Patents

Literature

494 results about "Volume percent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Volume percent is a common expression of a solution's concentration. It is the volume fraction expressed with a denominator of 100, and thus is defined as: Volume percent is usually used when the solution is made by mixing two fluids, such as liquids or gases. However, percentages are only additive for ideal gases. The percentage by volume is one way of expressing the composition of a mixture with a dimensionless quantity; mass fraction and mole fraction are others. In the case of a mixture of ethanol and water, which are miscible in all proportions, the designation of solvent and solute is arbitrary. The volume of such a mixture is slightly less than the sum of the volumes of the components. Thus, by the above definition, the term "40% alcohol by volume" refers to a mixture of 40 volume units of ethanol with enough water to make a final volume of 100 units, rather than a mixture of 40 units of ethanol with 60 units of water.

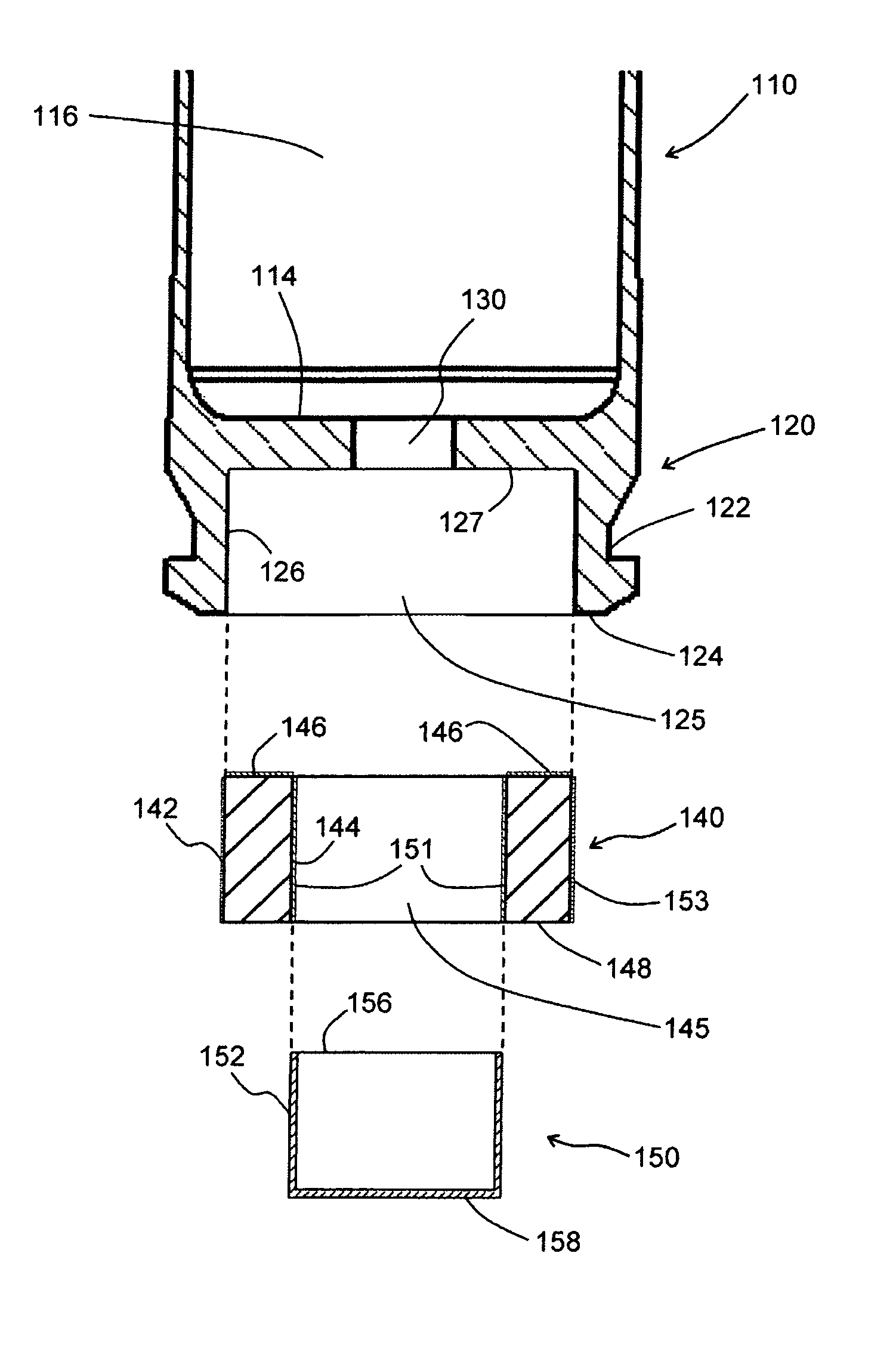

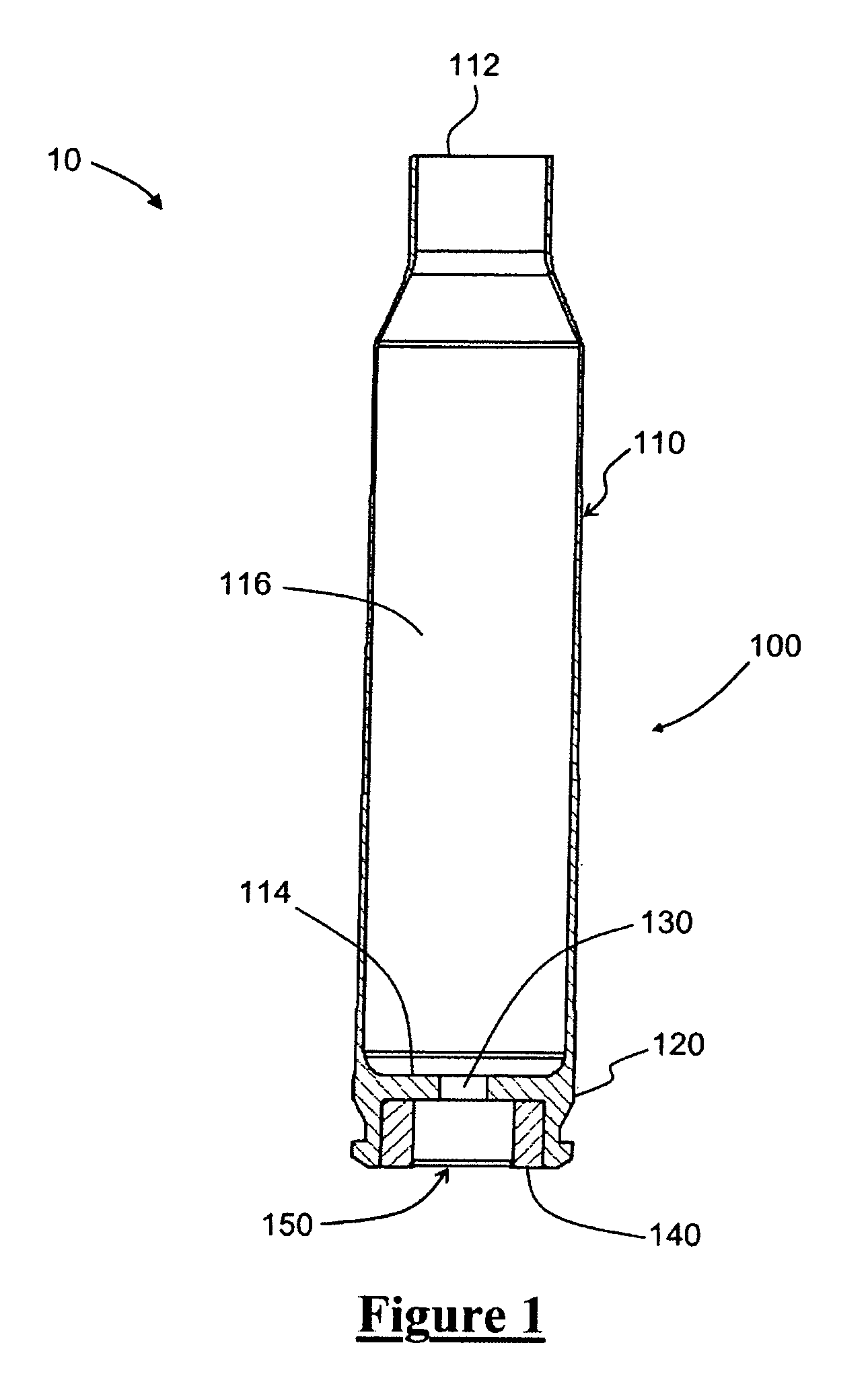

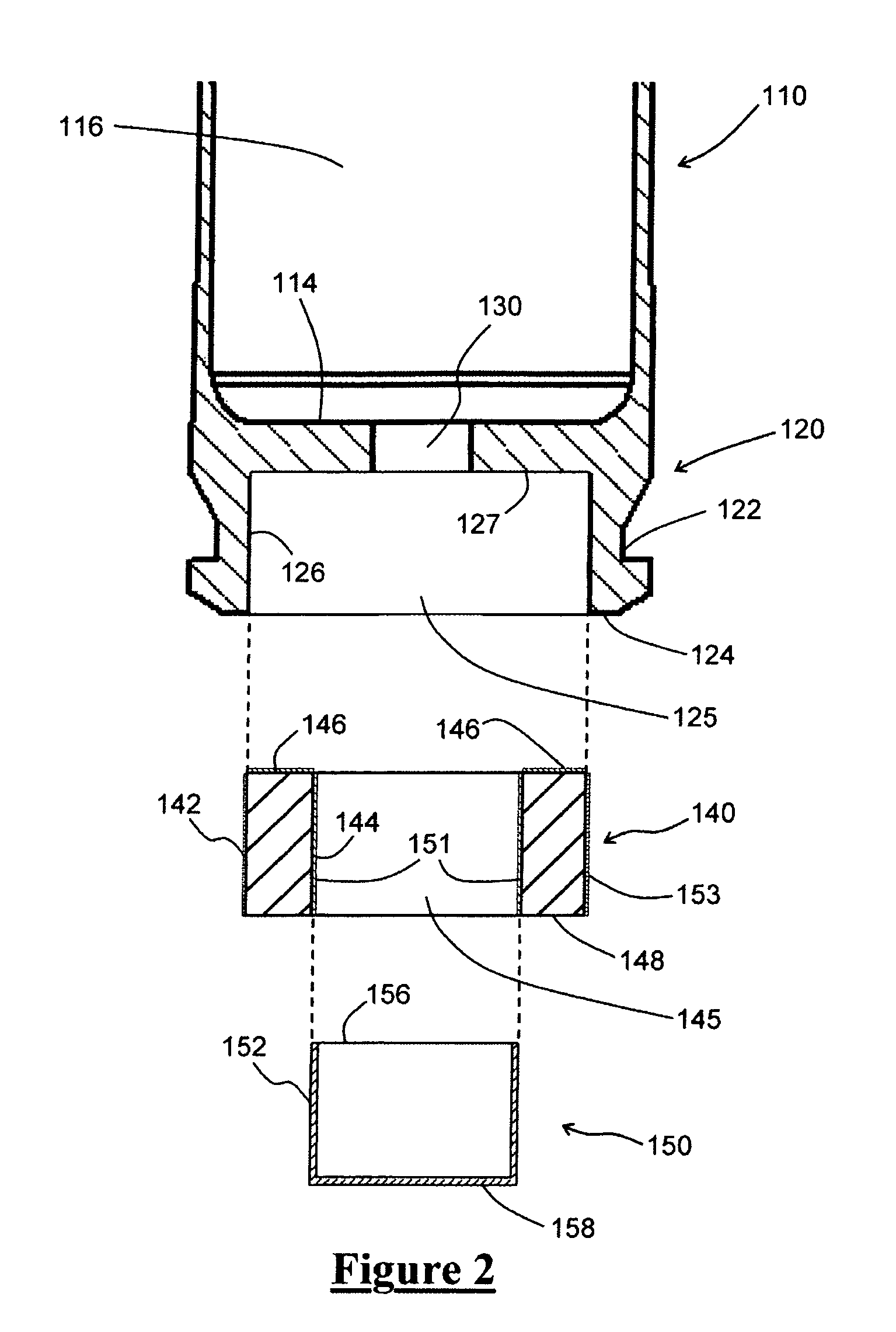

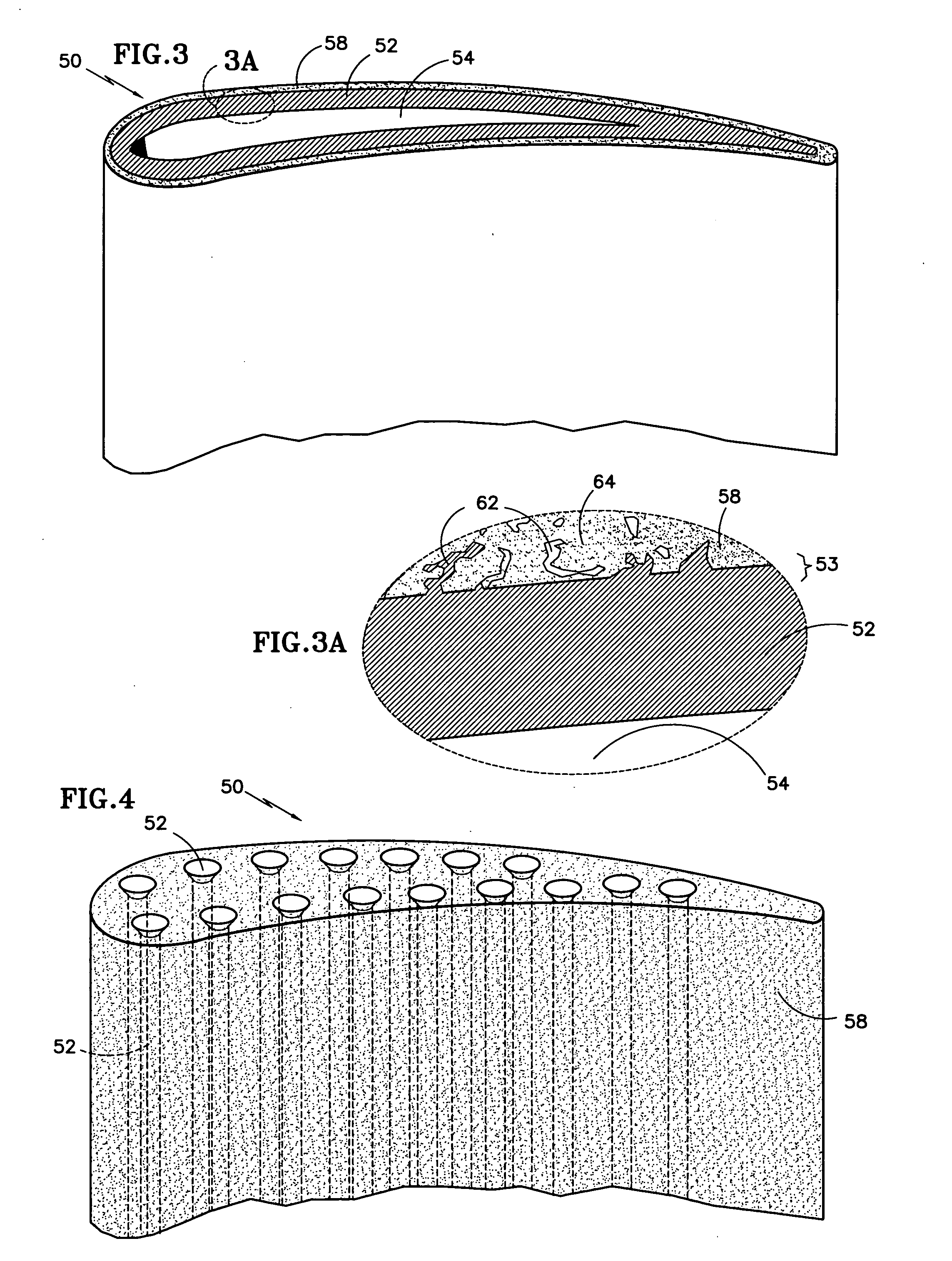

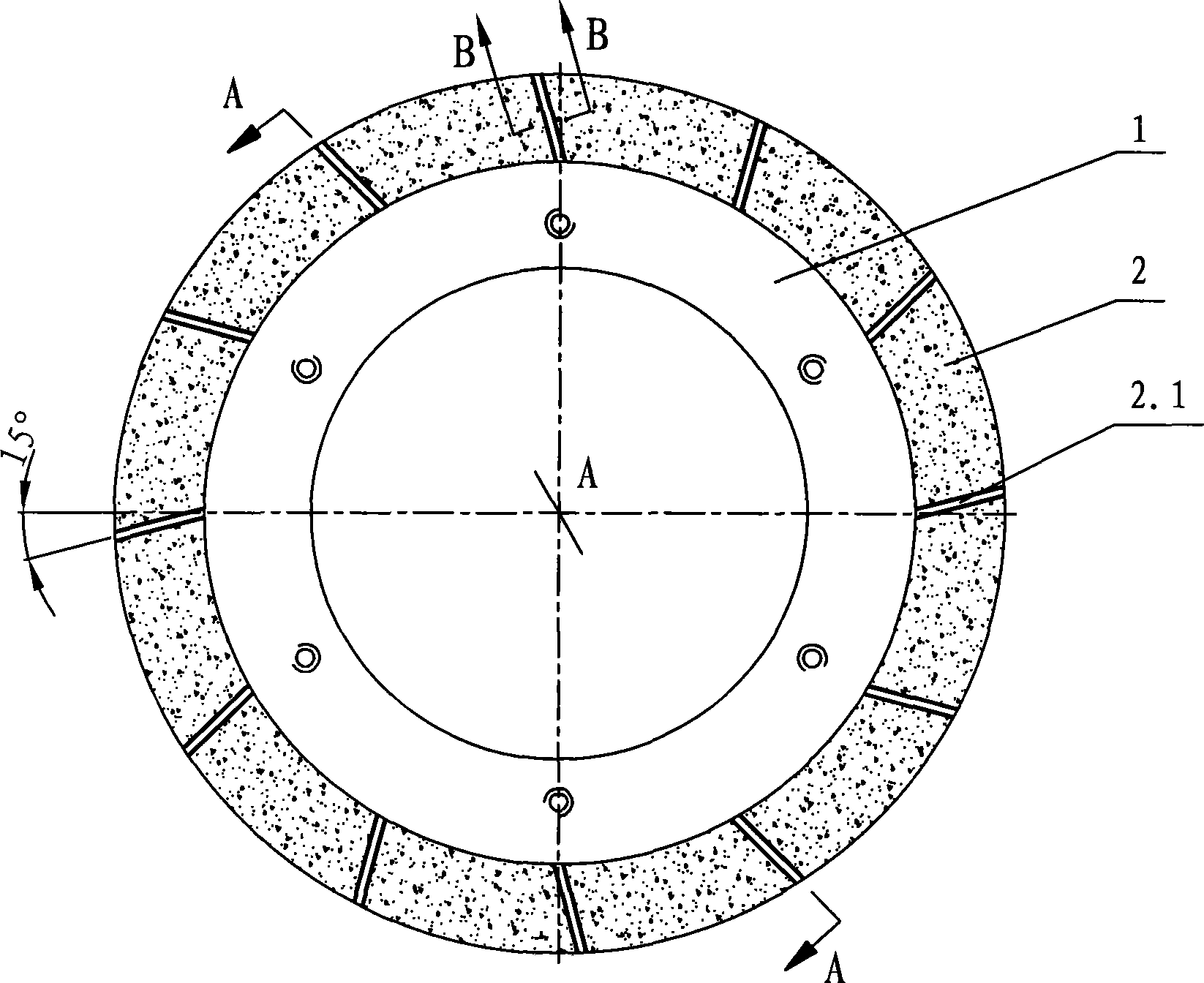

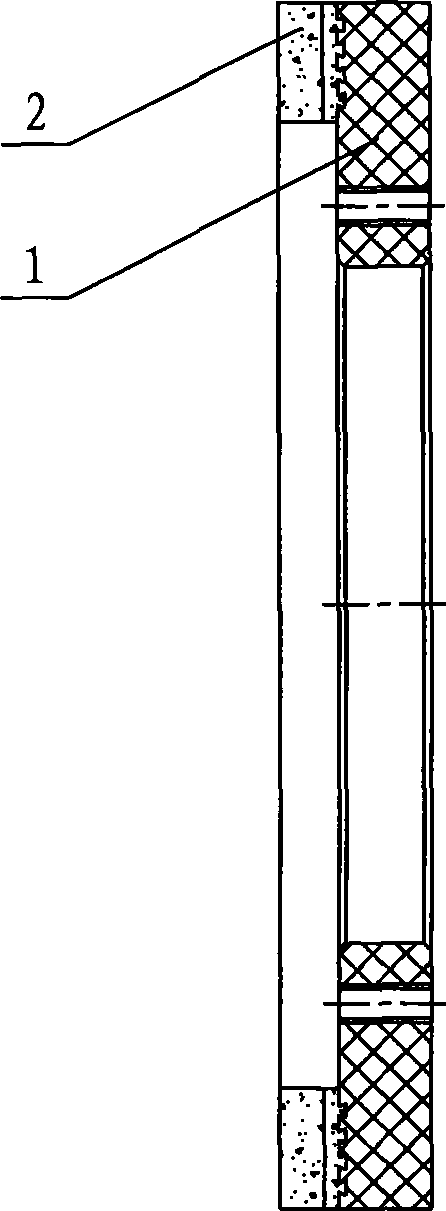

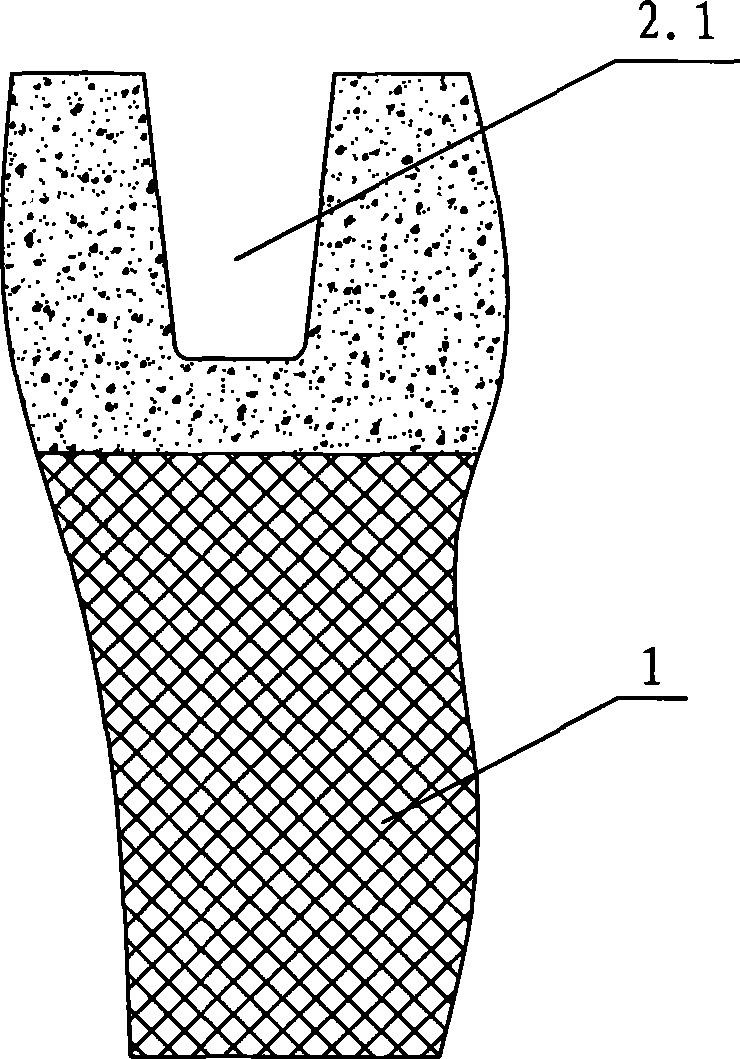

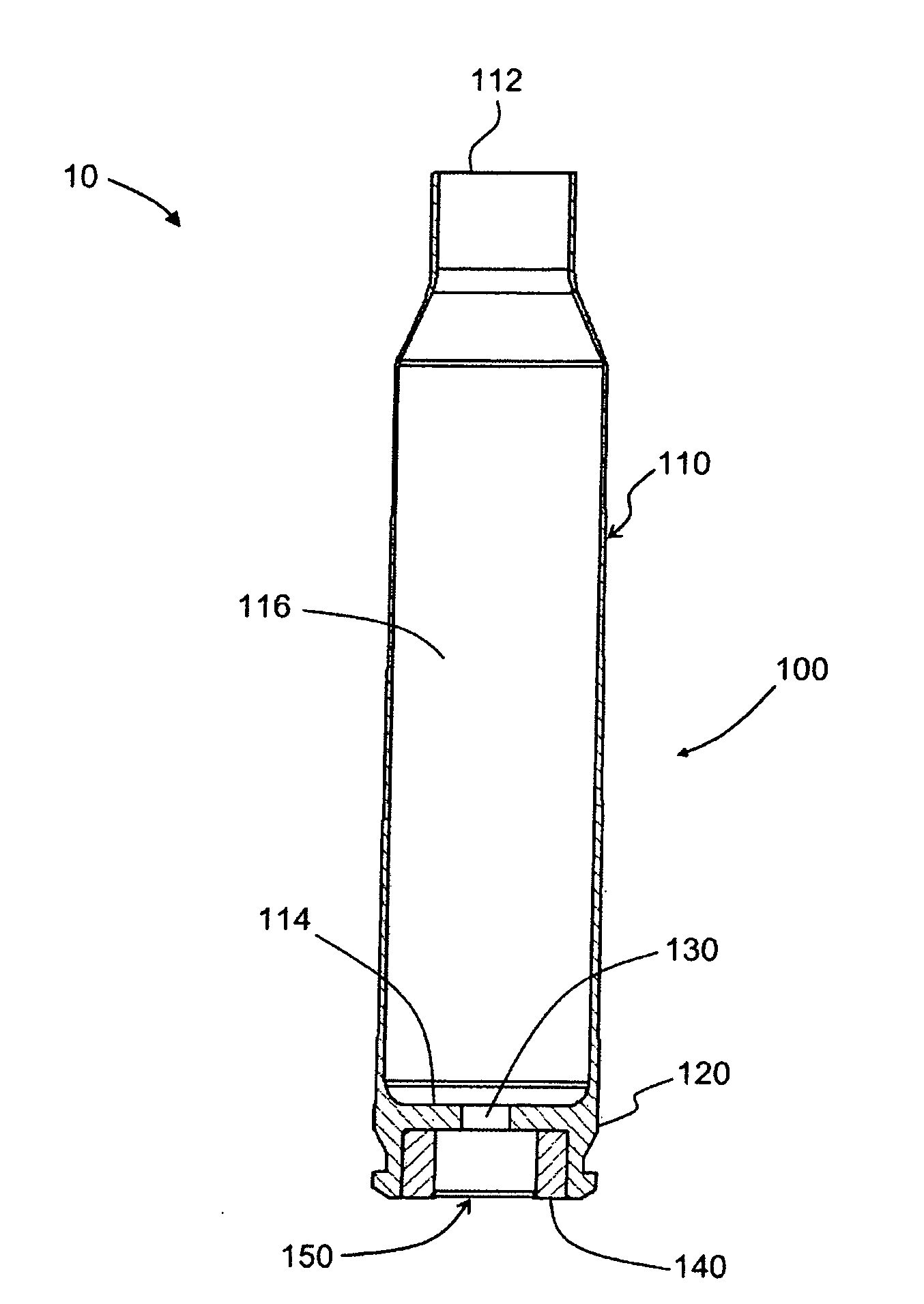

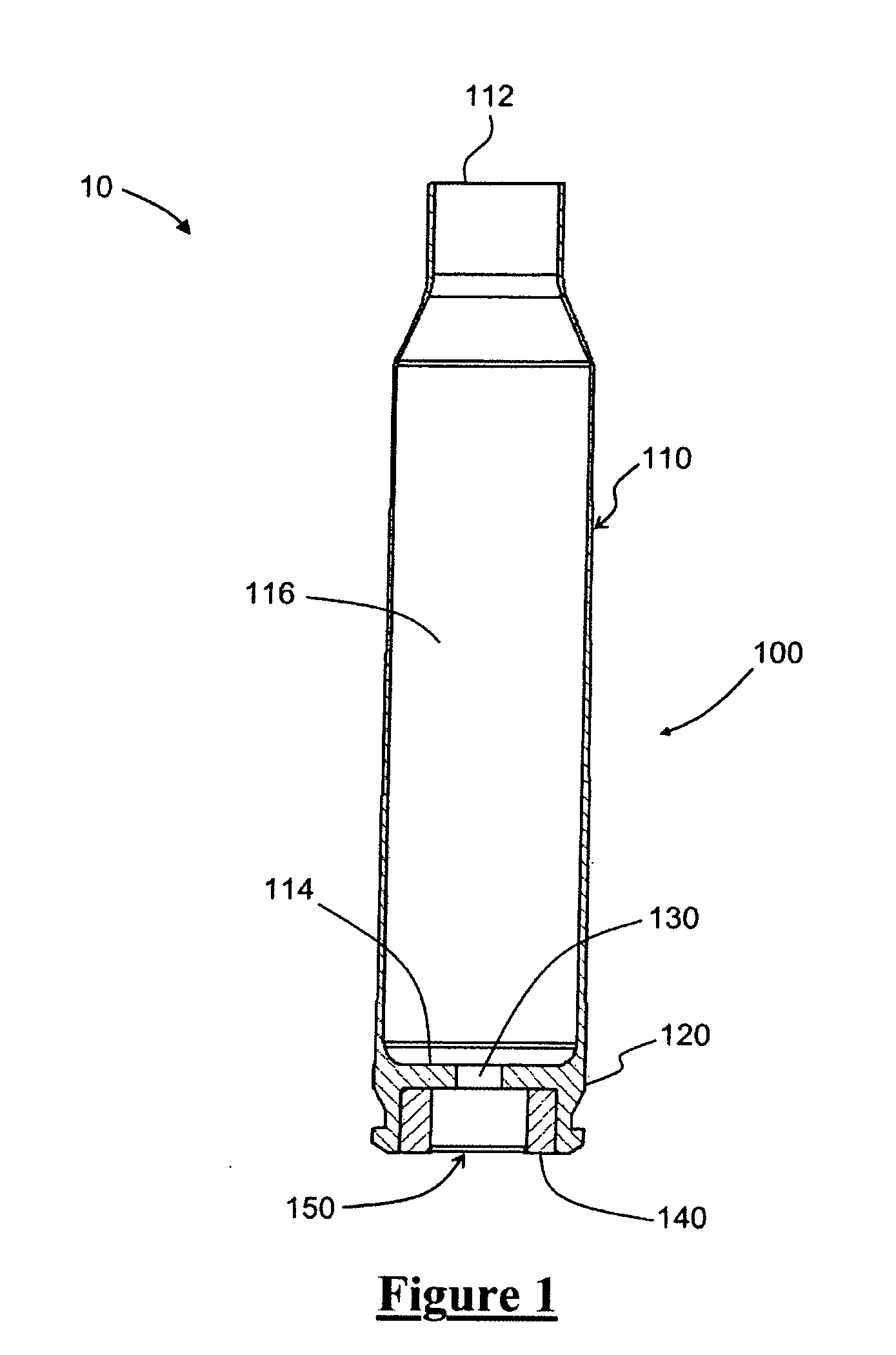

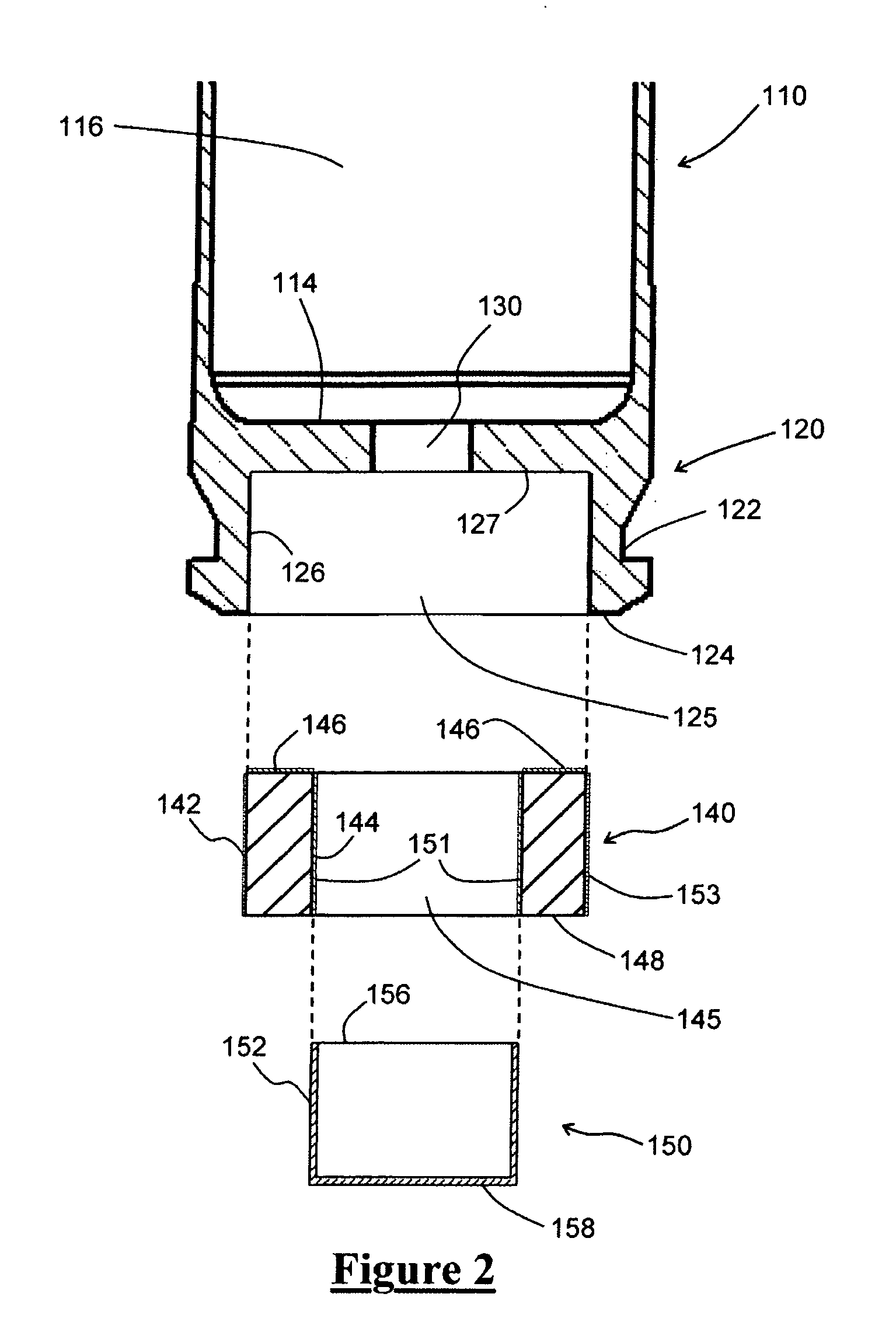

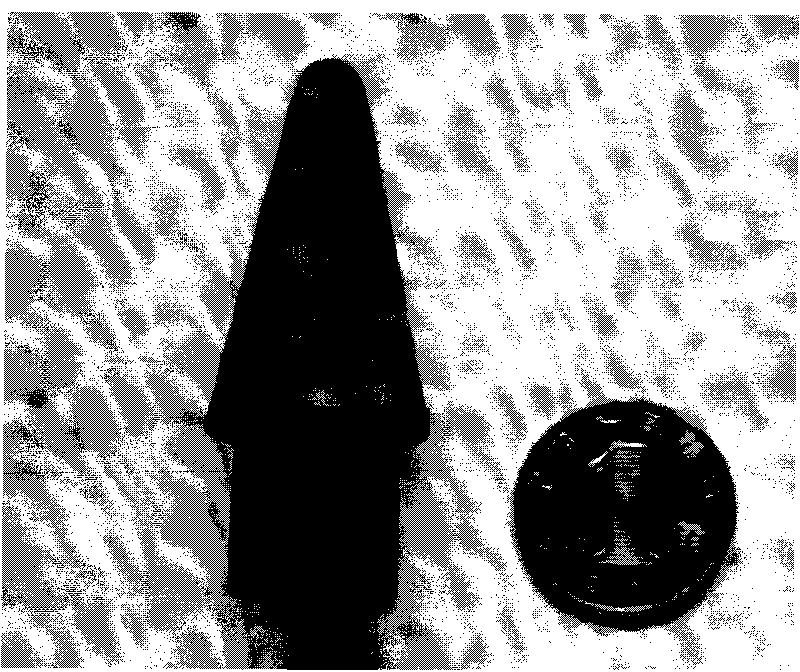

Lightweight cartridge case

Disclosed is an ammunition cartridge case that includes a sleeve, a base fixedly attached to the sleeve and a fiber reinforced polymer composite annulus that is at least partially within the base. In certain embodiments, the sleeve and the base are formed partly or entirely from a metal, for example steel or stainless steel. The base has a central aperture that affords for the annulus ring to fit within. The annulus is dimensioned such that it fits securely within the central aperture of the base and has a center aperture wherein a primer can be located. The annulus ring contains a volume of composite fibers ranging from 10 to 90 volume percent. The annulus isolates the primer from the cartridge case and thereby prevents galvanic corrosion between the primer and case. In addition, a metallic foil can be present between the annulus and the cartridge case in order to assure proper securement of the annulus therewithin.

Owner:ARMY US SEC THE THE

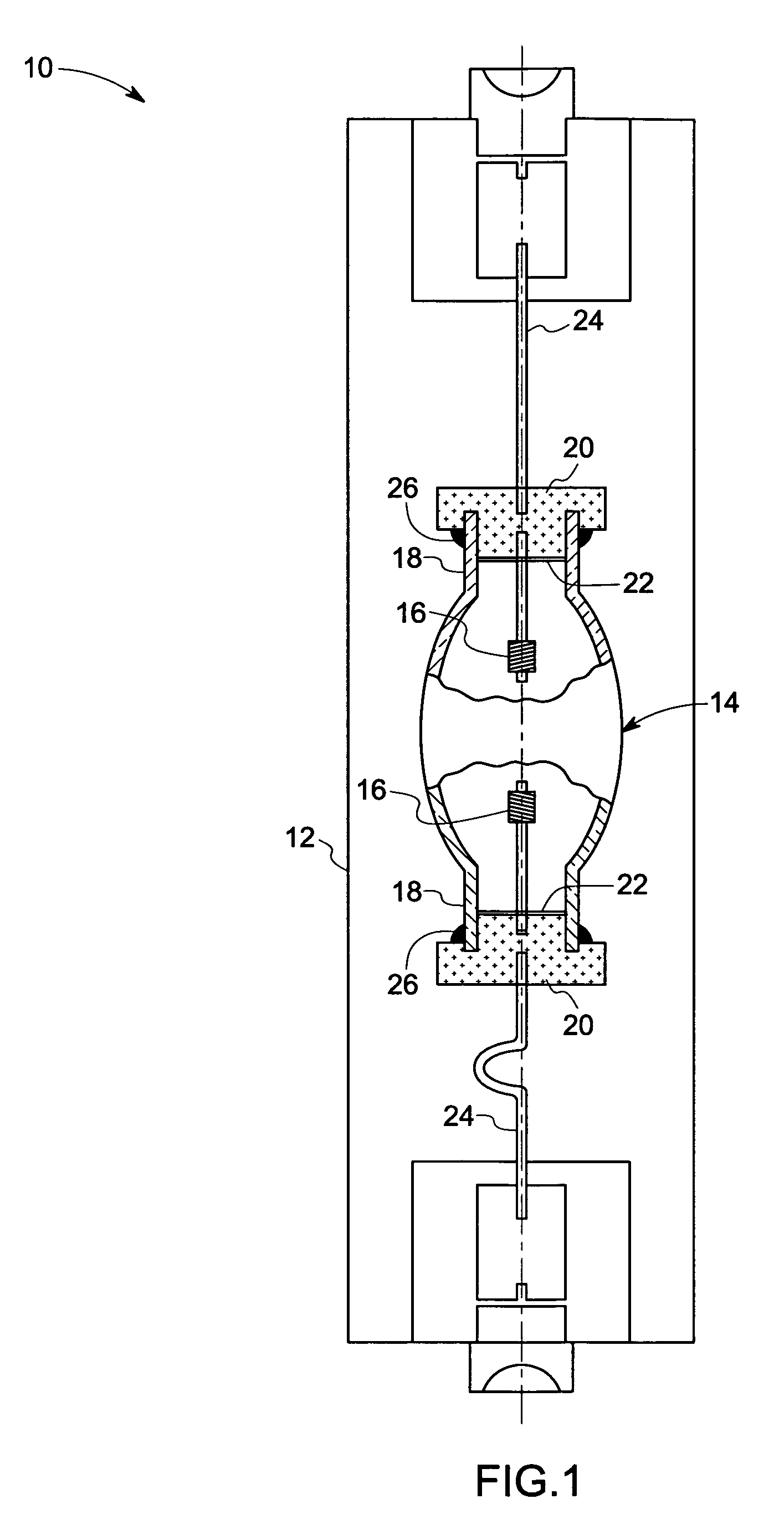

Durable concrete compositions

Methods of controlling the durability of and / or the amount of air in concrete formulations that include combining cement, water, and optionally aggregates, admixtures and / or additives to form a cement mixture; and adding prepuff particles to the cement mixture to form a concrete formulation. The prepuff particles have an average particle diameter of from 0.2 mm to 3 mm, a bulk density of from 0.015 g / cc to 0.35 g / cc, an aspect ratio of from 1 to 3, and a smooth continuous outer surface. The cured and hardened concrete formulation typically has a relative dynamic modulus of at least 70% determined according to Procedure A of ASTM C666 (2003). The amount of air in the concrete typically increases over the amount of air in similar formulations not containing prepuff particles, as determined according to ASTM C231, based on the volume percent of prepuff. The concrete formulations can be used to make articles.

Owner:NOVA CHEM INC

Integrated ceramic/metallic components and methods of making same

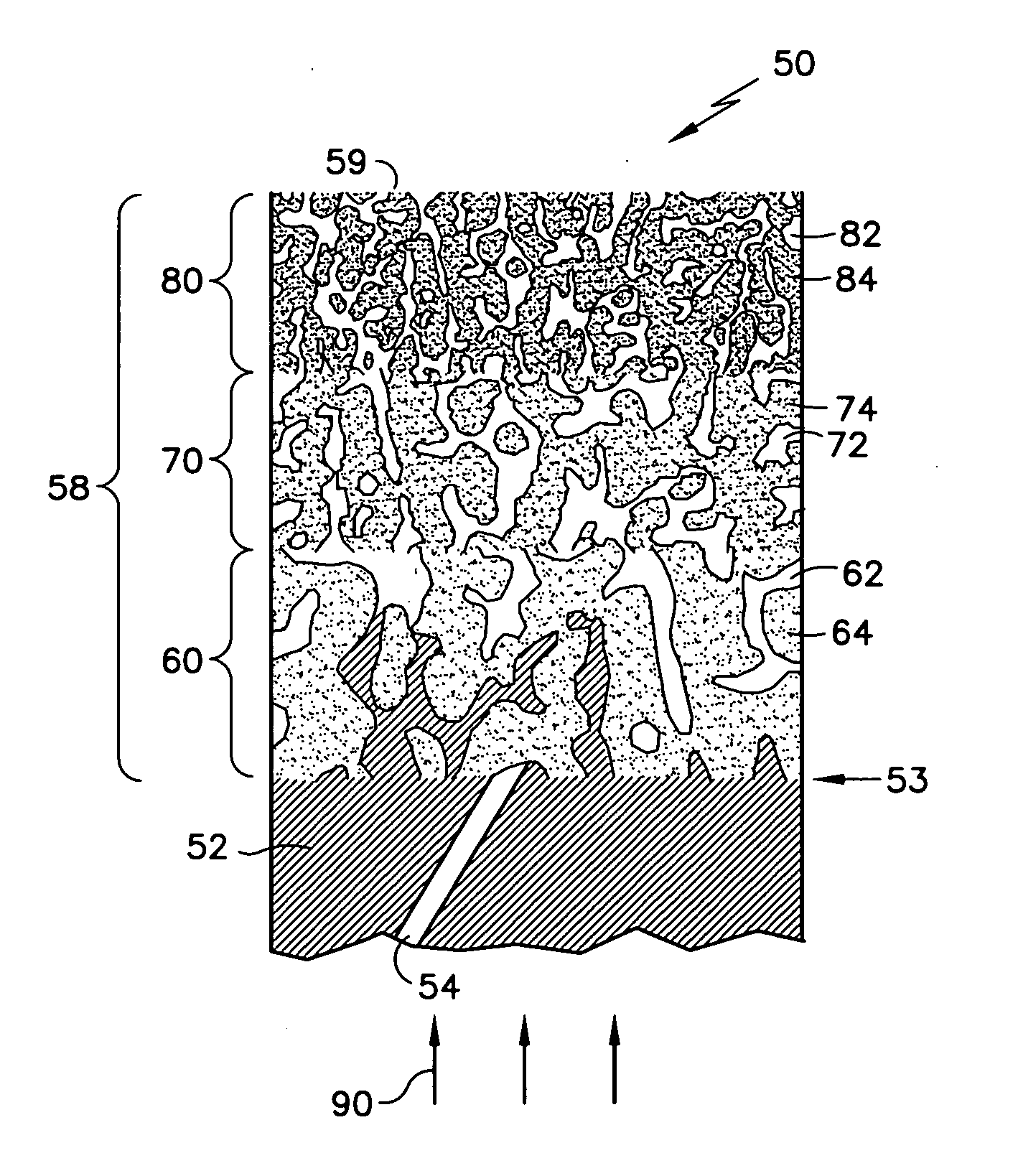

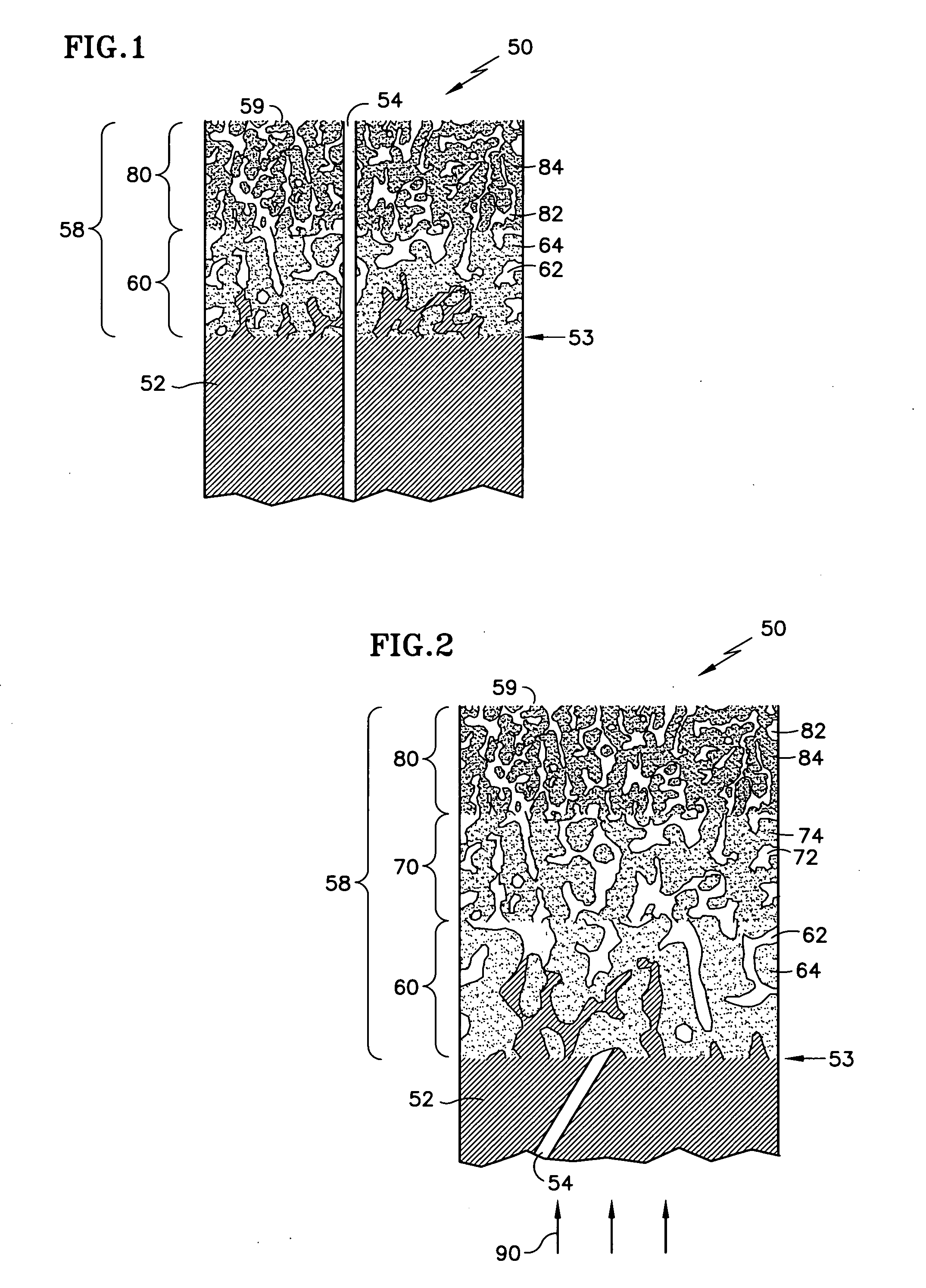

Integrated ceramic / metallic components and methods of making same are described herein. Embodiments of these integrated ceramic / metallic components comprise a metallic non-foam region; and a ceramic foam region comprising a gradient porosity therein, wherein the ceramic foam region and the metallic non-foam region are integrally formed together to create the integrated ceramic / metallic component. Embodiments of these integrated ceramic / metallic components comprise a metallic region; and a single piece ceramic foam construction comprising a plurality of ceramic foam regions therein, each ceramic foam region comprising a predetermined pore size and a predetermined volume percent porosity, wherein the single piece ceramic foam construction is integrally joined to the metallic region to form the integrated ceramic / metallic component. These components may be utilized in gas turbine engines.

Owner:UNITED TECH CORP

Method for the fracture stimulation of a subterranean formation having a wellbore by using thermoset polymer nanocomposite particles as proppants, where said particles are prepared by using formulations containing reactive ingredients obtained or derived from renewable feedstocks

InactiveUS20070181302A1Generality is degradedHigh trafficFluid removalDrilling compositionLiquid mediumHigh rate

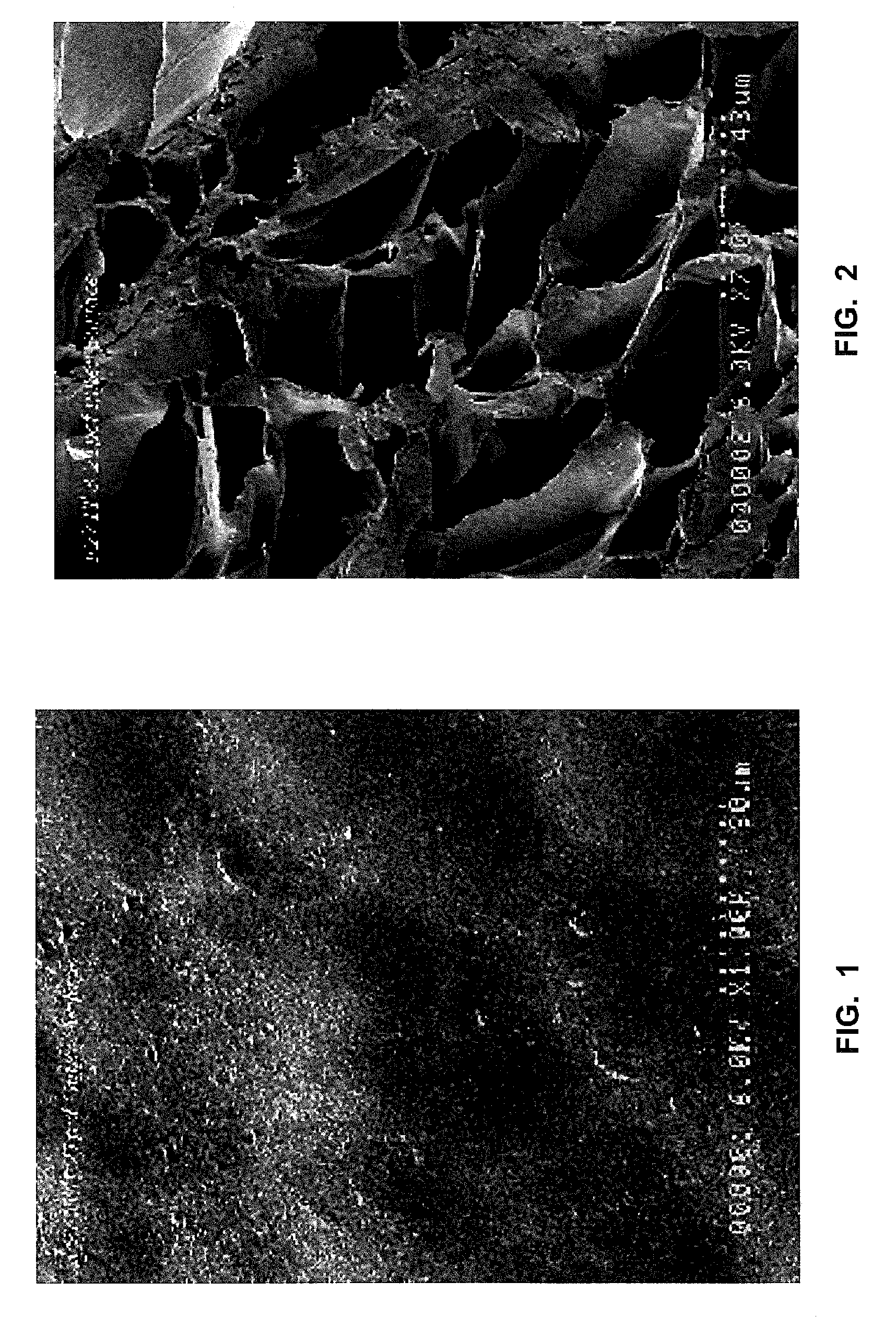

A method for fracture stimulation of a subterranean formation having a wellbore includes providing a thermoset polymer nanocomposite particle precursor composition comprising a polymer precursor mixture, dispersed within a liquid medium, containing at least one of a monomer, an oligomer or combinations thereof having three or more reactive functionalities capable of creating crosslinks between polymer chains, wherein 1% to 100% by weight of said polymer precursor mixture is obtained or derived from a renewable feedstock; and from 0.001 to 60 volume percent of nanofiller particles possessing a length that is less than 0.5 microns in at least one principal axis direction; subjecting the nanocomposite particle precursor composition to polymerizing conditions to form the polymeric nanocomposite particle, whereby said nanofiller particles are substantially incorporated into a polymer; forming a slurry comprising a fluid and a proppant, wherein said proppant comprises the nanocomposite particles, said nanocomposite particles being formed from a rigid thermoset polymer matrix; and injecting into the wellbore said slurry at sufficiently high rates and pressures such that said formation fails and fractures to accept said slurry.

Owner:SUN DRILLING PRODS

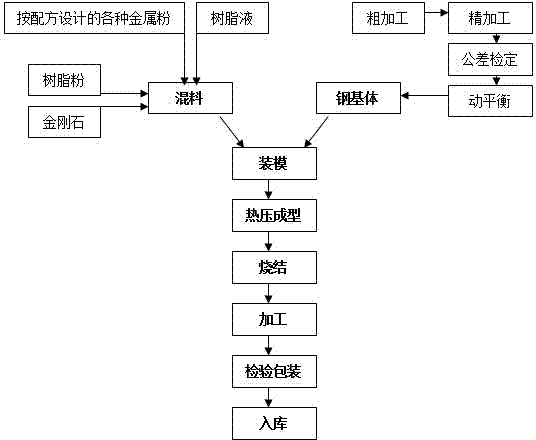

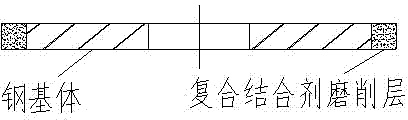

Resin anchoring agent diamond grinding wheel and production method thereof

ActiveCN101386154AIncreased durabilityImprove adhesionAbrasion apparatusGrinding devicesBoron carbideZirconia alumina

The invention relates to a resin bonding agent diamond grinding wheel and a manufacturing method thereof, and the grinding wheel comprises a grinding medium layer and a base body, wherein, the grinding medium layer is arranged on the base body and comprises diamond grinding medium, resin bonding agent, filling reinforcement which is a copper cladded iron powder and auxiliary abrasives which can be one or the combination of carborundum, boron carbide, white alundum, single alundum and fused zirconia alumina. The grinding medium layer comprises 5-15% of diamond grinding medium, 10-25% of auxiliary abrasive, 25-50% of thermosetting polyimide resin, 3-10% of copper cladded iron powder, 15-40% of silicon carbide powder and 0-8% of filling of metallic oxide in terms of volume percent. The diamond grinding wheel is characterized by low production cost, strong adhesive force, good sharpness and self-sharpness, long service life and good abrasion cutting effect.

Owner:广东奔朗新材料股份有限公司

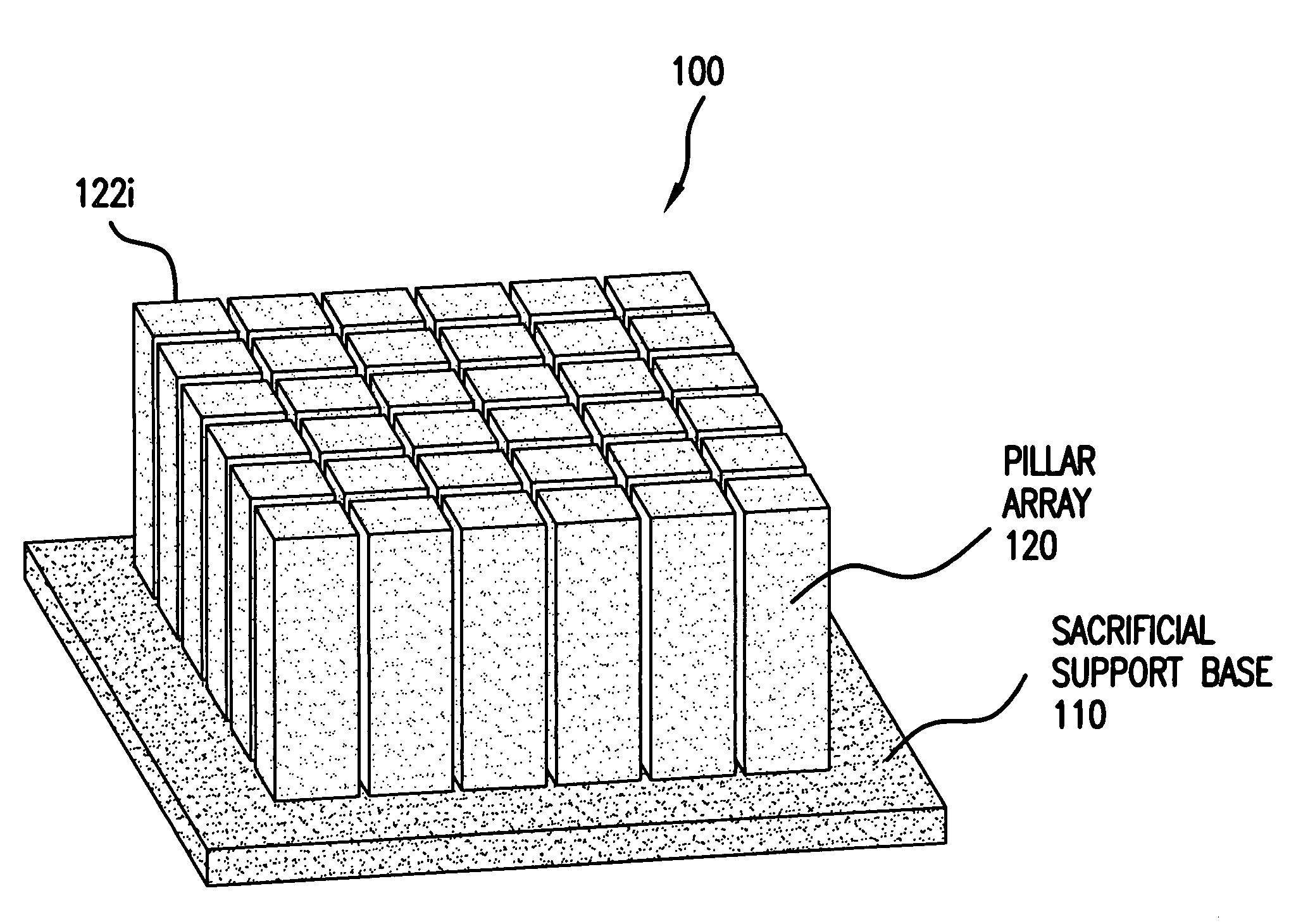

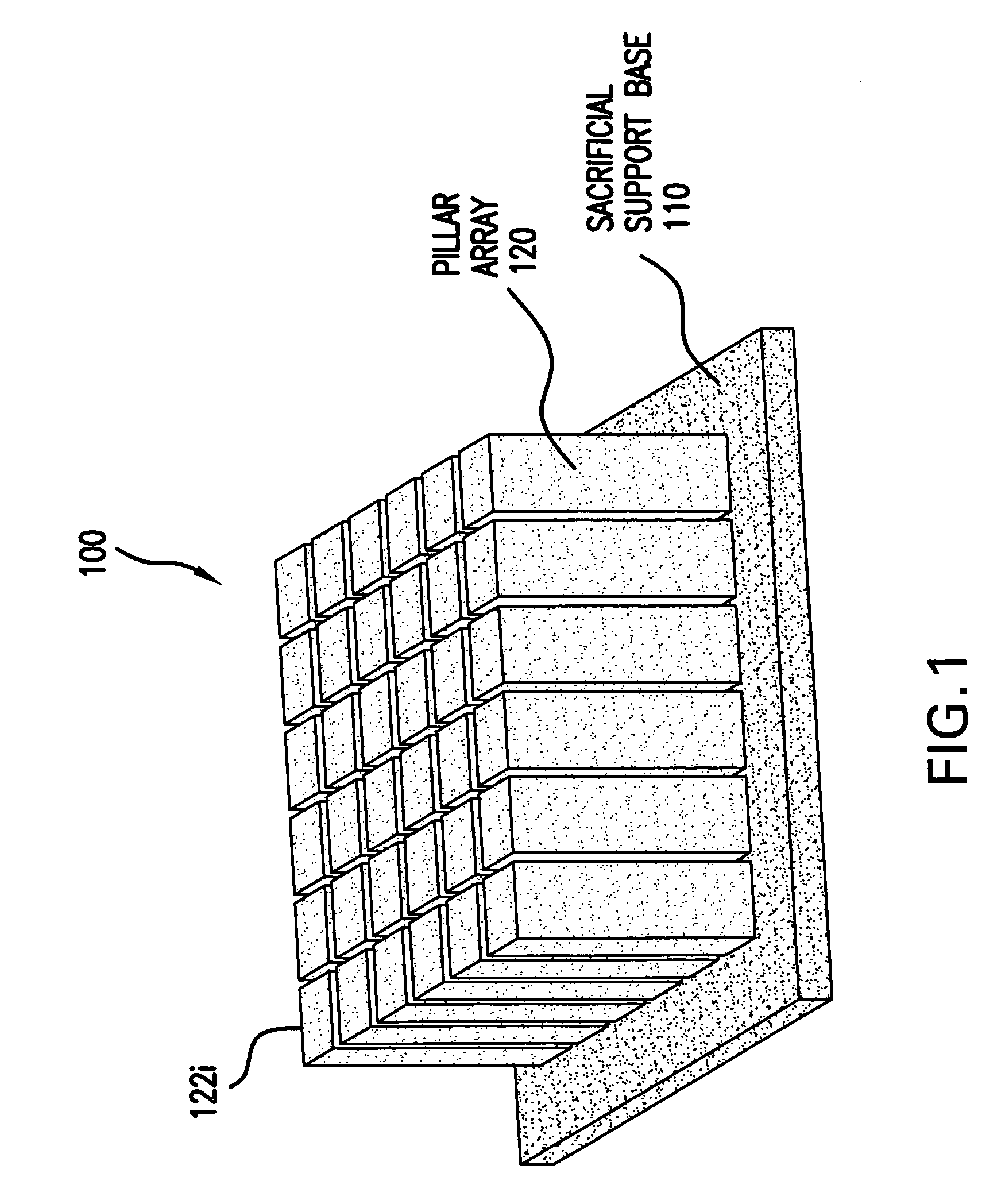

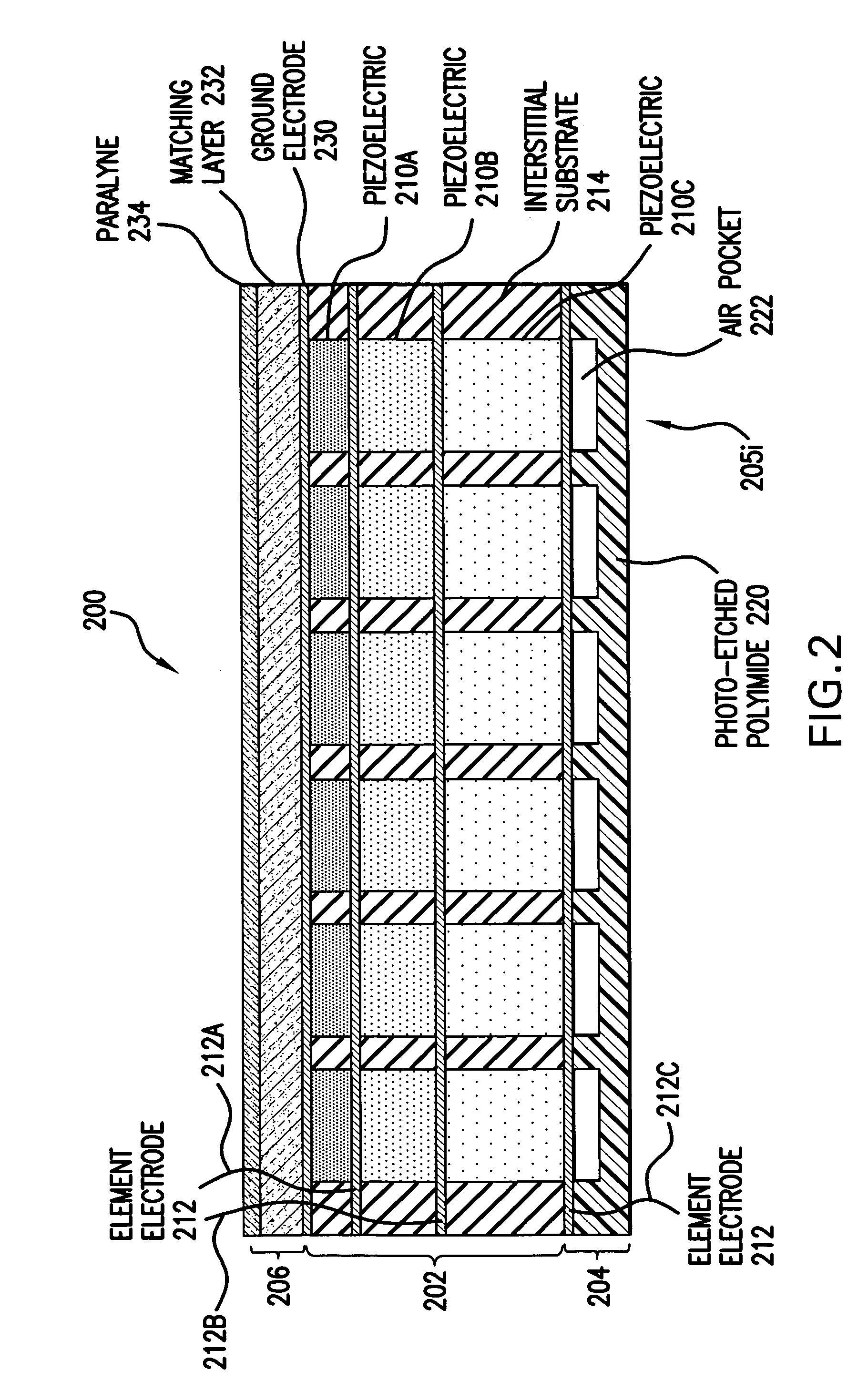

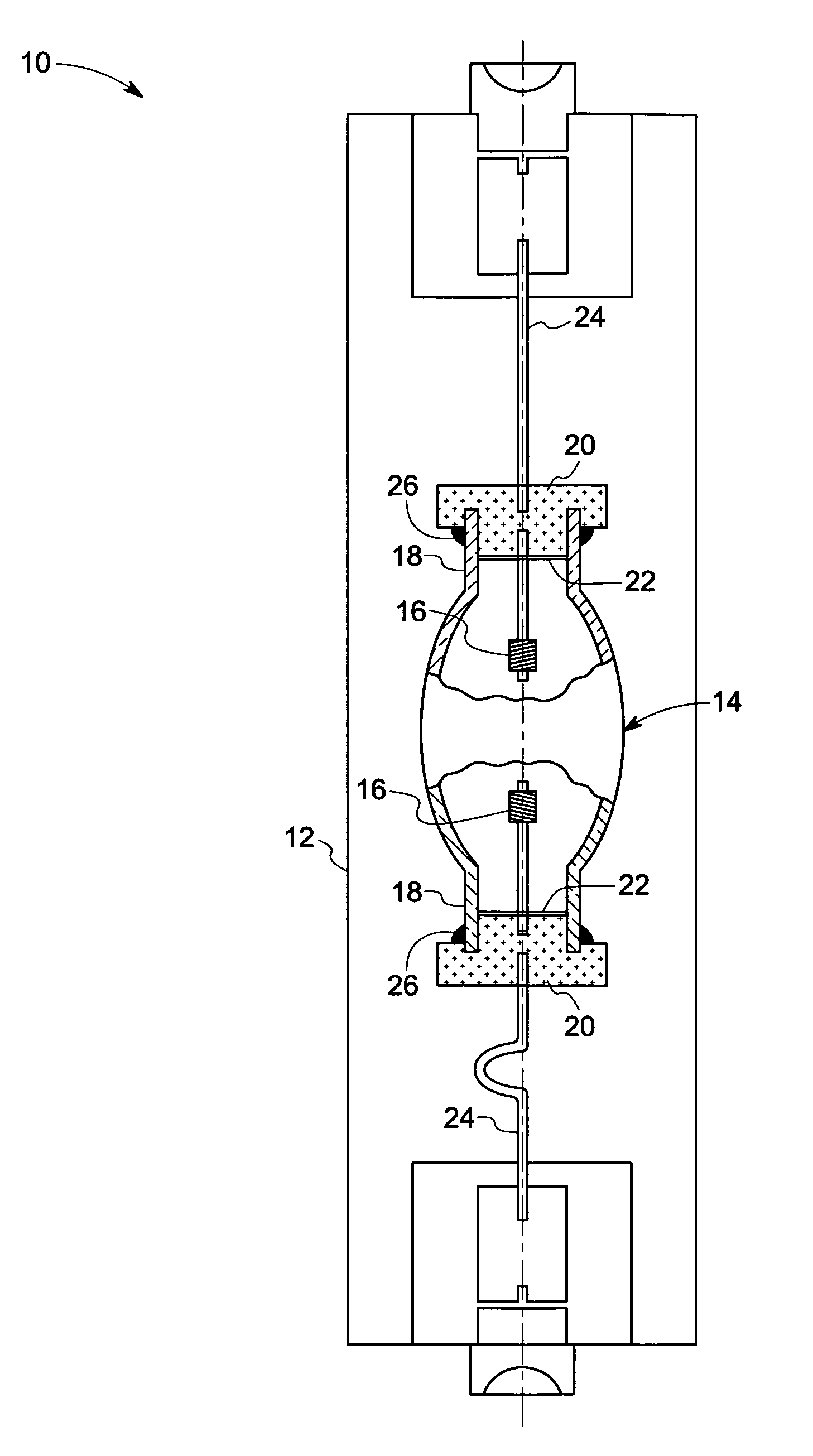

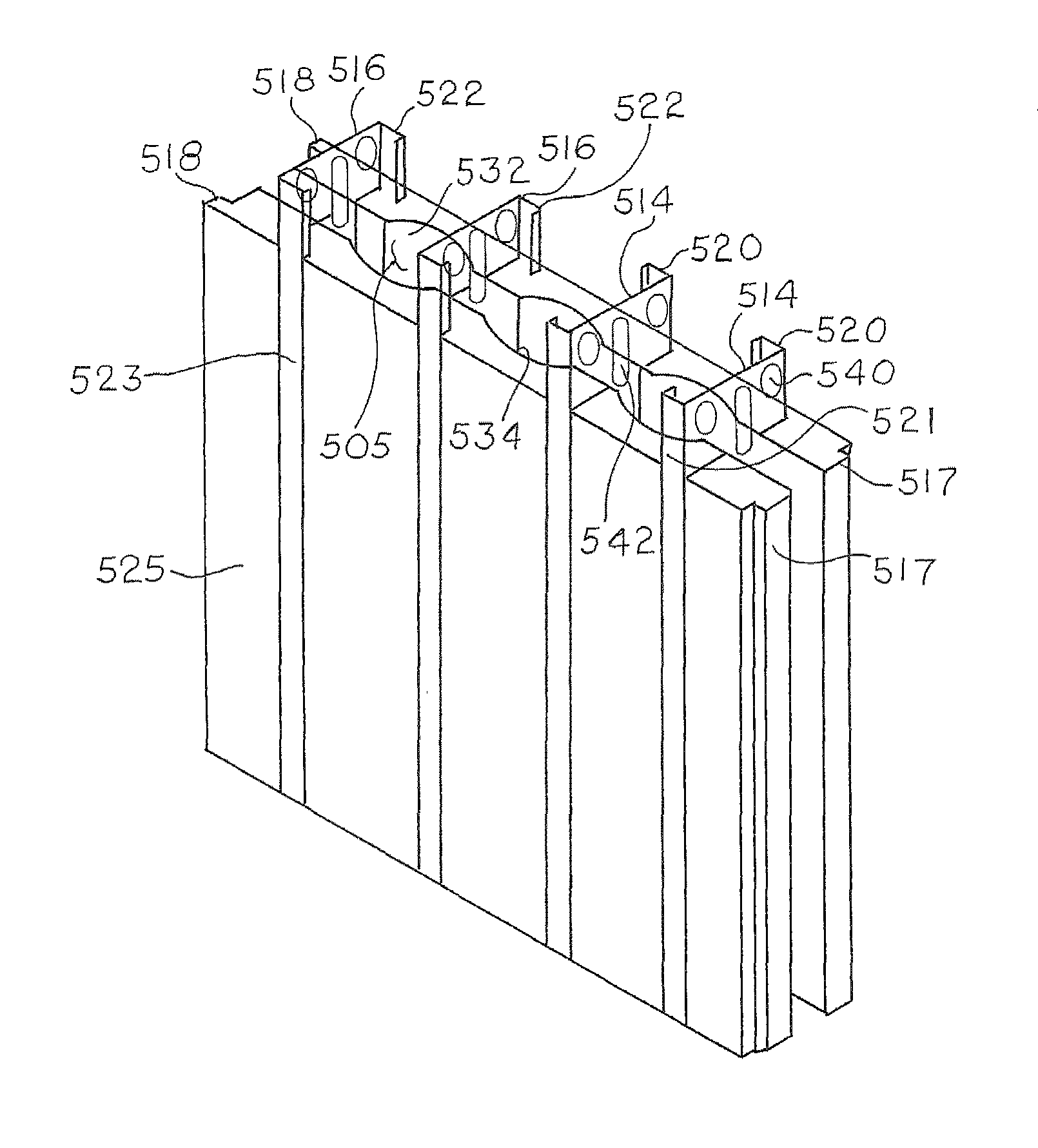

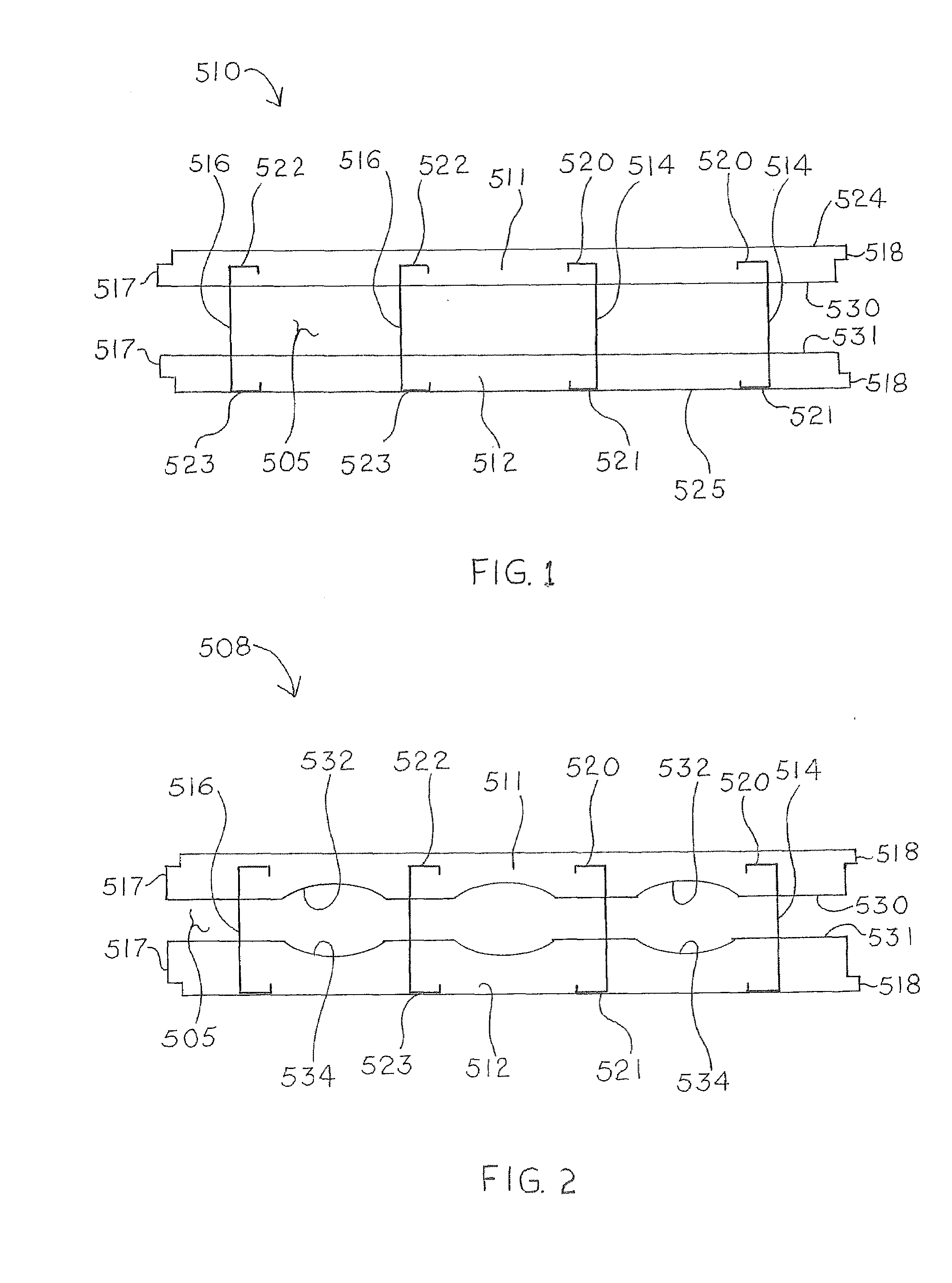

Composite piezoelectric apparatus and method

ActiveUS7109642B2Easy to disassemblePiezoelectric/electrostriction/magnetostriction machinesVacuum evaporation coatingTransducerVolume percent

The present invention relates to composite piezoelectric apparatus, transducers and methods of manufacture. In an embodiment, a composite piezoelectric apparatus has a sacrificial base and pillar array. Different volume percents of piezoelectric material are used in the sacrificial base and pillar array. A first volume percent in the base is lower than the second volume percent in the pillar array. In this way, the sacrificial base can be easily removed from the pillar array after the base and pillar array are sintered in the manufacture of a final composite piezoelectric transducer. A method of manufacturing a composite piezoelectric transducer from a sacrificial base and pillar array and a composite piezoelectric transducer made by the method are provided. A composite piezoelectric transducer stack is provided.

Owner:SONAVATION INC

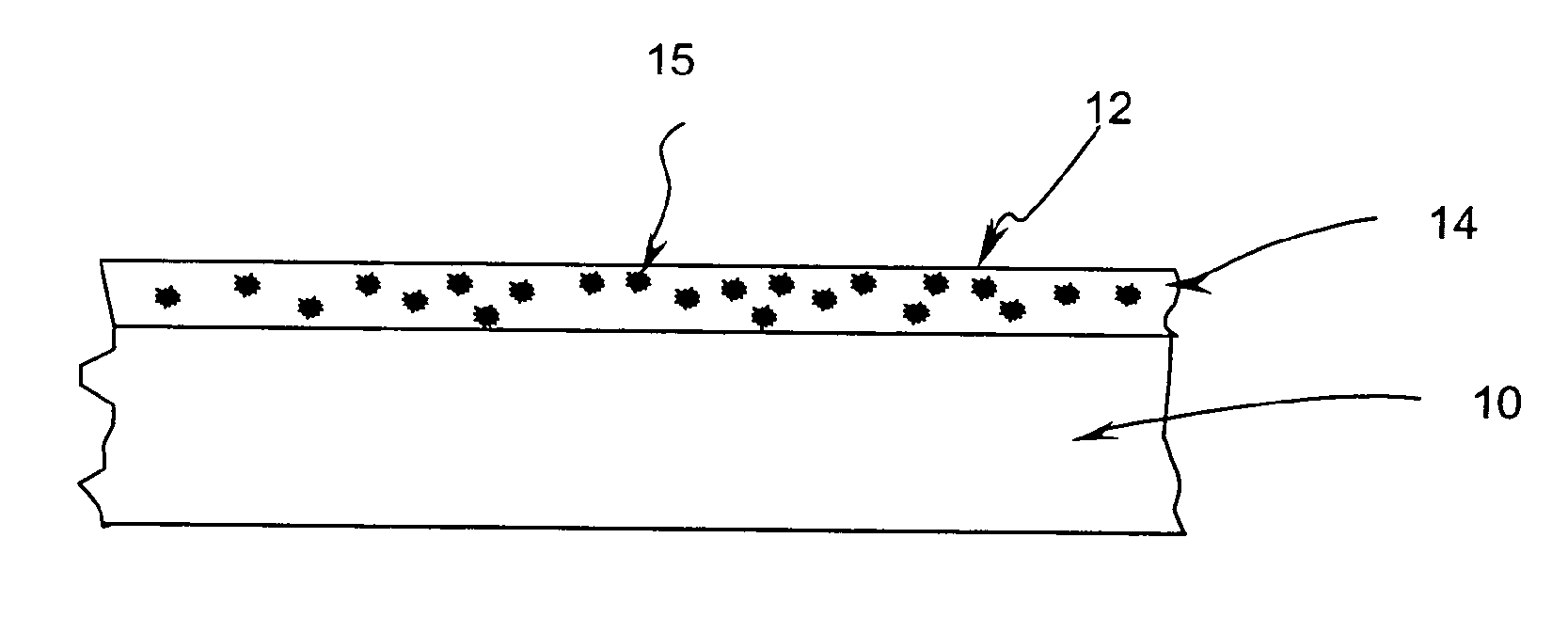

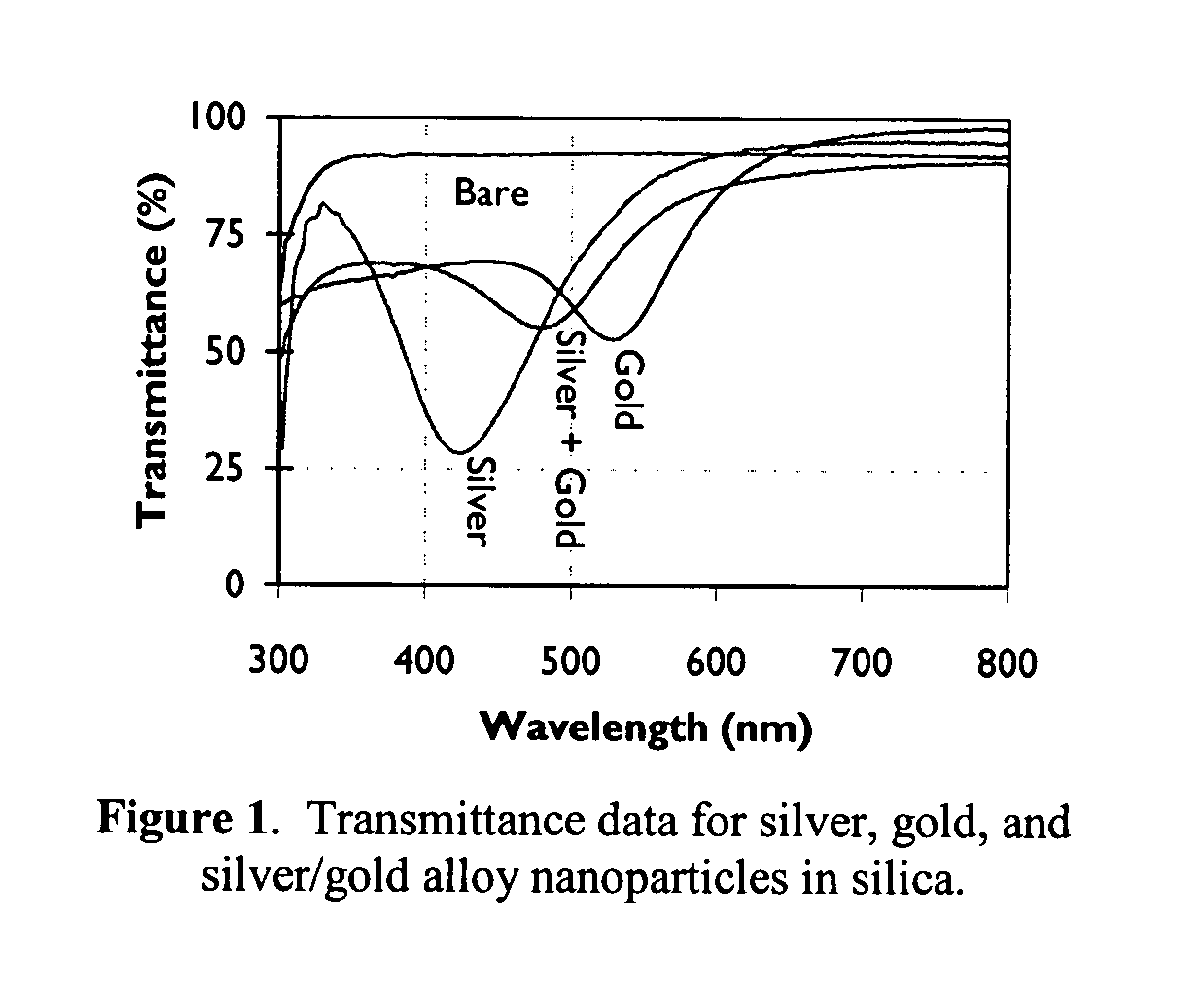

Optical coating

Optical coating materials comprise a transparent matrix material having dispersed nanoparticles comprising between 1 and 20 volume percent of the optical coating material. The coating materials are used to form optical coatings on substrates, such as glass / ceramic, polymer or metal, to alter the color or other optical properties. The nanoparticles are semiconductive material or elemental metals or elemental metal alloys that exhibit surface plasmon resonance.

Owner:POLLEY TODD A +4

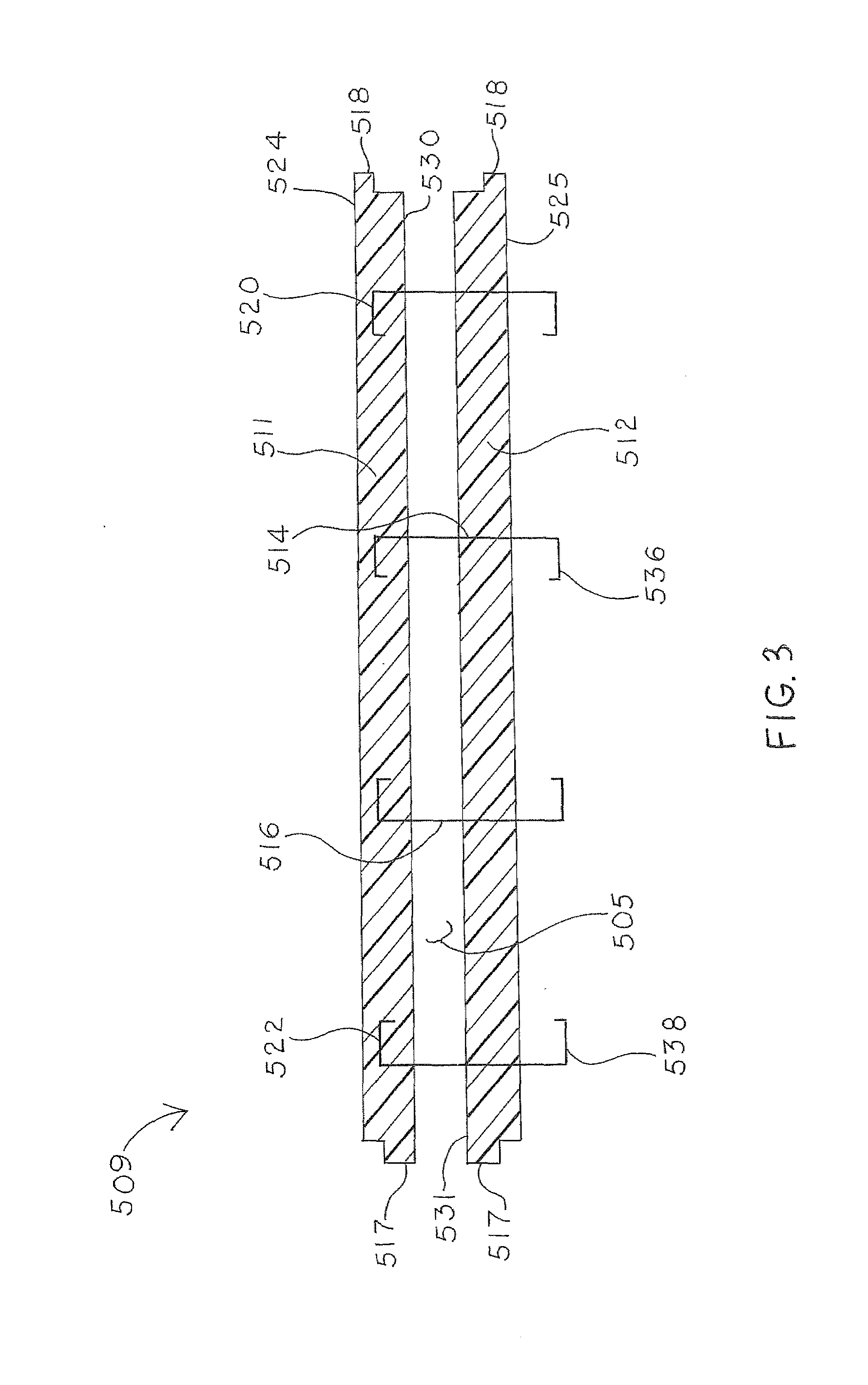

Lightweight cartridge case

Disclosed is an ammunition cartridge case that includes a sleeve, a base fixedly attached to the sleeve and a fiber reinforced polymer composite annulus that is at least partially within the base. In certain embodiments, the sleeve and the base are formed partly or entirely from a metal, for example steel or stainless steel. The base has a central aperture that affords for the annulus ring to fit within. The annulus is dimensioned such that it fits securely within the central aperture of the base and has a center aperture wherein a primer can be located. The annulus ring contains a volume of composite fibers ranging from 10 to 90 volume percent. The annulus isolates the primer from the cartridge case and thereby prevents galvanic corrosion between the primer and case. In addition, a metallic foil can be present between the annulus and the cartridge case in order to assure proper securement of the annulus therewithin.

Owner:ARMY US SEC THE THE

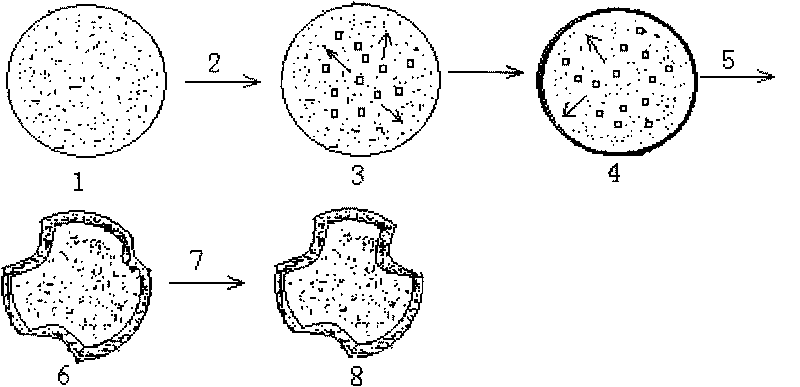

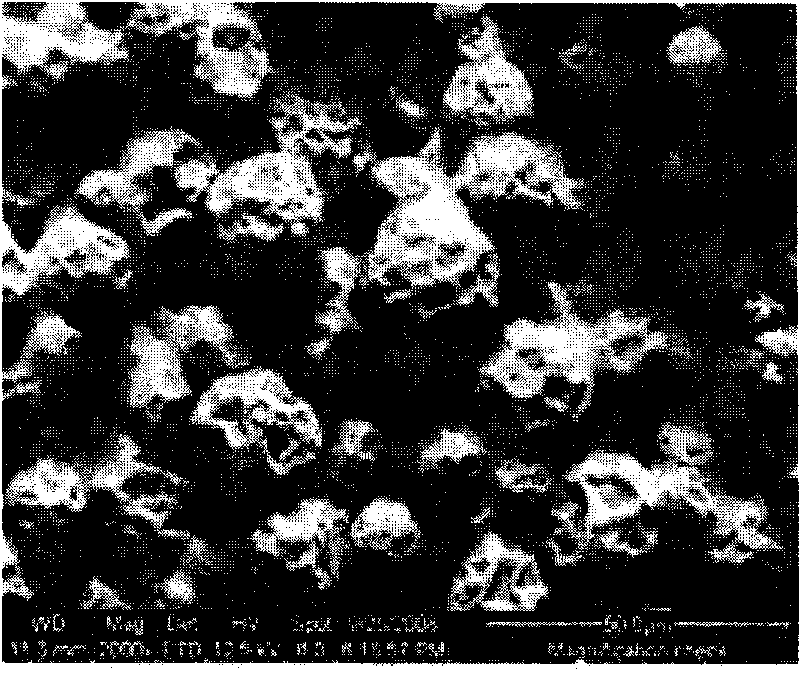

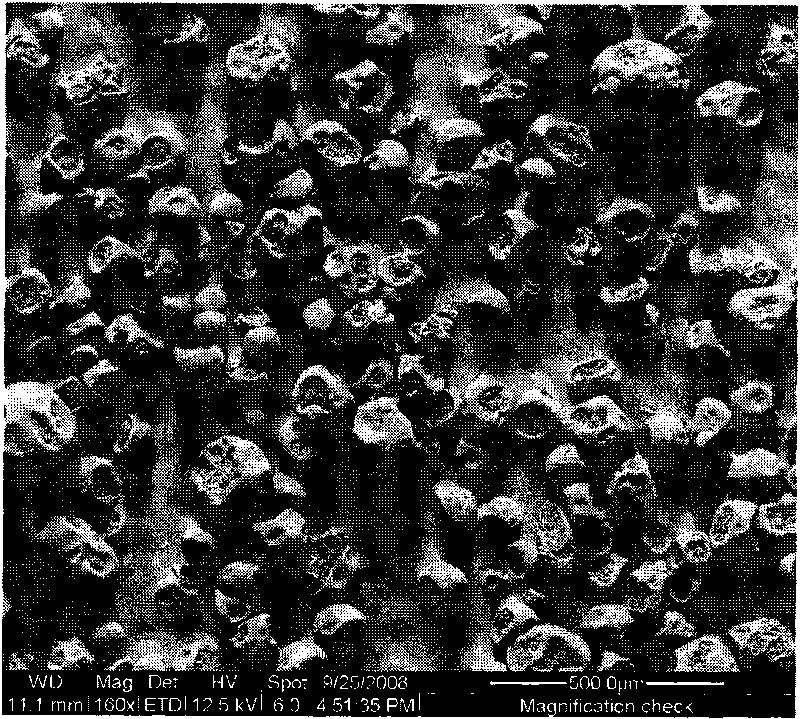

Phase-change material microcapsule and preparation method thereof

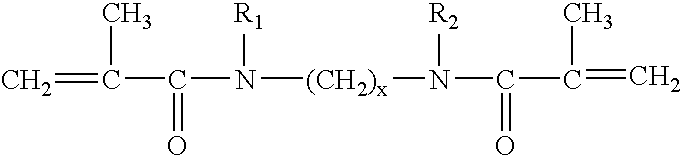

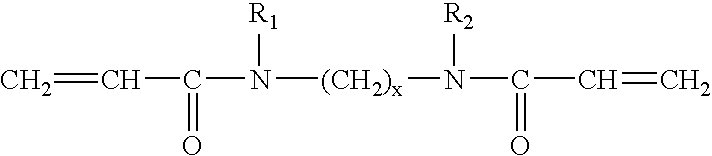

InactiveCN101701146ASmall particle sizeSimple processHeat-exchange elementsMicroballoon preparationOil phasePhase-change material

The invention relates to a phase-change material microcapsule and a preparation method thereof. The microcapsule is prepared by a mixed liquor of an oil-phase component and an aqueous phase component; the oil-phase component accounts for 9-30% of the mixed liquor according to the mass percentage (the same below); the oil-phase component comprises 28-49% of free radical polymerization monomer, 1-9% of crosslinker, 44-70% of organic phase-change material and 1-2% of initiating agent; the aqueous phase component comprises 80-90% of deionized water and 1-20% of emulsifier; the surface of the microcapsule has one or more than hollows, the average grain diameters of which are less than or equal to 90mum and the total volume of which accounts for 20-40% of the microcapsule according to the volume percent; the thermal decomposition temperature of the microcapsule is larger than or equal to 230 DEG C. The preparation method adopts the mass percent composition of the microcapsule and the following technique: firstly, the well-mixed oil phase component is added into the well-mixed aqueous phase solution in the temperature I and the stirring speed I, and stirred into a mixed emulsion in the stirring speed II; and then the temperature of the mixed emulsion is raised to II; and finally the mixed emulsion is filtered, separated, mixed, washed with deionized water for 2 to 5 times after being fully stirred, thus obtaining the microcapsule wet cake; or the microcapsule wet cake is dried till reaching constant weight, thus obtaining the microcapsule dry powder.

Owner:TIANJIN POLYTECHNIC UNIV

Resin metal composite bonding agent and composite bonding agent diamond grinding wheel

InactiveCN102350667AImprove temperature resistanceGood self-sharpeningAbrasion apparatusGrinding devicesNumerical controlHeavy load

The invention belongs to the field of diamond grinding wheels, and in particular relates to a resin metal composite bonding agent and a composite bonding agent diamond grinding wheel prepared by adopting the resin metal composite bonding agent. The resin metal composite bonding agent consists of the following raw materials in percentage by weight: polyimide resin powder, copper powder, tin powder, zinc powder, phosphorus powder and lead powder; and the composite bonding agent diamond grinding wheel consists of the following raw materials: 65 to 85 volume percent of composite bonding agent, 15to 35 volume percent of diamond abrasive, and 0.5 to 1 volume percent of resin liquid. When the diamond grinding wheel prepared by adopting the resin metal composite bonding agent is used on a numerical control grinder, the diamond grinding wheel has the original characteristics of high grinding efficiency and good self-sharpening property of a resin bonding agent diamond grinding wheel and also has the advantages of high rigidity, high heat resistance and good profile retaining property of a metal bonding agent diamond grinding wheel, one-way cutting depth of heavy-load powerful grinding canreach 6 millimeters, and the comprehensive economic benefit can be improved by over 100 percent.

Owner:SUZHOU SAILI PRECISION TOOLS

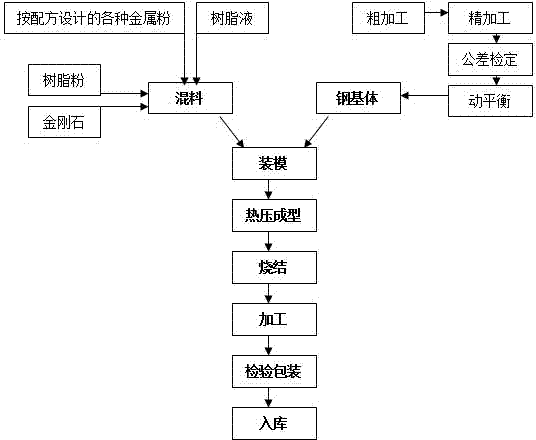

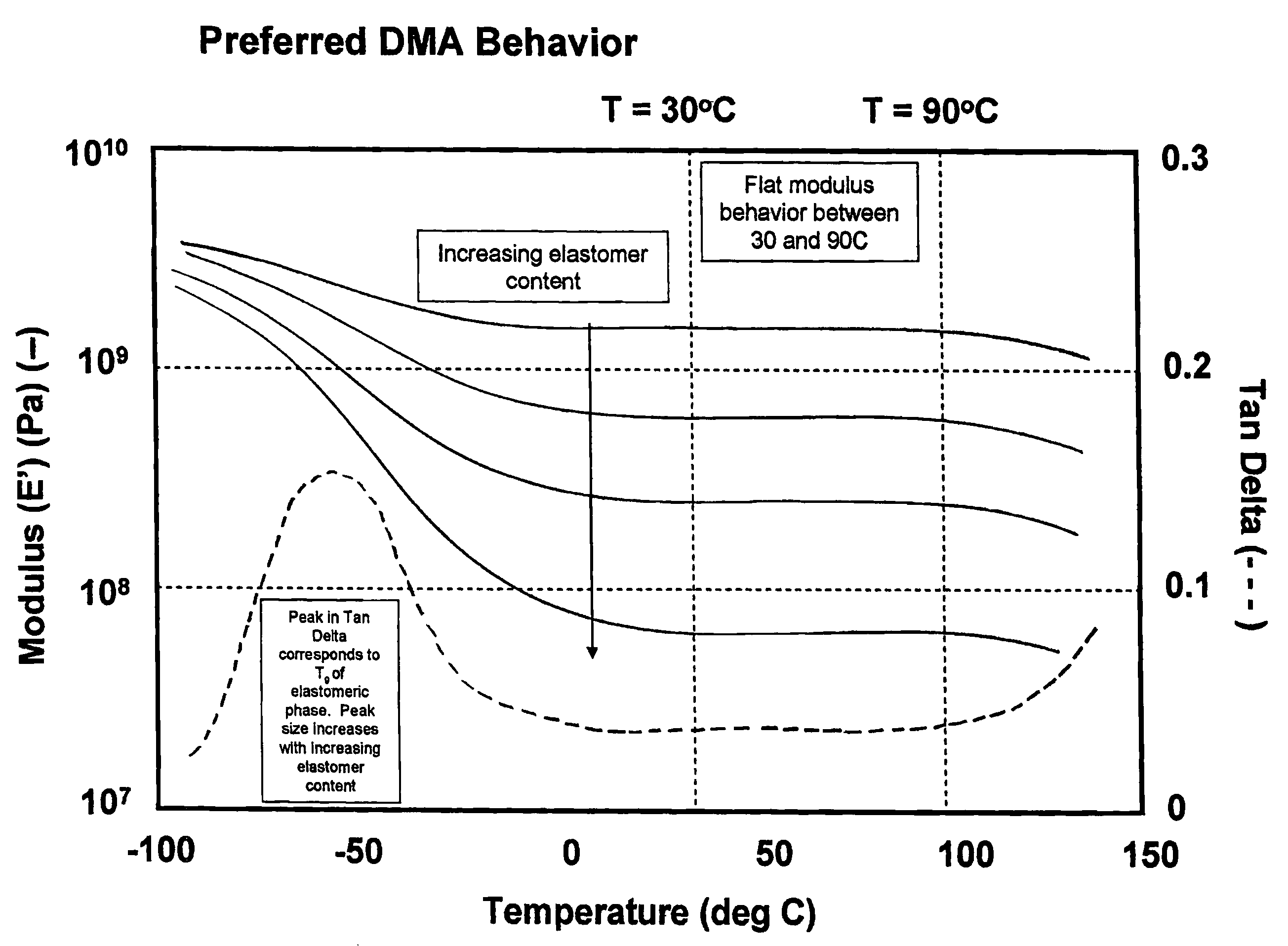

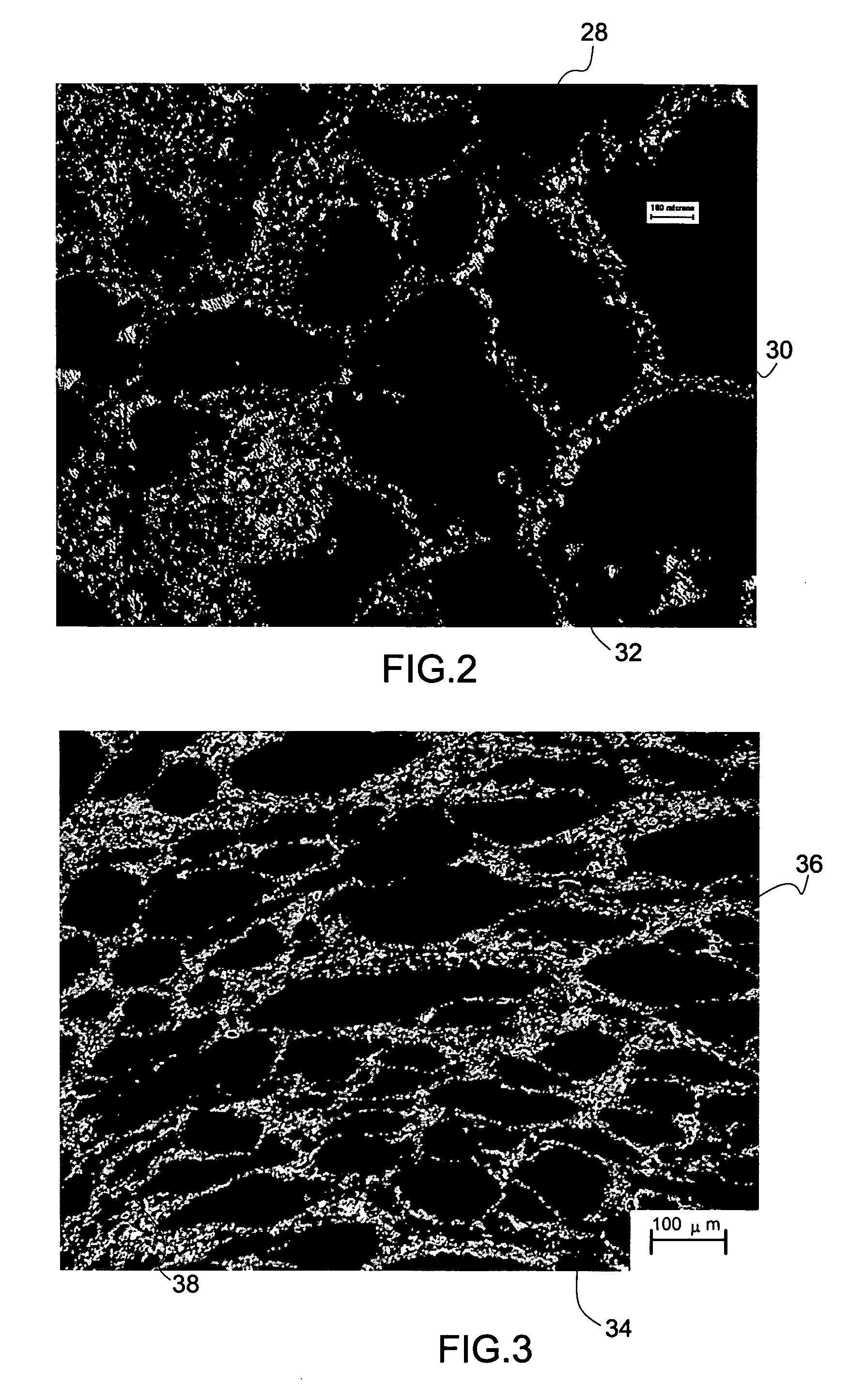

Elastomer-modified chemical mechanical polishing pad

ActiveUS7371160B1Fast cutting speedPigmenting treatmentOther chemical processesVitrificationElastomer

The chemical mechanical polishing pad is suitable for polishing at least one of semiconductor, optical and magnetic substrates. The polishing pad includes a polymeric matrix with an elastomeric polymer distributed within the polymeric matrix. The polymeric matrix has a glass transition above room temperature; and the elastomeric polymer has an average length of at least 0.1 μm in at least one direction, represents 1 to 45 volume percent of polishing pad and has a glass transition temperature below room temperature. The polishing pad has an increased diamond conditioner cut rate in comparison to a polishing pad formed from the polymeric matrix without the elastomeric polymer.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Alloy materials

InactiveUS6475311B1Improve the immunityLow Curie temperatureMetal layered productsAlloyVolume percent

An alloy having a cube textured substrate is disclosed. The alloy includes two different metals. The alloy can be used as a substrate for a superconductor. Optionally, one or more buffer layers can be disposed between the substrate and the superconductor material. The alloy can be prepared using a process that includes rolling the alloy and annealing the alloy. The alloy can have a relatively large volume percent that is formed of grains with cube texture.

Owner:AMERICAN SUPERCONDUCTOR

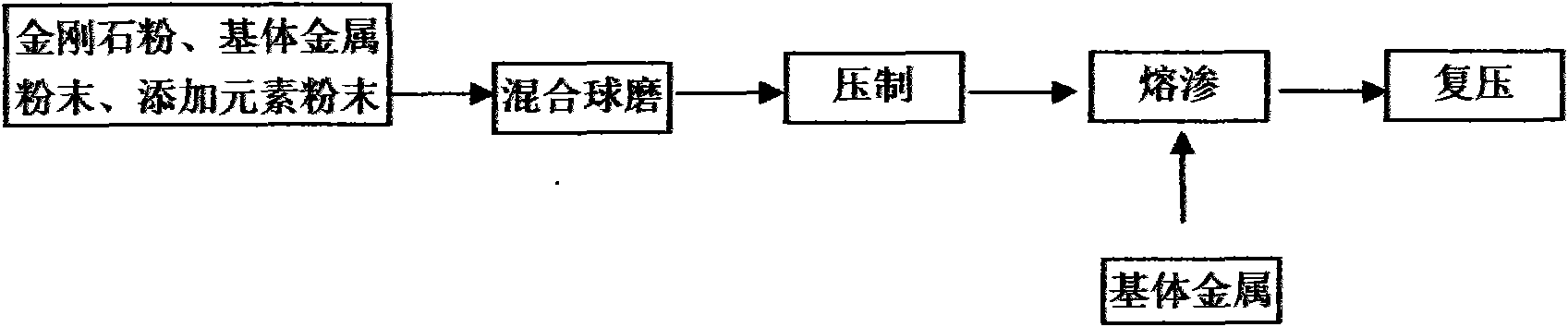

Diamond reinforced metal-base composite material for electronic packaging and preparation method thereof

ActiveCN101649400AImprove wettabilityImprove thermal conductivitySemiconductor/solid-state device manufacturingThermal expansionMetal matrix composite

The invention discloses a diamond reinforced metal-base composite material for electronic packaging and a preparation method thereof. The material comprises the following components by volume percent:30%-90% of diamond, 0.1%-5% of addition element and 10%-70% of metal substrate, wherein the addition element comprises one or more of Zr, Cr, Ti and B and the metal substrate comprises one metal of Ag, Cu and the like. The preparation method of the material comprises the following steps: mixing powder, pressing, infiltrating and pressing again. Owning to the adopted alloy element addition method,the wettability among phases is greatly improved. Therefore the material prepared by the method of the invention has better thermal conductivity, thermal expansion coefficient and mechanical properties compared with the former electronic packaging material and the adopted liquid phase infiltration method has the advantages of simple operation, low cost and capability of mass production.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Low refractive index composition

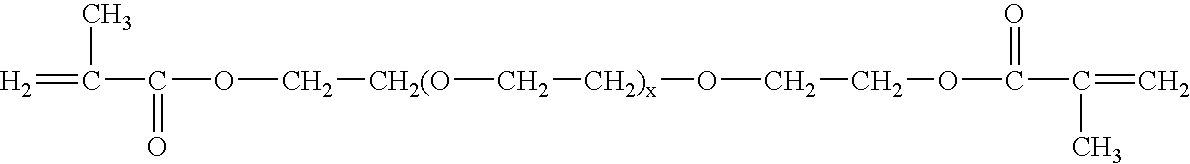

InactiveUS20080032053A1Low refractive indexExcellent abrasion resistanceMaterial nanotechnologyNon-macromolecular adhesive additivesAnti-reflective coatingSilica particle

A low refractive index composition is provided comprising the reaction product of: (i) a cross-linkable polymer; (ii) a multiolefinic crosslinker; and (iii) a plurality of solid nanosilica particles; (iv) a plurality of porous nanosilica particles; (v) an oxysilane having at least one polymerizable functional group and at least one of a hydrolysis and condensation product of said oxysilane; and (vi) a free radical polymerization initiator; wherein the volume percent of the solid nanosilica particles is greater than 0 and less than or equal to about 20; the sum of the volume percent of the solid nanosilica particles and the volume percent of the porous nanosilica particles is less than or equal to about 45; and wherein volume percent is based on the sum of the dry volumes of the cross-linkable polymer, the multiolefinic crosslinker, the solid nanosilica particles and the porous nanosilica particles. Further provided is a liquid mixture for forming a low refractive index coating, an article comprising a substrate having an anti-reflective coating, and a method for forming an anti-reflective coating on a substrate.

Owner:EI DU PONT DE NEMOURS & CO

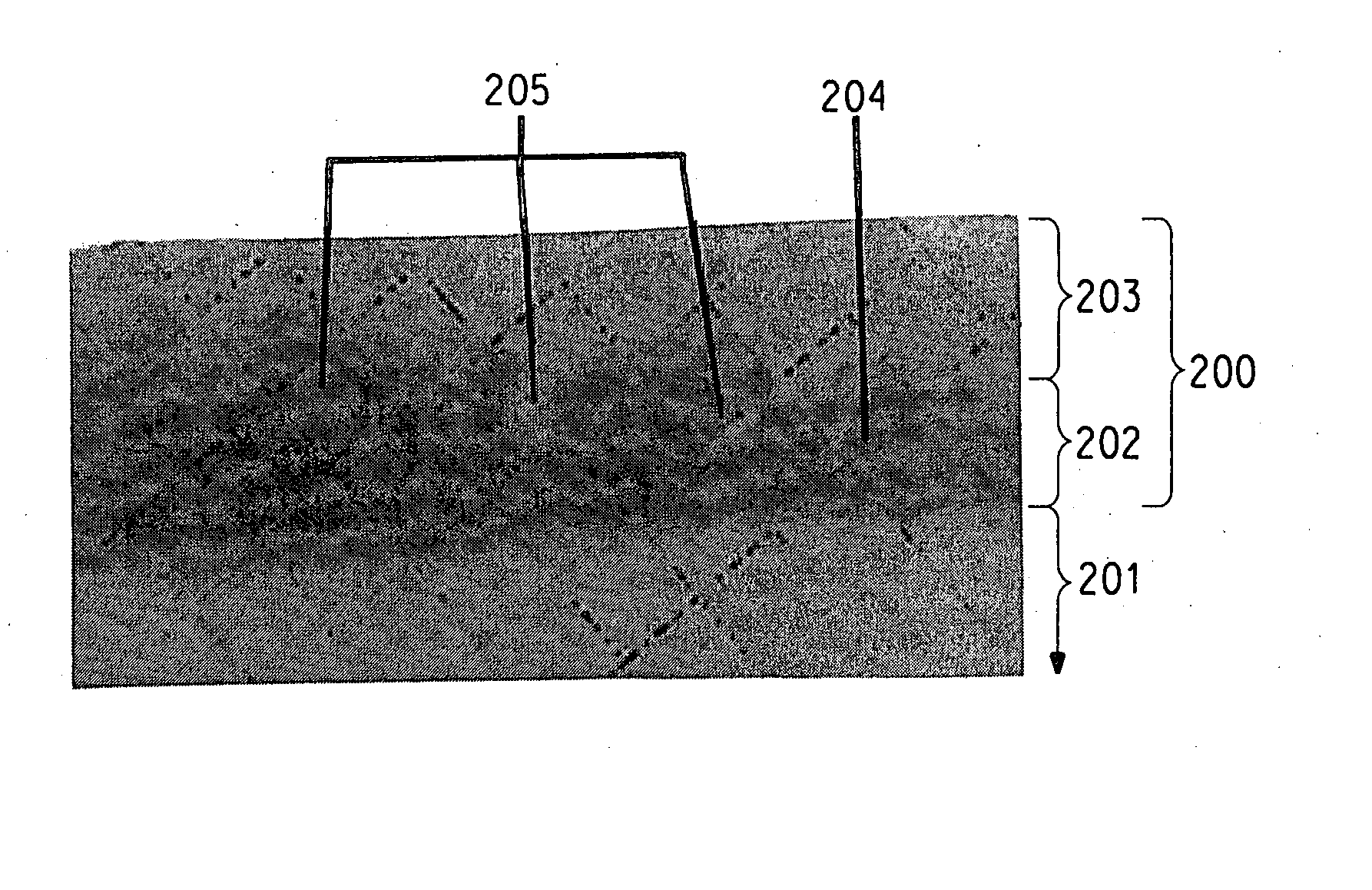

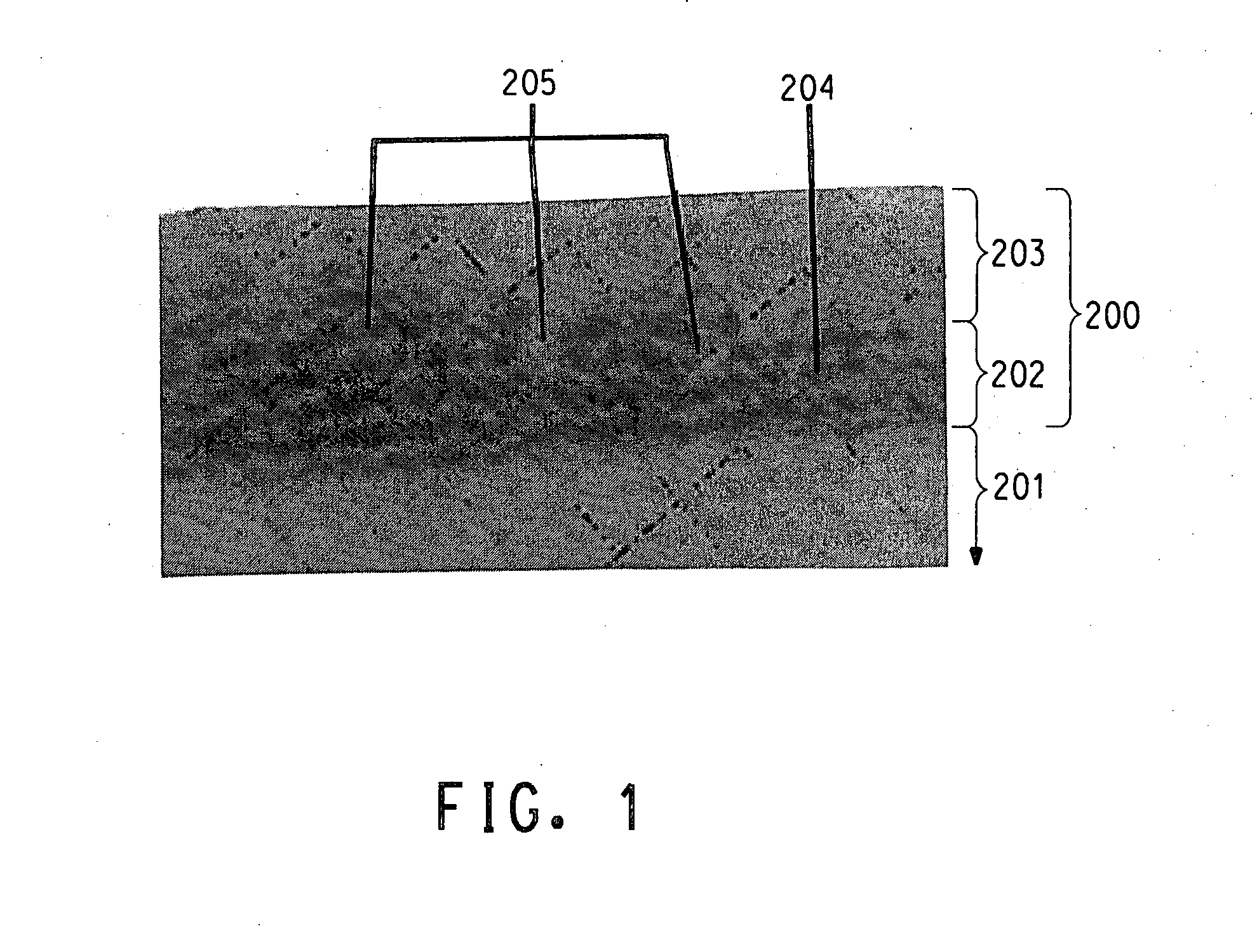

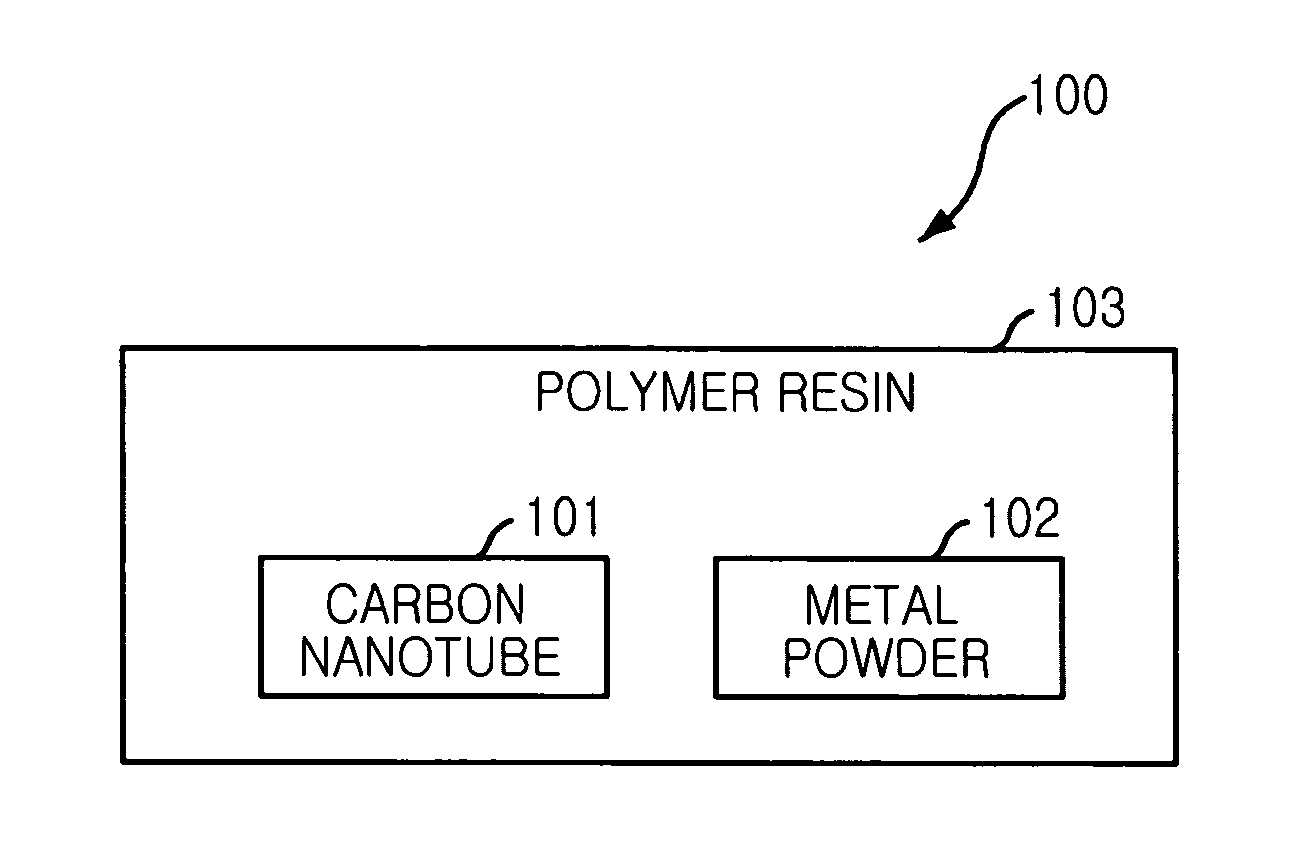

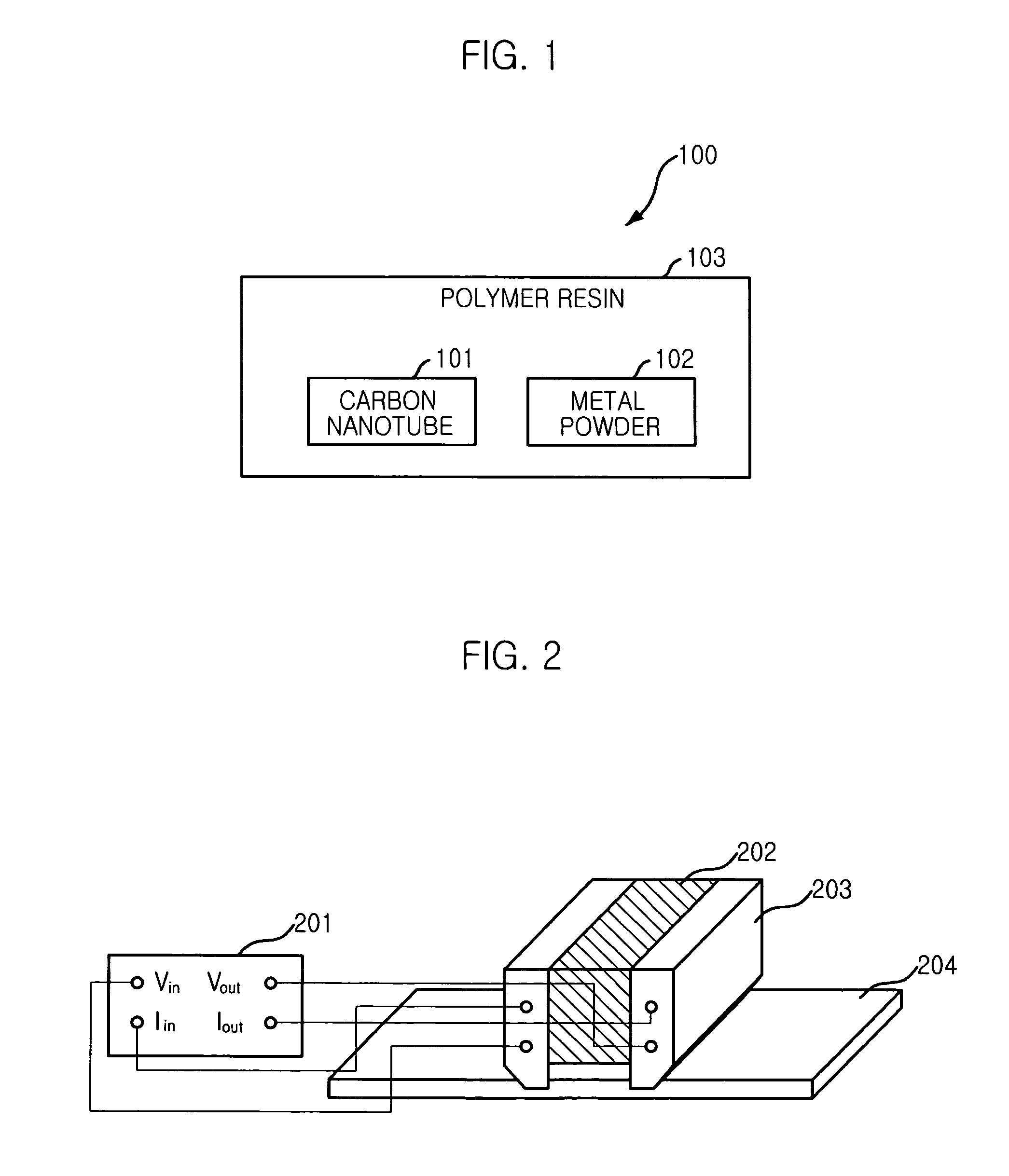

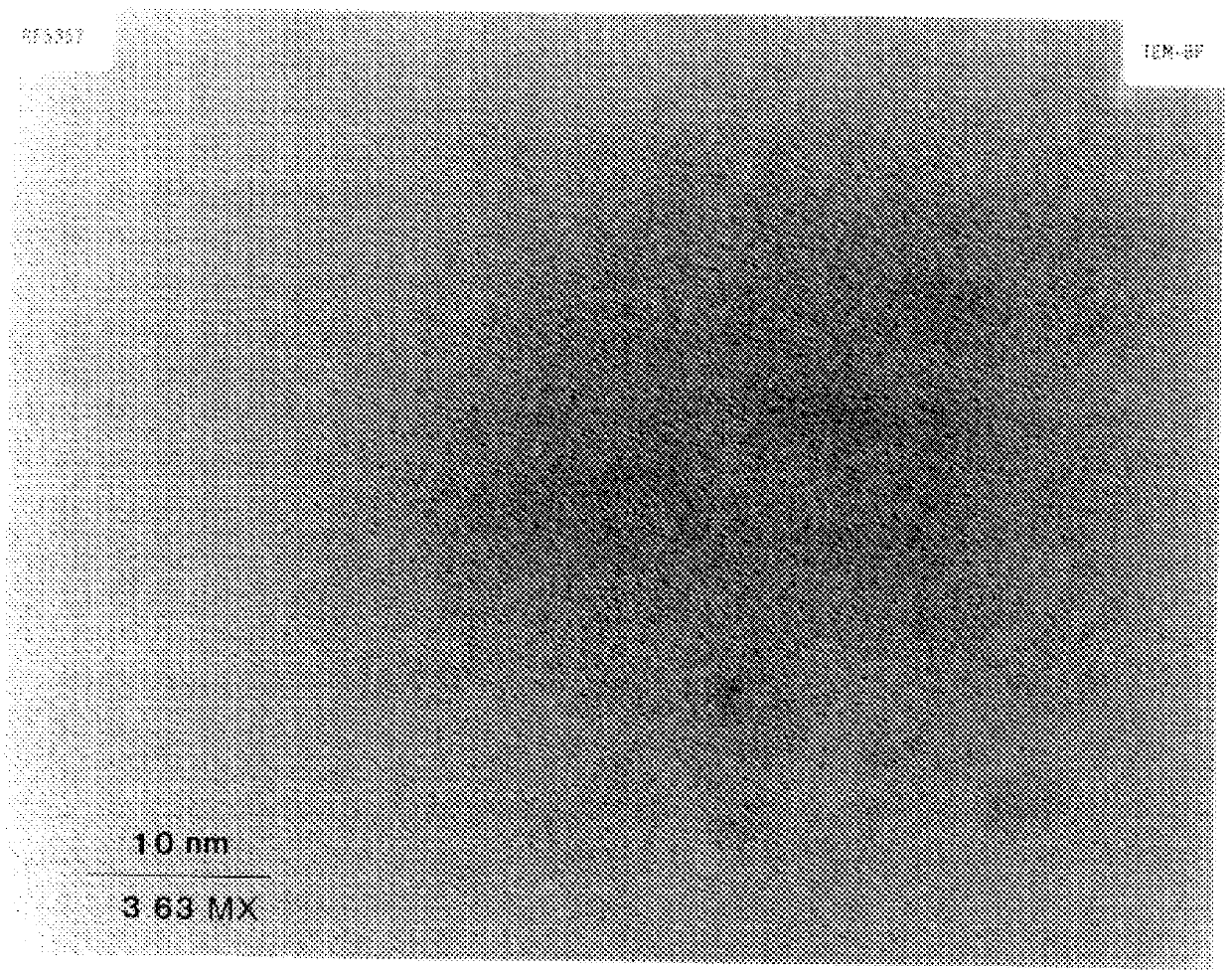

Electromagnetic shielding material having carbon nanotube and metal as electrical conductor

ActiveUS7588700B2Improved propertyMaterial nanotechnologyMagnetic/electric field screeningElectrical conductorPolymer resin

Disclosed is an electromagnetic shielding material with enhanced shielding effectiveness and mechanical property by employing a carbon nanotube and a metal as an electrical conductor. The electromagnetic shielding material includes a polymer resin for a matrix and two conductive fillers having a carbon nanotube and a metal, wherein a volume percent of the carbon nanotube ranges about 0.2% to about 10% and a volume percent of the metal powder ranges about 7.0% to about 30% so that the total volume percent of the conductive filler is in a range of about 7.2% to about 40%.

Owner:ELECTRONICS & TELECOMM RES INST

Method for removing aluminum from rare-earth feed liquid

ActiveCN101979680AGood aluminum removal effectLow cost of aluminum removalProcess efficiency improvementRare-earth elementKerosene

The invention discloses a method for removing aluminum from rare-earth feed liquid, belongs to rare-earth feed liquid treatment technology and aims to provide the method for removing the aluminum from the rare-earth feed liquid, of which the aluminum-removing effect is good, the aluminum-removing cost is low, the rare-earth recovery rate is high, the operation and control are convenient, the process is simple and the investment in equipment is small. The key point of the technical scheme mainly comprises the following steps of: (1) preparing an organic phase from 15 to 25 volume percent of naphthenic acid and 15 to 25 volume percent of alcohol-kerosene; (2) adding the prepared organic phase and the rare-earth feed liquid into a stirring tank in a volume ratio of 2-5:1, starting the tank, stirring and uniformly mixing; (3) adding alkaline solution into the mixed liquid obtained in the step (2) with stirring, wherein the total number of moles of the added alkali is 50 to 100 percent of that of rare-earth elements in the rare-earth feed liquid; and (4) after adding the alkaline solution, continuously stirring for a certain time, stopping stirring and standing for a certain time, wherein the solution is separated into an aqueous phase and an organic phase and the aqueous phase is the rare-earth feed liquid from which the aluminum is removed. The method is applied to aluminum removal for the rare-earth feed liquid.

Owner:广东省富远稀土有限公司 +1

Semiconductor having large volume fraction of intermediate range order material

A high quality non-single-crystal silicon alloy material including regions of intermediate range order (IRO) silicon alloy material up to but not including the volume percentage required to form a percolation path within the material. The remainder of the material being either amorphous or a mixture of amorphous and microcrystalline materials. The materials were prepared by CVD using differing amounts of hydrogen dilution to produce materials containing differing amounts of IRO material. Preferably the material includes at least 8 volume percent of IRO material.

Owner:BEKAERT ECD SOLAR SYST

Disinsection mold-proof method with no effect on tobacco mellowing

InactiveCN101416771AThoroughly kills insects and mildewTobacco preparationPackaging under vacuum/special atmosphereNitrogenMildew

The invention belongs to the fine chemical field and especially provides a pest-killing and mildew-resistent method during tobacco leaf without affecting tobacco leaf alcoholization. The invention is characterized by adopting two steps to control the storing environment during tobacco leaf alcoholization process: the first step is sealing and packing tobacco leaves with plastic membranes, decreasing the volume percent of oxygen concentration to 0.01-4% with an oxygen-absorbing material or nitrogen, corbon dioxide or inert gas and sealing for 10-400 days; the second step is supplying oxygen or air into the sealing bag after completely killing pests and mould in the tobacco leaves to increase the volume percent of oxygen concentration in the bag to 4-40%, and storing for 10-700 days. the invention has advantages of completely killing pests and mould in the tobacco leaves without affecting tobacco leaf alcoholization, a good tobacco leaf alcoholization effect and a thorough pest-killing and mould-resistant effect.

Owner:UNIV OF SCI & TECH BEIJING

Article having a dispersion of ultrafine titanium boride particles in a titanium-base matrix

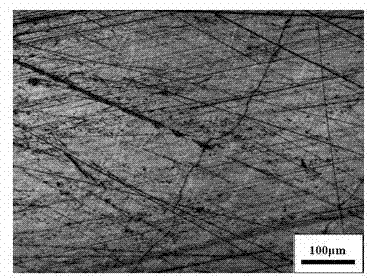

ActiveUS20060102255A1Improve creep strengthImprove static strengthThin material handlingMaximum dimensionMicrometer

An article includes a microscale composite material having a matrix with more titanium than any other element, and a dispersion of titanium boride particles in the matrix. At least about 50 volume percent of the titanium boride particles have a maximum dimension of less than about 2 micrometers.

Owner:GENERAL ELECTRIC CO

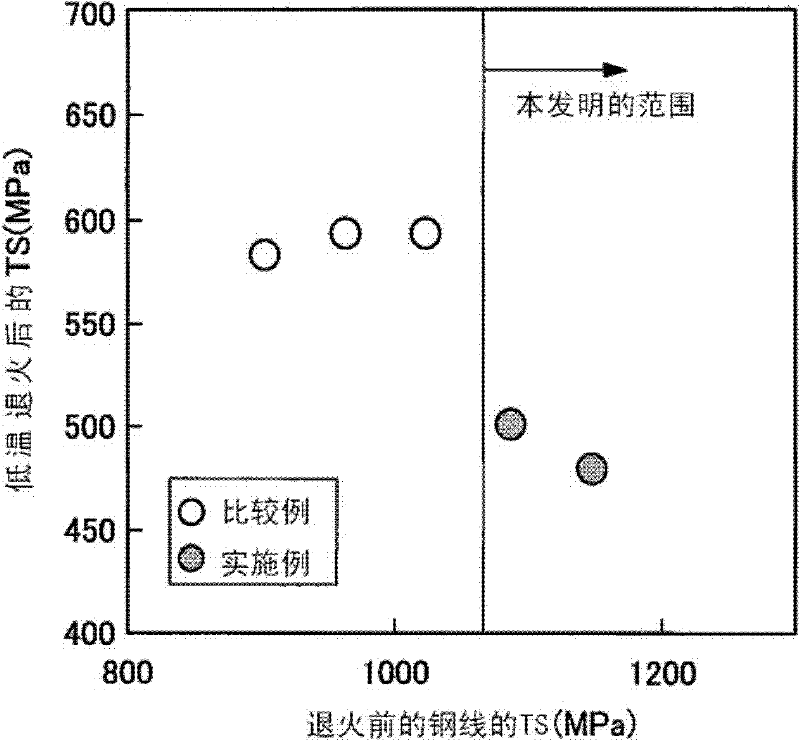

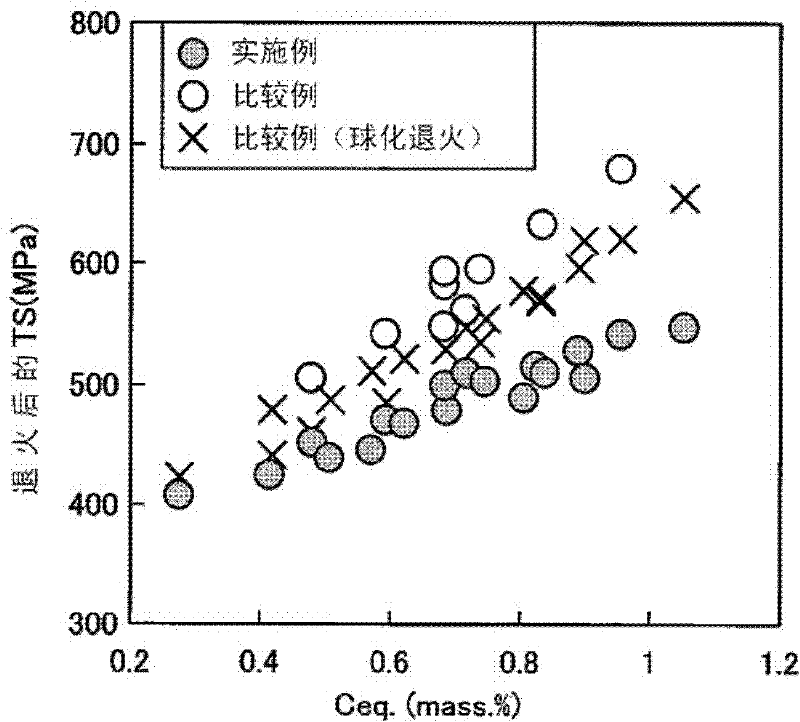

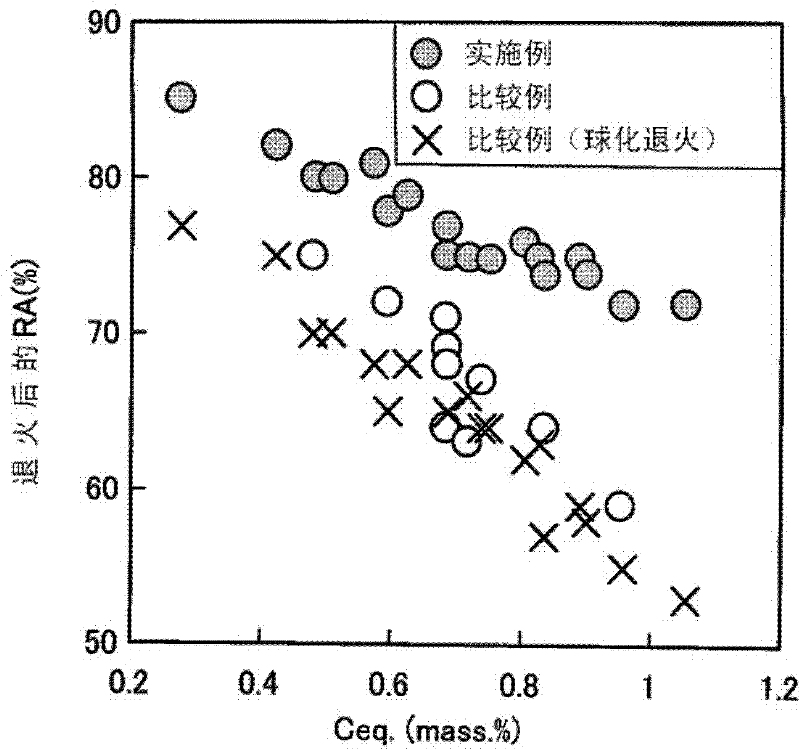

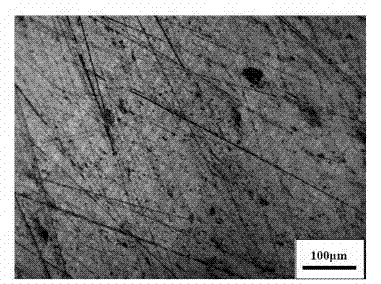

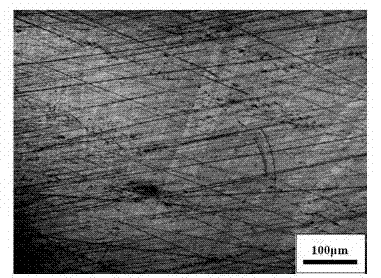

Steel wire for low-temperature annealing and method for producing same

ActiveCN102227512AImprove yieldImprove productivityFurnace typesHeat treatment bathsImpurityVolume percent

Provided is a steel wire for low-temperature annealing which comprises, by mass%, C: 0.10% to 0.60%, Si: 0.01% to 0.40%, Mn: 0.20% to 1.50%, P: 0% to 0.040%, S: 0% to 0.050%, and N: 0.0005% to 0.0300%, and further comprises one or more selected from Cr: 0.03% to 0.4%, V: 0.03% to 0.2%, and Mo: 0.03% to 0.2%, with Fe and inevitable impurities as the remainder. The volume percent of pearlite structure is between 1.40*(C%)*100% and 100%, the volume percent of proeutectoid ferrite is between 0% and (1 - 1.25*(C%))*50%, and the volume percent of bainite structure is between 0% and 40%. The tensile strength is between 480 + 850*Ceq. MPa and 580 + 1130 Ceq. MPa.

Owner:NIPPON STEEL CORP

Method for preparing high-purity mesophase pitch and prepared high-purity mesophase pitch

ActiveCN102899061ASimple processReduce manufacturing costWorking-up pitch/asphalt/bitumen by chemical meansFiberPolymer science

The invention relates to a method for preparing high-purity mesophase pitch and prepared high-purity mesophase pitch. According to the technical scheme, the method for preparing the high-purity mesophase pitch comprises the following steps of: reacting refined naphthalene taken as a raw material with anhydrous aluminum trioxide taken as a catalyst in oil bath at 100 to 220 DEG C and a stirring rate of 200 to 600 r / min for 5 to 20 hours; removing the catalyst to obtain naphthalene pitch; and polymerizing the naphthalene pitch at 350 to 480 DEG C and a stirring rate of 400 to 1,000 r / min for 3 to 24 hours to obtain the high-purity mesophase pitch. The preparation process is simple, production cost is relatively low, and a mesophase forming process and a mesophase composition structure are easy to design and control; the prepared mesophase pitch is high in purity (ash content is only 50 to 150 ppm), low in softening point (260 to 280 DEG C), and high in mesophase content (100 volume percent), and has a wide-area streamlined optical anisotropic structure, the rheological property after fusion is excellent, spinnability is good, and the mesophase pitch is suitable to be used as a quality raw material of novel carbon materials such as high-performance pitch-based carbon fibers.

Owner:济宁辰星碳素有限公司

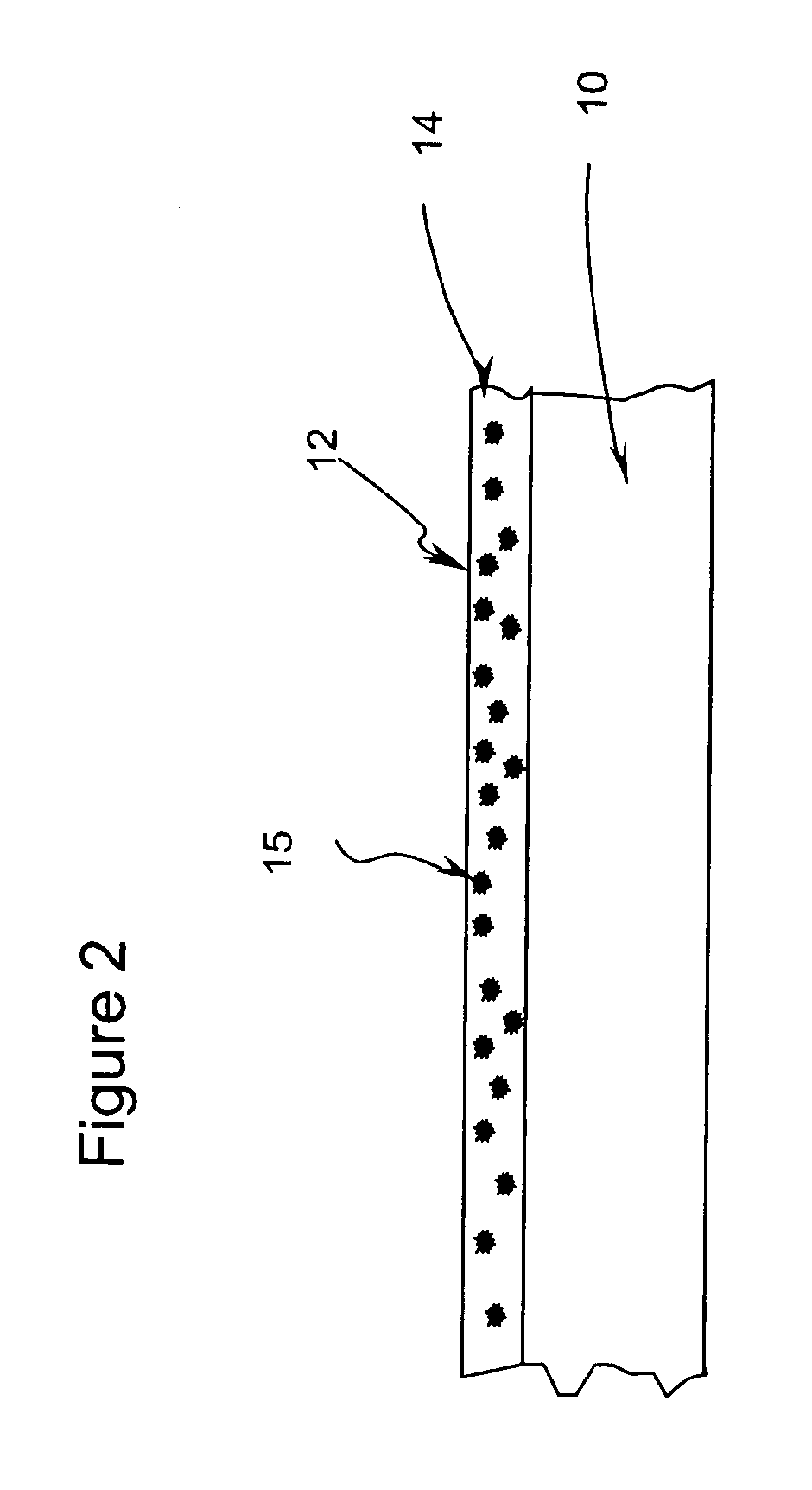

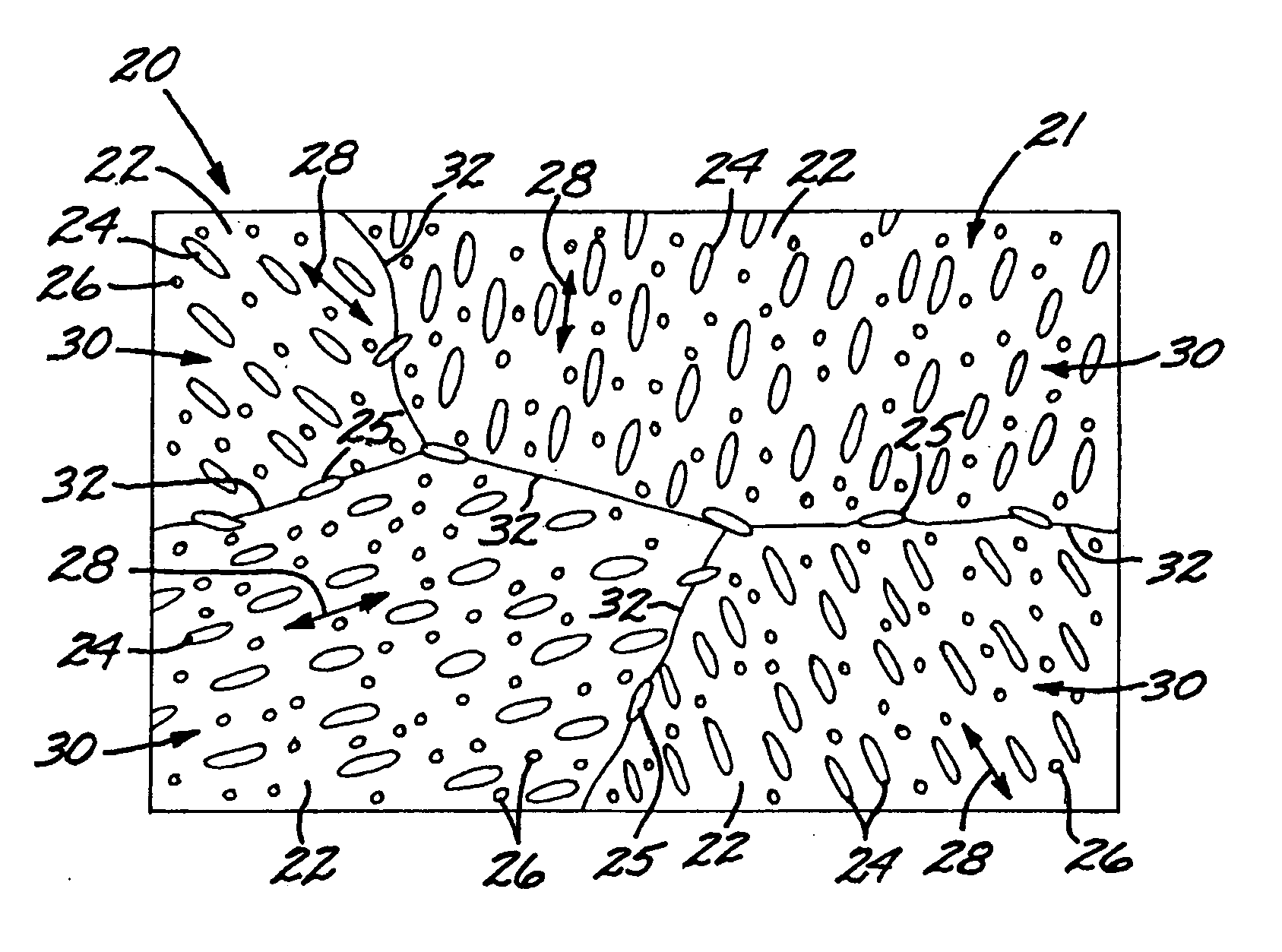

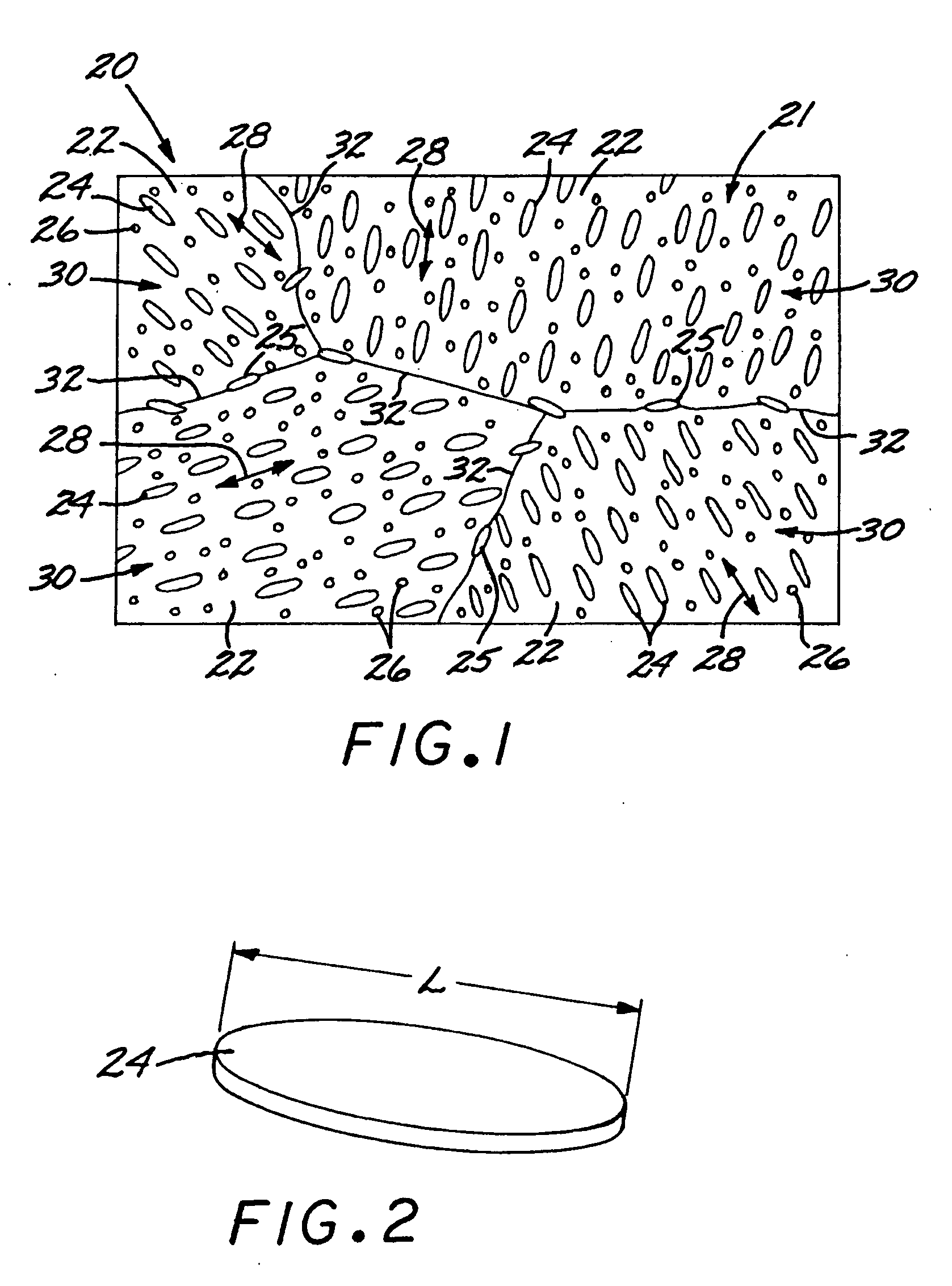

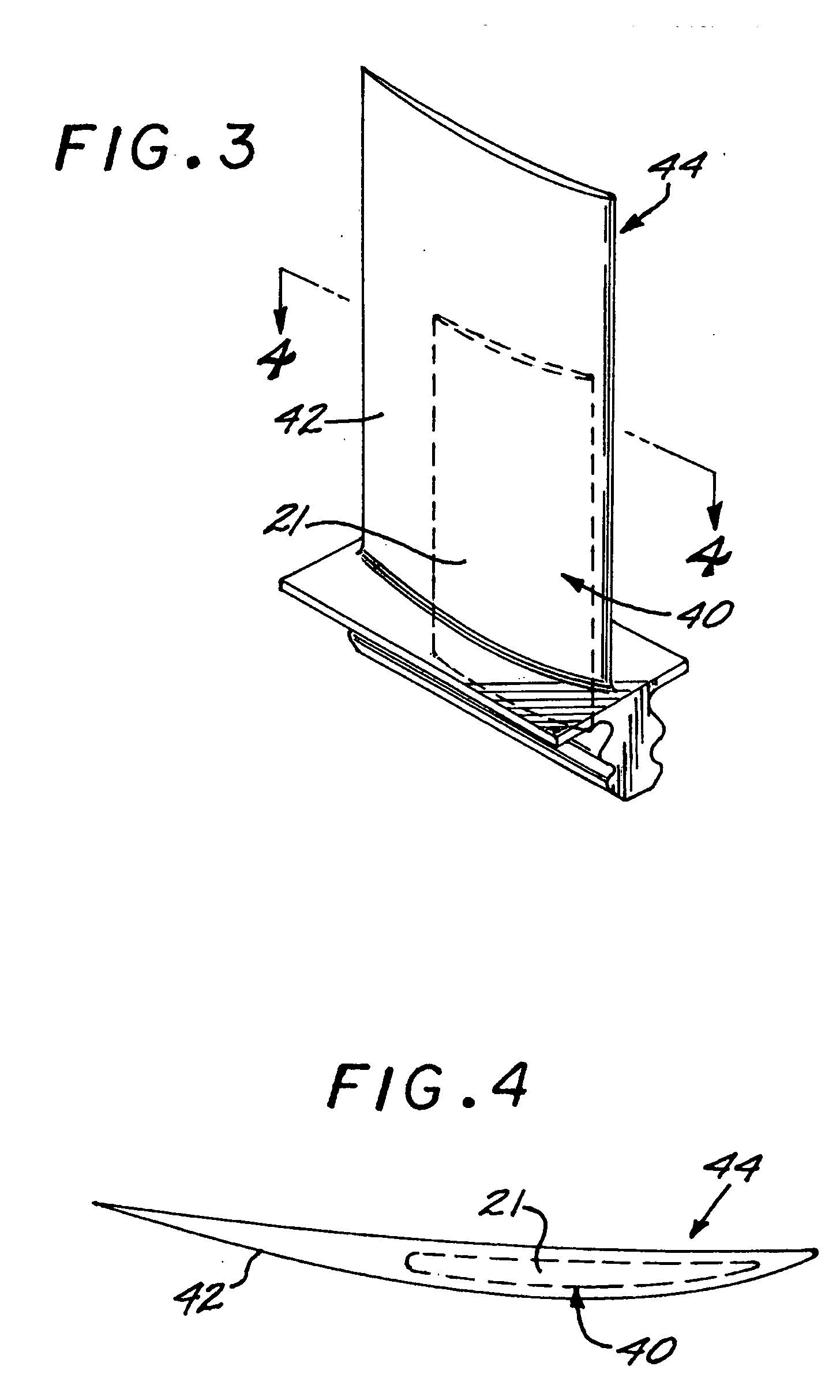

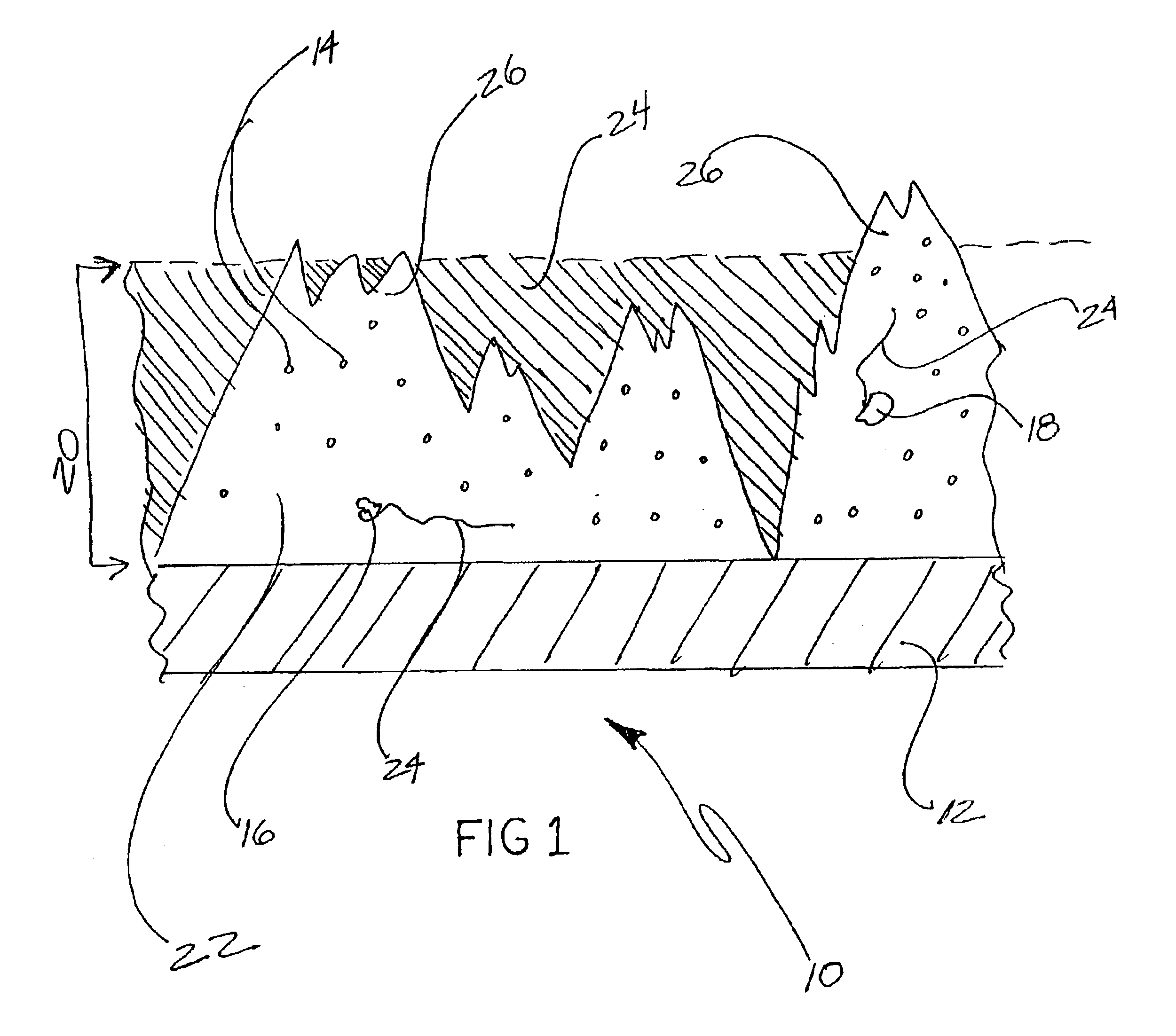

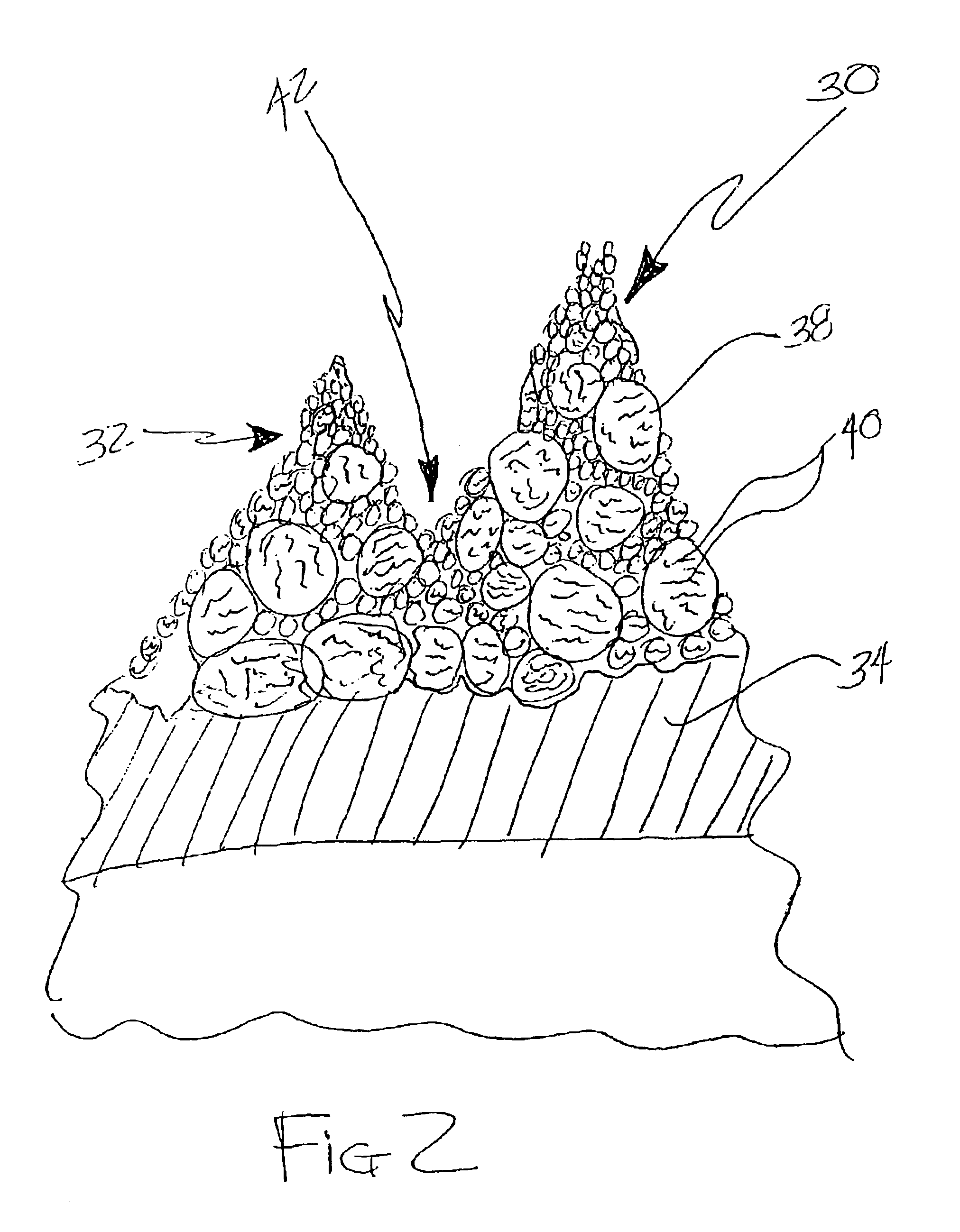

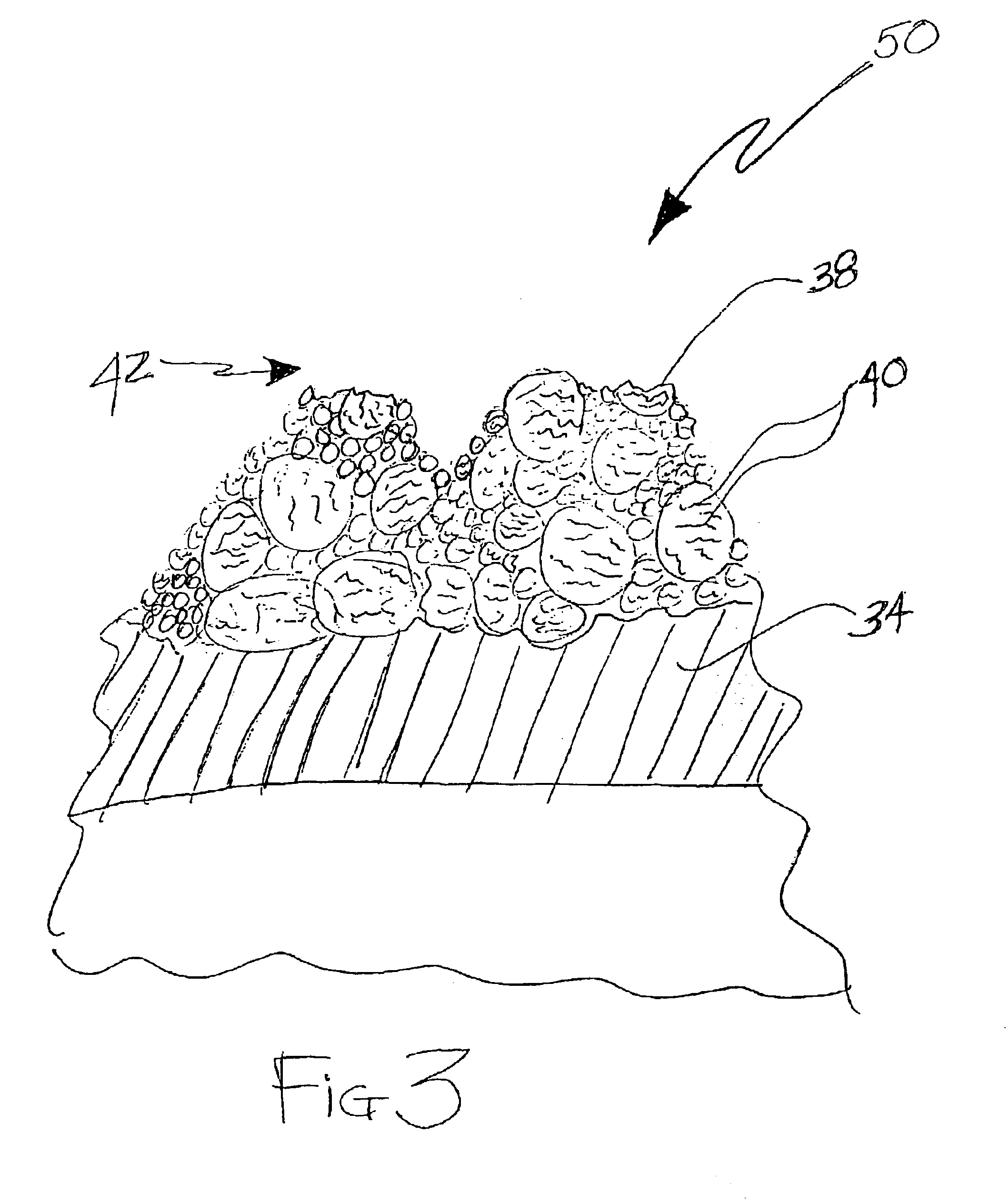

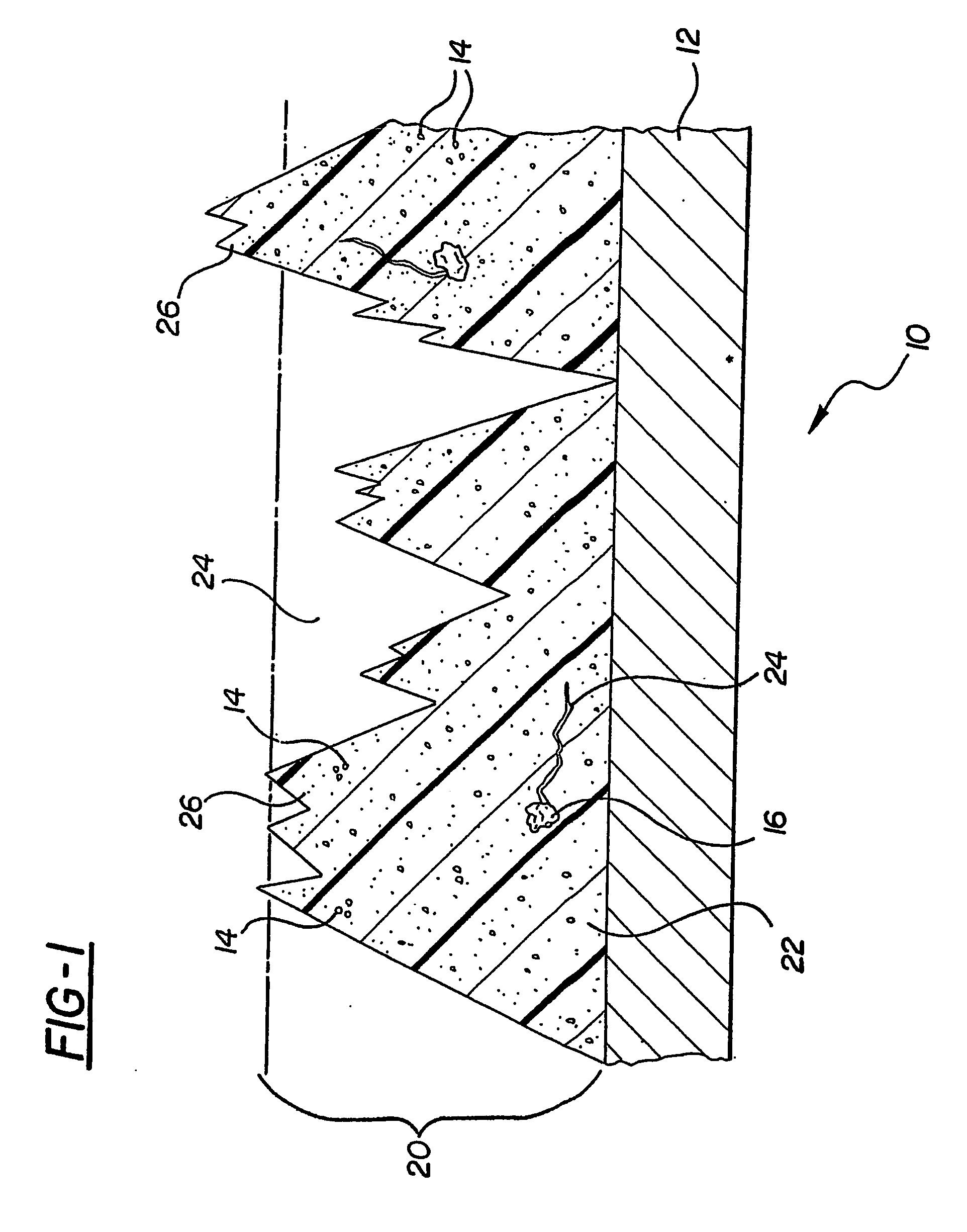

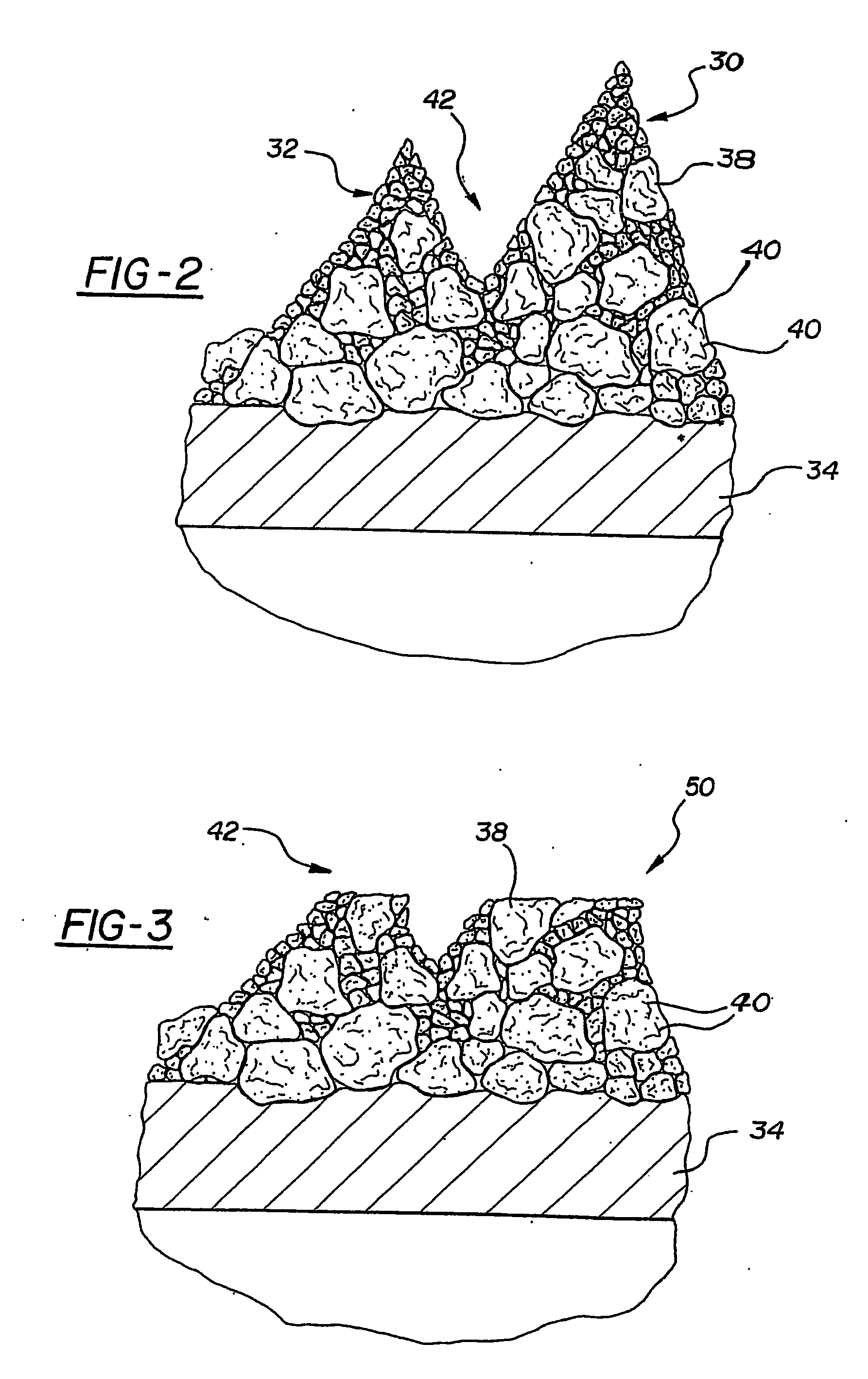

Abradable dry powder coatings, methods for making and coating, and coated articles therefrom

InactiveUS6844392B2Easy to appreciateNon-fibrous pulp additionEngine sealsElectrostatic coatingPolyresin

An abradable dry powder coating (22) composition for coating onto a surface (12) for subsequent curing to form into an abradable coating, including a powder (16) formed of uncured thermoset resin with at least 15 volume percent filler, wherein the filler does not substantially melt below the cure temperature of the resin. Method for making the coating composition includes melt-mixing the thermoset resin with at least 15 volume percent of filler, cooling the resulting mass composite, and then breaking the cooled mass composite into powder particles (16). Method of coating an article with an abradable coating includes applying the dry composite powder with the filler therein onto a substrate and curing the dry powder composition, preferably by electrostatic coating. An article is also disclosed which is coated with the abradable coating.

Owner:LINE 2 LINE INC

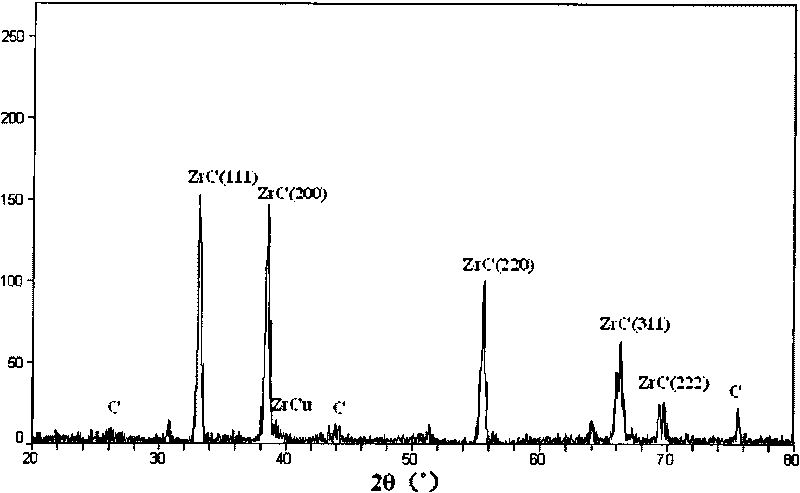

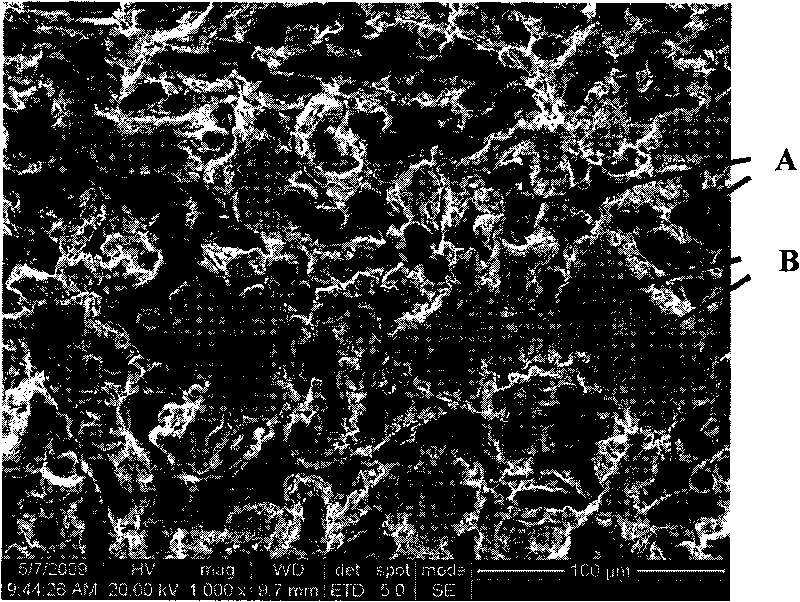

C/ZrC ceramic matrix composite and preparation method thereof

The invention discloses a C / ZrC ceramic matrix composite which uses ZrC as a matrix and uses carbon fiber as a reinforcing and toughening phase. The volume percent of the ZrC in the composite is 35%-65%, the volume percent of the carbon fiber in the composite is 25%-55%, and the porosity of the composite is 5%-15%. The preparation method of the composite comprises the steps of: preparing a C / C composite by using a carbon fiber preform as a matrix by using a chemical vapor deposition method or a resin liquid phase impregnating / cracking method or combining the chemical vapor deposition method and the resin liquid phase impregnating / cracking method; and then, obtaining the C / ZrC ceramic matrix composite by using metal Zr or the alloy of the Zr as a penetrating agent by the processes of metal infiltration reaction, high-temperature treatment after infiltration, and the like. The composite has ultra-temperature resistance, good fracture toughness, strong ablation resistance and good thermal shock resistance. The invention has simple preparation process, low cost, no corrosion to equipment, and no pollution to the environment.

Owner:NAT UNIV OF DEFENSE TECH

Lightweight ceramicite and preparation method thereof

InactiveCN101224972AHigh porosityLarge specific surface areaCeramic materials productionCeramicwareSlagAdhesive

The invention relates to a light ceramisite and a preparation method, comprising processes such as modification treatment of the raw material, the biological preparation, granulation, drying, baking and roasting etc. The invention is characterized in that the component and volume percent of the raw materials comprise: 30-70 percent of tailing of tungsten mine; 15-22.5 percent of cinder; 15-22.5 percent of fly ash; 10-14.5 percent of clay; 0.1-3 percent of pore-forming material; 0.2-1 percent of modified adhesive of biological material; the preparation technology is that after subject to modification treatment using 15-25 percent of HC1, the tailing of tungsten mine is prepared to be the ceramisite together with materials with different melting temperatures such as the cinder, the fly ash, the clay etc., as well as the pore forming agent and adhesive; then the tailing of tungsten mine is put into an oven below normal temperature for baking below 120 DEG C for 1 hour, and placed into a muffle furnace for gradually heating up to 500 DEG C within 1 hour; presintered after kept constant temperature for 10 min; then entered into a furnace up to 800 - 1120 DEG C for burning for 30 minutes, finally discharged to be naturally cooled down to normal temperature.

Owner:JIANGXI UNIV OF SCI & TECH

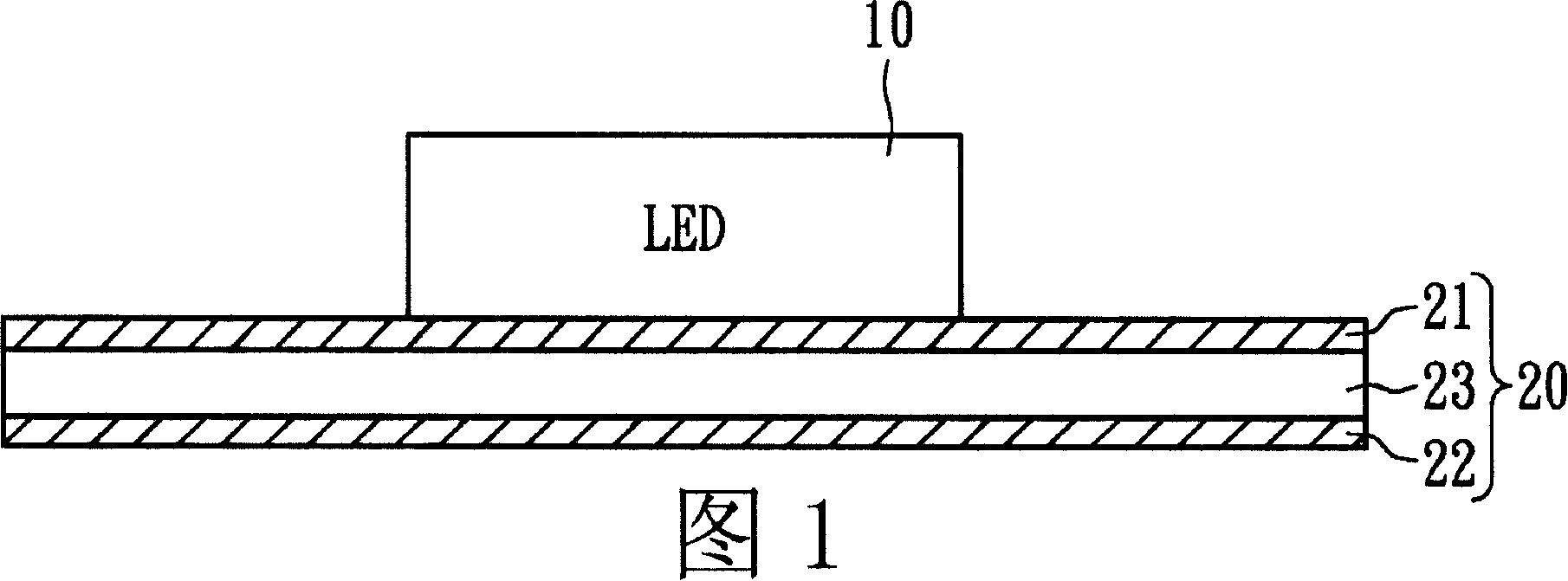

Heat radiation substrate of electronic element

InactiveCN101140915AHigh melting pointNot easy to catch fireSemiconductor/solid-state device detailsSolid-state devicesDielectricHeat conducting

A thermolytic underlay of the electronic component comprises a first metal layer, a second metal layer and a heat-conducting macromolecule dielectric insulated material layer. The said first metal layer surface bears the said electronic component like the LED component. The heat-conducting macromolecule dielectric insulated material layer is lapped between the first and second metal layer to form physical contact, wherein the interface includes at least one slightly rugged face with the roughness concentration larger than 7.0 Rz. The said slightly rugged face includes a plurality of grain diameters of the strumae mainly distributed between 0.1 and 100 micron. The coefficient of heat conductivity of the said heat-conducting macromolecule dielectric insulated material layer is larger than 1W / m is multiplied by K with thickness less than 0.5mm and contains fluorinated high molecular polymer (1) with the melting point higher than 150 degrees centigrade and the volume percent between 40% and 70%, and the heat-conducting stuffing (2) interspersed among the said fluorinated high molecular polymer with the volume percent between 40% and 70%.

Owner:POLYTRONICS TECH

Method of fracturing using ultra lightweight proppant suspensions and gaseous streams

ActiveUS7913762B2Increase the areaMinimize damageFluid removalDrilling compositionHydraulic fracturingVolume percent

In a method of hydraulically fracturing a hydrocarbon-bearing subterranean formation, a proppant stage is introduced into the fracture which contains a gaseous fluid and an ultra lightweight proppant suspended in a viscosified aqueous fluid. The gaseous fluid of the proppant stage contains at least about 90 volume percent of the combination of gaseous fluid and aqueous fluid. A pad fluid may first be introduced into the formation, the pad fluid containing a gaseous fluid and, optionally, an aqueous fluid. The gaseous fluid of the pad fluid mixture typically contains at least 70 volume percent of the mixture.

Owner:BAKER HUGHES INC

Electrically conductive cermet and method of making

An electrically conducting cermet comprises at least one transition metal element dispersed in a matrix of at least one refractory oxide selected from the group consisting of yttria, alumina, garnet, magnesium aluminum oxide, and combinations; wherein an amount of the at least one transition metal element is less than 15 volume percent of the total volume of the cermet. A device comprises the aforementioned electrically conducting cermet.

Owner:GENERAL ELECTRIC CO

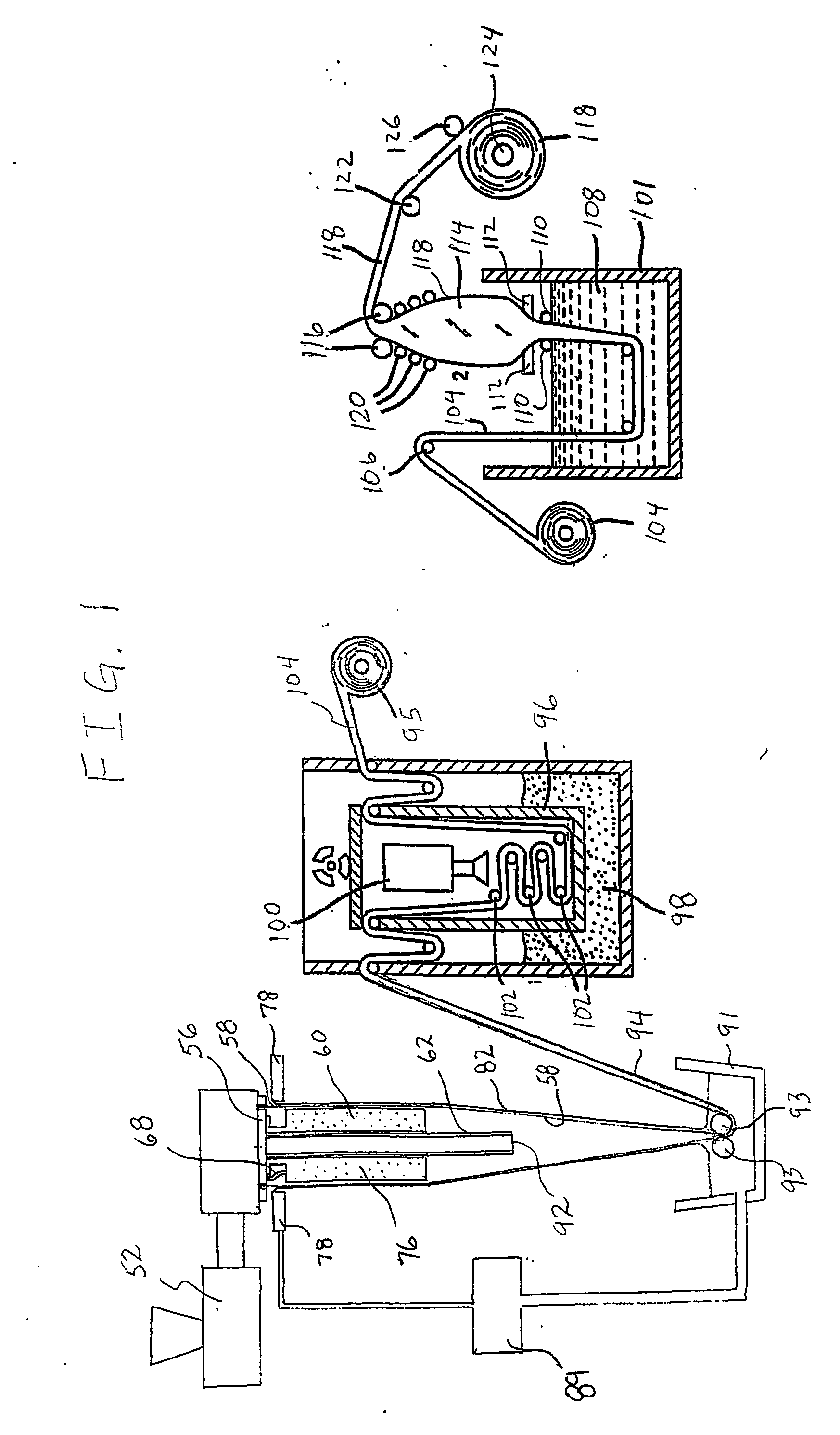

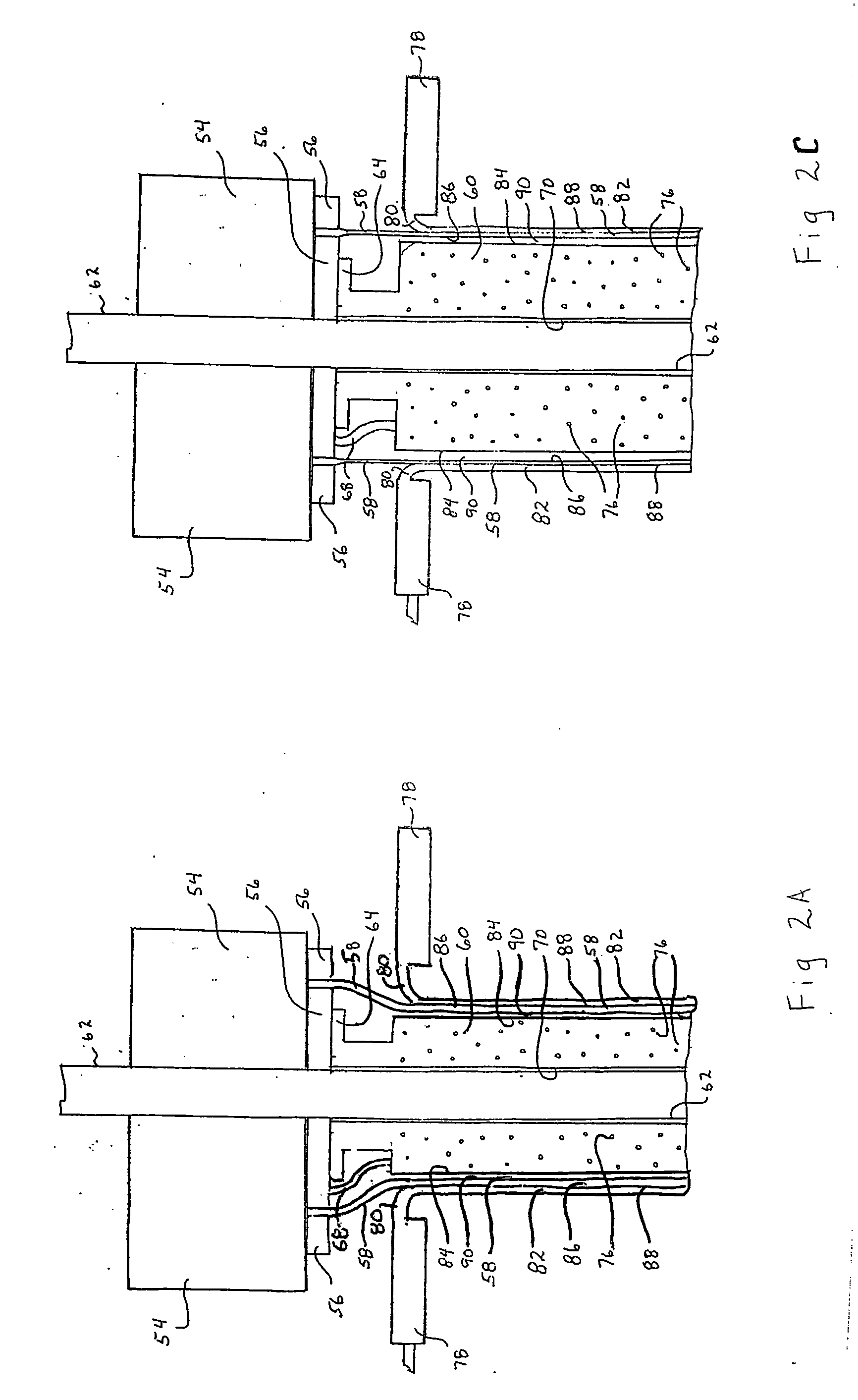

Process for making shrink film comprising rapidly-quenched semi-crystalline polyamide

ActiveUS20080179780A1Good orientationSimple processHollow filament manufactureSynthetic resin layered productsPolyamideQuenching

As a first aspect, the present invention is directed to a process for making a heat-shrinkable annular film, comprising: (A) extruding an annular extrudate downward from an annular die; (B) quenching the annular extrudate by applying a quenching liquid to the annular extrudate; (C) reheating the extrudate to an orientation temperature of from 130° F. to 210° F., resulting in a reheated annular extrudate; and (D) orienting the reheated annular extrudate while the reheated annular extrudate is in the solid state, the orientation being carried out with a total orientation factor of at least 2, so that the resulting oriented, heat-shrinkable film has a total free shrink at 185° F. of at least 10 percent. The extrudate comprises at least one semi-crystalline polyamide selected from the group consisting of: (i) polyamide 6, (ii) polyamide 66, (iii) polyamide 6 / 66, and (iv) polyamide 6 / 12. The semi-crystalline polyamide makes up at least 5 volume percent of the annular extrudate. At least 50% of the quenching liquid cascades down the annular extrudate for a distance of at least 2 inches. The quenching liquid makes initial contact with the annular extrudate within 0.1 to 8 inches of the annular die.

Owner:CRYOVAC INC

Lightweight compositions and articles containing such

ActiveUS20100088984A1Construction materialLayered productsCompressive strengthUltimate tensile strength

A lightweight cementitious composition containing from 22 to 90 volume percent of a cement composition and from 10 to 78 volume percent of particles having an average particle diameter of from 0.2 mm to 8 mm, a bulk density of from 0.03 g / cc to 0.64 g / cc, an aspect ratio of from 1 to 3, where after the lightweight cementitious composition is set it has a compressive strength of at least 1700 psi as tested according to ASTM C39. The cementitious composition can be used to make concrete masonry units, construction panels, road beds and other articles and can be included as a layer on wall panels and floor panels and can be used in insulated concrete forms. Aspects of the lightweight cementitious composition can be used to make lightweight structural units.

Owner:SYNTHEON HLDG SPA

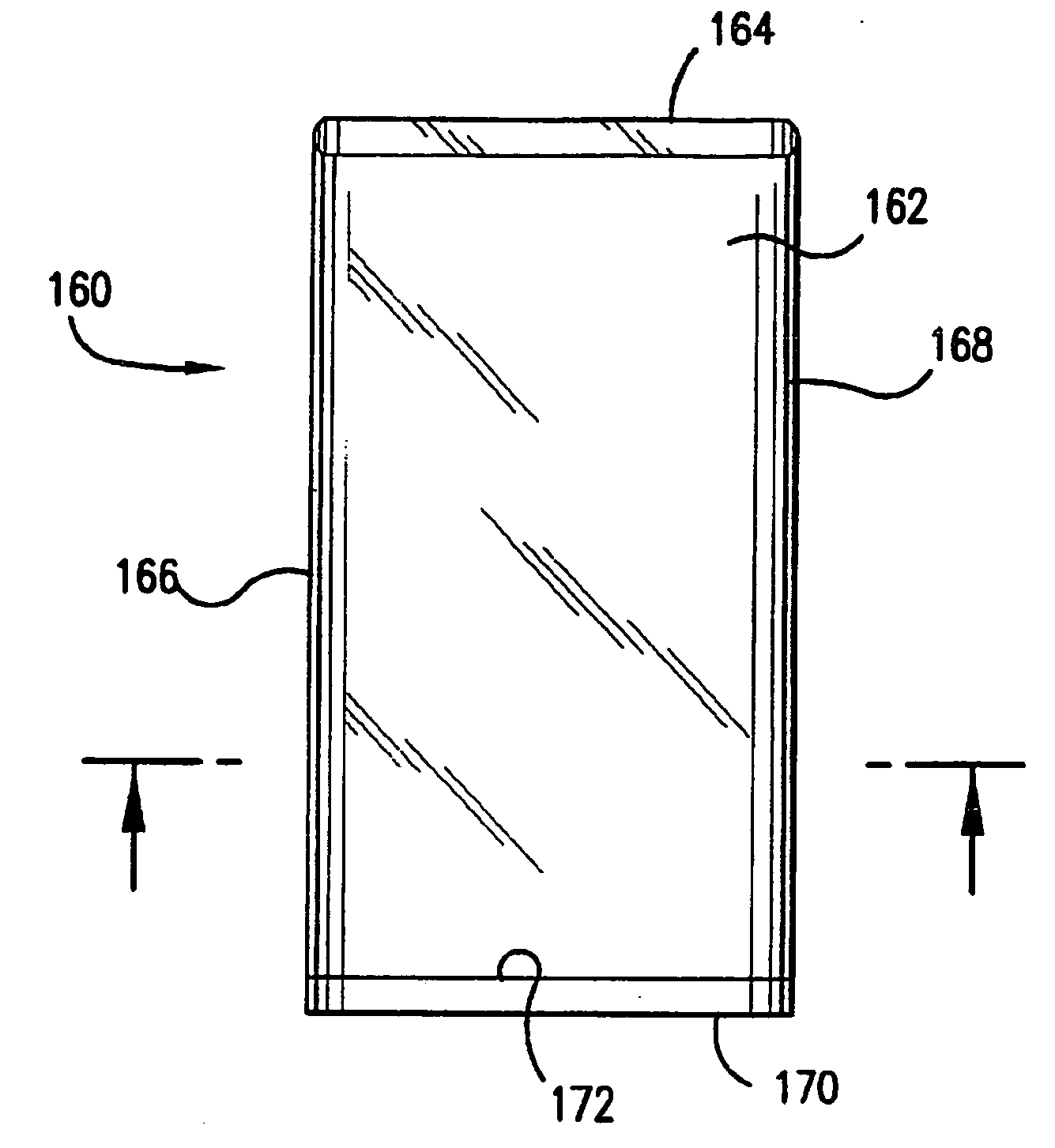

Abradable dry powder coatings on piston assembly components

InactiveUS20070071990A1Increase volumeLow costLiquid surface applicatorsLayered productsVolume percentPowder coating

An abradable dry powder coating composition (20) for coating onto a piston assembly component (12) for subsequent curing to form into an abradable coating, including a powder (16) formed of uncured thermoset resin with at least 5 volume percent filler, wherein the filler does not substantially melt below the cure temperature of the resin. Method for making and coating the coating composition includes melt-mixing the thermoset resin with at least 5 volume percent of filler, cooling the resulting mass composite, and then breaking the cooled mass composite into powder particles (16). Method of coating an article with an abradable coating includes applying the dry composite powder with the filler therein onto the piston assembly component and curing the dry powder composition, preferably by electrostatic powder coating.

Owner:SUMAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com