Patents

Literature

116results about How to "Change surface tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

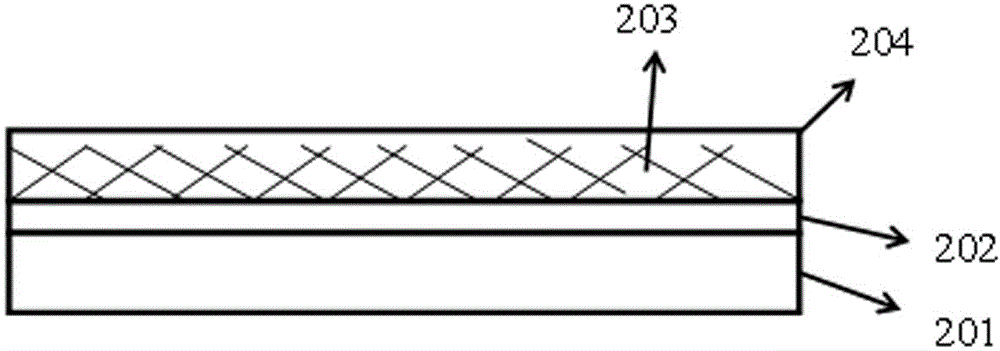

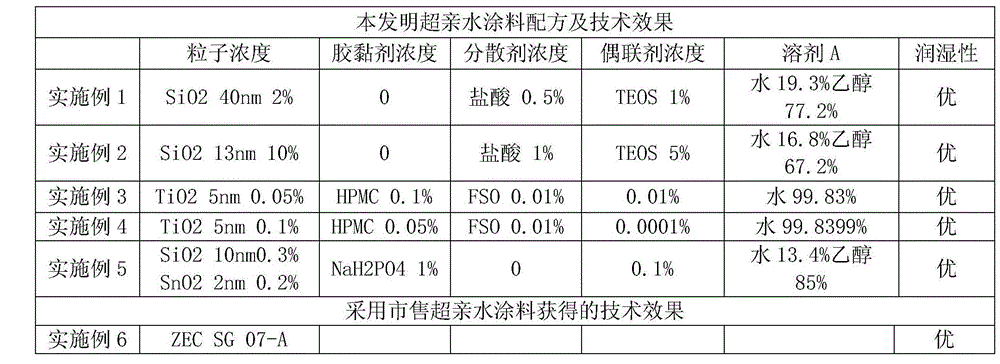

Low-haze transparent conductive film and preparation method thereof

ActiveCN104867540AEasy to apply evenlyChoose safety and environmental protectionConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialHydrophilic coatingTransmittance

The invention provides a low-haze transparent conductive film and a preparation method thereof. The low-haze transparent conductive film comprises a transparent substrate layer, wherein the transparent substrate layer is coated with a super hydrophilic coating formed by a super hydrophilic coating material, the super hydrophilic layer is coated with a transparent conductive layer formed by a conductive ink composition, and the wetting angle of water at the surface of the super hydrophilic coating is less than or equal to 5 degrees. After the super hydrophilic coating is coated, the light transmittance of the substrate is improved, the haze is reduced, an adhesive force between the transparent conductive layer and the substrate is enhanced, and the oxygen permeability of the transparent substrate is also reduced at the same time. By adopting the technical scheme provided by the invention, the total haze of the ultimately acquired transparent conductive film is reduced by 40% compared with that before super hydrophilic processing under the condition of keeping the conductivity to be unchanged, the light transmittance is improved by 2-5%, the adhesive force is also obviously improved, and the appearance is more transparent.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

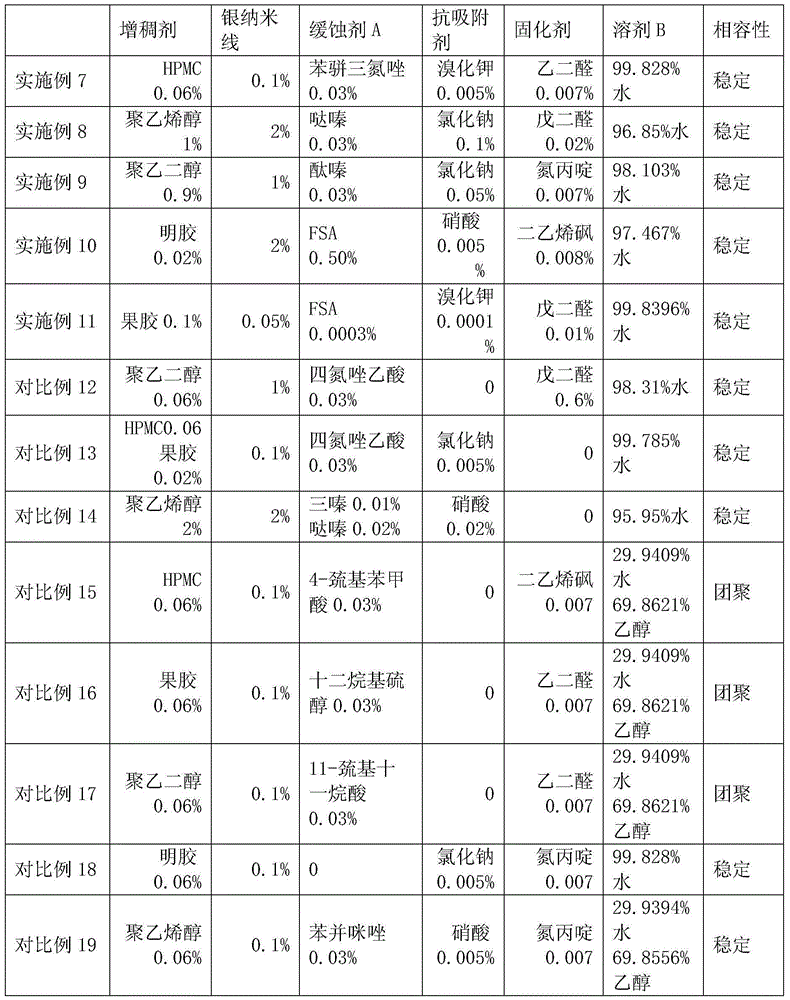

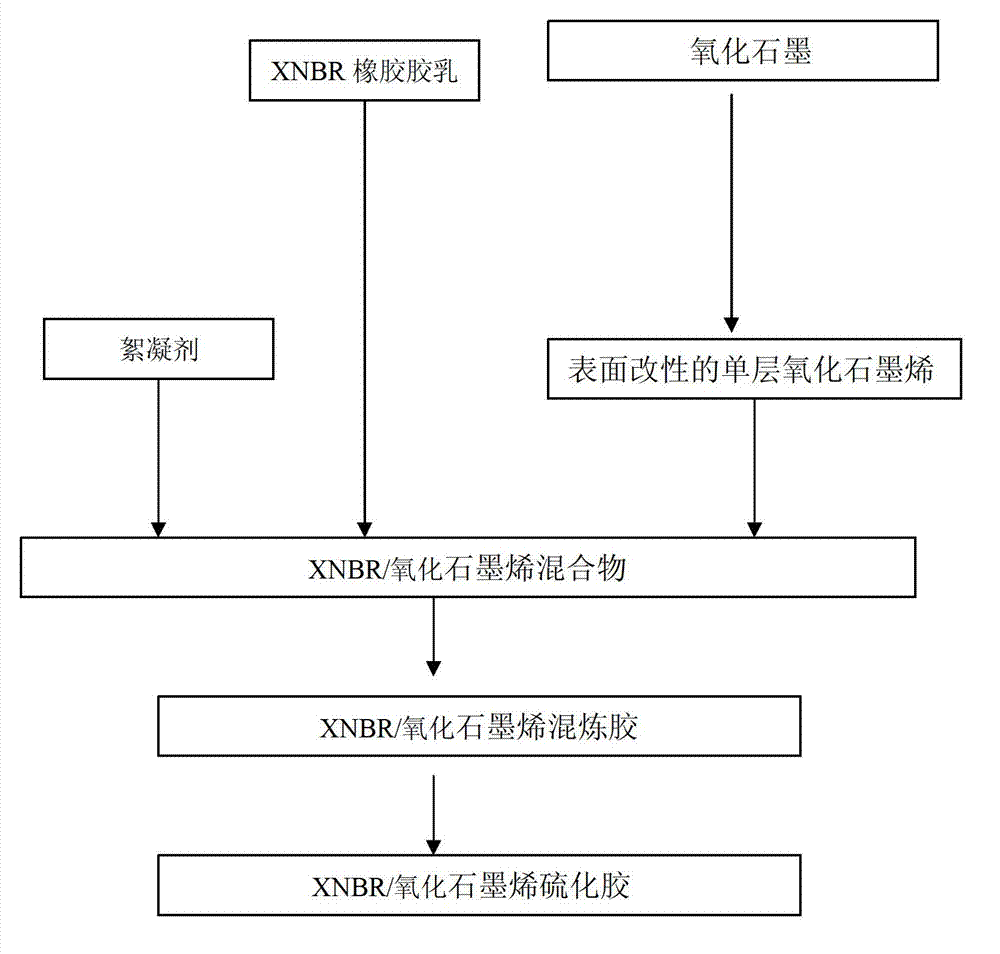

High performance XNBR vulcanized rubber containing graphene oxide and its preparation method

InactiveCN102786726AImprove the degree of uniform dispersionImprove mechanical strengthSingle layer grapheneSurface tension

The invention discloses a high performance XNBR rubber containing graphene oxide and its preparation method. The preparation method comprises the following steps: adding graphite oxide into a surface modifier for ultrasonic stripping; carrying out centrifugal separation so as to obtain surface modified single-layer graphene oxide; mixing the single-layer graphene oxide with XNBR rubber latex; then successively adding an anti-aging agent and a flocculant and preparing a rubber mixture by using a co-coagulation method; and adding a vulcanizing agent for vulcanization so as to obtain graphene oxide-containing XNBR vulcanized rubber with high mechanical properties and high thermal conductivity. According to the invention, since the surface modifier is added in the process of stripping, stability and surface tension of graphene oxide suspension are changed, graphene oxide and the latex are allowed be uniformly mixed, and the degree of homodisperse of graphene oxide in a polymer is improved, and therefore, the purpose of improving mechanical strength of XNBR is achieved.

Owner:NANJING UNIV OF SCI & TECH

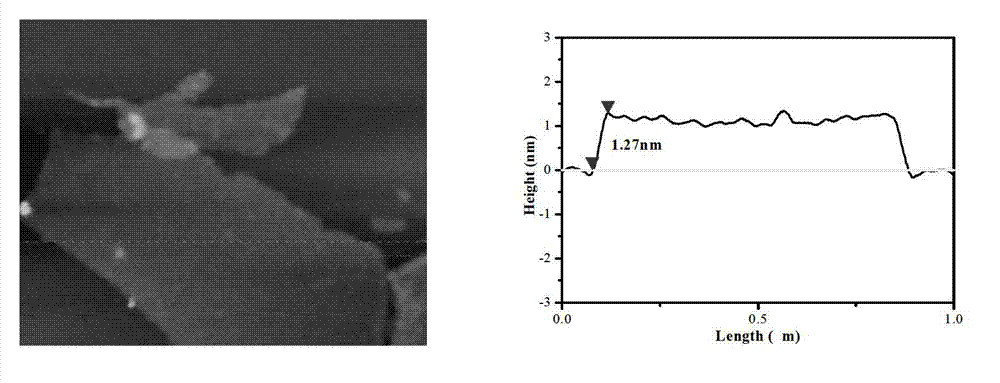

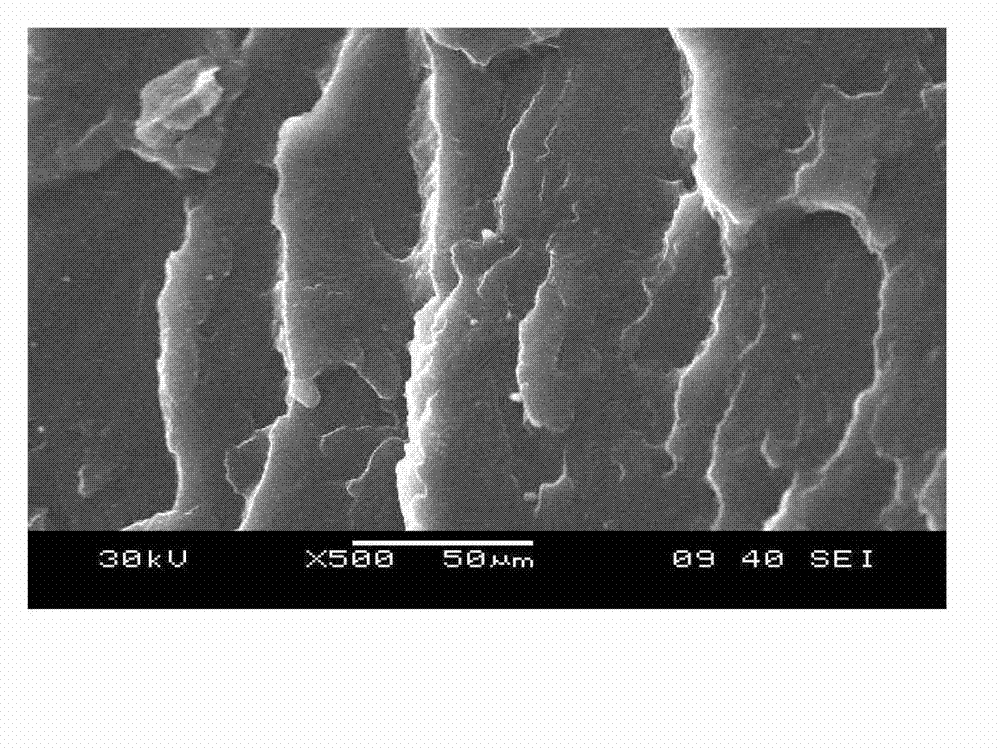

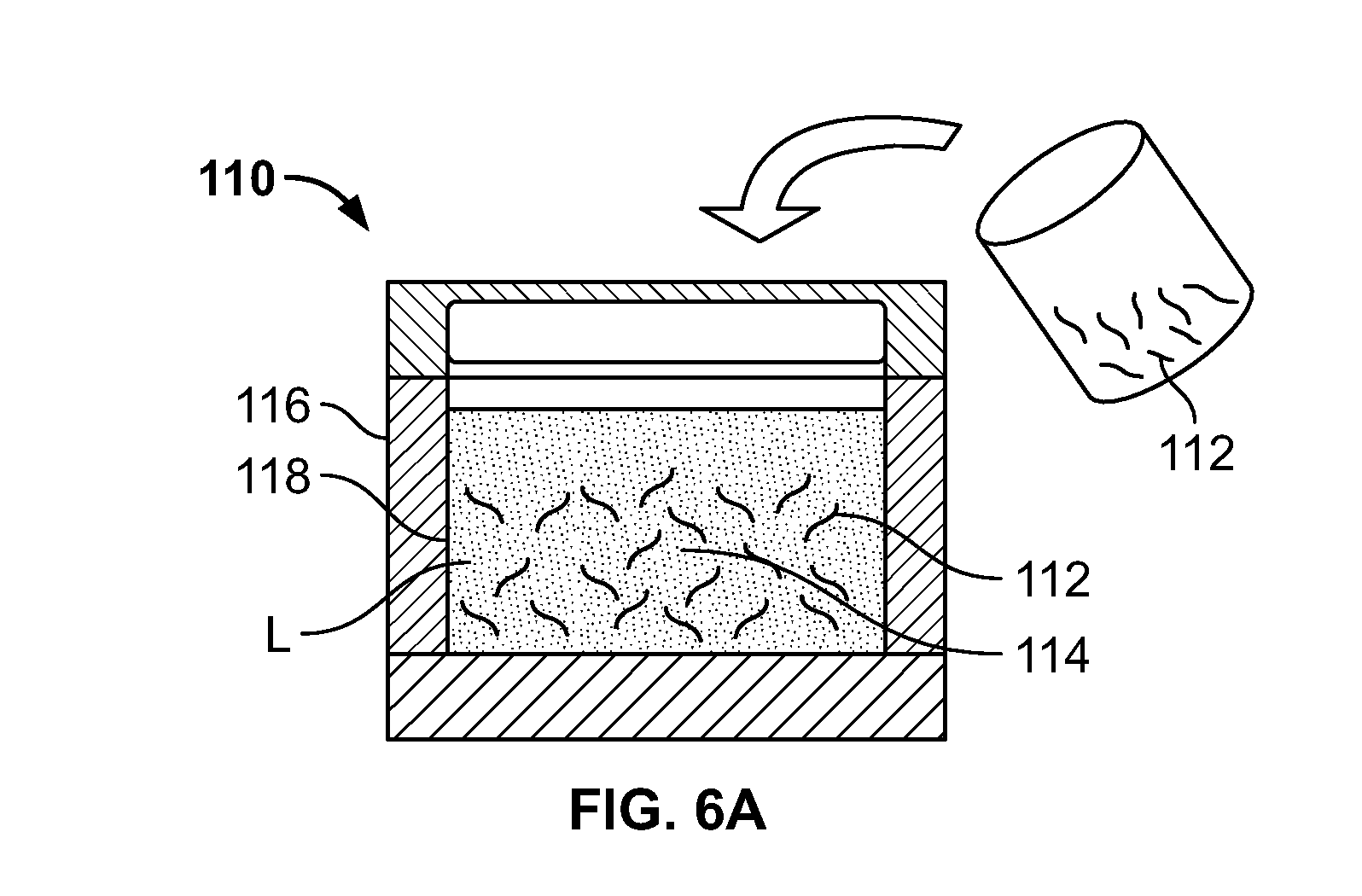

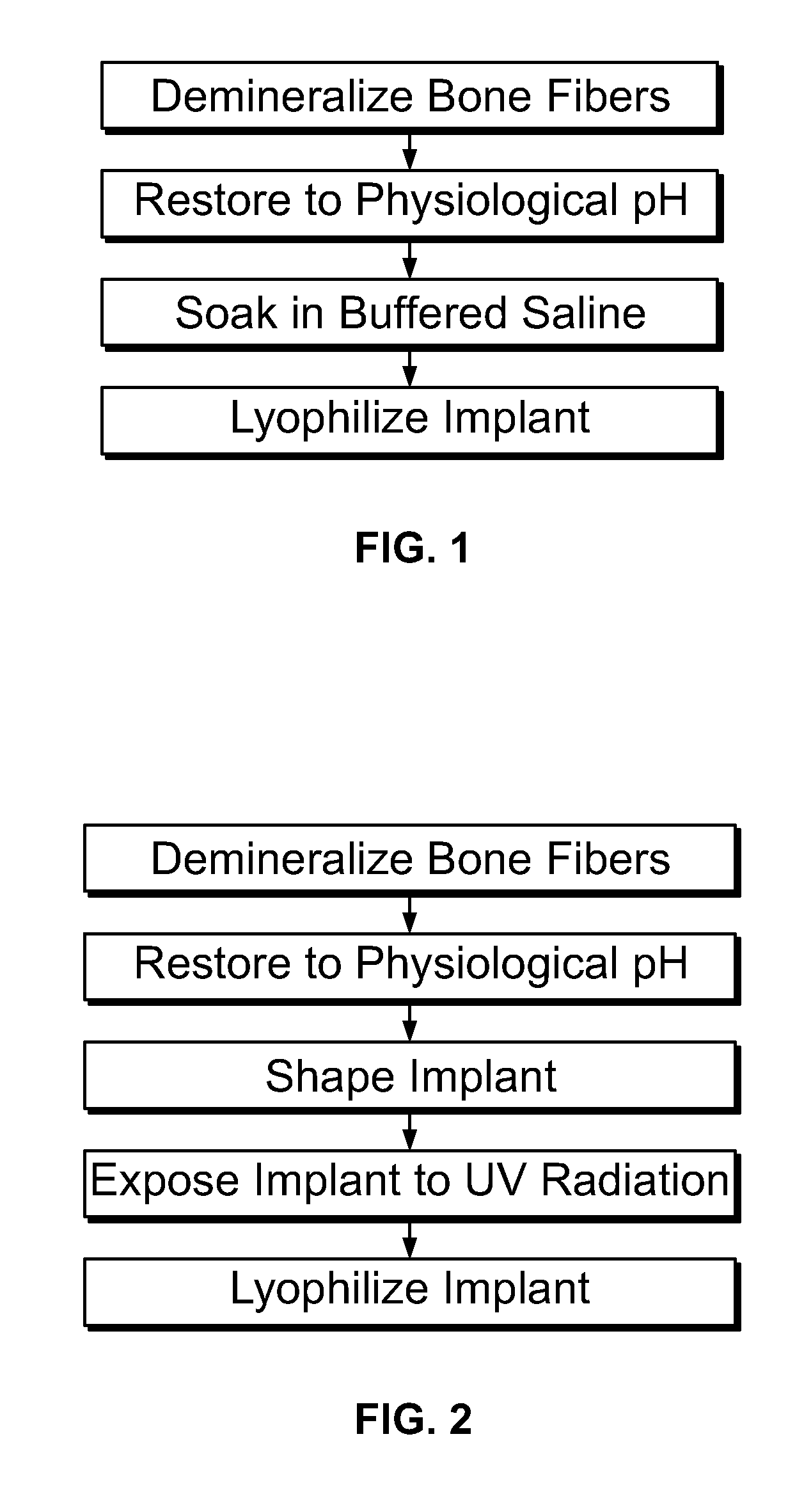

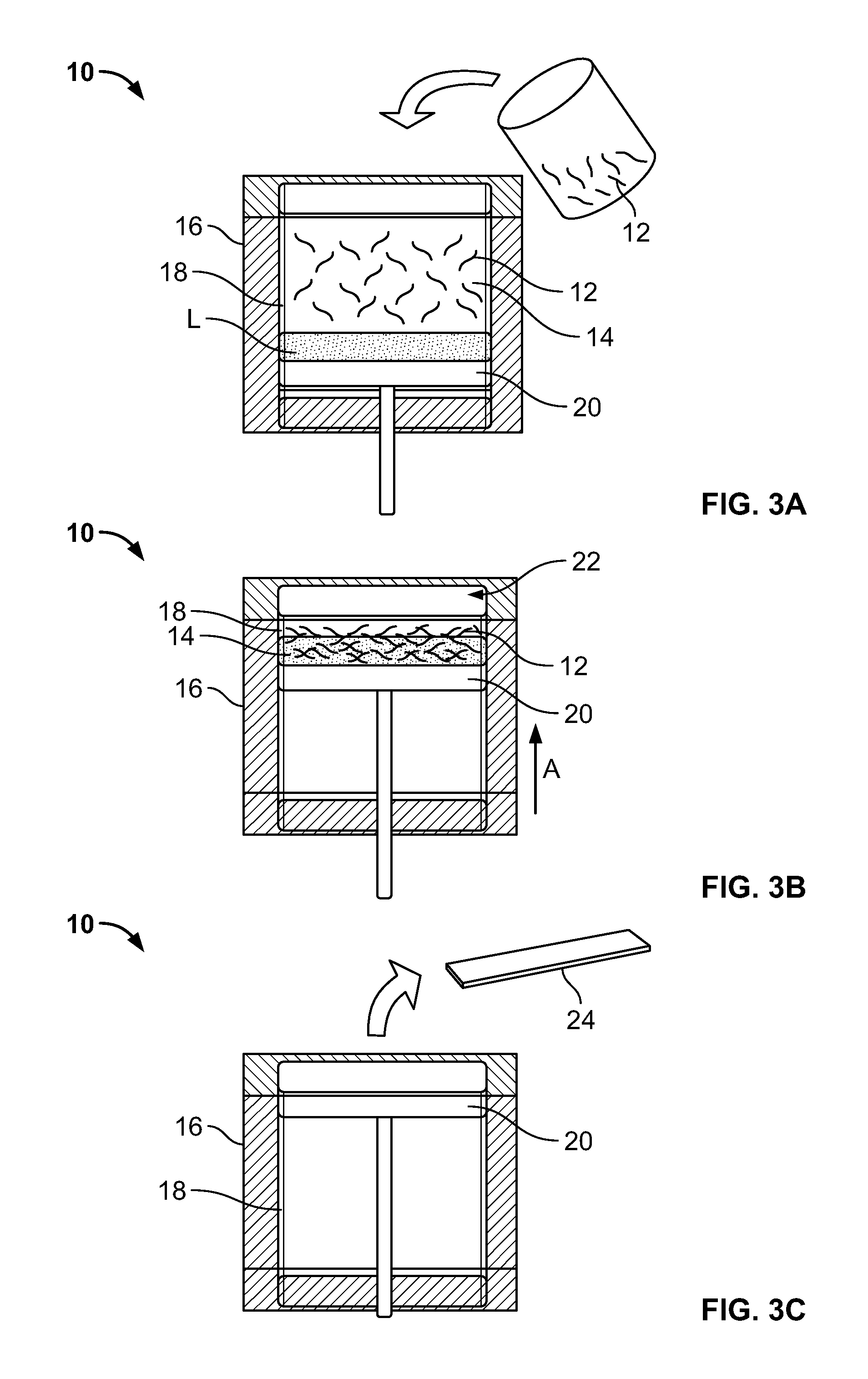

Modified demineralized cortical bone fibers

ActiveUS20160361171A1Reduce swellIncrease wettabilityBone implantPharmaceutical delivery mechanismFiberBone Cortex

Surgical grafts for the repair of bone defects, more particularly, surgical grafts that include demineralized bone fibers, are disclosed. Methods for making such grafts and for increasing their wettability and ensuring uniform density are also disclosed.

Owner:MUSCULOSKELETAL TRANSPLANT FOUND INC

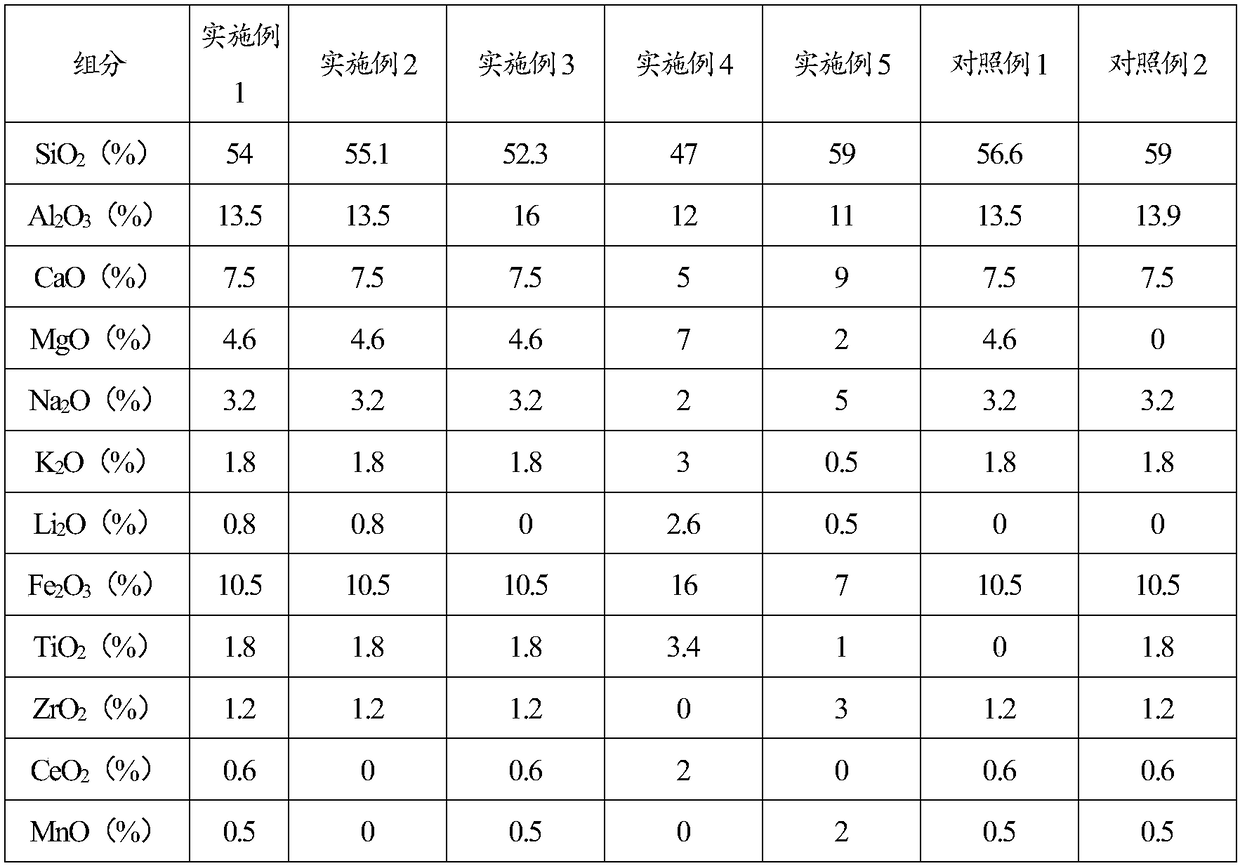

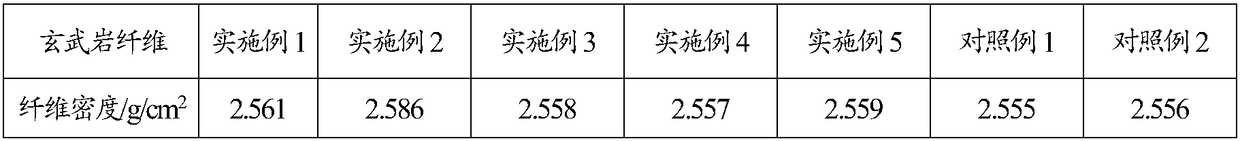

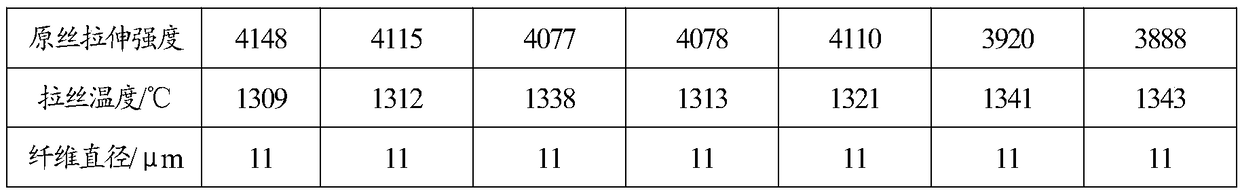

Basalt fiber preparation method, mineral mixture and production technology

The invention discloses a basalt fiber preparation method, a mineral mixture and a production technology. The preparation method comprises the step of grinding the mineral mixture into 200 to 300-meshpowder to obtain basalt fibers. The mineral mixture is prepared from the ingredients in weight percentage: 47% to 59% of SiO2, 11% to 16% of Al2O3, 5% to 9% of CaO, 2% to 7% of MgO, 2% to 5% of Na2O,0.5 to 3% of K2O, 0 to 2.6% of Li2O, 7% to 16% of Fe2O3, 1% to 3.4% of TiO2, 0 to 3% of ZrO2, 0 to 2% of CeO2 and 0 to 2% of MnO. The used mineral mixture is prepared from varieties of ores, so thatthe whole ingredient fluctuation range is reduced to the lowest, wiredrawing performance is improved, mineral mixture ingredient contents and mutual proportional relation are controlled, strength is improved, stability is improved, elasticity modulus is improved, a melting temperature is reduced, energy is saved, glass material characteristics are changed, and improving wiredrawing performance isachieved.

Owner:SICHUAN FIBERGLASS GRP

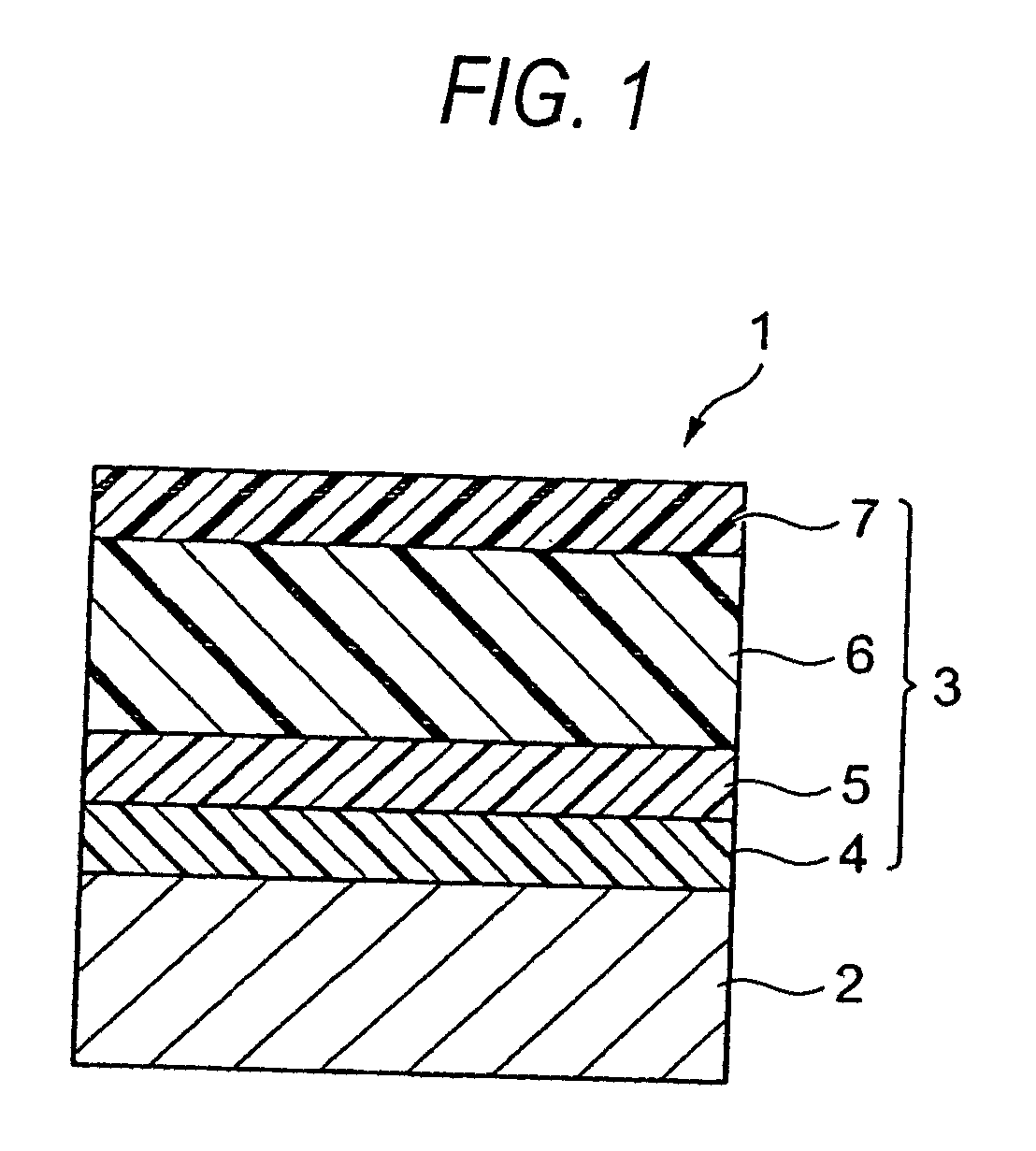

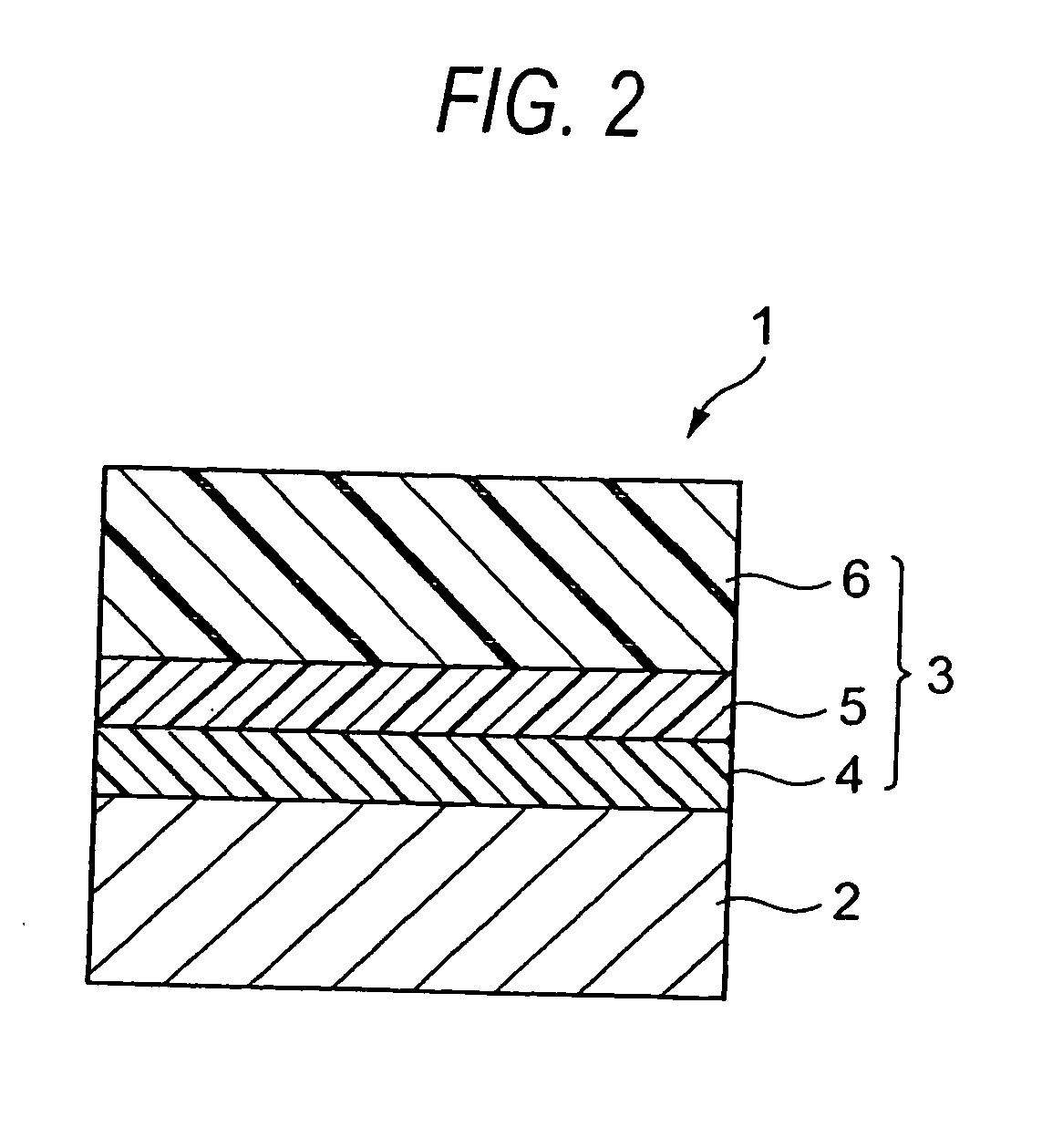

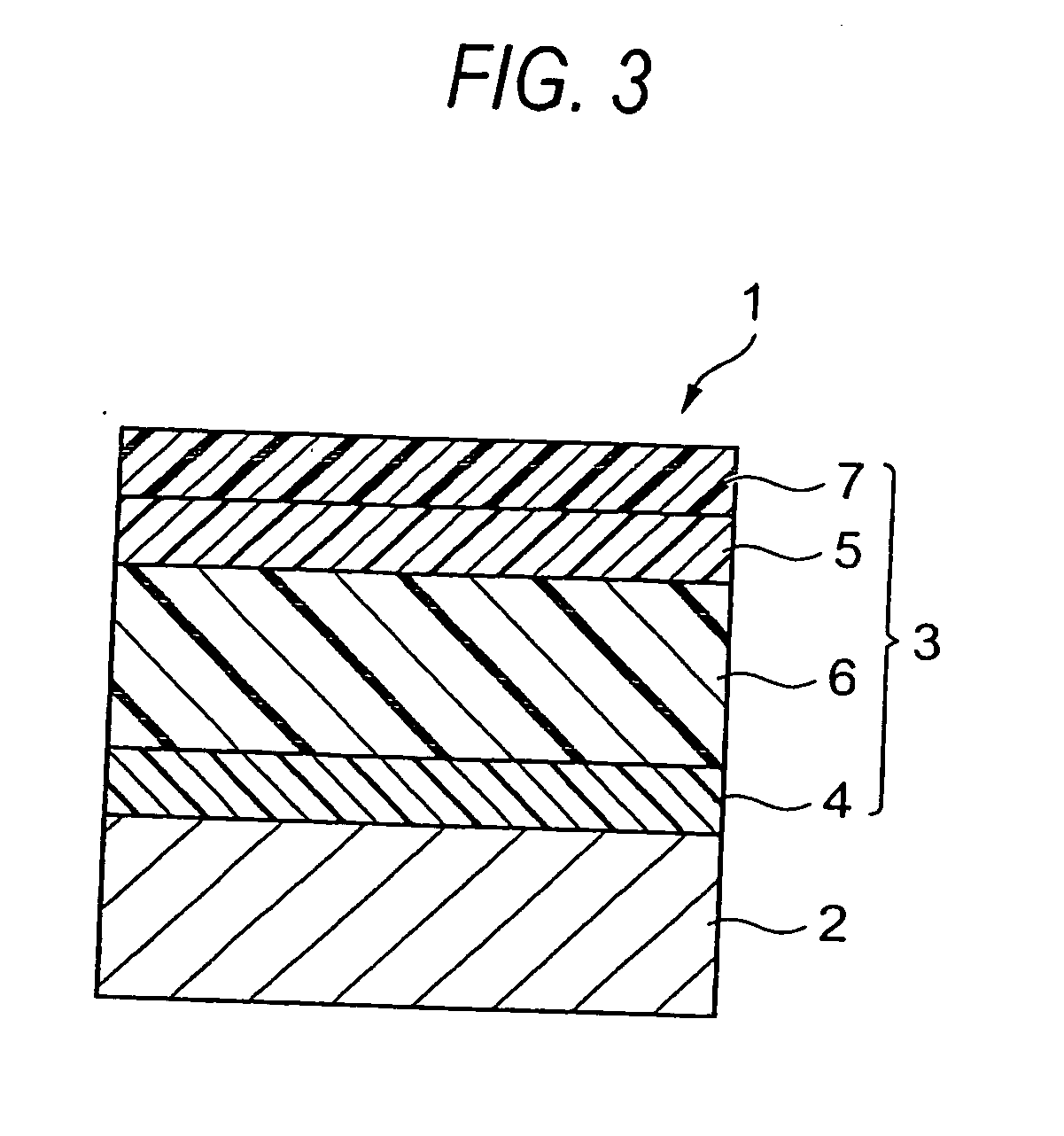

Electrophotographic photoreceptor, image-forming device, process cartridge and image-forming method

InactiveUS20060292464A1Improve film formationImprove image qualityElectrographic process apparatusCorona dischargeAlcoholSilicone oil

An electrophotographic photoreceptor comprising: a conductive support; and a photo-sensitive layer on the conductive support, wherein the photo-sensitive layer comprises a functional layer comprising a cured product of a curable resin composition, the curable resin composition comprising an alcohol-soluble, curable resin and a polyether-modified silicone oil.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Quantum dot ink used for preparing QDCF liquid crystal display panel through ink-jet printing and preparation method

The invention provides quantum dot ink used for preparing a QDCF liquid crystal display panel through ink-jet printing. The quantum dot ink comprises the following components in parts by weight: 60-80 parts of a nonpolar solvent, 15-20 parts of dispersion resin, 1-3 parts of a surface ligand and 5-20 parts of a quantum dot material. The quantum dot ink provided by the invention has the advantages that defects of a photoetching preparation method are overcome, loss of a quantum dot is reduced, preparation method of the QDCF panel is reduced, the solvent can be removed by adopting a low temperature evaporation way, QDCF preparation efficiency is improved, and a cadmium series quantum dot material can be applied to QDCF.

Owner:HISENSE VISUAL TECH CO LTD

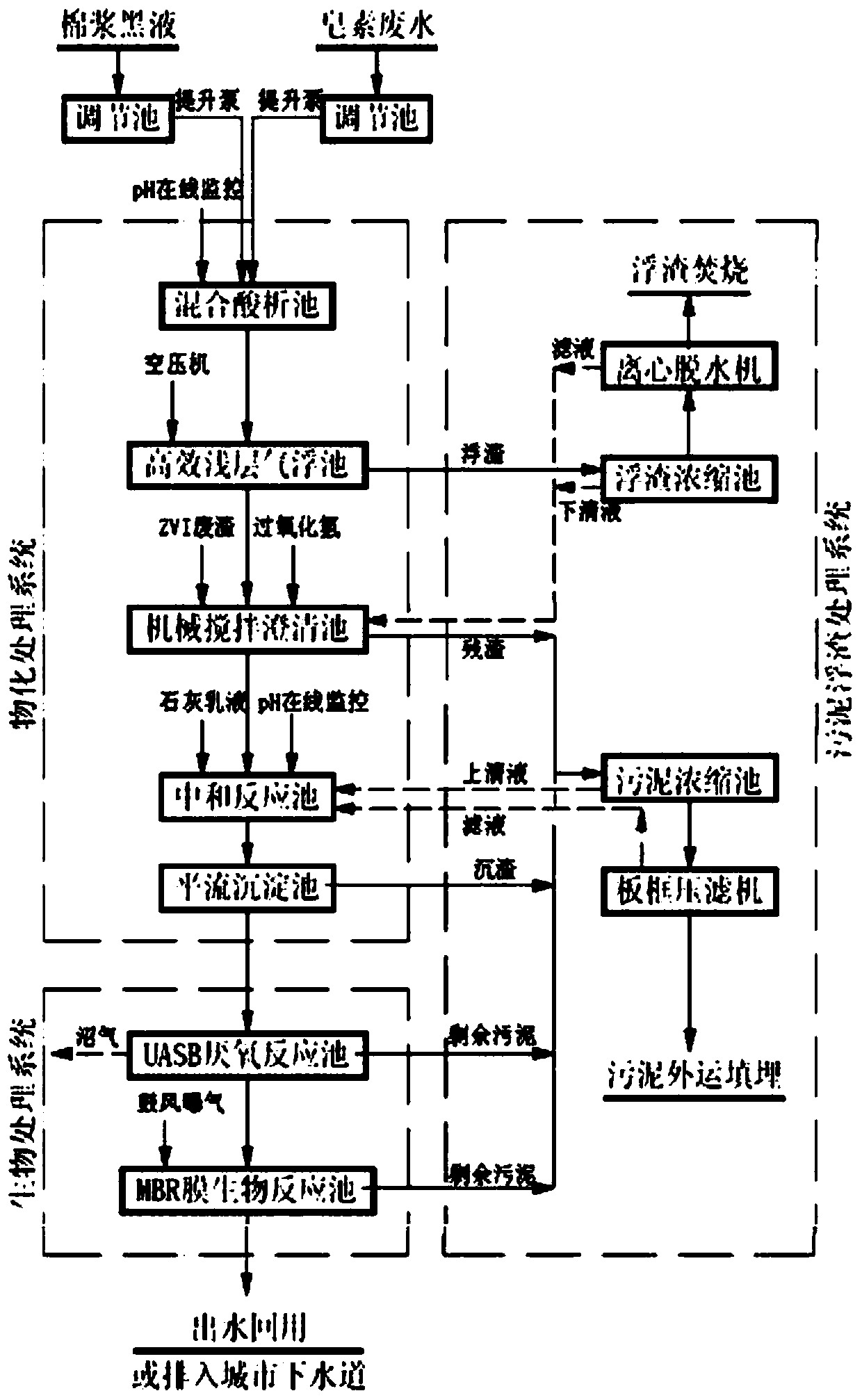

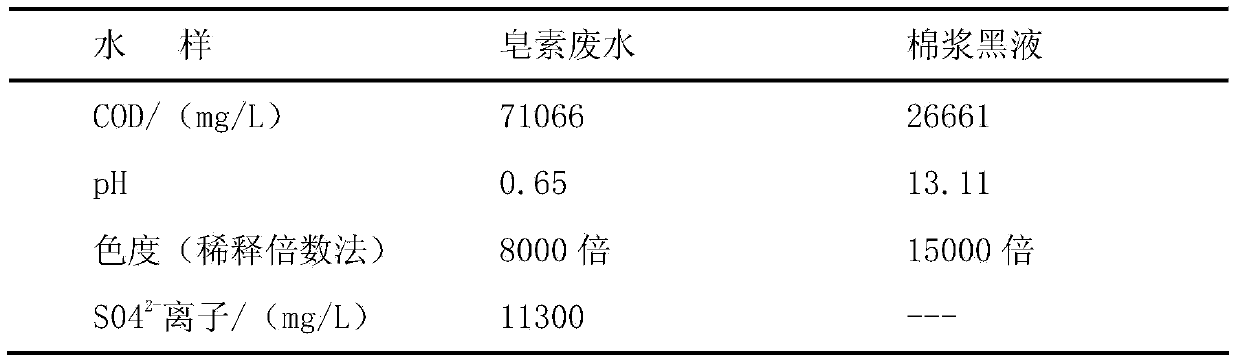

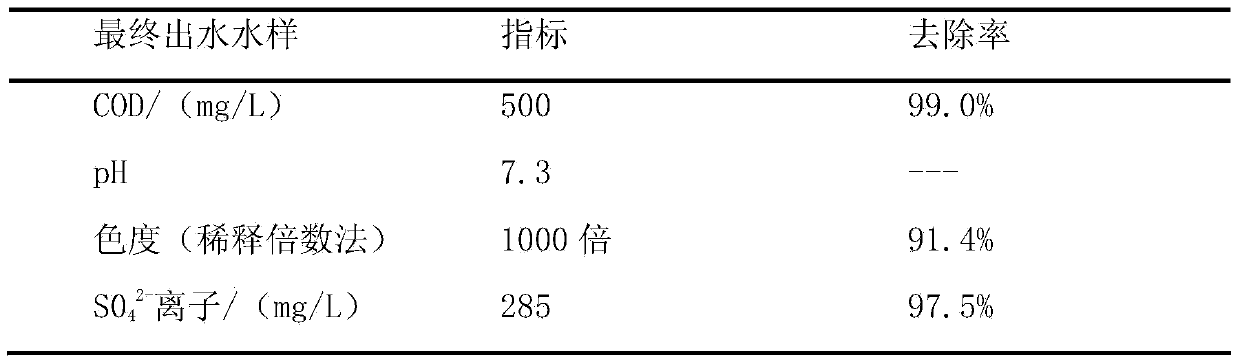

Combined treatment process for cotton pulping black liquid and saponin wastewater

The invention provides a combined treatment process for cotton pulping black liquid and saponin wastewater. The combined treatment process comprises the steps of mixing the cotton pulping black liquid and the saponin wastewater, carrying out acidification on the mixed liquid, separating the mixed liquid and removing lignin and suspended solids dissolved out in the mixed liquid to obtain treating fluid A; adding zero-valent iron and hydrogen peroxide into the treating fluid A, stirring for reaction and completing the reaction to obtain treating fluid B, wherein the structures of complex macromolecule organic matters in the treating fluid B are damaged; adding lime slurry into the treating fluid B, regulating pH value of the treating fluid B to be neutral, converting sulfate ions in the treating fluid into calcium sulfate to be precipitated out and dissolved out, separating to remove the calcium sulfate to obtain treating fluid C; treating the treating fluid C by an anaerobic UASB (Upflow Anaerobic Sludge Blanket) reactor and an MBR (Membrane Biological Reactor) for aerobic biological treatment, separating by a membrane separation system to obtain final yielding water, and reutilizing the final yielding water or discharging. The combined treatment process can realize treatment of wastes with processes of wastes against one another, is energy-saving, reduces energy consumption, improves the wastewater reuse rate and reduces the water consumption.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

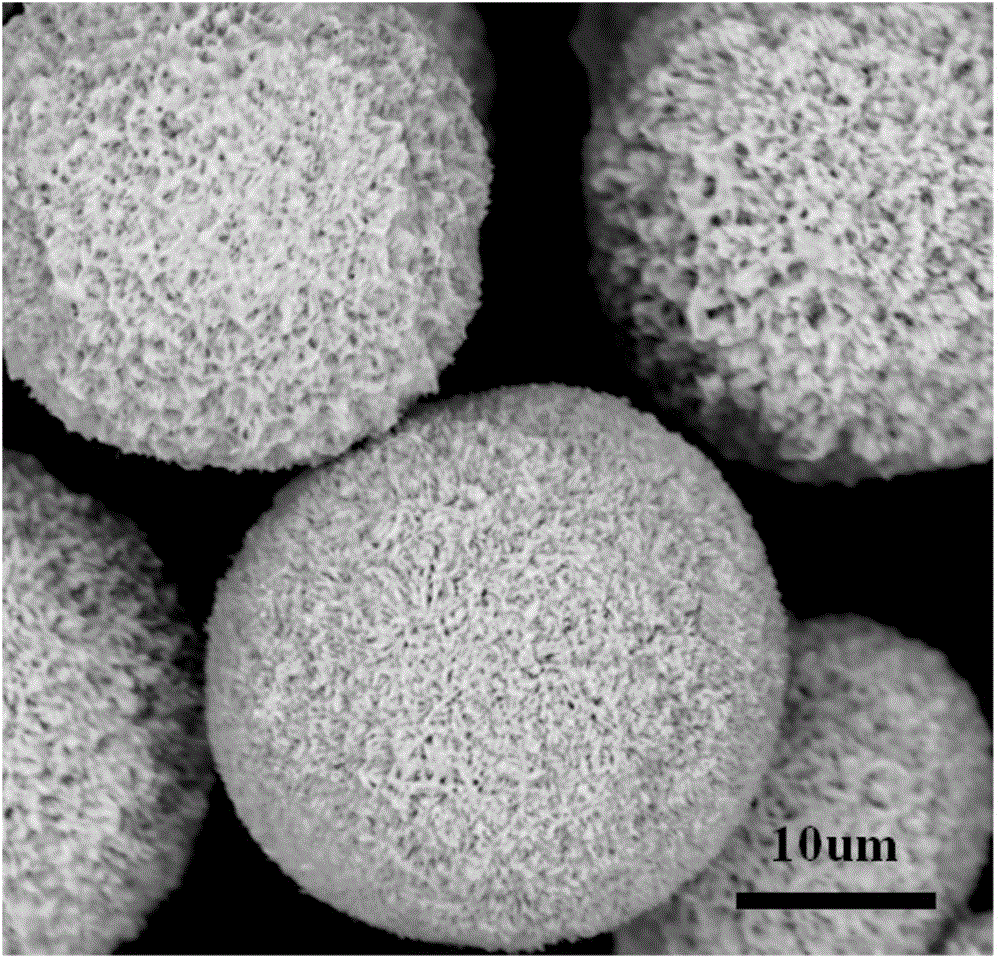

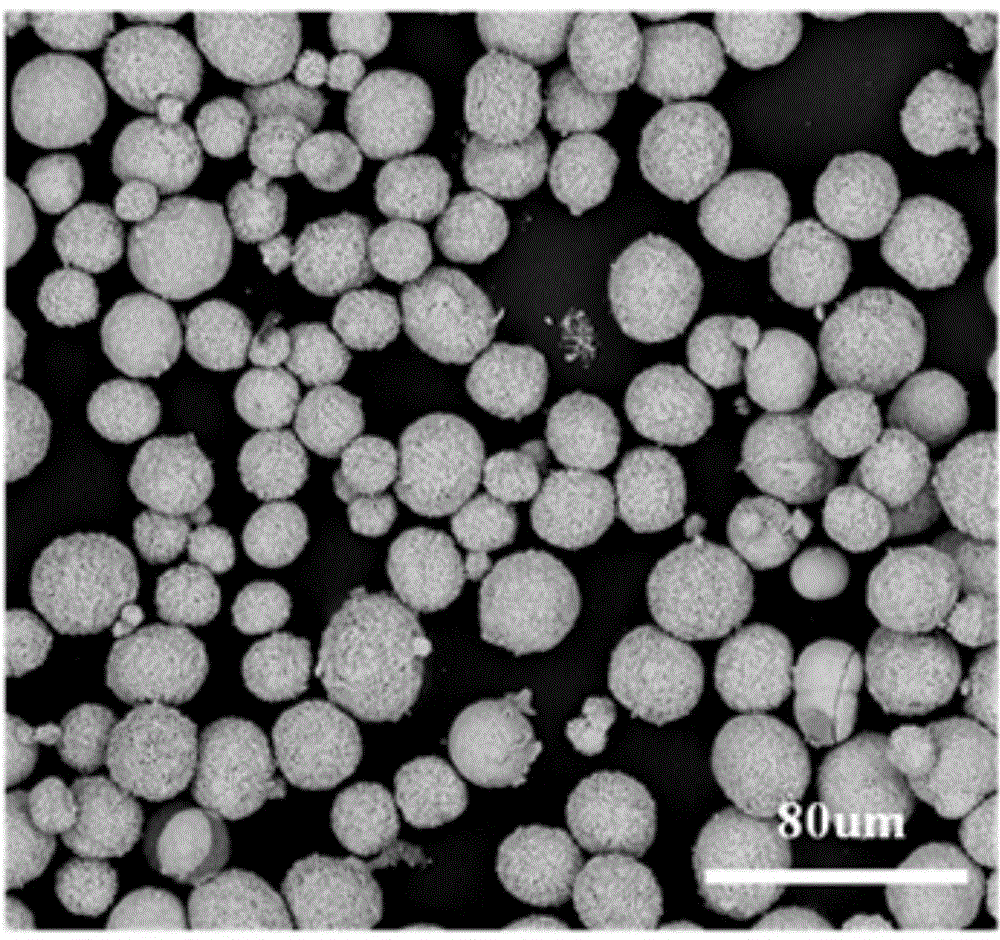

Method for preparing alkali type copper molybdate microsphere having surface nano-whisker structure

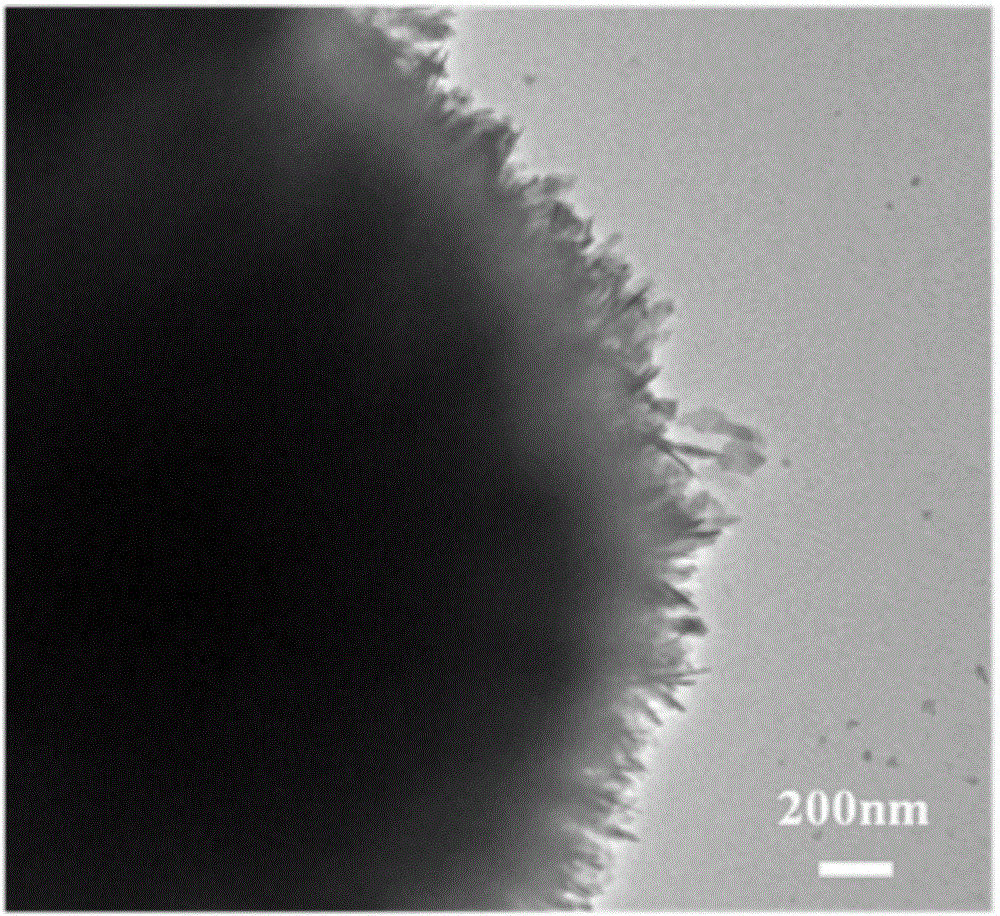

InactiveCN104692462ALarge specific surface areaIncrease contact areaMaterial nanotechnologyMolybdeum compoundsMolybdateMicrosphere

The invention relates to a method for preparing an alkali type copper molybdate microsphere having a surface nano-whisker structure. The method comprises the following steps of: (1), dropwise adding copper salt solution into molybdate solution, wherein the mol ratio of copper salt to molybdate is 1:1; (2), adjusting the pH of a mixed system obtained in the step (1) to 6, transferring the mixed system into a reaction kettle, stirring magnetically and ultrasonically so that the mixed system is uniformly dispersed, and keeping the temperature at 50-110 DEG C for 1-12h; and (3), cooling to room temperature by the end of the reaction, and centrifuging, washing, drying and collecting a sample so as to obtain the alkali type copper molybdate microsphere having the surface nano-whisker structure. Compared with the prior art, the method disclosed by the invention is simple in process, universal in preparation condition, steady in product morphology, high in purity and simple in product treatment, and is applied to medium-scale industrial production.

Owner:TONGJI UNIV

Synthetic method of photo-responsive linear azobenzene polyoxyethylene ether nonionic surfactant

ActiveCN107213843ARegulatory stabilityChange surface tensionTransportation and packagingFibre treatmentChemical industryPolyethylene glycol

The invention discloses a preparation method of a photo-responsive linear azobenzene polyoxyethylene ether nonionic surfactant, belonging to the technical fields of textile and chemical industry. The azobenzene polyoxyethylene ether nonionic surfactant is synthesized from 4-hydroxyazobenzene and polyethylene glycol. The azobenzene polyoxyethylene ether nonionic surfactant can be subjected to reversible heterogeneous treatment from an anti-form to a cis-form under the irradiation of ultraviolet light and visible light, and the tightness of the azobenzene polyoxyethylene ether nonionic surfactant arrayed on the surface of a foam liquid membrane is changed through steric hindrance, so that the effects of low concentration and high foam stabilizing property are achieved. The azobenzene polyoxyethylene ether nonionic surfactant can be used as a wetting permeating agent, a detergent and a low-concentration surfactant, so that the demand contradiction that foam has different stabilities before and after being dyed and finished is solved, the utilization rate of the foam can be increased, the foam can be effectively recycled, the pollution is alleviated, and the wasting of a chemical reagent is reduced.

Owner:JIANGNAN UNIV

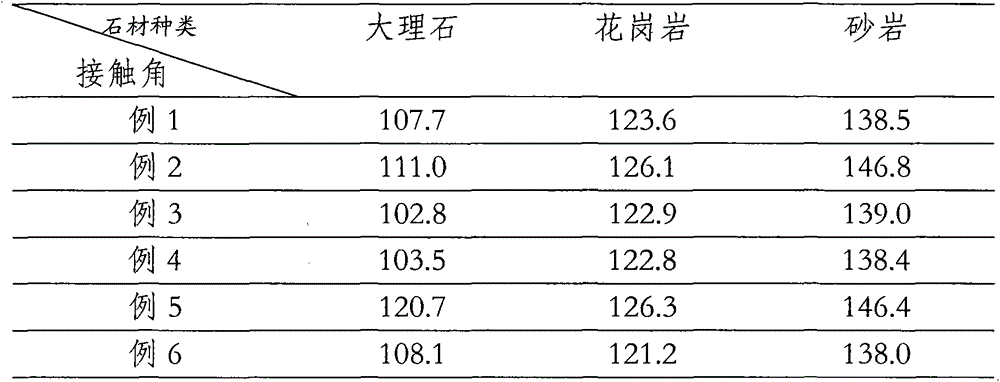

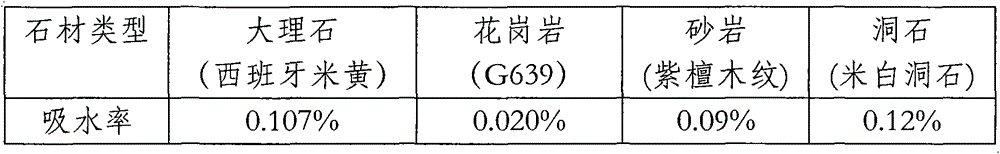

Solvent-type organic silicon stone protectant and preparation method thereof

The invention discloses a solvent-type organic silicon stone protectant and a preparation method thereof. The protectant is characterized by comprising the following polymer monomers by volume percent: at least one alkyl alkoxy silane of which the adding volume accounts for 1% to 10% of the total volume of the polymers, at least one polymethylhydrosiloxane of which the adding volume accounts for 1% to 10% of the total volume of the polymers, at least one titanate catalyst of which the adding volume accounts for 0.05% to 1% of the total volume of the polymers, and at least one solvent oil-type organic solvent of which the adding volume accounts for 79% to 97.95% of the total volume of the polymers. The preparation method comprises the following steps: evenly mixing the alkyl alkoxy silane and the polymethylhydrosiloxane in proportion in partial organic solvents at a room temperature; then carrying out a catalytic reaction by adding the catalyst; and finally, adding the organic solvent and diluting to reach a certain concentration. The protectant which has good permeability can be used for deeply protecting stone and is good in air permeability and recoatability. The protectant is simple in preparation method, simple and convenient to coat as well as relatively low in cost, thereby being suitable for industrial mass production.

Owner:XIAMEN NORNS TECH

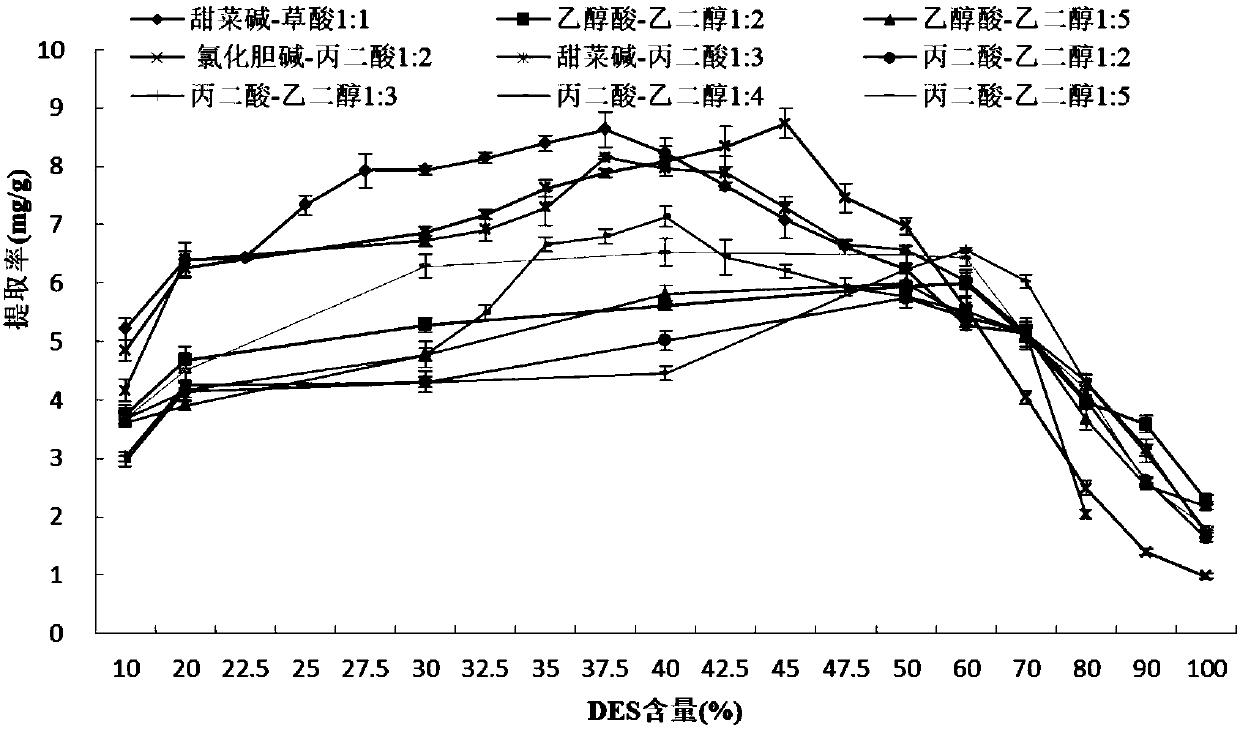

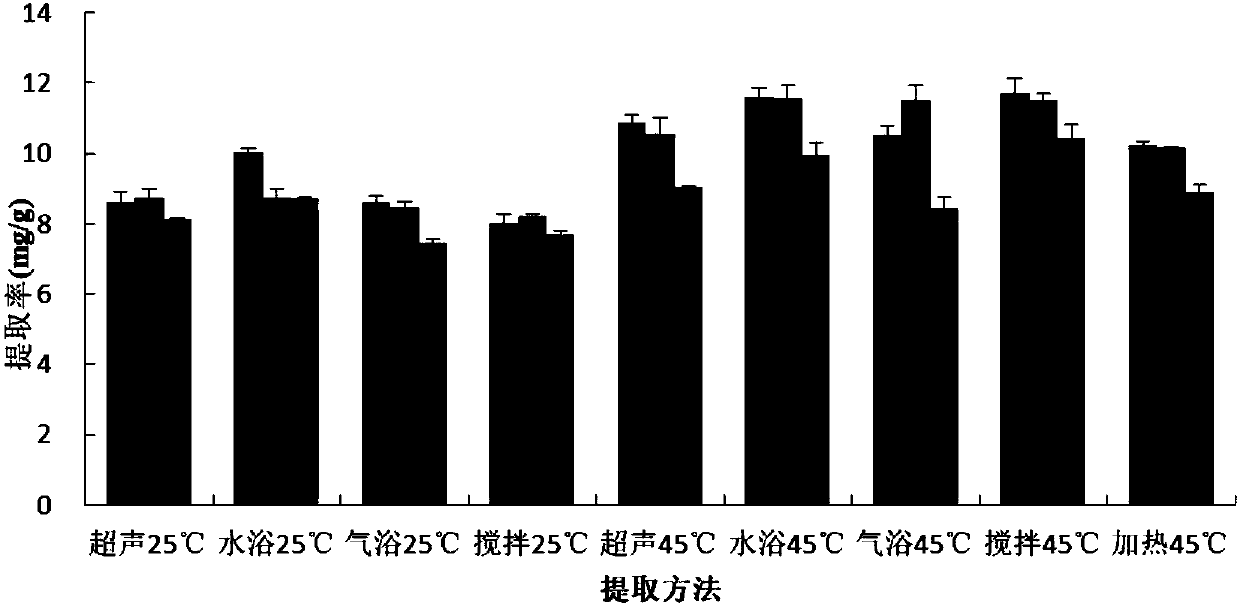

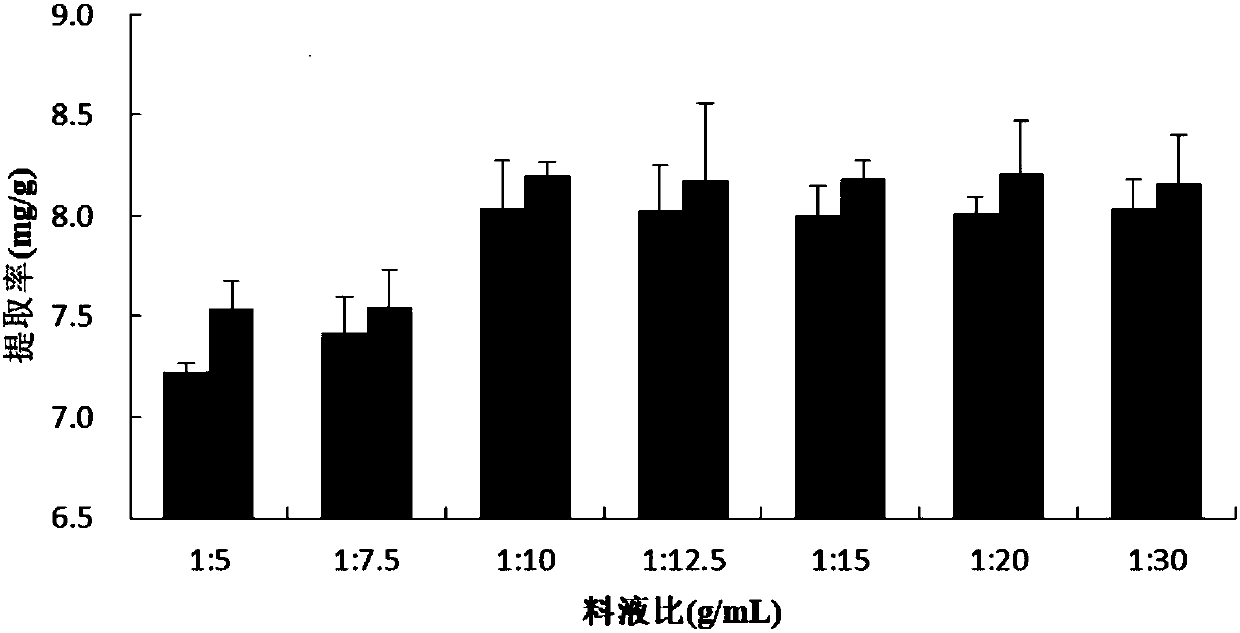

Deep eutectic solvent for extracting procyanidine of gingko leaves, preparation method of deep eutectic solvent and extraction method

ActiveCN107759556AChange viscosityChange surface tensionOrganic chemistrySolid solvent extractionSteam pressureGinkgo biloba

The invention discloses a deep eutectic solvent (DESs) for extracting procyanidine of gingko leaves, a preparation method of the deep eutectic solvent and an extraction method. The deep eutectic solvent is prepared from choline chloride and malonic acid in a molar ratio of 1 to (1-2.5). The prepared deep eutectic solvent is an environment-friendly solvent, is safe and free of pollution, can be repeatedly utilized and is easily biodegraded; furthermore, the preparation process is simple and low in cost, and the deep eutectic solvent has the properties of low steam pressure, incombustibility, excellent solubleness and electrical conductivity and stable electrochemical window and the like; and meanwhile, the prepared deep eutectic solvent is low in viscosity and good in fluidity, and a hydrogen bond is stable. According to the method for extracting the procyanidine of the gingko leaves by virtue of the deep eutectic solvent, the extraction time is shortened, the operation is safe, and noharm is caused to the environment and a human body. The preparation method of the deep eutectic solvent is simple and convenient, wide in raw material source, low in cost and high in biodegradability.

Owner:NANJING FORESTRY UNIV

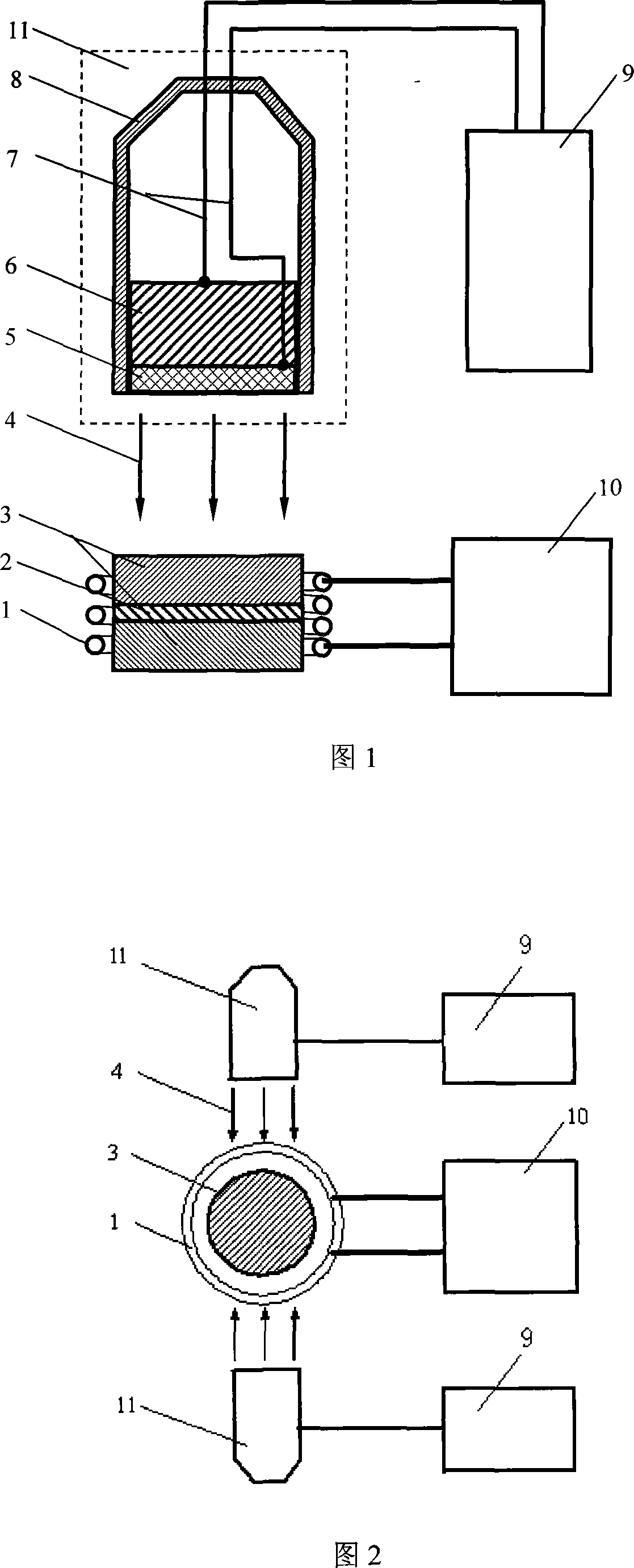

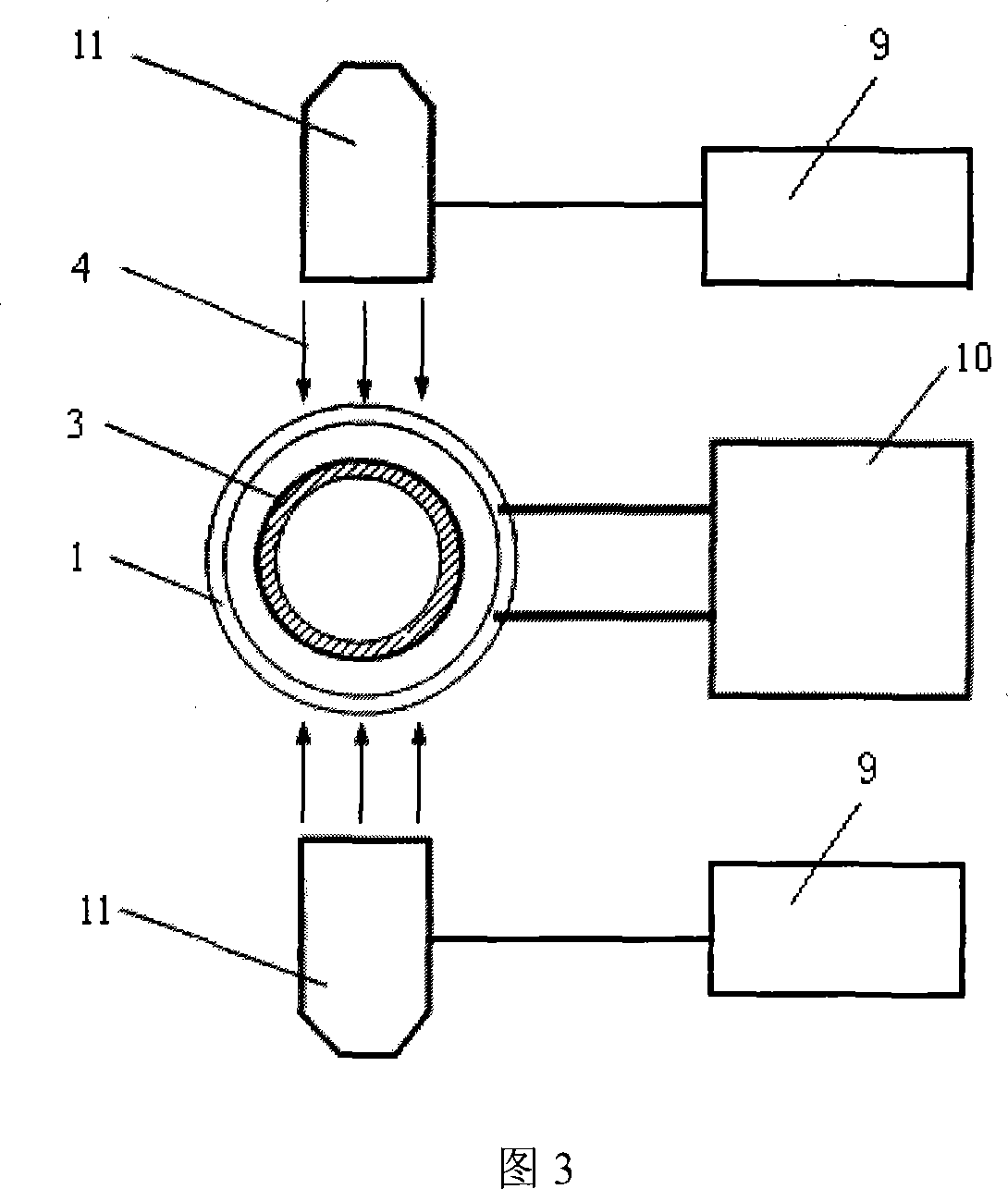

Induction brazing device and method thereof

InactiveCN101200012ASpread evenlyImprove brazing rateHeating appliancesVoltage amplitudeElectrical connection

The invention discloses an induction brazing device, comprising an induction power supply and induction coil. The invention is characterized in that an air-medium Ultrasonic probe is at least included; the air-medium ultrasonic probe is in electrical connection with a high frequency oscillator. The invention also discloses a high frequency braze welding method which uses the induction brazing device, and comprises the steps as follows: select at least one air-medium ultrasonic probe with different diameters according to the size of the connection area or complex degree; adjust the center frequency of the air-medium ultrasonic probe, the oscillating voltage amplitude of the high frequency oscillator output, and the distance between the air-medium ultrasonic probe and weld assembly connector; meanwhile connect the air-medium ultrasonic probe with the oscillator, and connect the induction coil with the induction power supply to complete the welding. Comparing with the dependant use of induction coil and induction power supply when welding the same diameter welding parts, the current output value of the induction power supply and the welding time are all reduced by 10 to 20 percent after being tested; the energy is saved and the welding efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

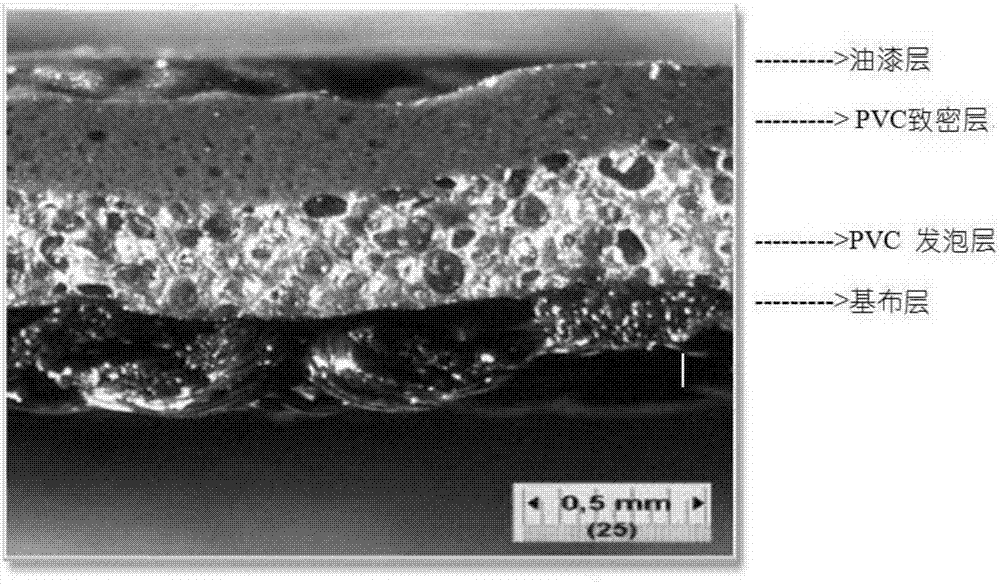

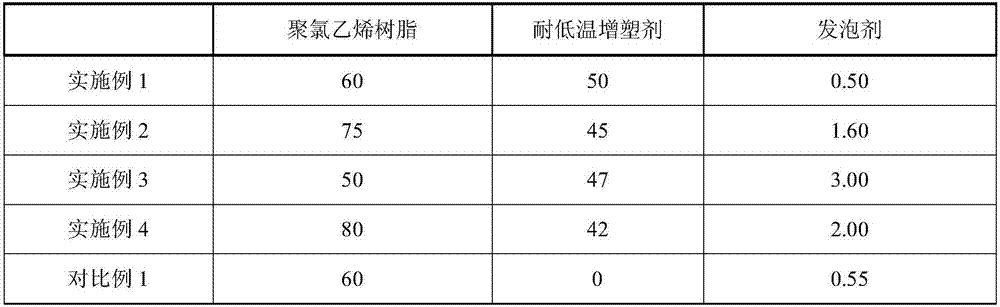

Low-temperature-deflection-resistant perforated gas-permeable polyvinyl chloride artificial leather and preparation method thereof

ActiveCN107354760AReduce volatilityLow mobilityCoatingsTextiles and paperPolyvinyl chlorideUltimate tensile strength

The invention discloses a low-temperature-deflection-resistant perforated gas-permeable polyvinyl chloride artificial leather and a preparation method thereof, wherein the artificial leather comprises a base cloth layer, a PVC foaming layer, a PVC compact layer and a paint layer. According to the present invention, the low-temperature-deflection-resistant perforated gas-permeable polyvinyl chloride artificial leather prepared by using the formula and the preparation method has characteristics of good mechanical strength, strong toughness, wear resistance and strong low-temperature-deflection resistance, further has advantages of gas permeability and comfort similar to the leather, and further has characteristics of good hand feeling and high security.

Owner:BENECKE CHANGSHUN AUTO TRIMZHANGJIAGANG

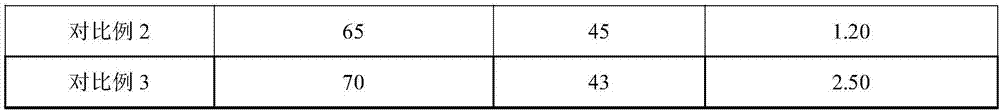

Method for regeneration treatment of industrial waster water treating water

InactiveCN101607770AImprove the effect of flocculation and decolorizationHigh removal rateSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentPolyacrylamideWater cycling

The invention relates to a method for regeneration treatment of industrial waster water treating water. The method comprises the following steps: firstly, pH valve of industrial waster water treating water entering into an adjusting tank is adjusted to 5 to 7; industrial waster water treating water, pH valve of which is adjusted, enters into a flocculation reactor; aluminium polychlorid, hexadecyl trimethyl ammonium bromide and starch-graft-polyacrylamide are simultaneously added into the flocculation reactor and are stirred for 2 to 10min in the temperature of 15 to 30 DEG C for flocculation decolorization reaction; industrial waster water treating water which is processed by flocculation decolorization reaction enters into an air-flotation separation cell, and then enters into a centrifugal machine for dehydration after a sediment scraper scrape out floc dross floating on the air-flotation separation cell; dehydrated floc dross is dehydrated by a pressure filter to form a filter cake; processed industrial waster water treating water can be used for dissolved-air water of the air-flotation separation cell and industrial water of regenerated water to be recycled. The method causes that COD of processed industrial waster water treating water is less than or equal to 60 Mg / L, chromacity is less than or equal to 30 degrees, thus achieving water quality standard of industrial water of regenerated water.

Owner:WUHAN UNIV OF SCI & TECH

Polishing leather producing method

ActiveCN104451001AImprove water absorptionHigh glossLeather softeningLeather surface mechanical treatmentEthyl EthersBiomedical engineering

The invention relates to the technical field of leather processing, in particular to a polishing leather producing method. The polishing leather producing method comprises the following steps of selecting a material, namely choosing an embryo skin material of pig skin; performing surface cleaning treatment, namely spraying a surface cleaning water solution on the embryo skin material, wherein the surface cleaning water solution is prepared by mixing ammonia water, isopropanol and glycol ether by mass ratio of 1.5-3:0.5-1.5:0.5-1.5; performing standing treatment, namely standing the embryo skin material sprayed with the surface cleaning water solution at the normal temperature for 12 to 48 hours; spraying cerate, namely spraying the cerate on the embryo skin surface after standing; performing lustering, namely conducting lustering treatment on the embryo skin material sprayed with the cerate through a natural luster finishing machine; performing softening, namely conducting softening treatment on the lustered embryo skin material through a softening rotary drum. Leather produced through surface cleaning treatment on the embryo skin material of the pig skin, standing absorption, cerate spraying, lustering and softening processing has polishing effect, can be used as a surface layer material for staple merchandises and is high in economic benefit.

Owner:DONGGUAN TIANYI LEATHER TECH CO LTD

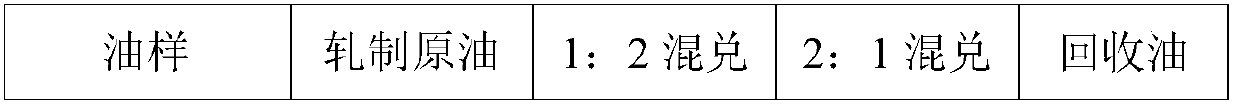

Recycling treatment agent for zero discharge of rolling waste liquid and treatment method

ActiveCN109609251AChange surface tensionEasy to separateFatty/oily/floating substances removal devicesNon-miscible liquid separationLiquid wasteOil phase

The invention discloses a recycling treatment agent for zero discharge of rolling waste liquid and also discloses a treatment method for achieving zero discharge of rolling waste liquid by adopting the recycling treatment. The treatment method can achieve thorough oil-water separation of rolling waste emulsion, a separated-out oil product can be mixed with rolled crude oil in proportion for reuse,a water phase can be used for daily water supplementation of a rolling mill, and accordingly zero discharge treatment of the waste emulsion is achieved. After the oil phase separated by the recyclingtreatment agent is blended with the rolled crude oil, the lubricating property of the obtained mixed oil is equivalent to the lubricating property of the rolled crude oil.

Owner:NANJING KERUN LUBRICANTS

White-light quantum dot light-emitting diode and preparation method thereof

ActiveCN109935718AEasy to set upReduce energy transferSolid-state devicesSemiconductor/solid-state device manufacturingSurface layerQuantum dot

The invention provides a white-light quantum dot light-emitting diode. The white-light quantum dot light-emitting diode comprises a bottom electrode, a light-emitting layer and a top electrode, wherein the light-emitting layer is a laminated light-emitting layer, the laminated light-emitting layer includes N light-emitting films which are laminated and combined, the first to the (N-1)th light-emitting films are quantum dot light-emitting films, the Nth light-emitting film is a quantum dot light-emitting film or an organic light-emitting film, and N is a positive integer which is greater than or equal to 2; in two oppositely laminated and combined surfaces of the adjacent quantum dot light-emitting films, the surface of quantum dots contained at least in the surface layer of at least one surface is bound with a displacement ligand, the structural general formula of the displacement ligand is X1-R-X2, R is an alkyl or alkyl derivative, X1 is a functional group crosslinked with the quantum dot, X2 is a polarity regulating functional group, and the crosslinking activity of the X1 and the quantum dot is greater than the crosslinking activity of the X2 and the quantum dot.

Owner:TCL CORPORATION

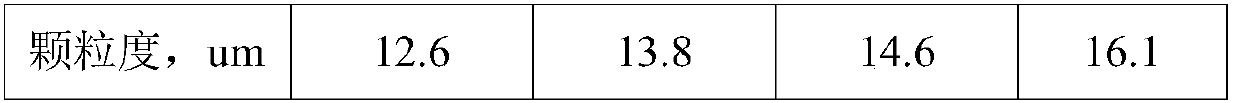

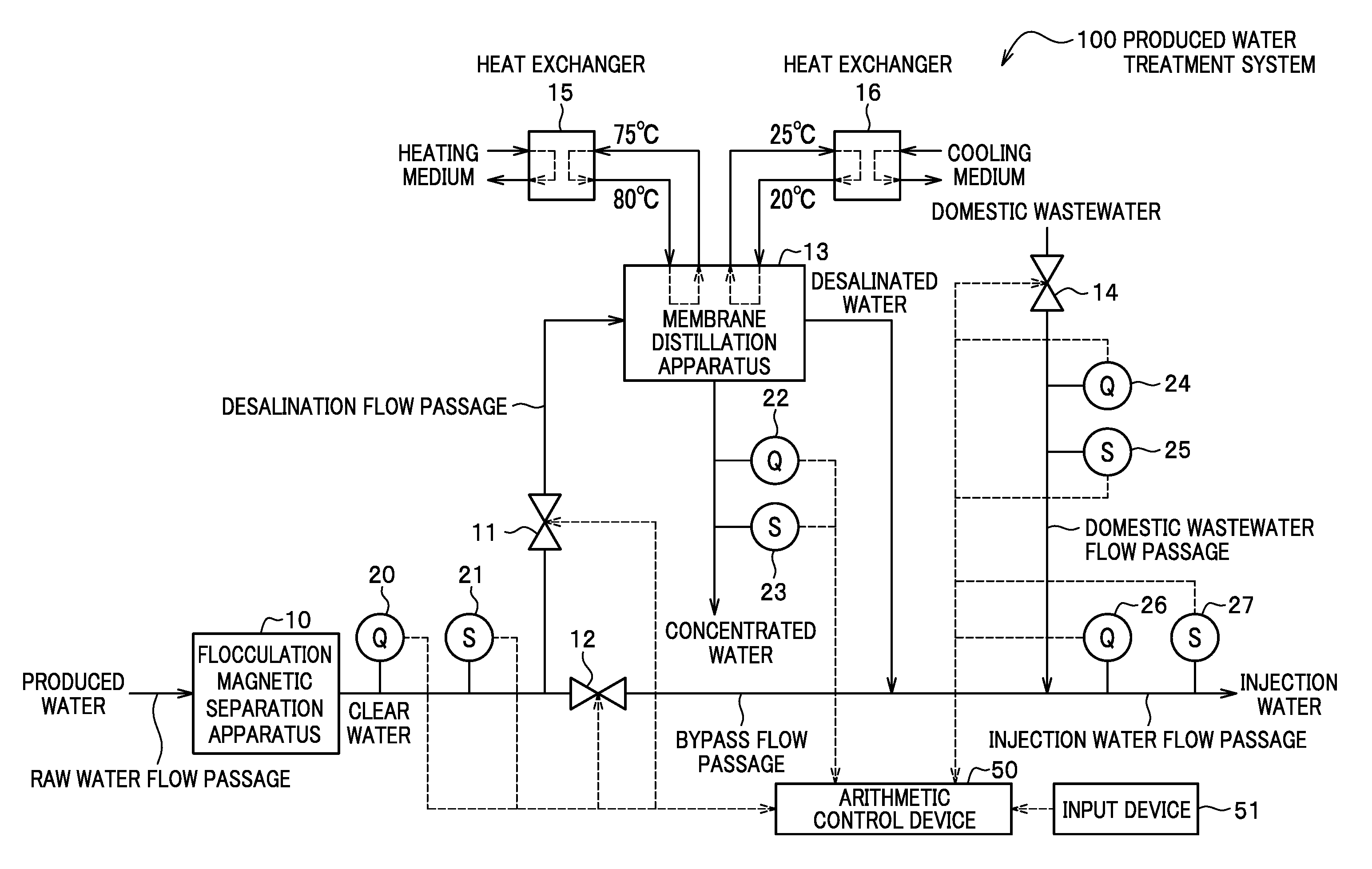

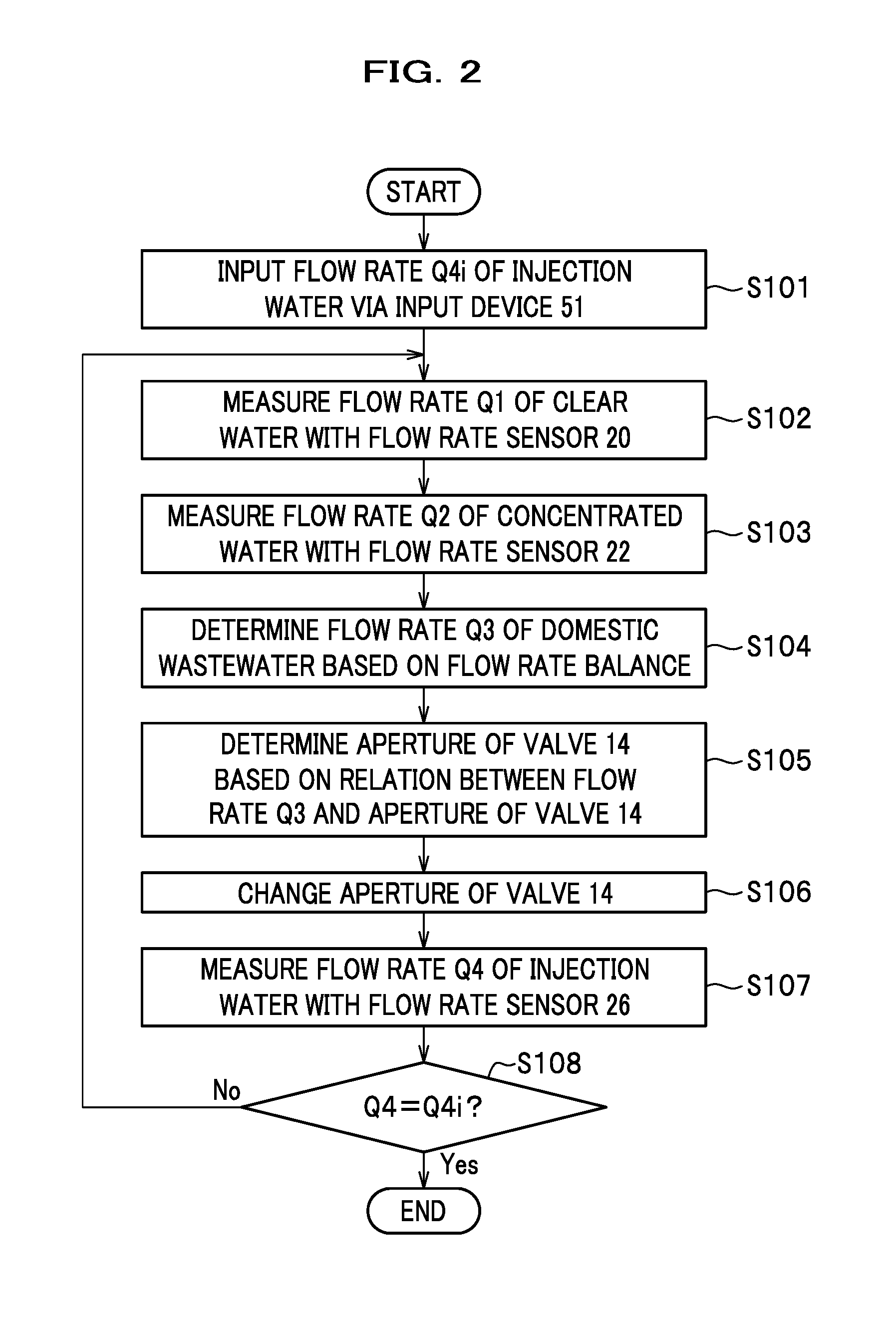

Produced water treatment system

InactiveUS20160304375A1Low costIncrease oil productionWaste water treatment from quariesGeneral water supply conservationSaline waterMembrane distillation

A produced water treatment system includes: a raw water flow passage to allow produced water to flow therethrough; a desalination flow passage connected to the raw water flow passage, and connected to a membrane distillation apparatus which removes a salt in the produced water flowing in from the raw water flow passage; and a bypass flow passage connected to the desalination flow passage and configured to supply the produced water to desalinated water obtained by desalination by the membrane distillation apparatus.

Owner:HITACHI LTD

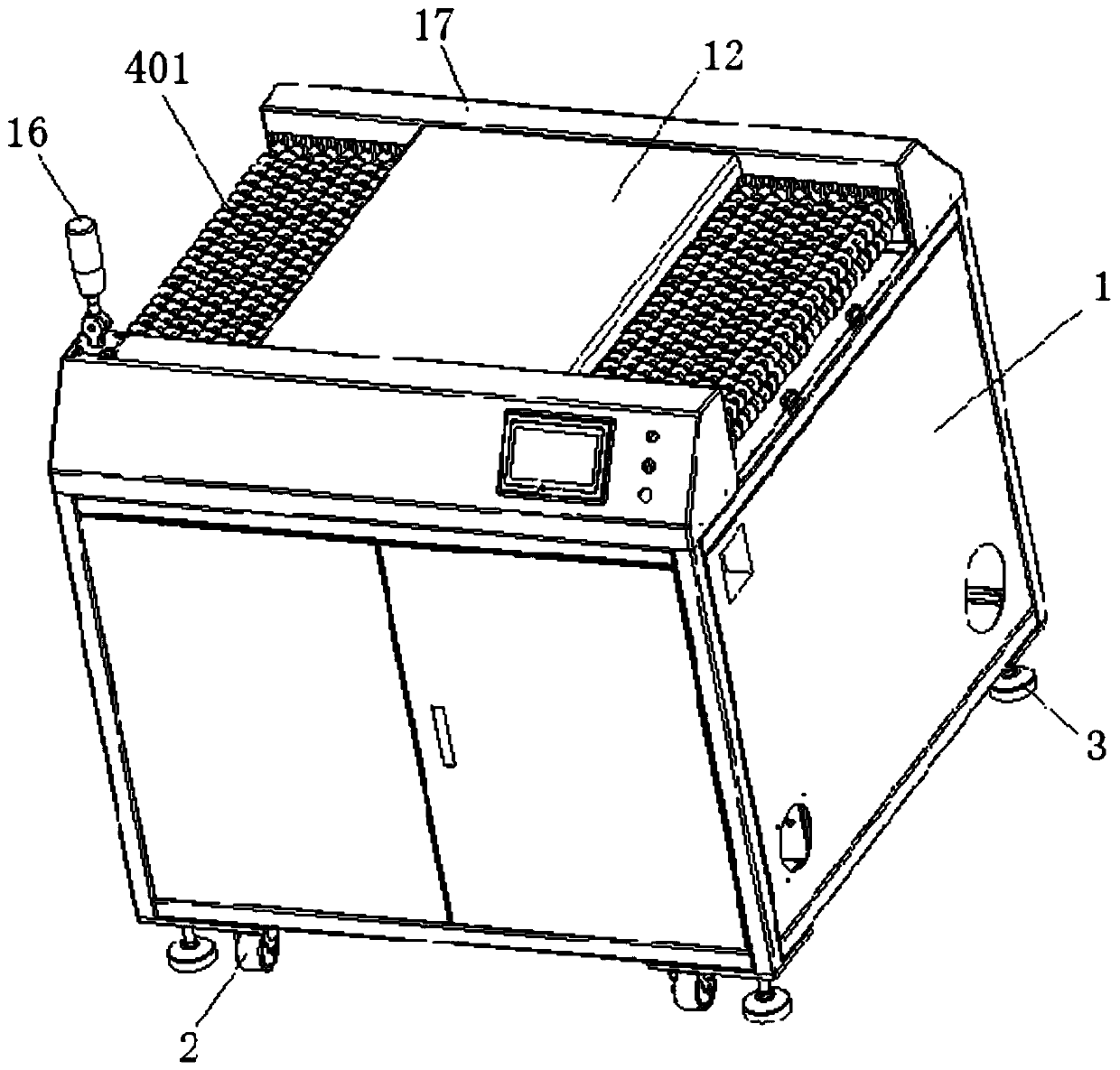

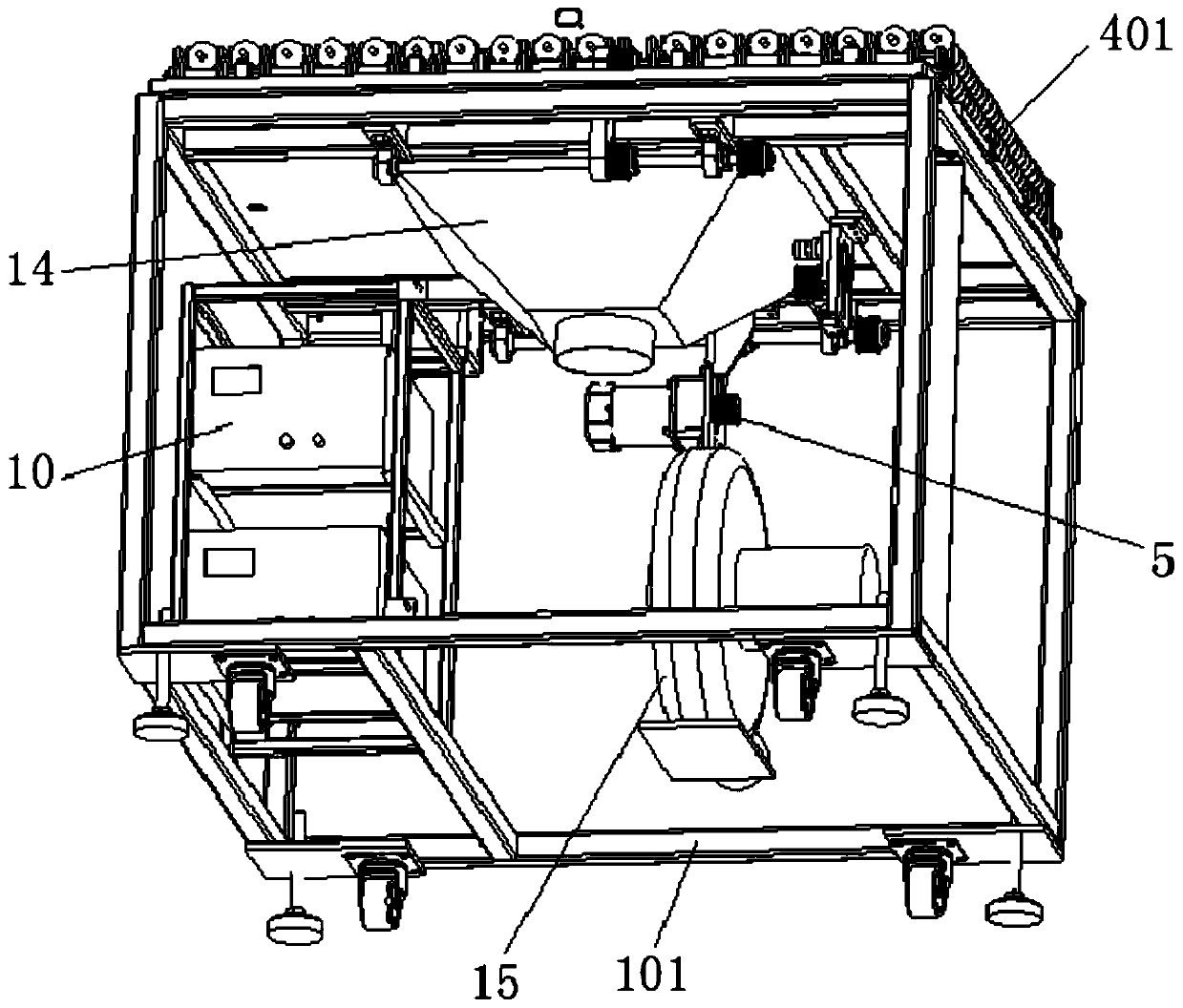

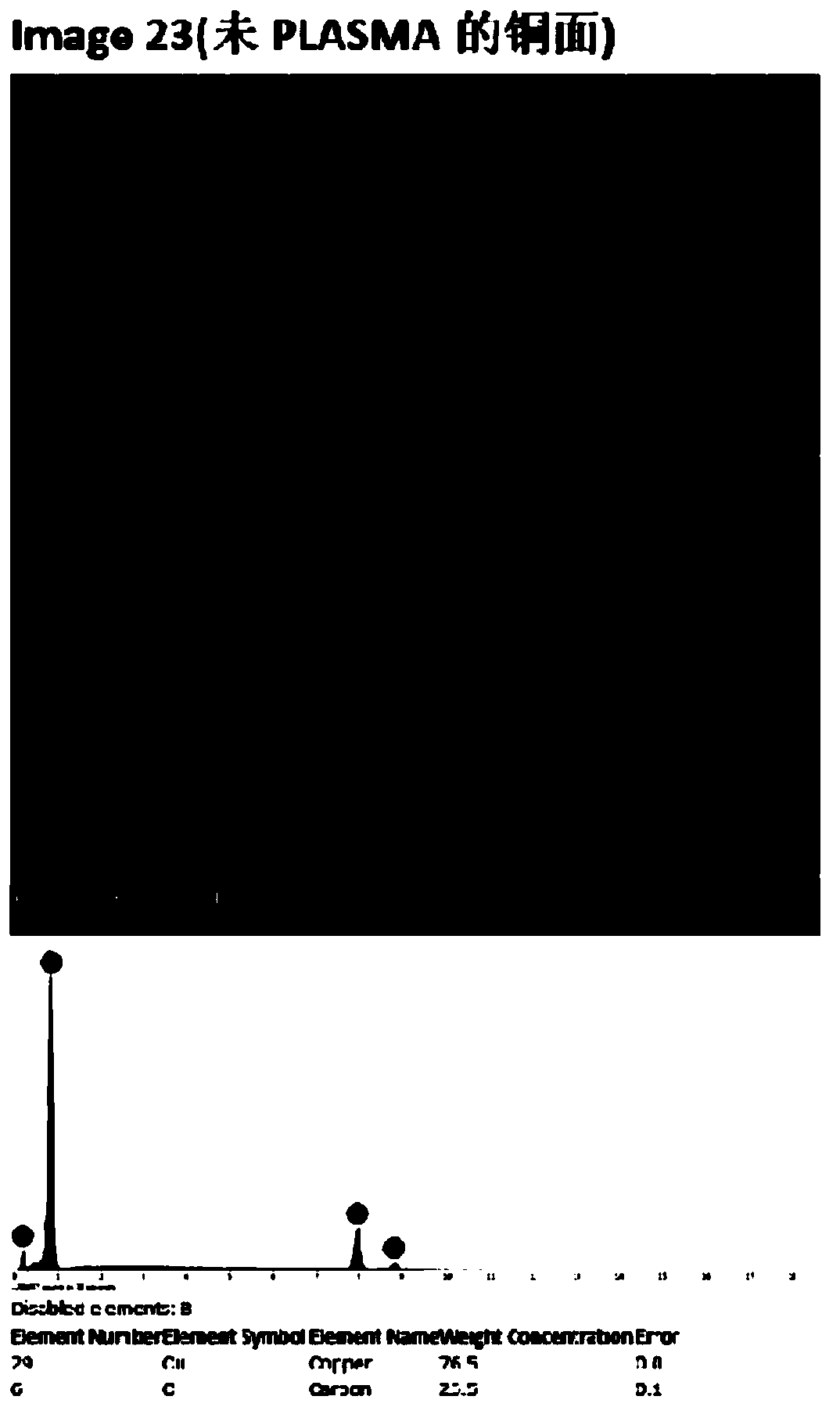

Horizontal line type plasma surface treatment machine

InactiveCN110012583AChange surface tensionIncrease surface polarityConductive pattern polishing/cleaningPlasma techniquePulp and paper industryPulley

The invention discloses a horizontal line type plasma surface treatment machine. The machine comprises a casing, a roller conveying module is mounted in the external top of the casing and connected with a synchronous belt pulley power module, the roller conveying module comprises upper and lower layers of antistatic roller trains, an air-discharge system is arranged under the antistatic roller trains and positioned in the casing, a plasmatron is arranged in the casing and connected with electrode tubes, and the electrode tubes are arranged in the antistatic roller trains correspondingly. The surface tension of a material is changed qualitatively, the dyne value is increased substantially, and the drip angle is changed substantially.

Owner:江苏长沐智能装备有限公司

Making method for physical anti-scaling nanocomposite ceramic ball particles

The invention relates to a making method for physical anti-scaling nanocoposite ceramic ball particles. The making method is simple and low in cost, and the nanocomposite ceramic ball particles made through the method should be able to effectively prevent water scales from being generated, and effectively remove the water scales. According to the technical scheme, the making method for the physical anti-scaling nanocomposite ceramic ball particles includes the following steps that step1, by weight, the following materials of 20-85 parts of tourmaline, 10-40 parts of kaolin, 1-8 parts of light rare earth and 3-27 parts of copper zinc alloys are prepared; step2, the materials are machined to be powder of which the particle size ranges from 100 nm to 900 nm; step3, the powder is evenly mixed to make ball particles of which the particle size ranges from 2 mm to 5 mm; step4, the ball particles are sintered for 0.1-5 hours at the temperature of 700 DEG C-1100 DEG C, and then kept warm for 4-24 hours at the temperature of 45 DEG C-100 DEG C.

Owner:天津健威泽节能环保科技股份有限公司

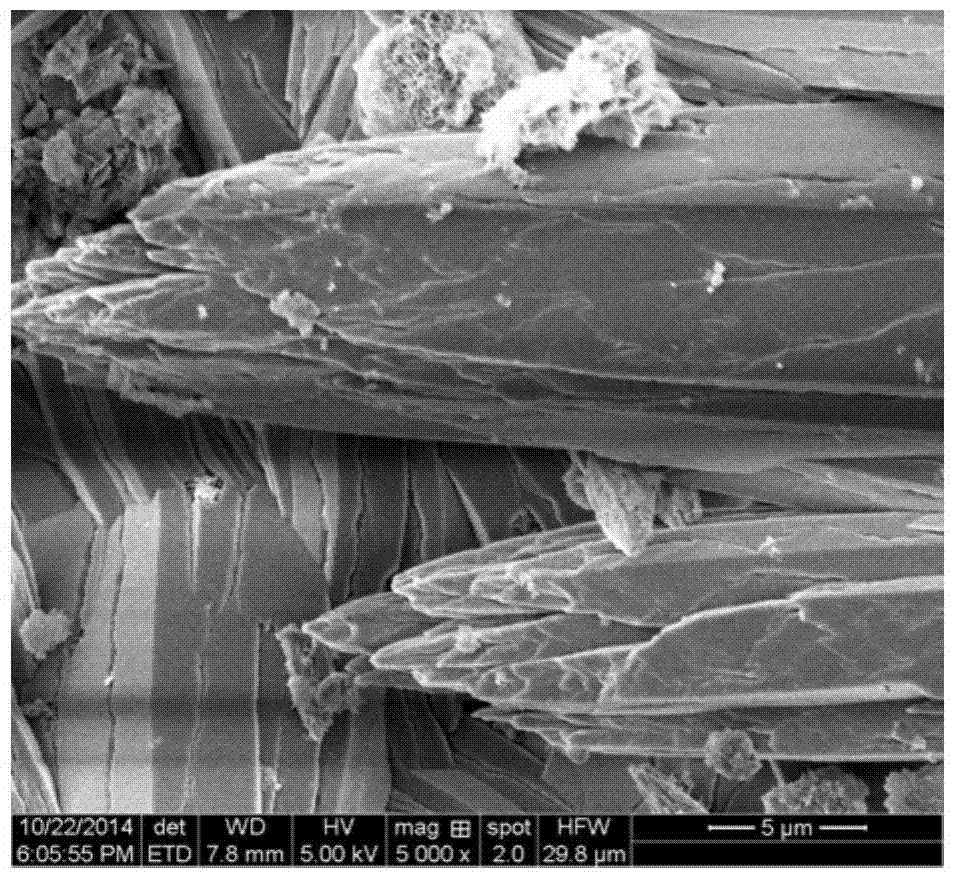

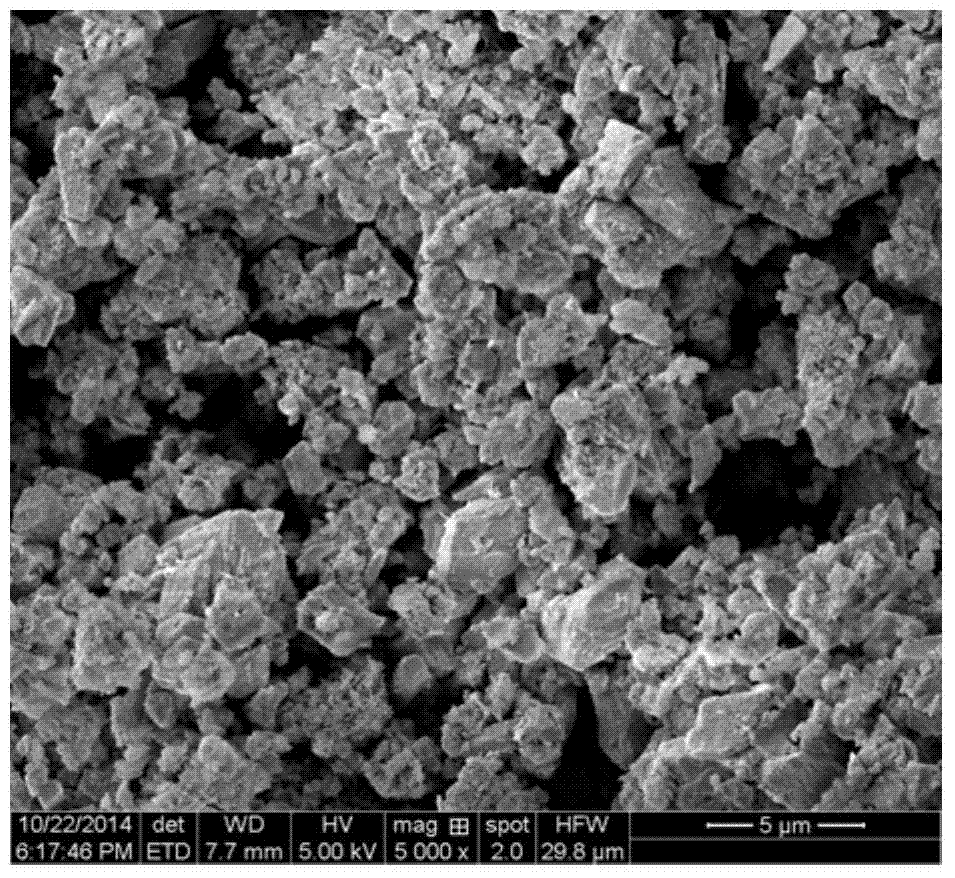

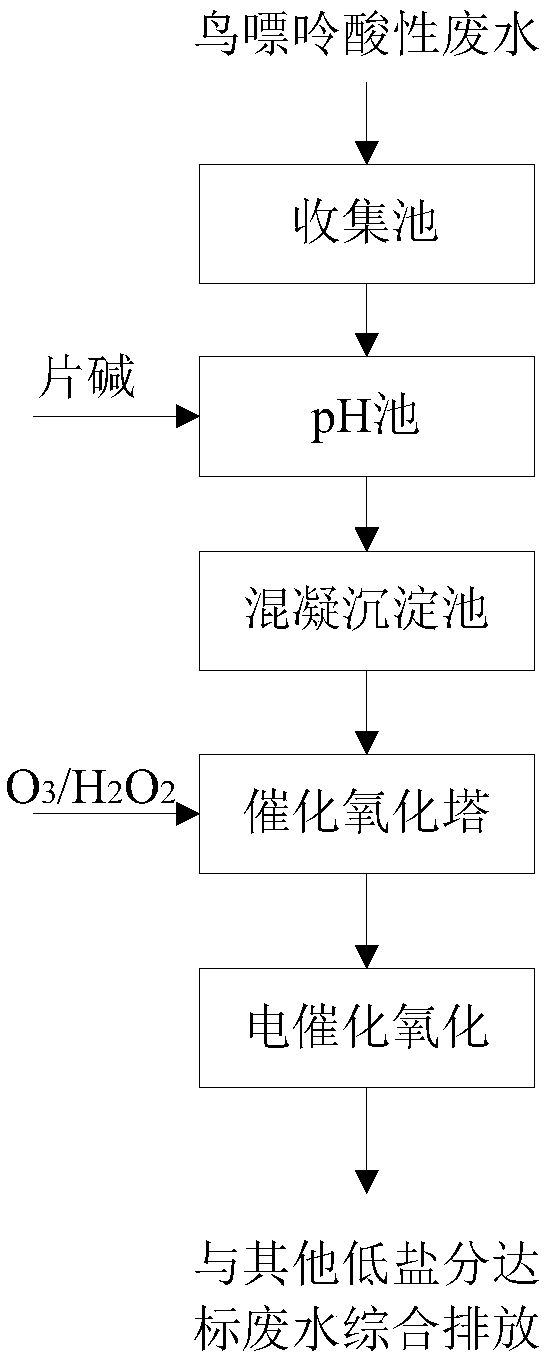

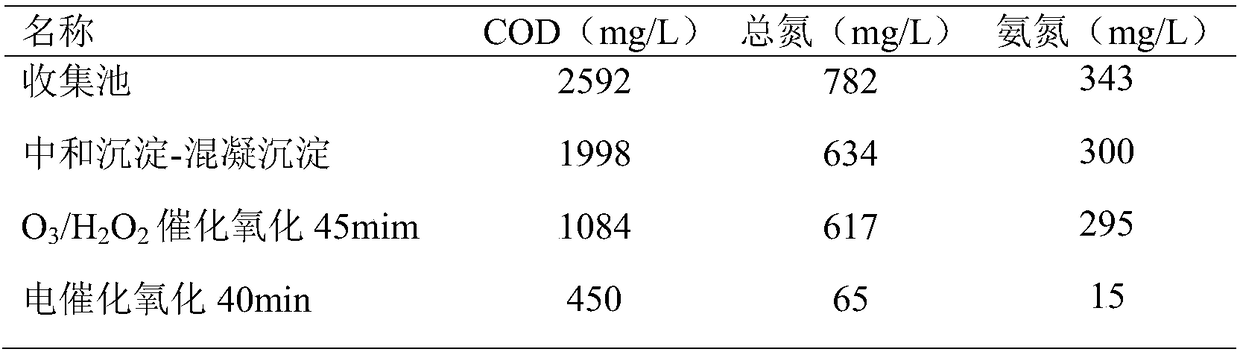

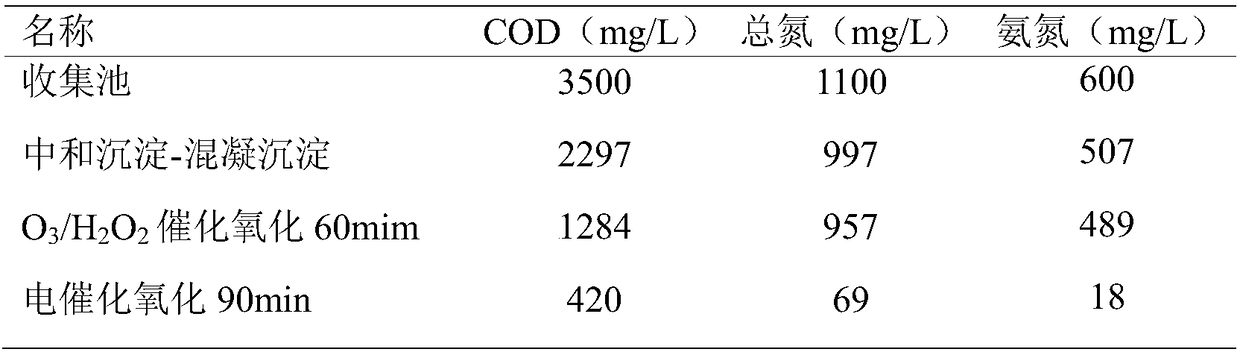

Pretreatment method of guanine wastewater

InactiveCN109437447AImprove biodegradabilityImprove BOD/COD ratioWater contaminantsMultistage water/sewage treatmentPretreatment methodChemical oxygen demand

The invention discloses a pretreatment method of guanine wastewater and belongs to the field of pharmaceutical wastewater treatment. According to the pretreatment method, neutralized sedimentation, coagulating sedimentation, O3 / H2O2 catalytic oxidation and electrocatalytic oxidation are orderly coupled together, cyclic and macromolecular organic matters can be damaged to open chains and transformed into biodegradable low molecular weight organic matters; part of pollutants is thoroughly mineralized, chemical oxygen demand in the guanine wastewater and synergetic degradation of total nitrogen are realized to the maximum extent, the ratio of BOD to COD is remarkably improved, the chemical oxygen demand and the contents of total nitrogen and ammonia nitrogen in effluent quality are enabled toreach sewage discharge standards and conditions can be created for subsequent treatment. The pretreatment method of the guanine wastewater, disclosed by the invention, has the advantages of high oxidation capacity, good synergistic effect, low consumption and high efficiency, is particularly suitable for pretreating refractory wastewater with low pH value, high salinity and high concentration andis an environment-friendly technology.

Owner:江苏南大华兴环保科技股份公司

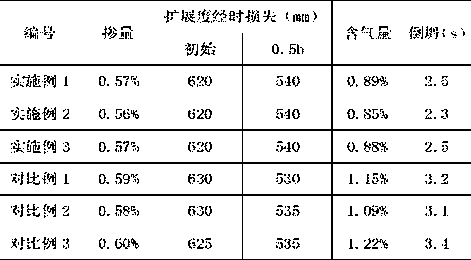

Low-air-entraining delayed coagulation type polycarboxylate superplasticizer and preparation method thereof

The invention discloses a low-air-entraining delayed coagulation type polycarboxylate superplasticizer. The composition comprises the following components in parts by mass: 0.5-1.2 parts of macromonomer, 0.1-0.3 part of acrylic acid, 0.05-0.2 part of sodium methallyl sulfonate, 0.01-0.035 part of 2-(2-hydroxyethyl) methacrylate phosphate ester, 0.002-0.005 part of silane modified graphene, 0.00015-0.0002 part of ammonium persulfate, 0.0001-0.0002 part of a neutralizer and 3-6 parts of water. The low-air-entraining delayed coagulation type polycarboxylate superplasticizer has advantages of favorable dispersity, favorable plasticity retention, high water reducing rate, effective reduction of gas introduction and favorable delayed coagulation effect under the condition of lower doping amount.The silane modified graphene is added so that the bonding effect among the components is better in the reaction process, gaps among molecules after reaction are smaller and the gas content is lower.

Owner:浙江和业科技有限公司

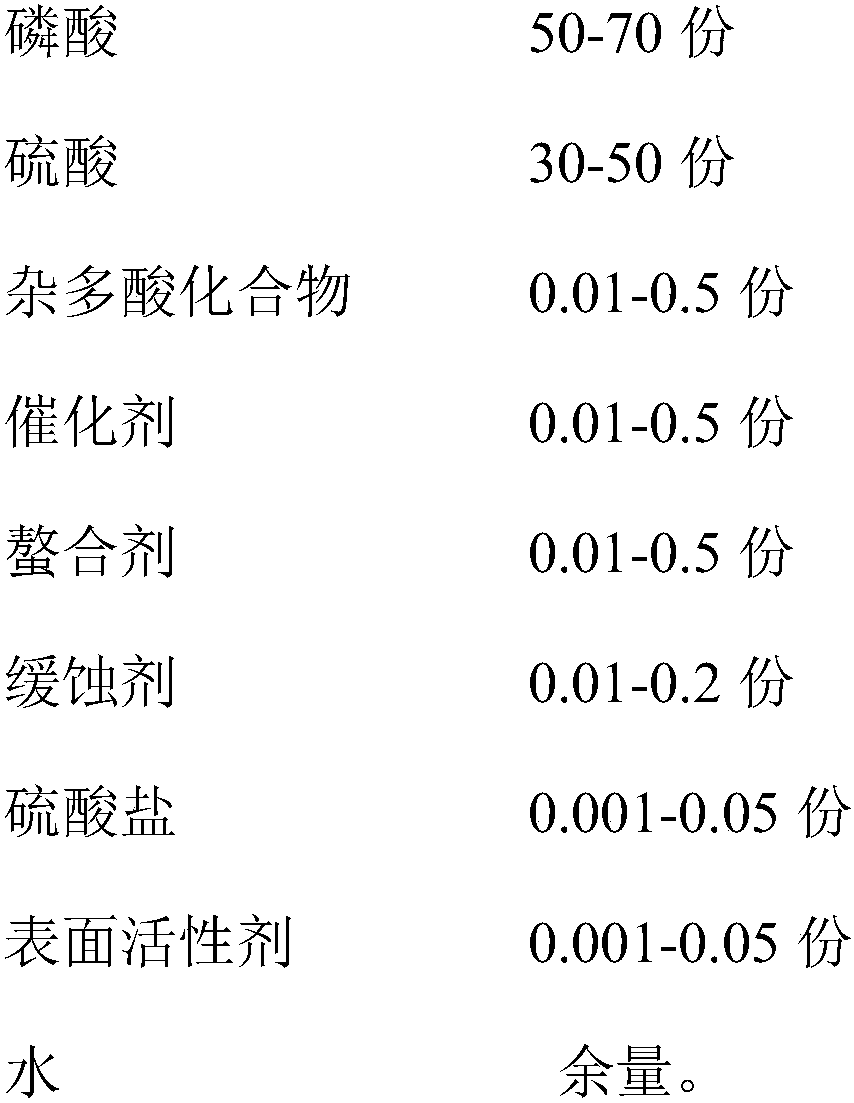

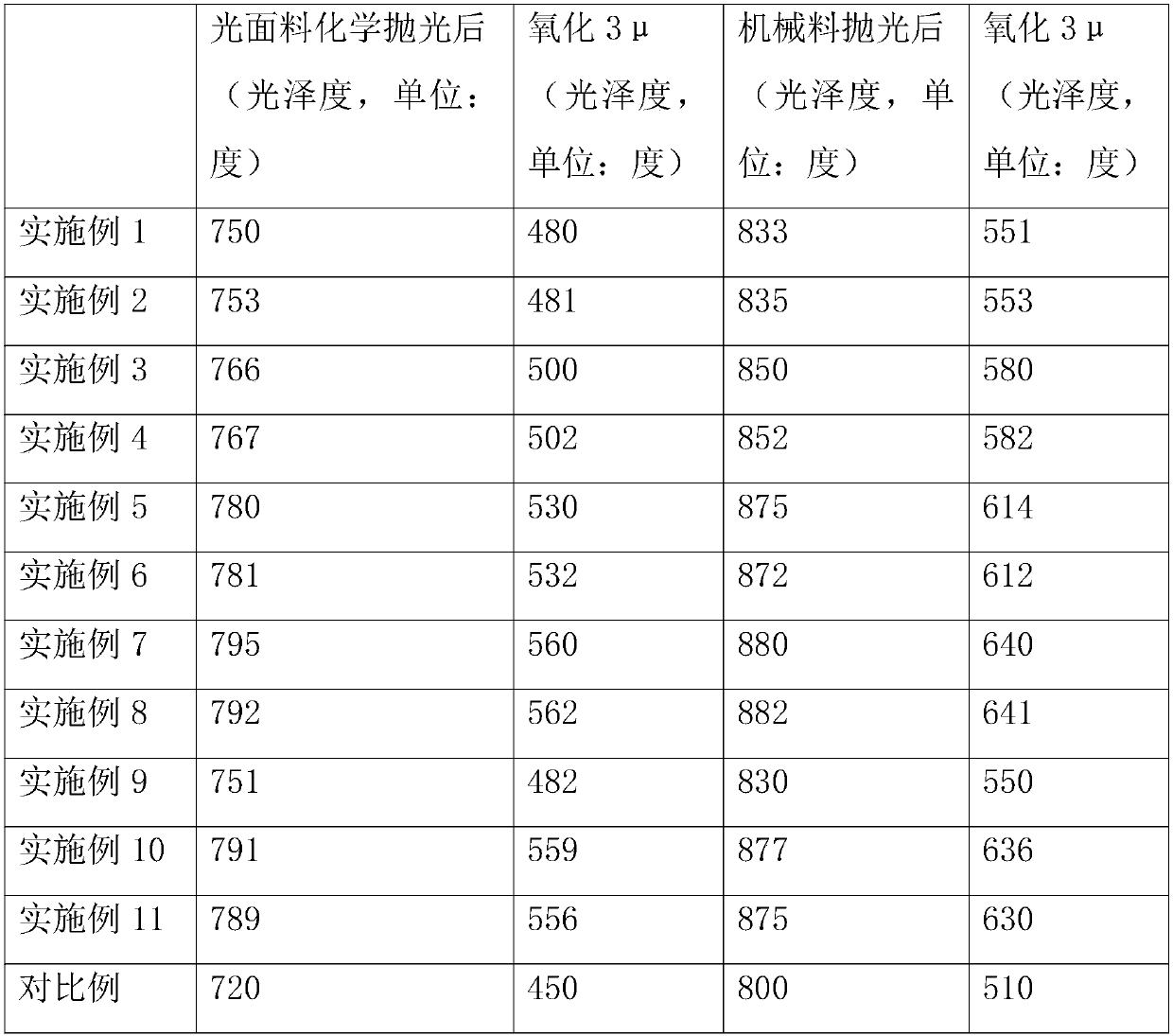

Vertical type oxidization wire recycled and reusable two-acid polishing solution and preparation method thereof

The invention relates to vertical type oxidization wire recycled and reusable two-acid polishing solution and a preparation method thereof. The polishing solution comprises the following components inparts by mass: 50-70 parts of phosphoric acid, 30-50 parts of sulfuric acid, 0.01-0.5 part of heteropolyacid compound, 0.01-0.5 part of a catalyst, 0.01-0.5 part of a chelating agent, 0.01-0.2 part of a corrosion inhibitor, 0.001-0.05 part of sulfate, 0.001-0.05 part of a surfactant and the balance of water, wherein the total mass parts of all components are 100. The vertical type oxidization wire recycled and reusable two-acid polishing solution is applied to the polishing process of aluminum and aluminum alloy, and the polishing effect of the vertical type oxidization wire recycled and reusable two-acid polishing solution is remarkably better than that of common three-acid polishing solution.

Owner:FOSHAN HAIHUA SURFACE TREATMENT TECH CO LTD

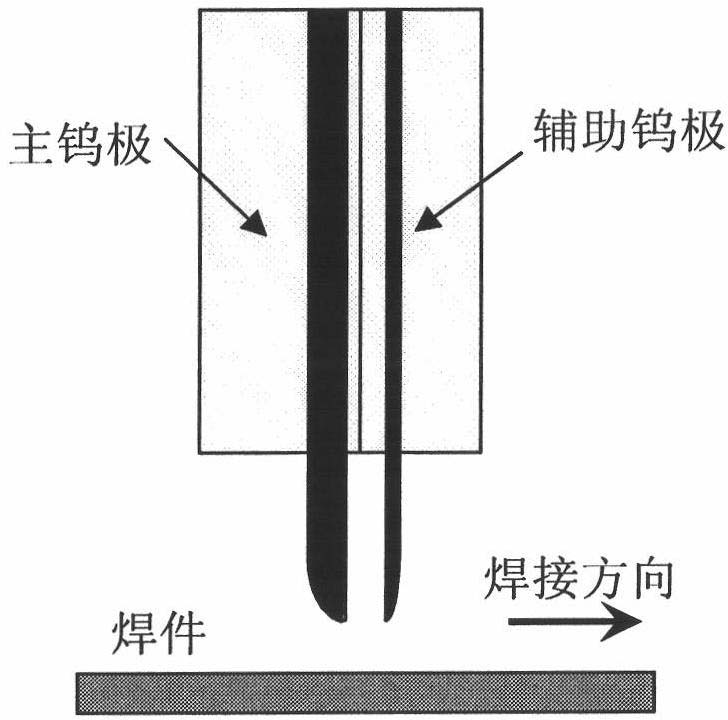

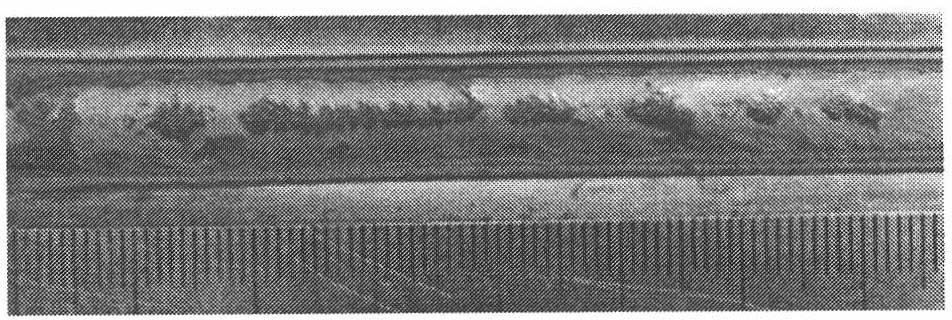

Coupling-arc AA-TIG welding method

InactiveCN102626813AEasy transferInhibition formationWelding electrode featuresShielding gasElectric current flow

The invention discloses a coupling-arc AA-TIG (argon arc-tungsten inert gas) welding method. Welding current induced into a main tungsten electrode is larger than welding current induced into an auxiliary tungsten electrode; protective gas passing through the auxiliary tungsten electrode is provided with an active element O; the main tungsten electrode adopts inert protective gas; a coupling arc is formed between the main tungsten electrode and the auxiliary tungsten electrode in a same welding gun, namely in the welding process, the two tungsten electrodes in the welding gun are arranged along the welding direction, the auxiliary tungsten electrode is arranged in the front and the main tungsten electrode at the back so as to form the coupling arc.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

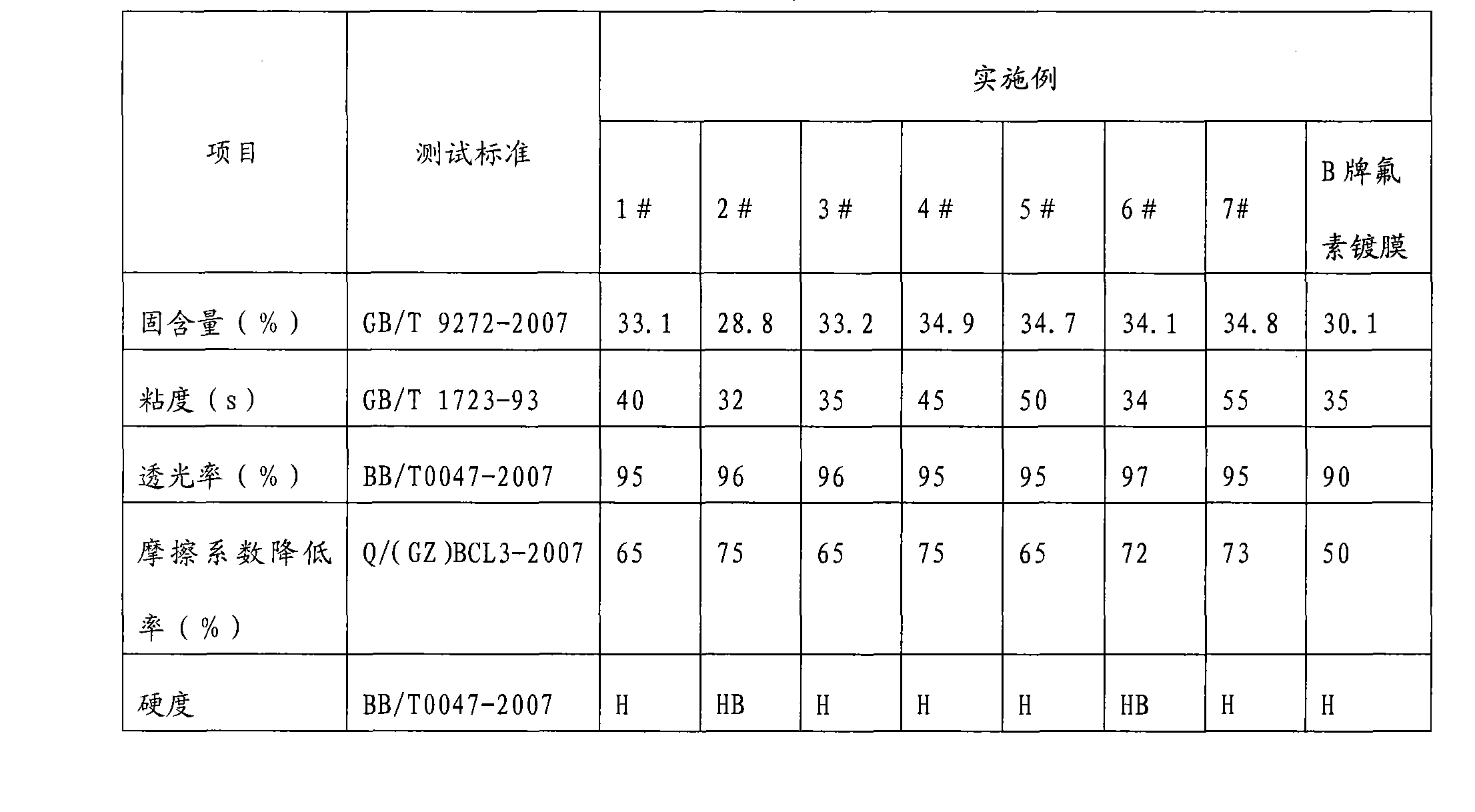

Multifunctional environmentally-friendly water-based paint and preparation method thereof

InactiveCN106883649AHigh porosityStrong porosityFireproof paintsAntifouling/underwater paintsWater basedPolyvinyl alcohol

The invention discloses multifunctional environmentally-friendly water-based paint. The multifunctional environmentally-friendly water-based paint comprises main materials, additives and deionized water, wherein the main materials include diatom ooze, maya blue, tourmaline, nanometer titania, ultra-fine aluminum silicate, sepiolite, silicon carbide and zinc fluosilicate; the additives include acrylate polymer emulsion, silver ion solution, fluoro-silicone emulsion, wetting dispersant, preservative, polyvinyl alcohol, a thickener, hydroxypropyl methyl cellulose, a buffering agent, a defoaming agent, an anticracking agent and inorganic pigment. The invention also discloses a preparation method of the multifunctional environmentally-friendly water-based paint. According to the multifunctional environmentally-friendly water-based paint, the raw materials are environmentally-friendly, nontoxic and pollution-free materials; maya blue, nanometer titania and diatom ooze are used in match to enable efficient function of resisting formaldehyde, ammonia and benzene; the silver ion solution and nanometer titania are used in match to enable effective antibacterial effect and long-lasting antibacterial effect; tourmaline and silicon carbide are added, so that the functions of health care, smell removing and fireproofing are realized.

Owner:程艳青

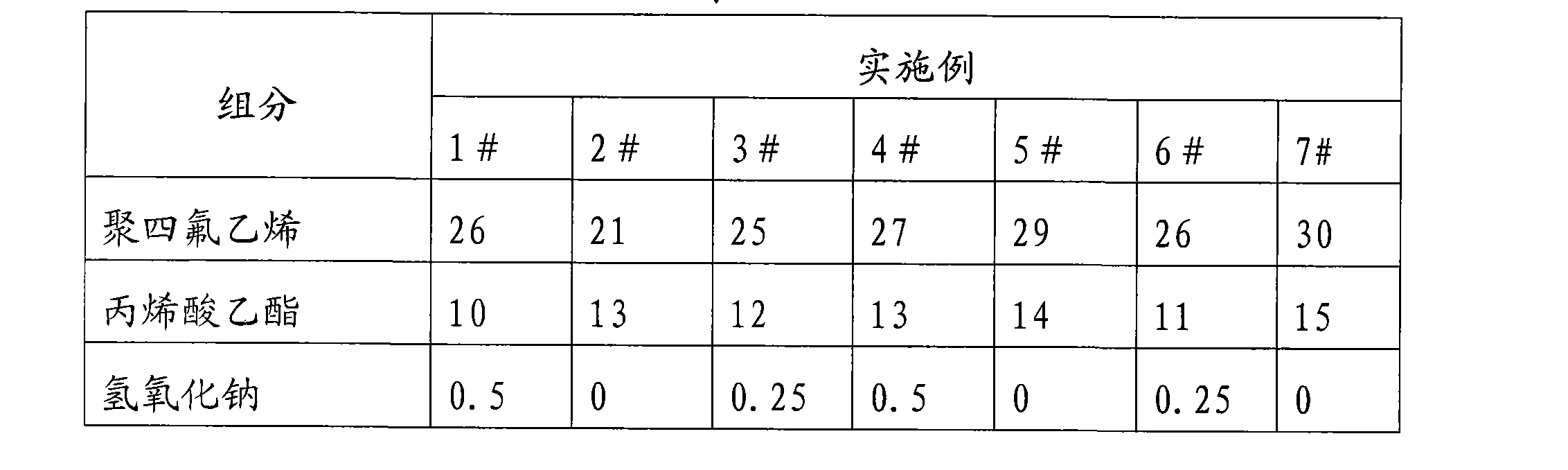

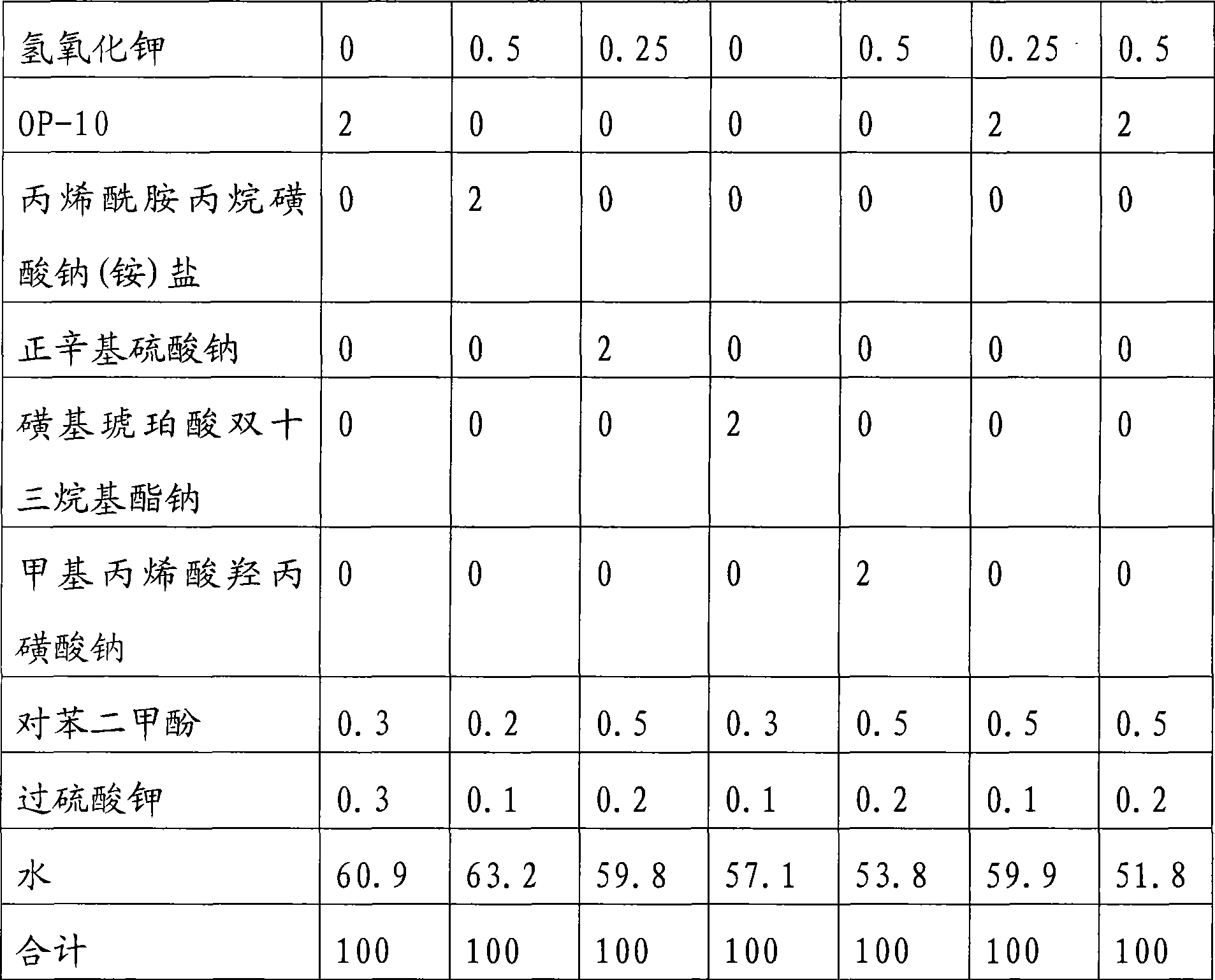

Raw material formula for automotive glass surface protective film and method of producing the same

ActiveCN101429405ADoes not affect visible light transmittanceGood weather resistanceCoatingsTectorial membraneEnd-group

The invention relates to a raw material formulation of a surface protective film for automobile glass and a preparation method thereof. The raw material formulation of the surface protective film for the automobile glass comprises the following components: polyfluortetraethylene, ethyl acrylate, a catalyst, an emulsifying agent and water, wherein the polyfluortetraethylene has an iodic active end group, the polymerization degree of the polyfluortetraethylene is 4 to 6, and the molecular weight of the polyfluortetraethylene is 200 to 600 thousand. The preparation method for the surface protective film for the automobile glass comprises the following steps: (1) weighing the raw materials according to a proportion; (2) making the polyfluortetraethylene and the water react for 2 to 4 hours at a temperature of between 120 and 140 DEG C in the presence of a catalyst; (3) and then adding the ethyl acrylate into the mixture to react for 1 to 2 hours at a temperature of between 110 and 118 DEG C; and (4) adding the emulsifying agent into the mixture to homogenize and emulsify the mixture to obtain the final product. The prepared surface protective film for the automobile glass has strong binding force with glass, can reduce surface tension and surface friction factor of the glass, and improve oil resistance and water resistance of the glass; and a coating is not easy to damage.

Owner:广州保赐利化工有限公司

PCB developing dry film/printing ink groove cleaning agent and use method thereof

InactiveCN111019430AChange wettabilityChange surface tensionChemical paints/ink removersPhotosensitive material processingO-Phosphoric AcidActive agent

The invention relates to a PCB developing dry film / ink groove cleaning agent, and a preparation method and a use method thereof. The invention relates to the field of fine chemical engineering, and aims to provide the PCB development dry film / ink tank cleaning agent, which comprises the following substances by mass: 5-12% of phosphoric acid (analytically pure), and 1, 8-15% of an acetic acid and linear alkyl benzene sulfonic acid mixture 1 with a mass ratio of 1: 1-1.5, 1-5% of a mixture 2 of ethylene glycol and ethylene glycol ethyl ether in a mass ratio of 1: 1; 1-5% of a mixture 3 of a polytrifluoropropyl methyl siloxane and a fatty alcohol polyoxyalkyl ether mixture with the mass ratio being 1: 3, 0.5-3% of EDTA,; 1-5% of OP-10, and the balance of water. The cleaning agent has the beneficial effects that the acid environment provided by the organic acid and the inorganic acid well acts on the metal precipitate, the chelating ability of active groups in the organic acid is good, a surface active agent can well change the wettability of the dry film adherend on the tank wall, and the surface tension of a system solution is changed.

Owner:四川省蜀爱新材料有限公司

A method for deep impurity removal in metal silicon smelting

The invention belongs to the field of metal silicon smelting technology, and in particular relates to a method for deep impurity removal in metal silicon smelting, comprising six steps of combined flocculent configuration, high temperature melting, oxygen blowing refining, sampling detection, deep aluminum removal and filtering impurity removal. The invention can reduce the aluminum content in metal silicon to within 0.18% in the traditional refining process, and can upgrade the metallurgical grade silicon to the grade of chemical grade silicon without increasing the refining procedure too much, with relatively good effect and low cost .

Owner:怒江宏盛锦盟硅业有限公司

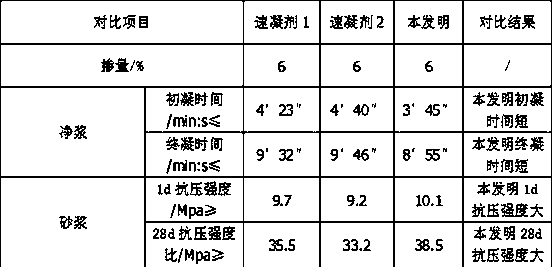

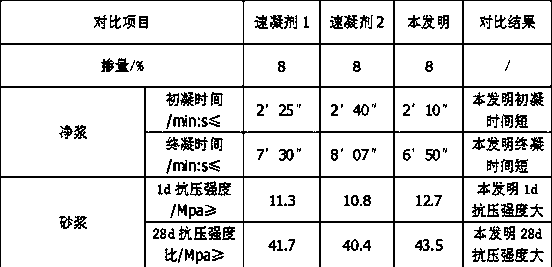

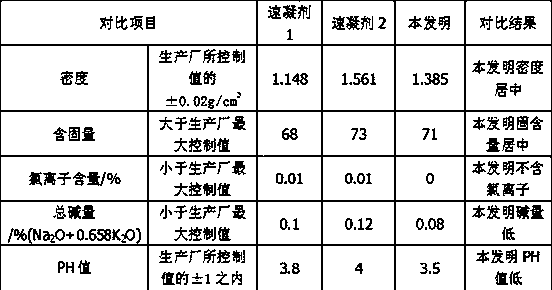

Preparation method of high-strength concrete accelerator

InactiveCN108249810AAdjust viscosityAdjust the degree of dispersionHigh strength concreteAlkali free

The invention discloses a preparation method of a high-strength concrete accelerator, which relates to a preparation method of a concrete admixture, in particular to the preparation method of the high-strength concrete accelerator. The method comprises the following steps of taking aluminum sulfate as a base stock of an alkali-free accelerator, and on the basis, adding adjuvants such as sodium fluoride, sodium silicate, xylene, naphthalenesulfonic acid-formaldehyde condensate, triethanolamine, calcium formate, hydroxyethyl carboxymethyl cellulose so as to play a part in increasing concrete strength, accelerating reaction rate and the like. When reaction is performed to a certain extent, phosphoric acid and methacrylic acid are added finally, an added acid solution plays a certain assistantpart to effectively adjust the pH value of a reaction system, so that a final product can effectively play a part in quick setting while not corroding steel materials in a concrete system to influence the strength of concrete in later stage. The preparation method is simple and good in effect.

Owner:云南森博混凝土外加剂有限公司

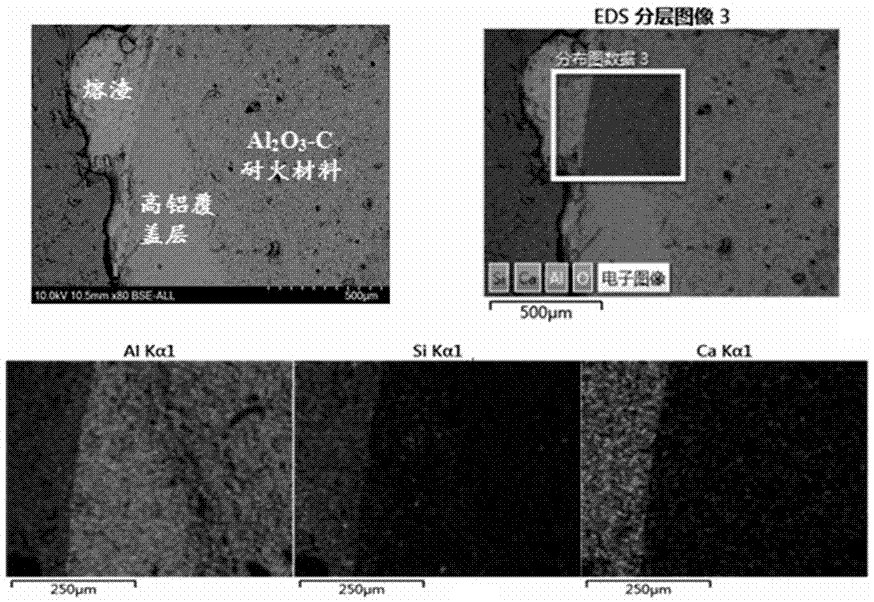

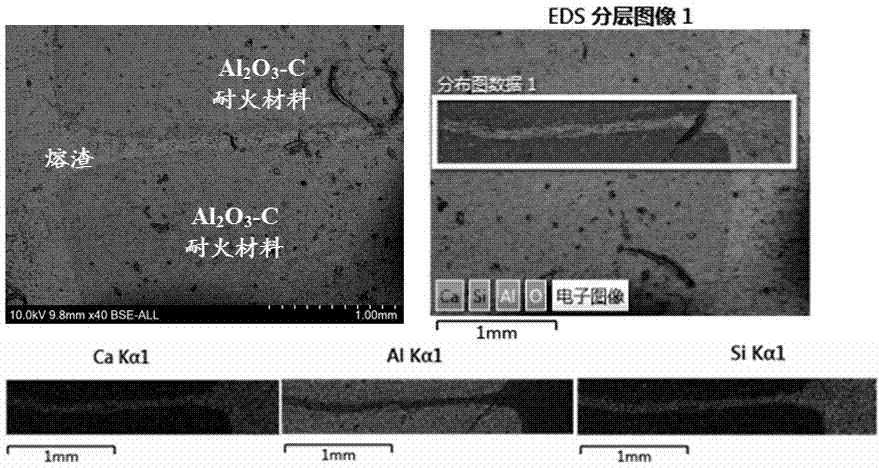

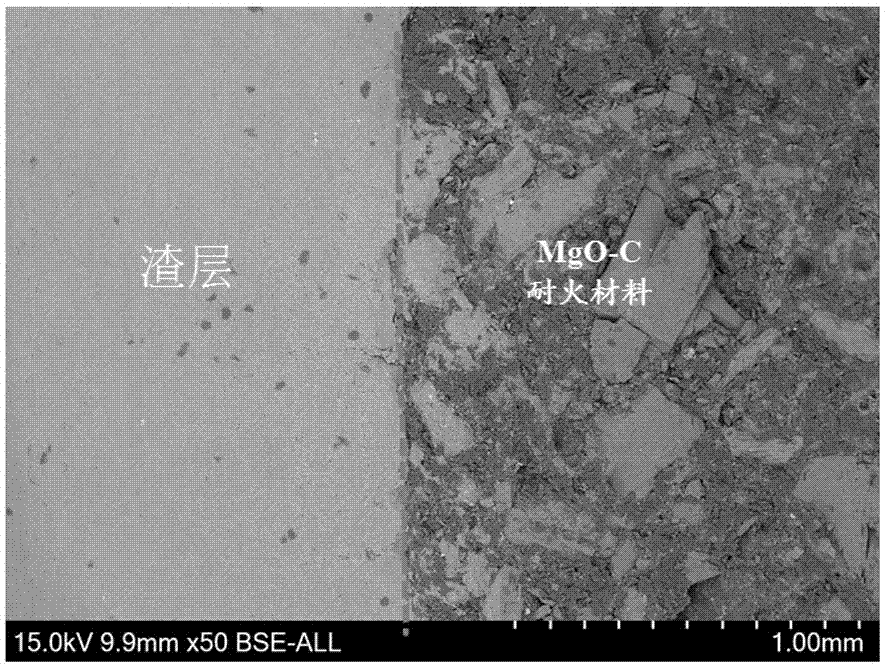

Method for preventing carbon-containing fireproof material from slag erosion

ActiveCN107253865AAchieve physical protectionReduce penetration depthMelt-holding vesselsAlkalinitySlag

The invention discloses a method for preventing carbon-containing fireproof material from slag erosion. Through providing a suitable external voltage for a slag system, the penetration depth f the slag in a fireproof material is delayed, and the physical protection of the fireproof material is realized. The method includes steps of taking aluminum oxide, silica, and calcium oxide as raw materials, and preparing to be the slag powder with alkalinity of 0.8-2.3; heating the mixed powder to 1550-1650 DEG C to melt down; after decarbonization, contacting the carbon-containing fireproof material with slag, and then connecting the fireproof material after decarbonizing treatment and the slag to both electrodes of the power source respectively; electrifying at 0-4V; realizing the protection of carbon-containing fireproof material from slag erosion. The method can effectively inhibit the physical penetration of slag in the carbon-containing fireproof material, significantly improve the slag erosion resistance of the carbon-containing fireproof material, and prolong 3-4 times of the service life of the carbon-containing fireproof material. The method is simple in operation, wide in applicable slag scale, and high in production practical value.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com