Patents

Literature

137 results about "Torrefaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Torrefaction of biomass, e.g., wood or grain, is a mild form of pyrolysis at temperatures typically between 200 and 320 °C. Torrefaction changes biomass properties to provide a better fuel quality for combustion and gasification applications. Torrefaction produces a dry product with no biological activity like rotting. Torrefaction combined with densification creates an energy-dense fuel carrier of 20 to 21 GJ/ton lower heating value (LHV). Torrefaction makes the material undergo Maillard reactions.

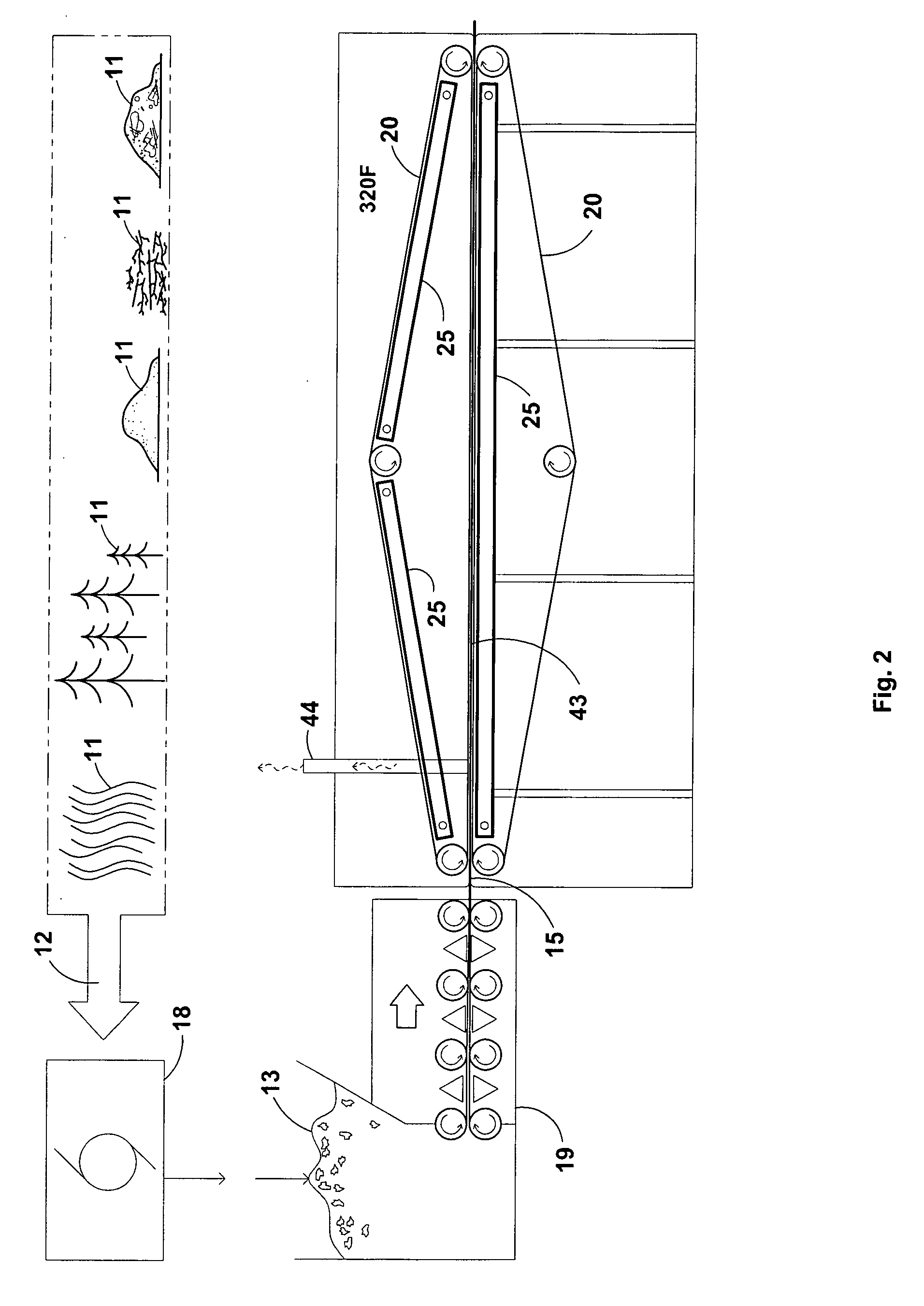

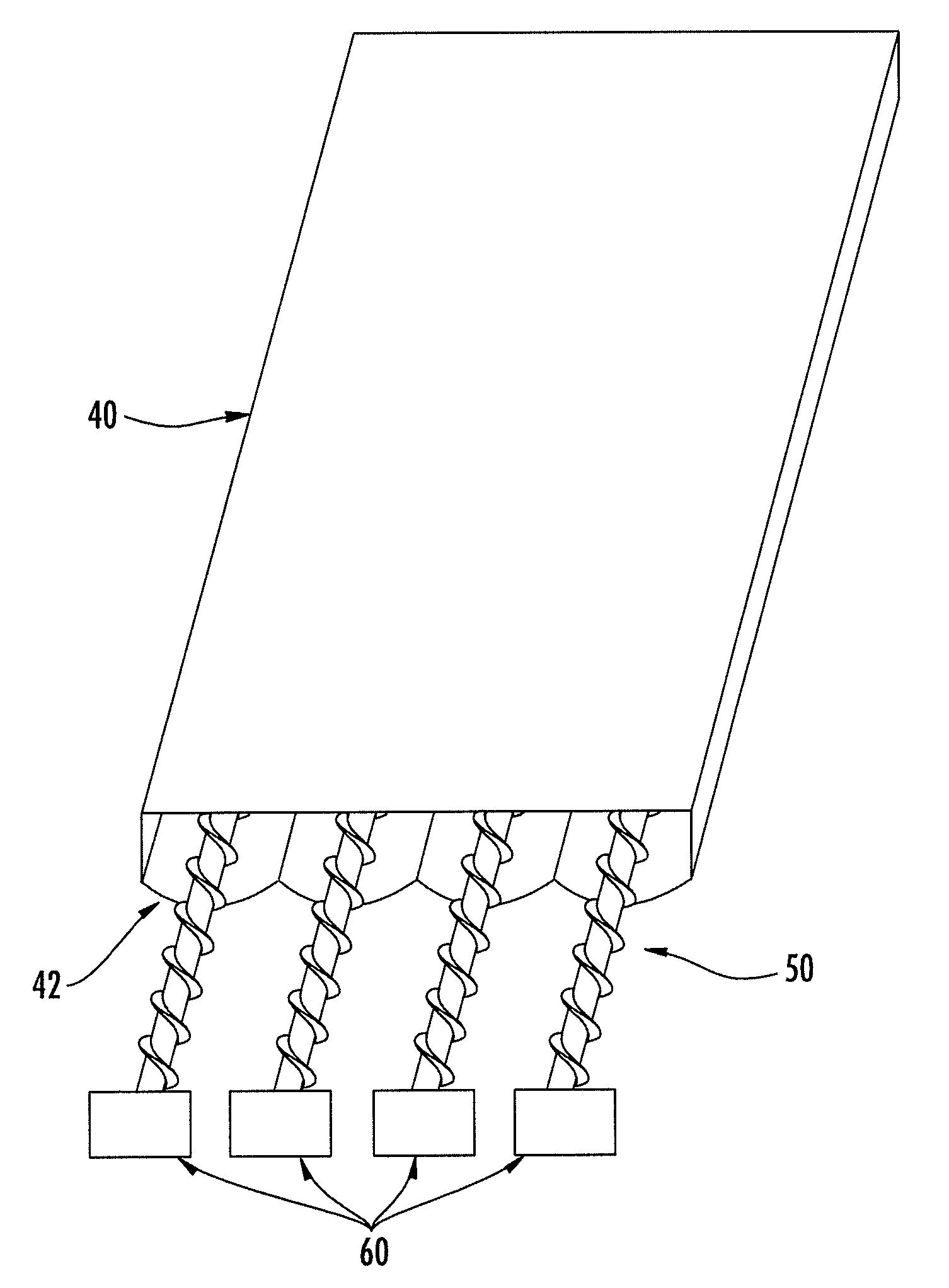

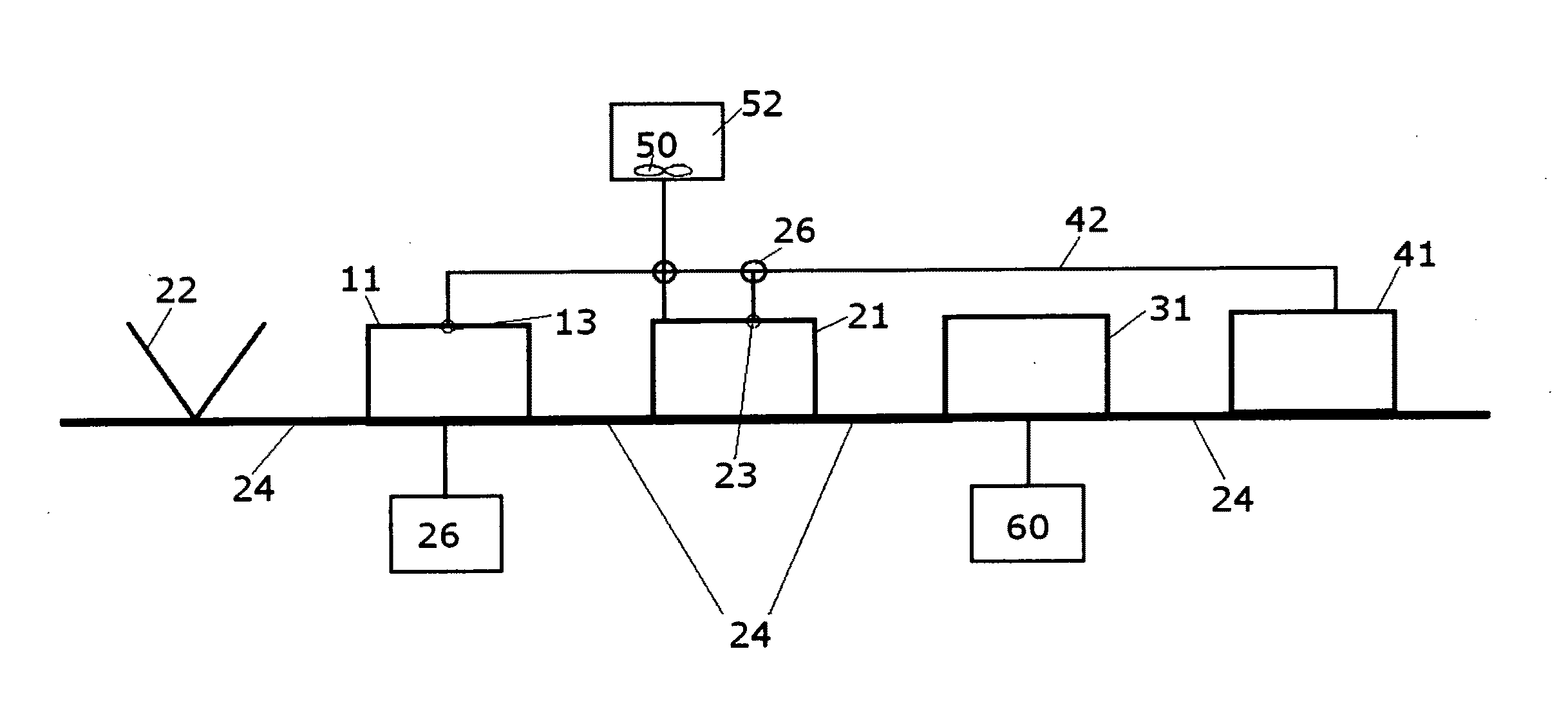

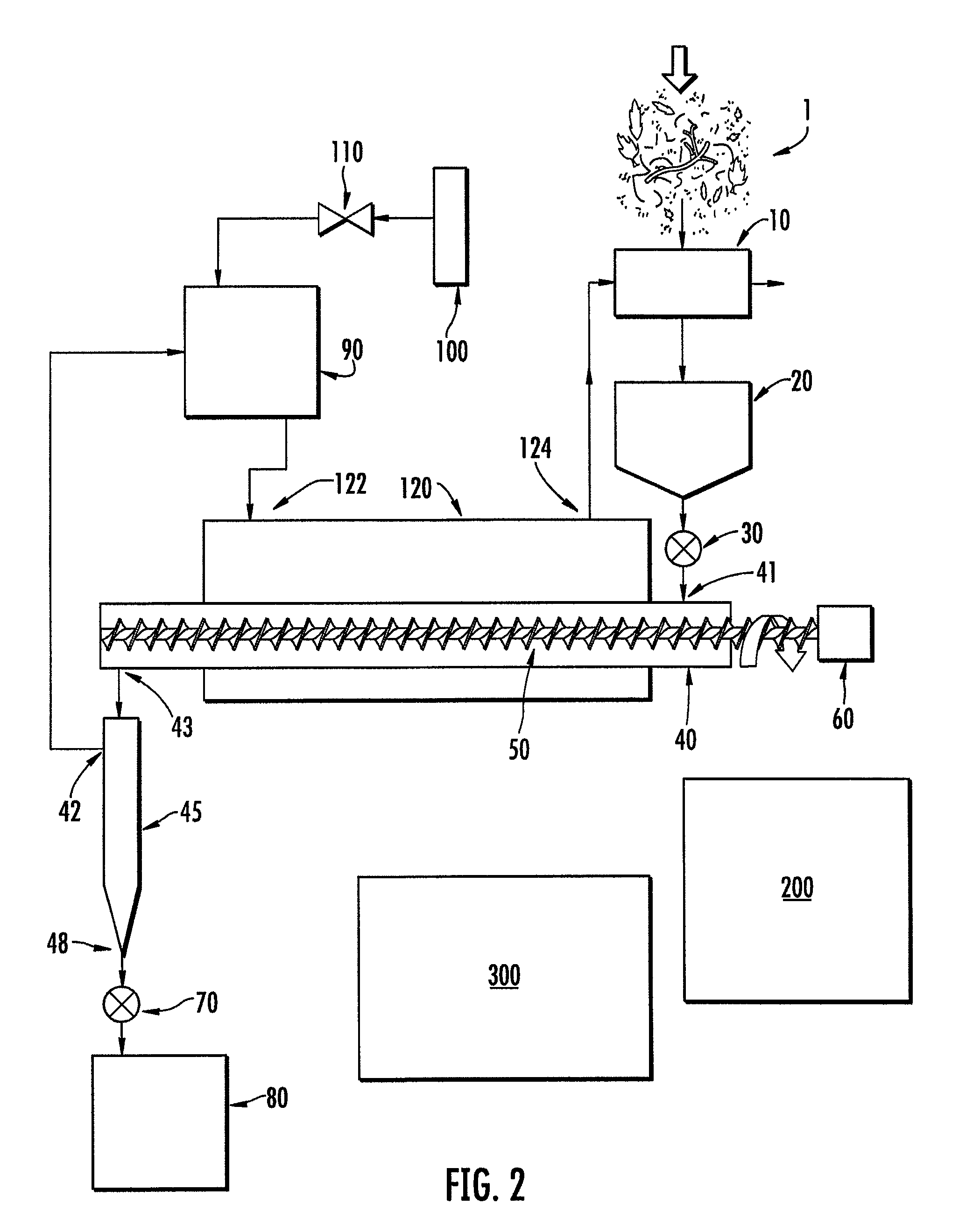

Method and apparatus for biomass torrefaction using conduction heating

InactiveUS20080223269A1Reduce air pollutionEasy to storeDrying solid materials with heatBiofuelsThermal contactConveyor belt

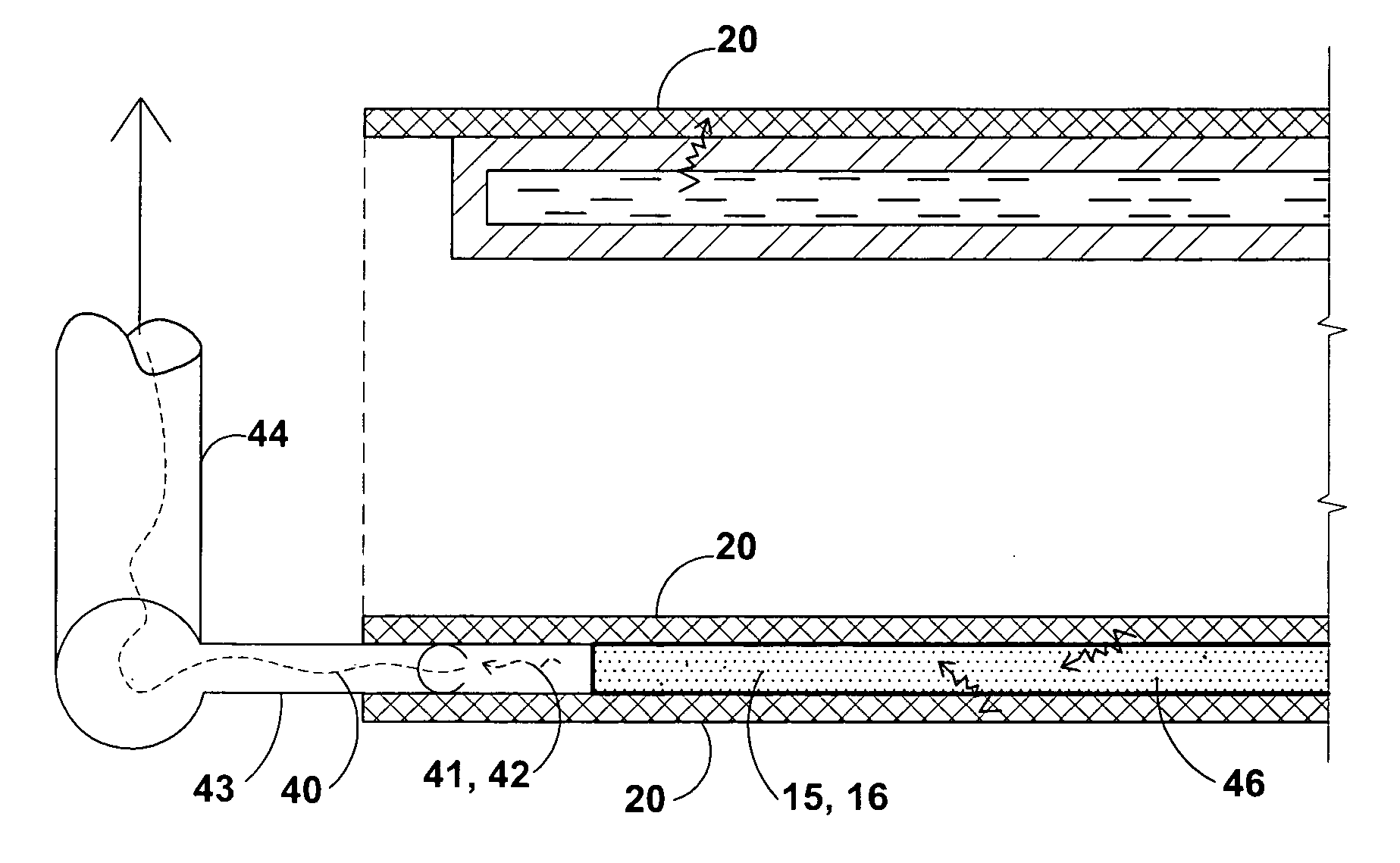

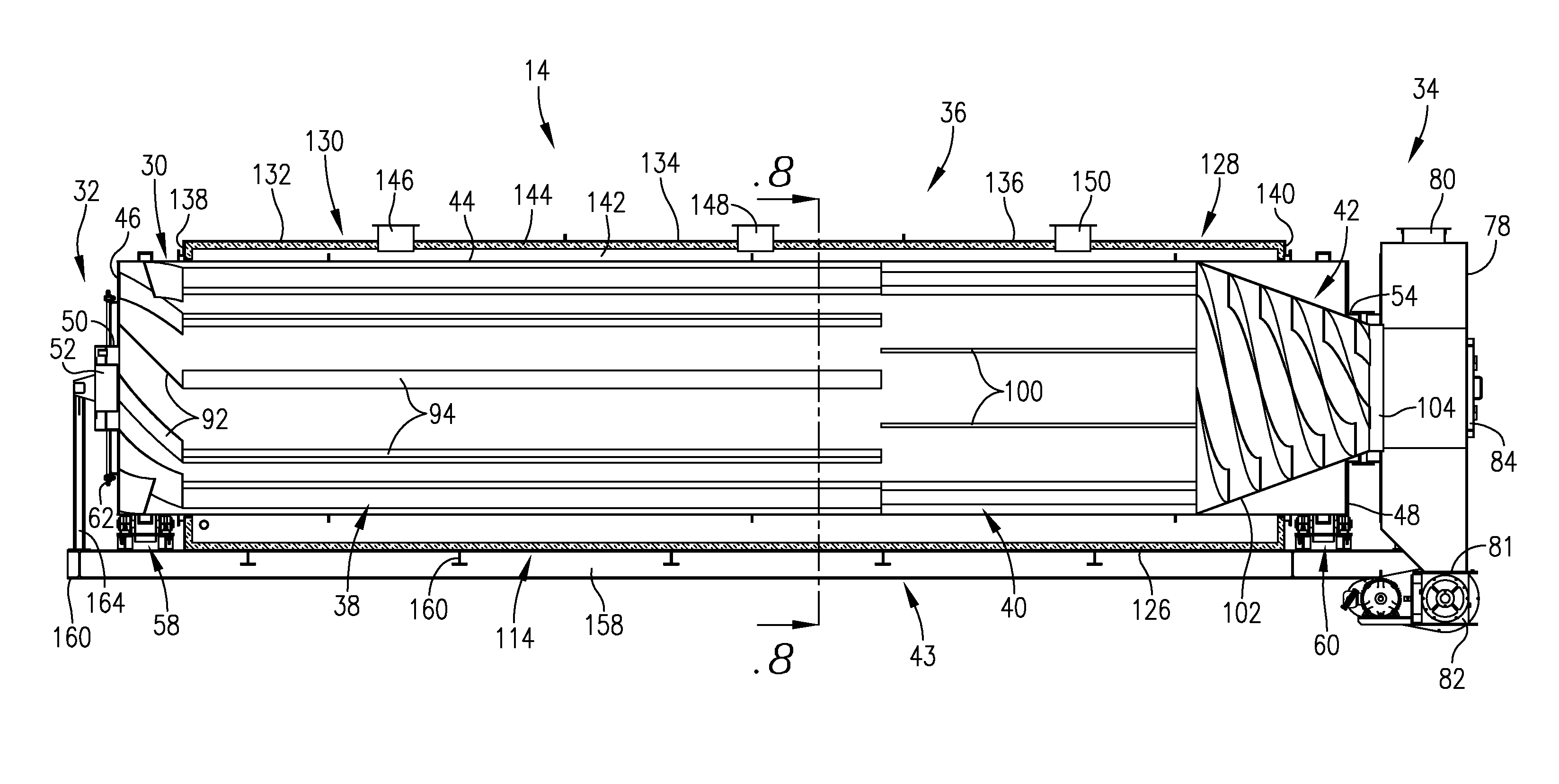

A method for torrefaction of wood which includes providing a first endless conveyor belt; heating the first endless belt; and positioning a planar wood product on the first belt to heat the wood product by conduction to achieve torrefaction. Other forms provide a second endless belt that disposed in sandwich relation to wood to be torrefied. Some embodiments of the method provide a metal chamber having opposed planar sides dimensioned and configured for receiving a wood sheet with the respective opposed sides of the wood sheet in intimate thermal contact with respective opposed sides of the metal chamber. Other embodiments include the apparatus for torrefaction of an associated wood sheet.

Owner:PAOLUCCIO JOHN A

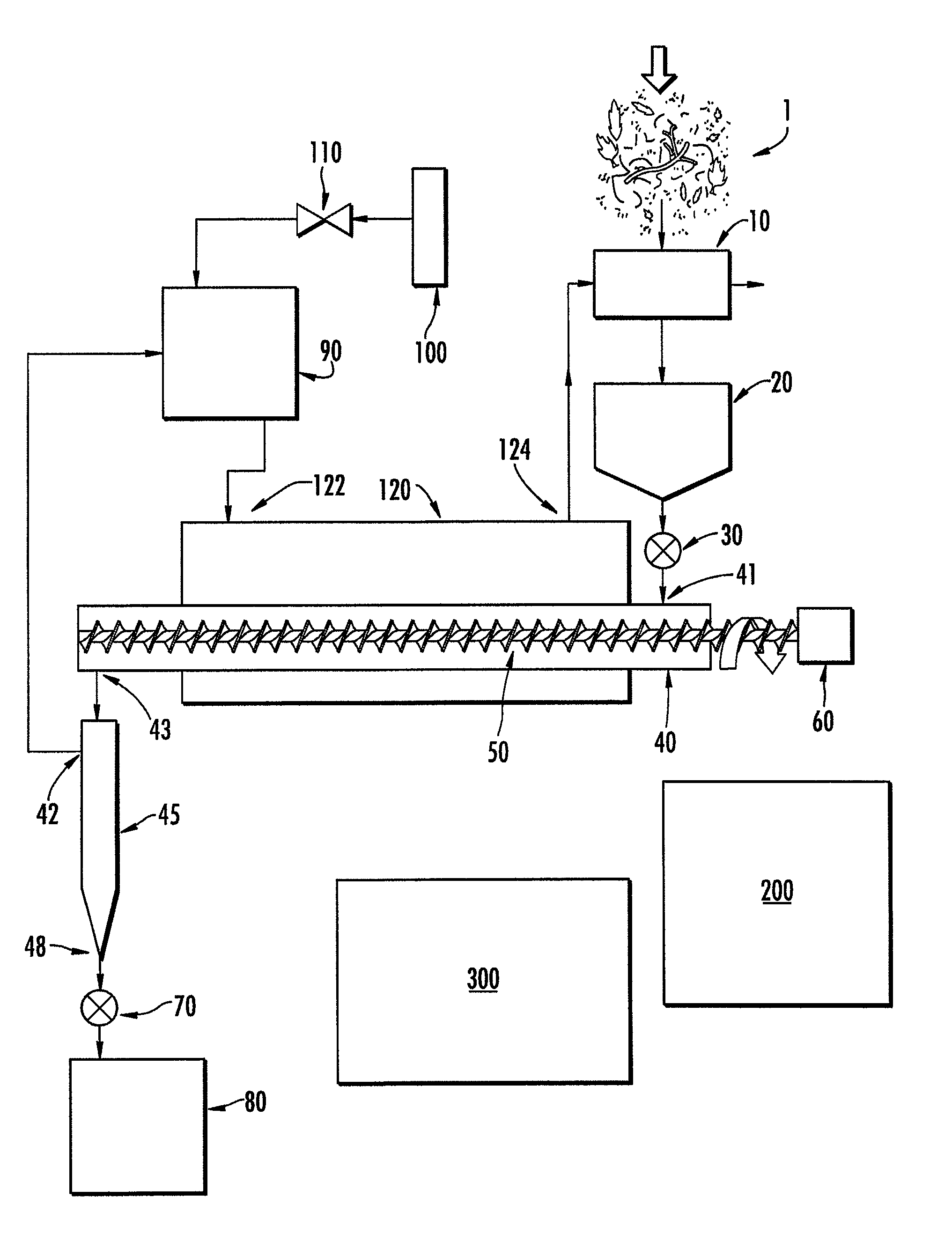

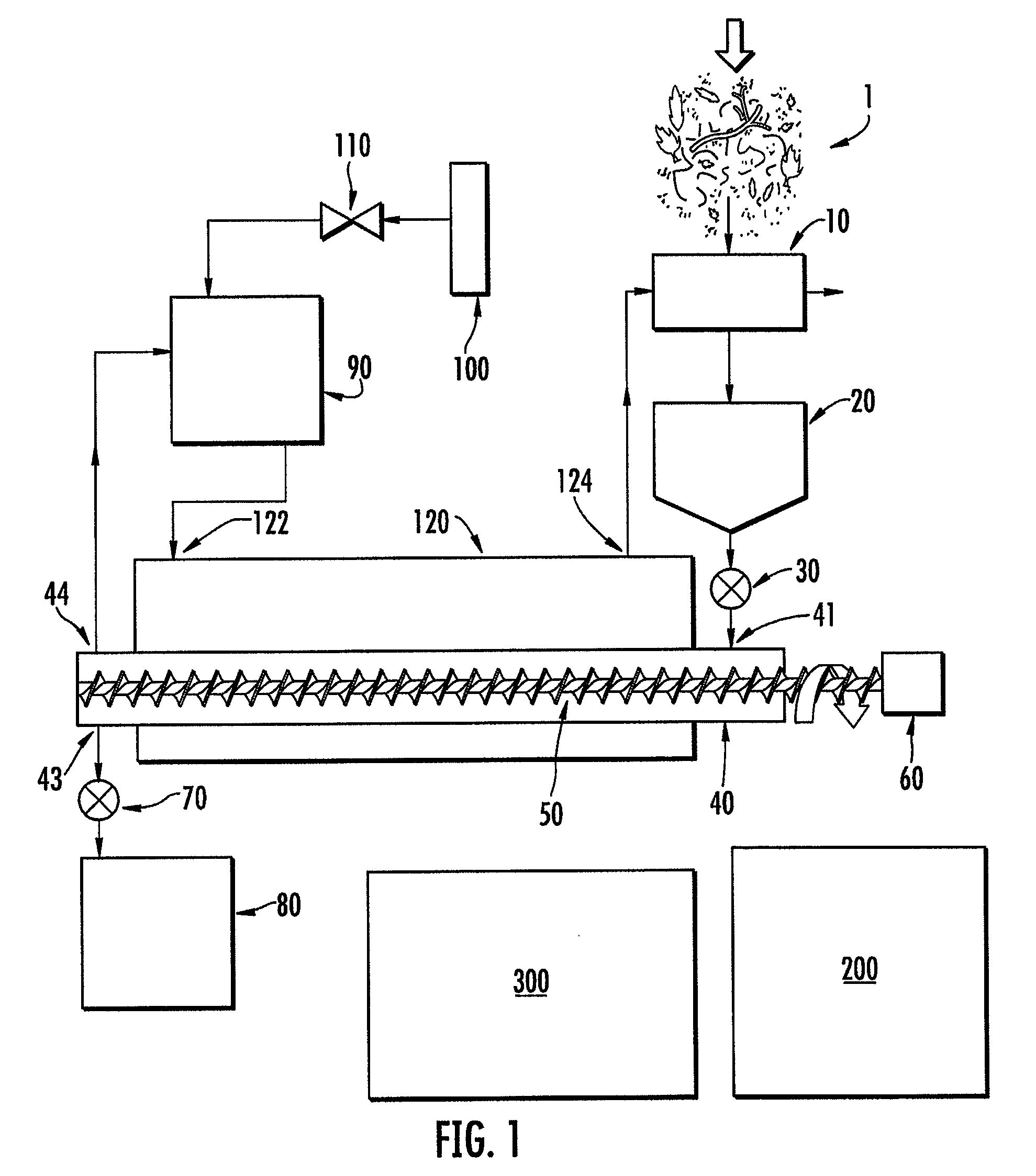

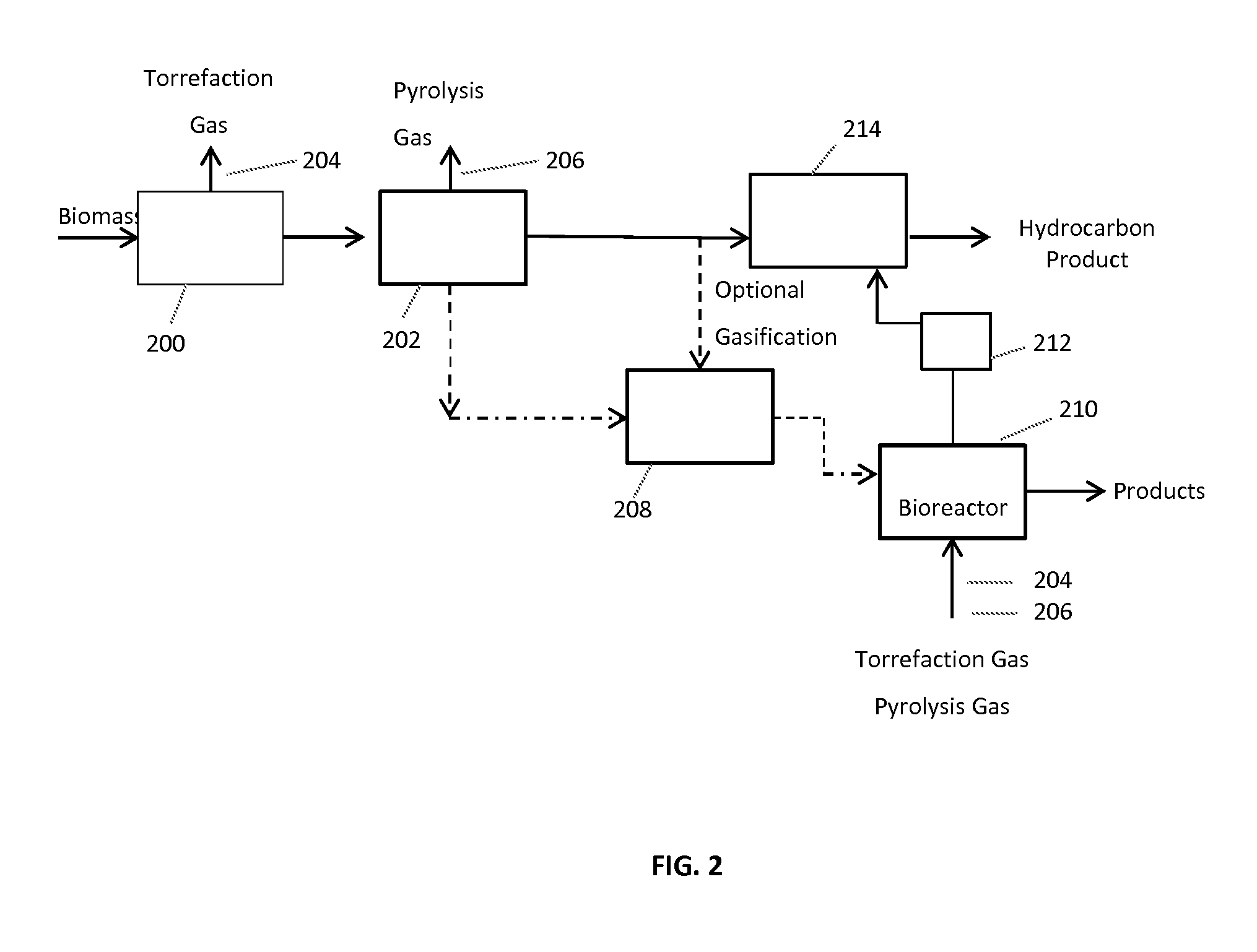

Methods and apparatus for producing syngas and alcohols

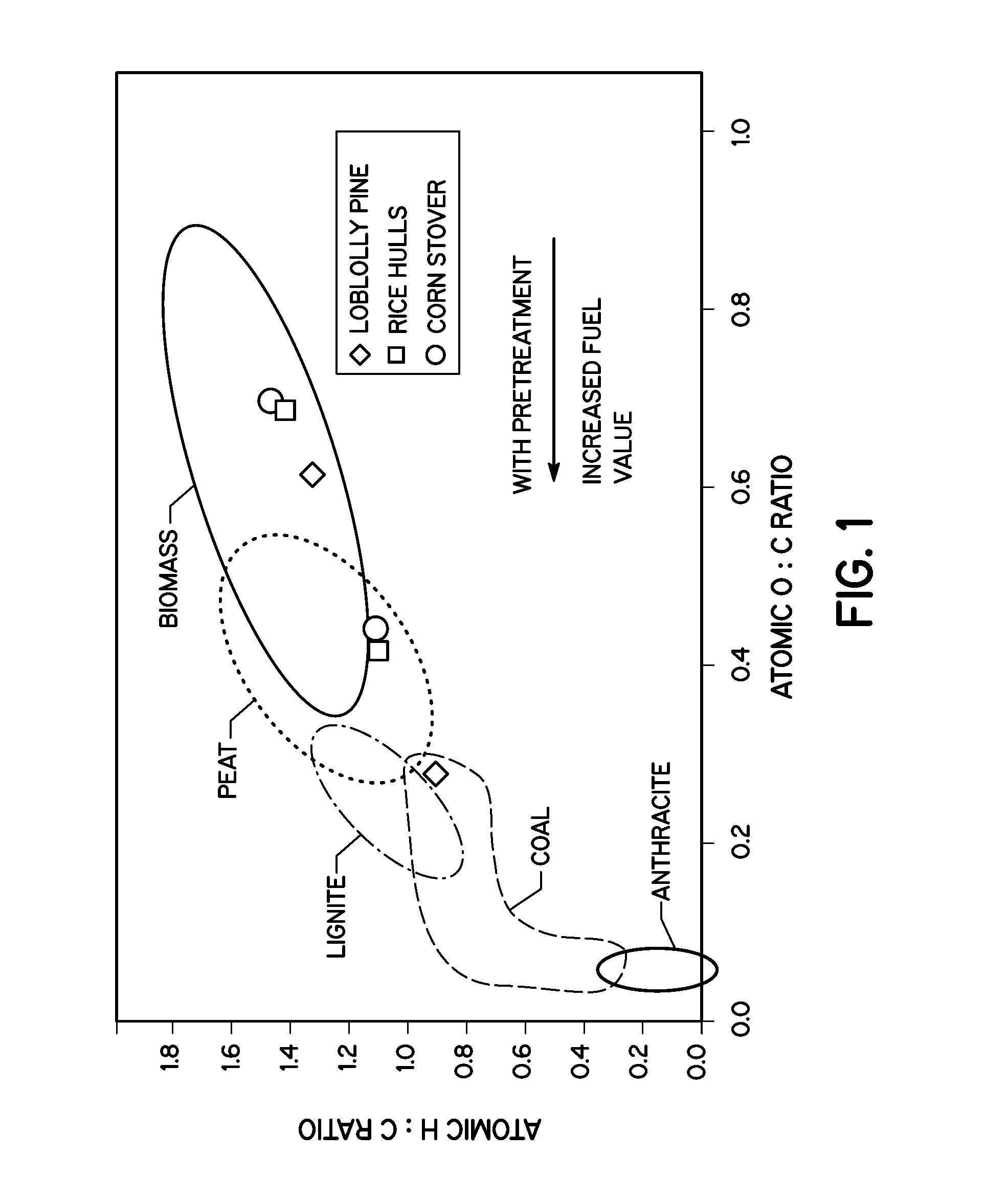

The present invention features methods and apparatus for the pyrolysis or torrefaction of a carbon-containing feedstock before it is converted to syngas. In some embodiments, biomass is first pretreated by torrefaction and / or pyrolysis, followed by devolatilization and / or steam reforming to produce syngas. Various mixtures of such pretreated biomass, combined with fresh biomass, can be employed to produce syngas. The syngas can be converted to alcohols, such as ethanol, or to other products.

Owner:RANGE FUELS INC

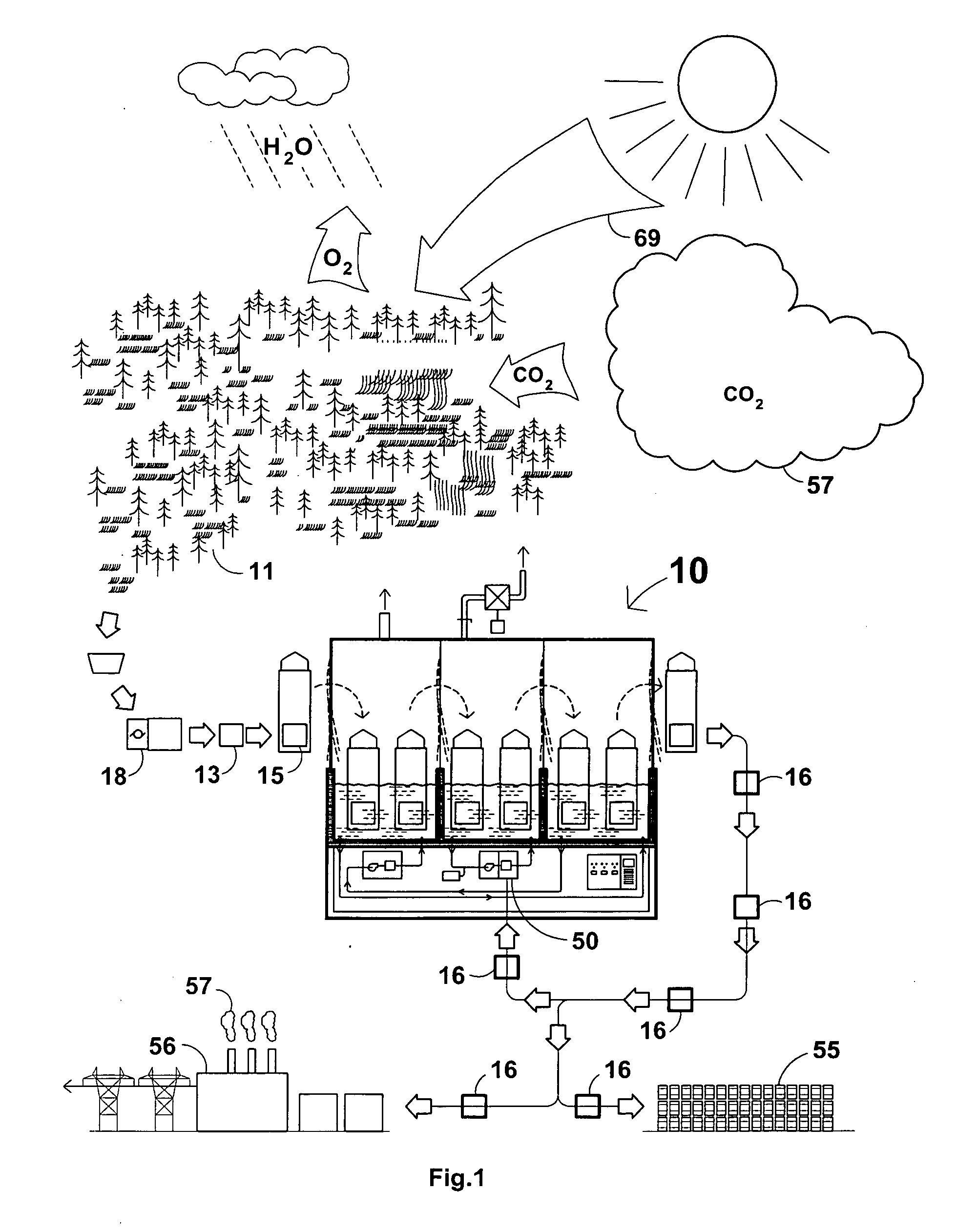

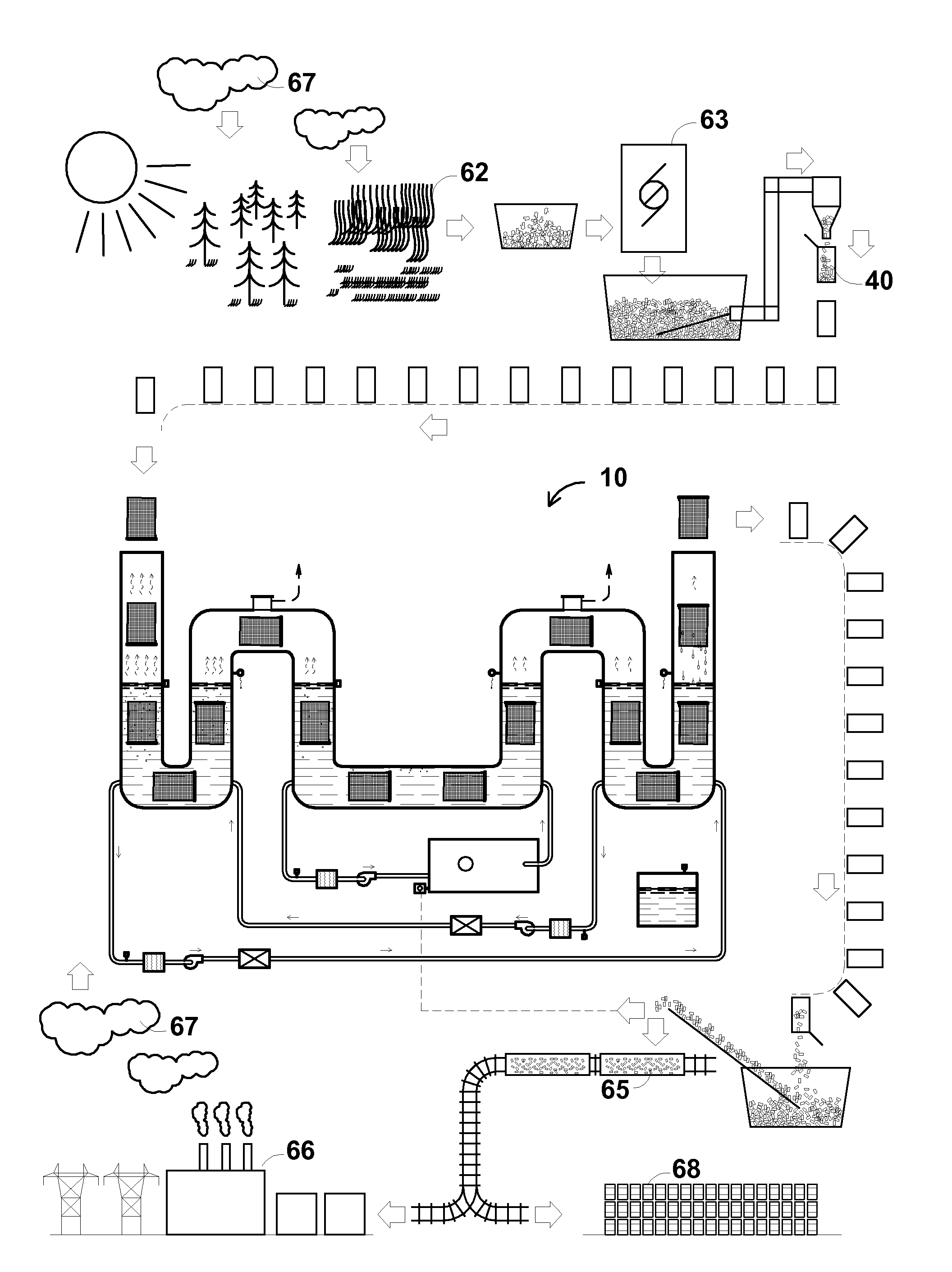

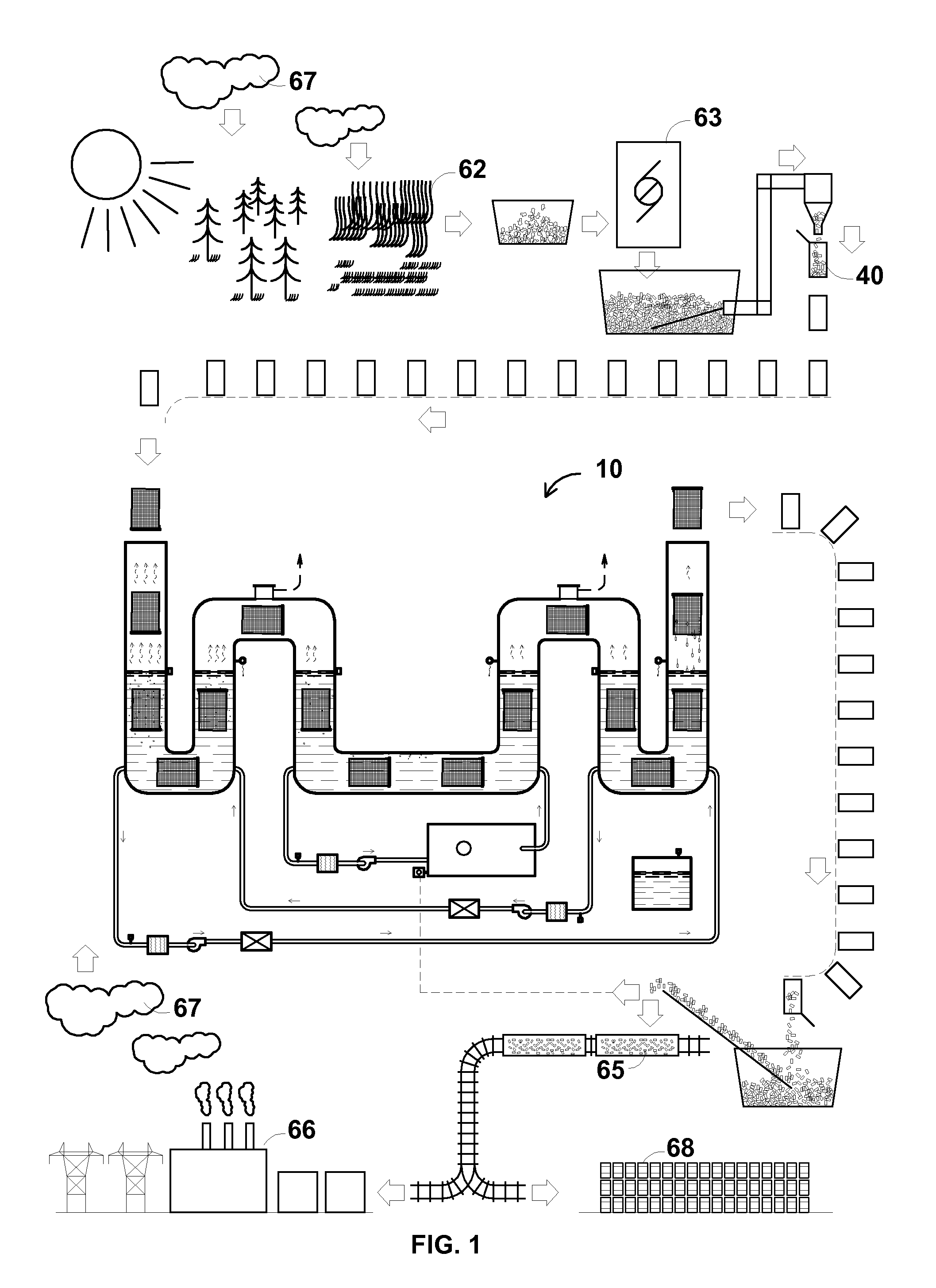

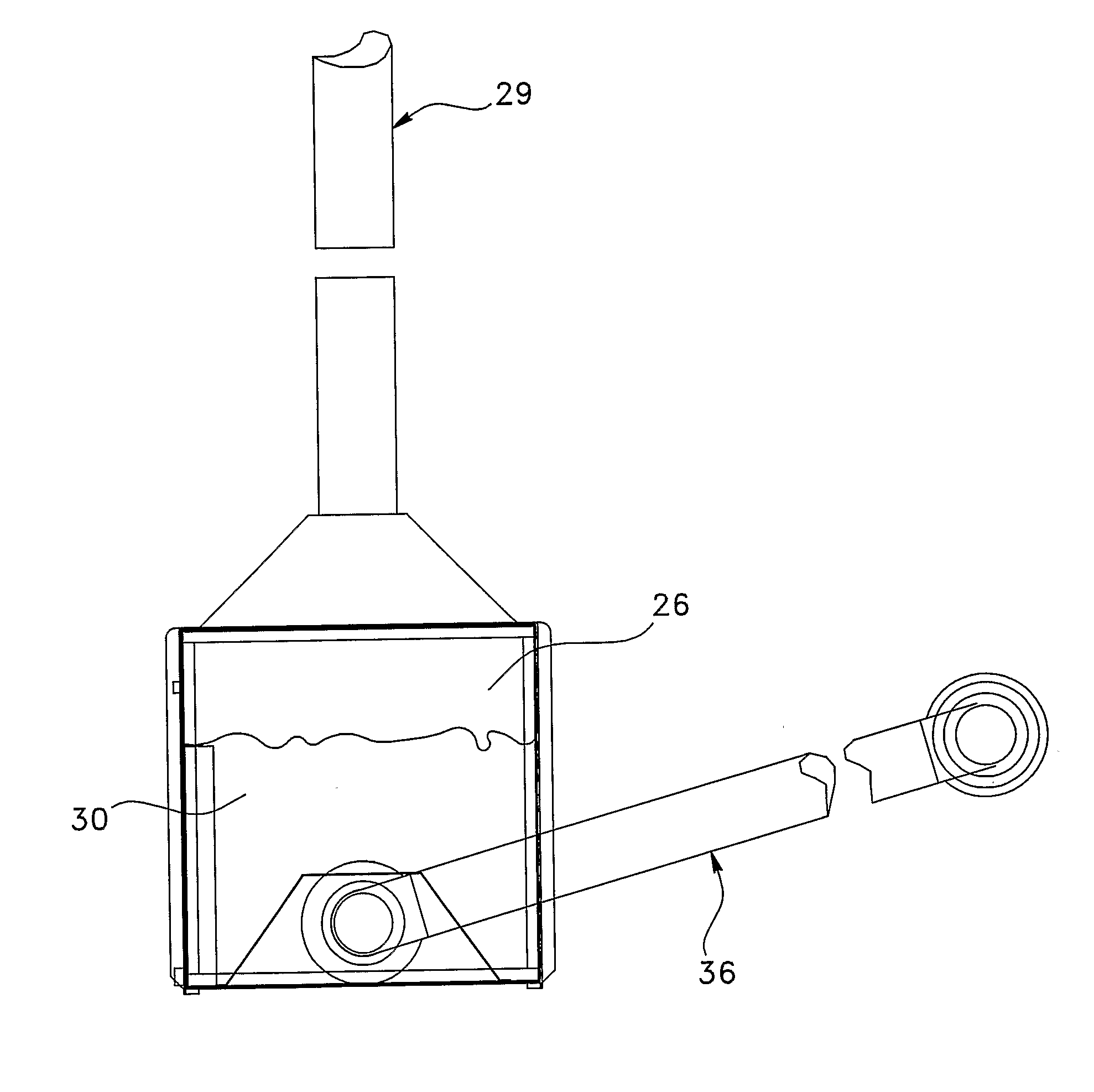

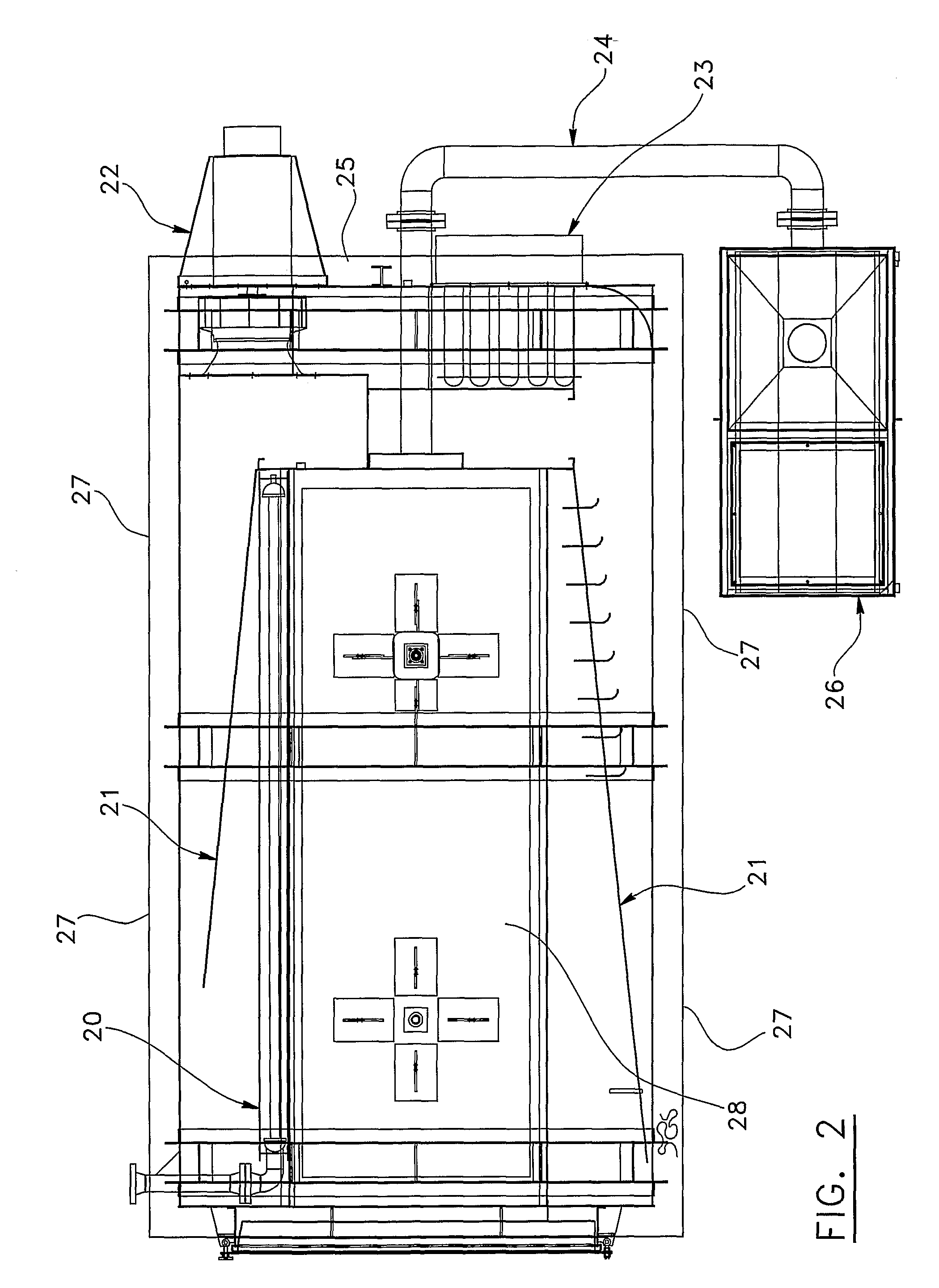

Method and apparatus for biomass torrefaction, manufacturing a storable fuel from biomass and producing offsets for the combustion products of fossil fuels and a combustible article of manufacture

ActiveUS20070266623A1Reduce air pollutionEasy to storeSolid fuel pretreatmentBiofuelsHigh elevationManufactured apparatus

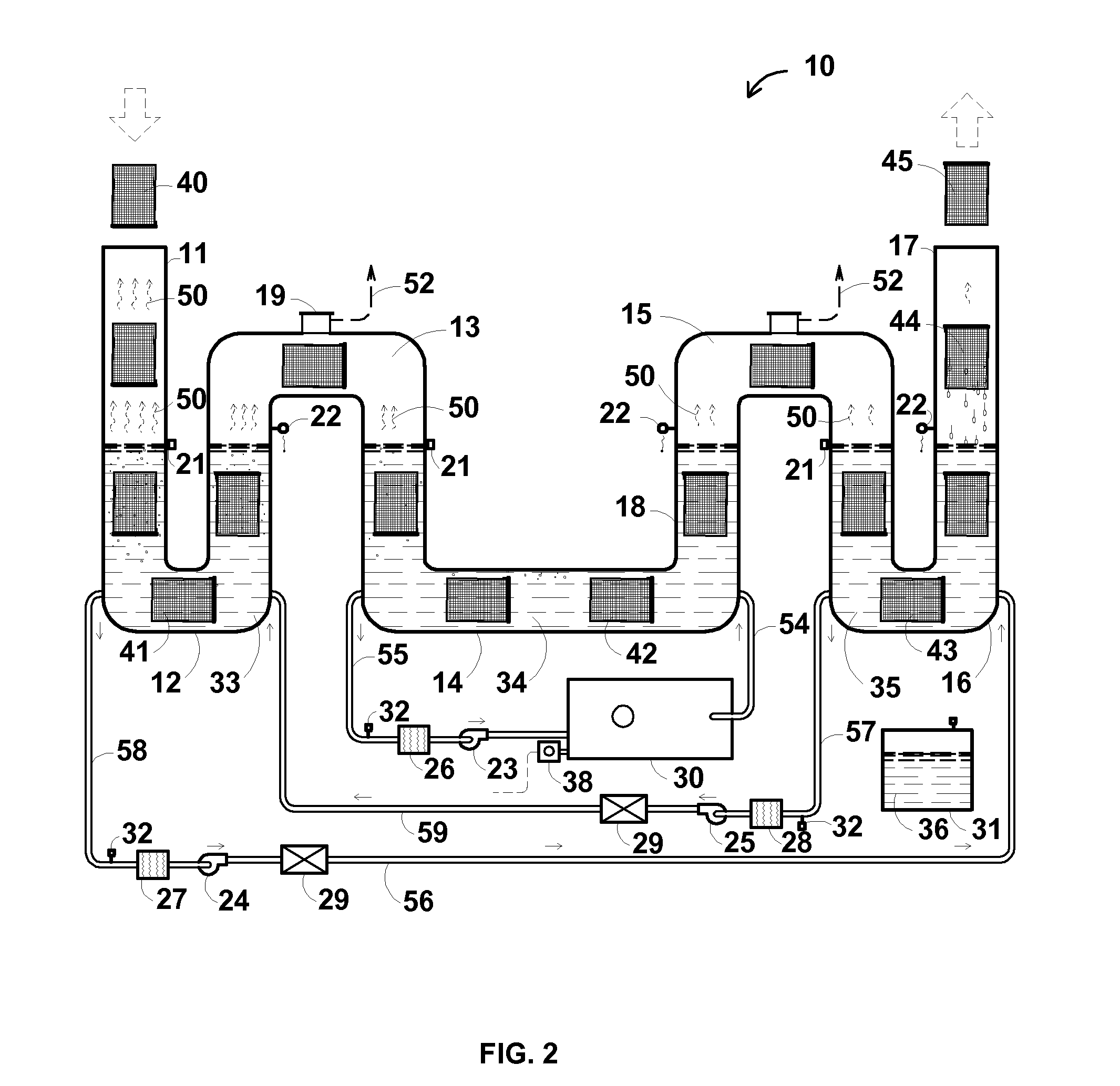

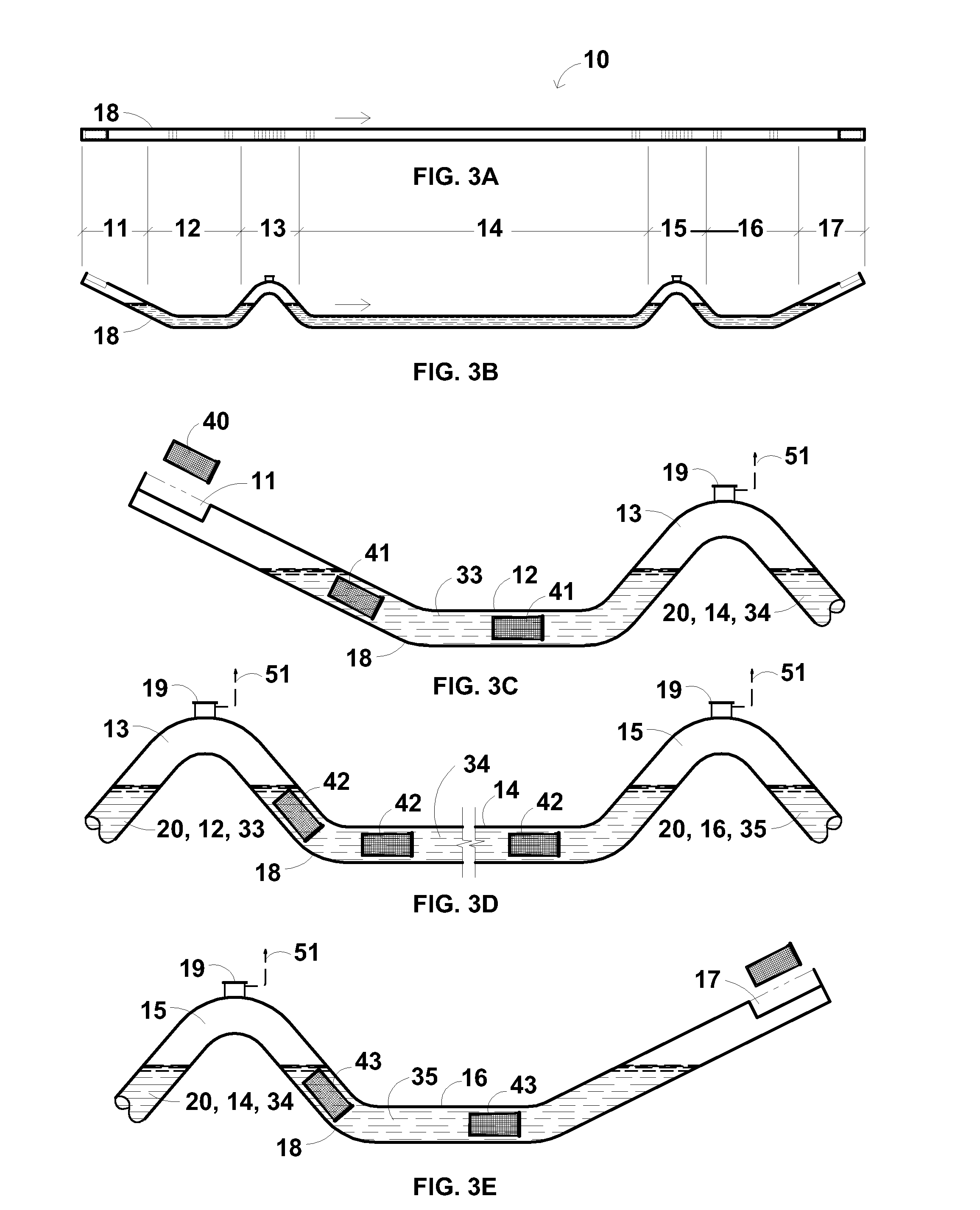

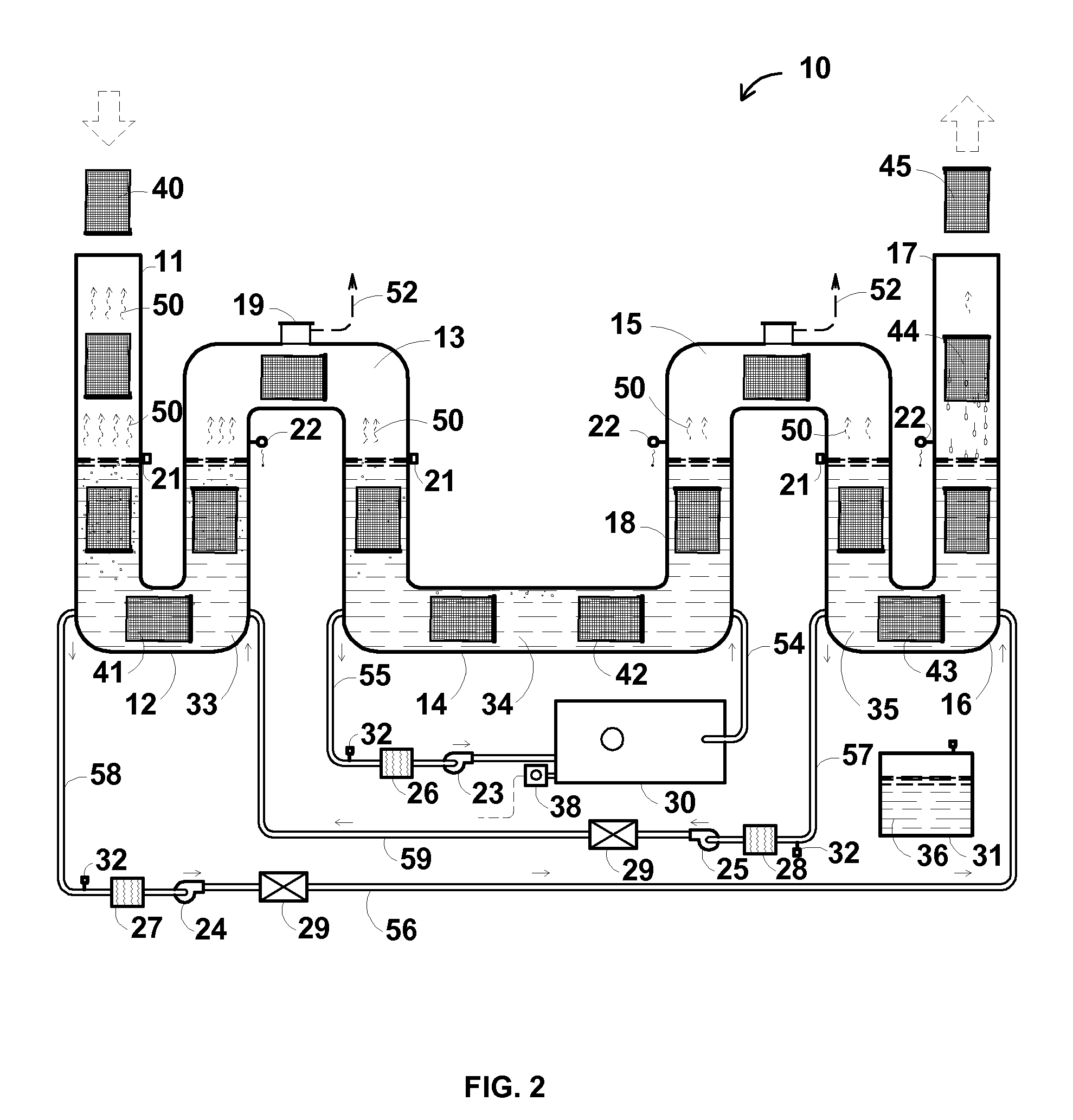

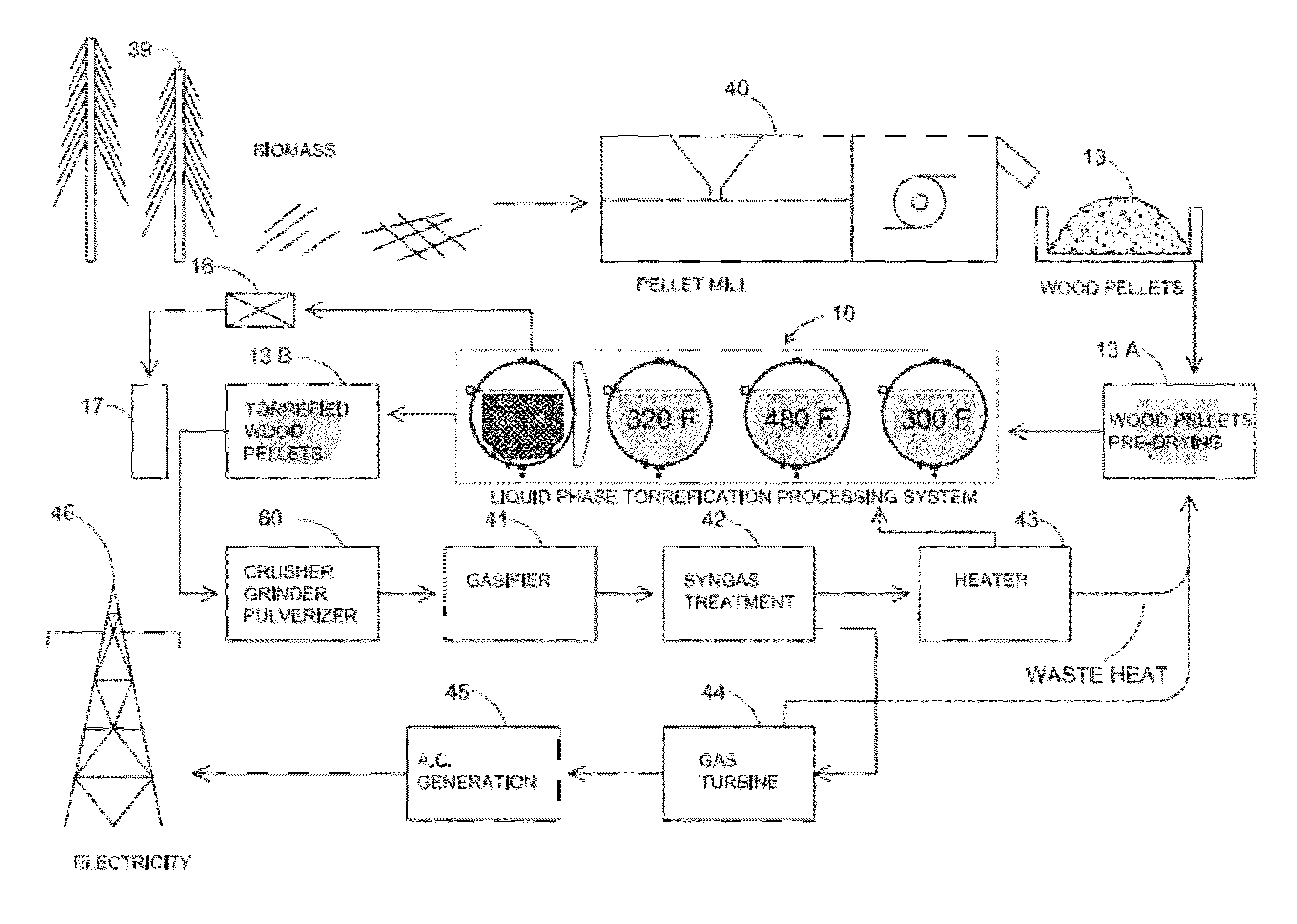

Apparatus for biomass torrefaction which includes a serpentine elongated housing, the housing having three generally U-shaped axial portions having first and second axial extremities and an intermediate section, the first and second axial extremities are disposed in normal use at a higher elevation than the first and second axial extremities, the intermediate section being configured for holding a liquid. Other forms of the invention include the method for biomass torrefaction which includes providing a quantity of biomass, providing a liquid heat transfer fluid, providing at least a first housing for holding the heat transfer liquid, elevating the temperature of the liquid heat transfer liquid, heat treating the biomass by passing it through the heat transfer liquid in the first housing at a temperature and duration sufficient to accomplish torrefaction of the wood. In some forms of the method, the process further includes the step of pelletizing the biomass prior to performing the treating step.

Owner:PAOLUCCIO JOHN A

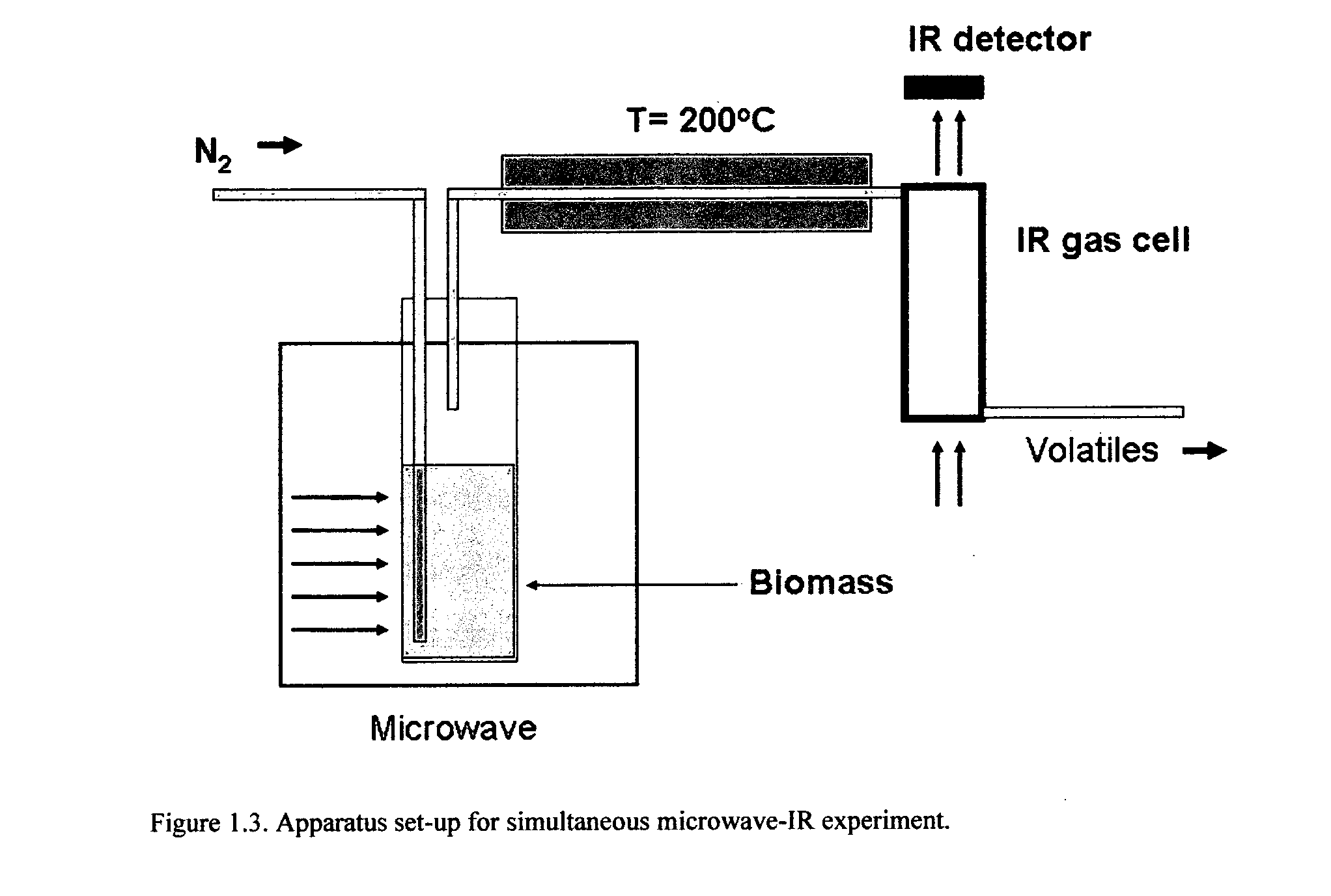

Microwave torrefaction of biomass

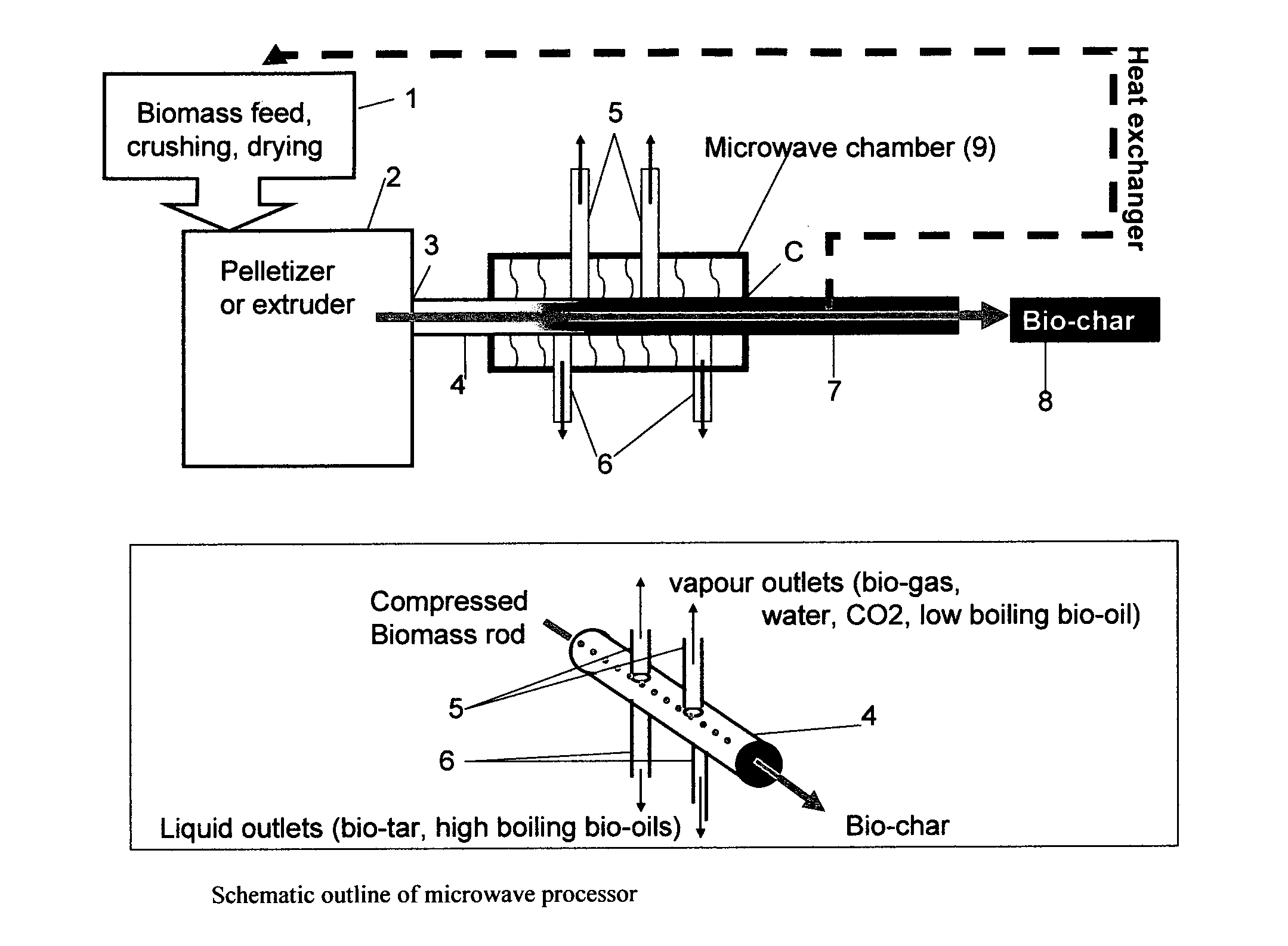

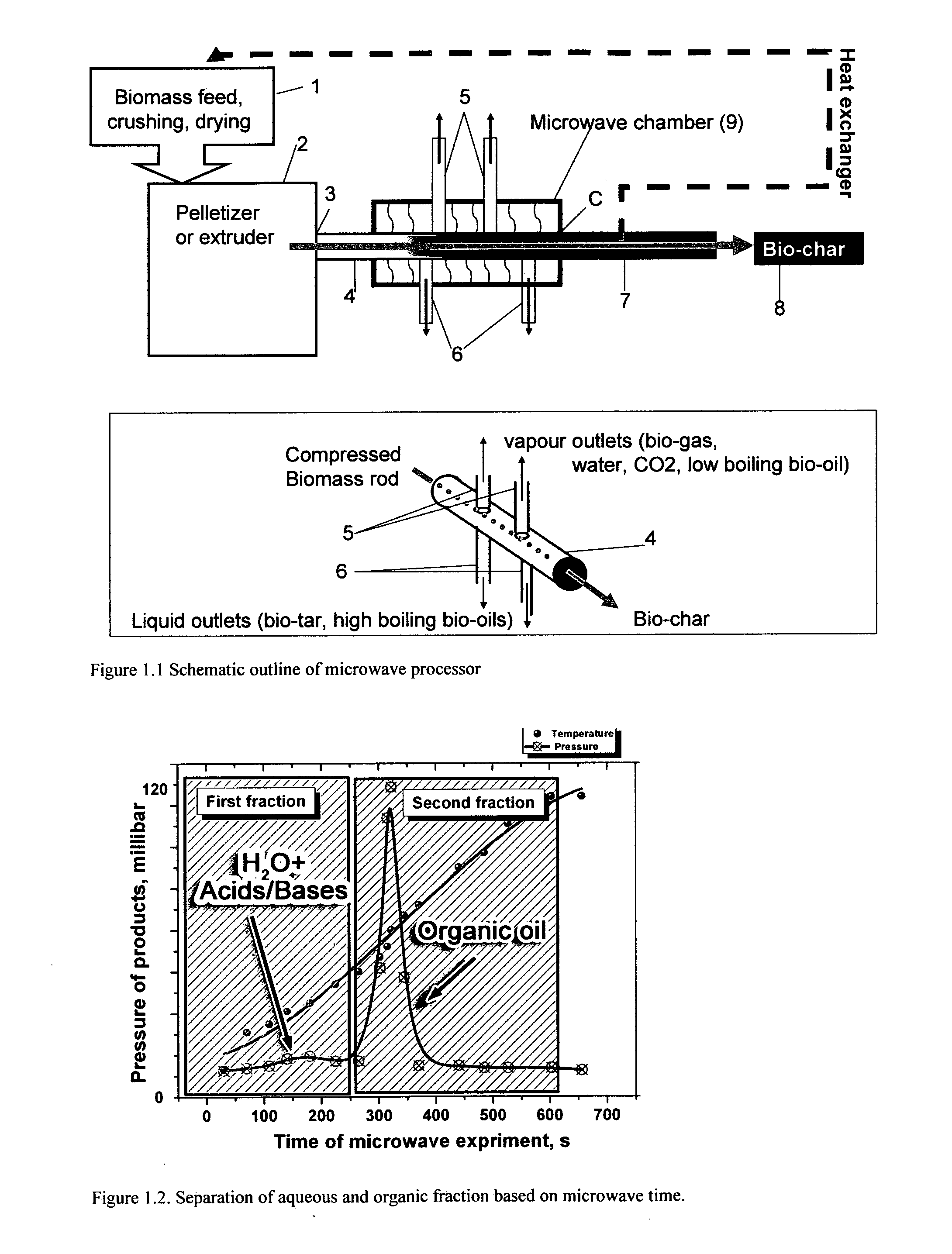

InactiveUS20110219679A1Increase flexibilityEasy to controlElectrical coke oven heatingBiofuelsMicrowaveTorrefaction

Owner:THE UNIV OF YORK

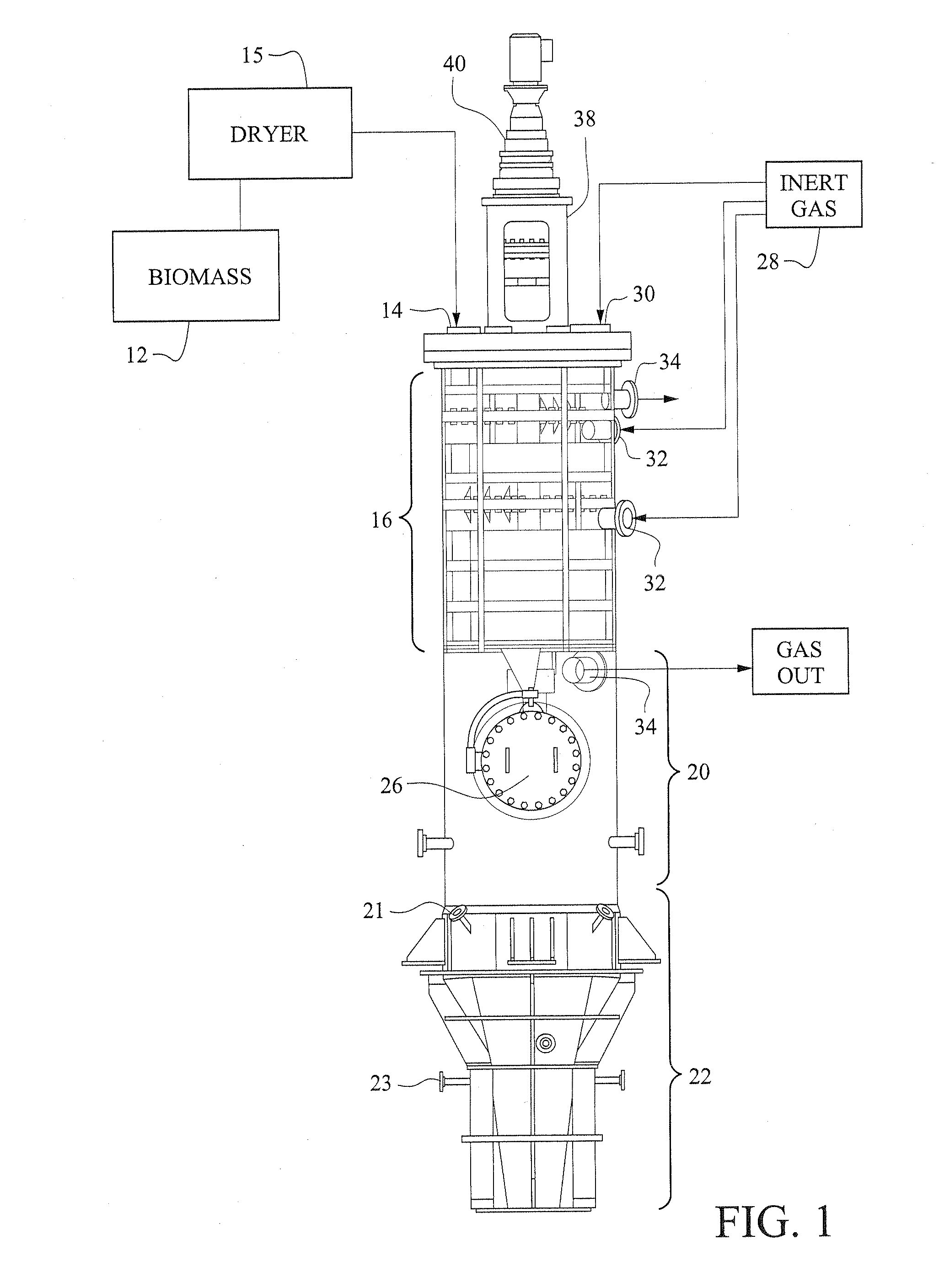

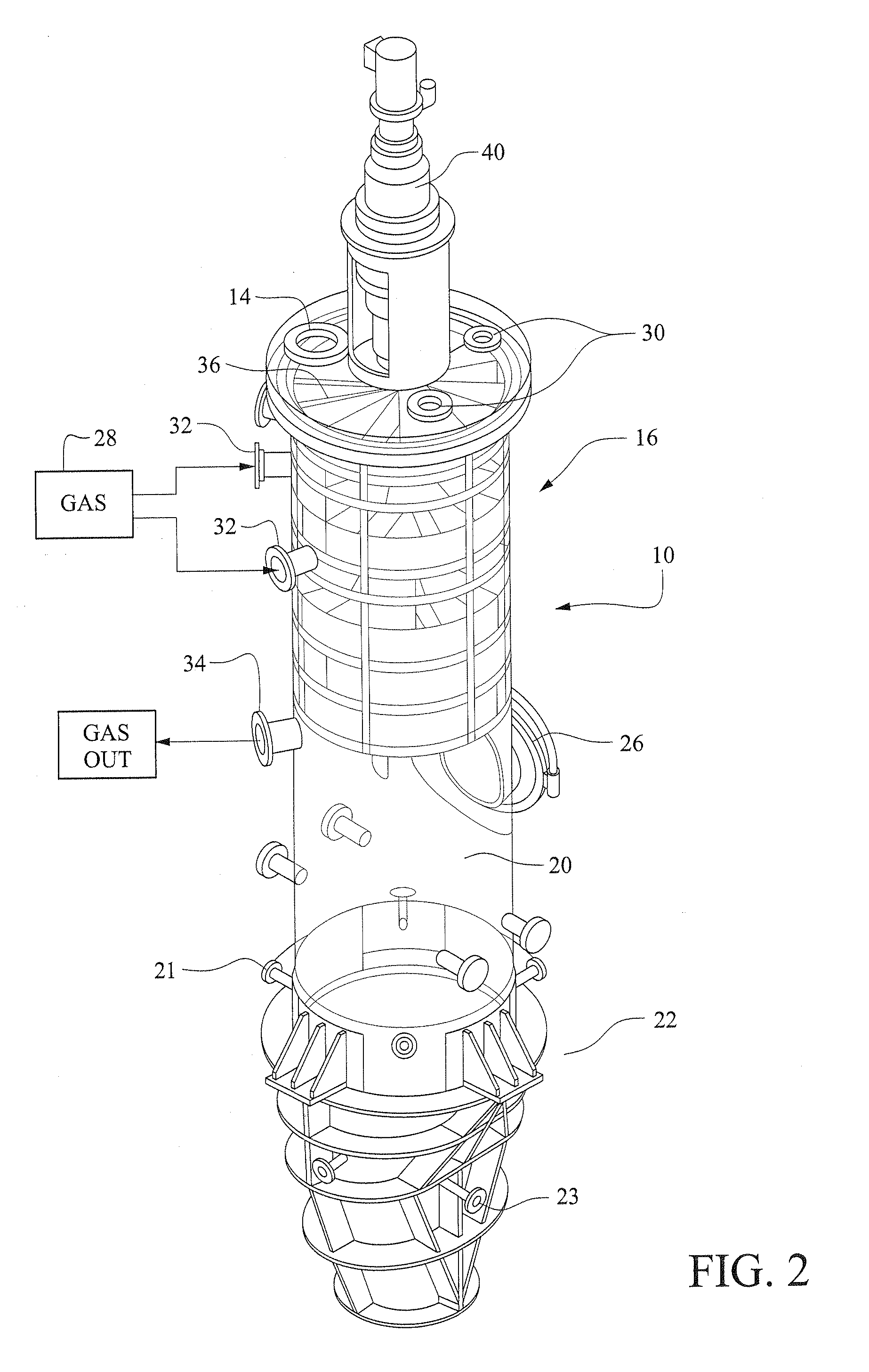

Autothermal and mobile torrefaction devices

ActiveUS20090250331A1Increased cost-effectivenessLow costCombustible gas coke oven heatingCharging-discharging device combinationsCombustorEngineering

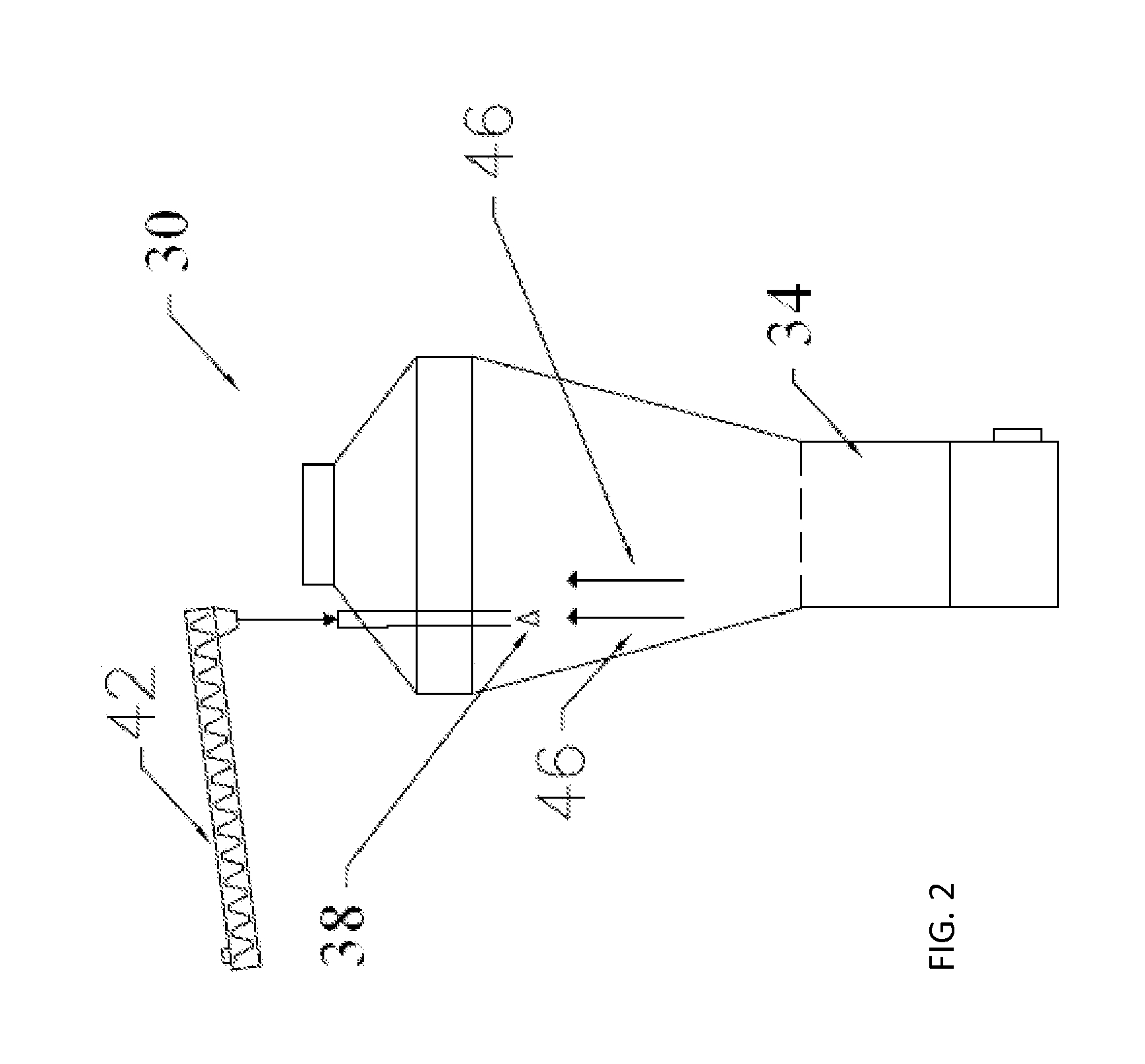

The present invention provides an autothermal torrefaction device, which can be either stationary of mobile. Embodiments of the present invention include a torrefaction chamber having a chamber inlet for receiving biomass and at least one chamber outlet. The torrefaction chamber can be substantially surrounded by an exterior housing defining an outer jacket and having a jacket inlet and a jacket outlet. The outer jacket and torrefaction chamber define a space therebetween such that a burner unit including an inlet operatively connected to the chamber outlet and an outlet operatively connected to the jacket inlet allows vapors produced or released from within the torrefaction chamber to travel into the burner unit for combustion of at least a portion of the vapors and subsequently travel through the space between the jacket and the torrefaction chamber to provide heat necessary for autothermal torrefaction of biomass.

Owner:NORTH CAROLINA STATE UNIV

Method and apparatus for biomass torrefaction, manufacturing a storable fuel from biomass and producing offsets for the combustion products of fossil fuels and a combustible article of manufacture

Apparatus for biomass torrefaction which includes a serpentine elongated housing, the housing having three generally U-shaped axial portions having first and second axial extremities and an intermediate section, the first and second axial extremities are disposed in normal use at a higher elevation than the first and second axial extremities, the intermediate section being configured for holding a liquid. Other forms of the invention include the method for biomass torrefaction which includes providing a quantity of biomass, providing a liquid heat transfer fluid, providing at least a first housing for holding the heat transfer liquid, elevating the temperature of the liquid heat transfer liquid, heat treating the biomass by passing it through the heat transfer liquid in the first housing at a temperature and duration sufficient to accomplish torrefaction of the wood. In some forms of the method, the process further includes the step of pelletizing the biomass prior to performing the treating step.

Owner:PAOLUCCIO JOHN A

Methods and apparatus for producing syngas and alcohols

The present invention features methods and apparatus for the pyrolysis or torrefaction of a carbon-containing feedstock before it is converted to syngas. In some embodiments, biomass is first pretreated by torrefaction and / or pyrolysis, followed by devolatilization and / or steam reforming to produce syngas. Various mixtures of such pretreated biomass, combined with fresh biomass, can be employed to produce syngas. The syngas can be converted to alcohols, such as ethanol, or to other products.

Owner:RANGE FUELS INC

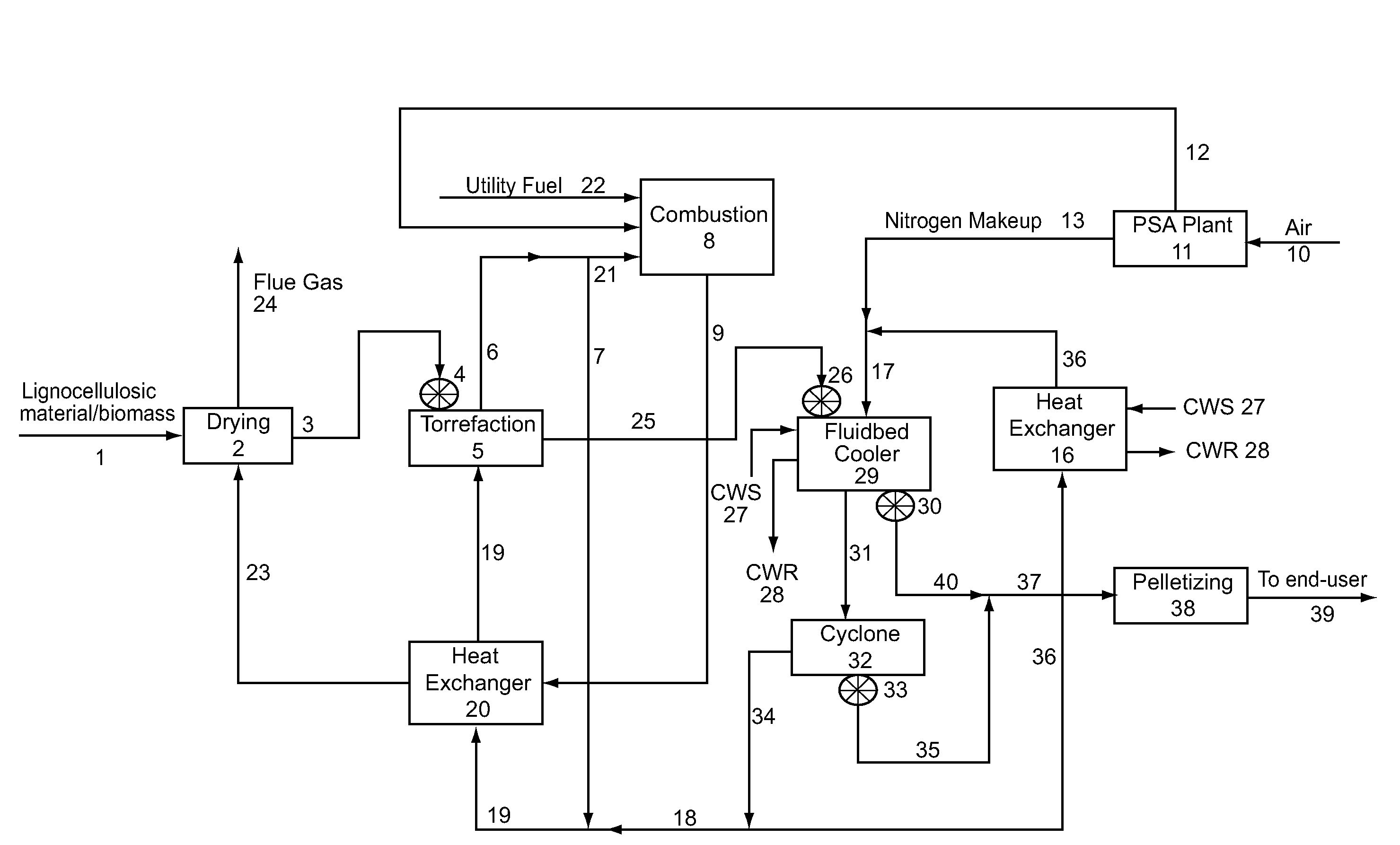

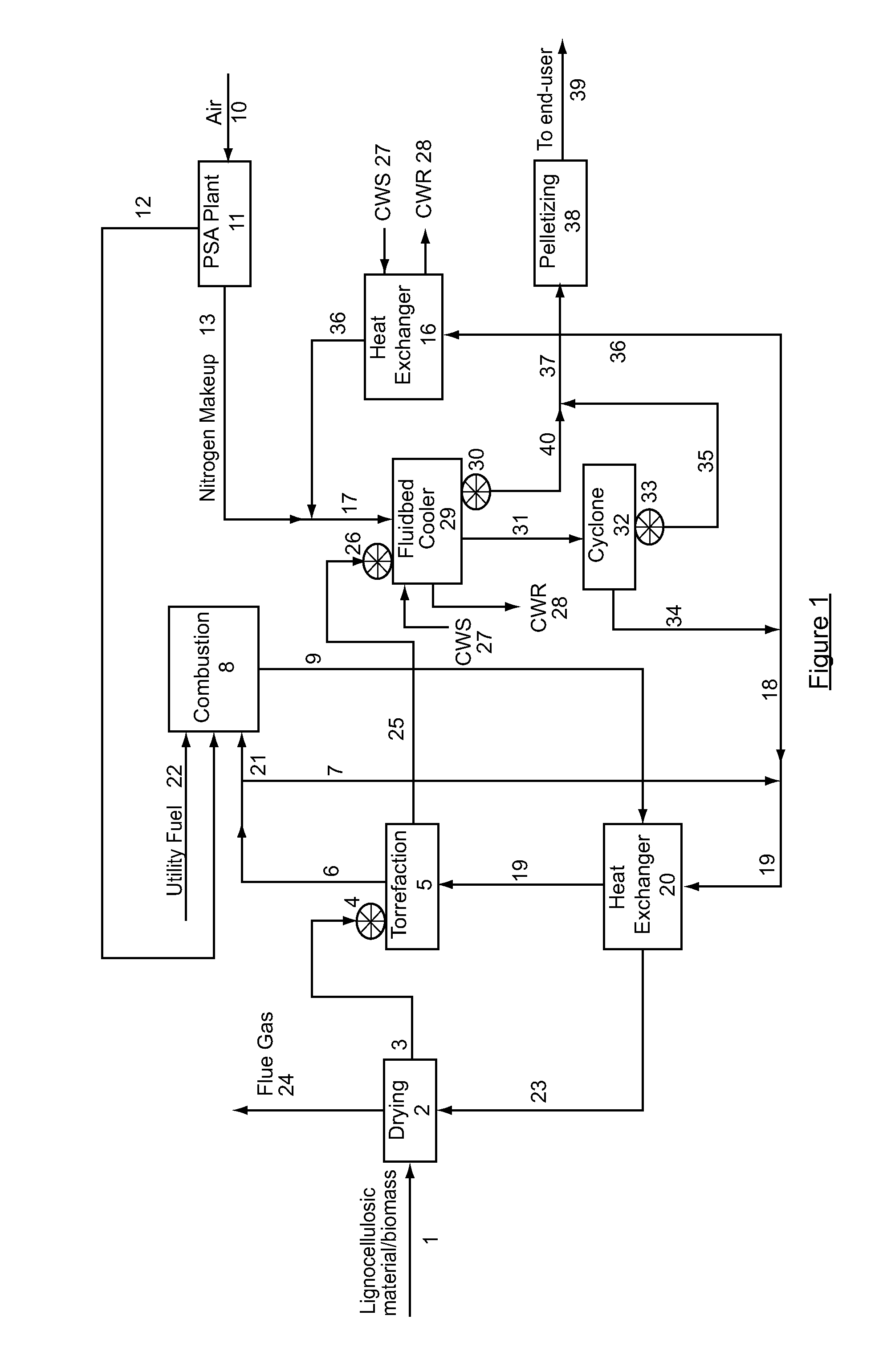

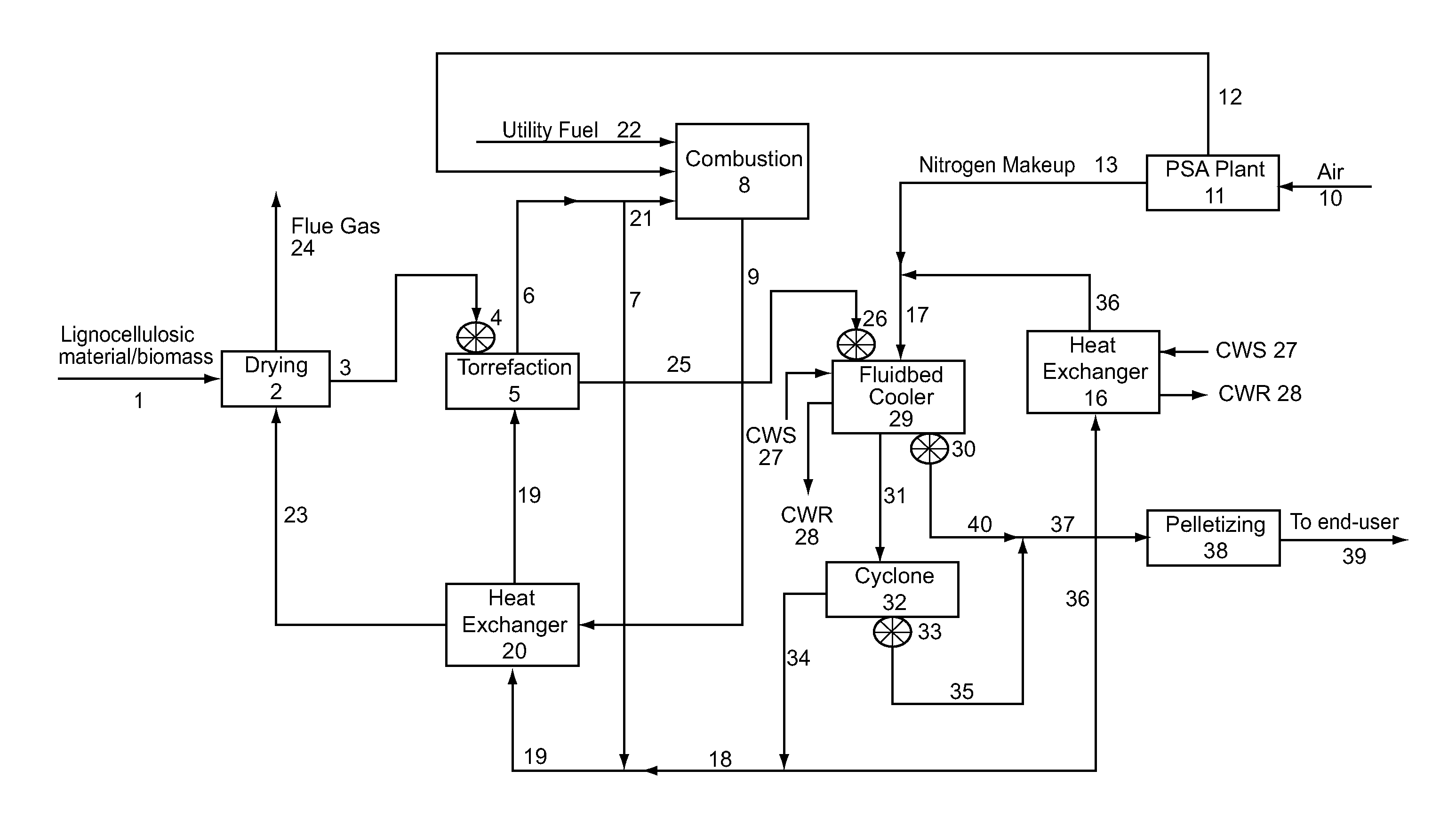

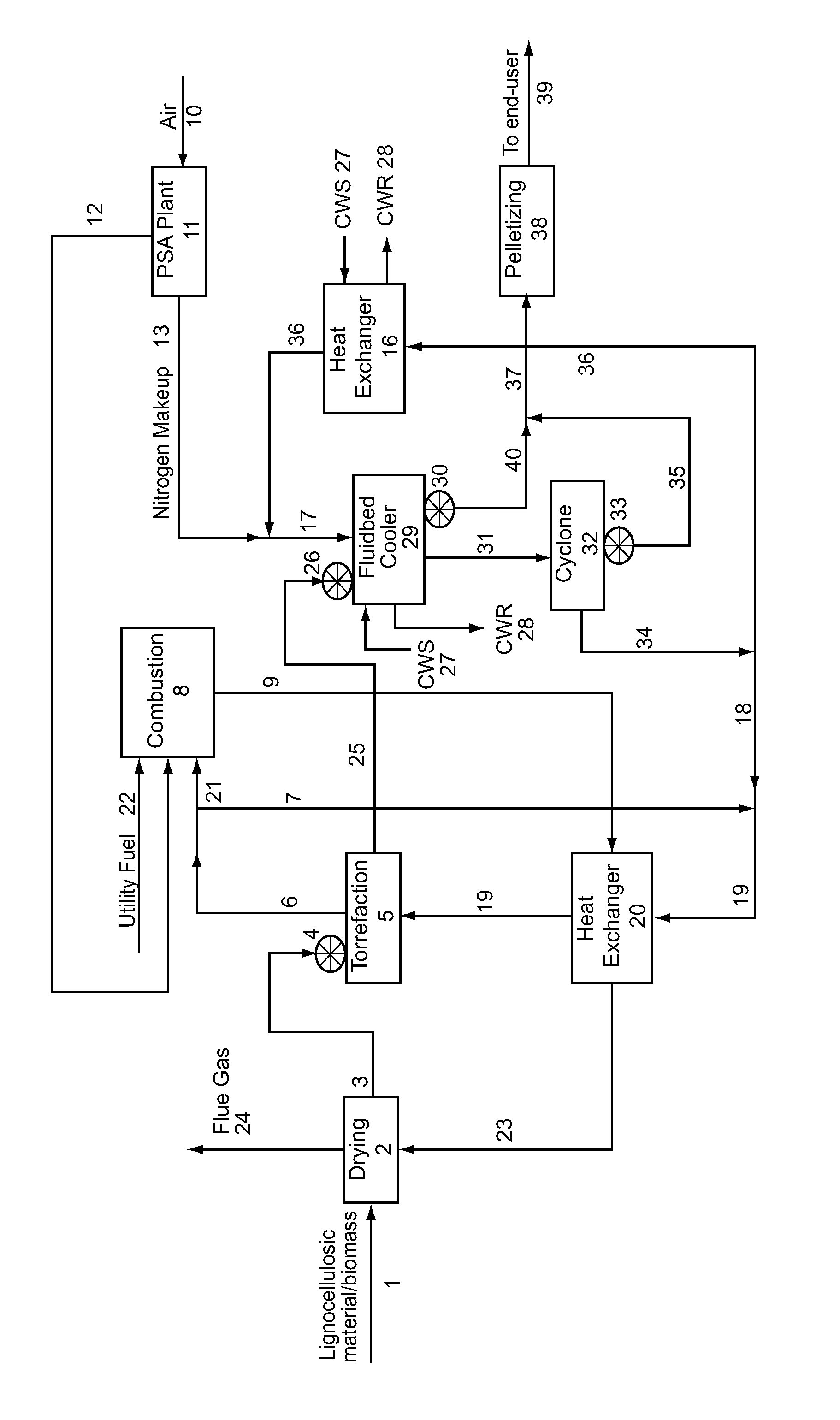

Method and system for the torrefaction of lignocellulosic material

InactiveUS20110041392A1BiofuelsIndirect and direct heating destructive distillationCelluloseProcess engineering

Owner:ANDRITZ TECH & ASSET MANAGEMENT

Method for wet torrefaction of a biomass

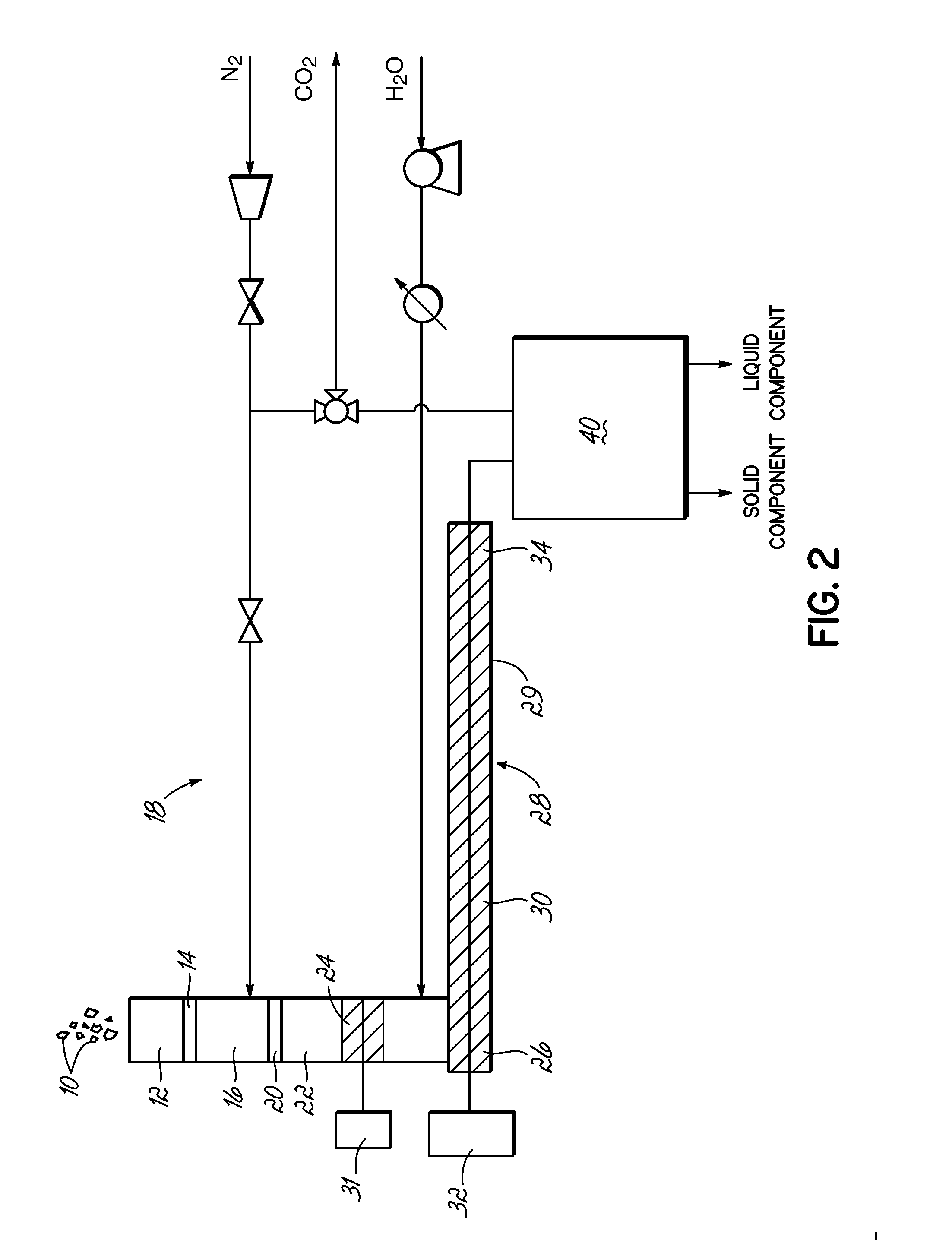

ActiveUS20120110896A1Increase energy densityIncrease mass densityHydrogenBiofuelsTorrefactionTemperature and pressure

A process for increasing the energy density of a biomass, which includes establishing a temperature and pressure within a reaction chamber that includes water and is at or above a desired reaction condition wherein the desired reaction condition is sufficient to increase the energy density of a reacted biomass; introducing a biomass into the reaction chamber such that the desired reaction condition is maintained or equilibrates thereto; and subjecting the biomass to the desired reaction condition for an amount of time effective to increase the energy density of the reacted biomass relative to the biomass prior to reaction.

Owner:BOARD OF RGT NEVADA SYST OF HIGHER EDUCATION ON BEHALF OF THE UNIV OF NEVADA RENO

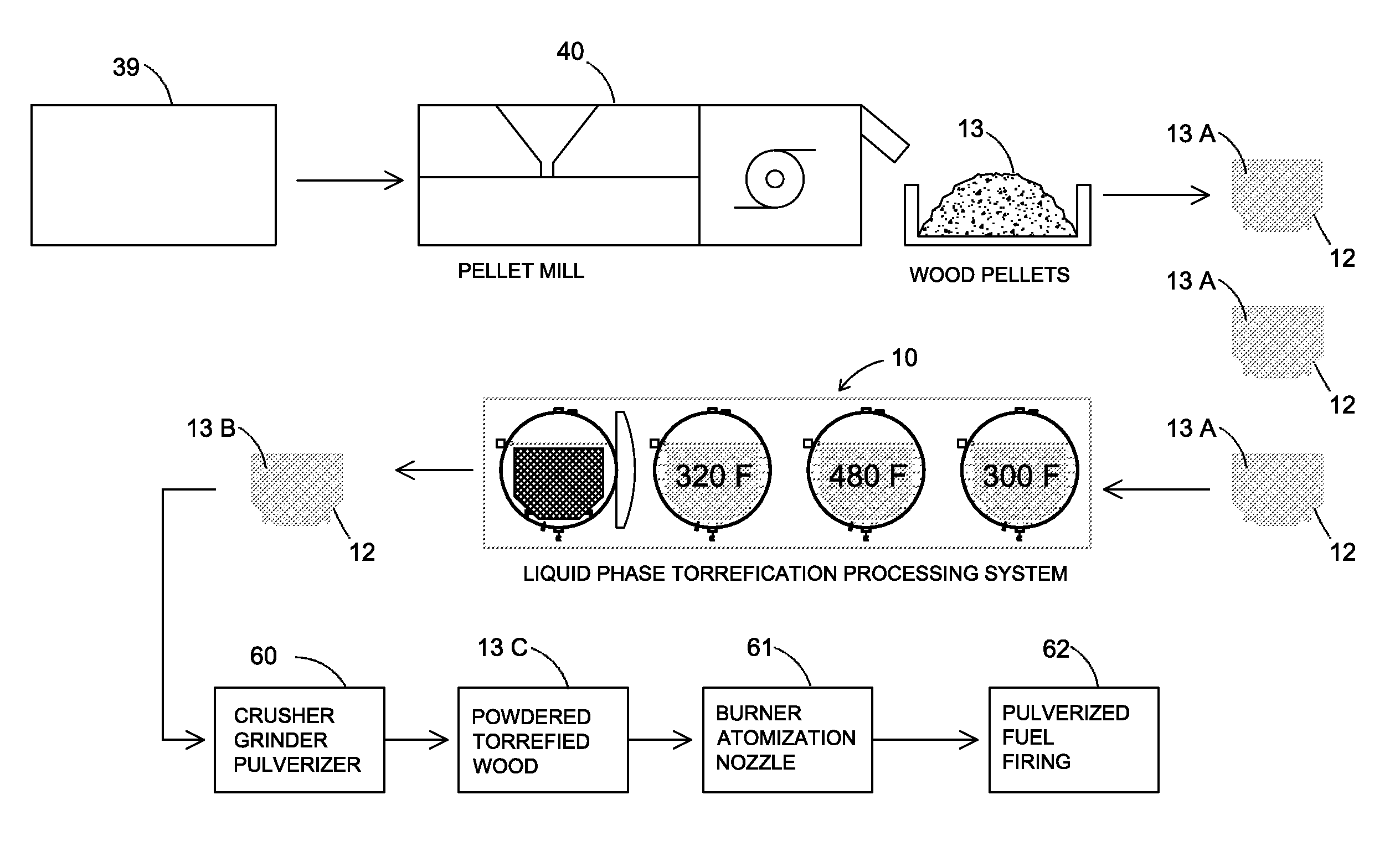

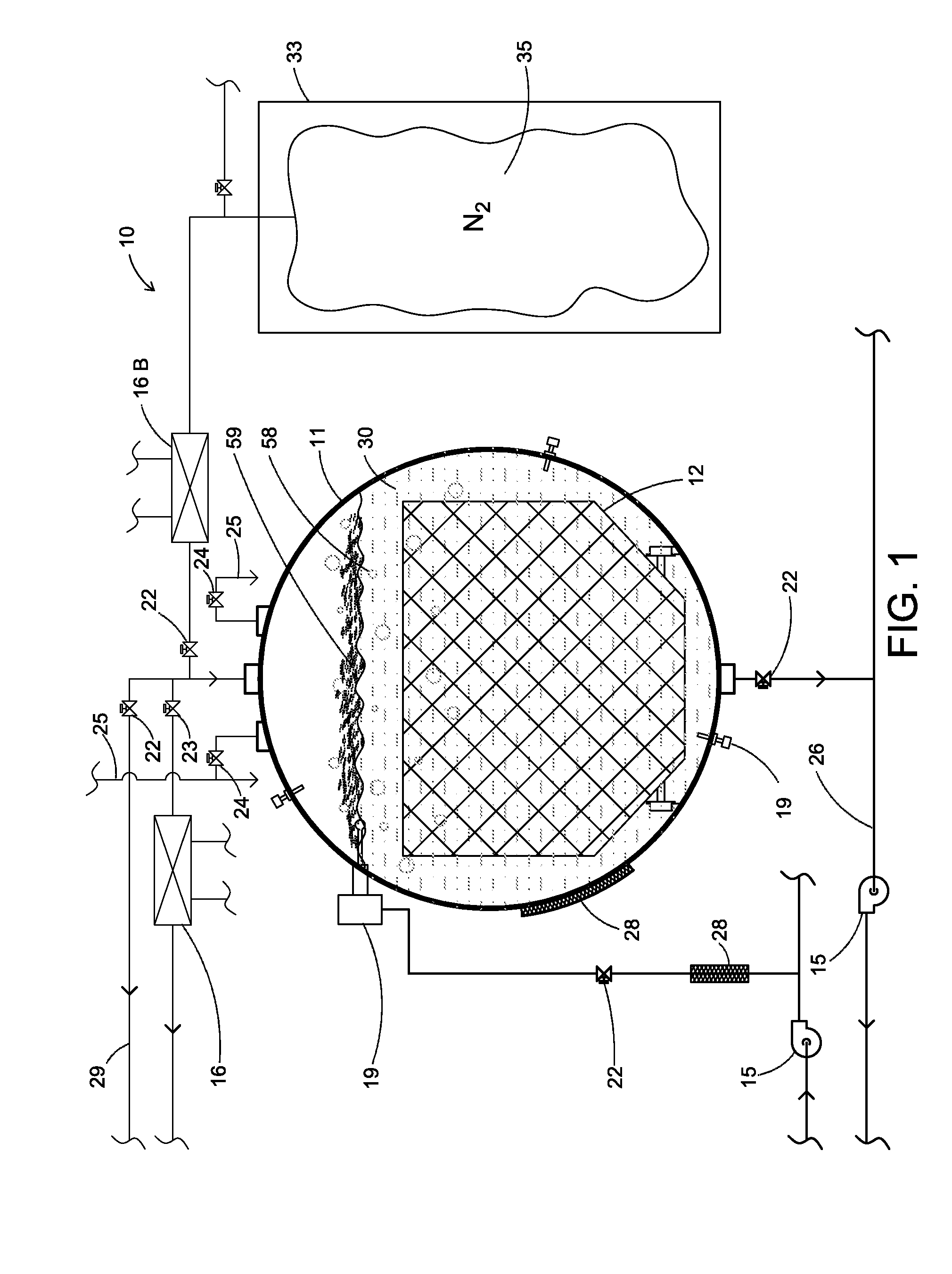

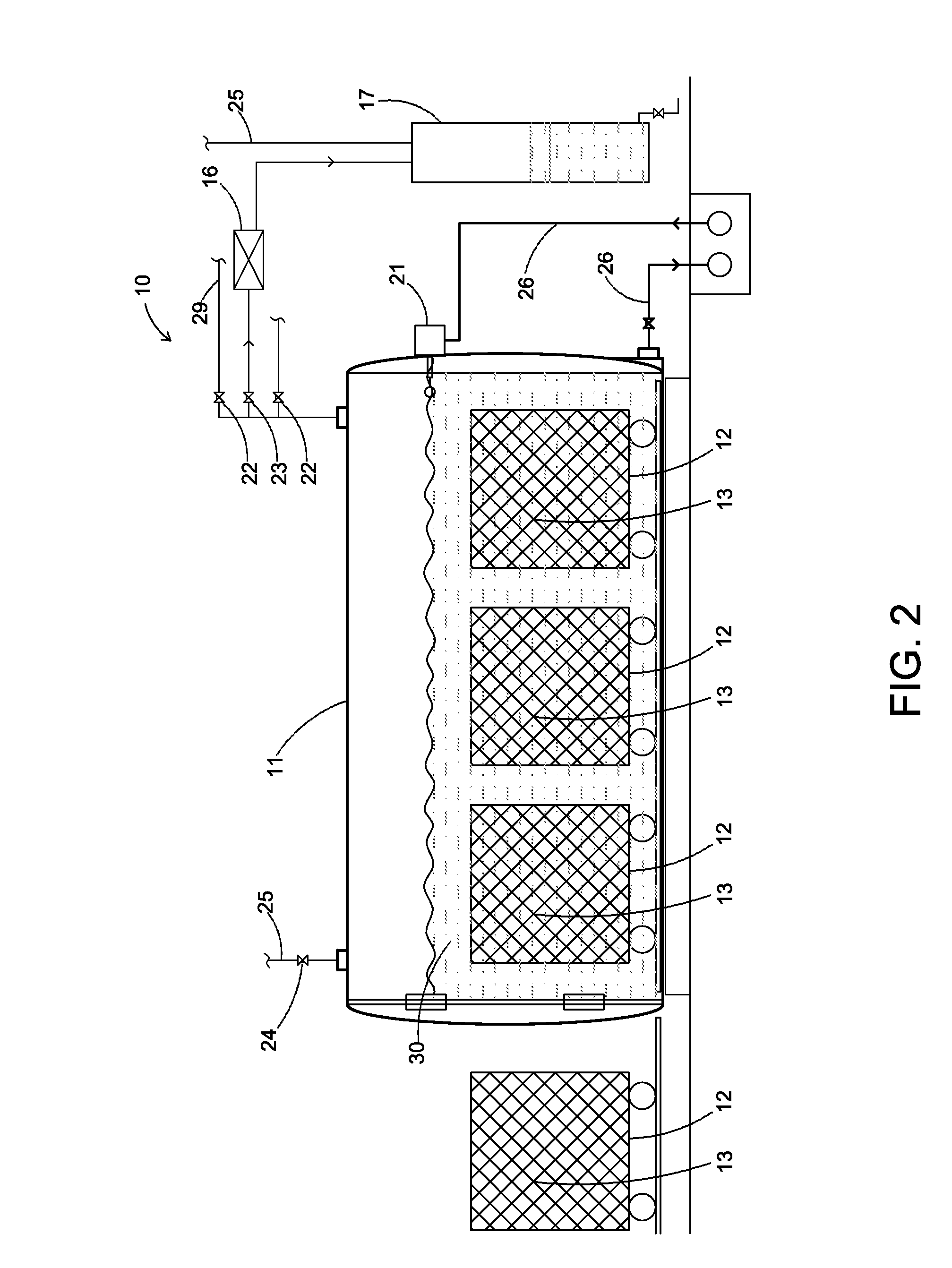

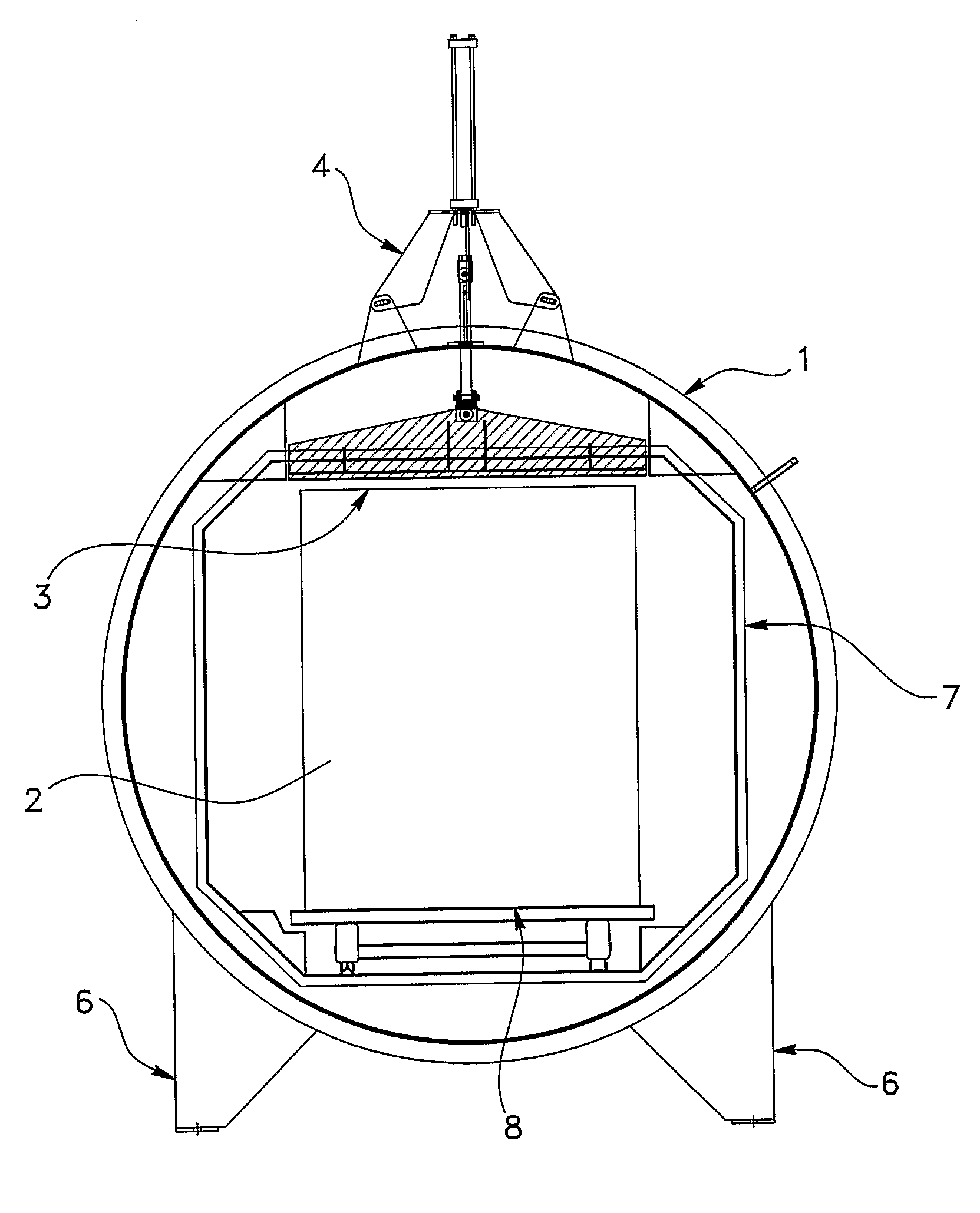

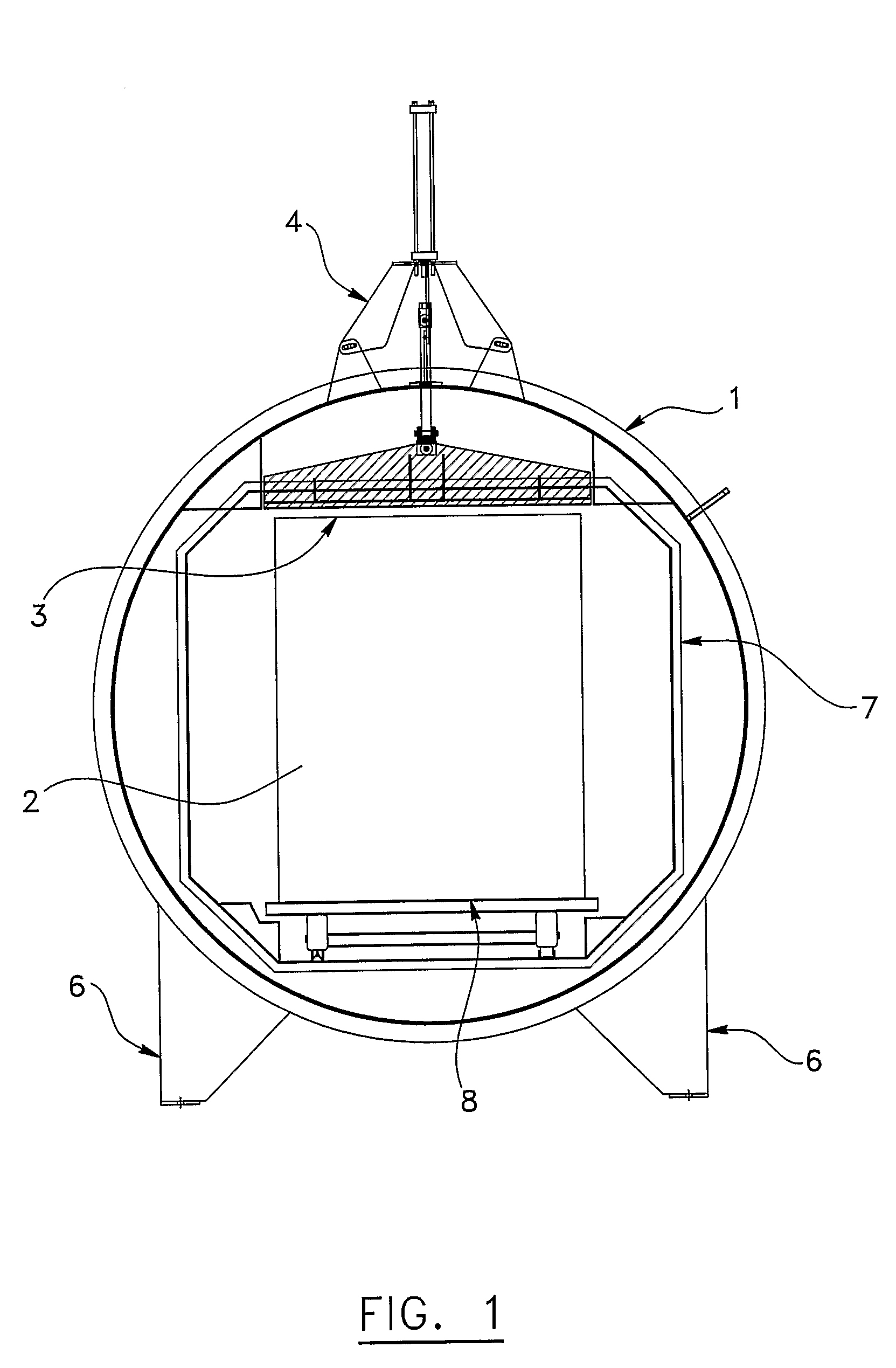

Sequencing retort liquid phase torrefication processing apparatus and method

ActiveUS20100251616A1Combustible gas coke oven heatingSolid waste disposalPositive pressureProduct gas

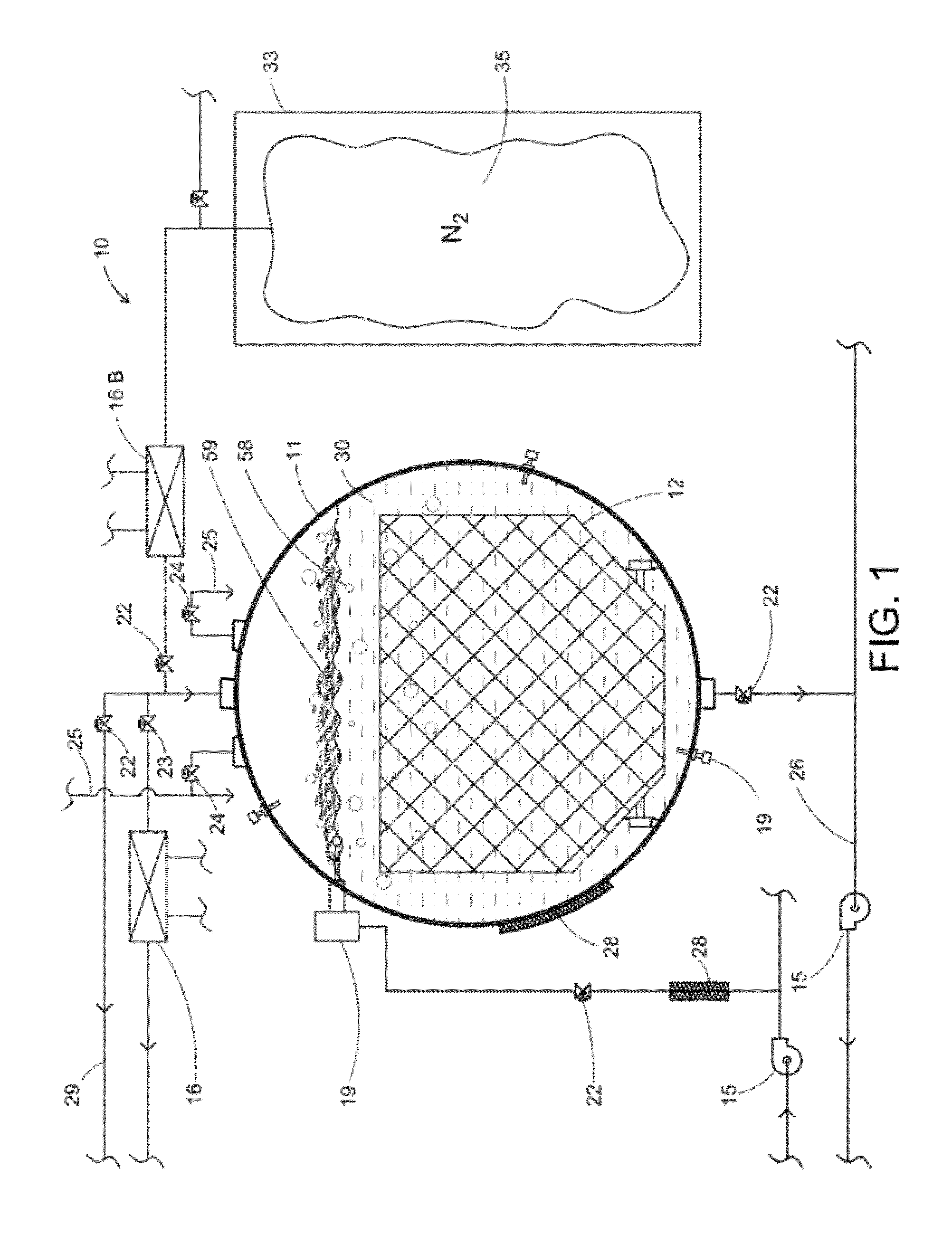

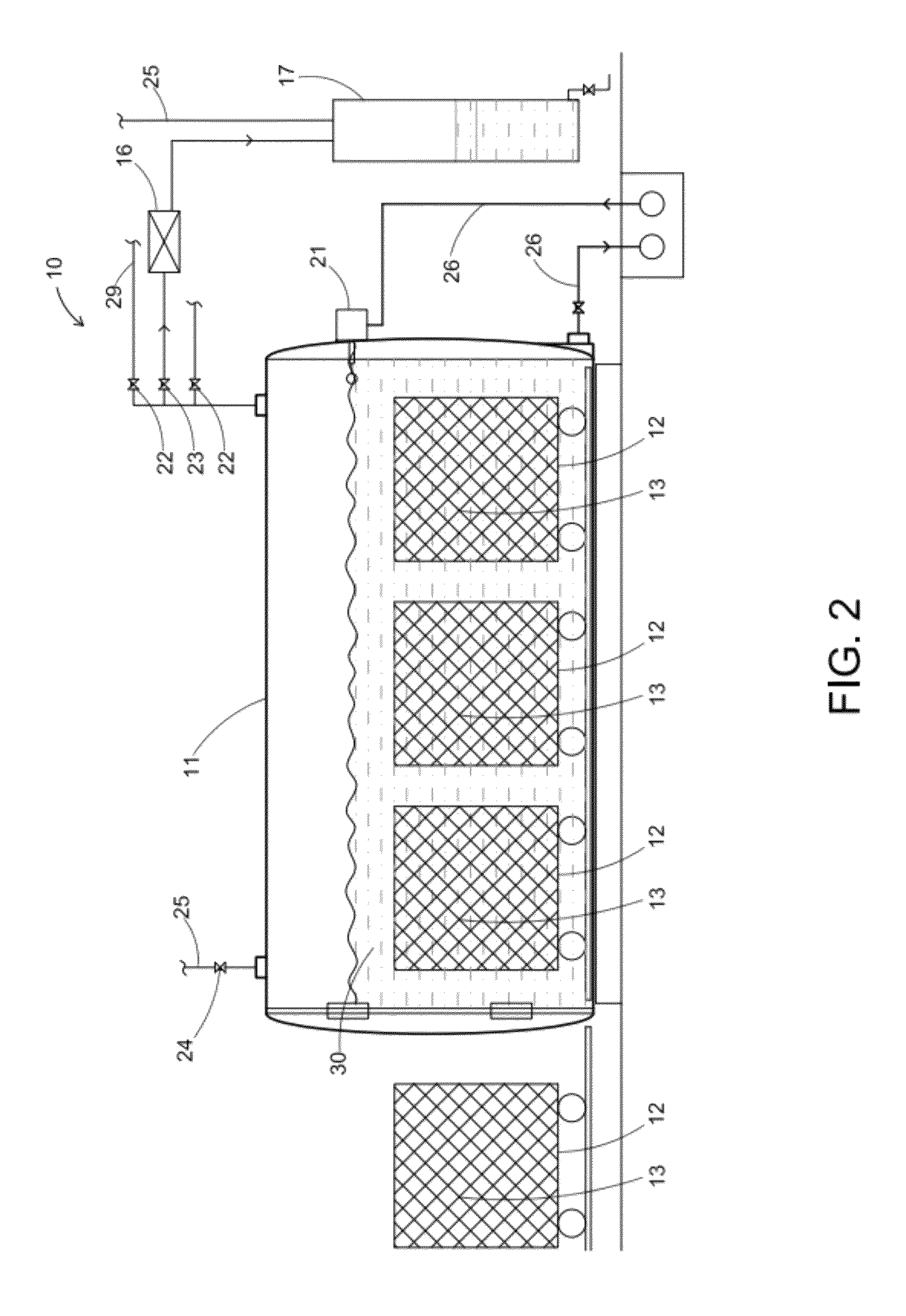

A method and related apparatus for torrefaction of associated biomass which includes providing an enclosed chamber having a body and a door having an open position allowing passage into and out of the enclosed chamber and a closed position in which the door is disposed in sealing engagement with the body, providing the enclosed chamber with walls capable of sustaining both a negative pressure and a positive pressure within the enclosed chamber; moving the door to an open position; depositing a liquid heat transfer fluid within the enclosed chamber at a temperature sufficient to achieve torrefication of the biomass and a first quantity of biomass material in the enclosed chamber that is substantially totally immersed in the liquid heat transfer fluid whereby heat transfer occurs between the liquid heat transfer fluid and the biomass immersed therein; moving the door to a closed position in sealing engagement with the body; and allowing the pressure within the enclosed chamber to rise to a pressure above the vapor pressure of the heat transfer fluid as a result of the expansion of liquids and gases entrained within the biomass.

Owner:PAOLUCCIO JOHN A +1

Torrefaction of ligno-cellulosic biomasses and mixtures

InactiveUS20110179701A1Consumes less energyFavorable energy balanceBiofuelsSolid fuelsCelluloseLignocellulosic biomass

A method of treating a biomass material to produce a fuel comprising the steps of preheating the biomass material to a temperature ranging from about 80° C. to about 100° C. and drying the biomass material until the biomass material has a maximum water content of no more than 3%. Microwave radiation is applied to the pre-dried biomass material in a range of 3.0 to 8.0 GHz to heat the biomass material to a temperature ranging from about 230° C. to about 280° C. resulting in torrefaction of the biomass material. The biomass material is then cooled.

Owner:G ENERGY TECH

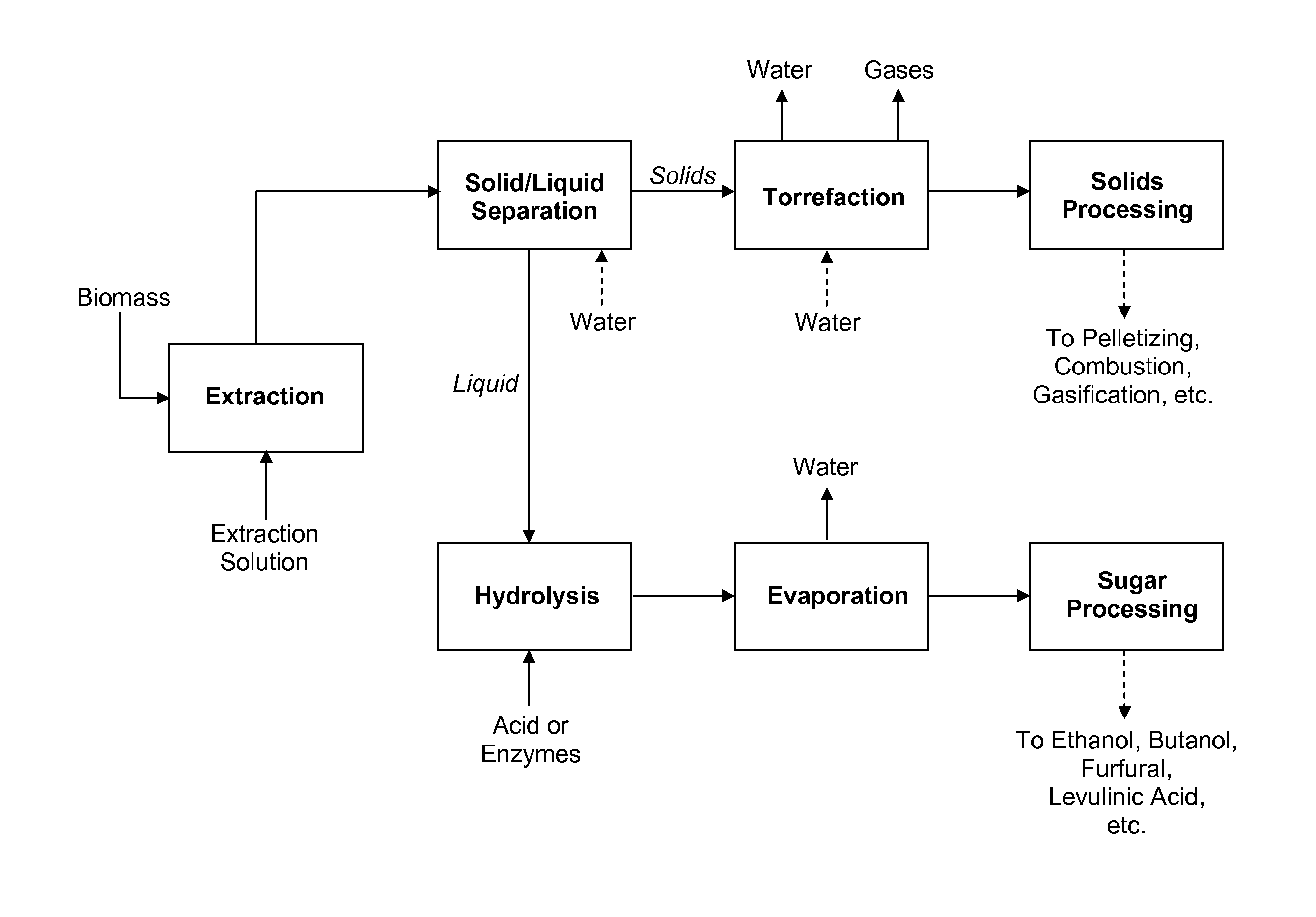

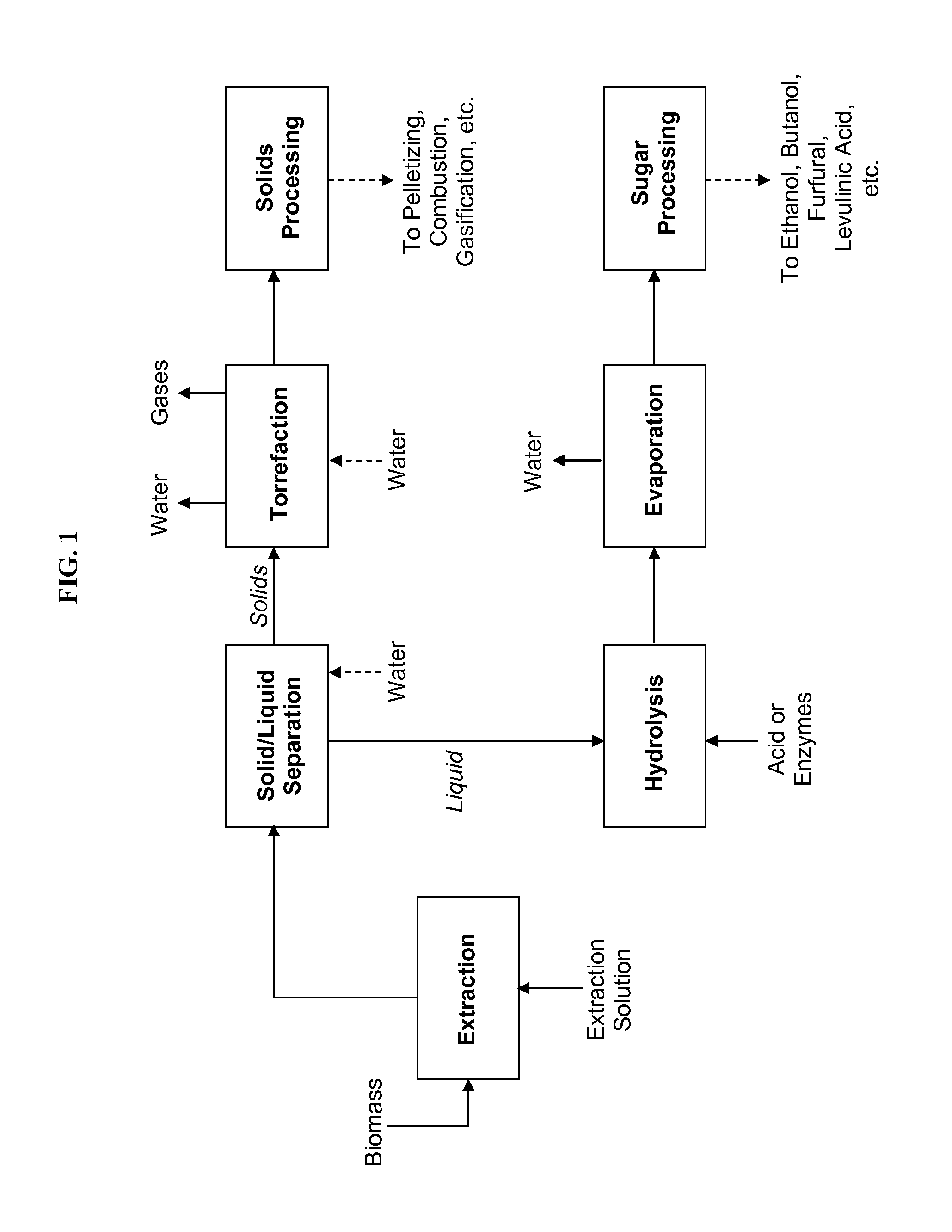

Processes for producing energy-dense biomass and sugars or sugar derivatives, by integrated hydrolysis and torrefaction

Owner:API INTELLECTUAL PROPERTY HOLDINGS LLC

Method for preparing petroleum distillate oil hydrotreating catalysts without torrefaction

InactiveCN101157058ASimple preparation stepsReduce manufacturing costMolecular sieve catalystsCatalyst activation/preparationHydrogenHydrodesulfurization

The invention provides a preparation method for roasting-free hydrotreating catalyst, the catalyst takes Al 2 O 3, SiO 2, TiO 2, and a composite oxide of two of the Al 2 O 3, the SiO 2 as carriers, and takes group 6B metals and group 8 metals as active metal components, a right amount of organic chelating agent is added into metal impregnation liquid, to adjust the pH value of the impregnation liquid, the active metal components are supported to the upper part of the carrier by adopting a co-impregnation method or a multi-step impregnation method, the carriers supporting the metal components are dried for 4 to 10 hours at 120 DEG C, without roasting, thereby the highly active hydrofining catalyst can be directly obtained. The metal components of the catalyst prepared by the invention have better dispersibility and sulfidization, thus the catalyst has good activity of hydrogen desulfurization and hydrodenitrification to petroleum fraction.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method of Drying Biomass

A process for torrefaction of biomass is provided in which biomass are passed into a fluidized bed reactor and heated to a predetermined temperature in an oxidizing environment. The dried biomass is then fed to a cooler where the temperature of the product is reduced to approximately 100 degrees Fahrenheit.

Owner:RIVER BASIN ENERGY

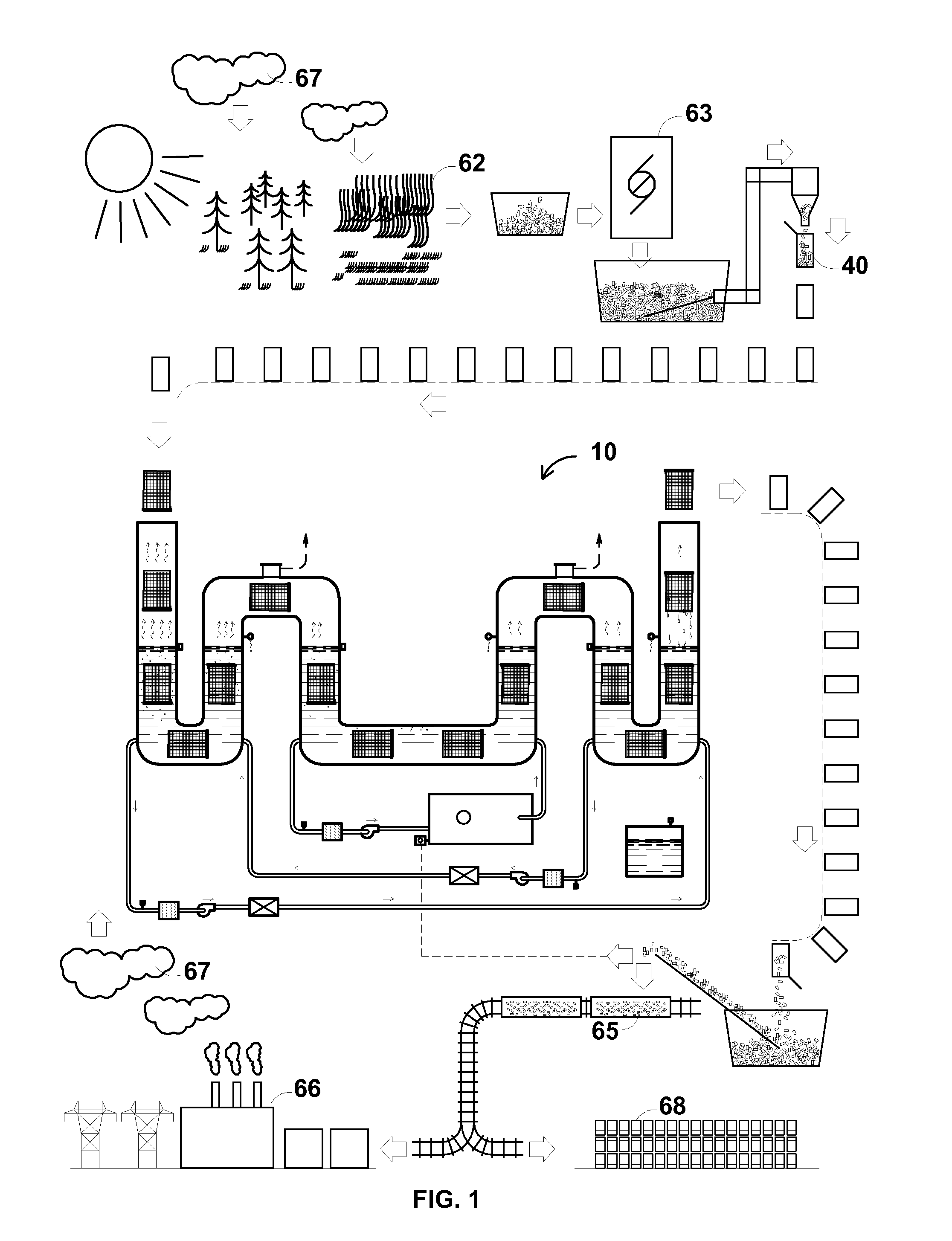

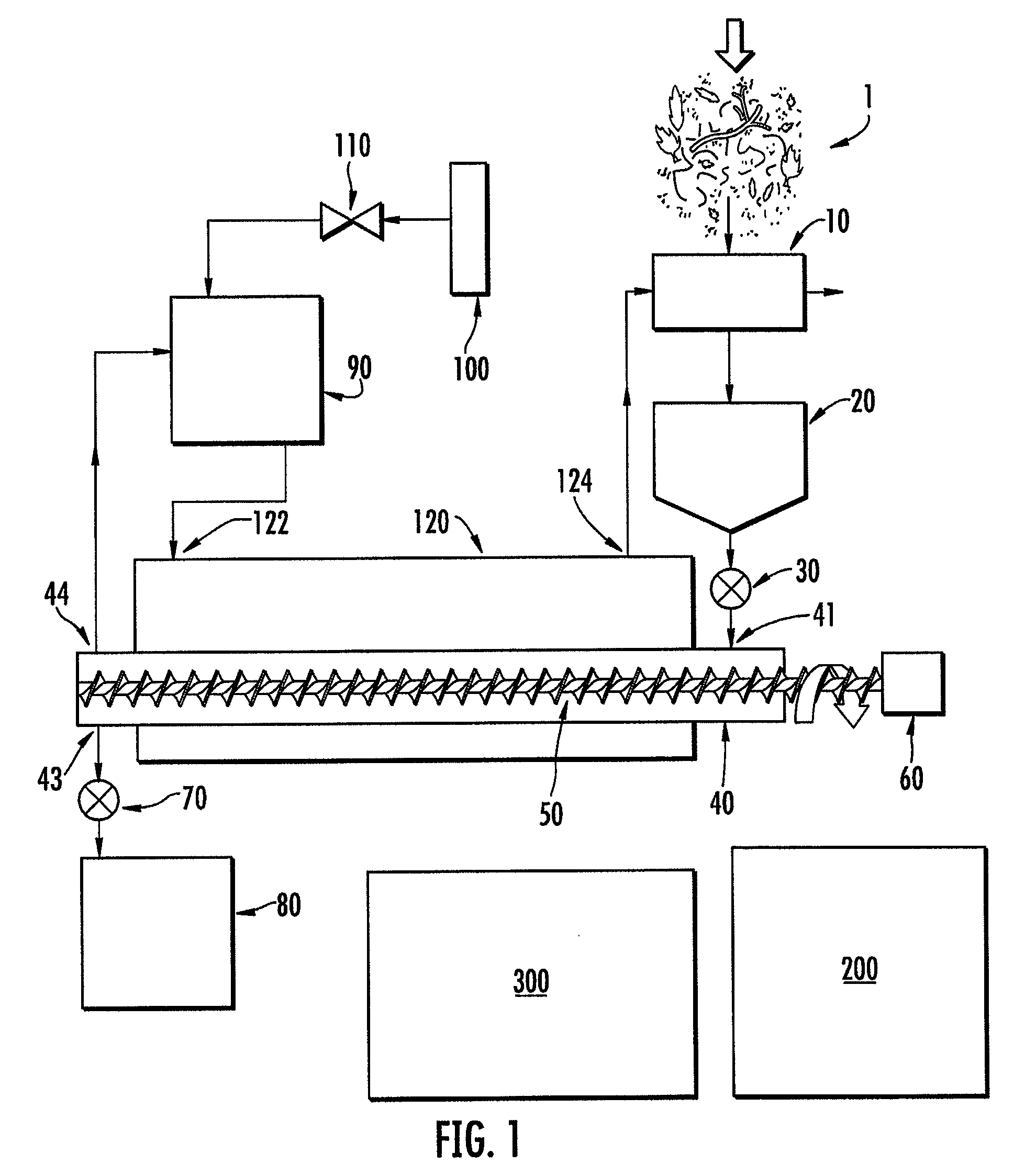

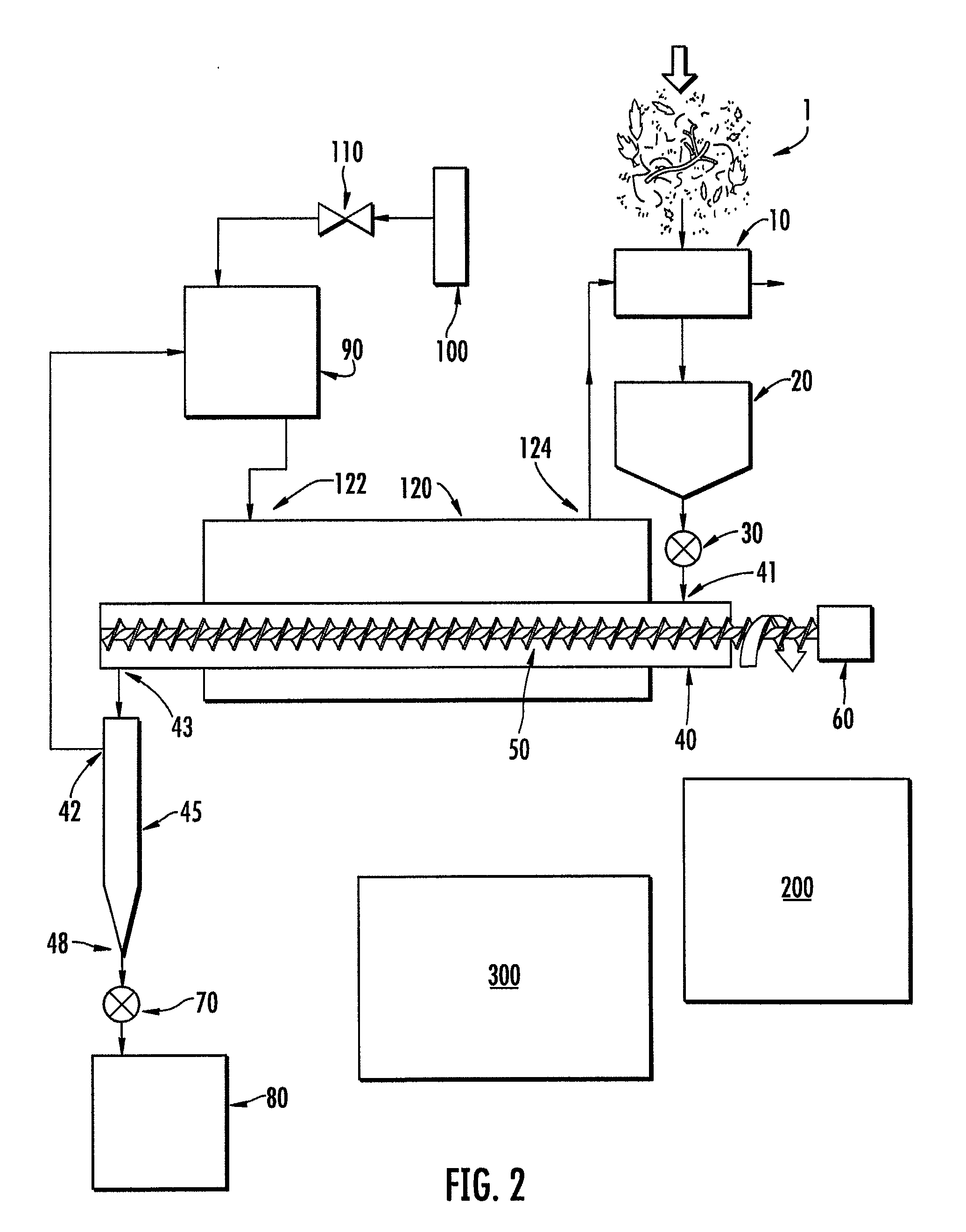

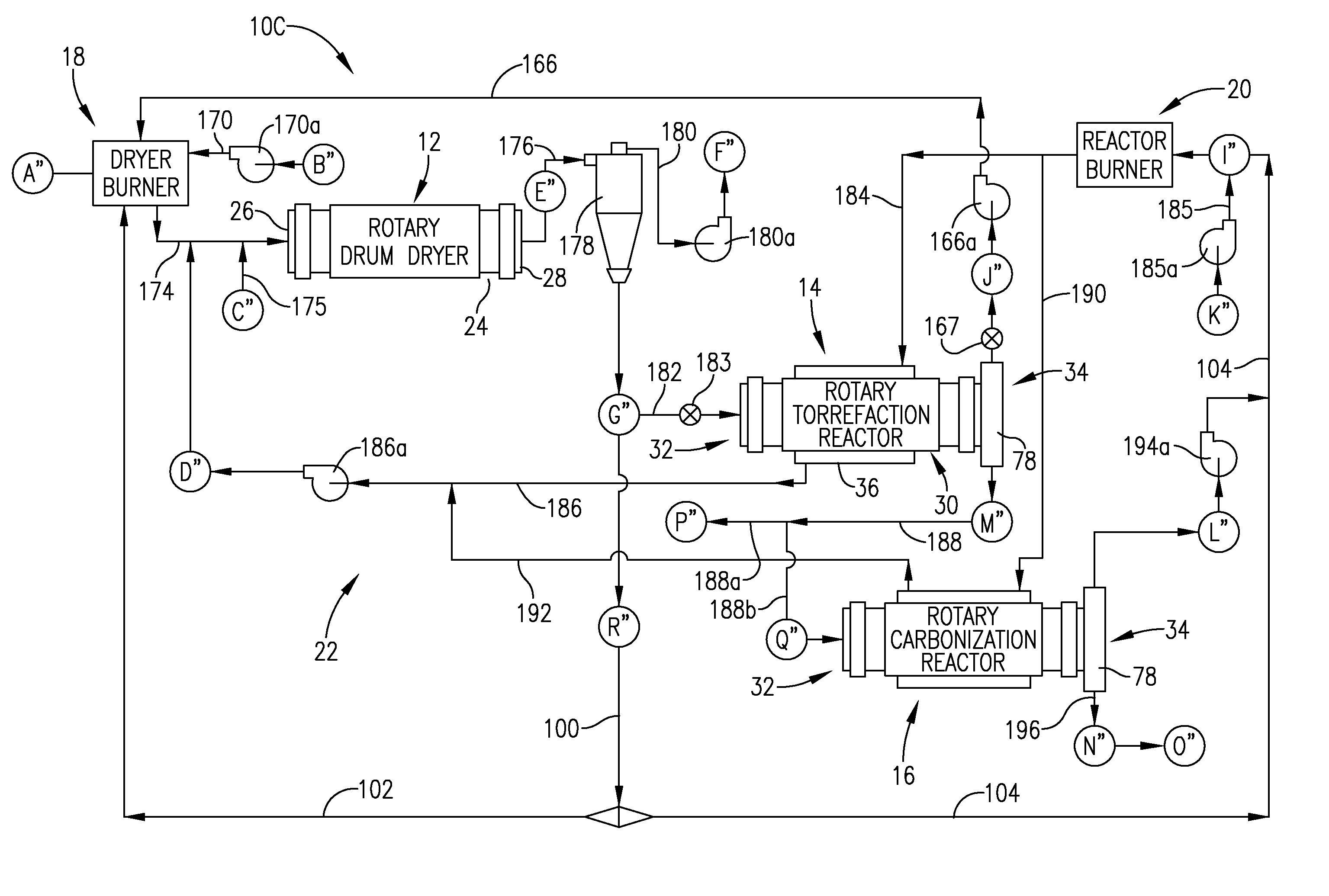

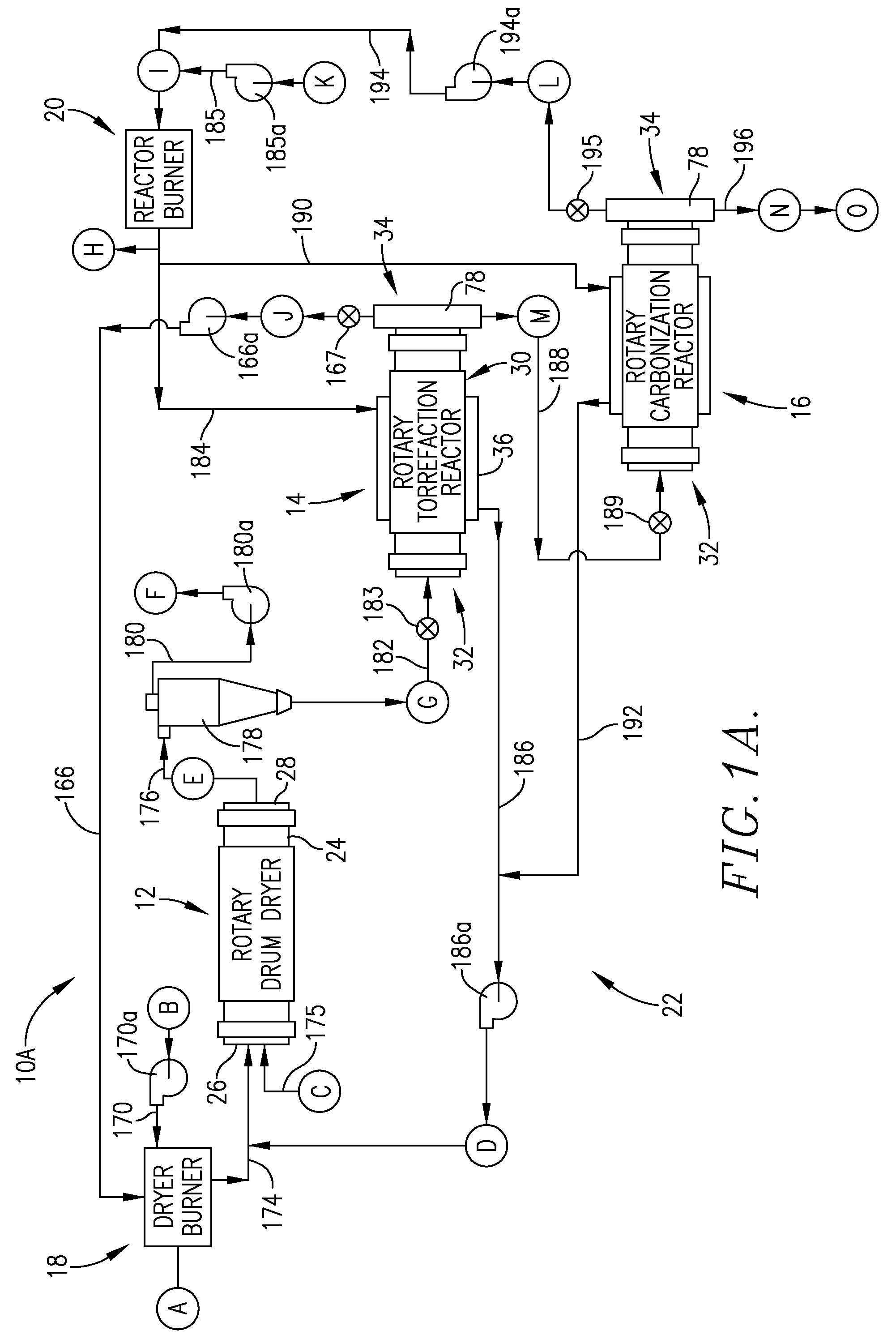

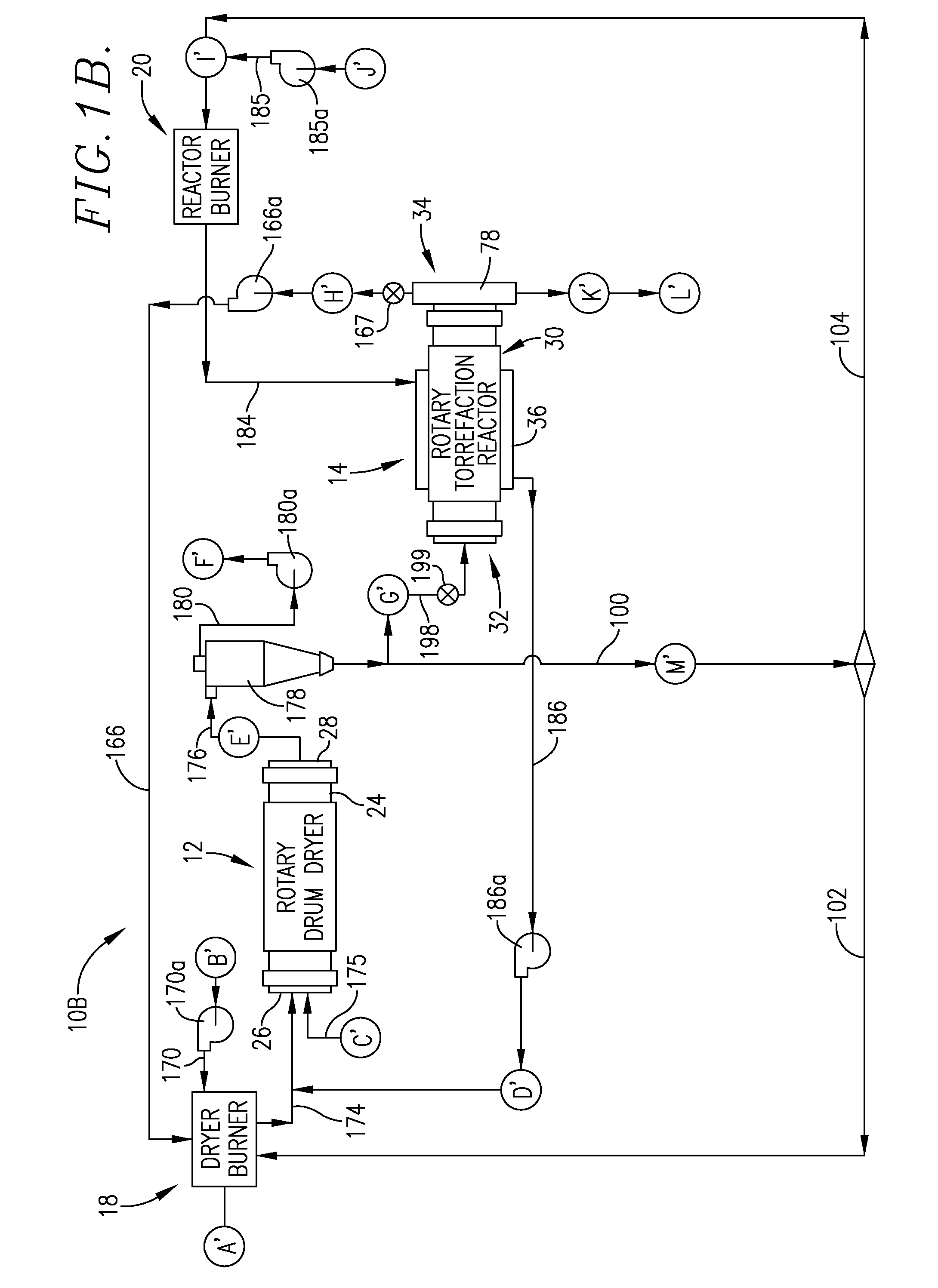

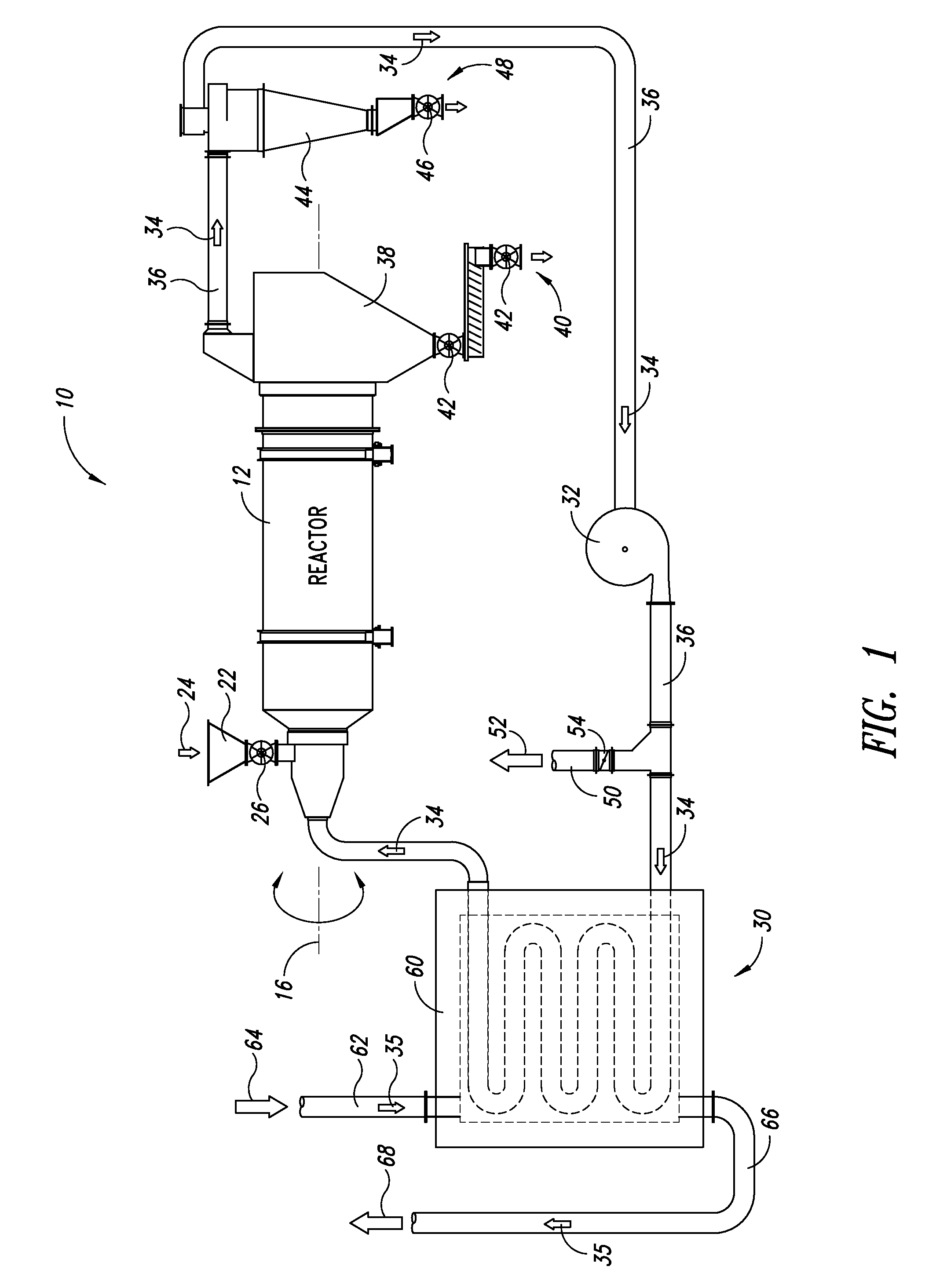

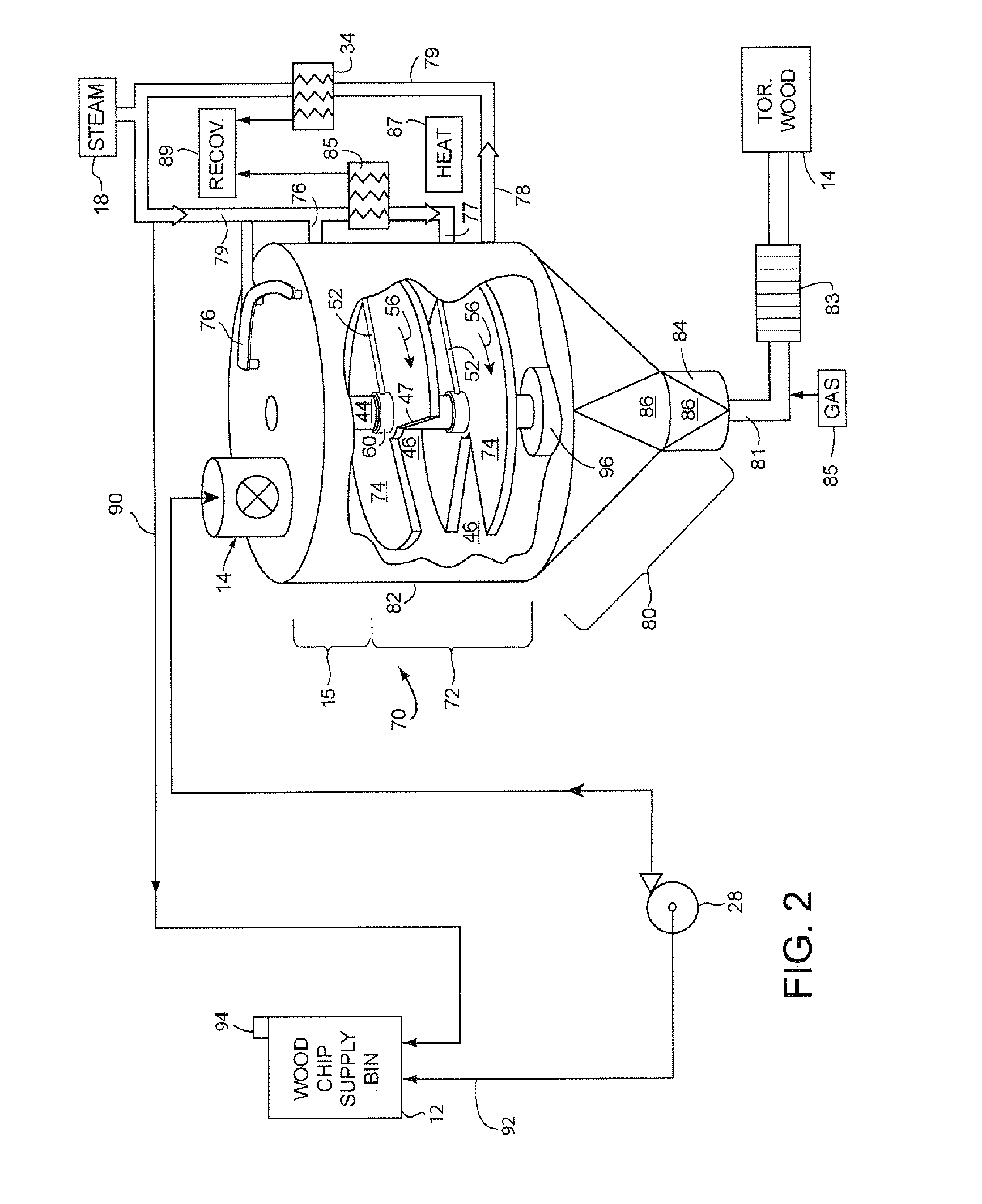

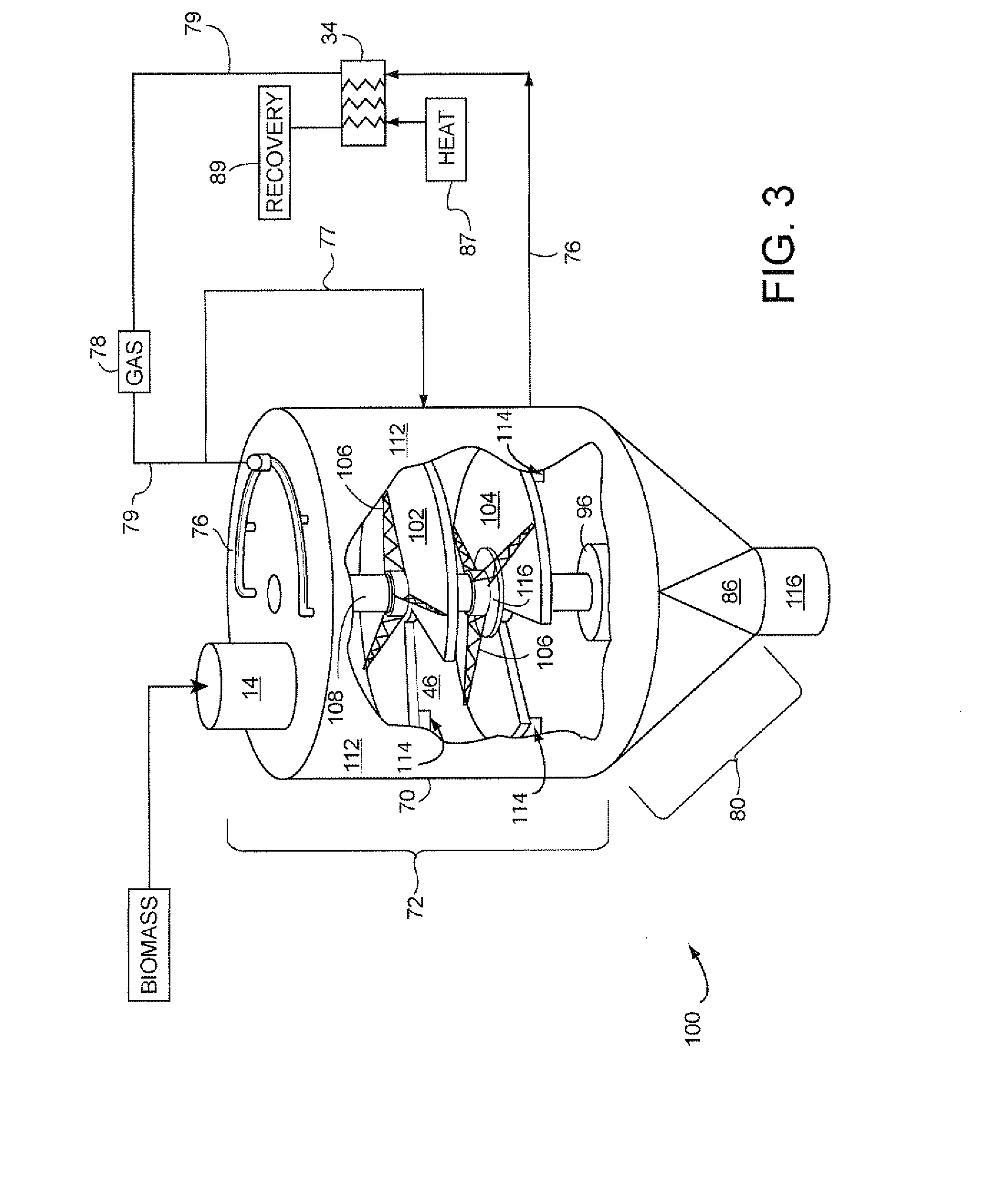

High energy efficiency biomass conversion process

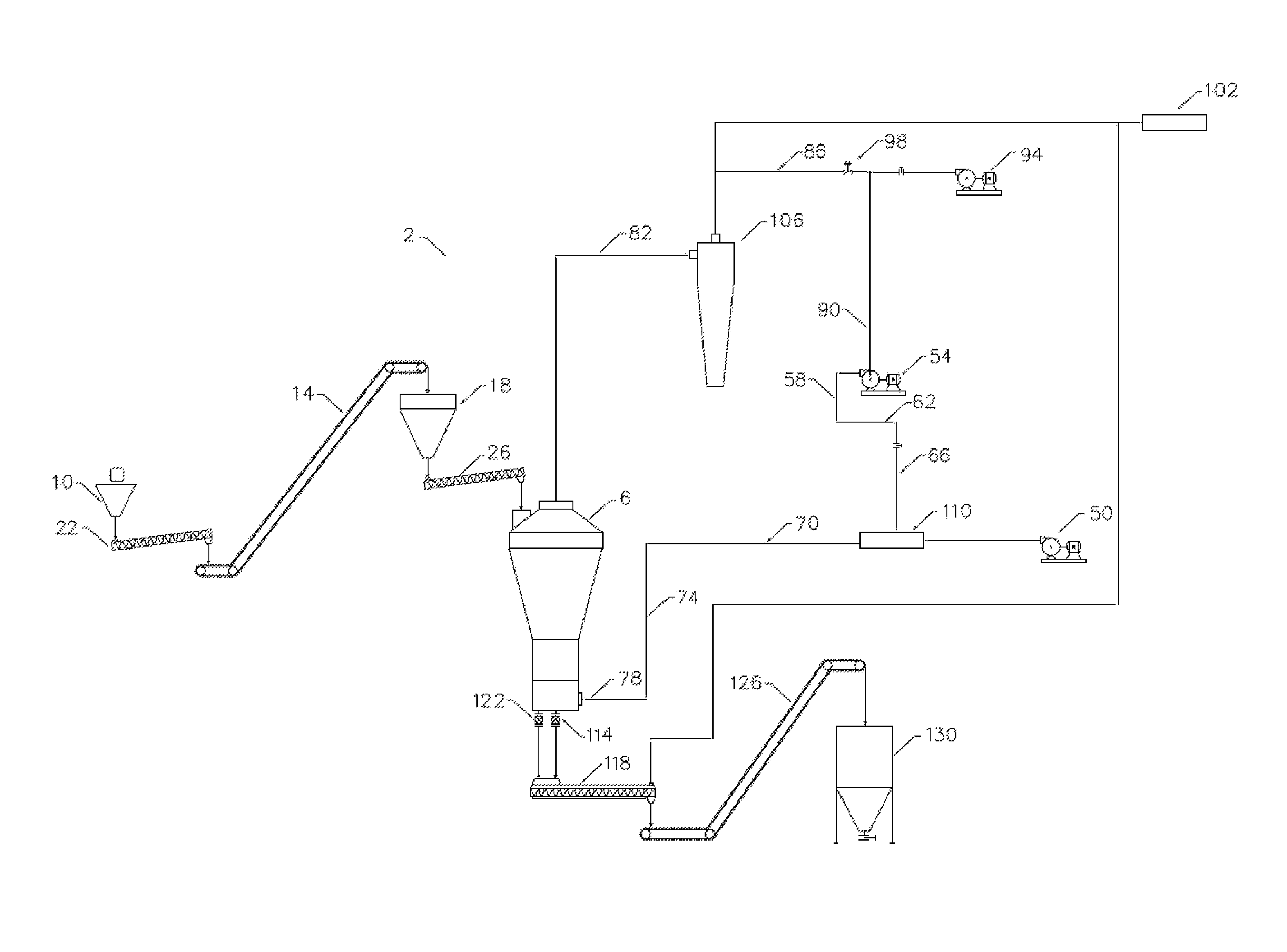

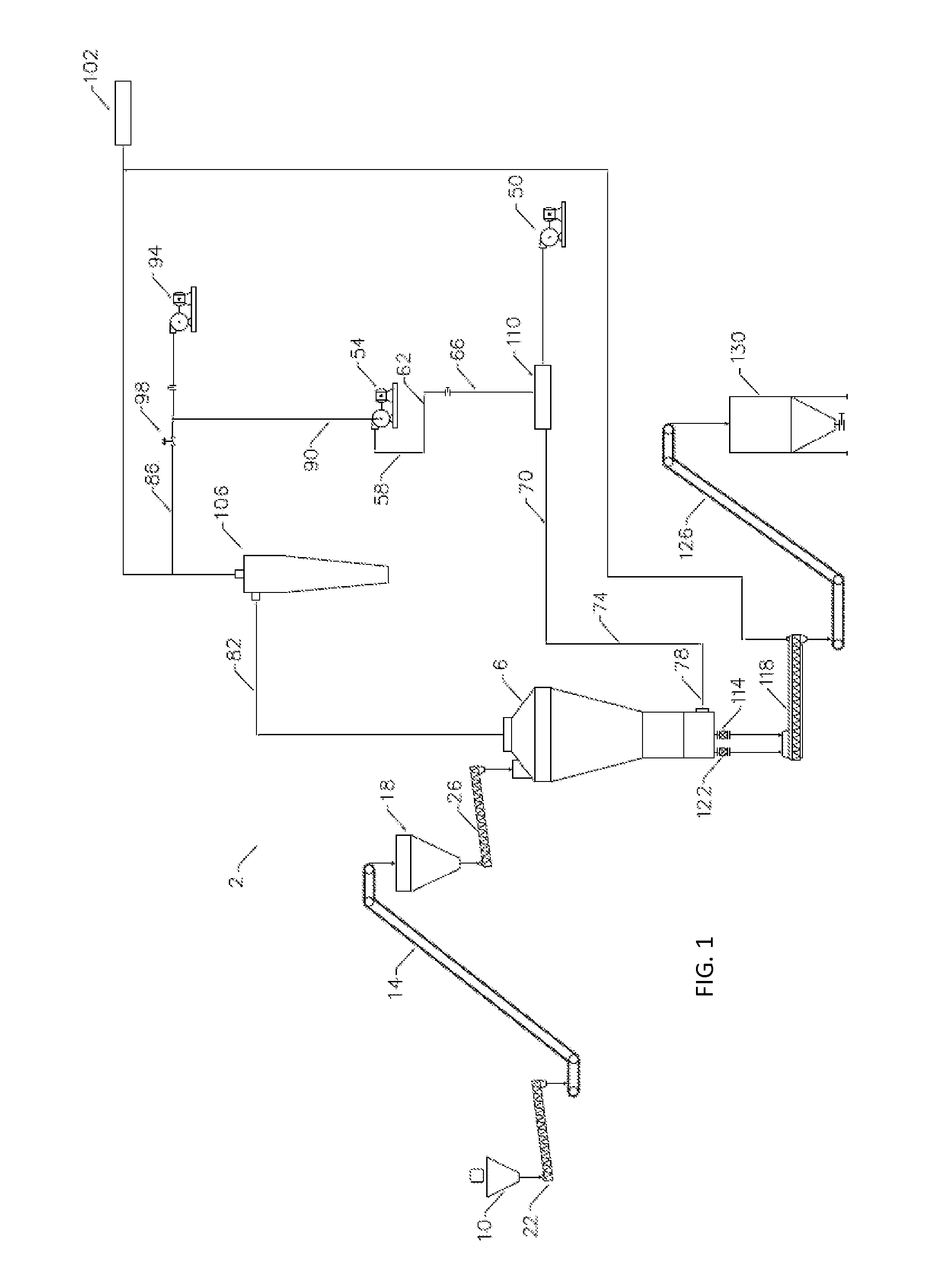

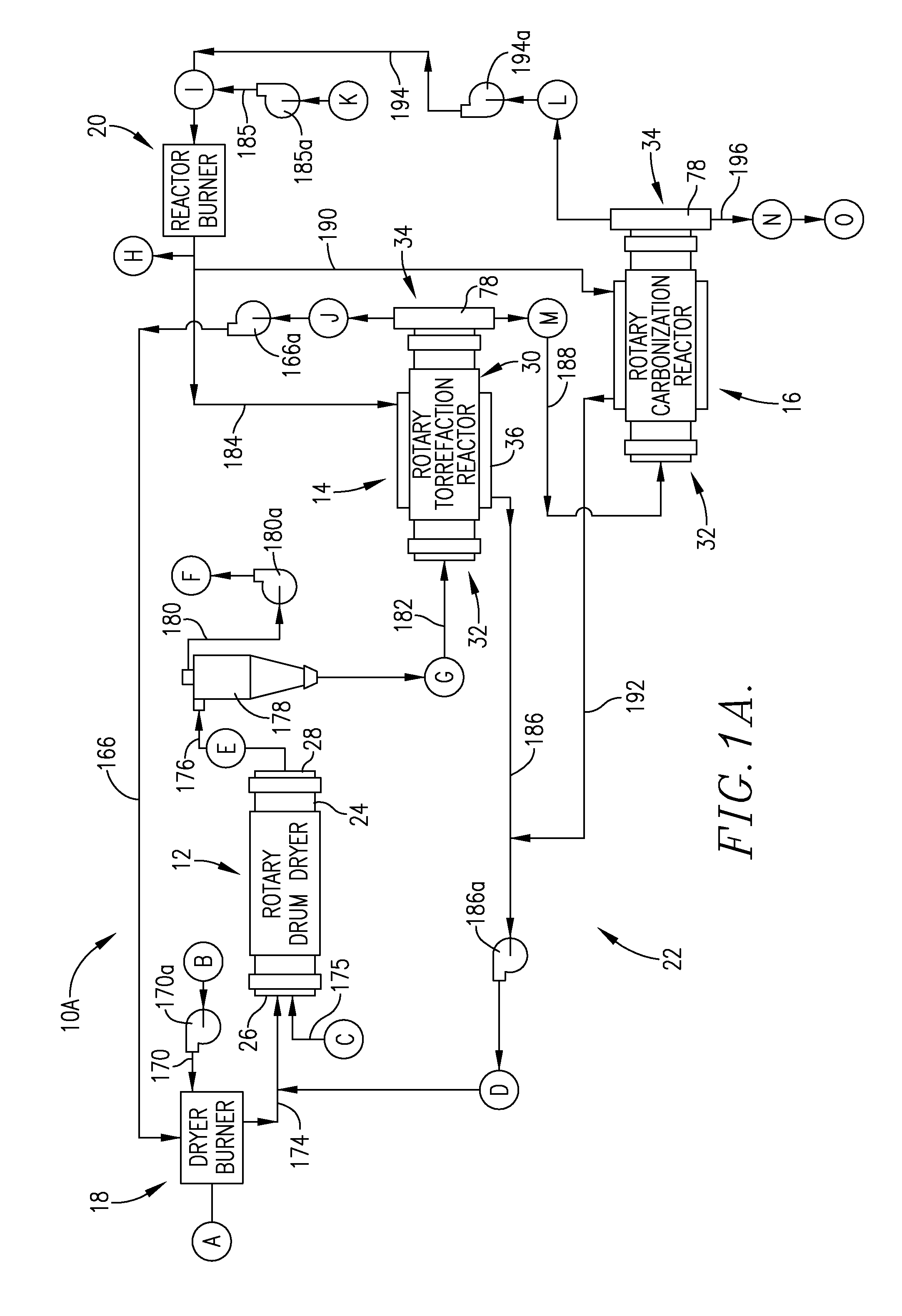

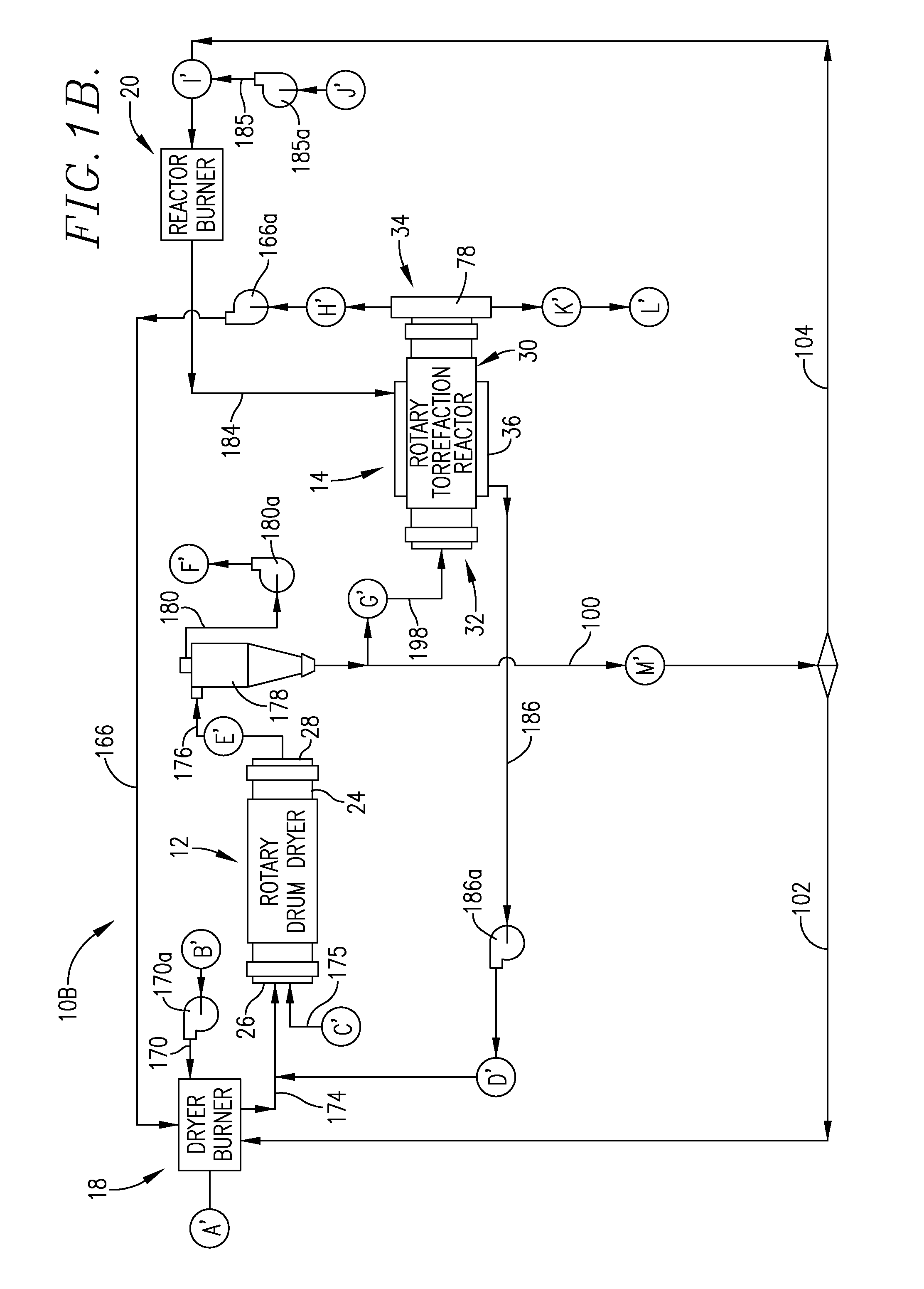

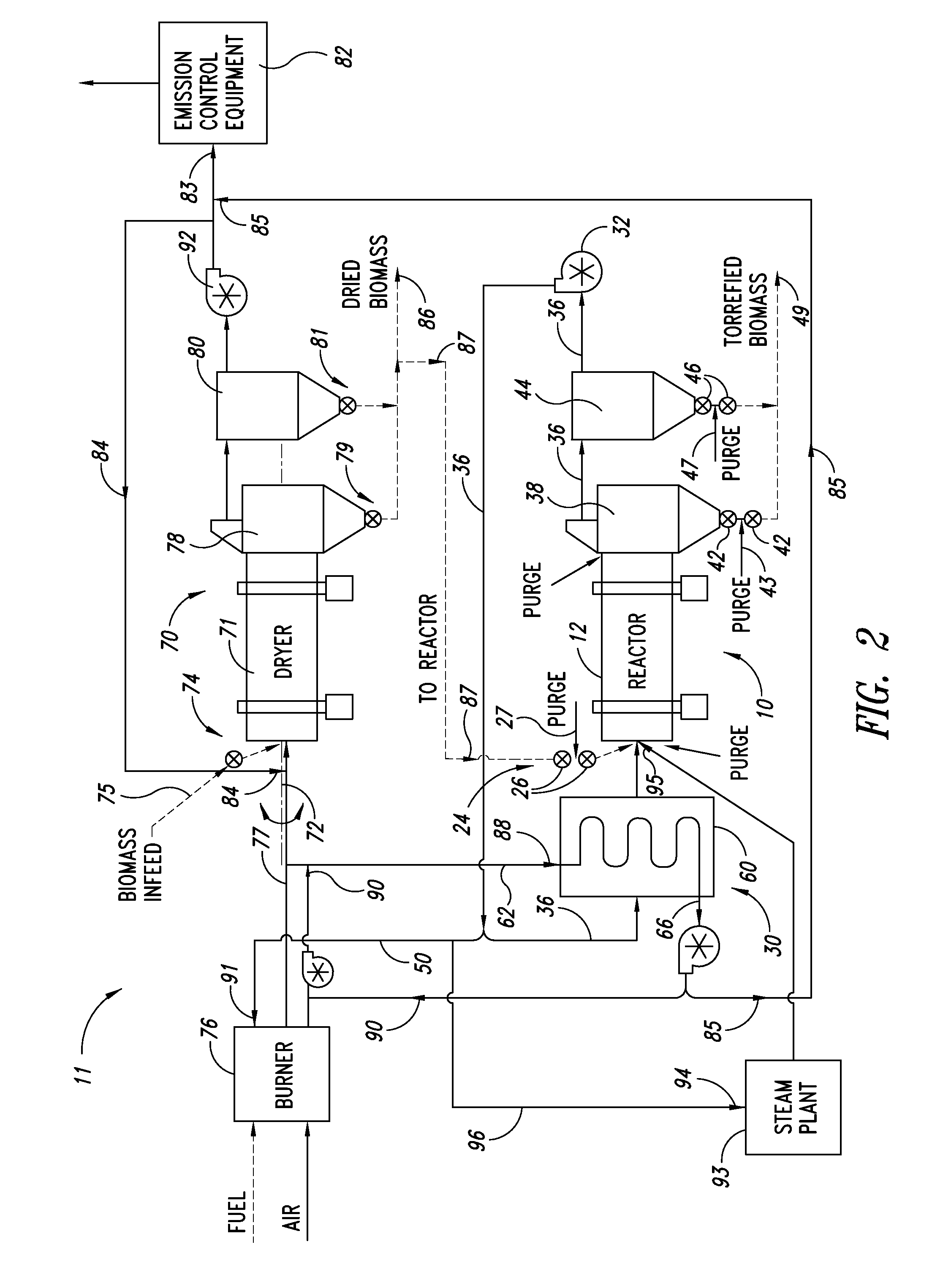

Improved, fuel-efficient systems are provided for the processing of biomass, such as wood or crop residues, food waste or animal waste in order to selectively obtain torrefied and / or carbonized final products. In general, the processes involve thermally drying incoming biomass using a dryer employing the hot gas output of a fuel-operated burner. Next, the dried product is torrefied in an indirect torrefaction reactor so as to evolve light volatile organic compounds which are used as a gaseous fuel source for the burner. The torrefied product can be recovered, or some or all of the torrefied product may be directed to a carbonization reactor coupled with a reactor burner. Carbonization serves to remove most of the remaining VOCs which are used as a gaseous fuel input to the dryer. In certain instances, portions of the dried biomass are directed to the burners, as an additional source of fuel.

Owner:SMART TERRA CARE LLC

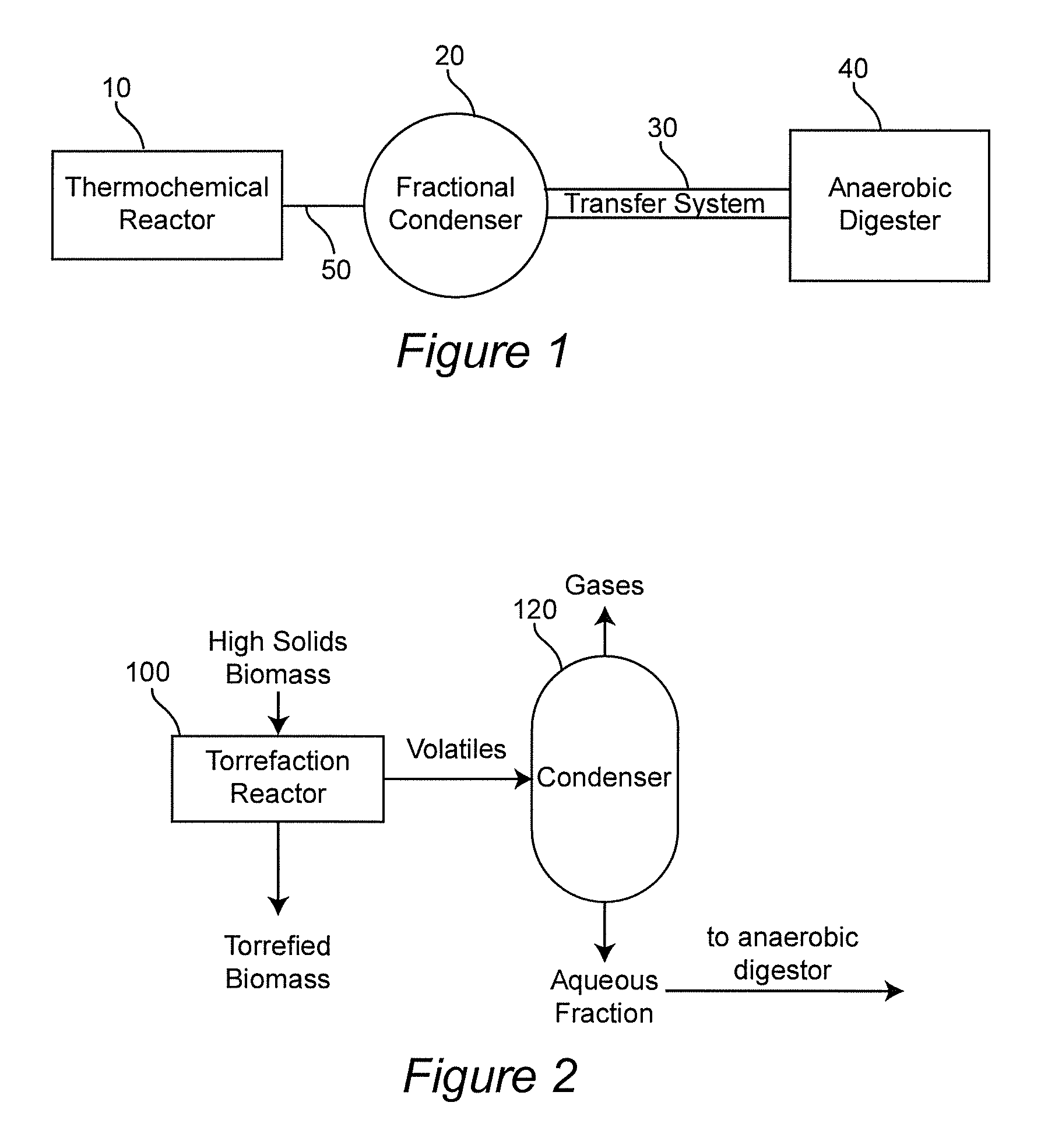

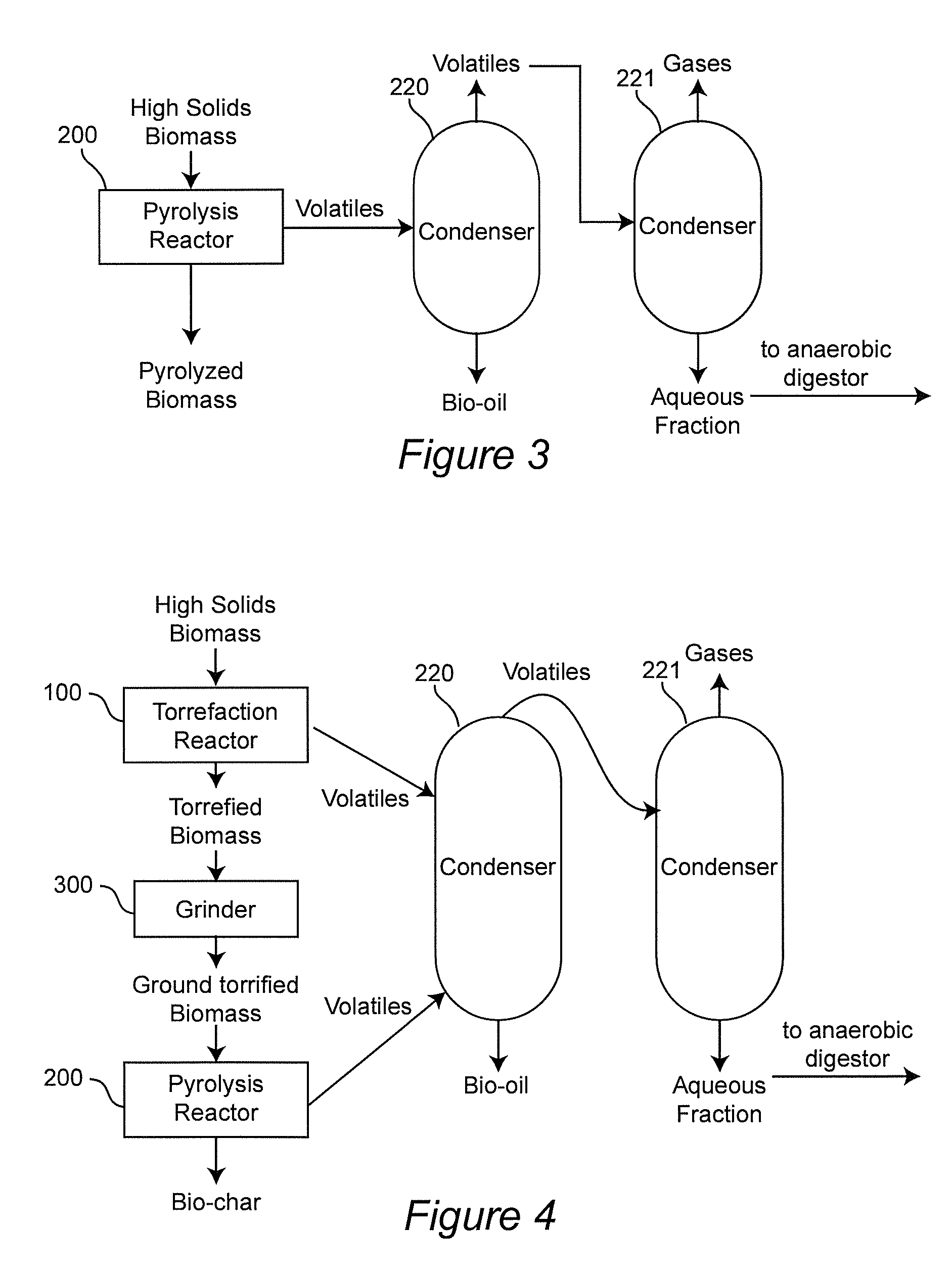

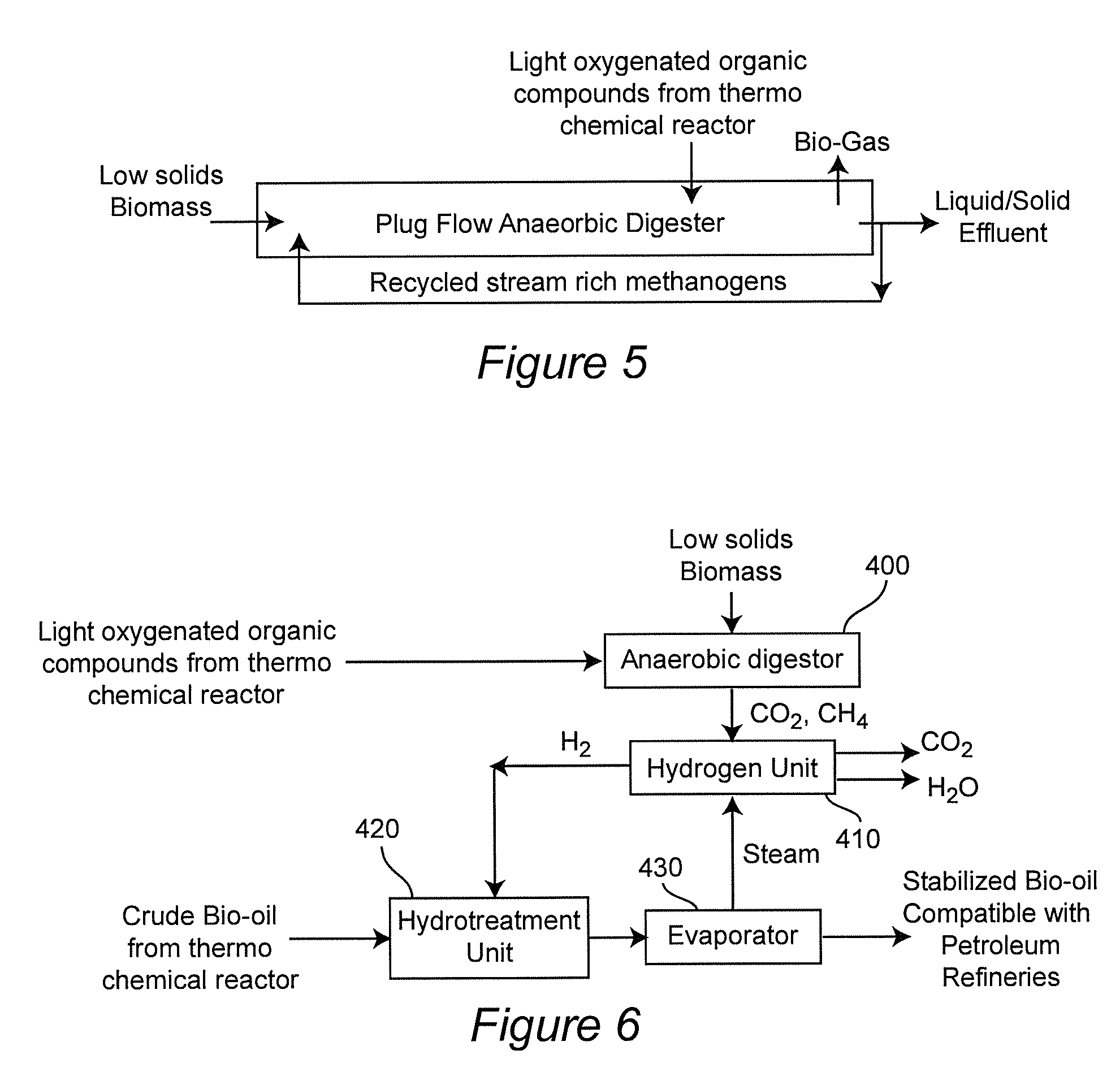

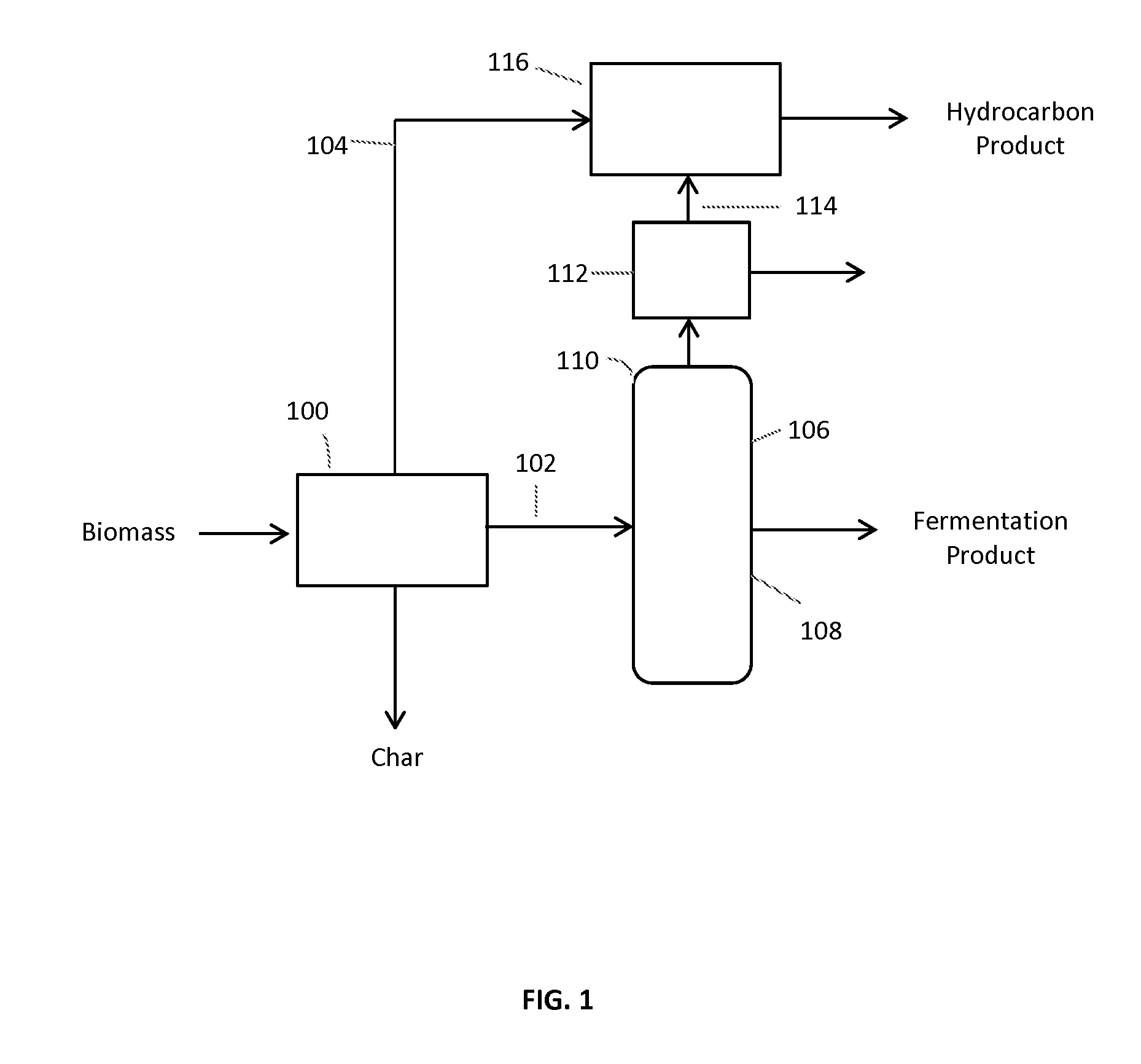

Processing biomass using thermochemical processing and anaerobic digestion in combination

ActiveUS20120322130A1Spur economic developmentEliminate wasteBioreactor/fermenter combinationsBiological substance pretreatmentsSimple Organic CompoundsAerobic digestion

Systems and methods for integrating thermochemical processing of biomass and anaerobic digestion are provided. Light oxygenated organic compounds are produced as byproducts of thermochemical biomass processing e.g. by torrefaction and / or pyrolysis, and are converted to methane by anaerobic digestion. Thermochemical processing units may or may not be co-located with the anaerobic digestion units, with co-location providing benefits for e.g. rural agricultural enterprises.

Owner:WASHINGTON STATE UNIV RES FOUND INC

Method and system for the torrefaction of lignocellulosic material

Owner:ANDRITZ TECH & ASSET MANAGEMENT

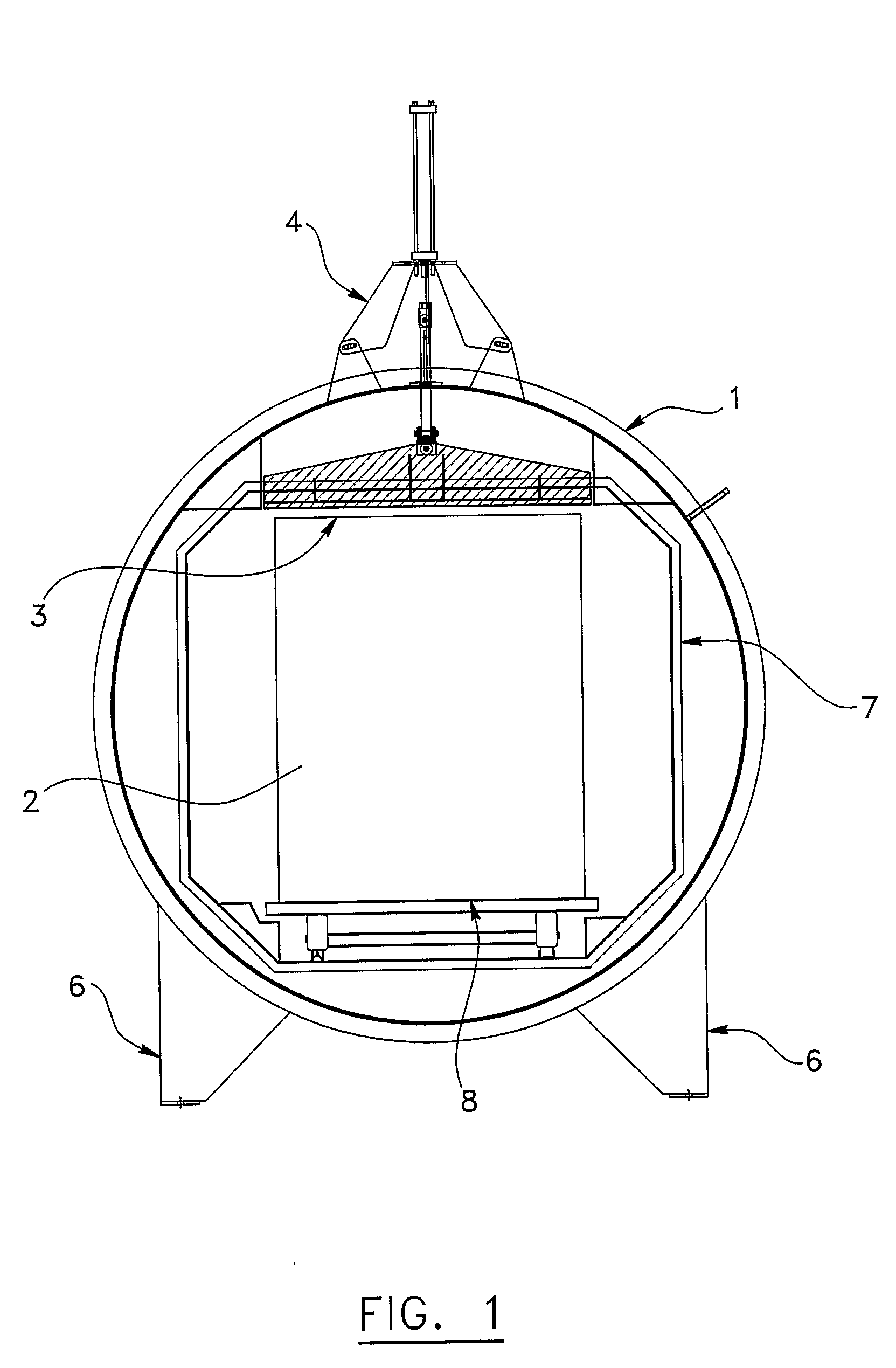

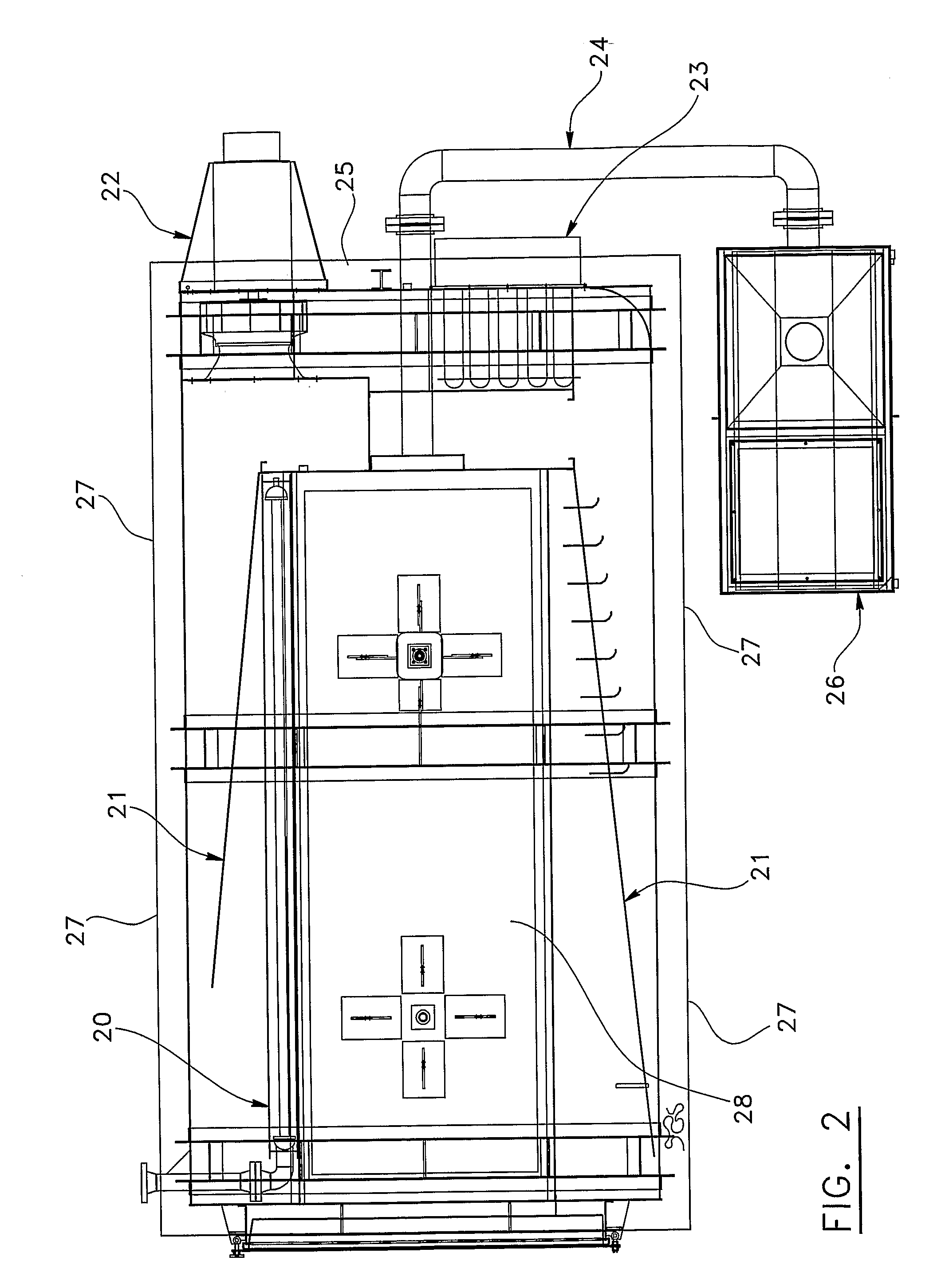

Process for Treating Lignocellulosic Material, and Apparatus for Carrying Out the Same

InactiveUS20080263891A1Satisfies needDrying using combination processesLiquid surface applicatorsCelluloseEngineering

A process for treating lignocellulosic material, such as wood for example, the process including the steps of: a) providing lignocellulosic material; b) evaluating parameters of the lignocellulosic material; c) preparing the lignocellulosic material; d) heating the lignocellulosic material in a treatment chamber following a given profile based on parameters of the lignocellulosic material; e) stabilizing the lignocellulosic material; and f) cooling down the lignocellulosic material. The process enables to improve the quality of the wood being treated, while ensuring a greater repeatability and uniformity of coloring results, and overcoming drawbacks associated with conventional torrefaction methods.

Owner:9103 7366 QUEBEC

Autothermal and mobile torrefaction devices

ActiveUS8304590B2Increased cost-effectivenessLow costCombustible gas coke oven heatingCharging-discharging device combinationsCombustorProcess engineering

Autothermal torrefaction devices, which can be either stationary of mobile, are provided and include a torrefaction chamber having a chamber inlet for receiving biomass and at least one chamber outlet. The torrefaction chamber can be substantially surrounded by an exterior housing defining an outer jacket and having a jacket inlet and a jacket outlet. The outer jacket and torrefaction chamber define a space therebetween such that a burner unit including an inlet operatively connected to the chamber outlet and an outlet operatively connected to the jacket inlet allows vapors produced or released from within the torrefaction chamber to travel into the burner unit for combustion of at least a portion of the vapors and subsequently travel through the space between the jacket and the torrefaction chamber to provide heat necessary for autothermal torrefaction of biomass.

Owner:NORTH CAROLINA STATE UNIV

High energy efficiency biomass conversion process

ActiveUS8198493B1Combustible gas coke oven heatingDirect heating destructive distillationCombustorHigh energy

Improved, fuel-efficient systems are provided for the processing of biomass, such as wood or crop residues, food waste or animal waste in order to selectively obtain thermally processed final products, such as a combination of torrefied and carbonized final products. The processes involve thermally drying incoming biomass using a dryer employing the hot gas output of a fuel-operated burner. Next, the dried product is torrefied in an indirect torrefaction reactor so as to evolve light volatile organic compounds which are used as a gaseous fuel source for the burner. Some or all of the torrefied product can be recovered, or some or all of the torrefied product is then directed to a separate carbonization reactor coupled with a reactor burner. Carbonization serves to remove most of the remaining VOCs which are used as a gaseous fuel input to the dryer.

Owner:SMART TERRA CARE LLC

Biomass liquefaction through gas fermentation

InactiveUS20140134686A1Improve filtration efficiencyEasy to separateBiological substance pretreatmentsGas production bioreactorsProduct gasTorrefaction

The invention provides methods and systems for the production of at least one product from the microbial fermentation of a gaseous susbtrate, wherein the gaseous substrate is derived from a biomass liquefaction process. The invention provides a method for improving efficiency of the fermentation by passing biomass accumulated in the fermentation process to the biomass liquefaction process for conversion to a gaseous substrate. In a particular aspect of the invention, the biomass liquefaction process is selected from pyrolysis or torrefaction.

Owner:LANZATECH NZ INC

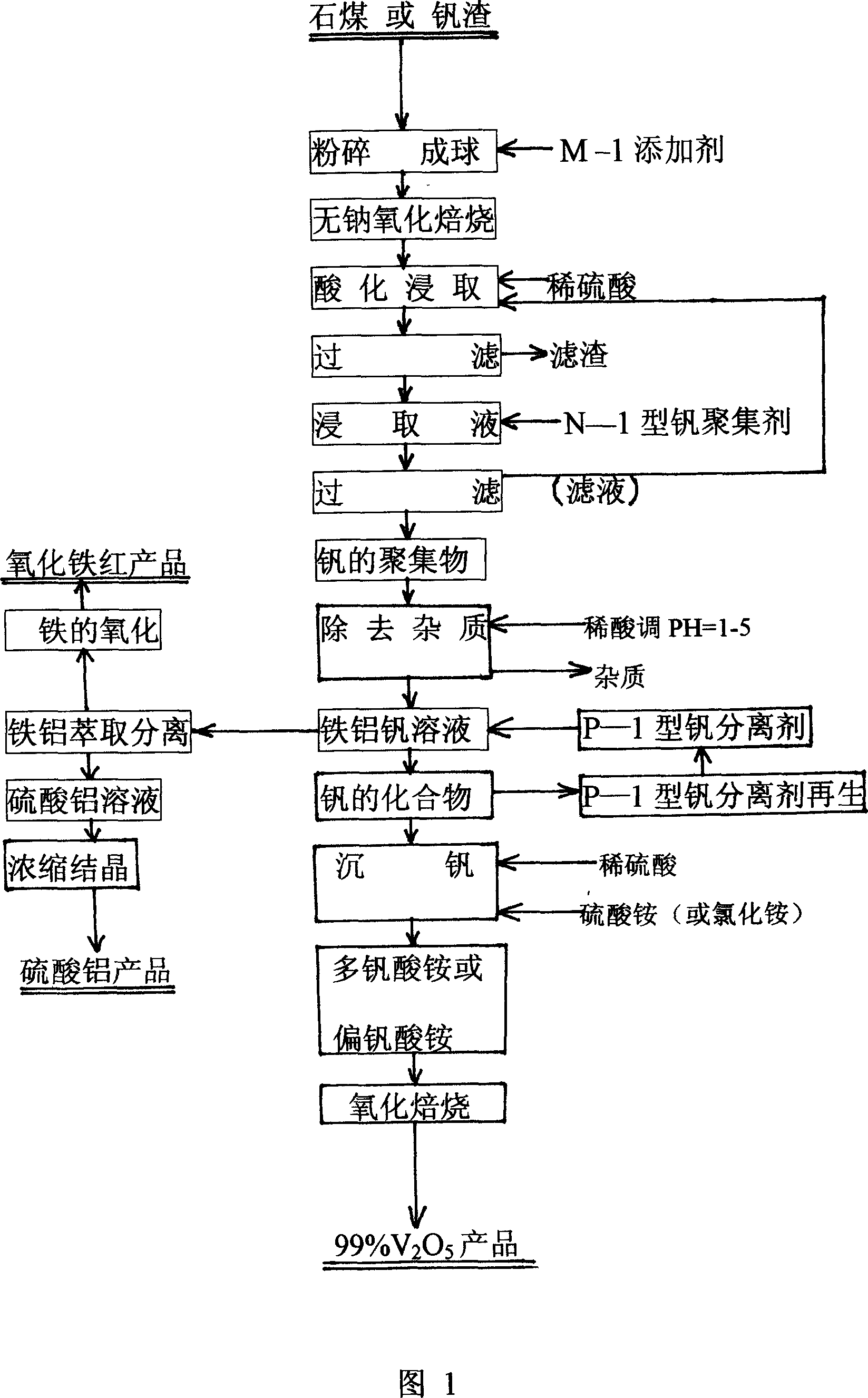

Technique for producing vanadium pentoxide

InactiveCN101092248AReduce dosageReduce pollutionVanadium oxidesProcess efficiency improvementAluminium sulfateSlag

This invention discloses a process for producing V2O5 from vanadium-containing stone coal or vanadium slag. The process comprises: adding M-1 type additive to vanadium-containing stone coal or vanadium slag, torrefying, leaching with diluted H2SO4 to obtain vanadium salt solution, extracting vanadium aggregate from the vanadium salt solution by using N-1 type aggregation agent, removing impurities, adding P-1 type separation agent for separation, precipitating vanadium, oxidizing to obtain V2O5, recovering Al and Fe from the system, and producing Al2 (SO4)3 and iron red. The process has such advantages as no Cl2 or HCl generation, high torrefaction yield (70-90%), no wastewater, little environmental pollution, high product yield, low production cost, high recovery rate of Al and Fe, high product purity (higher than 99%), simple process and stable oepration.

Owner:邓镇炎

Process for treating lignocellulosic material, and apparatus for carrying out the same

A process for treating lignocellulosic material, such as wood for example, the process including the steps of: a) providing lignocellulosic material; b) evaluating parameters of the lignocellulosic material; c) preparing the lignocellulosic material; d) heating the lignocellulosic material in a treatment chamber following a given profile based on parameters of the lignocellulosic material; e) stabilizing the lignocellulosic material; and f) cooling down the lignocellulosic material. The process enables to improve the quality of the wood being treated, while ensuring a greater repeatability and uniformity of coloring results, and overcoming drawbacks associated with conventional torrefaction methods.

Owner:9103 7366 QUEBEC

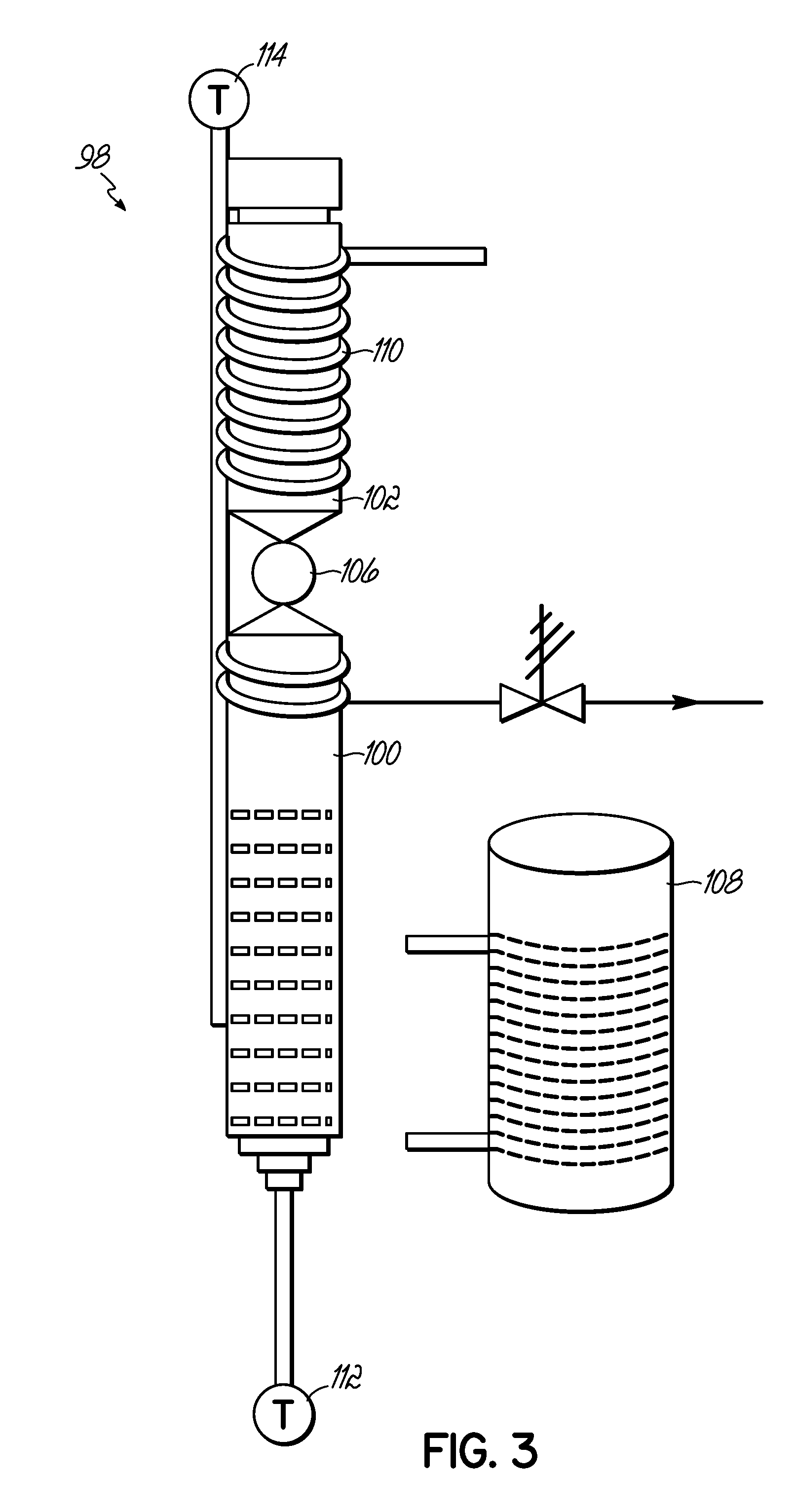

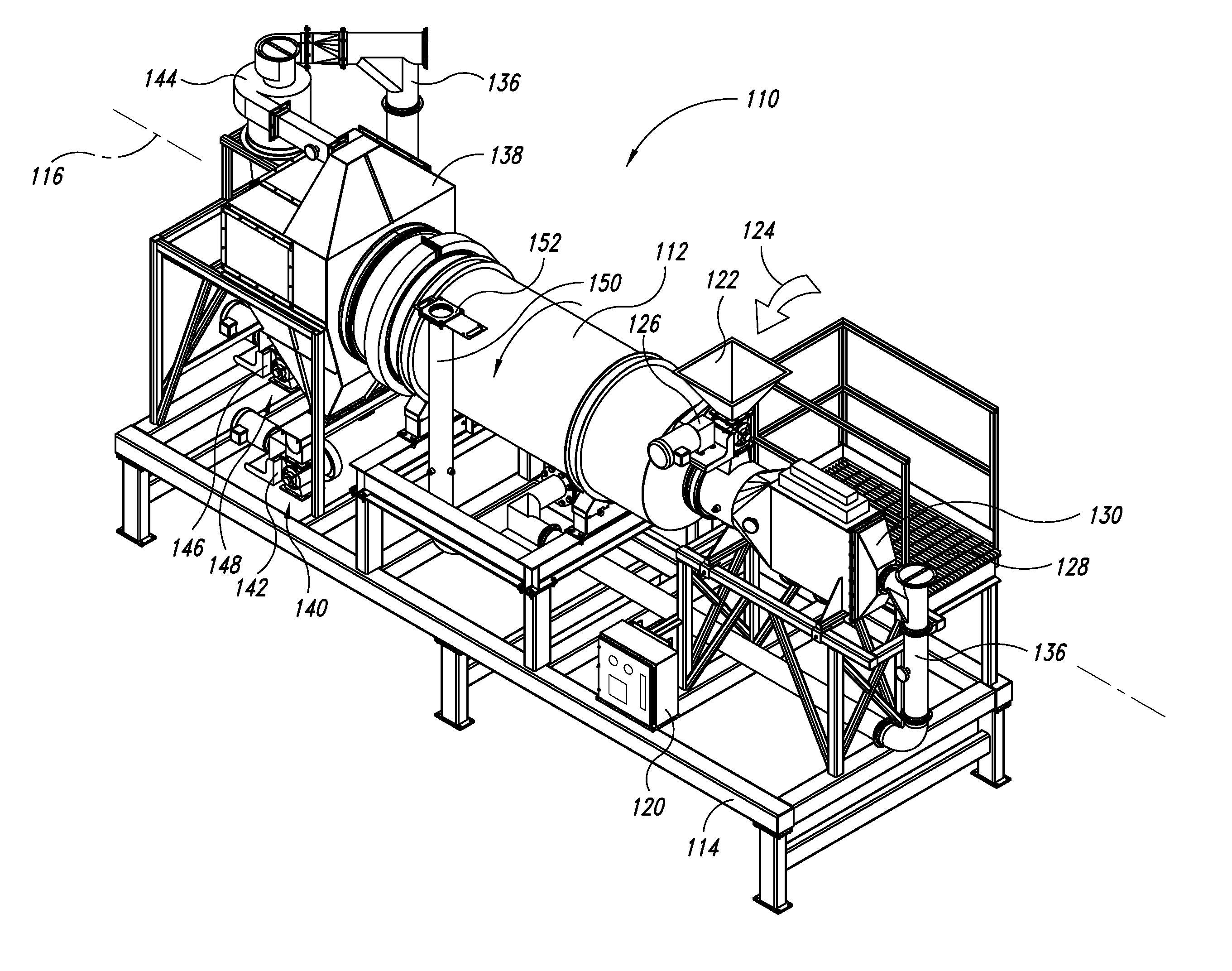

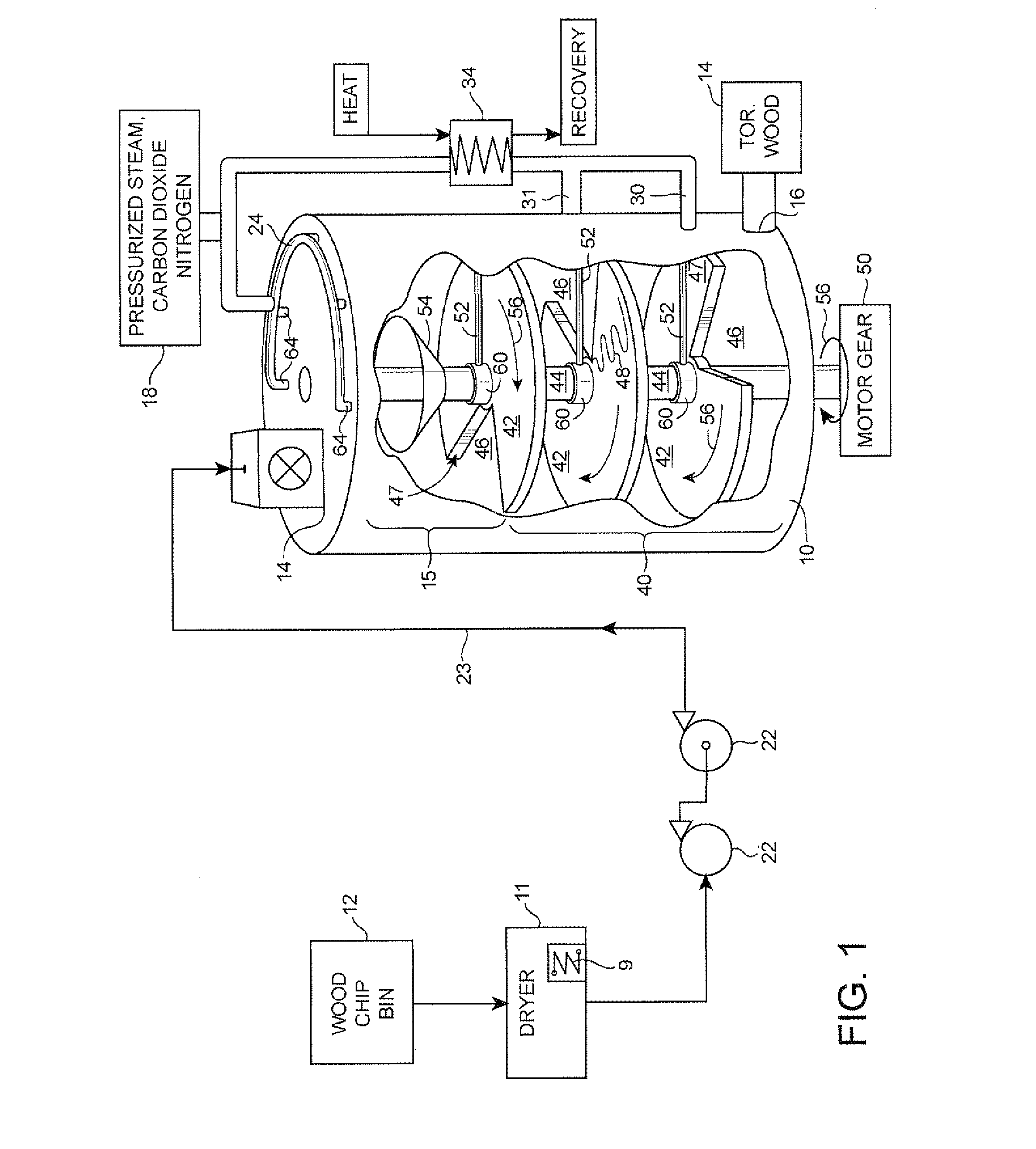

Biomass torrefaction system and method

ActiveUS8246788B2Improve scalabilityEasy to controlCombustible gas coke oven heatingDrying solid materials with heatProcess engineeringTorrefaction

A biomass torrefaction system is provided which enables a continuous torrefaction process that involves the introduction of biomass particles into a rotating reactor drum having a low oxygen environment. The particles are conveyed through the drum by a heated gas stream and simultaneously torrefied thereby. Gas exiting the drum is recirculated back to a heat source for reheating the gas prior to reentering the drum. A method of biomass torrefaction is also provided.

Owner:TEAL SALES

Sequencing retort liquid phase torrefication processing apparatus and method

ActiveUS8217212B2Combustible gas coke oven heatingSolid waste disposalPositive pressureHeat transfer fluid

A method and related apparatus for torrefaction of associated biomass which includes providing an enclosed chamber having a body and a door having an open position allowing passage into and out of the enclosed chamber and a closed position in which the door is disposed in sealing engagement with the body, providing the enclosed chamber with walls capable of sustaining both a negative pressure and a positive pressure within the enclosed chamber; moving the door to an open position; depositing a liquid heat transfer fluid within the enclosed chamber at a temperature sufficient to achieve torrefication of the biomass and a first quantity of biomass material in the enclosed chamber that is substantially totally immersed in the liquid heat transfer fluid whereby heat transfer occurs between the liquid heat transfer fluid and the biomass immersed therein; moving the door to a closed position in sealing engagement with the body; and allowing the pressure within the enclosed chamber to rise to a pressure above the vapor pressure of the heat transfer fluid as a result of the expansion of liquids and gases entrained within the biomass.

Owner:PAOLUCCIO JOHN A +1

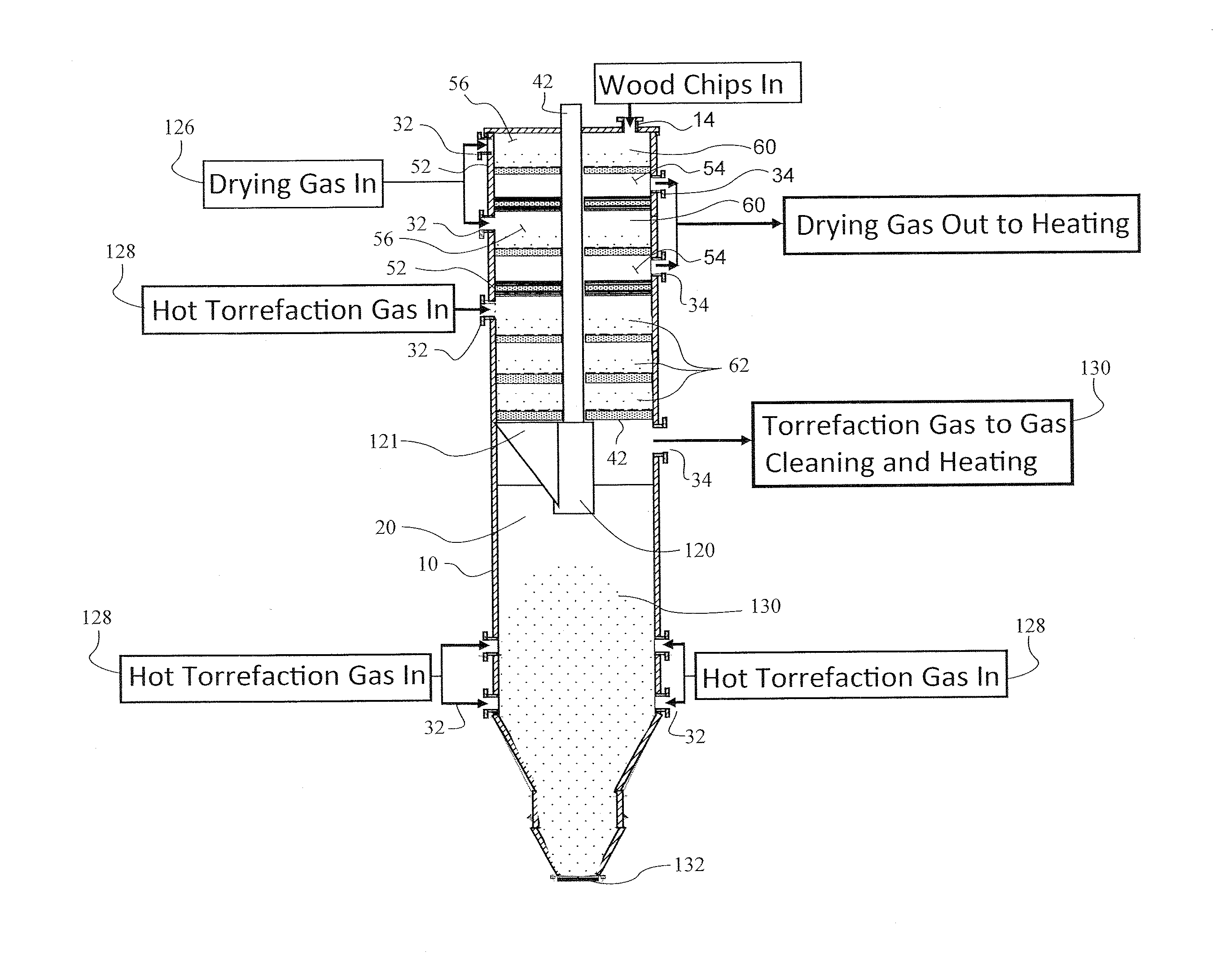

Method and system for the torrefaction of lignocellulosic material

InactiveUS20130075244A1Risk minimizationAvoid low surface temperaturesCombustible gas coke oven heatingDirect heating destructive distillationCelluloseEnvironmental engineering

A method for torrefaction of biomass using a torrefaction reactor vessel having stacked trays including: feeding the biomass to an upper inlet of the vessel; cascading the biomass down through the trays by passing the biomass through an opening in each of the trays to deposit the biomass on a lower tray; heating the biomass material with an oxygen deprived gas; extracting moisture from below each of the upper trays; as the biomass undergoes torrefaction in the lower trays retaining the gas with the biomass until the biomass falls from the stacked trays to a pile of biomass in the reactor vessel; exhausting gases containing organic compounds through a gas outlet at an elevation between the stacked trays and the pile of biomass, and discharging torrefied biomass from the torrefaction reactor vessel.

Owner:ECN ENERGY RES CENT OF THE NETHERLANDS +1

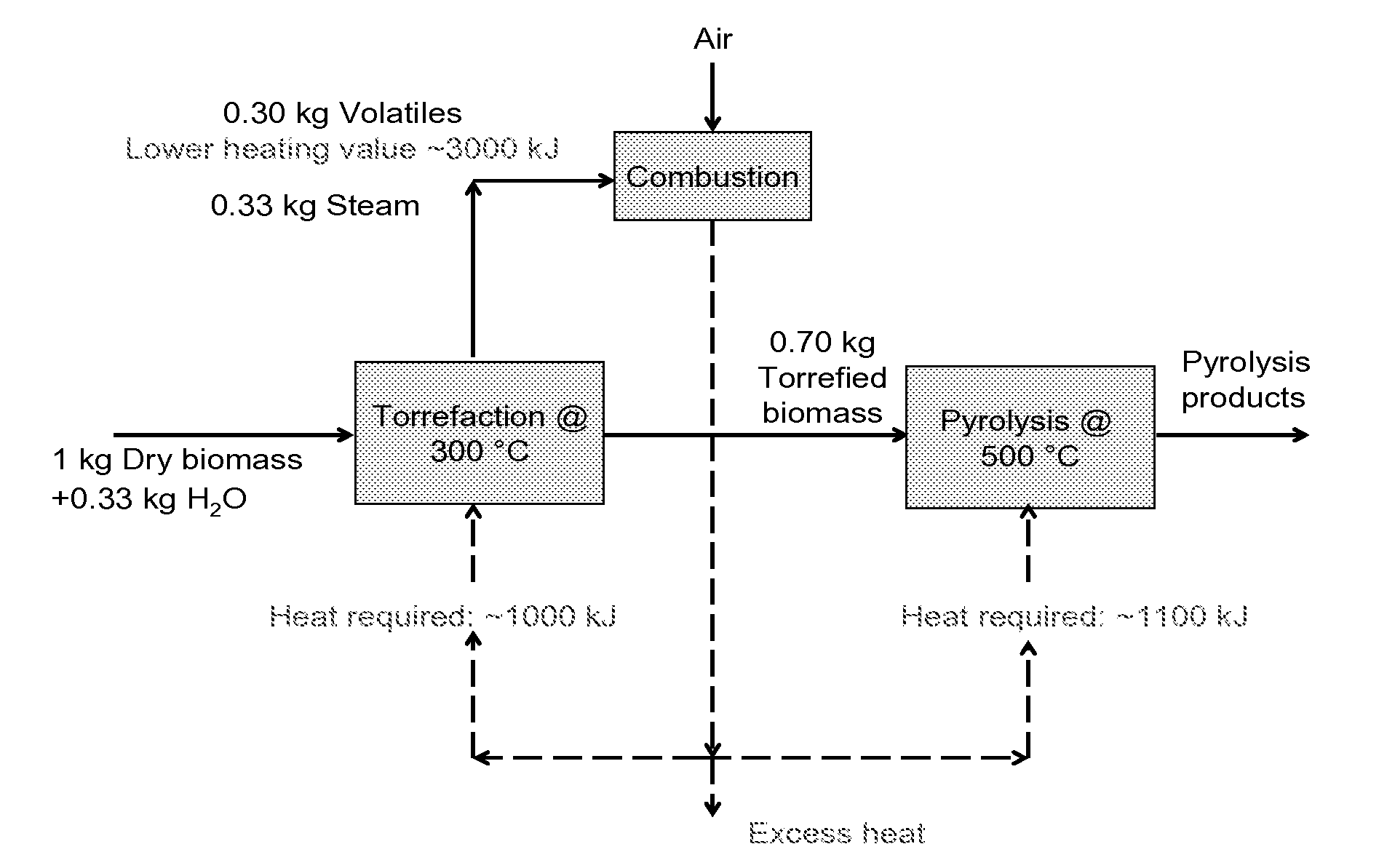

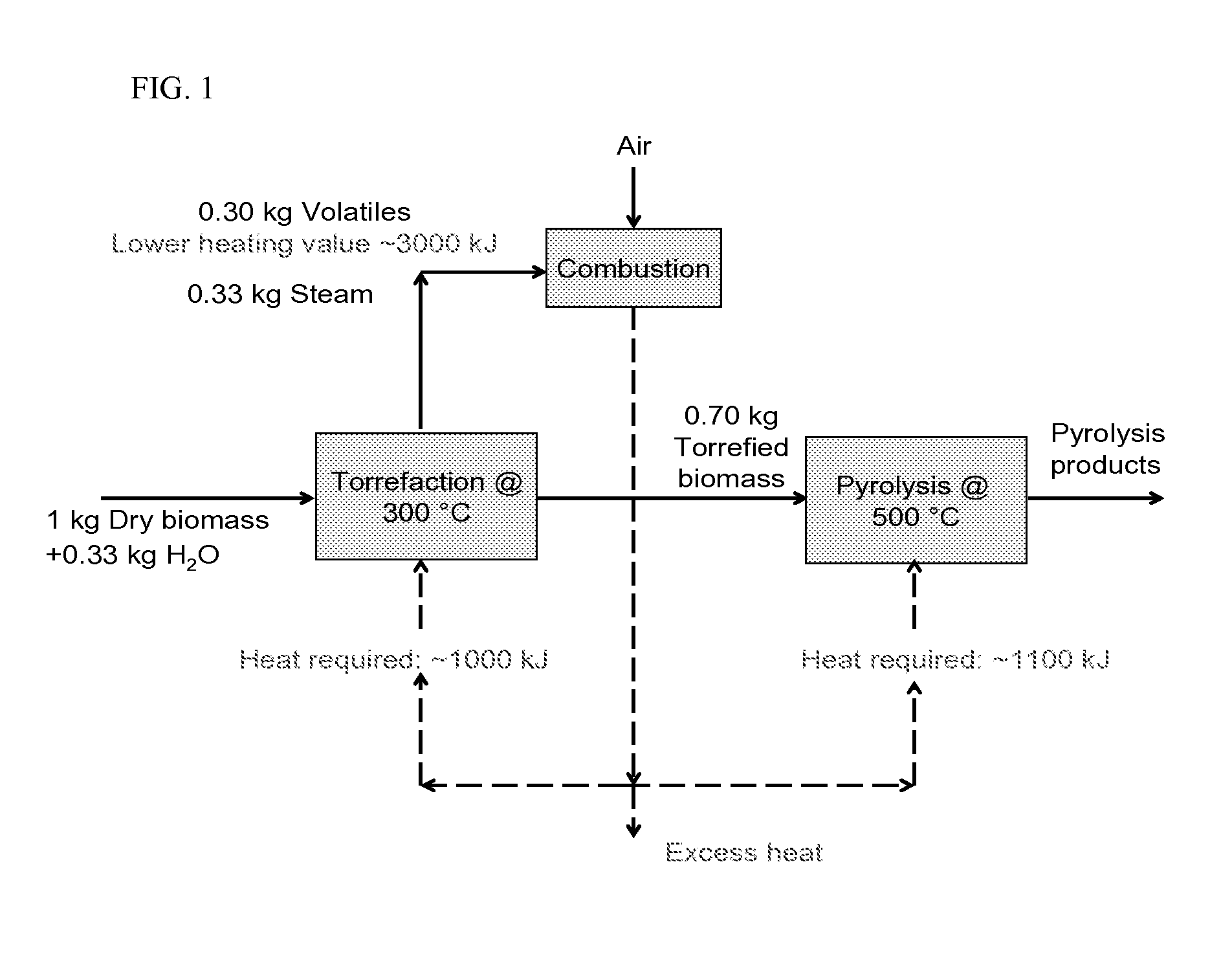

Heat integrated process for producing high quality pyrolysis oil from biomass

InactiveUS20120116135A1Quality improvementReduce acidityProductsReagentsProcess engineeringEngineering

This invention discloses a heat integrated and energy saving process for producing high quality pyrolysis oil from biomass by utilizing a torrefaction pretreatment step for biomass pyrolysis processing wherein the pretreatment step improves the quality of the pyrolysis oil by reducing acidity. This invention further utilizes the gaseous product of the torrefaction step through a combustion process for heat production and recovery.

Owner:PHILLIPS 66 CO

Method and system for the torrefaction of lignocellulosic material

A method for torrefaction of lignocellulosic biomass using a torrefaction reactor vessel having stacked trays, the method including: continuously feeding the biomass to an upper inlet of the torrefaction reactor vessel such that the biomass material is deposited on an upper tray of a plurality of trays stacked vertically within the reactor; as the biomass moves across an upper surface of each of the trays, heating and drying the biomass material with a gas injected into the vessel, wherein the gas is substantially non-oxidizing of the biomass, is under a pressure of at least 20 bar gauge and at a temperature of at least 200° C.; cascading the biomass down through the trays by passing the biomass through an opening in each of the trays to deposit the biomass on a lower tray; discharging torrefied biomass from a lower outlet of the torrefaction reactor vessel, and circulating gas extracted from a lower elevation of the reactor vessel to an upper region of the reactor vessel.

Owner:ANDRITZ TECH & ASSET MANAGEMENT

Process for producing high quality pyrolysis oil from biomass

InactiveUS20120108860A1Quality improvementReduce acidityBiofuelsLiquid hydrocarbon mixture productionAcetic acidPre treatment

This invention relates to a process to utilize a torrefaction pretreatment step for biomass pyrolysis process. This pretreatment improves the quality of the pyrolysis oil by reducing acidity. The inventive process shows that as a pretreatment to pyrolysis, resulting pyrolysis oil obtained from torrefied biomass has approximately 25% lower acetic acid than that from untorrefied biomass pyrolysis oil.

Owner:PHILLIPS 66 CO

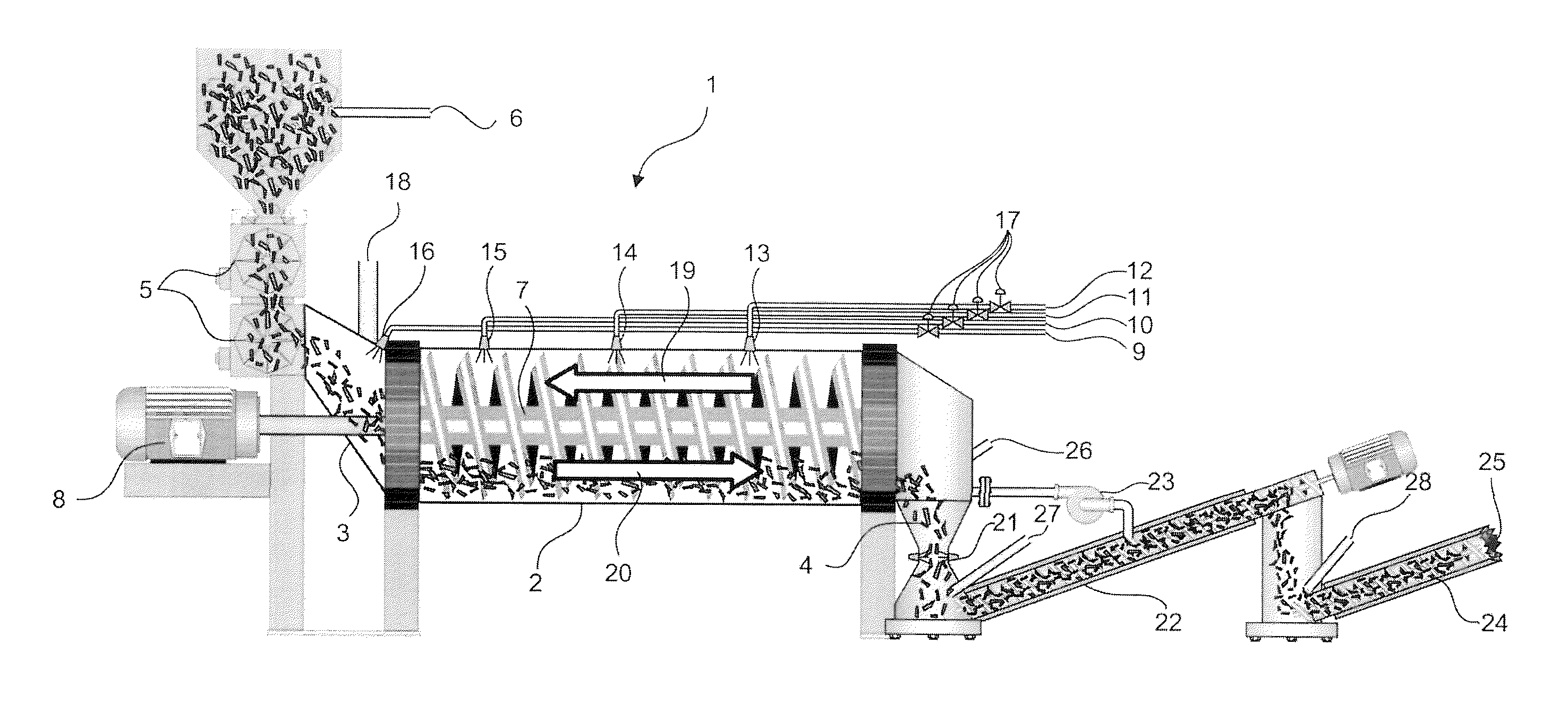

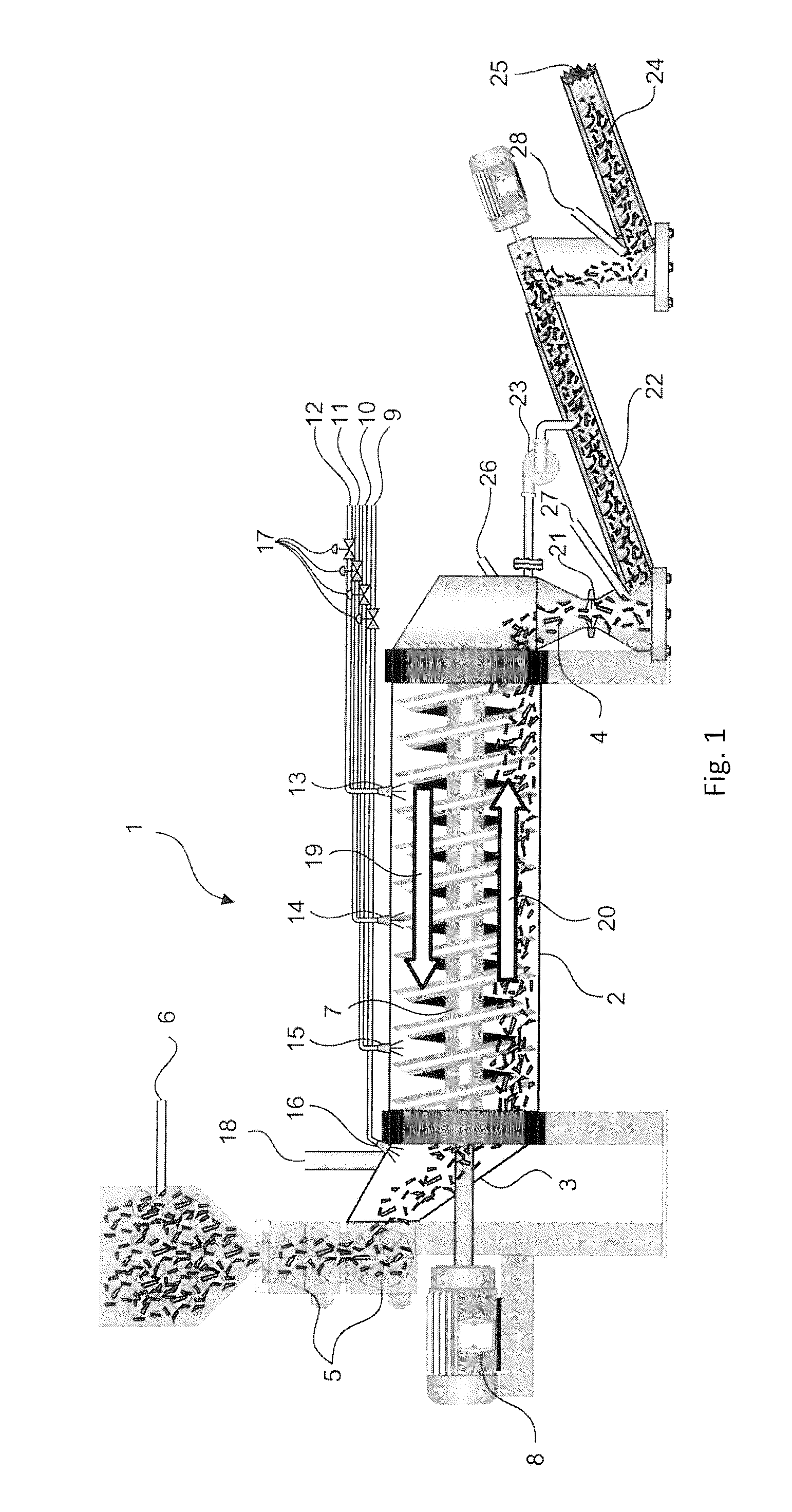

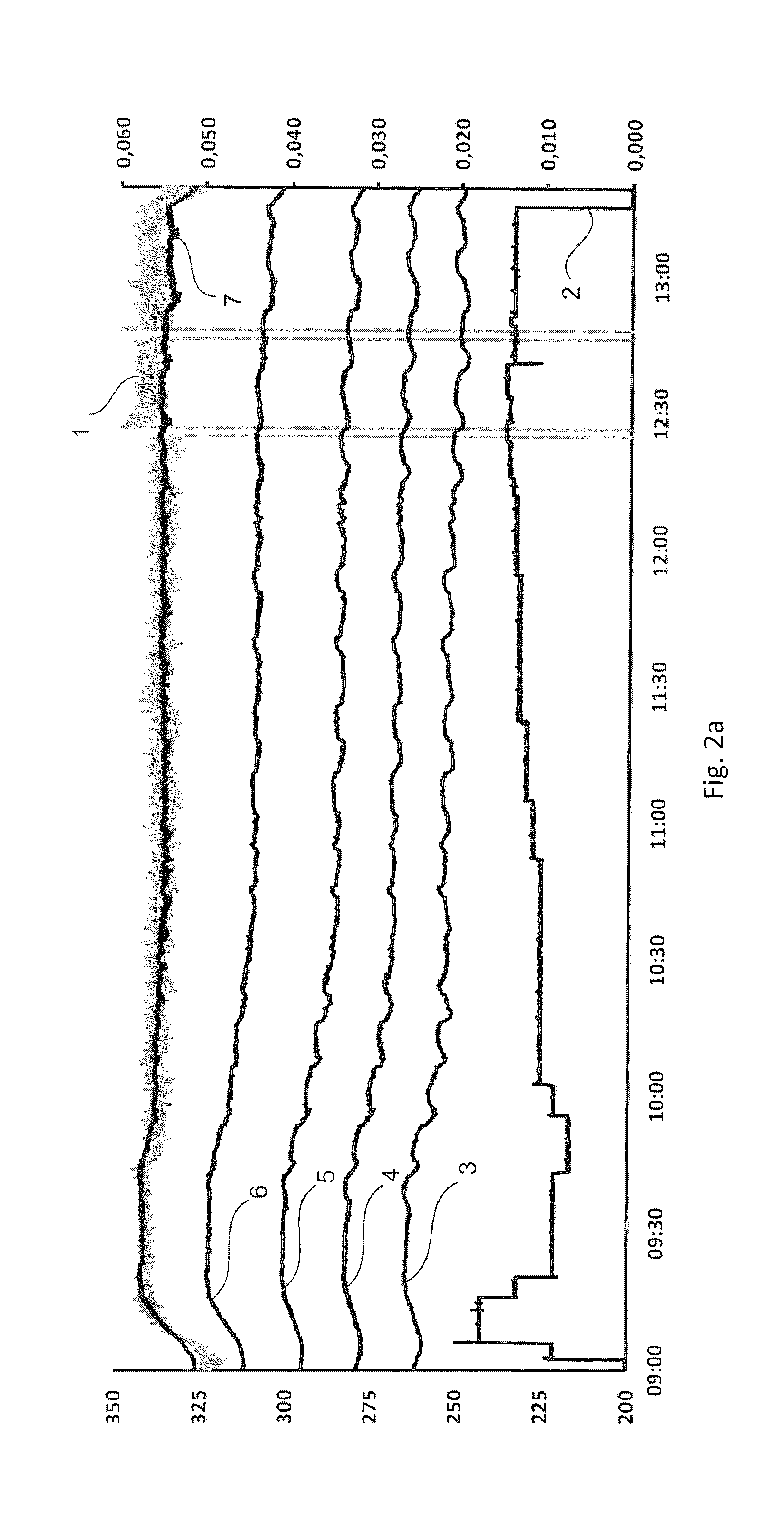

Countercurrent oxygen enhanced torrefaction

ActiveUS20140208995A1Reduce shipping costsLow calorific valueHydrogenHydrocarbon from carbon oxidesOxygen enhancedTorrefaction

The invention relates to a method of torrefaction of an optionally predried biomass in a torrefaction reactor such that torrefied biomass and torrefaction gases are obtained, and wherein an oxygen-containing gas is supplied to the torrefaction reactor at a first position in the reactor such that oxygen reacts with components of the torrefaction gases under the formation of heat and wherein torrefaction gases are withdrawn from the torrefaction reactor at a second position of the torrefaction reactor and wherein the first position is located downstream of the second position in relation to a biomass transport direction in the torrefaction reactor such that the torrefaction gases moves through the torrefaction reactor countercurrent with the biomass transport and wherein the optionally predried biomass has a temperature of between 30° C. and 230° C., preferably between 50° C. and 200° C., most preferably between 60° C. and 180° C. when entering the torrefaction rector.

Owner:BIOENDEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com