Patents

Literature

1377results about How to "Low refractive index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanocomposites

ActiveUS7068898B2Increase percentageEfficiently waveguidedSolar heating energyMaterial nanotechnologyNanowireNanoparticle

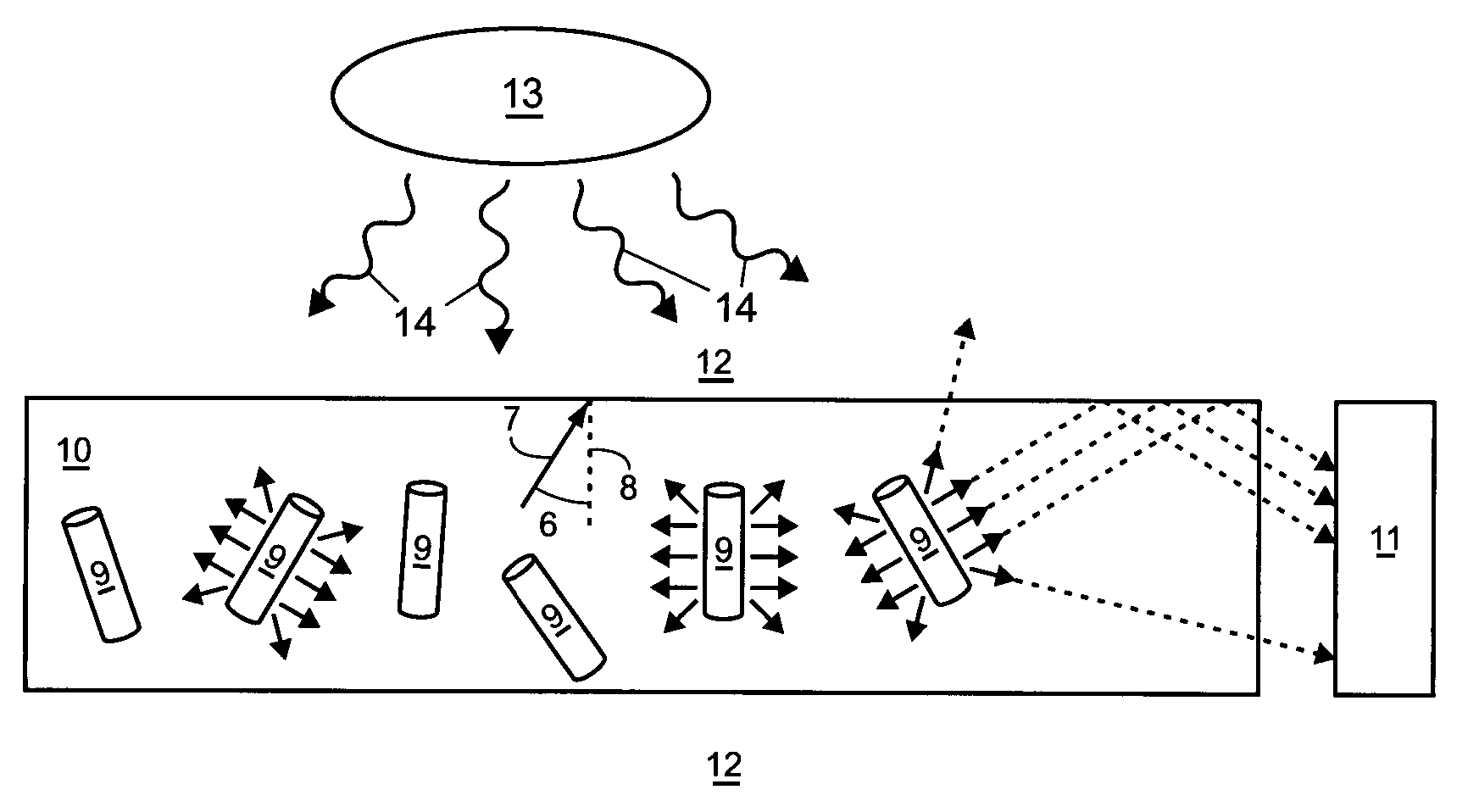

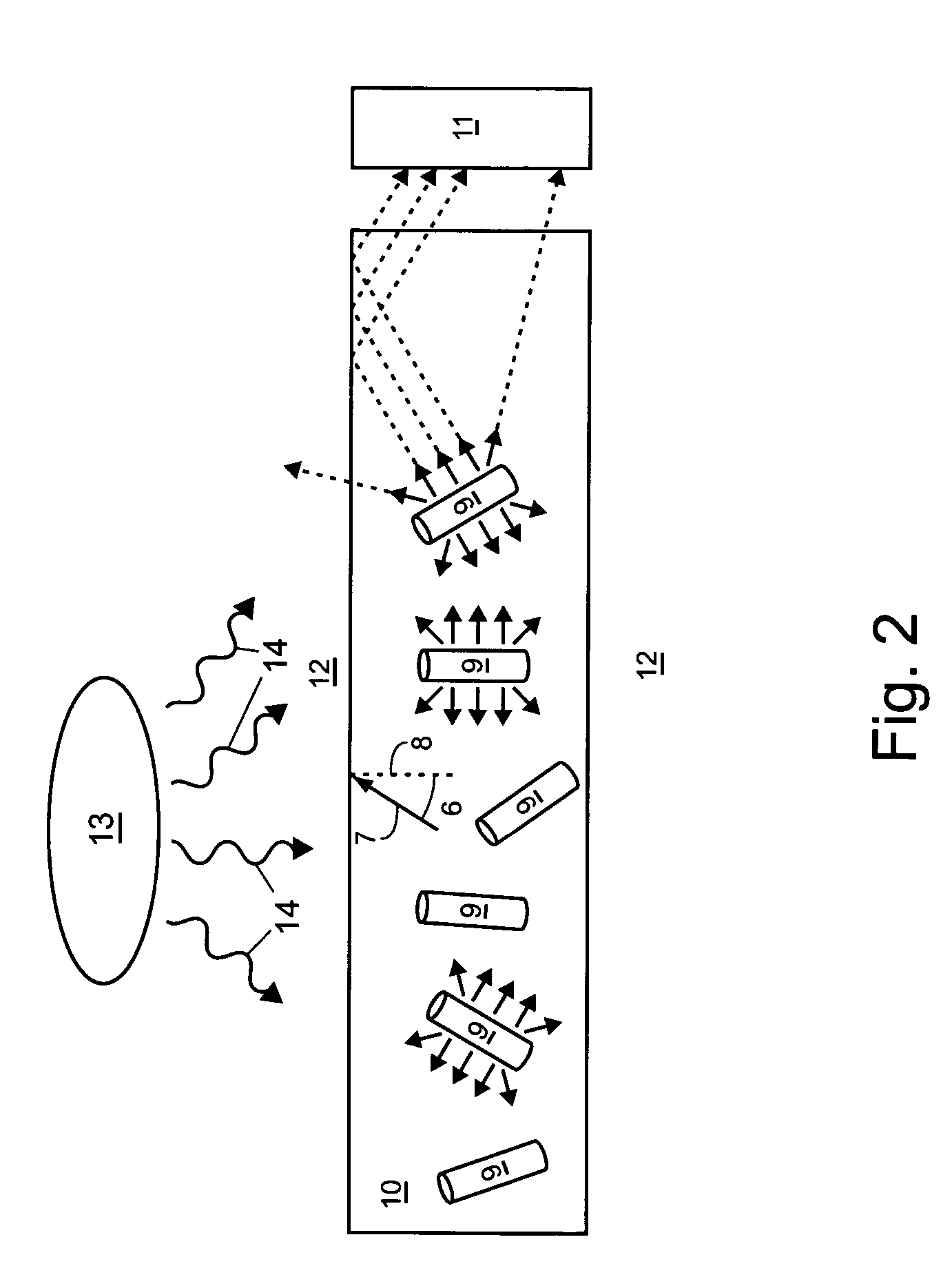

This invention provides composite materials comprising nanostructures (e.g., nanowires, branched nanowires, nanotetrapods, nanocrystals, and nanoparticles). Methods and compositions for making such nanocomposites are also provided, as are articles comprising such composites. Waveguides and light concentrators comprising nanostructures (not necessarily as part of a nanocomposite) are additional features of the invention.

Owner:ONED MATERIAL INC

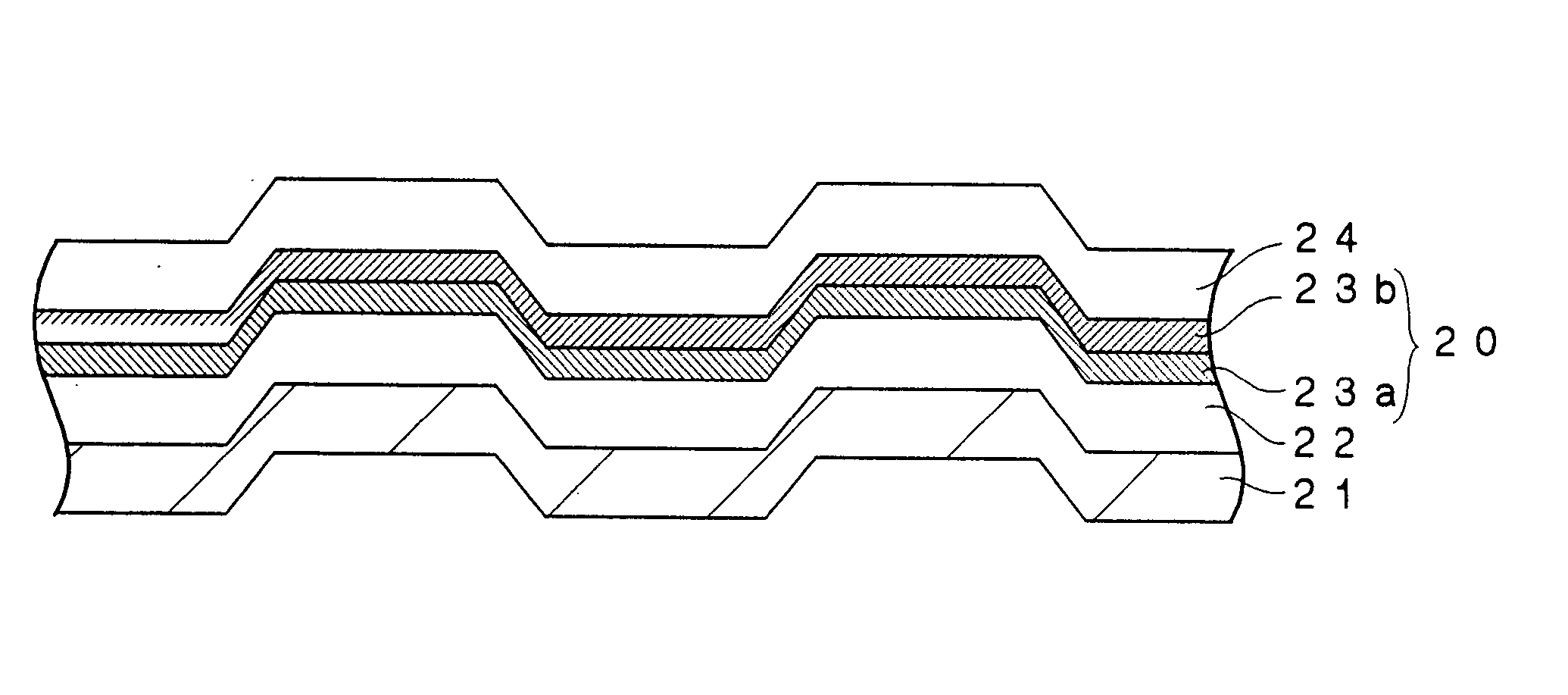

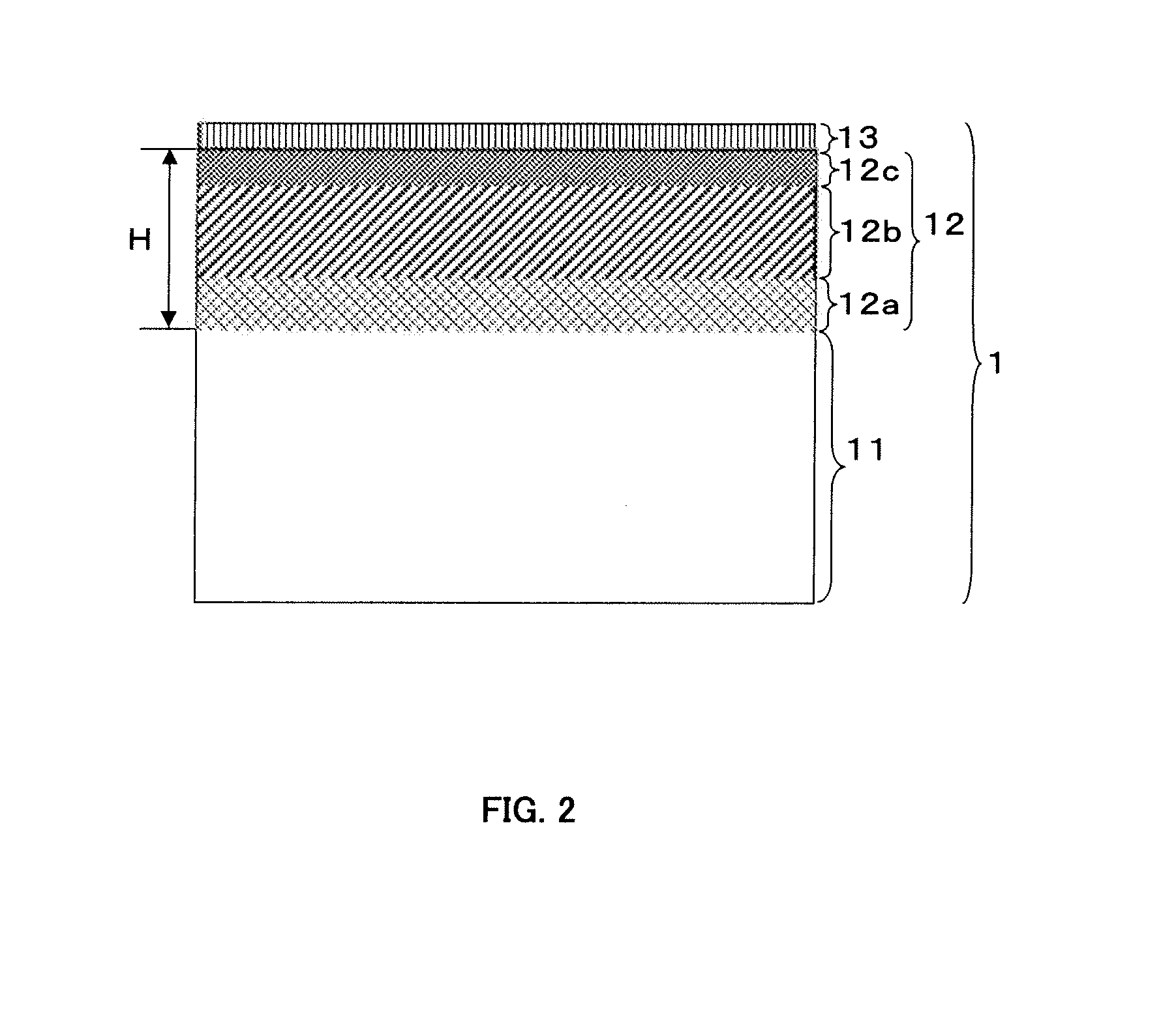

Photovoltaic device having multilayer antireflective layer supported by front substrate

InactiveUS20090032098A1Reduce reflectionConvenient coatingCoatingsPhotovoltaic energy generationRefractive indexLength wave

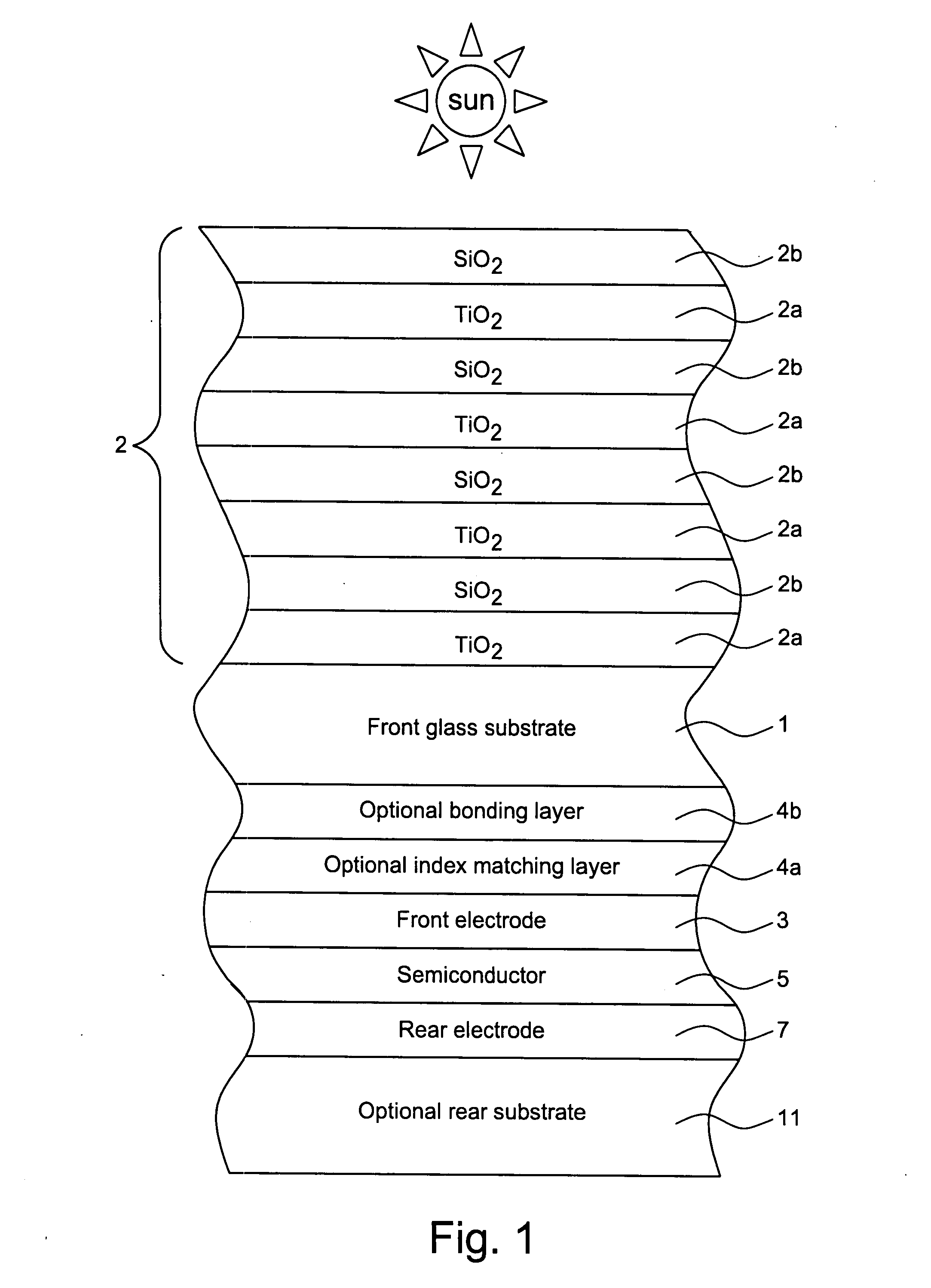

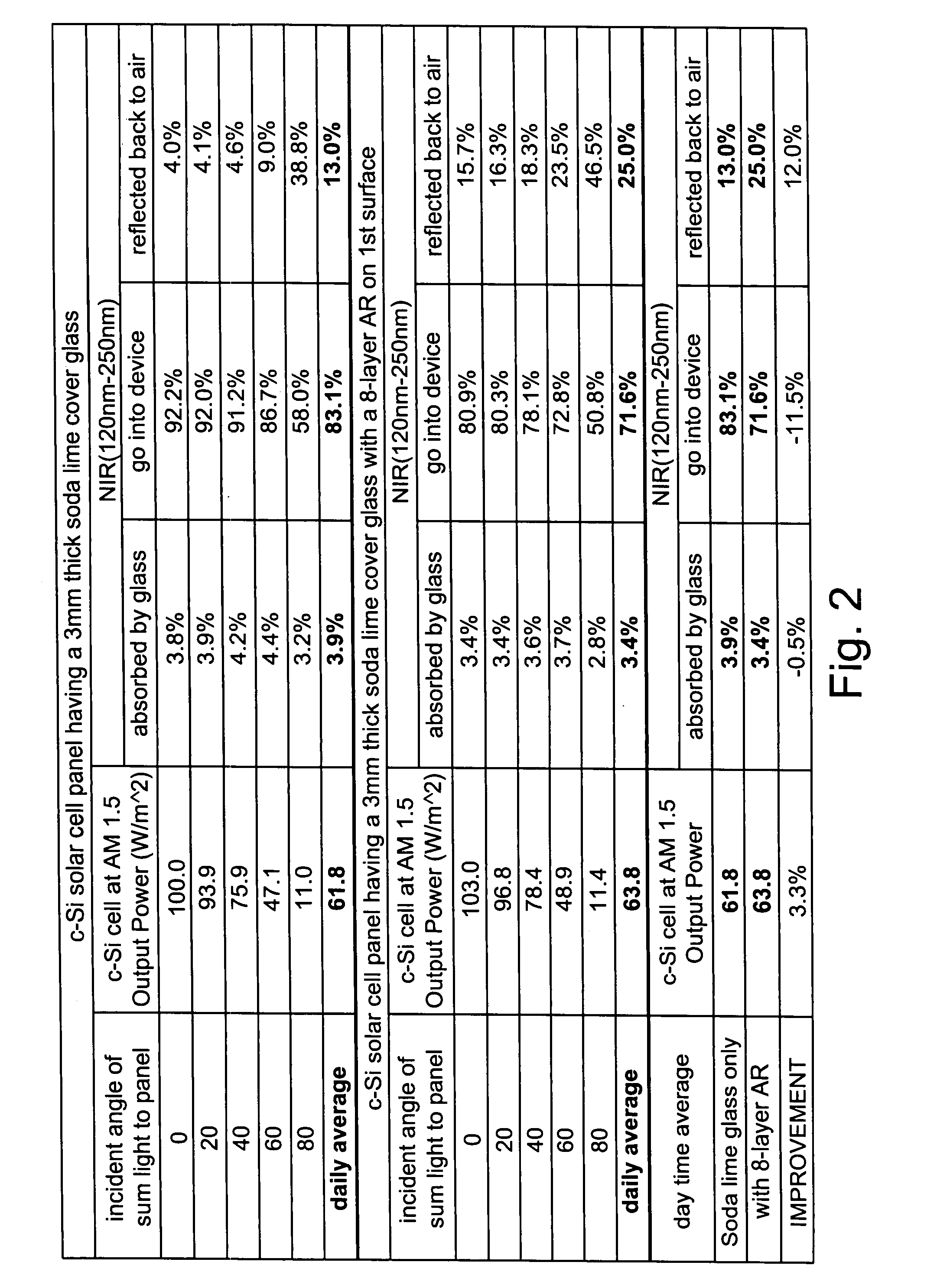

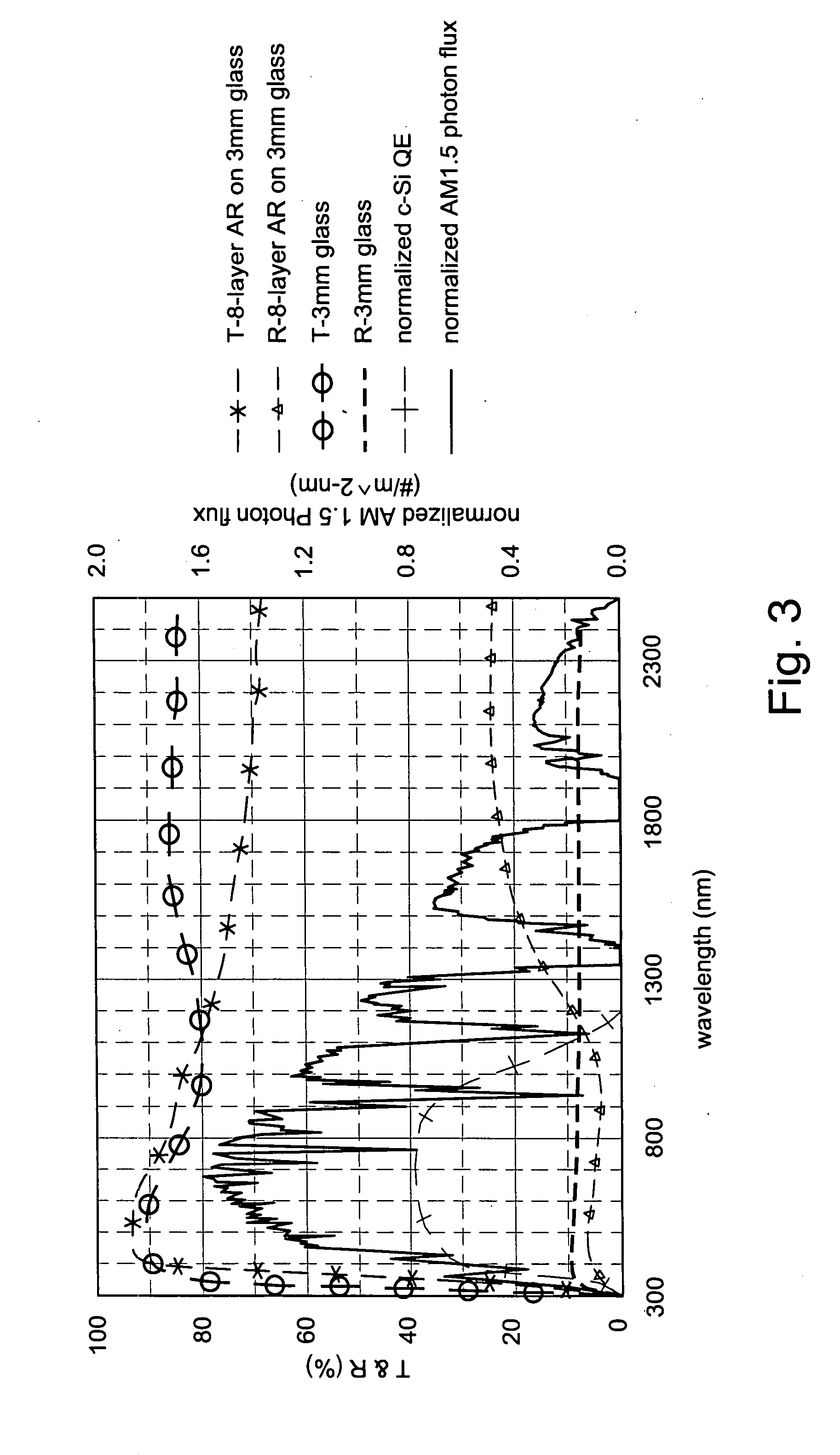

In certain embodiments of this invention, an improved multilayer anti-reflection (AR) coating is provided on the exterior surface of the front glass substrate of a photovoltaic device. This AR coating functions to reduce reflection of desirable wavelengths from the front glass substrate, thereby allowing more light within the desirable solar spectrum to pass through the incident glass substrate and reach the photovoltaic semiconductor film so that the photovoltaic device can operate more efficiently. Also, the AR coating can reduce the amount of undesirable light (e.g., at least some IR and / or UV radiation) which reaches the semiconductor film of the device. In certain example embodiments, the multilayer AR coating includes a plurality of pairs of alternating high refractive index and low refractive index layers.

Owner:GUARDIAN GLASS LLC

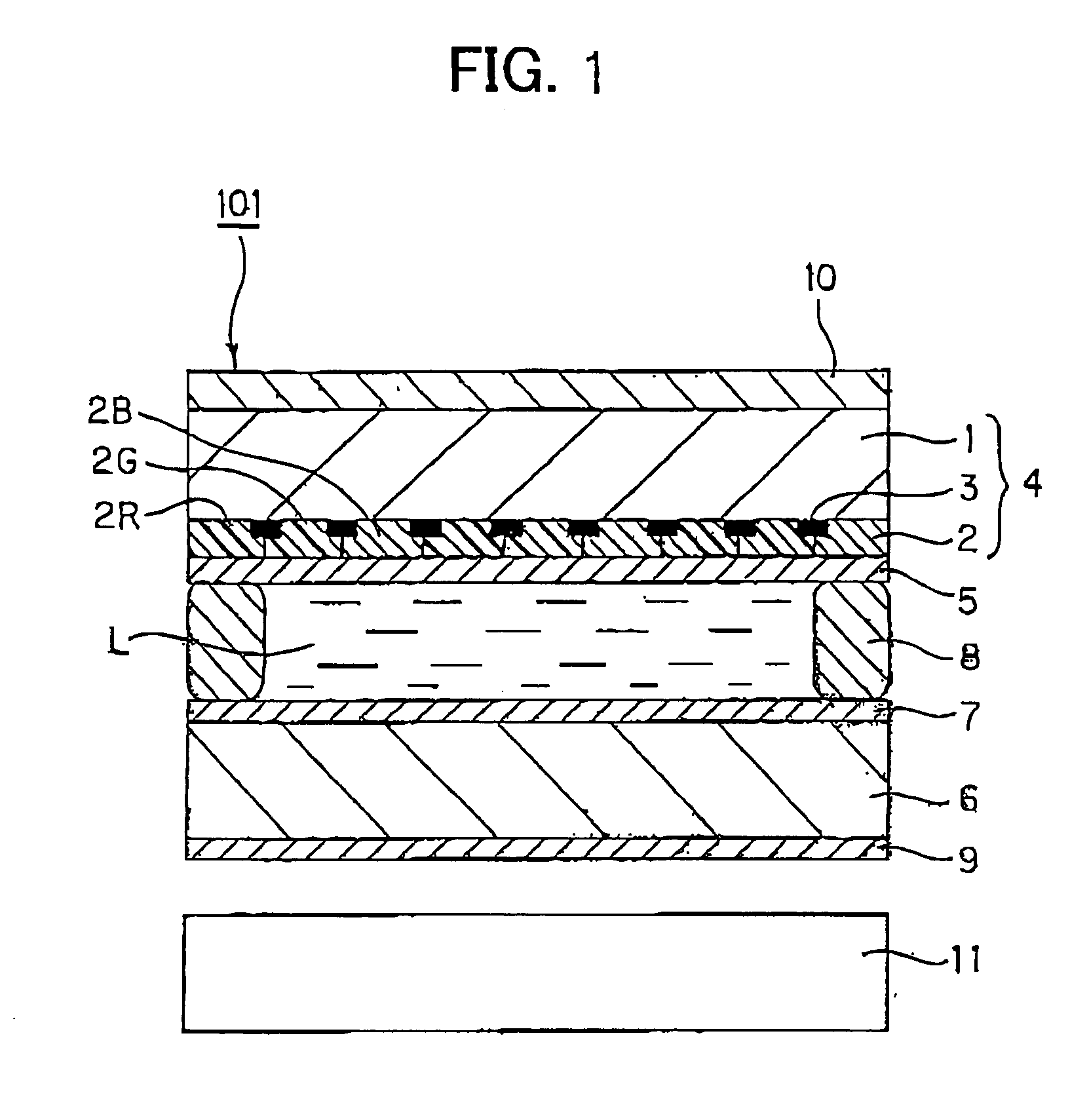

Anti-reflection film, polarizing plate comprising the same, and image display device using the anti-reflection film or the polarizing plate

InactiveUS6917400B2Suitable for mass productionGood staminaPolarising elementsCoatingsDisplay deviceRefractive index

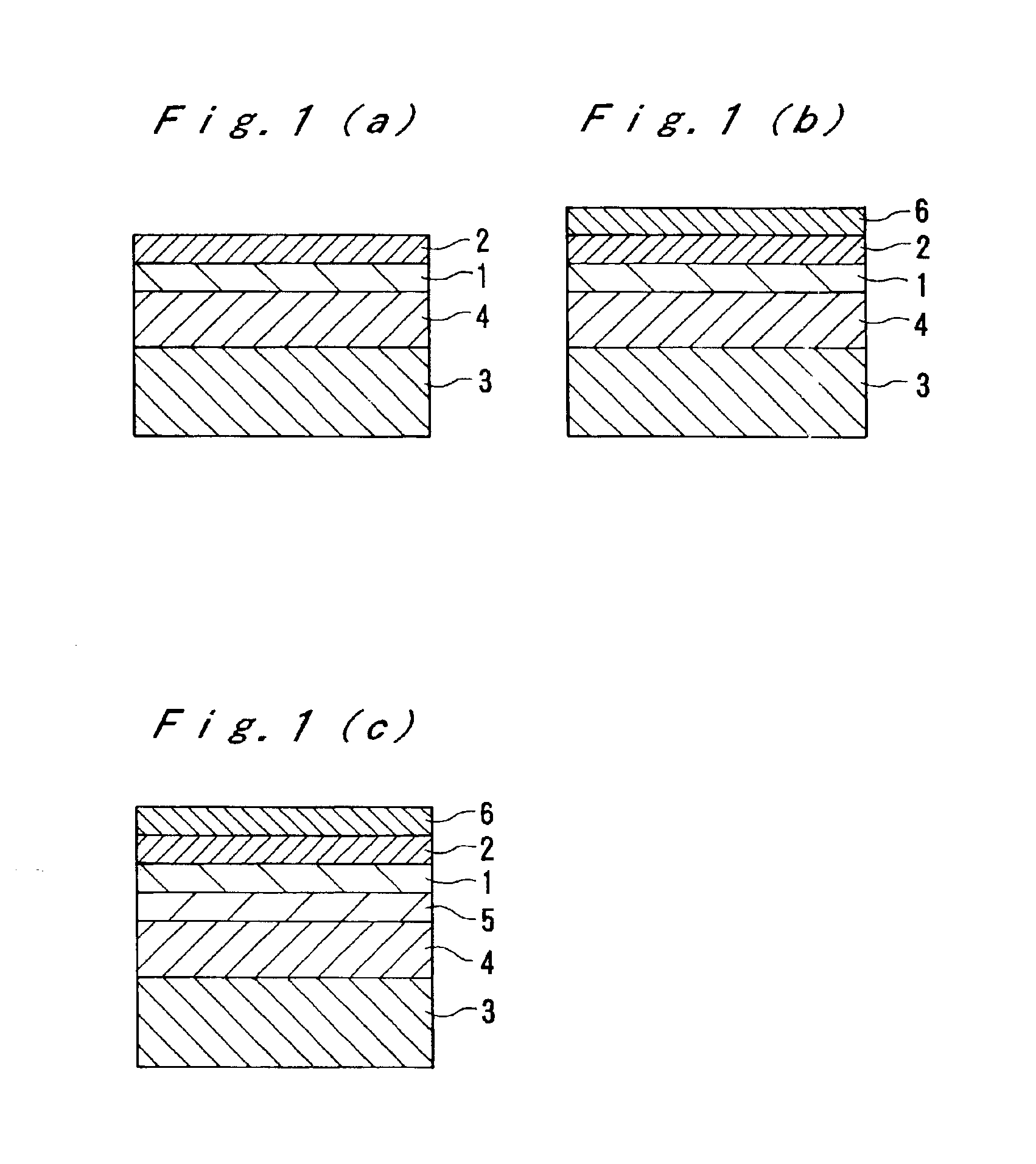

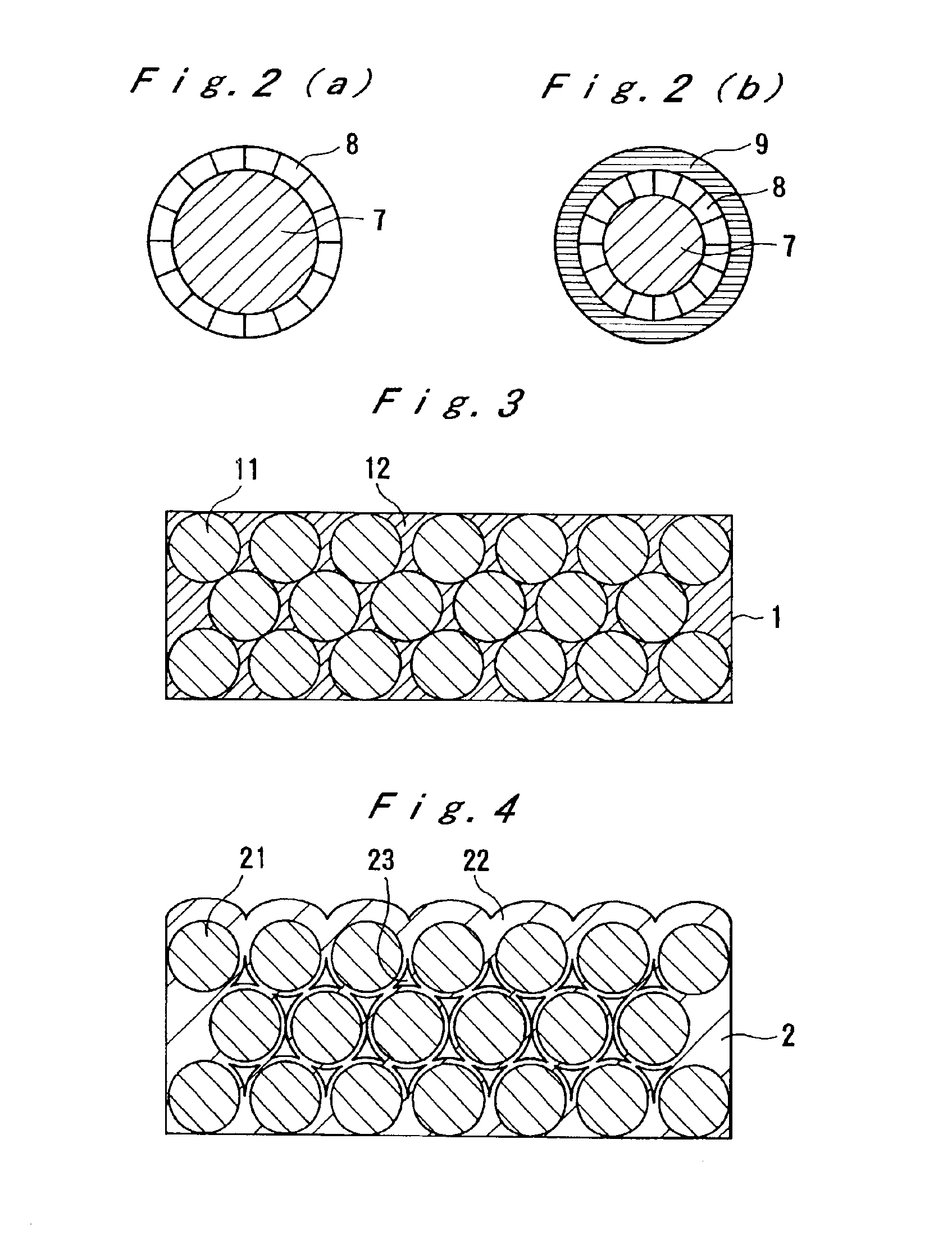

There is disclosed an anti-reflection film comprising 5-65% by volume of inorganic fine particles having an average particle size of 1-200 nm and having a core / shell structure, and 35-95% by volume of a polymer, wherein a high-refractive-index layer having a refractive index of 1.65-2.40 and a low-refractive-index layer having a refractive index of 1.30-1.55 are laminated. There is also disclosed a polarizing plate and image display device utilizing the anti-reflection film. The anti-reflection film is suitable for mass production.

Owner:FUJIFILM CORP

Antireflection laminate

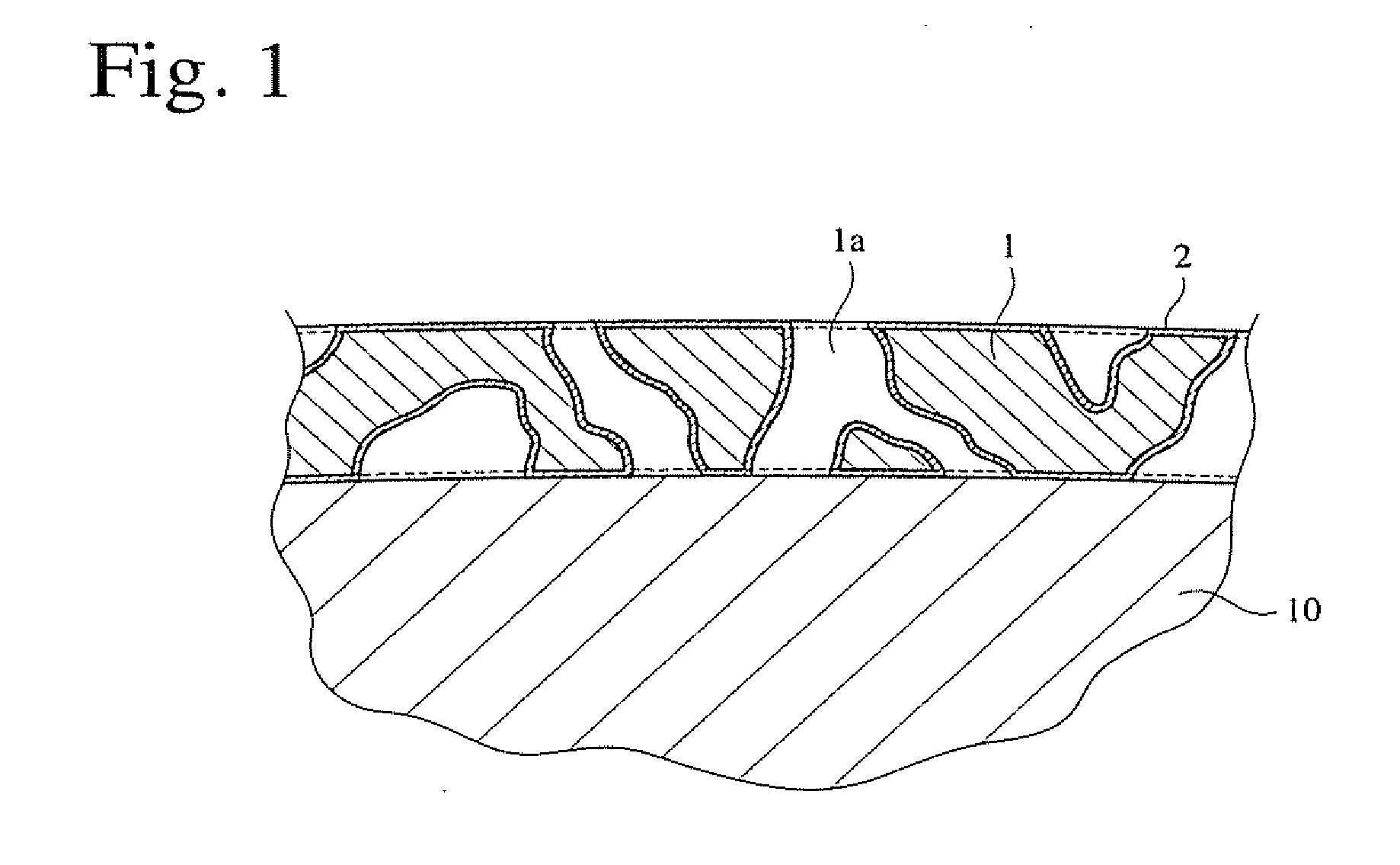

InactiveUS20060269733A1Improve mechanical strengthLow refractive indexSynthetic resin layered productsPretreated surfacesPolymer chemistryRefractive index

There is provided an antireflective laminate having a low refractive index and excellent mechanical strength, which comprises a coating layer of an ionizing radiation curing-type resin composition comprising ionizing radiation curing group-containing hollow silica fine particles. The antireflective laminate comprises a light transparent base material and at least a low refractive index layer having a refractive index of not more than 1.45 provided on the light transparent base material, wherein the low refractive index layer comprises an ionizing radiation curing-type resin composition and silica fine particles having an outer shell layer with the interior of the silica fine particles being porous or void, and, for a part or all of the silica fine particles, at least a part of the surface of the silica fine particle has been treated with an ionizing radiation curing group-containing silane coupling agent.

Owner:JGC CATALYSTS & CHEM LTD +1

Low Tg multilayer optical films

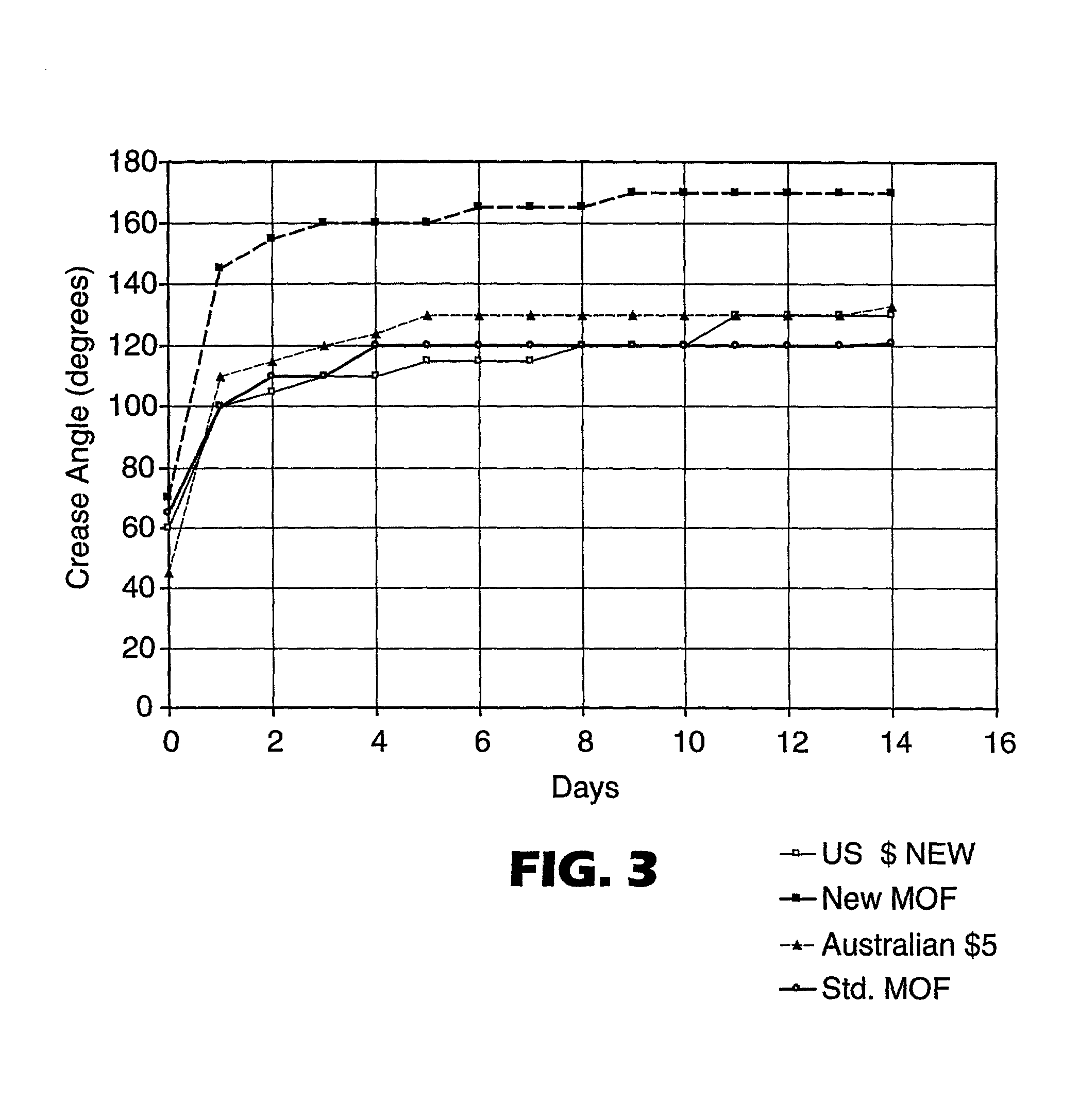

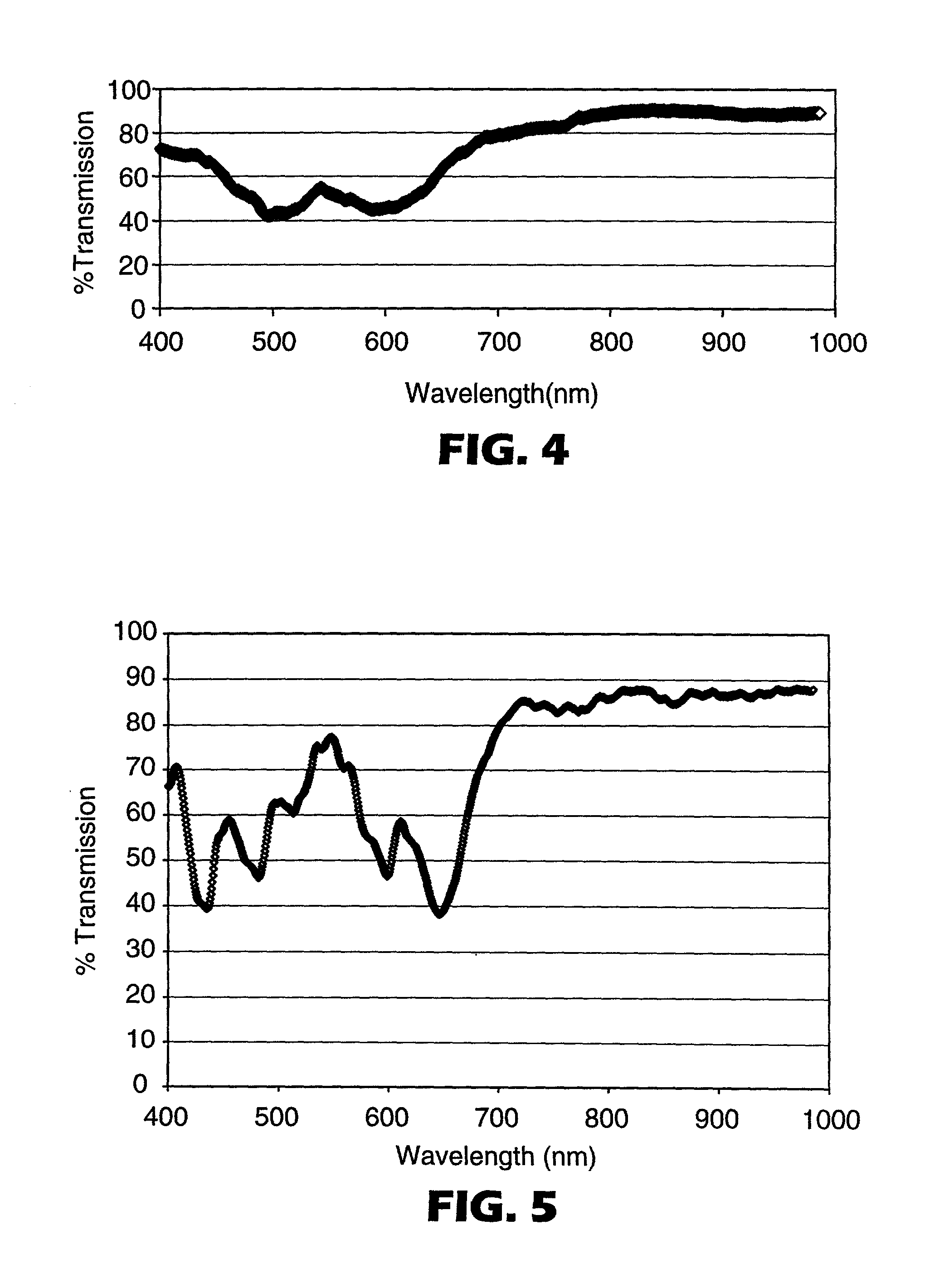

InactiveUS20030072931A1Fine creaseExcellent crumple recoveryLayered productsPolarising elementsThermoplasticPliability

Multilayer optical films are comprised of materials with glass transition temperatures below room temperature (<30° C.). The high refractive index polymers are unique in that they exhibit mechanical properties similar to other low Tg semi-crystalline polymers, yet have significant birefringence (>0.05) when strain induced oriented. Novel combinations of comonomers for thermoplastics control the rate of crystallinity for improved processability and flexibility, giving the films crease and crumple recovery advantages.

Owner:3M INNOVATIVE PROPERTIES CO

Wide field of view monocentric lens system for infrared aerial reconnaissance camera systems

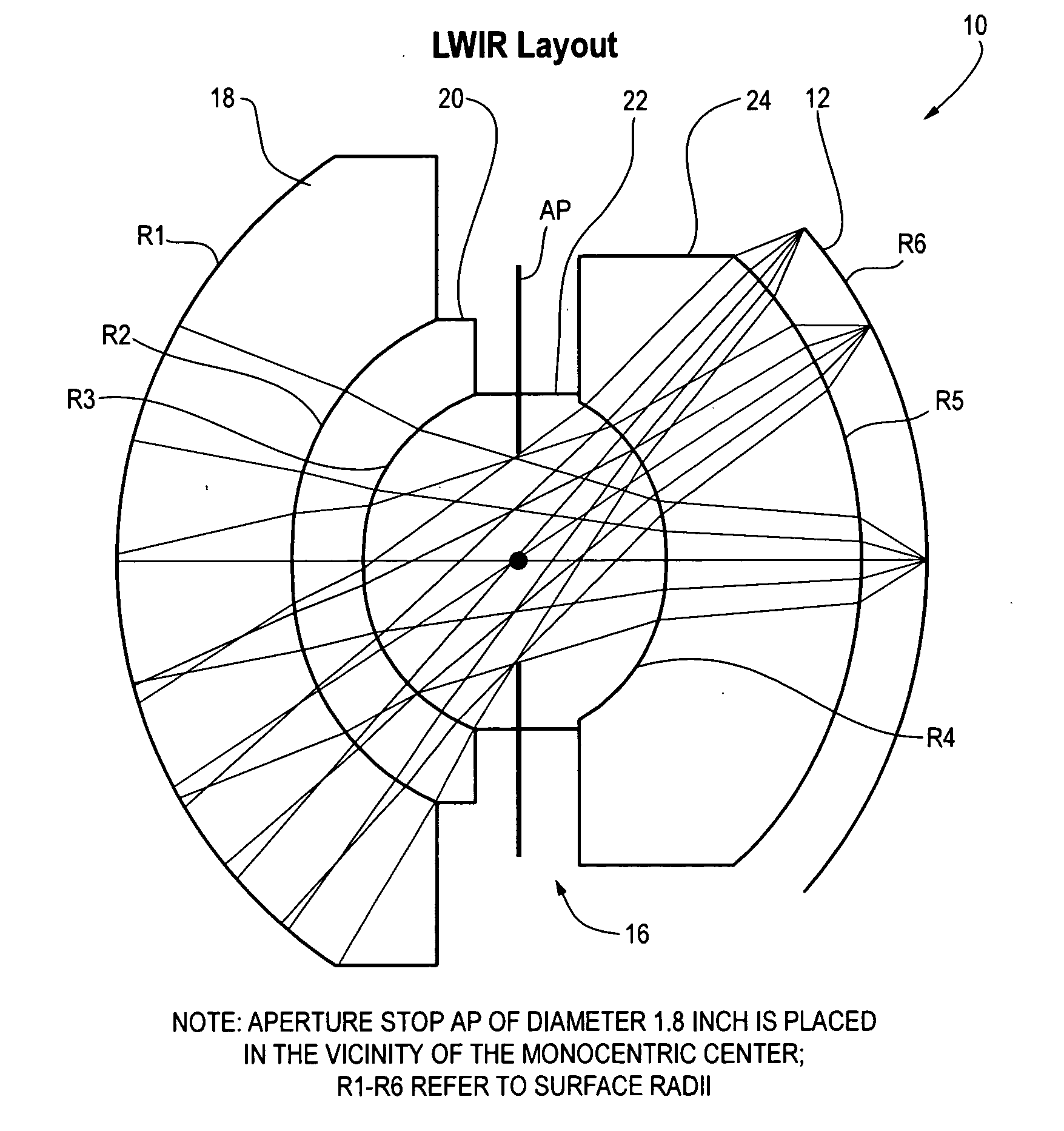

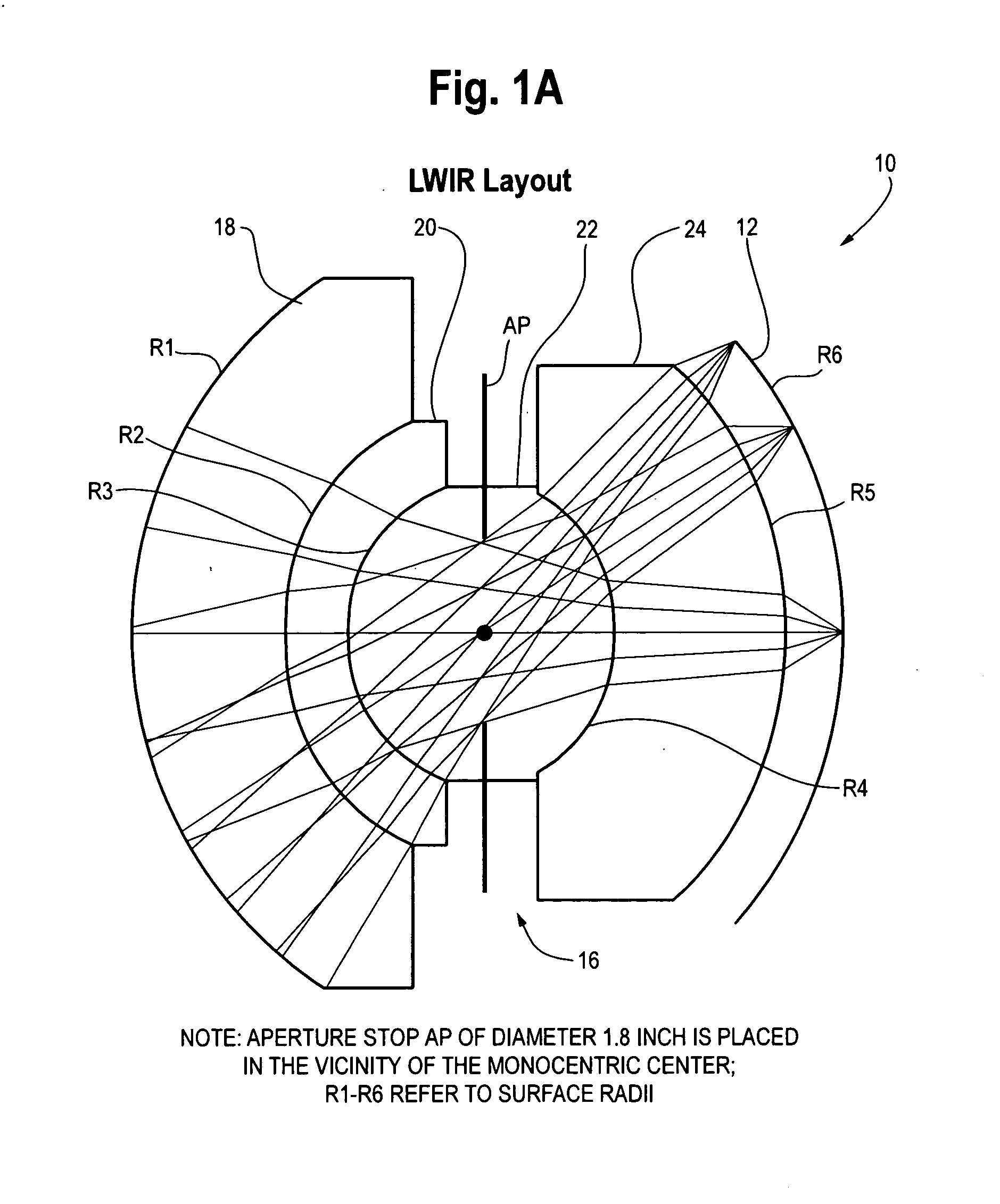

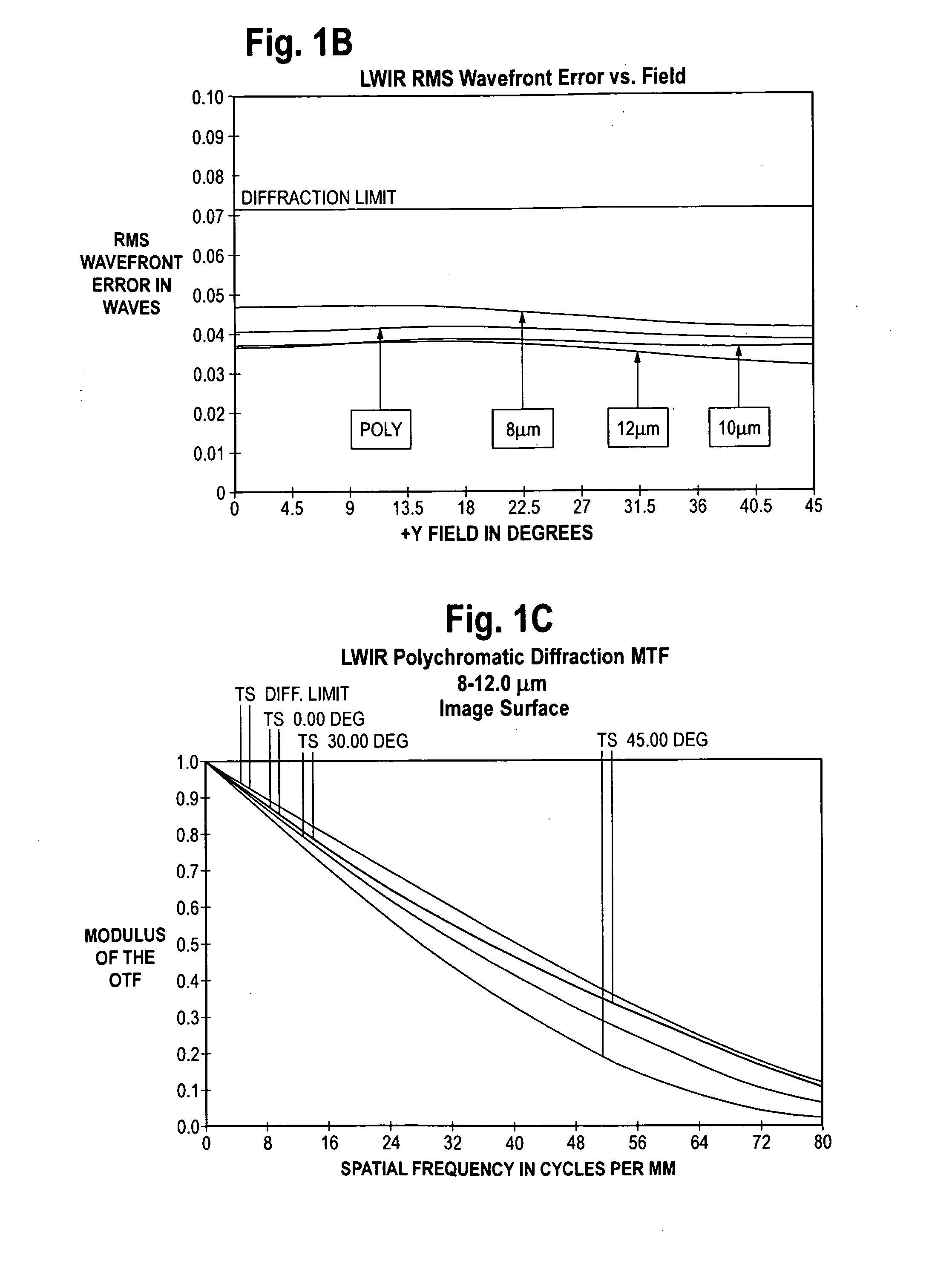

ActiveUS20130076900A1Minimize chromatic aberrationMinimize spherical aberrationTelevision system detailsSolid-state devicesAviationWide field

A wide field of view monocentric lens system for an infrared aerial reconnaissance camera includes front and rear lens shell elements and a core lens element, with the number of front and rear shell lens elements depending on the IR band of interest (LWIR, MWIR or SWIR). Infrared radiation entering the monocentric lens passes sequentially through the front shell lens element(s), the core lens element, and the rear shell lens element(s) and is focused onto a curved focal surface. The front shell lens element(s) and the rear shell lens element(s) are made of material having a relatively higher refractive index or a relatively higher optical dispersion, or both, in the band of interest, as compared to the core lens element.

Owner:THE BF GOODRICH CO

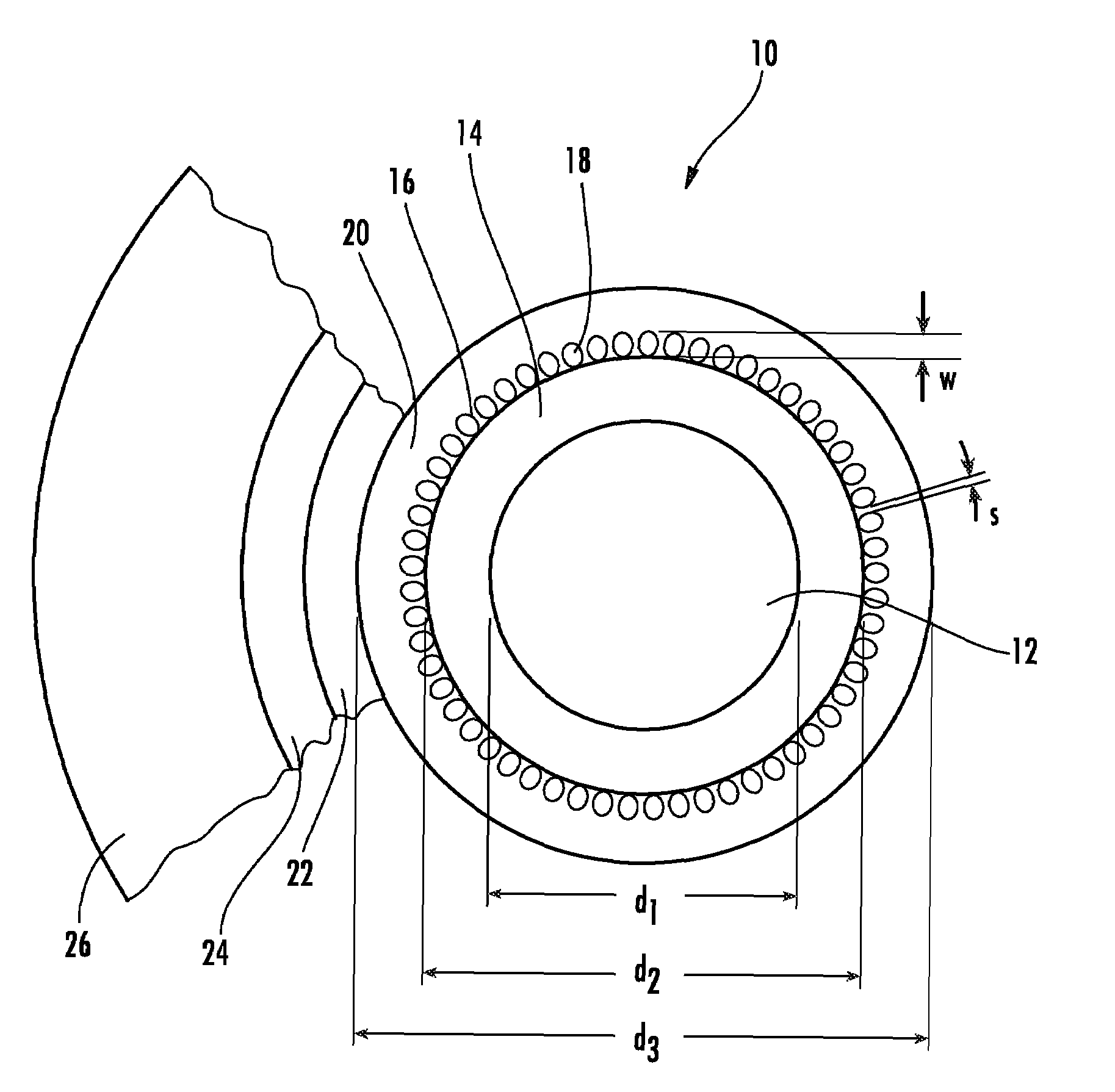

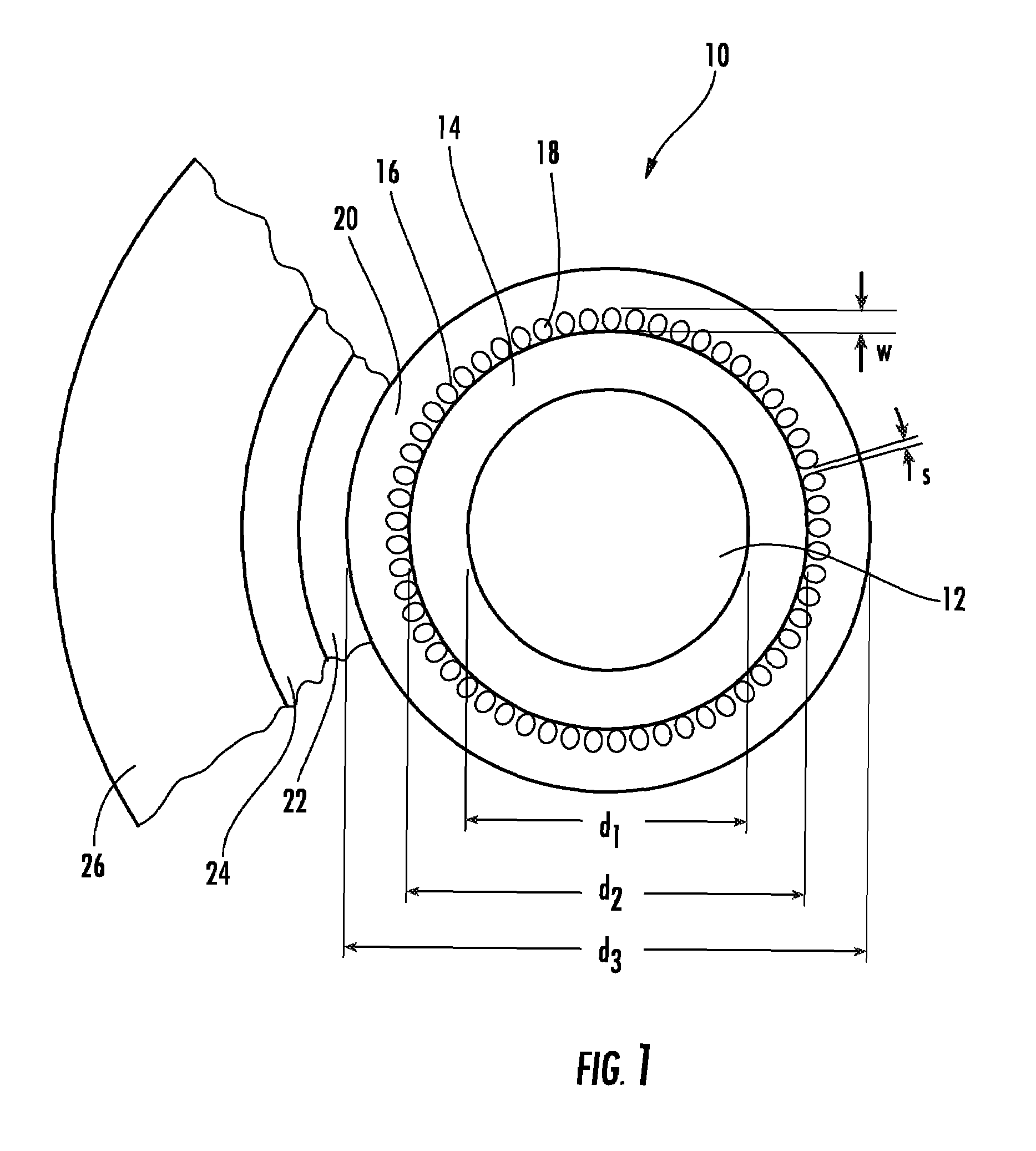

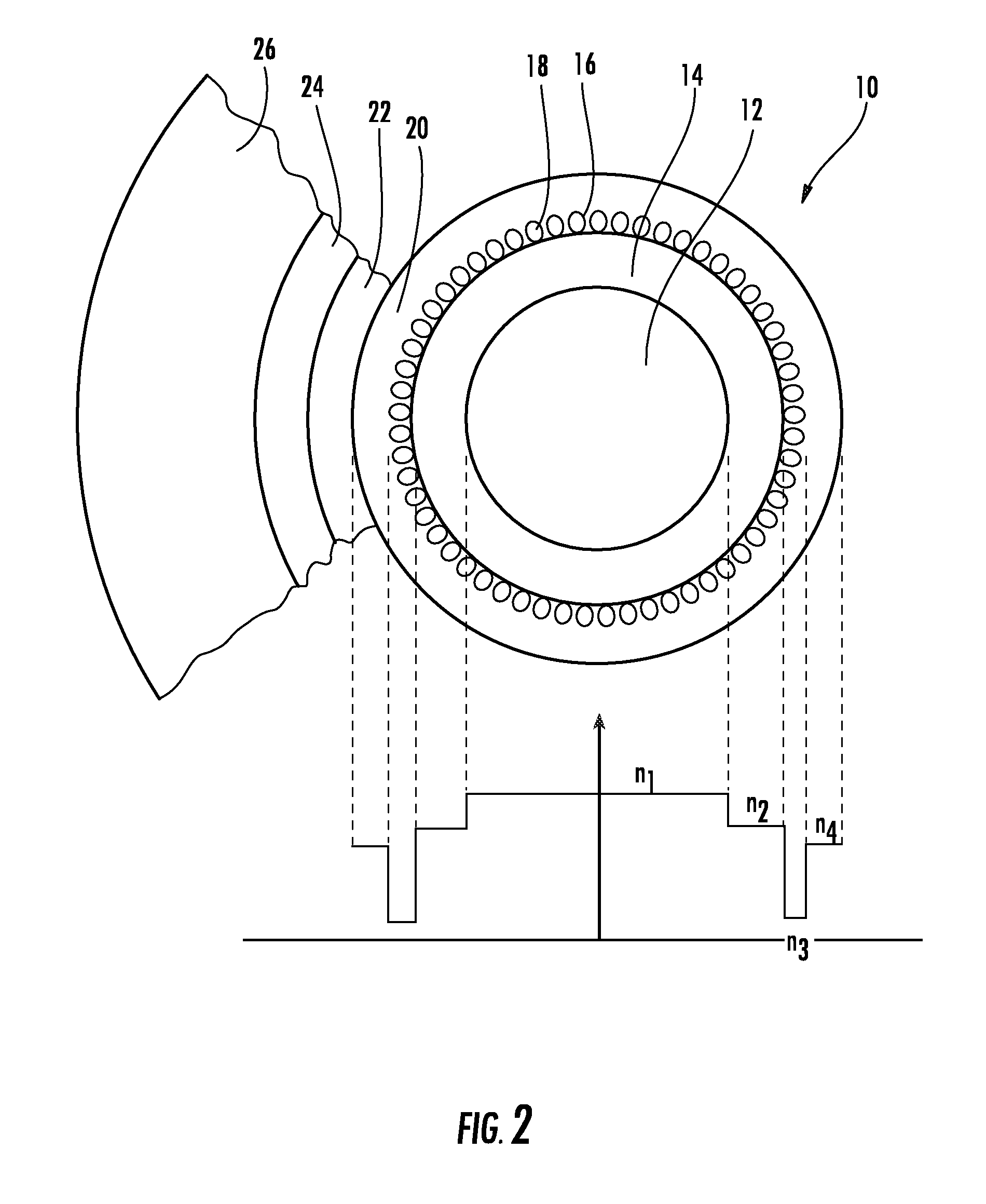

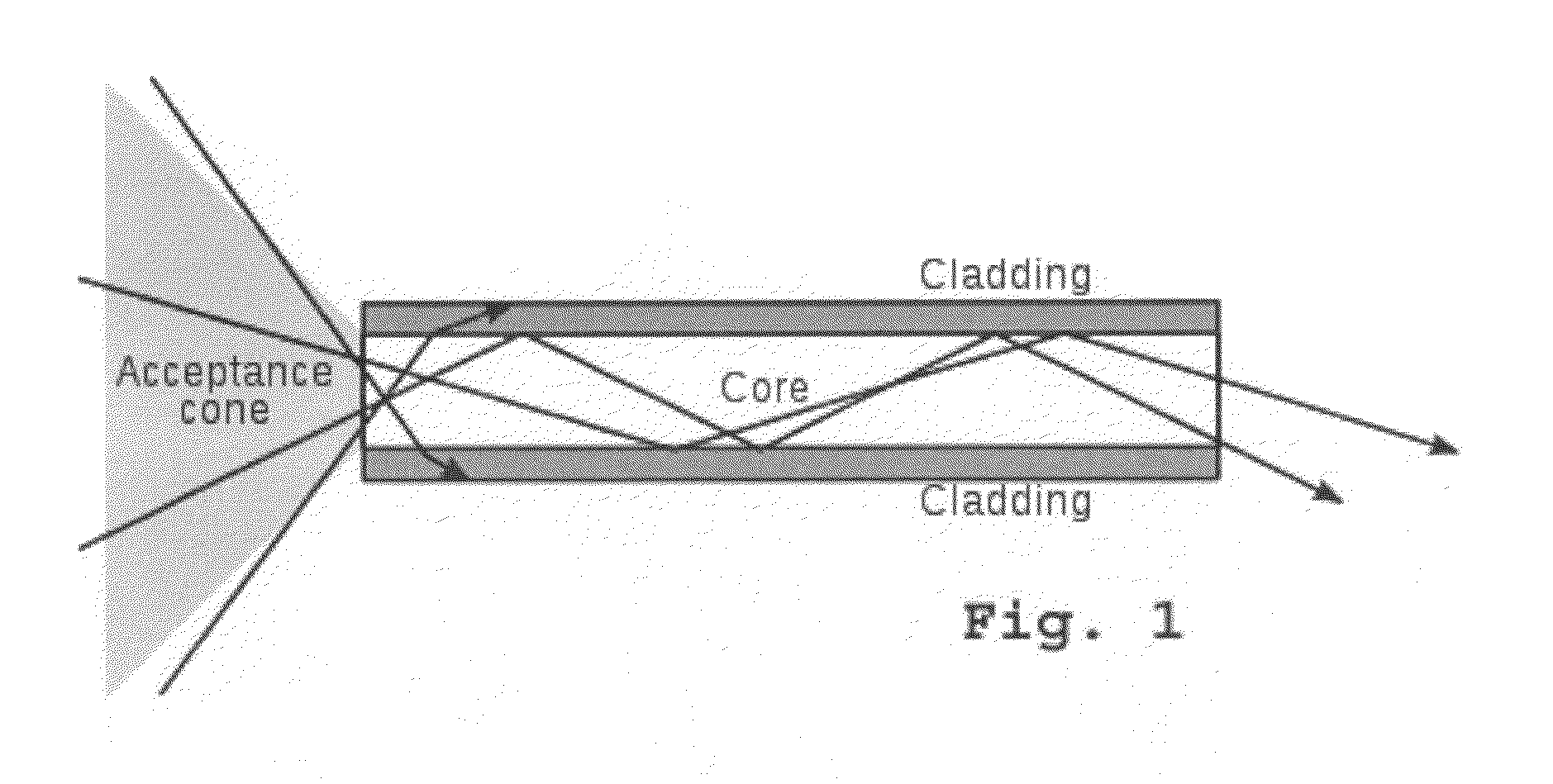

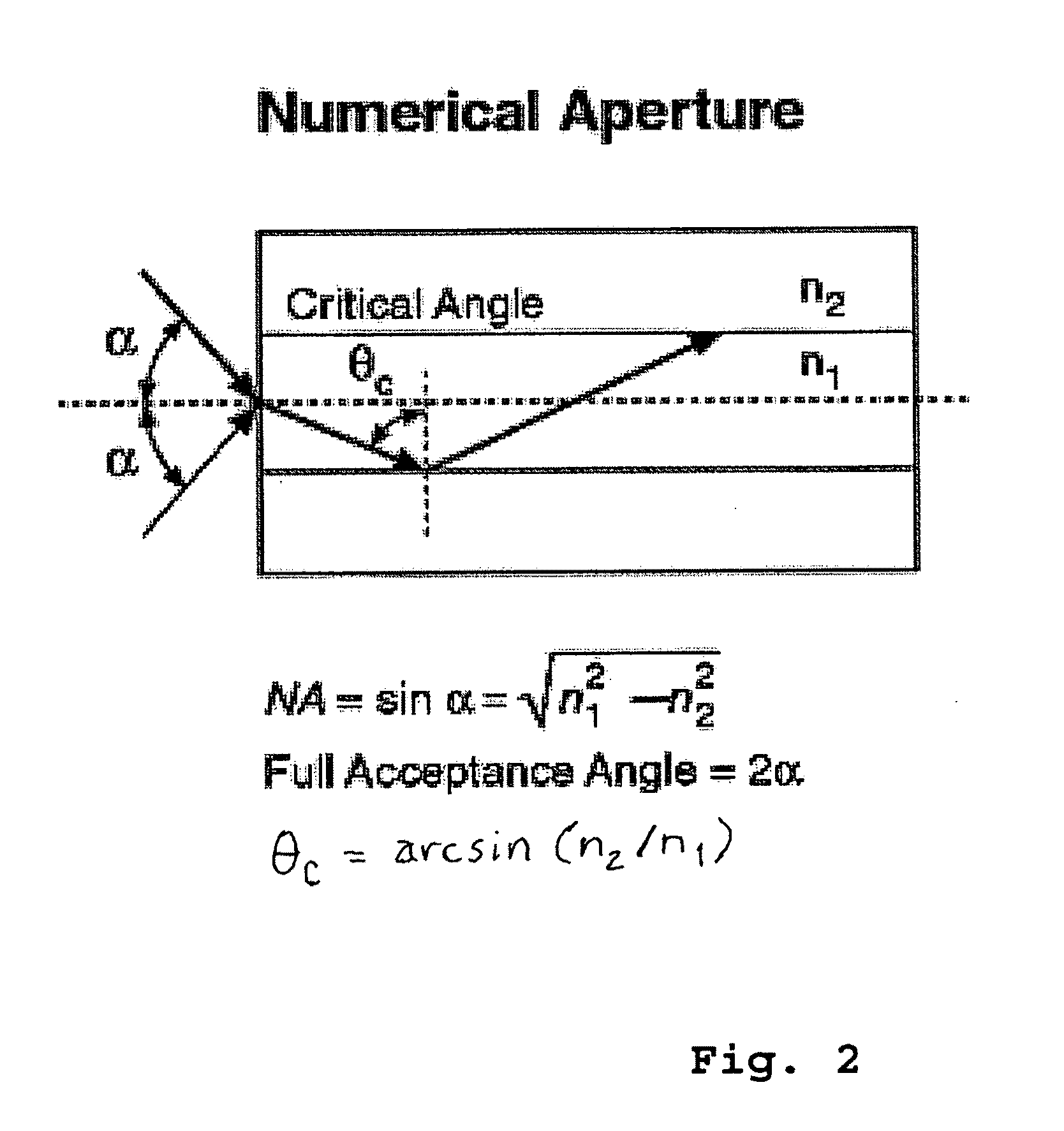

Large mode area fiber for low-loss transmission and amplification of single mode lasers

ActiveUS7283714B1Reliable and cost-effective couplingLarge mode areaLaser using scattering effectsOptical fibre with multilayer core/claddingFiberSingle mode laser

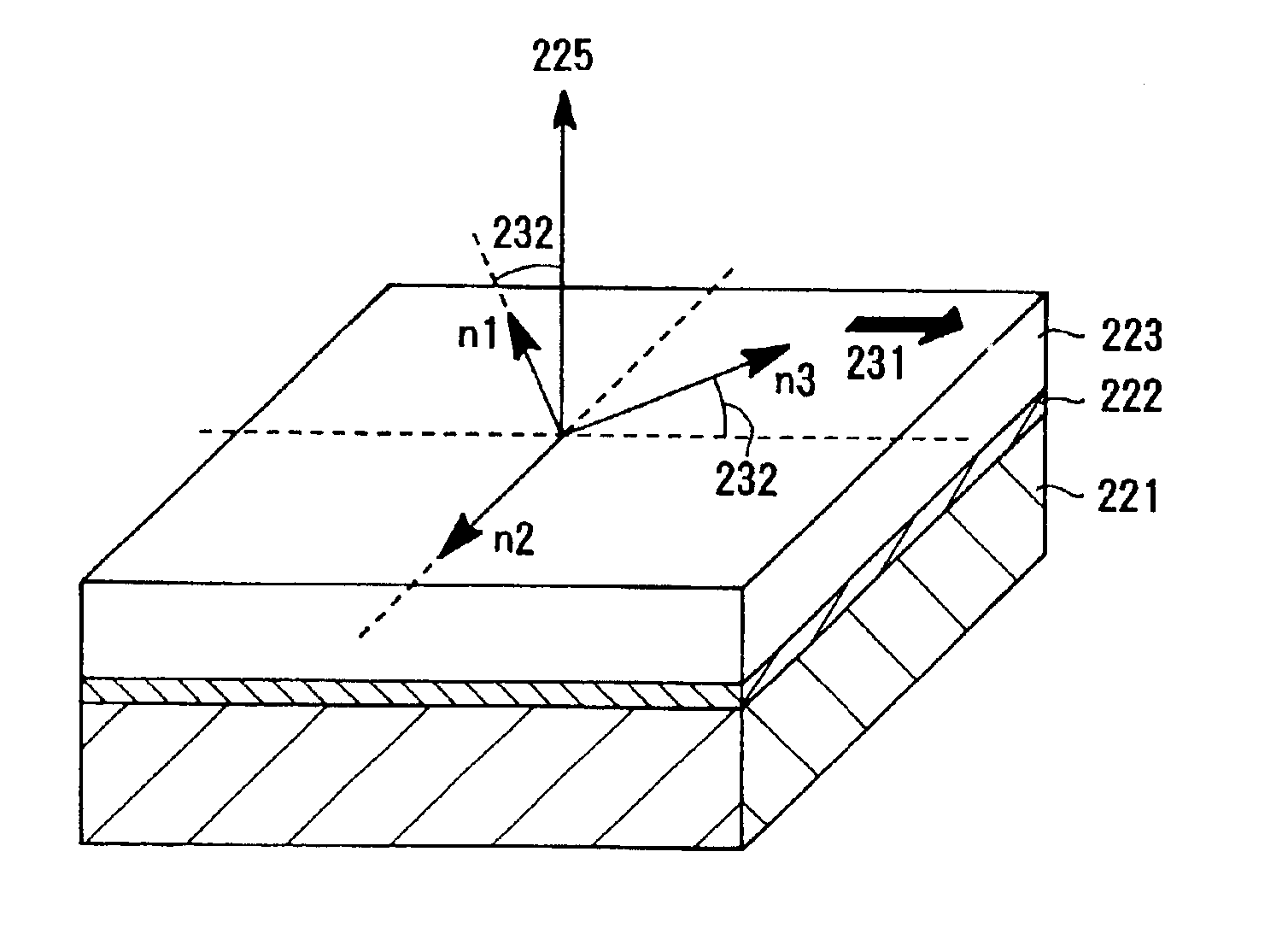

A large mode area optical fiber includes a large diameter core (d1 up to 60 μm), and a first cladding (diameter d2) wherein the difference between refractive index (n1) in the core and the first cladding (n2) is very small (Δn<0.002), thus providing a very low numerical aperture core (NA1 between 0.02 and 0.06). The preferred ratio of d2 / d1<2. The fiber further has a second cladding, preferably a layer of air holes, having a very low refractive index n3 as compared to the core and first cladding such that the first cladding has a relatively high numerical aperture (NA2>0.4) (n3 is preferably less than 1.3). The small change in refractive index between the core and inner cladding combined with a large change in refractive index between the first cladding and second cladding provides a significantly improved single mode holding waveguide.

Owner:IPG PHOTONICS CORP

Nanometer cellulose/polyvinyl alcohol gel composite material

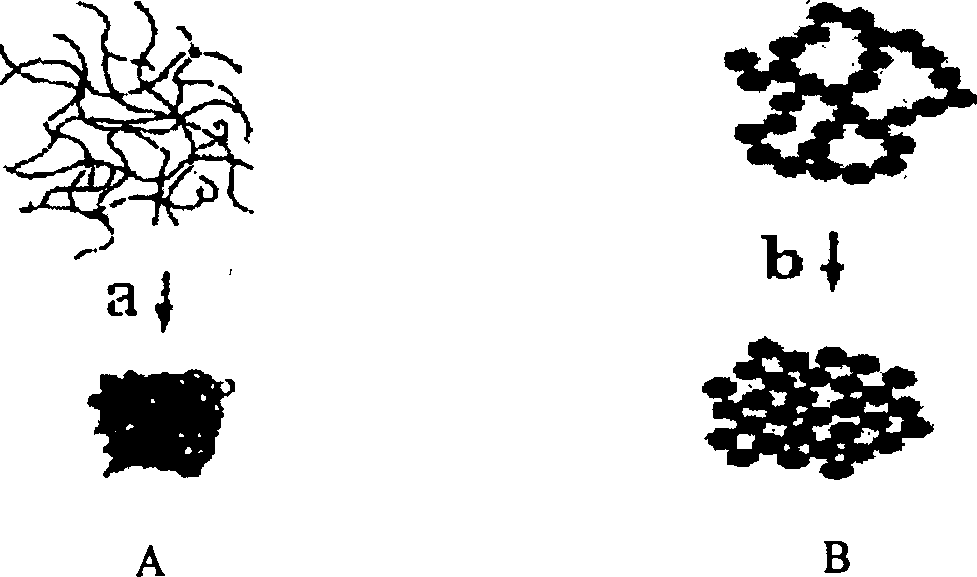

ActiveCN102786642ALarge specific surface areaHigh porosityChemical industryChemical industryPolyvinyl alcohol

The invention relates to a nanometer cellulose / polyvinyl alcohol gel composite material, which is characterized by comprising hydrogel and aerogel. A preparation method of the nanometer cellulose / polyvinyl alcohol gel composite material comprises the following process steps of 1, nanometer cellulose preparation by a chemical combination mechanical treatment method; 2, composite hydrogel preparation; and 3, composite aerogel preparation. The nanometer cellulose / polyvinyl alcohol gel composite material has the advantages that the composite aerogel belongs to a porous amorphous solid material consisting of nanometer level colloid particles or high-polymer molecules, and a unique open nanometer level porous structure and a continuous three-dimensional reticular structure are adopted, so the density is extremely low, the specific surface area is high, and the porosity is high, wherein the solid phase of the aerogel accounts for 0.2 percent to 20 percent of the total volume percentage, the characteristics of high adsorption catalytic capability, low thermal conductivity, low sound resistance, low refractive index and the like are shown, and wide application prospects are realized in the fields of aviation, spaceflight, chemical industry, metallurgy, energy-saving building and the like.

Owner:SHANDONG LVSEN WOOD PLASTIC COMPOSITE

Polymeric optical substrate method of treatment

InactiveUS6156394AImprove adhesionHigh hardnessVacuum evaporation coatingSputtering coatingPretreatment methodOptical coating

A pretreatment method for use in manufacturing an improved optical component comprises (i) providing a polymeric optical substrate; and (ii) exposing the polymeric optical substrate to electromagnetic energy having a wavelength of about 30 nm to about 350 nm. The exposure of the polymeric optical substrate to the electromagnetic energy substantially improves adhesion between the substrate and an optical coating deposited onto the substrate following pretreatment. The invention addresses the significant need for coated plastic optics by providing a method to achieve reliable adhesion of optical coatings placed on polymeric optical substrates. Specifically, this invention enables improved adhesion for even highly curved or shaped parts which have been historically more difficult to coat. The pretreatment method is particularly useful for molded substrates such as molded polymethylmethacrylate.

Owner:JDS UNIPHASE CORP

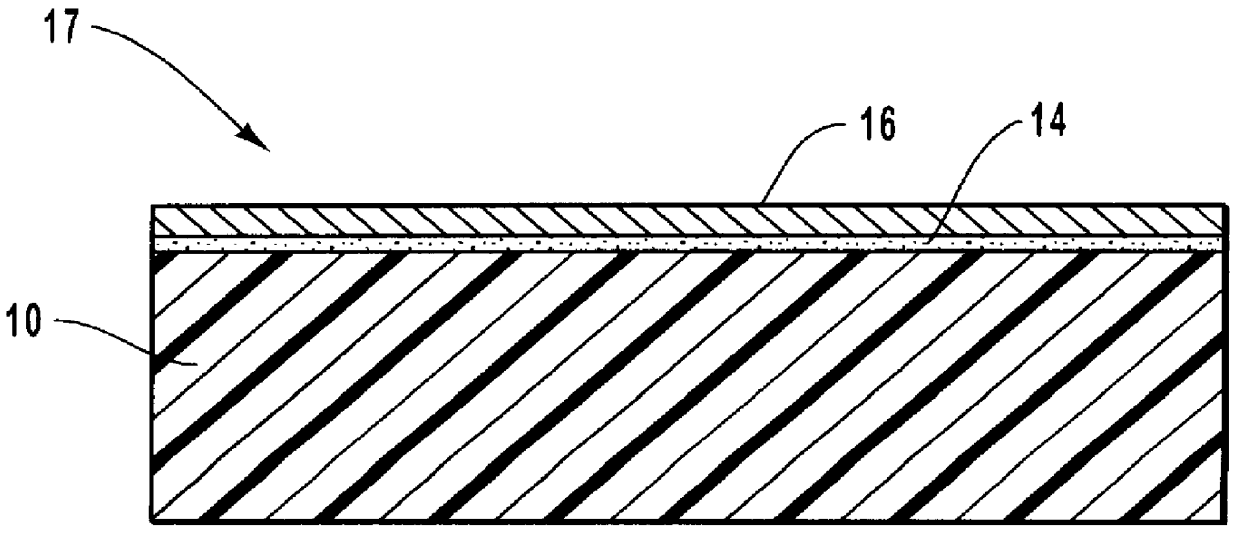

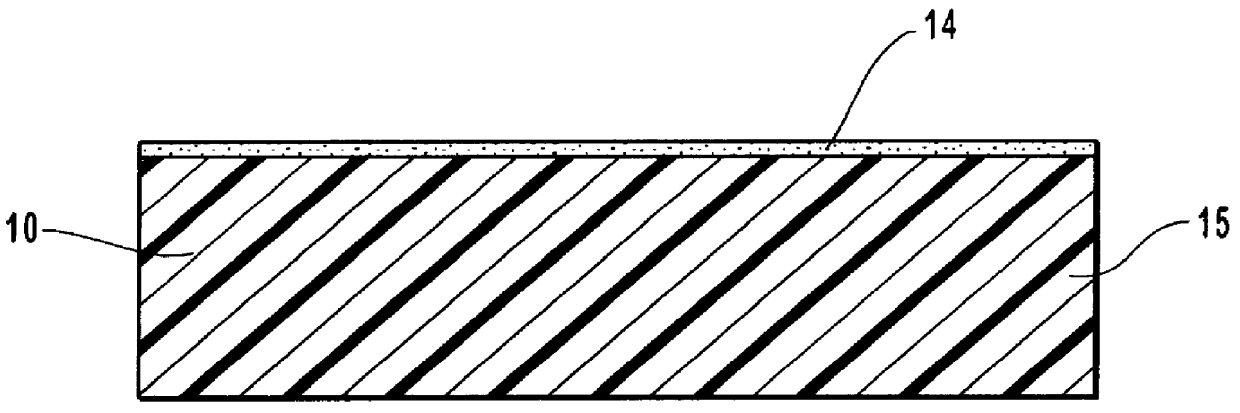

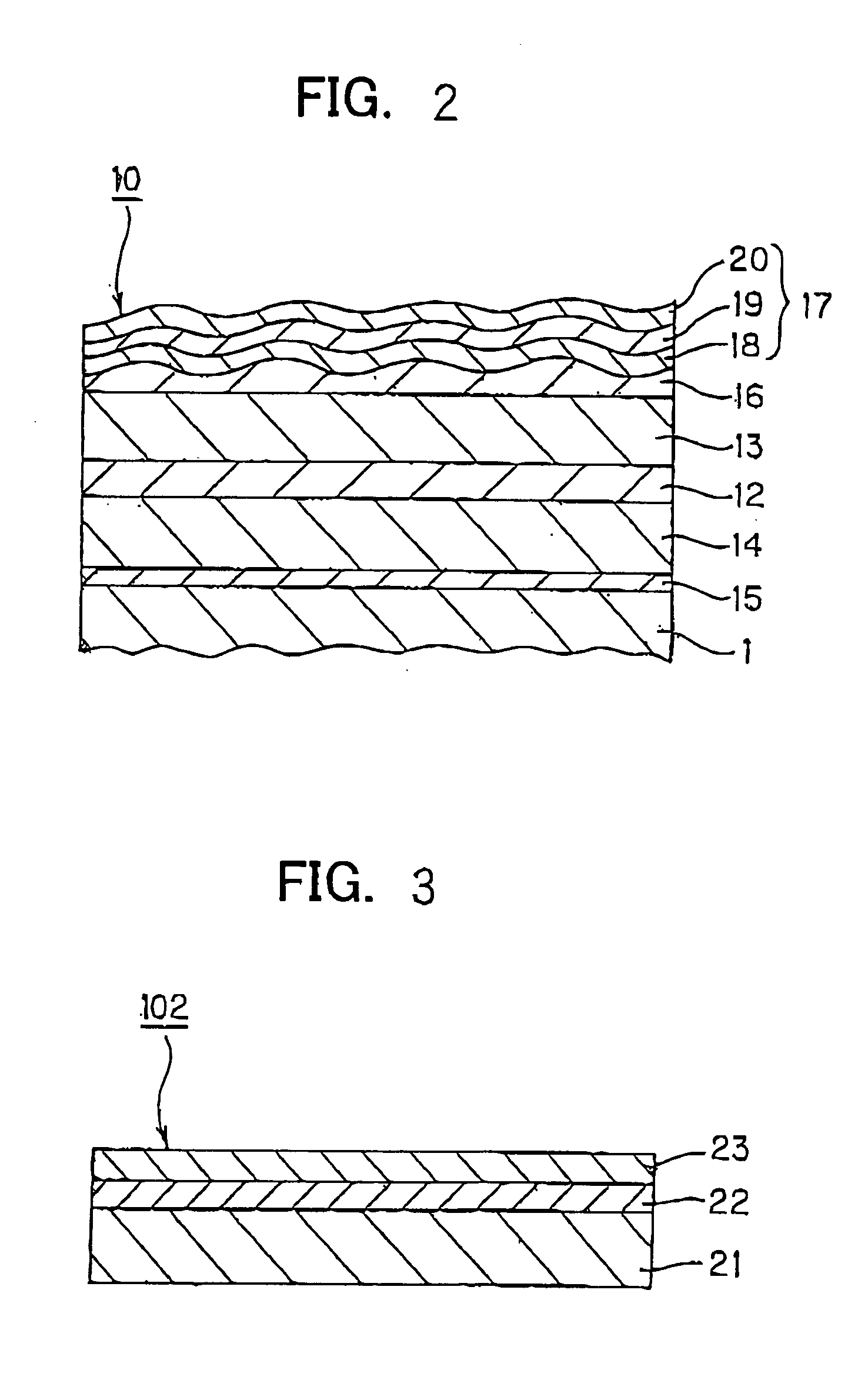

Coating composition, coating formed therefrom, anti-reflection coating, anti-reflection film, and image display device

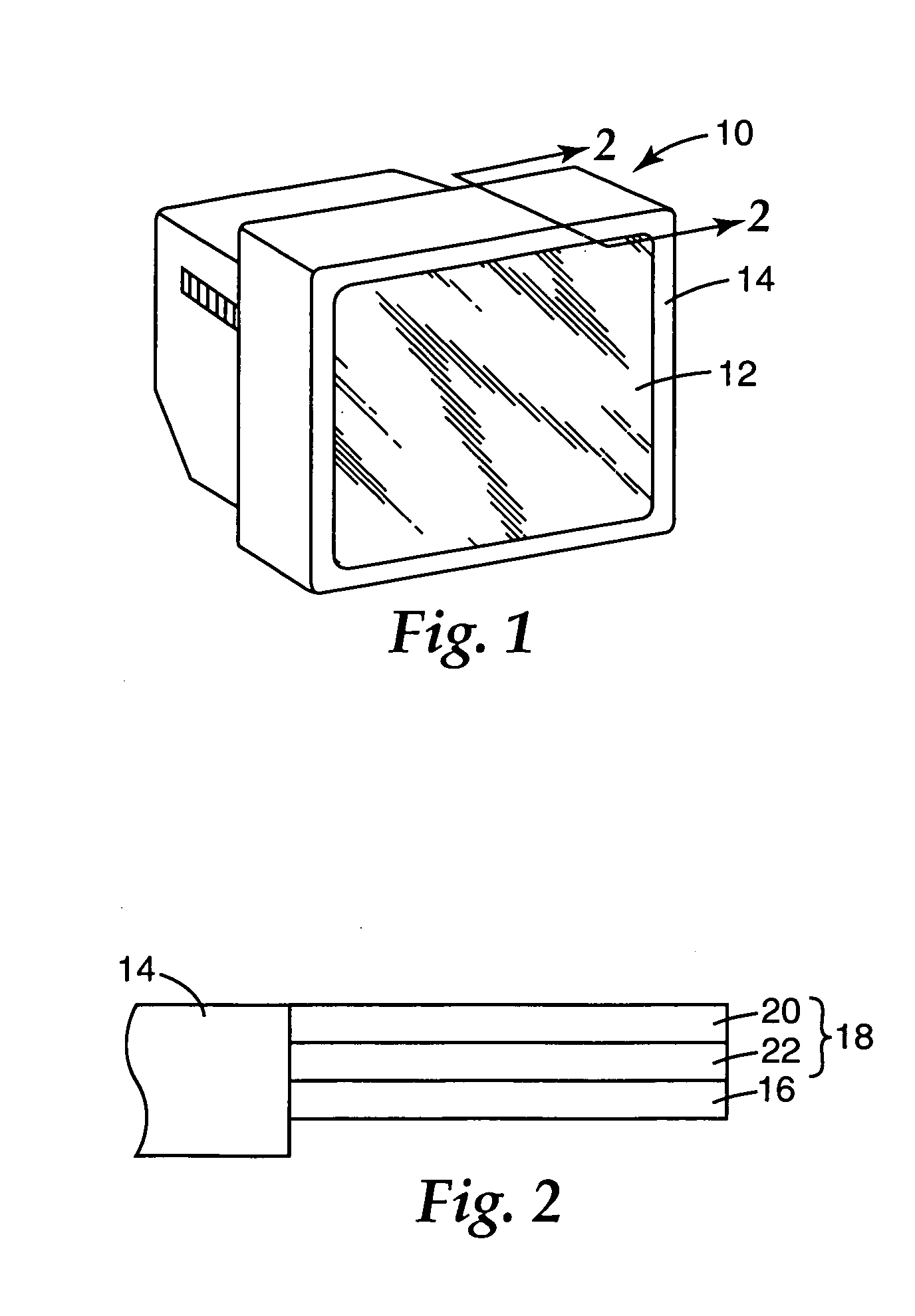

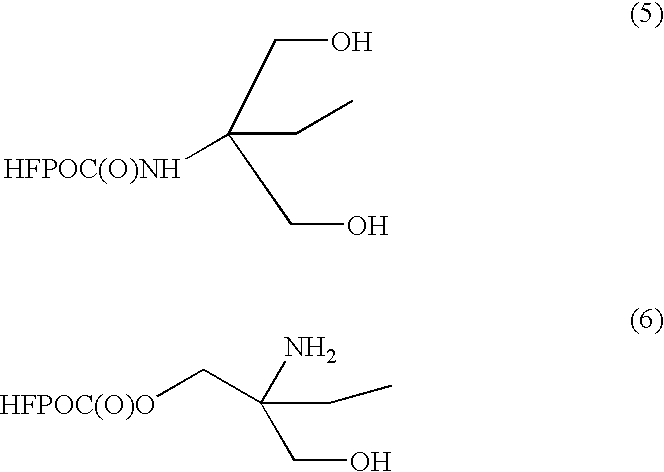

ActiveUS20050038137A1Low refractive indexImprove adhesionOther chemical processesConductive materialPolymer chemistryReflection function

The present invention provides a coating composition capable of forming a fluorine-containing coating layer having a low refractive index and a high hardness, a coating layer formed by using the coating composition, an anti-reflecting layer using the coating layer and an anti-reflecting film and an image display device to which the anti-reflecting layer is applied. The coating composition according to the present invention comprises (A) a binder system containing a fluorine-containing component (a) having one or both of a functional group which can be cured by ionizing radiation and a polar group which can be heat-cured, and contains both an ionizing radiation-curable group and a heatcurable polar group as a whole and (B) an inorganic superfine particle of the order of submicron in size which can be dispersed in a colloidal state in a liquid medium for preparing a coating liquid. The coating layer formed using this coating composition is preferable for forming a light-transmitting layer, particularly, a low-refractive index layer 20, constituting a monolayer type or multilayer type anti-reflecting layer 17.

Owner:DAI NIPPON PRINTING CO LTD

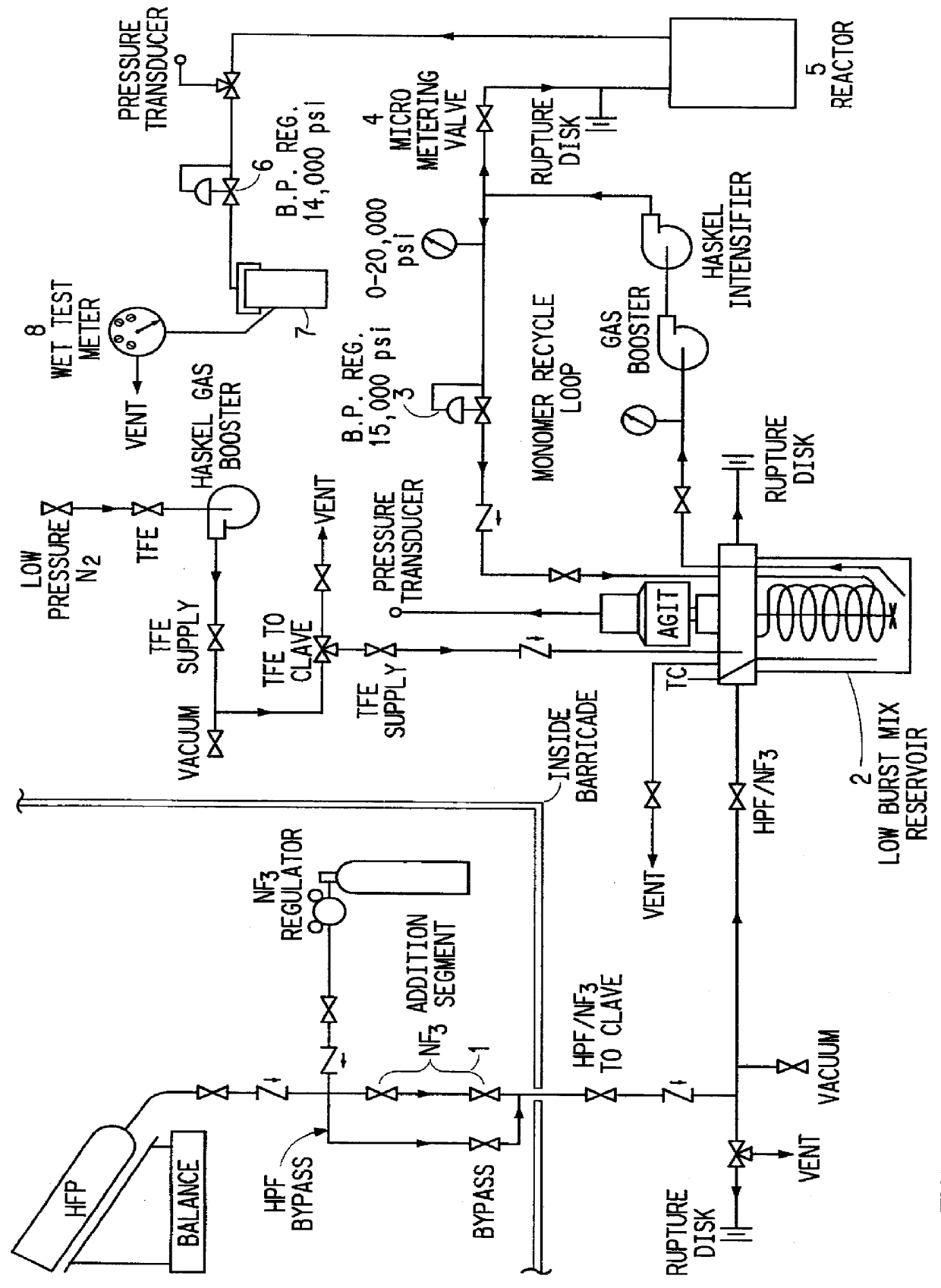

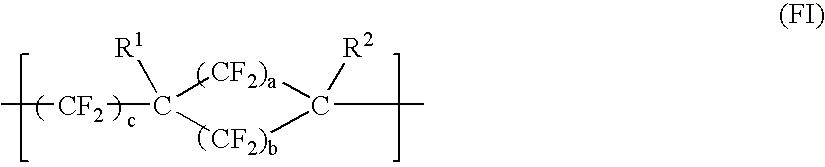

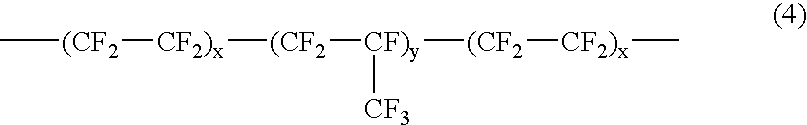

Amorphous tetrafluoroethylene-hexafluoropropylene copolymers

InactiveUS6133389AThin coatingIncrease coating thicknessOrganic chemistryCoatingsPolymer scienceHexafluoropropylene

Disclosed herein are novel amorphous tetrafluoroethylene-hexafluoropropylene (TFE-HFP) dipolymers, and other copolymers containing TFE, HFP and a third monomer, many of which are more random than previous amorphous TFE-HFP copolymers, as well as a novel high productivity continuous process for making these polymers. The polymers are particularly useful in the form of coatings, films and encapsulants.

Owner:THE CHEMOURS CO FC LLC

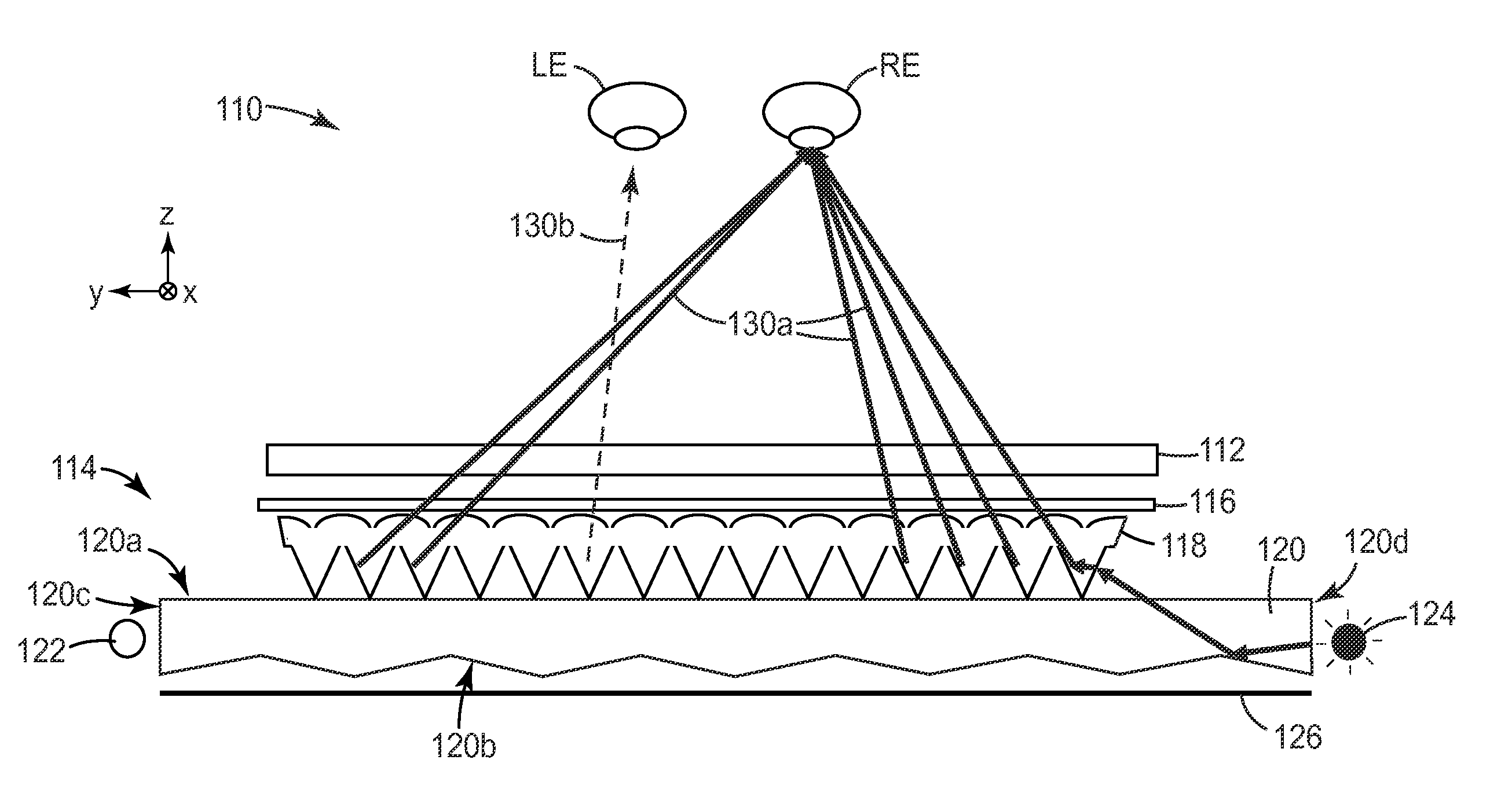

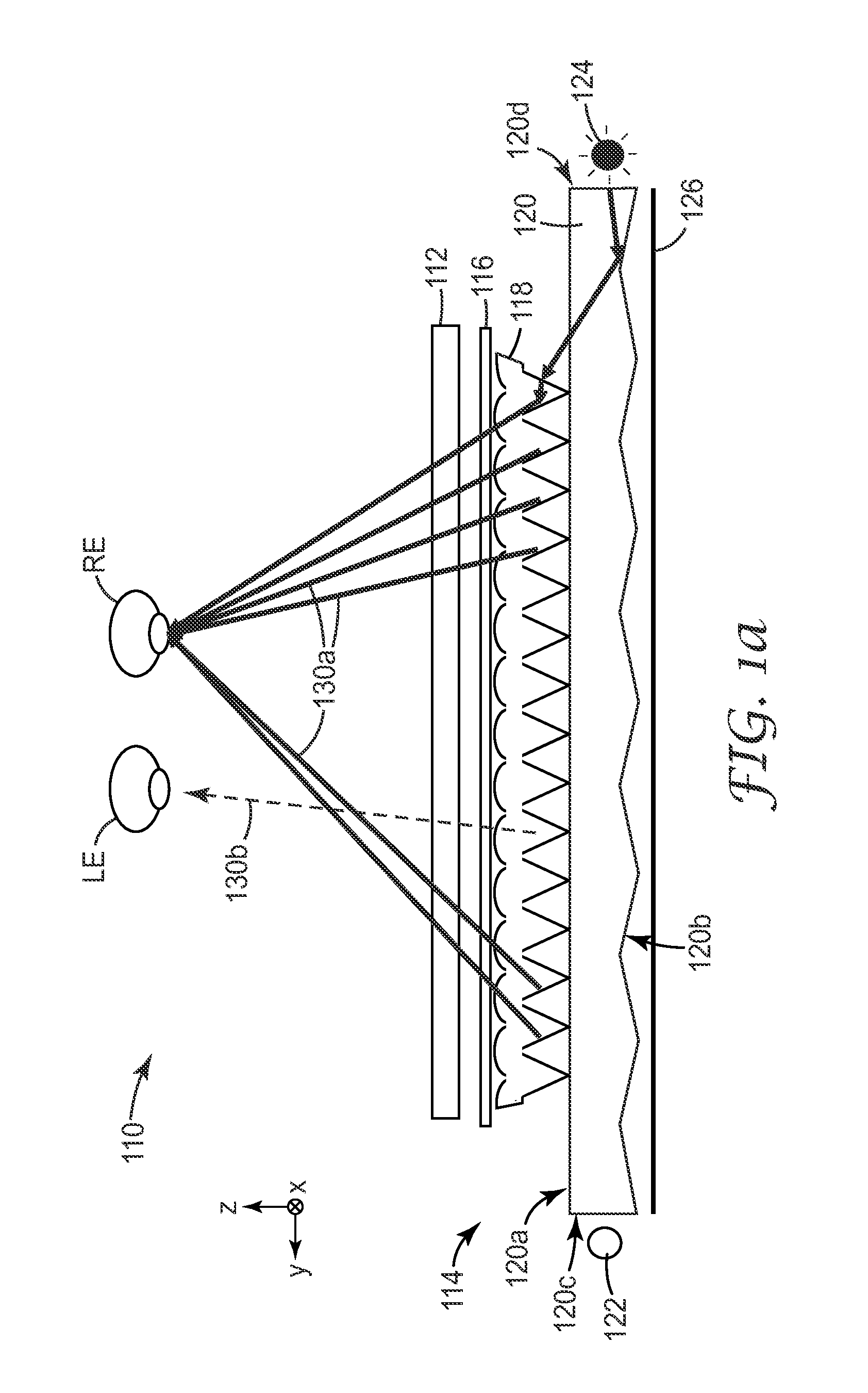

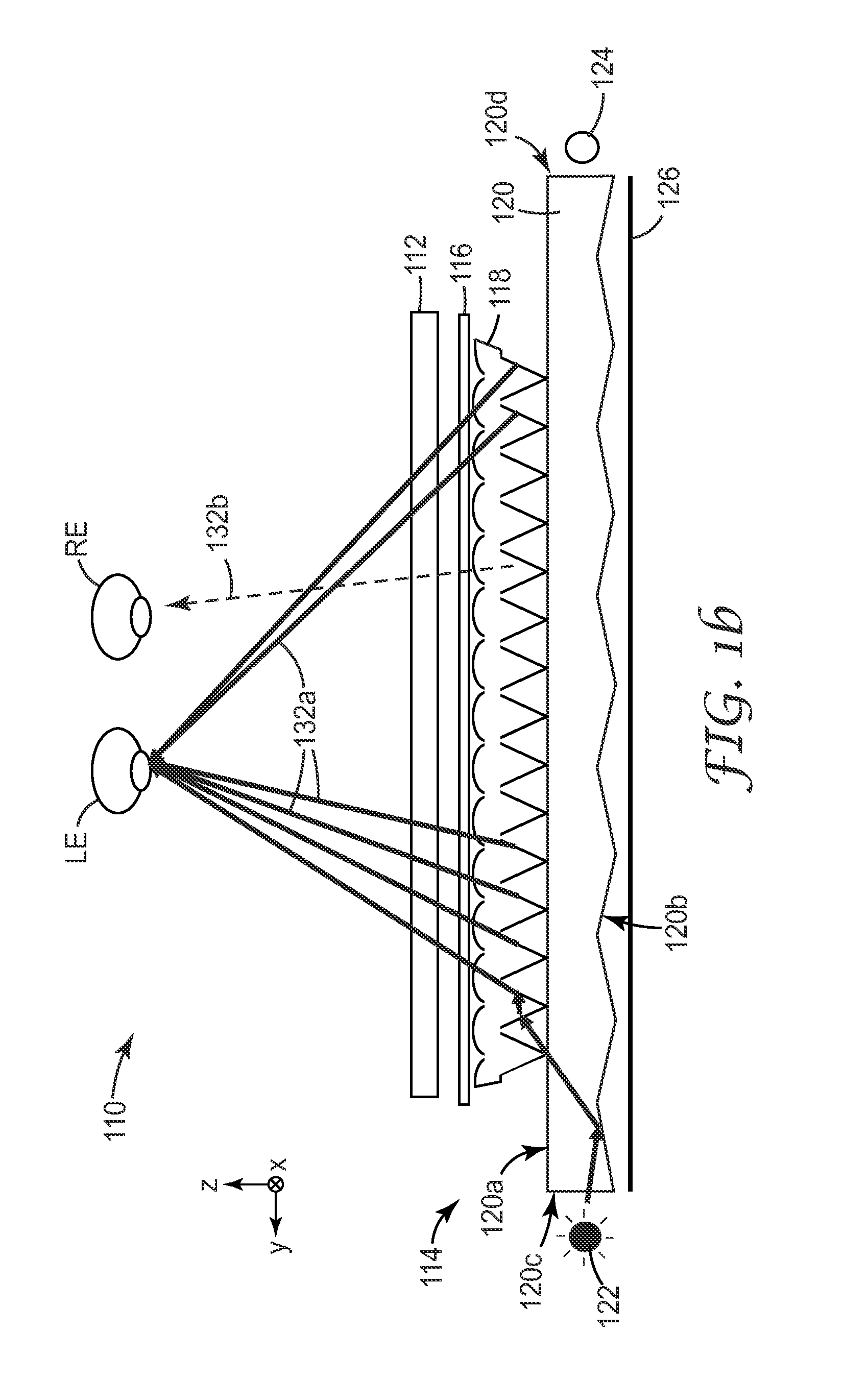

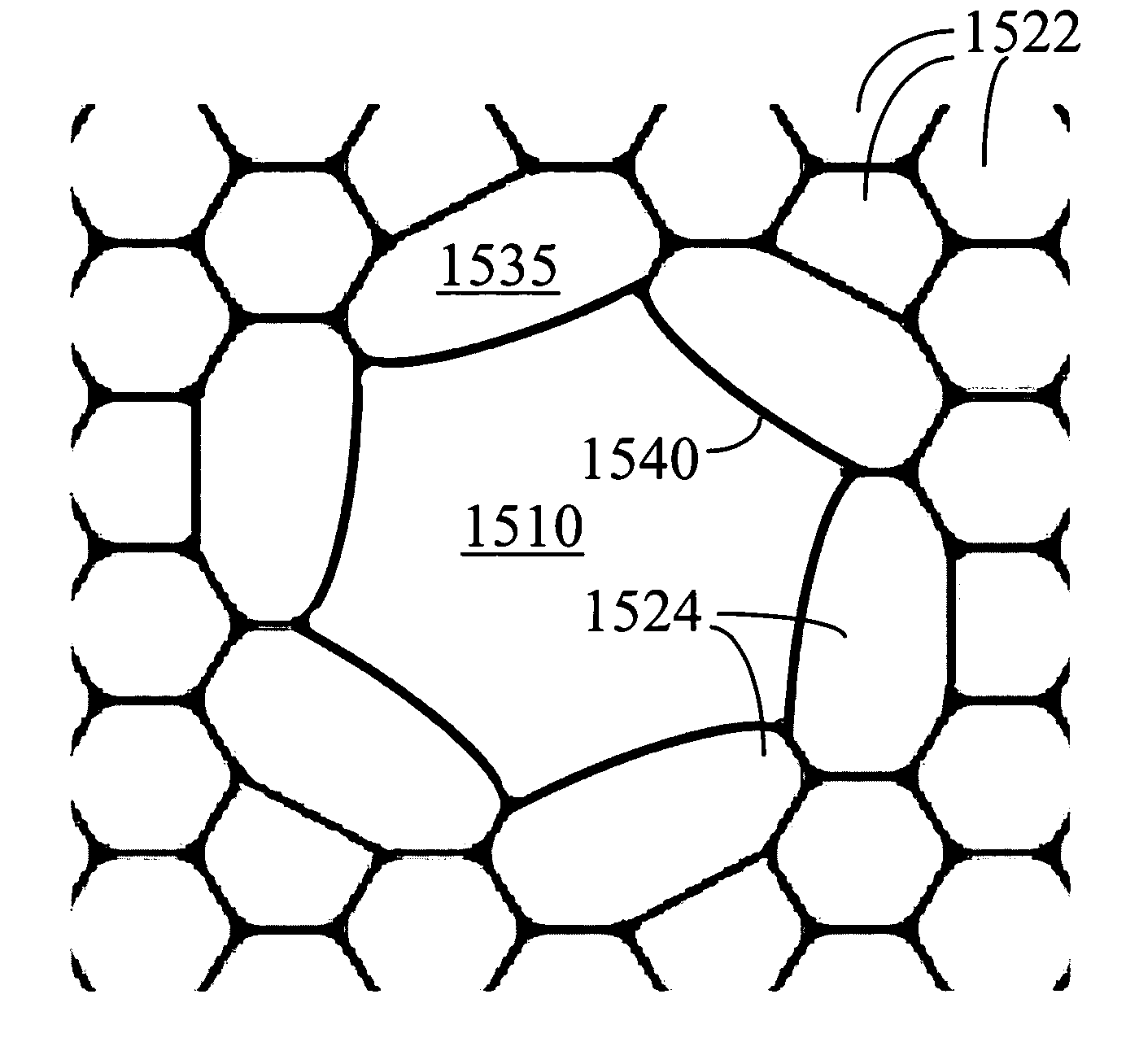

Microreplicated Film for Attachment to Autostereoscopic Display Components

InactiveUS20110170184A1Low refractive indexSuitable for usePrismsCoupling light guidesPhysicsStereo display

Microreplicated light redirecting films suitable for use in autostereoscopic displays and backlights are made to incorporate at least one nanovoided layer whose interface with another layer forms an embedded structured surface of the light redirecting film. The nanovoided layer includes a polymer binder and optional nanoparticles, and may have a refractive index less than 1.35 or 1.3. The light redirecting films may be adapted for attachment to one or more other components of an autostereoscopic display, such as a display panel and / or a light guide of a backlight.

Owner:3M INNOVATIVE PROPERTIES CO

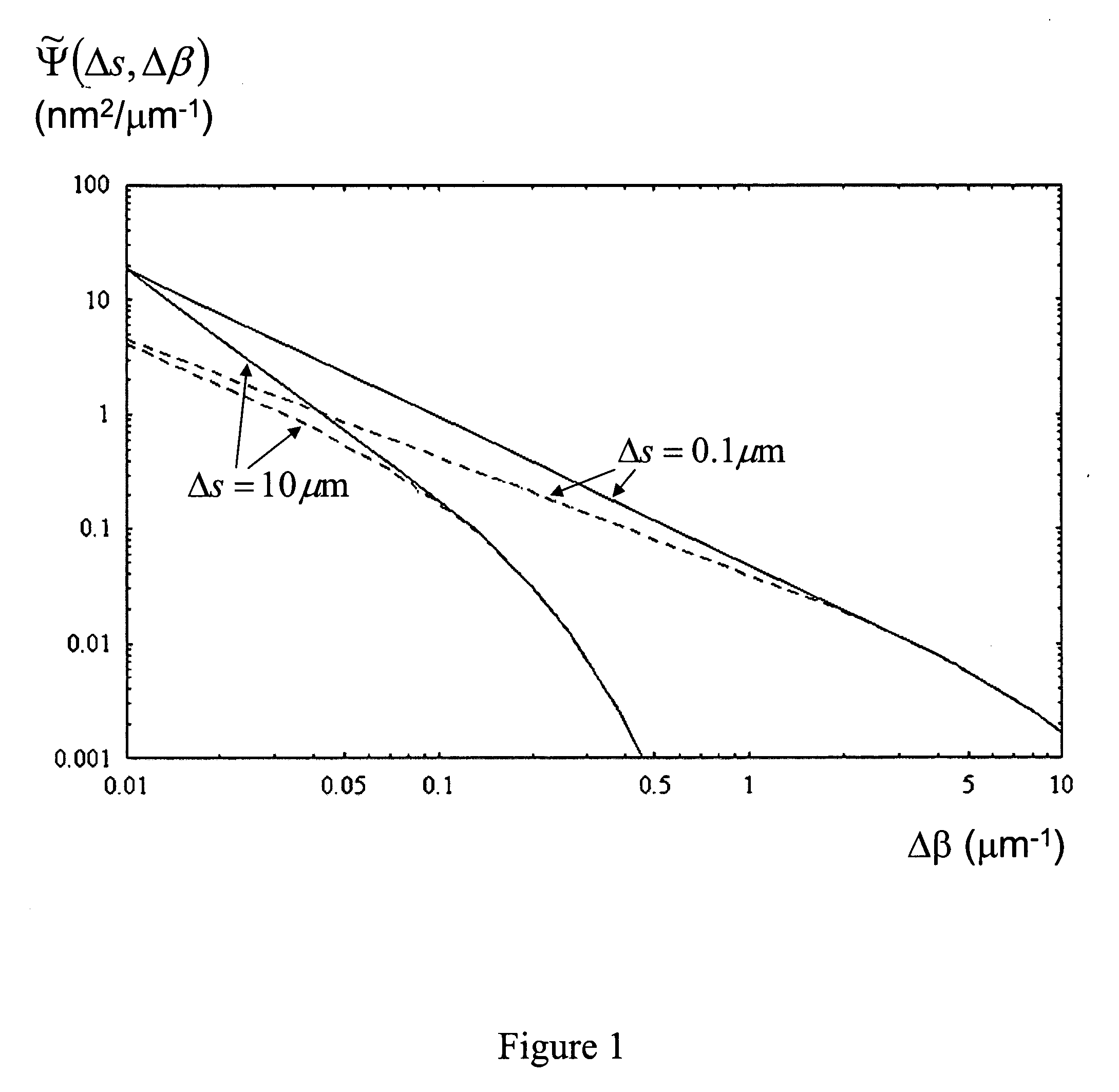

Hollow-core optical fiber and method of making same

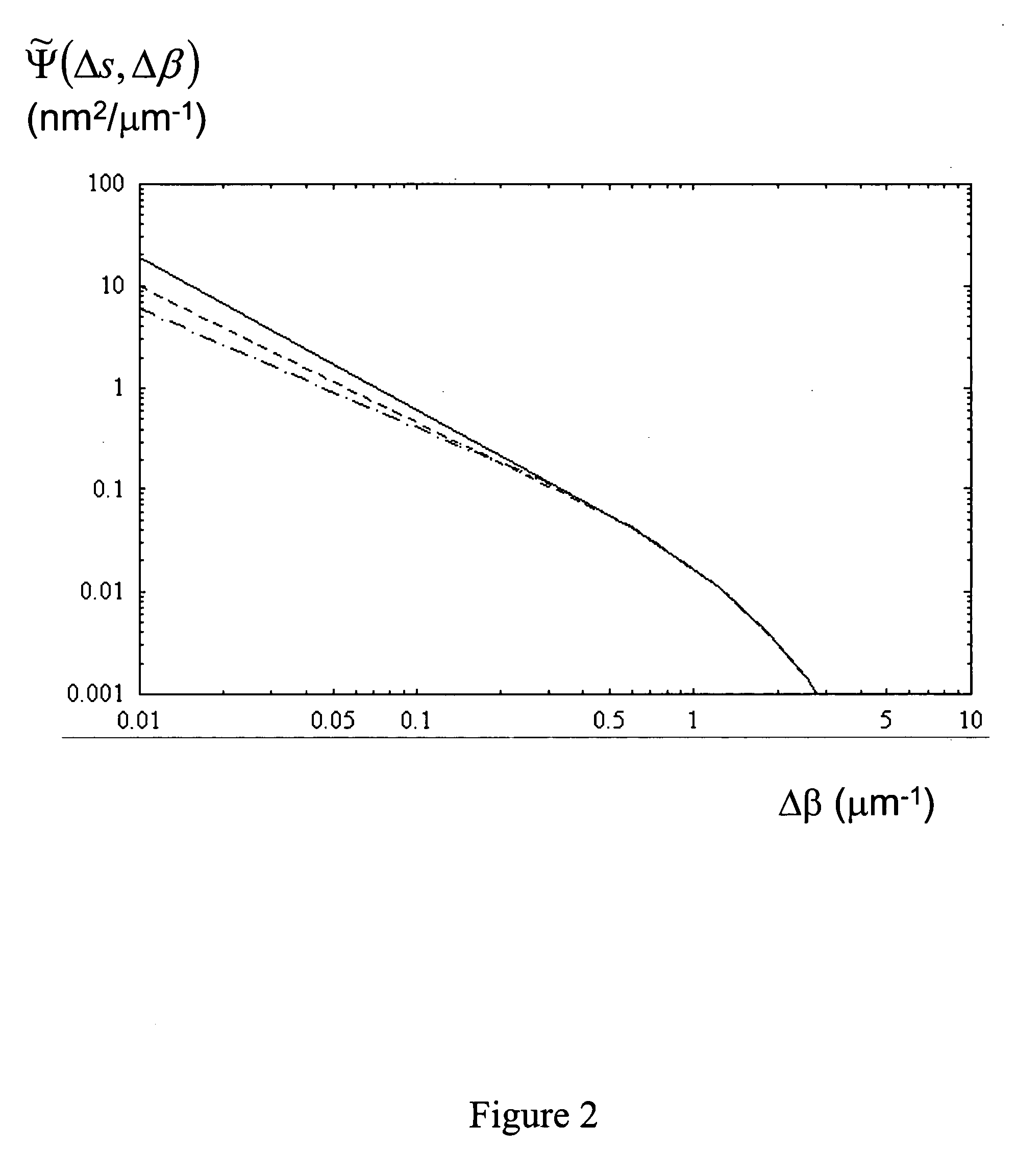

InactiveUS20050185908A1Increase surface tensionReduce surface tensionGlass making apparatusCladded optical fibreFiberSurface roughness

An optical fiber having a cladding region surrounding a core region having an elongate core hole, the inner or outer surface of the core hole having a surface roughness with a spatial period equal to or less than 5 μm by a spectral power below 0.0017 nm2μm−1. A method of making an optical fiber including a cladding region having an arrangement of elongate cladding holes in a matrix material, surrounding an elongate core region having an elongate core hole, the method including the step of increasing the surface tension of the matrix material prior to or during the step of heating and drawing the fiber.

Owner:CRYSTAL FIBRE AS

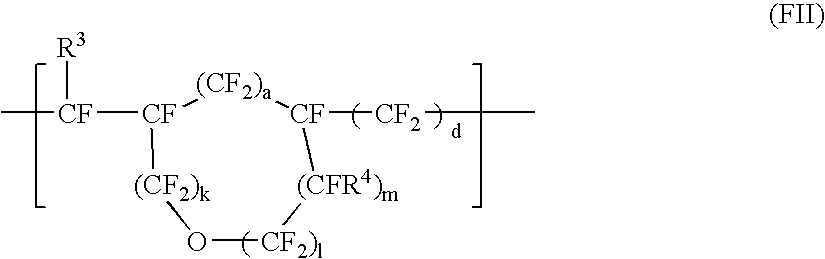

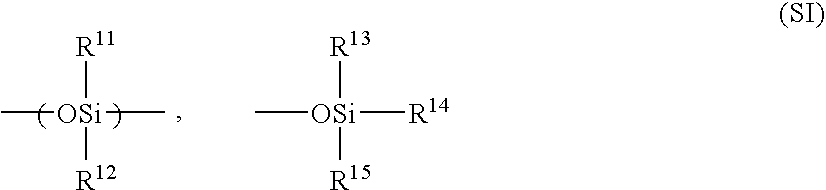

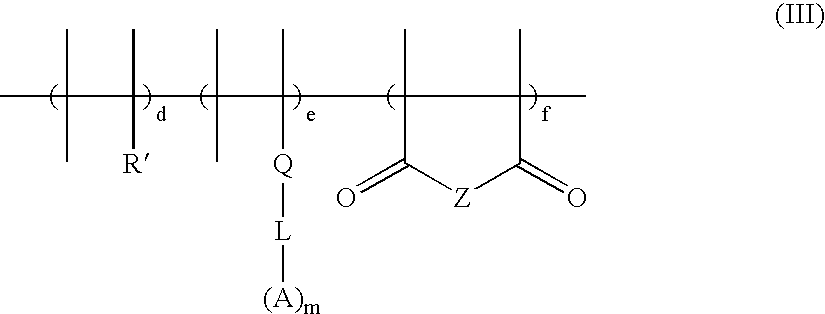

Film-forming composition, anti-reflection film, polarizing plate, image display apparatus, anti-pollution coating composition and anti-pollution article

InactiveUS20050053790A1Increased durabilityMeet growth requirementsAntifouling/underwater paintsSynthetic resin layered productsPolymer scienceFluorine containing

A film-forming composition comprising (a) a block copolymer that comprises: at least a polymer block [A] containing a specific fluorine-containing alicyclic structure; at least a polymer block [B] containing a specific siloxane structure; and a repeating unit (H) having at least one reactive group capable of being involved in crosslinking reaction, the repeating unit (H) being in at least one of the polymer block [A] and the polymer block [B], and (b) at least one of a curing agent and a curing accelerator.

Owner:FUJIFILM CORP

Core-shell particles for electrophoretic display

InactiveUS20060132896A1High refractive indexLow refractive indexPigmenting treatmentOrganic dyesElectrophoresisRefractive index

The invention relates to electrophoretic displays comprising core-shell pigment particles having a core of low specific gravity and low refractive index and a shell of high refractive index.

Owner:E INK CALIFORNIA

Preparing method for nanometer porous silica thin-membrane

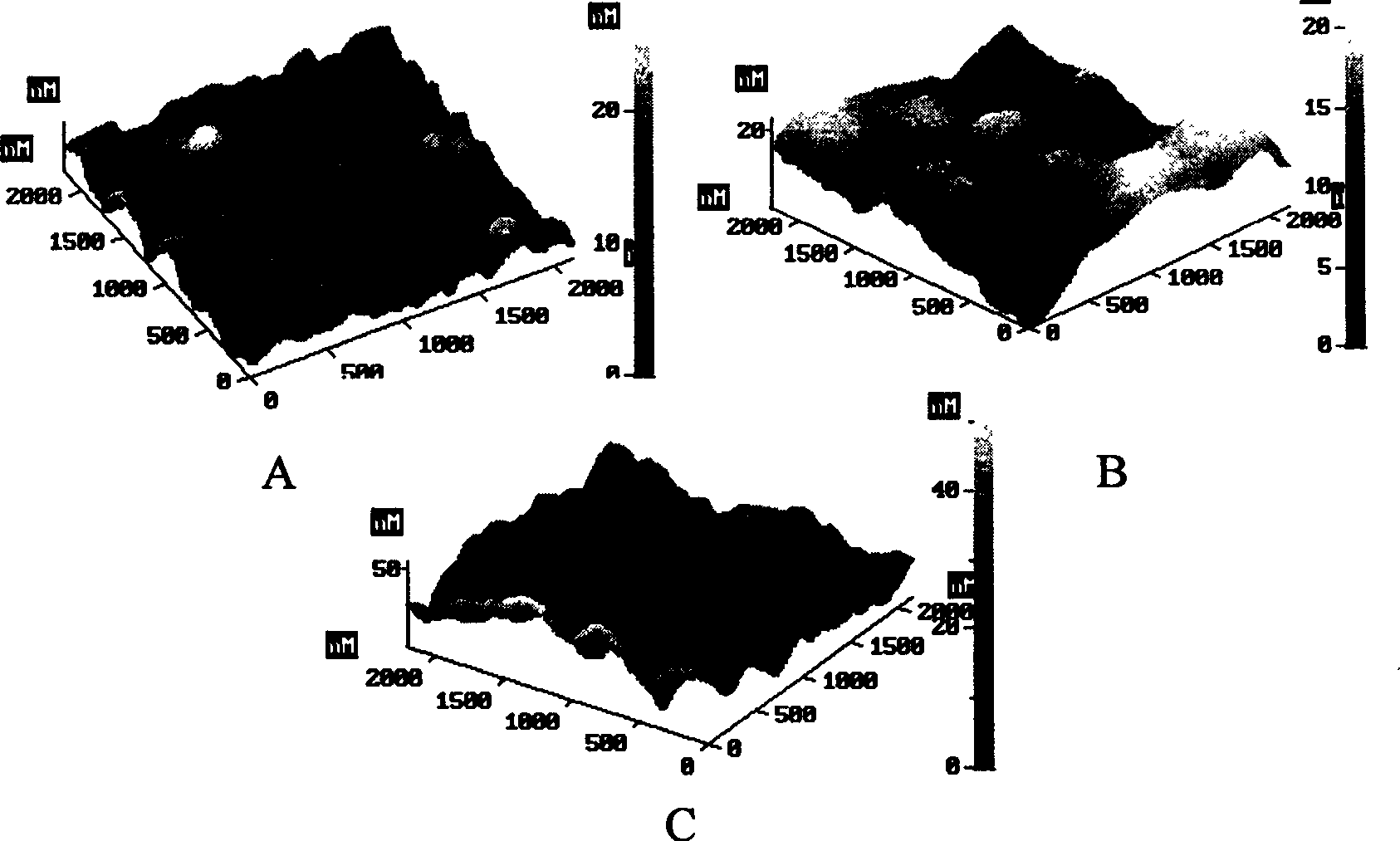

InactiveCN1553219AHigh refractive indexLow refractive indexOptical elementsPtru catalystSilicic acid

The preparing method is as the follows, positive silester is used as presoma alcohol as solvent and ammonia water as well as hydrochloric acid as catalysts, they are become basic and acidic soliquid after hydrolyzation and polycondensation are carried out silica soliquid can be obtained by further polycondensation and hydrolyzation after basic silica soliquid is agitated in some acidic soliquid, a complete nanomultihole network structure which is not simply piled up can be formed by closely combining particles to be film when using acidic soliquid as coupling agent to link basic soliquid particles together.

Owner:TONGJI UNIV

Core-shell particles for electrophoretic display

InactiveUS7382514B2High refractive indexLow refractive indexPigmenting treatmentSludge treatmentElectrophoresisRefractive index

The invention relates to electrophoretic displays comprising core-shell pigment particles having a core of low specific gravity and low refractive index and a shell of high refractive index.

Owner:E INK CALIFORNIA

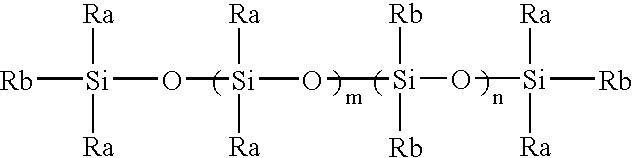

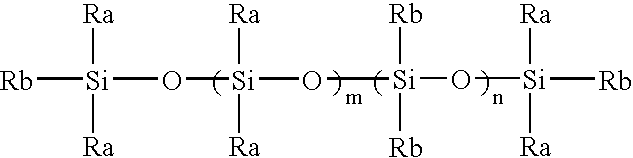

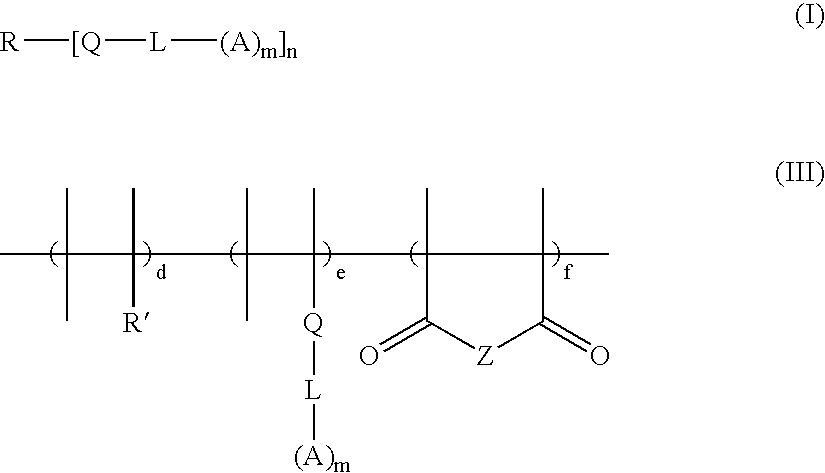

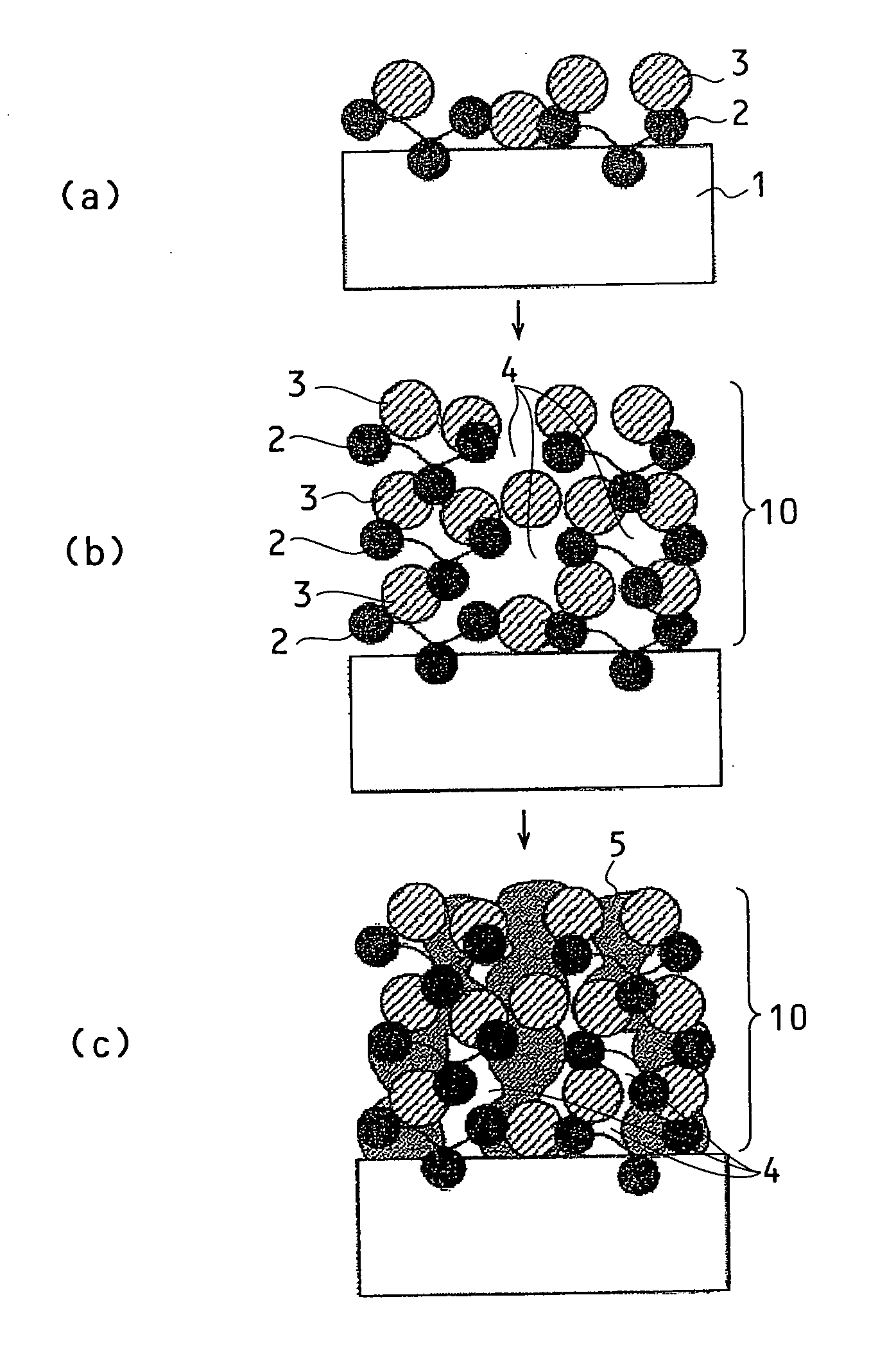

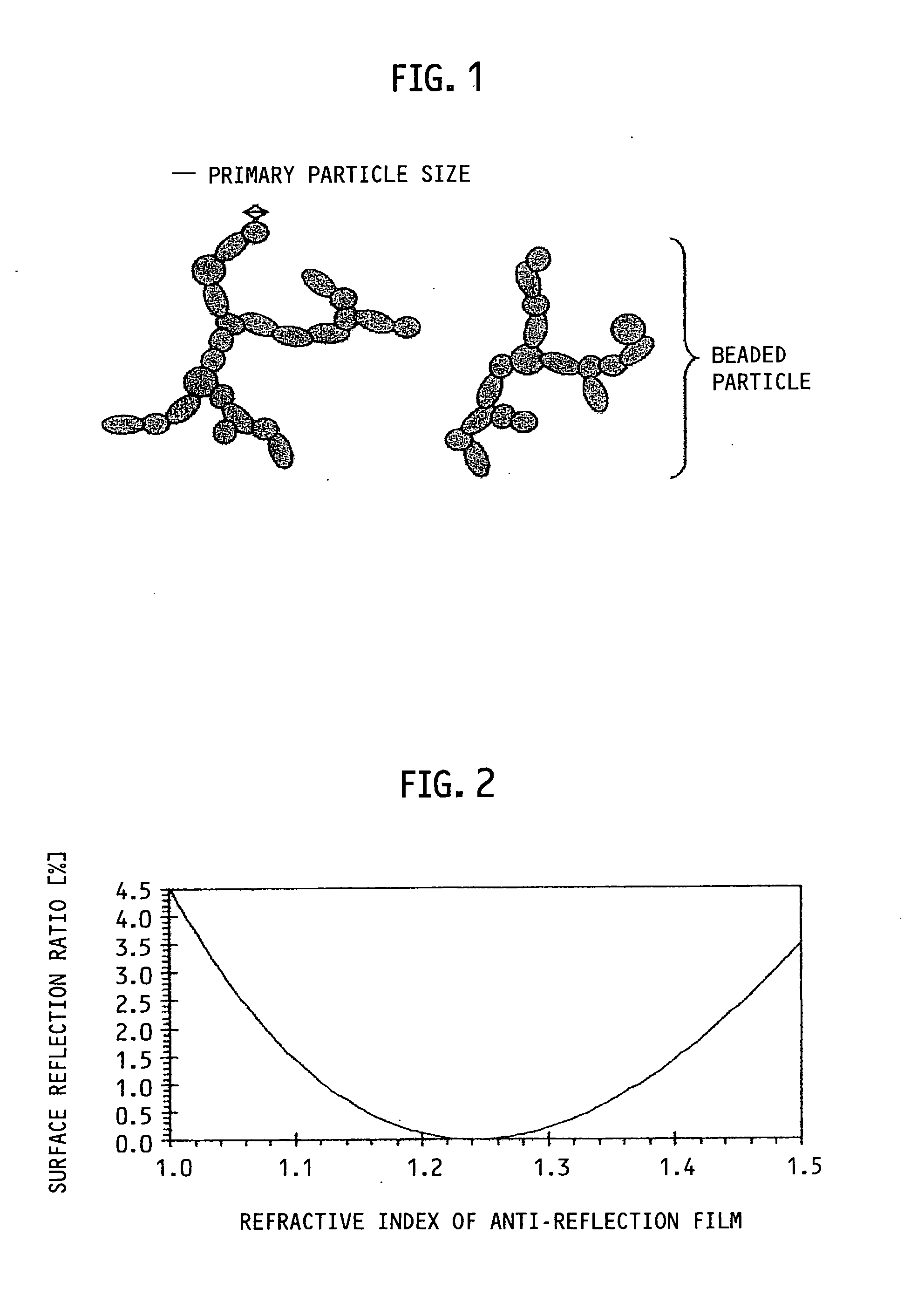

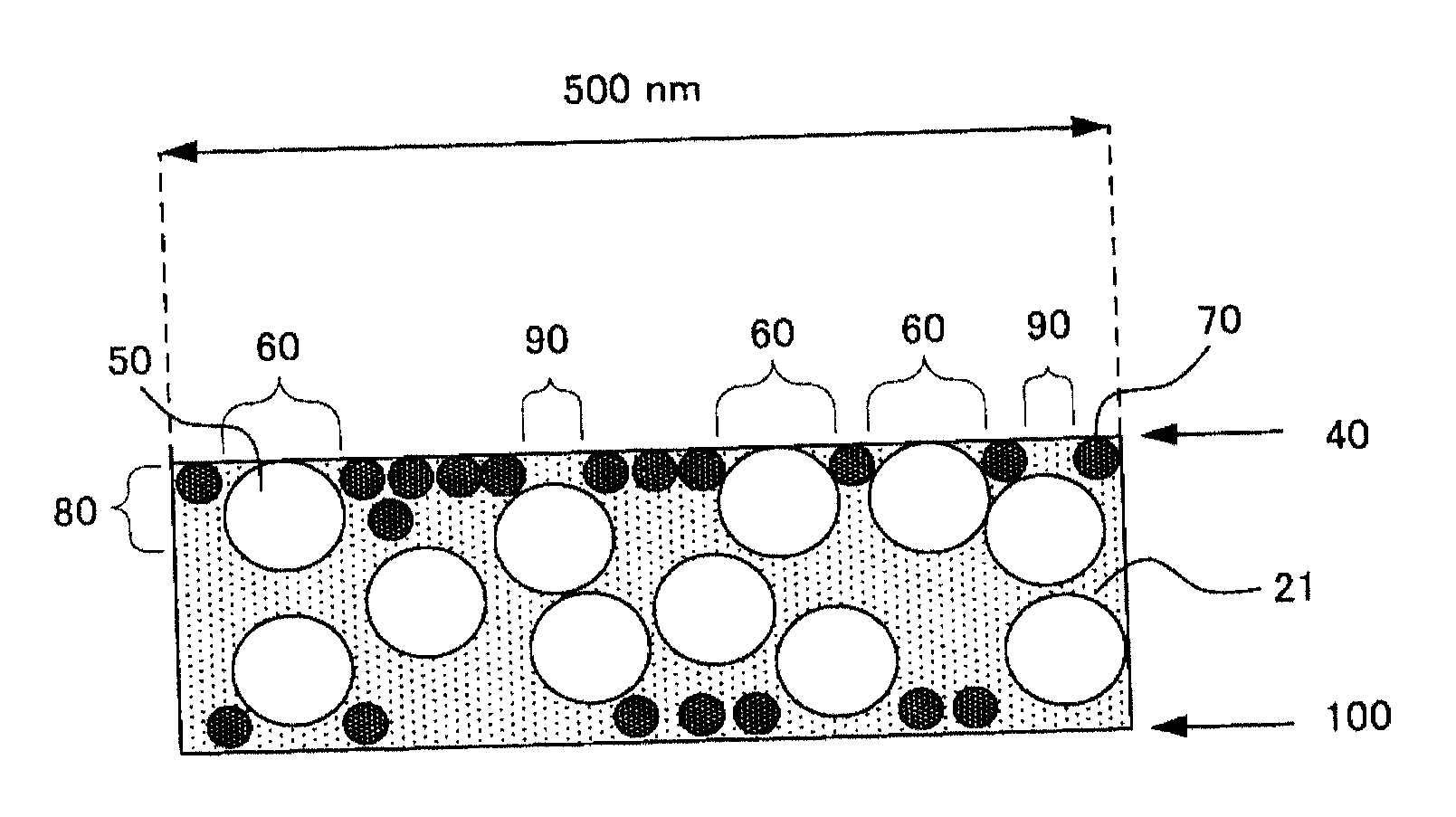

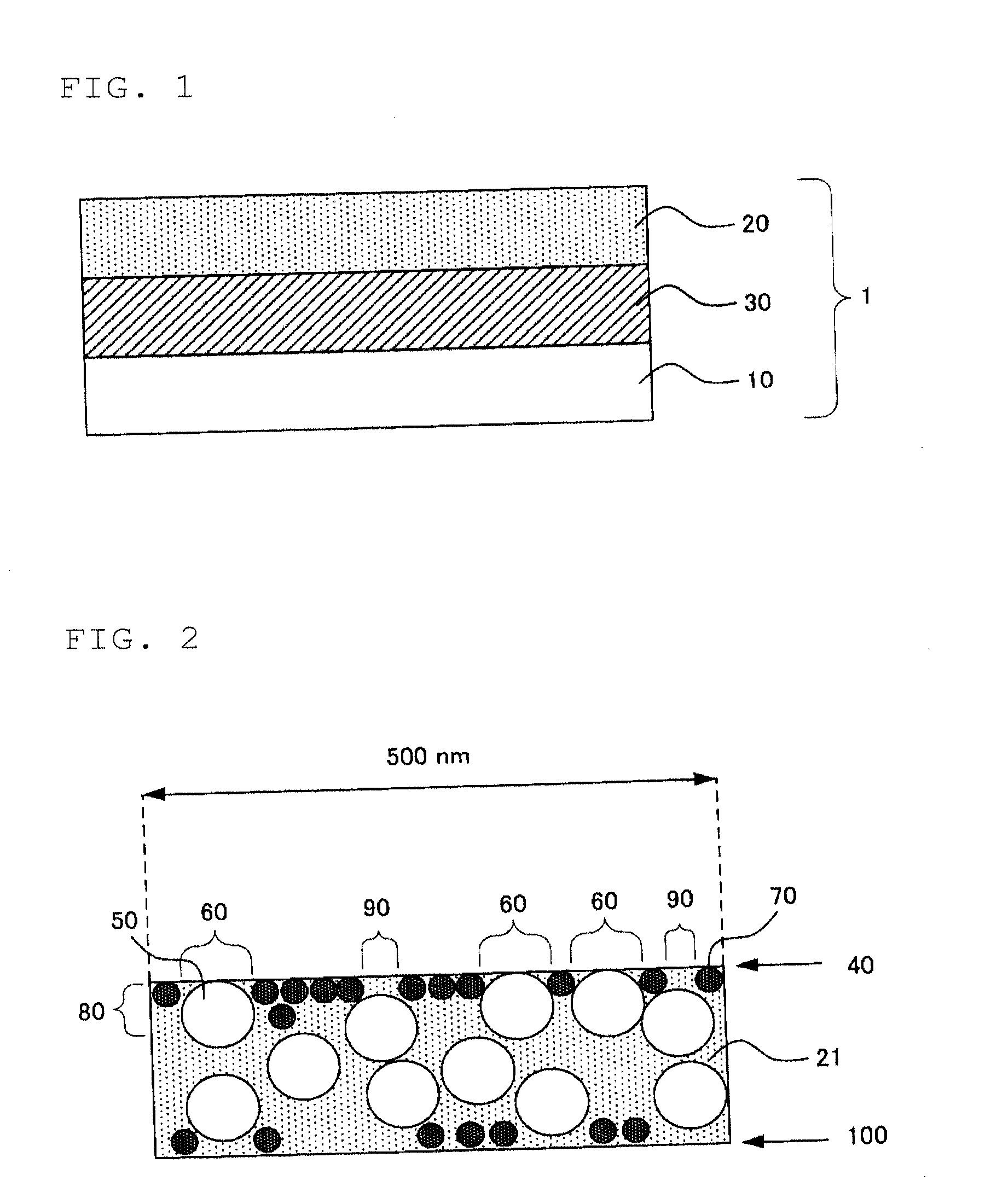

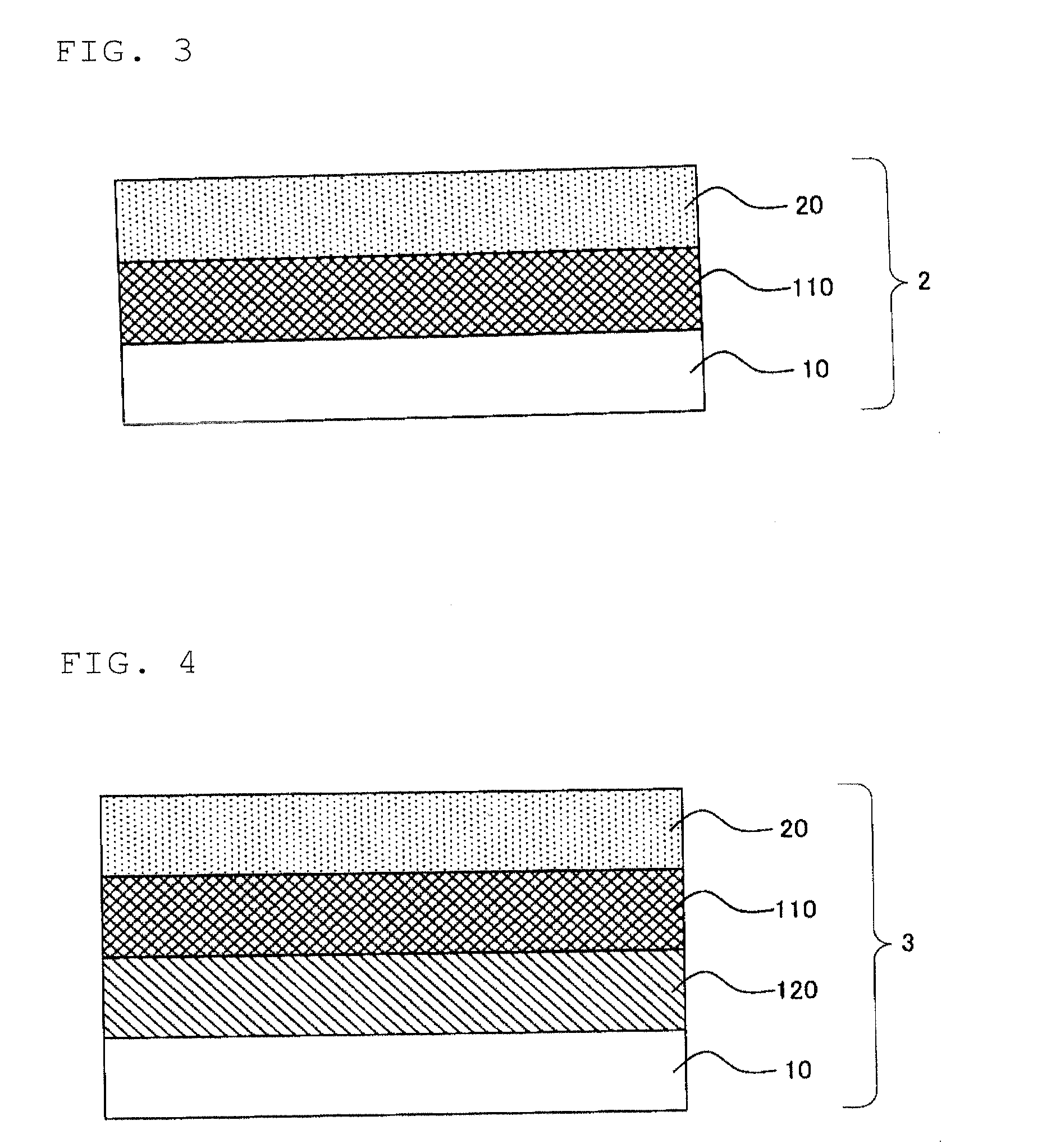

Film having low refractive index film and method for producing the same, Anti-relection film and method for producing the same, coating liquid set for low refractive index film, substrate having microparticle-laminated thin film and method for producing the same, and optical member

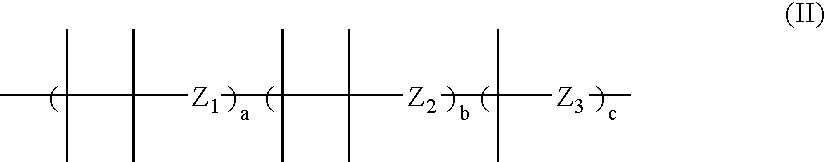

ActiveUS20110195239A1Low refractive indexImprove adhesionMaterial nanotechnologyCladded optical fibrePolymer scienceSilanes

Provided is a film having a low refractive index, which can be formed under normal temperature and pressure while obtaining a lower refractive index, has excellent adhesion with a solid substrate, and does not lose geometric optical properties, such as the diffusibility or light-harvesting capability attributed to the microstructure. Also disclosed is a method for producing the same. The film having a low refractive index is obtained by causing an electrolyte polymer and microparticles to be alternately adsorbed on the surface of a solid substrate and bringing the resulting microparticle-laminated film into contact with a silicon compound solution in order to bond the solid substrate with microparticles and microparticles with microparticles. The silicon compound solution is selected from (1) the hydrolysis product of alkoxysilane (I) wherein the functional groups are formed from hydrolyzable groups and non-hydrolyzable organic groups, and the condensation reaction product thereof, (2) the hydrolysis product of a mixture of alkoxysilane (I) and alkoxysilane (II) wherein the functional groups are formed from hydrolyzable groups alone, and the condensation reaction product thereof; and (3) a mixture of hydrolysis product and condensation product thereof according to (1) and alkoxysilane (II).

Owner:RESONAC CORP

Optical film and display panel

ActiveUS20120200933A1Improve wear resistanceImprove anti-reflection abilityCoatingsNon-linear opticsRefractive indexDisplay device

An optical film having an optically-transparent substrate, and a low refractive index layer having a thickness d on one side of the optically-transparent substrate, a polarizing plate and a display panel provided with the same, and a display provided with the same.

Owner:DAI NIPPON PRINTING CO LTD

Method for producing silica aerogel coating

InactiveUS20060281828A1Low refractive indexImprove toughnessImpression capsPretreated surfacesUltravioletAerogel

A silica aerogel coating is produced by reacting a wet gel obtained by the hydrolysis and polymerization of alkoxysilane with an organic-modifying agent to form organically modified silica, dispersing the organically modified silica by an ultrasonic treatment to form an organically modified silica dispersion, adding an ultraviolet-curable resin and a photo-polymerization initiator to the dispersion to prepare a coating liquid, applying the coating liquid to a substrate, and then irradiating ultraviolet rays to the coated layer.

Owner:PENTAX RICOH IMAGING CO LTD

Fluoropolymer coating compositions with multifunctional fluoroalkyl crosslinkers for anti-reflective polymer films

InactiveUS20050182199A1Low compositionEnhances low surface energy characteristicFibre treatmentGolf ballsPolymer scienceRefractive index

An economic, optically transmissive, stain and ink repellent, durable low refractive index fluoropolymer composition for use in an antireflection film or coupled to an optical display. In one aspect of the invention, the composition is formed from the reaction product of a fluoropolymer and a fluoroalkyl containing multi-olefinic crosslinker. In another aspect of the invention, the composition further includes surface modified inorganic nanoparticles.

Owner:3M INNOVATIVE PROPERTIES CO

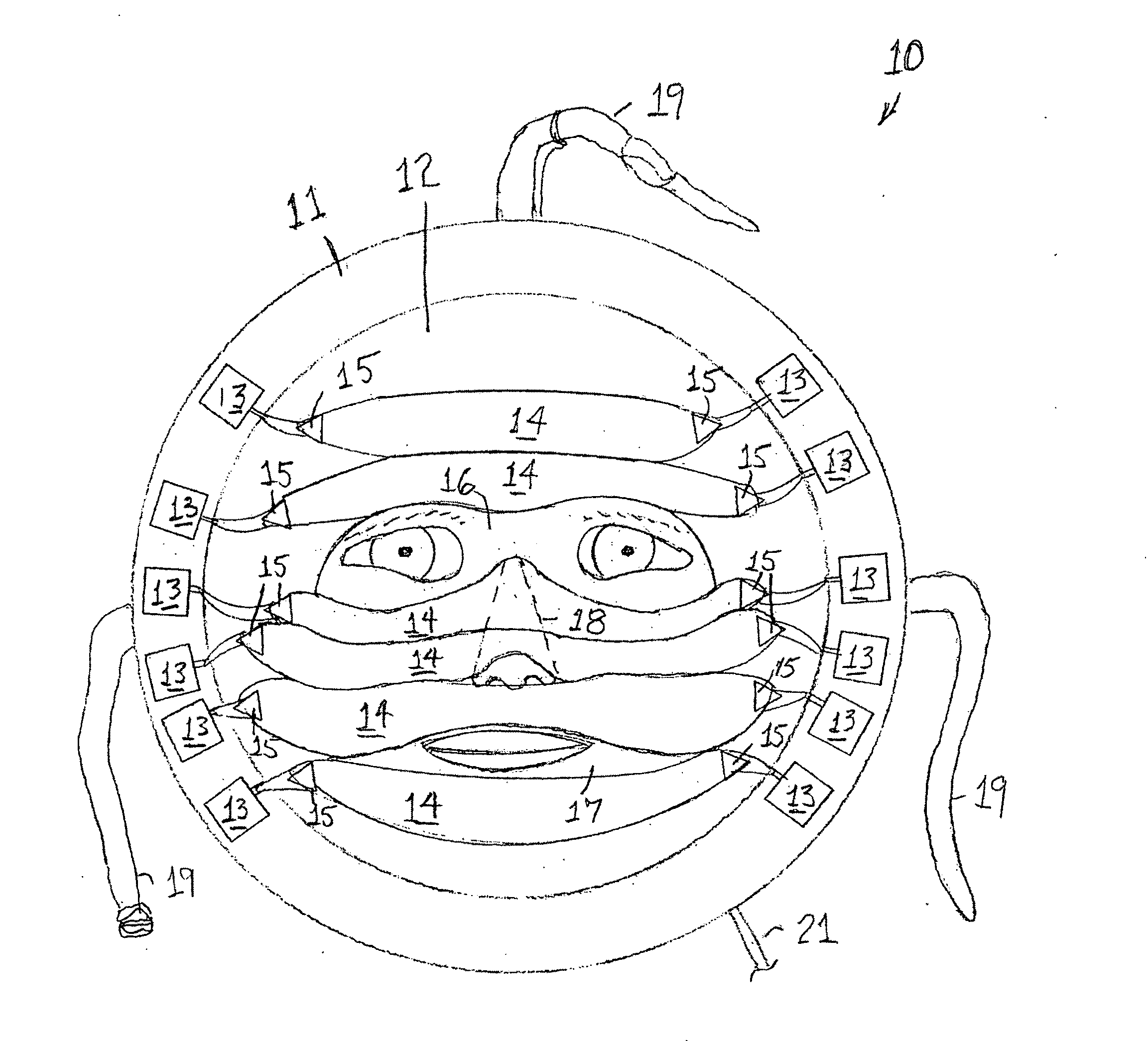

Phototherapy mask

InactiveUS20110040355A1Low refractive indexReduce diffuseLight therapySingle-mode optical fiberMulti-mode optical fiber

A phototherapy mask uses optical fibers coupled to LEDs to irradiate a treated epidermal skin area on or around a person's face with specific wavelengths of light in selected dosages (J / cm2). Peripheral configuration of LEDs on the mask eliminates problems of heat dissipation, and multi-mode optical fiber is employed for diffusion of light uniformly over the treated epidermal skin area.

Owner:FRANCIS STACY

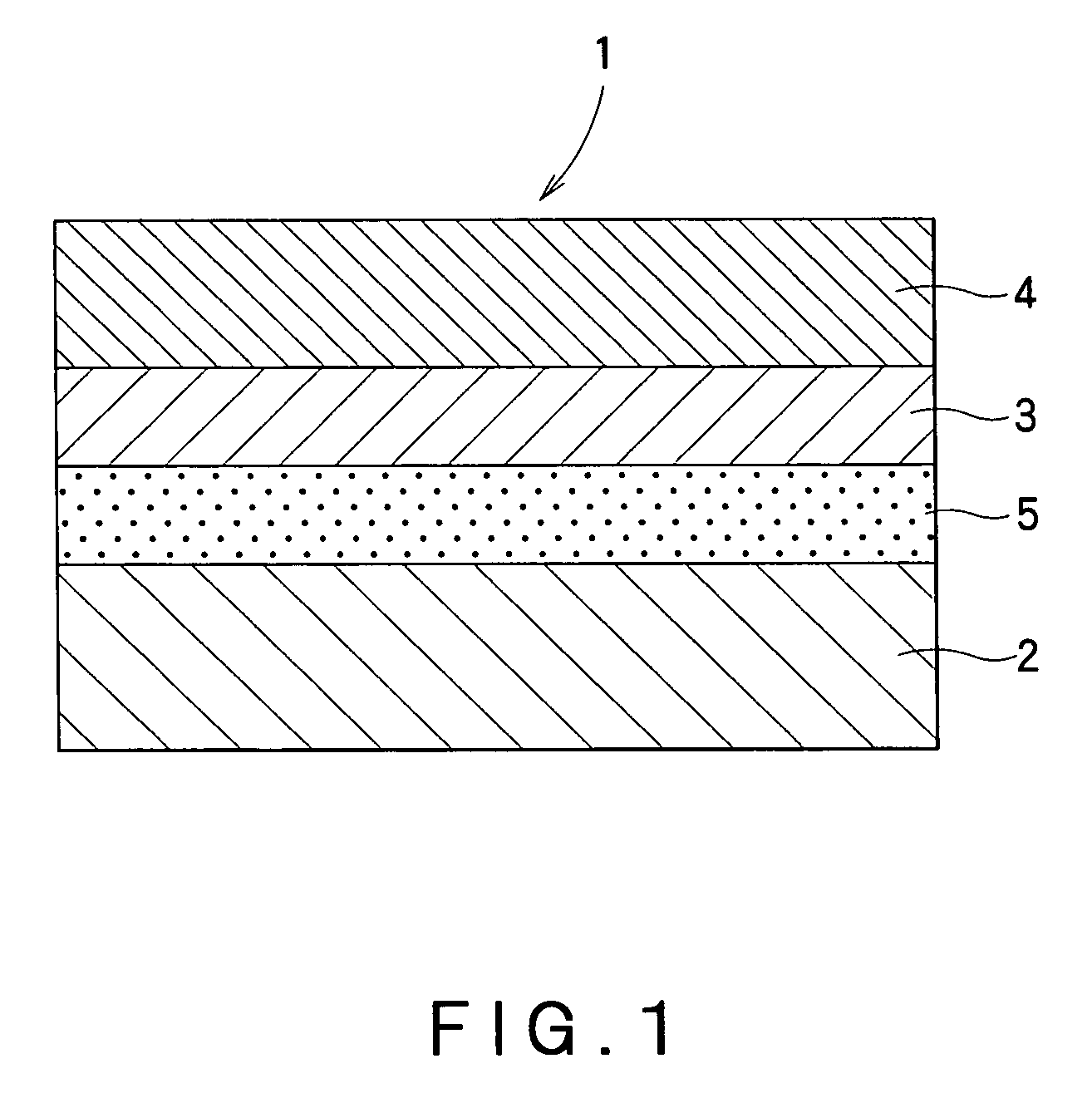

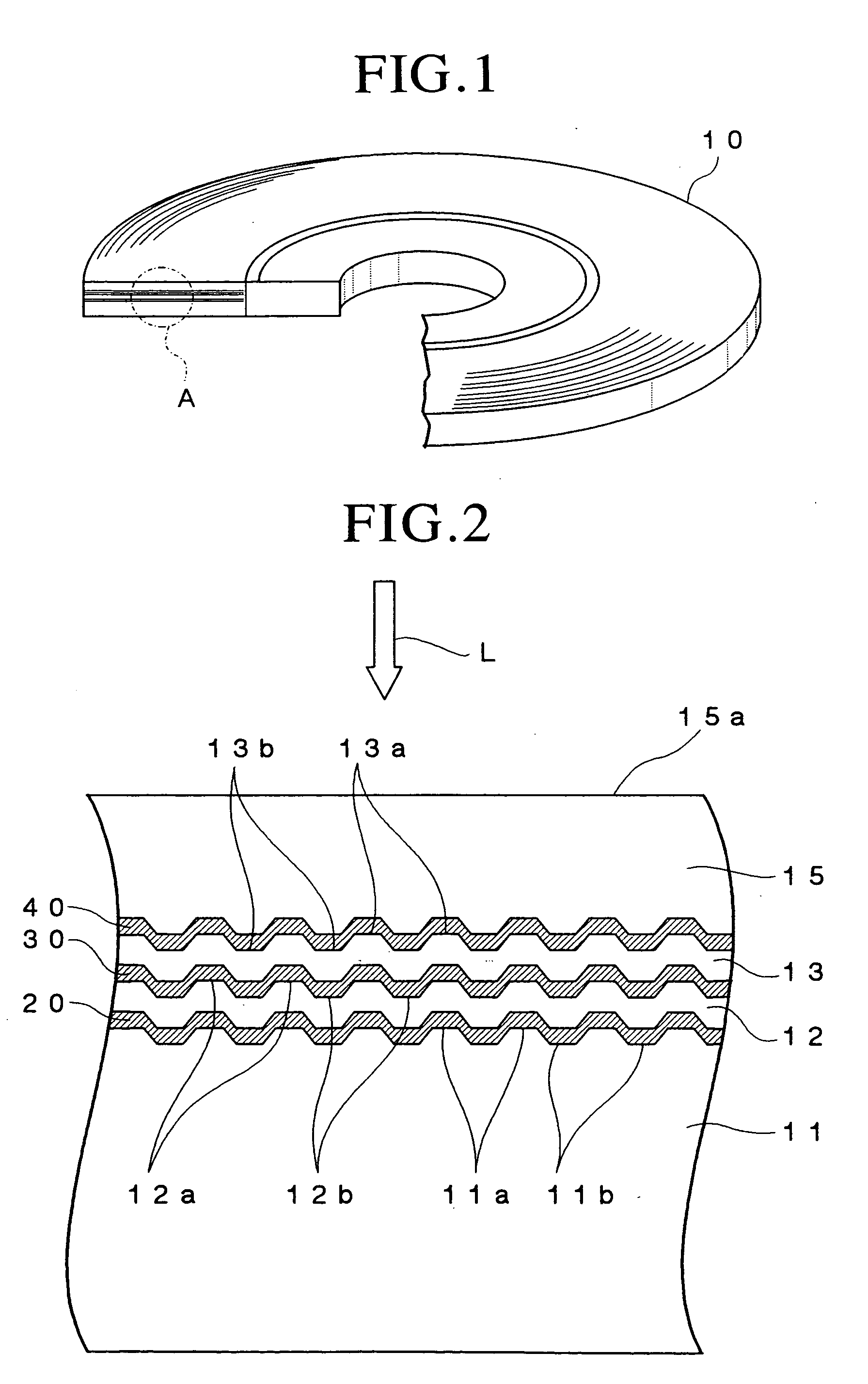

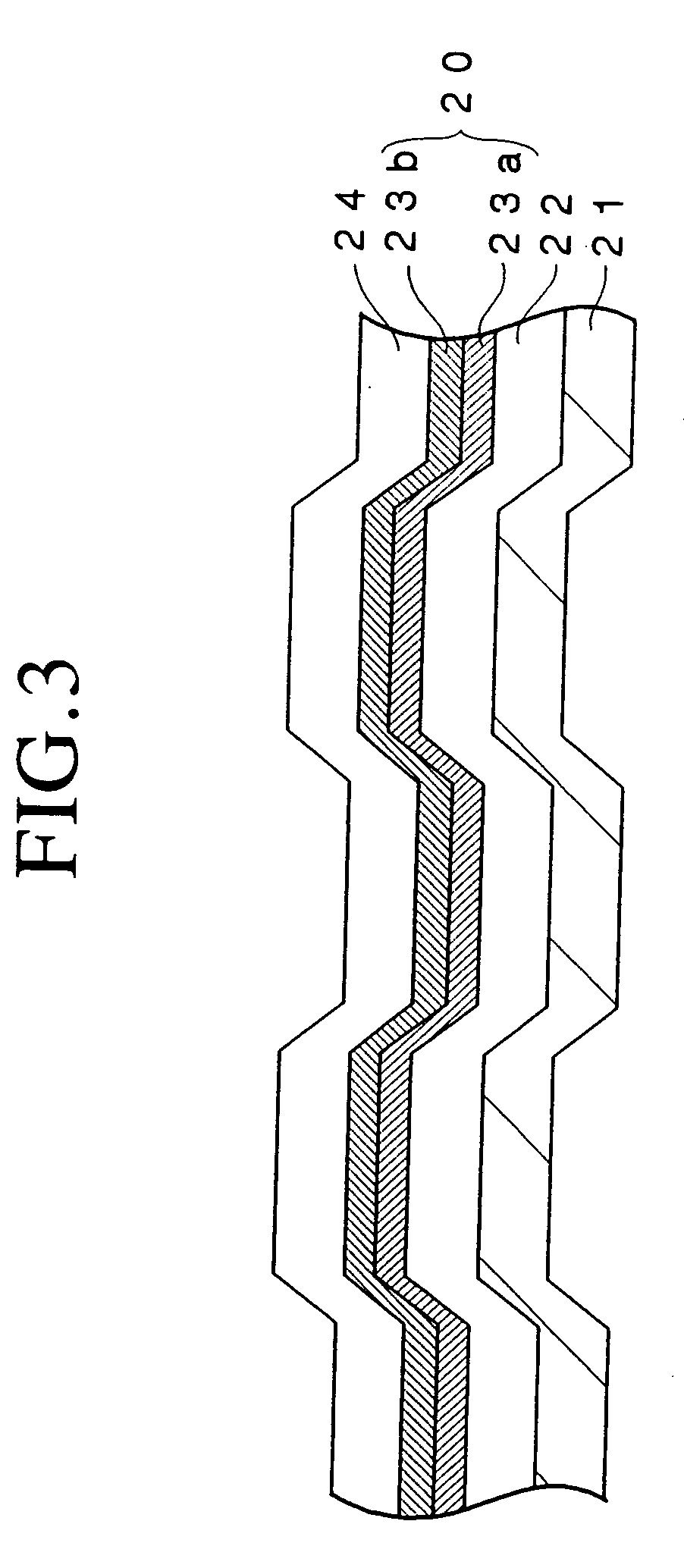

Optical recording medium

InactiveUS20040152016A1Suppress reduction in powerReduce the required powerRadiation applicationsMechanical record carriersData recordingOptical recording

An optical recording medium includes a substrate and a plurality of recording layers laminated via at least intermediate layers, at least one of the recording layers other than a recording layer farthest from a light incidence plane among the plurality of recording layers containing at least one metal M selected from a group consisting of Ni, Cu, Si, Ti, Ge, Zr, Nb, Mo, In, Sn, W, Pb, Bi, Zn and La and an element X which can combine with the metal M upon being irradiated with a laser beam for recording data, thereby forming a crystal of a compound of the element X with the metal M. According to the thus constituted optical recording medium, it is possible to record data in and reproduce from a farthest recording layer from a light incidence plane in a desired manner and it is possible to record data in and reproduce from recording layer(s) other than the farthest recording layer from the light incidence plane in a desired manner.

Owner:TDK CORPARATION

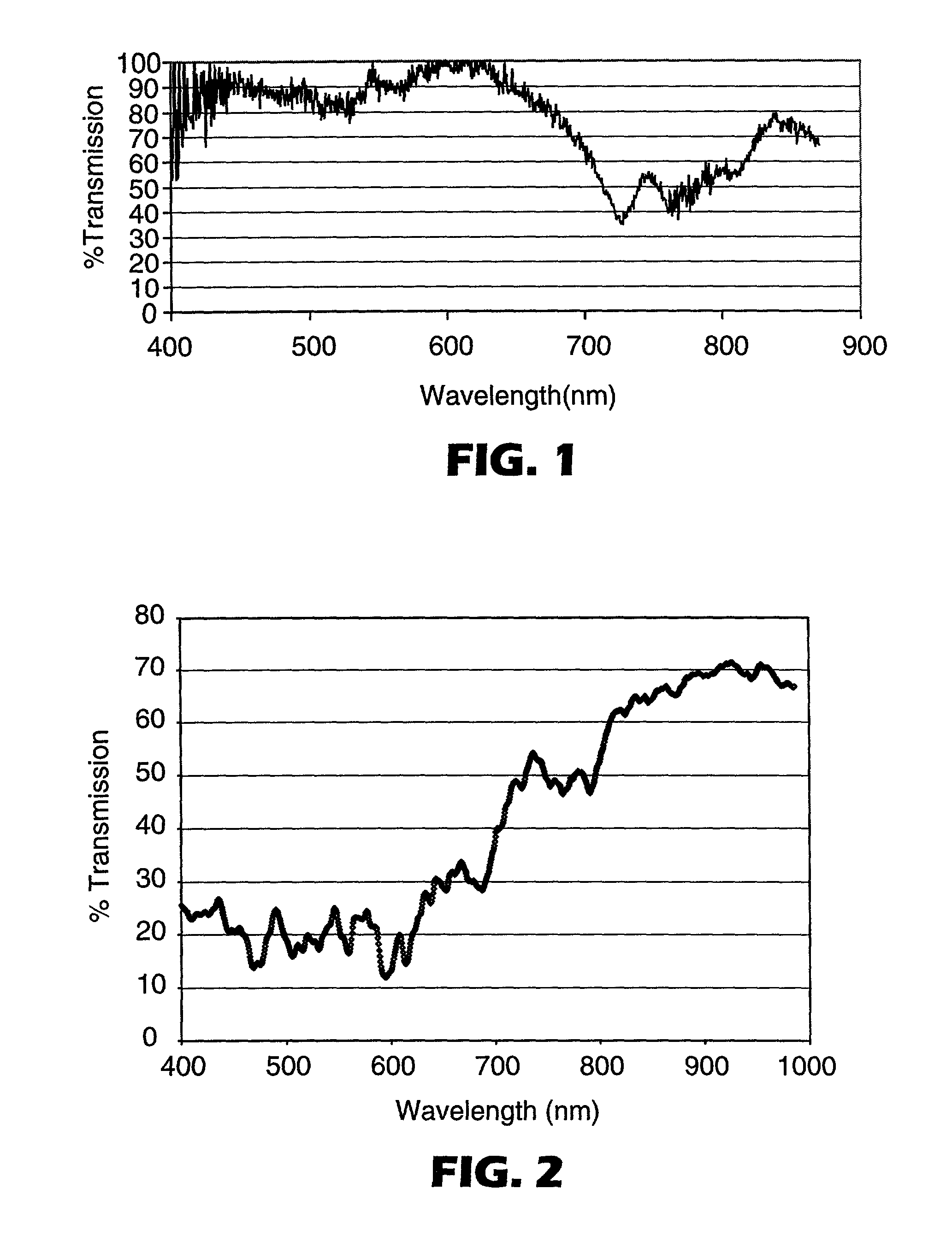

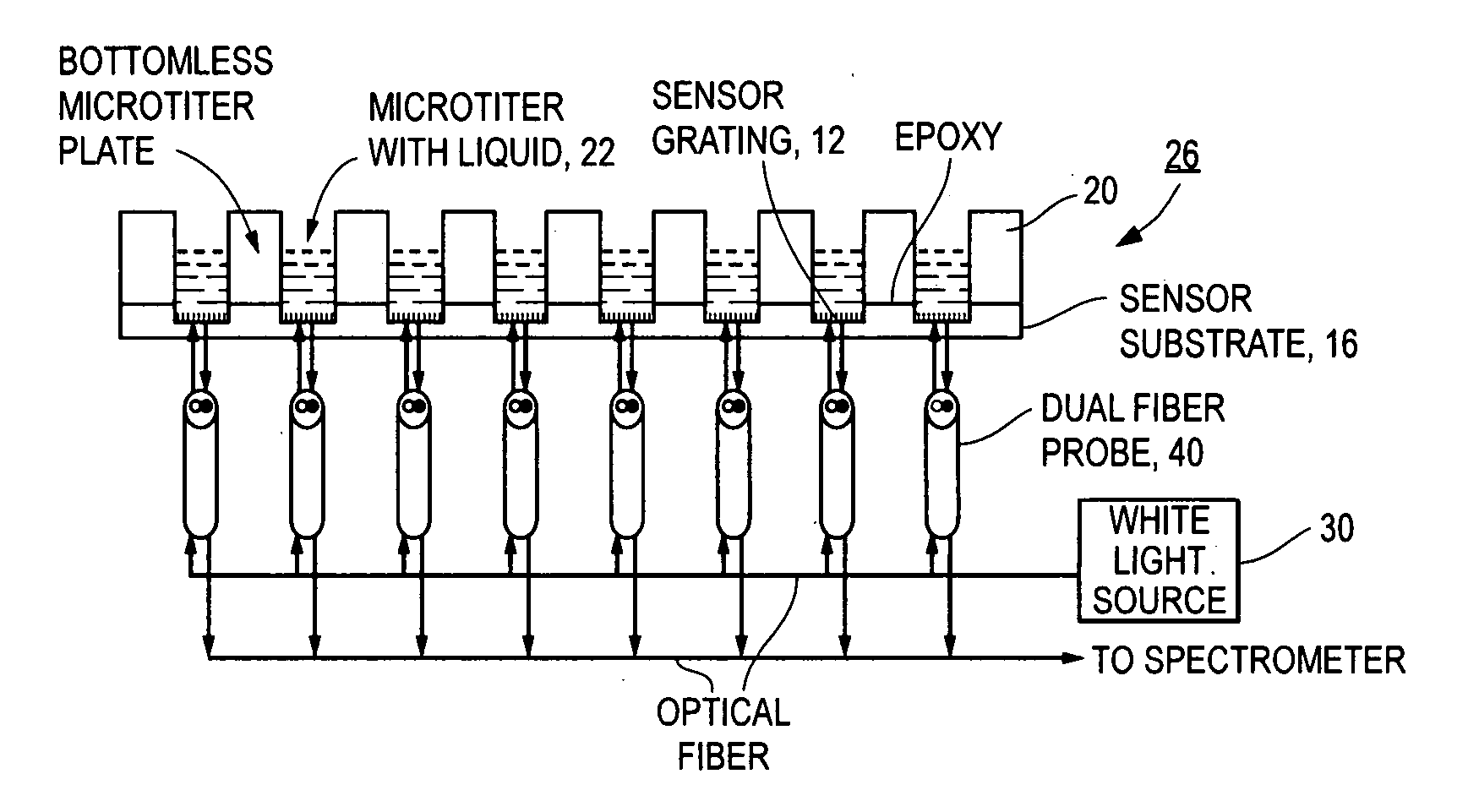

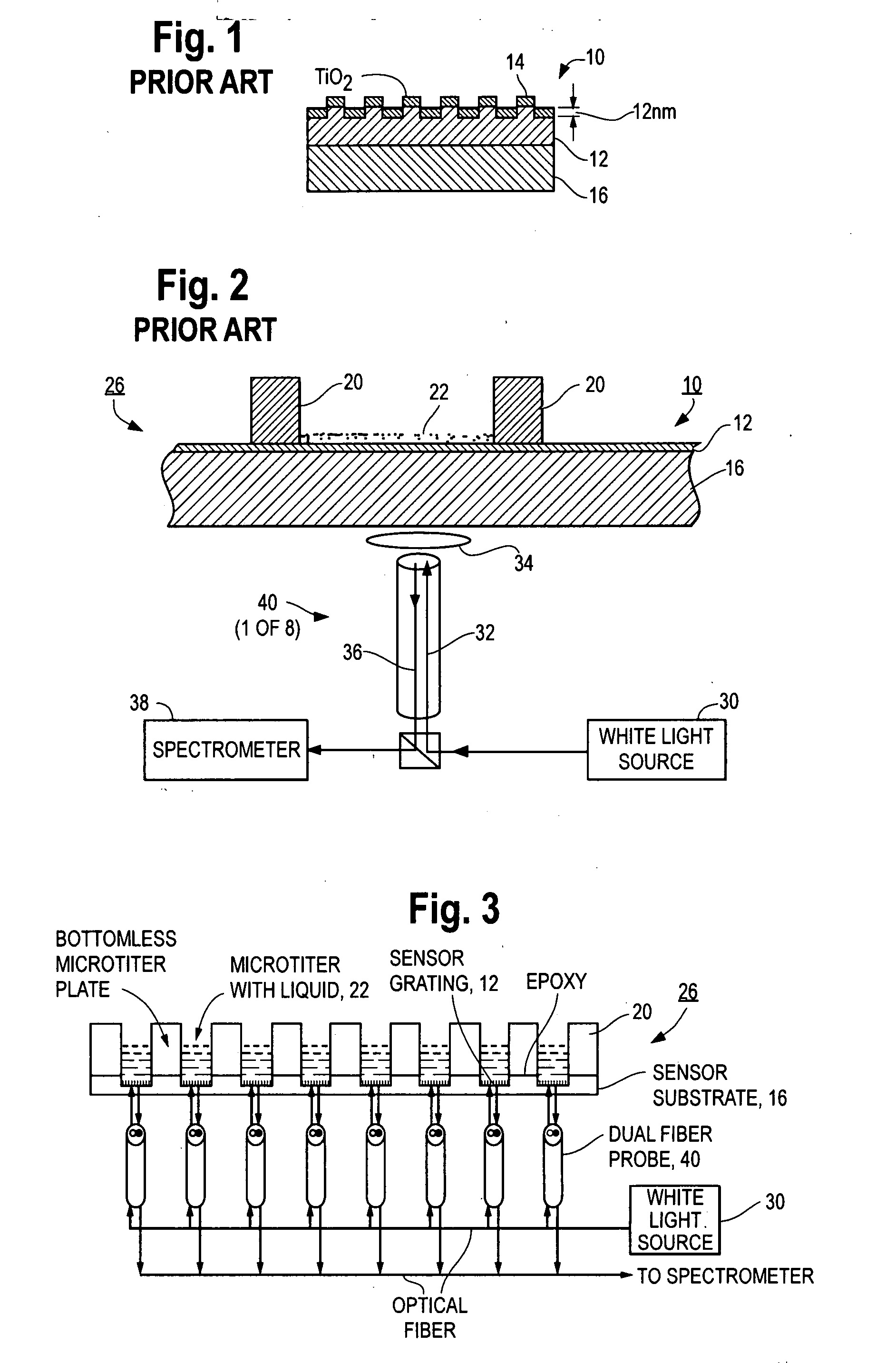

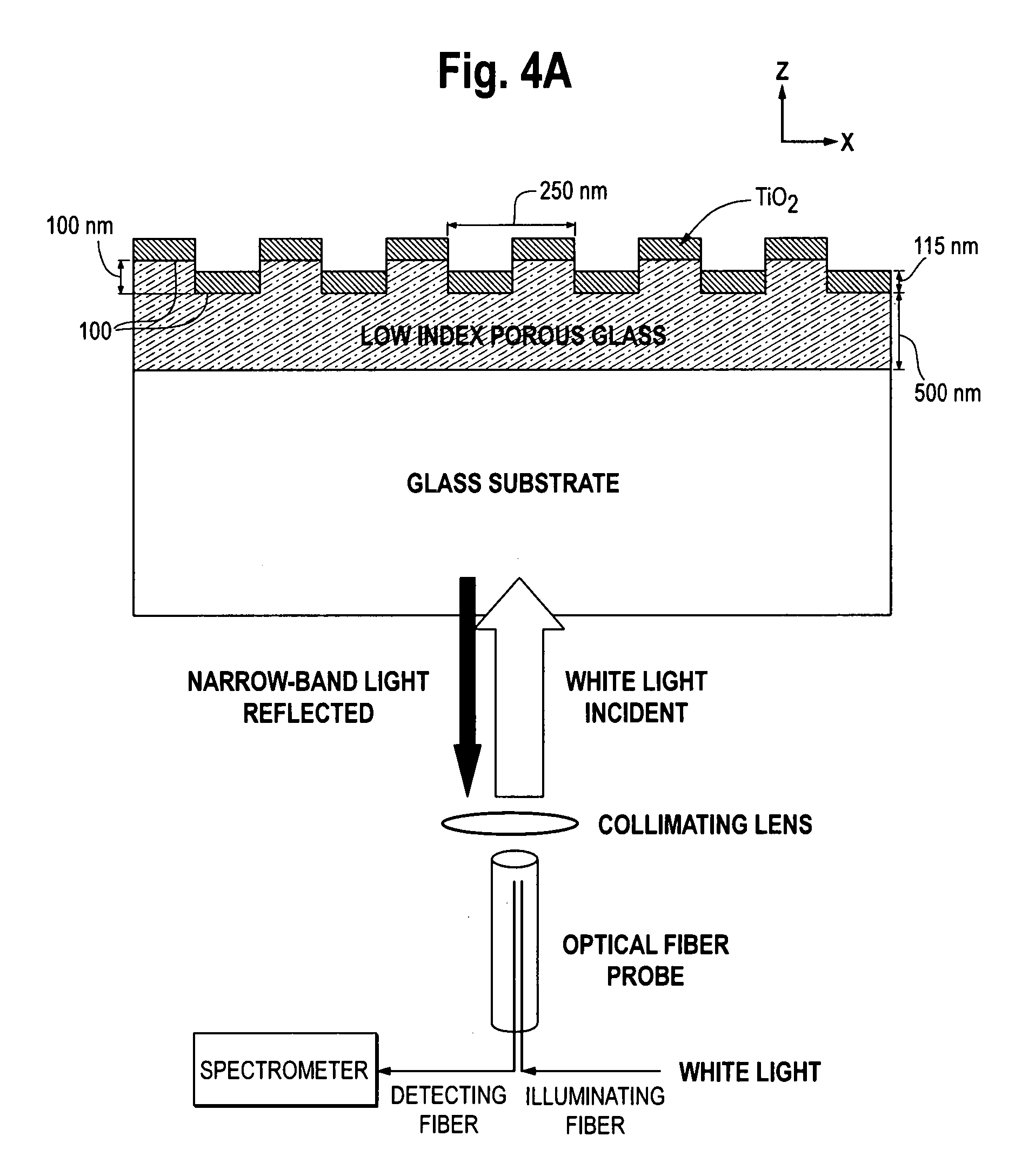

Near ultraviolet-wavelength photonic-crystal biosensor with enhanced surface to bulk sensitivity ratio

ActiveUS20080014632A1Improve detection resolutionEasy to adjustBioreactor/fermenter combinationsBiological substance pretreatmentsElectric fieldReflectivity

Biosensors are disclosed based on one- or two-dimensional photonic-crystal reflectance filters operating at near-ultraviolet wavelengths. Rigorous Coupled-Wave Analysis simulations predict a more tightly confined resonant electric field at the surface of this biosensor as compared to previously fabricated near-infrared photonic-crystal biosensors. This change in the resonant electric field provides an improvement of over 4.5 times in the surface-sensitivity to bulk-sensitivity ratio, and therefore enables enhanced detection resolution for biomolecules adsorbed on the biosensor surface. These new biosensors can be fabricated in mass by replica molding. They are especially well suited for applications requiring the detection of small molecules or ultra-low analyte concentrations.

Owner:X BODY

Thin film thickness and refractivity optical measurement method and its device

InactiveCN101261116ASimple processing methodEasy to getPhase-affecting property measurementsUsing optical meansInformation processingFourier transform on finite groups

The invention discloses an optical measurement method and devices used for measuring film thickness and refractive index. Light emitted out of a broadband light source generates an interference signal through interference structure, the spectrum information of the interference signal is detected and the fourier transform of the spectrum information is carried out, thus obtaining the optical path difference information of two optical paths which can generate the interference signal. Under known refractive index, a sample is arranged in an interference arm in the same type and is measured again, and the film thickness can be obtained by comparing the information of twice optical path differences. If the refractive index is unknown, the film is required to be rotated by an angle, and the refractive index and the thickness of the film can be worked out by the measurement of a third time. The optical measurement method and the devices used for measuring film thickness and refractive index adopt an optical method and have no damage to the sample; the resolution is micro level and the measured range can achieve millimeter level. Furthermore, the sample is not required to be strictly attached onto a sample platform; meanwhile, the information processing method is simple, and the information of the thickness and the refractive index of transparent or half-transparent film can be conveniently obtained in real time.

Owner:HUAZHONG UNIV OF SCI & TECH

Silica-magnesium fluoride hydrate composite sols and process for their preparation

InactiveUS6291535B1Low refractive indexEasy to prepareMagnesium fluoridesMaterial nanotechnologyOrganic solventMagnesium salt

A sol comprising silica-magnesium fluoride hydrate composite colloidal particles used in an anti-reflection coating material for forming an anti-reflection coating and a process for its preparation are provided. A sol comprising silica-magnesium fluoride hydrate composite colloidal particles having a ratio of silica to magnesium fluoride hydrate MgF2.nH2O, n being in the range between 0.25 and 0.5, in terms of a SiO2 / MgF2 weight ratio of from 0.01 to 5 and a primary particle size of 5 to 50 nm. A process for the preparation of an aqueous sol comprising silica-magnesium fluoride hydrate composite colloidal particles which comprises the steps of adding an aqueous fluoride solution to a mixture liquid of a silica sol and an aqueous magnesium salt solution to produce a slurry of an agglomerate comprising silica-magnesium fluoride hydrate composite colloidal particles and removing the salts formed as by-products. A process for the preparation of an organosol further comprising the step of replacing water in the aqueous sol with an organic solvent.

Owner:NISSAN CHEM IND LTD

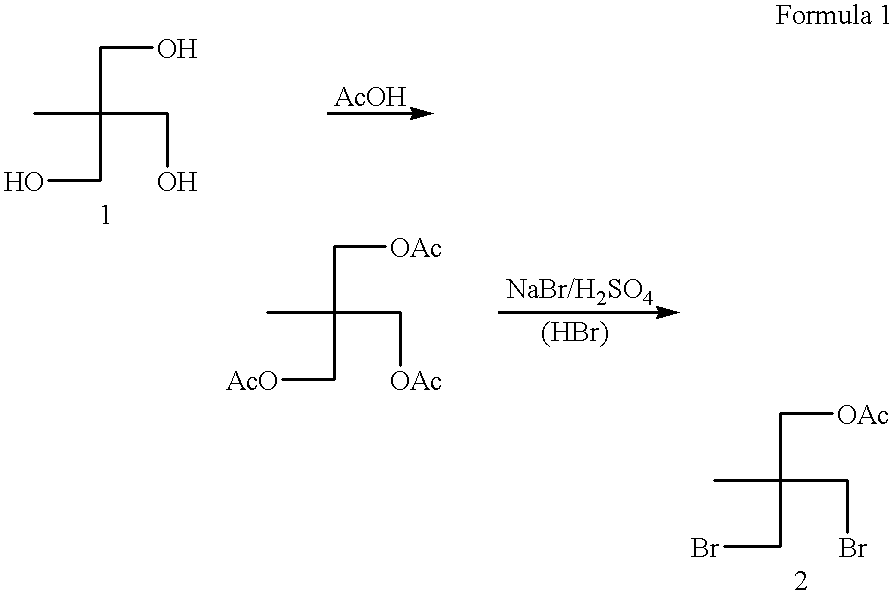

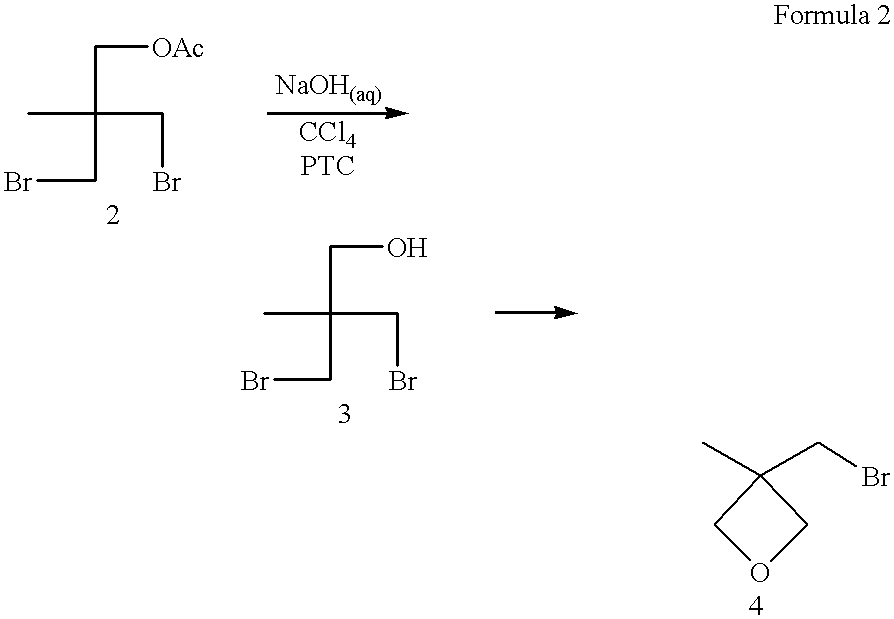

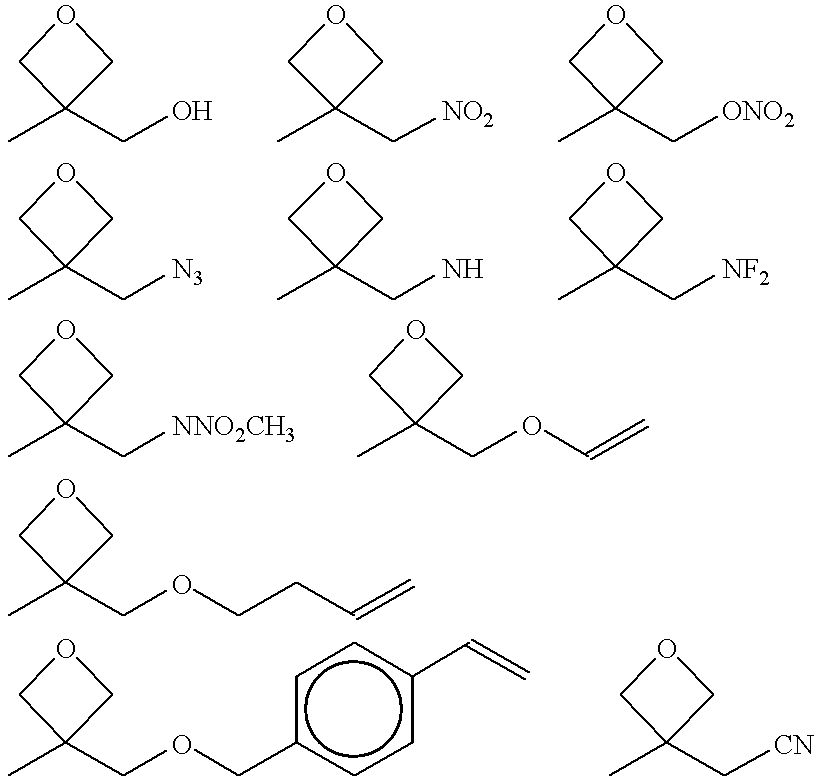

Copolymers and coprepolymers formed from mono-substituted fluorinated oxetane monomers and tetrahydrofuran

InactiveUS6380351B1Improve hydrophobicityLower surface energyOrganic chemistry methodsPolyurea/polyurethane coatingsSide chainButane

Owner:AEROJET GENERAL CORP +1

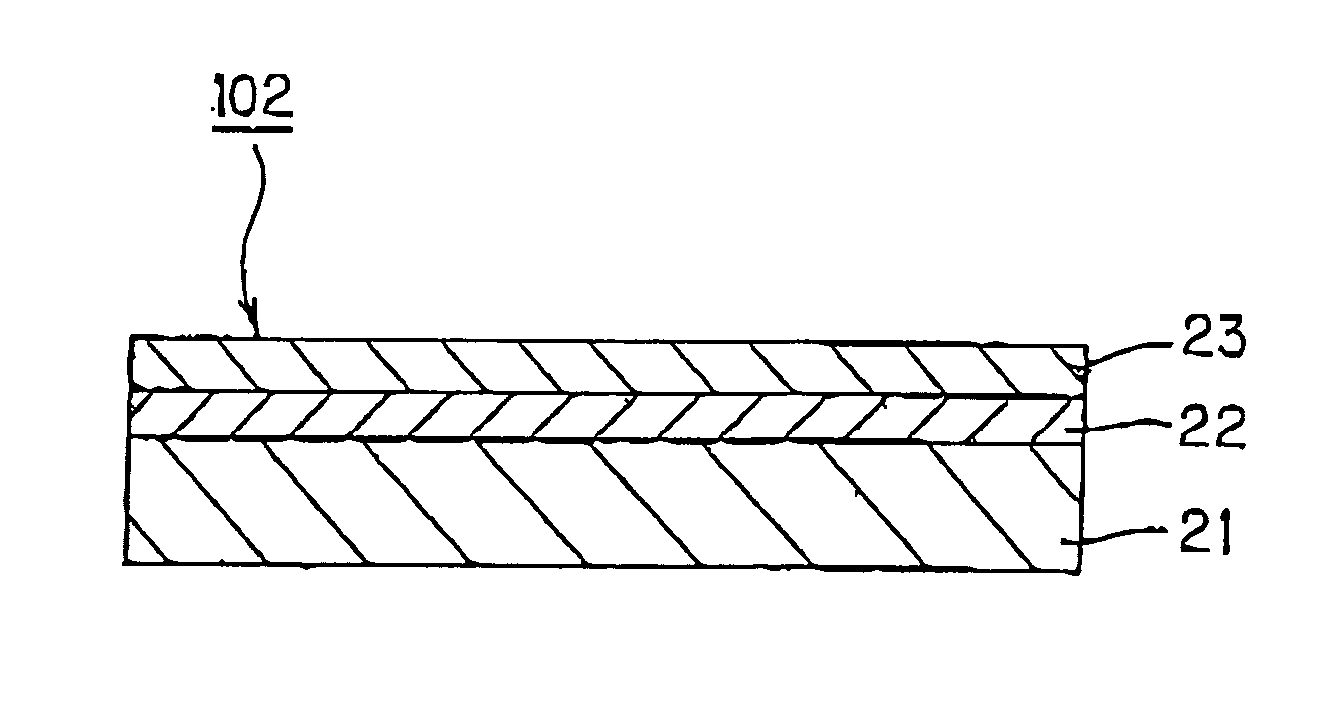

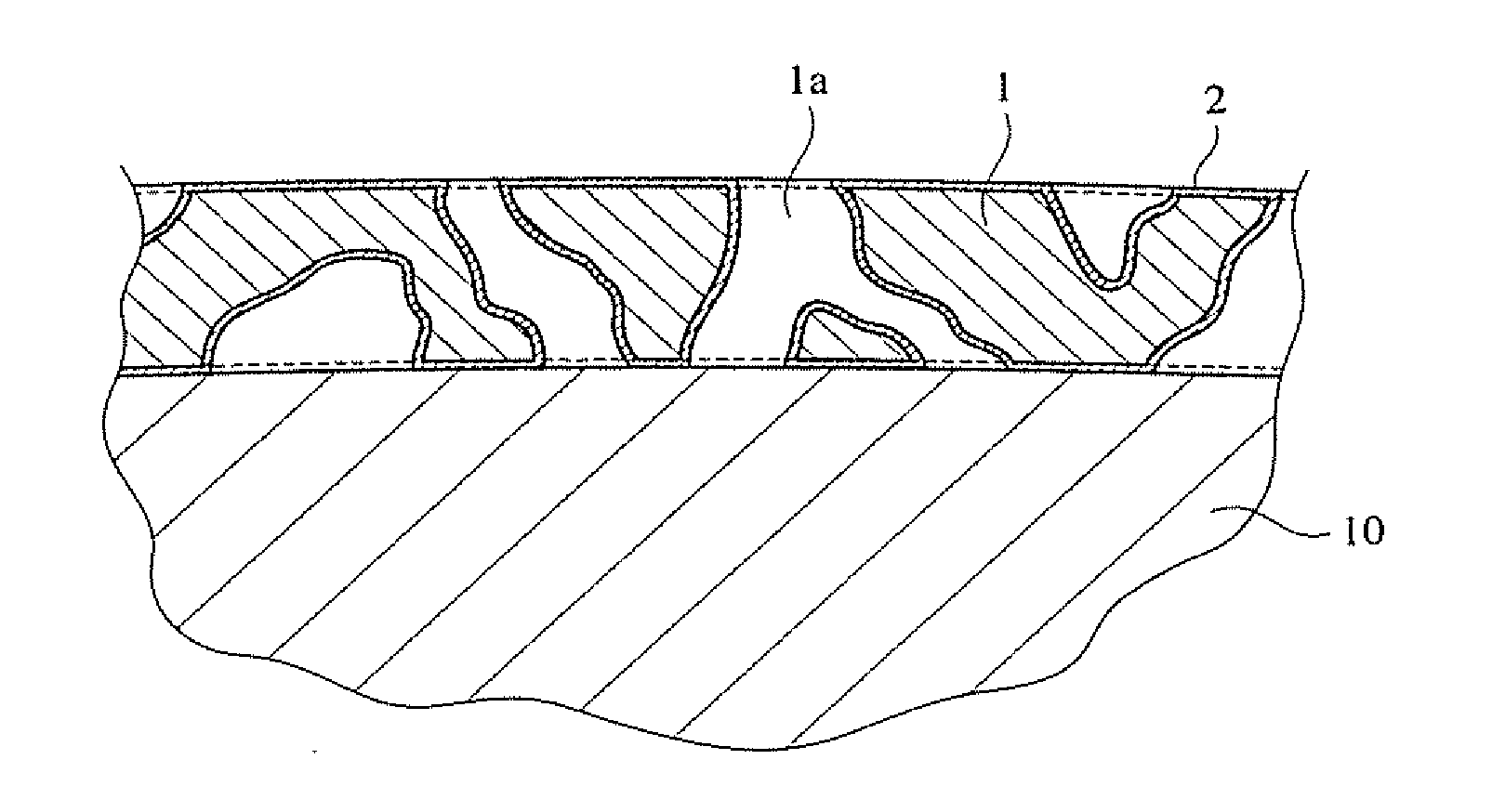

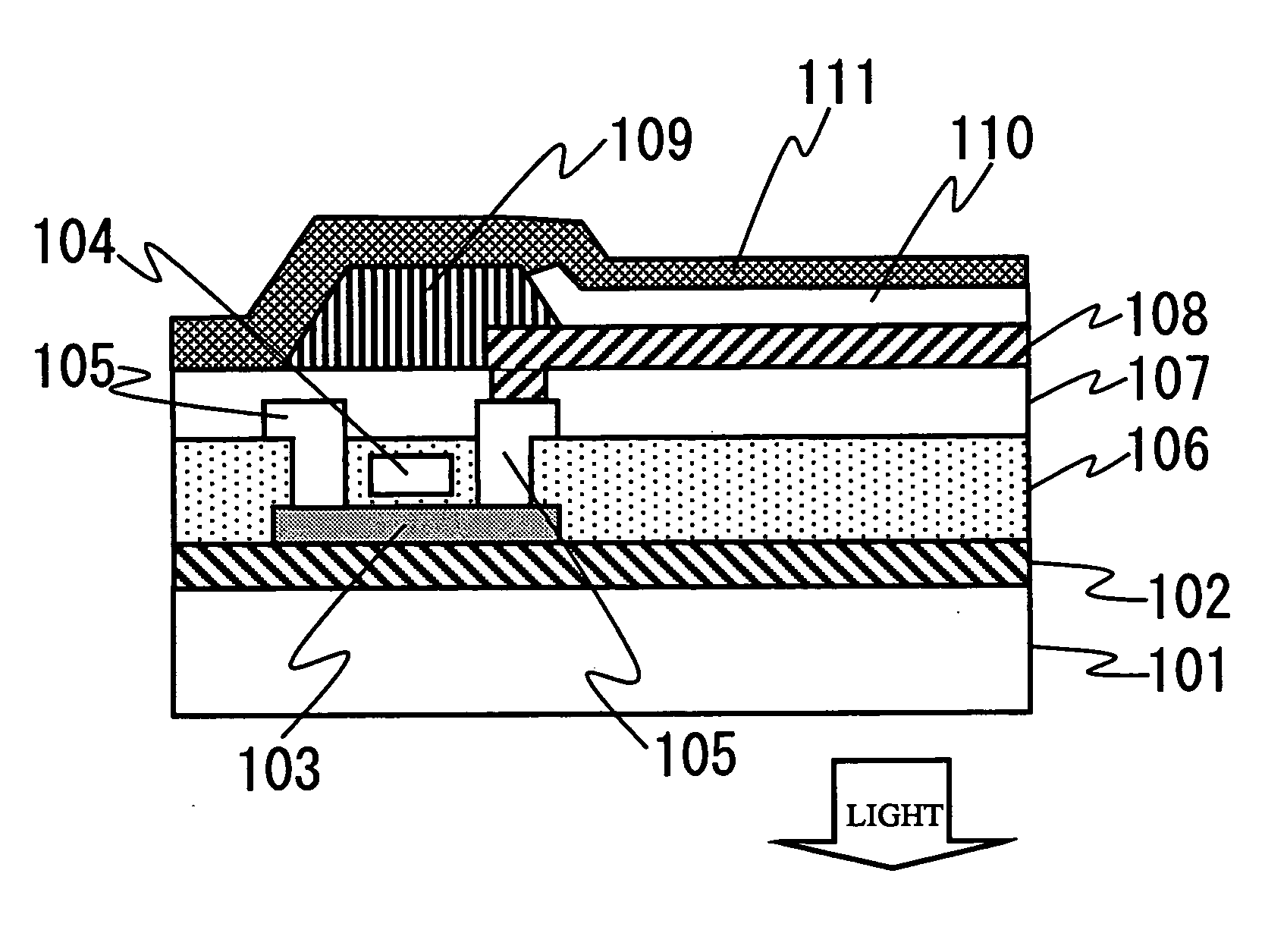

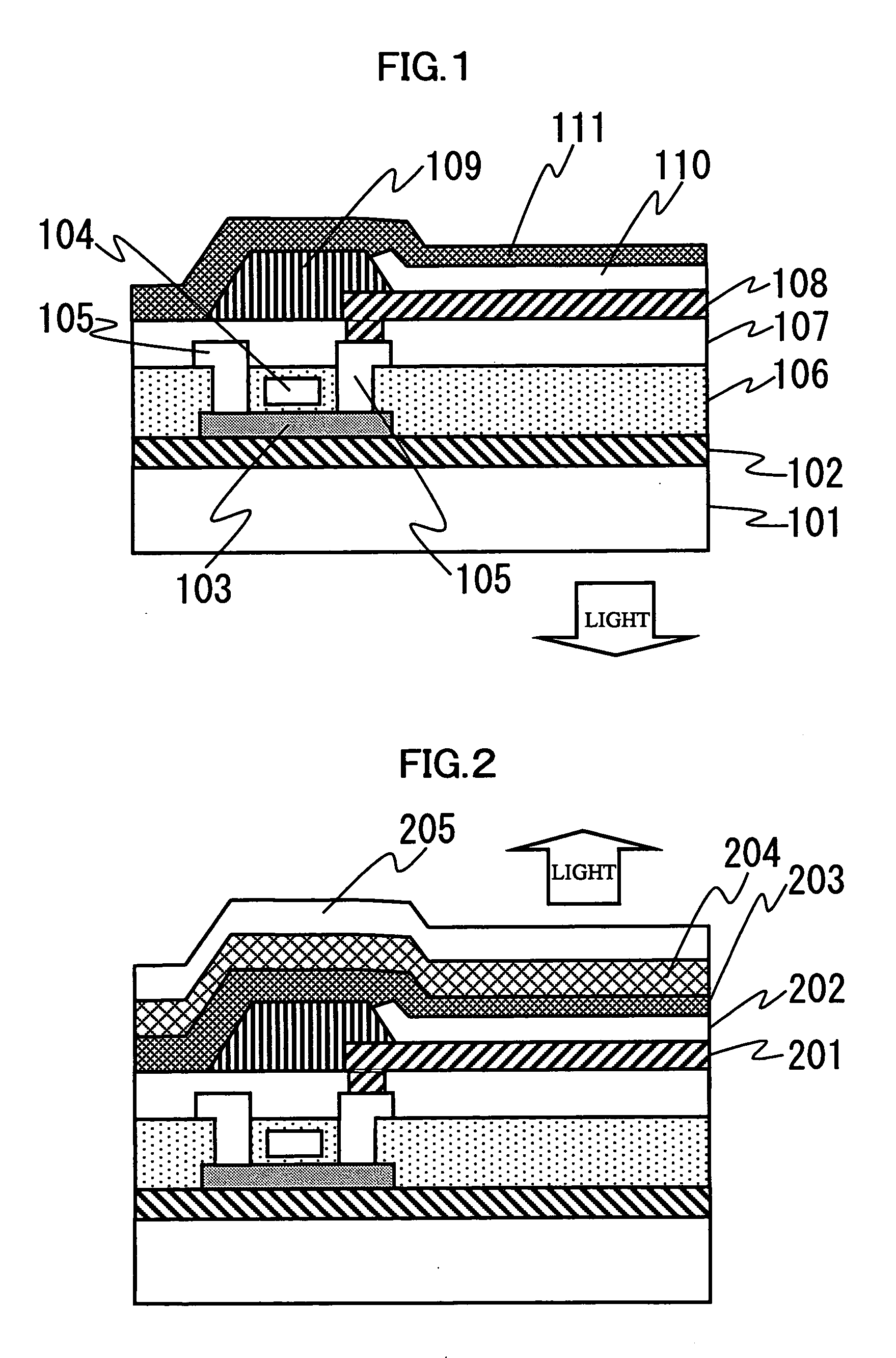

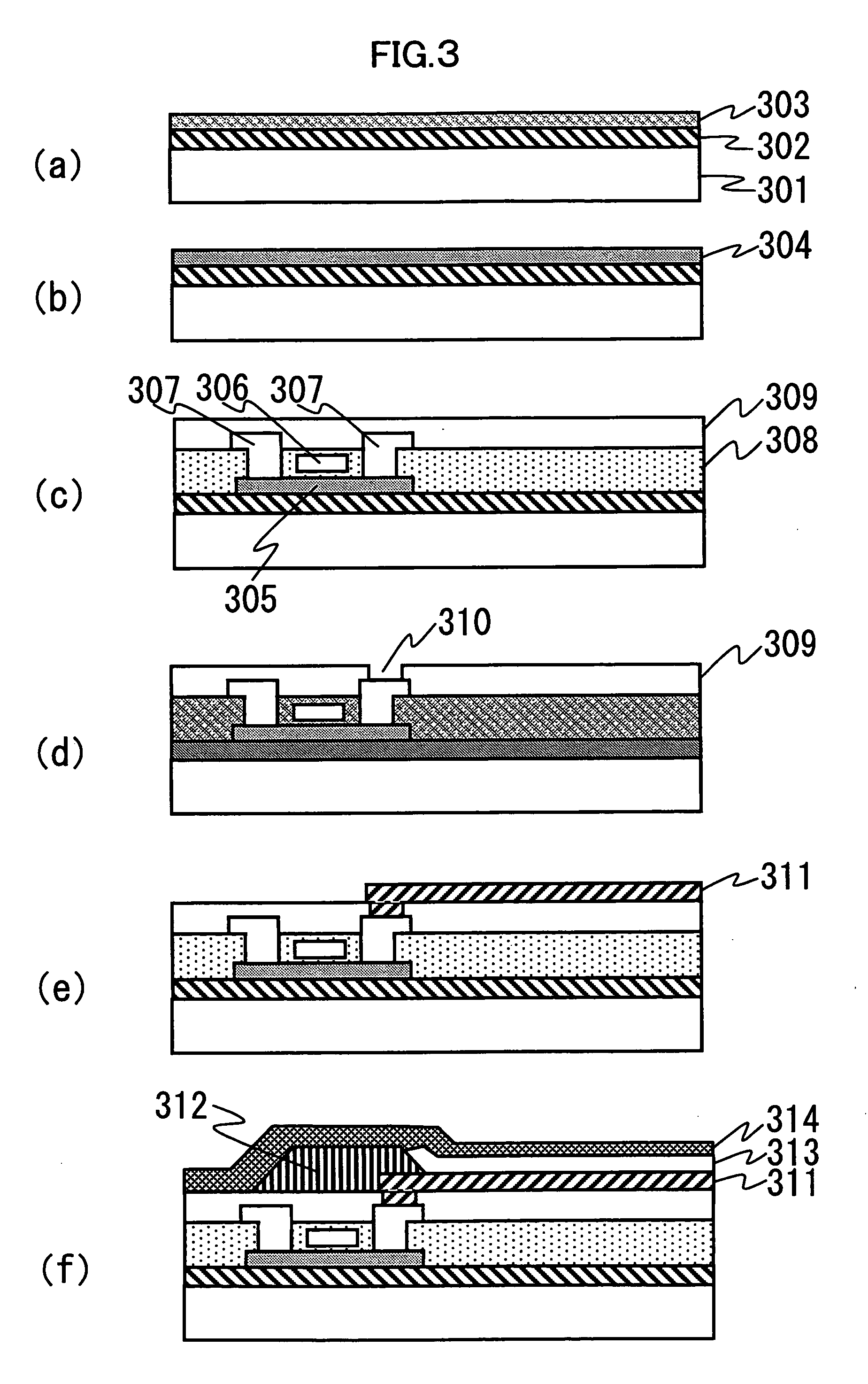

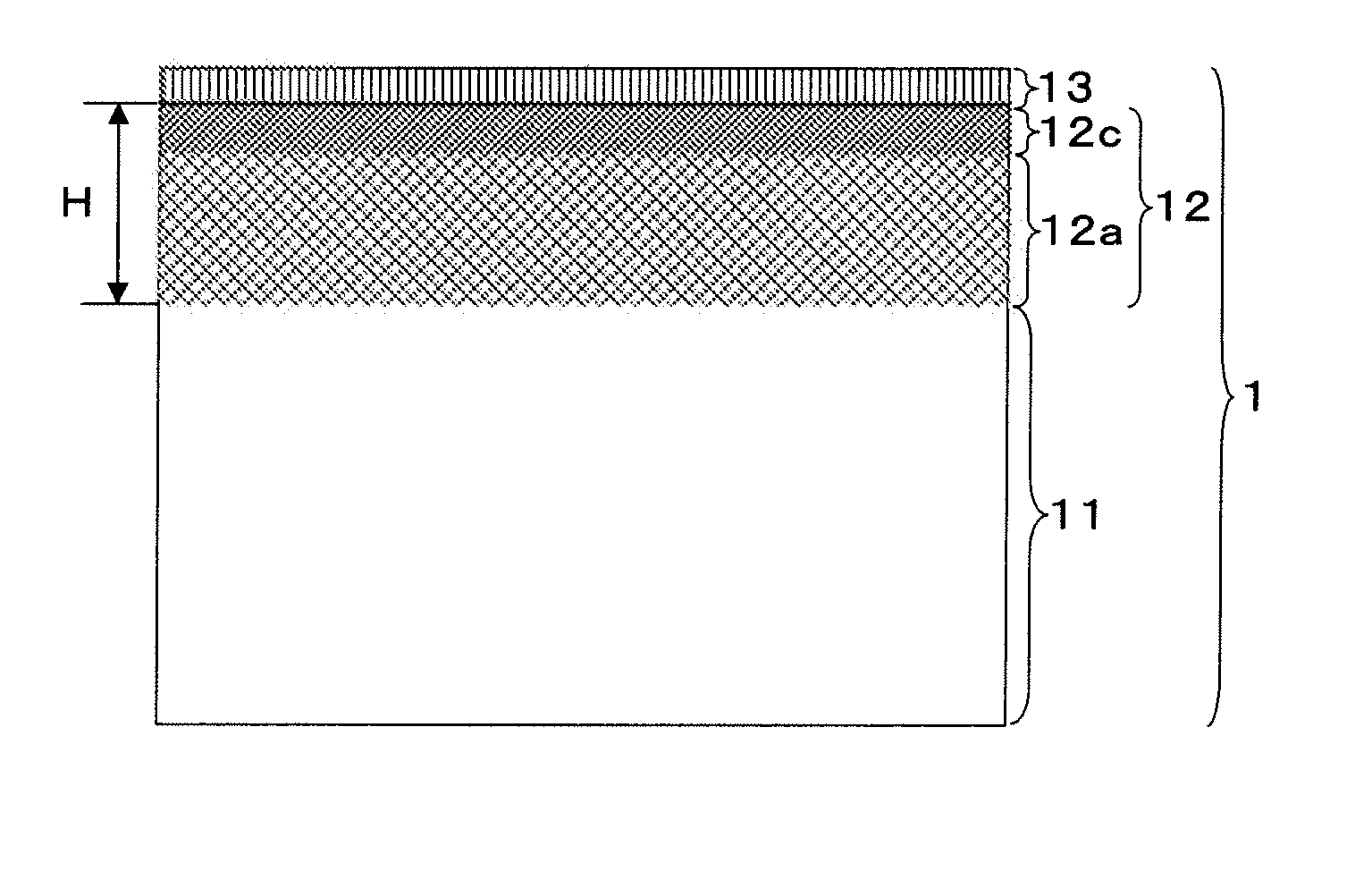

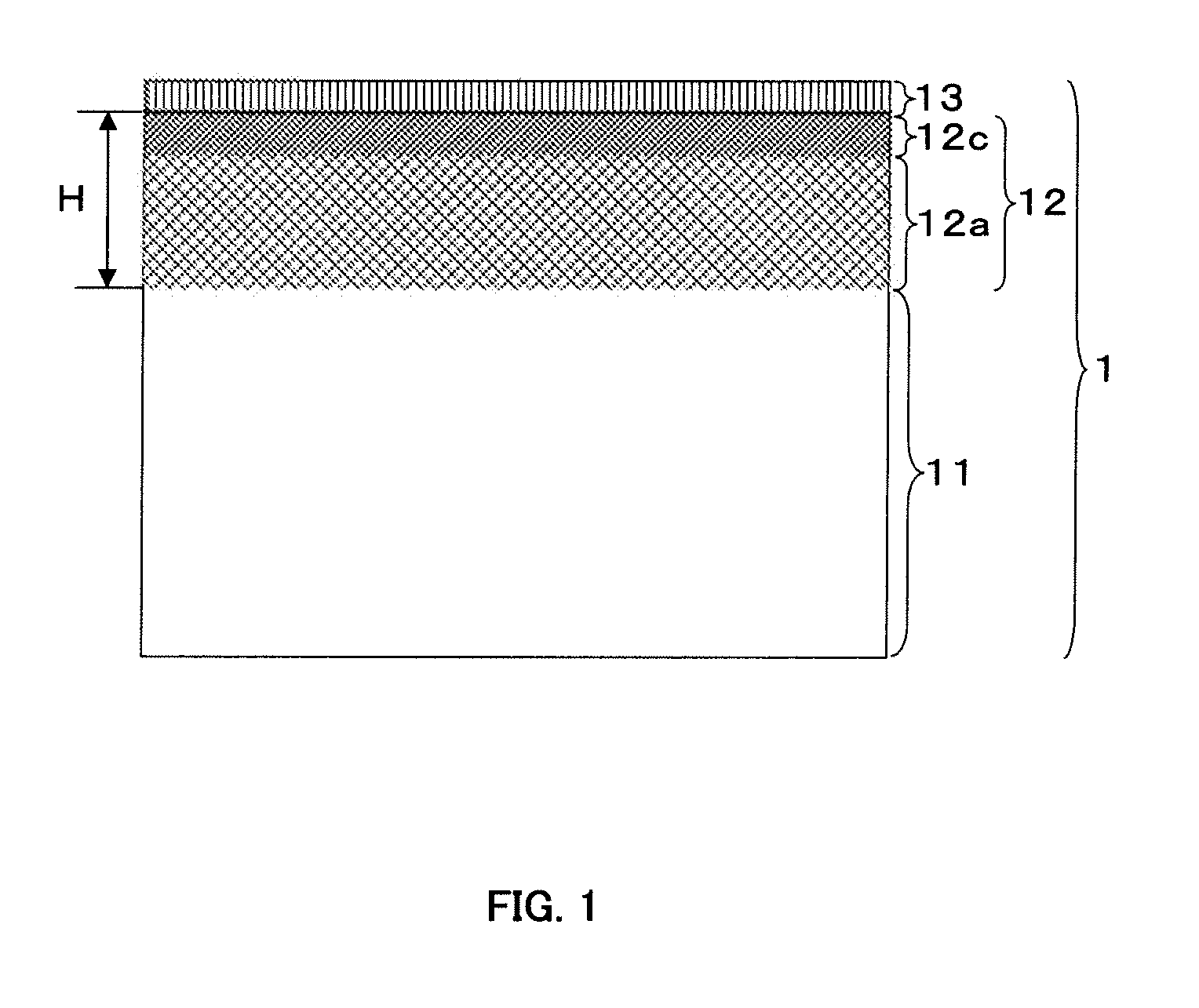

Organic light emitting diode display and method for manufacturing the same

ActiveUS20050156520A1Decreasing density of filmCoefficient loweredDischarge tube luminescnet screensElectroluminescent light sourcesActive matrixRefractive index

An active matrix type organic light emitting diode display serving as a bottom emission type device coupling out emission of an organic electroluminescence layer from a substrate where thin film transistors are formed or as a top emission type device coupling out the emission on the opposite side to the substrate. In a suitable layer (102, 106, 107) in each device, an insulating film containing SiO is formed. The insulating film is porous with nano pores in the film. The porous insulating film is controlled as to film density, film refractive index, nano pore diameter in film, average nano pore diameter in film and maximum nano pore diameter in film so that the refractive index is lower than that of a transparent electrode or a transparent substrate of the display holding the organic electroluminescence layer therebetween, and nano pores are present in the film. Light scattering effect can be obtained so that emission from the organic electroluminescence layer (110) can be coupled out to the outside efficiently.

Owner:SAMSUNG DISPLAY CO LTD +1

Anti-Reflection Film And Manufacturing Method Thereof

ActiveUS20100208350A1Good optical performanceLow refractive indexLayered productsPolarising elementsOptical propertyRefractive index

The present invention provides an anti-reflection film which has not only sufficient anti-reflection properties and antistatic properties but also excellent optical properties. The anti-reflection film of the present invention includes an antistatic hard coat layer and a low refractive index layer on a transparent substrate, the antistatic hard coat layer containing conductive particles and a binder matrix, the antistatic hard coat layer including a mixed layer in which the transparent substrate component and the binder matrix blend together with a gradient and a localized layer, the mixed layer being optically indistinguishable and the localized layer being optically distinguishable, and the localized layer having an optical thickness in the range of 50-400 nm.

Owner:TOPPAN PRINTING CO LTD

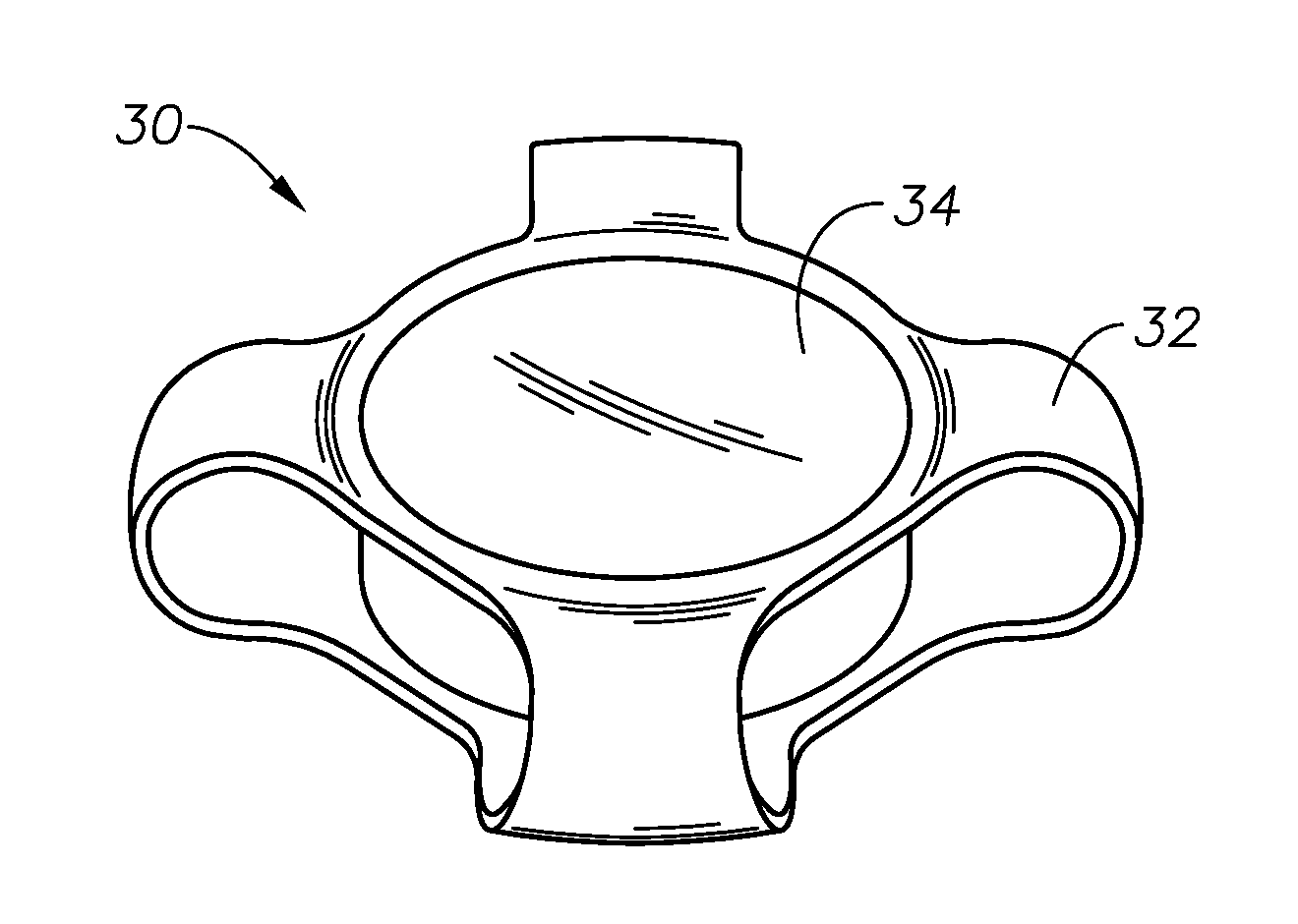

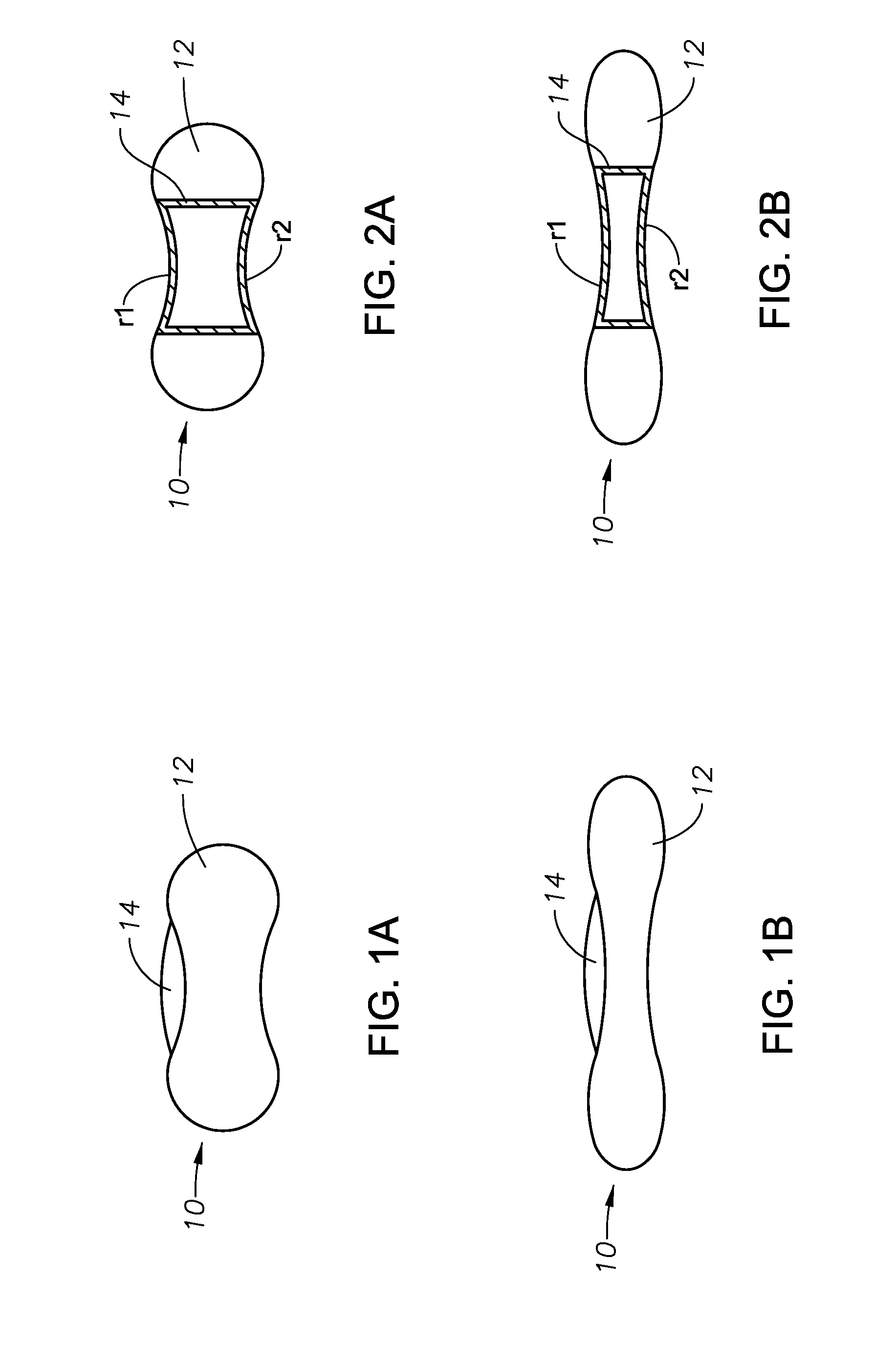

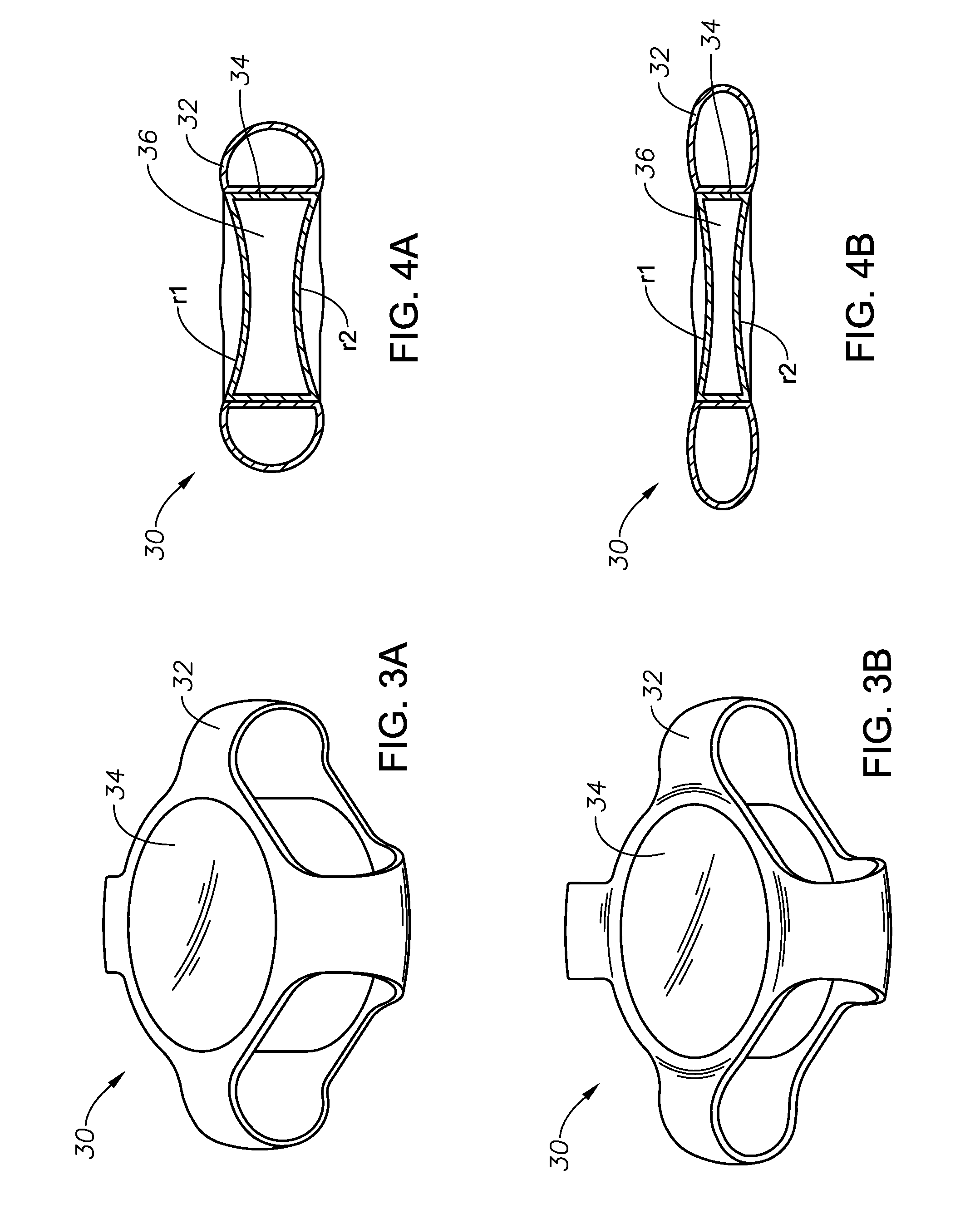

Presbyopia-correcting iol using curvature change of an air chamber

ActiveUS20140172092A1Improve accommodation effectOptimization rangeOptical articlesIntraocular lensIntraocular lensRefractive index

An accommodative intraocular lens (IOL) system is disclosed for insertion into an eye to provide accommodative vision, the system including a deformable air chamber filled with a transparent, low refractive index medium disposed between the first and second optics; and at least one haptic connected to the air chamber and configured to facilitate a change in the curvature of at least one surface of the chamber, such that when the lens system is positioned in an eye, cilliary muscle movements can alter the curvature of the air chamber and vary the overall lens power of the system.

Owner:ALCON INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com