Environment-friendly composite corrosion and scale inhibitor and preparation method and use method thereof

A corrosion and scale inhibitor, an environmentally friendly technology, applied in the field of environmentally friendly composite corrosion and scale inhibitors, to achieve excellent penetration and wetting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] According to the above preparation method, an environment-friendly composite corrosion and scale inhibitor is prepared, wherein the weight percentage of each component consists of: sodium gluconate 75%, high-efficiency phosphorus-free corrosion inhibitor NPAA-21 (fatty acid polyoxyethylene ether and secondary alkyl sulfonate Sodium acid compound) 11%, the balance is deionized water.

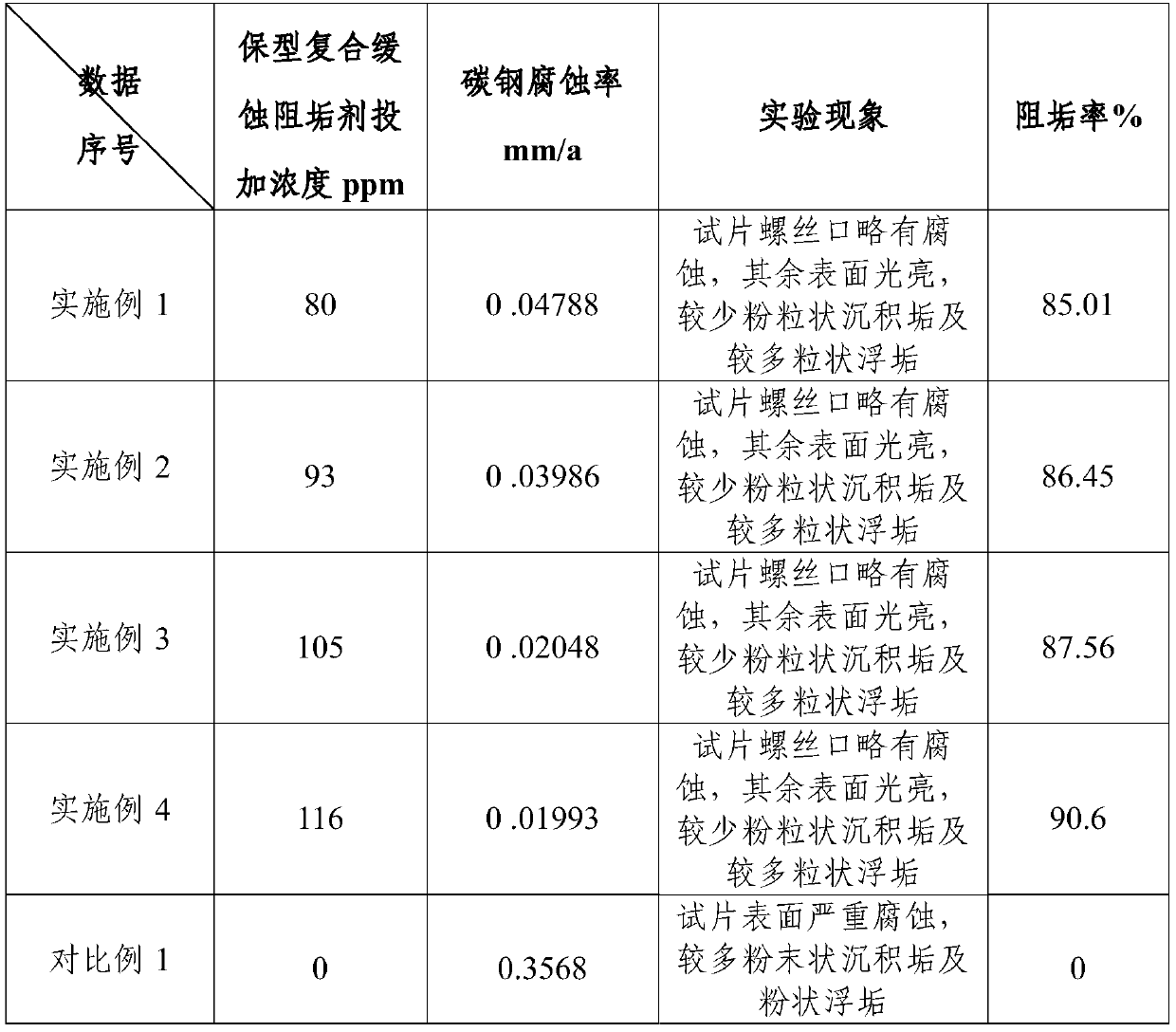

[0024] Using "GBT 18175-2000 Determination of Corrosion Inhibition Performance of Water Treatment Agents by Rotary Coupon Method" and "GBT 16632-2008 Determination of Scale Inhibition Performance of Water Treatment Agents by Calcium Carbonate Deposition Method" to evaluate its corrosion and scale inhibition performance, The dosing concentration of the environment-friendly composite corrosion and scale inhibitor is 80ppm, the corrosion rate of carbon steel is 0.04788mm / a, the screw mouth of the test piece is slightly corroded, and the rest of the surface is bright, with less powdery sediment...

Embodiment 2

[0026] According to the above-mentioned preparation method, an environment-friendly composite corrosion and scale inhibitor is prepared, wherein the weight percentage of each component is composed of: sodium gluconate 37%, disodium edetate 30%, high-efficiency phosphorus-free corrosion inhibitor NPAA-1 ( Fatty acid polyoxyethylene ether and secondary alkyl sodium sulfonate) 15%, the balance is deionized water.

[0027] Using "GBT 18175-2000 Determination of Corrosion Inhibition Performance of Water Treatment Agents by Rotary Coupon Method" and "GBT 16632-2008 Determination of Scale Inhibition Performance of Water Treatment Agents by Calcium Carbonate Deposition Method" to evaluate its corrosion and scale inhibition performance, The dosing concentration of the environment-friendly compound corrosion and scale inhibitor is 93ppm, the corrosion rate of carbon steel is 0.03986mm / a, the screw mouth of the test piece is slightly corroded, and the rest of the surface is bright, with l...

Embodiment 3

[0029] According to the above preparation method, an environment-friendly composite corrosion and scale inhibitor is prepared, wherein the weight percentage of each component is composed of: sodium gluconate 10%, disodium edetate 5%, acrylic acid-2-acrylamide-2-methanol Propylene sulfonic acid copolymer 35%, high-efficiency phosphorus-free corrosion inhibitor NPAA-1 (compound of fatty acid polyoxyethylene ether and secondary alkyl sodium sulfonate) 18% and benzotriazole 1%, the balance is Deionized water.

[0030] Using "GBT 18175-2000 Determination of Corrosion Inhibition Performance of Water Treatment Agents by Rotary Coupon Method" and "GBT 16632-2008 Determination of Scale Inhibition Performance of Water Treatment Agents by Calcium Carbonate Deposition Method" to evaluate its corrosion and scale inhibition performance, The dosing concentration of the environment-friendly compound corrosion and scale inhibitor is 105ppm, the corrosion rate of carbon steel is 0.02048mm / a, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com