Melt-blown polypropylene material as well as preparation method and application thereof

A technology of melt-blown polypropylene and polypropylene resin, which is applied in the field of melt-blown polypropylene materials and its preparation, can solve the problems of infection risk and limited anti-virus ability, achieve excellent anti-virus performance, excellent antibacterial performance, and improve filtration efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

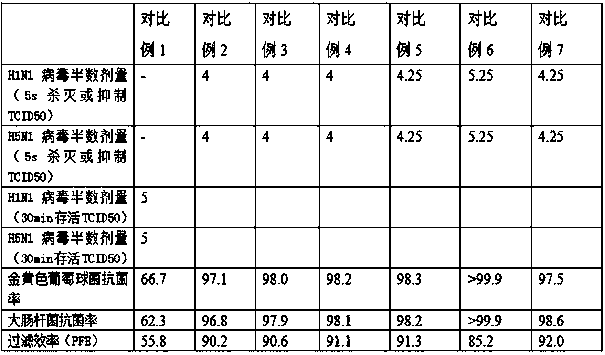

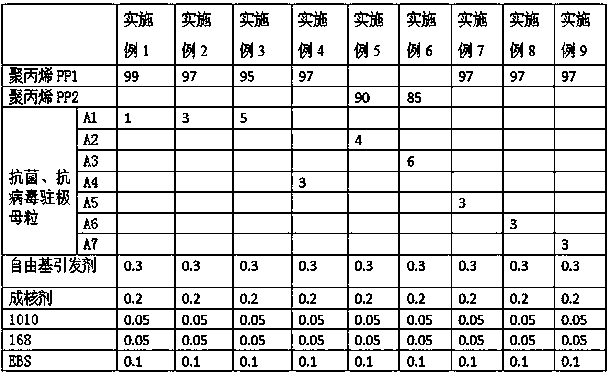

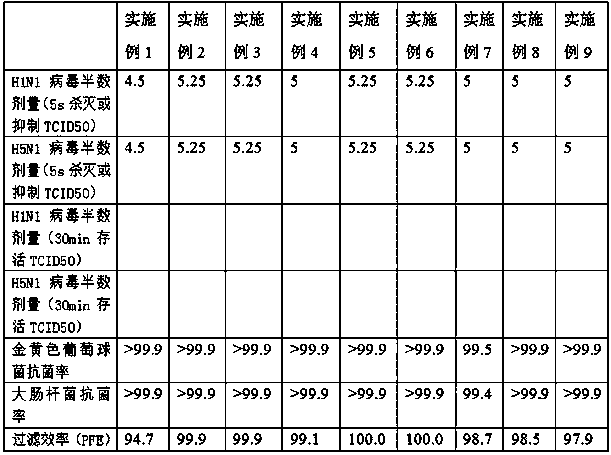

Embodiment 1-9 and comparative example 1-6

[0063] (1) by the proportioning of table 1, weigh each component in proportion and mix homogeneously, extrude strands and pelletize through a twin-screw extruder to obtain antibacterial and antiviral electret masterbatches;

[0064] (2) According to the ratio in Table 2, the prepared antibacterial, antiviral electret masterbatch and other components are mixed evenly in proportion, and the melt-blown polypropylene material is obtained by extruding strands and pelletizing through a twin-screw extruder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com