Patents

Literature

9191results about How to "Improve filtration efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

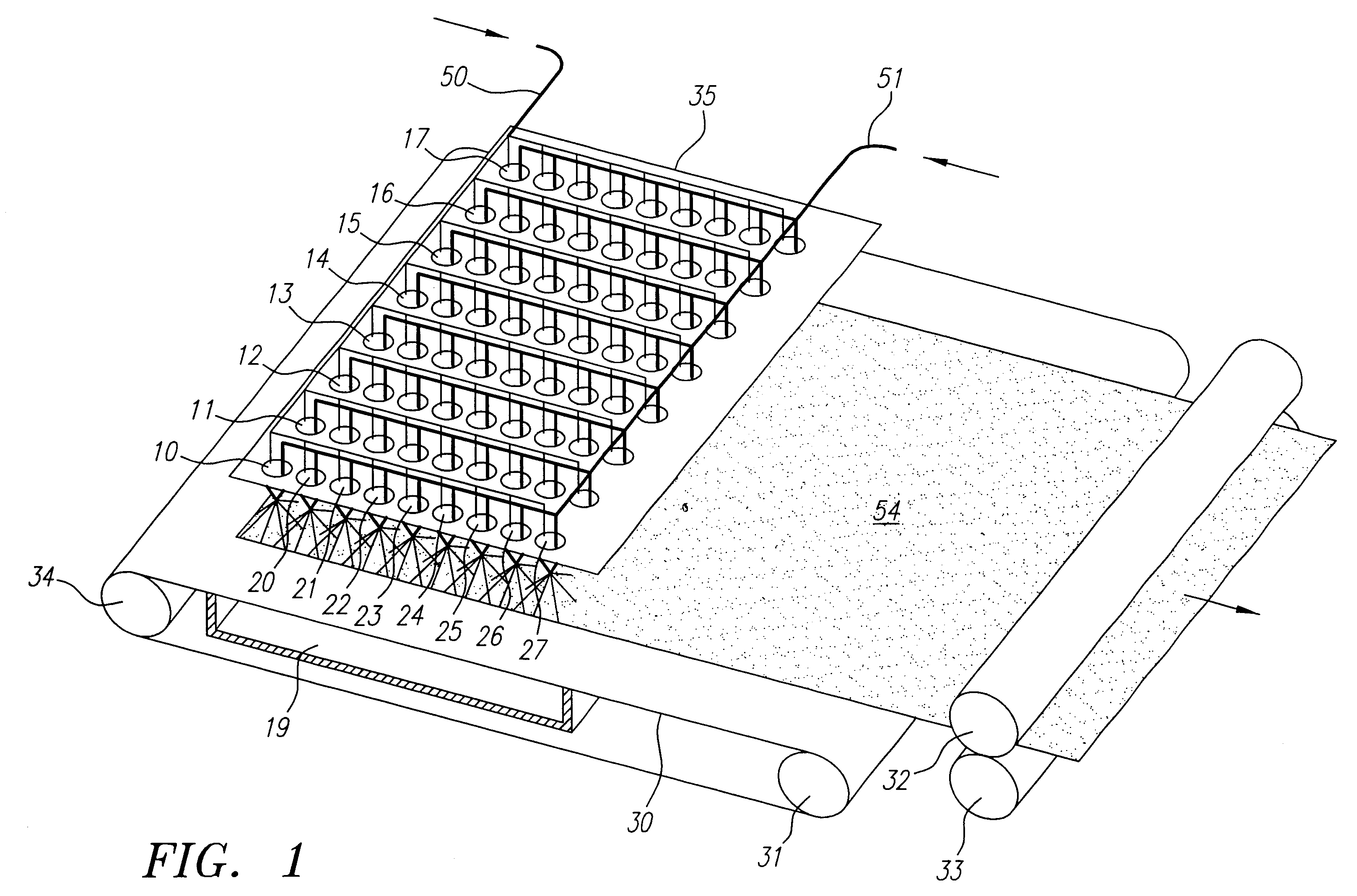

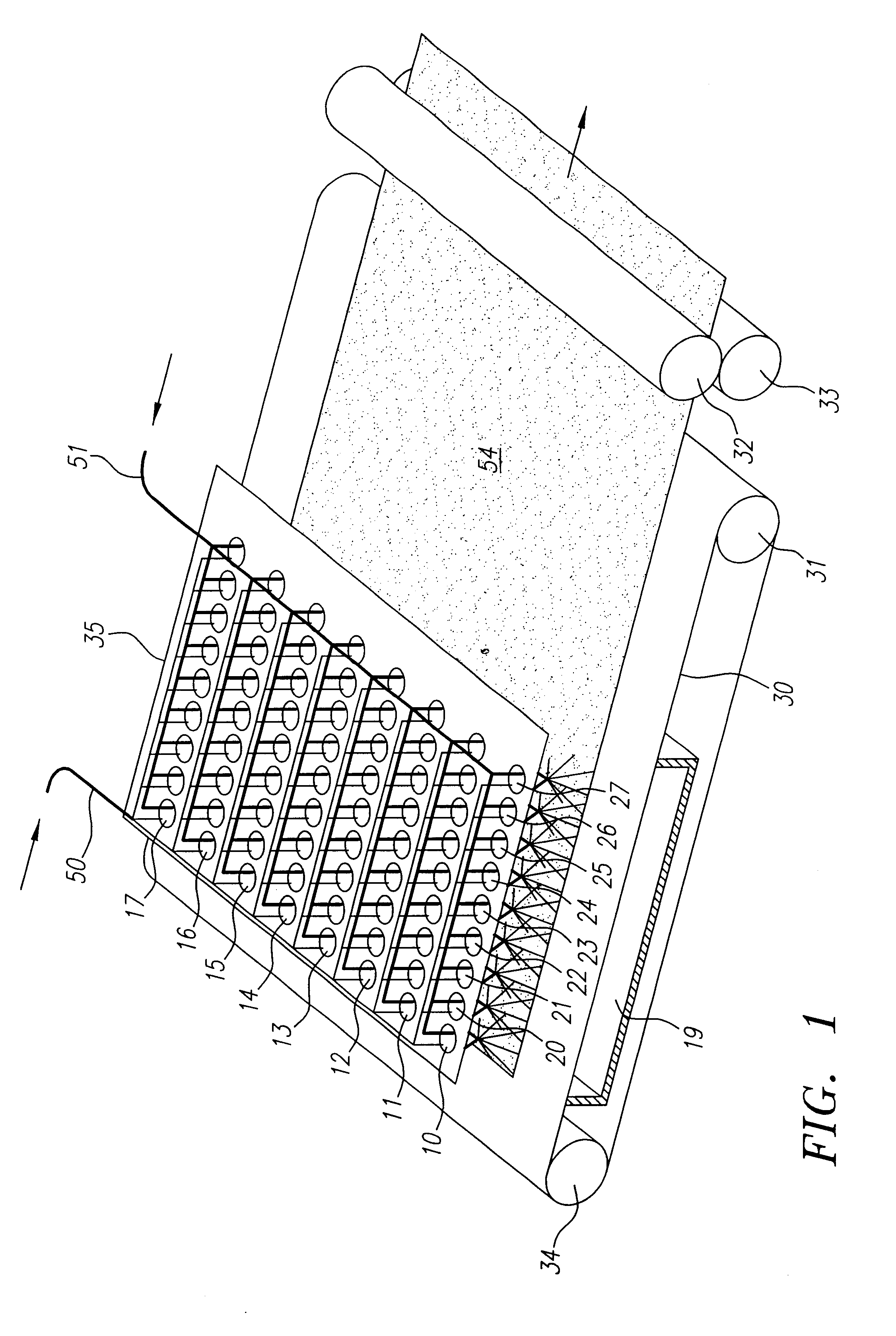

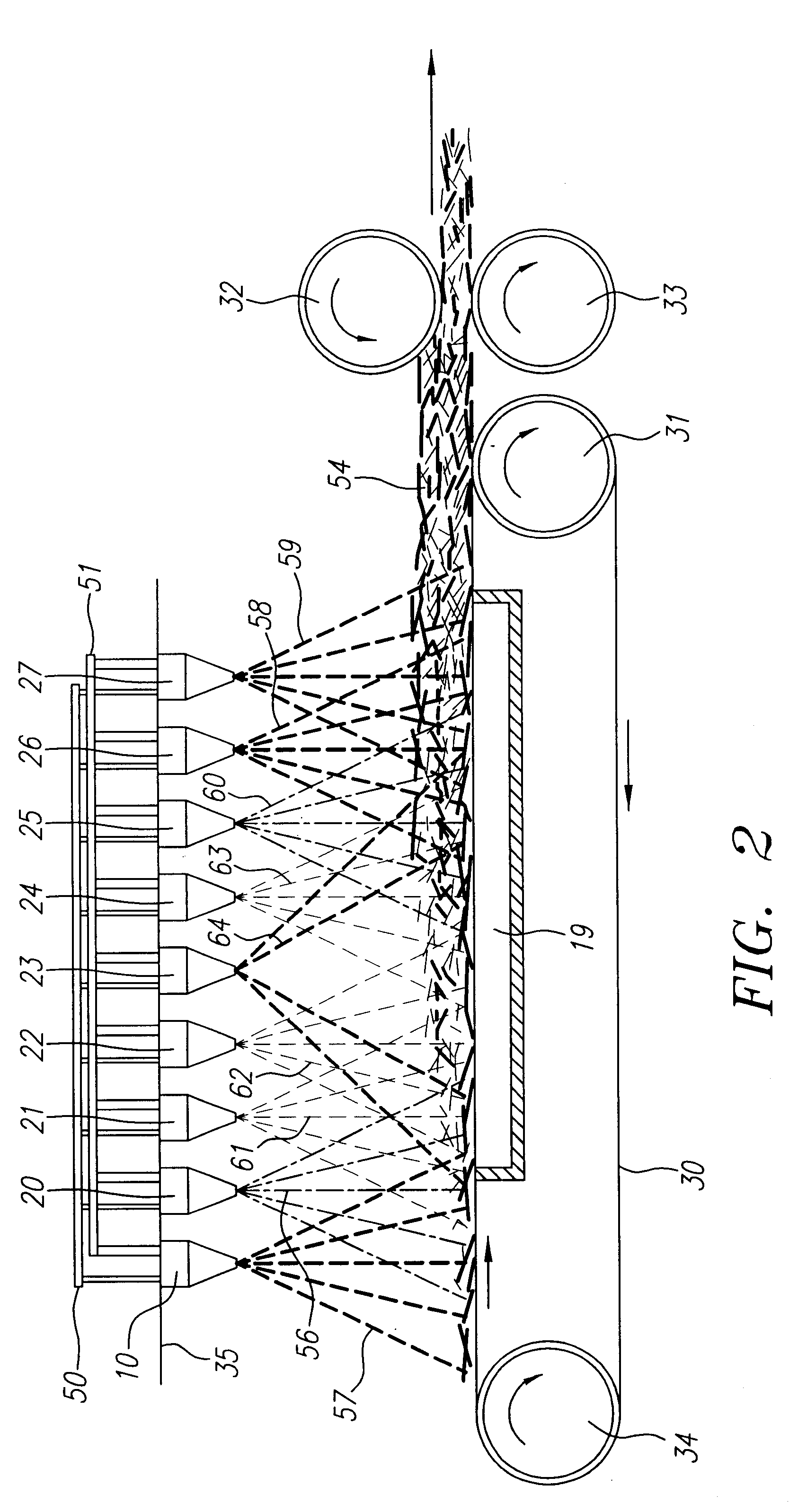

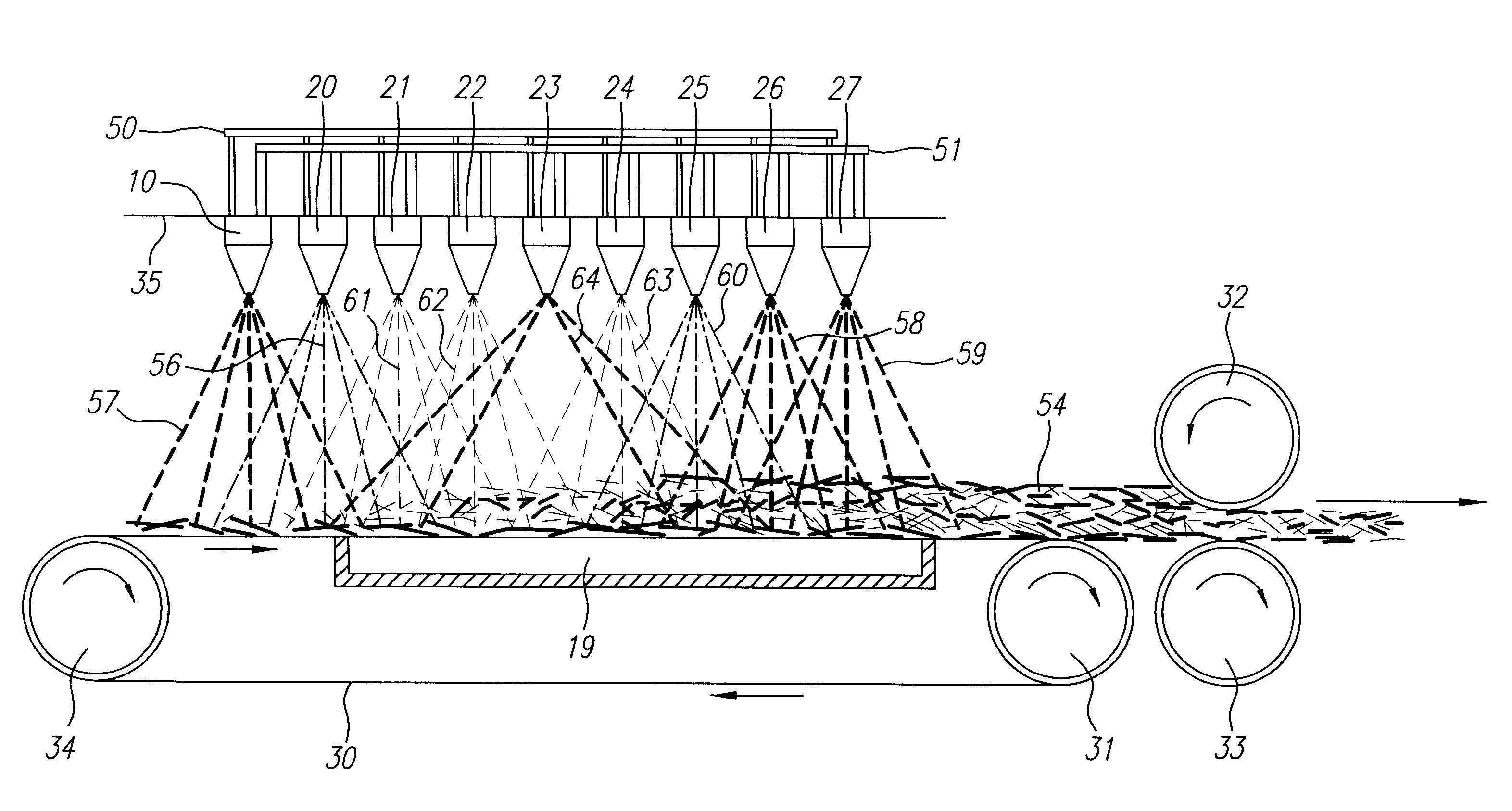

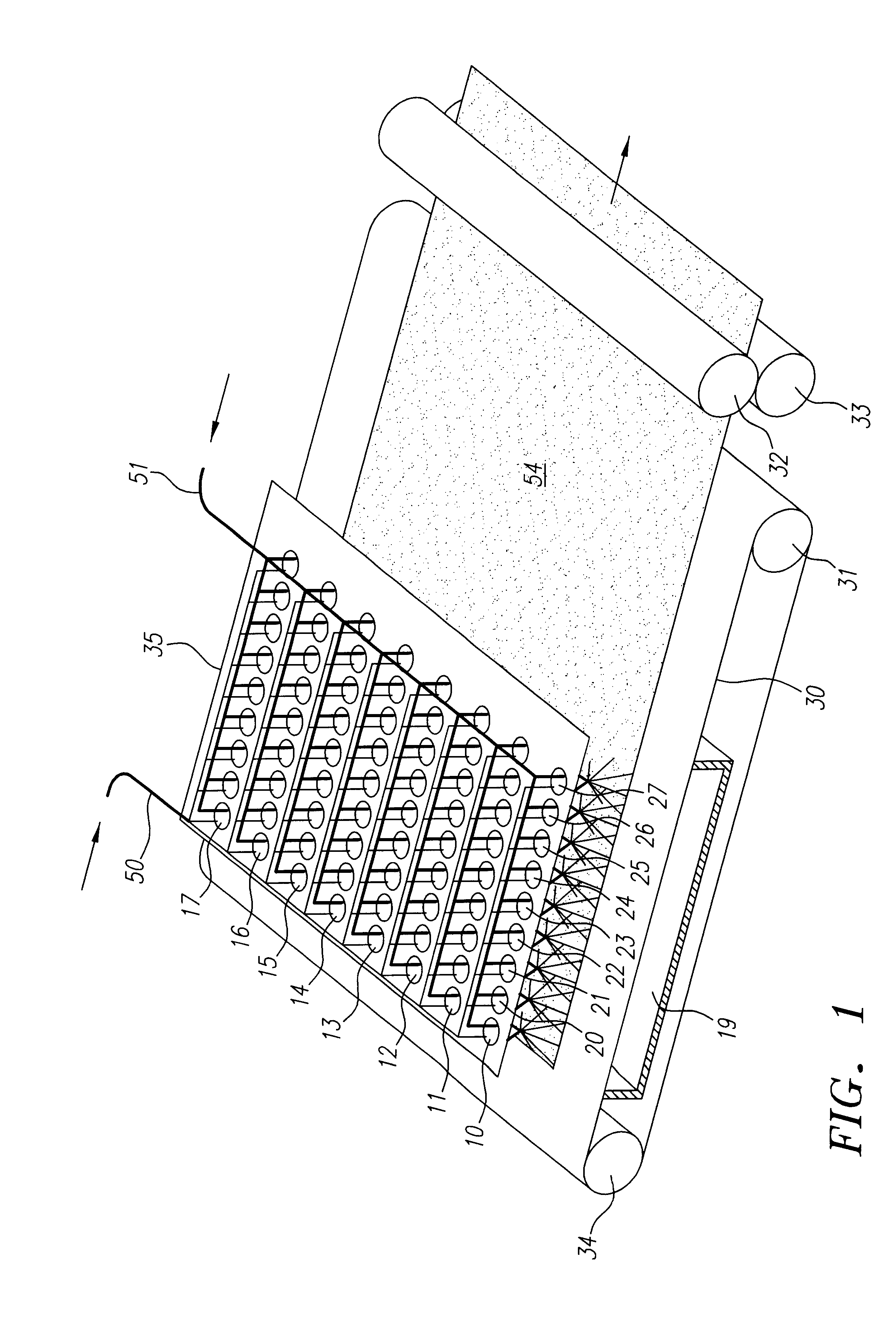

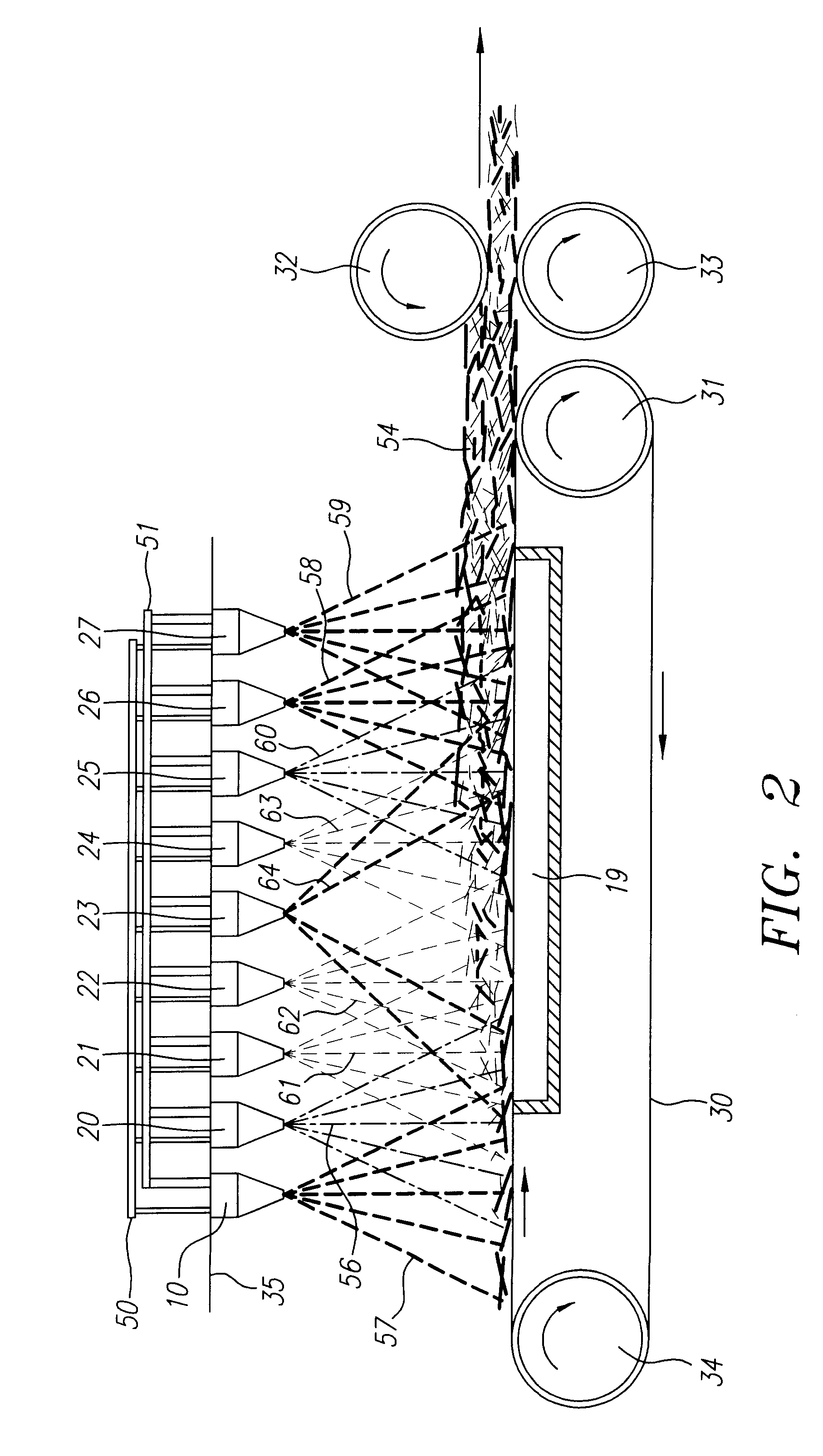

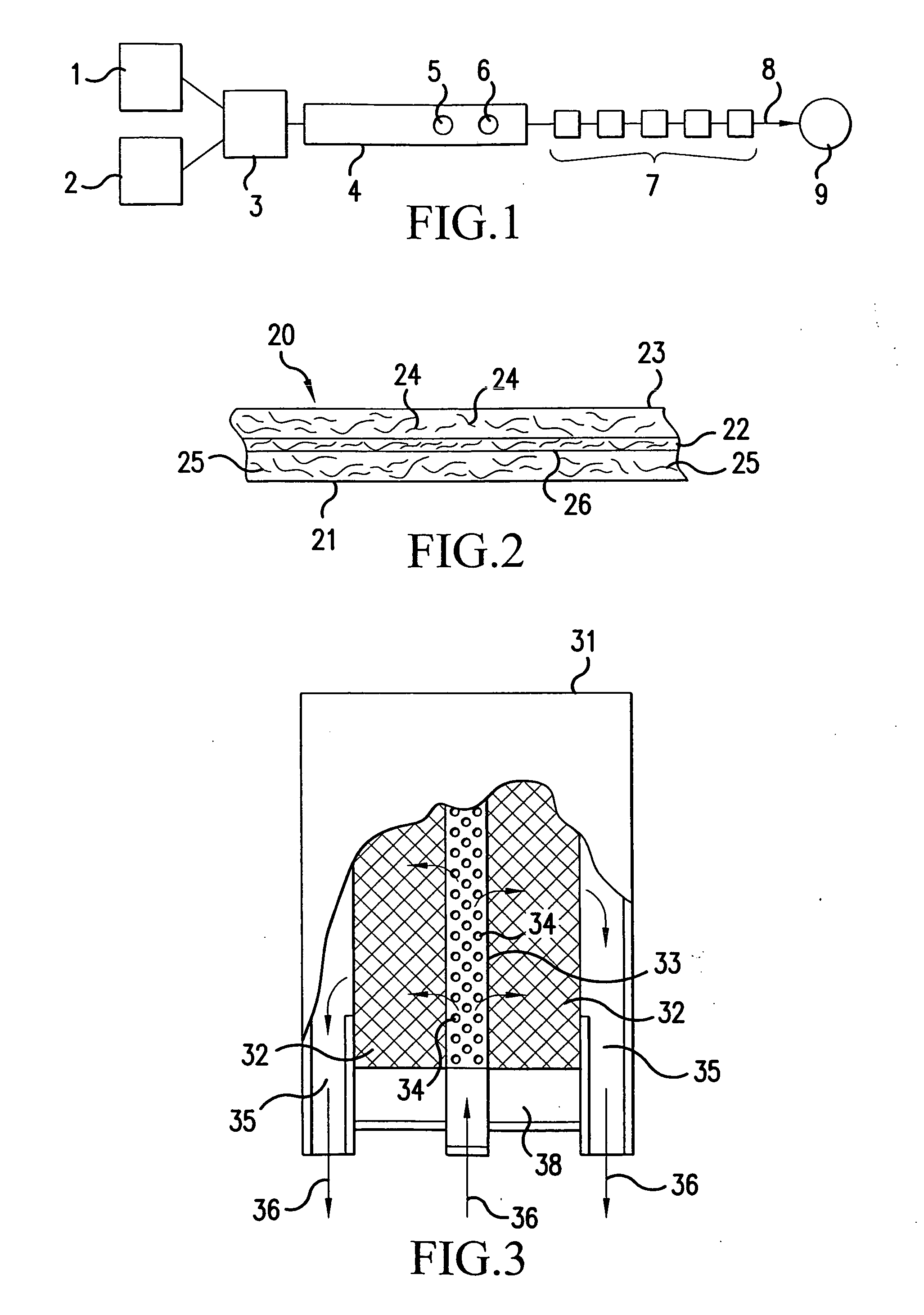

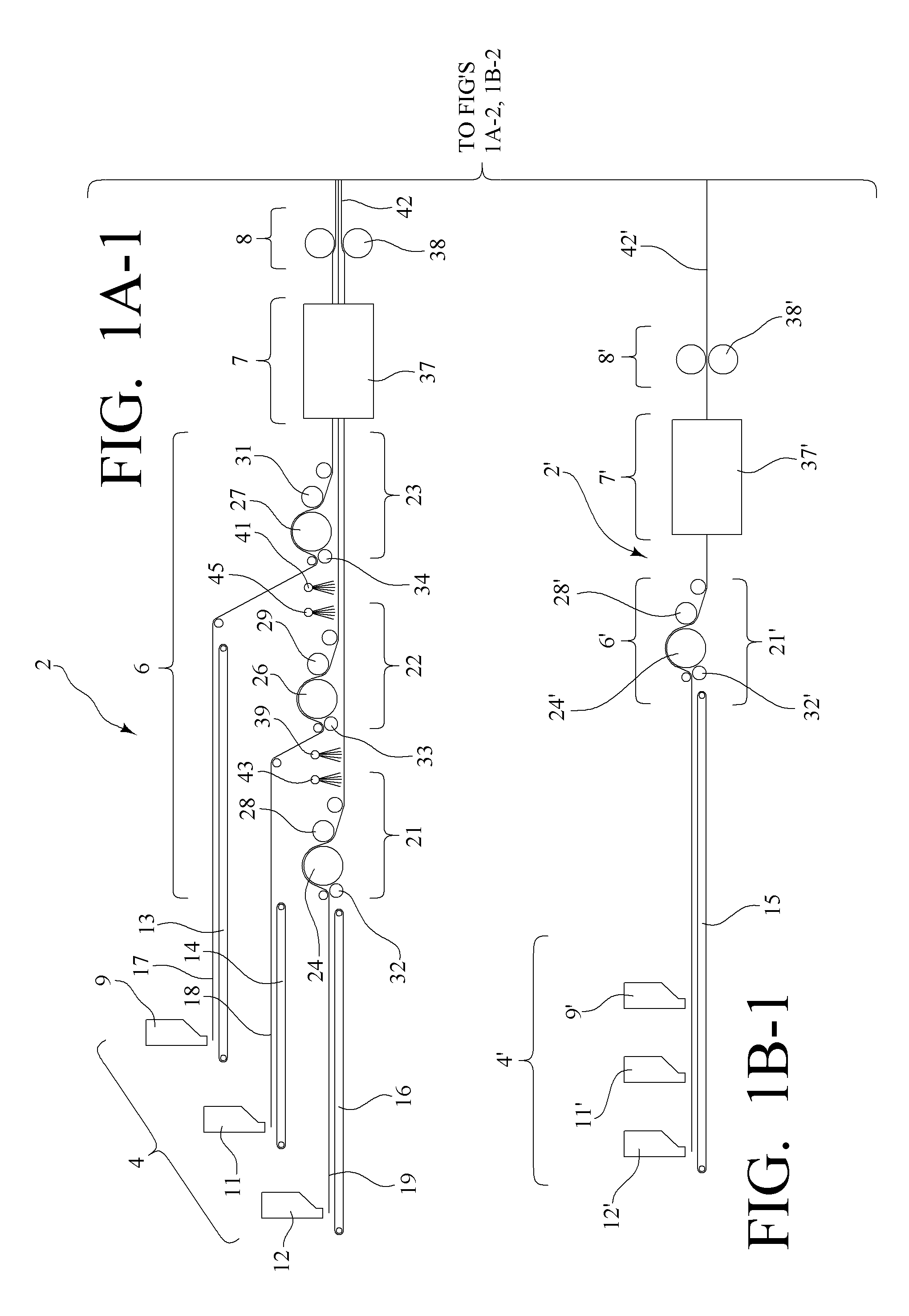

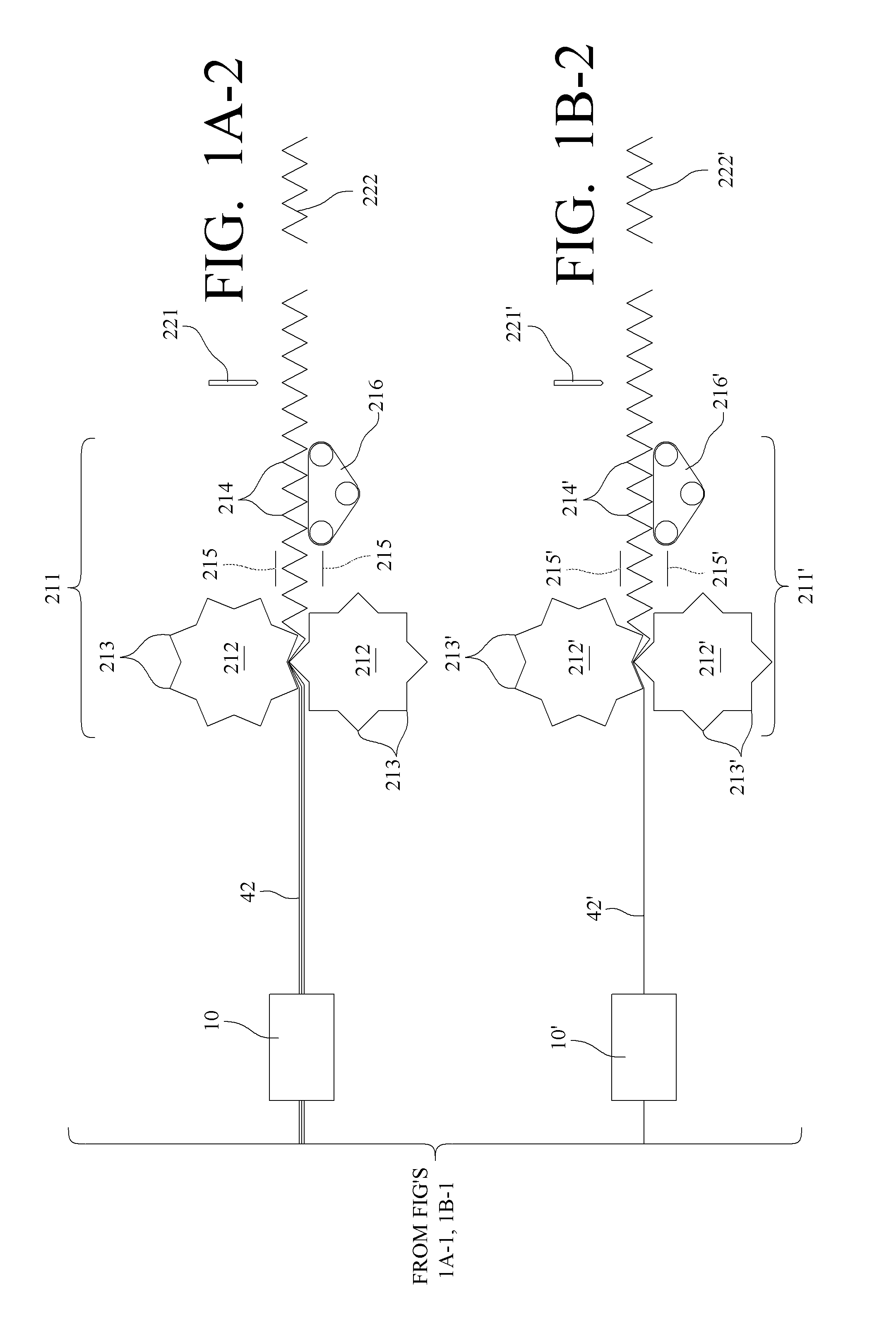

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6315806B1Increase distanceReduce resistanceFilament/thread formingLoose filtering material filtersMean diameterFiber

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6183670B1Increase collisionImprove compactionFilament/thread formingAuxillary shaping apparatusMean diameterFiber

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

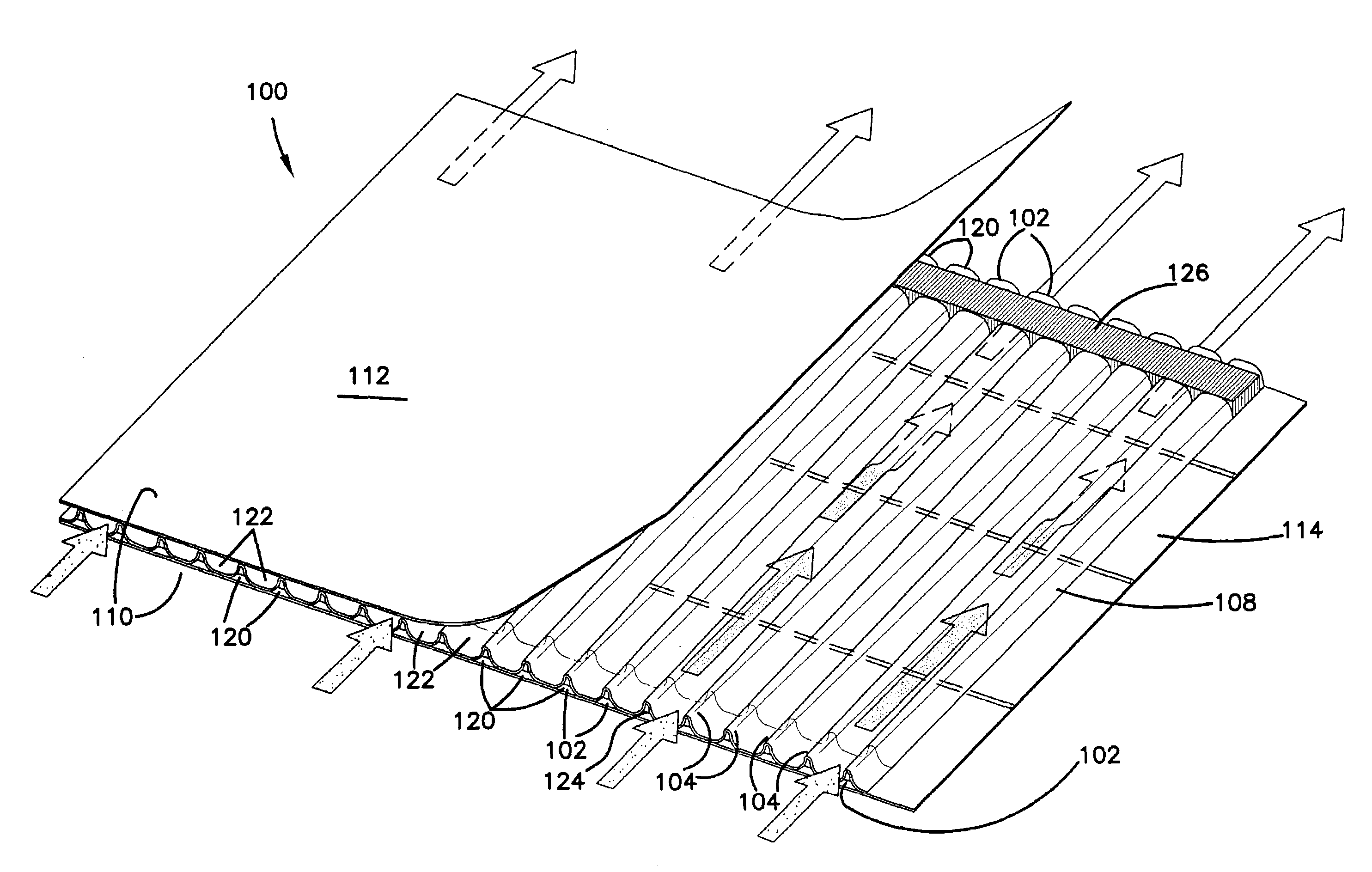

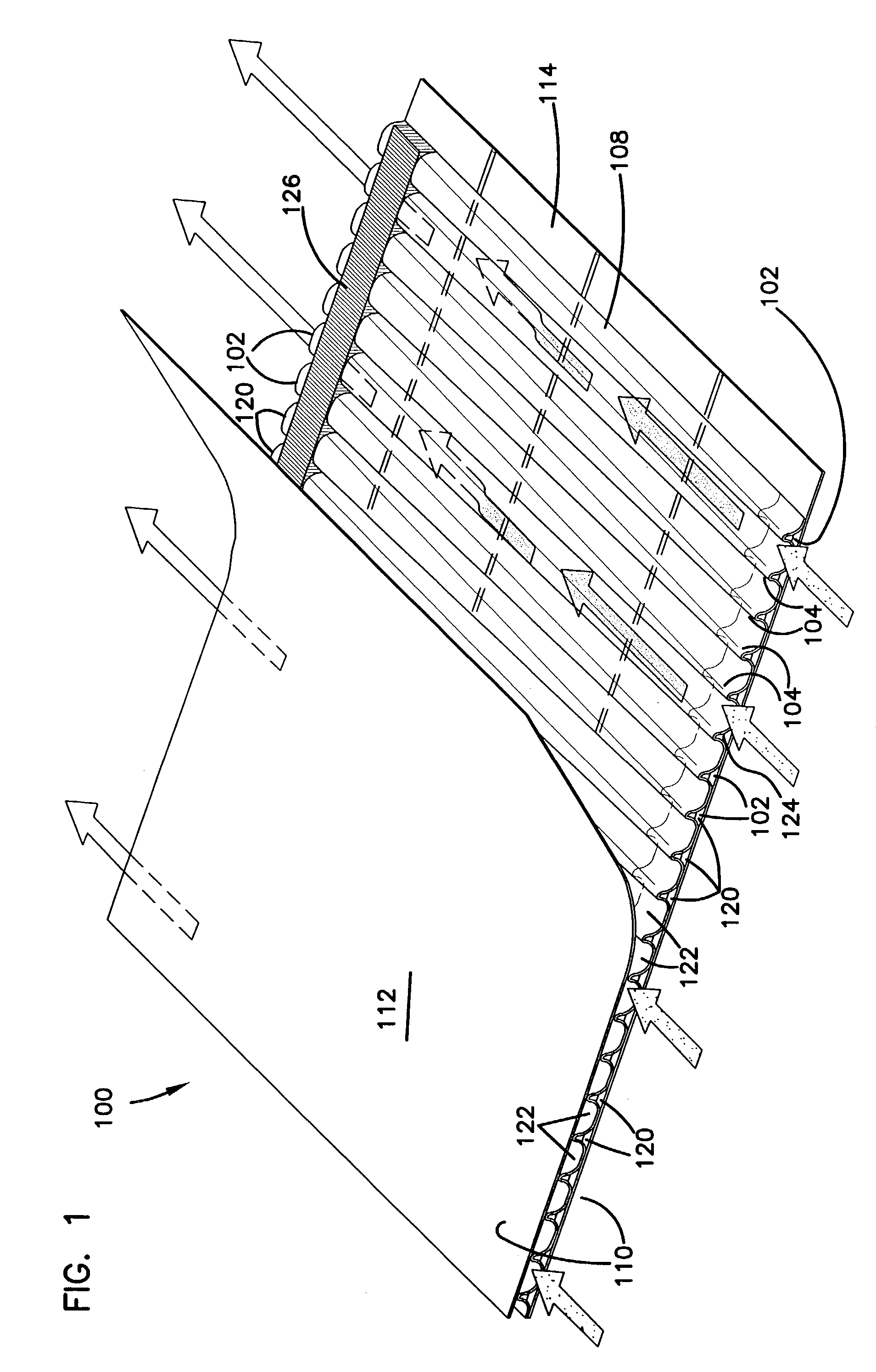

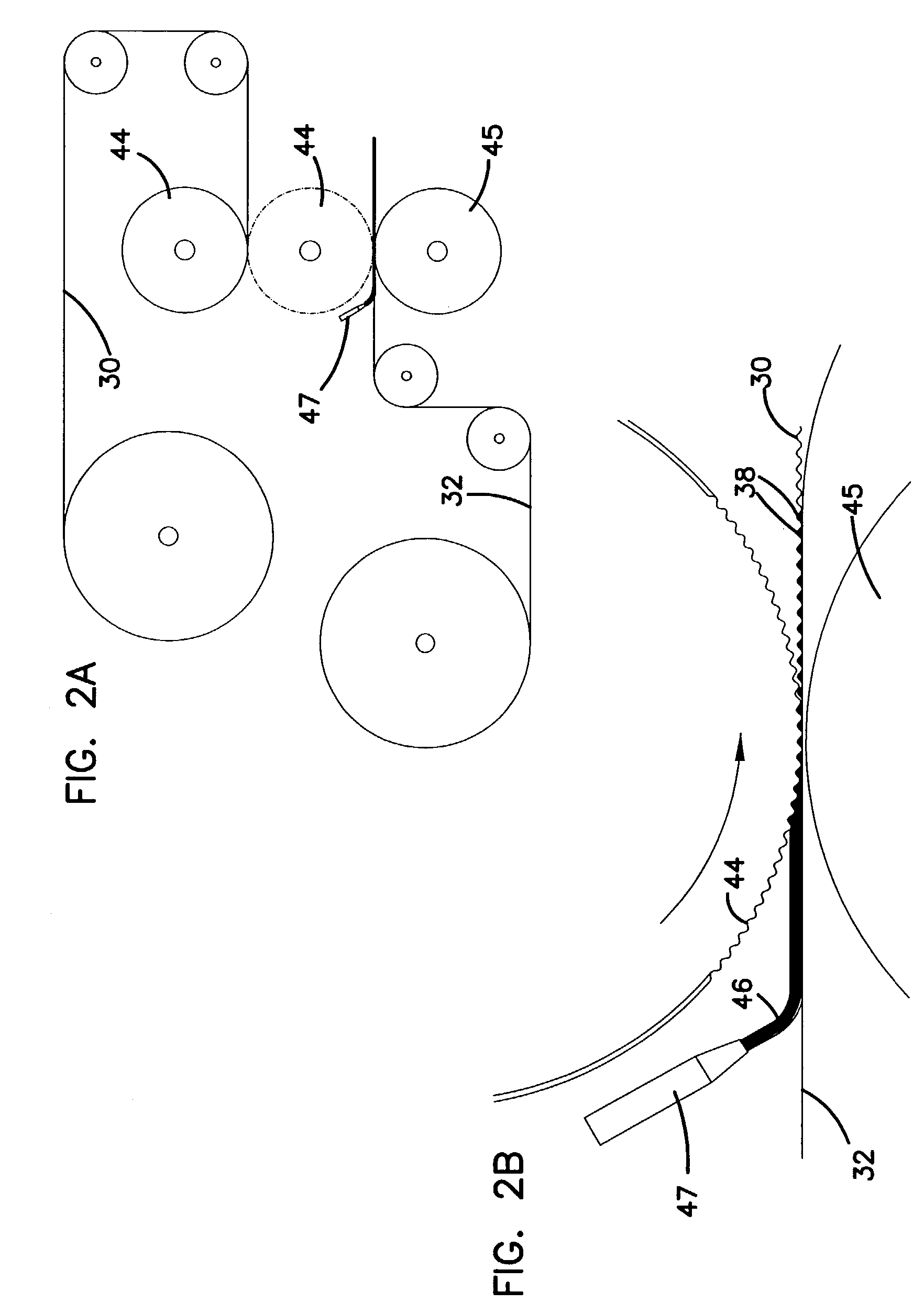

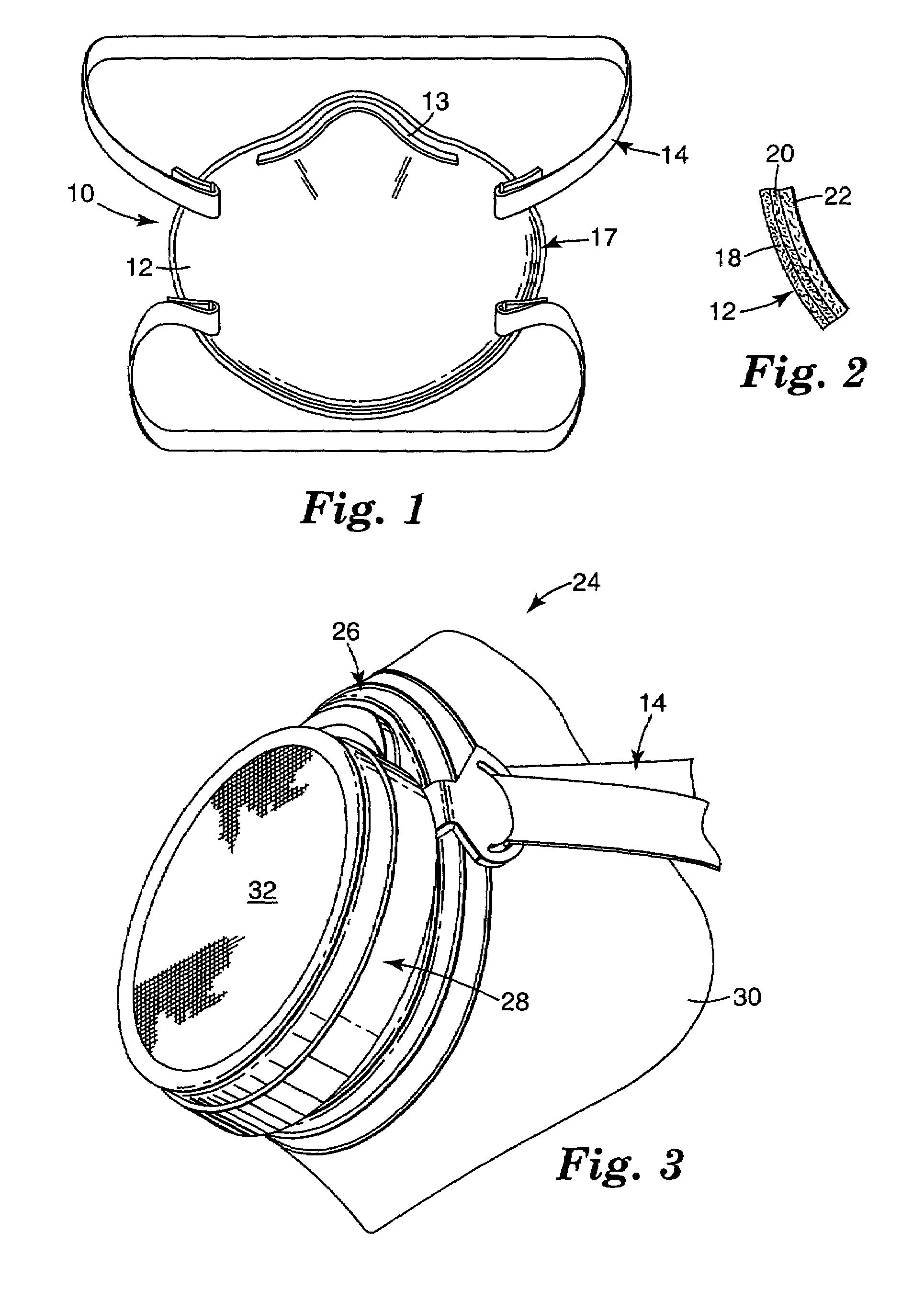

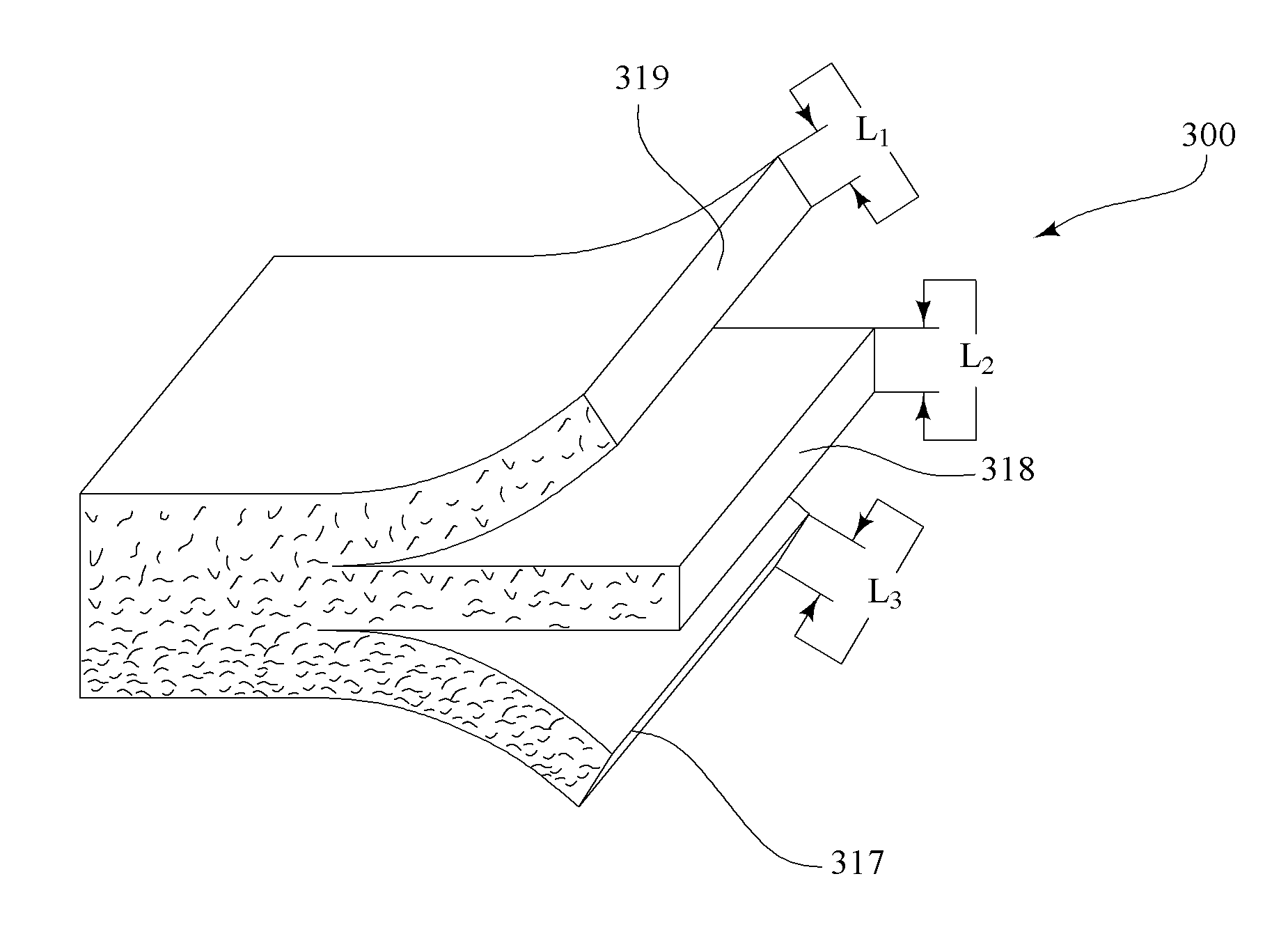

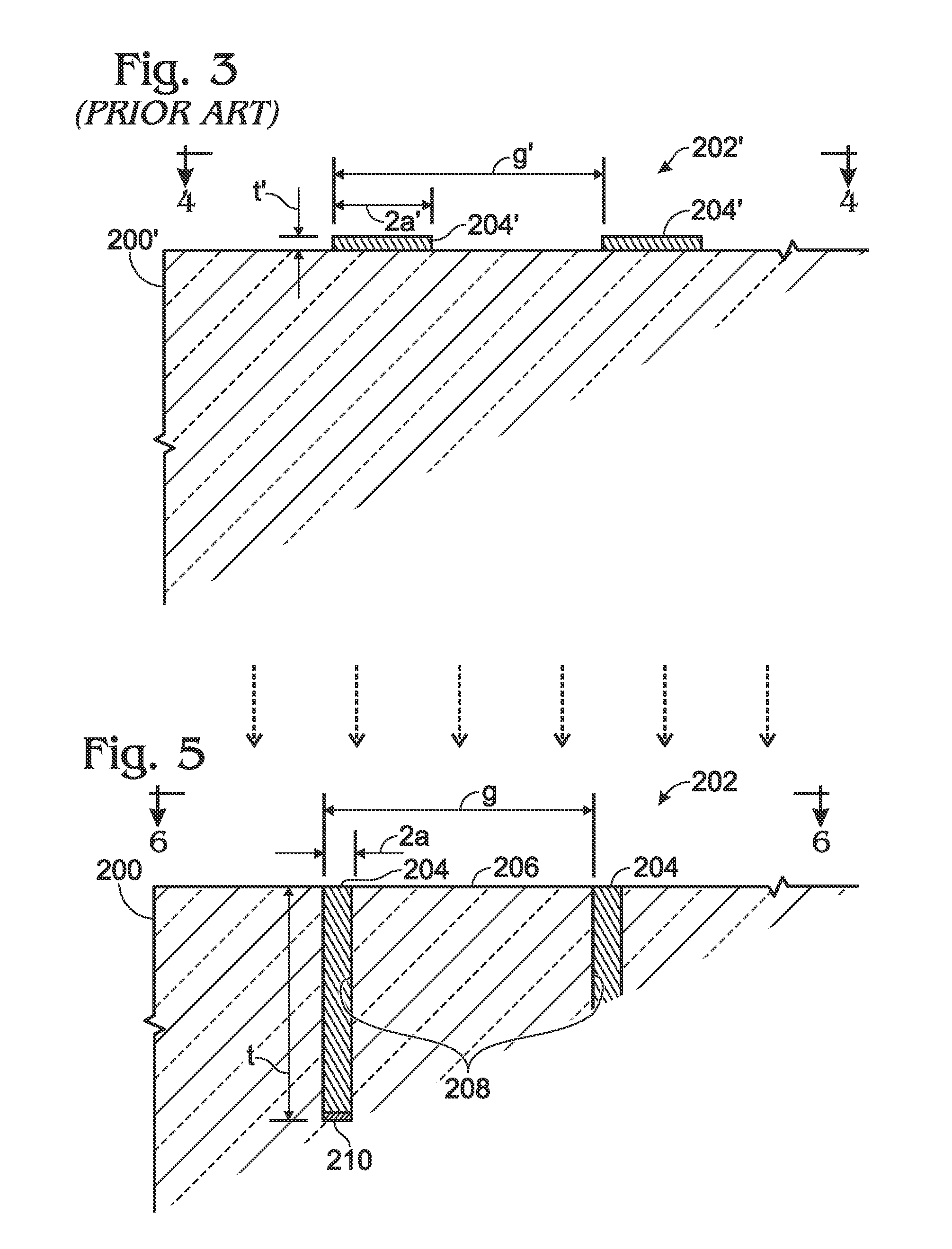

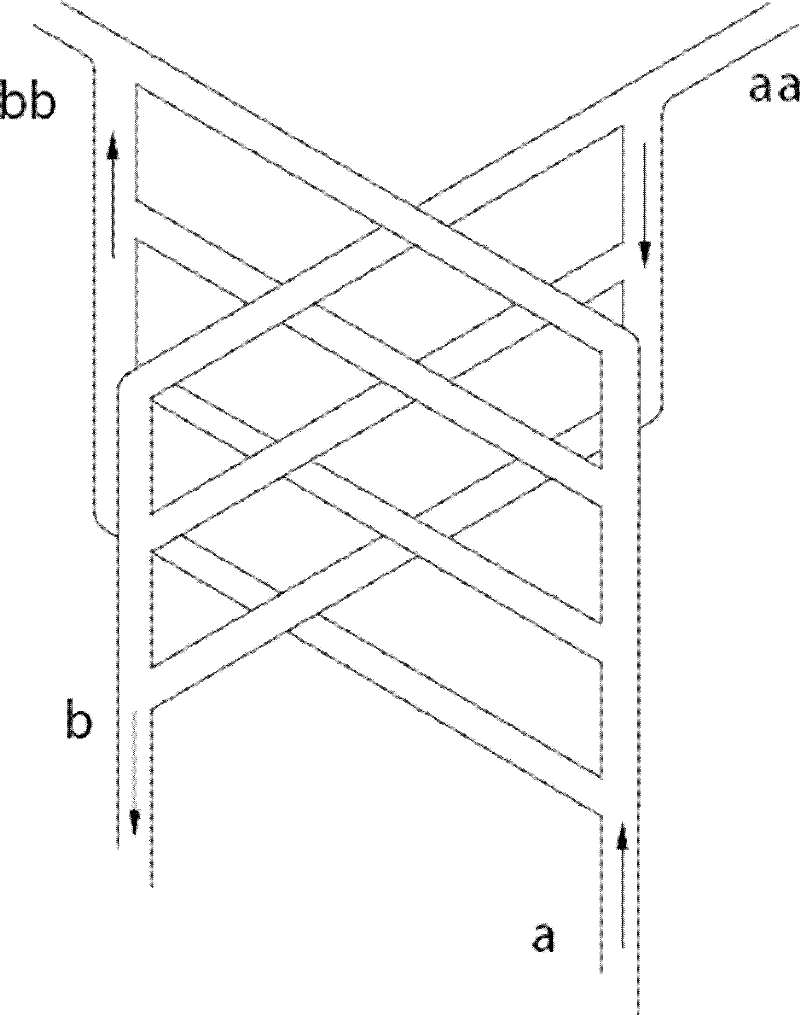

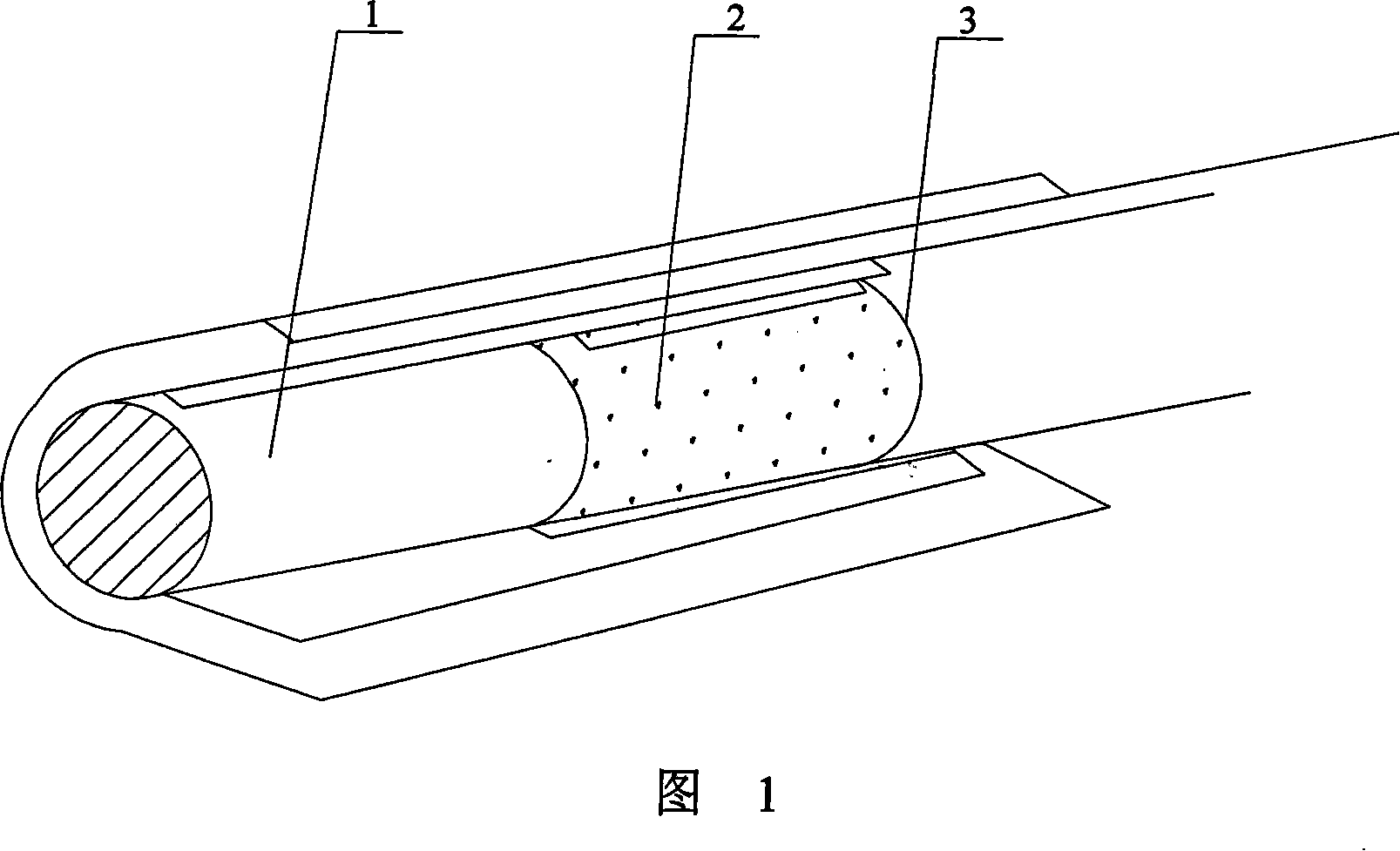

Method of making a fluted filter media for air filter

InactiveUS7329326B2Improve flow characteristicsReduce restrictionsMechanical working/deformationLamination ancillary operationsFluteAir filter

Fluted filter media includes filter material having a plurality of flutes formed therein having alternating ends of adjacent flutes closed to force fluid through filter material. A first embodiment of the filter media includes tapered flutes which have the open ends of the flutes larger in cross-section than the closed flutes, wherein the upstream open flutes converge toward the downstream end and the upstream closed end flutes diverge toward the downstream end. A second embodiment includes filter media which is asymmetric formed with dissimilar upstream and downstream flute cross-sections with larger flute openings to the upstream side of the filter. A third embodiment includes filter media with an upstream edge crushed to improve flow at the upstream edge. A fourth embodiment includes filter media with the upstream sealing material recessed from the upstream edge for reducing effects from blockages at the upstream edge of the filter.

Owner:DONALDSON CO INC

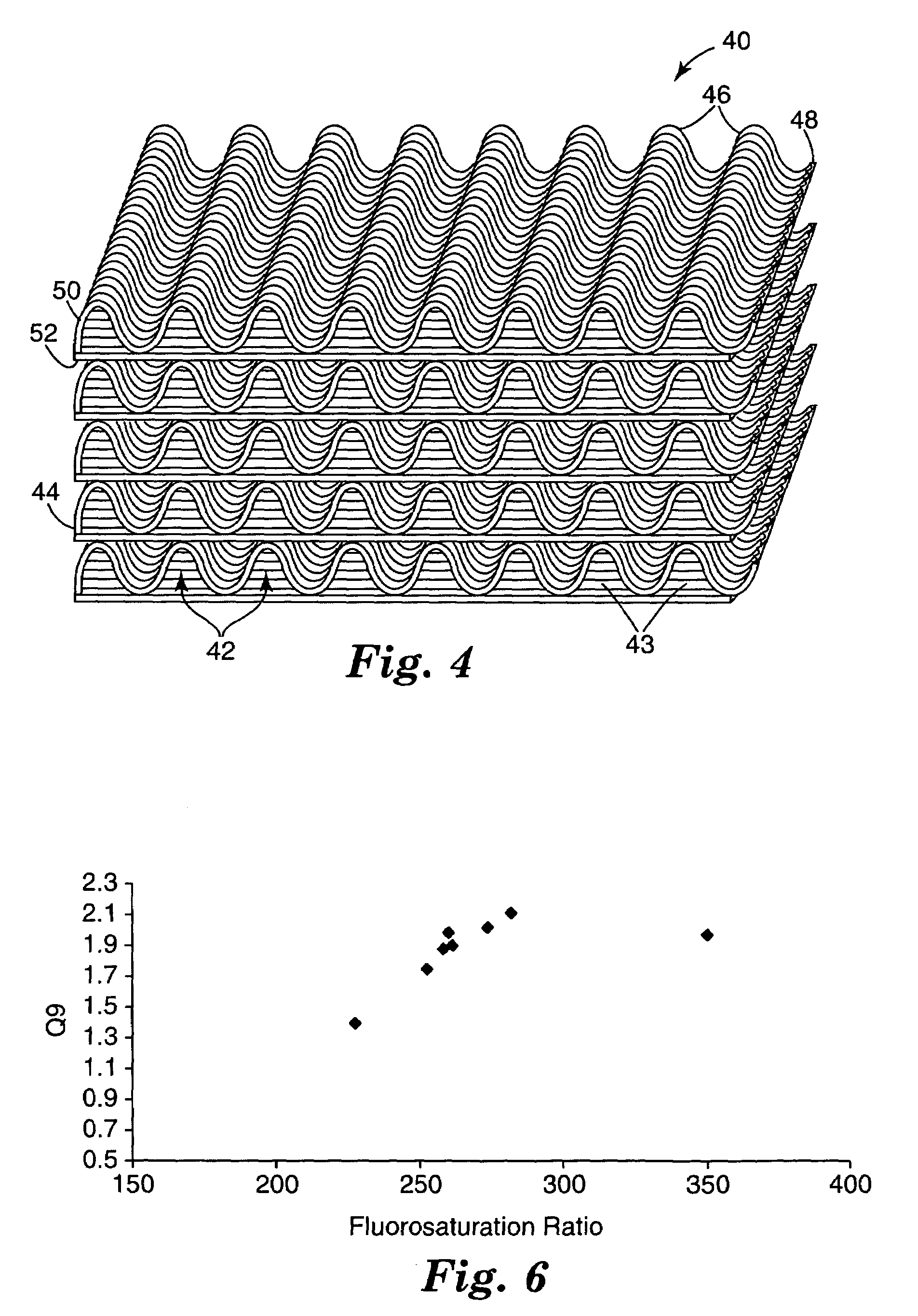

Electret article having high fluorosaturation ratio

ActiveUS7244291B2Improve thermal stabilityIncreased thermal stability—asBreathing filtersElectrostatic separationFiberPolymer chemistry

Owner:3M INNOVATIVE PROPERTIES CO

Micro and ultrafilters with controlled pore sizes and pore size distribution and methods for making

InactiveUS6309546B1High permeabilityMinimal pressure dropSemi-permeable membranesMembranesMicrometerPore diameter

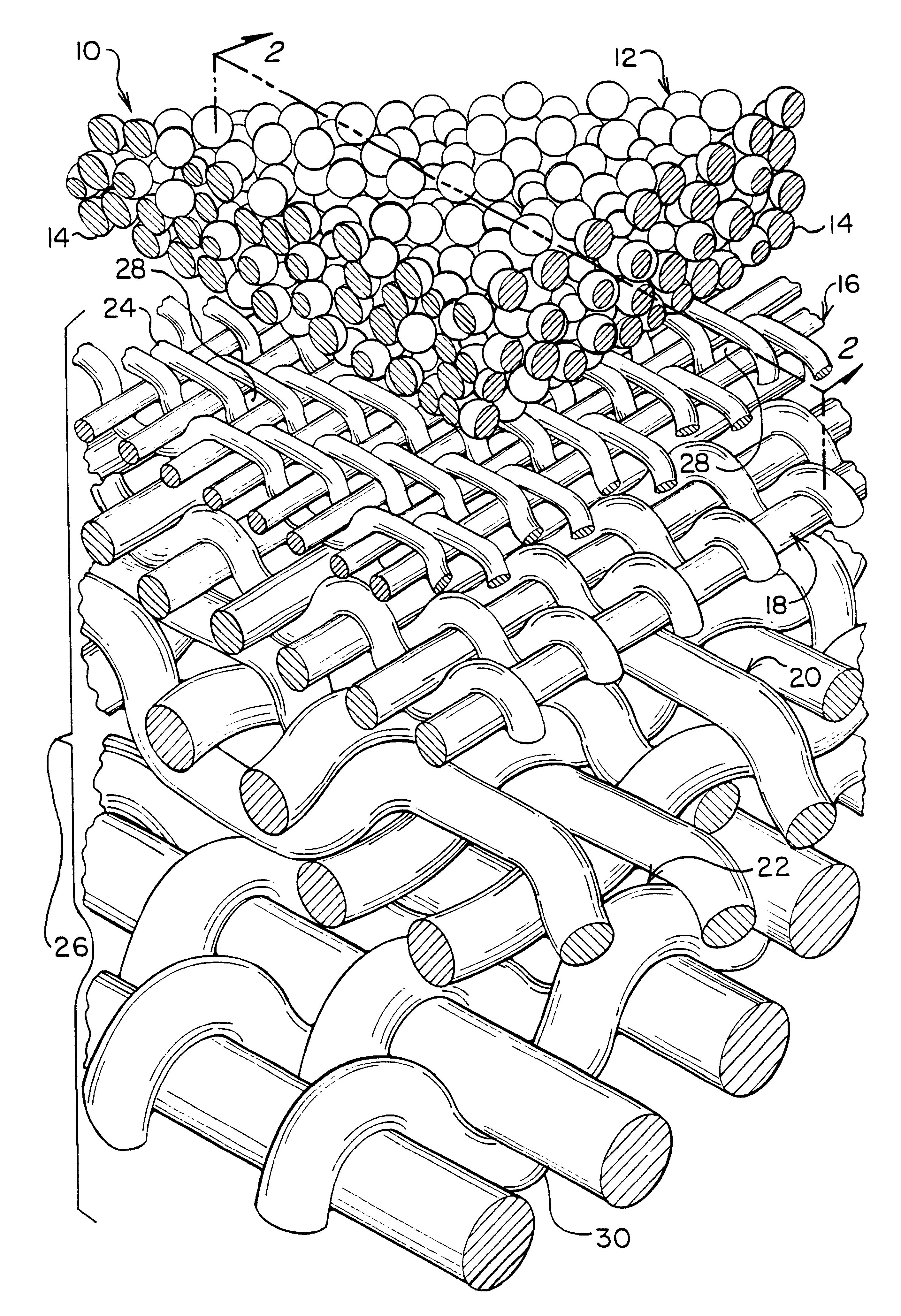

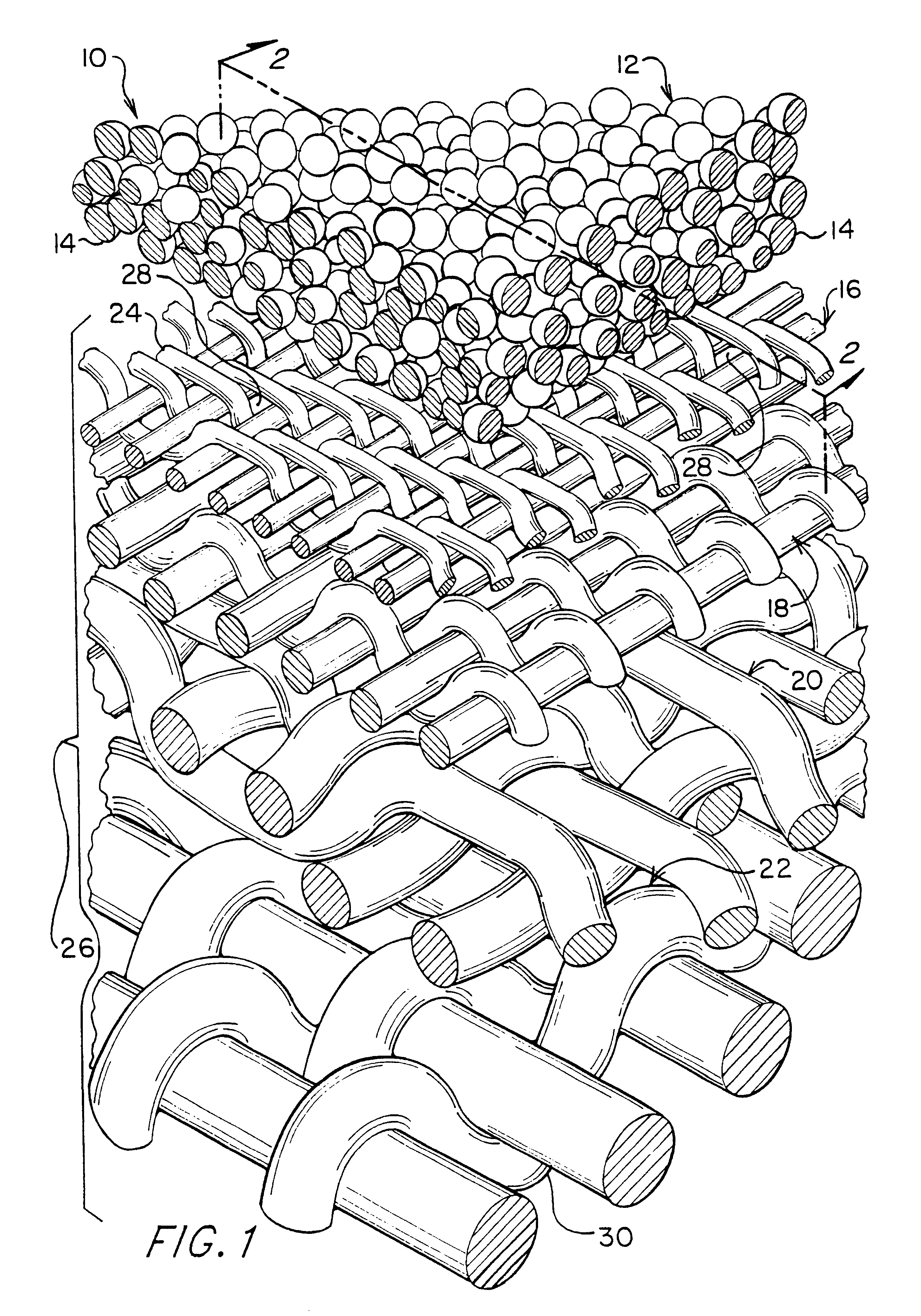

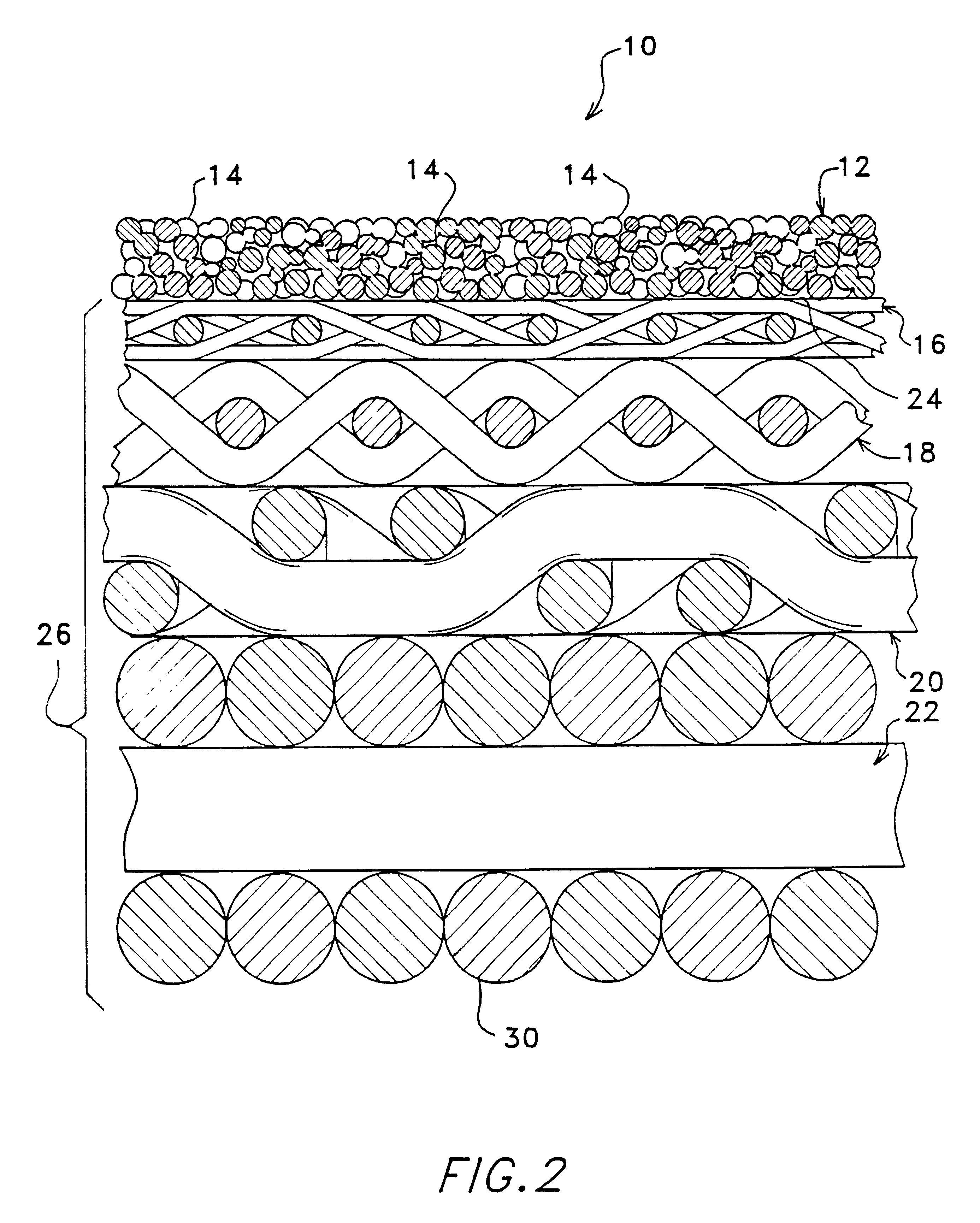

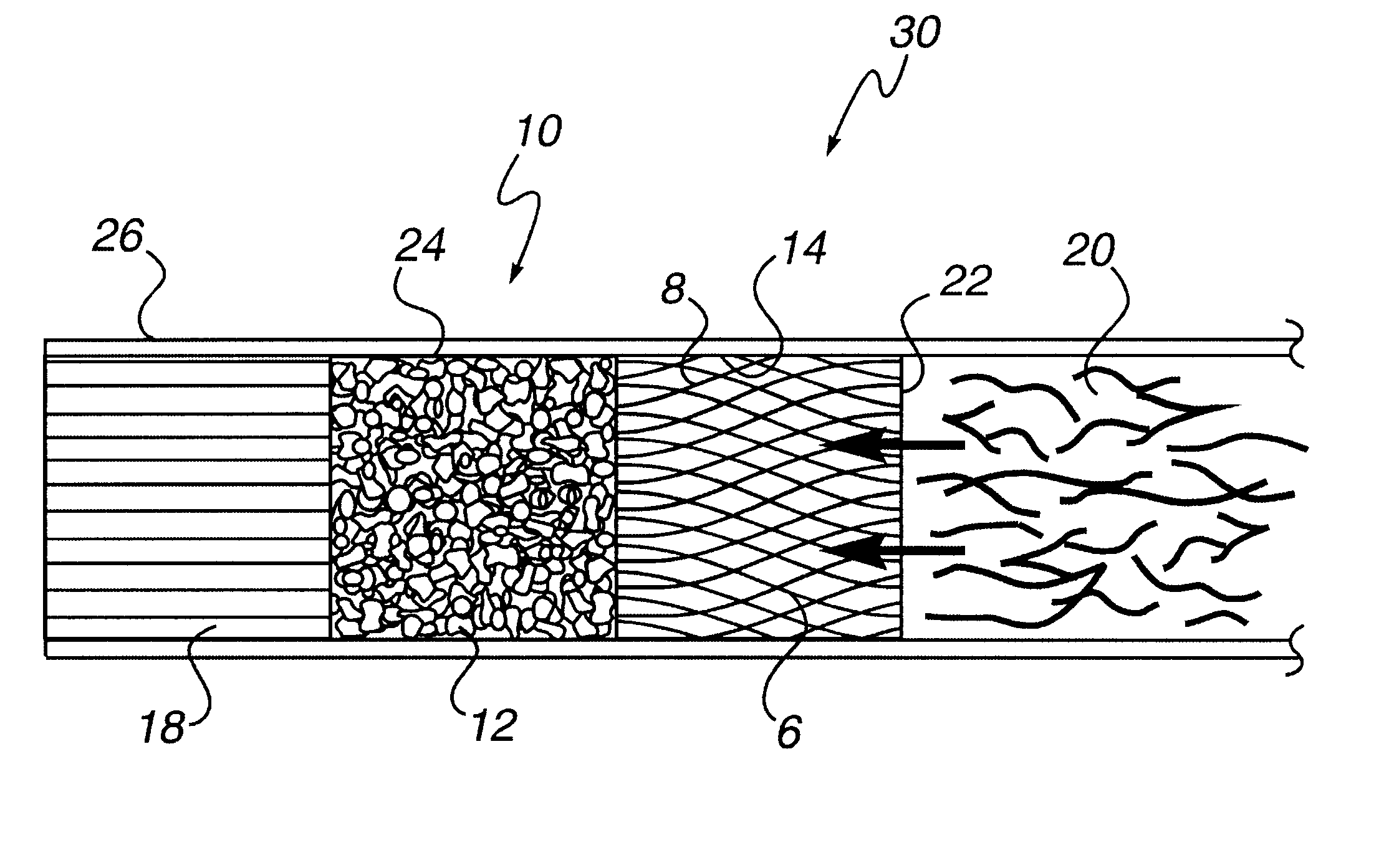

A micro / ultrafiltering element (10) and method for making a filter element are provided. The filtering element comprises a multi-level support (26) having a filtering membrane layer (12) formed thereon comprising sintered particles (14) of uniform diameter. The filtering membrane preferably has an average pore size of from about 0.005-10 micrometers. The filter element is capable of being formed in a variety of geometrical shapes based on the shape of the porous support,

Owner:ELLIPSIS CORP

Filter element

InactiveUS6257242B1Improve filtration efficiencyReduce decreaseTobacco treatmentOther chemical processesActivated carbonEnvironmental engineering

A filter element for reducing or eliminating the harmful vapor phase components of air or smoke. The filter element includes a first section and a second section. The first section is positioned relative to and in fluid communication with the second section and contains an activated carbon fabric. The second section contains a mixture of catalytic activated carbon and coconut activated carbon.

Owner:MUNDET TECH

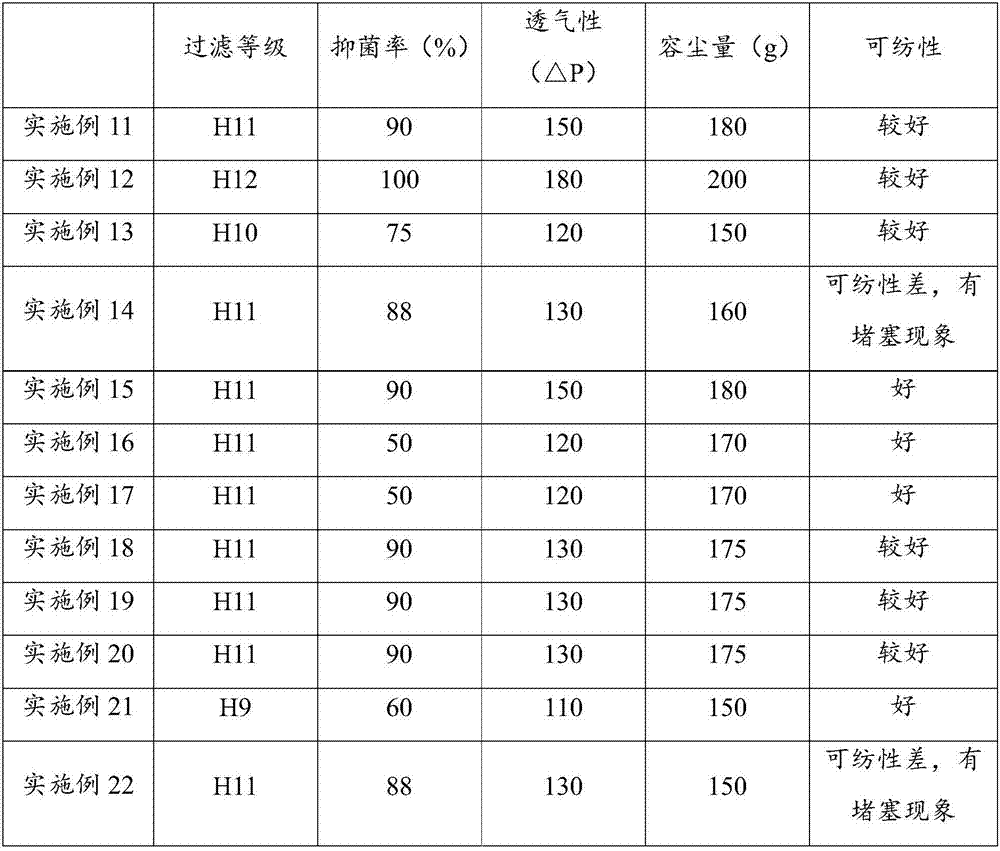

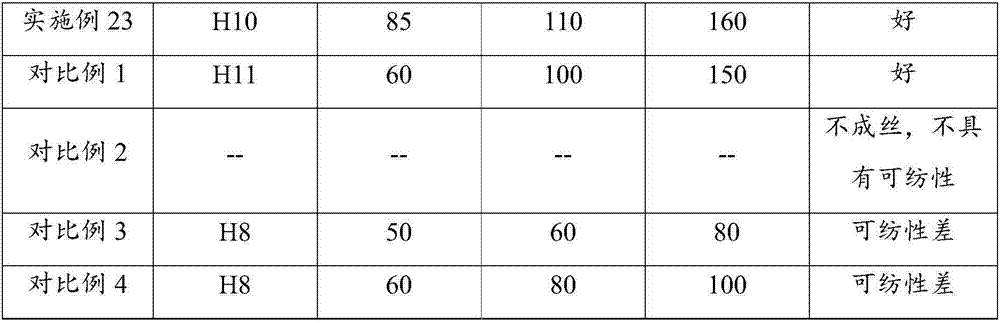

Antibacterial polypropylene melt-blow non-woven filter material and preparation method thereof

ActiveCN102836594AImprove filtering effectImprove filtration efficiencyFiltration separationNon-woven fabricsPolymer sciencePolypropylene

The invention relates to a polypropylene melt-blow non-woven filter material, in particular to an antibacterial polypropylene melt-blow non-woven filter material and a preparation method thereof. The polypropylene melt-blow non-woven filter material is prepared from the following raw materials in parts by weight: 85-95 parts of melt-blow polypropylene slices, 1-5 parts of nanometer tourmaline, 1-3 parts of nanometer titanium oxide, 1-3 parts of nanometer zinc oxide, 0.1-3 parts of a coupling agent, 0.1-2 parts of a dispersing agent and 0-0.5 part of an antioxidant. According to the antibacterial polypropylene melt-blow non-woven filter material prepared with the method, a formula and a preparation process are improved, so that the electret polarity time of the prepared filter material can be up to 5-6 years, and the antibacterial performance is superior to the prior art.

Owner:XINGNUO ECONOMIC & TRADE DEV SHANGHAI

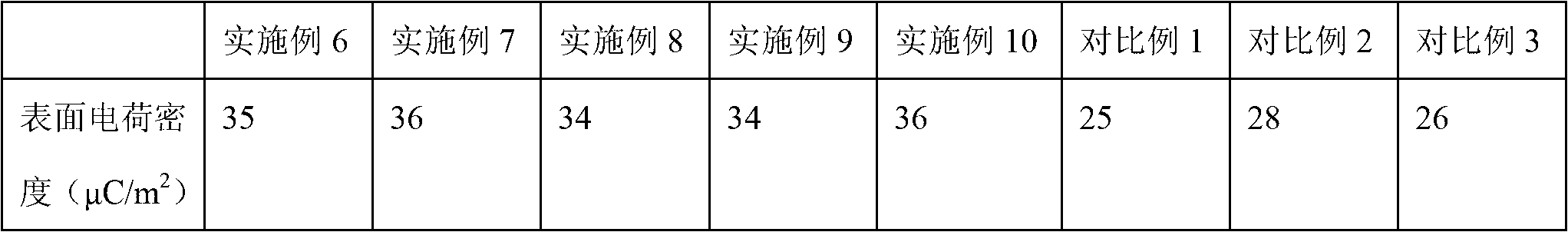

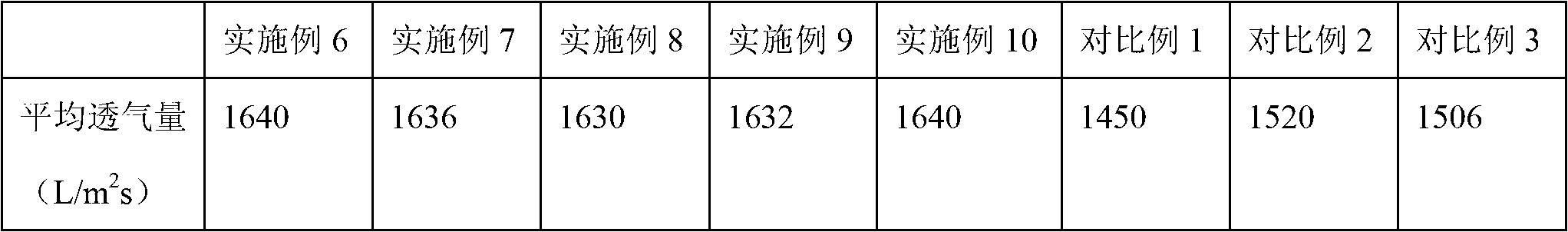

Electrospinning nano-fiber electret filtering material and its preparation method

ActiveCN104289042AHigh surface electrostatic potentialHigh super strong electrostatic adsorption performanceSynthetic resin layered productsFiltration separationPorosityFiber

The invention relates to an electrospinning nano-fiber electret filtering material and its preparation method. The high-efficiency and low-resistsance nano-fiber electret filtering material having no interfibrous adhesion and having a fluffy three-dimensional netted intercommunication structure is prepared through controlling the component and the temperatures of a polymer solution in an electrospinning process and carrying out one-step forming in the nano-fiber forming rapid cooling process, wherein the gram weight of the above nanofiber layer is 0.01-70g / m<2>, and the porosity is not less than 80%. The surface electrostatic potential of the nano-fiber electret filtering material is 800-6000V, and the surface charges have lasting storage stability, the hydrophobic angle is greater than 150DEG, the filtering efficiency of the material to particles of 0.006-1[mu]m can reach above 99.999%, the piezoresistance is less than 20Pa, and the dust containing capacity is 300-3600g / m<2>. The preparation method is simple, and the filtering material has wide application prospects in the fields of individual protection mouth mask filtration, indoor air purification and filtration, and high efficiency / ultrahigh efficiency air filtration.

Owner:DONGHUA UNIV

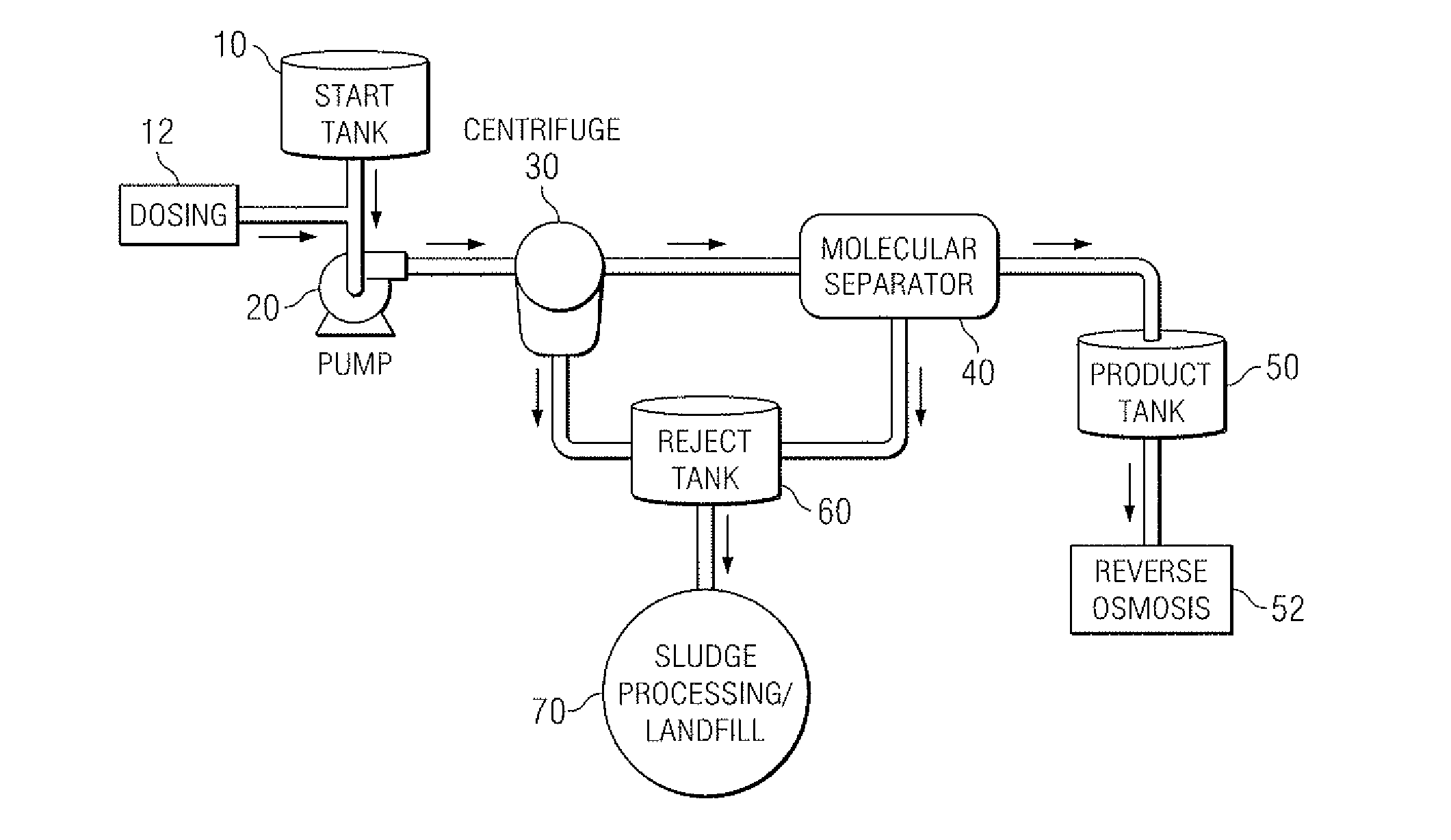

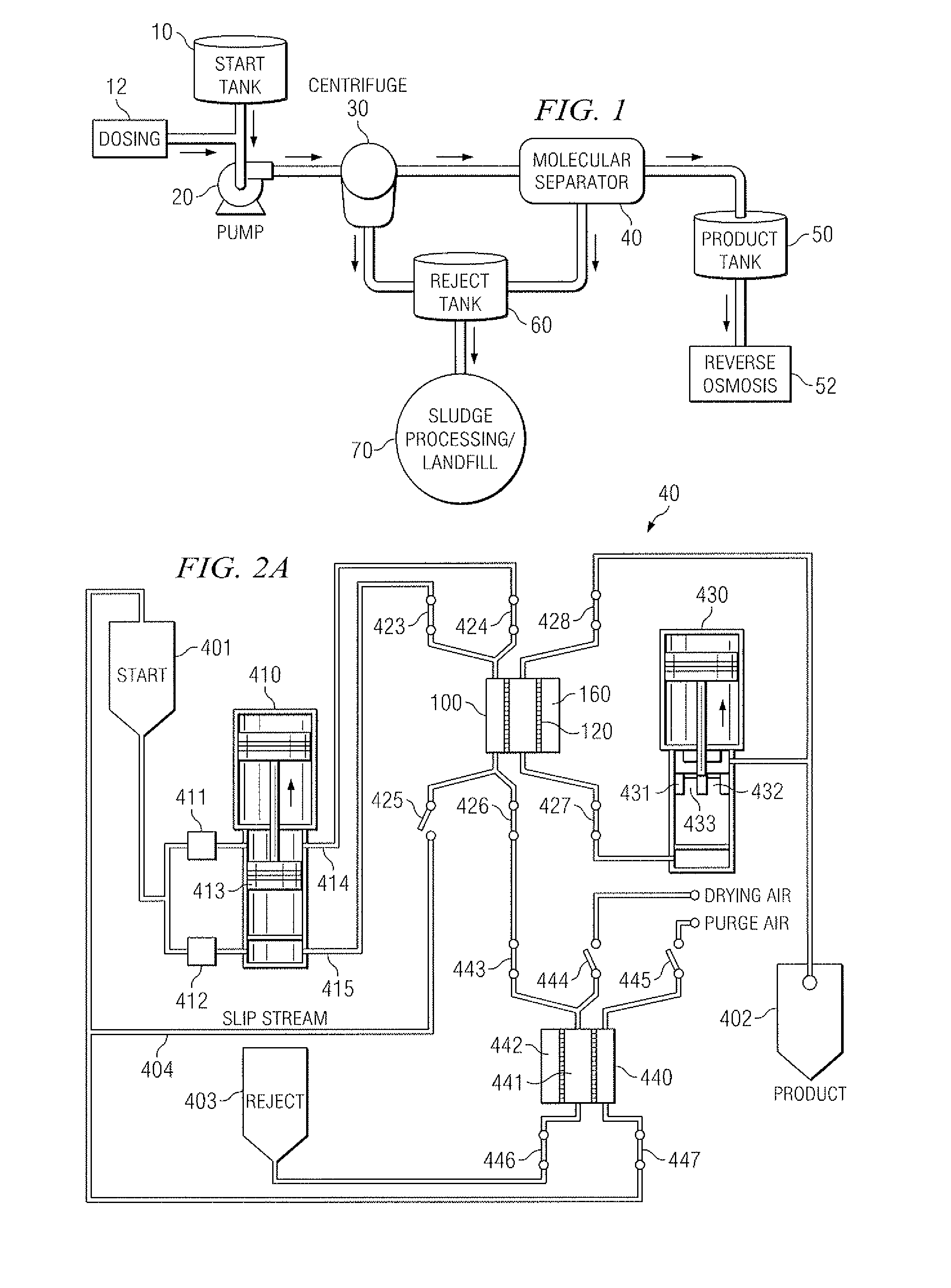

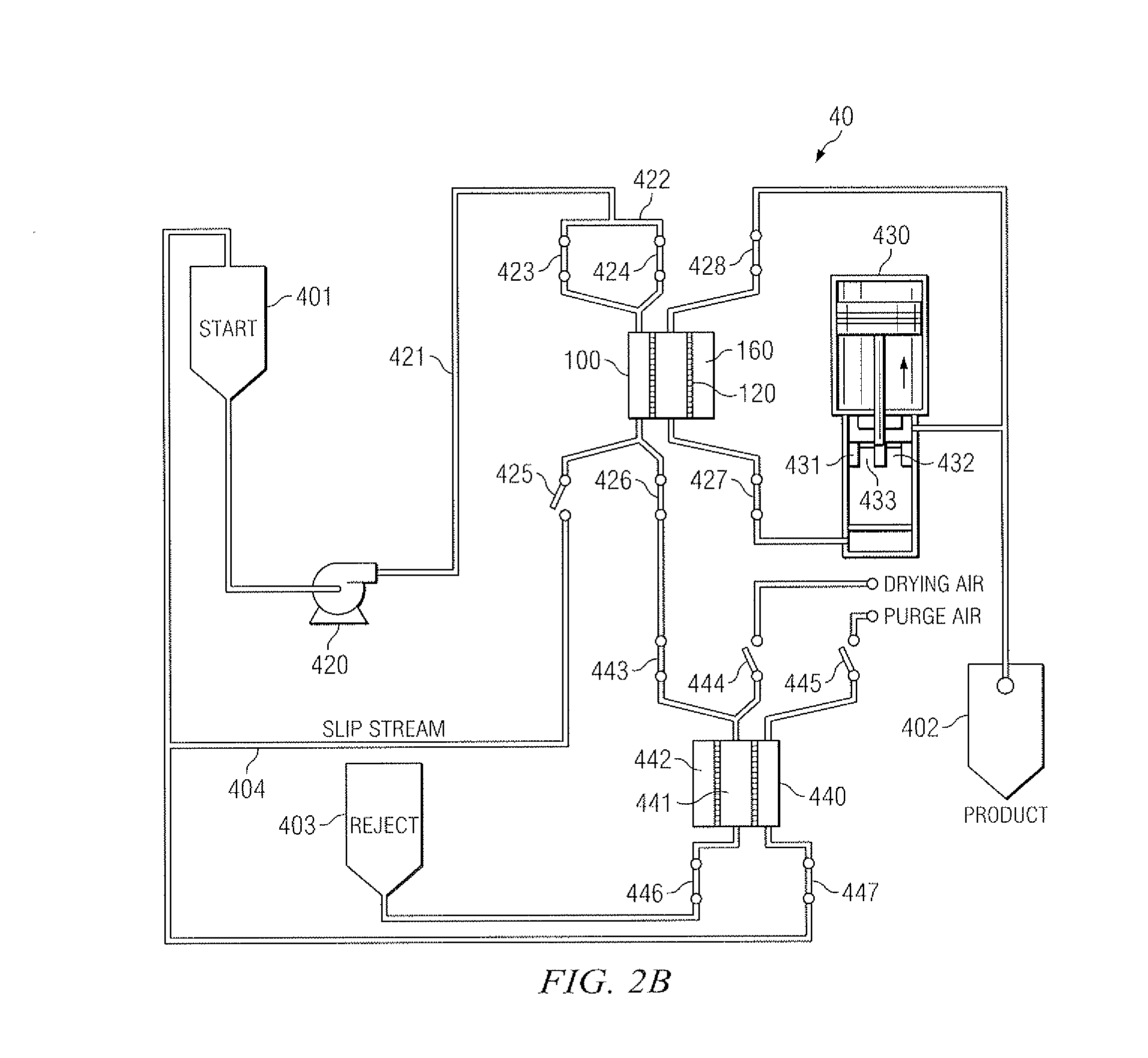

Produced water treatment method and apparatus

InactiveUS20080156709A1Improve filtration efficiencyEnhanced cavitationUltrafiltrationLoose filtering material filtersCavitationWaste collection

The present invention discloses a method and apparatus for separating particles and dissolved matter from a produced water fluid stream. Specifically, the present invention includes a first pressure source which transports untreated produced water or contaminated aqueous fluid into a separator annulus with a filter element disposed therein. The untreated fluid is placed under appropriate pressure sufficient to produce turbulent flow, increased particle kinetics and / or cavitation allowing the desired fluid to penetrate and pass into and through the filter media. The treated fluid is then transported to a collection tank. The contaminant matter retained by the filter media may be removed by the nearly instantaneous reverse pressurization of the separator annulus by a second pressure source thereby removing the contaminant particles away from contact with the filter media, and which may then be transported to a waste collection tank or a separator for further treatment.

Owner:TERVITA +1

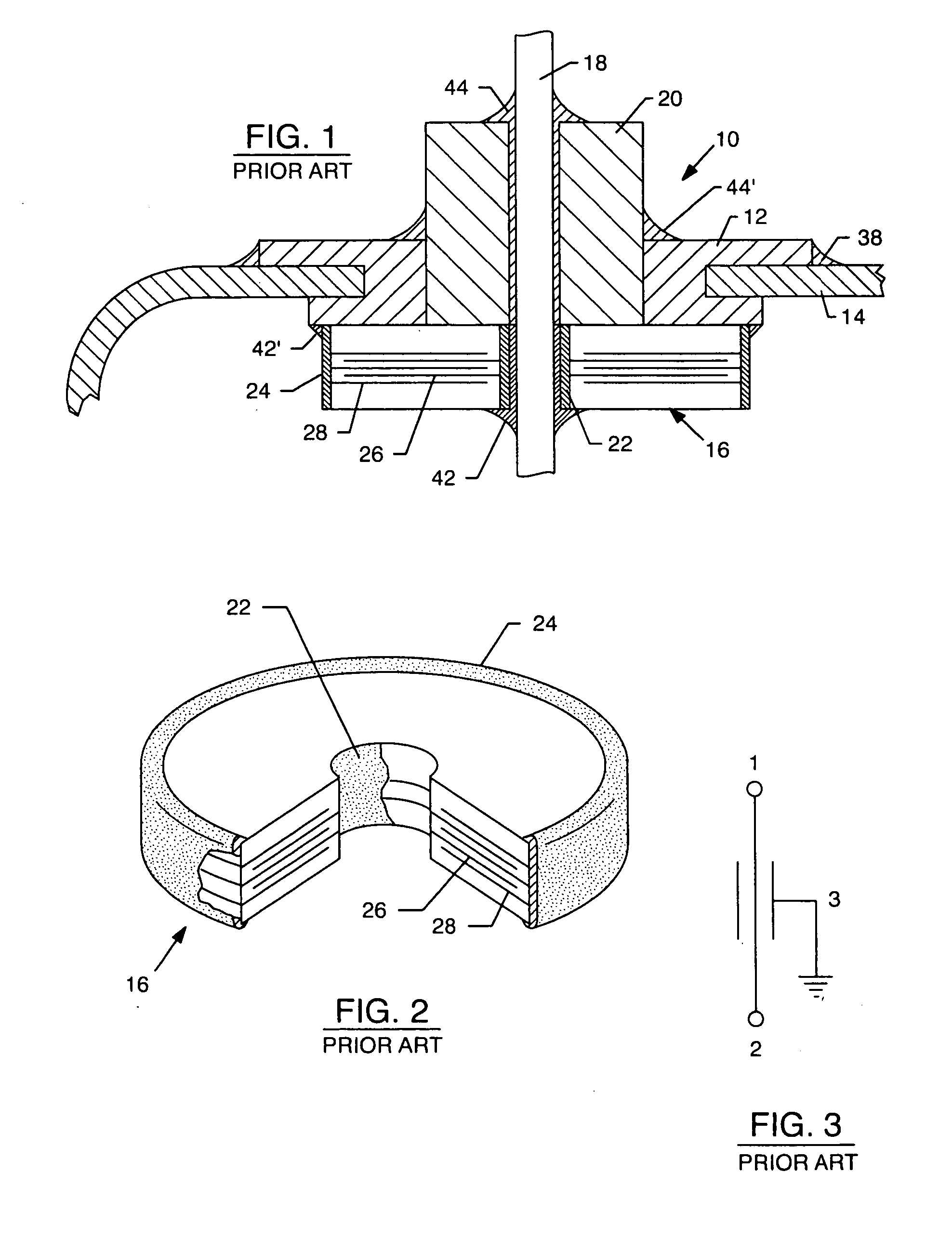

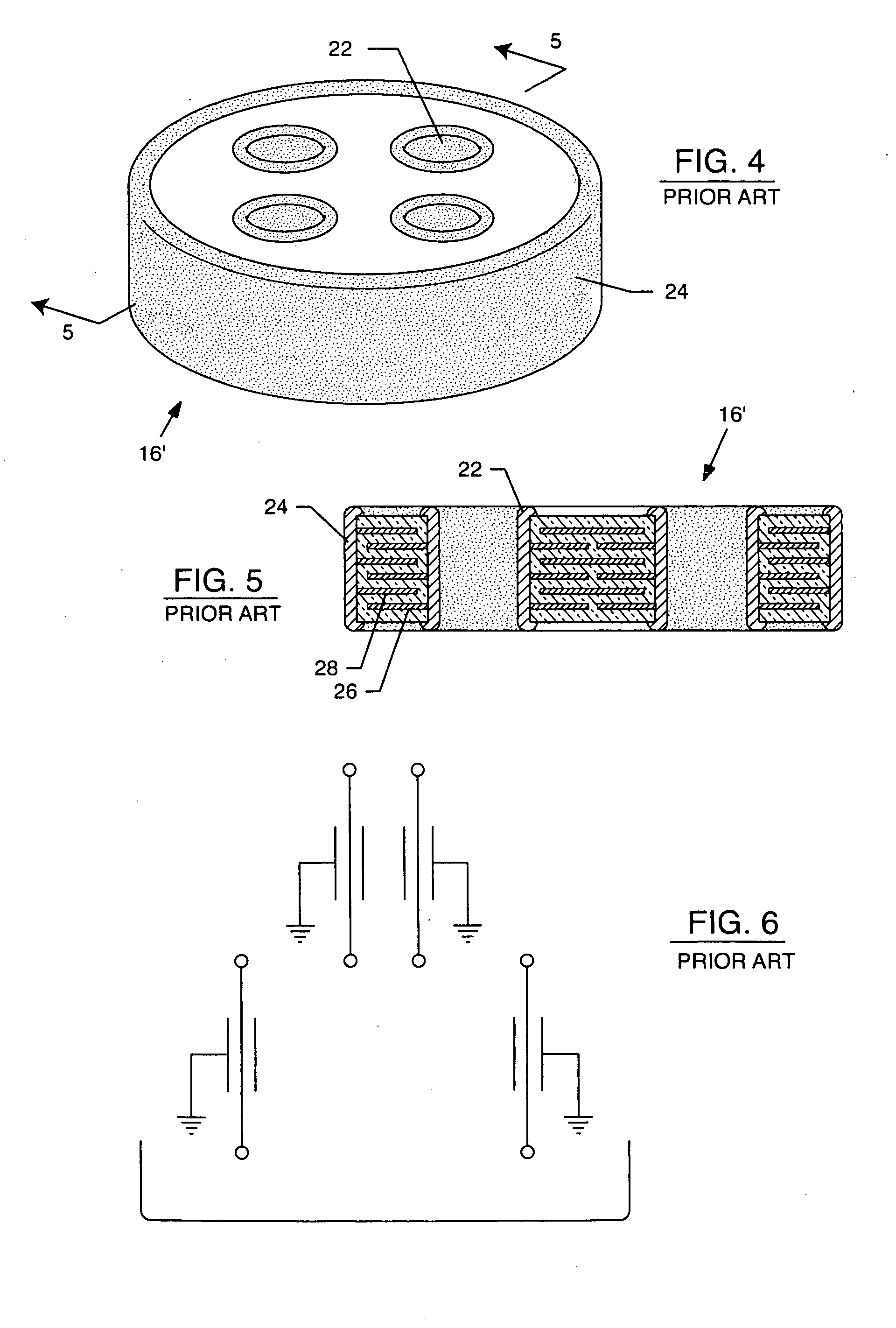

Inductor capacitor EMI filter for human implant applications

InactiveUS20050201039A1Easy to optimizeWide frequency rangeMultiple-port networksAnti-noise capacitorsCapacitanceInductor

A feedthrough terminal assembly for an active implantable medical device includes a conductive ferrule conductively coupled to a housing of the medical device, a feedthrough capacitor conductively coupled to the ferrule, an inductor closely associated with the capacitor in non-conductive relation, and a conductive terminal pin extending through the capacitor and the inductor. The terminal pin extends through the inductor in non-conductive relation and is conductively coupled to active electrode plates of the capacitor. In one preferred form, the terminal pin is wound about the inductor. Additionally, the inductor may be maintained in close association with the capacitor without forming a direct physical attachment therebetween.

Owner:STEVENSON ROBERT A +3

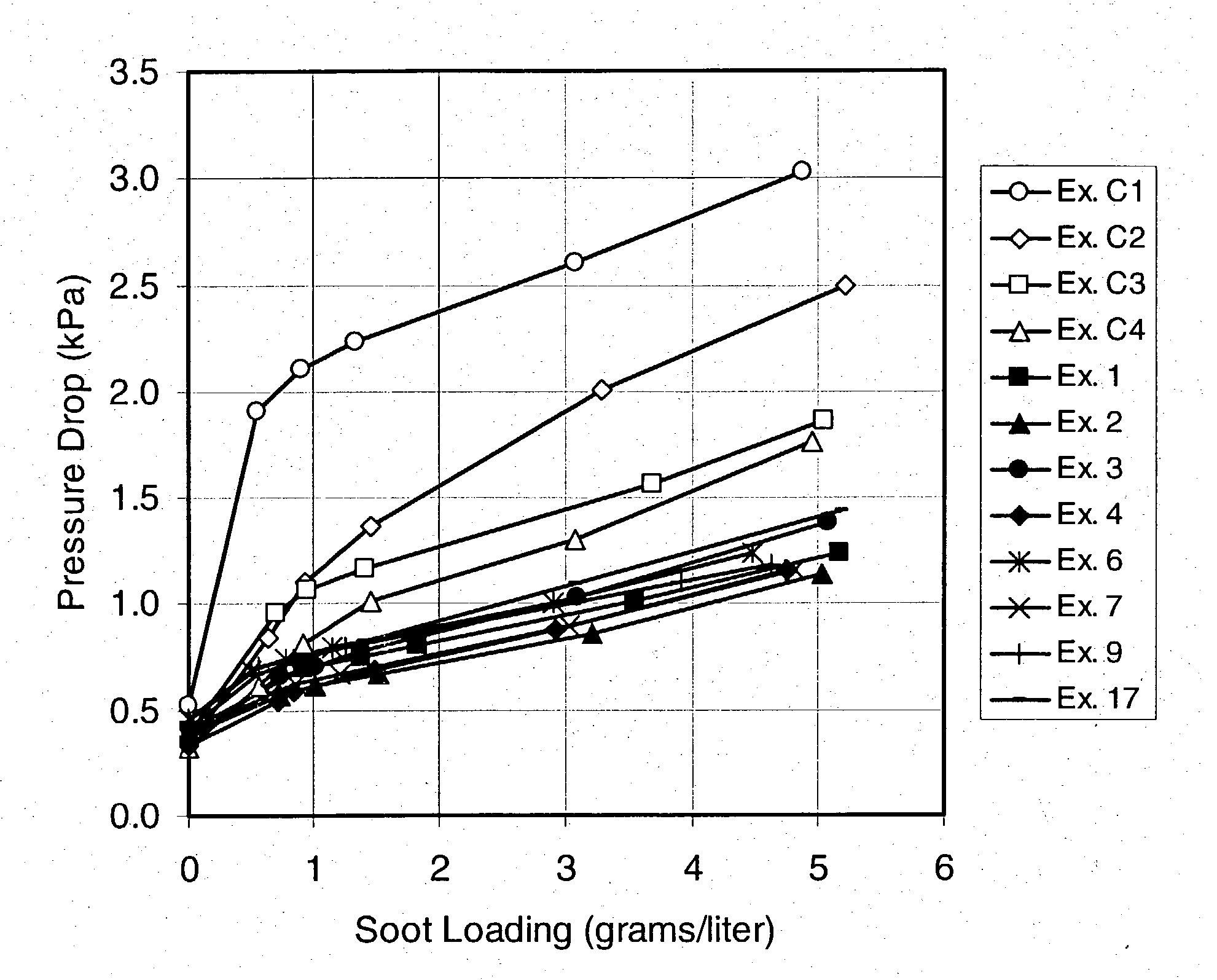

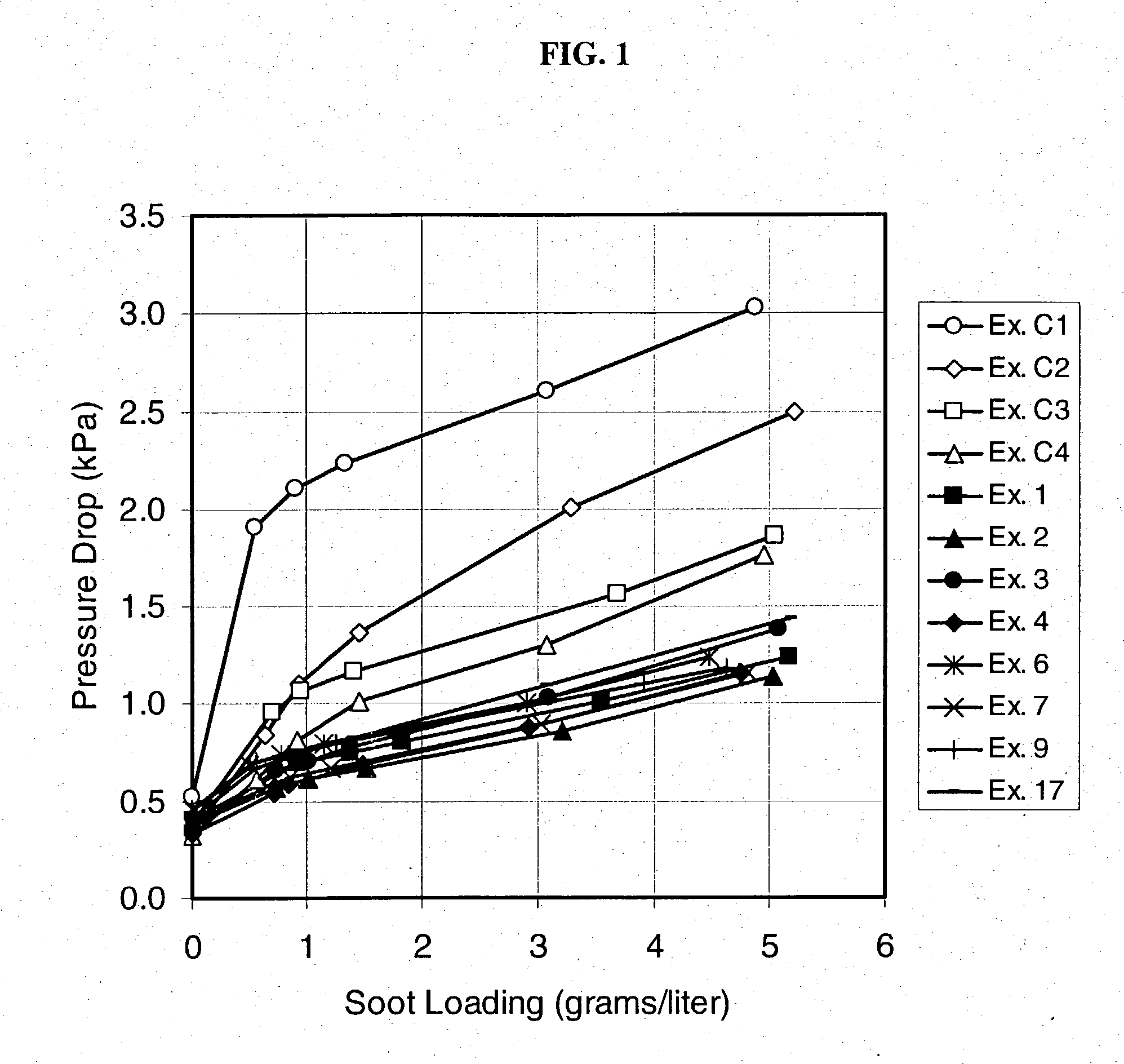

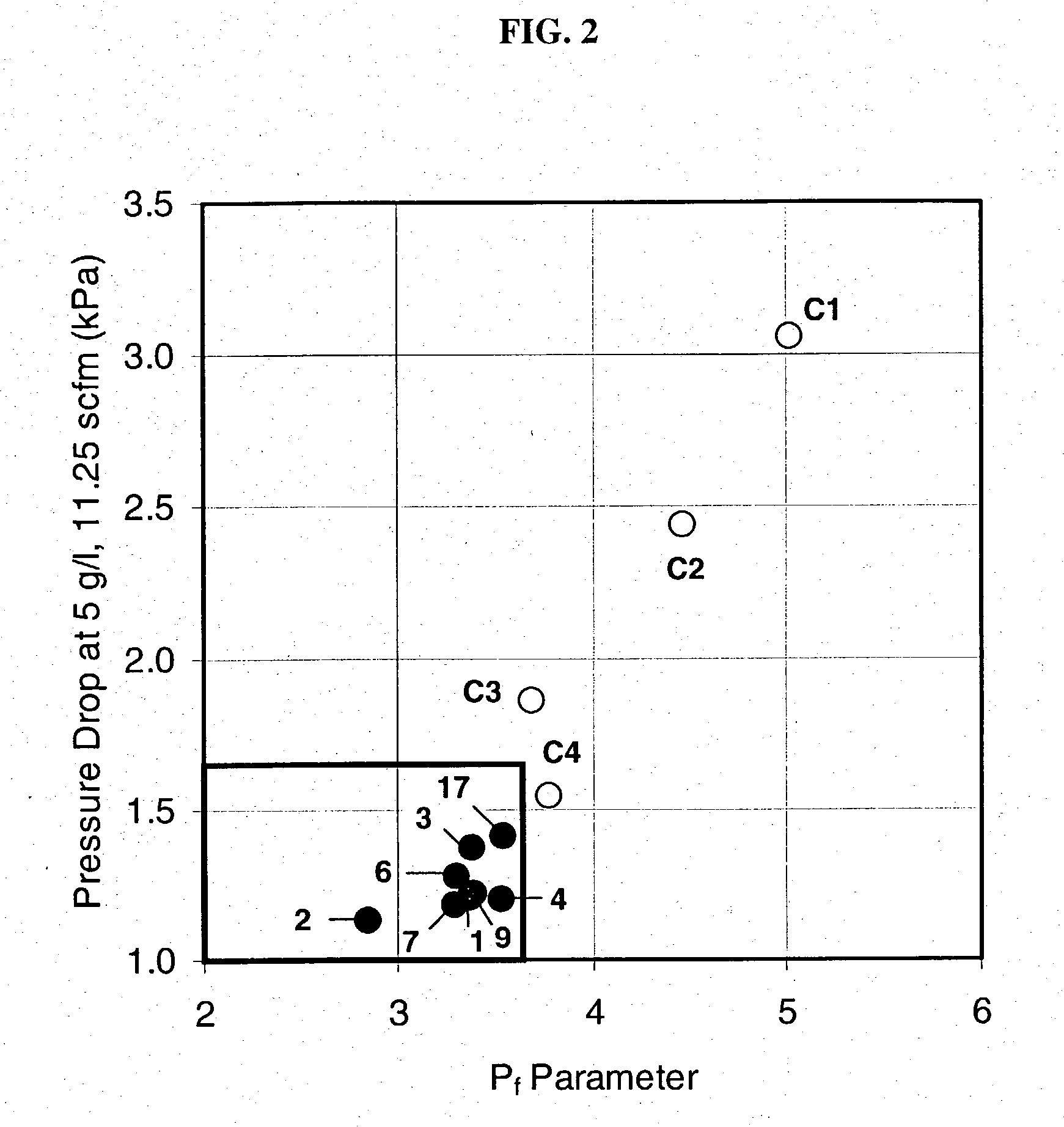

Cordierite ceramic body and method

InactiveUS20040148916A1Reduce stressImprove filtration efficiencyDispersed particle filtrationTransportation and packagingCordieriteDiesel particulate filter

A cordierite ceramic body having (i) a pore size distribution and a porosity which satisfy the relationship 10.2474 / [(d50)<2>(pore fraction)]+0.0366183(d90)-0.00040119(d90)<2>+0.468815(1 / pore fraction)<2>+0.0297715(d50)+1.61 639(d50-d10) / d50<=3.65, and (ii) a CTE (25°-800° C.) of <=15X10<-7> / ° C., wherein the cordierite ceramic body is produced from a moldable mixture comprising cordierite-forming raw materials including (a) a fine talc having a median particle diameter, as measured by laser diffraction, of less than 10 micrometers, and a B.E.T. specific surface area of greater than 5 m<2> / g, and (b) a pore former. The cordierite ceramic body is suitable in the fabrication of cellular, wall-flow diesel particulate filters having a low pressure drop, high filtration efficiency and improved strength.

Owner:CORNING INC

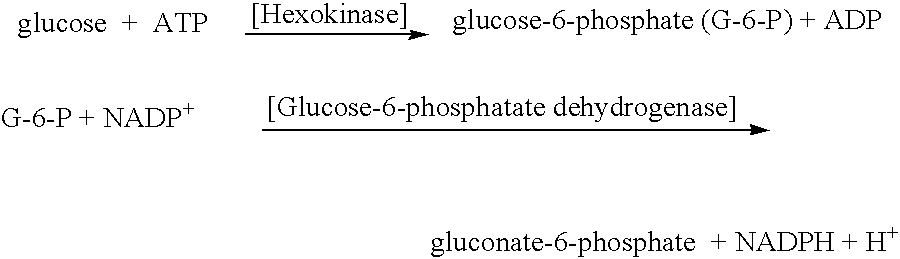

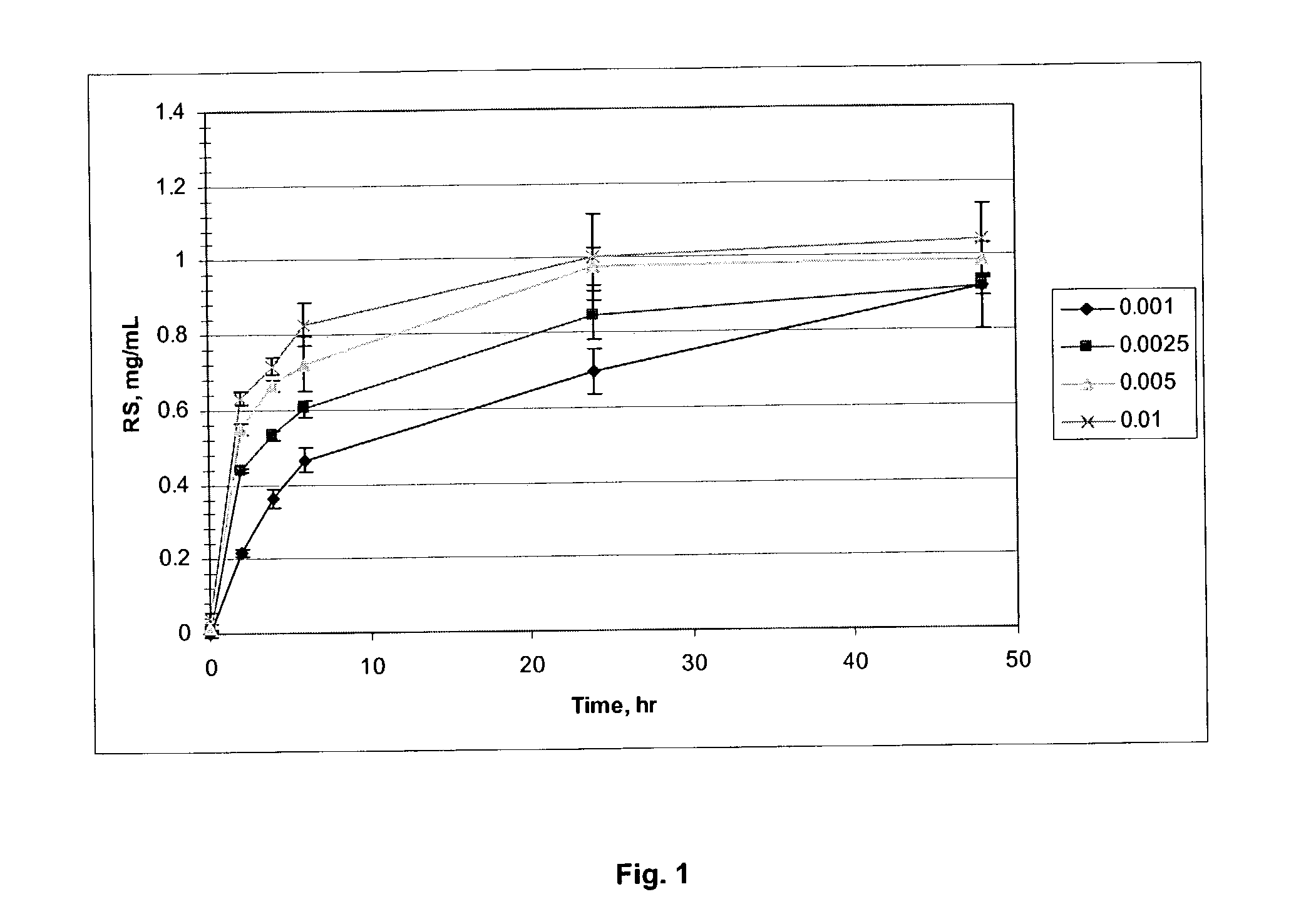

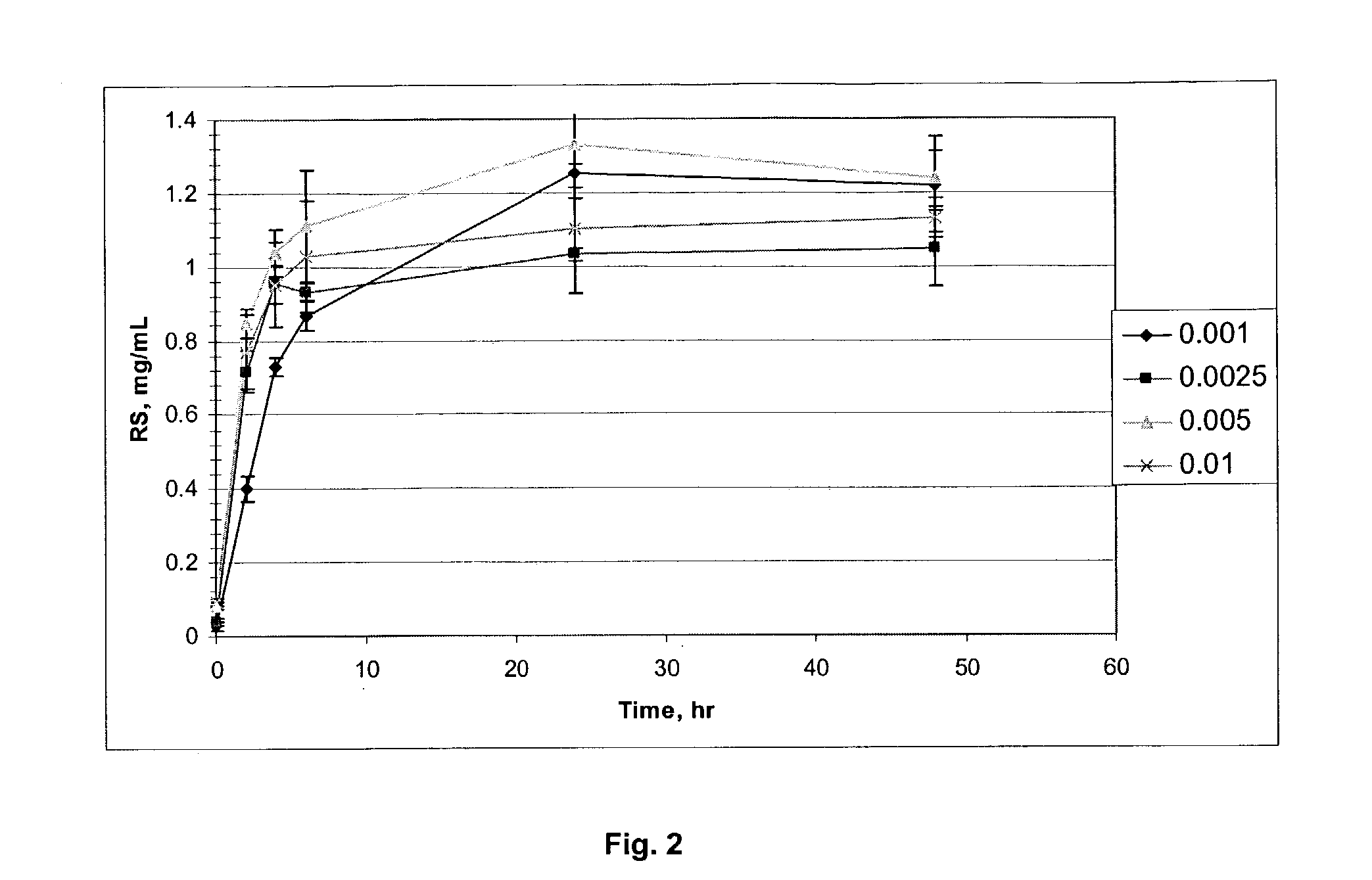

Processes for making ethanol

The present invention provides improved processes for recovering components of distillers' grain, such as, the components of distillers' dried grain (DDG), for use in various applications, including in the production of ethanol.

Owner:NOVOZYMES NORTH AMERICA INC +1

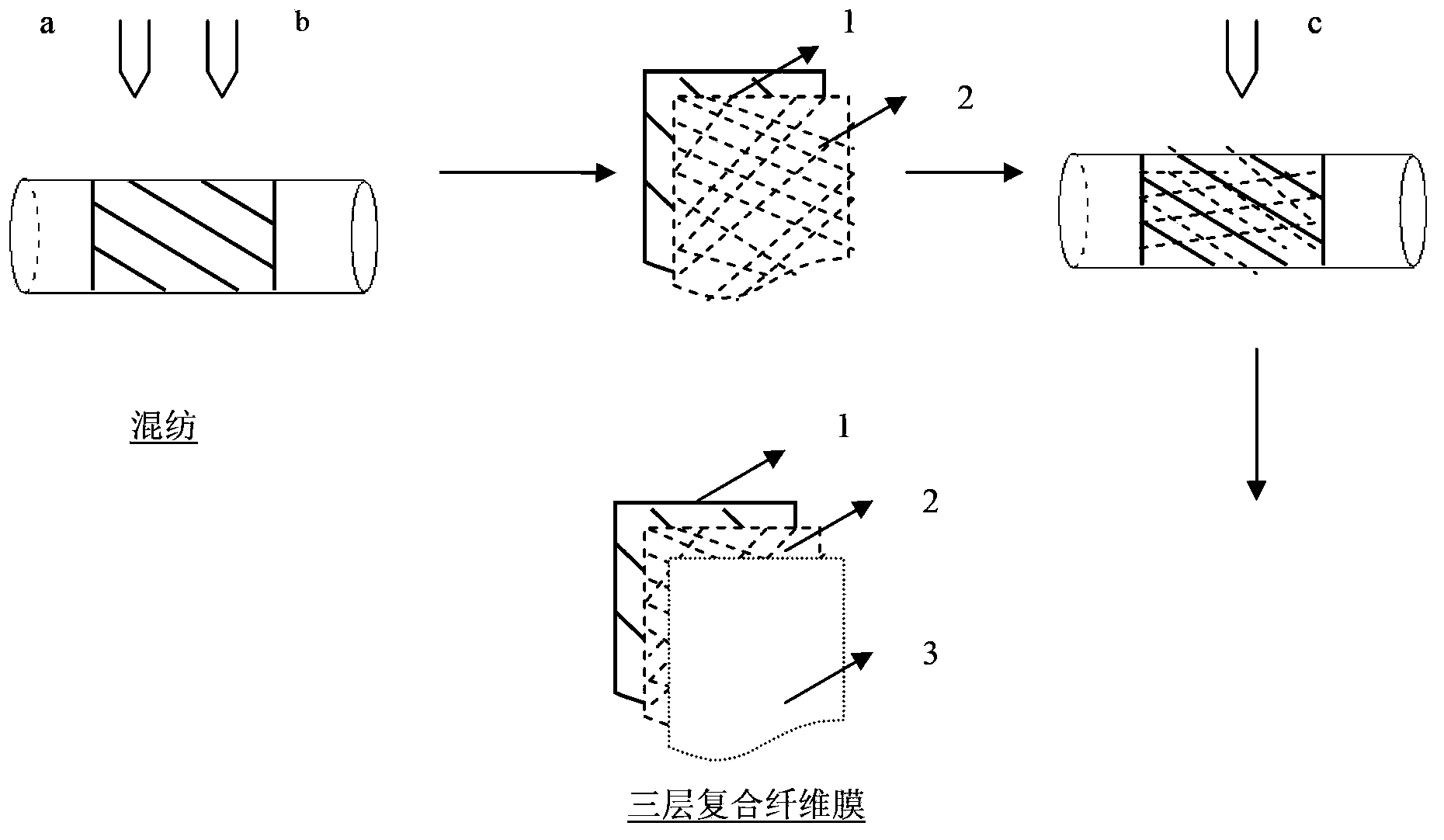

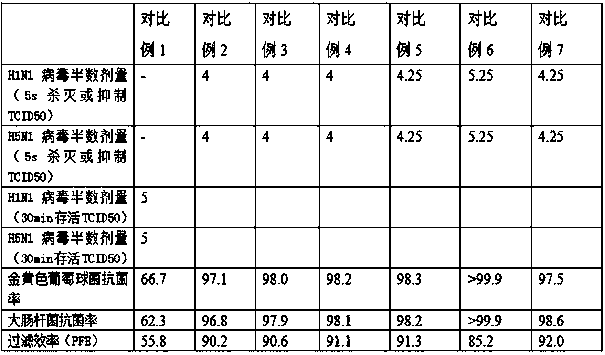

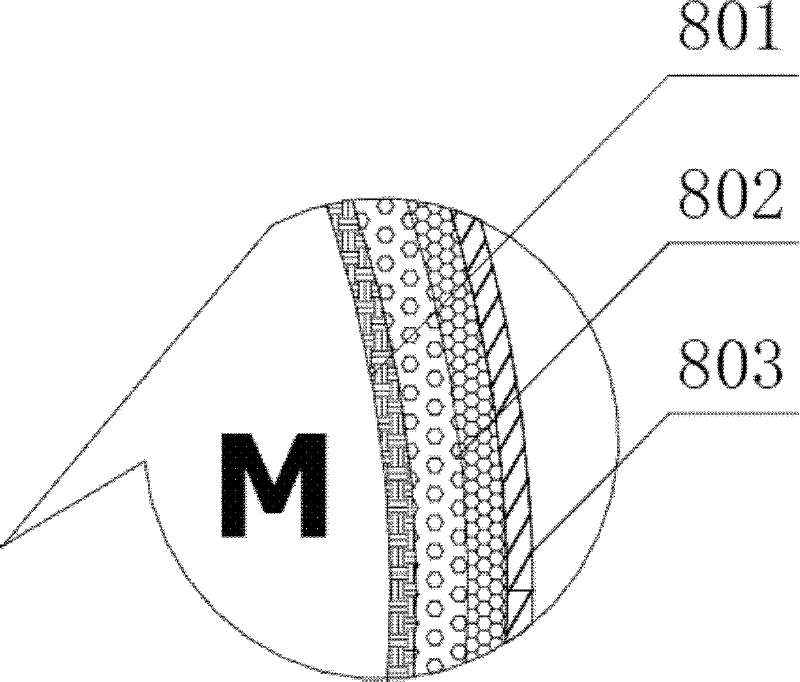

Antibacterial composite nanometer fiber high-efficiency air filtering material and preparation method thereof

ActiveCN103520999AGood air filtration efficiencyImprove adhesionSynthetic resin layered productsFiltration separationFiberComposite nanofibers

The invention relates to an antibacterial composite nanometer fiber high-efficiency air filtering material and a preparation method thereof, and belongs to the field of preparation of air filtering materials. The antibacterial composite nanometer fiber high-efficiency air filtering material sequentially comprises a non-woven fabric support layer, a filter layer and a nanometer fiber filter layer, wherein the filter layer is obtained by blending antibacterial fibers and micrometer fibers. When harmful air which contains bacteria and viruses passes through the antibacterial composite nanometer fiber high-efficiency air filtering material, the antibacterial composite nanometer fiber high-efficiency air filtering material disclosed by the invention can achieve antiviral and antibacterial effects and has high filter efficiency effect on tiny particles contained in air; the antibacterial composite nanometer fiber high-efficiency air filtering material disclosed by the invention has the advantages of antibacterial effect, and high filter efficiency and relatively lower resistance on the tiny particles contained in air, can achieve the filter efficiency on oily DOP (Dioctyl-Phthalate) particles with the grain diameters of 0.3 micrometers at 99.99% and achieve the filter efficiency on sodium chloride particles of 0.07-0.2 micrometers more than 99.99%, has the advantages of light weight, softness, and the like in practical application and can be used for preparing antibacterial protective articles, such as a mask, a protective mask and application protective clothes.

Owner:BEIJING INST OF CLOTHING TECH

High efficiency fuel filter

InactiveUS20060277877A1Improve efficiencyImprove tear resistanceCombination devicesDispersed particle filtrationGlass fiberEpoxy

Provided is a composite fuel filter material which comprises (A) a support layer made of wet laid cellulose and / or synthetic fibers, (B) a barrier layer having wet laid glass fibers for providing increased efficiency to the filter material, (C) a thermosetting bonding agent dispersed through the composite and in an amount sufficient for bonding the composite into a strong, tear resistant and pleatable material, and (D) a water repellant agent dispersed in the composite for removing and coalescing water dispersed in a fuel to be filtered. In a preferred embodiment for a diesel fuel filter, the glass fibers have an average diameter of about 0.1 to 2.0 microns and the thermosetting bonding agent is an epoxy resin in the composite in an amount of between 1 and 5% by weight. A filter efficiency of at least 90% or even 99% can be achieved, along with a water removal of 90 to 99.9%. Preferably, the barrier layer has a small amount of synthetic fibers therein and an interface between the support layer and the barrier layer is mechanically interlocked.

Owner:LYDALL INC

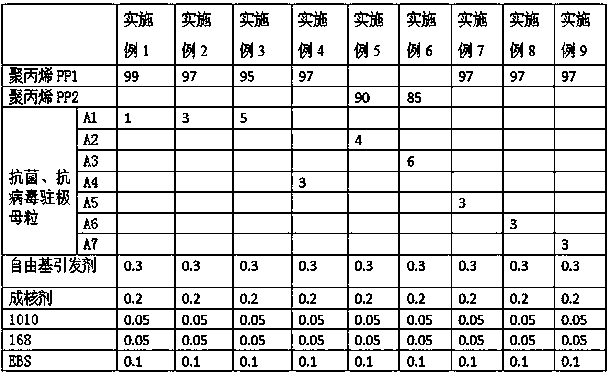

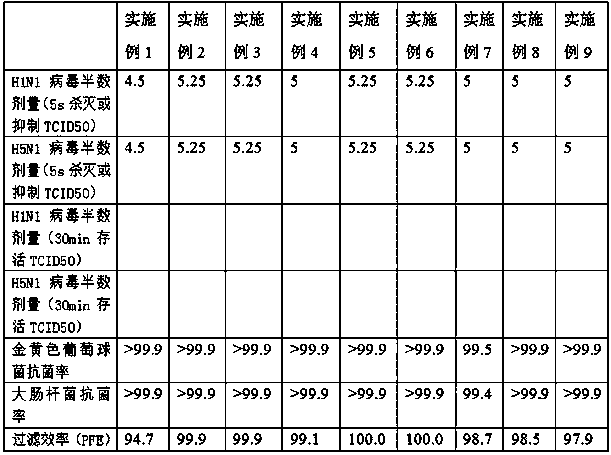

Melt-blown polypropylene material as well as preparation method and application thereof

ActiveCN111393754AReach killImprove filtration efficiencyDispersed particle filtrationNon-woven fabricsMasterbatchNonwoven fabric

The invention discloses a melt-blown polypropylene material as well as a preparation method and application thereof. The melt-blown polypropylene material comprises the following components: 80-99 parts of polypropylene resin; 0.5 to 10 parts of antibacterial and antiviral electret masterbatch; 0.1 to 1 part of a free radical initiator; 0.1 to 0.5 part of a nucleating agent; 0.01 to 3 parts of anantioxidant; 0-3 parts of a lubricant. According to the invention, inorganic antibacterial and antiviral particles are introduced into melt-blown polypropylene; the material is endowed with intrinsicantibacterial and antiviral characteristics; after the melt-blown non-woven fabric is prepared, when viruses and bacteria are filtered, the viruses and bacteria remain on the melt-blown layer, the nano material on the composite material can rapidly wrap the viruses and bacteria, attack the bacteria and viruses, synergistically destroy the structure of the bacteria and viruses and block electron transfer of the bacteria and viruses, so that the effects of killing the viruses and bacteria and the like are achieved, and the material has excellent antibacterial performance and antiviral performance and high filtering efficiency.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +2

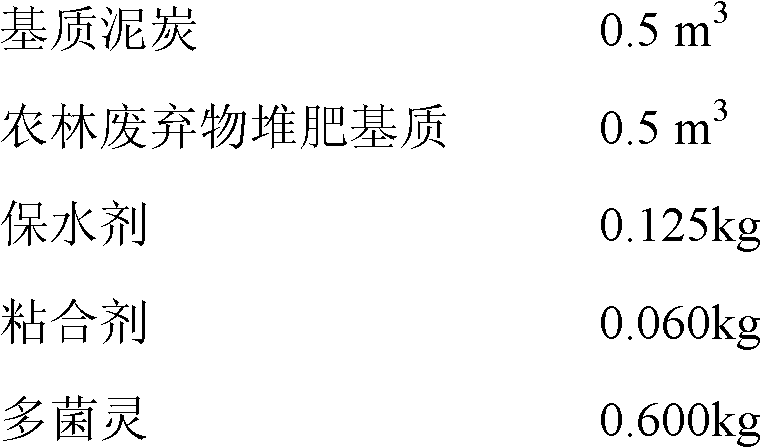

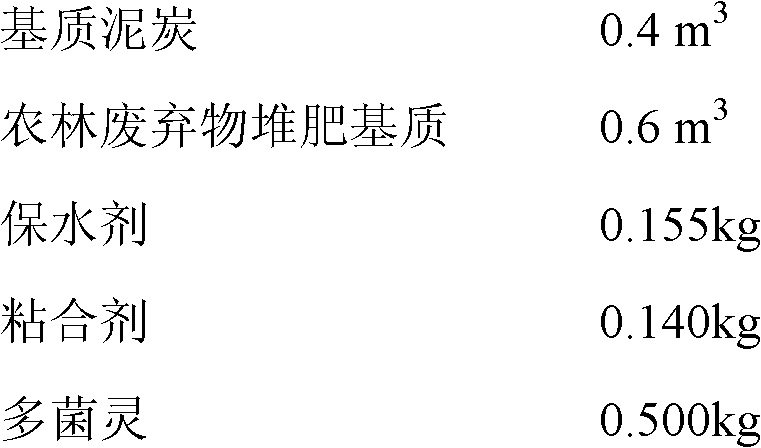

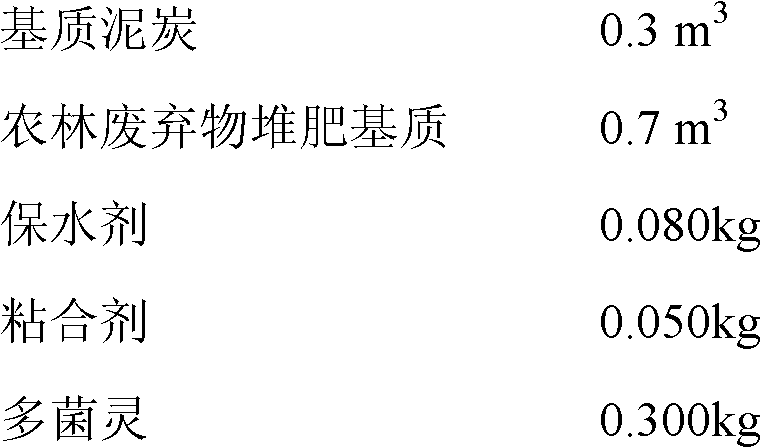

A kind of mixed substrate for plant cultivation and preparation method thereof

InactiveCN102295488AIncrease added valueOvercoming a disrupted status quoFertilizer mixturesPeatPlant cultivation

The invention discloses a mixed plant culture medium and a preparation method thereof. The culture medium comprises peat and an agricultural and forest residue compositing fermentation medium, wherein the volume proportion of peat to agricultural and forest residue compositing fermentation medium is (30-50):(50-70). The mixed culture medium prepared by the method in the invention has the advantages of balanced nutrition, high nutrition component contents and stable physical property. The mixed culture medium prepared by the method in the invention is reasonable in nutrition structure and convenient for absorption of foliage plants and meets the growth requirement of the foliage plants, thereby improving the culture survival rate and viewing effect of the foliage plants.

Owner:BEIJING FORESTRY UNIVERSITY

Product and Method of Forming a Gradient Density Fibrous Filter

InactiveUS20070227359A1Improve filtering effectImprove filtration efficiencyCombination devicesIsotope separationPolymer scienceFilter media

A filter media product and method of making the same wherein at least two filter media thicknesses of differing average coarse and fine fiber sizes are held in intertangled relationship forming a gradient density fibrous filter media with the fiber sizes having an overall average in successive thicknesses being either greater or less than the average fiber size of the intertangled fiber thickness(es).

Owner:AAF MCQUAY INC

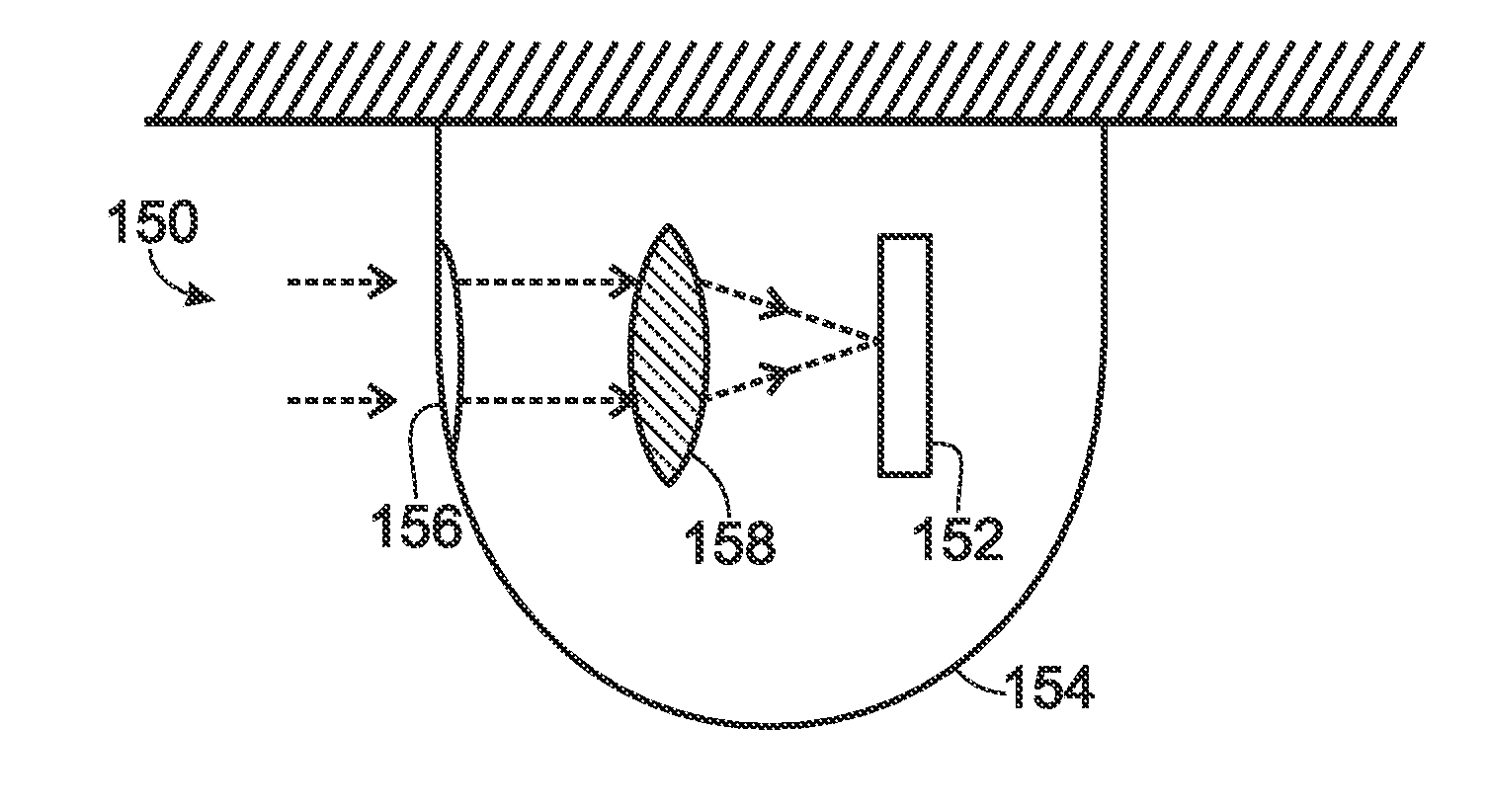

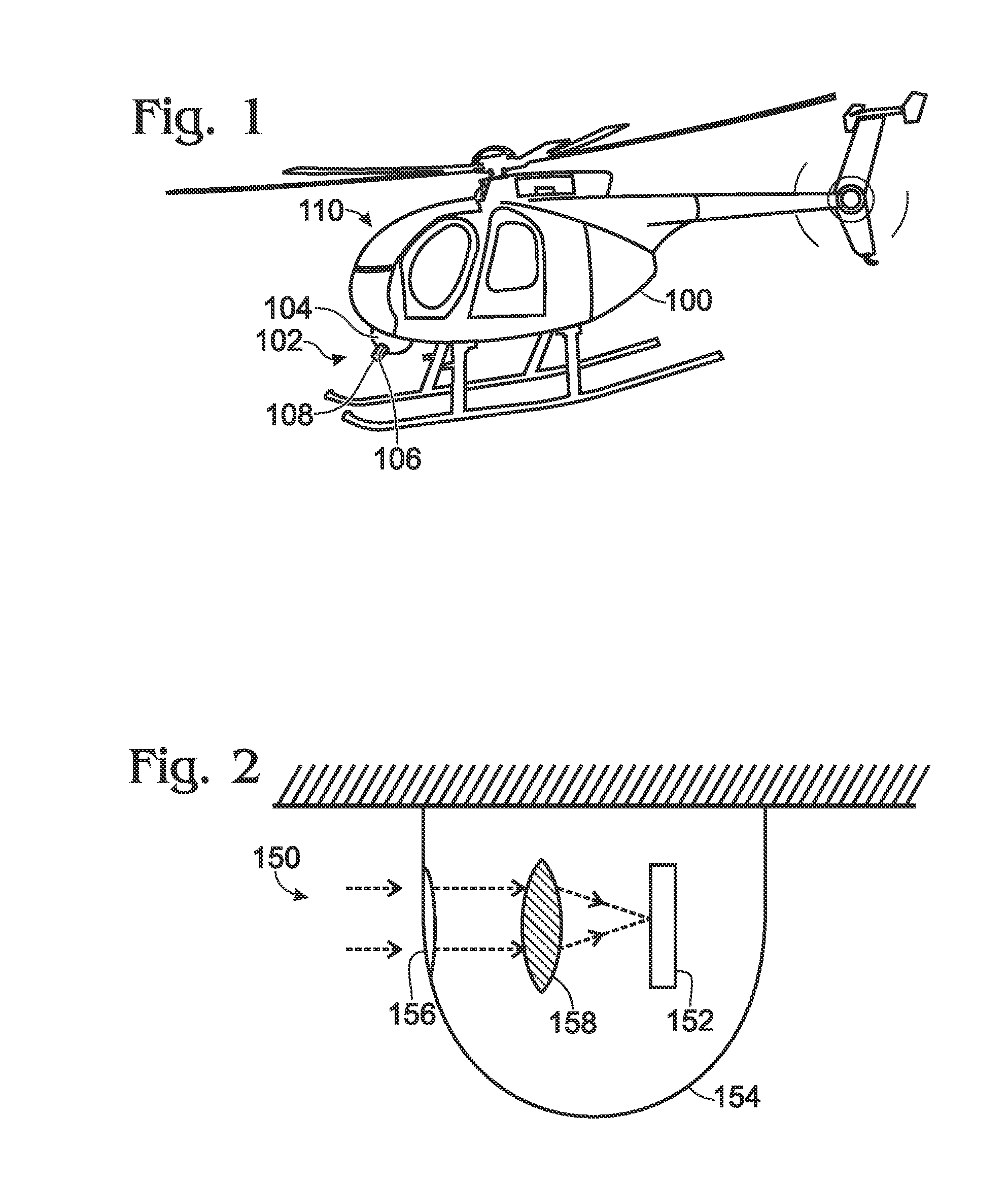

Electromagnetic interference shield

InactiveUS20120037803A1Improve blockageSubstantial transparencyRadiation pyrometryWave amplification devicesMicrowaveElectromagnetic interference

An improved EMI shielded detection system. The disclosed system may include features configured to increase radio wave and microwave absorbance while retaining significant transparency at visible and / or infrared wavelengths, thus increasing EMI shielding efficiency. This may be accomplished through the use of a conductive mesh having appropriately chosen dimensions and spacing, and embedded in a transparent medium. To minimize the impact of the mesh on the effective aperture of the medium, the strands of the mesh may be made relatively narrow, and to provide sufficient shielding despite the narrow strand width, the mesh may be embedded relatively deeply in the medium.

Owner:FLIR SYST INC

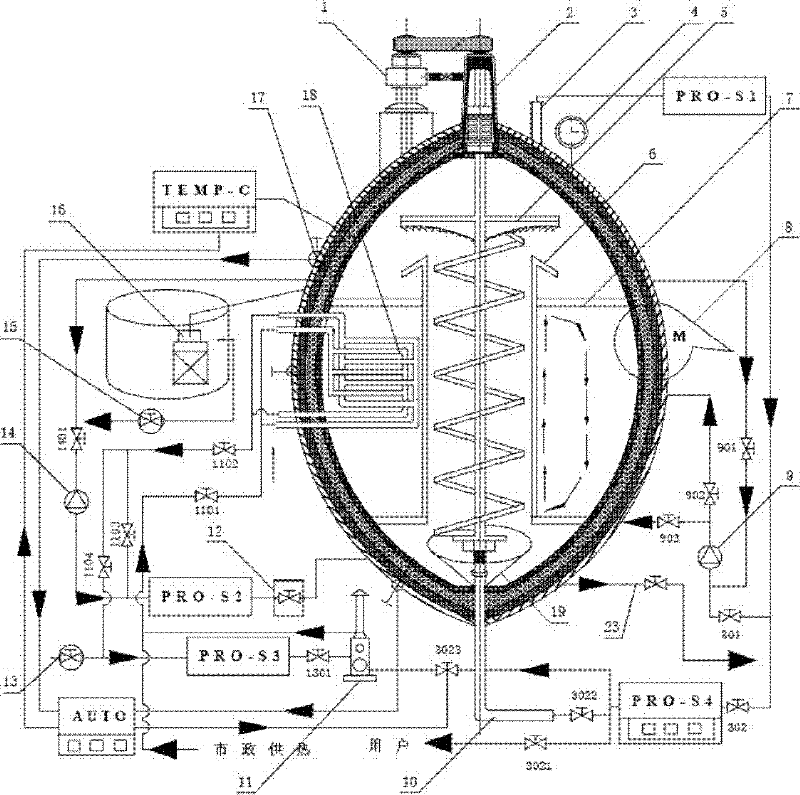

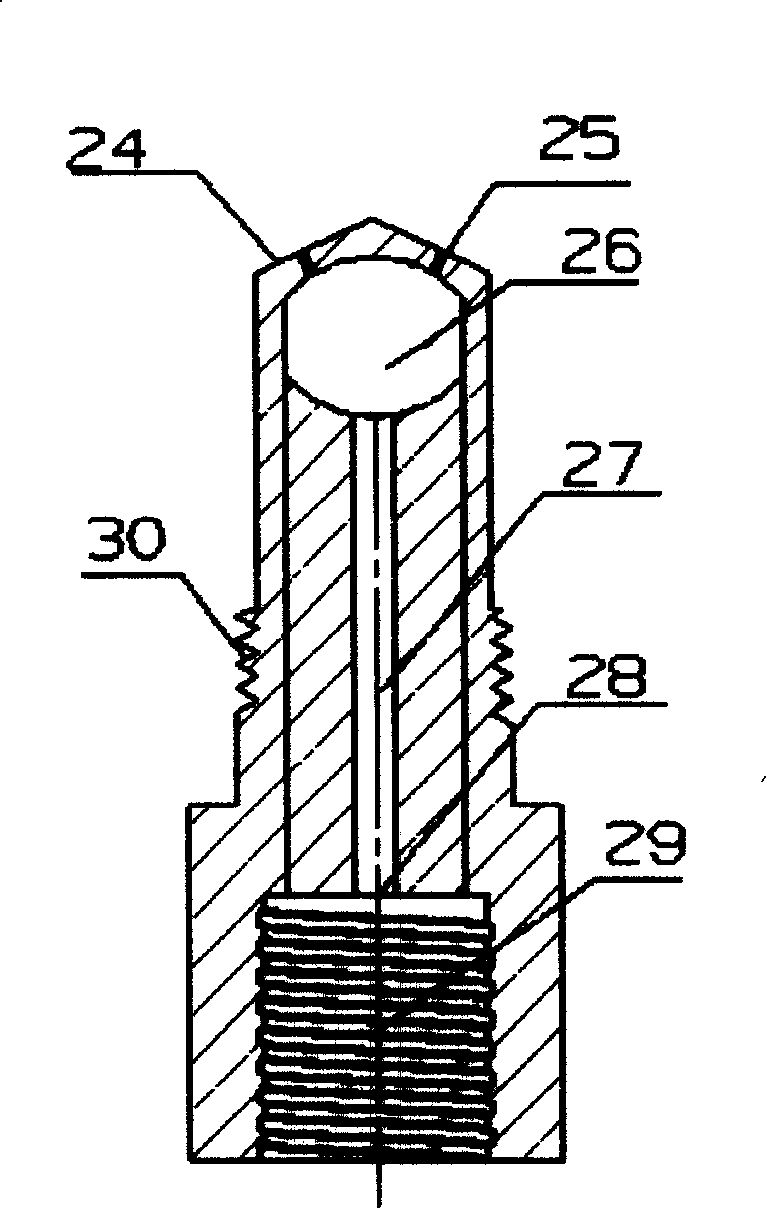

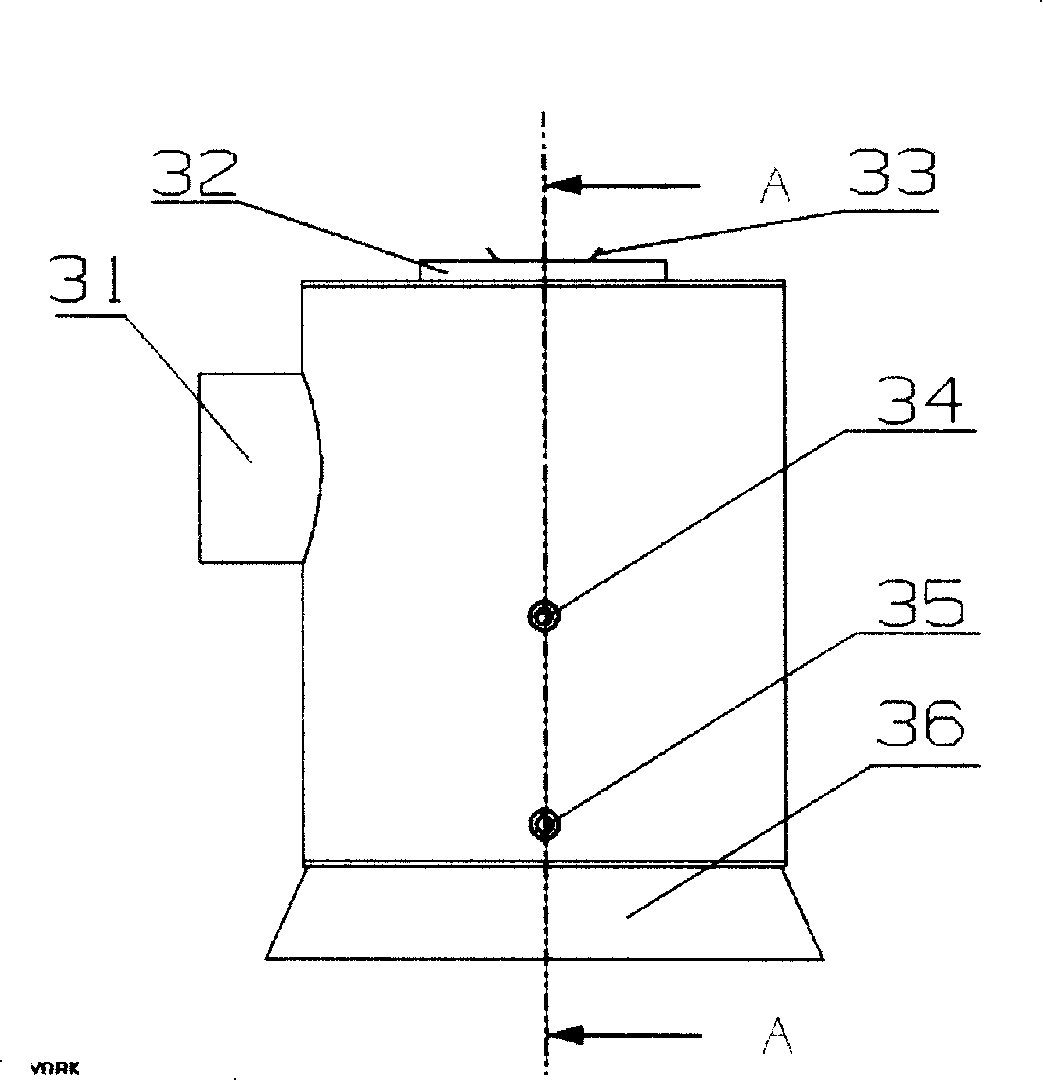

Multi-cycle stirring egg-shaped anaerobic fermentation system

ActiveCN102517199ASimple structureReasonable designBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringSlurry

The invention discloses a multi-cycle stirring egg-shaped anaerobic fermentation system. The system comprises a fermentation tank body and a driving device arranged on the fermentation tank body, wherein the fermentation tank body is egg-shaped, the center of the inner cavity of the fermentation tank body is provided with an inner barrel type spiral stirrer, the outside of the inner barrel type spiral stirrer is provided with a stirrer inner barrel, a temperature heating device is arranged between the wall of the fermentation tank body and the stirrer inner barrel, the bottom of the inside ofthe tank is provided with an umbrella-shaped gas flow distribution device; the upper part of the fermentation tank body is provided with a vent pipe and a pressure control device, the bottom of the fermentation tank body is provided with an umbrella-shaped gas flow distribution device gas inlet pipe and a mud-discharging and sand-discharging outlet; and the side wall of the fermentation tank bodyis communicated with a biogas circulation system, a biogas slurry circulation system, a gas-liquid circulation system, a heating system, a temperature control system and a biogas residue and biogas slurry storage pool respectively. The multi-cycle stirring egg-shaped anaerobic fermentation system adopts multi-cycle stirring to increase the stirring efficiency of the system; and the anaerobic fermentation environment is improved, the fluid is mixed evenly, the temperature difference slightly fluctuates, the energy consumption of the system is low, the fermentation rate is high and the system is suitable for popularization and application.

Owner:INNER MONGOLIA HUAMENG KECHUANG ENVIRONMENTAL PROTECTION TECH ENG CO LTD

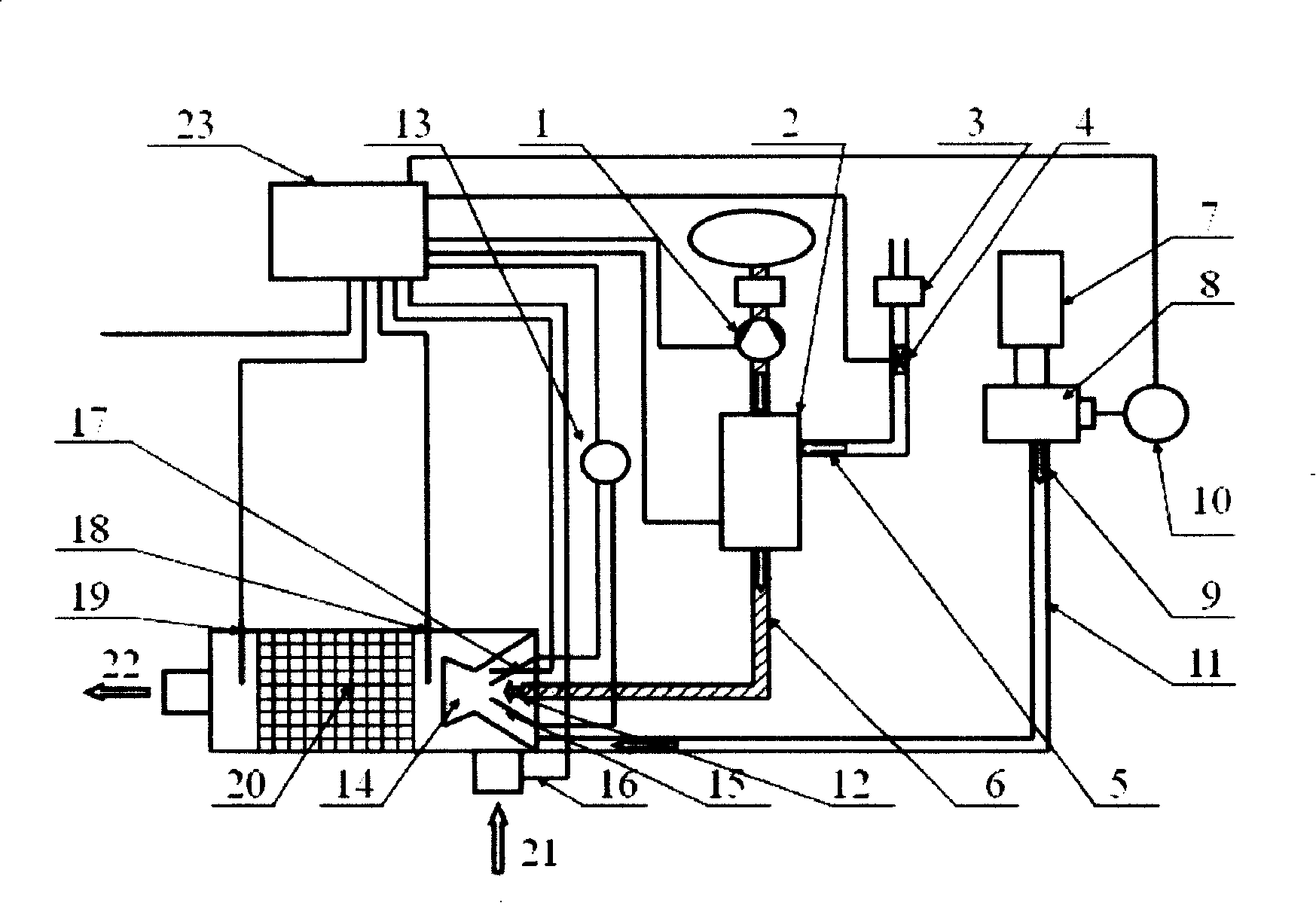

Diesel engine exhaust emission purifying system

InactiveCN101178020AImprove filtration efficiencyExhaust apparatusSilencing apparatusCombustion chamberIgnition coil

The invention discloses a purification system of vent gas of diesel engine. The purification system of vent gas of diesel engine essentially consists of a wall-flow diesel particle filter (DPF) and a heating regeneration device used for regeneration of the wall-flow diesel particle filter (DPF). The heating regeneration device consists of an electronic control unit (ECU), a combustion chamber and an ignition system. The ignition system comprises a spark plug, a high voltage wire and an ignition coil, a combustion air generating device and relevant pipes, ejector components and pipes, an oil nozzle, relevant temperature and pressure sensor and other gas paths, a valve of oil circuit and an automatic protection device. Compared with the prior art, the invention is characterized by reliable regeneration, efficient purification and no restriction of the way vehicle driving, etc.

Owner:YANTAI HUALONG BUSINESS MACHINE

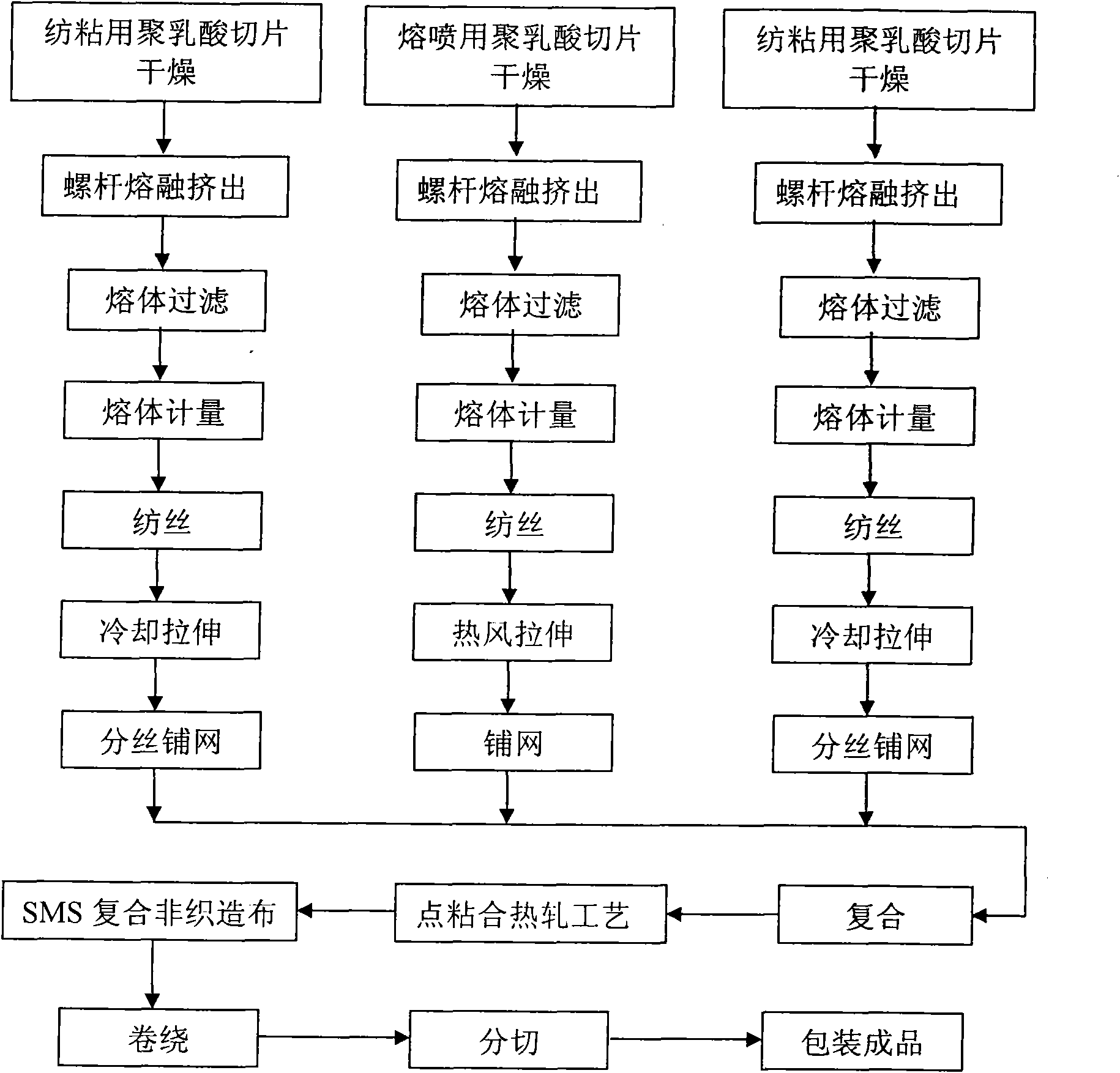

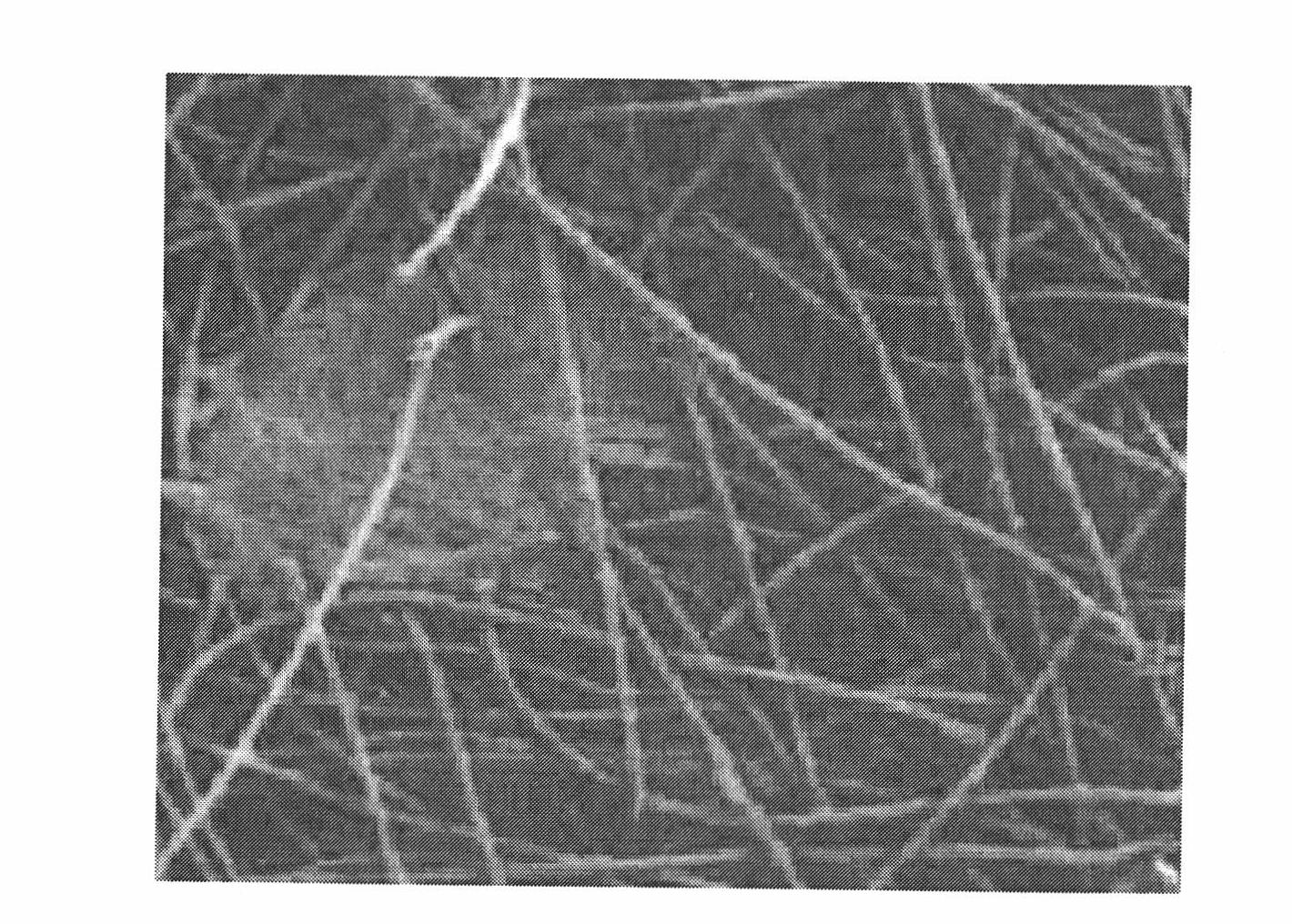

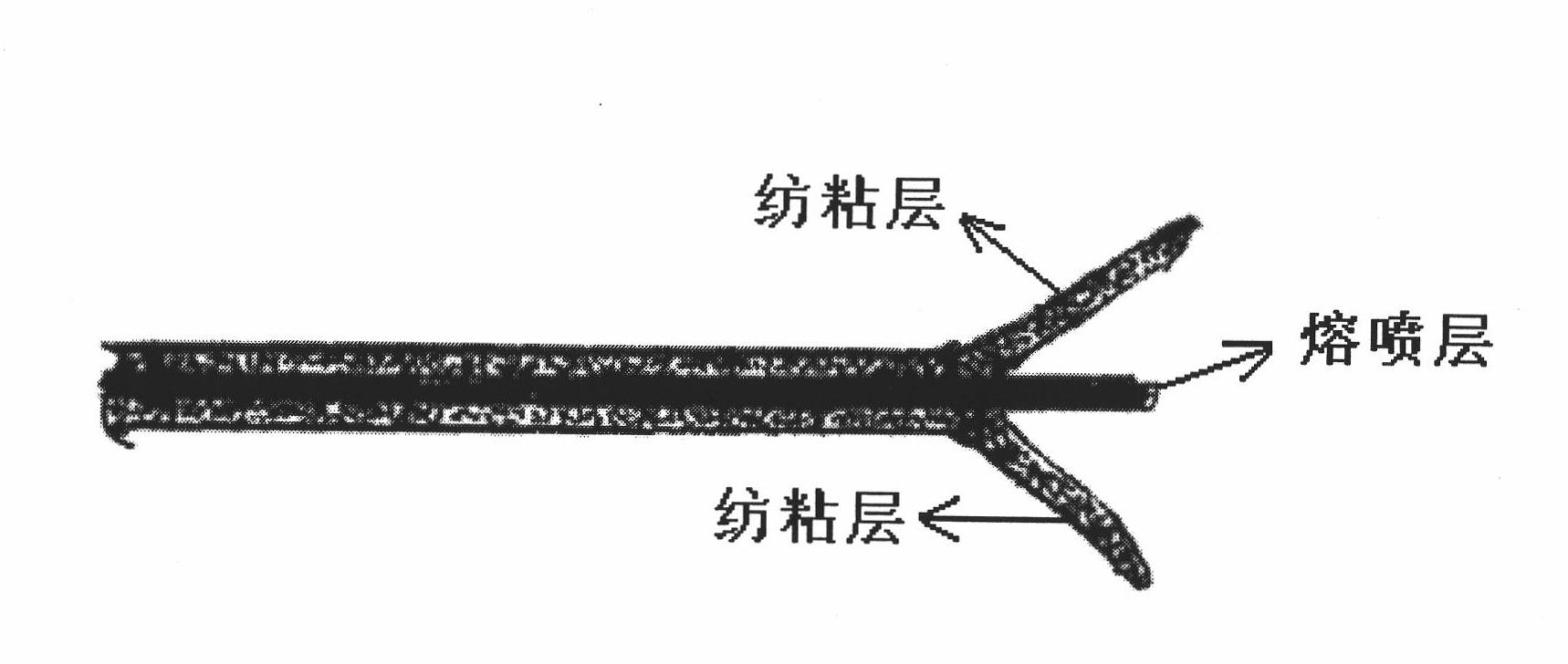

Fully-degradable polylactic acid fiber SMS compound non-woven and manufacturing method thereof

InactiveCN101851830APromote growthCapable of biocompostingSpinning head liquid feederMelt spinning methodsNonwoven fabricPhysical property

The invention discloses a fully-degradable polylactic acid fiber SMS compound non-woven and a manufacturing method thereof. The non-woven is compounded by three layers of non-woven by self-bonding or hot rolling, wherein the middle layer is polylactic acid meltblown non-woven, and the upper layer and the lower layer of the middle layer are both polylactic acid spunbonded non-woven. The SMS non-woven is even and has stable quality and excellent physical property, filtering property and shielding property. A thin SMS product has favourable waterproof permeability and is especially suitable for the fields of hygienic materials, packaging materials and the like; an SMS product with medium thickness is suitable for the disposable products of the field of medical treatments, and a thick SMS product is suitable for the field of industrial filtering. The production technology of the invention is easy to operate and control, has favorable stability and can carry out industrial production.

Owner:豆丁乐园(南京)婴儿用品有限公司

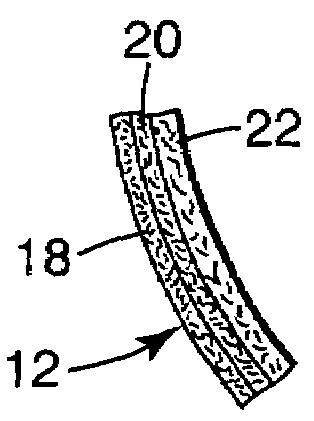

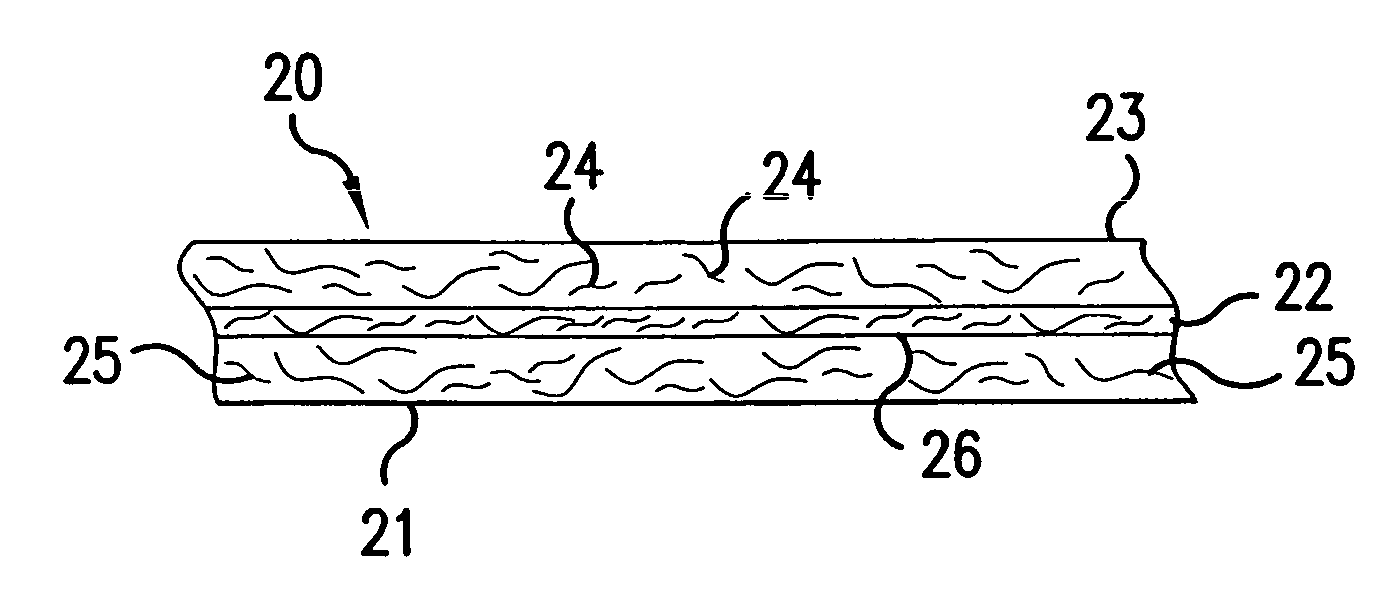

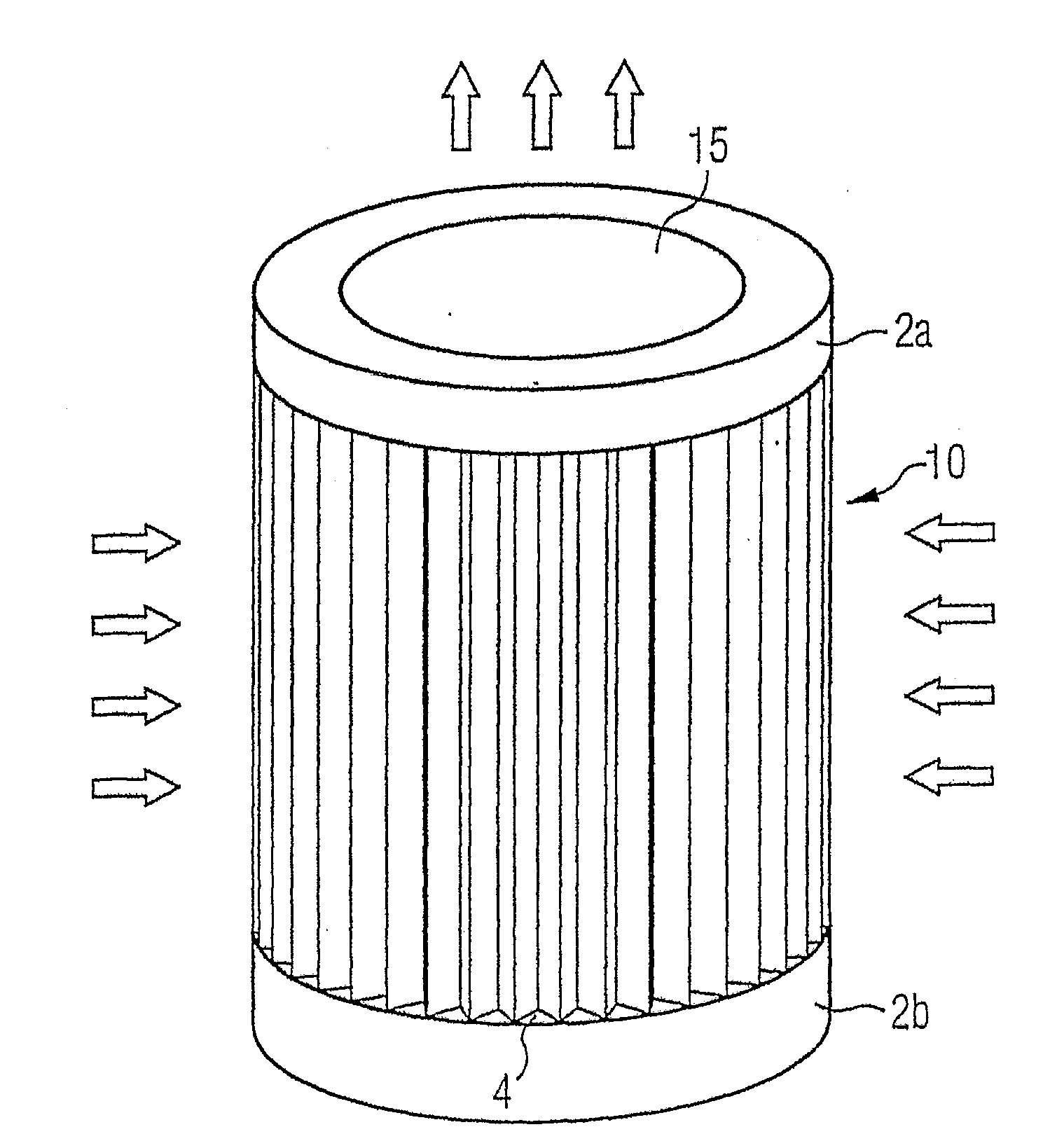

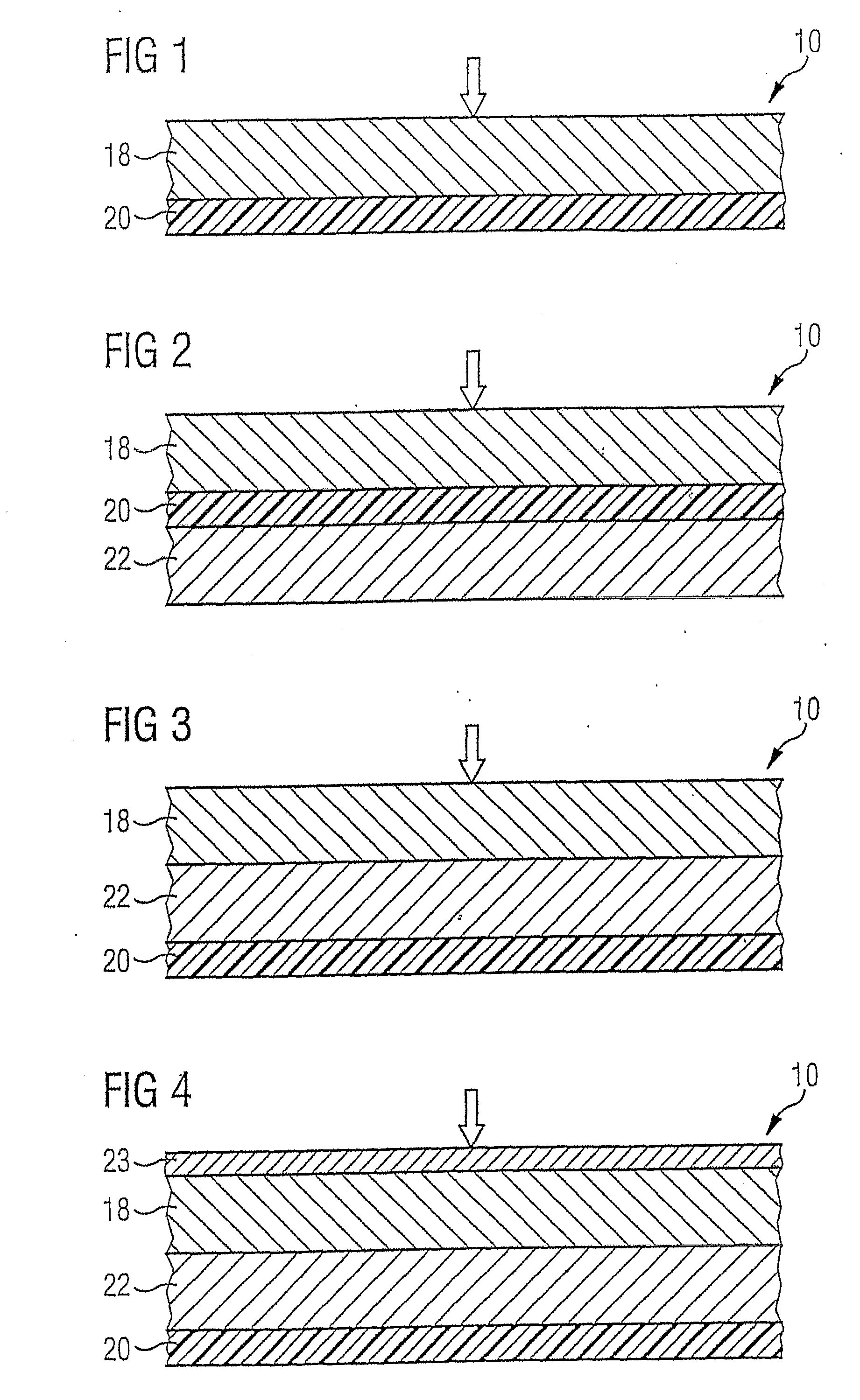

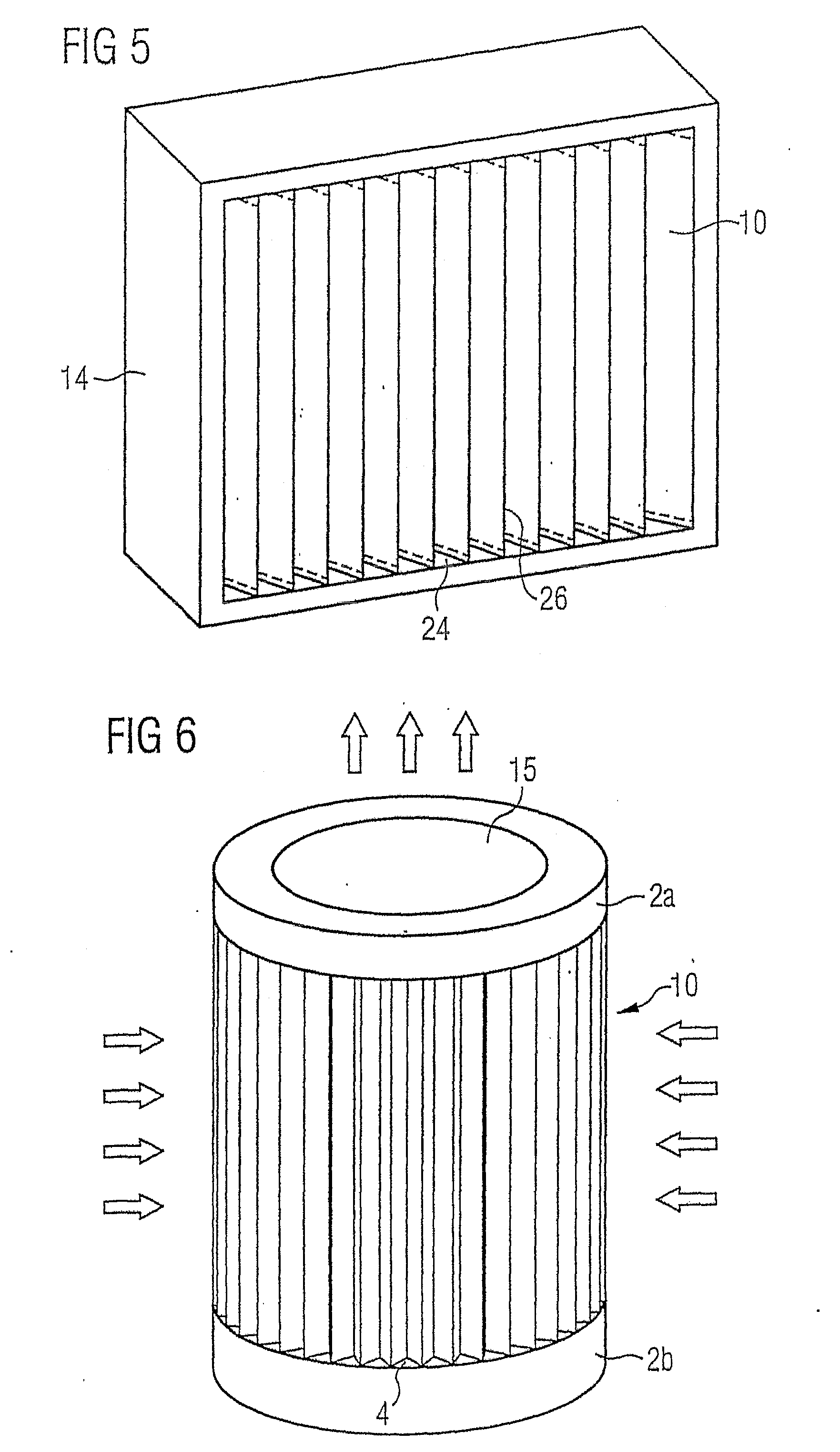

Turbine Air-Intake Filter

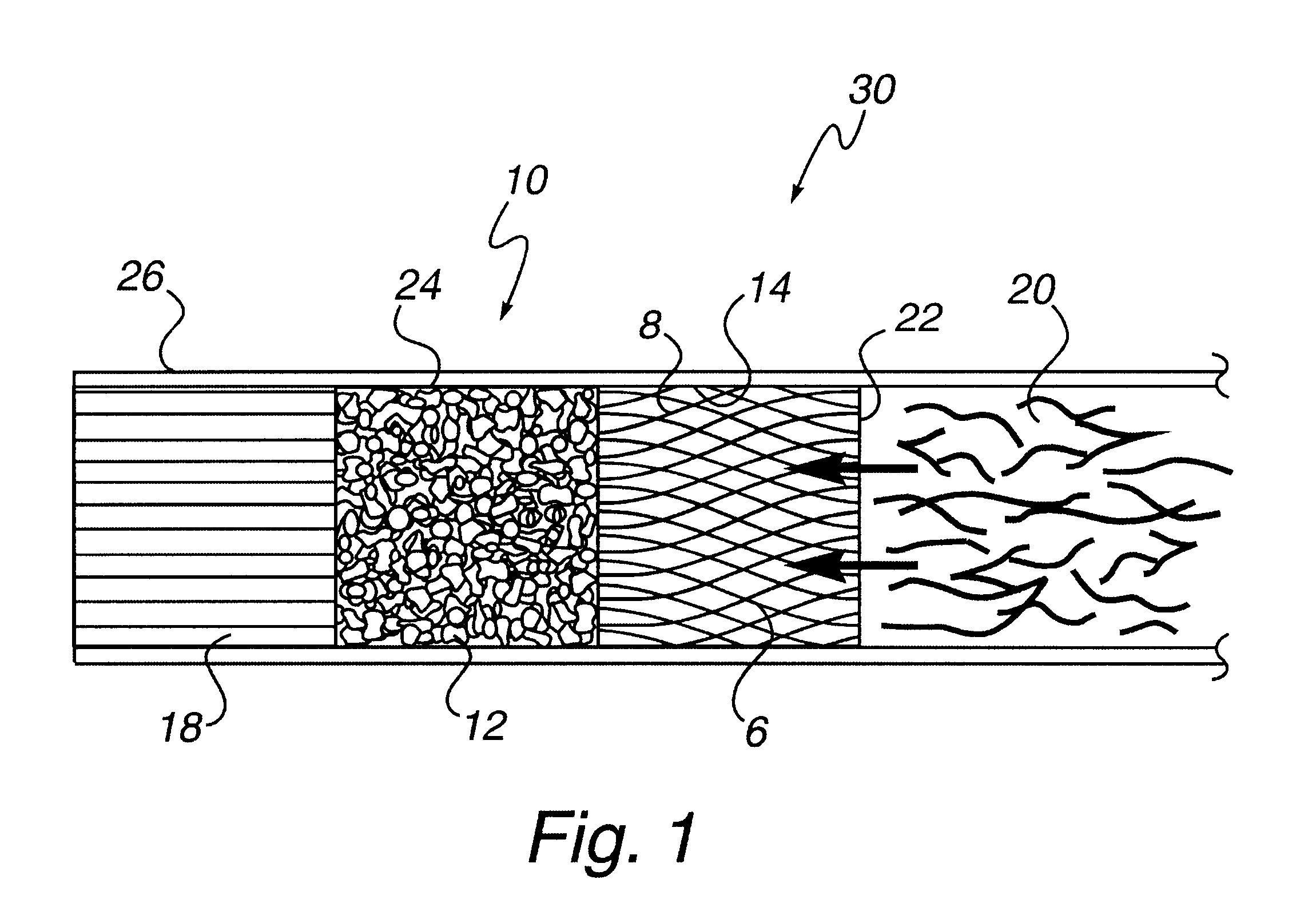

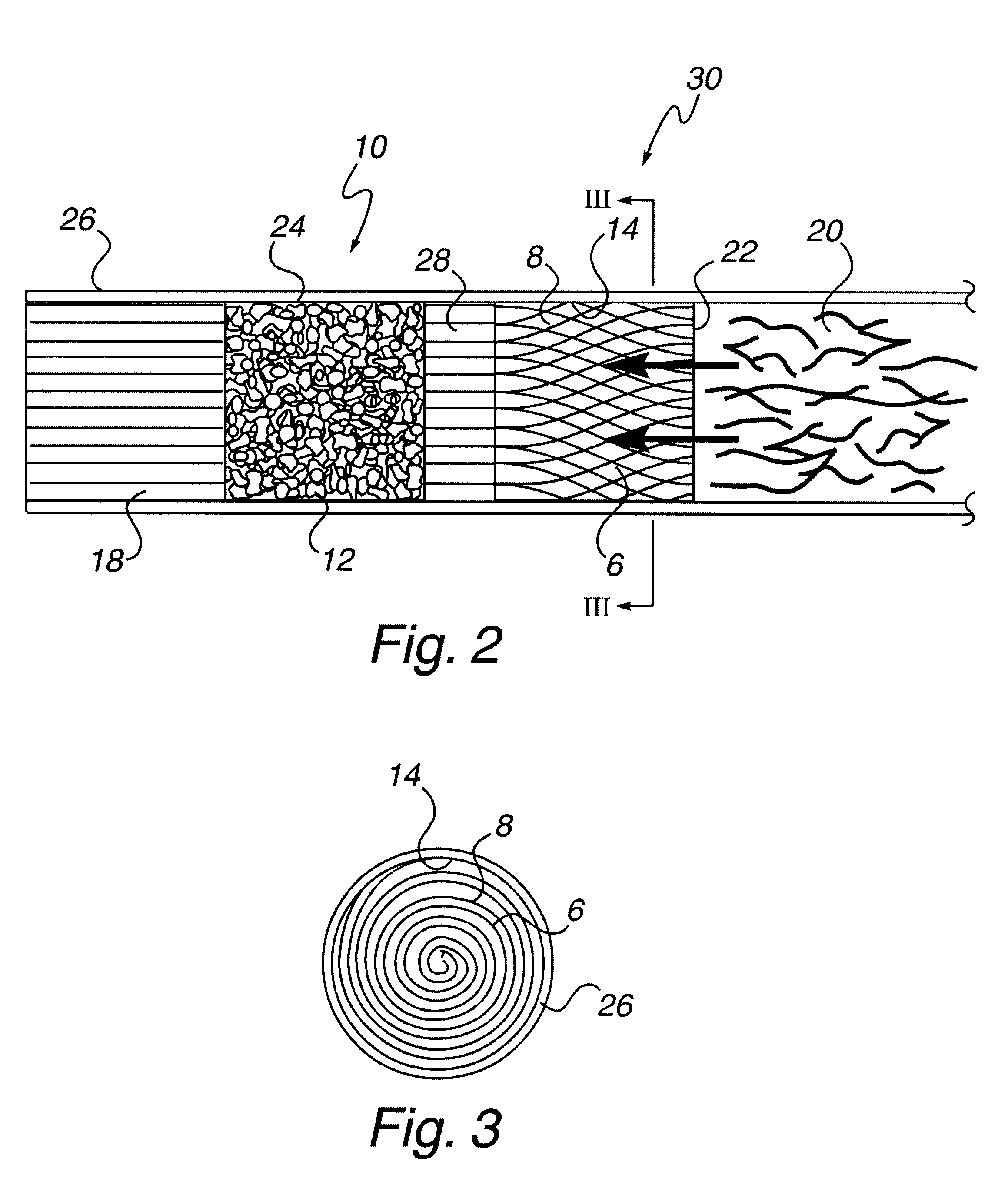

InactiveUS20090266048A1Improve filtering effectSimple wayGas treatmentDispersed particle filtrationFiberFiltration

A turbine air-intake filter for removal of particles from an air stream entering a gas turbine comprises a composite filter media (10) being made from a membrane filtration layer (20) comprising a porous polymeric membrane, such as porous polytetrafluoroethylene (ePTFE), and at least one depth filtration media layer (18) comprising fibers, such as a melt blown web, and being disposed on an upstream side of the membrane filtration layer (20) relative to a direction of gas flow through the filter. The fibers of the depth filtration media layer (18) have an electrostatic charge. The ePTFE membrane is preferably made from a blend of a PTFE homopolymer and a modified PTFE polymer.

Owner:SCHWARZ ROBERT

Long-acting electrostatic holding meltblown polypropylene electret and preparation method and application thereof

ActiveCN111235666AImprove filtration efficiencyImprove adsorption capacityArtificial thread manufacturing machinesMembrane filtersPolypropyleneHigh polymer

The invention belongs to the field of high polymer materials, and provides a long-acting electrostatic holding meltblown polypropylene electret and a preparation method and an application thereof. Themeltblown polypropylene electret provided by the invention contains blended master batch and meltblown polypropylene; the master batch contains a matrix material, an electret filler, a modifier, a dispersing agent, a coupling agent and an antioxidant, wherein the matrix material is polypropylene; the electrets filler is tourmaline and / or a fluorine-containing polymer, and the modifier is a nucleating agent. The meltblown polypropylene electret provided by the invention is obtained by adding the master batch into the meltblown polypropylene for spinning and by passing through a corona electrets, and the obtained meltblown polypropylene electrets material is stable in charge storage, high in filtering efficiency and high in temperature resistance.

Owner:道恩高材(北京)科技有限公司 +2

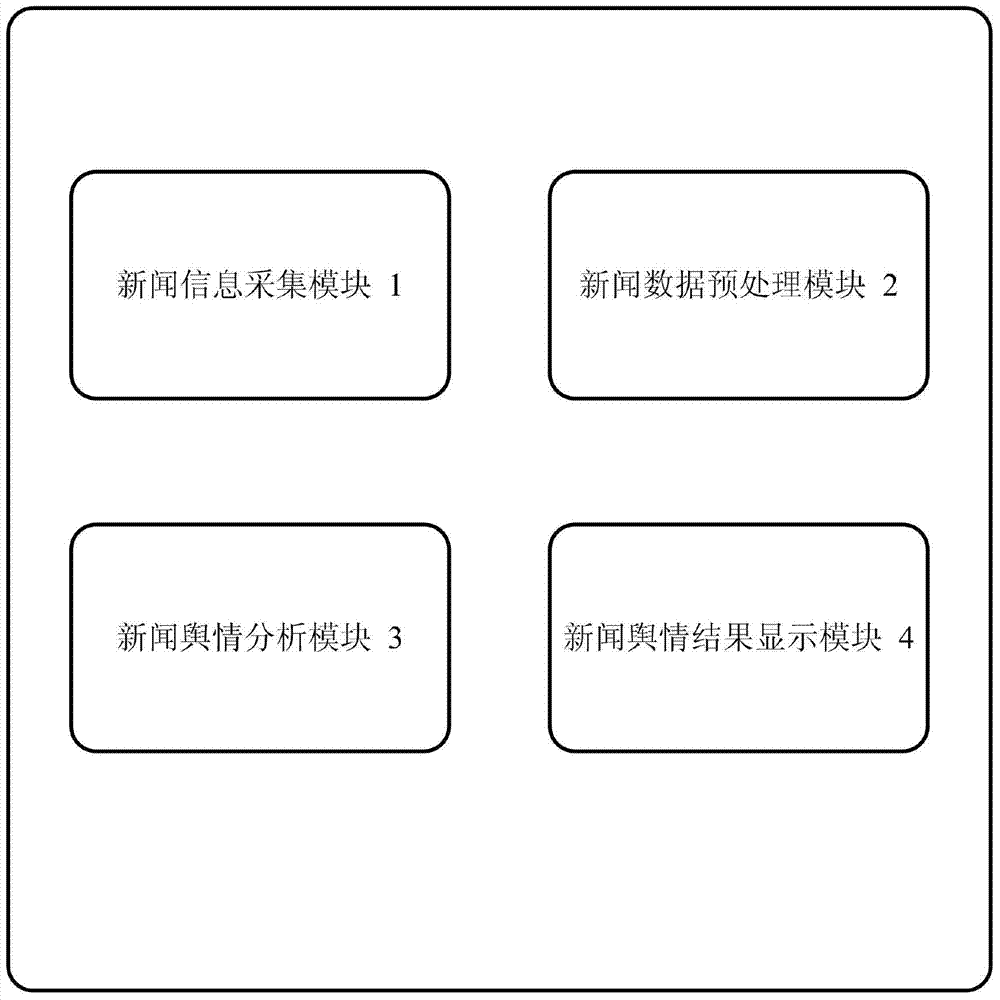

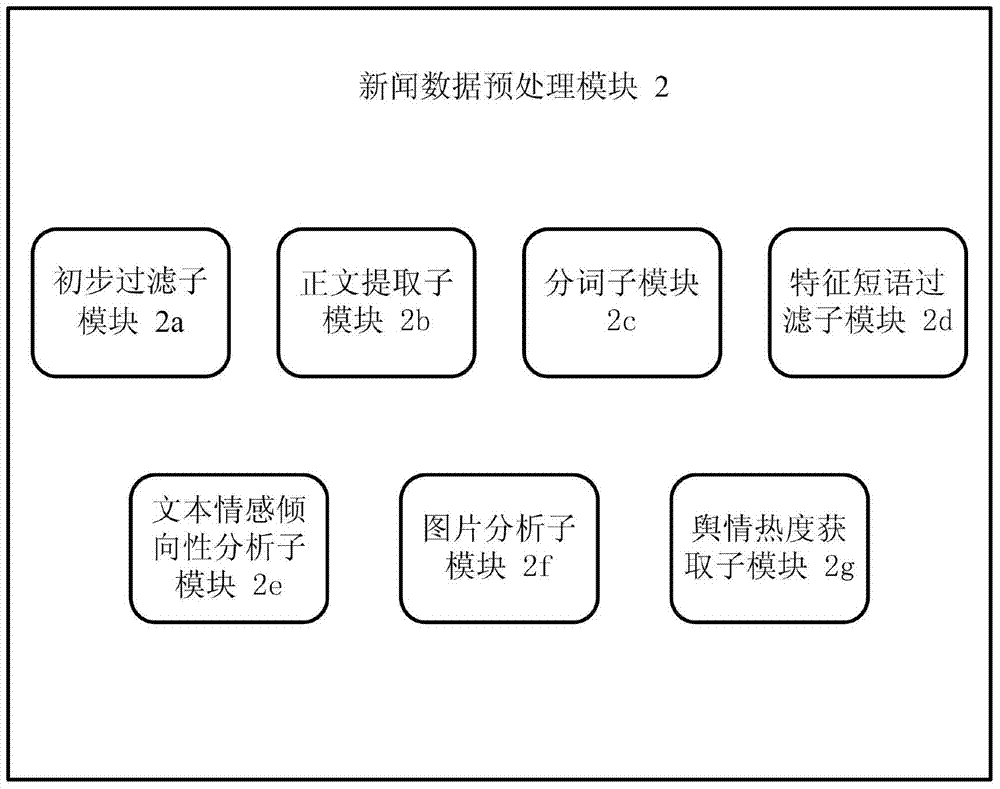

News public opinion monitoring system

InactiveCN104504150AImprove filtration efficiencyImprove accuracySemantic analysisWebsite content managementMonitoring systemData pre-processing

The invention discloses a news public opinion monitoring system. The news public opinion monitoring system comprises a news information gathering module, a news data pre-processing module, a news public opinion analyzing module and a news public opinion result display module; the news data pre-processing module comprises a primary filtering sub-module, a text extracting sub-module, a word segmentation sub-module, a feature phrase filtering sub-module, a text emotion tendency analyzing sub-module, a picture analyzing sub-module and a public opinion popularity acquiring sub-module. A distributed cloud computing mode is used for the data pre-processed by the news data pre-processing module, various news public opinion monitoring algorithm sub-modules are used for acquiring the hot spots of news public opinions, and the hot spots of news public opinions are comprehensively judged, classified and evaluated to effectively and precisely monitor hot topics of the news public opinions.

Owner:珠海横琴粉丝豆信息科技有限公司

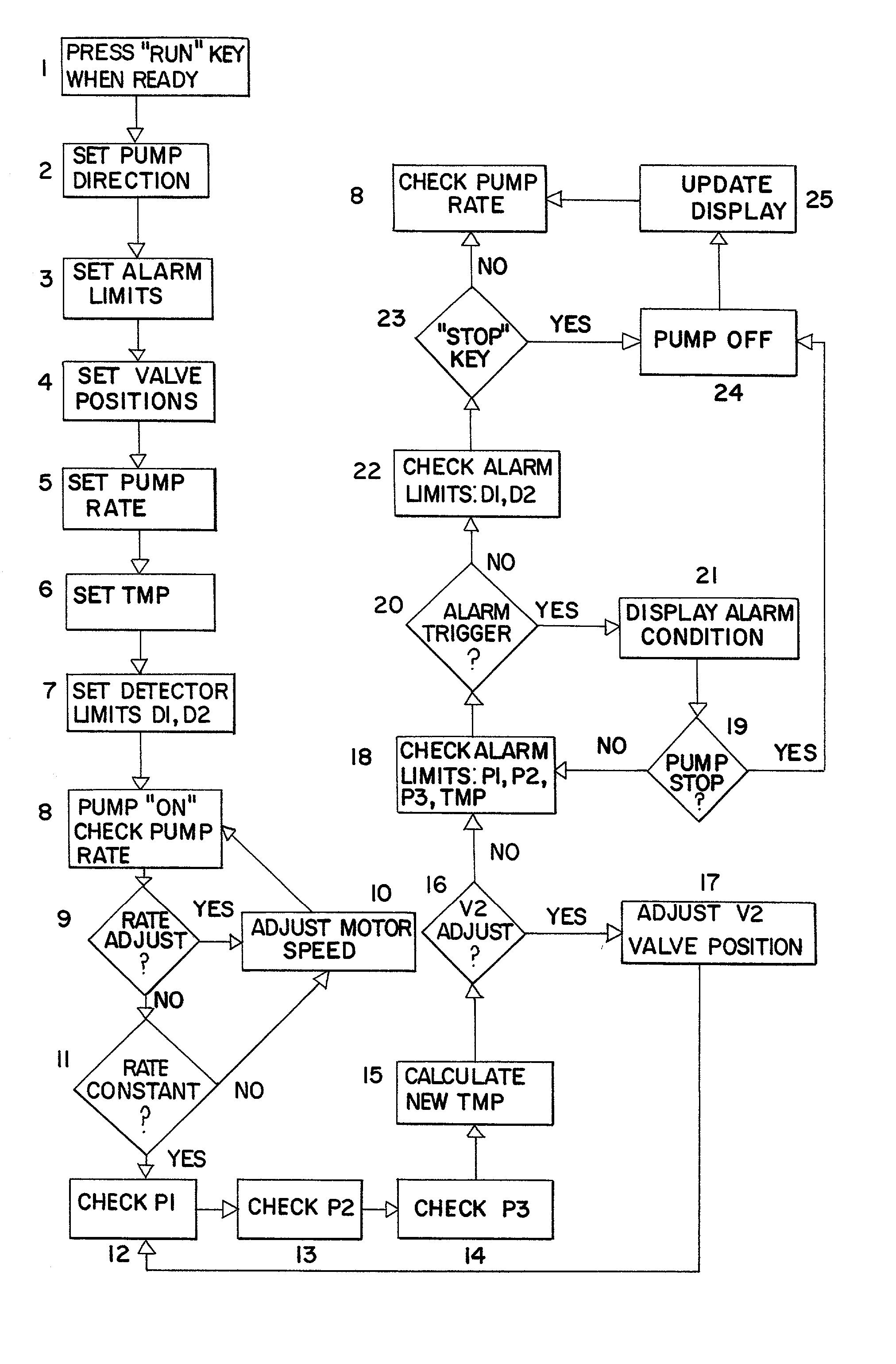

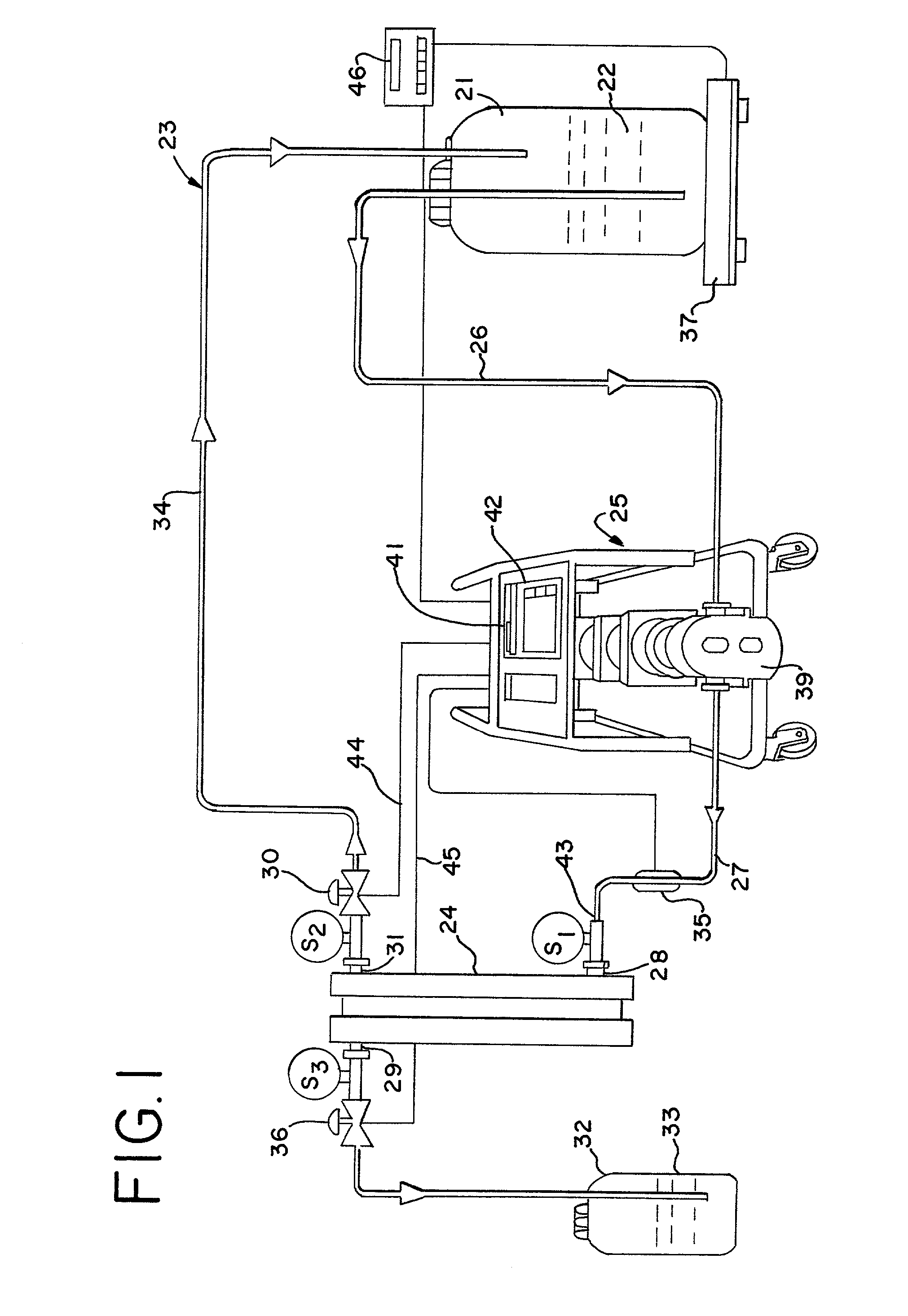

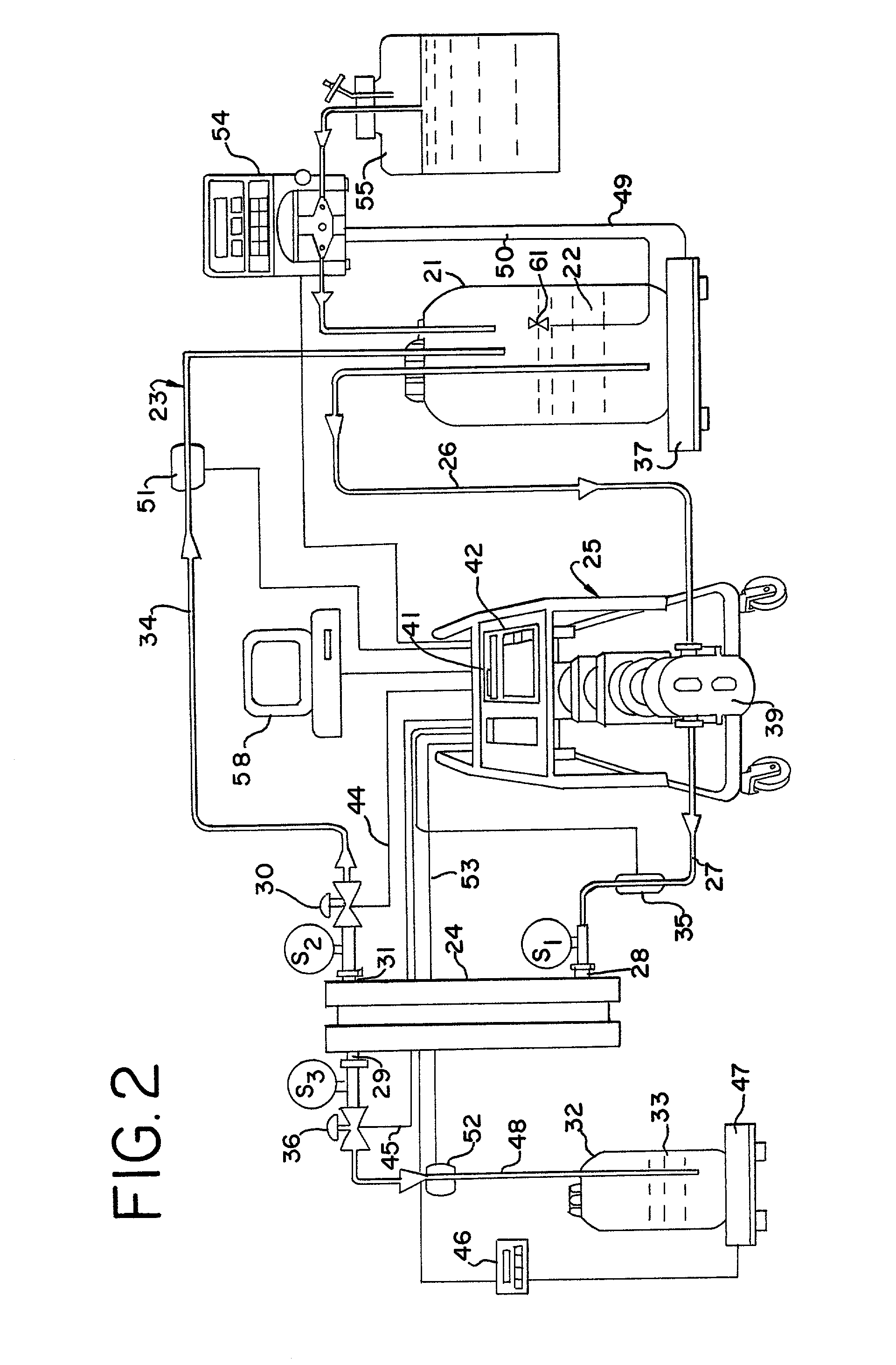

Method and apparatus for enhancing filtration yields in tangential flow filtration

InactiveUS20020043487A1High precision separationEasy to separateMembranesUltrafiltrationFiltrationEngineering

A system is provided for proceeding with filtration of liquids in a manner having enhanced control characteristics. Yields are enhanced. The system and method can be used to maintain a substantially constant trans-membrane pressure. When desired, that constant trans-membrane pressure is especially well-suited to yield enhancement for the particular liquid being filtered, concentrated or collected, while minimizing a risk of damage to or loss of valuable components. Additionally, a constant feed rate or pump output can be maintained.

Owner:PARKER INTANGIBLES LLC

Filtering material for cigarette filter tip and its preparation method

ActiveCN101103845AEasy to shapeConducive to the manufacture of cigarettesTobacco preparationTobacco treatmentEconomic benefitsTar

The invention discloses a filter material for cigarette filter and the preparation method. Based on the expanded cabo particles from <The Preparation Method of an Expanded Cabo Particles and Relevant Equipment> (Application No.: 200710065892.3), the expanded cabo particles are extracted, shaped and selected as so to become the required filter material. The filter material utilizes the waste in the cigarette production, which not only has significant economic benefits, but also is not necessary to be recycled, and will not cause the abrasion of equipment and affect the sensory quality of cigarette. The filter material is uniformly arranged on the filter tows so as to make a composite filter; as the composite is applicable to the cigarette, the smell of the cigarette will be more clear and soft, and the tar and nicotine content in the smoke gas can be reduced effectively. The invention has the advantages that: the operation is simple; the effect is remarkable, therefore the invention has a good applicable prospect.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD +1

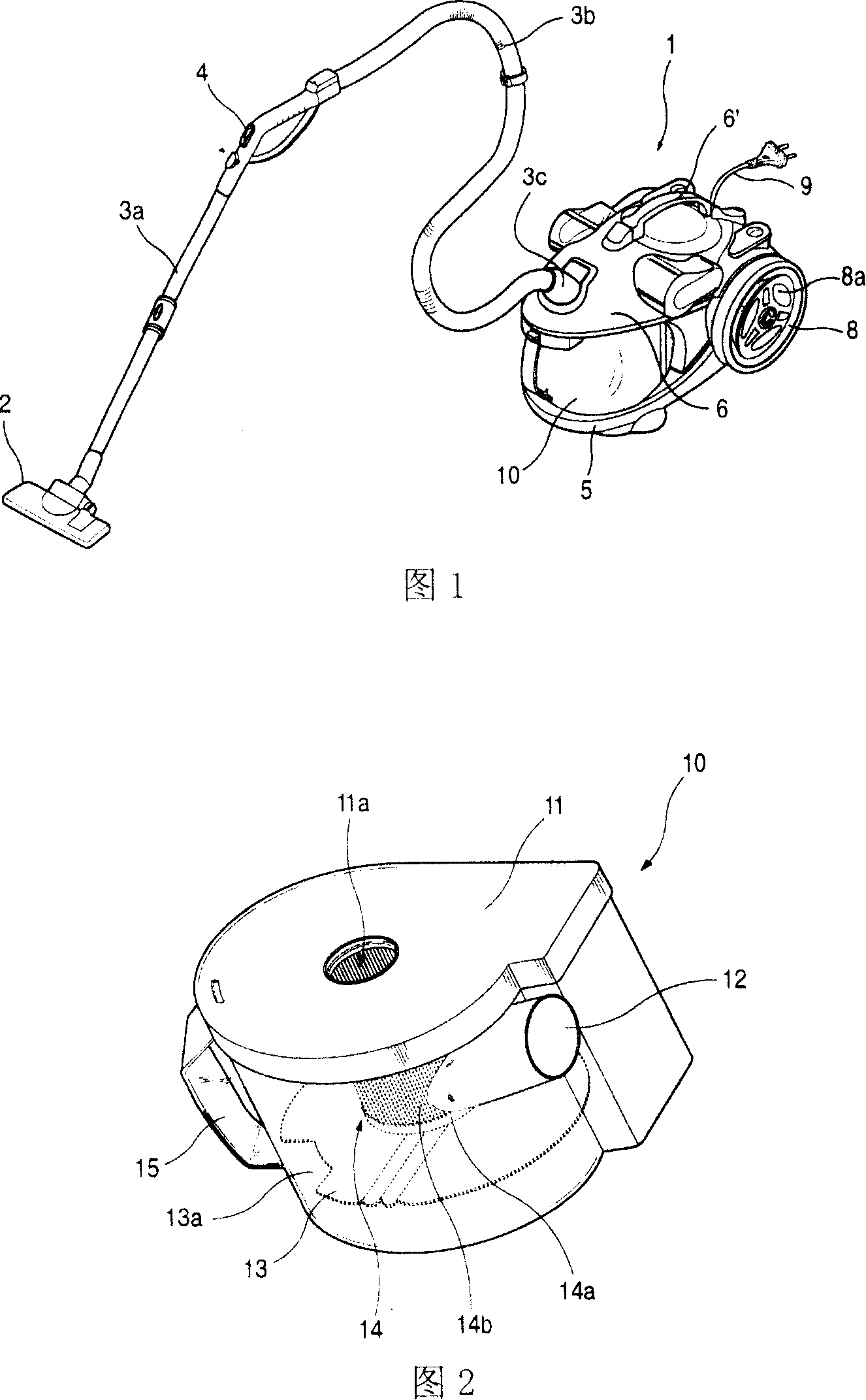

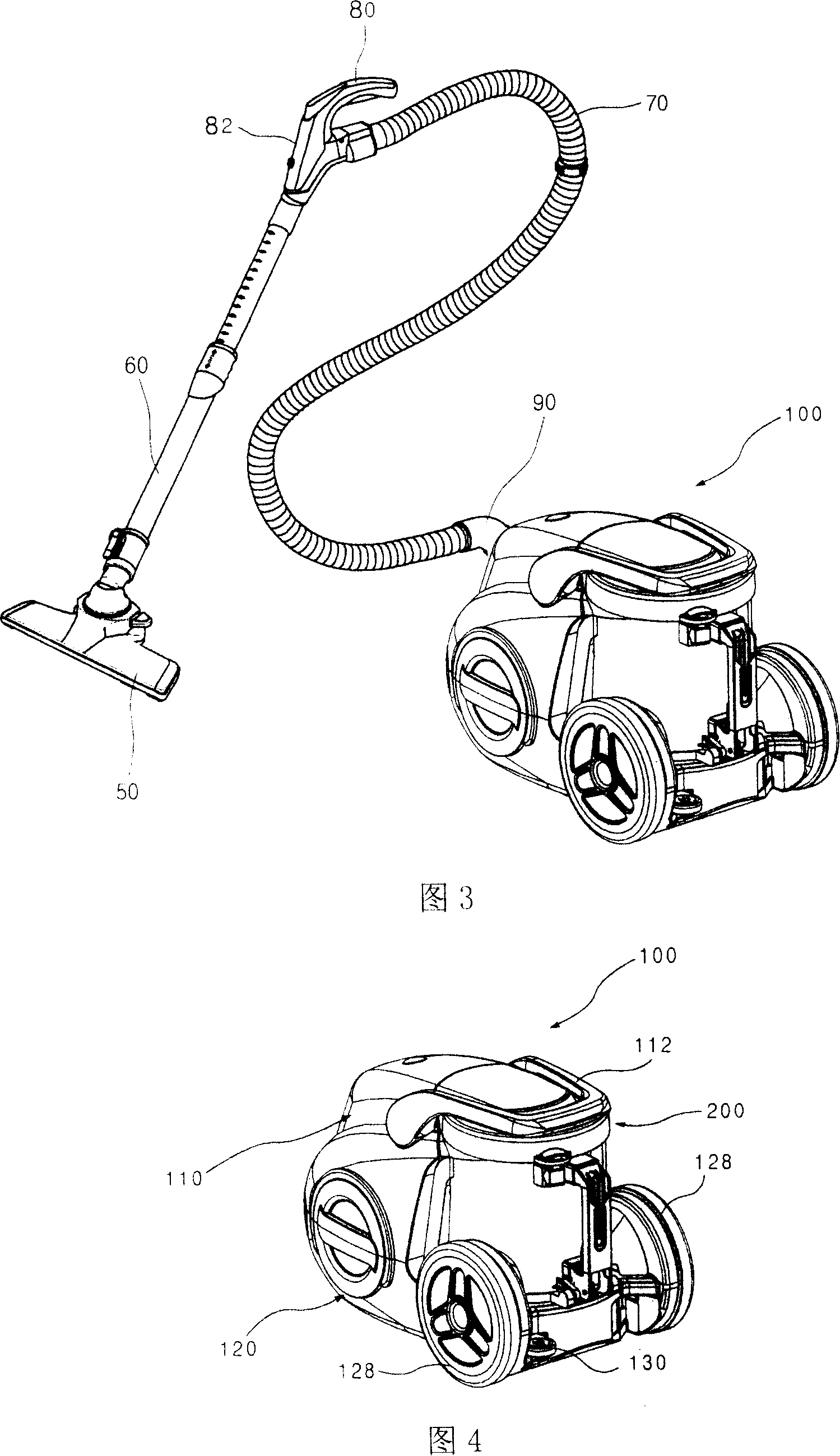

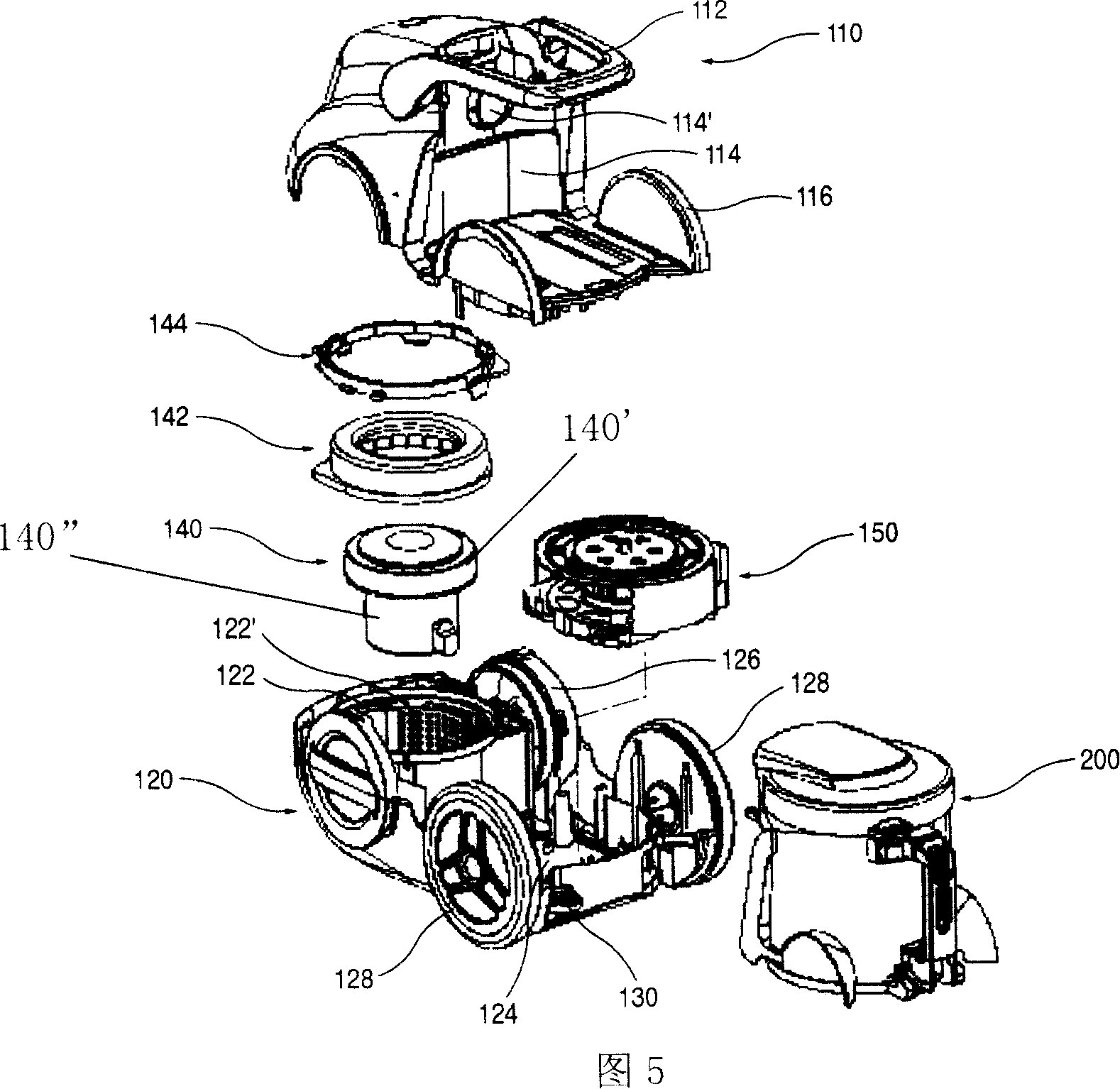

Dust collecting unit of vacuum cleaner

InactiveCN101108110AImprove air purification effectEasy to confirmSuction filtersCycloneForeign matter

The invention discloses a dust collecting unit of vacuum cleaner, which mainly comprises a first cyclone device for filtering the foreign bodies in air for first time, a second cyclone device used for filtering the foreign bodies in air passing through the first cyclone device for the second time, over three dust collecting cylinders of dust collecting chambers used for separating foreign bodies in the air collected, an upper surface cover used for covering the upper surface of the dust collecting cylinder and a lower surface cover used for covering the lower surface of the dust collecting cylinder. The invention has the advantages that: the foreign bodies in air absorbed from outside in the vacuum cleaner are double filtered through the flow of the cyclone, therefore, is can enhance the air purify capacity of the vacuum cleaner, namely the filtering capacity. The invention has three dust collecting chambers to collect the foreign bodies in air, thus the foreign bodies will be separated gradually, which improves the filtering efficiency; besides, the dust collecting cylinder is made of transparent material, which enables users conveniently confirm the foreign bodies quantity collected without needing to separating the dust collecting unit out from the cleaner body.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

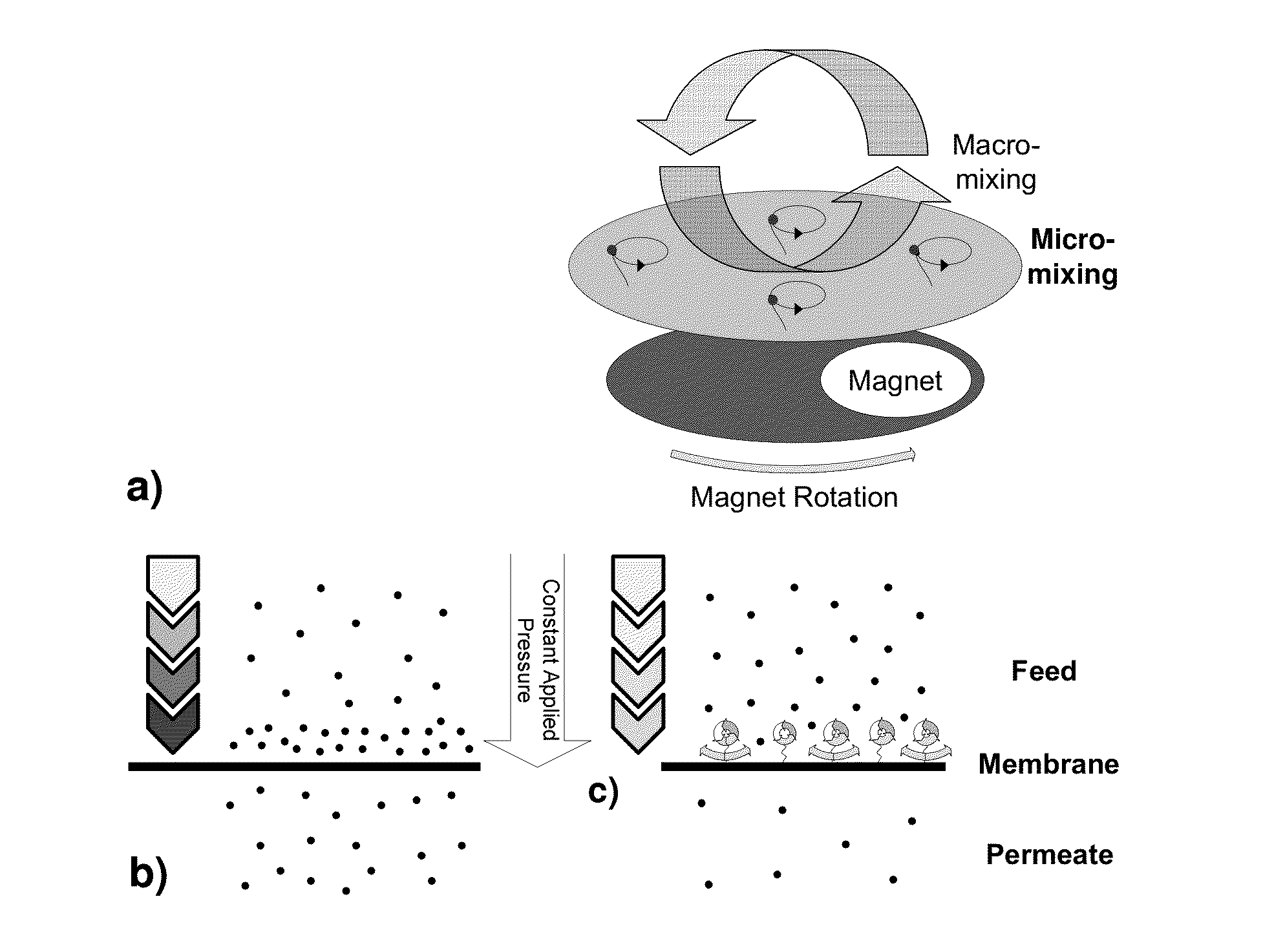

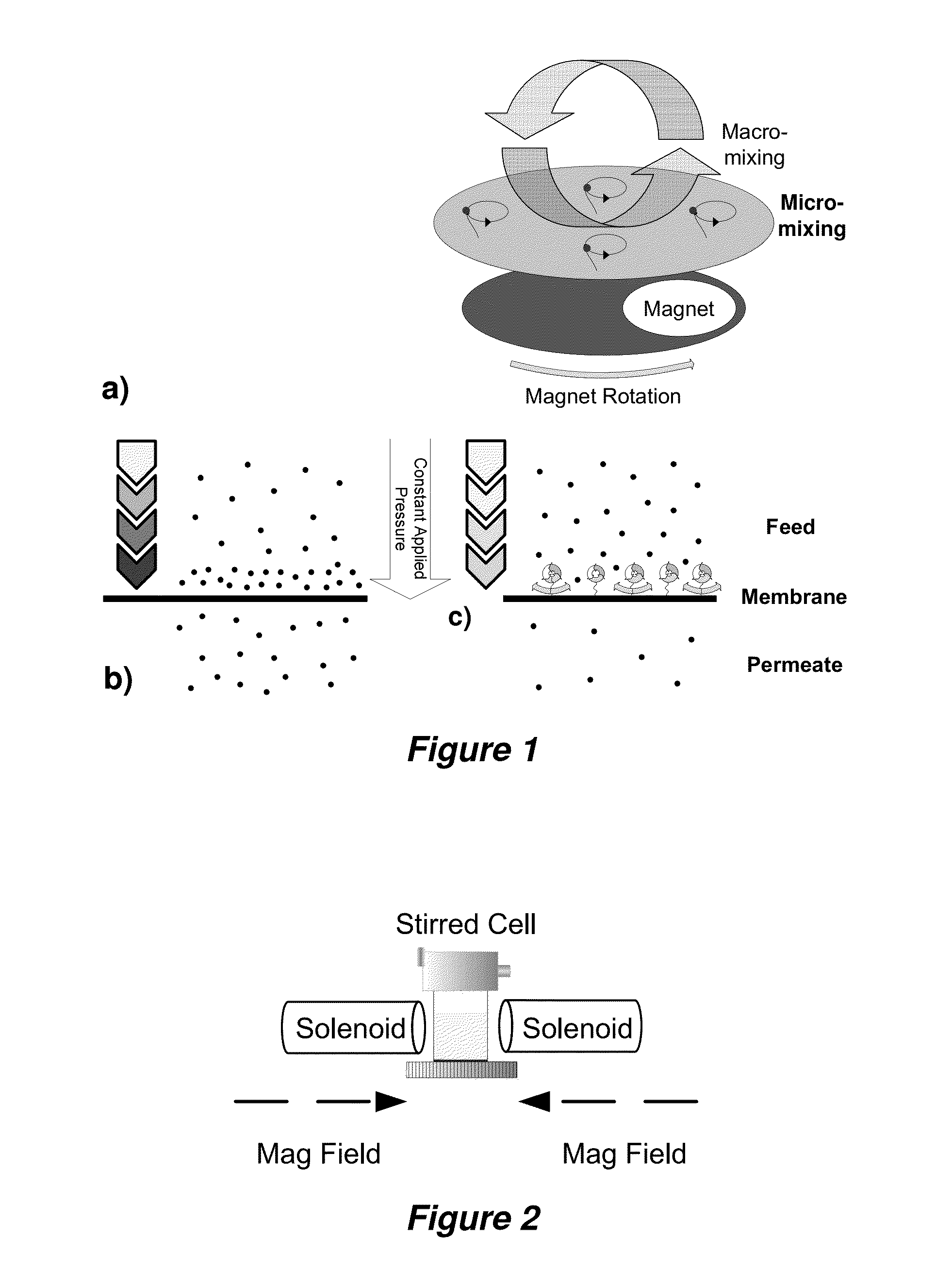

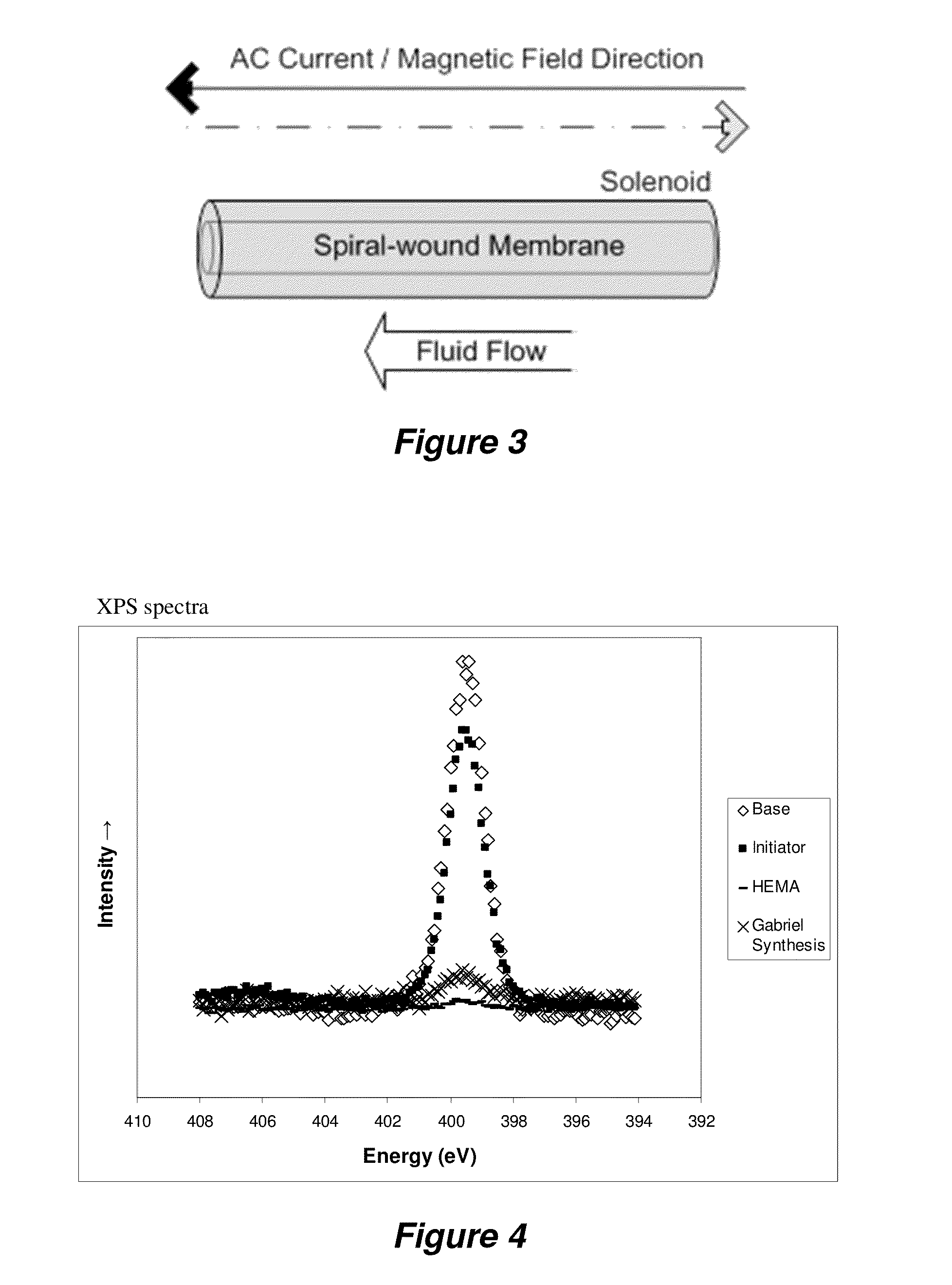

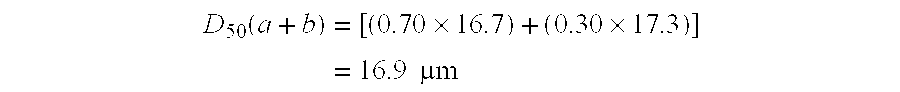

Magnetically responsive membranes

ActiveUS20140231351A1Low purityReduced effectivenessMembranesWater/sewage treatment bu osmosis/dialysisPolymer scienceHydrophilic polymers

The invention provides permeable magnetically responsive filtration membranes that include a filtration membrane polymer base suitable for fluid filtration; hydrophilic polymers conjugated to the surface of the filtration membrane polymer; and magnetic nanoparticles affixed to the ends of a plurality of the hydrophilic polymers, wherein the hydrophilic polymers are movable with respect to the surface of the filtration membrane polymer surface in the presence of an oscillating magnetic field.

Owner:LEHRSTUHL FUR TECHN CHEM II UNIV DUISBURG ESSEN +2

Advanced composite media

InactiveUS6524489B1Enhance propertyDecrease in hardness and viscositySemi-permeable membranesCatalyst protectionSponge spiculeThermoplastic

This invention relates to advanced composite filtration media comprising a functional filtration component and a matrix component, and methods for preparing and using same. More particularly, this invention pertains to advanced composite filtration media and advanced composite filtration media products comprised of a functional filtration component, such as a biogenic silica product (e.g., diatomite), a natural glass product (e.g., expanded perlite), or a natural or synthetic crystalline mineral (e.g., titanium dioxide), which is thermally sintered to a matrix component, such as an engineering polymer (e.g., glasses, natural or synthetic crystalline minerals, thermoplastics, and metals) or a suitable natural material (e.g., rice hull ash, sponge spicules) that has a softening temperature below that of the functional filtration component. This invention also relates to advanced composite media and advanced composite media products, generally, which are also useful in non-filtration applications.

Owner:ADVANCED MINERALS

Modified polypropylene master batch, melt-blow cloth, preparation method and application thereof

InactiveCN107286473ALarge specific surface areaHigh conductivityFiltration separationNon-woven fabricsGraphene derivativesAntioxidant

The invention provides a modified polypropylene master batch, melt-blow cloth, a preparation method and an application thereof. The modified polypropylene master batch is mainly produced from, by weight, 77-90% of polypropylene, 5-20% of a graphene material and 1-5% of an additive. The graphene material includes any one or more of graphene, graphene oxide and graphene derivative. The additive includes any one or more of a coupling agent, a dispersant and an antioxidant and preferably includes the coupling agent, the dispersant and the antioxidant. The modified polypropylene master batch, when being used for manufacturing the melt-blow cloth, not only improves antibacterial and electrification property but also increases the filtering efficiency and dust capacity of the melt-blow cloth.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com