Patents

Literature

9784results about "Special form destructive distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

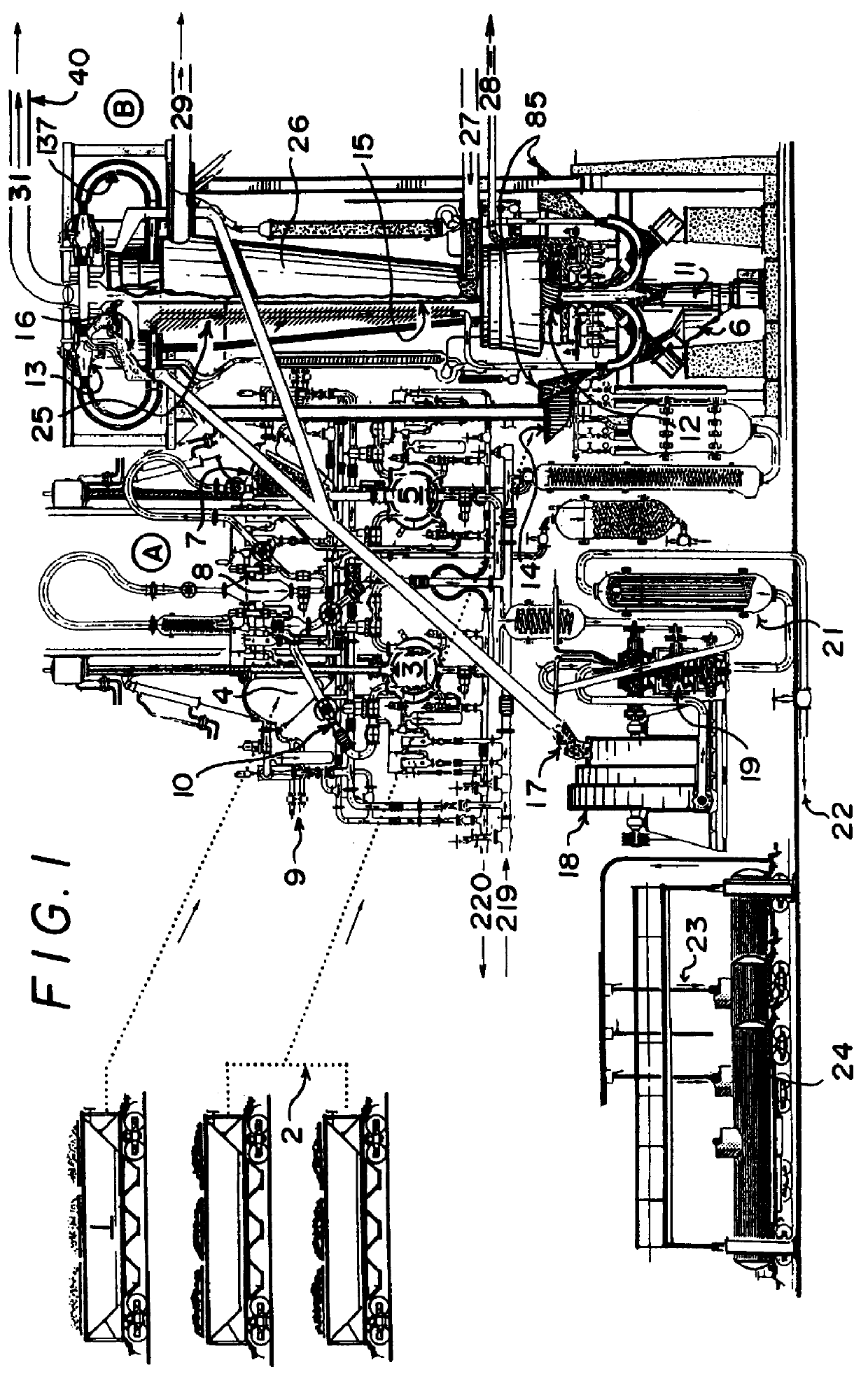

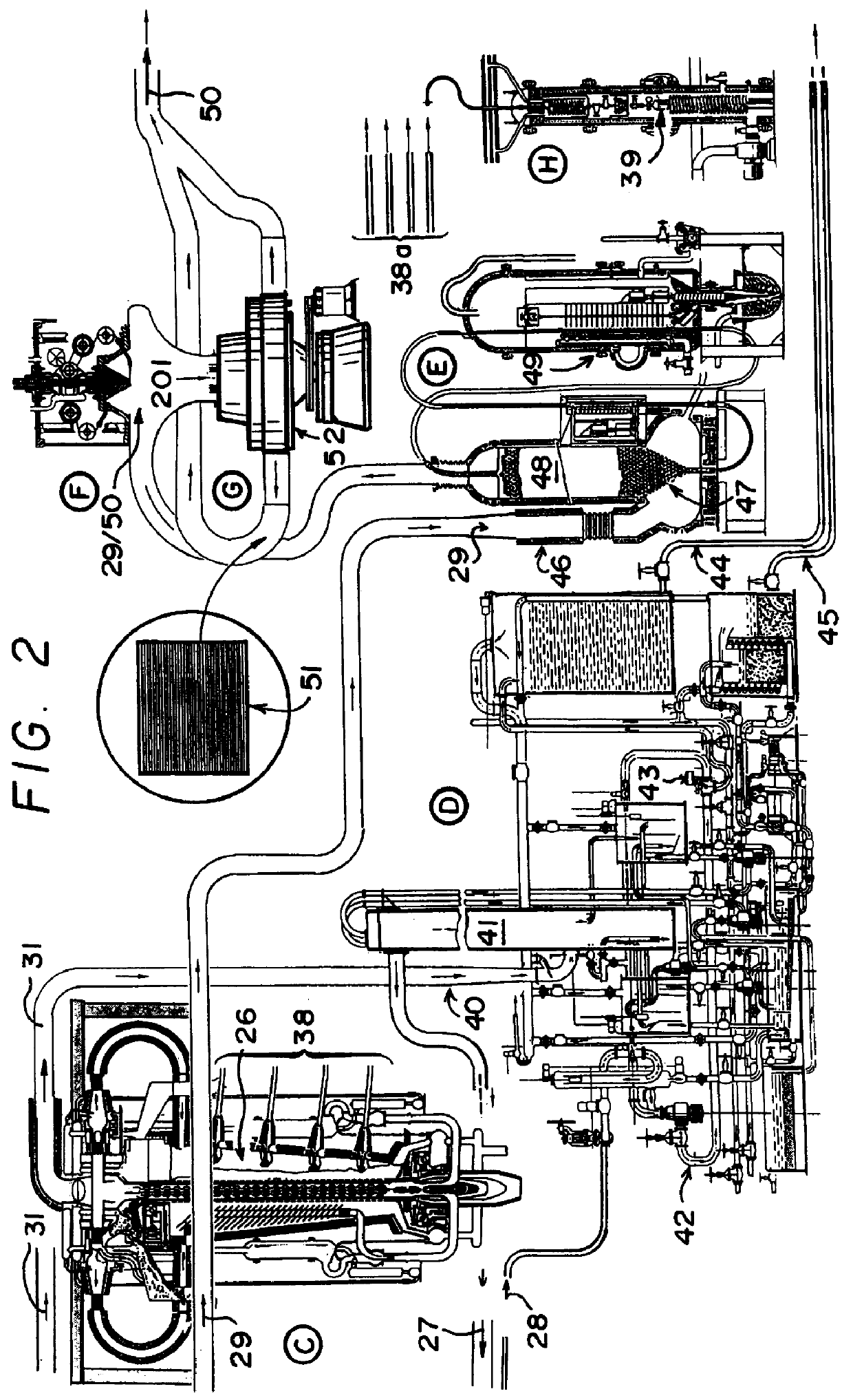

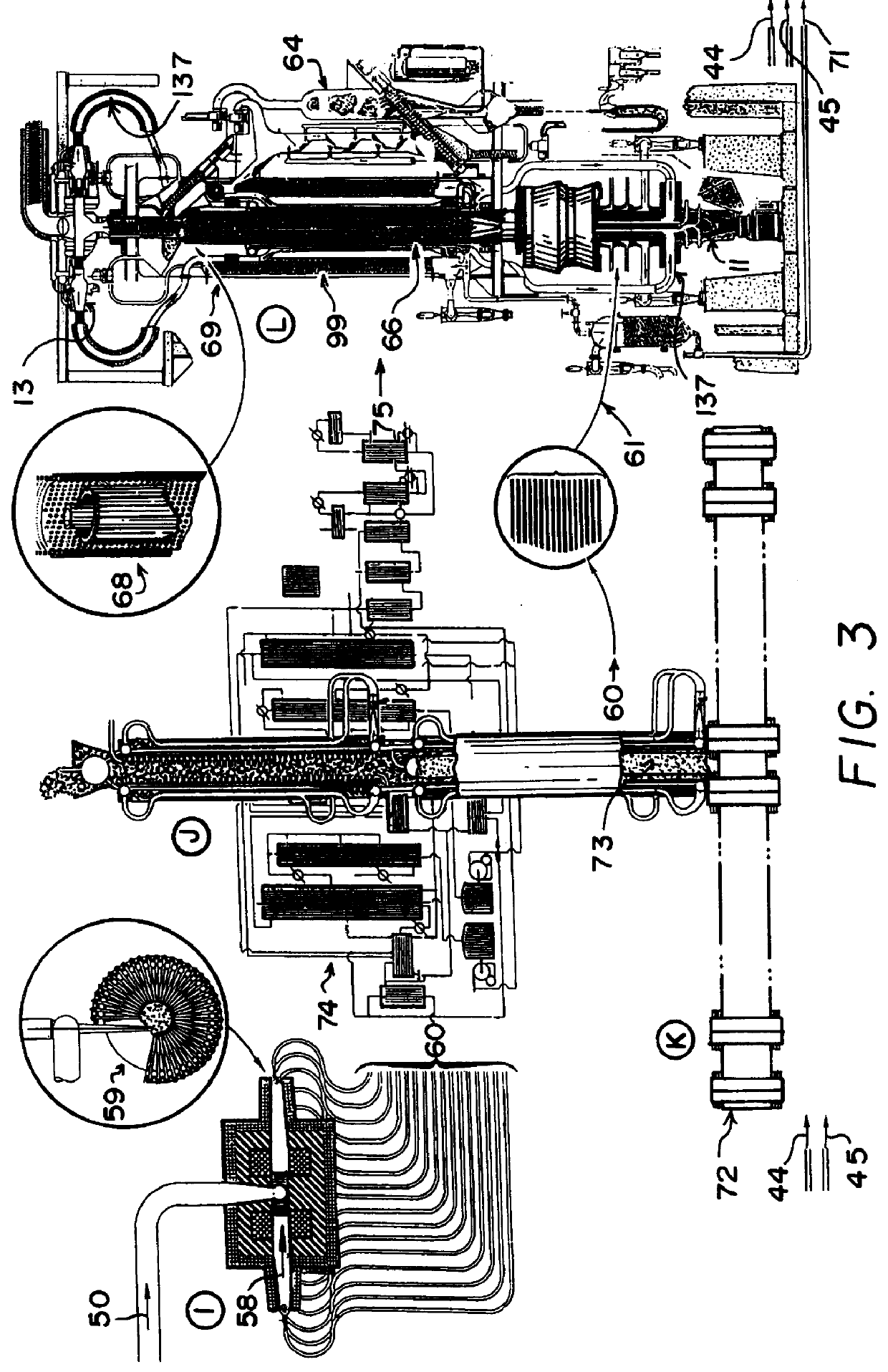

Apparatus for converting coal to hydrocarbons

InactiveUS6013158ALess producedLow costCombustible gas coke oven heatingDirect heating destructive distillationParticulatesSuspended particles

An apparatus for forming liquid hydrocarbons from solid coal. The coal is pulverized to provide a particulate coal feed, which is then extruded to provide a hollow tube of compressed coal supported inside of a support tube. A clay feed is extruded to provide a hollow tube of compressed clay supported inside of the coal tube and a combustible fuel is burned inside of the clay tube. The temperature of combustion is sufficient to fire the extruded clay and pyrolyze the extruded coal to produce hydrocarbon gases and coal char. The support tube has holes for releasing the hydrocarbon gases, which contain suspended particles formed during combustion. The suspended particles are removed from the hydrocarbon gases to provide clean gases, which are passed through an ionizing chamber to ionize at least a portion thereof. The ionized gases are then passed through a magnetic field to separate them from each other according to their molecular weight. Selected portions of at least some of the separated gases are mixed, and the mixed gases are cooled to provide at least one liquid hydrocarbon product of predetermined composition. Portions of the separated gases may also be mixed with the coal char and other input streams, such as waste plastics, and further treated to provide other hydrocarbon products.

Owner:WOOTTEN WILLIAM A

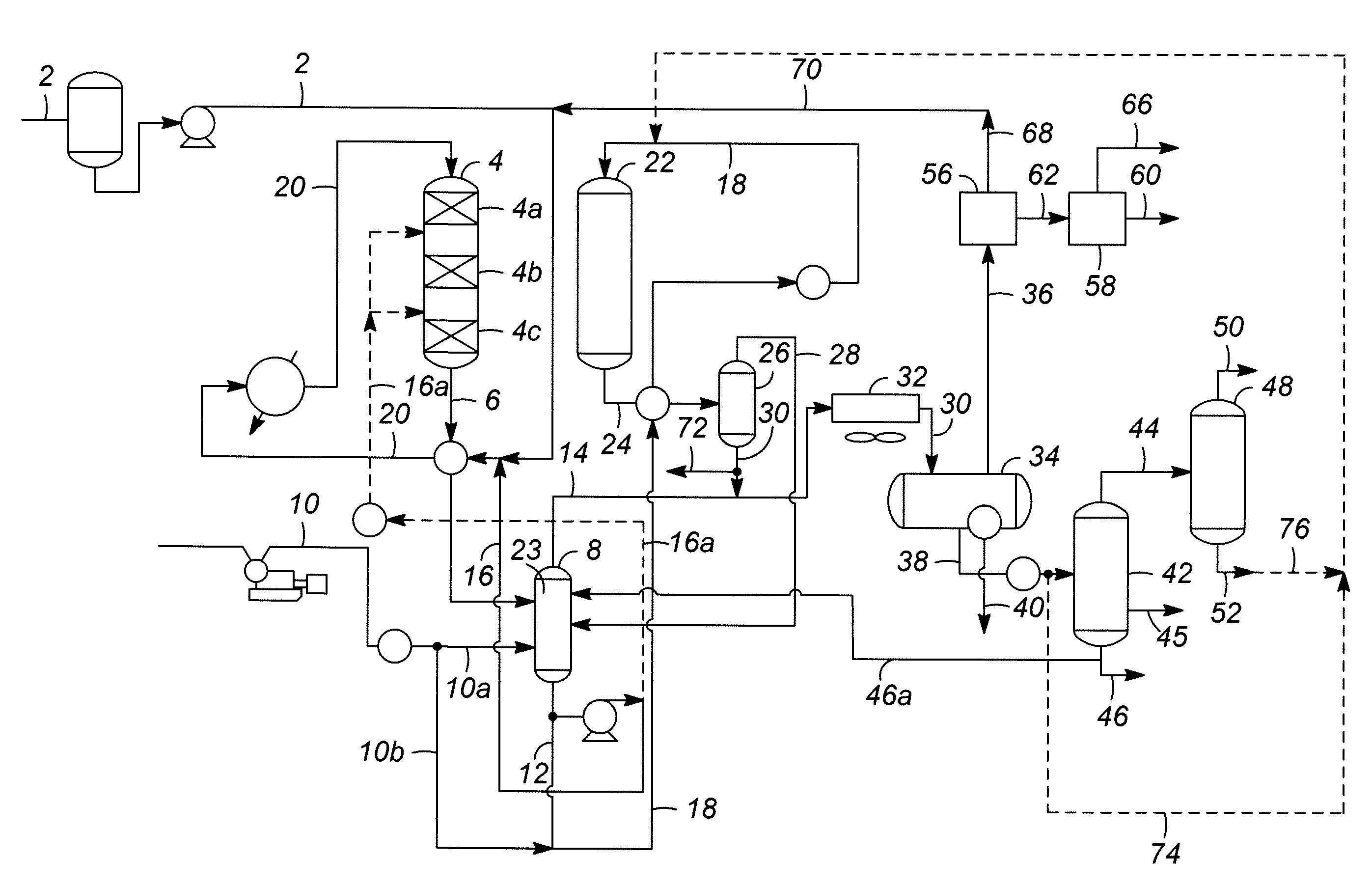

Production of Blended Fuel from Renewable Feedstocks

A process for producing a blended fuel from a paraffin rich component and a cyclic rich component, where each of the components are generated from a renewable feedstock, is presented. The paraffin rich component is generated from a first renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, biomass, lignocellulose, free sugars, and combinations thereof. The cyclic rich component is generated from a second renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, free fatty alkyl esters, biomass, lignocellulose, free sugars, and combinations thereof. The blended fuel may a gasoline boiling point range blended fuel, a diesel boiling point range blended fuel, an aviation boiling point range blended fuel, any combination thereof, or any mixture thereof.

Owner:UOP LLC

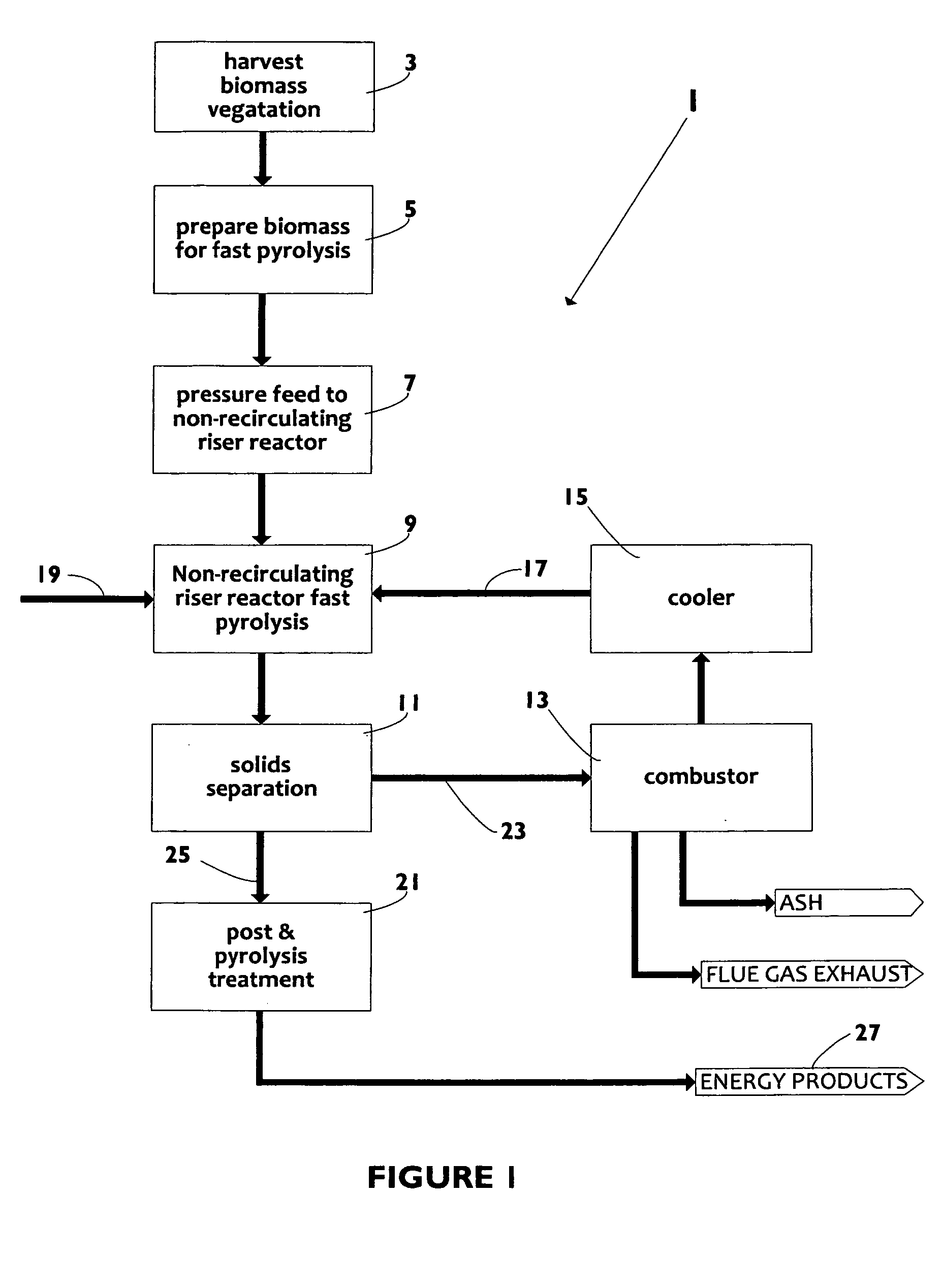

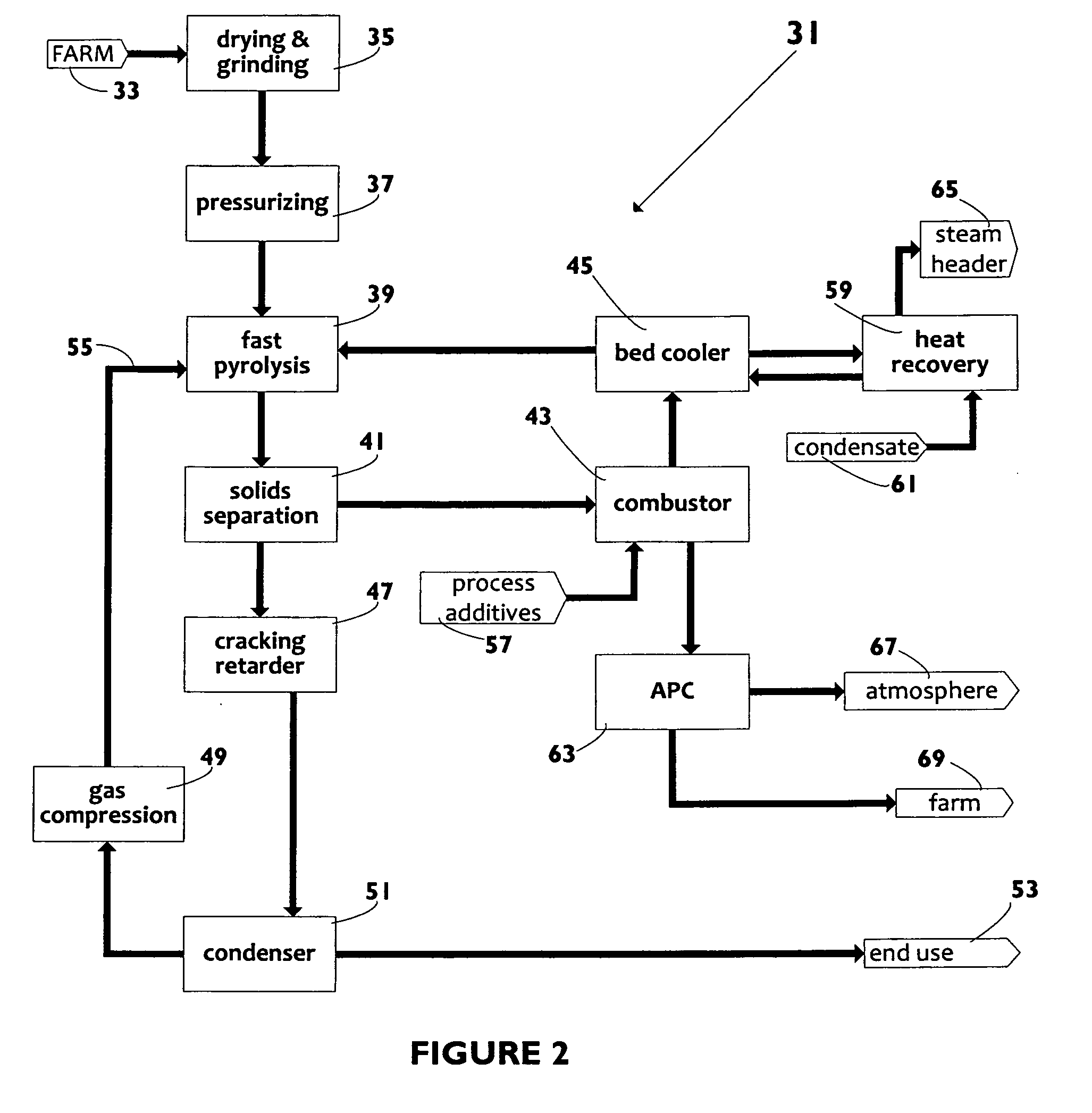

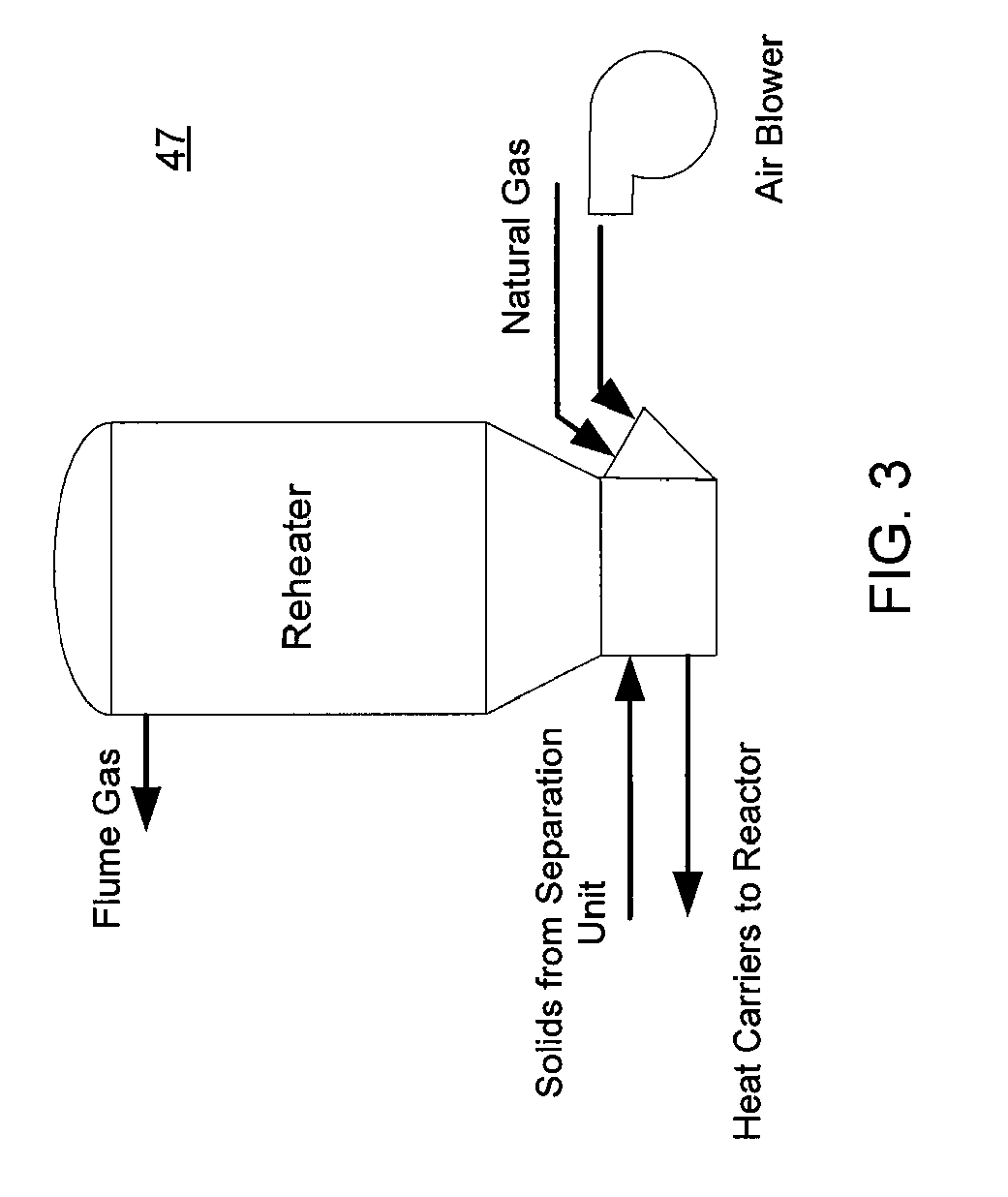

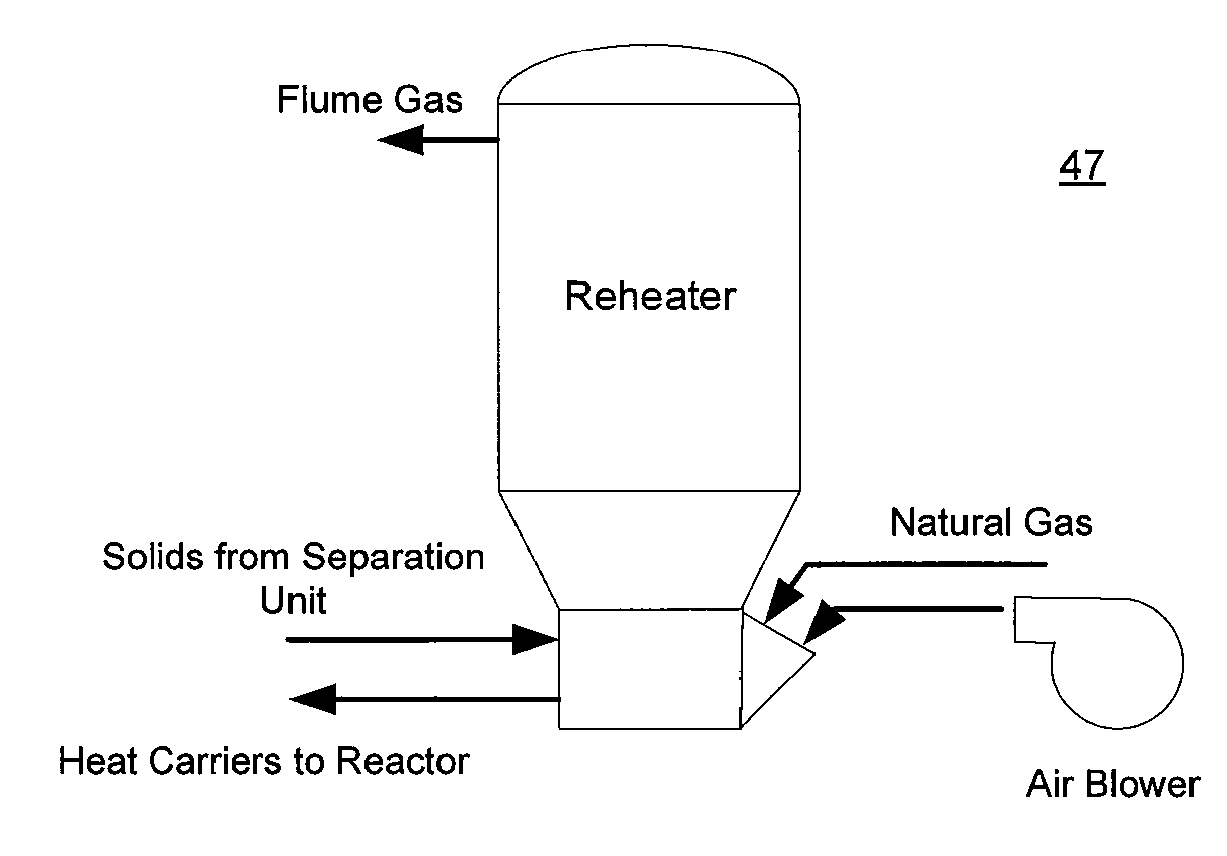

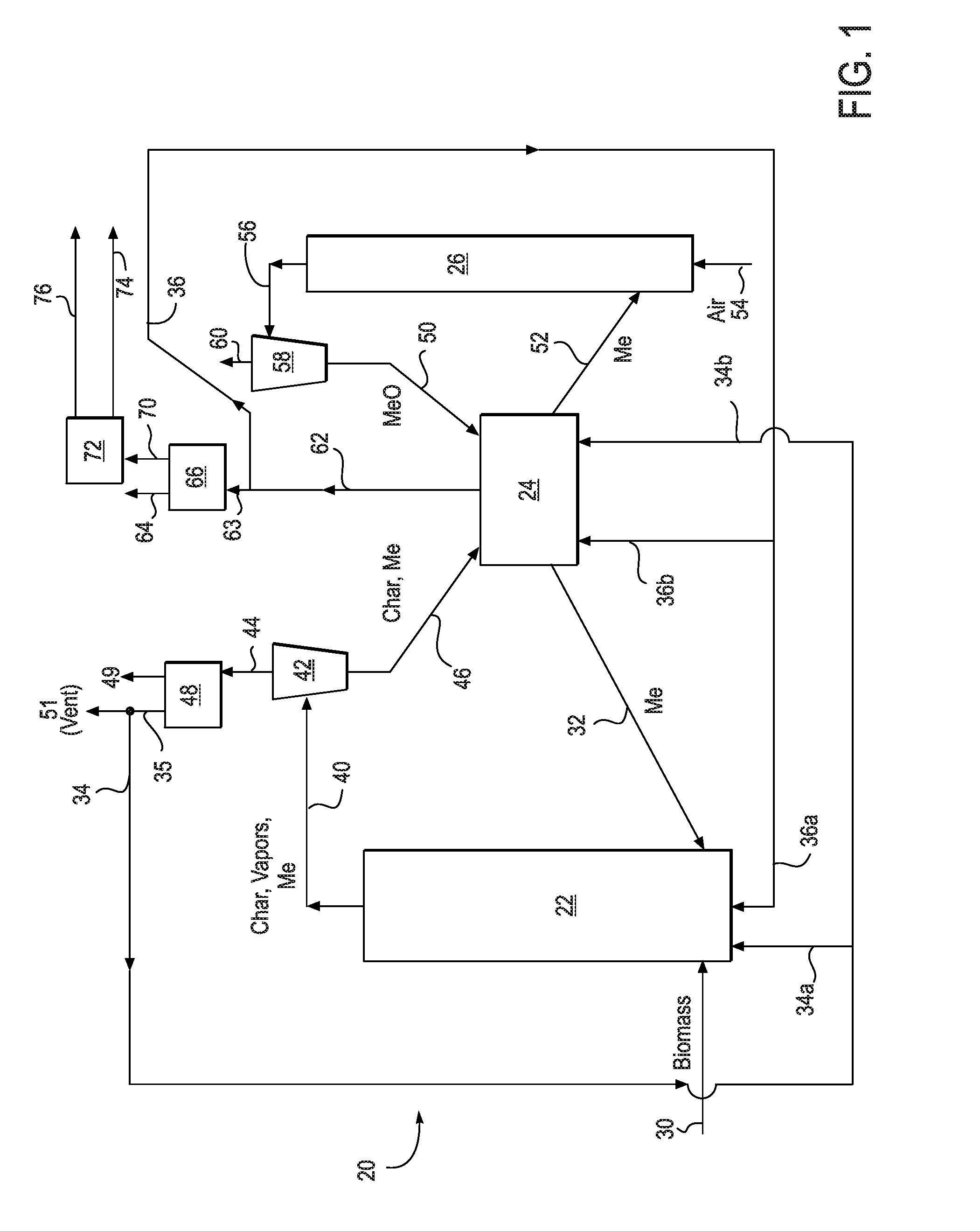

Biomass fast pyrolysis system utilizing non-circulating riser reactor

A biomass fast pyrolysis system for conversion of biomass vegetation to synthetic gas and liquid fuels includes: a) a non-circulating riser reactor for pyrolysis of biomass vegetation feedstock utilizing a heat carrier, the non-circulating riser reactor being physically structured and adapted to have a rate of reaction of at least 8,000 biomass vegetation feedstock lbs / hr / ft2, utilizing a ratio of heat carrier to biomass vegetation feedstock of about 7:1 to about 11.5:1, the riser reactor having a base input region at its bottom, a central reaction region and an output region at its top, the riser reactor including a cyclone disengager at its output region for separation of pyrolysis resulting char and heat carrier from the pyrolysis product gases, the cyclone disengager having an output downcomer and an output upcomer, the cyclone disengager output downcomer being connected to and feeding into a side combustor unit, the riser reactor being a non-circulating riser reactor in that the heat carrier is not returned directly to the riser reactor from the cyclone disengager and travels first down the cyclone disengager output downcomer to the side combustor unit; and, b) the side combustor unit for combusting pyrolysis resultant char and reheating the heat carrier the side combustor having a heat carrier downcomer connected to the base input region of the riser reactor.

Owner:INNOVATIVE ENERGY GLOBAL

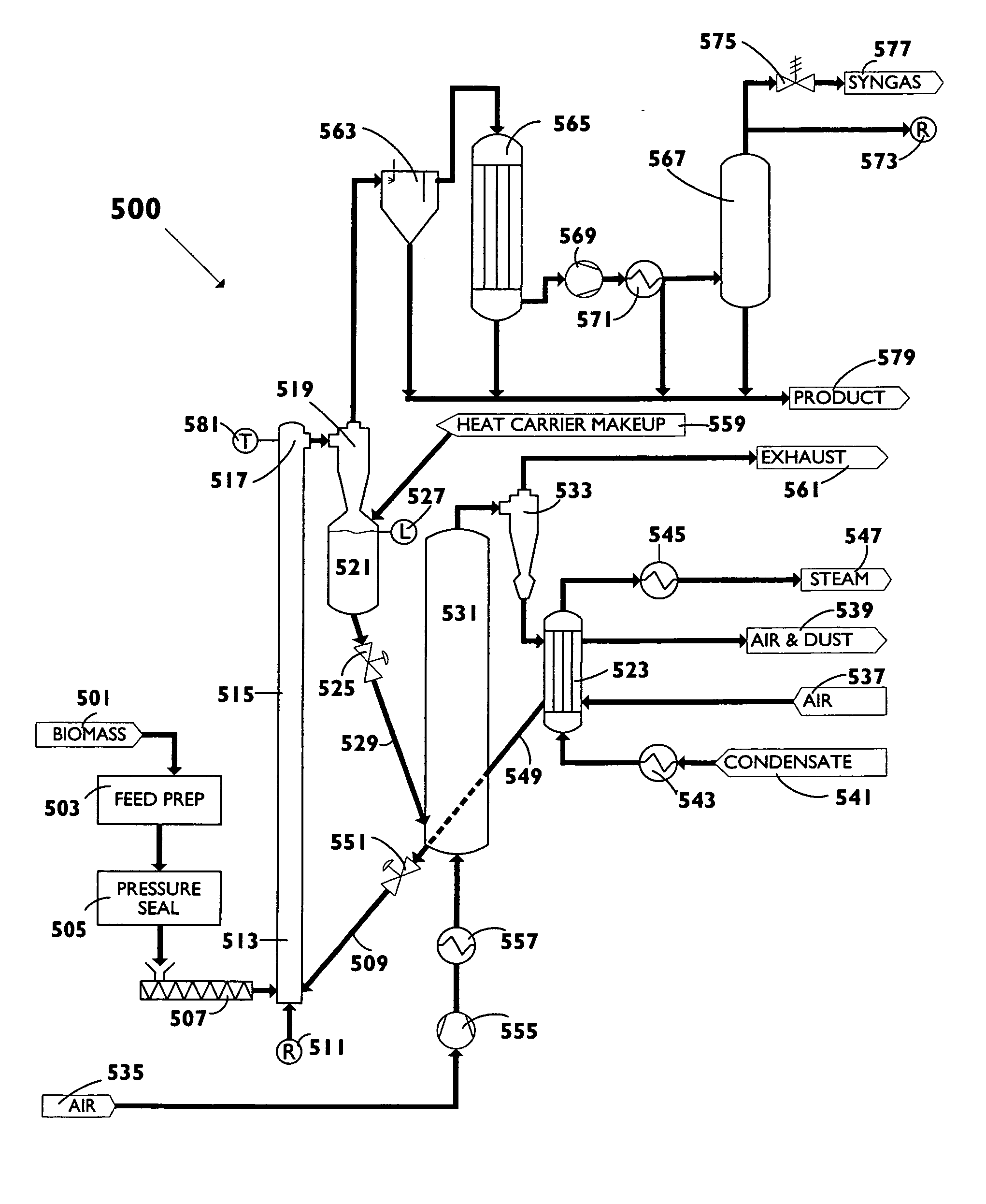

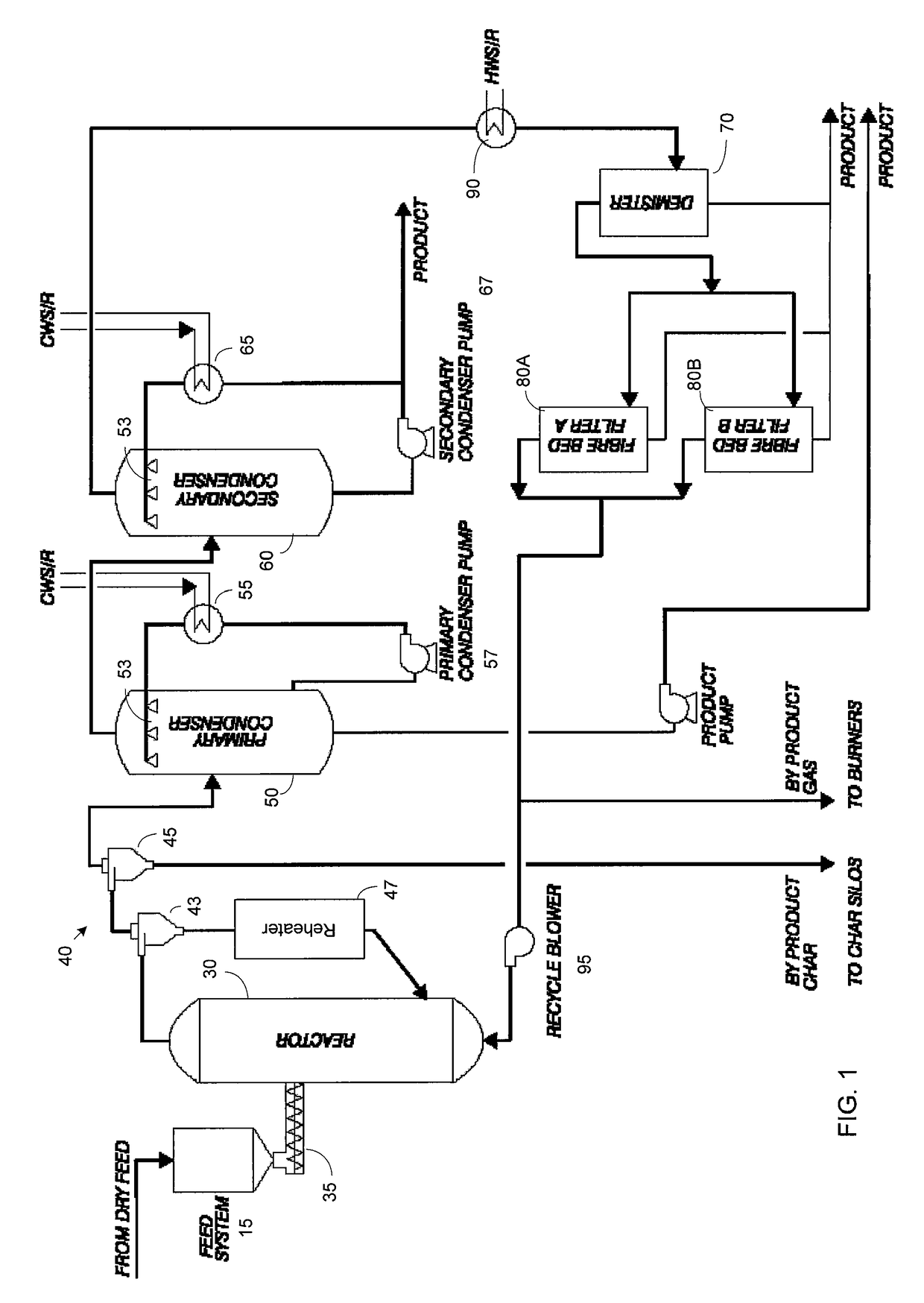

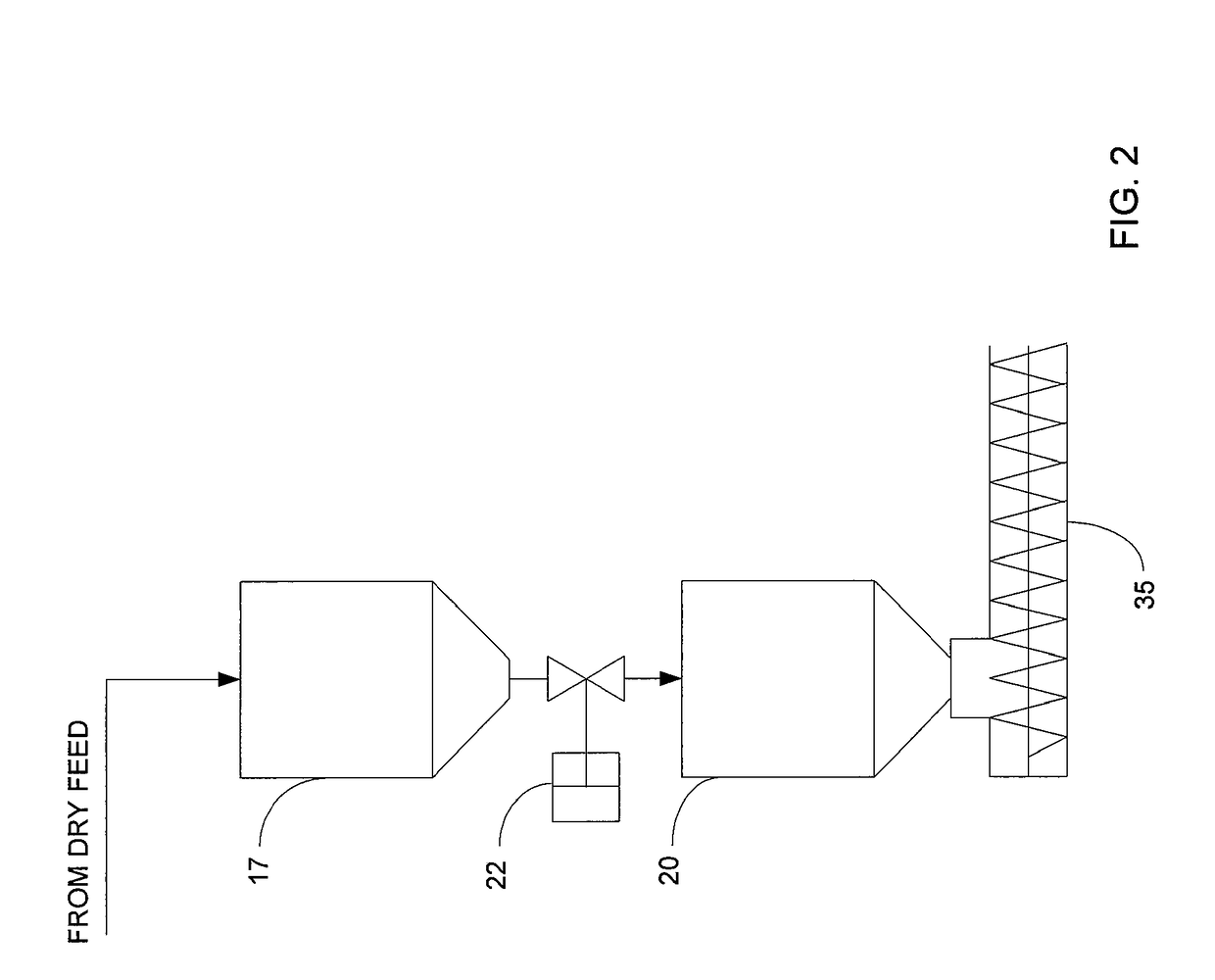

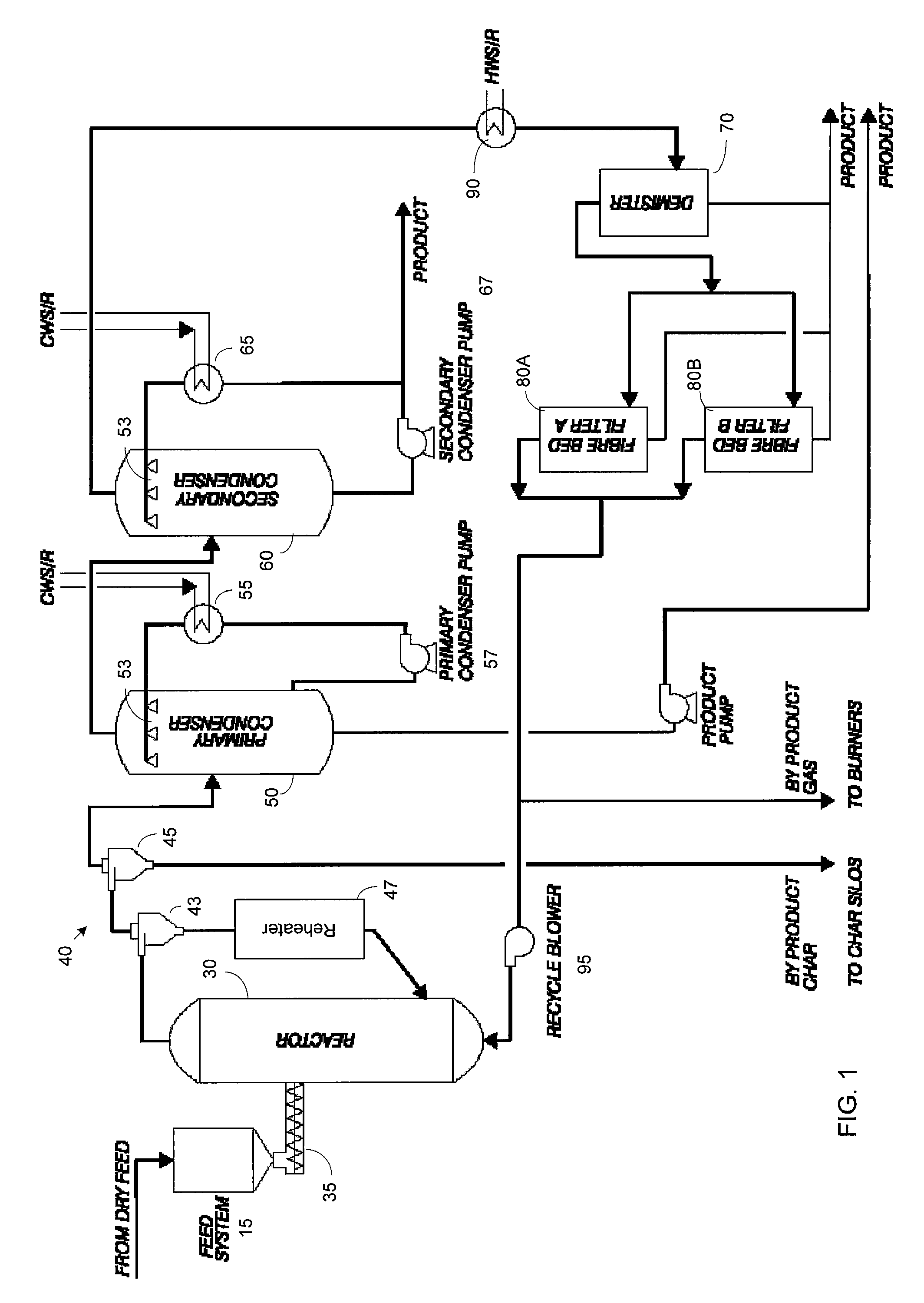

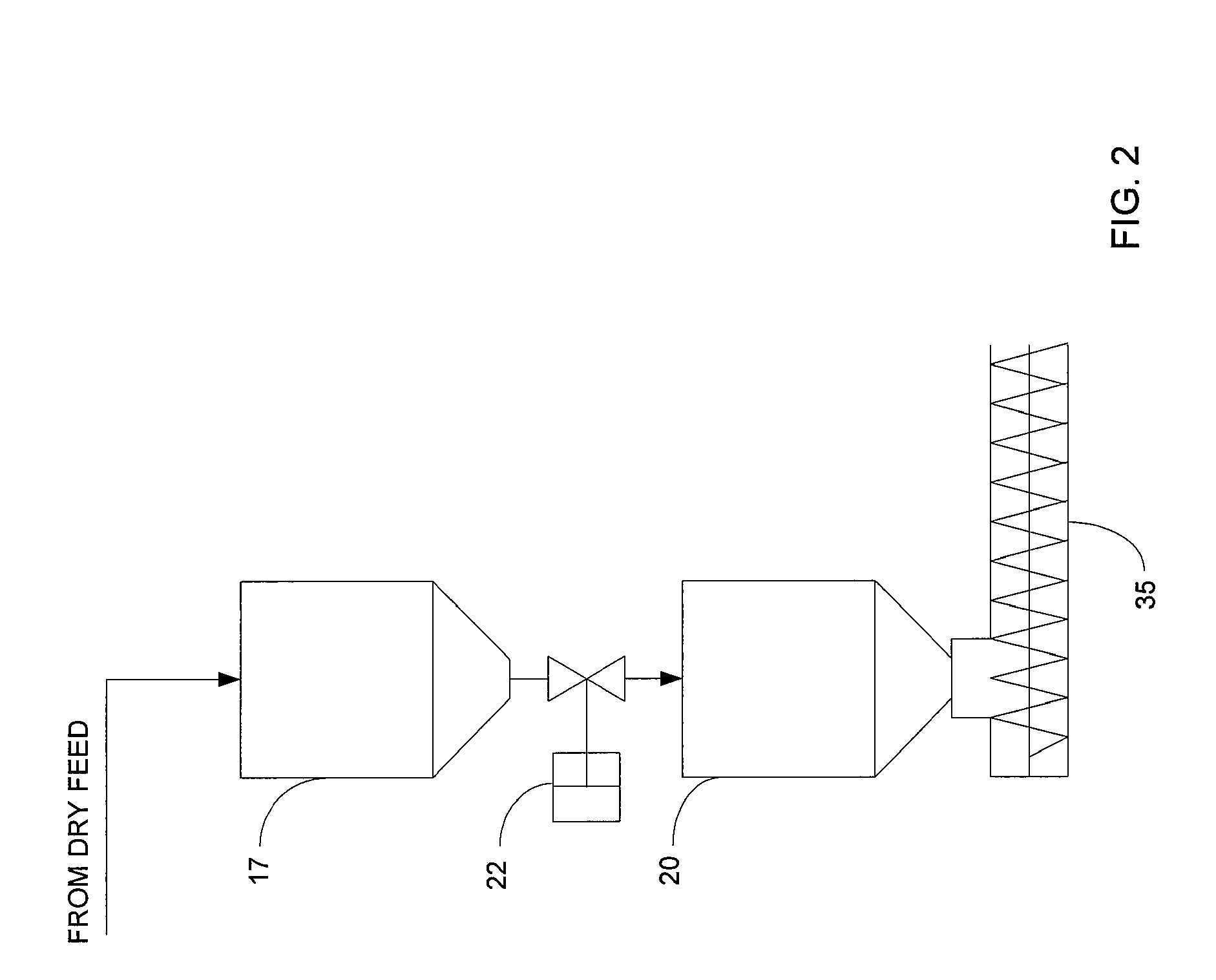

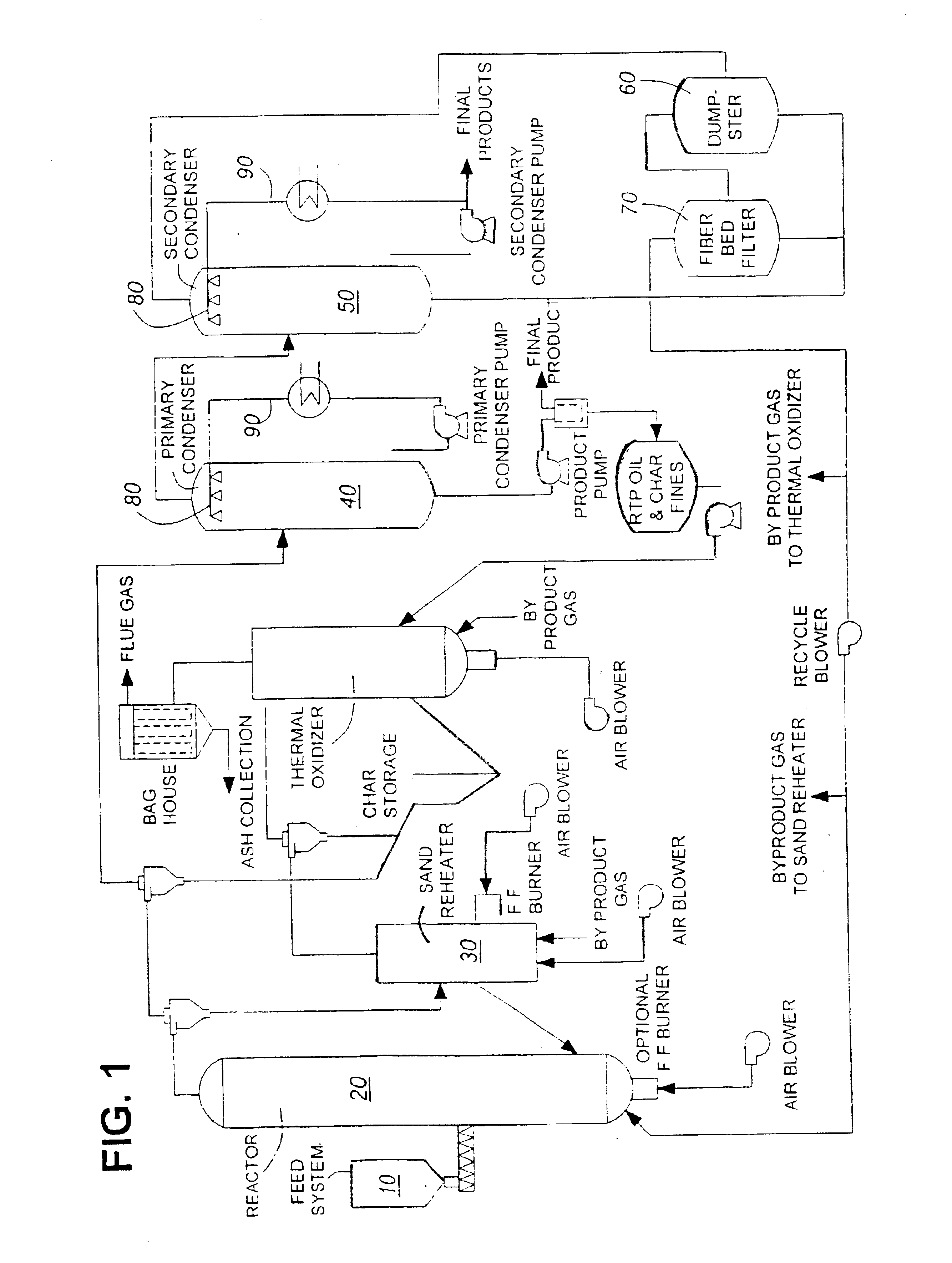

Rapid thermal conversion of biomass

ActiveUS7905990B2Improved rapid thermal conversion processEffective recoveryThermal non-catalytic crackingSolid waste disposalLiquid productHeat carrier

A rapid thermal conversion process for efficiently converting wood, other biomass materials, and other carbonaceous feedstock (including hydrocarbons) into high yields of valuable liquid product, e.g., bio-oil, on a large scale production. Biomass material, e.g., wood, is feed to a conversion system where the biomass material is mixed with an upward stream of hot heat carriers, e.g., sand, that thermally convert the biomass into a hot vapor stream. The hot vapor stream is rapidly quenched with quench media in one or more condensing chambers located downstream of the conversion system. The rapid quenching condenses the vapor stream into liquid product, which is collected from the condensing chambers as a valuable liquid product. The liquid product may itself be used as the quench media.

Owner:ENSYN RENEWABLES

Waste conversion process

InactiveUS20060280669A1Good yieldMinimization requirementsBiofuelsIndirect and direct heating destructive distillationEnvironmental engineeringSand granules

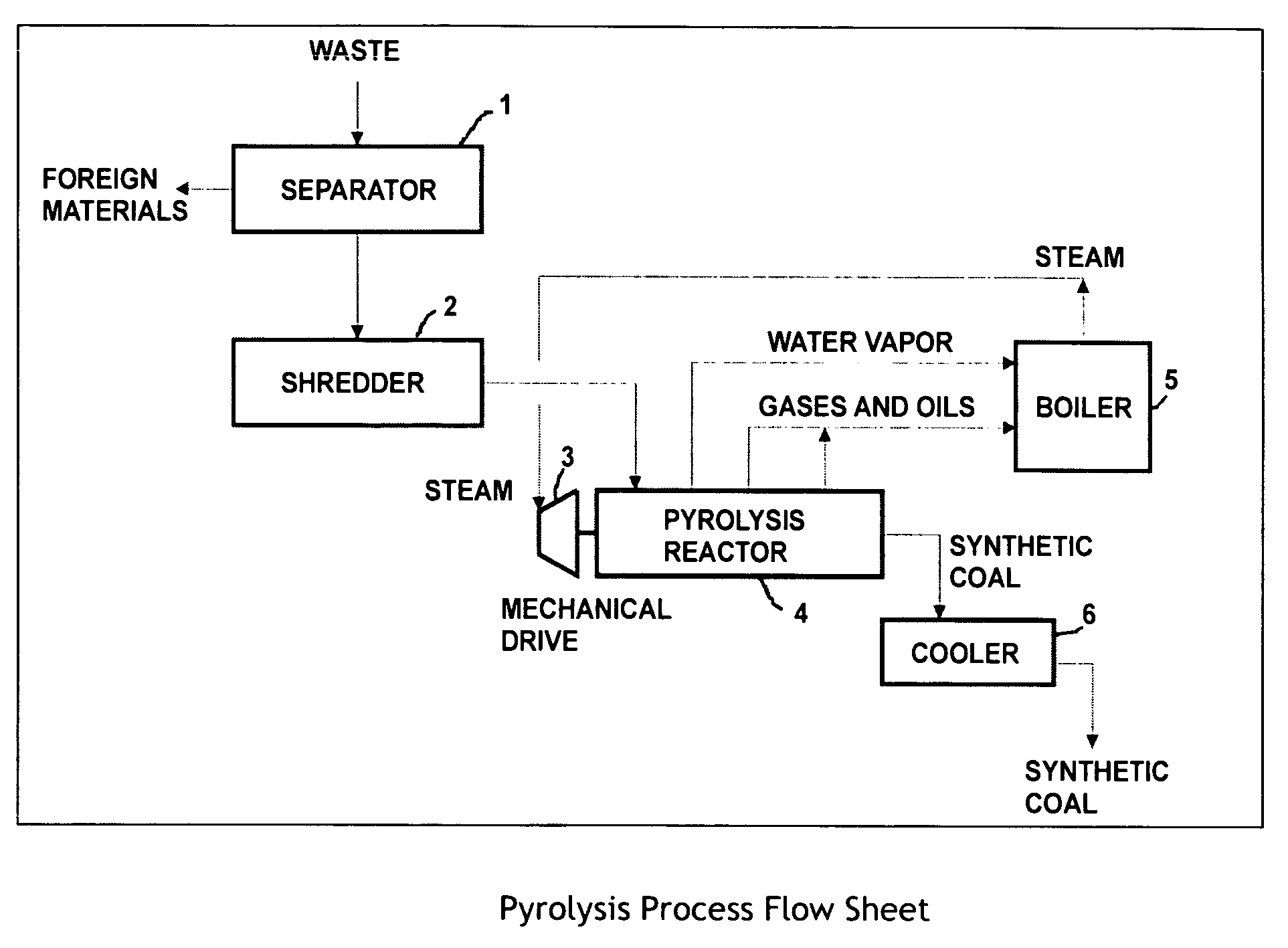

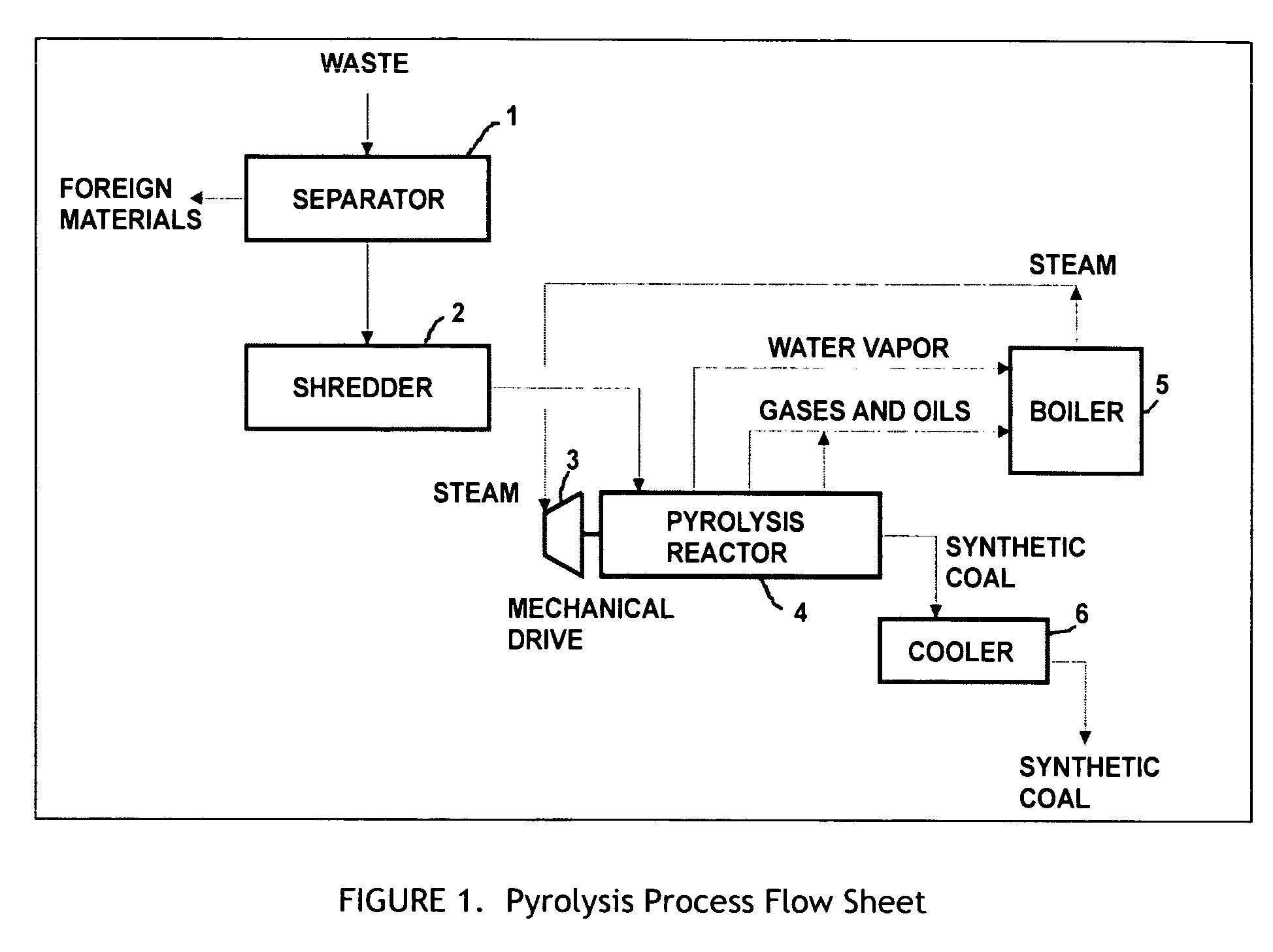

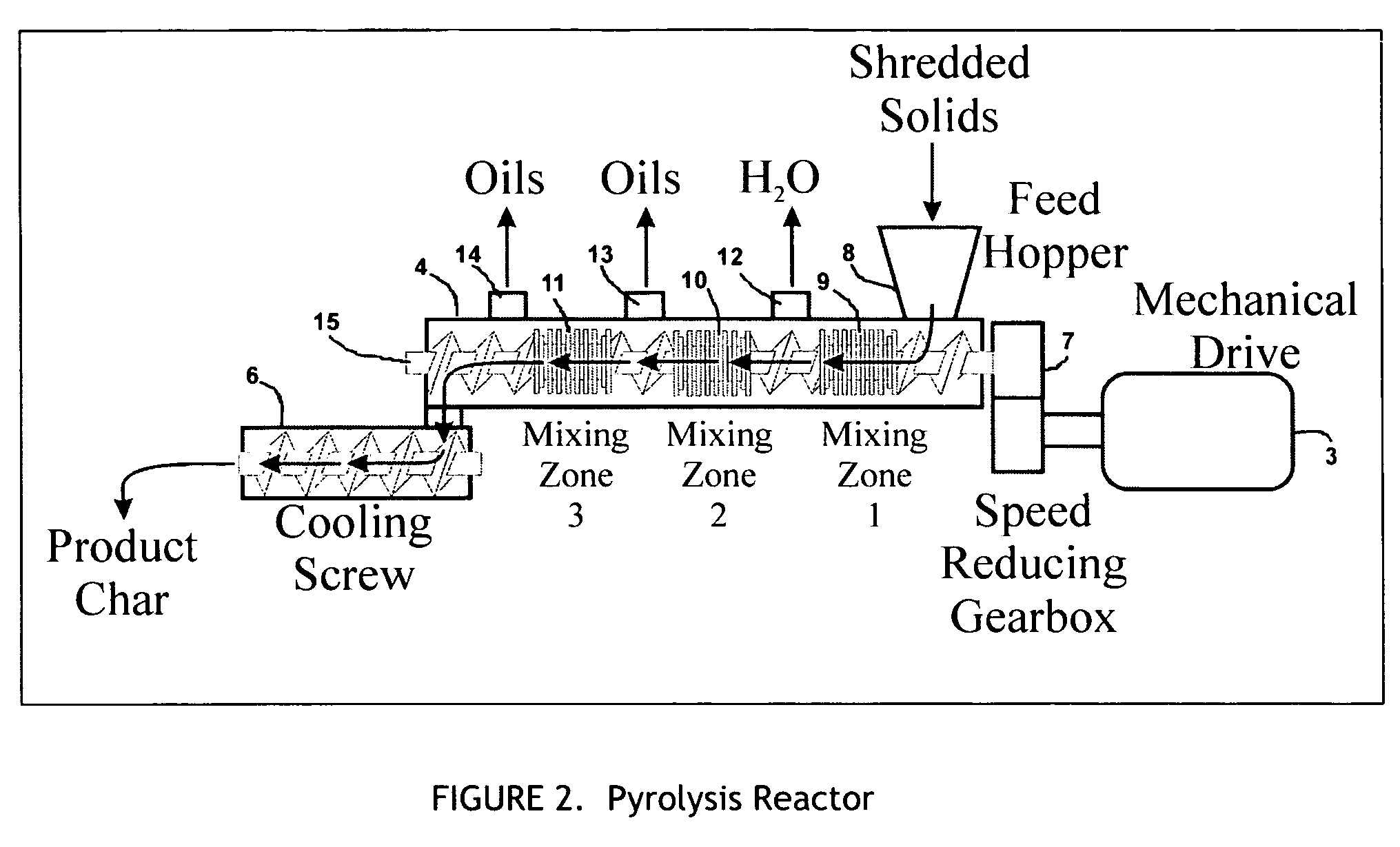

A process for the preparation of high quality char from organic waste materials. The waste is first sorted to remove recyclable inorganic materials of economic value (metals, glass) and other foreign materials that would be detrimental to the quality of the final product (stone, sand, construction debris, etc.). After size reduction, the waste is pyrolyzed at a temperature range of 250 to 600° F., in a high capacity, continuous mixer reactor, using in-situ viscous heating of the waste materials, to produce a highly uniform, granular synthetic product similar in energy content and handling characteristics to, but much cleaner burning than, natural coal.

Owner:ENTROPIC TECH CORP

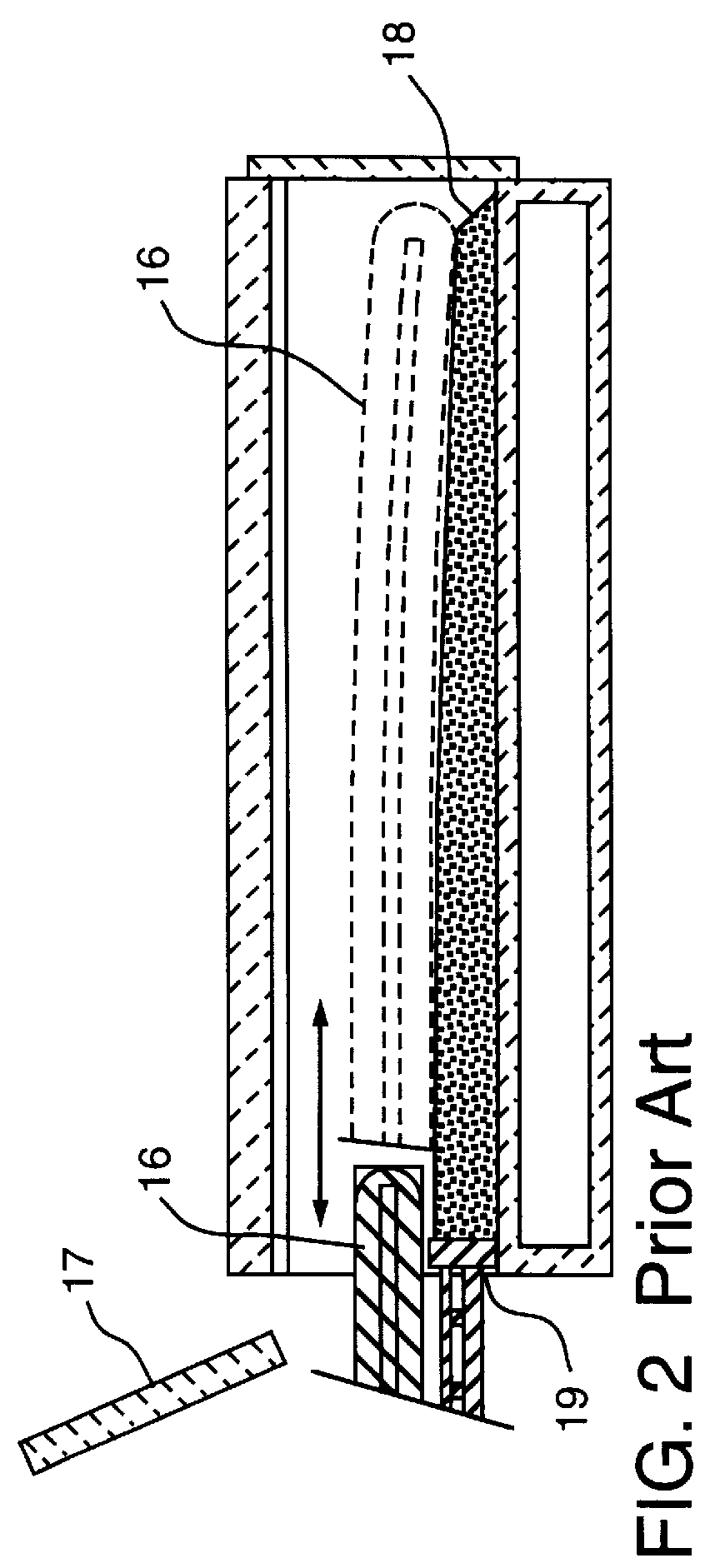

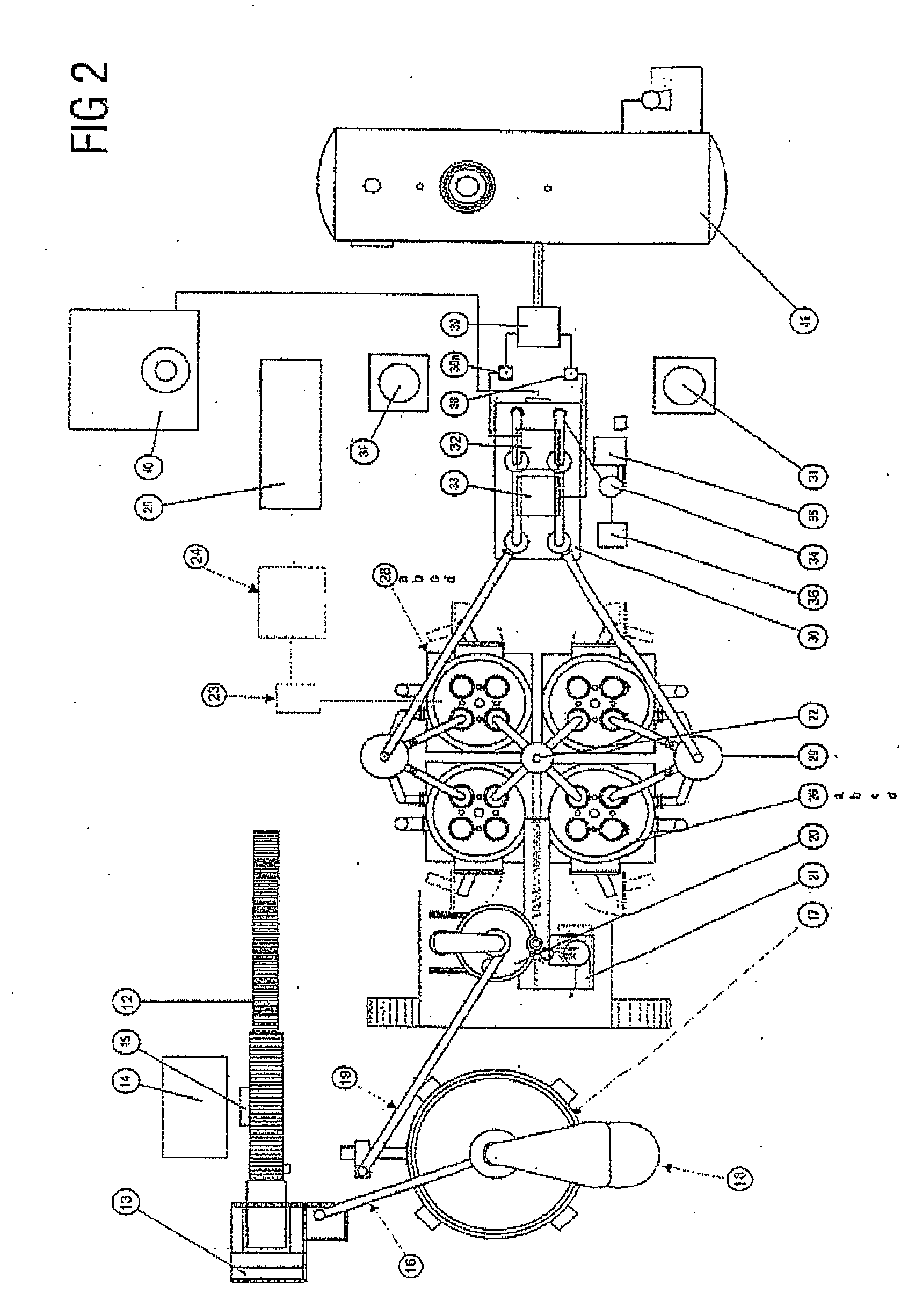

Coal bed vibration compactor for non-recovery coke oven

InactiveUS6059932AMechanical conveying coke ovensCharging-discharging device combinationsEngineeringCoke oven

A coal compaction system and method for a non-recovery coke oven having refractory roof, floor, side walls and end doors for coal charging and coke discharge provides an improved coal charging machine carrying a coal conveyor supported intermediate the ends of the conveyor to avoid conveyor sagging and non-uniform depth of a deposited coal bed, a number of pressurized fluid-driven vibratory compactors mounted on an end of the charging machine and spaced-apart across the width of the coal bed and serving to compact the coal bed on a retraction stroke of the charging machine, a pivoted lifting frame mounted on the charging machine above the compactors and from which the compactors individually are suspended and are provided with individual supply of pressurized fluid, and a coke pusher head mounted on the charging machine behind the compactors and serving, when the lifting frame and associated compactors are raised, to push finished coke from the coke oven.

Owner:PENNSYLVANIA COKE TECH

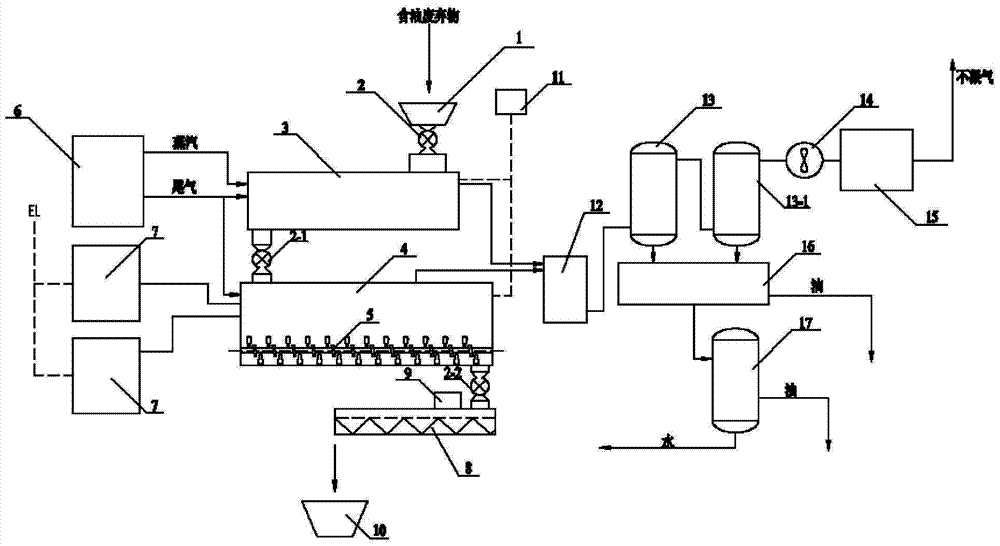

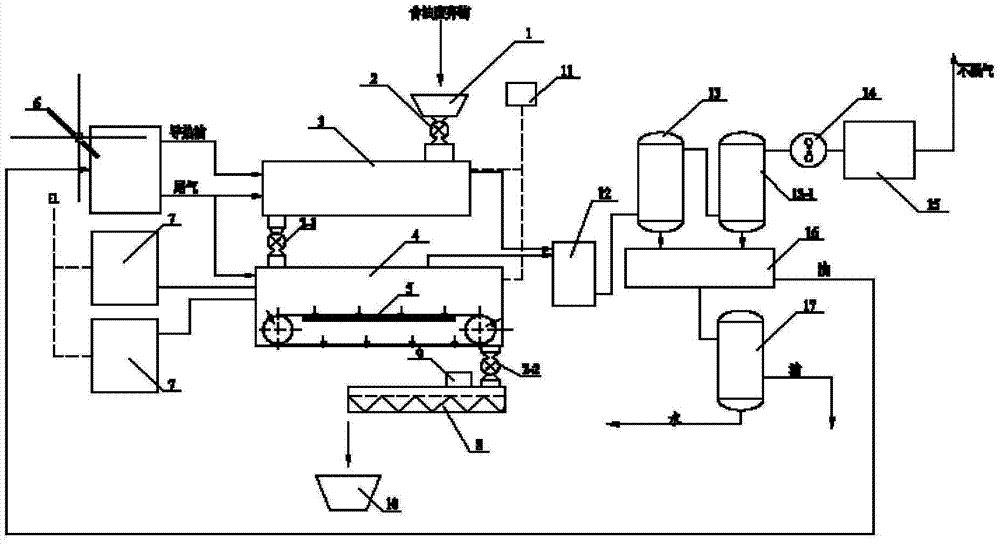

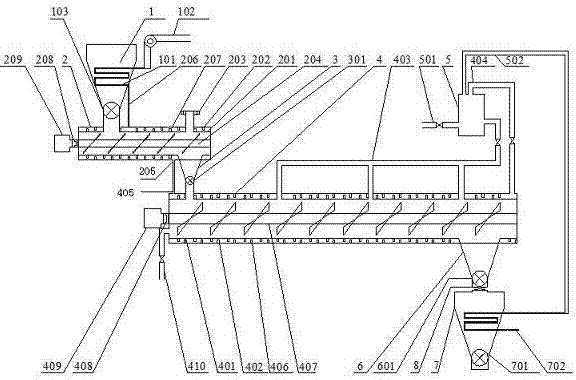

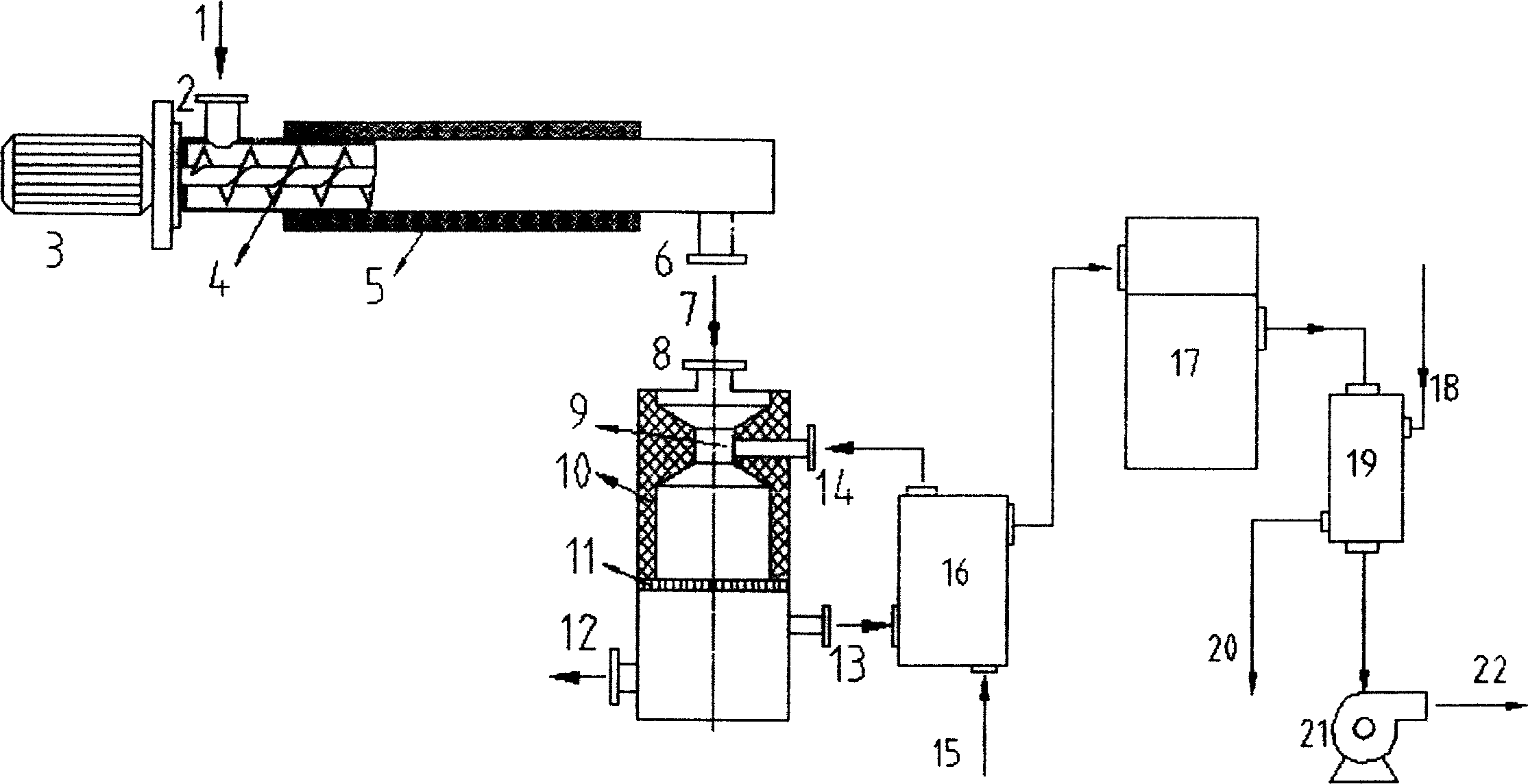

Industrial treatment method and industrial treatment device for oil field waste

ActiveCN103923670ALow boiling pointIncrease gasification rateElectrical coke oven heatingLiquid hydrocarbon mixture productionMicrowave pyrolysisEnvironmental engineering

The invention provides an industrial treatment method for oil field waste. The industrial treatment method for oil field waste comprises the following steps: carrying out sampling analysis on the oil field waste, preheating to 80-300 DEG C by using high-temperature steam or conduction oil, then carrying out microwave pyrolysis treatment, controlling pressure at minus 5000 to minus 100 Pa, thus obtaining solid treatment substances and gas, condensing, separating and purifying the gas, and finally recycling so as to obtain water, oil and non-condensable gas. An industrial treatment device for oil field waste comprises a feed hopper, a dryer, a microwave heating cavity, a microwave generator, a heating device and a condensation separation purification device, wherein the feed hopper is connected to the dryer which is connected to the microwave heating cavity, a steam or conduction oil outlet of the heating device is connected to a steam or conduction oil outlet of the dryer; gas outlets of the dryer and the microwave heating cavity are connected to the condensation separation purification device; the microwave generator is connected to the microwave heating cavity. The industrial treatment method and the industrial treatment device have good treatment effects, high utilization rate of energy sources and good economical efficiency.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

Fractional catalytic pyrolysis of biomass

ActiveUS20090165378A1Eliminate needBiofuelsIndirect heating destructive distillationCatalytic pyrolysisReactive gas

Methods for fractional catalytic pyrolysis which allow for conversion of biomass into a slate of desired products without the need for post-pyrolysis separation are described. The methods involve use of a fluid catalytic bed which is maintained at a suitable pyrolysis temperature. Biomass is added to the catalytic bed, preferably while entrained in a non-reactive gas such as nitrogen, causing the biomass to become pyrolyzed and forming the desired products in vapor and gas forms, allowing the desired products to be easily separated.

Owner:VIRGINIA TECH INTPROP INC

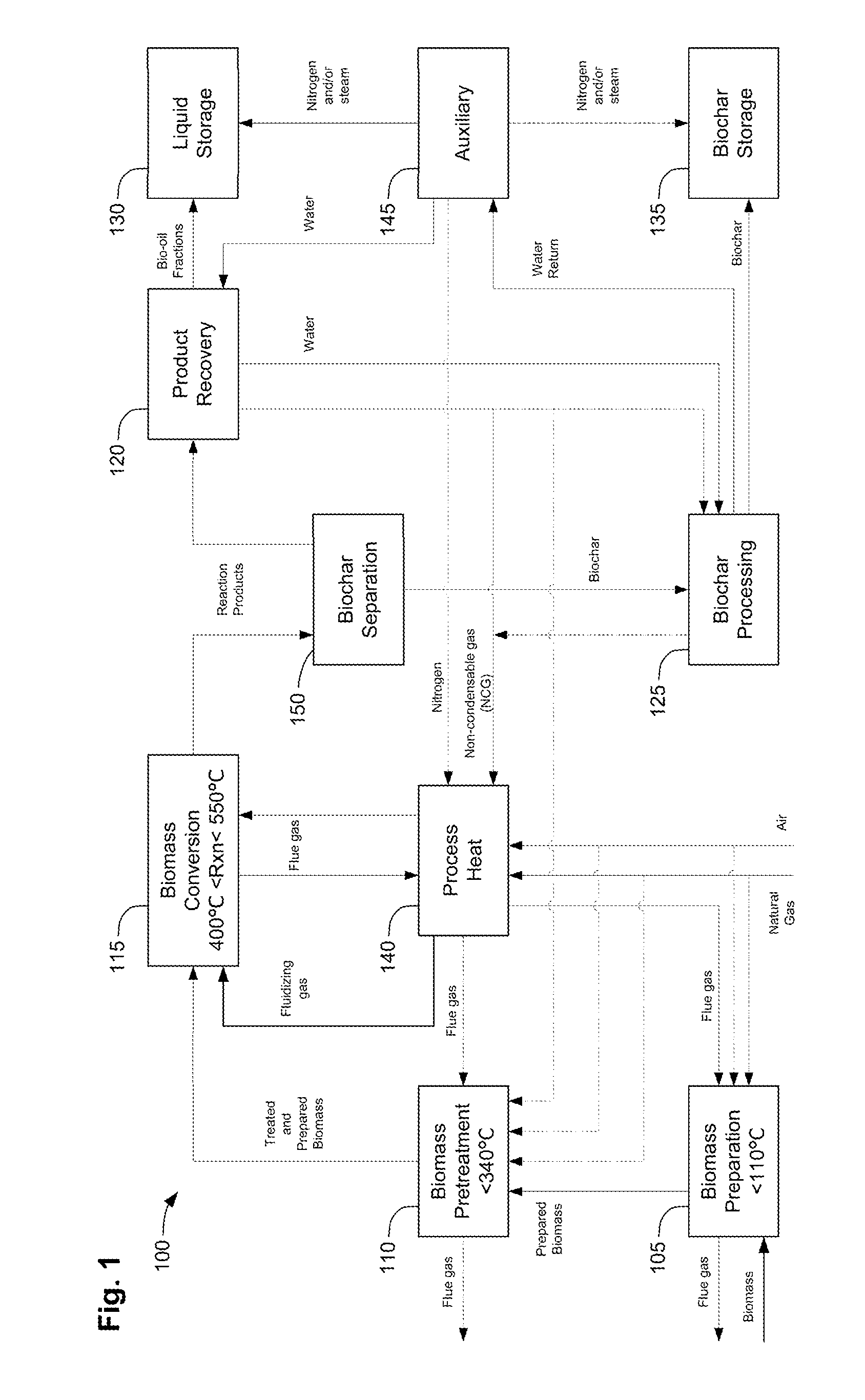

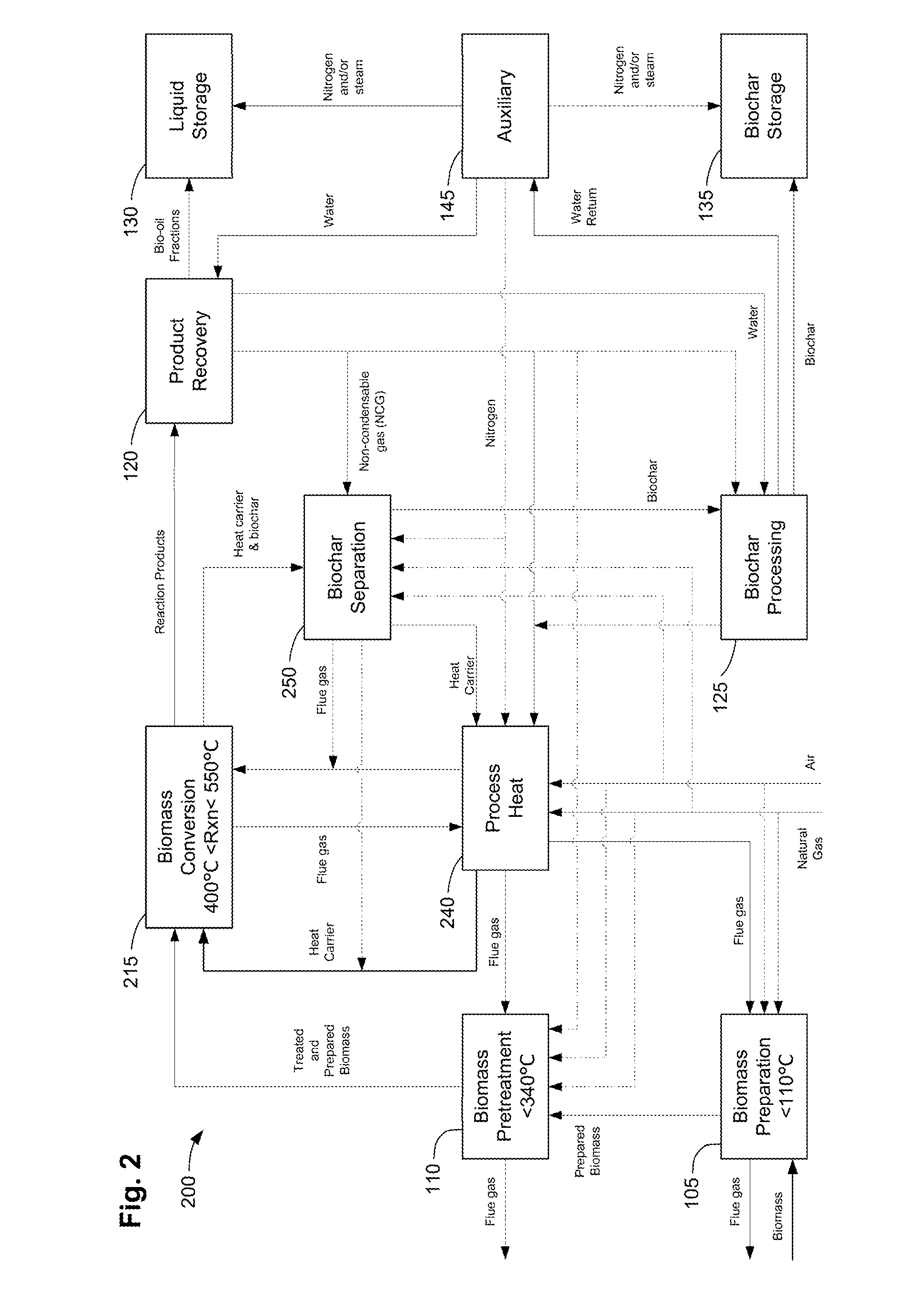

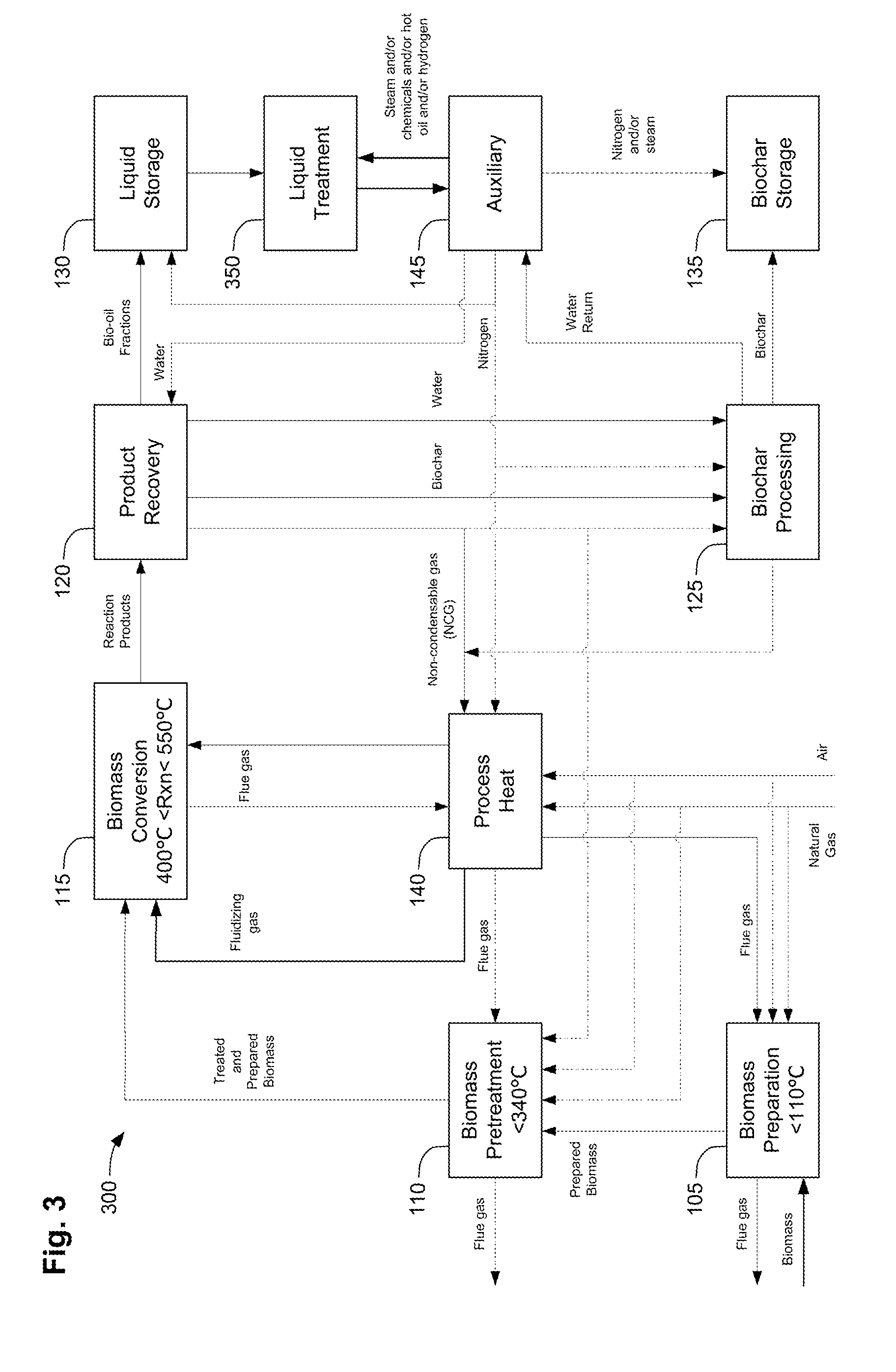

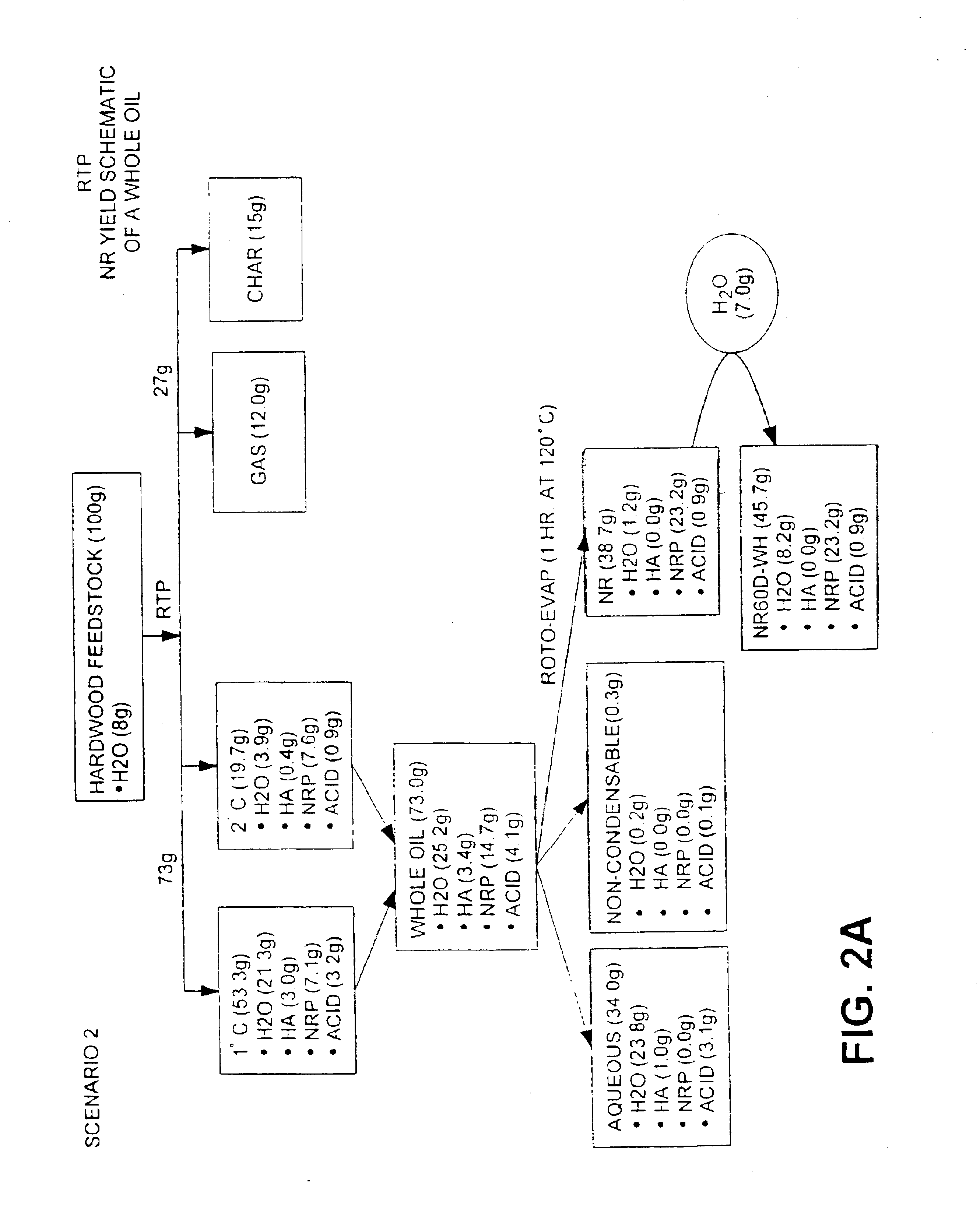

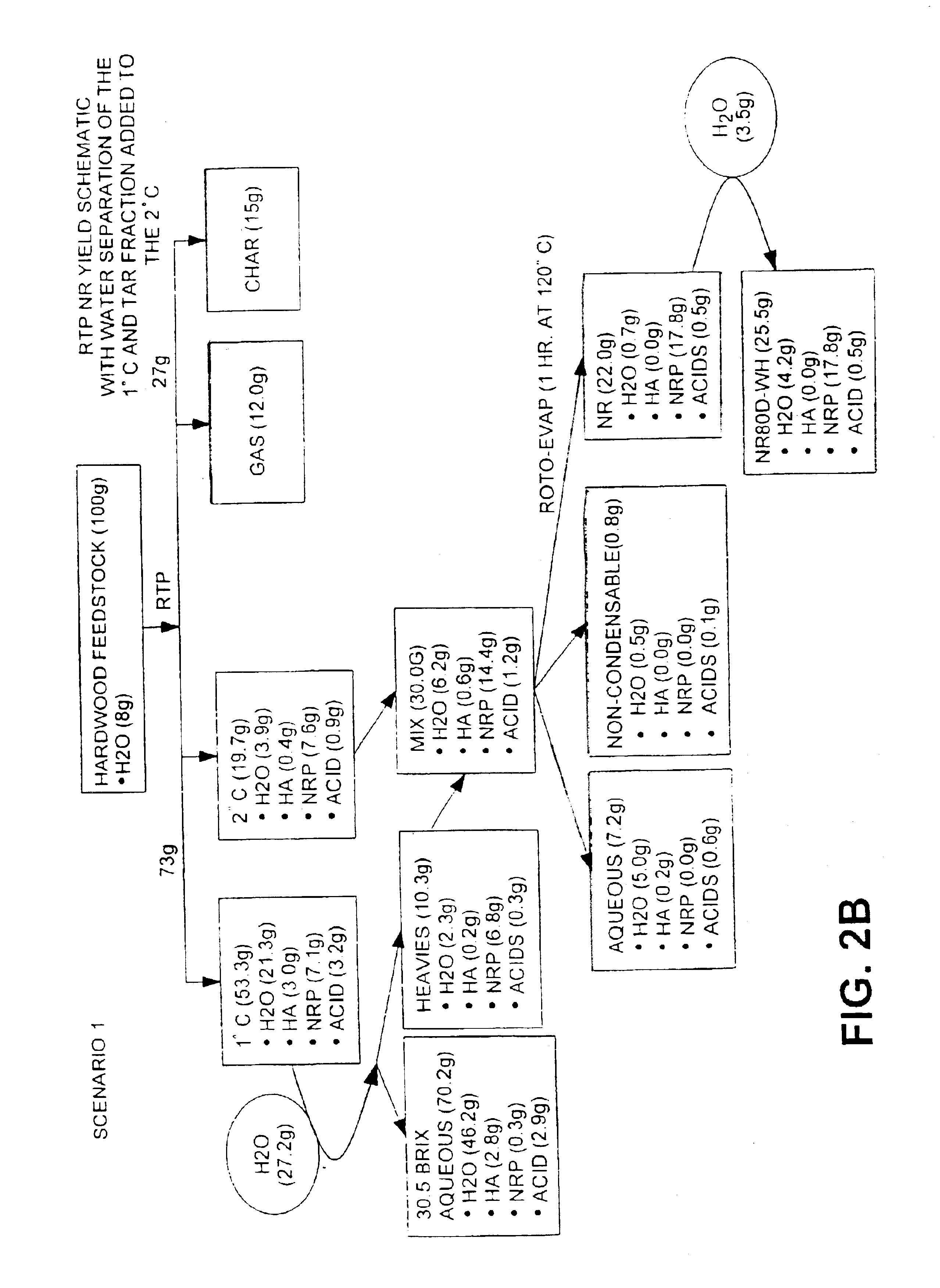

Methods for integrated fast pyrolysis processing of biomass

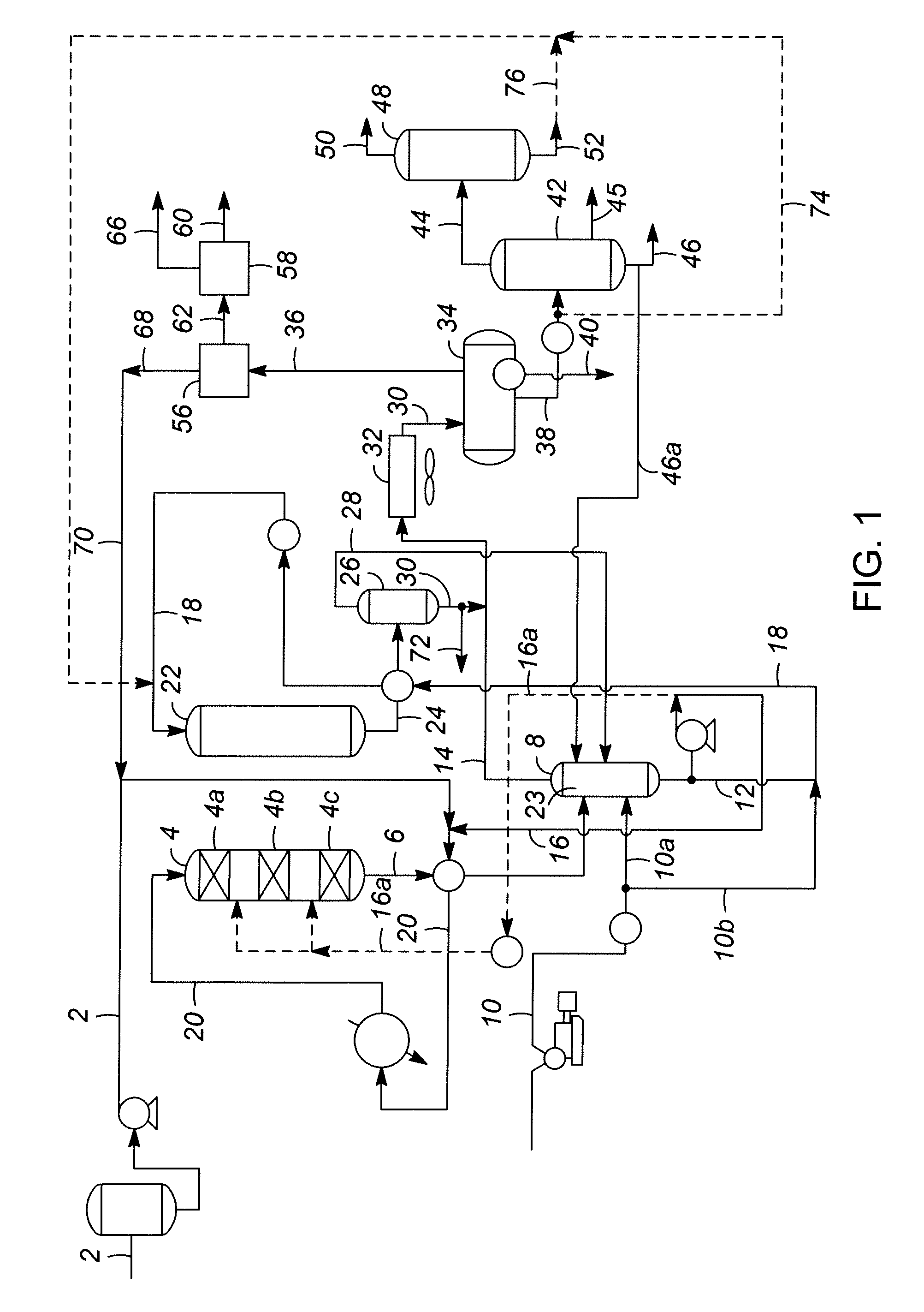

ActiveUS20110258914A1Improve collection efficiencyMinimizes water contentDirect heating destructive distillationBiofuelsPre treatmentSafe handling

Methods, process, apparatus, equipment, and systems are disclosed for converting biomass into bio-oil fractions for chemicals, materials, feedstocks and fuels using a low-cost, integrated fast pyrolysis system. The system improves upon prior art by creating stable, bio-oil fractions which have unique properties that make them individually superior to conventional bio-oil. The invention enables water and low-molecular weight compounds to be separated into a final value-added fraction suitable for upgrading or extracting into value-added chemicals, fuels and water. Initial bio-oil fractions from the process are chemically distinct, have low-water content and acidity which reduces processing costs normally associated with conventional bio-oil post-production upgrading since fewer separation steps, milder processing conditions and lower auxiliary inputs are required. Biochar is stabilized so that it can be handled safely. The integrated fast pyrolysis process includes biomass storage, preparation, pretreatment, and conversion, product recovery and processing to create and store stable biochar and bio-oil fractions.

Owner:AVELLO BIOENERGY

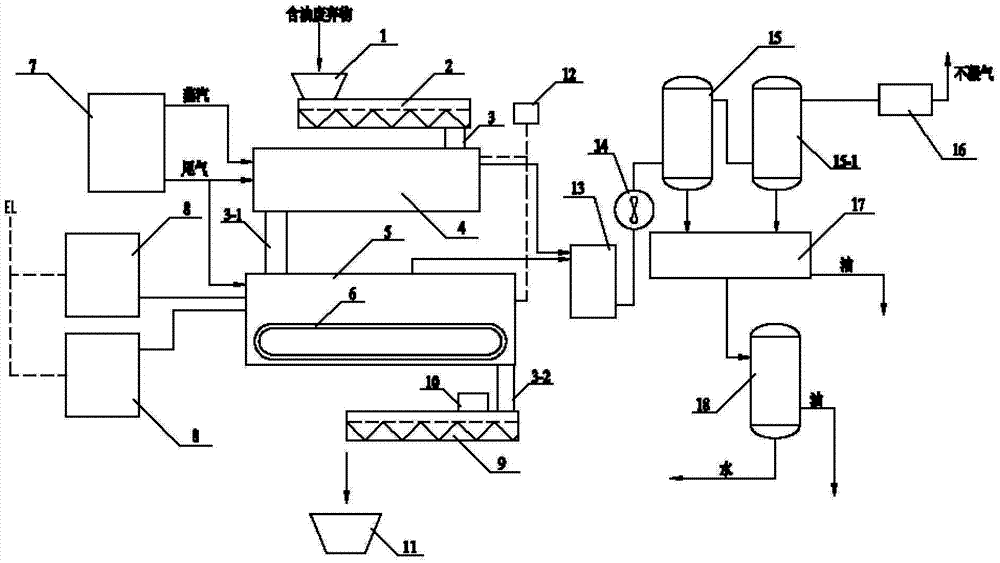

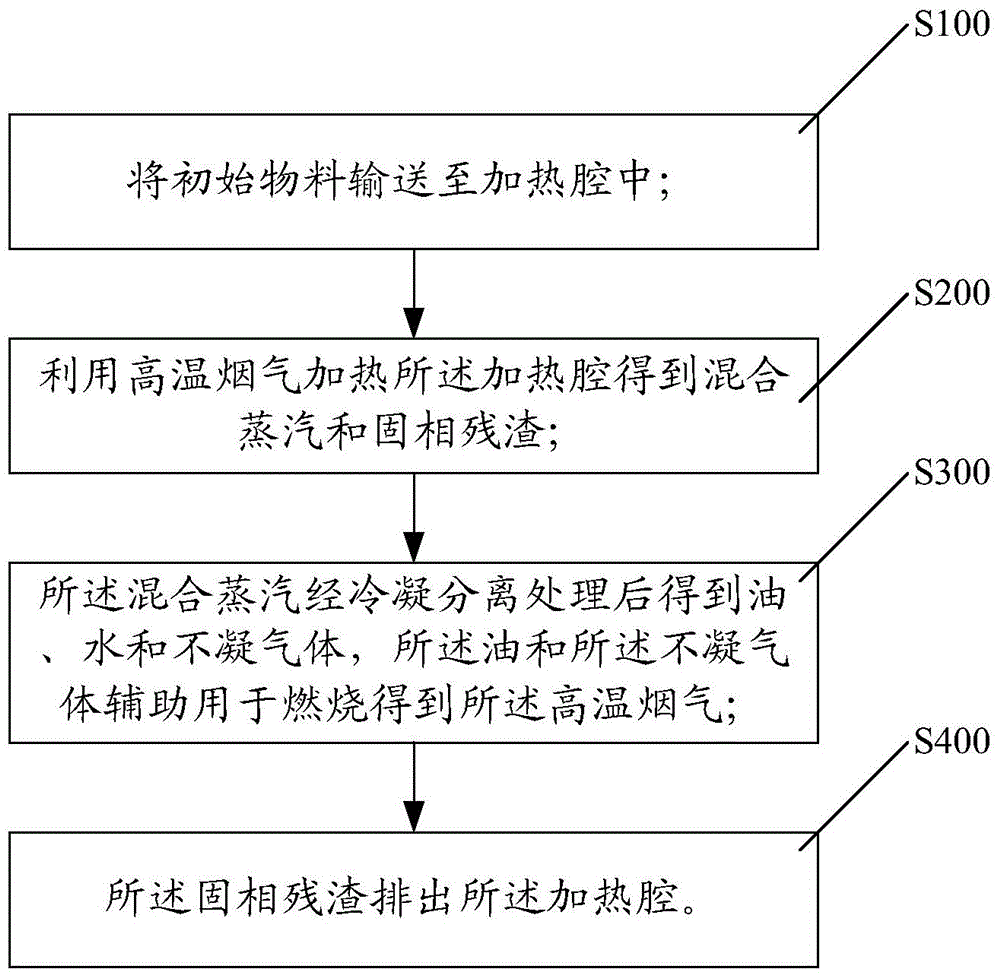

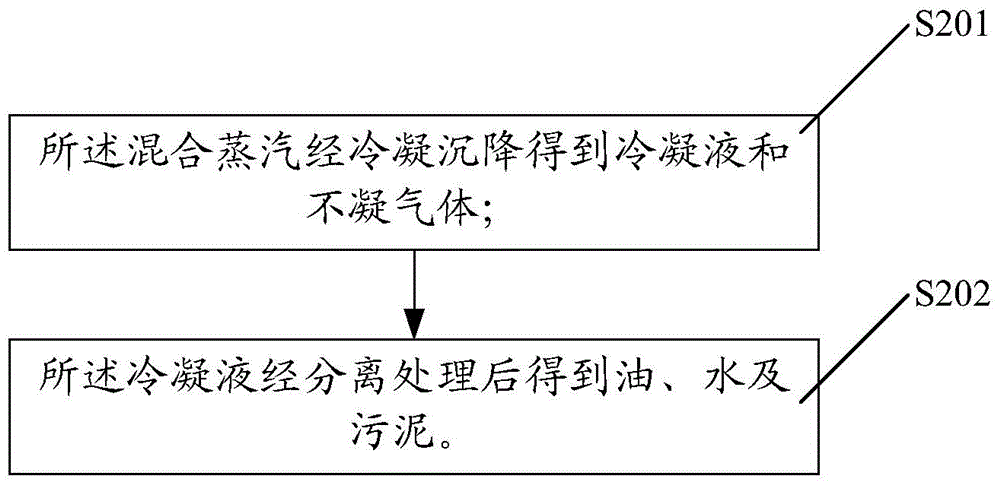

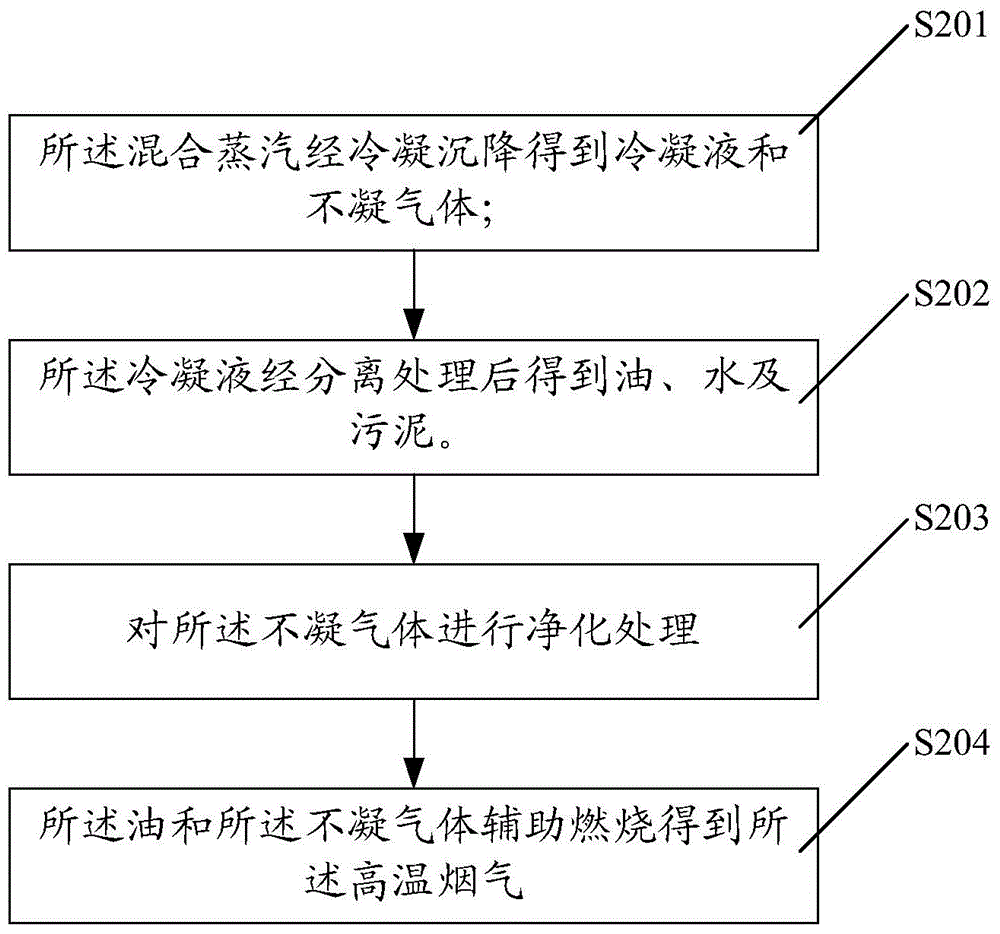

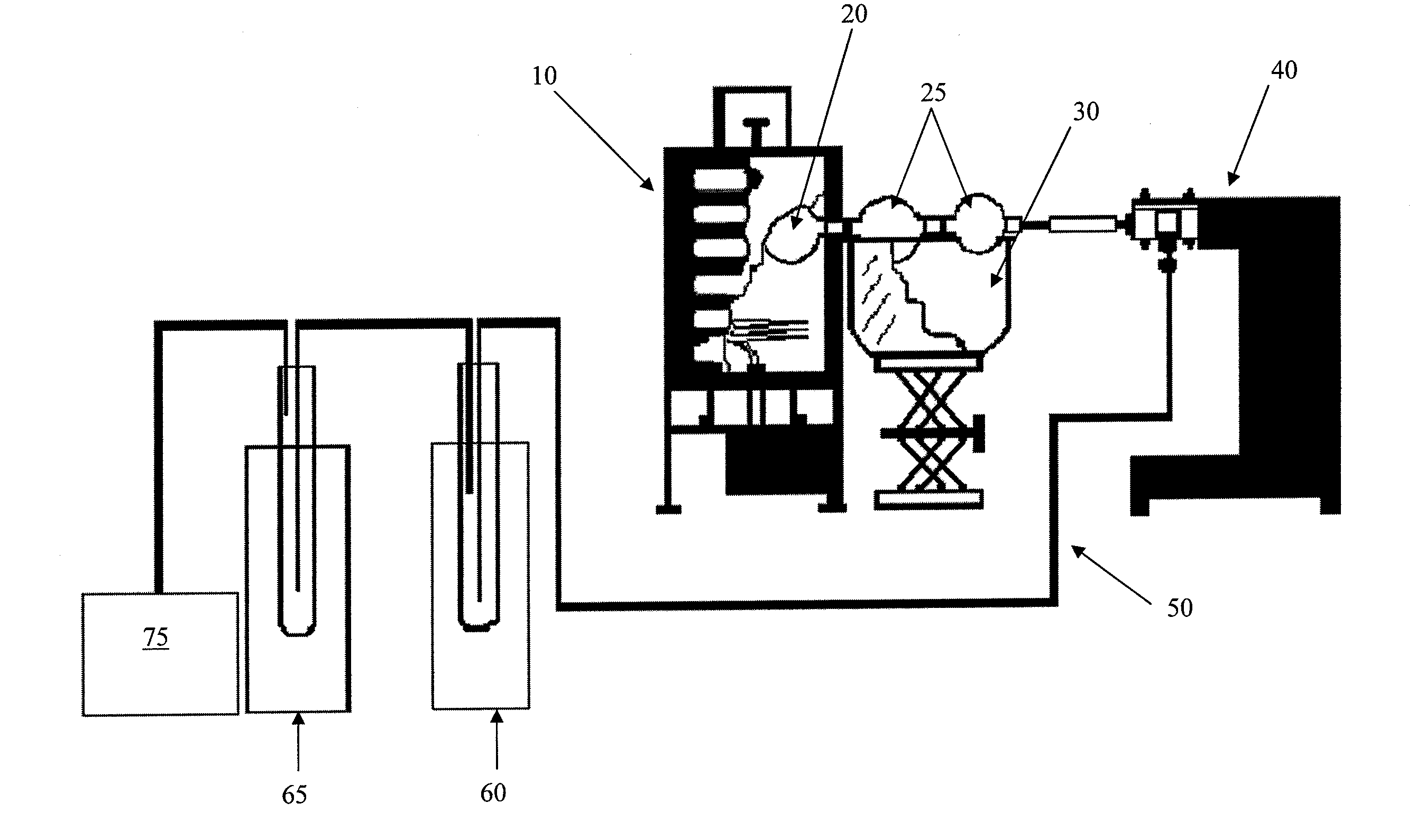

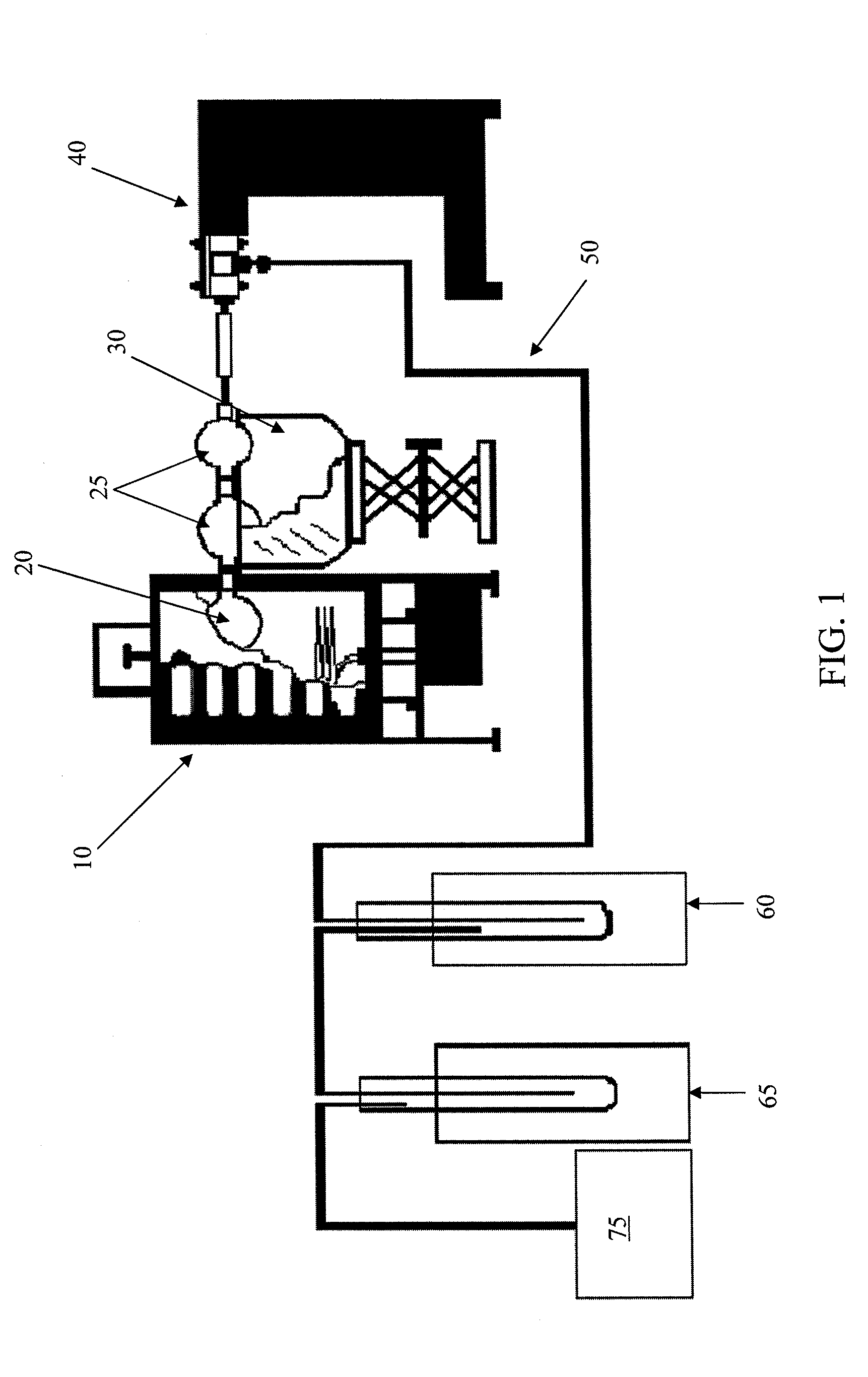

Method and system for processing oil field wastes

ActiveCN104150728AImprove versatilitySludge treatment by pyrolysisLiquid hydrocarbon mixture productionFlue gasDecomposition

The embodiment of the invention discloses a method and a system for processing oil field wastes. The method for processing the oil field wastes comprises the following steps: conveying initial materials to a heating cavity, and heating the heating cavity by using high-temperature flue gas, so as to obtain mixed steam and solid residues; carrying out condensation and separation on the mixed steam, so as to obtain oil, water and a noncondensable gas, wherein the oil and the noncondensable gas are used for combusting to obtain the high-temperature flue gas, and the solid residues are discharged out of the heating cavity. According to the method, the heating cavity is indirectly heated by using the high-temperature flue gas, so that the initial materials inside the heating cavity are subjected to thermal decomposition, solid residues free of oil, the noncondensable gas and oil are obtained from the mixed steam generated by thermal decomposition after a series of treatments, and then the noncondensable gas and oil are used for combusting to generate the high-temperature flue gas. Compared with the prior art, the method disclosed by the invention has the advantages that decomposition is carried out without adding a cracking agent, and thermal decomposition can be directly carried out on the oil field wastes in different regions, therefore, the method and the system are better in universality.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

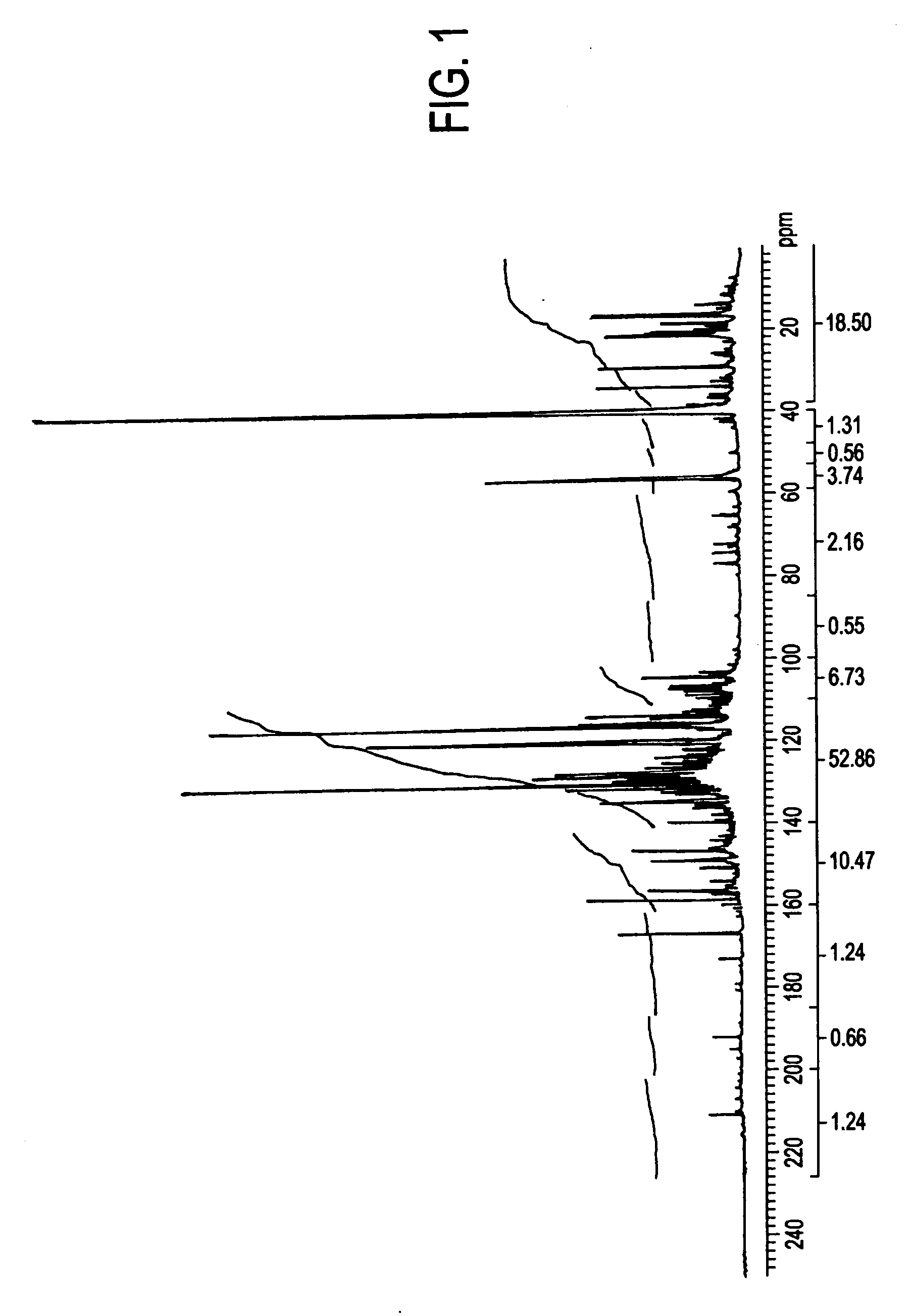

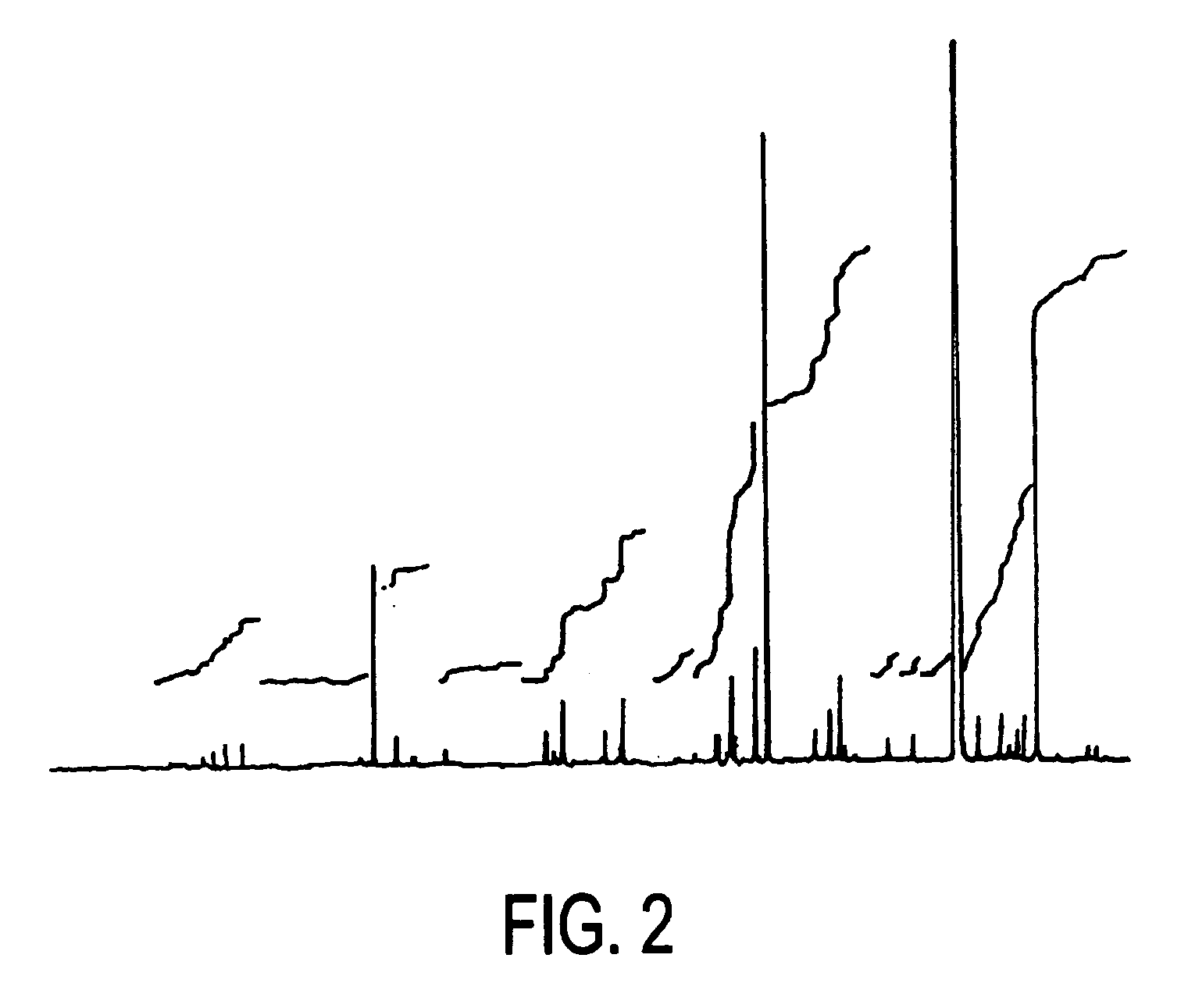

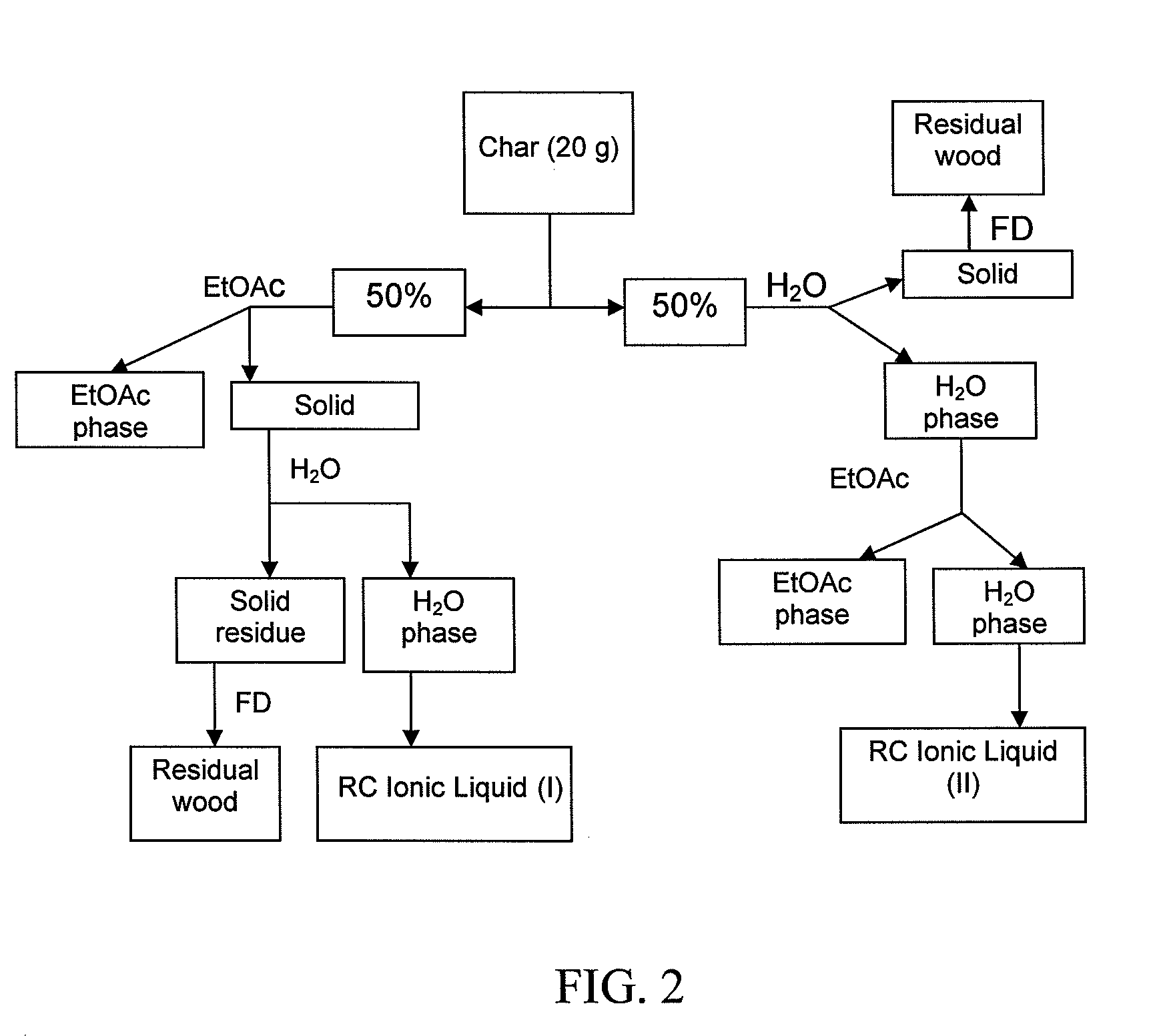

Product preparation and recovery from thermolysis of lignocellulosics in ionic liquids

InactiveUS20080185112A1Increase productionCellulosic pulp after-treatmentCoal charges mechanical treatmentCelluloseIonic liquid

The present invention provides methods for the thermolysis of lignocellulosic materials, such as wood, cellulose, lignin, and lignocellulose. In specific embodiments, the methods comprise combining the lignocellulosic material with an ionic liquid and subjecting the mixture of the lignocellulosic material and the ionic media to pyrolytic conditions to form a recoverable product, such as a commodity chemical.

Owner:NORTH CAROLINA STATE UNIV

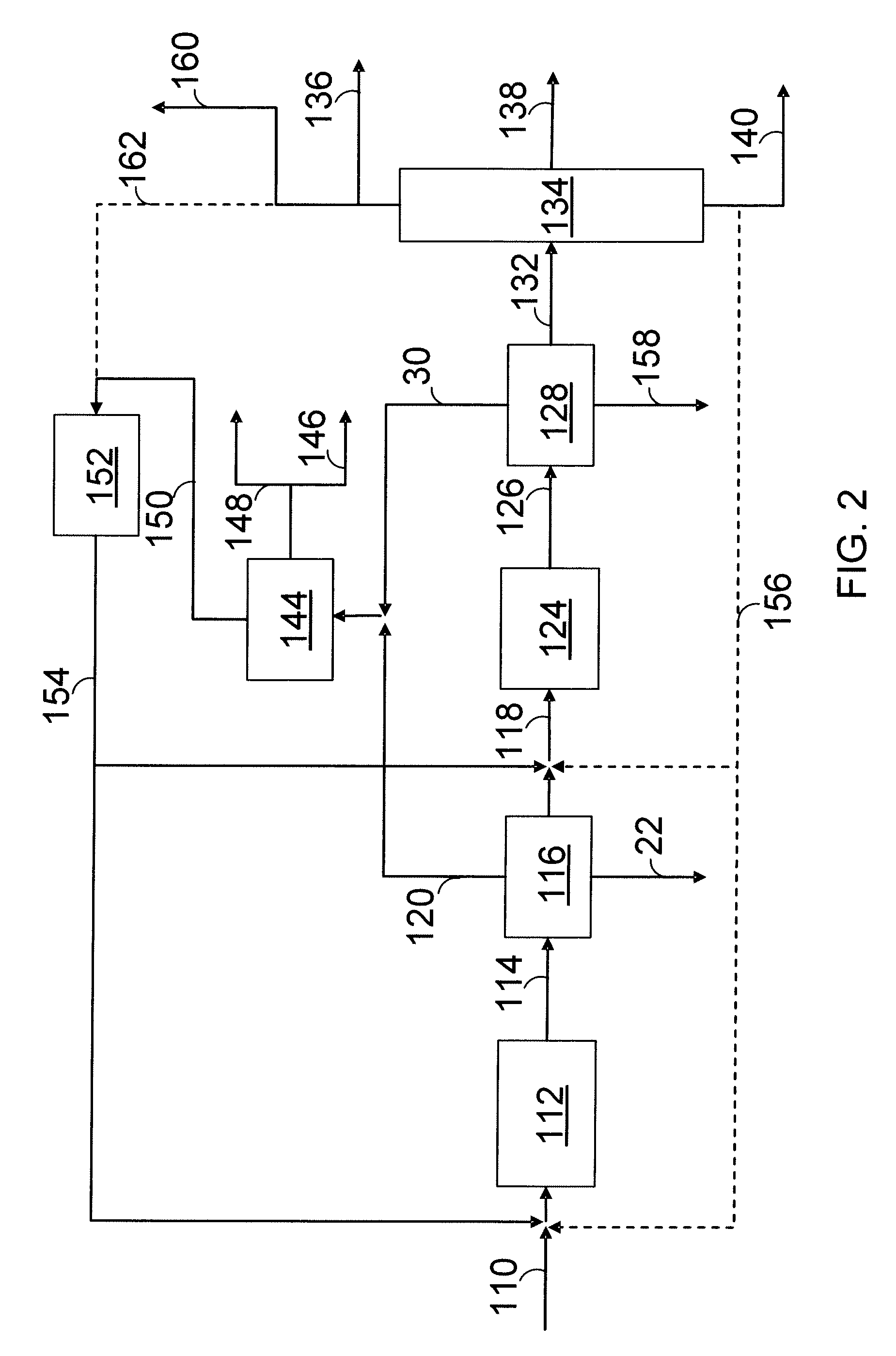

Rapid thermal conversion of biomass

ActiveUS20090139851A1Improved rapid thermal conversion processEffective recoveryThermal non-catalytic crackingCoke quenchingLiquid productHeat carrier

The present invent provides improved rapid thermal conversion processes for efficiently converting wood, other biomass materials, and other carbonaceous feedstock (including hydrocarbons) into high yields of valuable liquid product, e.g., bio-oil, on a large scale production. In an embodiment, biomass material, e.g., wood, is feed to a conversion system where the biomass material is mixed with an upward stream of hot heat carriers, e.g., sand, that thermally convert the biomass into a hot vapor stream. The hot vapor stream is rapidly quenched with quench media in one or more condensing chambers located downstream of the conversion system. The rapid quenching condenses the vapor stream into liquid product, which is collected from the condensing chambers as a valuable liquid product. In one embodiment, the liquid product itself is used as the quench media.

Owner:ENSYN RENEWABLES

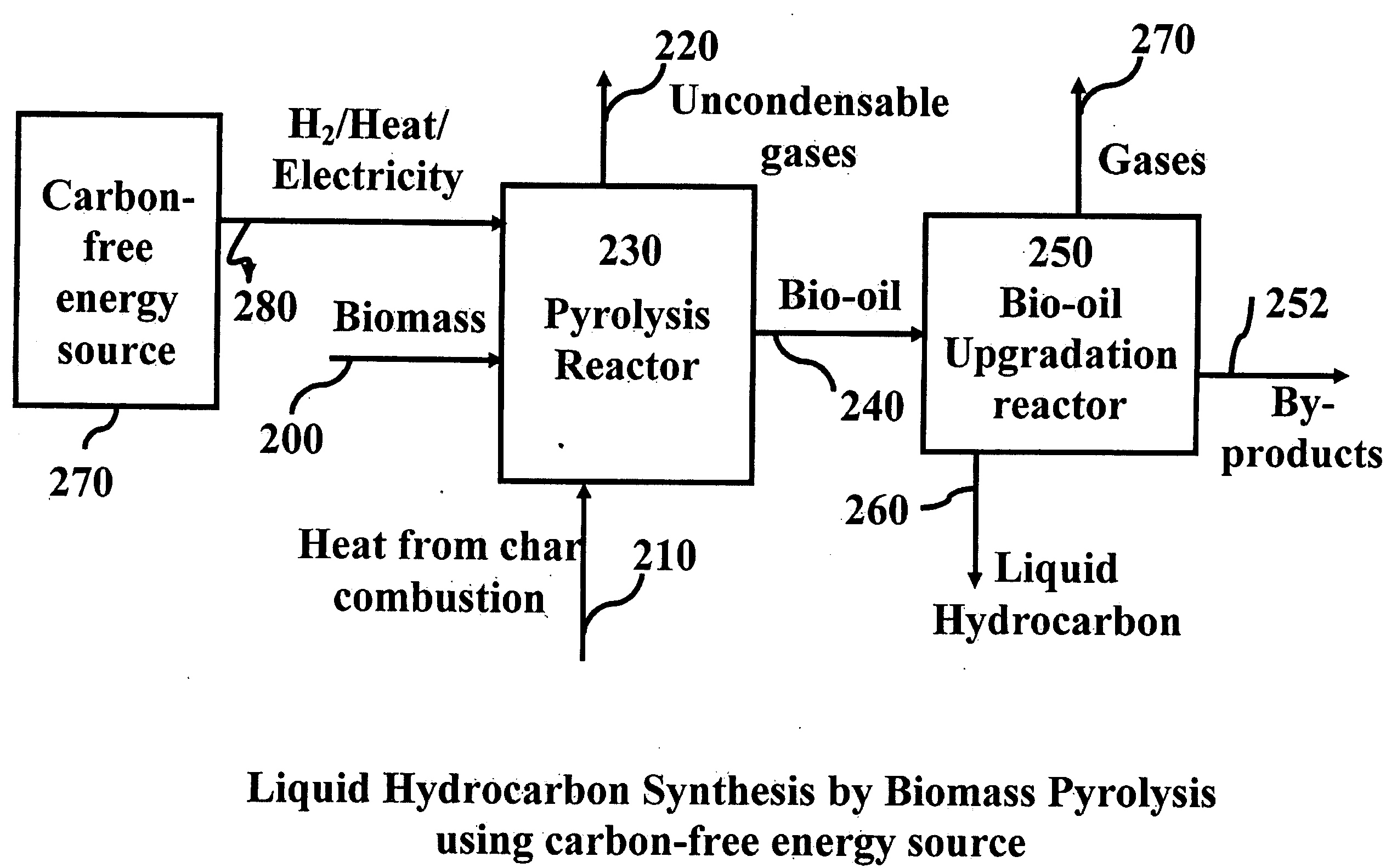

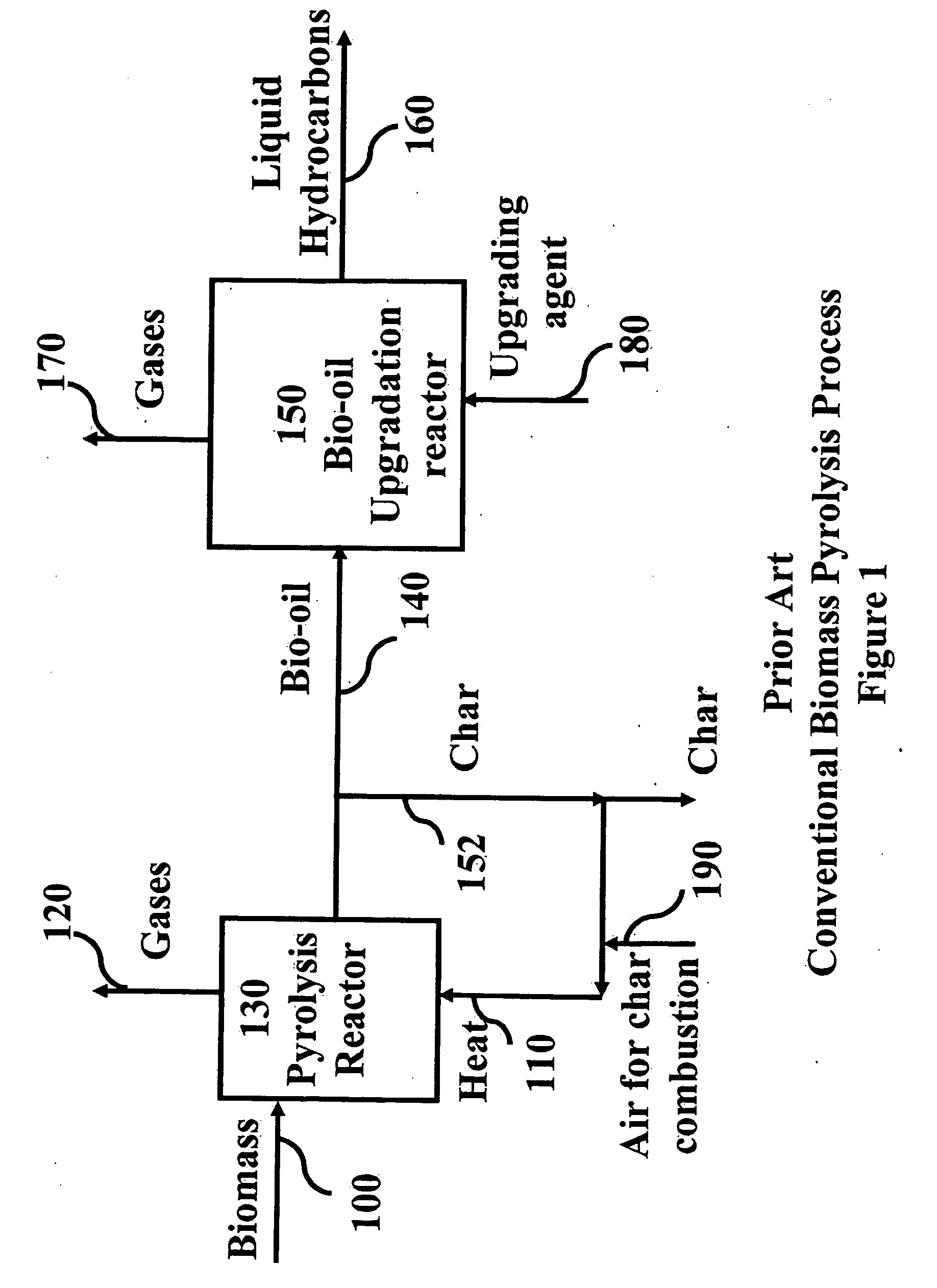

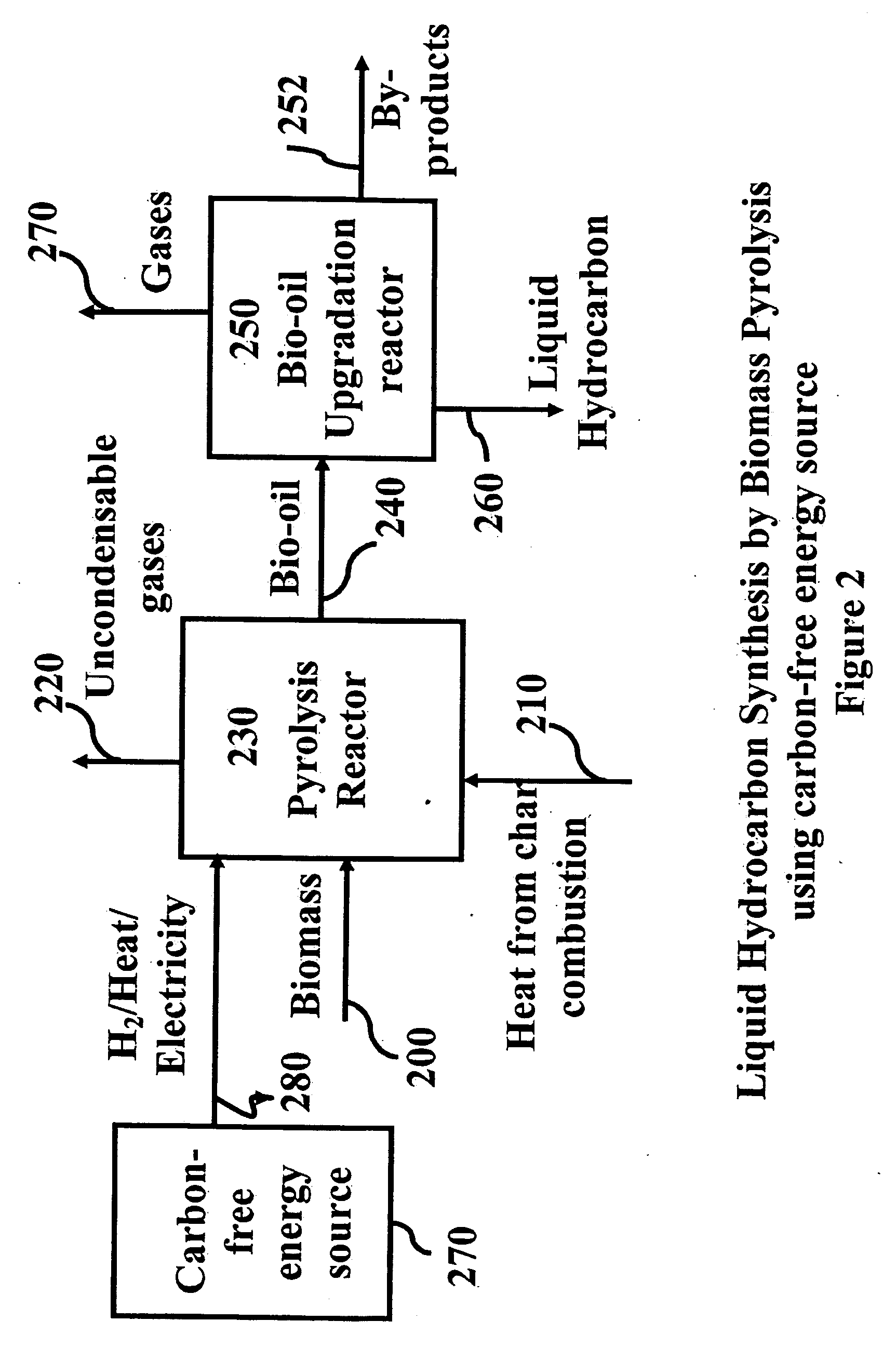

Novel process for producing liquid hydrocarbon by pyrolysis of biomass in presence of hydrogen from a carbon-free energy source

ActiveUS20090082604A1Process stabilityIncrease energy contentBioreactor/fermenter combinationsBiological substance pretreatmentsAlkaneHydrogen

In at least one embodiment of the present invention, a method for producing liquid hydrocarbons from biomass is provided. The method comprises pyrolizing the biomass with hydrogen (H2) to form bio-oil. The bio-oil comprises alkanes, alkenes, alcohols, aldehydes, ketones, aromatics, hydrocarbons or mixtures thereof. The H2 is formed from a carbon-free energy source.

Owner:PURDUE RES FOUND INC

System and method for atmospheric carbon sequestration

ActiveUS20100257775A1Increase carbon emissionsLiquid surface applicatorsSolid waste disposalCarbon sequestrationCoal

This invention relates to systems and methods for converting biomass into highly inert carbon. Specifically, some embodiments densify the carbon into anthracite-style carbon aggregations and store it in geologically stable underground deposits. The use of certain embodiments yield a net effect of removing atmospheric carbon via the process of photosynthesis and converting it into hard coal, which can be stored in underground beds that mimic existing coal deposits which are known to be stable for thousands of years.

Owner:COOL PLANET ENERGY SYST

System and method for biomass fractioning

ActiveUS20100180805A1Easy inputIncrease productionDrying solid materials with heatBiofuelsSyngasThin sheet

A biomass fractionator and method are described for inputting ground biomass and outputting several vapor streams of bio-intermediate compounds along with syngas and biochar. In one embodiment, a method for biomass fractioning, comprises dispensing biomass into thin sheets of ground biomass; subjecting the thin sheets to ramps of temperature; and selectively collecting various groups of compounds as they are released from the thin sheets.

Owner:COOL PLANET ENERGY SYST

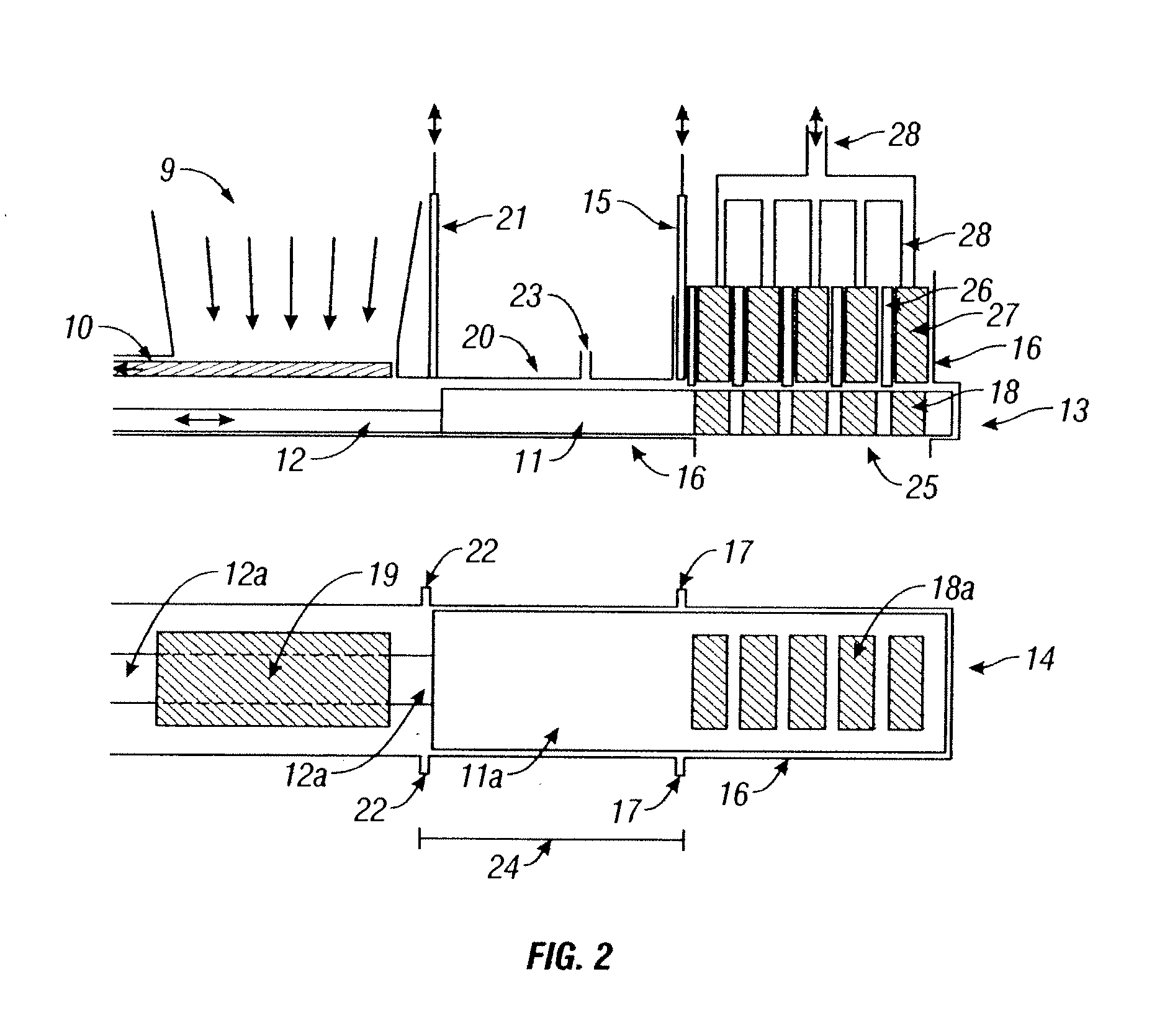

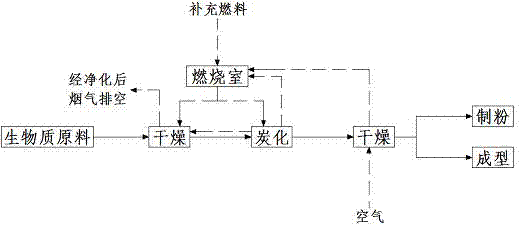

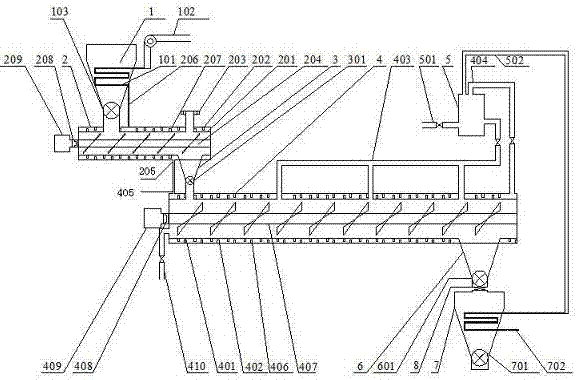

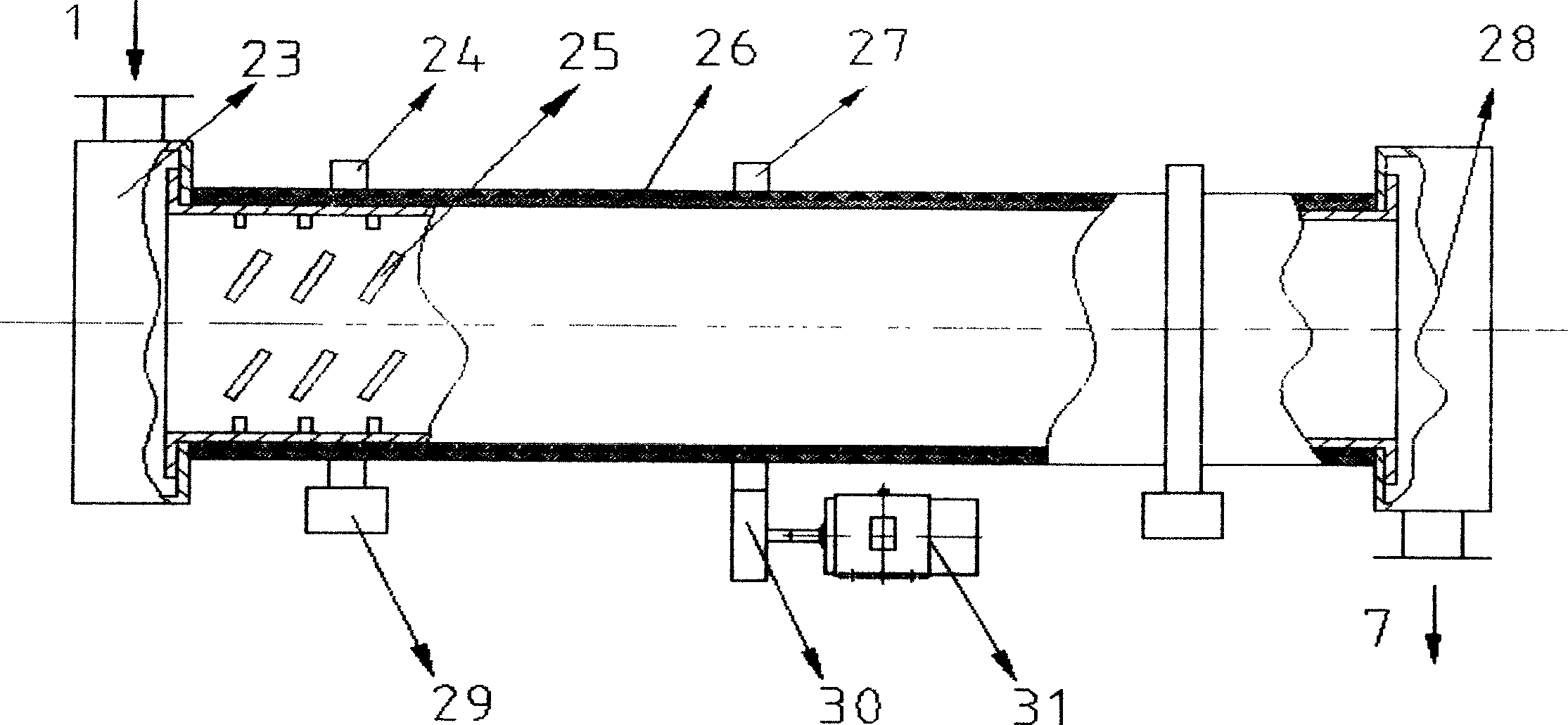

Continuous biomass low-temperature pyrolytic charring method and charring furnace thereof

InactiveCN102226092ARealize continuous carbonization productionImprove raw material adaptabilityDirect heating destructive distillationBiofuelsCombustion chamberRetention time

The invention discloses a continuous biomass low-temperature pyrolytic charring method and a charring furnace thereof, belonging to the fields of biomass charring and biomass energy source utilization. The furnace body of the charring furnace adopts a screw propelling feed mode, and the power is derived from the drive of a motor; an external heating cylinder is sheathed outside an internal heating cylinder of the furnace body, the internal cylinder and the external cylinder are spaced, and the internal flue inside the sleeve has a labyrinth path to ensure heat supply from hot flue gas to pyrolytic reaction to uniformly heat a biomass raw material; and during charring, the generated flue gas supplies heat to a reaction cylinder after combustion in a combustion chamber, and the hot flue gas enters a heat exchanger device to dry the raw material after flowing through the sleeve. Through screw propelling, the method disclosed by the invention realizes continuous low-temperature pyrolytic charring reaction, and realizes accuracy control of the retention time of the biomass inside the charring furnace; and the furnace body adopts a sleeve structure, which fully utilizes the afterheat of the charring flue gas, and the reaction cylinder adopts interior heating and outer wall heating together, which enhances the uniformity characteristic of the temperature inside the reaction cylinder and prolongs the service life of an auger shaft.

Owner:NANJING NORMAL UNIVERSITY

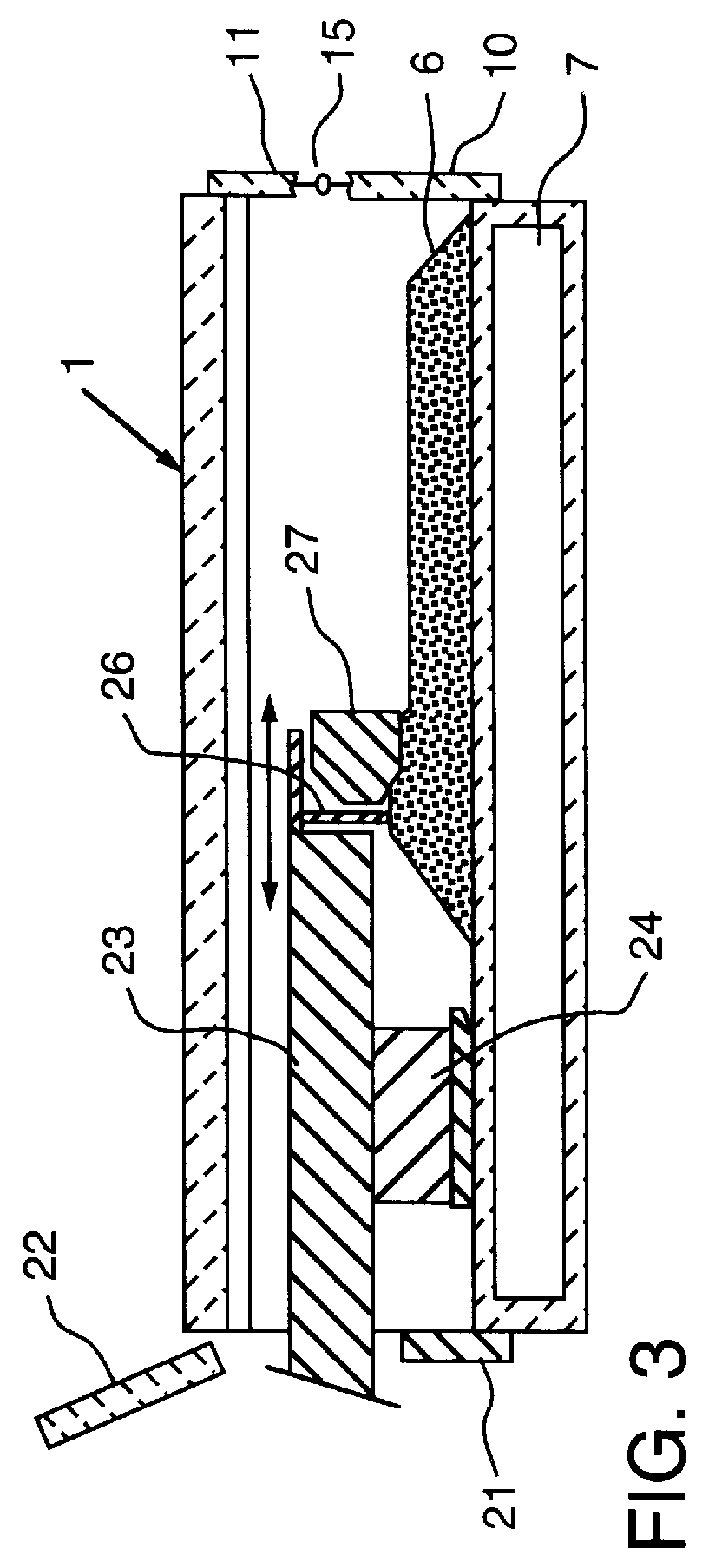

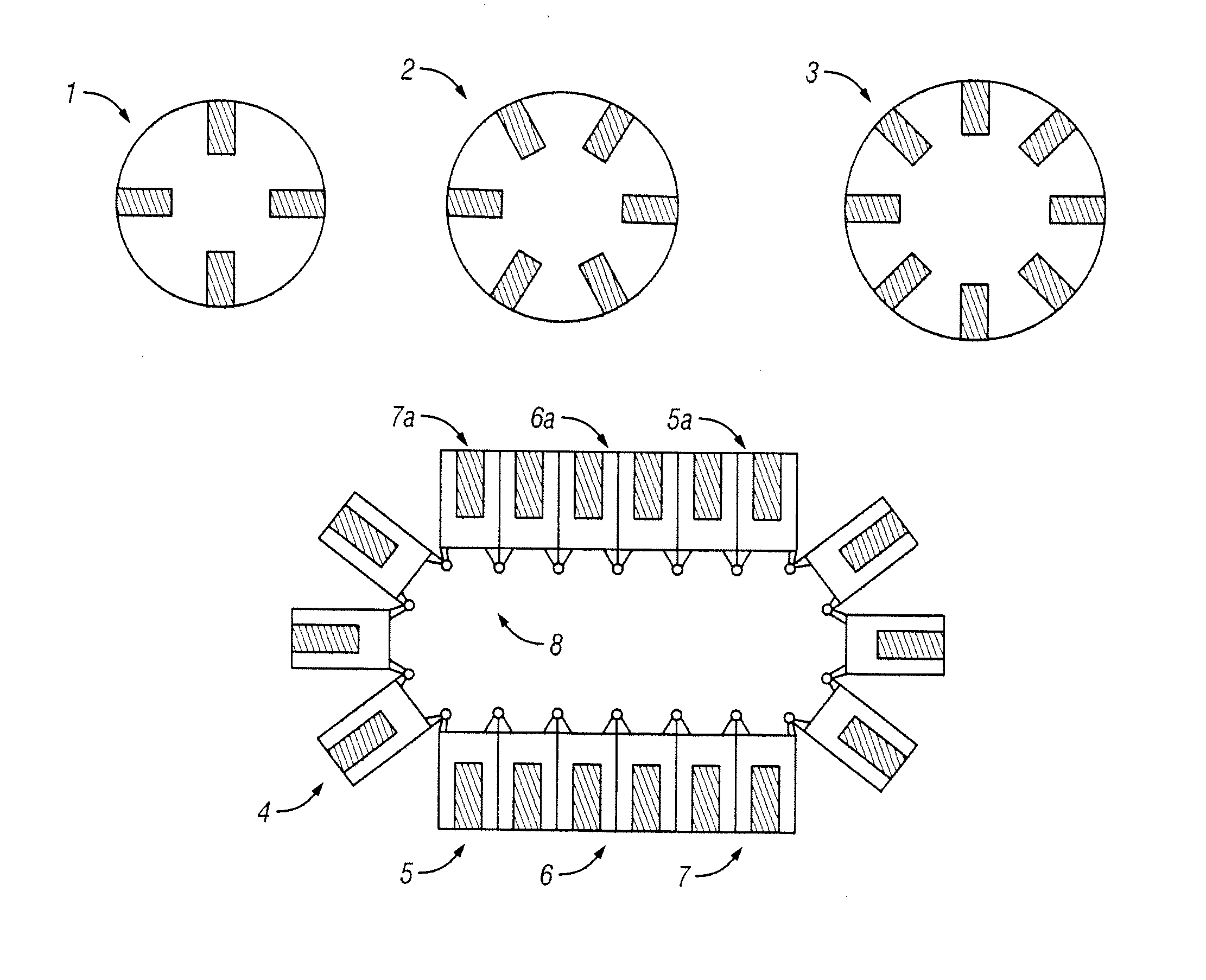

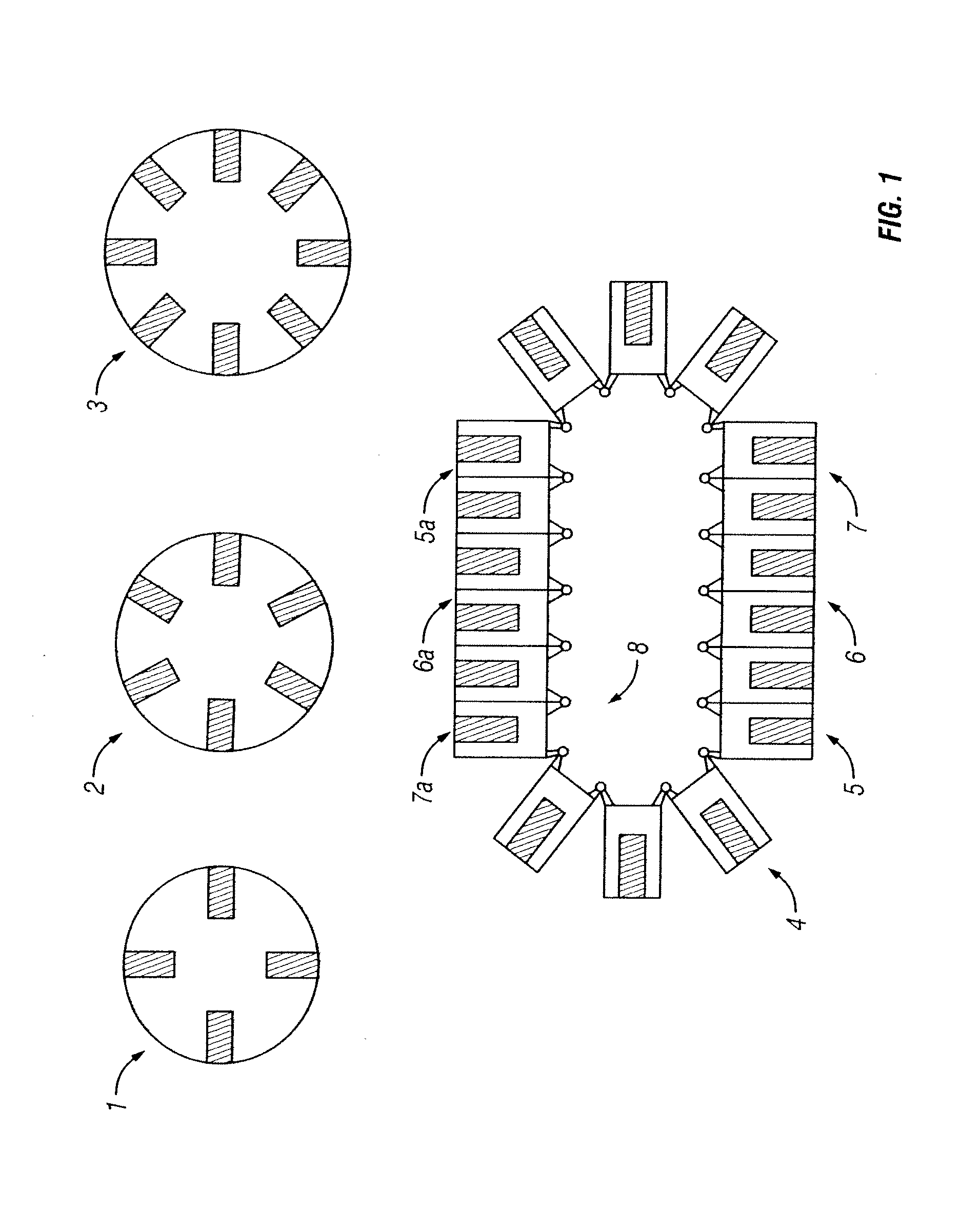

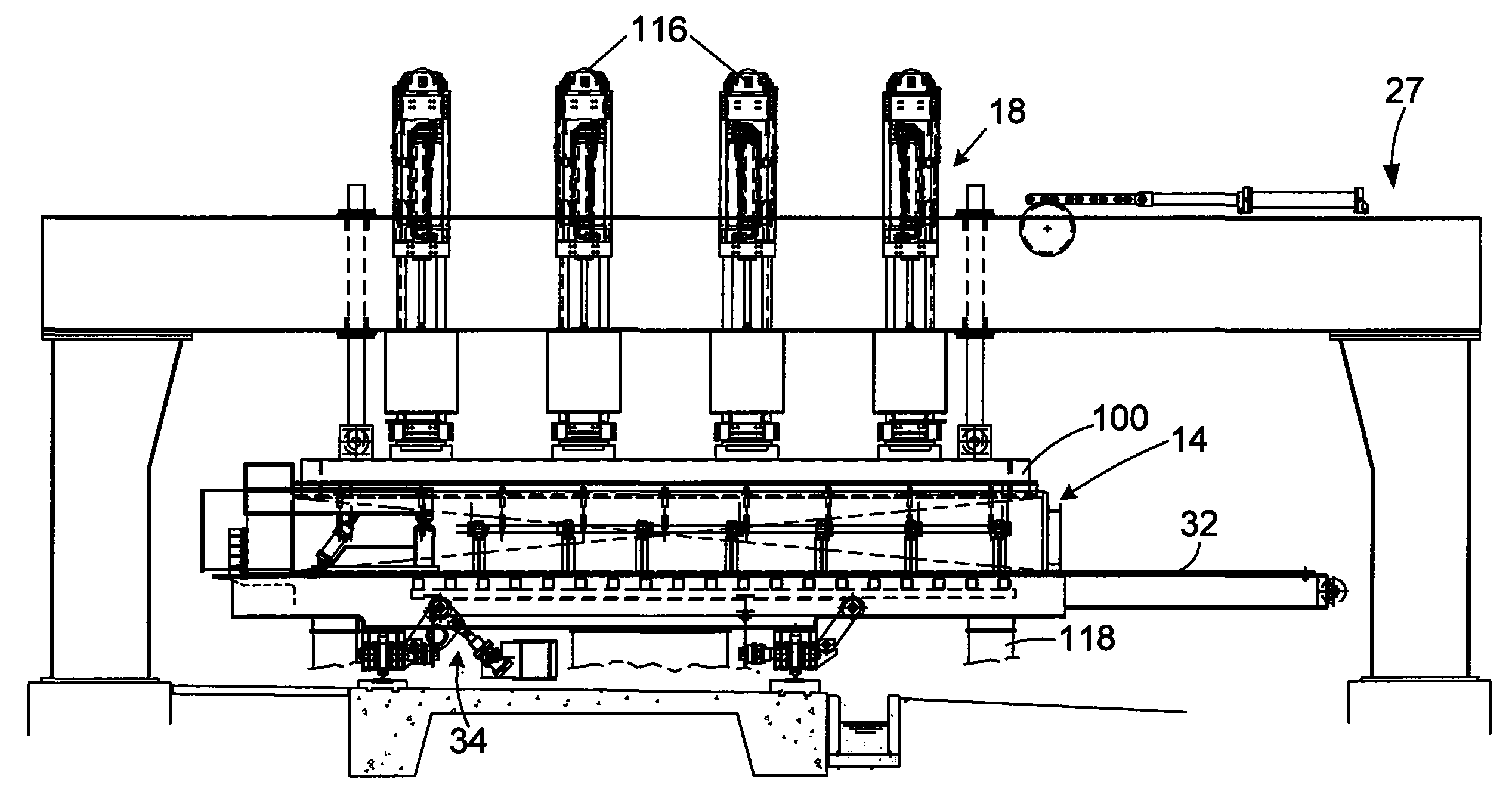

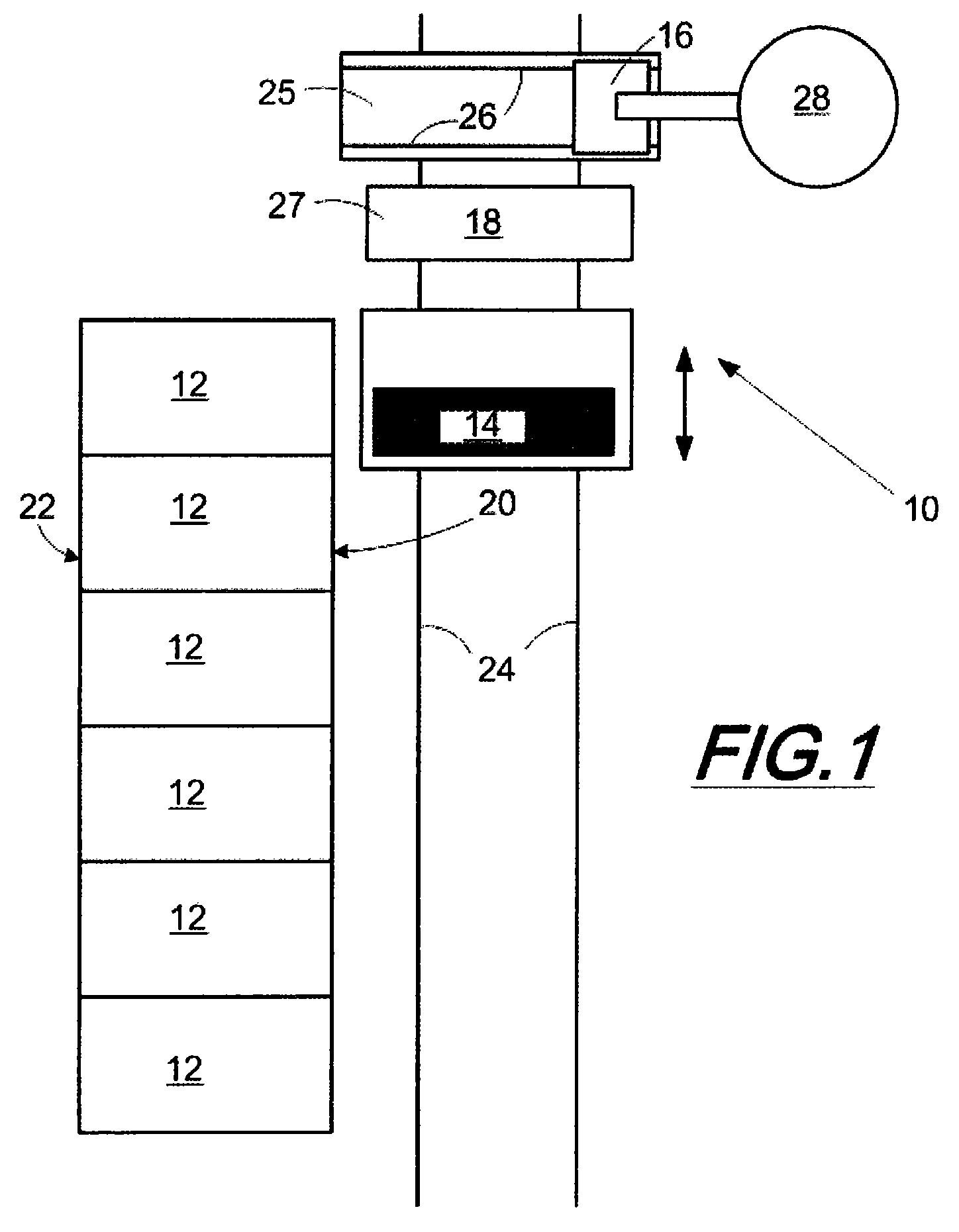

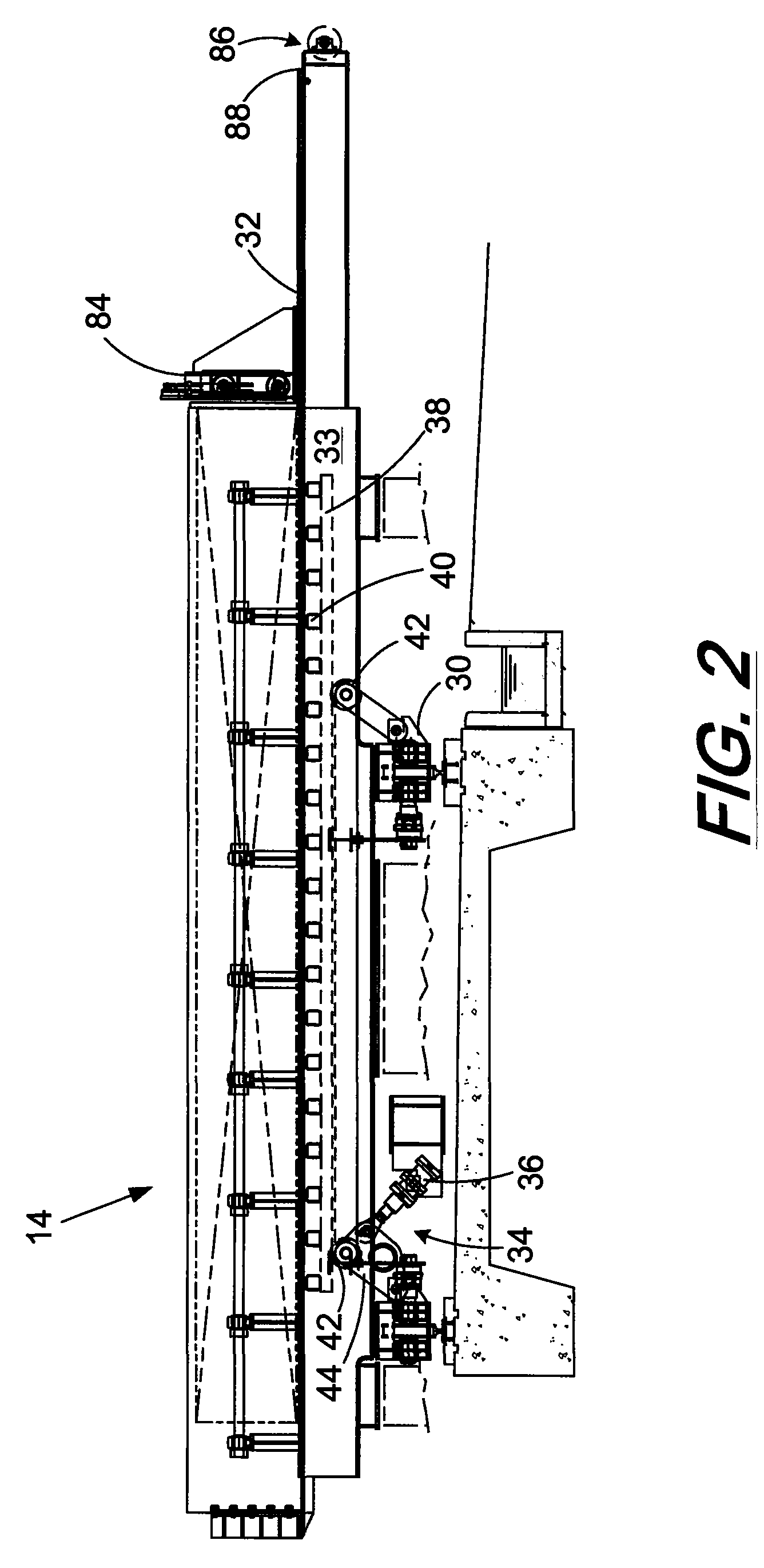

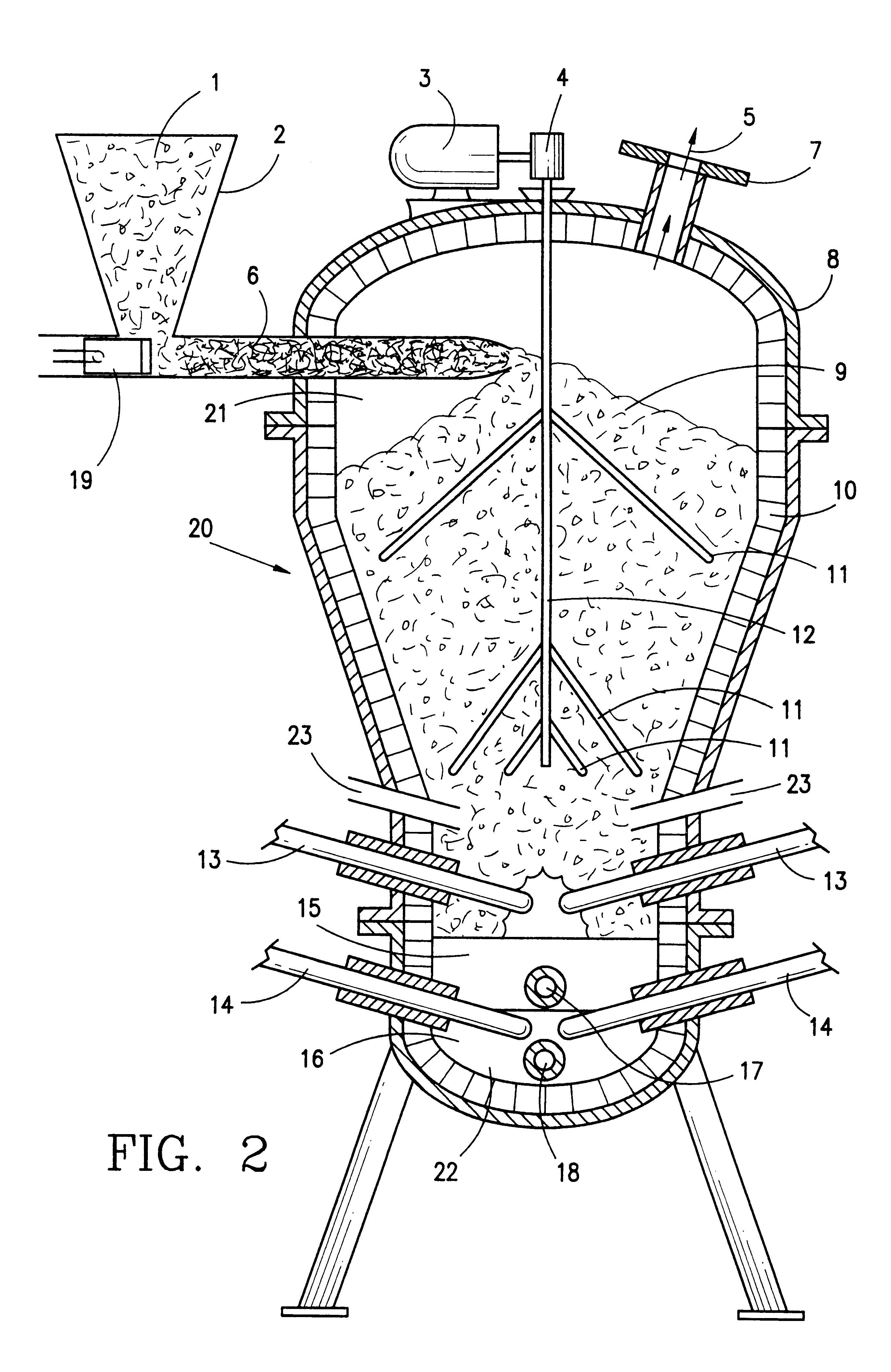

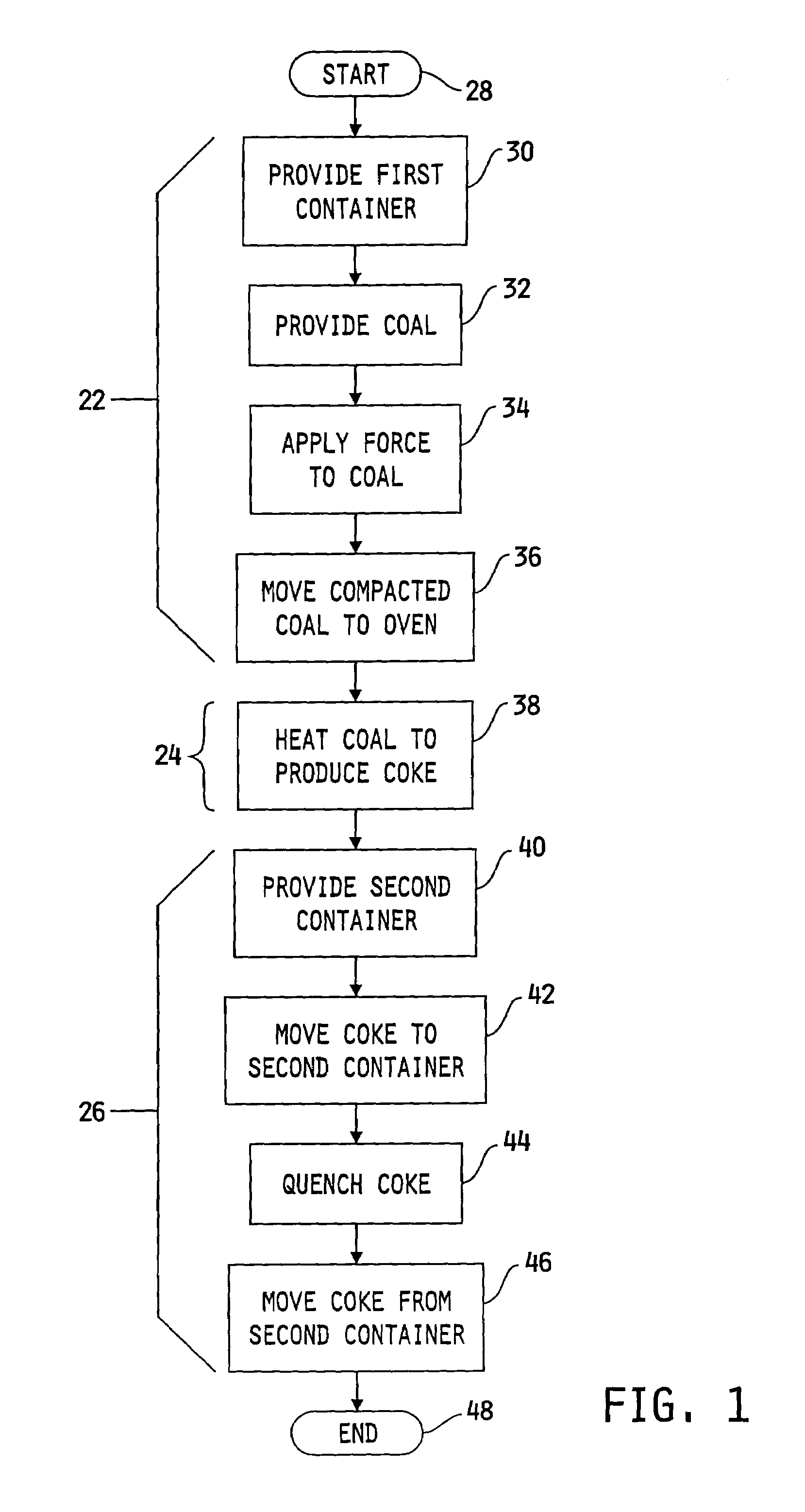

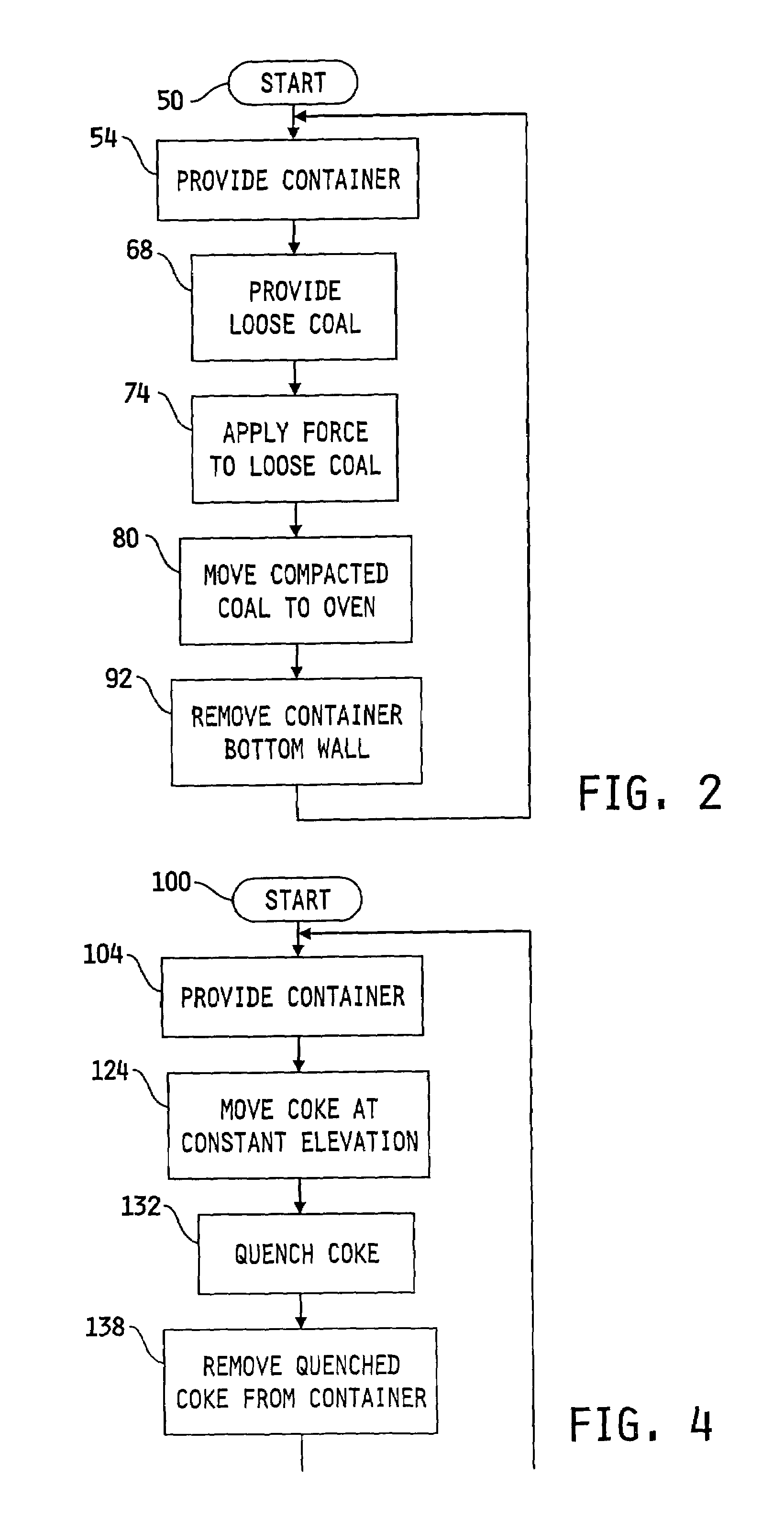

Method and apparatus for compacting coal for a coal coking process

InactiveUS7497930B2Minimize amount of timeUniform bulk densityCoke quenchingCharging-discharging device combinationsEngineeringCoke oven

Relatively high speed methods for increasing the bulk density of coal particles, apparatus for increasing the bulk density of coal particles and methods for making metallurgical coke. Once such method includes depositing coal particles onto a charging plate external to a coking oven to provide an elongate bed of dry, uncompacted coal having an upper surface of the charging plate. The charging plate has side walls, and at least one movable end wall An impact pressure is applied to the upper surface of the bed of dry, uncompacted coal while degassing the coal to provide a dry, compacted coal bed having a bulk density ranging from about 960 to about 1200 kilograms per cubic meter.

Owner:SUNCOKE TECH & DEV LLC

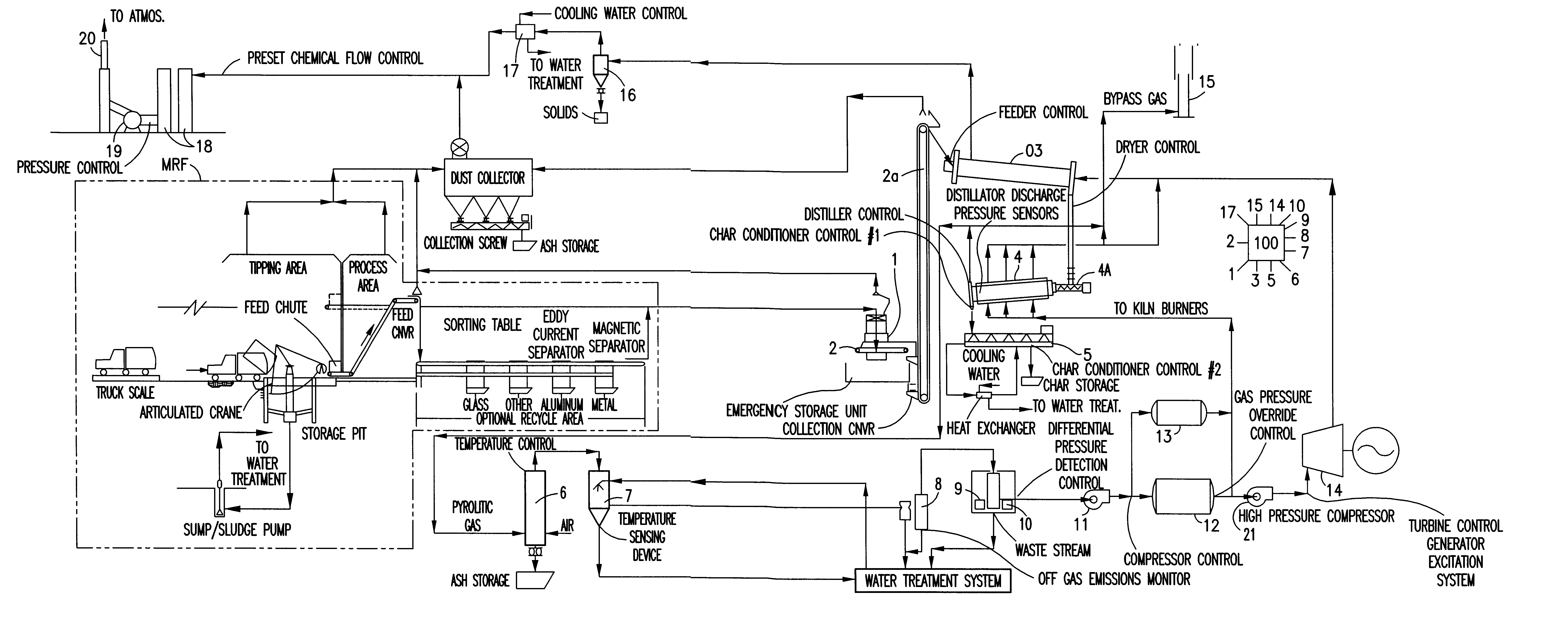

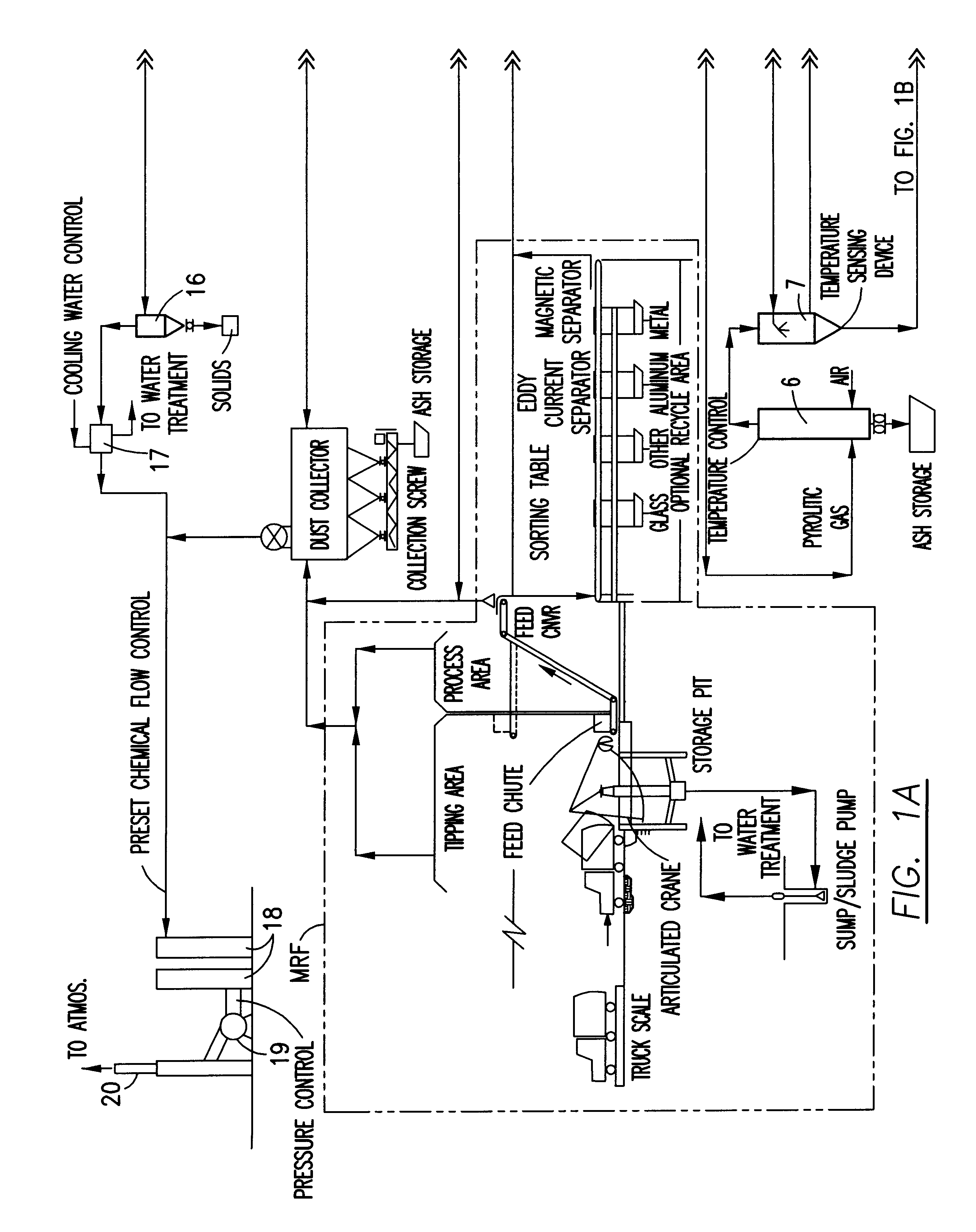

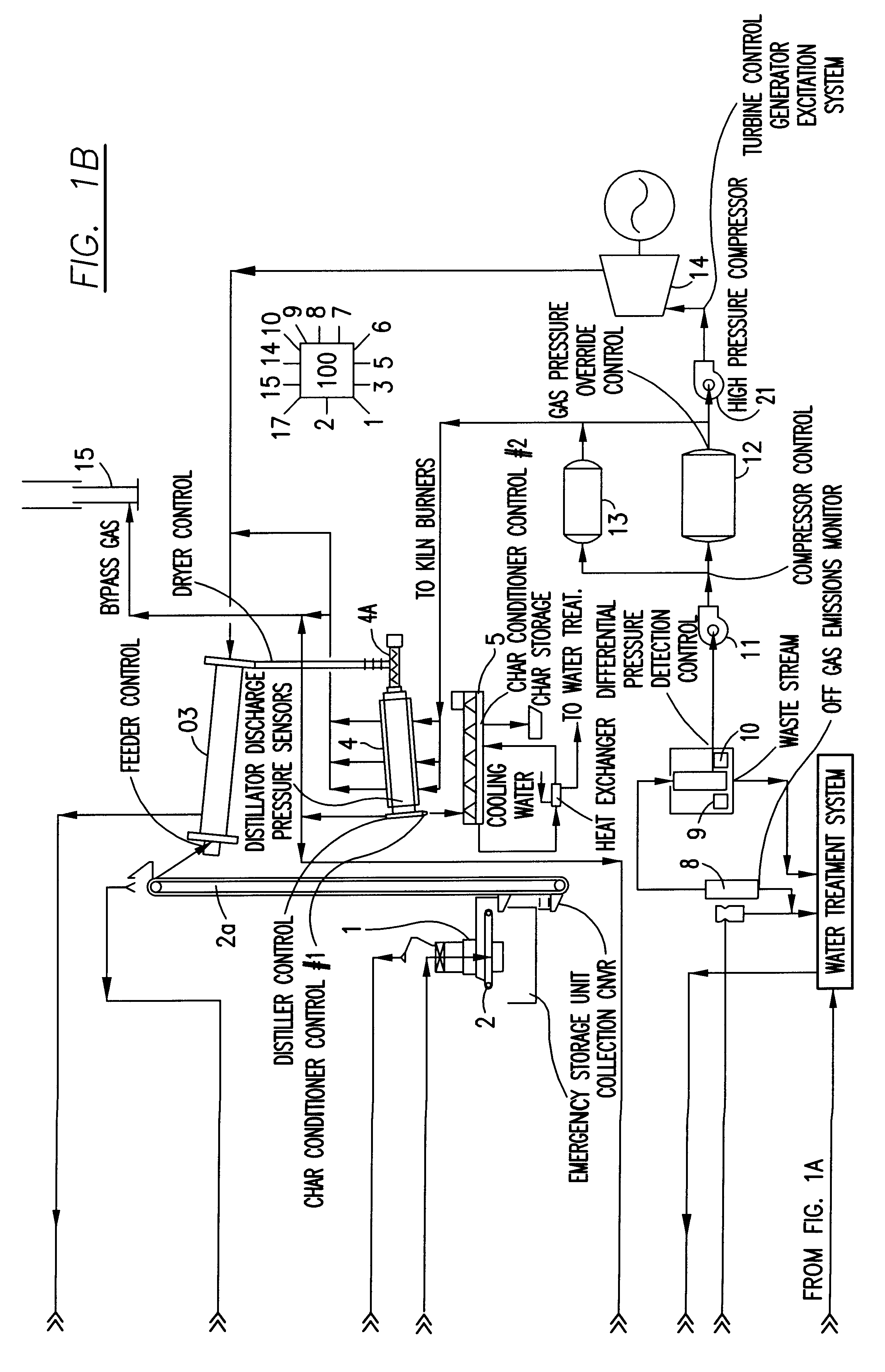

Integrated control and destructive distillation of carbonaceous waste

InactiveUS6182584B1High quantity and qualityEnhanced yield quantity and qualityHorizontal chamber coke ovensEmission preventionComputer control systemWaste stream

A system and process to provide integrated control for the pyrolytic composition of organic (biomass) waste products especially for municipal solid waste systems. The system includes integrated control that monitors biomass waste stream throughout the entire system and the products produced therefrom and includes presorting, controlling the amount of material processed in a continuous manner, shredding, removing moisture in a continuous process that is controlled and providing the waste stream to the distillation unit for pyrolytic action where it is converted into gaseous fuel and a char residue. The gaseous fuel is scrubbed clean and monitored and stored and reused to provide heat to the system. The entire system may be self-sustaining and continuous with very little or no human intervention. An integrated real time computer control system includes sensors and measuring devices with all the major components to ensure integrated efficiency.

Owner:ENVIRONMENTAL SOLUTIONS & TECH

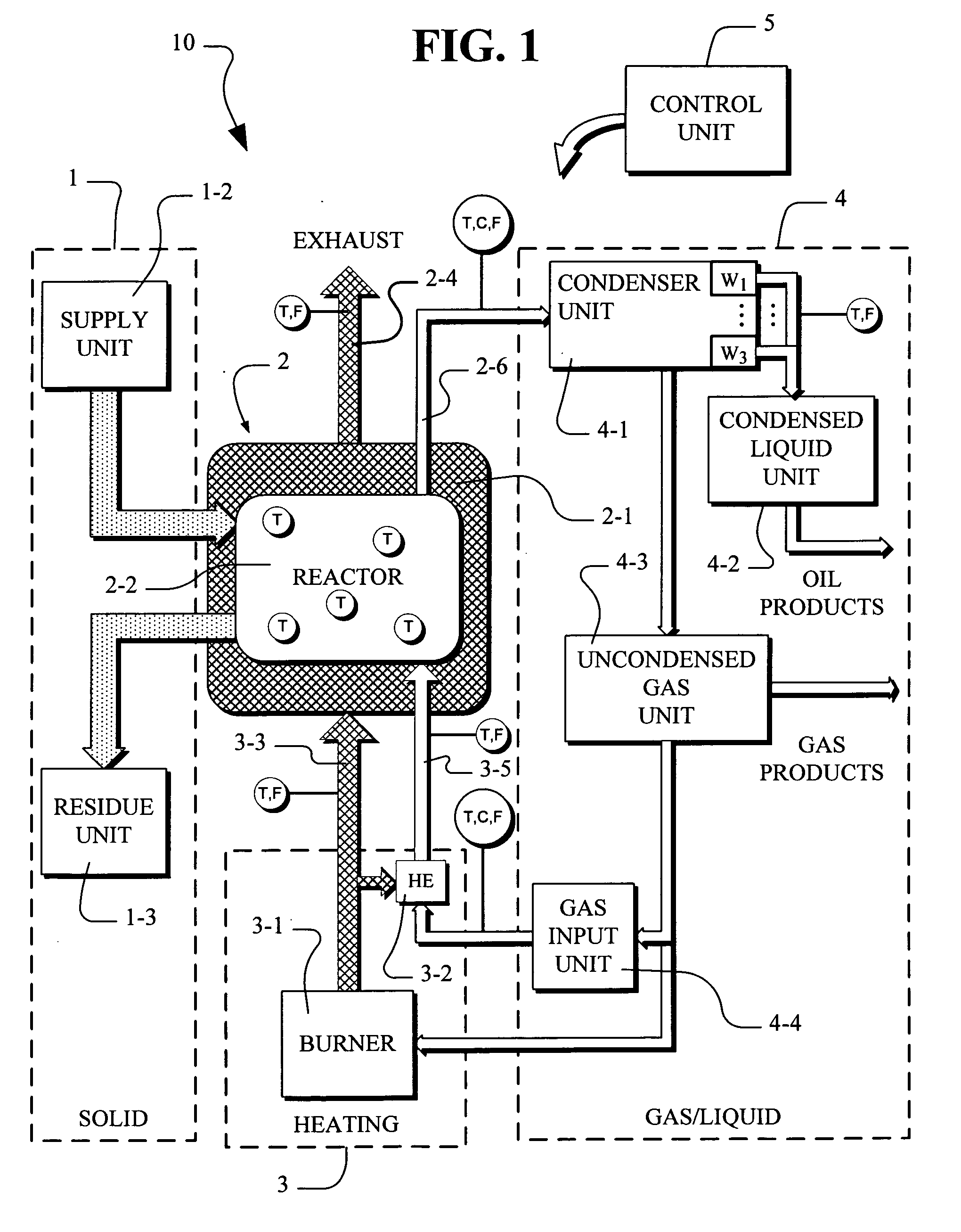

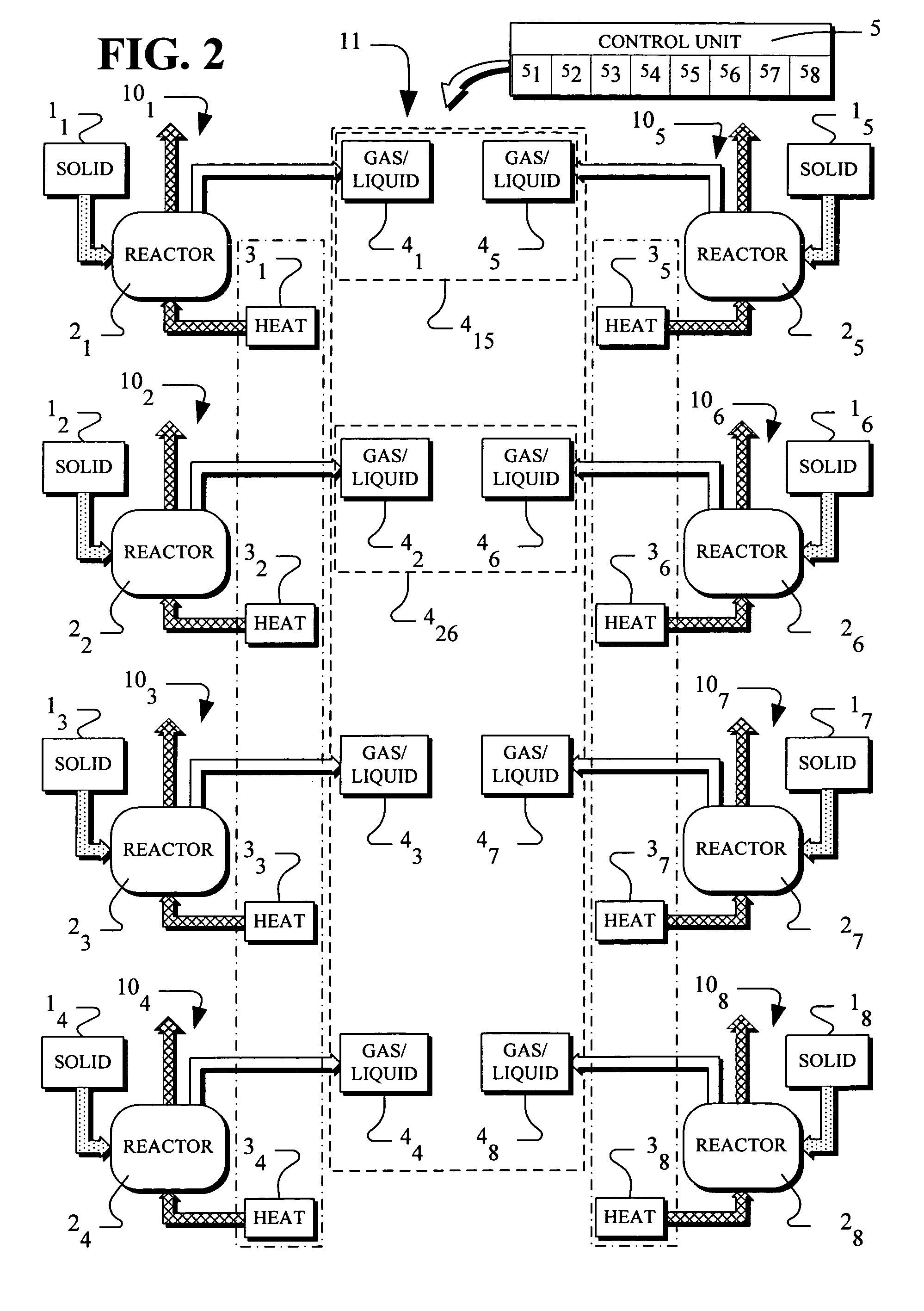

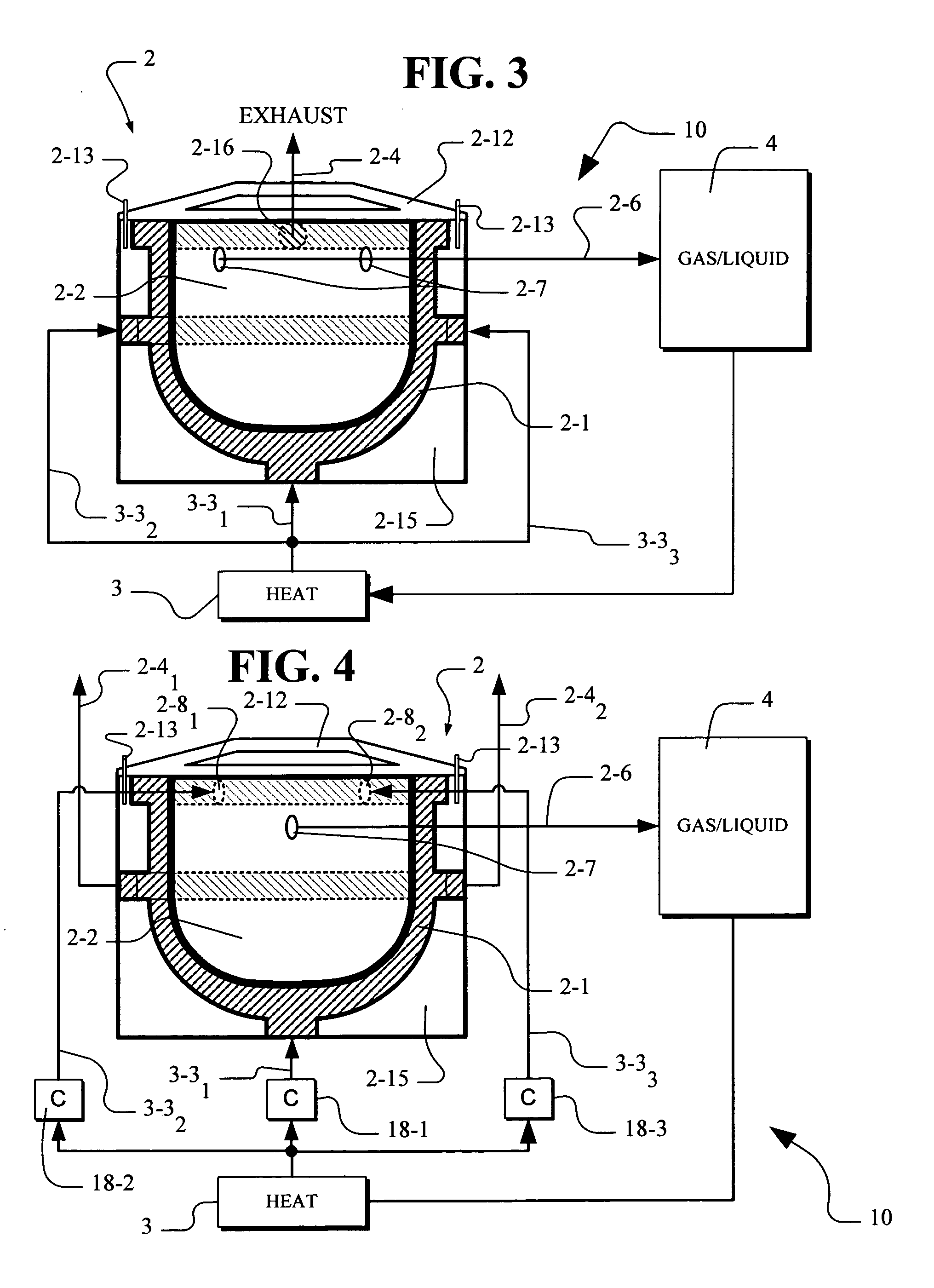

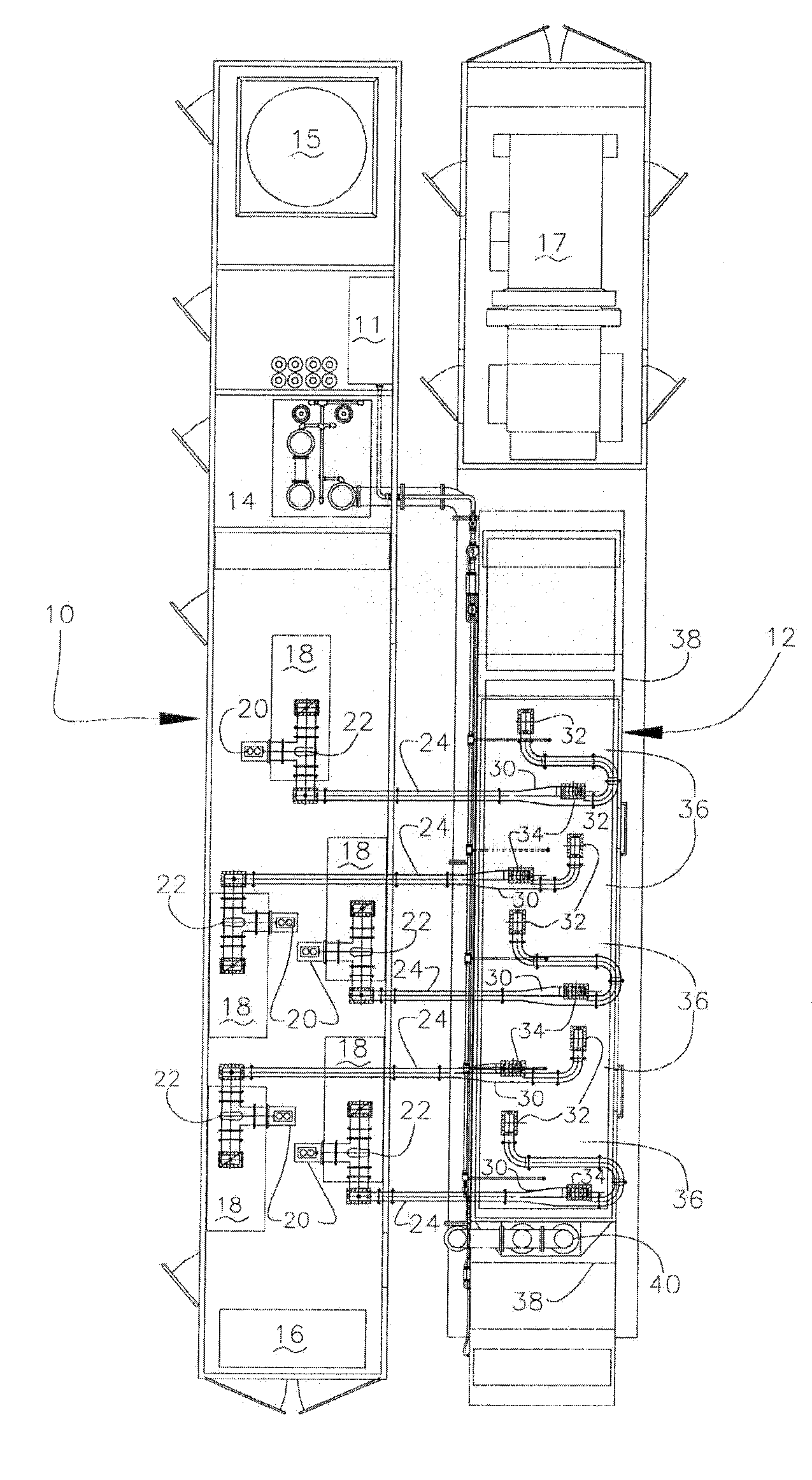

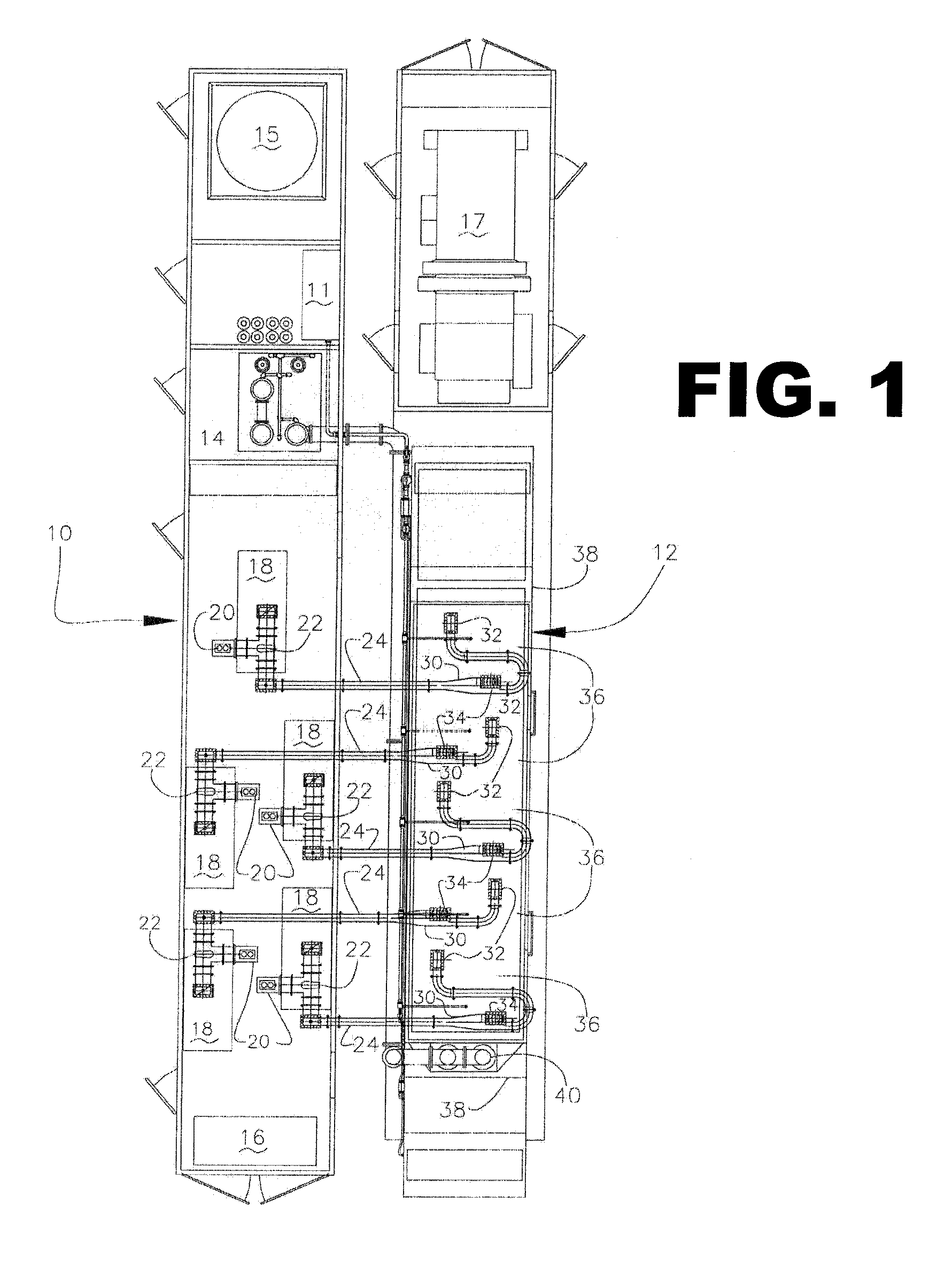

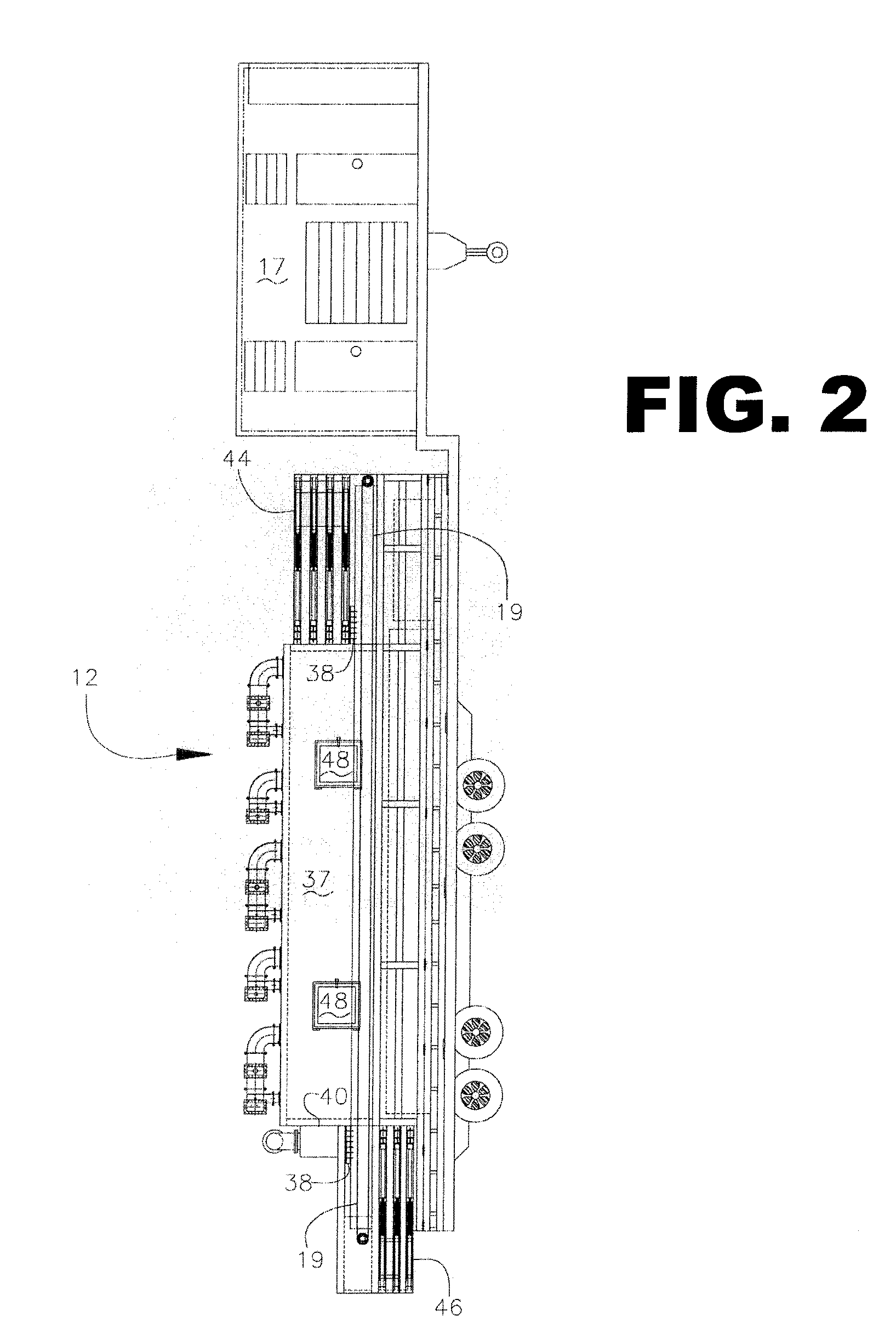

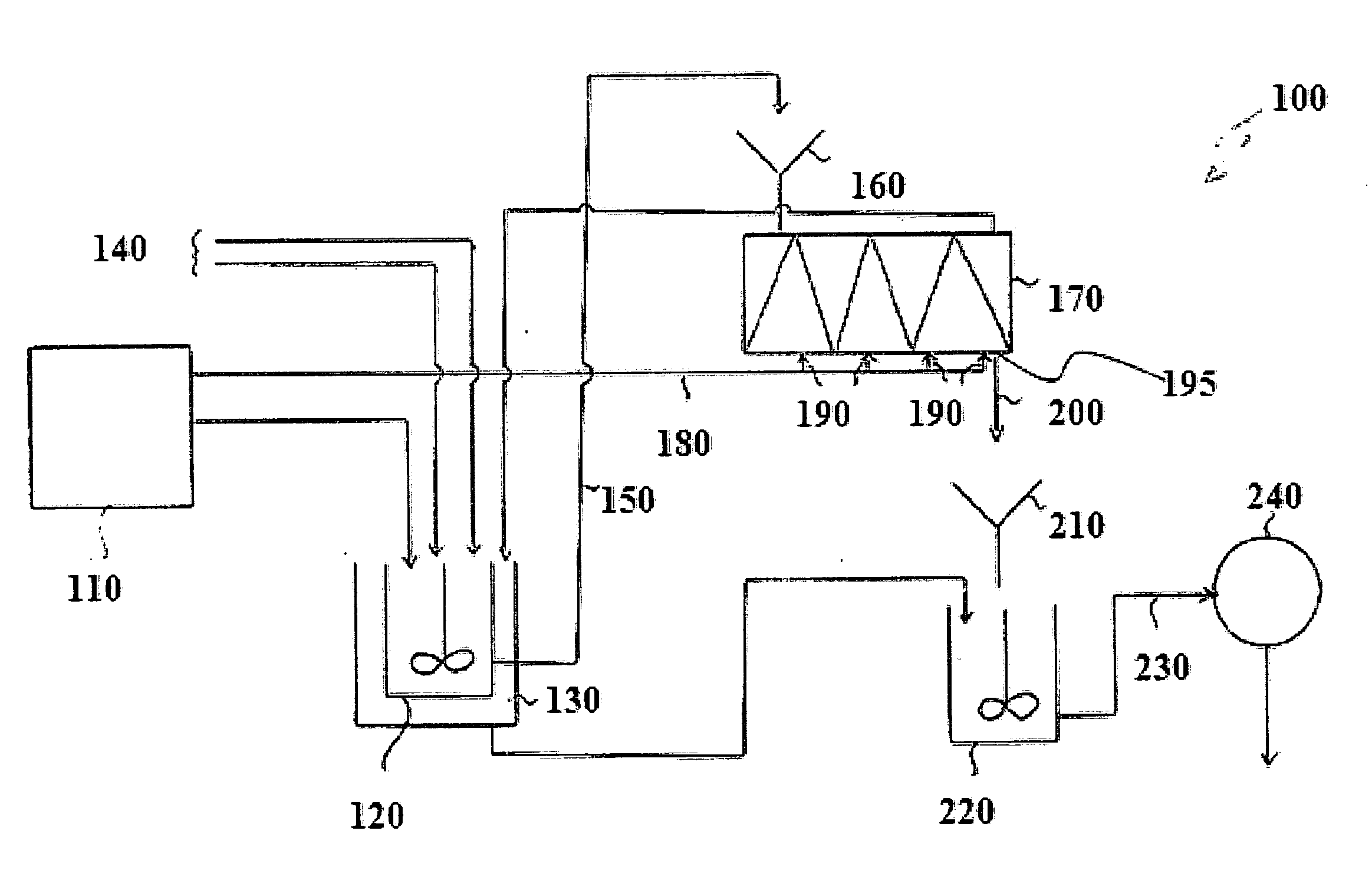

Batch pyrolysis system

InactiveUS20060163053A1Quality improvementImprove throughputProductsBeehive ovensBatch processingProcess engineering

Disclosed is a scaleable pyrolysis system for batch processing of waste vehicle tires and other waste to provide pyrolysis products. The core pyrolysis system includes one or more batch reactors, heating units, solids processing units, gas / liquid processing units and control units. In operation, the temperature gradients internal to the reactor are controlled by preferential channeling of heat to provide pyrolysis products that are of high quality, and hence commercially advantageous, while facilitating high throughput.

Owner:ERSHAG BENGT STURE

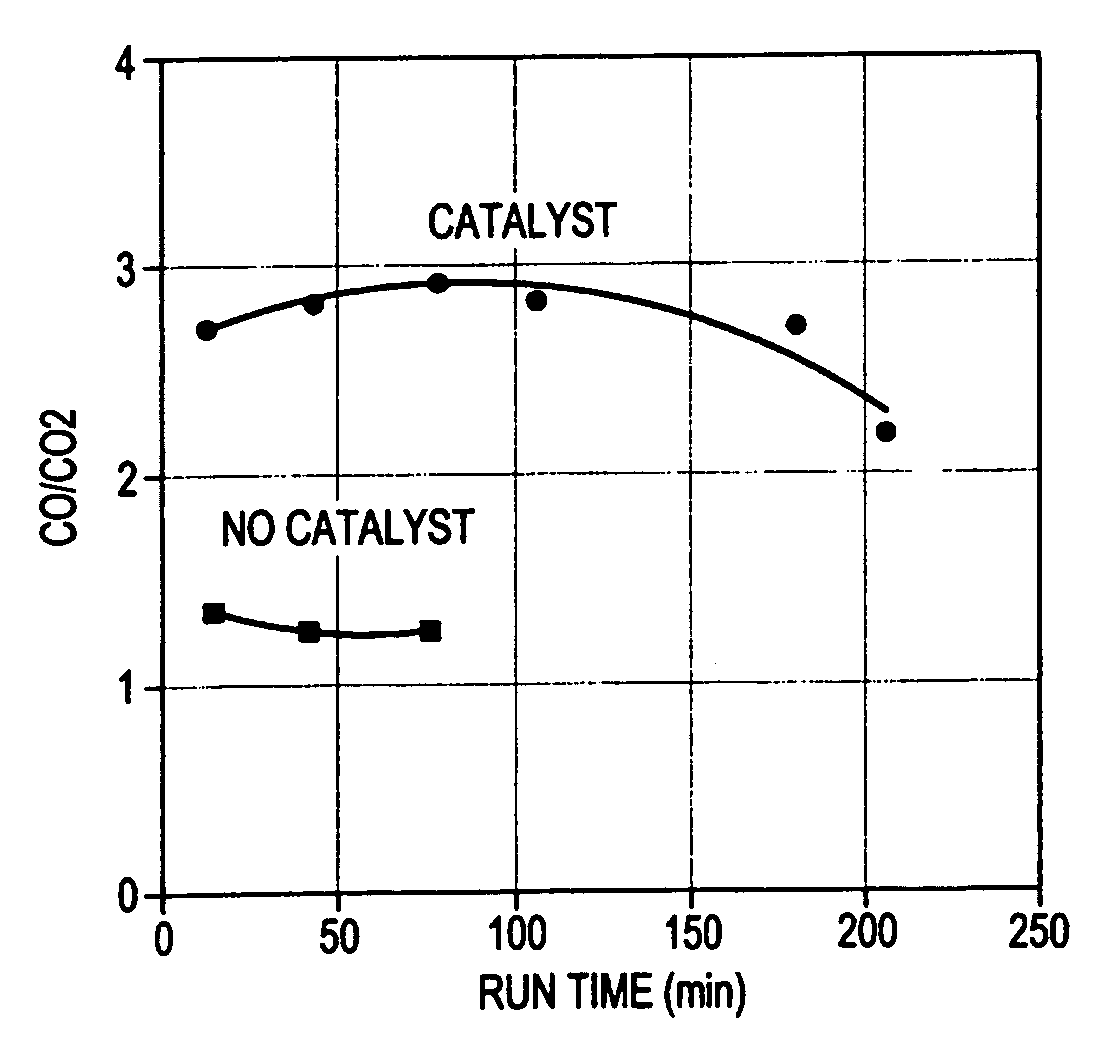

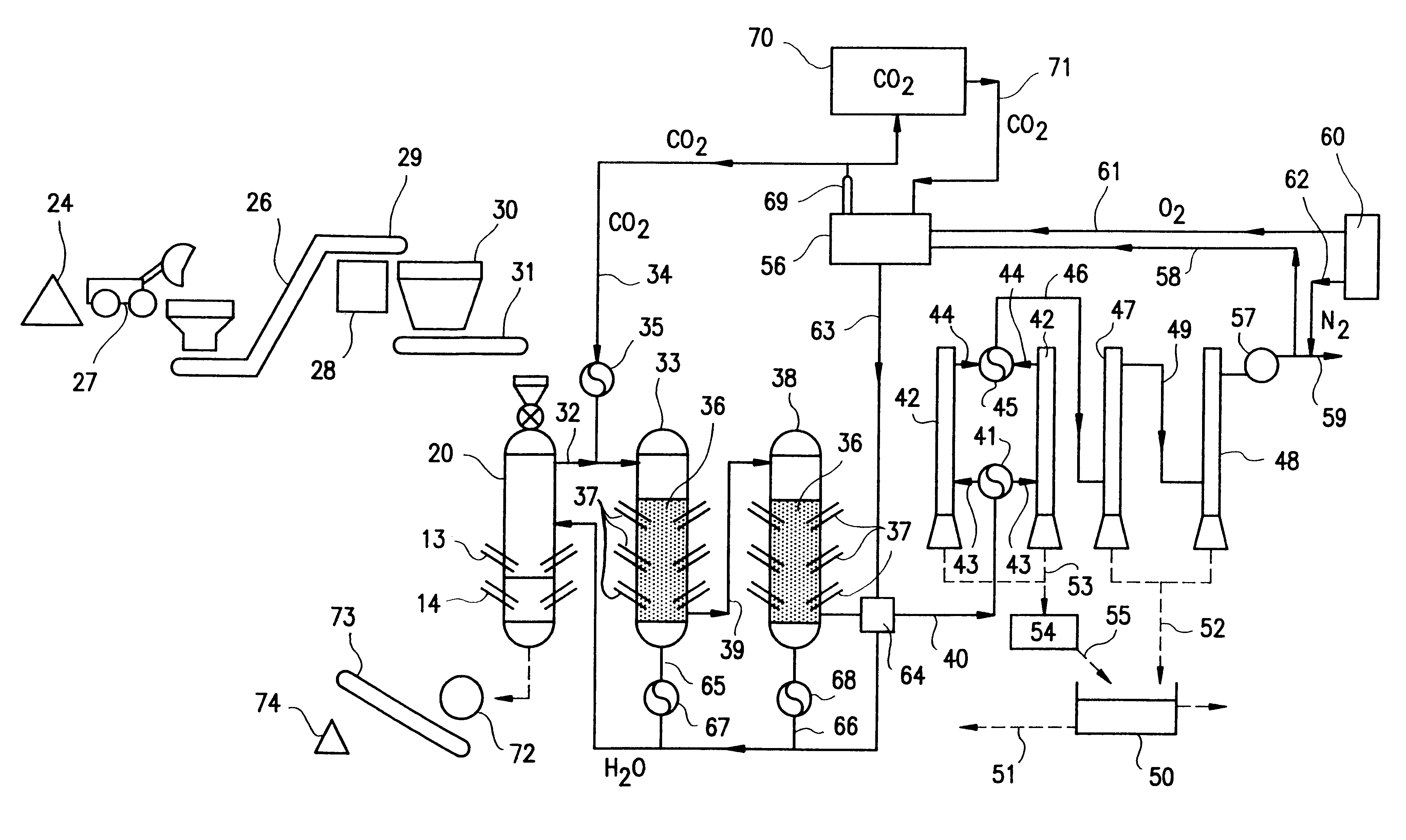

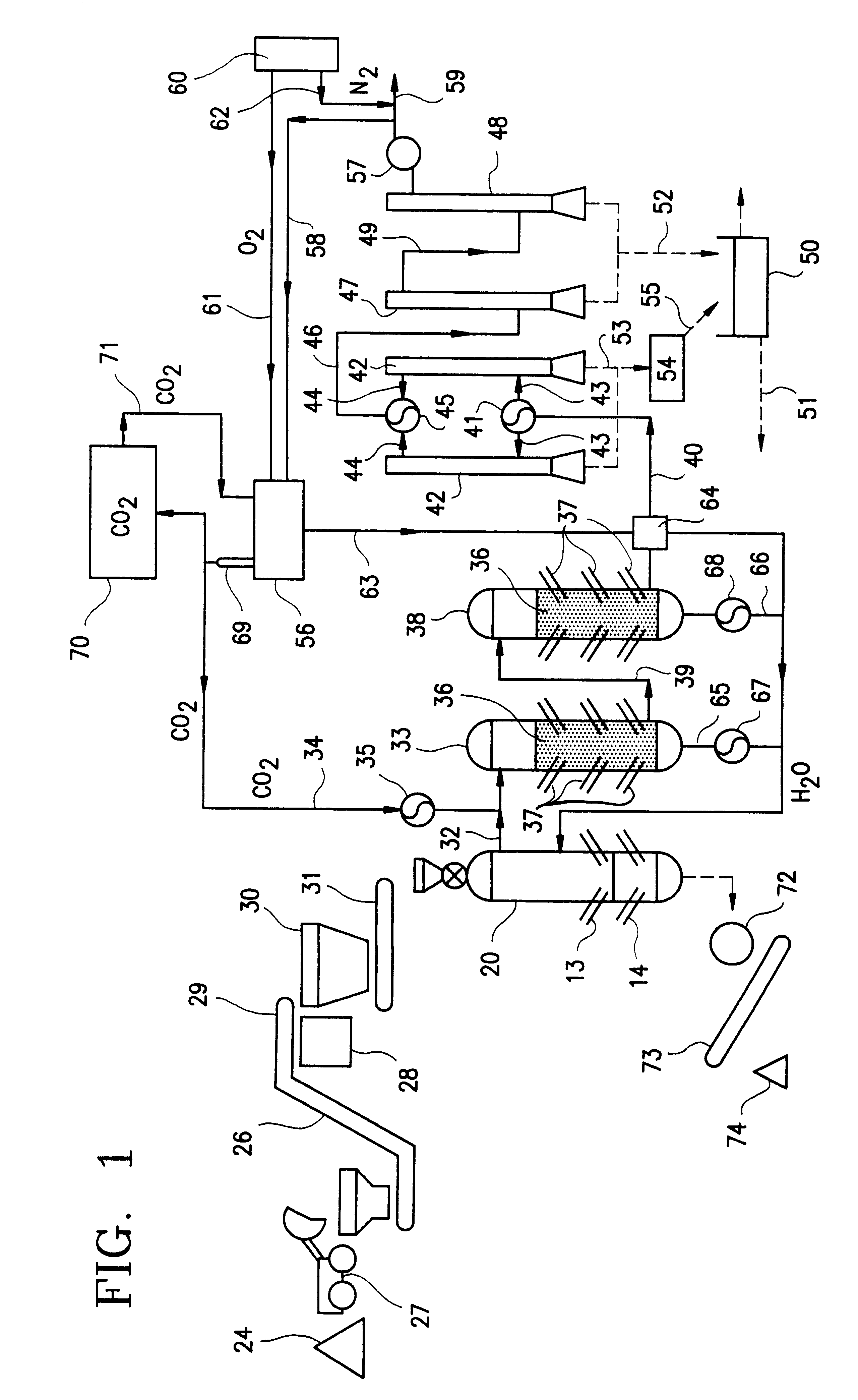

Synthesis gas production and power generation with zero emissions

InactiveUS6333015B1Avoid water pollutionEliminate needElectrical coke oven heatingGasifier electrodesClosed loopProduct gas

A process and apparatus for producing and burning synthesis gas. Carbonaceous waste material is pyrolytically decomposed in a primary reactor in the presence of steam to produce raw product gas containing H2 and CO. The raw product gas and CO2 is then introduced into a coke containing secondary reactor under pyrolyzing conditions, so that the CO2 and coke react to produce combustible gas having an increased CO content. The combustible gas is mixed with oxygen and CO2 to produce a combustible mixture which is burned as a fuel to produce heat, CO2 and H2O. A portion of the produced CO2 is recovered and used as the source of CO2 gas in the combustible mixture and as a source of CO2 gas for the secondary reactor. Preferably filters and scrubbers are used in a closed loop system to avoid undesirable emissions into the environment.

Owner:LEWIS GLORIA B

Method and Apparatus for Microwave Reduction of Organic Compounds

InactiveUS20070102279A1Maximum protectionElectrical coke oven heatingSolid waste disposalEngineeringVolumetric Mass Density

The invention described herein generally pertains to utilization of high power density microwave energy to reduce organic compounds to carbon and their constituents, primarily in a gaseous state. The process includes, but is not limited to, scrap tires, plastics, asphalt roofing shingles, computer waste, medical waste, municipal solid waste, construction waste, shale oil, and PCB / PAH / HCB-laden materials. The process includes the steps of feeding organic material into a microwave applicator and exposing the material to microwave energy fed from at least two linear polarized sources in non-parallel alignment to each other, and collecting the material. The at least two sources of microwave energy are from a bifurcated waveguide assembly, whose outputs are perpendicular to each other and fed through waveguide of proper impedance, such that the microwave sources are physically and electrically 90° out of phase to each other. The microwave frequency is between 894 and 1000 MHz, preferably approximately 915 MHz.

Owner:NOVAK JUDITH

Low-tar biomass gasifying method and apparatus

InactiveCN1710023AWide adaptability of raw materialsSpecial form destructive distillationCarbon layerDecomposition

The invention discloses a kind of biomass gasifying method and device. The technology through separating the two courses of solid biomass pyrogenation and decomposition and gasification of the pyrogenation outcome, then transform the biomass into flammable gas of rather low tar content. Firstly send biomass into the pyrogenation reactor, without oxidant in; have pyrogenation reaction at 400 - 650 Deg. C, the pyrogenation outcome including pyrogenation gas and remaining charcoal gets into pyrogenation carburetor, and have incomplete oxidizing combustion reaction with sent oxidant, to form a high temperature of 900 - 1100 Deg. C. At the time, the heavy hydrocarbon substance of tar decomposes into small molecule gas, and the decomposed gas leaves out of the carburetor after having deoxidizing reaction with the nether blazing carbon layer. The high temperature gas is provided for consumers' use after depurated and cooled. The gas produced by the invention has very low tar content, which makes the following depurating equipment simple, won't produce second pollution and makes the raw materials widely used. The produced fuel gas can be used in civil filed and directly used for generating electricity.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

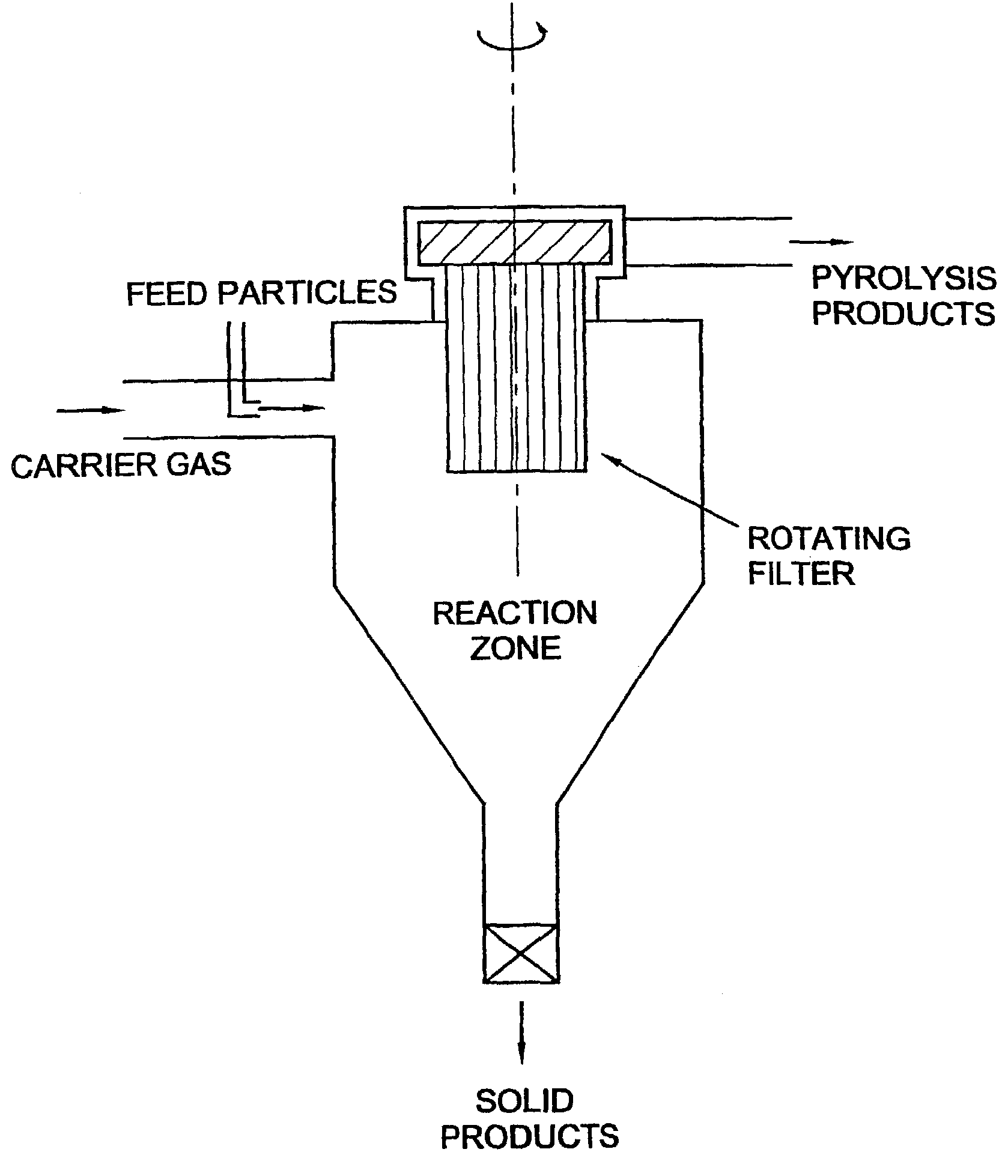

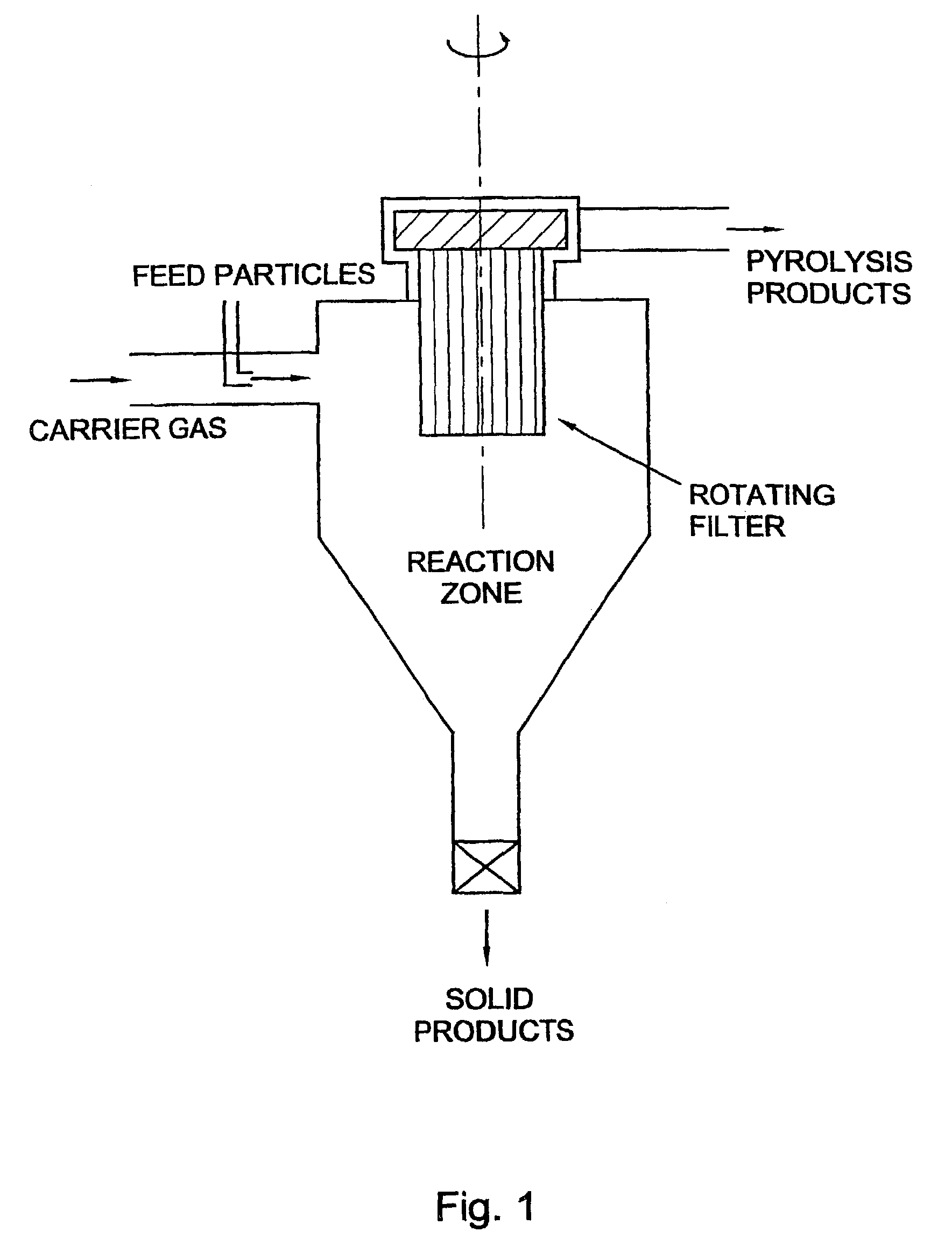

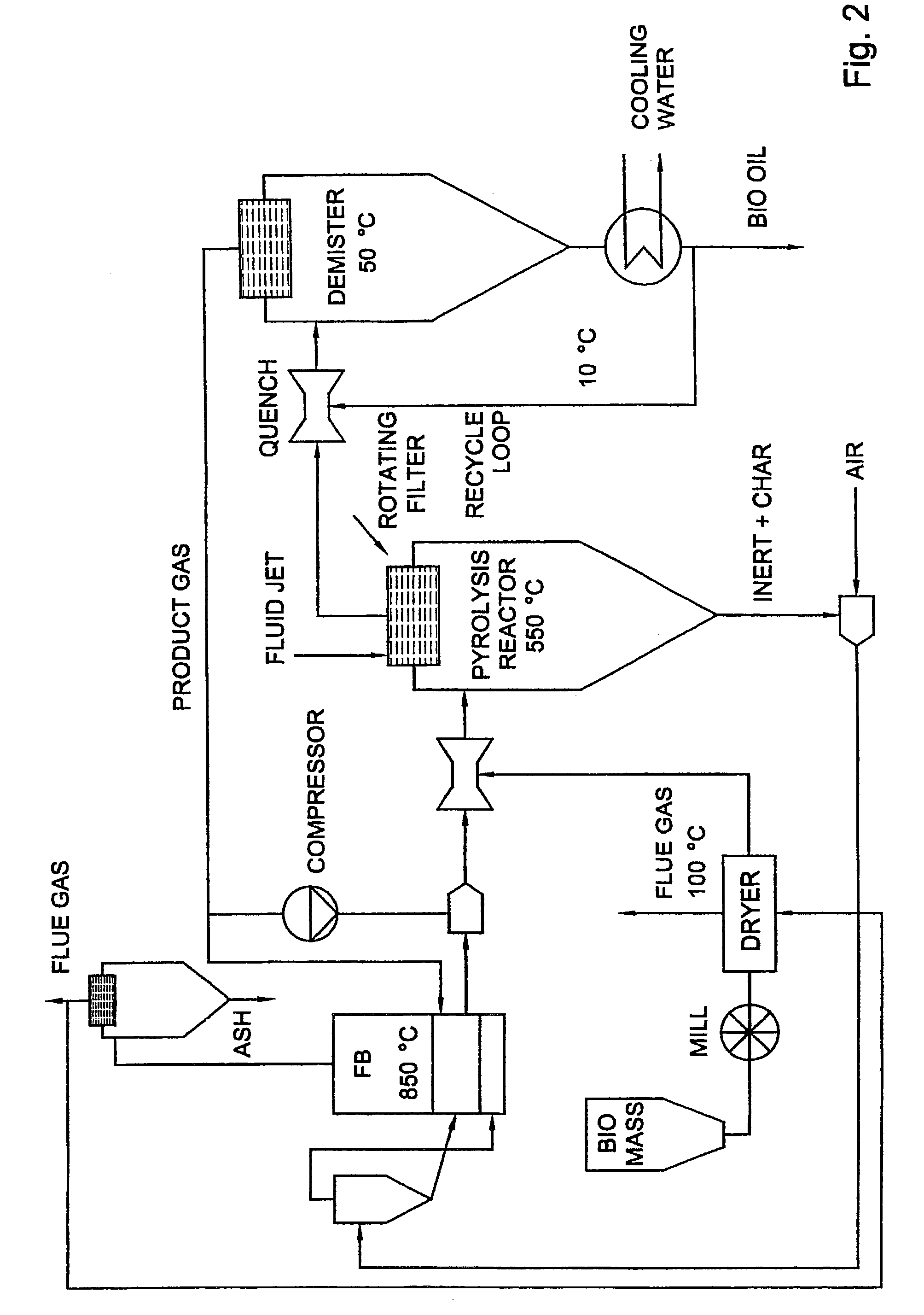

Flash-pyrolysis in a cyclone

InactiveUS7202389B1Excessive crackingCombination devicesDispersed particle filtrationParticulatesCyclone

A process for the pyrolysis of carbonaceous material is carried out in a cyclone reactor which is fitted with enhanced filtering equipment. In addition the invention relates to the use of a cyclone fitted with a rotating filter as a pyrolysis reactor. By using a cyclone of the rotating separator type as a pyrolysis reactor, carbonaceous material, such as biomass, can effectively be converted in a product having excellent chemical properties and which product is free from particulate matter.

Owner:UNIVERSITY OF TWENTE

Natural resin formulations

InactiveUS6844420B1Low viscosityImprove liquidityFatty oils/acids recovery from wasteBiofuelsNatural resinDistillation

This invention is directed to a method of preparing a natural resin by liquefying wood, bark, forest residues, wood industry residues, or other biomass using rapid destructive distillation (fast pyrolysis). Fast pyrolysis produces both vapors and char from biomass, and following removal of the char from the product vapors, a liquid pitch product is recovered and processed by distillation, evaporation, or a combination thereof, in order to obtain a natural resin which may be in either liquid or solid form. The natural resin comprises a total phenolic content from about 30% to about 80% (w / w), and is a highly-reactive ligninic compound that has been found to be suitable for use within resin formulations without requiring any further extraction or fractionation procedures. Resins comprising up to 60% natural resin have been prepared and tested in board production and found to exhibit similar properties associated with commercially available resins. The natural resin may substitute for phenol, or for both phenol and formaldehyde within phenol-containing resins. Similarly, the natural resin can replace a substantial part of the components within urea-containing resins.

Owner:ENSYN RENEWABLES

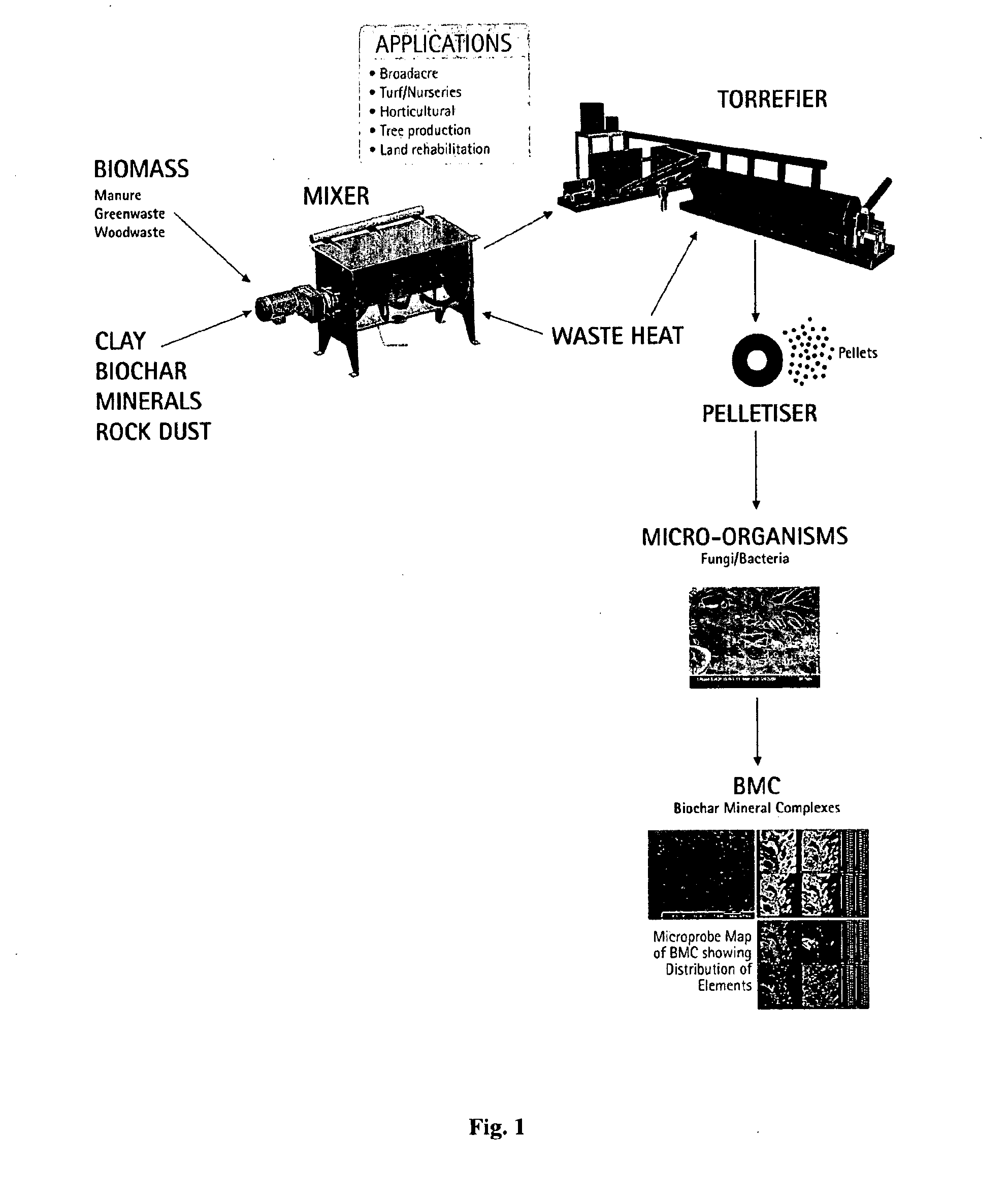

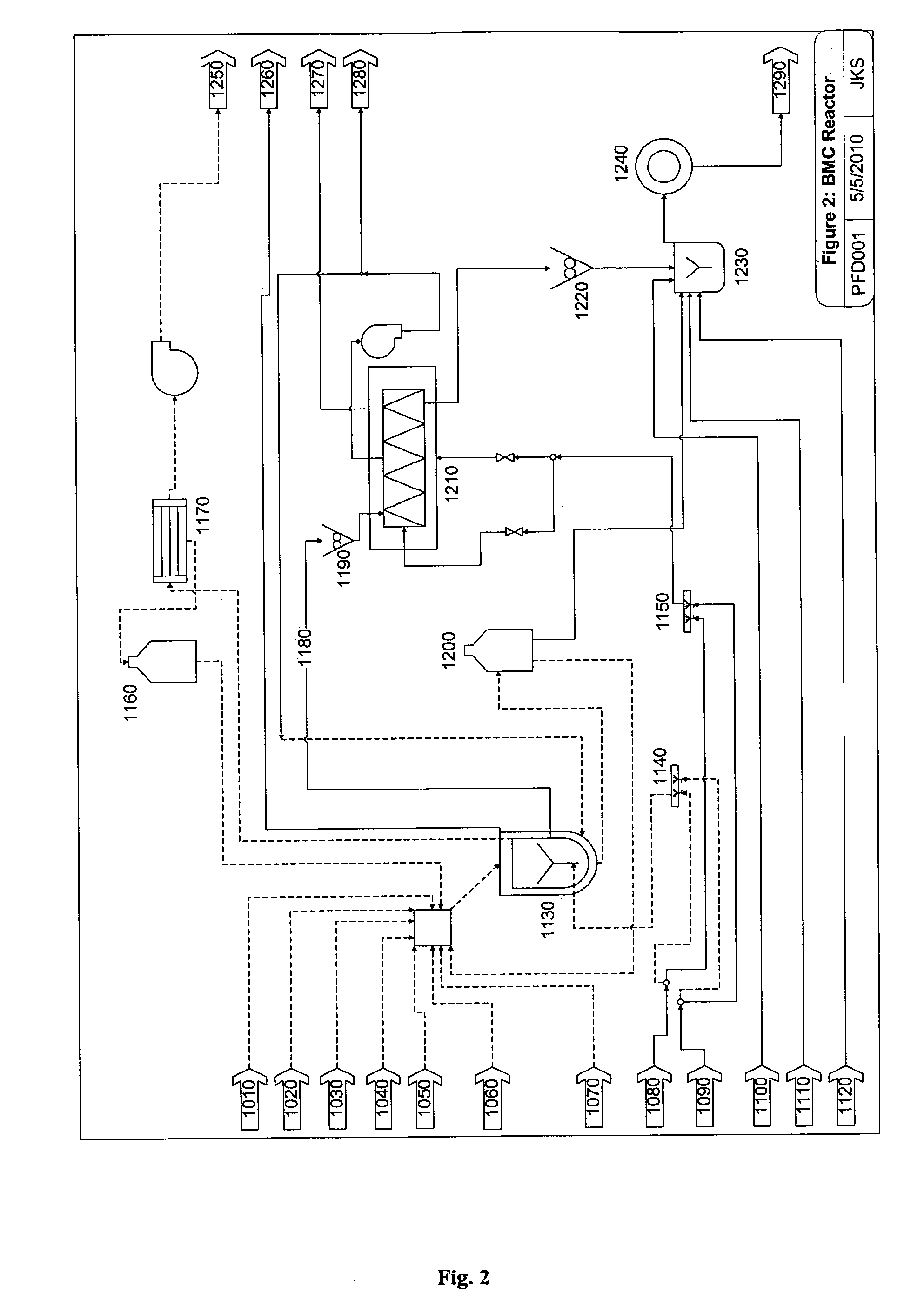

Biochar complex

InactiveUS20120125064A1Increase productionLow application rateDirect heating destructive distillationBiofuelsGrowth plantClay minerals

The invention relates to a biochar-containing composition comprising biochar having organic matter therein and / or thereon, clay associated, optionally intercalated, with the organic matter, a non-clay mineral and optionally also a plant growth promoter.

Owner:VENEARTH GRP

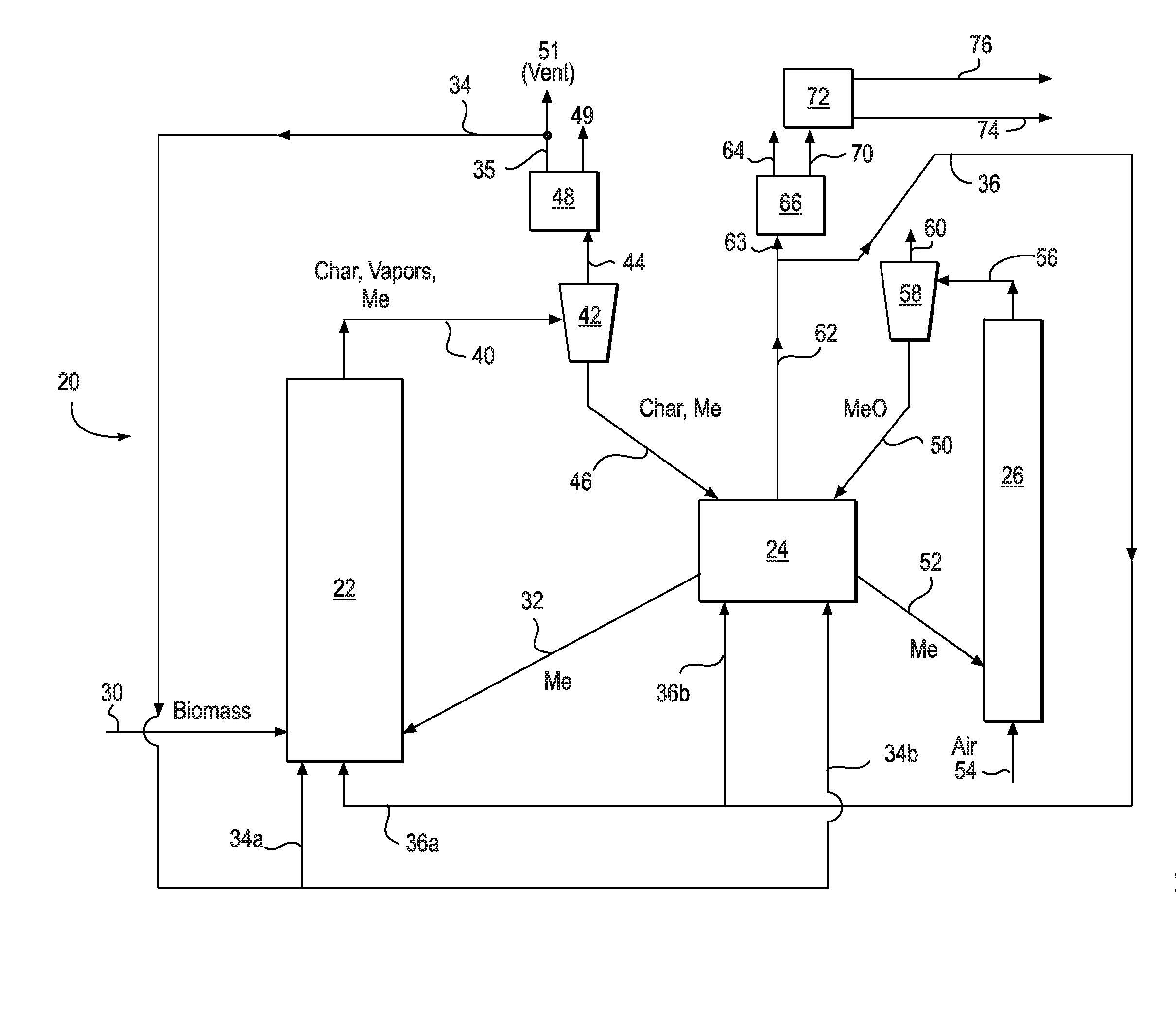

Method and system for capturing carbon dioxide from biomass pyrolysis process

A system and method for biomass pyrolysis utilizing chemical looping combustion of a produced char to capture carbon dioxide is disclosed. The system includes a biomass pyrolysis reactor, a char combustor, and oxidation reactor and a separator for separating carbon dioxide from flue gas produced by the char combustion. The pyrolysis reactor pyrolyzes biomass in the presence of reduced metal oxide sorbents producing char and pyrolysis oil vapor. The char is separated and combusted in the char combustor, in the presence of oxidized metal oxide sorbents, into a gaseous stream of carbon dioxide and water vapor. The carbon dioxide and water are separated so that a stream of carbon dioxide may be captured. The oxidation reactor oxidizes, in the presence of air, a portion of reduced metal oxide sorbents into oxidized metal oxide sorbents that are looped back to the char combustor to provide oxygen for combustion. A second portion of the reduced metal oxide sorbents is recycled from the char combustor to the pyrolysis reactor to provide heat to drive the pyrolysis. Pyrolysis oil upgrading catalyst particles may be used in addition to the metal oxide sorbents as heat energy carrier particles to improve the quality of the pyrolysis oil vapors produced in the pyrolysis reactor. Also, the metal oxide sorbents may have metals incorporated therein which serve to upgrade the pyrolysis vapors produced during pyrolysis. Non-limiting examples of such metals include Ni, Mo, Co, Cr, W, Rh, Ir, Re, and Ru.

Owner:CHEVROU USA INC

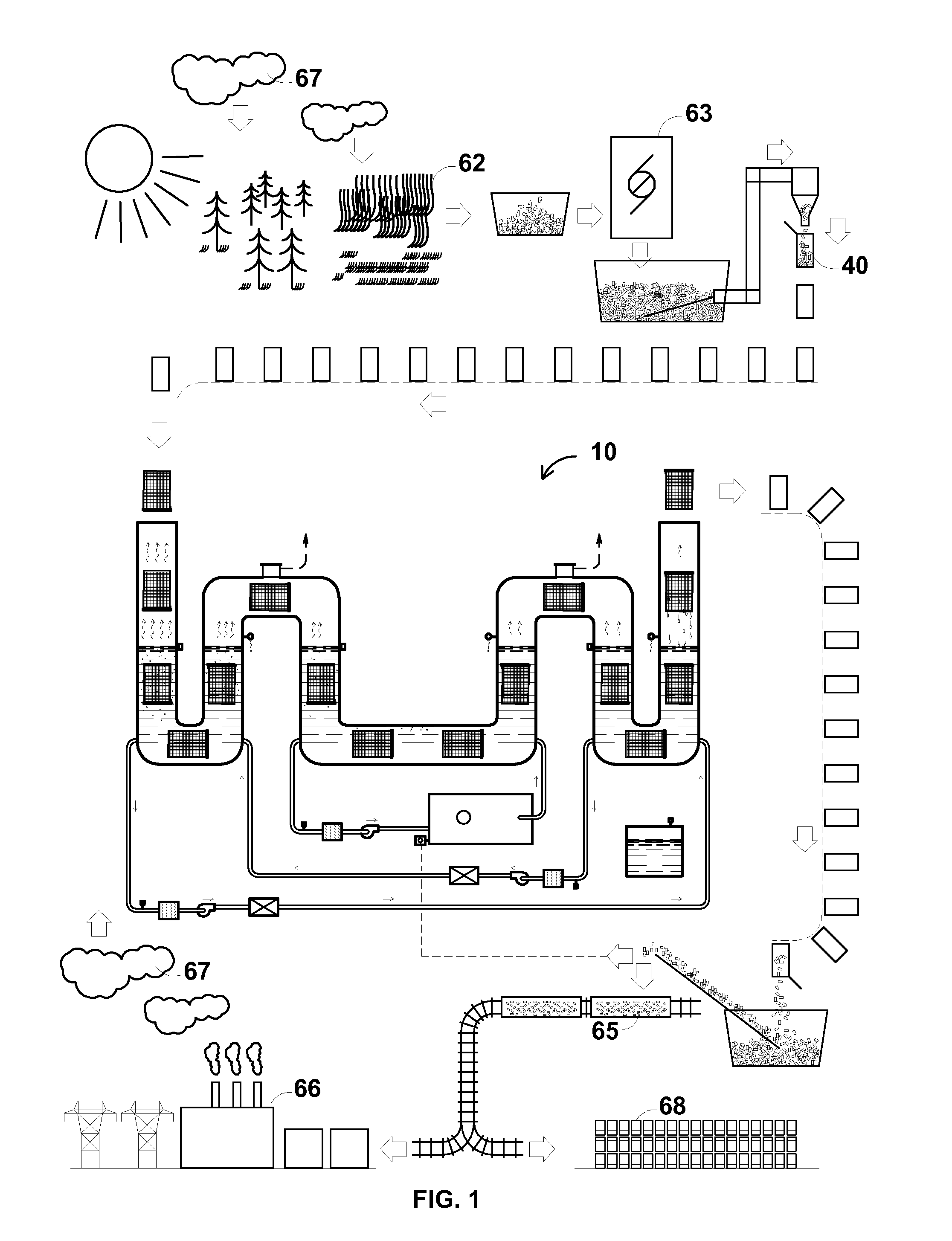

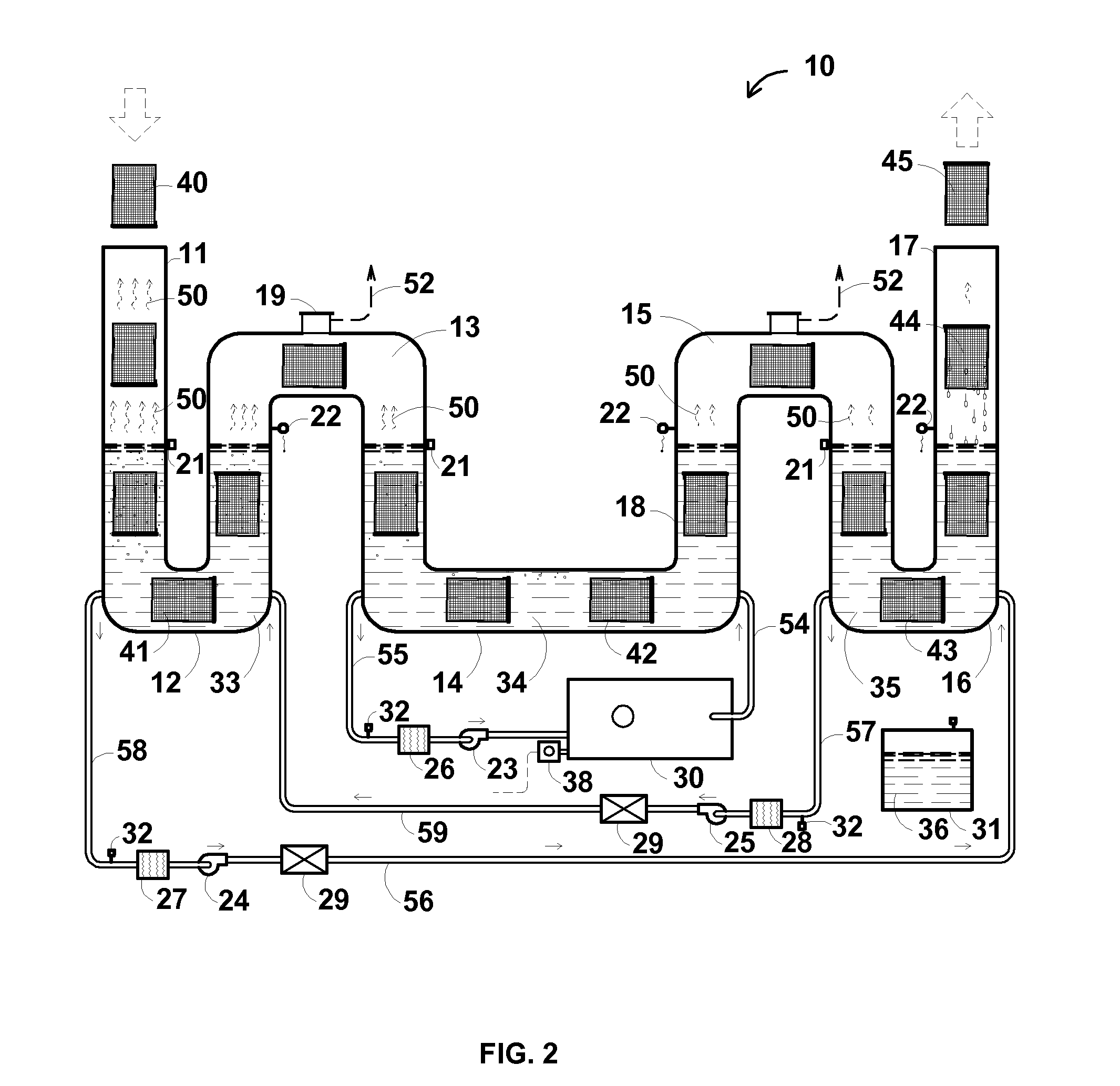

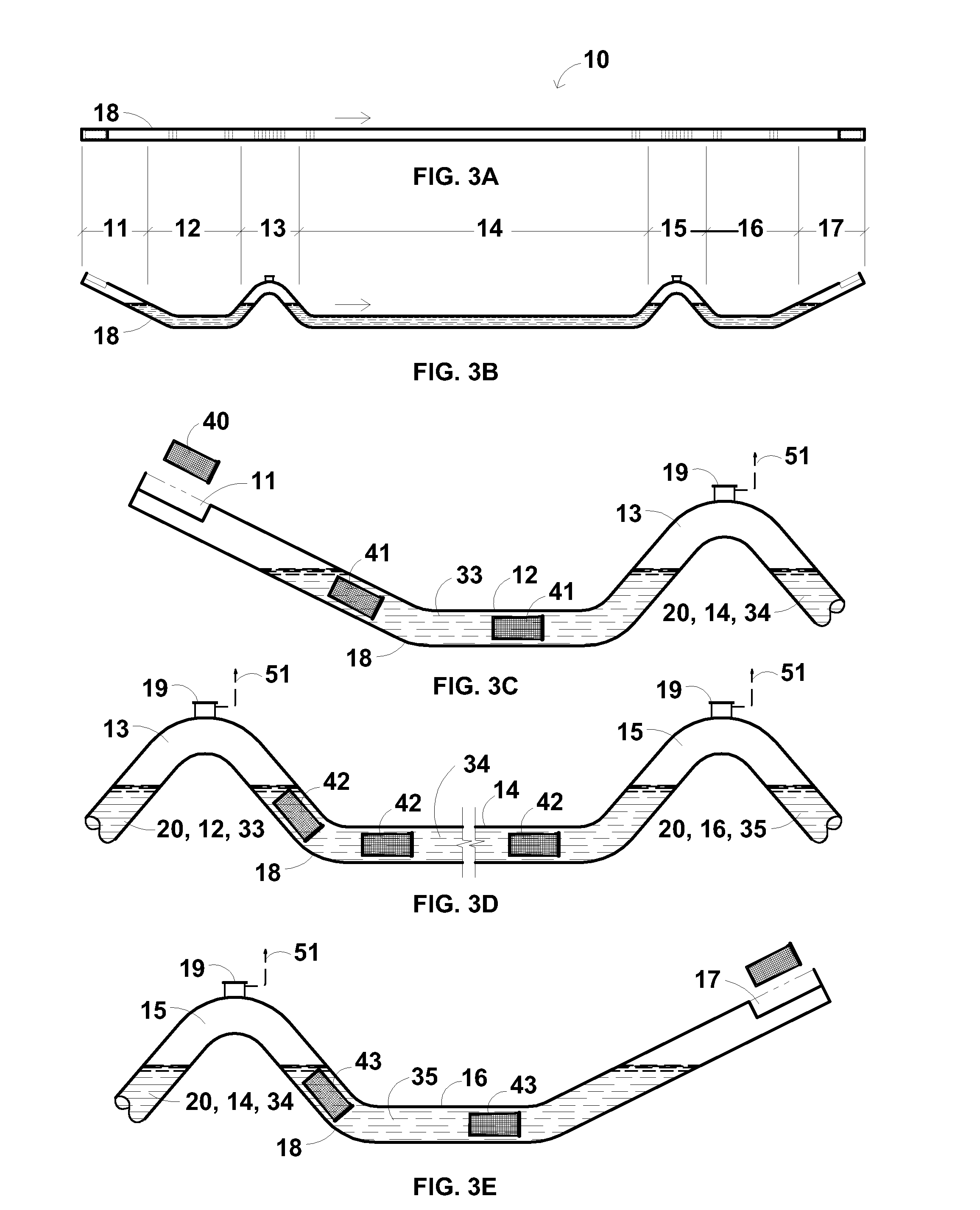

Method and apparatus for biomass torrefaction, manufacturing a storable fuel from biomass and producing offsets for the combustion products of fossil fuels and a combustible article of manufacture

ActiveUS20070266623A1Reduce air pollutionEasy to storeSolid fuel pretreatmentBiofuelsHigh elevationManufactured apparatus

Apparatus for biomass torrefaction which includes a serpentine elongated housing, the housing having three generally U-shaped axial portions having first and second axial extremities and an intermediate section, the first and second axial extremities are disposed in normal use at a higher elevation than the first and second axial extremities, the intermediate section being configured for holding a liquid. Other forms of the invention include the method for biomass torrefaction which includes providing a quantity of biomass, providing a liquid heat transfer fluid, providing at least a first housing for holding the heat transfer liquid, elevating the temperature of the liquid heat transfer liquid, heat treating the biomass by passing it through the heat transfer liquid in the first housing at a temperature and duration sufficient to accomplish torrefaction of the wood. In some forms of the method, the process further includes the step of pelletizing the biomass prior to performing the treating step.

Owner:PAOLUCCIO JOHN A

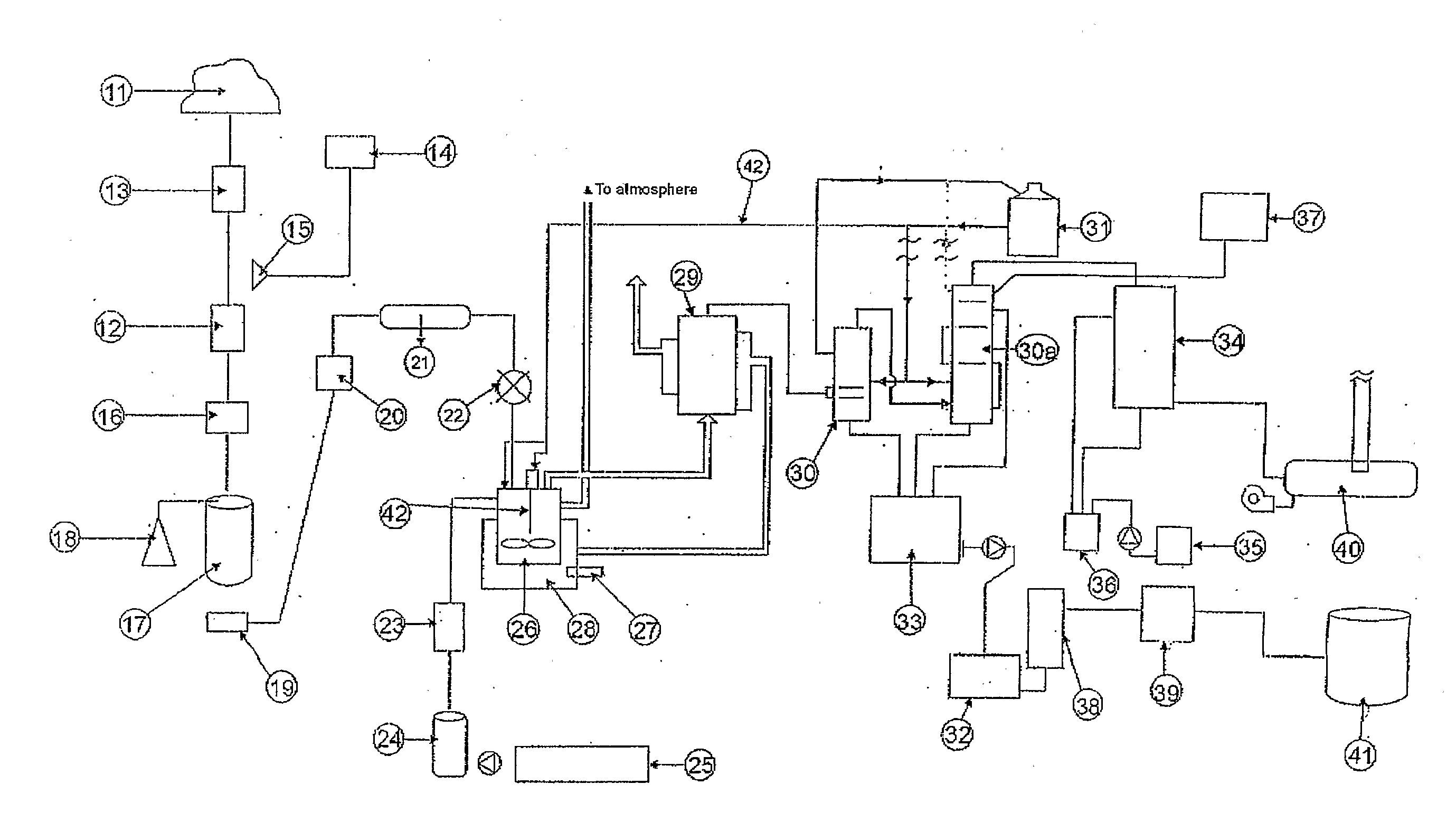

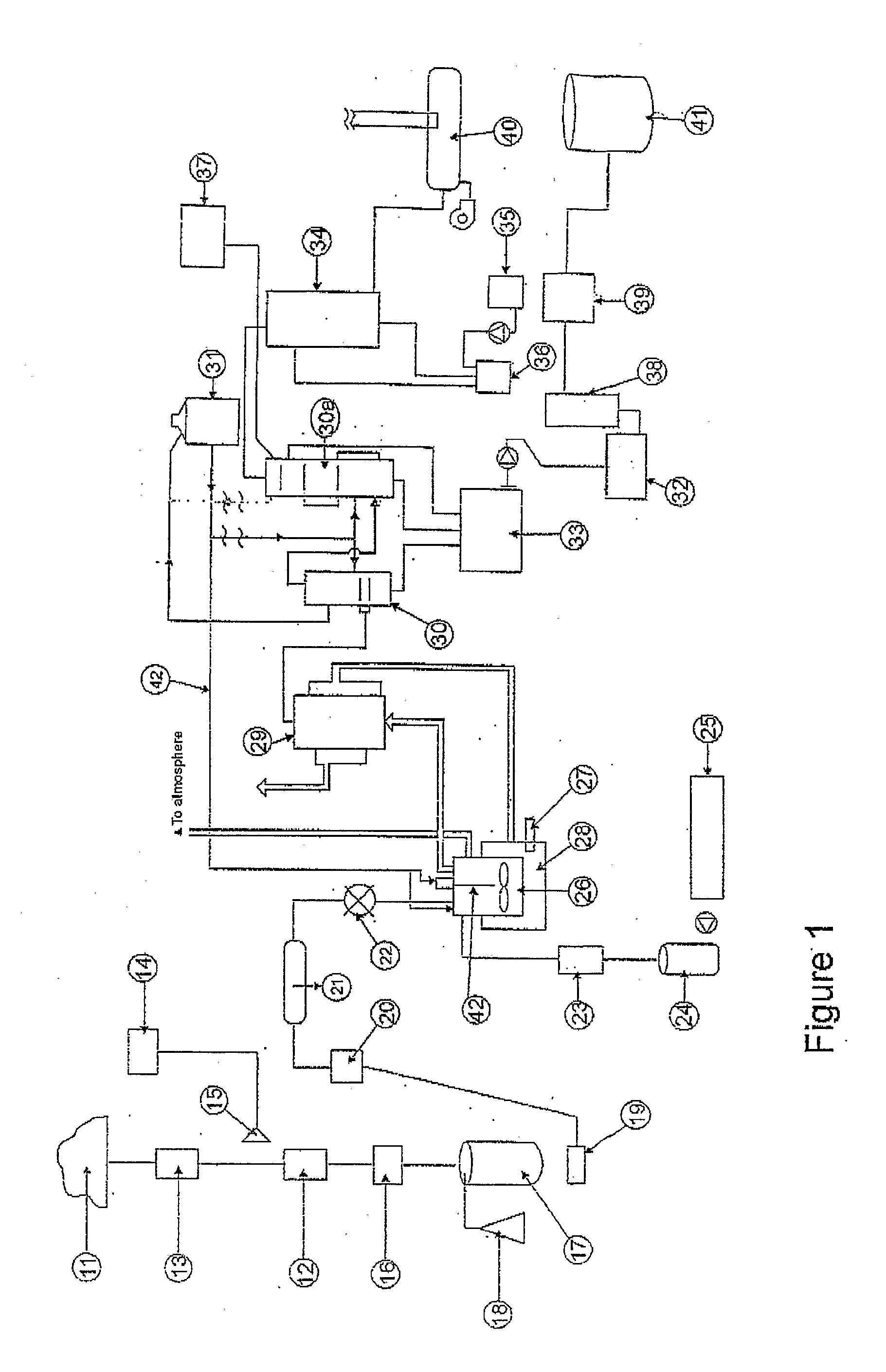

Process and plant for conversion of waste material to liquid fuel

ActiveUS20070179326A1Easy to wasteEasy feedingCatalytic crackingIndirect and direct heating destructive distillationEnvironmental engineeringLiquid fuel

A process and plant for the thermocatalytic conversion of waste materials into reusable fuels and a fuel produced by the process, involving the steps of delivering melted waste material (11) to one or more pyrolysis chambers (26) via heated and valved manifolds (22) and effecting pyrolysis of the waste material into a gascous state in an oxygen purged and pressure controlled environment. Pyrolytic gases are, then transferred to a catalytic converter (29) where the molecular structure of the gaseous material is altered in structure and form, with gases then transferred to one or more condensers (30a) to distil and cool gases in to their respective fractions. After post pyrolysis treatment, fuel fractions thon form a useable fuel. Includes the melting of waste (plastic) material (11) before delivery into any of the pyrolysis chambers (26), making the movement of material into the catalytic tower (29) a semi-continuous operation, directing melted waste material into one or more, but preferably four, pyrolysis chambers (26a, b, c, d), making each chamber capable of independent operation, optionally mechanically removing waste char from the pyrolysis chamber (107) by use of an internet auger (112) or other suitable means.

Owner:FUTURE ENERGY INVESTMENTS PTY LTD

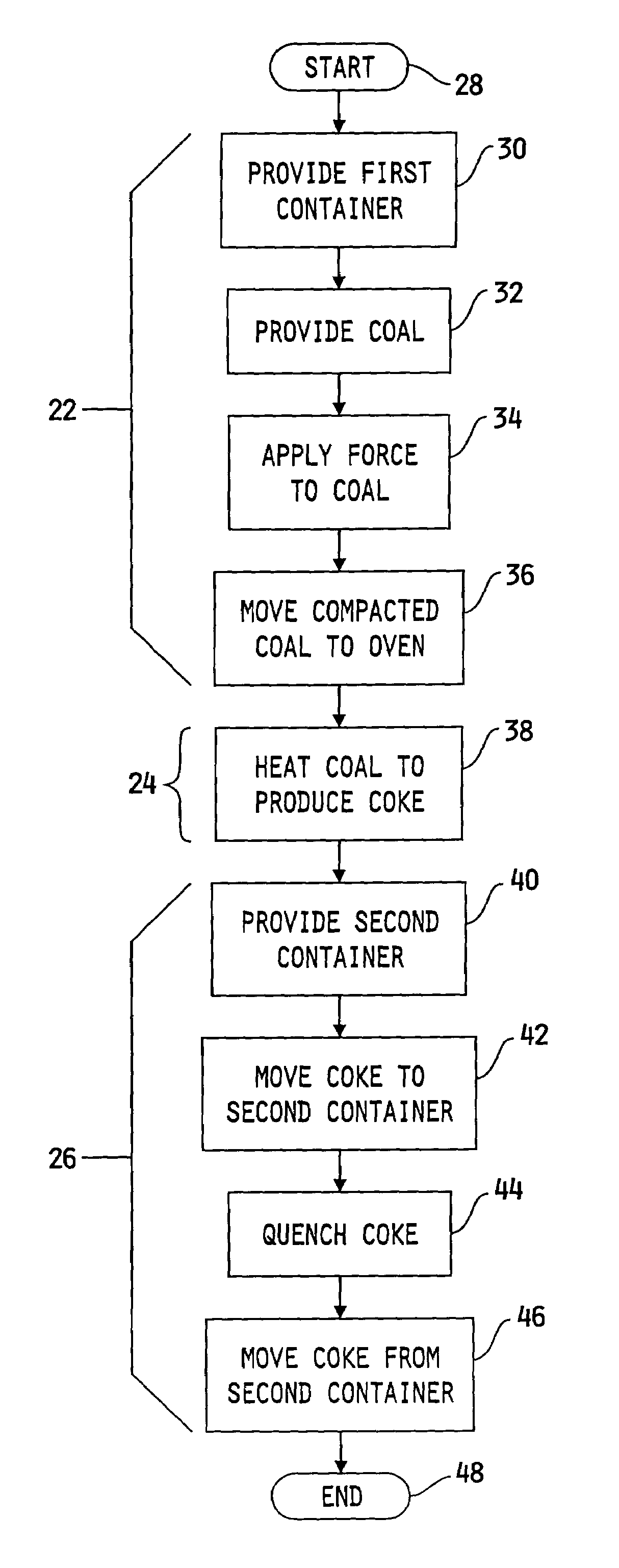

Method for producing blast furnace coke through coal compaction in a non-recovery or heat recovery type oven

A method for producing non-recovery / heat recovery coke may include the steps of providing a container, disposing a volume of loose coal into the container such that a vertical dimension of the volume of loose coal in the container is smaller than a horizontal dimension of the volume of loose coal, applying a force to the coal in the container to produce a volume of compacted coal having a substantially uniform density which is larger than that of the loose coal, disposing the compacted coal into a non-recovery / heat recovery type oven, and heating the compacted coal to produce coke. The method may also include the steps of providing a container, and moving the non-recovery / heat recovery coke mass from the oven at a substantially constant elevation to the container, quenching the coke mass in the container to produce a quenched coke mass, and removing the quenched coke mass from the container.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

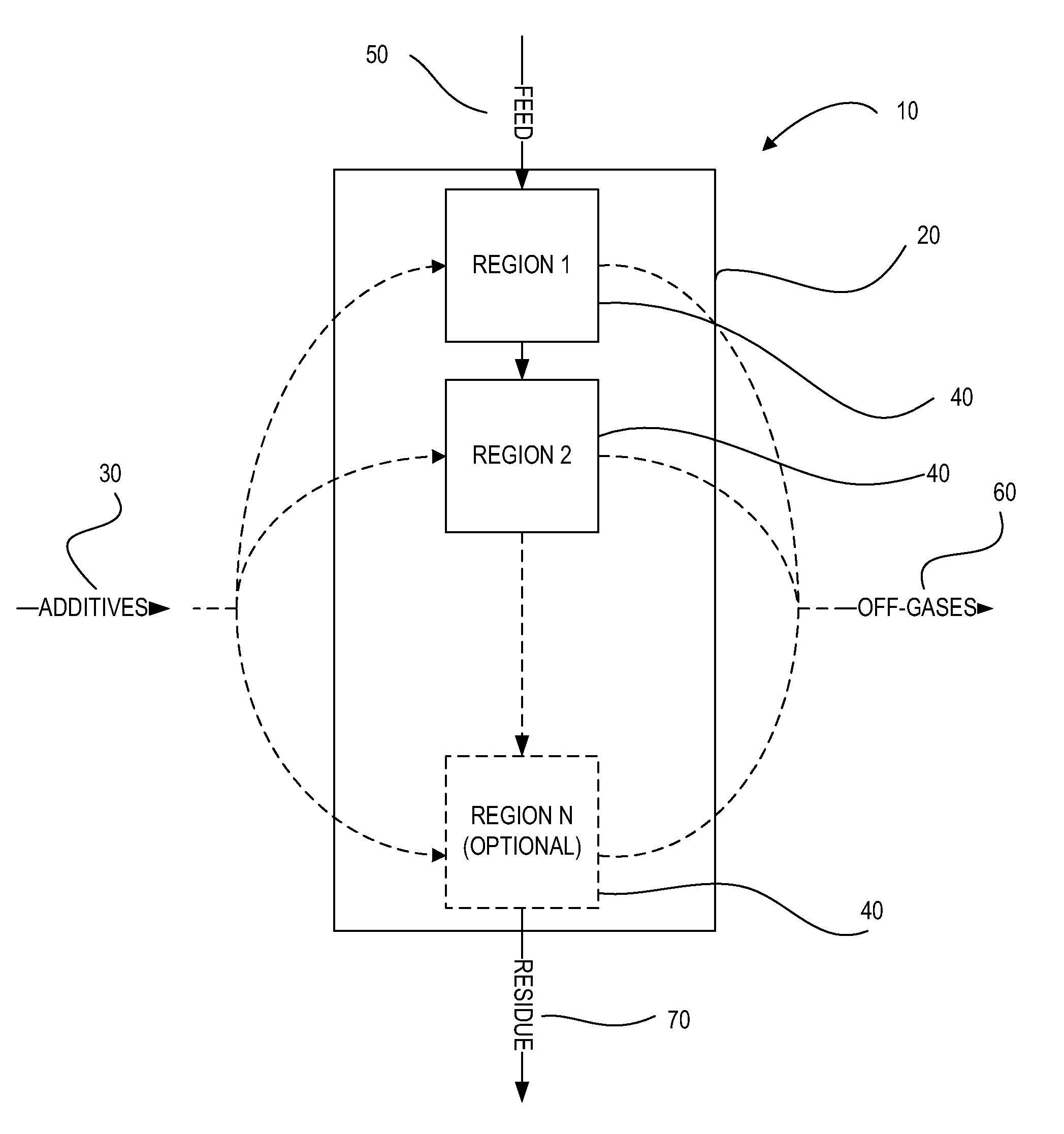

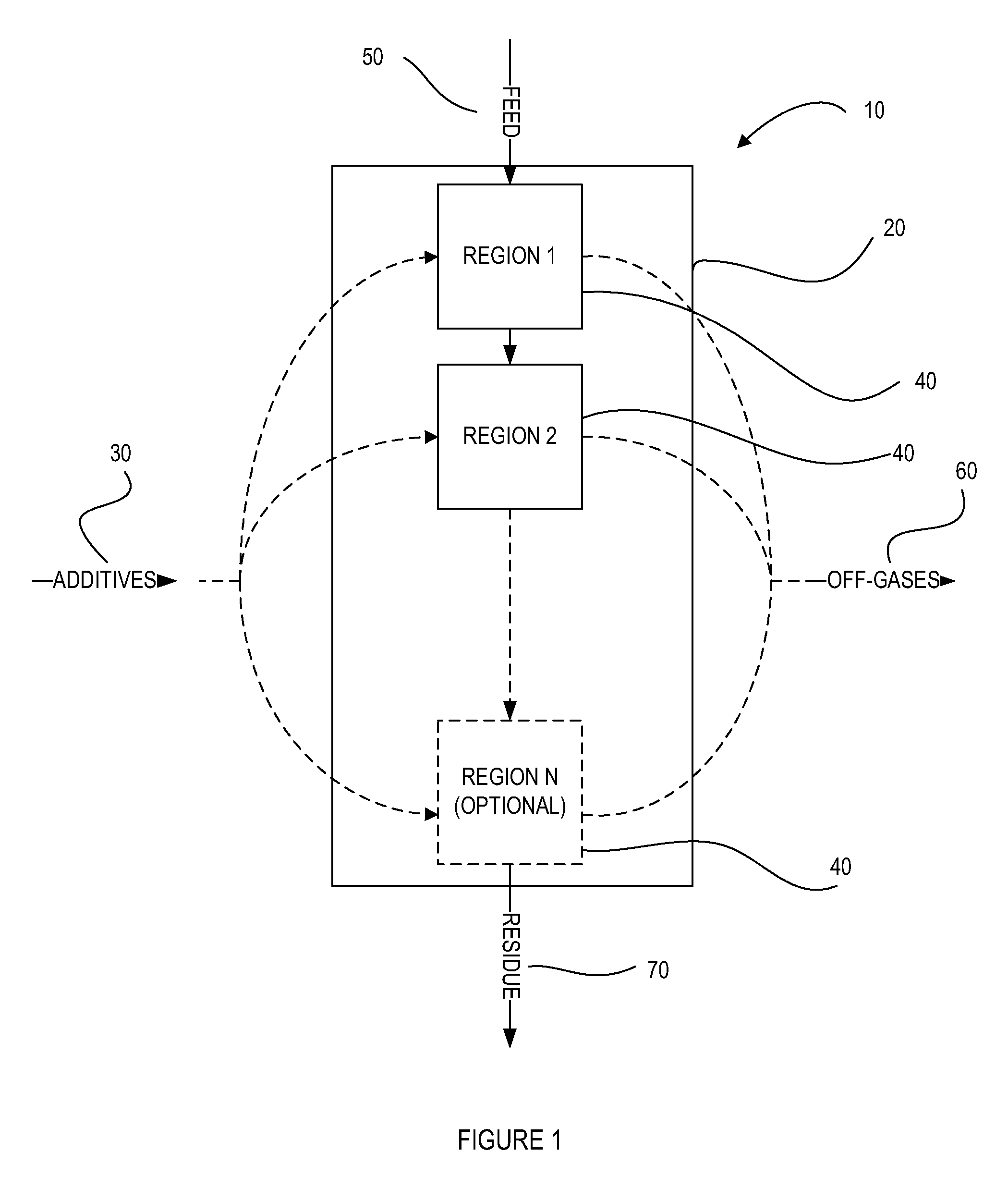

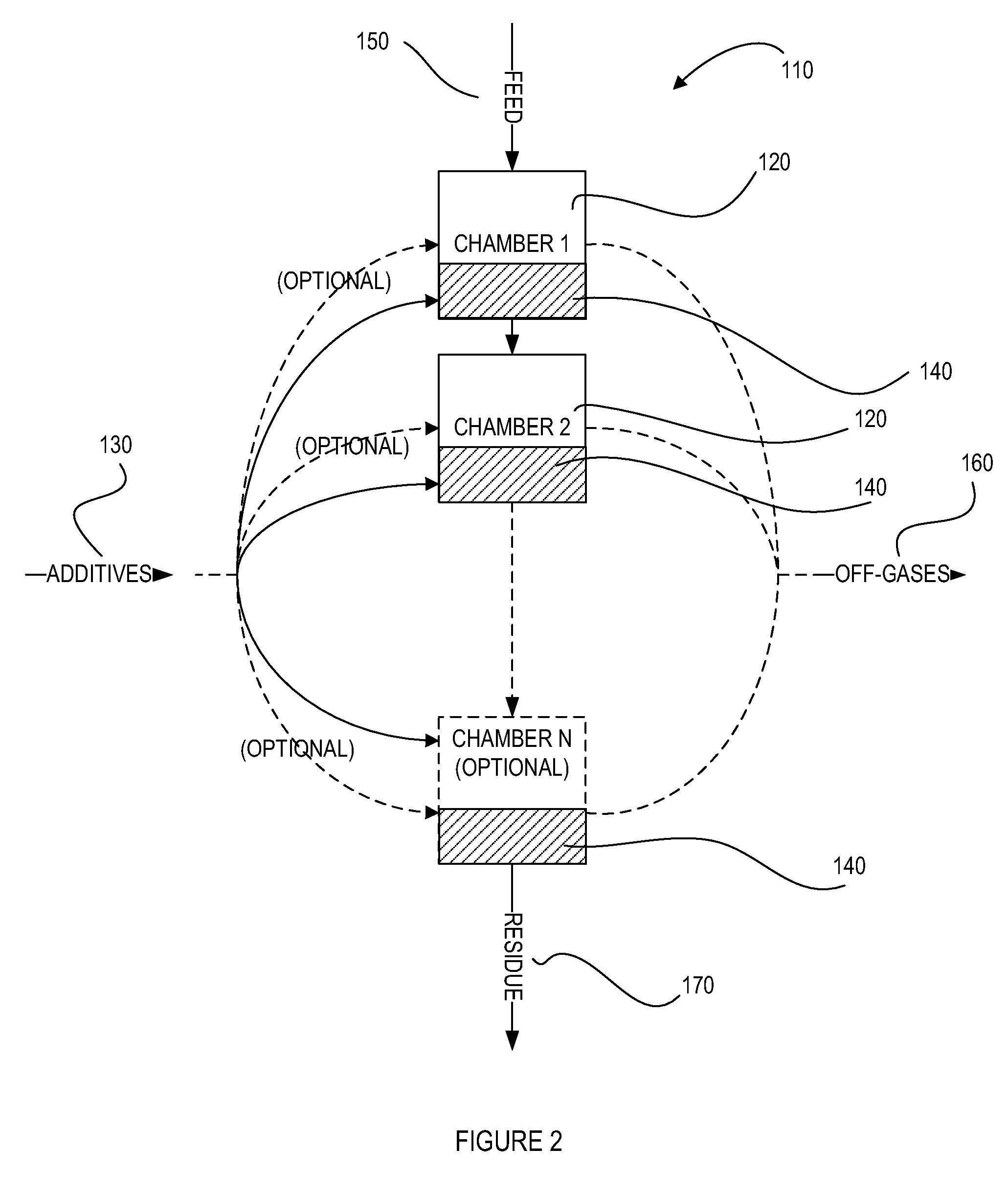

Gasifier comprising vertically successive processing regions

InactiveUS20070289216A1Suitable for processingGasifier feeding meansMuffle furnacesEngineeringProduct gas

The present invention provides a vertically oriented gasifier comprising vertically successive processing regions for conversion of carbonaceous feedstock into gas. The gasifier comprises of: one or more processing chambers with two or more vertically successive processing regions being distributed within said one or more processing chambers, within each one of which a respective process selected from the group consisting of drying, volatilization and carbon conversion is at least partially favoured, The processing regions are identified by temperature ranges respectively enabling each said respective process. One or more additive input elements are associated with the processing regions for inputting additives to promote each said at least partially favoured process therein. In addition, the gasifier comprises one or more material displacement control modules adapted to control a vertical movement of the feedstock through said processing regions to enhance each said at least partially favoured process, one or more feedstock inputs located near a first of said processing regions and one or more gas outputs and one or more residue outputs.

Owner:PLASCO ENERGY GROUP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com