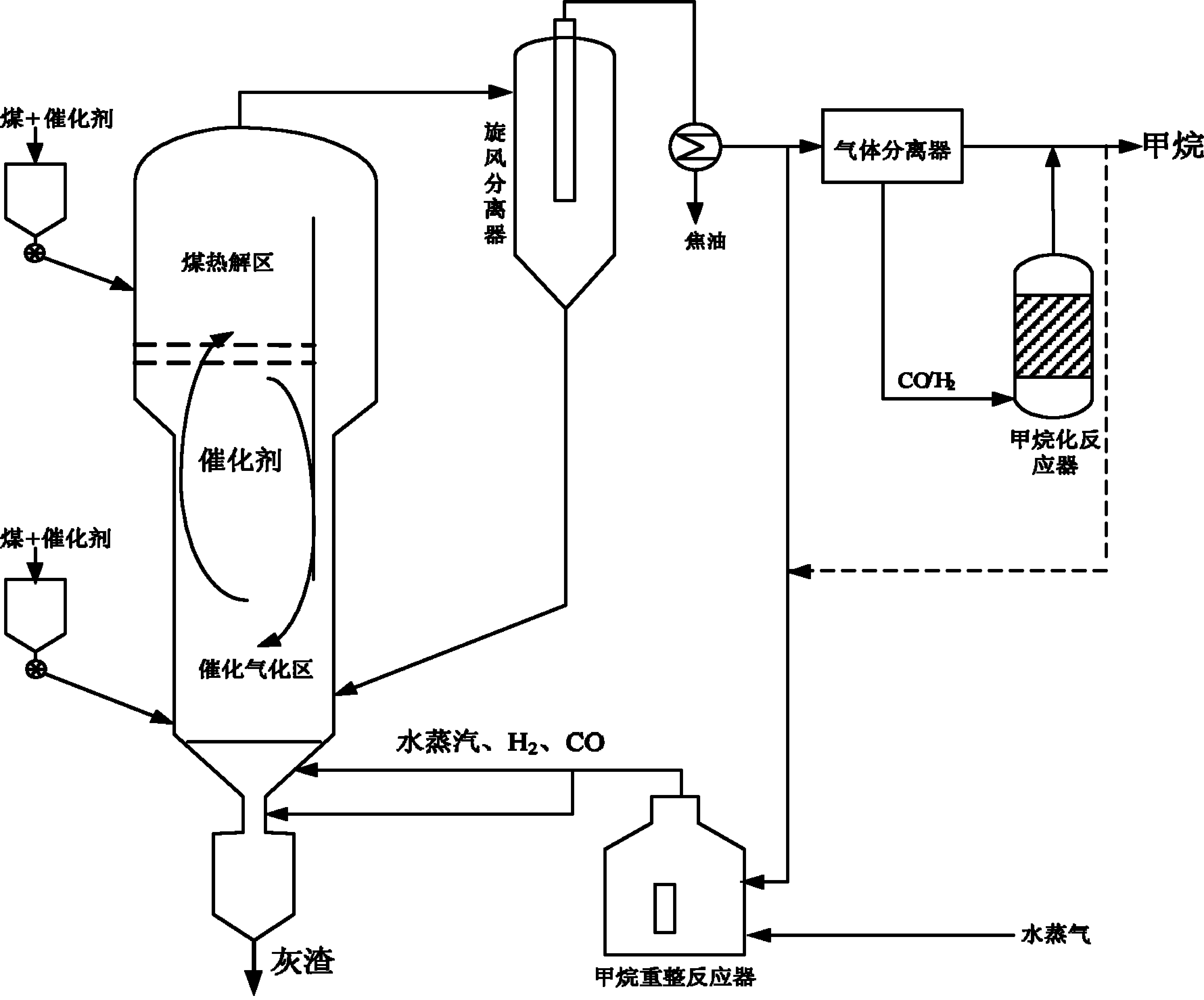

Method and device for preparing methane-containing gas by using coal

The invention discloses a method for preparing a methane-containing gas by using coal, which comprises the following steps that: a. pulverized coal is added to a coal pyrolysis area of a gasifier which sequentially comprises the coal pyrolysis area and a catalytic gasification area from top to bottom, and in the coal pyrolysis area, the pulverized coal is in contact with a gasification product stream from the catalytic gasification area to at least partially pyrolyze the pulverized coal to form a methane-containing gas stream and at least partial pyrolyzed pulverized coal; b. the at least partial pyrolyzed pulverized coal is sent to the catalytic gasification area and is in contact with a gasifying agent introduced into the catalytic gasification area under the action of a catalyst, the generated gasification product stream flows upwardly into the coal pyrolysis area, and fully unreacted coal residue is discharged out of the catalytic gasification area; and the gasifying agent comprises water vapor, hydrogen and carbon monoxide. The invention also discloses a device for preparing the methane-containing gas by using coal, and the device uses the method.

Owner:ENN SCI & TECH DEV

Coal-gas-circulation coal whole-size-grading pyrolytic coupling hot-pressing formed coke preparation technique and system

ActiveCN104178193AAchieve reuseImprove utilization efficiencyChemical industryDirect heating destructive distillationAdhesiveSlag

The invention provides a coal-gas-circulation coal whole-size-grading pyrolytic coupling hot-pressing formed coke preparation technique and system. Raw coal is divided into slack coal and pea coal by a raw coal preheating grading system; the coal gas generated by the method is used as a heat source for slack coal pyrolysis in a slack coal pyrolyzing furnace, and pyrolytic coal gas generated by slack coal pyrolysis is used as a heat source for pea coal pyrolysis; hot semicoke obtained after the slack coal and pea coal pyrolysis is used as a raw material for preparing the hot-pressing formed coke; and tar slag collected at the coal pyrolysis section is used instead of part of the adhesive for preparing the hot-pressing formed coke. The coal pyrolysis technique and hot-pressing formed coke preparation technique are coupled to produce the formed coke, thereby implementing graded utilization of coal and coke making of mill coal, saving the rare coke resources for the nation, and implementing high added value utilization of the product semicoke. The tar slag generated at the coal pyrolysis section is used as part of the adhesive instead of part of high-price coal pitch, thereby achieving the goal of waste reutilization. By using the hot semicoke as the raw material, the formed coke is formed under hot conditions, so that the heat utilization efficiency is high.

Owner:新疆乾海环保科技有限公司

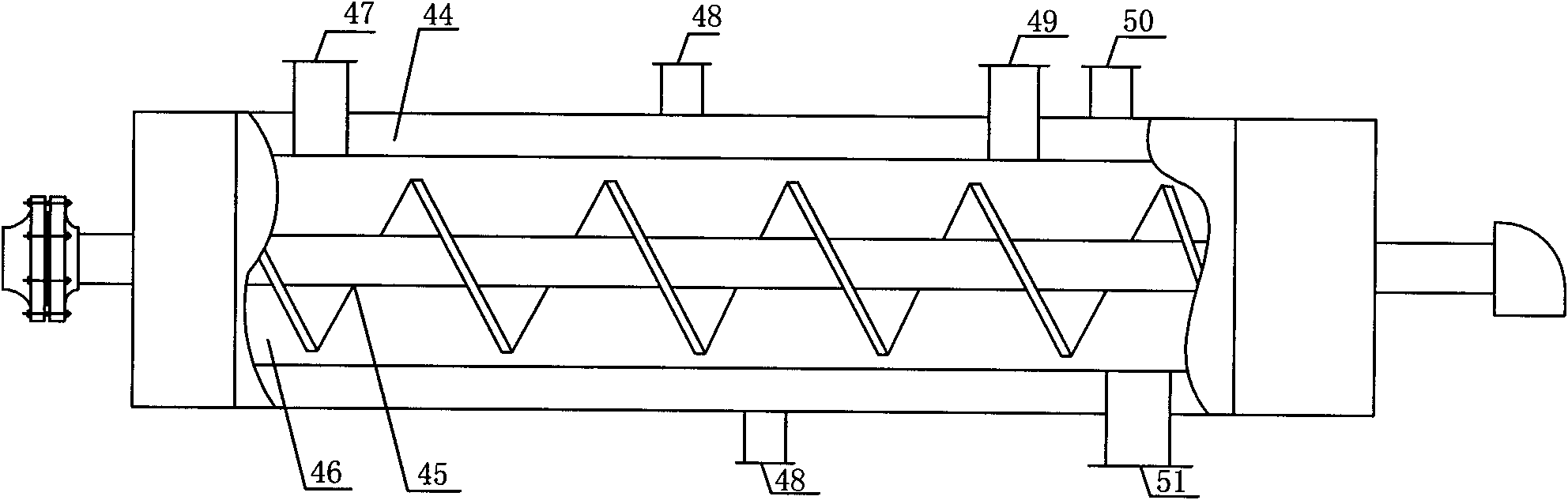

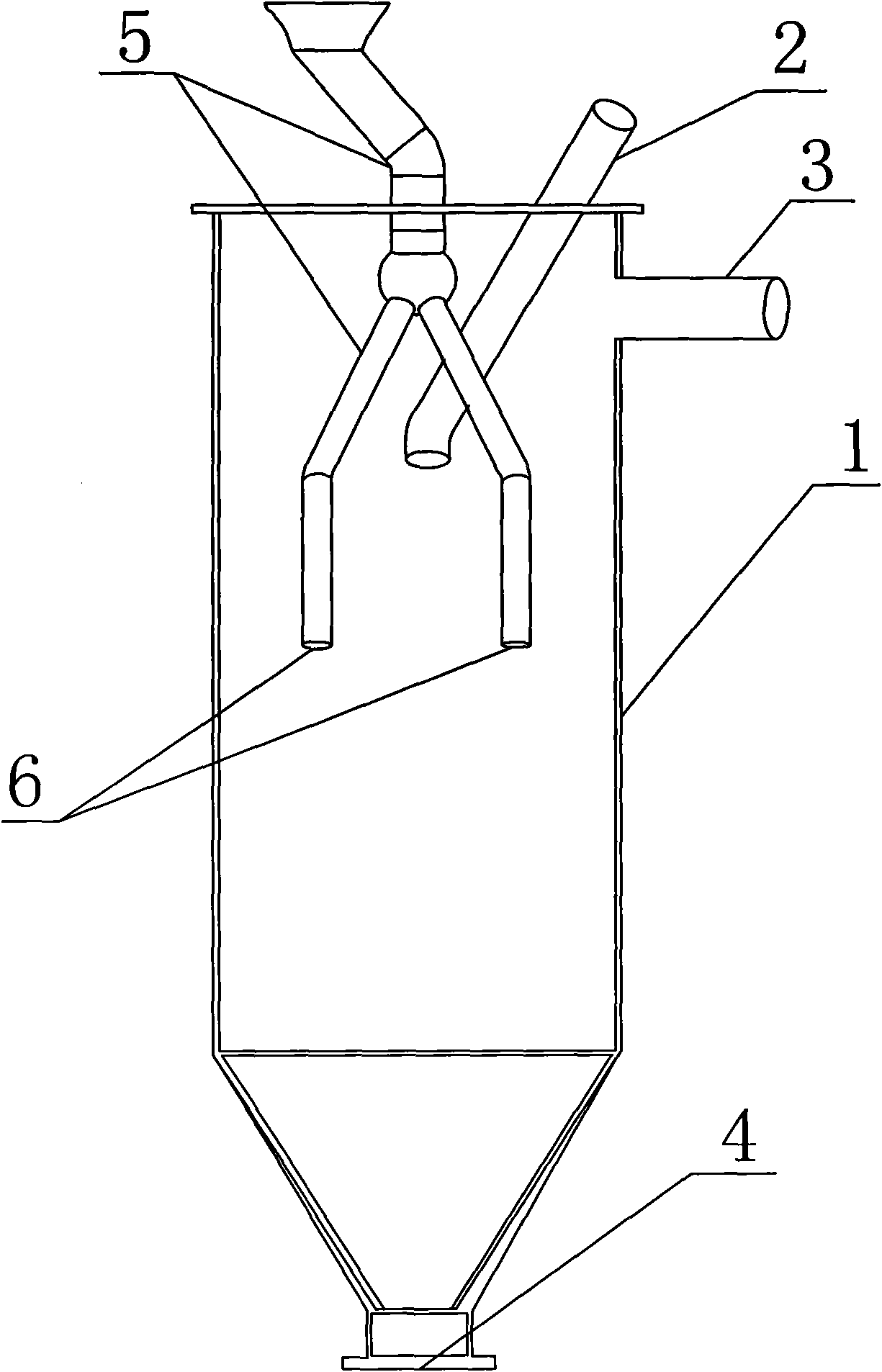

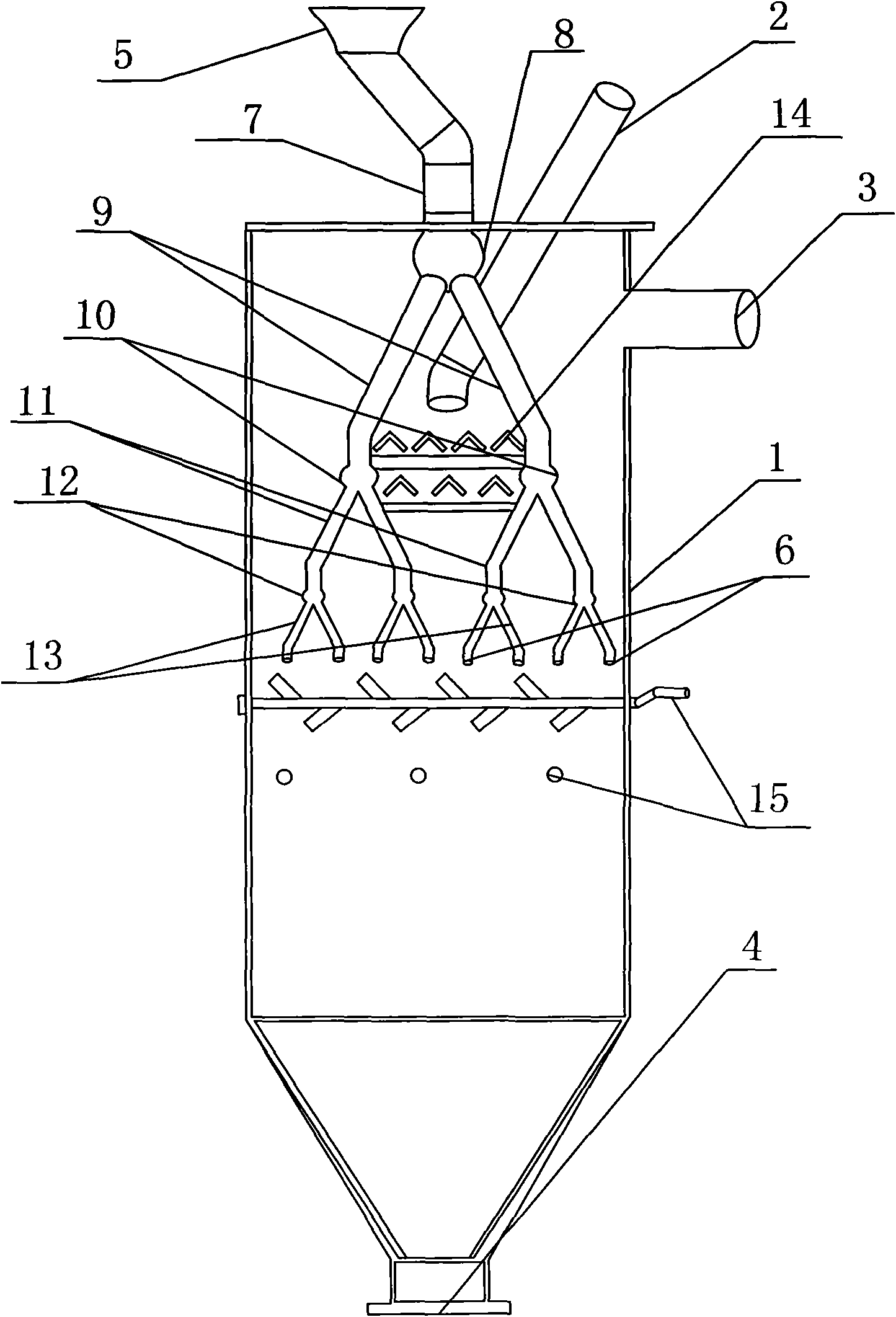

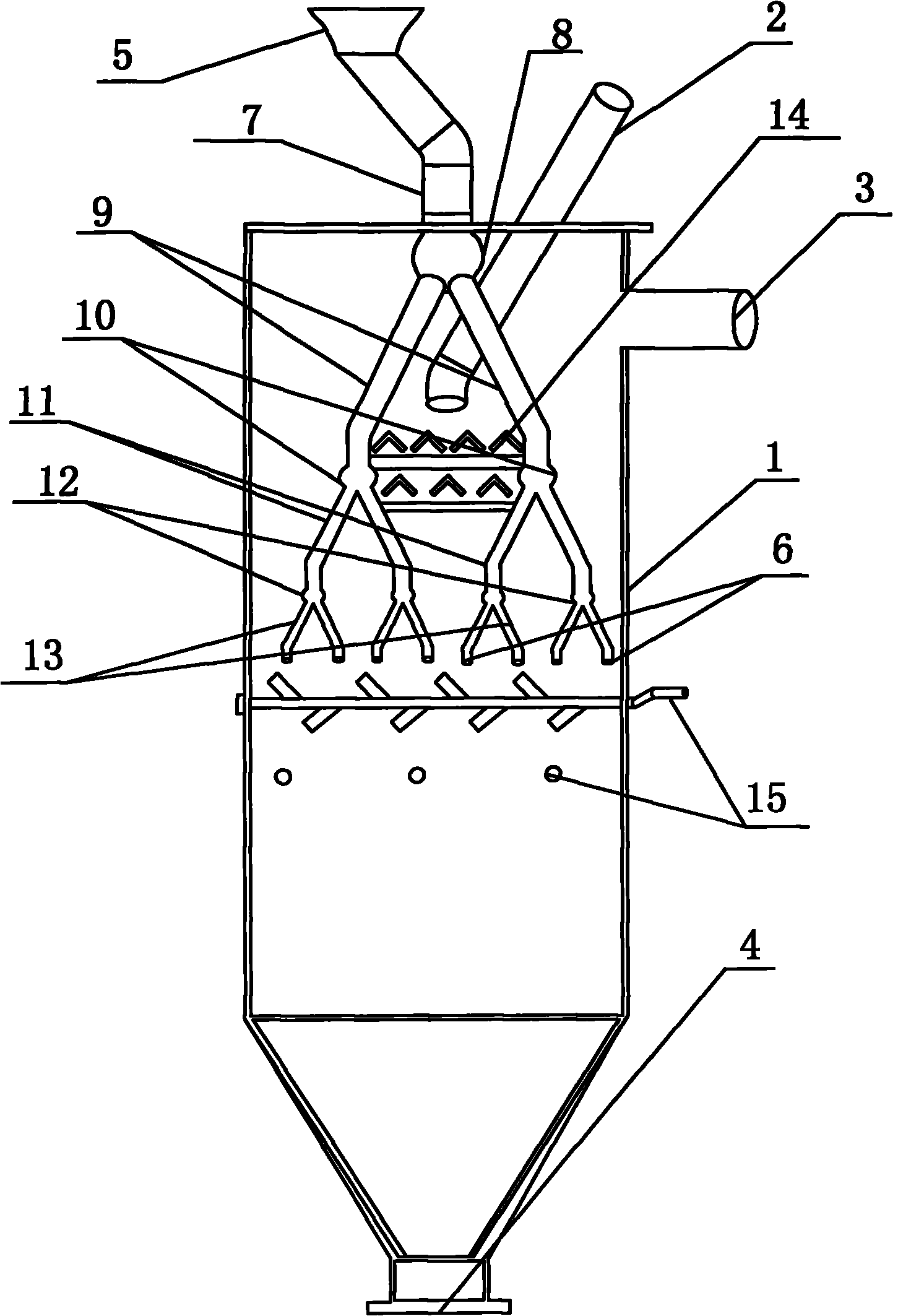

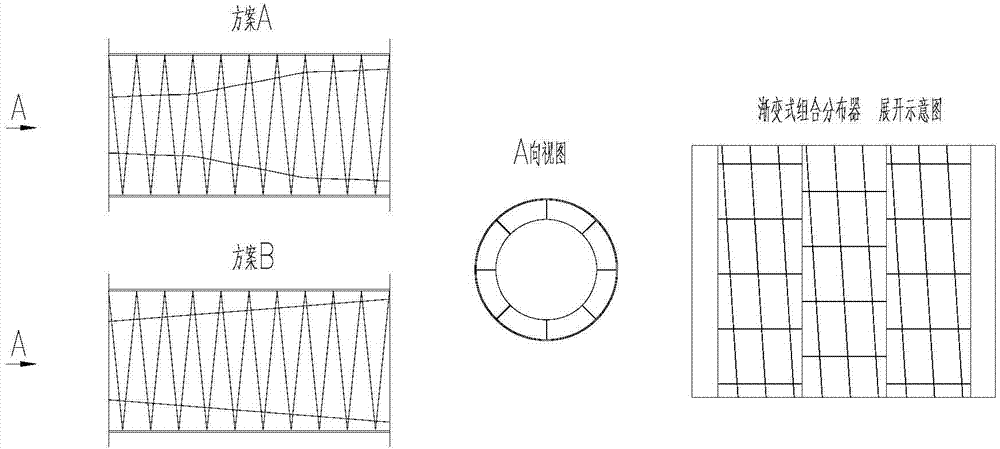

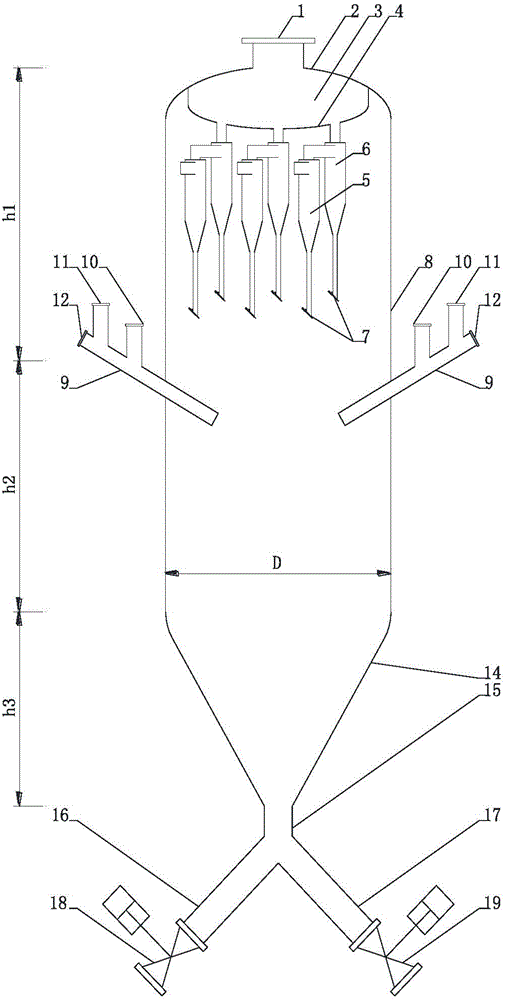

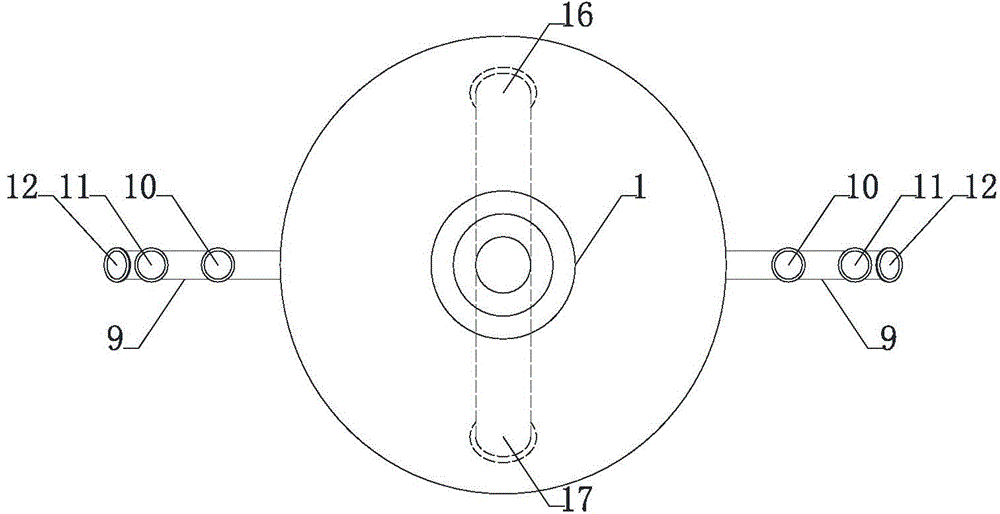

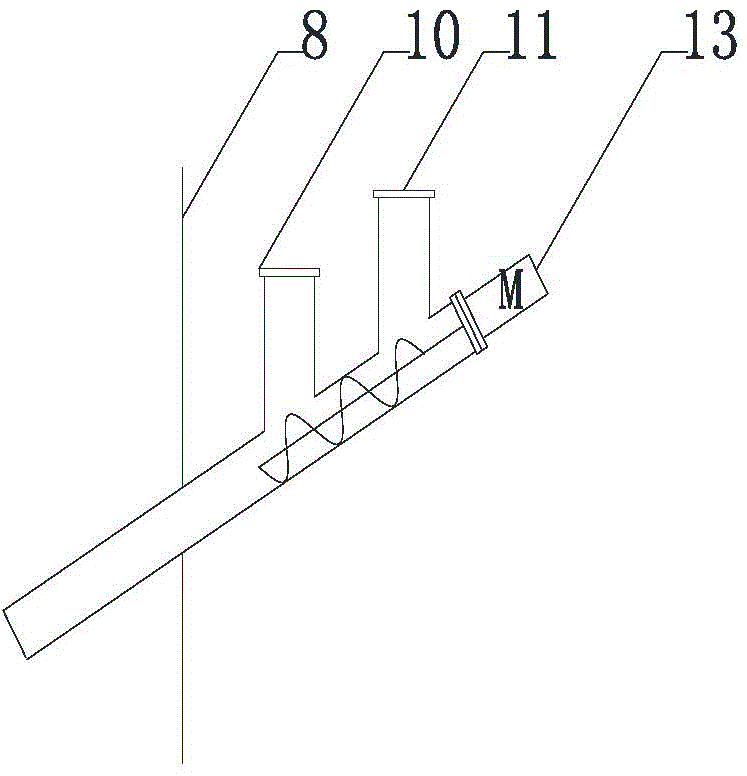

Internally rotary dedusting type solid heat carrier and moving bed pulverized coal pyrolysis method and device

InactiveCN104893747APyrolysis gas contains less dustImprove pyrolysis effectSpecial form destructive distillationHeat carrierEngineering

The invention discloses an internally rotary dedusting type solid heat carrier and moving bed pulverized coal pyrolysis method and device. The internally rotary dedusting type solid heat carrier and moving bed pulverized coal pyrolysis device comprises a cylinder body, wherein an upper sealing head is arranged at the top of the cylinder body; a pyrolysis gas outlet is formed in the middle of the upper sealing head; a collecting pipe box is defined between the upper sealing head and a collecting pipe box sealing head connected with the upper sealing head; a plurality of cyclone separator sets communicated with the collecting pipe box are arranged at the lower part of the collecting pipe box sealing head; a plurality of mixing pipes are symmetrically arranged on the two sides of the cylinder body; a coal gas inlet, a pulverized coal inlet and a heat carrier inlet are formed in each mixing pipe; a tapered lower sealing head is arranged at the lower part of the cylinder body; a discharge pipe is arranged at the bottom of the lower sealing head; a circulating semicoke blanking pipe and a product semicoke blanking pipe are symmetrically connected to the discharge pipe, and the discharge pipe and the blanking pipes form an inverted Y-shaped pipe branch; a valve is arranged on each of the circulating semicoke blanking pipe and the product semicoke blanking pipe. The pulverized coal used as the raw material is adequate in source, cheap, and easy to obtain; the device and the method have the characteristics of being wide in application range, simple in technological process, relatively low in investment, easy to operate, safe, stable and the like.

Owner:神木市锦丰源洁净煤科技有限公司

Method for increasing tar yield by coupling aromatization of hydrocarbons with coal pyrolysis

ActiveCN102161904AHigh yieldReduce the cost of hydropyrolysisLiquid hydrocarbon mixture productionHydrogenVapor–liquid separator

The utility model provides a method for increasing tar yield by coupling aromatization of hydrocarbons with coal pyrolysis. According to the method, hydrocarbon components taken as pyrolysis atmosphere are fed into a pyrolysis reactor through an inlet, activated by load-type metal catalysts and subjected to the aromatization, and then enter a coal pyrolysis layer for coupling pyrolysis with coal; and the reaction conditions are as follows: the temperature ranges from 300 DEG C to 1000 DEG C, the pressure ranges from 0.1 MPa to 3.0 MPa, the gas hourly space velocity ranges from 60 mL / g / h to 48000 mL / g / h, and the temperature is maintained constant for 0 minutes to 240 minutes. The method adopts hydrocarbons as the pyrolysis atmosphere instead of pure hydrogen gas for the pyrolysis, and increases the tar yield by coupling aromatization of hydrocarbons with coal pyrolysis. In the process, the cost of hydropyrolysis is reduced while the yield of tar is higher than the yield of tar produced by hydropyrolysis under the same conditions. Besides, the catalysts are not mixed with coal, and thus the catalysts are easy to be recycled and used repeatedly.

Owner:DALIAN UNIV OF TECH

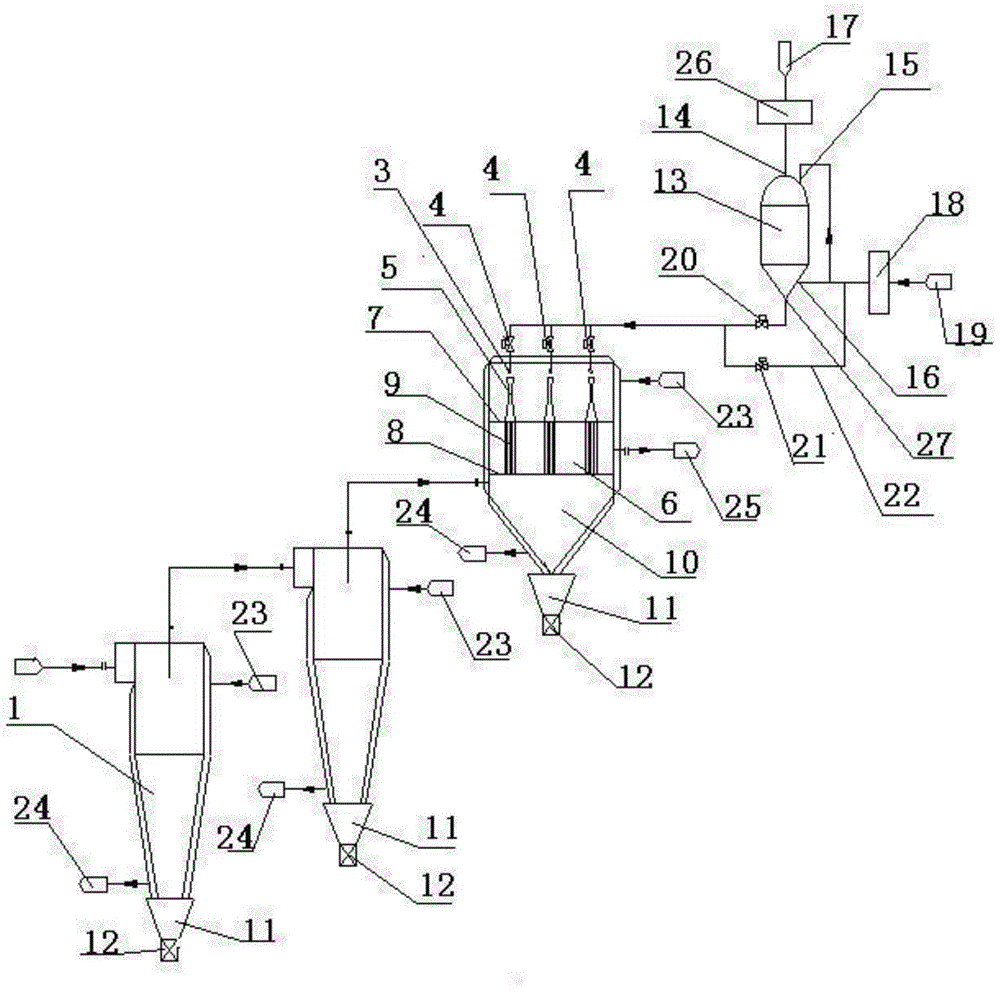

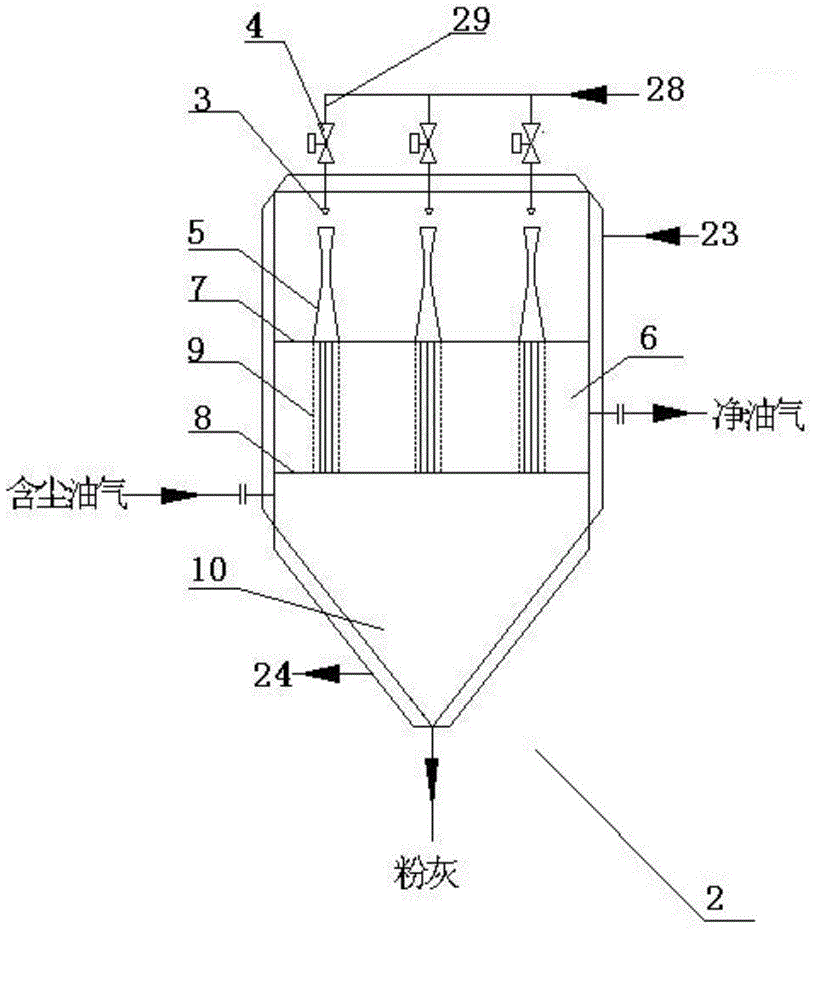

Dust removal device and method for oil gas during pulverized coal pyrolysis/retorting

The invention provides a dust removal device and method for oil gas during pulverized coal pyrolysis / retorting. The device comprises a dust removal pretreatment unit, an oil gas filter and a sand-blasting tank which are sequentially connected, wherein the dust removal pretreatment unit comprises at least two stages of cyclone separators connected in series; the oil gas filter adopts a closed tank, and nozzles, venture tubes, an oil gas purification chamber, a gas collecting chamber and dust hoppers are arranged in the oil gas filer from top to bottom sequentially; the nozzles are arranged at the top of the tank and communicated with the outside; the venture tubes are correspondingly and perpendicularly arranged below the nozzles; the oil gas purification chamber is perpendicular to the venture tubes and provided with hollow filter element groups inside, and the hollow filter element groups are in sealing connection with an upper tube plate and a lower tube plate of the oil gas purification chamber; the gas collecting chamber is coaxially communicated with filter elements; dust valves are arranged at the lower ends of the dust hoppers; the sand-blasting tank is a closed tank, a sand inlet is formed in the top and communicated with a sand pipeline inlet through a sand preheater, gas inlets are formed in the top and in the lower side part respectively and are communicated with a reverse blowing gas pipeline inlet through a reverse blowing gas preheater, and a sand outlet is formed in the bottom and communicated with the oil gas filter. The problems of poor oil gas dust removal effect, low efficiency, instable operation and the like of an existing device are solved.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

High-efficiency clean low-carbon coal graded utilization method and device

ActiveCN103320175AImprove utilization efficiencyHigh purityGranular/pulverulent flues gasificationHigh concentrationSludge

The invention discloses a high-efficiency clean low-carbon coal graded utilization method and a device thereof. The invention aims at realizing coal graded conversion and high-efficiency clean utilization. With the method and the device, fuel (especially solid fuel and coal powder) high-efficiency utilization and high-concentration CO2 enrichment can be ensured; fuel comprehensive utilization value can be improved; poly-generation of electricity, gas, and tar can be realized; and the discharge of CO2 and other pollutants (such as NOx and SOx) can be reduced. According to the method provided by the invention, a coal crude product processing (coal pyrolysis) process and a coal combustion (chemical chain oxygen decoupling) process are coupled. The device mainly comprises a coal feeder, a pyrolyzer reactor, a cyclone separator, a primary cooler, a secondary cooler, a tar collector, a fuel reactor, a mobile sealing valve, an air reactor, a condenser, a coal dust collector, and an oxygen carrier collector. The device and the method are suitable for various solid fuels such as petroleum coke, biomass, municipal solid waste, and sludge, and different coal types.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com