Patents

Literature

1346results about How to "High temperature strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength and high-corrosion-resistance cast aluminum alloy and pressure casting preparation method thereof

The invention provides high-strength and high-corrosion-resistance cast aluminum alloy and a pressure casting preparation method thereof. The alloy is prepared from, by a certain weight percent, Si, Mg, Fe, Mg, Zn, Sr, Cu, M and the balance Al, wherein M is at least one element of Ti, Zr and V, or the element RE is added in M. After the high-strength and high-corrosion-resistance cast aluminum alloy is subjected to pressure casting, the room temperature tensile strength sigma b of alloy not subjected to heat treatment is larger than or equal to 315 MPa, the room temperature ductility sigma of the alloy not subjected to heat treatment is larger than or equal to 3.0%, and good corrosion resistance is achieved; and the alloy can be applied to automobile parts without ageing or solid solution heat treatment, and the requirement for light automobile development is met.

Owner:SHANGHAI JIAO TONG UNIV

Heat-resistant austenitic stainless steel and a production process thereof

InactiveUS20050194073A1Low costHigh-temperature strengthAustenitic stainless steelWorking temperature

Owner:DAIDO STEEL CO LTD

Lost foam paint and method for producing the same

InactiveCN101497104AGood flow parallelEasy to clean upFoundry mouldsFoundry coresEmulsionWater soluble

The invention discloses an expendable pattern casting (EPC) coating and a method for producing the same. The EPC coating comprises a refractory aggregate, a bonding agent, a suspending agent, a wetting agent, a defoaming agent, an addition agent and a dispersing agent, wherein the refractory aggregate comprises high aluminum powder, quartz powder and olivine powder; the bonding agent comprises B01 water soluble resin or polyvinyl alcohol resin aqueous solution, polyvinyl acetate emulsion, bentonite and sodium hexametaphosphate; the suspending agent comprises sodium carboxymethyl cellulose; the wetting agent comprises tween or / and span; the defoaming agent comprises monobasic alcohol octanol; the addition agent comprises sodium carbonate, cryolite and ferric oxide powder; and the dispersing agent is water. The EPC coating has the advantages that by selecting proper coating components and adjusting the contents thereof, and selecting a proper mixing process, the normal temperature and high temperature strengths, the suitable high temperature air permeability, and the excellent flow parallel and suspension properties and the brushability for a coating layer are completely satisfied. The coating is applicable to gray cast iron pieces with different brands, and particularly the coating layer sheds off automatically and gradually in the cooling process of a cast after pouring and mold dismantling so that the surface of the cast is bright and clean, and the process for cleaning the cast is greatly simplified and saved.

Owner:杨玉光

High-temperature alloy and articles made therefrom

InactiveUS6554920B1High costHigh densityPolycrystalline material growthAfter-treatment detailsChromiumRepair material

An alloy and repair material comprising the alloy, articles comprising the alloy and repair material, and methods for repairing articles including provision of the alloy as repair material are described, with the alloy comprising ruthenium, nickel, aluminum, and chromium, wherein a microstructure of the alloy is essentially free of an L12-structured phase at temperatures greater than about 1000° C. and comprises an A3-structured phase and up to about 40 volume percent of a B2-structured phase.

Owner:GENERAL ELECTRIC CO

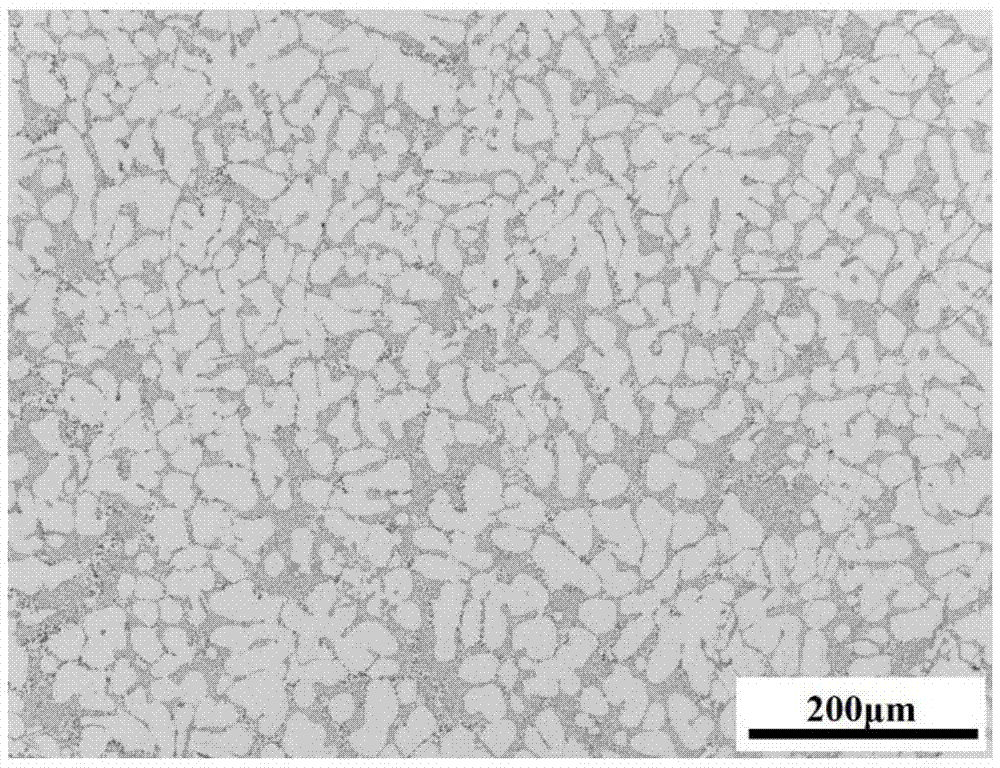

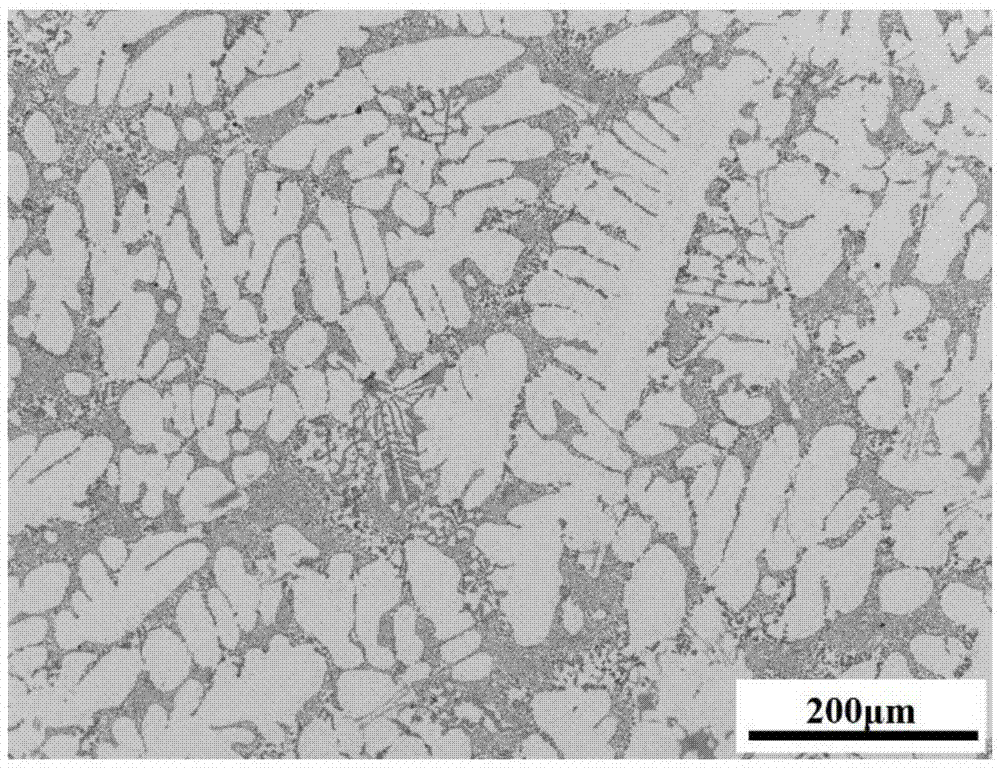

High-strength high-corrosion-resistance cast aluminum alloy and gravity casting manufacturing method thereof

The invention provides high-strength high-corrosion-resistance cast aluminum alloy and a gravity casting manufacturing method of the high-strength high-corrosion-resistance cast aluminum alloy. The alloy is composed of Si, Mg, Fe, Mg, Zn, Sr, Cu, M and the balance Al according to certain weight percentages, wherein the M is at least one of Ti, Zr and V or the RE element is added to the M. The cast aluminum alloy has the excellent cast performance and good mechanical property. The tensile strength, the yield strength and elongation are improved, good corrosion resistance is achieved, the aluminum alloy can be applied to automobile parts without solid solution heat treatment, and the requirement of low-weight development of automobiles is met.

Owner:SHANGHAI JIAO TONG UNIV

Copper alloy materials with high-strength and conducting performances and production thereof

InactiveCN1818109AHigh temperature strengthImprove plasticityHigh intensityUltimate tensile strength

The invention opened a high strength and conductance aldary material which includes: Cr 0.05%-0.10wt%; Zr 0.05%-0.50%; Mg 0.05-0.20wt%; (Ce+Y)<=0.20%; The residue is Cu. The process is : water quench for 1h in 900-960DEG C->30%-45% of cold-drawing deformation->aging treatment for 0.5-4h in 440-520 ->formed by cold-drawing. The strength can reach above 550-600MPa and the specific conductivity can keep above 80% IACS, and the life is improved to 3-5 times, the sintering can reach 550DEG C; the slip is less than 10% in the 300DEG C, the elongation percentage is above 5%, also the alloy has the performance of resistance to elevated temperatures and stand wear and tear.

Owner:HENAN UNIV OF SCI & TECH

Novel nanometer phase dispersion strengthening cuprum as well as preparation method and product producing technique thereof

The invention relates to a dispersion-strengthened copper, the process for preparation thereof and the productive technology of products. The content of dispersion strengthening phase in dispersion-strengthened copper is 0.5-1.25wt%, the size of dispersion strengthening phase particle is 0.01-0.05um, and the distance is 0.1-0.5um. The process for preparing the nano-phase dispersion-strengthened copper comprises the following steps: firstly, mixing aluminium, ytterbium, lanthanum, cerium or zirconium powder with cuprous oxide powder in indoor temperature or inactive gas, and forming copper alloy powder with nanometer reinforcing phase in a copper base body through an in situ reaction synthesis method and through mechanical alloy, secondly, annealing under inactive gas, thirdly, milling compound powder and electrolytic copper powder in a second step with high energy to get nano-phase dispersion-strengthened copper alloy. Section bars which are needed are prepared through utilizing dispersion-strengthened copper which is got to anneal and do isostatic cool pressing, sintering densification and cold working. The process for preparing dispersion-strengthened copper has the advantages of low production cost, high yield and simple technique, and relative products which are prepared have excellent combination properties such as heat conductivity and electric conductivity.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

High-strength high conduction copper alloy and its preparation method

InactiveCN1733953AHigh temperature strengthImprove plasticityHigh intensityUltimate tensile strength

The invention discloses a high-strength high-conductive copper alloy, which comprises 0.04~0.16 Ag, 0.02~0.4% Zr and copper. The opposite method comprises: melting alloy; solidifying alloy; deformation treating and failure treating. This invention overcomes the conflicting problem for high-strength and high-conductive. The product prolongs service life 3~5 times, has strength 500~600MPa, conductivity more than 80%IACS, softening temperature more than 400Deg, strength reduction rate less than 10% and extension rate more than 5% at 300Deg, and fit to all request for copper alloy.

Owner:HENAN UNIV OF SCI & TECH

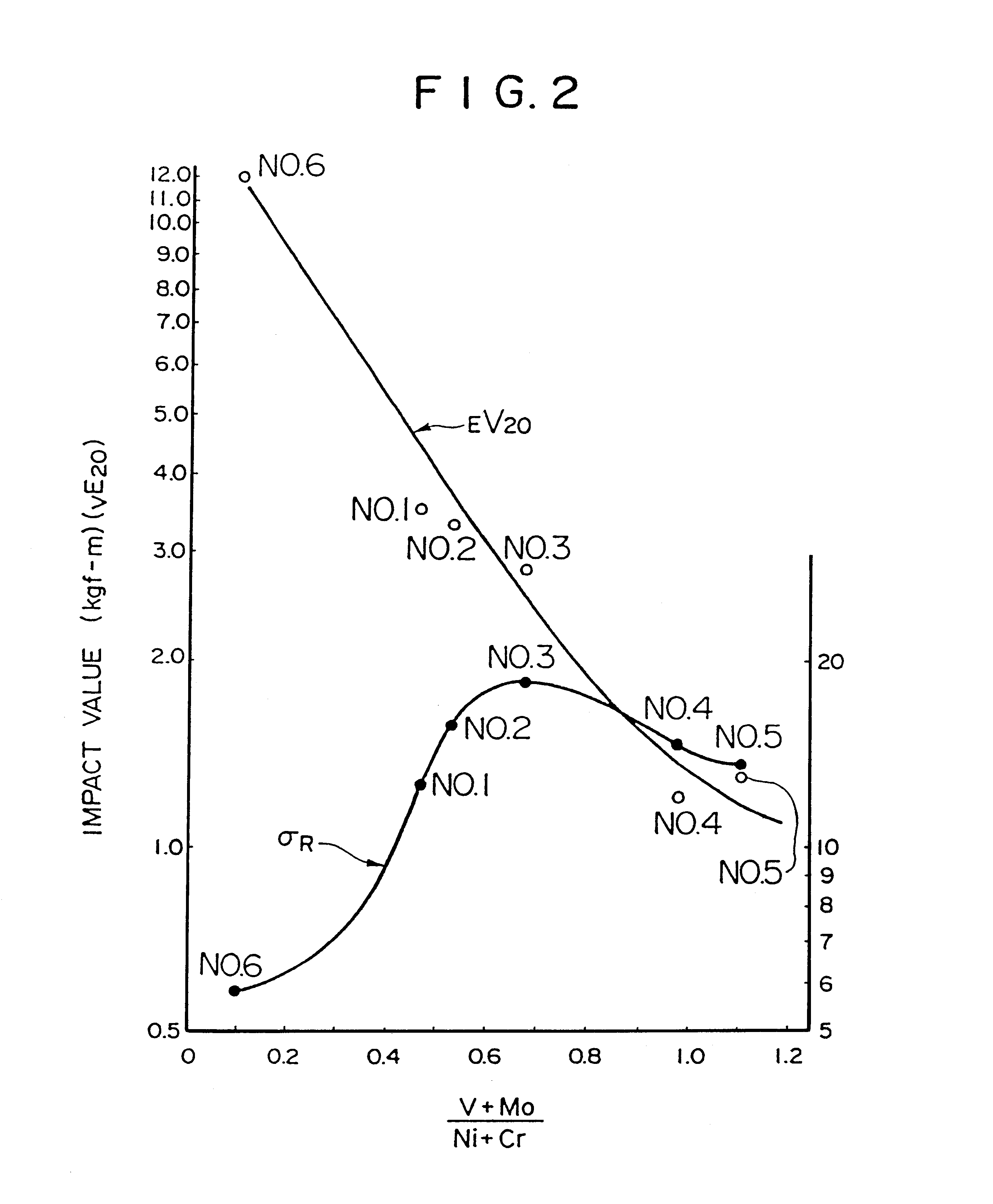

Alloy cast steel for high speed train brake disc, heat treatment method thereof and high speed train brake disc manufactured by the alloy cast steel

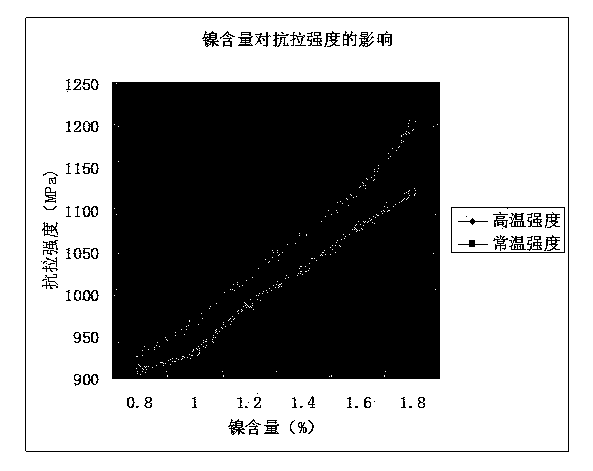

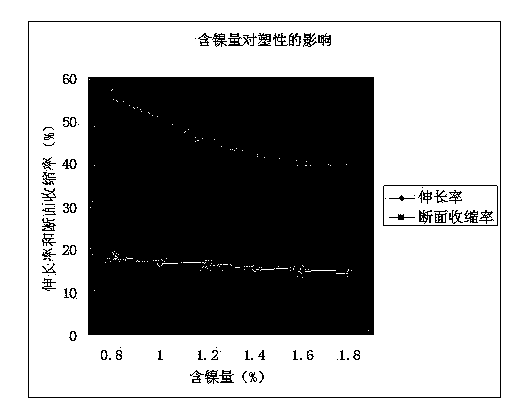

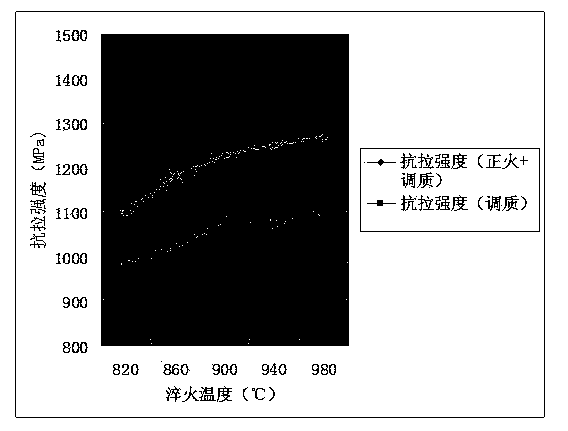

The invention discloses an alloy cast steel for a high speed train brake disc, a heat treatment method thereof and a high speed train brake disc manufactured by the alloy cast steel. The alloy cast steel is composed of the following components in percentage by weight: 0.18-0.26% of carbon, 0.16-0.50% of silicon, 0.55-1.40% of manganese, not larger than 0.03% of phosphorus, not larger than 0.03% of sulfur, 0.90-2.00% of chromium, 0.71-1.80% of nickel, 0.65-1.20% of molybdenum, 0.20-0.35% of vanadium, not larger than 0.30% of other components, smaller than 0.1% of tungsten and the balance of ferrum; and the heat treatment method comprises two steps of normalizing and tempering. The alloy cast steel disclosed by the invention has the beneficial effects that such alloy elements as manganese, nickel, chromium, molybdenum, vanadium, and the like, and such main components in the cast steel material as carbon, silicon and the like are reasonably mixed and are effectively thermally treated to refine the crystalline grain and improve the hardenability and heat resistant properties of the alloy cast steel material, and the normal temperature strength and the high temperature strength are greatly improved, so that the alloy cast steel material has excellent comprehensive mechanical properties. A brake disc manufactured by the alloy cast steel can meet the application requirements of high speed trains.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

Dry type working liner material for erosion resistance continuous casting tundish

InactiveCN1800105AImprove high temperature strength and slag erosion resistanceExtended service lifeTundishOxide

The invention relates to an amorphous refractory; especially to an erosion resistance concast intermedium finish-go-home work sark. It uses magnetite as main raw material and the light-burned magnesium oxide, boric acid, silicon powder and aluminum powder as accelerator and the resin, starch gum and so on as insurance contract. It adds one or some kinds of chrome green, compound chrome-magnesite brick, magnesite-chrome brick. The raw material is that (wt%): the magnesite 5-1mm is 10-35%, 1-0.2mm is 10-35%, <=0.074mm is 20-40%, <=0.088mm admixture is 5-20%, <=0.088mm accelerator is 1-5%, starch gum is 5-12%. Each raw material has a certain quality technology index.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

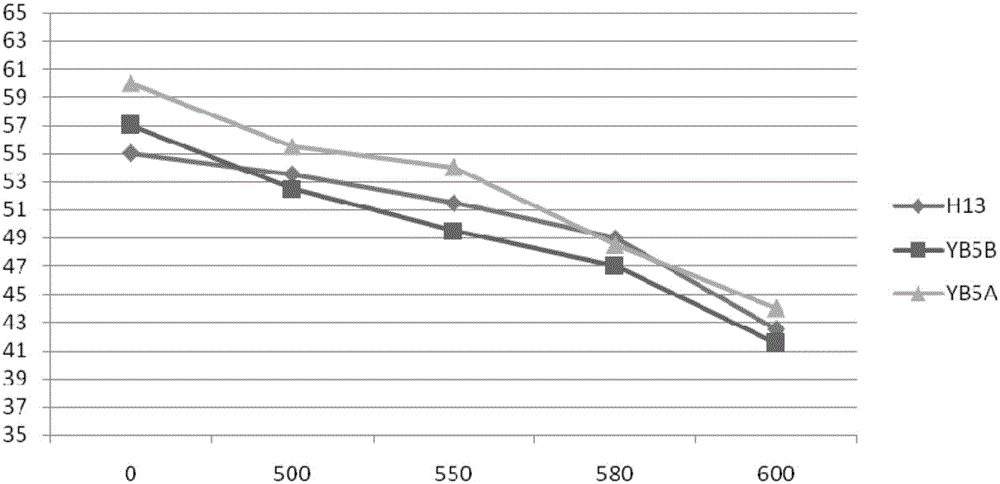

Cr5 series hot work die steel

The invention provides Cr5 series hot work die steel which comprises, by weight, 0.40-0.48% of C, 0.20-1.2% of Si, 0.40-0.80% of Mn, no more than 0.020% of P, no more than 0.010% of S, 4.80-5.50% of Cr, 1.40-2.0% of Ni, 0.80-1.50% of Mo, 0.50-0.70% of V, 0.50-1.00% of W, 0-0.75% of Co, 0.01-0.20% of Al, 0.02-0.20% of Nb, and the balance Fe. The chemical composition formula of the novel Cr5 series hot work die steel provided by the invention is recorded as the YB5 series, and compared with existing Cr5 series (H13) hot work die steel, the YB5 series die steel is higher in C content and Mn content and lower in Si content (YB5A and YB5C), Mo content and V content, and Ni, W, Co (YB5C) and Al (YB5A and YB5C) are added. Accordingly, the toughness of the steel is improved, and the high-temperature strength and creep resistance are improved.

Owner:YINGKOU SPECIAL STEEL FORGING

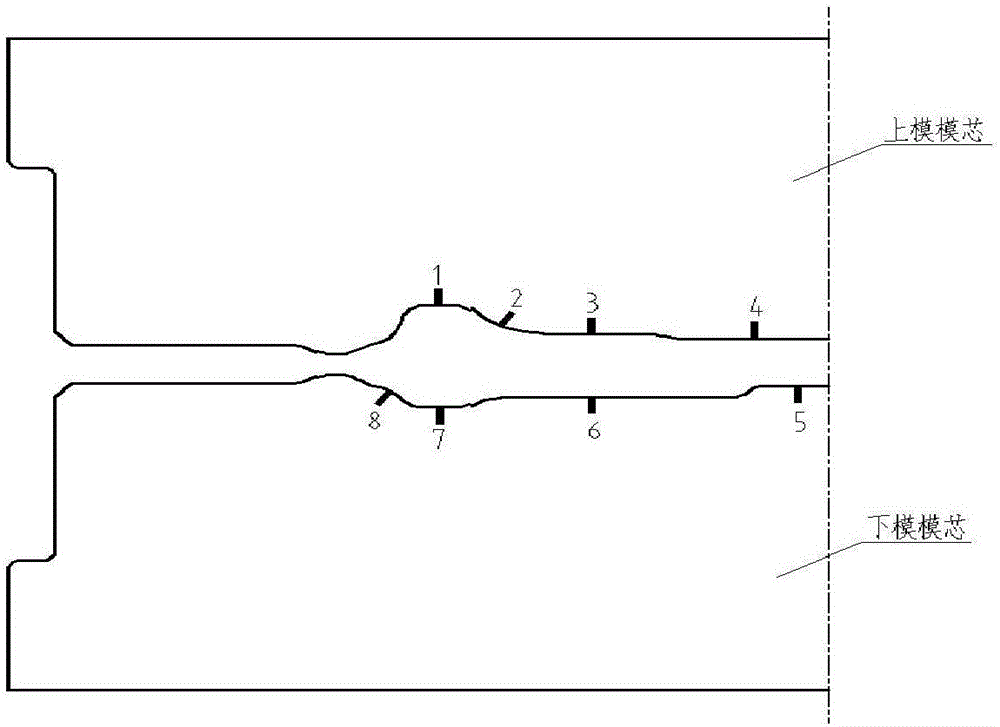

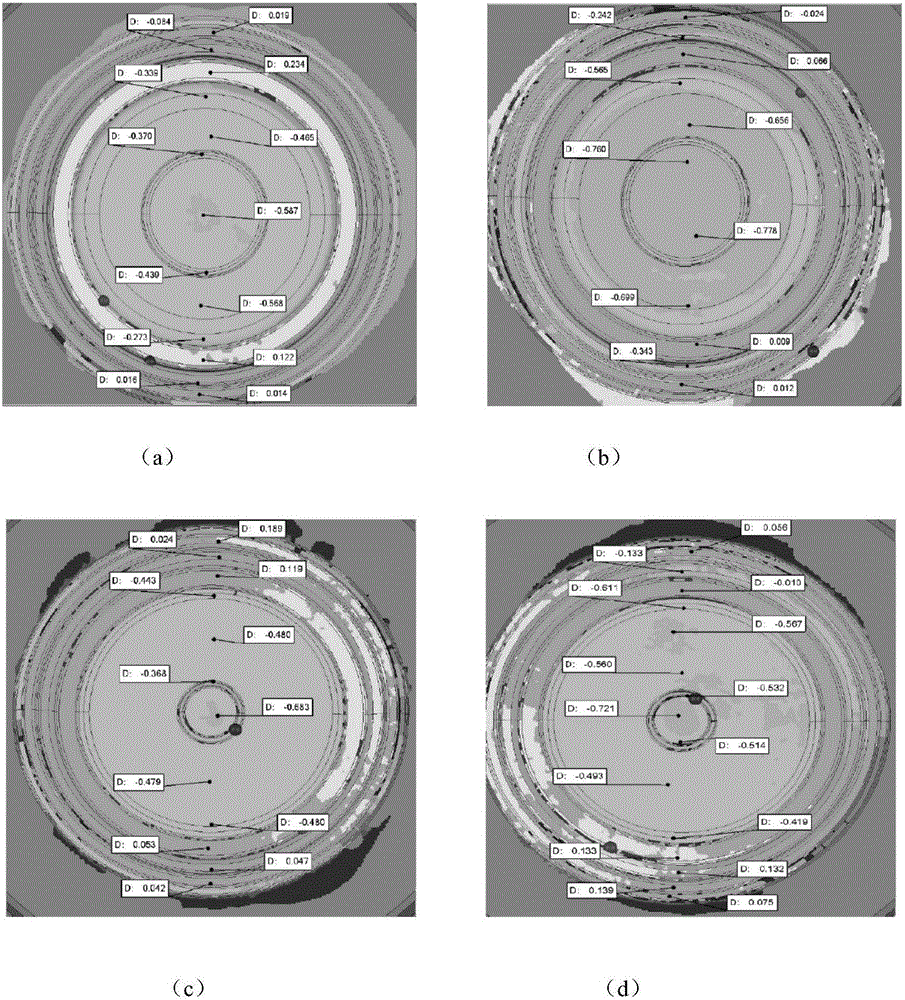

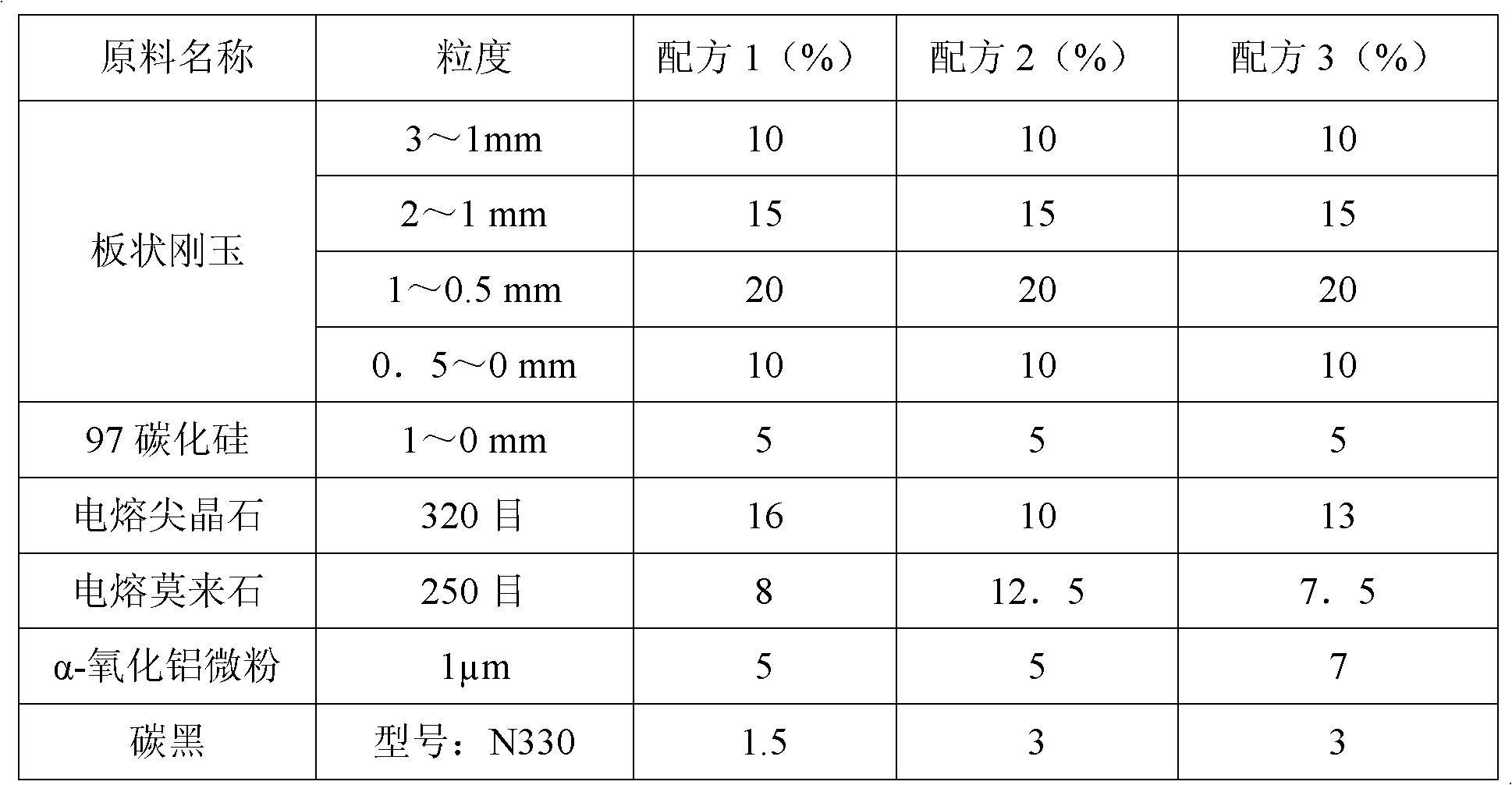

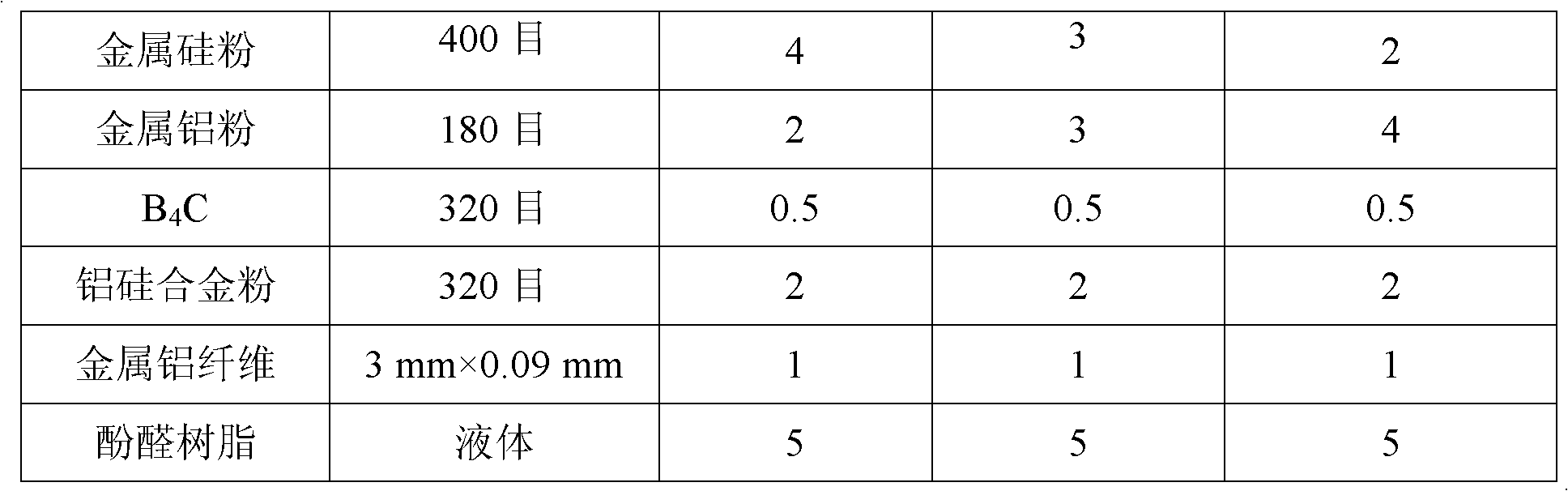

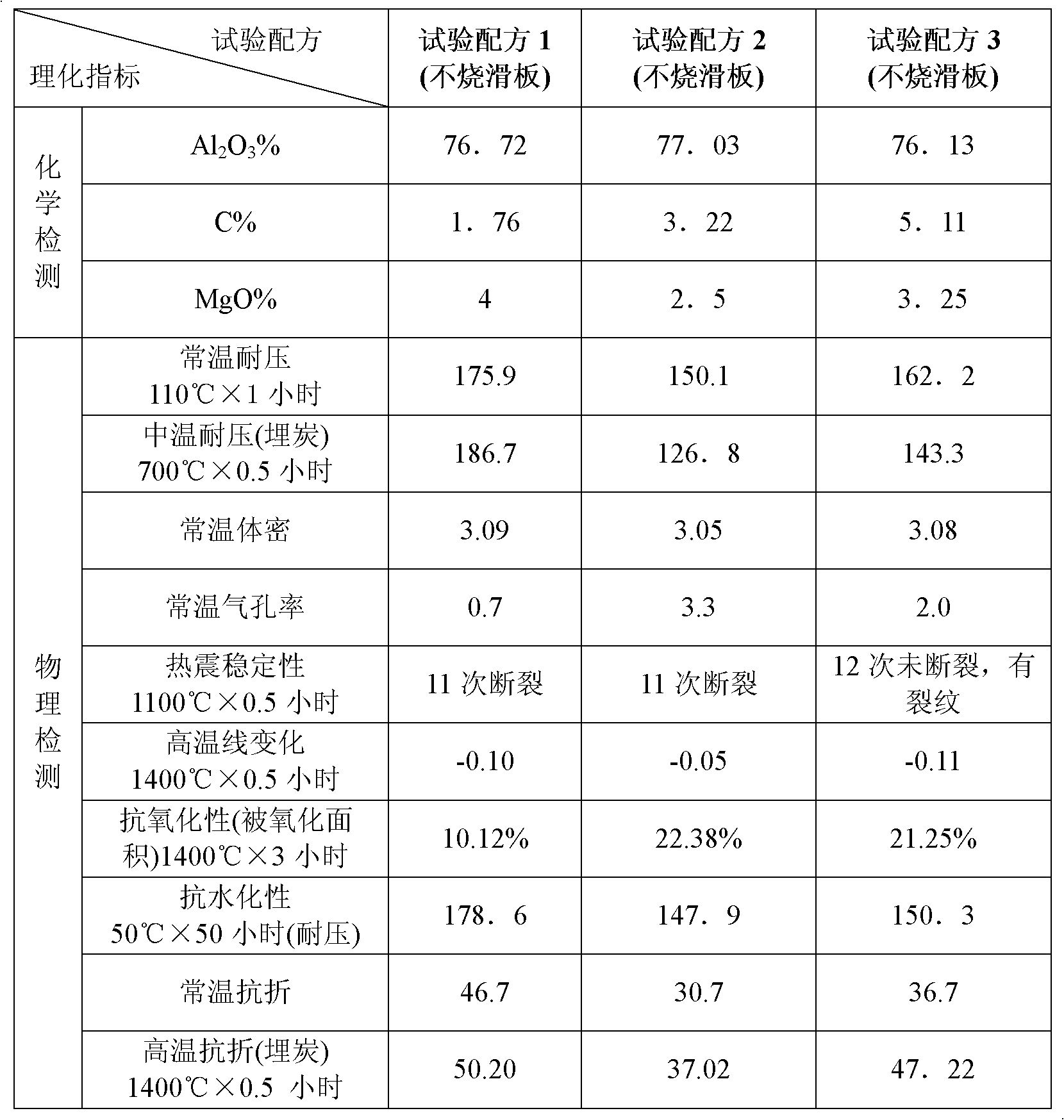

Metal ceramic combination sintering free low carbon sliding plate brick and preparation method thereof

The invention discloses a metal ceramic combination sintering free low carbon sliding plate brick and a preparation method thereof. The sliding plate brick comprises the following components according to weight percentage: 50%-60% of sintered plate shape alundum, 10%-25% of electric melting akerite, 5%-15% of electric melting mullite, 1%-3% of soot carbon, 3%-8% of Alpha- aluminum oxide micropowder, 5%-10% of silicon carbide, 2%-5% of metallic silicon powder,1%-5% of metallic aluminium powder, 0.5%-1% of boron carbide, 1%-3% of aluminum-silicon alloy powder, and 0.5%-2% of metallic aluminium fiber. In the invention, the product has low carbon, high thermal state strength, thermal shock resistance and good oxidation resistance, hole reaming is uniform, galling is less and the crack is verysmall; the process of the invention is characterized in that drying is carried out at a low temperature, the production cycle is shortened from 30 days originally to 7 days, the natural gas consumption is reduced to 2.5% of original technology, and the sintering free low carbon sliding plate brick is indeed belongs to the environmental protective and energy-saving and environmental material resistance product.

Owner:无锡市南方耐材有限公司

Calcium titanium-aluminate prefabricated part for vanadium smelting reverberatory furnace lining and preparation method thereof

The invention relates to a calcium titanium-aluminate prefabricated part for a vanadium smelting reverberatory furnace lining and a preparation method thereof. According to the technical scheme, 60-75 wt% of calcium titanium-aluminate particles, 10-20 wt% of calcium titanium-aluminate fine powder, 2-7 wt% of titanium dioxide micro powder, 5-10 wt% of alpha-Al2O3 micro powder and 1-6 wt% of rho-Al2O3 micro powder are used as raw materials; 0.05-0.30 wt% of water reducing agent and 3.5-6.0 wt% of water of the raw materials are added; stirring is conducted for 5-8 minutes, vibration forming is achieved, maintenance is carried out for 18-24 hours under the natural condition, demolding is performed, heat preservation is conducted for 18-24 hours at the temperature of 90-110 DEG C, and accordingly the calcium titanium-aluminate prefabricated part for the vanadium smelting reverberatory furnace lining is obtained. The calcium titanium-aluminate prefabricated part has the advantages of being low in production cost, and capable of saving resources and protecting the environment. The obtained calcium titanium-aluminate prefabricated part for a vanadium smelting reverberatory furnace is high in high-temperature strength, good in acidity vanadium slag corrosion resistance and good in permeability.

Owner:WUHAN UNIV OF SCI & TECH

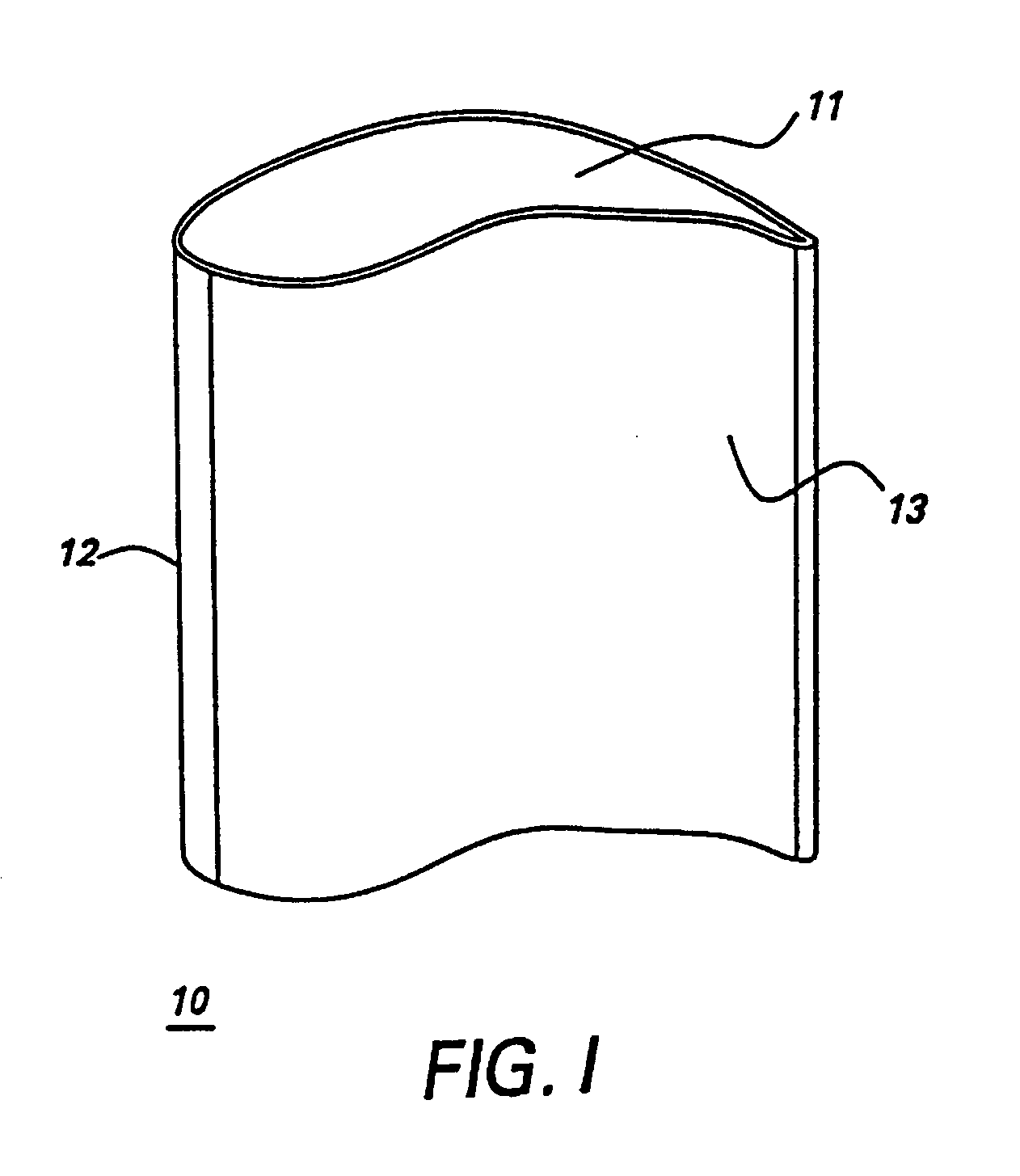

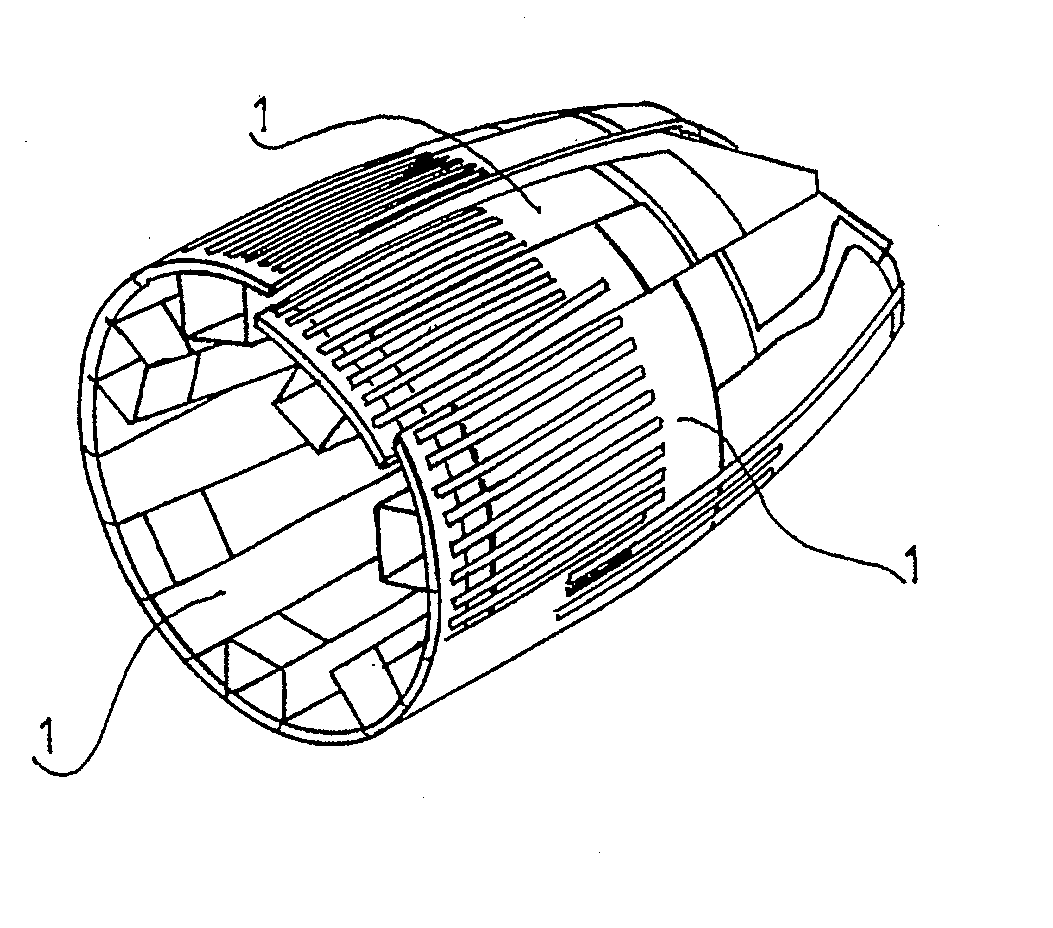

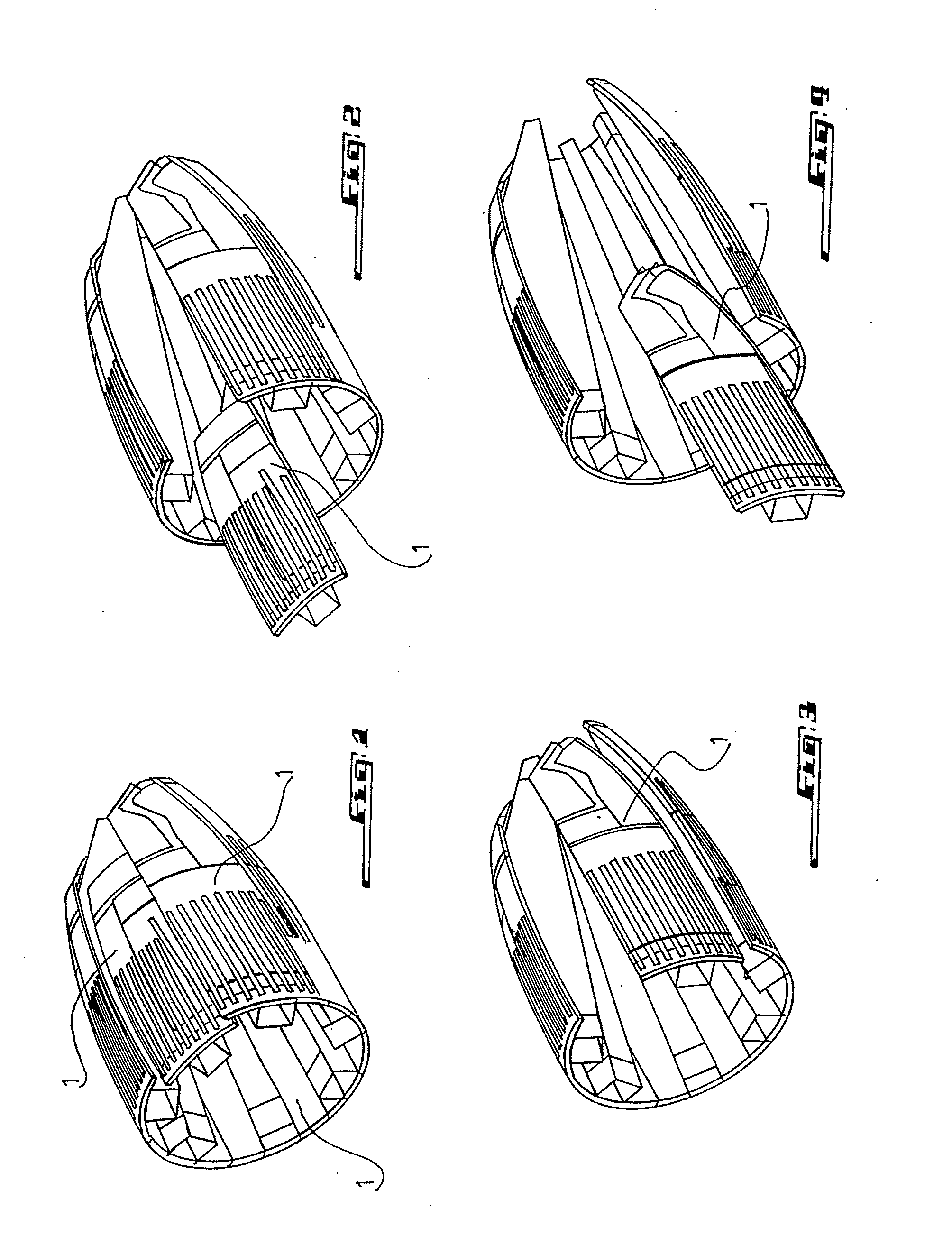

Composite tool for molding cylindrical parts

ActiveUS20100032862A1Simple procedureFacilitate mandrel removal operationConfectionerySweetmeatsEngineeringFibrous composites

A tool of a composite material for making a cylindrical part of a composite material. The tool is used for forming a mandrel on which the cylindrical part is to be formed. The tool comprises a set of members, each member defining a cylindrical sector of the tool, each member having a bearing structure of a fiber composite and a skin molded on the bearing structure. The tool further includes a seal located at the junctions between the tool members.

Owner:CONSTR NAVALES & IND DE LA MEDITERRANEE CNIM

Unburned magnesium-aluminum spinel brick

The invention discloses an unburned magnesium-aluminum spinel brick, which comprises the following components by mass: 50-80% of corundum, 5-30% of magnesia-alumina spinels, 2-5% of magnesia powder, 3-10% of alumina powder, and the balance at least one of elemental silicon powder, metallic aluminum powder and boron carbide powder. All the components of the unburned magnesium-aluminum spinel brick are combined through an additionally added binder. The unburned magnesium-aluminum spinel brick causes no pollution to the environment, has excellent molten steel erosion resistance, slag penetration resistance and scouring resistance, and has a long service life additionally.

Owner:BAOSHAN IRON & STEEL CO LTD

Water-based paint for iron casting through lost foam casting die

InactiveCN102921880AHigh temperature strengthSuitable for high temperature breathabilityFoundry mouldsFoundry coresSODIUM METAPHOSPHATECellulose

The invention discloses a water-based paint for an iron casting through a lost foam casting die. The paint comprises refractory aggregate, binders, a suspending agent, additives and a dispersing agent, wherein the refractory aggregate comprises high aluminum powder, zircon powder and pyrophyllite; the binders comprise silica sol or white emulsion, polyvinyl acetate emulsion, bentonite and sodium hexametaphosphate; the suspending agent comprises sodium carboxymethylcellulose; the additives comprise Tween, octanol, sodium carbonate, cryolite and iron oxide powder; and the dispersing agent is water. According to the paint, suitable ingredients are chosen, the content is adjusted, a suitable mixing process is adopted, and therefore performances such as normal temperature and high-temperature strength, suitable high-temperature permeability and good leveling property, suspension property and painting performance of a coating can be satisfied completely. The paint is suitable for gray iron castings with different trademarks and enables the expendable casting die to be stripped with the iron casting easily, particularly for stripping in flakiness of a sintered coating during cleaning, and the possibilities for diverse defect generation on the surface of the iron casting are reduced; and simultaneously, pollution of coating components to the environment is reduced greatly due to the selection of phosphate assistant.

Owner:XUZHOU PENGJU SNAPDRAGON ARTS & CRAFTS

Ultrathin hard alloy with high hardness and preparation method thereof

Owner:CHONGQING ACADEMY OF SCI & TECH

Silver-copper-based metal oxide electrical contact material containing additive elements and preparation method thereof

The invention discloses a silver copper based metal oxide electrical contact material containing adding elements and a preparation method thereof. The electrical contact material is characterized by comprising the following components in percentage by weight: (20-50)% of silver metal oxide alloy, (0.3-9)% of electric conductive ceramics, (0.7-1.8)% of lanthanum nickel alloy, (0.7-4.9)% of adding elements, and the balance of silver copper alloy; and the contact material provided by the invention comprises the following simple substance elements in percentage by weight: (15-63)% of silver, (4-25)% of metal oxide, (0.3-9)% of electric conductive ceramics, (0.01-5)% of rear earth, (0.7-4.9)% of adding elements, and the balance of copper. The preparation method is characterized by comprising the following steps: smelting, pulverizing and milling (silver metal alloy power, and silver copper alloy powder) in proportion for optimization performances of the material, cladding electric conductive ceramic micro powder by silver, mixing powder of the adding elements in a certain mass ratio, pressing an ingot blank, sintering and extruding, rolling or drawing, thus obtaining the contact material. The electrical contact material provided by the invention has the advantages of low cost and excellent overall performance.

Owner:张树堂

High-strength silicon carbide ceramic pipe and manufacturing method thereof

The invention discloses a high-strength silicon carbide ceramic pipe and manufacturing method thereof, and belongs to the technical field of engineering ceramic materials. Silicon carbide ceramic powders with different granularities are used as the main raw materials, graphite powder and carbon black are used as binders, and resin is used as a binder. The materials are uniformly mixed by a spray granulation process; an organic plasticizer of cellulose and a lubrication agent are added into the mixture; and vacuum pugging, decaying and extrusion molding are conducted to obtain a pipe base substrate; and the base substrate is subjected to drying solidification, high temperature sintering reaction, sandblast and heat treatment to obtain the high strength silicon carbide ceramic pipe. The pipe biscuit manufactured by the process has high strength and length of more than 4000mm; after sintering, the pipe has strength of 300MPa or more, and has the advantages of moderate density, high thermal conductivity, high fracture toughness, good thermal shock resistance and low cost, and can be widely applied to chemical and metallurgy fields, such as acid and alkaline corrosion and high temperature erosion.

Owner:NANTONG SANZER PRECISION CERAMICS CO LTD

Rare earth copper alloy and its preparation method

The invention discloses a rare earth copper alloy and its preparation method, which comprises charging electrolytic copper by weight percentage, smelting 20-30 minutes, then charging 0.03-0.1% of zirconium, 0.02-0.16% of silver, 0.02-0.155 of rare-earth elements, smelting 1-3 minutes and casting, subjecting the cast alloy to heat preservation 1-4 hours at 800-850 deg C, forming bar stock through processing, the forging deformation amount is 50-80%, loading the bar stock into heat treatment furnace, thermally insulating 30-60 minutes at 800-950 deg C, then carrying out quenching treatment, subjecting the quenched alloy to 30-80% deformation treatment, cold drawing the alloy, thermally insulating 1-8 hours at 440-520 deg C, carrying out 50-70% deformation treatment to the alloy undergone ageing treatment. The invention can achieve high-strength and high conductivity.

Owner:HENAN UNIV OF SCI & TECH

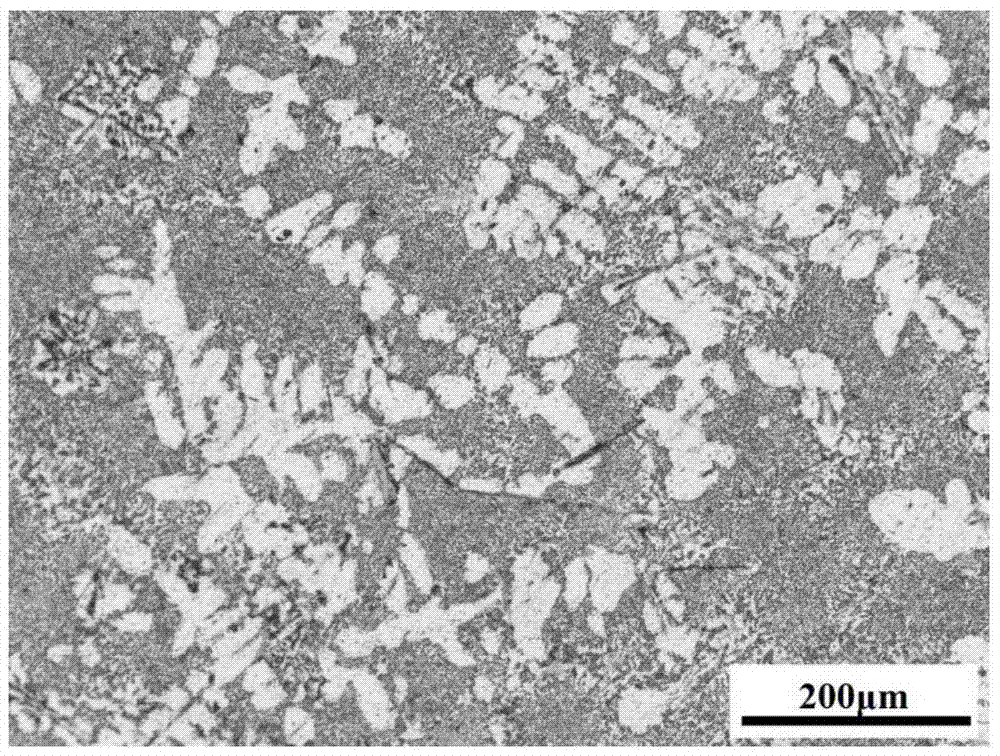

Heat-resistant cast aluminum alloy and extrusion casting method thereof

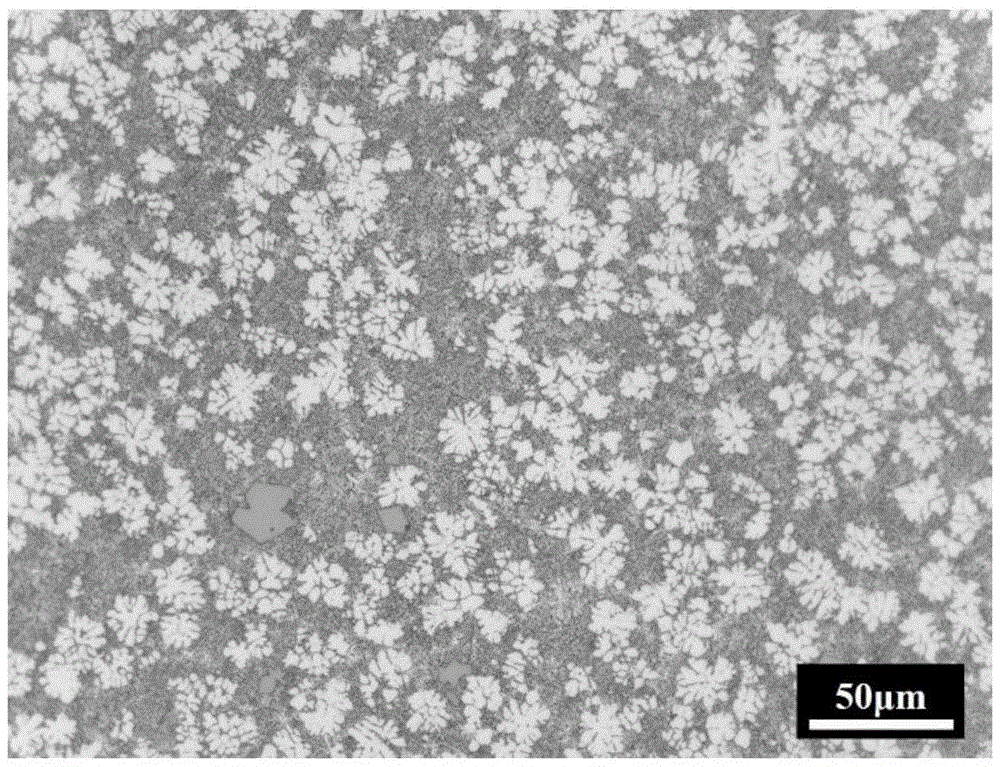

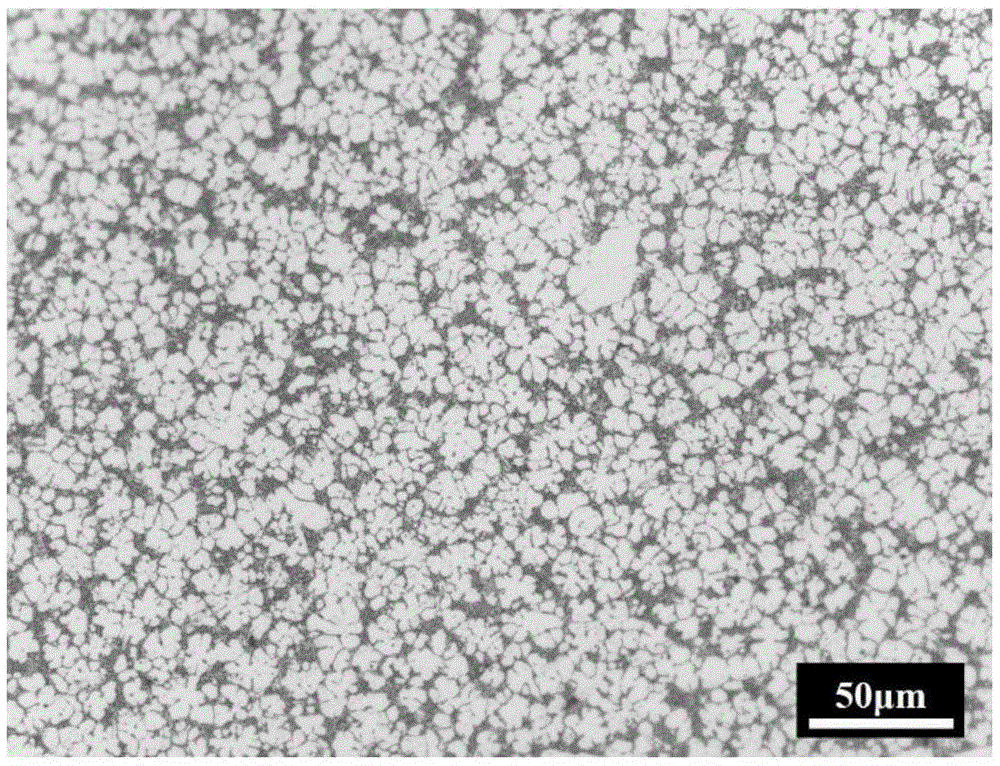

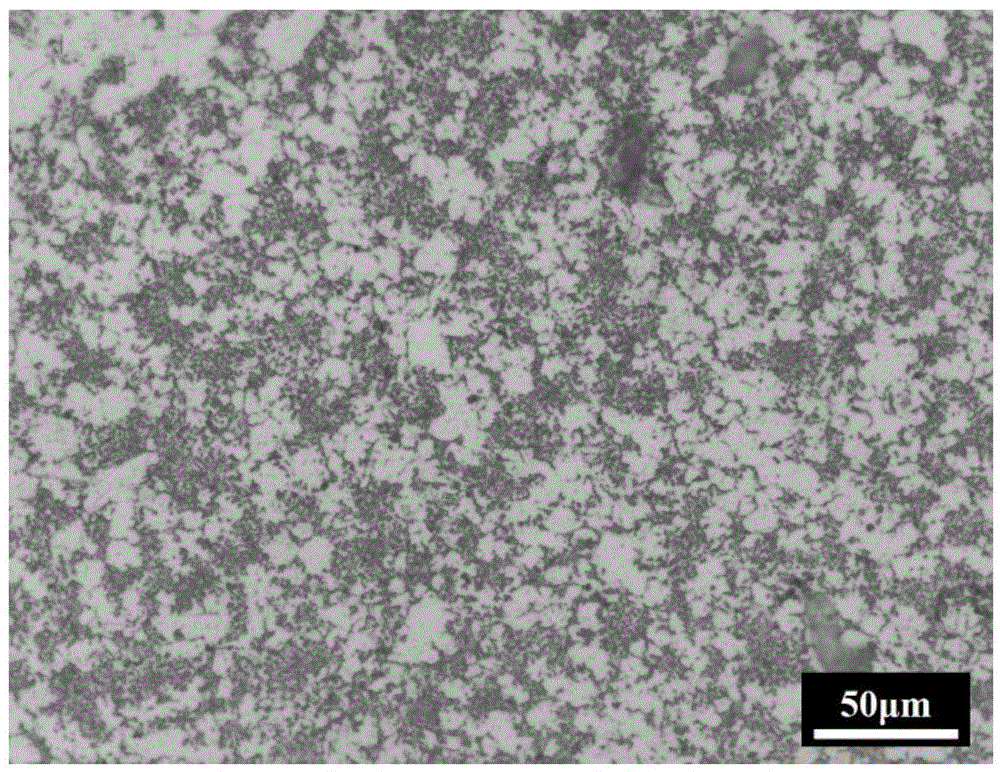

ActiveCN104561689AGood high temperature performanceHigh hardnessMetallic materialsSolution treatment

The invention relates to a heat-resistant cast aluminum alloy and an extrusion casting method thereof, and belongs to the fields of metallic materials and metallurgy. The alloy consists of the following elements in percentage by weight: Si, Cu, Ni, Mg, Ti, RE, Mn, Fe and Al. The heat-resistant cast aluminum alloy is prepared by virtue of extrusion casting, and after performing solution treatment and artificial aging treatment on the alloy, the room temperature tensile strength sigma b of the alloy is more than or equal to 420MPa, the tensile strength sigma b at 300 DEG C is more than or equal to 220MPa, the tensile strength sigma b at 350 DEG C is more than or equal to 140MPa, the room temperature extensibility delta is more than or equal to 2.5%, the extensibility delta at 300 DEG C is more than or equal to 6.5%, and the extensibility delta at 350 DEG C is more than or equal to 14.5%. According to the alloy and the extrusion casting method thereof provided by the invention, the casting performance is improved, the room-temperature and high-temperature mechanical properties of the alloy are greatly improved, and the application range of Al-Si series cast aluminum alloys is expanded.

Owner:SHANGHAI JIAO TONG UNIV

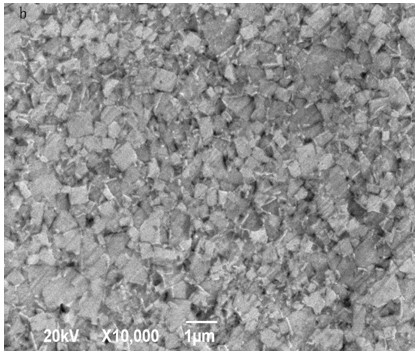

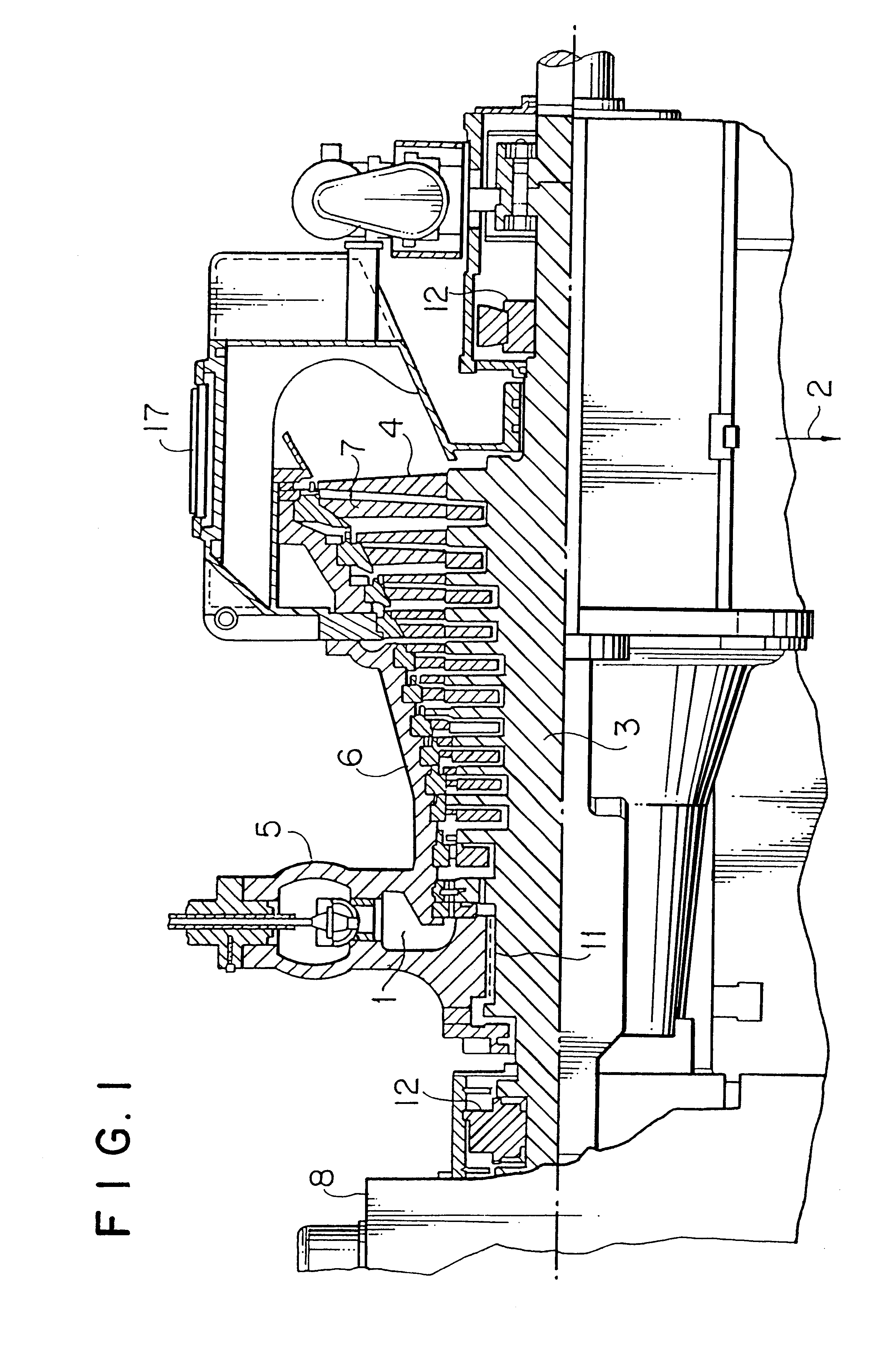

Steam turbine, rotor shaft thereof, and heat resisting steel

A steam turbine comprising a rotor shaft integrating high and low pressure portions provided with blades at the final stage thereof having a length not less than 30 inches, wherein a steam temperature at first stage blades is 530° C., a ratio (L / D) of a length (L) defined between bearings of the rotor shaft to a diameter (D) measured between the terminal ends of final stage blades is 1.4 to 2.3. This rotor shaft is composed of heat resisting steel containing by weight 0.15 to 0.4% C, not more than 0.1% Si, 0.05 to 0.25% Mn, 1.5 to 2.5% Ni, 0.8 to 2.5% Cr, 0.8 to 2.5% Mo and 0.15 to 0.35% V and, further, the heat resisting steel may contain at least one of Nb, Ta, W, Ti, Al, Zr, B, Ca, and rare earth elements.

Owner:HITACHI LTD

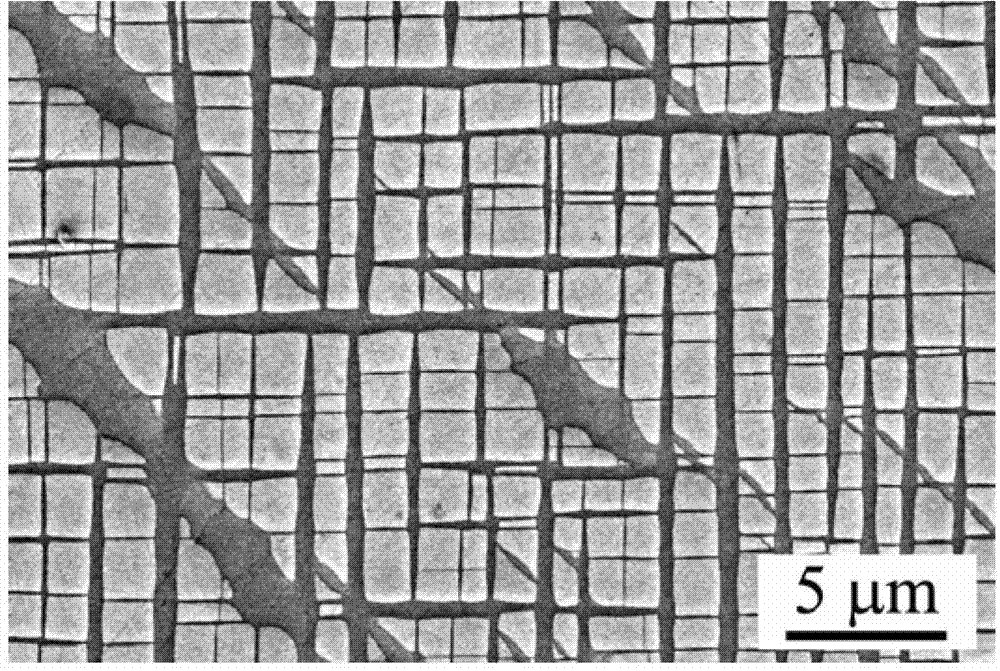

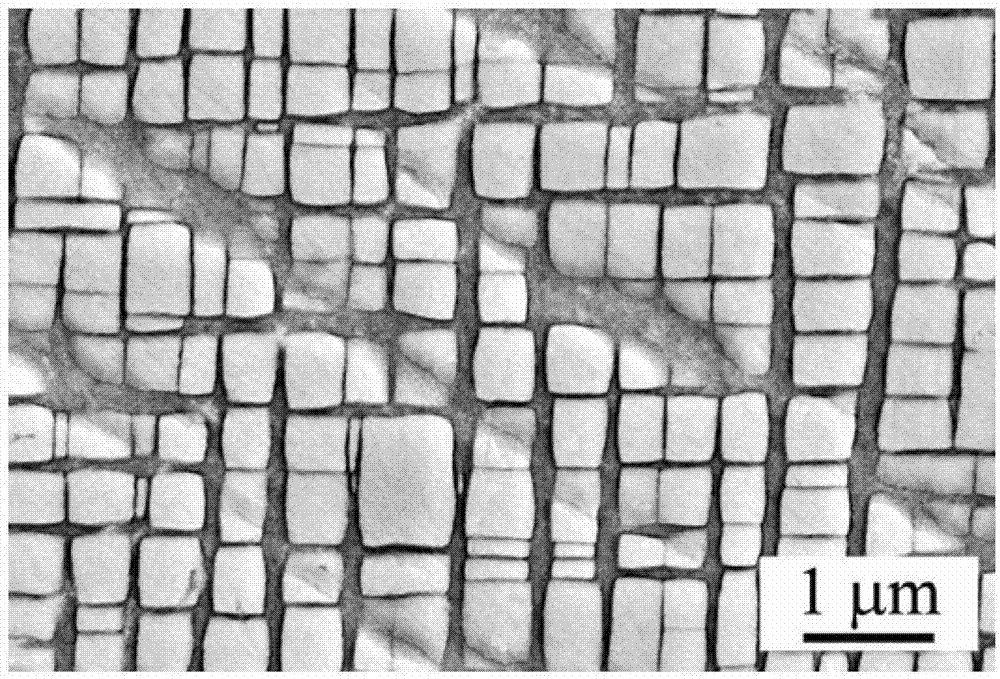

High-temperature-stability gamma'-phase-reinforced cobalt-base high-temperature alloy and preparation method thereof

The invention belongs to the technical field of new materials, and relates to a gamma'-phase high-temperature-stability cobalt-base high-temperature alloy with gamma / gamma' two-phase structure, which is a candidate material for high-temperature hot end components of gas turbines for aviation, spaceflight, vessels, power generation and the like. The alloy comprises the following components in atomic percentage: 4-12% of Al, 4-12% of W, 1-4% of Ta, 1-6% of Ti, 0-10% of Cr, 0-3% of Mo, 0-2% of Hf, 0-1% of C, 0-1% of B and the balance of Co. The preparation method comprises the following steps: smelting in a vacuum induction furnace, carrying out solid solution heat treatment at 1250-1300 DEG C, and carrying out aging heat treatment at 1000-1100 DEG C. After carrying out L12-type gamma'-phase high-temperature reinforcement, the gamma' shape is cubic, the volume percent is higher than 60%, and the gamma'-phase is uniformly distributed in the gamma-phase. Compared with the traditional cobalt-base high-temperature alloy, the alloy provided by the invention has higher application temperature; and compared with the recently developed similar cobalt-base alloys, the alloy provided by the invention has higher gamma'-phase solution temperature and gamma / gamma' two-phase structure stable existence temperature.

Owner:UNIV OF SCI & TECH BEIJING

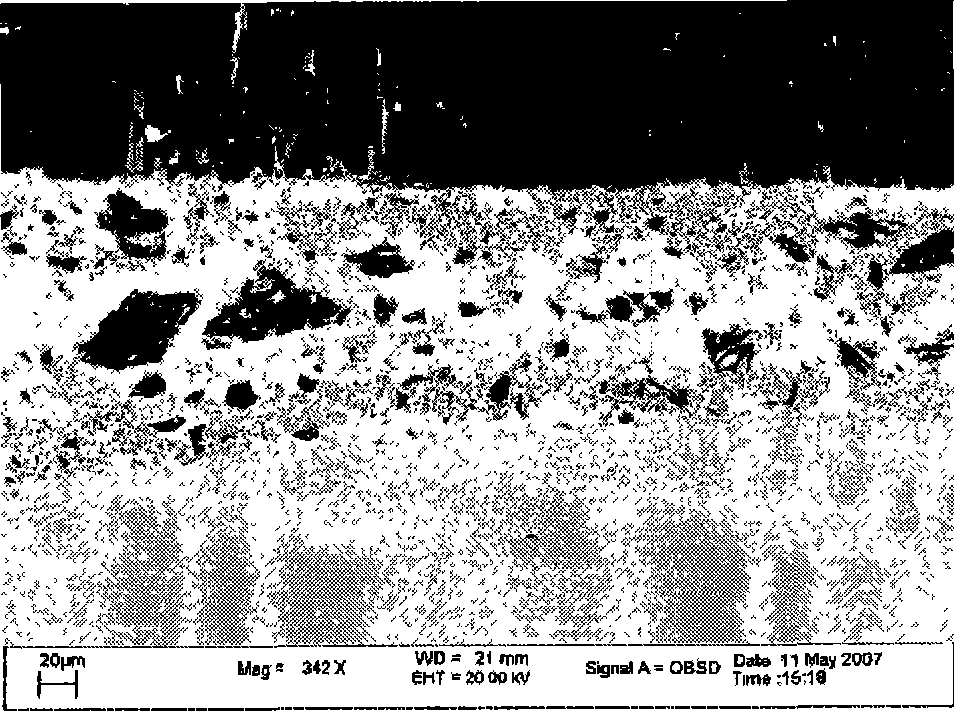

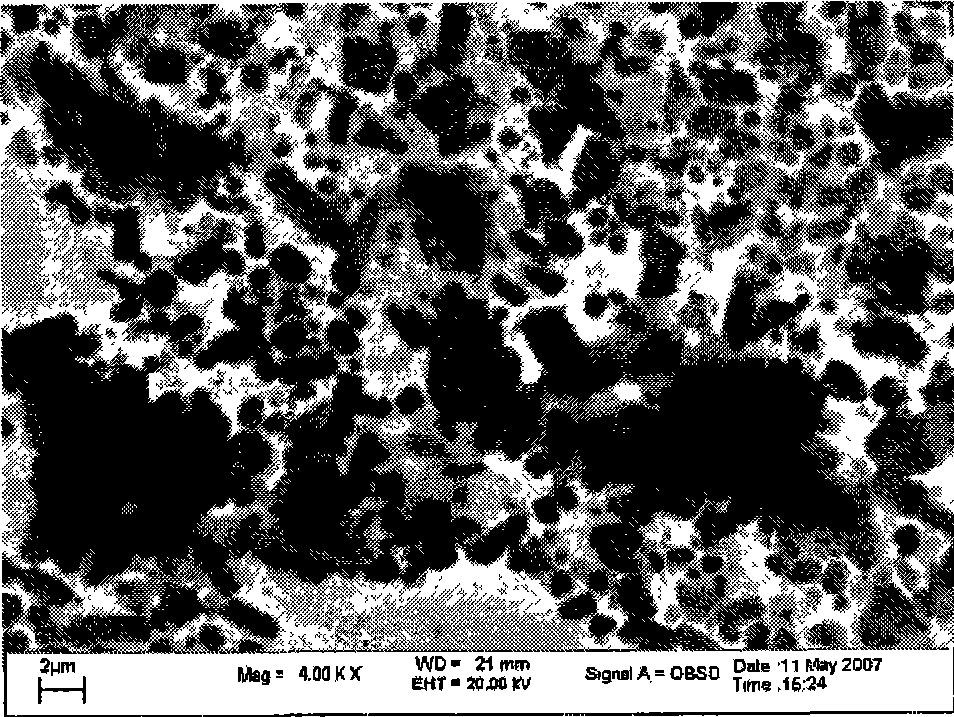

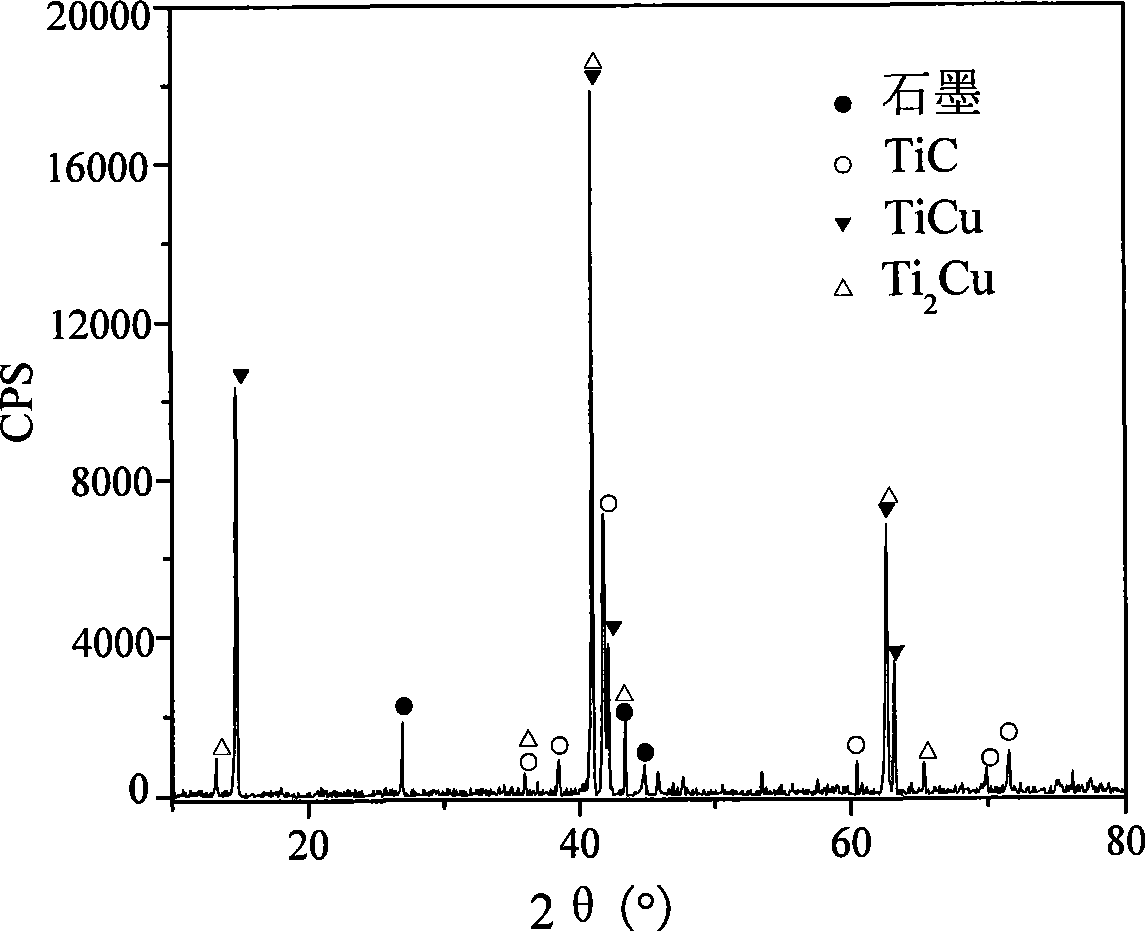

Connecting method for Cf/SiC composite material and titanium alloy

InactiveCN101462890ASmall coefficient of thermal expansionRelief of residual thermal stressRoom temperatureGraphite

A connection method of a Cf / SiC composite material and a titanium alloy belongs to the technical field of dissimilar material connection. The method comprises the following steps: Cu, Ti and graphite powder are evenly mixed at certain proportion and prepared to a pasty solder with alcohol, the prepared pasty solder is spread between the materials to be soldered to solder the Cf / SiC ceramic-based composite material with the titanium alloy in vacuum without applying pressure. A reaction in situ occurs in a connection layer to produce a high-melting-point TiC wild phase in soldering and form a composite connection layer which is similar to a particle reinforced metal-based composite material, thus reducing the thermal expansion coefficient of the whole connection layer, relieving thermal stress of a joint and significantly improving the strength of the joint at room temperature and high temperature. The connection method has the advantages of simple process, easy preparation of connection materials, low cost, low soldering temperature, good joint performance and the like.

Owner:UNIV OF SCI & TECH BEIJING

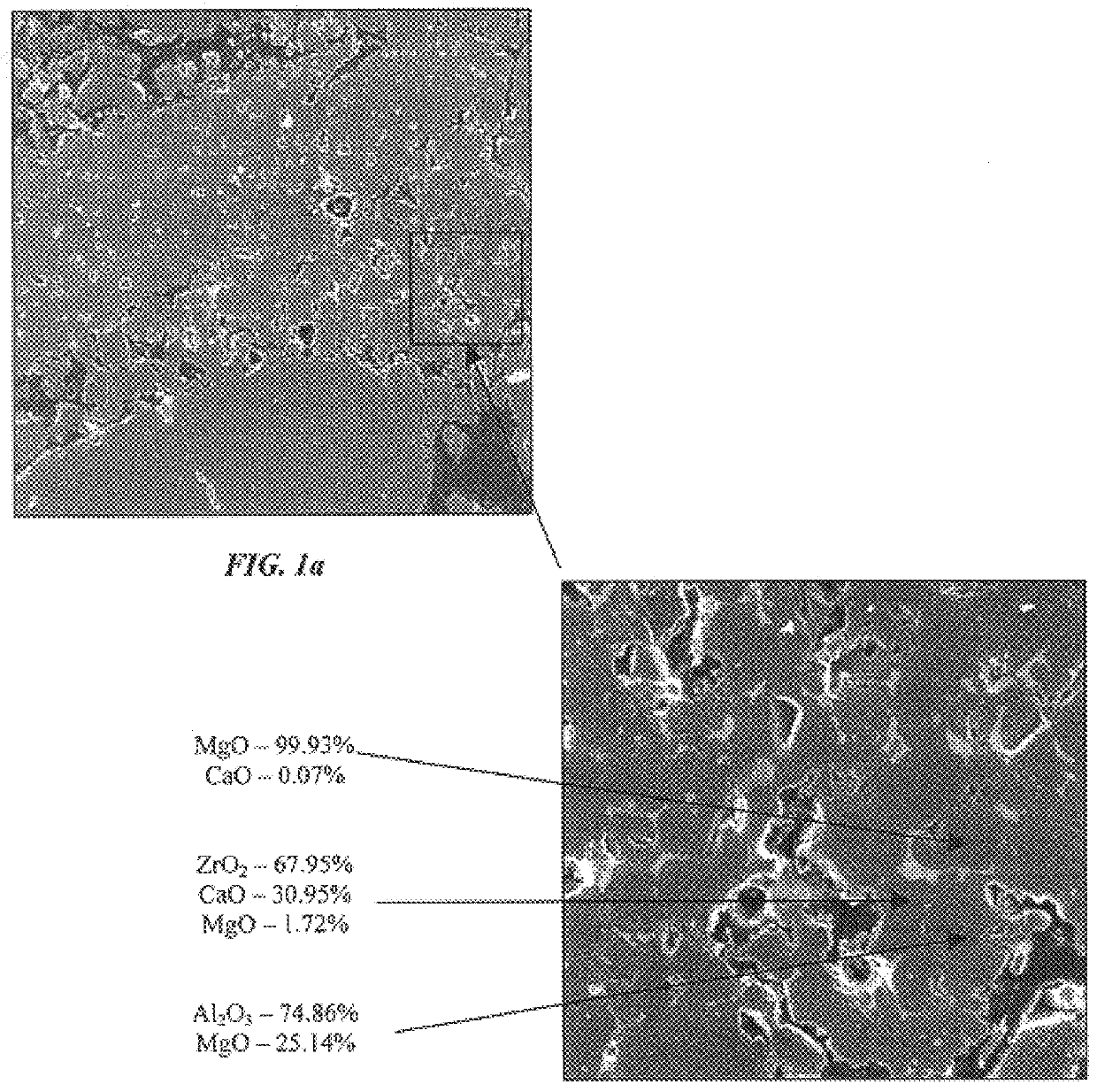

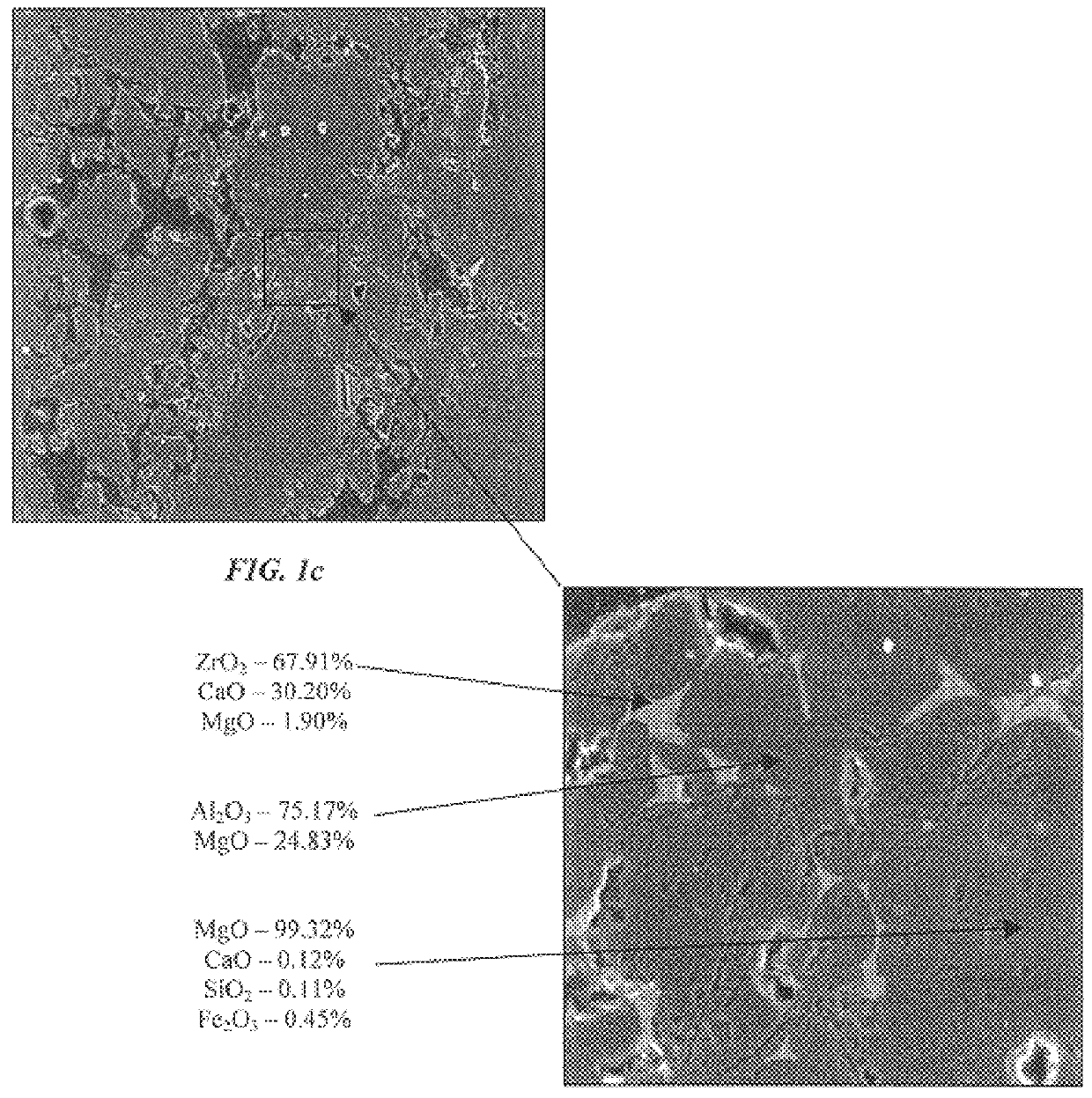

Magnesia spinel refractory brick

The present invention discloses novel magnesia-spinel refractory compositions and bricks formed thereof that exhibit longer lining life, greater hot strength and reduced tendency to spall under high thermal loading conditions. The invention is designed to slow or retard the reaction between spinel and lime through the addition of zirconia in the form of an alumina-zirconia grain to the refractory mix. Zirconia reacts more readily with the lime in the refractory composition and surrounding environment to form calcium zirconate.

Owner:BAKER REFRACTORIE

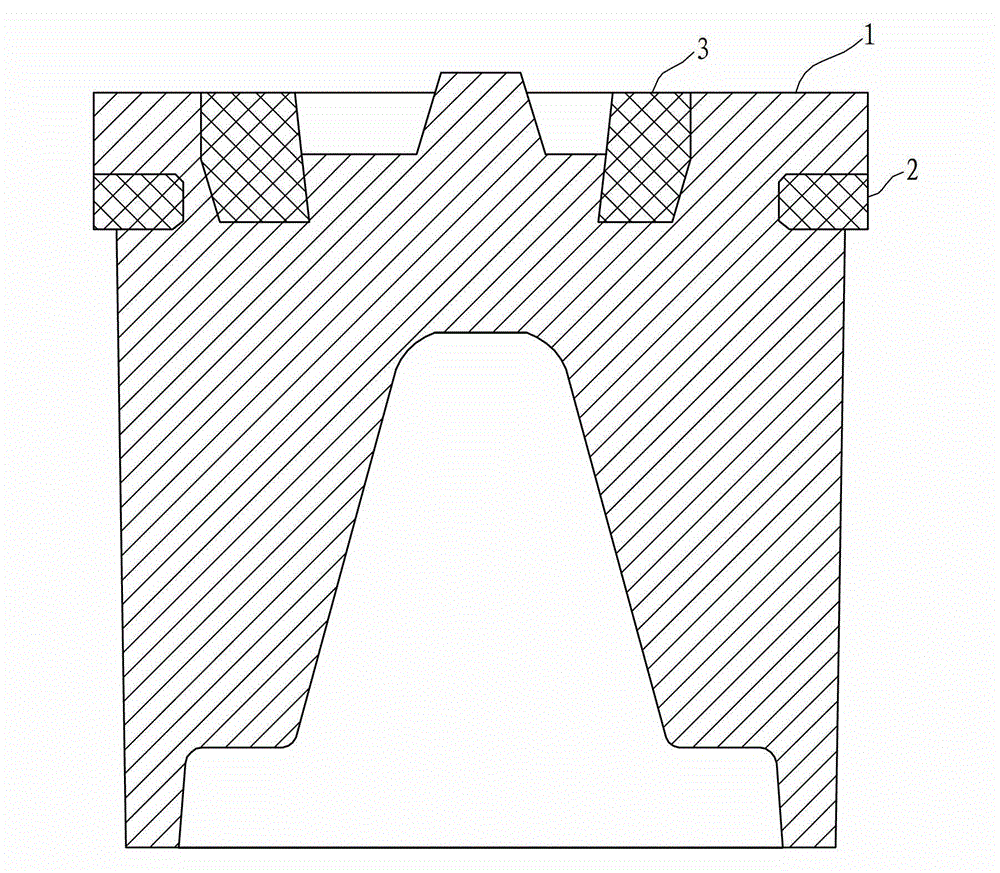

Aluminum piston manufacturing method

InactiveCN102943192AHigh temperature strengthImprove thermal fatigue resistancePlungersTrunk pistonsFiberPiston

The invention relates to an aluminum piston manufacturing method, which is characterized by comprising the following steps: (1) preparing an aluminum alloy for a piston; (2) carrying out a smelting treatment, wherein the prepared piston alloy is placed into a melting furnace to carry out melting, and the melted aluminum alloy liquid is subjected to primary refining, modification, refinement and secondary refining to provide a spare use for casting; (3) manufacturing an alumina ceramic short fiber preform; (4) preheating the alumina ceramic short fiber preform; (5) preheating a mold; (6) carrying out extrusion casting; (7) carrying out solidification piece taking; (8) carrying out a heat treatment on an aluminum piston blank; and (9) carrying out mechanical processing and a surface treatment on the aluminum piston blank to obtain the aluminum piston finished product. Compared to the aluminum piston in the prior art, the aluminum piston of the present invention has advantages of high strength and good ablation resistance.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

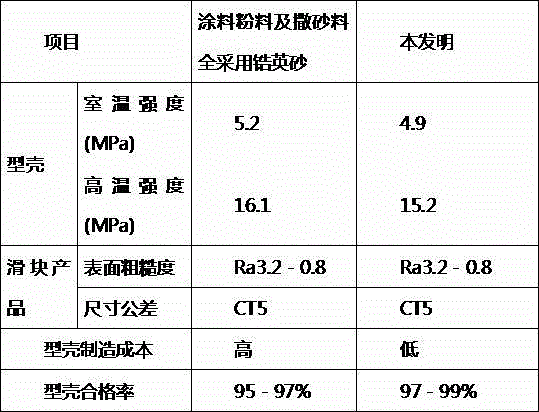

Preparation method of heat-resisting alloy sliding-block shell by investment casting

InactiveCN103600030AImprove room temperature strengthImprove pass rateFoundry mouldsFoundry coresAlloySurface coating

The invention discloses a preparation method of a heat-resisting alloy sliding-block shell by investment casting. The preparation method is characterized in that: the method comprises a first step of preparing coating, wherein surface coating comprises silica sol and a refractory powder material is fused alumina; and transition layer coating and back layer coating comprise the silica sol and a refractory powder material is one selected from the fused quartz, kaolin clinker and bauxite clinker; a second step of coating a wax mould with the surface coating, scattering the sand material of the fused alumina, drying and repeating for 2 times; coating the surface layer with the transistion layer coating, scattering one of the fused quartz, the kaolin clinker and the bauxite clinker, drying, and repeating for 5 times; and finally coating with a back layer coating, scattering one of the fused alumina, the kaolin clinker and the bauxite clinker and drying; and a third step of dewaxing and calcinating; and the shell produced by the method has advantages of high room-temperature strength and high-temperature strength, good internal surface quality, high percent of pass, low production cost and good economic benefit.

Owner:泰州枫叶冶金设备有限公司

Aluminum-magnesium lightweight refractory material and preparation method thereof

The invention relates to an aluminum-magnesium lightweight refractory material and a preparation method thereof. The technical scheme comprises the following steps of: taking 60-85wt% of microporous corundum particles as an aggregate, taking 5-30wt% of fine corundum powder, and taking 2-10% of magnesium oxide micropowder and 4-9wt% of alpha-alumina micropowder as matrix materials; adding the matrix materials into the aggregate, additionally adding an adhesive which is 3-10wt% of the sum of the aggregate and the matrix materials, stirring uniformly and then mixing and milling for 15-30 minutes by a mixing mill, and molding by a brick pressing machine; and thermally processing the molded green body for 12-24 hours at 100-220 DEG C to obtain the aluminum-magnesium lightweight refractory material. The product prepared by the preparation method has the characteristics of small volume density, low apparent porosity, small average aperture, high refractoriness, large high-temperature strength, low thermal conductivity, good thermal shock resistance and strong capability resistant against the corrosion of media such as steel slag; and the prepared product is applicable to a working lining of a high-temperature industrial furnace.

Owner:WUHAN UNIV OF SCI & TECH

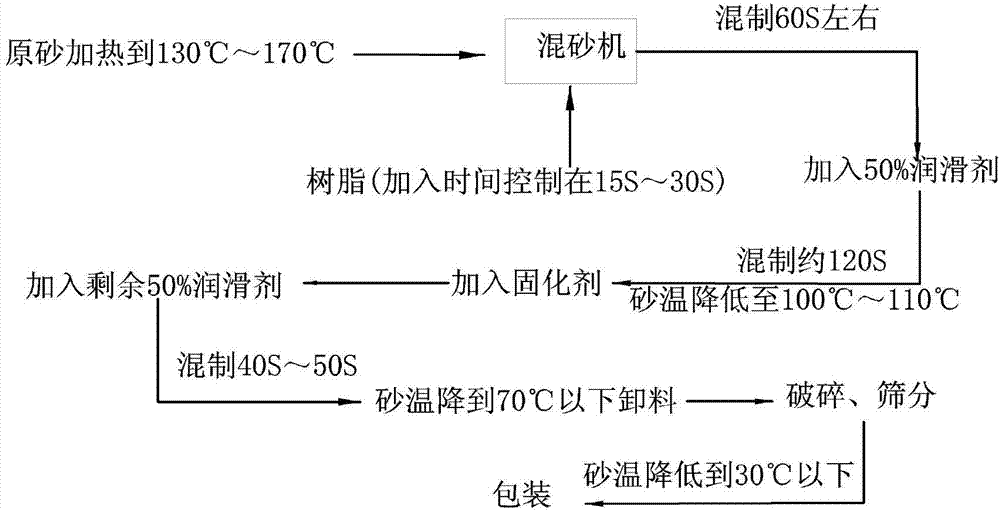

Easy-to-fill precoated sand and preparation process thereof

ActiveCN103658506AHigh molding strengthHigh temperature strengthFoundry mouldsMould handling/dressing devicesUltimate tensile strengthHot Temperature

The invention discloses easy-to-fill precoated sand and a preparation method thereof. Raw materials comprise roughing sand, phenolic resin, curing agents, lubricating agents and additives. The preparation method comprises the following steps that the roughing sand is heated to 130 to 170 DEG C, then, the phenolic rein, a half quantity of the lubricating agents, the curing agents and the rest half quantity of lubricating agents are sequentially added, finally, the discharging is carried out, and then, crushing, sieving and package are carried out. Through the improvement on the raw material ingredients and the preparation process, the forming intensity of the precoated sand is high, the high-temperature intensity is high, the deformation quantity is small, the flowability is good, complicated sand cores can be produced, the surface smoothness of the molding sand is good, the collapsibility performance is excellent, castings can be easily subjected to the vibration sand falling treatment, the precoated sand gas producing quantity is reduced, and the high-temperature performance and other casting performance of the precoated sand are improved.

Owner:ANSHUN UNIV

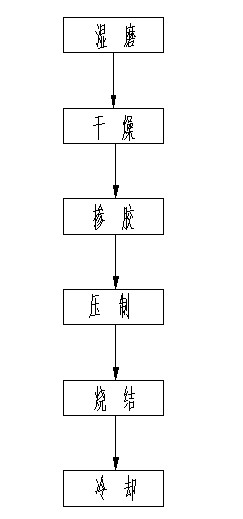

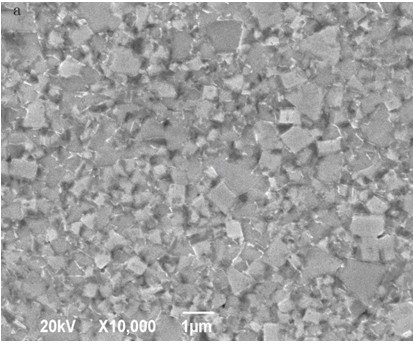

Ceramic part and production method thereof

PendingCN106977184AHigh densityImprove uniformityCeramic shaping apparatusInjection molding machineHigh heat

The invention relates to the technical field of powder metallurgy and particularly relates to a ceramic part and a production method thereof. The production method comprises (1) mixing granulation: putting ceramic powder into a mixer, heating the ceramic powder, adding a binder into the ceramic powder, carrying out mixing, and carrying out granulation through an extruder to obtain feed, (2) injection molding: placing the feed in an injection molding machine and carrying out injection molding to obtain an injected blank, (3) degreasing: placing the injected blank into an air furnace, carrying out hot degreasing, carrying out heating pre-sintering, carrying out furnace cooling and taking out a blank, and (4) sintering: putting the blank in a sintering furnace, carrying out sintering, and carrying out grinding and polishing to obtain a ceramic part. Through powder injection molding process and final degreasing and high temperature sintering, a fine ceramic part having a complex shape is obtained, the product has high compactness and good uniformity and is obtained by one step molding, the operation and control are simple, product quality is stable, production efficiency is high, a production cost is low and large-scale industrial production is realized.

Owner:深圳市星迪伟业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com