Patents

Literature

222 results about "Back cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

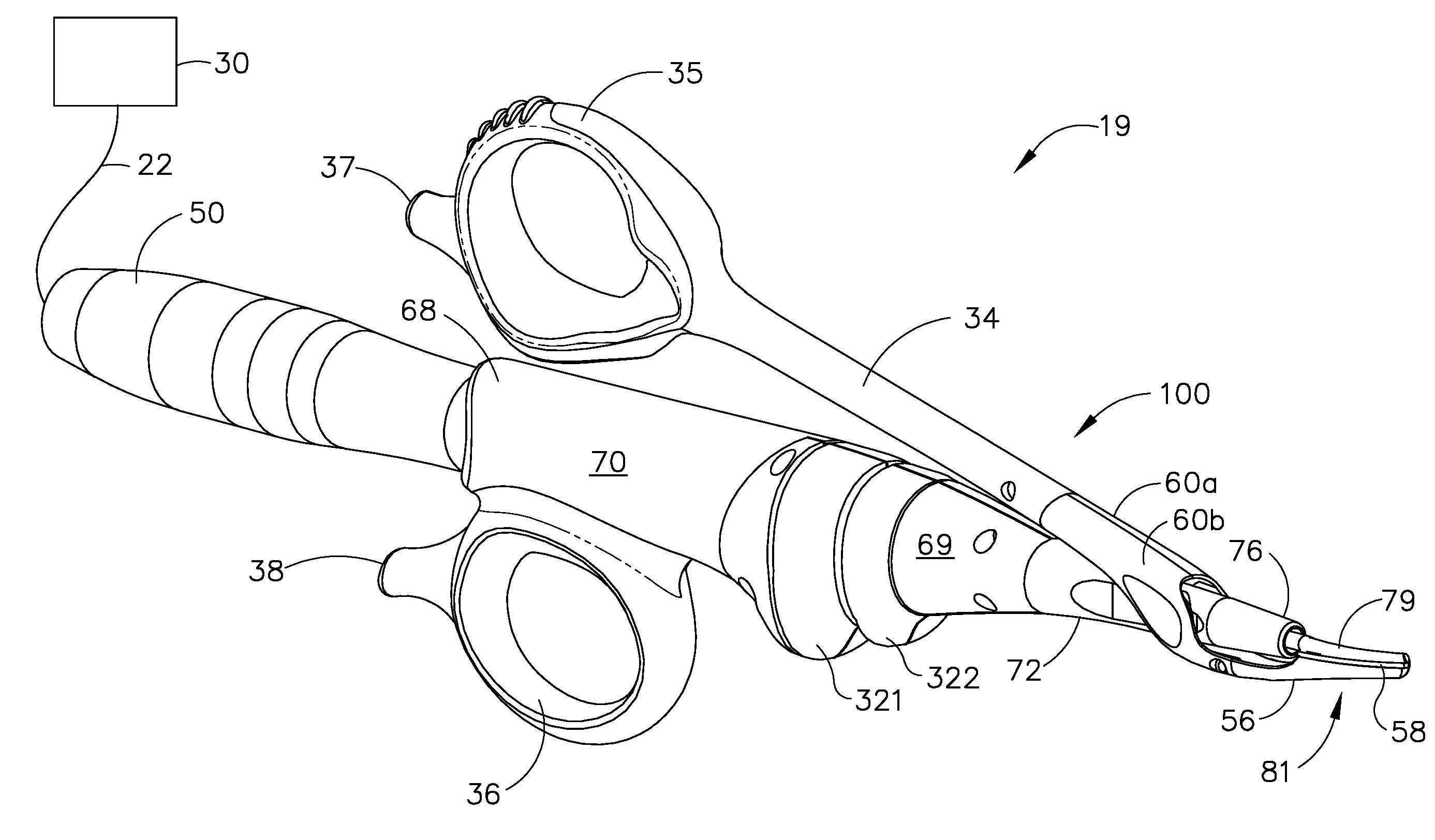

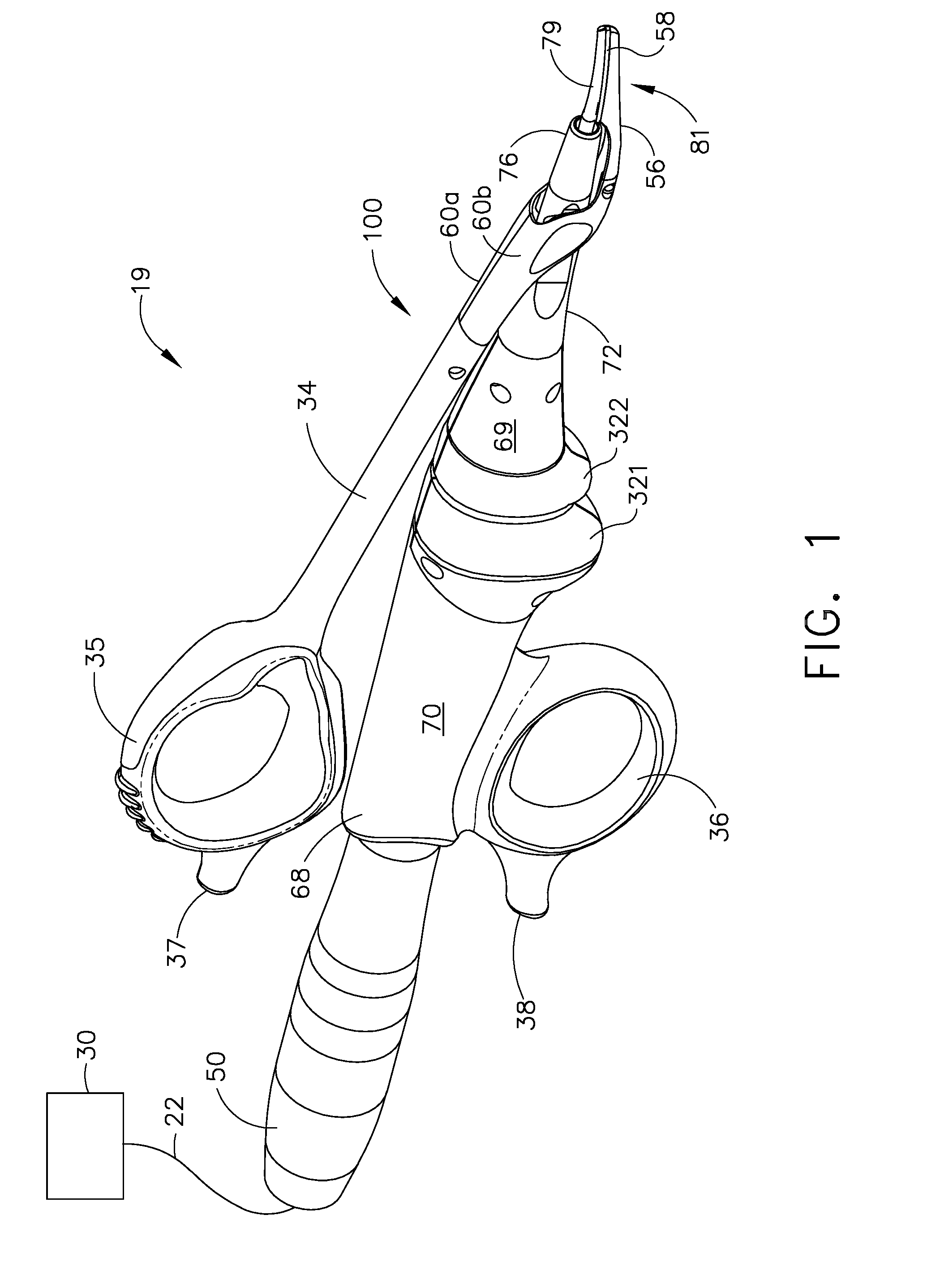

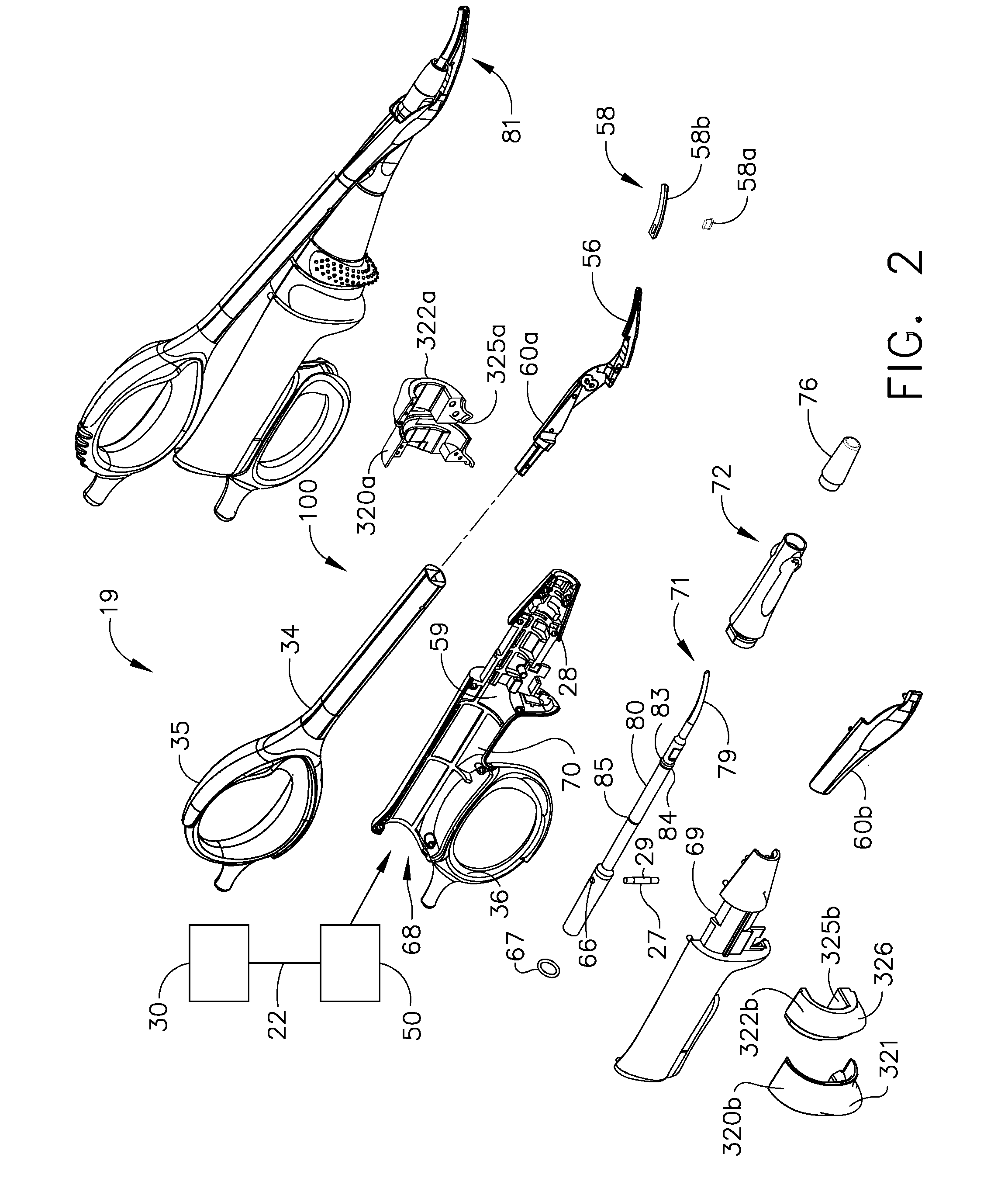

Ultrasonic device for cutting and coagulating

InactiveUS20070191713A1Improve wear resistanceLoad moreUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsBack cuttingBiological activation

An ultrasonic clamp coagulator assembly that is configured to permit selective cutting, coagulation, and fine dissection required in fine and delicate surgical procedures. The assembly includes a clamping mechanism, including a clamp arm cam-mounted at the distal portion of the instrument, which is specifically configured to create a desired level of tissue clamping forces. The balanced blade provides a functional asymmetry for improved visibility at the blade tip and a multitude of edges and surfaces, designed to provide a multitude of tissue effects: clamped coagulation, clamped cutting, grasping, back-cutting, dissection, spot coagulation, tip penetration and tip scoring. The assembly also features hand activation configured to provide an ergonomical grip and operation for the surgeon. Hand switches are placed in the range of the natural axial motion of the user's index or middle fingers, whether gripping the surgical instrument right-handed or left handed.

Owner:CILAG GMBH INT +1

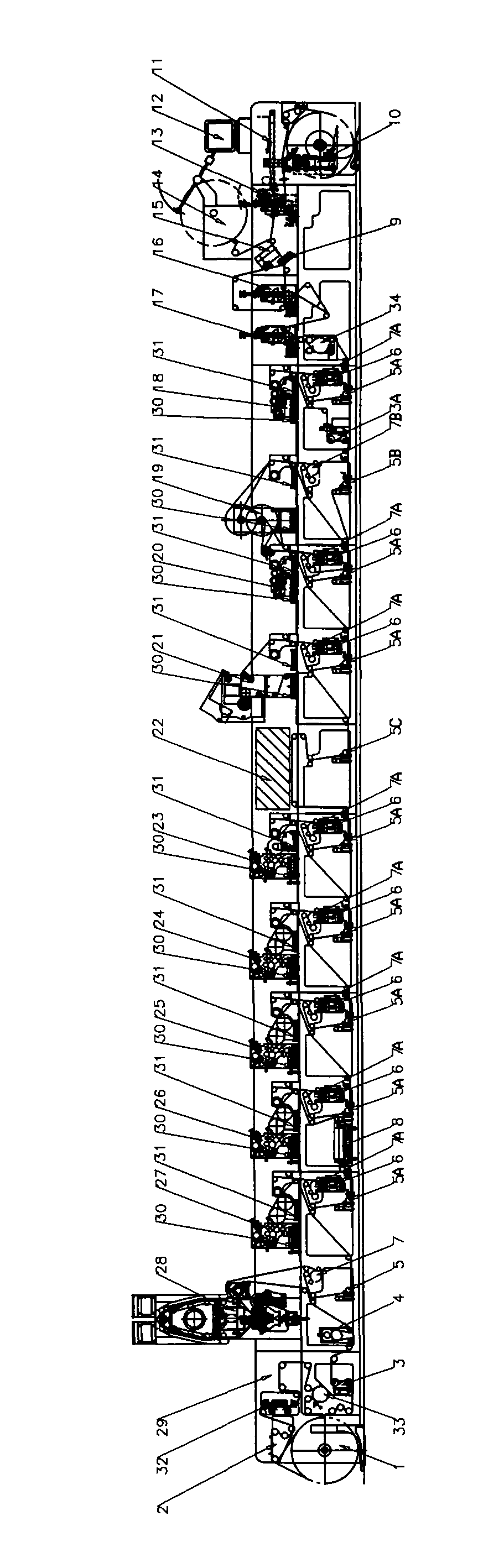

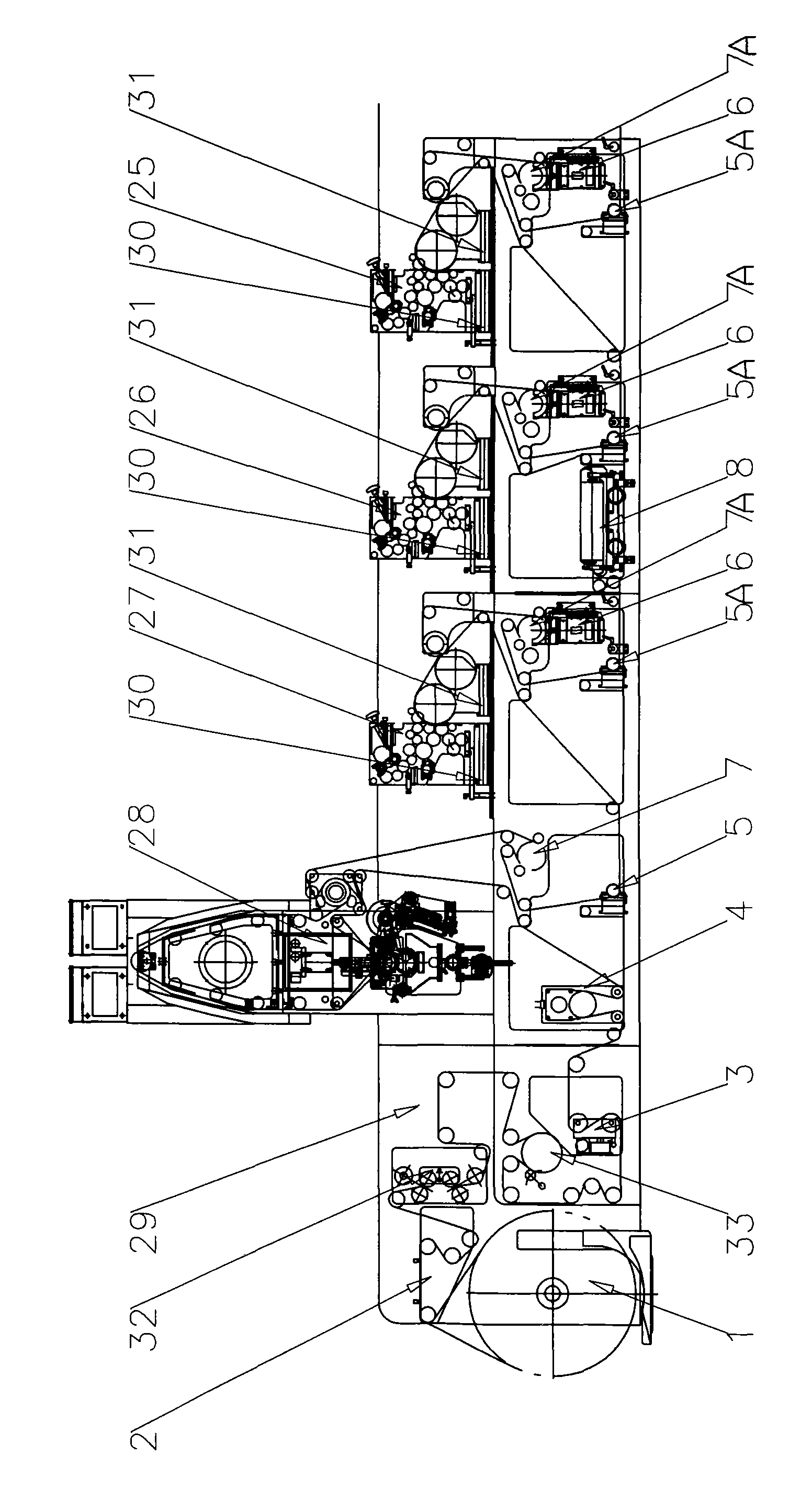

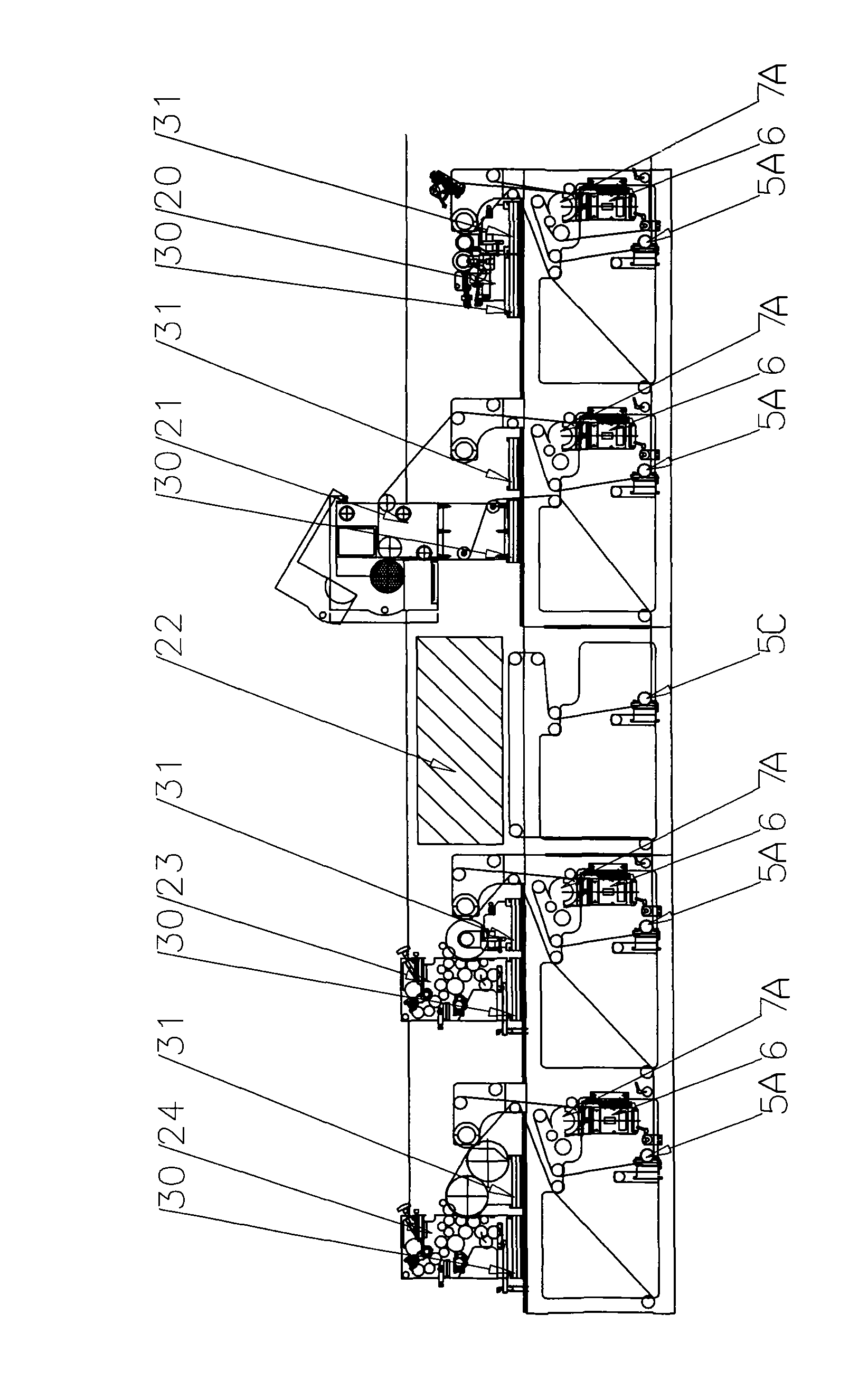

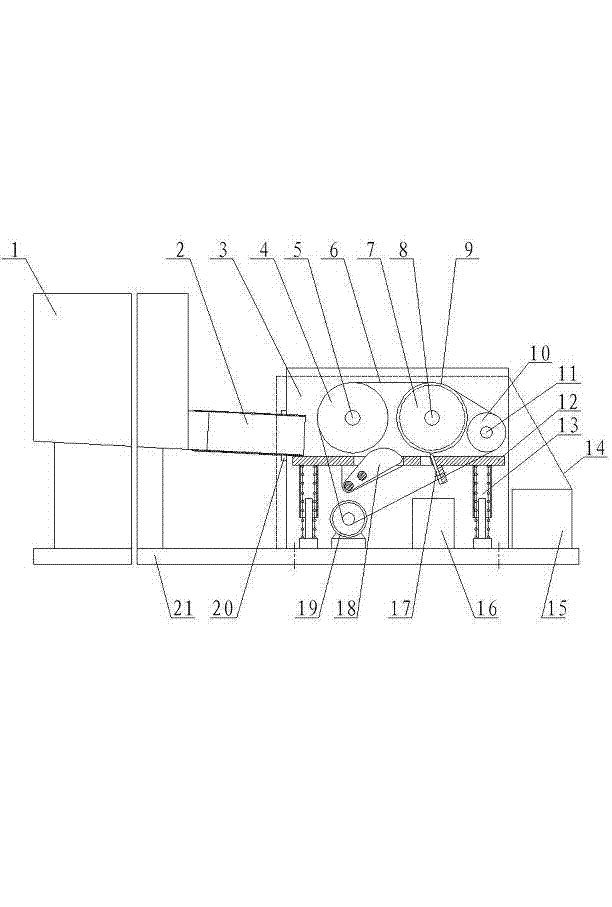

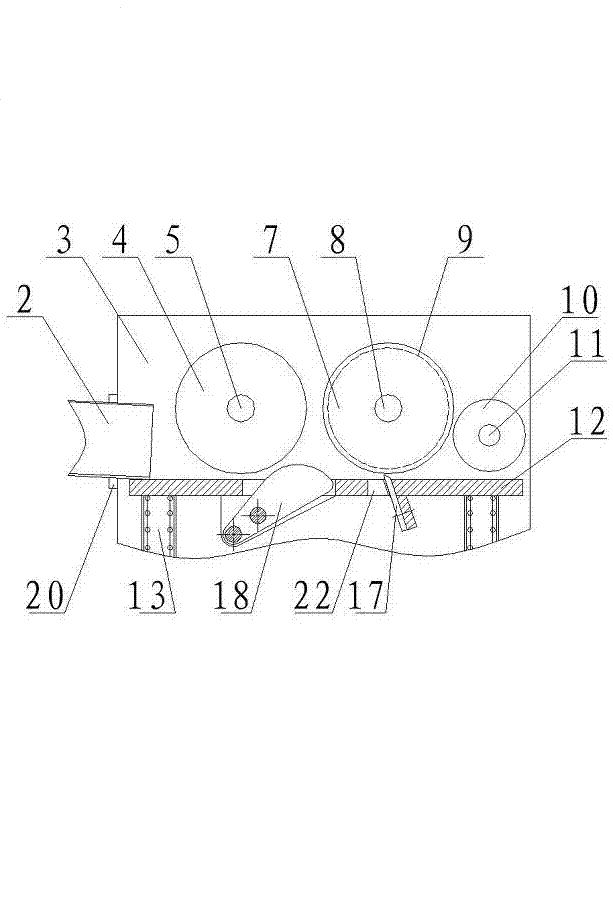

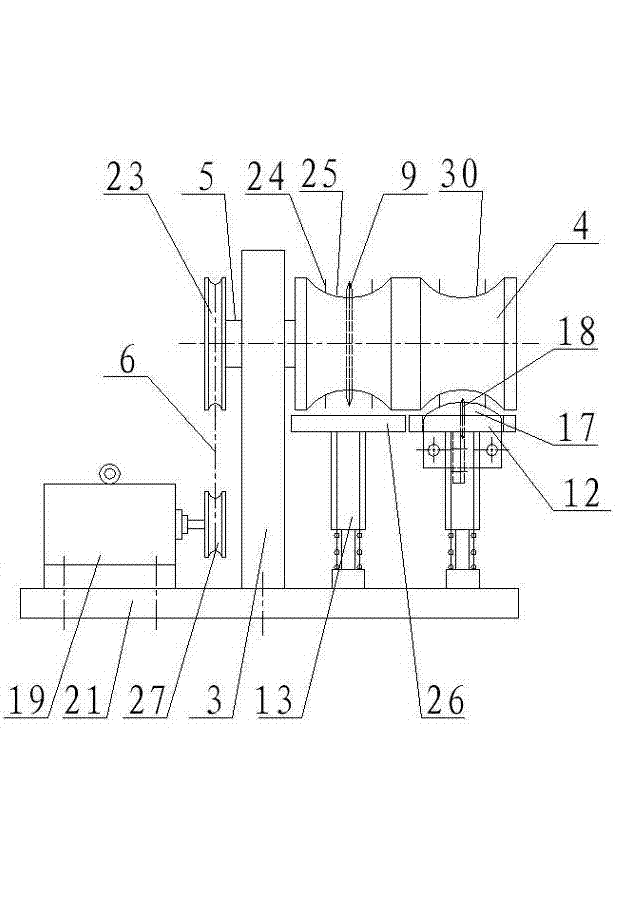

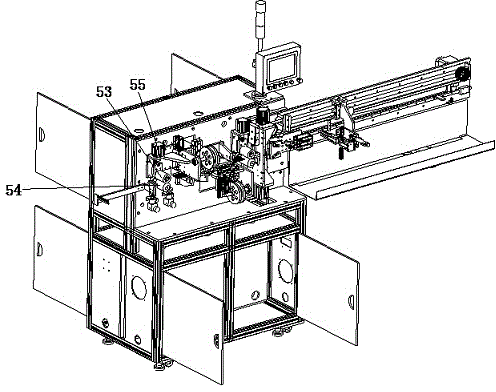

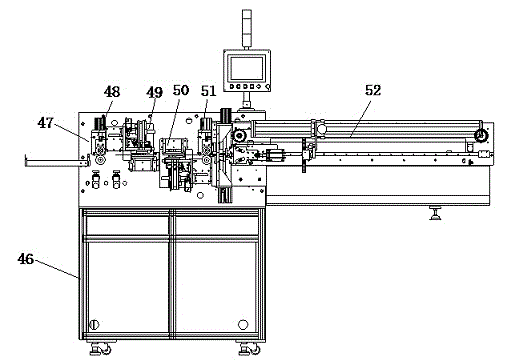

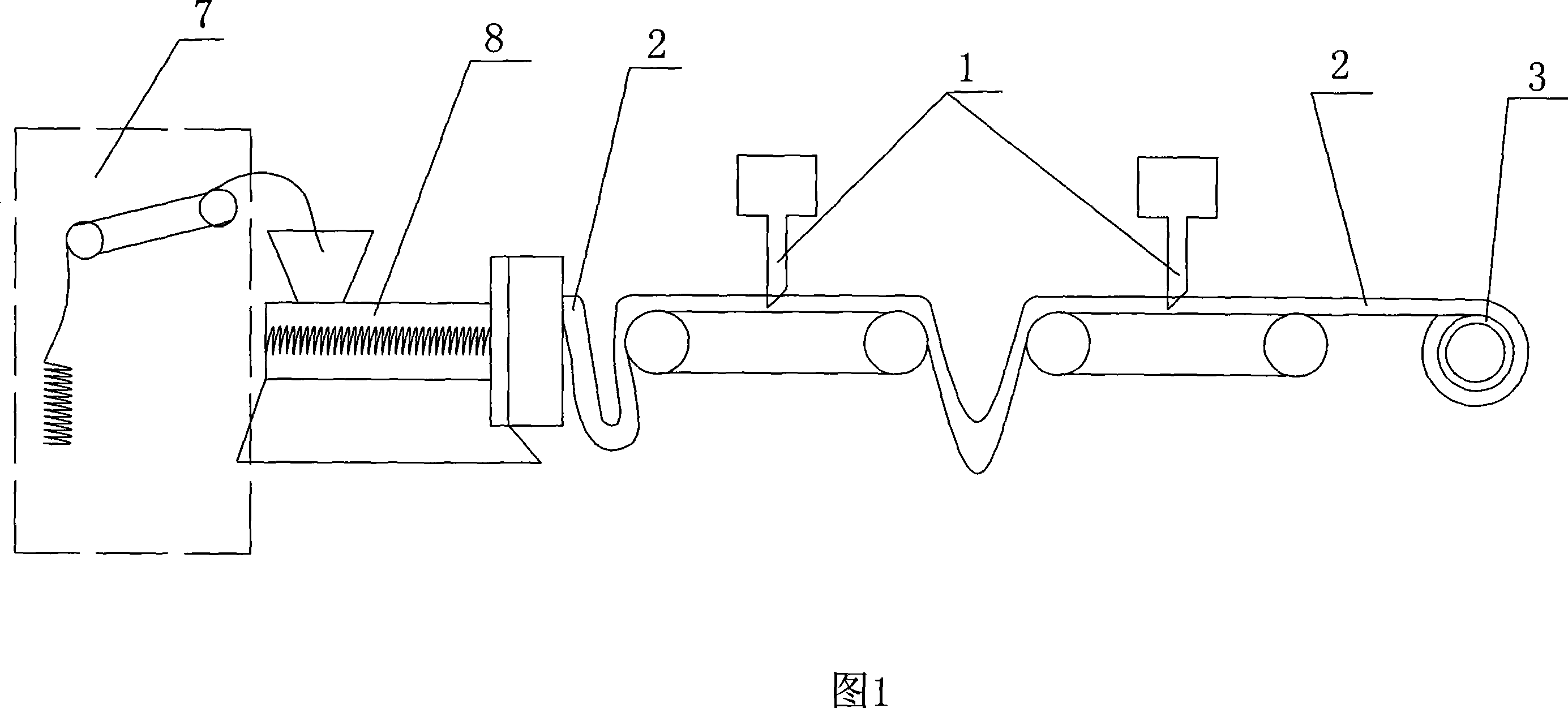

Multifunctional complex printer

InactiveCN101524912AControllable tensionHigh sensitivityTypewritersRotary pressesScreen printingLetterpress printing

The invention relates to a multifunctional complex printer. The multifunctional complex printer comprises a lifting device of a paper feed part. The multifunctional complex printer is characterized in that a corona device, a first AC servo tension detection device and a first cooling pull roll device are sequentially arranged at right side of a first deviation correction device, an intaglio printing unit is arranged above the corona device, the first AC servo tension detection device and the first cooling pull roll device, a first interchangeable hectograph unit, a second interchangeable hectograph unit, a third interchangeable hectograph unit, a fourth interchangeable hectograph unit, an interchangeable letterpress printing unit, an interchangeable screen printing unit and a first interchangeable flexography printing unit are sequentially arranged at the right side of the intaglio printing unit, a fourth AC servo tension detection device is arranged below a reserved platform of an inkjet device, and a second two-cylinder die cutting device, a back cutting device and a television monitoring camera are sequentially arranged at the right side of a first two-cylinder die cutting device. The multifunctional complex printer has the advantages of flexibly combining various printing modes according to pluralism of products and optionally exchanging printing modes of various color classes.

Owner:SHANGHAI XINMIN TAIYO KIKAI

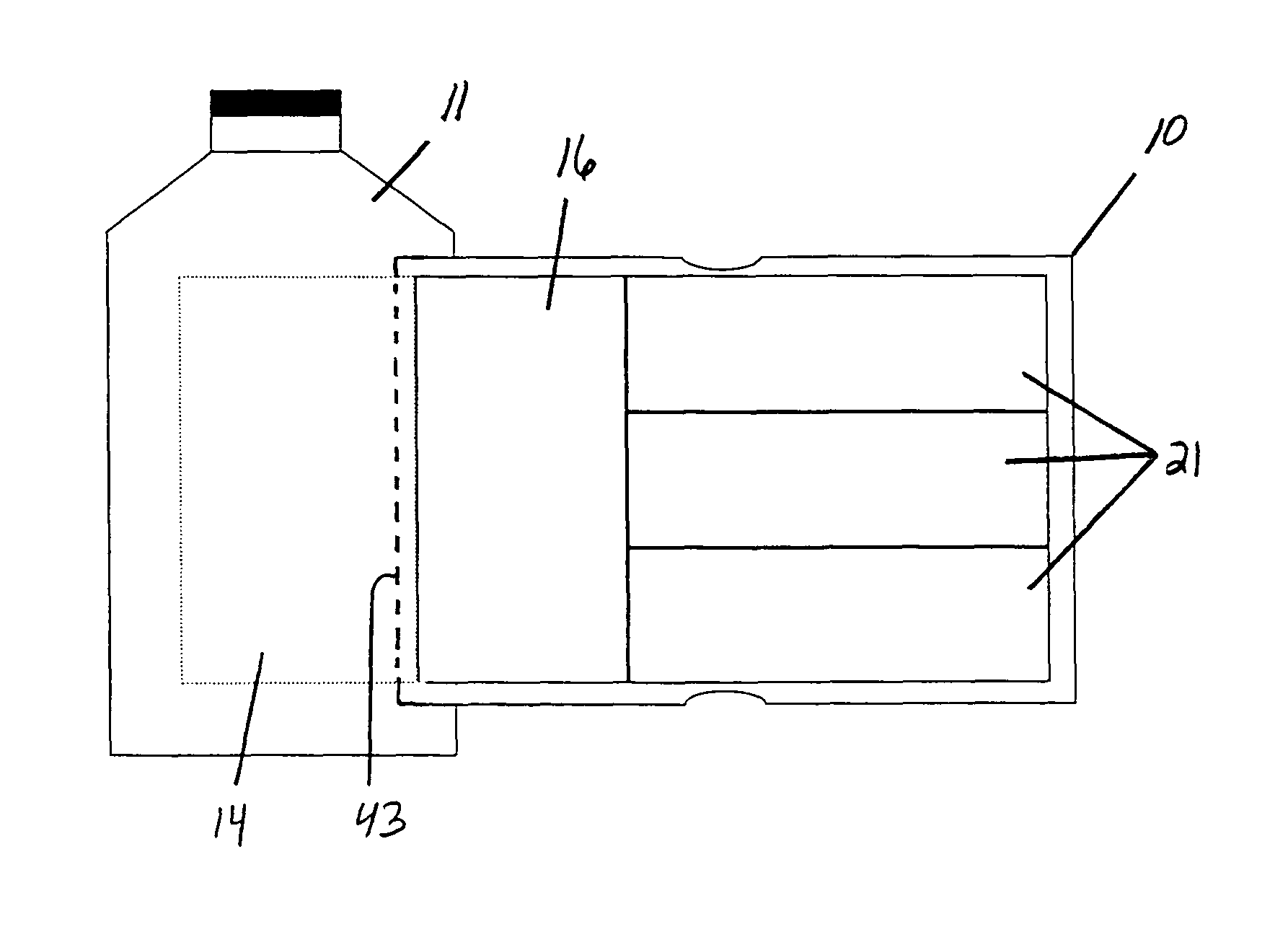

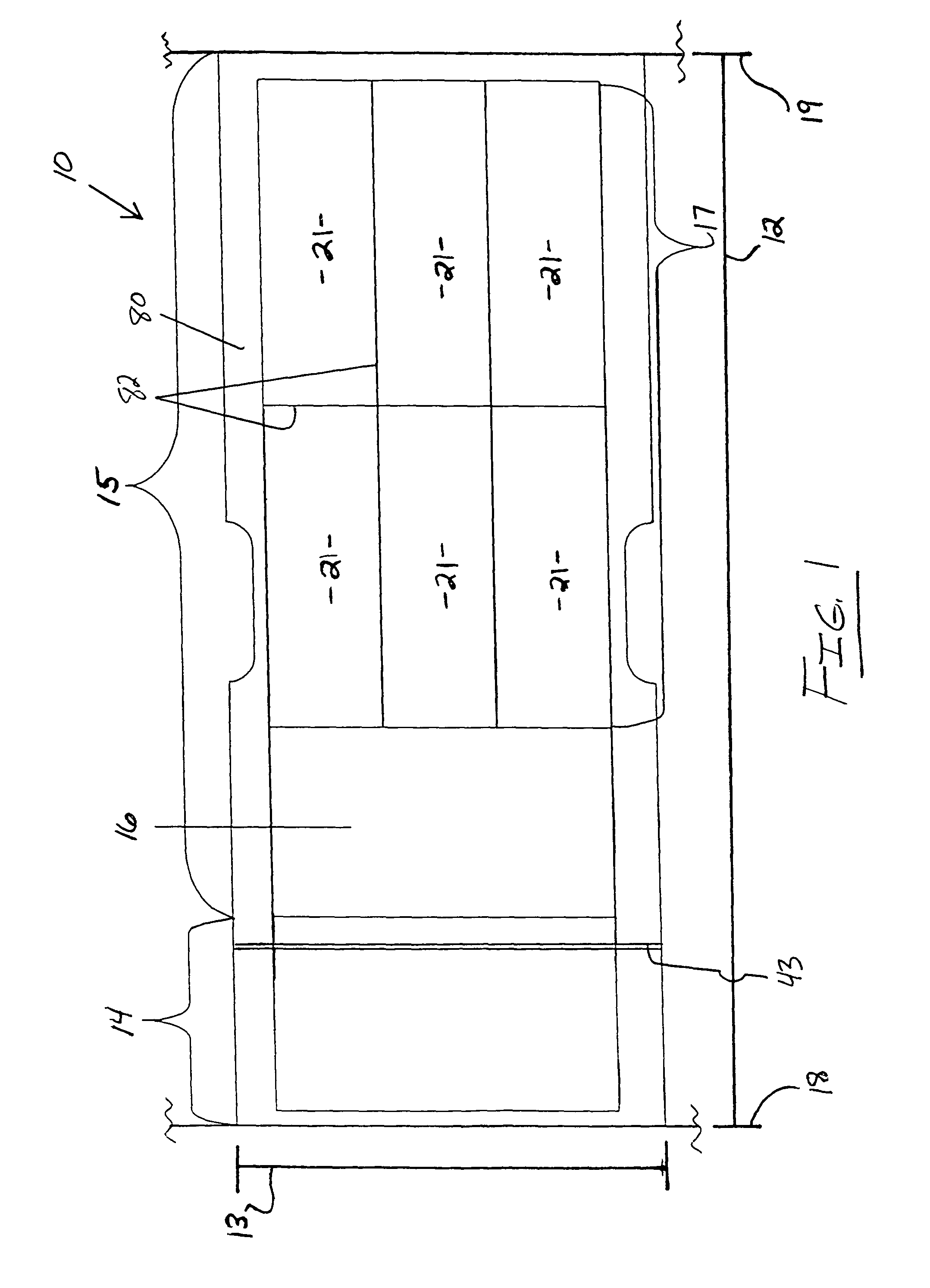

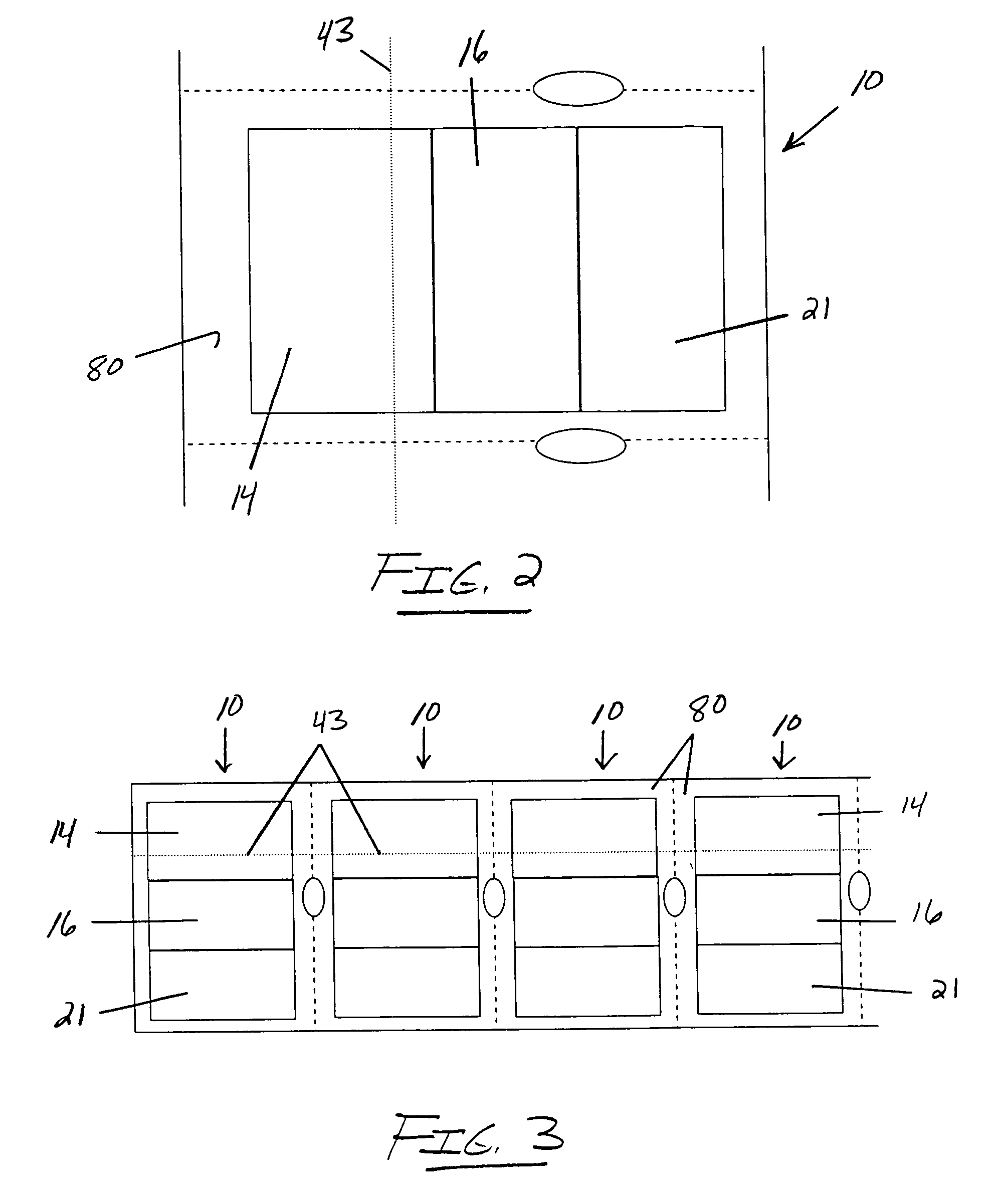

Multi-flag label

ActiveUS7941949B2Quickly and reliably inputtingEasy to disassembleStampsOther printing matterCross-linkBack cutting

A multi-flag label label-links a primary container to at least one secondary container. The multi-flag label comprises multiple layers and multiple regions intermediate its length. A back cut separates a first layer into unequal segment lengths. A transparent second layer is removably and adhesively attached to the first layer and is dimensioned such that the first layer frames the second layer with a peripheral boundary. A third layer is permanently bonded to the second layer and terminates adjacent the back cut, thereby exposing the back cut via the second layer. The third and second layers adjacent the back cut provide a parent label region; the remainder of the second and third layers provide a child label region, which region may be die cut into patterns for effecting child label(s). The parent and child labels may comprise information for cross-linking a source container to at least one secondary dose container.

Owner:ACCU CHART PLUS HEALTHCARE SYST INC

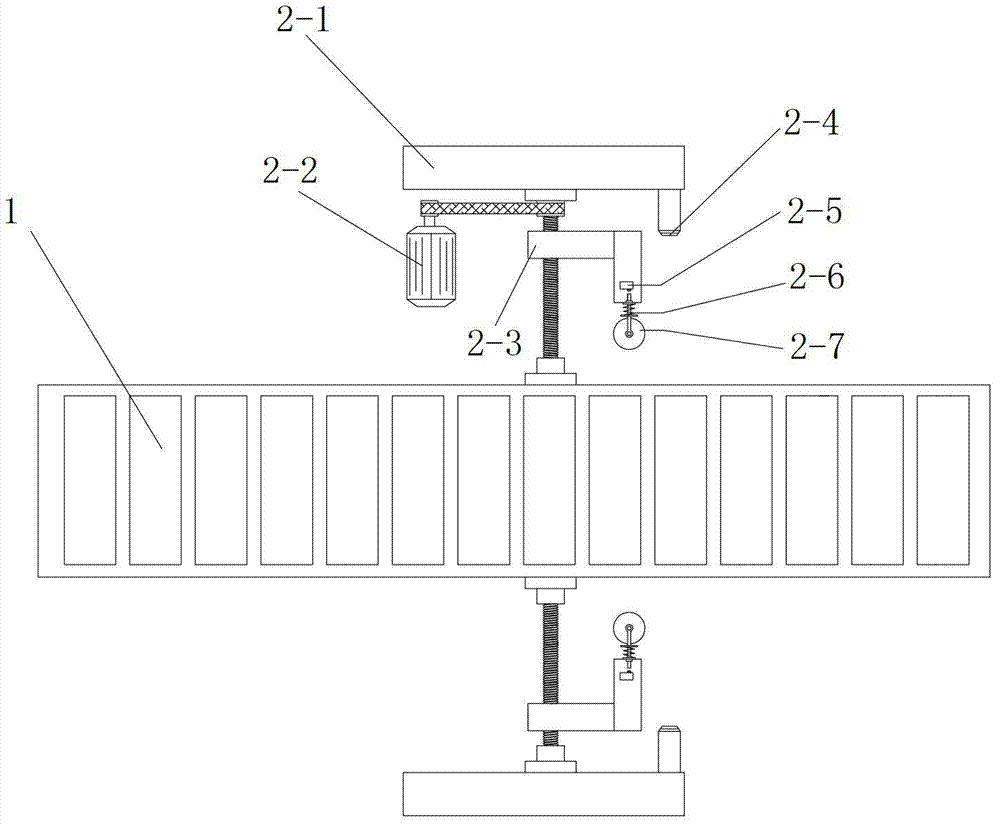

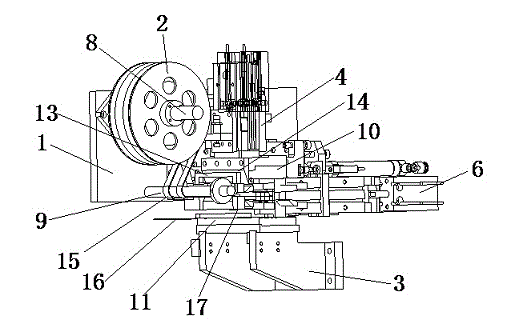

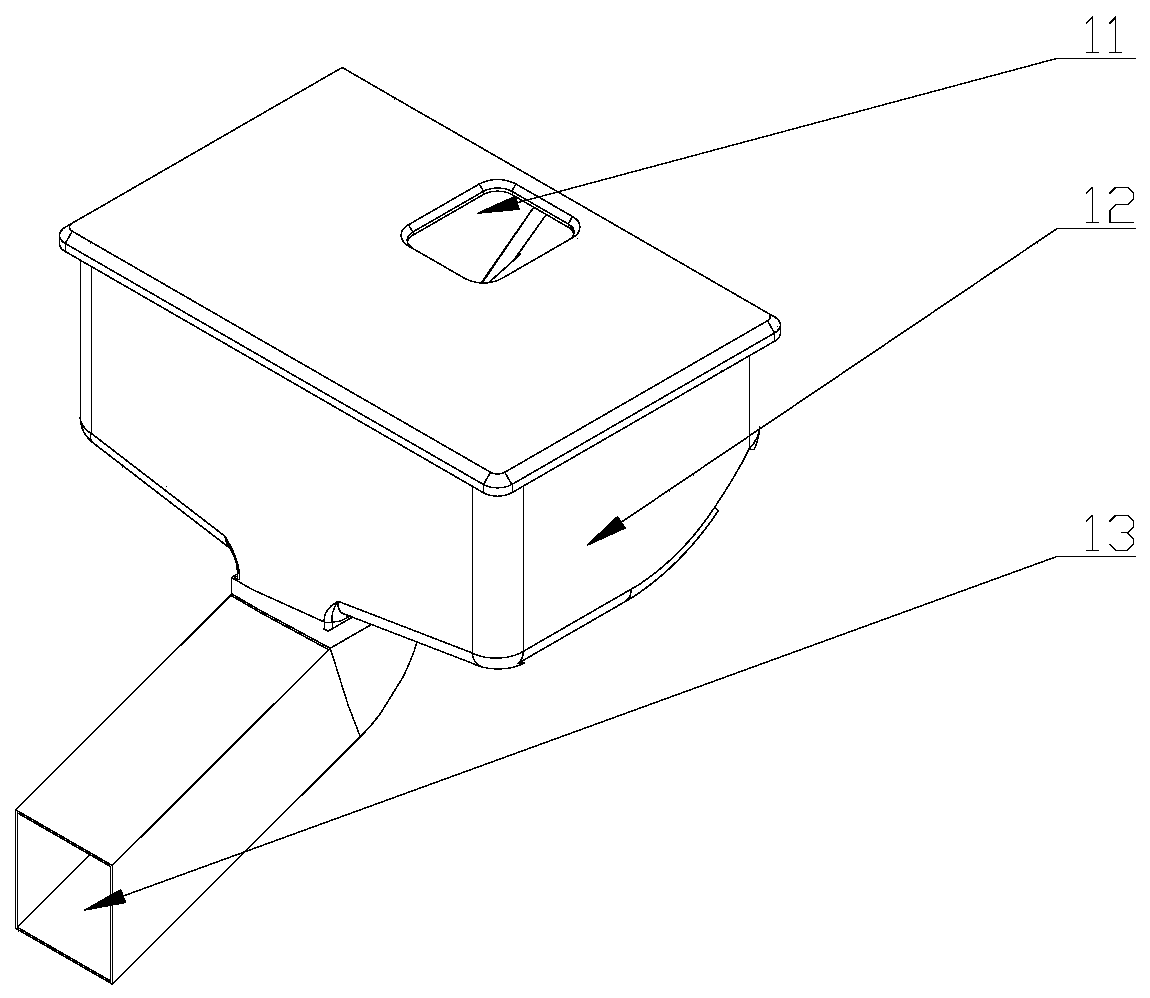

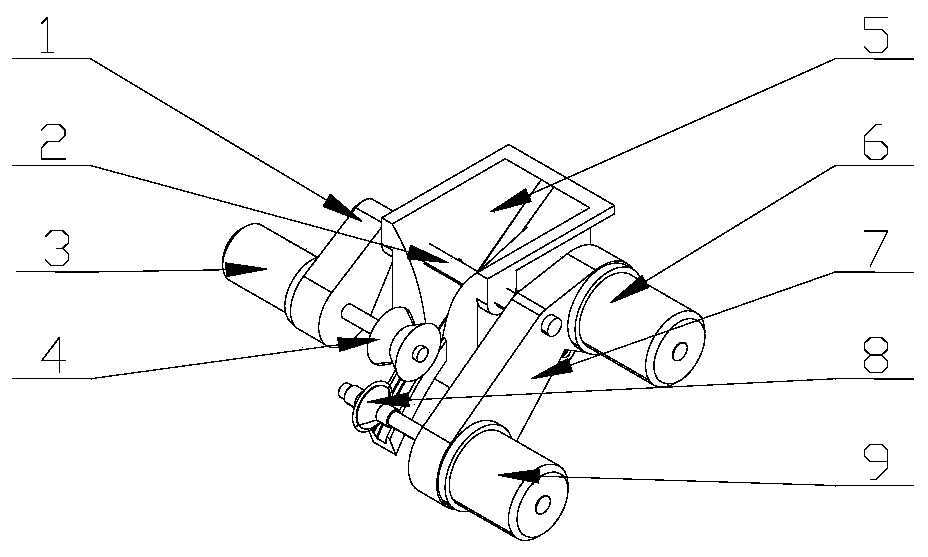

Eel and loach slaughtering machine

InactiveCN103168819ASolve the problemSolve the problem of missed killingPoultry/fish slaughtering/stunningAquatic productBack cutting

The invention relates to an eel and loach slaughtering machine which belongs to the field of an aquatic product processing machine. The eel and loach slaughtering machine is formed by a rack, a feeding barrel and a slaughtering device, wherein the feeding barrel is mounted at the one end of the rack and the slaughtering device is arranged at the other end of the rack; the feeding barrel and the slaughtering device are movably connected through a feeding hose and a hose clamp; and the slaughtering device is provided with a protection cover. The eel and loach slaughtering machine disclosed by the invention adopts a feeding roller to randomly grasp and convey eel and loach, the slaughtering speed is high, the slaughtering requirements on eel and loach with different sizes can be met, and the frequent problems that some eel and loach are not correctly slaughtered or are not slaughtered when an existing slaughtering machine is used for slaughtering eel and loach with different sizes are solved. When the eel and loach slaughtering machine disclosed by the invention is used for slaughtering eel and loach, eel and loach do not need to be classified according to specifications and sizes in advance, so that the labor intensity of workers is reduced and the working efficiency is improved; and eel and loach can be slaughtered from abdomens or from backs through the selection connection between the feeding hose and a back cutting supporting plate and between the feeding hose and an abdomen cutting supporting plate, and furthermore, the requirements on deep processing of eel and loach can be met.

Owner:李平

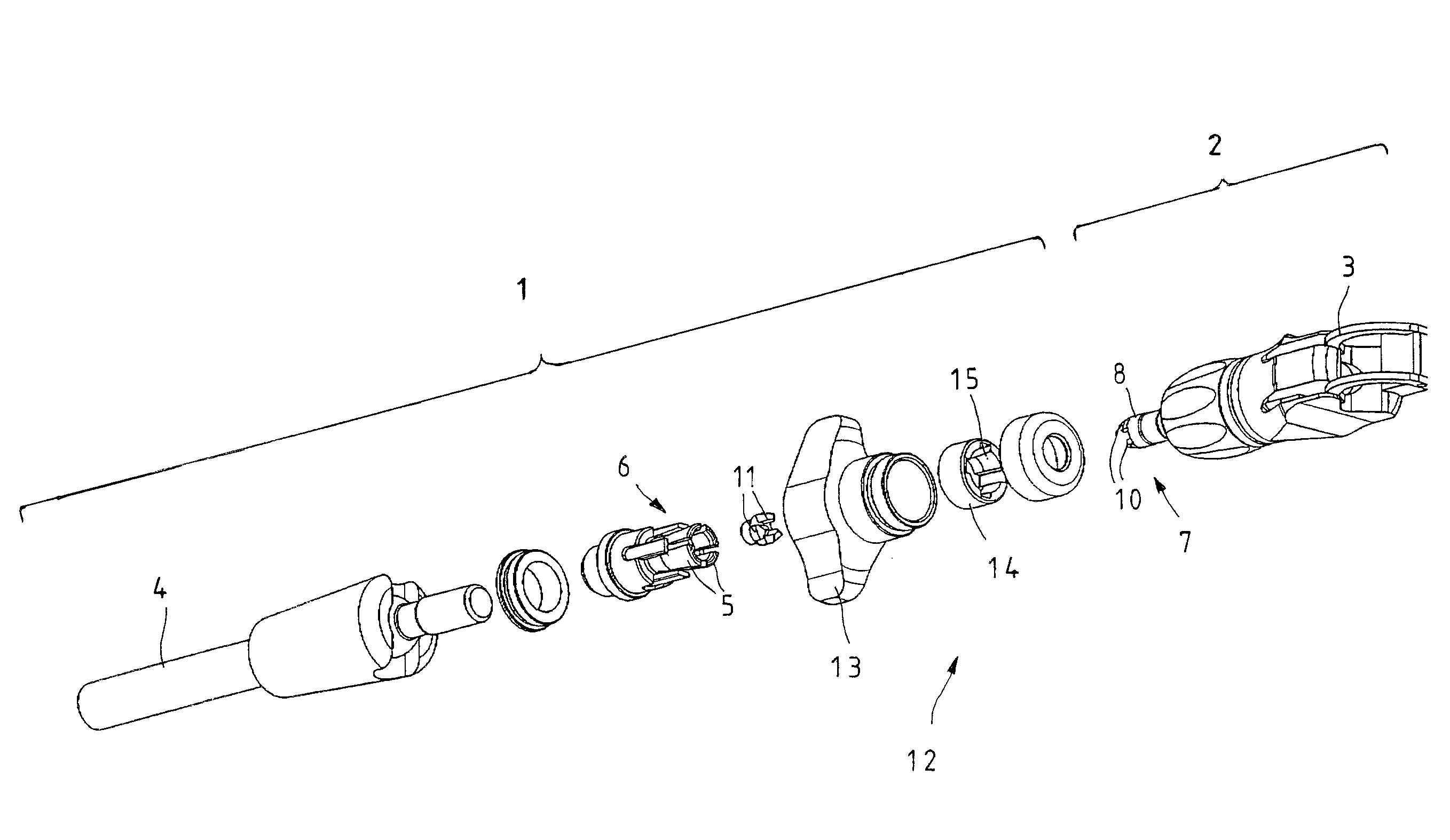

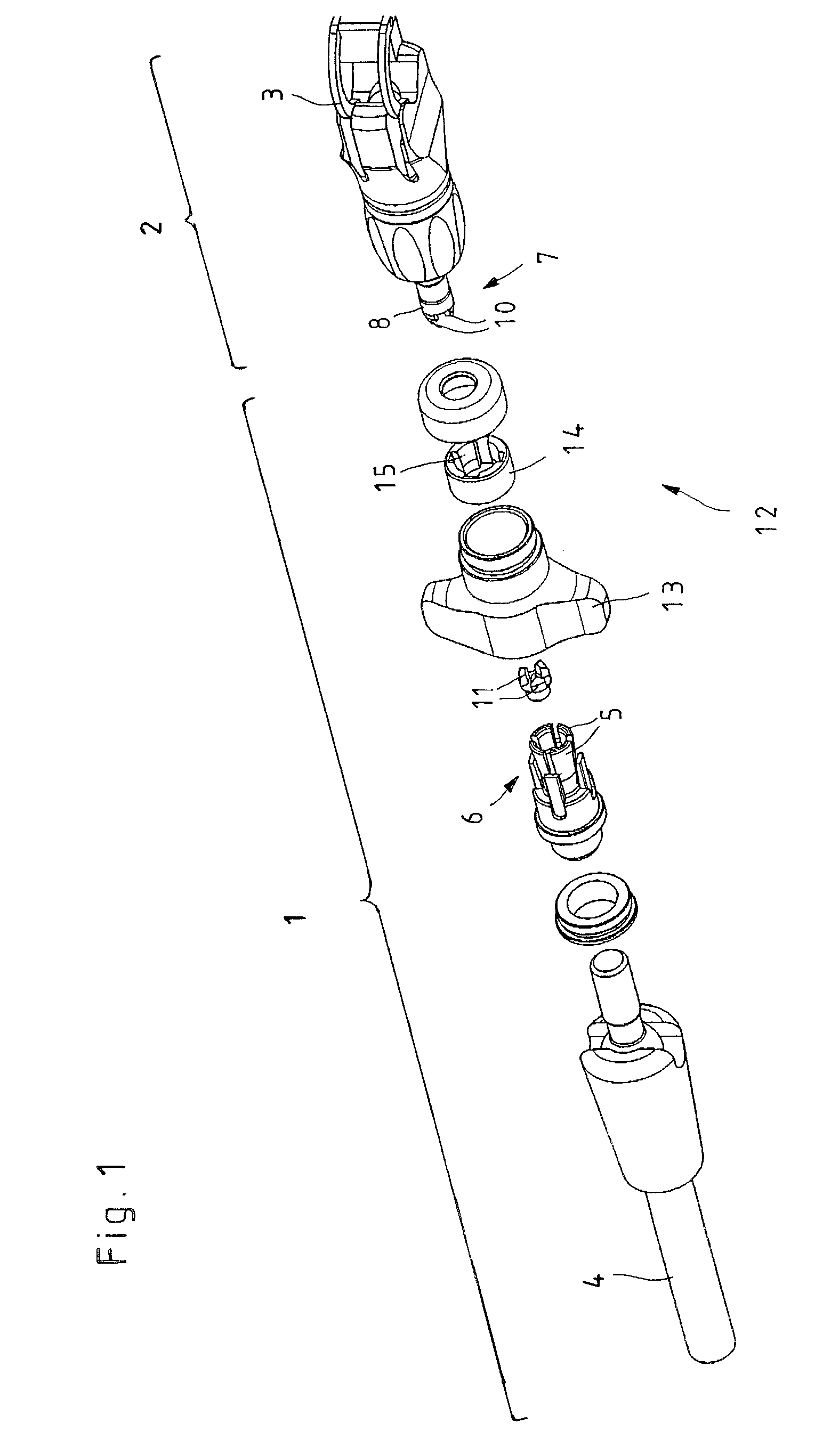

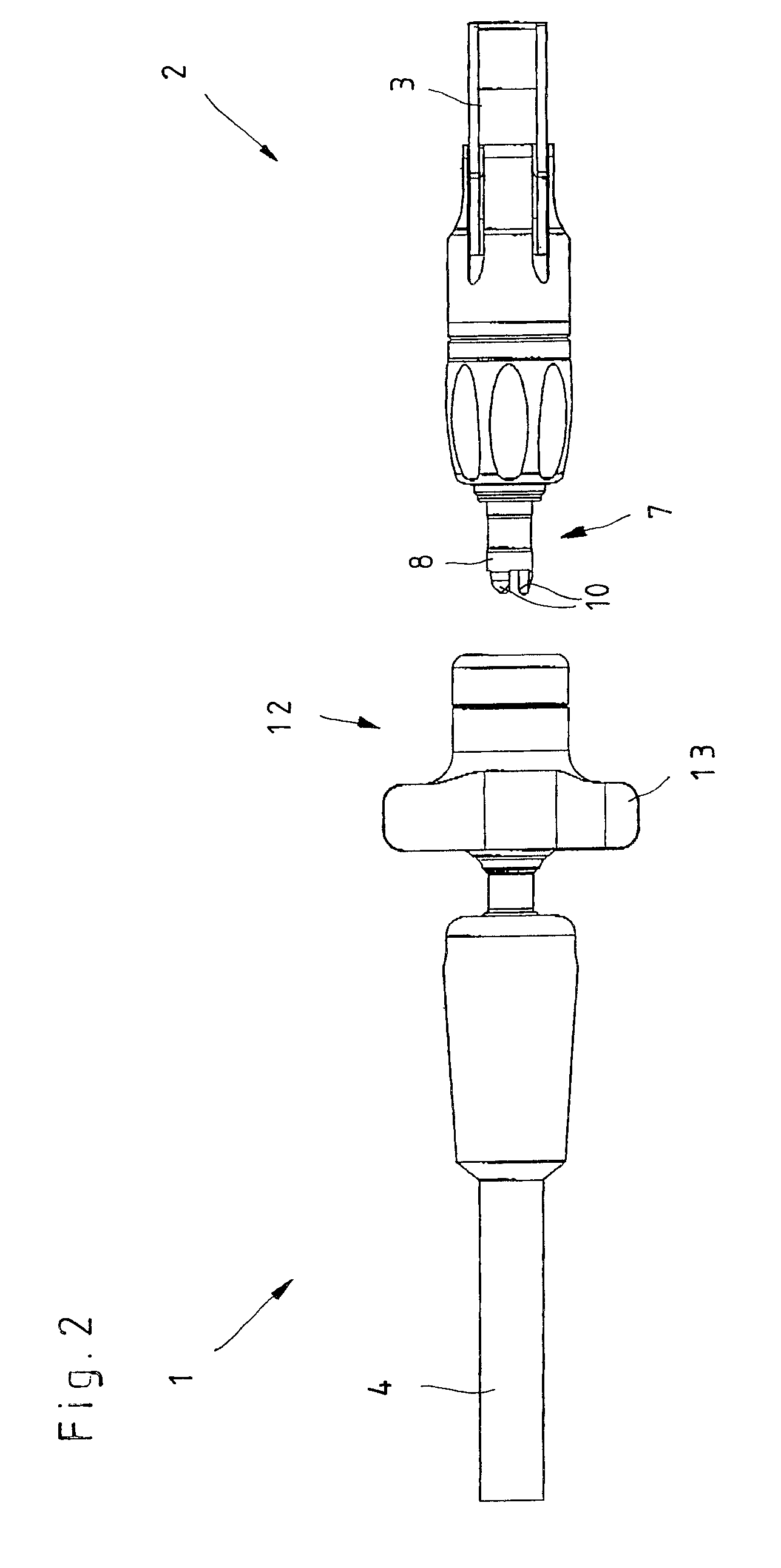

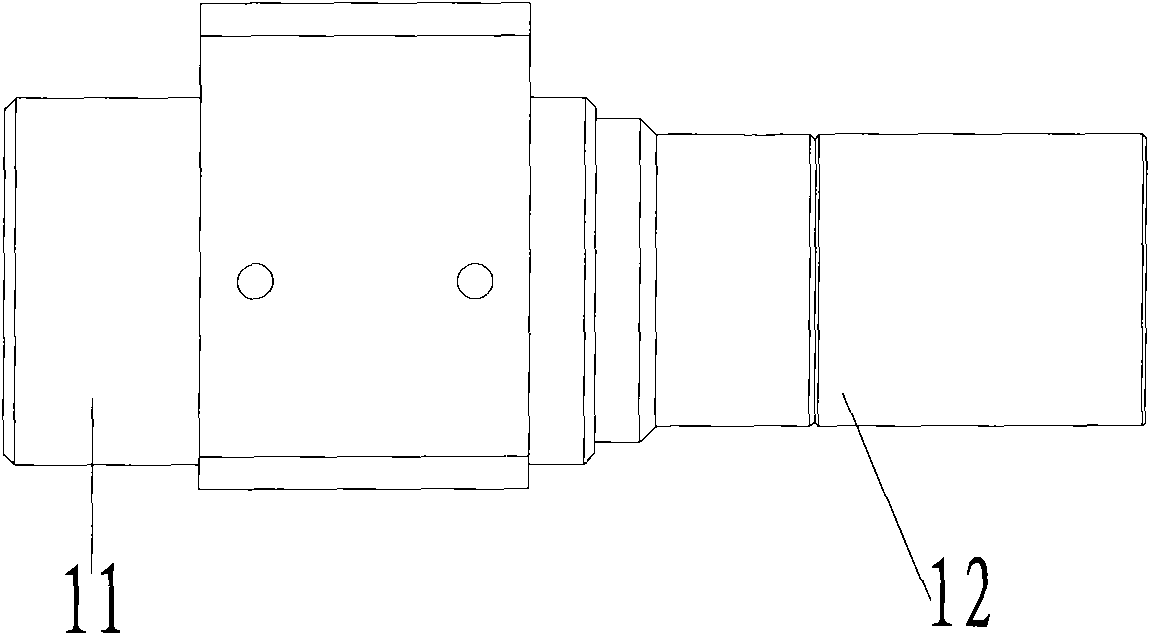

Coupling device for attaching medical instruments to a holding device

A coupling device for securing medical instruments to a holding device allows for simple and rapid handling and exact positioning of the medical instrument. A coupler socket is configured on one component and a coupler plug is configured on the other component, wherein the coupler socket and coupler plug can be fixed in mutually connected position with respect to one another by means of at least one locking element. The coupler socket is configured as a sleeve-shaped collet chuck including several mutually distanced spring arms. The coupler plug includes a coupling pin equipped with at least one radially outward-pointing catch cam. When coupled, at least one catch cam of the coupling pin catches on a corresponding back-cut on the collet chuck. The locking element can be screwed onto the collet chuck so that the spring arms of the collet chuck in the coupled position are affixed facing radially outward.

Owner:KARL STORZ GMBH & CO KG

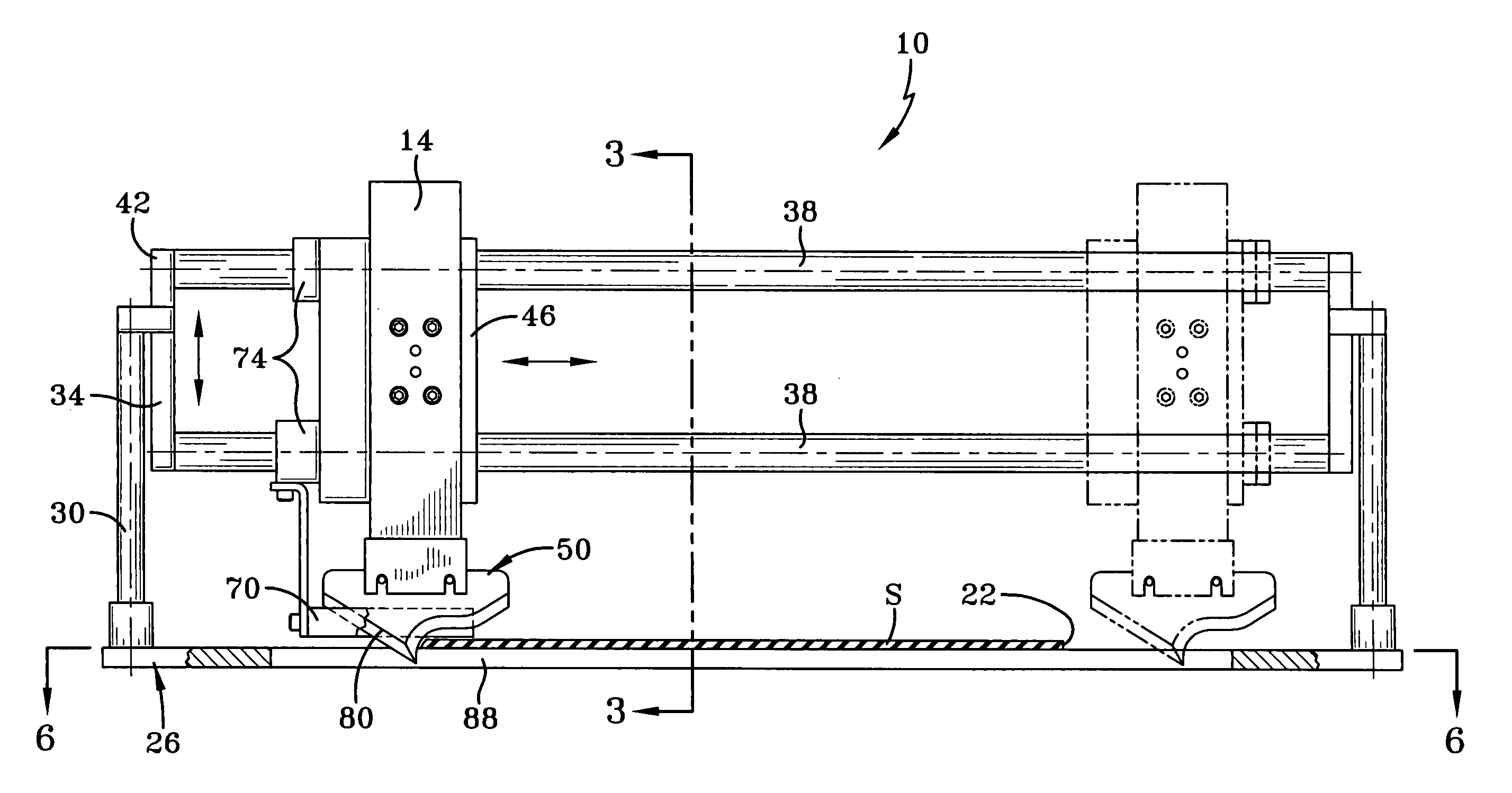

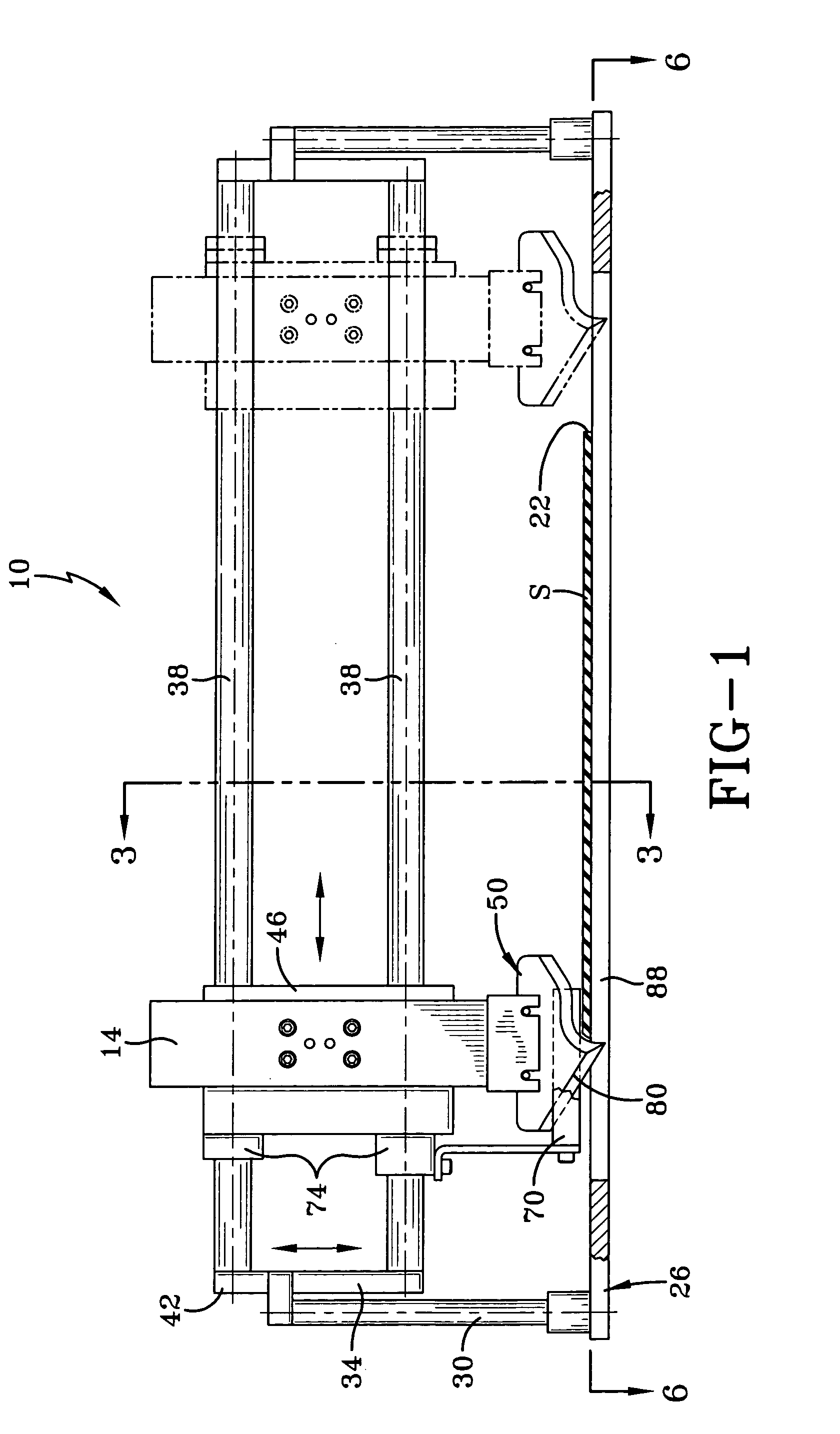

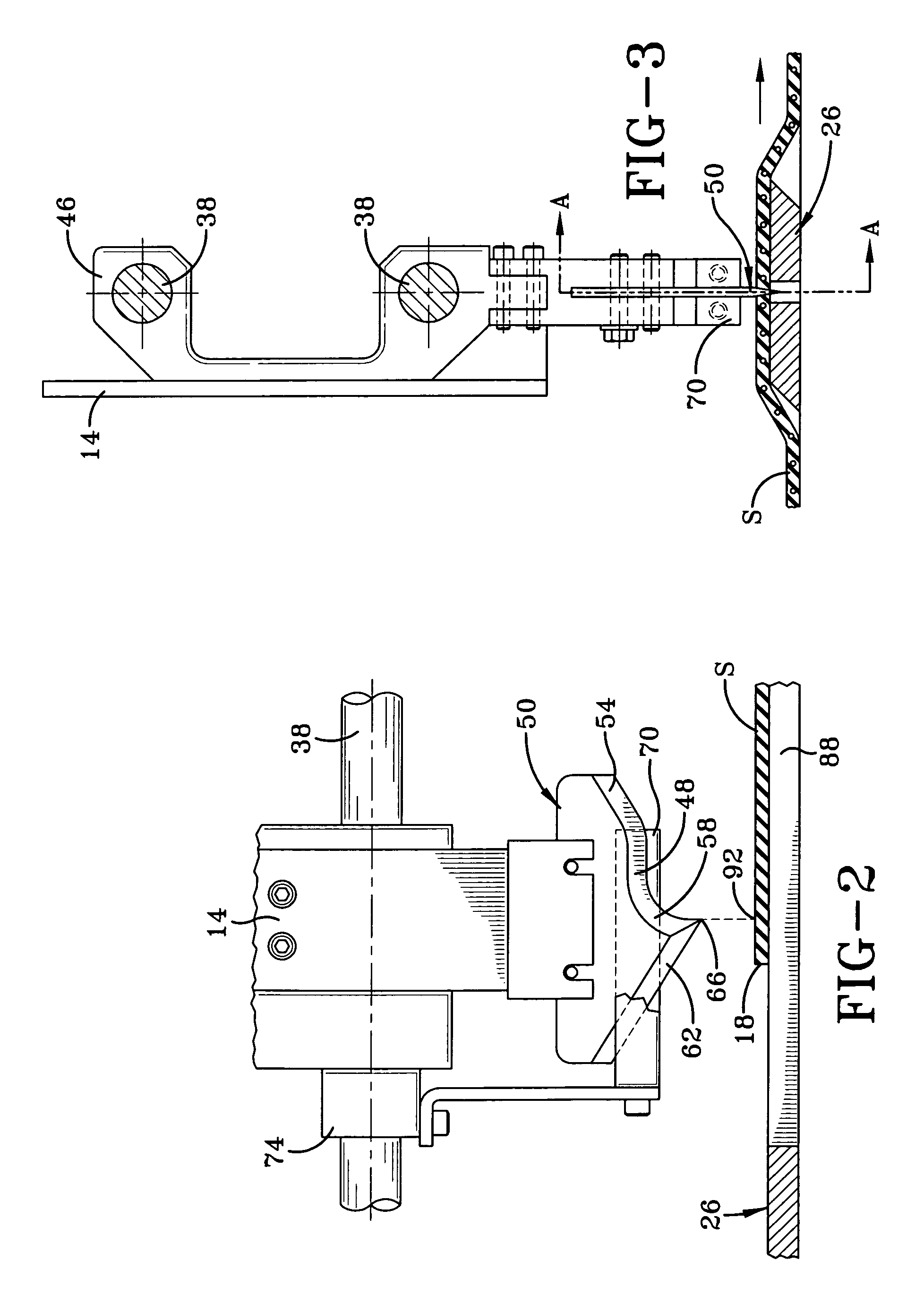

Method and apparatus for cutting tire ply stock

Method and apparatus for severing tire ply stock (S) wherein the apparatus includes a knife assembly (14) utilizing a blade (50) having a curved leading edge (58) and a straight trailing edge (62) which meet at a leading point (66). The ply stock (S) is supported by a slotted anvil (26) in the area immediately adjacent a cut line. In operation, the knife assembly (14) is lowered and the leading point (66) pierces the ply stock (S) between adjacent cords. During the downward stroke, the trailing edge (62) back-cuts the ply stock (S) from the insertion point (98) to a first lateral edge (18). The leading edge (58) severs the remainder of the ply stocks (S) as the knife assembly (14) traverses the ply stock to a second lateral edge (22).

Owner:THE GOODYEAR TIRE & RUBBER CO

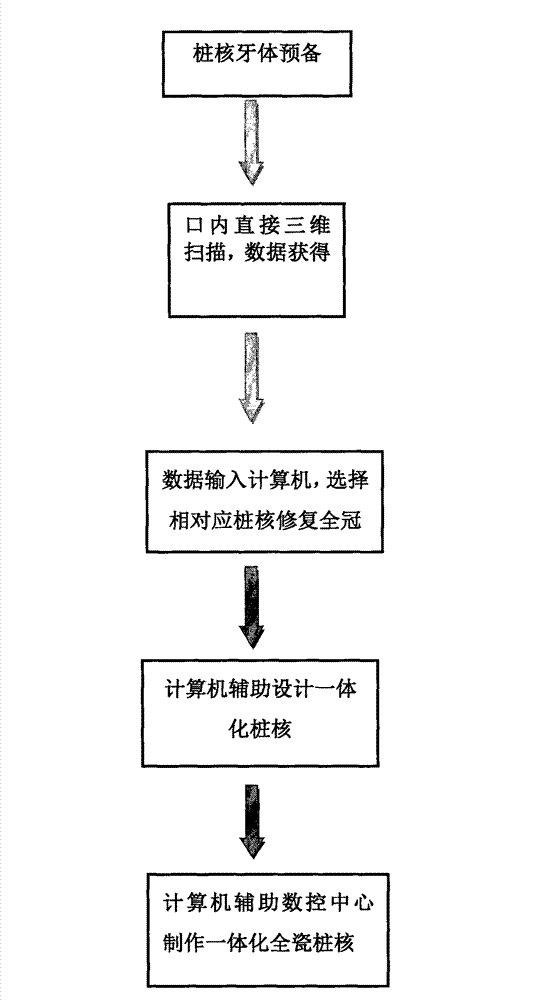

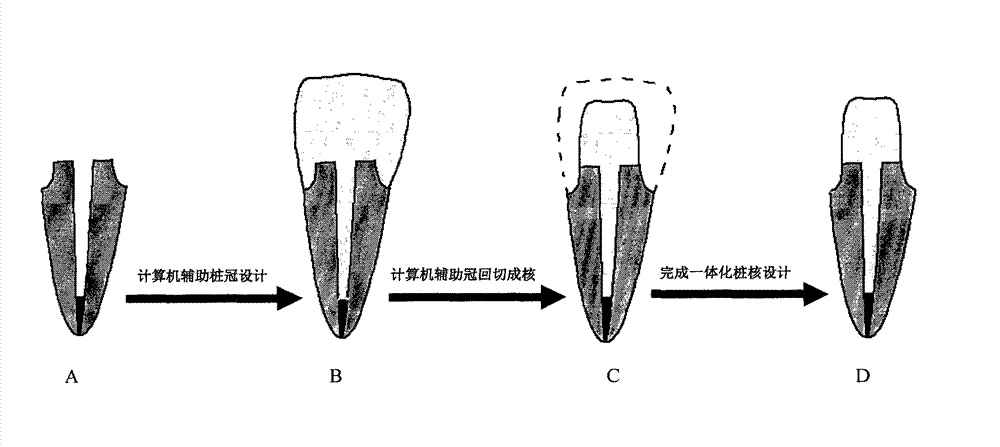

Preparation method of personalized and integrated all-ceramic post-and-core of dentistry

InactiveCN103083094AShorten visit timeShorten the overall cycleMechanical/radiation/invasive therapiesFastening prosthesisPersonalizationNumerical control

The invention provides a manufacture method of a clinical personalized and integrated all-ceramic post-and-core of dentistry. The manufacture method is characterized in that a high-precision and short-wavelength visible scanner is adopted and directly used for scanning intraoral defected teeth subjected to root canal preparation, the CAD / CAM (Computer Aided Design / Computer Aided Manufacturing) central incisor prosthetic design is adopted, the design of integrating the post and the core is accomplished, and then the incisor back-cut method design is carried out to accomplish the design of the integrated all-ceramic post-and-core, and numerical control processing equipment is adopted and used for processing in order to accomplish the manufacture of the all-ceramic post-and-core.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

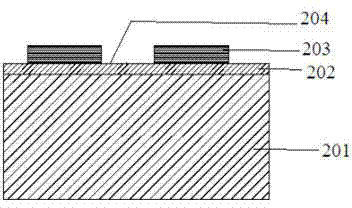

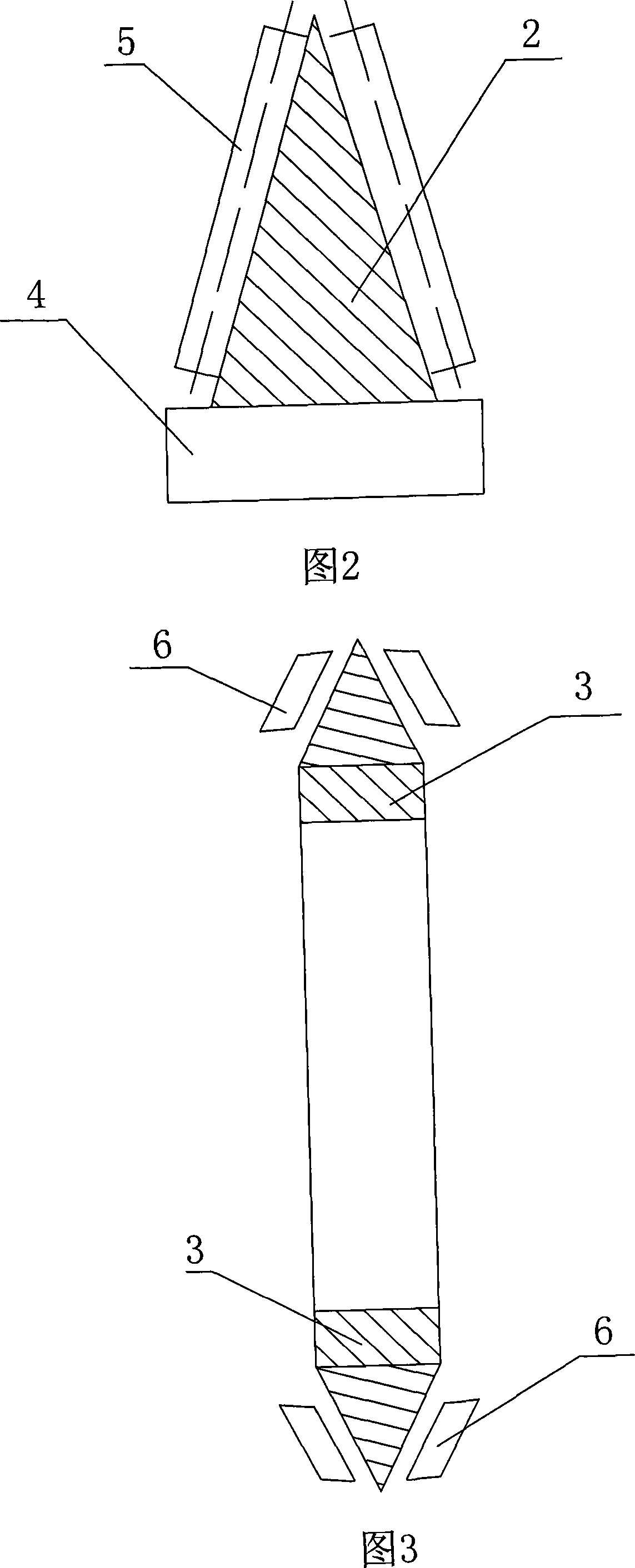

Cutting method of LED chip

InactiveCN104347760AAvoid ablationDoes not affect electrical characteristicsSemiconductor/solid-state device manufacturingFine working devicesEngineeringLaser cutting

The invention discloses a cutting method of an LED chip. The method comprises drawing scratches by use of laser on the back surface of the chip and performing saw cutting by use of a diamond saw blade knife, wherein the saw blade knife is an isosceles inverted triangle with a symmetrical left portion and right portion, and the included angle between a knife side surface and a horizontal line is 30 DEG to 60 DEG. The method further comprises performing overturning and film reversing on the back-cut chip and cutting the front surface of the chip along grooves to form crystal grains by use of a splinter knife. According to the invention, the problems of backside collapse, burr and the like by use of a conventional saw blade process are solved, the problem of ablation brought by laser cutting is avoided, and the method is simple to operate and easy to realize.

Owner:LATTICE POWER (JIANGXI) CORP

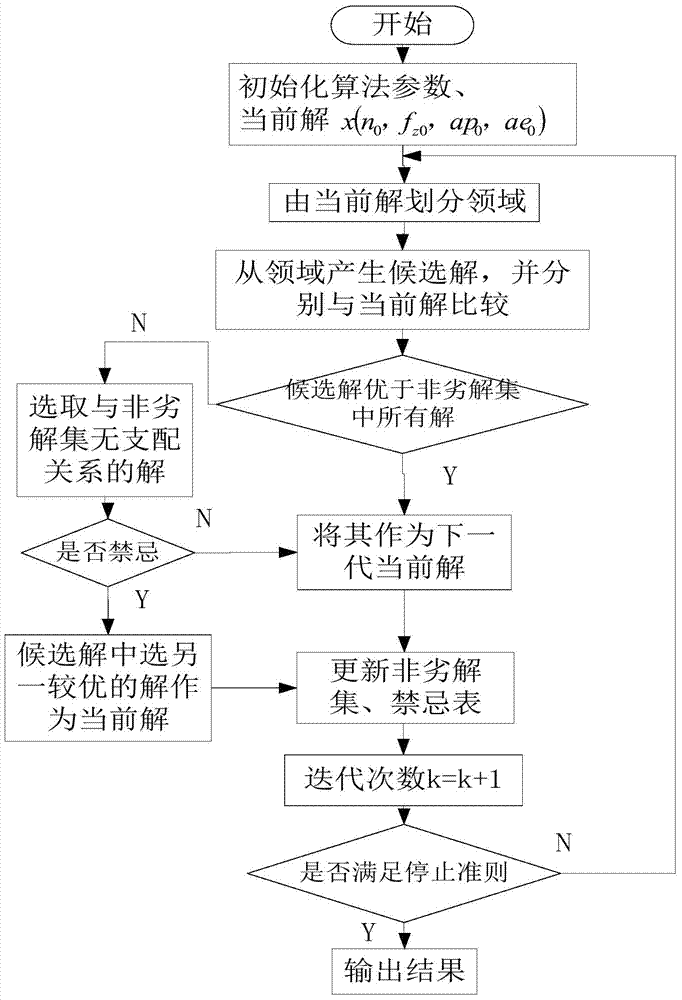

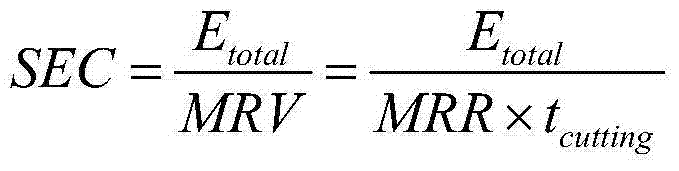

Multi-target optimization method for numerical control machining technological parameters facing energy efficiency

ActiveCN104517033AIncrease productivityReduce manufacturing costProgramme controlComputer controlNumerical controlBack cutting

The invention discloses a multi-target optimization method for numerical control machining technological parameters facing energy efficiency, aiming at realizing the aims of the technical scheme. The multi-target optimization method comprises the following steps: (1) setting a main shaft rotary speed n, a feeding mount of each tooth fz, back cutting depth ap and side cutting depth ae of numerical control cutting machining; (2) establishing a multi-target optimization model of the numerical control machining technological parameters, wherein minF(n, fv, ap, ae)=(minSEC, minTp); (3) determining a constraint condition; (4) optimizing the target model to obtain values of the corresponding n, fz, ap and ae when the minF(n, fv, ap, ae) is obtained; and (5) carrying out cutting machining on a workpiece by adopting the main shaft rotary speed n, the feeding mount of each tooth fz, the back cutting depth ap and the side cutting depth ae of the step (4).

Owner:CHONGQING UNIV

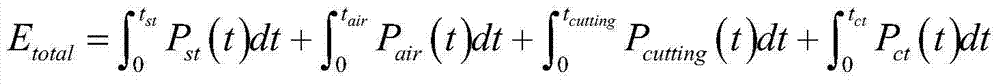

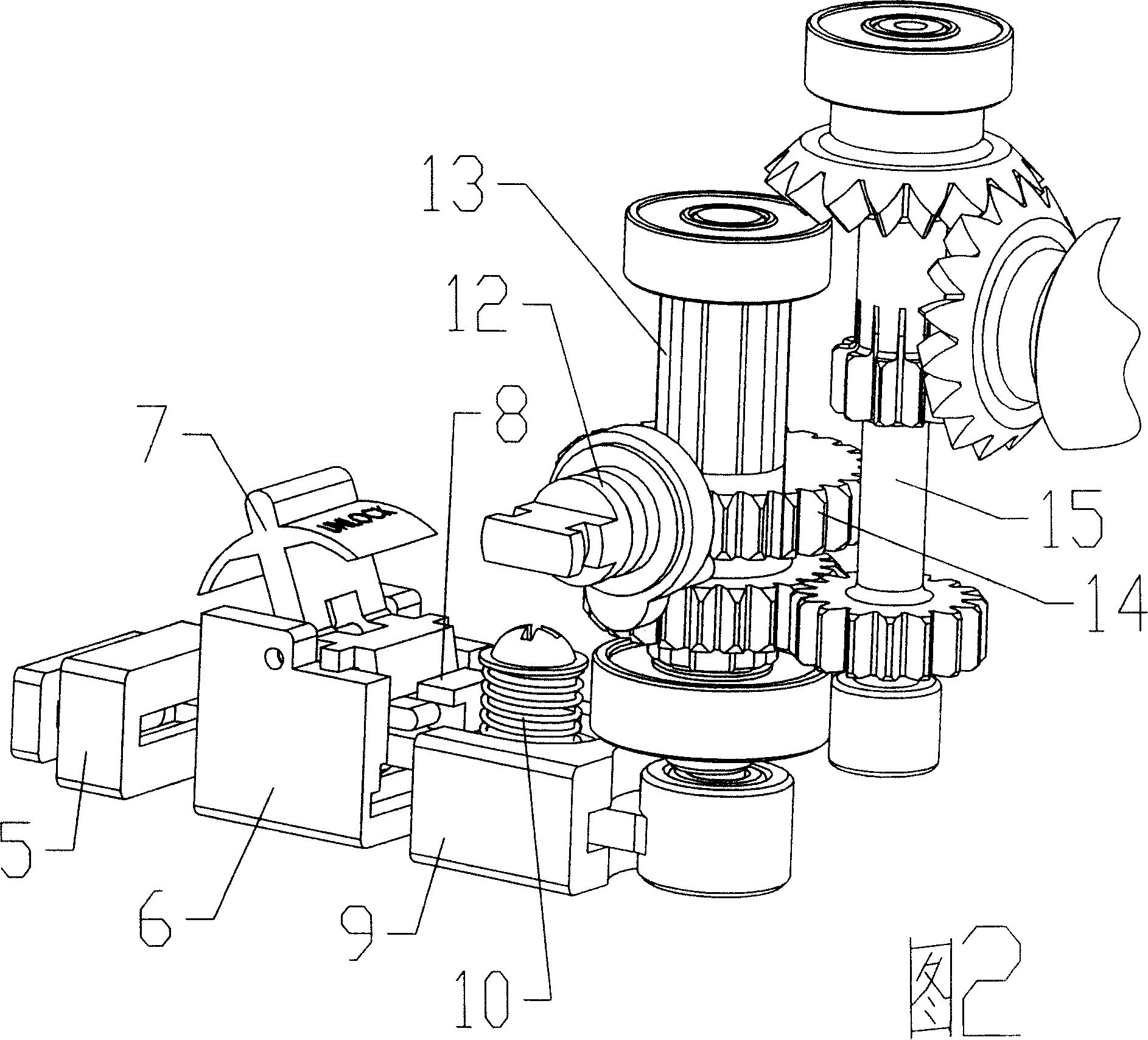

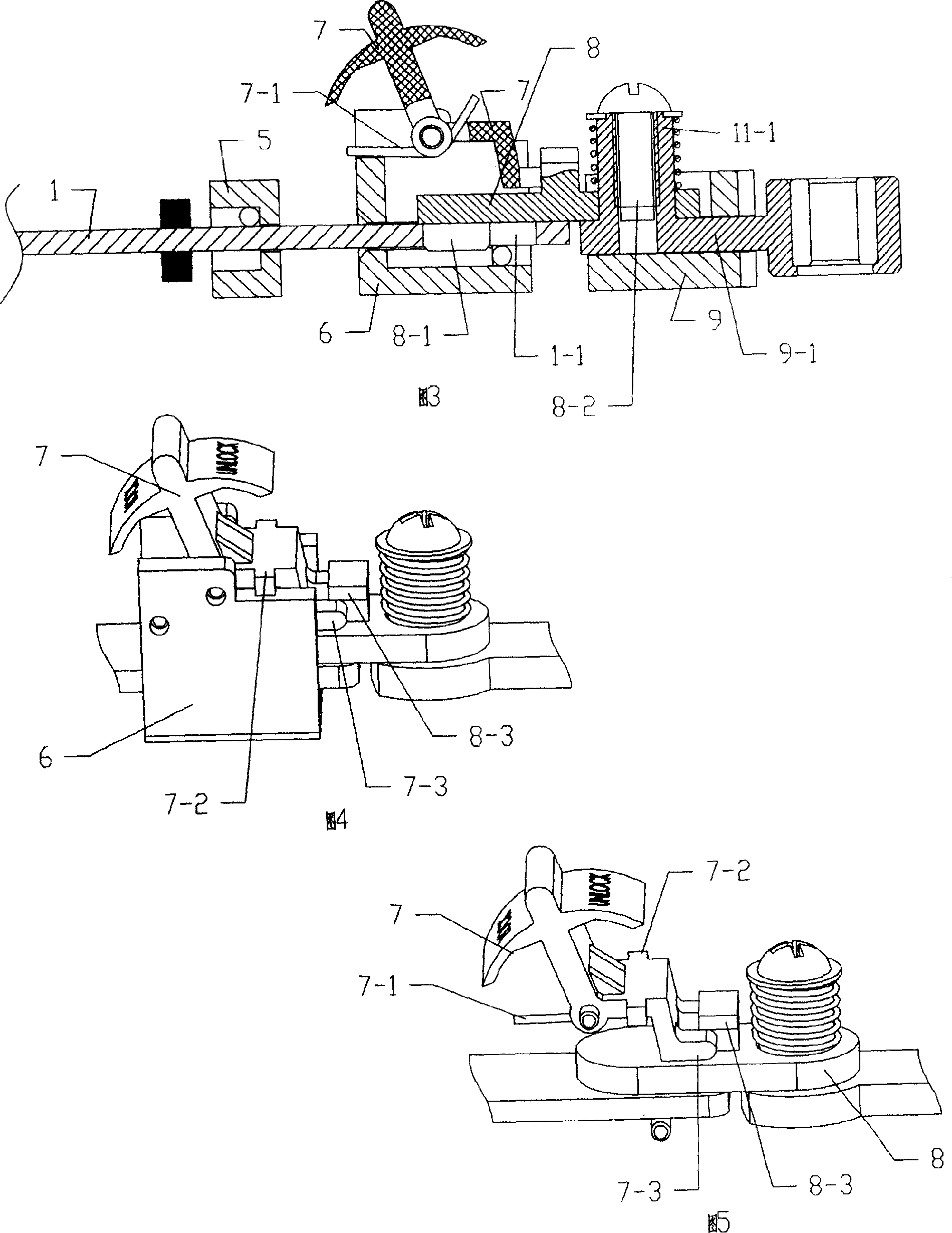

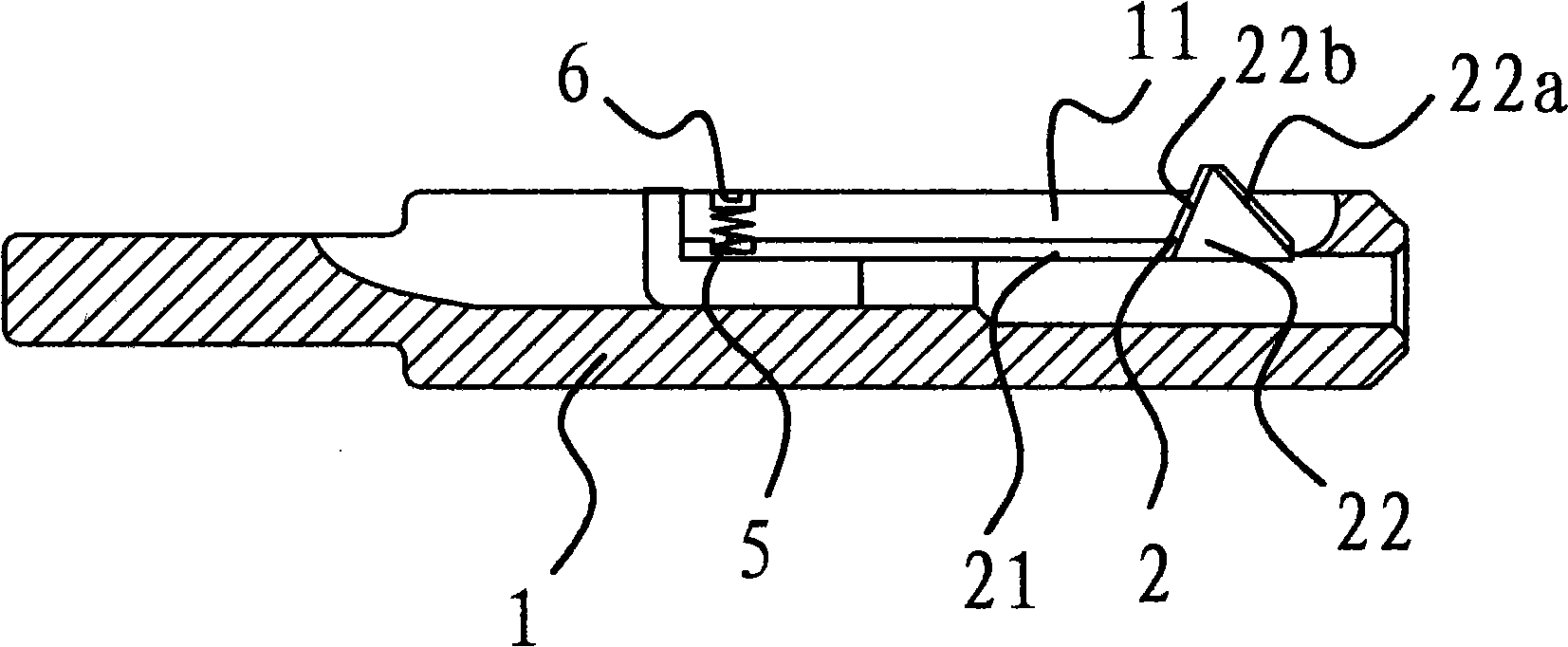

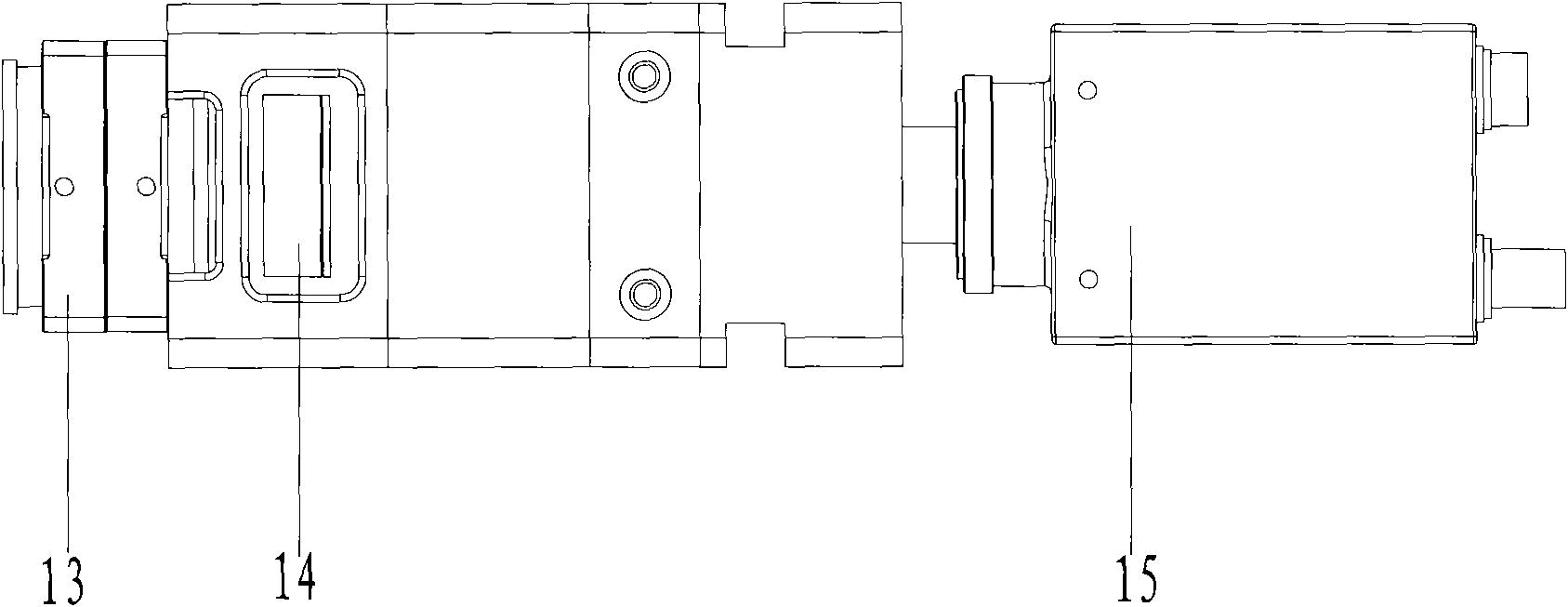

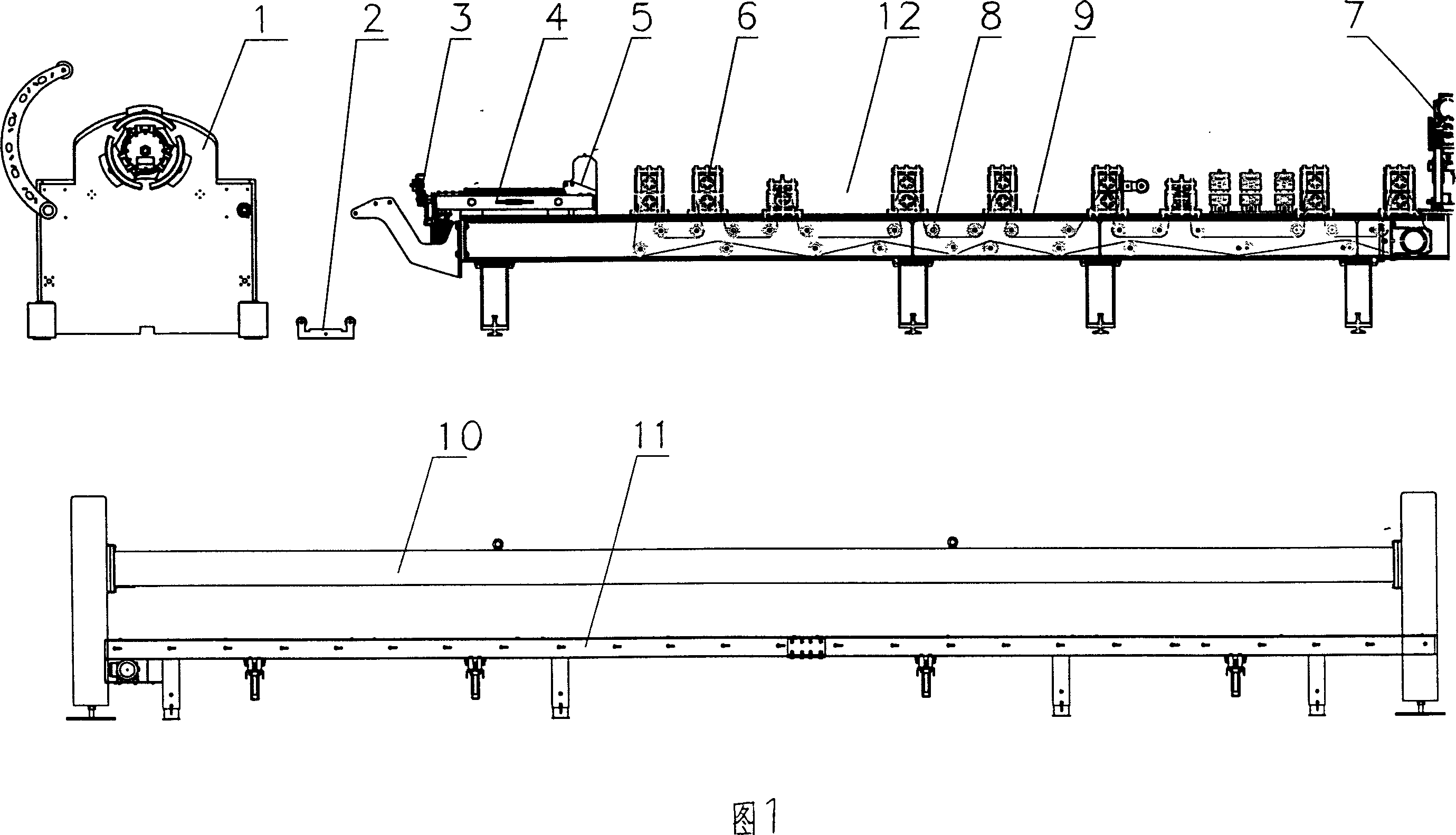

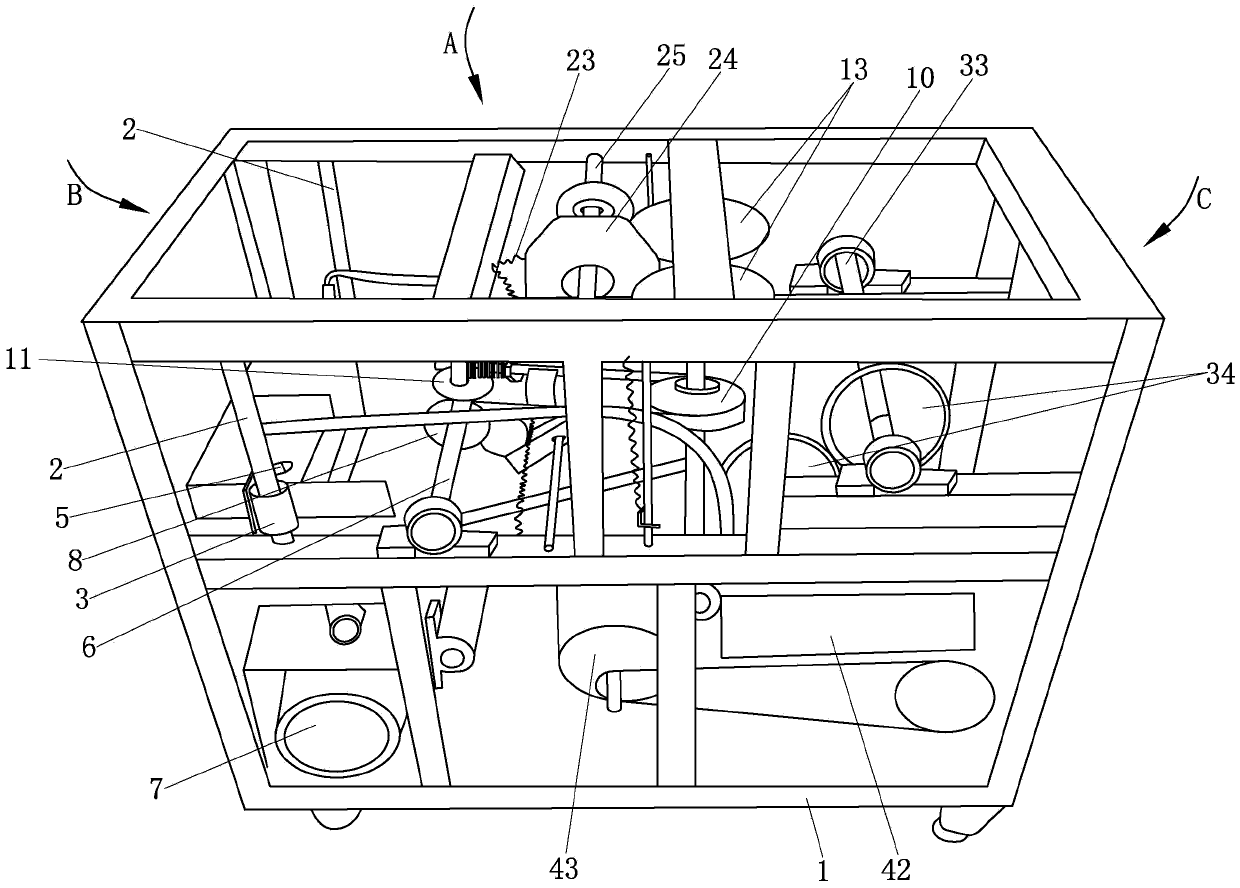

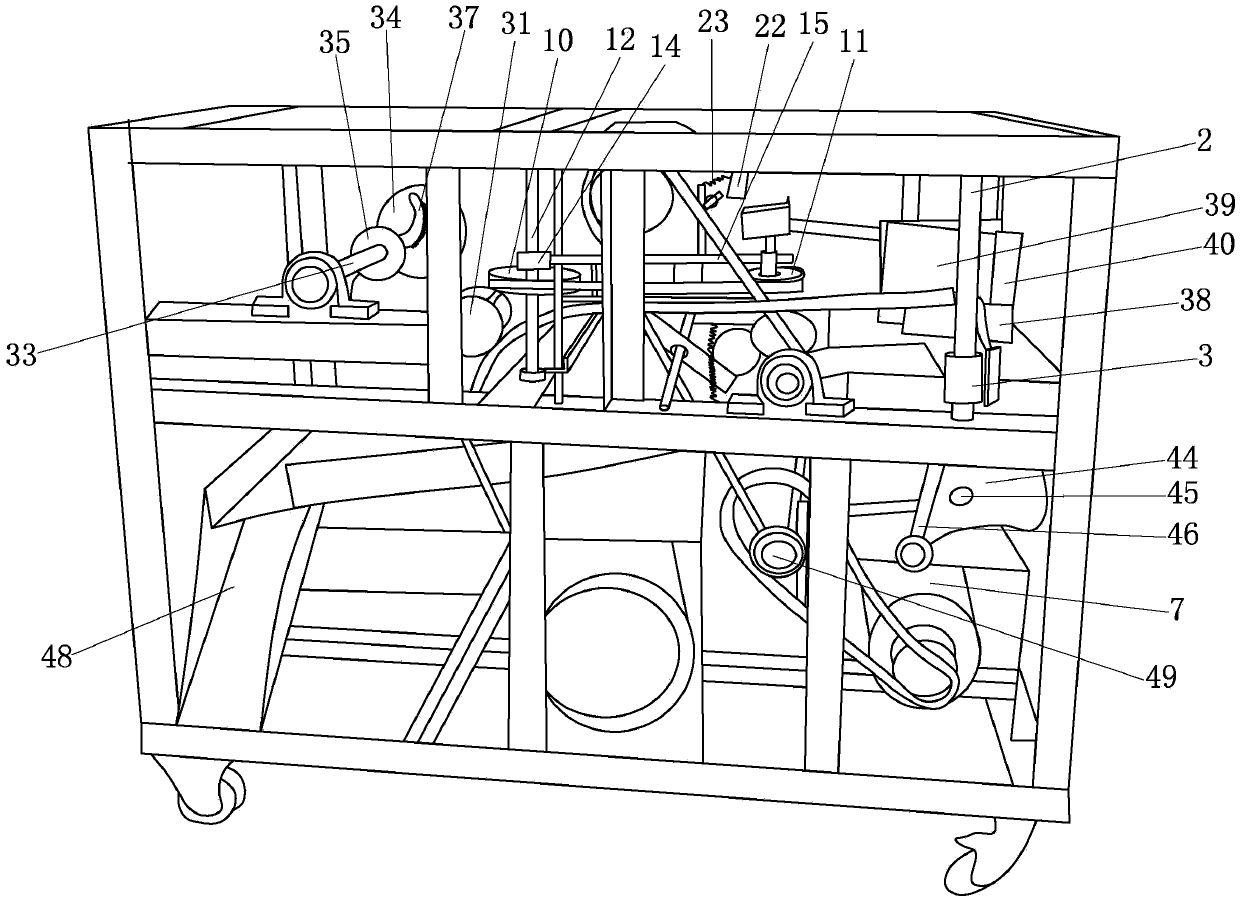

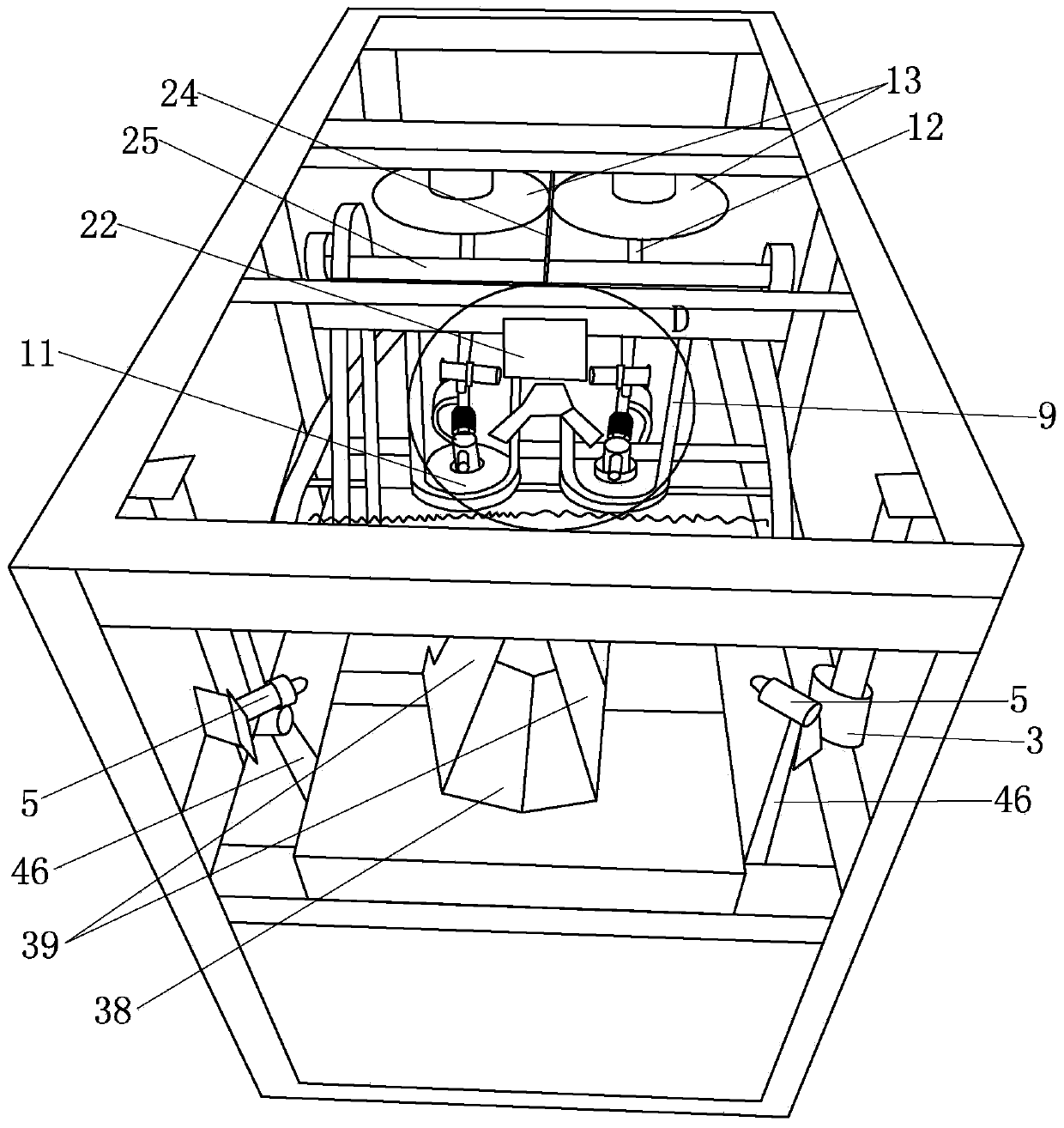

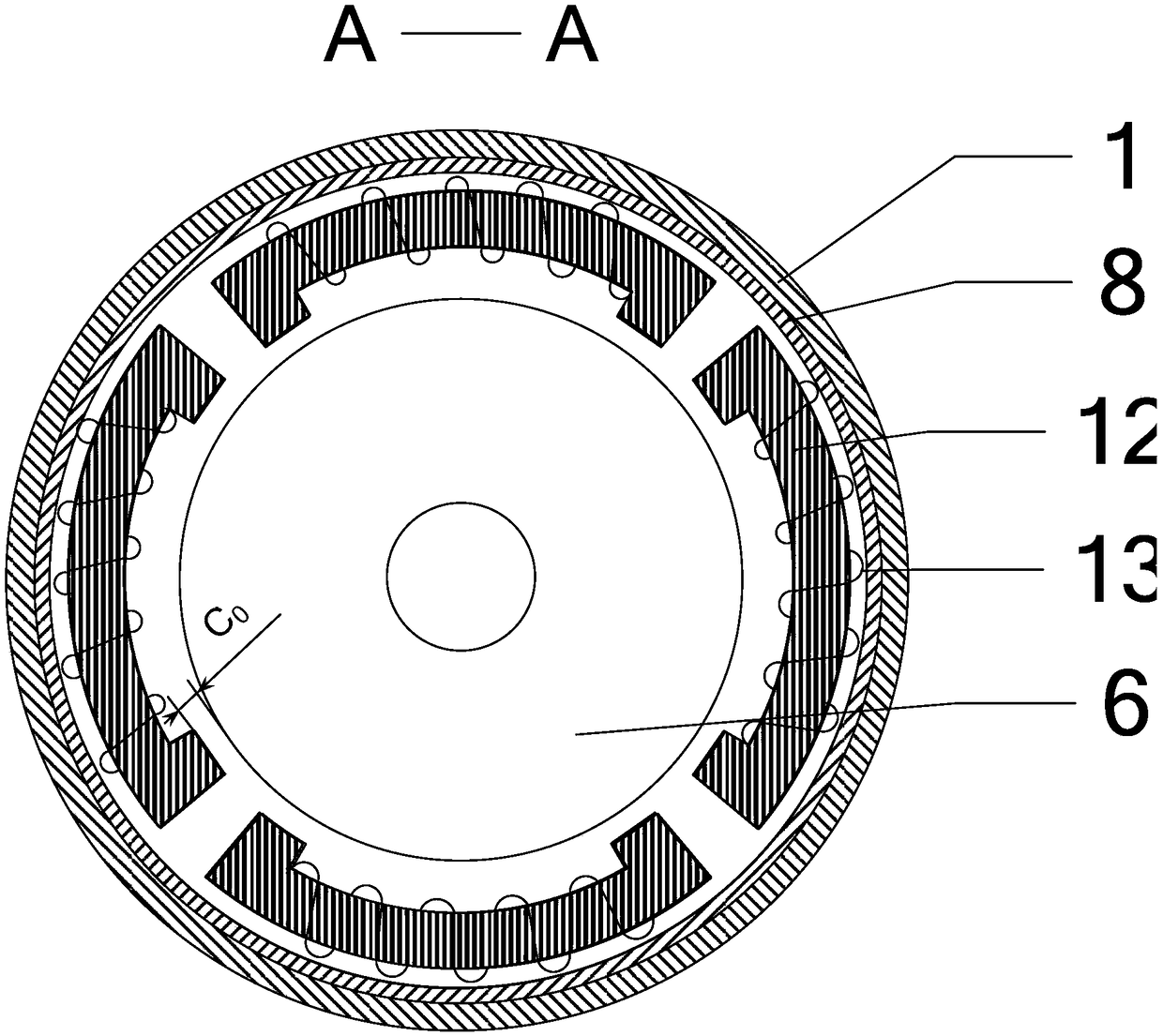

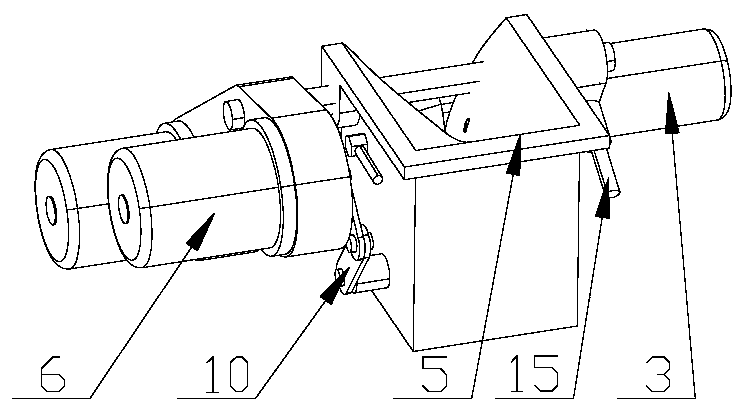

Multi-functional electric tools

The invention provides an electric tool in reciprocating model which can change cutting tools. The electric tool can realize the functions of shoveling, sanding, sawing and filing through the cutting tools being changed. A cutting tool (1) is connected with a reciprocating linear motion mechanism, which is connected with a power mechanism through a speed change mechanism, through a cutting tool loading and unloading mechanism; the back end of the handle of the cutting tool (1) is provided with a hole (1-1); the cutting tool loading and unloading mechanism comprises a front cutting tool holder (5), a back cutting tool hold (6) and a sliding plate (8); the handle of the cutting tool is connected with the front cutting tool holder (5), the back cutting tool holder (6) in sliding along the axial direction of the cutting tool; the front end of the sliding plate (8) is provided with a boss (8-1) extending to the hole (1-1) and is connected with the reciprocating linear motion mechanism in sliding along the axial line of the hole (1-1). The cutting tool can be locked through the boss one the sliding plate hooking the hole (1-1) at the back end of the tool. When the sliding plate slides along the axial line of the hole (1-1) and the boss (8-1) detaches from the hole (1-1), the cutting tool can be get out and be changed.

Owner:CHANGZHOU SAIDI ELECTRIC MFG +1

Changeable one-shot forming edge-neatening rose reamer and process for manufacturing the same

The invention relates to a changeable and once-forming trimming chamfer cutter and a manufacturing process thereof, being particularly suitable for double-sided chamfering and deburring of through holes, composite holes and half through holes of various composite complex bodies. The device comprises a core shaft and a cutting tool which is arranged on the core shaft. The device is characterized in that the cutting tool is provided with a strip-shaped arbor and a knife head which is at one end of the arbor, the knife head is provided with a front cutting edge and a back cutting edge, the core shaft is opened with an elastic closed slot, the knife head is arranged in the elastic closed slot and a governing mechanism is arranged between the core shaft and the arbor of the cutting tool. Compared with the prior art, the invention has the following advantages: 1. the chamfer cutter has reasonable design and simple structure, and the cutting tool can be changed conveniently without any damage to work pieces, and the processed products have high precision. 2. chamfering and deburring of the two ends of the hole can be completed once with wide application range. 3. the chamfer cutter has simple processing technology, easy processing and manufacture and convenient assembly and disassembly.

Owner:王建波

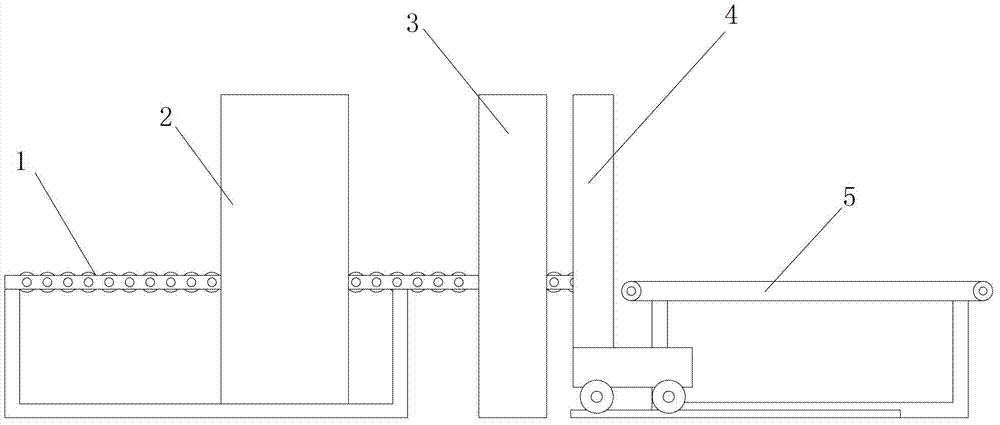

Cutting machine for forming external wall heat-insulating plates

The invention belongs to the technical field of plate machining equipment, in particular to a cutting machine for forming external wall heat-insulating plates. The cutting machine comprises a charging conveyor and a discharging conveyor, wherein a centering device, a main cutting device and a fixed-length cutting device are sequentially arranged in a plate flowing direction of the charging conveyor; the centering device is used for adjusting positions of blanks to make the blanks align with the center of a back cutting device; the main cutting device is used for performing peeled cutting and layered cutting on the blanks; the fixed-length cutting device is used for cutting the blanks subjected to peeled cutting and layered cutting according to fixed length; and the discharging conveyor is positioned behind the fixed-length cutting device. The cutting machine is rational in structural design; the whole process of cutting the blanks and final plates are divided into three steps, namely centering, peeled cutting and layered cutting, and fixed-length cutting, so that division of labor of devices is clear, and the devices are matched closely; and the cutting machine has high automaticity, and good cutting and forming effects are achieved.

Owner:天津中科合捷节能科技有限公司

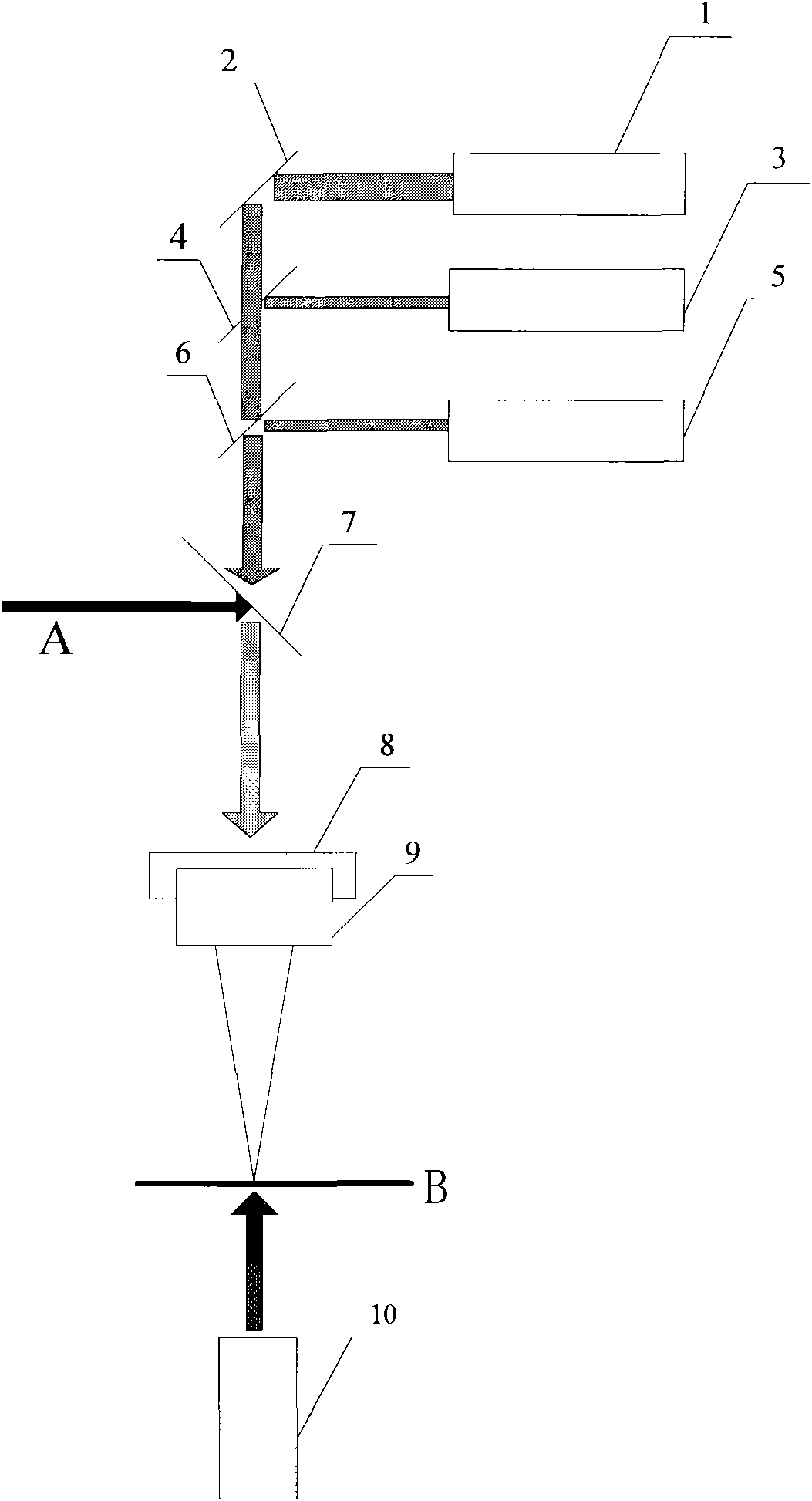

Coaxial image system applied to LED laser cutting device

ActiveCN101559629AAchieve clear imagingAchieving measurement precisionUsing optical meansWorking accessoriesMicrometerLaser cutting

The invention relates to a coaxial image system applied to an LED laser cutting device, comprising a coaxial LED point light source module, a 45-degree total reflection mirror, a wide-angle CCD module, a first 45-degree spectroscope, a small-vision field high-magnification upper CCD module, a second 45-degree spectroscope, a wavelength selection mirror, an LED ring light source, a focusing lens and a small-vision field high-magnification lower CCD module; the coaxial LED point light source module, the wide-angle CCD module and the small-vision field high-magnification upper CCD module are arrayed in parallel from top to bottom, the wavelength selection mirror is mounted between the CCD module and the focusing lens, the LED ring light source clings to the focusing lens which faces directly towards a workpiece, the small-vision field high-magnification lower CCD module is mounted below the workpiece. The invention realizes coaxial real-time image positioning function in the LED laser cutting device, combined usage of the wide-angle CCD and the small-vision field high-magnification upper CCD realizes micrometer-grade measurement accuracy, and the convenient switch of the small-vision field high-magnification upper CCD and the small-vision field high-magnification lower CCD meets the demands of front-cutting, back-cutting, surface coarsening and the cutting of back-aluminized wafer.

Owner:SUZHOU DELPHI LASER +1

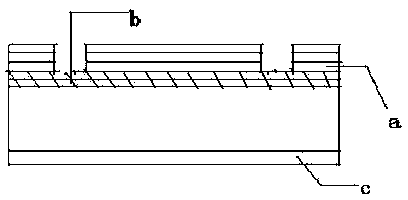

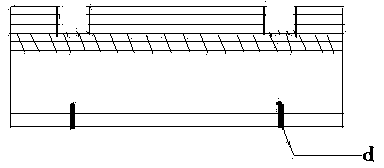

Cutting method of wafer grade white-light LED chip

InactiveCN104752571AAchieve separationImprove production yieldSemiconductor/solid-state device manufacturingSemiconductor devicesCooking & bakingFluorescence

The invention provides a cutting method of a wafer grade white-light LED chip. The method comprises the steps of preparing a vertical structural GaNLED wafer chip by the substrate transfer process; cutting a cutting channel in the front surface of the wafer through laser to form a concave groove; coating a fluorescent coating on the wafer chip; baking and solidifying; thinning the rear surface of the wafer chip; evaporating a back metal layer; performing back cutting for the wafer chip through a blade, wherein the cutting position is corresponding to the concave groove in the front surface; splitting along the concave groove in the wafer ship to obtain single white-light LED chip. With the adoption of the method, the wafer grade white-light LED chip can be smoothly separated without damaging the fluorescent glue layer on the surface of the LED chip, so that the phenomena of breaking and cracking in the traditional cutting process can be avoided, and the yield of white-light LED can be increased.

Owner:LATTICE POWER (JIANGXI) CORP

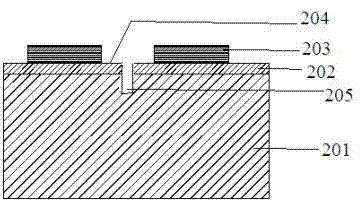

High speed roller pressing forming machine

InactiveCN1931465ASpeed up feedingSpray evenlyShaping toolsMetal-working feeding devicesManufacturing technologyBack cutting

The present invention is high speed rolling forming machine, and belongs to the field of metal plate cold bending apparatus manufacturing technology. The high speed rolling forming machine consists of a frame with a transmission mechanism, an ultrasonic device and an active unwinding device set in the front part of the frame, a front cutting device, a front guiding device, a lubricating device, a rolling set, a back cutting device, a stocking device and a roller conveyer, etc. The present invention has high automation, high operation efficiency and high product quality.

Owner:ZHEJIANG JINGGONG SCI & TECH

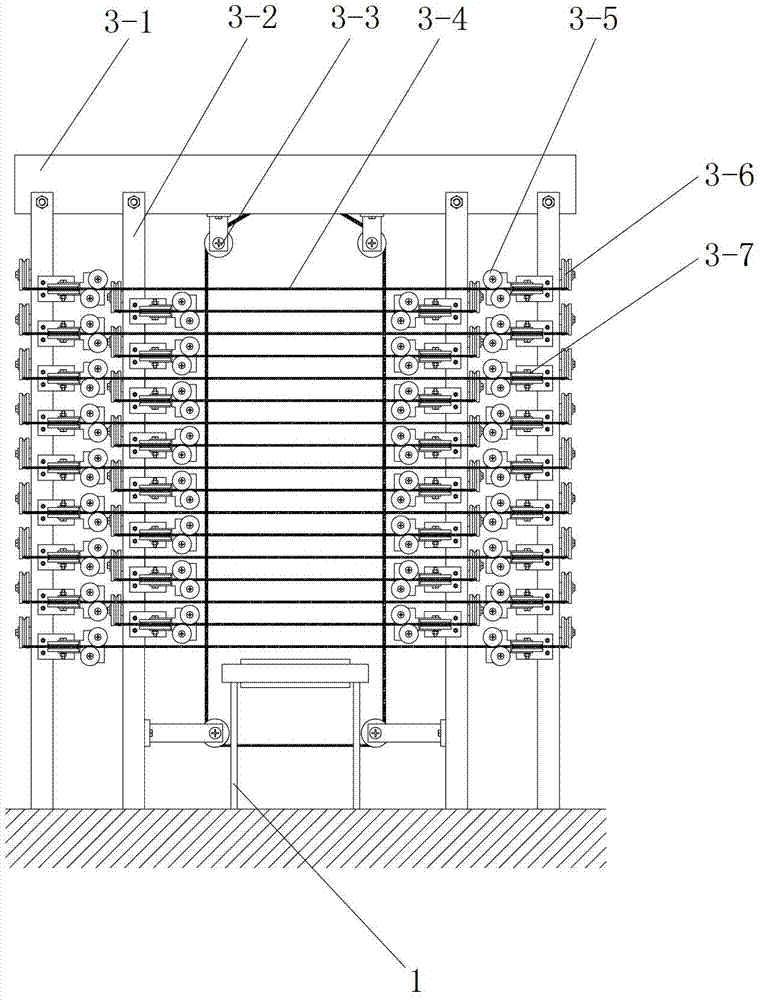

Fish killing machine

The invention discloses a fish killing machine. A scaling mechanism, a traction mechanism, a back cutting mechanism and an intestine scraping mechanism are arranged on a rack of the fish killing machine, wherein two first vertical rods are arranged in parallel in sequence in the scaling mechanism; a sliding sleeve movably sleeves each first vertical rod; the two sliding sleeves can vertically reciprocate synchronously; a high-pressure nozzle is fixedly arranged on each sliding sleeve through a connecting part; the two high-pressure nozzles are supplied with water through one same high-pressure water supply system; the water ejection holes of the two high-pressure nozzles both face rightwards; scales on the back and two sides of fish are flushed off through high-pressure water columns ejected from the two high-pressure nozzles; a first rotating shaft is horizontally arranged between the vertical rods and the traction mechanism; a scaling roller for removing the scales on the fish belly fixedly sleeves the middle of the first rotating shaft. By adopting the fish killing machine, scaling, back cutting, intestine scraping and viscus removing are rapidly and efficiently achieved, so that manual work can be replaced to automatically kill fishes, both the scales, the intestines and the viscera can be removed and the fish meat cannot be damaged, and the fish meat loss is small.

Owner:龙泽良

Method for adjusting flowering time of loquats

InactiveCN102204498AControl pumpingGood ventilation and light transmissionCultivating equipmentsCataphyllLoquat Tree

The invention discloses a method for adjusting the flowering time of loquats. The method for adjusting the flowering time of loquat comprises the steps of: A. after fruit picking, appropriately removing over-dense branches of crowns of loquat trees planted in ecoregions of dry-hot valleys of the Jinsha River, and cutting the side shoots of dense branches with more than 2 shoots on the periphery of the crowns; shearing off cross and overlaid branches and weak branches; back cutting slim and fragile braches to a large extent, and back cutting strong bearing branches slightly; and back cutting the branches with young shoots at the connecting part of the old shoots and young shoots; B. heavily applying organic fertilizer within 5 to 7 days after shearing, and watering in time; and C. applying 25 to 40 kilograms of phosphatic fertilizer, 8 to 12 kilograms of potash fertilizer, 6 to 8 kilograms of nitrogenous fertilizer per 667 square meters of field from June to July, and spraying leaf fertilizer twice or three times in the period when the summer shoots and leaves turn green; and simultaneously, bending or cutting vertical branches, the diameter of which is larger than 1.5 centimeters, in a twisting way. The method for adjusting the flowering time of loquats can be used for delaying the flowering time of loquats planted in the ecoregions of dry-hot valleys of the Jinsha River, preventing the loquats from flowering in June or before June, and enabling the spikes to blossom in July to August concentratedly, the flowering ratio and fruiting rate to be high, the fruit quality to be high, and the fruit to be supplied on the market in a fruit off-season relatively concentratedly.

Owner:SICHUAN AAS HORTICULTURE RES INST

Method for machining spiral grooved-sided hobbing rear waved edge

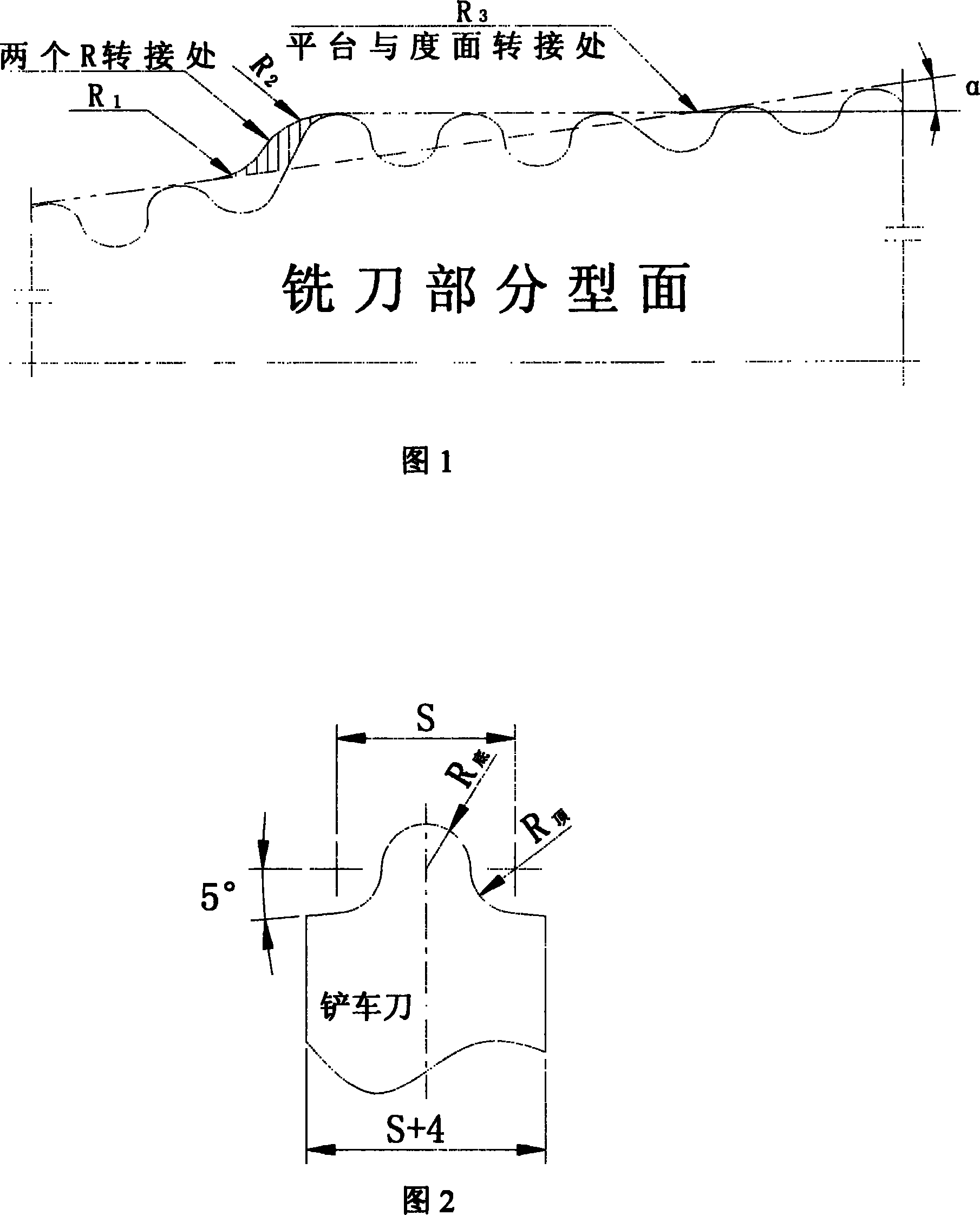

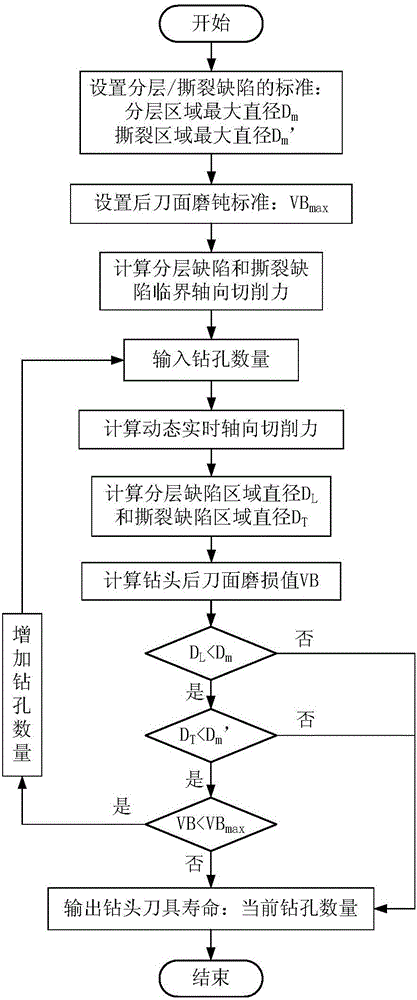

ActiveCN1981984ANo damage to the rotating profileEliminate the effects ofMilling cuttersTurning machinesHobbingManufacturing technology

A method for machining the waved back cutting edge of the milling cutter used to machine spirally slotted surface on workpiece includes such steps as installing a copying plate, trimming the machining surface of abrasive disc, arranging change gear, clamping the workpiece to be machined, aligning cutter, and grinding.

Owner:AECC AVIATION POWER CO LTD

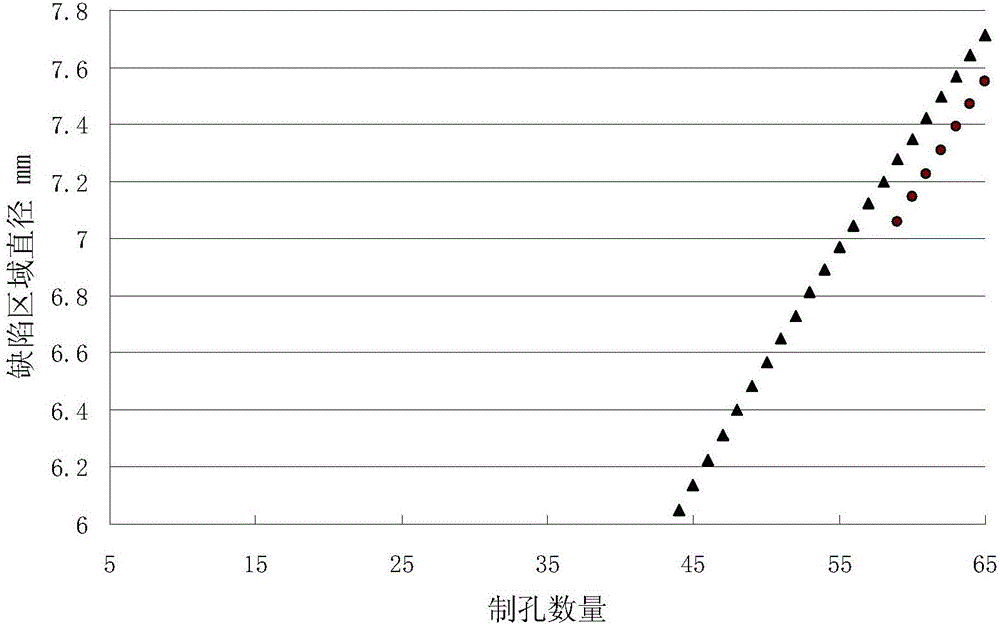

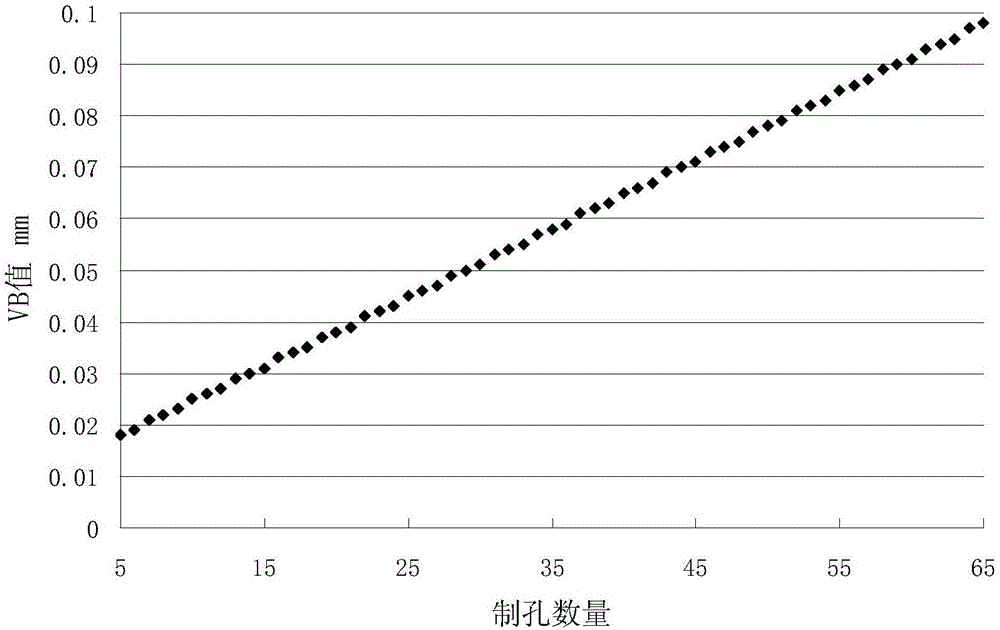

Prediction method of service life of drilling tool with CFRP(carbon fiber reinforced plastic) and titanium alloy laminated structure

ActiveCN106650119AImprove accuracyReduce scrap rateDesign optimisation/simulationConstraint-based CADStructure of the EarthBack cutting

The invention provides a prediction method of service life of a drilling tool with CFRP(carbon fiber reinforced plastic) and titanium alloy laminated structure, and relates to the technical field of carbon fiber composite material and titanium alloy laminated assembling. According to the prediction method, a carbon fiber composite material and titanium alloy laminated structure drilling dynamic real-time cutting force analysis module, a composite material lamination defect analysis module, a composite material tearing defect analysis module, and a drill bit back cutting side attrition value analysis model are built, and the effective service life of the drill bit is predicted and analyzed according to current drill bit structure parameter and drilling process parameter. The prominent problem that service life of the drilling tool with CFRP and titanium alloy laminated structure is not easy to predict accurately so that the low qualification rate and the high part scrap rate are caused due to the fact that effective service life of the tool is exceeded is solved; the composite material drilling defect and the drilling tool back cutting side abrasion are taken into consideration comprehensively, the maximum hole drilling quality of the laminated structure can be predicted effectively, the part scrap rate caused by exceeding of the service life of the tool is reduced, and the highest drilling effect of the tool is achieved.

Owner:SHENYANG AEROSPACE UNIVERSITY

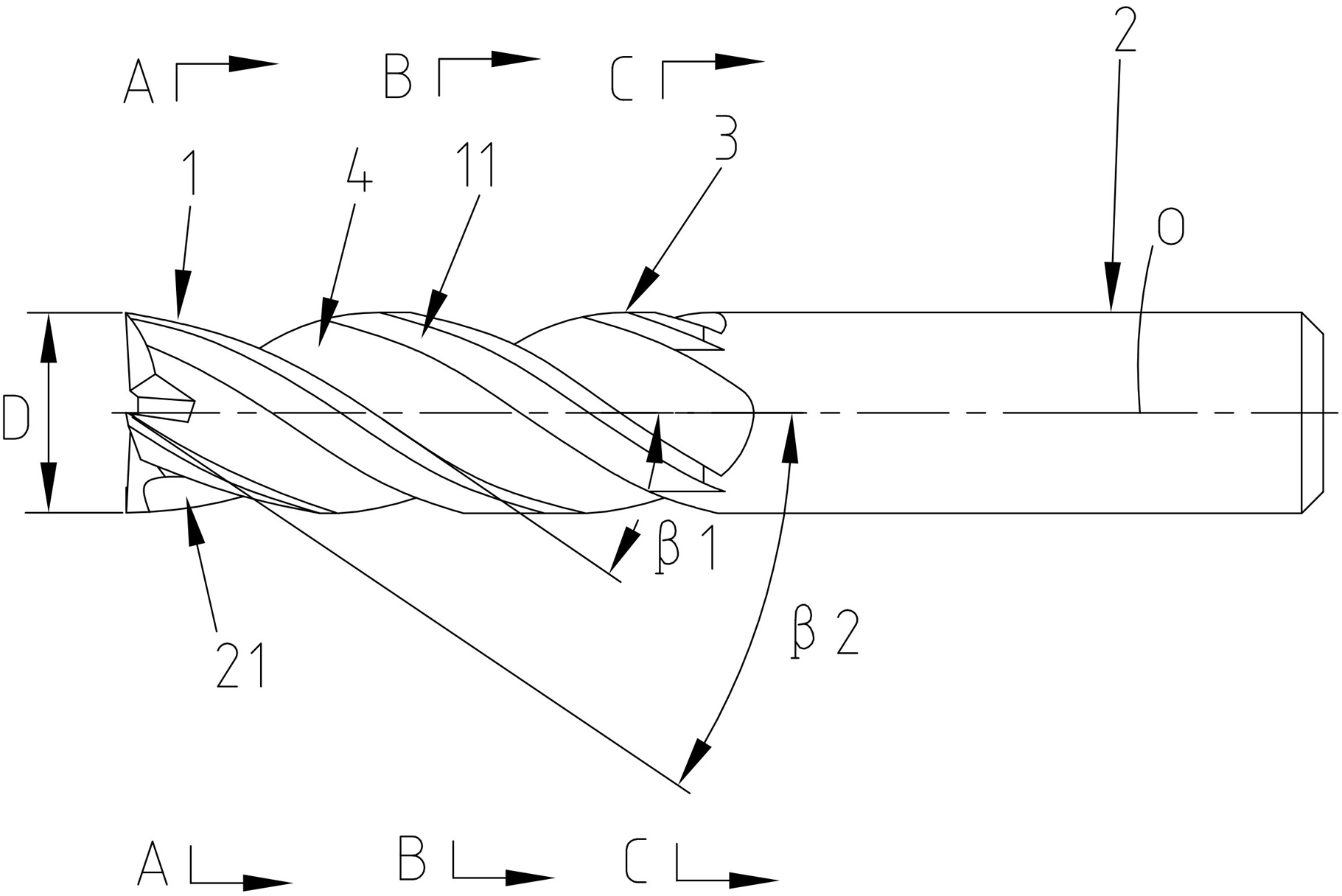

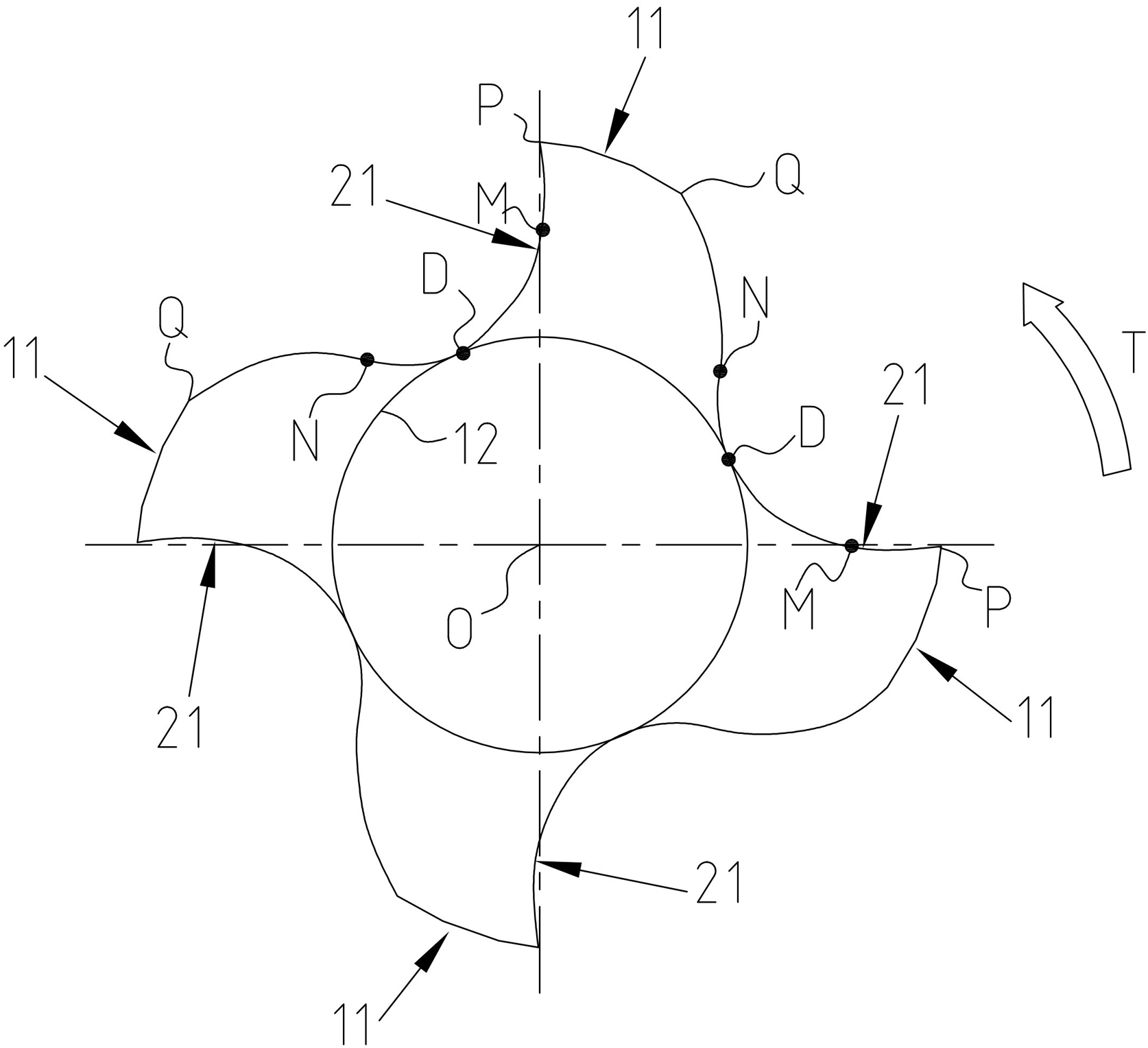

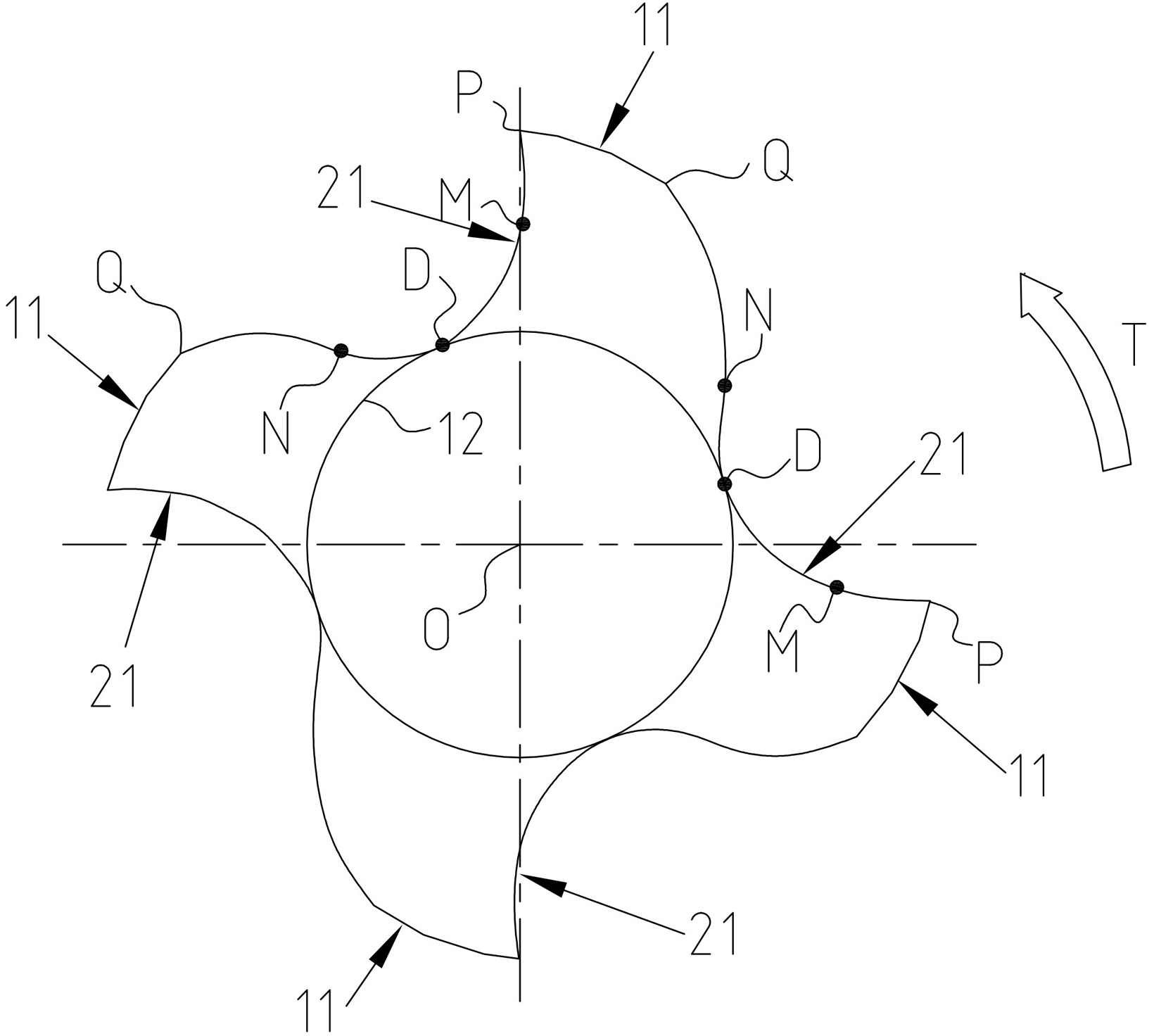

End mill with unequal helical angles

The invention discloses an end mill with unequal helical angles, which comprises a cutting part and a handle part, wherein the whole cutting part is provided with a plurality of chip discharging grooves which helically extend from the bottom end to the handle part; the surface of each chip discharging groove facing the cutting rotation direction is a front cutting surface; each front cutting surface is crossed with the peripheral surface of the cutting part to form a peripheral blade; the helical angle of at least one peripheral blade is different from the helical angles of other peripheral blades; the surface connected with each peripheral blade in the peripheral surface of the cutting part is a back cutting surface positioned on a plane which is perpendicular to the rotary axis of the end mill; the outline of each chip discharging groove is formed by smoothly connecting a curve PM, a curve MN and a curve NQ; each chip discharging groove extends from a projection point P of each peripheral blade to a projection point M of each front cutting surface in the shape of a concave curve, extends from the point M to a point N in the shape of a concave curve, and extends from the point N in the shape of a convex curve and is crossed with the back cutting surface of each peripheral blade at a point Q; and the curve MN is tangential with the thick-core circle of the end mill at a point D. The end mill with unequal helical angles has the advantages of simple structure and strong vibration resistance and can improve the chip discharging property.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

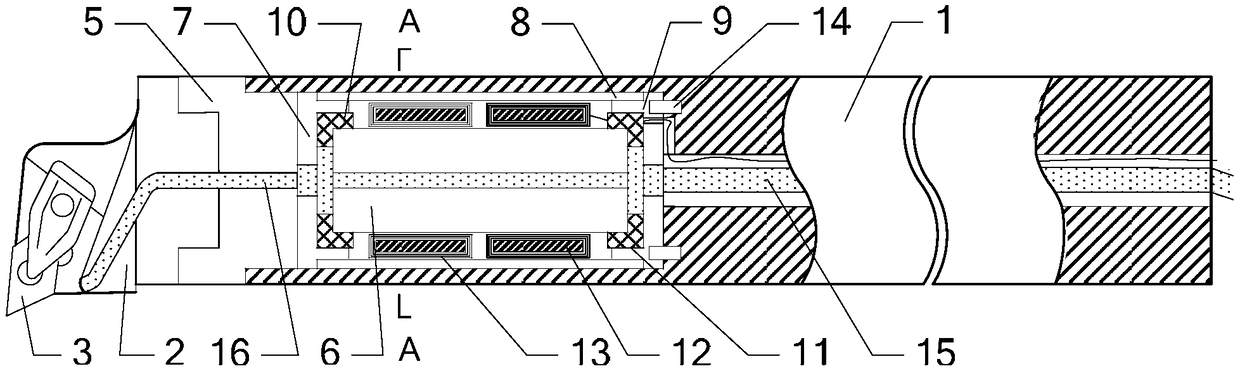

Adjustable type electromagnetic damping vibration absorption boring bar

InactiveCN108927538AReduce radial vibrationSolve the problem of failureBoring barsPower flowExcitation current

The invention discloses an adjustable type electromagnetic damping vibration absorption boring bar, and belongs to the field of mechanical machining. The problems that an existing vibration absorptionboring bar based on a damping device is prone to failing, or complex in structure and large in manufacturing difficulty are solved. The vibration absorption boring bar is characterized in that corresponding relation tables of process parameter combinations and optimal exciting current are preset in a master controller, each process parameter combination comprises rotating speed, the feeding amount, the back cutting depth amount, the workpiece material and boring cutter geometric parameters, the electromagnetic damping device is motivated by the optimal exciting current to enable the radial vibration of a bar body under the corresponding process parameter combination to be minimum, and the master controller searches the process parameter combination closest to the input actual process parameter combination and the corresponding optimal exciting current from the corresponding relation table before the vibration absorption boring bar is used for boring and machining, the master controller is further used for controlling an excitation current source to carry out excitation on an electromagnetic damping device when the vibration absorption boring bar is used for boring, and the electromagnetic damping device is motivated by the optimal exciting current to carry out vibration absorption on the bar body.

Owner:HARBIN UNIV OF SCI & TECH

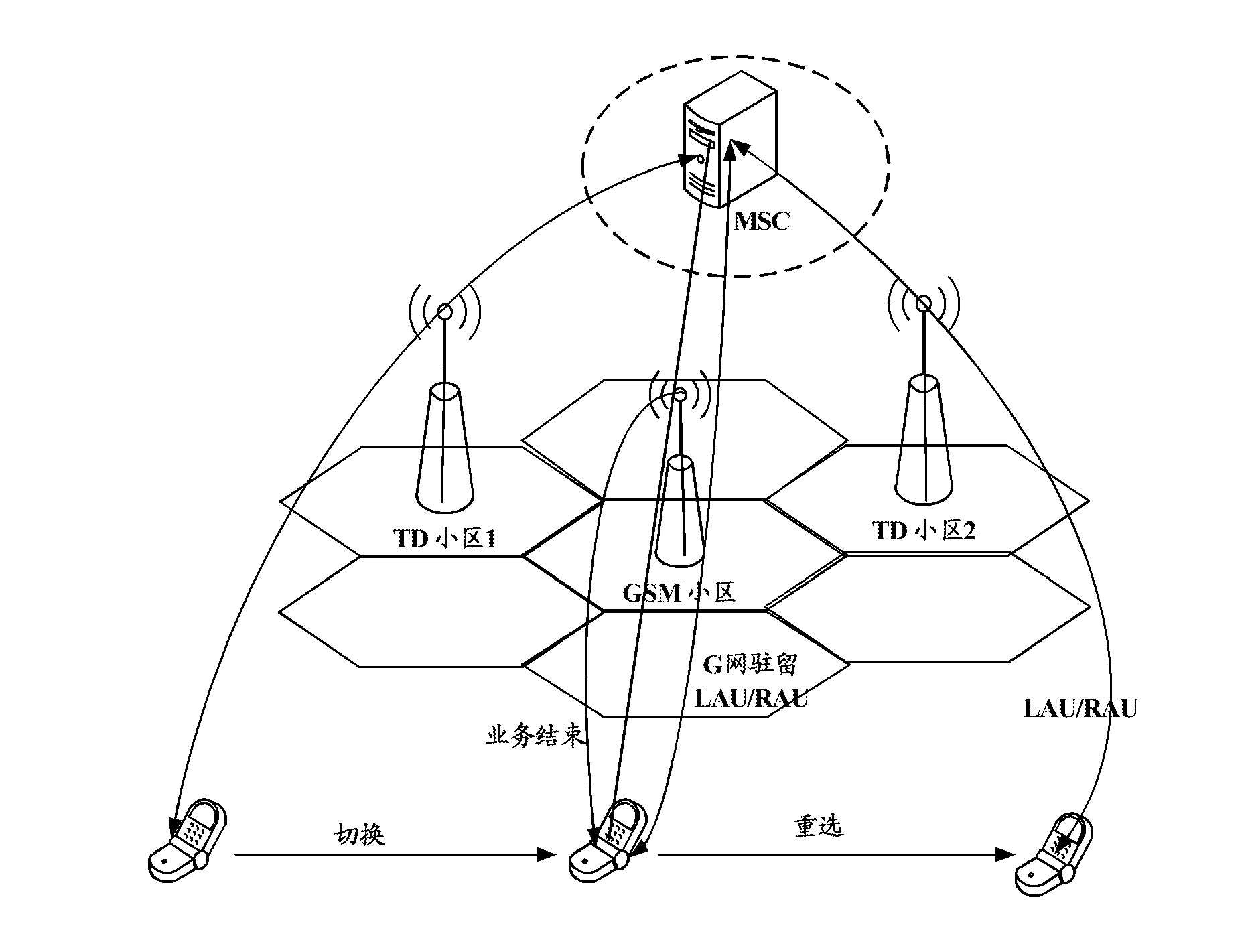

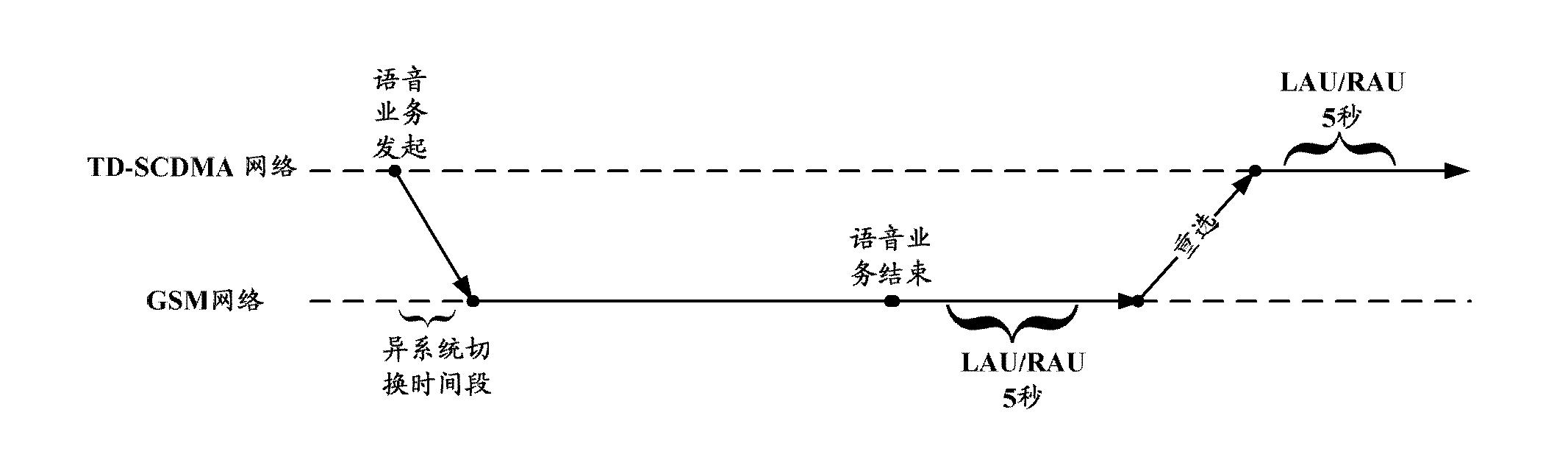

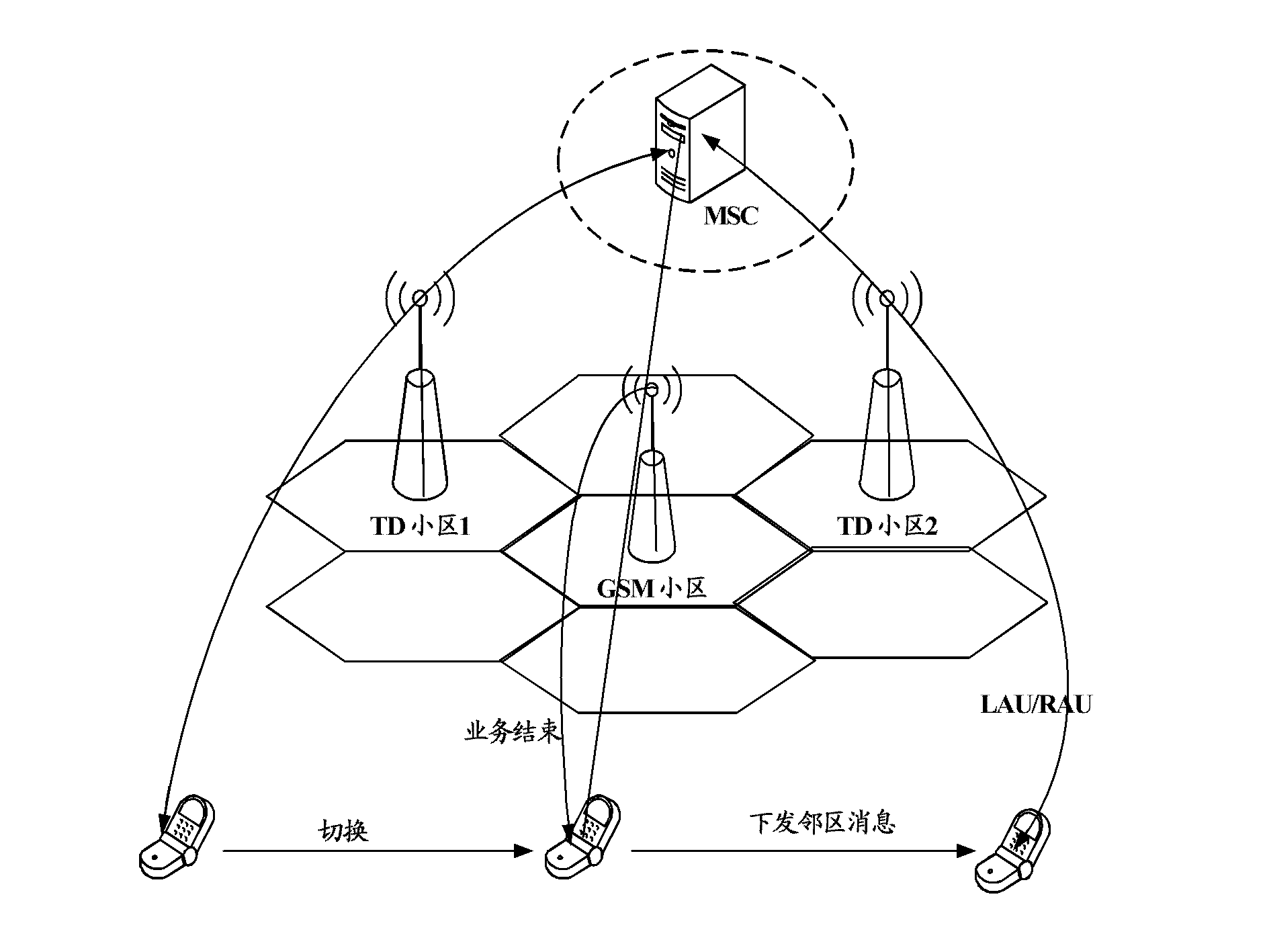

Method and device for inter-system back cutting and equipment and terminal for inter-system back cutting

ActiveCN103108367AAvoid the problem of switchback failureImprove reliabilityWireless communicationBack cuttingRemote access unit

The invention discloses a method and a device for inter-system back cutting, and equipment and a terminal for the inter-system back cutting. The method includes that through capacity identification reported by the terminal, when the terminal carries out inter-system switching, whether the terminal supports the function of Fast Return or not can be judged according to the capacity identification reported by the terminal, for a terminal supporting the function of the Fast Return, adjacent cell information is issued to the terminal, and the terminal is permitted to obtaining a network cell capable of carrying out inter-system back cutting to achieve inter-system back cutting; and for a terminal not supporting the function of the Fast Return, adjacent cell information is not issued to the terminal, at the moment, the terminal starts line access unit (LAU) / remote access unit (RAU) in the resident cell of the terminal to achieve cell reselection, and the inter-system back cutting is completed. Therefore, occasions of inter-system back cutting failure occurring when the terminal carries out the inter-system back cutting are avoided, and reliability and the success rate of the inter-system back cutting are further improved.

Owner:CHINA MOBILE COMM GRP CO LTD

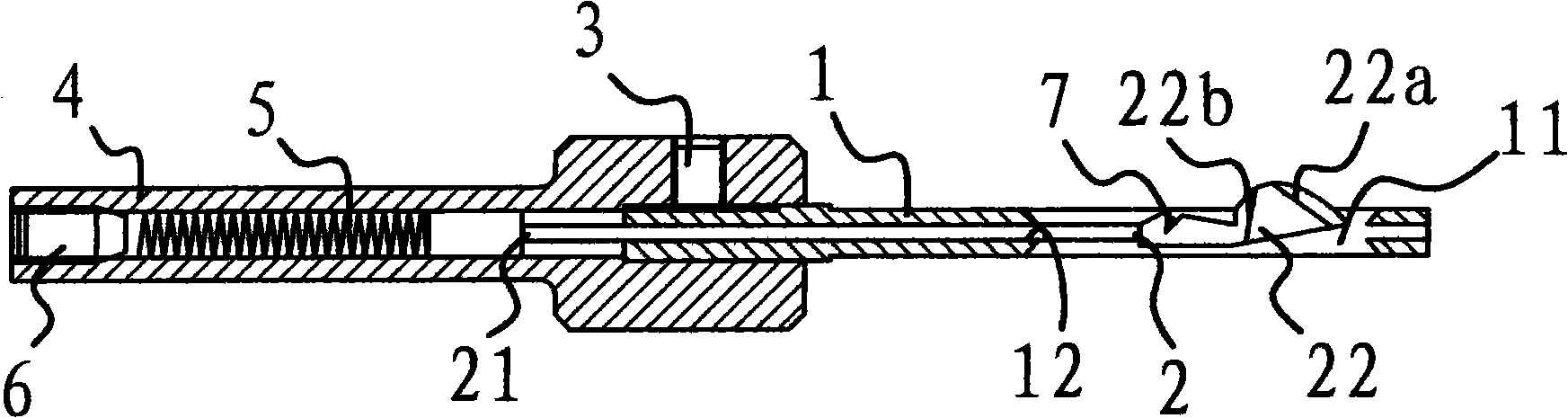

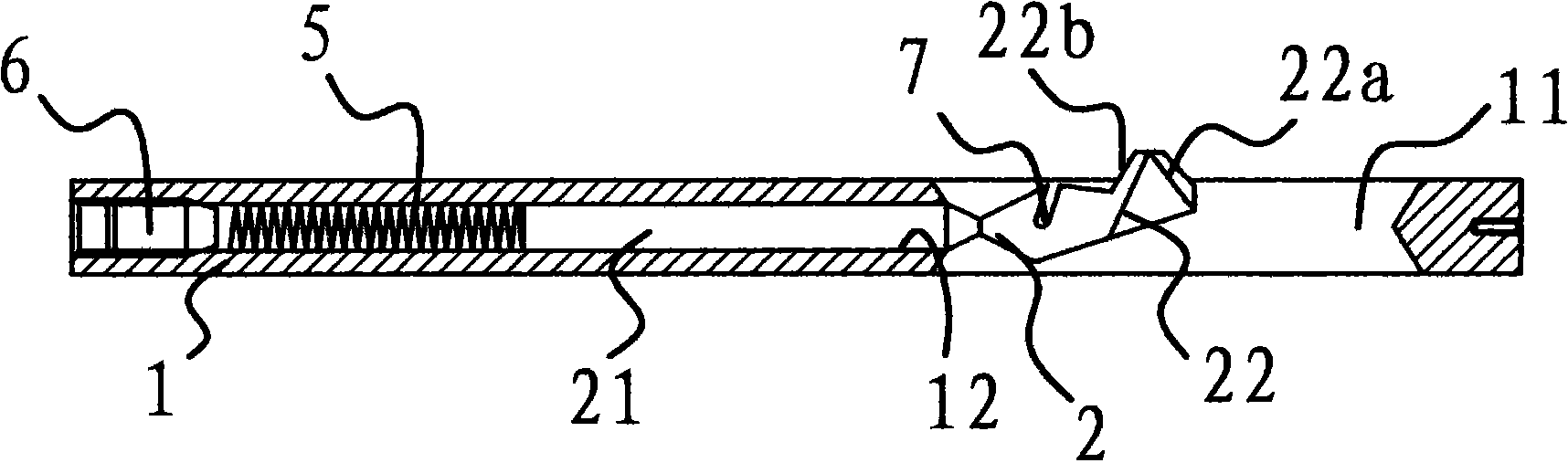

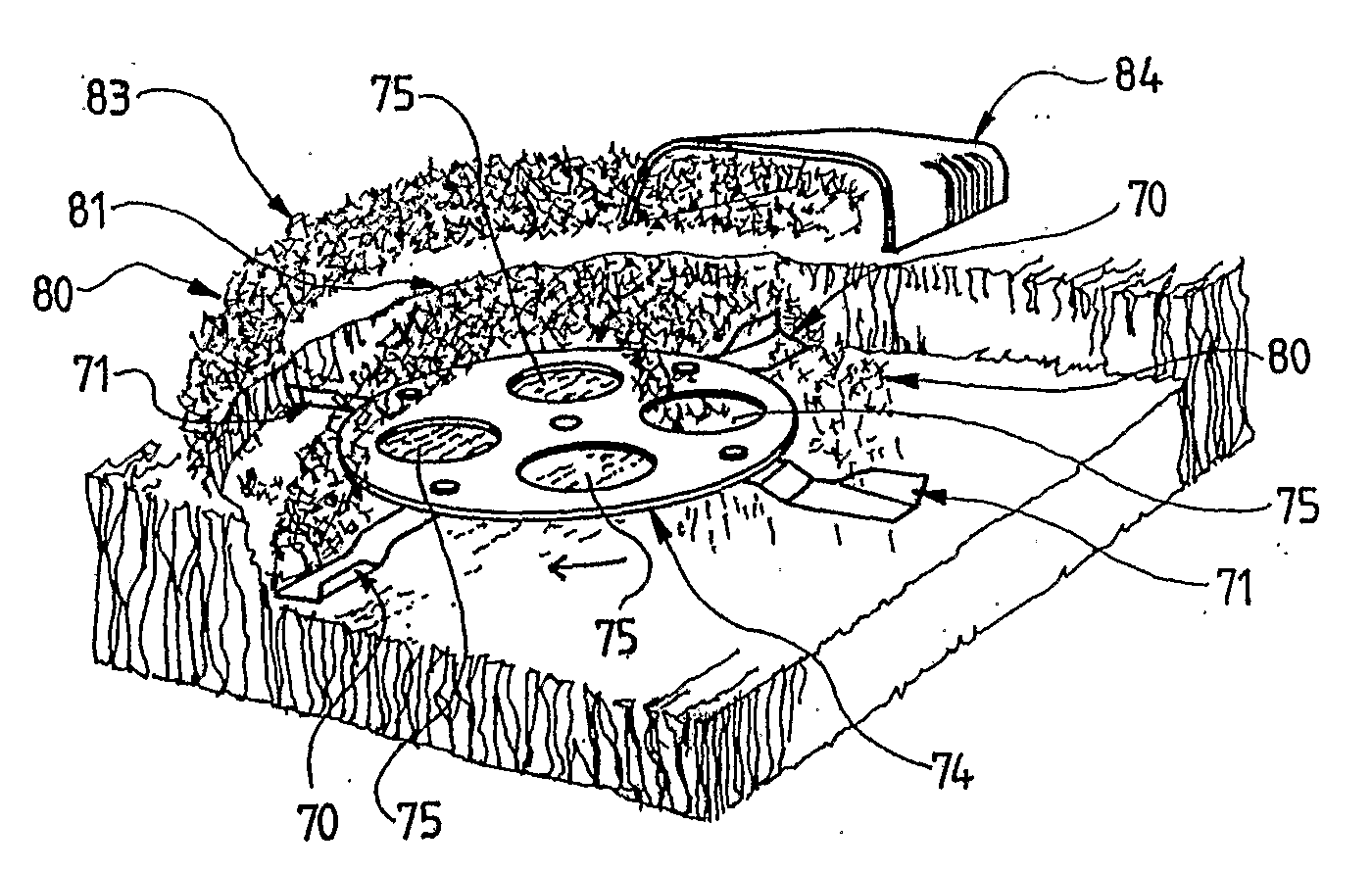

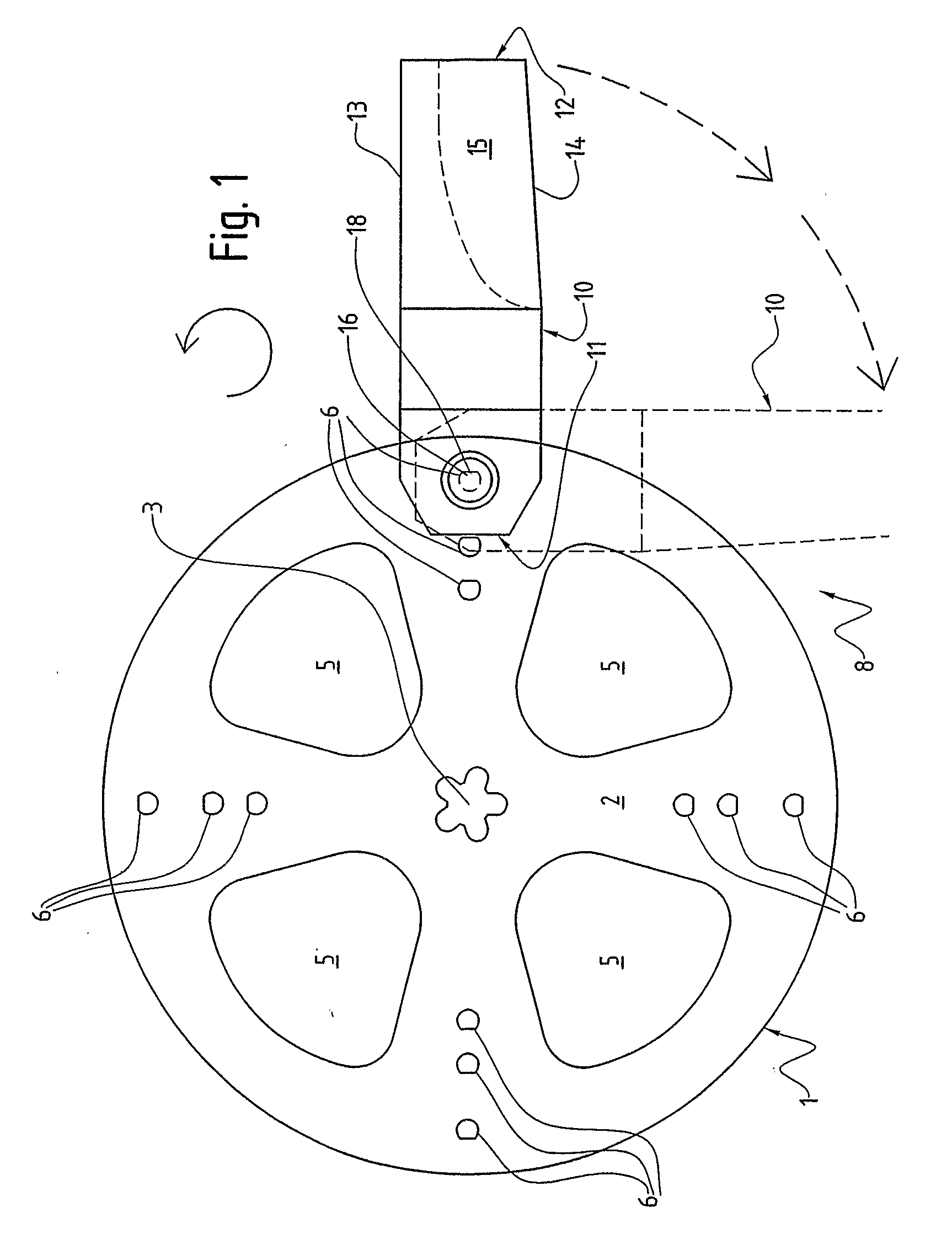

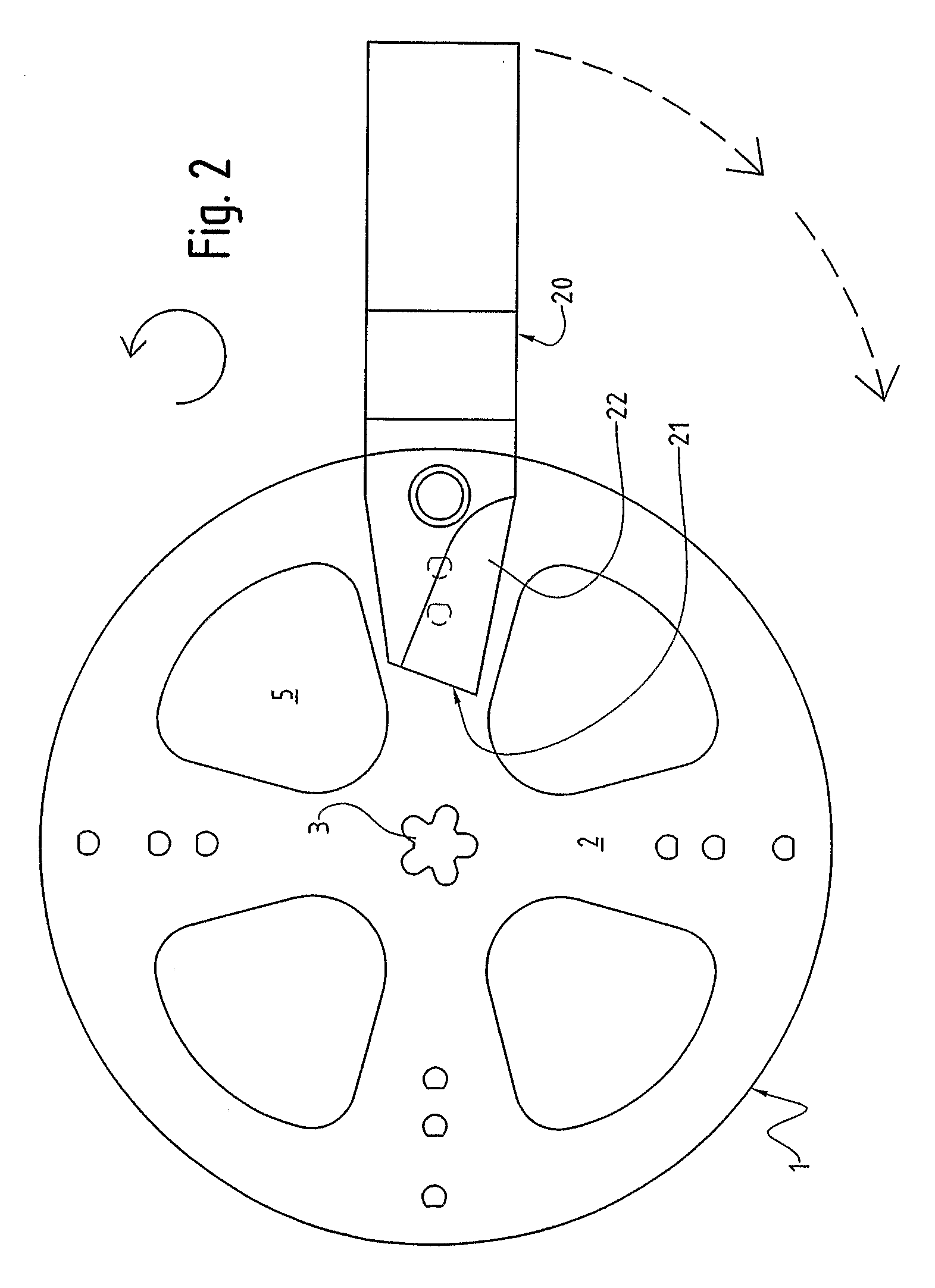

Cutting blade assembly for a mower

A cutting blade assembly (8) for a rotary mower. The assembly (8) comprises a blade carrier (1) and four swing-back cutting blades (10) (only one of which is shown). The blade carrier (1) has a substantially planar discoid body (2), a mount (3) for mounting the body (2) to a drive shaft assembly (not shown) of the mower, four airflow passages (5) extending through the body (2), and a blade connecting mechanism (6) for connecting the blades (10) to the body (2). The body (2) is made of laser- or plasma-cut, high-strength steel (Bisplate 80™) having a thickness in the order of 5 to 6 mm.

Owner:ABERNETHY RAYMOND ERIC

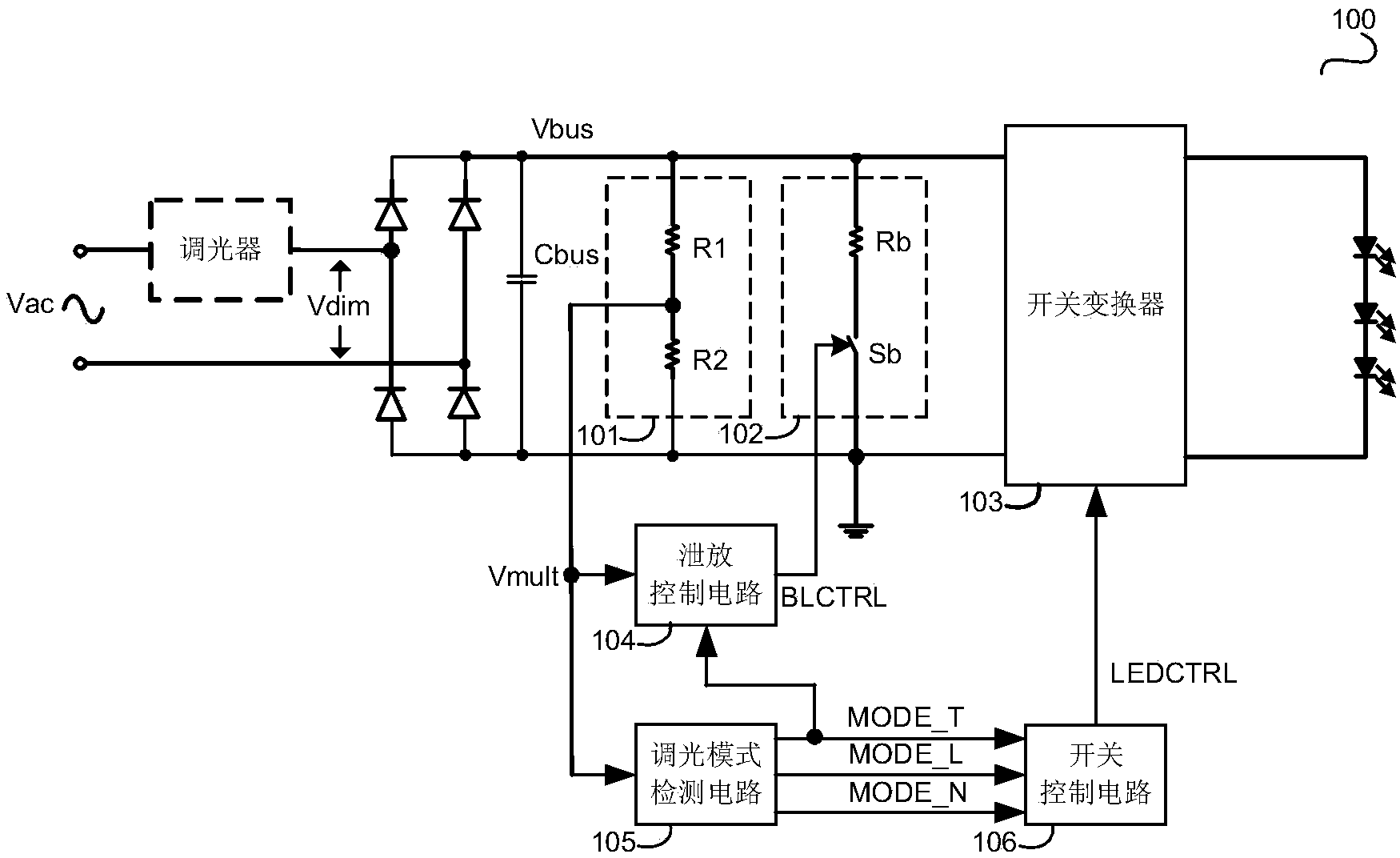

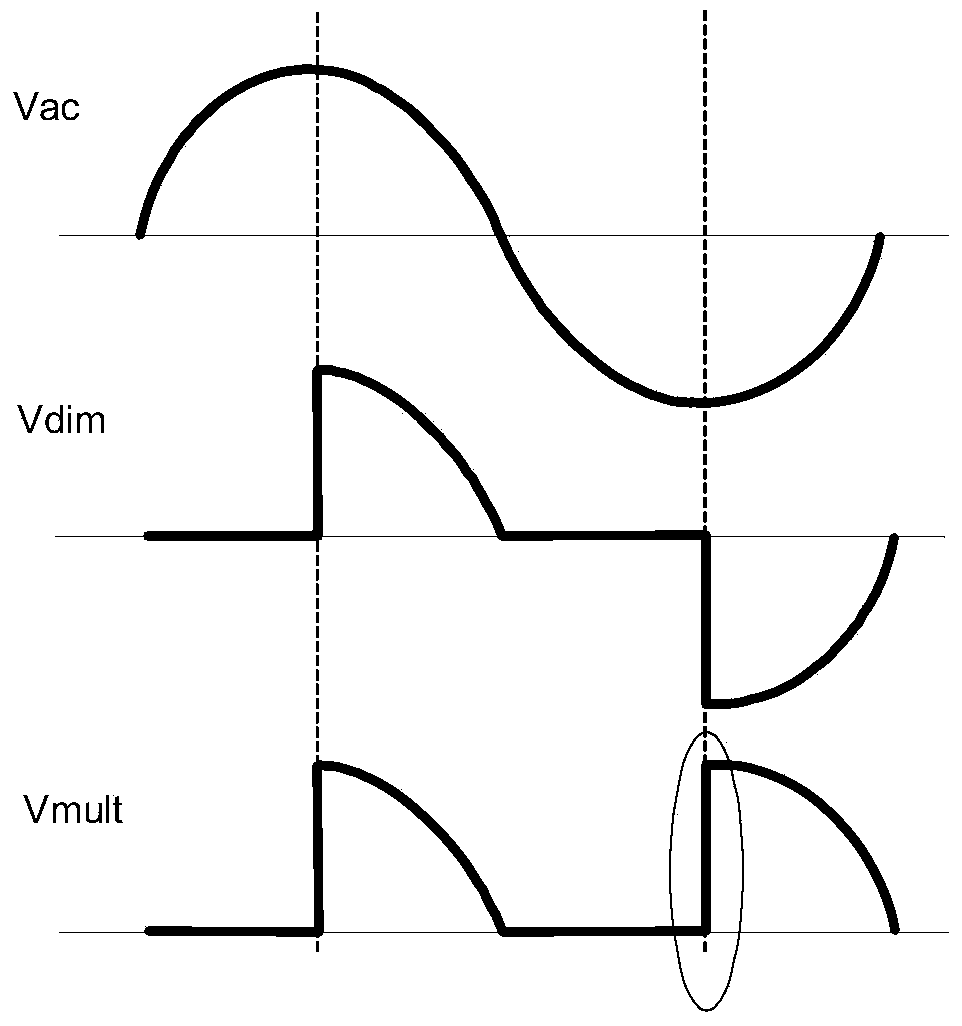

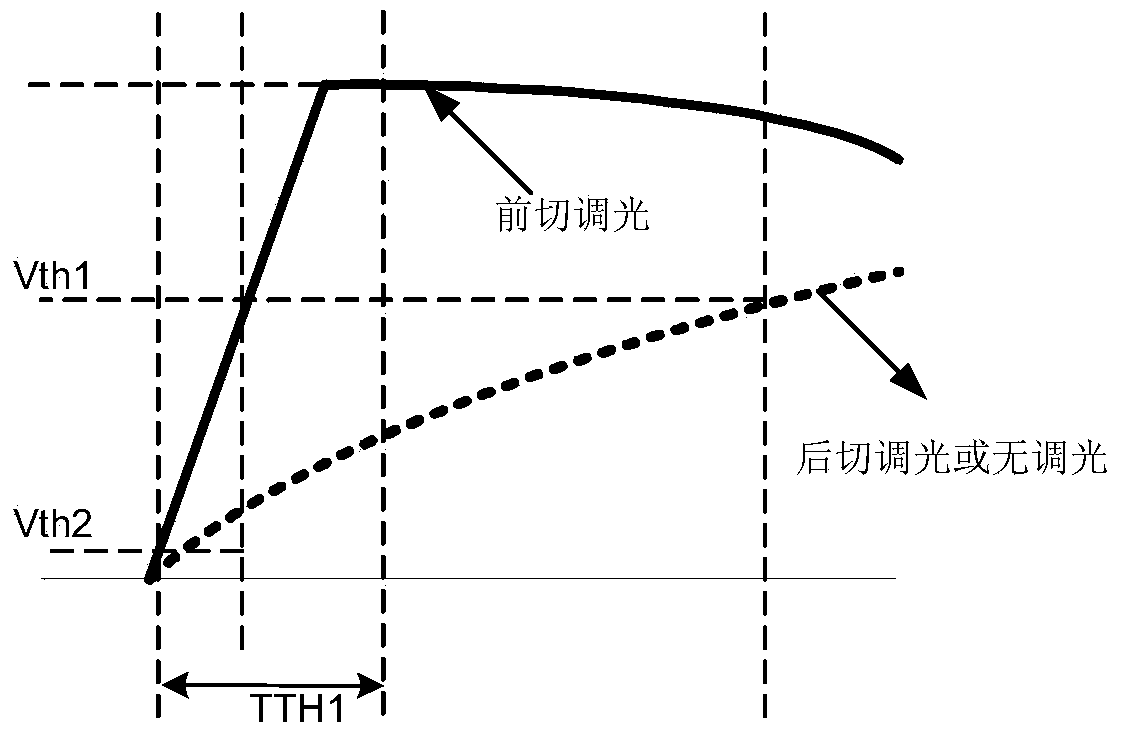

LED drive device, controller thereof and dimming mode detection method

InactiveCN104020377AThe detection method is easy to implementLow costElectrical apparatusElectroluminescent light sourcesFall timeDimmer

The invention discloses an LED drive device, a controller of the LED drive device and a dimming mode detection method. The dimming mode detection method comprises the steps that direct current bus voltages are sampled to generate voltage sampling signals; the rise time needed by the voltage sampling signals increasing from a second threshold value to a first threshold value is compared with a first time threshold value so as to judge whether the LED drive device is connected to a front cut dimmer or not; the fall time needed by the voltage sampling signals reduced from a third threshold value to a fourth threshold value is compared with a second time threshold value so as to judge whether the LED drive device is connected to a back cut dimmer or not; if whether the LED drive device is connected to the front cut dimmer or the back cut dimmer is not detected within preset duration, the LED drive device is not connected to the dimmers.

Owner:CHENGDU MONOLITHIC POWER SYST

Automatic winding displacement fixed length cutting machine

The invention discloses an automatic winding displacement fixed length cutting machine, which comprises a machine table and is characterized by also comprising a front pressing part, an upper cotton paper pasting mechanism, a lower cotton paper pasting mechanism, a rear pressing part and a cutting wire coiling mechanism, wherein a total fixing plate is arranged on the machine table, the front pressing part, the upper cotton paper pasting mechanism, the lower cotton paper pasting mechanism and the rear pressing part are sequentially arranged on the total fixing plate, the cutting wire coiling mechanism is arranged at the back end of the rear pressing part, the front pressing part and the rear pressing part respectively comprise air cylinders, upper press wheels and lower press wheels, the lower press wheels are fixedly arranged on the total fixing plate through a rotating shaft, the air cylinders are arranged above the lower press wheels, and air cylinder rods of the air cylinders are connected with the upper press wheels positioned on the tops of the lower press wheels. The invention provides the automatic winding displacement fixed length cutting machine with the advantages that the structure is simple, the automation degree is higher, the processing speed is high, the wire harness cotton paper pasting position can be fast and accurately found, in addition, the wire harness can be fast cut, and in addition, the front and back cutting length consistency is ensured.

Owner:KUNSHAN XINTAILI PRECISION COMPONENTS CO LTD

Method for shortening the production period of mango

InactiveCN101699970AImprove the survival rate of graftingControl leggyPlant genotype modificationHorticultureFruit setRootstock

The invention relates to the plant hybridization breeding and cultivation technology and provides a method for shortening the production period of mango. The method is characterized by comprising the following steps: 1) sowing seedlings and transplanting; 2) selecting polyembryonic varieties to be grafted trees, performing heading-back cut to grafted trees half treetop to use as stock; 3) selecting robust seedlings for grafting, top-grafting the seedlings on the stock of grafted trees; and 4) dressing multi-effect triazole in the soil, digging shallow ridges on the two sides of the tree covers of the grafted trees after grafting, irrigating multi-effect triazole and earthing. The invention has the following prominent substantive features and significant progresses: 1. seedling high grafting technology is adopted in the method so as to increase the grafting survival ratio; 2. the dressing multi-effect triazole technology is used to control the spindling of branch tips of grafts, promote the branch tips for aging and create beneficial nutrient conditions for advancing blossom and fruiting and promoting fruit-bearing; 3. the invention is simple and practical, potential hybrids can bear fruits after half a year so that potential hybrids and false hybrids can be identified directly and fast and the breeding process of mango is greatly shortened; and 4. the method of the invention can be popularized to the mango production so that the economic benefit of the method is remarkable owning to early fruiting and appearing on the market.

Owner:GUANGZHOU SUGARCANE IND RES INST

Safety easy-to-use device for shrimp back cutting and vein removal

PendingCN110692696AImprove work efficiencyShrimp/lobster processingClimate change adaptationShrimpMarine engineering

The invention discloses a safety easy-to-use device for shrimp back cutting and vein removal, which comprises a shrimp holding and adjusting groove, a fixing device for fixing shrimps to be cut and acutting device for cutting shrimp backs; a slideway for transporting shrimps is arranged in the bottom of the shrimp holding and adjusting groove, a roller is arranged above the slideway, and the slideway and the roller jointly form the fixing device; the cutting device at least comprises a cutter that is arranged above the slideway and behind the roller. The safety easy-to-use device for shrimp back cutting and vein removal requires a worker only to put shrimps into the shrimp holding and adjusting groove that is in a static state during operation, the worker does not worry about hurting hands mentally during operation, and working efficiency can be improved.

Owner:郑州尺良科技有限公司

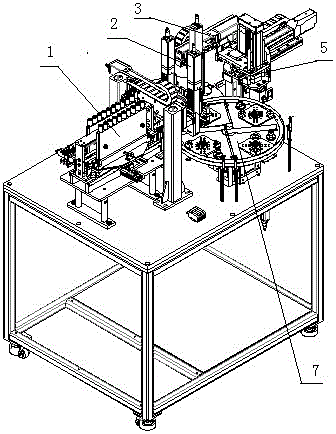

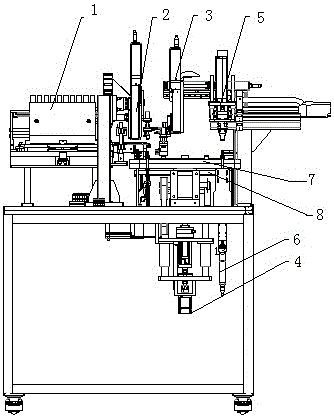

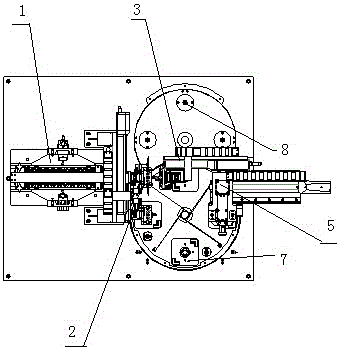

Fan assembling machine

The invention relates to the technical field of semi-automatic assembly of cooling fans, in particular to a fan assembling machine. The fan assembling machine comprises a rack and is characterized in that a bearing loading mechanism, a bearing carrying mechanism, a blade rotor pressing-in mechanism, a lower bearing, snap spring and backing ring pressing-in mechanism, a finished product unloading mechanism, an image detecting mechanism and two rotating disks are arranged on the rack; the bearing loading mechanism comprises a bearing casing pipe group, a bearing pushing assembly, a laser sensor, a front cutting air cylinder and a back cutting air cylinder; and all the mechanisms share the work and cooperate with one another, casings and fan blade rotors are manually placed on the discharging station of the upper rotating disk, snap springs, backing rings and lower bearings are manually placed on the discharging station of the lower rotating disk, and other assembling actions are completed automatically. The machine has the advantages of being convenient to operate, high in working efficiency, stable in working performance, capable of realizing semi-automatic assembly and the like.

Owner:SHANGHAI ZHAOCHENG COMMUTATOR TECH

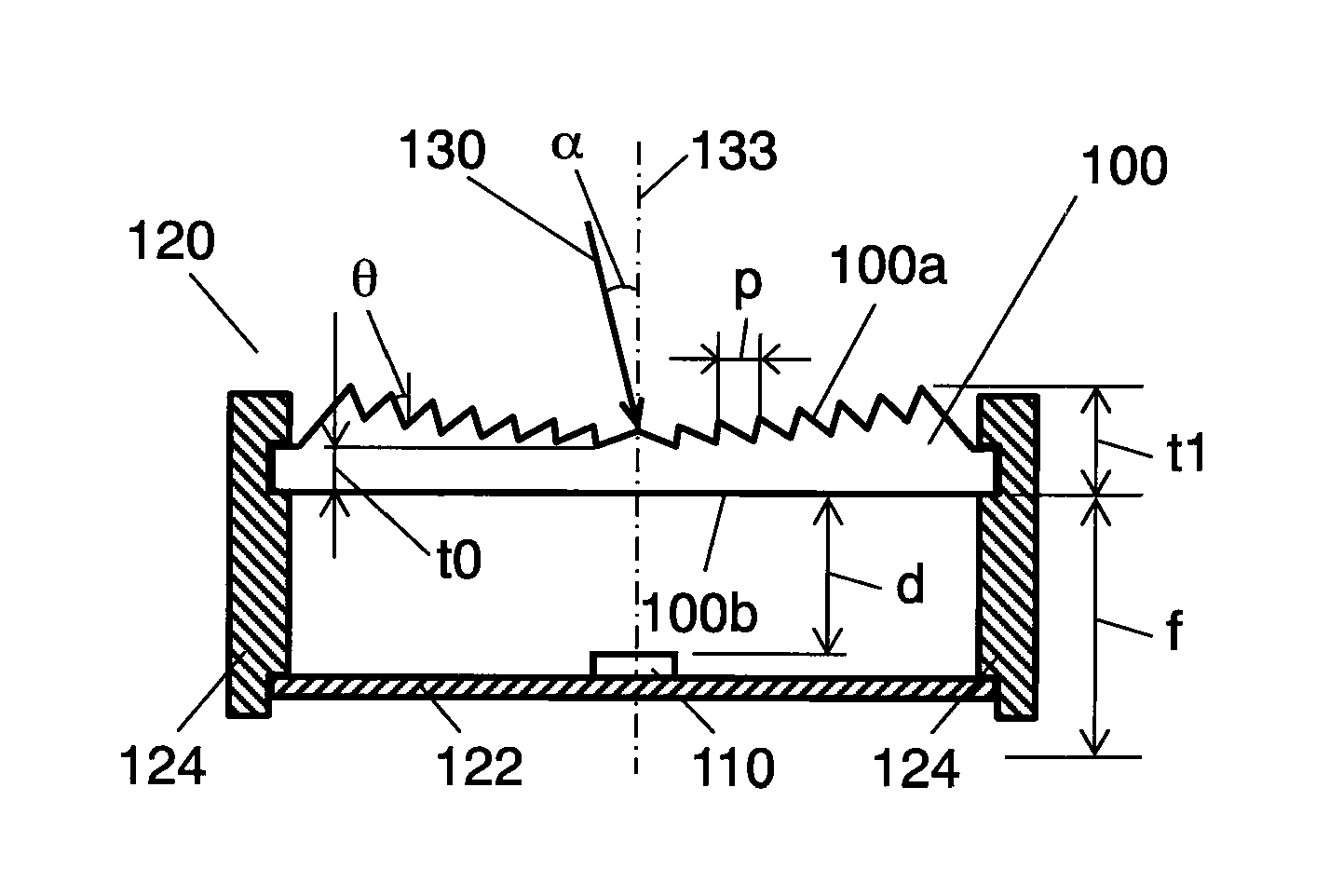

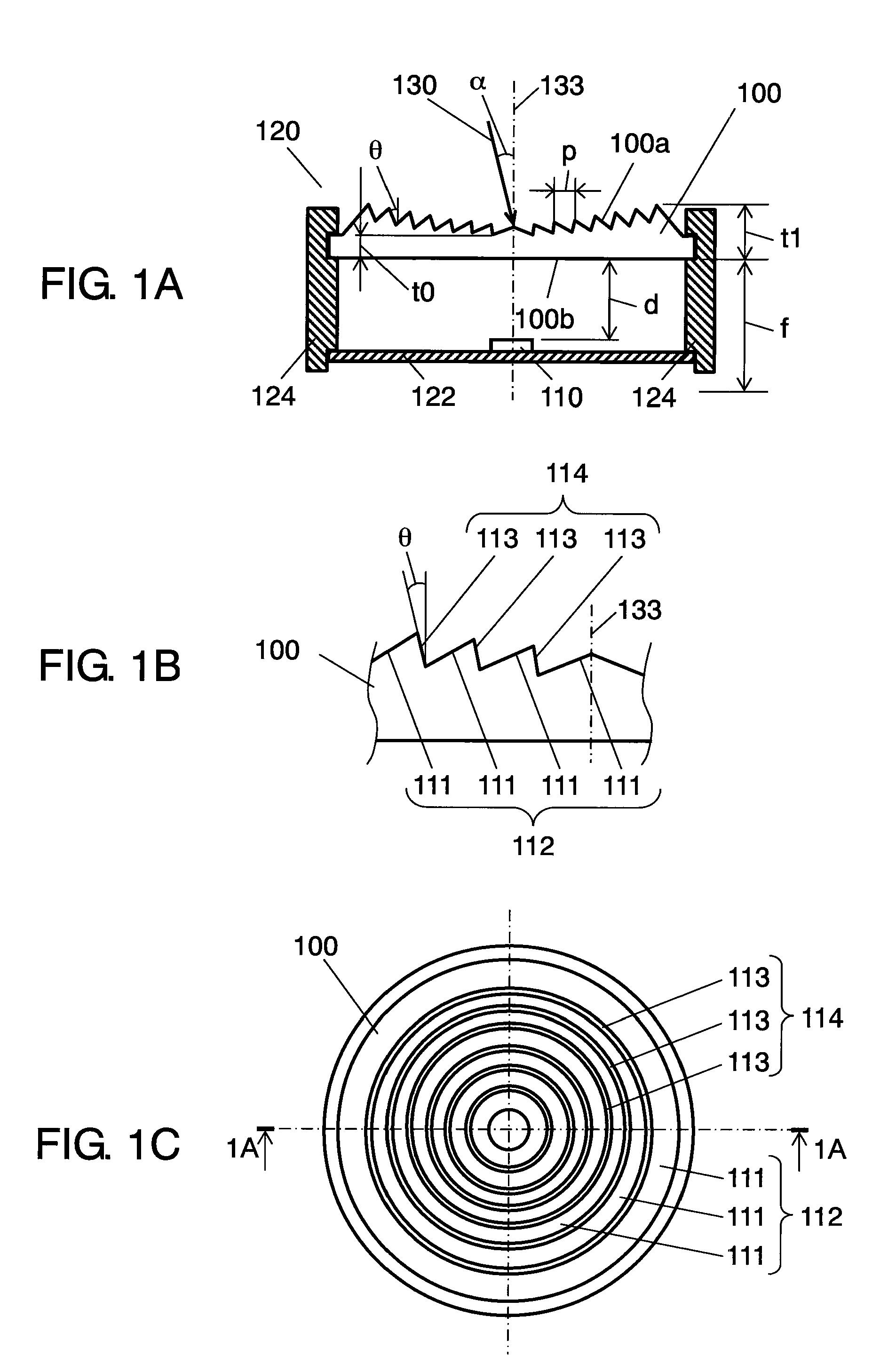

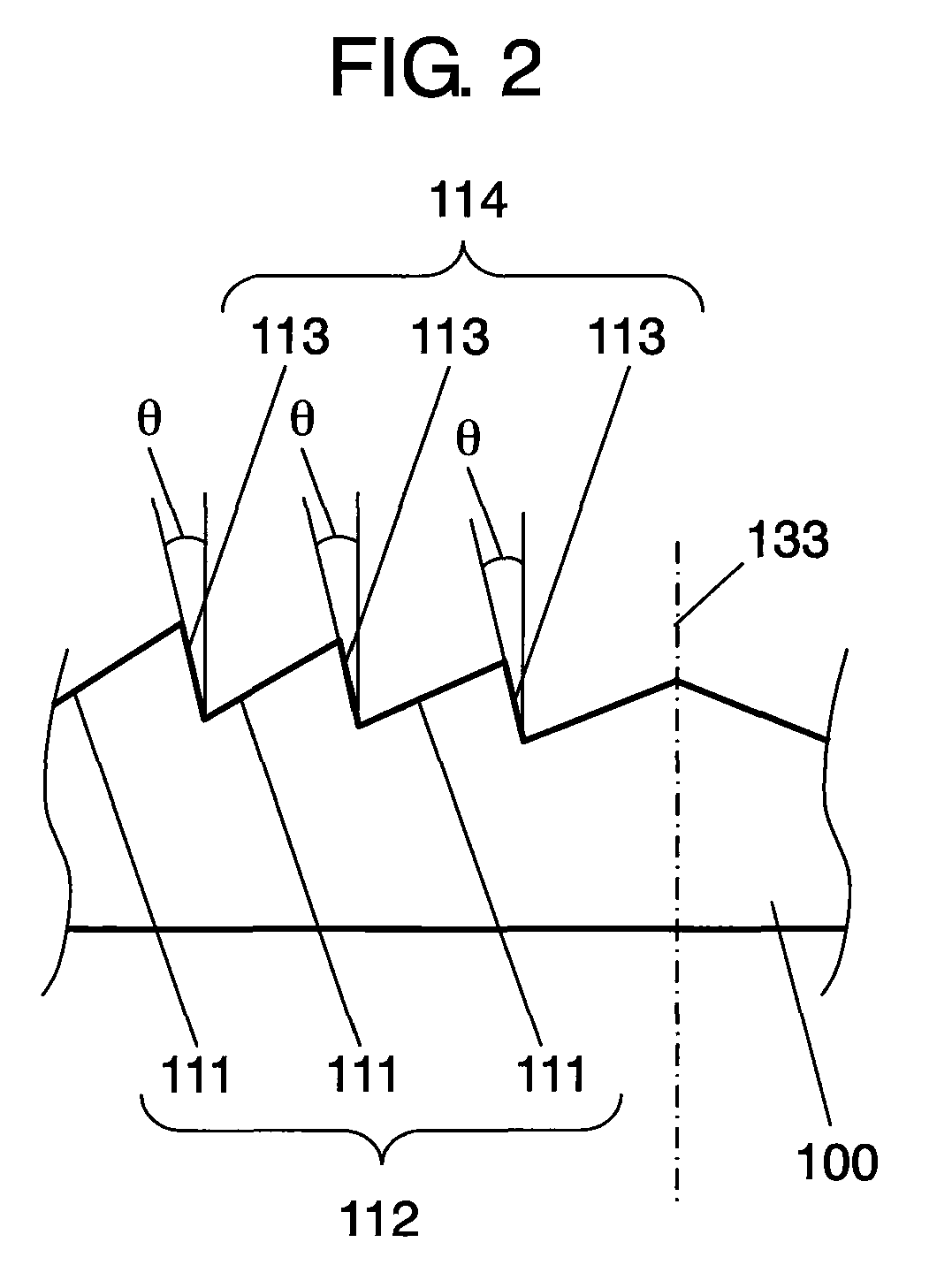

Light receiver and Fresnel lens used therein

A light receiver comprises a Fresnel lens for collecting light signals, and a light receiving element disposed closer to the Fresnel lens than the focal point of the Fresnel lens for receiving the light signals collected by the Fresnel lens. The Fresnel lens comprises a lens surface group having a plurality of lens surfaces, and a back cut surface group having a plurality of back cut surfaces connecting the lens surfaces. The back cut surfaces are inclined with respect to the center axis of the Fresnel lens. Thus, the light receiver has a high light collection efficiency of light signals incident within a certain acceptance angle.

Owner:PANASONIC CORP

Triangular glue adhering machine

InactiveCN101069993ARealize automatic productionSolve compound problemsTyresAutomatic controlAdhesive

The invention discloses a triangle adhesive attaching machine of tire manufacture production. It contains a product line including adhesive feeding machine, extrusion machine, adhesive delivery device, fixed length cut-off device and winding attaching device. Its invention characters are: the adhesive delivery device contains a guide positioning mechanism which erectly delivery the triangle adhesive into the winding device. The fixed length cut-off device contains front-back cut-off cutter which locates on the delivery path of the triangle adhesive and can realize whole moving and swinging angle. The winding attaching device contains winding device which drives the traveler rotating and compacting mechanism which press and attach the triangle adhesive on the traveler. The guide positioning mechanism is composed of a guide roller and multi-group holding rolls. The movement of the cut-off cutter is controlled by the cut-off signal from the winging device. The compacting mechanism is composed of multi-group press rolls which distribute uniformly on the circle and can release and tighten along the radial. The invention is fit for the composite pressing of triangle adhesive and traveler in the huge tires, which has advantages of simple structure, high mechanization degree and automatic control.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com