Patents

Literature

34 results about "Methallyl sulfonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

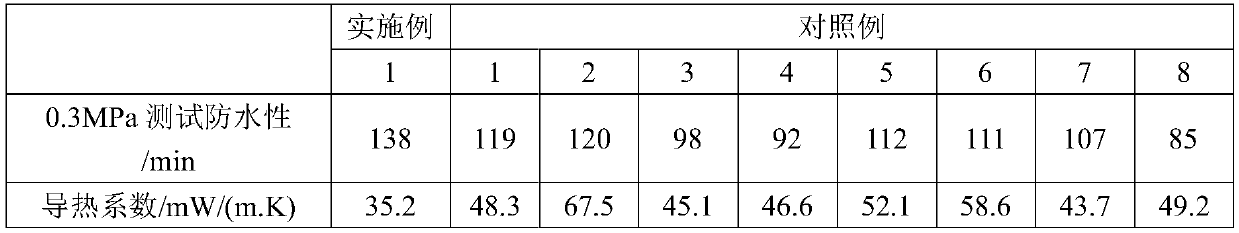

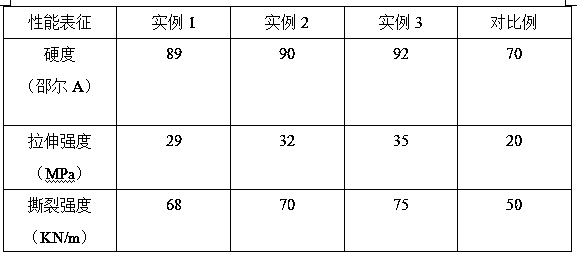

Shock absorption foaming material for sneakers and preparation method and application thereof

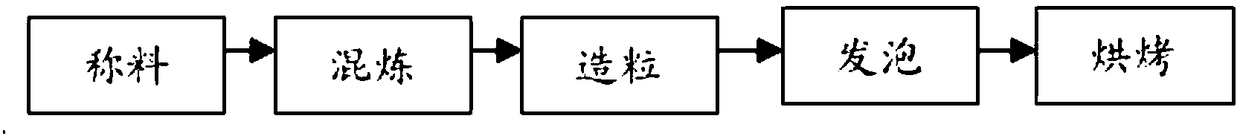

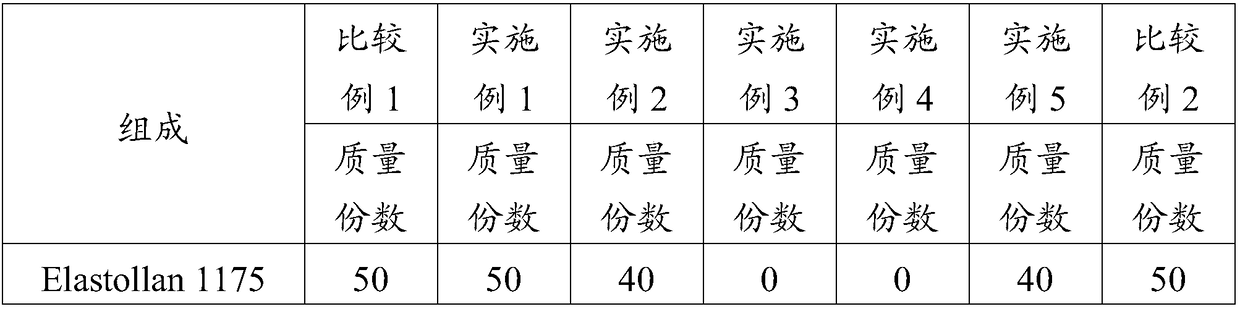

The invention provides a shock absorption foaming material for sneakers and a preparation method and application thereof, and the absorption foaming material is prepared by blending and foaming materials comprising the following components in parts by weight: 30-80 parts of a polyester elastomer; 20-40 parts of an ethylene-vinyl acetate copolymer; 20-50 parts of an alpha-olefin thermoplastic copolymer; 10-20 parts of a styrene polymer; 1-2 parts of a grafting agent; 0.7-1.1 parts of a peroxide; 2-5 parts of a chemical foaming agent; 3-3.5 parts of an active agent and 3-6 parts of a polymerization component, and the polymerization component is selected from one or more of styrene, methallyl sulfonate, triallyl isocyanurate and 1,2-polybutadiene. The foaming material provided by the invention has good shock absorption performance and good mechanical property, and can be used as a shoe sole material for the sneakers. According to the method disclosed by the invention, the process flow issaved, and the method has the advantages of cost and efficiency.

Owner:ANTA CHINA

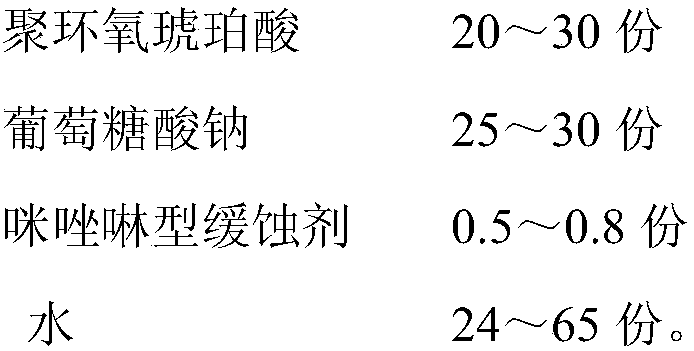

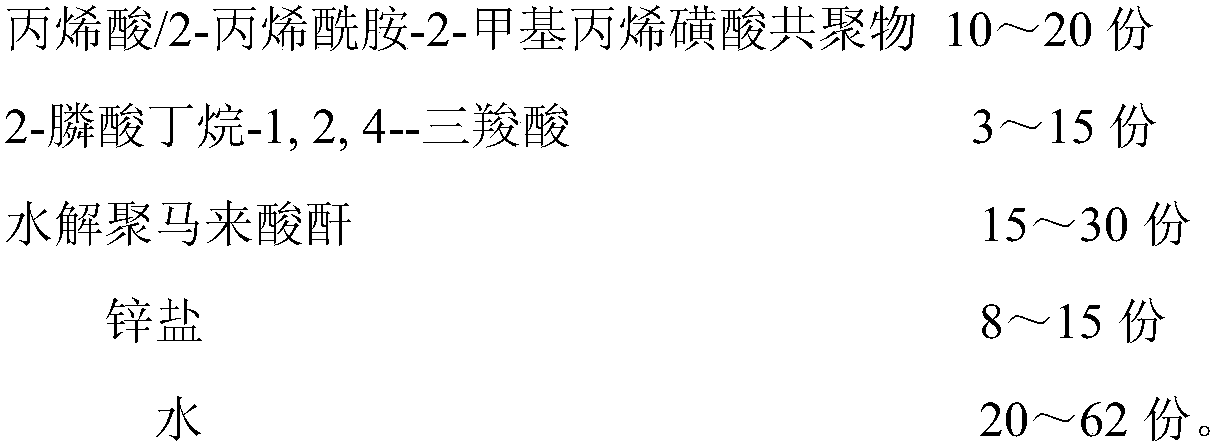

Low-phosphorus efficient scale and corrosion inhibitor for circulating water treatment, and preparation method thereof

InactiveCN107777789AGood synergyNo distractionTreatment using complexing/solubilising chemicalsHigh concentrationTricarboxylic acid

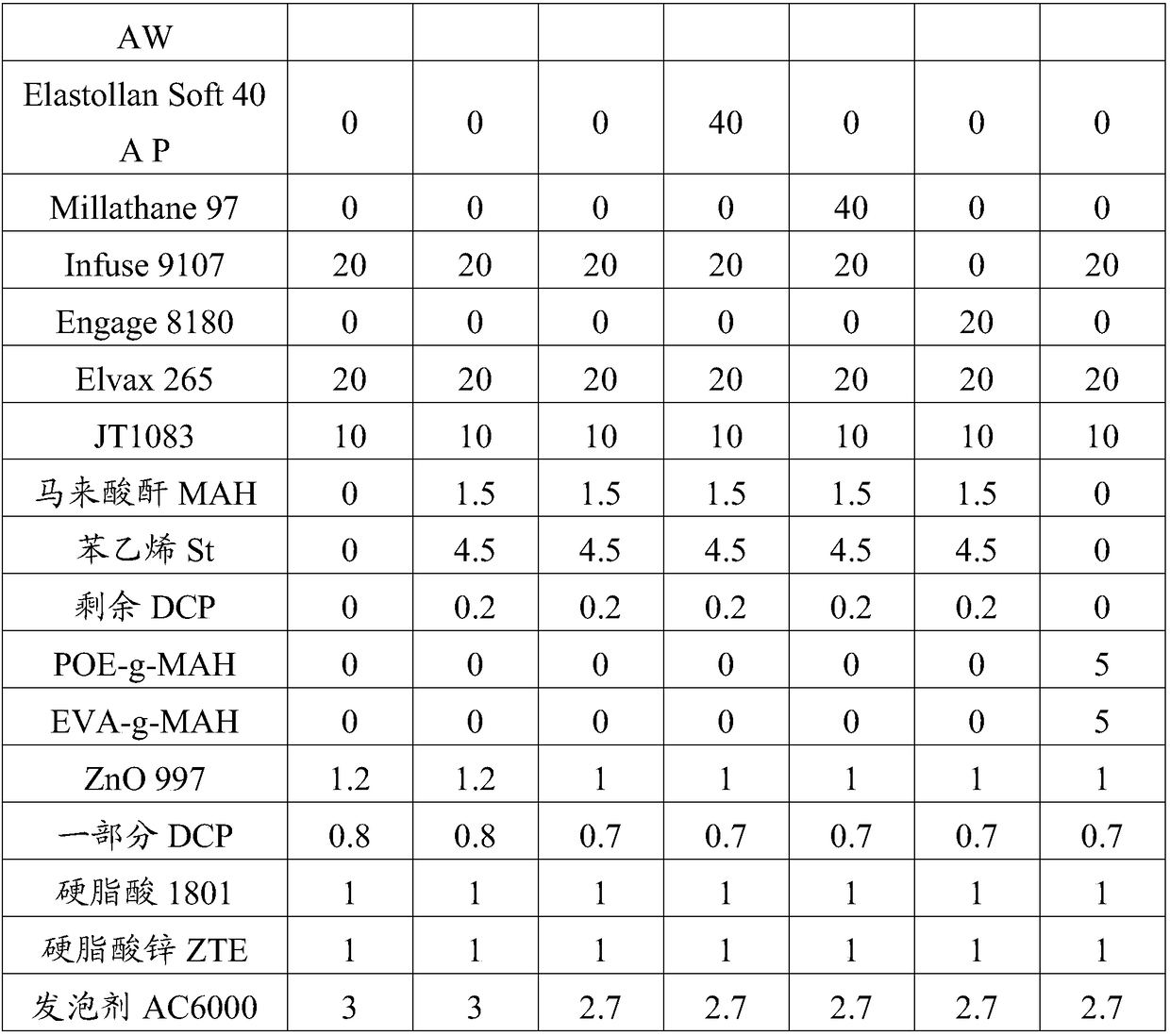

The invention relates to a low-phosphorus efficient scale and corrosion inhibitor for circulating water treatment, and a preparation method thereof, and belongs to the technical field of circulating cooling water treatment. The low-phosphorus efficient scale and corrosion inhibitor for circulating water treatment is prepared by compounding a scale and a corrosion inhibitor A and a scale and a corrosion inhibitor B according to the weight ratio of 1:1 to 1:5, wherein the scale and corrosion inhibitor A is prepared by mixing polyepoxysuccinic acid, sodium gluconate, an imidazoline type corrosioninhibitor and water; and the scale and corrosion inhibitor B is prepared by mixing hydrolytic polymaleic anhydride, an acrylic acid / 2-acrylamide-2-methallyl sulfonate copolymer, 2-phosphonic acid butane-1,2,4-tricarboxylic acid, zinc salt and water. The low-phosphorus efficient scale and corrosion inhibitor for circulating water treatment has low phosphorus content and high calcium and alkali tolerance, can resist corrosion of high-concentration Cl<-> and SO4<2->, and has good corrosion and scale inhibition effects; meanwhile, the invention provides a simple, convenient and rapid preparationmethod.

Owner:CHINA PETROLEUM & CHEM CORP

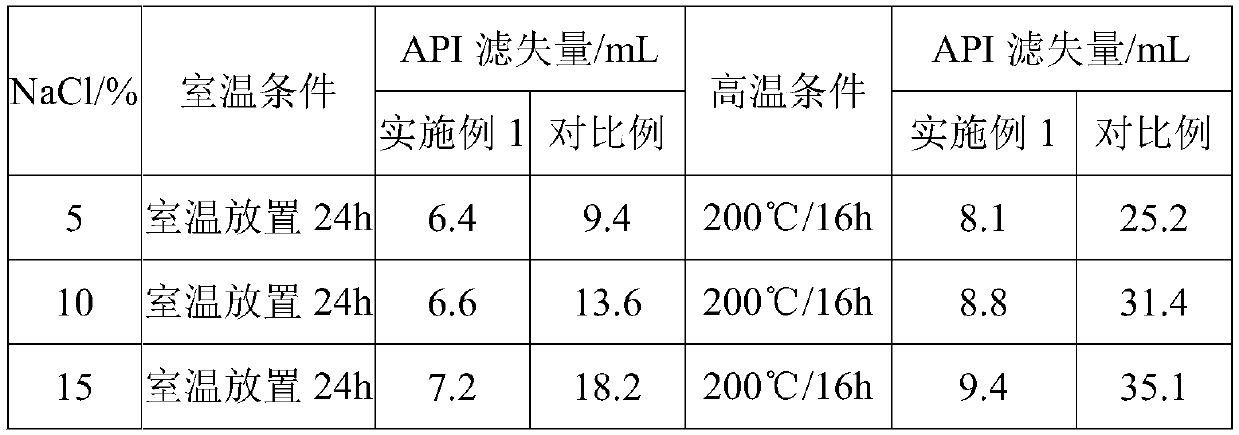

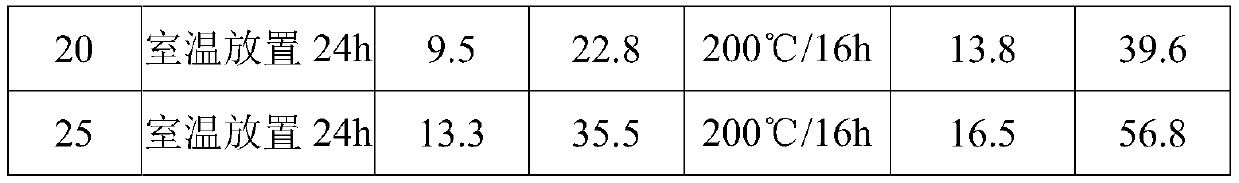

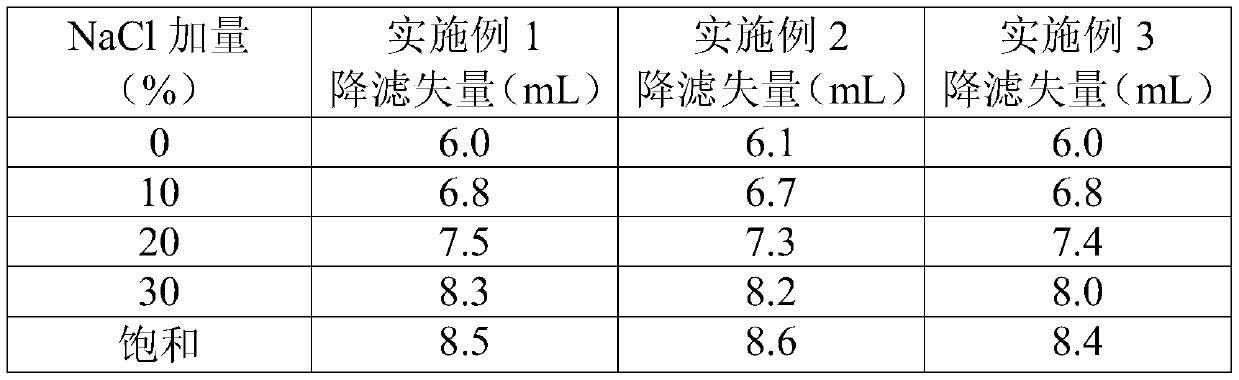

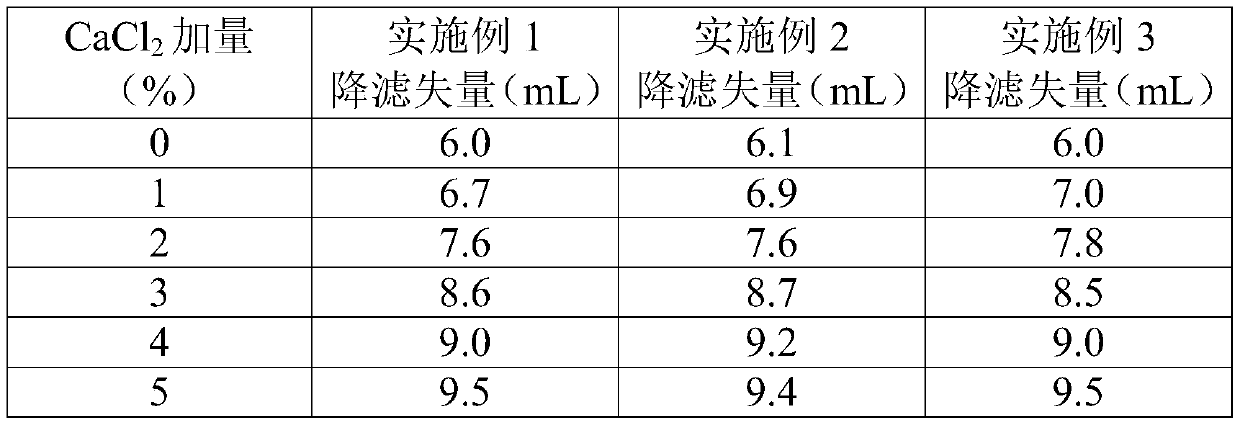

High-temperature-resistant salt-resistant anti-collapse filtrate reducer for drilling fluid and preparation method of high-temperature-resistant salt-resistant anti-collapse filtrate reducer

InactiveCN104194741AHigh temperature resistanceStrong salt resistanceDrilling compositionMethallyl sulfonateParaformaldehyde

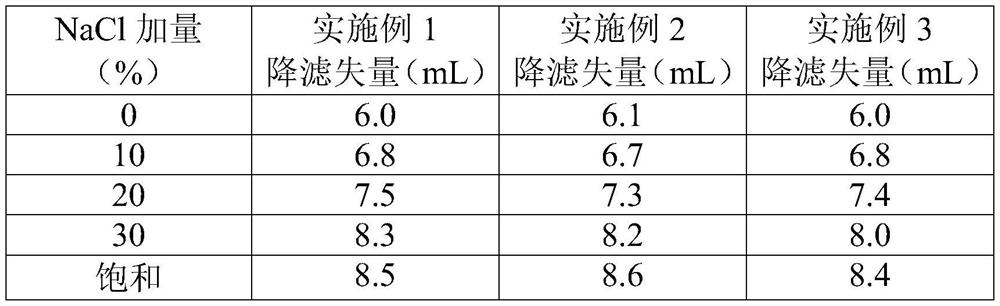

The invention discloses a high-temperature-resistant salt-resistant anti-collapse filtrate reducer for a drilling fluid and a preparation method of the High-temperature-resistant salt-resistant anti-collapse filtrate reducer. The key point of the technical scheme is that the high-temperature-resistant salt-resistant anti-collapse filtrate reducer for the drilling fluid is mainly prepared from the following raw materials in parts by weight: 20-35 parts of starch, 0.5-5 parts of caustic soda, 20-40 parts of acrylamide, 5-15 parts of sodium 2-acrylamide-2-methallyl sulfonate, 5-15 parts of diethyl diallyl ammonium chloride, 5-15 parts of sodium pyrosulfite, 5-15 parts of paraformaldehyde and 0.5-5 parts of ammonium persulfate. The invention further discloses a preparation method and a using method of the high-temperature-resistant salt-resistant anti-collapse filtrate reducer for the drilling fluid. The product filtrate reducer obtained by the preparation method has relatively high high-temperature resistance and salt resistance and good anti-collapse performance, can be used for greatly lowering the filtrate loss while being added into the drilling fluid, and capable of forming a firm, thin and compact mud cake, so that an oil-gas reservoir is not polluted by the drilling fluid to achieve effects of protecting the oil-gas reservoir.

Owner:XINXIANG FUBANG TECH

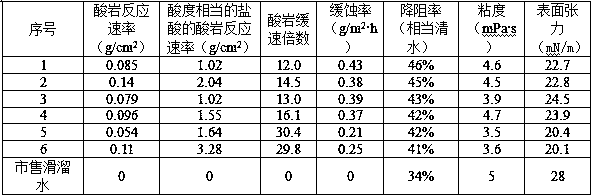

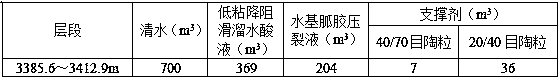

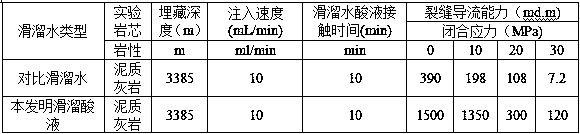

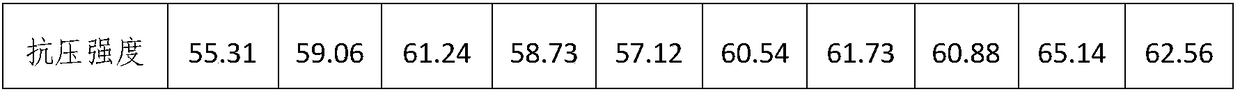

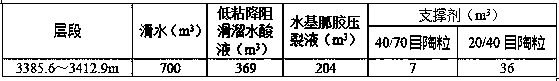

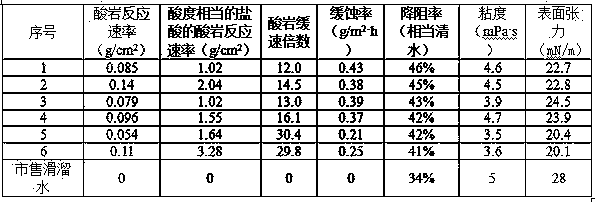

Method for volume acid-fracturing reformation of seam net of carbonate reservoir

InactiveCN107216866AGood resistance reduction effectImprove responseFluid removalDrilling compositionWater basedSodium ascorbate

The invention provides a method for volume acid-fracturing reformation of a seam net of a carbonate reservoir. The method specifically comprises the following steps: (1) injecting low-viscose resistance-reducing sliding acid liquor, performing plunger injection for at least three times and performing volume fracturing reformation of the seam net; (2) injecting a water-based sand-carrying fracturing fluid and forming sand-filling cracks in length not less than 120 meters on the two sides of a well shaft; (3) injecting a displacement fluid, closing the well and then draining the liquid, wherein the low-viscose resistance-reducing sliding acid liquor is composed of 5-20% of acid, 1-3% of alkyl quaternary ammonium salt, 0.5-2% of sodium ascorbate, 0.1-0.5% of emulsion corrosion inhibitor, 0.5-1% of citric acid, 1-3% of discharge aiding agent and the balance of water; the emulsion corrosion inhibitor is selected from any one of polypropylene glycol emulsion, polyvinylpyrrolidone emulsion, acrylamide and 2-crylic acid-2-methallyl sulfonate copolymer emulsion; and the acid is selected from hydrochloric acid, formic acid, acetic acid or bionic acid. The method is simple in construction, the flow conductivity of the seam net is high and the yield-increasing effect is excellent.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

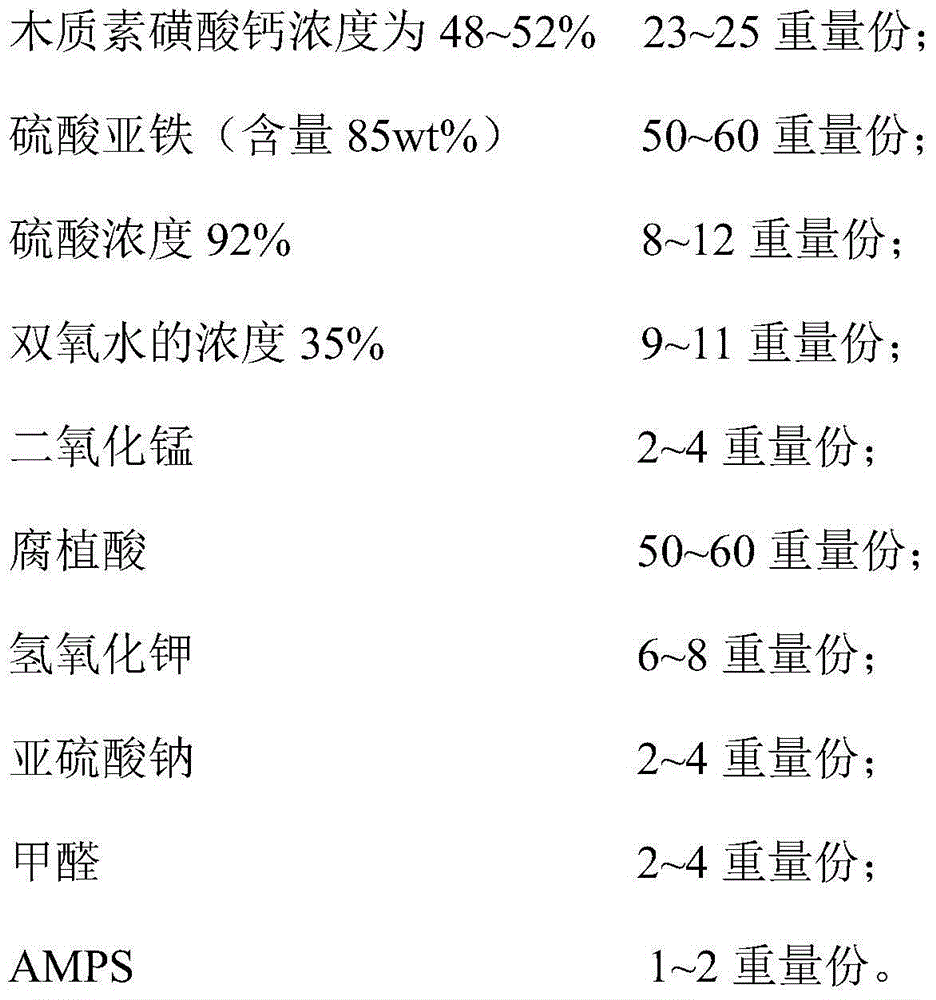

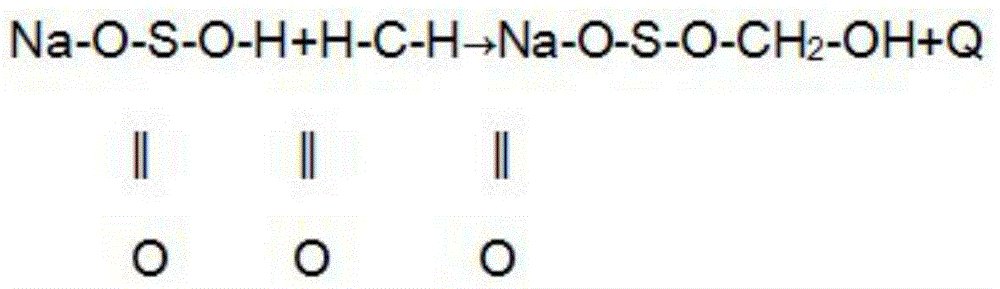

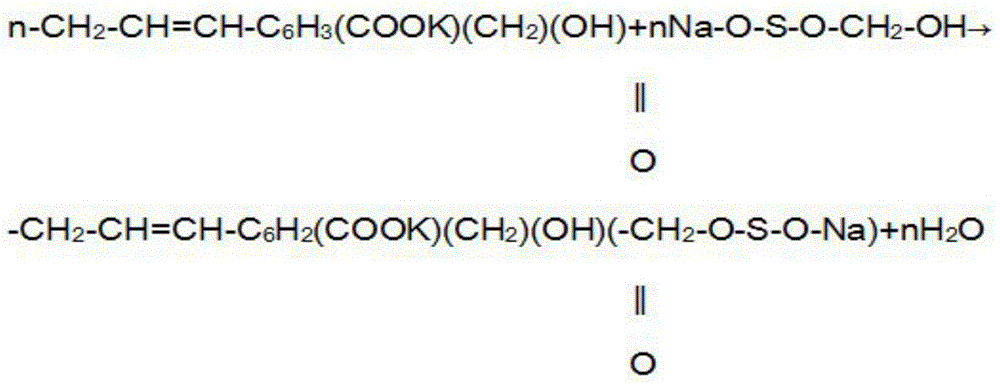

Diluent for high temperature resistant salt-tolerant drilling fluid and preparation method of diluent

The invention discloses a diluent for a high temperature resistant salt-tolerant drilling fluid and a preparation method of the diluent. The diluent comprises the following raw materials: calcium lignosulphonate, ferrous sulfate, sulfuric acid, manganese dioxide, hydrogen peroxide, humic acid, potassium hydroxide, sodium sulfite, formaldehyde and 2-acrylamide-2-methallyl sulfonate (AMPS). The viscosity reduction rate of the thermal stability test fresh water base slurry of the diluent is greater than 85% after being aged for 16 hours at 180 DEG C, and the viscosity reduction rate of the brine base slurry is greater than 85% after being aged for 16 hours at 180 DEG C.

Owner:MUDANJIANG HUAXIN CHEM ADDITIVE

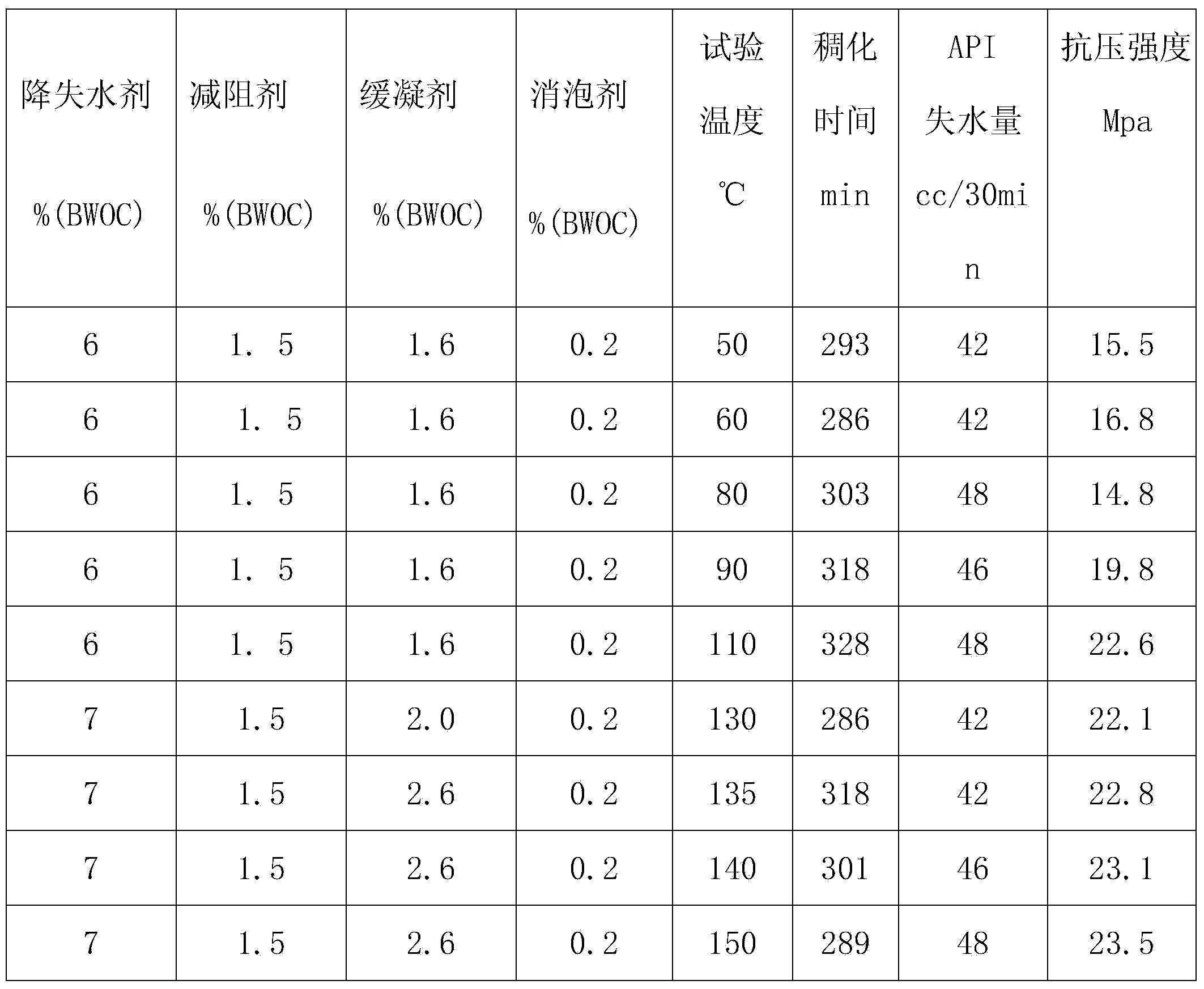

Oil well cement retarder with high-temperature controlled-release and delayed-coagulation groups

InactiveCN103923253AStable thickening timeThe effect of thickening time is smoothDrilling composition(Hydroxyethyl)methacrylateMethallyl sulfonate

The invention discloses an oil well cement retarder with high-temperature controlled-release and delayed-coagulation groups. The oil well cement retarder comprises the following raw materials: itaconic acid, hydroxyethyl methylacrylate, 2-acrylamide-2-methallyl sulfonate, and one methylolpropane acrylate compound with two or more alkene unsaturated bonds. The invention further discloses a production method of the oil well cement retarder. The influence of cement paste thickening time of the retarder synthesized in the invention on temperature is insensitive; the thickening time at high temperature meets the construction requirement, and the strength of the set cement can be more rapidly developed under conditions of low temperature, medium temperature and high temperature. The retarder synthesized in the invention can be used in well cementation of a sealing section.

Owner:兰德(廊坊)石化环保设备有限公司

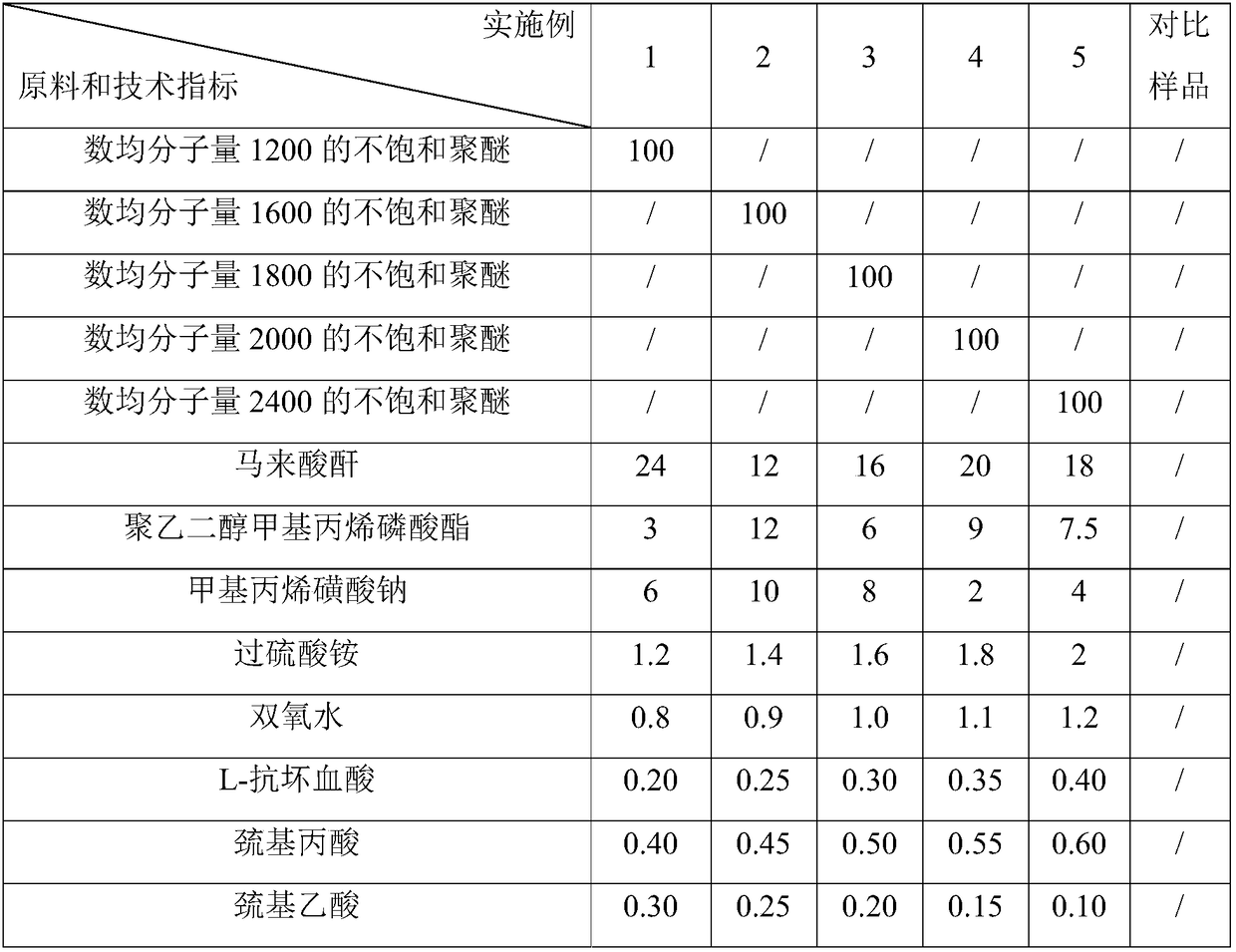

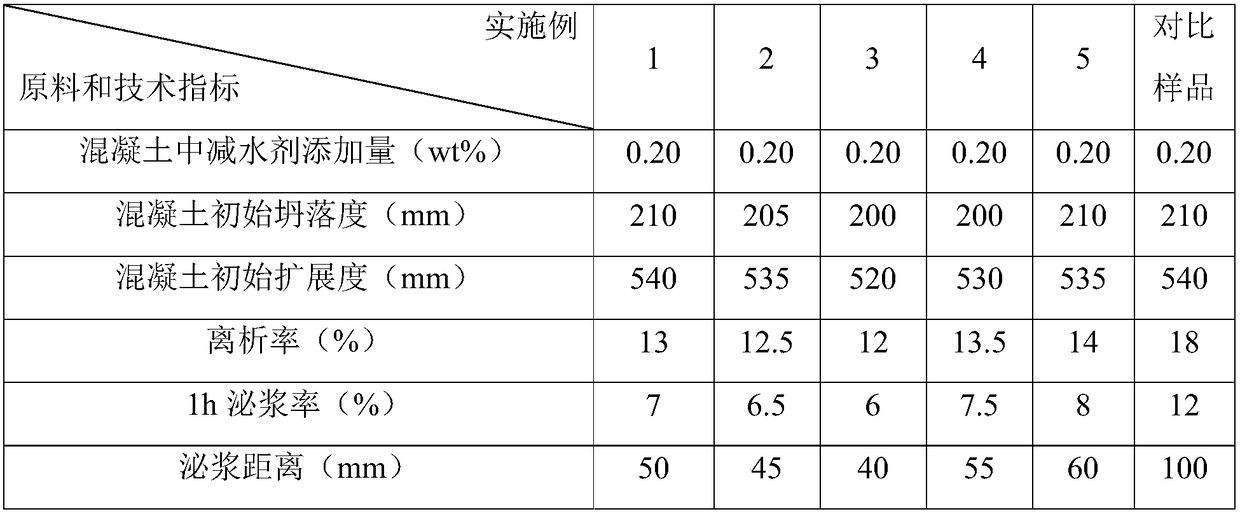

High-workability polycarboxylic water reducer and preparation method and use method thereof

The invention discloses a high-workability polycarboxylic water reducer and a preparation method and a use method thereof. The high-workability polycarboxylic water reducer is prepared from raw materials comprising the following components in parts by weight: 100 parts of unsaturated polyether, 12-24 parts of maleic anhydride, 3-12 parts of polyethylene glycol methacrylate phosphate, 2-10 parts ofsodium methallyl sulfonate, 1.2-2 parts of ammonium persulfate, 0.8-1.2 parts of hydrogen peroxide, 0.20-0.40 part of L-ascorbic acid, 0.40-0.60 part of mercaptopropionic acid, 0.10-0.30 part of mercaptoacetic acid, 5-7 parts of sodium hydroxide and 140-260 parts of water, wherein the unsaturated polyether is allyl alcohol polyoxyethylene ether of which the number-average molecular weight is 1200-2400. The high-workability polycarboxylic water reducer disclosed by the invention has good performance and has obvious economic benefit, social benefit and environmental benefit; and the preparationprocess is simple and convenient to operate.

Owner:SHANGHAI DONGDA CHEM

Environment-friendly filtrate reducer for water-based drilling fluid and preparation method and drilling fluid of environment-friendly filtrate reducer

ActiveCN110591670AQuality improvementImprove stabilityDrilling compositionWater basedMethallyl sulfonate

The invention provides an environment-friendly filtrate reducer for a water-based drilling fluid and a preparation method and a drilling fluid of the environment-friendly filtrate reducer and aims tosolve the technical problems that in the prior art, a filtrate reducer is poor in filter cake quality and large in filter loss. The filtrate reducer is prepared from low-viscosity carboxymethylcellulose as a raw material after grafting modification, and acrylamide, 2-acrylamide group-2-methallyl sulfonate and dimethyl diallyl ammonium chloride are adopted as grafting monomers. The filtrate reducerprovided by the invention is capable of improving the quality of filter cakes, reducing the filter loss and in addition is environment-friendly and excellent in temperature resistance.

Owner:SOUTHWEST PETROLEUM UNIV

Comb type structure amphiprotic ionic polymer filtrate reducer and preparation method thereof

ActiveCN108676129ASimple preparation processLower requirementDrilling compositionQuaternary ammonium cationType specific

The invention relates to a comb type structure amphiprotic ionic polymer fitrate reducer and a preparation method thereof. The fitrate reducer is prepared from the following monomers in parts by weight through copolymerization: 20 to 40 parts of 2-acrylamide-2-methallyl sulfonate, 5 to 30 parts of polyethylene glycol monomethyl ether methyl acrylate, 10 to 60 parts of N,N-dimethyl acrylamide and 5to 20 parts of dimethyl diallyl ammonium chloride. The fitrate reducer contains molecule groups such as quaternary ammonium groups, amido groups and sulfonic groups, wherein the sulfonic groups havehigh hydration capability; the amido groups and quaternary ammonium salts have high adsorption capacity on clay; the adsorption stability of the fitrate reducer under the high temperature condition; aproduct obtained through graft copolymerization on macromolecule monomers of polyethylene glycol monomethyl ether methyl acrylate and other monomers is of a comb type specific structure; the anti-shearing performance and the high-temperature stability can be further improved; the fluid loss performance is ensured; meanwhile, the temperature resistant and salt resistant effects are good; the fitrate reducer can be effectively applied to drilling fluid in high-temperature complex formation environment.

Owner:中石化石油工程技术服务有限公司 +1

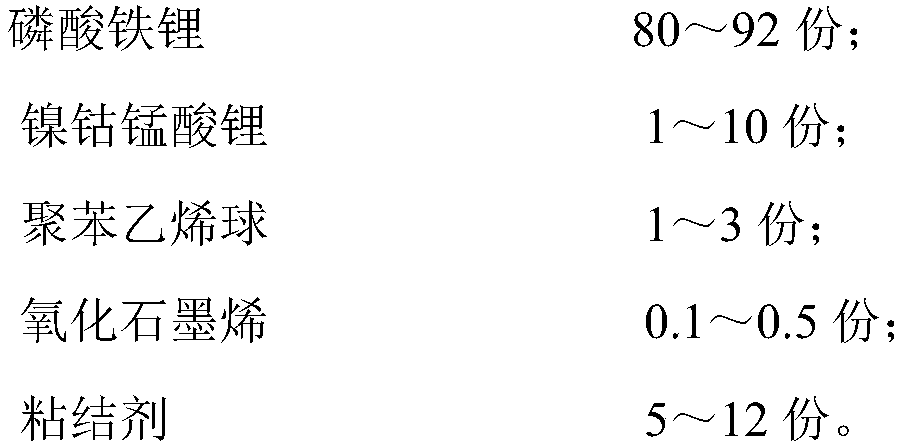

High-energy solid-state battery and preparation method thereof

ActiveCN108346819ASolid electrolytesFinal product manufactureSolid state electrolytePolyethylene oxide

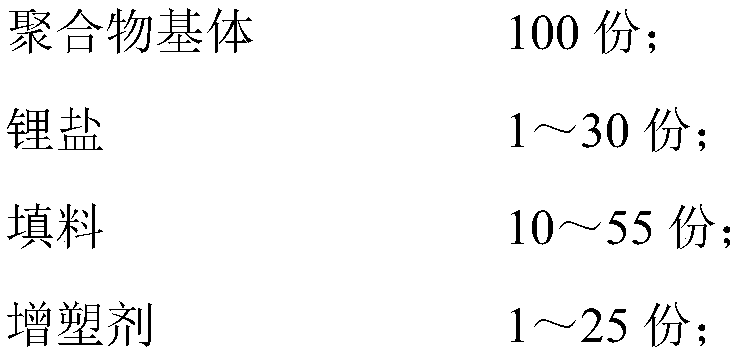

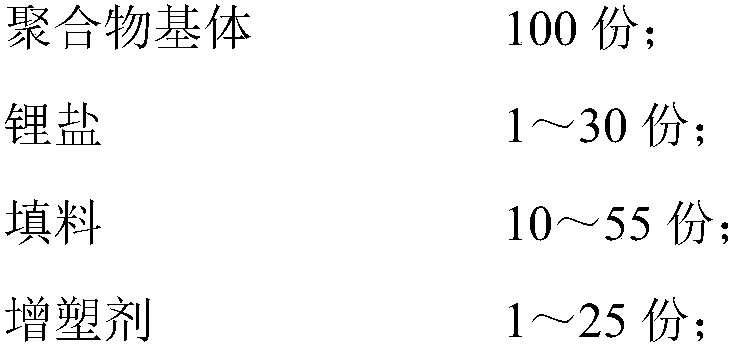

The invention relates to the field of a battery, in particular to a high-energy solid-state battery and a preparation method thereof. The high-energy solid-state battery comprises a battery positive electrode, a battery negative electrode and a solid-state electrolyte membrane, wherein the solid-state electrolyte membrane is arranged between the battery positive electrode and the battery negativeelectrode and at least comprises the following constituents based on part by weight: 100 parts of polymer matrix, 1-30 parts of lithium salt, 10-55 parts of filler and 1-25 parts of plasticizer, the polymer matrix is selected from polyethylene oxide, polyethylene terephthalate, polyimide, polyvinylidene fluoride, polymethyl methacrylate, polyacrylonitrile, polypropylene carbonate, polyvinyl chloride, vinylidene fluoride / 2-acrylamide-2-methallyl sulfonate / trimethylolpropane triacrylate / hyperbranched polyacrylate / methyl methacrylate copolymer, and the lithium salt is selected from a mixture of arbitrary one or more of LiPF6, LiBF4, LiClO4, LiAsF6, LiCF3SO3 and LiN(CF3SO2)2.

Owner:郑州英诺贝森能源科技有限公司

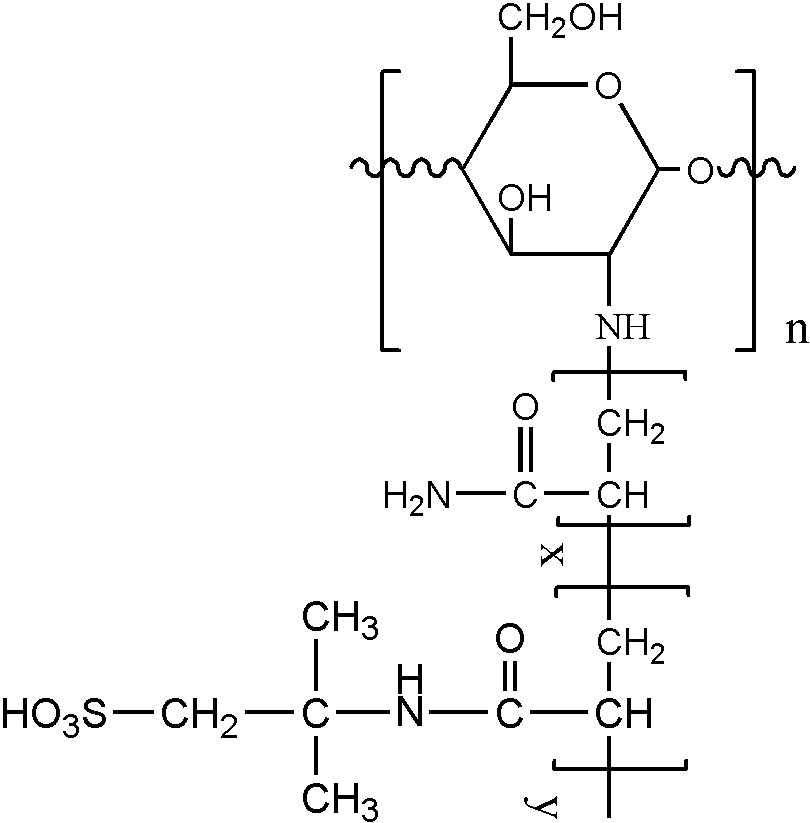

Preparation method for anion chitosan-based flocculant

InactiveCN109400814AReduce consumptionEasy to operateWater/sewage treatment by flocculation/precipitationSolubilityTherapeutic effect

The invention discloses a preparation method for an anion chitosan-based flocculant. The preparation method comprises the following steps: taking chitosan and 2-acrylamide-2-methallyl sulfonate (AMPS)as raw materials and taking acrylamide as a crosslinking agent; adding the three materials into a reactor, adding a defined amount of water, fully uniform mixing the three materials and fully dissolving under the condition of quick stirring; introducing nitrogen and removing interference of oxygen, and adding ceric ammonium nitrate initiator; placing the reactor under the temperature at 35-45 DEGC and reacting for 2-4h; curing after the ending of reaction, and then extracting and purifying the product, thereby acquiring the anion chitosan-based flocculant with sulfonic acid group. The preparation method disclosed by the invention is simple, with reaction stability, easiness in control and few side effects. The acquired modified chitosan flocculant has excellent solubility and flocculating performance, has an excellent treatment effect to hematite wastewater and is an efficient water treatment flocculant.

Owner:CHONGQING TECH & BUSINESS UNIV

High-polymer curing resin of coating agent for drilling fluid

ActiveCN110358511AExcellent anti-salt and anti-calcium performanceGood water solubilityDrilling compositionPotassium persulfateMethallyl sulfonate

High-polymer curing resin of a coating agent for a drilling fluid is prepared from raw materials as follows: 800-1,000 parts of clear water, 100-120 parts of vegetable gum, 0.5-1.0 part of a catalyst,0.2-0.7 parts of an initiator, 80-100 parts of 2-acryloylamino-2-methallyl sulfonate, 30-50 parts of N,N-dimethylacrylamide, 10-20 parts of 4-vinylpyridine, a pH regulator, 3-7 parts of talc powder and 2-5 parts of calcium carbonate, wherein the dosage of the pH regulator should meet the requirements for pH value of a solution after regulation; the vegetable gum is water-soluble vegetable gum; the catalyst is sulfuric acid; the initiator is one or two of an ammonium persulfate-sodium hydrogen sulfite system and a potassium persulfate-sodium hydrogen sulfite system. At the high temperature of200 DEG C, the resin has good coating inhibition performance, and the rolling recovery rate of mud shale can reach 90%; the high-polymer curing resin has good salt and calcium pollution resistance, filtrate loss reduction ability and capability of improving rheological property of the drilling fluid. A preparation process is simple, low in cost, good in environmental protection effect and wide inapplication range.

Owner:石家庄华莱鼎盛科技有限公司

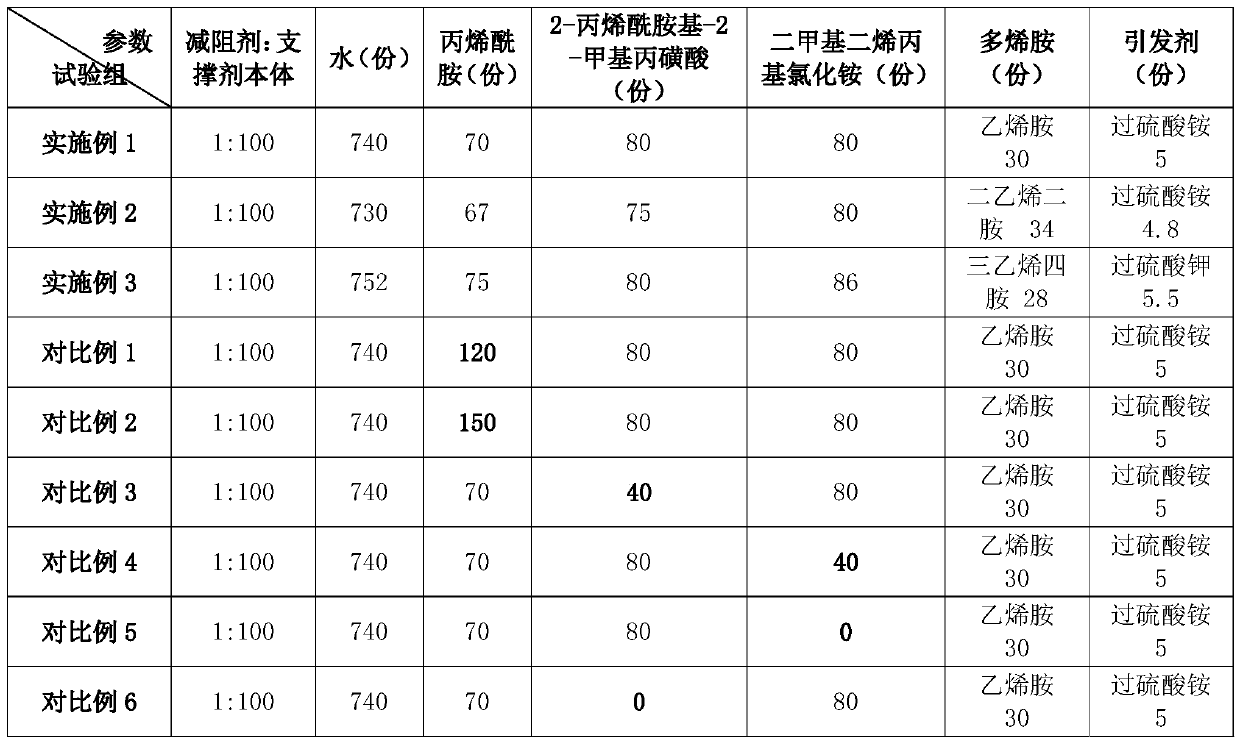

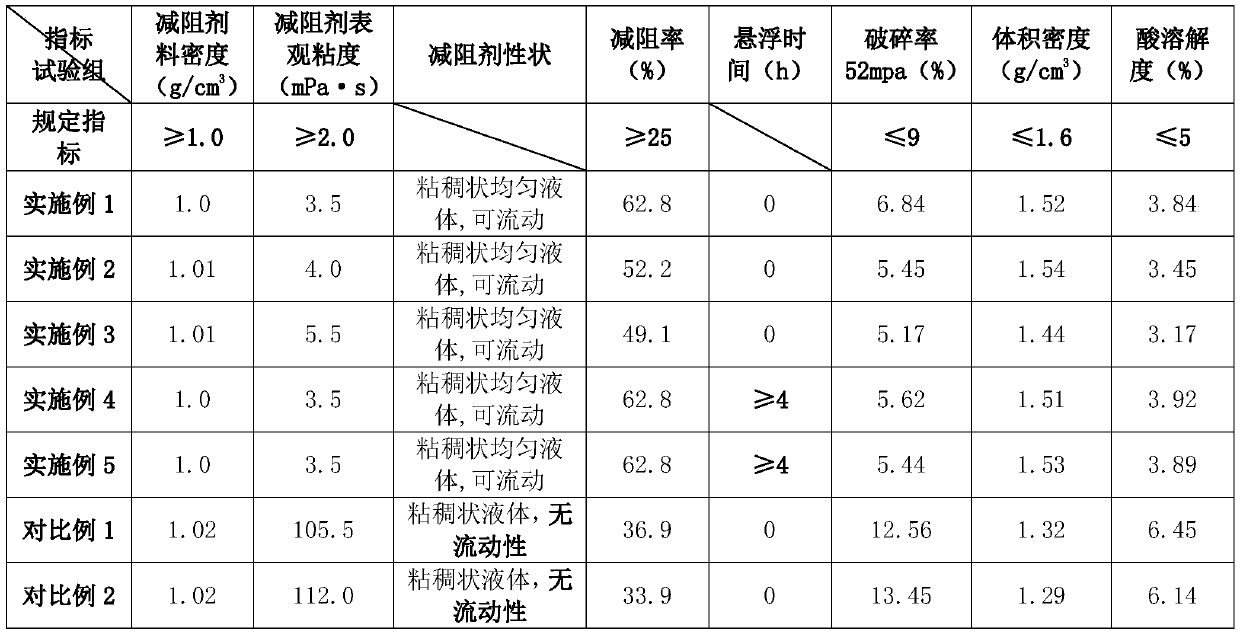

Preparation method of film covered supporting agent for fracturing

The invention belongs to the technical field of compositions for improving breaking effects, and specifically discloses a preparation method of a film covered supporting agent for fracturing. The method comprises the following steps: (1) preparing raw materials; (2) adding water to a reaction kettle, and increasing the temperature; (3) stirring; adding acrylamide, 2-acryloylamino-2-methallyl sulfonate, polyene amine and dimethyl diallyl ammonium chloride; and continuously stirring after adding the raw materials; (4) stirring when the temperature of the materials is maintained at 65-75 DEG C; adding an initiator; and continuously stirring for 4-7min; (5) reacting for 3.5-4.5h to obtain a drag reducer; and discharging when the drag reducing rate of the drag reducer is more than 25%; otherwise, adding a sodium hydroxide solution for adjusting; and (6) mixing the drag reducer and a supporting agent body on the basis of the mass ratio of 0.8-1.5 to 100; and covering the drag reducer on thesurface of the supporting agent body to obtain the film covered supporting agent for fracturing.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

Humic acid modified filtrate reducer for water-based drilling fluid and preparation method and drilling fluid

InactiveCN110591021AImprove temperature resistanceQuality improvementDrilling compositionEnvironmental resistanceWater based

The invention provides a humic acid modified filtrate reducer for a water-based drilling fluid and a preparation method and the water-based drilling fluid and aims to solve the technical problems thatin the prior art, a filtrate reducer is generally poor in both temperature resistance and salt resistance. The filtrate reducer is prepared from sodium humate as a raw material through grafting modification on the sodium humate with 2-acrylamide group-2-methallyl sulfonate, acrylamide and silicon dioxide through a copolymerization reaction. The temperature resistance of the filtrate reducer provided by the invention can be improved to 230 DEG C, the salt resistance can be up to 5% or greater, in addition, the quality of filter cakes can be effectively improved in application, and the filter loss can be reduced; and in addition, the filtrate reducer is nontoxic and degradable, environment protection requirements can be met, environment pollution can be avoided, and stratums and oil productquality are not damaged.

Owner:SOUTHWEST PETROLEUM UNIV

Coating agent polymer curing resin for drilling fluid

ActiveCN110358511BImprove performanceExcellent anti-salt and anti-calcium performanceDrilling compositionPotassium persulfateMeth-

High-polymer curing resin of a coating agent for a drilling fluid is prepared from raw materials as follows: 800-1,000 parts of clear water, 100-120 parts of vegetable gum, 0.5-1.0 part of a catalyst,0.2-0.7 parts of an initiator, 80-100 parts of 2-acryloylamino-2-methallyl sulfonate, 30-50 parts of N,N-dimethylacrylamide, 10-20 parts of 4-vinylpyridine, a pH regulator, 3-7 parts of talc powder and 2-5 parts of calcium carbonate, wherein the dosage of the pH regulator should meet the requirements for pH value of a solution after regulation; the vegetable gum is water-soluble vegetable gum; the catalyst is sulfuric acid; the initiator is one or two of an ammonium persulfate-sodium hydrogen sulfite system and a potassium persulfate-sodium hydrogen sulfite system. At the high temperature of200 DEG C, the resin has good coating inhibition performance, and the rolling recovery rate of mud shale can reach 90%; the high-polymer curing resin has good salt and calcium pollution resistance, filtrate loss reduction ability and capability of improving rheological property of the drilling fluid. A preparation process is simple, low in cost, good in environmental protection effect and wide inapplication range.

Owner:石家庄华莱鼎盛科技有限公司

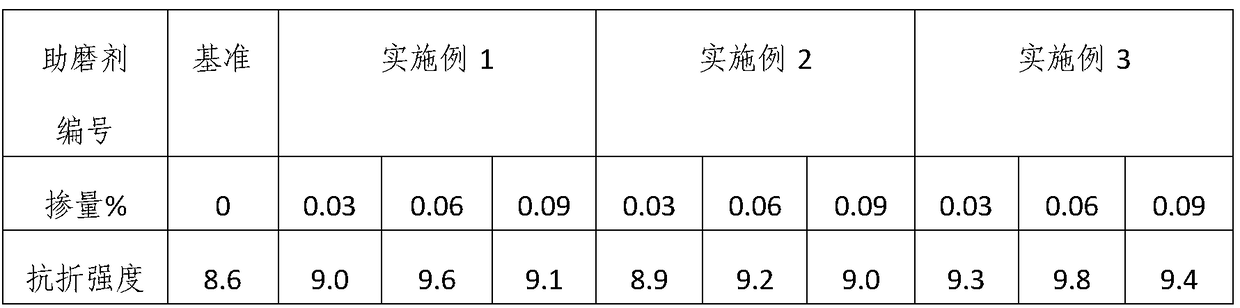

Sintering-free brick containing engineering muck and manufacturing method thereof

InactiveCN110041037ARealize resource utilizationReduce pollutionCeramic shaping apparatusCement mixing apparatusBrickSlag

The invention belongs to the field of waste recycling and specifically relates to a sintering-free brick containing engineering muck and a manufacturing method thereof. The sintering-free brick comprises the following raw materials in parts by weight: 15-20 parts of engineering muck, 3-5 parts of iron-ore slag, 10-12 parts of gangue, 4-7 parts of gypsum, 6-8 parts of shale, 1-2 parts of celluloseether, 1-2 parts of fine white carbon black and 0.5-0.8 part of viscosity modifier. Before use, the engineering muck is treated with the viscosity modifier which is prepared according to the followingsteps: mixing methallyl sulfonate, sodium persulfate and urea at a mass ratio of (1-1.2):(2-2.5):(0.2-0.3):(0.1-0.2), and then putting into a 3-5% sodium hydroxide solution and reacting for 60-70minat 55-60 DEG C. Thus, the viscosity of engineering muck can be effectively increased, so that the strength and quality of the prepared end product of brick can be effectively promoted. Cellulose etherand fine white carbon black are added into the raw materials, so that the strength and compressive property of the prepared end product can be promoted.

Owner:普定县银丰农业科技发展有限公司

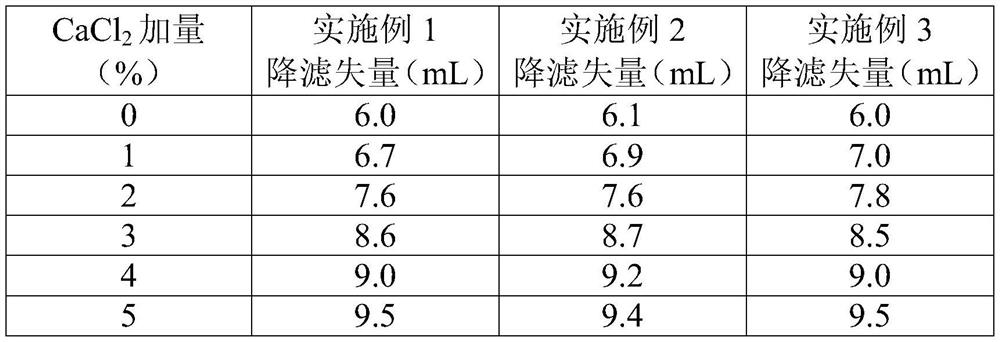

Environment-friendly composite corrosion and scale inhibitor and preparation method and use method thereof

InactiveCN110104803APromote chelationGood dispersionSpecific water treatment objectivesScale removal and water softeningMethallyl sulfonateFatty acid

The invention discloses an environment-friendly composite corrosion and scale inhibitor and a preparation method and use method thereof. The environment-friendly composite corrosion and scale inhibitor is prepared from, by weight percentage, 37-75% of a phosphorus-free and zinc-free scale inhibitor, 10-22% of a phosphorus-free and zinc-free corrosion inhibitor and the balance deionized water, wherein the phosphorus-free and zinc-free scale inhibitor is one or more of sodium gluconate, disodium ethylene diamine tetraacetate or an acrylic acid-2-acrylamide-2-methallyl sulfonate copolymer, and the phosphorus-free and zinc-free corrosion inhibitor is a compound of fatty acid polyoxyethylene ether and secondary alkyl sodium sulfonate. The composite corrosion and scale inhibitor does not containphosphorus and zinc, environmental pollution caused by phosphorus or zinc in water is avoided, and the requirement of environmental protection is met. Moreover, the preparation method and use methodof the environment-friendly composite corrosion and scale inhibitor are simple, and the environment-friendly composite corrosion and scale inhibitor is conveniently prepared and applied.

Owner:CHANGZHOU JINGKE XIAFENG FINE CHEM

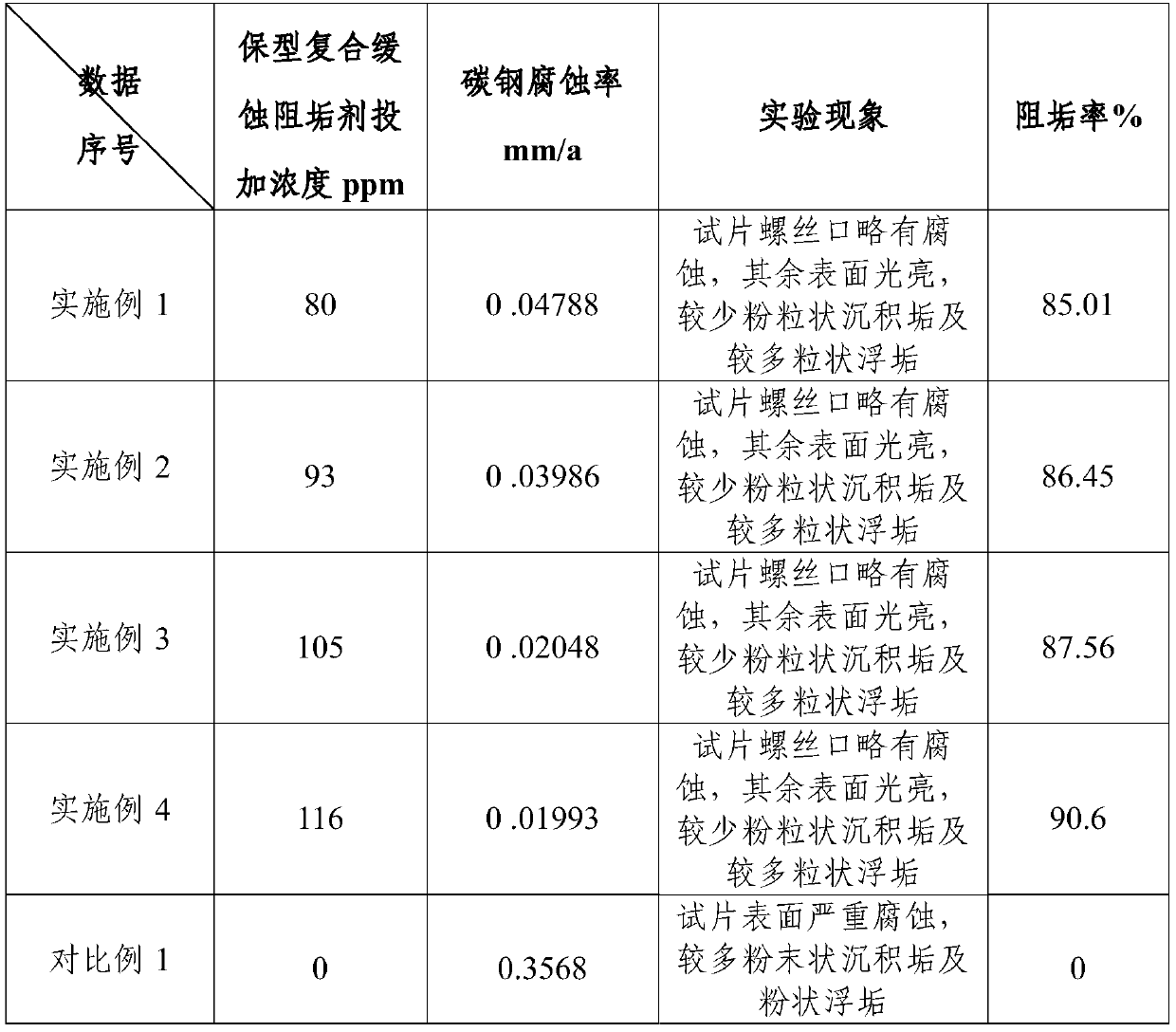

Environment-friendly foamed high-performance concrete and preparation method thereof

The invention relates to environment-friendly foamed high-performance concrete and a preparation method thereof. The environment-friendly foamed high-performance concrete consists of cement, coal ash,sand, modified rubber, silicon ash, waterproof emulsion and a foamed material, the modified rubber is prepared by virtue of the reaction of terminated-hydroxyl liquid nitrile rubber, tetrabutyl titanate, water, ethanol, silicasol, sodium silicate and oxalic acid, the waterproof emulsion is prepared by virtue of the reaction of 2-acrylamide-2-methallyl sulfonate, 2-ethylhexyl acrylate, water, SE-10 emulsifier, tetraethyl orthosilicate, silicasol, ammonium persulfate and acrylic acid, the foamed material is prepared by virtue of the reaction of hydroxyl-terminated silicone rubber, ammonium oxalate, ethanol, nano titanium dioxide, urea, KH-550 coupling agent and poly N-isopropylacrylamide, and the nano titanium dioxide is prepared by virtue of the reaction of tetrabutyl titanate, stearic acid, oleic acid, ethanol, polyoxyethylene stearates SG-12, water and glycerinum. The environment-friendly foamed high-performance concrete provided by the invention is excellent in heat preservation performance and waterproof performance.

Owner:TAIZHOU WEIHUA CONCRETE CO LTD

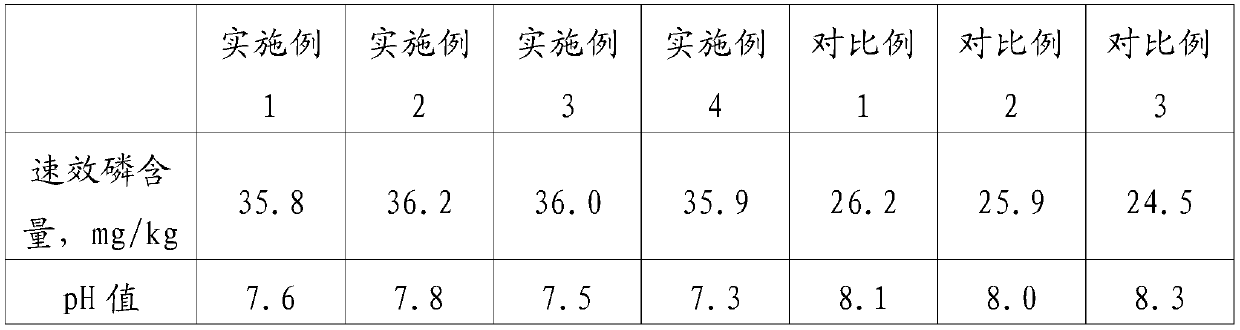

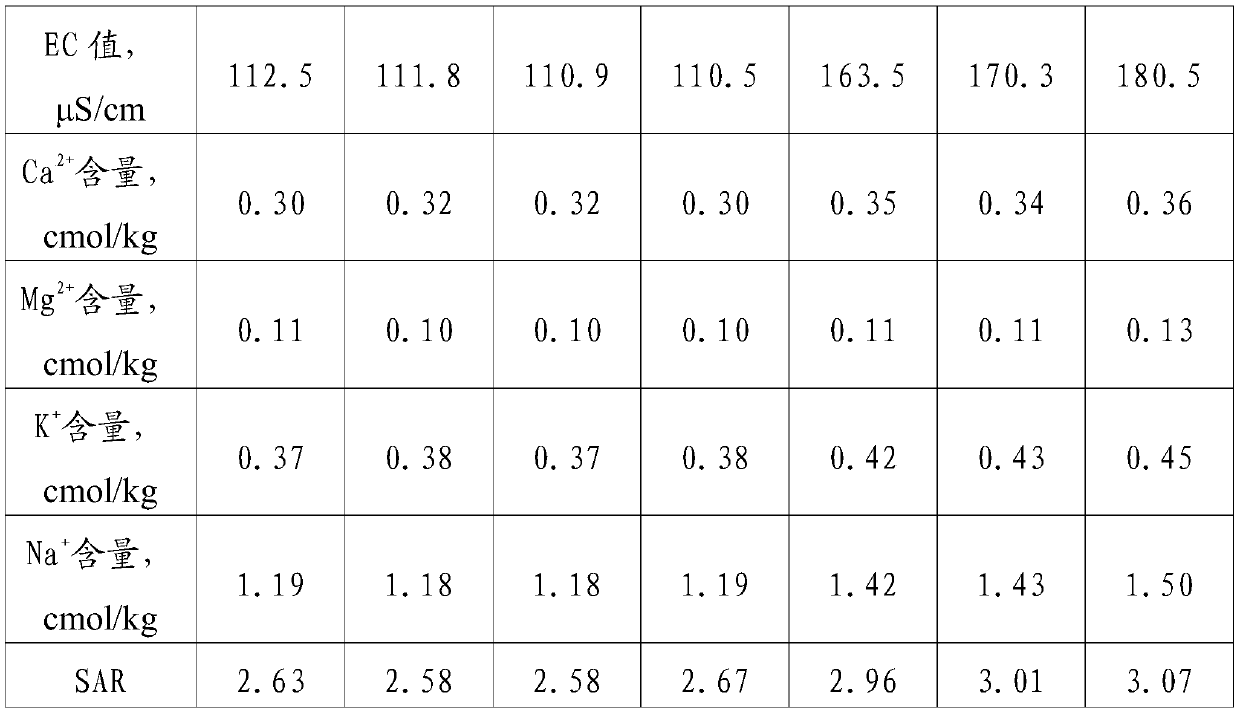

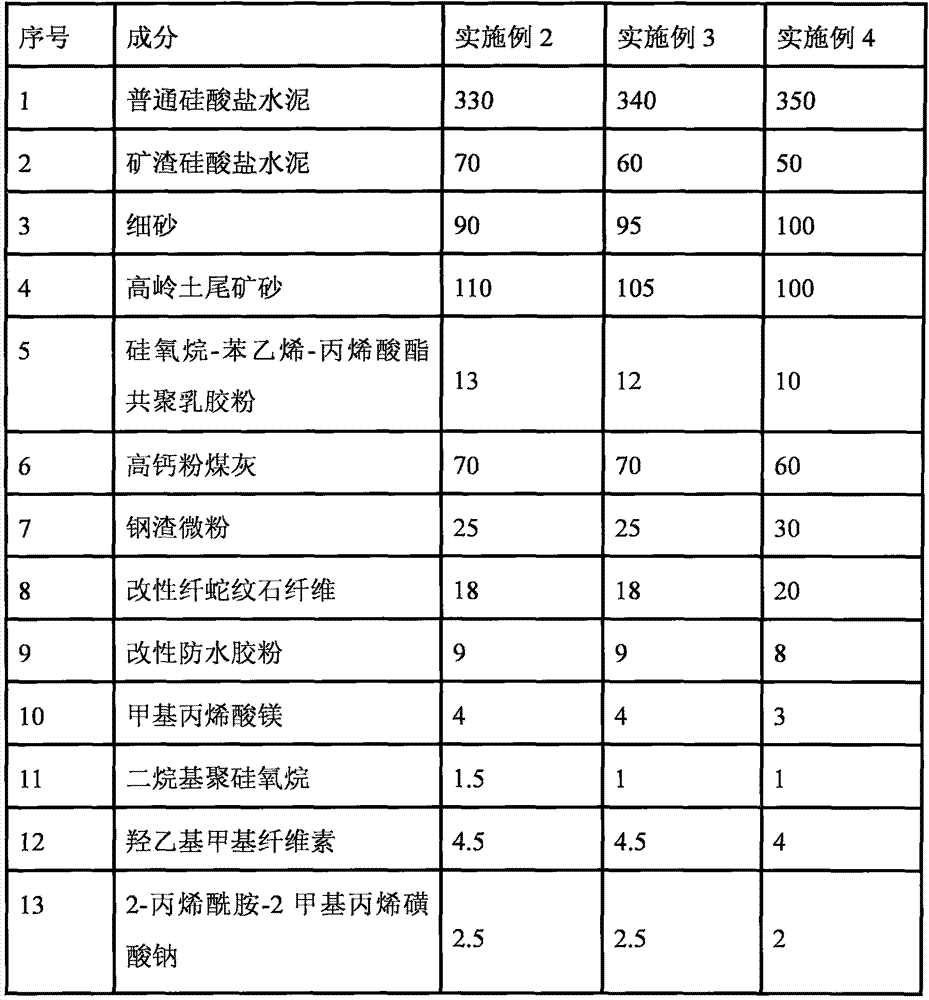

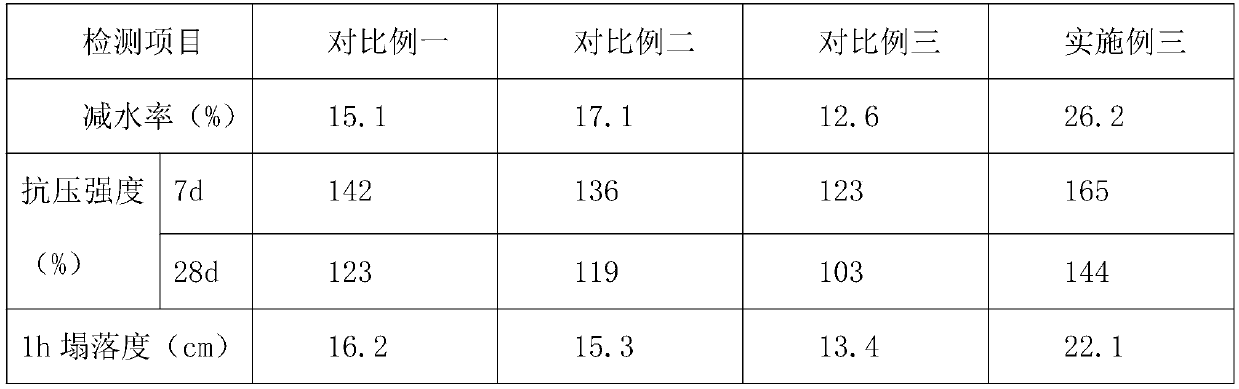

Composite environment-friendly waterproof dry-mixed mortar and preparation method thereof

The invention provides composite environment-friendly waterproof dry-mixed mortar and a preparation method thereof. The composite environment-friendly waterproof dry-mixed mortar is prepared from cement, sand, modified polymer latex powder, admixtures and chemical additives, wherein the sand is composed of fine sand and kaolin tailing sand, the modified polymer latex powder is siloxane-styrene-acrylate copolymer latex powder, the admixtures comprise high-calcium fly ash, steel slag micropowder and modified chrysotile fibers, and the chemical additives comprise modified waterproof adhesive powder, dialkyl polysiloxane, methacrylic acid, hydroxyethyl methyl cellulose and 2-acrylamide sodium 2-methallyl sulfonate. In this way, the composite environment-friendly waterproof dry-mixed mortar is high in compressive strength, good in waterproof performance, high in cracking resistance and shrinkage resistance and low in cost.

Owner:FUJIAN MINGNENG NEW BUILDING MATERIAL CO LTD

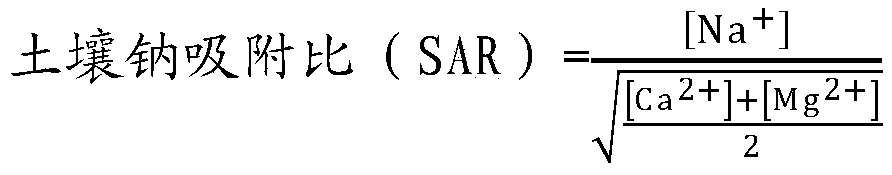

Composite improvement method for saline and alkaline land

InactiveCN110959327AImprove salt toleranceGood water permeabilitySoil-working methodsAlkali soilPorous carbon

The invention discloses a composite improvement method for a saline and alkaline land. The method specifically comprises the following steps: laying concealed conduits; performing mixed coal cinder salt washing; laying crushed plant straw in soil of a salt washed saline and alkaline land; uniformly throwing a mixture of biological bacterial agents and urea, and performing deep ploughing, turning and burying; applying a multi-stage porous carbon material, an acrylic acid-2-acrylamide-2-methallyl sulfonate copolymer, a nano humic acid-based composite resin, an inorganic fertilizer, humic acid and an excrement fertilizer into each mu of deeply ploughed, turned and buried soil of the saline and alkaline land, and uniformly mixing the inorganic fertilizer, the humic acid and the excrement fertilizer into a ploughing layer by using a rotary cultivator; performing three years of planting of salt-resistant alfalfa after domestication culture in the treated soil of the saline and alkaline land,and further planting crops such as wheat or corn. By adopting the method, salt contents in the soil can be effectively reduced, the fertility of the soil of the saline and alkaline land can be improved, and the physical and chemical properties of the soil of the saline and alkaline land can be improved.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

A kind of composite environmental protection waterproof dry powder mortar and preparation method thereof

The invention provides composite environment-friendly waterproof dry-mixed mortar and a preparation method thereof. The composite environment-friendly waterproof dry-mixed mortar is prepared from cement, sand, modified polymer latex powder, admixtures and chemical additives, wherein the sand is composed of fine sand and kaolin tailing sand, the modified polymer latex powder is siloxane-styrene-acrylate copolymer latex powder, the admixtures comprise high-calcium fly ash, steel slag micropowder and modified chrysotile fibers, and the chemical additives comprise modified waterproof adhesive powder, dialkyl polysiloxane, methacrylic acid, hydroxyethyl methyl cellulose and 2-acrylamide sodium 2-methallyl sulfonate. In this way, the composite environment-friendly waterproof dry-mixed mortar is high in compressive strength, good in waterproof performance, high in cracking resistance and shrinkage resistance and low in cost.

Owner:FUJIAN MINGNENG NEW BUILDING MATERIAL CO LTD

Concrete water-reducing agent with high pressure resistance as well as preparation method thereof

The invention discloses the technical field of a building auxiliary material and relates to a concrete water-reducing agent with high pressure resistance as well as a preparation method thereof. The water-reducing agent comprises the following raw materials in parts by weight: 20 to 32 parts of methyl allyl alcohol polyoxyethylene ether, 8 to 16 parts of potassium fatty acid soap, 3 to 9 parts ofsodium methallyl sulfonate, 5 to 10 parts of bone glue, 2 to 6 parts of sodium tripolyphosphate, 2 to 5 parts of coconut diethanolamine, 1 to 5 parts of shell powder, 2 to 8 parts of methyl propyleneglycol, 1 to 5 parts of supersaturated urea solution, 8 to 18 parts of melamino-formaldehyde resin, 3 to 6 parts of a defoaming agent, 2 to 10 parts of a thickening agent, 1 to 5 parts of mercaptoacetic acid and 10 to 22 parts of deionized water. According to the concrete water-reducing agent provided by the invention, the concrete has high slump maintaining performance and pressure resistance, the concrete can maintain the construction property for a long time, and the collapse resistance is enhanced.

Owner:广州华隆建筑材料有限公司

Octadecanol methyl propionate, preparation method thereof, water-soluble thickener and preparation method of water-soluble thickener

InactiveCN109912411ASimple methodEasy to implementOrganic compound preparationCarboxylic acid esters preparationMethallyl sulfonateOil production

The invention relates to the technical field of thickeners, in particular to octadecanol methyl propionate, a preparation method thereof, a water-soluble thickener and a preparation method of the water-soluble thickener. The water-soluble thickener comprises raw materials including acrylamide, 2-acrylamide-2-methallyl sulfonate, octadecanol methyl propionate, hexadecyl trimethyl ammonium chloride,sodium bisulfite, ammonium persulfate, ethylene diamine tetraacetic acid, urea, sodium carbonate and deionized water. The preparation methods of the octadecanol methyl propionate and the water-soluble thickener are simple and easy to implement, the water-soluble thickener is convenient to use, can be applied to oil production and increase the recovery ratio and has a hydrophobic function as wellas hydrophilic performance, besides, the water-soluble thickener has good viscoelasticity after being dissolved in water, and by comparison of the water-soluble thickener with conventional polymer thickeners commonly used at present in oil field sewage and water with mineralization degree of 150,000 mg / L after application, and the water-soluble thickener is found to better increase viscosity of liquids.

Owner:KARAMAY ZHENGCHENG

Method for preparing heavy calcium carbonate dispersing agent for papermaking

InactiveCN106220775AEasy to useReduce usagePaper/cardboardDispersing agents additionSodium stearate(Hydroxyethyl)methacrylate

The invention discloses a method for preparing a heavy calcium carbonate dispersing agent for papermaking. The method comprises the following steps: (1) mixing water, maleic anhydride, itaconic acid and ethylene diamine tetraacetic acid disodium salt, adding an initiating system reducing agent, preparing a solution A, stirring at a speed of 200 revolutions per minute, heating at the temperature of 85 DEG C, and introducing N2; (2) mixing methacrylic acid, hydroxyethyl methylacrylat and water, and preparing a dropping solution B; (3) preparing 2-acrylamide-2-methallyl sulfonate, an initiating system oxidizing agent and water into a dropping solution C; (4) preparing water and the initiating system oxidizing agent into a 10% solution D; (5) simultaneously dripping the dropping solution B and the dropping solution C into the solution A, completing dropping within an hour, maintaining the temperature and reacting for an hour; finally, dripping the solution D, completing dropping within half an hour, maintaining the temperature and reacting for 2.5 hours; (6) cooling to the temperature of 50 DEG C, regulating the pH value to 7.0 by using a 40% NaOH solution, obtaining a quadripolymer, and compounding the quadripolymer with sodium stearate according to a mass ratio of 5:1, thereby obtaining the heavy calcium carbonate dispersing agent for papermaking.

Owner:朱燕华

Gel packing material and preparation method thereof

InactiveCN108795399AGood water solubilityHigh reactivityDrilling compositionNetwork structureSodium methacrylate

The invention relates to a gel packing material and a preparation method thereof, and belongs to the technical field of gel materials. By use of the natures that alkali lignin cannot be dissolved in acid and separates out sediments easily, the alkali lignin is modified and is then grafted with acrylamide, sodium methacrylate and 2-acryloylamino-2-methallyl sulfonate to improve the water solubilityand the reaction activity of a copolymerization product; meanwhile, under the action of a crosslinking agent, crosslinking reaction occurs, so that the density of crosslinking points is increased, athree-dimensional network structure is formed, the intensity of gel is increased, and the gelling time is shortened; a flexibilizer is a macromolecular polymer for adhering and twisting a mesh structure of an alkali lignin gel system, reinforcing an alkali lignin spatial mesh structure and improving the stability and the flexibility of the whole structure, so as to achieve toughening and anti-shearing effects; an alkaline alkali lignin solution is injected into a mine and is in contact with acidic fluid in the mine or injected in the later stage, so that alkali lignin is separated out continuously to form the sediments and complete blocking.

Owner:FOSHAN CHAOHONG NEW MATERIAL TECH CO LTD

Process for preparing salts of methallylsulfonic acid

InactiveUS6864388B2Reduce formationIncrease productionElectrolysis componentsOrganic chemistry methodsMedicinal chemistryMethallyl sulfonate

Owner:OXENO OLEFINCHEMIE GMBH

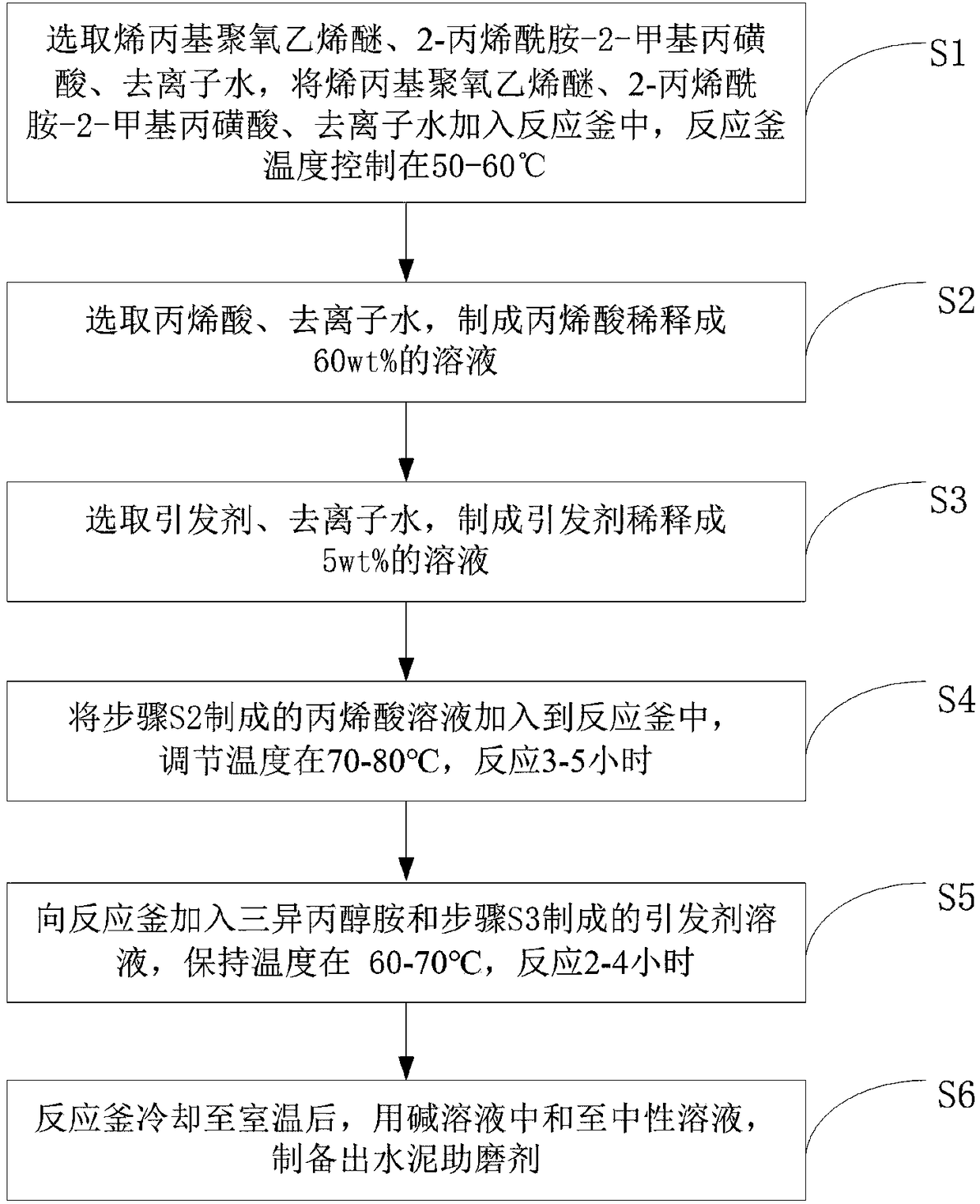

Method for preparing grinding aid for cement

The invention provides a method for preparing a grinding aid for cement and relates to the technical field of cement grinding aid production and processing. A macromolecule cement grinding aid is prepared from allyl polyethenoxy ether, 2-acrylamide-2-methallyl sulfonate, deionized water, acrylic acid, ammonium persulfate as an initiator, triisopropanolamine and a NaOH solution as raw materials through chemical modification synthesis. By adopting the method for preparing the grinding aid for cement, the prepared cement grinding aid is low in cost, good in property and high in comprehensive benefit, and has wide application prospects, and grinding aiding and reinforcement properties of the cement grinding aid upon cement clinkers and mixed materials are improved through chemical modification.

Owner:池州市知识产权服务中心有限公司

Metal surface dewaxing agent

The invention discloses a metal surface dewaxing agent, and belongs to the field of metal surface treatment. A prepared solubilizing additive is a polymer with amphiprotic hydrophobic association prepared by emulsifying through the compounding of Span-80 and alkanolamide, and the grafted-copolymerization of acrylamide and 2-acryloylamino-2-methallyl sulfonate, and has high stability, corrosion resistance and an anti-static performance; an adhered waxy molecule is quickly dispersed in water by utilizing a hydrophilic group, so that the dewaxing efficiency is improved; a prepared adsorption corrosion-inhibition protection agent is added with benzyl chloride and epoxy chloropropane so as to carry out quaterisation, and a film can be quickly formed on ta metal surface by utilizing a good micelle assembling performance, so that a workpiece protection performance is improved; and an added dewaxing cleaning active agent is compounded by fatty alcohol polyoxyethylene ether and the like, and the solvent is used for solubilizing so as to accelerate the stripping speed, so that the dewaxing efficiency is improved, and a workpiece is protected. The metal surface dewaxing agent provided by theinvention solves the problems that a current dewaxing agent is low in dewaxing efficiency and easy to corrode the workpiece.

Owner:梁生

A Method for Volumetric Acid Fracturing of Carbonate Reservoir Fracture Network

InactiveCN107216866BGood resistance reduction effectImprove responseFluid removalDrilling compositionWater basedSodium ascorbate

The invention provides a method for volume acid-fracturing reformation of a seam net of a carbonate reservoir. The method specifically comprises the following steps: (1) injecting low-viscose resistance-reducing sliding acid liquor, performing plunger injection for at least three times and performing volume fracturing reformation of the seam net; (2) injecting a water-based sand-carrying fracturing fluid and forming sand-filling cracks in length not less than 120 meters on the two sides of a well shaft; (3) injecting a displacement fluid, closing the well and then draining the liquid, wherein the low-viscose resistance-reducing sliding acid liquor is composed of 5-20% of acid, 1-3% of alkyl quaternary ammonium salt, 0.5-2% of sodium ascorbate, 0.1-0.5% of emulsion corrosion inhibitor, 0.5-1% of citric acid, 1-3% of discharge aiding agent and the balance of water; the emulsion corrosion inhibitor is selected from any one of polypropylene glycol emulsion, polyvinylpyrrolidone emulsion, acrylamide and 2-crylic acid-2-methallyl sulfonate copolymer emulsion; and the acid is selected from hydrochloric acid, formic acid, acetic acid or bionic acid. The method is simple in construction, the flow conductivity of the seam net is high and the yield-increasing effect is excellent.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

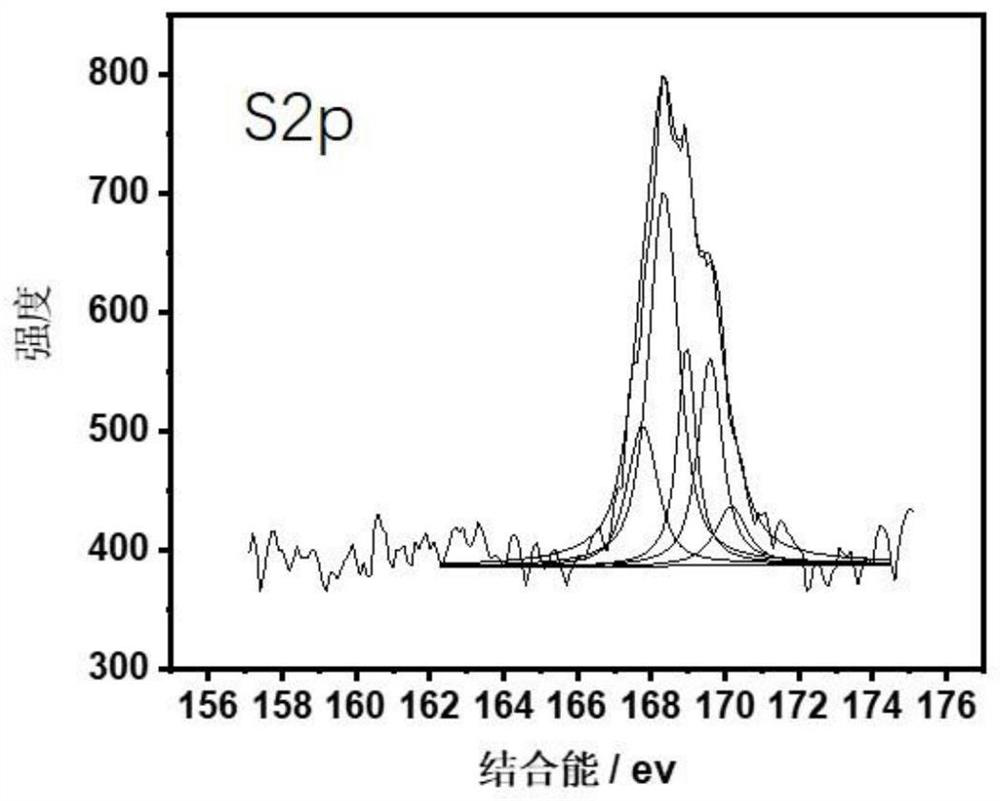

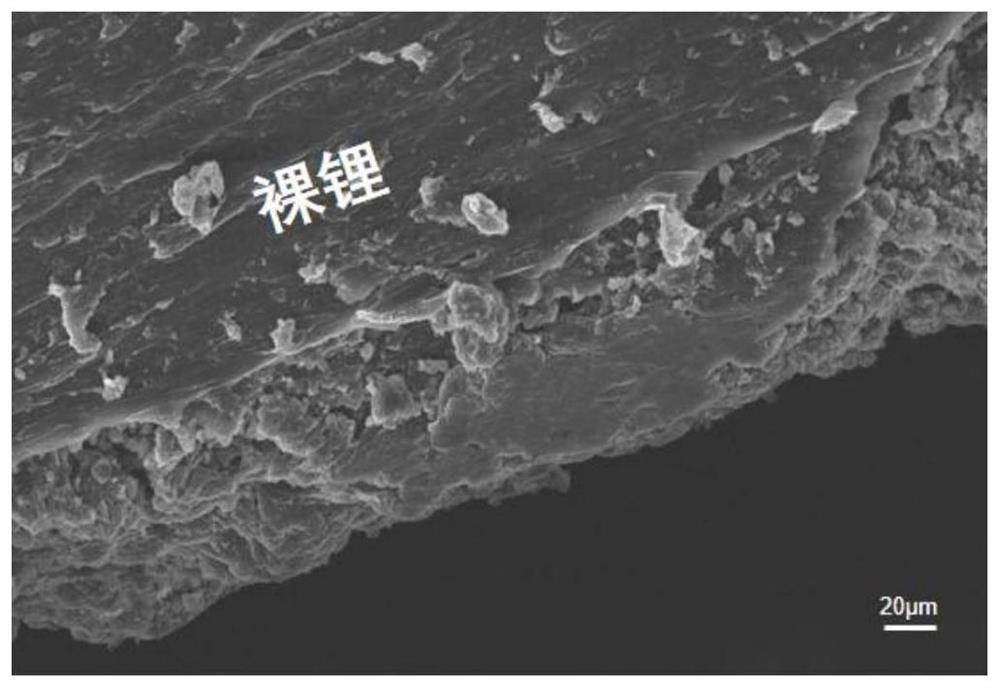

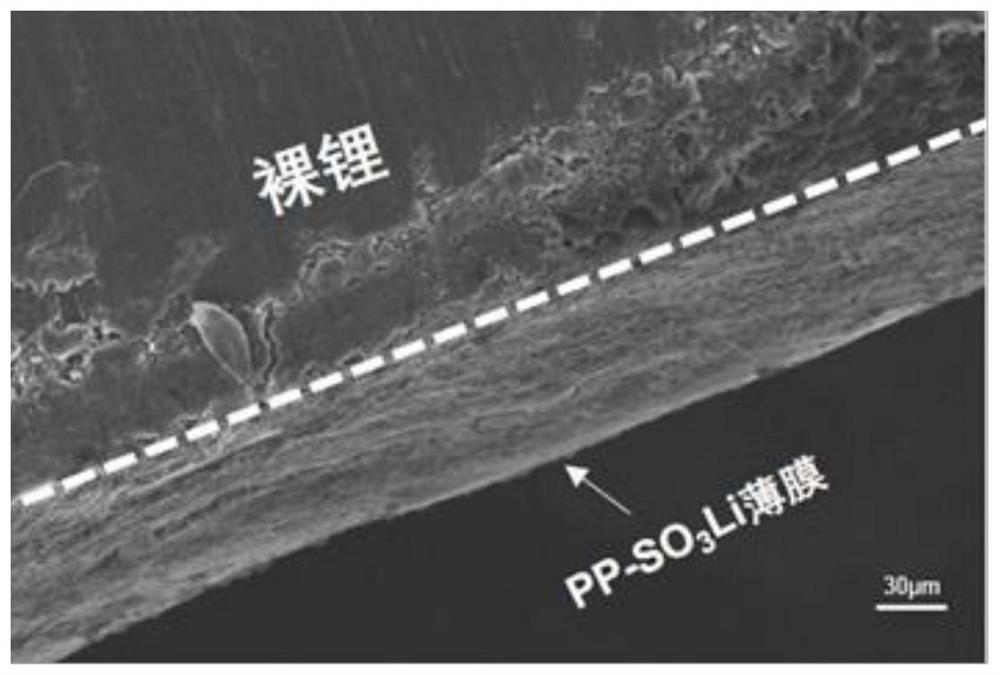

Preparation and application of lithium polymethylallyl sulfonate for lithium battery negative electrode protection

ActiveCN113461848AImprove cycle performanceExtended service lifeNegative electrodesSecondary cellsElectrochemical responseLithium oxide

The invention relates to the field of lithium ion batteries, and discloses preparation and application of a lithium battery negative electrode protective layer lithium polymethylallyl sulfonate aiming at the problem that an existing lithium battery is lack of an excellent lithium battery negative electrode protective layer, and the preparation method comprises the following steps: (1) dissolving methallyl sulfonic acid in water, adding a lithium hydroxide aqueous solution for reaction under the conditions of ice bath and nitrogen, after the reaction is finished, adding diluted hydrochloric acid until a solid is separated out, fully conducting stirring, conducting filtering, and collecting the solid to obtain lithium methallyl sulfonate; and (2) carrying out heating reaction on lithium methallyl sulfonate, triethyl aluminum and a solid catalyst, adding acidified ethanol to terminate the reaction, conducting filtering, and conducting drying to obtain the lithium polymethallyl sulfonate. The lithium negative electrode is spin-coated with a lithium polymethallyl sulfonate functional protection layer, so that the cycle performance of the lithium battery is effectively improved, the loss of active substances caused by corrosion reaction of electrochemical reaction products and the lithium metal negative electrode is reduced, the growth of lithium dendrites is prevented, the cycle performance of the lithium battery is improved, and the service life of the lithium battery is prolonged.

Owner:HANGZHOU NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com