Patents

Literature

548 results about "Mass fraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, the mass fraction of a substance within a mixture is the ratio wᵢ (alternatively denoted Yᵢ) of the mass mᵢ of that substance to the total mass mₜₒₜ of the mixture. Expressed as a formula, the mass fraction is: wᵢ=mᵢ/mₜₒₜ. Because the individual masses of the ingredients of a mixture sum to mₜₒₜ, their mass fractions sum to unity: ∑ᵢ₌₁ⁿwᵢ=1. Mass fraction can also be expressed, with a denominator of 100, as percentage by mass (in commercial contexts often called percentage by weight, abbreviated wt%; see mass versus weight).

Method for preparing graphene reinforced metal-based composite material through discharge plasma (SPS) sintering

The present invention relates to a method for preparing a graphene reinforced metal-based composite material through discharge plasma (SPS) sintering. The method is characterized in that the graphene reinforced metal-based block material is prepared through SPS sintering and has the following advantages that: the preparation method is simple, the material is compact and does not have pores, the graphene mass fraction can be arbitrarily regulated, the distribution is uniform, no aggregation is generated, the material mechanical property isotropy is provided, and the wettability of the metal and the graphene interface is good. The method comprises: (1) reducing graphene oxide through a chemical method or a hydrothermal method to obtain graphene sheets with a sheet layer thickness of not more than 4 nm and sheet layer diameter of not more than 50 [mu]m; and (2) preparing metal powder with a particle size of not more than 200 [mu]m through a rotating electrode atomization method, mechanical crushing or a high-speed ball milling method; (3) carrying out mechanical or ball milling mixing on the graphene powder and the metal powder according to the required mass ratio; and (4) carrying out SPS sintering forming on the mixed powder, wherein the obtained material has characteristics of improved mechanical property, decreased density, good heat conduction capability, and good electric conduction capability, and the performance customizing can be achieved by adjusting the preparation parameters.

Owner:BEIHANG UNIV

Hypoeutectic high-chromium white cast iron and preparation method thereof

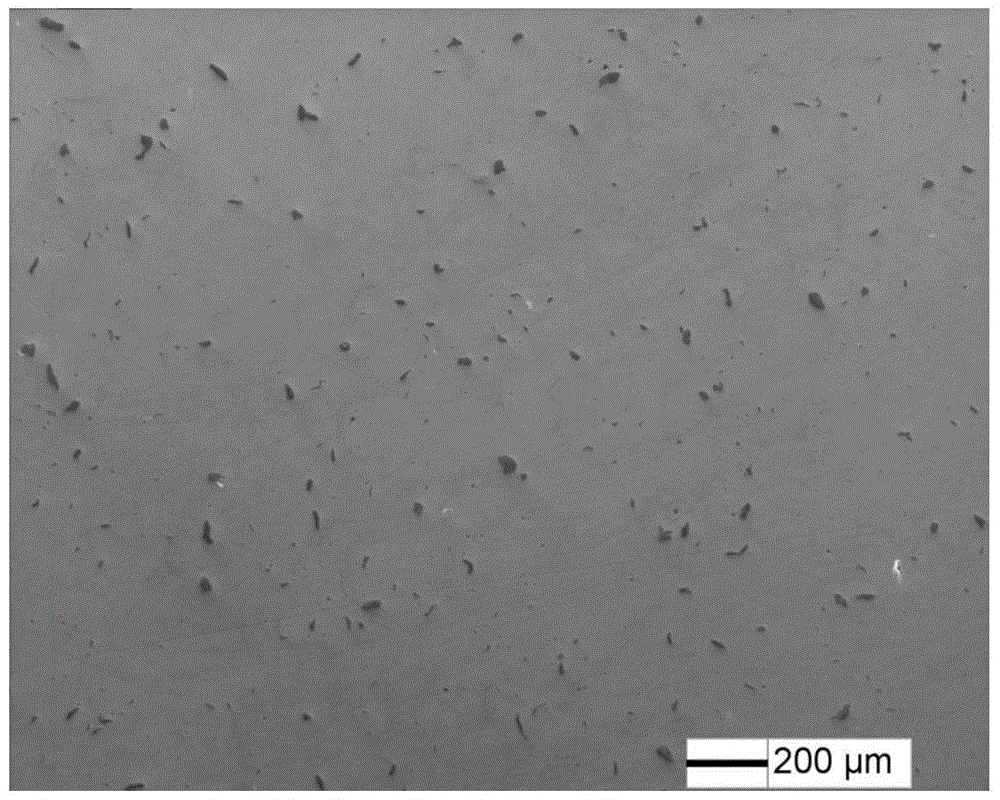

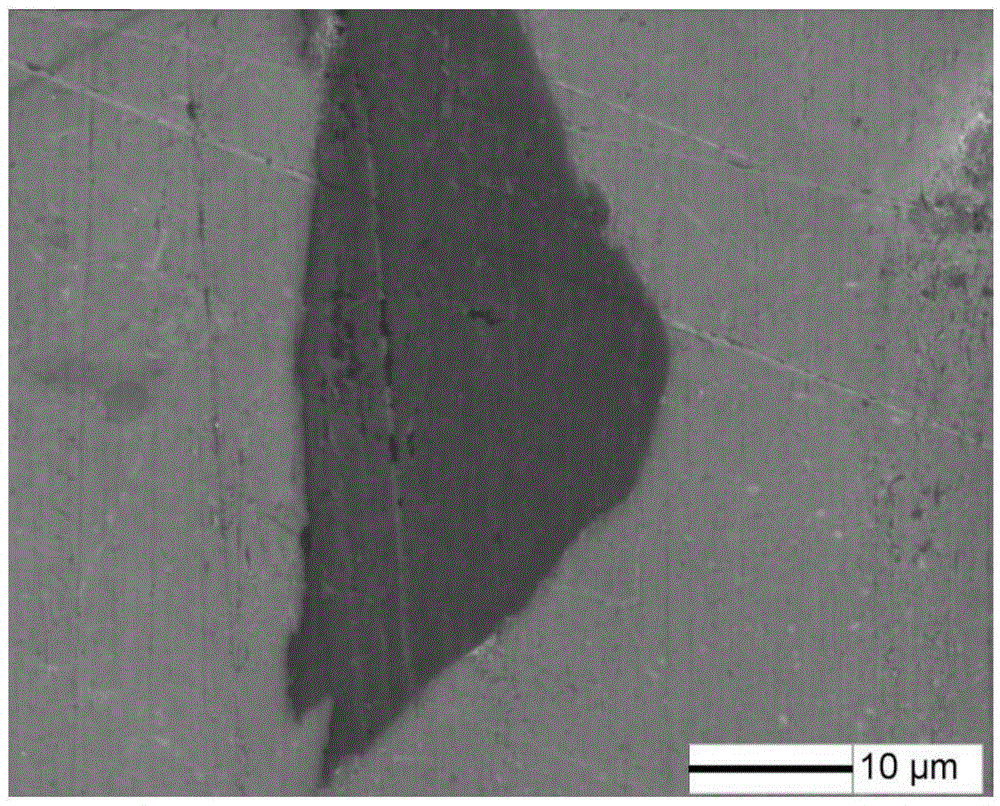

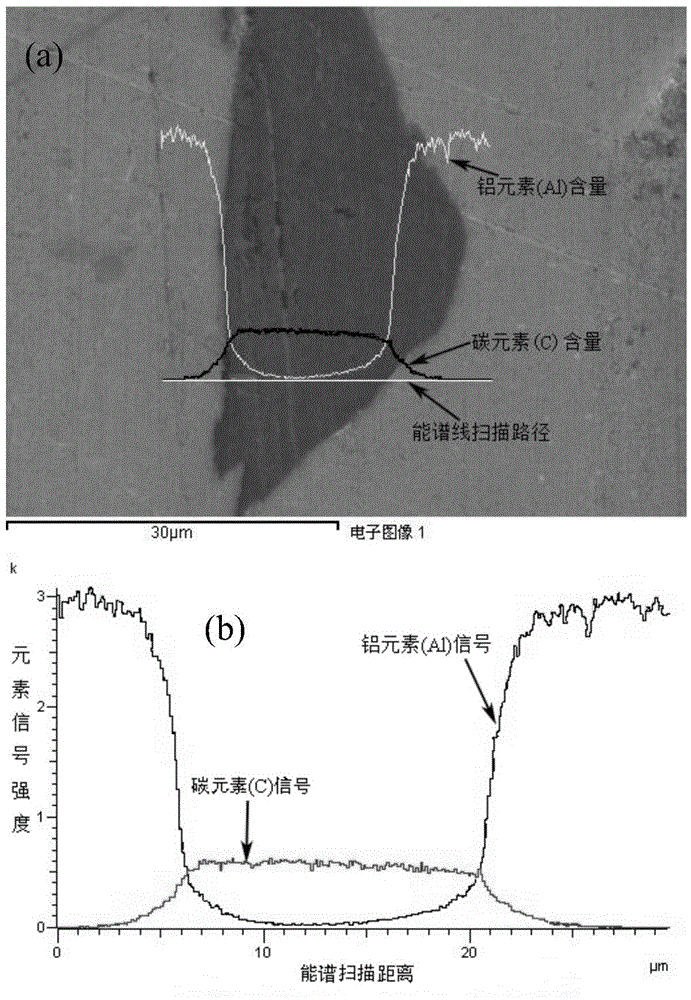

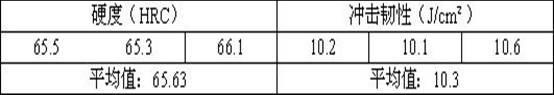

The invention discloses a hypoeutectic high-chromium white cast iron, which comprises the following components calculated according to mass fraction: 1.9-2.4 of C, 16-22 of Cr, less than or equal to 0.8 of Si, less than or equal to 0.7 of Mn, 0.5-1.0 of Ni, 1.0-1.7 of Mo, less than 0.04 of S, less than 0.06 of P, 0.05-0.4 of RE, 0.5-1.0 of Cu, 0.05-0.15 of Zn, 0.1-0.3 of V and the balance of Fe. The preparation method comprises the following steps of: defining the mixture ratio according to the requirement of mass fraction and mixing; mixing scrap steel and pig iron in an intermediate-frequency induction furnace and heating the mixture to be melt; after molten iron is smelt, sequentially adding high carbon ferro-chrome, manganese iron, nickel and molybdenum and smelting again; feeding a zinc ingot with small granularity and rare earth or vanadium at the bottom of a casting ladle, covering a steel sheet or scrap iron and compacting; pouring the molten iron into the casting ladle and carrying out metamorphism and deslagging treatment; casting the molten iron and forming to obtain a hypoeutectic high-chromium white cast iron piece; then placing the hypoeutectic high-chromium white cast iron piece into a heat treatment furnace for thermally treating; and quenching and tempering to obtain a hypoeutectic high-chromium white cast iron material with the hardness of 60-66HRC (Hardness Rockwell) and the impact ductility of 10-14J / cm<2>. The hypoeutectic high-chromium white cast iron has the advantages of low cost, high wear resistance and reliable use safety. In addition, the preparation method of the hypoeutectic high-chromium white cast iron is simpler, and is easy in operation and strong in practicability.

Owner:云南化铸科技有限责任公司

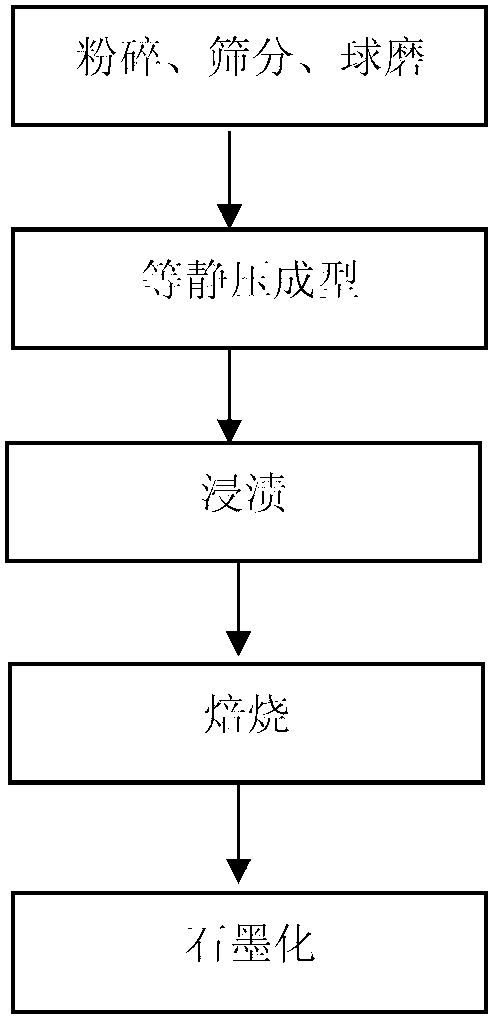

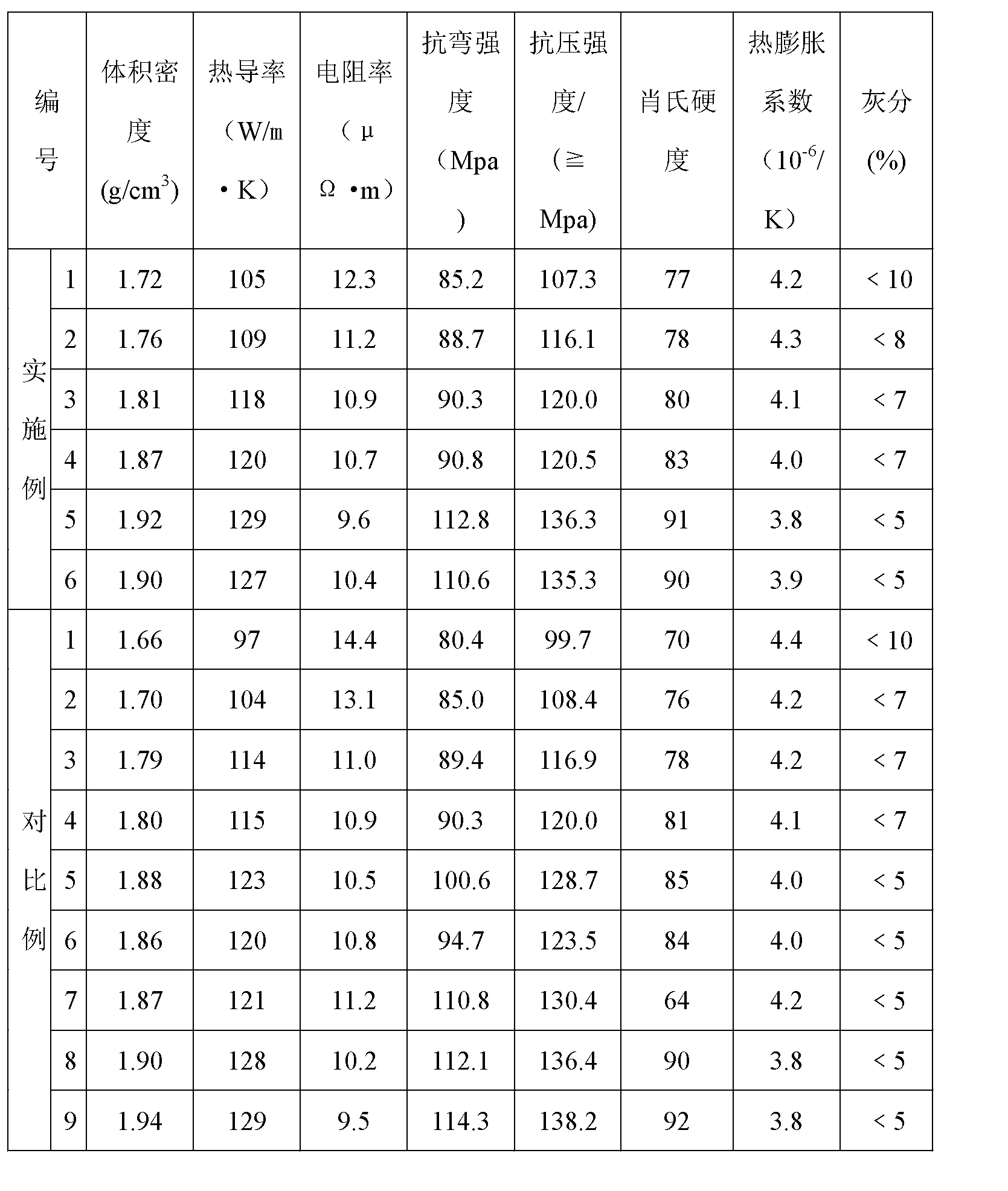

High-hardness isostatic graphite and preparation method thereof

The invention relates to isostatic graphite and a preparation method of isostatic graphite. Isostatic graphite is prepared by uniformly mixing raw materials with 1-15wt% carbon black, and directly carrying out isostatic shaping, wherein the raw materials are obtained by mixing one or more of petroleum coke and pitch coke with 50-100wt% interphase carbon microspheres. According to the invention, autohesion of the interphase carbon microspheres is sufficiently utilized, an extra adhesive is not needed to be added, the defects of higher porosity, poor structure uniformity, lower mechanical strength and the like caused by volume shrinkage difference between the filler and the adhesive are overcome, the working procedures of pugging, repeatedly immersing and calcine and the like are omitted, and carbon black with adaptation mass fraction is added to the raw materials to reduce the friction between raw material fine powder is reduced, so that the porosity is reduced, the volume density and flexural strength are improved, and the fluidity and pressing property of the raw material fine powder are improved. The prepared graphite material has the advantages of compact structure, good uniformity, high mechanical strength and the like.

Owner:天津市贝特瑞新能源科技有限公司

TiO2-WO3-SiO2 composite powder used as catalyst carrier and preparation method thereof

InactiveCN102553655AHigh catalytic efficiencyHigh strengthCatalyst carriersDispersed particle separationPtru catalystAmmonium paratungstate

The invention discloses and provides a preparation method of TiO2-WO3-SiO2 composite powder used as a catalyst carrier. The method sequentially comprises the following steps: dispersing a metatitanic acid raw material into the slurry through beating, and regulating the concentration of the slurry having the mass fraction of 10 percent to 20 percent and counted with titanium dioxide; respectively adding ammonium paratungstate and white carbon black into the slurry; adding ammonia water and regulating the pH value to be within the range of 5.5 to 8.5; filtering and dehydrating the slurry to obtain a blocky filter cake; mechanically grinding the blocky filter cake obtained after filtering and dehydrating, drying the ground filter cake for 2.5 hours at a temperature of 200 DEG C to 380 DEG C and calcining the dried filter cake for 4.5 hours at a temperature of 380 DEG C to 680 DEG C; and obtaining the TiO2-WO3-SiO2 composite powder after grinding calcined falling materials. The method disclosed by the invention has the advantages of low manufacturing cost, simple process, high specific surface area of a product, high surface chemical activity, and good processing performance. A denitration catalyst prepared from the product has the advantages of high strength, long service life, high catalytic efficiency and the like.

Owner:四川华铁钒钛科技股份有限公司

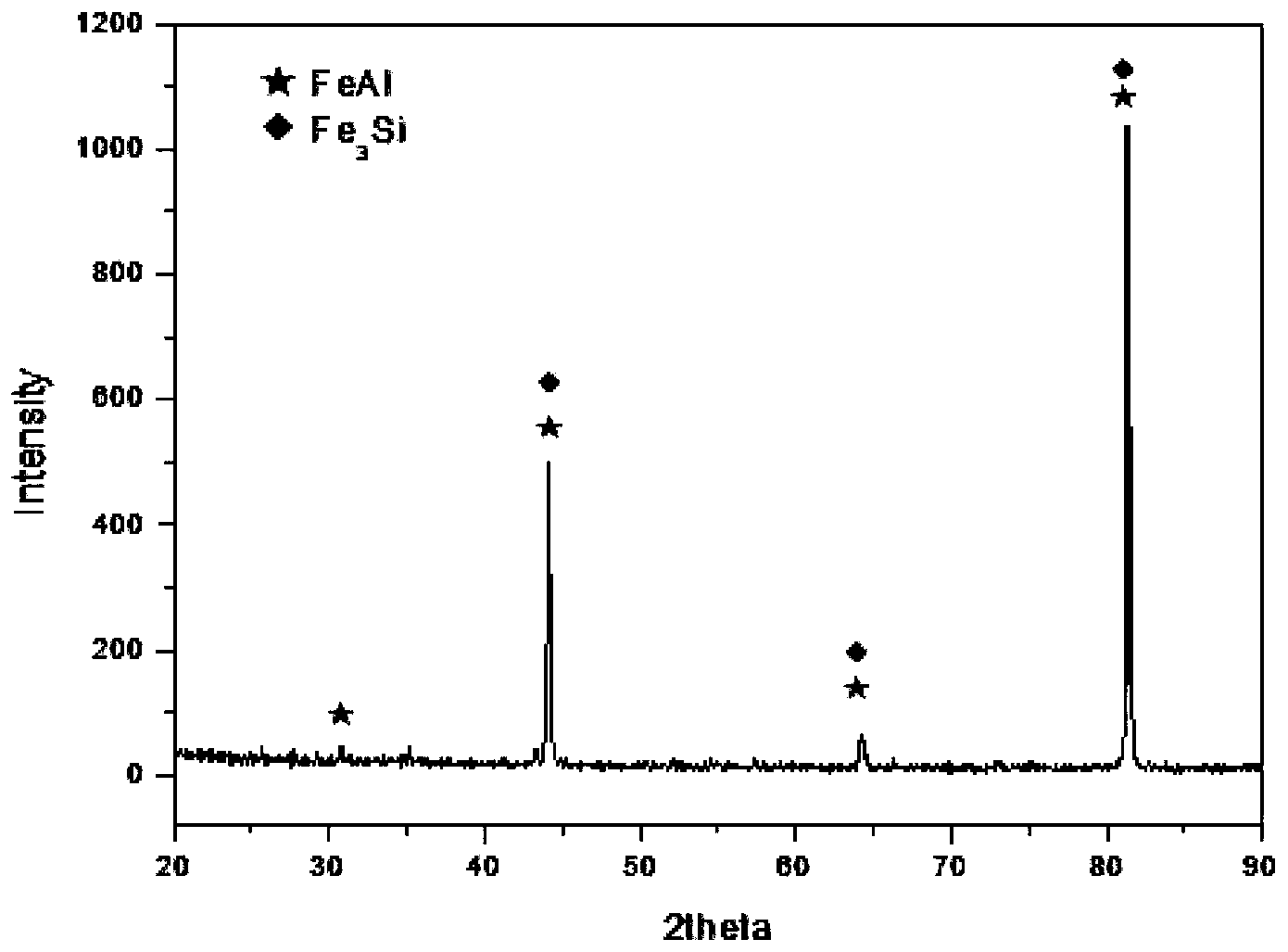

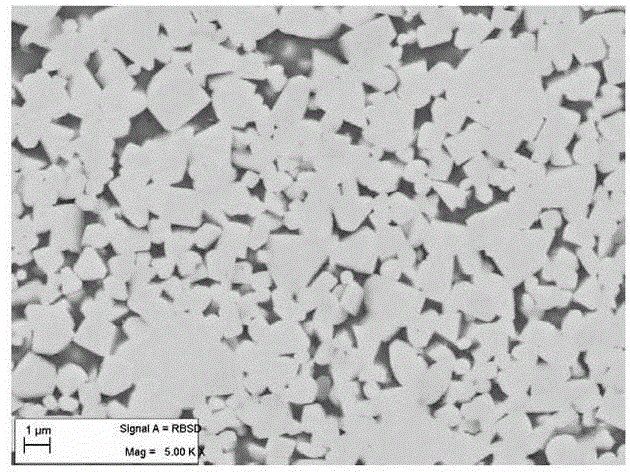

Sintered Fe-Al-based alloy porous material and filtering element employing same

ActiveCN103409678AHigh tensile strengthImprove antioxidant capacityFiltration separationElemental compositionWeight gaining

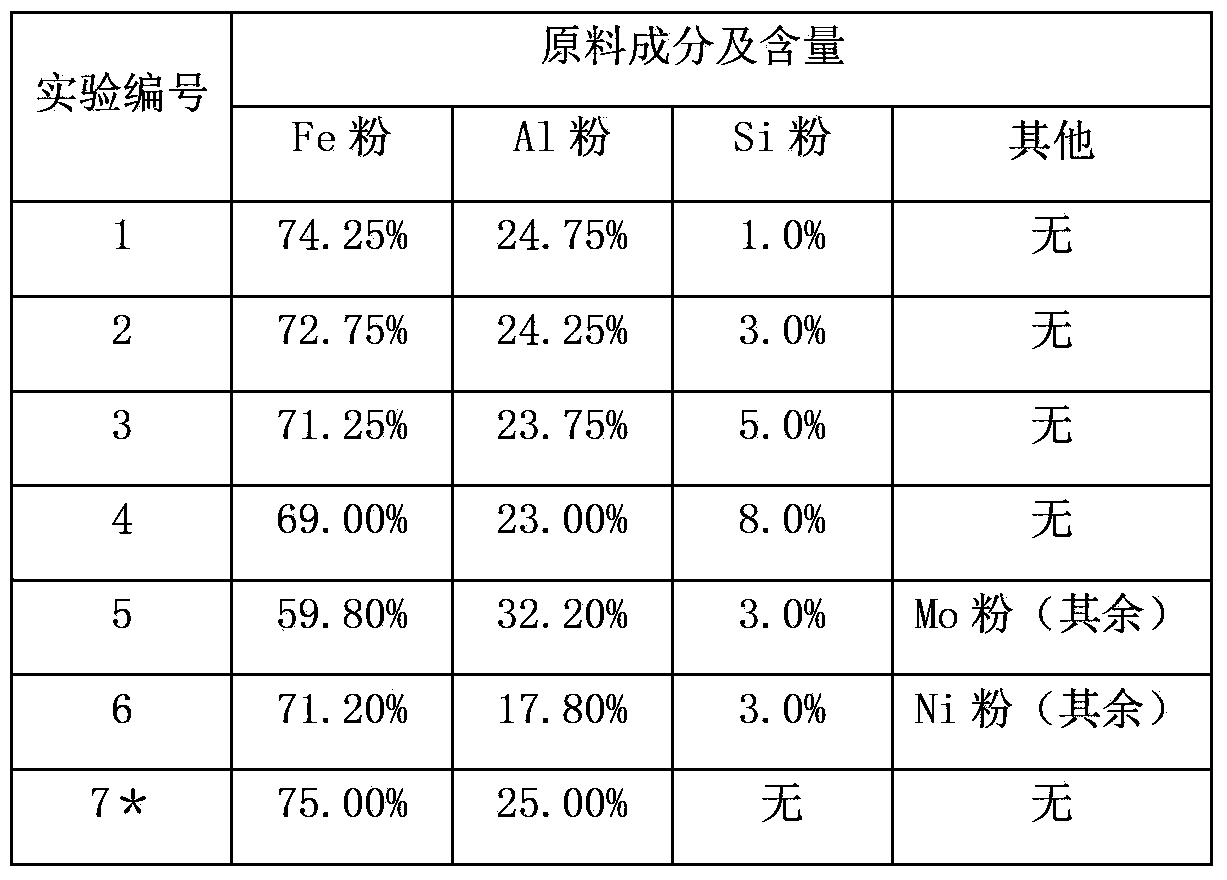

The invention discloses a sintered Fe-Al-based alloy porous material with better high temperature resistance and antioxidant activity, and a filtering element employing the material. The porosity of the sintered Fe-Al-based alloy porous material is 30% to 60%, and the average pore diameter is 0.5 to 50 mum m; the sintered Fe-Al-based alloy porous material is characterized in that the material is mainly composed of Fe, Al and Si; the sum of the weights of the three elements and accounts for more than 90% of the weight of the sintered Fe-Al-based alloy porous material, wherein the weight of Fe accounts for 60% to 85% of the total weight of Fe and Al, and the weight of Si accounts for 0.5% to 8% of the total weight of Fe, Al and Si; Si in the sintered Fe-Al-based alloy porous material exists mainly in the form of silicon solid solution of Fe-Al-based compound or in the form of Fe5Si and is uniformly distributed in the material approximately; the tensile strength of the sintered Fe-Al-based alloy porous material is larger than or equal to 45 MPa, the thickness is smaller than or equal to 5 mm, and the air flux is large than or equal to 80 m<3> / m<2> / kpa / h; after the material is soaked in NaOH solution with the mass fraction of 5% under the ambient temperature for 15 days, the weight loss ratio is less than 0.5%, and after the material is kept in the atmosphere with the temperature of 800 DEG C for 90 hours, the weight gain rate of the material is tested to be lower than 25%.

Owner:CHENGDU INTERMENT TECH

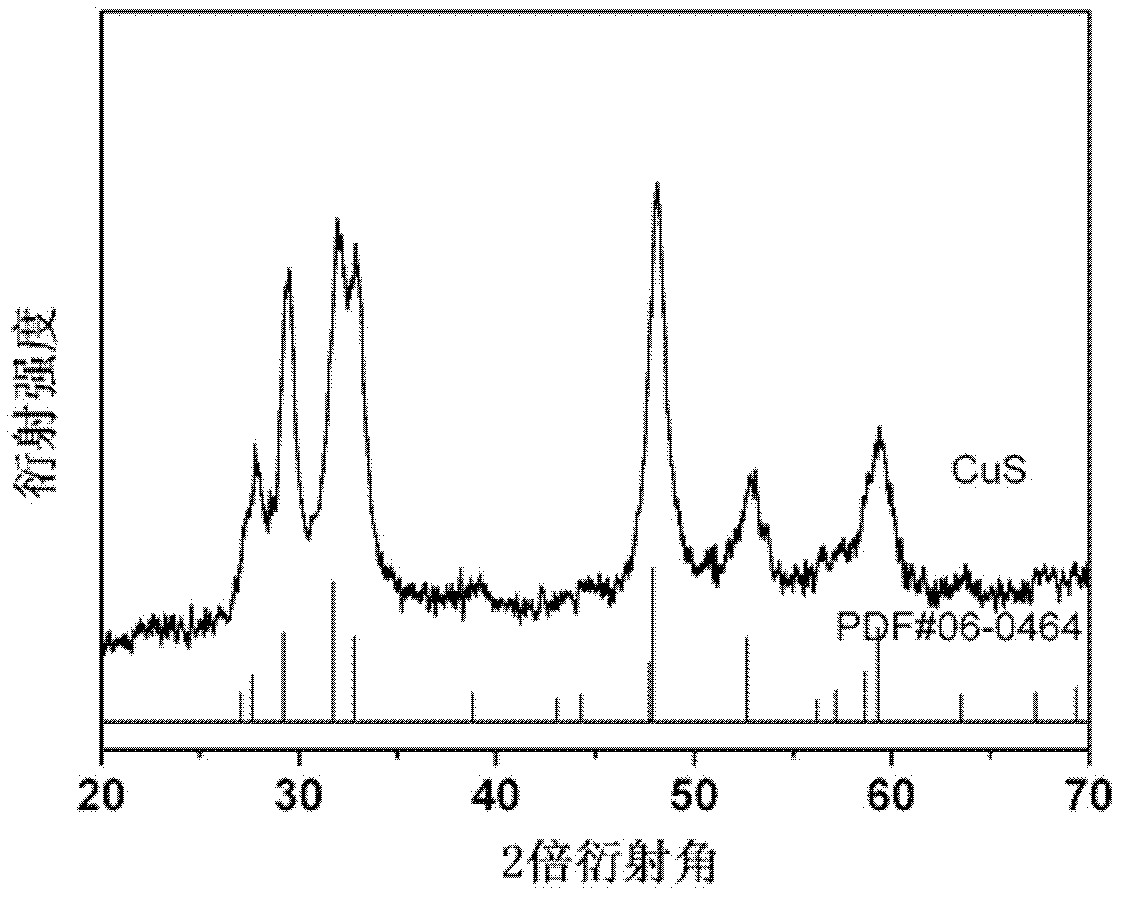

Preparation method of copper sulphide nano-powder with different stoichiometric ratios

InactiveCN102320647AStoichiometric ratio is easy to controlRaw materials are easy to getNanotechnologyCopper sulfidesArgon atmospherePhysical chemistry

The invention discloses a preparation method of copper sulphide nano-powder with different stoichiometric ratios, and belongs to the technical field of nanometer materials. The preparation method is characterized in that elemental copper powder (having a mass fraction above 99.9%) and elemental sulfur power (with a mass fraction above 99.8%) are utilized as raw materials and mixed according to a general chemical formula of Cu2-xS, wherein x is great than or equal to -0.5 and less than or equal to 1.5; and the mixture is subjected to ball-milling at a ball-milling rate of 100 to 425rpm in an argon atmosphere for 5 to 600 minutes to obtain stoichiometric ratio-adjustable single-phase copper sulphide nano-powder with particle sizes of 1 to 500 nanometers. The preparation method has the advantages of cheap and easily available raw materials, simple equipment, good operability of equipment, short process flow, convenience and quickness of large-scale production of copper sulphide nano-powder with different stoichiometric ratios, and wide application prospects.

Owner:UNIV OF SCI & TECH BEIJING

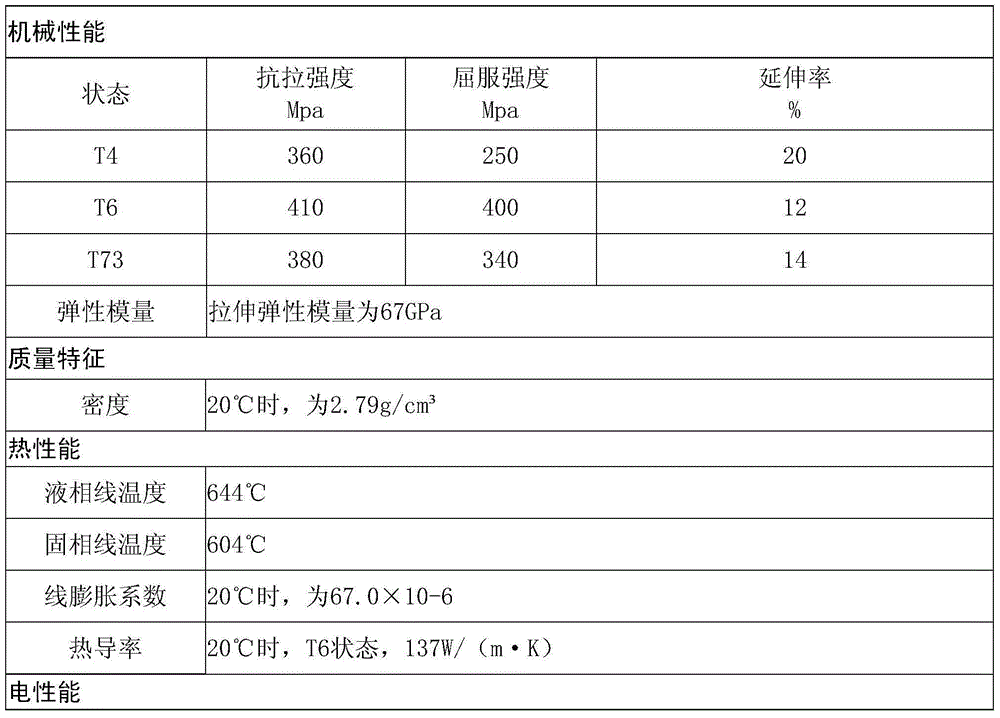

7XXX aluminum alloy

The invention relates to 7XXX aluminum alloy. The 7XXX aluminum alloy comprises the following components by weight percent: 6.6 to 7.6 percent of zinc, 1.25 to 1.80 percent of magnesium, 0.18 to 0.44 percent of copper, less than or equal to 0.06 percent of silicon, less than or equal to 0.16 percent of iron, , less than or equal to 0.03 percent of manganese, less than or equal to 0.03 percent of chromium, less than or equal to 0.02 percent of germanium, less than or equal to 0.02 percent of vanadium, less than or equal to 0.03 percent of titanium, less than or equal to 0.02 percent of zirconium, and less than or equal to 0.03 percent of total weight of manganese and chromium, less than or equal to 0.03 percent of each rest impurity element, less than or equal to 0.10 percent of total weight of rest impurity elements, and the balance of aluminum. On the basis of experiment, the material strength is improved by re-designing the mass fraction and a ratio of Zn to Mg; by re-designing the mass fraction of Cu, the alloy has excellent corrosion resistance, and the oxidation different color problem of silver white can be solved. By strictly controlling the weight percent of the impurity elements such as Mn and Cr, the crystal grains of the alloy material are uniform. Compared with the existing disclosed Al-Zn alloy system, the alloy has better comprehensive performance, and an oxidized membrane formed by oxidizing the material by virtue of anode is more delicate and beautiful.

Owner:TAISHAN CITY KAM KIU ALUMINUM EXTRUSION

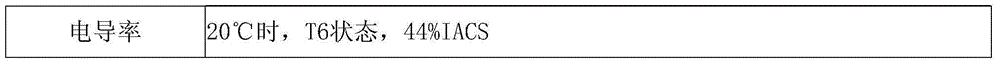

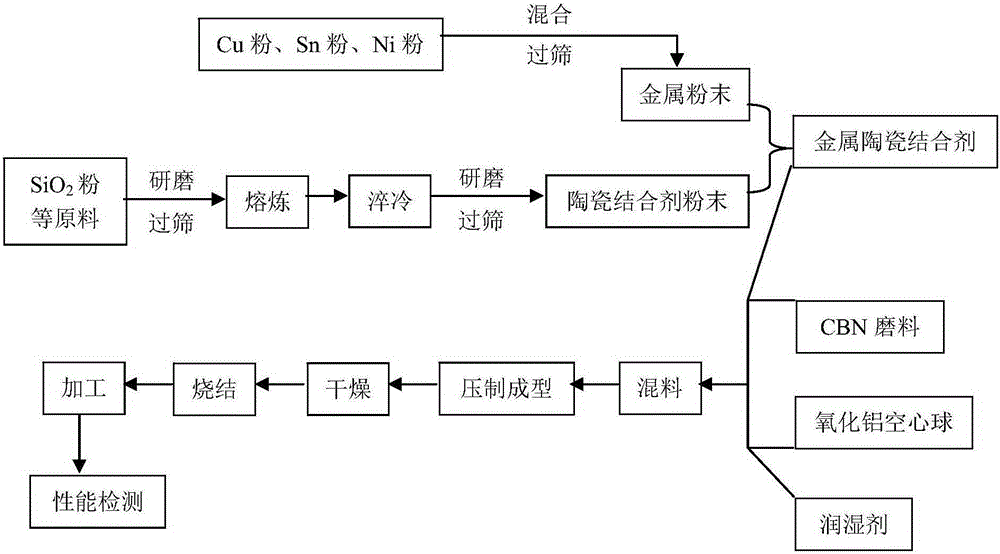

Metal and ceramic bonding agent and preparation method of metal and ceramic bonding agent, CBN grinding wheel and manufacturing method of CBN grinding wheel

ActiveCN105349868AImprove sharpnessGood self-sharpeningAbrasion apparatusGrinding devicesSurface roughnessGrinding wheel

The invention discloses a metal and ceramic bonding agent and a preparation method of the metal and ceramic bonding agent, a CBN grinding wheel and a manufacturing method of the CBN grinding wheel. The metal and ceramic bonding agent is composed of, by mass fraction, 75%-92% of ceramic and 8%-25% of metal. The ceramic is composed of, by mass fraction, 40%-65% of SiO2, 8%-35% of B2O3, 6%-20% of Al2O3, 5%-18% of Na2O5, 0.5%-5% of CaO, 3%-10% K2O, 0.5%-2% of MgO and 2%-6% of TiO2. The metal is composed of, by mass fraction, 55%-80% of Cu, 15%-30% of Sn and 5%-20% of Ni. The metal and ceramic bonding agent can be used as a CBN grinding wheel bonding agent and overcomes the defects that in the grinding process of the ceramic CBN grinding wheel, the surface roughness of a workpiece is large, chatter marks are generated easily, and impact resistance is poor.

Owner:白鸽磨料磨具有限公司

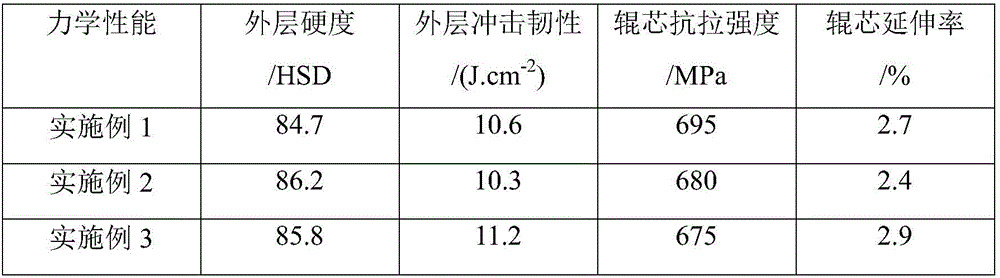

High-tungsten high-abrasion-resistant high-speed steel composite roller and preparation method thereof

ActiveCN105750529AHigh hardnessImprove wear resistanceFurnace typesHeat treatment furnacesChemical compositionDuctile iron

Owner:枣庄瑞兴机械制造有限公司

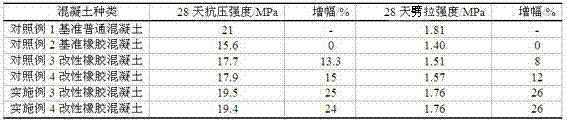

Modification method of rubber particles and modified rubber concrete

ActiveCN103787605AHigh compressive strengthWork performance is not adversely affectedSolid waste managementPolymer scienceAlcohol

The invention belongs to the technical field of building materials, and specifically discloses a modification method of rubber particles and modified rubber concrete. The modification method of the rubber particles comprises the steps of soaking the rubber particles by using a NaOH solution with mass concentration of 18-23%, cleaning the rubber particles for 1-3 times by using water, diluting KH570 which is 1-1.3% of the rubber particles in aspect of mass fraction by using ethyl alcohol, fully moistening the rubber particles by using the KH570, and airing and sealing the rubber particles for later use. According to the method, the modified rubber particles are used for isopyknic replacing for 5-15% of sand so as to obtain the rubber concrete. Compared with the standard rubber concrete without any treatment, the rubber concrete treated through the method has higher compressive strength and split tensile strength, and no adverse effect is caused to the working performance of concrete mixtures.

Owner:HENAN PROVINCIAL WATER CONSERVANCY RES INST

Amorphous inorganic ceramic material and method of producing same

InactiveUS20080057817A1Improve heat resistanceHigh strengthLayered productsWoven fabricsHydrogenHeat resistance

An amorphous inorganic ceramic material including silicon, carbon and oxygen is provided. In the ceramic material, the average elemental ratio between silicon, carbon and oxygen is represented by a compositional formula: SiCaOb wherein, a is a number that satisfies: 0.5≦a≦3.0, and b is a number that satisfies 0.5≦b≦4.0), the material has a siloxane skeleton formed of Si—O—Si bonds, and the hydrogen mass fraction is within a range from 0 to 1% by mass. The material exhibits excellent heat resistance, wettability with other materials, strength and elastic modulus, and is useful as a reinforcing material for composite materials, or as an exhaust gas filter material or the like.

Owner:SHIN ETSU CHEM IND CO LTD

Amorphous inorganic ceramic material and method of producing same

InactiveUS7662473B2Excellent levels of strengthImprove the level ofLayered productsWoven fabricsHydrogenHeat resistance

An amorphous inorganic ceramic material including silicon, carbon and oxygen is provided. In the ceramic material, the average elemental ratio between silicon, carbon and oxygen is represented by a compositional formula:SiCaOb wherein, a is a number that satisfies: 0.5≦a≦3.0, and b is a number that satisfies 0.5≦b≦4.0), the material has a siloxane skeleton formed of Si—O—Si bonds, and the hydrogen mass fraction is within a range from 0 to 1% by mass. The material exhibits excellent heat resistance, wettability with other materials, strength and elastic modulus, and is useful as a reinforcing material for composite materials, or as an exhaust gas filter material or the like.

Owner:SHIN ETSU CHEM IND CO LTD

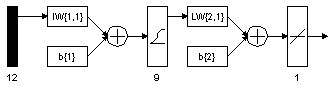

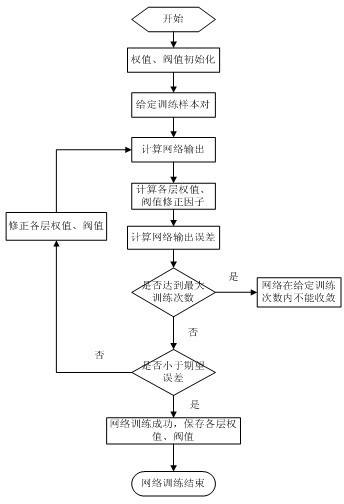

Method for forecasting Ac1 point of martensite refractory-steel weld metal with 9 percent of Cr

ActiveCN102663498AResolution timeSolve the costChemical property predictionChemical machine learningRefractoryAlloy

The invention relates to a method for forecasting the Ac1 point of martensite refractory-steel weld metal with 9 percent of Cr. The A1 point data of T groups of weld metal with different alloy components are obtained by applying an alloy thermodynamics theory through calculation, a neural network based on error back propagation is constructed, the back propagation (BP) network is trained and tested by utilizing the obtained data, and finally, the output threshold of the trained and tested network is corrected by combining the measured data of the Ac1 point of steel weld metal with 9 percent of Cr so as to obtain a method which can be used for forecasting the Ac1 point of martensite refractory-steel weld metal with 9 percent of Cr. As long as the components (mass fraction) of known weld metal are input, the Ac1 point of weld metal under the condition of the components can be quickly forecasted by utilizing the model. The method for forecasting the Ac1 point of the martensite refractory-steel weld metal with 9 percent of Cr can be used for calculating the Ac1 point of martensite refractory-steel weld metal with 9 percent of Cr under the condition of some kinds of components so as to provide a basis for selecting the postweld heat treatment temperature of the martensite refractory-steel weld metal with 9 percent of Cr. Meanwhile, the method for forecasting the Ac1 point of the martensite refractory-steel weld metal with 9 percent of Cr can also be used for directing the alloying design of the welding material of the martensite refractory-steel weld metal with 9 percent of Cr.

Owner:WUHAN UNIV

Preprocessing agent for molten iron and method for preparing same

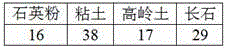

InactiveCN1690228AEffective dephosphorizationEfficient desulfurizationChemical compositionResource recovery

The invention relates to a production process using red mud as hot-metal preparation compound. The technical project is that mix equably the dried red mud with Fe2O3, CaO, Na2CO3, MnO2, CaCl2, SiO2 or other smeltery wastes that contain these compositions. The mass fraction of the mixture is: red mud being15 to 30 percent, Fe2O3 being 38 to 45 percent, CaO being 25 to 40 percent, Na2CO3 equal to or less than 5 percent, CaCl2 equal to or less than 5 percent, SiO2 equal to or less than 10 percent, and CaO / SiO2 being 3.0 to 7.0. The mass fraction of main chemical constituent in red mud is: SiO2 equal to or less than 25 percent, Fe2O3 equal to or more than 20 percent or CaO equal to or more than 40 percent. The invention with red mud as raw material has a characteristic of resource recovery, cleaning production, protecting environment, low cost, and no needing of changing the present equipment and operation.

Owner:WUHAN UNIV OF SCI & TECH

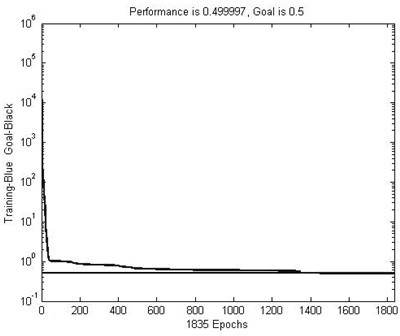

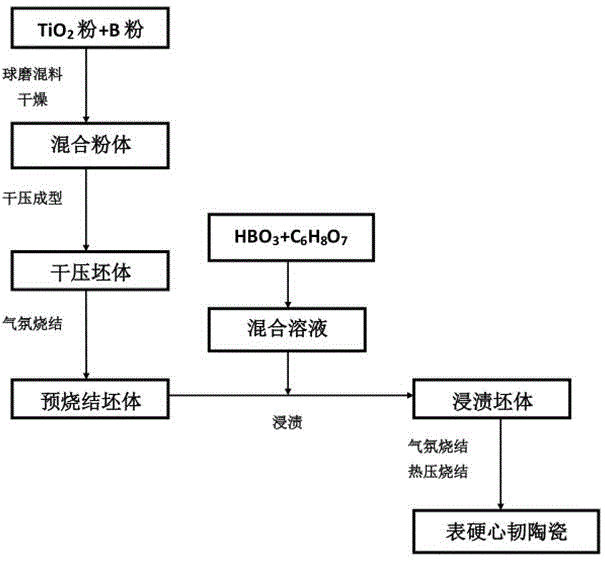

Preparation method of TiB2 (titanium diboride) gradient ceramic with hard surface and tough core

The invention relates to a preparation method of TiB2 (titanium diboride) gradient ceramic with a hard surface and a tough core. The surface layer of the TiB2 gradient ceramic is rich in B4C (boron carbide). Titanium dioxide (TiO2) powder, boron (B) powder, boracic acid (HBO3), and citric acid (C6H8O7) are used as raw materials, and are prepared by a two-step sintering and middle impregnation technology. The preparation method comprises the following steps of firstly, mixing the TiO2 powder and the B powder according to the mass fraction ratio of (62-76%):(24-38%), drying, heating to 600-1200 DEG C, maintaining the temperature for 0.5-10h, and obtaining a TiB2-B2O3 (boric oxide) presintering body; putting the presintering body into a saturated solution of the HBO3 and the C6H8O7 with the mass ratio of (25-35%):(65-75%); performing multiple times of impregnation; finally, rising the temperature of the impregnated presintering body to 1400-1800 DEG C in an Ar (argon) atmosphere, maintaining the temperature for 0.5-5h, continuously rising to 1800-2000 DEG C, maintaining the temperature for 0.5-4h, performing hot pressing sintering, and maintaining the pressure to 10-50MPa, so as to obtain the TiB2 gradient ceramic with the surface rich in B4C. The TiB2 gradient ceramic has the advantages that at the surface layer of the ceramic, the hardness is 25-40GPa, and the fracture toughness is 3-6MPa m1 / 2; at the core of the ceramic, the hardness is 20-30GPa, and the fracture toughness is 5-10MPa m1 / 2; by utilizing the gradient change of the B4C content in the surface layer, the excellent property of hard surface and tough core of the TiB2 ceramic is realized.

Owner:吉林长玉特陶新材料技术股份有限公司

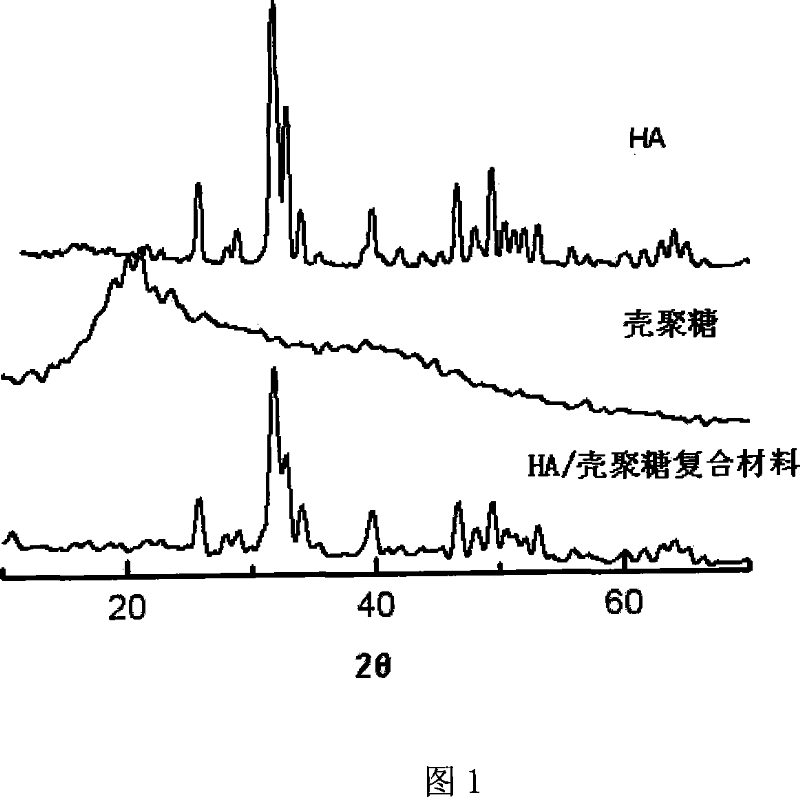

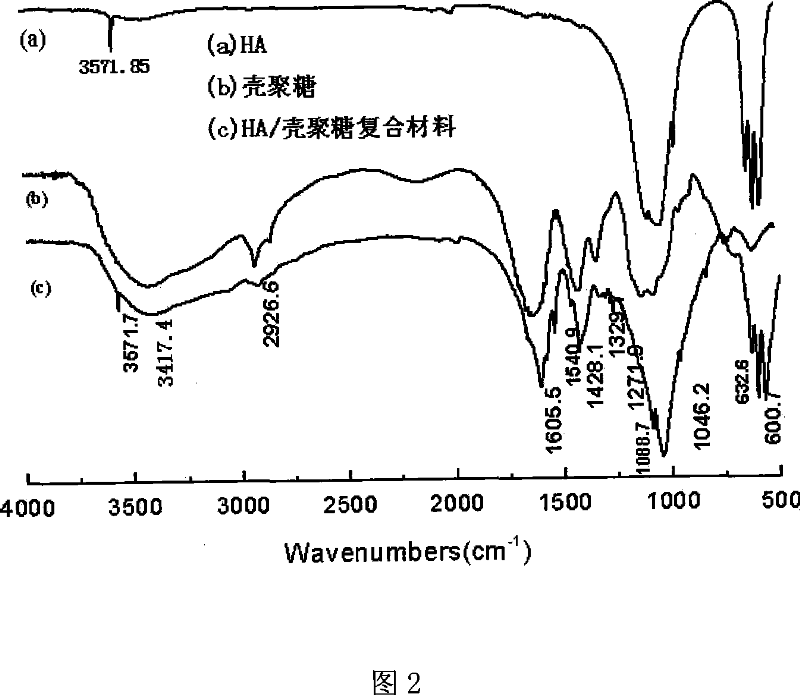

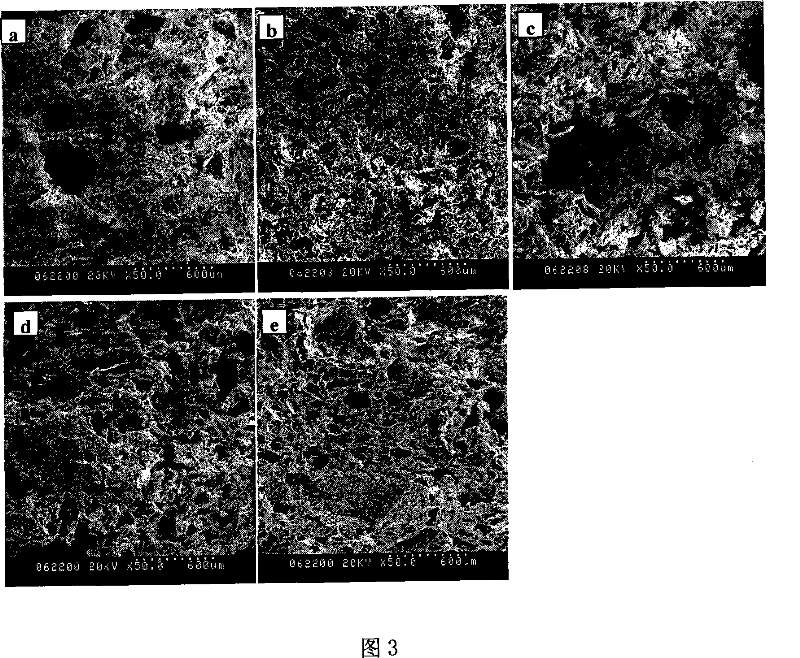

Composite material for repairing bone defect

The invention discloses composite material for repair of bone defect and preparation method. The invention synthesizes nanosized hydroxyapatite powders(HAP)by chemical precipitation, using anhydrous alcohol as leaching reagant and 16.7%(by mass fraction)of citric acid aqueous solution as binder. HA / CMCS porous material is prepared by particulate leaching and the IR, XRD, SEM, porosity, and compressive strength thereof are tested. The results show that two chemical compositions of HA / CMCS composite material have not remarkably changed before and after being compounded, but the two phases interacted with each other. The porosity of porous material is high, and the range of pore size distribution is wide, in shape of mainly rotundity, wherein the size distribution is about from several microns to 600 microns, with good interconnectivity, very beneficial to tissue growth and extending. When the CMCS content is 40% in composite material, the mass ratio of composite material and pore former is 1:1, the porosity of porous material is near 75% and the compressive strength is above 21MPa, meeting the requirements of scaffold materials for bone tissue engineering.

Owner:SHANDONG UNIV

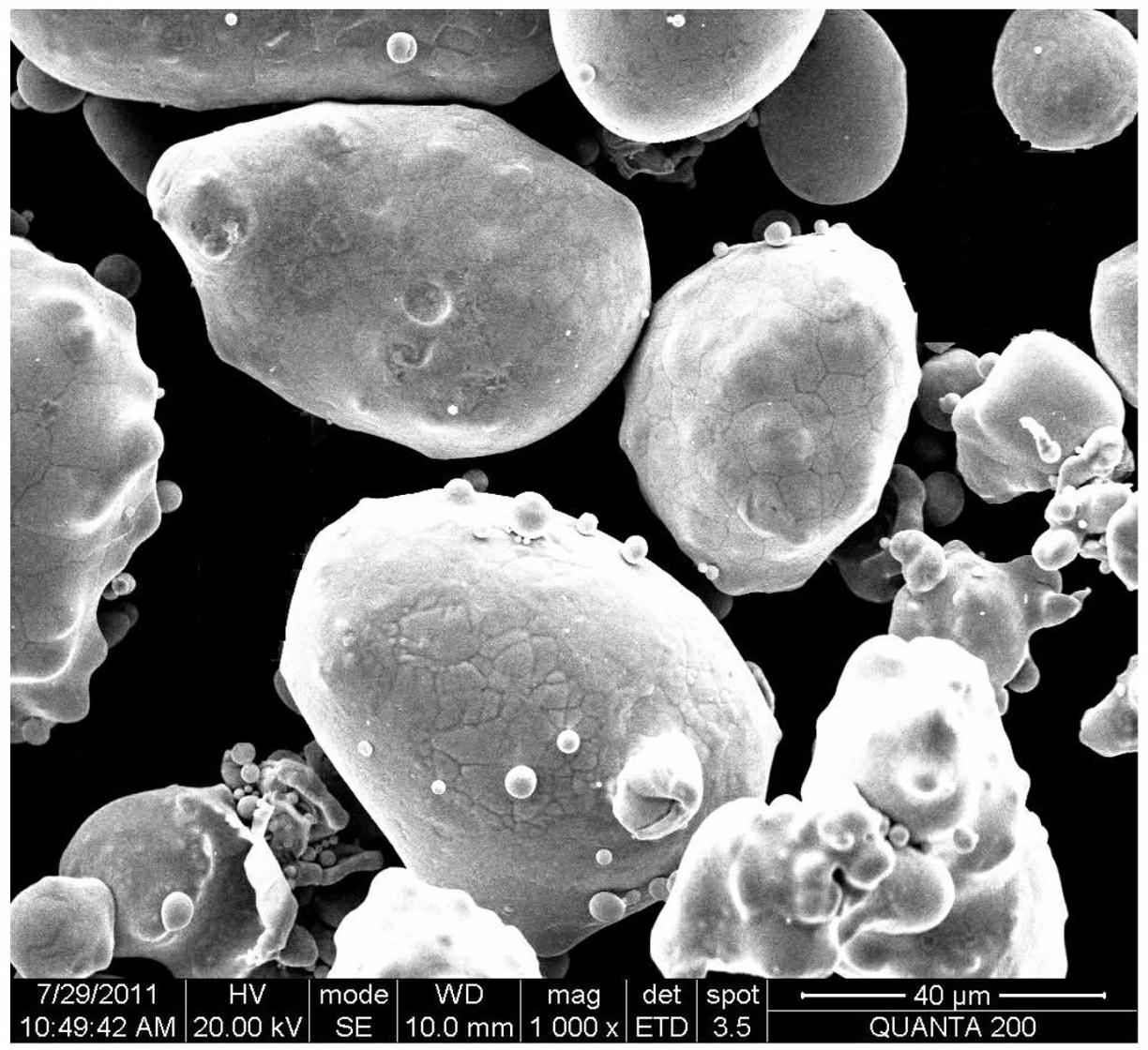

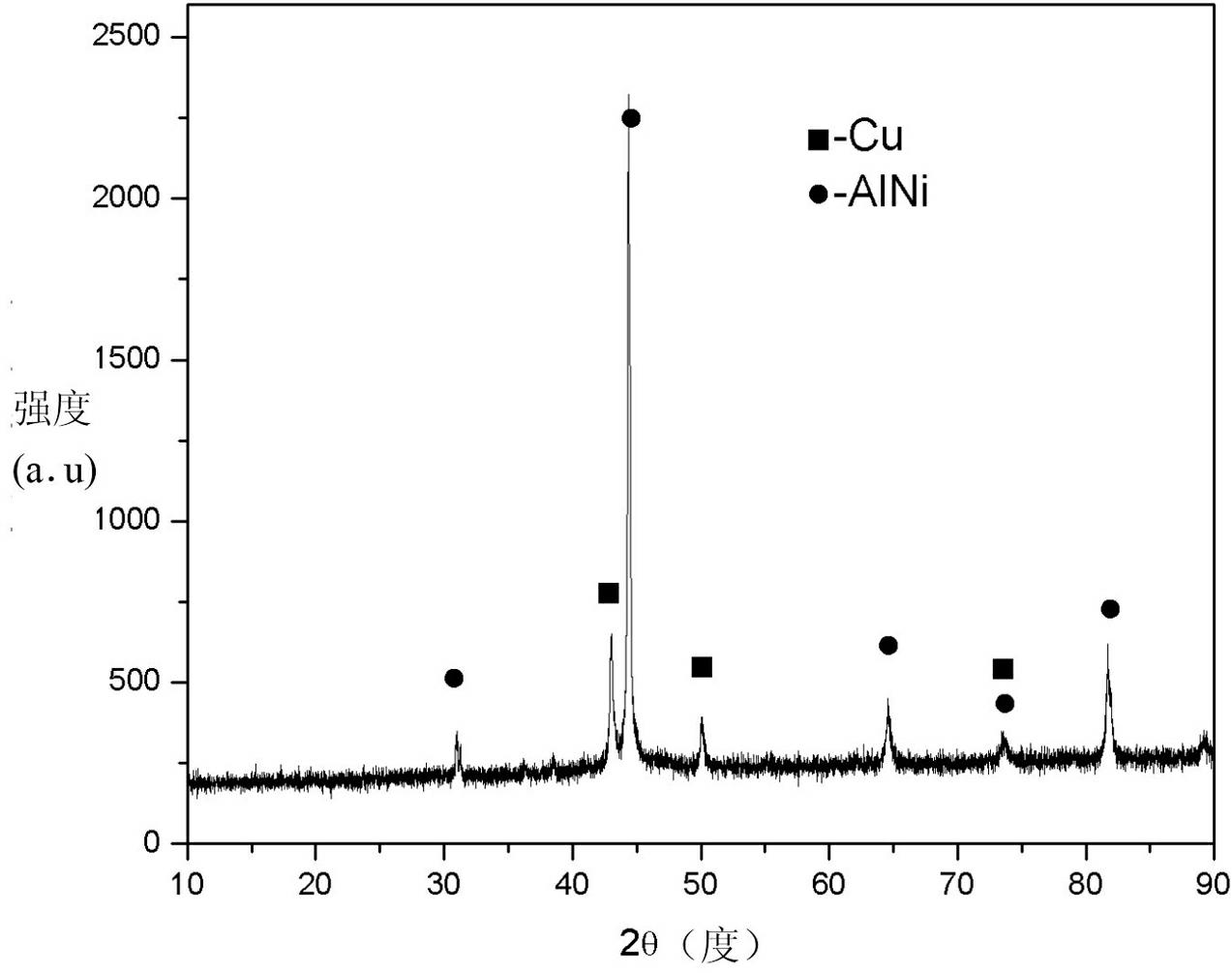

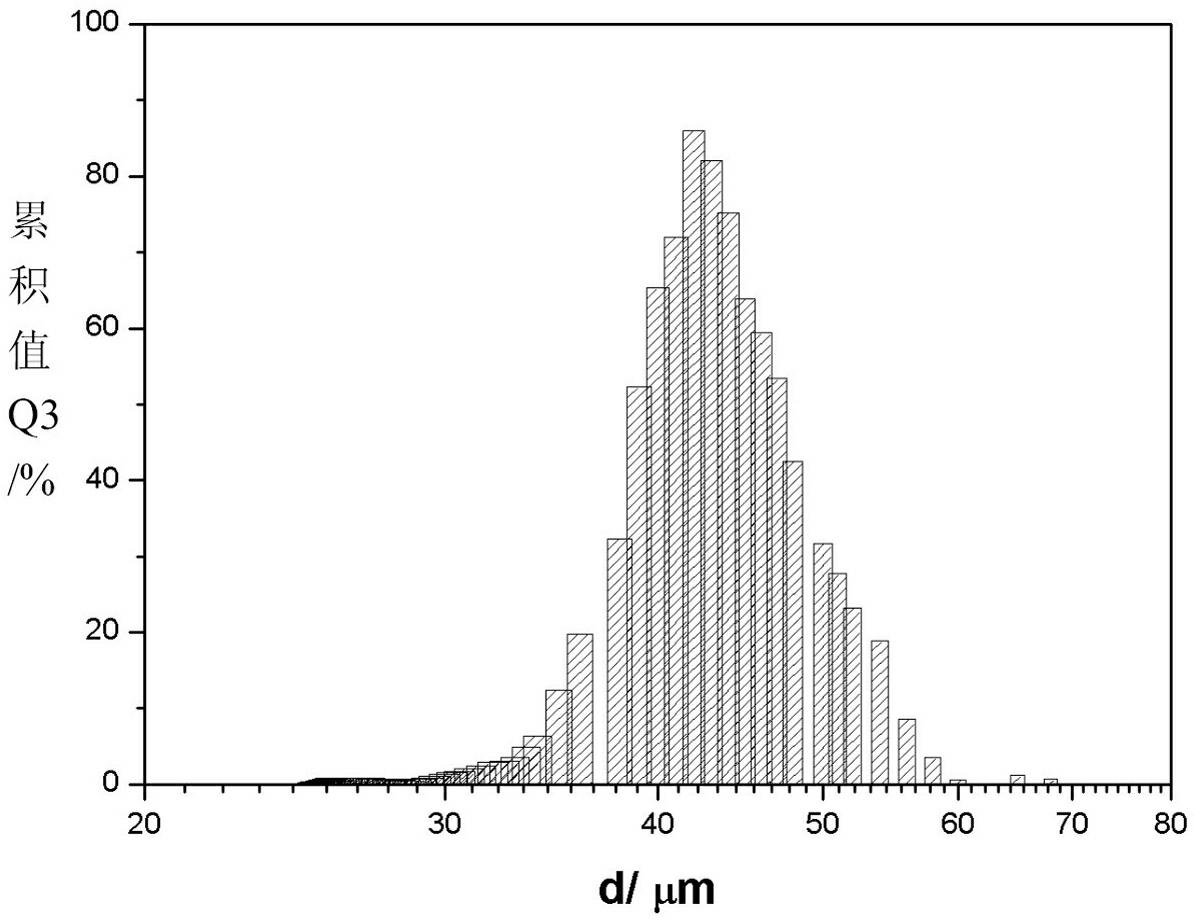

Cu-Ni-Al alloy powder and preparation method thereof

The invention discloses Cu-Ni-Al alloy powder, which is composed of metal Cu phases and AlNi intermediate phases, is free from macroscopic segregation and low in oxygen content and comprises the following components in mass fraction respectively: 25-35% of Ni, 10-15% of Al and the balance of Cu. The preparation method of the alloy powder comprises the steps of: firstly, proportioning metal Cu, metal Ni and metal Al, then heating the Cu and Ni, and adding Al for smelting after the Cu and Ni are molten; adding wood charcoal after the temperature of molten alloy reaches 1450-1550 DEG C, then adding a refining and slagclearing agent, and stirring, deslagging and refining the molten alloy; and finally, pouring the refined molten alloy into a crucible of an atomizing and rapid condensing device, and atomizing by using the atomizing and rapid condensing device for producing powder to prepare the Cu-Ni-Al alloy powder. The alloy powder disclosed by the invention has the advantages of high alloy element content, good powder purity, uniform chemical components, slight segregation, good crystallinity and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

In-situ synthesized Al2O3 reinforced molybdenum based composite material and preparation method thereof

The invention discloses an in situ authigenic Al2O3 granule reinforced molybdenum base composite material and a preparation method thereof. The in situ authigenic Al2O3 granule reinforced molybdenum base composite material is prepared with aluminum powder and molybdenum oxide powder, wherein, the mass fraction of the aluminum powder is 0.5 percent to 2.5 percent. Composite material organization prepared is molybdenum base and Al2O3 with the volume fraction of 5 percent to 15 percent, and Al2O3 is distributed evenly in the molybdenum base. The preparation method is as follows: (1) mixing powder is obtained by evenly mixing the aluminum powder and molybdenum oxide; (2) the mixing powder, after heat preservation for 3h in a vacuum sintering furnace at the temperature of 530 DEG C to 550 DEG C under the nitrogen protection, is reduced; (3) the mixing powder is reduced by use of hydrogen at the temperature of 500 DEG C to 550 DEG C for 4h, and at the temperature of 920 DEG C to 950 DEG C for 7h; (4) an isostatic cool pressing is carried out under the pressure of 180MPa to 220MPa and a blank sheet is made by maintaining pressure for 8 minutes to 10 minutes; and (5) the sintering is carried out in the vacuum sintering furnace at the temperature of 1,600 DEG C to 2,000 DEG C for 16h to 18h. The Al2O3 granules are adopted to enhance molybdenum base composite materials, recrystallization temperature reaches more than 1,500 DEG C, the high-temperature strength and rigidity thereof are improved by more than 50 percent compared with TZM molybdenum alloy, and the high-temperature wear resistance thereof is 2 times to 4 times higher than that of the TZM molybdenum alloy. The in situ authigenic Al2O3 granule reinforced molybdenum base composite material has broad application prospect in the high-temperature wear resistance field.

Owner:HENAN UNIV OF SCI & TECH

Quaternization lignin-base dispersing agent and preparation process and application thereof

The invention discloses a quaternization lignin-base dispersing agent and a preparation process and application thereof. The preparation process comprises the following steps: reacting benzoic acid, phenol and an aldehyde compound for 0.5-3h at the temperature of 60-110 DEG C, wherein the mass fraction of the aldehyde compound is 1.0-9.0 percent; adding black pulping liquor of which the solid content is 18.3-60 percent, raising the temperature to 20-80 DEG C, adding a sulfonic amino compound of which the mass fraction is 1.3-8.0 percent, adjusting the pH value to 10.0-13.5, and adding a sulfonating agent of which the mass fraction is 2.5-11.0 percent; enabling reaction for 2-5h at the temperature of 95-180 DEG C, and then adding a quaternization reagent of which the mass fraction is 4.0-10.0 percent, enabling reaction for 2-4h at the temperature of 70-100 DEG C, performing cooling and discharging to obtain brown liquid, and performing spray drying to obtain a solid powder product. The quaternization lignin-base dispersing agent has multiple functions of dispersing, complexing, chelating and the like, and can be applied to multiple fields of dye dispersing agents, concrete water reducing agents, ceramic additives and the like.

Owner:FUZHOU UNIV

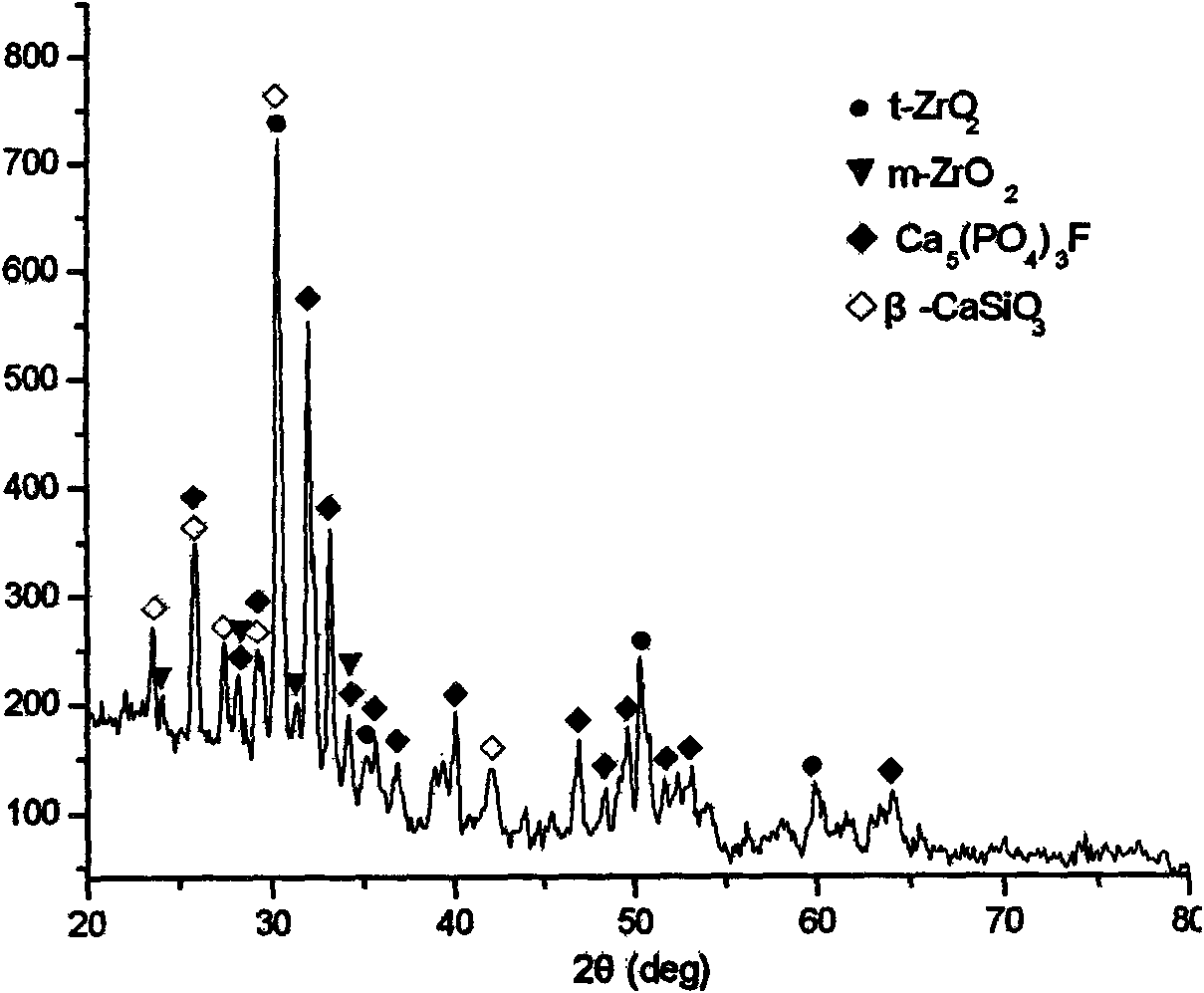

ZrO2 toughened bioactive glass-ceramics of MgO-CaO-SiO2-P2O5-CaF2 system and preparation method thereof

InactiveCN101559237AImprove bending strengthLower precipitation temperatureCoatingsProsthesisFlexural strengthArtificial bone

The invention discloses a ZrO2 toughened bioactive glass-ceramics of MgO-CaO-SiO2-P2O5-CaF2 system. The glass comprises the components with mass fractions as follows: 25.7-34.1% of SiO2, 3.4-4.6% of MgO, 33.7-44.8% of CaO, 12.2-16.3% of P2O5, 0.1-5% of CaF2 and 0.1-20% of ZrO2; wherein, the ZrO2 is tetragonal zirconia. The prepared ZrO2 toughened bioactive glass-ceramics of MgO-CaO-SiO2-P2O5-CaF2 system witnesses obviously improved bending strength and fracture toughness; the elastic module index of the bioactive glass-ceramics can serve as materials for restoring or replacing artificial bones and the linear expansibility index thereof meets the requirement of similarity to the linear expansibility of titanium and titanium alloy coating materials. The bioactive glass-ceramics show good bioactivity in the immersion test in the simulated body fluid.

Owner:SHANDONG UNIV

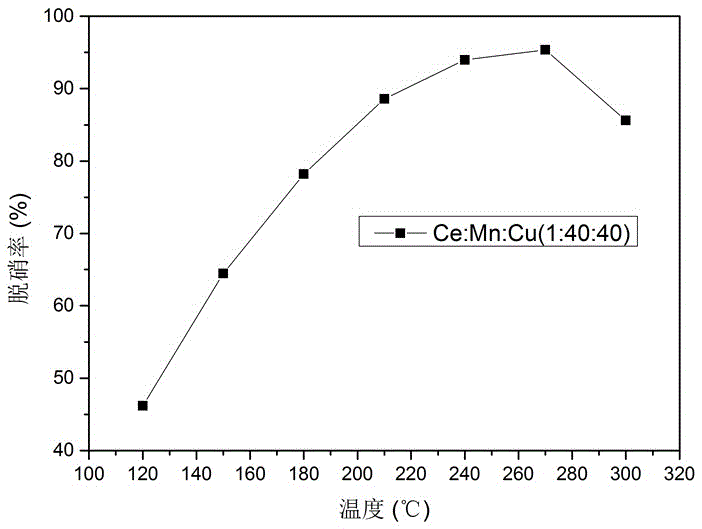

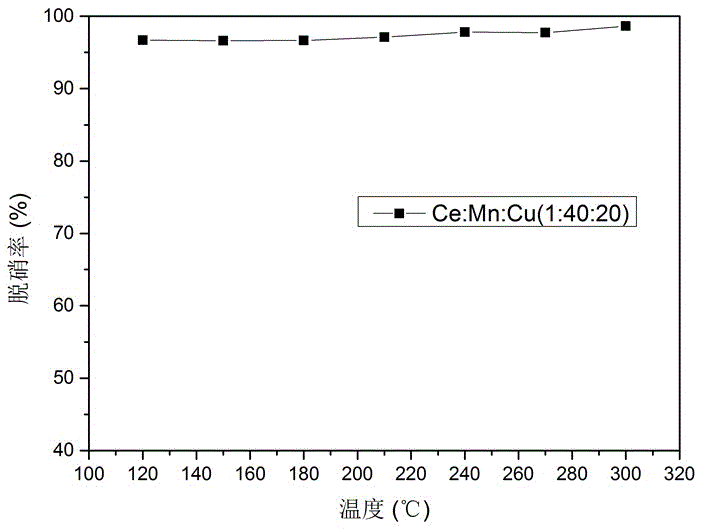

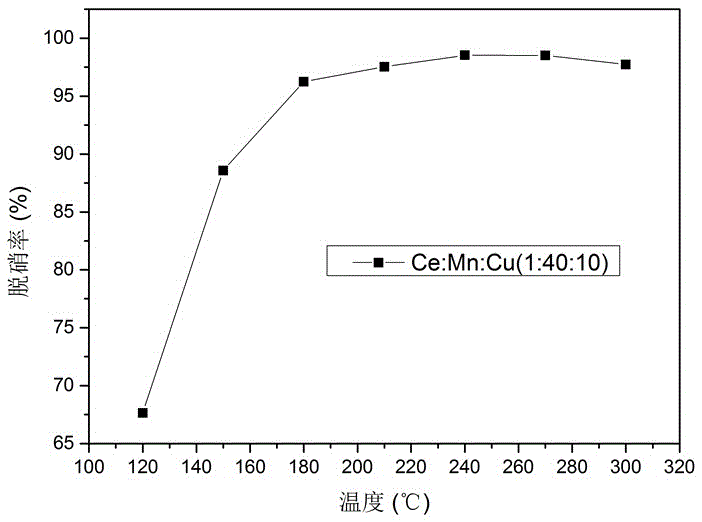

Low temperature wide-active temperature window SCR denitration catalyst and preparation method thereof

InactiveCN105903477AReduce manufacturing costEasy to prepareGas treatmentHeterogenous catalyst chemical elementsPtru catalystCopper nitrate

The invention relates to a low temperature wide-active temperature window SCR denitration catalyst. The catalyst comprises a carrier and an active component, wherein the carrier is attapulgite, and the active component is a composition comprising manganese-containing oxide, cerium-containing oxide and copper-containing oxide. The use amount of attapulgite meets a ratio of metal elements to attapulgite of 0.03-0.06mol / 20g, the mole percentage of the manganese element in the active component is 50-80%, and a molar ratio of the cerium element to the copper element is 1:10 ~ 1:40. The invention also relates to a preparation method of the catalyst. The preparation method comprises the following steps: adding 20g of purified attapulgite to 100mL of distilled water, sequentially adding 20mL of a manganese nitrate solution with the mass fraction of 50% and certain amounts of cerium nitrate hexahydrate and copper nitrate trihydrate, continuously stirring above added materials for 1h, standing the obtained solution for 4h, drying the obtained material at 80DEG C for 12h, and roasting the dried material in air atmosphere at 500DEG C for 5h; and grinding the roasted material, and sieving the ground material to obtain a 40-60 mesh material used as the catalyst.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

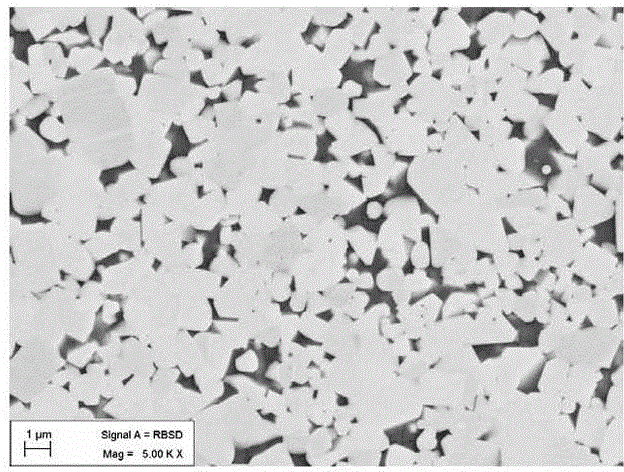

Cemented carbide having nearly spherical WC grains and preparing method thereof

The invention discloses cemented carbide having nearly spherical WC grains and a preparing method thereof. The cemented carbide comprises the components in mass fraction: 3%-15% of Co, 0.1%-12% of a cubic phase, and the balance being WC; the C / W ratio of the cemented carbide is 0.78-0.89. The WC grains are nearly spherical in shape, and the spherical degree is 0.7-1. The preparation method comprises the steps of mixing a Co powder, a cubic phase powder and a WC powder, carrying out roller ball milling of the mixed powder, then drying, granulating and pressing the obtained slurry to obtain a half finished product, and then sintering to obtain the cemented carbide. The cemented carbide has relatively high hardness, toughness and strength, and the preparation method is simple in process and low in cost.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

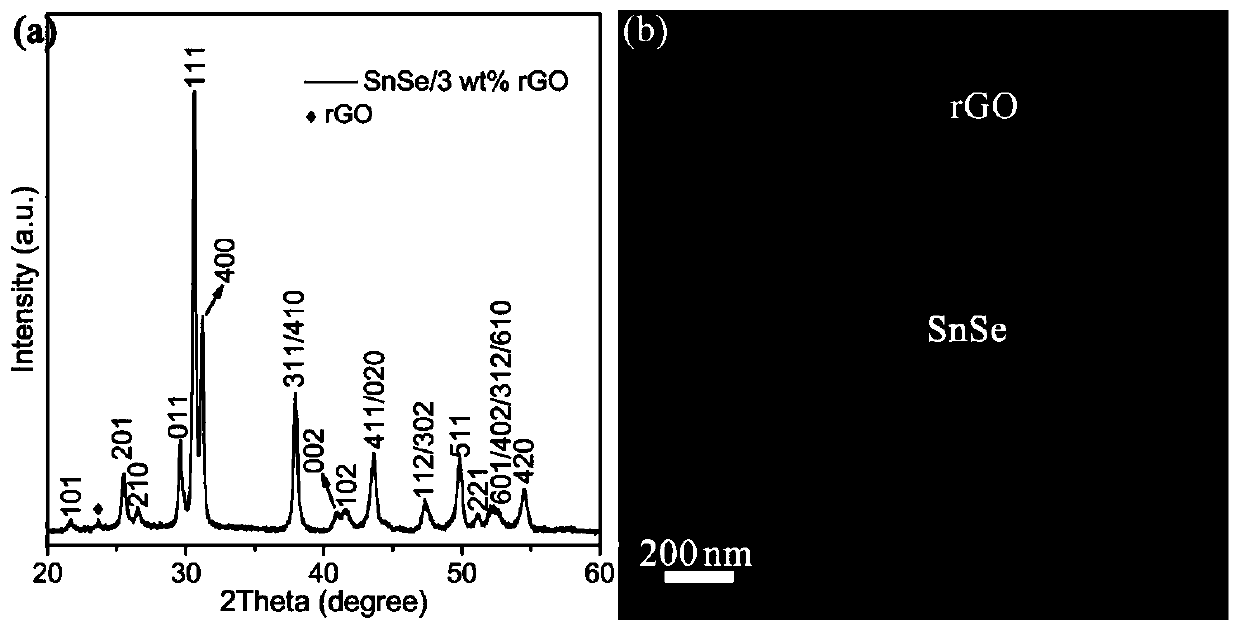

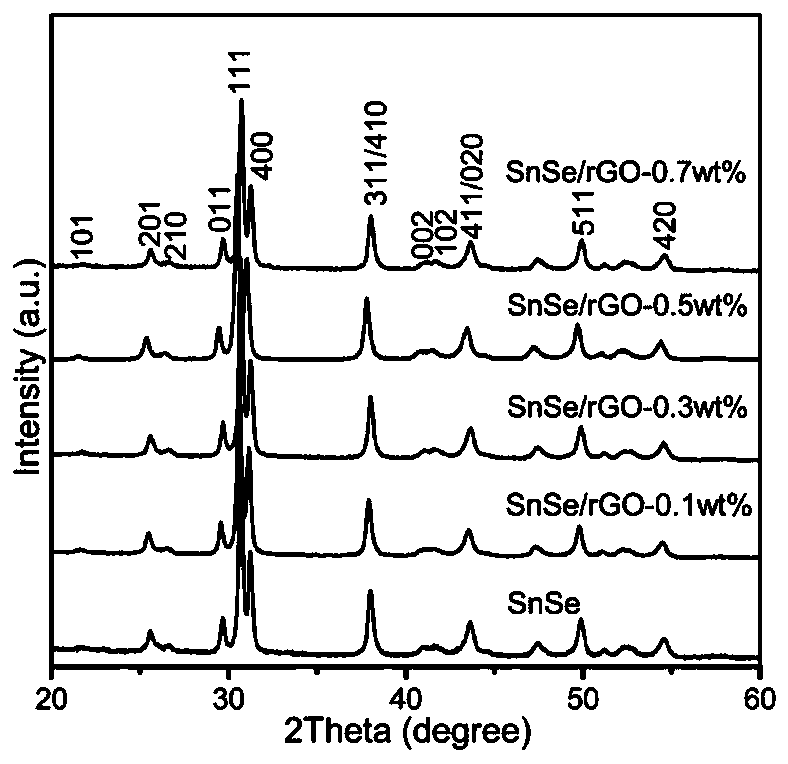

SnSe/rGO thermoelectric composite material and preparation method thereof

ActiveCN110707206AComposite uniformSynthesis temperature is lowMaterial nanotechnologyThermoelectric device manufacture/treatmentAqueous solutionMass fraction

The invention relates to a SnSe / rGO thermoelectric composite material and a preparation method thereof. The mass fraction x of rGO in the thermoelectric composite material ranges from 0.1 wt% to 3 wt%, and the preparation method comprises the steps of s1, preparing graphene oxide dispersion liquid for standby application; s2, SnCl2. 2H2O and NaOH are fully reacted in deionized water according to acertain proportion; s3, adding NaBH4 into the Na2SnO2 aqueous solution obtained in the S2, and uniformly mixing the NaBH4 and the Na2SnO2 aqueous solution; s4, adding the graphene oxide dispersion liquid obtained in the step S1 into the solution obtained in the step S3, mixing and stirring in an argon environment, and then heating to boil; s5, preparing a NaHSe solution with the same amount of substance as Na2SnO2 in S2, and then adding the NaHSe solution into the mixed solution obtained in S4; S6, keeping the stirring rate in S4 and reacting at the boiling temperature; and S7, after the reaction is finished and cooling is conducted, performing suction filtration and collection on the reaction solution and then placing the solution in a vacuum drying box to be fully dried, and s8, performing the spark plasma sintering on the composite powder obtained in the S7, and obtaining the SnSe / rGO thermoelectric composite material.

Owner:CHONGQING UNIV

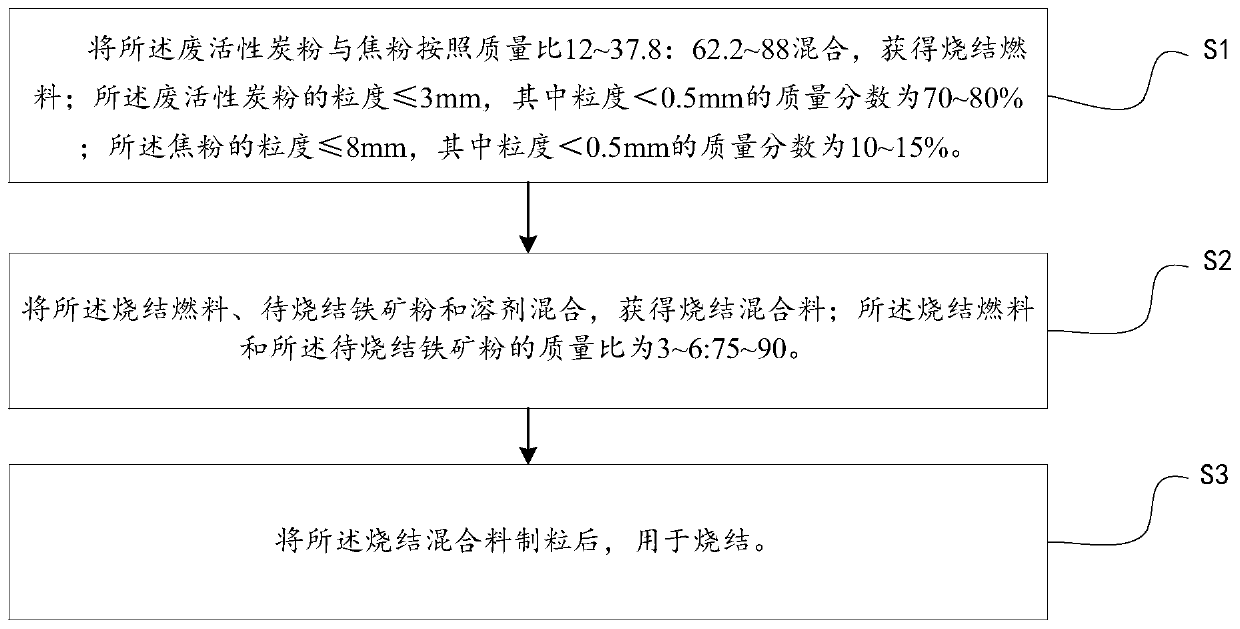

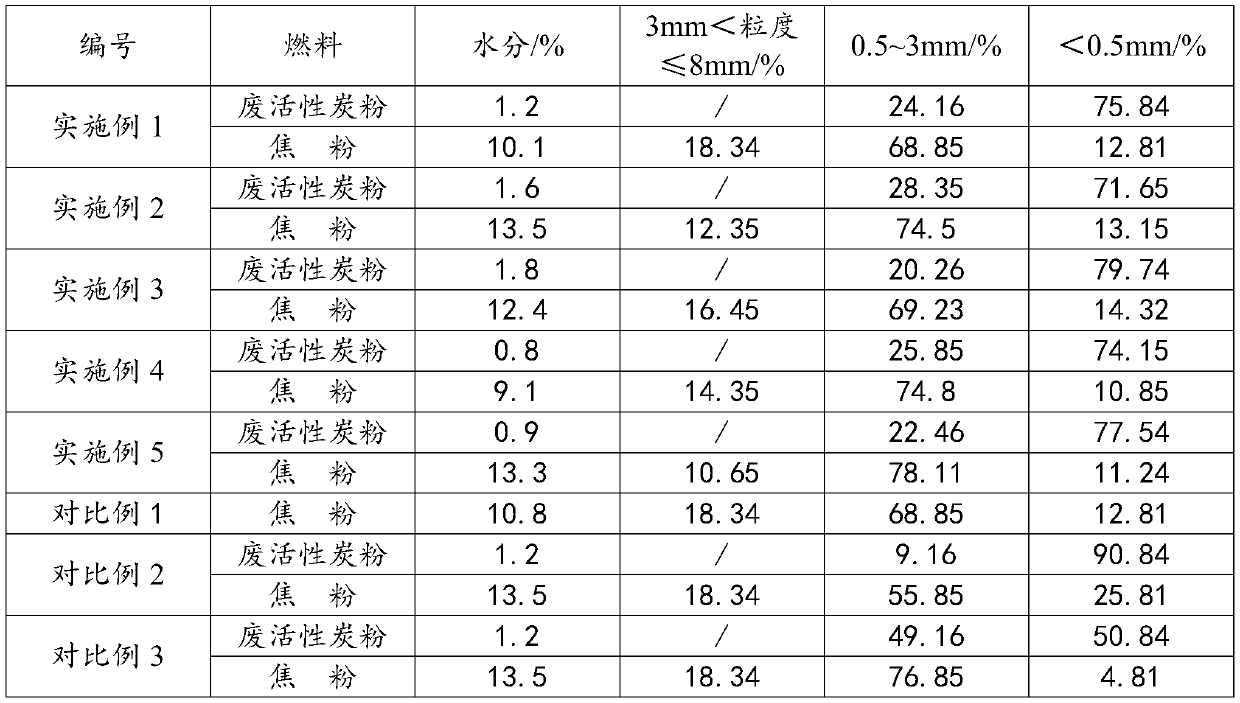

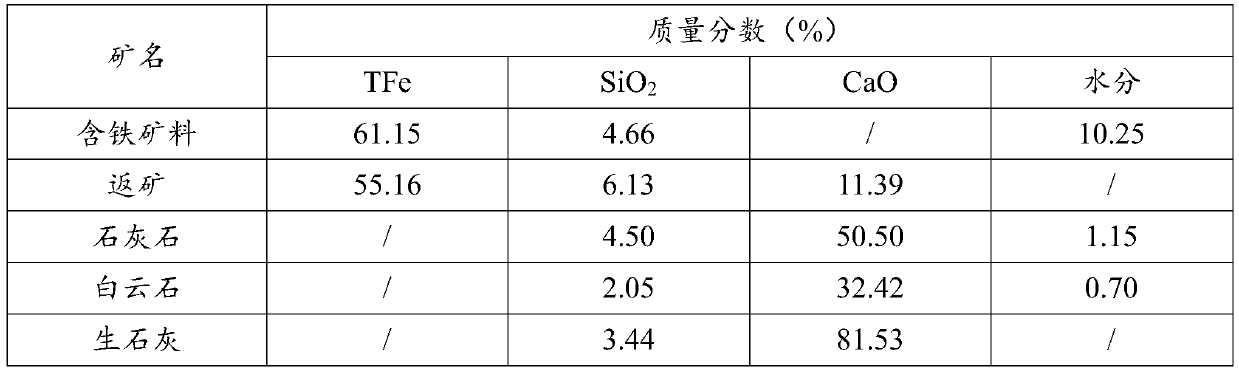

Method for enabling waste active carbon powder to be used for sintering, sintering mixture and sinter

ActiveCN111471852AUniform particle size distributionGuaranteed breathabilityBlast furnace detailsActivated carbonActivated charcoal powder

The embodiment of the invention provides a method for enabling waste active carbon powder to be used for sintering, a sintering mixture and sinter. The waste active carbon powder is generated when sintering smoke is purified by active carbon. The method includes the steps that the waste active carbon powder and coke powder are mixed according to the mass ratio of (12-37.8):(62.2-88), and sinteringfuel is obtained; the granularity of the waste active carbon powder is smaller than or equal to 3 mm, wherein the mass fraction of the waste active carbon powder with the granularity smaller than 0.5mm is 70%-80%; the granularity of the coke powder is smaller than or equal to 8 mm, wherein the mass fraction of the coke powder with the granularity smaller than 0.5 mm is 10%-15%; the sintering fuel, to-be-sintered iron ore powder and a solvent are mixed, and the sintering mixture is obtained; the mass ratio of the sintering fuel to the to-be-sintered iron ore powder is (3-6):(75-90); and afterbeing pelletized, the sintering mixture is sintered. By the adoption of the method, the sintering rate can reach 88.87%, the yield of the sinter can reach 76.44%, the prepared sinter is good in metallurgical performance, the drum strength of the sinter is larger than 81%, the SO2 concentration of exhausted smoke is not larger than 38 mg / m<3>, and the NOx concentration is not larger than 94 mg / m<3>. Meanwhile, secondary utilization of the waste active carbon powder is achieved.

Owner:武汉钢铁有限公司

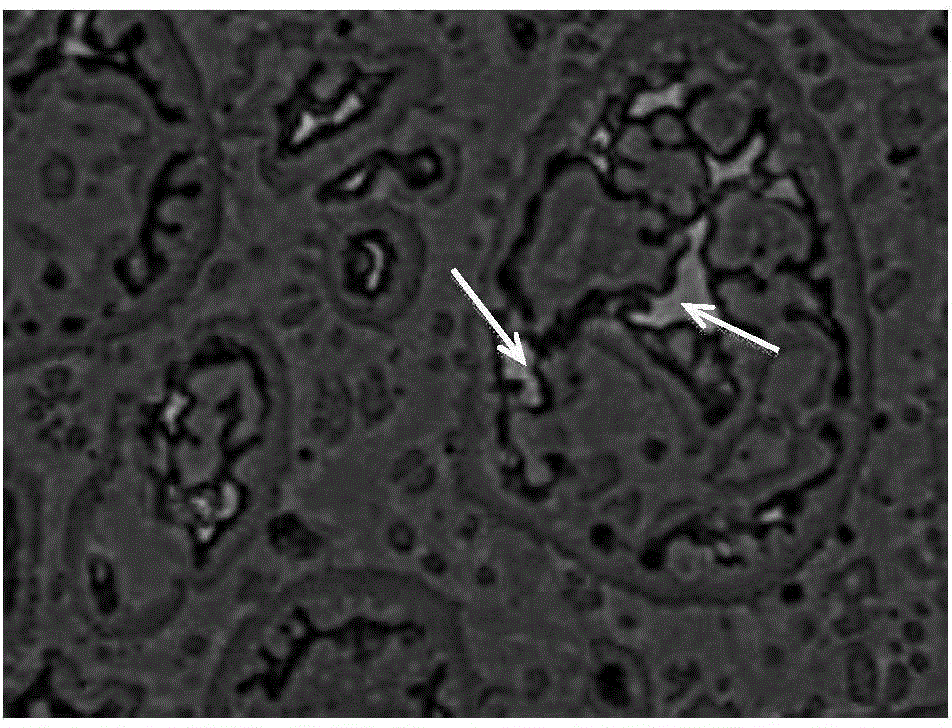

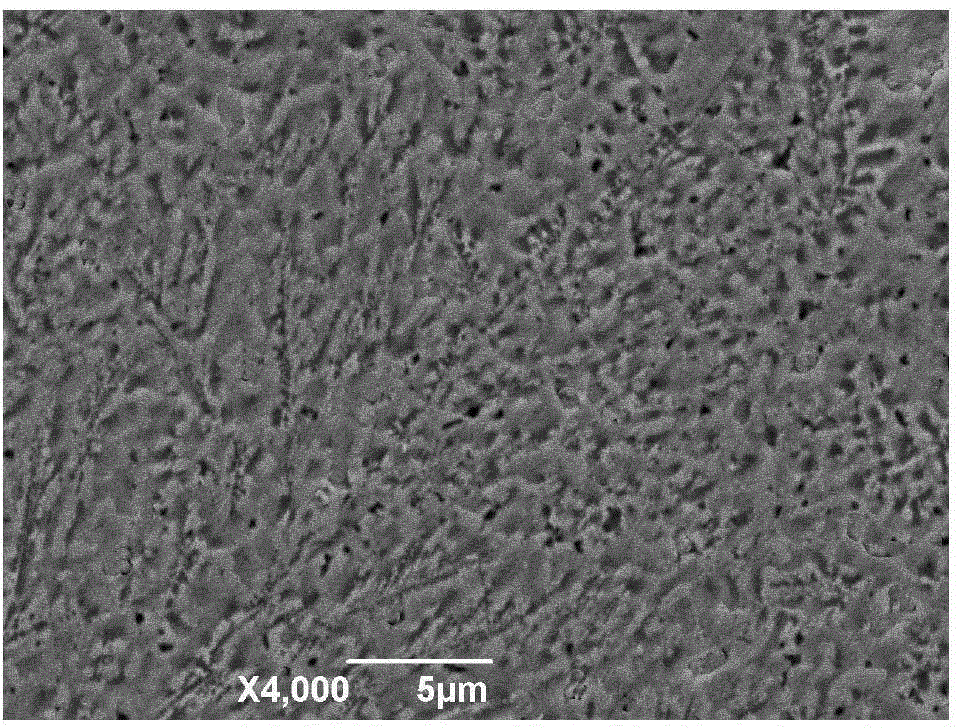

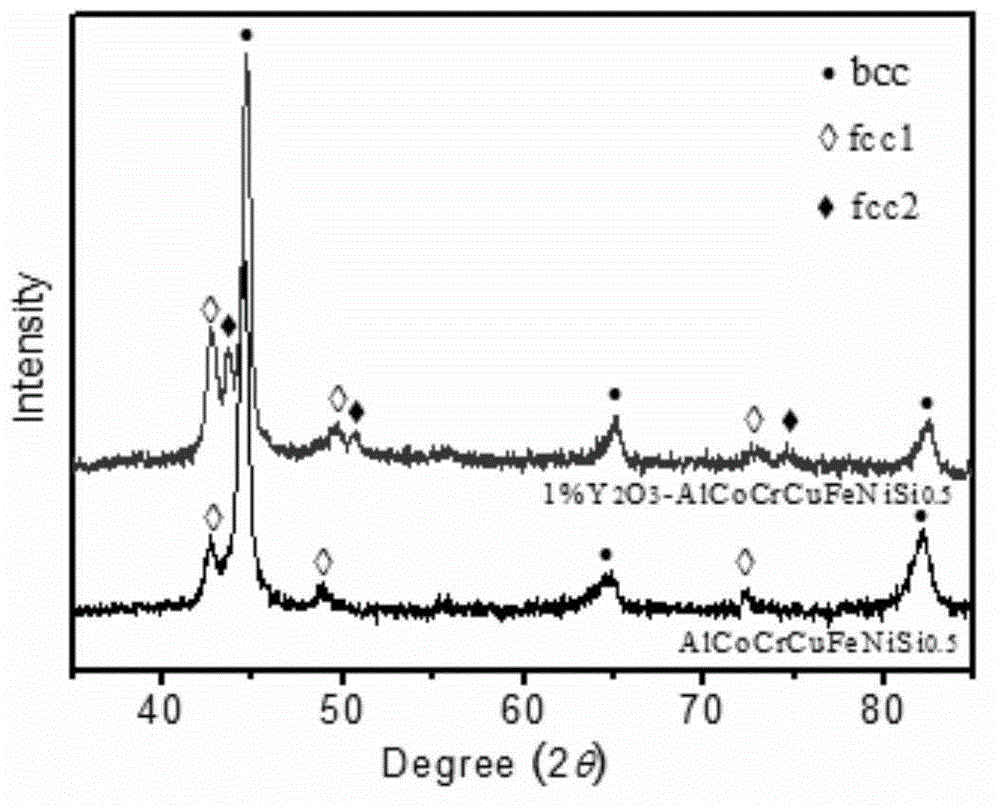

Cu-containing high-entropy alloy coating with liquid phase separation tissue and preparation method thereof

ActiveCN104911581AOptimize the preparation processChange the single-phase structureMetallic material coating processesHigh entropy alloysSingle phase

The invention discloses a Cu-containing high-entropy alloy coating with liquid phase separation tissue and a preparation method thereof, and belongs to the field of alloy material design. According to the invention, a small amount of nano Y2O3 (mass fraction of 0.5-3%) is added to the Cu-containing high-entropy alloy composition, and can promote laser cladding of the Cu-containing high-entropy alloy coating and formation of liquid phase separation tissue. The Cu-containing high-entropy alloy is composed of five or more metallic or non-metallic elements, and the compulsory Cu element accounts for 15-35% of the total moles of the high-entropy alloy composition. The nano Y2O3 has a large surface effect and small size effect, can promote separation of liquid copper from the alloy melt in the laser cladding of Cu-containing high-entropy alloy coating; and a large number of copper-rich particles in dispersed distribution grow in situ on the coating solidified matrix tissue, thus changing the single-phase structure of the coating, and providing a novel method for designing complex phase tissue and expanding capability of the high-entropy alloy by liquid phase separation.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

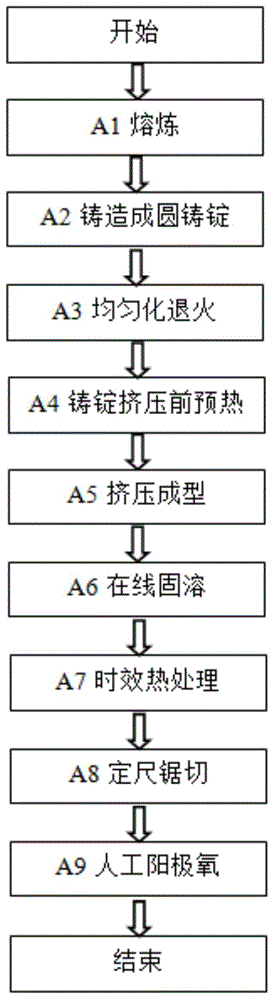

Low-cost high-plasticity soluble magnesium alloy material and preparation method thereof

The invention discloses a low-cost high-plasticity soluble magnesium alloy material and a preparation method thereof. The magnesium alloy comprises the components of MgAlZn<c>Mn<d>Ca<e>Ni<f>Si<g>Sn<h>, wherein a, b, c, d, e, f, g and h represent the mass fraction of each element, b ranges from 0.5%-15%, c is in the range of 0.1%-6%, d is in the range of 0.05%-2%, e is in the range of 0.01%-3%, f is in the range of 0.01%-6%, g is in the range of 0%-2%, h is in the range of 0%-5%, and the sum of a, b, c, d, e, f, g, and h is equal to 100%; and after smelting, casting, homogenization treatment, hot extrusion and aging treatment are carried out, the required alloy material is obtained. According to the low-cost high-plasticity soluble magnesium alloy material and the preparation method thereof, compared with the prior art, the magnesium alloy material prepared by the components and the process is adopted, the cost is low, the production is convenient and fast, a finished product hasgood strength and high plasticity, and can be rapidly dissolved in a solution containing a microscale electrolyte, the low-cost high-plasticity soluble magnesium alloy material is suitable for a soluble downhole tool used in oil processing and preparing and gas field fracturing process, the downhole tool prepared by the material is adopted and can be self-dissolved after service is finished, the subsequent procedures such as flowback, drilling and milling can be omitted, the construction efficiency is greatly improved, the construction cost is saved, and the energy consumption is reduced.

Owner:大同高镁科技有限公司

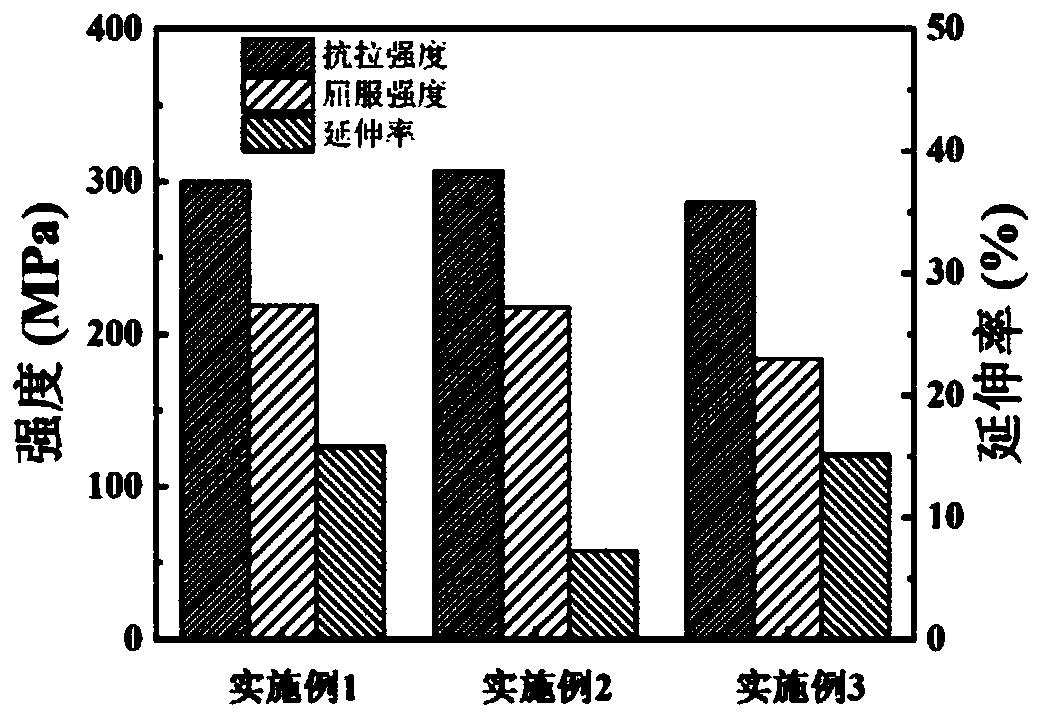

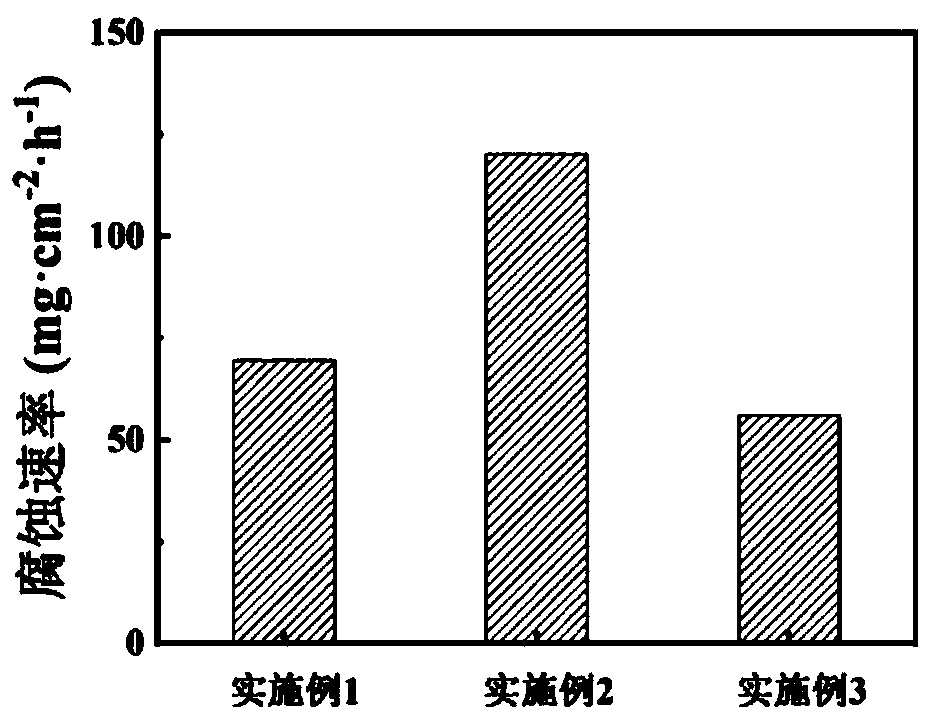

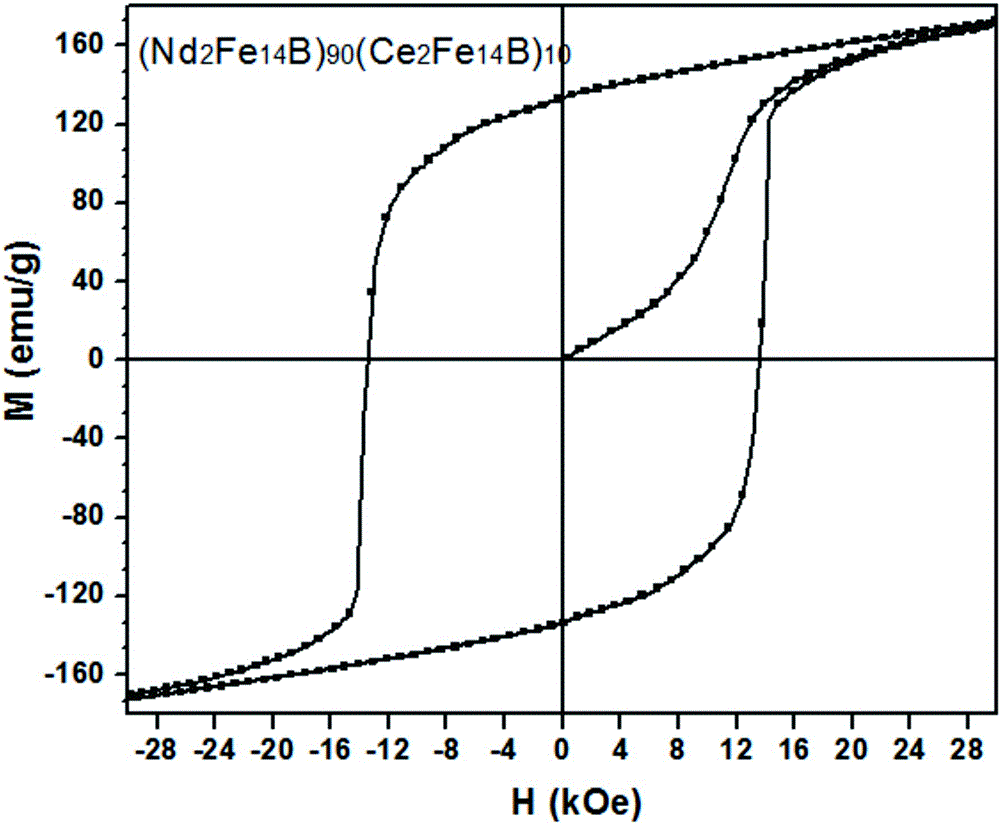

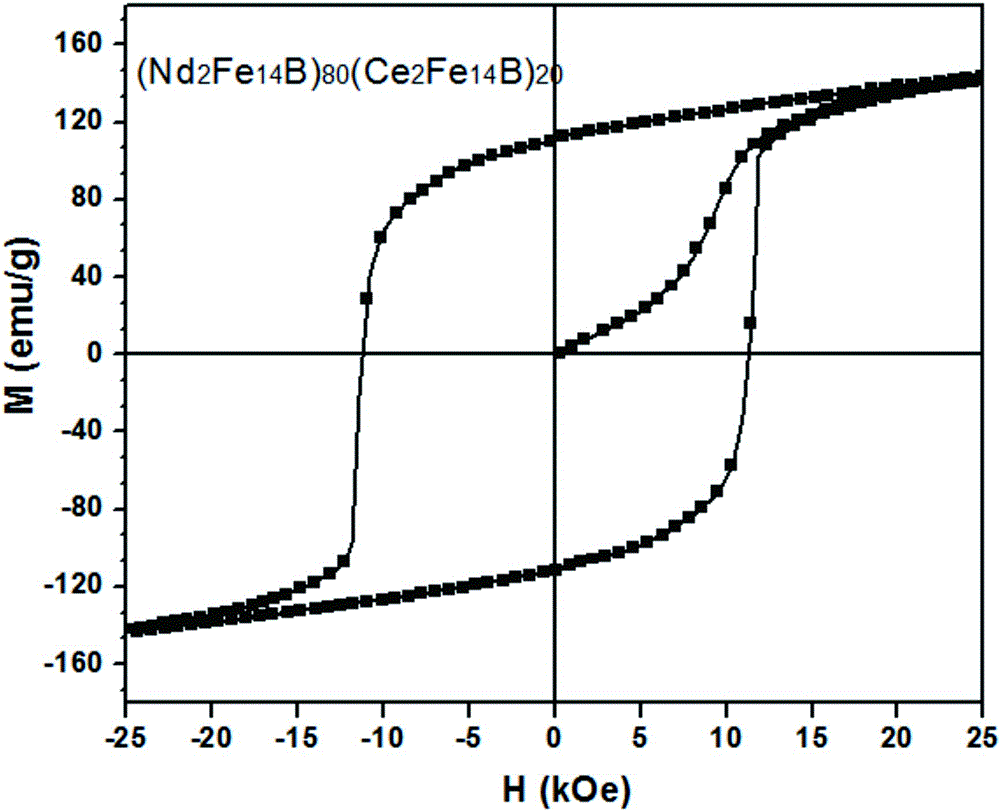

Double-main-phase Nd2Fe14B-Ce2Fe14B composite permanent magnet and preparation method thereof

ActiveCN106356175ABalanced utilizationLow costInductances/transformers/magnets manufactureMagnetic materialsIce waterHydrogen

The invention discloses a double-main-phase Nd2Fe14B-Ce2Fe14B composite permanent magnet. Mass fractions of Nd2Fe14B and Ce2Fe14B are 80%-90% and 10%-20% respectively. A preparation method includes: (1) weighing substances according to requirements, and smelting in a vacuum arc smelting furnace to obtain two alloys uniform in component; (2) putting the alloys into vacuum glass tubes respectively, putting into an annealing furnace, keeping the temperature at 700-800 DEG C for 10-12 days, and quenching in ice water; (3) making strip-casting flakes; (4) subjecting the strip-casting flakes to a hydrogen explosion process to obtain powder; (5) mixing the powder with a magnetic powder protection agent to obtain powder; (6) pressing; (7) sintering; (8) annealing. The preparation method is simple, the magnet is high in coercivity, and balance use of rare earth resources can be promoted.

Owner:四川省有色冶金研究院有限公司

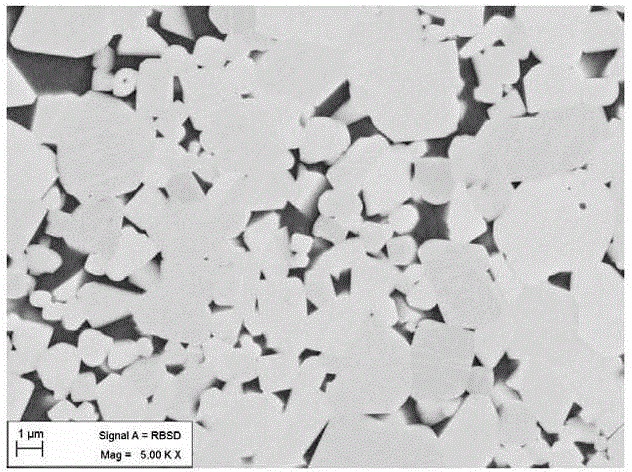

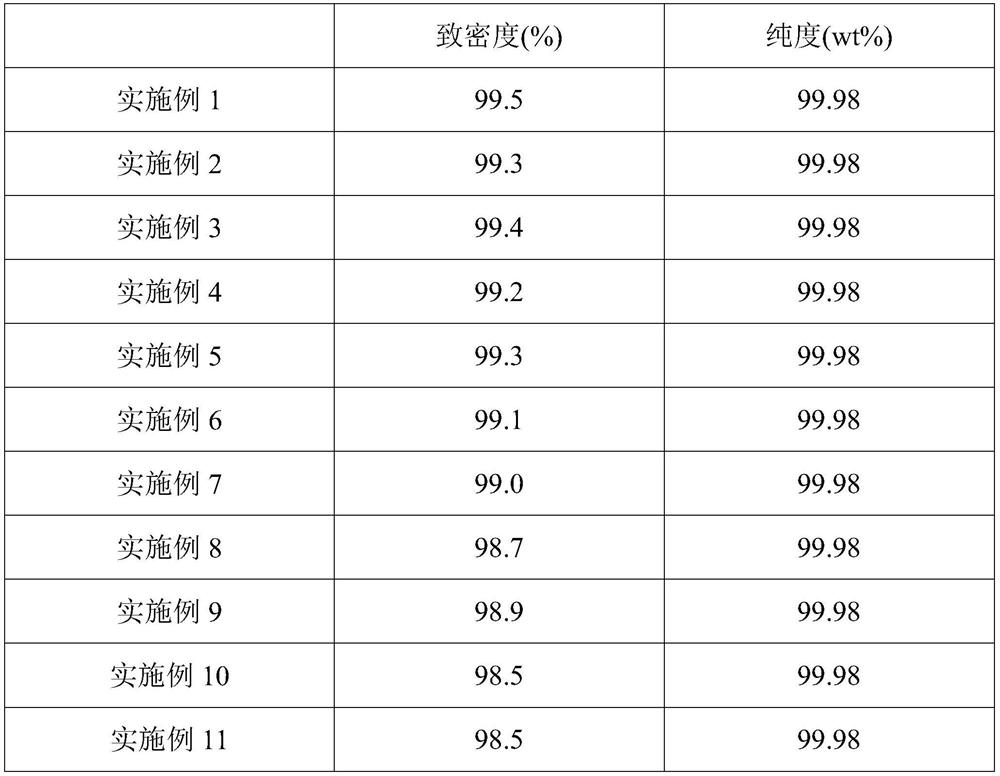

Preparation method of chromium-silicon alloy sputtering target material

ActiveCN113073299AEasy to prepareVacuum evaporation coatingSputtering coatingSilicon alloyPumping vacuum

The invention provides a preparation method of a chromium-silicon alloy sputtering target material. The preparation method comprises the following steps that chromium powder and silicon powder are subjected to ball-milling and mixing in a protective atmosphere to obtain a mixture, and the mass fraction of the silicon powder in the mixture is not more than 16wt%; the obtained mixture is loaded into a mold and compacted, and then vacuum-pumping treatment is carried out; after the vacuumizing treatment is completed, first heat treatment is carried out, and the pressure in the first heat treatment process does not exceed 6 MPa; second heat treatment, first pressurization, second pressurization and heat preservation and pressure maintaining are carried out in sequence; after heat preservation and pressure maintaining are finished, protective gas replacement is carried out till the pressure ranges from-0.06 MPag to-0.08 MPag, and then cooling in furnace is carried out; and machining is carried out to a required size to complete the preparation of the chromium-silicon alloy sputtering target material. According to the preparation method, the chromium-silicon alloy target material with the silicon content not exceeding 16wt% can be prepared, and the density of the prepared target material is greater than 99%, the purity is greater than or equal to 99.95%, and the requirements of magnetron sputtering on the purity and density of the target material are met.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

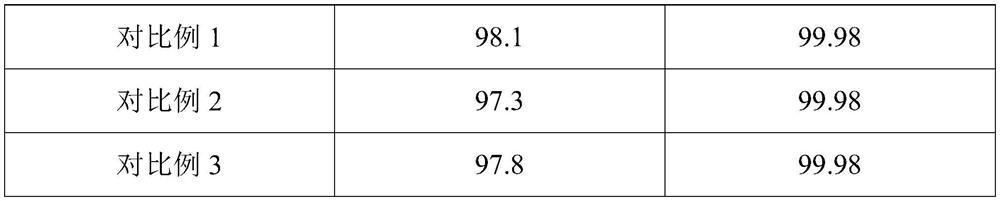

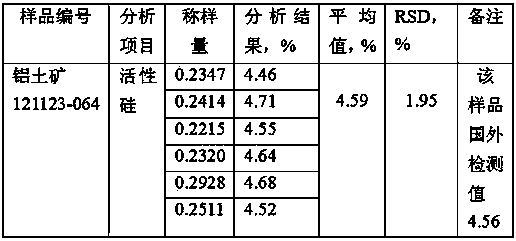

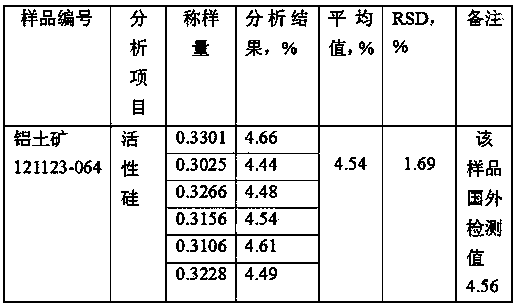

Method for detecting content of active silicon in bauxite

ActiveCN104111207AThe result is accurateReliable resultsWeighing by removing componentPreparing sample for investigationAnalysis dataRelative standard deviation

The invention discloses a method for detecting content of active silicon in bauxite. The method comprises the following steps: processing a bauxite sample by using a microwave digestion method, putting the processed bauxite sample into a beaker, filtering, adding residual slag containing insoluble substances into hydrochloric acid for dipping and combining with a previous filtrate, evaporating the mixture on an electric heating plate, adding perchloric acid for desilicification, filtering and burning at high temperature, subsequently calculating mass fraction of the active silicon in the bauxite sample. According to the method for detecting content of active silicon in bauxite, a relative standard deviation (RSD) is less than 2% and a standard sample recovery rate is greater than 97%; compared with a foreign estimated value, the analysis data is basically consistent, and the method has an accurate and reliable result.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

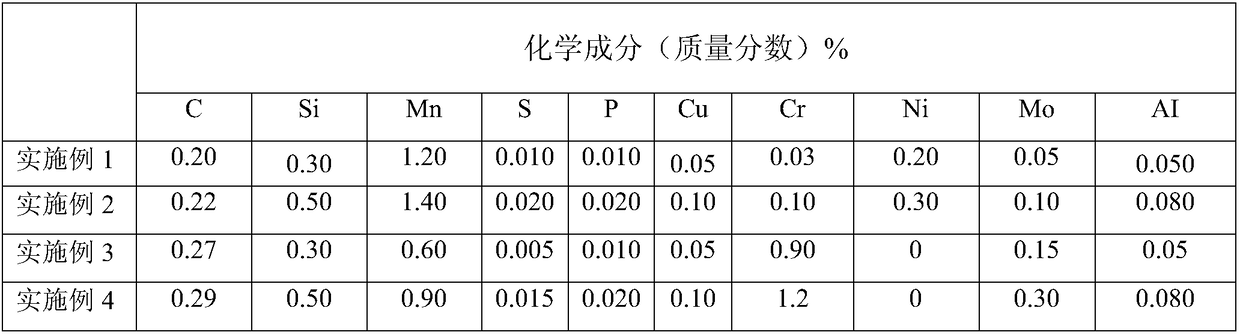

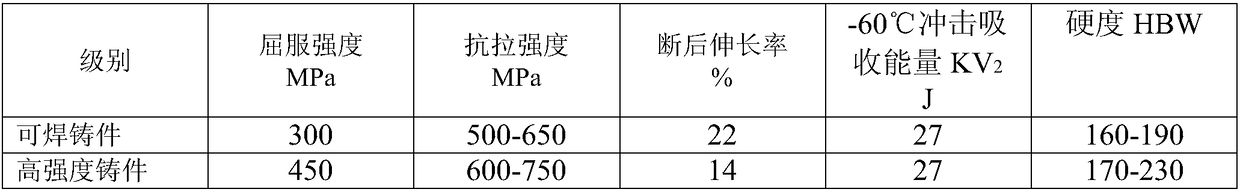

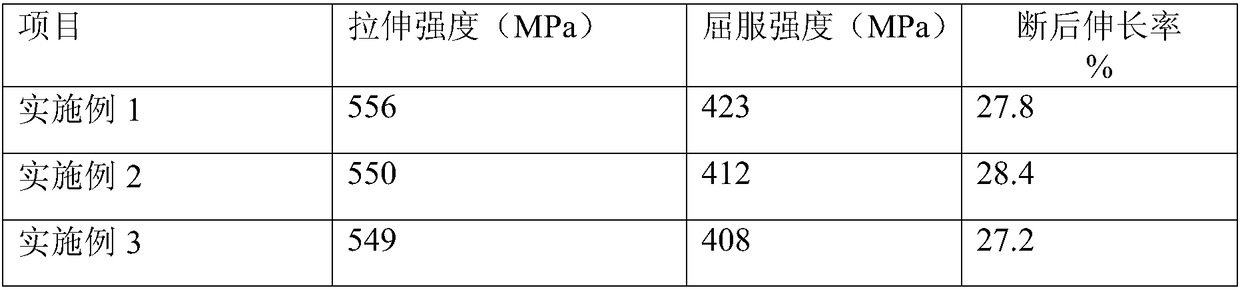

Low temperature resisting cast steel material and thermal treatment process of casting made from low temperature resisting cast steel material

The invention relates to a low temperature resisting cast steel material. The low temperature resisting cast steel material comprises the following chemical ingredients in mass fraction: 0.17% to 0.29% of C, 0.30% to 0.50% of Si, 0.60% to 1.80% of Mn, smaller than or equal to 0.020% of S, smaller than or equal to 0.020% of P, smaller than or equal to 0.10% of Cu, smaller than or equal to 1.20% ofCr, smaller than or equal to 0.30% of Ni, smaller than or equal to 0.30% of Mo, smaller than or equal to 0.080% of AI and the balance of Fe and inevitable impurities. The cast steel material providedby the invention can maintain good strength and toughness for a long time under the condition that the temperature is -60 DEG C, the invention also provides a thermal treatment process of a casting matched with the designed cast steel, and a finished product which is good in toughness, excellent in welding performance and remarkable in other comprehensive mechanical properties can be obtained.

Owner:QINGDAO SANHESHAN CASTING GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com