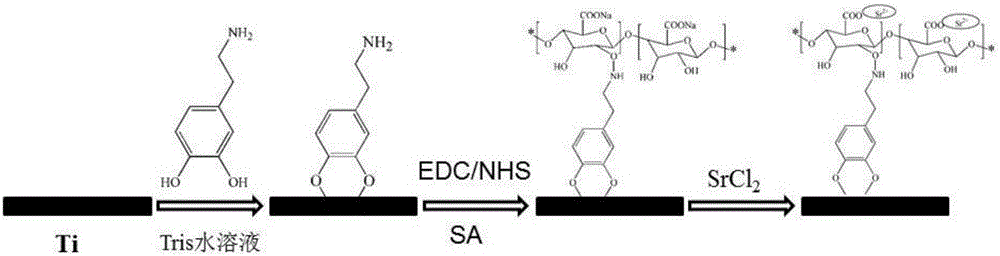

Preparation method of strontium chelated sodium alginate coating on titanium surface

A sodium alginate and chelation technology, which is applied in the field of surface modification of biomedical materials, can solve the problems of graft failure, poor bone integration between graft materials and hosts, and short osteoinductive action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

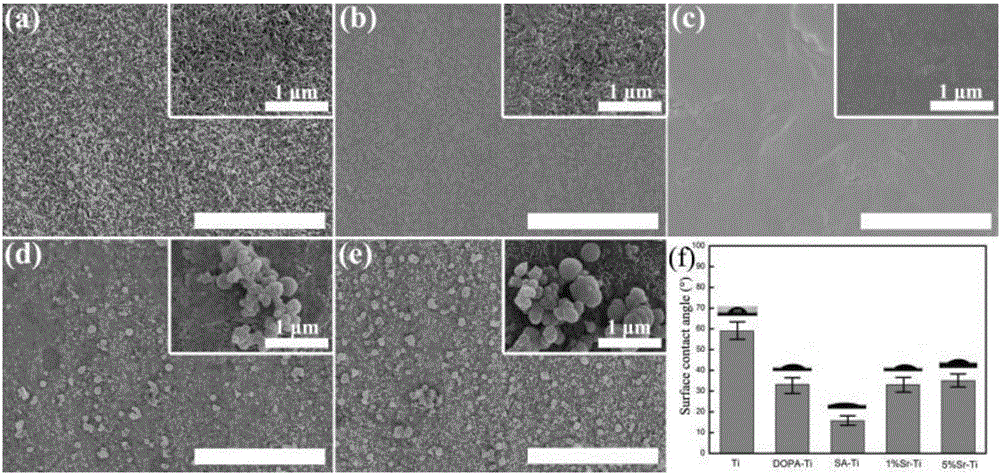

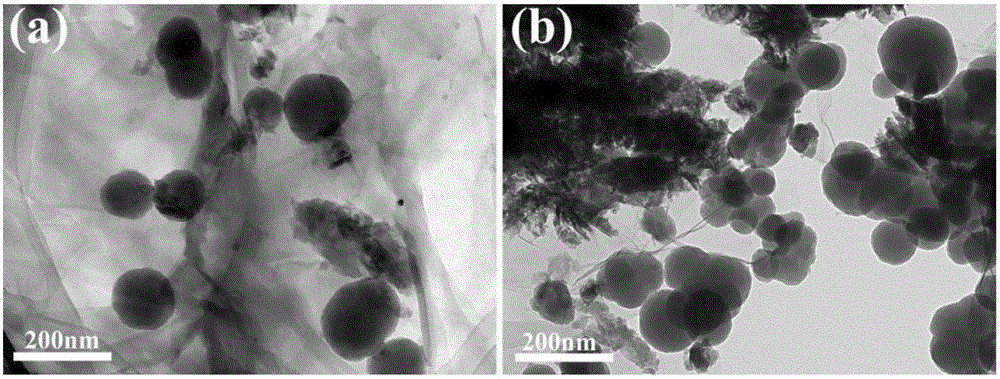

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: This example is to prepare the sodium alginate coating of chelating strontium on the surface of titanium sheet, the pH=8 of the Tris-HCl solution that configures dopamine solution to use, the strontium concentration that adopts when soaking is the SrCl of mass fraction 0.1% 2 solution. The specific experimental steps are as follows:

[0033] 1) The titanium sheet is placed in HNO with a mass fraction of 40% 3 , corrode at room temperature for 40min, then take out the titanium piece, rinse it with deionized water and dry it, put it in 5mol / L NaOH solution, keep it in a water bath at 90°C for 5h, and then wash it with absolute ethanol and deionized water successively Ultrasonic cleaning was performed for 10 min, and the titanium sheets obtained in this step were denoted as Ti.

[0034] 2) Dissolve 0.0606g Tris in 50ml of deionized water, add 0.05g DOPA after fully dissolved, and adjust the pH of the solution to 8 with 1mol / L HCl and 1mol / L NaOH, and immers...

Embodiment 2

[0038] Embodiment 2: This example is to prepare the sodium alginate coating of chelating strontium on the surface of titanium sheet, the pH=8 of the Tris-HCl solution that configures dopamine solution to use, the strontium concentration that adopts when soaking is the SrCl of mass fraction 0.3% 2 solution. The specific experimental steps are as follows:

[0039] 5) The titanium sheet is placed in HNO with a mass fraction of 40% 3 , corrode at room temperature for 40min, then take out the titanium piece, rinse it with deionized water and dry it, put it in 5mol / L NaOH solution, keep it in a water bath at 90°C for 5h, and then wash it with absolute ethanol and deionized water successively Ultrasonic cleaning was performed for 10 min, and the titanium sheets obtained in this step were denoted as Ti.

[0040] 6) Dissolve 0.0606g Tris in 50ml of deionized water, add 0.05g DOPA after fully dissolved, and adjust the pH of the solution to 8 with 1mol / L HCl and 1mol / L NaOH, and immers...

Embodiment 3

[0044] Embodiment 3: This example is to prepare the sodium alginate coating of chelating strontium on the surface of titanium sheet, the pH=8 of the Tris-HCl solution that configures dopamine solution to use, the strontium concentration that adopts when soaking is the SrCl of mass fraction 0.5% 2 solution. The specific experimental steps are as follows:

[0045] 1) The titanium sheet is placed in HNO with a mass fraction of 40% 3 , corrode at room temperature for 40min, then take out the titanium piece, rinse it with deionized water and dry it, put it in 5mol / L NaOH solution, keep it in a water bath at 90°C for 5h, and then wash it with absolute ethanol and deionized water successively Ultrasonic cleaning was performed for 10 min, and the titanium sheets obtained in this step were denoted as Ti.

[0046] 2) Dissolve 0.0606g Tris in 50ml of deionized water, add 0.05g DOPA after fully dissolved, and adjust the pH of the solution to 8 with 1mol / L HCl and 1mol / L NaOH, and immers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com