Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73772results about How to "Improve wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

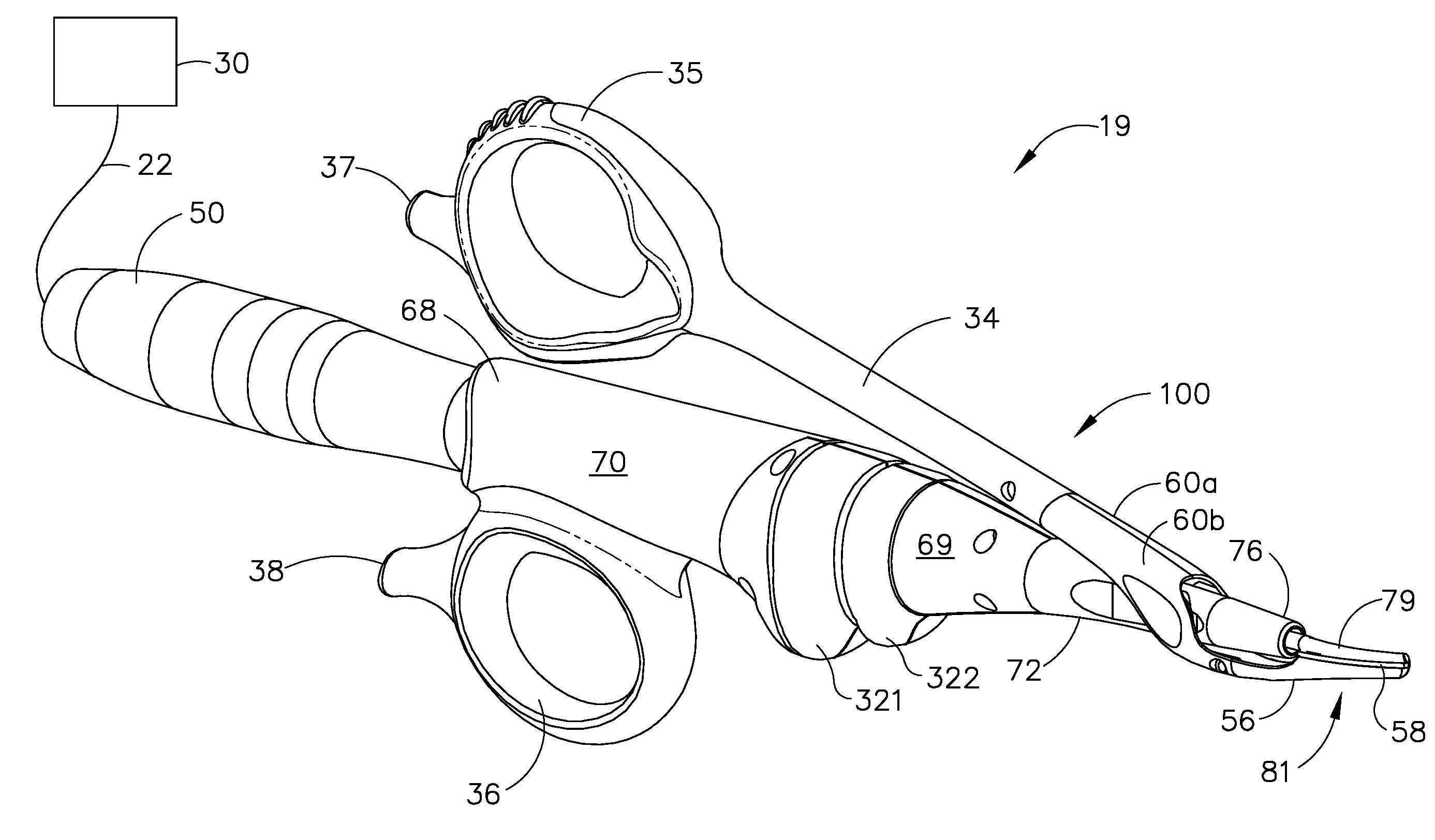

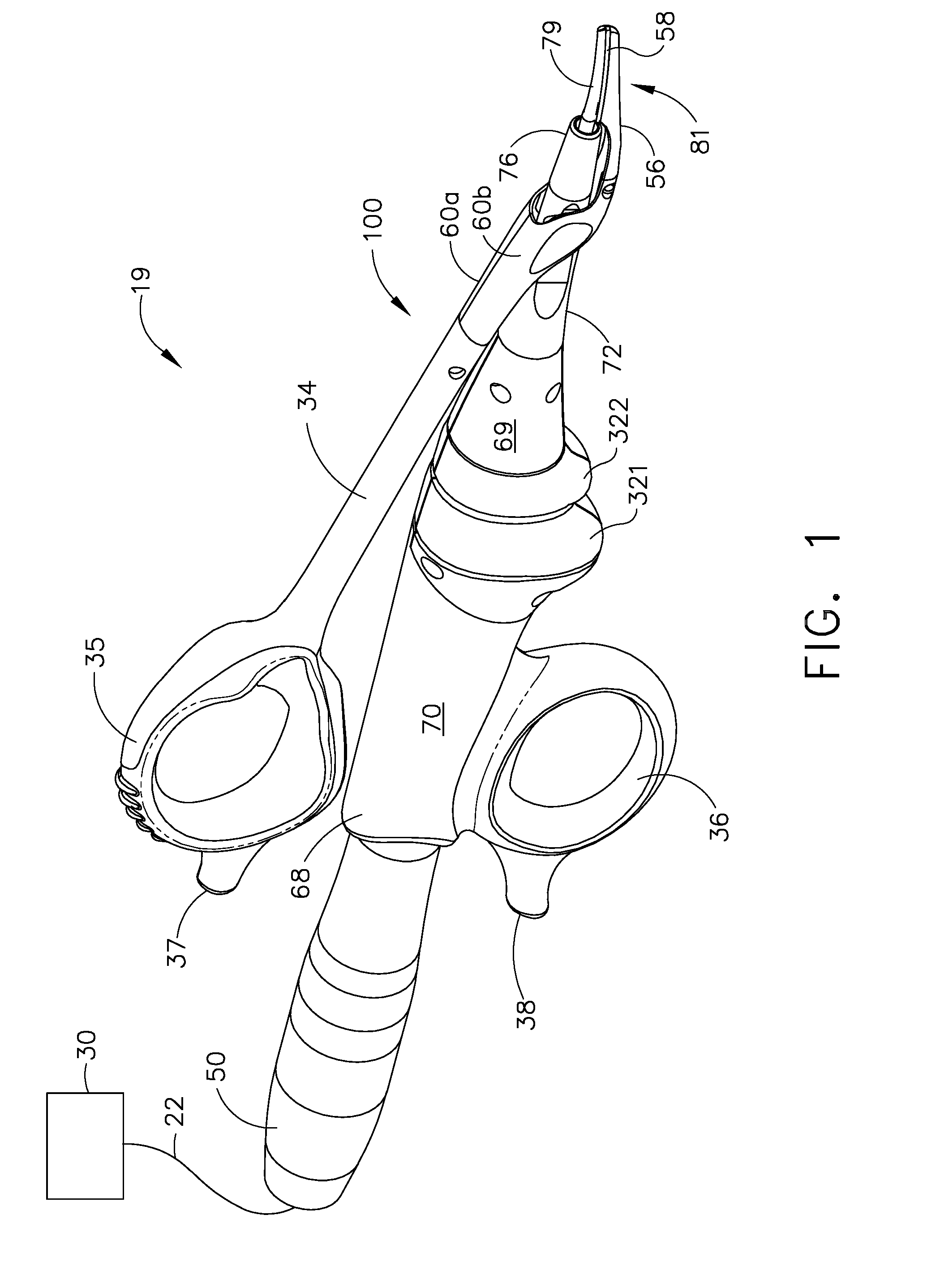

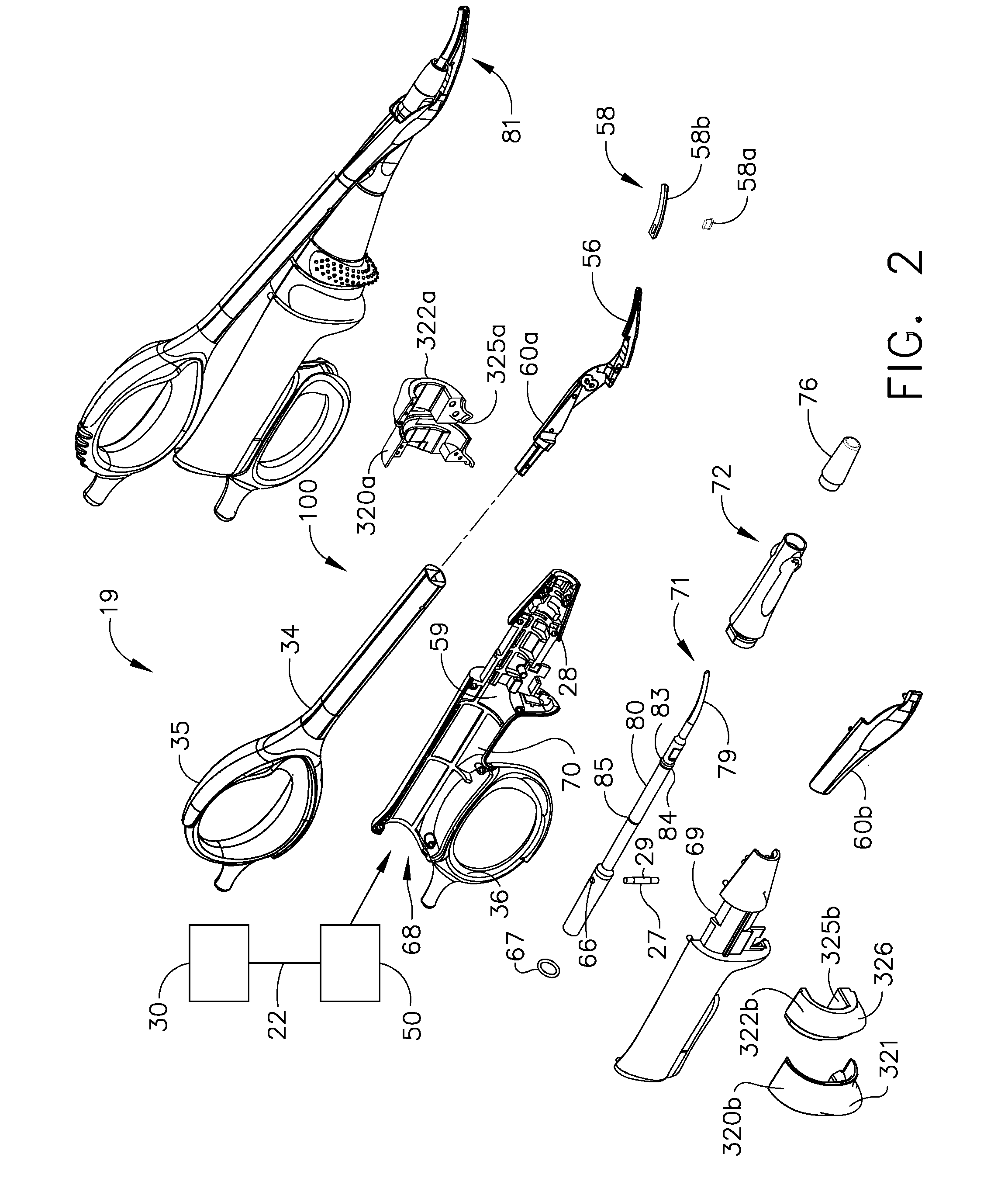

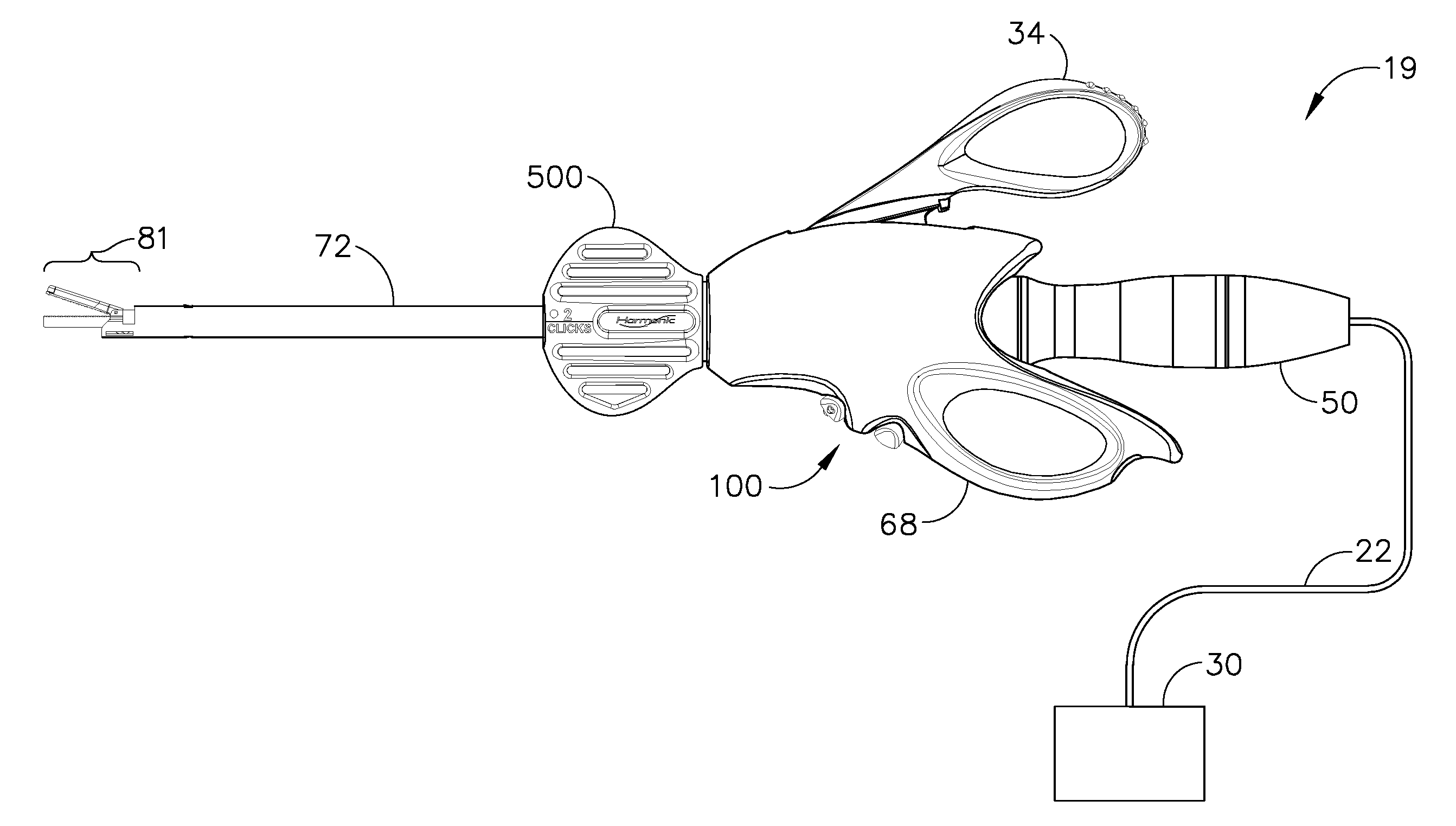

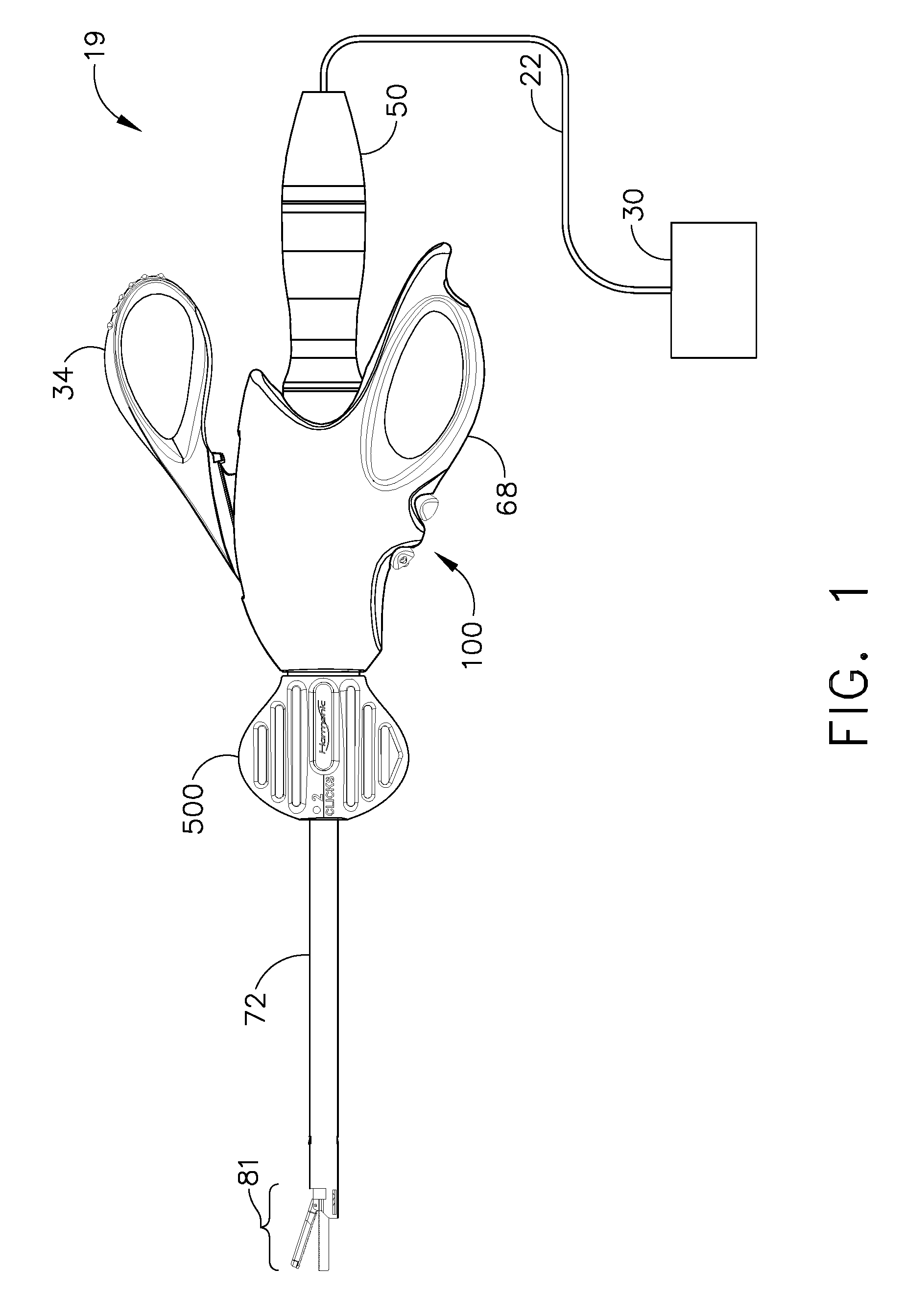

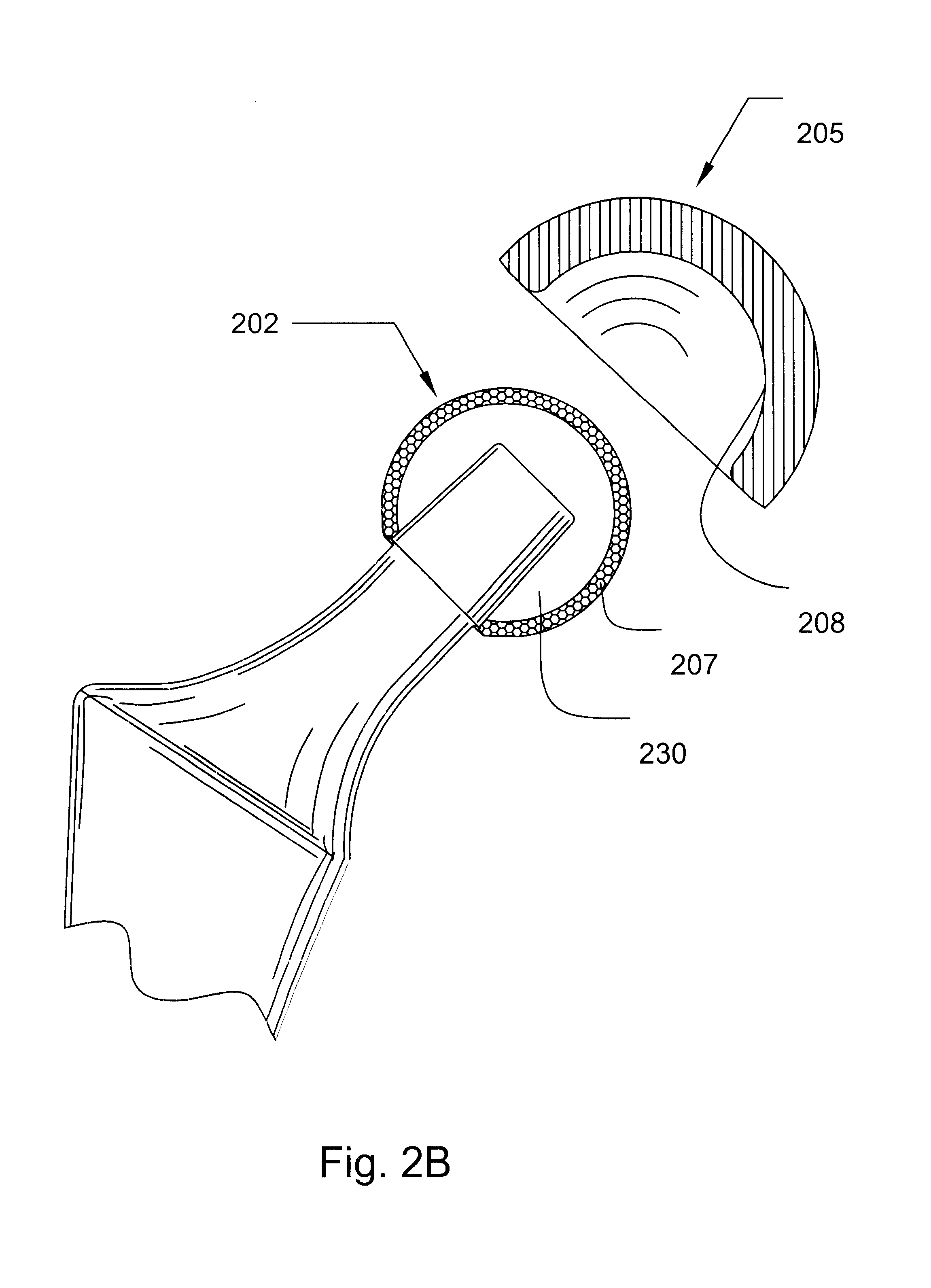

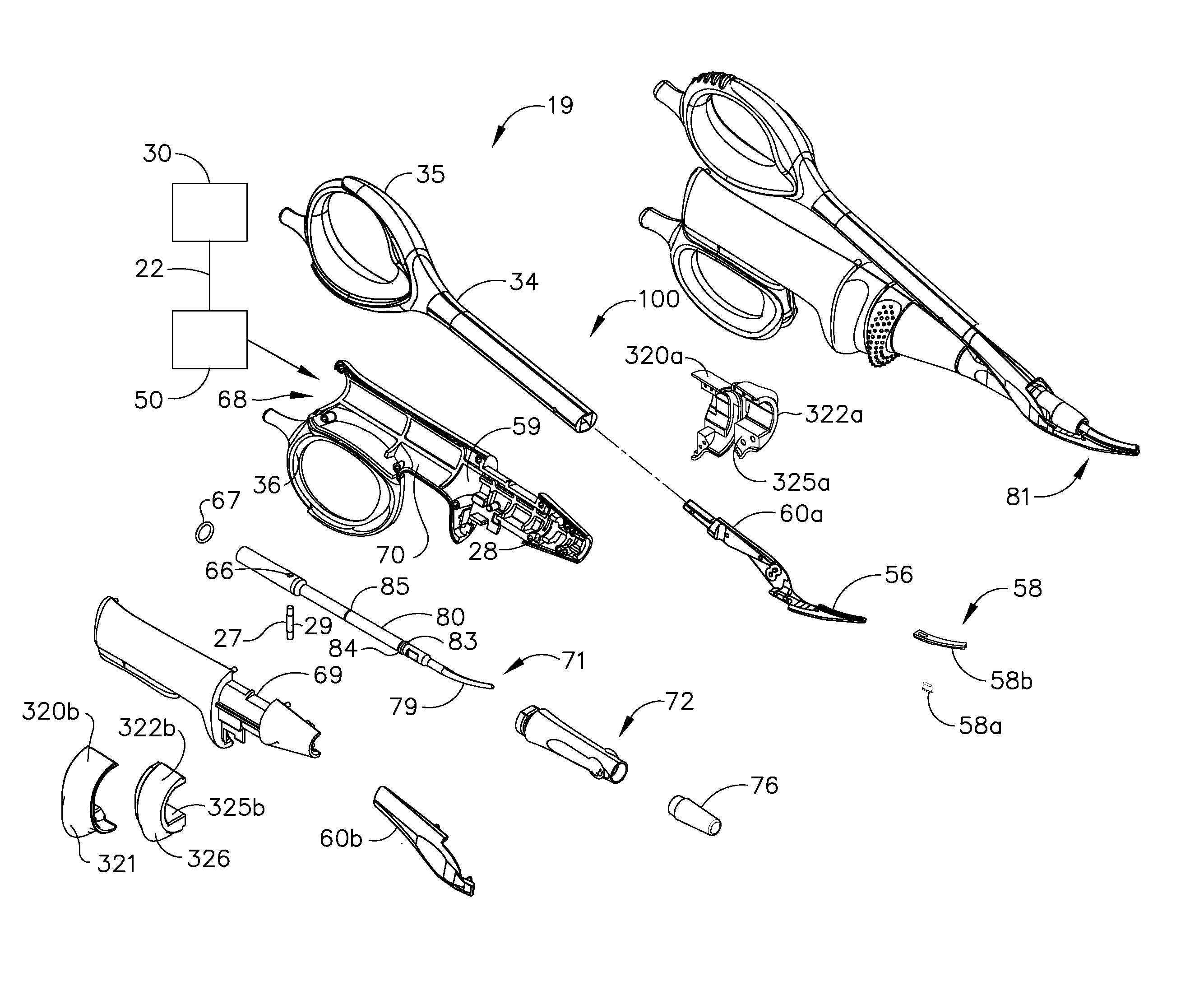

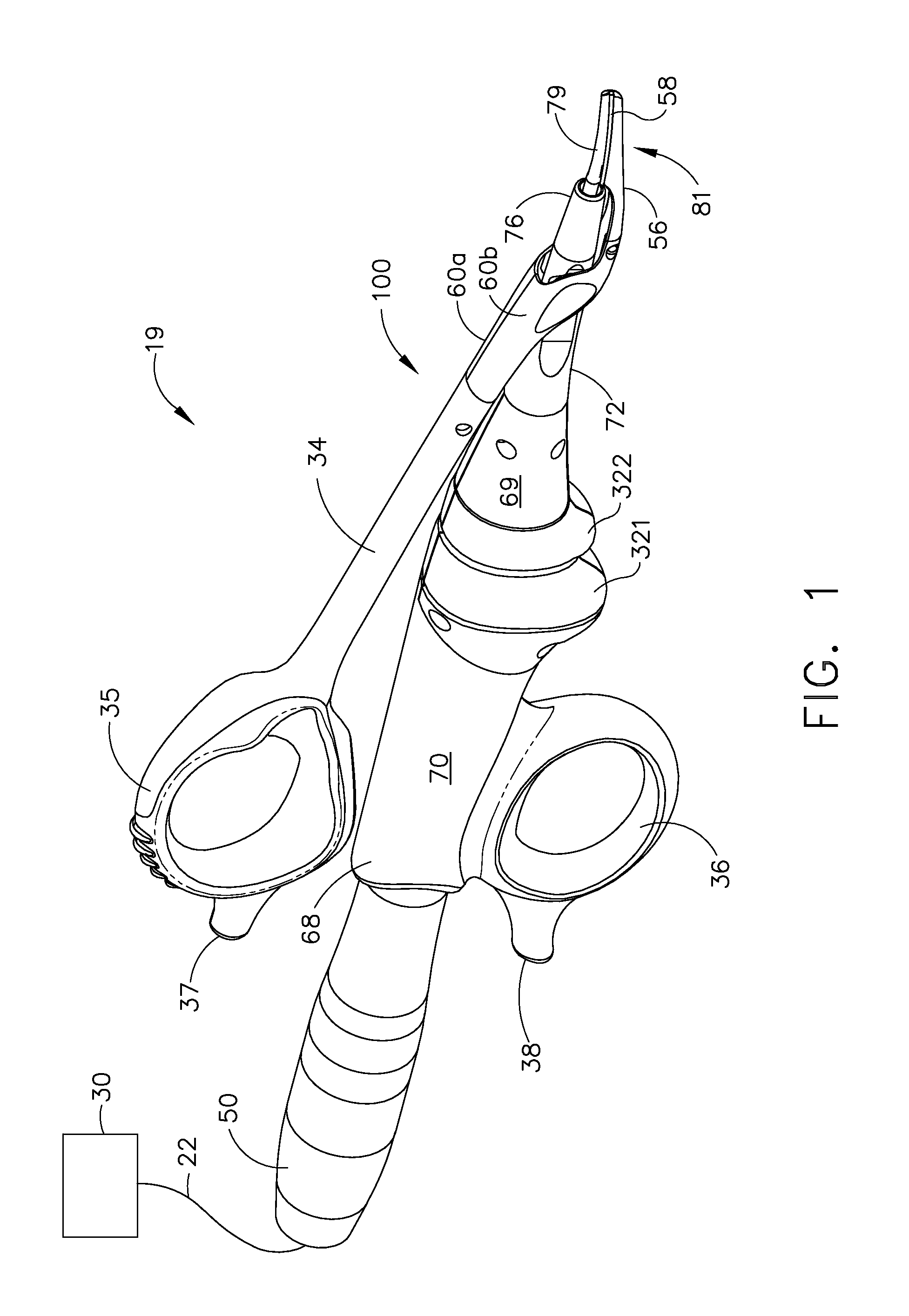

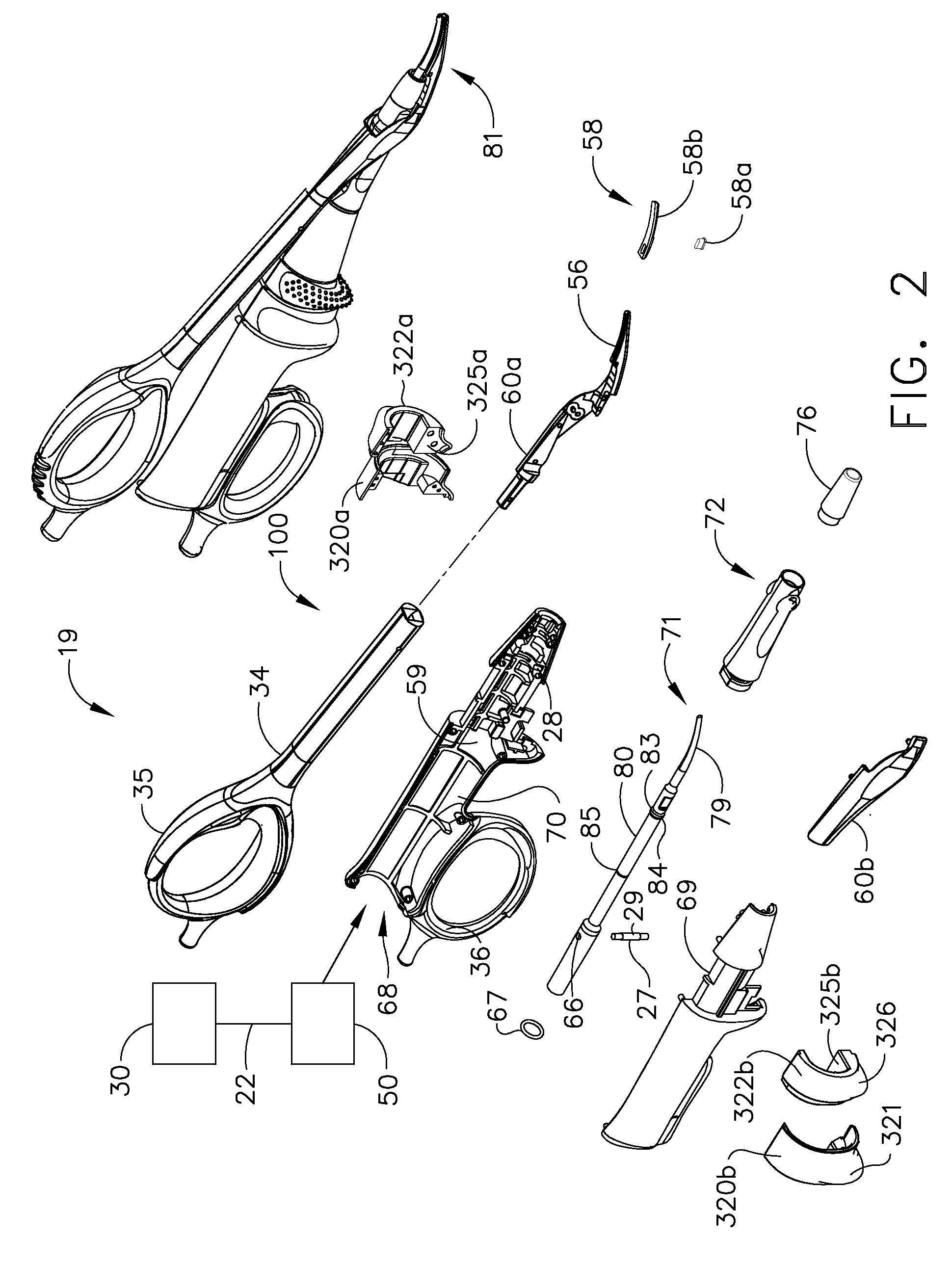

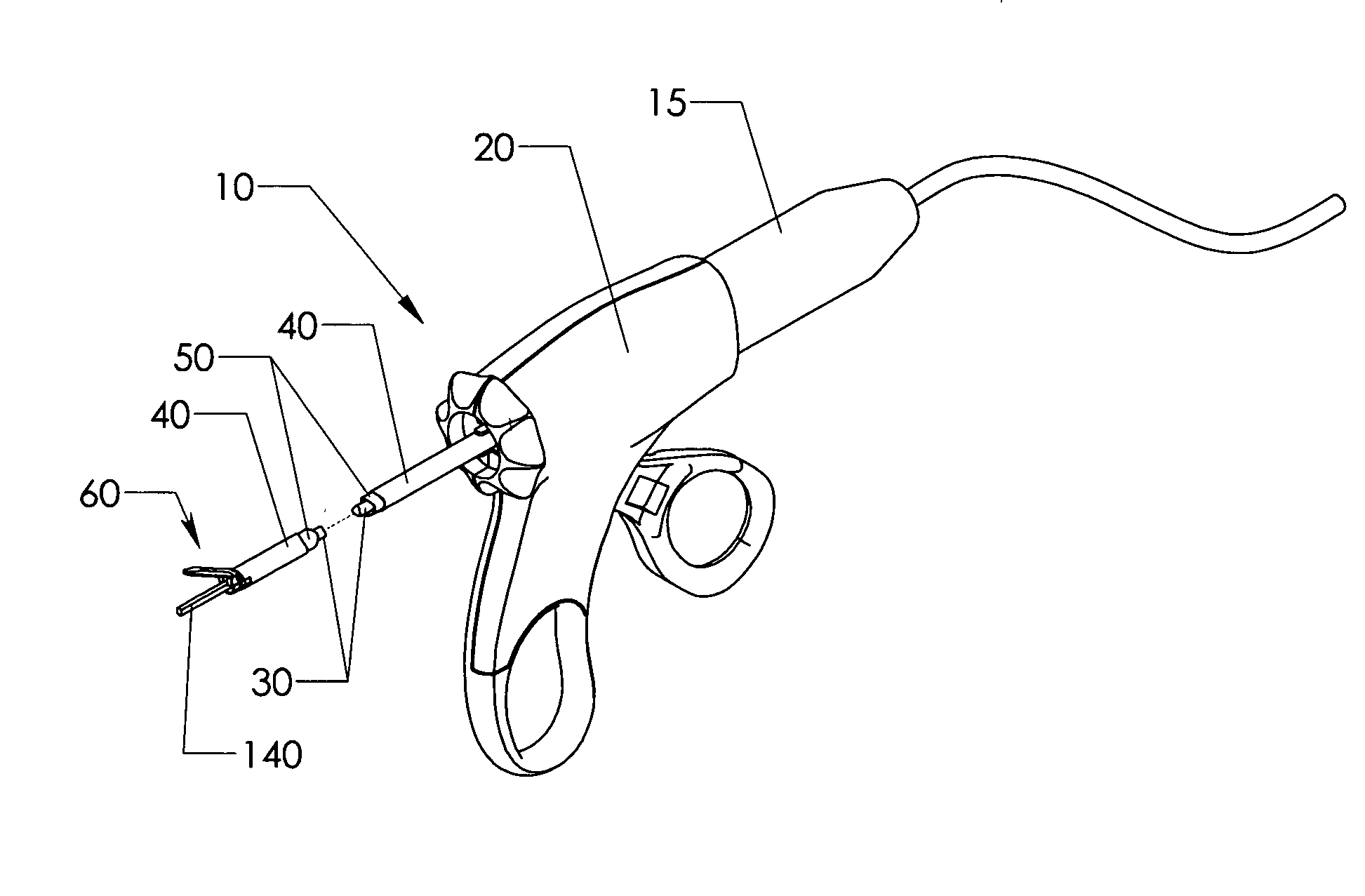

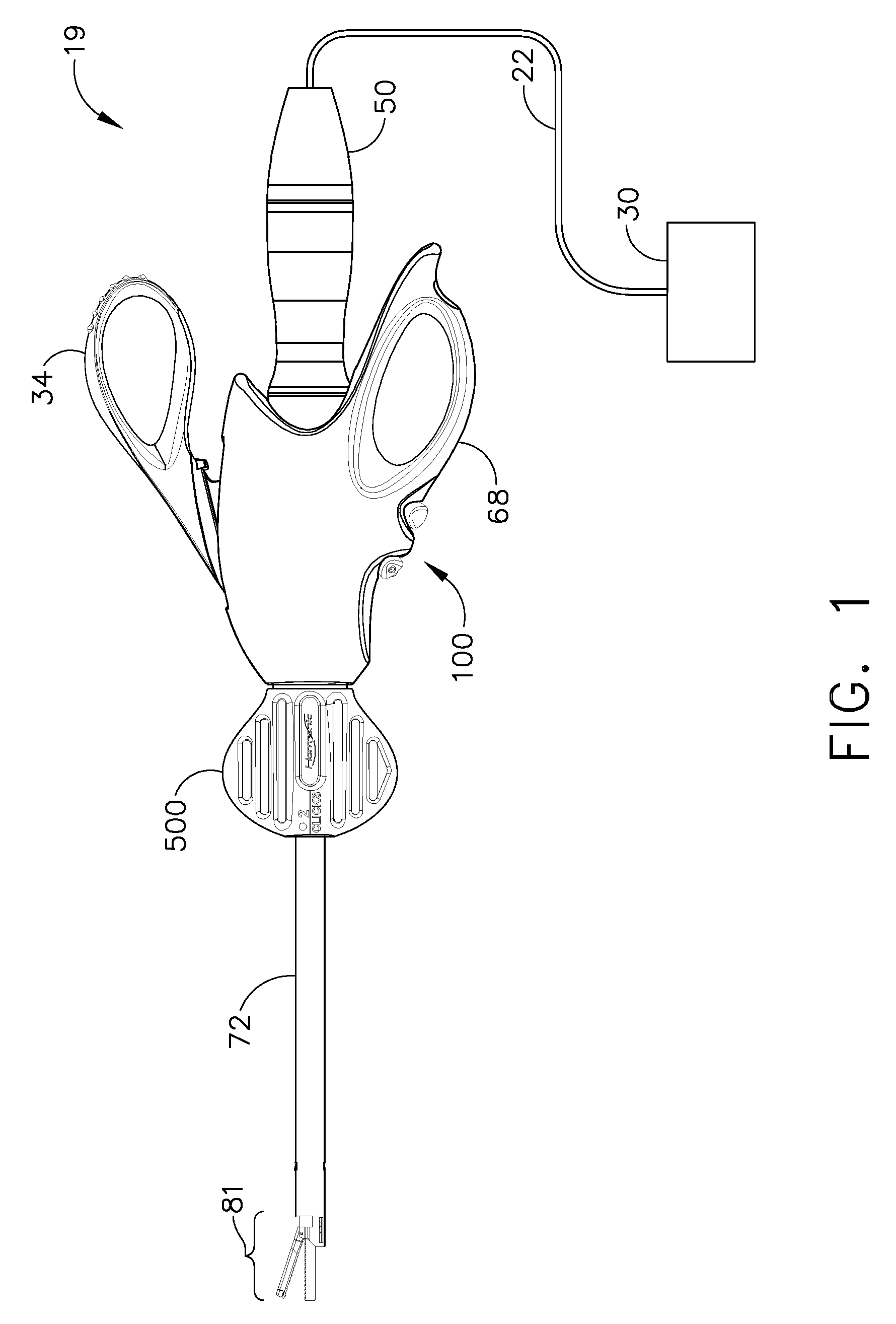

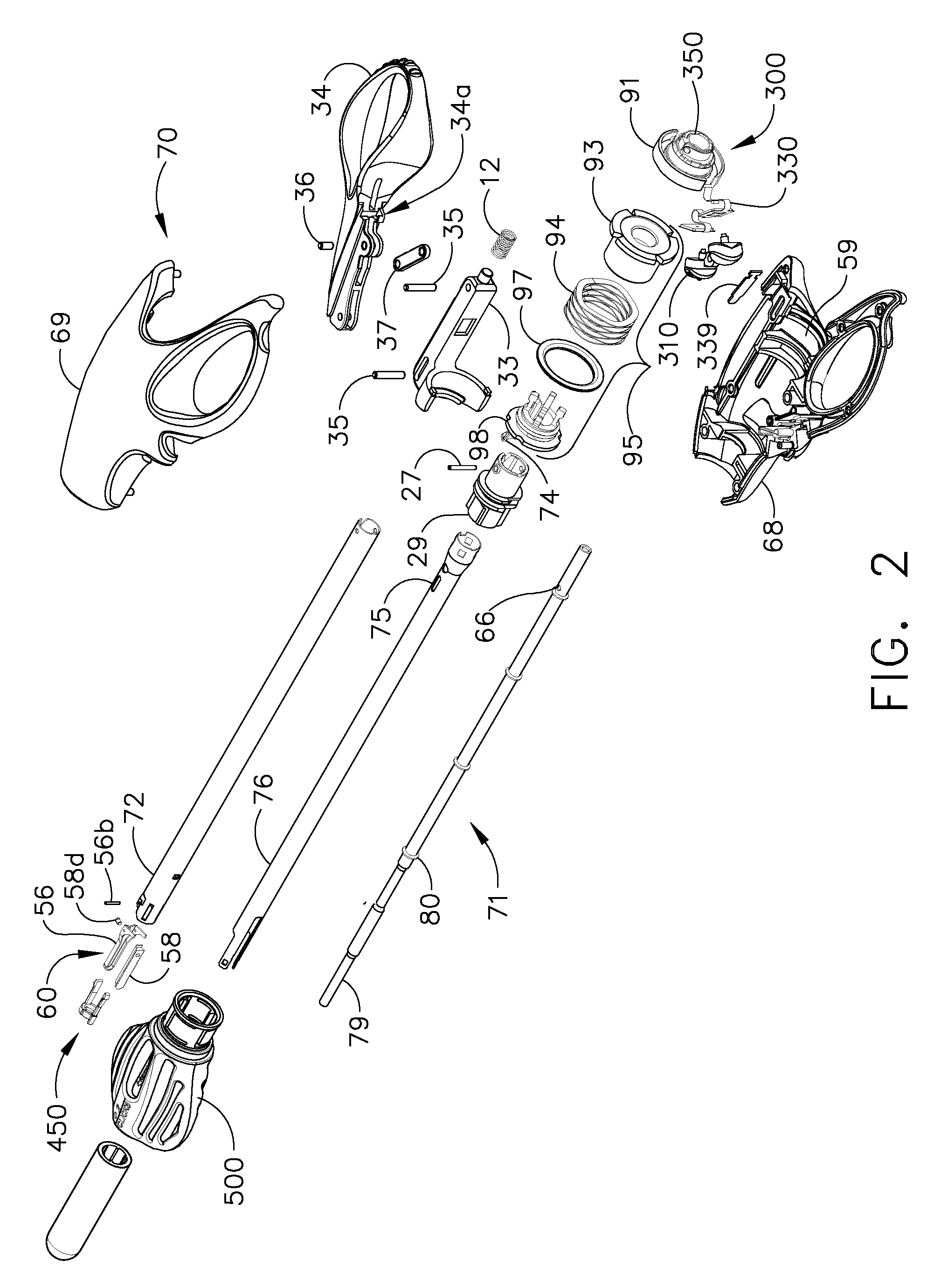

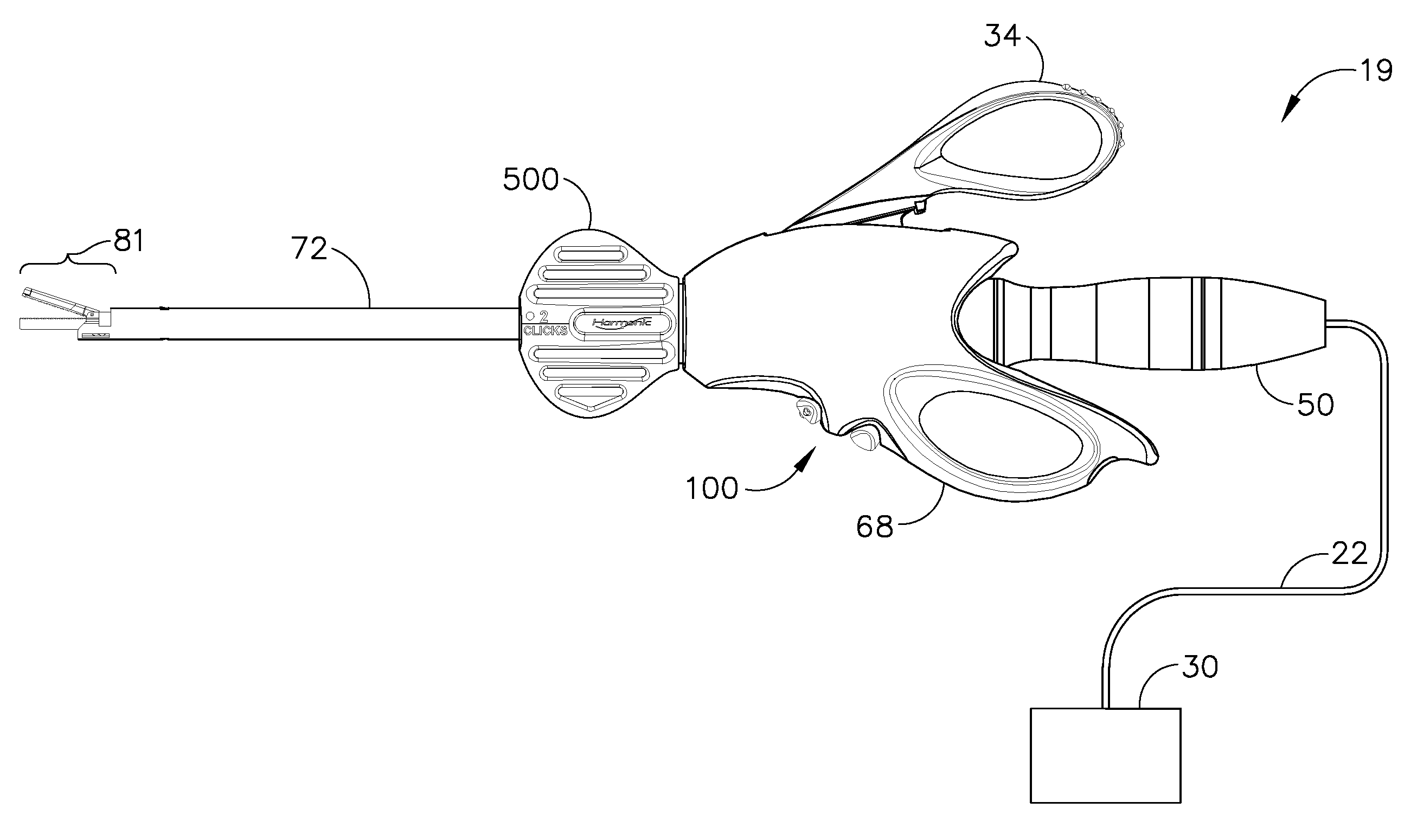

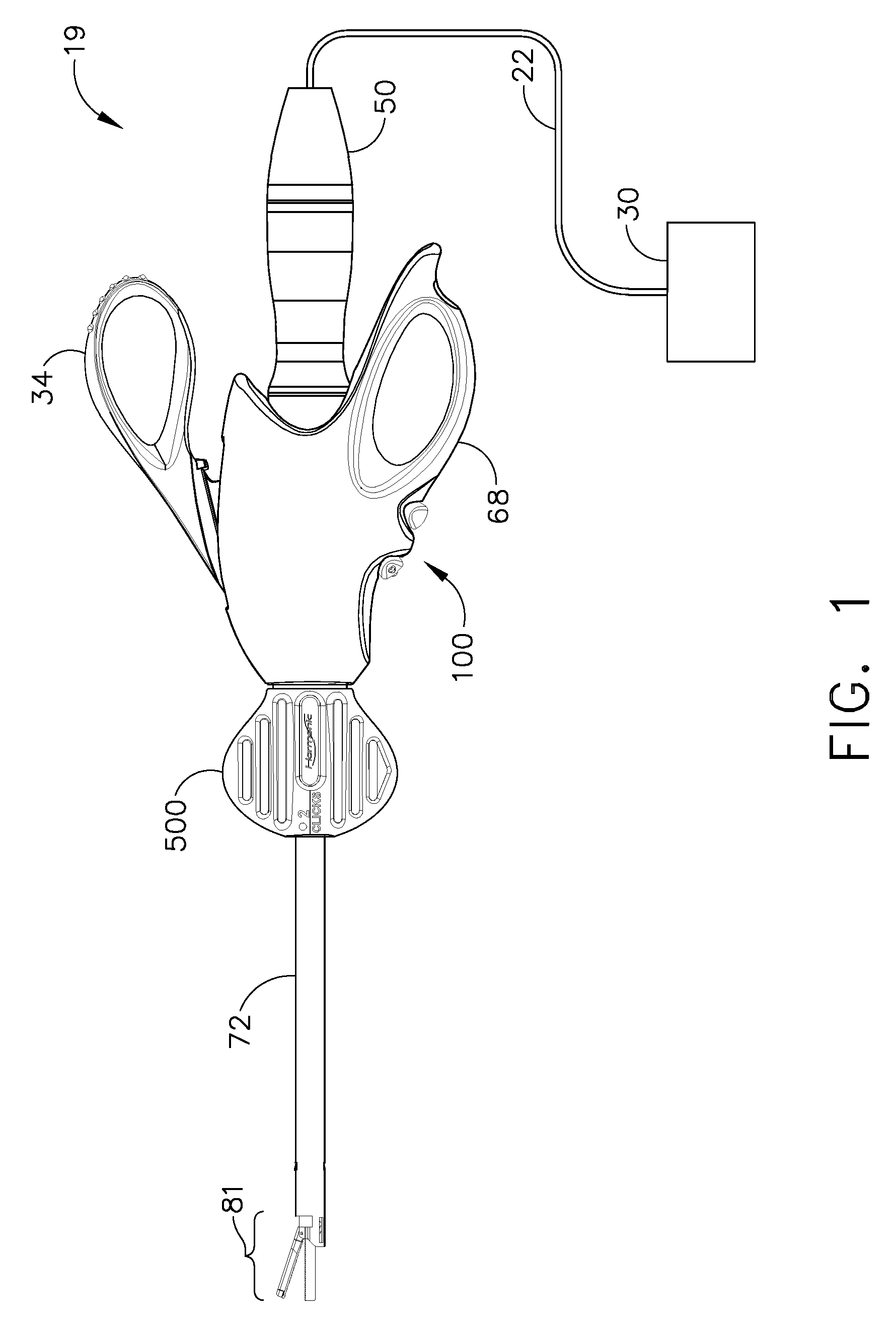

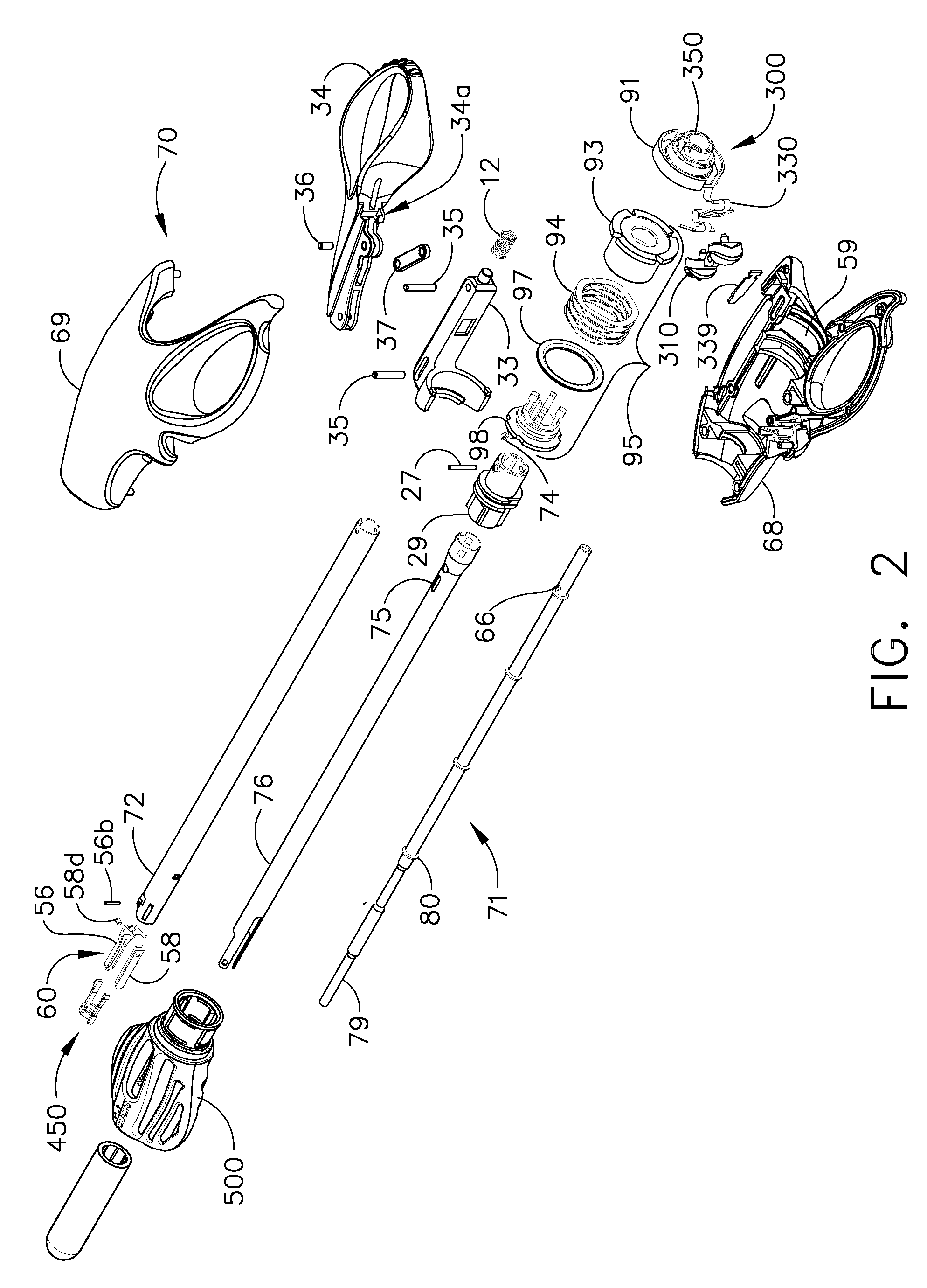

Ultrasonic device for cutting and coagulating

InactiveUS20070191713A1Improve wear resistanceLoad moreUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsBack cuttingBiological activation

An ultrasonic clamp coagulator assembly that is configured to permit selective cutting, coagulation, and fine dissection required in fine and delicate surgical procedures. The assembly includes a clamping mechanism, including a clamp arm cam-mounted at the distal portion of the instrument, which is specifically configured to create a desired level of tissue clamping forces. The balanced blade provides a functional asymmetry for improved visibility at the blade tip and a multitude of edges and surfaces, designed to provide a multitude of tissue effects: clamped coagulation, clamped cutting, grasping, back-cutting, dissection, spot coagulation, tip penetration and tip scoring. The assembly also features hand activation configured to provide an ergonomical grip and operation for the surgeon. Hand switches are placed in the range of the natural axial motion of the user's index or middle fingers, whether gripping the surgical instrument right-handed or left handed.

Owner:CILAG GMBH INT +1

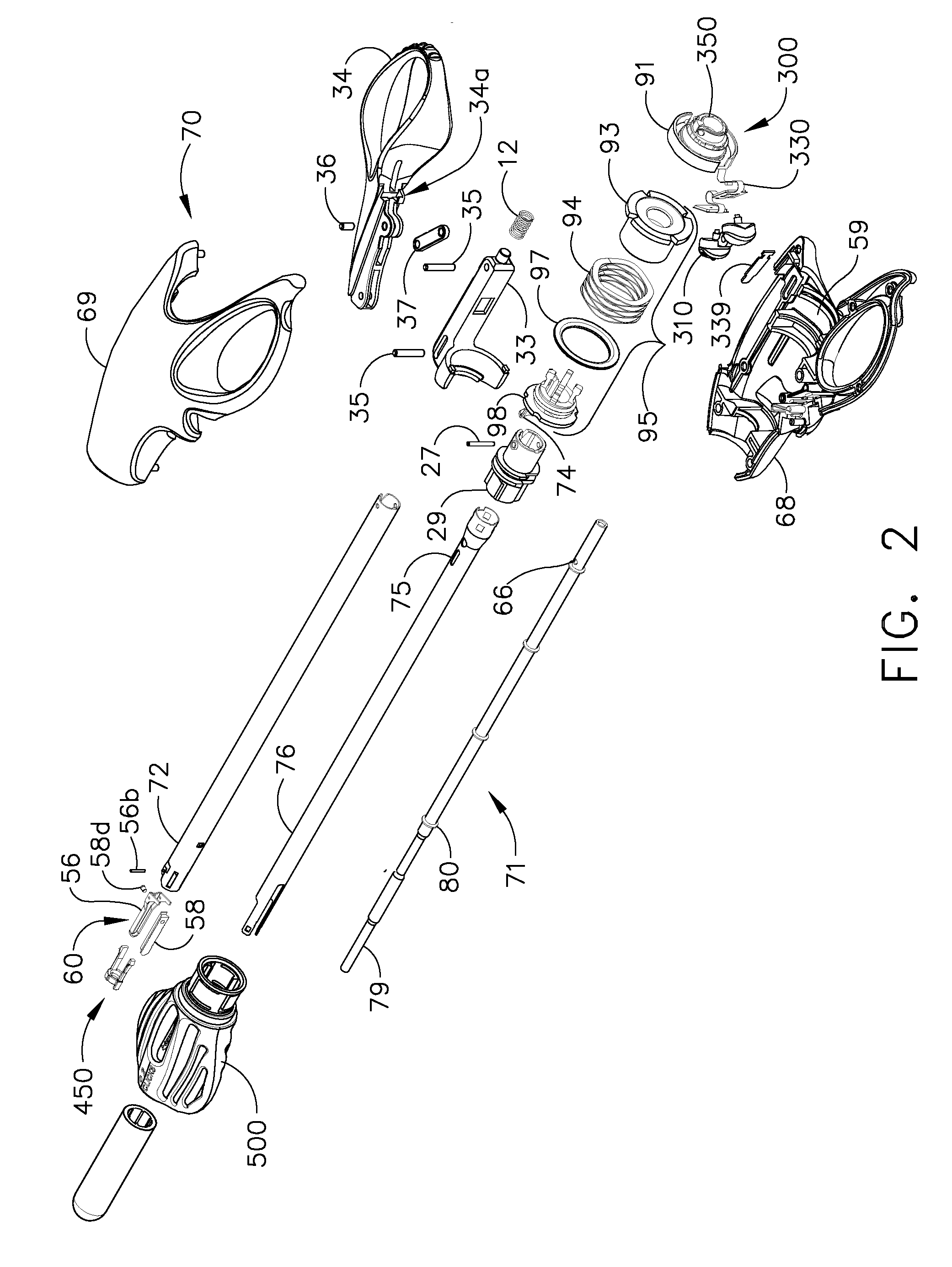

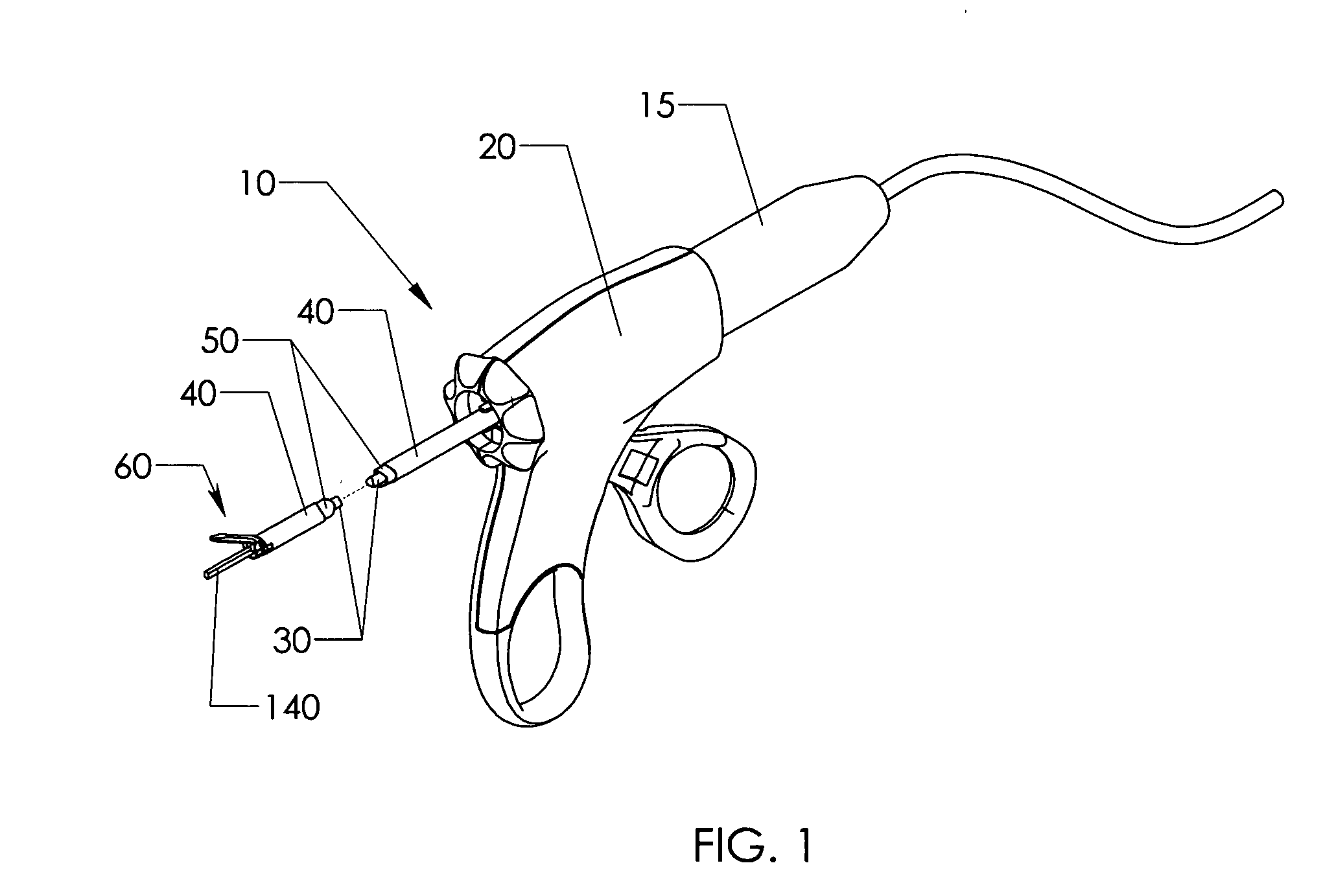

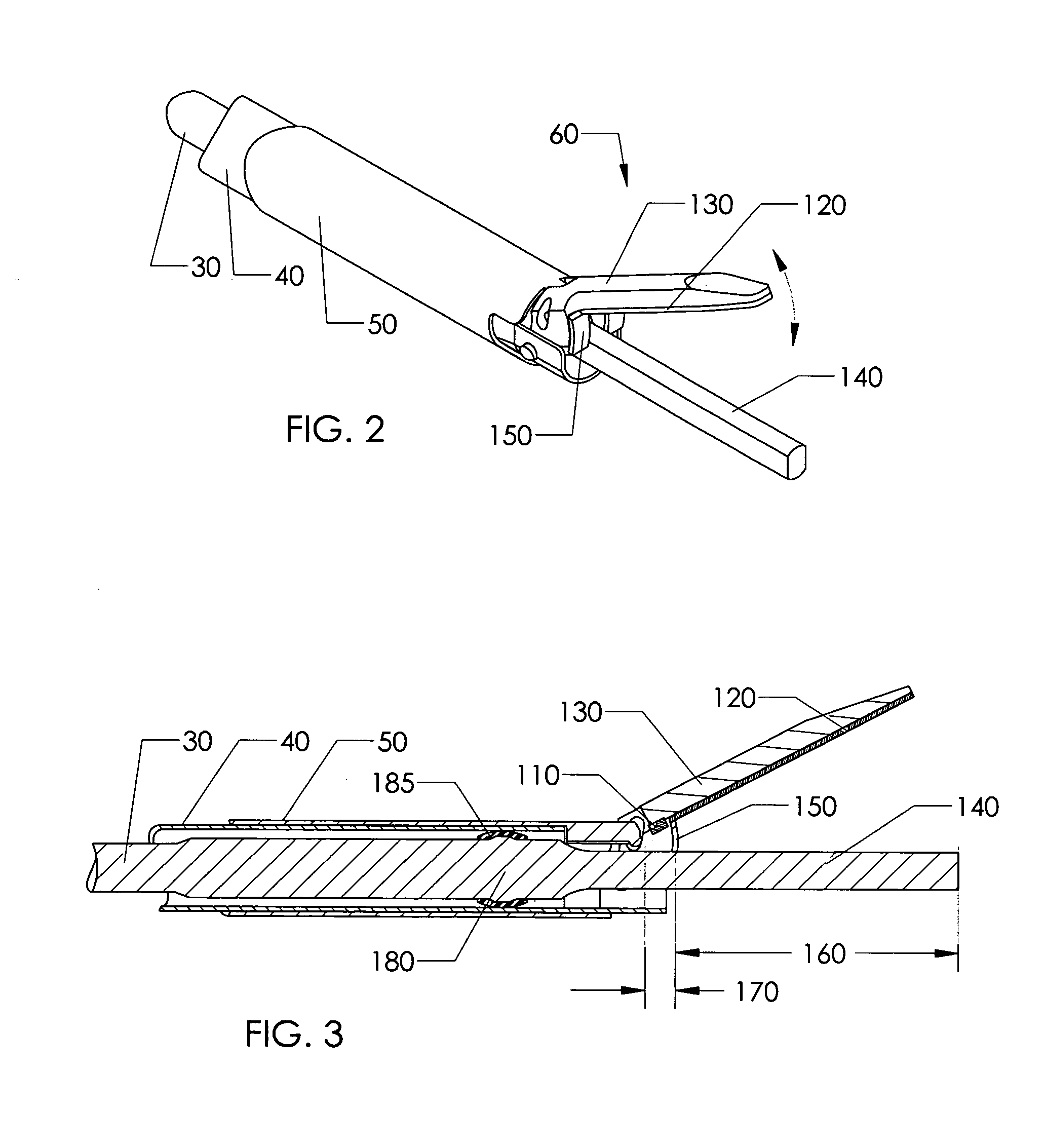

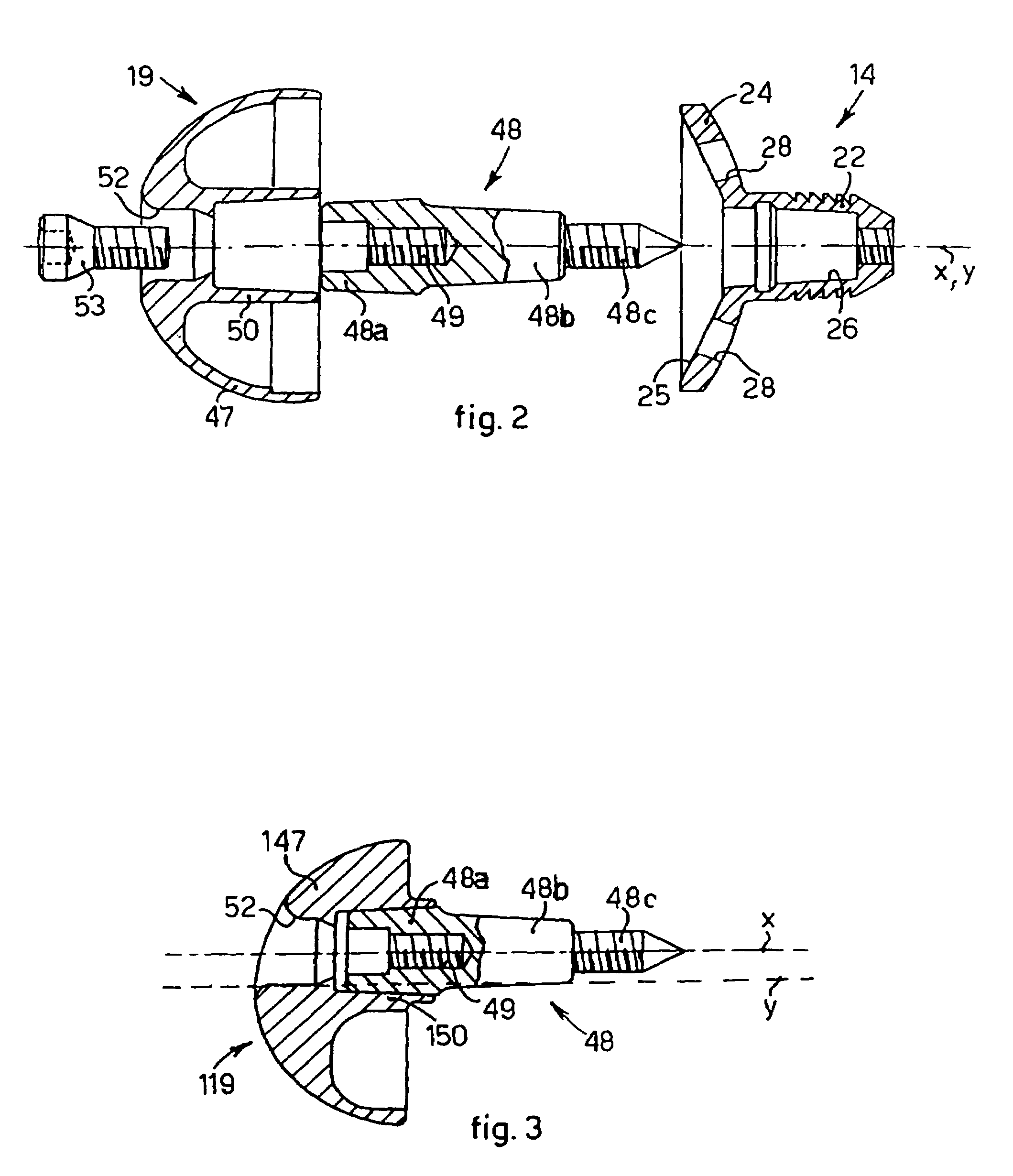

Ultrasonic waveguide and blade

InactiveUS20070282333A1Improve wear resistanceDiagnosticsSurgical instrument detailsDistal portionEngineering

An ultrasonic clamp coagulator assembly that is configured to permit selective cutting, coagulation and clamping of tissue during surgical procedures. An elongated portion of the instrument can be configured for endoscopic applications and has an outside diameter of less than 6 mm. The construction includes a waveguide and blade that enable larger wave amplitude and a longer active blade length and still provide sufficient frequency margin or window. The waveguide is provided with a series of gain steps located at the distal portion of the waveguide preferably at the two most distal nodes in relation to the handpiece, or the two most proximal nodes in relation to the blade tip.

Owner:CILAG GMBH INT +1

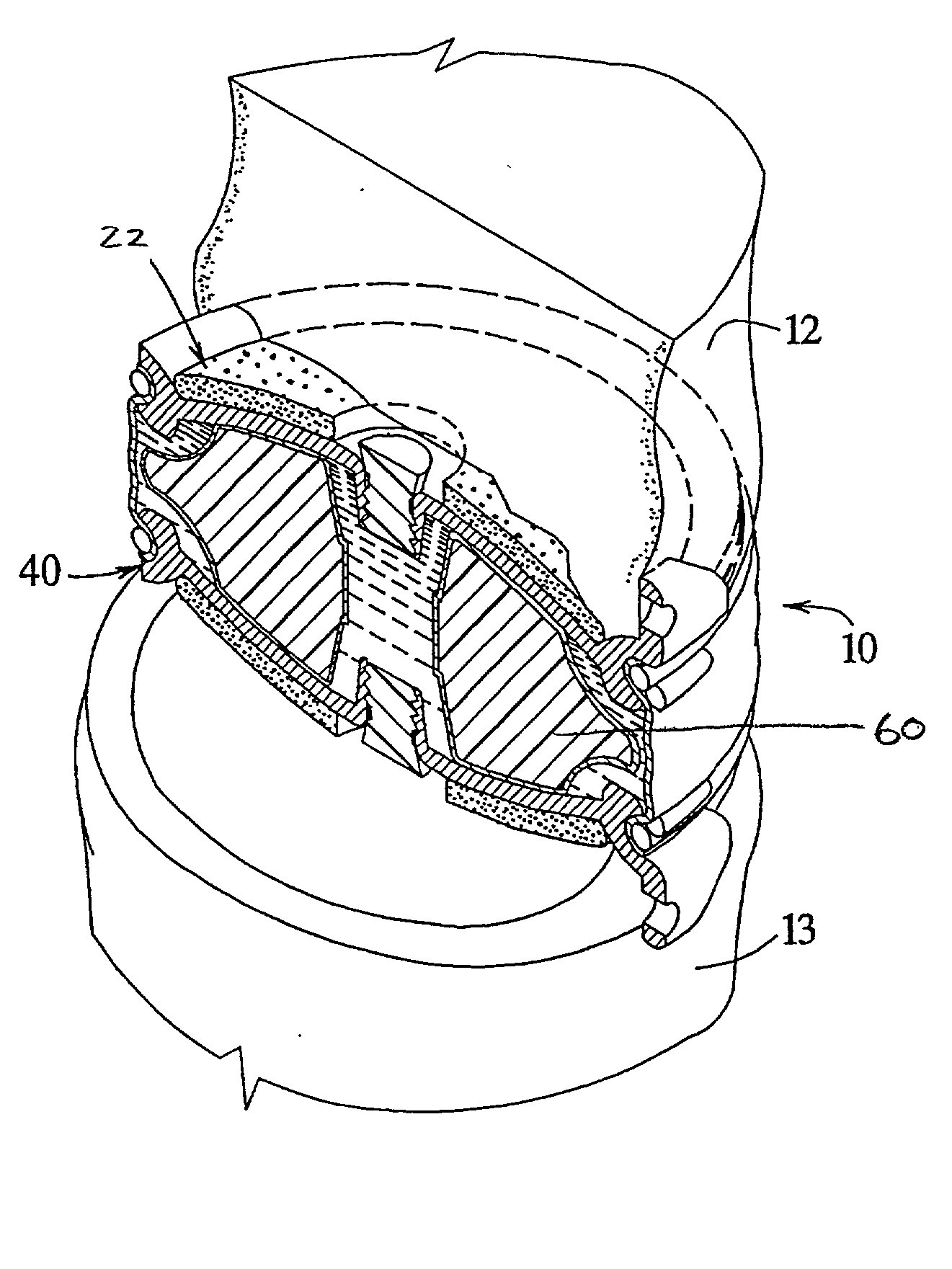

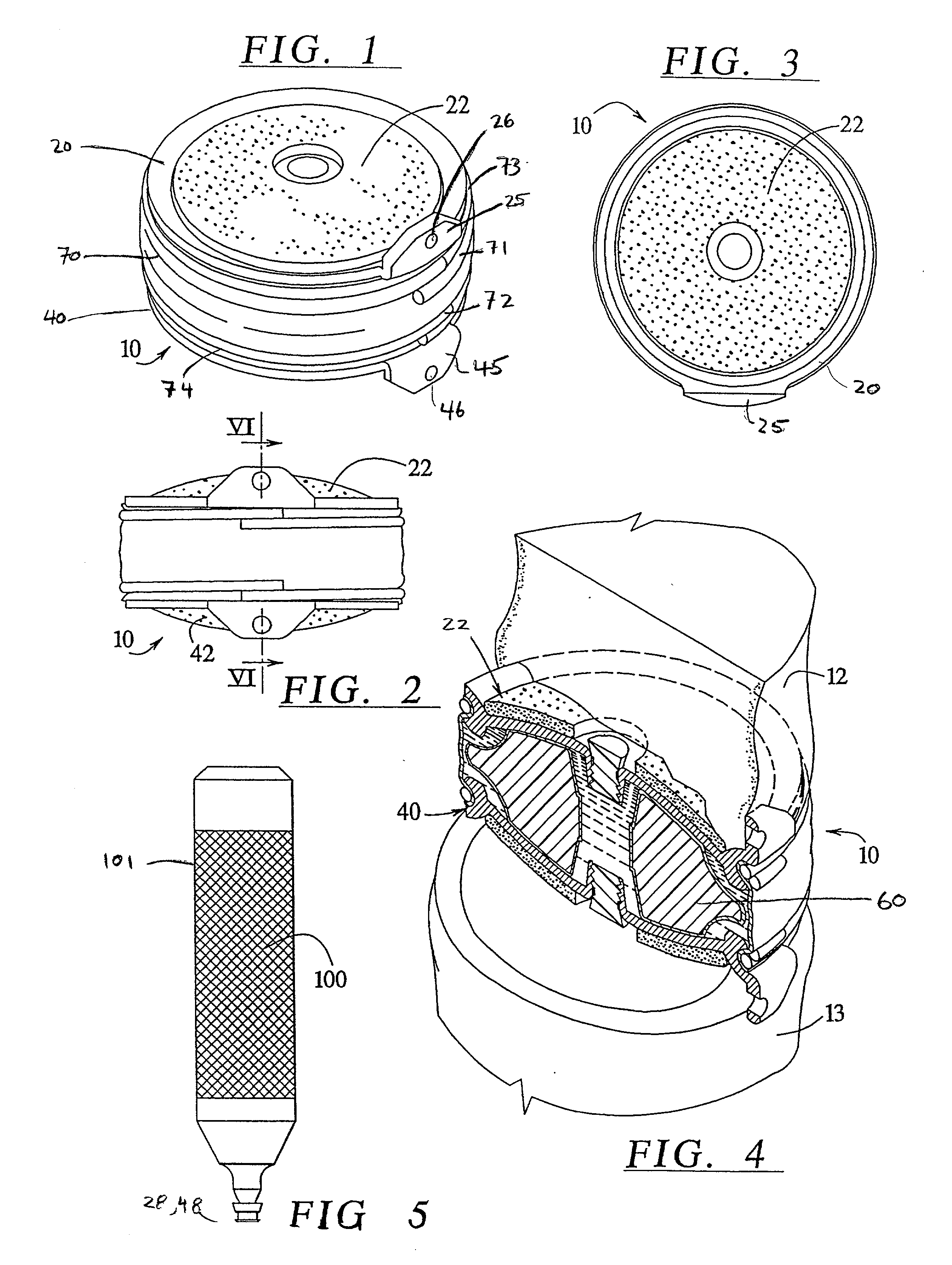

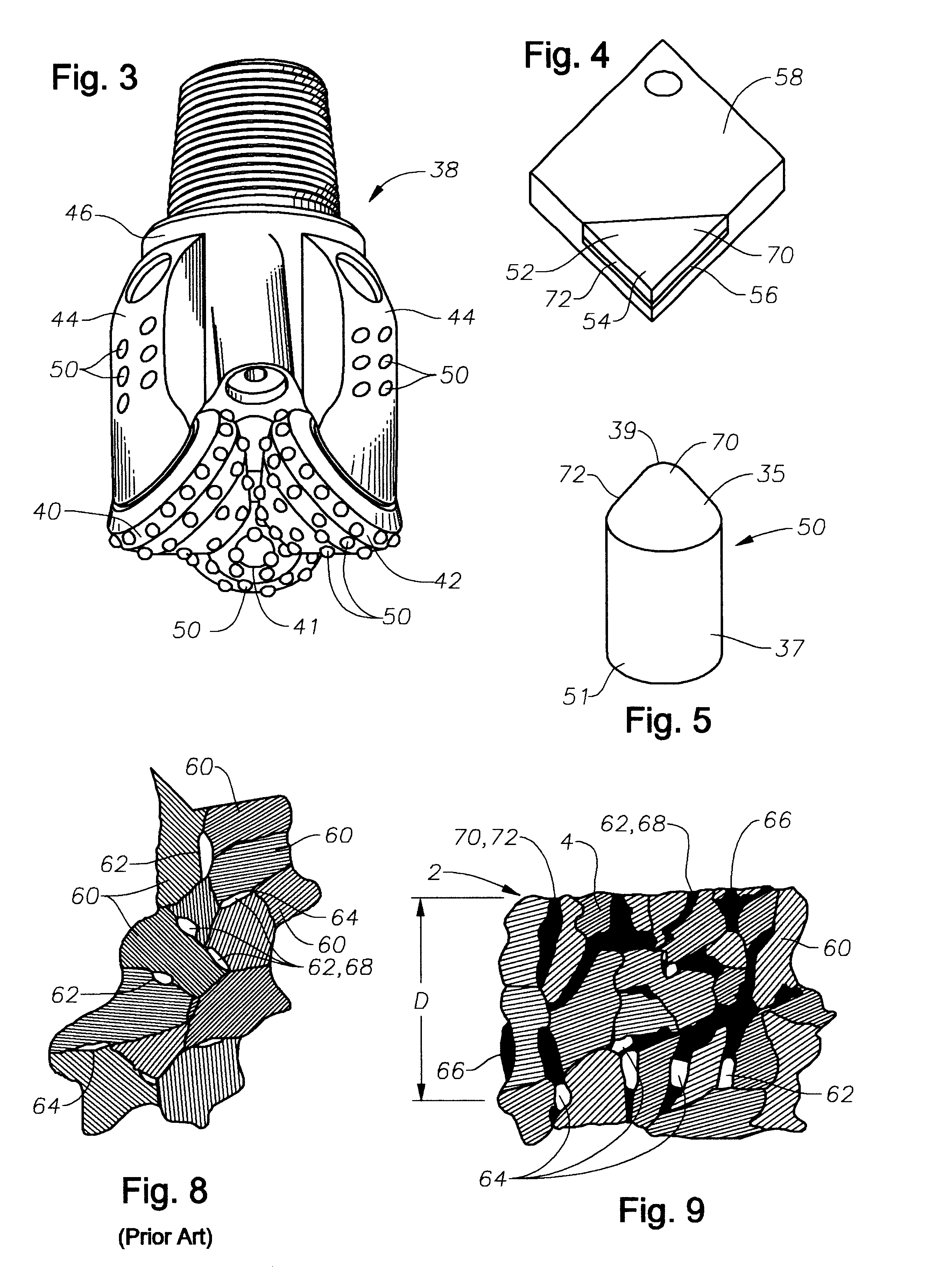

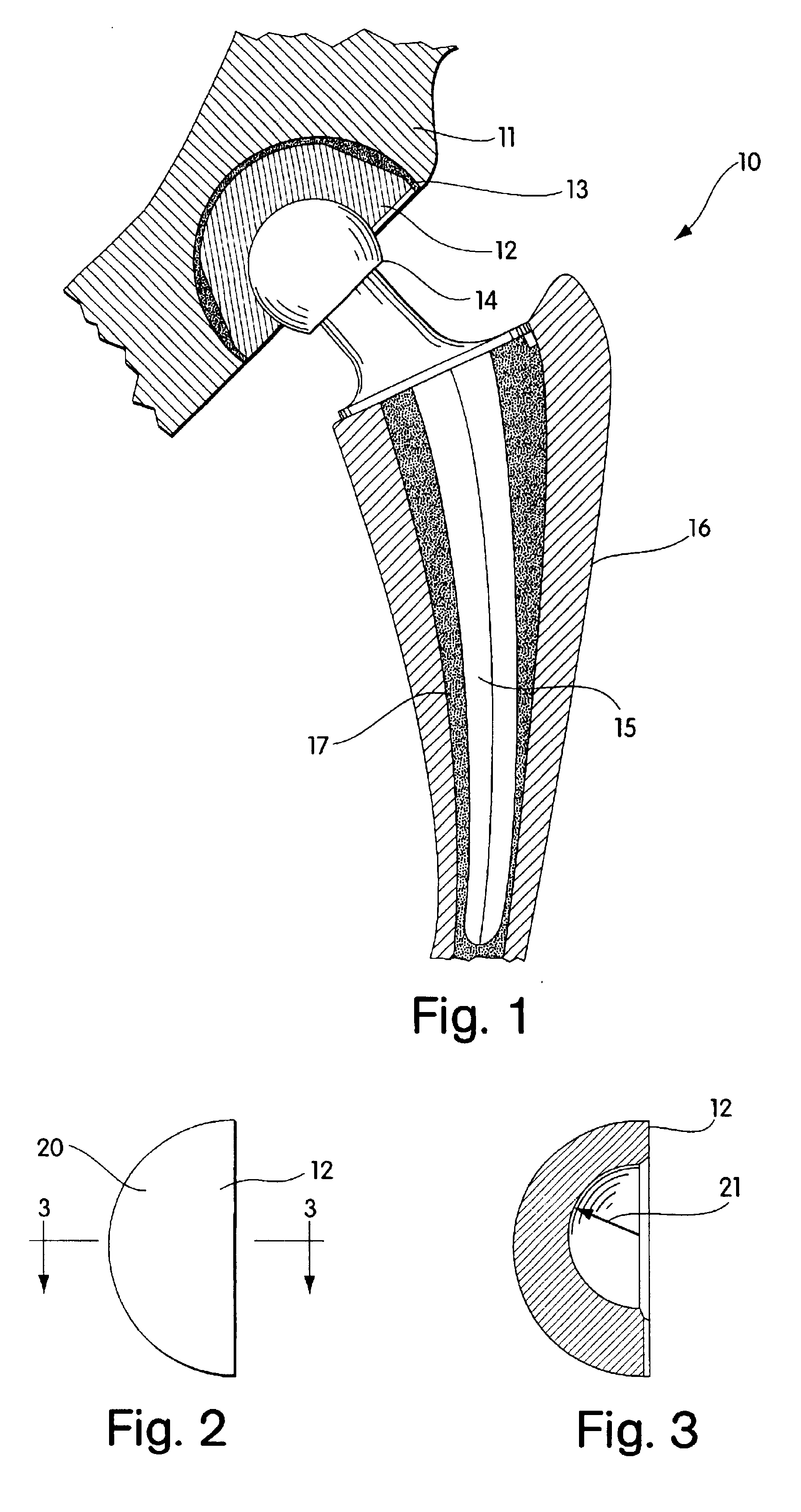

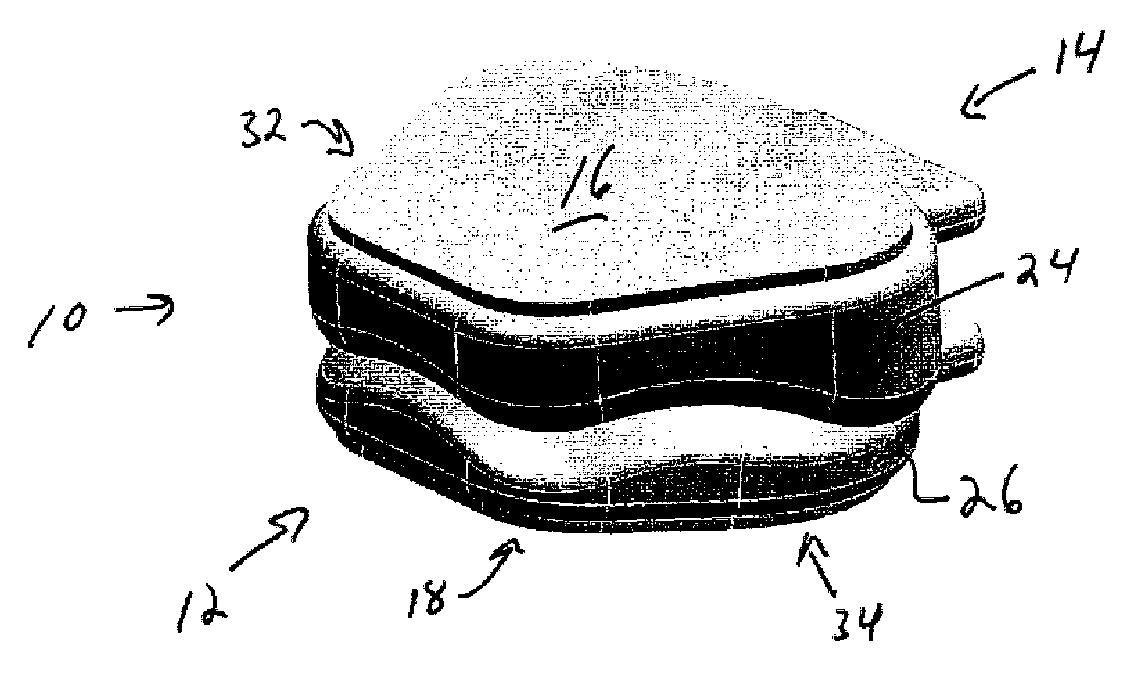

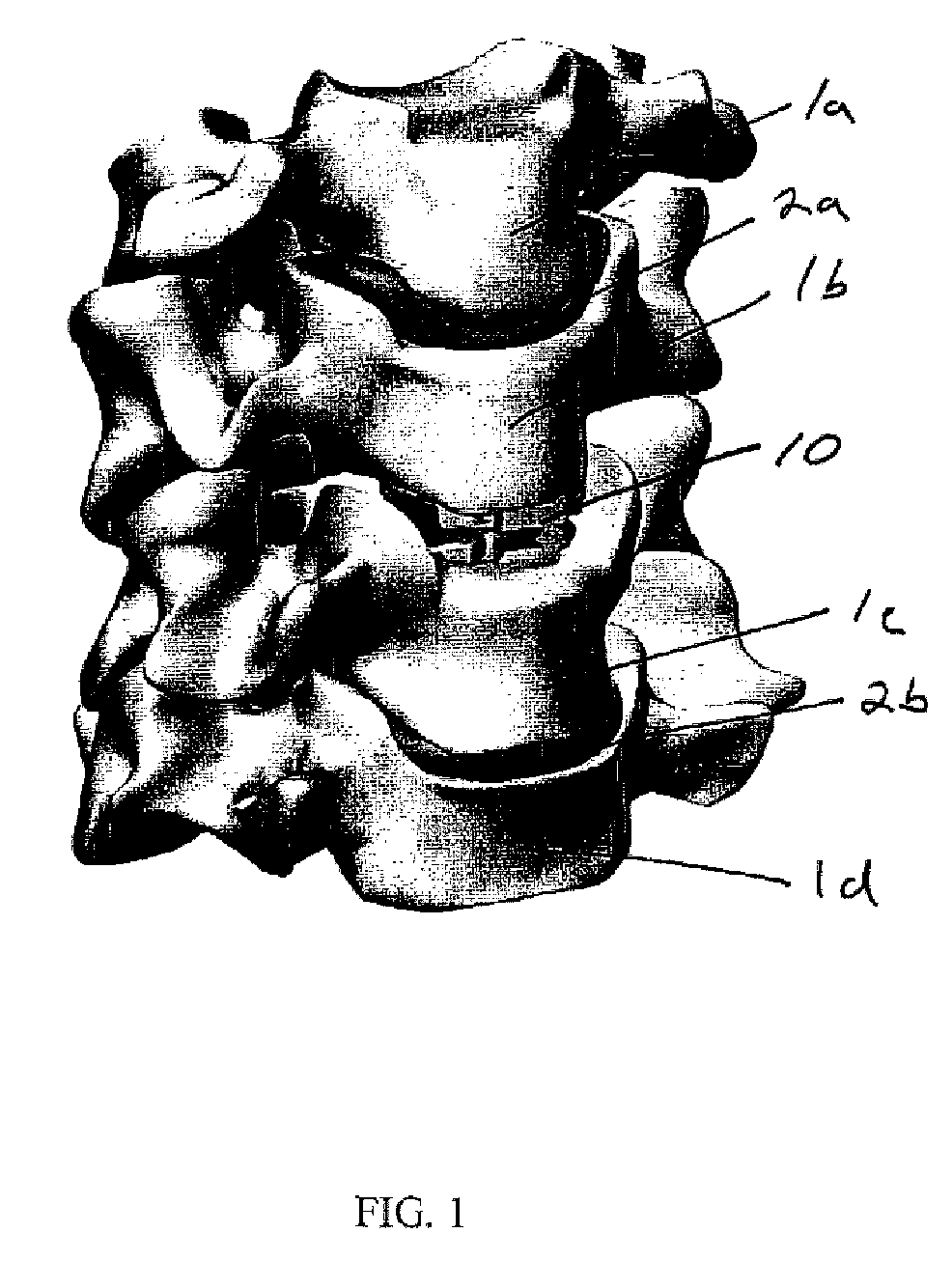

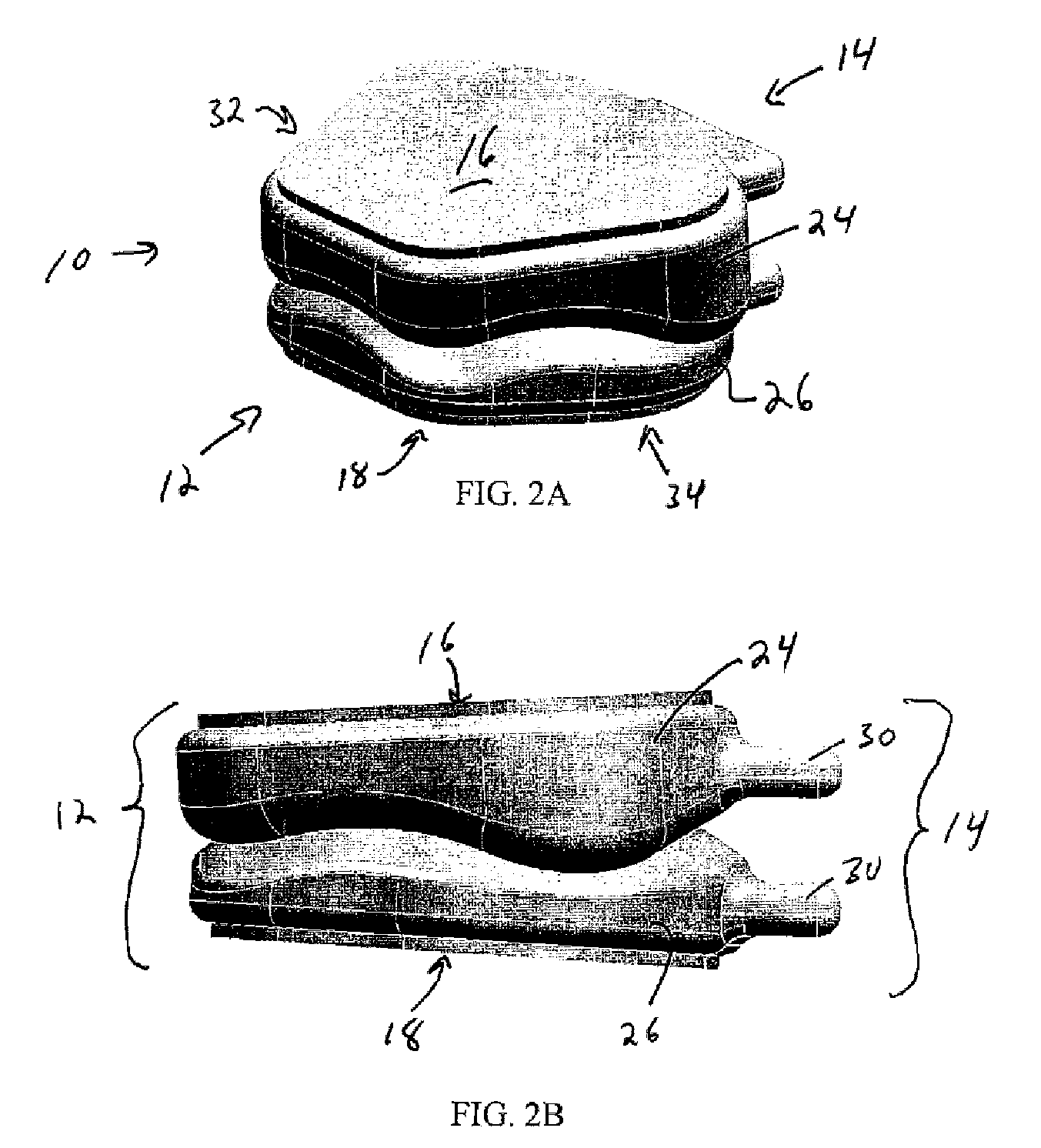

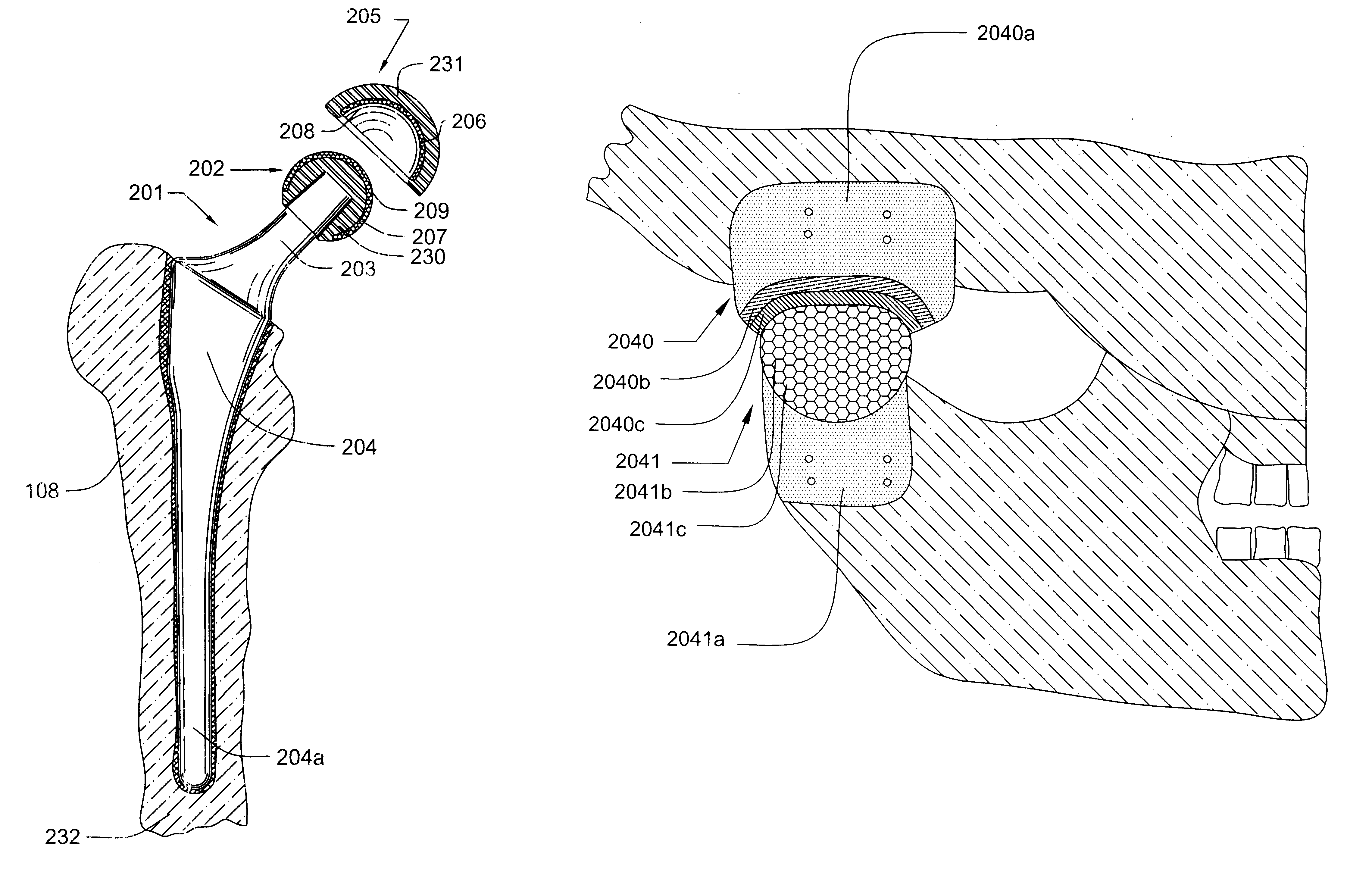

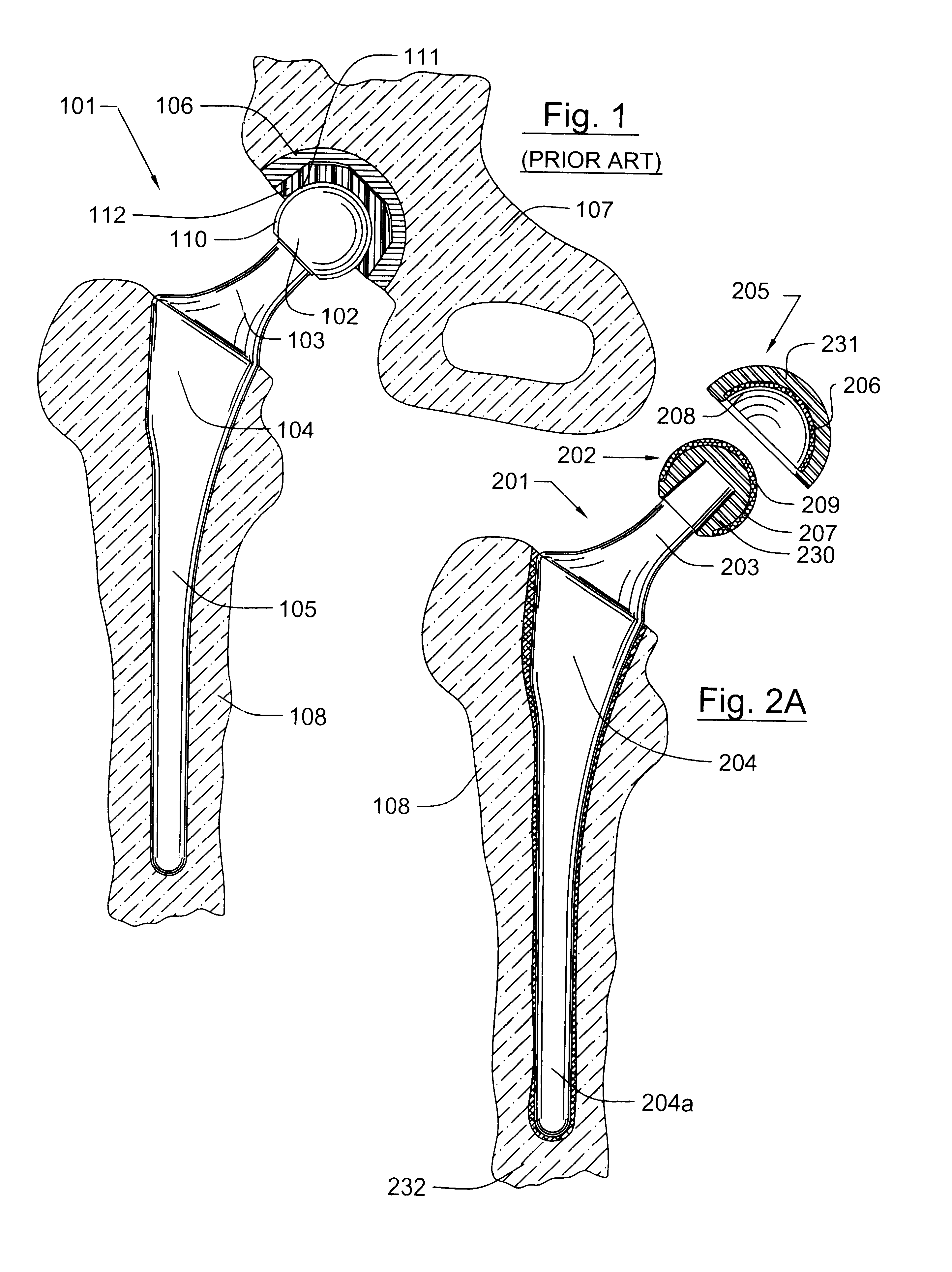

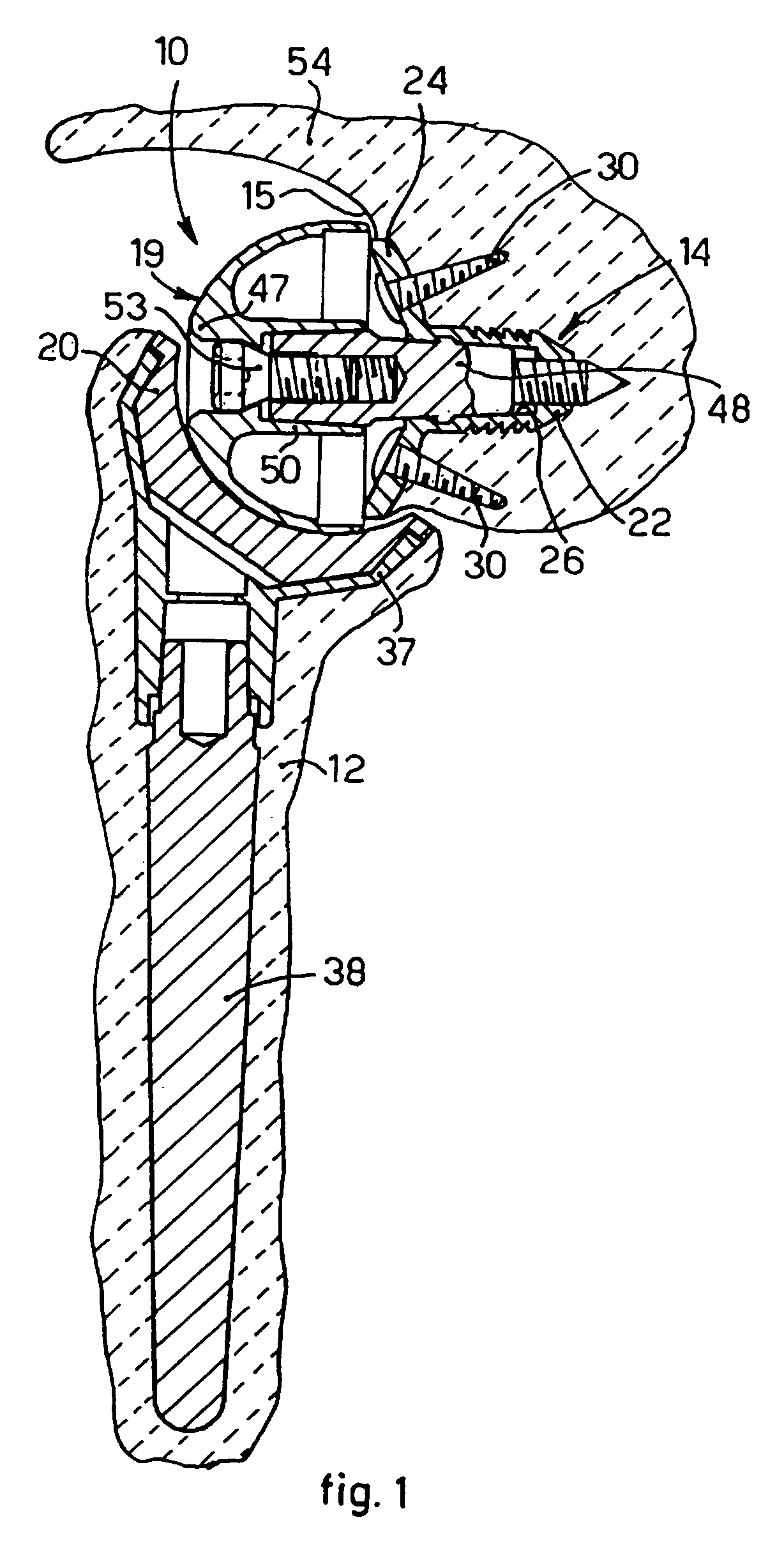

Implantable joint prosthesis

InactiveUS20020035400A1Improve wear resistanceImprove tribological propertiesDiagnosticsJoint implantsRange of motionIntervertebral disc

The invention relates to a surgical implant that provides an artificial diarthroidal-like joint, suitable for use in replacing any joint, but particularly suitable for use as an intervertebral disc endoprosthesis. The invention contains two rigid opposing shells, each having an outer surface adapted to engage the surfaces of the bones of a joint in such a way that the shells are immobilized by friction between their outer surfaces and the surfaces of the bone. These outer surfaces are sufficiently rough that large frictional forces strongly resist any slippage between the outer surface and the bone surfaces in the joint. They may be convex, and when inserted into a milled concavity, are immediately mechanically stable. Desirably, the outer surfaces of the shells are adapted to allow for bony ingrowth, which further stabilizes the shells in place. The inner surfaces of the shells are relatively smooth, and adapted to slide easily across a portion of the outer surface of a central body disposed between the shells. The central body has a shape that cooperates with the shape of the inner surface of the shell so as to provide a range of motion similar to that provided by a healthy joint. A flexible sheath extends between edges of the opposing shells. The inner surface of this sheath, together with the inner surfaces of the rigid shells, defines a cavity encasing the central body. At least a portion of this cavity is filled with a fluid lubricant, further decreasing the frictional force between inner surfaces of the shell and the surface of the central body.

Owner:SPINAL DYNAMICS CORP

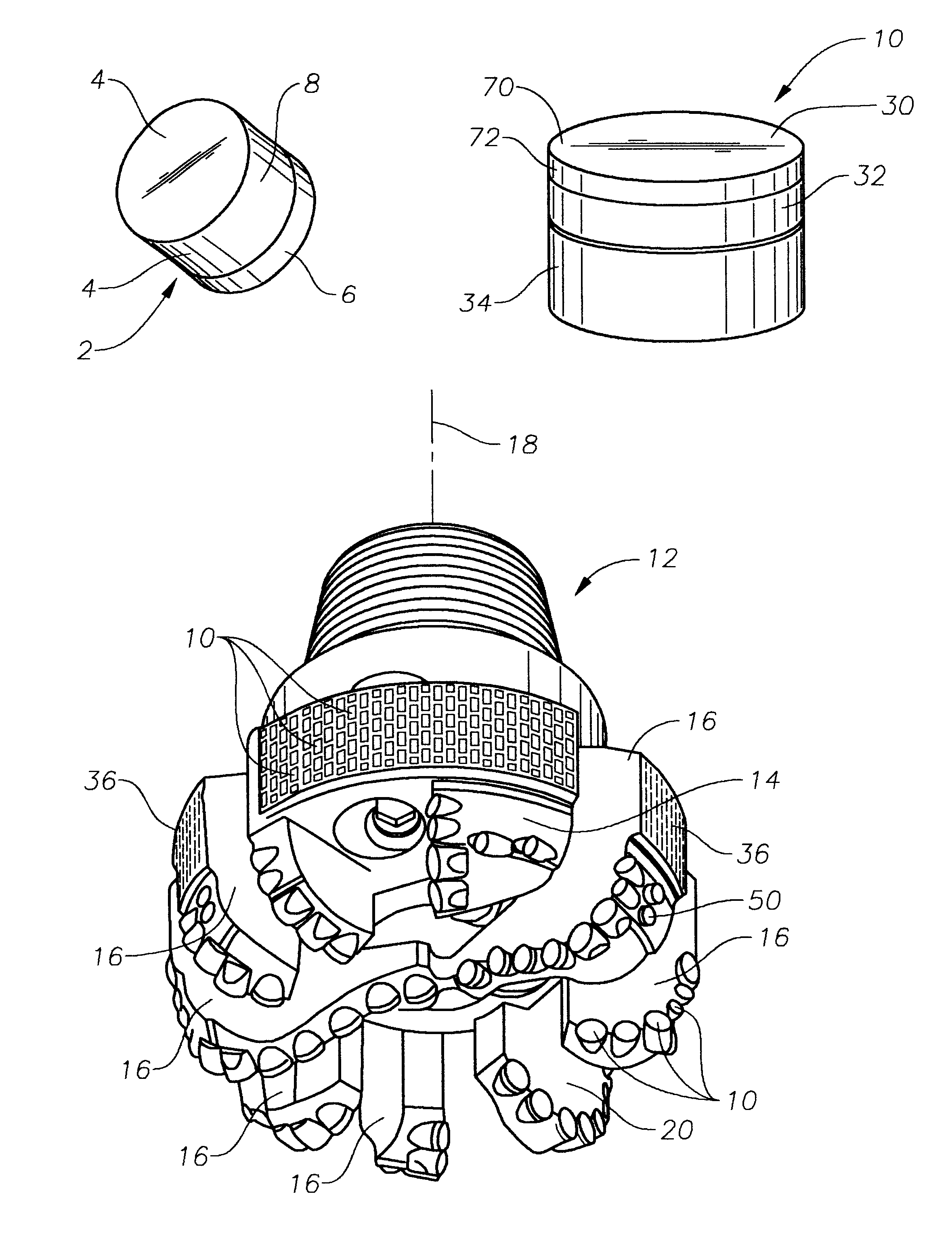

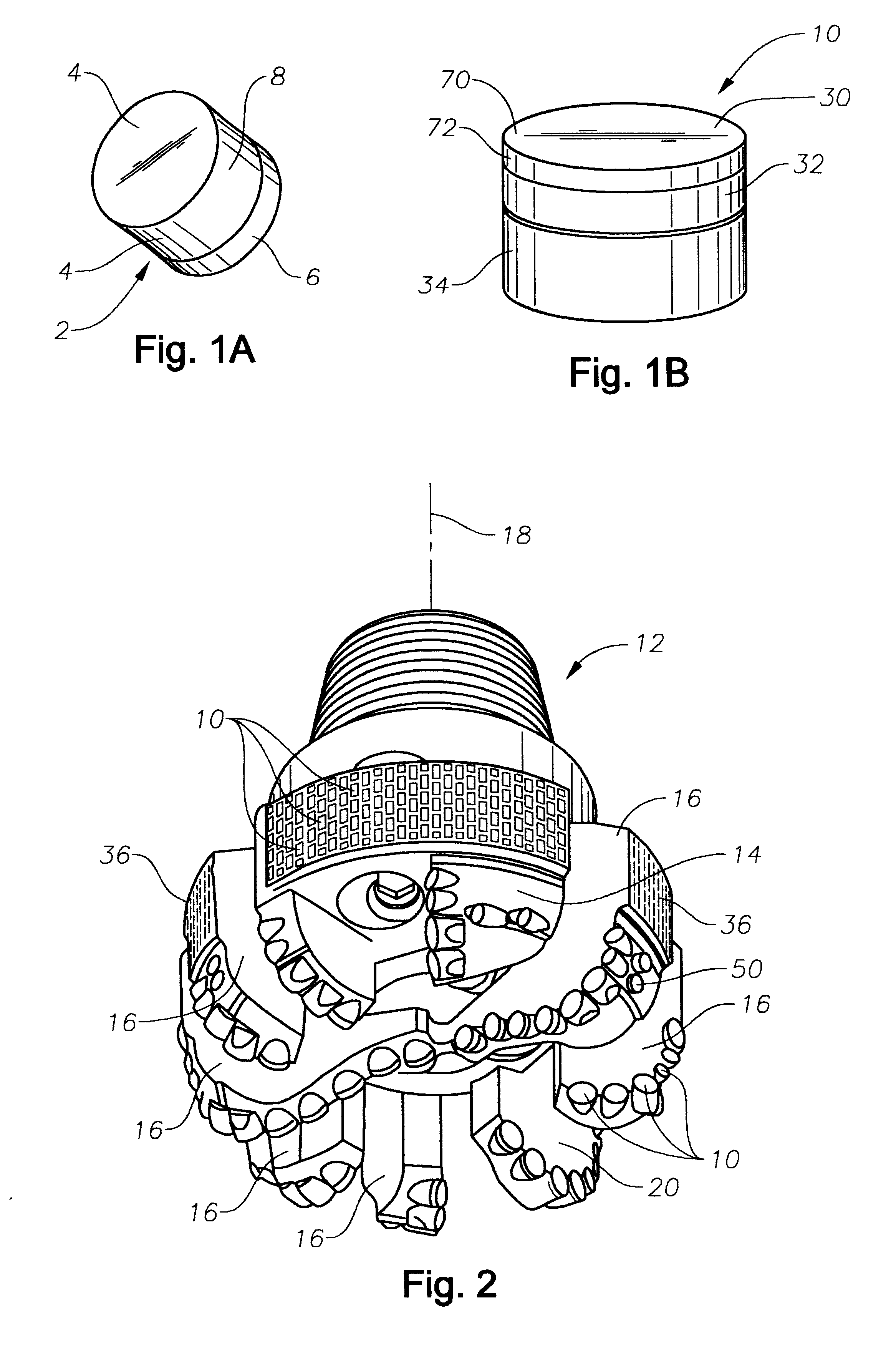

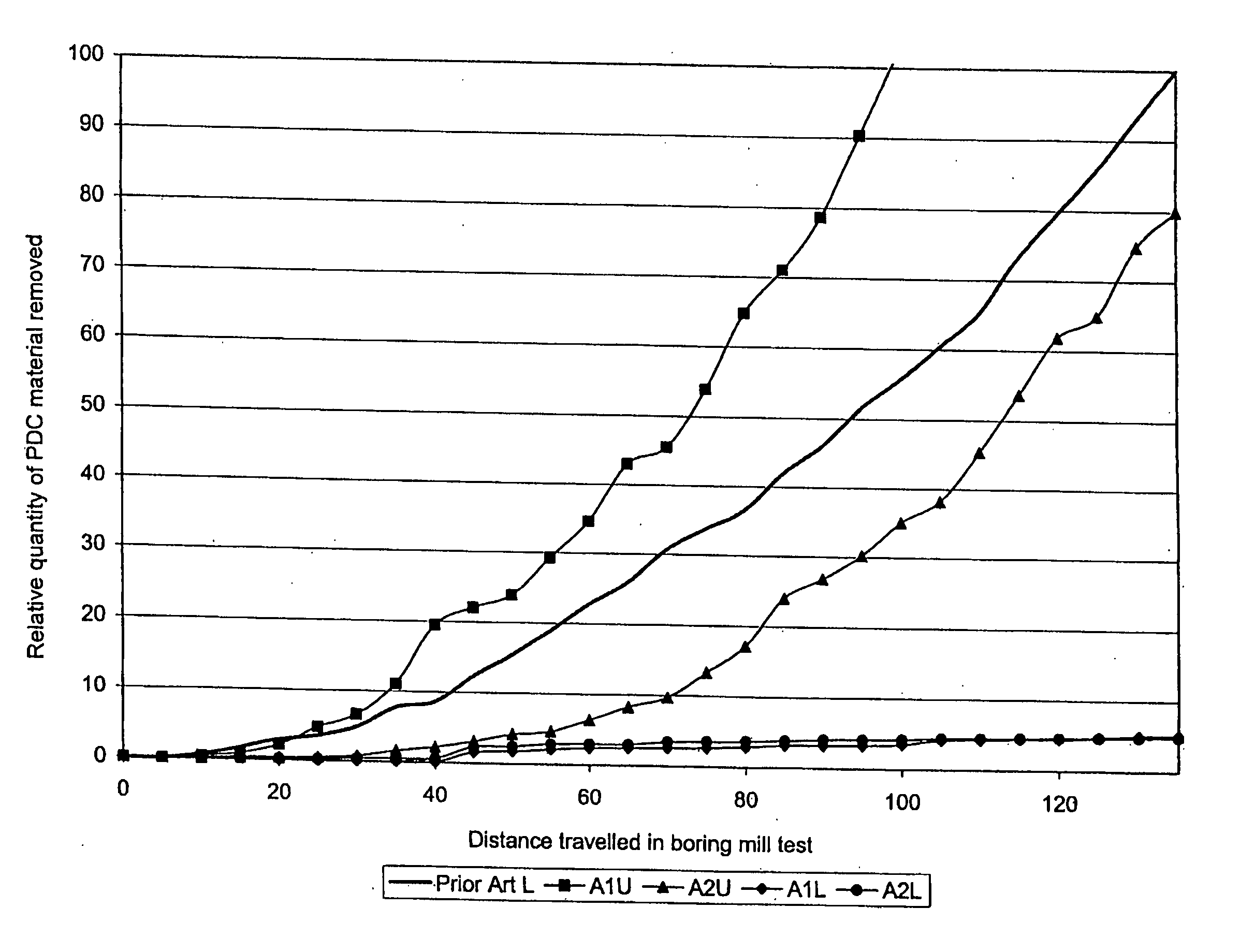

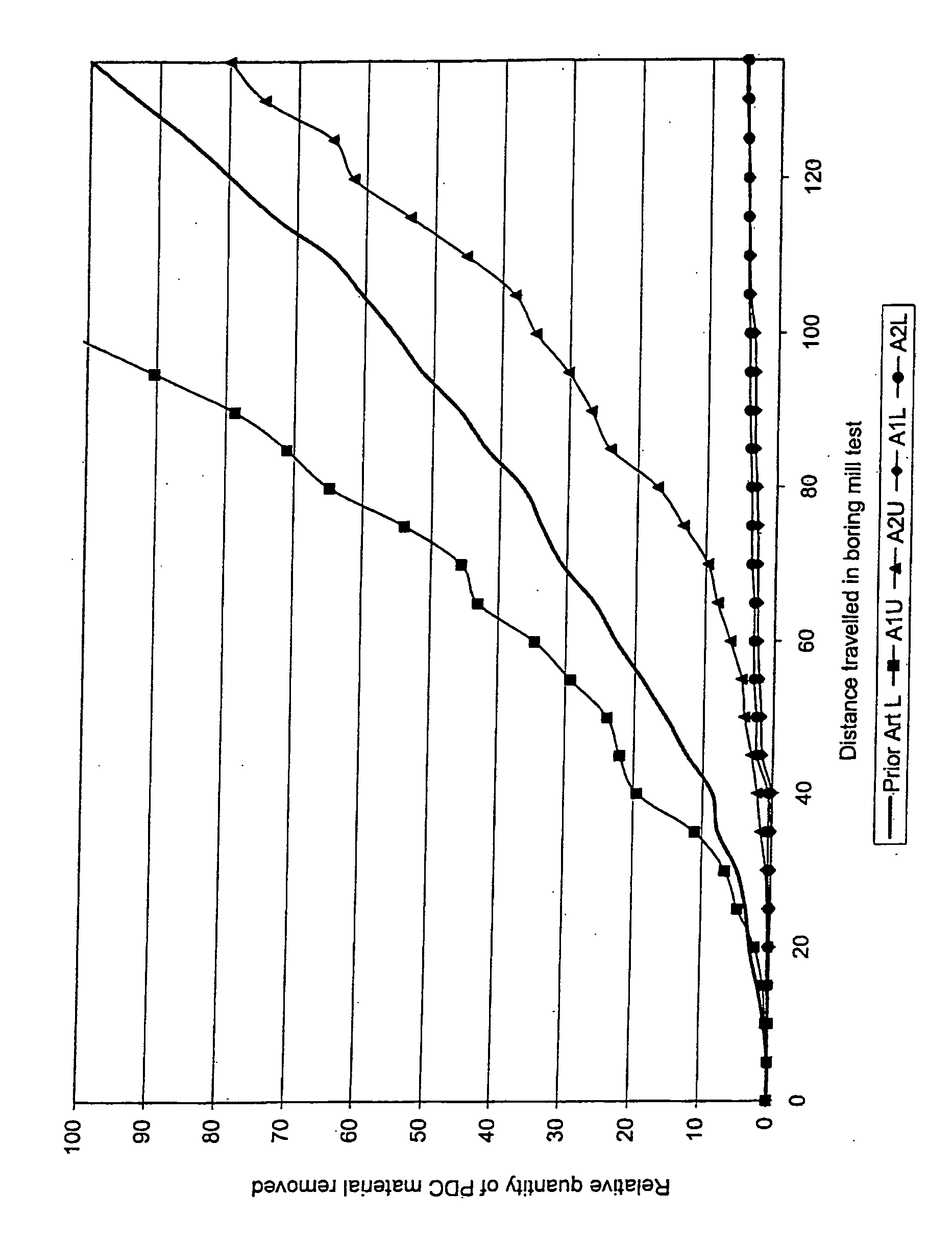

Polycrystalline diamond cutters with working surfaces having varied wear resistance while maintaining impact strength

InactiveUS6601662B2Improve wear resistanceMaintain strengthDrill bitsConstructionsDiamond crystalPolycrystalline diamond

Disclosed is a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a first portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and a second portion of the interstitial matrix in the body adjacent to the working surface contains the catalyzing material. The first portion of the interstitial matrix and the second portion of the interstitial matrix have substantially the same impact strength.

Owner:REEDHYCALOG UK

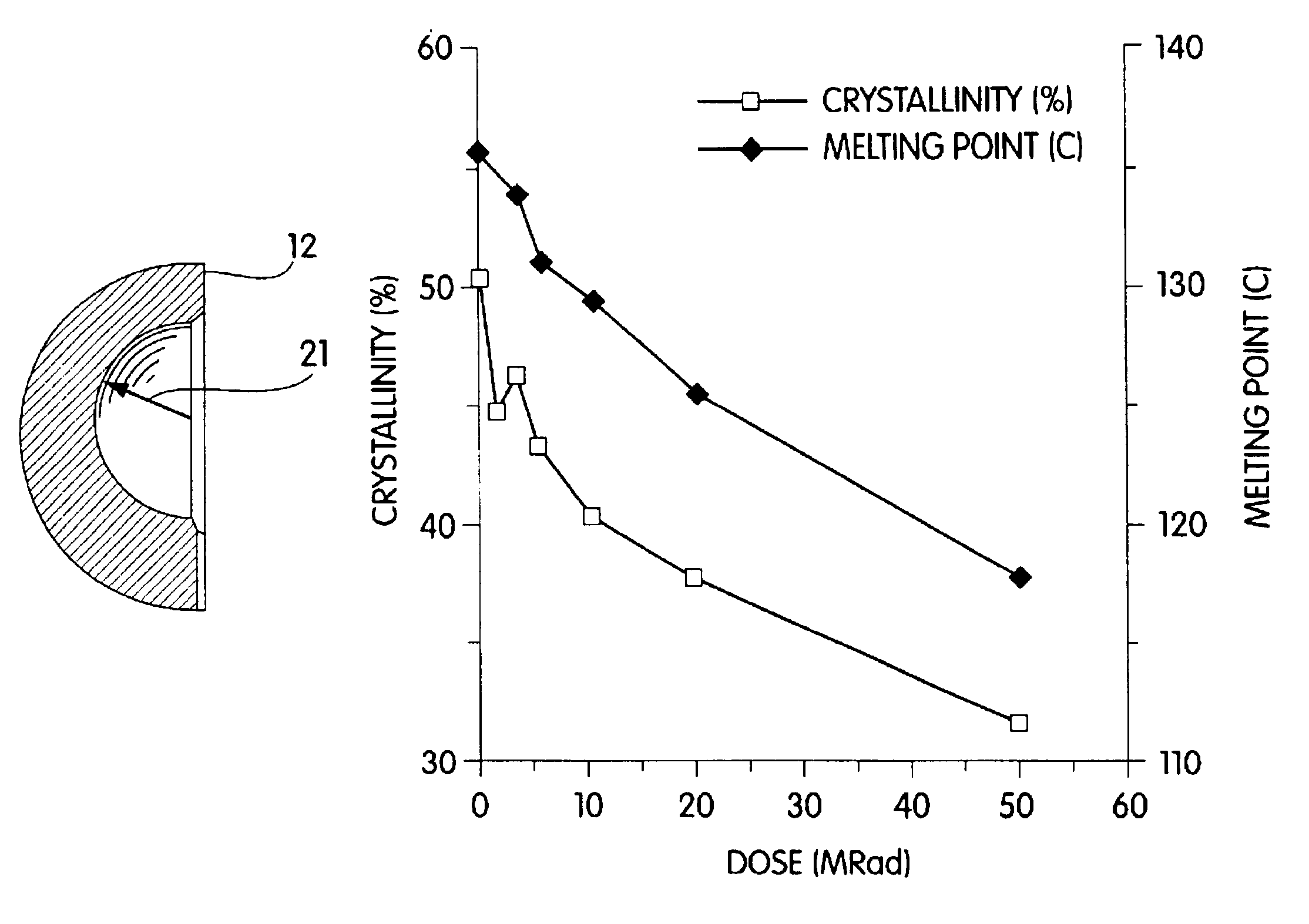

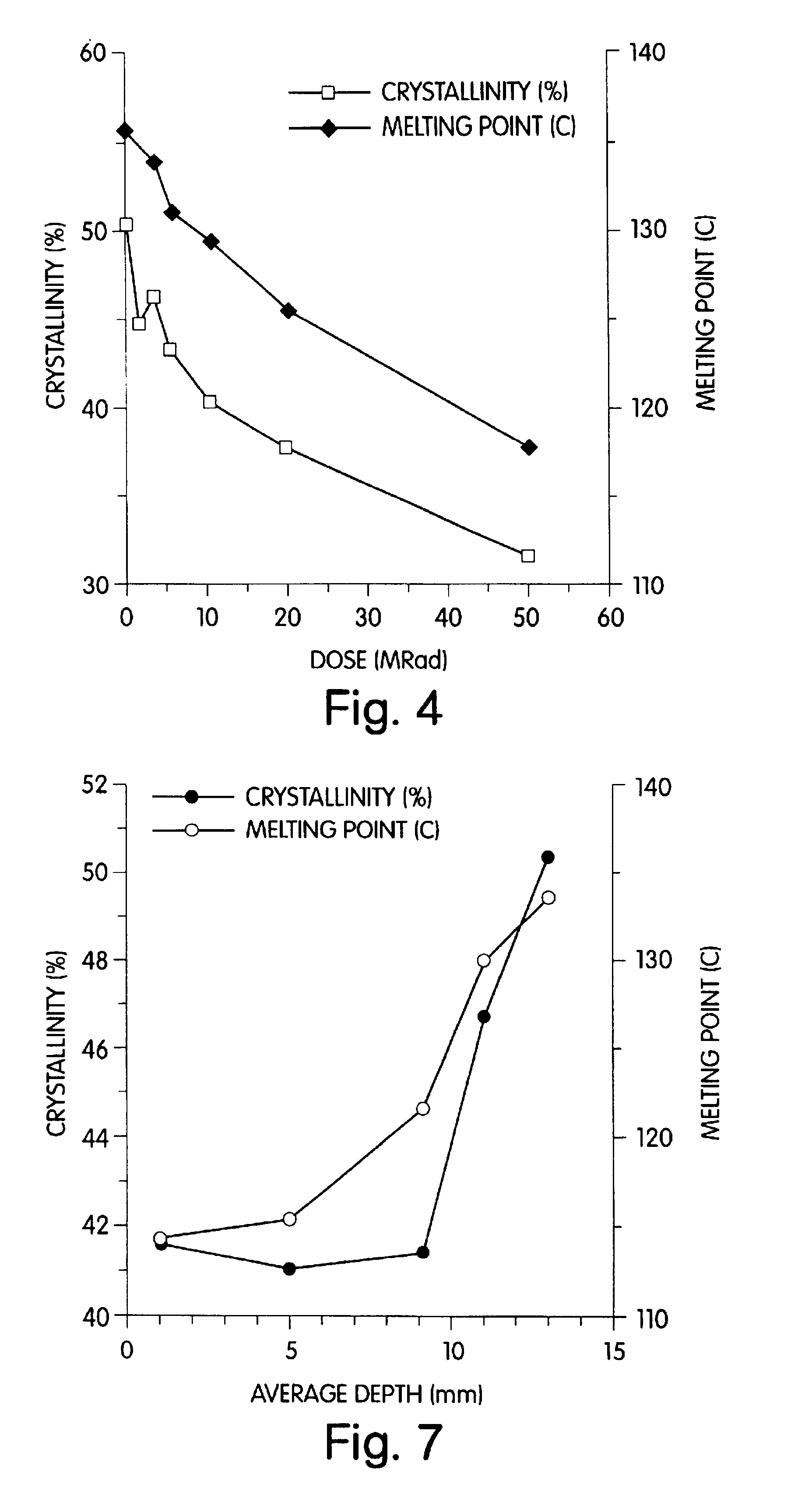

Radiation and melt treated ultra high molecular weight polyethylene prosthetic device and method

InactiveUS6641617B1Reduce productionReduce osteolysis and inflammatory reactionBone implantJoint implantsOxidation resistantPeriprosthetic

A medical prosthesis for use within the body which is formed of radiation treated ultra high molecular weight polyethylene having substantially no detectable free radicals, is described. Preferred prostheses exhibit reduced production of particles from the prosthesis during wear of the prosthesis, and are substantially oxidation resistant. Methods of manufacture of such devices and material used therein are also provided.

Owner:CENTPULSE ORTHOPEDICS +1

Ceramic disc prosthesis

ActiveUS20060004453A1Improve wear resistanceOptimizing post-operative imagingSpinal implantsCoatingsProsthesisIntervertebral disk

A prosthetic is provided for replacing a vertebral disc. The prosthesis can comprise first and second endplates formed of a ceramic material, each including an articulating contact surface and a bone facing surface. The contact surface of the first endplate can have a shape complementary to the contact surface of the second endplate, thereby facilitating articulation of the first and second endplates while in contact with one another. The device can further include at least one non-ceramic bone attachment element mated with at least one of the bone facing surfaces, such that the bone attachment element covers less than a full area of the bone facing surface.

Owner:DEPUY SPINE INC (US)

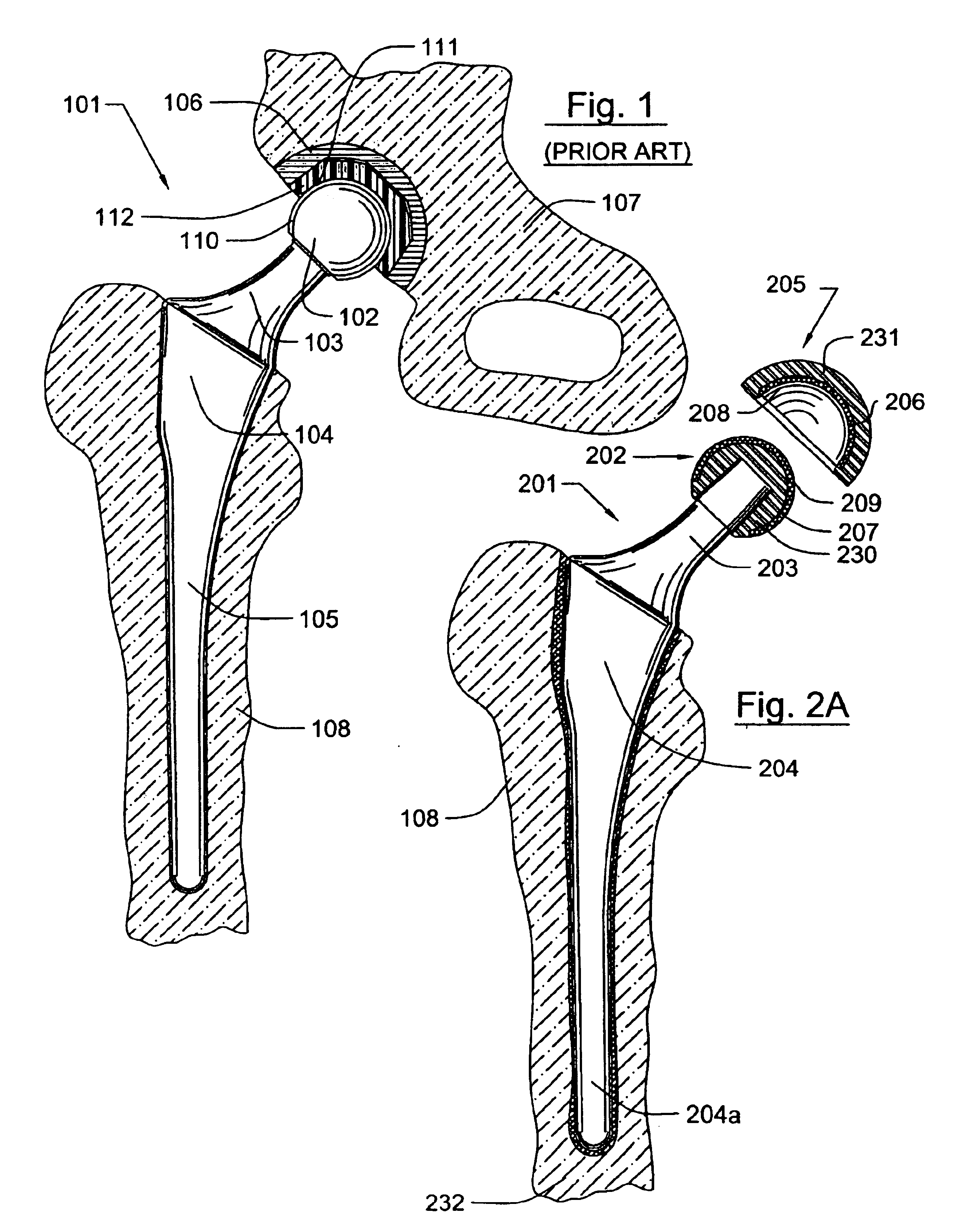

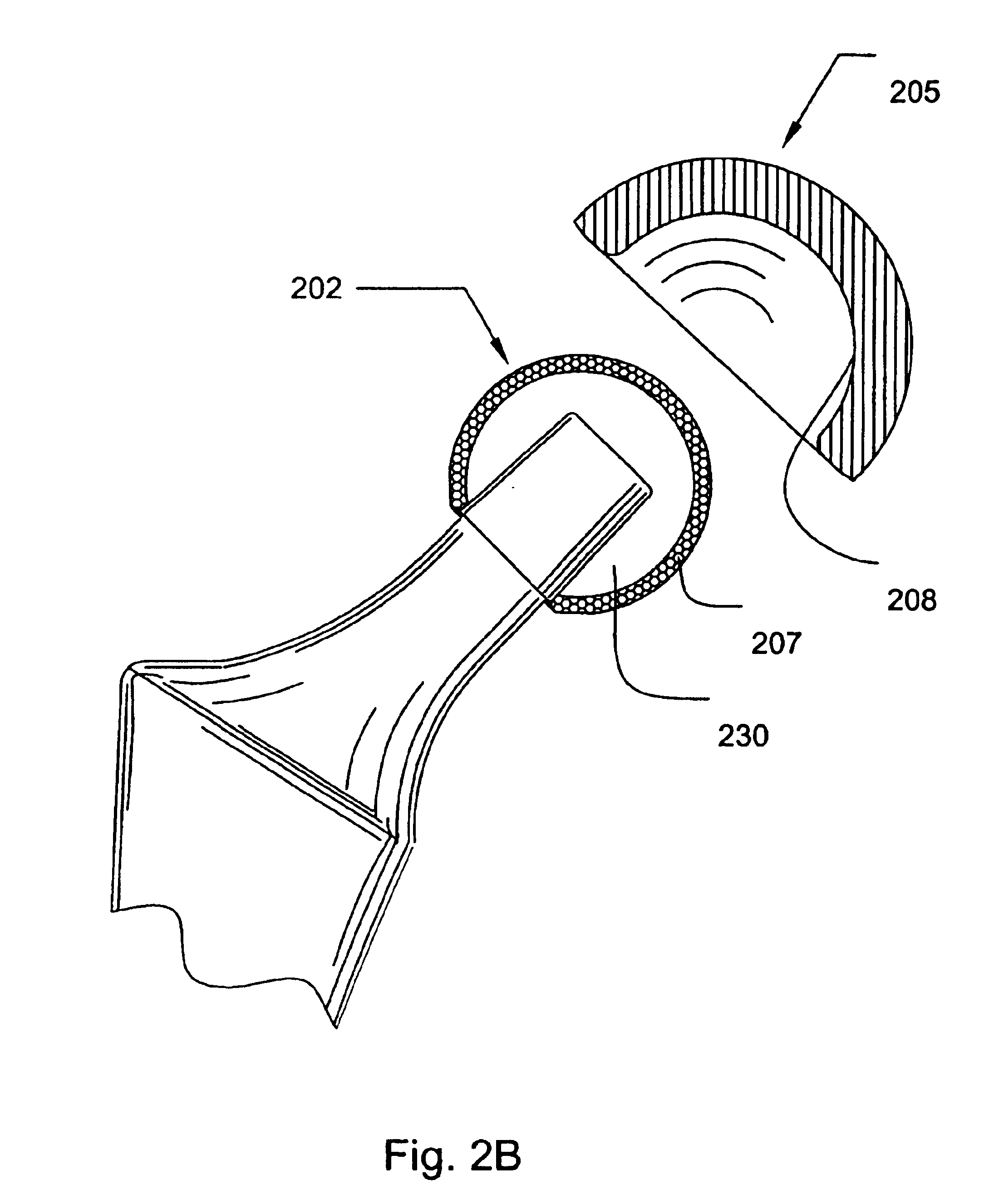

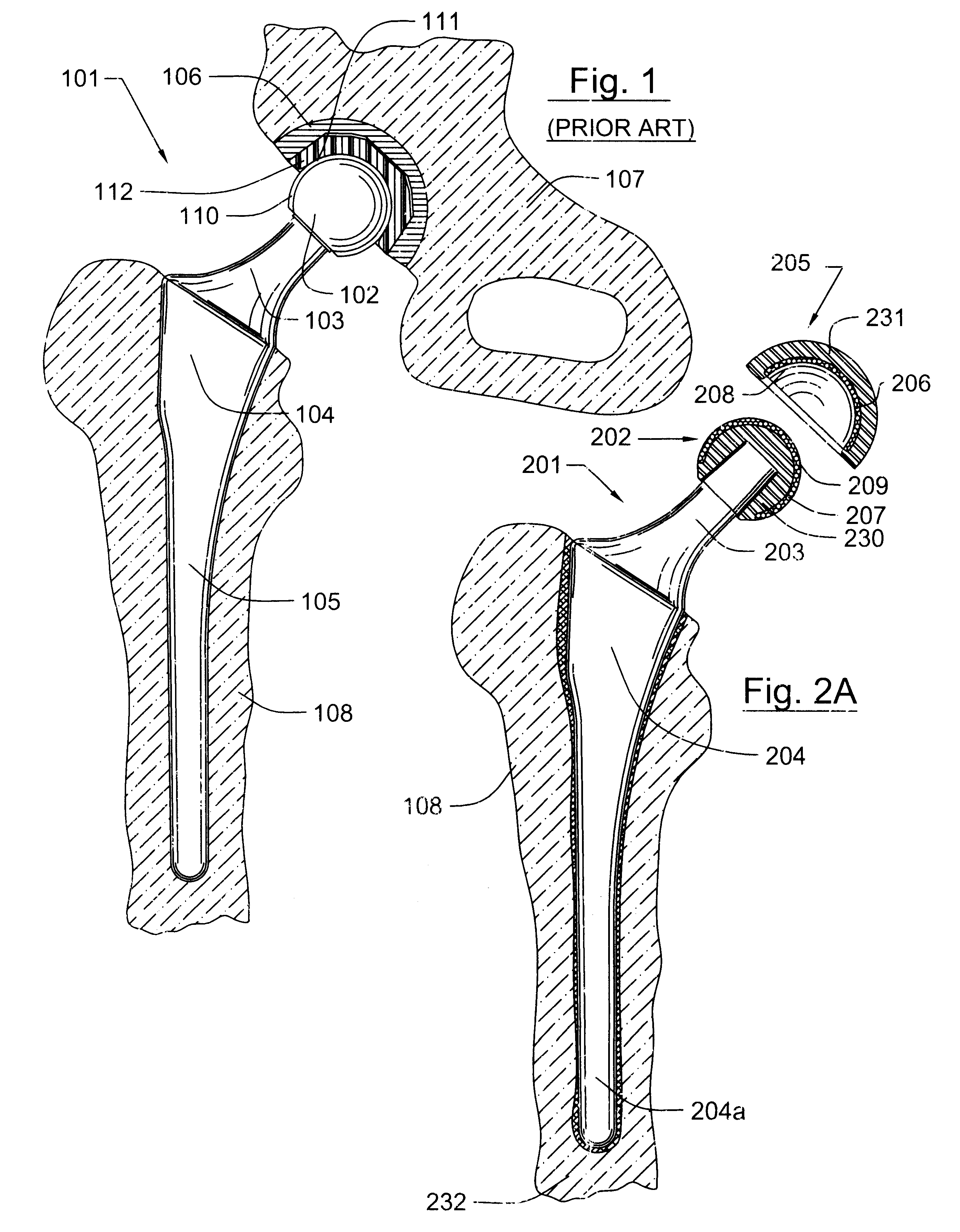

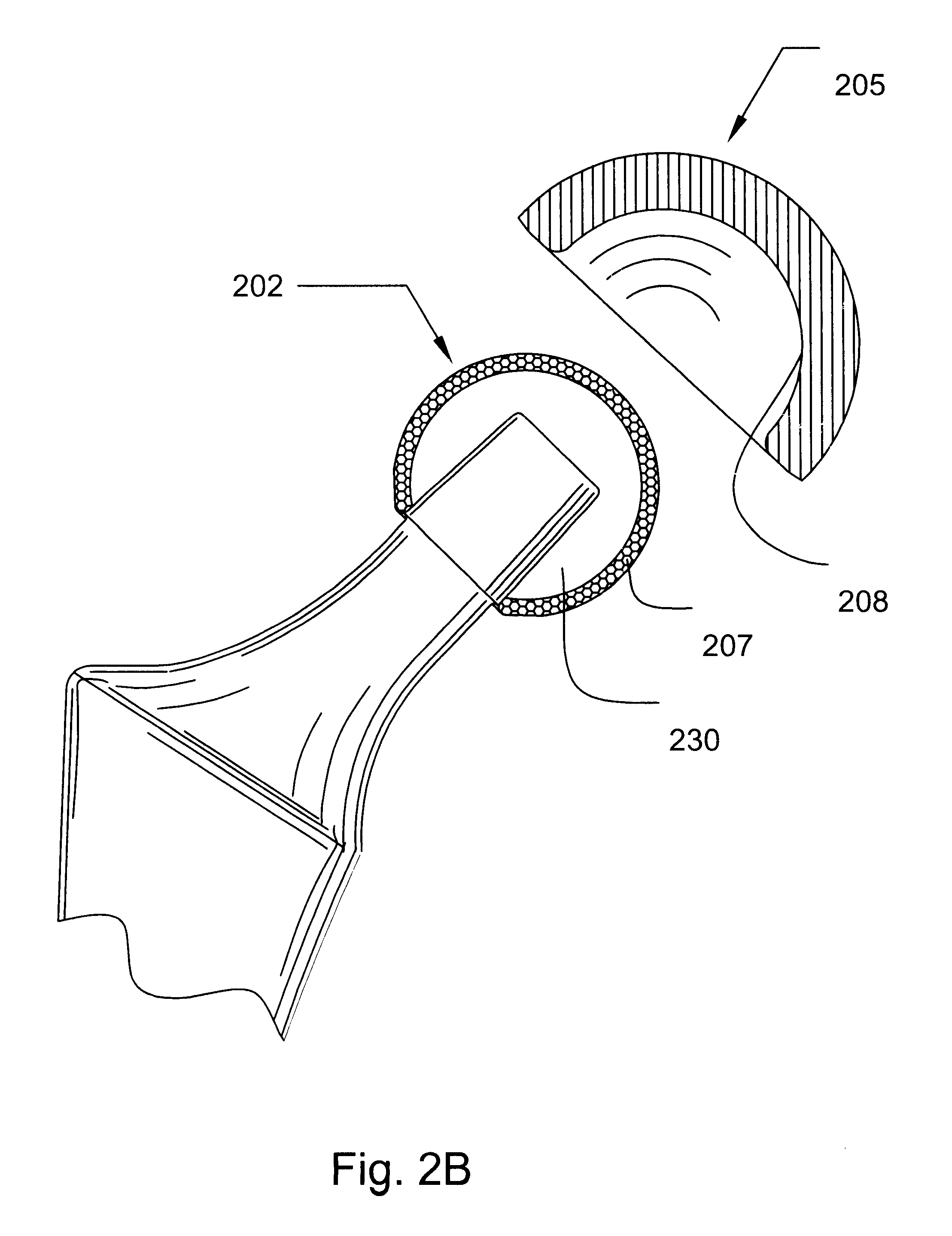

Prosthetic hip joint having a polycrystalline diamond articulation surface and a plurality of substrate layers

InactiveUS6793681B1Less disruptiveLimit stressJoint implantsFemoral headsPolycrystalline diamondProsthesis

Prosthetic joints, components for prosthetic joints, superhard bearing and articulation surfaces, diamond bearing and articulation surfaces, substrate surface topographical features, materials for making joints, bearing and articulation surfaces, and methods for manufacturing and finishing the same, and related information are disclosed, including a prosthetic hip joint having a polycrystalline diamond articulation surface and a plurality of substrate layers.

Owner:DIAMICRON

Prosthetic hip joint having sintered polycrystalline diamond compact articulation surfaces

InactiveUS6290726B1Improve wear resistanceReduce coefficient of frictionFinger jointsWrist jointsArticular surfacesProsthesis

Prosthetic joints, components for prosthetic joints, superhard bearing and articulation surfaces, diamond bearing and articulation surfaces, substrate surface topographical features, materials for making joints, bearing and articulation surfaces, and methods for manufacturing and finishing the same, and related information are disclosed, including a prosthetic hip joint having sintered polycrystalline diamond articulation.

Owner:DIAMICRON

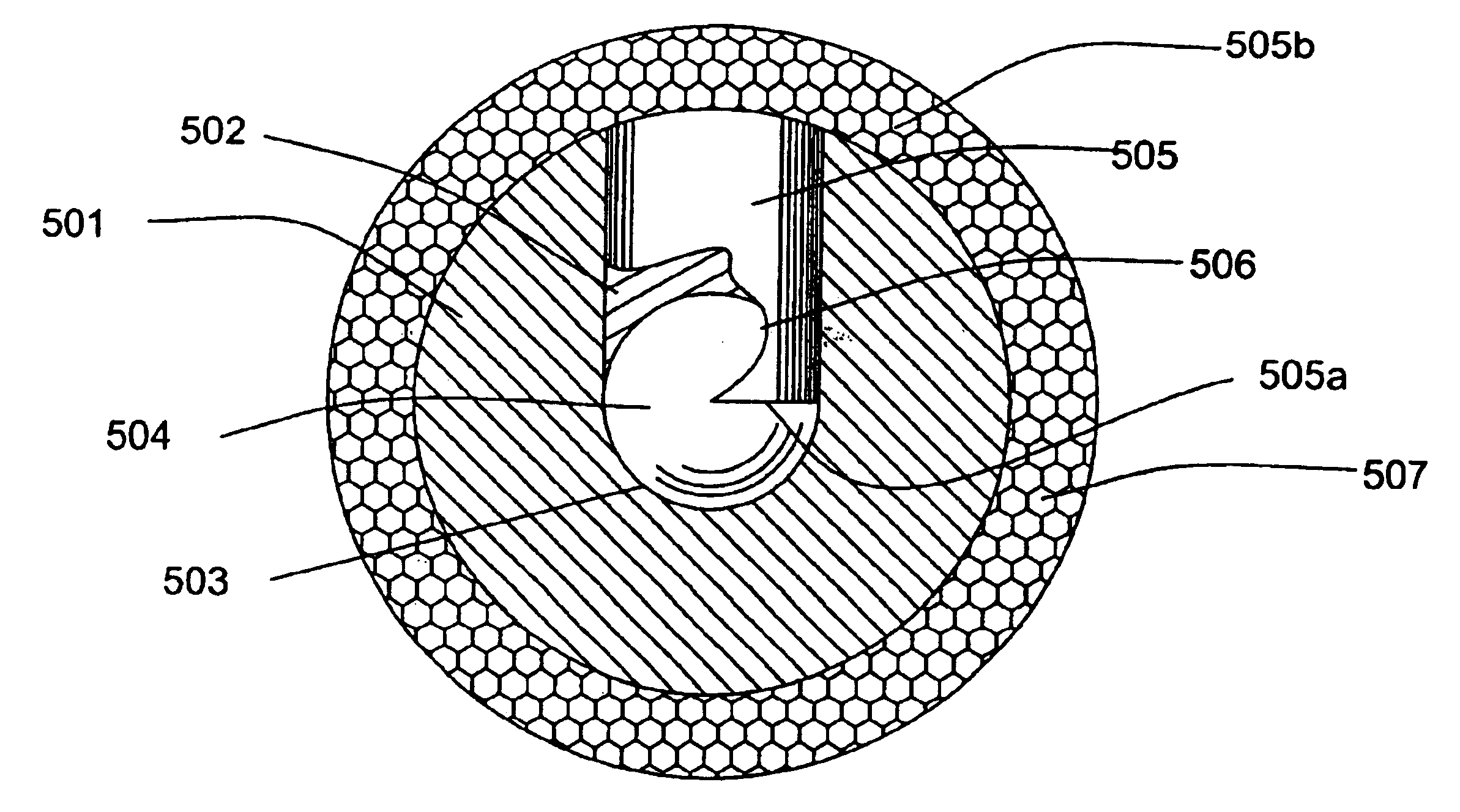

Artificial heart valve

InactiveUS6991649B2Increase flow ratePrevent thrombosisHeart valvesJoint implantsMitral valve leafletPivot joint

Owner:SIEVERS HANS HINRICH

Diamond-surfaced cup for use in a prosthetic joint

InactiveUS6488715B1Improve wear resistanceReduce coefficient of frictionFinger jointsWrist jointsArticular surfacesSacroiliac joint

Prosthetic joints, components for prosthetic joints, superhard bearing and articulation surfaces, diamond bearing and articulation surfaces, substrate surface topographical features, materials for making joints, bearing and articulation surfaces, and methods for manufacturing and finishing the same, and related information are disclosed, including a diamond-surfaced cup for use in a prosthetic joint.

Owner:DIAMICRON

Tissue pad for an ultrasonic device for cutting and coagulating

InactiveUS20100094323A1Improve wear resistanceLoad moreLaminationLamination apparatusActuatorDissection

Owner:CILAG GMBH INT

Tool with a molybdenum sulfide containing coating and method for its production

InactiveUS6528171B1Improve wear resistanceRecord information storageMagnetic recordingMetallic materialsMonolayer

The invention relates to a tool, especially a cutting insert for cutting metallic materials, which consist of a hard metal, cermet ceramics or steel base, especially of a high speed steel base, and at least one layer deposited thereon. The single layer, or in the case of several layers the outer layer or the layer underneath the outer layer, contains molybdenum sulfide. The aim of the invention is to improve the resistance to wear of the friction-reducing, molybdenum sulfide containing layer even at high pressures. To this end, the molybdenum sulfide containing layer consists of an alternating sequence of two layer that are different from one another. The first layer contains 51 to 100% by weight of metallic molybdenum and the second layer contains 21 to 100% by weight of MoS2 which substantially consists of hexagonal crystals that are at least substantially oriented in a plane parallel to the tool surface.

Owner:WIDIA

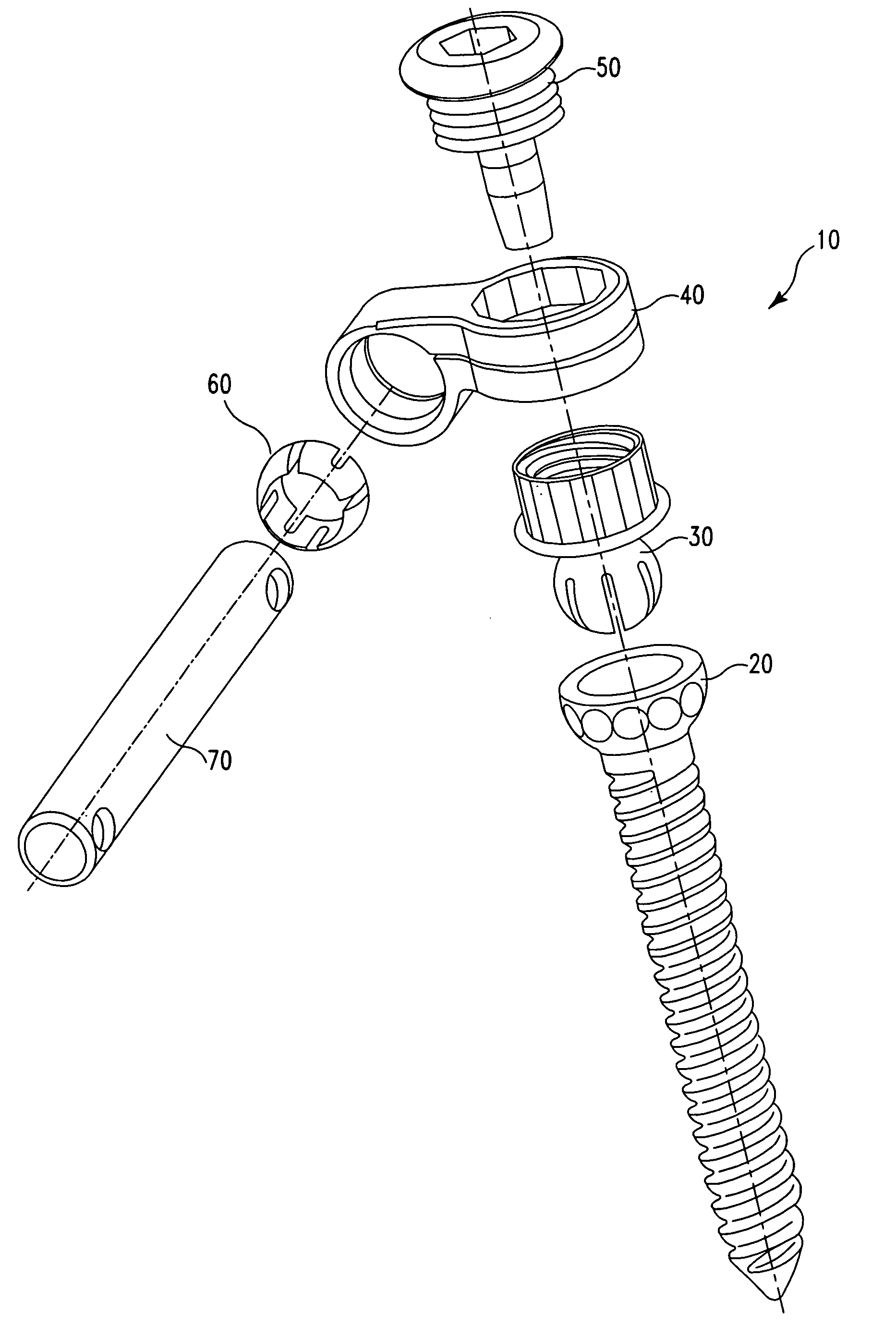

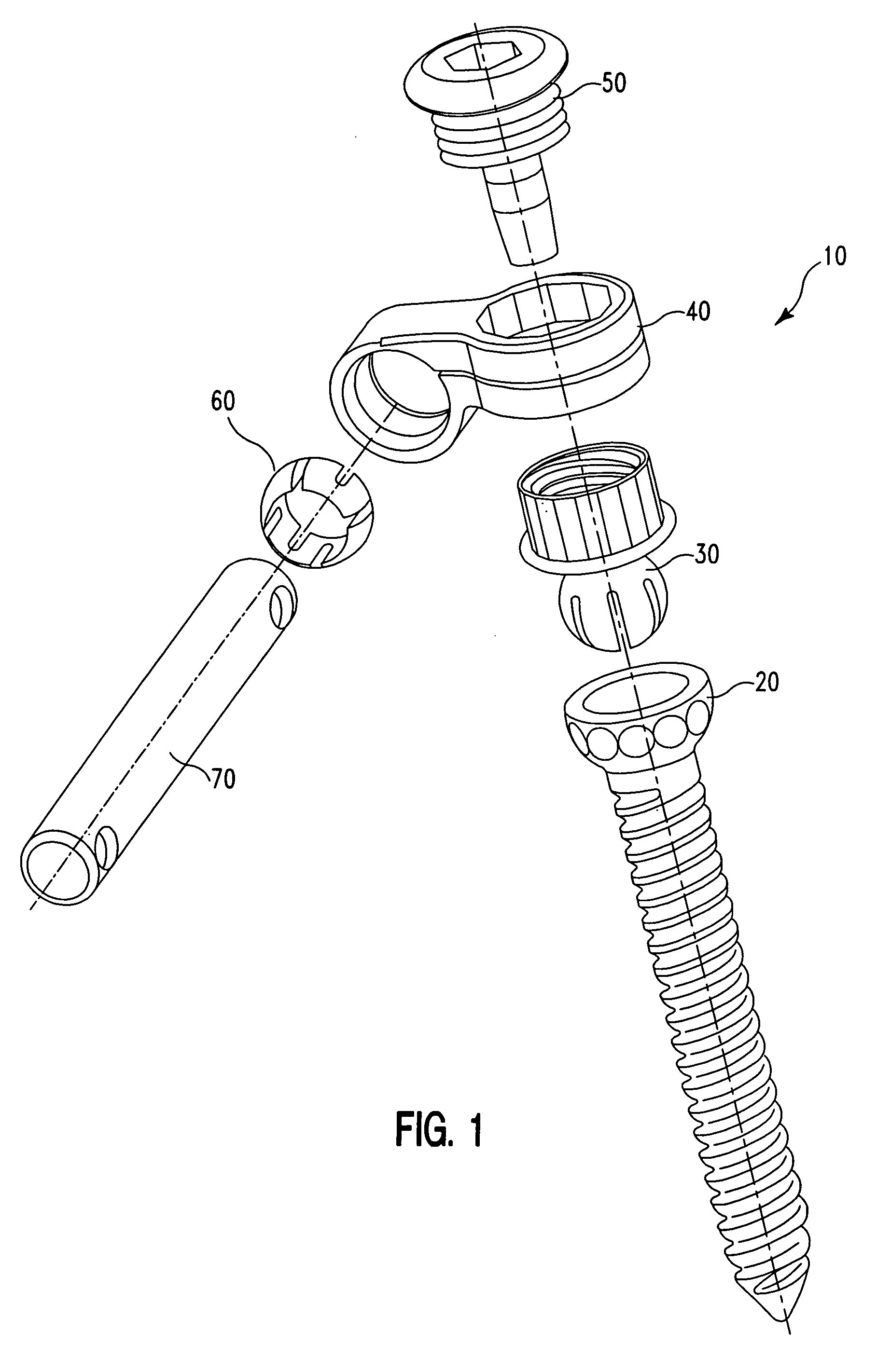

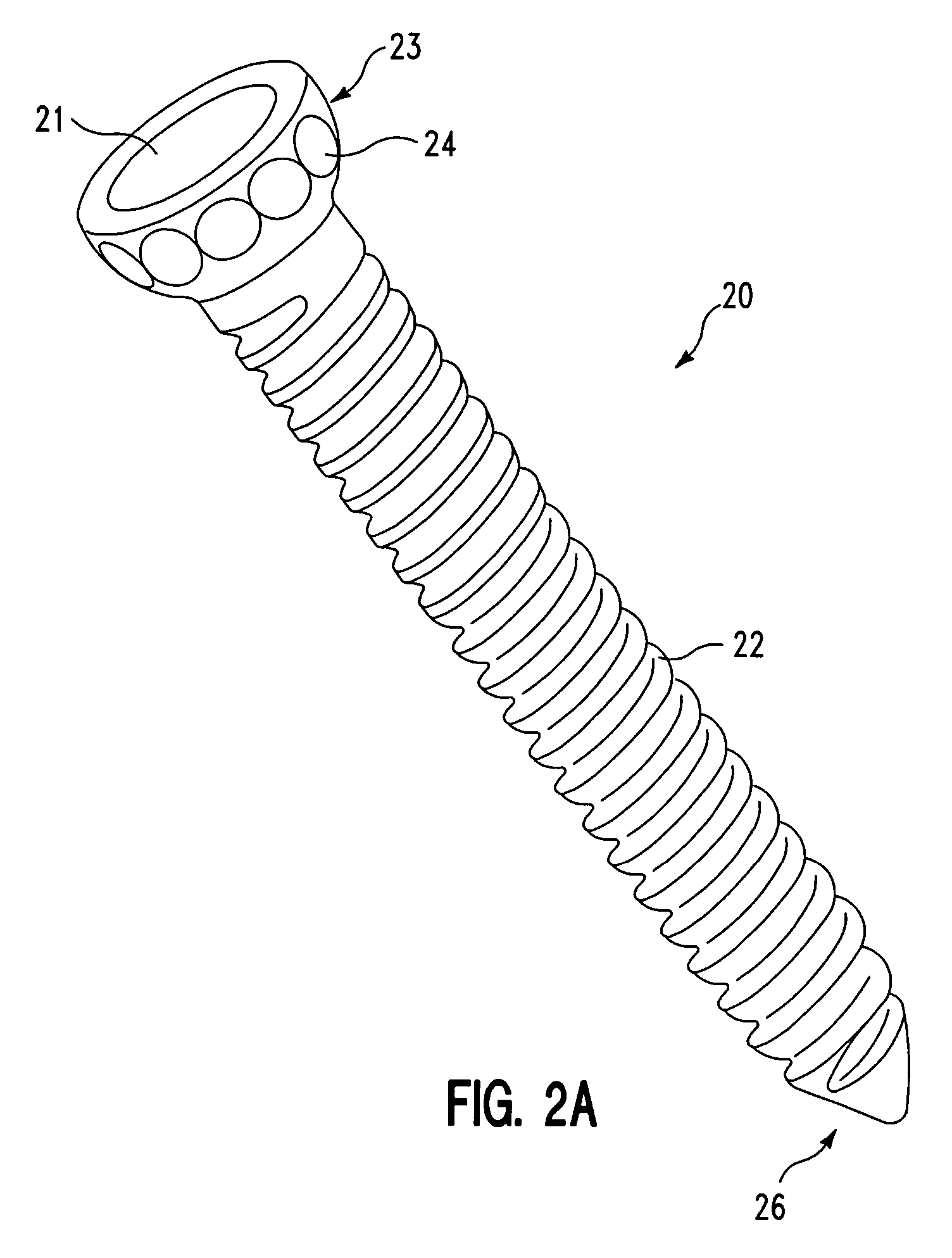

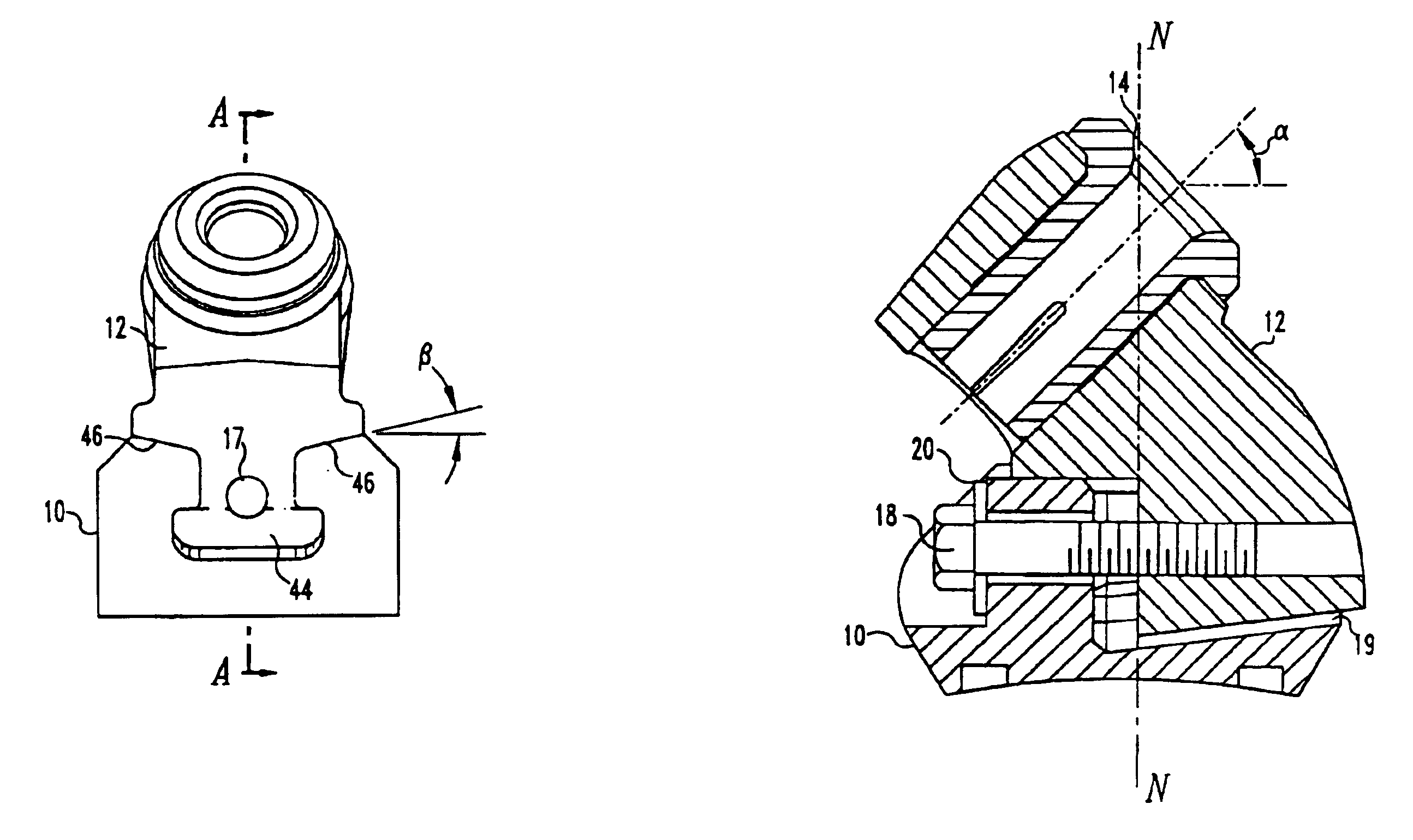

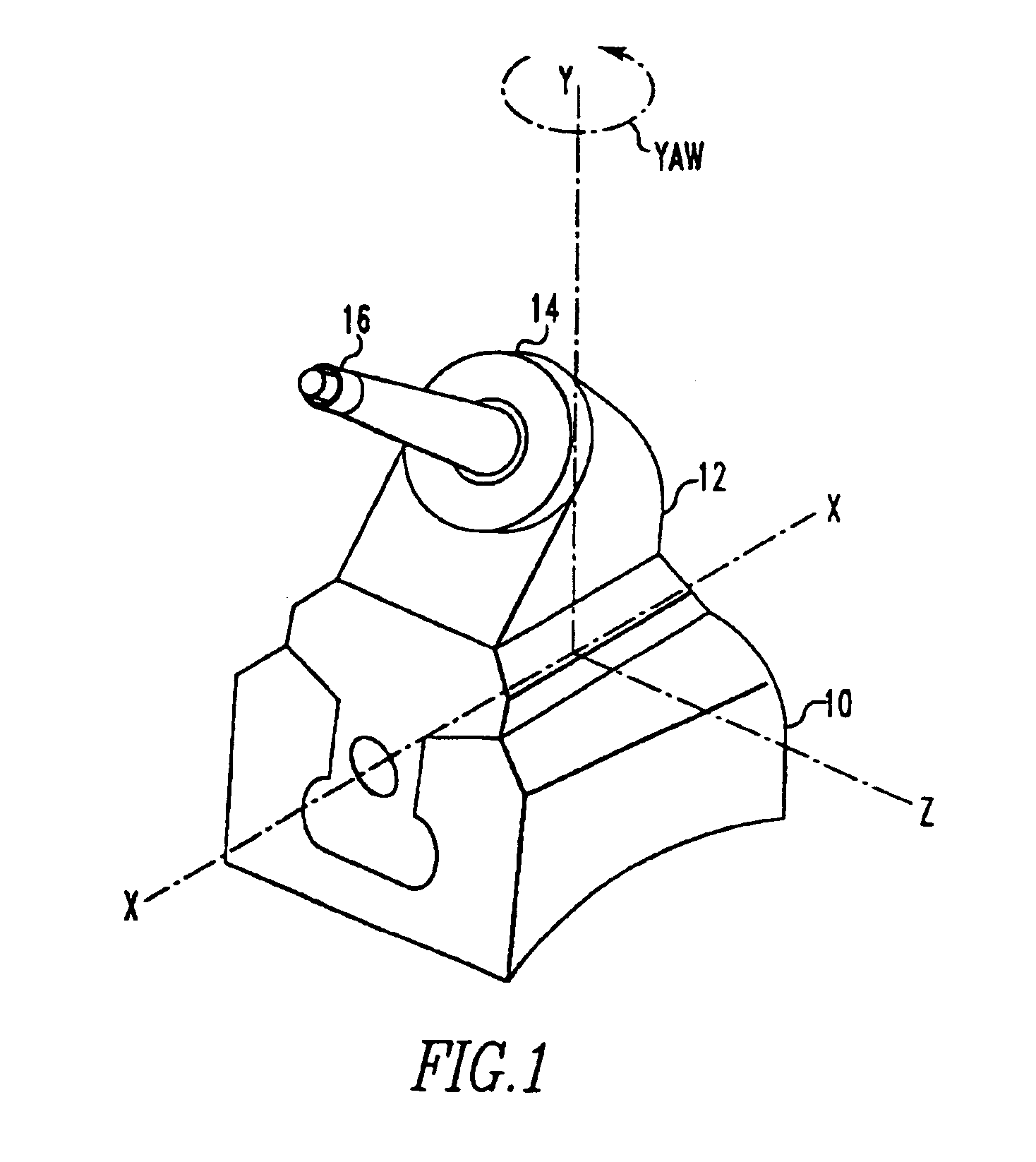

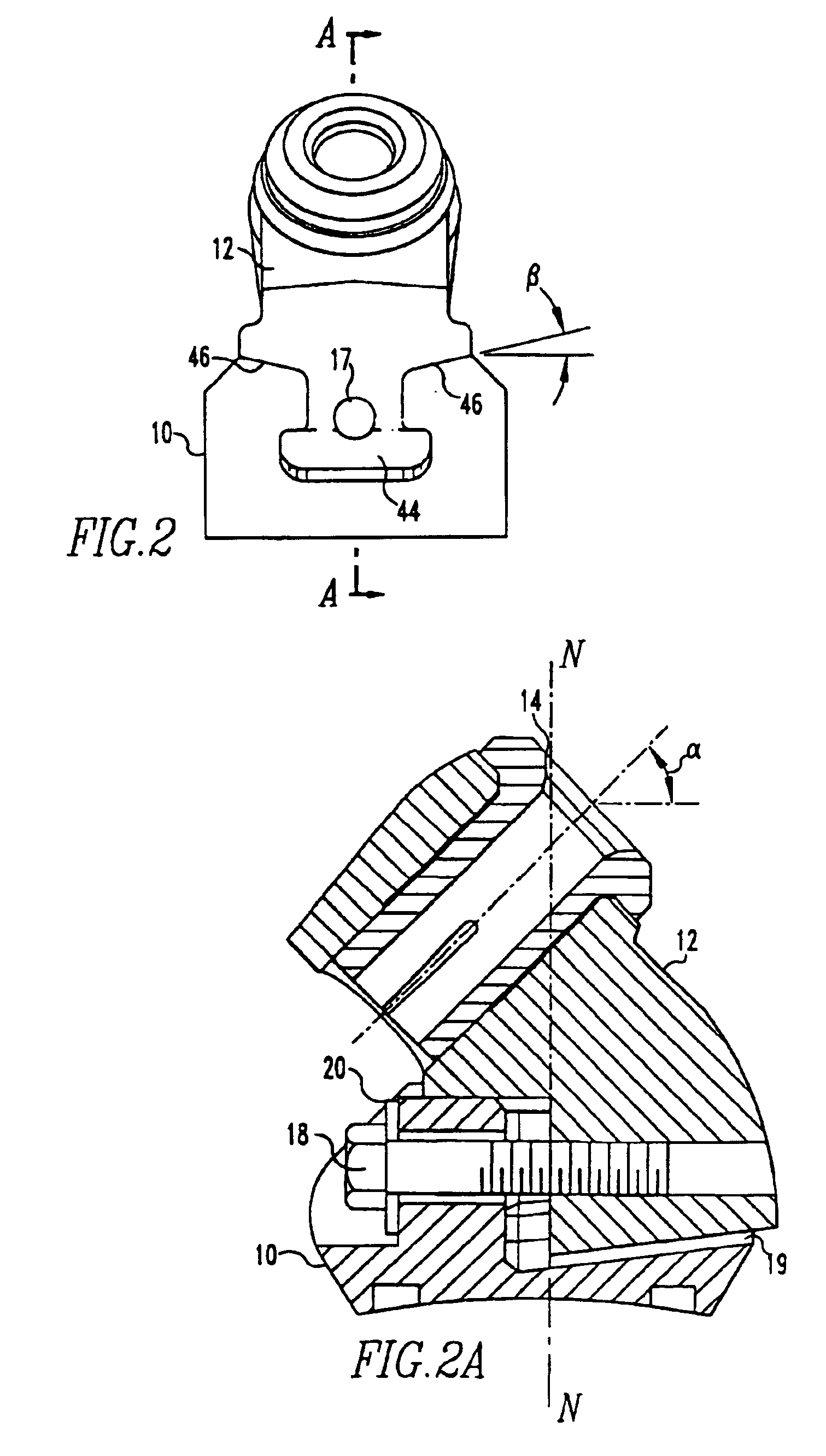

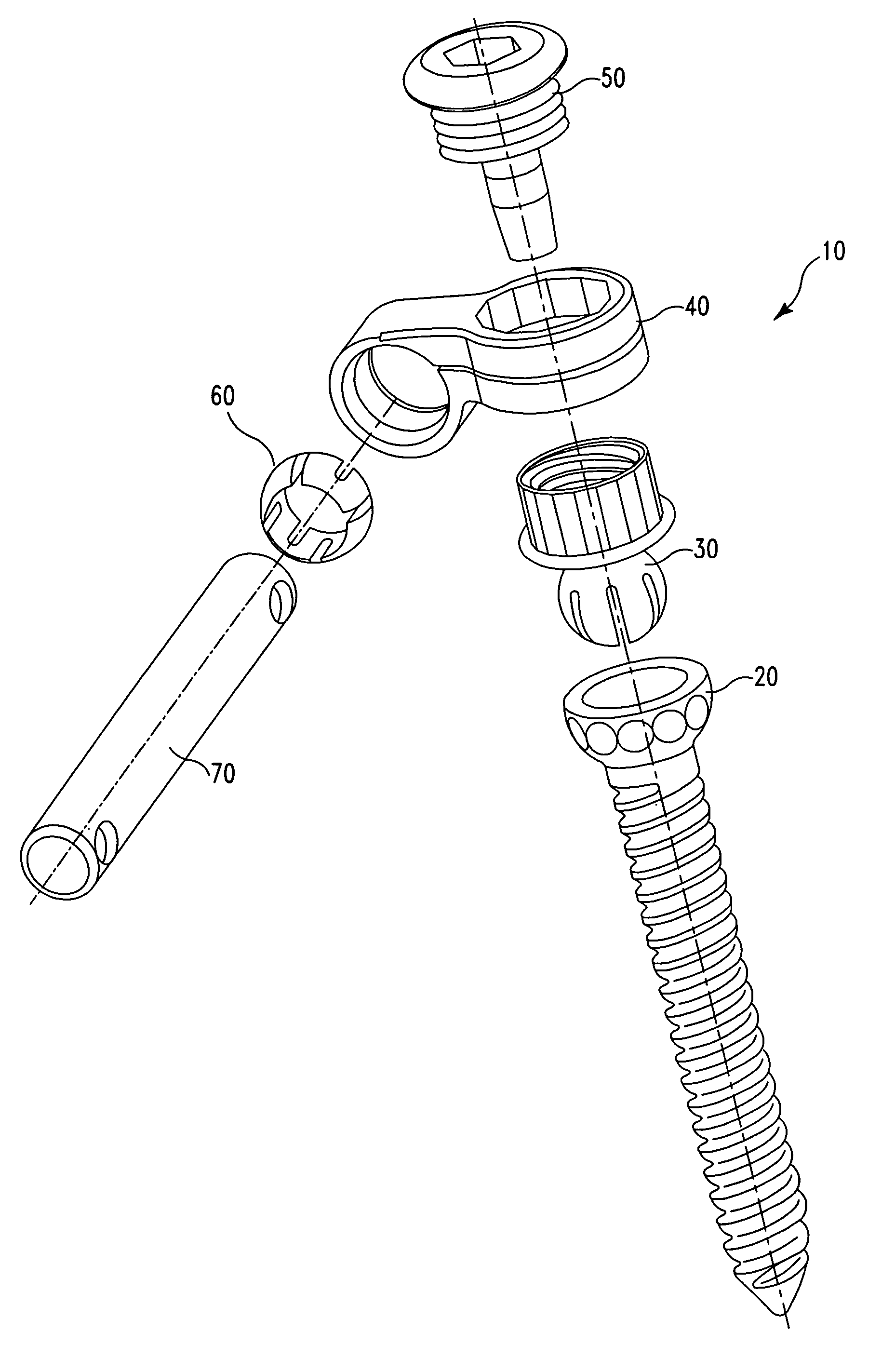

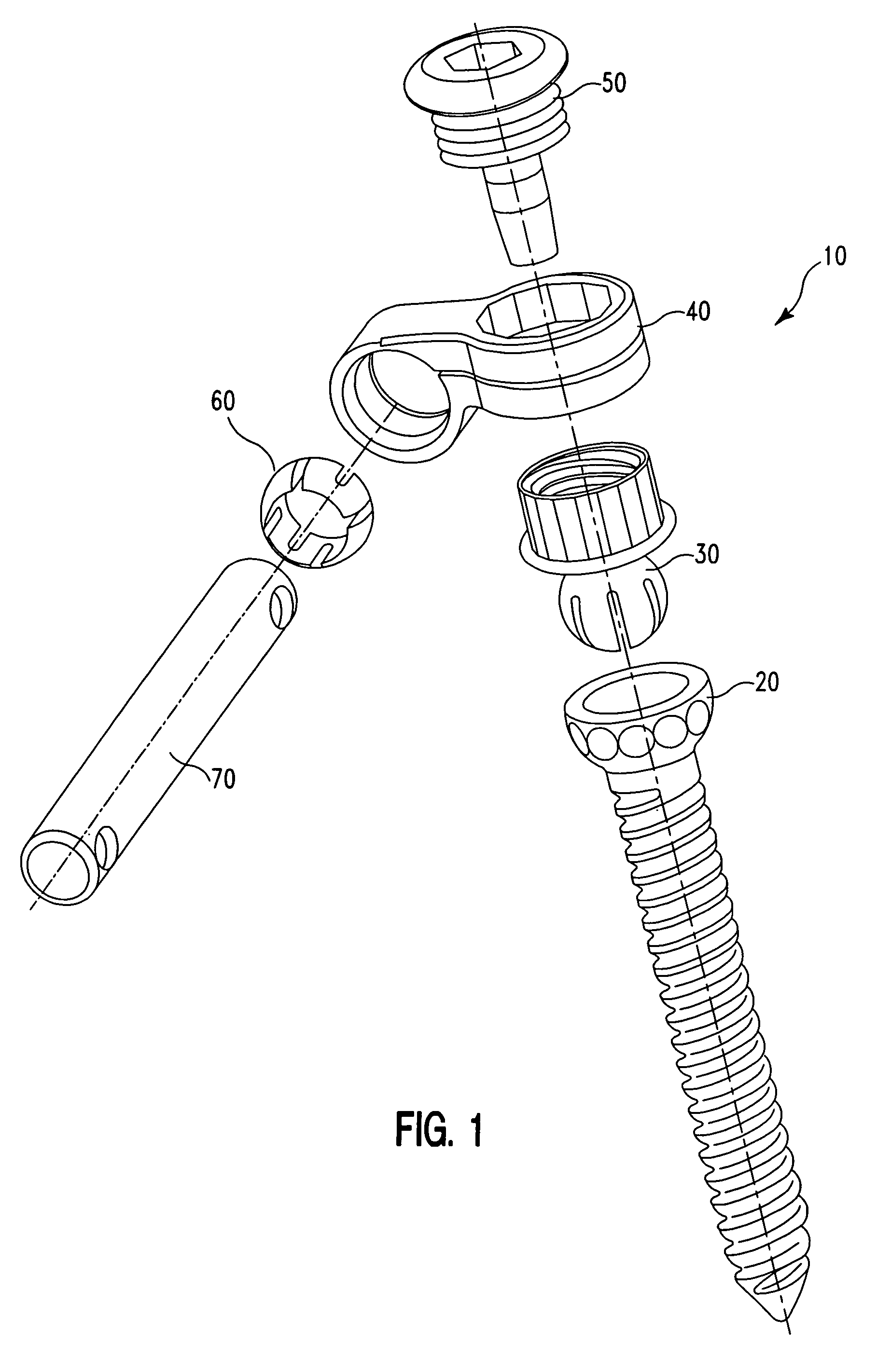

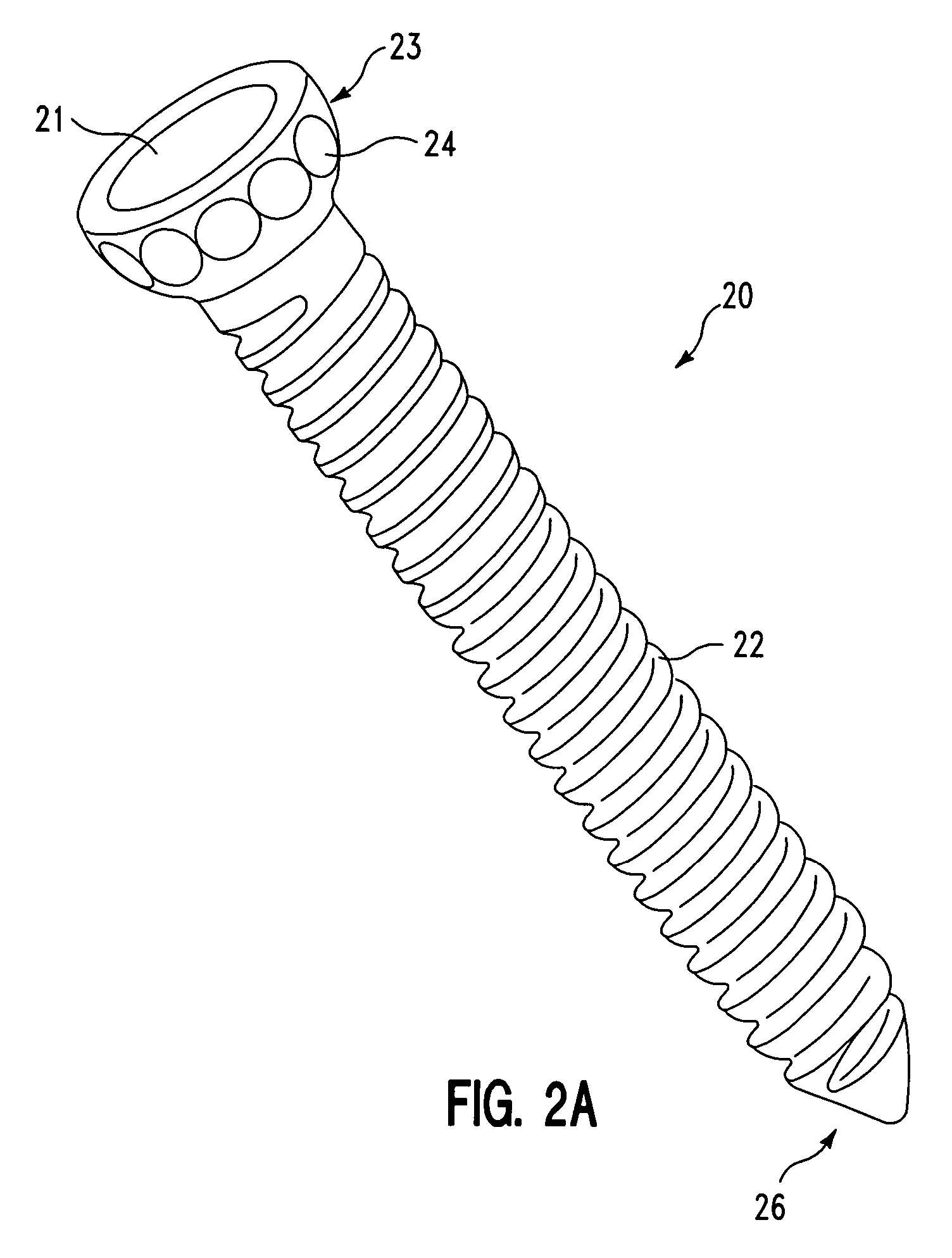

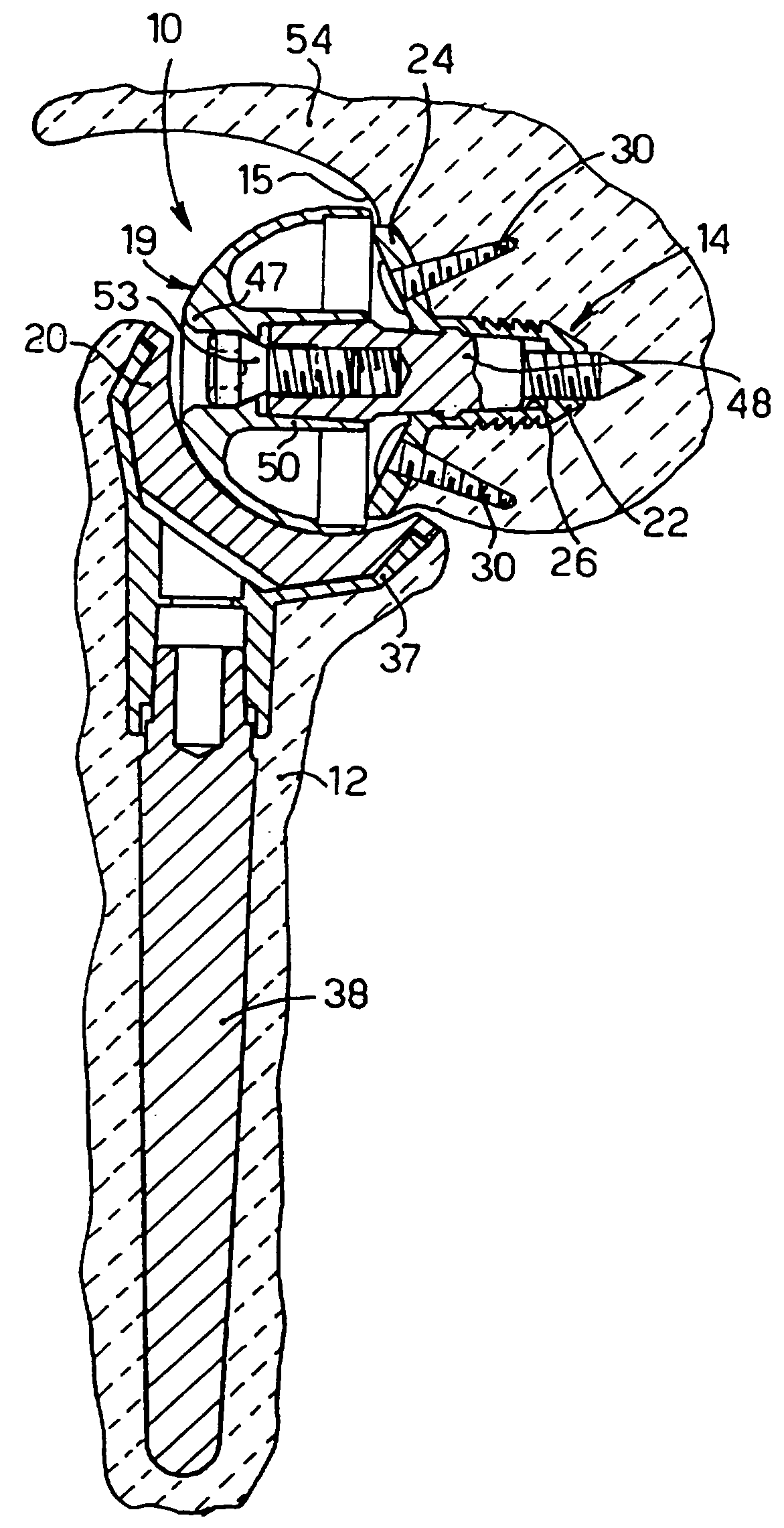

Medialised rod pedicle screw assembly

InactiveUS20050192572A1Great freedomAdequate profileSuture equipmentsInternal osteosythesisEngineeringIliac screw

A pedicle screw assembly and method of assembly comprises a longitudinal member; a bendable ball ring adapted to receive the longitudinal member; a poly stem comprising a bendable male bulbous end; and a connector comprising a pair of first apertures adapted to receive the poly stem; and a second aperture adapted to receive the ball ring and the longitudinal member, wherein the second aperture is transverse to the first aperture. The assembly further comprises a bone fixator component comprising a female socket adapted to receive the poly stem; and a blocker pin adapted to engage the poly stem and to secure the longitudinal member.

Owner:CUSTOM SPINE INC

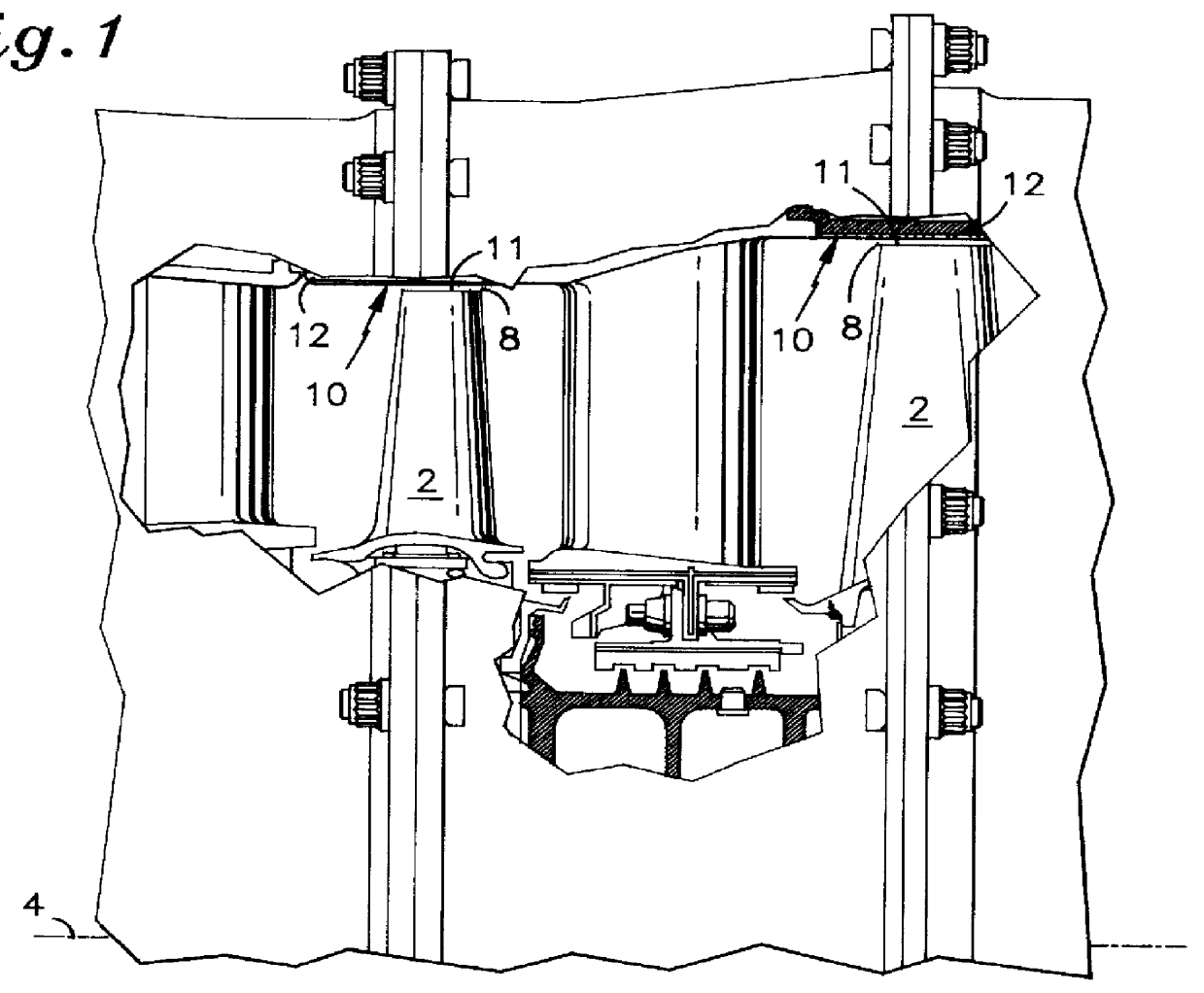

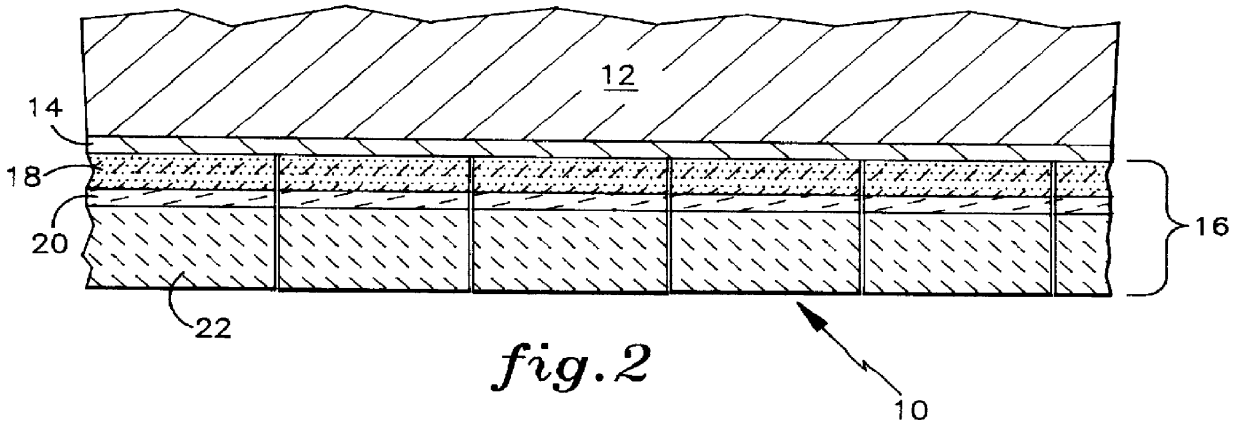

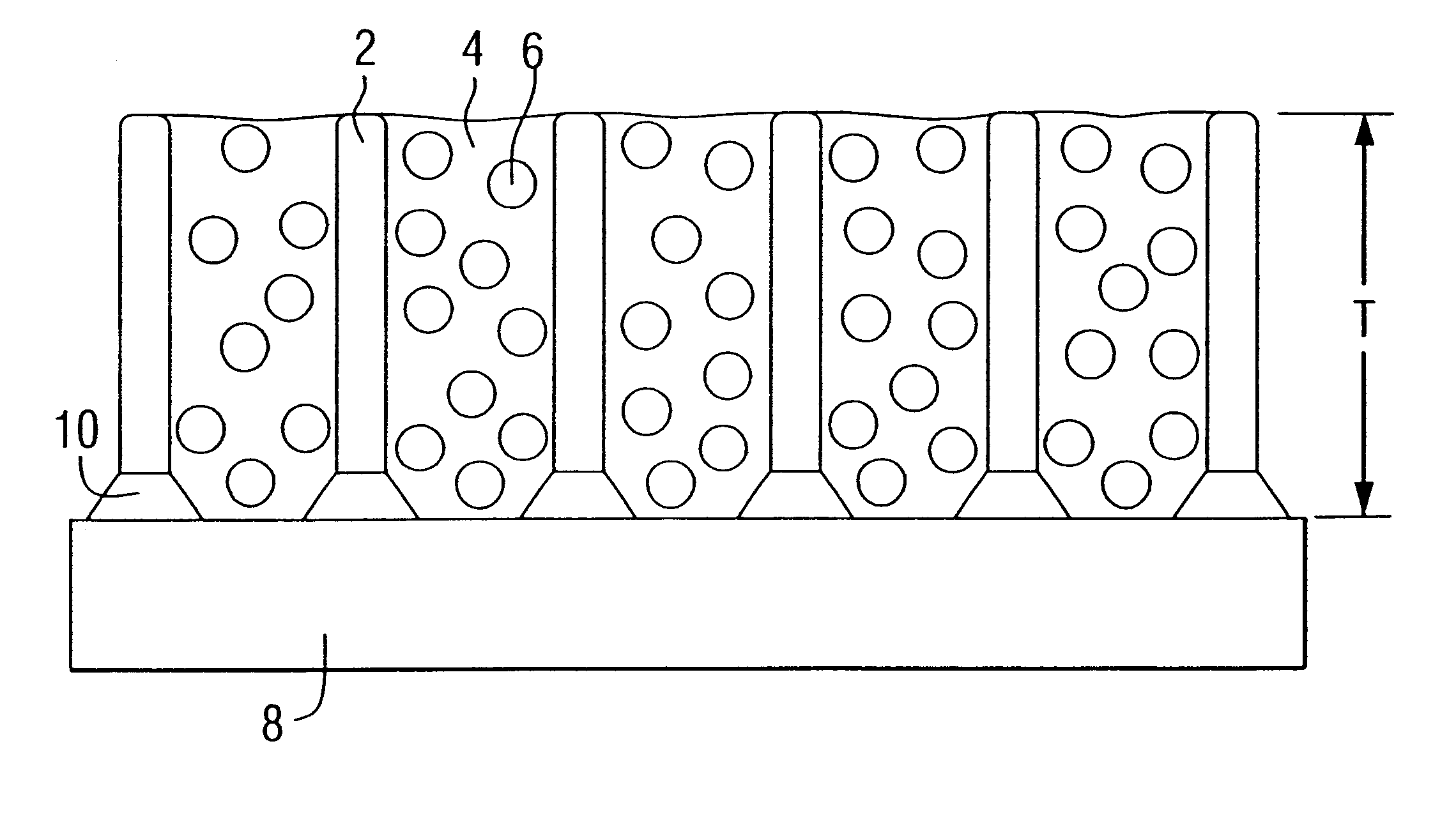

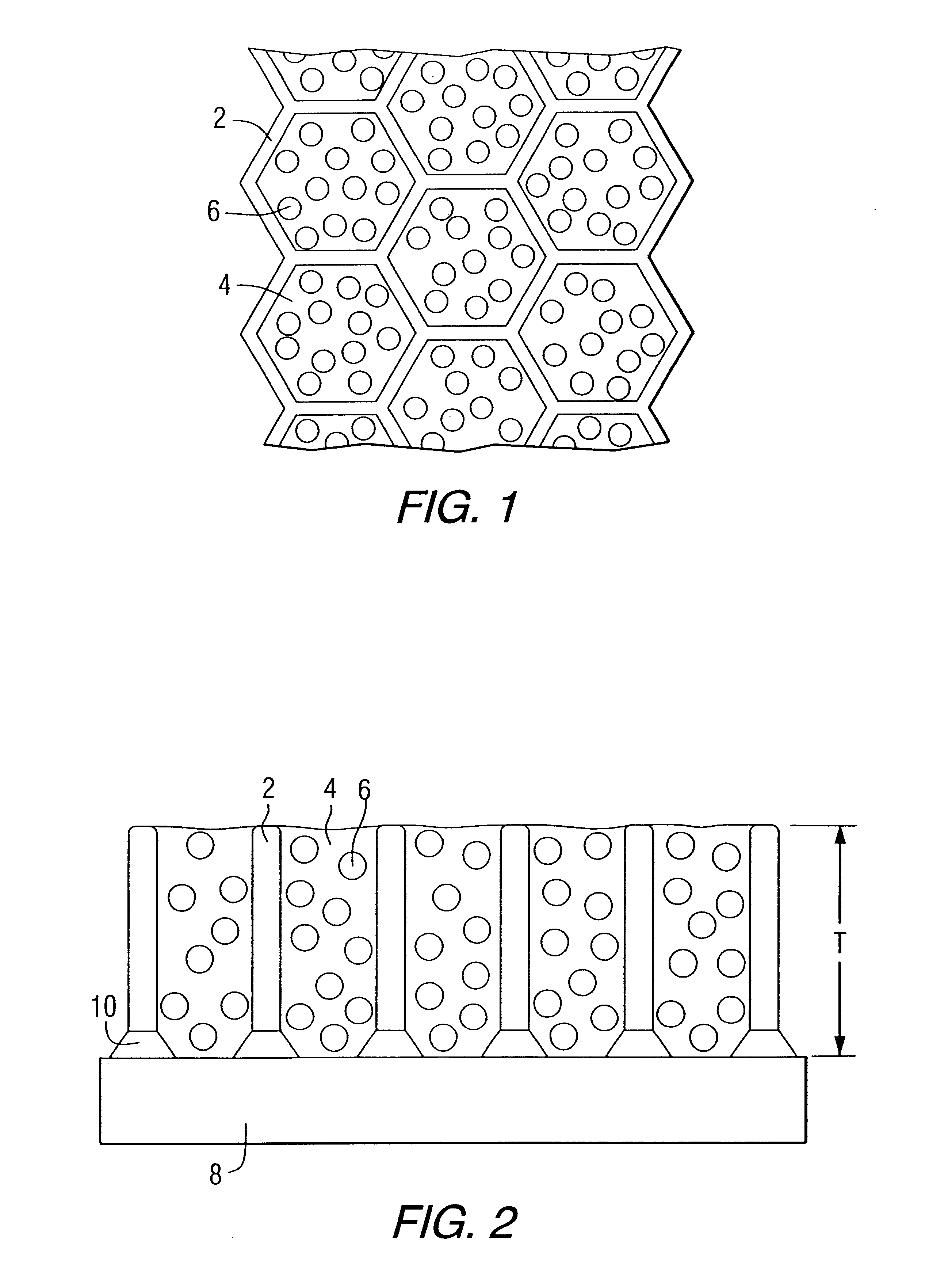

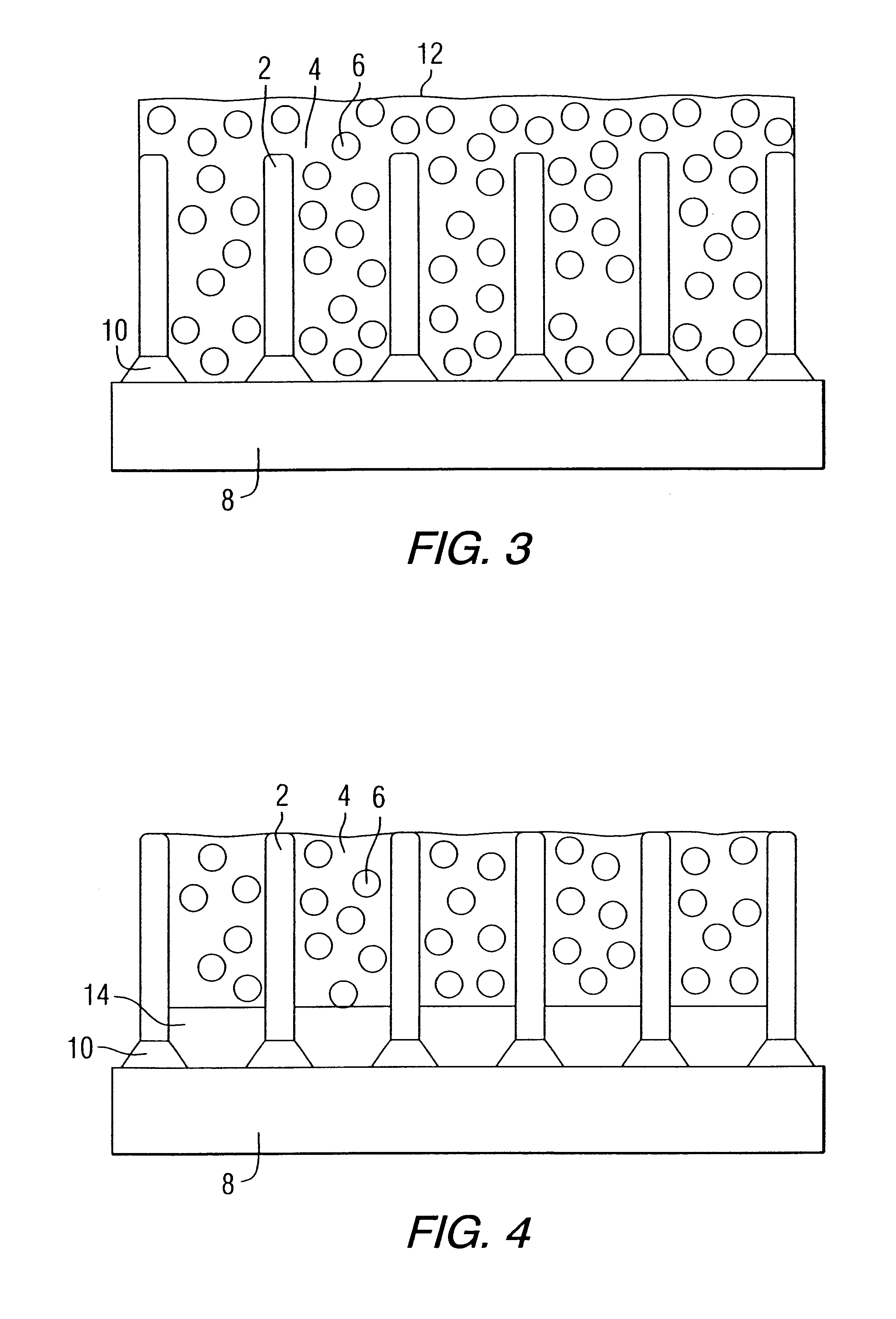

Segmented abradable ceramic coating

InactiveUS6102656AImprove wear resistanceSufficient resistanceMolten spray coatingPump componentsCeramic coatingWear resistance

A segmented abradable ceramic coating system having superior abradability and erosion resistance is disclosed. The system includes a duct segment having a metallic substrate, a MCrAlY bond coat on the substrate and a segmented abradable ceramic coating on the bond coat. The segmented abradable ceramic coating includes a base coat foundation layer, a graded interlayer and an abradable top layer for an overall thickness of preferably about 50 mils (1.270 mm). The coating is characterized by a plurality of vertical microcracks. By precisely controlling the deposition parameters, composition of the layers and layer particle morphology, segmentation is achieved, as well as superior abradability and erosion resistance.

Owner:UNITED TECH CORP

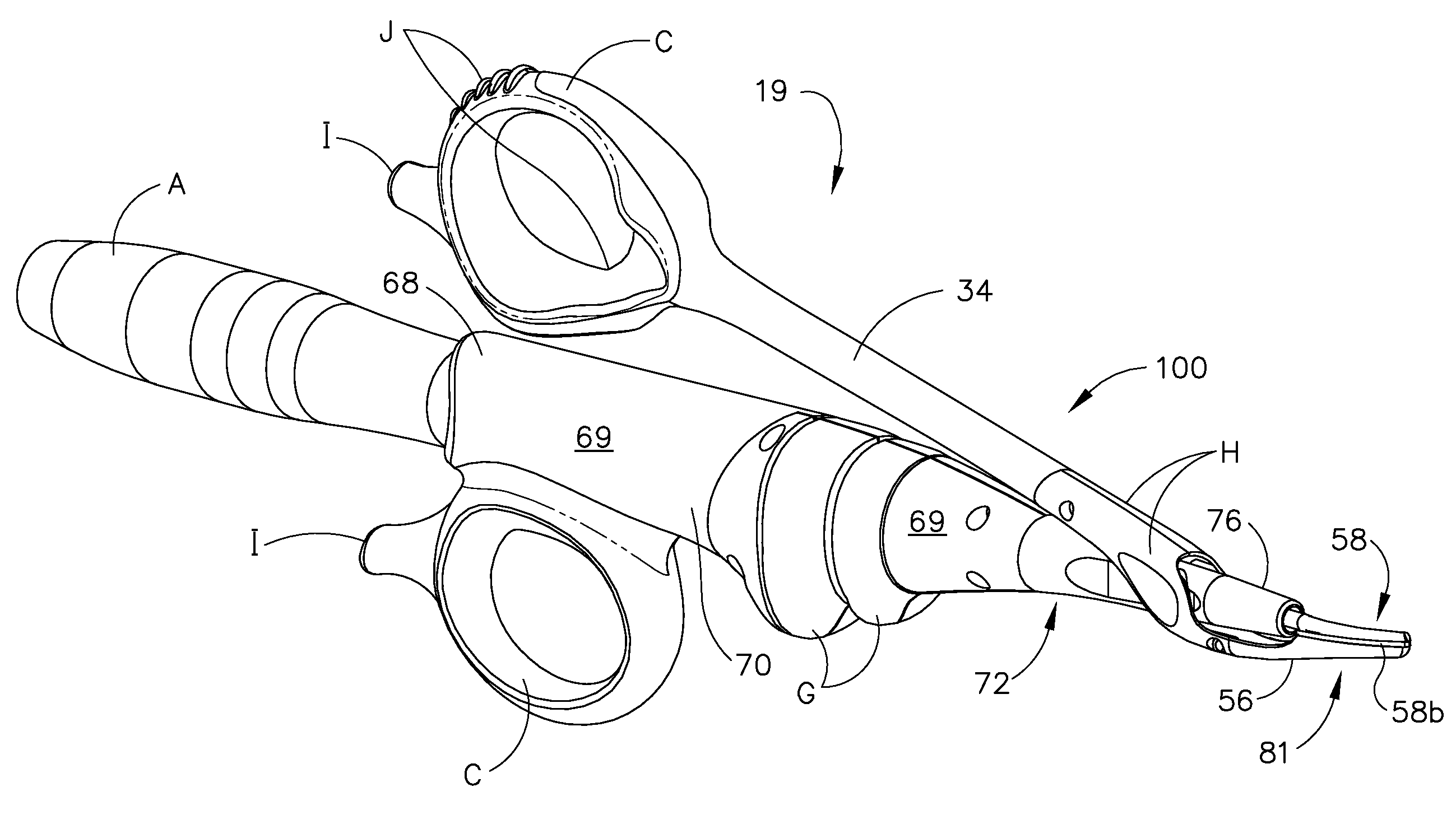

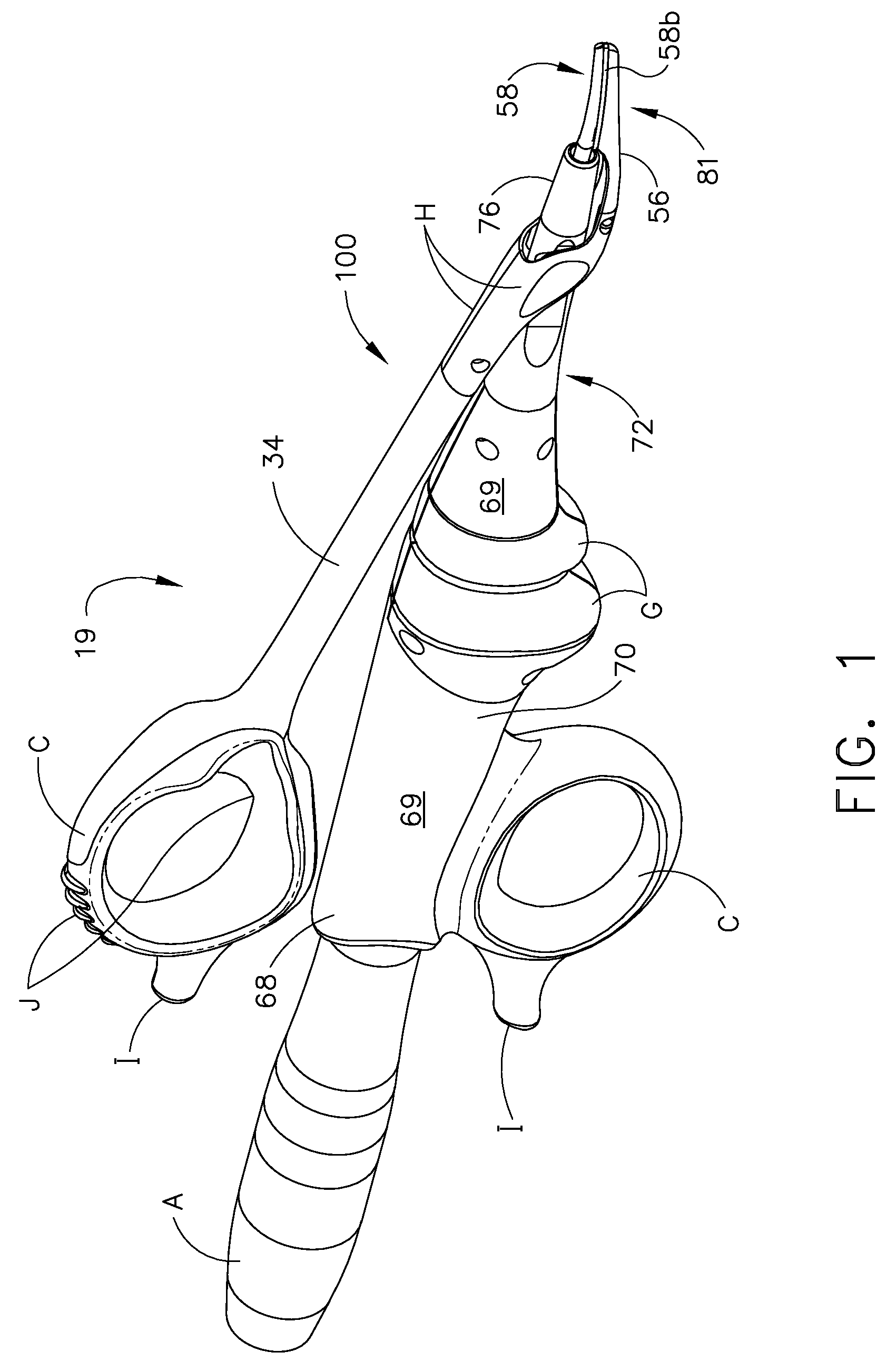

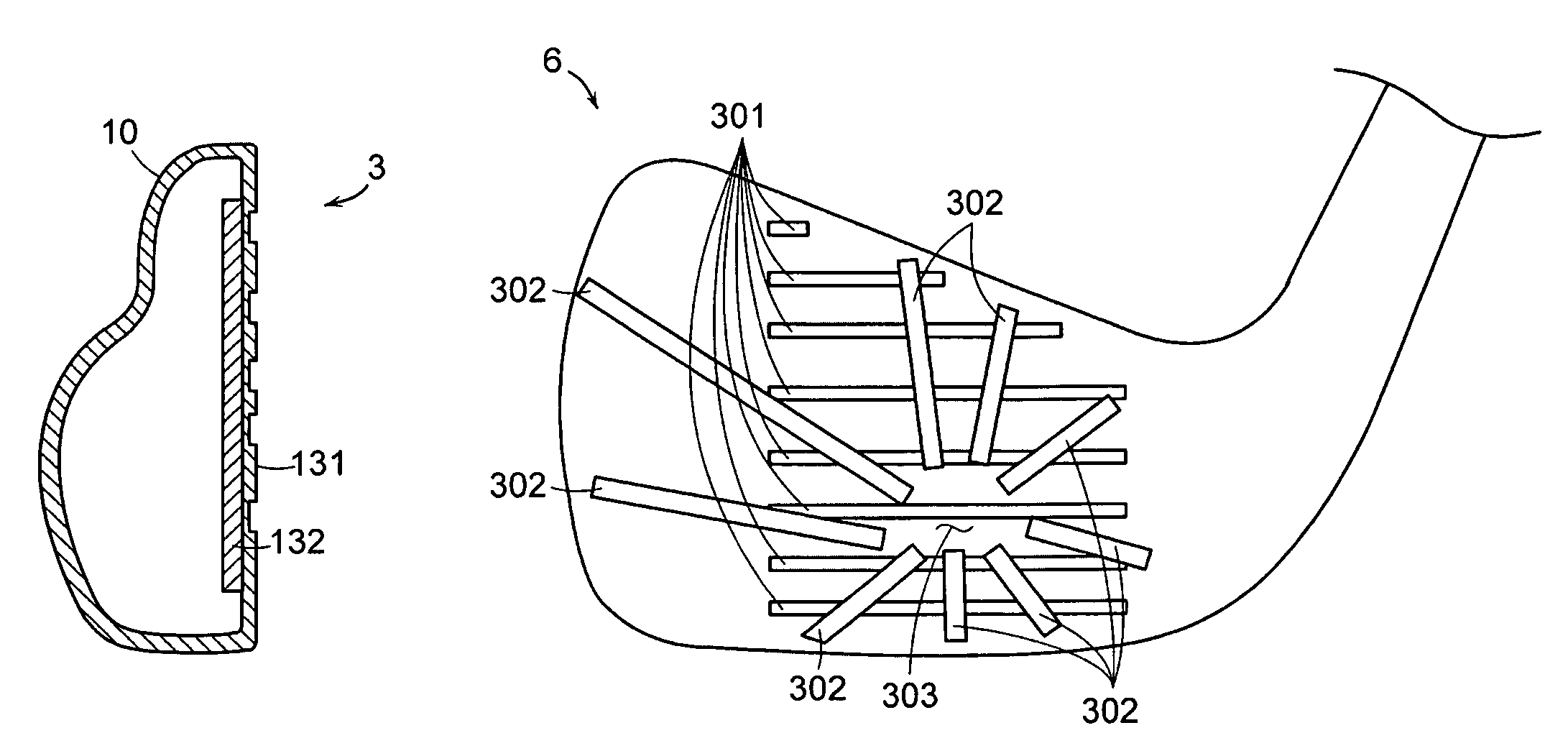

Ultrasonic device for cutting and coagulating

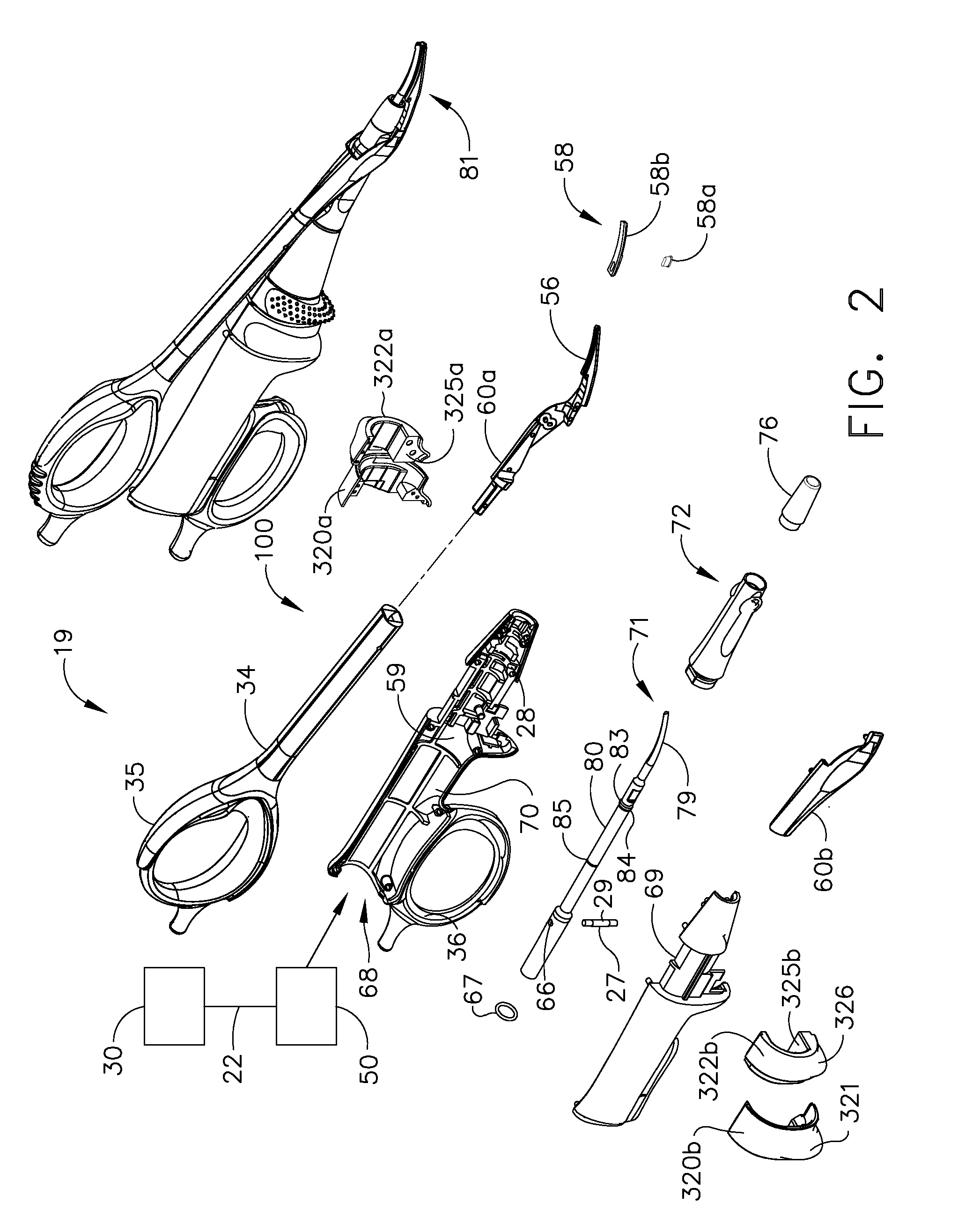

ActiveUS8328834B2Improve wear resistanceLoad moreSurgical scissorsSurgical forcepsSurgical departmentBiomedical engineering

An ultrasonic clamp coagulator assembly that is configured to permit selective cutting, coagulation, and fine dissection required in fine and delicate surgical procedures. The assembly includes a housing, a curved blade assembly and a first shroud and a second shroud.

Owner:CILAG GMBH INT

T-shaped cutter tool assembly with wear sleeve

InactiveUS6854810B2Quick and cheap to manufactureEasy to removeSlitting machinesCutting machinesEngineeringDrill bit

The wear sleeve in the present cutter tool assembly comprises a rearward split ring portion and an intermediate cylindrical ring portion adjacent a forward shoulder portion. The outer diameter of the wear sleeve intermediate portion and rearward split ring portion is uniform. The wear sleeve is inserted into the bit holder's stepped bore aperture. The split ring portion is radially compressed by the smaller diameter rearward end as the sleeve is hammered and axially displaced into the bit holder. The split ring portion forms frictional contact with the opposite end portion of the aperture. The wear sleeve friction fit can be easily removed manually in the field. The bit holder and cooperating support block are designed to limit the amount of relative yaw between the two members during operation to reduce the overall wear there between. The cutter tool assembly includes a groove having side surfaces that are inclined at least 15 degrees with respect to the horizontal axis and the cutting bit is positioned more aft of the central axis of the support block than prior art designs.

Owner:KENNAMETAL INC

Ultrasonic shears stop pad

InactiveUS20090264909A1Negative frictional effectImprove wear resistanceSurgical scissorsSurgical bladeFilling materials

An ultrasonic-surgical-shears stop pad has a stop-pad body including a base material and at least one filler material. An alternate ultrasonic-surgical-shears stop pad has a stop-pad body adjacent to tissue pad. An ultrasonic surgical shears includes an ultrasonic surgical blade and a clamping arm which is operable to open and close toward the blade and which has a transversely and resiliently flexible distal tip. An alternate ultrasonic surgical shears includes an ultrasonic surgical blade, a clamping arm operable to open and close toward the blade, and a stop pad attached to the clamping arm and having a blade contact surface, wherein at least a portion of the stop pad is resiliently flexible in a direction substantially perpendicular to the blade contact surface.

Owner:ETHICON ENDO SURGERY INC

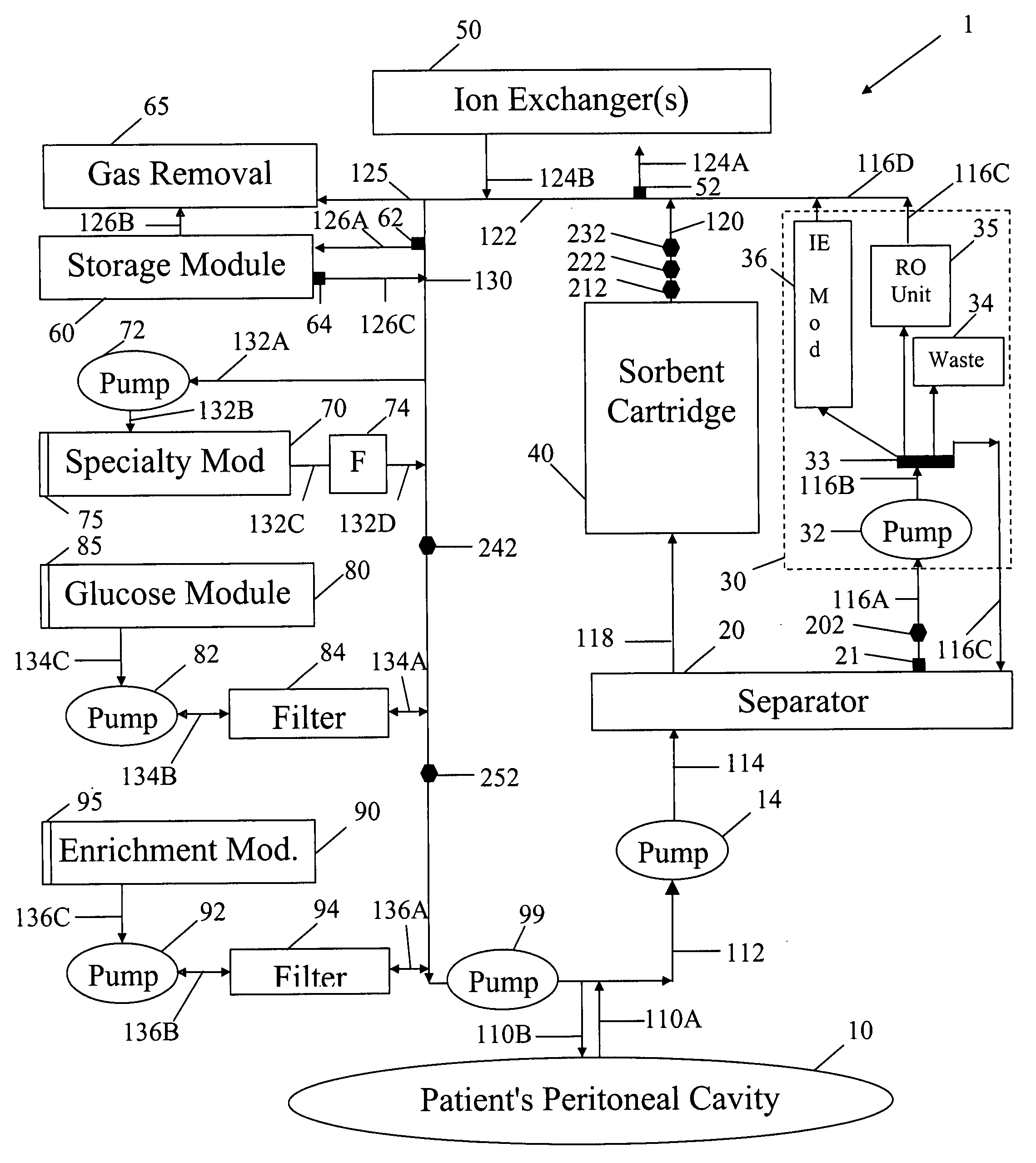

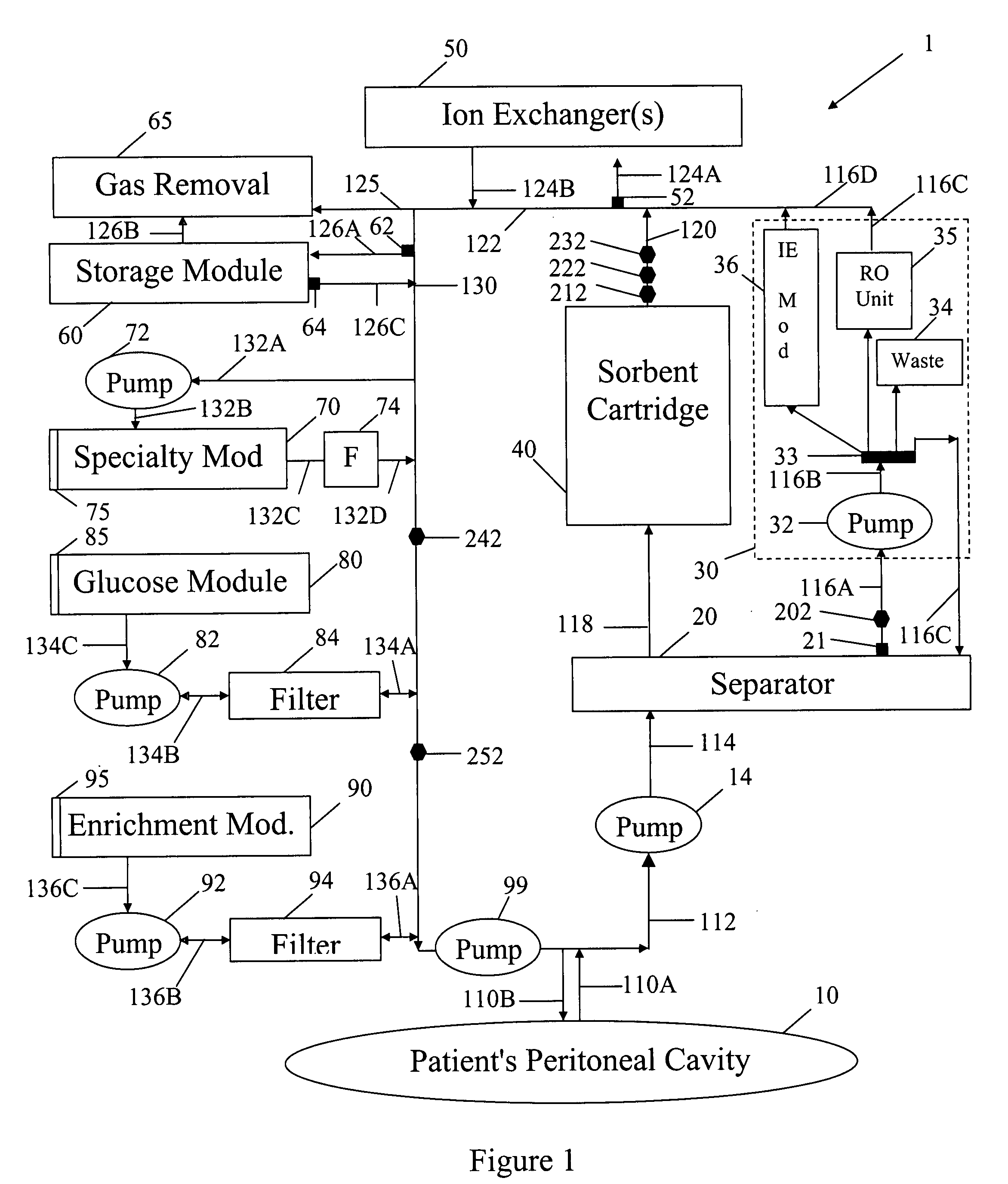

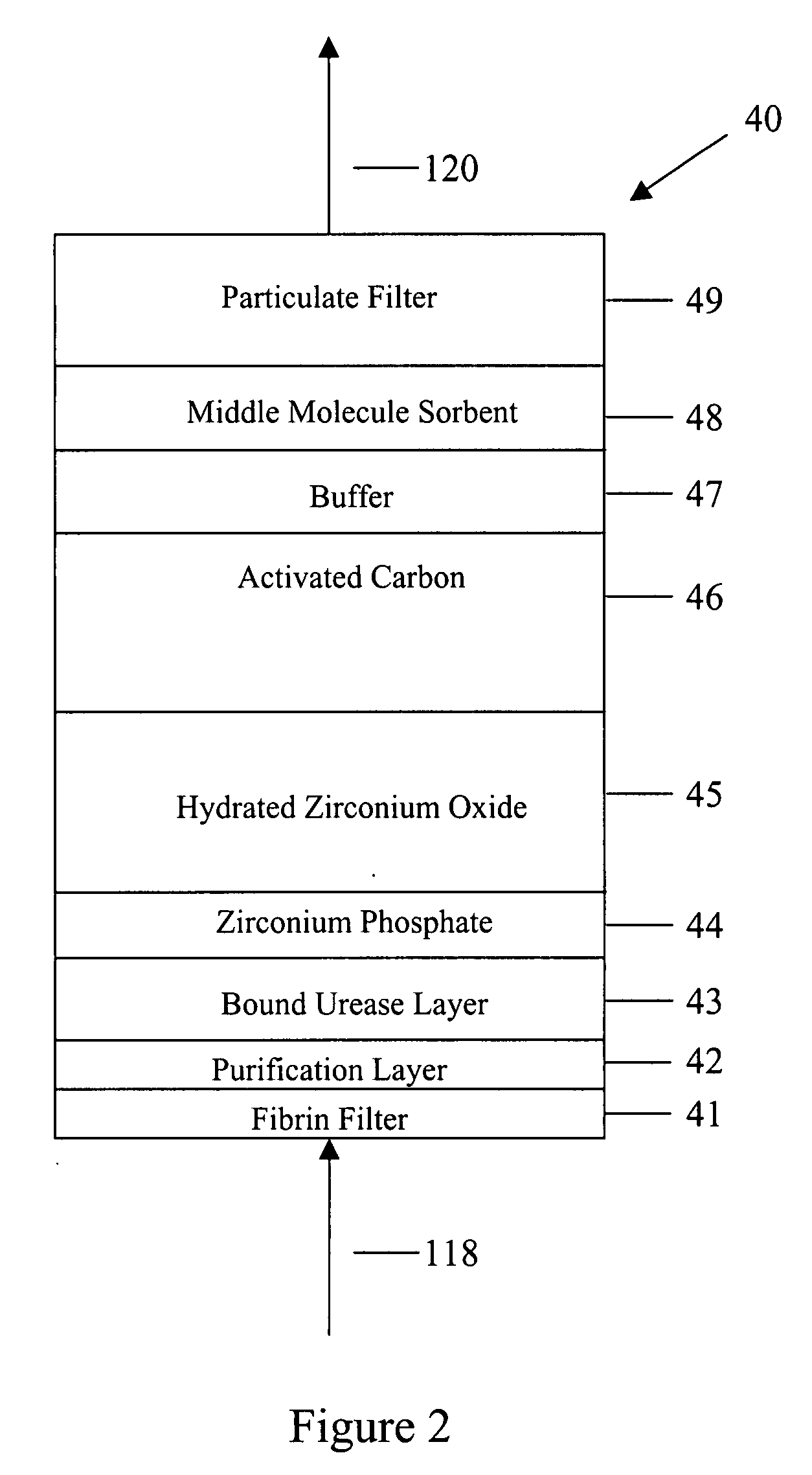

Peritoneal dialysis methods and apparatus

ActiveUS20070179431A1Increase percentageImprove wear resistancePeritoneal dialysisProtein compositionPeritoneal fluid

A peritoneal-based (“bloodless”) artificial kidney processes peritoneal fluid without need for additional fluids (“waterless”). Fluid is separated into a protein-rich stream and a protein-free stream. The protein-rich stream is regenerated using a sorbent assembly, and its protein composition can be modified by removal of selected protein(s) (“dialysate-pheresis”). It is then reconstituted with additives and returned into the peritoneal cavity, thereby reducing protein-loss and providing oncotic-pressure for ultrafiltration. The protein-free stream is used to produce free water, and an alkaline or acid fluid for optimization of the composition of the regenerated stream. The unused protein-free stream can be used to “reverse flush” the separator to maintain its patency and the excess discarded for fluid-balance regulation. Compared to prior art, immobilization of urease allows more protein rich fluid to be regenerated and re-circulated into the peritoneal cavity for toxin removal and allows practicable development of portable and wearable artificial kidneys.

Owner:RGT UNIV OF CALIFORNIA +1

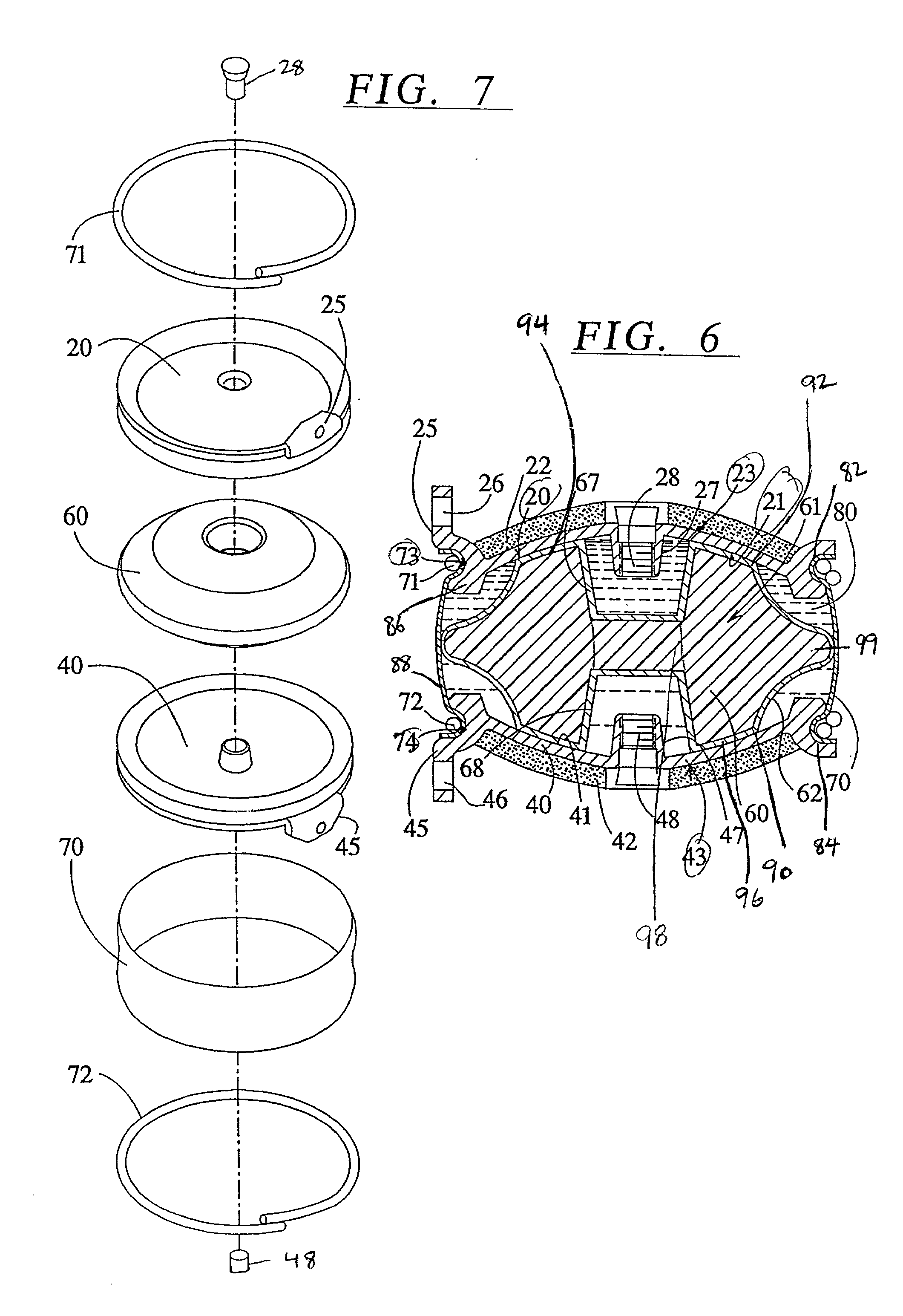

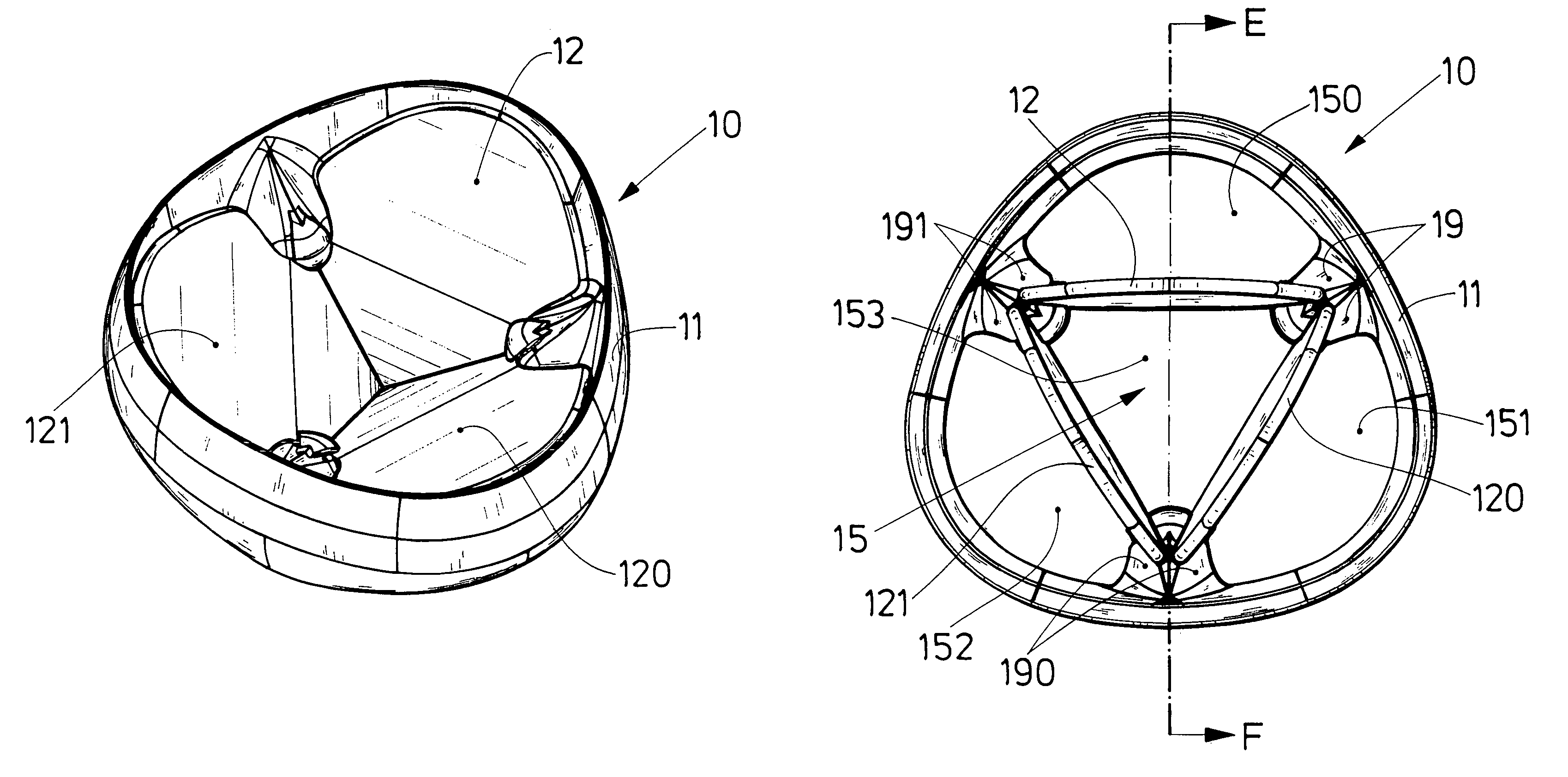

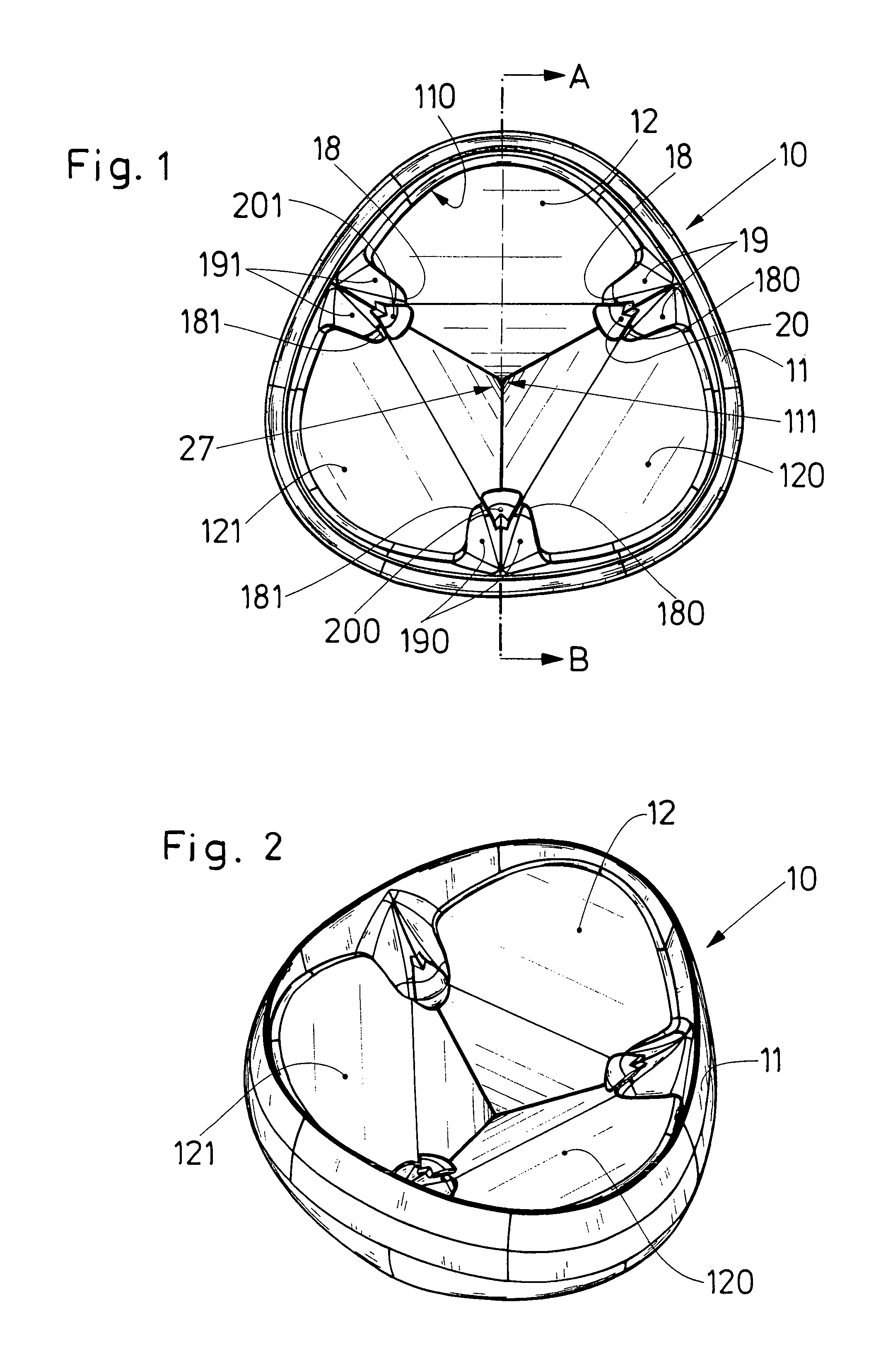

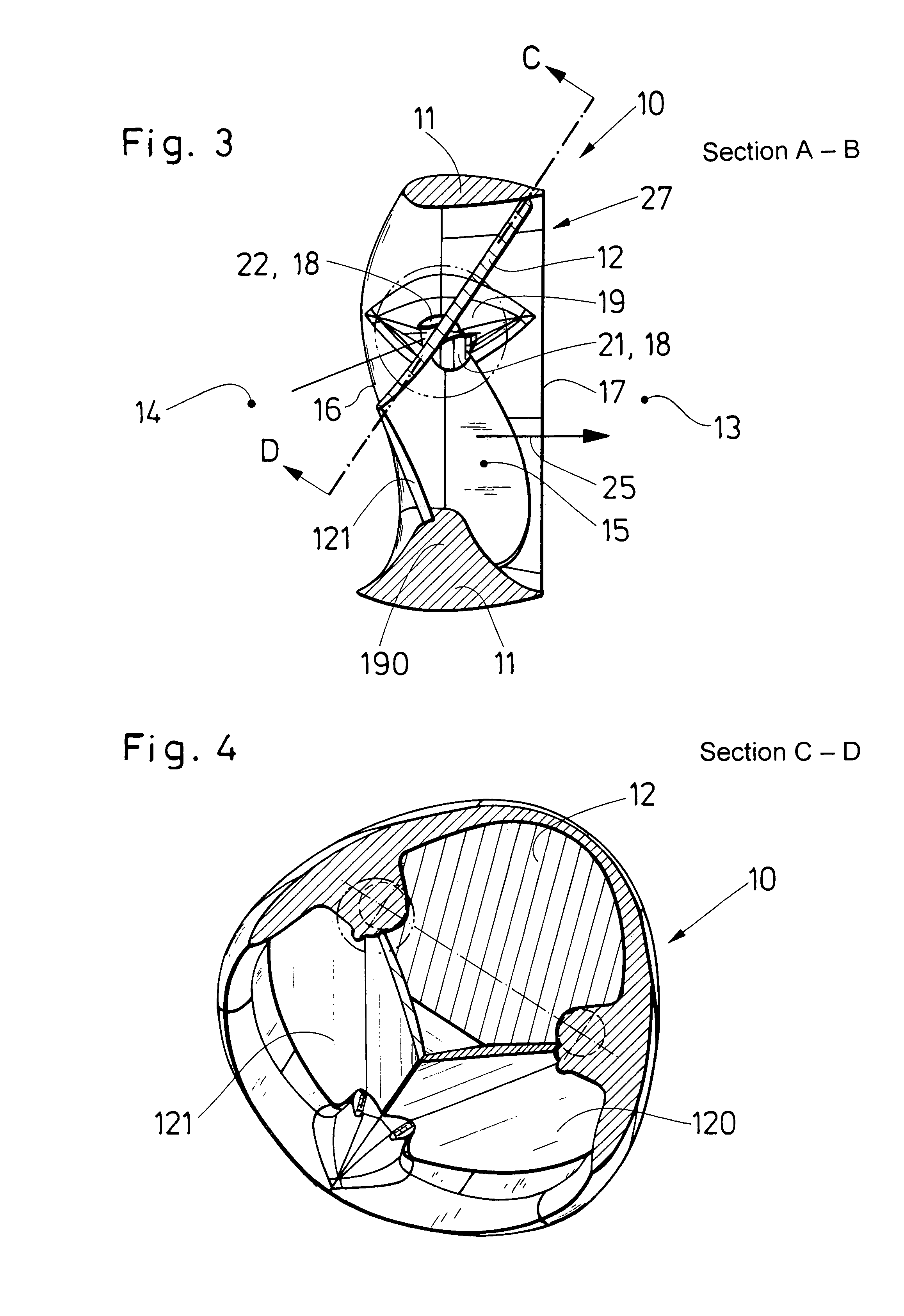

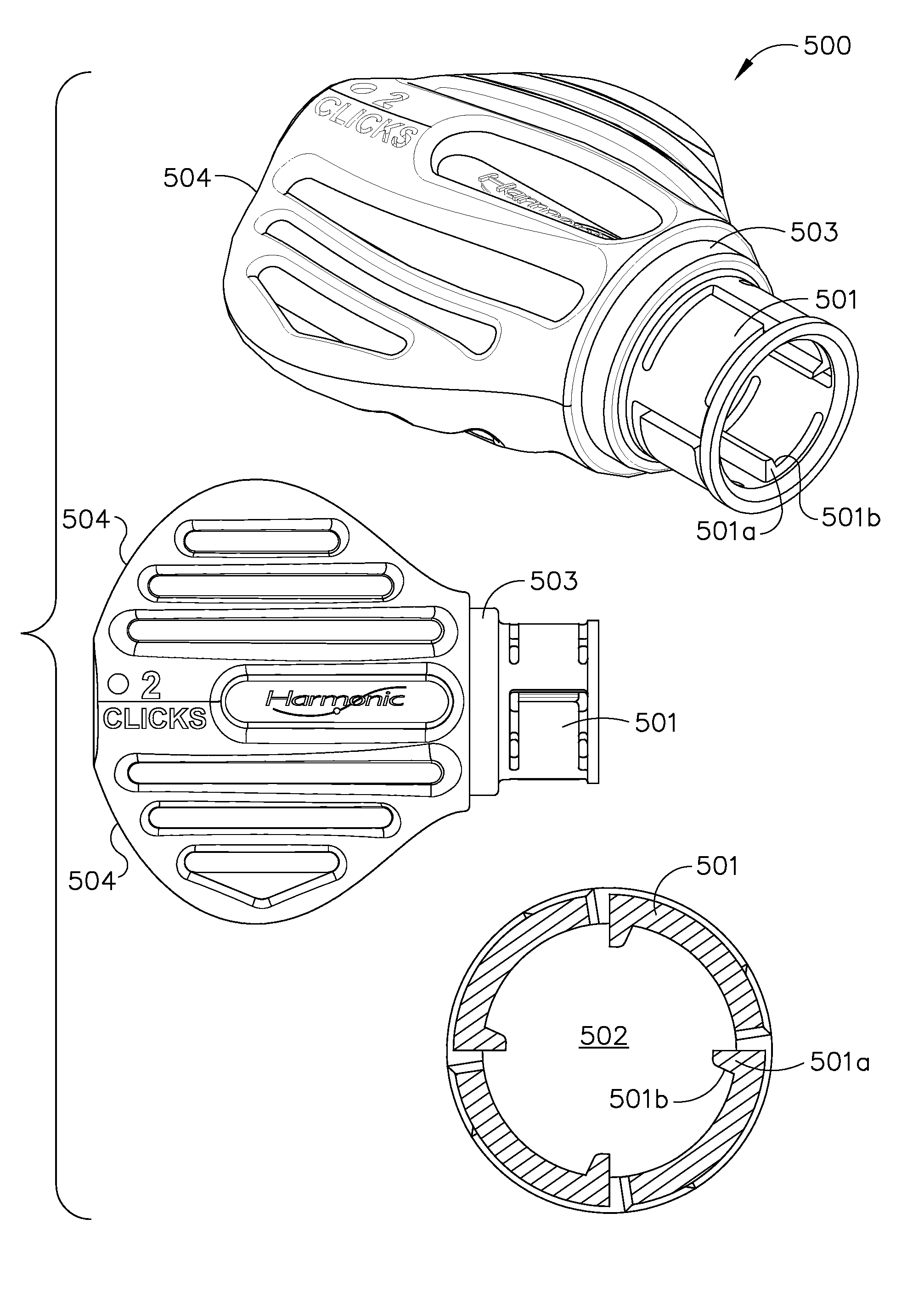

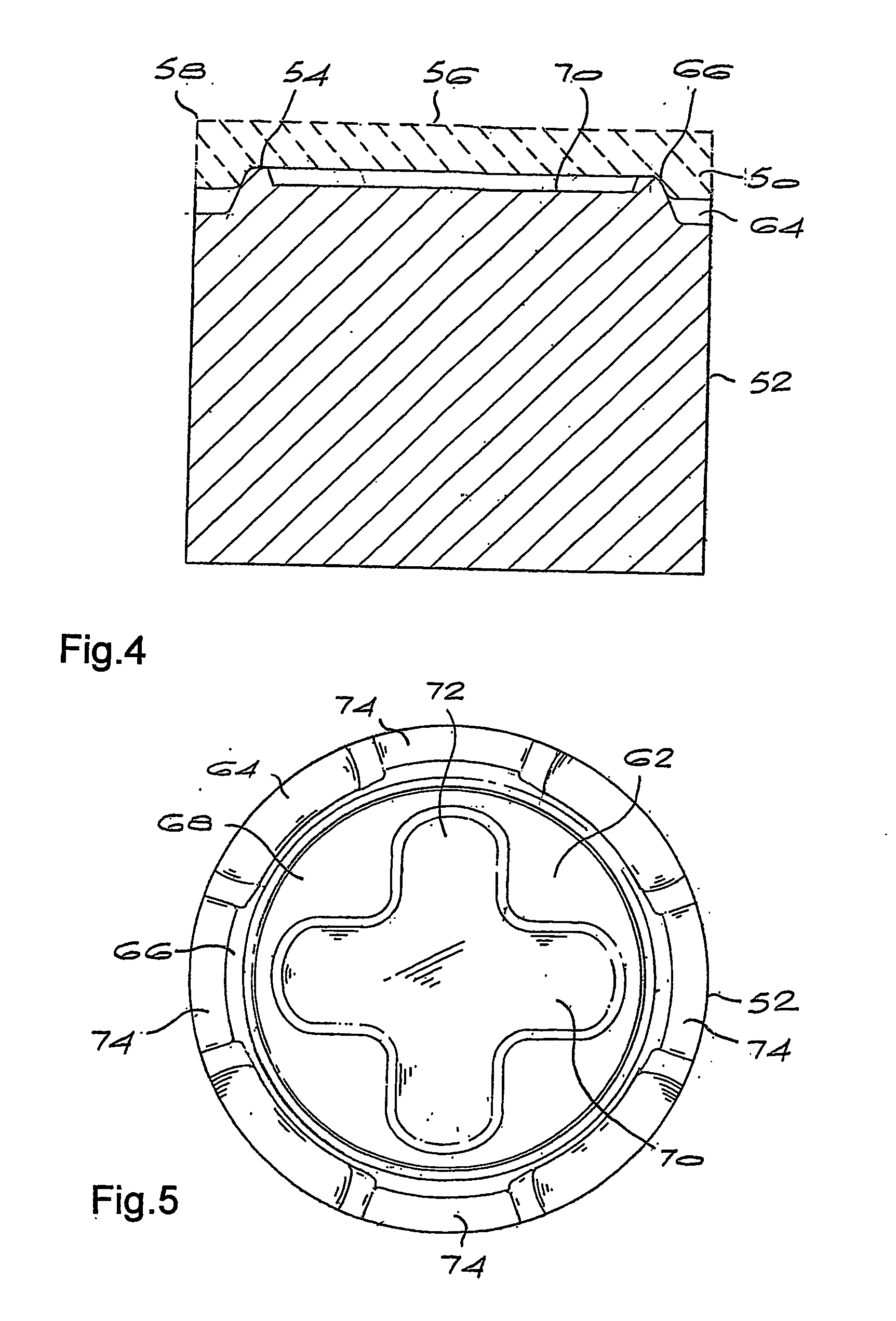

Mechanism for assembly of ultrasonic instrument

An ultrasonic clamp coagulator system that is configured to permit selective cutting, coagulation and clamping of tissue during surgical procedures. An elongated portion of the instrument can be configured for endoscopic applications and has an outside diameter of less than 6 mm. The system includes a one-piece torque wrench that is provided with cantilever arms aligned in an annular fashion about the centerline of the torque wrench. The cantilever arms include teeth in an inward perpendicular fashion in relation to cantilever arms. The clamp coagulator includes an outer tube retainer that includes spline gears projecting in a perpendicular fashion along the outer circumference of retainer. Torque is transmitted through the cantilever arms to the spline gears for attaching a handpiece to the clamp coagulator.

Owner:CILAG GMBH INT

High temperature erosion resistant, abradable thermal barrier composite coating

InactiveUS6235370B1Improve wear resistanceImprove adhesionMolten spray coatingPump componentsCombustorHoneycomb

A composite thermal barrier coating system includes a honeycomb metallic structure filled with high thermal expansion ceramic hollow spheres in a phosphate bonded matrix. The composite thermal barrier coating system may be manufactured to thicknesses in excess of current thermal barrier coating systems, thereby imparting greater thermal protection. Superior erosion resistance and abrasion properties are also achieved. The composite thermal barrier coating is useful on combustion turbine components such as ring seal segments, vane segment shrouds, transitions and combustors.

Owner:SIEMENS ENERGY INC

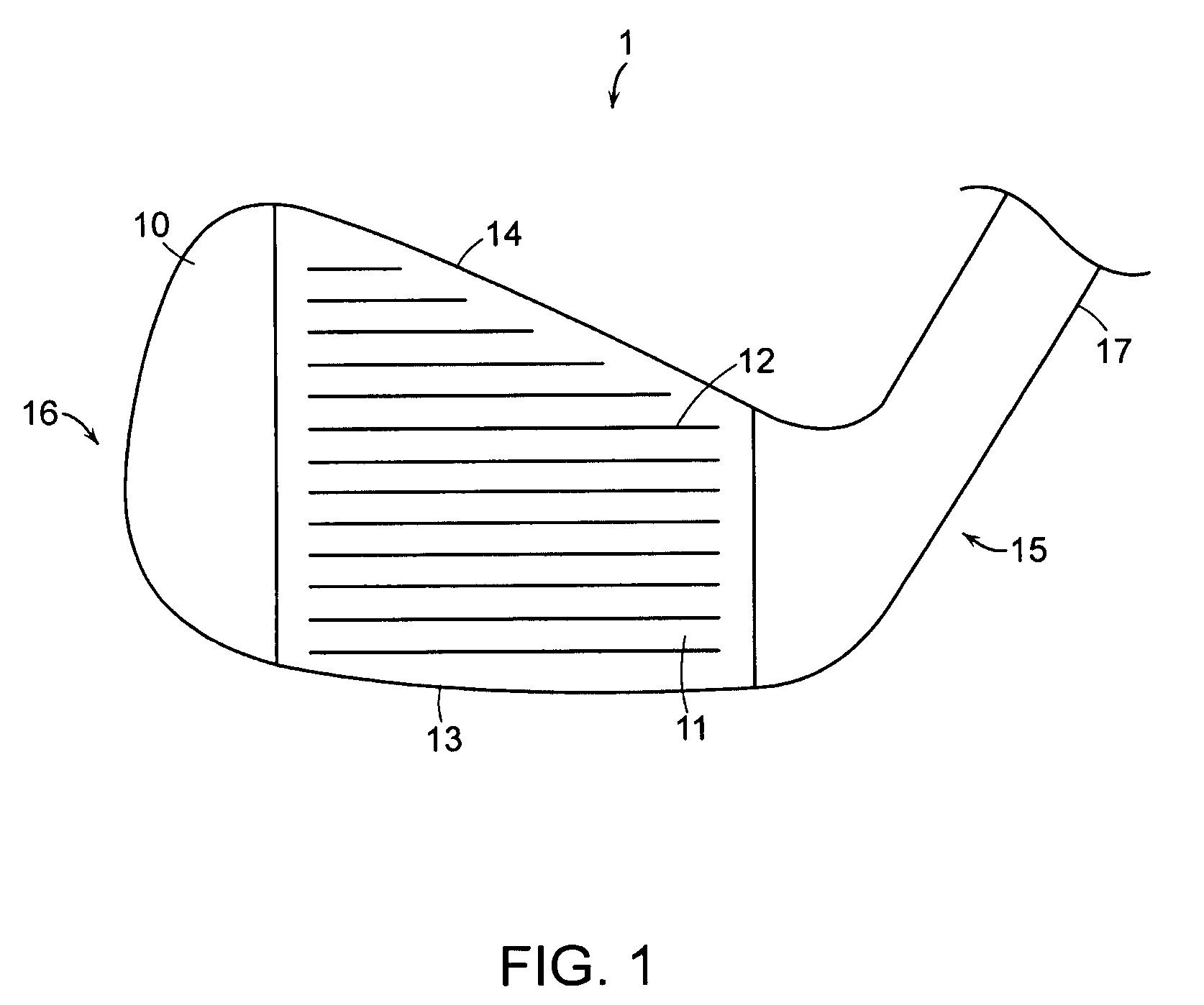

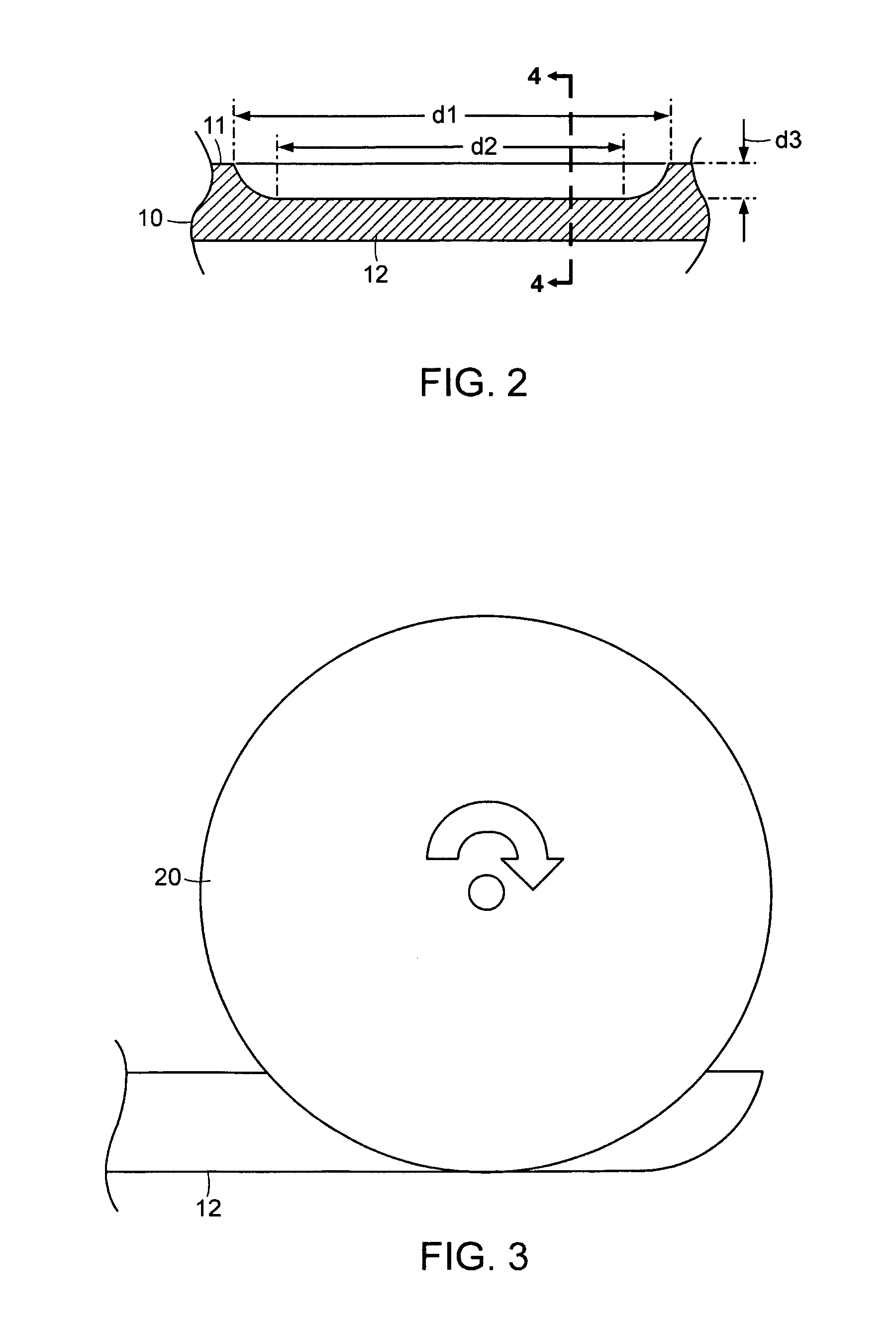

Golf club head

InactiveUS7594862B2Feel goodImprove wear resistanceGolf clubsRacket sportsMulti materialWear resistant

A golf club head having a multi-material face. The golf club head has a hard, wear resistant material as the ball-impacting face surface coupled to a softer material, allowing the multi-material face to be joined to a soft body material such that the body can be bent and customized. The multi-material face allows for improved playing characteristics by allowing the club designer to use a thinner face and lighter body material while still providing improved face wear resistance and durability.

Owner:ACUSHNET CO

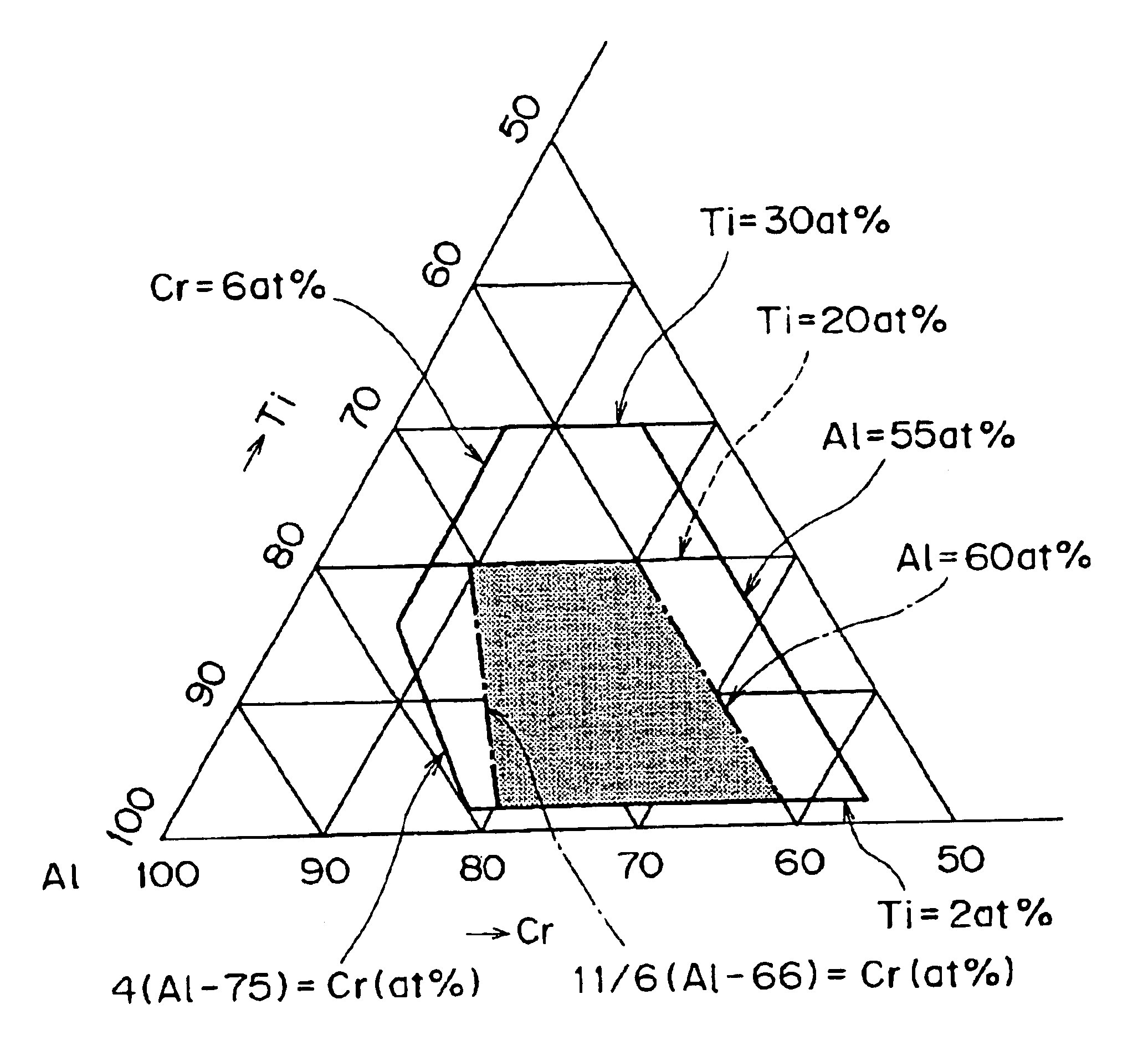

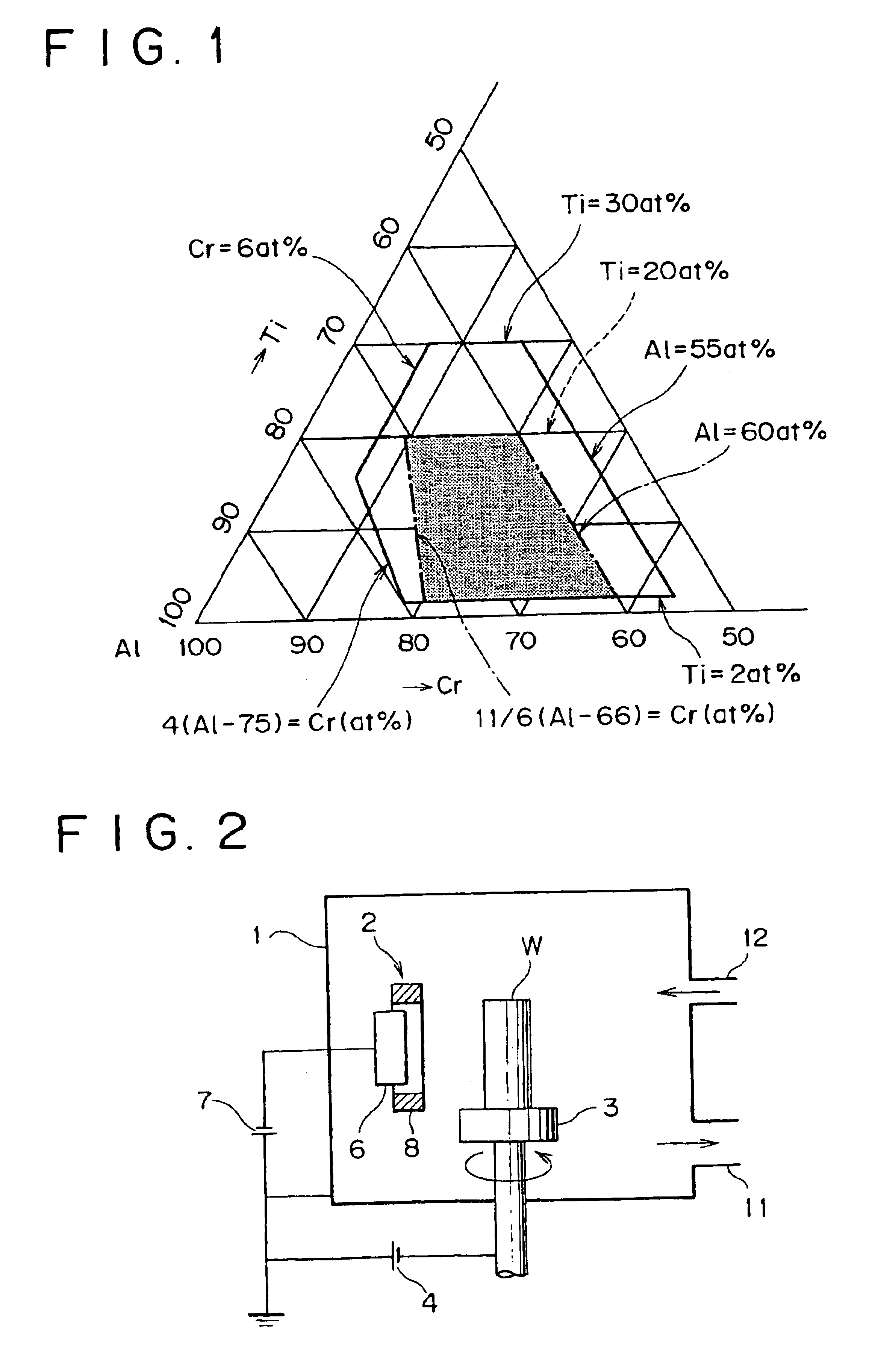

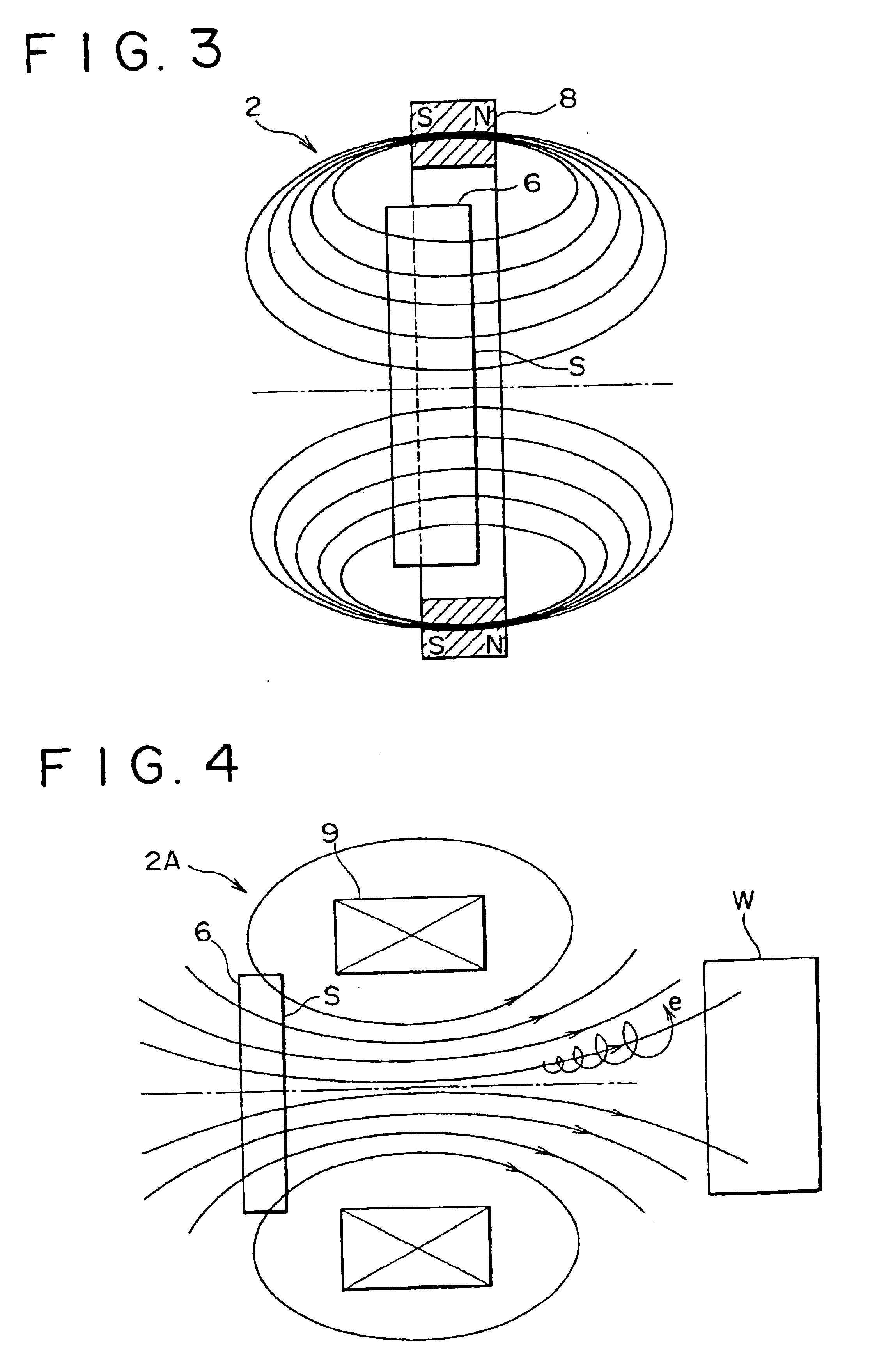

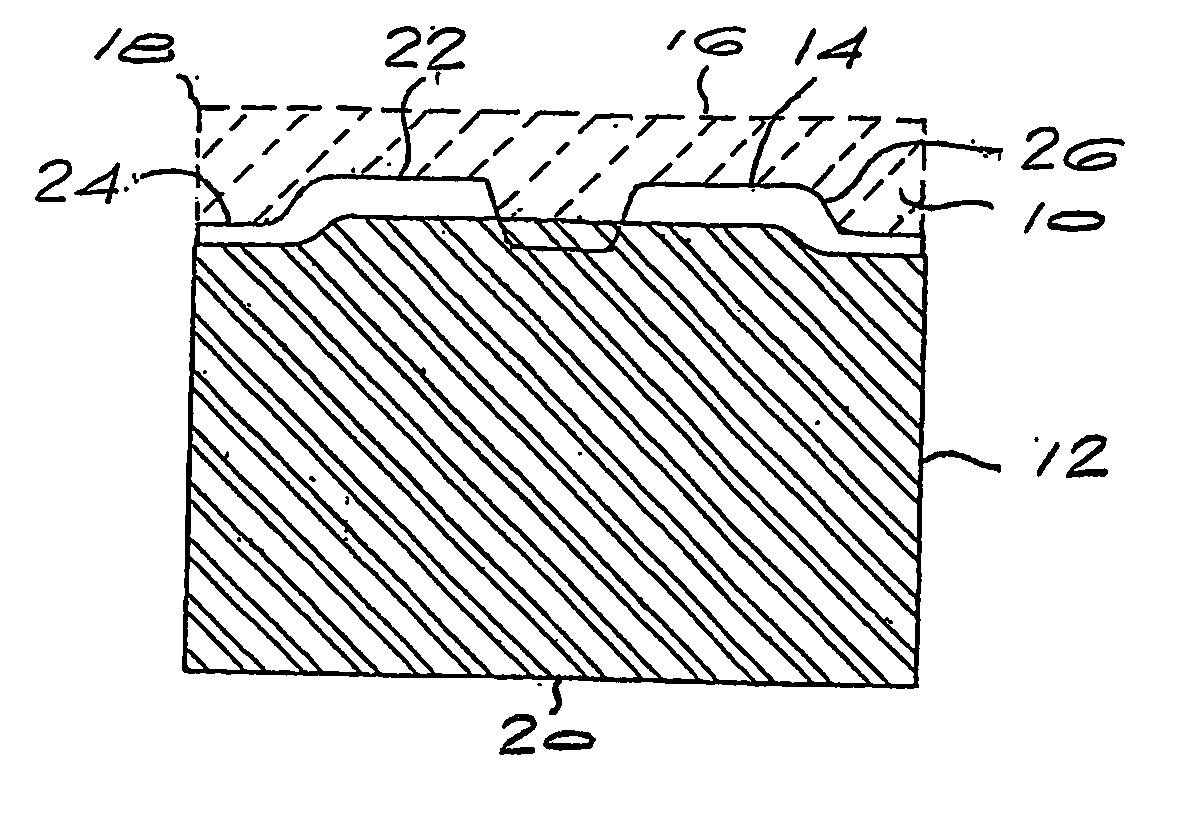

Hard film for cutting tools, cutting tool coated with hard film, process for forming hard film, and target used to form hard film

InactiveUS6824601B2Improve wear resistanceHigh-speed efficient cuttingMolten spray coatingOther chemical processesMetallurgyAtomic ratio

A hard film for cutting tools which is composed of(where a, b, c, and d denote respectively the atomic ratios Al, Cr, Si, and B, and e denotes the atomic ratio of N.)

Owner:KOBE STEEL LTD

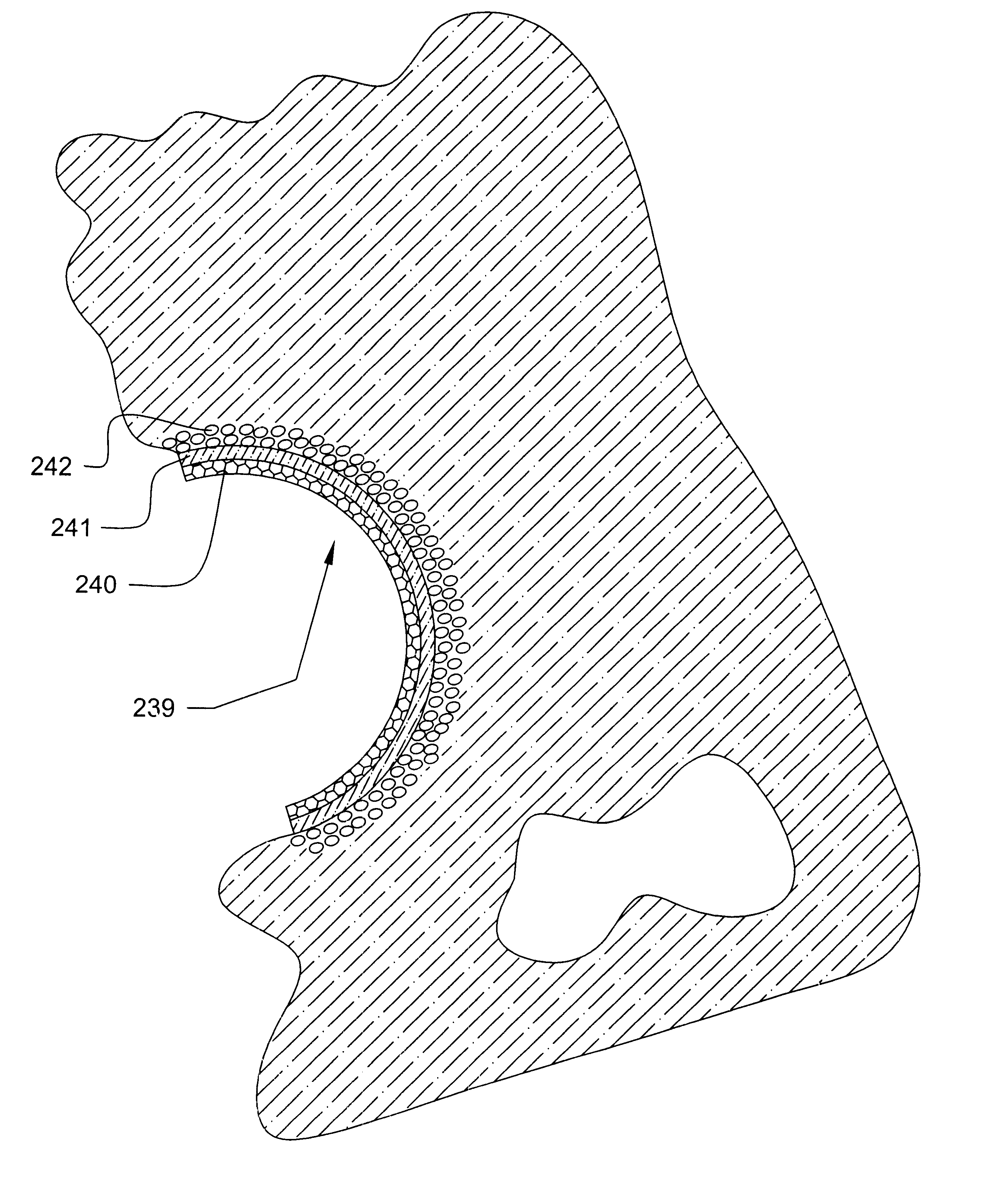

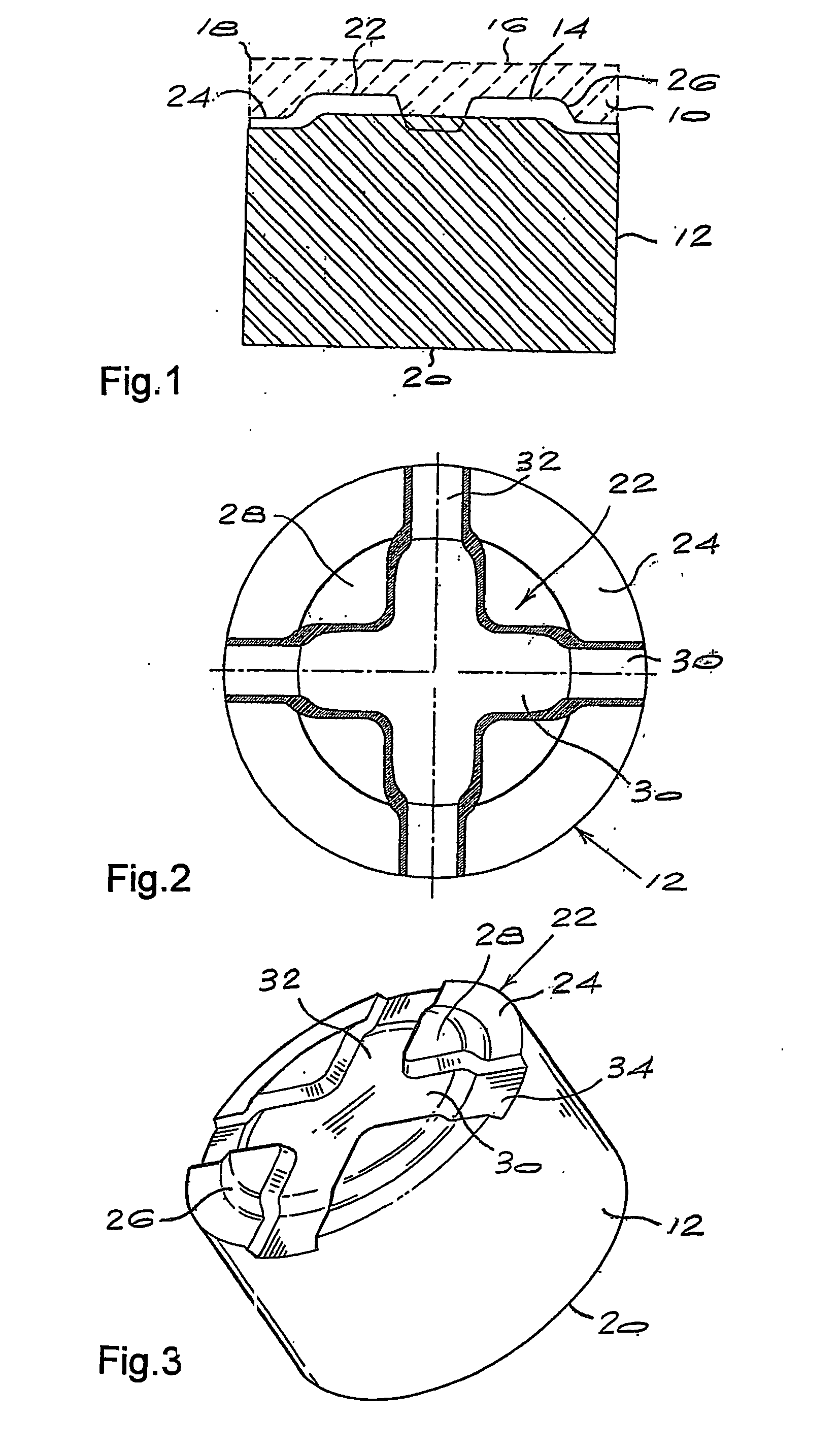

Polycrystalline diamond abrasive elements

A polycrystalline diamond abrasive element, particularly a cutting element, comprises a table of polycrystalline diamond bonded to a substrate, particularly a cemented carbide substrate, along a non-planar interface. The non-planar interface typically has a cruciform configuration. The polycrystalline diamond has a high wear-resistance, and has a region adjacent the working surface lean in catalysing material and a region rich in catalysing material. The region lean in catalysing material extends to a depth of 40 to 90 microns, which is much shallower than in the prior art. Notwithstanding the shallow region lean in catalysing material, the polycrystalline diamond cutters have a wear resistance, impact strength and cutter life comparable to that of prior art cutter, but requiring only 20% of the treatment times of the prior art cutters.

Owner:BAKER HUGHES INC

Wood-plastic composite material and prepration method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin and the like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

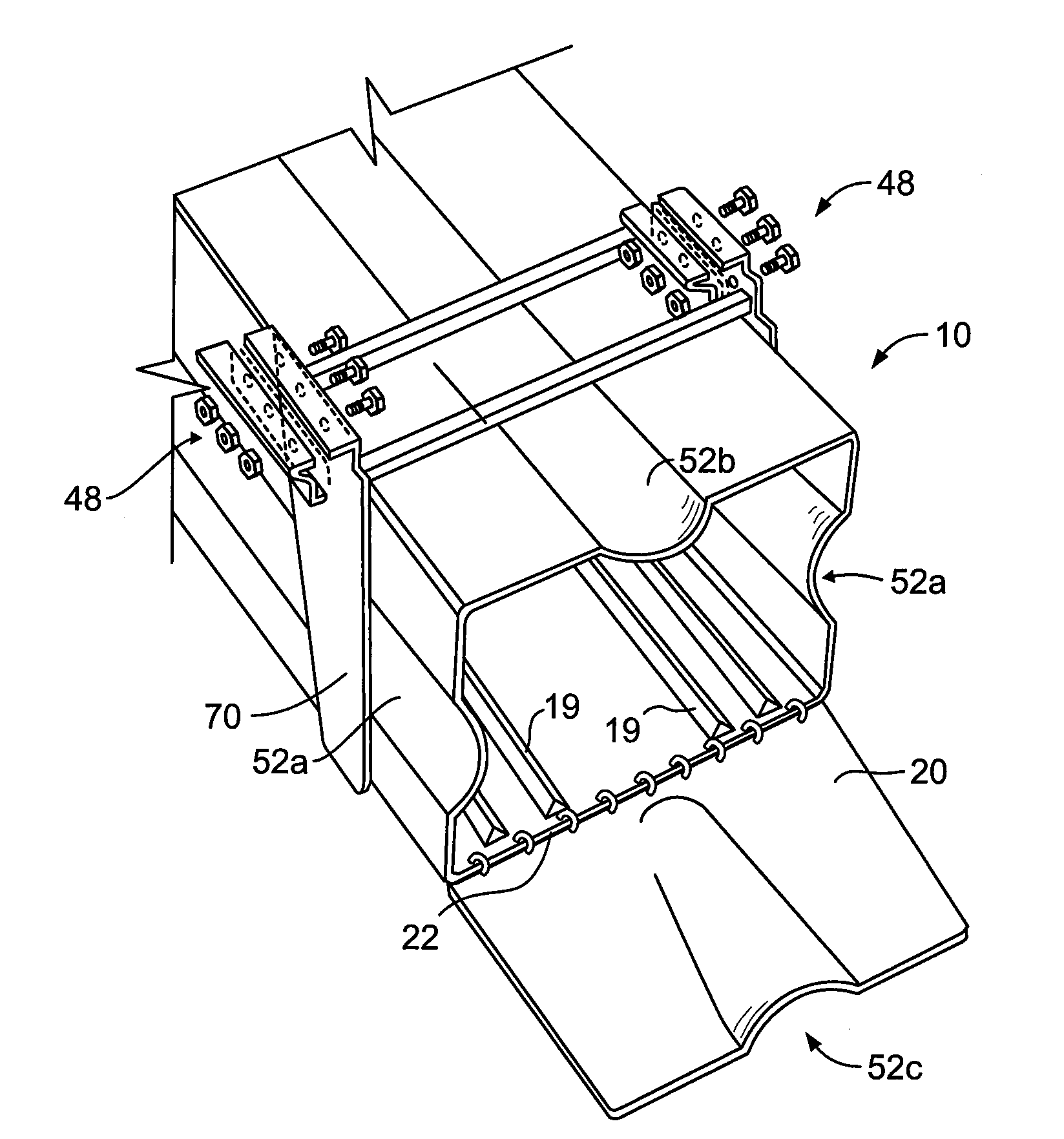

Mechanism for assembly of ultrasonic instrument

ActiveUS20070282335A1Improve wear resistanceDiagnosticsSurgical instrument detailsGear wheelEngineering

An ultrasonic clamp coagulator system that is configured to permit selective cutting, coagulation and clamping of tissue during surgical procedures. An elongated portion of the instrument can be configured for endoscopic applications and has an outside diameter of less than 6 mm. The system includes a one-piece torque wrench that is provided with cantilever arms aligned in an annular fashion about the centerline of the torque wrench. The cantilever arms include teeth in an inward perpendicular fashion in relation to cantilever arms. The clamp coagulator includes an outer tube retainer that includes spline gears projecting in a perpendicular fashion along the outer circumference of retainer. Torque is transmitted through the cantilever arms to the spline gears for attaching a handpiece to the clamp coagulator.

Owner:CILAG GMBH INT

Medialised rod pedicle screw assembly

InactiveUS7819902B2Great freedomAdequate profileInternal osteosythesisJoint implantsEngineeringIliac screw

A pedicle screw assembly and method of assembly comprises a longitudinal member; a bendable ball ring adapted to receive the longitudinal member; a poly stem comprising a bendable male bulbous end; and a connector comprising a pair of first apertures adapted to receive the poly stem; and a second aperture adapted to receive the ball ring and the longitudinal member, wherein the second aperture is transverse to the first aperture. The assembly further comprises a bone fixator component comprising a female socket adapted to receive the poly stem; and a blocker pin adapted to engage the poly stem and to secure the longitudinal member.

Owner:CUSTOM SPINE INC

Inverse prosthesis for the articulation of the shoulder

ActiveUS7169184B2Improve wear resistanceEasy to integrateJoint implantsShoulder jointsMedicineProsthesis

Inverse prosthesis of the shoulder for the articulation of a humerus in a scapula of a shoulder comprising a glenoid cavity. The prosthesis includes an at least partly convex articulation element, including elements for support and attachment to the glenoid cavity, and able to articulate with an at least partly concave mating articulation element, associated with the top of the humerus. The articulation element includes a substantially hemi-spherical element and a pin-type implant element made as distinct and reciprocally removable elements, so as to allow them to be assembled sequentially with respect to the glenoid cavity.

Owner:LIMA CORPORATE SPA

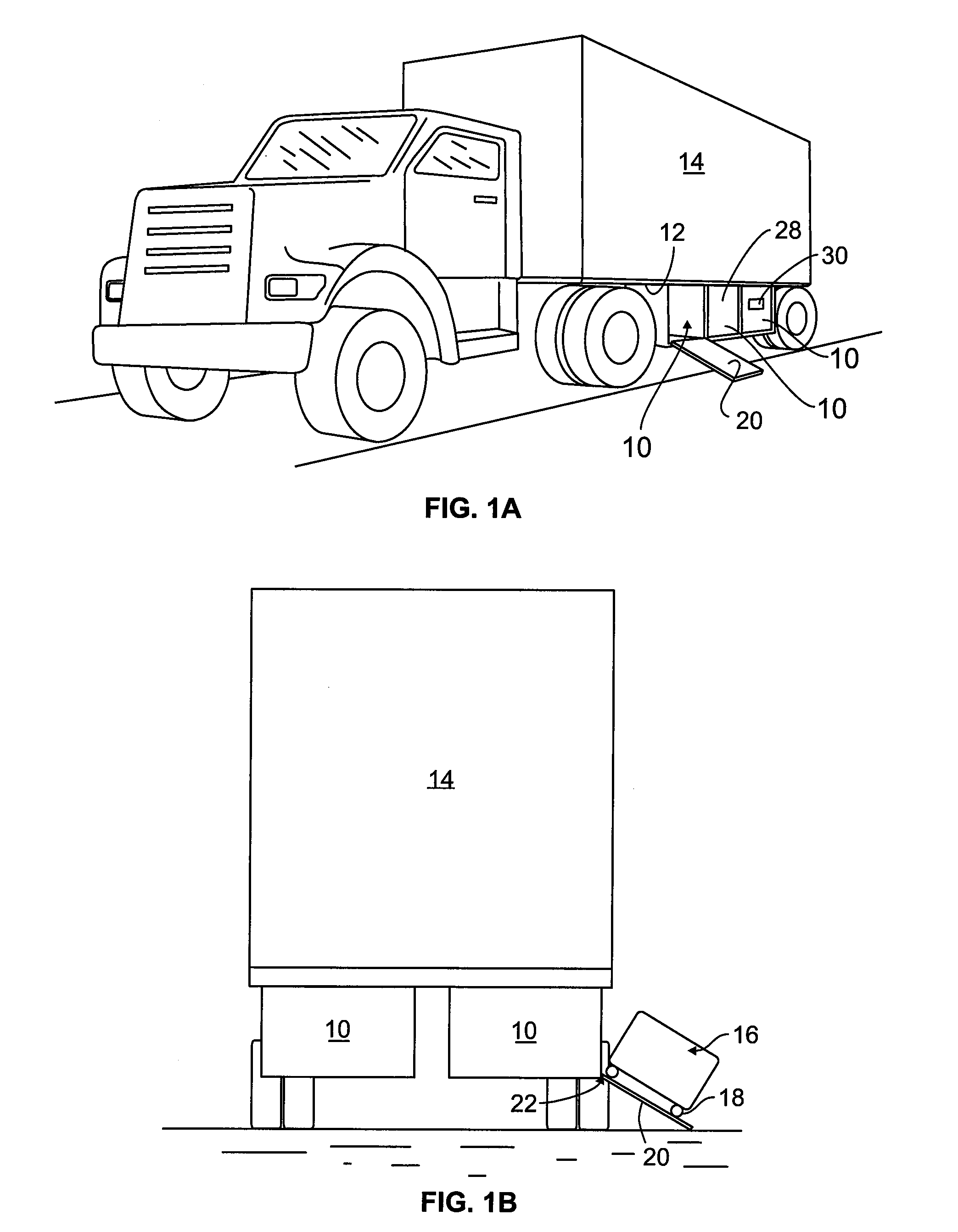

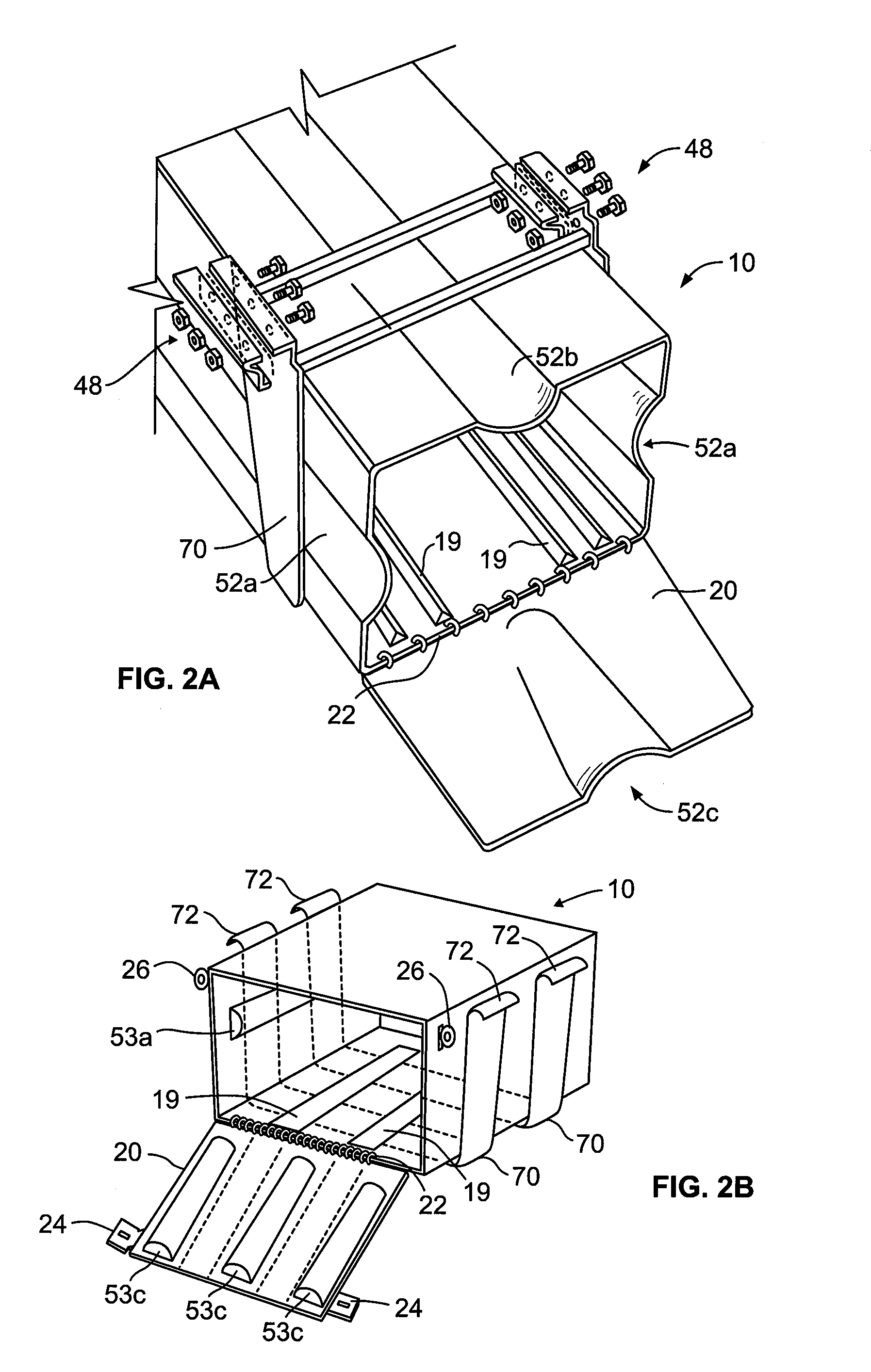

Underdeck carrier system for mobile containers for segregating product types in common shipment

InactiveUS20100253519A1Reduces carton cost carton cost cartonReduces carton cost carton packing cost cartonSatellite radio beaconingItem transportation vehiclesProduct typeTransit system

A transportation system for secure, auditable and trackable smart mobile containers (SMC) for securely shipping less than truckload volumes of products that require special handing segregation as controlled products, such as ethical drugs, along with general, non-controlled merchandise. Dedicated semi-trailer lockers are secured under the deck I-beam framing, including lockable fold-down doors that become ramps for loading / unloading. The lockers are mounted back to back along the center line of the trailer under-deck. Each SMC includes a electronics package that can read RFID tags, has condition sensors and an RF module to permit remote monitoring of location and cargo / container conditions. The SMC can include an electronic lock that provides access security, and an audit trail of all opening and closing events.

Owner:PRIVATE PALLET SECURITY SYST

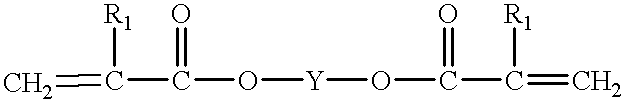

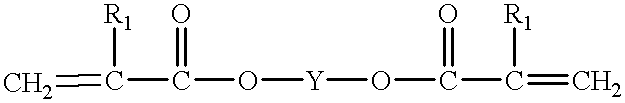

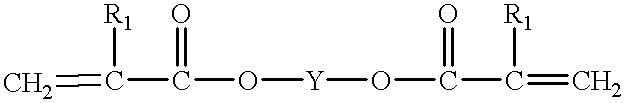

Abrasion resistant urethane coatings

InactiveUS6228433B1Improve wear resistanceResistant to stainsPolyurea/polyurethane coatingsThin material handlingOligomerReactive diluent

A radiation curable and abrasion resistant coating composition is provided comprising: (a) 70% to 98% by weight of an urethane-acrylate oligomer; (b) 2% to 30% of fine particles of a filler capable of imparting abrasion resistance having an average particle size in the range of 1-20 microns; (c) optionally a reactive diluent; and (d) optionally an synthetic resin. The coatings when applied to wood floorings impart superior abrasion resistance.

Owner:PRISM ENTERPRISES

Polycrystalline diamond abrasive elements

ActiveUS20050139397A1Improved wear behaviorImprove wear resistanceDrill bitsConstructionsMetallurgyPolycrystalline diamond

A polycrystalline diamond abrasive element, particularly a cutting element, comprises a layer of polycrystalline diamond having a working surface and bonded to a substrate, particularly a cemented carbide substrate, along an interface. The polycrystalline diamond abrasive element is characterised by using a binder phase that is homogeneously distributed through the polycrystalline diamond layer and that is of a fine scale. The polycrystalline diamond also has a region adjacent the working surface lean in catalysing material and a region rich in catalysing material.

Owner:ELEMENT SIX PRODION +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com