Fine coal pyrolysis reaction carbon burning circulation system

A technology of pyrolysis reaction and circulation system, applied in the direction of direct heating dry distillation, special form dry distillation, petroleum industry, etc., can solve the problems of single pulverized coal utilization way, dust pollution environment, low resource utilization rate, etc., to achieve easy control of gas quality , The effect of good tar quality and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

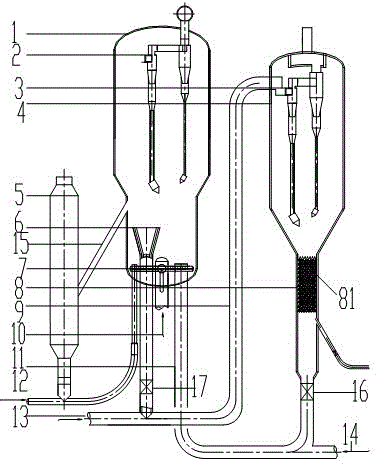

[0012] like figure 1 As shown, the pulverized coal pyrolysis reaction charcoal burning circulation system of the present invention comprises a charcoal burner 1, a cyclone separator 2 of the charcoal burner, a cyclone separator 3 of a settler, a settler 4, an external heat extractor 5, a heat carrier stand Pipe 6, main air distributor 7, airlift section 8, riser reactor 9, main air pipe 10, heat carrier circulation U-shaped pipe 11, cyclone separator 2 of the charcoal burner is located in the charcoal burner 1, and the settler The cyclone separator 3 is located in the settler 4, and the settler 4 is located on one side of the charcoal burner 1. The external heat extractor 5 communicates with the charcoal burner 1 through an inclined pipe 15, and the heat carrier standpipe 6 passes through After the bottom of the charcoal burner 1 is connected with the riser reactor 9, the main air distributor 7 is located in the bottom of the charcoal burner 1, and one end of the heat carrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com